Patents

Literature

14180results about "Photosensitive material processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

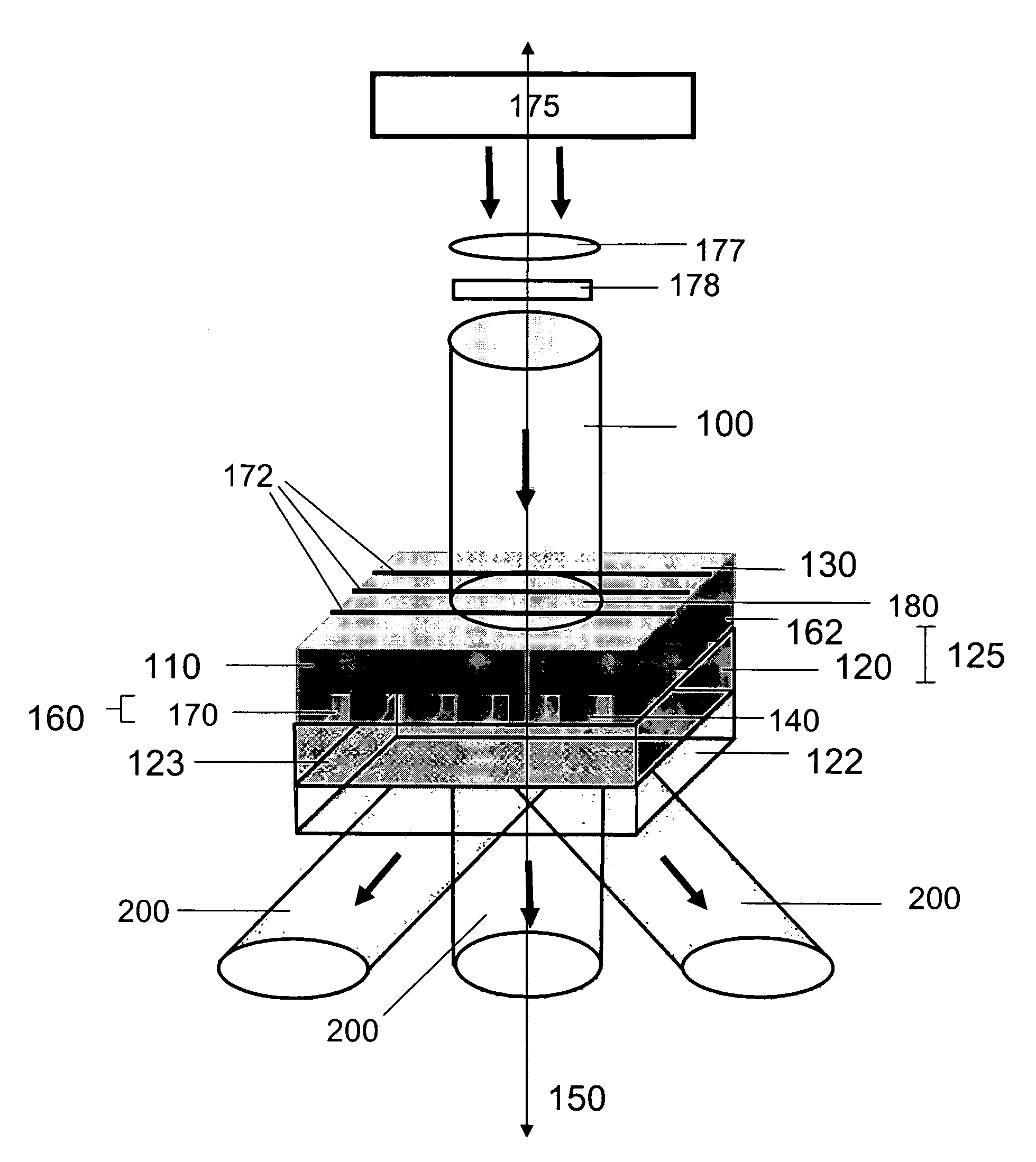

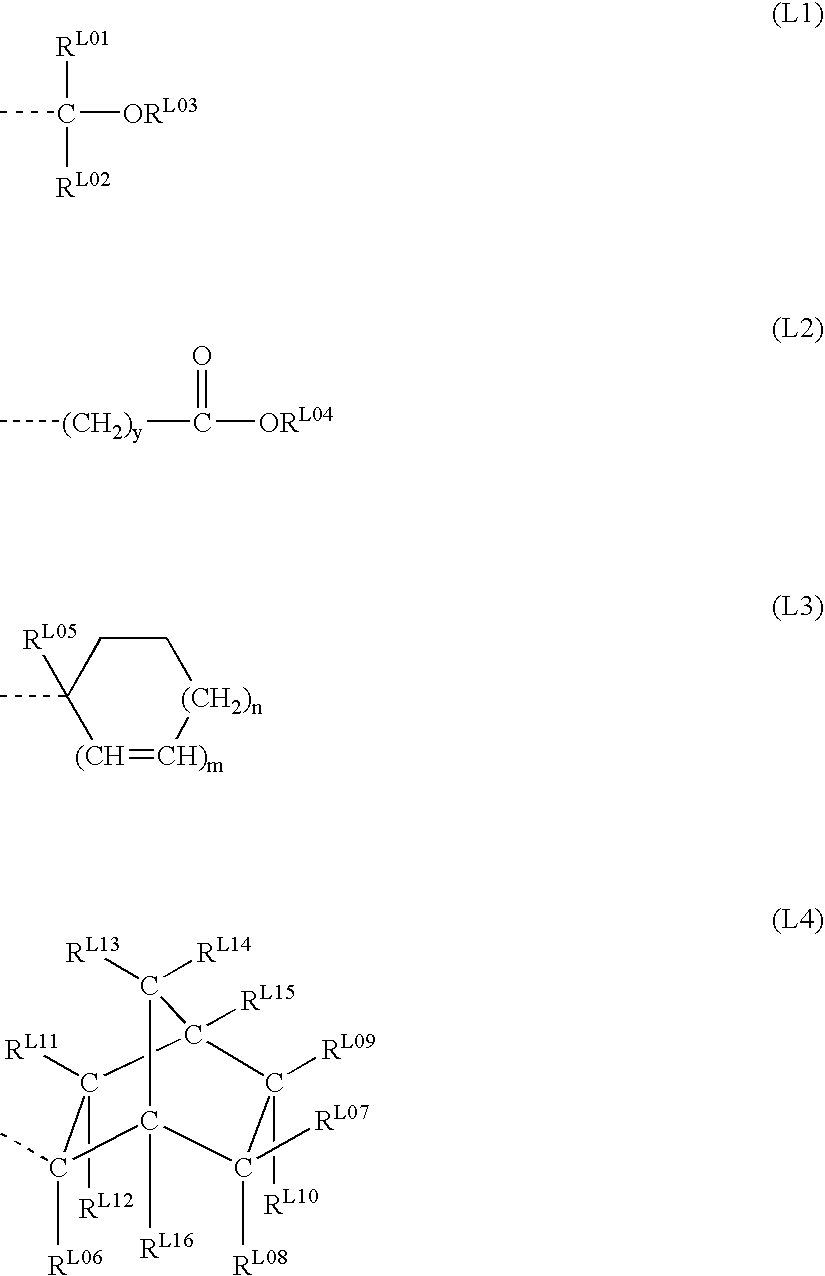

Method and system for drying a substrate

ActiveUS20050046934A1Good pattern uniformityImprove uniformityMicroscopesPhotomechanical exposure apparatusCooking & bakingThin membrane

A method and system is described for drying a thin film on a substrate following liquid immersion lithography. Drying the thin film to remove immersion fluid from the thin film is performed prior to baking the thin film, thereby reducing the likely hood for interaction of immersion fluid with the baking process. This interaction has been shown to cause non-uniformity in critical dimension for the pattern formed in the thin film following the developing process.

Owner:TOKYO ELECTRON LTD

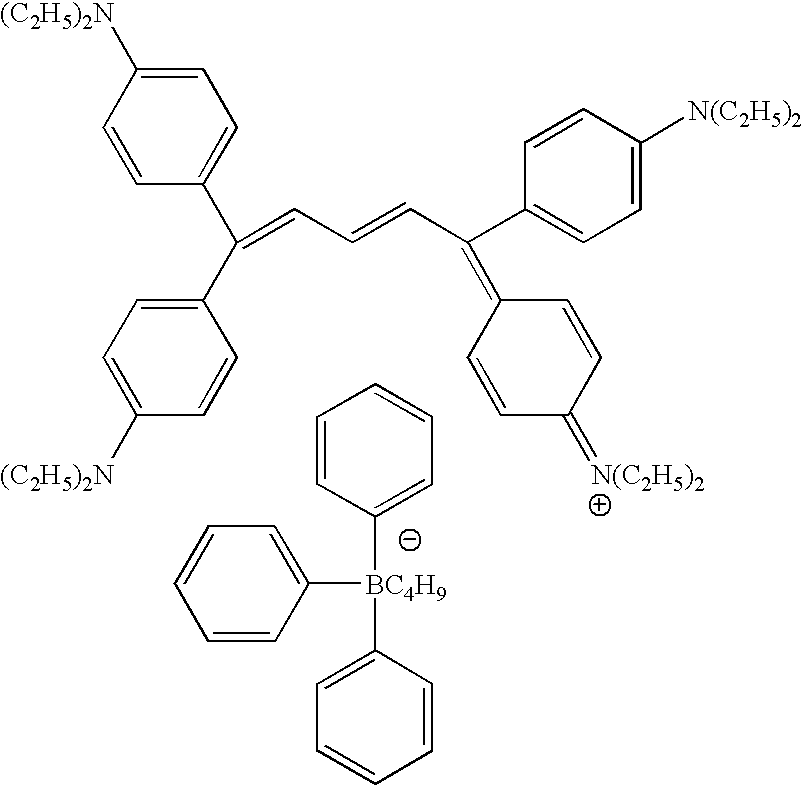

On-press developable IR sensitive printing plates using binder resins having polyethylene oxide segments

InactiveUS6899994B2Prevent steppingRadiation applicationsSemiconductor/solid-state device manufacturingPolymer sciencePolyethylene oxide

The present invention relates to a polymerizable coating composition suitable for the manufacture of printing plates developable on-press. The coating composition comprises (i) a polymerizable compound and (ii) a polymeric binder comprising polyethylene oxide segments, wherein the polymeric binder is selected from the group consisting of at least one graft copolymer comprising a main chain polymer and polyethylene oxide side chains, a block copolymer having at least one polyethylene oxide block and at least one non-polyethylene oxide block, and a combination thereof. The invention is also directed to an imageable element comprising a substrate and the polymerizable coating composition.

