Patents

Literature

27911results about How to "Reasonable structural design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

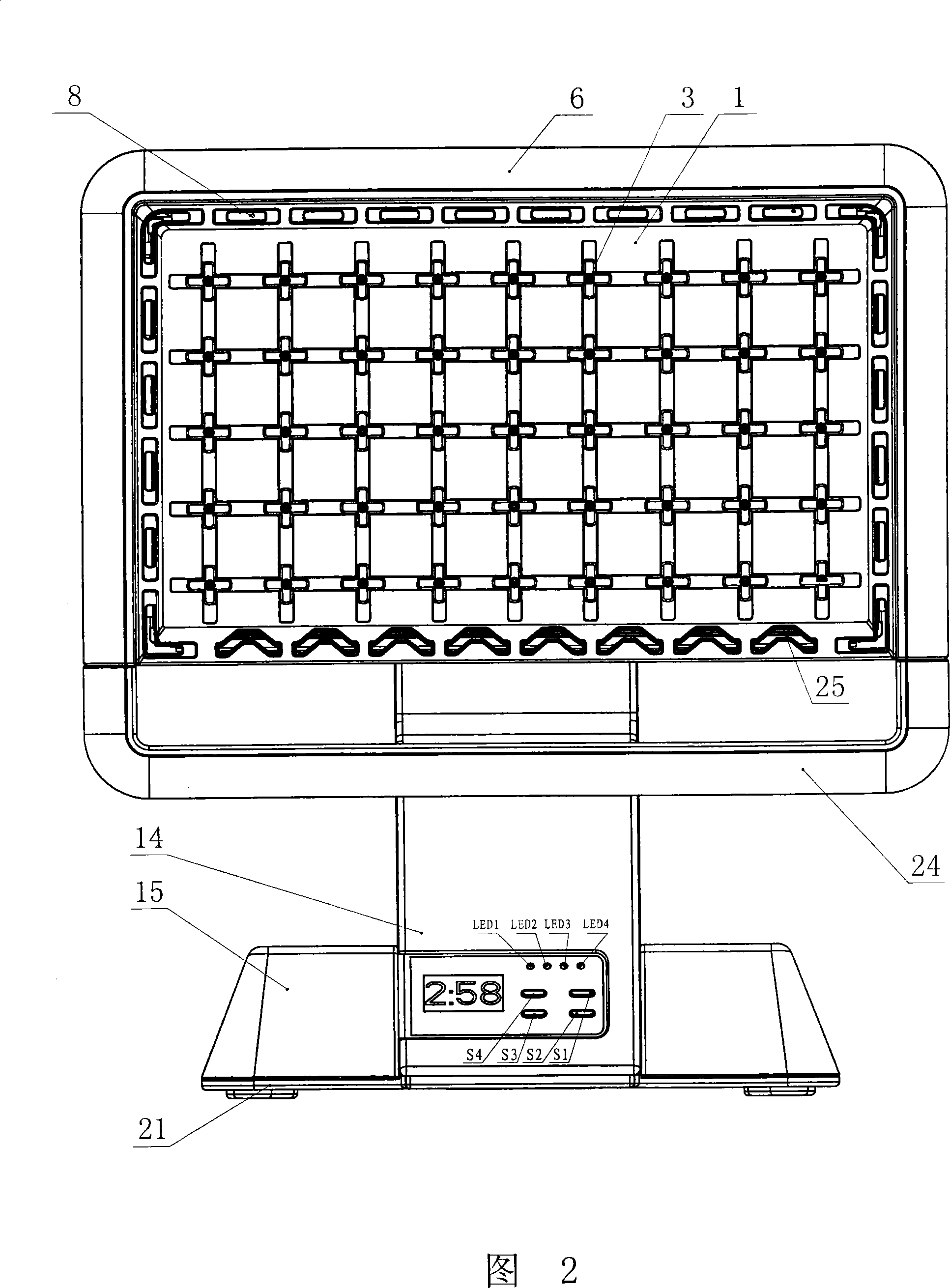

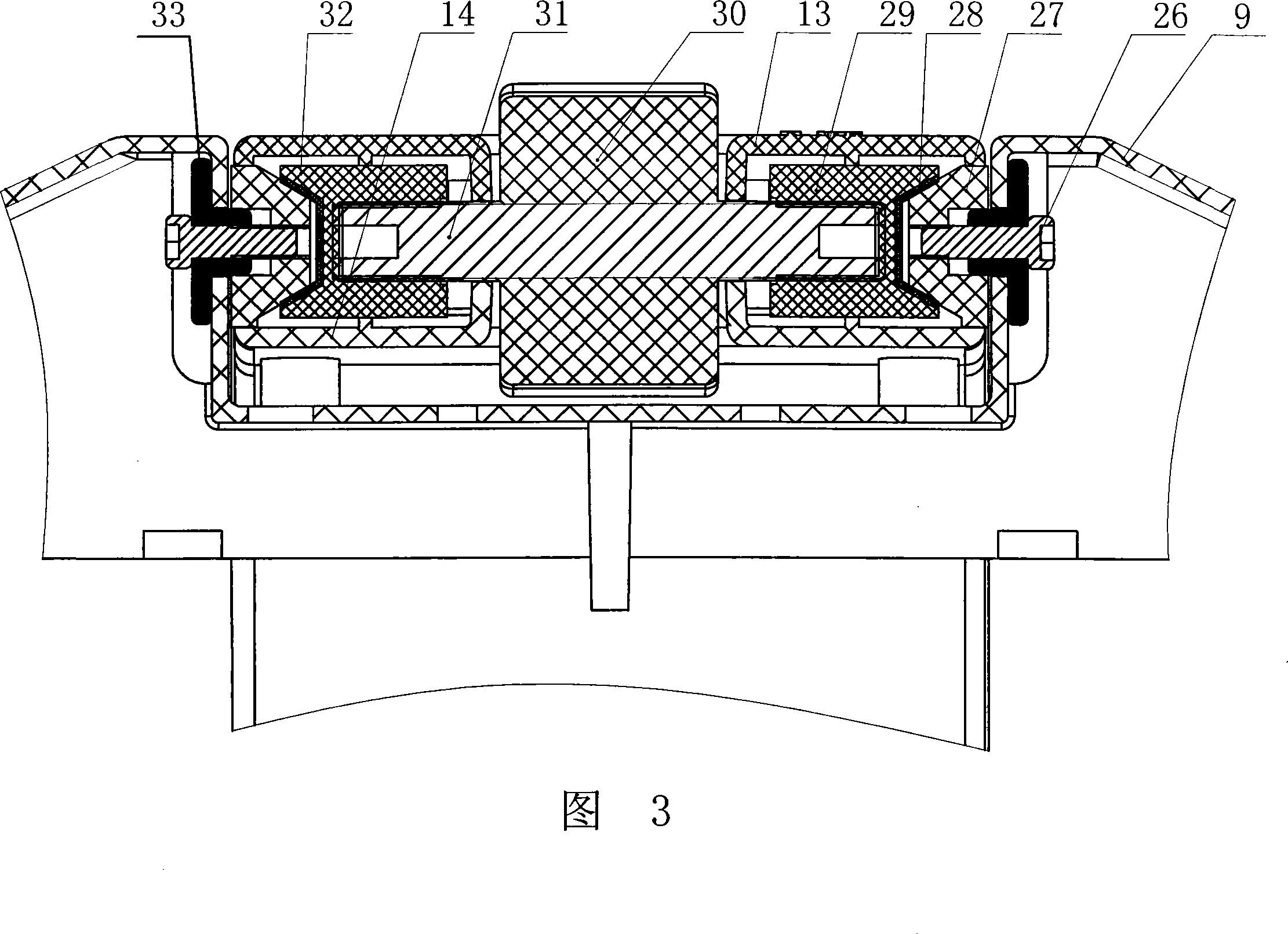

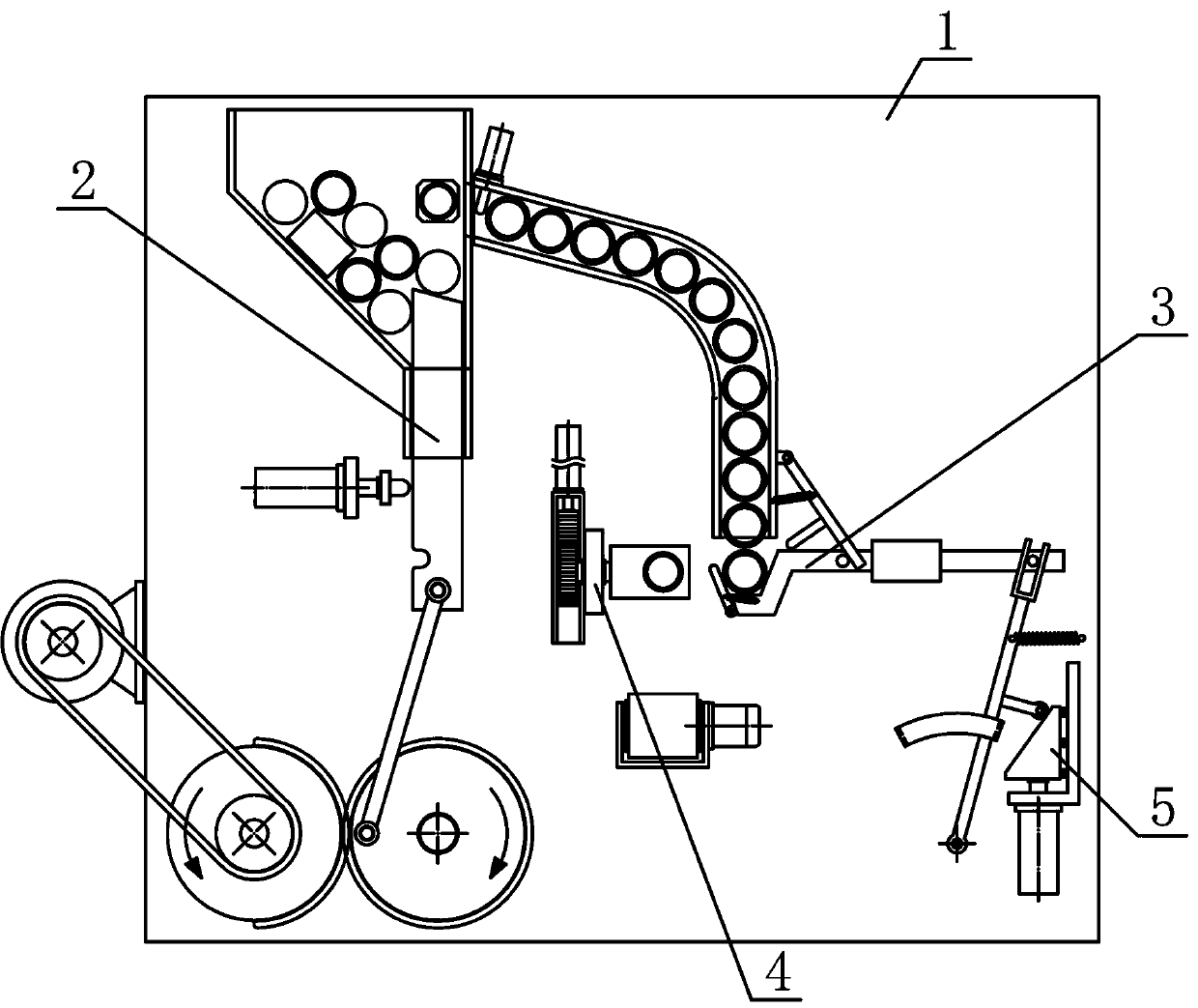

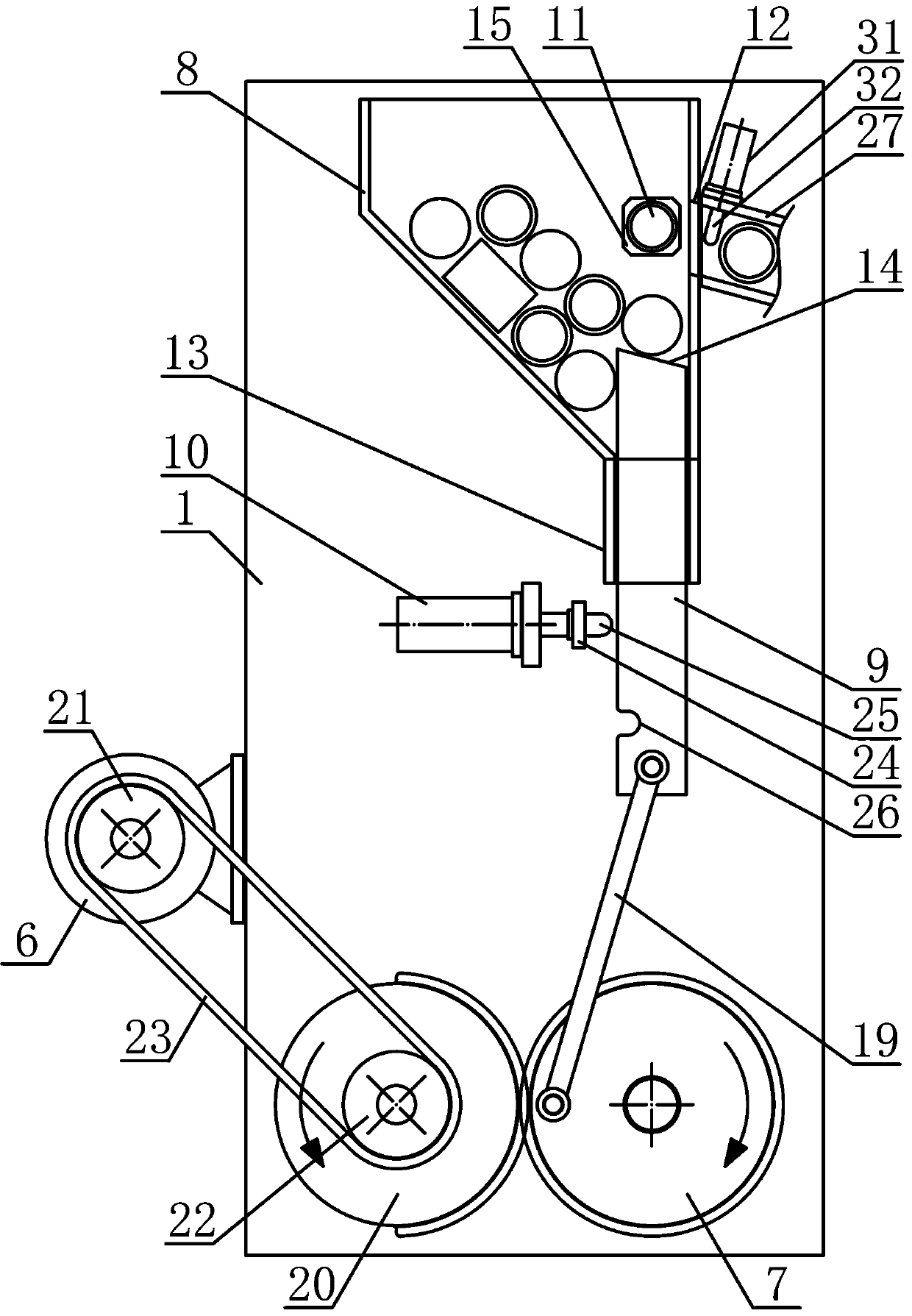

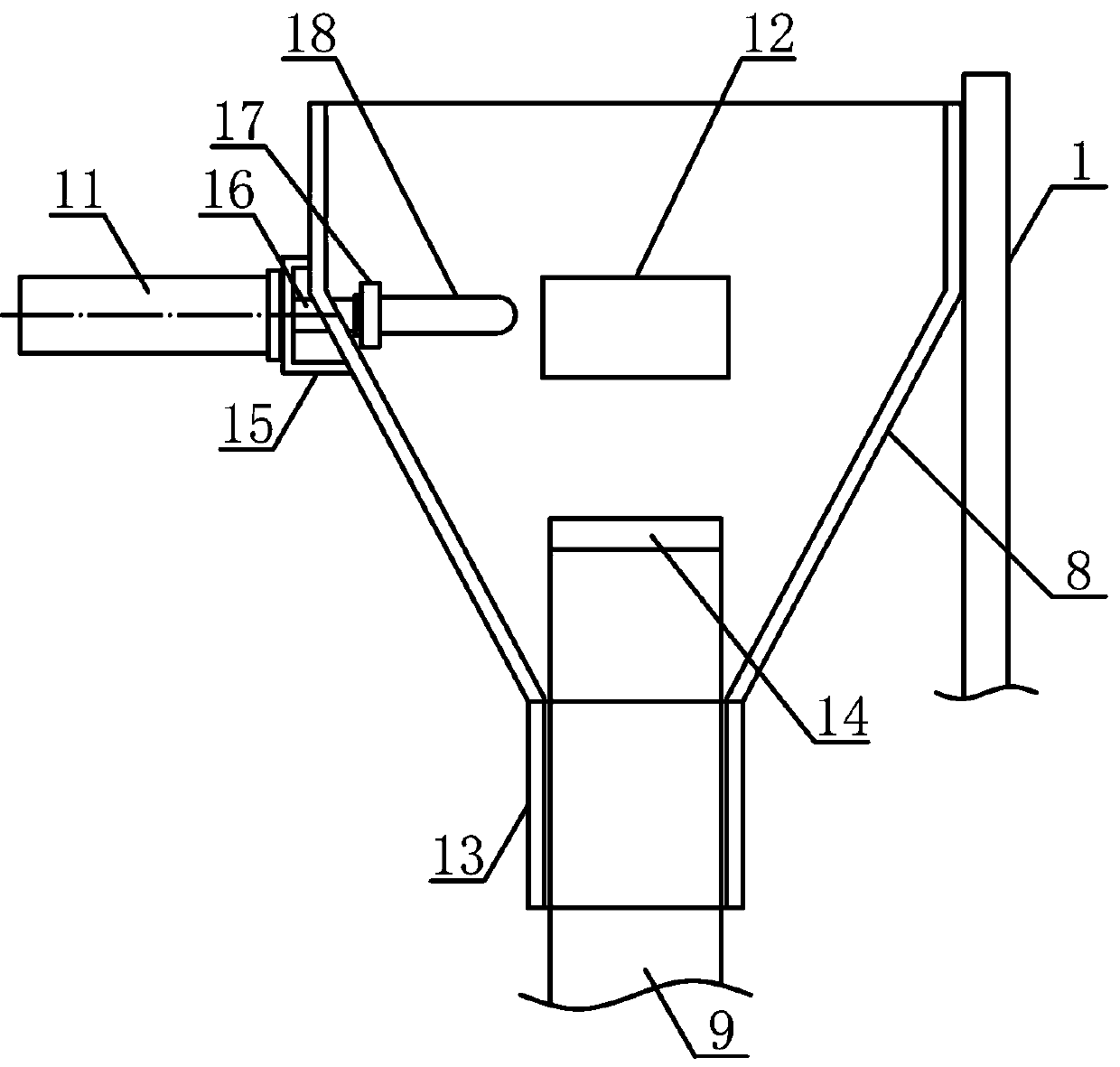

Piling machine

ActiveCN101168415AReasonable structural designLow costStacking articlesConveyor partsOutput deviceElectric control

The invention relates to a pallet machine which can automatically pallet bagged materials as bulked cement, chemical materials, rice or the like. The invention comprises a feeder, a bag rotation transmitter, a compression transmitter, a buffer transmitter, a grouped transmitter, a grouped bag pusher, a layering machine, a side face shape corrector, a vibration shape corrector, a lifter, a disc feeder, a pallet bearing outputting device, an output transmitter, a pallet disc storage transmitter, an electric control cabinet, a walk bench, and an arm rest lift. The invention has reasonable structure, low cost, and high speed, which combines a plurality of single machines, with clear and reasonable structure and simple maintenance.

Owner:HEBEI HANGUANG HEAVY IND

Negative ion generating device

ActiveCN101214390AQuality improvementLarge particle sizeDeodrantsCorona dischargeFiberHigh concentration

An anion generator includes a base and a shell assembled on the base, needle stripes of homopolar spray points vertically lined with equal spacing fixed between a partition plate and a window grating, and a control circuit. The technical proposal is that the shell consists of a rear shell and a front shell; the window grating is moveably connected with the rear shell; the homopolar tungsten alloy spray points vertically lined with equal spacing are fixed between the needle stripes and press plates through the one-off sealing and packaging technique; the carbide fibre fixed on the needle stripes is communicated with the small high voltage blocks; a closed carbide fibre ring is arranged in a circular slot on the circumference of the needle stripes; the high voltage block assembly components fixed in the shell are sealed and packaged in a shield screen; the base and the shell are hinged together by a rotary positioning device. The invention has the advantages of reasonable structure design, convenience in adjustment and positioning, good transmission direction of the anion, high concentration and small grain size of the generated anion, large output quantity within unit time and obvious improvement of the air quality, thus obviously improving the curative effect of diseases and the air purification efficiency, and obviously extending the service life.

Owner:柏学红

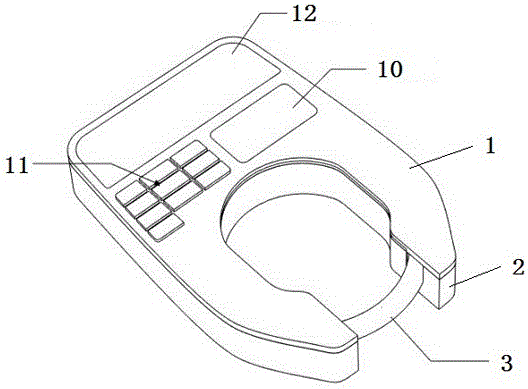

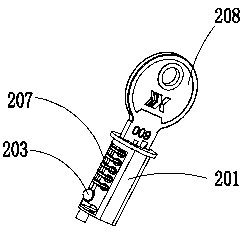

Smart coded lock and system for bicycle and operation method thereof

PendingCN106355772AReasonable structural designEasy to operateBicycle locksNon-mechanical controlsElectric bicycleElectrical and Electronics engineering

The invention relates to a smart coded lock for a bicycle and belongs to the technical field of bicycles and electric bicycles. The smart coded lock comprises a lock cylinder, a spring, a battery, a circuit board, a lock pin, a motor, a locking mechanism, a display panel, a digital keyboard, a lock upper cover and a lock lower cover, wherein the lock upper cover and the lock lower cover are matched with each other. The spring, the battery, the circuit board, the lock pin, the motor and the locking mechanism are fixed in the lock lower cover; the display panel and the digital keyboard are arranged on the lock upper cover; and the circuit board is connected with the battery, the motor, the display panel and the digital keyboard. The invention further provides a smart coded lock system used for the bicycle and convenient to use and an operation method thereof. The smart coded lock is reasonable in structure, safe and reliable, a password is variable, and whether a user has locked the bicycle can be detected when he returns the bicycle.

Owner:杭州行我行网络有限公司

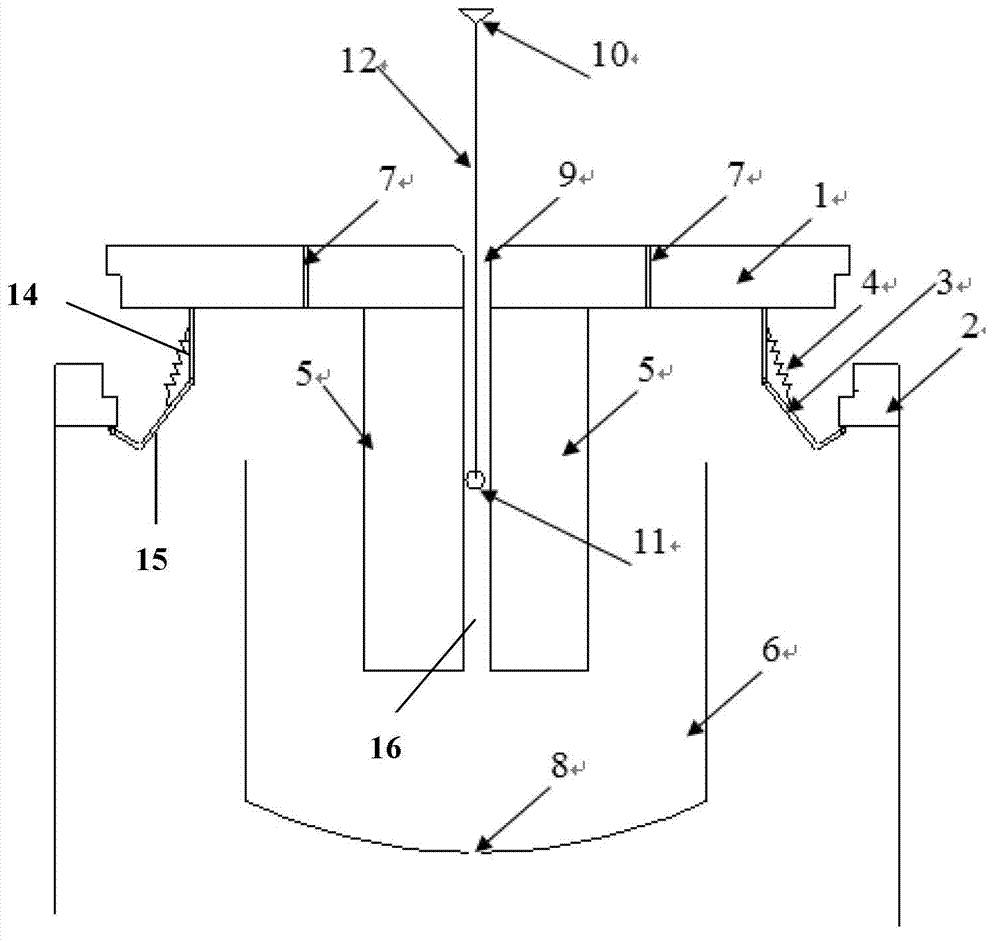

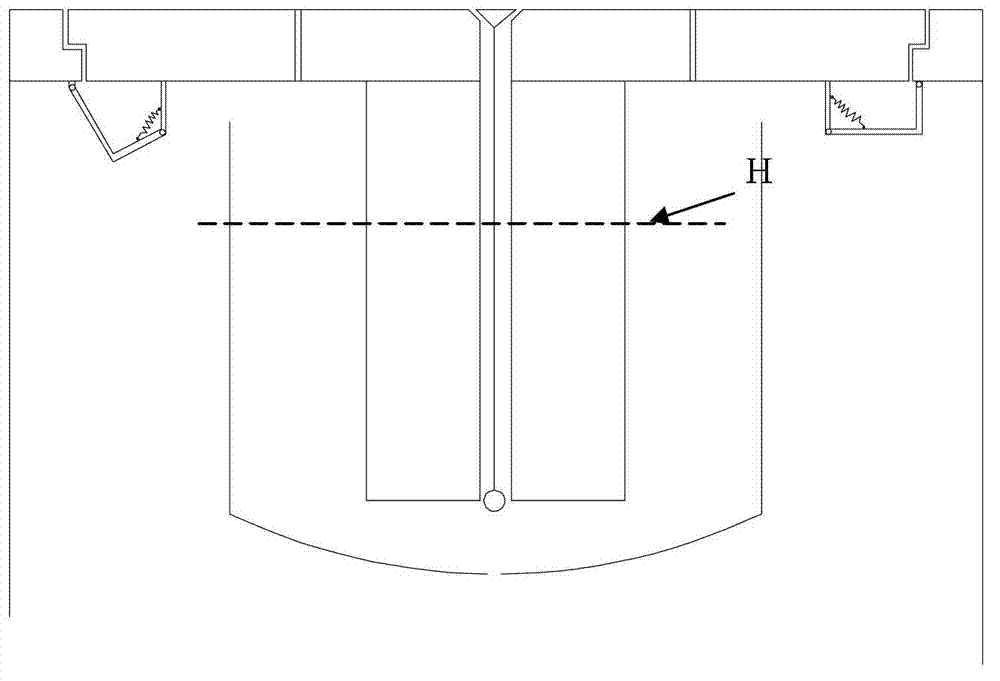

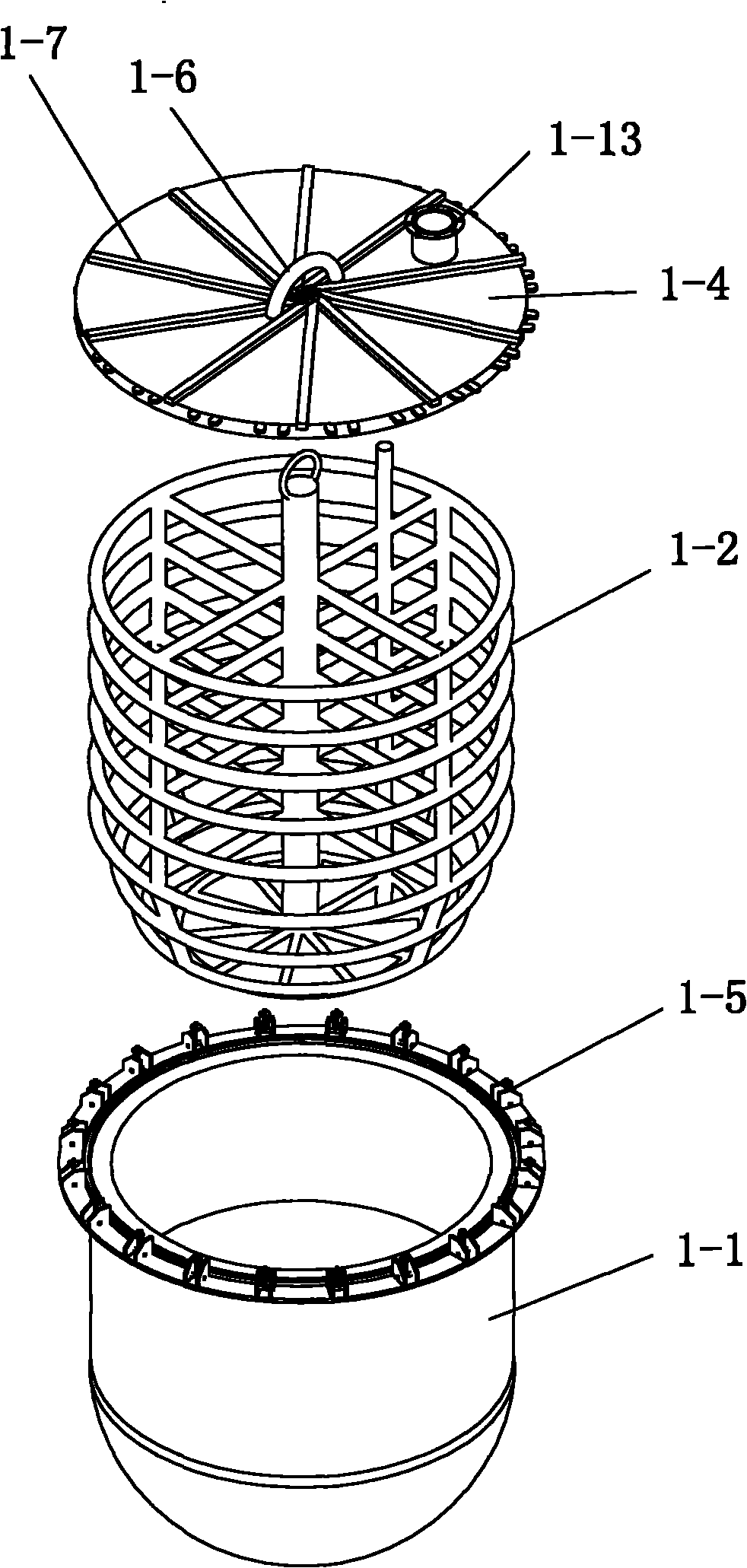

Water discharging manhole cover capable of automatically hoisting

InactiveCN102852162AVersatileReasonable structural designArtificial islandsSewerage structuresRainwater harvestingWellhead

