Patents

Literature

310results about How to "High degree of processing automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

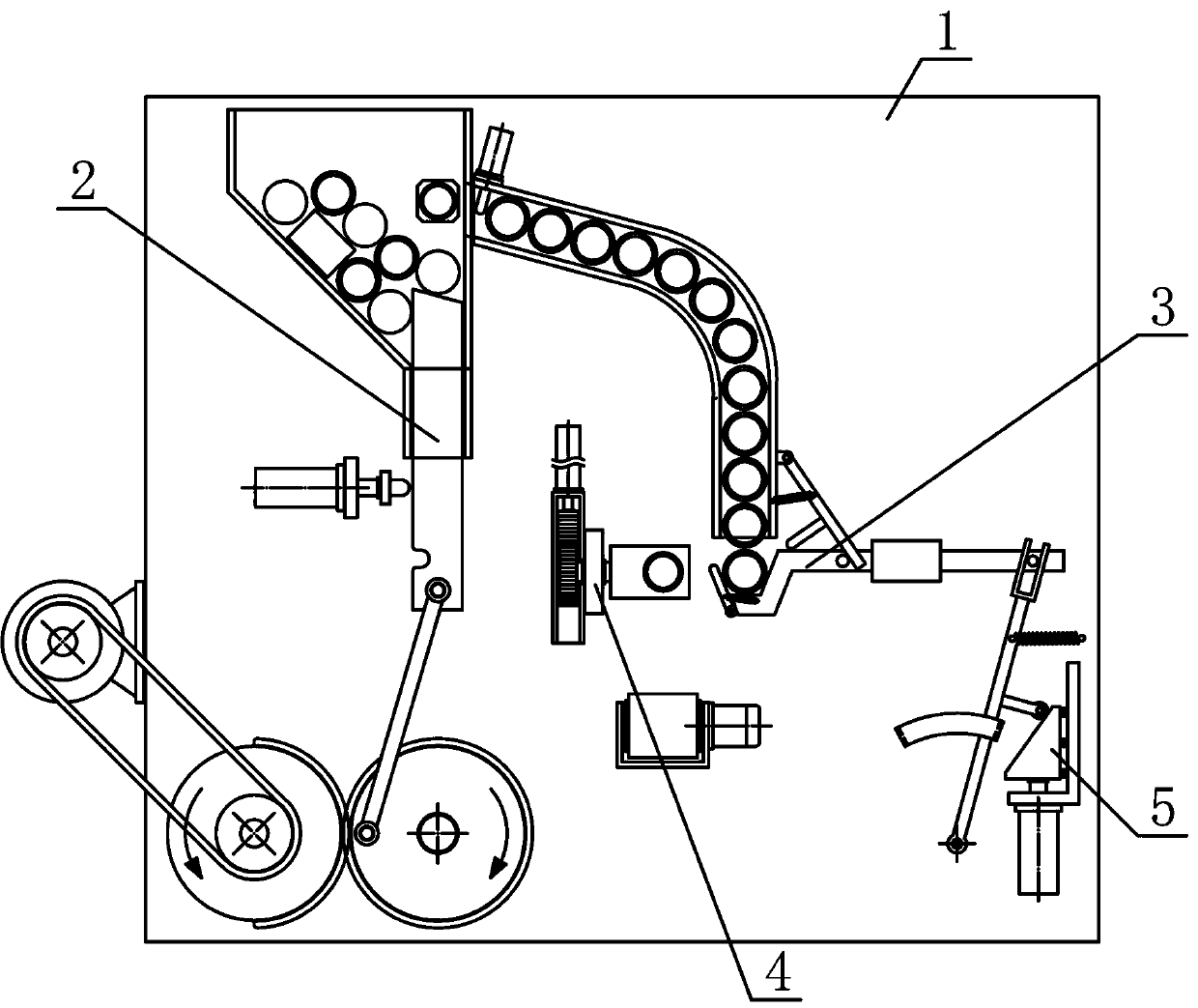

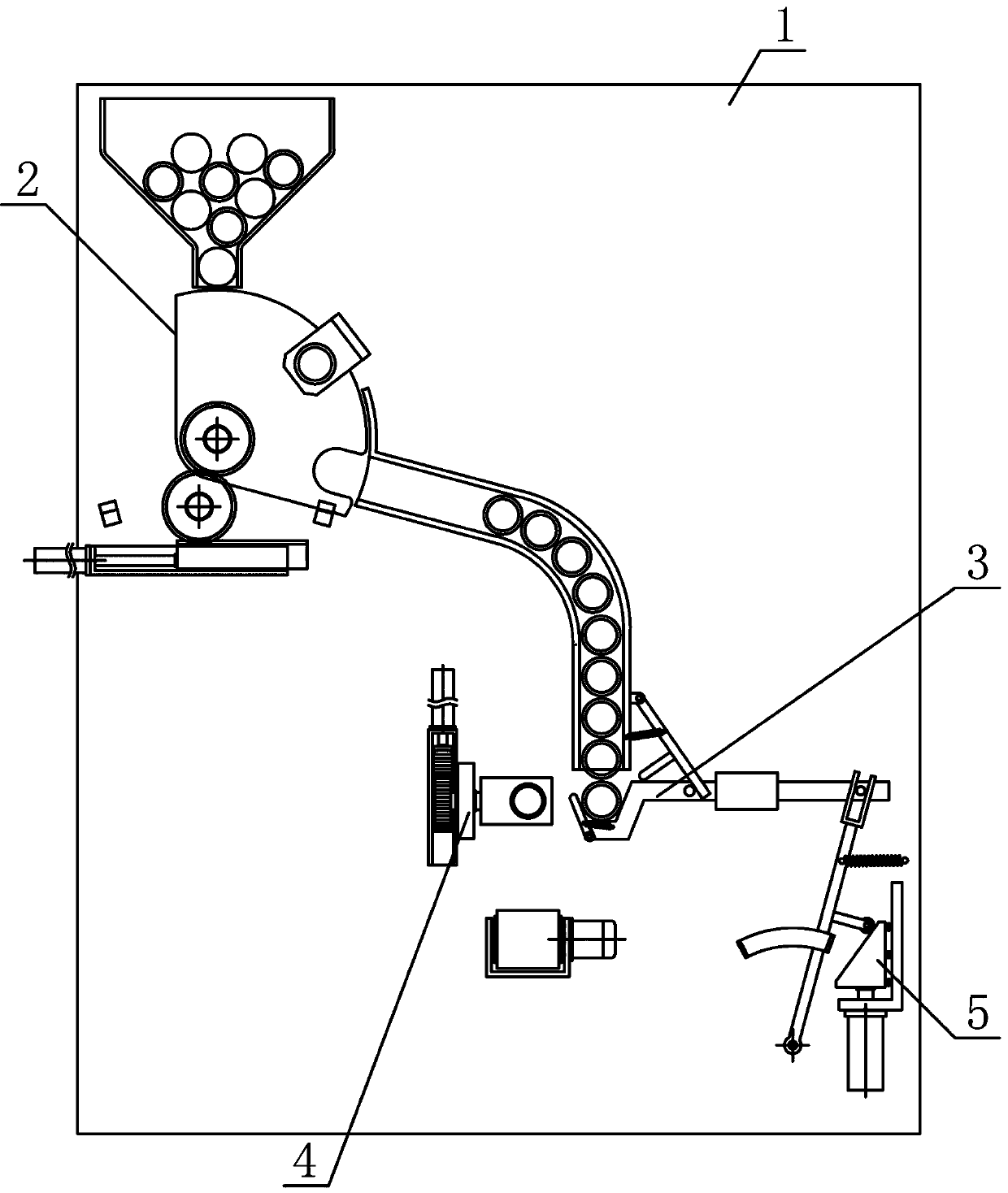

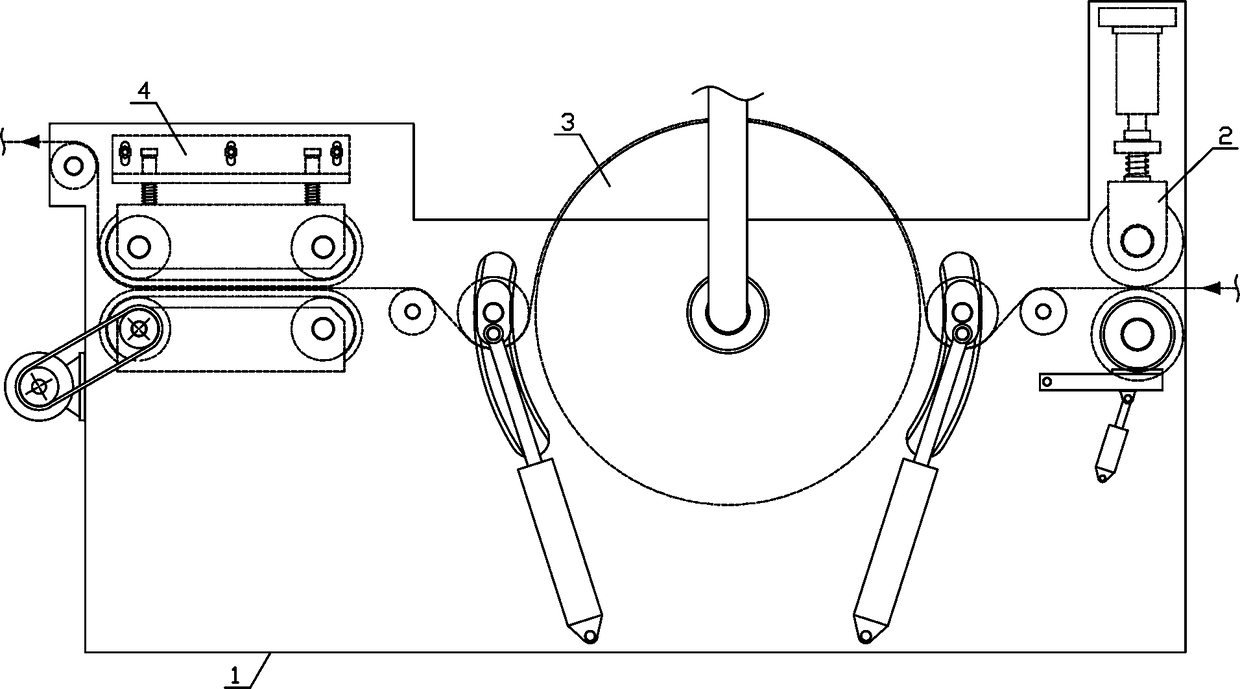

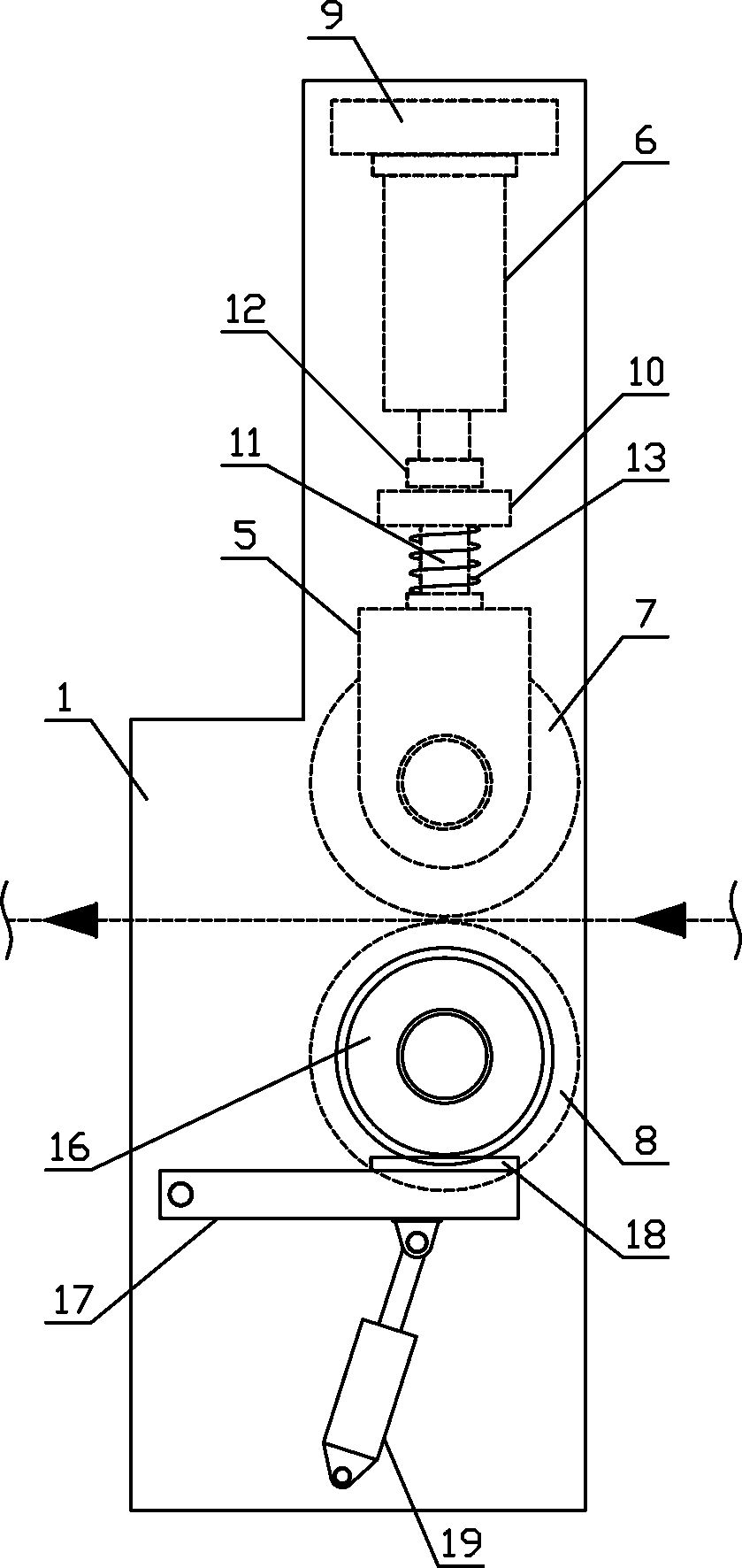

