Patents

Literature

88 results about "Structural Problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

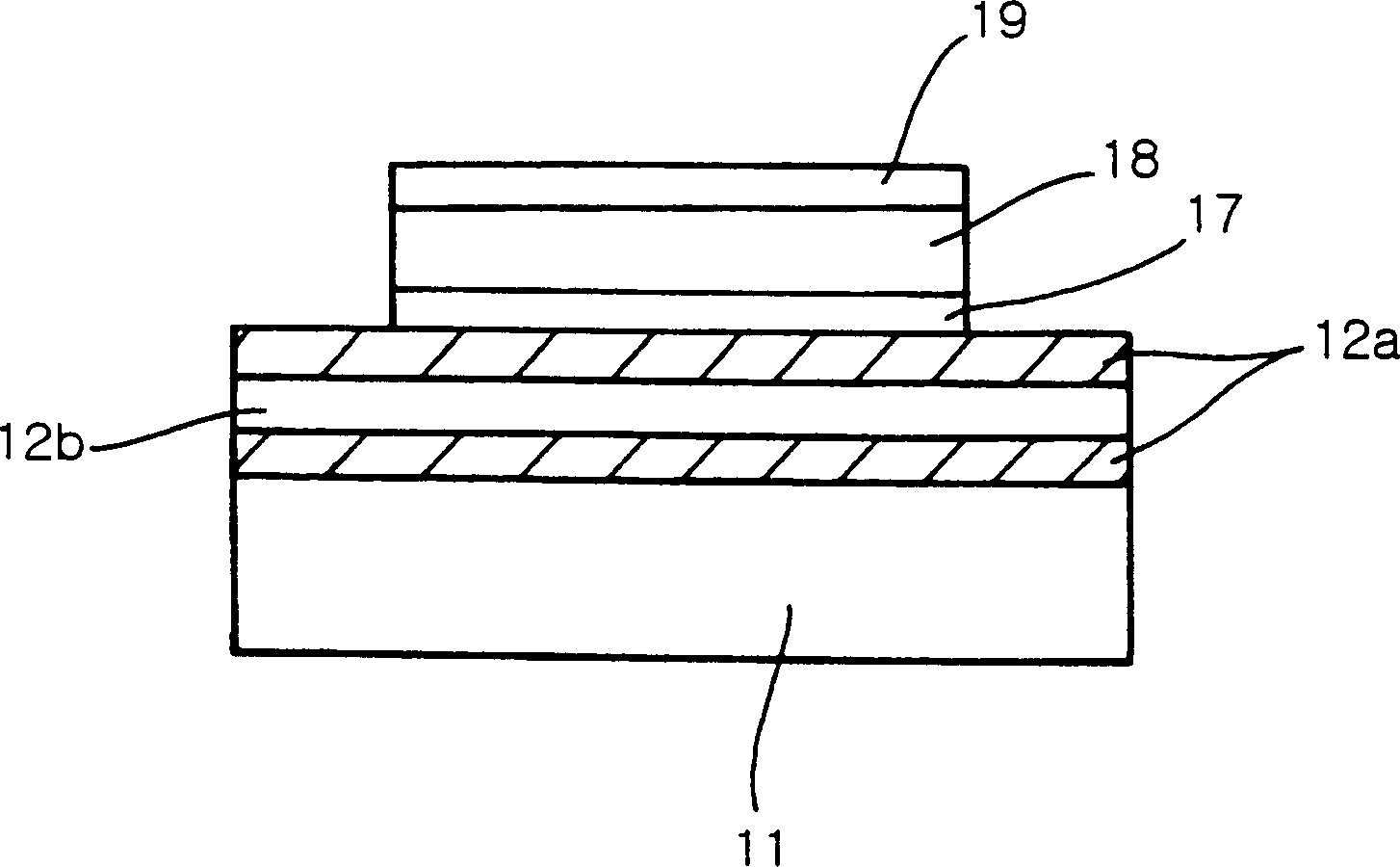

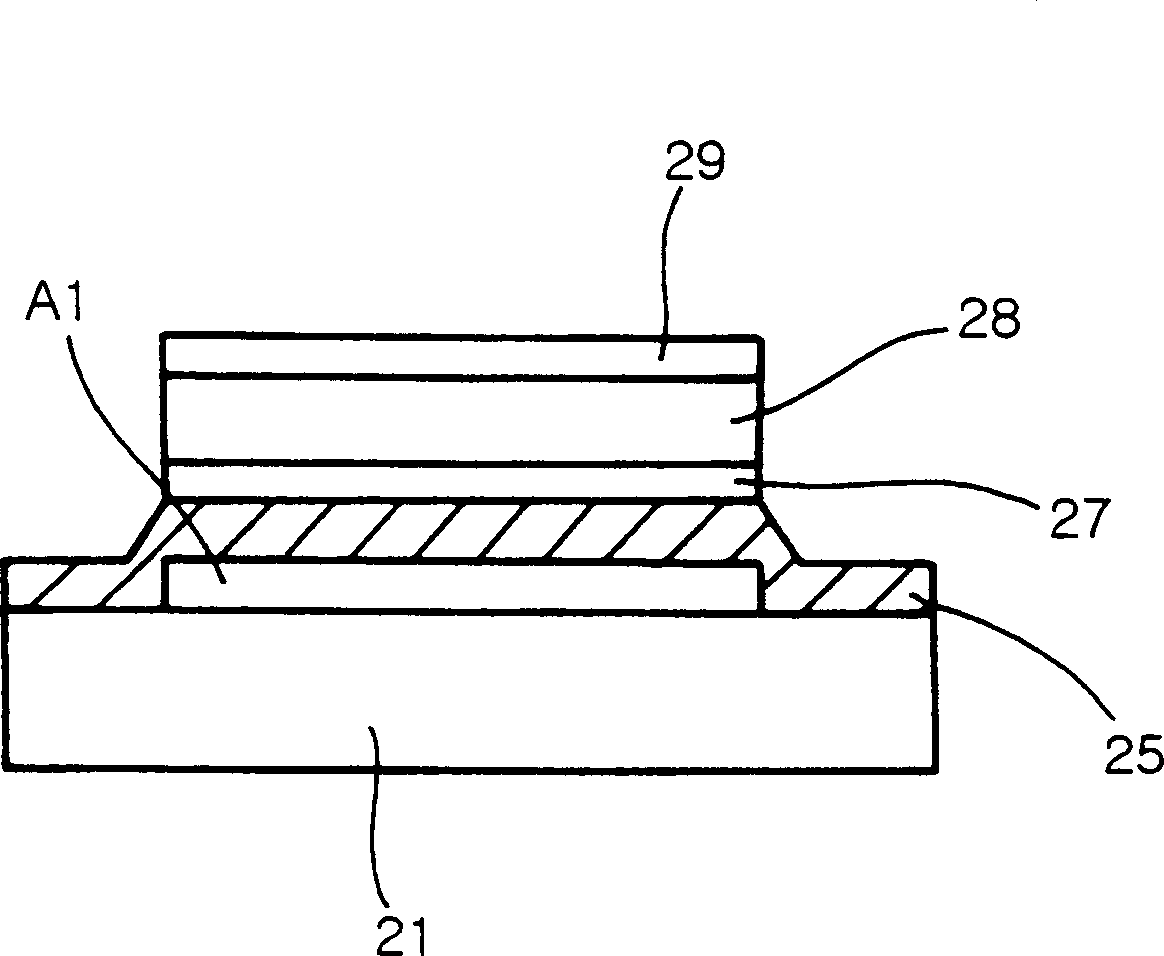

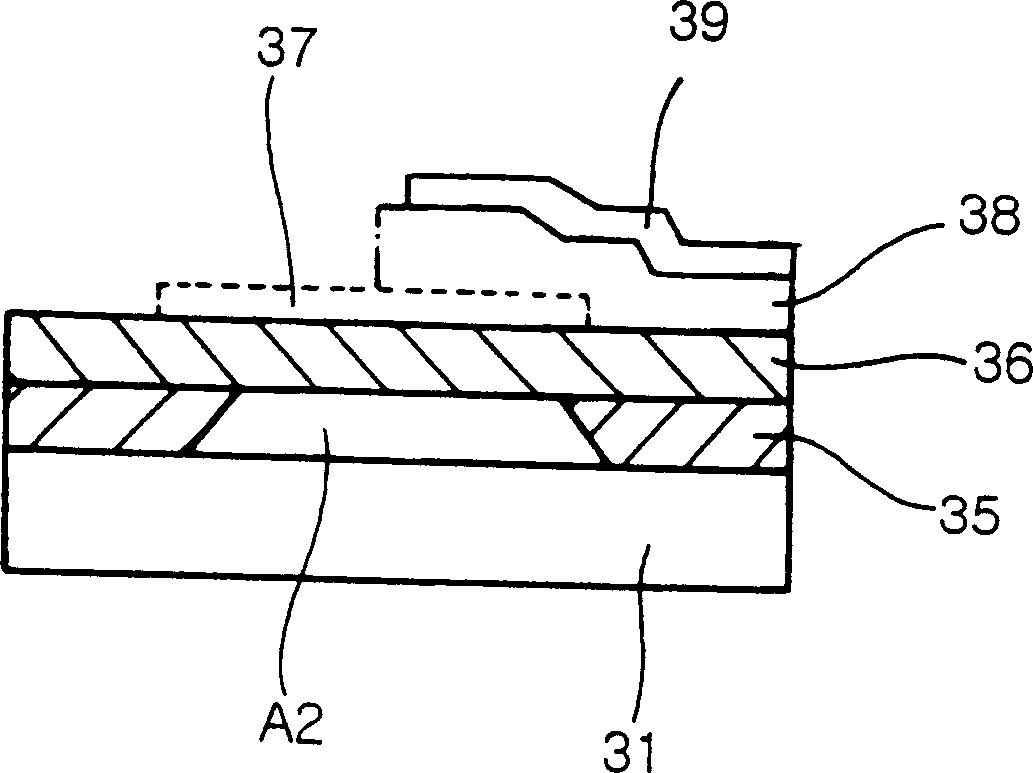

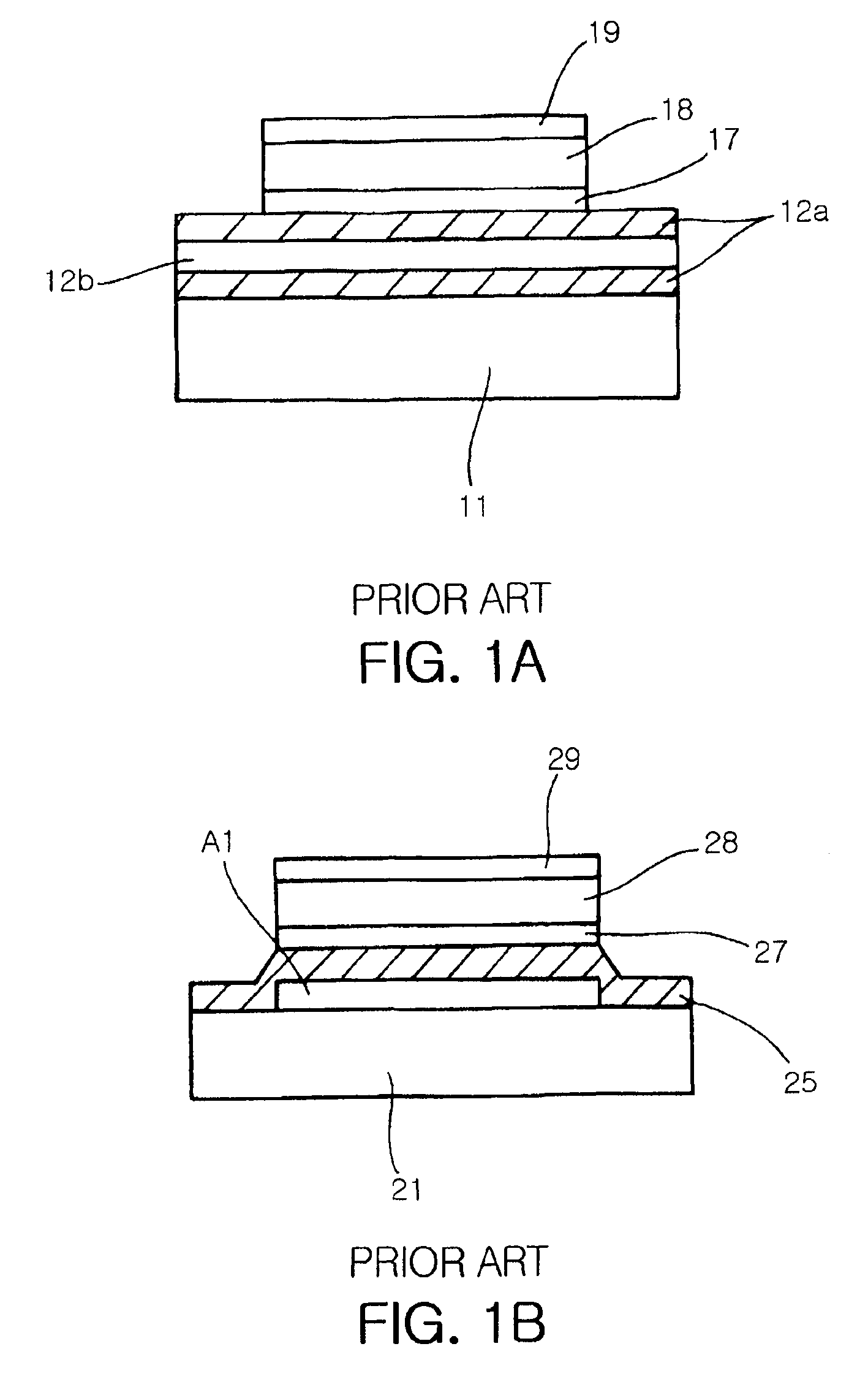

Film bulk acoustic resonator and method of forming the same

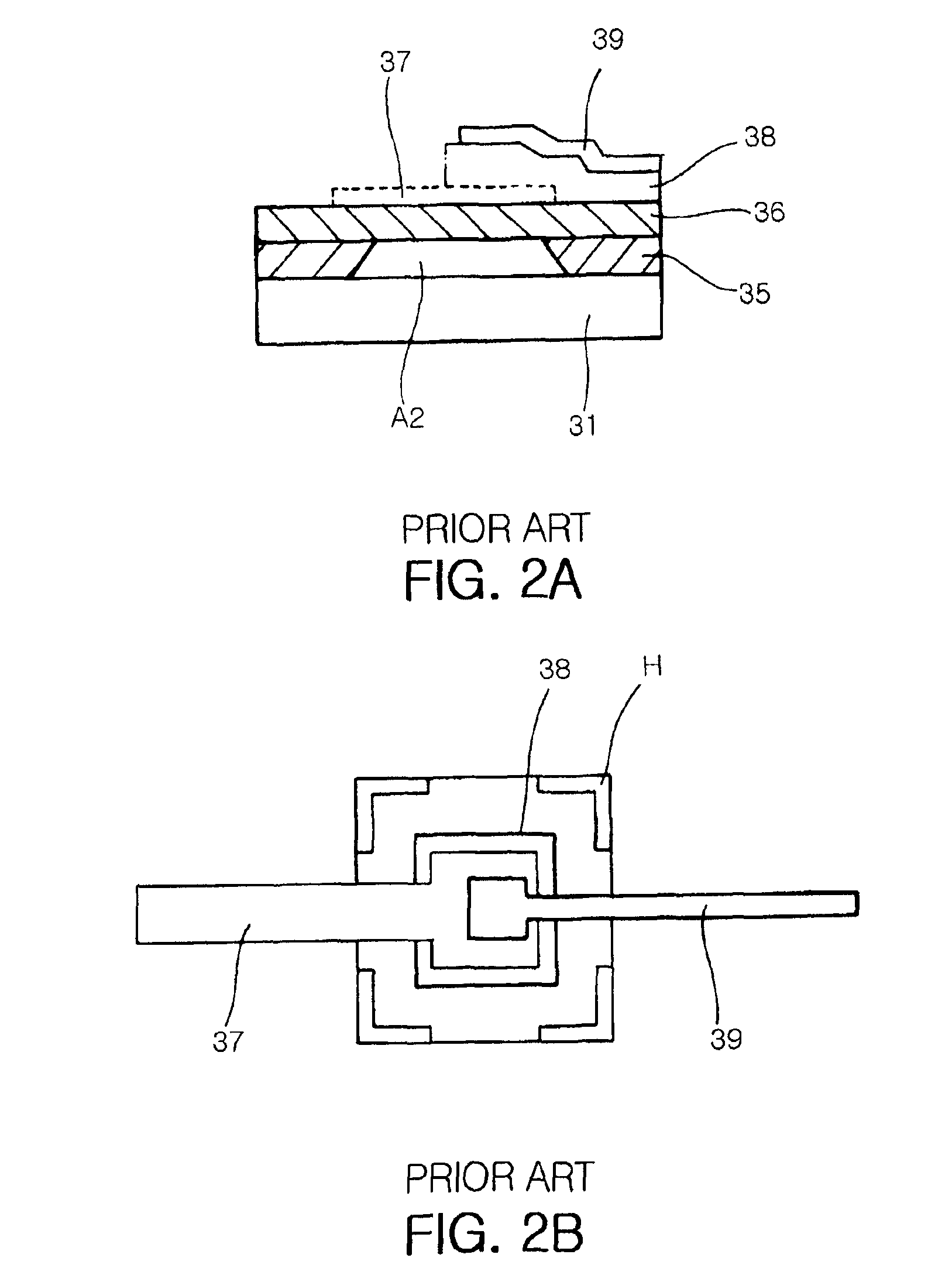

InactiveCN1450719ALow insertion lossPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksThin-film bulk acoustic resonatorStructural Problem

A film bulk acoustic resonator (FBAR) includes an insulation layer on a substrate to prevent a signal from being transmitted to a substrate. The FBAR includes a portion of a membrane layer corresponding to an activation area to adjust a resonance frequency band and improve a transmission gain of the resonance frequency band, the portion of the membrane layer being partially etched to have a thickness less than the other portion of the membrane layer. A method of forming the FBAR includes forming an sacrificing layer made of polysilicon, forming an air gap using a dry etching process, and forming a via hole. The method prevents structural problems occurred in a conventional air gap forming process and provides locations and the number of the via holes to be controlled.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

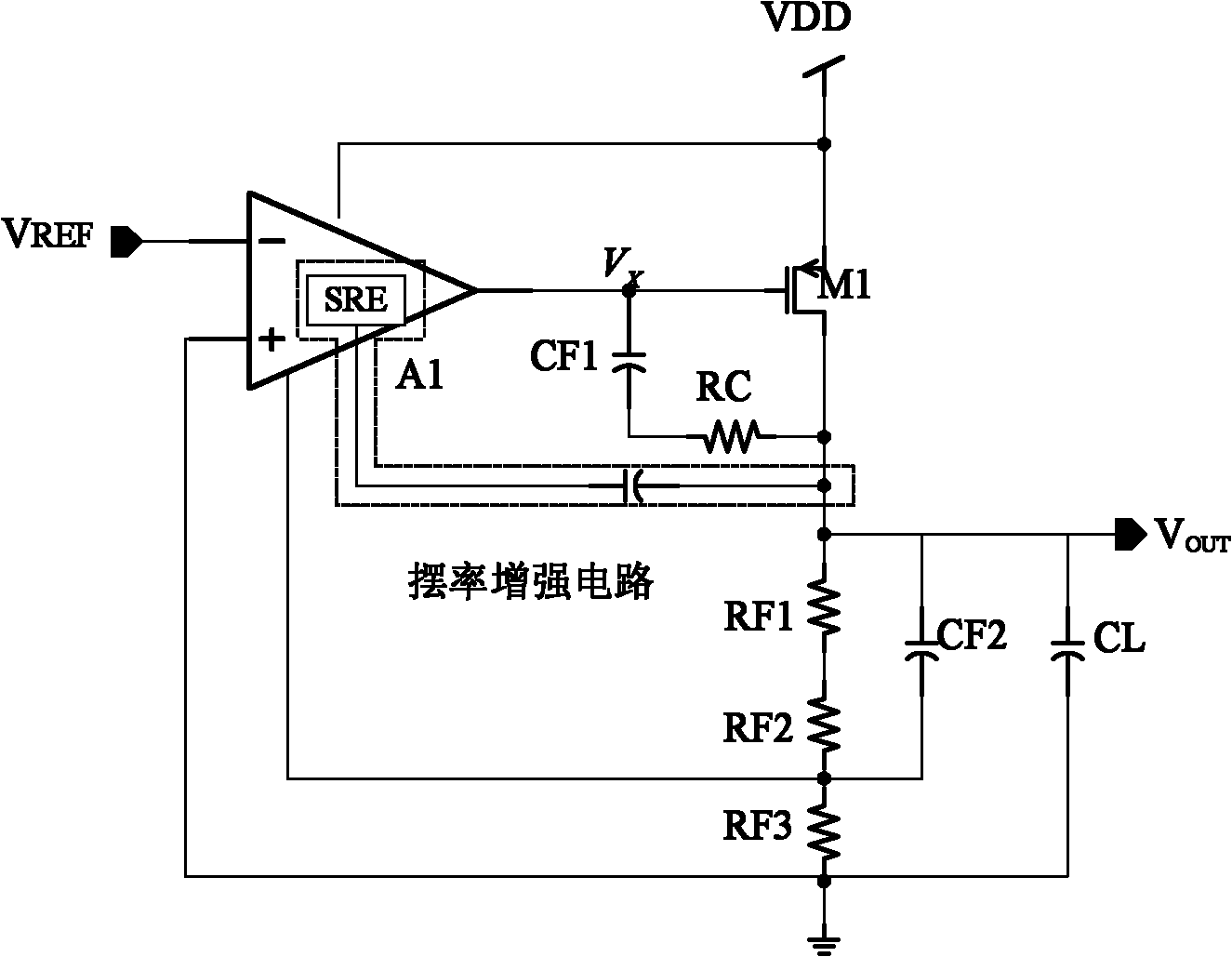

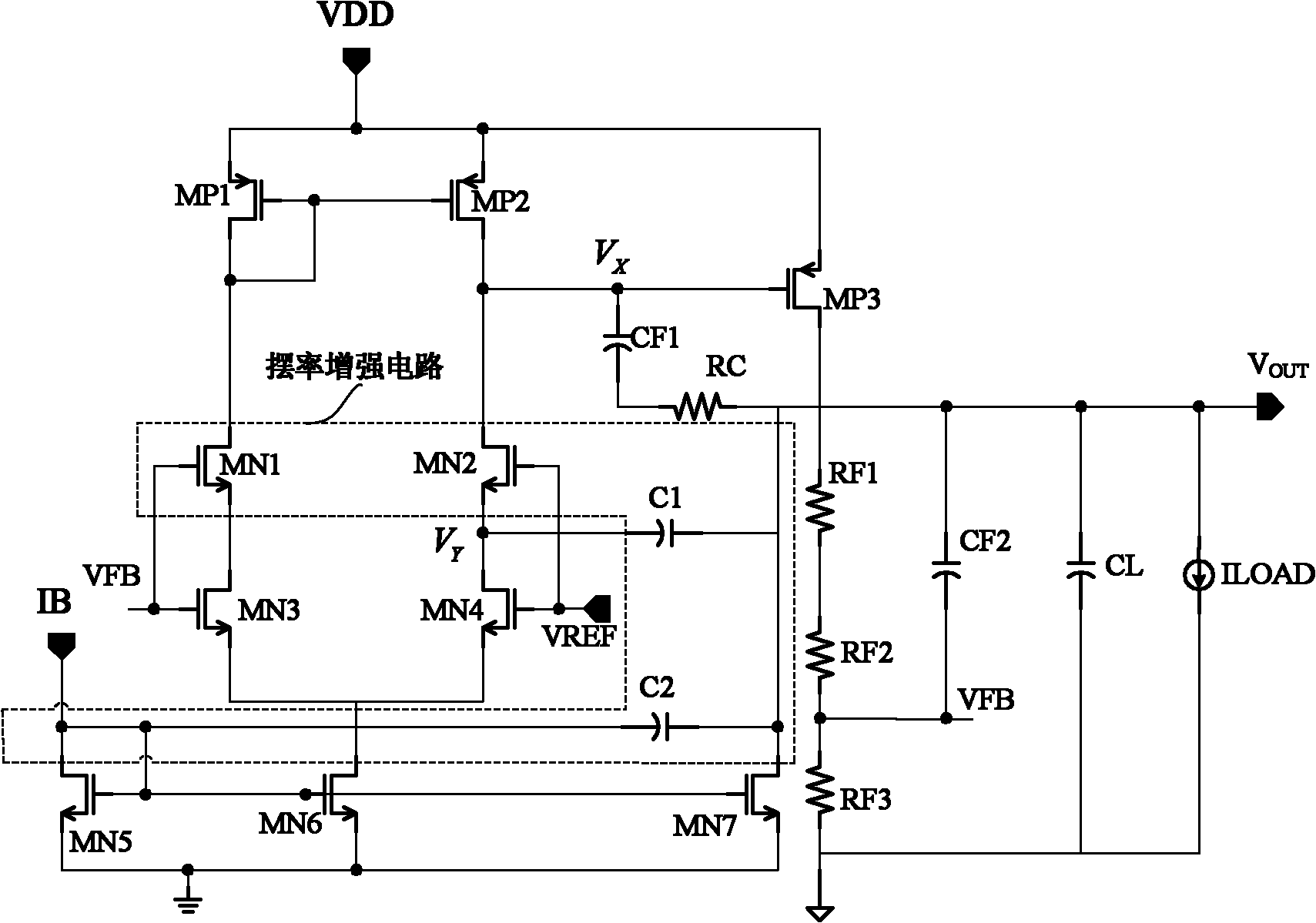

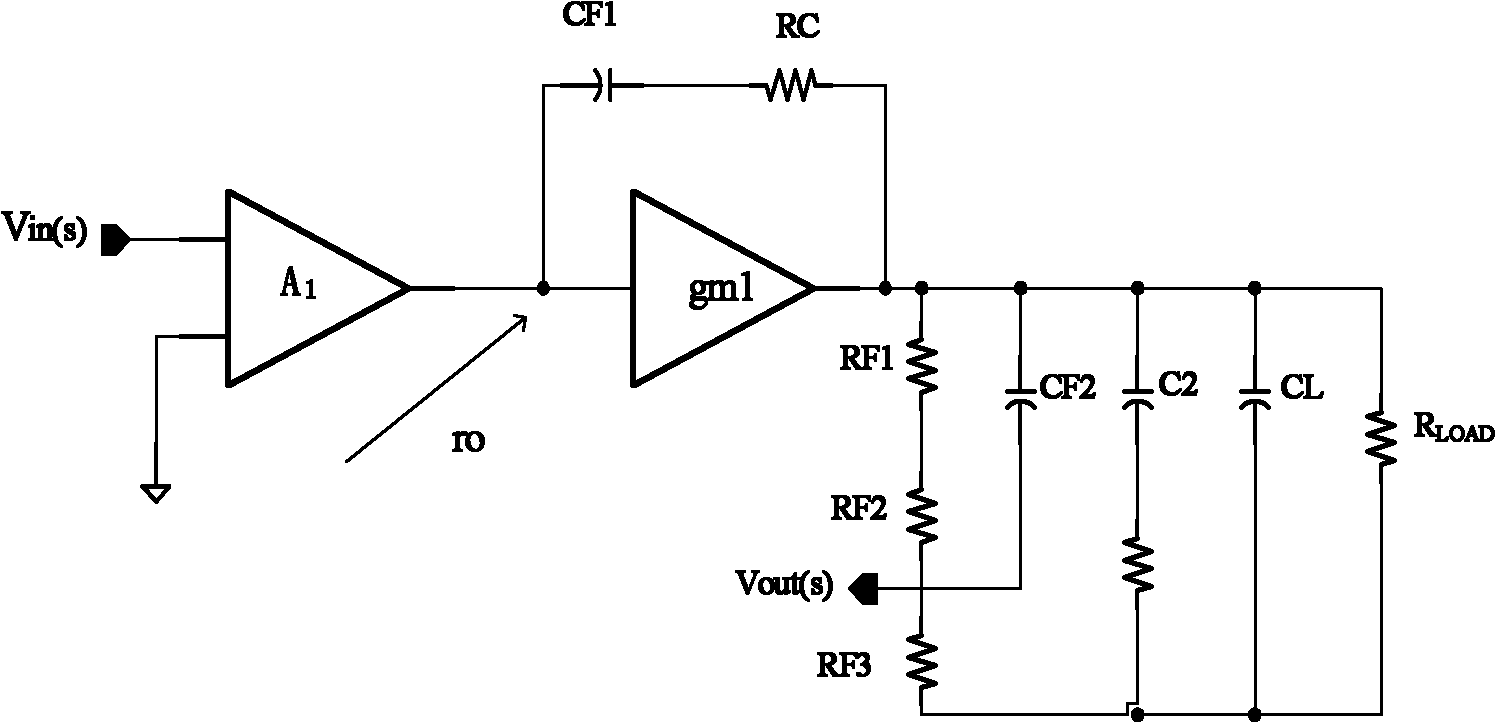

A low dropout linear regulator

InactiveCN102279612ASimple structureReduce power consumptionElectric variable regulationCapacitanceLinear regulator

