Automatic assembly line for automotive rear door glass

An automatic assembly and production line technology, which is applied in the direction of coating, etc., can solve the problems of unable to produce normally, extrusion and fracture of guide rails, and inability to meet diversified product designs, etc., to achieve good promotion and practical value, reasonable structural design, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

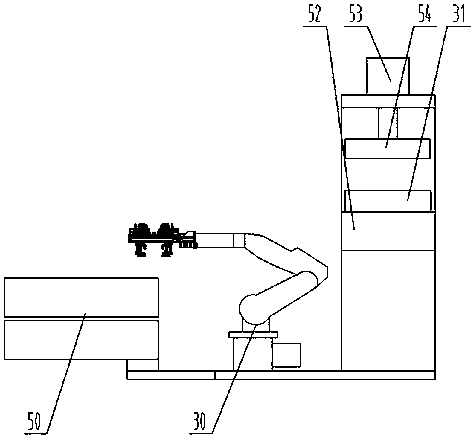

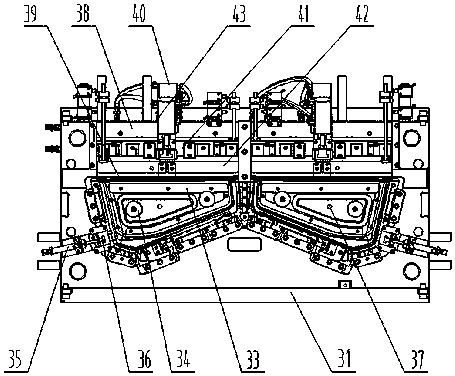

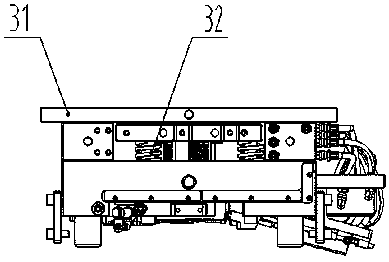

[0019]As shown in the accompanying drawings, the present invention includes a pair of glass conveyors 50, a transfer mechanism based on the manipulator 30, and a glass injection molding machine. The transfer mechanism based on the manipulator 30 includes a manipulator 30 and a finished glass lower sheet manipulator clamp. The base of the manipulator 30 is fixedly installed on one side of a pair of glass conveyors 50. The manipulator fixture for the finished glass sheet includes a mounting plate 1, an aluminum profile frame 2, a semi-finished glass sucker mechanism, a set of glass support columns 5, and a set of nails. Column clamping mechanism, a set of finished glass sucker mechanism and a set of handle grabbing mechanism, one end of the aluminum profile frame 2 is fixedly installed on the mounting plate 1, and the semi-finished glass sucker mechanism includes a set of sucker integrated blocks 3 and A set of semi-finished glass suction cups 4, the set of suction cup integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com