Patents

Literature

474results about How to "Molding stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pattern forming method, resist composition for multiple development used in the pattern forming method, developer for negative development used in the pattern forming method, and rinsing solution for negative development used in the pattern forming method

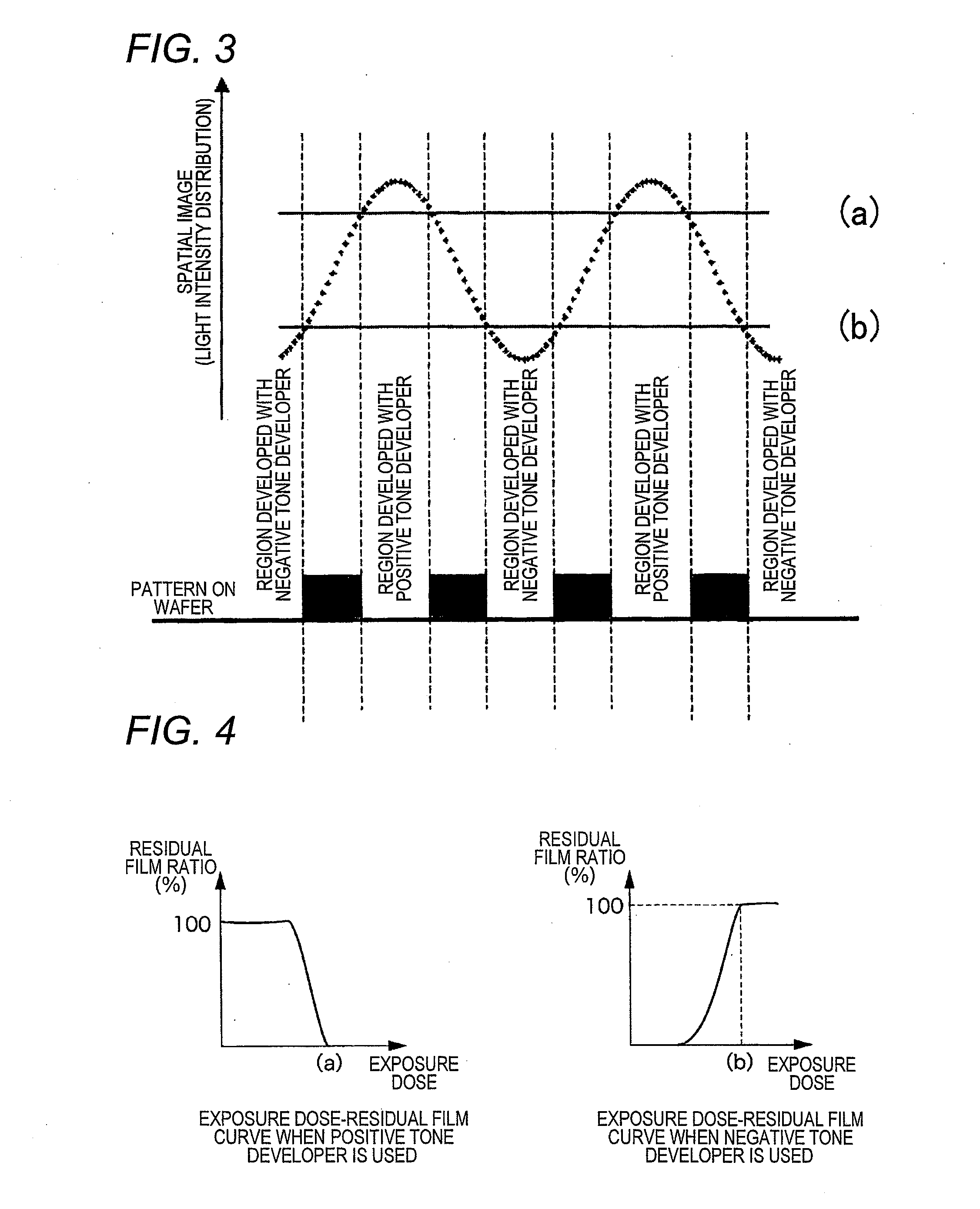

ActiveUS20080187860A1Improve accuracyMolding stabilityPhotosensitive materialsLayered productsActinic RaysPhotochemistry