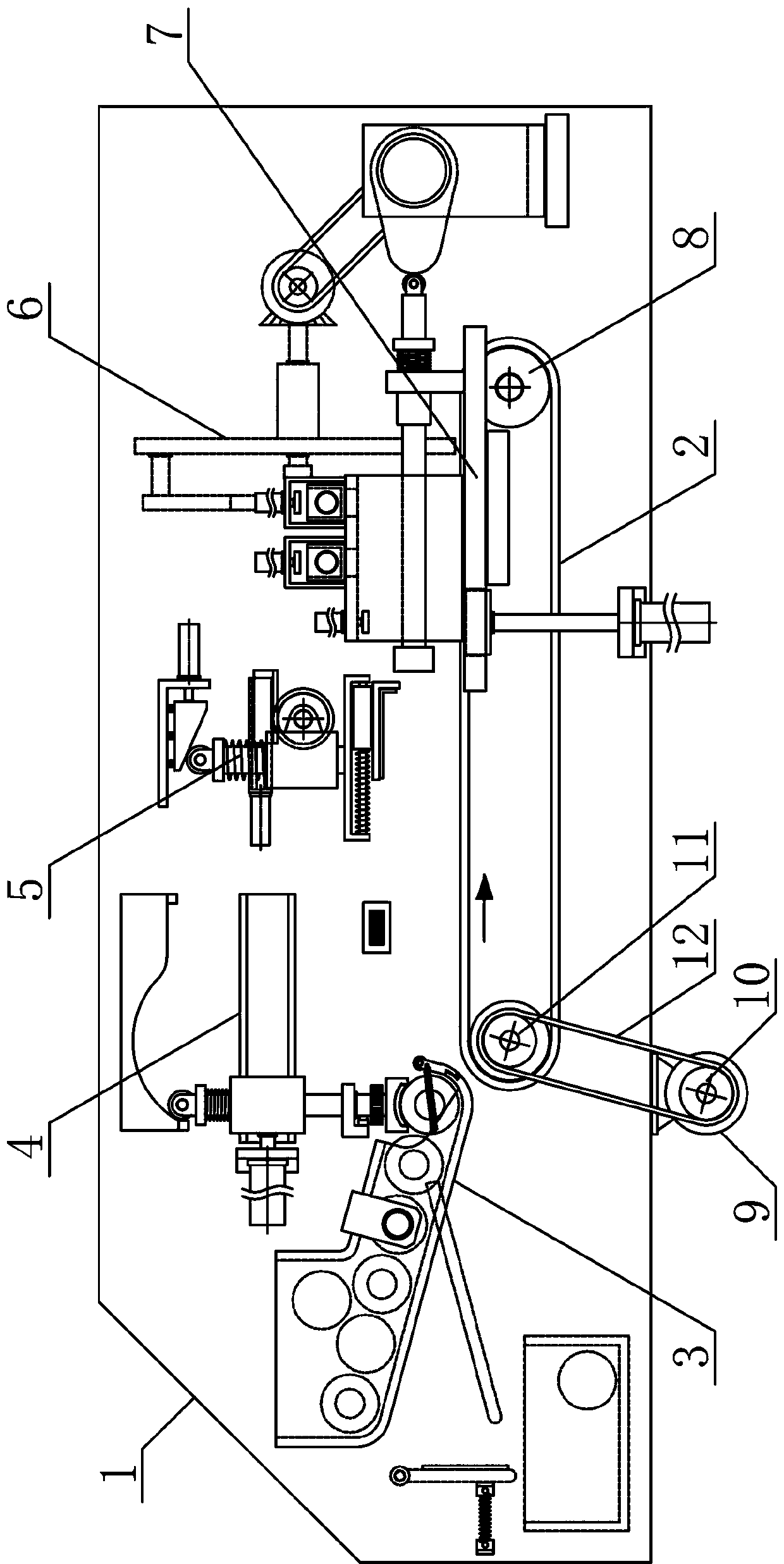

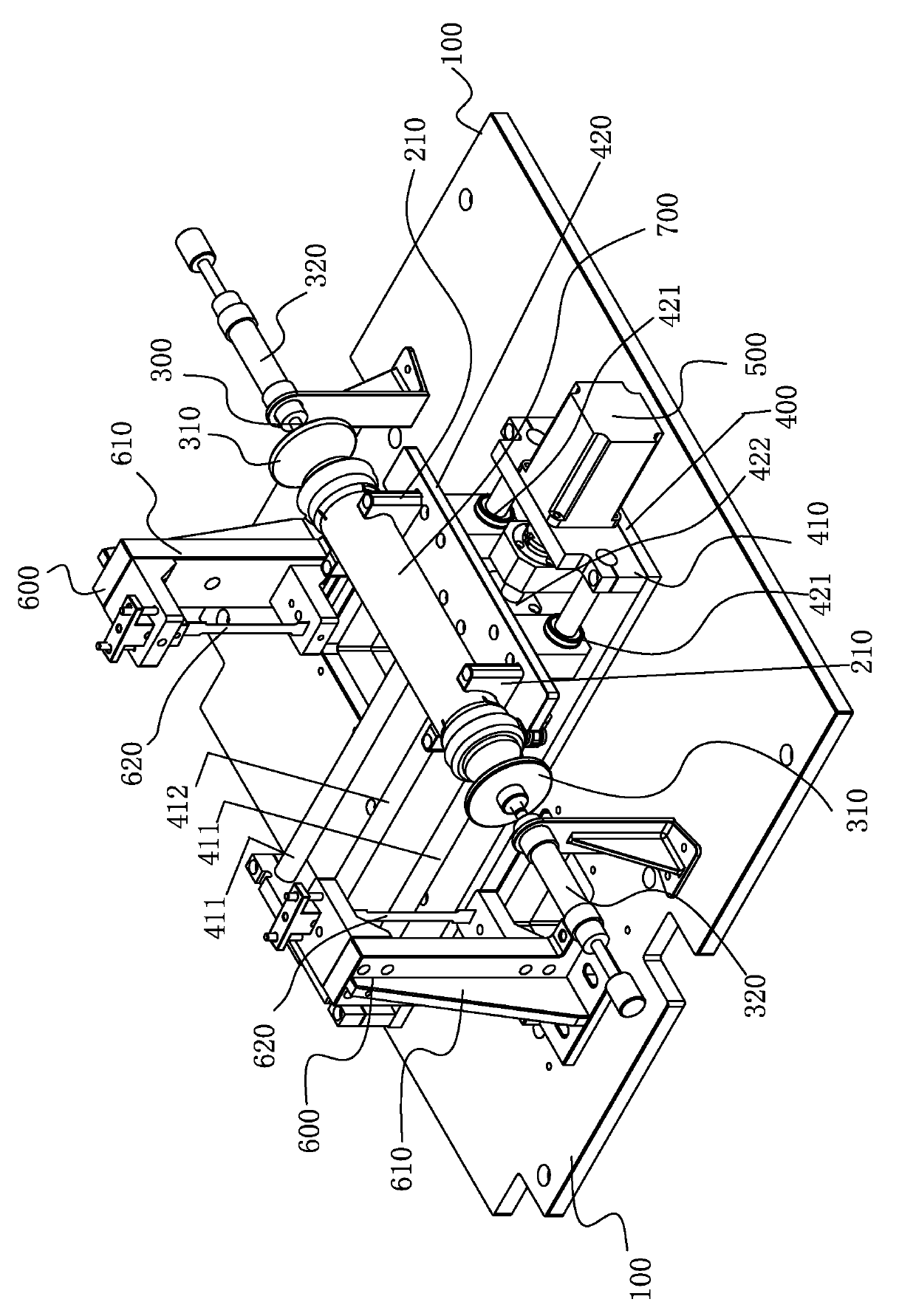

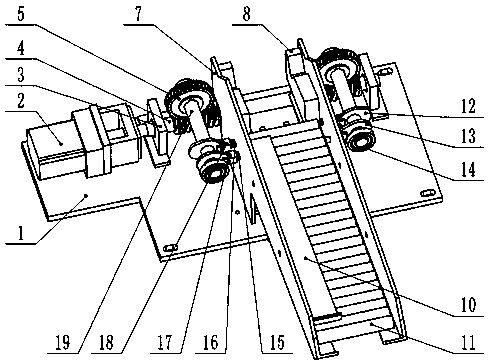

Feeding and transferring mechanism for pipe fittings with end portions closed

InactiveCN109704046AHigh degree of processing automationReasonable structural designConveyor partsMotor drivePipe fitting