The invention provides a water discharging manhole cover capable of automatically hoisting. The water discharging manhole cover comprises a manhole cover, a manhole cover base, two spring hinging mechanisms, a manhole cover floating cabin, a rainwater collector and an alarming device, wherein the manhole cover base is fixedly arranged on a well opening of a water discharging well; the manhole cover is placed on the manhole cover base; the two spring hinging mechanisms are connected between the manhole cover and the manhole cover base; the rainwater collector is located below the manhole cover floating cabin; and the alarming device is arranged in a central hole of the manhole cover and a manhole cover floating cabin through hole in a penetrating manner. The manhole cover of the water discharging manhole cover is made of a high-strength and light-mass material and can be automatically opened and closed by the manhole cover floating cabin according to the water depositing amount above the manhole cover, namely the water discharging manhole cover has a function of automatically and vertically hoisting, so that the discharging capability of water deposited at a road surface is enhanced. Furthermore, the manhole cover is connected with the manhole cover base through the spring hinging mechanisms so that the manhole cover is prevented from being washed away by the water; and the alarming device is used for providing alarms to pedestrians and vehicles so that the safety is good. Furthermore, the water discharging manhole cover also has the advantages of reasonable and simple structural design, complete functions, convenience for maintenance and the like.

Owner:CIVIL AVIATION UNIV OF CHINA

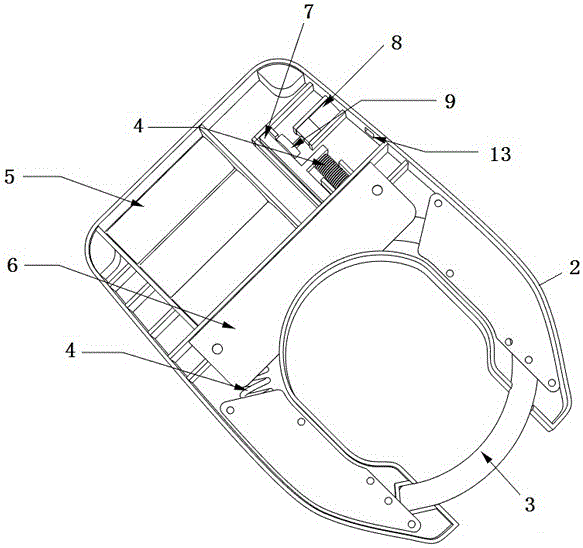

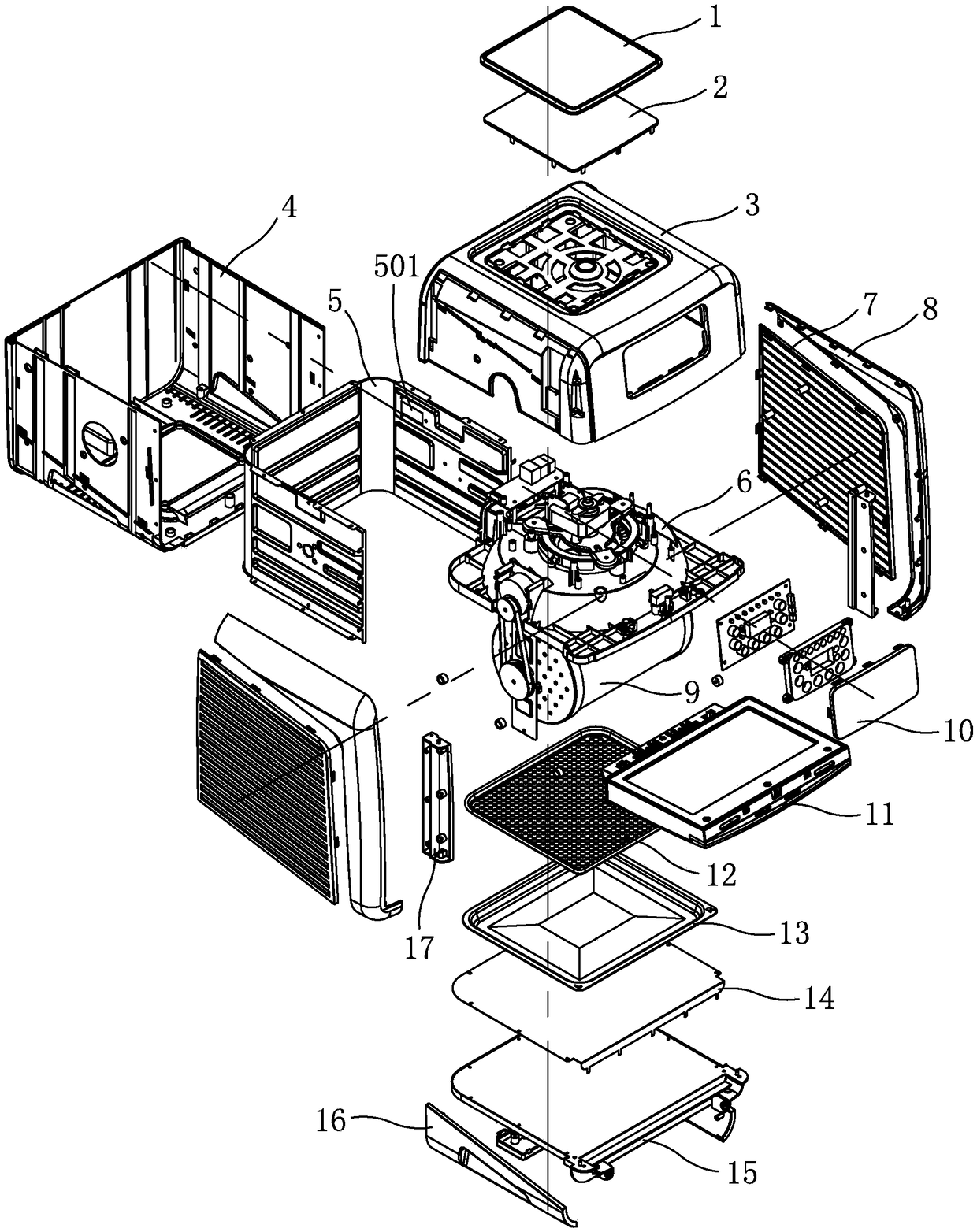

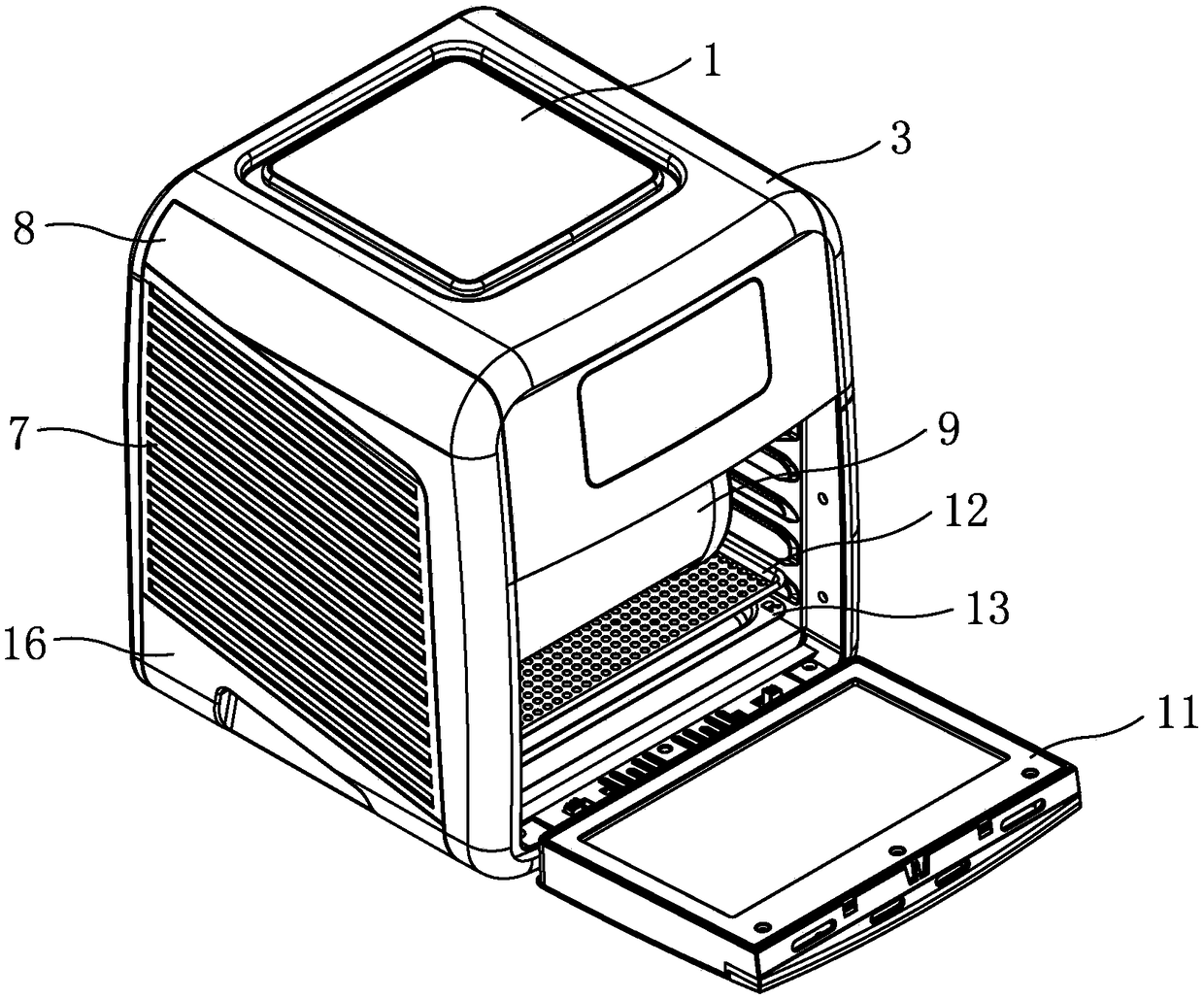

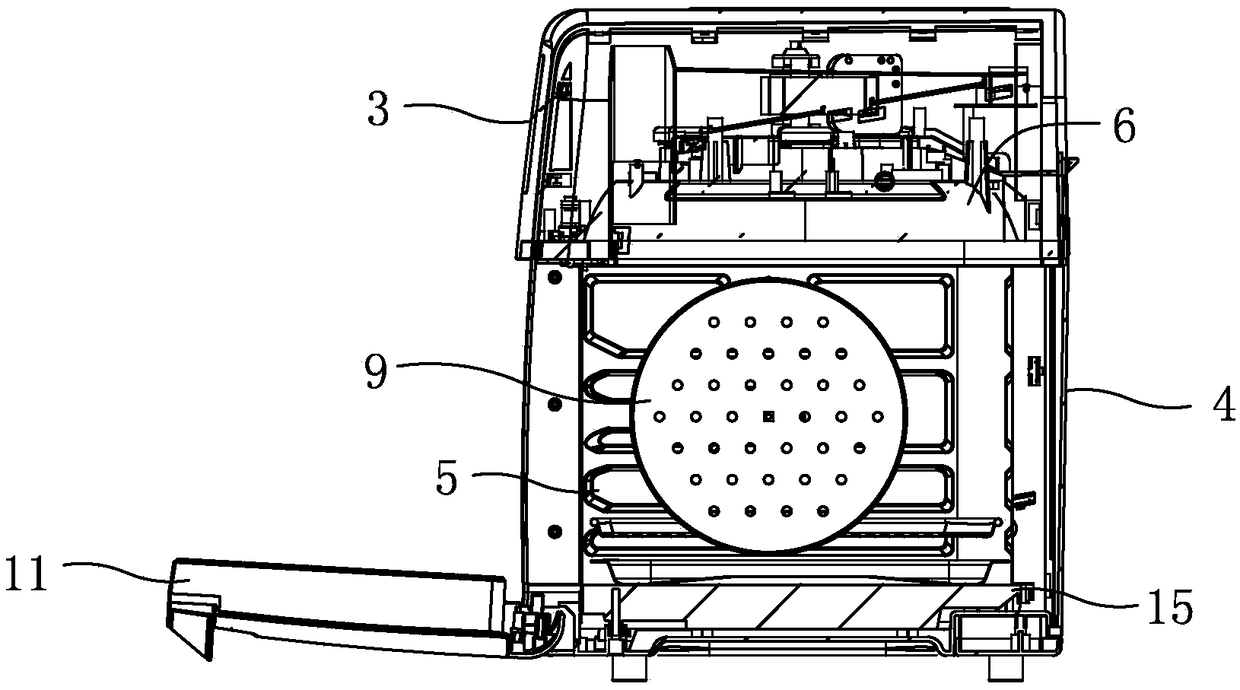

Air-fryer oven

The invention relates to an air-fryer oven, aiming at solving the technical problems in the existing congeneric products such as the poor, structural design of the rotating cage of side-door oven, theinability of using rotating cage and the oil filter net at the same time, the poor effect of cold and hot air circulation, and the convenient disassembling and cleaning of the side door. A shell dooris arranged at the opening of one side of the machine body of the oven, inner brackets are arranged on the inner walls of the three sides of the cover shell body, support frames are symmetrically arranged at the front opening of the inner brackets, a base shell and an inner bottom plate are arranged at the bottom inside the cover shell body, and a rotating cage is arranged in the machine body; The air-fryer oven is characterized in that a belt motor is arranged on the top inner cover of one side of the front opening of the cover shell body, the belt motor on one side of the top inner cover isconnected with a belt pulley on one side of the central shaft of the rotating cage through a belt, the other side of the central shaft is fixedly buckled on a first shaft block of the inner wall of the inner bracket, the center shaft of the rotating cage is arranged at the end cover at two sides of the rotating cage, the rotating cage is provided with a rotating cage door, the shell door is buckled and hinged with the base shell through a sliding buckle, the inner wall of the inner bracket is provided with a lighting lamp, and the hot air in the machine body is circulated through the shell door.

Owner:NINGBO BIYI ELECTRIC APPLIANCE

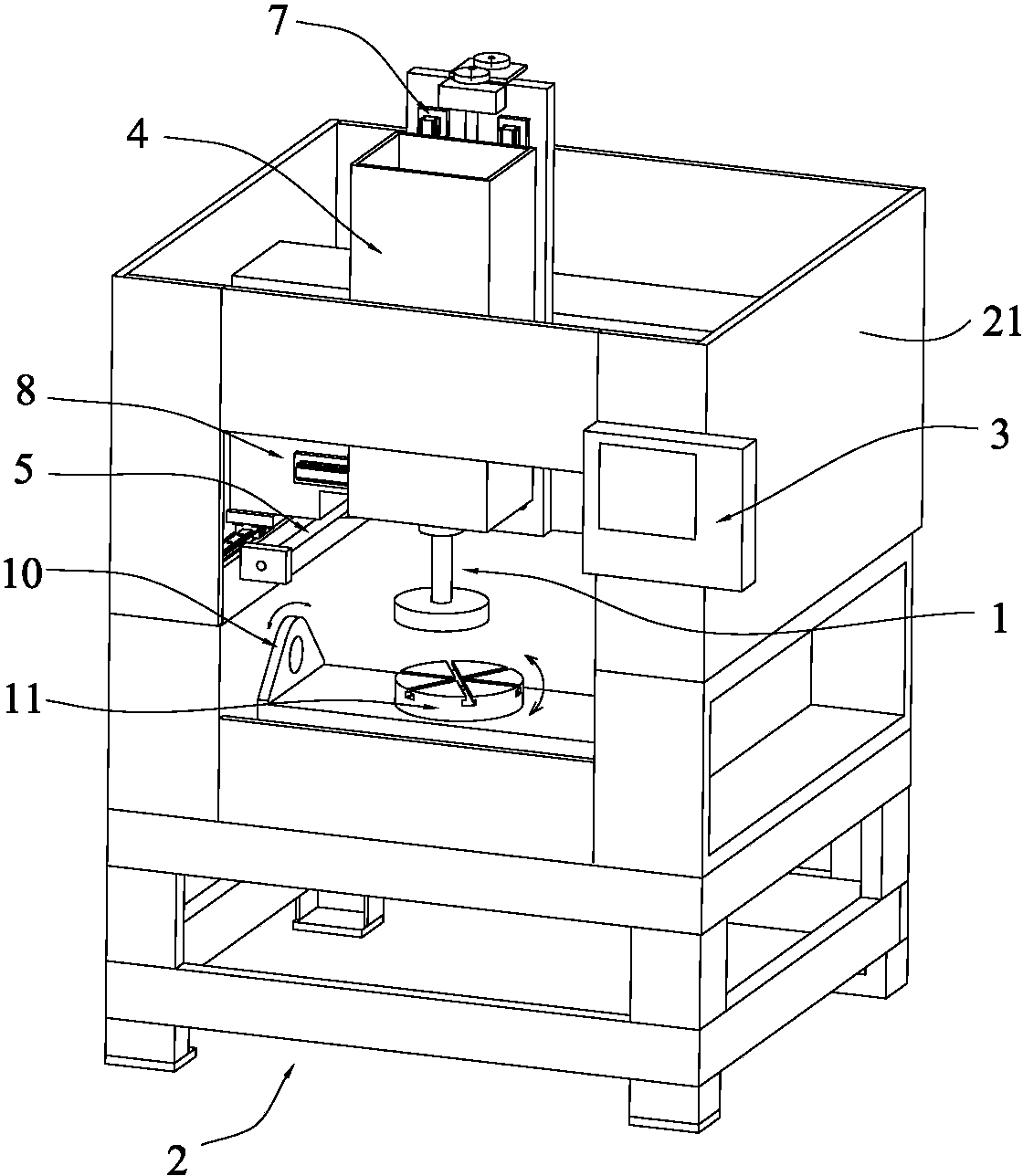

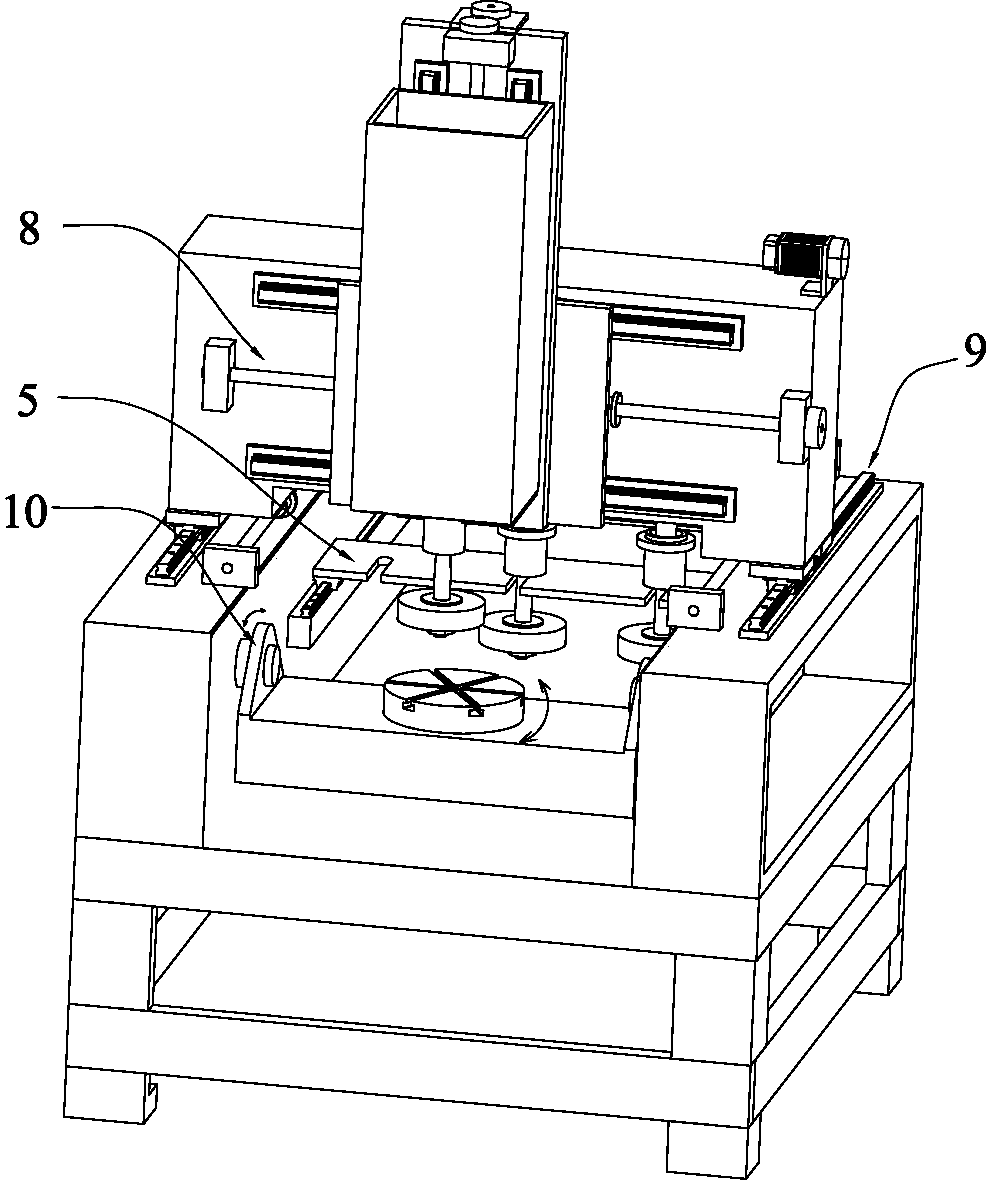

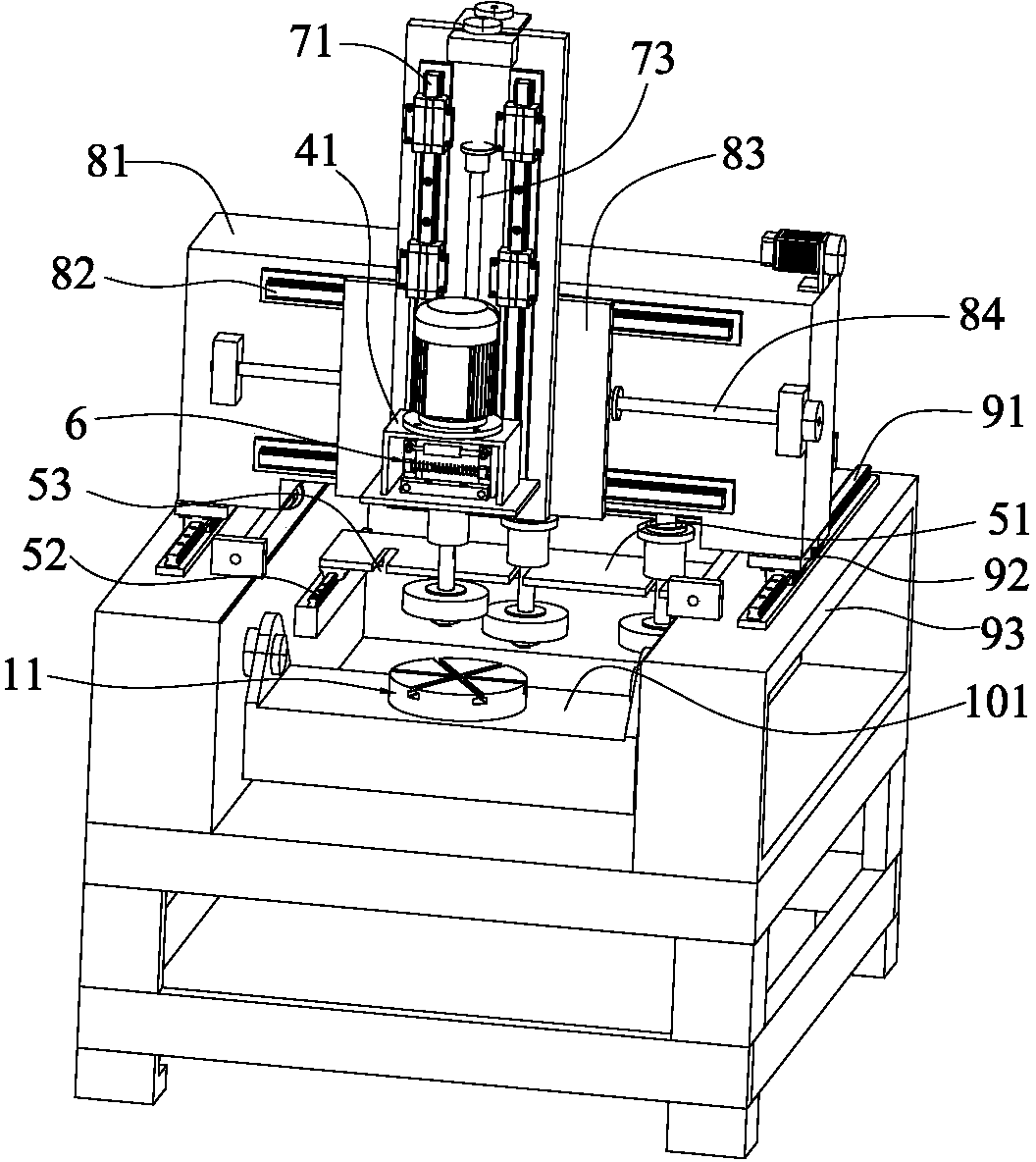

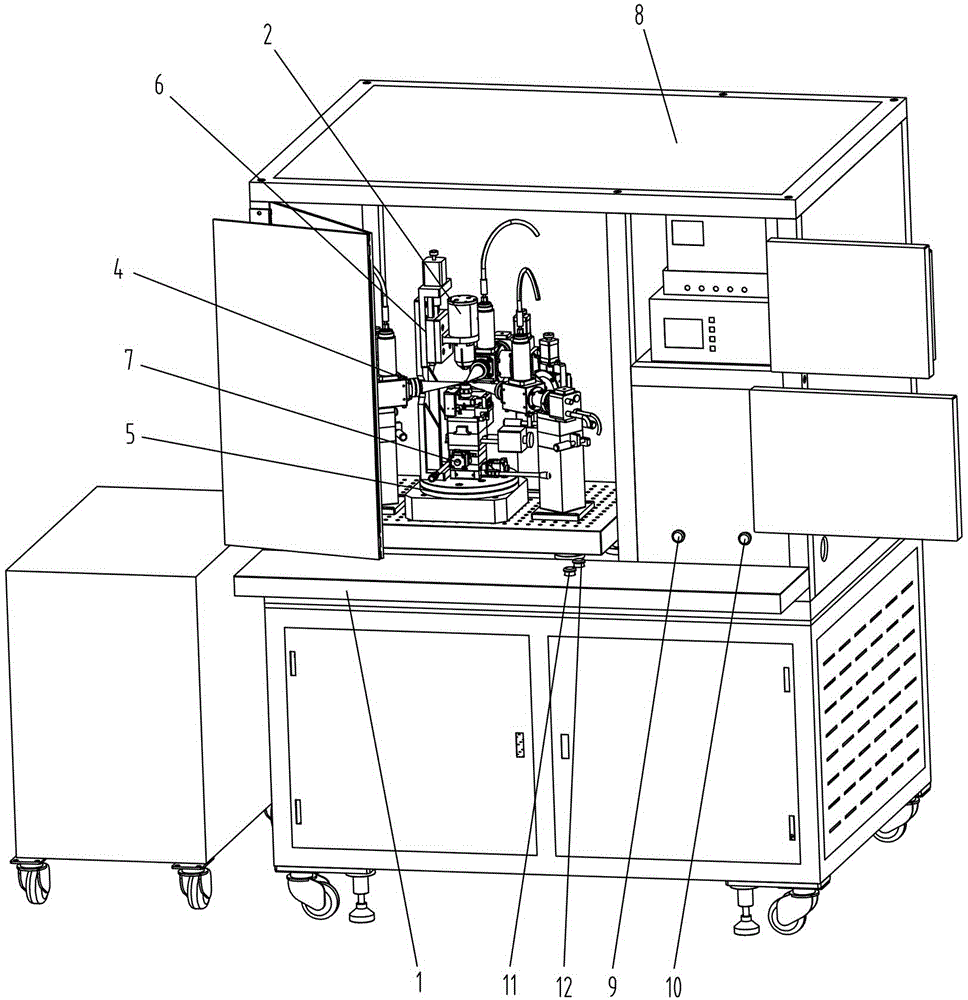

Five-axis numerical control polishing machine capable of changing grinding heads automatically