The invention discloses a low dropout linear regulator. Aiming at the problem of complicated structure of the existing low-dropout linear regulator, the LDO of the present invention includes an error amplifier, a feedback sampling network, a bias circuit and a slew rate enhancement circuit, and is characterized in that a part of the slew rate enhancement circuit is included in the error amplifier Among them, the error amplifier includes a first PMOS transistor, a second PMOS transistor, a first NMOS transistor, a second NMOS transistor, a third NMOS transistor, and a fourth NMOS transistor; wherein the first NMOS transistor and the second NMOS transistor serve as slew rate enhancement As a component of the circuit, the slew rate enhancing circuit further includes a first capacitor and a second capacitor. The voltage stabilizer of the present invention constitutes a slew rate enhancement circuit through two NMOS transistors and two capacitors, does not require too many additional auxiliary circuits, has a simple structure and low power consumption, and can be applied without reducing performance. Under low voltage, it has extremely fast transient response.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

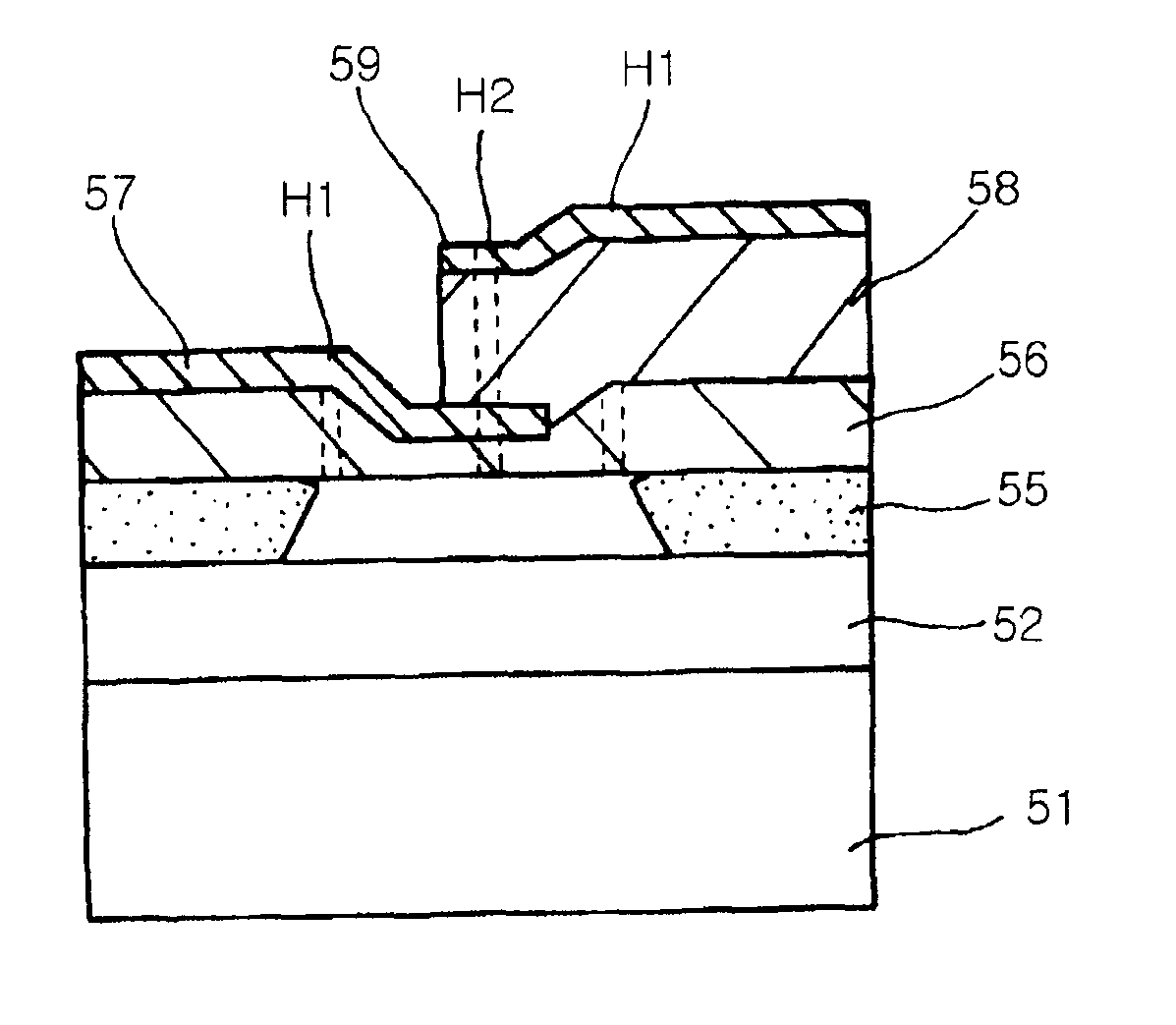

Film bulk acoustic resonator and method of forming the same

InactiveUS6992420B2Good reflective propertiesReduced insertion lossPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksStructural ProblemInsulation layer

A film bulk acoustic resonator (FBAR) includes an insulation layer on a substrate to prevent a signal from being transmitted to a substrate. The FBAR includes a portion of a membrane layer corresponding to an activation area to adjust a resonance frequency band and improve a transmission gain of the resonance frequency band, the portion of the membrane layer being partially etched to have a thickness less than the other portion of the membrane layer. A method of forming the FBAR includes forming an sacrificing layer made of polysilicon, forming an air gap using a dry etching process, and forming a via hole. The method prevents structural problems occurred in a conventional air gap forming process and provides locations and the number of the via holes to be controlled.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

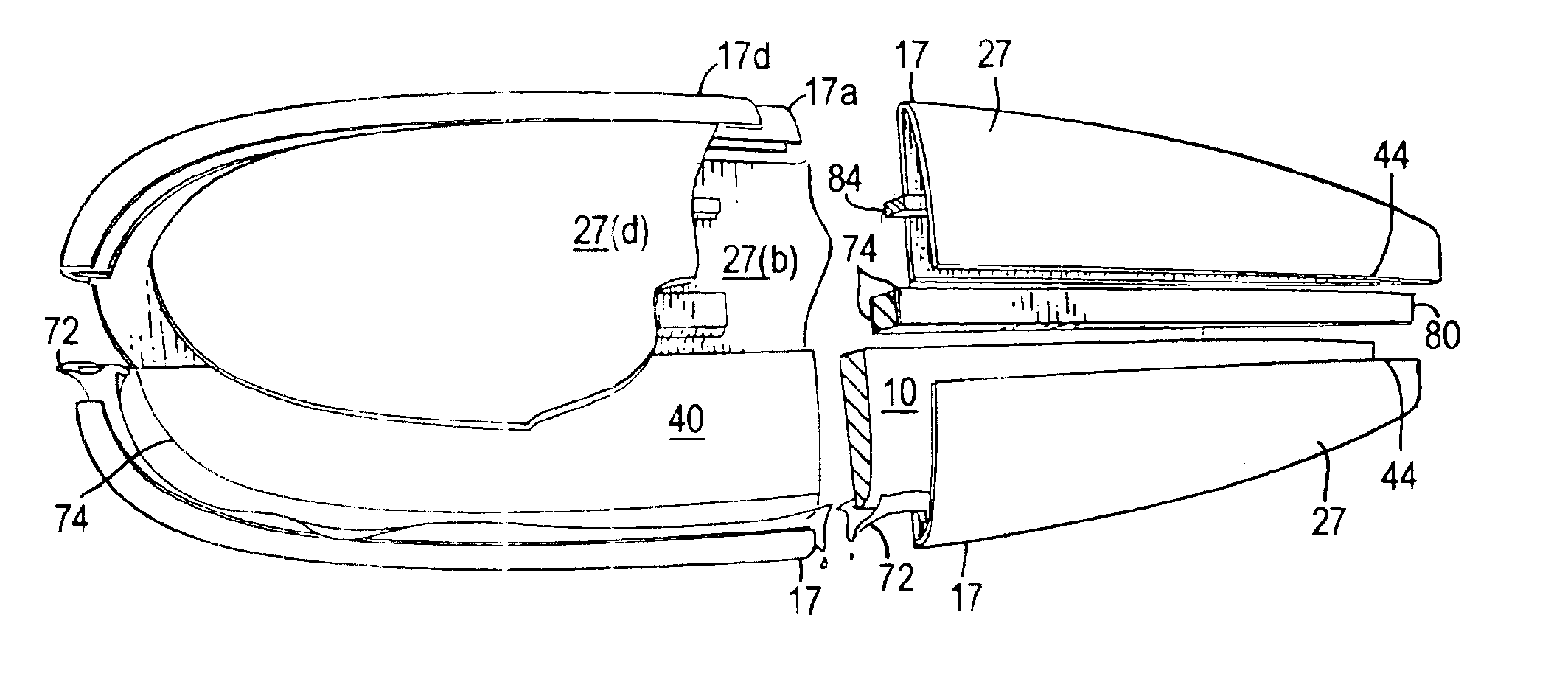

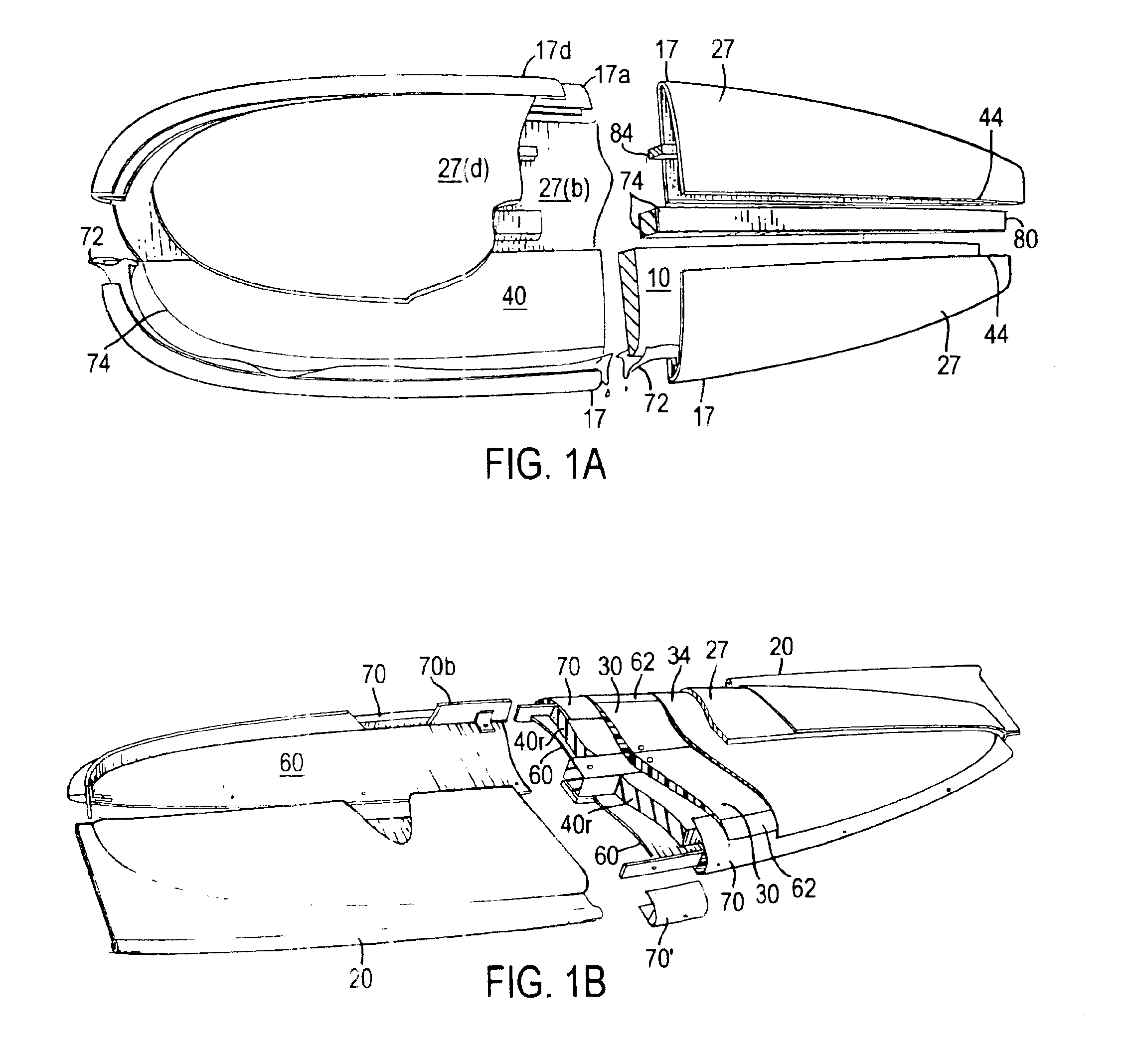

Shape-adjustable mold, skin and interior-core structures for custom board production

InactiveUS6878025B2Rapid production-quicklyFlat surfaceNon-magnetic metal hullsWater sport boardsStructural ProblemBiomedical engineering

Discloses skin and interior core structures made shape-adjustable with a layer of skin core forming a pre-molded perimeter rail; exterior structural skin can be molded using a convex shape-defining mold to produce a plurality of different shapes; separate subparts give the mold the capacity to describe different curves and modify different parameters of the board's design. Mold is reversible; male / female configurations produce convex shape-defining substrates allowing a wide array of different shapes. Board is fabricated without use of any concave shape-defining surface, and therefore without the high manufacturing costs and structural problems of prior art female molds.

Owner:MEAD KIRBY J

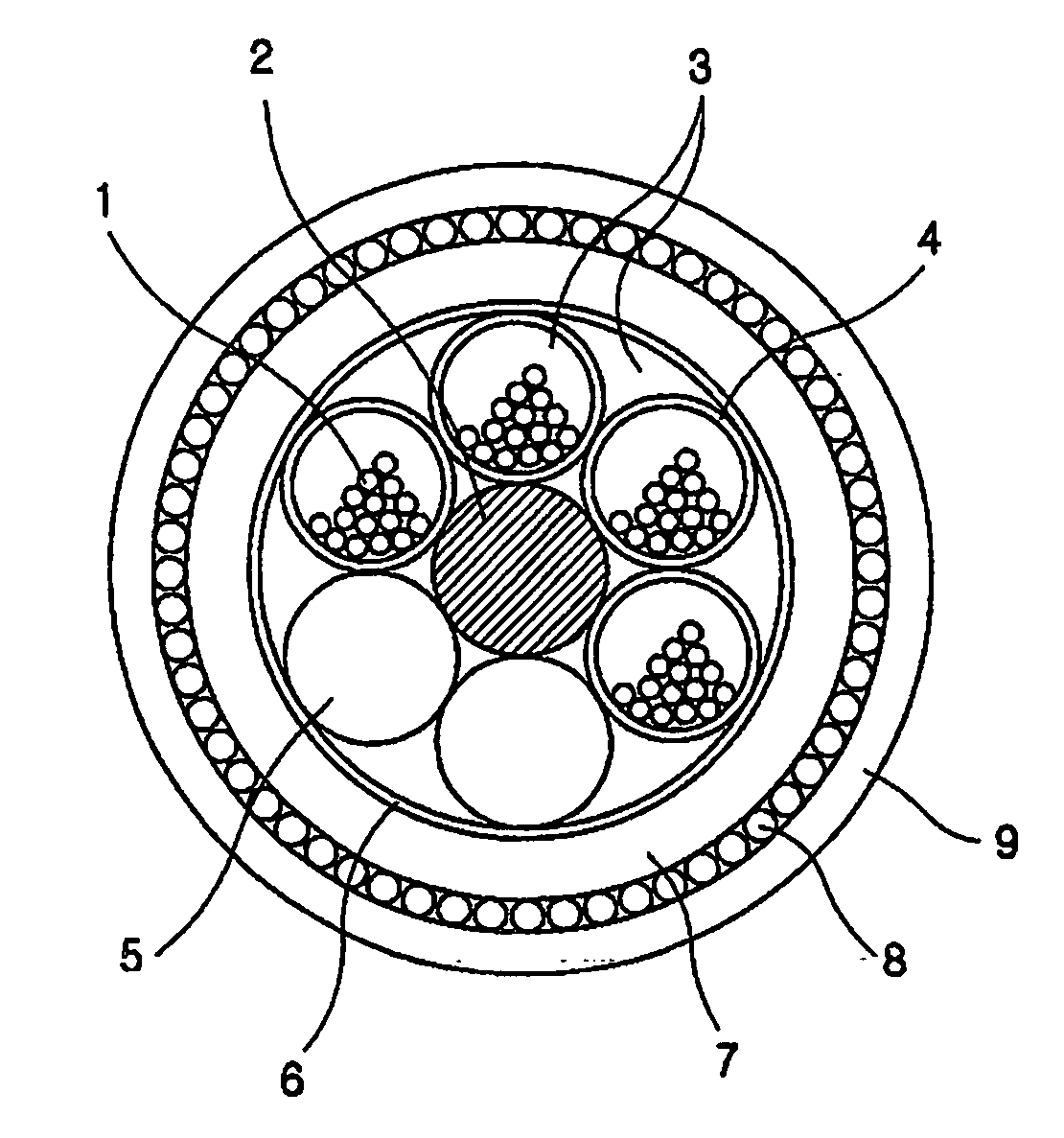

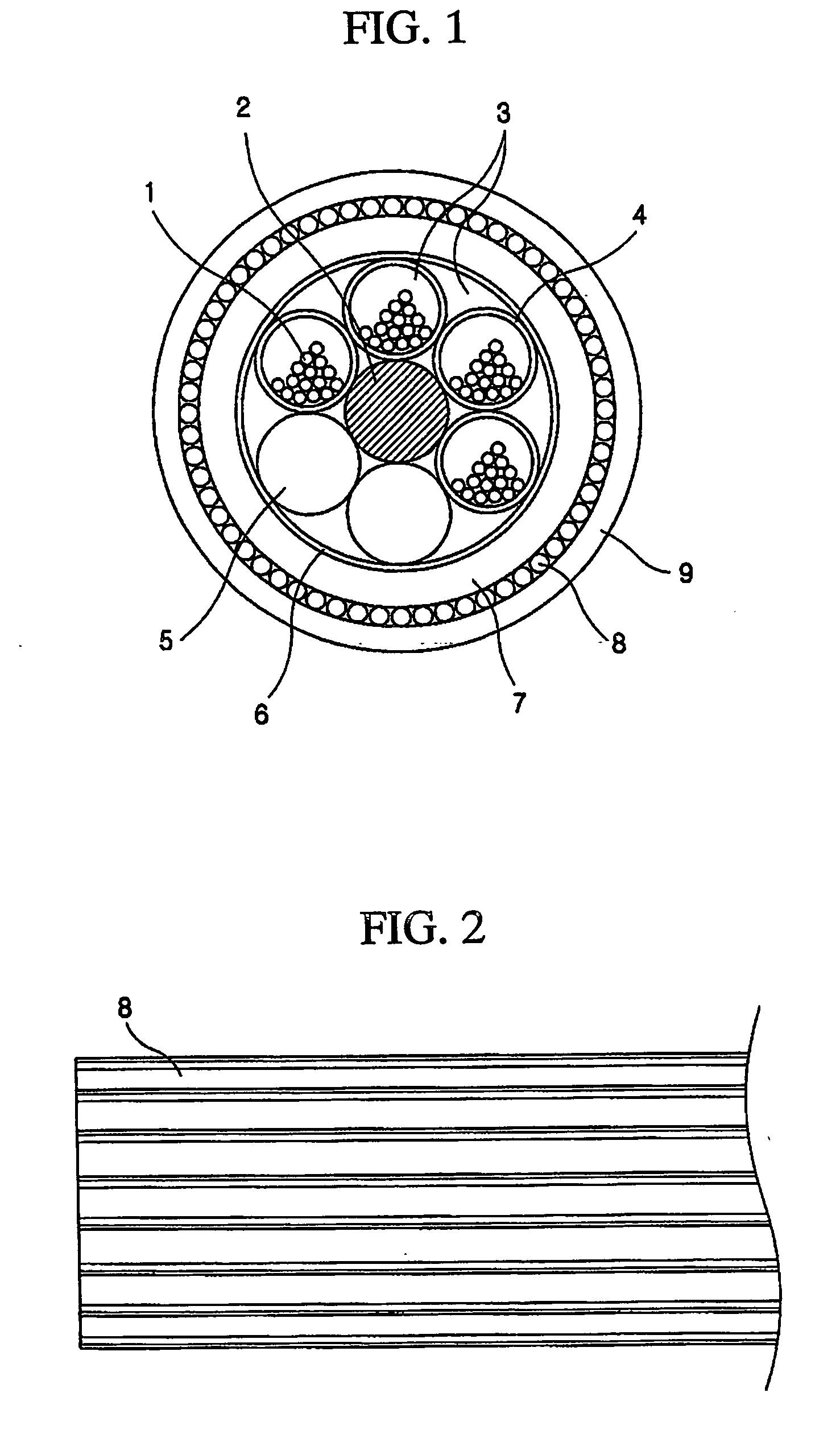

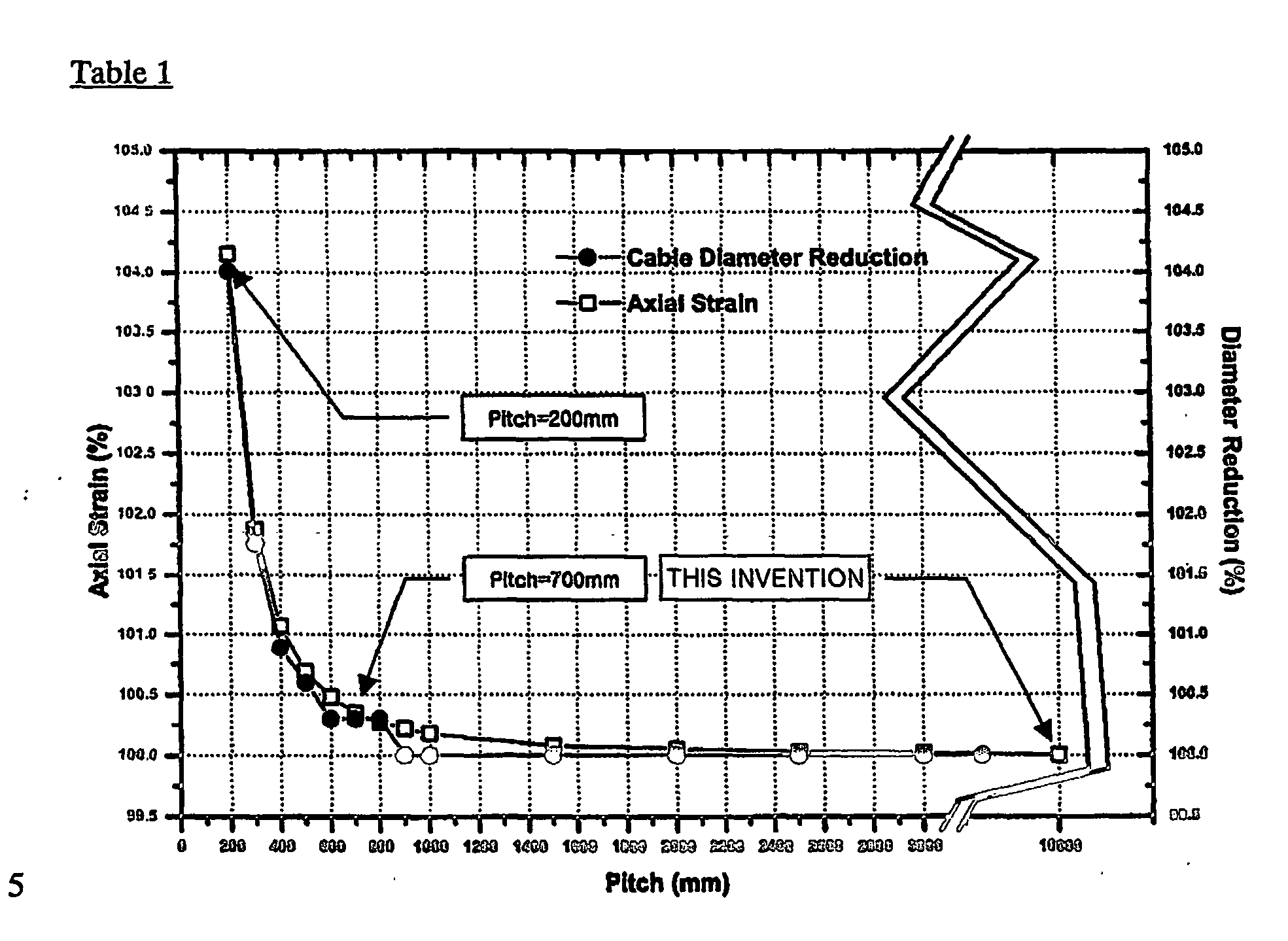

All-dielectric, self-supporting, loose-tube optical fiber cable

InactiveUS20060159408A1Improve tensile propertiesAvoid structural instabilityFibre mechanical structuresElectricityEpoxy

Owner:LG CABLE LTD (KR)

Efficient certificate revocation

InactiveUS20080163338A1Easy to implementLow costDigital data processing detailsUser identity/authority verificationStructural ProblemOperating system

We propose new systems for certificate revocation that are more economical and efficient than traditional ones. We also point out what we believe to be a structural problem in traditional public-key infrastructures, and various ways to solve it.