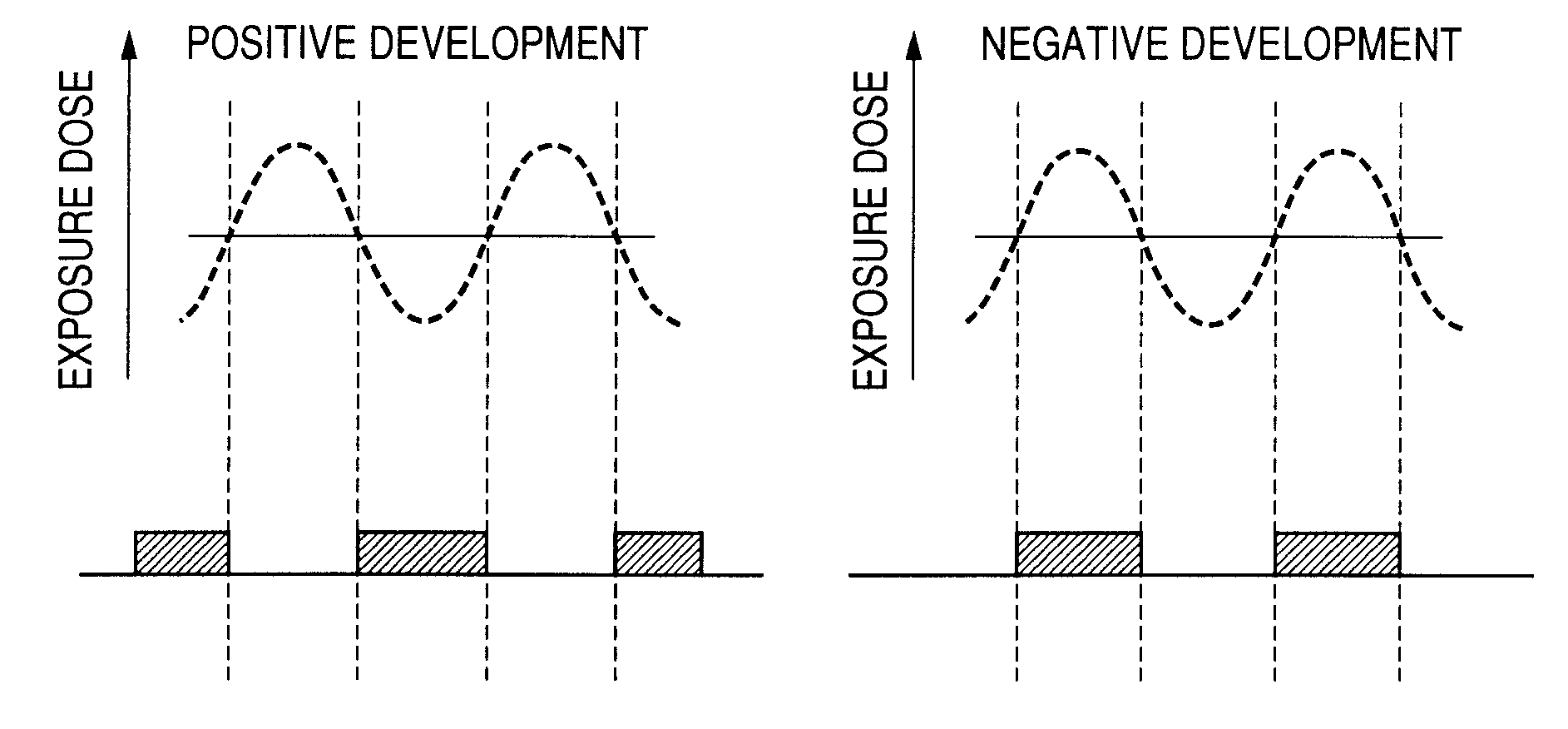

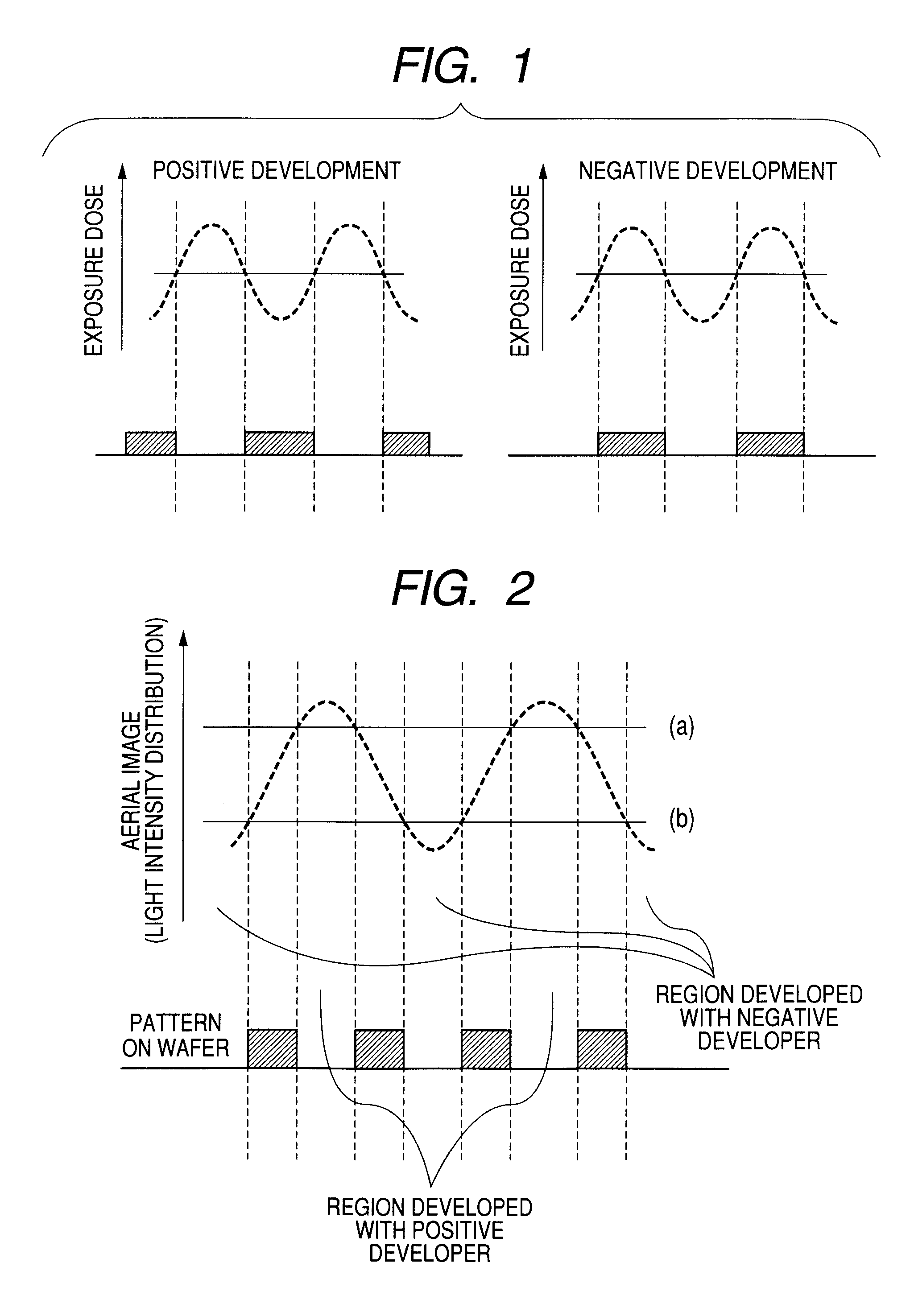

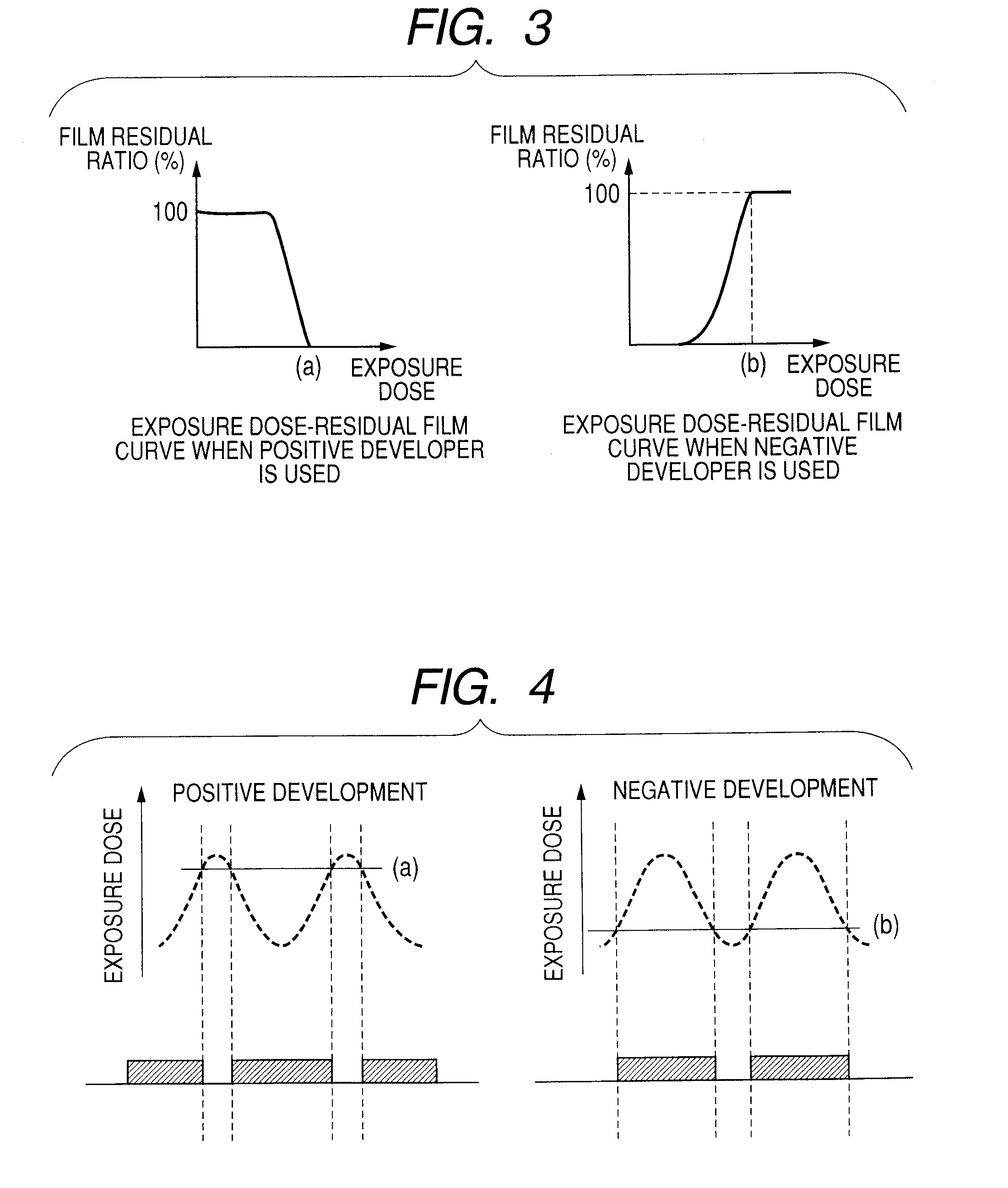

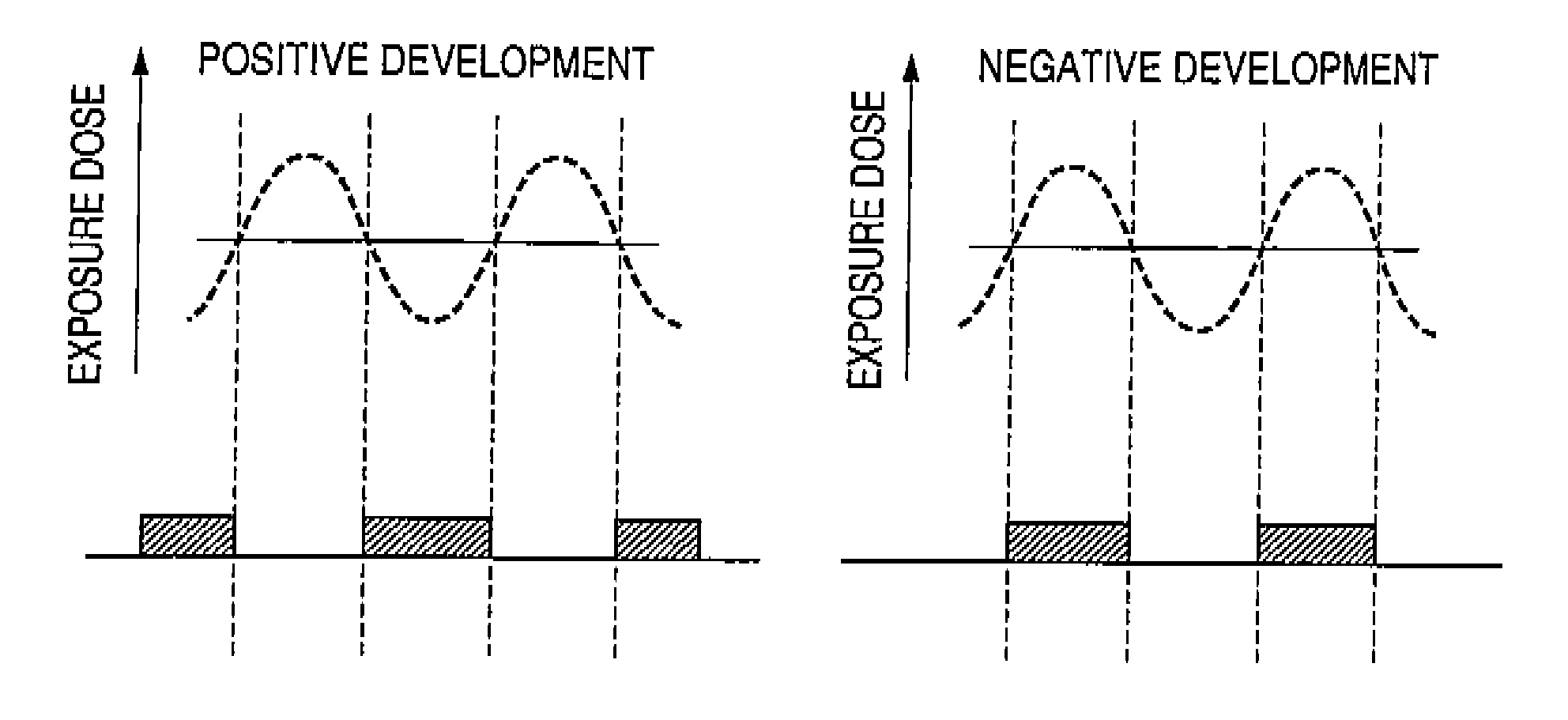

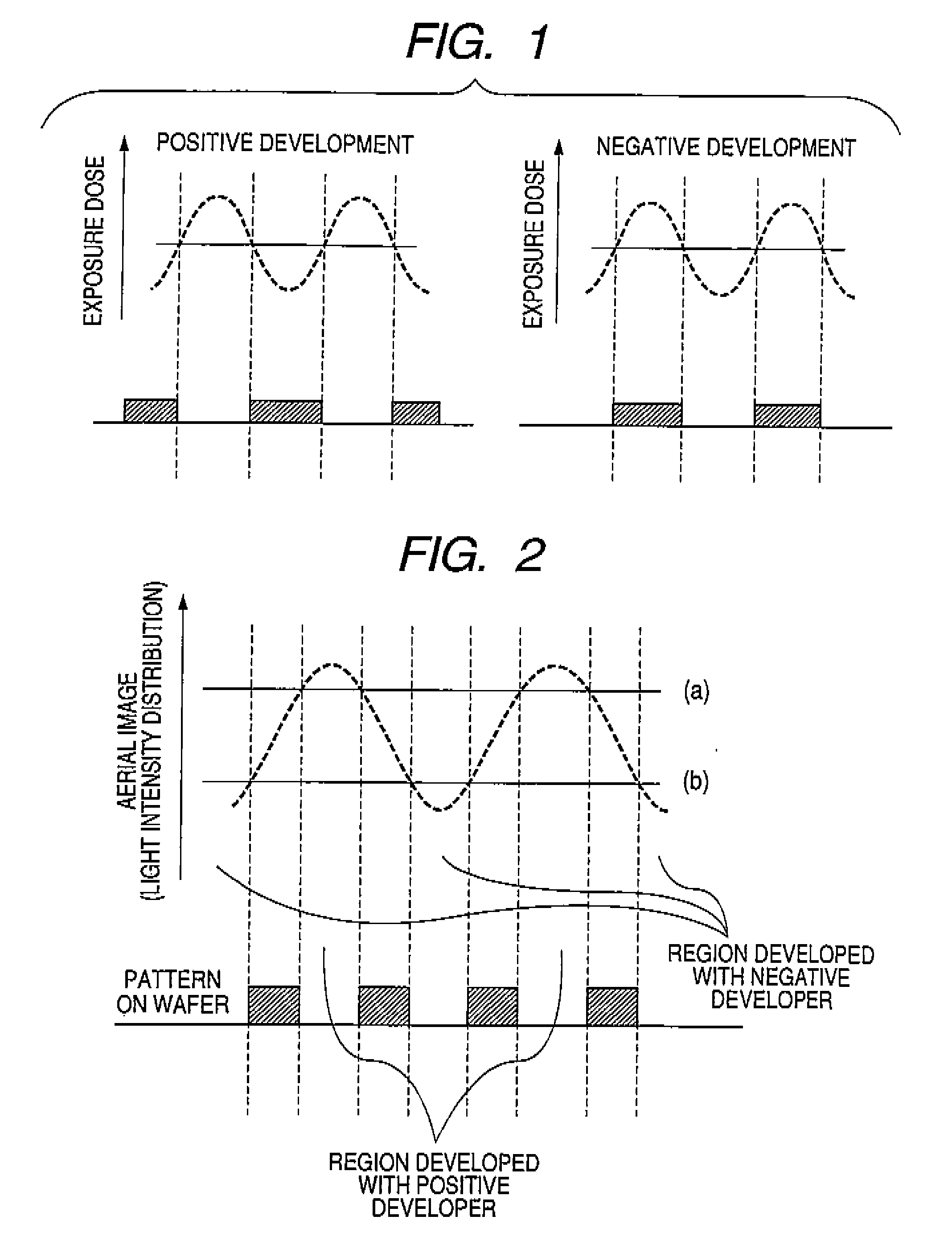

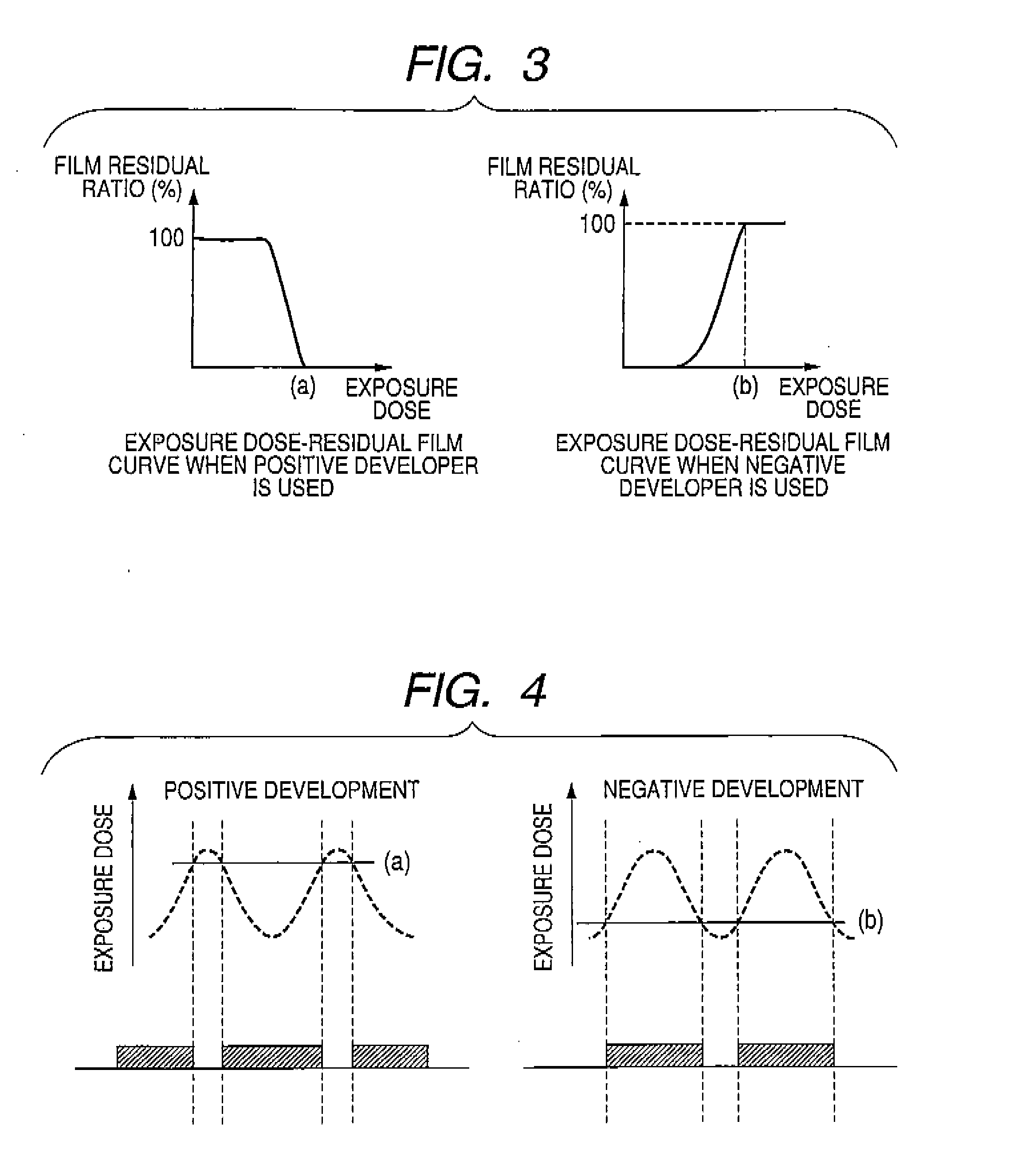

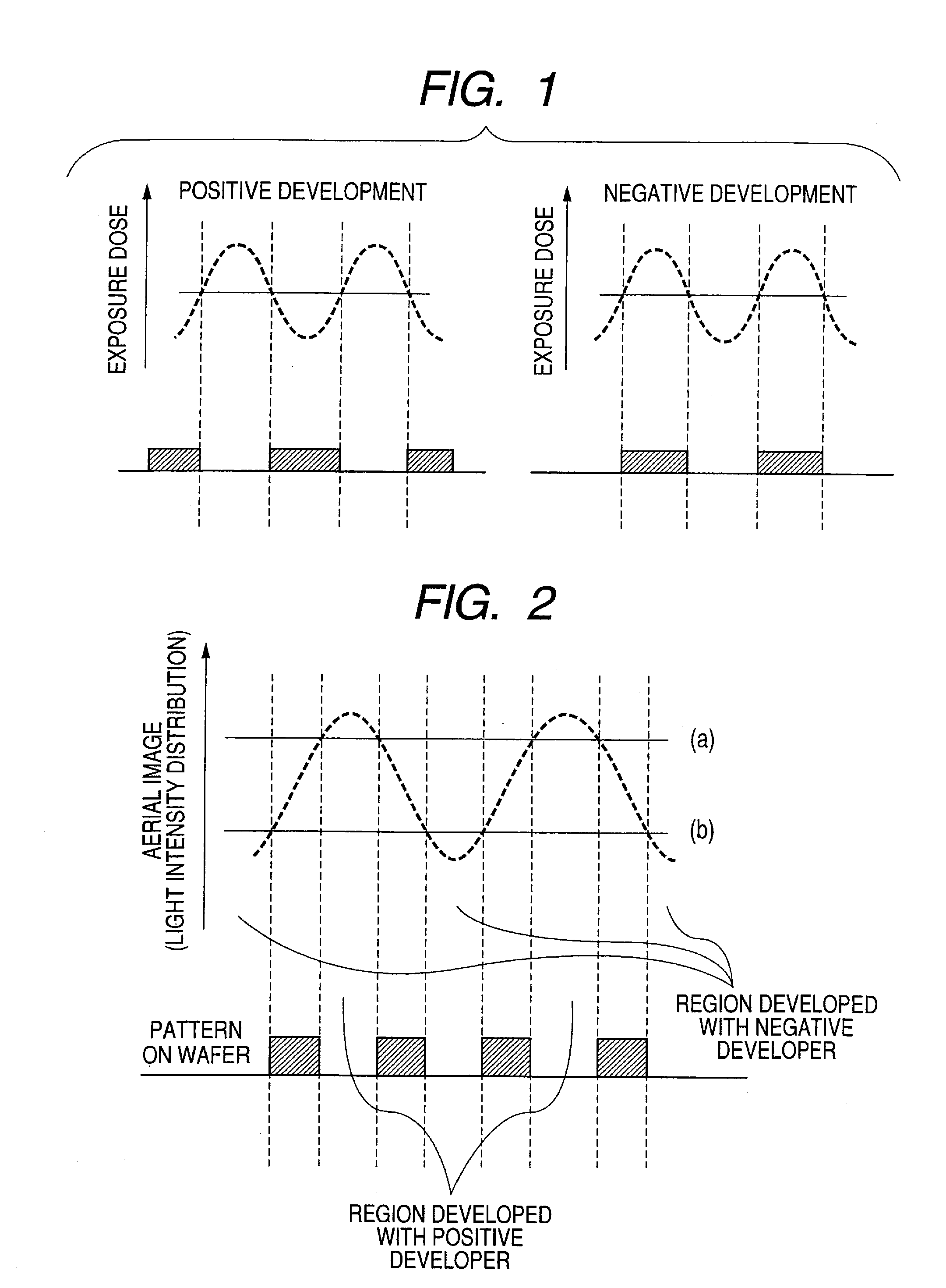

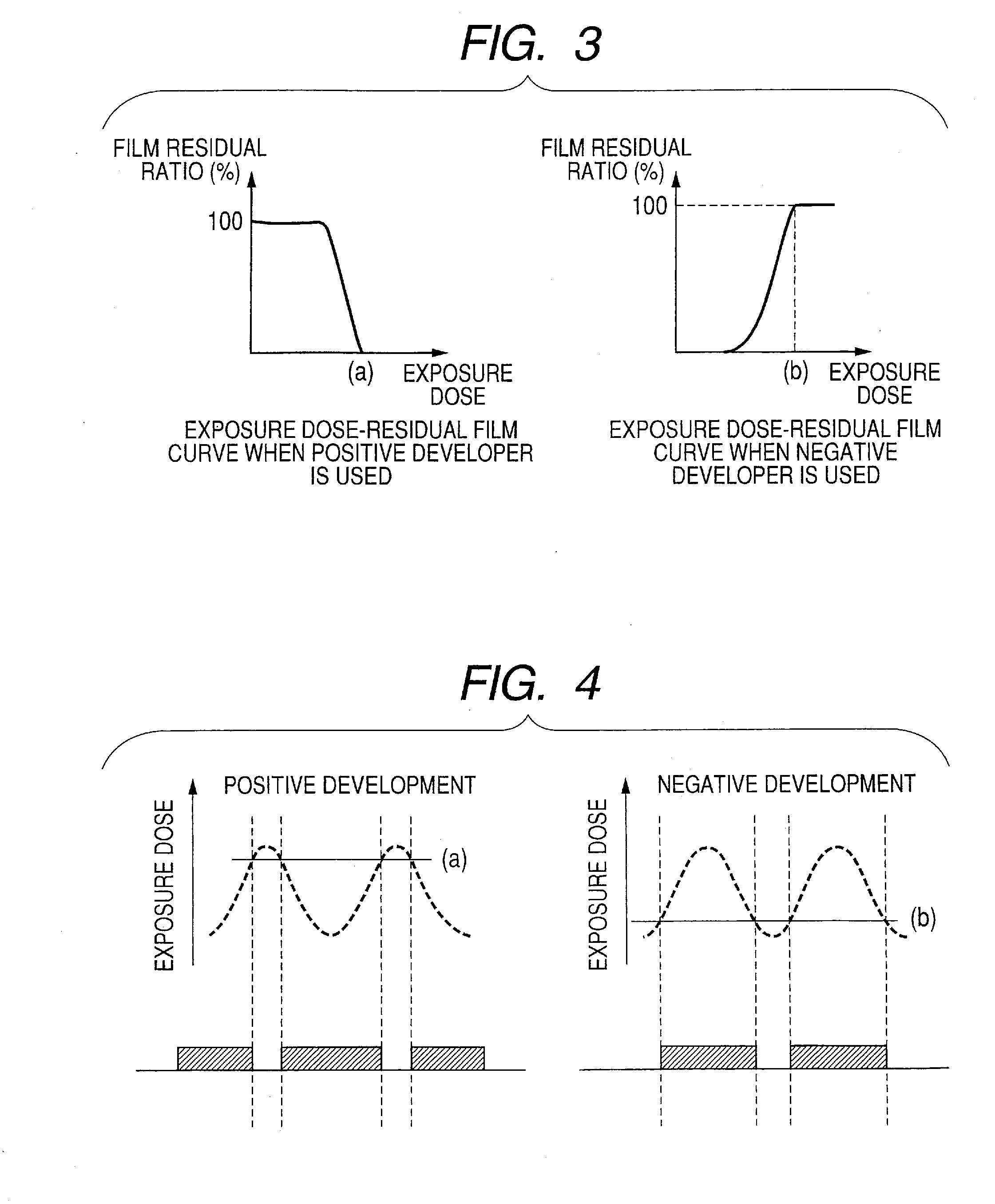

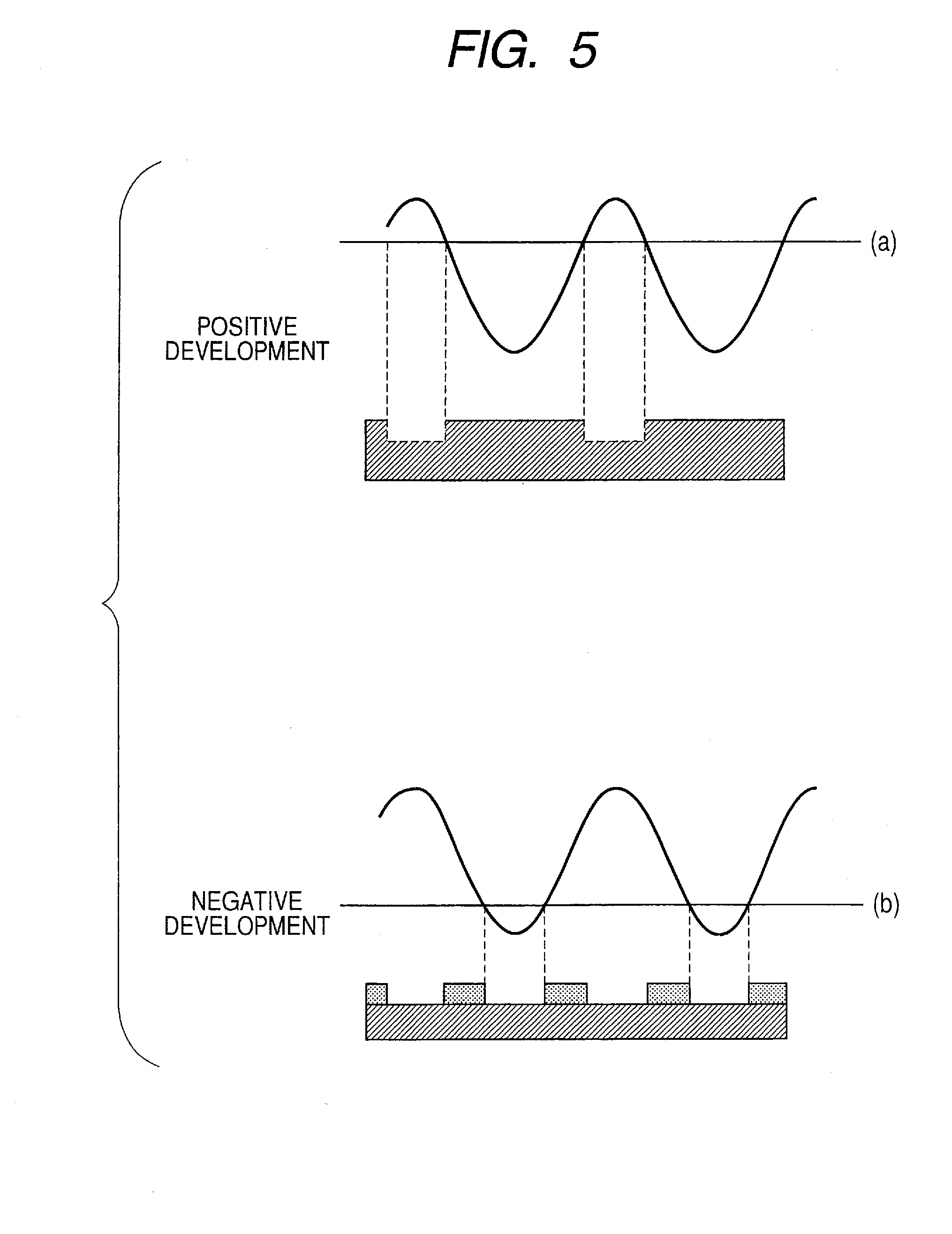

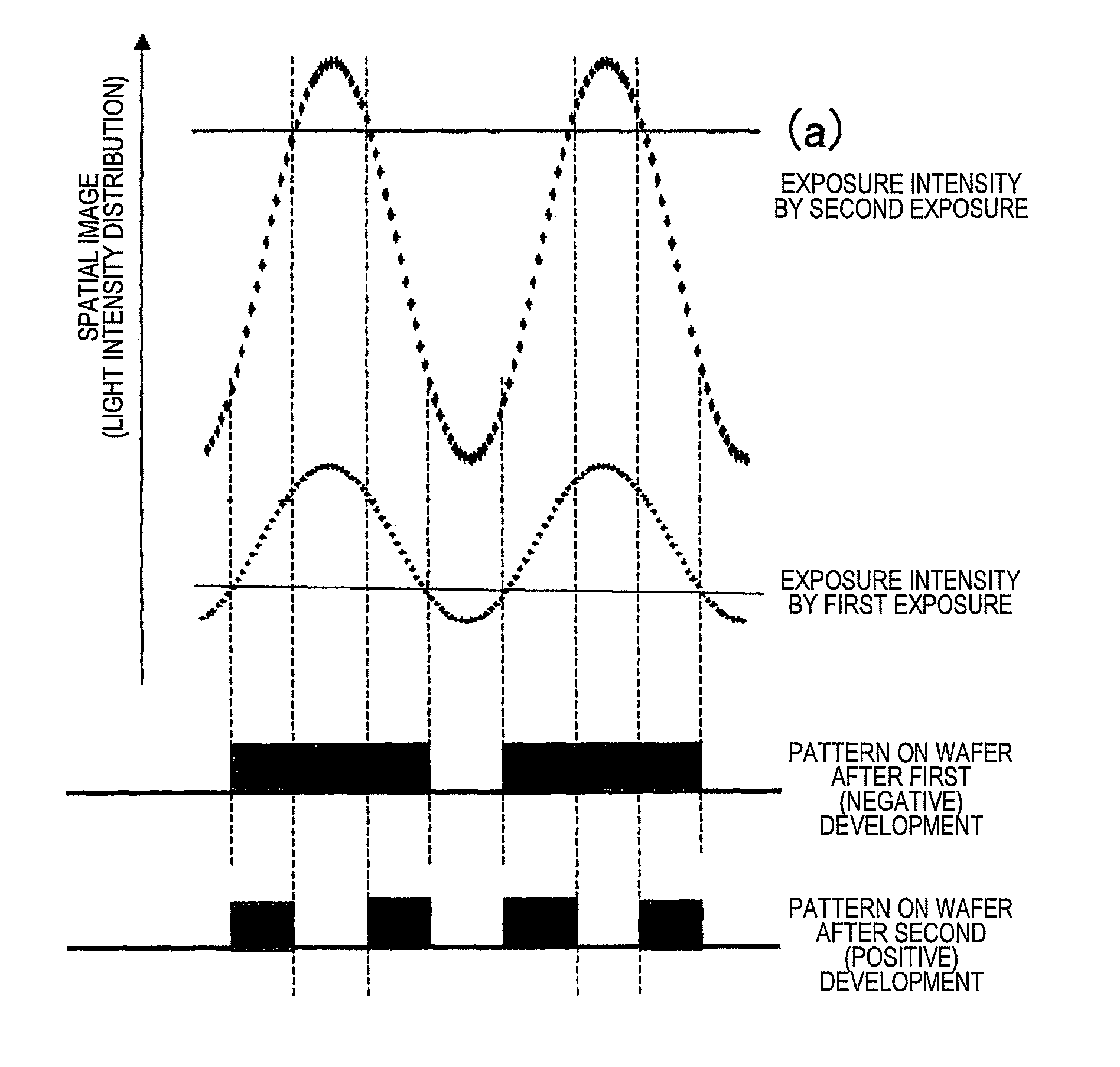

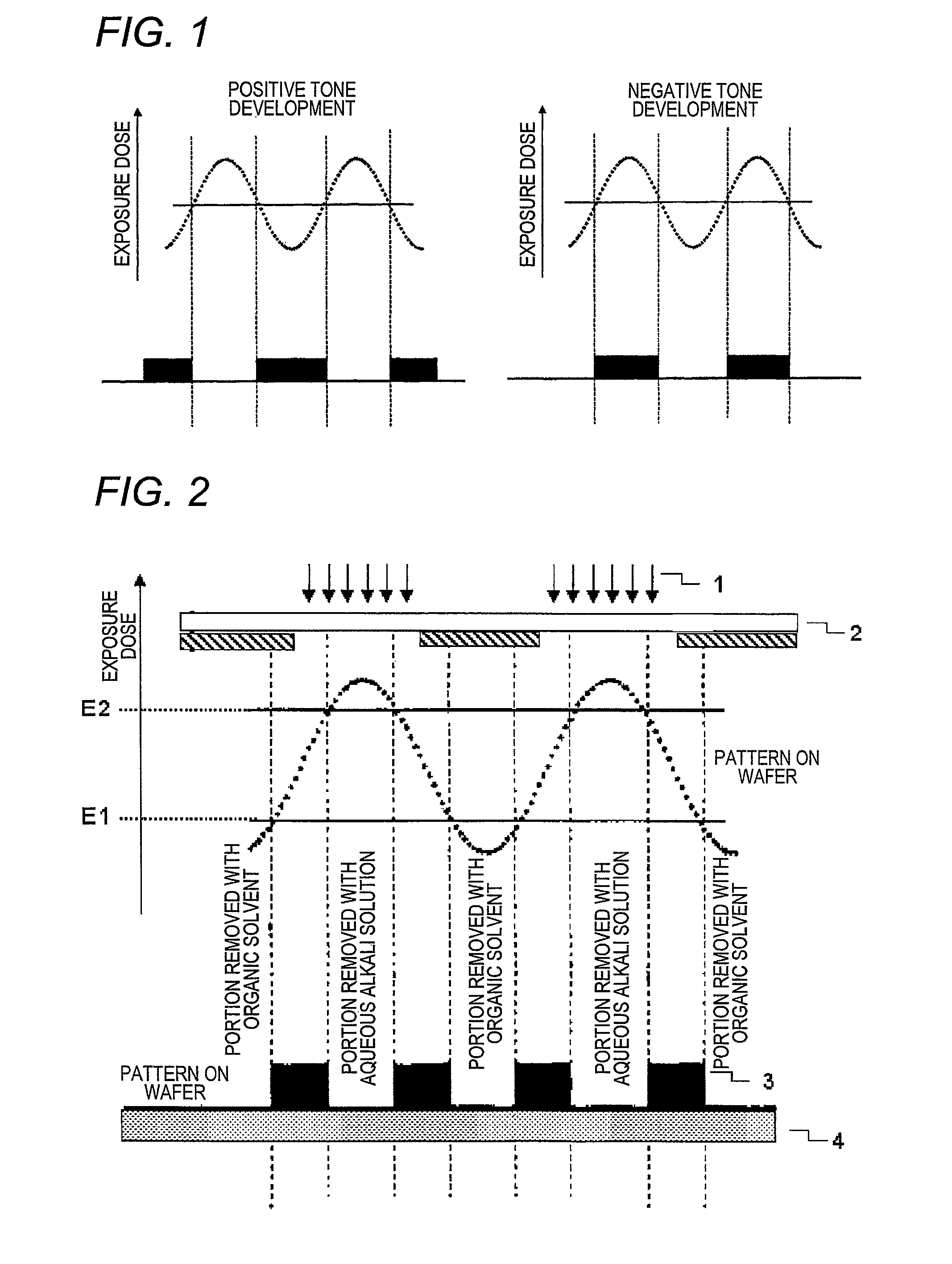

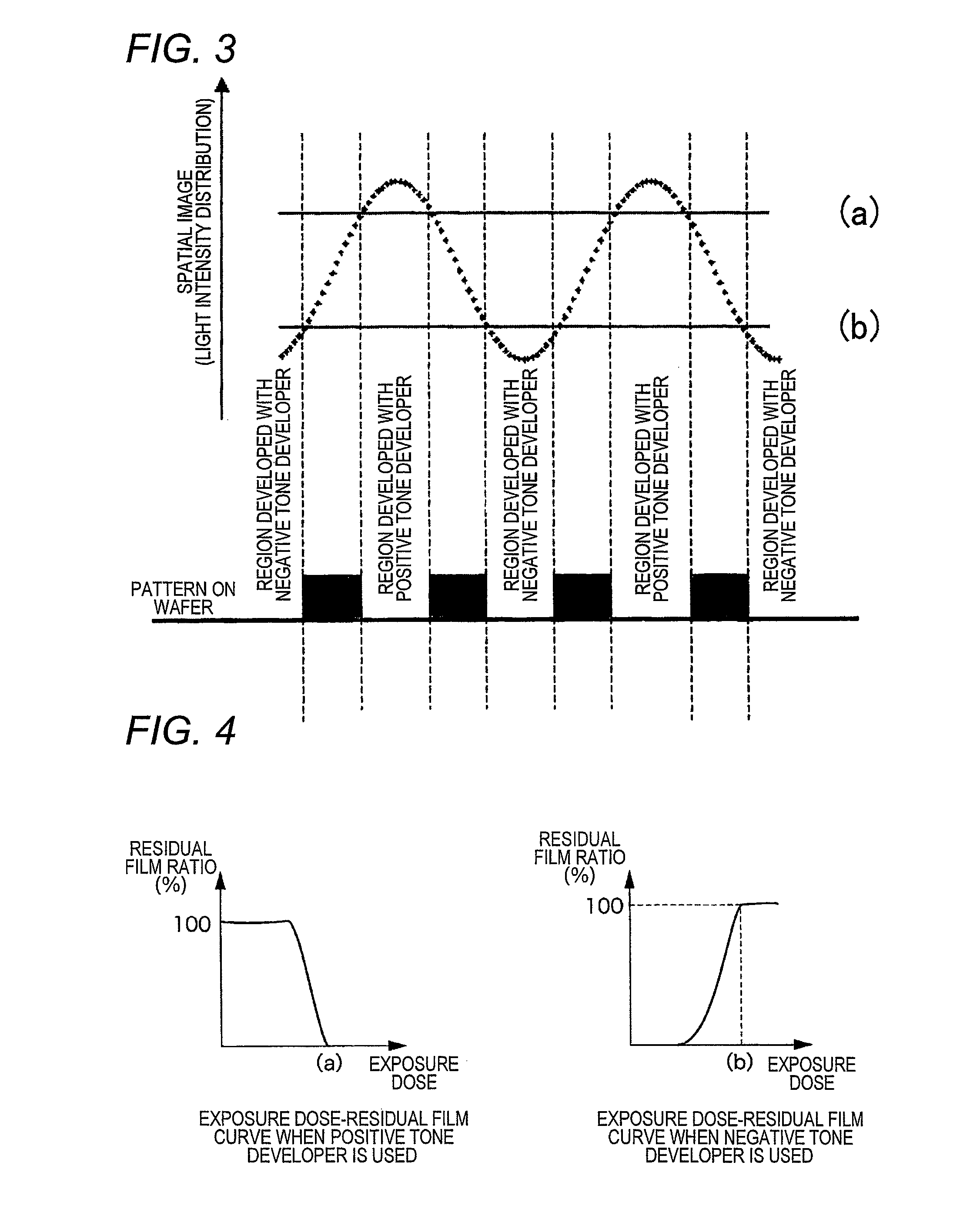

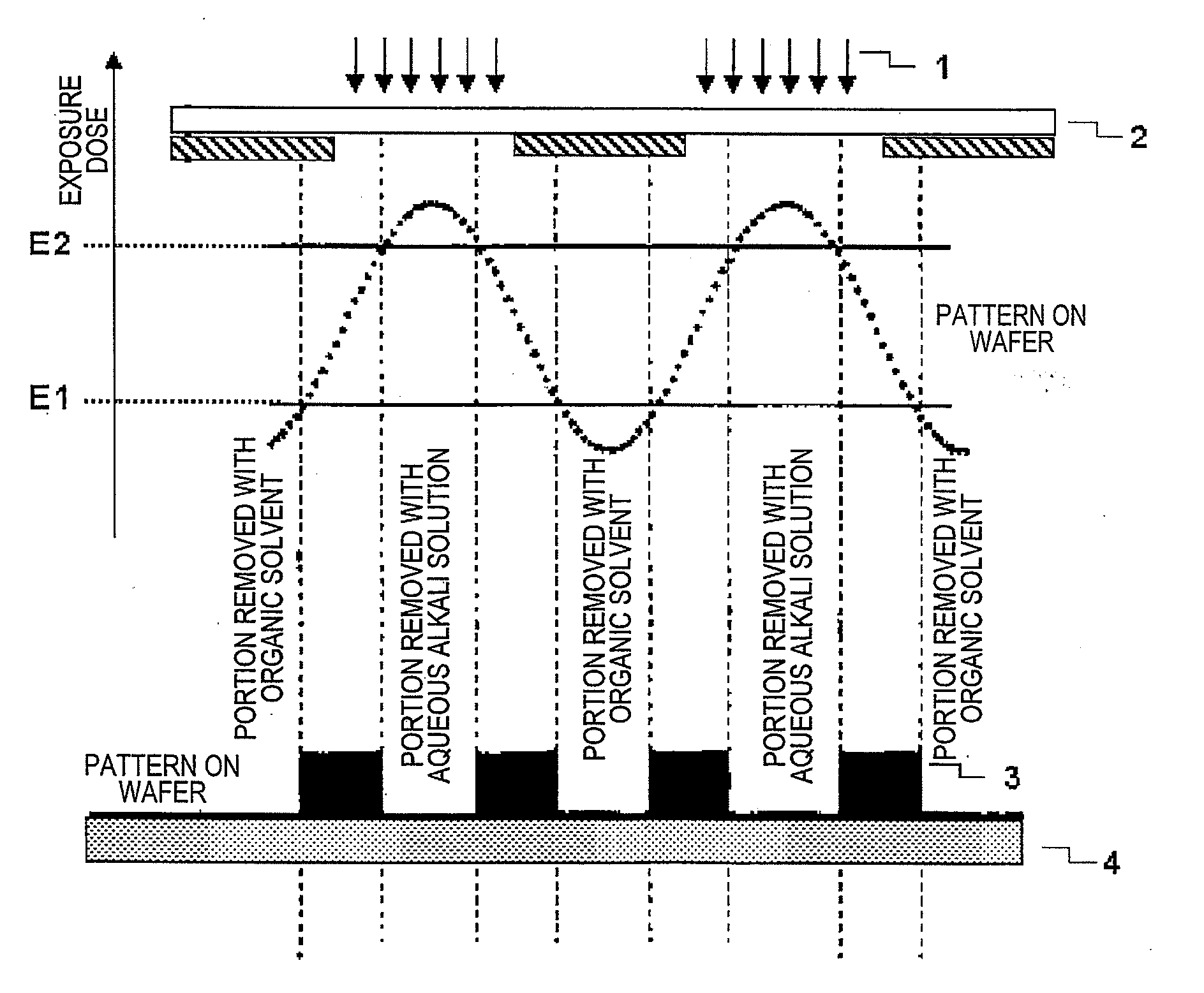

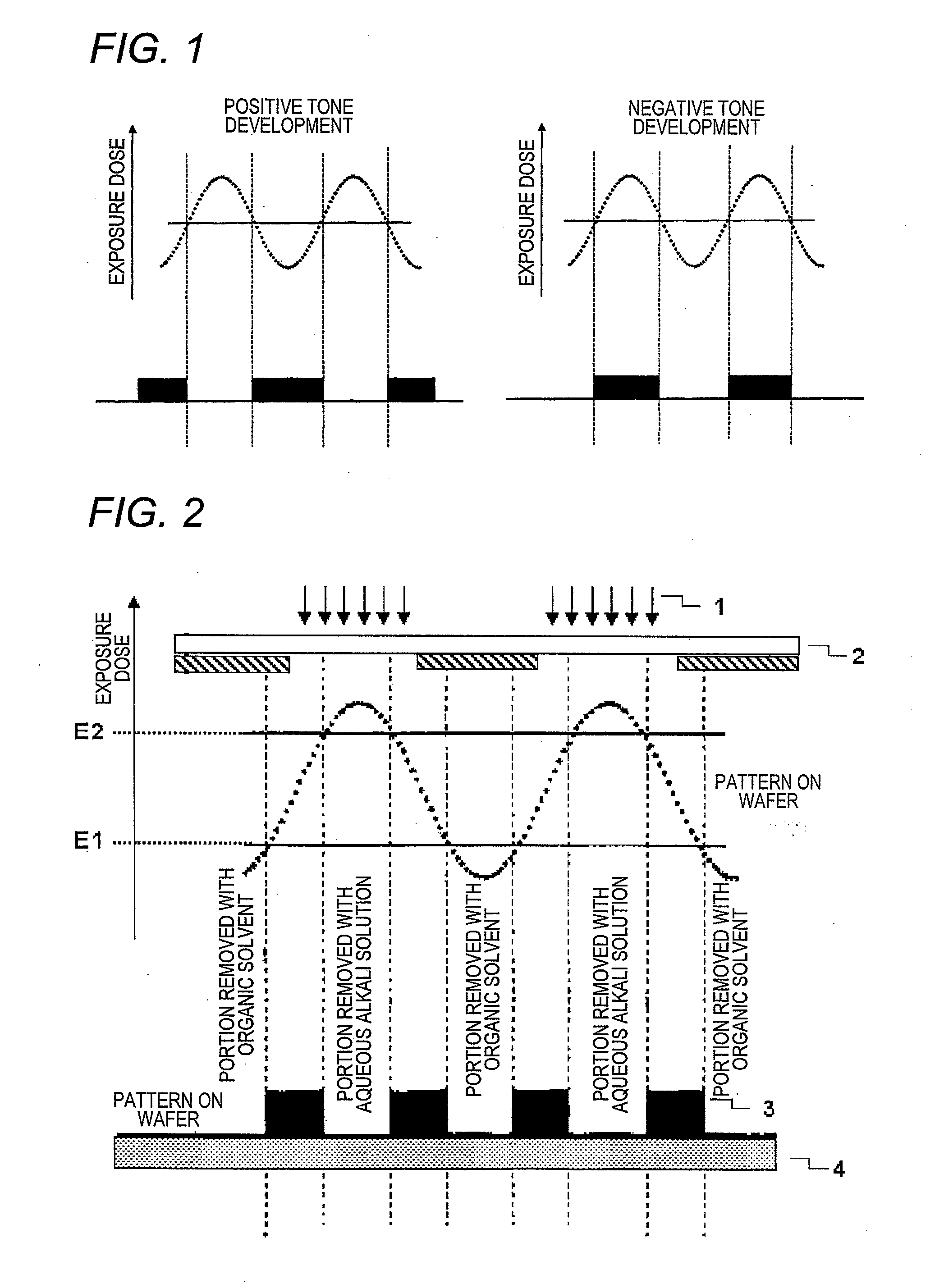

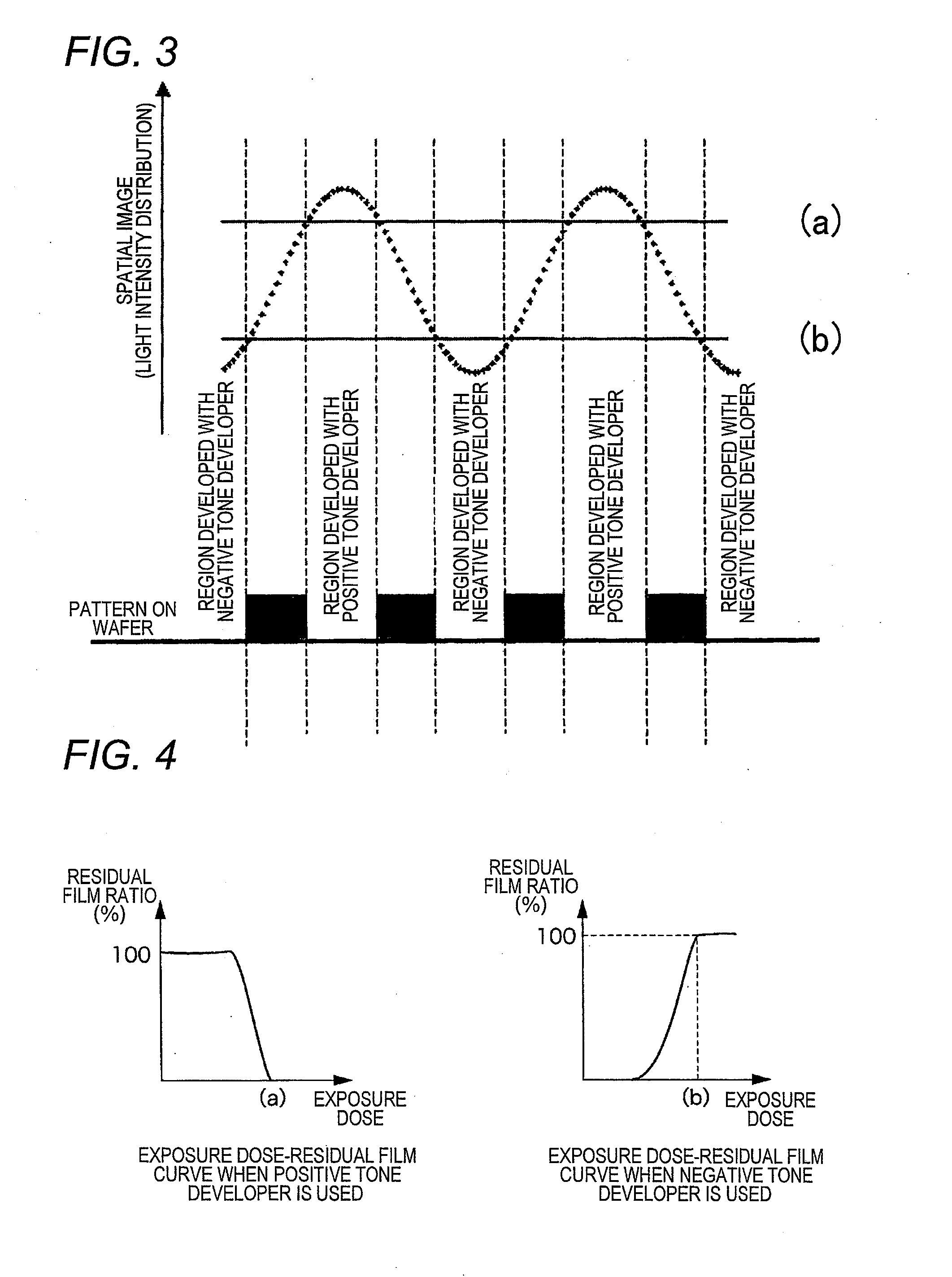

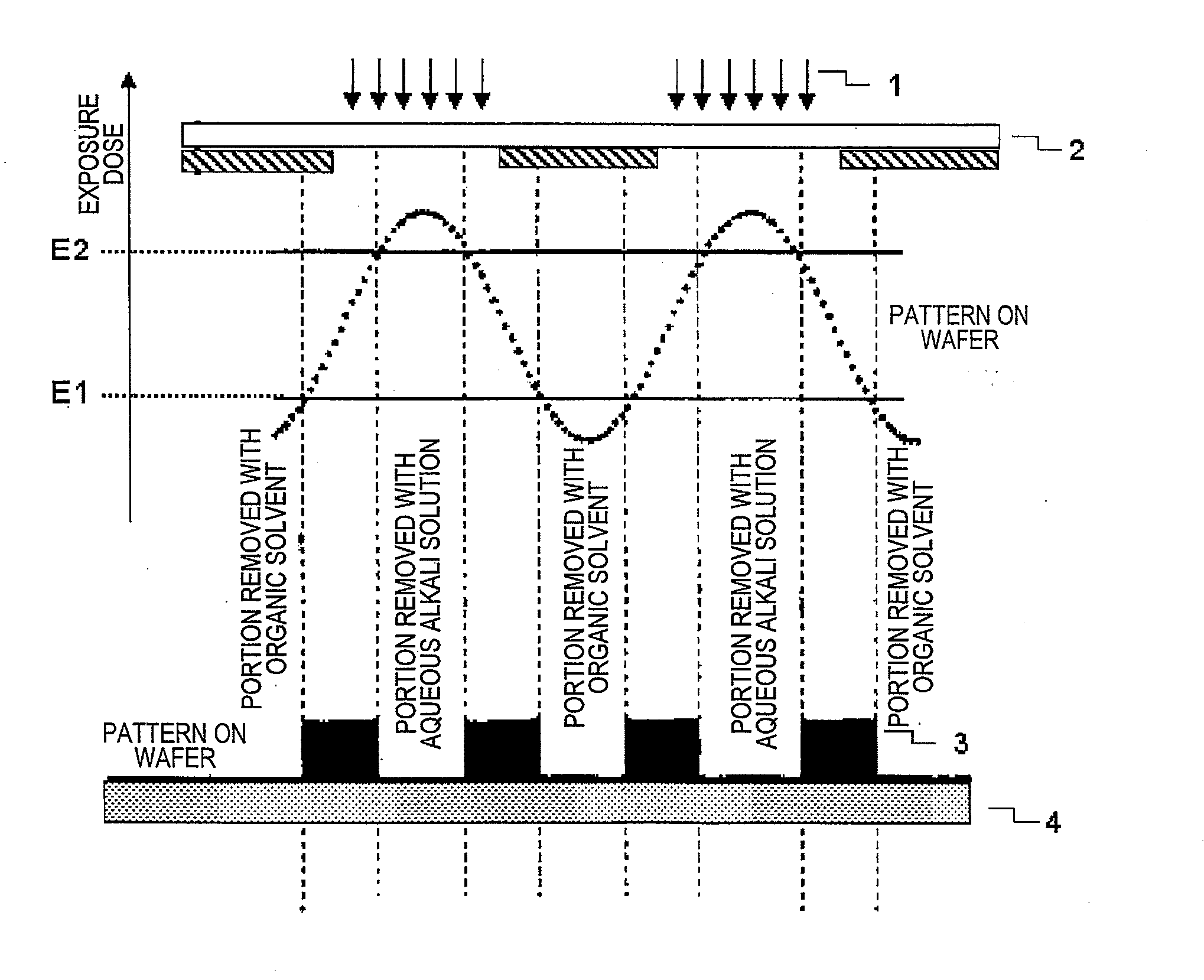

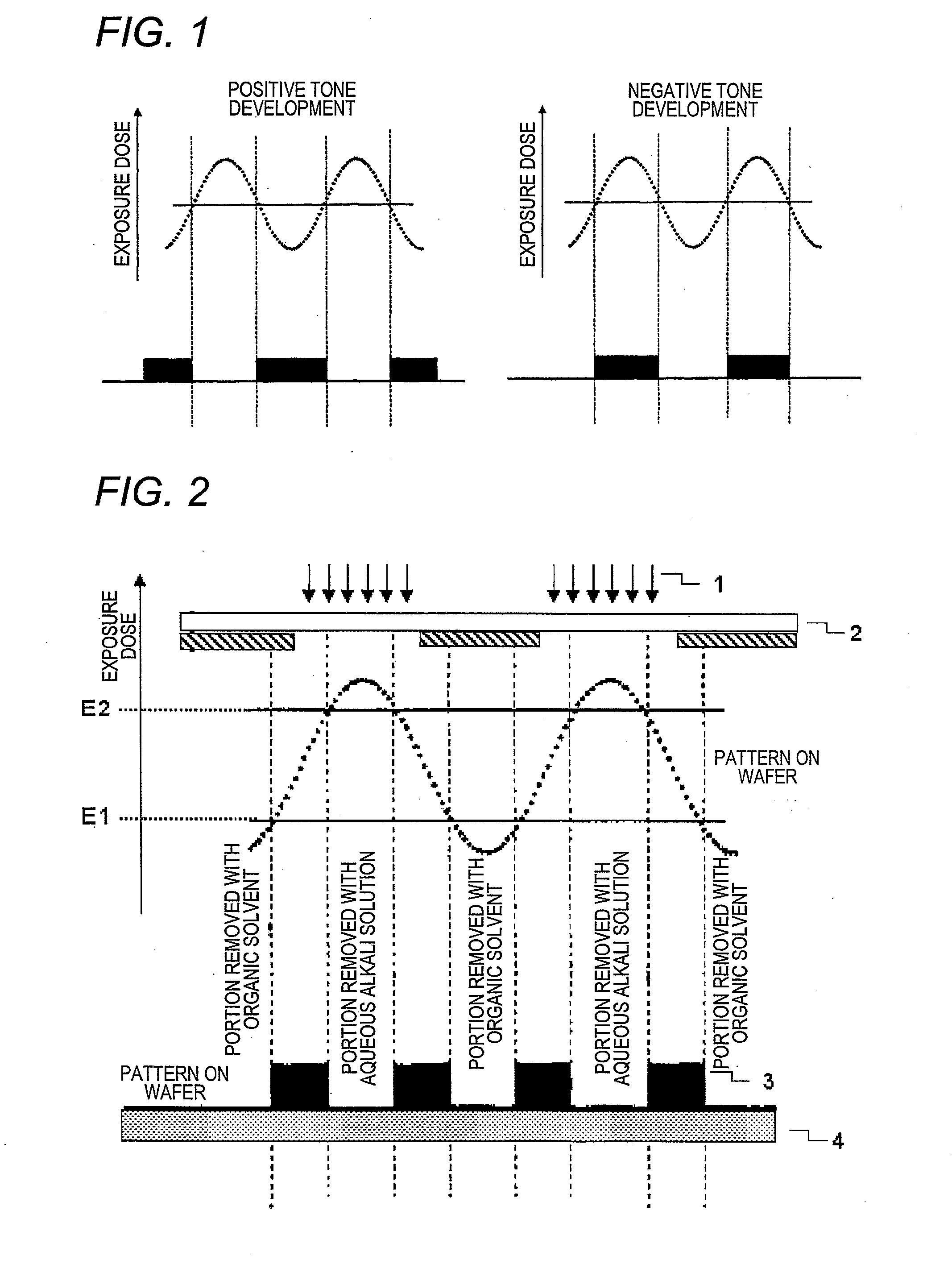

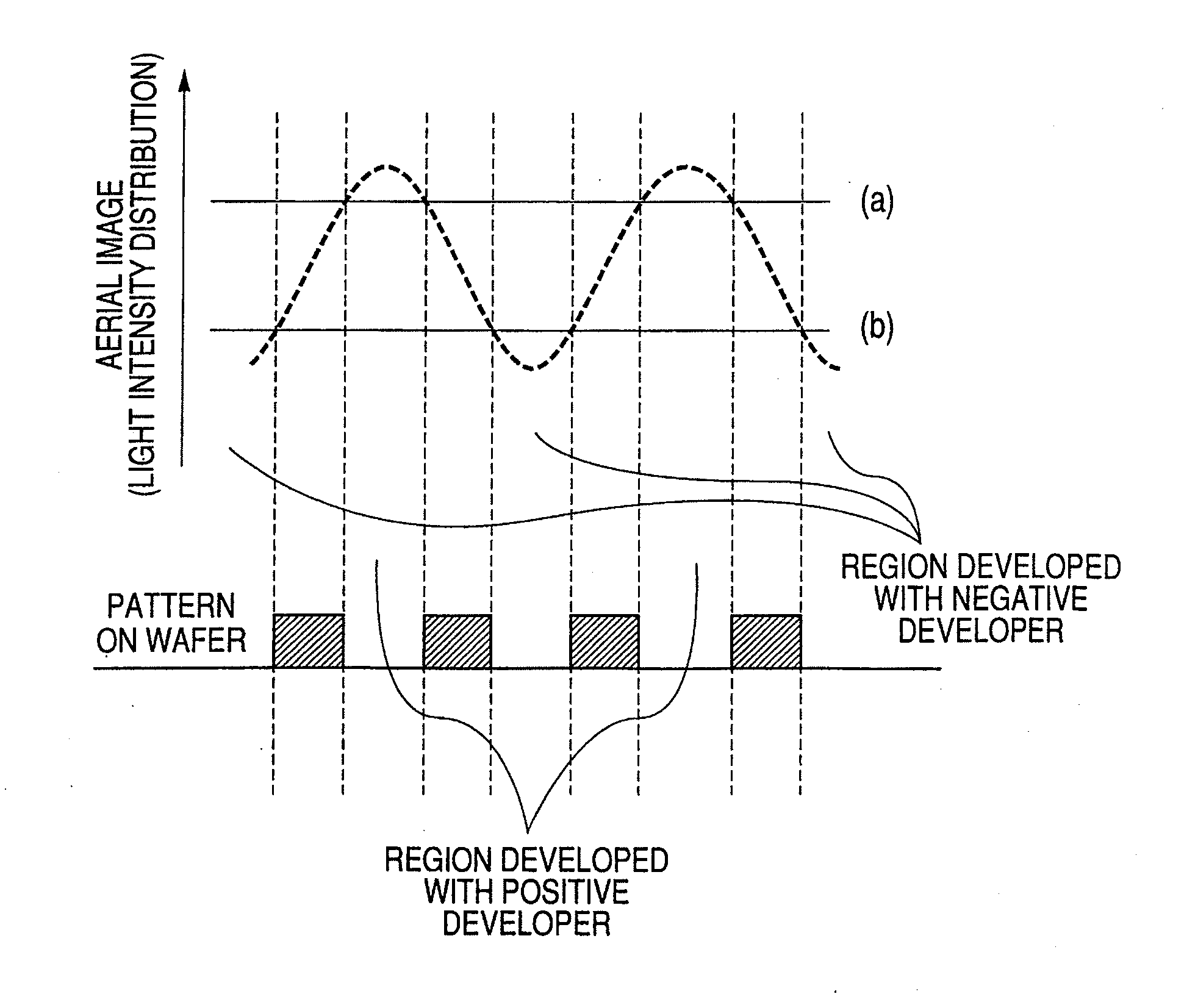

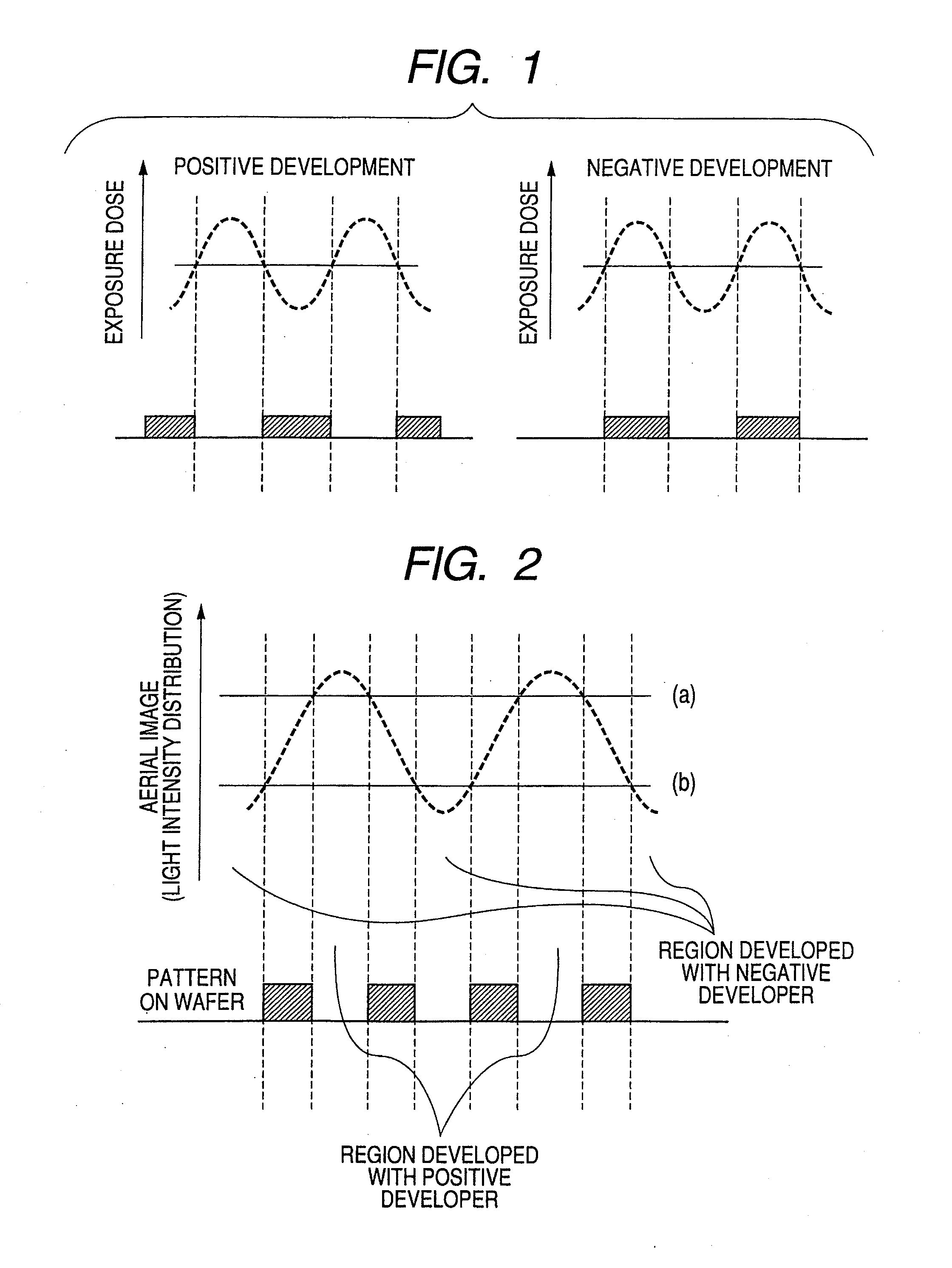

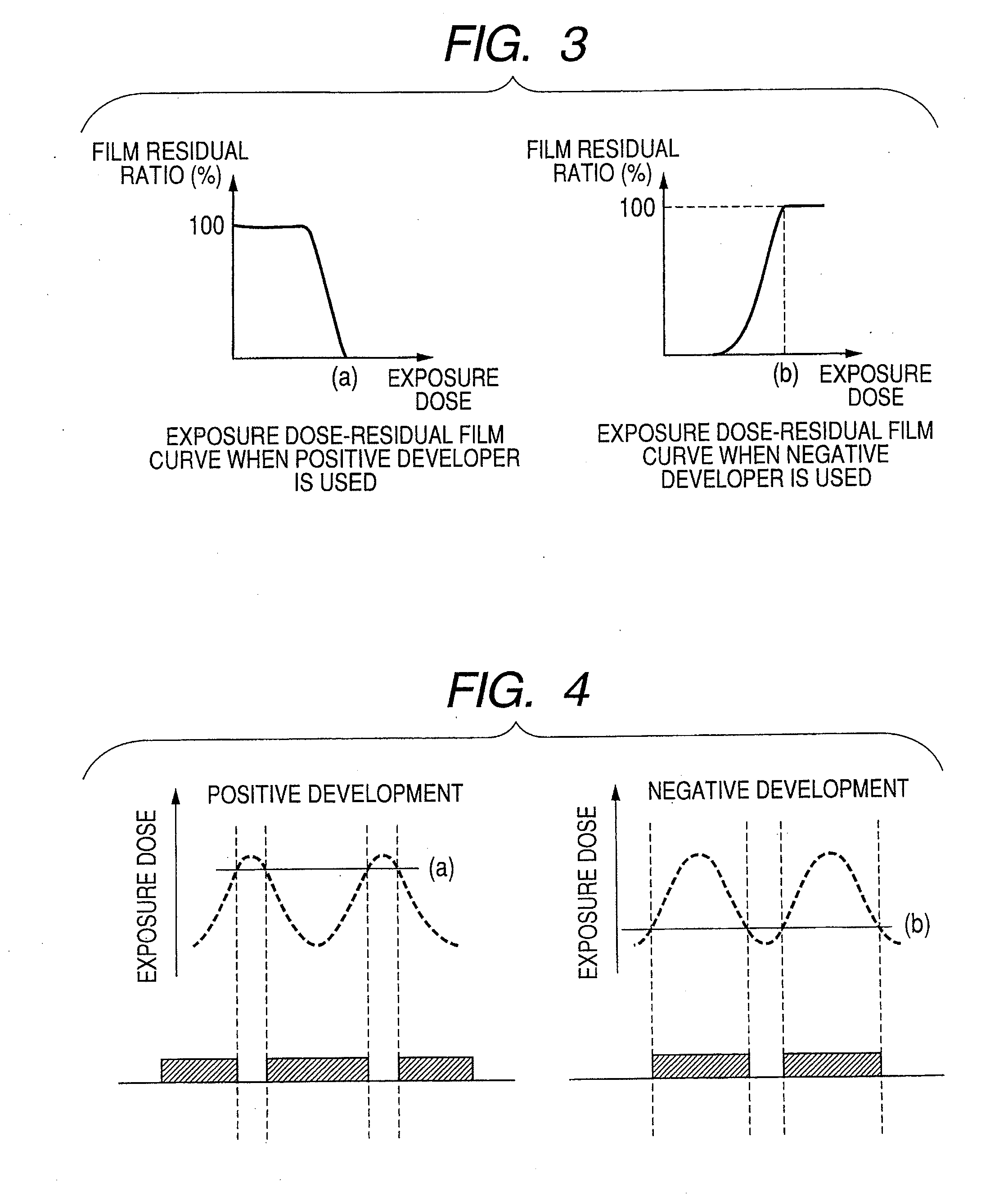

A pattern forming method, including: (A) coating a substrate with a positive resist composition of which solubility in a positive developer increases and solubility in a negative developer decreases upon irradiation with actinic rays or radiation, so as to form a resist film; (B) exposing the resist film; and (D) developing the resist film with a negative developer; a positive resist composition for multiple development used in the method; a developer for use in the method; and a rinsing solution for negative development used in the method.