Owner:KODAK POLYCHROME GRAPHICS

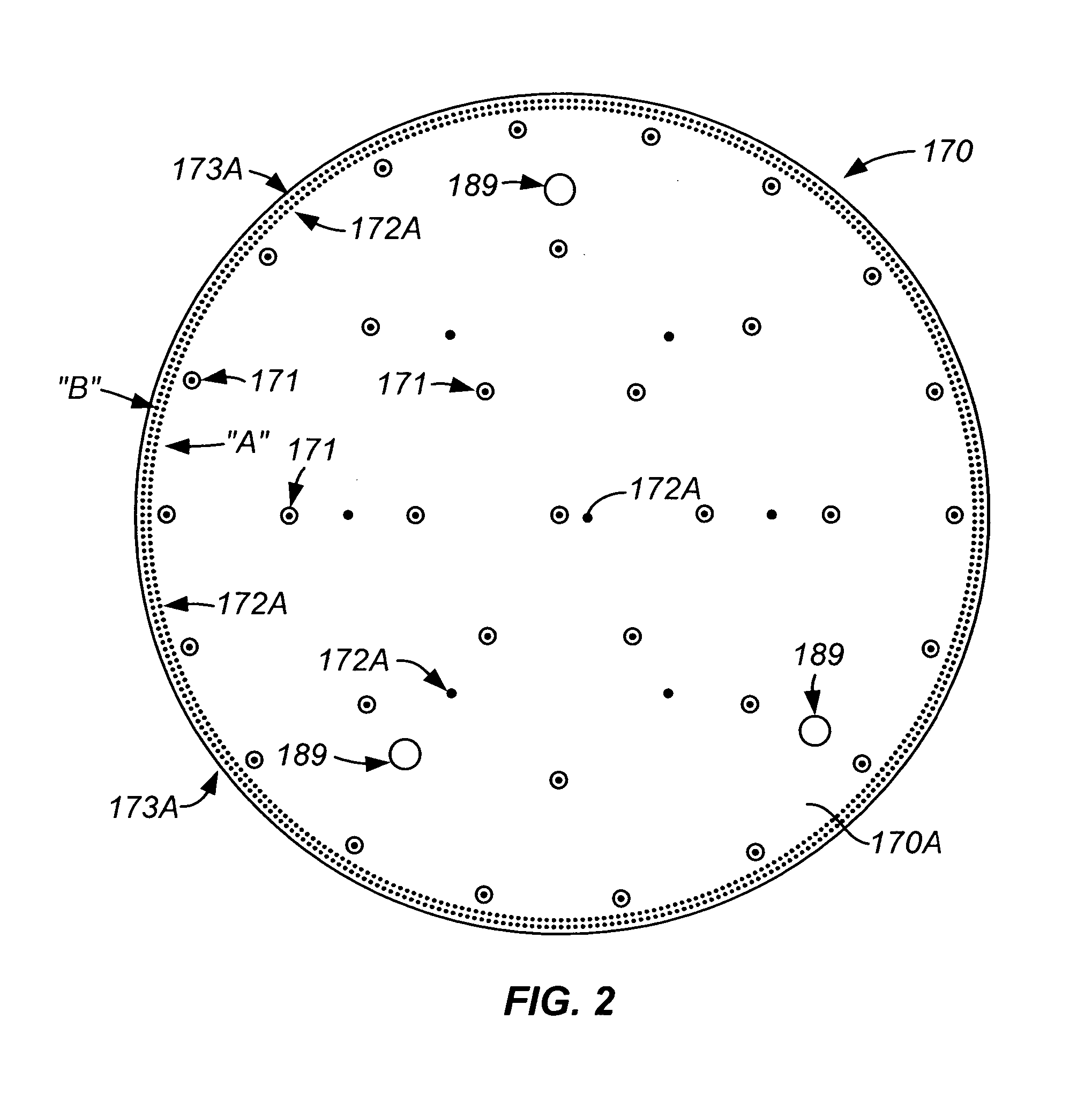

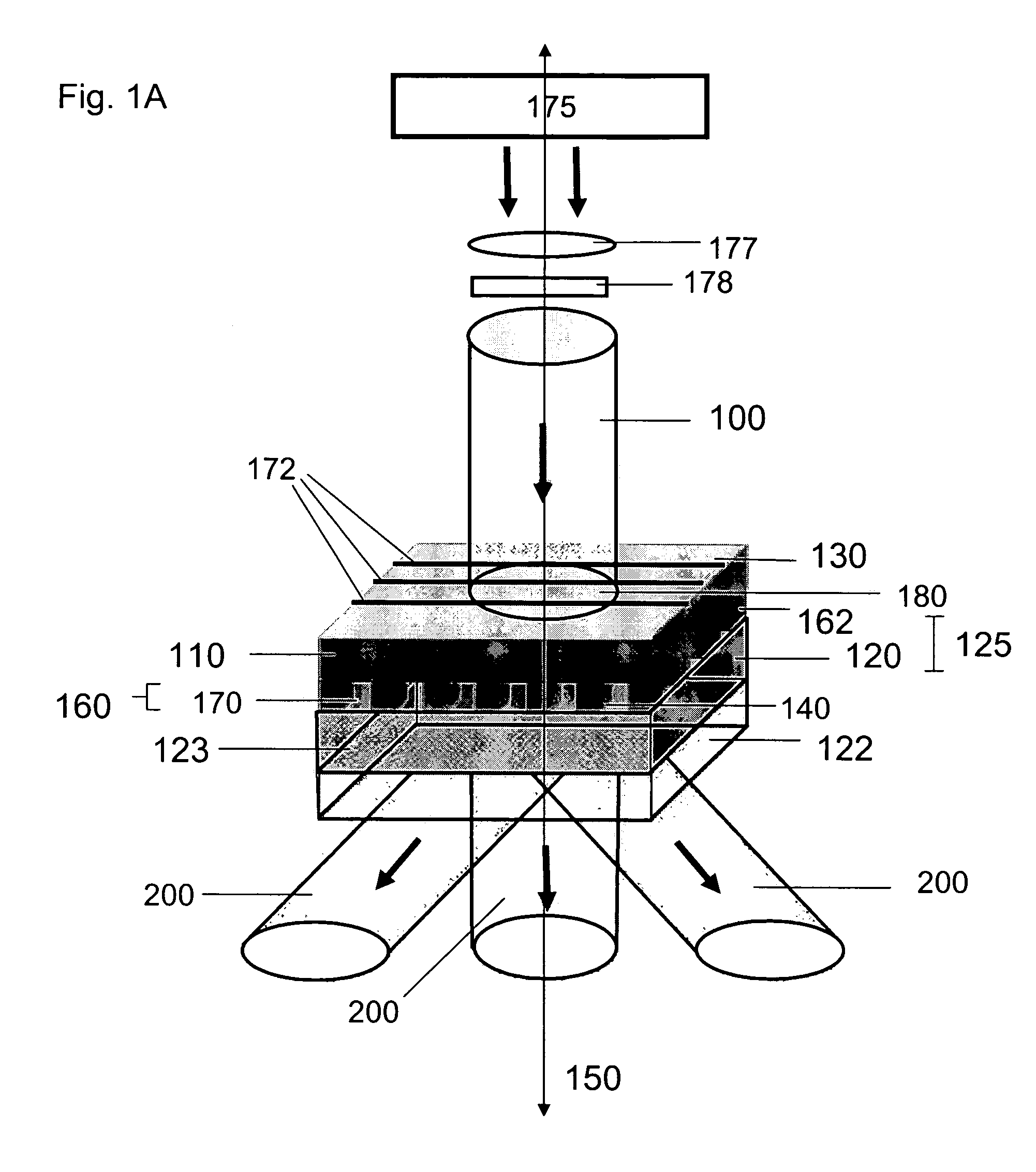

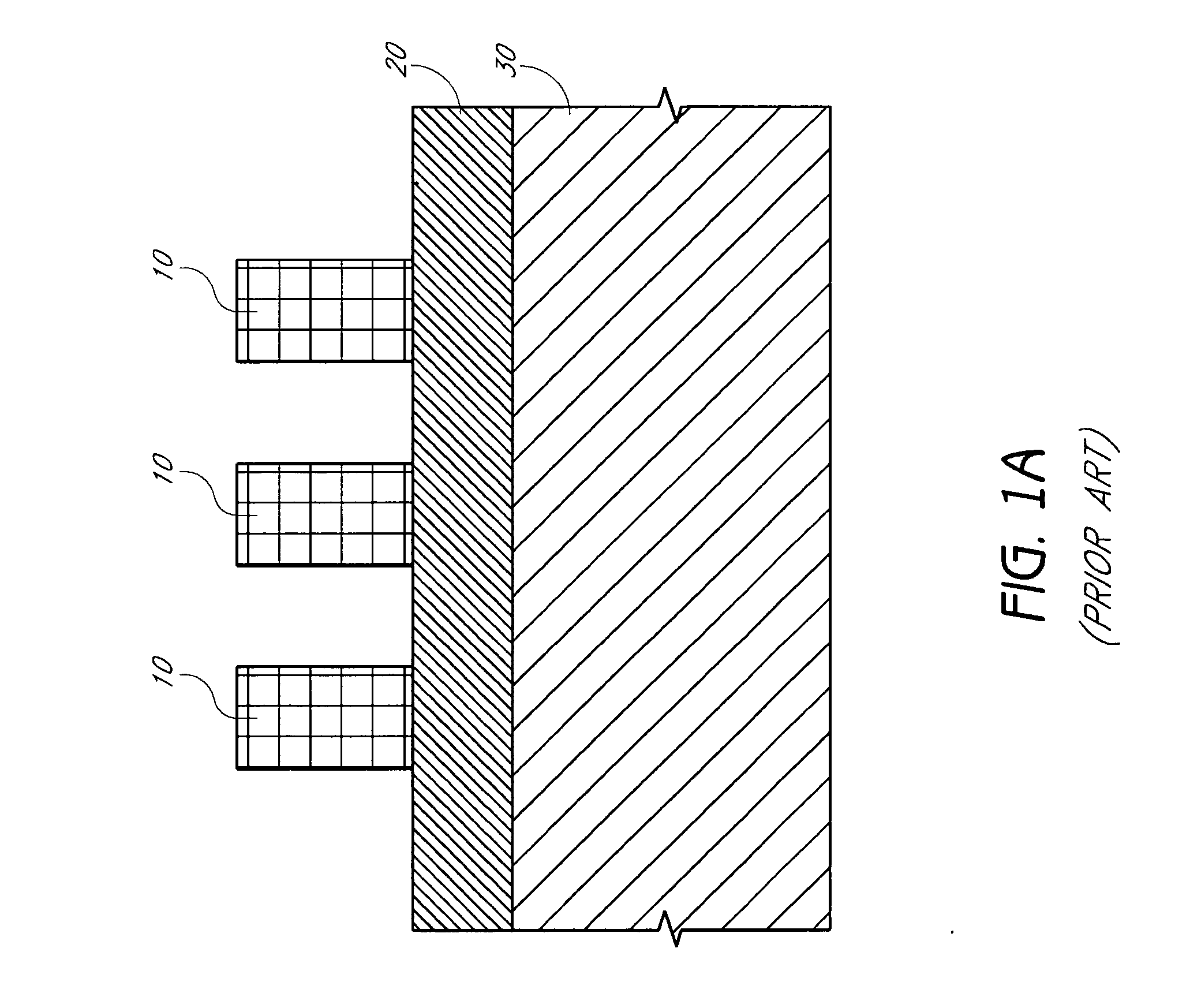

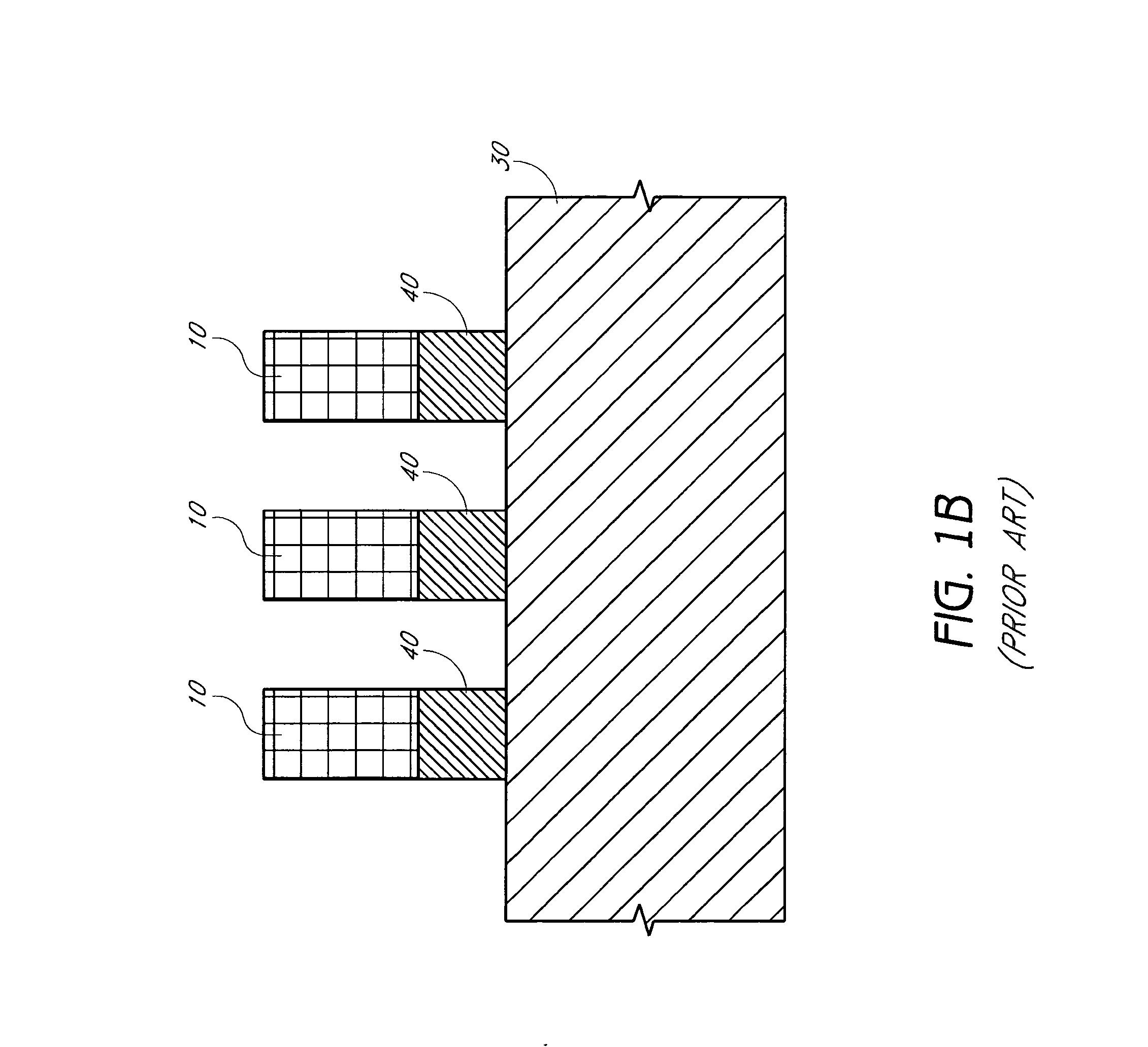

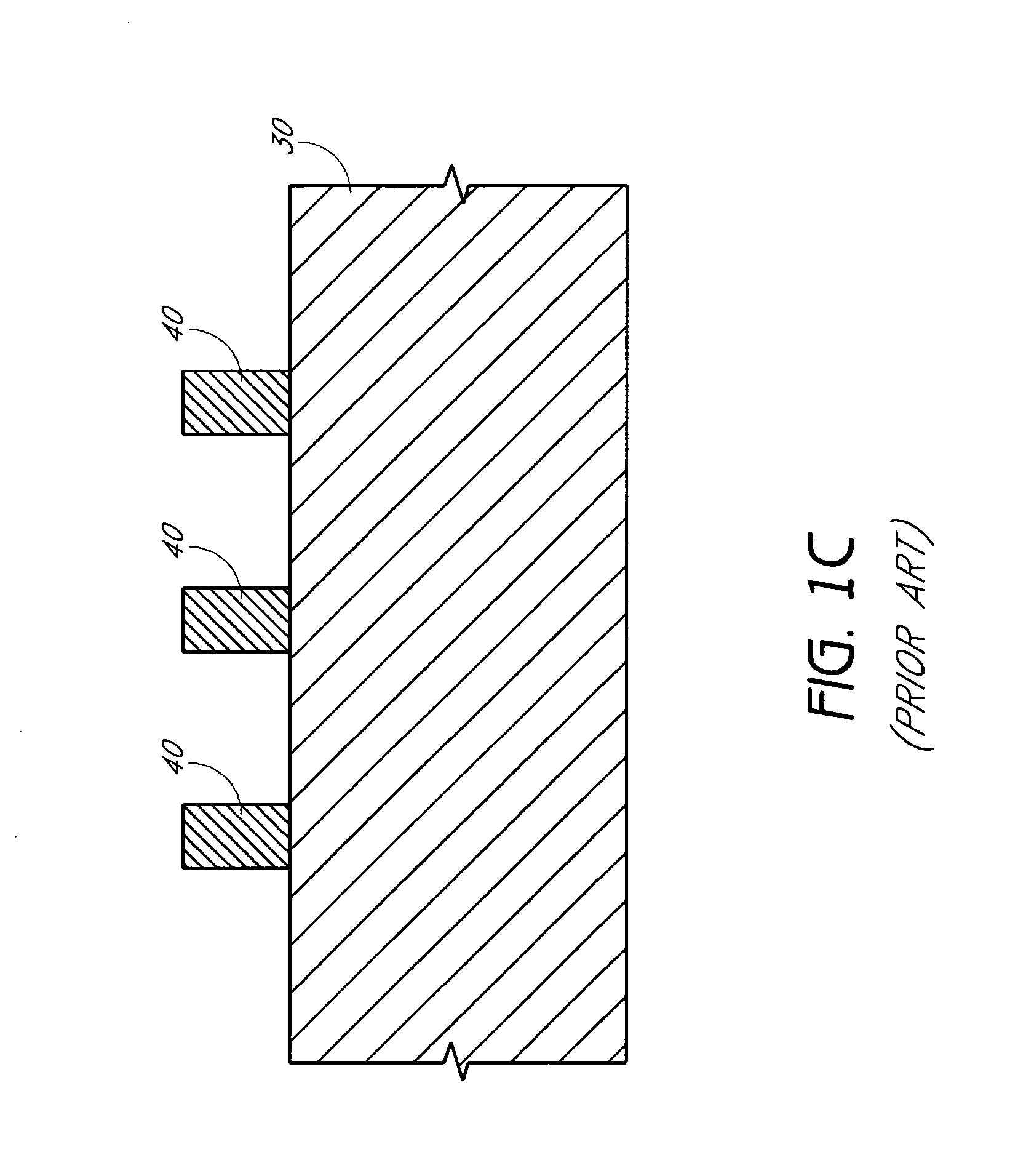

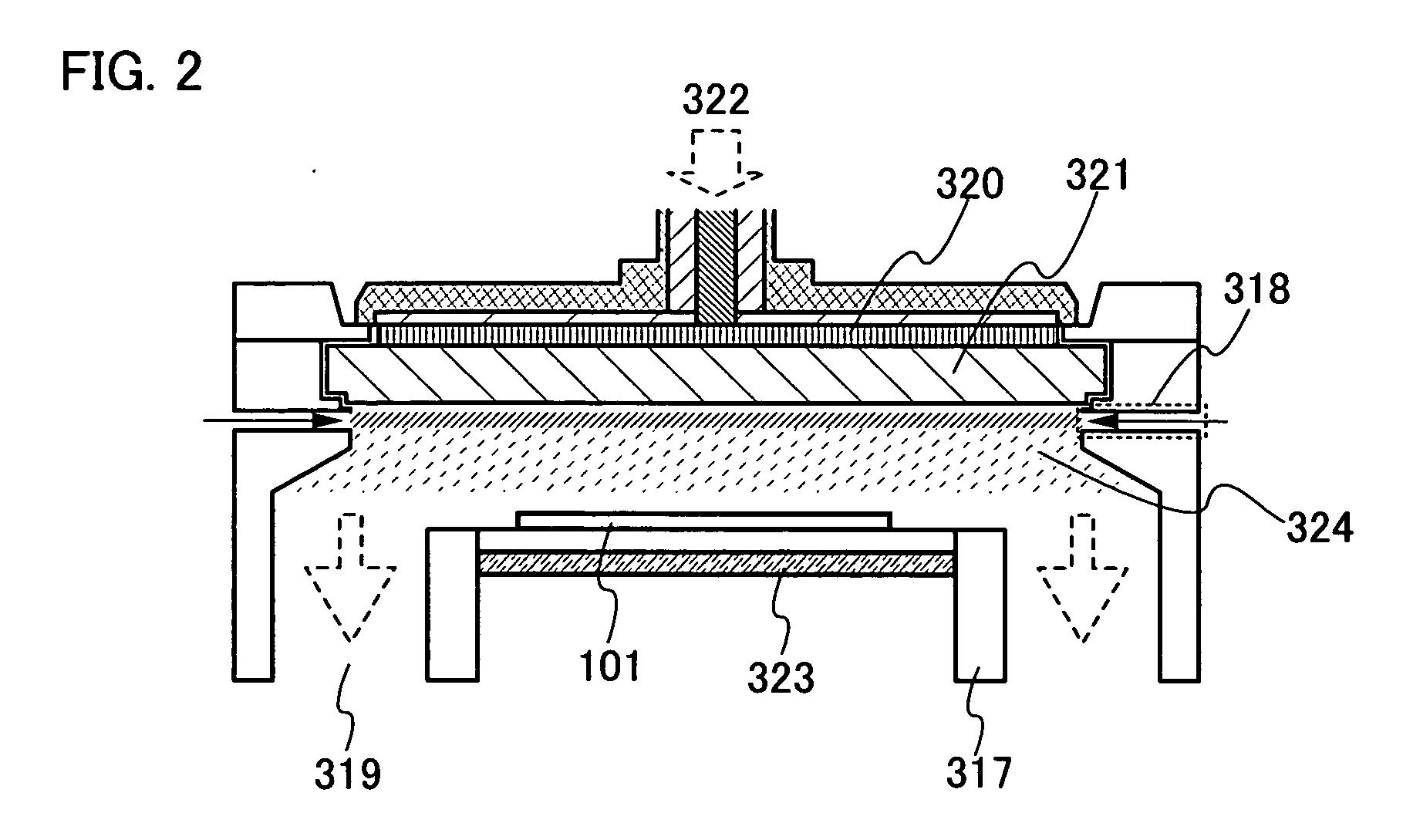

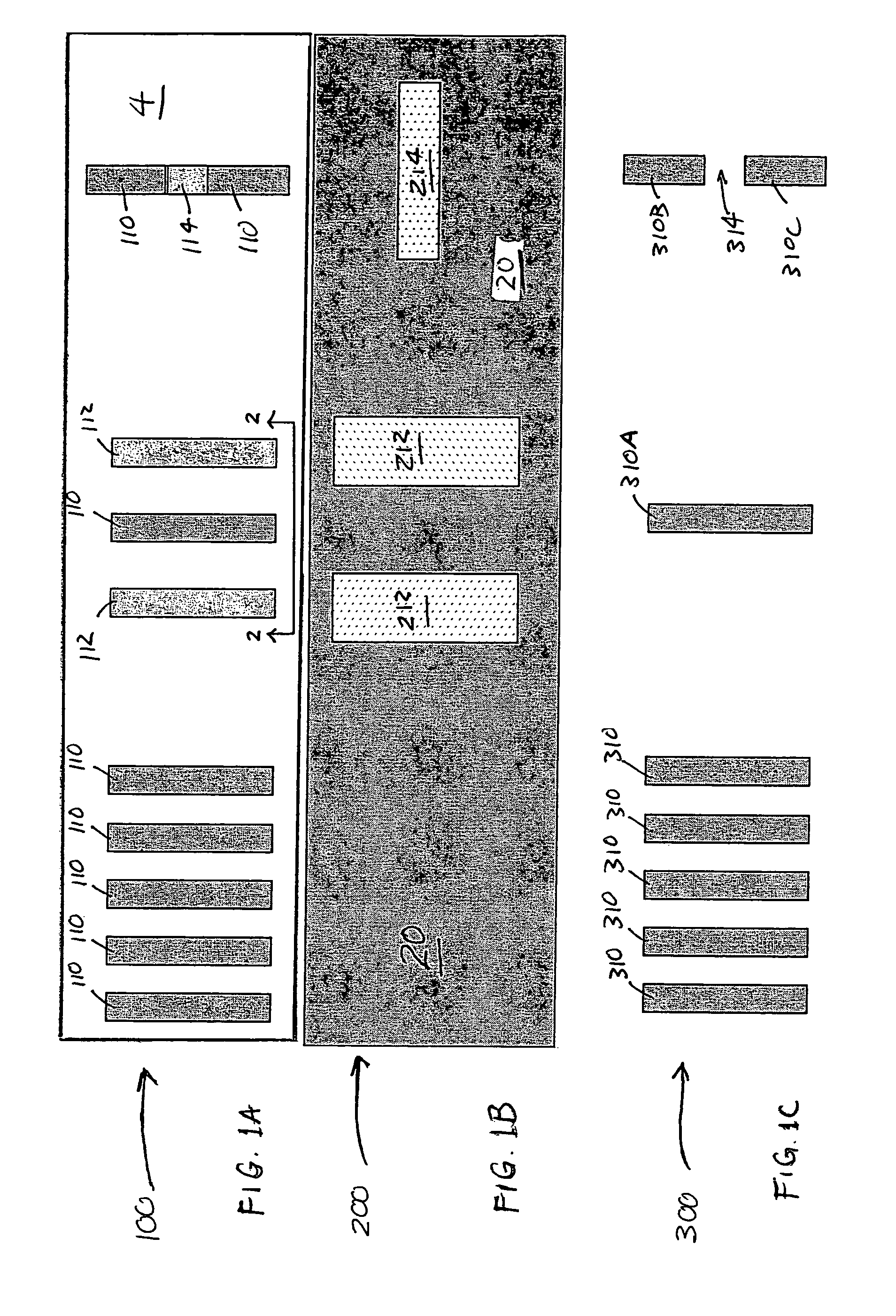

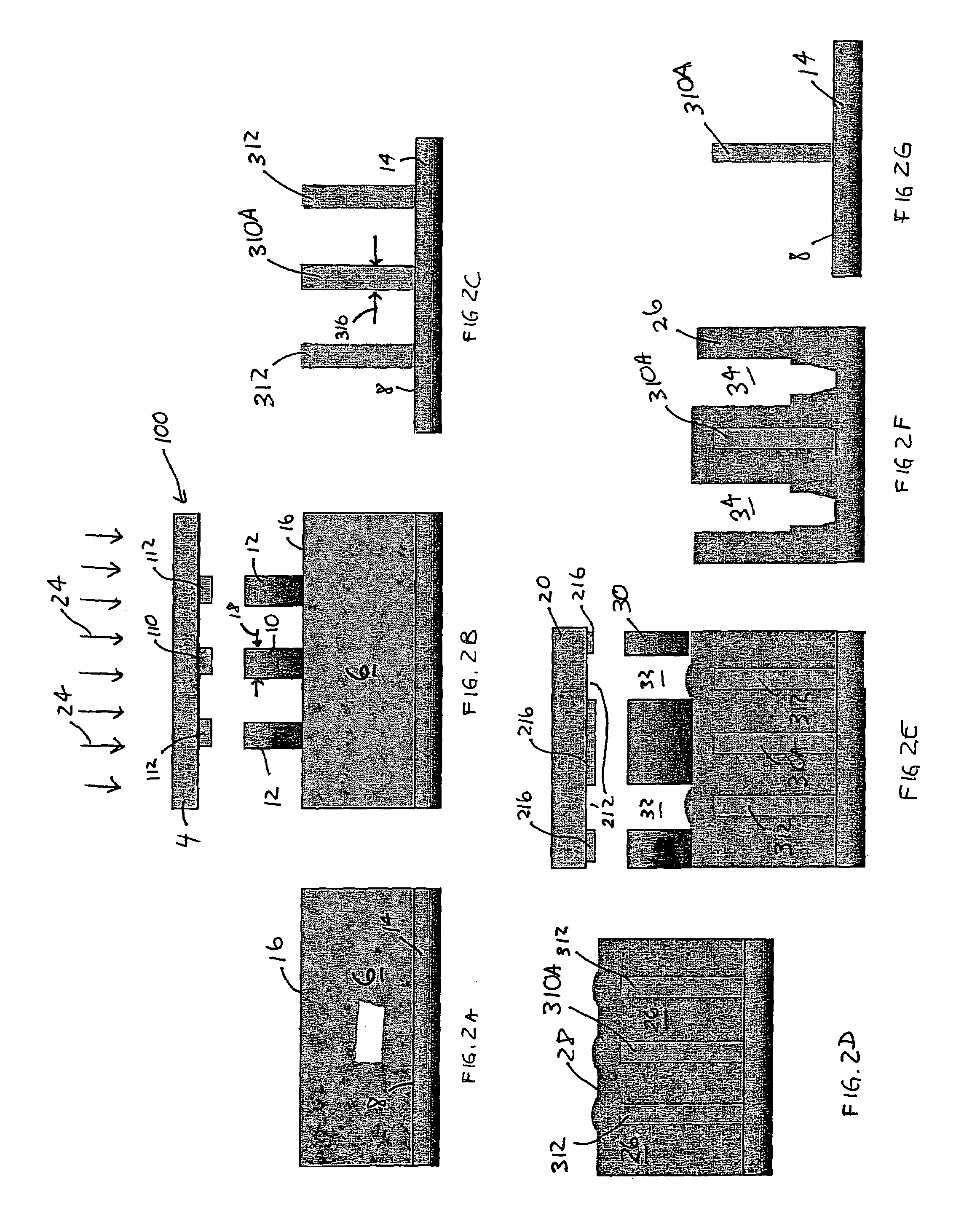

Purged vacuum chuck with proximity pins

InactiveUS20060130767A1Reduce the overall heightImprove heat transfer rateProgramme controlSemiconductor/solid-state device testing/measurementEngineeringFree space

A substrate support structure comprising a first surface and a second surface opposite the first surface. The substrate support structure also comprises a plurality of proximity pins projecting to a first height above the first surface, the first height being less than 100 μm. In addition, the substrate support structure further comprises a plurality of purge ports passing from the second surface to the first surface and a plurality of vacuum ports passing from the second surface to the first surface. In one embodiment, the plurality of purge ports are arranged in a first circular pattern, the first circular pattern having a first radial dimension less than the radius of the substrate support, and the plurality of vacuum ports are arranged in a second circular pattern, the second circular pattern having a second radial dimension less than the first radial dimension.

Owner:SOKUDO CO LTD

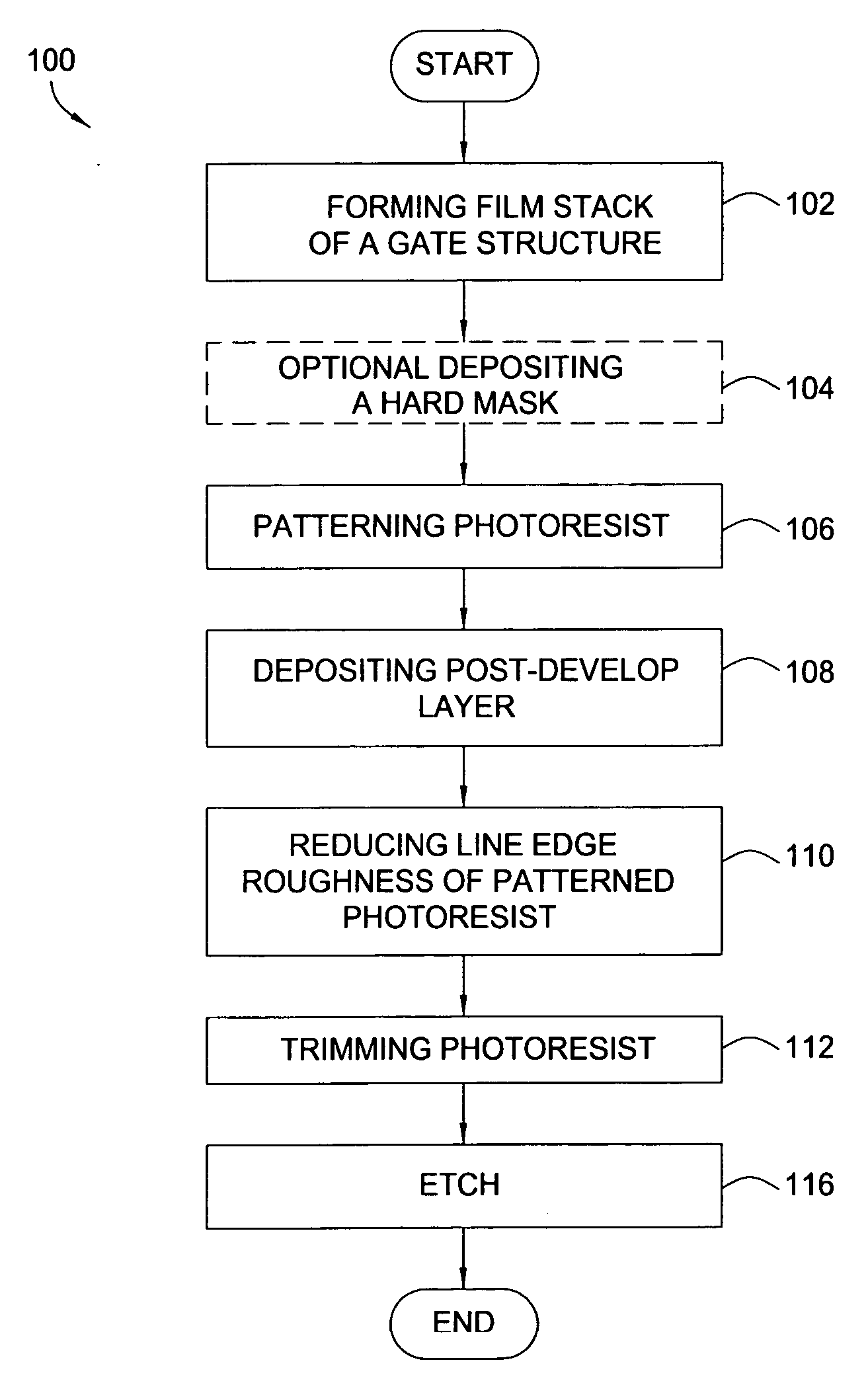

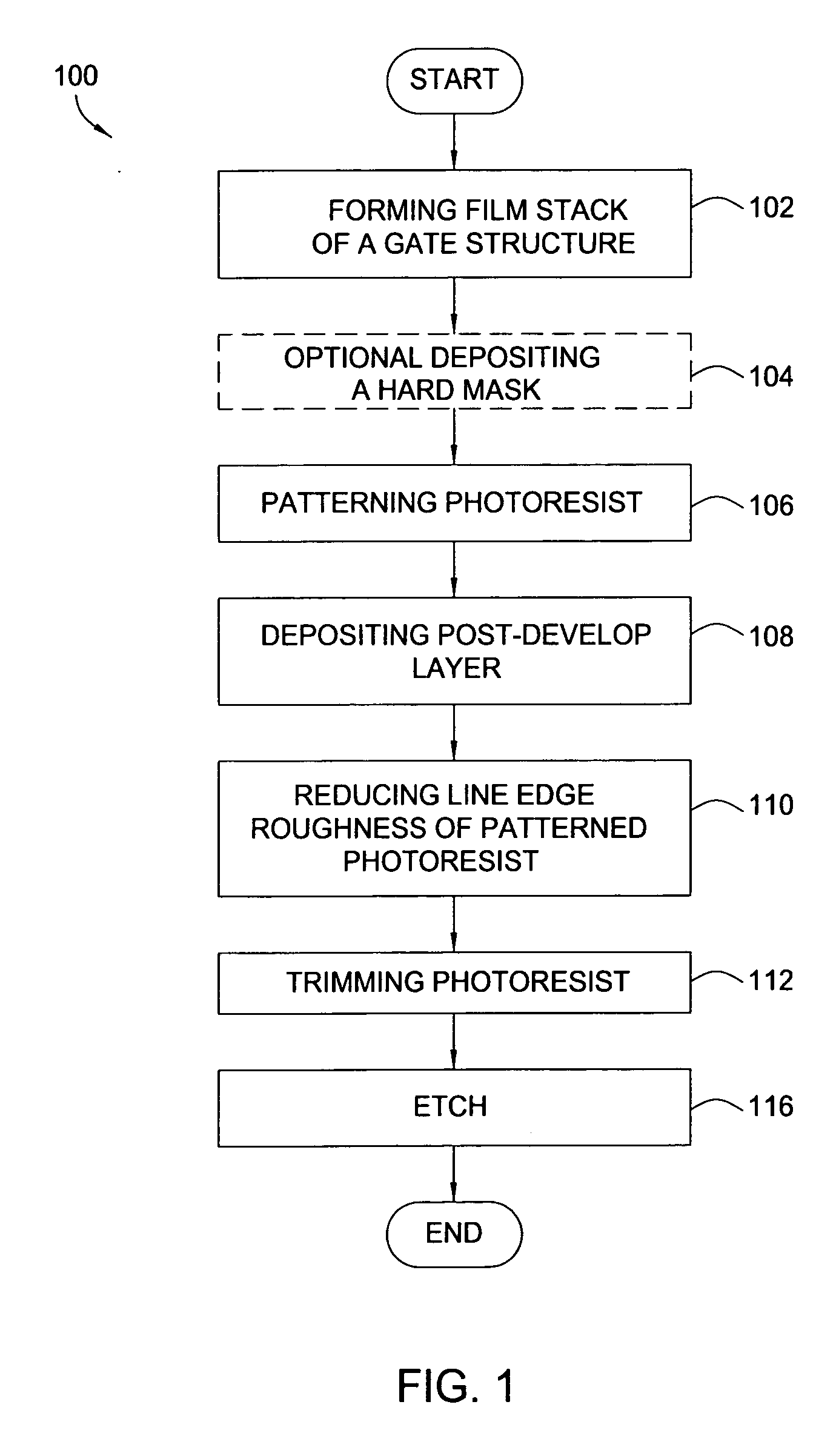

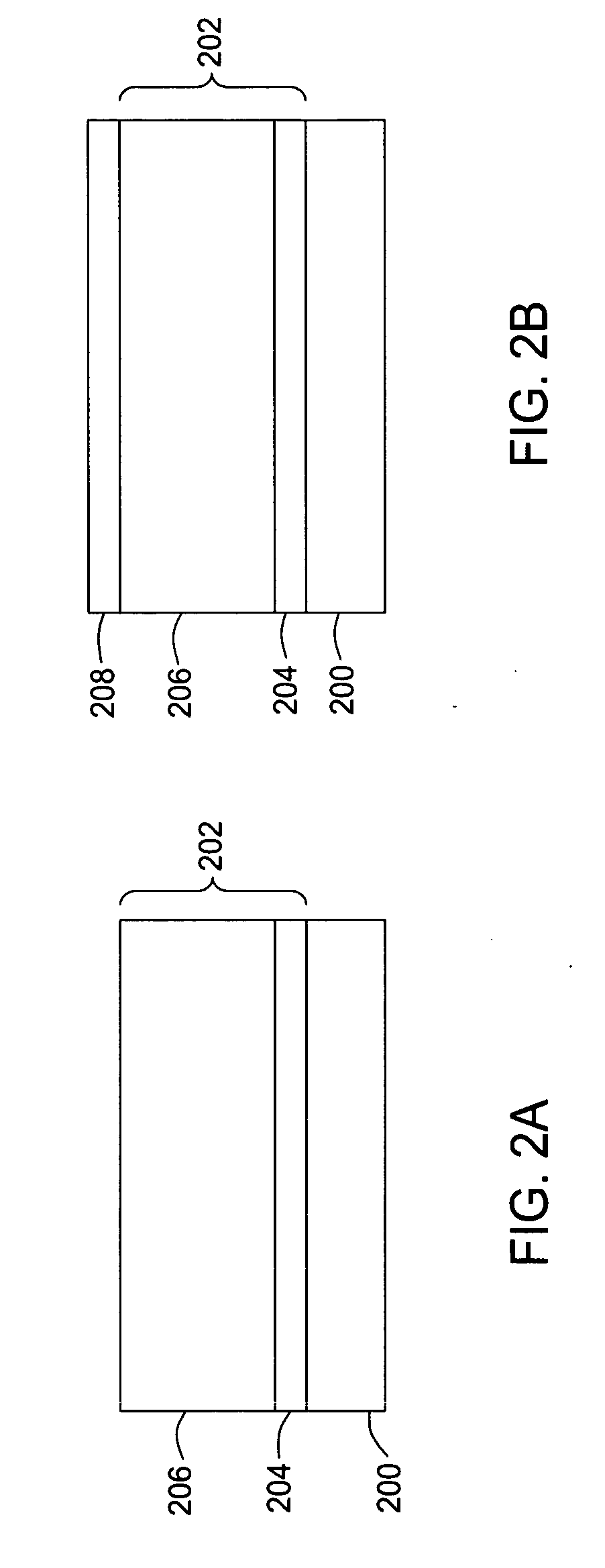

Line edge roughness reduction compatible with trimming

InactiveUS20060205223A1Semiconductor/solid-state device manufacturingPhotosensitive material processingEngineeringPhotoresist

A method and apparatus for reducing line edge roughness, comprising patterning a photoresist to define lines for etching an underlying layer, depositing a post development material between the lines, curing and removing the post development material to reduce line edge roughness, trimming the lines in the underlying layer, and then etching the underlying layer.