InactiveCN103465145AAutomatic replacementReduce labor intensityPolishing machinesNumerical controlCurve shape

The invention discloses a five-axis numerical control polishing machine capable of changing grinding heads automatically. The five-axis numerical control polishing machine comprises a plurality of semi-axis grinding heads, a machine body frame, a controller, a polishing head, a grinding head supply mechanism, a spindle clamping device, a Z-axis drive mechanism, an X-axis drive mechanism, a Y-axis drive mechanism, an A-axis rotary workbench and a C-axis rotating mechanism. The polishing head, the grinding head supply mechanism, the spindle clamping device, the Z-axis drive mechanism, the X-axis drive mechanism, the Y-axis drive mechanism, the A-axis rotary workbench and the C-axis rotating mechanism are respectively connected with the controlled and controlled by the same. The five-axis numerical control polishing machine capable of changing grinding heads automatically has the advantages that the polishing machine is ingenious and reasonable in structural design, high in automation level, convenient and fast to operate, high in flexibility by the five-axis linkage structure, and widely applicable; multiple polishing procedures such as rough polishing, fine polishing and mirror polishing can be completed at one-step clamping, clamping time is saved, machining efficiency and precision are increased greatly, polishing effect is guaranteed, work efficiency is increased, labor intensity of workers is lowered, enterprise competitiveness is increased effectively, and polishing of surfaces of complex curve shapes can be achieved.

Owner:东莞市钜铧机械有限公司

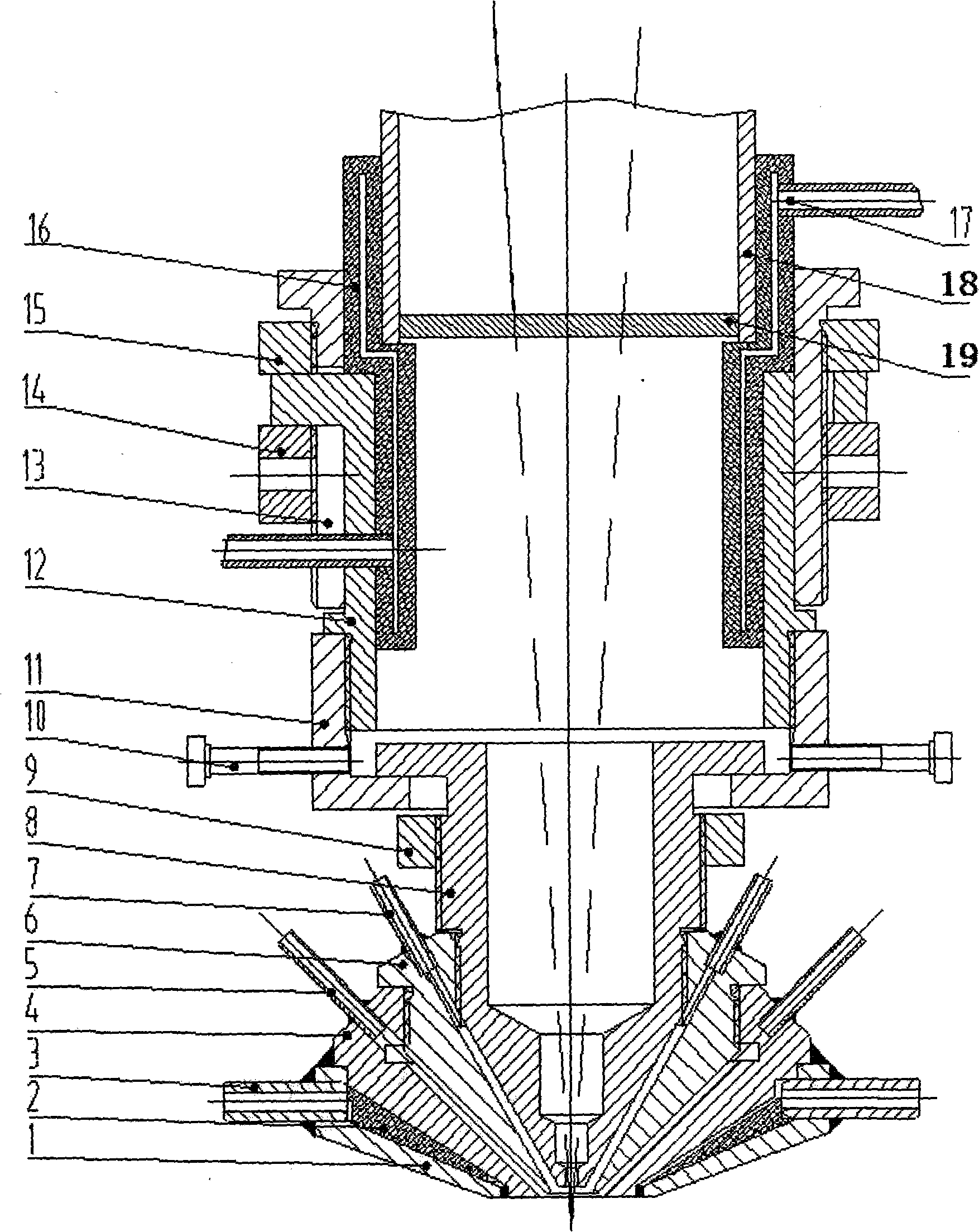

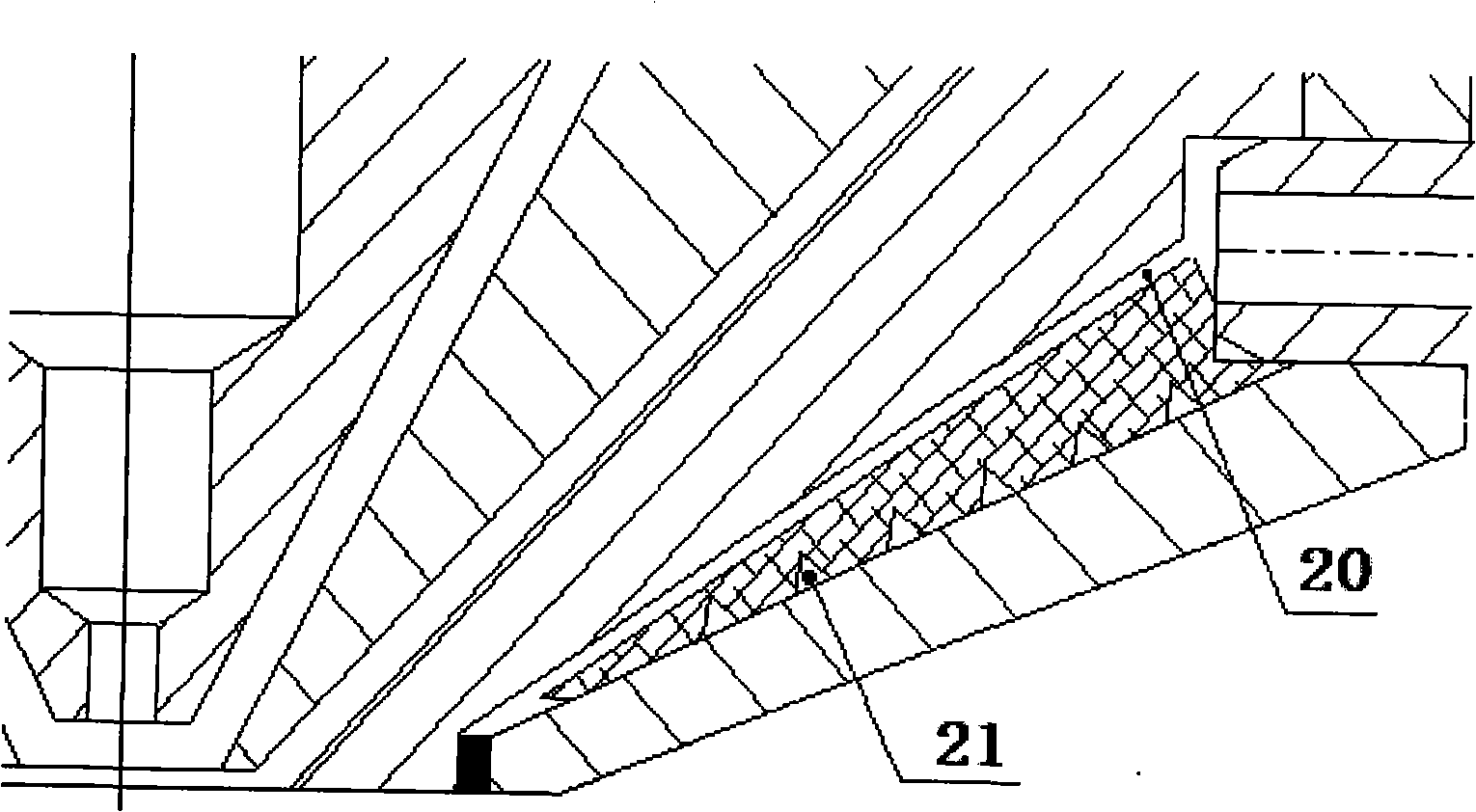

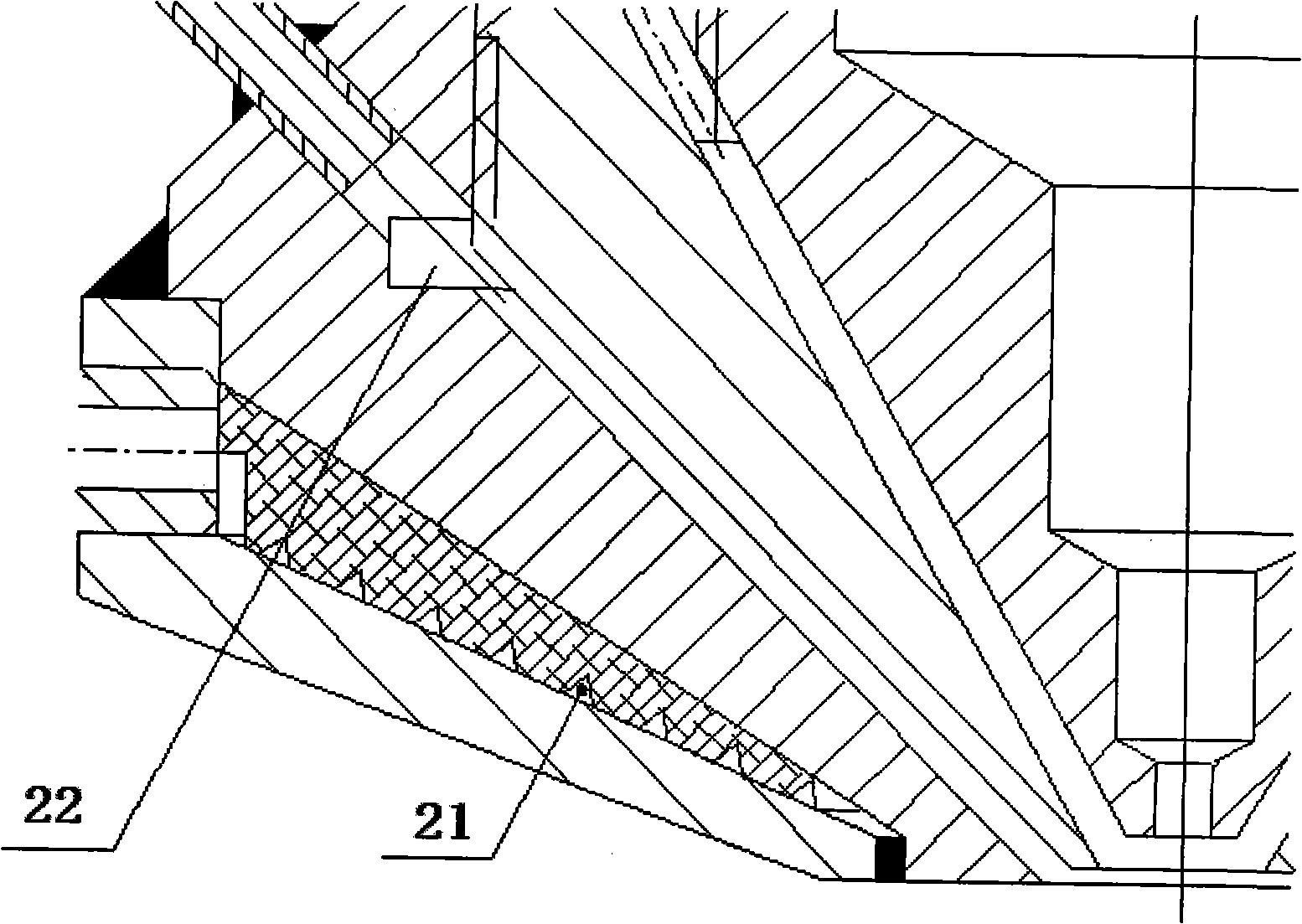

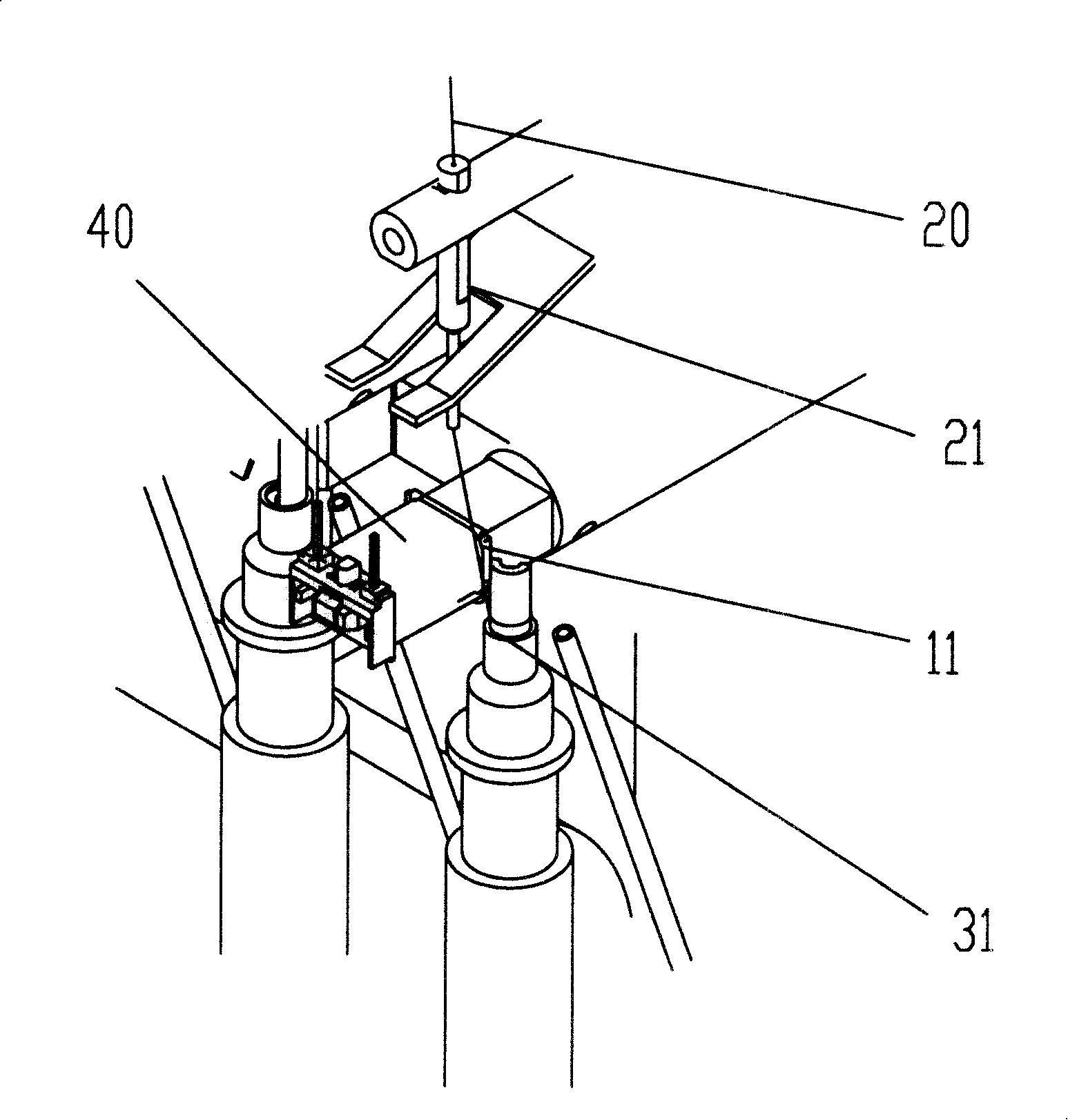

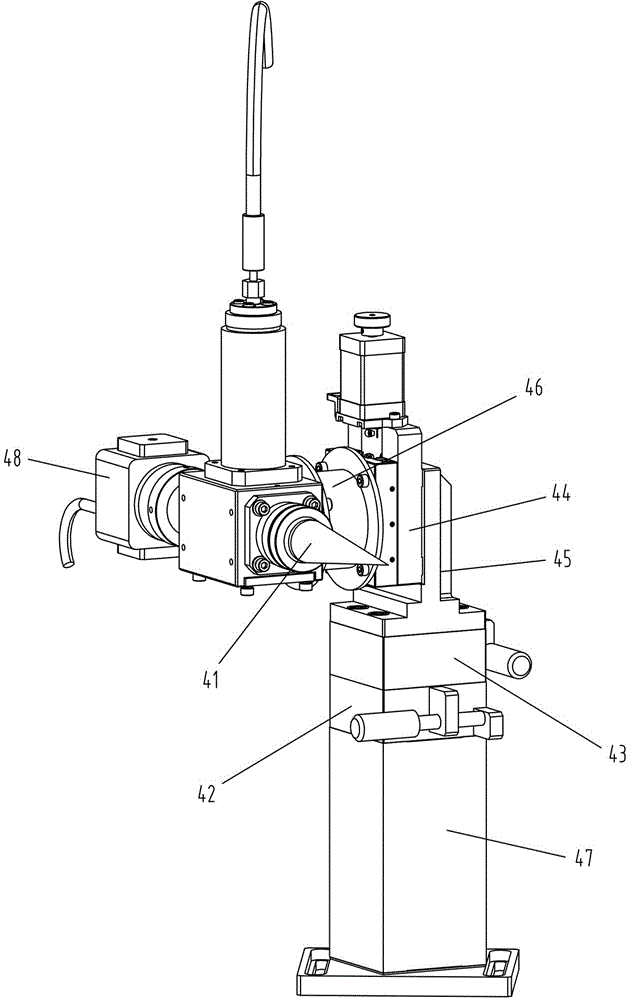

Adjustable laser coaxial powder feeding nozzle

The invention discloses an adjustable coaxial laser nozzle for sending powder, comprising a laser head, a protection lens, a water-cooling sleeve for the protection lens and a column laser cavity arranged on the upper part, a coaxial conical laser cavity which is formed by the inner layer of a laser sleeve and arranged in the middle part, wherein a powder cavity, a secondary external protective cavity and an external water-cooling cavity are arranged on the lower part of the external part of the laser sleeve; the powder cavity is formed between the laser sleeve and a power cavity sleeve screwed together; the secondary external protective cavity is formed between the powder cavity and a protective air casing screwed together; the powder cavity and the protective sir casing are screwed together and adjustable between 1mm to 3mm; 4 to 6 power transmitting pipes and 4 to 6 air tubes are respectively positioned around the top parts of the cones of the powder cavity and the protective air cavity. The adjustable coaxial laser nozzle for sending powder has the advantages that the focus length of the focus lamp fit for the coaxial powder-sending nozzle is between 100mm to 300mm, which ensures convenient assembly and disassembly, even velocity, flexible adjustment of the powder converge diameter, convenient changeable lower coaxial conical parts (the powder cavity, the air casing and the water cavity).

Owner:XI AN JIAOTONG UNIV

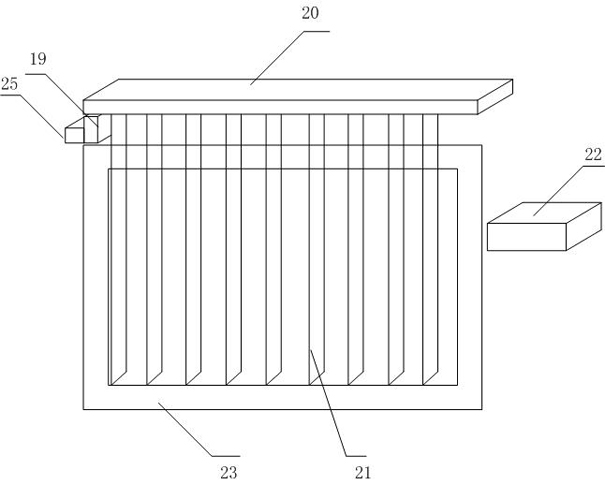

Screen printing and digital printing combined printing device and printing method thereof

ActiveCN103350561AReasonable structural designReliable performanceDuplicating/marking methodsRotary pressesDigital printingPrint-through

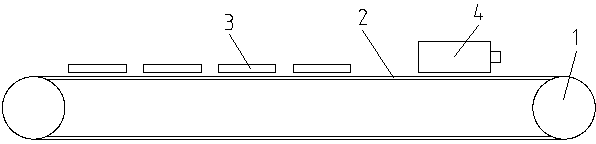

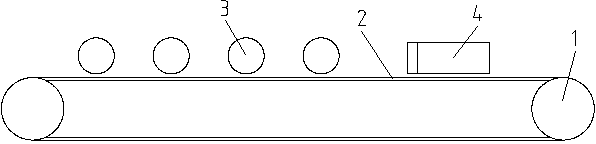

The invention relates to a screen printing and digital printing combined printing device and a printing method of the screen printing and digital printing combined printing device. At present, no printing method or printing method which is high in printing precision and printing speed exist. The printing device is characterized by comprising a machine frame, a rotating roller, a conveyer belt, a screen printing mechanism and a digital printing mechanism, the conveyer belt is installed on the rotating roller, the screen printing mechanism is installed on the machine frame, the digital printing mechanism is installed on the machine frame, and the screen printing mechanism is matched with the digital printing mechanism. The printing method is characterized in that shell fabric is driven to move through the conveyer belt, the shell fabric is printed through the screen printing mechanism and the digital printing mechanism, and if patterns needing to be printed on the shell fabric include large pieces of patterns, the patterns are printed through the screen printing mechanism; if the patterns needing to be printed on the shell fabric include high-precision patterns, the patterns are printed through the digital printing mechanism. The printing device and the printing method are reasonable in structural design, reliable in performance, high in printing precision and high in printing speed.