Owner:ASSA ABLOY AB

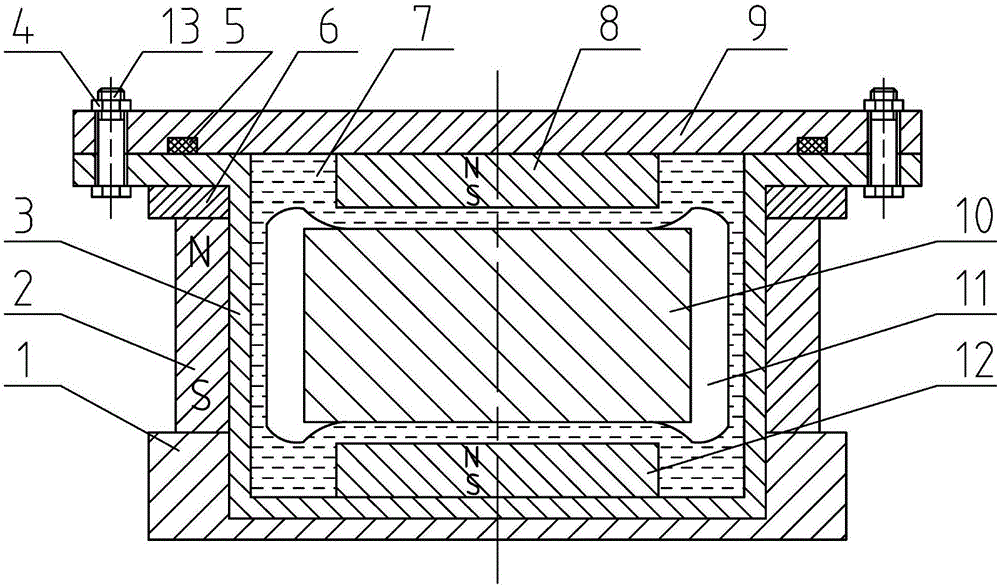

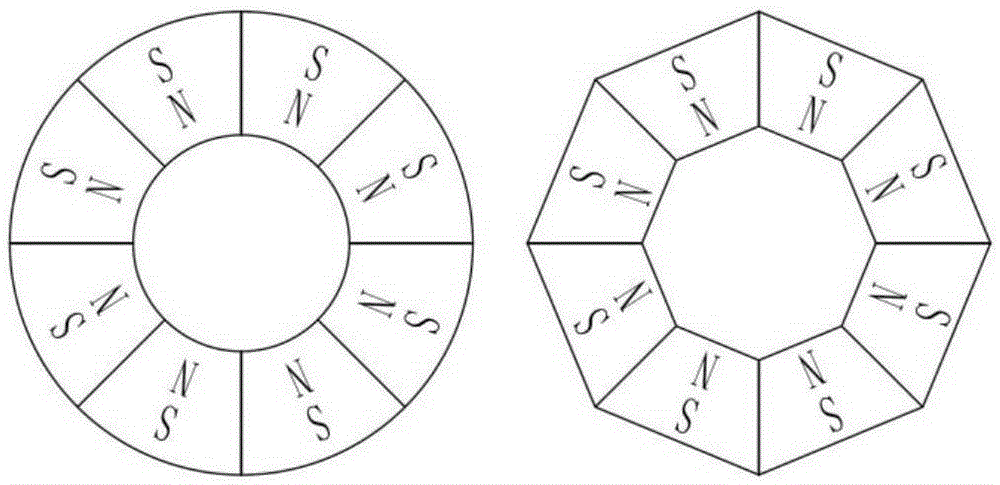

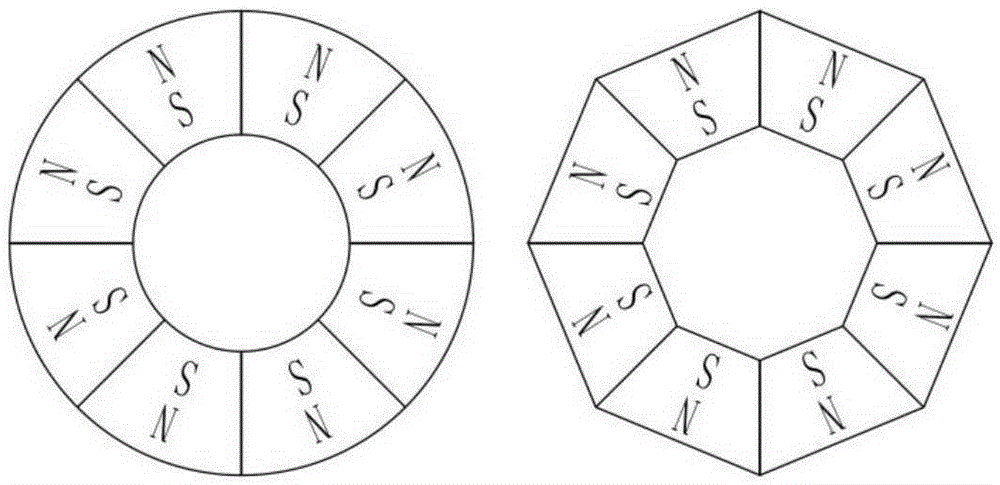

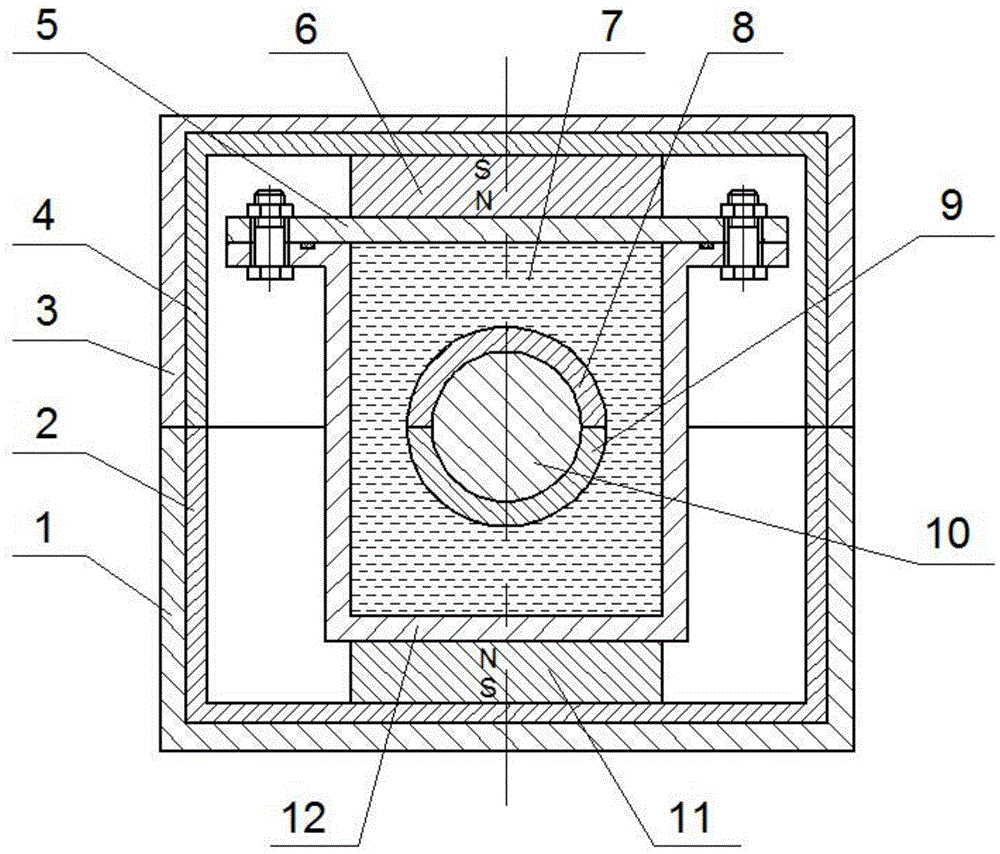

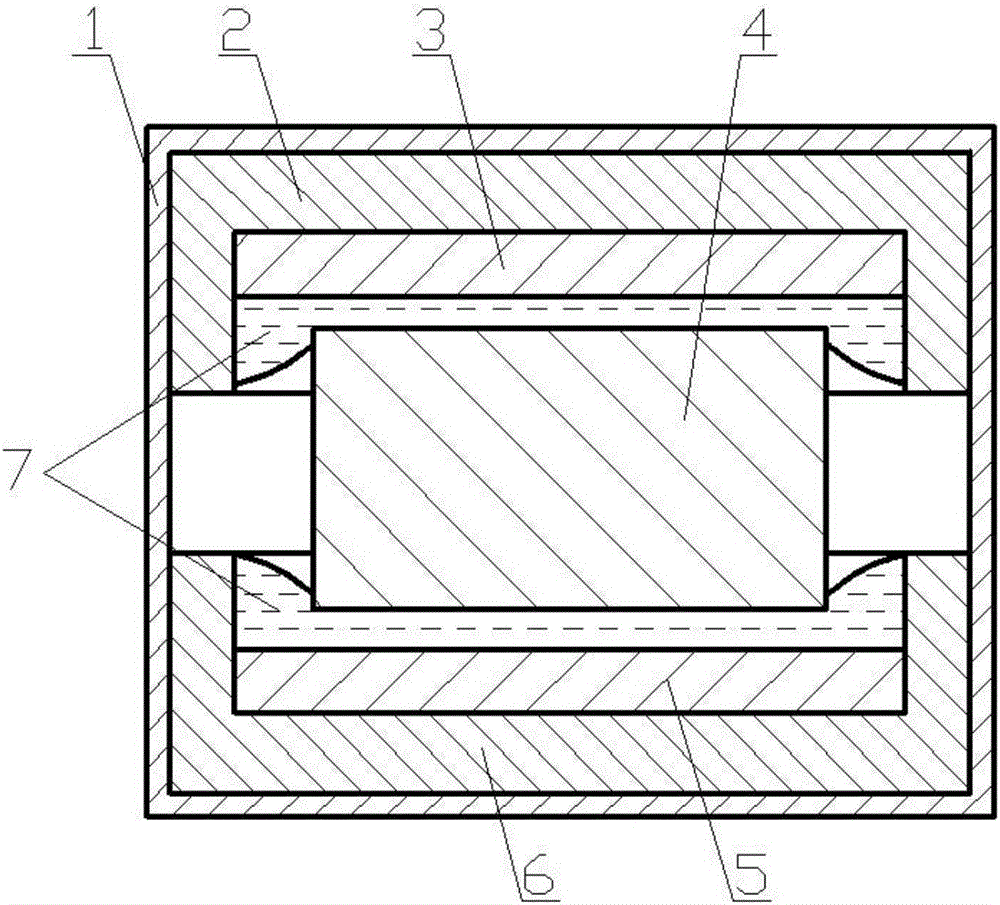

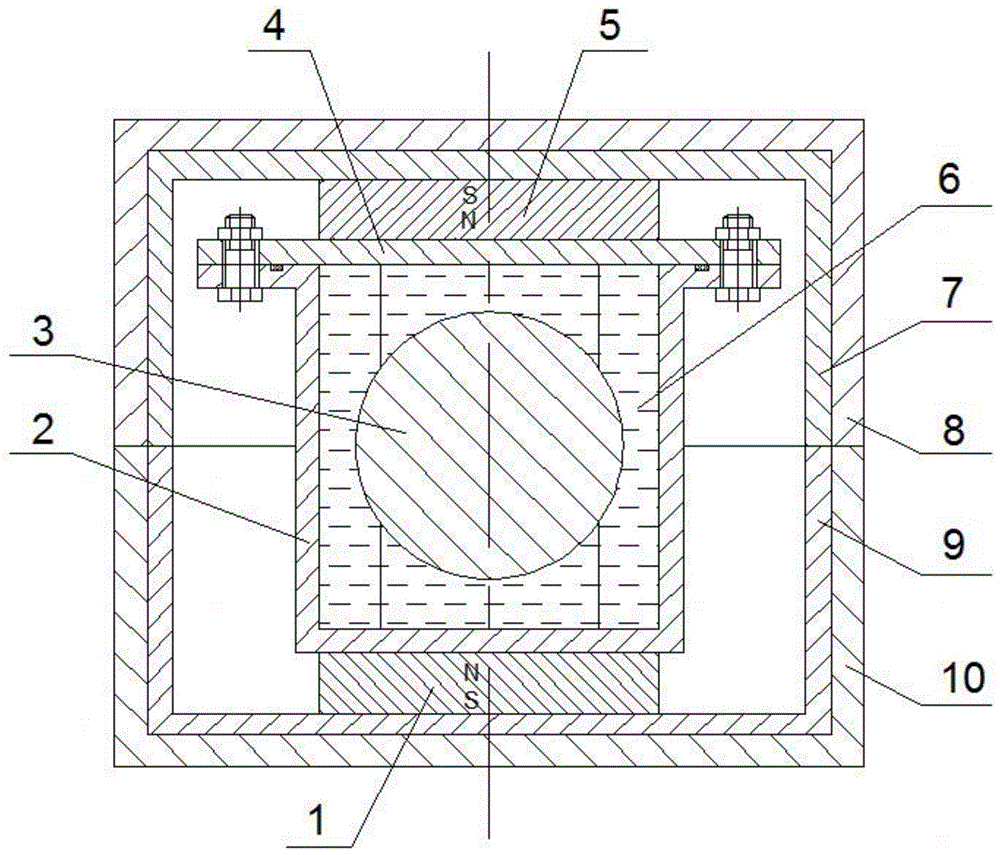

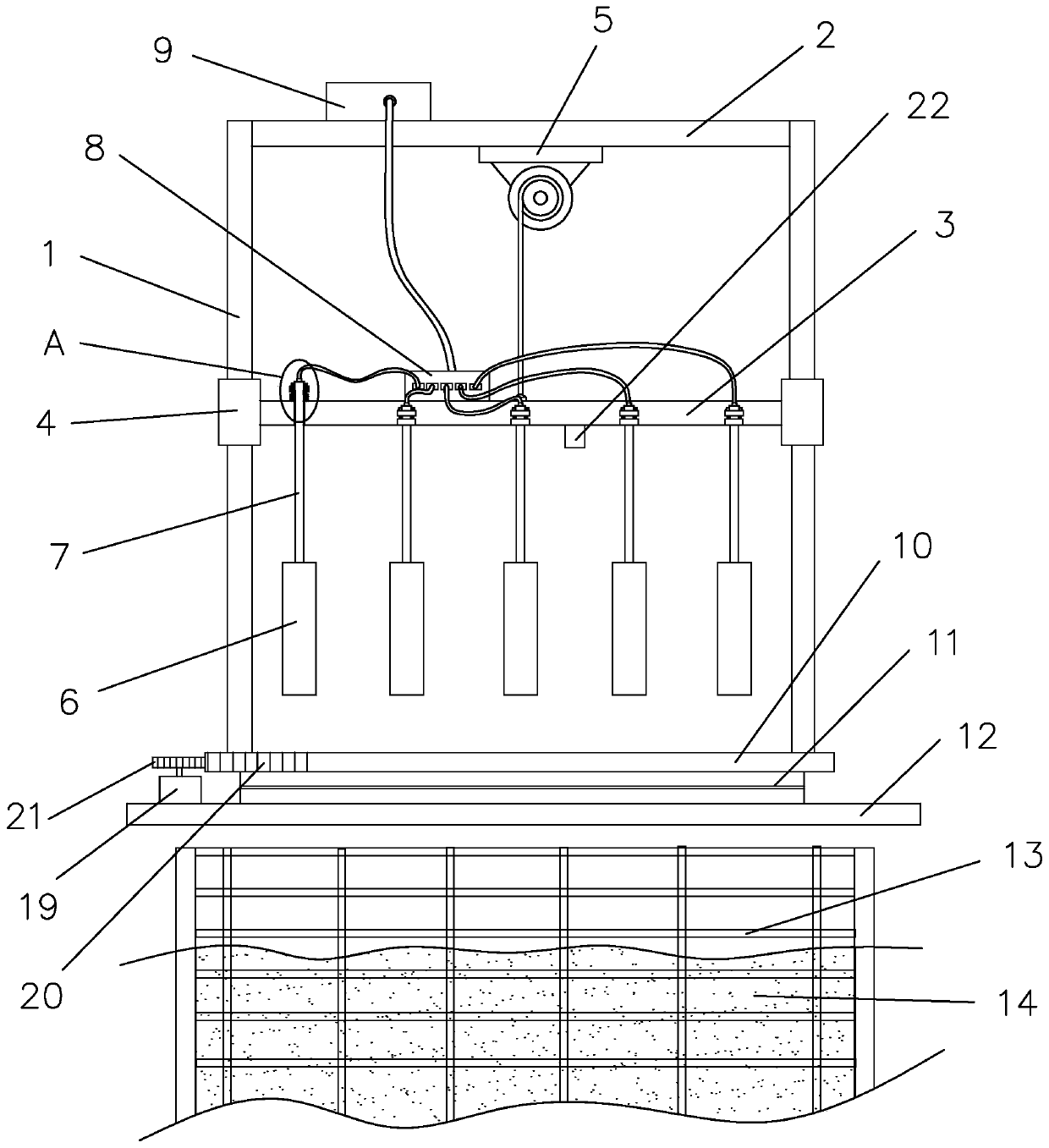

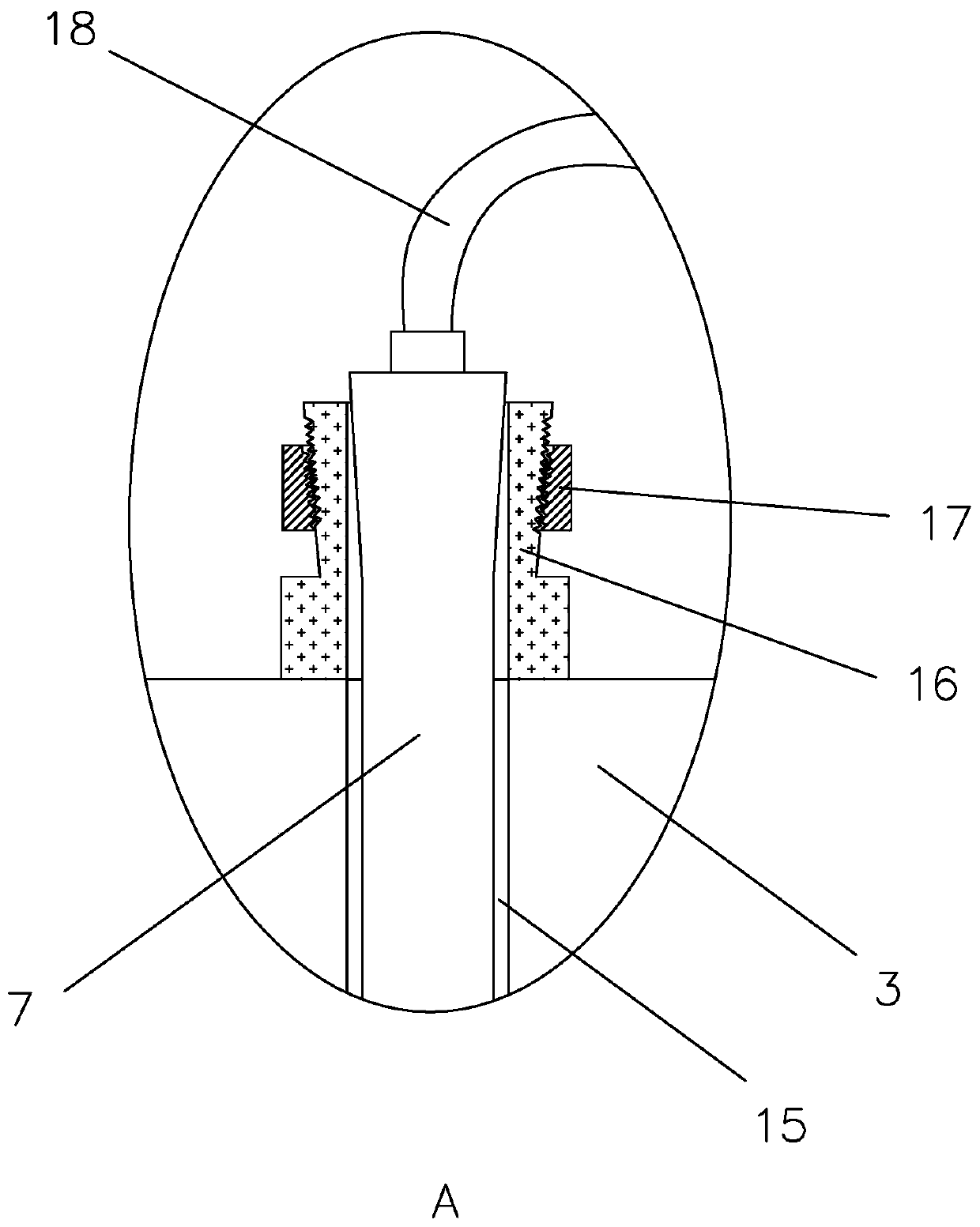

Underfilled magnetic liquid shock absorber adopting first-order buoyancy principle

InactiveCN106838089AFlexible movementGood suspensionMagnetic springsViscous shearElectrical conductor

The invention discloses an underfilled magnetic liquid shock absorber adopting a first-order buoyancy principle, belongs to the field of vibration in mechanical engineering, and successfully solves the problem that an existing magnetic liquid shock absorber cannot be applied in engineering practice due to many structural problems. The device comprises a base (1), an annular permanent magnet (2), a shell body (3), nuts (4), a sealing ring (5), a washer (6), a magnetic liquid (7), a first circular permanent magnet (8), an end cover (9), a mass block (10), a cavity (11), a second circular permanent magnet (12) and bolts (13), wherein the shell body is not completely filled with the magnetic liquid (7); the non-magnetic mass block (10) moves in the shell body (3), and generates friction, collision and viscous shearing with the magnetic liquid (7) to consume energy in the case of external vibration; and an electrical eddy current is generated in the mass block (10) to accelerate consumption for the vibration energy and achieve the purpose of shock absorption when the mass block (10) is made from a conductor material.

Owner:BEIJING JIAOTONG UNIV

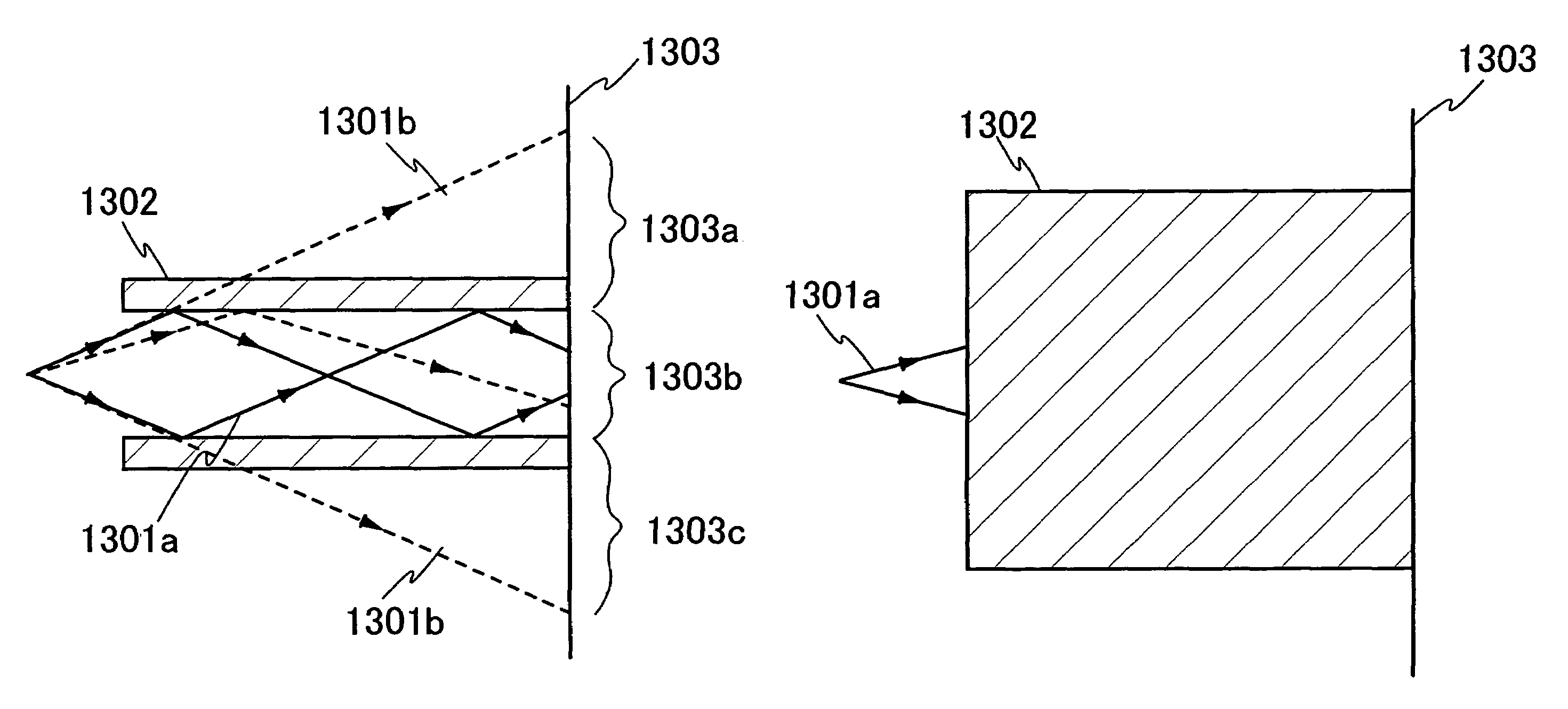

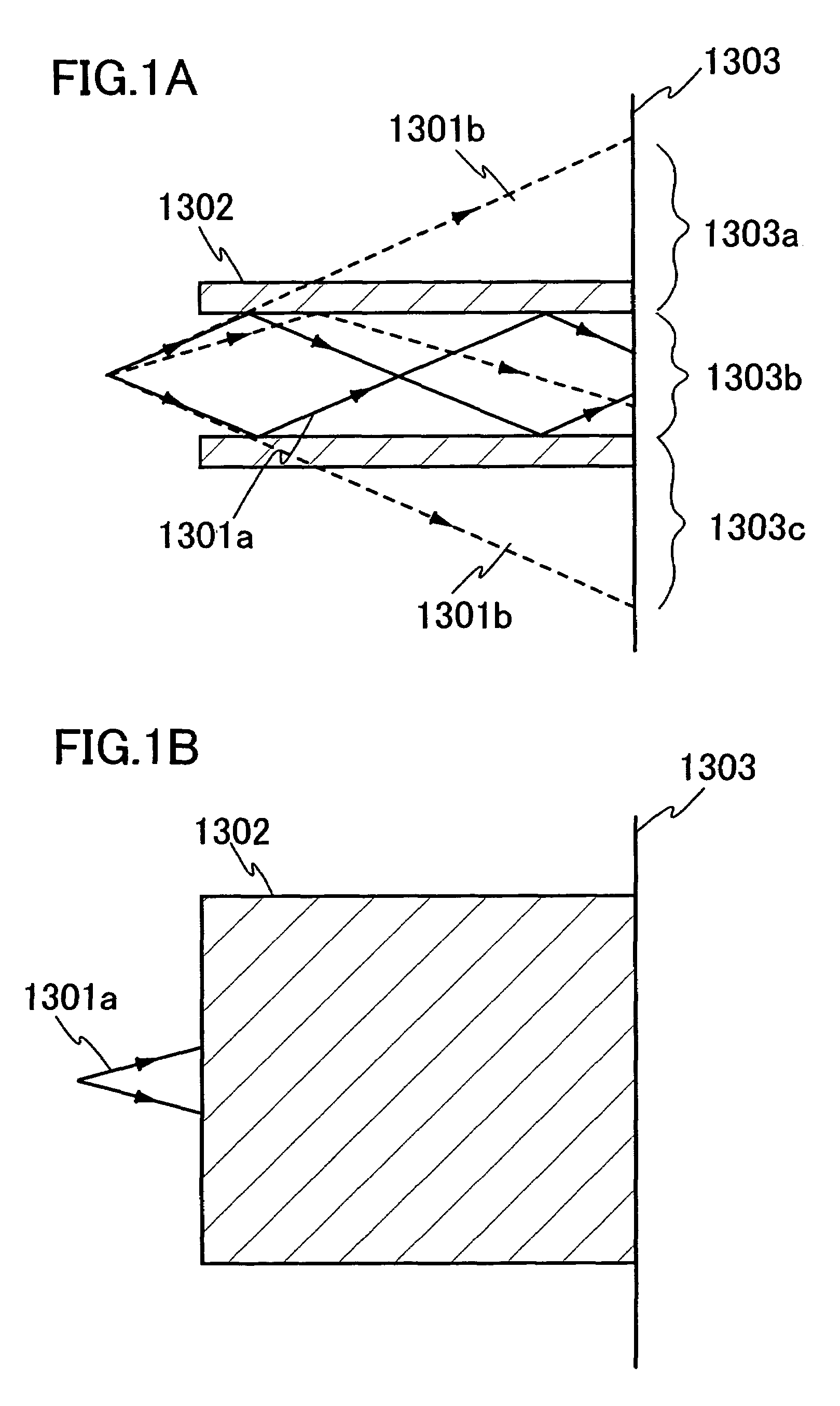

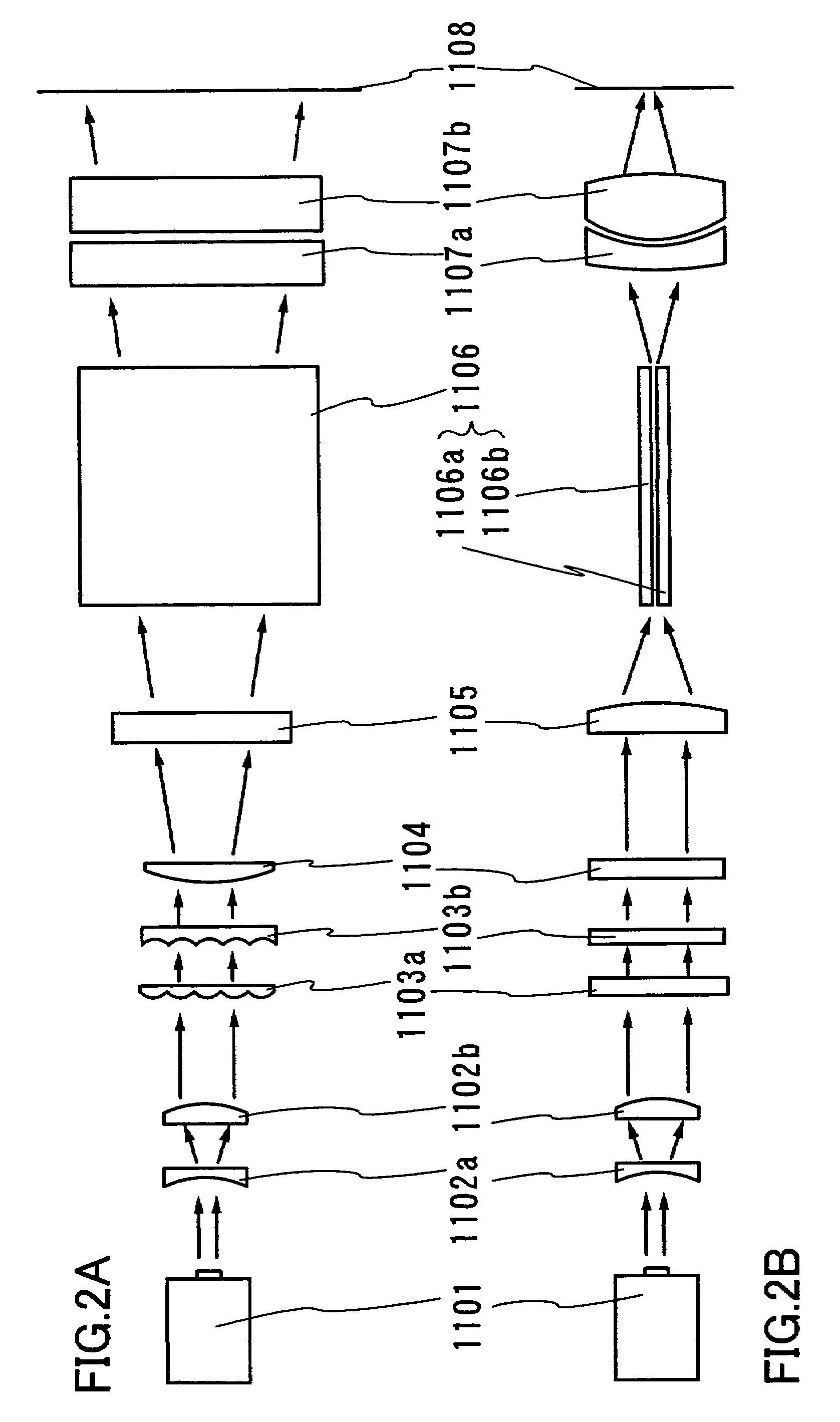

Beam homogenizer and laser irradiation apparatus and method of manufacturing semiconductor device