Owner:APPLIED MATERIALS INC

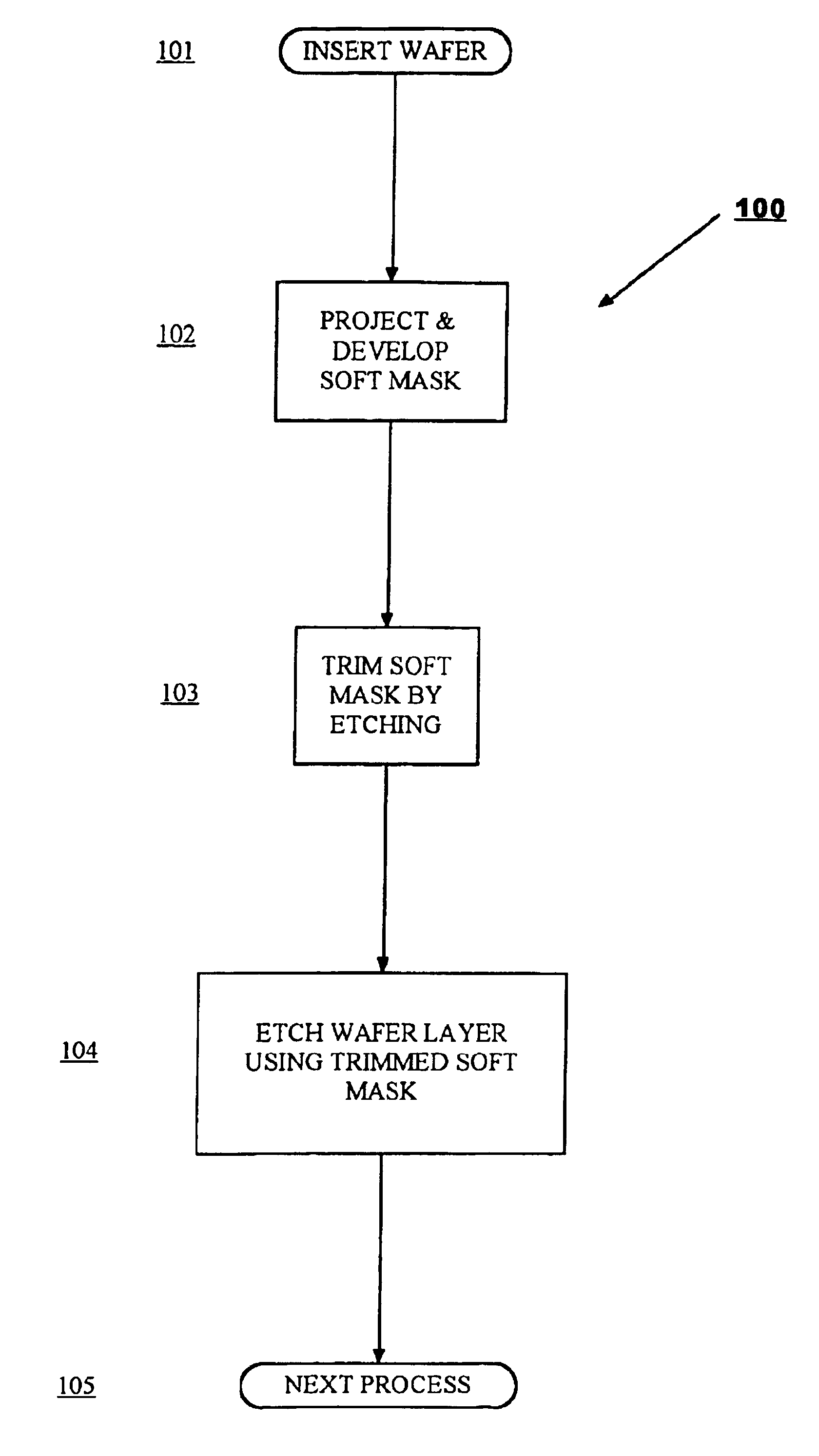

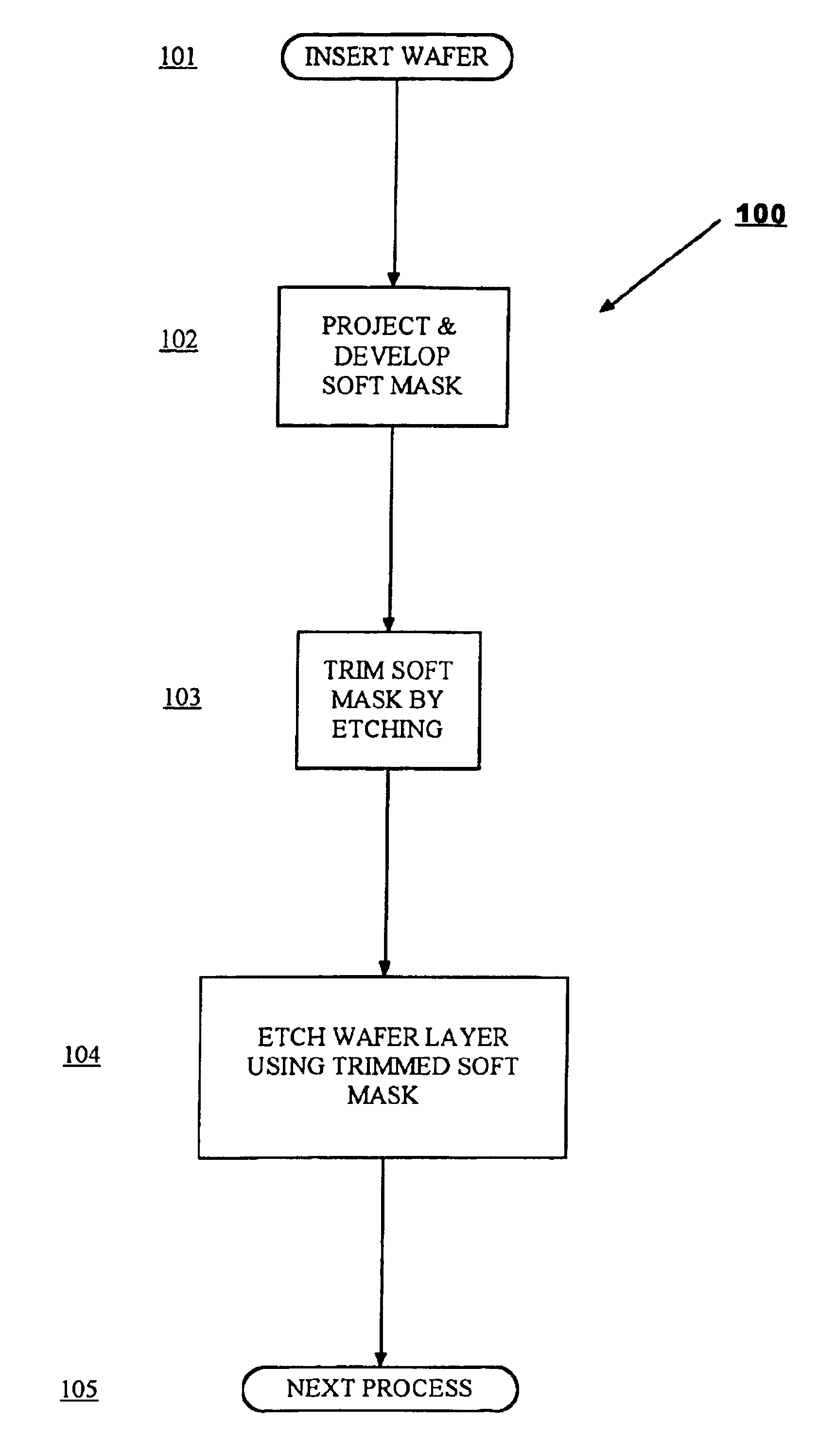

Gate linewidth tailoring and critical dimension control for sub-100 nm devices using plasma etching

InactiveUS6864041B2Tight tolerance variationMinimal variationVacuum gauge using ionisation effectsDecorative surface effectsImage resolutionLine width

A method of fabricating an electronic chip on a wafer in which a first mask at a predetermined lower resolution is developed on the wafer and then etched under a first set of conditions for a predetermined period to achieve a mask that is below the resolution limit of current lithography. The etched mask is then used as a hard mask for etching material on a lower layer.

Owner:INT BUSINESS MASCH CORP

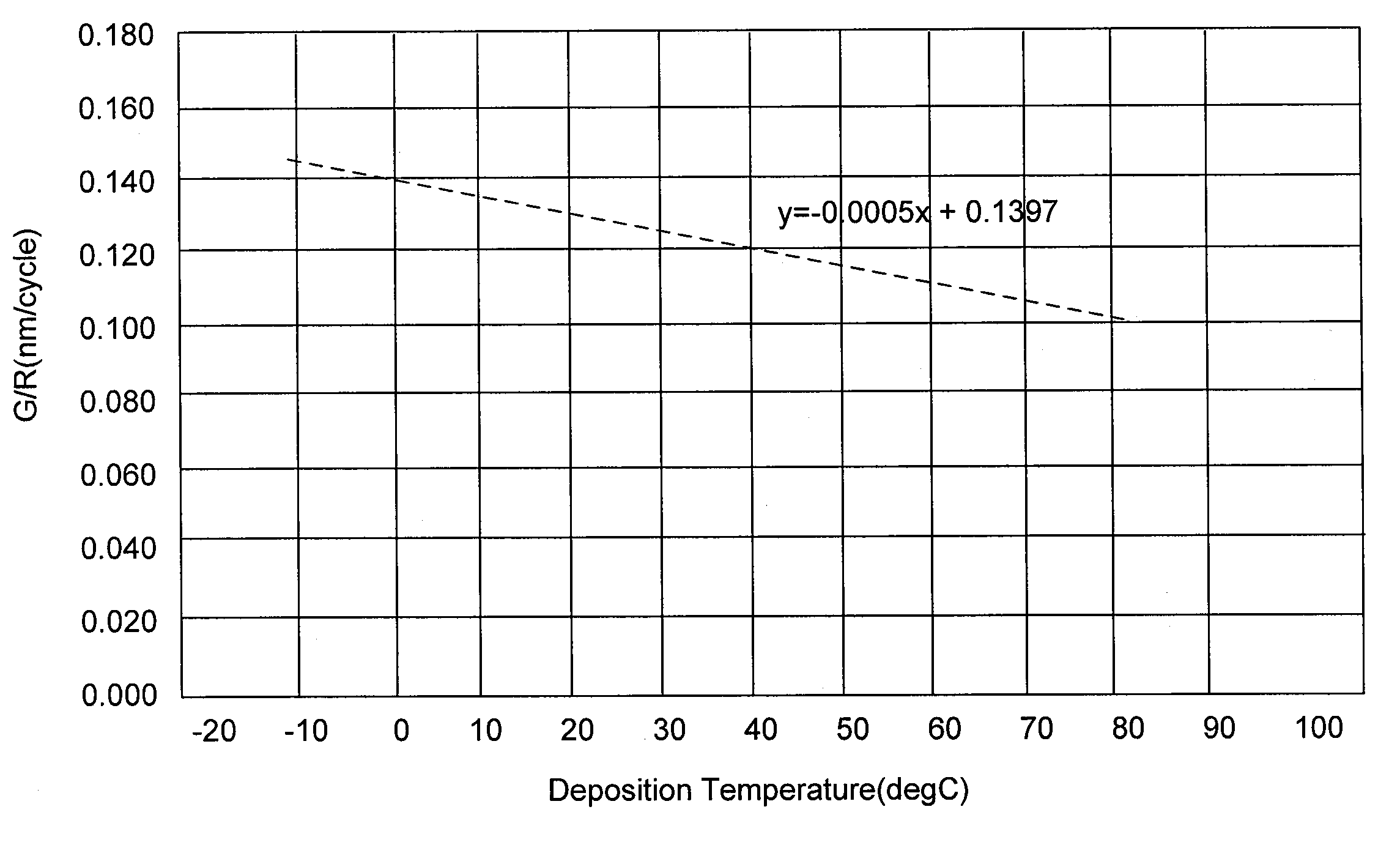

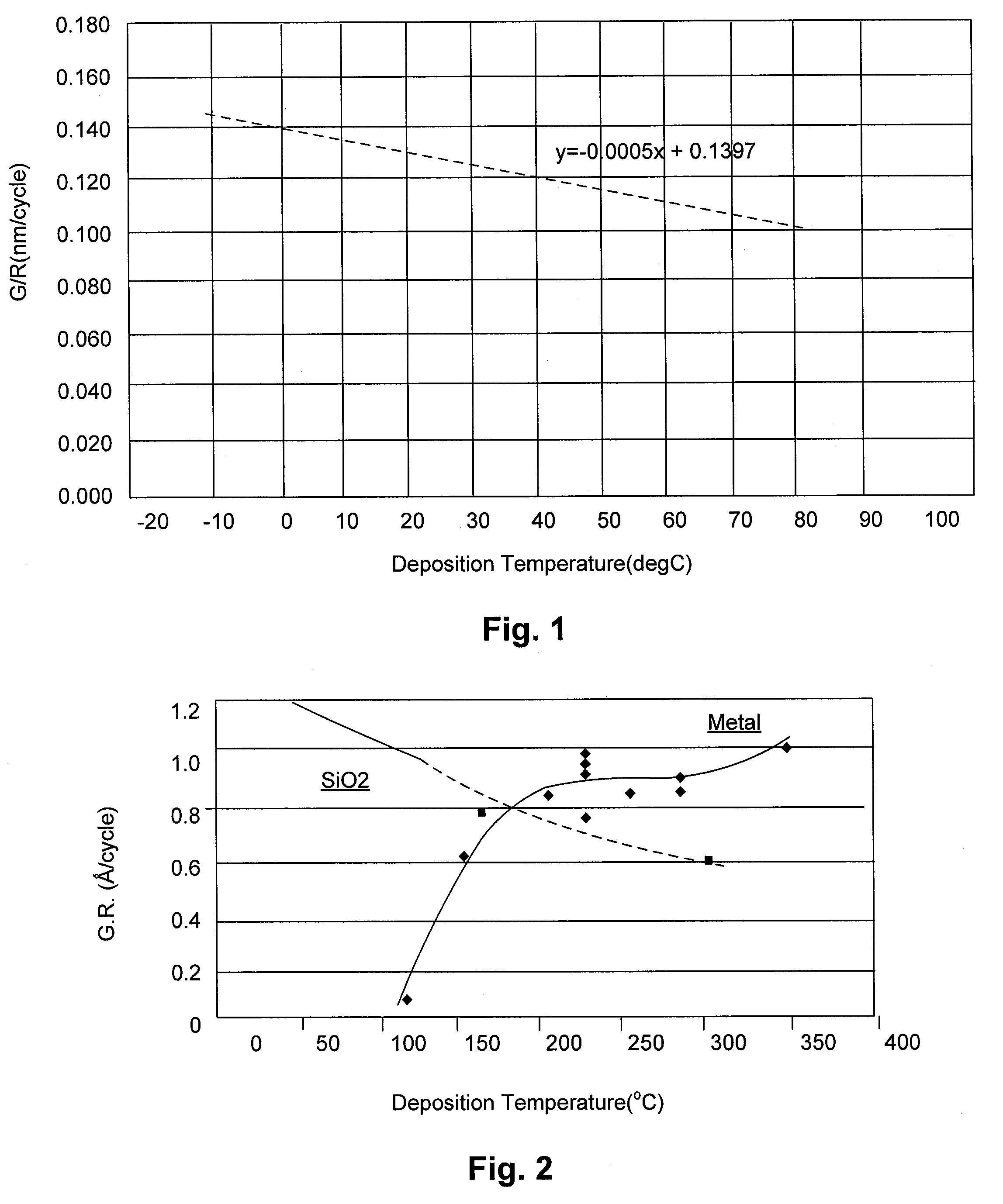

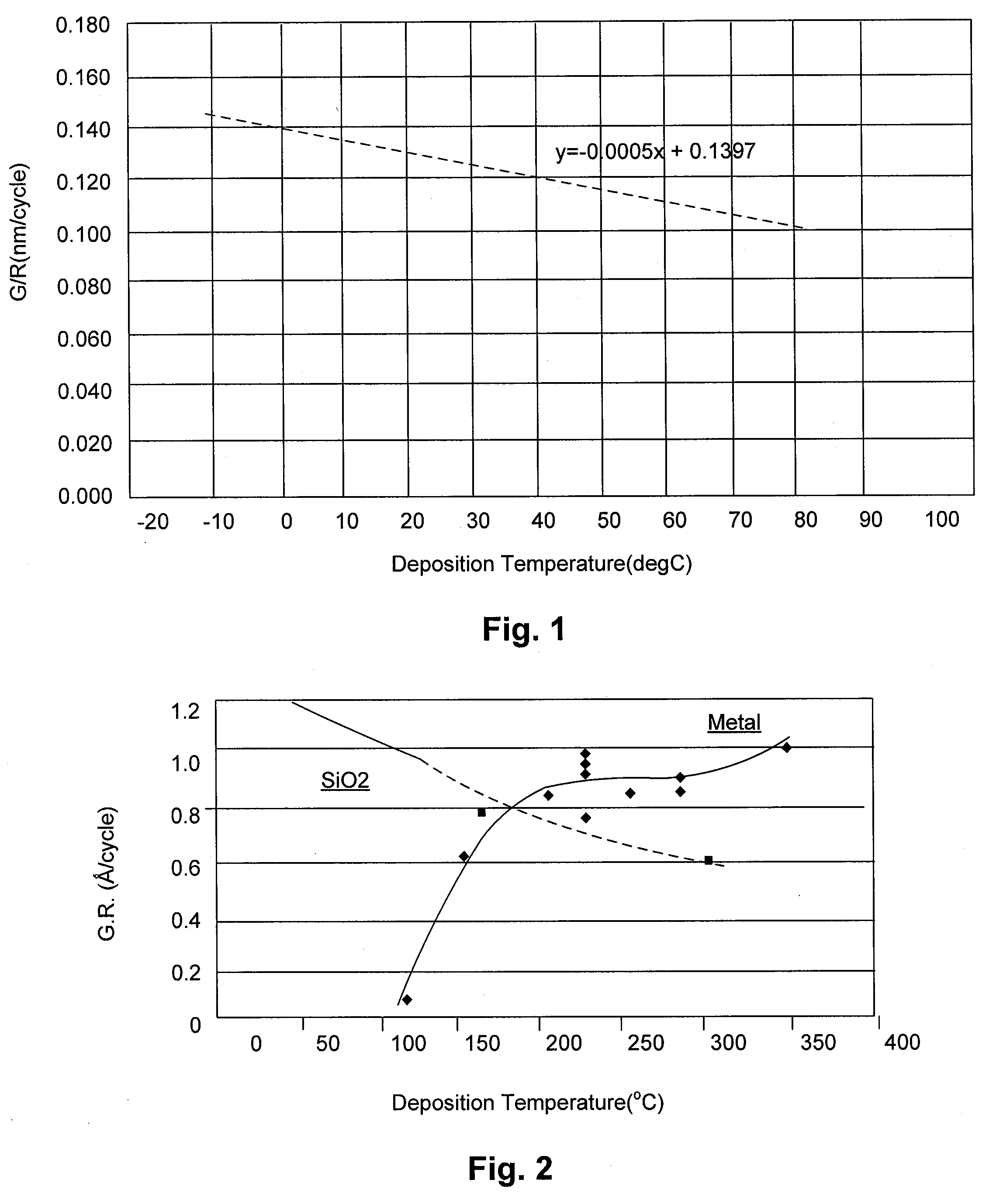

Method of depositing silicon oxide film by plasma enhanced atomic layer deposition at low temperature

ActiveUS8197915B2Increase deposition rateInhibition is effectiveSemiconductor/solid-state device manufacturingPhotosensitive material processingResistDeposition temperature

Owner:ASM JAPAN

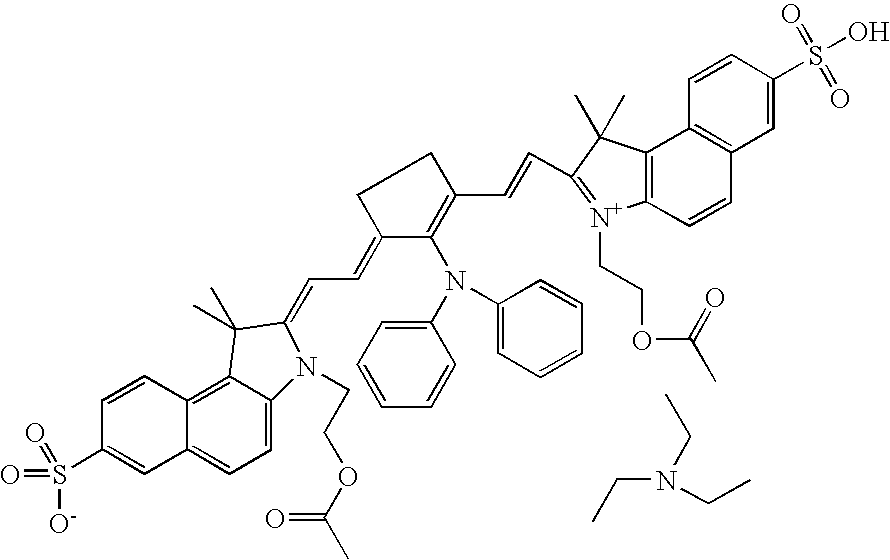

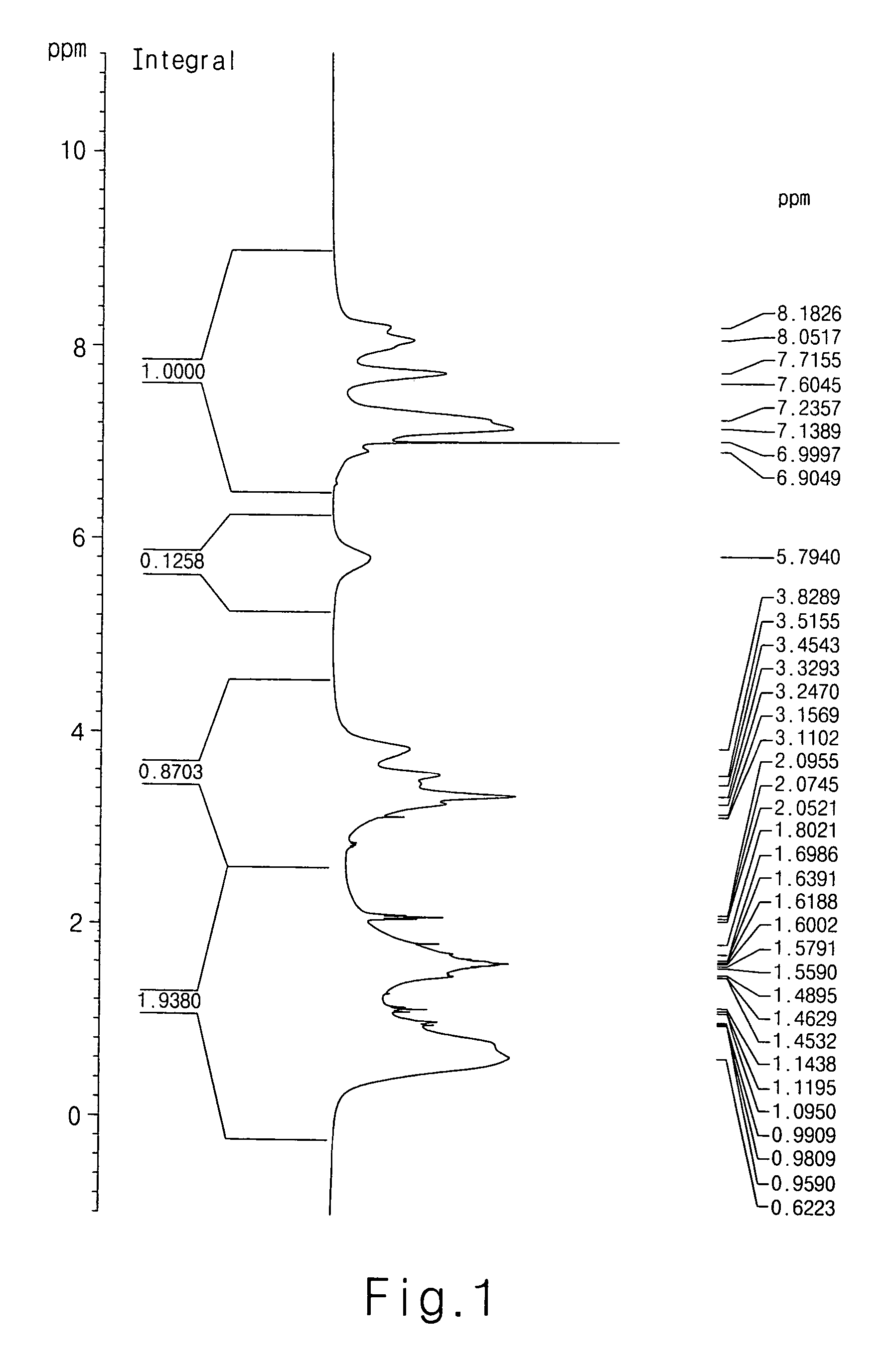

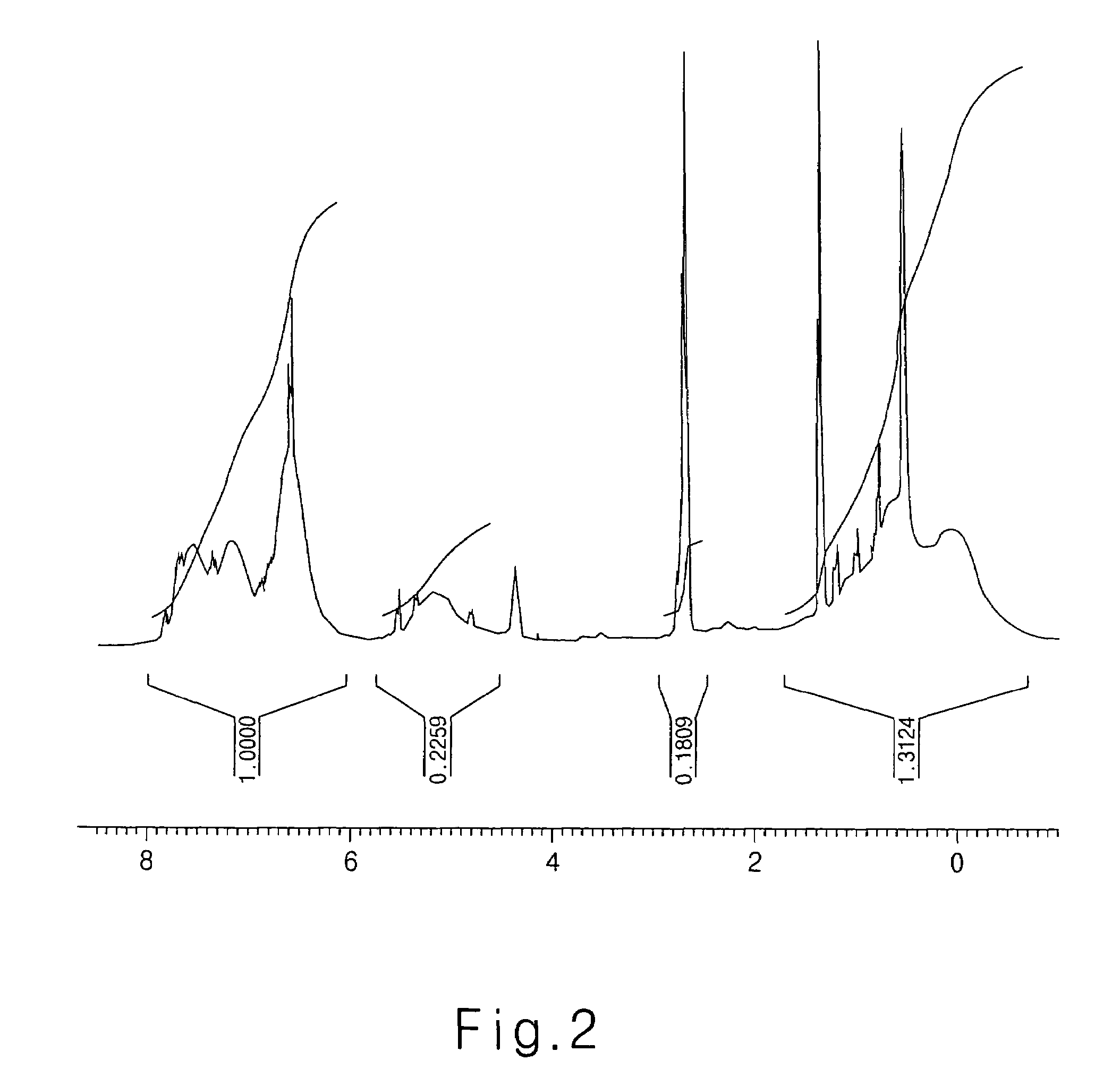

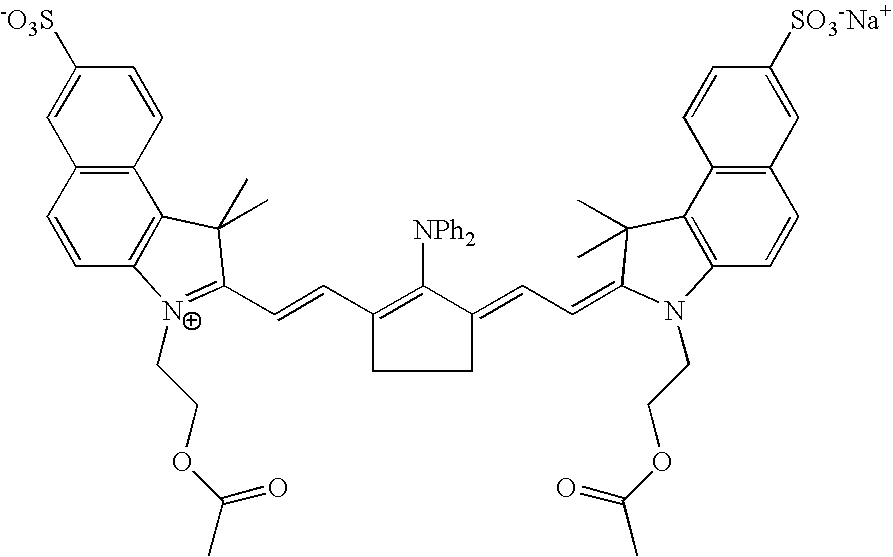

Radiation-sensitive compositions and imageable materials

InactiveUS7153632B1Maintaining photo speedMaintaining visible print outPhotosensitive materialsRadiation applicationsPolymer sciencePolymer

A radiation-sensitive composition includes a radically polymerizable component that comprises carboxy groups, an initiator composition to generate radicals, and a polymeric binder comprising poly(alkylene oxide) segments and optionally pendant cyano groups. This composition can be used to prepare imageable elements such as negative-working, on-press developable printing plate precursors.