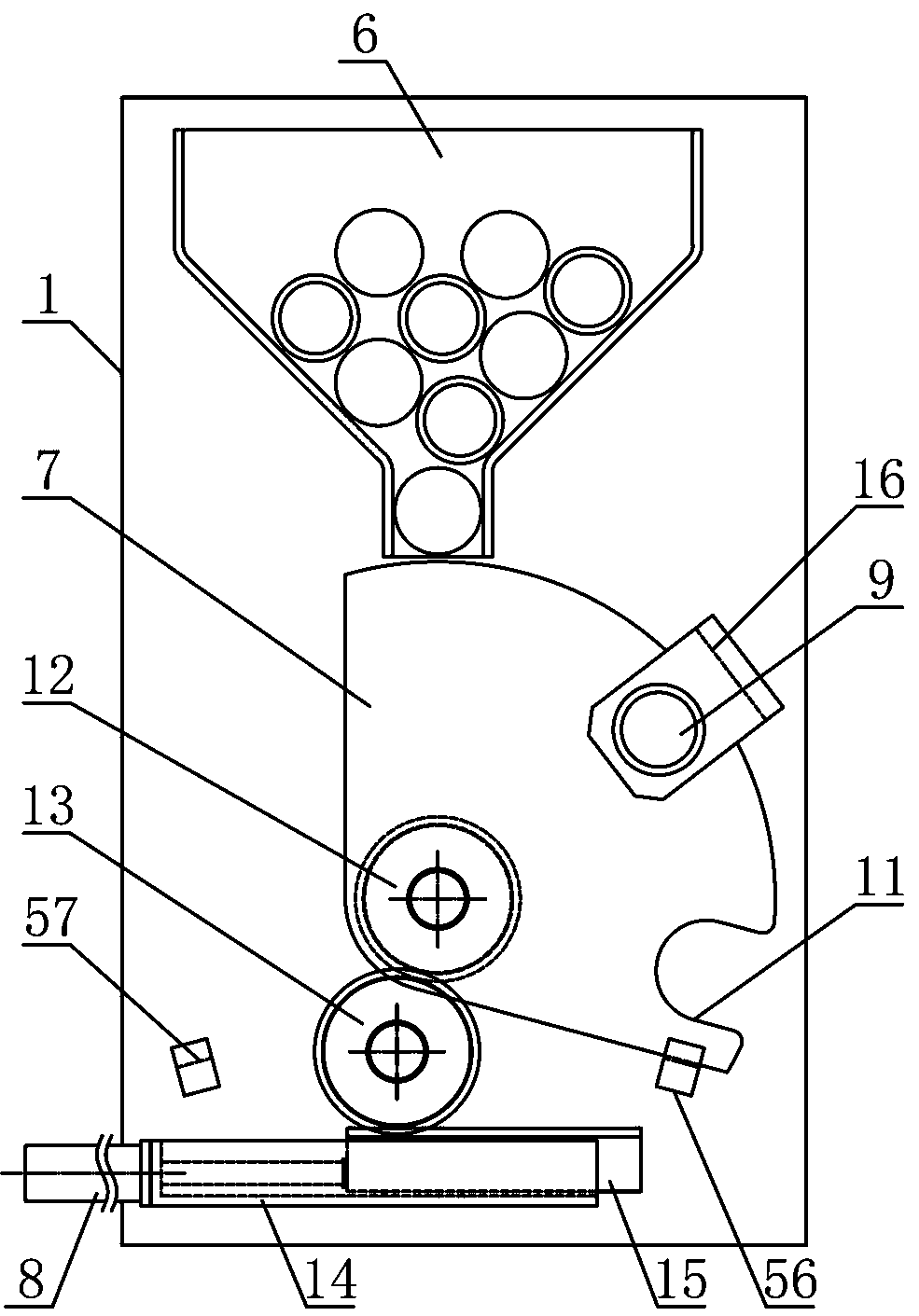

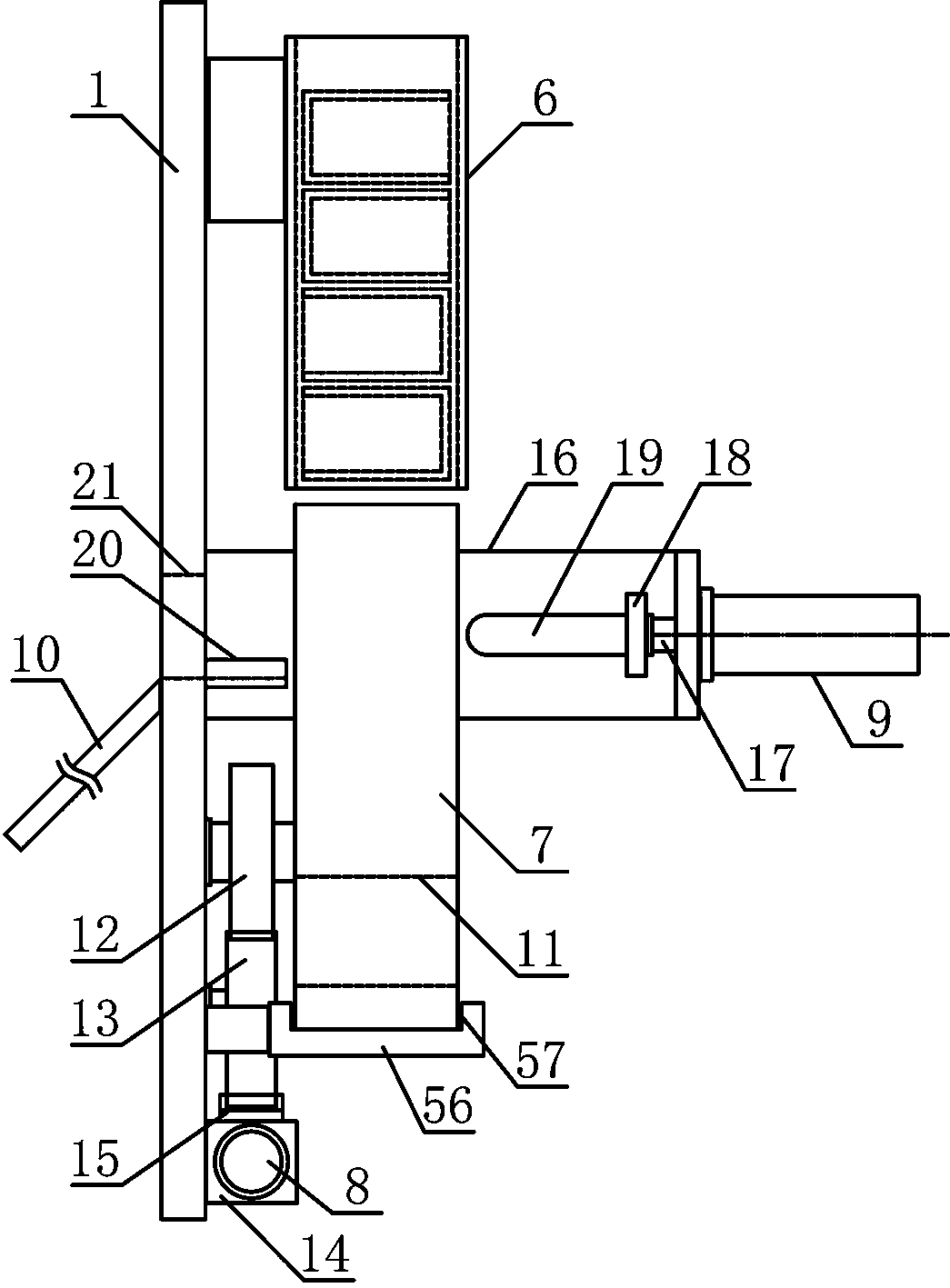

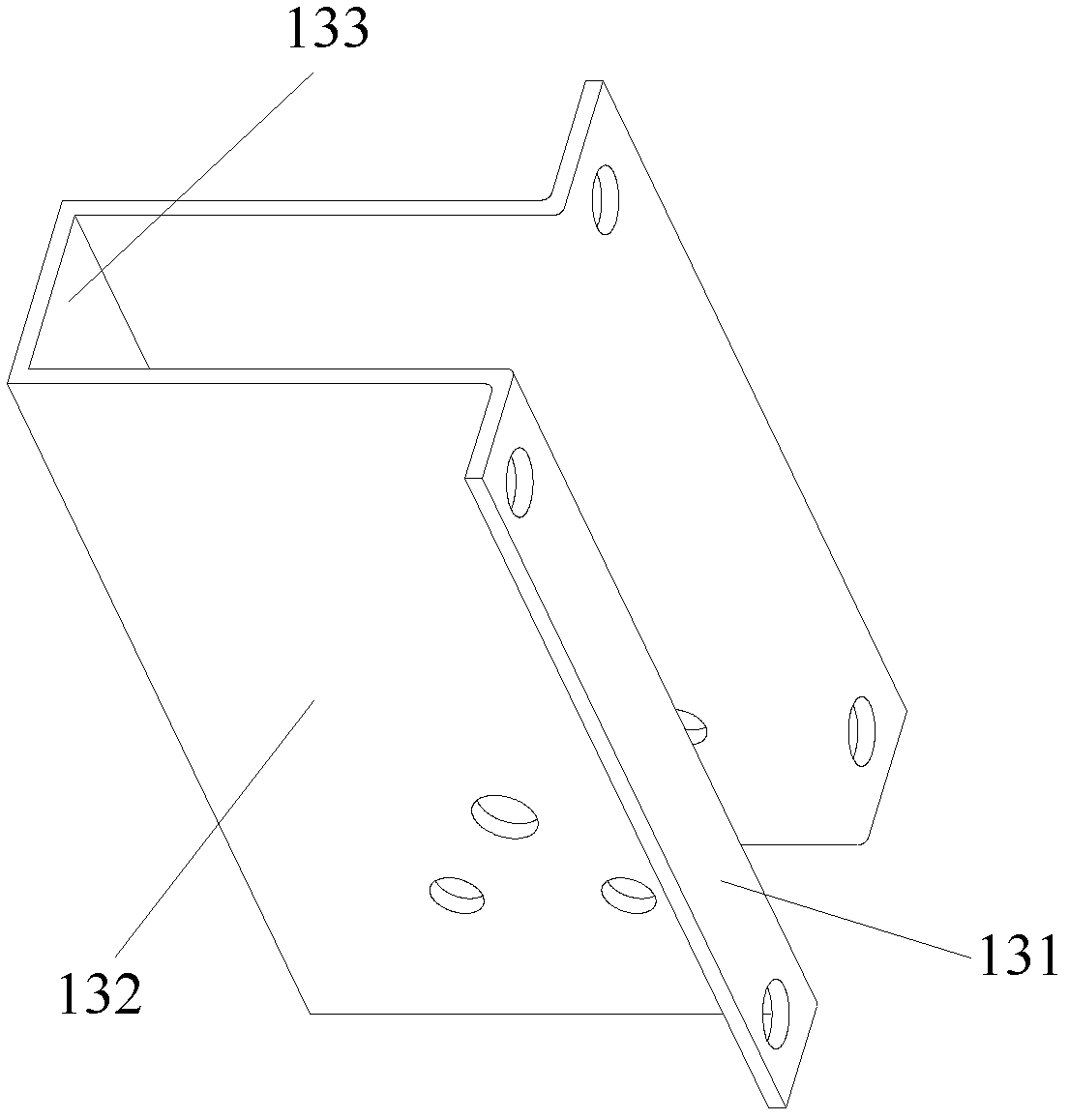

The invention discloses a feeding and transferring mechanism for pipe fittings with end portions closed, and belongs to the field of workpiece machining mechanical equipment. A guide pipe through holeis formed in the upper end of a pipe storage hopper of the feeding and transferring mechanism. A lifting push plate is arranged on a push plate sleeve on the lower side of the pipe storage hopper ina sliding manner. A pipe movement guide plate is arranged on a guide pipe support on the lower side of a discharge guide pipe. A clamping rod limiting clamp is arranged at the upper end of a reciprocating swinging rod. A turnover gear is fixedly arranged on the end portion of one side of a fixed rotating shaft. The middle portion of one side of a turnover connection plate is fixedly arranged on the end portion, along the side of the pipe movement guide plate, of the fixed rotating shaft. The two sides of a pipe transferring belt are wound on and connected to pipe transferring rotation rollerson the two sides of a pipe transferring support correspondingly. A pipe transferring motor drives the pipe transferring rotation rollers to rotate. The feeding and transferring mechanism is reasonablein structural design, the pipe fittings can be conveniently and efficiently arranged and fed in an oriented manner one by one, the pipe fittings can be stably and accurately overturned vertically oneby one, and therefore the pipe fittings can be sequentially conveyed through vertical stations, the automation degree of pipe fitting feeding and processing can be improved, and requirements of machining and using can be met.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