Owner:HANGZHOU HONGHUA DIGITAL TECH

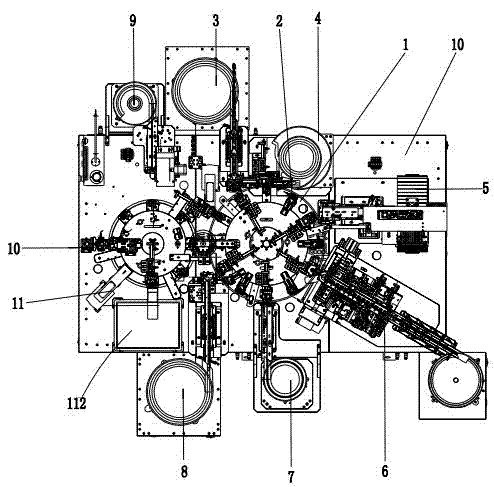

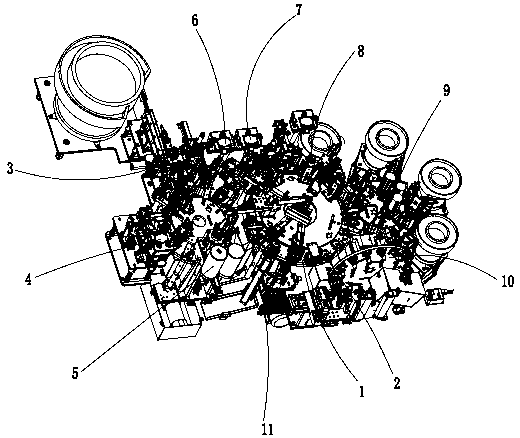

Automated assembly device of light-emitting diode (LED) finger lamps

InactiveCN103111842AReasonable structural designReduce labor intensityAssembly machinesMetal working apparatusLight detectionEngineering

The invention relates to an automated assembly device of light-emitting diode (LED) finger lamps. The automated assembly device of LED finger lamps comprises a machine frame and a workbench disposed on the machine frame. A big rotary disk is disposed on the workbench. A clamp for placing a bottom cover is arranged on the big rotary disk. An upper bottom cover assembly, an upper slice assembly, an upper battery assembly, an upper LED lamp assembly, an upper switch assembly, an upper top cover assembly, an upper top ring assembly, a lighting detection assembly and a blanking assembly are arranged on the periphery of the big rotary disk. The assemblies are respectively connected with a master control circuit and controlled by the master control circuit. The automated assembly device of LED finger lamps is reasonable in structural design. Automatic feed, detection, assembly and blanking of the assemblies of finger lamps are electrically controlled, production efficiency and product quality are improved, labor intensity of workers is greatly lowered, production cost is reduced, the automated assembly device of LED finger lamp is especially suitable for mass production of key cylinders, and market competitiveness of enterprises can be enhanced.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

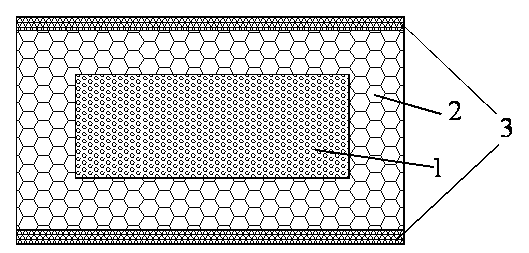

Building wall insulation composite board and preparation method thereof

ActiveCN103104046AReasonable structural designImprove fire performanceClimate change adaptationPolyureas/polyurethane adhesivesBuilding energyThermal insulation

The invention relates to a building wall insulation composite board and a preparation method of the building wall insulation composite board, and belongs to the technical field of building energy-saving insulation materials and preparation methods. A wall insulation hard foam polyurethane composite board comprises inner cores, protective layers coated on the peripheries of the inner cores and interface layers coated on the upper surfaces and the lower surfaces of the protective layers in an attached mode. The inner cores are vacuum insulation boards. The preparation method of the wall insulation hard foam polyurethane composite board comprises preparation of interface coiled materials: coating prepared flame-retarded polymer mucilage on base materials to produce the interface coiled materials, and manufacturing of the protective layers and the wall insulation hard foam polyurethane composite board. The insulation composite board has good thermal insulation performance, waterproof performance and heat insulation performance, can satisfy 65% requirements of building energy efficiency very well, is high in bonding strength and convenient to construct and operate, greatly increases overall fireproof performance of the whole wall heat-insulation system after being arranged on a wall, and can be widely applied to the inner portions of walls, outer walls, and roof covering thermal insulation systems, heat insulation systems and waterproof systems.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

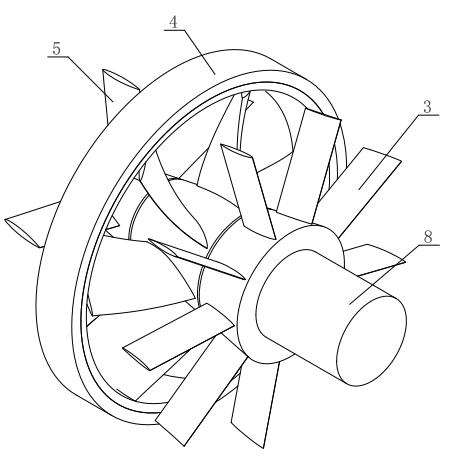

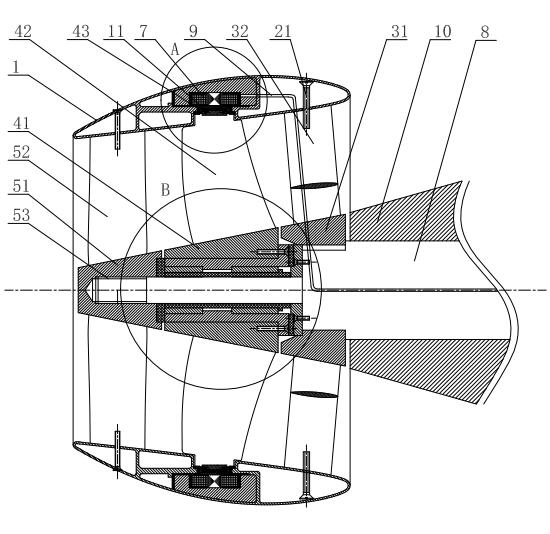

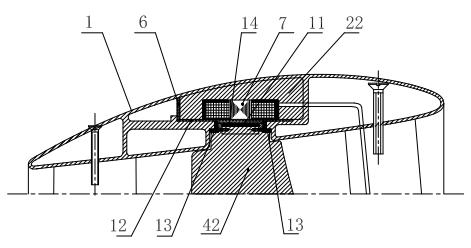

Shaftless driven type integrated motor propeller

InactiveCN102632982ALarge diameterIncrease output torqueRotary propellersPropulsive transmission driveCavitationPropeller

The invention discloses a shaftless driven type integrated motor propeller which is arranged on the tail part of a boat body of a water vehicle or underwater vehicle and comprises a front stator, a rotor propeller and a rear stator which are serially arranged on a solid non-rotating shaft, wherein the periphery of the propeller is connected with the circumferential rim of the annular propeller, a rotor permanent magnet is embedded in the circumferential rim of the propeller, a stator winding is arranged in the inner cavity of a guide pipe, the rotor permanent magnet and the stator winding are sealed by adopting water, and a gap is arranged between the rotor permanent magnet and the stator winding to form an annular motor. The rotor permanent magnet and the stator winding as well as the guide pipe are organically combined to form a modular unit, thus the shaftless driven type integrated motor propeller can be easily installed on a water platform or underwater platform, is suitable for large-power main propelling of a water boat or underwater submergible device, and has the advantages of reasonable structure, high propelling efficiency, low hydrodynamic force radiation noise, excellent cavitation property, safety and reliability.

Owner:中国船舶重工集团公司第七〇二研究所

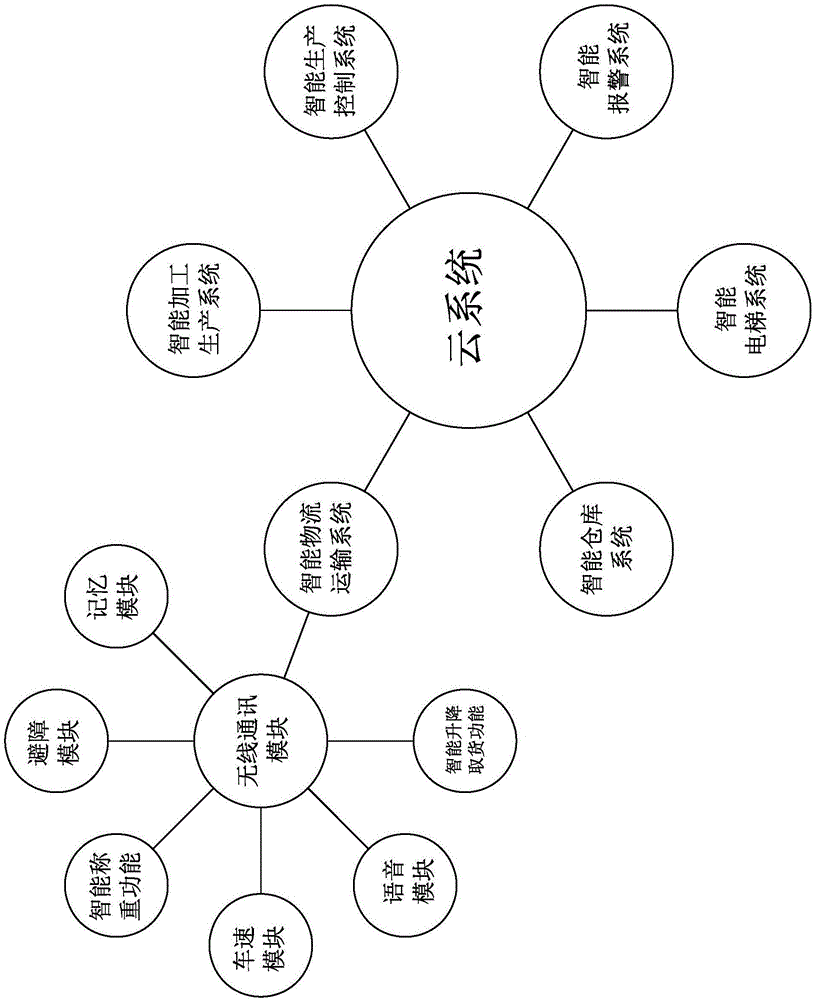

Factory intelligent workshop real-time scheduling system

ActiveCN106056298AIntelligent Management ScienceManagement scienceResourcesProduction control systemStorage garage

The invention relates to a factory intelligent workshop real-time scheduling system, and is designed to solve the technical problem that a management system of an existing factory intelligent workshop needs further improvement. The system is mainly characterized in that an intelligent processing production line of the scheduling system finishes research and purchase as well as installation and debugging of workshop machining equipment; an intelligent warehouse and logistics transportation system carries out scientific classification, storage and transportation on raw materials and substances, management of finished and semi-finished products, and analysis and management on storage data of the raw materials, the semi-finished products and the finished products; an intelligent production control system, by fully utilizing information technology, carries out control in multiple dimensions of production plan issuing, material delivery, production scheduling, completion confirmation, standard operation guidance, quality control and finished product bar code acquisition, and accurately conveys on-site information to a production manager and a decision maker in real time through a network; and an intelligent alarm system is used for monitoring environment and temperature and reminding a transfer robot to return, avoid obstacles and charge.

Owner:宁波赛夫科技有限公司

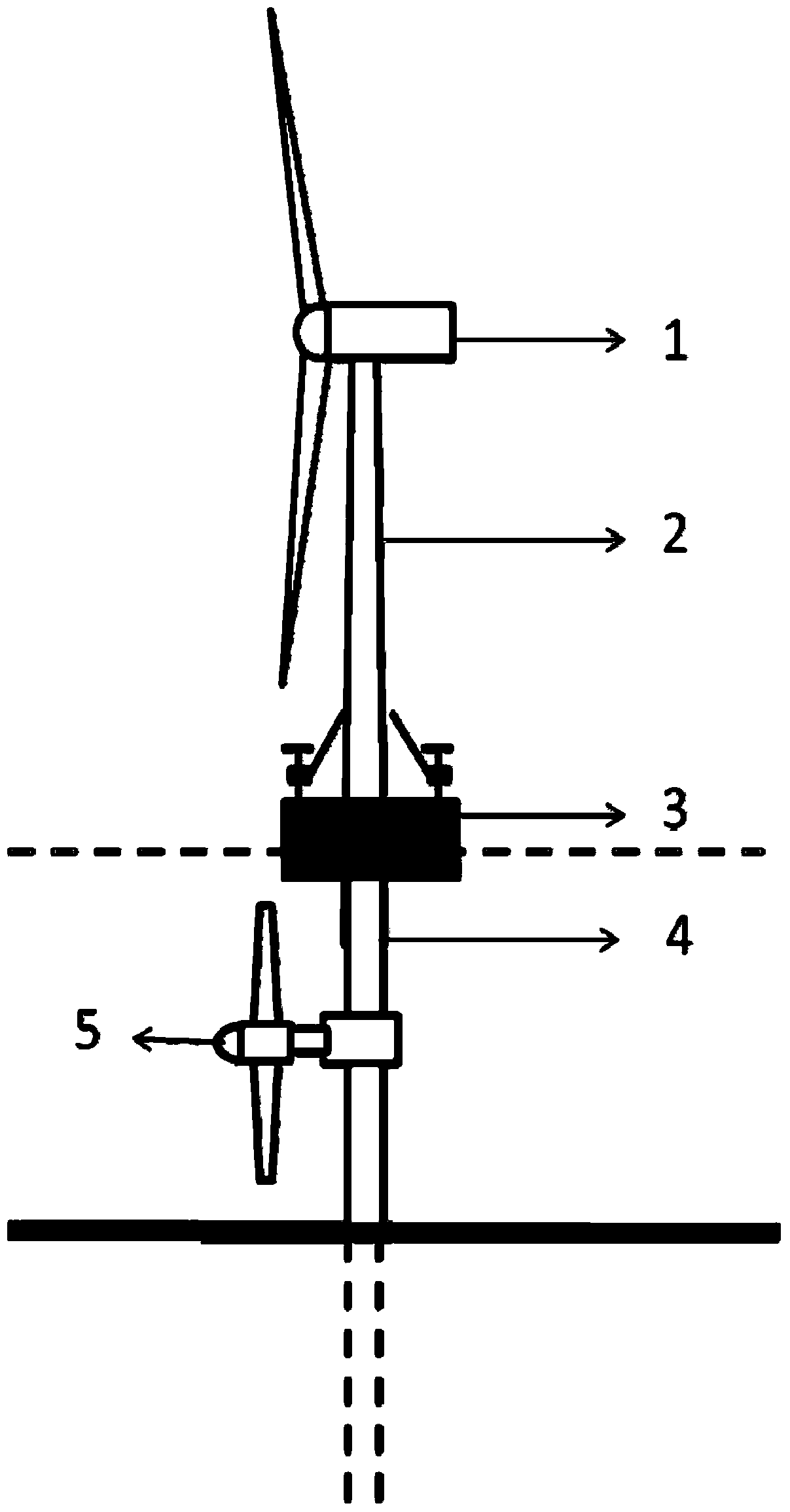

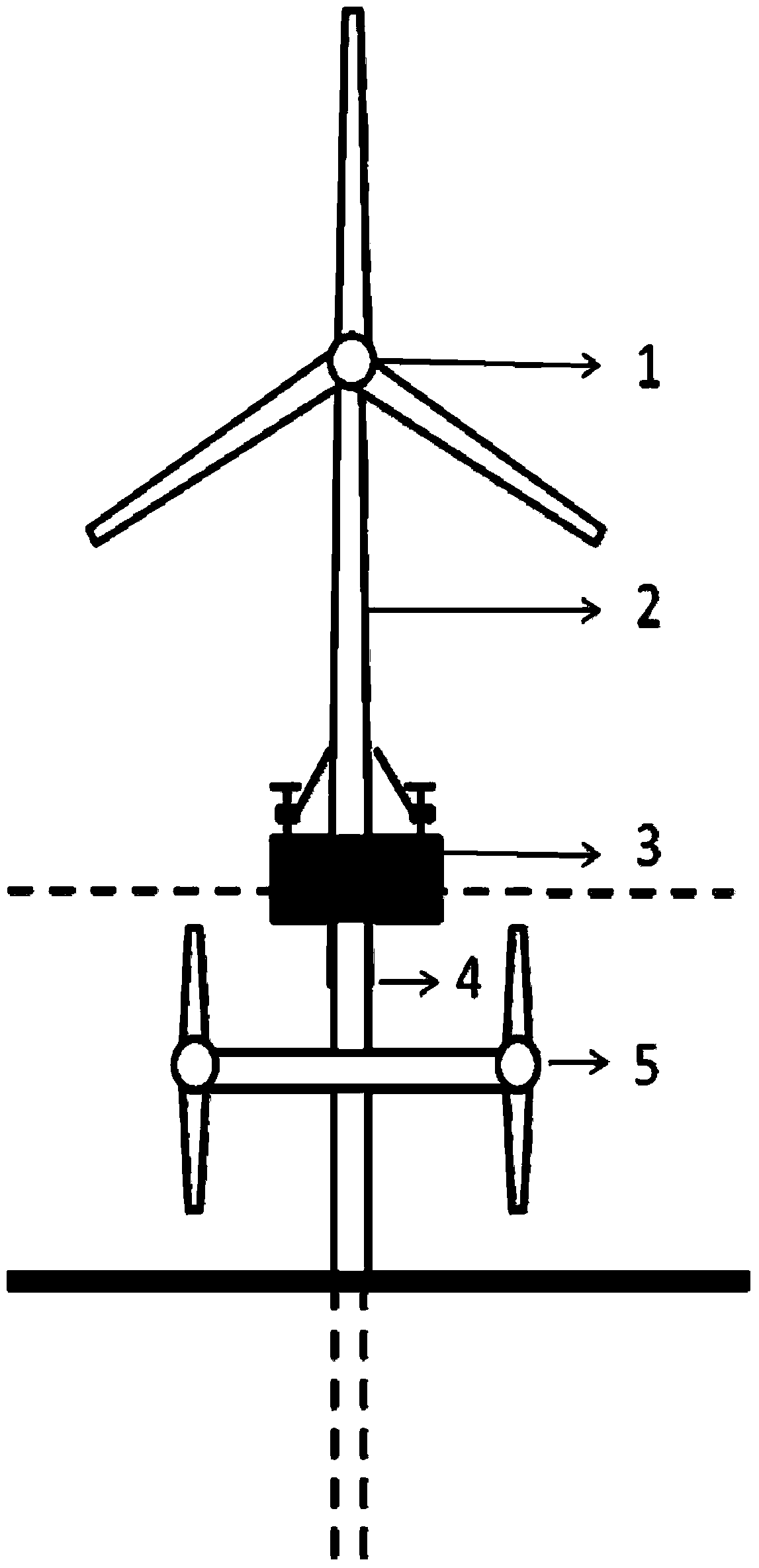

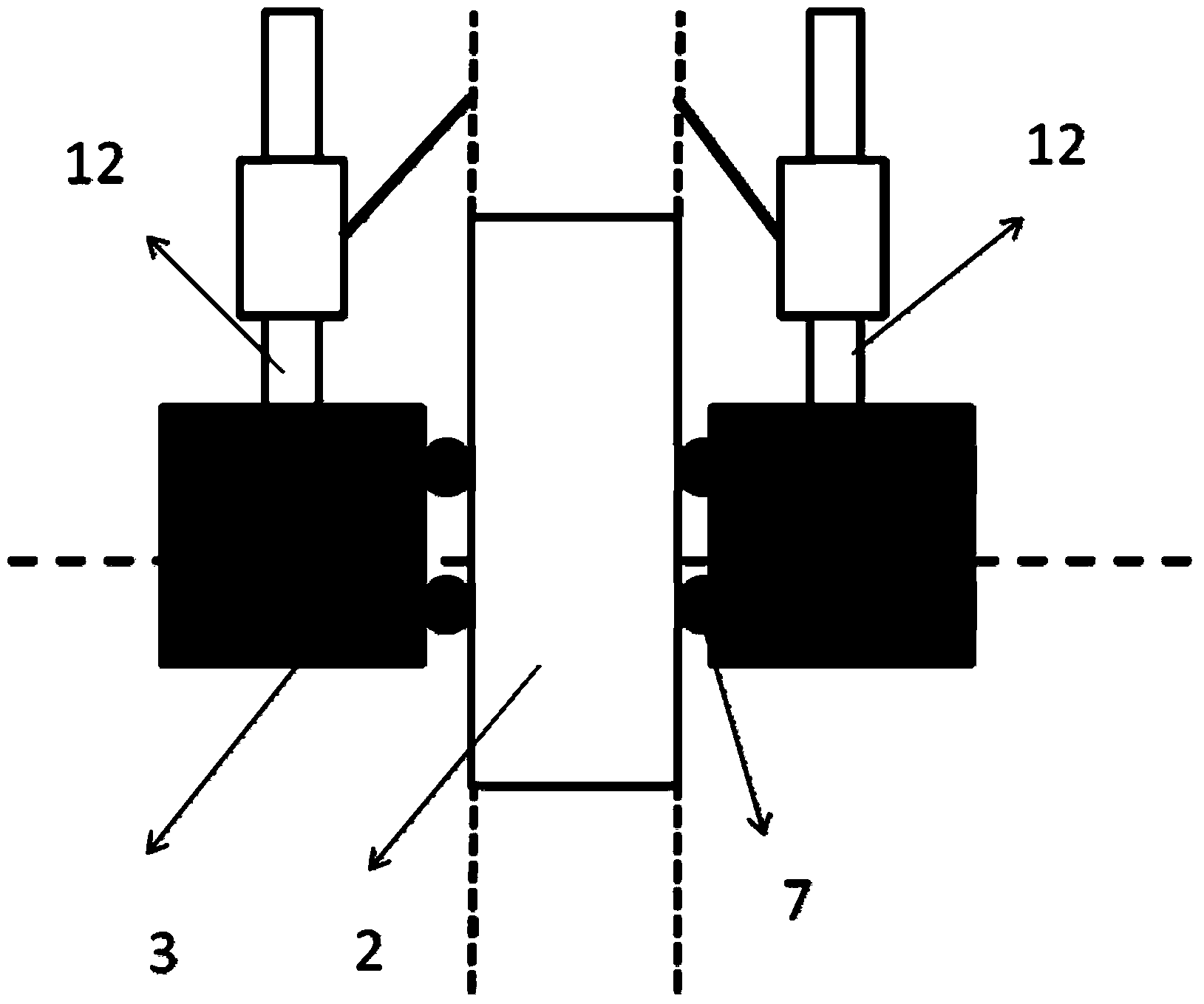

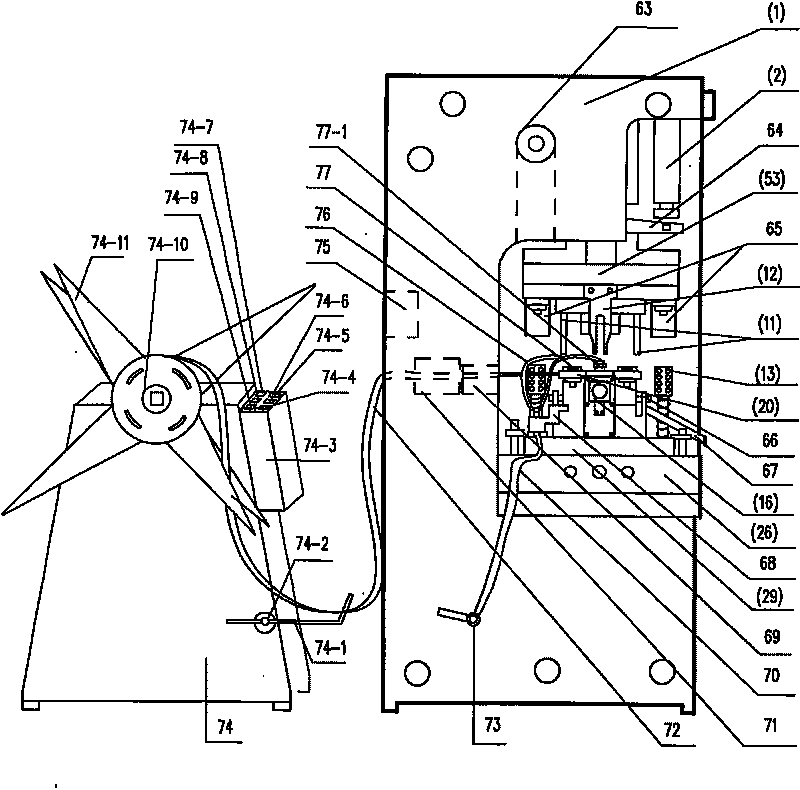

Wind energy-wave energy-tidal current energy integrated power generation structure based on single pile platform

InactiveCN103967714AEasy structure constructionReduce construction costsWind motor combinationsMachines/enginesElectric power transmissionWinding machine

A wind energy-wave energy-tidal current energy integrated power generation structure based on a single pile platform comprises a single pile platform wind power generation structure, a wave energy power generation device and a tidal current energy power generation device, the single pile platform wind power generation structure comprises a wind machine, a tower frame structure, a single pile supporting structure and a matched power transmission system, the wave energy power generation device is arranged on the water surface of the tower frame structure, and the tidal current energy power generation device is arranged on an underwater single pile supporting structure. The wind energy-wave energy-tidal current energy integrated power generation structure has the advantages that the single pile platform structure is convenient to construct, low in construction cost and wide in application range, the wind power generation structure, the wave energy power generation device and the tidal current energy power generation device share the single pile supporting structure and the power transmission system, the unit power generation cost can be effectively reduced, the structural design is reasonable and stable, the construction scheme is mature in technology, existing commercial products can be selected by a wind power generator and a tidal current power generator, modeling is simple and convenient to achieve, and performance optimizing design can be performed on a wave energy power generator by combining wave statistical features of a site selecting place.

Owner:DALIAN UNIV OF TECH

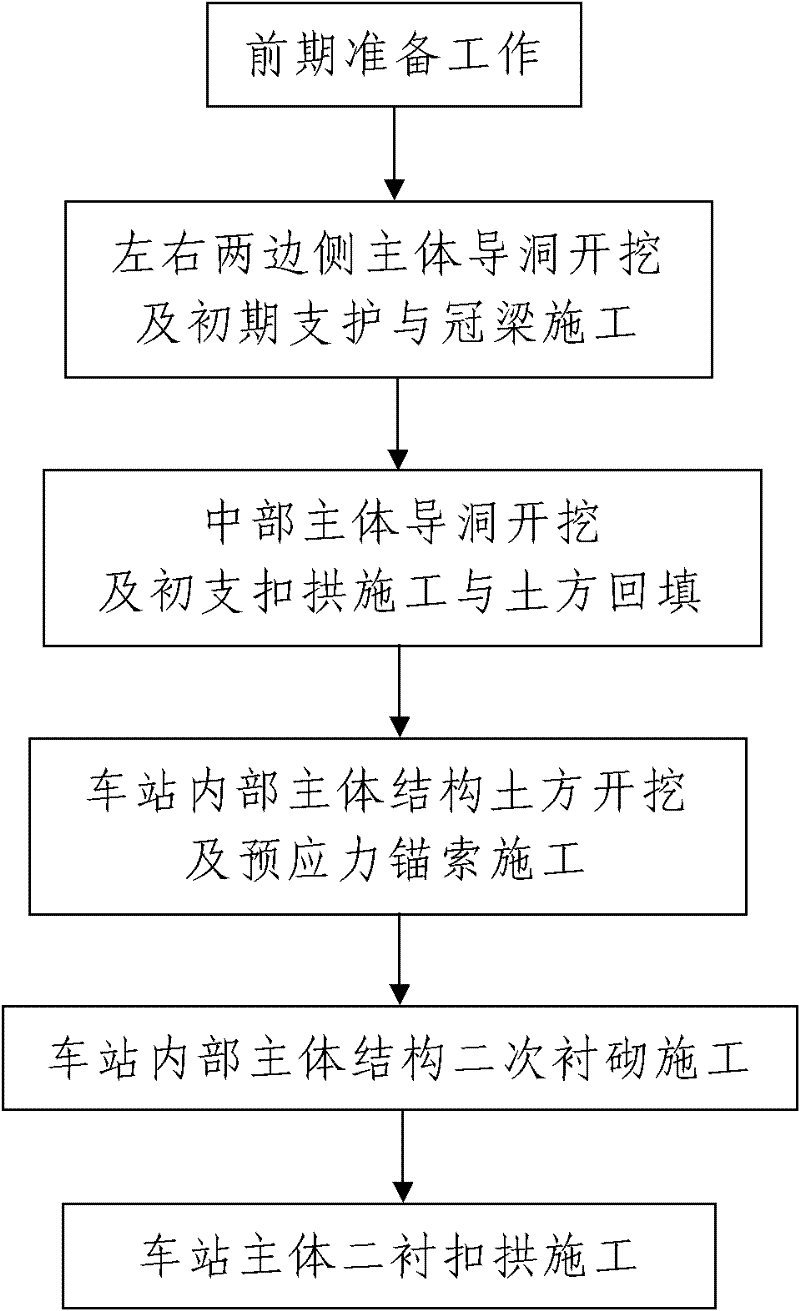

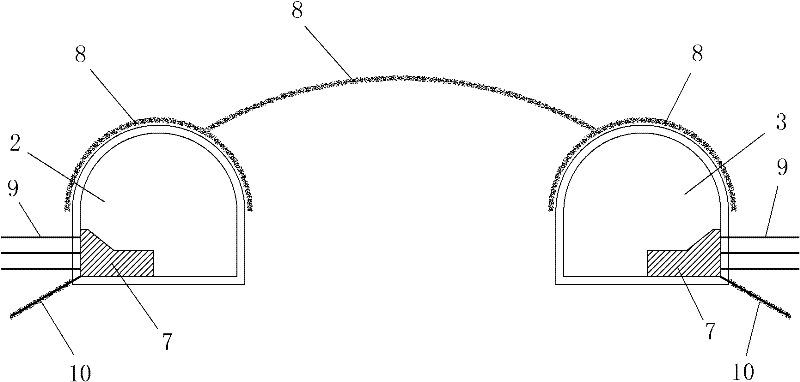

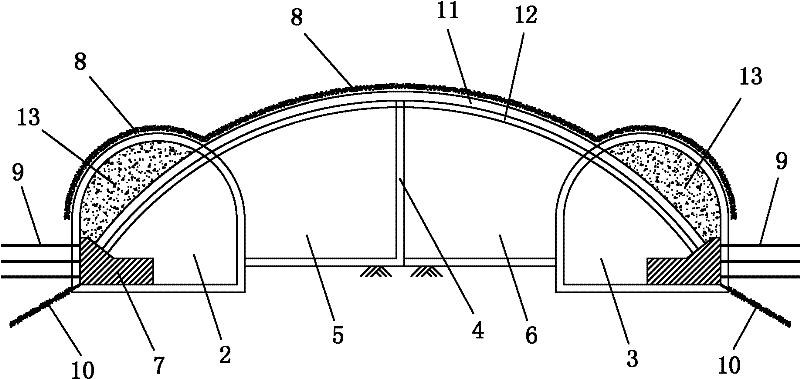

Construction method of large-span subway station main body by using arched cover method and station main body structure