InactiveUS7594965B2High evennessIncrease the number ofFrom gel stateFrom solid stateStructural ProblemLight guide

The inhomogeneous energy distribution at the beam spot on the irradiated surface is caused by a structural problem and processing accuracy of the cylindrical lens array forming an optical system.According to the present invention, in the optical system for forming a rectangular beam spot, an optical system for homogenizing the energy distribution of the shorter side direction of a rectangular beam spot of a laser light on an irradiated surface is replaced with a light guide. The light guide is a circuit that can confine emitted beams in a certain region and guide and transmit its energy flow in parallel with the axis of a path thereof.

Owner:SEMICON ENERGY LAB CO LTD

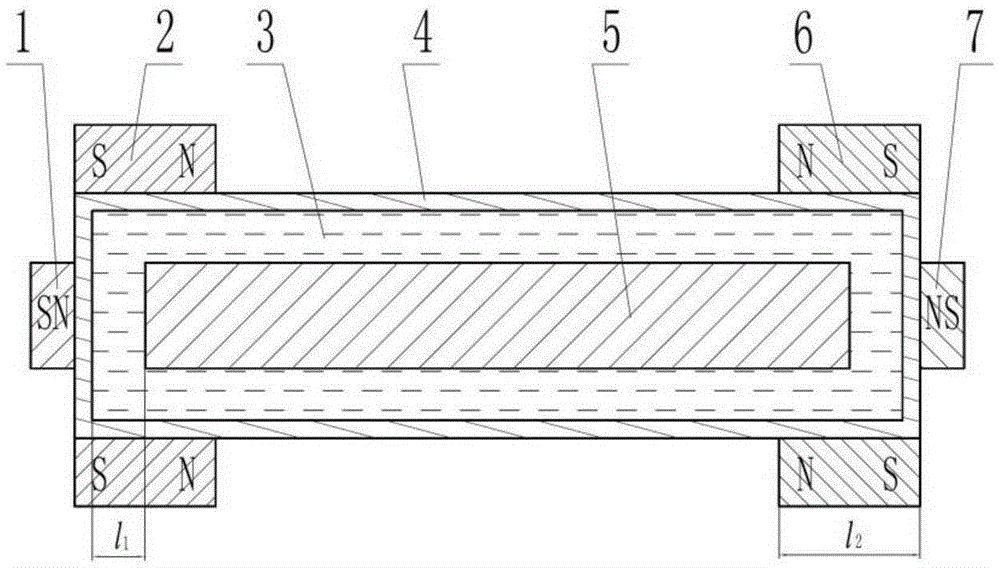

First-order buoyancy magnetic liquid shock absorber used in outer space

InactiveCN105240432ASuspension stabilityResolve fragmentationMagnetic springsStructural ProblemMagnetic liquids

The invention discloses a first-order buoyancy magnetic liquid shock absorber used in the outer space, and belongs to the field of mechanical engineering shock. The problem that an existing magnetic liquid damping shock absorber cannot be actually applied in the engineering due to various structural problems is successfully solved. The first-order buoyancy magnetic liquid shock absorber used in the outer space comprises a first limiting permanent magnet (1), a first suspension permanent magnet (2), magnetic liquid (3), a shell (4), a mass block (5), a second suspension permanent magnet (6) and a second limiting permanent magnet (7). When the outside vibrates, the mass block (5) moves in a cavity, the magnetic liquid (3) flows in the gap between a hole wall and the mass block (5) in the shell (4), and therefore energy is absorbed, and the purpose of shock absorption is realized.

Owner:BEIJING JIAOTONG UNIV

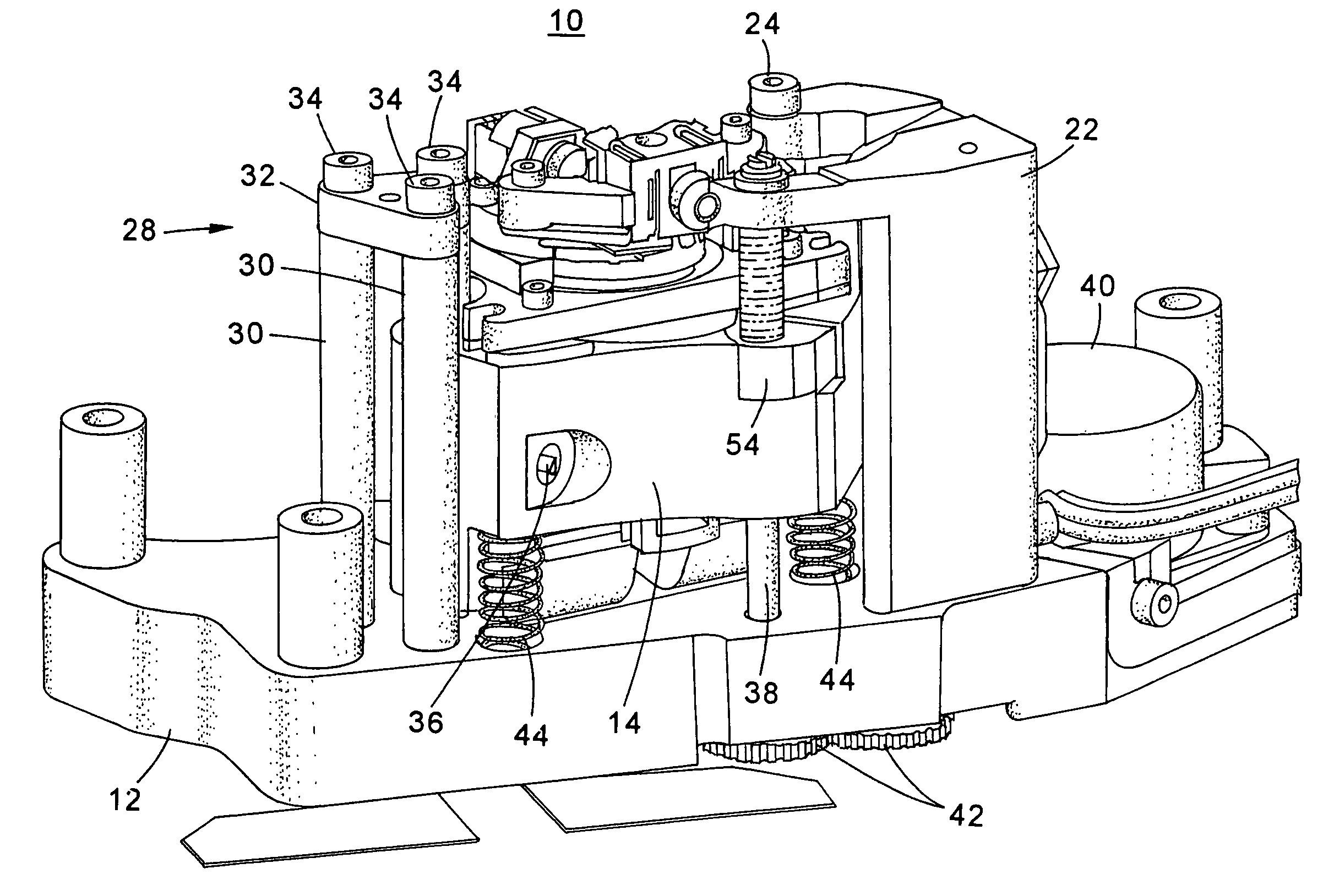

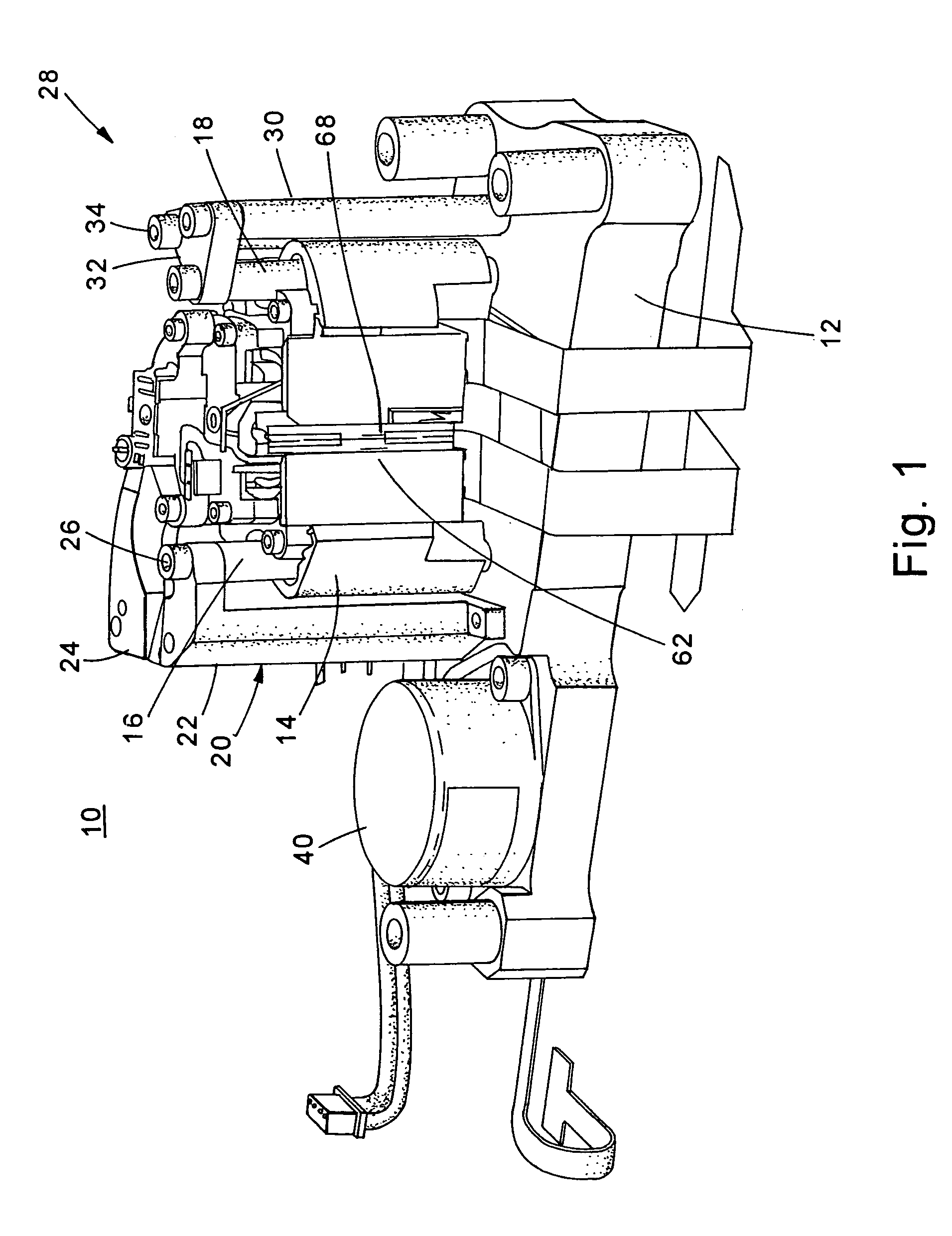

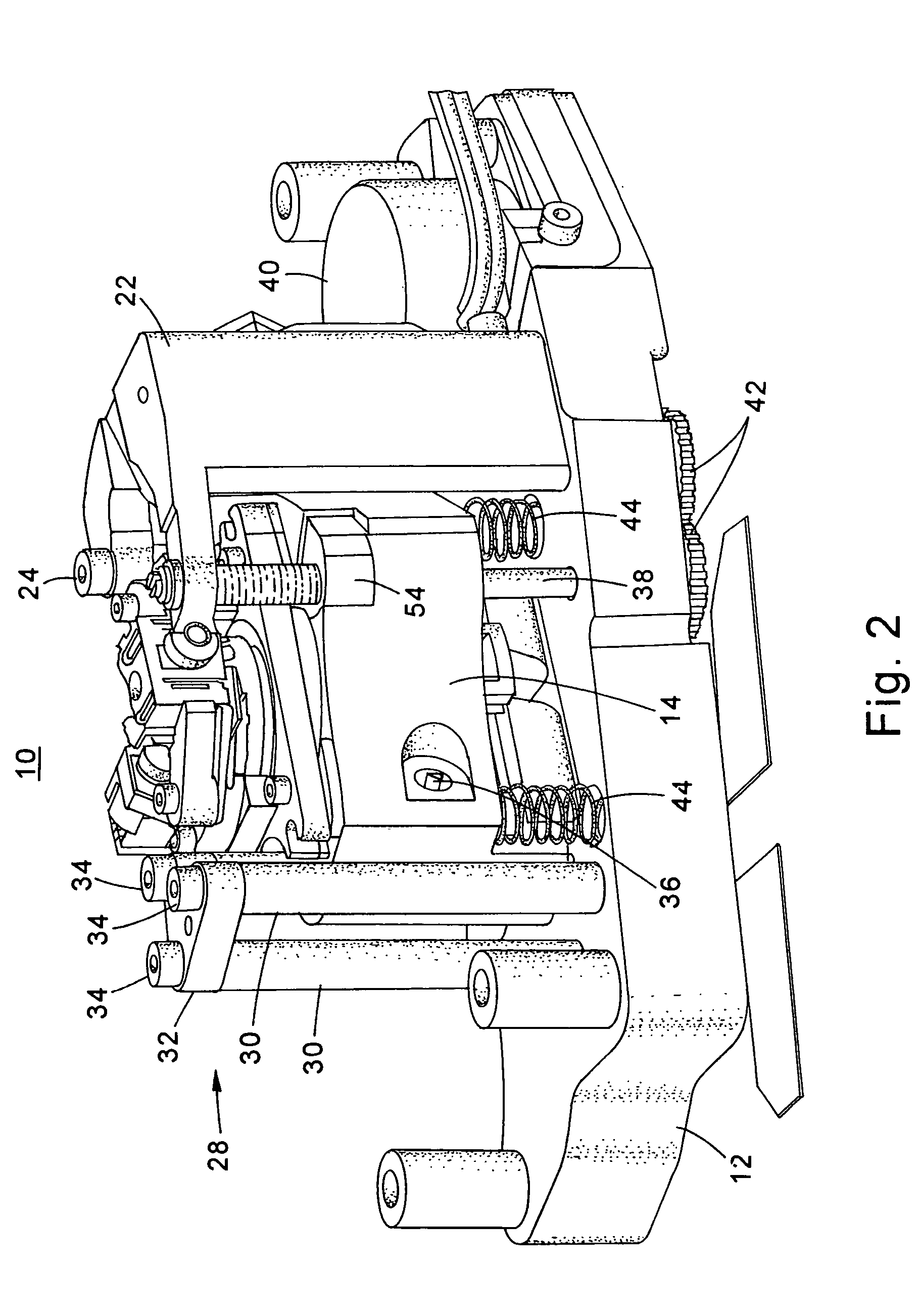

Head actuator assembly for a tape drive

InactiveUS7227724B2Improve structural rigidityEfficient assemblyDisposition/mounting of recording headsRecord information storageStructural ProblemEngineering

A head actuator assembly includes a coarse positioner base assembly that is mounted on a guide shaft and an anti-rotation shaft and provides increased structural rigidity due to a four-point support and spring loading of the coarse positioner base against the anti-rotation shaft. A two-part head-carriage and voice coil holder system permits different materials to be used for the head-carriage and the voice coil holder, obviating structural problems of a single-structured head-carriage and coil-holder system. A flexible printed circuit bracket eases manufacture and allows flexible printed circuits to be slid into the bracket and retained in place without the need for locating tabs and screws.