Owner:FUJIFILM CORP

Pattern forming method, resist composition for multiple development used in the pattern forming method, developer for negative development used in the pattern forming method, and rinsing solution for negative development used in the pattern forming method

ActiveUS20080261150A1Improve accuracyMolding stabilityPhotosensitive materialsPhotoprinting processesActinic RaysPhotochemistry

A pattern forming method, including: (A) coating a substrate with a positive resist composition of which solubility in a positive developer increases and solubility in a negative developer decreases upon irradiation with actinic rays or radiation, so as to form a resist film; (B) exposing the resist film; and (D) developing the resist film with a negative developer; a positive resist composition for multiple development used in the method; a developer for use in the method; and a rinsing solution for negative development used in the method.

Owner:FUJIFILM CORP

Pattern forming method, resist composition for multiple development used in the pattern forming method, developer for negative development used in the pattern forming method, and rinsing solution for negative development used in the pattern forming method

ActiveUS20100323305A1Improve accuracyMolding stabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusChemistryActinic Rays

A pattern forming method, including: (A) coating a substrate with a positive resist composition of which solubility in a positive developer increases and solubility in a negative developer decreases upon irradiation with actinic rays or radiation, so as to form a resist film; (B) exposing the resist film; and (D) developing the resist film with a negative developer; a positive resist composition for multiple development used in the method; a developer for use in the method; and a rinsing solution for negative development used in the method.

Owner:FUJIFILM CORP

Pattern forming method, and resist composition, developer and rinsing solution used in the pattern forming method

ActiveUS8017304B2Molding stabilityReduce roughnessPhotosensitive materialsPhotoprinting processesDispersityActinic Rays

A pattern forming method comprising a step of applying a resist composition whose solubility in a negative tone developer decreases upon irradiation with an actinic ray or radiation and which contains a resin having an alicyclic hydrocarbon structure and a dispersity of 1.7 or less and being capable of increasing the polarity by the action of an acid, an exposure step, and a development step using a negative tone developer; a resist composition for use in the method; and a developer and a rinsing solution for use in the method, are provided, whereby a pattern with reduced line edge roughness and high dimensional uniformity can be formed.

Owner:FUJIFILM CORP

Pattern forming method, and resist composition, developer and rinsing solution used in the pattern forming method

InactiveUS20100040971A1Reduced line edge roughnessGood size uniformityPhotosensitive materialsPhotomechanical exposure apparatusDispersityActinic Rays

A pattern forming method comprising a step of applying a resist composition whose solubility in a negative tone developer decreases upon irradiation with an actinic ray or radiation and which contains a resin having an alicyclic hydrocarbon structure and a dispersity of 1.7 or less and being capable of increasing the polarity by the action of an acid, an exposure step, and a development step using a negative tone developer; a resist composition for use in the method; and a developer and a rinsing solution for use in the method, are provided, whereby a pattern with reduced line edge roughness and high dimensional uniformity can be formed.

Owner:FUJIFILM CORP

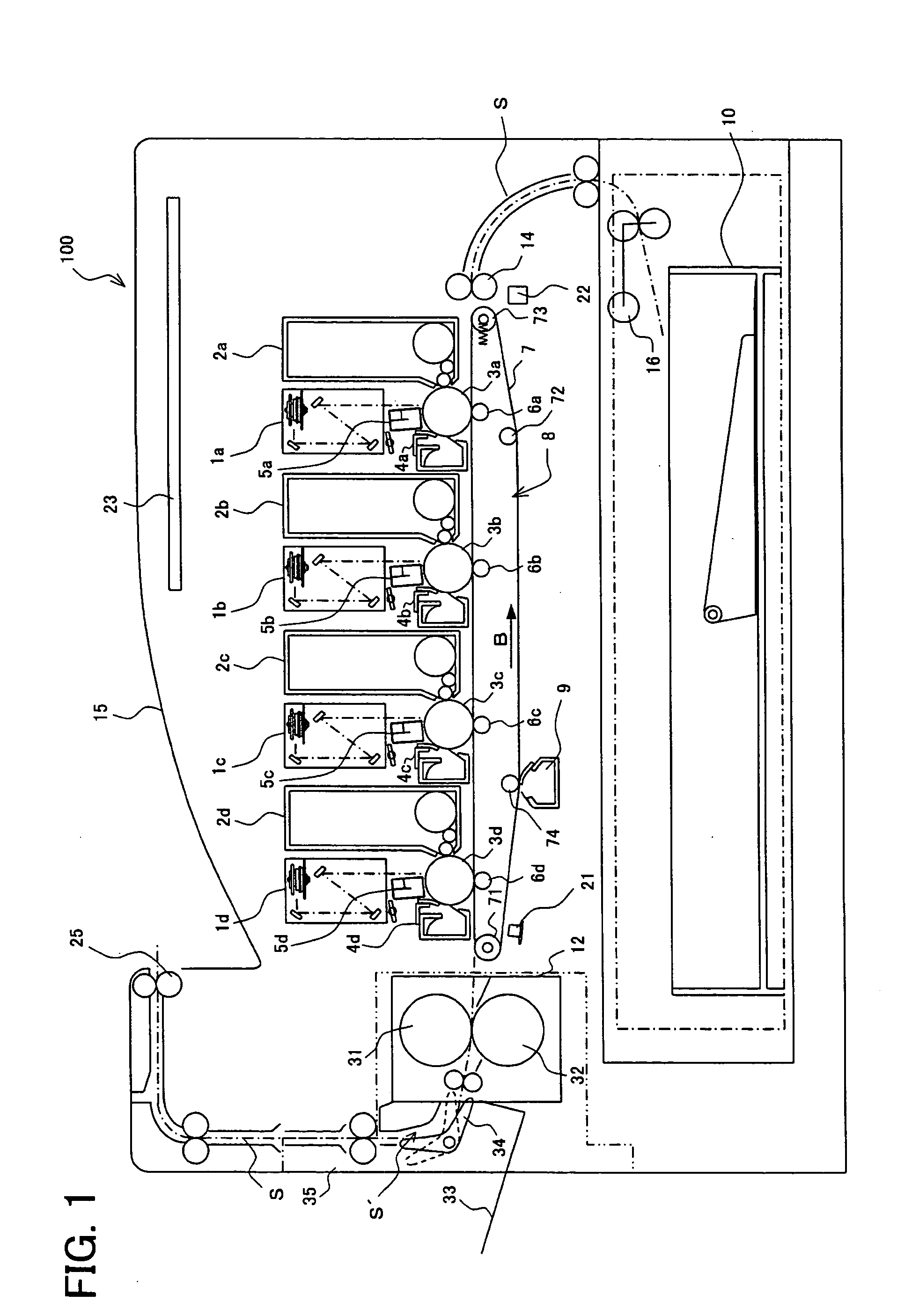

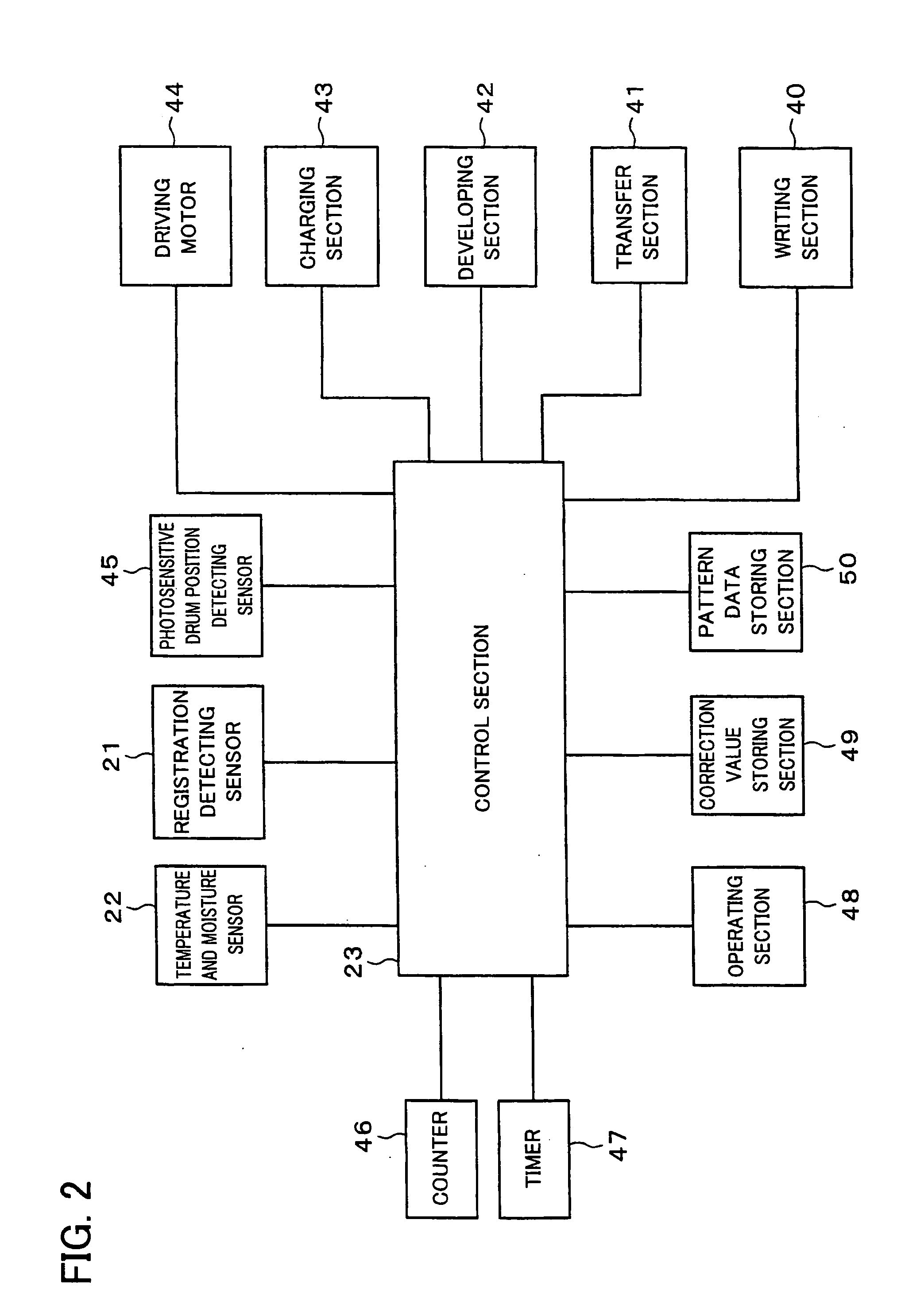

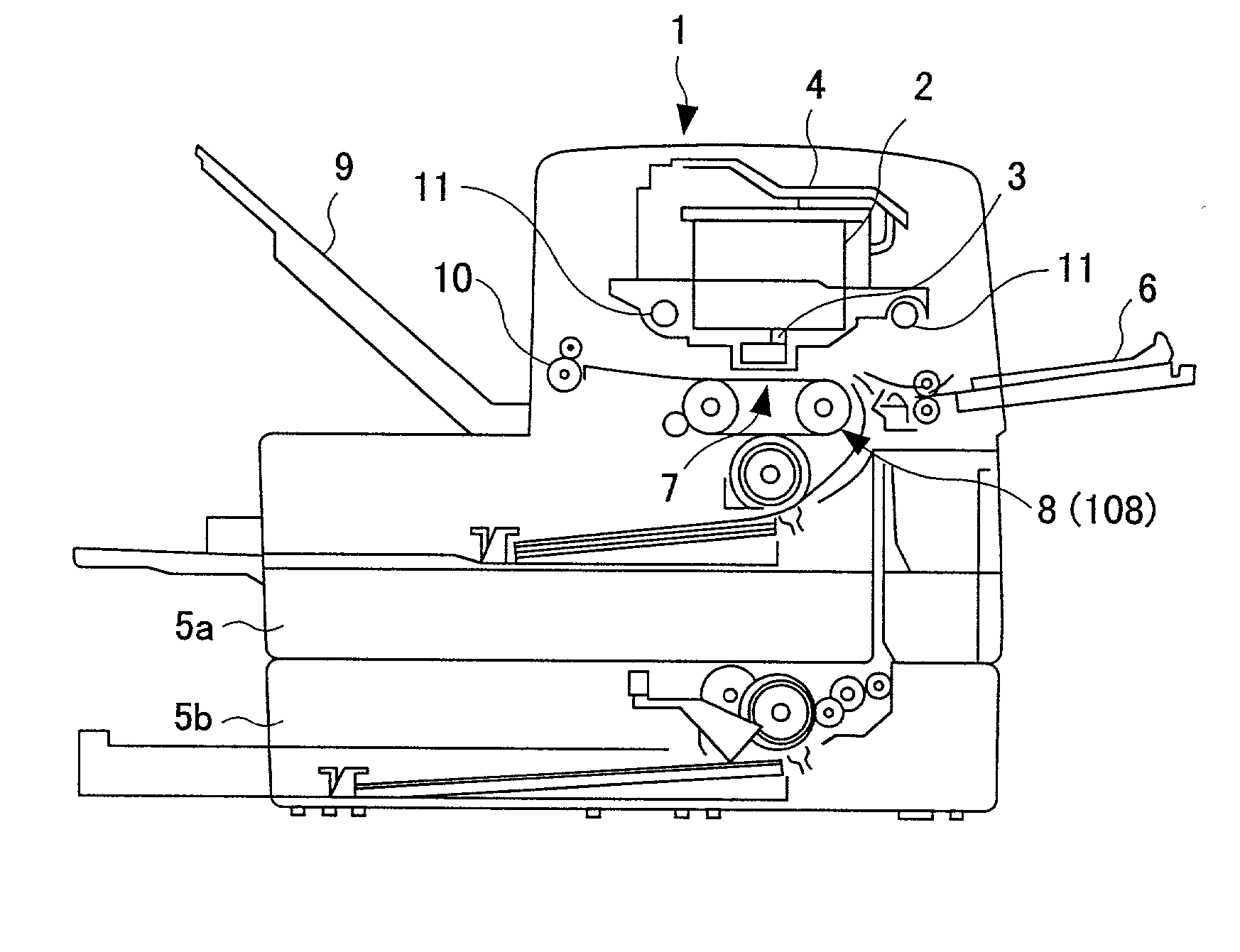

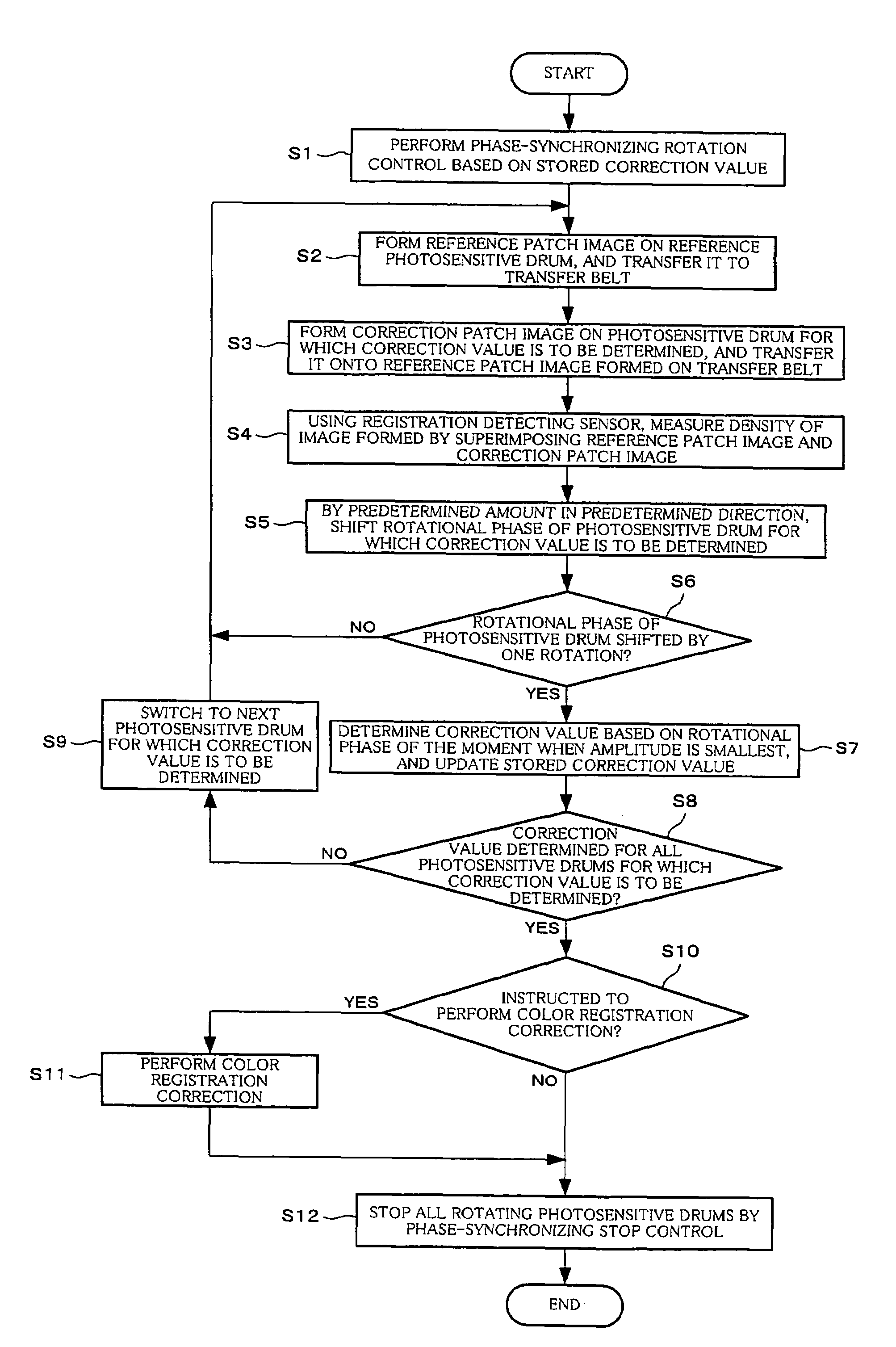

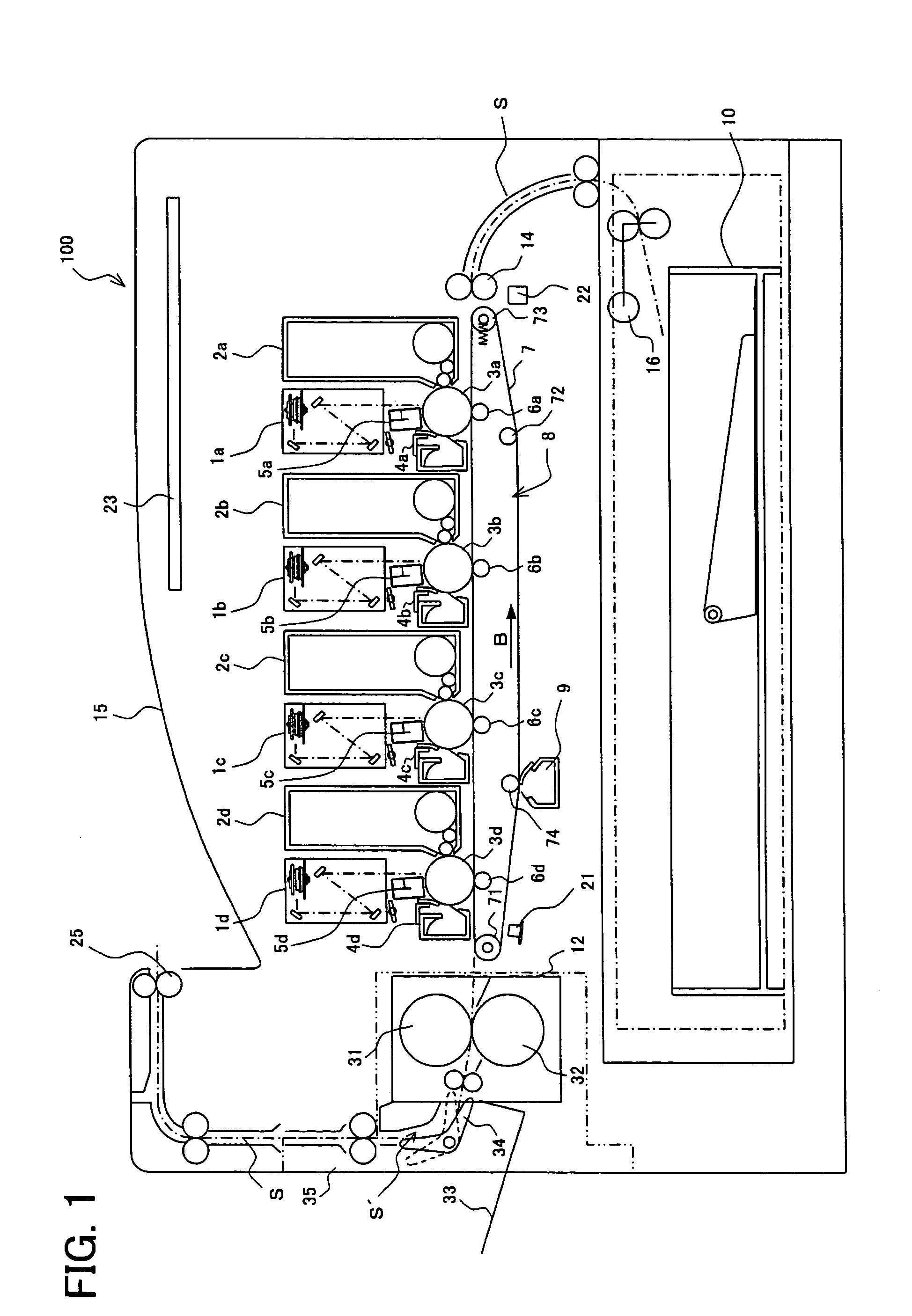

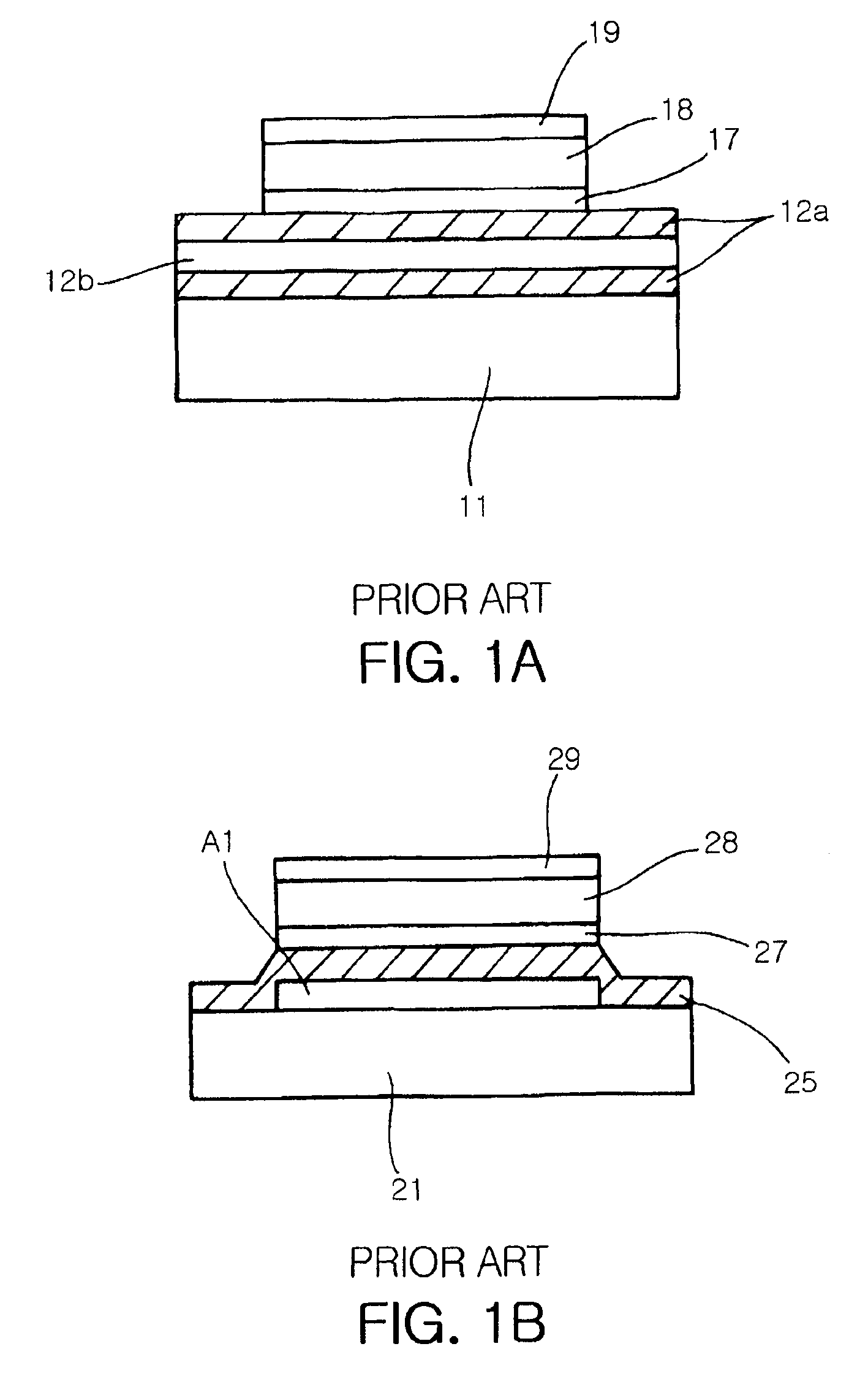

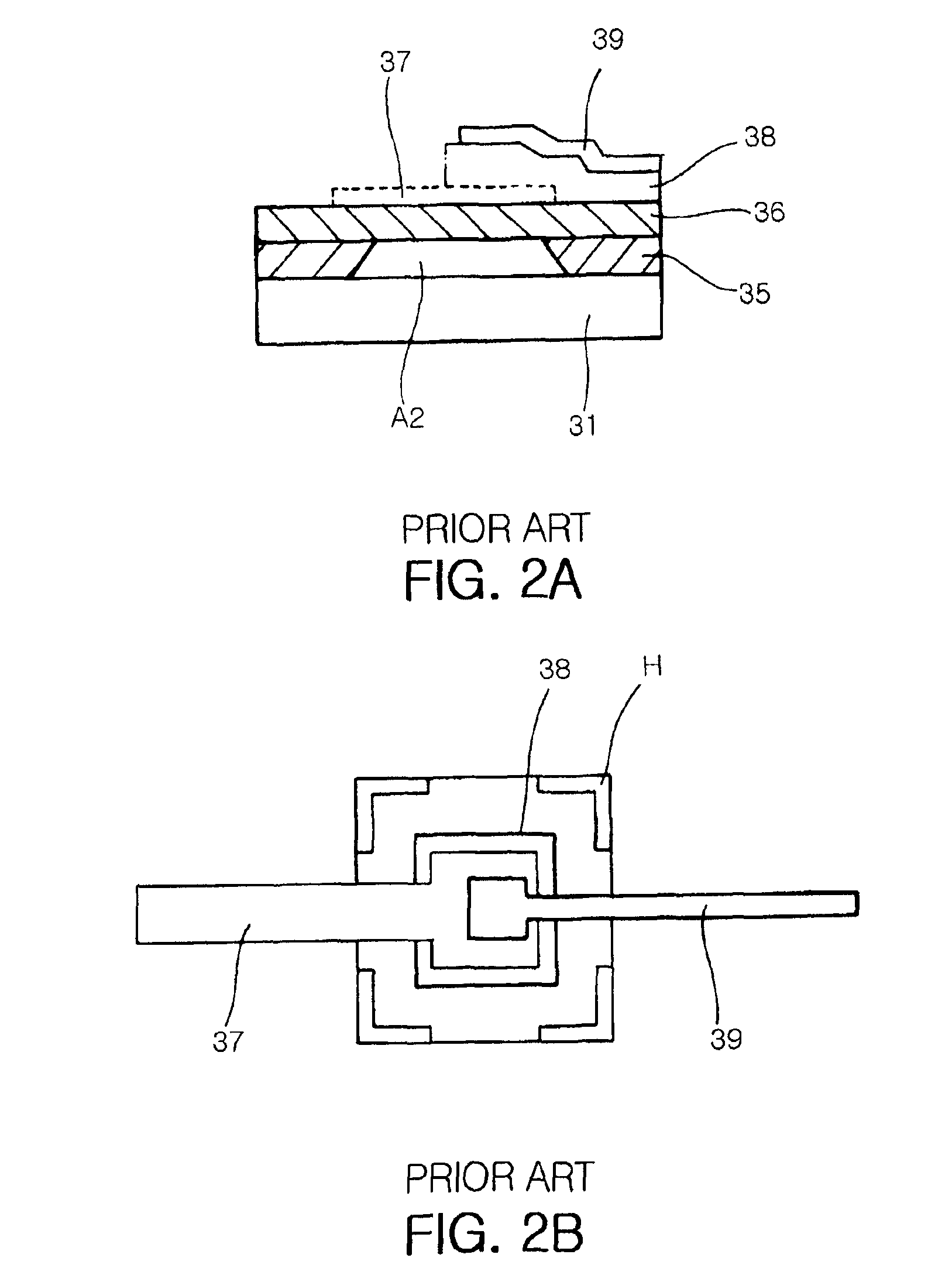

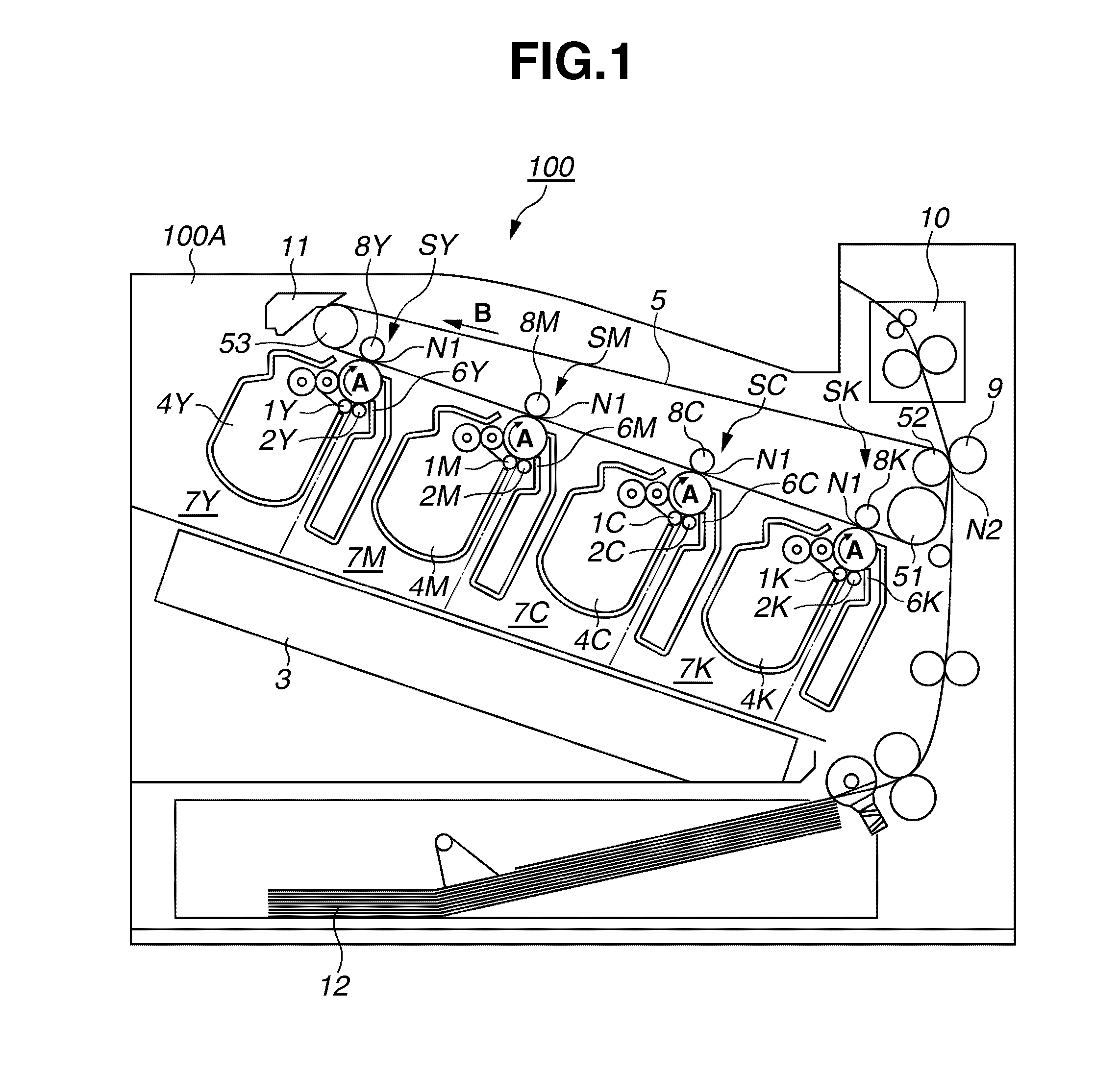

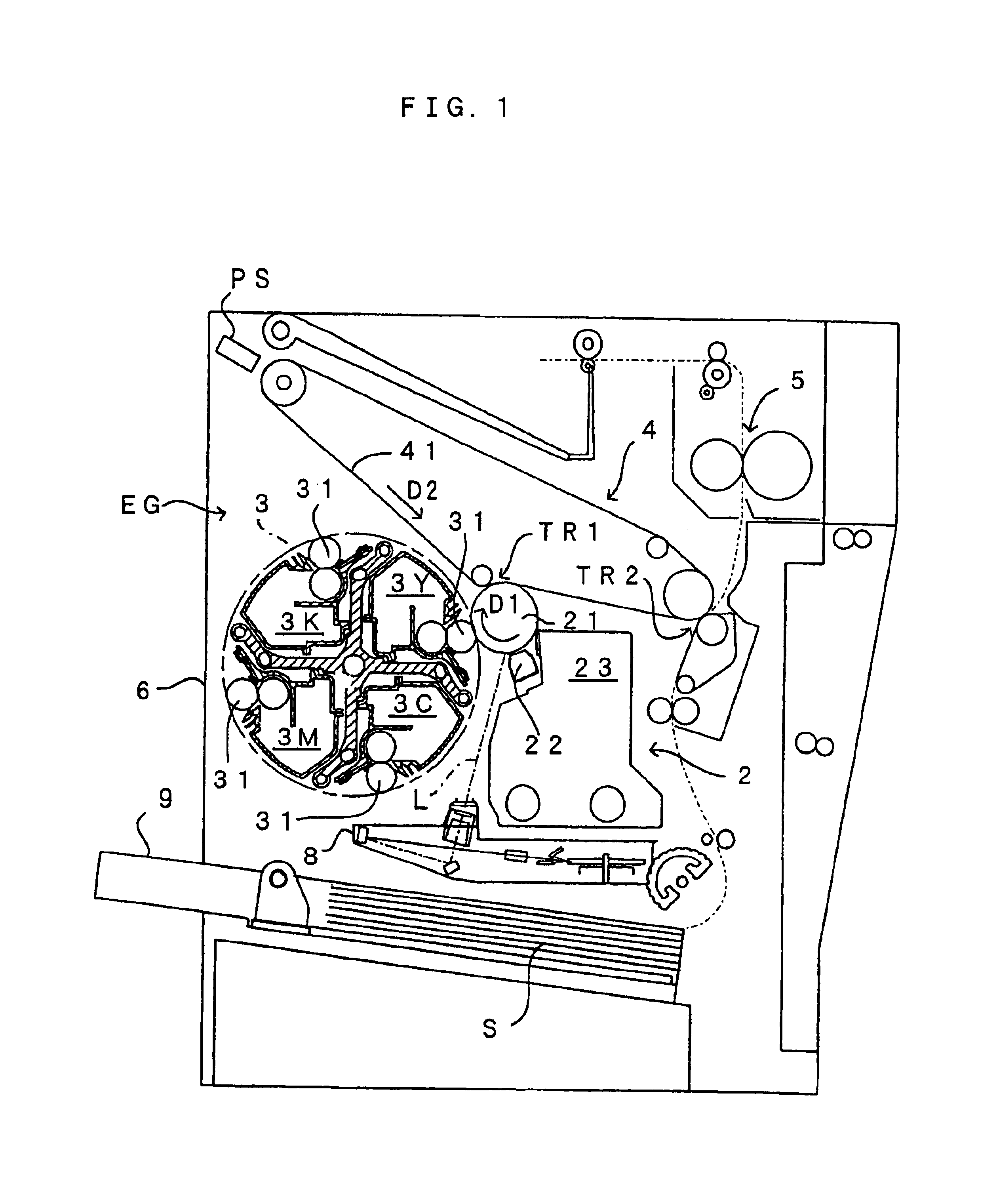

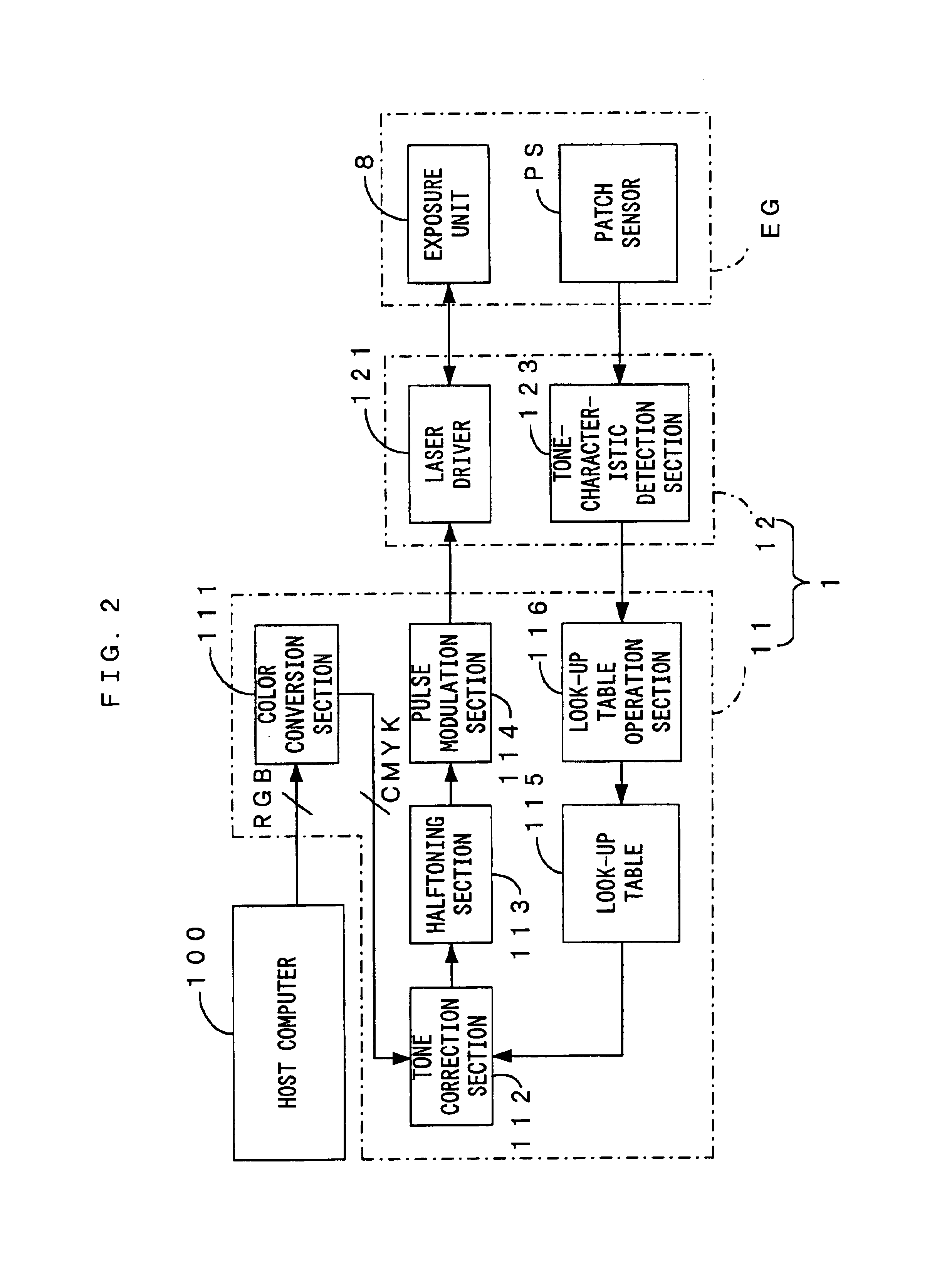

Image forming device and color misregistration correction method for image forming device