Owner:EASTMAN KODAK CO

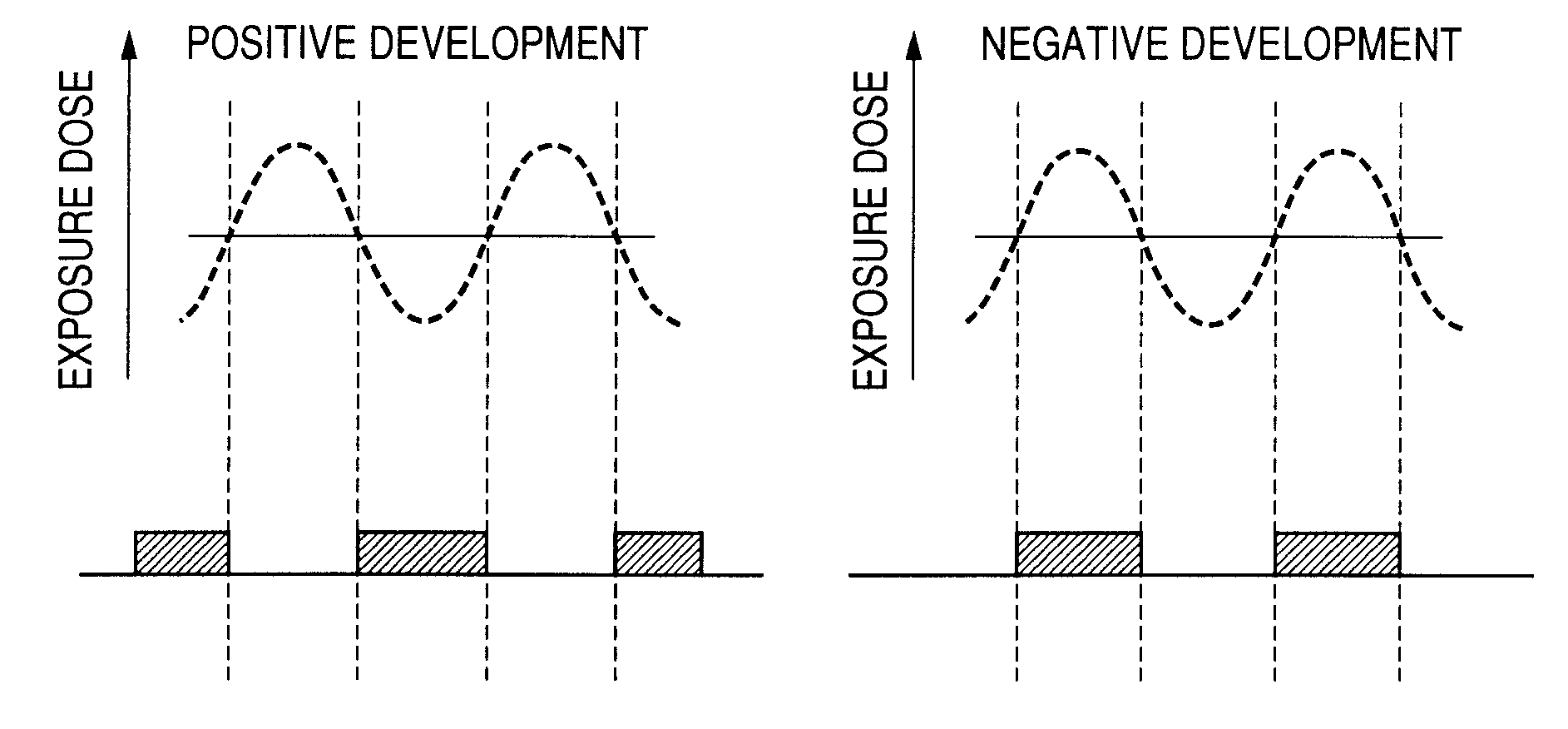

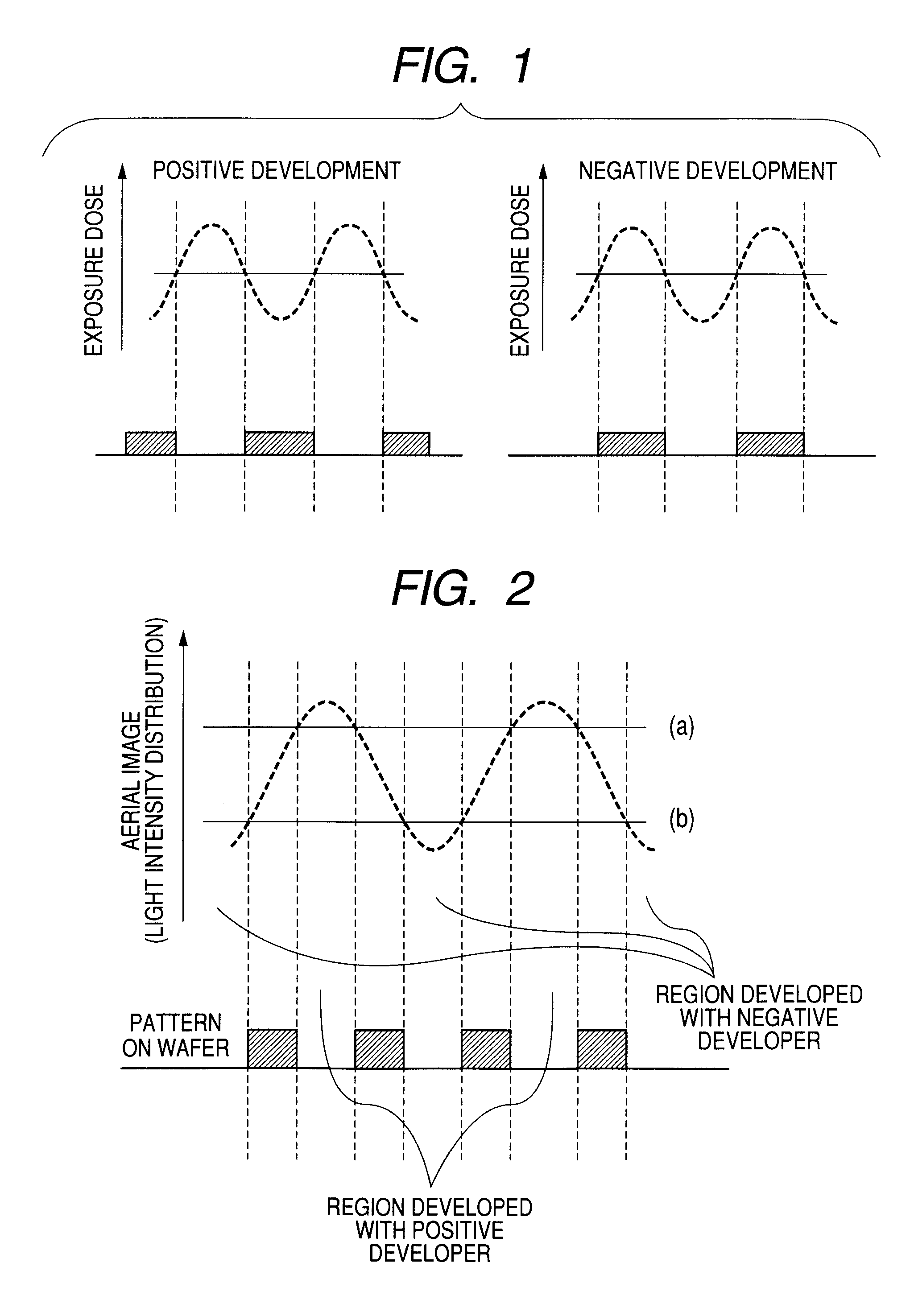

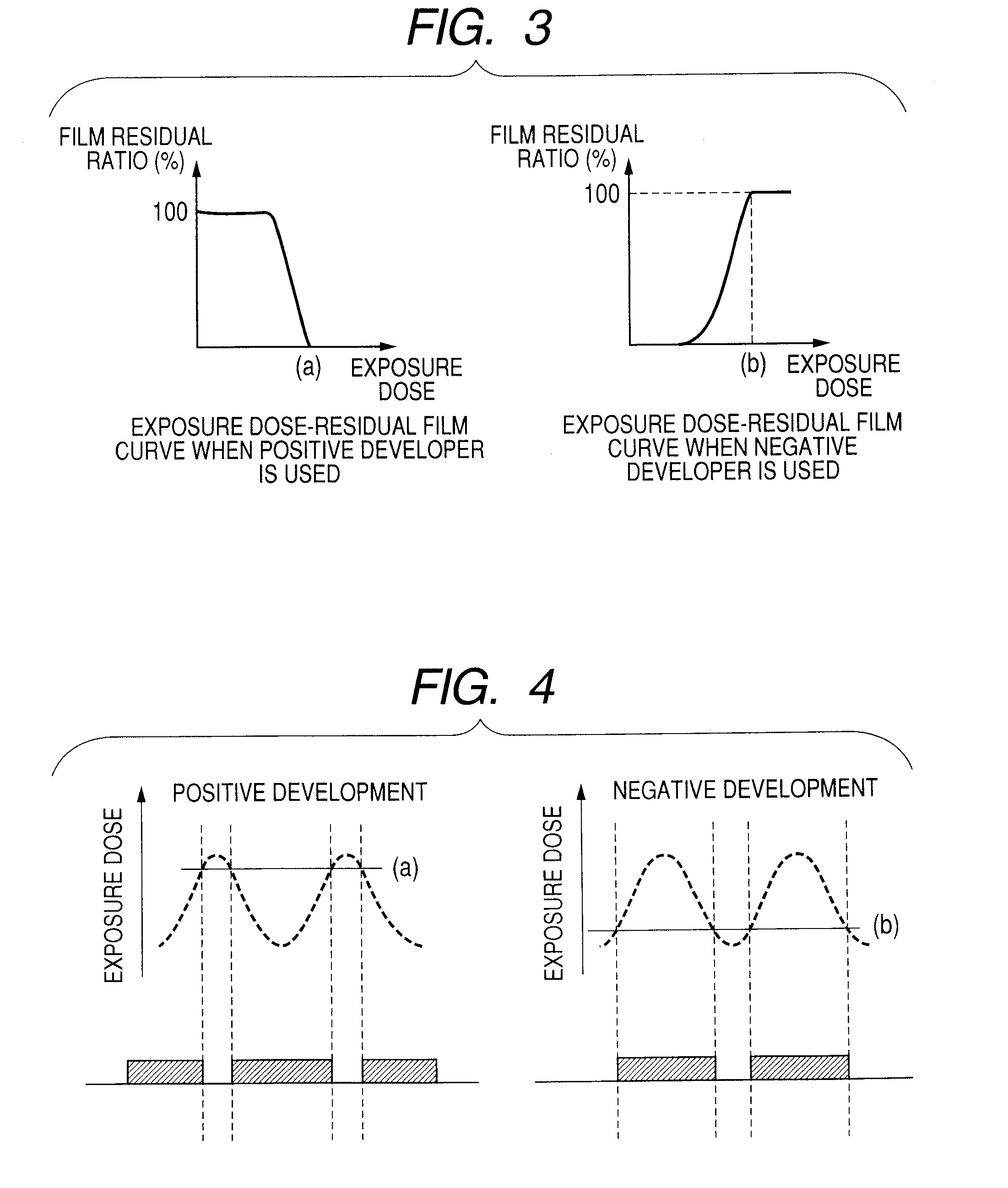

Pattern forming method, resist composition for multiple development used in the pattern forming method, developer for negative development used in the pattern forming method, and rinsing solution for negative development used in the pattern forming method

ActiveUS20080187860A1Improve accuracyMolding stabilityPhotosensitive materialsLayered productsActinic RaysPhotochemistry

A pattern forming method, including: (A) coating a substrate with a positive resist composition of which solubility in a positive developer increases and solubility in a negative developer decreases upon irradiation with actinic rays or radiation, so as to form a resist film; (B) exposing the resist film; and (D) developing the resist film with a negative developer; a positive resist composition for multiple development used in the method; a developer for use in the method; and a rinsing solution for negative development used in the method.

Owner:FUJIFILM CORP

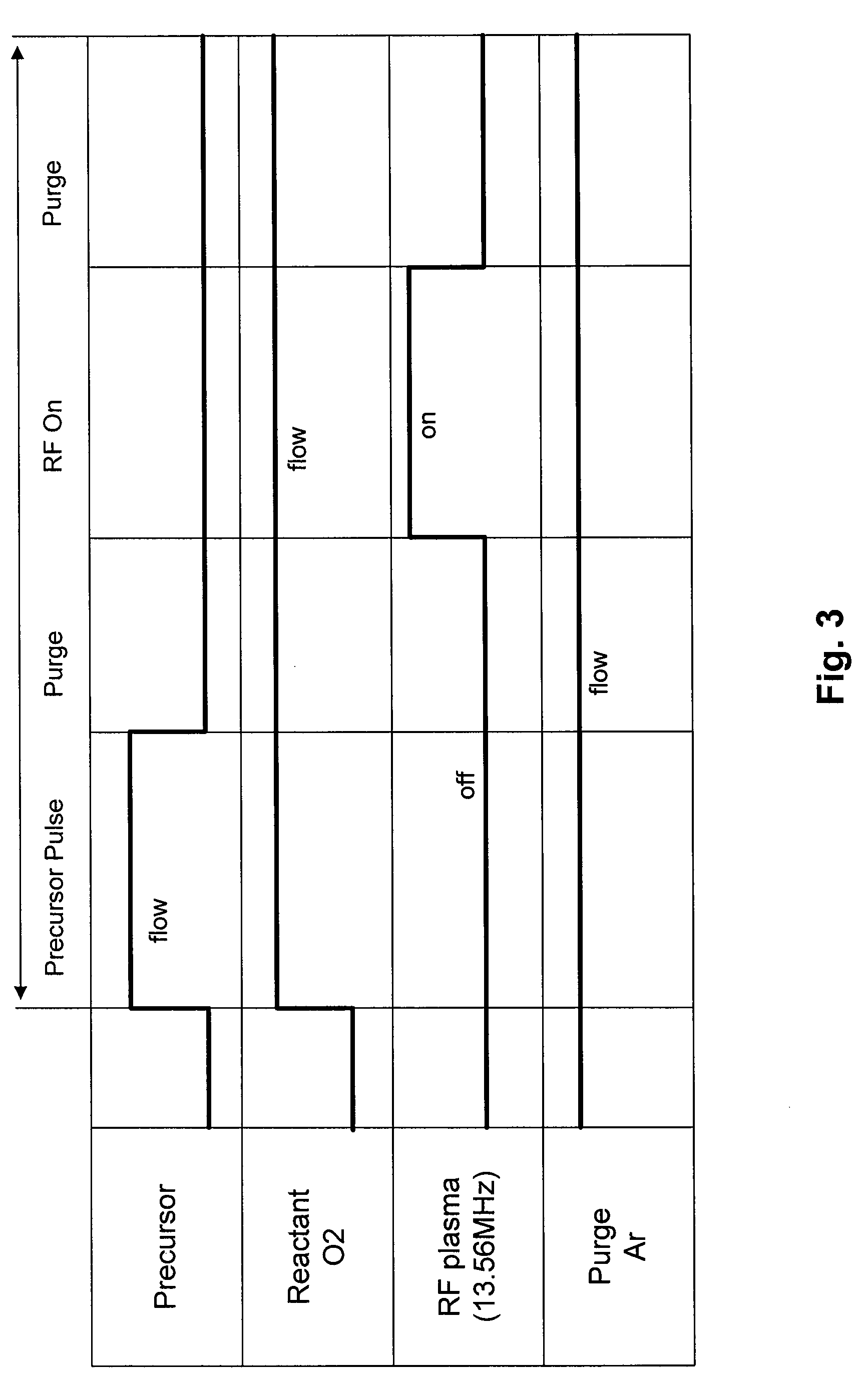

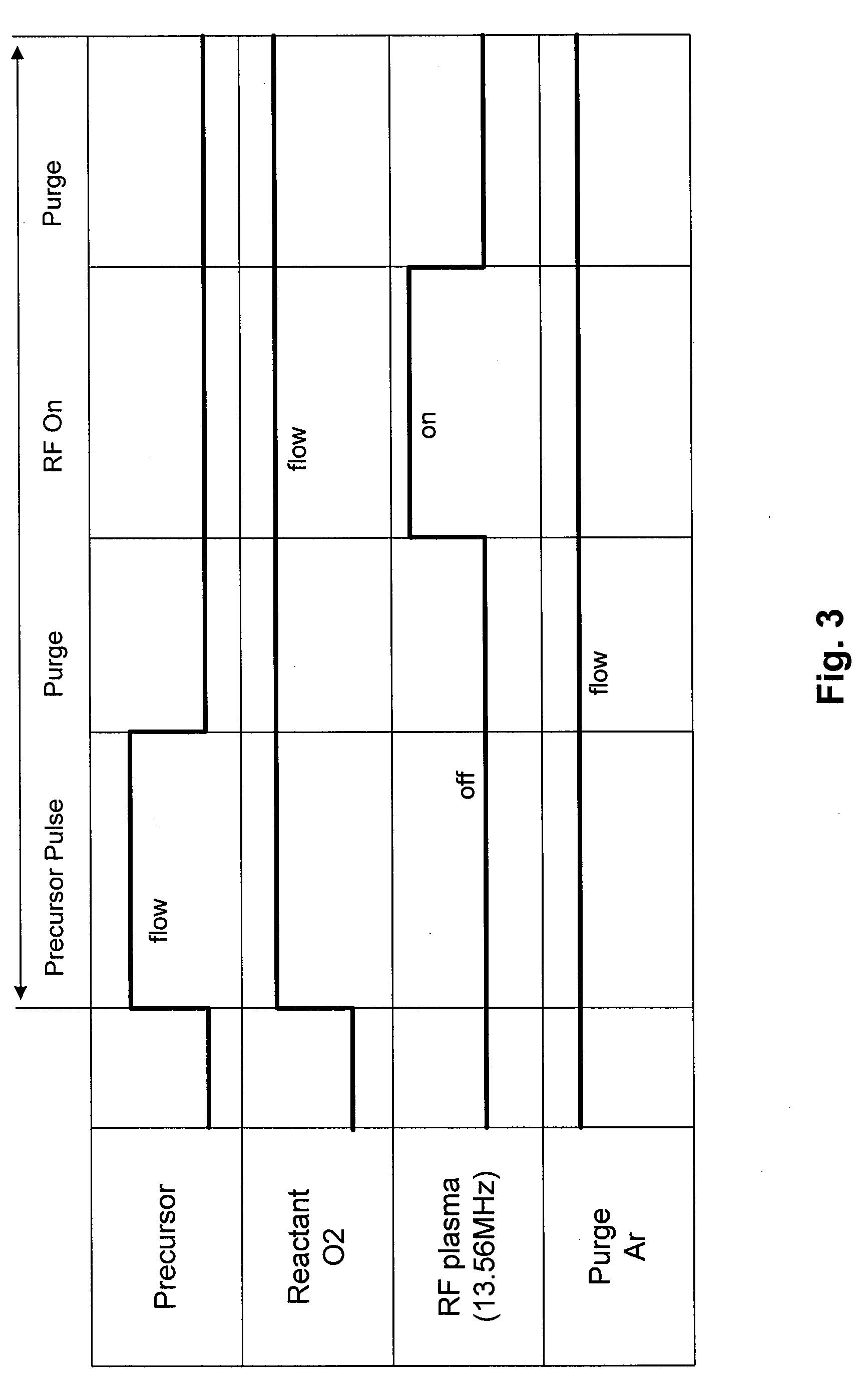

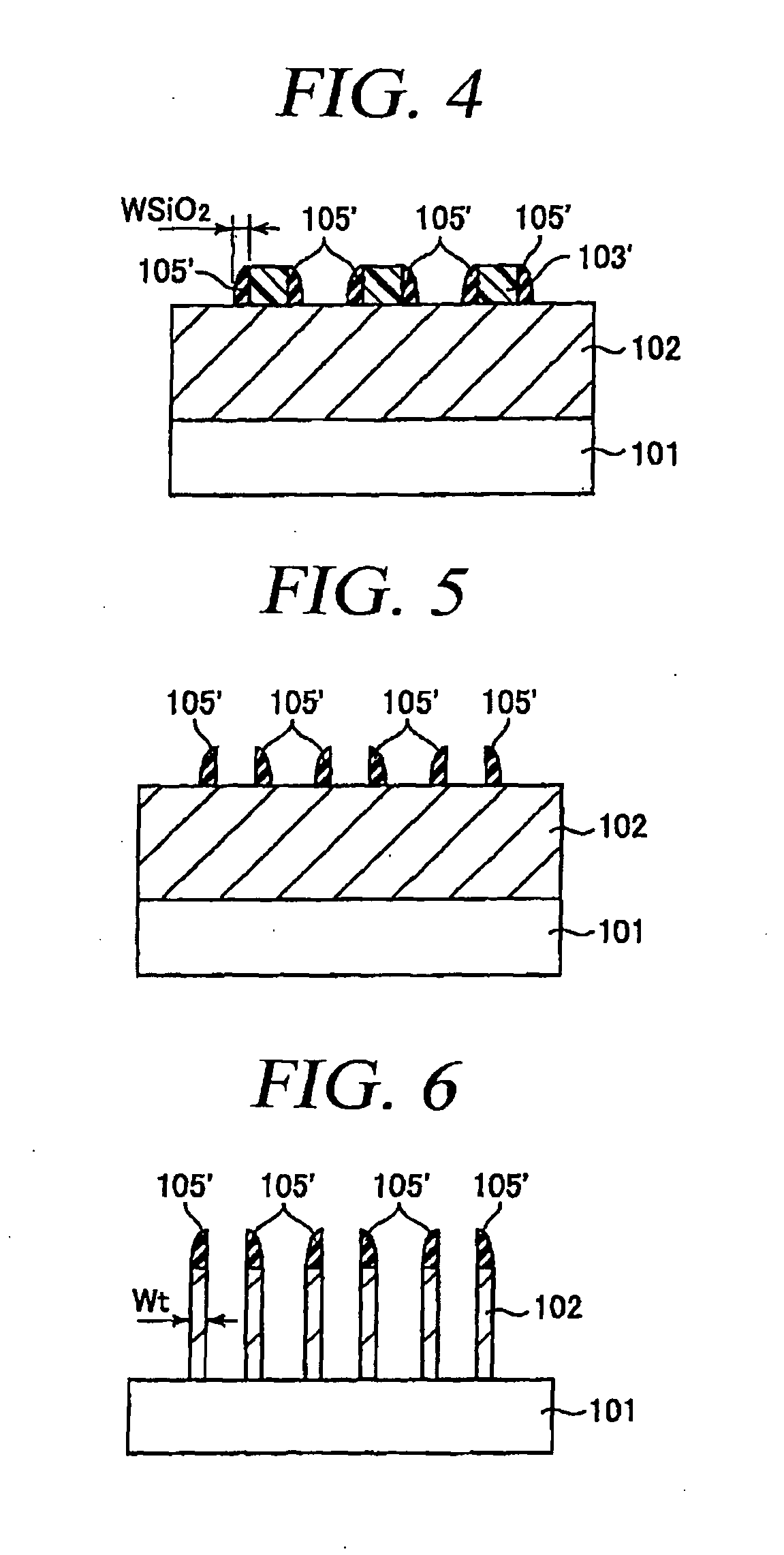

Method of Depositing Silicon Oxide Film by Plasma Enhanced Atomic Layer Deposition at Low Temperature

ActiveUS20100255218A1Increase deposition rateInhibition is effectiveLiquid surface applicatorsSemiconductor/solid-state device manufacturingResistDeposition temperature

A method of depositing a silicon oxide film on a resist pattern or etched lines formed on a substrate by plasma enhanced atomic layer deposition (PEALD) includes: providing a substrate on which a resist pattern or etched lines are formed in a PEALD reactor; controlling a temperature of a susceptor on which the substrate is placed at less than 50° C. as a deposition temperature; introducing a silicon-containing precursor and an oxygen-supplying reactant to the PEALD reactor and applying RF power therein in a cycle, while the deposition temperature is controlled substantially or nearly at a constant temperature of less than 50° C., thereby depositing a silicon oxide atomic layer on the resist pattern or etched lines; and repeating the cycle multiple times substantially or nearly at the constant temperature to deposit a silicon oxide atomic film on the resist pattern or etched lines.