Owner:QUANTUM CORP

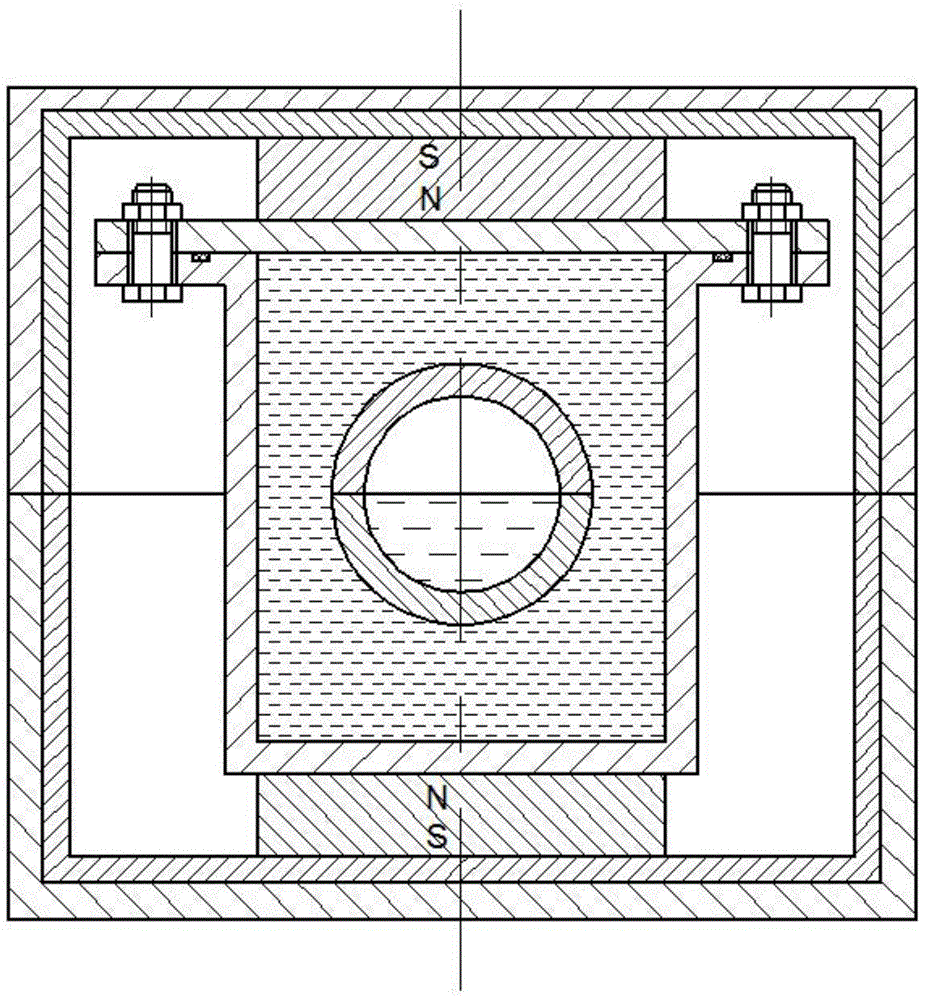

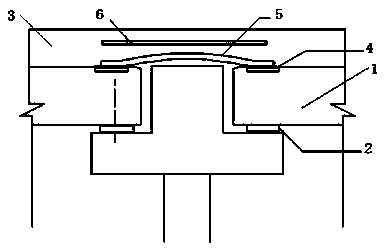

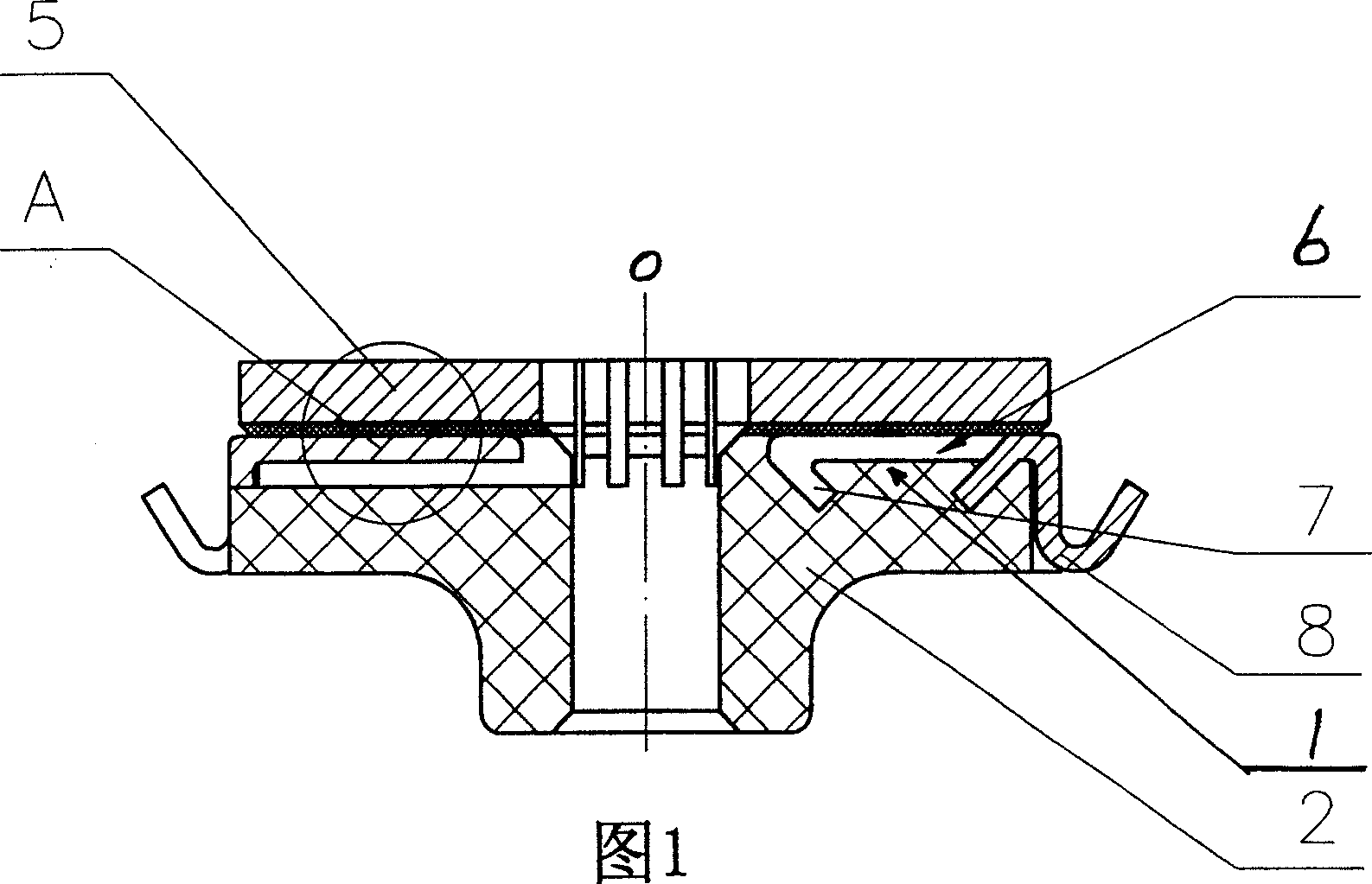

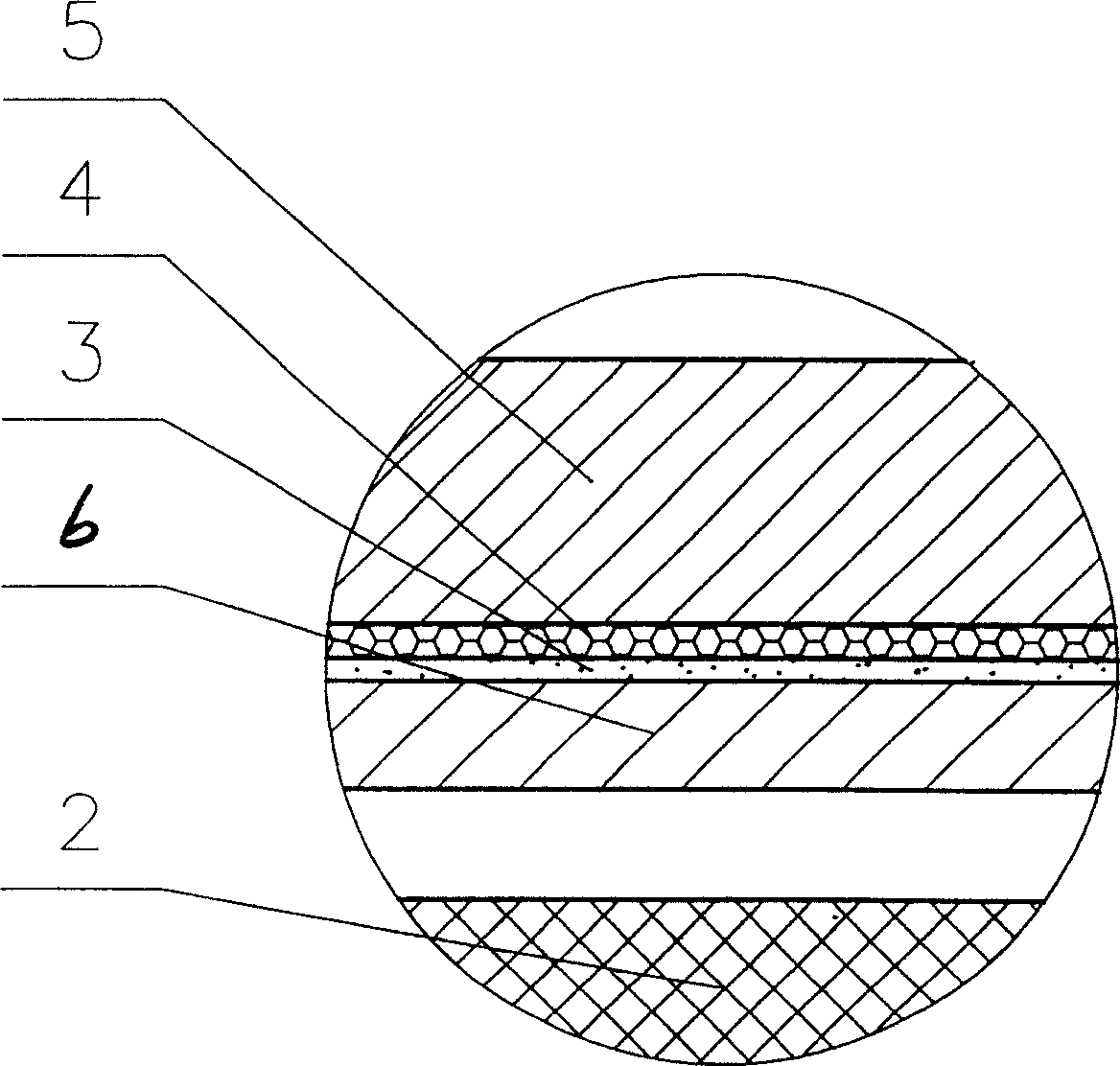

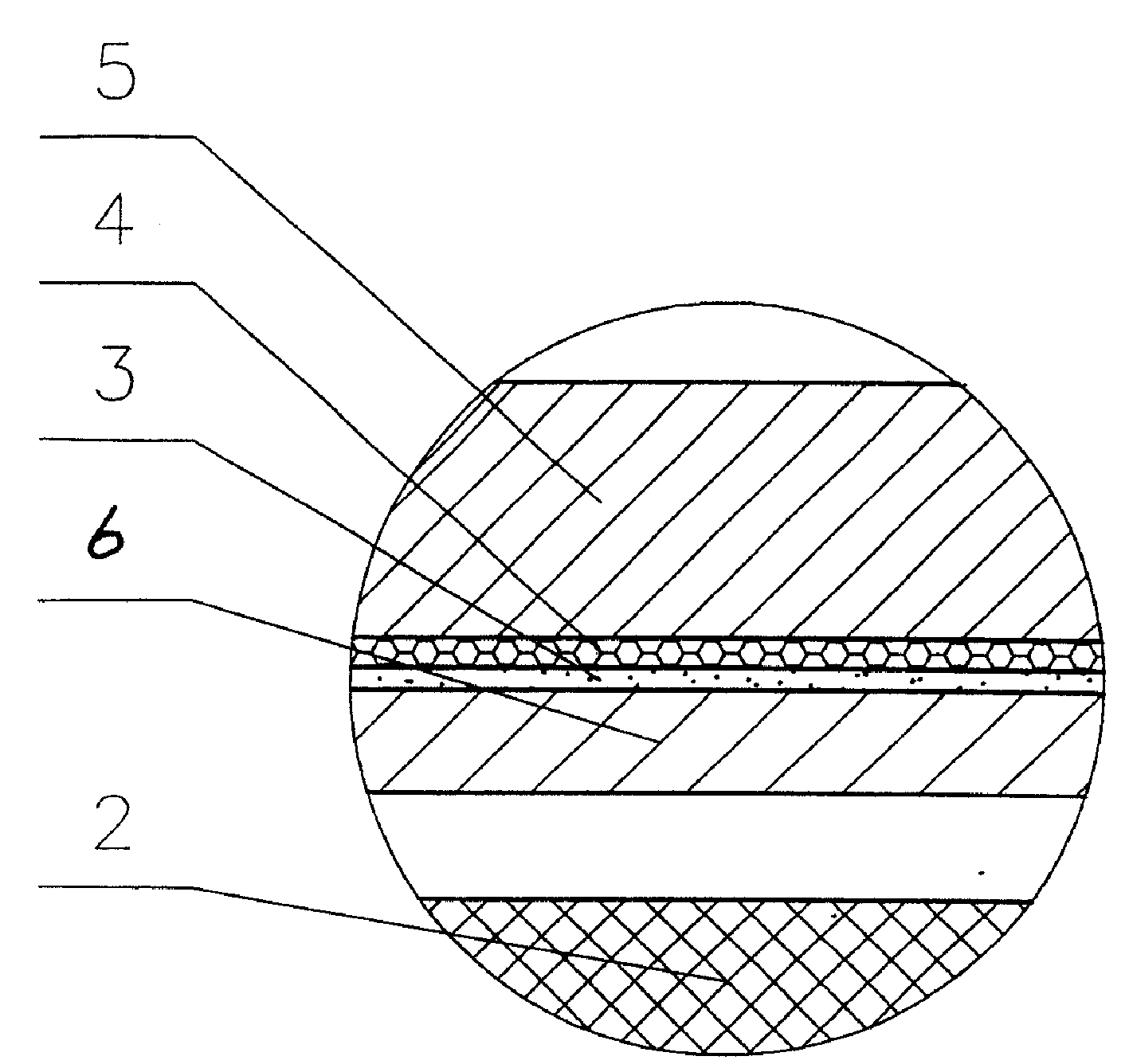

Damping vibration absorber with magnetism-isolating covers, magnetic liquid and application of first-order buoyancy principle

InactiveCN104879412ASolve the deformationWell centeredMagnetic springsStructural ProblemMagnetic liquids

The invention discloses a damping vibration absorber with magnetism-isolating covers, magnetic liquid and application of a first-order buoyancy principle, and belongs to the field of mechanical engineering vibration. By the aid of the damping vibration absorber, the difficult problem that existing damping vibration absorbers with magnetic liquid cannot be applied to engineering practice due to diversified structural problems can be successfully solved. The damping vibration absorber comprises a lower magnetism-isolating outer sleeve (1), a lower magnetic inner sleeve (2), an upper magnetism-isolating outer sleeve (3), an upper magnetic inner sleeve (4), an end cover (5), a first permanent magnet (6), the magnetic liquid (7), an upper spherical shell (8), a lower spherical shell (9), a counterweight (10), a second permanent magnet (11) and a shell (12). The damping vibration absorber has the advantages that non-magnetic mass blocks formed by the upper spherical shell, the lower spherical shell and the counterweight (10) can move in a cavity when the external vibrates, the magnetic liquid flows in the shell (12), accordingly, energy can be absorbed, frequency difference between the mass blocks and the shell (12) can be formed by first-order buoyancy generated by the first permanent magnet (6) and the second permanent magnet (11) inside the magnetic liquid, and magnetic flux leakage of the permanent magnets can be effectively prevented by the upper magnetism-isolating cover and the lower magnetism-isolating cover.

Owner:BEIJING JIAOTONG UNIV

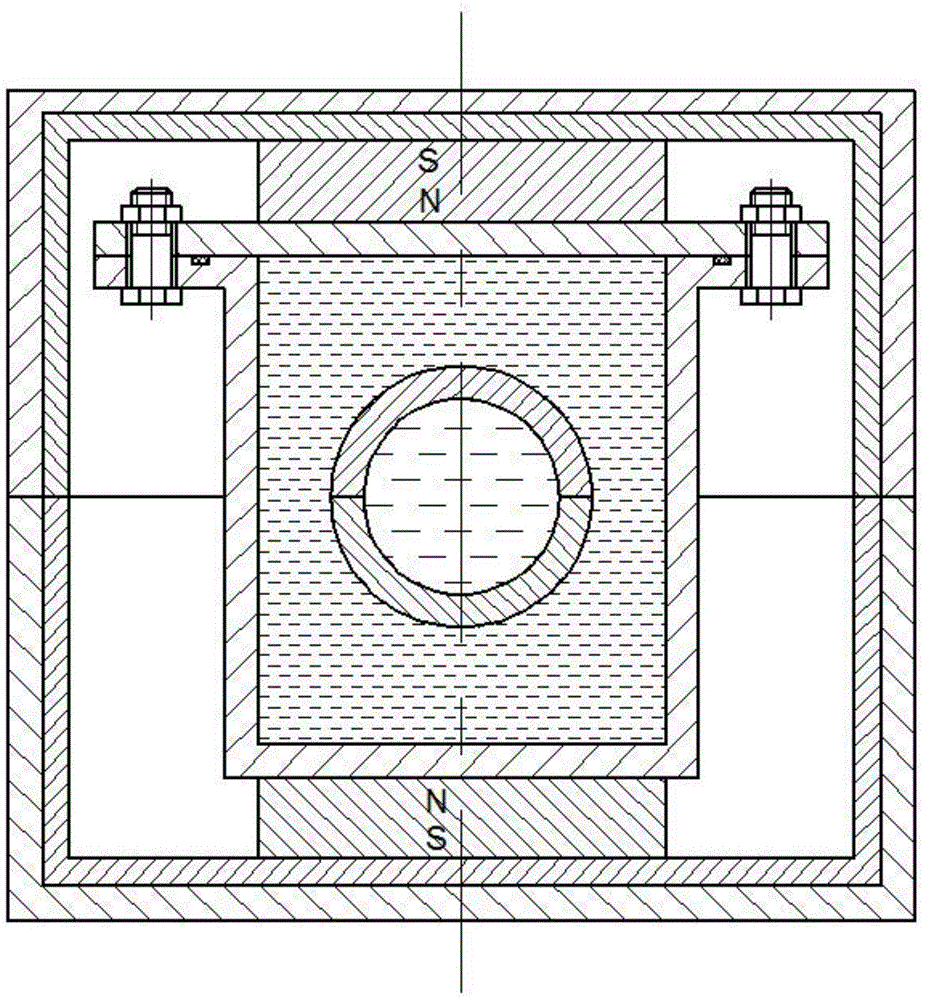

First-order buoyancy magnetic liquid damping vibration absorber for magnetic shielding

InactiveCN106678255ALight in massGood centering effectSpringsNon-rotating vibration suppressionStructural ProblemMagnetic liquids

The invention discloses a first-order buoyancy magnetic liquid damping vibration absorber for magnetic shielding, and belongs to the field of mechanical engineering vibration. The problem that existing magnetic liquid damping vibration absorbers cannot be applied in engineering practice due to various structural problems is successfully solved. The first-order buoyancy magnetic liquid damping vibration absorber comprises a shell (1), an upper shielding cover (2), an upper permanent magnet (3), a mass block (4), a lower permanent magnet (5), a lower shielding cove (6) and magnetic liquid (7). When external vibration is produced, the mass block (4) moves in the upper shielding cover and the lower shielding cover, the magnetic liquid (7) flows in the gap between the upper and lower permanent magnets and the mass block (4), and therefore energy is absorbed to achieve the vibration absorption purpose; and a frequency difference is formed between the mass block (4) and the shell (1) due to first-order buoyancy formed by the upper permanent magnet (3) and the lower permanent magnet (5) inside the magnetic liquid (7), and the vibration absorption efficiency reaches the maximum.

Owner:BEIJING JIAOTONG UNIV

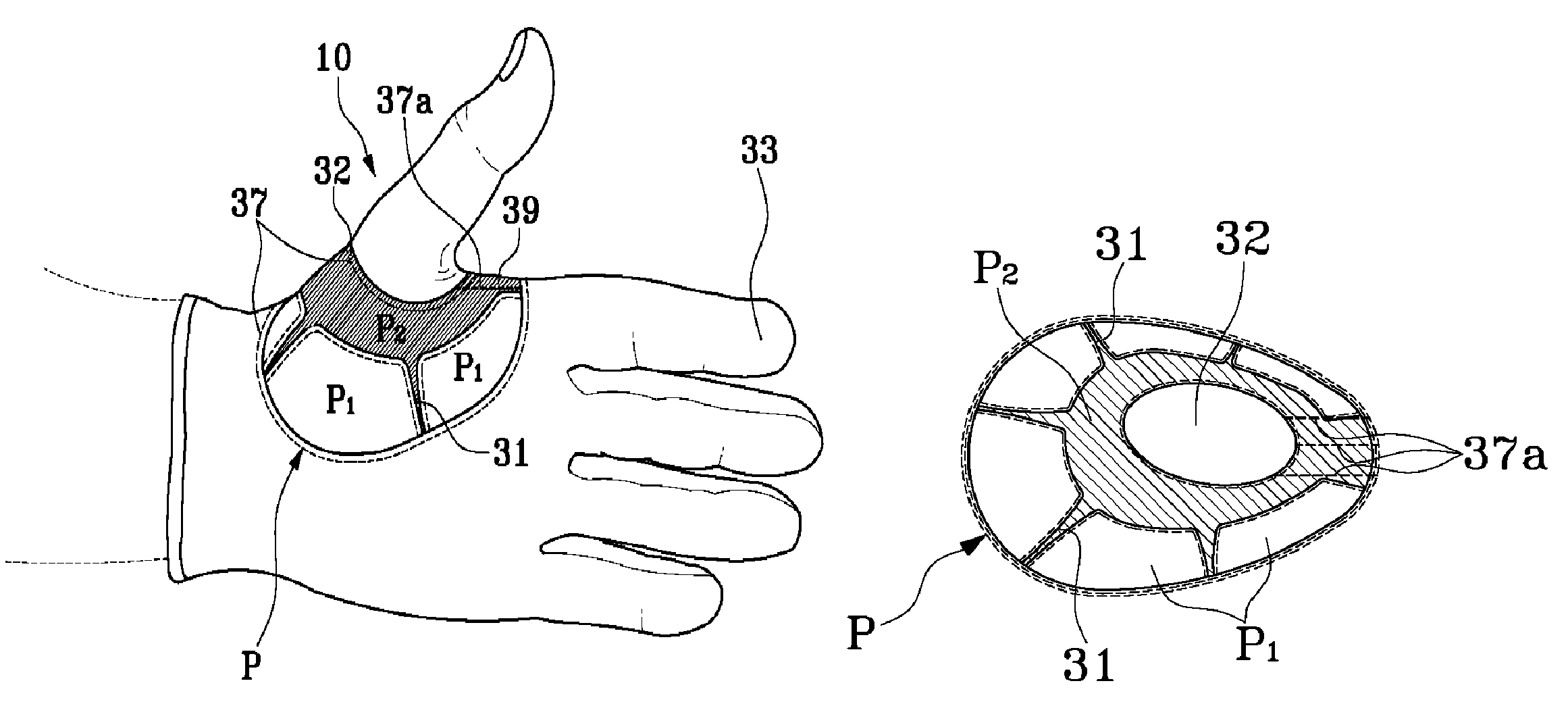

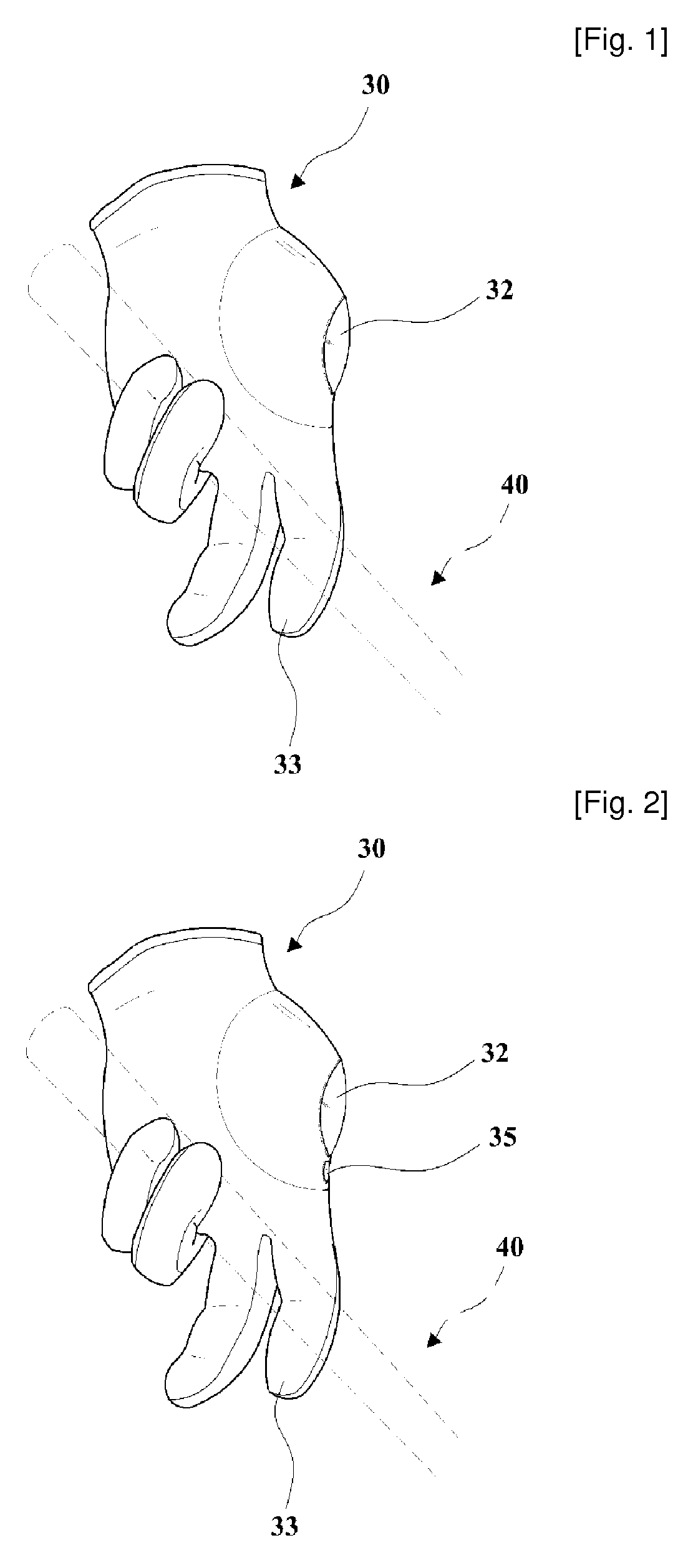

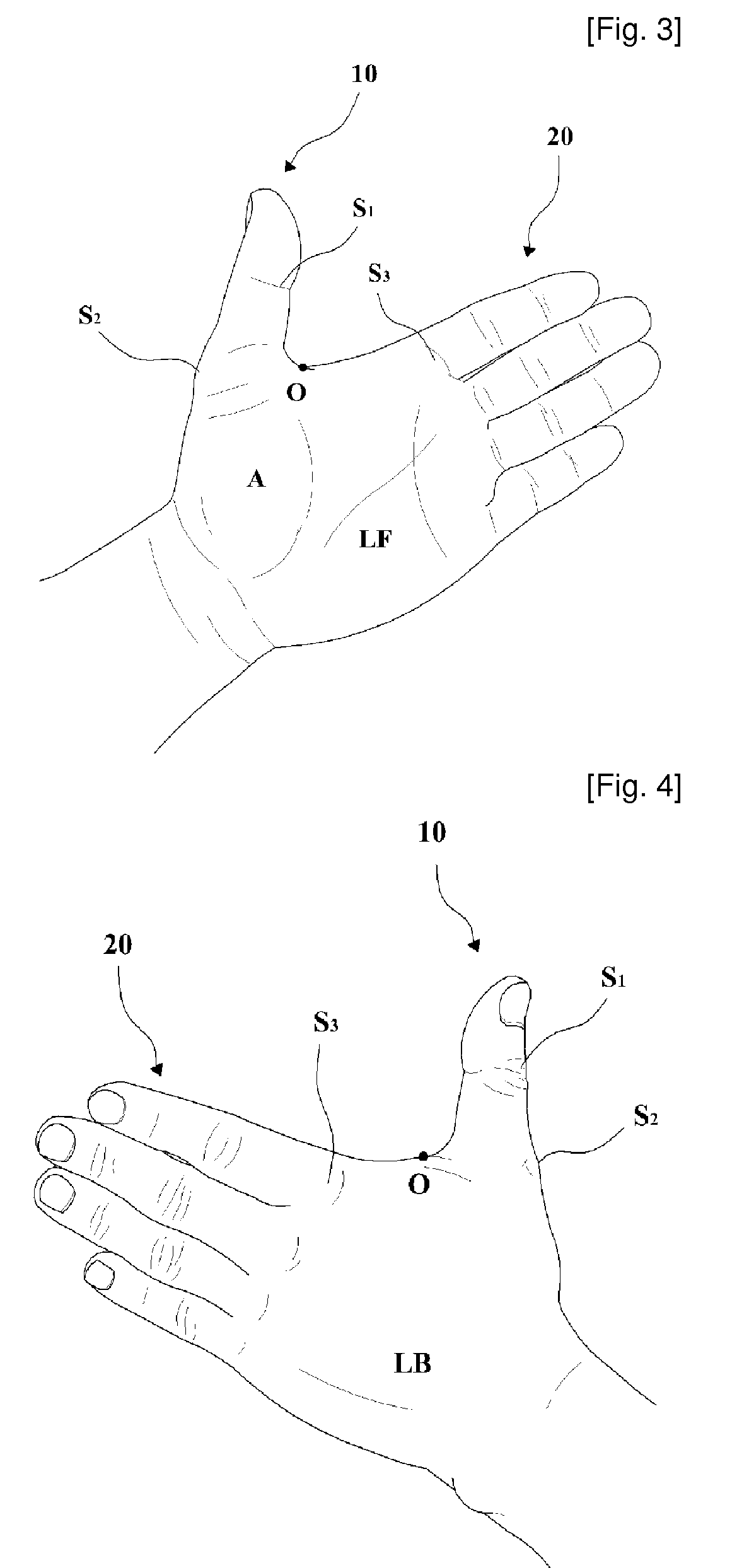

Golf glove for right grip and suitable swing

The present invention is a golf club which induces proper grip and suitable swing by removing the thumb-covering portion of a golf glove so as to extend the Skin Contact Length between the thumb and forefinger. Due to the absence of a thumb covering, structural problems with the glove covering stretching from the thumb area toward the palm may arise when centrifugal force is imparted by the golf club. If the glove covering has been stretched, the covering will become folded when the club is gripped; this causes a pull on the left thumb when gloves are worn and leads to improper grip. Therefore, in order to provide elasticity with regard to stretching, in place of sheepskin the area subject to stretching is processed with a Spandex material having excellent elasticity and flexibility.

Owner:KIM JEONG YONG

First-order buoyancy principle based magnetic liquid damping shock absorber with magnetic shielding covers

InactiveCN104948627ASuspension stabilityAvoid liquidityVibration dampersMagnetic springsStructural ProblemAbsorbed energy

The invention relates to a first-order buoyancy principle based magnetic liquid damping shock absorber with magnetic shielding covers, belongs to the field of mechanical engineering vibration, and successfully solves the problem that the existing magnetic liquid damping shock absorbers cannot be applied in engineering practice due to various structural problems. The absorber comprises a first permanent magnet (1), a housing (2), a mass (3), an end cap (4), a second permanent magnet (5), magnetic fluid (6), an upper magnetic inner sleeve (7), an upper magnetic shielding outer sleeve (8), a lower magnetic inner sleeve (9) and a lower magnetic shielding outer sleeve (10). When the external vibration occurs, a non-magnetic ball moves in a chamber, the magnetic fluid flows in a recess of the housing (2) to absorb energy, first-order buoyancy formed within the magnetic fluid by the first permanent magnet (1) and the second permanent magnet (5) allows frequency difference to be formed between the mass (3) and the housing (2), so that the maximum vibration damping efficiency is achieved, and the upper and lower magnetic shielding covers effectively prevent magnetic flux leakage of the permanent magnets.