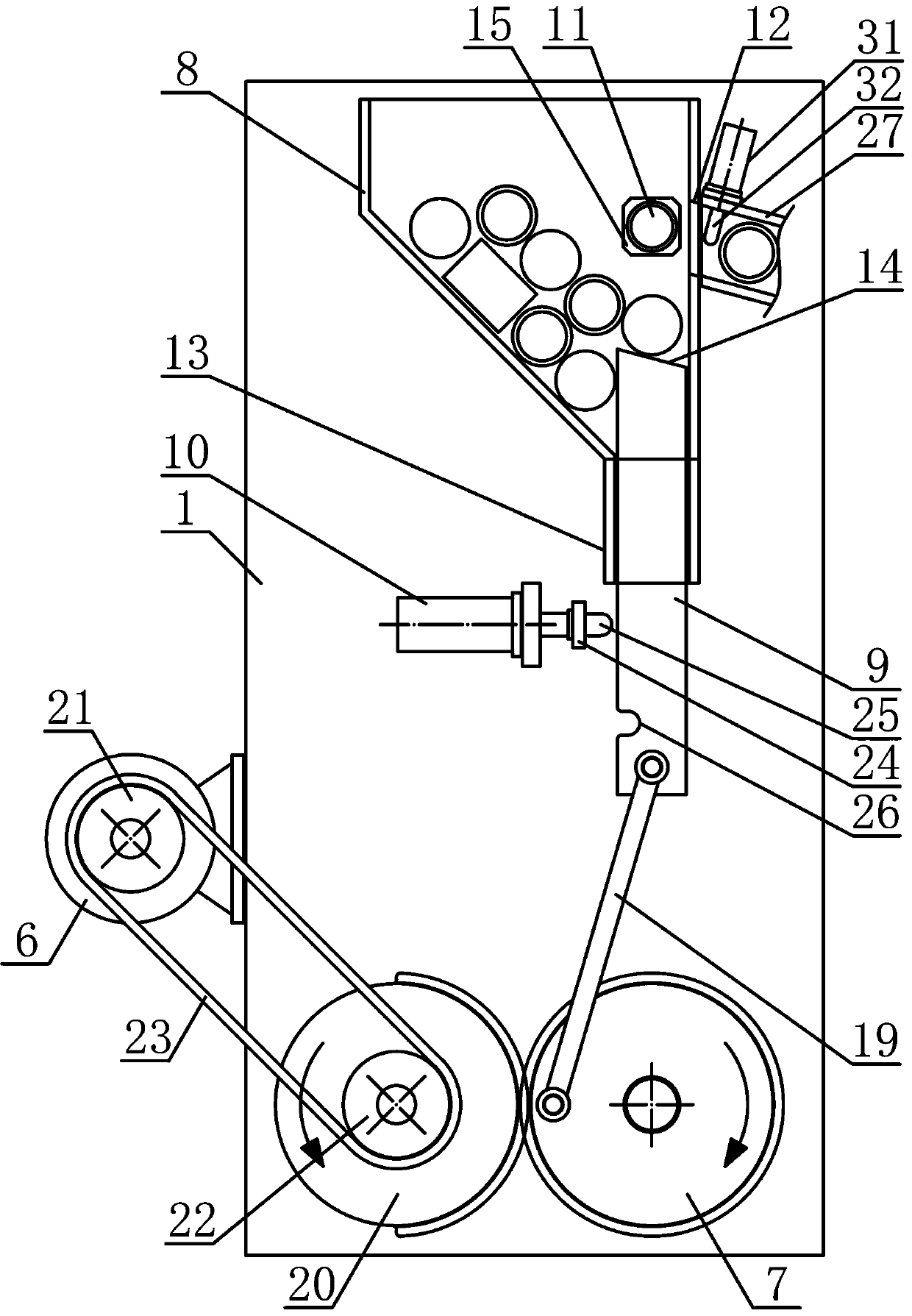

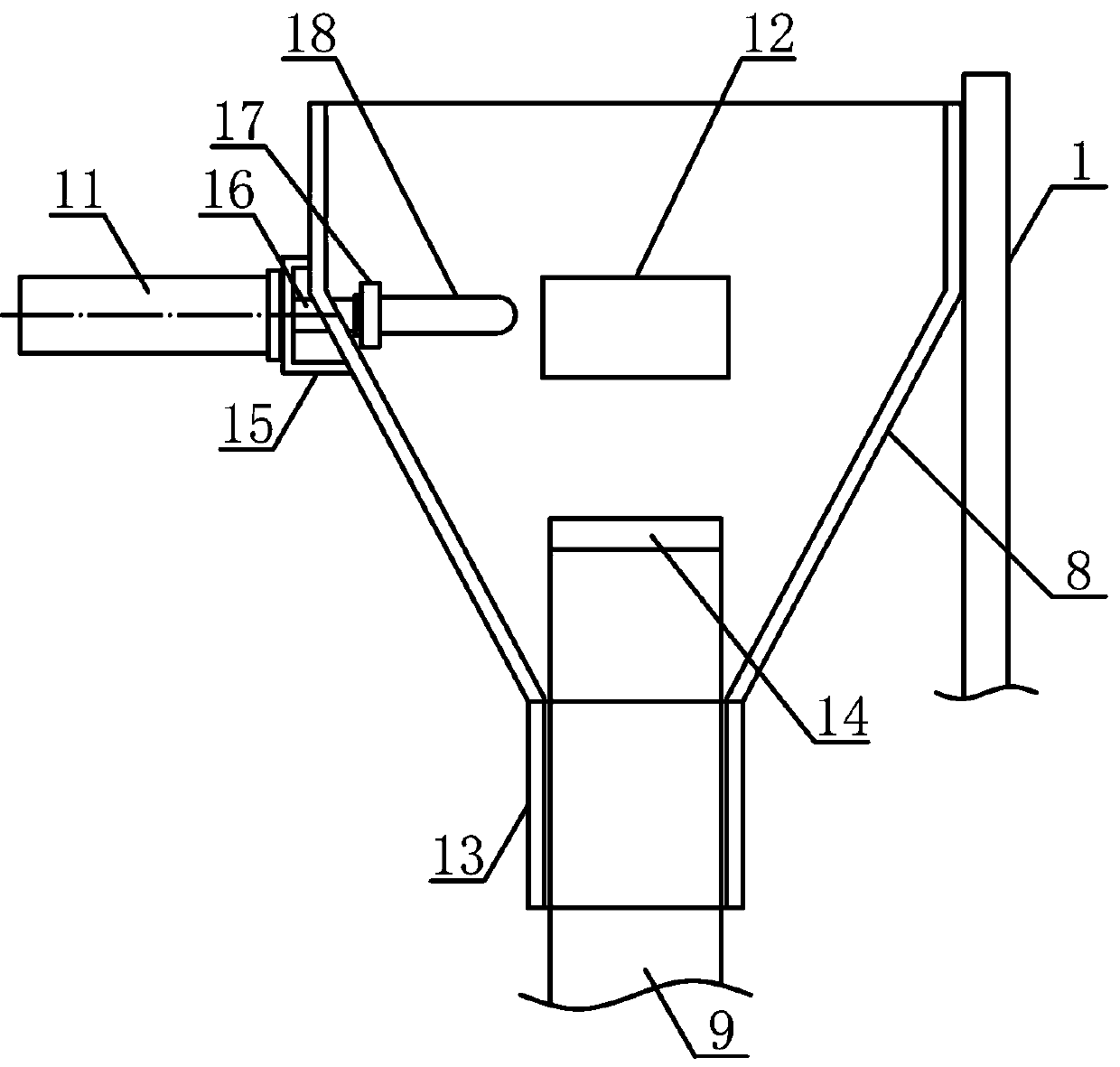

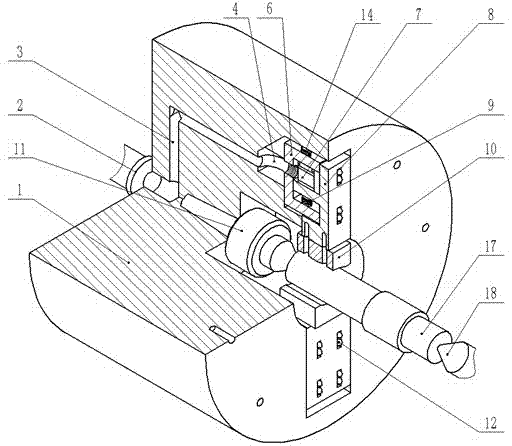

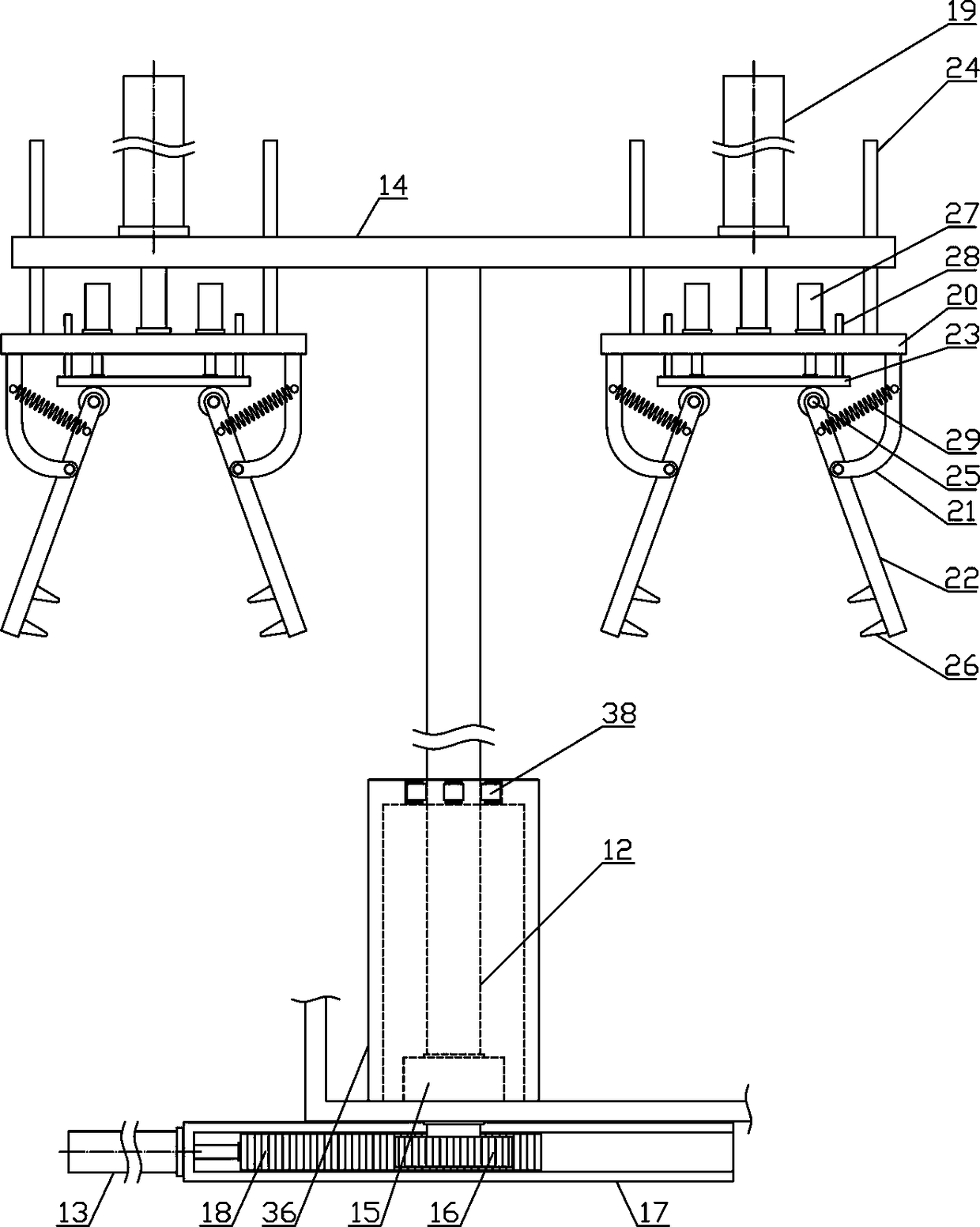

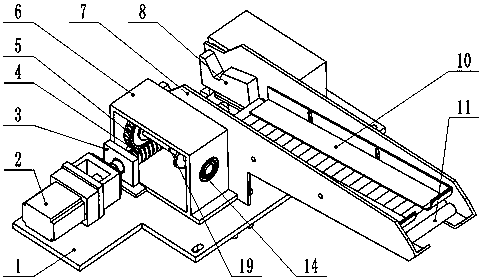

Material guide turning mechanism for end closed pipe fittings

InactiveCN109704025AReasonable structural designHigh degree of automationConveyor partsRound barEngineering

The invention discloses a material guide turning mechanism for end closed pipe fittings, and belongs to the field of workpiece processing mechanical equipment. The outer end of a pipe guide rotating plate on the lower side of a pipe storage hopper of the material guide turning mechanism is provided with a transfer pipe groove, a pipe moving guide plate is slidably arranged on a guide plate sleeve,the end of the pipe moving guide plate is provided with a pipe containing clamping slot, a reciprocating swing rod is arranged on a pipe guide support on the lower side of the pipe moving guide plate, the lower end of the reciprocating swing rod is hinged to the pipe guide support, the middle portion of one side of a turning connecting plate is fixedly arranged at the end of the side, along the pipe moving guide plate, of a fixed rotating shaft, a pipe bearing round bar is fixedly arranged on one side of a pipe bearing baffle at the output end of a pipe bearing air cylinder, and a pipe transferring belt is horizontally arranged on the upper side of a pipe transfer support. The material guide turning mechanism is reasonable in structural design, the pipe fittings can be conveniently and efficiently fed in an oriented manner one by one, the pipe fittings can be vertically turned one by one stably and accurately, the pipe fittings can be sequentially conveyed at a vertical working position, the automation degree of pipe fitting feeding and processing is carried out, and the processing and using needs are met.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

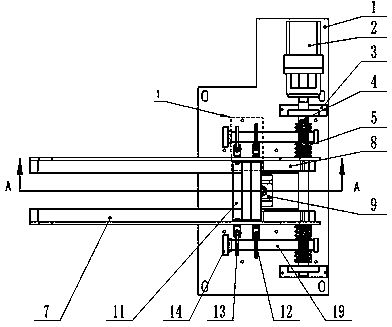

Workpiece drilling clamp

InactiveCN102430942ASimple structureEasy clampingPositioning apparatusDrill jigsBiochemical engineeringAutomation