ActiveCN102226403ASimplify construction stepsEasy constructionUnderground chambersSupporting systemArchitectural engineering

The invention discloses a construction method of a large-span subway station main body by using an arched cover method and a station main body structure. The construction method comprises the following steps: 1. making first-phase preparations; 2. excavating main body pilot tunnels at the left side and the right side, and carrying out primary support and top beam construction; 3. excavating a middle-part main body pilot tunnel, carrying out primary support and arch buckling construction, and refilling the earthwork; 4. carrying out earthwork excavation on a main body structure in the station, and prestressing force anchor cable construction; 5. carrying out secondary lining construction on the main body structure in the station; and 6. carrying out secondary lining and arch buckling construction on the station main body. The station main body structure comprises the main body structure in the station, a central post, a central plate and a main body arch part, wherein, the main body arch part comprises a middle arch fragment and two side arch fragments respectively arranged in the two side main body pilot tunnels formed by excavation in advance; and the main body arch part comprises a primary support system and a station main body arch buckling secondary lining structure from the outside to the inside. The station main body structure provided by the invention has reasonable design, simple construction steps, convenience in realization, small construction difficulty and rapid construction speed; the subway station formed by the construction method has a stable structure and a good use effect.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

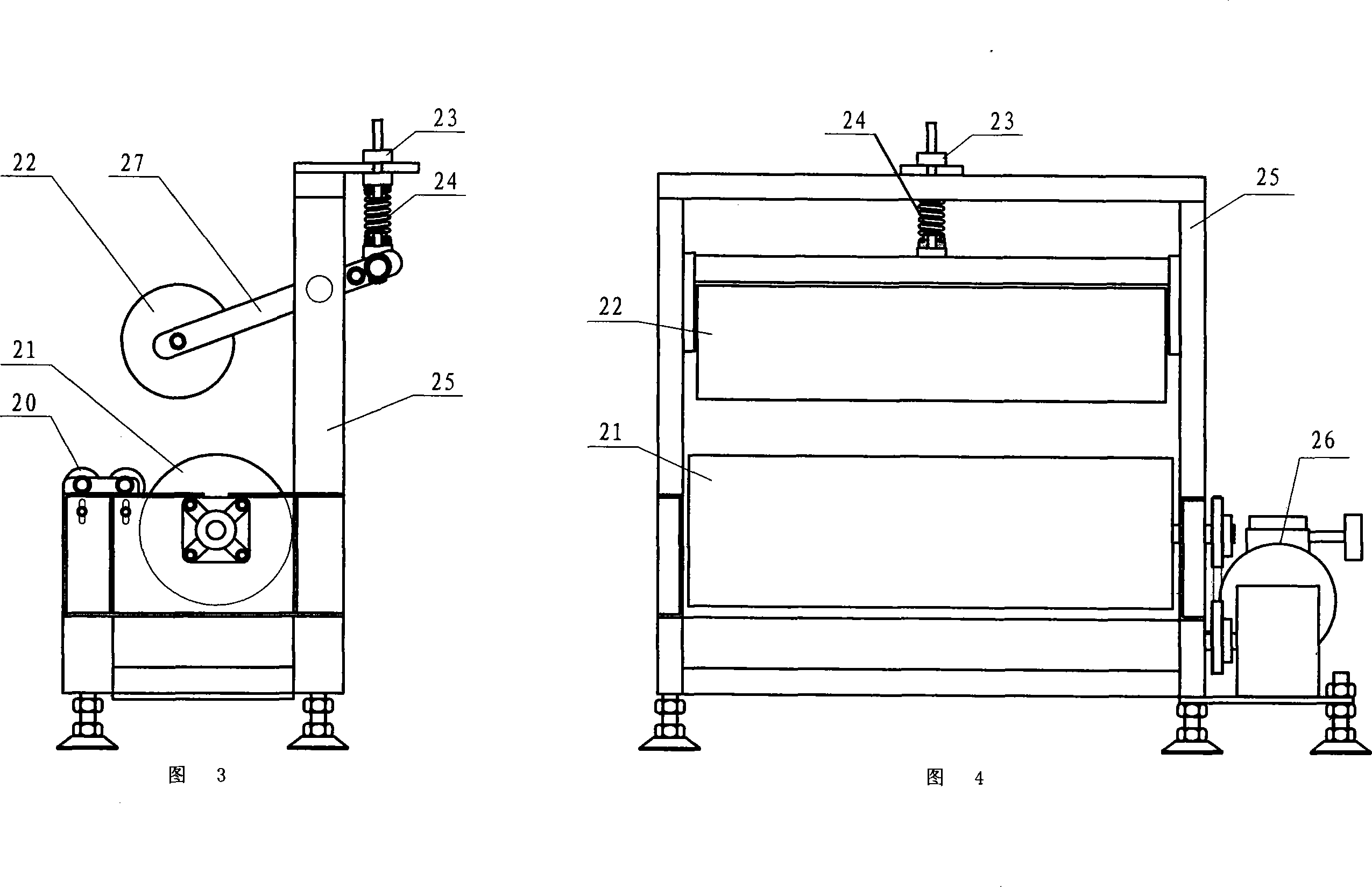

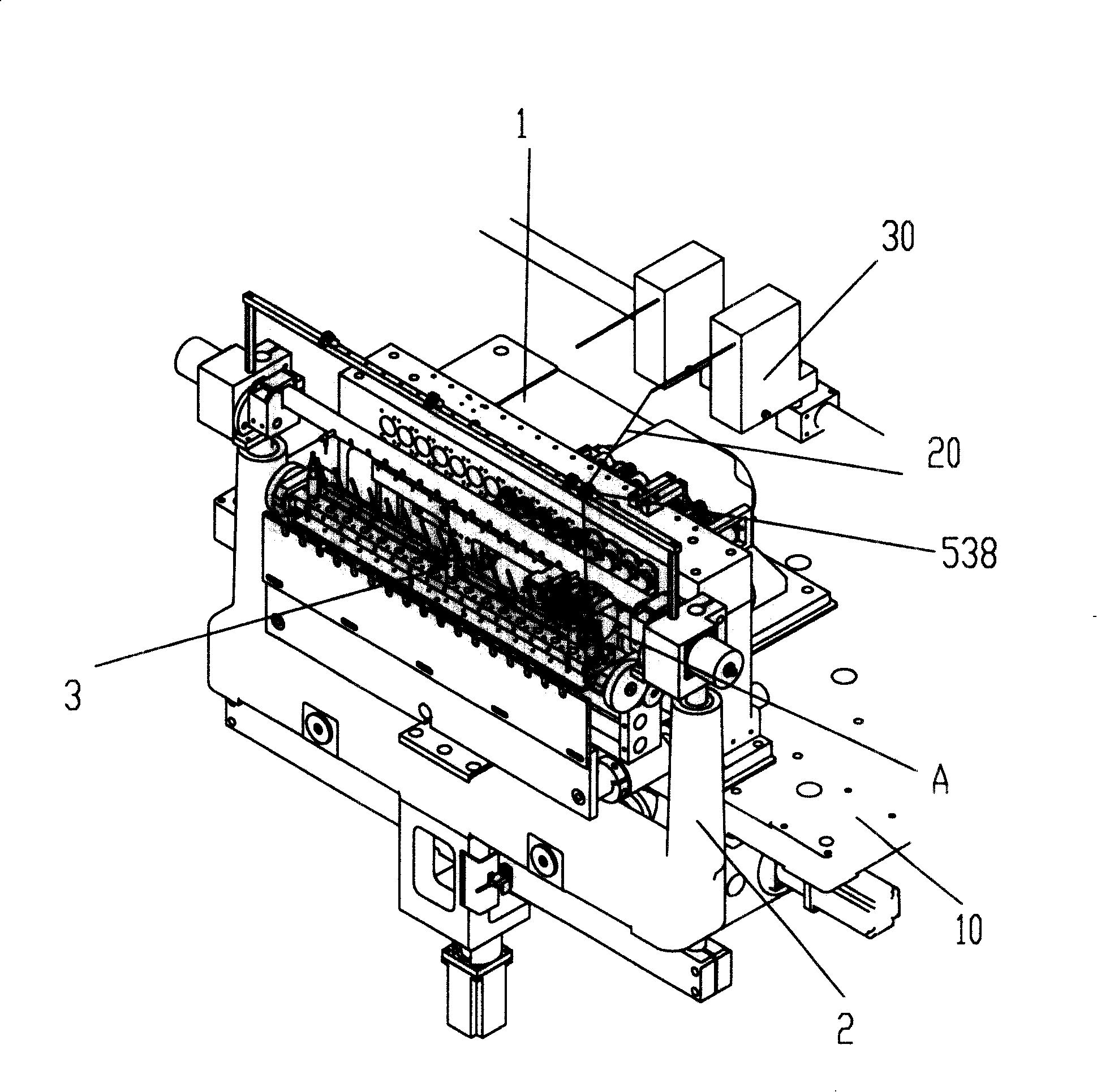

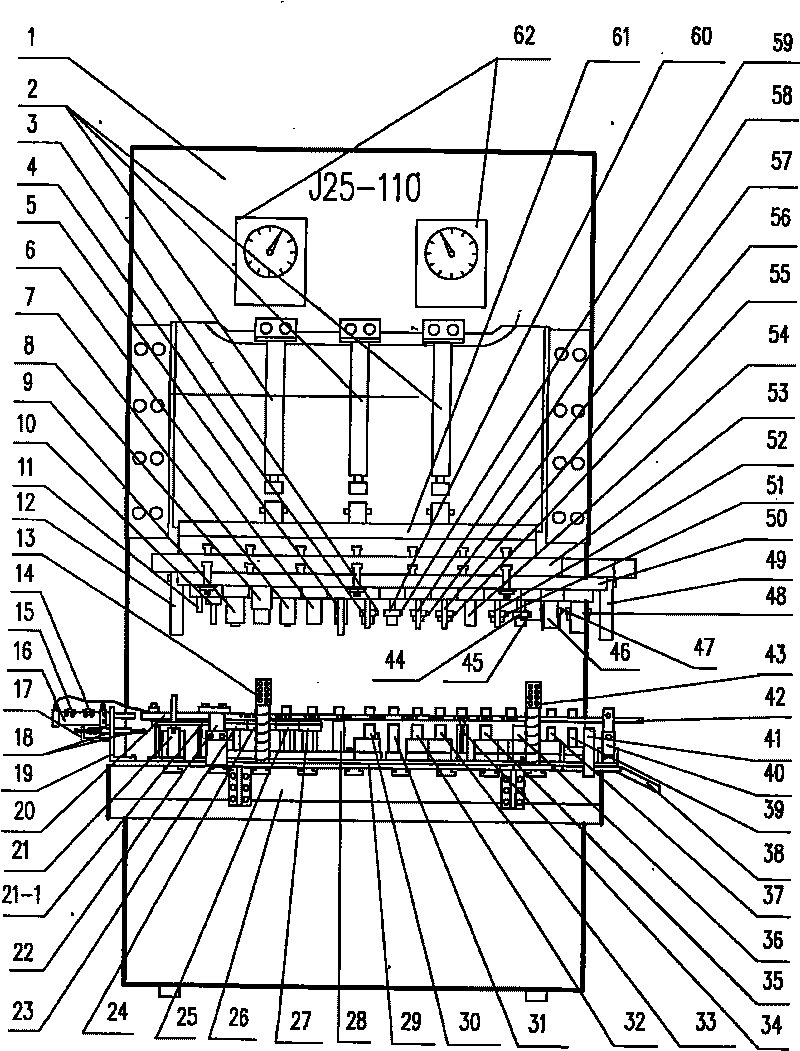

Multiheaded full-automatic wire winder

ActiveCN101211691AImprove motion control response timePrecise positioningCoils manufactureWinding machineElectrical control

The invention discloses a bull full-automatic winding machine, which comprises a main shaft winding mechanism driving a coil frame so as to realize the winding, an automatic line arrangement mechanism for X, Y and Z three axles which can move freely along the transverse, longitudinal and vertical directions so as to realize the winding of the coil frame, a line clamping and cutting mechanism used for realizing clamping the end of the enameled wire at the initiation of the winding and cutting off the outgoing lines of the pins after the pins of the coil frame are wound and an electrical control mechanism used for realizing the control of the main shaft winding mechanism, the automatic line arrangement mechanism for X, Y and Z three axles and the line clamping and cutting mechanism. The invention has the advantages of reasonable structure, high automation degree, extended installation of automatic material loading, material allocating, twisting, flake drip and material unloading systems so as to realize the automation in the entire process, tidy line arrangement, accurate and reliable number of winding rounds, high control accuracy, convenient operation and adjustment, etc.

Owner:XIAMEN HONGFA IND ROBOT CO LTD

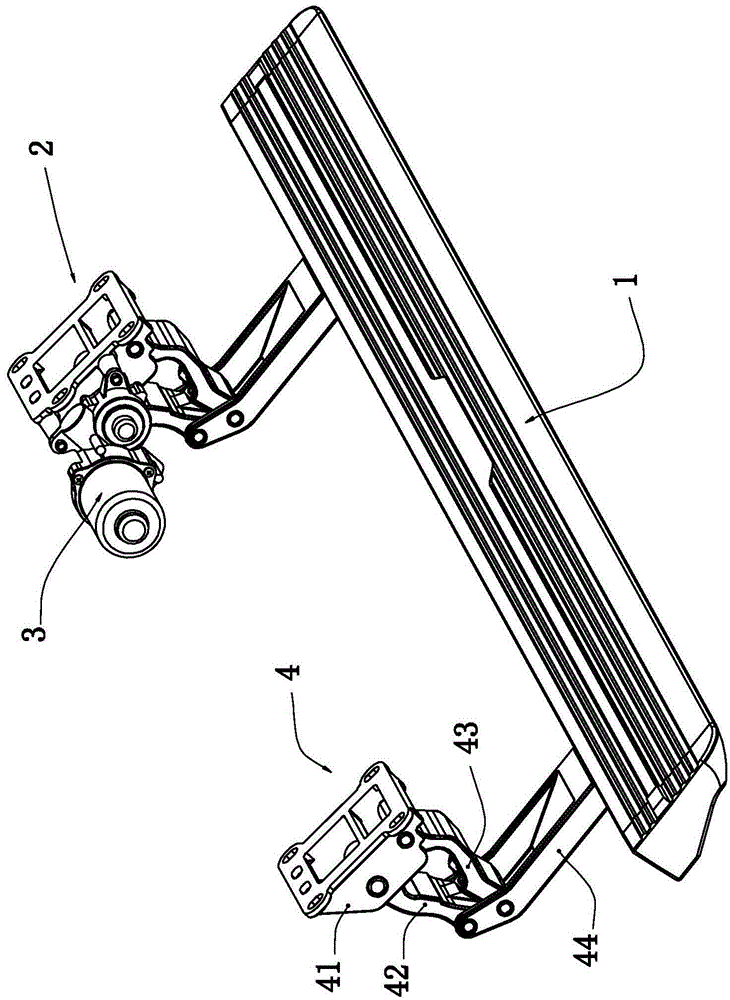

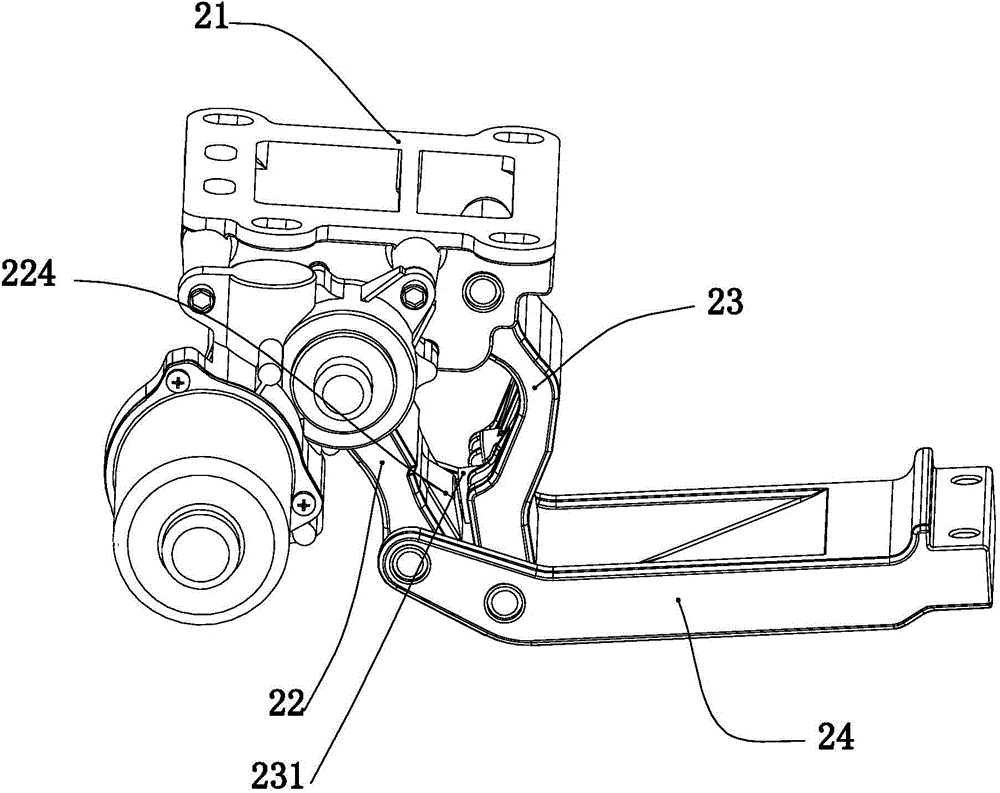

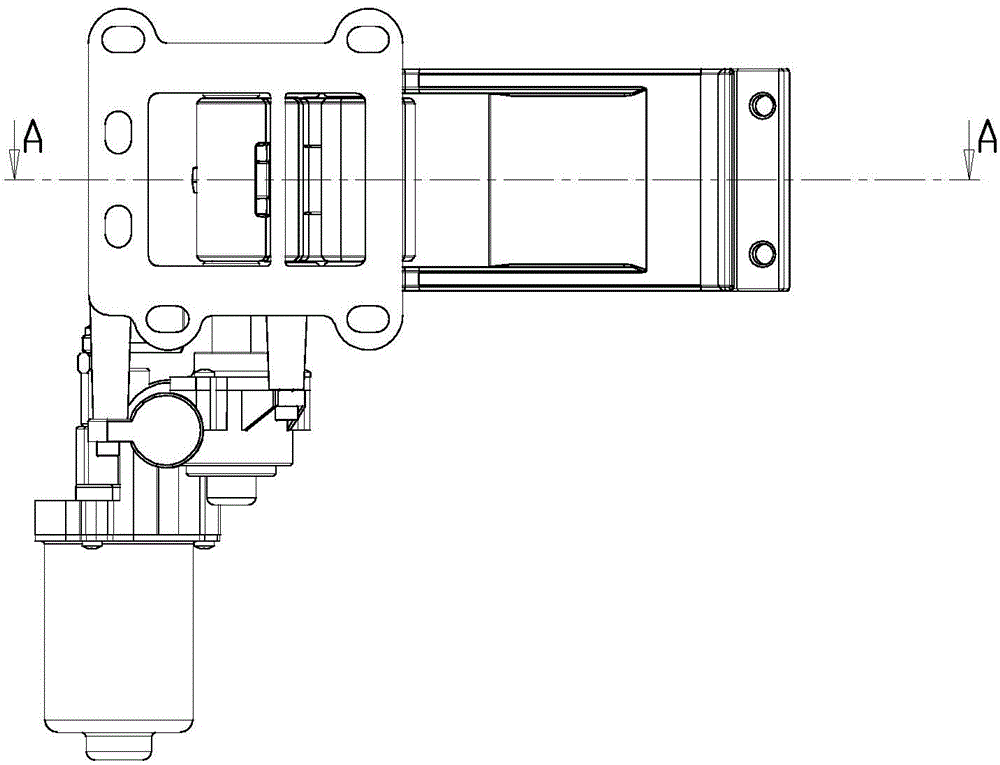

Automobile electric telescopic pedal with double-station support function

ActiveCN104385989AAvoid forceExtended service lifeSteps arrangementMechanical engineeringEngineering

The invention discloses an automobile electric telescopic pedal with a double-station support function. The automobile electric telescopic pedal comprises a pedal body, a first pedal mounting bracket assembly and a positive and reverse rotation motor, wherein the first pedal mounting bracket assembly comprises a first motor mounting frame, a first main driving plate, a first auxiliary connecting plate and a first telescopic bracket, the outer end of the first telescopic bracket is fixedly connected with the pedal body in a support fit way, and the upper ends and the lower ends of the first main driving plate and the first auxiliary connecting plate are respectively hinged and fit with the inner ends of the first motor mounting frame and the first telescopic bracket to form a plane four-connecting rod structure; when the first telescopic bracket is controlled in the extending station state, a limiting convex block of the first main driving plate and a limiting convex block of the first auxiliary connecting plate are mutually abutted, jacked, limited and fit; when the first telescopic bracket is controlled in the retraction station state, the outer contour surface of the first main driving plate is provided with an outer convex part of the first main driving plate, and the outer convex part of the first main driving plate and the upper end surface of the first telescopic bracket are mutually limited and jacked. The automobile electric telescopic pedal has the advantages that the structure design is reasonable, the service life of the motor is prolonged, and the support stability of the pedal is guaranteed.