Owner:BEIJING JIAOTONG UNIV

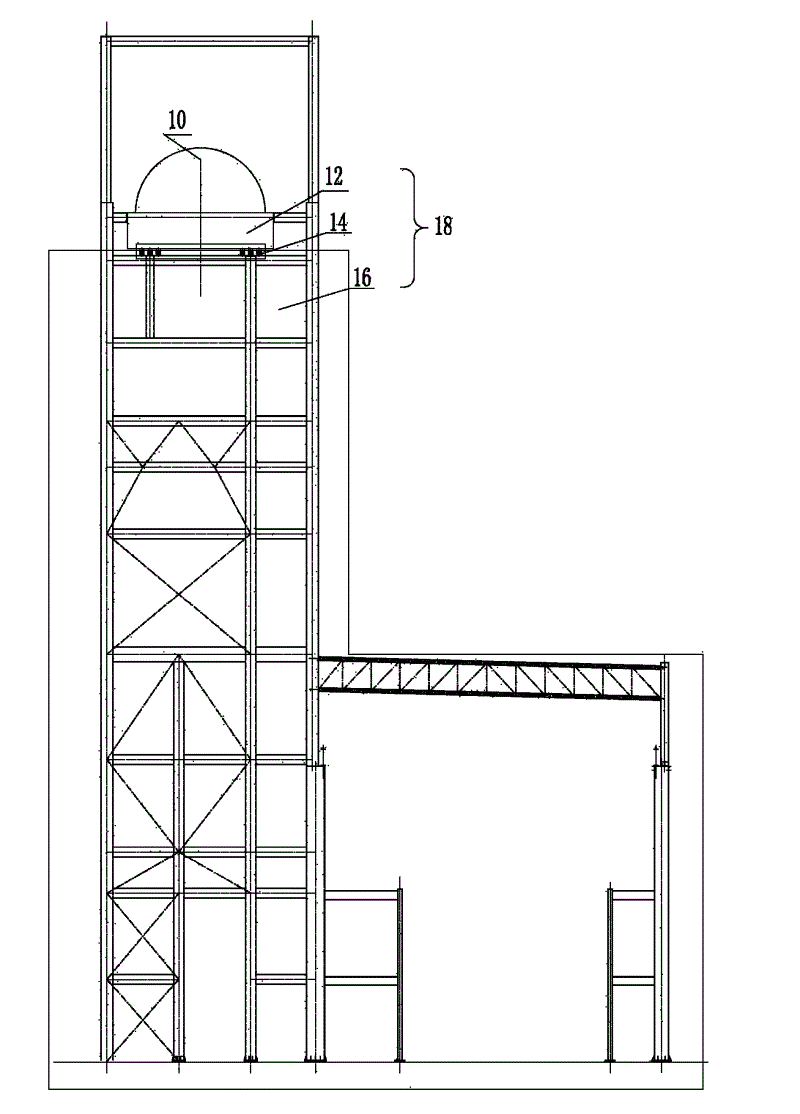

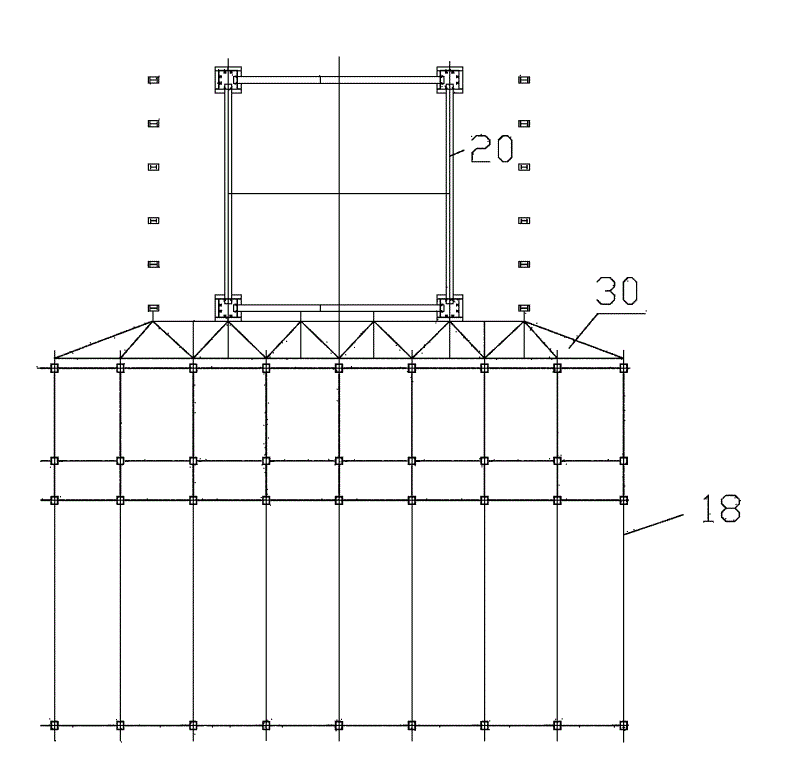

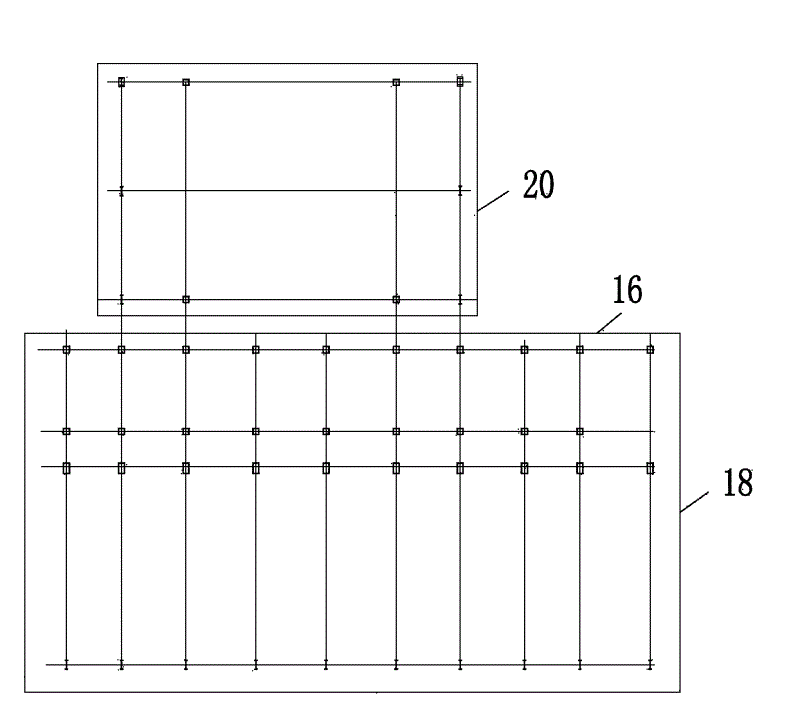

Building structure system of turbo generator set arranged at high position

ActiveCN102619361AMeet comfort requirementsMeet the settlement requirementsMachines/enginesEngine componentsStructural ProblemEngineering

The invention discloses a building structure system of a turbo generator set arranged at a high position. The utilization of the turbo generator set arranged at the high position in a practical project becomes possible, and a series of structural problems which are caused by the high-position arrangement of the turbo generator set are solved. The technical scheme adopted by the invention is that: the system comprises a supporting platform system and a boiler frame, wherein the supporting platform system comprises a table plate, a vibration isolating system and a platform main body frame; the table plate is used for placing the turbo generator set arranged at the high position; the vibration isolating system is arranged below the table plate; the platform main body frame is arranged on the ground and is used for placing the vibration isolating system; and the platform main body frame and a power plant main workshop structure are integrated into a whole.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

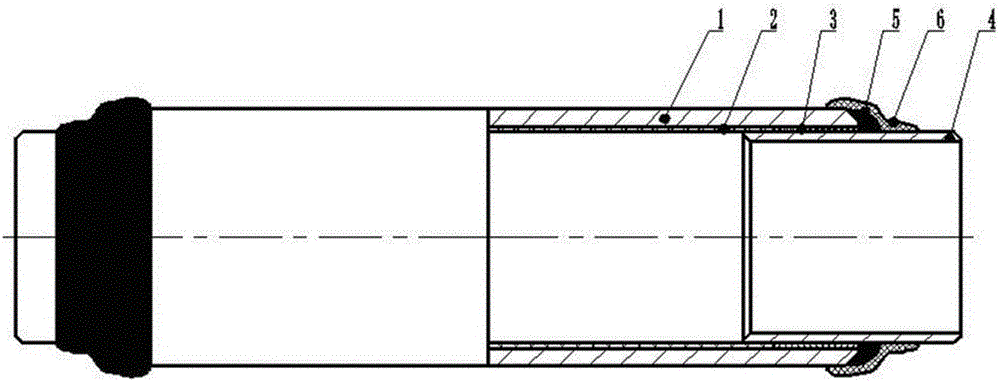

Slightly-arched seam crossing type bridge continuous seam structure

InactiveCN103510465ASimple structureNot easy to damageBridge structural detailsDensity reductionSheet steel

The invention relates to a slightly-arched seam crossing type bridge continuous seam structure. The slightly-arched seam crossing type bridge continuous seam structure comprises beams, supports and a pavement layer. The slightly-arched seam crossing type bridge continuous seam structure is characterized in that the upper surfaces of the beams on two sides are respectively provided with a pre-embedded steel plate, the centerline of each pre-embedded steel plate and the centerline of the support below each pre-embedded steel plate are located in the same vertical plane, a slightly-arched seam crossing steel plate is arranged, the contact surfaces of the two ends of the slightly-arched seam crossing steel plate are welded to the pre-embedded steel plates of the beams of the two sides, the middle of the slightly-arched seam crossing steel plate is slightly arched, and the two ends of each reinforcing rib in the pavement layer are arranged in a gradual density-reduction mode; the two ends of each reinforcing rib in the pavement layer are arranged in the gradual density-reduction mode, so that some of the reinforcing ribs are long and some of the reinforcing ribs are short. The slightly-arched seam crossing type bridge continuous seam structure has the advantages that by additionally installing the slightly-arched seam crossing steel plate, a pavement structure on a continuous seam is completely separated from the beams; because the arched structure has relatively strong anti-pressure ability, the seam does not have great influence even if the seam is large, and the structural problem that the continuous seam is damaged is solved.

Owner:上海申继交通科技有限公司

Efficient certificate revocation

InactiveUS7827401B2Low costEasy to implementDigital data processing detailsUser identity/authority verificationStructural ProblemOperating system

We propose new systems for certificate revocation that are more economical and efficient than traditional ones. We also point out what we believe to be a structural problem in traditional public-key infrastructures, and various ways to solve it.

Owner:ASSA ABLOY AB

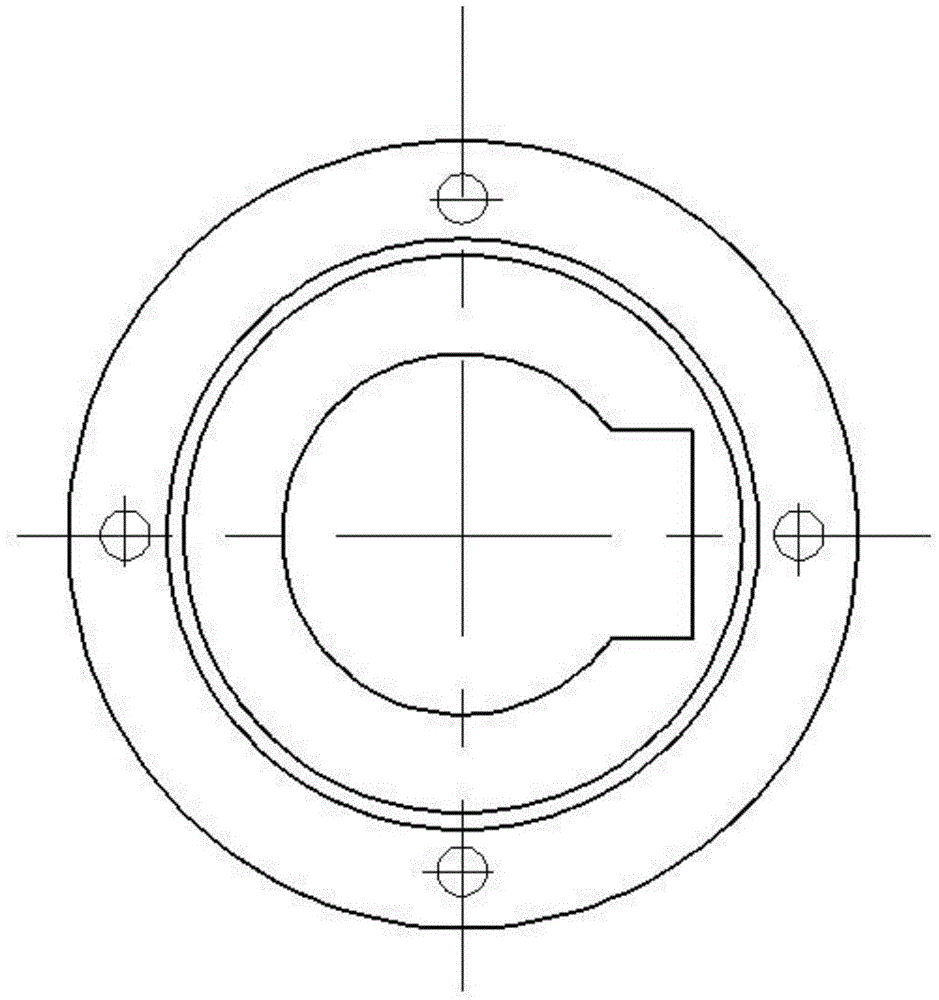

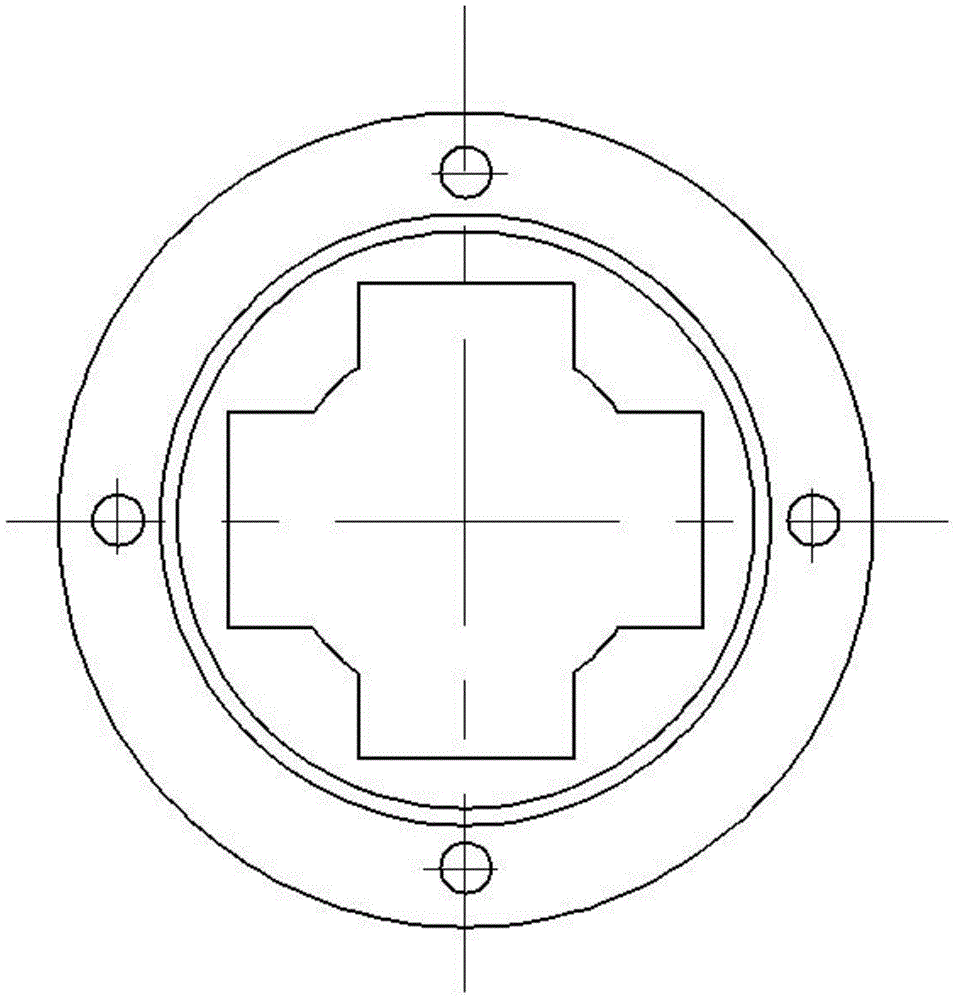

Planar carbon commutator

InactiveCN1234198CSimple structureEasy to manufactureRotary current collectorStructural ProblemSilver plate

The invention discloses a planar carbon commutator for a motor, which comprises a commutator segment (1), a molding compound (2), a carbon block (5), a body (6) of the commutator segment (1), and the commutator The axis of rotation of the commutator is perpendicular, and the commutator segment (1) is arranged in the molding compound (2) and exposes the outer surface of the body (6) of the commutator segment, on the outer surface of the body (6) of the commutator segment The silver-copper alloy layer (3) is coated with a mixed strong adhesive layer (4) on the silver-copper alloy layer (3) and the carbon block (5) is arranged on the mixed strong adhesive layer (4) . The invention solves the problem of complex structure of the existing planar carbon commutator, has the advantages of simple structure and convenient manufacture, thereby saving labor time and reducing production cost, and can fully meet various uses such as motor sparks, noise, and service life performance requirements.

Owner:ZHEJIANG GREATWALL COMMUTATOR

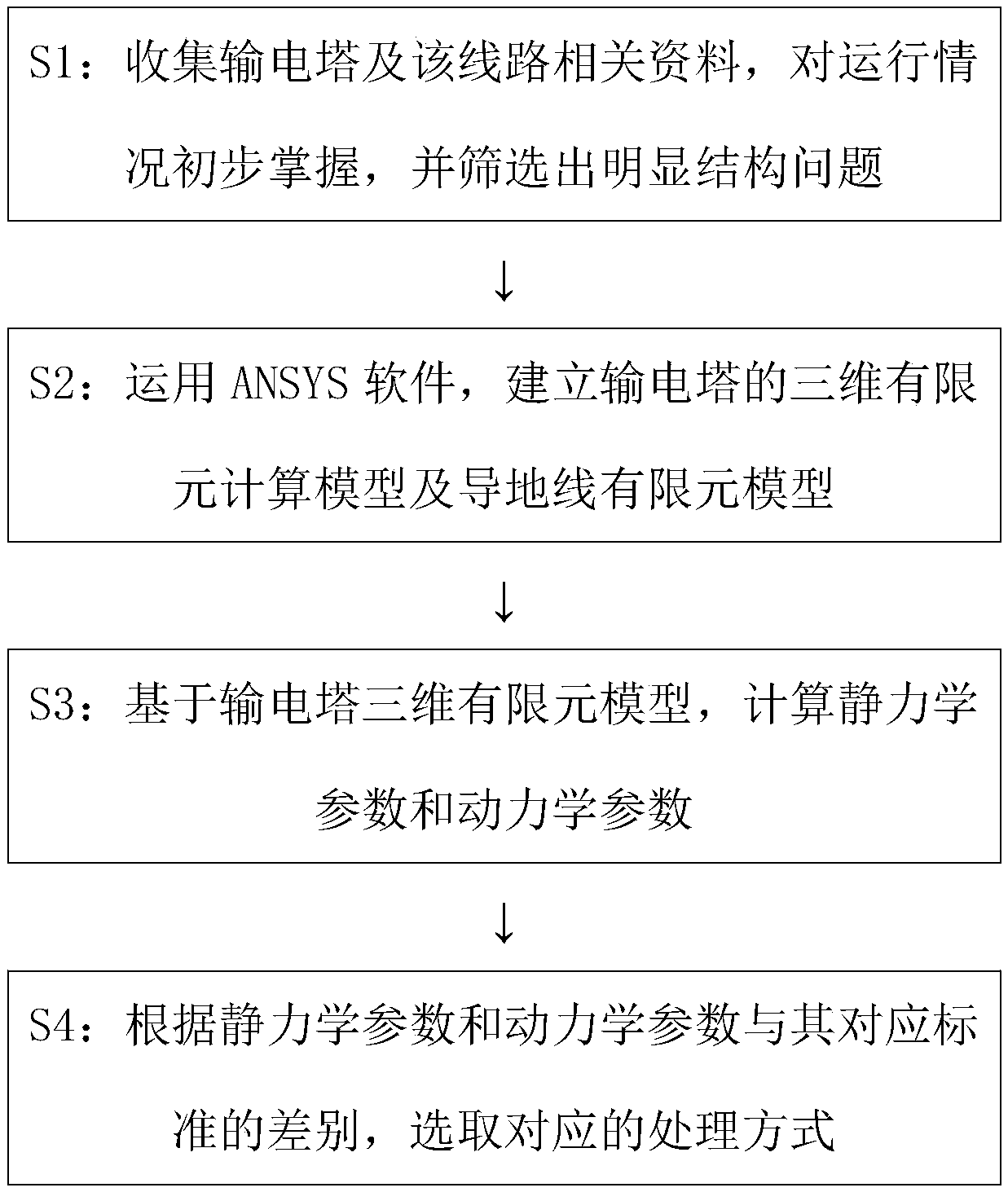

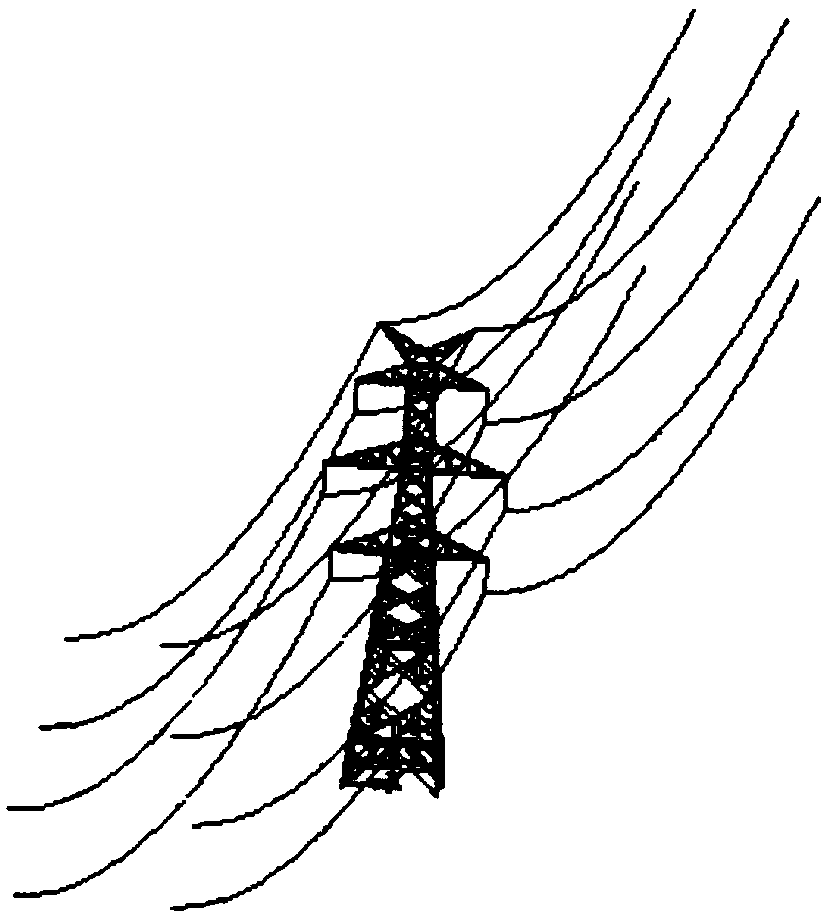

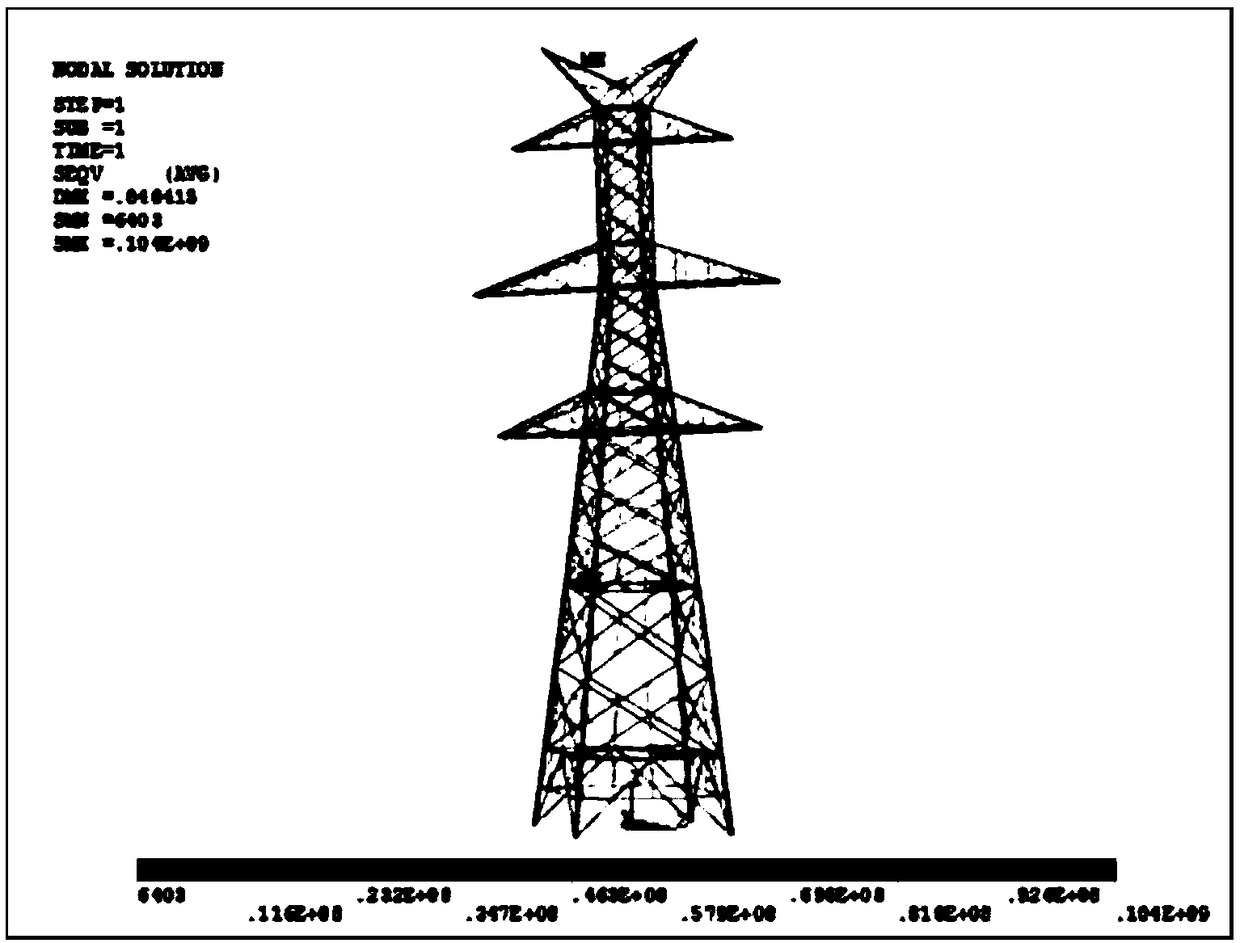

A method for evaluating the structural state of a transmission tower

PendingCN109344430AThe evaluation process is scientific and rigorousGood application effectGeometric CADDesign optimisation/simulationTransmission towerElement model

The invention provides a method for evaluating the structural state of a transmission tower. The method comprises the following steps of S1 collecting the relevant data of the transmission tower and the transmission line, initially grasping the operation situation, and screening out obvious structural problems; S2 establishing the three-dimensional finite element model of the transmission tower and the finite element model of a conductor by the ANSYS software; 3 calculating the static parameters and the dynamic parameter based on the three-dimensional finite element model of the transmission tower; S4 according to the difference between the static and dynamic parameters and their corresponding standards, selecting the corresponding treatment mode.. Based on the finite element to evaluate the structural state of the transmission tower, the method is convenient for transmission line maintenance and repair personnel and related scientific research personnel to evaluate the operation stateof the transmission tower, and then take corresponding measures to ensure the structural safety of the transmission tower.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

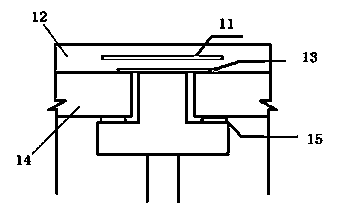

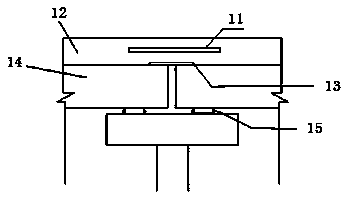

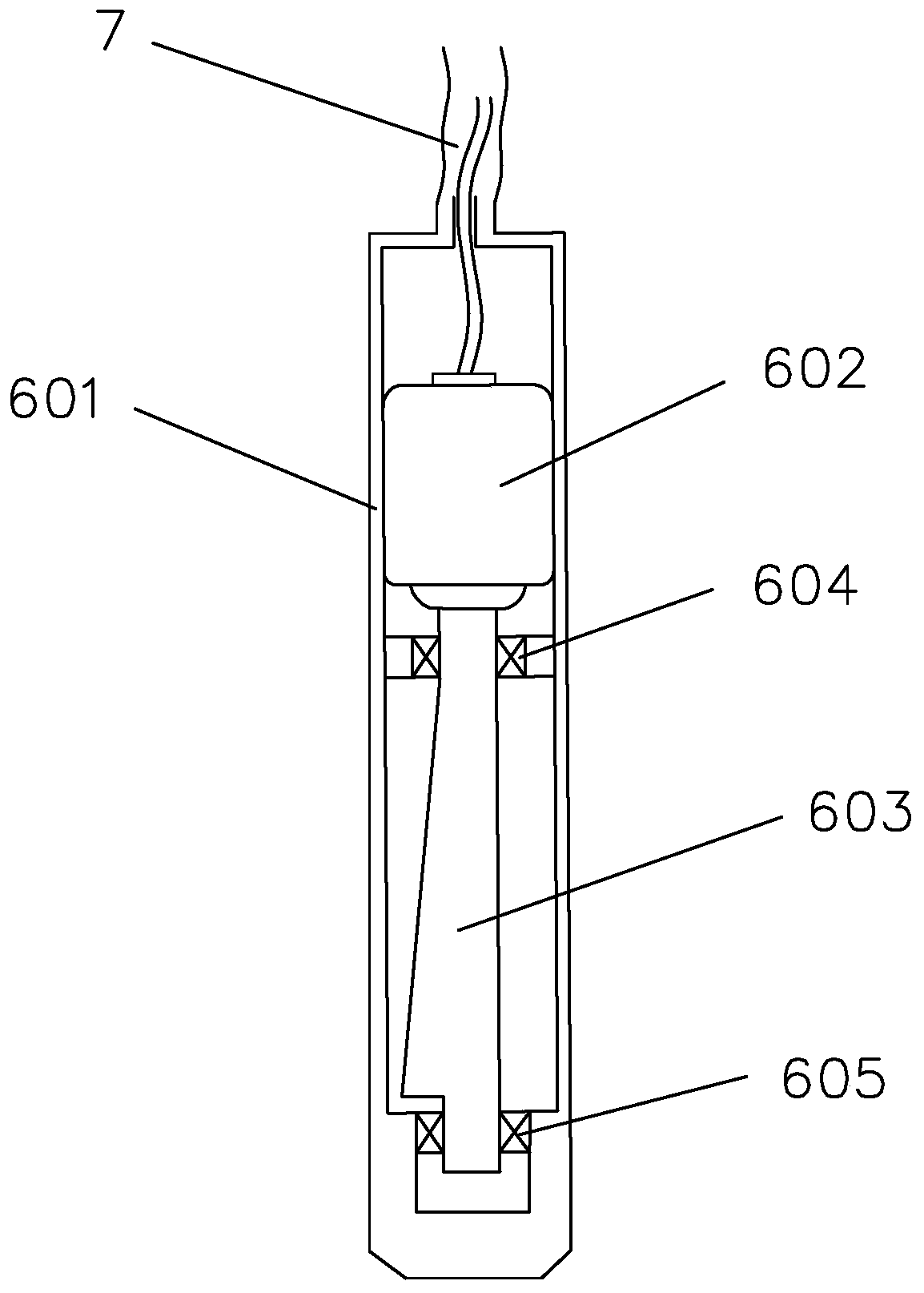

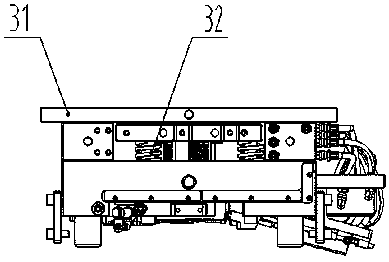

Vibration equipment and concrete pouring vibration method for tall special-shaped column

ActiveCN109853389AUniform colorReduce the presence of air bubblesBridge erection/assemblyStructural ProblemEngineering

The invention relates to vibration equipment and a concrete pouring vibration method for a tall special-shaped column. The vibration equipment and the vibration method thereof can replace manual construction, a vibration rod is lifted with the rise of concrete height, so that the surface color of concrete is uniform and air bubbles are less, the structural problems caused by cutting steel bars andthe problems of missed-vibration and over-vibration caused by manual operation errors are avoided, and the vibration rod is suitable for pouring concrete with different shapes of special-shaped columns. The equipment and the vibration method thereof are not only low in investment and simple in operation, but also high in efficiency and safety.