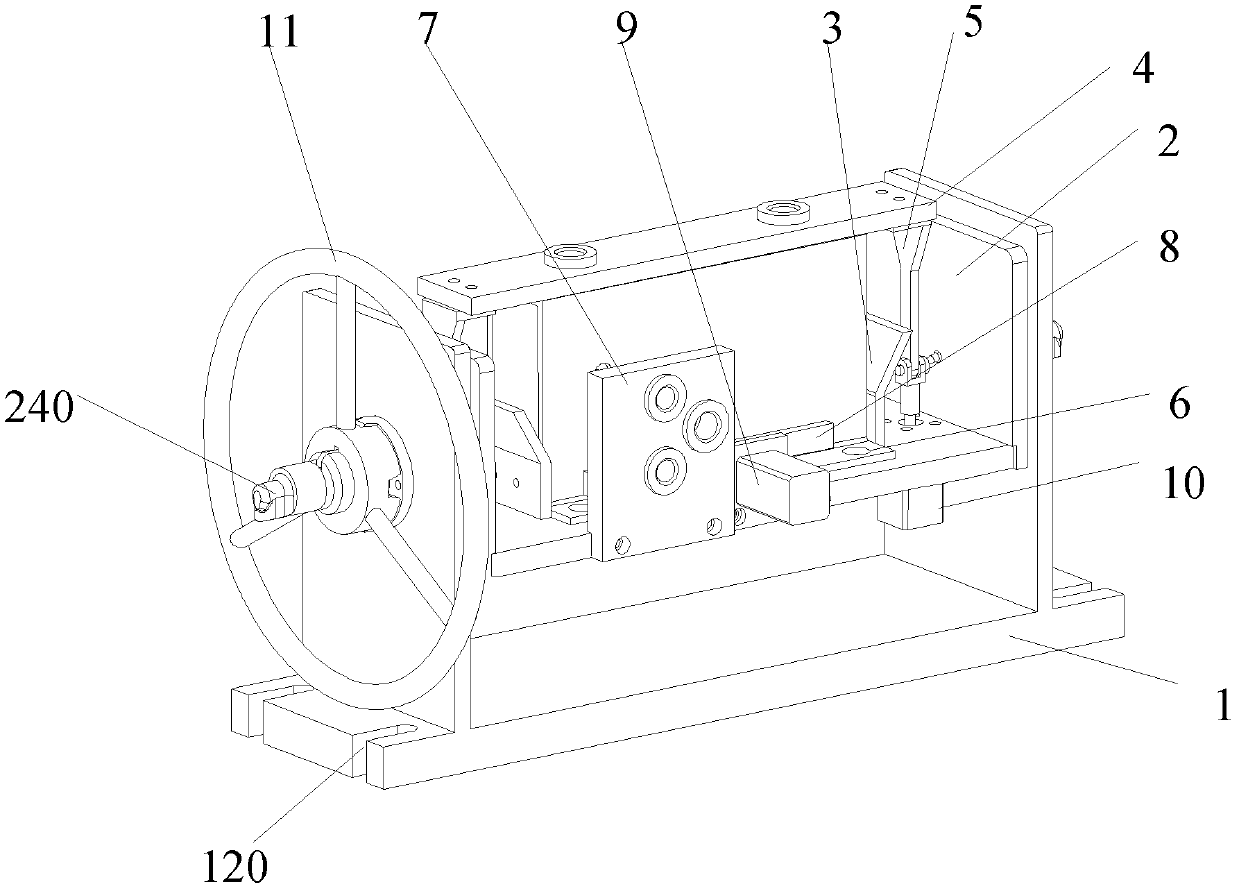

The invention provides a workpiece drilling clamp, which comprises a base, a rotation support, a positioning mechanism, a clamping mechanism and two first drilling templates, wherein the base comprises a first base plate, a first side plate and a second side plate, and the first side plate and the second side plate are fixedly connected with the first base plate; the rotation support comprises a second base plate, a third side plate and a fourth side plate, and the third side plate and the fourth are fixedly connected with the second base plate; the rotation support is arrange inside the base, the first side plate is in rotating connection with the third side plate, and the second side plate is in rotating connection with the fourth side plate; the positioning mechanism is fixedly connected to the second base plate; the clamping mechanism comprises a first clamping mechanism and a second clamping mechanism, which are respectively arranged at both sides of the positioning mechanism; and the two first drilling templates are respectively arranged at both sides of the positioning mechanism and fixedly connected with the second base plate. The workpiece drilling clamp provided by the invention has the advantages of simple structure, convenience in assembling and clamping and high processing precision and automation degree, can greatly improve product assembly efficiency, and is suitable for volume-production.

Owner:SANY HEAVY IND CO LTD (CN)