Owner:RUIAN NOBLE AUTO PARTS

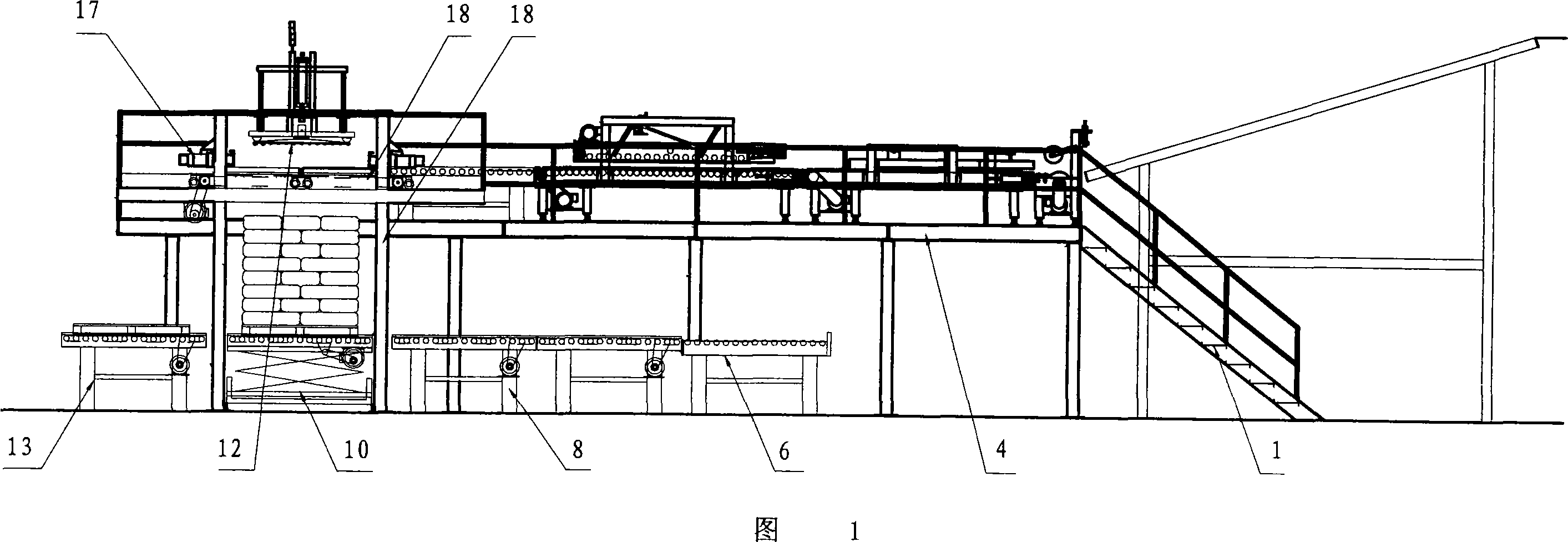

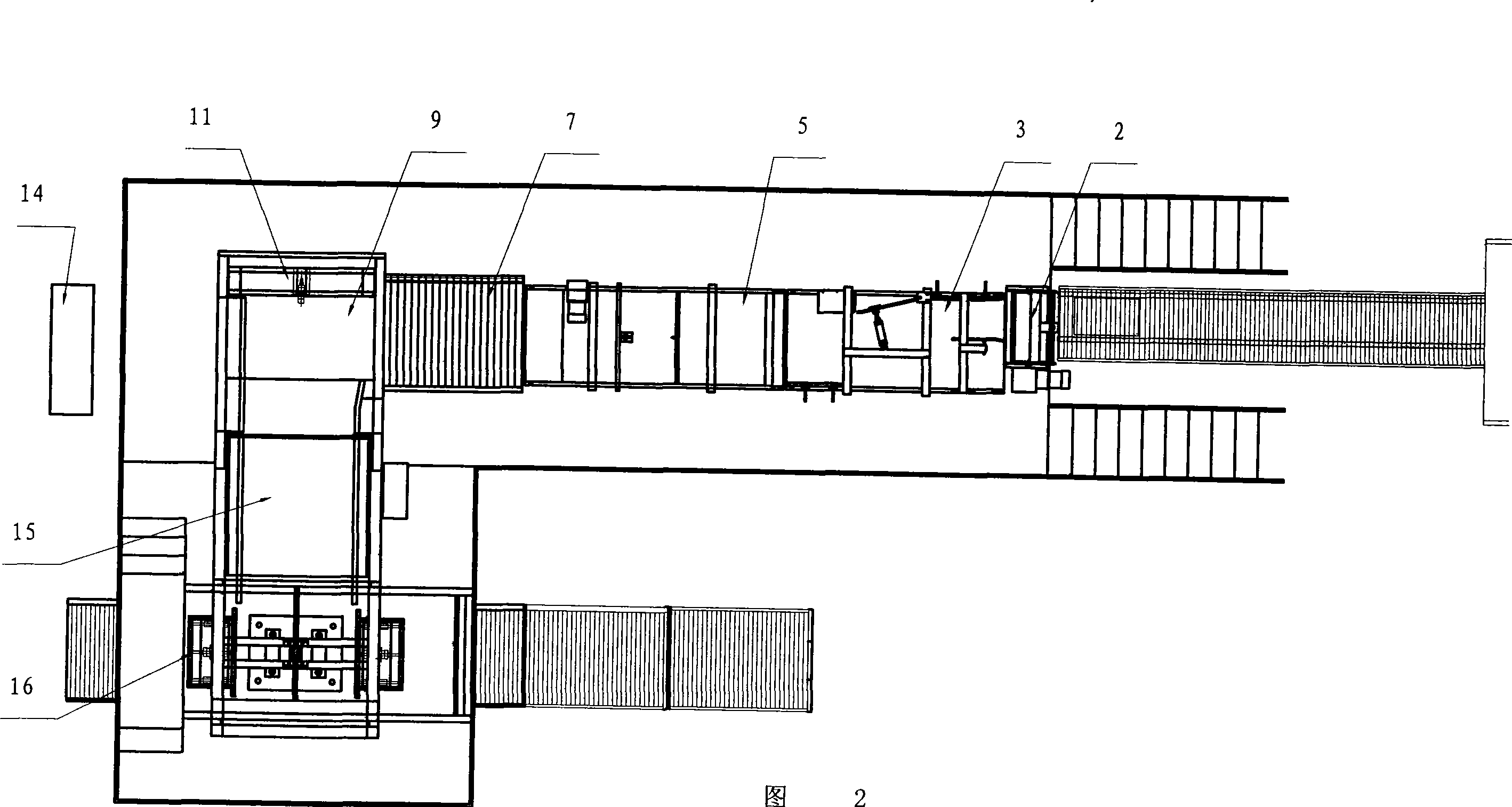

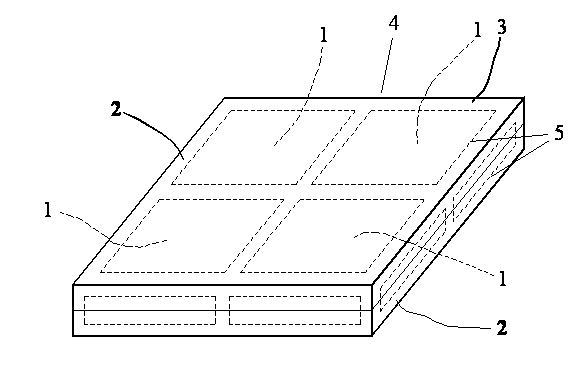

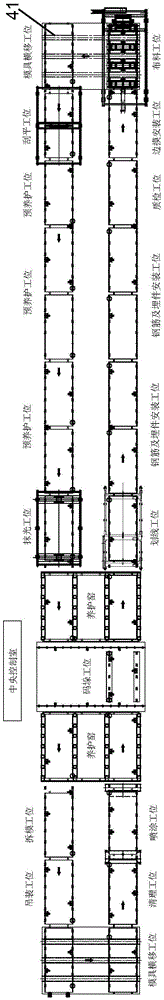

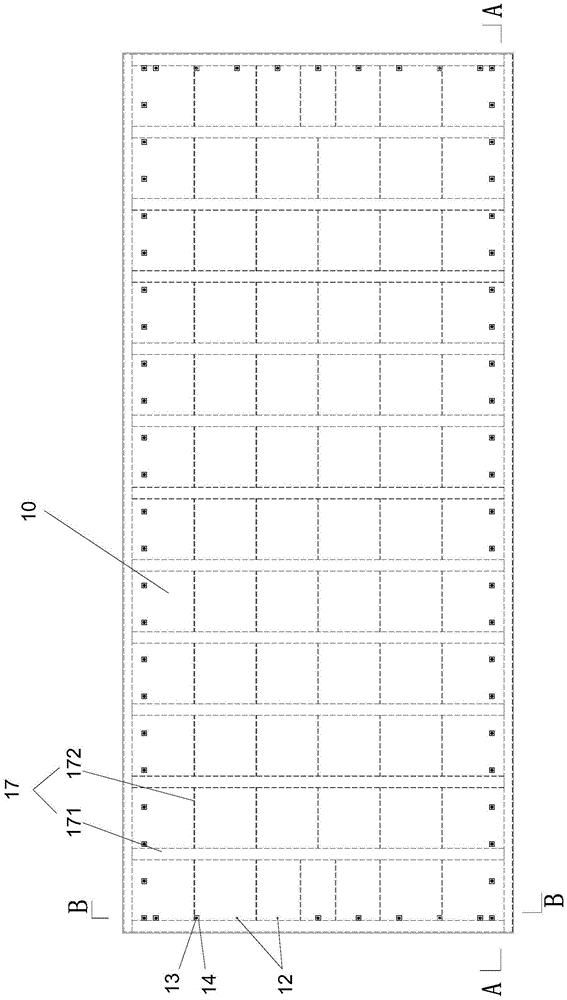

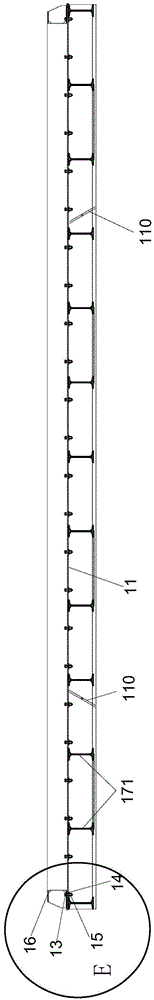

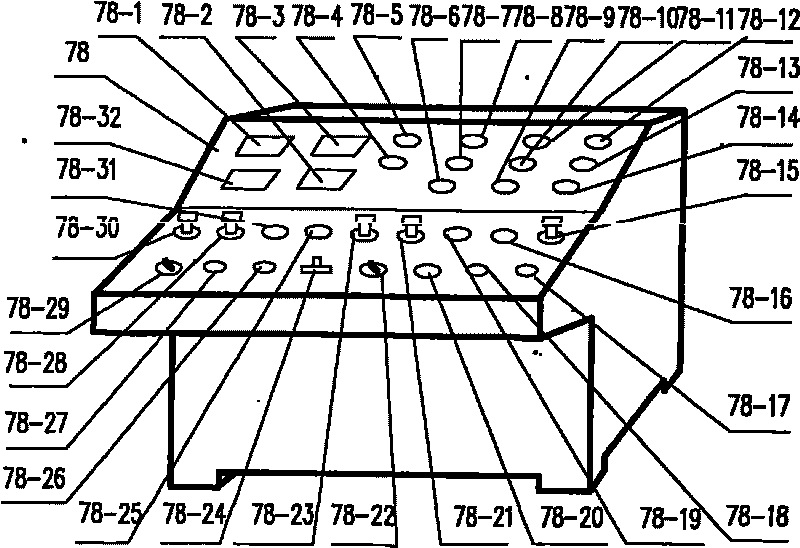

PC component production line

ActiveCN105459258AReduce wasteReduce manufacturing costCeramic shaping plantsFeeding arrangmentsProduction lineMaterial resources

The invention provides a PC component production line. The PC component production line comprises a clearing work station, a spraying work station, a scribing work station, a reinforcing steel bar and embedded part mounting work station, a quality inspection work station, a side die mounting work station, a laying work station, a die transverse movement work station, a leveling work station, a pre-curing work station, a smoothing work station, a curing kiln, a stacking work station, a die removing work station, a lifting work station and the like, which are connected by a conveying rail. A die component moves with the conveying rail in the order of the work stations and is processed by the procedures of all the work stations. Various models and sizes of PC components can be produced and manufactured. The layout of the production line is reasonable. Various PC components can be cyclically produced on one production line, so that various sizes of fixing dies do not need to be manufactured. The waste of material resources is greatly reduced, the production cost is reduced, and the production efficiency is improved.

Owner:HEBEI YUGOU BUILDING MATERIALS CO LTD

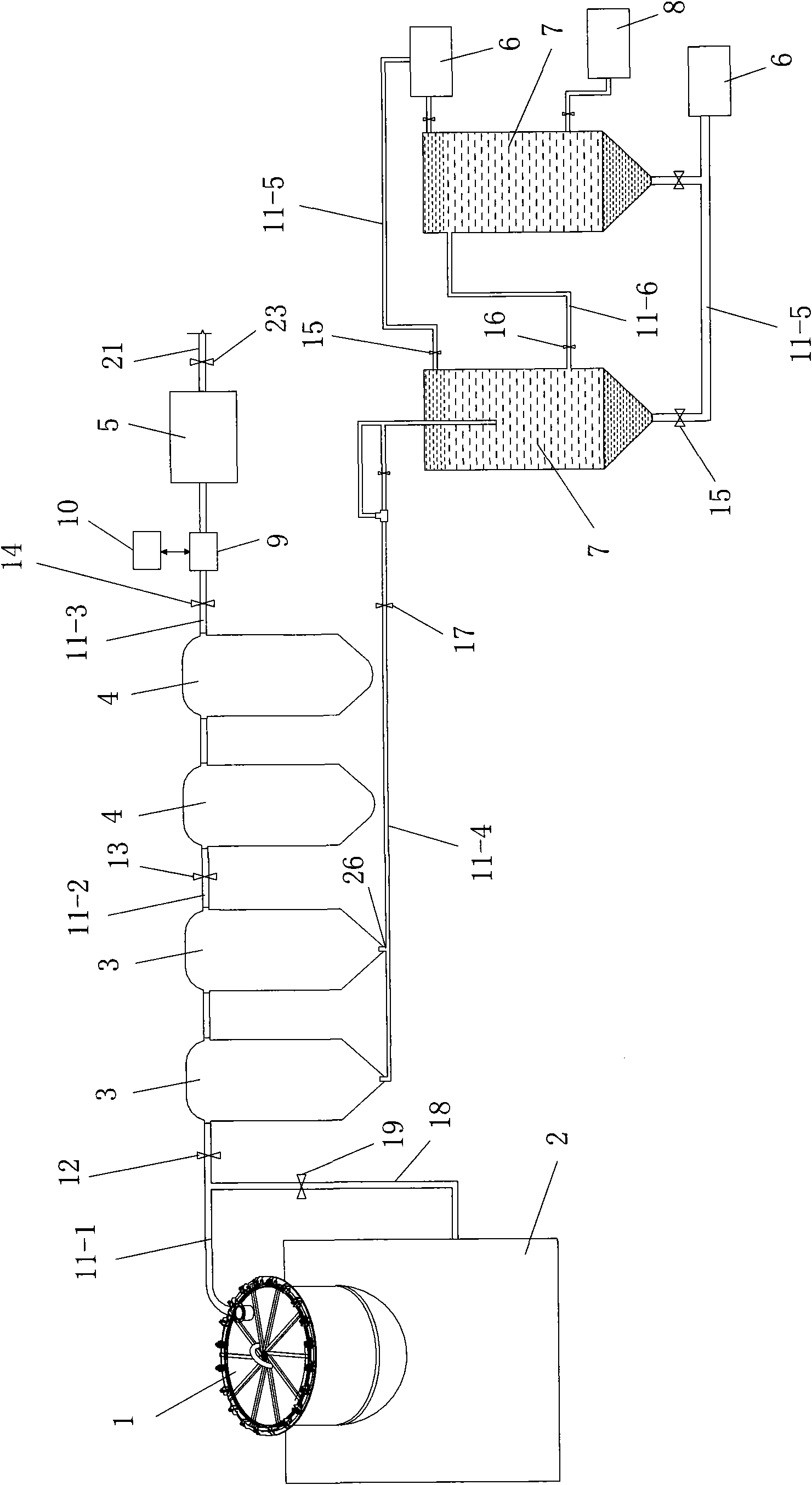

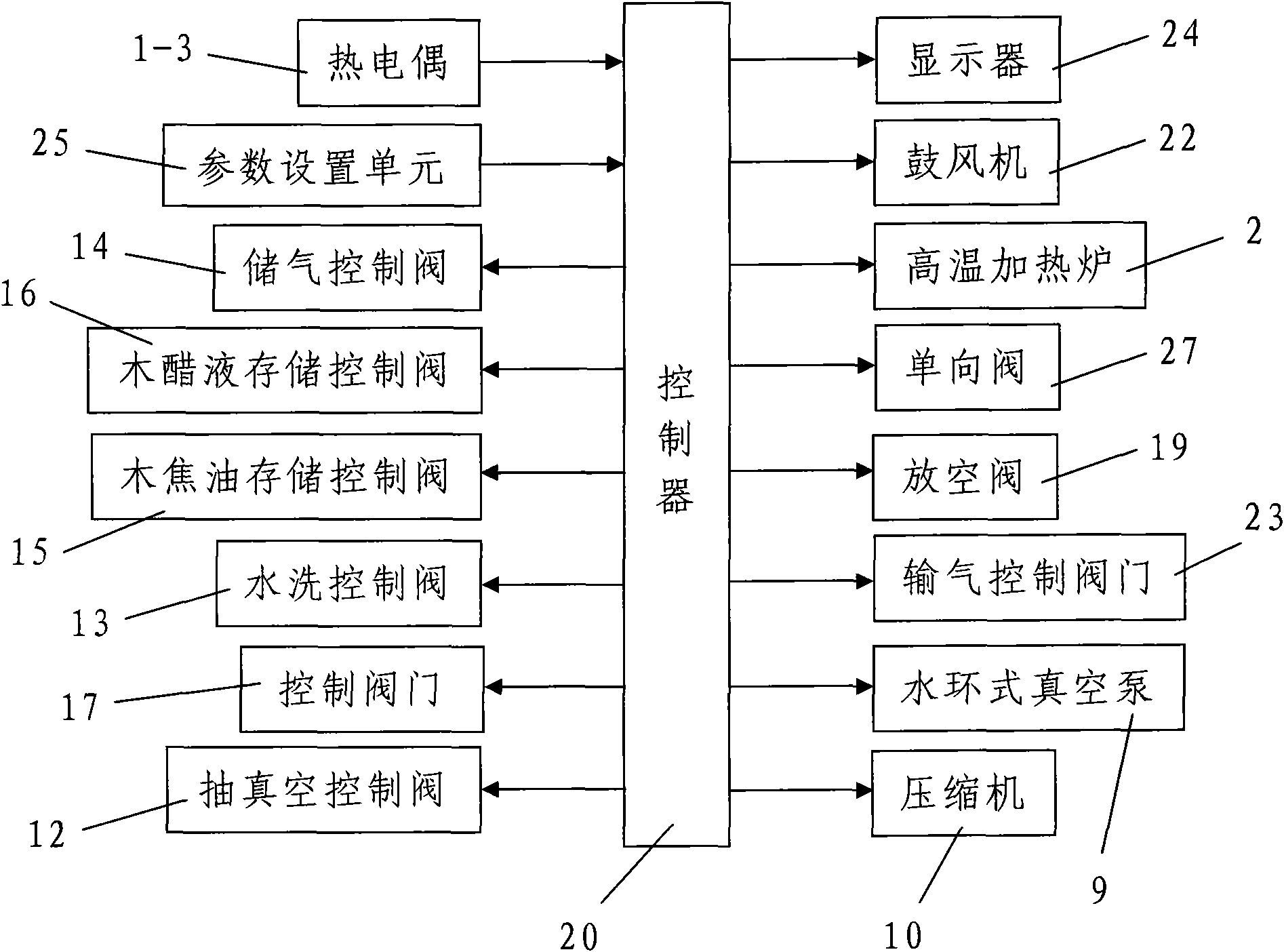

Co-production system and co-production method for biomass carbon, gas, wood tar and wood vinegar

InactiveCN101955780AFirmly connectedReasonable designBiofuelsPyroligneous acid productionSocial benefitsBiomass carbon

The invention discloses a co-production system and a co-production method for biomass carbon, gas, wood tar and wood vinegar. The co-production system comprises a biomass dry distillation kettle, a high-temperature heating furnace, a water cooling device, a washing device, a liquid separation device, a gas storage tank, a water-ring vacuum pump, a compressor, wood tar storage tank and a wood vinegar storage tank, wherein the liquid separation device separates wood vinegar and wood tar in the mixed liquid obtained by gas-liquid separation of the water cooling device; the co-production method comprises the following steps: 1, charging; 2, high-temperature carbonization: water cooling and gas-liquid separation, washing, gas storage and separation and storage of liquid matters; and 3, obtaining of the biomass carbon after the high-temperature carbonization. The co-production system for the biomass carbon, gas, wood tar and wood vinegar has the advantages of reasonable design, convenient processing, simple mounting arrangement, easy operation and good effect; and the co-production method has the advantages of convenient realization, high yield, low cost, fast co-production and relatively high production purity and has obvious economic and social benefits and wide popularization and application prospect.

Owner:陕西亿鑫生物能源科技开发有限公司

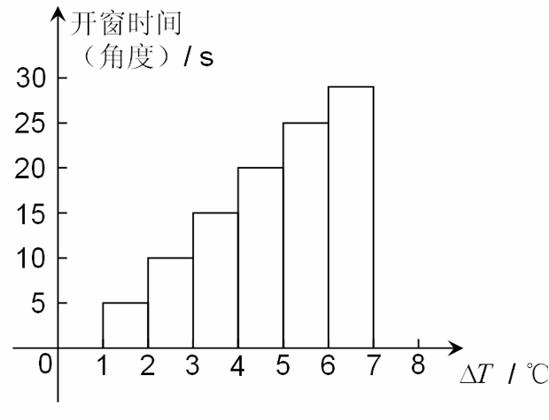

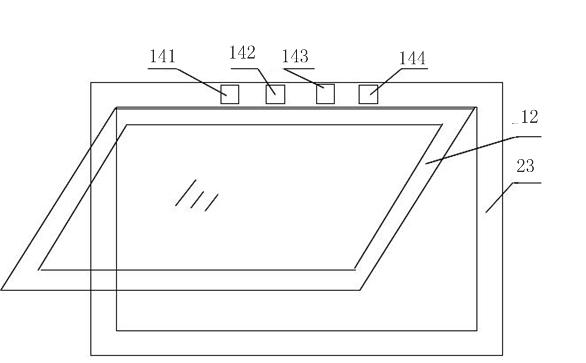

Multifunctional intelligent window

InactiveCN101949252AReasonable structural designGood energy saving effectLight protection screensWing arrangementsControl modeEngineering

The invention provides a multifunctional intelligent window. The intelligent window comprises a window frame, an upper suspended window body accommodated in the window frame, a shutter fixed on one inward side of the window frame and a transmission mechanism for adjusting the states of the upper suspended window body and the shutter; the intelligent window also comprises an outdoor environment detector, an indoor environment detector and a control system; the outdoor environment detector and the indoor environment detector are electrically connected with the control system; and the control system adjusts the states of the upper suspended window body and the shutter through the transmission mechanism. The intelligent window has the advantage of more reasonable structural design. The upper suspended window body, the shutter and the execution mechanism of the multifunctional intelligent window are relatively independent, but the signal and the control mode for controlling the intelligent window by the control system are integral, namely the upper suspended window body and the shutter are designed to be independently used in a remote control operating mode and also can be used as a whole for realizing all intelligent functions in a self-control mode.

Owner:SHENZHEN POLYTECHNIC

Feeding and transferring mechanism for pipe fittings with end portions closed

InactiveCN109704046AHigh degree of processing automationReasonable structural designConveyor partsMotor drivePipe fitting

The invention discloses a feeding and transferring mechanism for pipe fittings with end portions closed, and belongs to the field of workpiece machining mechanical equipment. A guide pipe through holeis formed in the upper end of a pipe storage hopper of the feeding and transferring mechanism. A lifting push plate is arranged on a push plate sleeve on the lower side of the pipe storage hopper ina sliding manner. A pipe movement guide plate is arranged on a guide pipe support on the lower side of a discharge guide pipe. A clamping rod limiting clamp is arranged at the upper end of a reciprocating swinging rod. A turnover gear is fixedly arranged on the end portion of one side of a fixed rotating shaft. The middle portion of one side of a turnover connection plate is fixedly arranged on the end portion, along the side of the pipe movement guide plate, of the fixed rotating shaft. The two sides of a pipe transferring belt are wound on and connected to pipe transferring rotation rollerson the two sides of a pipe transferring support correspondingly. A pipe transferring motor drives the pipe transferring rotation rollers to rotate. The feeding and transferring mechanism is reasonablein structural design, the pipe fittings can be conveniently and efficiently arranged and fed in an oriented manner one by one, the pipe fittings can be stably and accurately overturned vertically oneby one, and therefore the pipe fittings can be sequentially conveyed through vertical stations, the automation degree of pipe fitting feeding and processing can be improved, and requirements of machining and using can be met.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

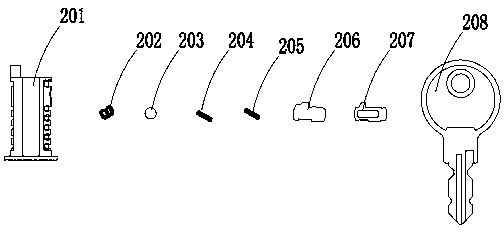

Automatic assembling device for lock cylinder

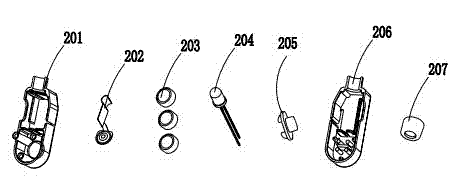

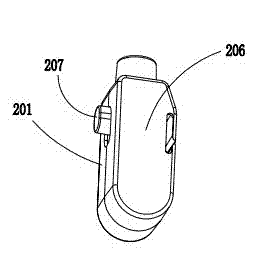

ActiveCN103111846AReasonable structural designReduce labor intensityAssembly machinesHigh volume manufacturingEngineering

The invention relates to an automatic assembling device for a lock cylinder. The automatic assembling device comprises a frame and a workbench arranged on the frame. A big rotary table is arranged on the workbench, a clamps for holding a tumbler is arranged on the big rotary table, a tumbler mounting component, an glass bead spring mounting component, an glass bead mounting component, an locking plate spring mounting component, an lock piece mounting component, an tail piece mounting component, an locking plate mounting component, an key mounting component and a discharging component are arranged along the circumference of the big rotary table, and all the components are connected with a main circuit respectively and are controlled by the main circuit. Structure design of the automatic assembling device of lock cylinder is reasonable. Since the components of the lock cylinder are fed, detected, assembled and discharged automatically under electric control, producing efficiency and product quality are improved, labor force of workers is greatly reduced, and producing cost is saved; requirement of large amount producing is adaptably met, and market competitiveness of a company is increased.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

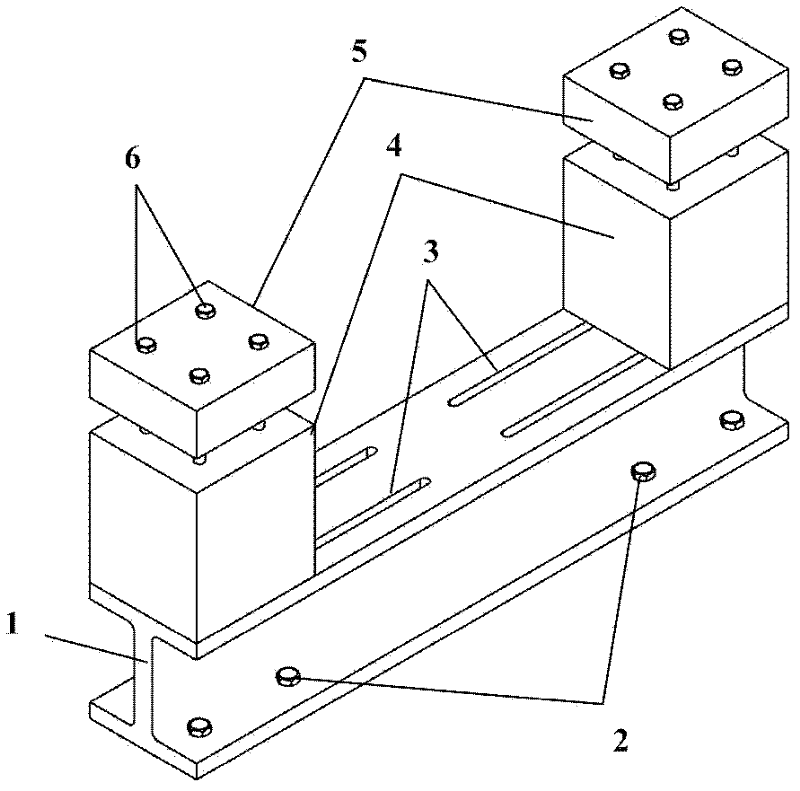

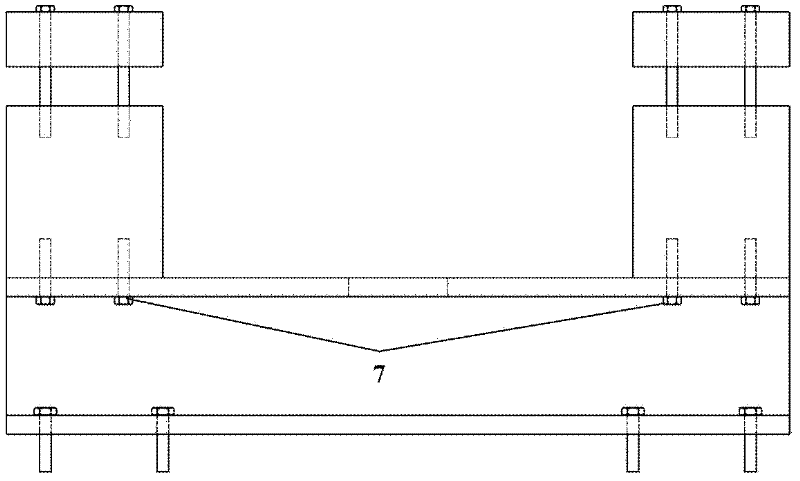

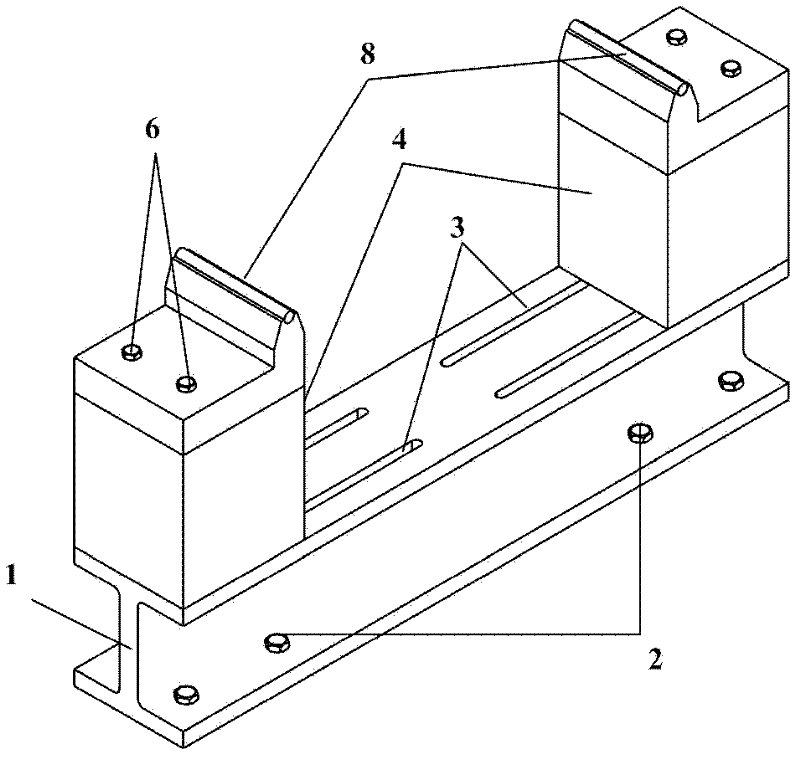

Adjustable test fixture

InactiveCN102494943AReasonable structural designAdjustable spacingShock testingStrength propertiesEngineeringTest fixture

The invention discloses an adjustable test fixture device, which comprises an H beam base, two support bases arranged on the H beam base and clamped pressure sheets arranged on the tops of the support bases; two pairs of support base guide grooves are arranged on an upper wing plate of the H beam base; and one support base is movably connected to each pair of support base guide grooves. The device disclosed by the invention is simple for operation and high in precision; the positions of the support bases can be adjusted through the guide grooves on the upper wing plate of an H beam, so that the distance between the support bases can be adjusted, thus, the purpose of applying to test pieces with different geometrical sizes can be achieved; different boundary types can be realized by replacing the types of the support bases on the upper wing plate of the H beam; and the H beam base can move, thus, the adjustable test fixture is convenient to experiment and test in different places and has a certain portability.