Owner:苏州交通工程集团有限公司

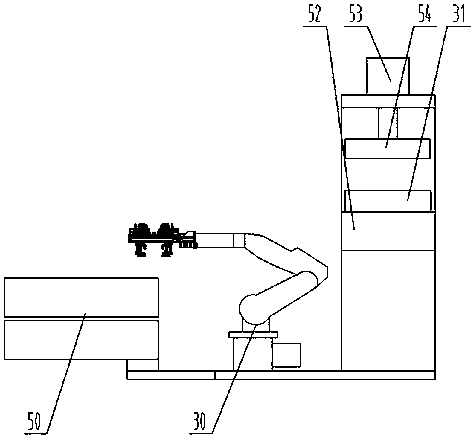

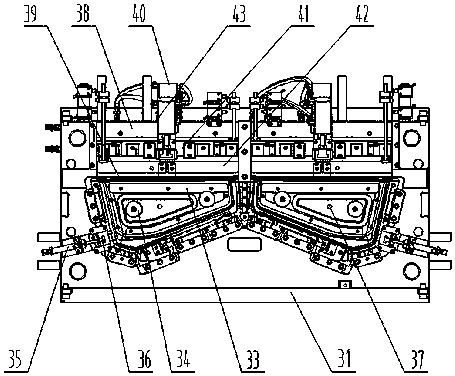

Automatic assembly line for automotive rear door glass

PendingCN107738399AHigh degree of automationReasonable structural designCoatingsGlass productionStructural ProblemEngineering

Disclosed is an automatic assembly line for automotive rear door glass. The automatic assembly line includes a pair of glass conveyors, a transferring mechanism based on a manipulator and a glass injection-molding covering machine. The transferring mechanism based on the manipulator comprises the manipulator and a finished glass unloading manipulator fixture. A base of the manipulator is fixedly installed on one side of the pair of glass conveyors. The automatic assembly line adopts the manipulator to be matched with transferring of the automotive glass; the finished glass unloading manipulator fixture is high in degree of automation, can be well matched with the manipulator to automatically complete works of automotive triangular glass loading, nail column installing and placing, glass unloading and material grasping, and is efficient, stable and reliable; and an automotive rear door glass covering injection-molding mold is reasonable in structural design and high in degree of automation, and installation of an automotive rear door glass diversified design guiding rail can be achieved; injection molding and covering are completed simultaneously, so that the efficiency is high; thedemolding problem caused by the structure is eliminated, so that the damage rate of the glass guiding rail is reduced; and the good promotion value and practical value are achieved.

Owner:福耀集团(沈阳)汽车玻璃有限公司

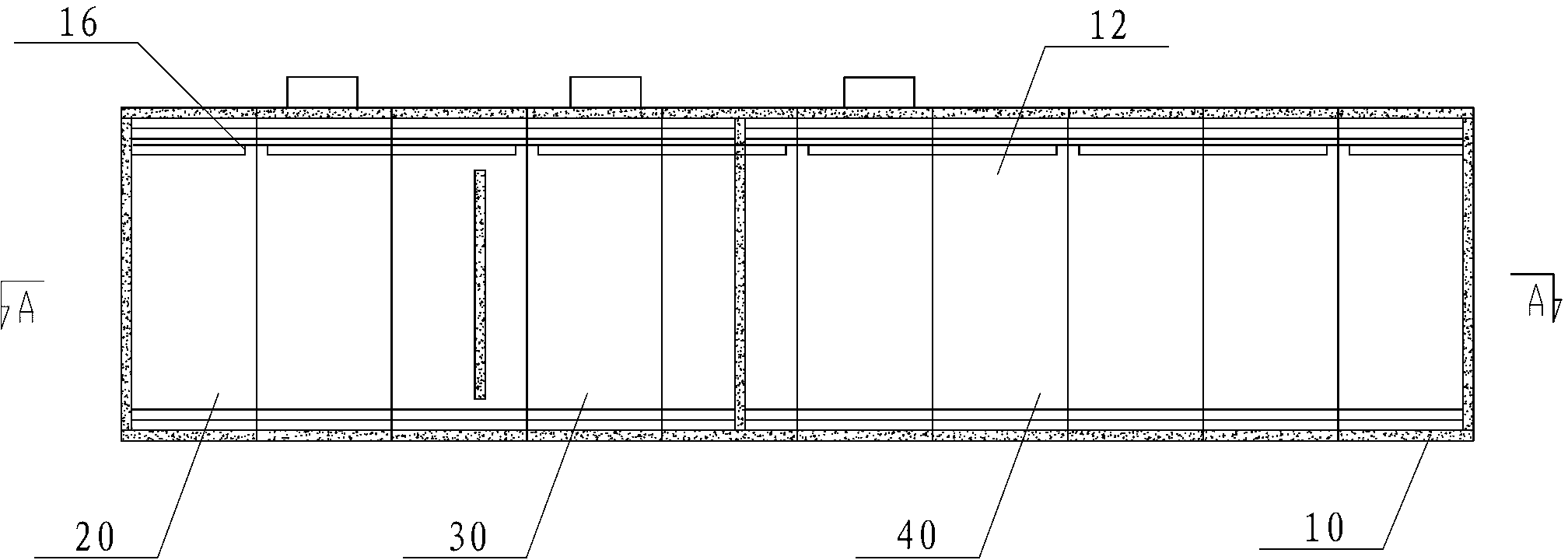

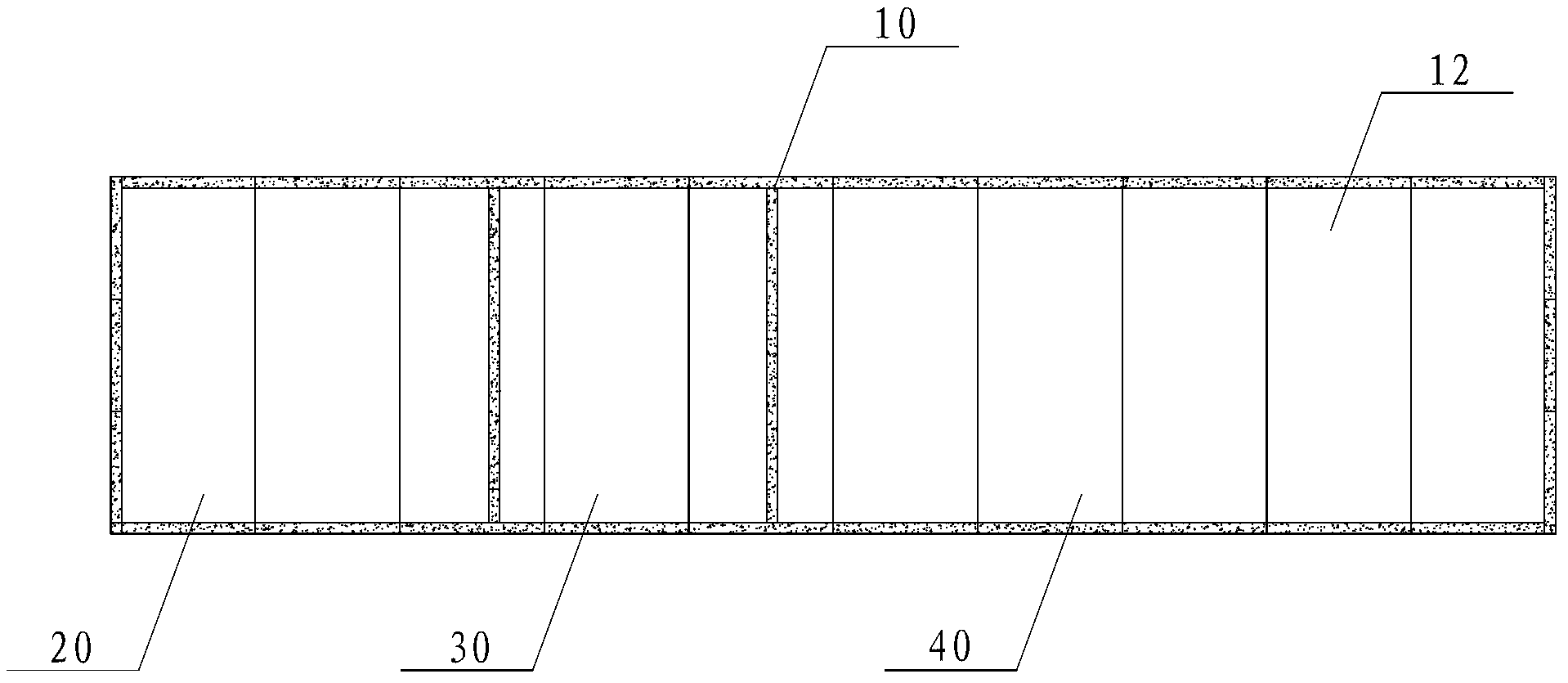

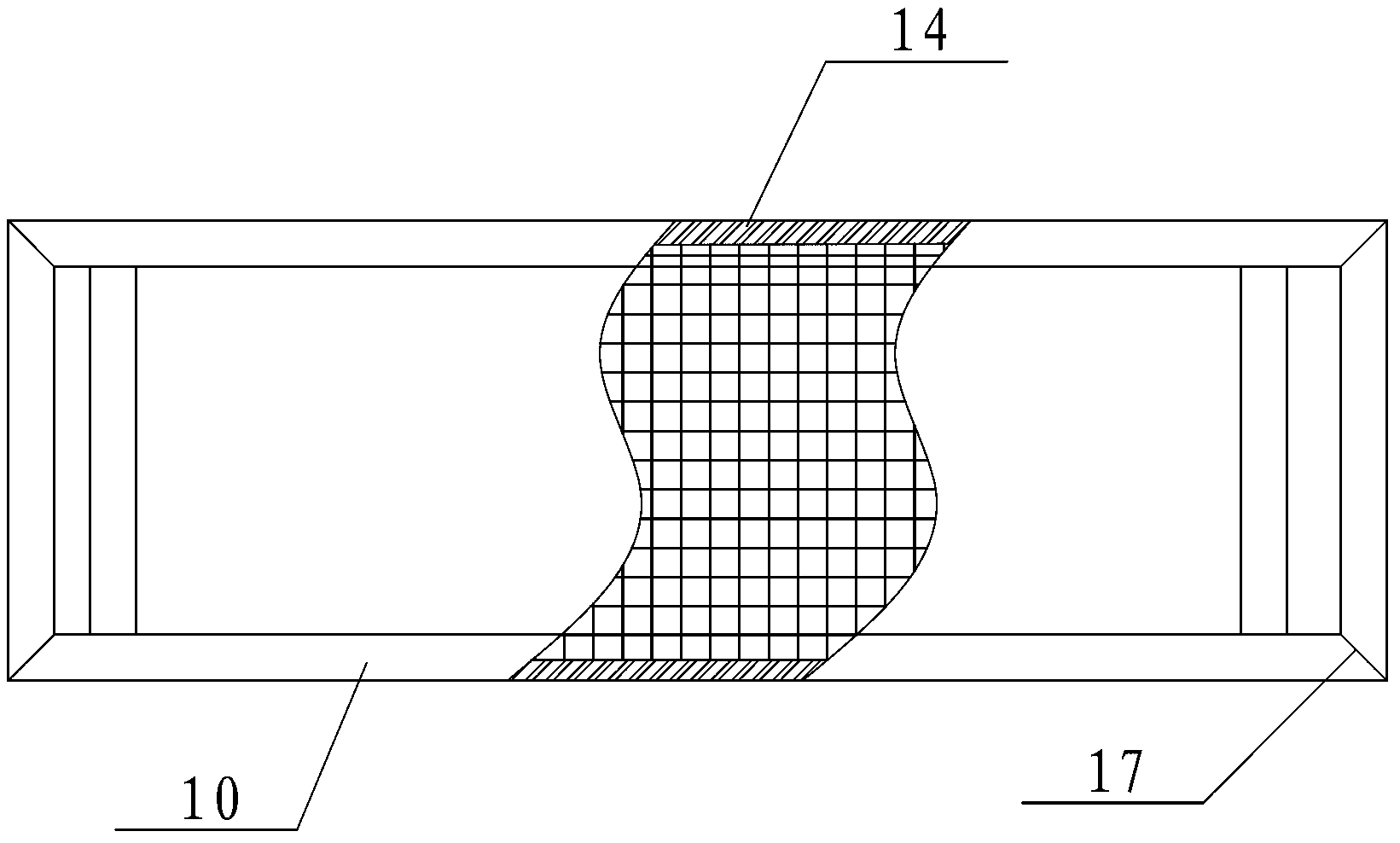

SBBR modular sewage processing equipment and its intelligence control system and method

ActiveCN103224310AReduce processing costsImprove reliabilityMultistage water/sewage treatmentStructural ProblemSludge

The invention relates to the technical field of sewage processing and recycling and specifically discloses SBBR modular sewage processing equipment and its intelligence control system and method. The method comprises the following steps: Step a, inflowing stage: aeration scale factor K1 is obtained by detecting water level difference between any water level of an anaerobic pond higher than a water inlet and the lower edge of the water inlet; Step b, when K1 is greater than 0.5, an aeration stage starts, wherein the aeration stage is divided into six sections; Step c, primary sedimentation stage; Step d, sludge returning stage; Step e, secondary sedimentation stage: mud and water are separated in an aerobic biochemical pool and sludge settles to form a mud-water separated interface; Step f, draining stage; and Step g, standing stage: standing time t7 is less than or equal to 1 hour, and waiting for the next new operation cycle. By the modular design, only one blower fan is needed, and through an original pneumatic means, present engineering and structural problems are well solved. According to the utility model, biological process requirements can be met, and under the most energy-saving and economical condition, sewage processing costs can be reduced.

Owner:广西神州环保设施运营有限责任公司

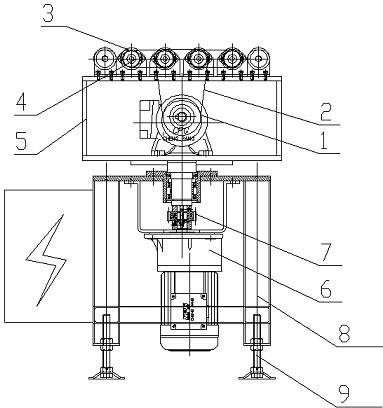

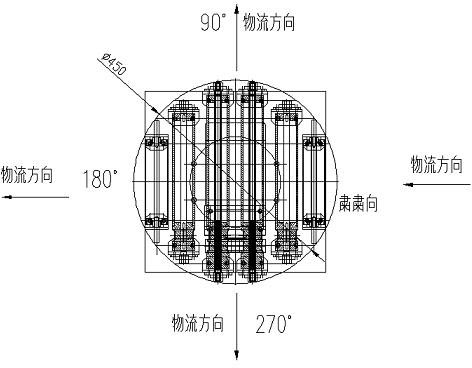

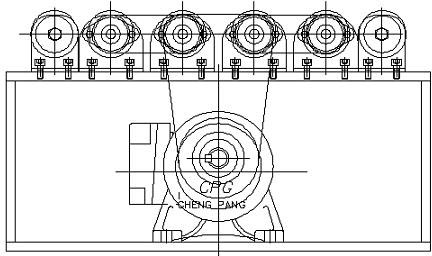

Horizontal rotary roller conveyer

The invention discloses a horizontal rotary roller conveyer, comprising a frame, two driving devices, a roller machine, a rotary seat, a bracket, a gear set and foundation bolts, wherein the foundation bolts are mounted at the bottom end of the frame; the two ends of the roller machine are mounted on the bracket of the rotary bracket through a pillow block bearing; the two driving devices are mounted at the lower part of the roller machine and at the lower part of the gear set respectively; a synchronous belt is connected to the driving device at the lower part the roller machine; and the synchronous belt drives the roller machine to rotate. The horizontal rotary roller conveyer disclosed by the invention solves the structural problem of use requirements of transplanting and conveying materials in different angles; the horizontal conveyance is carried out by employing a roller; according to the requirements of transplanting and conveying in different angles, angular rotation is carried out on the roller machine by a rotating mechanism, thereby achieving use requirements of transplanting and conveying materials in different angles respectively.

Owner:DALIAN JIALIN EQUIP MFG

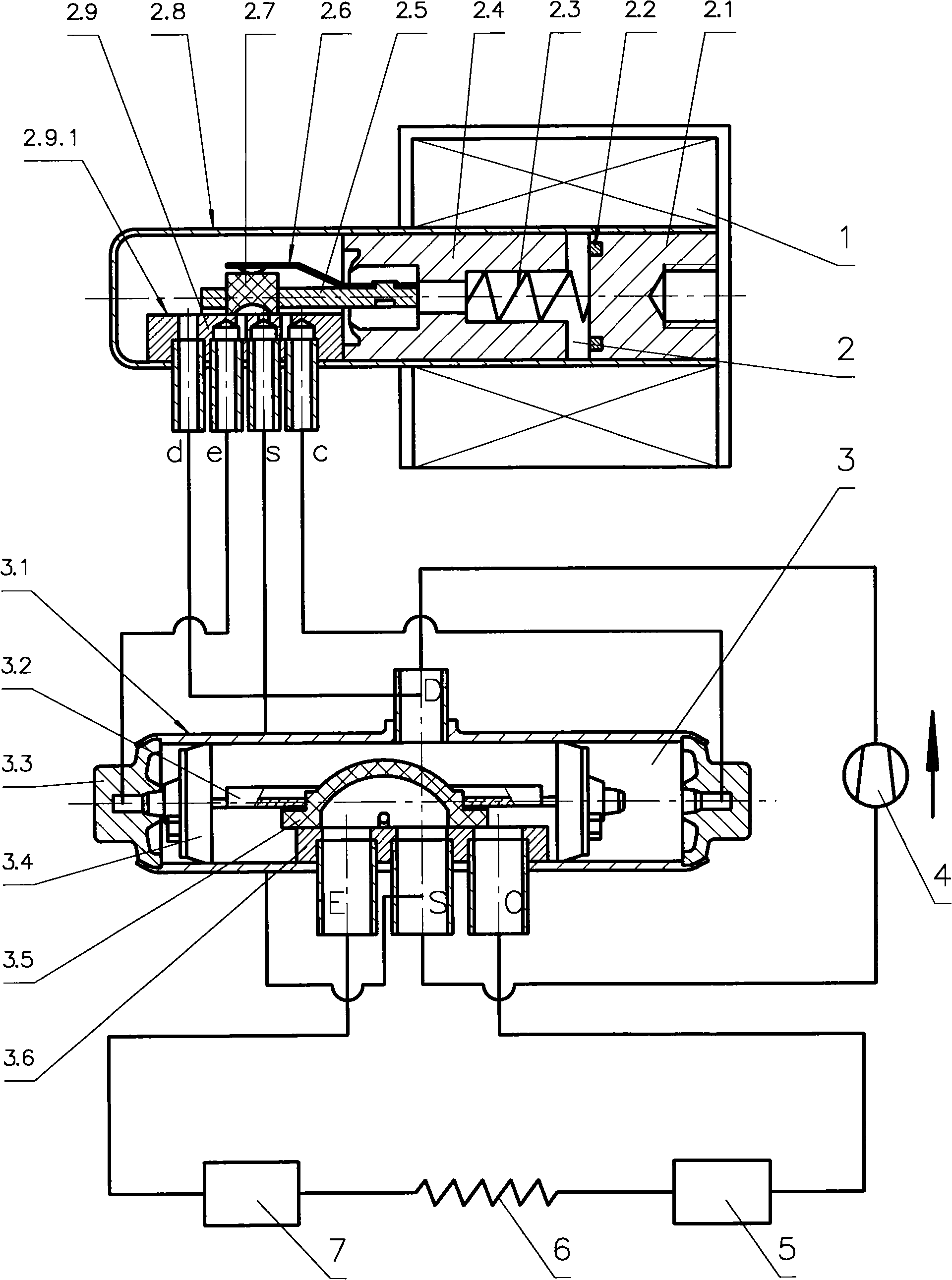

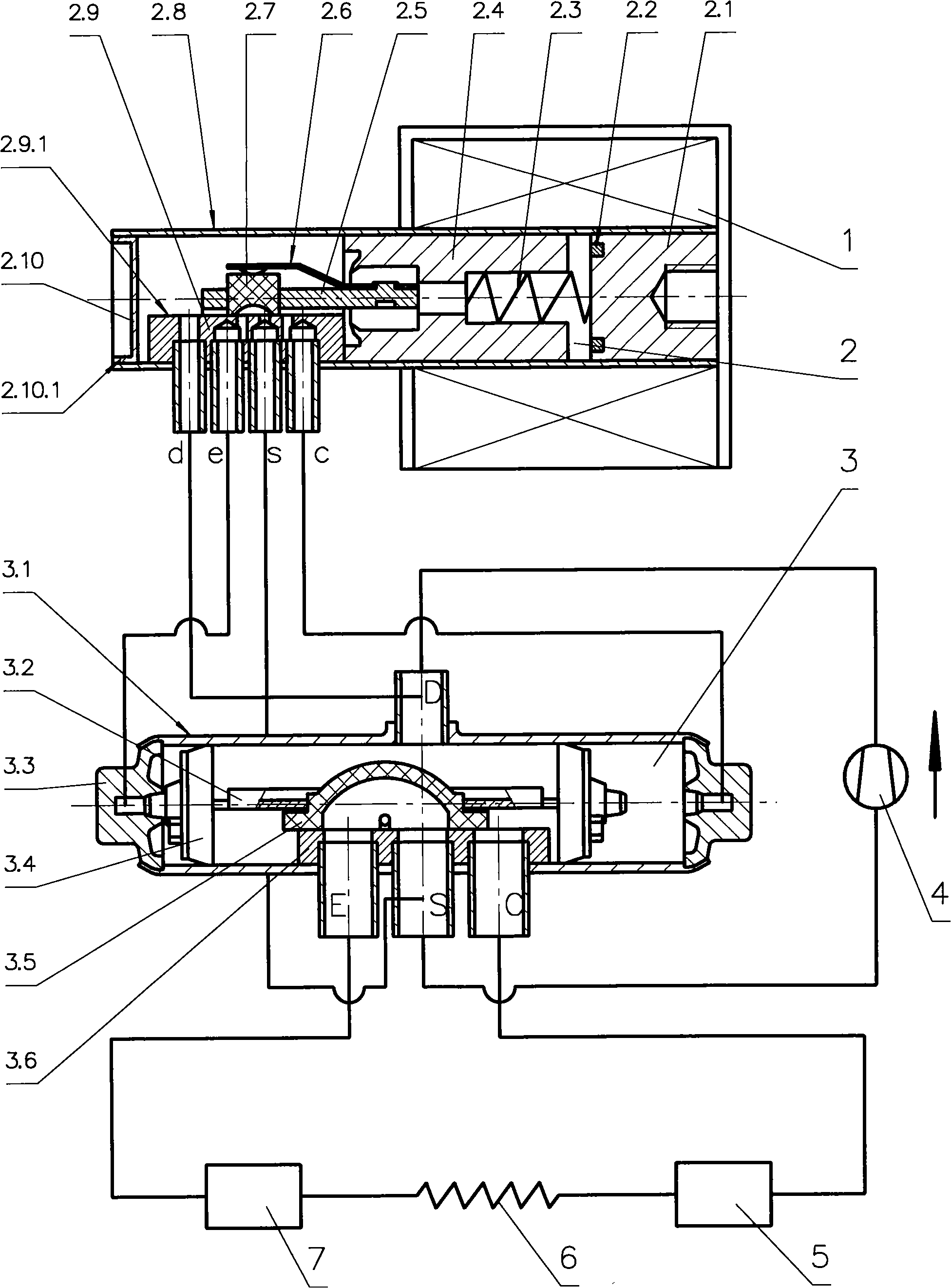

Electromagnetic valve

InactiveCN101338825AEase of precision machiningGuaranteed Surface PrecisionMultiple way valvesValve housingsStructural ProblemEngineering

The present invention relates to a novel electromagnetic valve with a pilot valve structure, which belongs to a system control element in a refrigeration-circulating system. The prior art has the defect that the structural problem causes the injury of the surface quality of a small valve seat, which reduces the qualified rate of products. The electromagnetic valve comprises a main valve, a pilot valve and an electromagnetic coil; wherein, the pilot valve is provided with a bushing; a small valve seat is welded in the cavity of the bushing; the end of the bushing, which is close to the electromagnetic coil, is hermetically welded with an end enclosure, and the other end of the bushing is blocked by an end cover. Since the end of the bushing, which is close to the small valve seat, is blocked by the end cover, both ends of the bushing are open, particularly, the end of the bushing, which is close to the small valve seat, is open, thereby, after being welded, the small valve seat can be precisely processed in order to avoid the injury of the surface quality of the small valve seat caused by welding, ensure the precision degree of the surface of the small valve seat and increase the qualified rate of products. Meanwhile, since the structure is simple, the qualified rate of mass production can be ensured.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