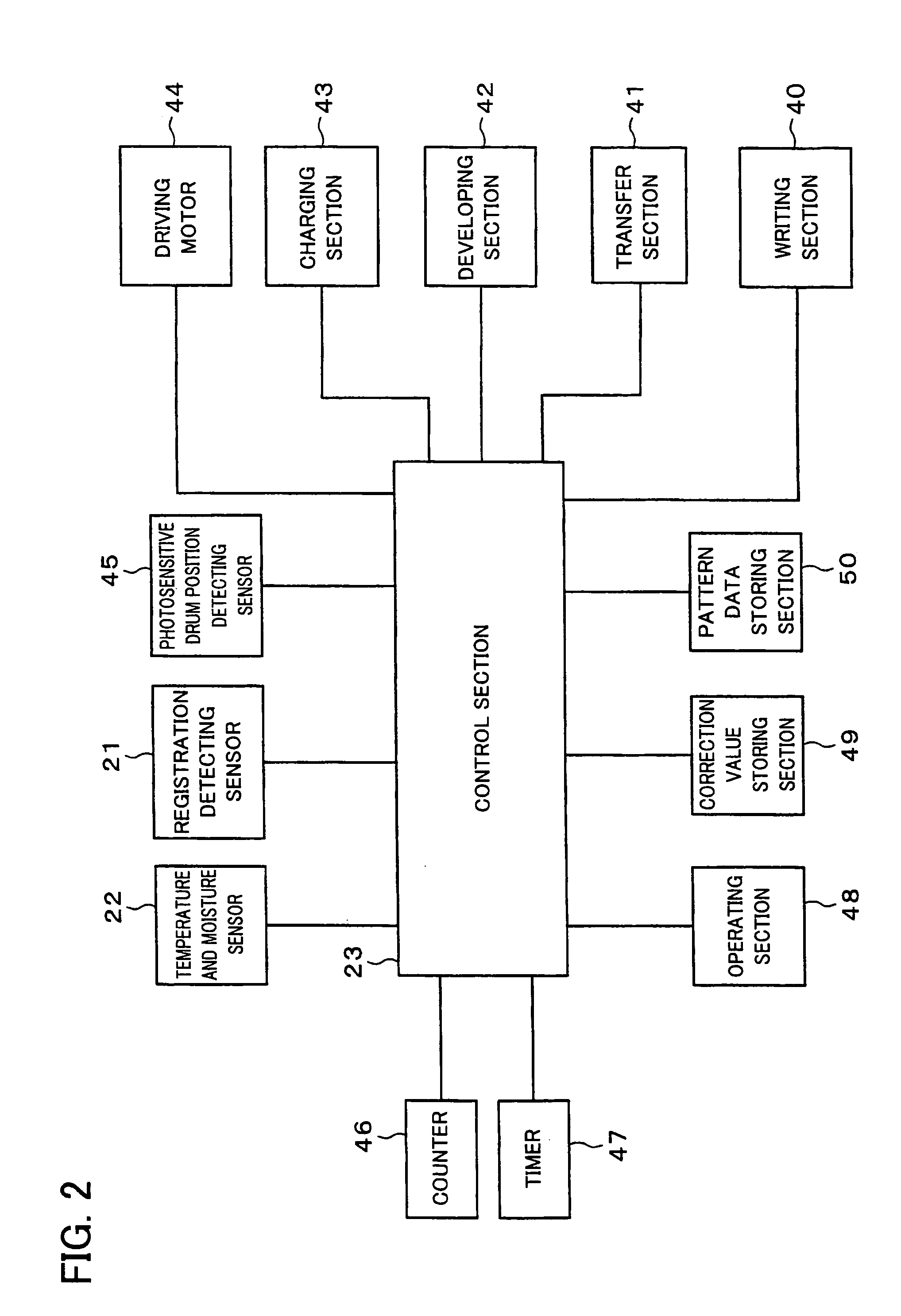

ActiveUS20050047834A1Molding stabilityEnhance the imageElectrographic process apparatusPrintingImage formation

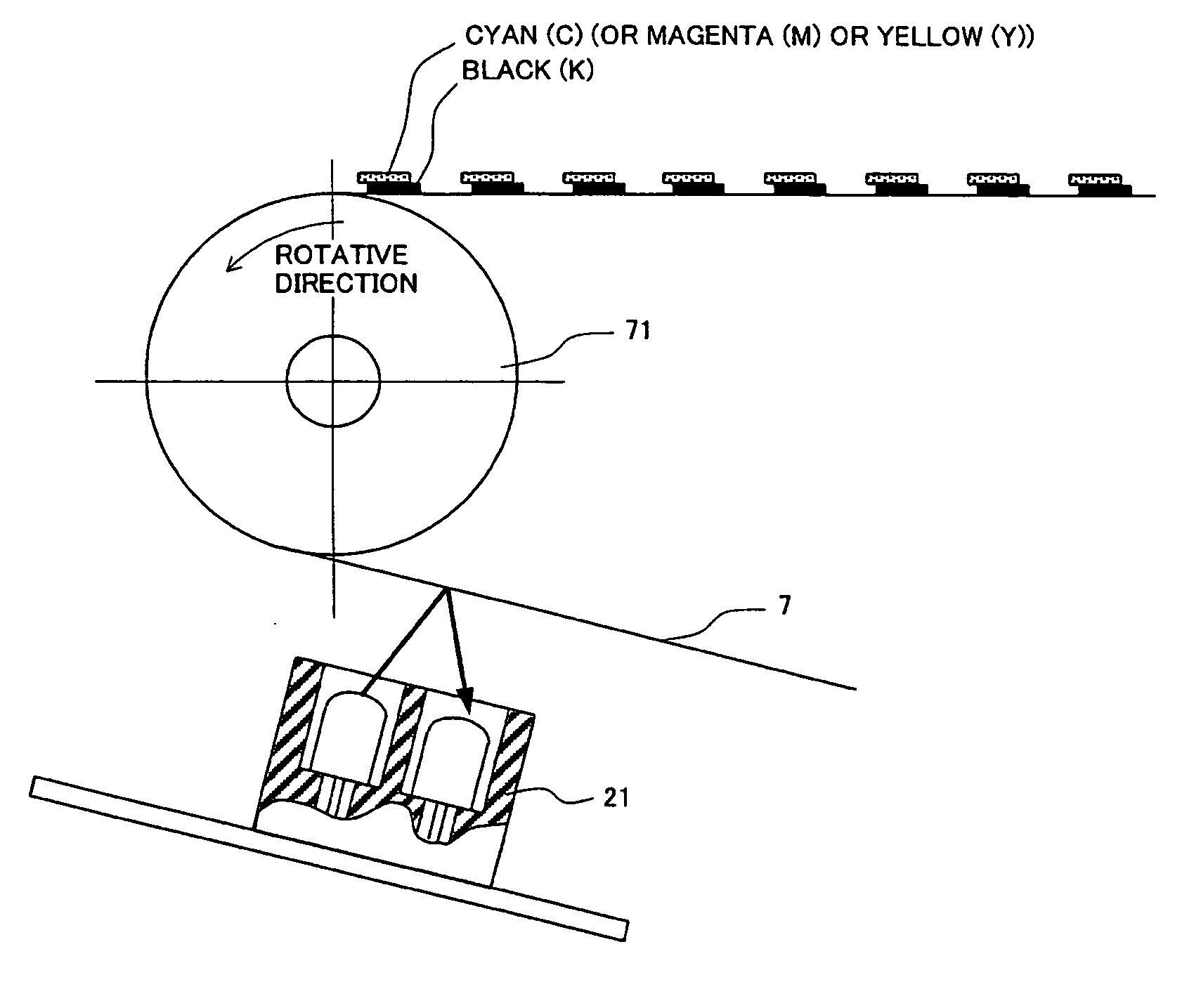

An image forming device and a color misregistration correction method allow for stable formation of excellent images with little color misregistration. A reference patch image is formed on a reference photosensitive drum 3, and transferred to a transfer belt 7. A correction patch image is formed on a correction-target photosensitive drum 3, and transferred onto the reference patch image by superimposition. A registration detecting sensor 21 detects a density average value of the reference patch image and the correction patch image. Based on the density average value, a correction value for controlling the correction-target photosensitive drum 3 is calculated, and rotational phase control is performed in accordance with the correction value.

Owner:SHARP KK

Pattern forming method, and resist composition, developer and rinsing solution used in the pattern forming method

ActiveUS20100040972A1Reduced line edge roughnessGood size uniformityPhotosensitive materialsPhotoprinting processesDispersityActinic Rays

A pattern forming method comprising a step of applying a resist composition whose solubility in a negative tone developer decreases upon irradiation with an actinic ray or radiation and which contains a resin having an alicyclic hydrocarbon structure and a dispersity of 1.7 or less and being capable of increasing the polarity by the action of an acid, an exposure step, and a development step using a negative tone developer; a resist composition for use in the method; and a developer and a rinsing solution for use in the method, are provided, whereby a pattern with reduced line edge roughness and high dimensional uniformity can be formed.

Owner:FUJIFILM CORP

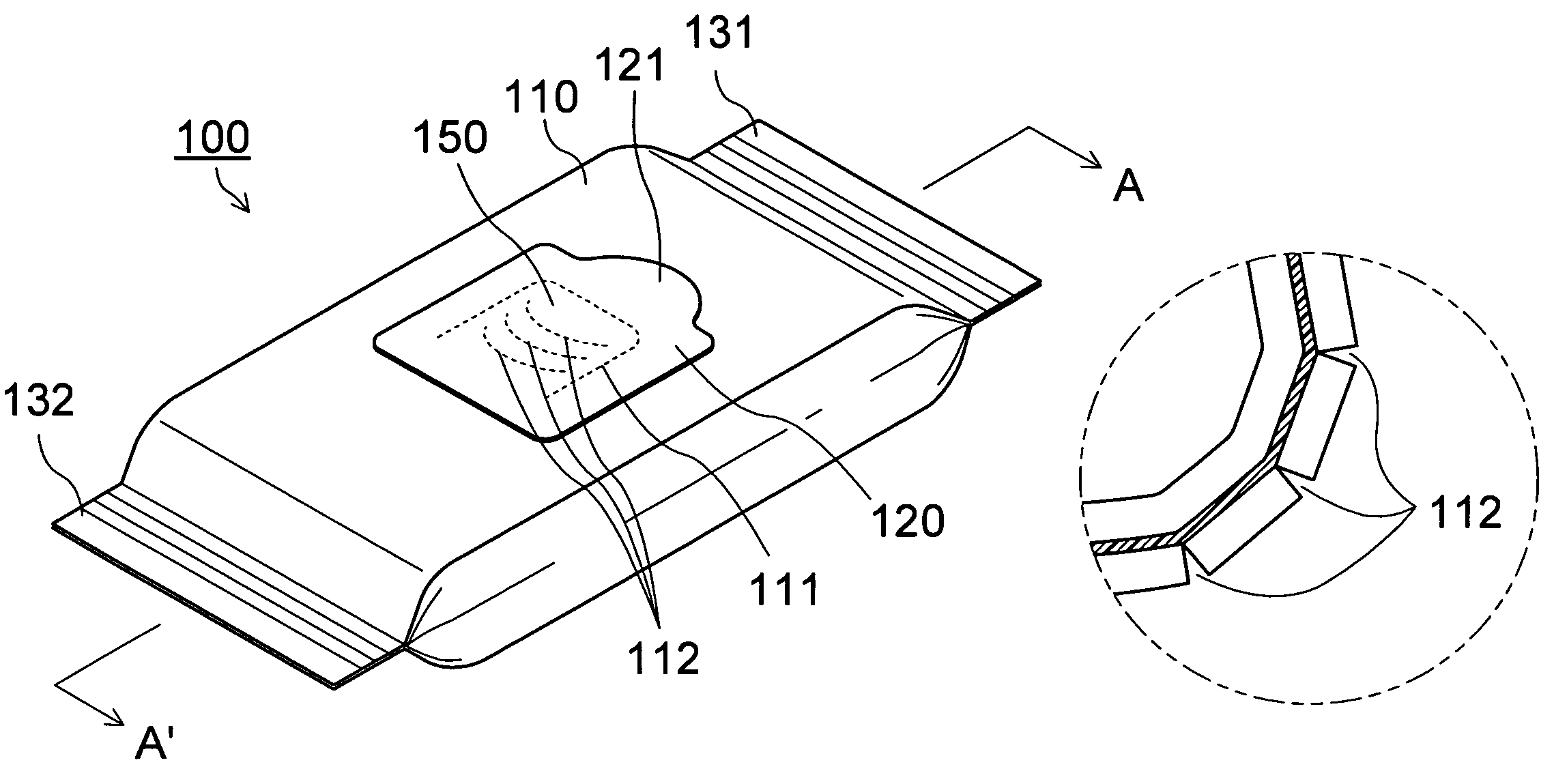

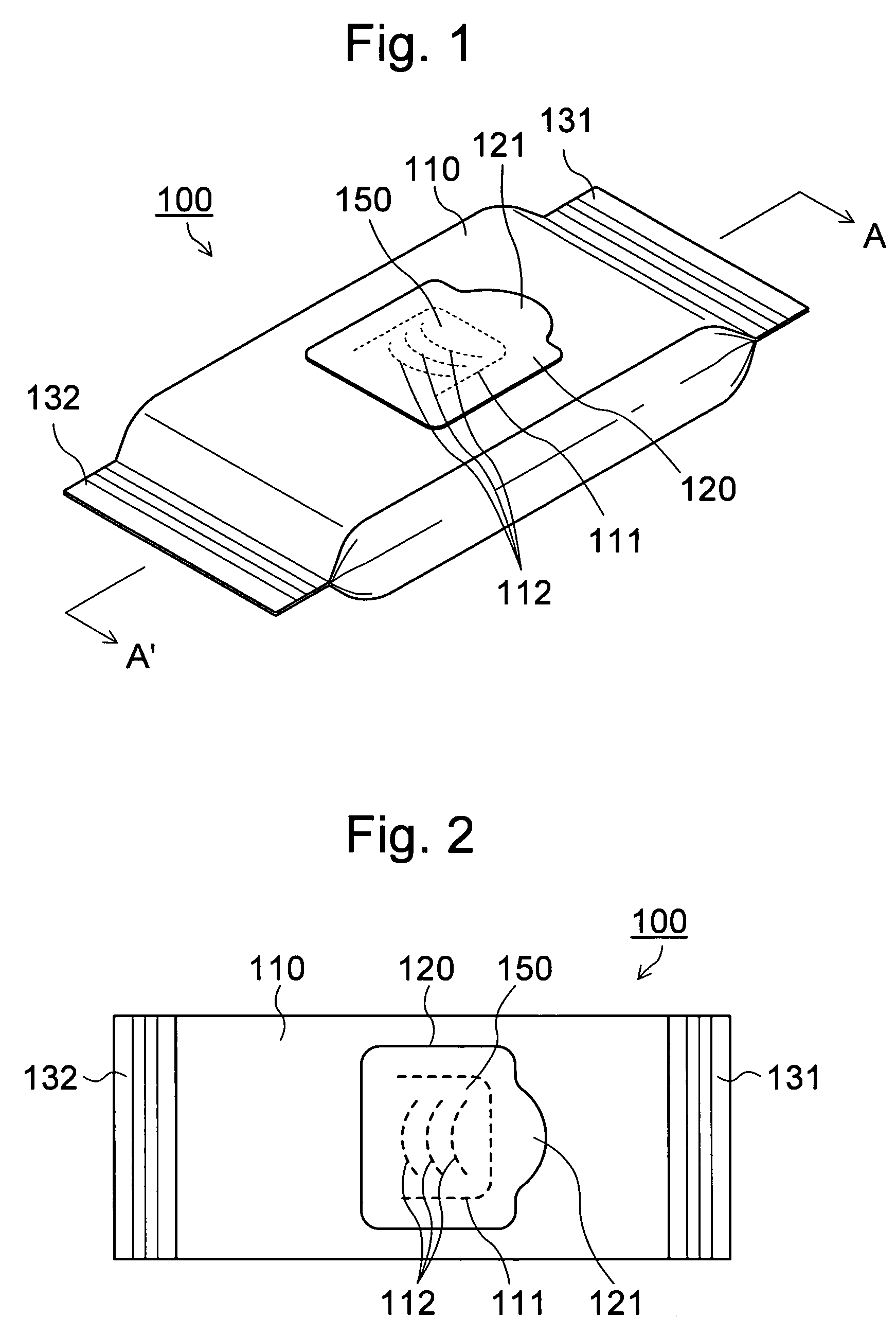

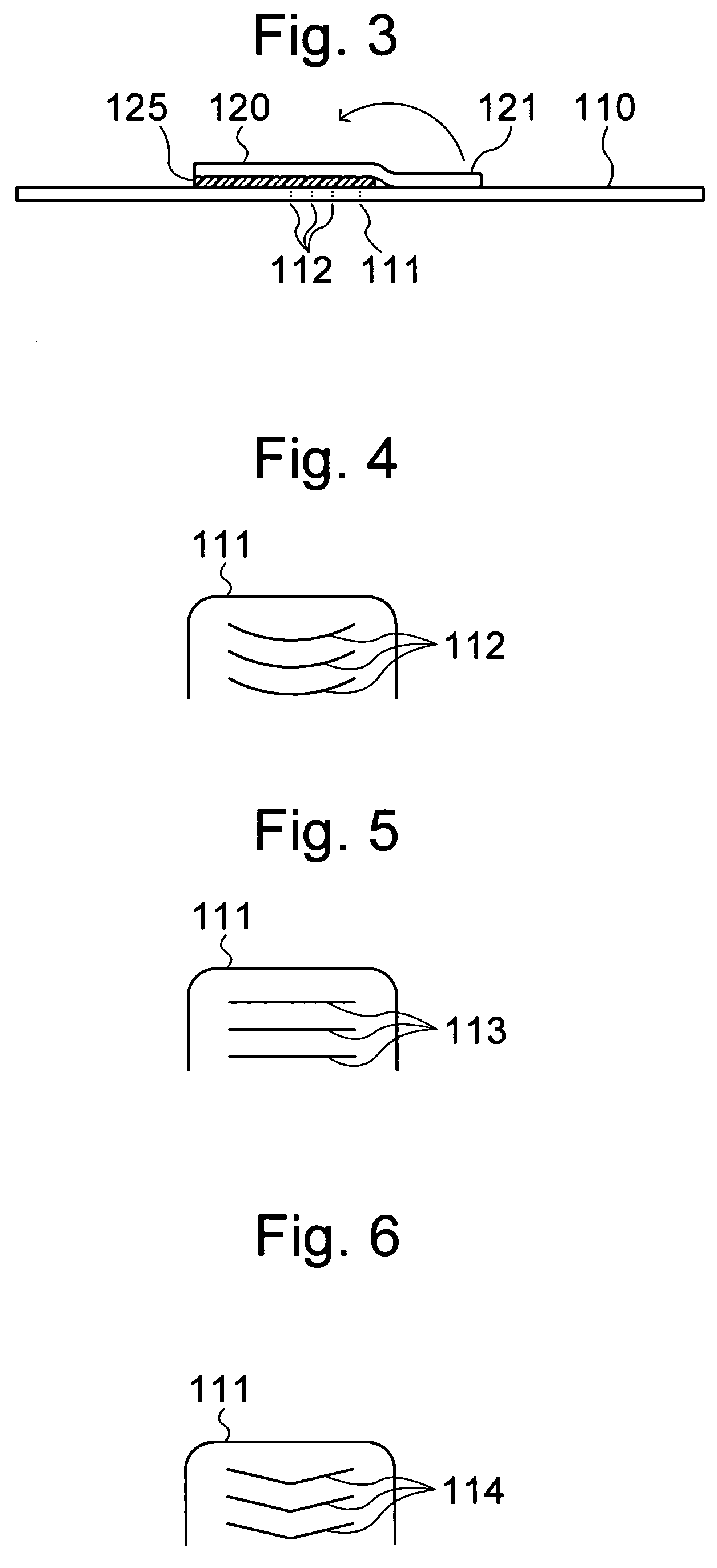

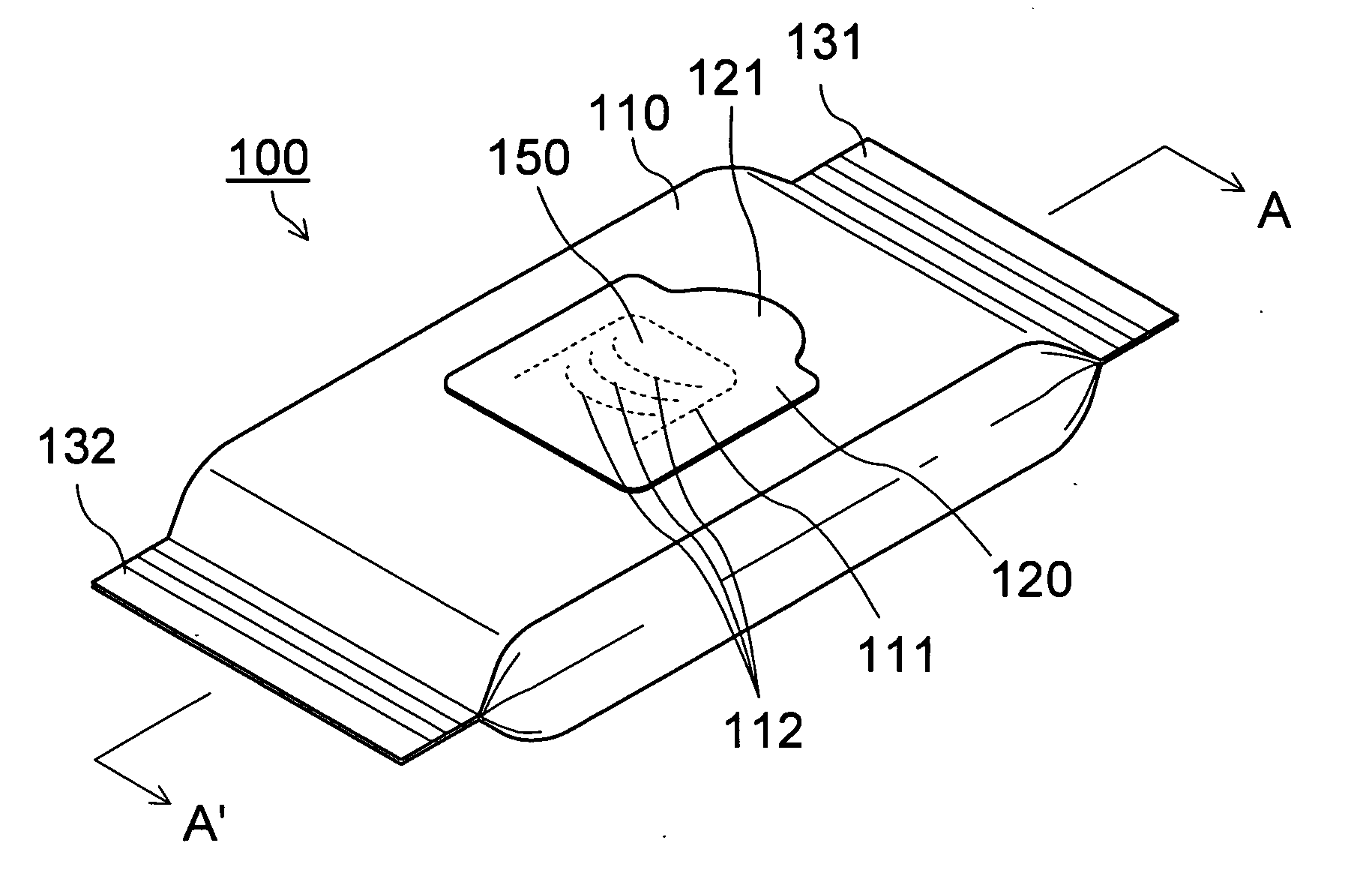

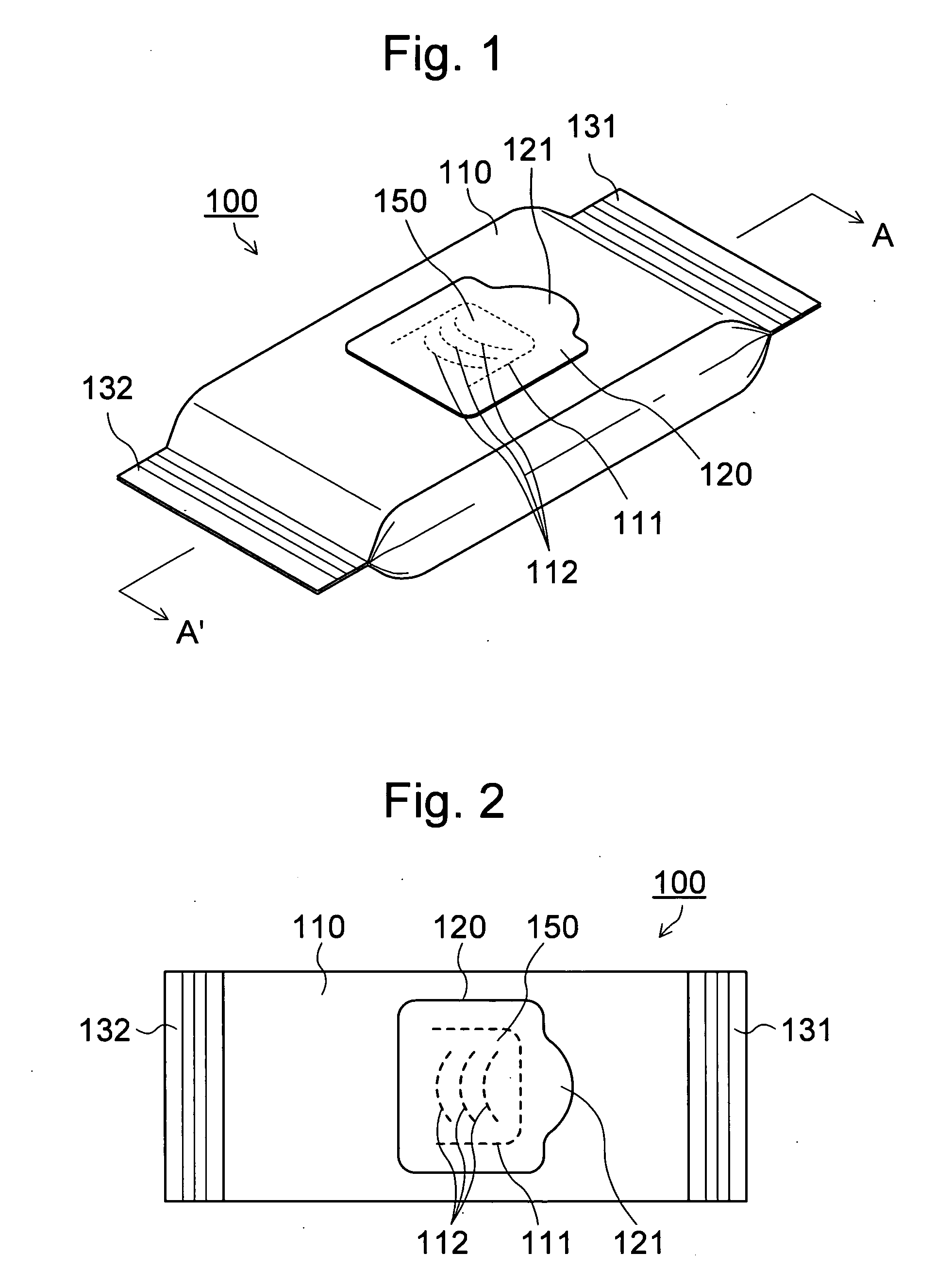

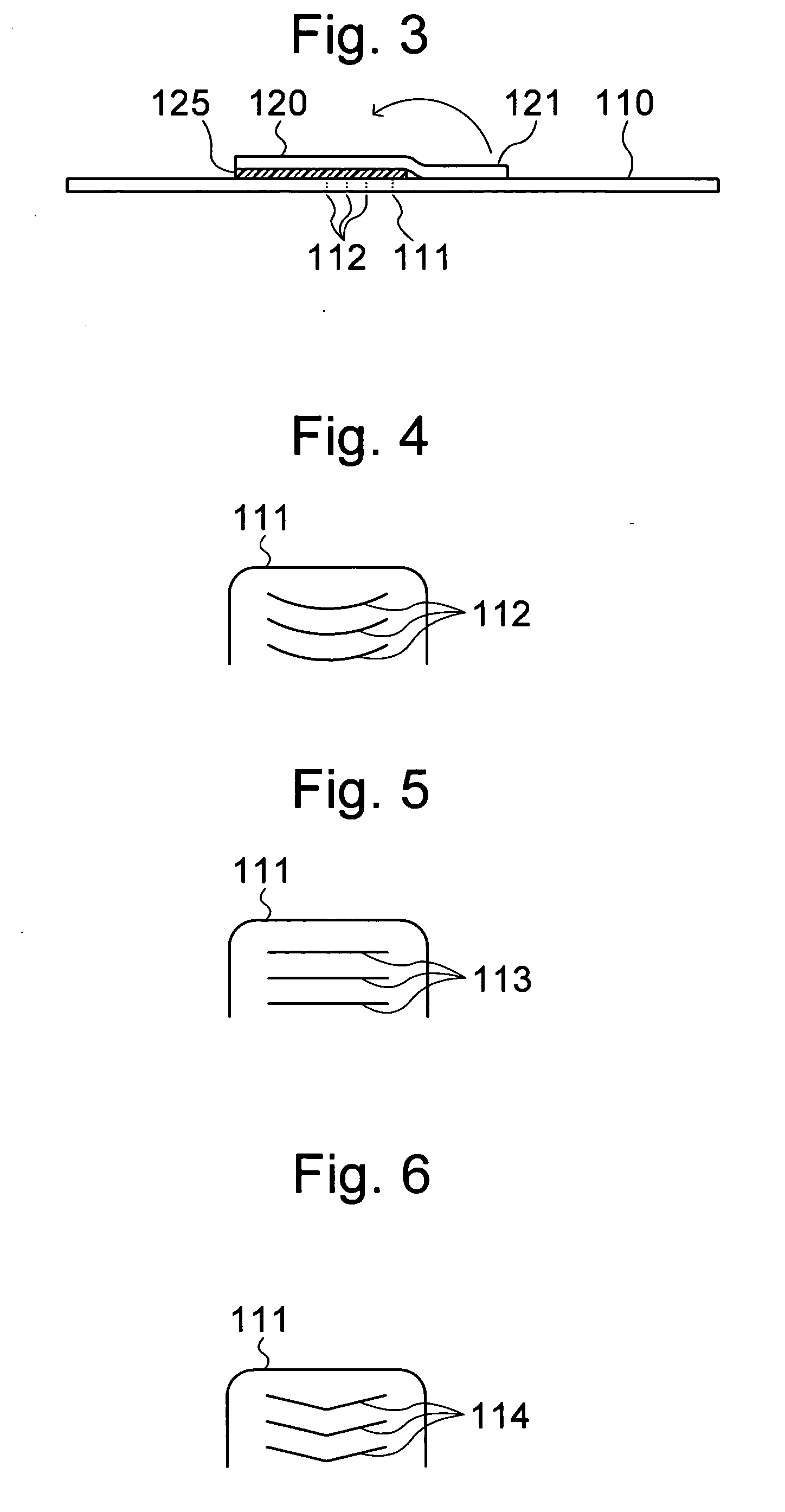

Easy-open package

InactiveUS7475781B2Reduce stiffnessEasy to stickWrappersDiagnosticsMechanical engineeringEngineering

A package is presented from which contents can be easily taken out. This package includes a film with a soft packaging material. On the surface of the soft packaging material is a cut line, such that, inside the cut line, an openable region is formed for taking contents out from the package. Further, inside the openable region, dashed lines are provided. When a lid member adhering to cover the openable region is peeled, the openable region easily adheres to the lid member side owing to the dashed lines to reliably form the opened portion.

Owner:UNI CHARM CORP

Easy-open package

InactiveUS20050284776A1Reduce stiffnessEasy to stickDiagnosticsSurgical needlesBiomedical engineeringEngineering

A package is presented from which contents can be easily taken out. This package includes a film with a soft packaging material. On the surface of the soft packaging material is a cut line, such that, inside the cut line, an openable region is formed for taking contents out from the package. Further, inside the openable region, dashed lines are provided. When a lid member adhering to cover the openable region is peeled, the openable region easily adheres to the lid member side owing to the dashed lines to reliably form the opened portion.