Owner:XI AN JIAOTONG UNIV

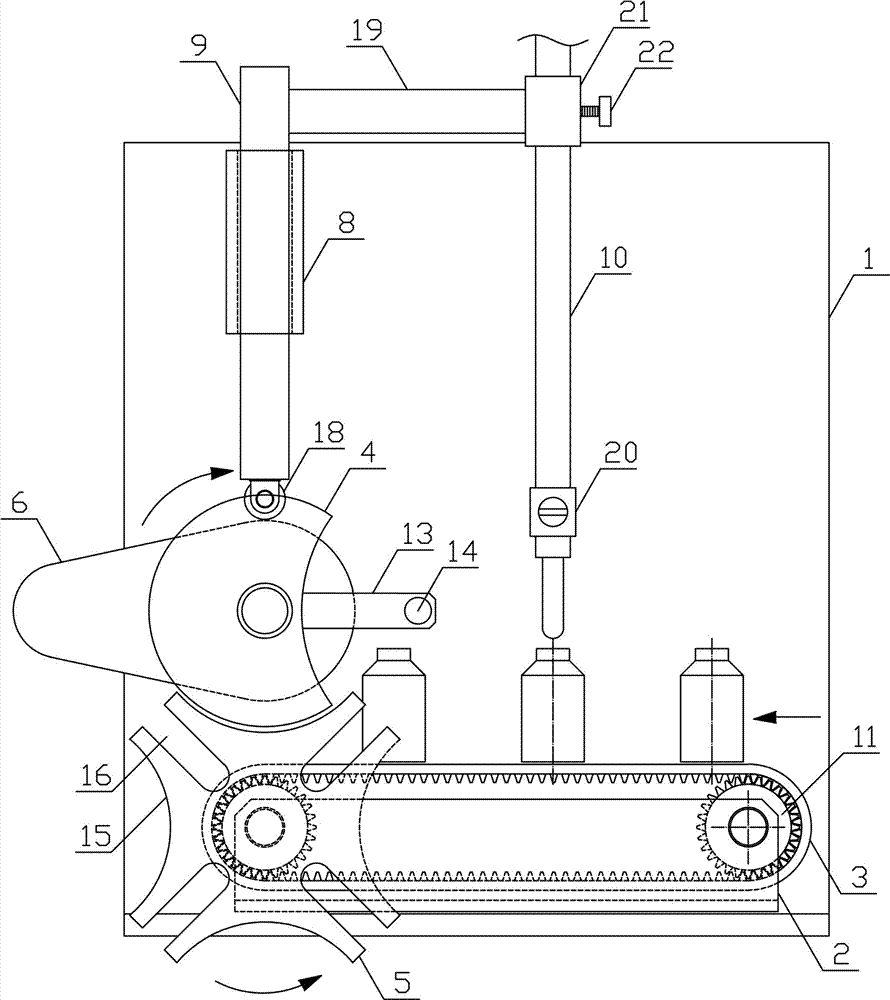

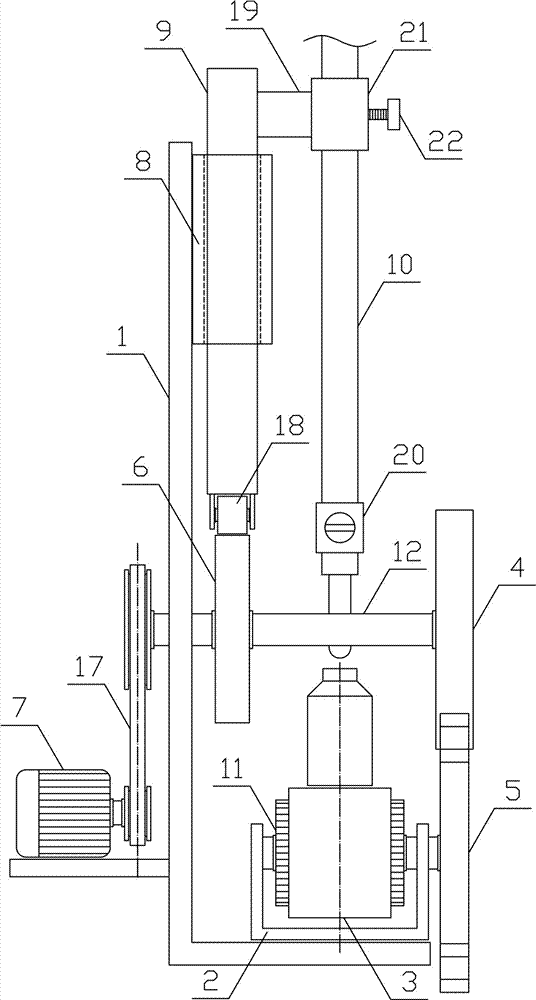

Continuous filling mechanism

InactiveCN107055439ASmooth transmissionThe conveyor belt can be moved intermittently according to the needs, and the transmission is smoothLiquid bottlingFilling materialsEngineering

The invention discloses a continuous filling mechanism, which belongs to the field of material filling machinery and equipment. The invention includes a fixed bracket, a transmission bracket, a round can conveyor belt, a rotating circular plate, a slotted rotary plate, a rotating cam, a rotating motor, a lifting sleeve, a lifting guide rod and a filling material tube, and the round can conveyor belt is horizontally arranged on the transmission bracket. On the side, the rotating circular plate is vertically arranged at one end of the rotating shaft, and the card slot rotating plate is vertically arranged on one side of the translation pulley. Between two adjacent rotating arc surfaces, there are drive slots along the radial direction of the card slot rotating plate. The rotating card slot matching the wheel, the rotating motor and the rotating shaft are connected by a transmission belt transmission, the lifting sleeve is slid along the vertical direction and a lifting guide rod is installed, and the filling material tube is vertically set at one end of the filling support plate . The invention has a reasonable structural design, can quickly, efficiently and smoothly fill the round cans one by one continuously, improves the efficiency and quality of filling, and meets the needs of production and use.

Owner:屠明州

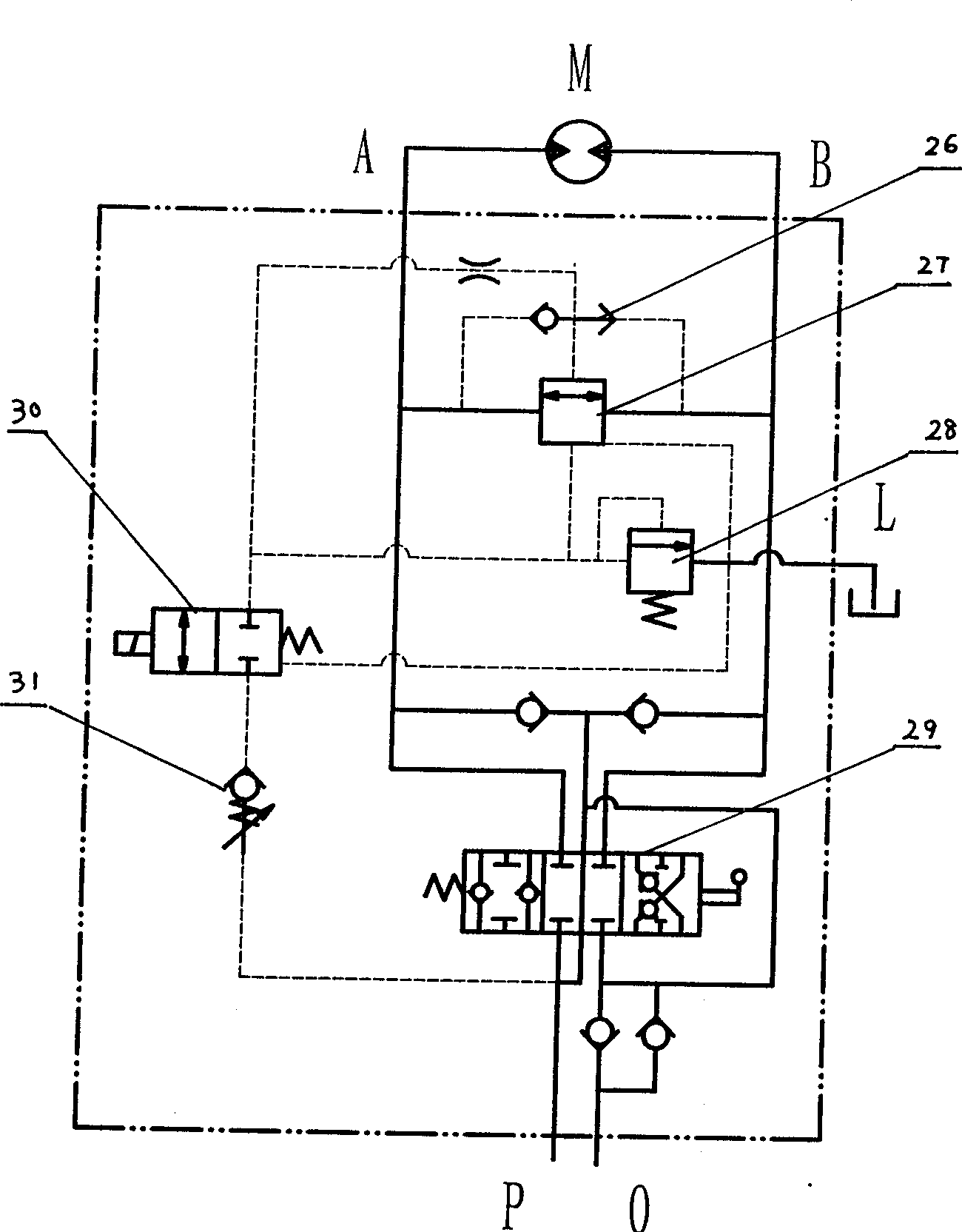

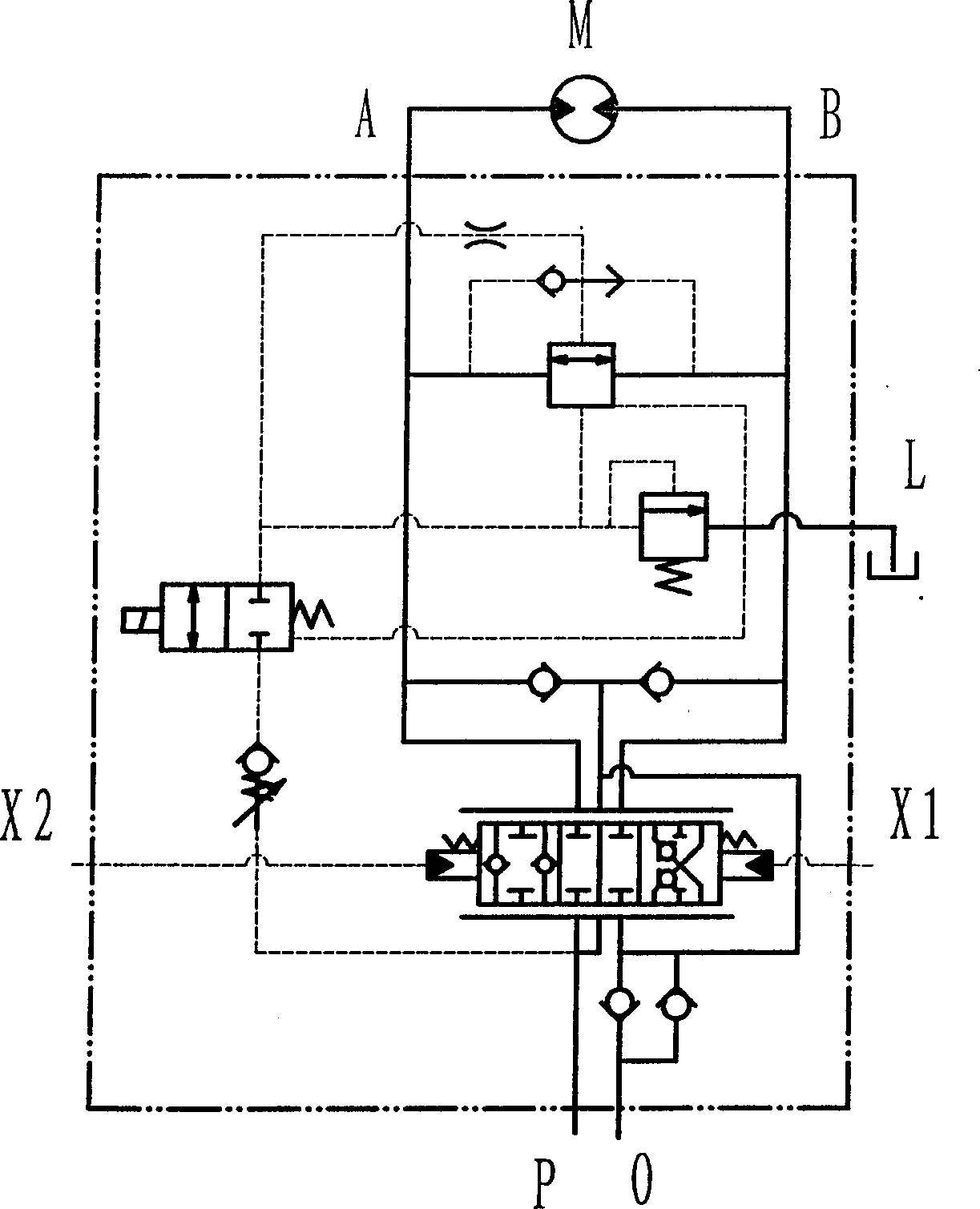

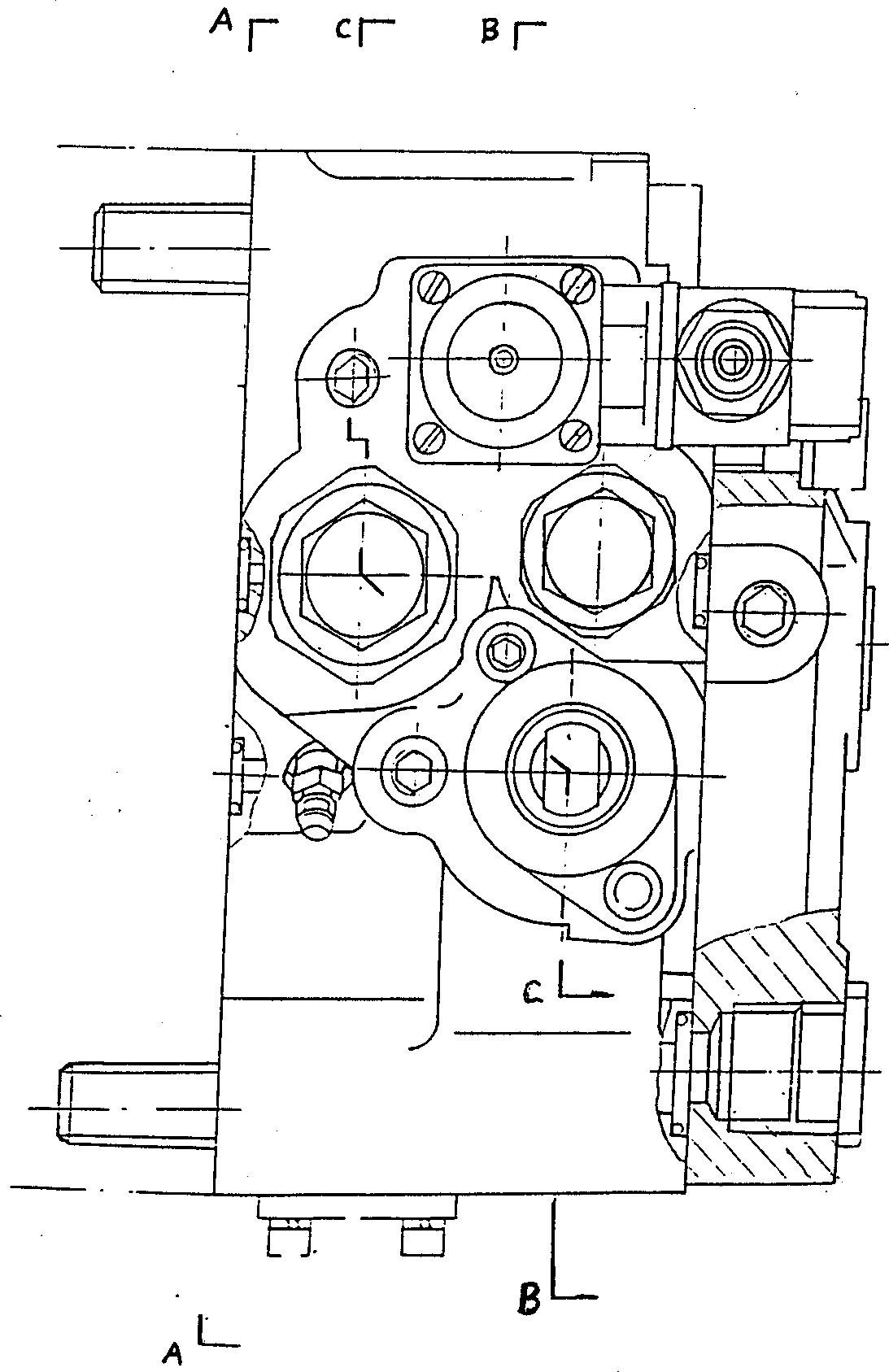

Rotary buffering valve

InactiveCN1350126AReduce jitterSo as not to damageServomotor componentsCranesEngineeringControl valves

The present invention relates to the turning buffer valve technology in crane, which is characterized by that in the main valve body through the installation of cavity, built-in channel and necessaryparts, the buffer valve, electromagnetic valve, adjustable backpressure valve, control valve and non-way valve are detachly combined in the main valve body to make it possess several functions of turning buffer valve in crane. Said invention possesses the advantages of reasonable compact structure, small volume and safe and convenient use, etc.

Owner:卢永松

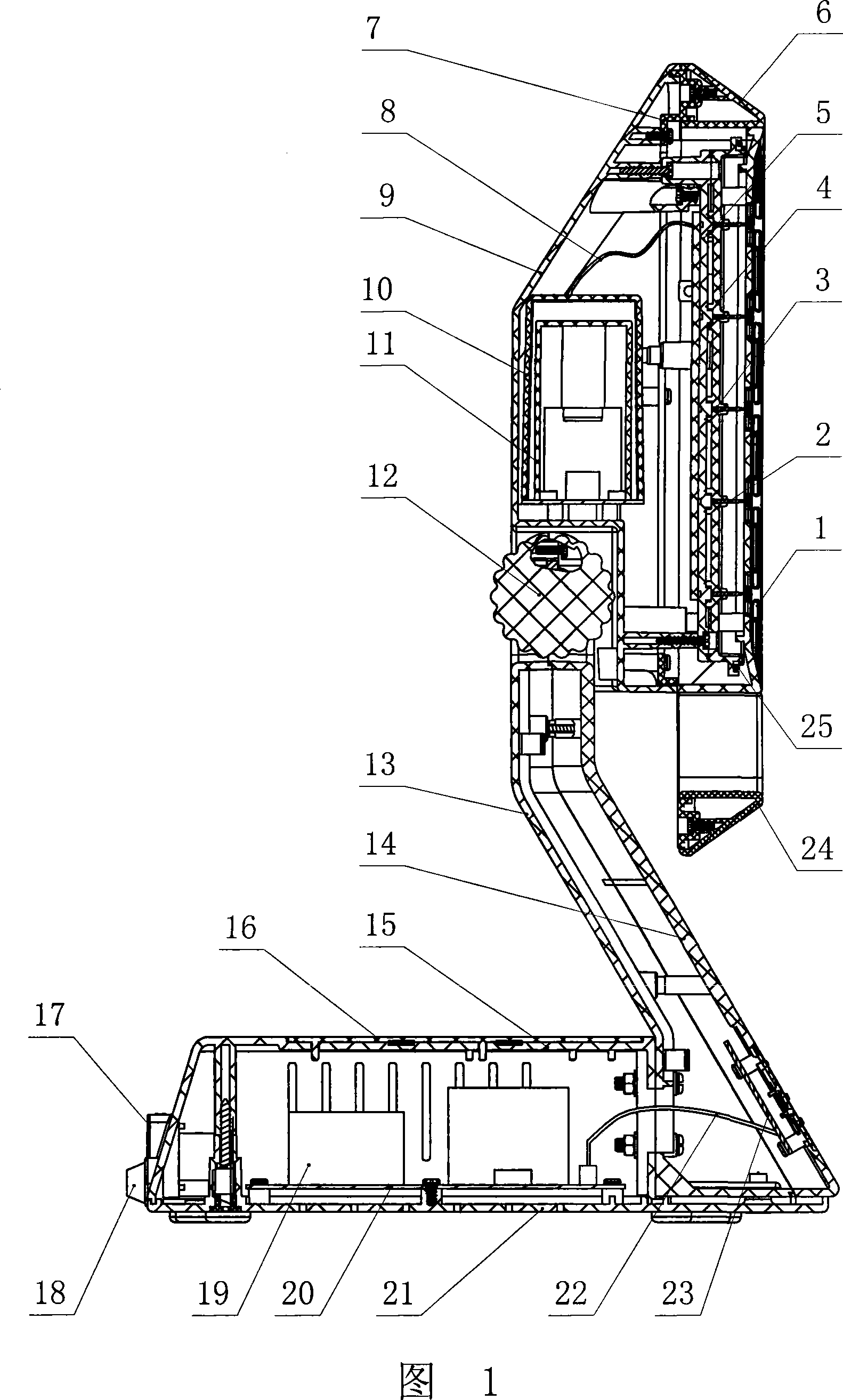

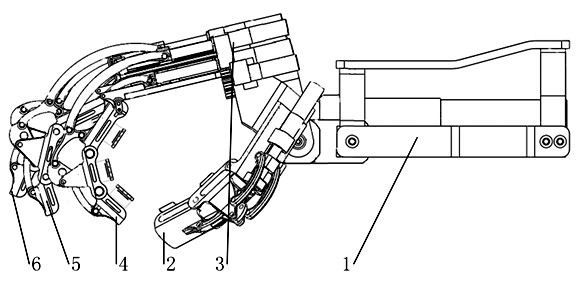

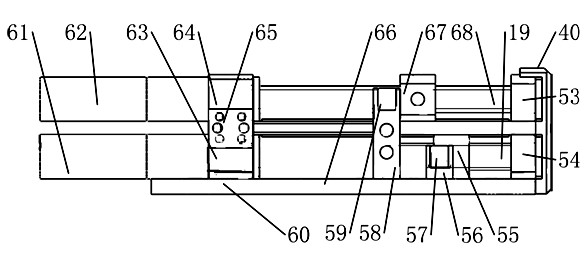

Hand and wrist exoskeleton rehabilitation training device

ActiveCN102579227ASimple structureEasy to implementChiropractic devicesMotor driveDegrees of freedom

The invention discloses a hand and wrist exoskeleton rehabilitation training device, comprising a wrist, a thumb, a power source, an index finger, a middle finger and a ring finger, wherein the power source is fixed on the wrist, and the thumb, the index finger, the middle finger and the ring finger are respectively connected with the power source. A motor drives a feed screw nut, so that the rehabilitation training device obtains power; the rehabilitation training device is simple in structure and easy to implement; weight of hand exoskeleton is born by a support part, so that a patient has no burden; and the rehabilitation training device realizes movements with more degrees of freedom, and can complete more and more skillful rehabilitation training actions.

Owner:ZHEJIANG UNIV

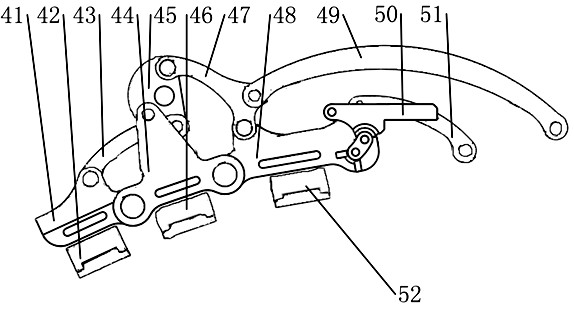

Automatic feed multi-station progressive die

ActiveCN101722229AReasonable structural designImprove ergonomicsShaping toolsPerforating toolsMachine pressAutomation

The invention relates to an automatic feed multi-station progressive die. The structure is as follows: a feed sectioning upper die, a feed sectioning lower die, a drawing upper die A, a drawing lower die A, a drawing upper die B, a drawing lower die B, a drawing upper die C, a drawing lower die C, a shaping upper die A, a gibbous shaping lower die, a top rush hole upper die, a top rush hole lower die, a material pressing upper die A, a profile four-hole punching die, a material pressing upper die B, a rotation die with a hole, a material pressing upper die C, a profile technology hole punching die, a material pressing upper die D, a profile U-shaped hole punching die, a shaping upper die G, a square hole shaping die, a sectioning upper die and a sectioning lower die are respectively fixed on an upper die and a lower die, wherein the upper die is connected with a pressure machine, and the lower die is fixed on a work table. Compared with the prior art, the automatic feed multi-station progressive die has reasonable structure and design, high work efficiency, low material cost, reliable performance, stable quality and high automation degree.

Owner:浙江人人集团有限公司

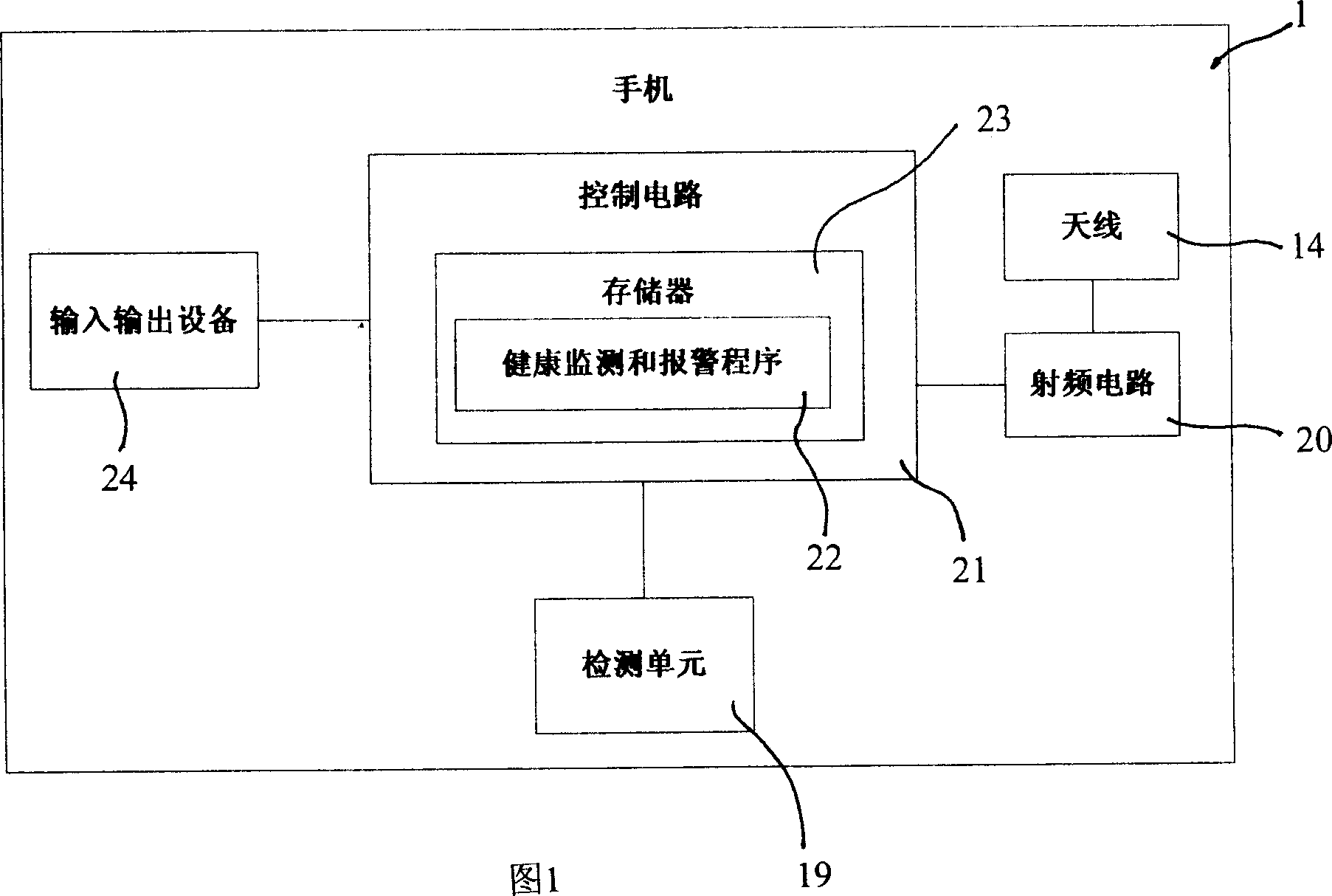

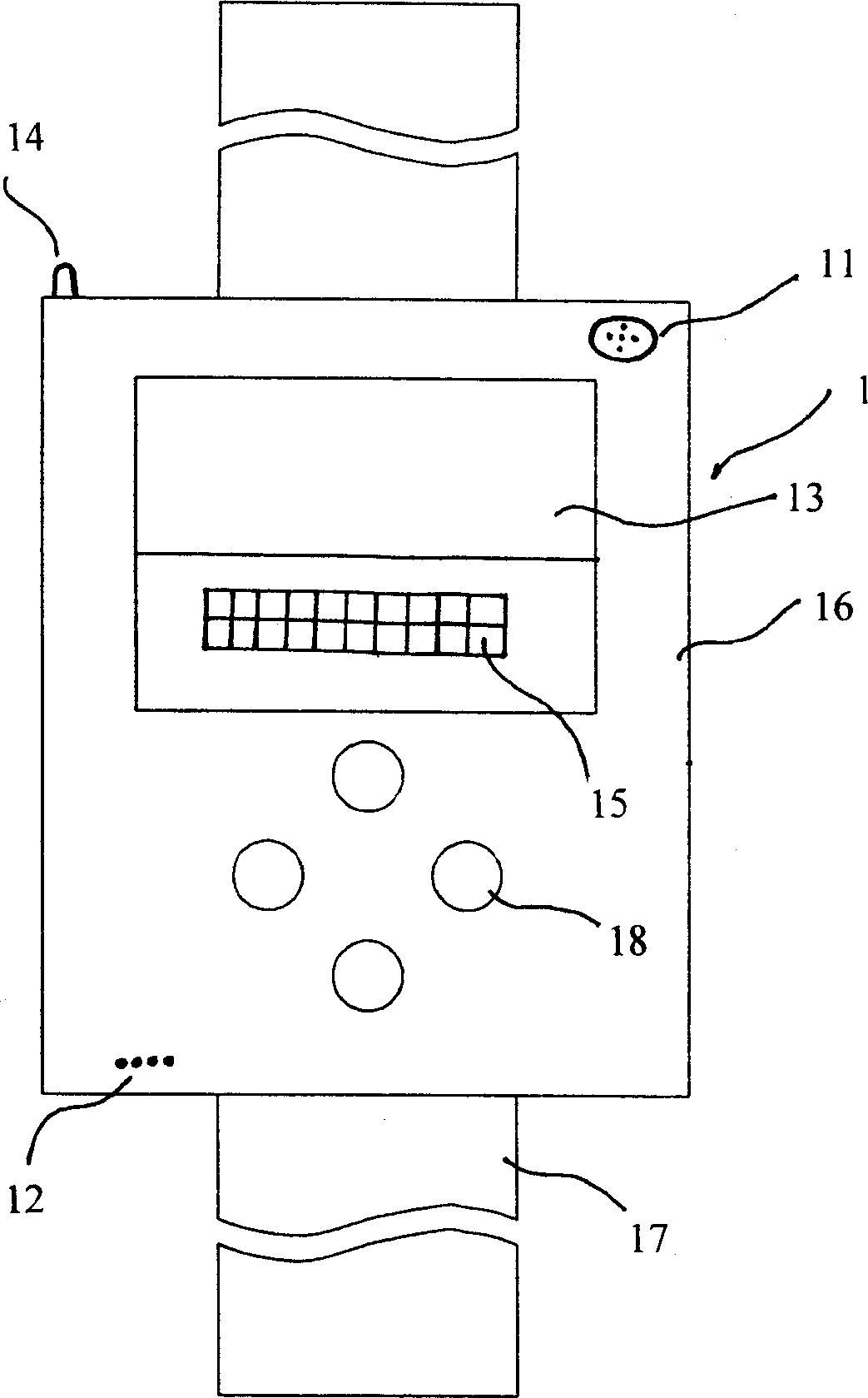

Health mobile phone

InactiveCN1885863AThe overall structure design is reasonableEasy to useDiagnostic recording/measuringSensorsEngineeringRf circuit

The related healthy mobile phone comprises: based on a traditional phone, a control circuit in the shell connected to both an I / O device and a RF circuit with output connected to an antenna, a detection unit for people physiological index with output end connected to signal input end of control circuit, and the healthy monitor and alarm program in memory. This invention has simple structure and convenient to utility.