Owner:ASM JAPAN

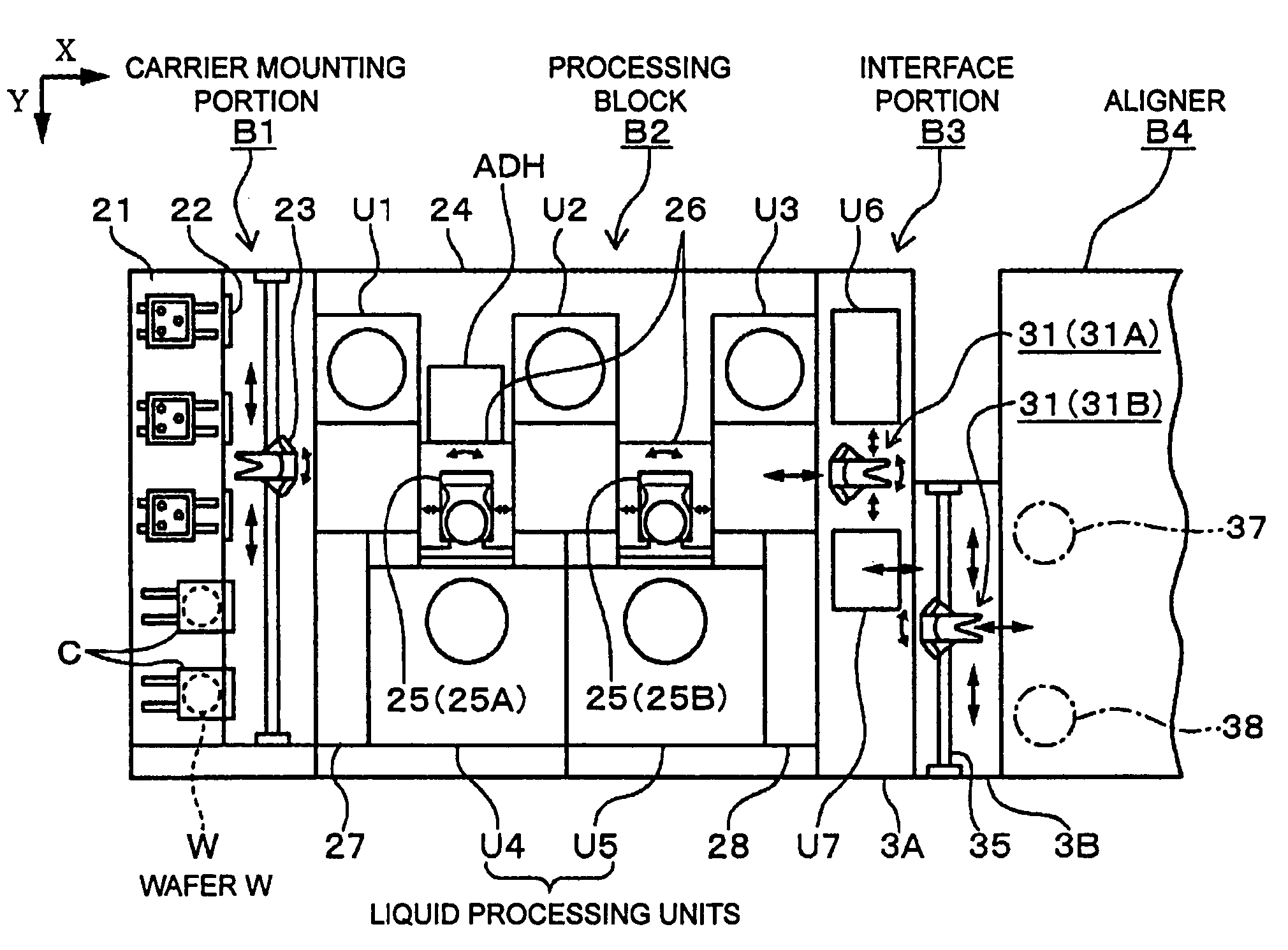

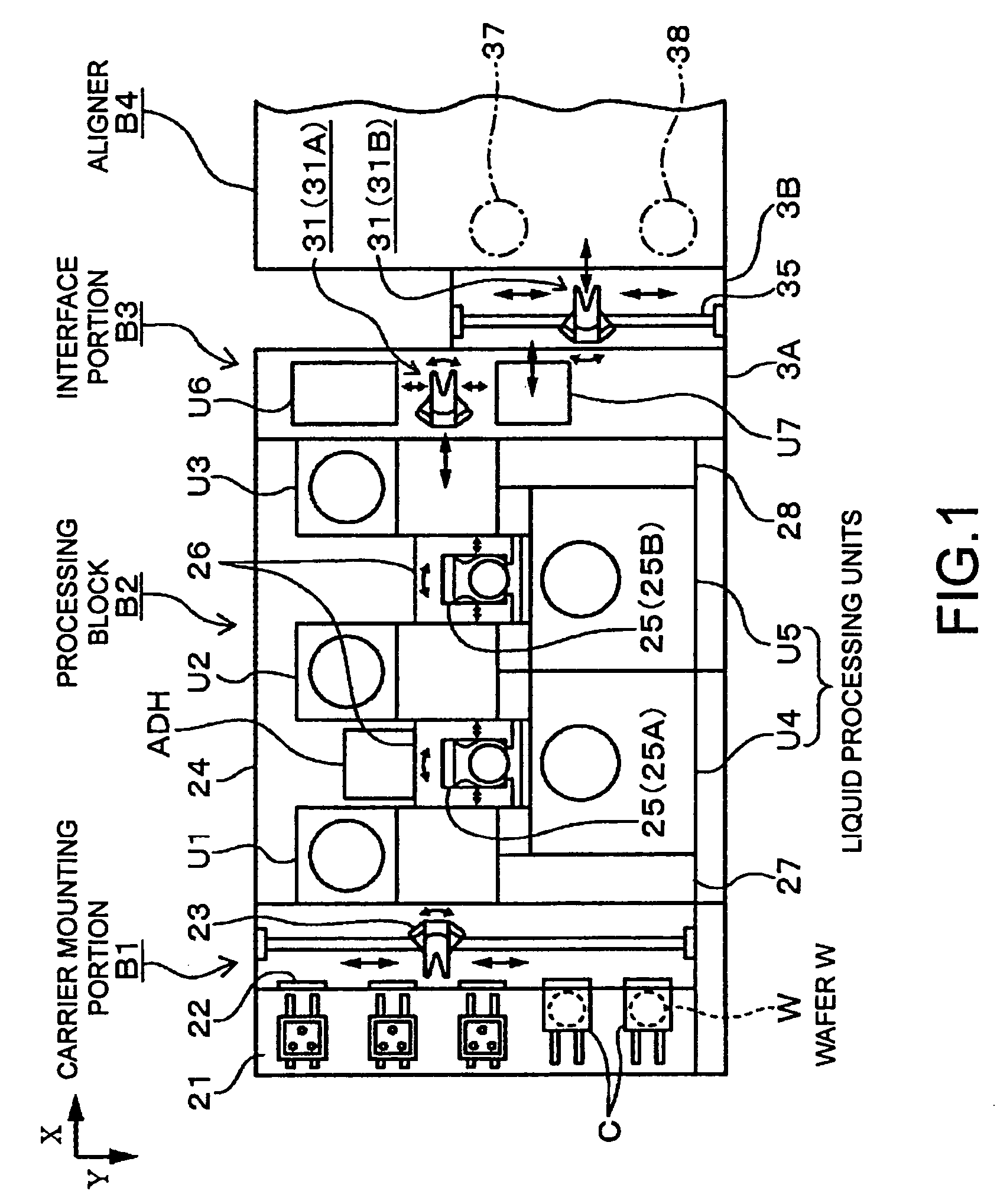

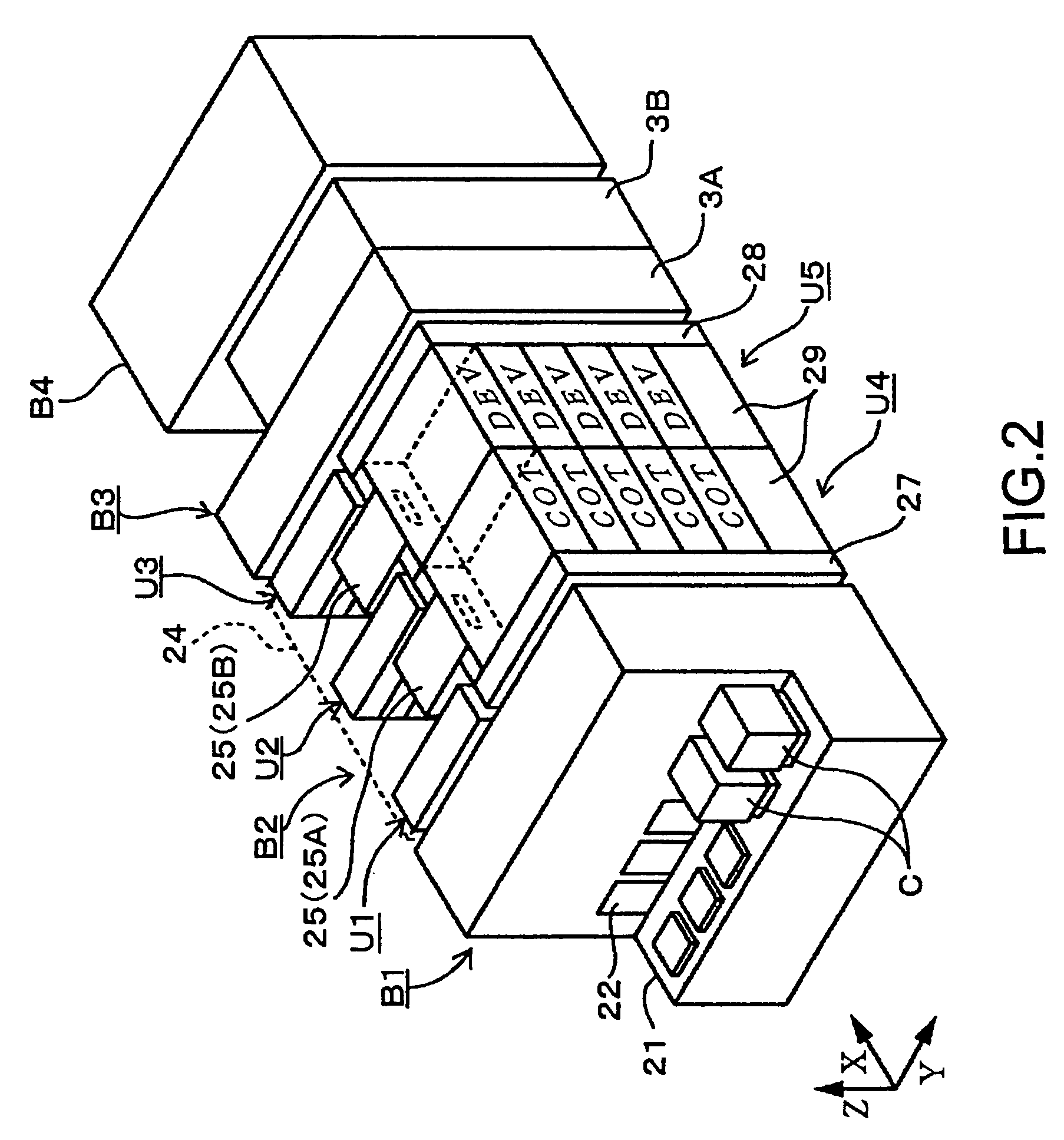

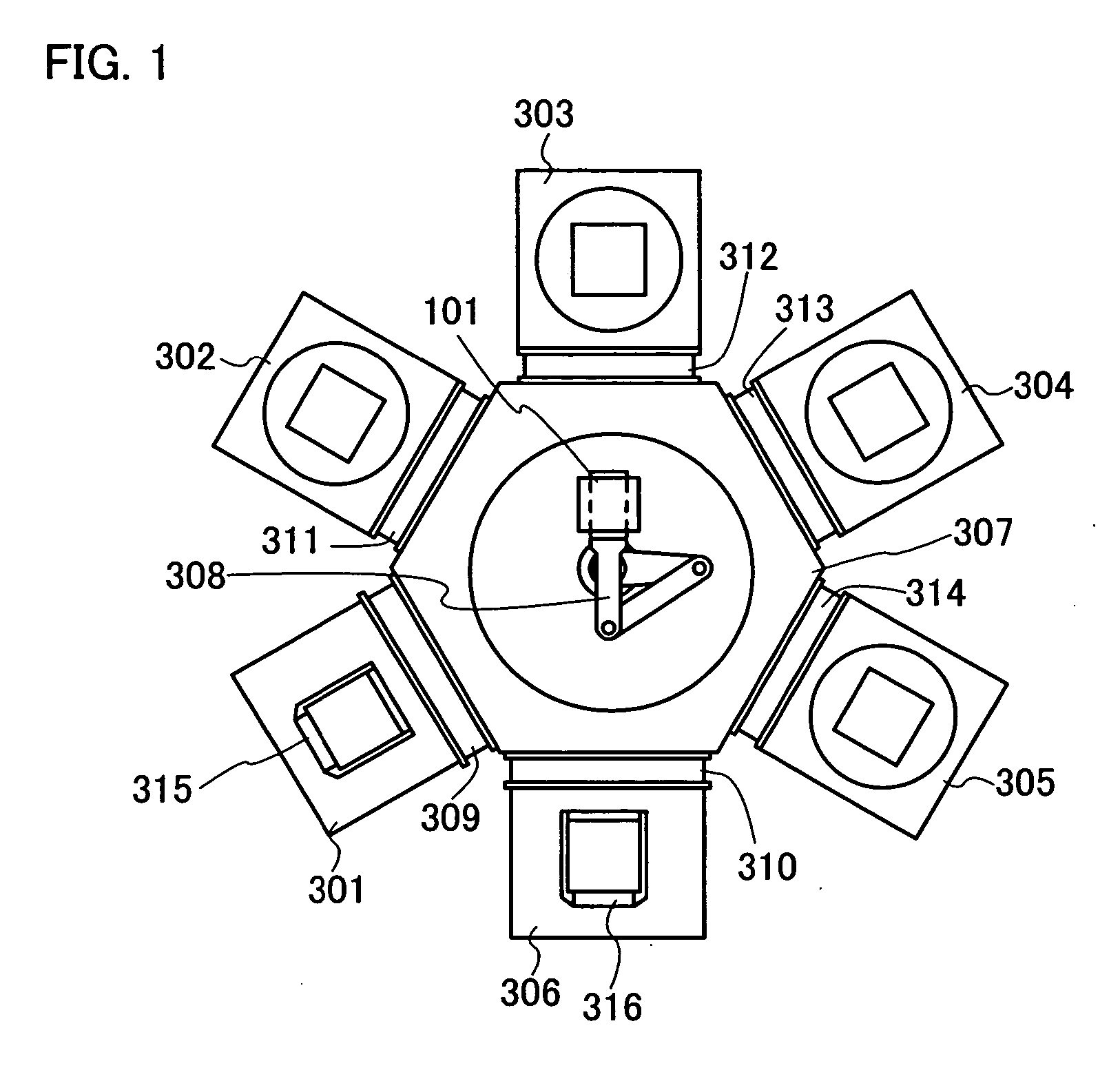

Substrate processing system, coating/developing apparatus, and substrate processing apparatus

InactiveUS7379785B2Substrates can be prevented from beingQuick uninstallSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusResistComputer module

In a coating and developing apparatus that forms a resist film on substrates such as semiconductor wafers, and develops substrates exposed by an aligner, times after the aligner unloads substrates until heating units (PEB) start heating the substrates are kept uniform. Exposed wafers are prevented from being left stagnant in an interface portion disposed between a region in which resist is coated and developed and the aligner. In the region in which resist is coated and developed, a first transferring means that successively executes transportation cycles to transfer substrates from upstream side modules to downstream side modules in a flow of processes of substrates. N heating units (PEB) are disposed (n is for example 5). Exposed wafers loaded into the heating units (PEB) are unloaded by the first transferring means after (n−1) cycles including the transferring cycle of the first transferring means have elapsed.

Owner:TOKYO ELECTRON LTD

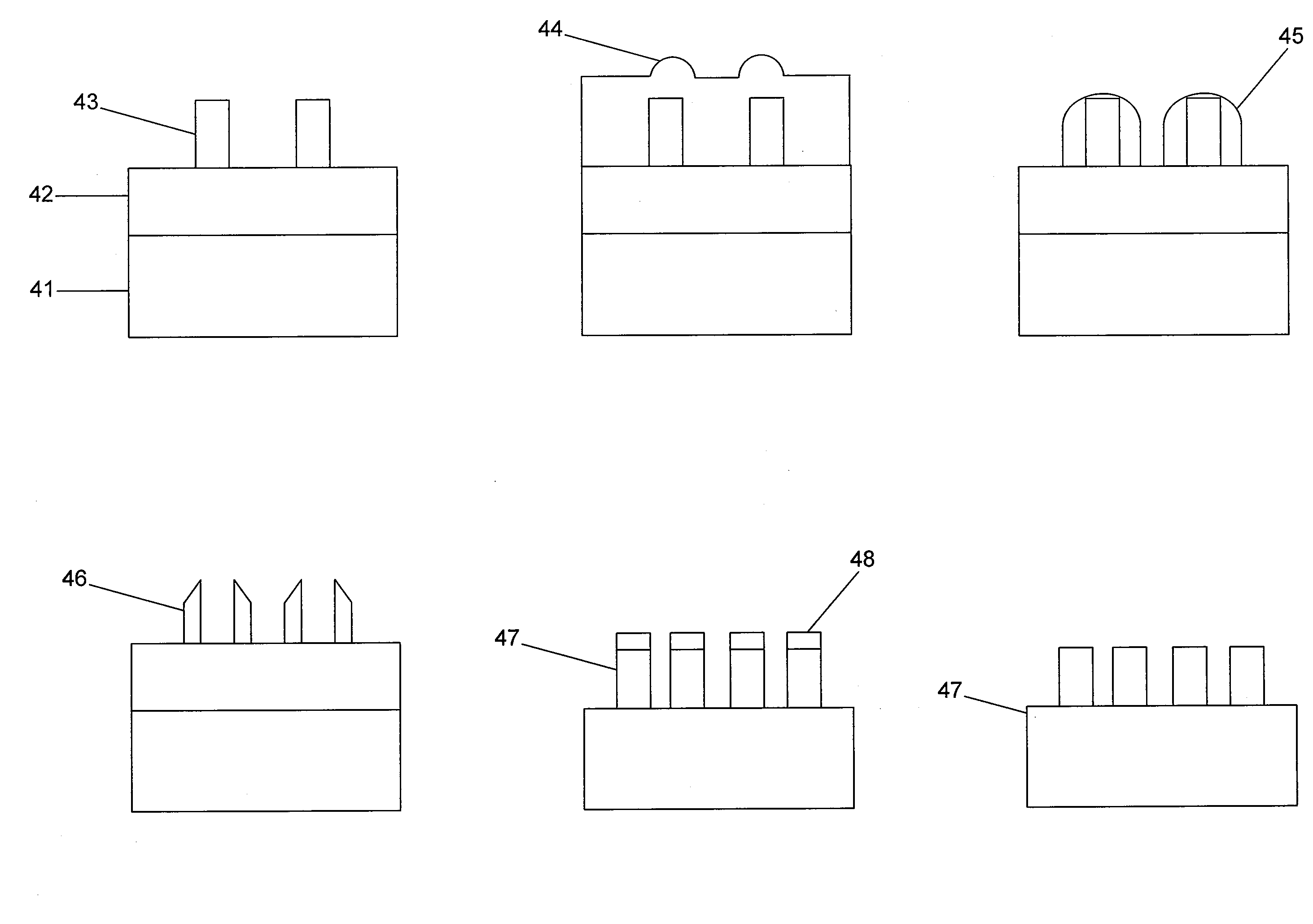

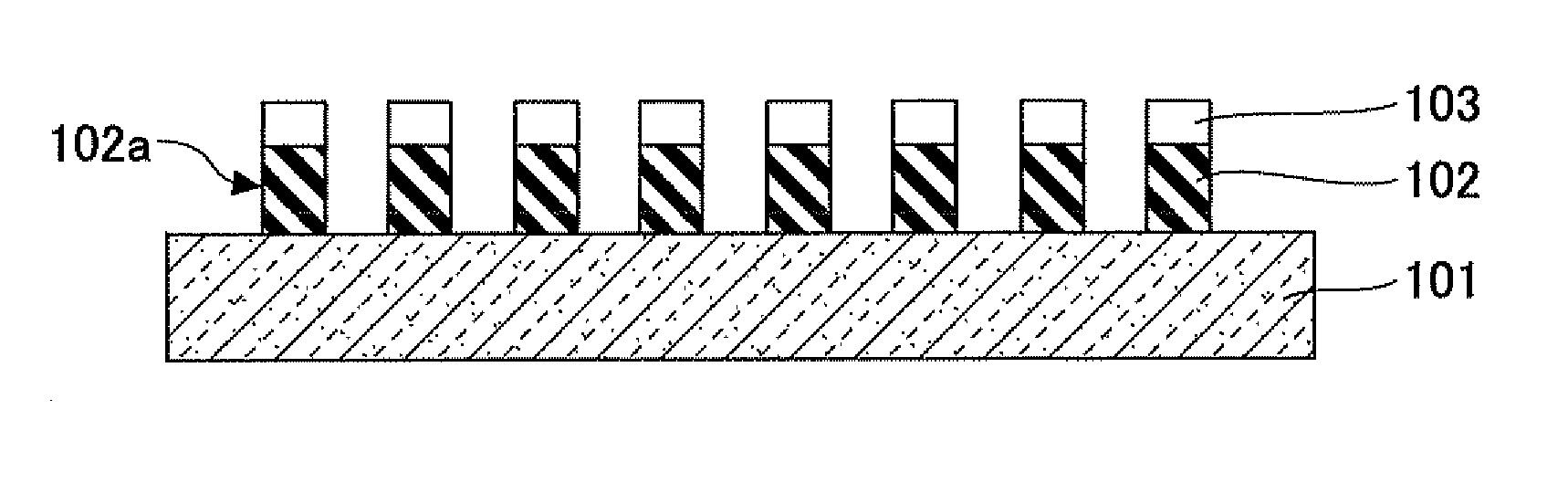

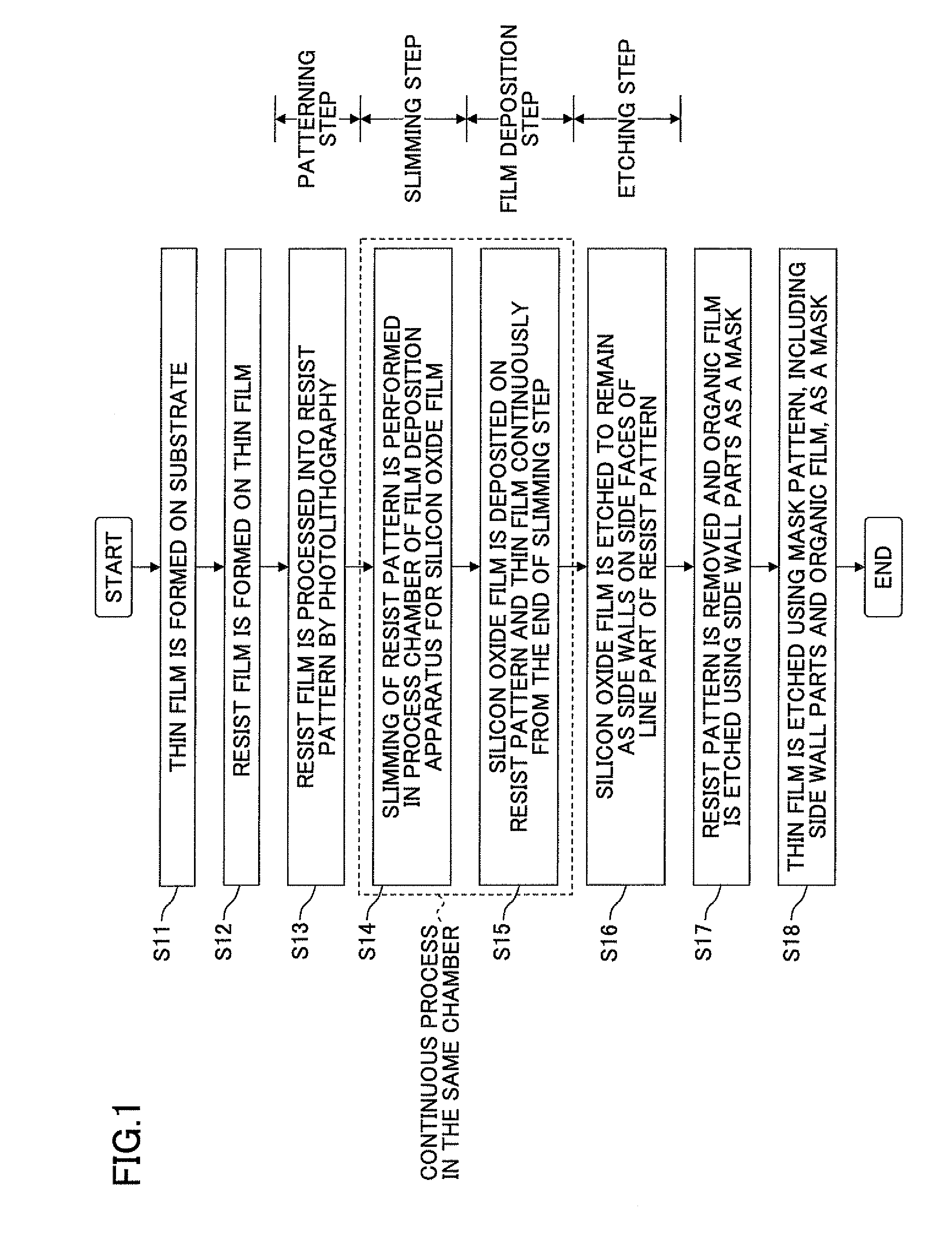

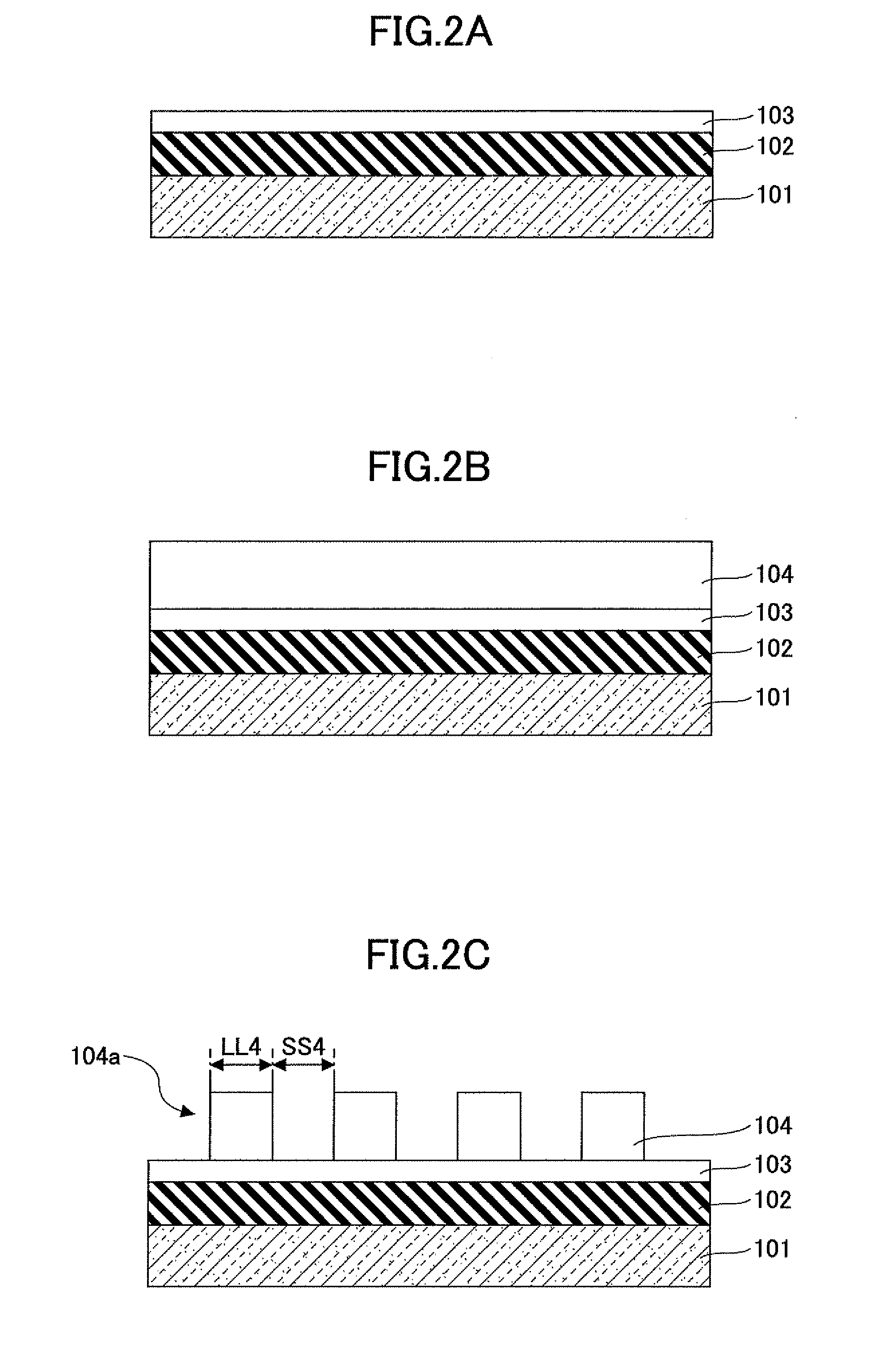

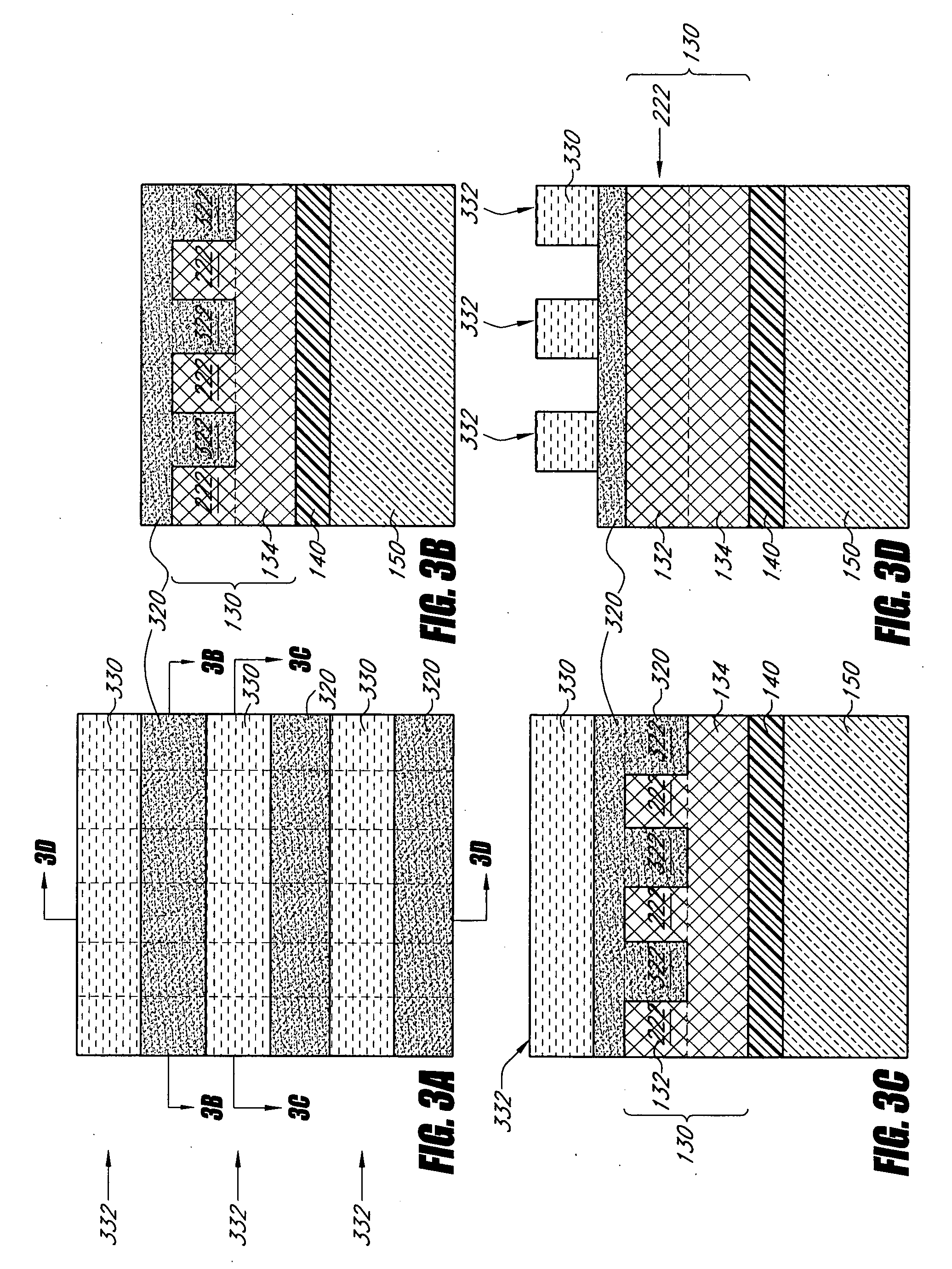

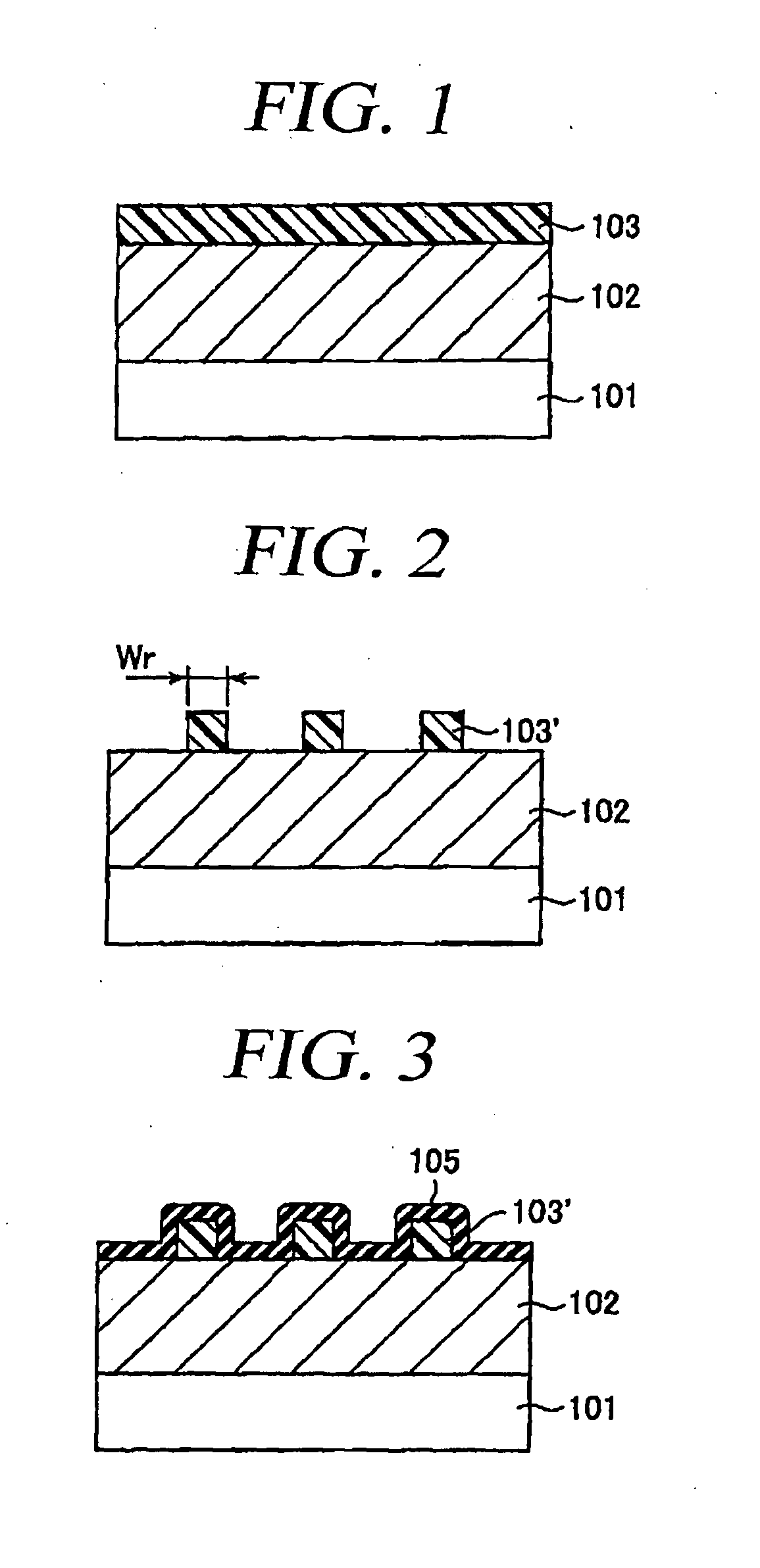

Mask pattern forming method, fine pattern forming method, and film deposition apparatus