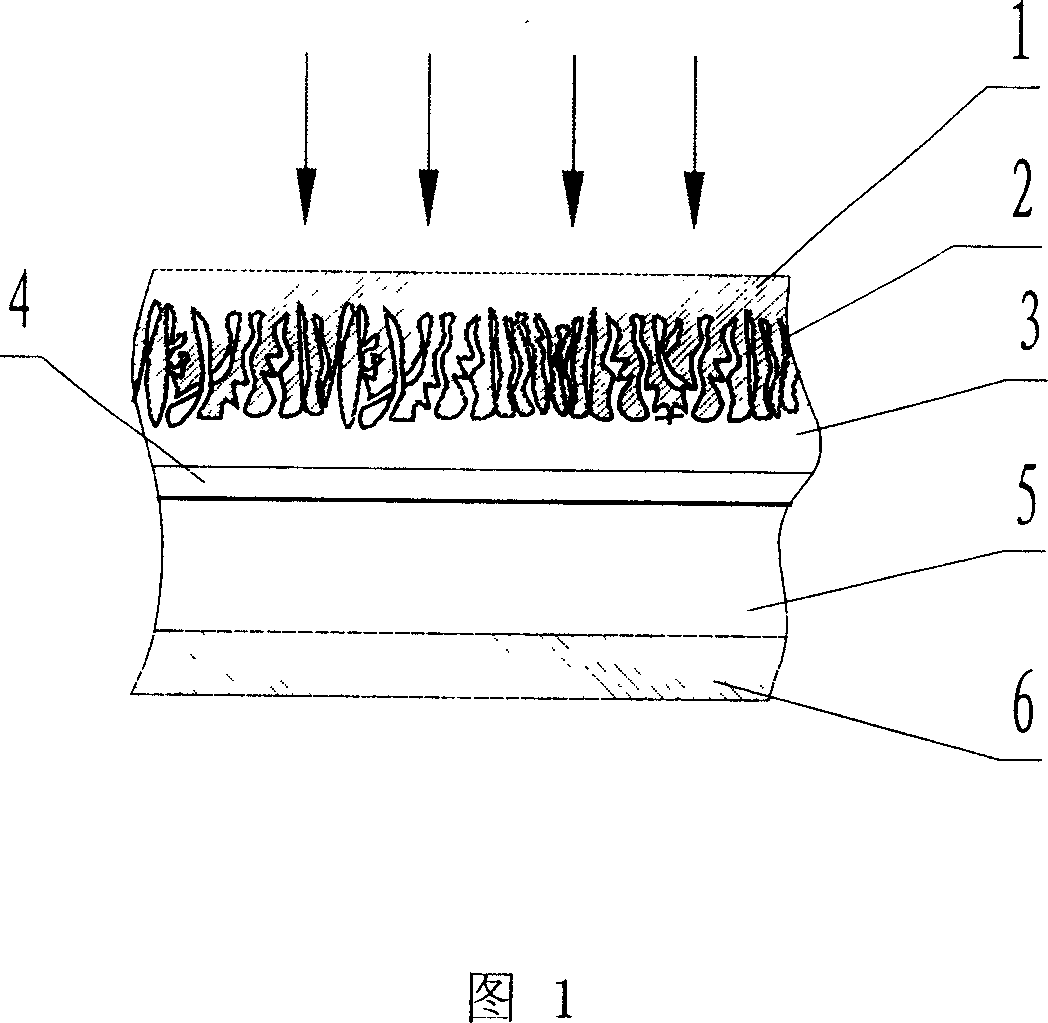

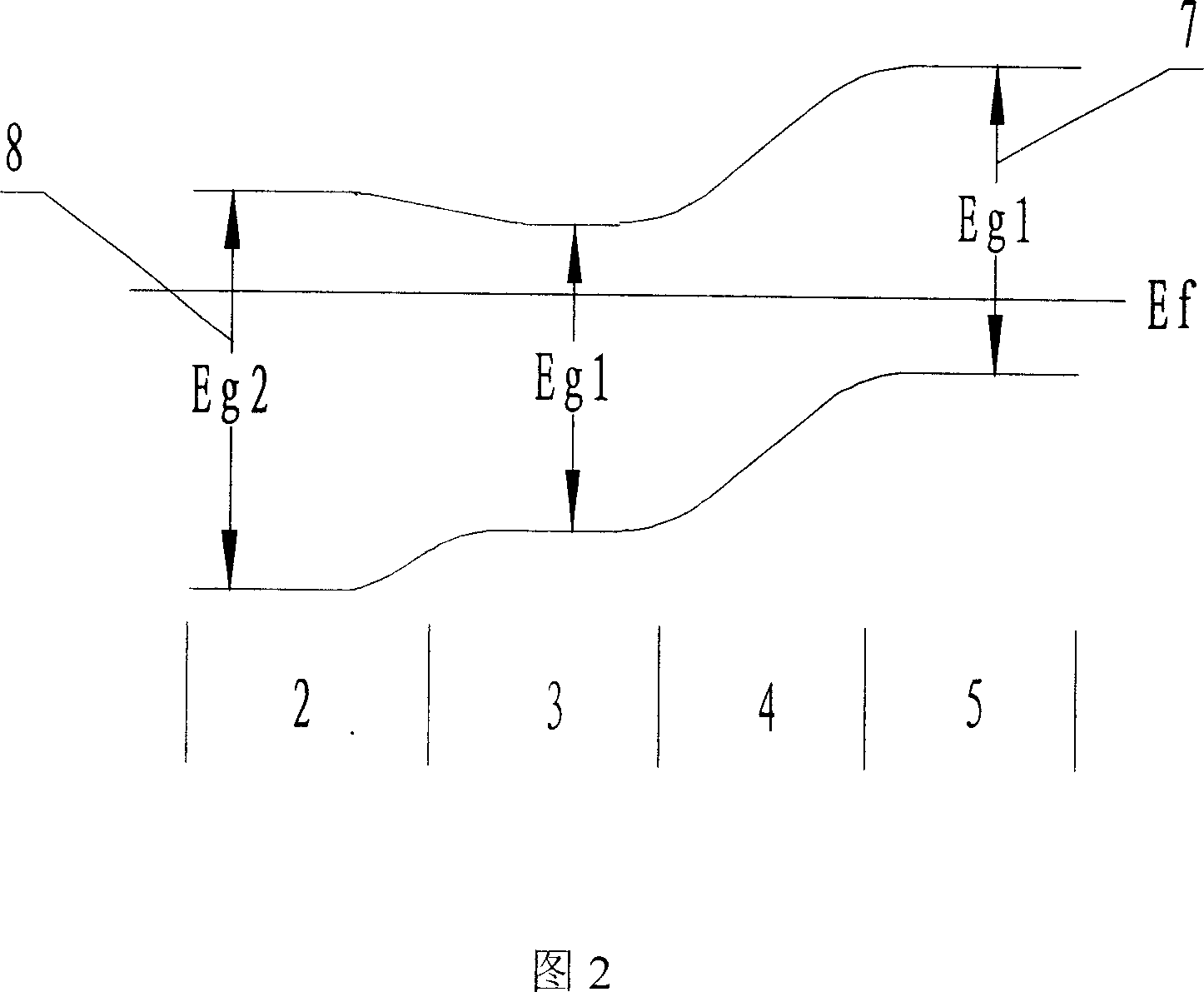

Crystal silicon solar battery with multi-hole silicon layer structure

InactiveCN101055899AIncrease the output voltageImprove photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesSilicon solar cellP type silicon

The invention relates to a solar cell, in order to solve the structural problem of the crystal silicon solar cell. The invention discloses a porous silicon layer structural crystal silicon solar cell, whose structure comprise in sequence: a N-type silicon layer, a P-type silicon layer, a back electrode, and a PN junction with photovoltaic effect formed on the boundary of the N-type silicon layer and the P-type silicon layer, which is charactered in that a nanometer porous silicon layer is provided on the silicon material surface at one side near to the light-receiving surface, and there are nesa structure on the surface of the nanometer porous silicon layer. The invention has made improvement in the existing structure, increasing a nanometer porous silicon layer, thus raising the photoelectric conversion efficiency of the solar cell. Because the dimension of quasi aperture and quasi hole wall of the nanometer porous silicon layer is between 2 nanometer to 300 nanometer, and the thickness of nanometer porous silicon layer is thinner, the thinner crystal silicon layer can be used to achieve the same light quantum turnout with a thicker crystal silicon layer. Therefore it saves the valuable semiconductor silicon material, and reduces the cost.

Owner:SHANGHAI SOLAR ENERGY S&T

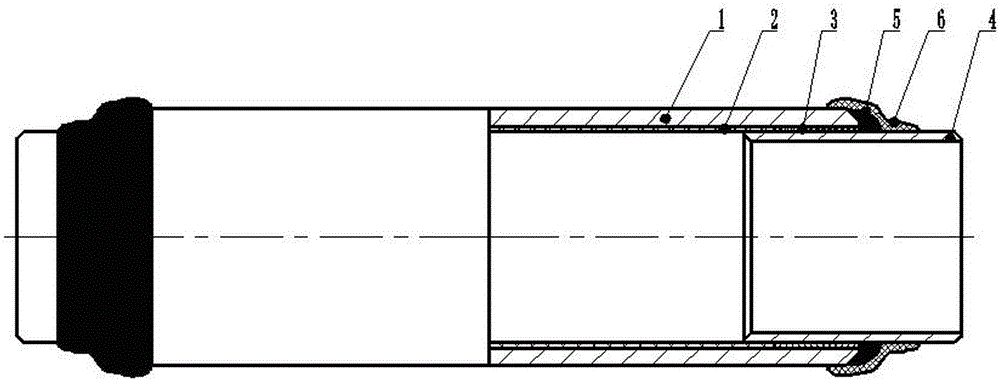

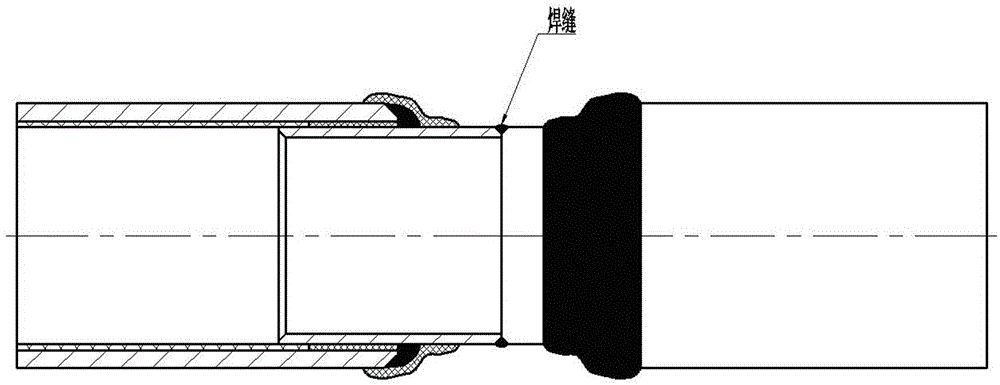

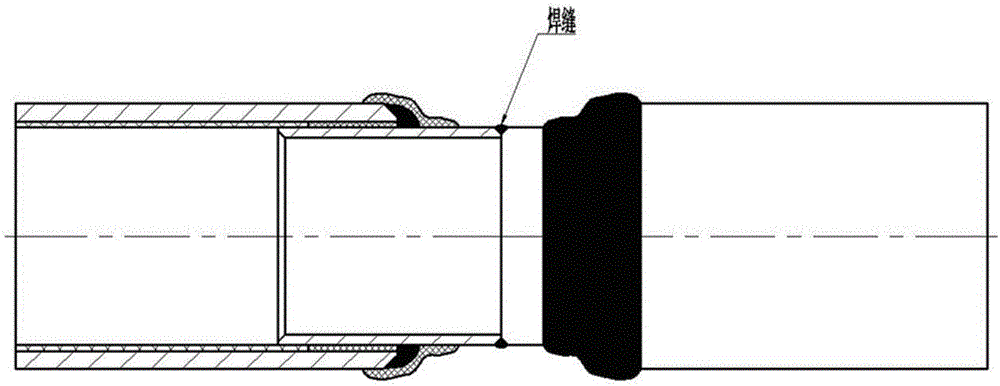

Method for manufacturing lining plastic pipe by using welded connection

ActiveCN105697896ASolve the problem of electrochemical corrosionSolve the defects of utility modelsCoatingsRigid pipesStructural ProblemEngineering

The present invention discloses a method for manufacturing lining plastic pipe by using welded connection. The method comprises the following steps: (1) stripping one section of the plastic anticorrosive coating of the lining plastic pipe port that has been subjected to lining plastic recombination, wherein the lining plastic pipe port being stripped the plastic anticorrosive coating is the connection end of the external steel pipe; (2) lining the inner wall of the connection end that is not lined with the plastic anticorrosive coating with a hot melt adhesive, wherein the hot melt adhesive is adhered to the inner wall of the connection end to form a hot melt adhesive layer; (3) inserting a stainless steel pipe into the external steel pipe from the connection end of the external steel pipe, wherein the outer wall of the stainless steel pipe is adhered with the hot melt adhesive layer; and (4) welding the outer wall of the stainless steel pipe and the port of the external steel pipe. The lining plastic pipe manufactured by this method can efficiently solve the problem of electrochemical corrosion after welding the dissimilar steel, solve the structural problem that the steel-plastic pipe cannot directly adopt welded connection, and expands the application of the stainless steel in steel-plastic pipe manufacture.

Owner:SICHUAN XIN YUAN TONG STEEL PLASTIC PIPE CO LTD

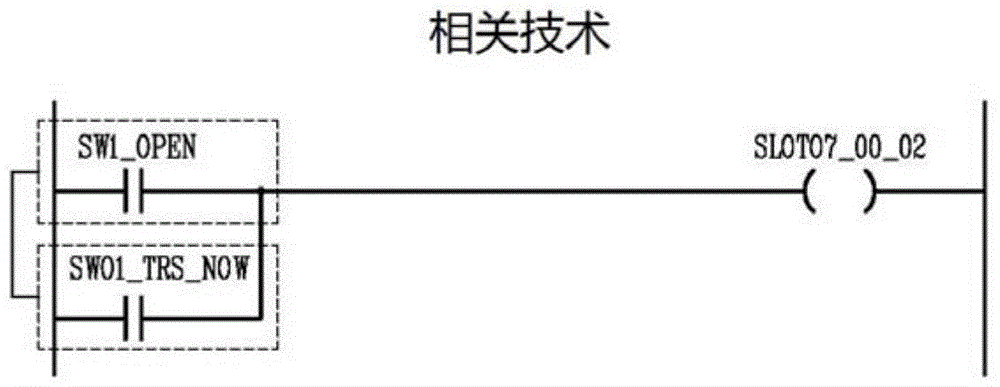

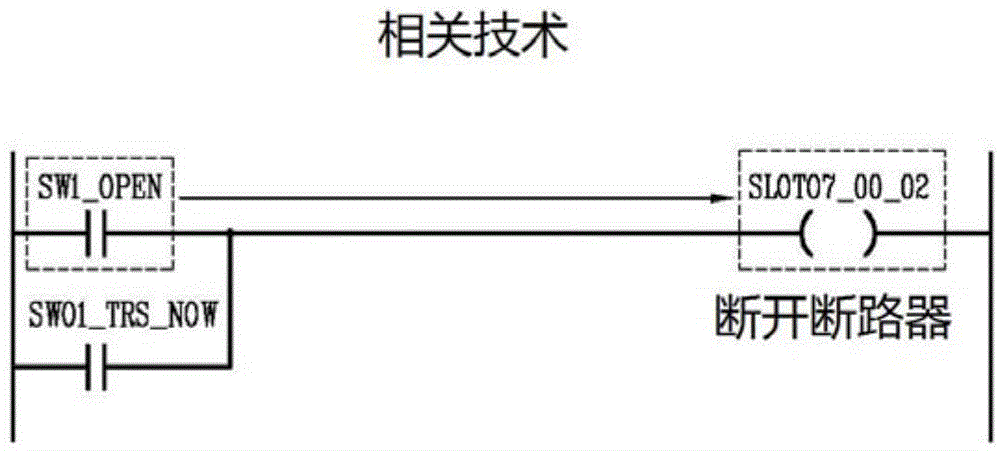

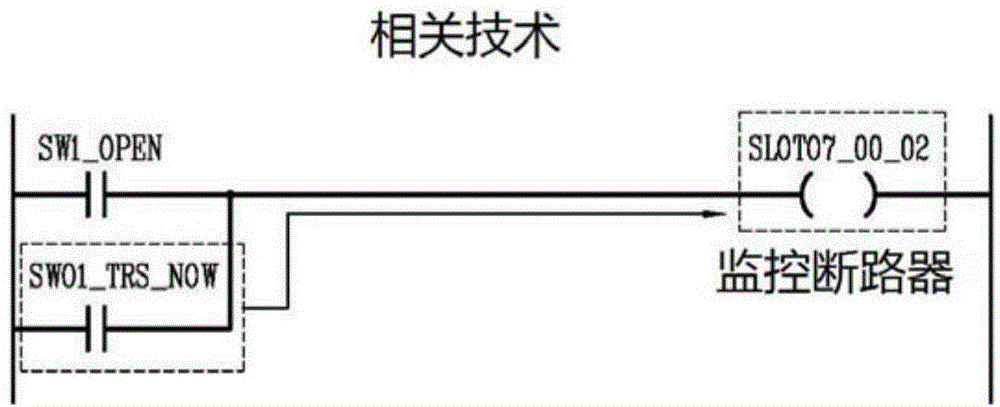

Circuit breaker and method of controlling the same

InactiveCN105302051AEasy to controlSimple designEmergency actuatorsContact operating partsStructural ProblemControl signal

The present invention relates to a circuit breaker and a method of controlling the same. More specifically, the present invention is to provide a circuit breaker capable of performing an interruption operation and an interruption monitoring function through an integrated control contact for transmitting a control signal, in order to solve the conventional problem, i.e., a structural problem due to separation of control contacts, and a malfunction of a monitoring function when an interlock is set, and a method of controlling the circuit breaker. With such a configuration, the circuit breaker can have a simplified structure, and can be designed and controlled more easily and simply.

Owner:LSIS CO LTD

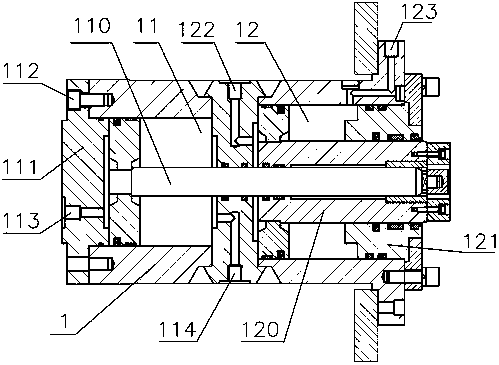

Hydraulic oil cylinder

InactiveCN109185265ACompact structureEasy to assembleFluid-pressure actuatorsHydraulic cylinderStructural Problem

The invention provides a hydraulic oil cylinder. The hydraulic oil cylinder comprises a hydraulic cylinder body, a piston and a piston rod, wherein the hydraulic cylinder body is provided with two cavities, the two cavities are a first cylinder body and a second cylinder body respectively, the piston comprises a first piston and a second piston, the piston rod comprises a first piston rod and a second piston rod, and the first piston and the first piston rod are located in the first cylinder body, the second piston and the second piston rod are located in the second cylinder body, a through hole is formed in the axial direction of the second piston rod, the first piston rod penetrates through the through hole of the second piston rod, the first cylinder body and the second cylinder body are combined into a complete hydraulic cylinder body, different action requirements can be controlled respectively, the second piston rod of the second cylinder body realizes the working locking action,and the first piston rod of the first cylinder body realizes the stamping workpiece action. The hydraulic oil cylinder has the beneficial effect that the structure is compact, the assembly is simple,the maintenance are convenient, and the structural problem is solved for hydraulic intelligent control.

Owner:常州华睿新能源汽车发展有限公司

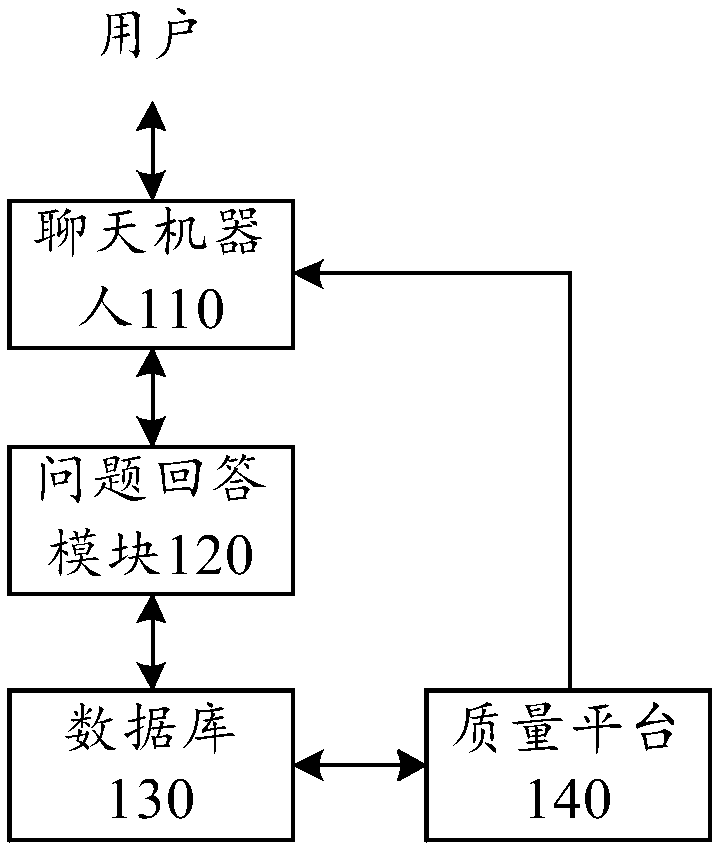

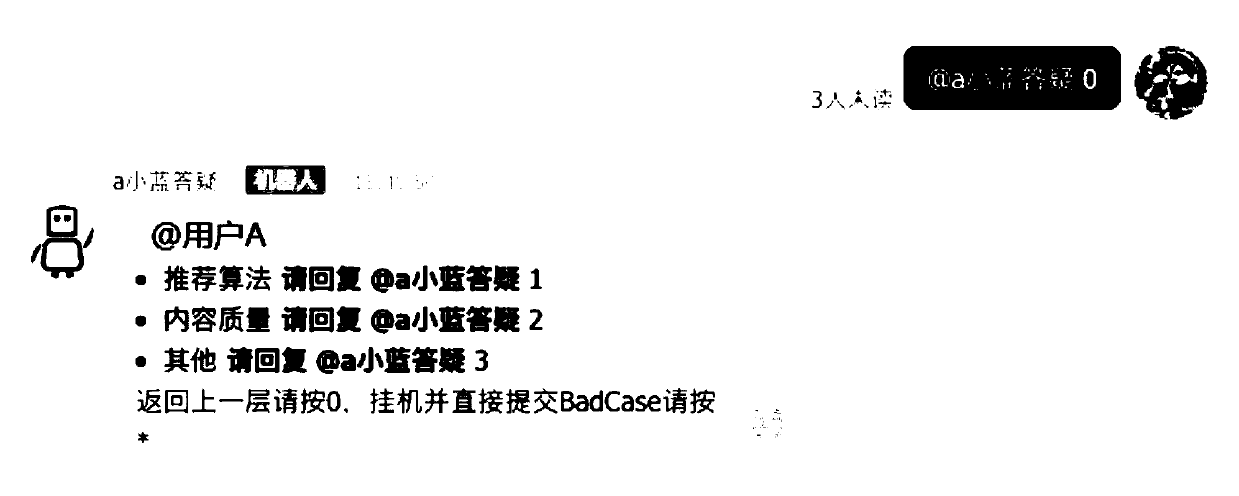

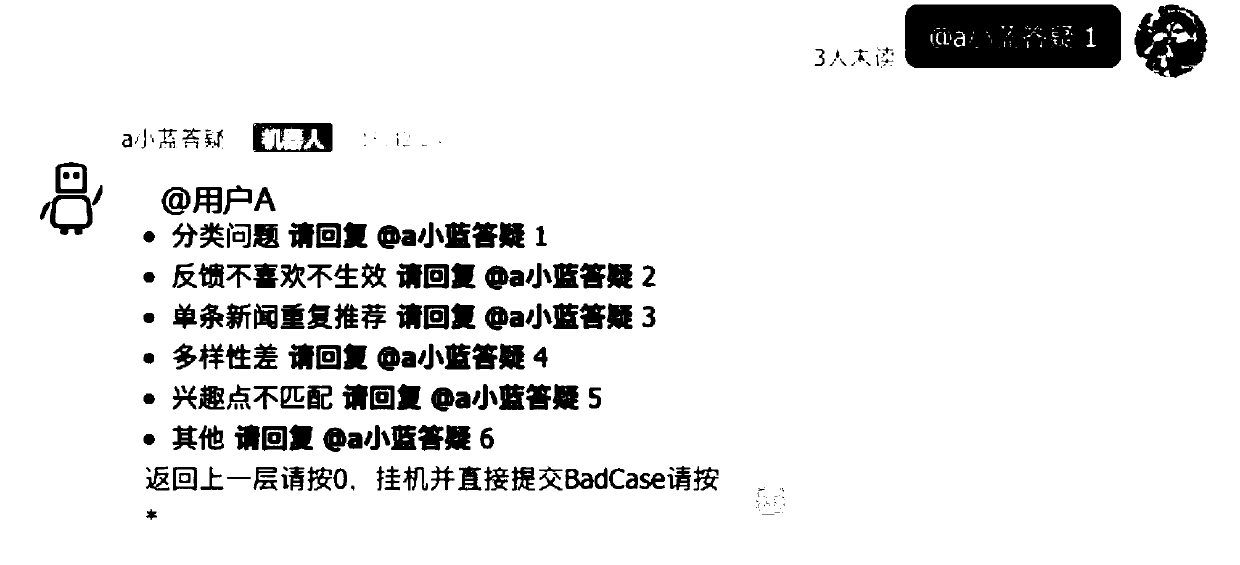

System and method for collecting user question

ActiveCN109525480AImprove online qualityEasy to trainData switching networksStructural ProblemInformation Harvesting

The invention discloses a system and a method for collecting user questions. The system comprises a chat robot, a question answering module, a database, and a quality platform. The chat robot is usedfor actual interaction with a user. The question answering module is used for guiding the chat robot to interact with the user to locate user question types and obtaining questions reported by the user and user information. The database is used for storing the located user question types, the questions reported by the user, and the user information. The quality platform obtains the user question types, the questions reported by the user, and the user information for analysis. Thus, the process of recording the entire process of problem classification, information collection, problem analysis and problem tracking is realized without human participation by taking the chat robot as a front end entrance. The structural problem obtained through analysis can be automatically provided to the back-end research personnel, thereby improving the recommendation precision of the whole recommendation system.

Owner:ALIBABA (CHINA) CO LTD

Preparation method of plastic lining steel tube in welded connection

InactiveCN106583954ASolve the problem of electrochemical corrosionSolve the defects of utility modelsWelding/cutting auxillary devicesAuxillary welding devicesStructural ProblemPreservative

The invention discloses a preparation method of a plastic lining steel tube in welded connection. The preparation method comprises the following steps: (1) peeling a section of a plastic preservative layer at the port of the plastic lining steel tube which is lined with plastic, wherein the port of the preservative plastic lining steel tube without the plastic is a connecting end of an outer steel tube; (2) lining the inner wall of the connecting end without the plastic preservative layer with a hot melt adhesive, wherein the hot melt adhesive is attached to the inner wall of the connecting end to form a hot melt adhesive layer; (3) inserting a stainless steel tube into the outer steel tube from the connecting end of the outer steel tube, wherein the outer wall of the stainless steel tube is bonded to the hot melt adhesive layer; and (4) then welding the outer wall of the stainless steel tube with the port of the outer steel tube. The plastic lining steel tube prepared by the method not only can effectively solve the problem of electrochemical corrosion after heterogeneous steel welding, but also can solve the structural problem that steel plastic tubes cannot be directly in welded connection, and the application of stainless steel in steel plastic tube manufacturing is expanded.

Owner:王有洪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com