Owner:UNI CHARM CORP

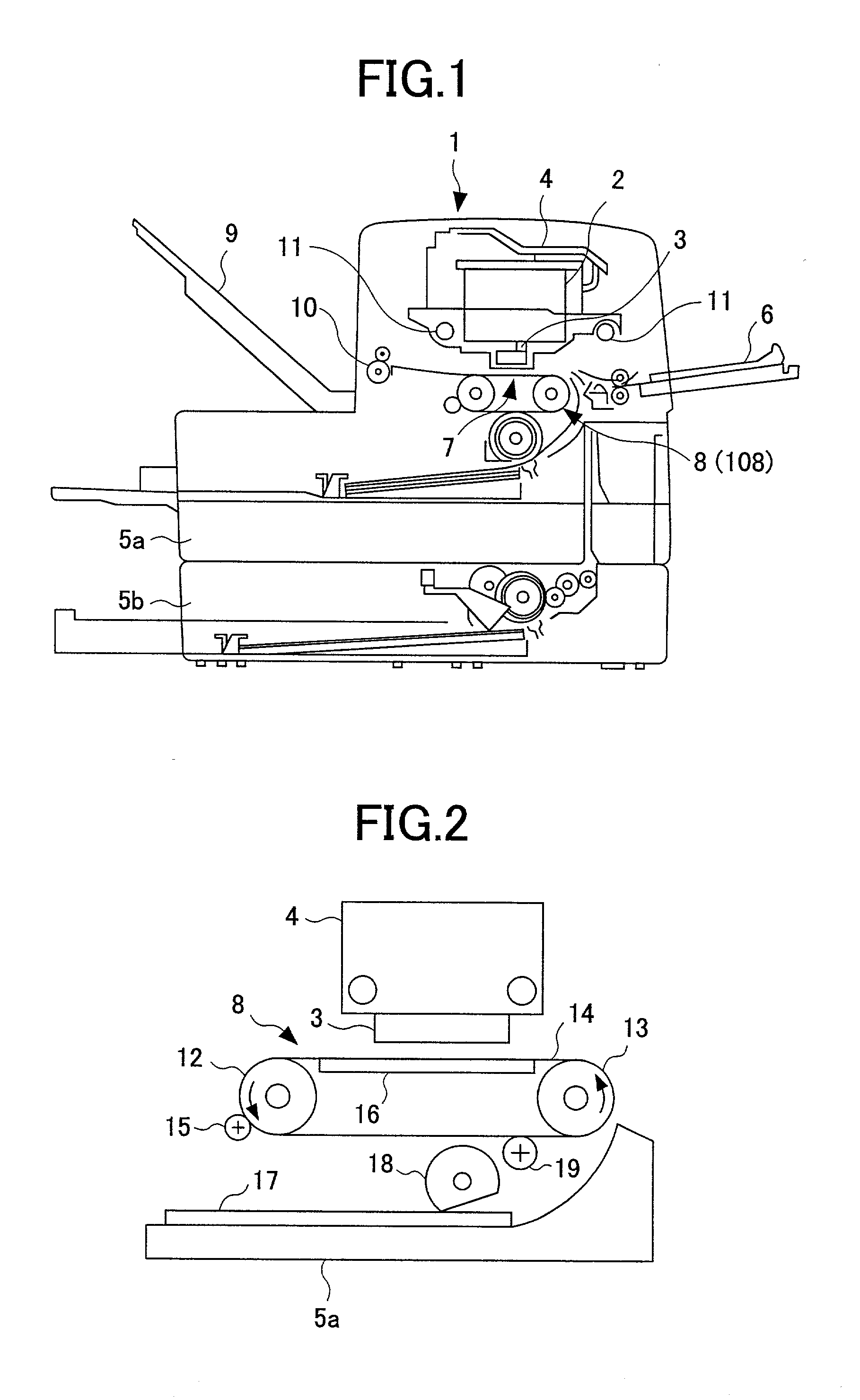

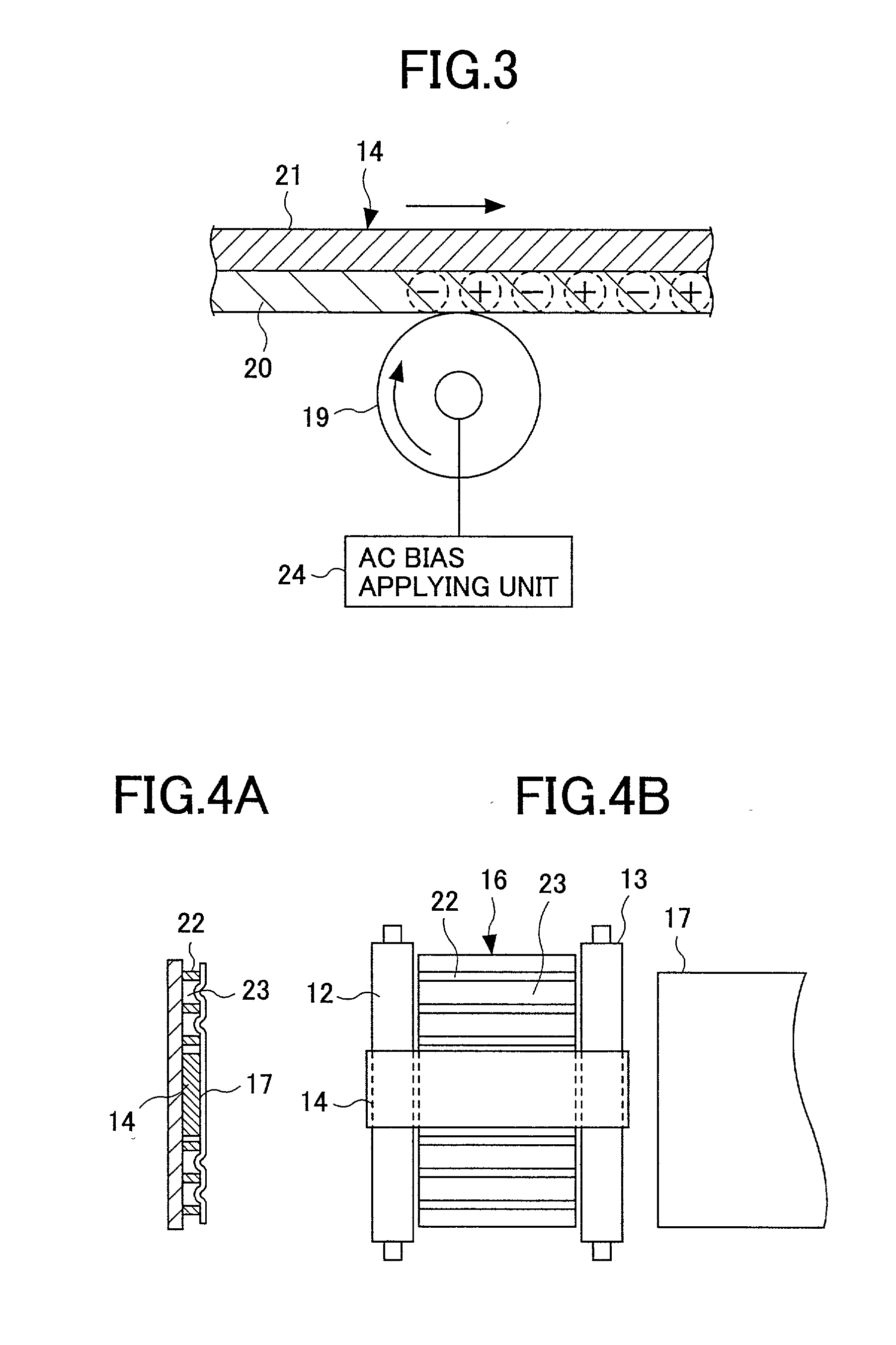

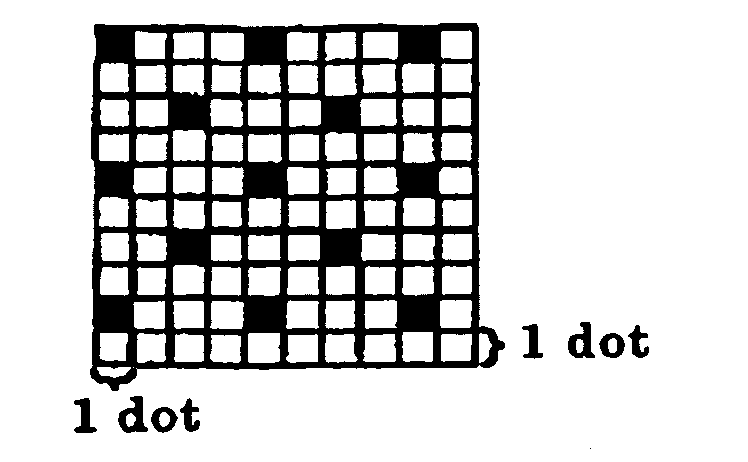

Recording-medium conveying device conveying a recording medium on a conveying belt charged with a positive charge and a negative charge alternately

InactiveUS20020126193A1Eliminate the problemHigh precisionOther printing apparatusArticle feedersImage recordingEngineering

This recording-medium conveying device comprises a conveying belt, the conveying belt, a belt charging unit, and a pressing roller. The conveying belt is wound around a driving roller and a driven roller so as to convey a recording medium to an image recording part. The conveying belt includes an insulating layer formed at one side contacting the recording medium. The belt charging unit is provided in contact with the insulating layer so as to charge the insulating layer with a positive charge and a negative charge alternately in a moving direction of the conveying belt by applying an AC bias to the conveying belt. The pressing roller presses the conveying belt against the driving roller so as to prevent the conveying belt from slipping on the driving roller.

Owner:RICOH KK

Image forming device and color misregistration correction method for image forming device

ActiveUS7239833B2Molding stabilityStable formElectrographic process apparatusPrintingRadiologyImage formation

An image forming device and a color misregistration correction method allow for stable formation of excellent images with little color misregistration. A reference patch image is formed on a reference photosensitive drum 3, and transferred to a transfer belt 7. A correction patch image is formed on a correction-target photosensitive drum 3, and transferred onto the reference patch image by superimposition. A registration detecting sensor 21 detects a density average value of the reference patch image and the correction patch image. Based on the density average value, a correction value for controlling the correction-target photosensitive drum 3 is calculated, and rotational phase control is performed in accordance with the correction value.

Owner:SHARP KK

Pattern forming method, resist composition for multiple development used in the pattern forming method, developer for negative development used in the pattern forming method, and rinsing solution for negative development used in the pattern forming method

InactiveUS20120058436A1Molding stabilityHigh-precision fine patternLayered productsSemiconductor/solid-state device manufacturingActinic RaysFluence

A pattern forming method, including: (A) coating a substrate with a positive resist composition of which solubility in a positive developer increases and solubility in a negative developer decreases upon irradiation with actinic rays or radiation, so as to form a resist film; (B) exposing the resist film; and (D) developing the resist film with a negative developer; a positive resist composition for multiple development used in the method; a developer for use in the method; and a rinsing solution for negative development used in the method.

Owner:FUJIFILM CORP

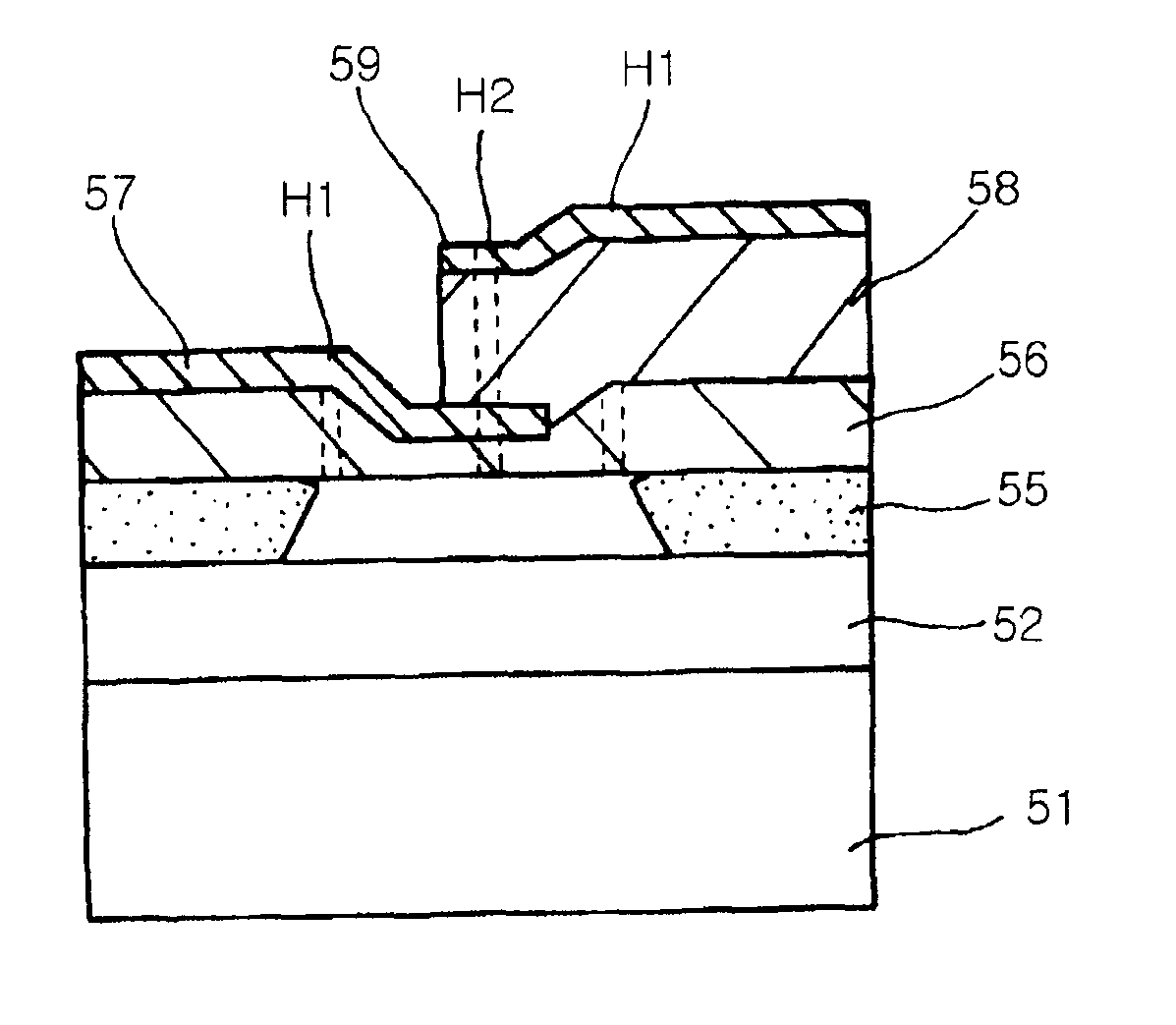

Film bulk acoustic resonator and method of forming the same

InactiveUS6992420B2Good reflective propertiesReduced insertion lossPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksStructural ProblemInsulation layer

A film bulk acoustic resonator (FBAR) includes an insulation layer on a substrate to prevent a signal from being transmitted to a substrate. The FBAR includes a portion of a membrane layer corresponding to an activation area to adjust a resonance frequency band and improve a transmission gain of the resonance frequency band, the portion of the membrane layer being partially etched to have a thickness less than the other portion of the membrane layer. A method of forming the FBAR includes forming an sacrificing layer made of polysilicon, forming an air gap using a dry etching process, and forming a via hole. The method prevents structural problems occurred in a conventional air gap forming process and provides locations and the number of the via holes to be controlled.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Color toner and two-component developer

The present invention relates to a toner which has good property such as fixability, coloring power, developability, durability, and environmental stability and so on. More specifically, the present invention relates to a color toner containing at least a binder resin, a colorant, and a wax, in which: a wax concentration of an extract obtained by dispersing the toner into n-hexane at a concentration of 15 mg / cm3 at 23° C. and by subjecting the resultant dispersion to extraction treatment at 23° C. for 1 minute is in the range of 0.080 to 0.500 mg / cm3; an average circularity of particles each having a circle-equivalent diameter of 3 μm or more in the toner is in the range of 0.925 to 0.965; and a content of the wax is in the range of 1 to 15 parts by mass with respect to 100 parts by mass of the binder resin.

Owner:CANON KK

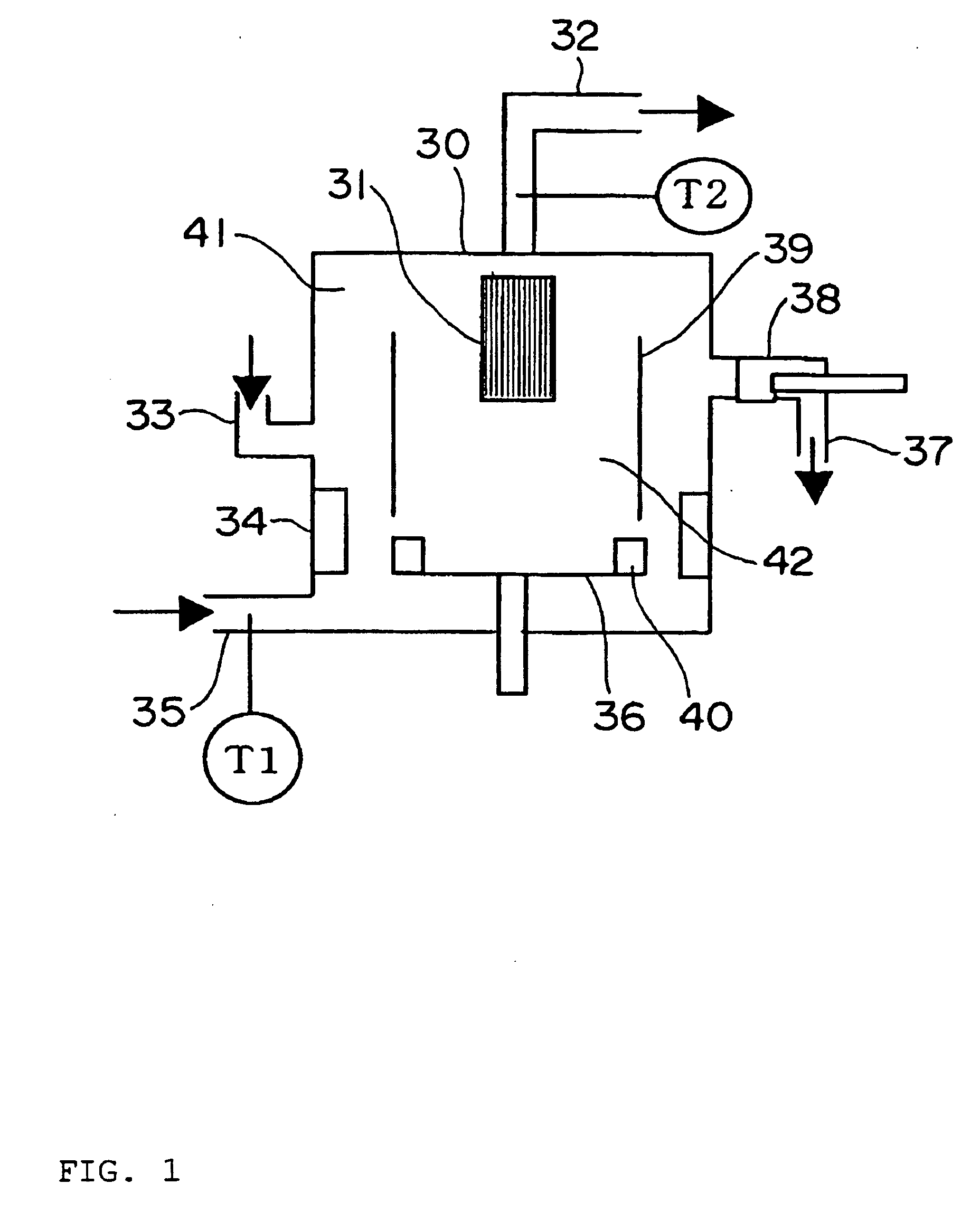

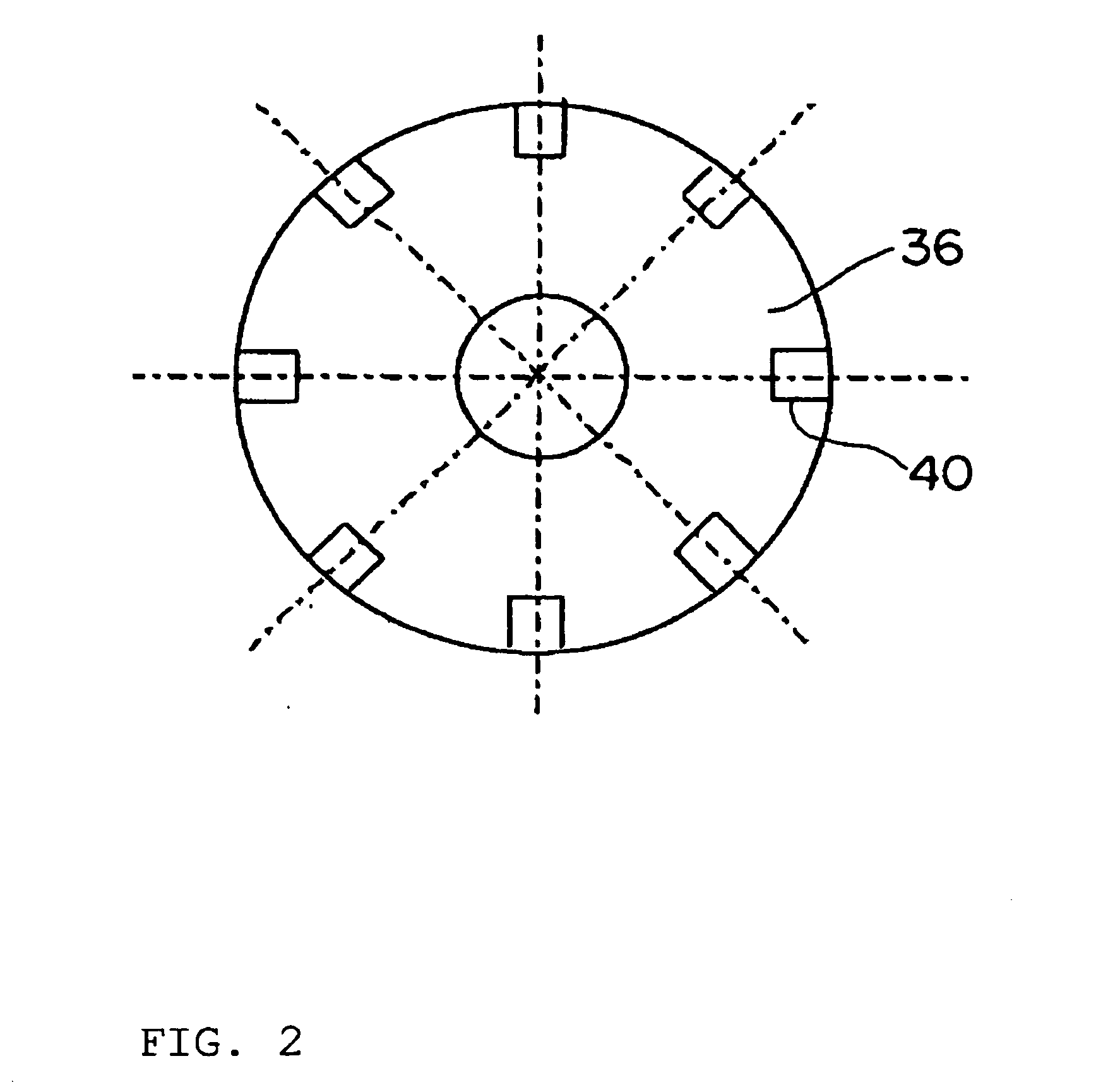

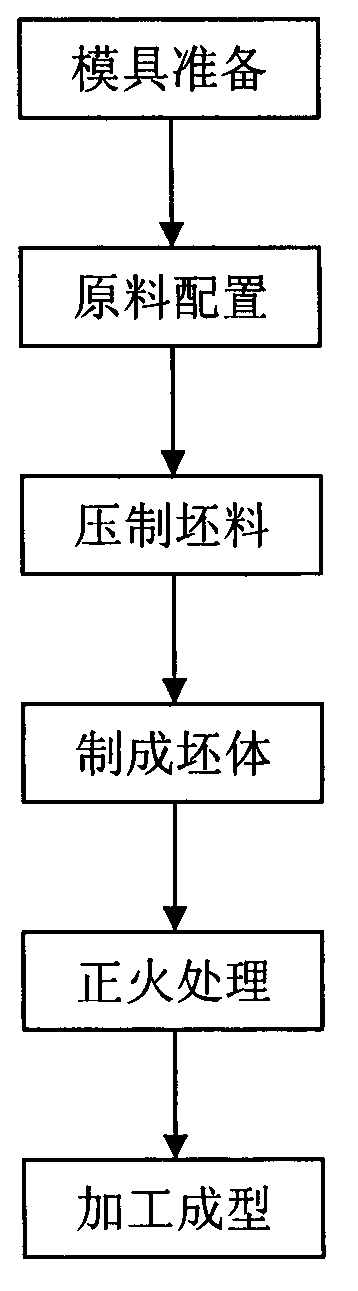

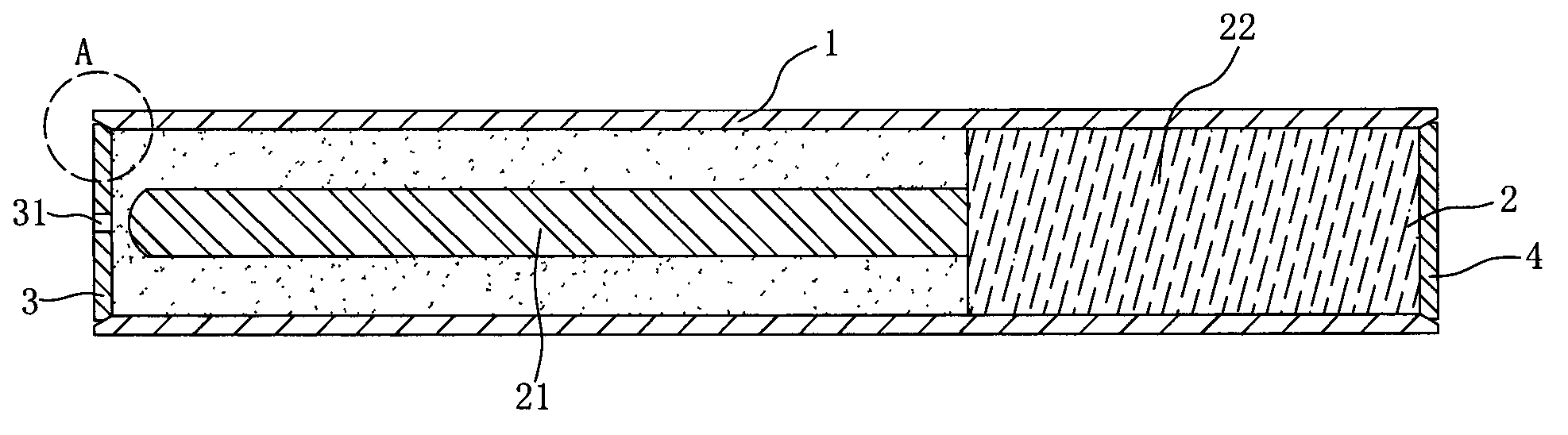

Alloy screw material and production technology of screws by adopting material

The invention relates to the technical field of injection screw production, and discloses an alloy screw material and a production technology of screws by adopting the material. The alloy screw material is prepared from the following raw material powder: 20-60% of Mo, 10-40% of FeB, 5-20% of Cr, 2-30% of Ni, 1-7% of Mn, 0.1-1% of C, and the balance of Fe. The production technology comprises the steps of die preparation, raw material preparation, blank pressing (isostatic cool pressing / die pressing), blank making (hot isostatic pressing / vacuum furnace sintering, normalizing treatment, and processing and molding. The alloy screw material provided by the invention is high in hardness, excellent in bending strength, high in breaking tenacity, excellent in abrasive resistance, and excellent in corrosion resistance, and the density of the material is close to that of a steel body ; the production technology for producing alloy screws by adopting the material is adopted, so that the plastic molding is more stable, the yield ratio for producing the alloy screws is greatly increased, and the long-term stability of injection screws during production is guaranteed.

Owner:东莞杰宇机械有限公司

Spicy bean curd snack food

InactiveCN104642559AGreat tasteUniform tasteCheese manufactureFood scienceNutritive valuesSnack food

The invention discloses a spicy bean curd snack food, which is prepared from the following raw materials in parts by weight: 30,000 parts of bean curd, and spicy accessories including 500-700 parts of red oil, 80-120 parts of chilli powder, 30 parts of beef essential oil, 80-120 parts of cumin powder, 100 parts of thirteen spices, 30 parts of sesame oil essence and 30,000 parts of brine. The preparation method comprises the following steps: selecting the raw materials; pulping; boiling; curdling; shaping; baking; marinating; stirring; packaging; sterilizing; cleaning; airing; and warehousing. The invention aims at providing the spicy bean curd snack food which is spicy, good in taste, high in nutritive value and long in storage time.