ActiveUS20100081094A1Low costOptimizationElectric discharge tubesSemiconductor/solid-state device manufacturingResistEngineering

In a mask pattern forming method, a resist film is formed over a thin film, the resist film is processed into resist patterns having a predetermined pitch by photolithography, slimming of the resist patterns is performed, and an oxide film is formed on the thin film and the resist patterns after an end of the slimming step in a film deposition apparatus by supplying a source gas and an oxygen radical or an oxygen-containing gas. In the mask pattern forming method, the slimming and the oxide film forming are continuously performed in the film deposition apparatus.

Owner:TOKYO ELECTRON LTD

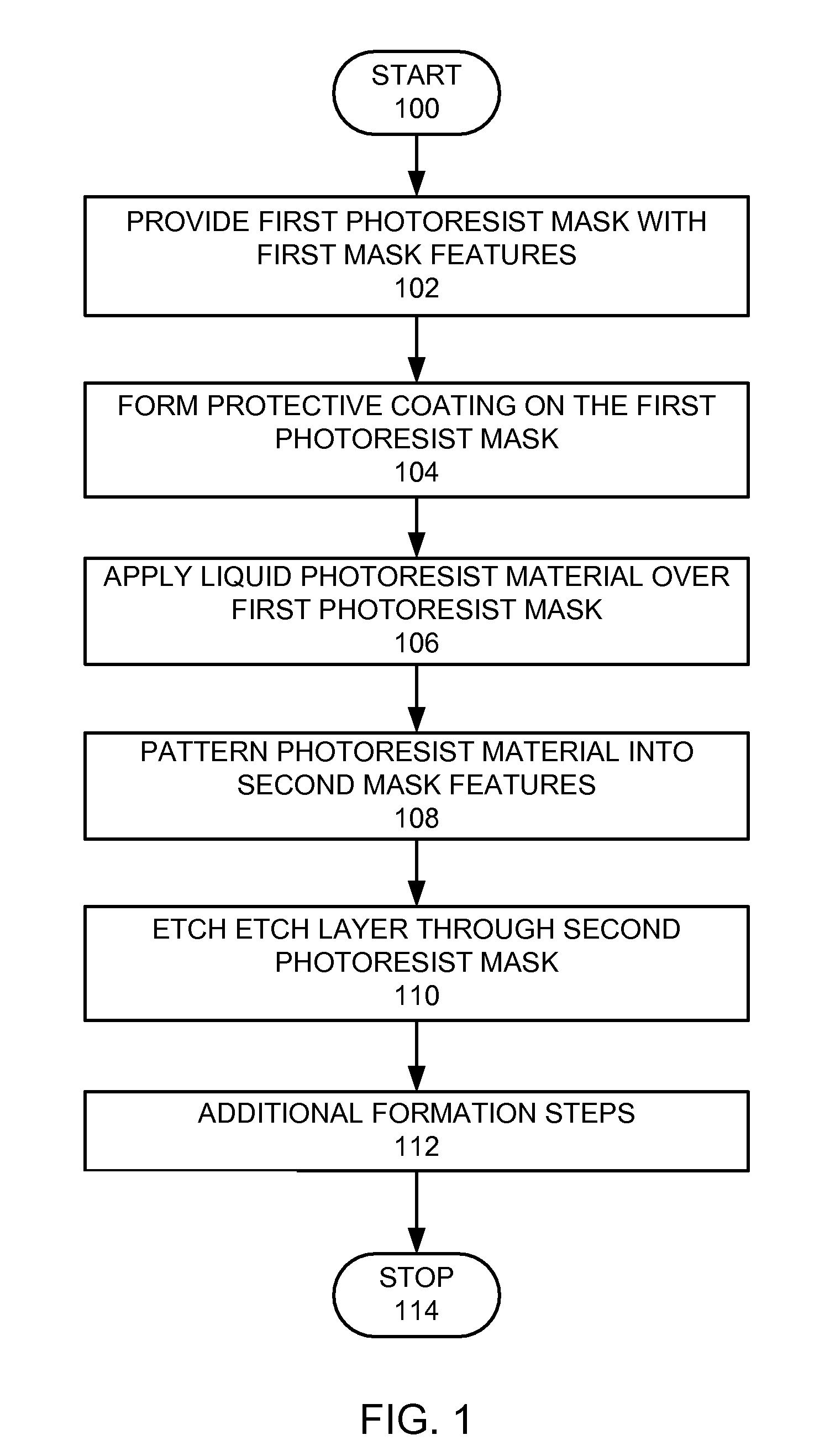

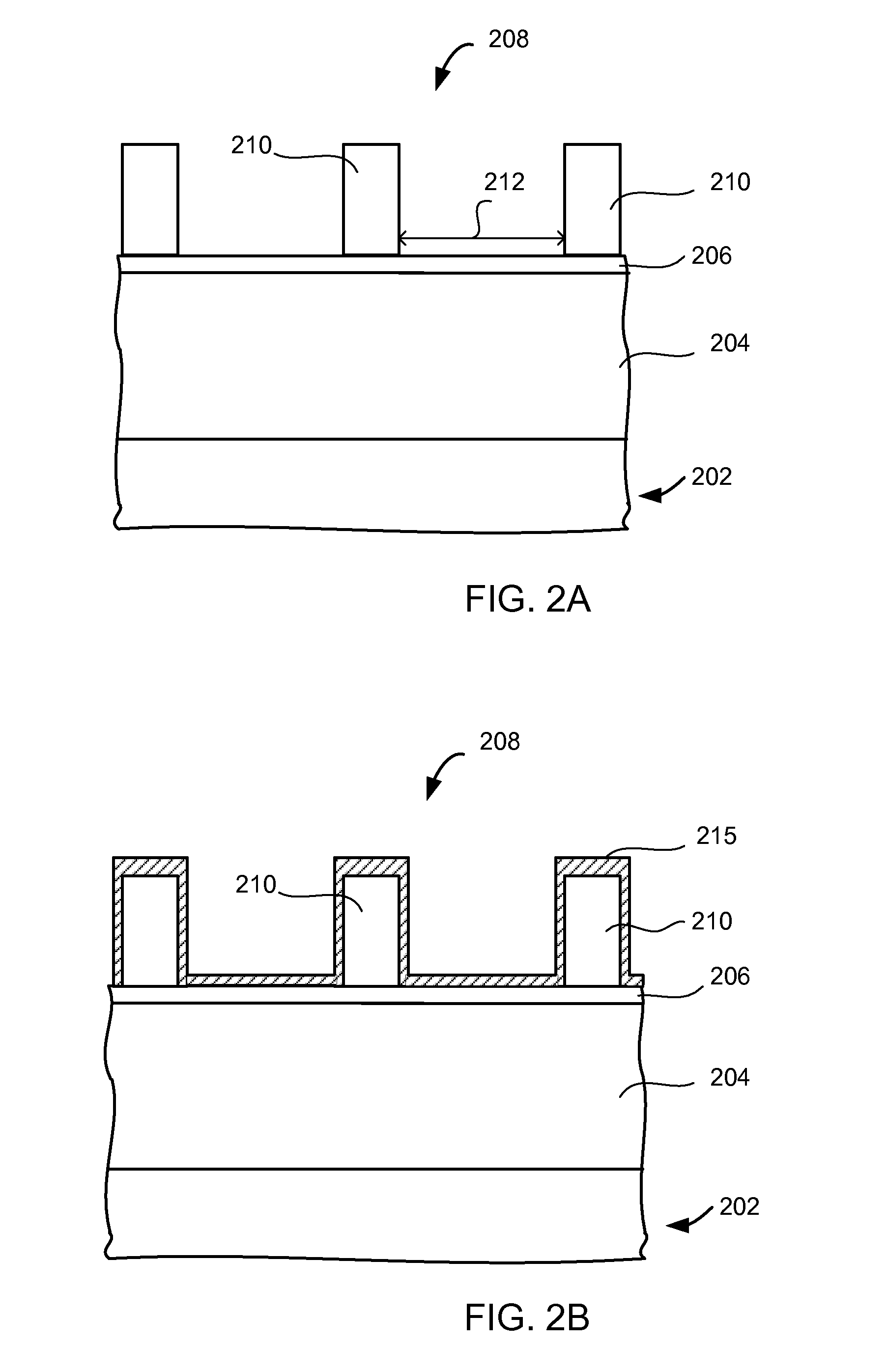

Photoresist double patterning

A method for etching an etch layer formed on a substrate is provided. A first photoresist (PR) mask with first mask features is provided on the etch layer. A protective coating is provided on the first PR mask by a process including at least one cycle. Each cycle includes (a) a deposition phase for depositing a deposition layer over the surface of the first mask features using a deposition gas, and (b) a profile shaping phase for shaping the profile of the deposition layer using a profile shaping gas. A liquid PR material is applied over the first PR mask having the protective coating. The PR material is patterned into a second mask features, where the first and second mask features form a second PR mask. The etch layer is etched though the second PR mask.

Owner:LAM RES CORP

Methods for forming arrays of small, closely spaced features

Methods of forming arrays of small, densely spaced holes or pillars for use in integrated circuits are disclosed. Various pattern transfer and etching steps can be used, in combination with pitch-reduction techniques, to create densely-packed features. Conventional photolithography steps can be used in combination with pitch-reduction techniques to form superimposed patterns of crossing elongate features with pillars at the intersections. Spacers are simultaneously applied to sidewalls of both sets of crossing lines to produce a pitch-doubled grid pattern. The pillars facilitate rows of spacers bridging columns of spacers.

Owner:MICRON TECH INC

Cleaning solution for photoresist and method for forming pattern using the same

ActiveUS7238653B2Use cleanOrganic detergent compounding agentsTransportation and packagingResistAlcohol

Cleaning solutions for photoresist are disclosed which are useful for cleaning a semiconductor substrate in the last step of development when photoresist patterns are formed. Also, methods for forming photoresist patterns using the same are disclosed. The disclosed cleaning solution comprises H2O as a solution, a surfactant which is phosphate-alcoholamine salt represented by Formula 1, and an alcohol compound. The disclosed cleaning solution has lower surface tension than that of distilled water which has been used for conventional cleaning solutions, thereby improving resistance to photoresist pattern collapse and stabilizing the photoresist pattern formation.wherein R, x, y, z, a and b are as defined in the specification.

Owner:SK HYNIX INC

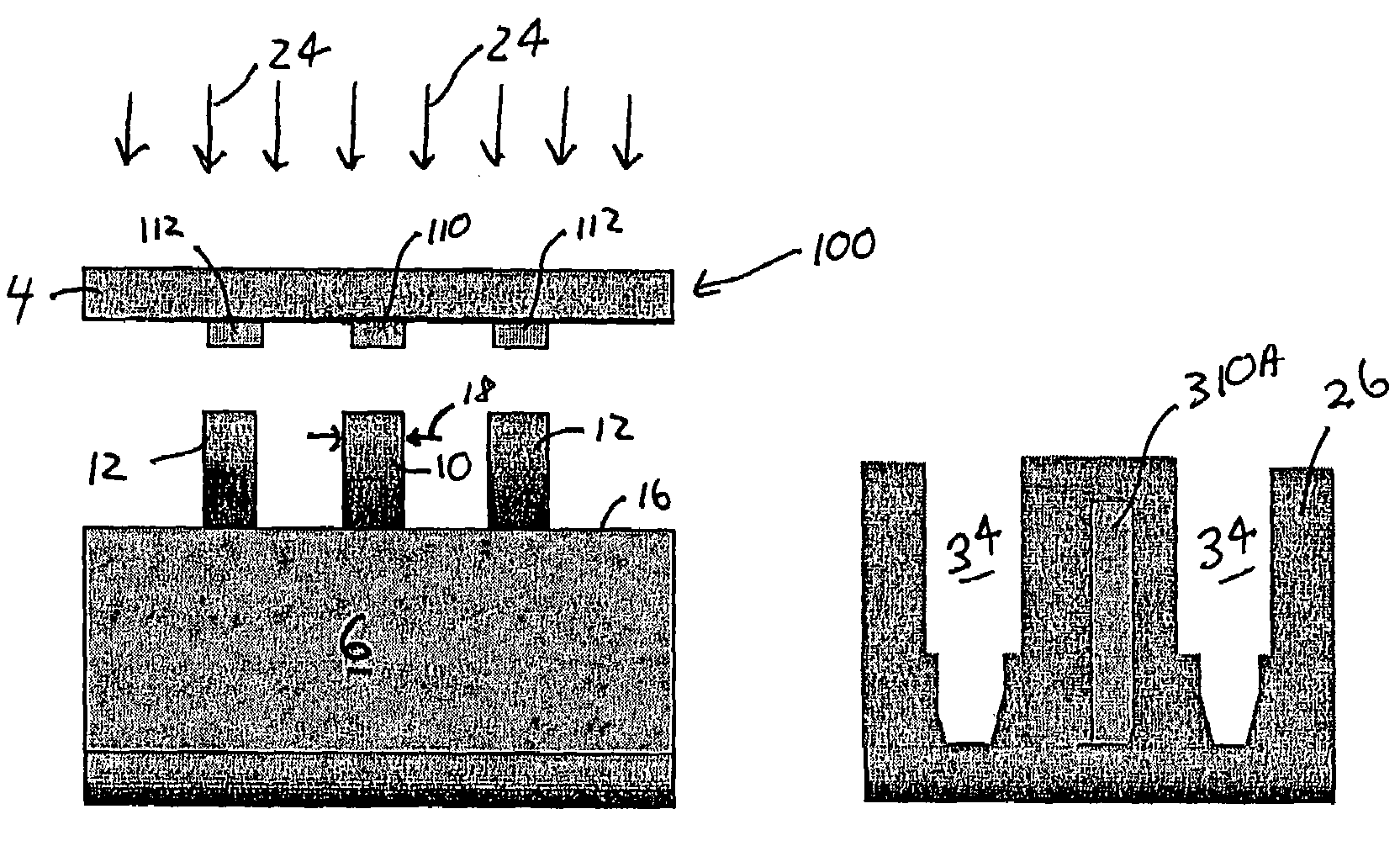

Photoresist polymer and photoresist composition containing the same

InactiveUS7361447B2Semiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersResistPolymer science

Photoresist polymers and photoresist compositions containing the same. Photoresist patterns of less than 50 nm are achieved with EUV (Extreme Ultraviolet) as an exposure light source with photoresist compositions comprising (i) a photoresist polymer comprising a polymerization repeating unit of Formula 2 or (ii) a photoresist polymer comprising a polymerization repeating unit of Formula 3 with polyvinylphenol. As a result, excellent etching resistance can be secured although the photoresist patterns have a very small thickness.wherein R1, R2, R3, R4, R5, R6, R7, R8, R9, R10, R11, R12, a, b, c, d, e, f and g are as defined in the specification.

Owner:SK HYNIX INC

Methods and devices for fabricating three-dimensional nanoscale structures

ActiveUS7704684B2Convenient ArrangementEfficiently patternMaterial nanotechnologyNanostructure manufactureEngineeringElectromagnetic radiation

The present invention provides methods and devices for fabricating 3D structures and patterns of 3D structures on substrate surfaces, including symmetrical and asymmetrical patterns of 3D structures. Methods of the present invention provide a means of fabricating 3D structures having accurately selected physical dimensions, including lateral and vertical dimensions ranging from 10s of nanometers to 1000s of nanometers. In one aspect, methods are provided using a mask element comprising a conformable, elastomeric phase mask capable of establishing conformal contact with a radiation sensitive material undergoing photoprocessing. In another aspect, the temporal and / or spatial coherence of electromagnetic radiation using for photoprocessing is selected to fabricate complex structures having nanoscale features that do not extend entirely through the thickness of the structure fabricated.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Photoresist monomers, polymers and photoresist compositions for preventing acid diffusion

Photoresist monomers, polymers thereof, photoresist compositions containing the same for preventing acid generated in the exposed area during the course of a photolithography process from being diffused to the unexposed area. The line edge roughness and slope pattern are improved when an ultrafine photoresist pattern is formed using photoresist copolymer having a multi-oxygen-containing compound as a repeating unit such as an ethyleneoxy moiety represented by Formula 1 with at least one polymerizable carbon-carbon double bond. In addition, the shape of pattern is improved by eliminating top loss and the adhesion of pattern to the substrate is improved. wherein n is an integer ranging from 1 to 5.

Owner:SK HYNIX INC +1

Patterning method

ActiveUS20100112496A1Photosensitive materialsSemiconductor/solid-state device manufacturingResistSilicon oxide

Owner:TOKYO ELECTRON LTD

One component EUV photoresist

In one embodiment, a photoactive compound may be attached to a polymer backbone. This embodiment may be more resistant to the generation of reactive outgassing components and may exhibit better contrast.

Owner:INTEL CORP

Method for forming a photoresist pattern

InactiveUS20070163625A1Inhibition formationSurface-active detergent compositionsNon-surface-active detergent compositionsResistPhotoresist

A photoresist cleaning solution and method for forming photoresist patterns using the same. More specifically, disclosed are a photoresist cleaning solution comprising H2o and an ionic surfactant represented by Formula 1, and a method for forming a photoresist pattern using the same. By spraying the cleaning solution of the present invention over photoresist film before and / or after exposing step, pattern formation in an undesired region caused by ghost images can be removed.

Owner:SK HYNIX INC

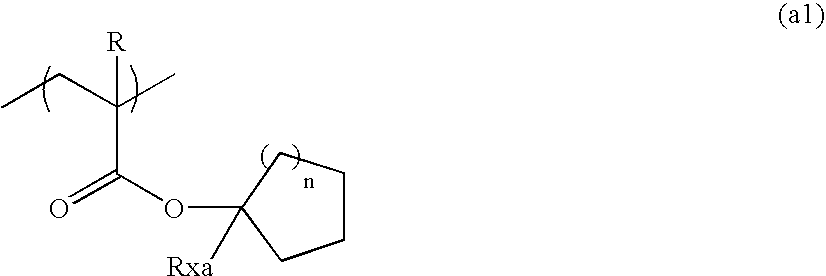

Positive resist composition and pattern-forming method

ActiveUS20080248425A1Suppress generationPhotosensitive materialsRadiation applicationsPolymer scienceActinic Rays

A positive resist composition comprises: (A) a resin that has a repeating unit represented by general formula (a1) and increases its solubility in an alkali developer by action of an acid; (B) a compound which generates an acid upon irradiation with an actinic ray or a radiation; and (C) a resin that has at least one of a fluorine atom and a silicon atom and has a group selected from the group consisting of (x), (y) and (z); and (D) a solvent:(x) an alkali-soluble group;(y) a group capable that decomposes by action of an alkali developer to undergo an increase in a solubility of the resin (C) in an alkali developer; and(z) a group that decomposes by action of an acid,wherein R represents a hydrogen atom or a methyl group, Rxa represents an alkyl group or a cycloalkyl group, and n represents an integer of 1 to 8.

Owner:FUJIFILM CORP

Imageable element with solvent-resistant polymeric binder

InactiveUS20050003285A1Enhances on-press solvent resistanceProlong lifeRadiation applicationsSemiconductor/solid-state device manufacturingSolventPendant group

The present invention provides an imageable element including a lithographic substrate and an imageable layer disposed on the substrate. The imageable layer includes a radically polymerizable component, an initiator system capable of generating radicals sufficient to initiate a polymerization reaction upon exposure to imaging radiation, and a polymeric binder having a hydrophobic backbone and including both constitutional units having a pendant cyano group attached directly to the hydrophobic backbone, and constitutional units having a pendant group including a hydrophilic poly(alkylene oxide) segment. When the imageable element is imaged and developed, the resulting printing plate may exhibit improved on-press solvent resistance and longer press life.

Owner:KODAK POLYCHROME GRAPHICS

Methods for forming arrays of a small, closely spaced features

ActiveUS20060263699A1Solid-state devicesSemiconductor/solid-state device manufacturingCombined useEngineering

Methods of forming arrays of small, densely spaced holes or pillars for use in integrated circuits are disclosed. Various pattern transfer and etching steps can be used, in combination with pitch-reduction techniques, to create densely-packed features. Conventional photolithography steps can be used in combination with pitch-reduction techniques to form sumperimposed, pitch-reduced patterns of crossing elongate features that can be consolidated into a single layer.