Owner:杭州波导软件有限公司

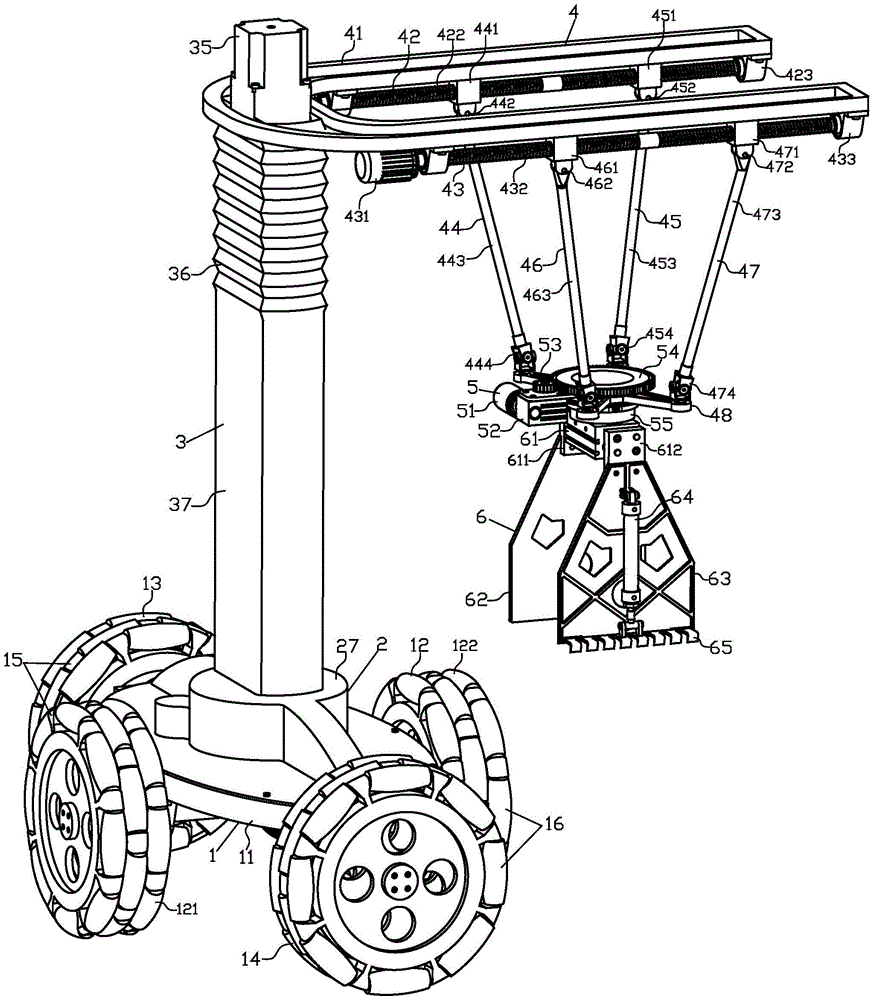

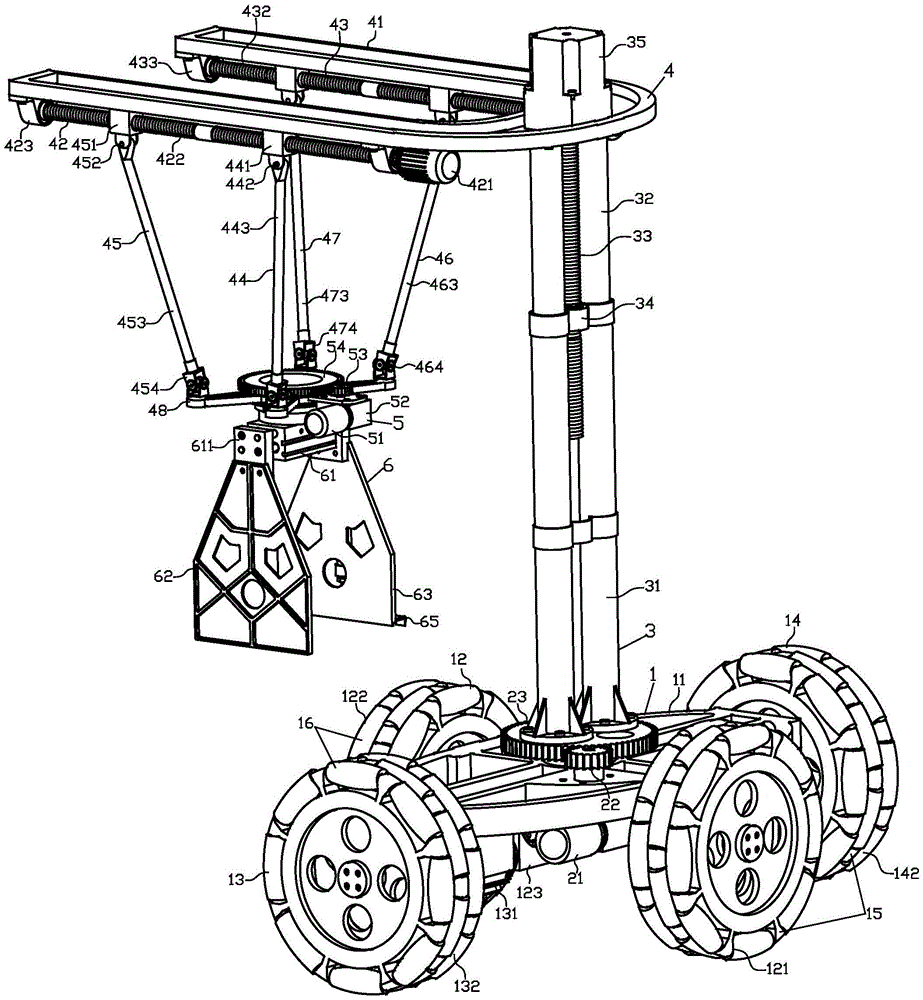

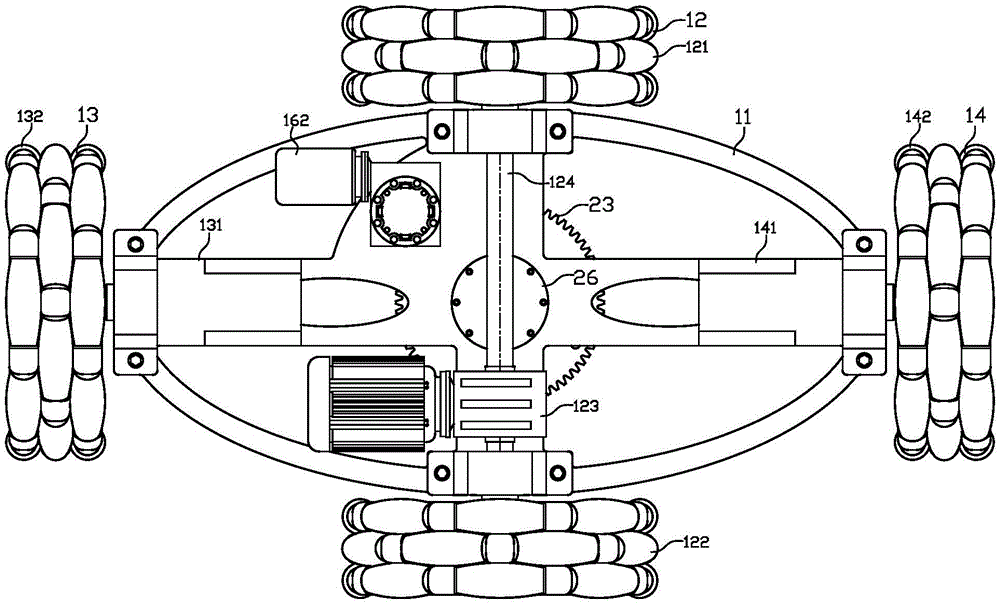

Three-freedom-degree series-parallel omni-directional mobile transfer robot

ActiveCN105459095AIncrease stiffnessImprove carrying capacityProgramme-controlled manipulatorGripping headsIndependent motionCarrying capacity

The invention discloses a three-freedom-degree series-parallel omni-directional mobile transfer robot. The transfer robot comprises an omni-directional mobile chassis, a main slewing gear, a lifting device, parallel working arms, a tail end slewing gear and a clamp holder. The omni-directional mobile chassis is used for executing walking and steering tasks, the lifting device is connected with the omni-directional mobile chassis through the main slewing gear, the parallel working arms installed at the top of the lifting device are connected with the clamp holder through the tail end slewing gear and are used for adjusting the operation posture of the clamp holder. A series-parallel is adopted in a robot body, and the omni-directional mobile transfer robot has the advantages of being high in rigidity, large in carrying capacity, high in motion precision, large in operation space and the like; the clamp holder has six motion ranges and three independent motion freedom degrees and is high in motion flexibility; the tri-drive omni-directional mobile chassis can realize walking tasks of moving forward, or moving backward, or turning left or turning right, and is reasonable in structural design, and high in anti-overturning ability. In addition, the omni-directional mobile transfer robot has the advantages of being convenient to manipulate, and high in adaptability to road conditions.

Owner:ANHUI UNIV OF SCI & TECH

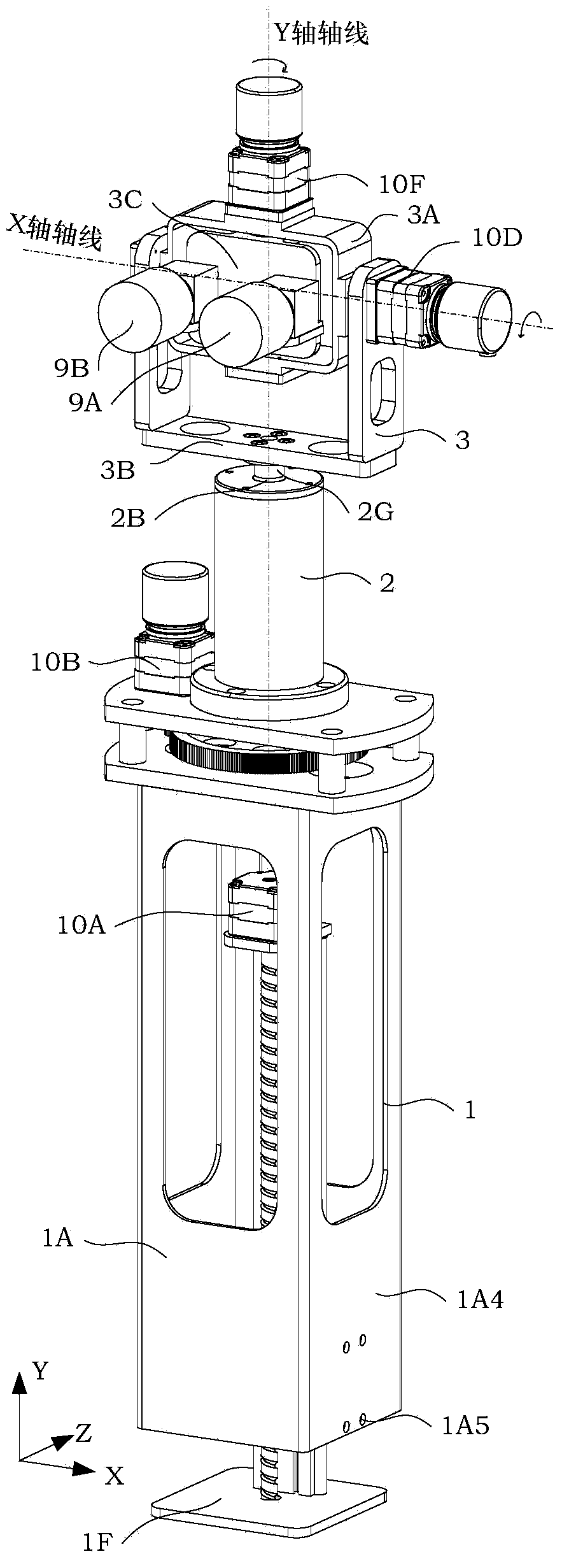

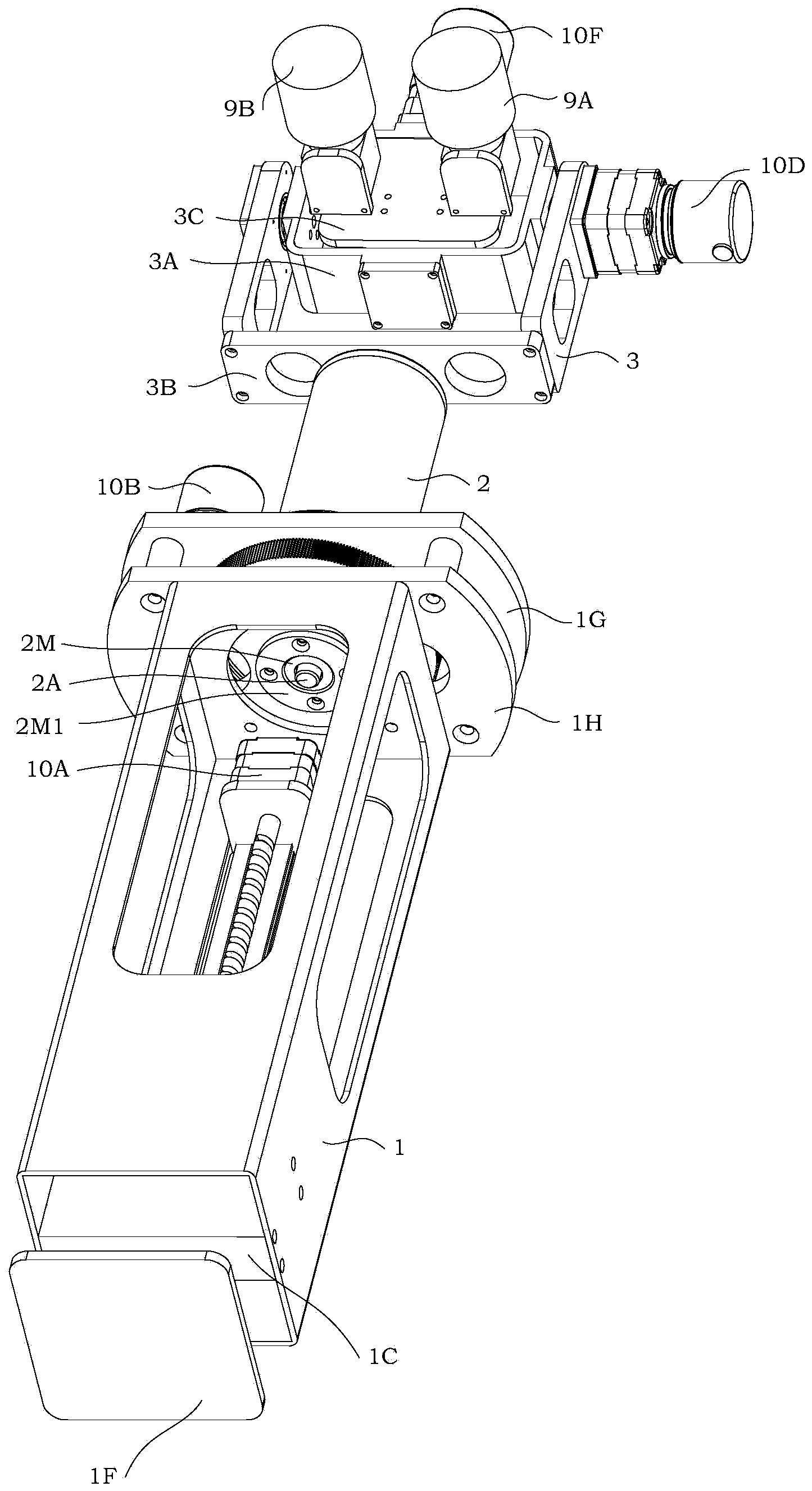

Cervical-vertebra-simulated cradle head mechanism and motor control method of cervical-vertebra-simulated cradle head

The invention discloses a cervical-vertebra-simulated cradle head mechanism and a motor control method of the cervical-vertebra-simulated cradle head. The mechanical structure of the cervical-vertebra-simulated cradle head mechanism is designed by simulating a series of specific motions when a person tracks an observation target. The cervical-vertebra-simulated cradle head mechanism comprises a vertical lifting assembly, a horizontal rotating assembly and an angle adjusting assembly. The vertical lifting motion of the cradle head mechanism is achieved through the adoption of a ball screw, the horizontal rotating motion is completed in the mode that a pair of reduction gear mechanisms are driven by a direct current servo motor, and the pitching motion and the left-and-right fine adjustment motion are achieved through direct driving of the direct current servo motor. The control method that the PID algorithm is adopted in the motor is adopted and is characterized in that the tracking precision is improved through composite control, the dynamic lag problem is solved, and tracking errors are reduced. The cervical-vertebra-simulated cradle head mechanism is reasonable in structure, light in weight, large in view field, stable in imaging and suitable for machine visual tracking and aviation shooting occasions.

Owner:BEIHANG UNIV

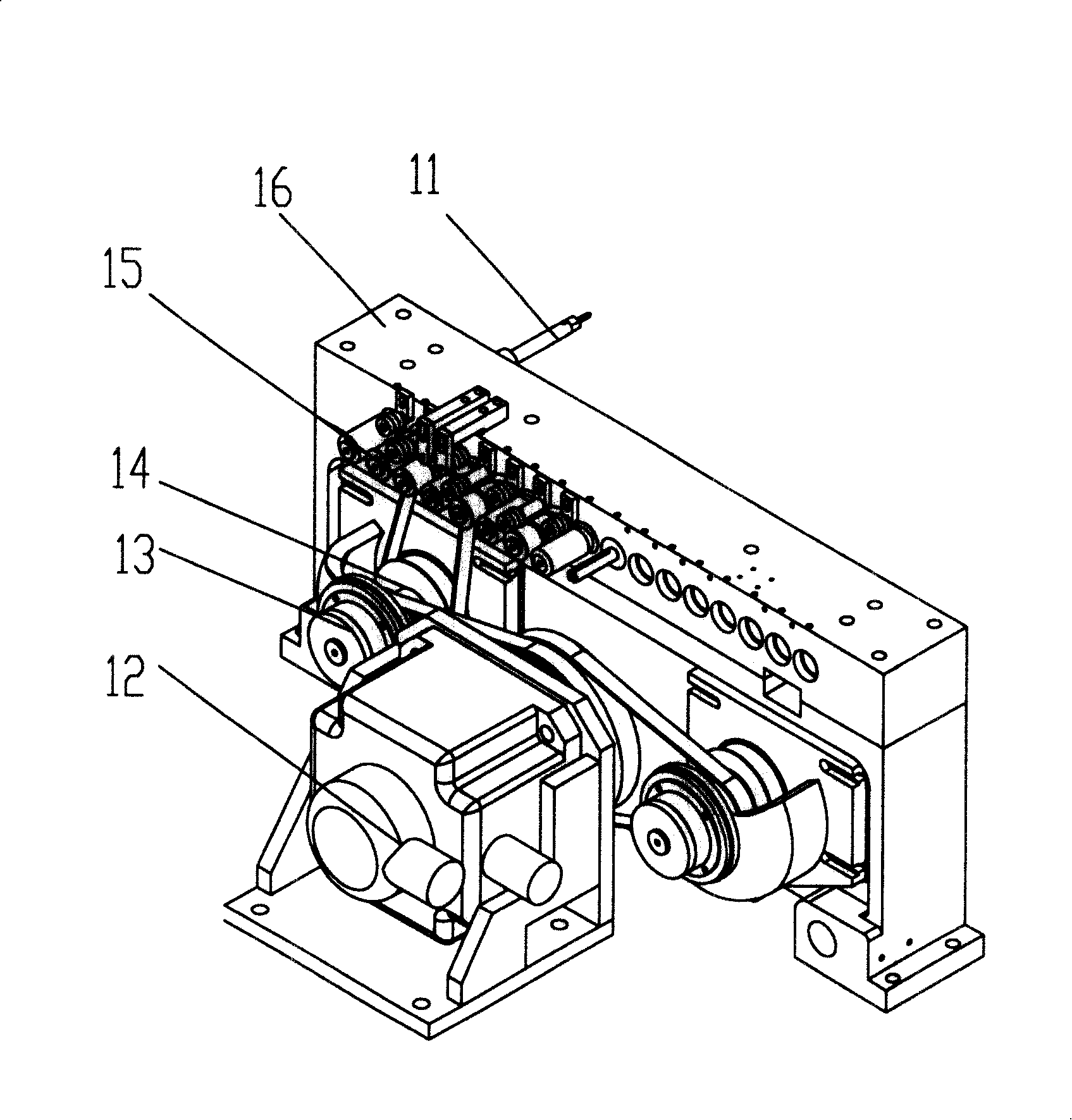

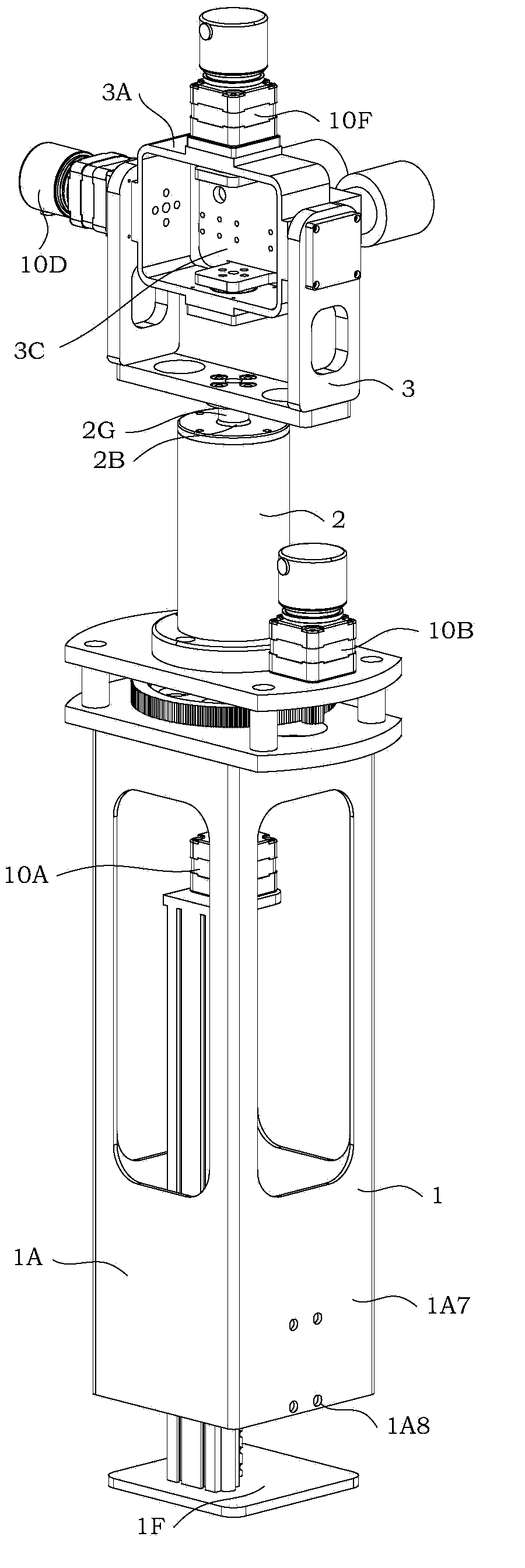

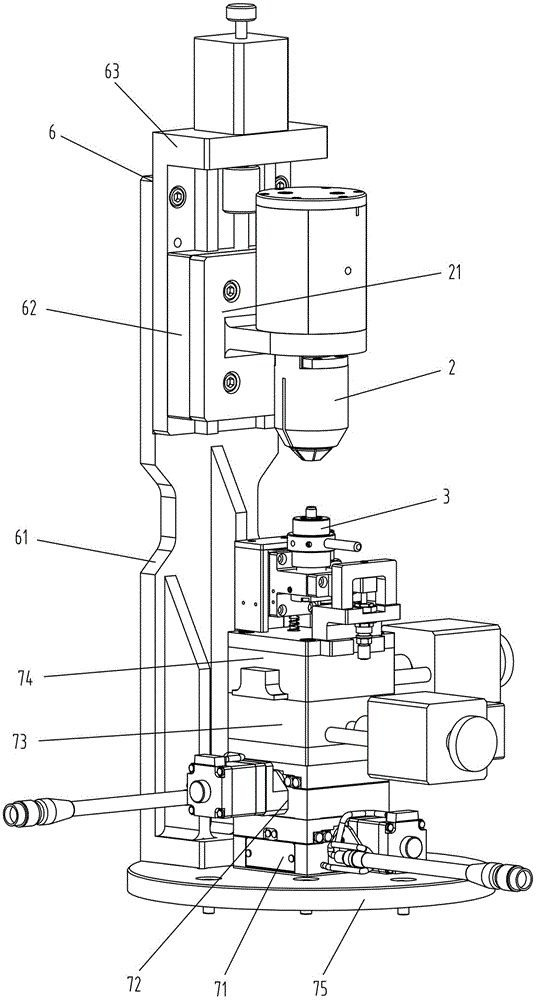

Coupling alignment device and coupling alignment method of coaxial type optoelectronic device

ActiveCN104101966AHigh degree of automationIncrease productivityCoupling light guidesEngineeringMechanical engineering

The invention discloses a coupling alignment device and a coupling alignment method of a coaxial type optoelectronic device. The coupling alignment device comprises a mounting base, an upper clamp and a lower clamp, wherein the upper clamp is arranged on the mounting base through a lifting device; the lower clamp is arranged on the mounting base through an alignment device and can move respectively along an X-axis and a Y-axis and swing respectively around the X-axis and Y-axis under the driving of the alignment device; the lower clamp comprises a base and a clamp component; the base is provided with a bearing component for bearing the clamp component by a constant bearing force and enabling the clamp component to slide up and down; the coupling alignment device further comprises a displacement detection component and a controller. The coupling alignment method comprises the steps of clamping devices, adjusting position of a Z-axis, aligning angles, aligning coarsely, aligning precisely and the like. The coupling alignment device and the coupling alignment method of the coaxial type optoelectronic device have the advantages of rational structure design, adjustment in multiple degrees of freedom, high automation degree, capabilities of greatly improving production efficiency and product quality, and the like.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com