Owner:XINHUANG XIAOFEINIU FOOD

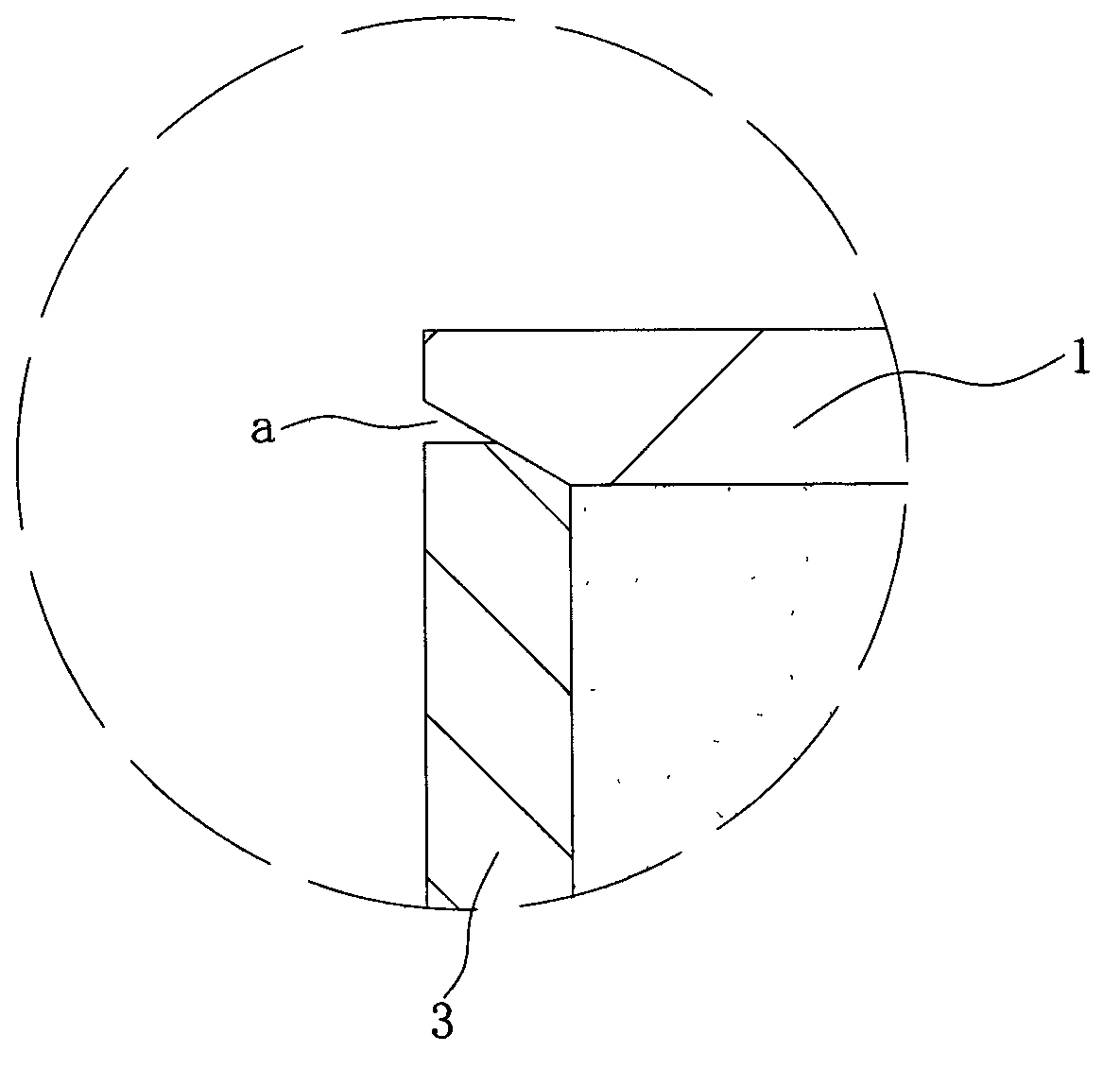

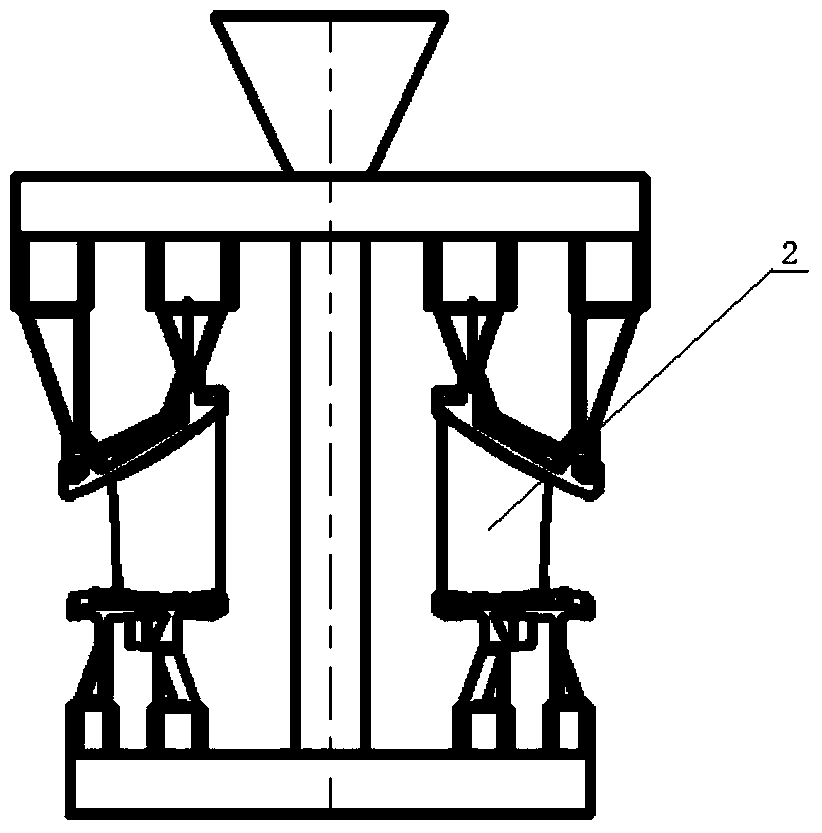

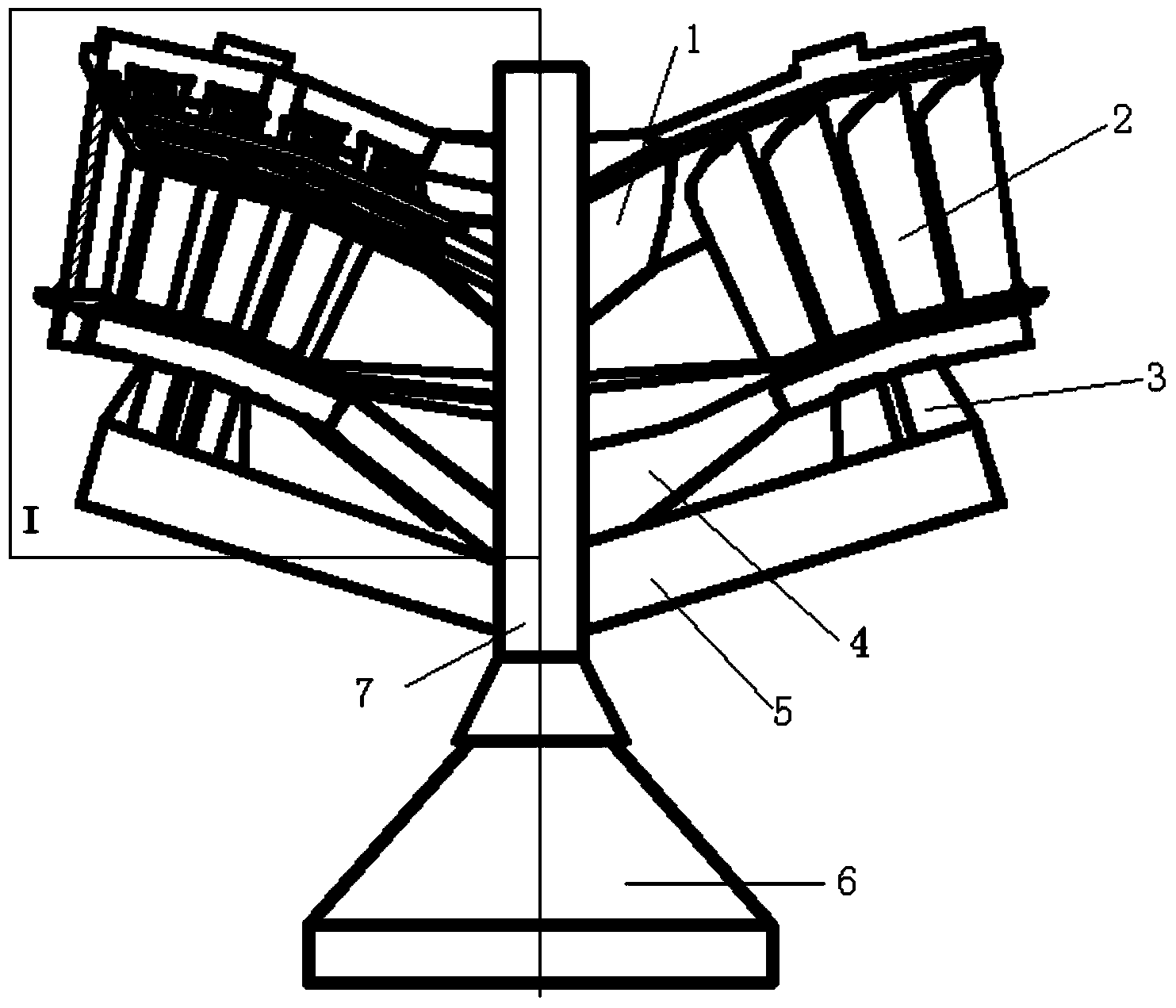

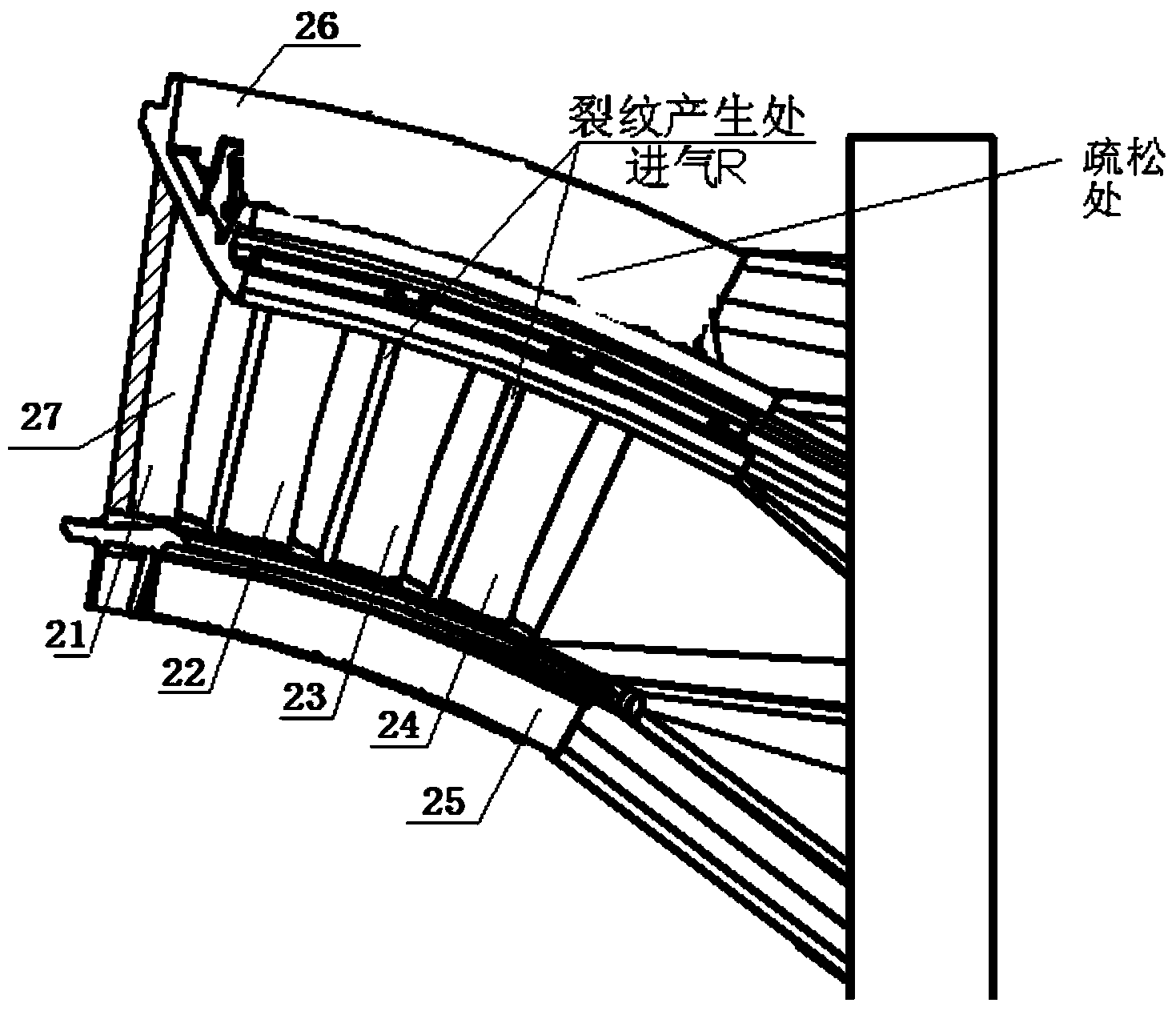

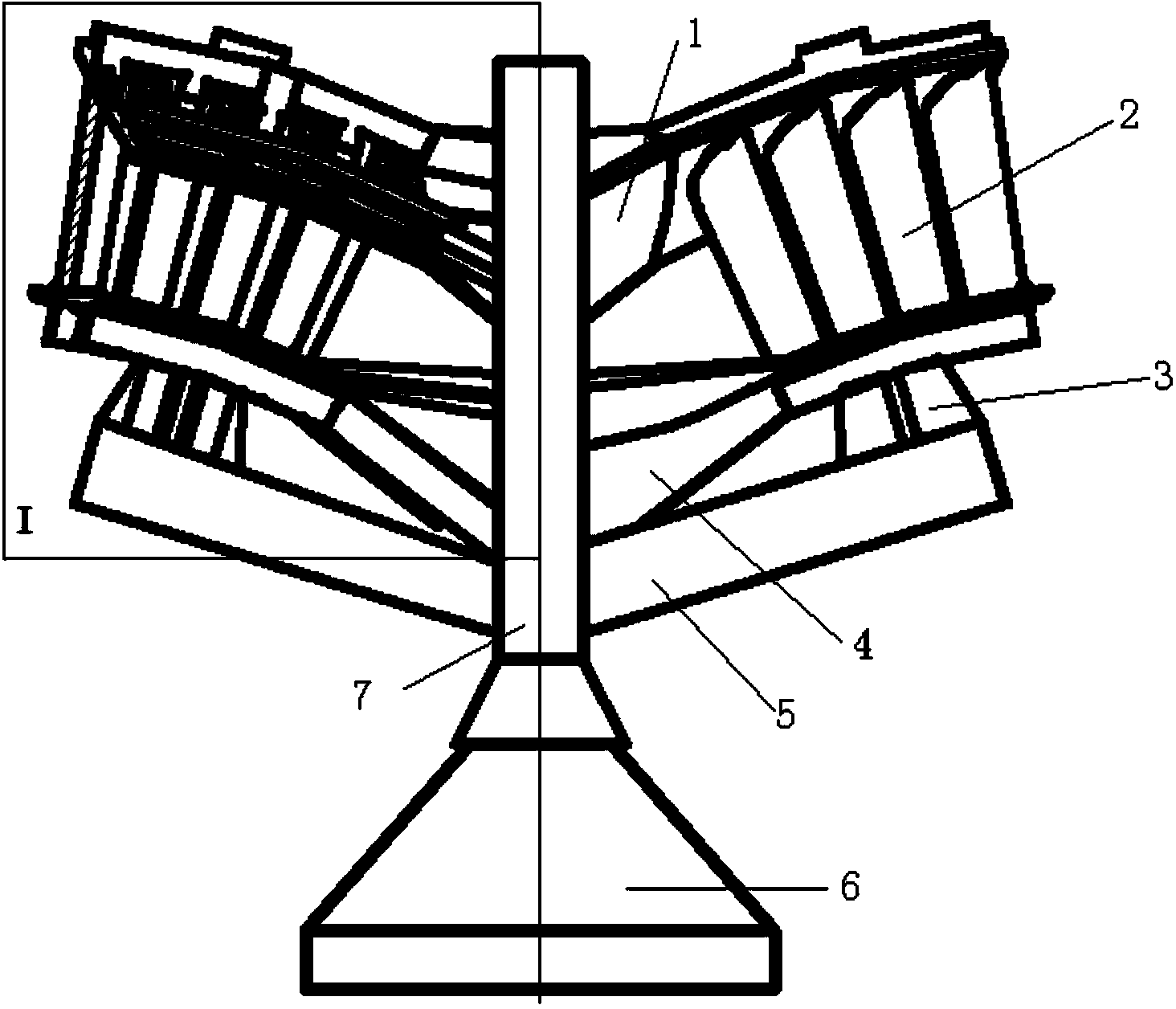

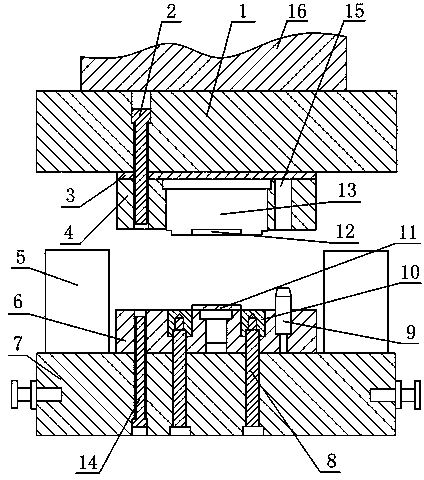

Wax mold combination of four-connection hollow turbine guide vane and precision casting method of wax mold combination

The invention provides a wax mold combination of a four-connection hollow turbine guide vane, which has high product quality and can completely solve the problems that a rotary connection R part of an edge plate and a vane body is hotly cracked and loosened, and a precision casting method of the wax mold combination. The wax mold combination comprises a sprue cup and a straight pouring gate which is communicated with an outlet end of the sprue cup, wherein inner sprue assemblies are arranged on the side wall of the straight pouring gate; each inner sprue assembly comprises a lower edge inner sprue communicated with one side of a vane lower edge plate cavity, and an upper edge inner sprue communicated with one side of a vane upper edge plate cavity; and each lower edge inner sprue and each upper edge inner sprue are sequentially arranged along the flow direction of the straight pouring gate. The precision casting method comprises the following steps: (1) manufacturing the wax mold combination; (2) carrying out shell making on the wax mold combination prepared in the step (1) to obtain a four-connection hollow turbine guide vane shell; and (3) covering one layer of ceramic heat-preservation cotton on a shell vane body part and covering two layers of ceramic cotton on the whole shell; and putting the treated shell into a roasting furnace for carrying out casting.

Owner:AECC AVIATION POWER CO LTD

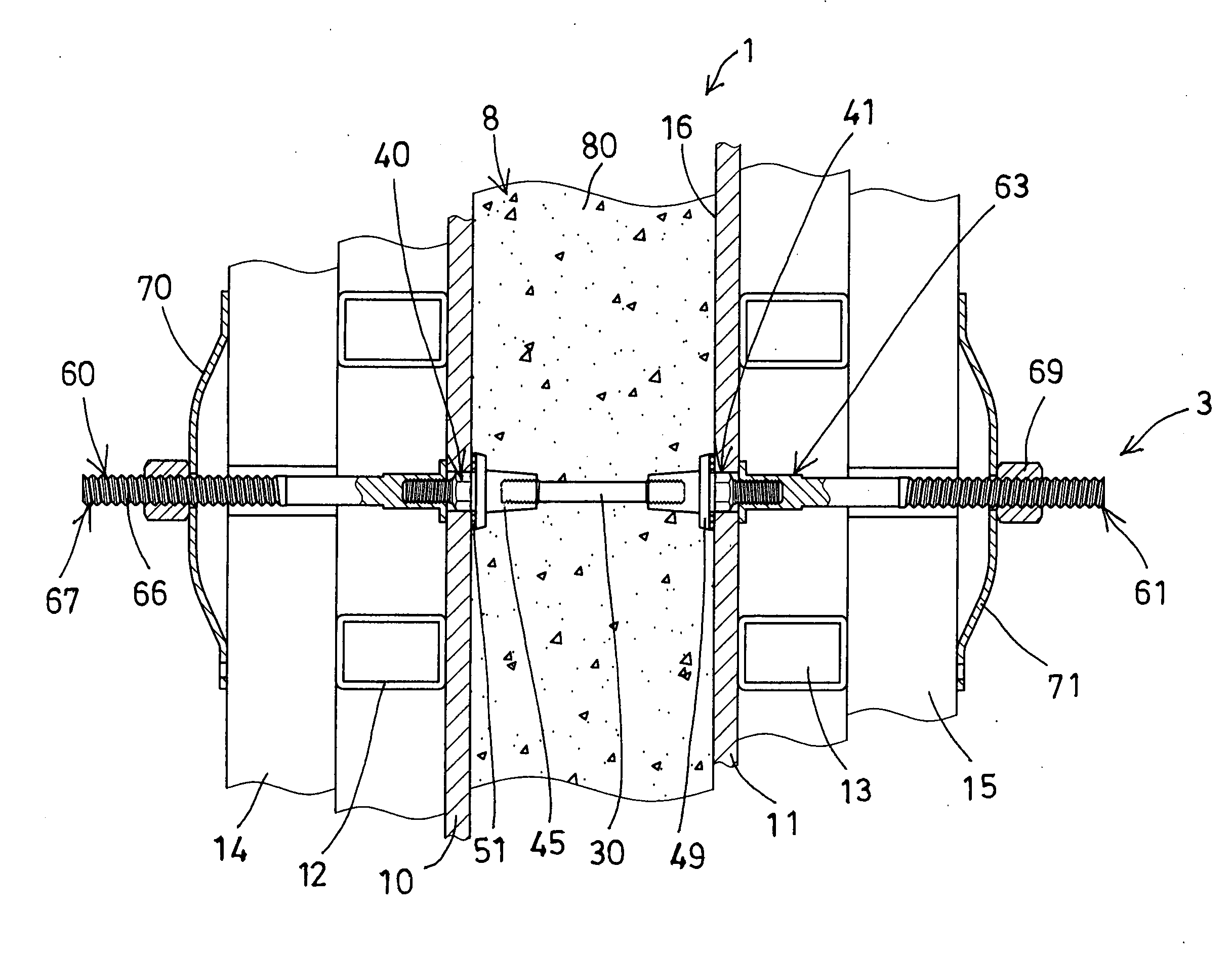

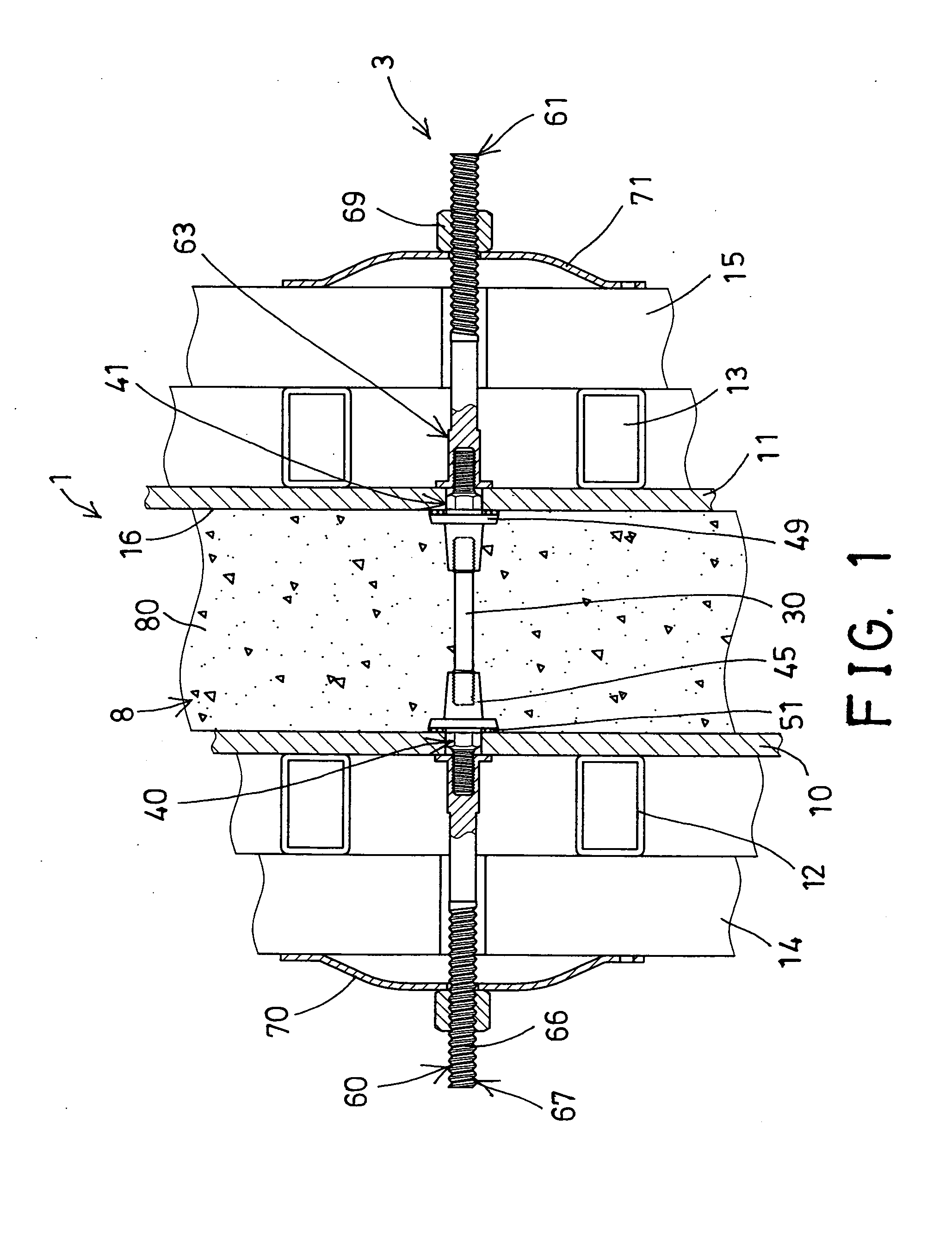

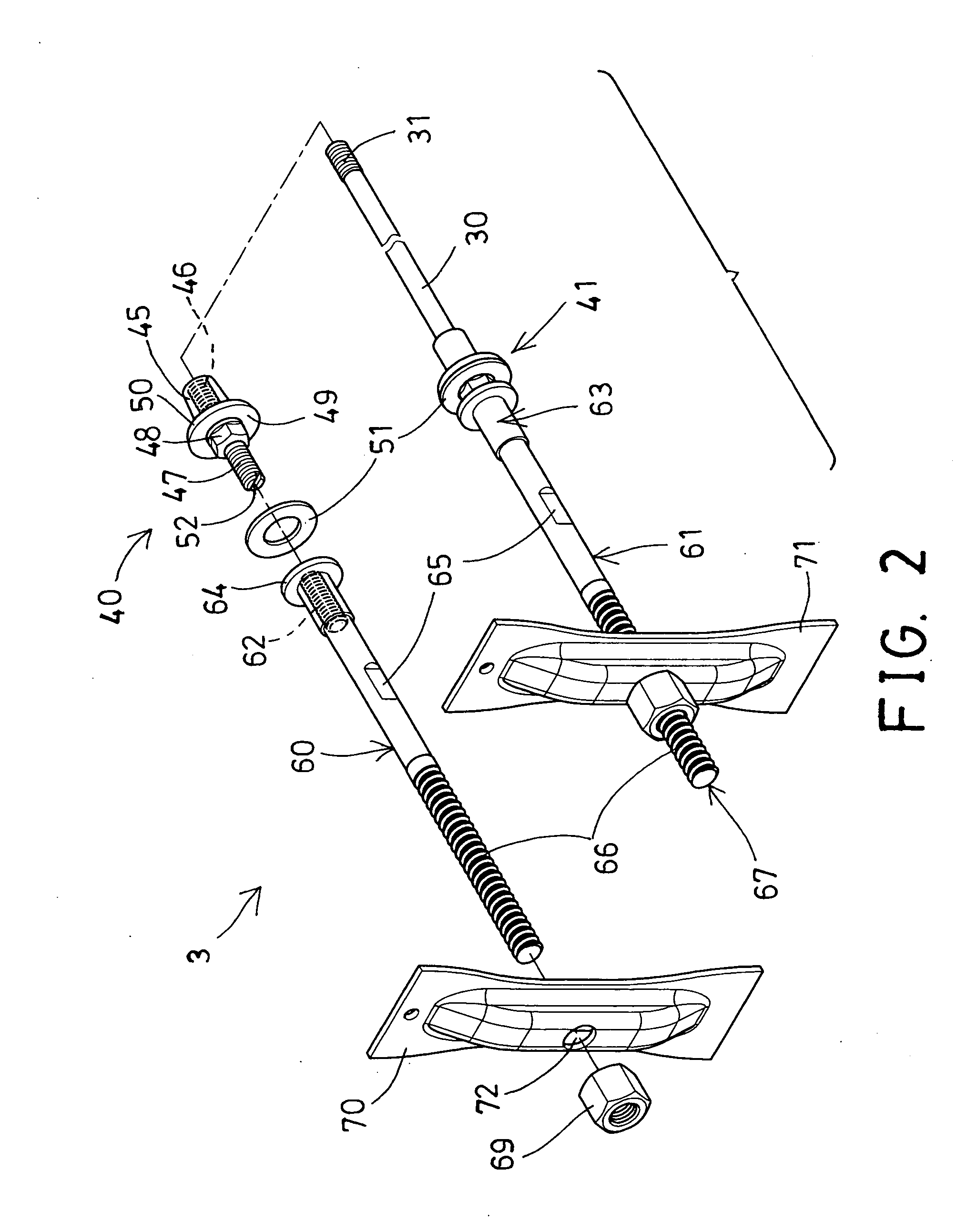

Fastener device for wall construction

InactiveUS20110272556A1Easily and solidly securingMolding stabilityWallsForms/shuttering/falseworksFastenerBuilding construction

Owner:LIN LI MEI

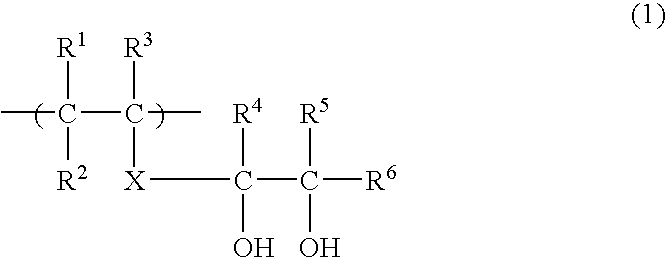

Water-soluble polyvinyl alcohol resin filament and nonwoven fabric made by using the same

InactiveUS20090061719A1Good water solubilityRadiation suppressionLayered productsMonocomponent synthetic polymer artificial filamentSolubilityDissolution

A water-soluble polyvinyl alcohol resin filament is provided, which is formed by melt-spinning a material consisting essentially of a water-soluble polyvinyl alcohol resin having a 1,2-diol structural unit represented by the following general formula (1). A nonwoven fabric is also provided, which is produced by using the water-soluble polyvinyl alcohol resin filament. Therefore, the nonwoven fabric is excellent in water solubility at a lower temperature, and substantially free from bubbling during dissolution thereof in water. In addition, a fully saponified PVA can be used for melt-forming. This suppresses emanation of acetic acid odor, thereby improving the working environment.wherein R1, R2, R3, R4, R5 and R6, which may be the same or different, are each a hydrogen atom or a monovalent organic group, and X is a single bond or a connecting chain.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD

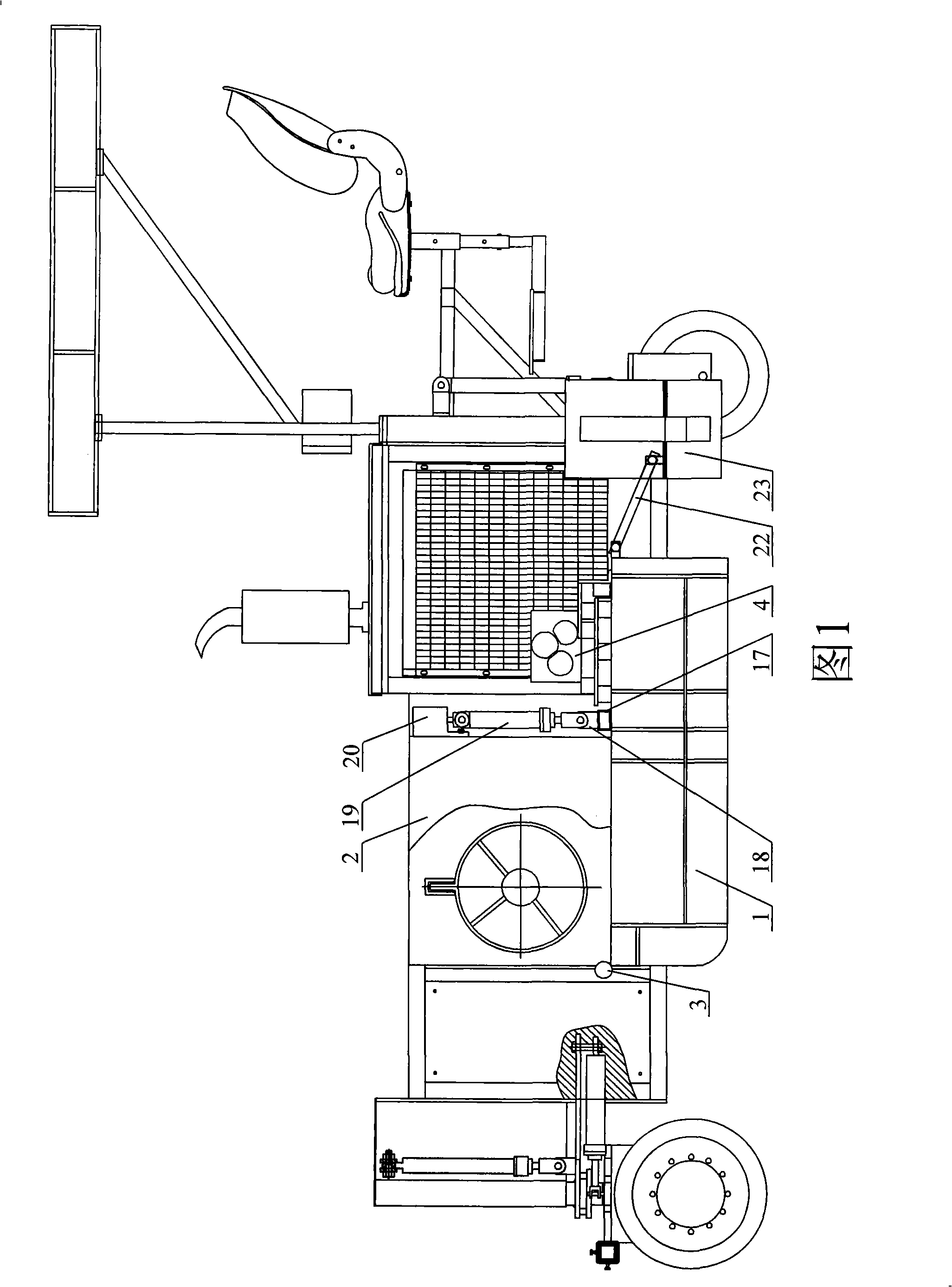

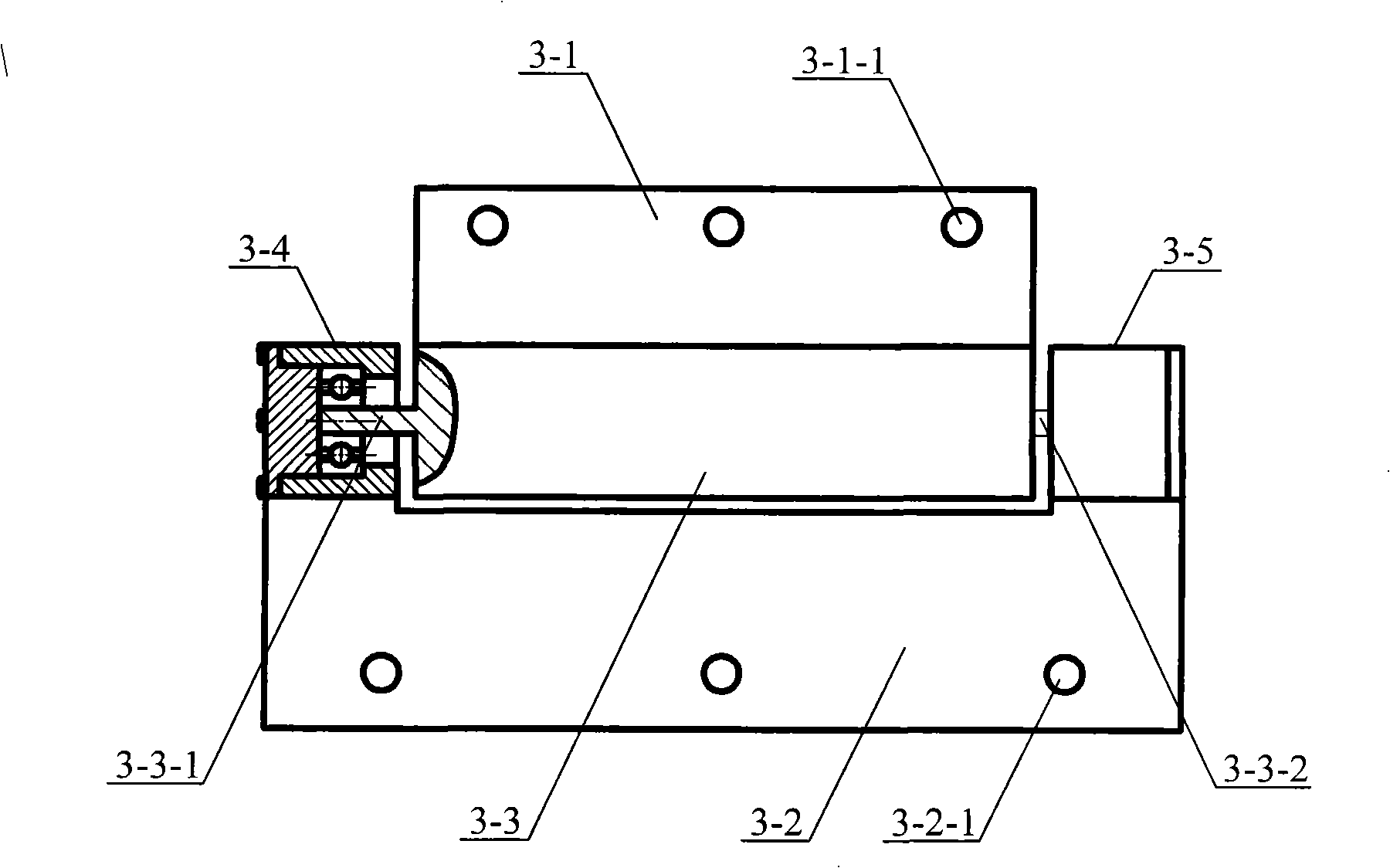

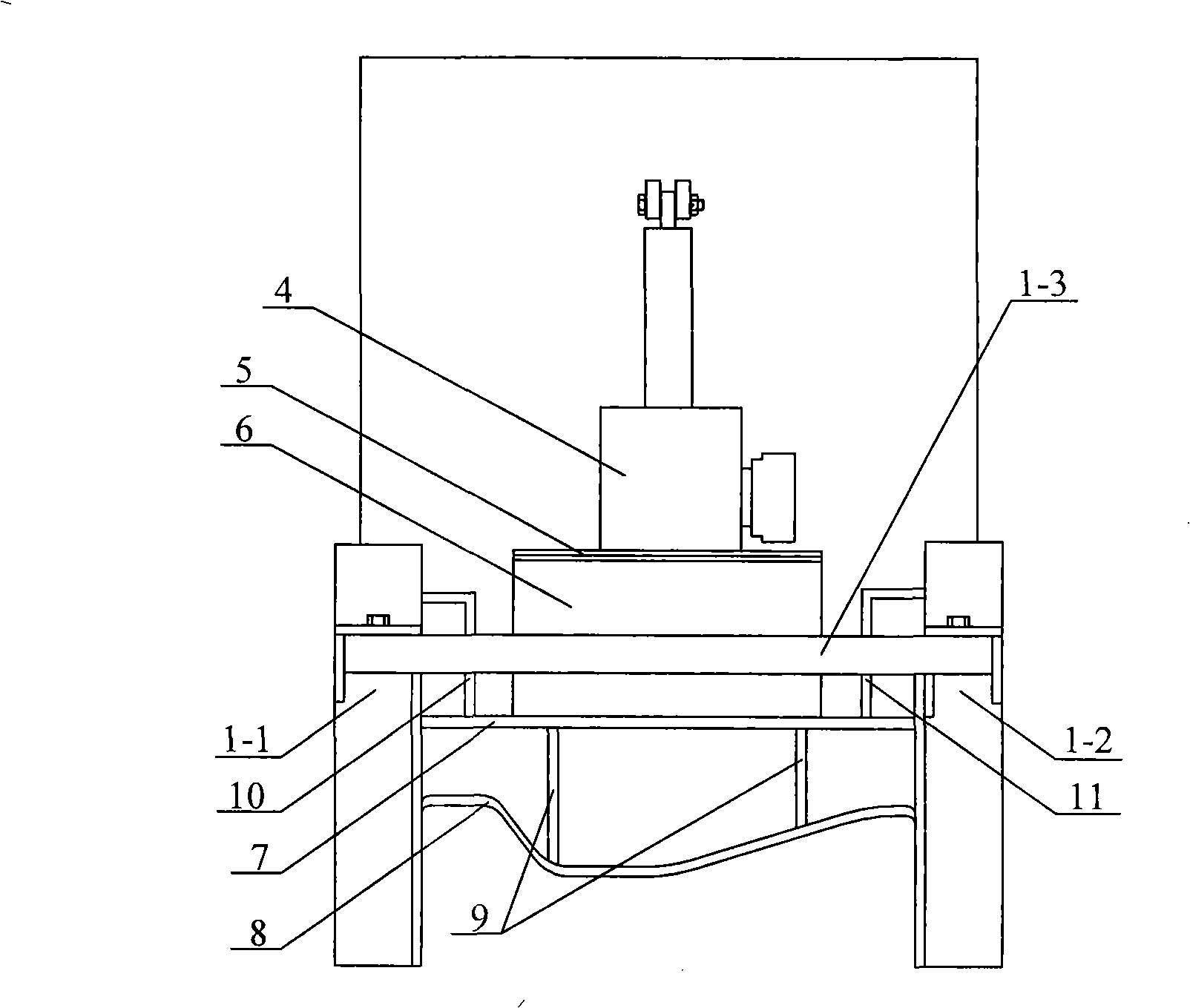

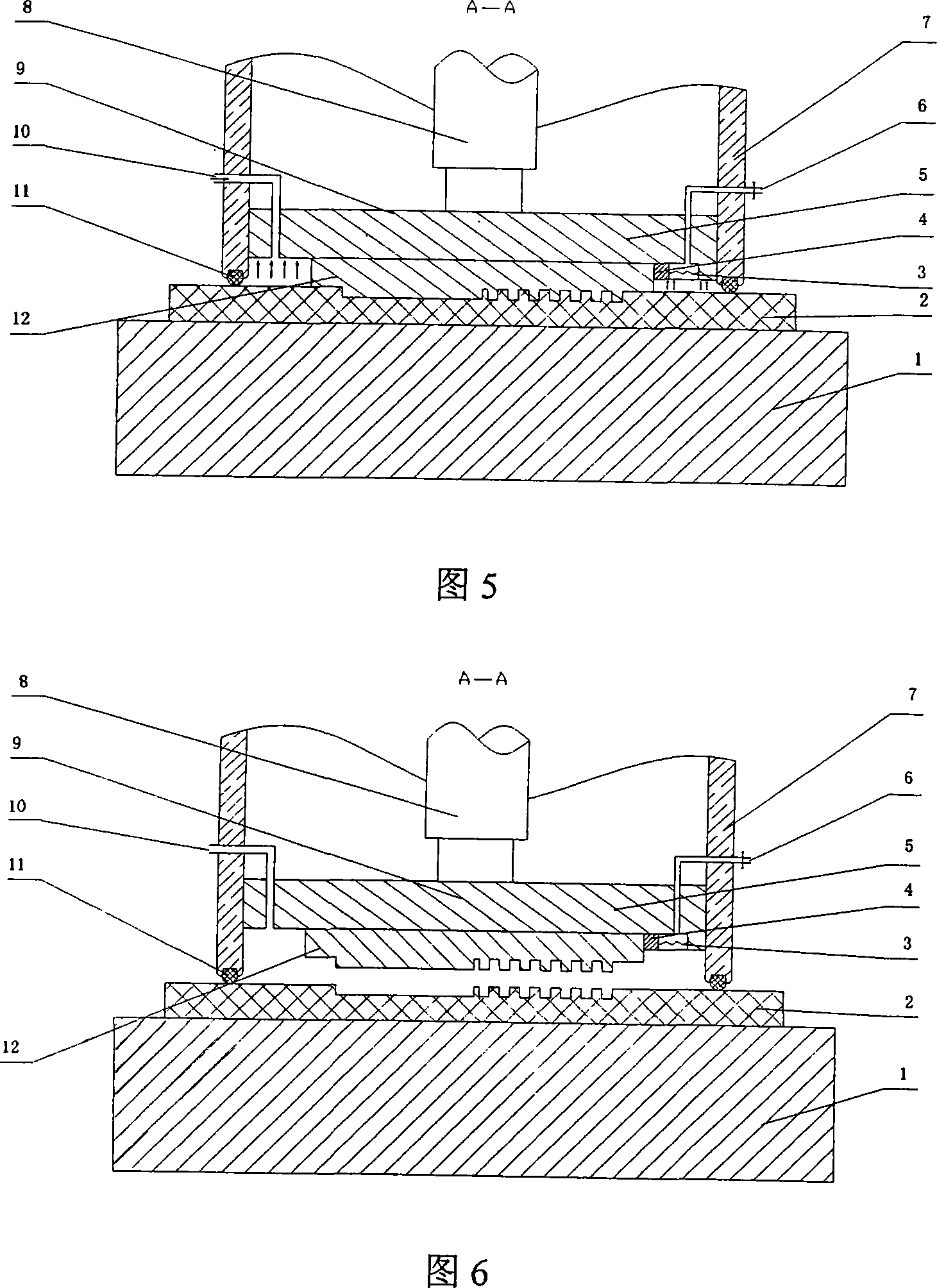

Operation mechanism of self-propelled multifunctional border stone slip form machine

The invention discloses a forming die working mechanism of a self-propelled type multifunctional curb sliding mode machine in the technical field of concrete continuous paving device. When the working mechanism paves dry hard concrete, a construction has the advantages of stable shaping, high compactness and good planeness; the working mechanism includes a shaping die and a die hopper; the shaping die is arranged below the die hopper; the shaping die includes a front plate, a first side plate and a second side plate; the first side plate and the second side plate are respectively connected at the two sides of the front plate; a template is arranged between the first side plate and the second side plate; the shaping die is hinged with the die hopper through a pivot device; the pivot device is connected with the front plate of the shaping die and the front side surface of the die hopper; besides, the working mechanism also includes an externally arranged oscillator; the oscillator is connected with the template through a connecting frame.