Owner:MICRON TECH INC

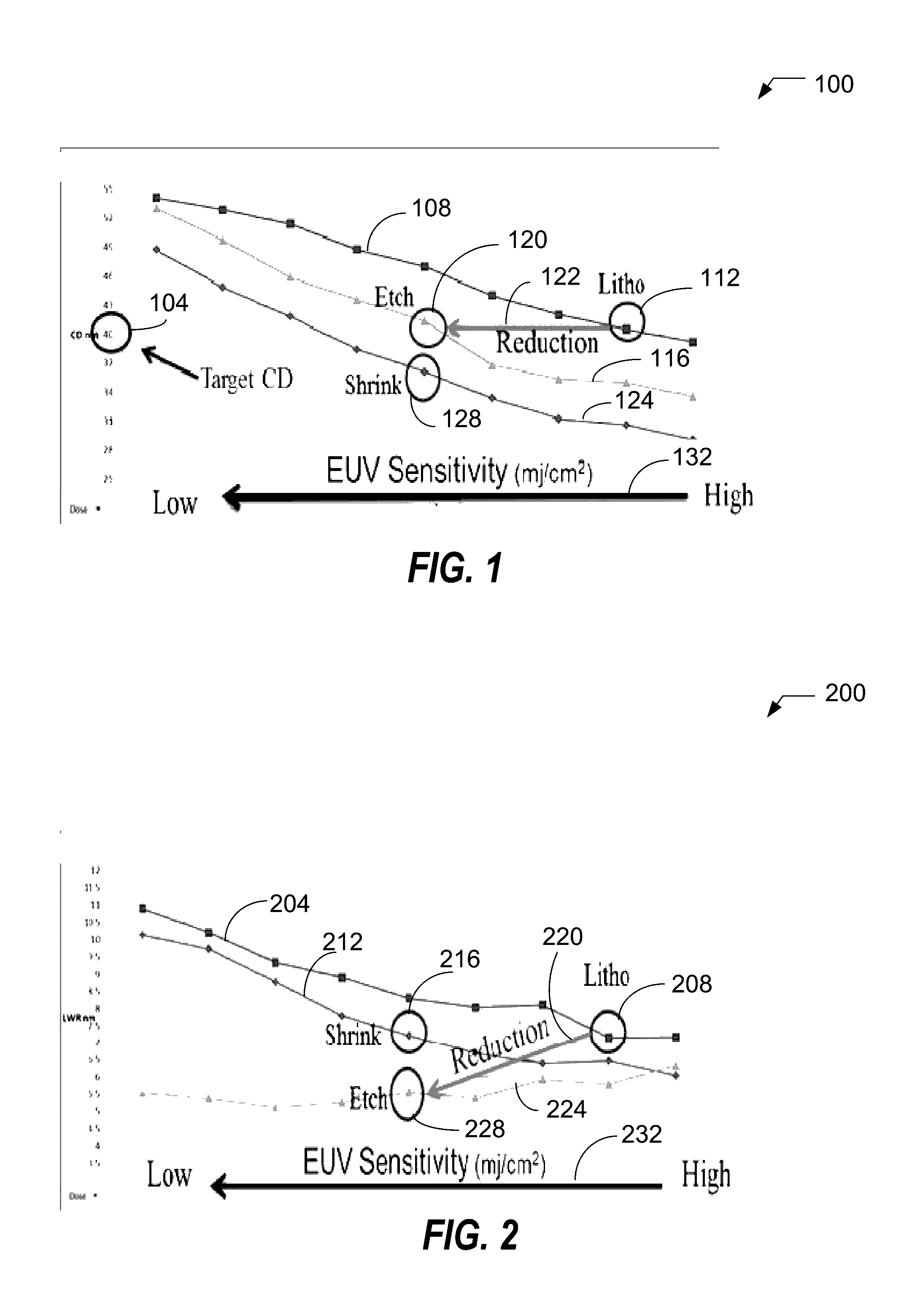

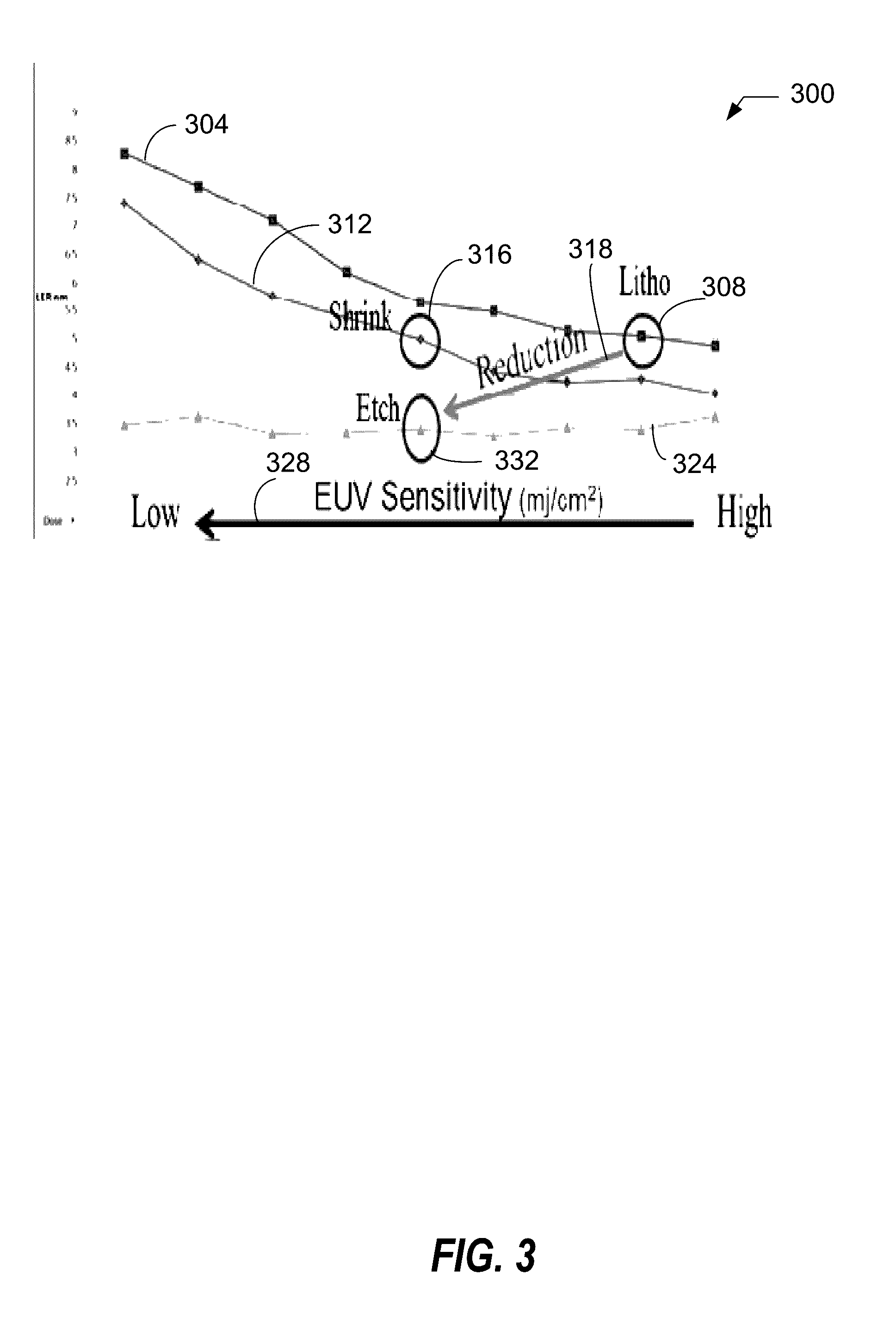

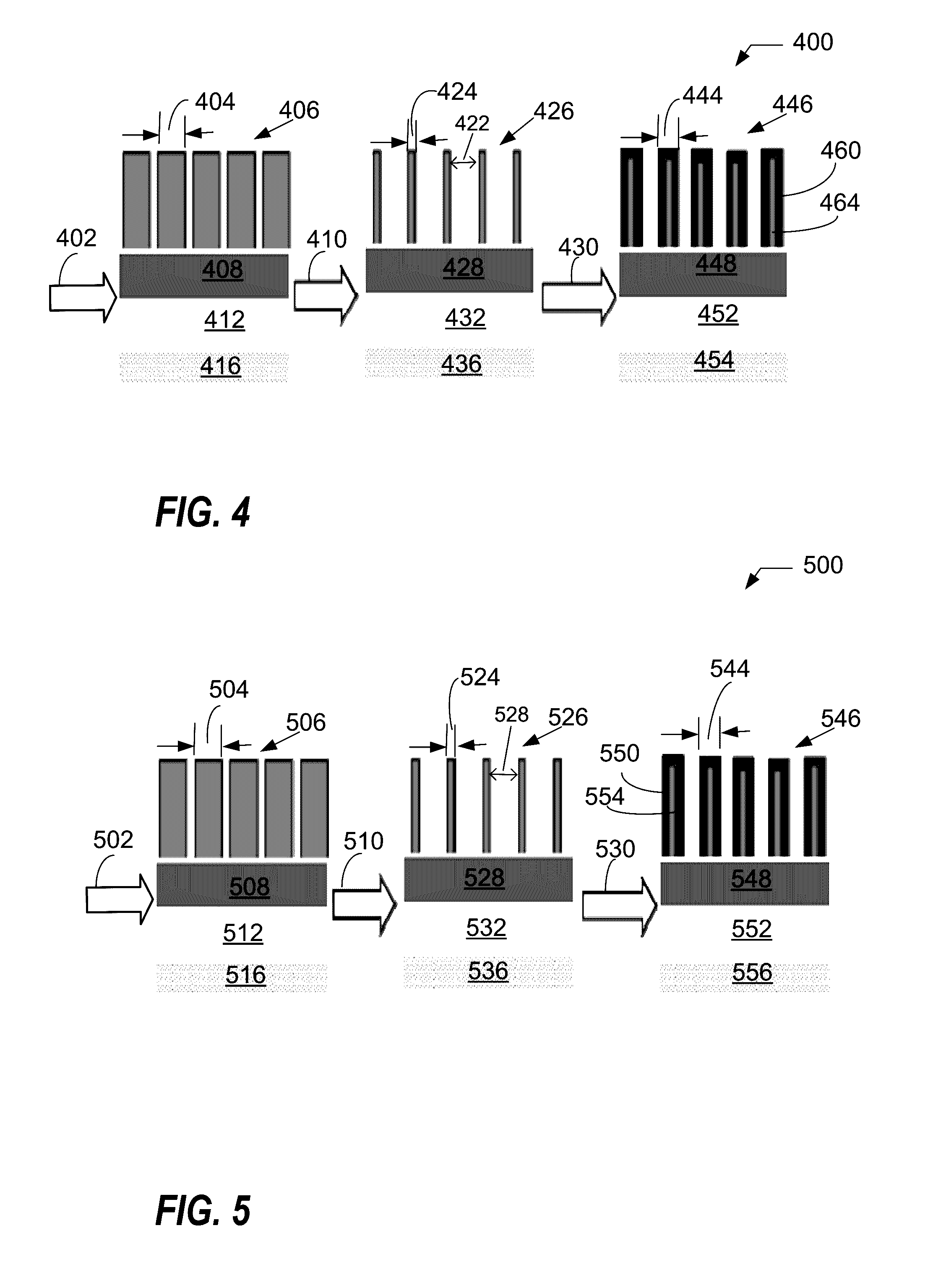

Extreme ultra-violet sensitivity reduction using shrink and growth method

ActiveUS20160334709A1Substrate throughput can be increasedImprove throughputPhotomechanical exposure apparatusPhotosensitive material processingCooking & bakingLine width

Provided is a method for patterning a substrate, comprising: forming a layer of radiation-sensitive material on a substrate; preparing a pattern in the layer of radiation-sensitive material using a lithographic process, the pattern being characterized by a critical dimension (CD) and a roughness; following the preparing the pattern, performing a CD shrink process to reduce the CD to a reduced CD; and performing a growth process to grow the reduced CD to a target CD. Roughness includes a line edge roughness (LER), a line width roughness (LWR), or both LER and LWR. Performing the CD shrink process comprises: coating the pattern with a hard mask, the coating generating a hard mask coated resist; baking the hard mask coated resist in a temperature range for a time period, the baking generating a baked coated resist; and developing the baked coated resist in deionized water.

Owner:TOKYO ELECTRON LTD

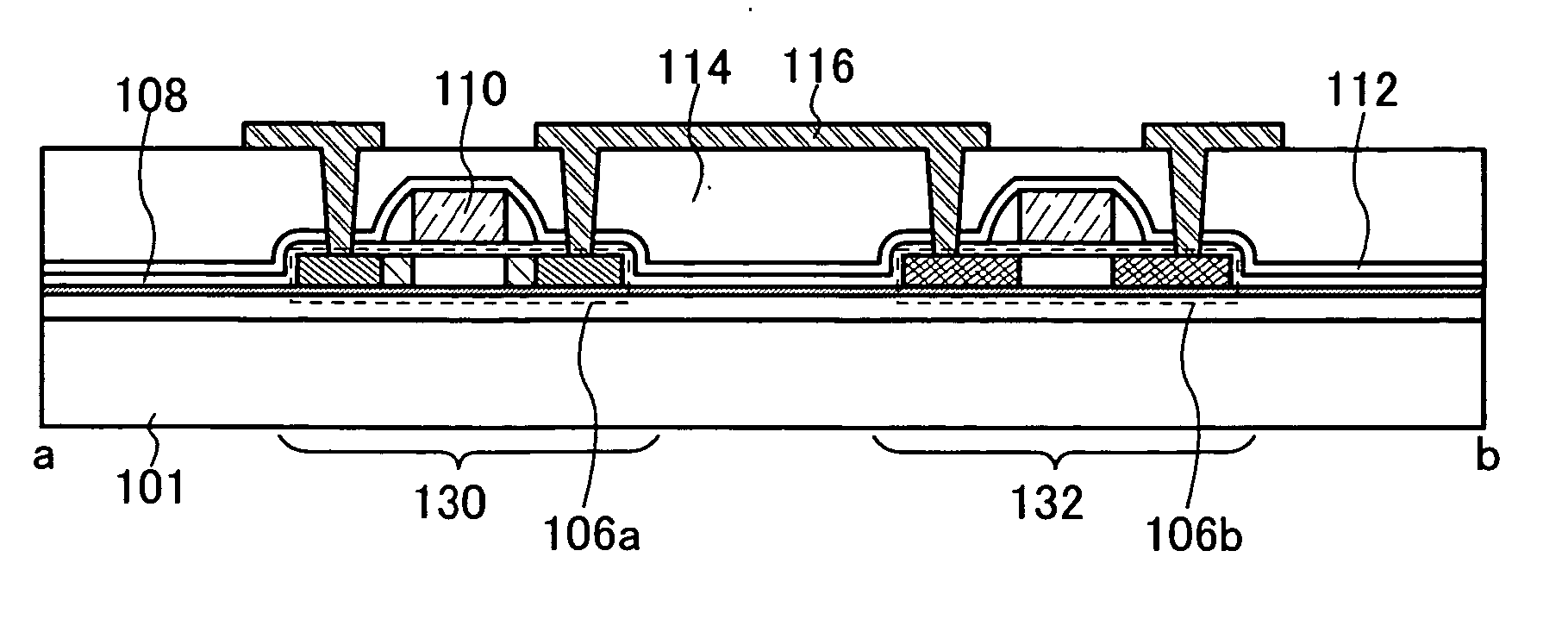

Semiconductor device and manufacturing method thereof

InactiveUS20060275710A1Reduce light intensityImprove routing densitySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialContinuous wave laser beam

To provide a semiconductor device having a circuit with high operating performance and high reliability, and improve the reliability of the semiconductor device, thereby improving the reliability of an electronic device having the same. The aforementioned object is achieved by combining a step of crystallizing a semiconductor layer by irradiation with continuous wave laser beams or pulsed laser beams with a repetition rate of 10 MHz or more, while scanning in one direction; a step of photolithography with the use of a photomask or a leticle including an auxiliary pattern which is formed of a diffraction grating pattern or a semi-transmissive film having a function of reducing the light intensity; and a step of performing oxidation, nitridation, or surface-modification to the surface of the semiconductor film, an insulating film, or a conductive film, with high-density plasma with a low electron temperature.

Owner:SEMICON ENERGY LAB CO LTD

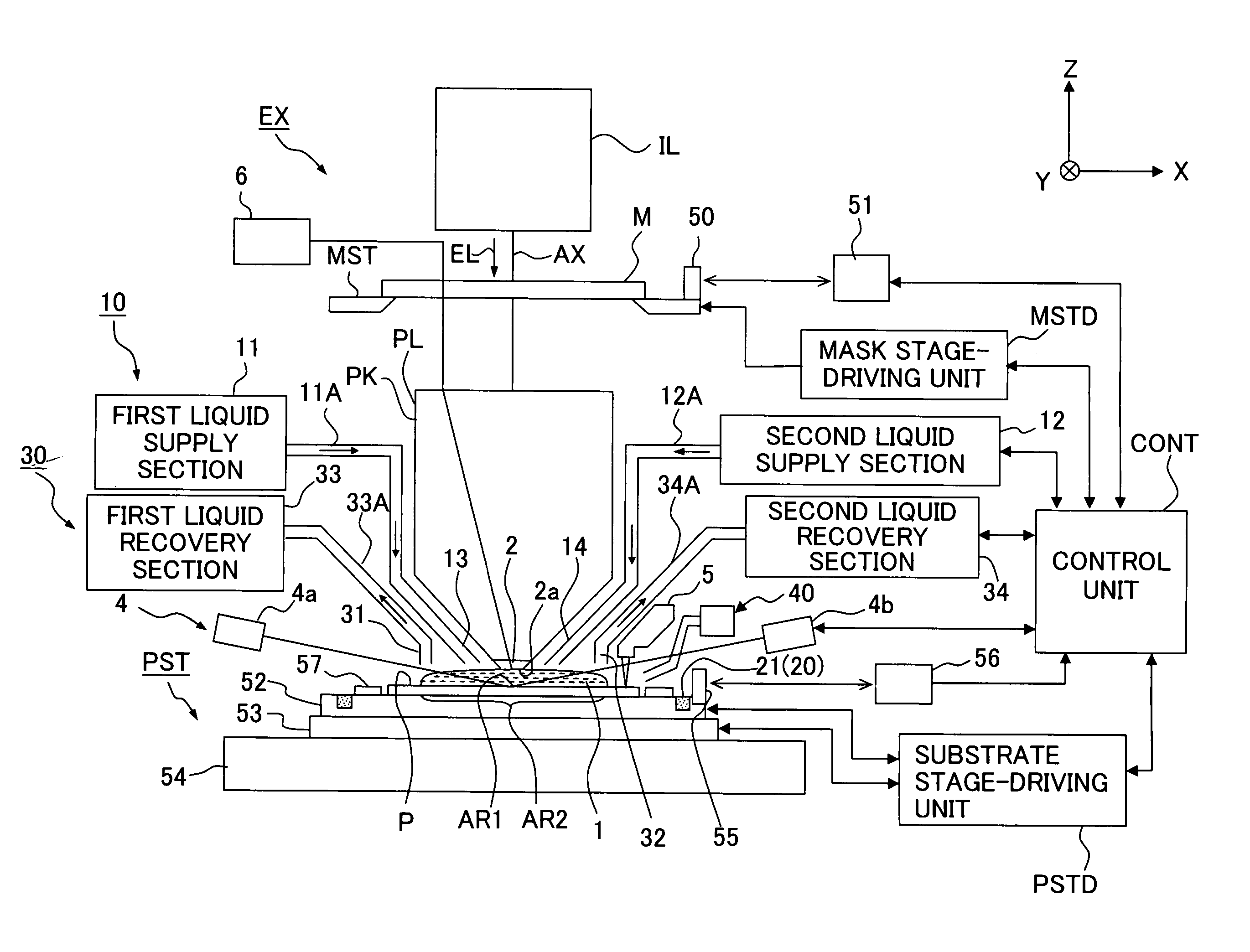

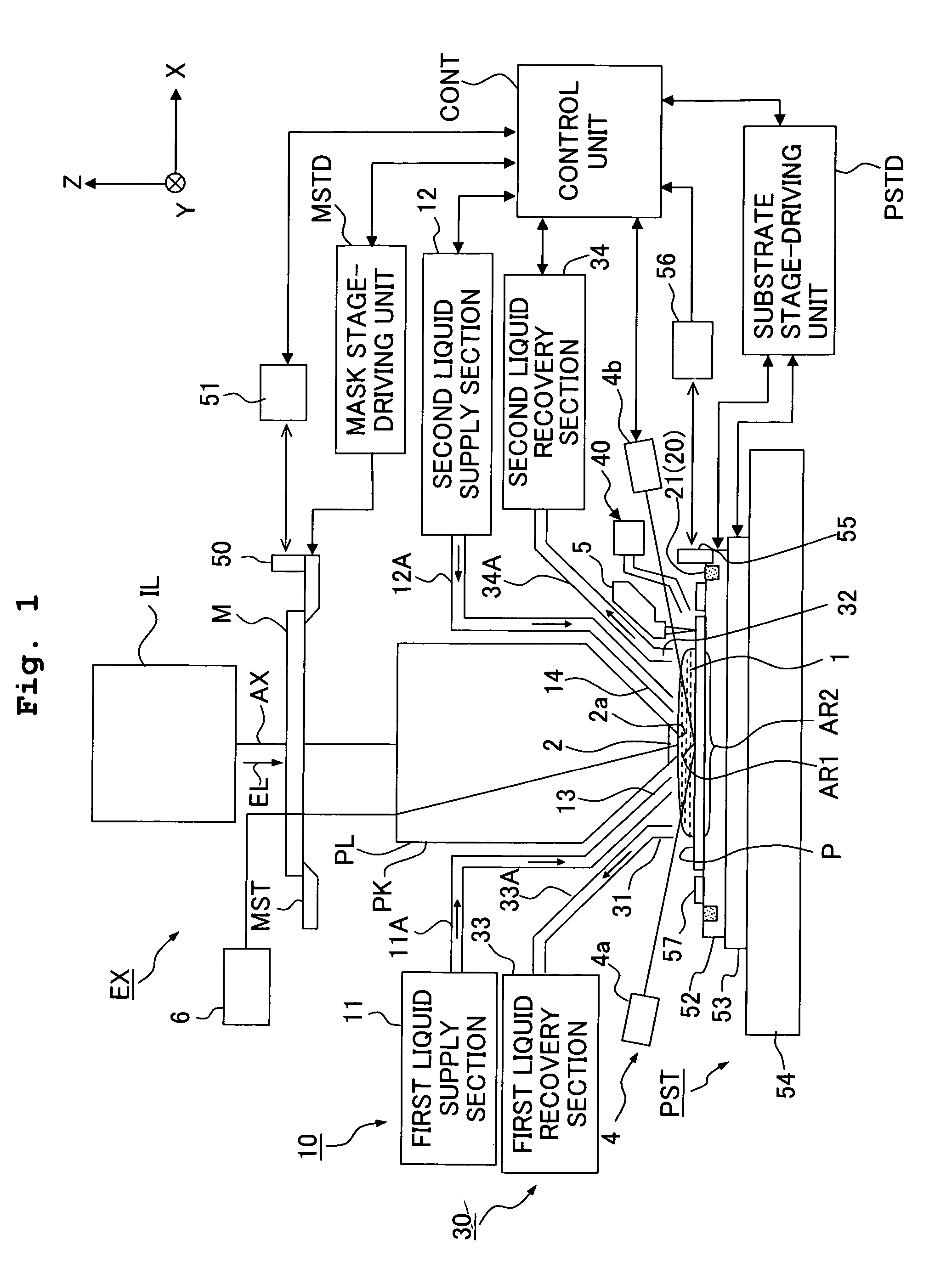

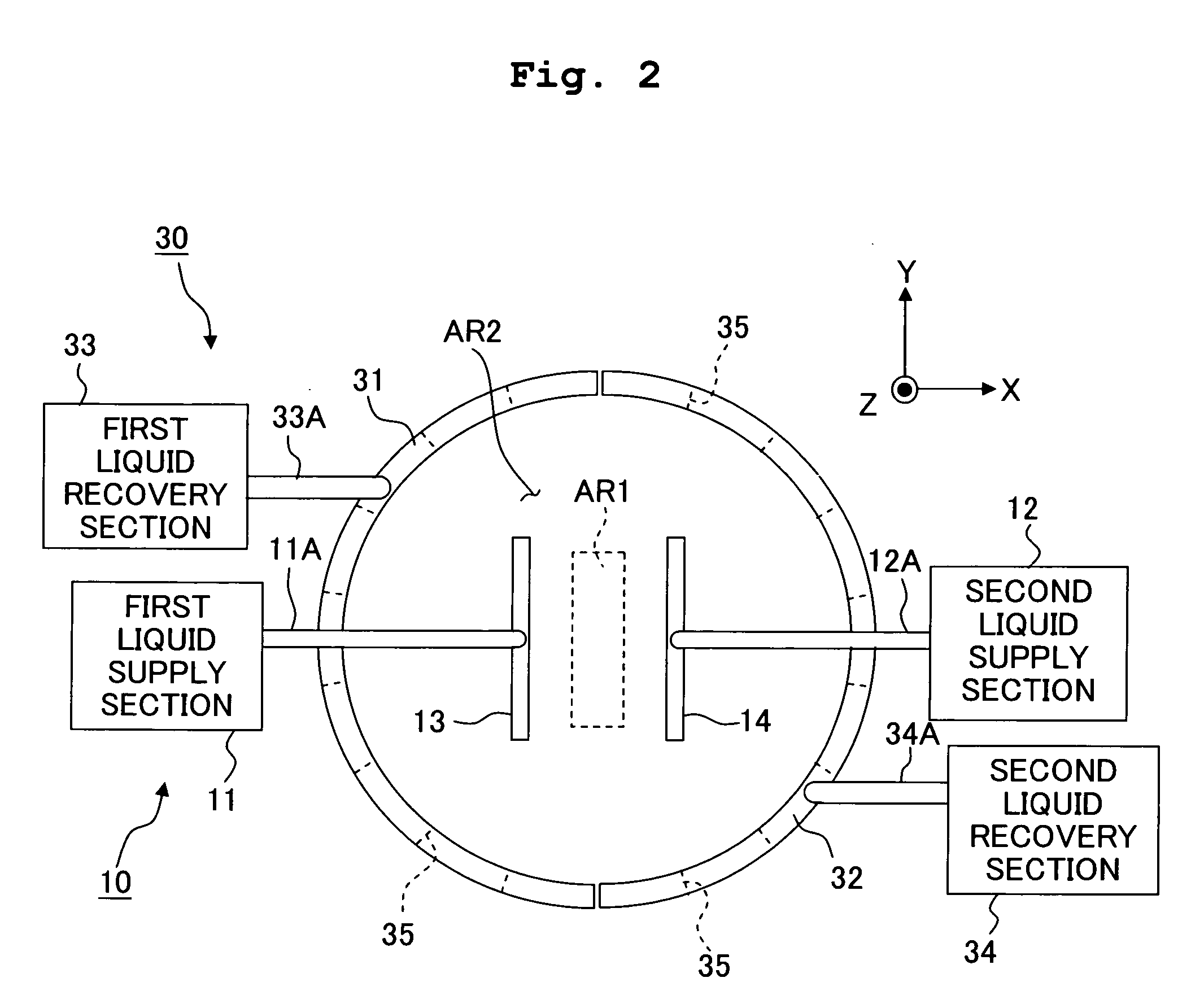

Exposure apparatus and method for producing device

InactiveUS20060077367A1Forming accuratelySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringImage plane

There is provided an exposure apparatus capable of forming a desirable device pattern by removing unnecessary liquid when performing exposure by projecting a pattern onto the substrate via a projection optical system and the liquid. The exposure device projects an image of the pattern onto the substrate P via the projection optical system and the liquid so as to expose the substrate P. The exposure device includes a liquid removing mechanism 40 which removes the liquid remaining on a part 7 arranged in the vicinity of the image plane of the projection optical system.