Owner:JIANGSU SIMING ENG MACHINERY

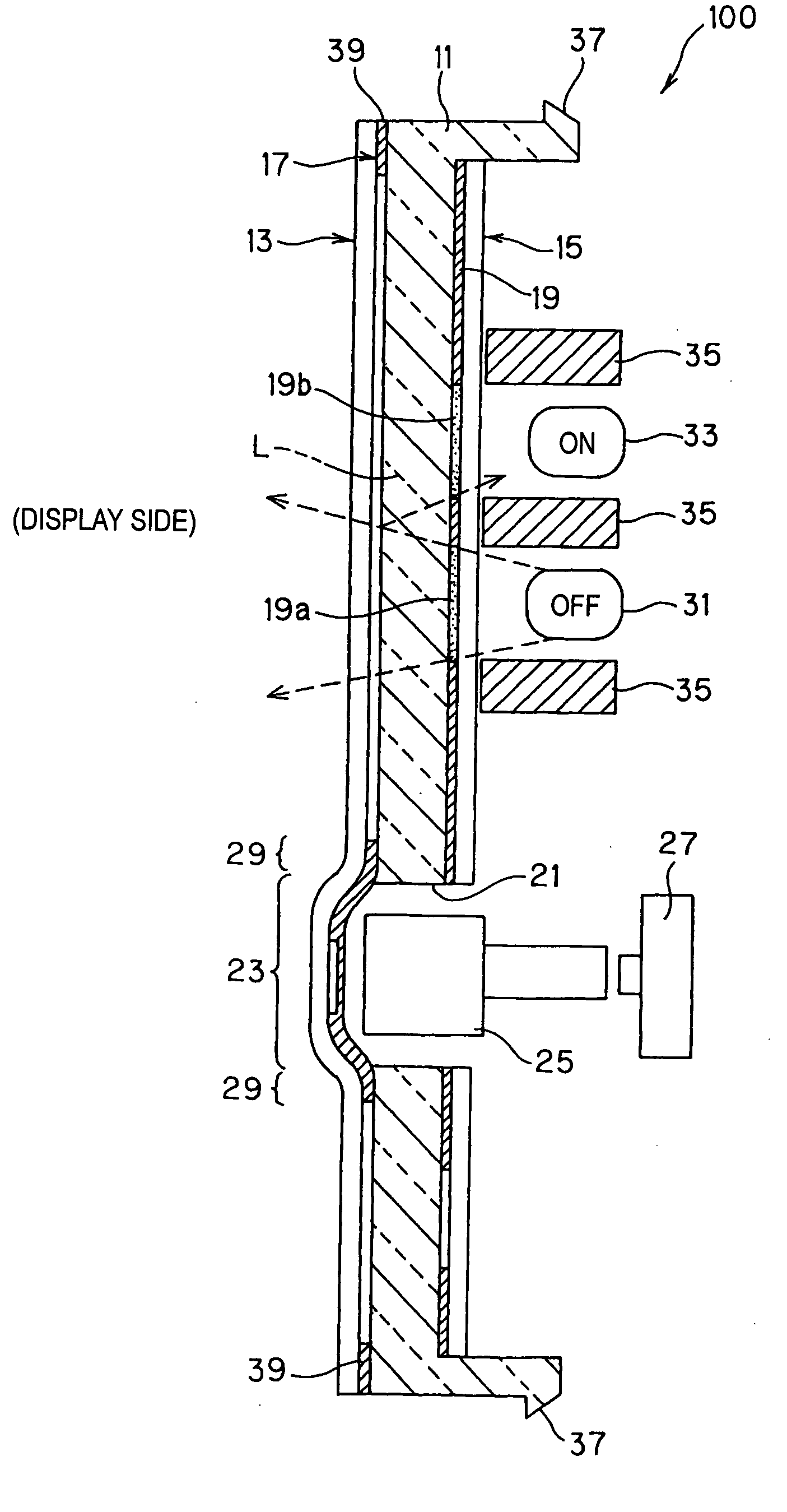

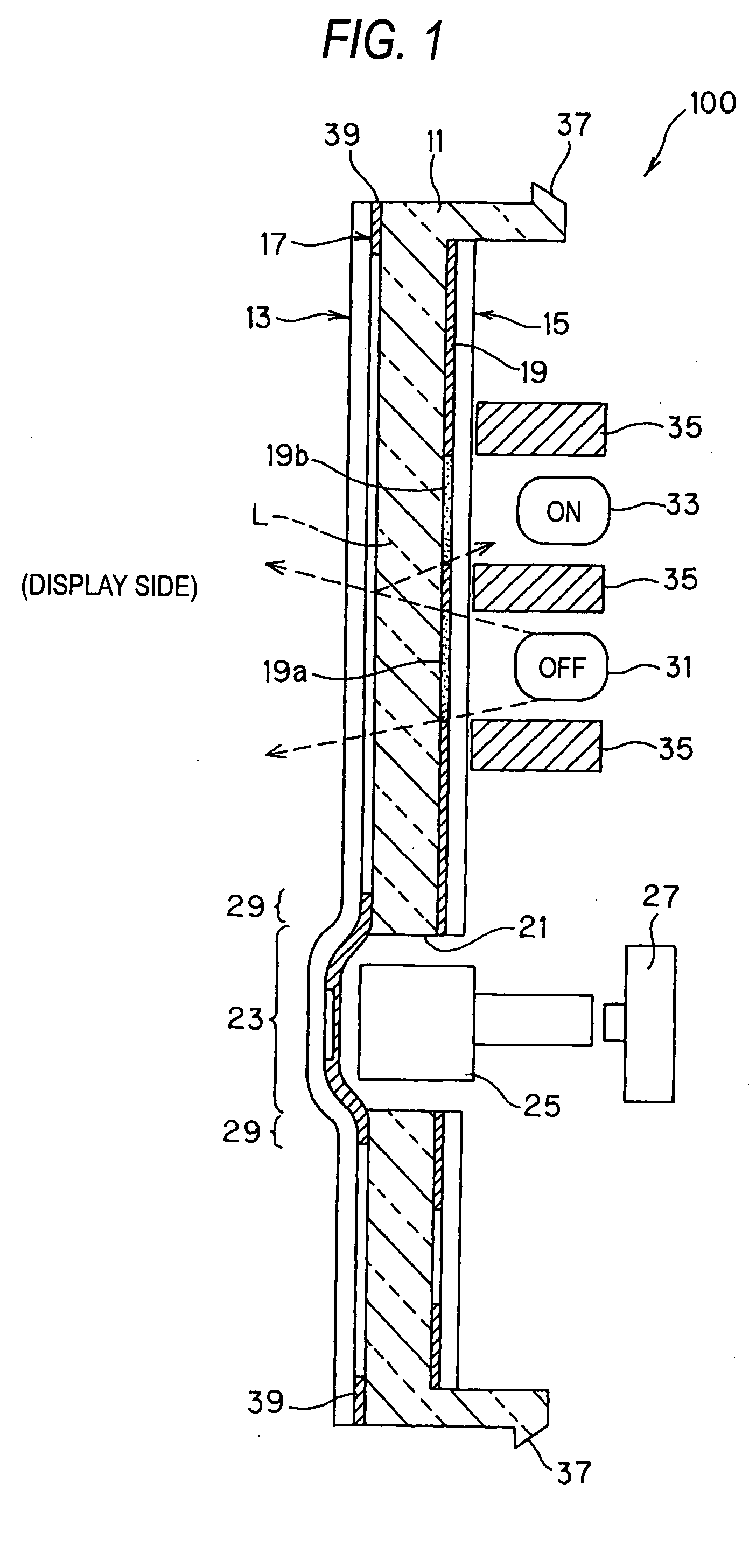

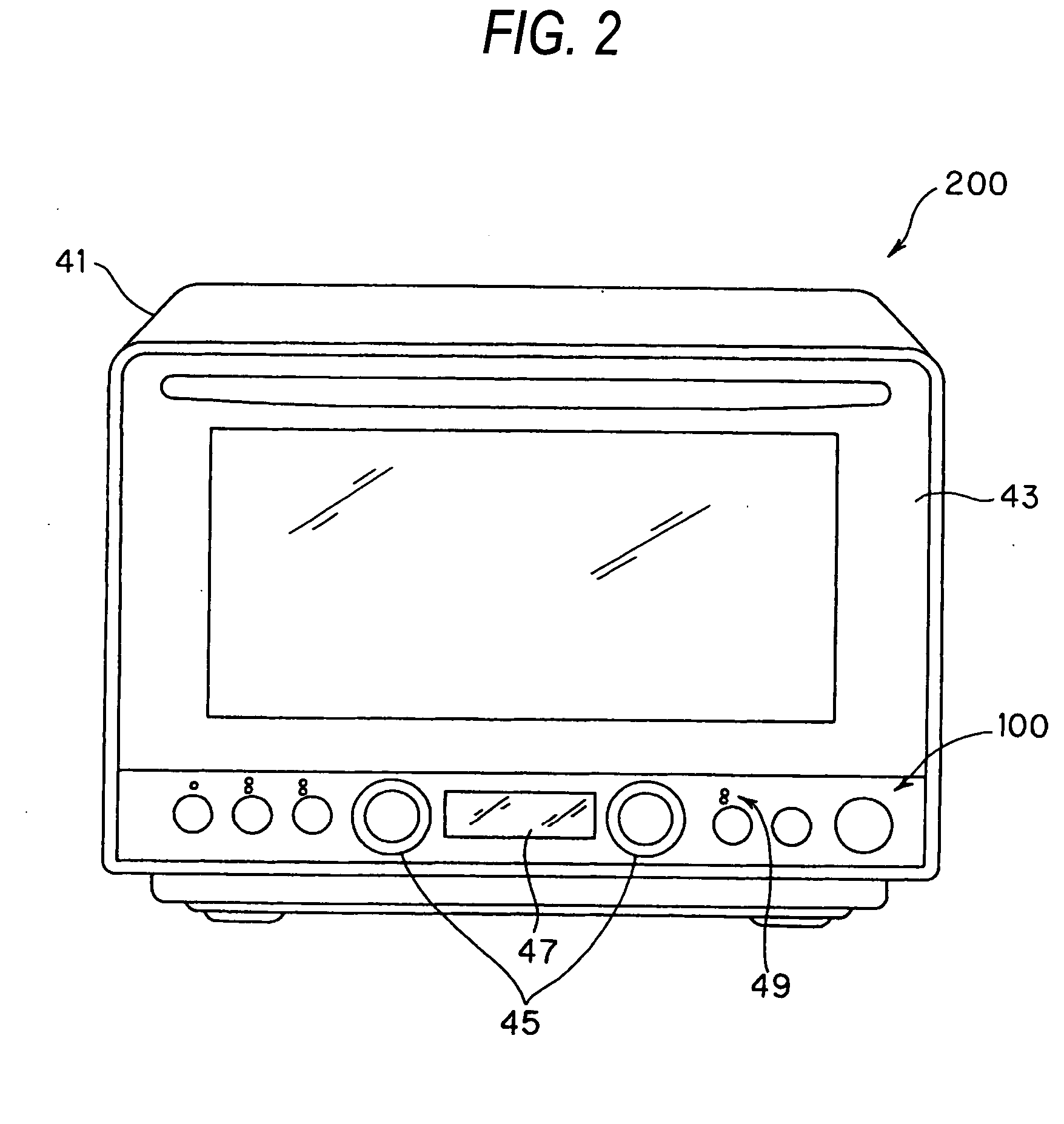

Display panel, control display panel and method for integrally molding insert material

ActiveUS20050183305A1Simple structureEasy to operateAdvertisingCathode-ray tube indicatorsElectronic equipmentElectrical and Electronics engineering

Owner:PANASONIC CORP

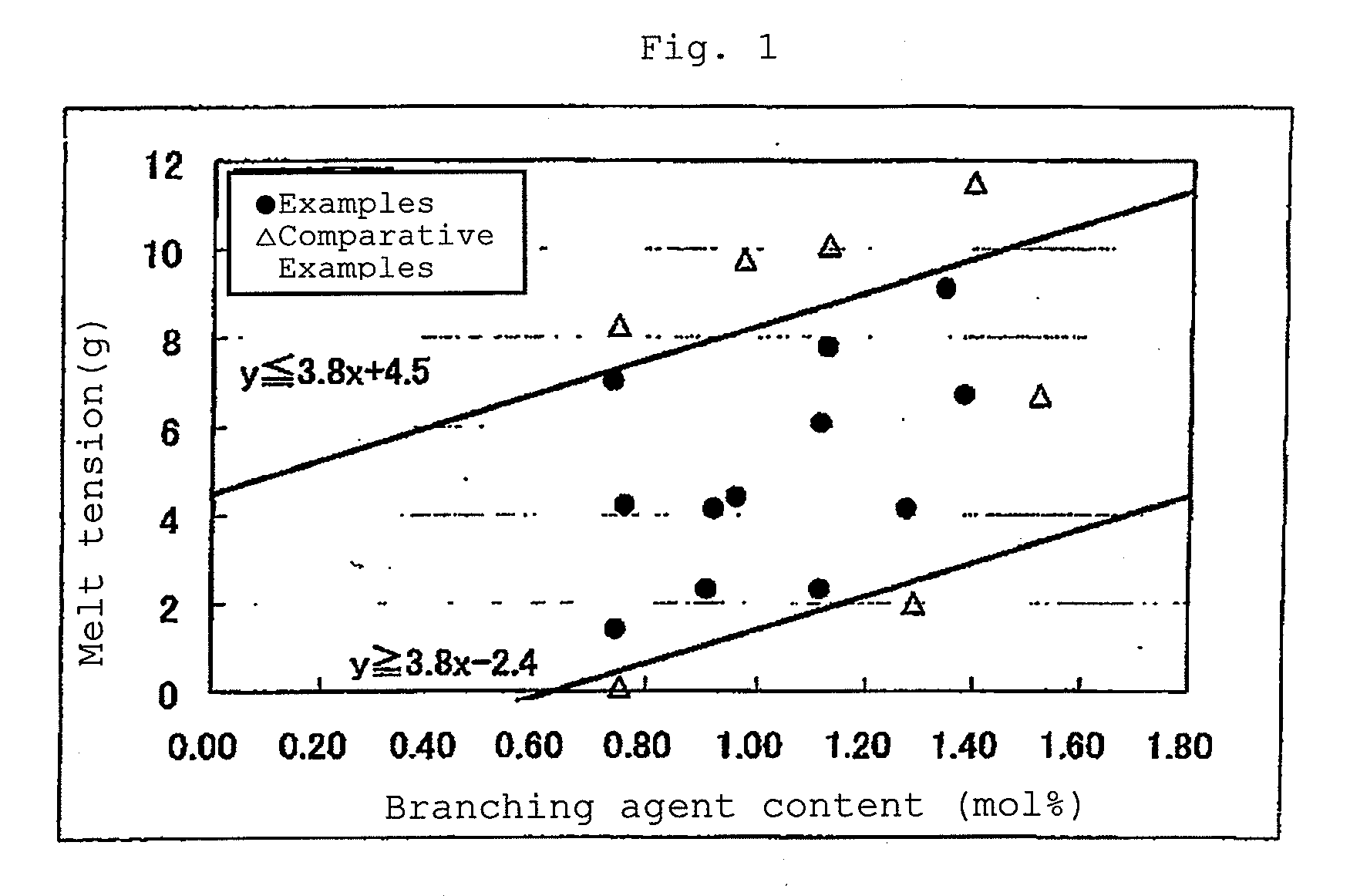

Branched polycarbonate resin and process for producing the same

The invention seeks to provide a branched polycarbonate resin having a high branching agent content, which has a good melt tension, virtually causes no drawdown and permits stable molding when it is molded in extrusion molding, blow molding, injection molding, vacuum molding, etc., and a process for producing the same.This invention provides a branched polycarbonate resin obtained from a dihydric phenol compound, a branching agent, monohydric phenols and phosgene by an interfacial polymerization reaction method in the presence of an alkali aqueous solution and an organic solvent, the branched polycarbonate resin having features that:(i) the branching agent content (X) thereof is over 0.70 mol % but 1.50 mol % or less,(ii) the branching agent content (X) and the melt tension (Y) thereof at 280° C. satisfy the following expression (1),3.8X−2.4≦Y—3.8X+4.5 (1),and(iii) the entire N content in the branched polycarbonate resin is 0 to 7 ppm.

Owner:TEIJIN KASEK KK

Pouring method of hollow turbine guide vane

ActiveCN104308082AUniform temperature fieldEliminate casting stressFoundry mouldsFoundry coresWaxTurbine

The invention provides a pouring method of a hollow turbine guide vane. The pouring method comprises the following steps: (1) manufacturing a wax mold combination; (2) carrying out shell making on the wax mold combination to obtain a hollow turbine guide vane shell; (3) covering one layer of ceramic heat-preservation cotton on a shell vane body part; covering two layers of ceramic cotton on the whole shell; and putting the treated shell into a roasting furnace and carrying out casting, wherein in a casting process, the temperature of casting the shell is 1065-1085 DEG C and the pouring temperature is 1460-1480 DEG C. According to the pouring method of the hollow turbine guide vane, a pouring system of the hollow turbine guide vane is not changed and the shell temperature and the pouring temperature are adjusted so that the casting temperature field is changed; the two layers of ceramic cotton on the whole body and one layer of the ceramic heat-preservation cotton on the vane body part are matched so that after the temperature of the whole shell is improved, the temperature field is uniform, the casting stress is eliminated and the casting temperature is reduced; and furthermore, the temperature field on a casting vane body and an edge plate keeps uniform, the shell is effectively insulated and the casting stress is eliminated.

Owner:AECC AVIATION POWER CO LTD

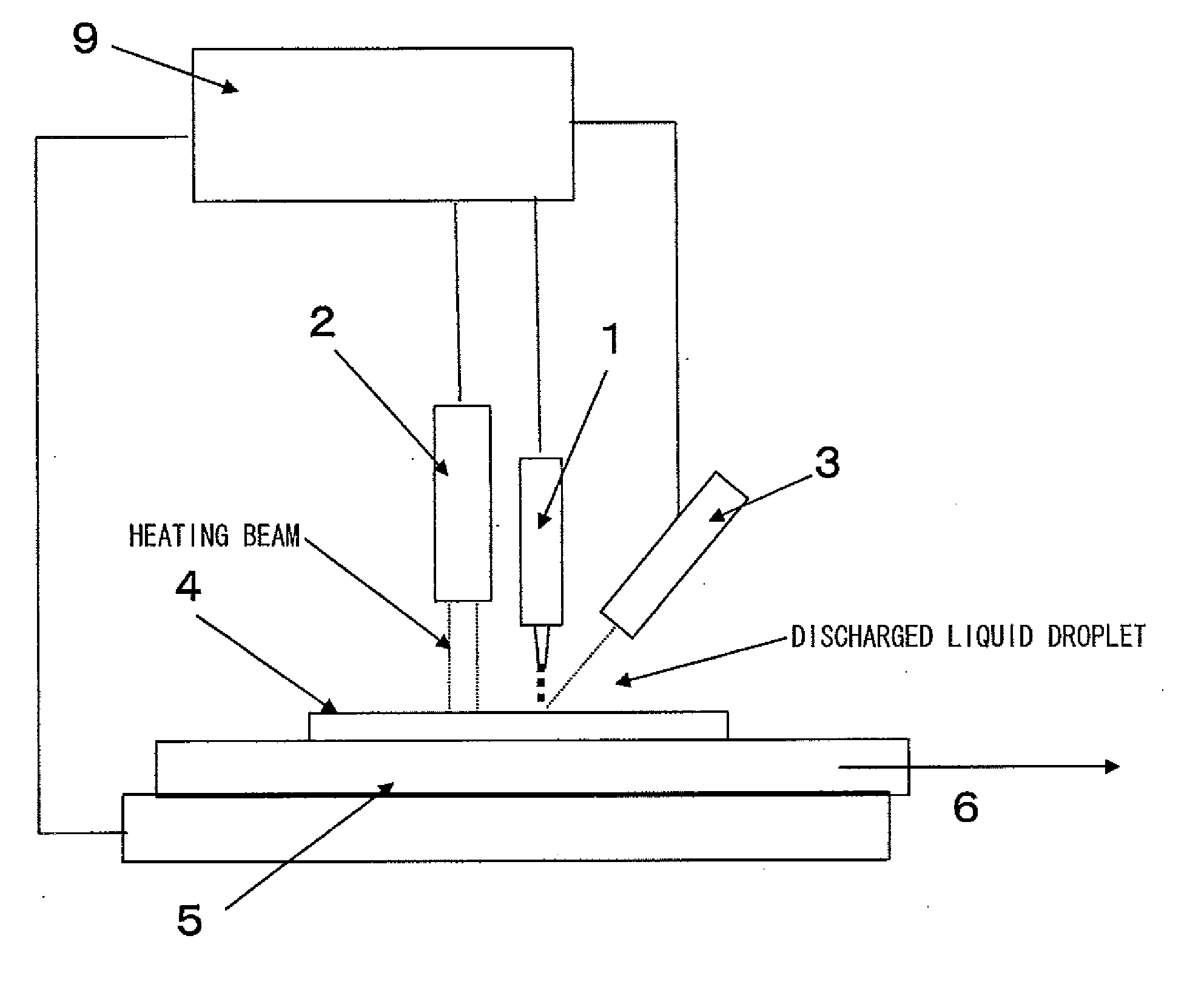

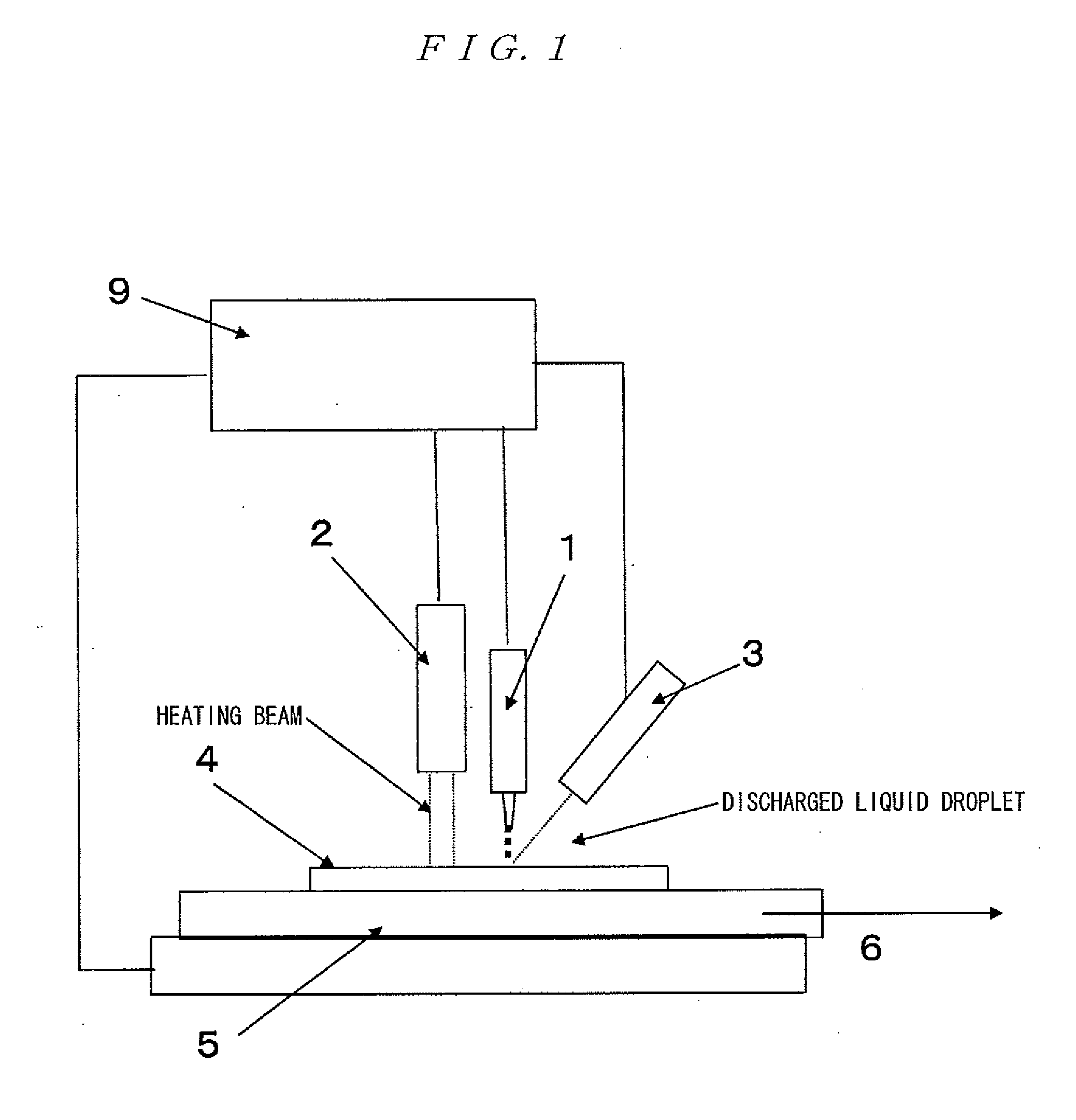

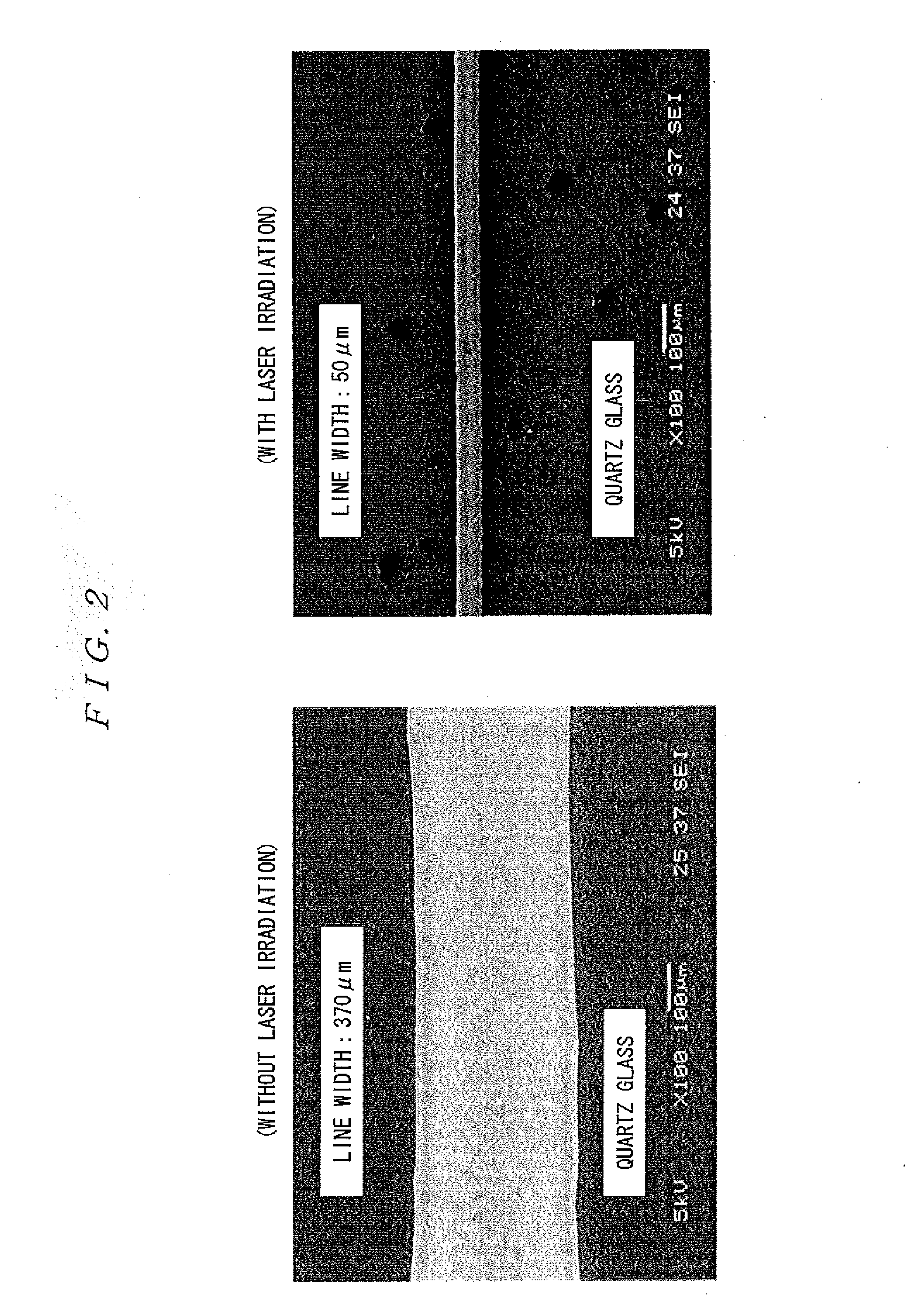

Pattern drawing method and pattern drawing apparatus

ActiveUS20100302319A1Increase deposition rateHighly practical fine pattern drawing techniquePrinted circuit manufacturePrintingThin lineDroplet size

Disclosed herein is a fine and thick wiring drawn at high speed in such a manner that a region on the substrate, on which region the liquid droplet is scheduled to impact, is heated beforehand, and that immediately after the impact of the liquid droplet on the substrate, the liquid droplet is promptly solidified so as thereby to suppress the spread of the liquid droplet due to the wettability of the liquid droplet to the substrate, and also to suppress the clogging of the nozzle due to the heating of the substrate. Thereby, even in the case where a liquid droplet having a larger volume than before is used, high-speed drawing of a thick and fine wiring having a line width approximately equal to the liquid droplet size is realized independently of the substrate material.

Owner:NAT INST OF ADVANCED IND SCI & TECH

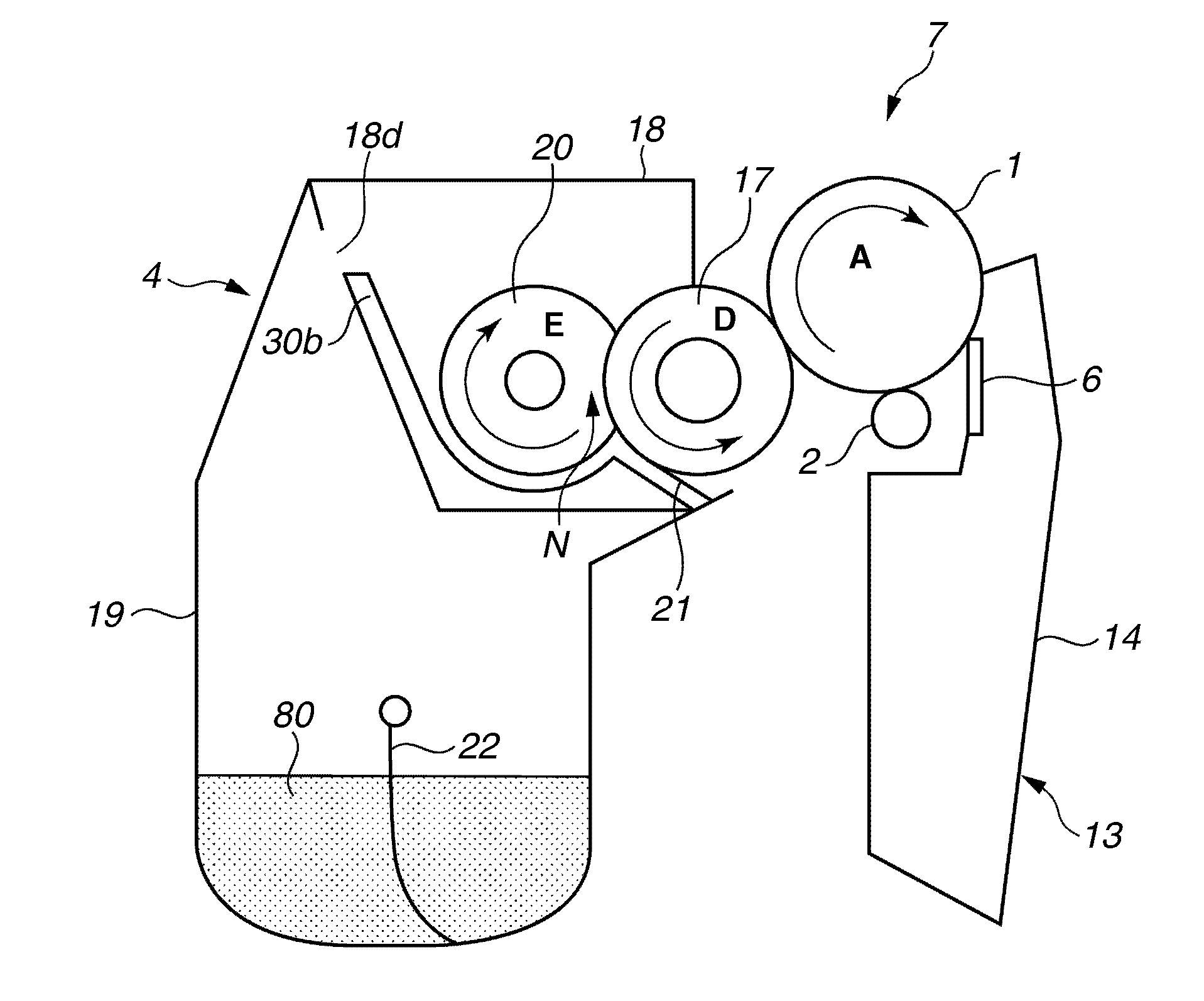

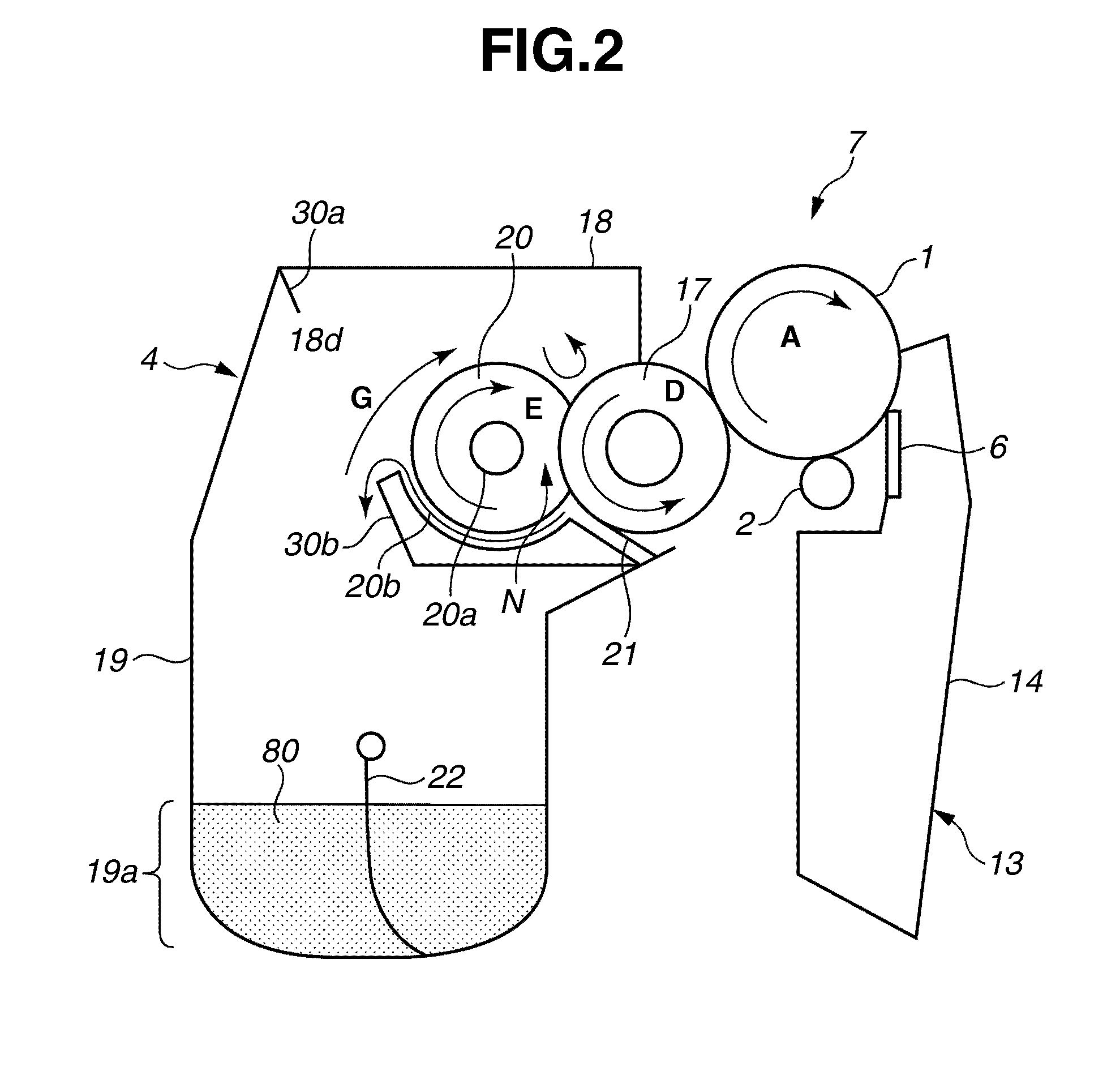

Development device, process cartridge, and image forming apparatus

ActiveUS20130287452A1Simple configurationHigh quality imageElectrographic process apparatusMechanical engineeringEngineering