Owner:NIKON CORP

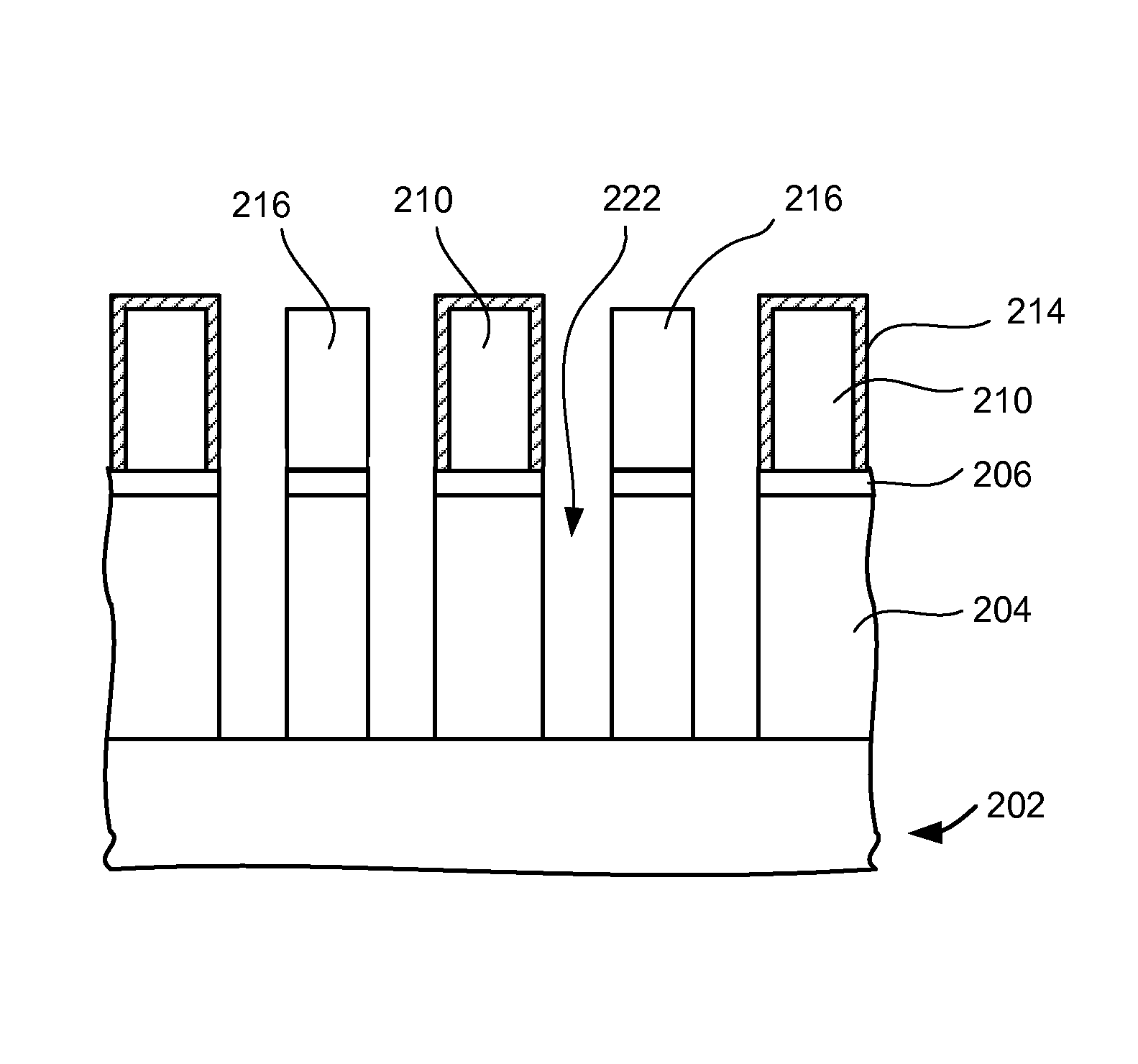

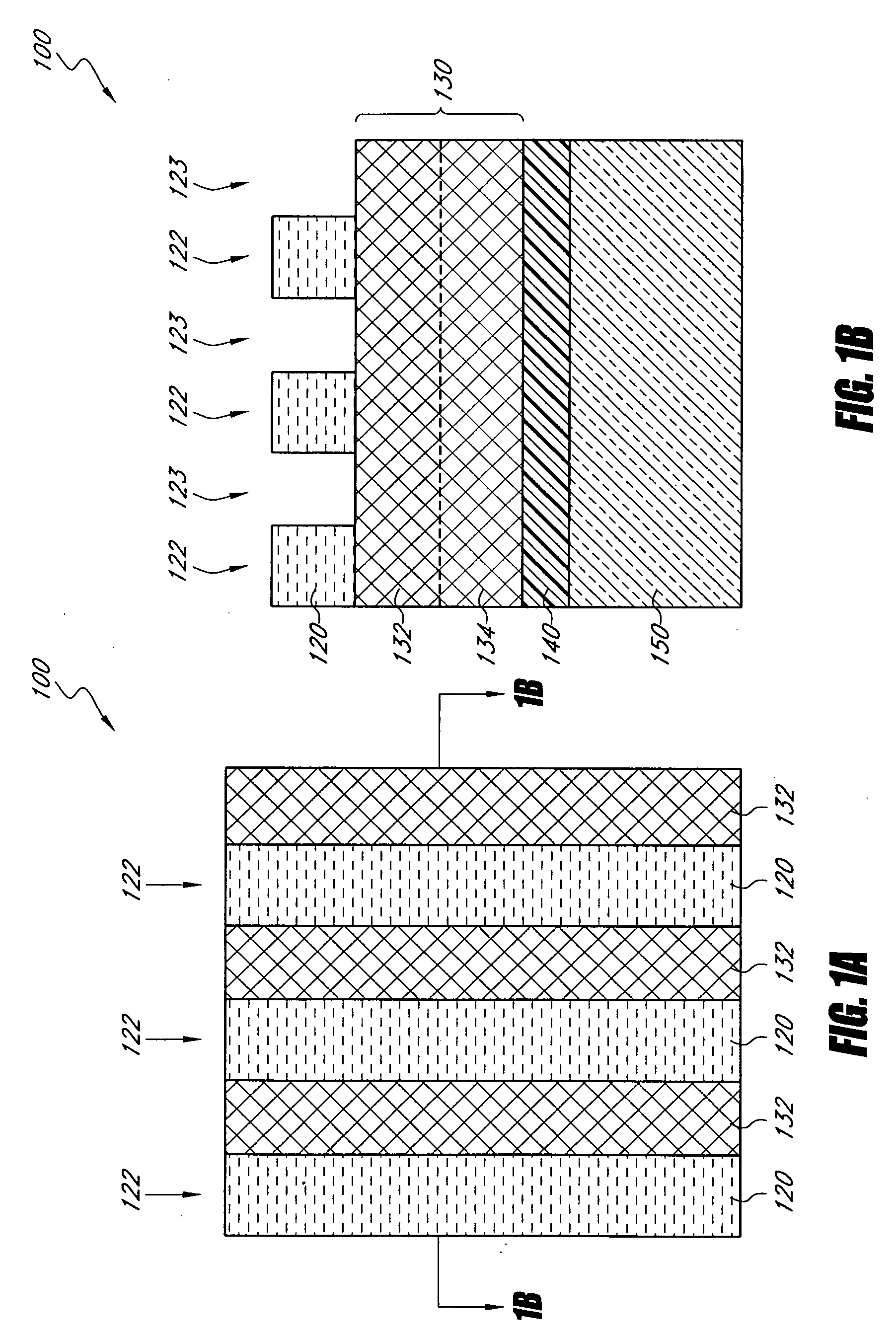

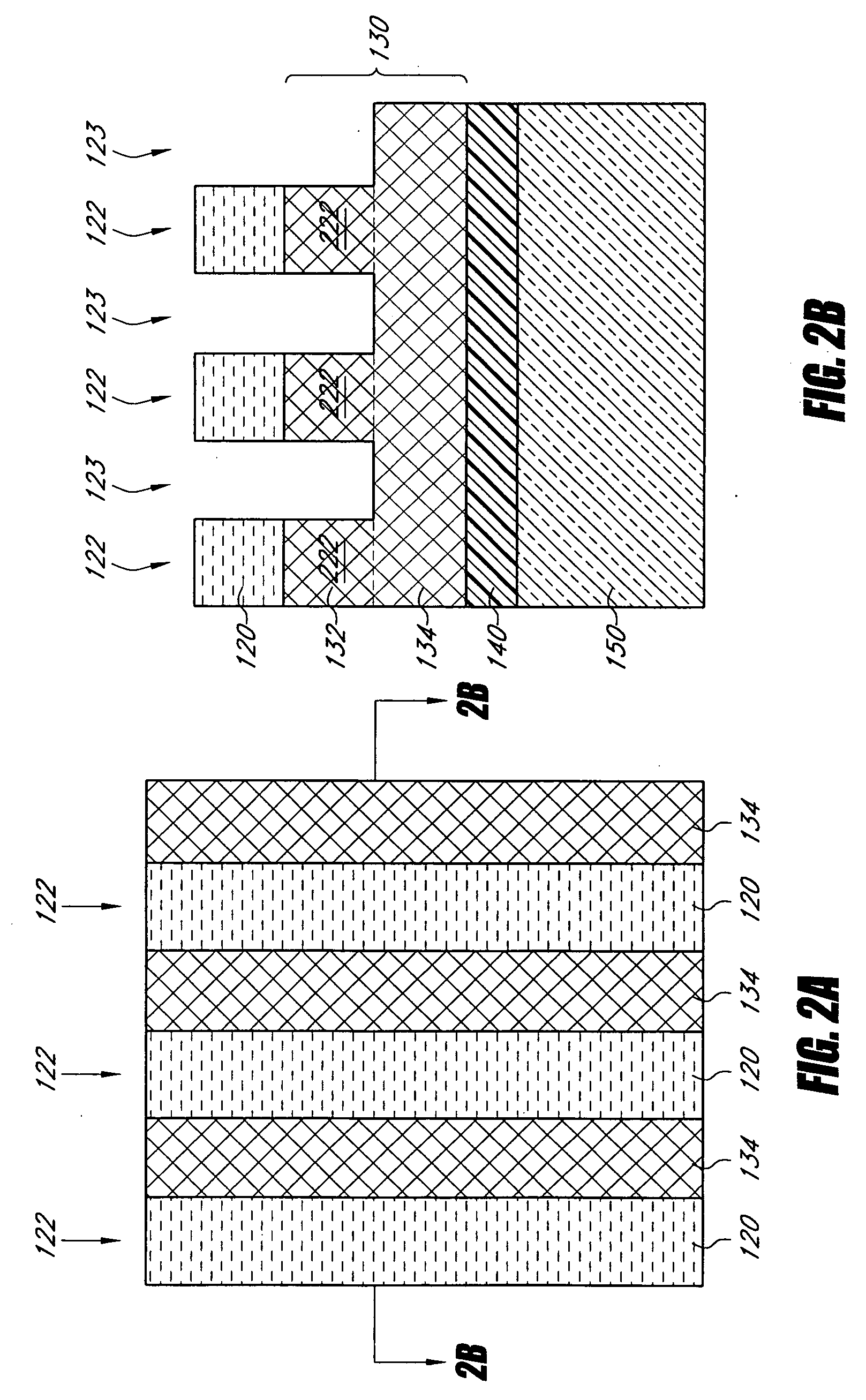

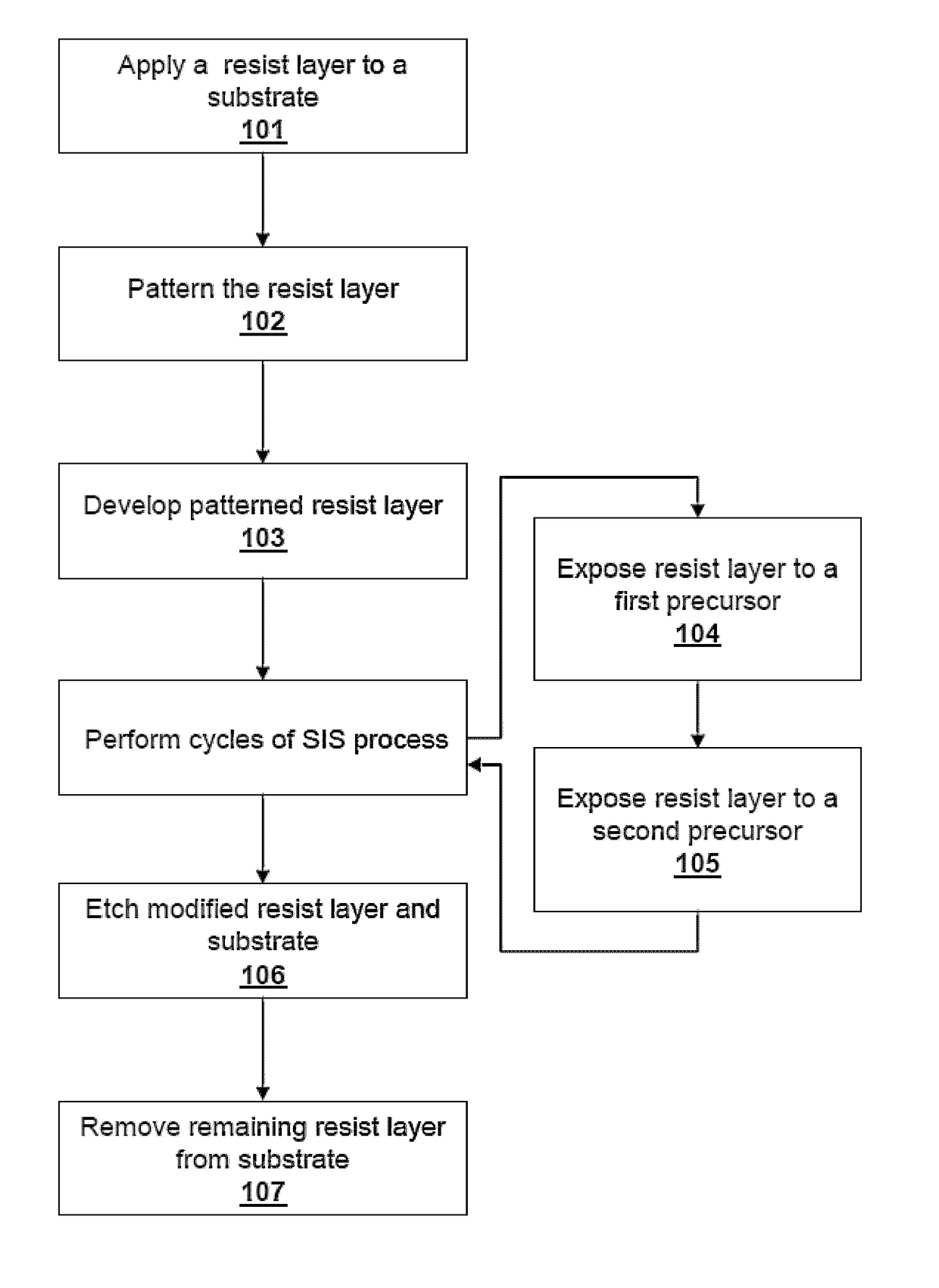

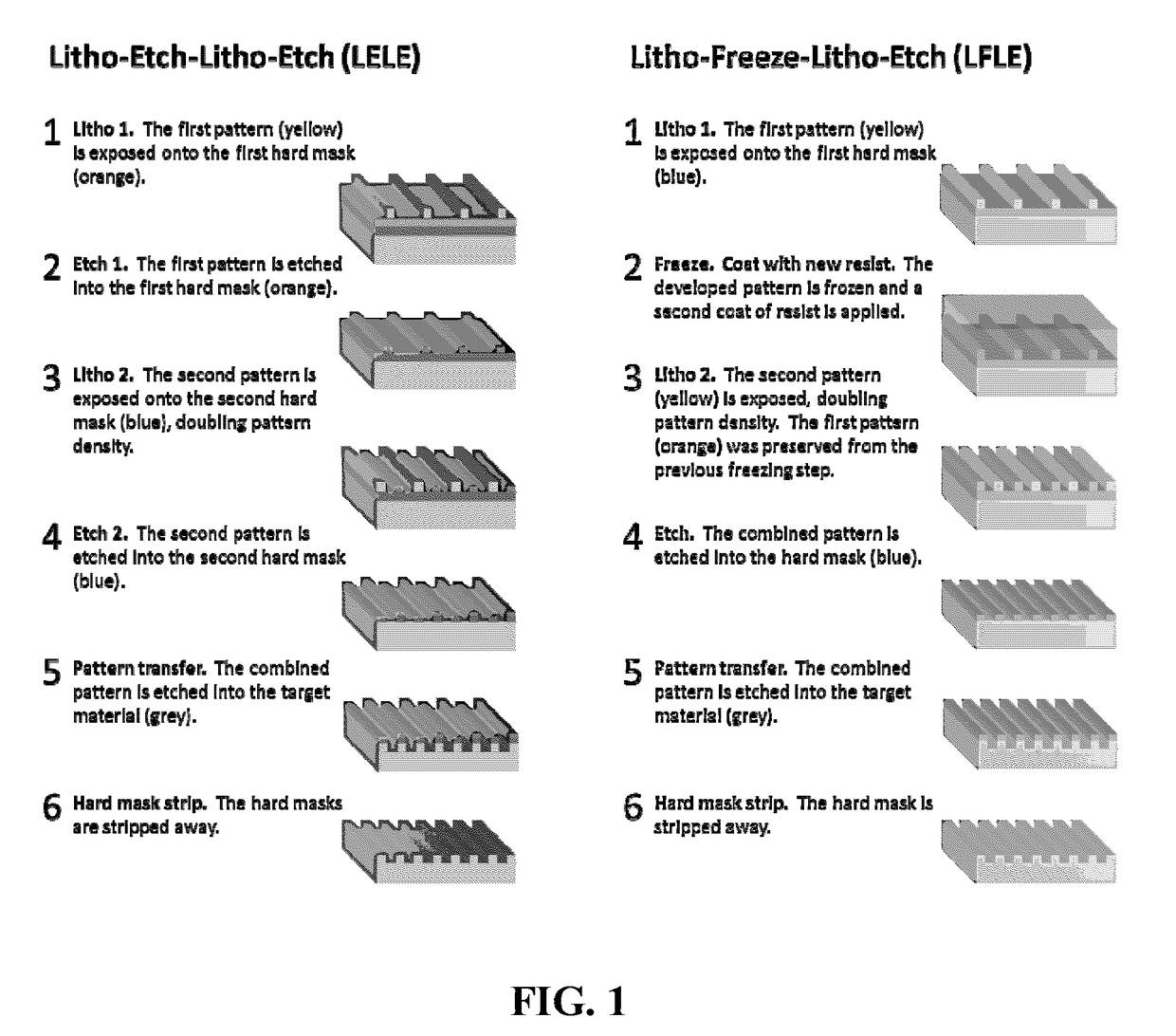

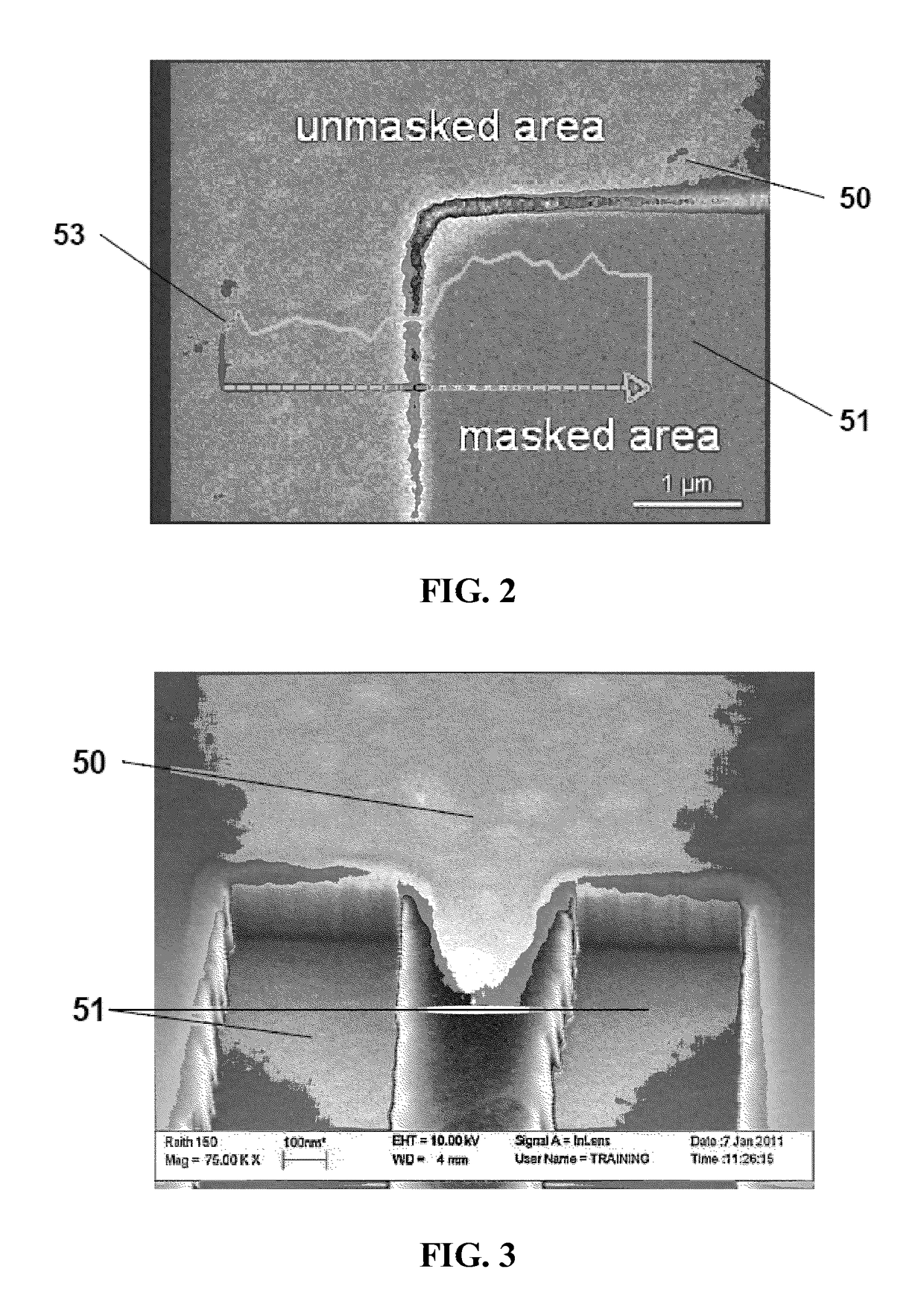

Sequential infiltration synthesis for enhancing multiple-patterning lithography

ActiveUS9684234B2Reduce in quantityImprove throughputDecorative surface effectsSemiconductor/solid-state device manufacturingPhotoresistMultiple patterning lithography

Simplified methods of multiple-patterning photolithography using sequential infiltration synthesis to modify the photoresist such that it withstands plasma etching better than unmodified resist and replaces one or more hard masks and / or a freezing step in MPL processes including litho-etch-litho-etch photolithography or litho-freeze-litho-etch photolithography.

Owner:UCHICAGO ARGONNE LLC

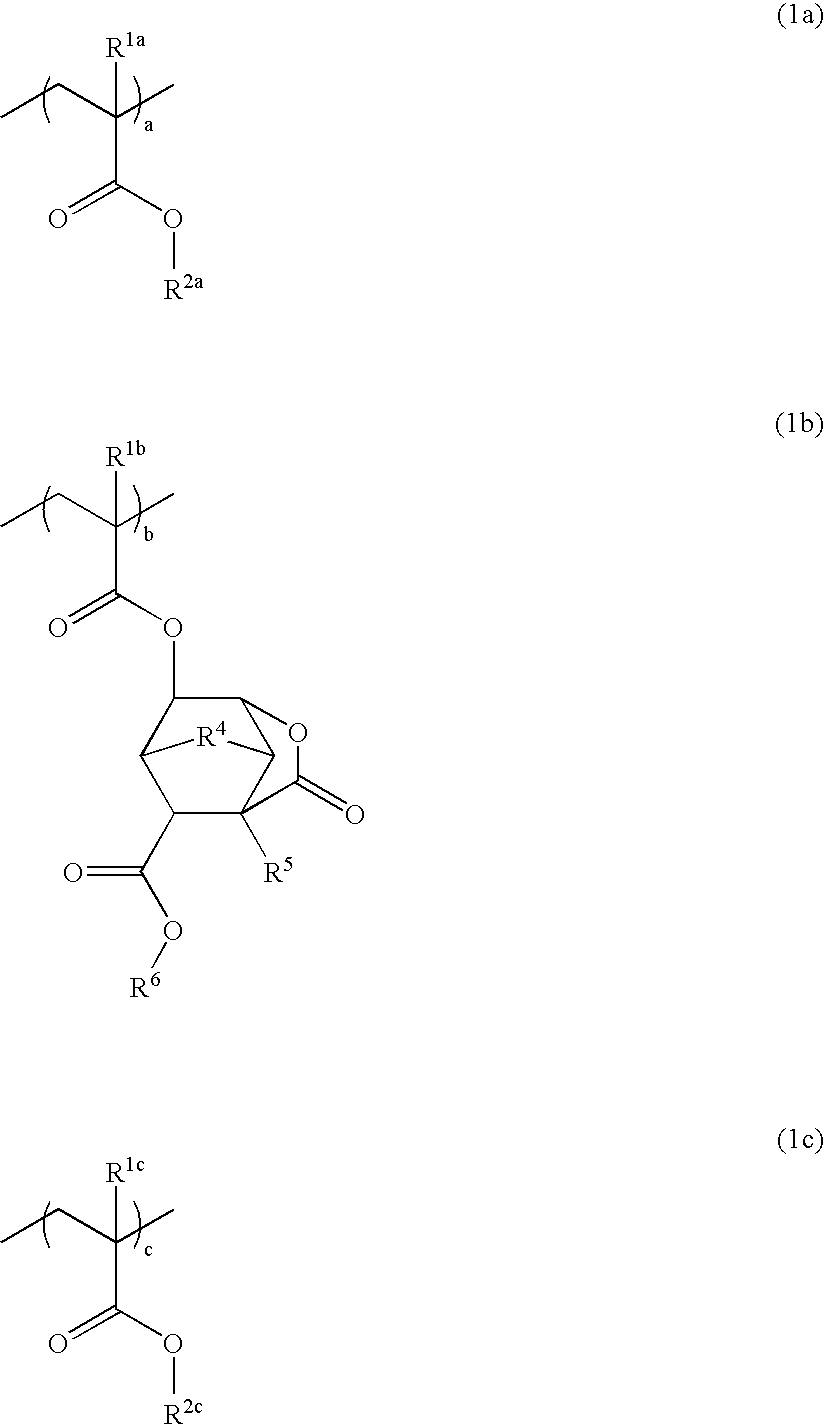

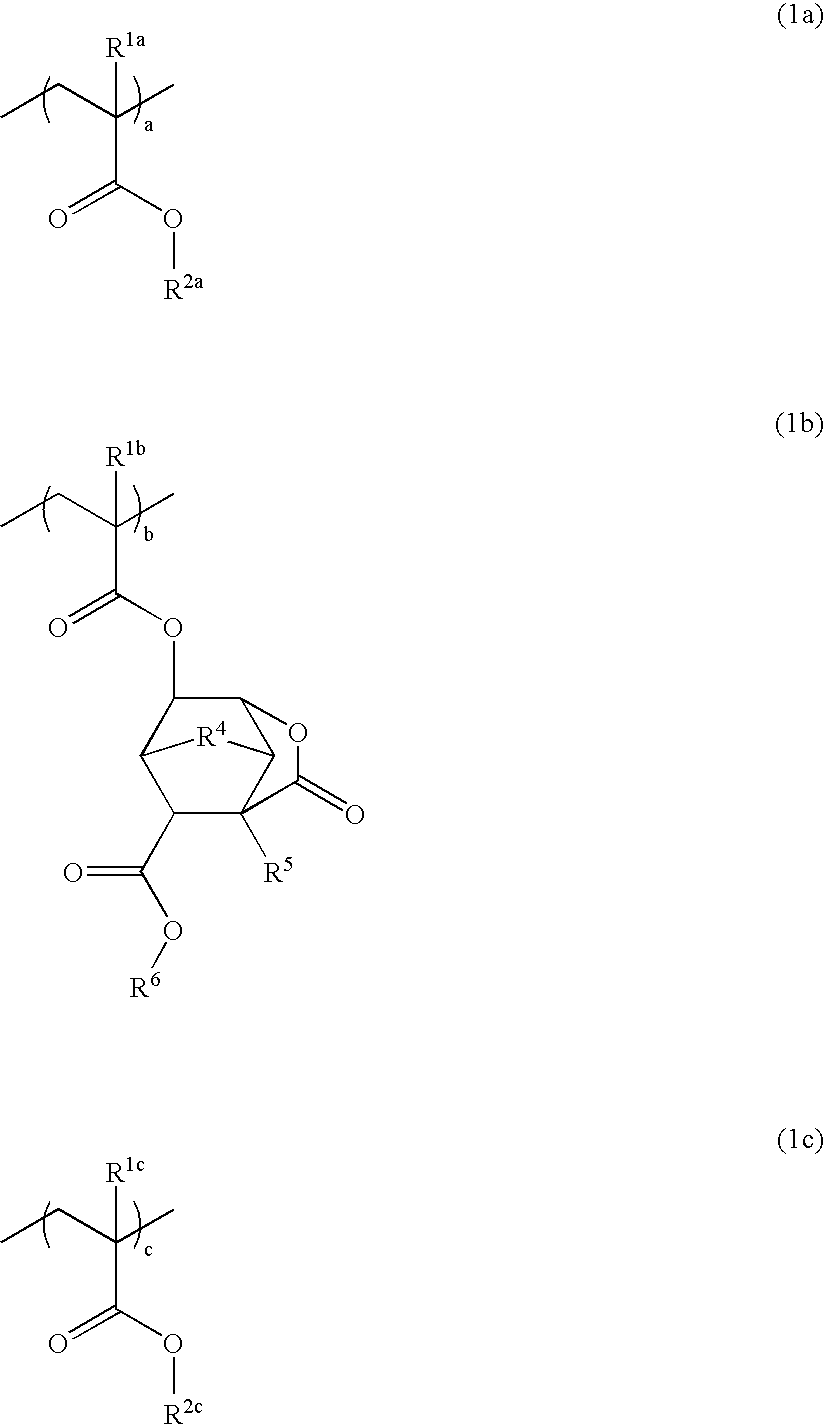

Polymer, resist composition, and patterning process

To a resist composition, an alkali-soluble polymer having fluorinated ester-containing lactone units incorporated therein is included as an additive. The resist composition forms a resist film having a reduced contact angle after development. The resist film prevents water penetration during immersion lithography.

Owner:SHIN ETSU CHEM IND CO LTD

Photoresist composition for deep UV radiation containing an additive

InactiveUS6723488B2Reduce impactPrevent degradationPhotosensitive materialsElectric discharge tubesUltravioletAqueous solution

Owner:AZ ELECTRONICS MATERIALS USA CORP

Method utilizing compensation features in semiconductor processing

InactiveUS7202148B2Increased process windowReduce depthRadiation applicationsSemiconductor/solid-state device manufacturingEngineeringFlare

A photolithography and etch process sequence includes a photomask having a pattern with compensation features that alleviate patterning variations due to the proximity effect and depth of focus concerns during photolithography. The compensation features may be disposed near isolated or outermost lines of a device pattern. A photoresist pattern is formed to include the compensation features and the pattern etched to form a corresponding etched pattern including the compensation features. After etching, a protection material is formed over the layer and a trim mask is used to form a further photoresist pattern over the protection material. A subsequent etching pattern etches the protection material and removes the compensation features and results in the device lines being formed unaffected by proximity effects. Flare dummies may additionally be added to the mask pattern to increase pattern density and assist in endpoint detection. Flare dummies, like the compensation features, are subsequently removed by a photolithography and etching process sequence.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com