Owner:CANON KK

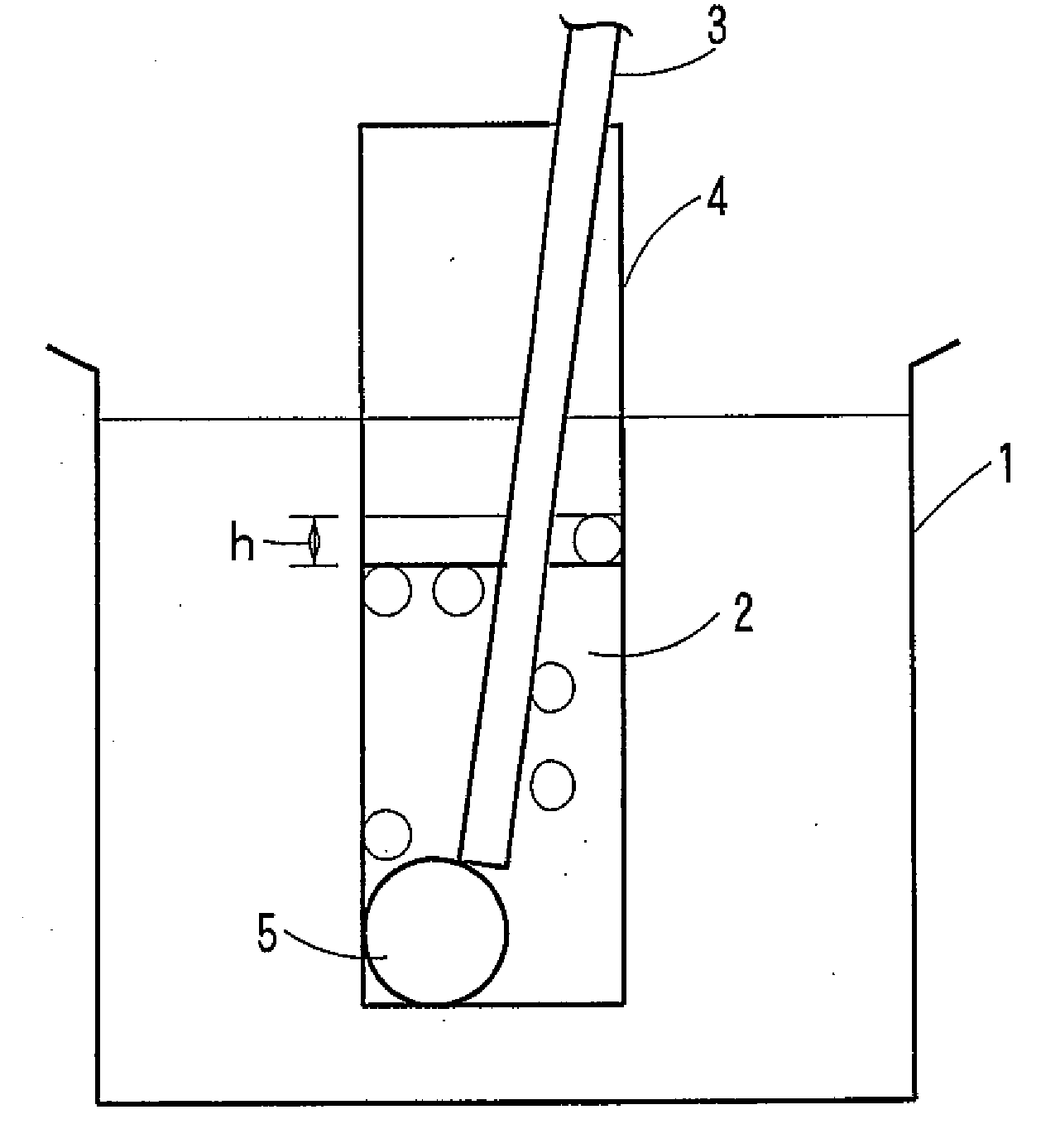

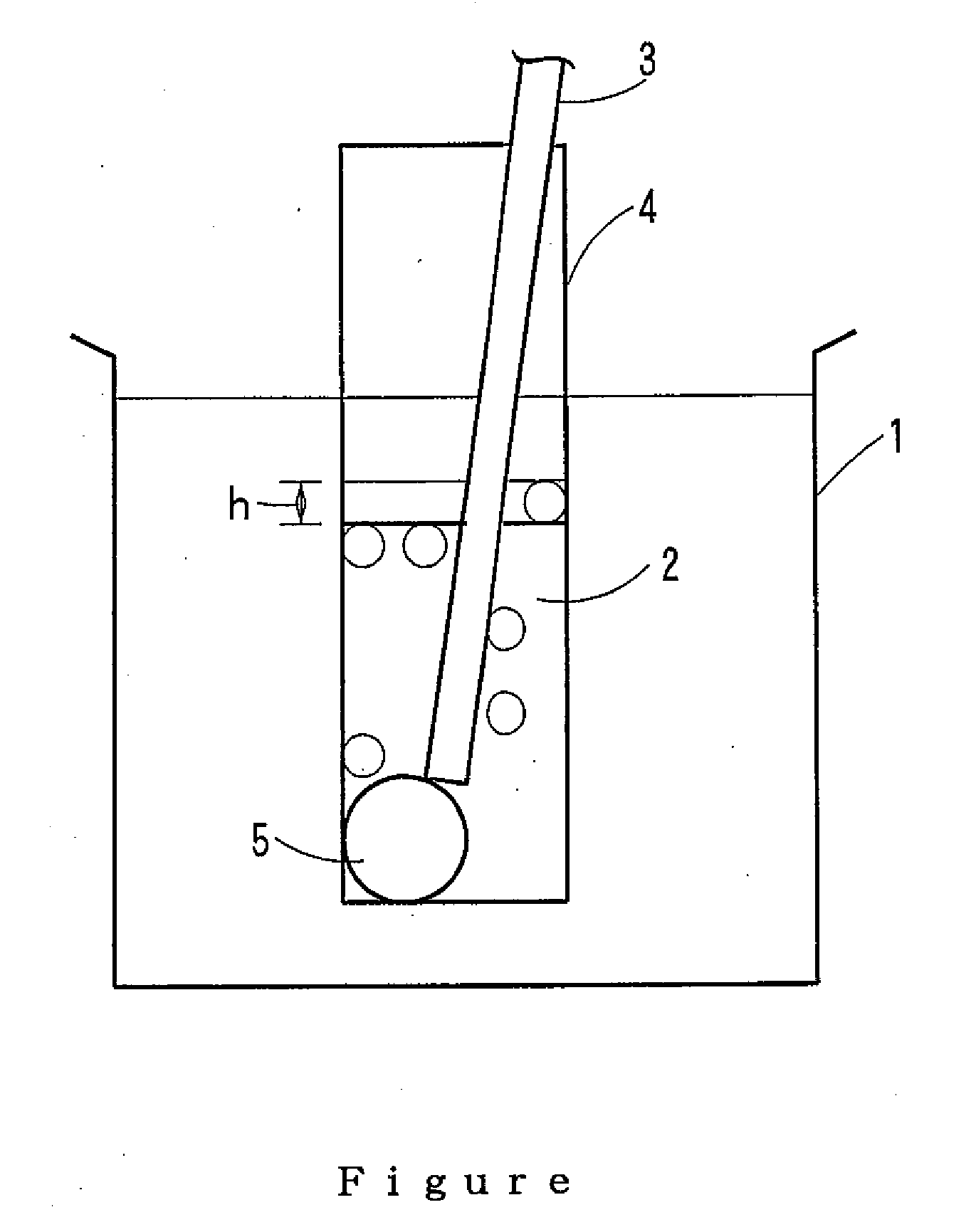

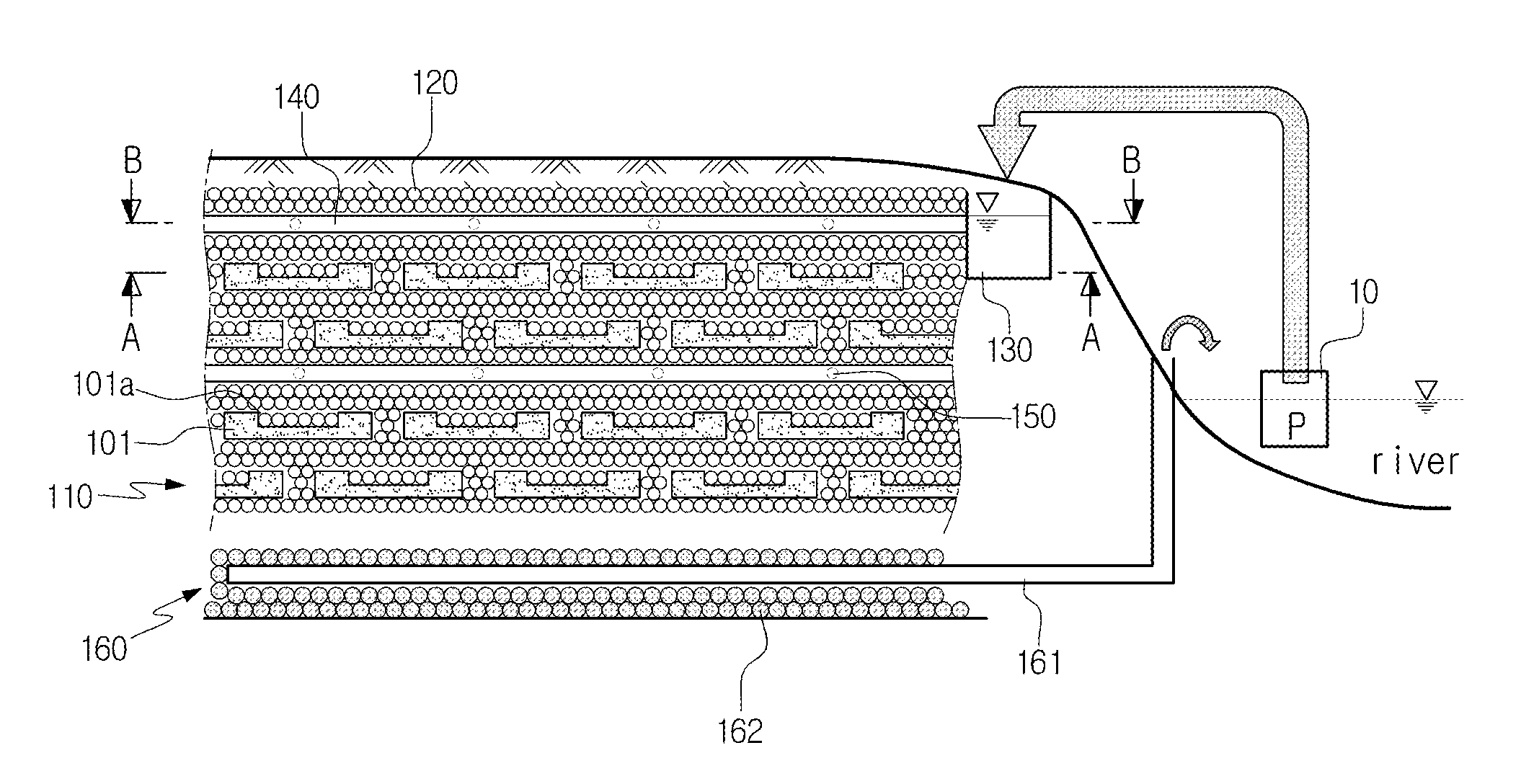

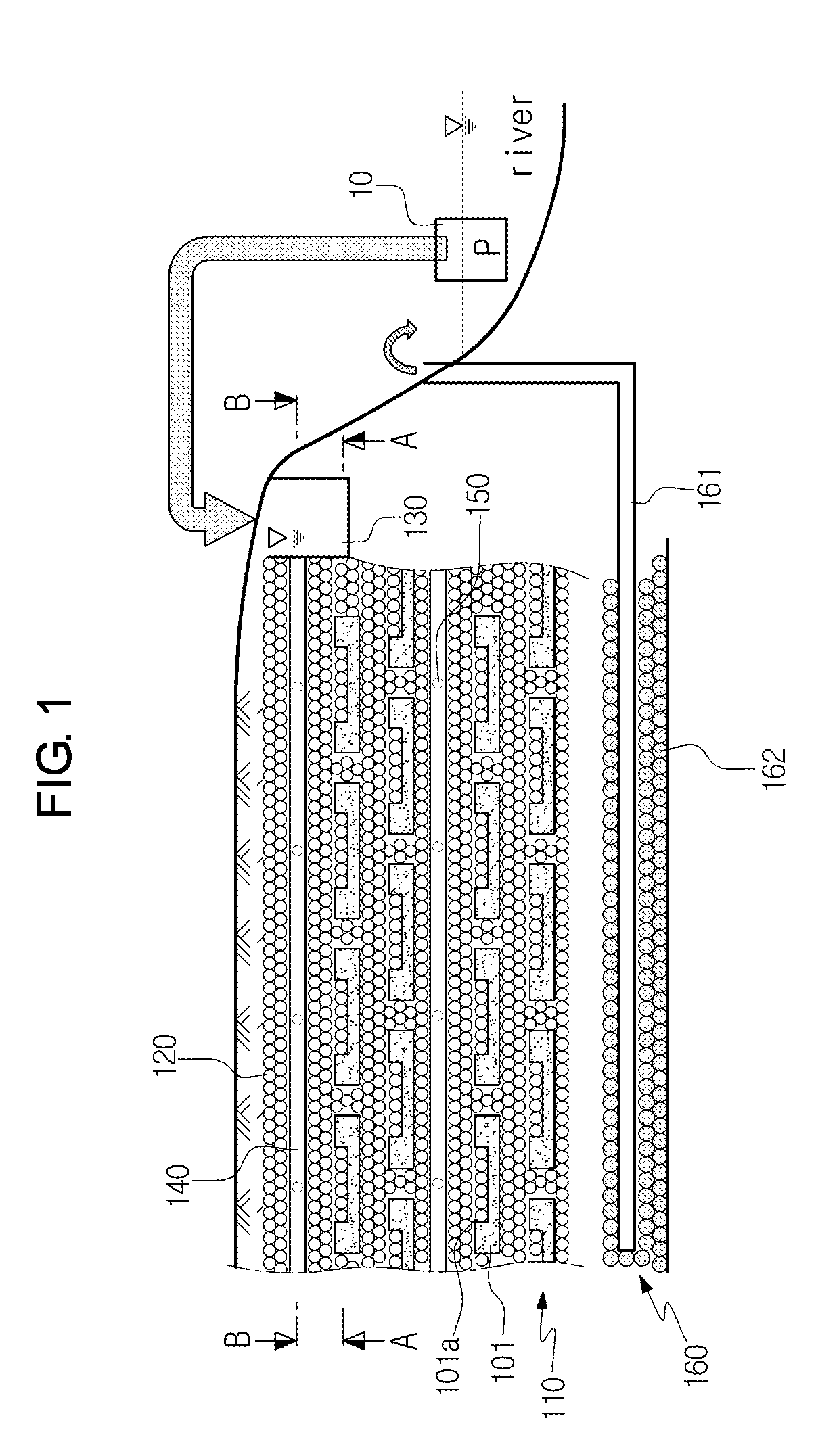

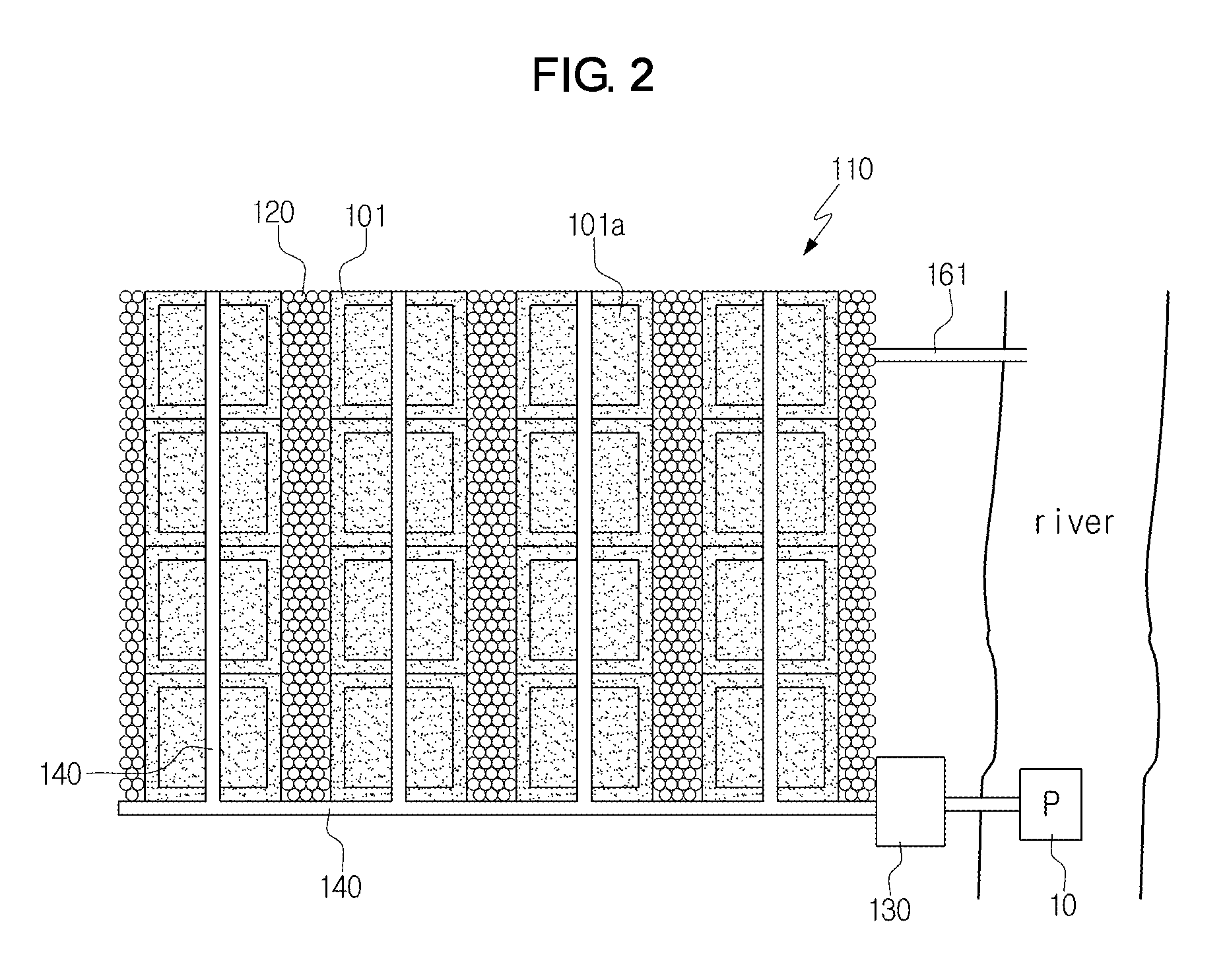

River water purification apparatus and method using treatment soil layer and permeable filtering medium layer

InactiveUS20110100905A1Convenient treatmentEfficient removalWater cleaningWater contaminantsFilter mediaNitrogen

Provided are an apparatus and a method for river water purification using a treatment soil layer and a permeable filtering medium layer. The river water purification apparatus includes a treatment soil layer and a permeable filtering medium layer which are sequentially and alternately stacked. The treatment soil layer includes a plurality of unit soil layers which are arranged at intervals. A reservoir part which stores a predetermined amount of river water and supplies the river water to an inside of the unit soil layer is provided in an upper end part of the unit soil layer. The permeable filtering medium layer has a higher hydraulic conductivity than that of the treatment soil layer. The river water purification apparatus increases a treatment flux of river water regardless of a coefficient of water permeability of soil and effectively removes nitrogen, phosphorus and nutrient salts by stably forming an anaerobic condition.

Owner:KOREA INST OF SCI & TECH

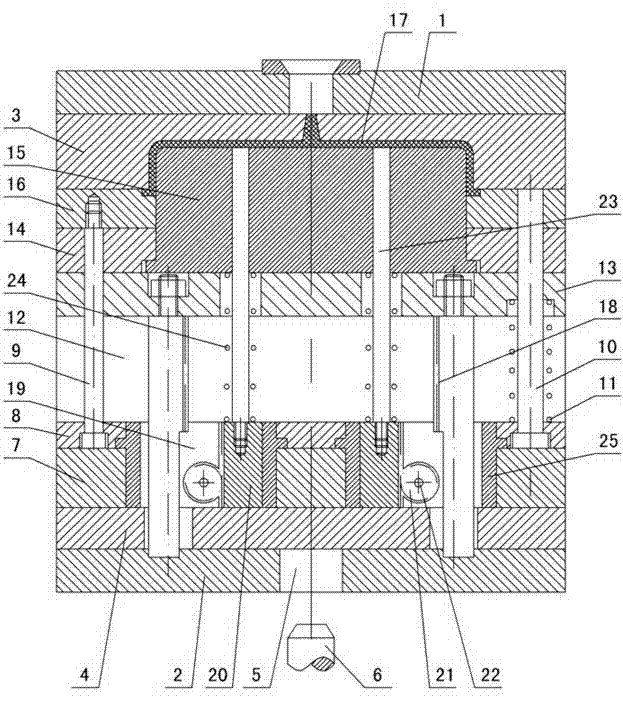

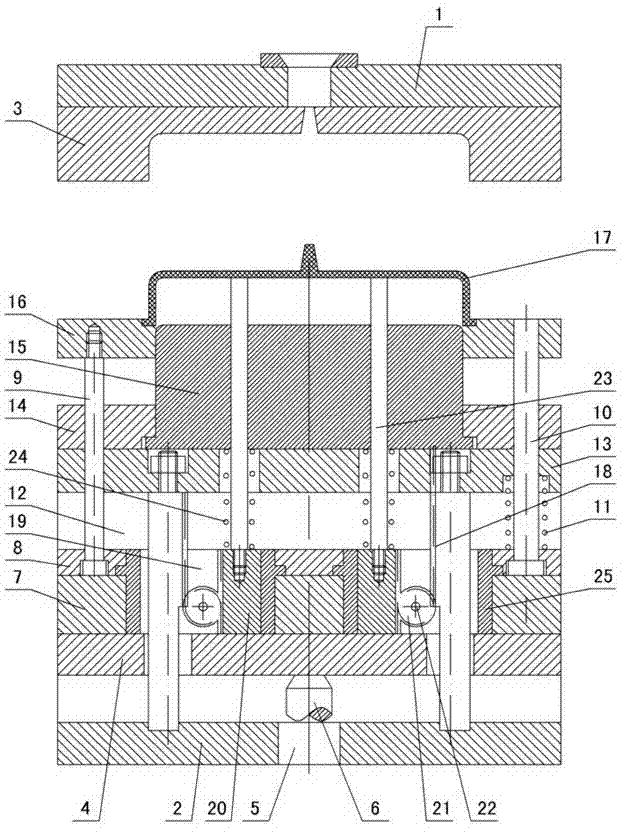

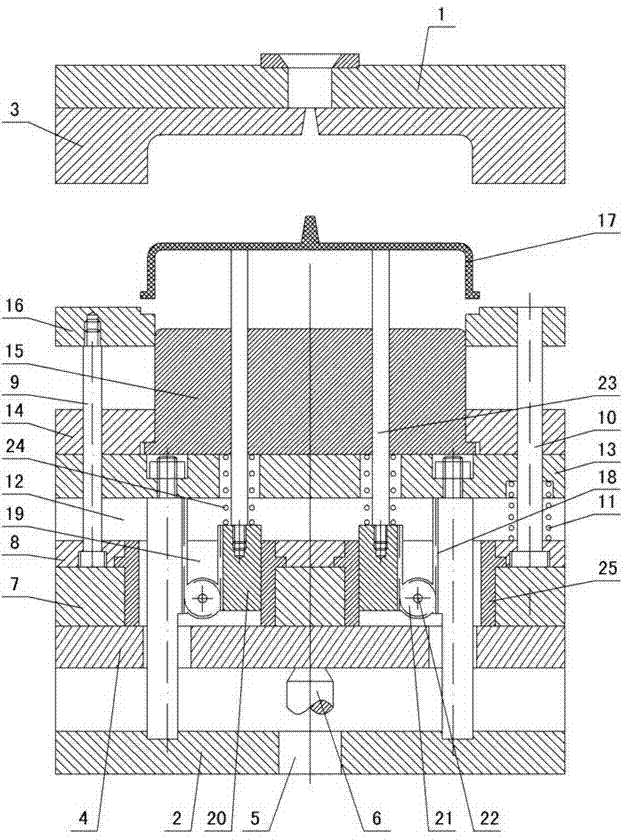

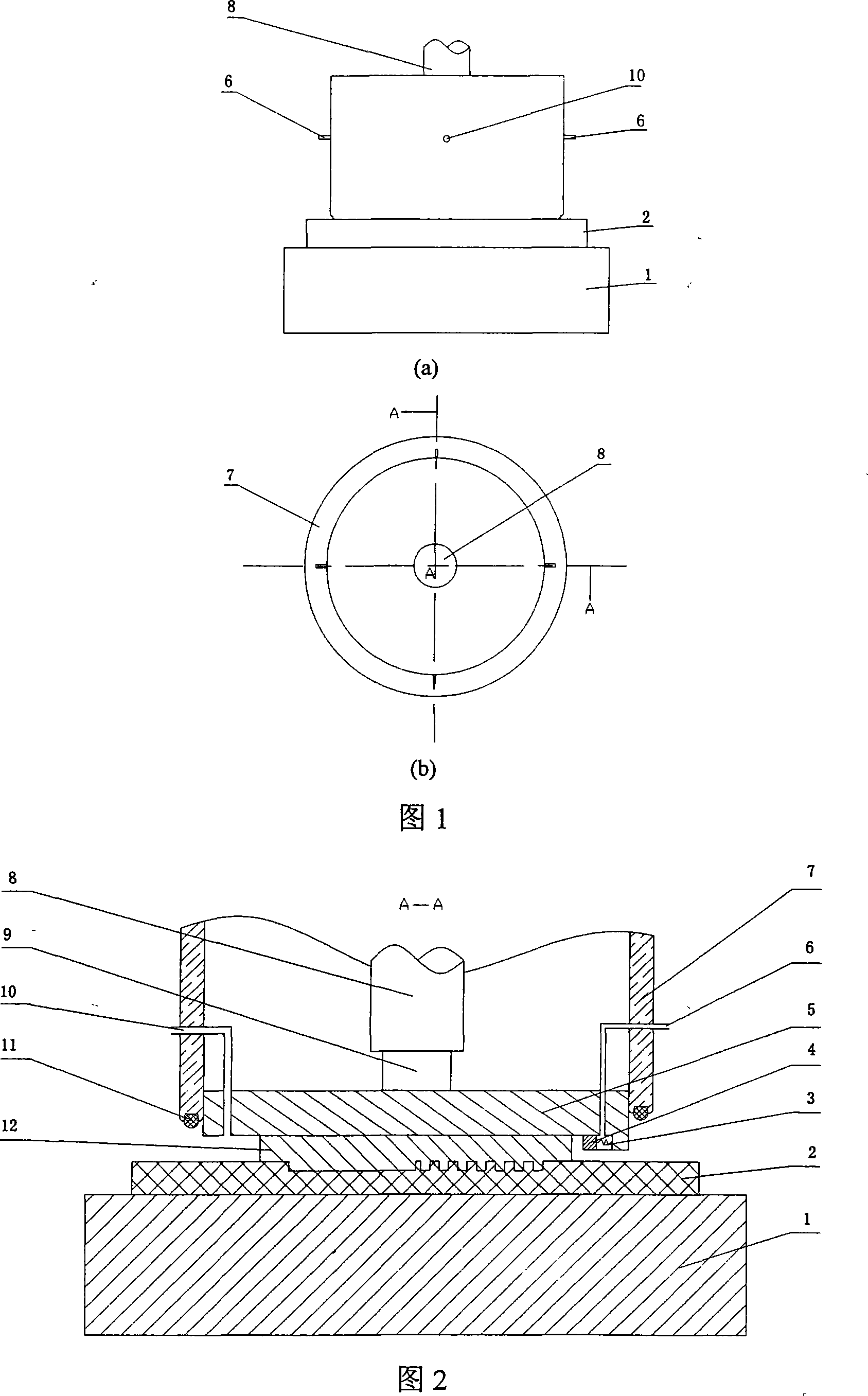

Secondary demoulding mechanism with gear and racks for injection mould

The invention discloses a secondary demoulding mechanism with a gear and racks for an injection mould, comprising an upper compound plate and a lower compound plate, wherein a cavity is installed below the upper compound plate; an ejection support plate is installed on the lower compound plate; a through hole is formed in the lower compound plate; the ejection rod of an injection moulding machine penetrates through the through hole and then contacts with the ejection support plate; an ejection needle pushing plate and an ejection needle fixing plate are installed on the ejection support plate; a stripping plate push rod and a return rod are fixed in the ejection needle fixing plate; a return spring is installed outside the return rod; a mould leg is installed on the lower compound plate; a support plate is installed on the mould leg; a core fixing plate, a core and a stripping plate are installed on the support plate; and a moulded plastic part is arranged among the core, the stripping plate and the cavity. The secondary demoulding mechanism with a gear and racks is characterized in that an acceleration rack is fixed between the lower compound plate and the support plate; installation holes are formed in the ejection needle pushing plate and the ejection needle fixing plate; an ejection needle rack and the gear are installed in the installation holes; the gear is fixed in the ejection needle pushing plate via a rotary shaft; the gear is matched with the acceleration rack and the ejection needle rack respectively; an ejection needle is installed on the ejection needle rack; and the ejection needle penetrates through the core and then contacts with the plastic part.

Owner:TAIZHOU KAIHUA AUTOMOBILE MOULD CO LTD

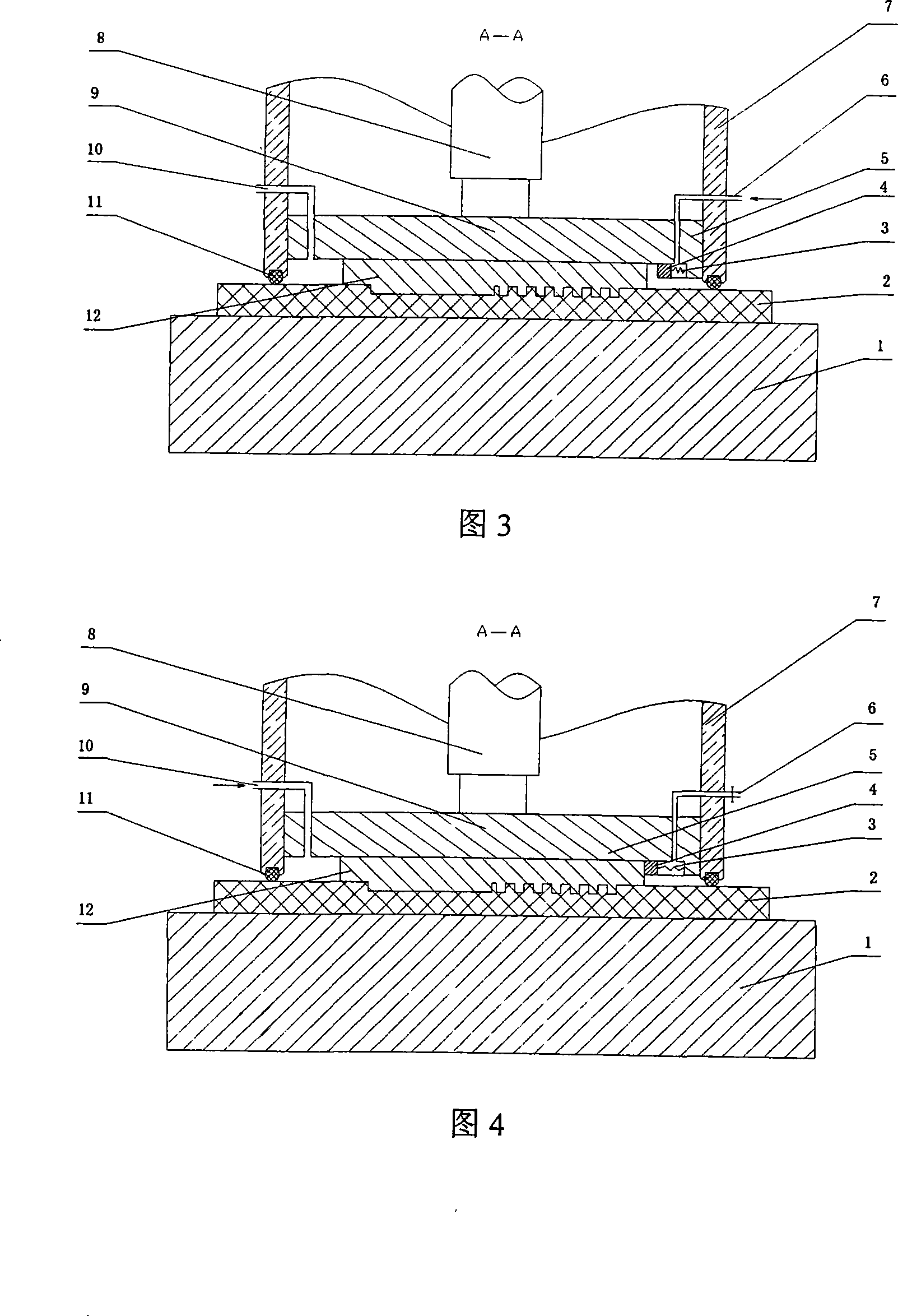

Pneumatic micro-nano imprint demoulding structure

InactiveCN101249938AReduce distortionReduce deformation and even damageNanostructure manufactureMicro nanoEngineering

The invention discloses a nano imprint demoulding structure based on air driving, wherein a polymer clamping casing is arranged on a work bench, a mould plate is arranged at the lower end of the clamping casing, a plunger is arranged on the upper end surface of the mould plate, a sleeve is fixedly connected with the clamping casing, the sleeve and the plunger move from up to down, thereby the mould plate can move from up to down in the clamping casing, a sliding passage arranged on the lower end surface of the mould plate is provided with a spring and a slide block, a mould clamping air passage connected to the clamping casing is led into the slide passage via the mould plate, thereby the slide block can slide in the slide passage on the lower end surface of the mould plate, a demoulding air passage is switched in from the clamping casing and passes through the mould plate, and a sealing ring is arranged on the lower end surface of the clamping casing. The nano imprint demoulding structure is capable of demoulding smoothly, and stress of the polymer and the mould is uniform, further damages of the microstructure imprinted can be reduced to the minimum, the mould can be protested, and the cost of imprinting can be reduced.

Owner:ZHEJIANG UNIV

Automobile air-conditioner sucking cup punch forming die

InactiveCN103962456AMolding stabilityQuality improvementShaping toolsStripping-off devicesEngineeringMechanical engineering

Owner:AIMBON (CHENGDU) ELECTRIC APPLICANCE CO LTD

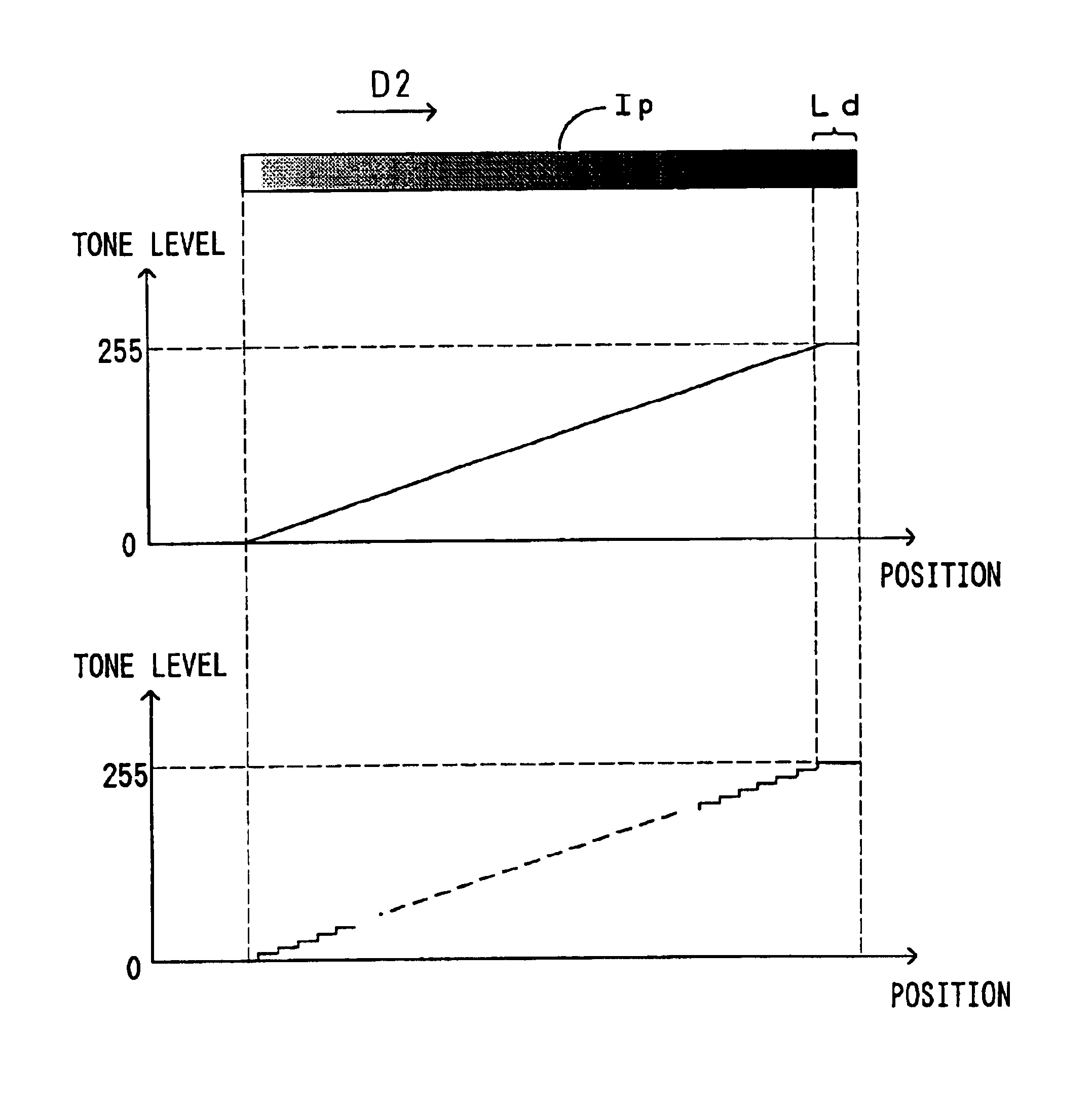

Image forming apparatus and image forming method

InactiveUS6934481B2Quality improvementImprove accuracyElectrographic process apparatusPrintingImage formationEngineering

A gradation patch image Ip used for determination of tone characteristics of an apparatus is progressively varied in the tone level thereof from the maximum tone level (level 255) to the minimum tone level (level 0). The gradation patch image is either a toner image continuously and consistently varied in the tone level thereof or a toner image having the tone levels varied stepwise at a smaller pitch than a width of a detection region of a patch sensor. In density detection of such a gradation patch image Ip, toner image densities at portions on either sides in the detection region of the patch sensor are canceled each other out by averaging and hence, only a toner image density substantially at the center of the detection region can be obtained.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com