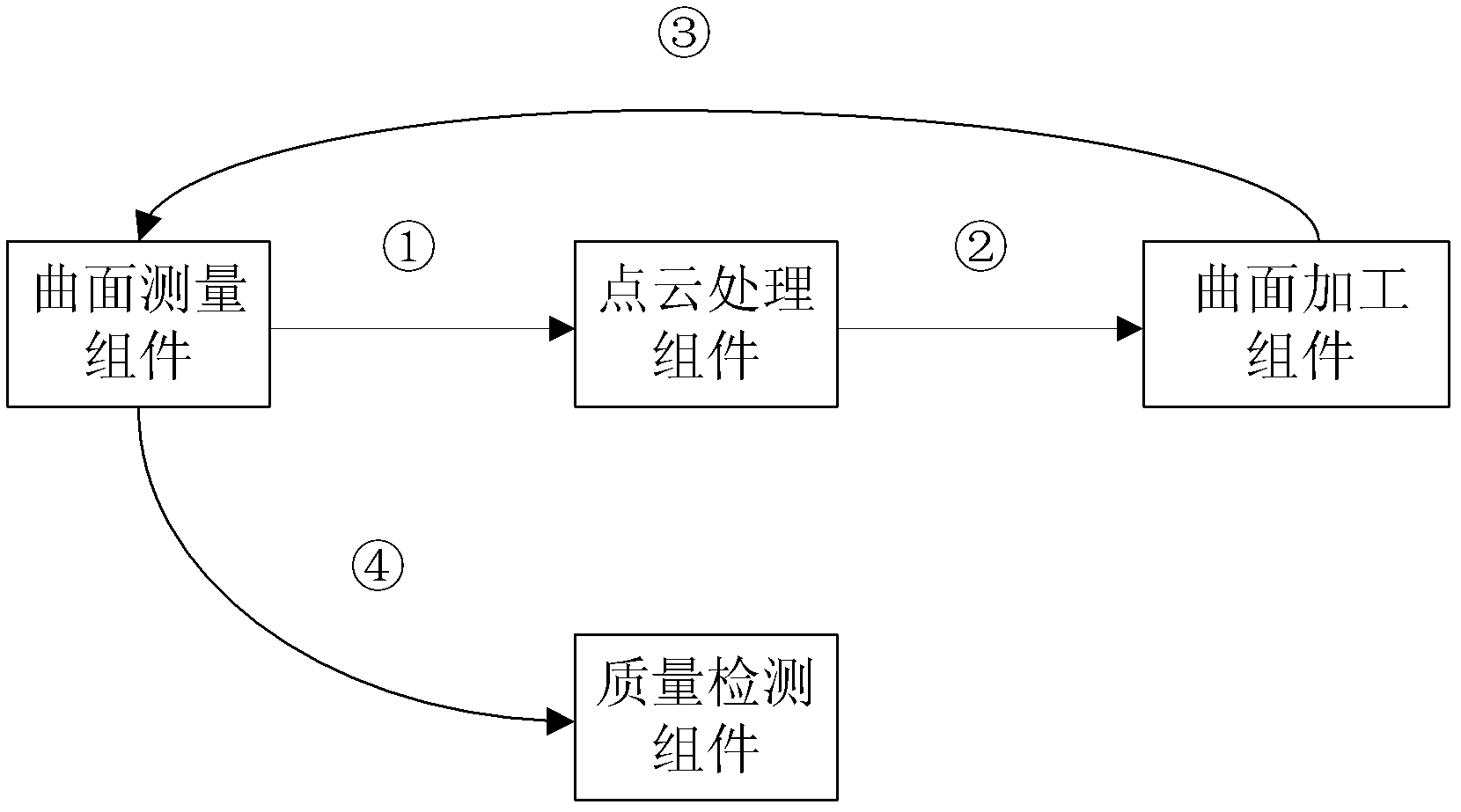

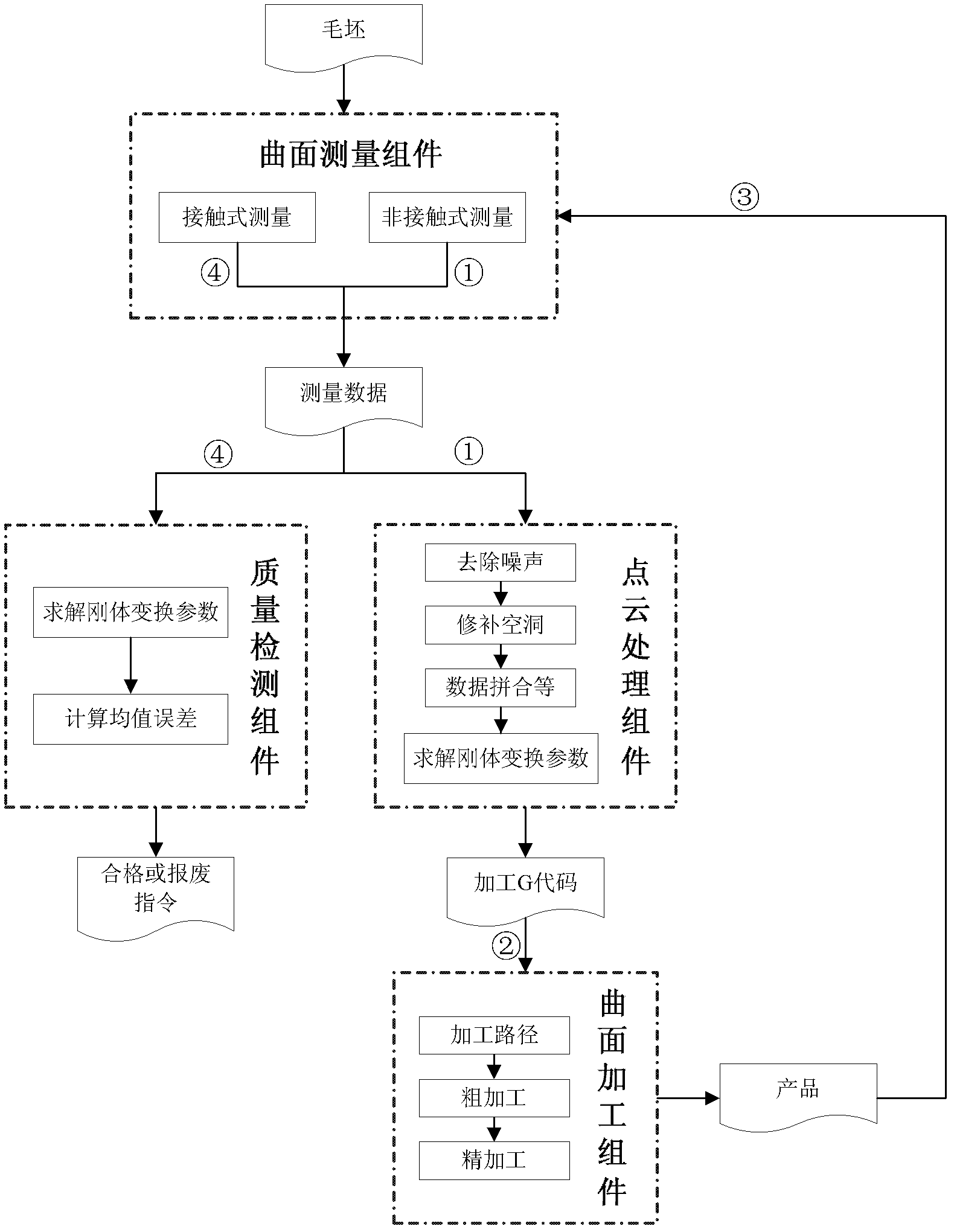

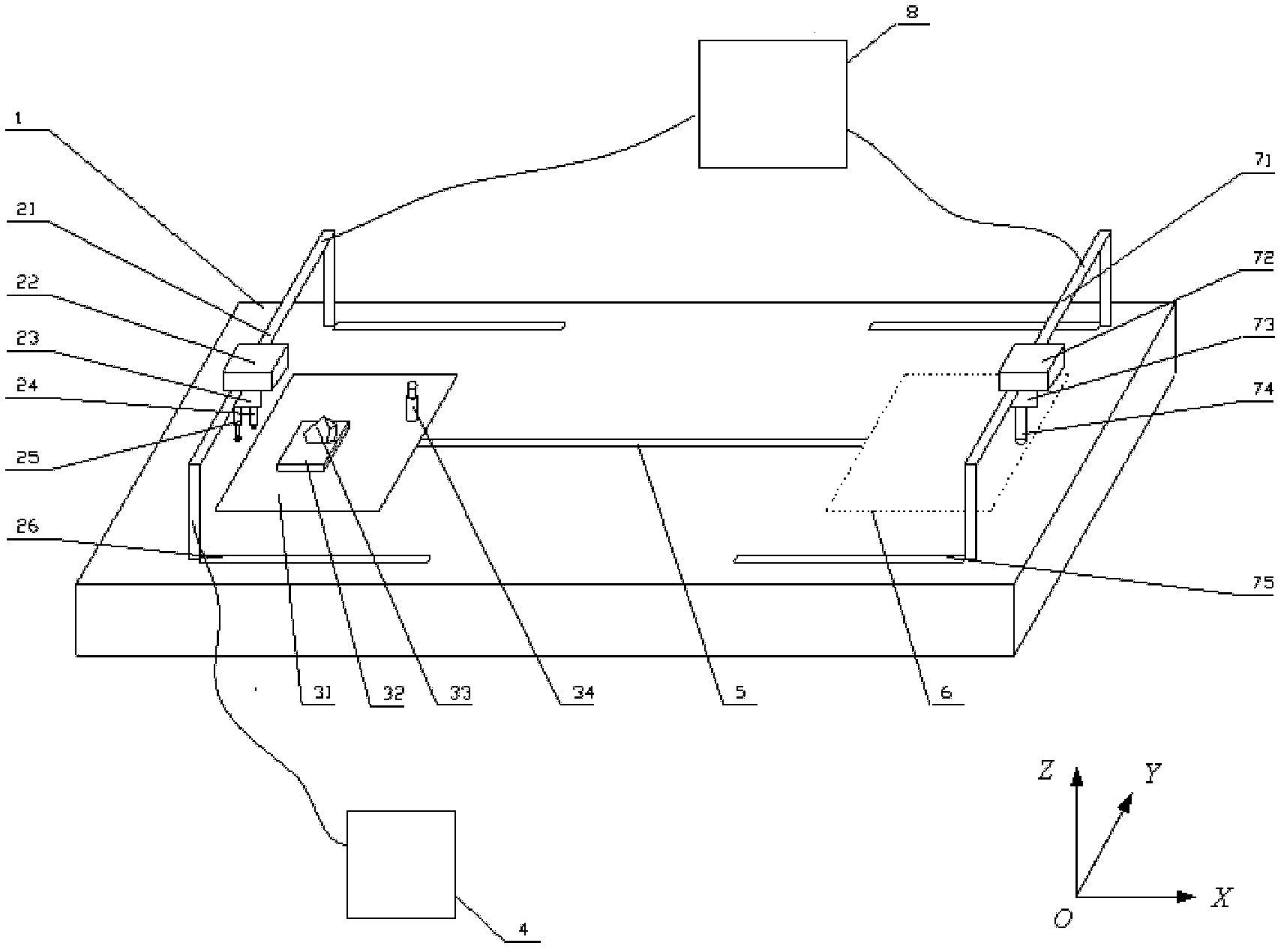

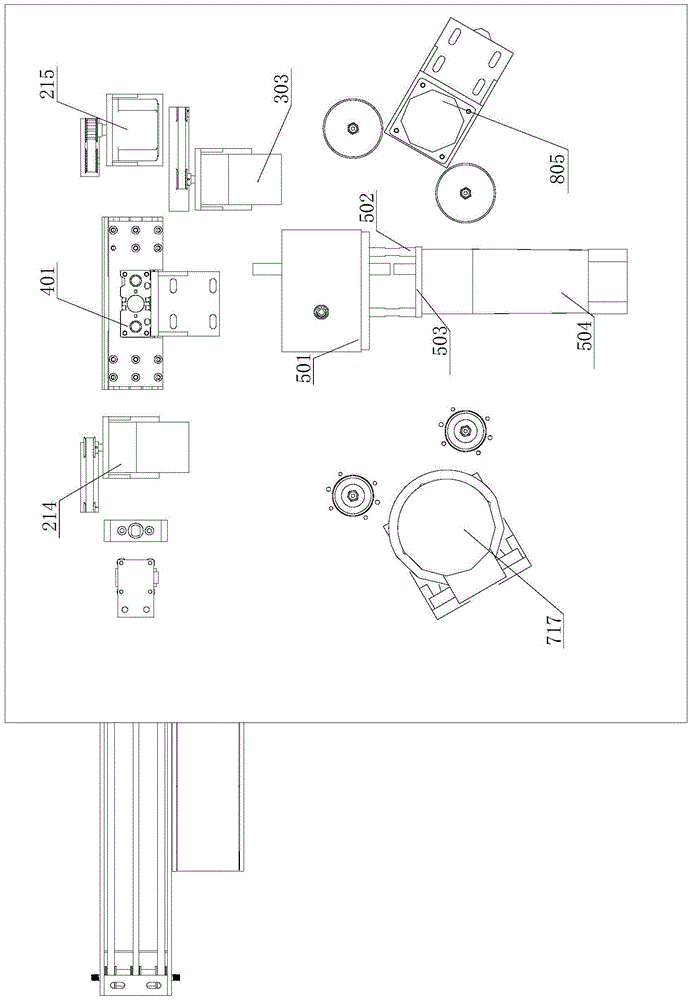

Free-form surface part processing system based on multi-sensor integrated measurement technology

ActiveCN102430961AQuick calculationGet a large amount of dataMeasurement/indication equipmentsMilling equipment detailsMilling cutterFree form

The invention discloses a free-form surface part processing system based on the multi-sensor integrated measurement technology. A non-contact type sensor and a contact type sensor are integrated to form a surface measuring component, a surface processing component is provided with a milling cutter, and the surface measuring component is connected with the surface processing component by a linear guide rail. A point-cloud processing component is used for realizing geometric processing for point-cloud data obtained by the non-contact type sensor, and provides processing G codes which can be directly actuated by a current work table to the surface processing component for processing. The surface measuring component measures a workpiece in a non-contact manner, and then measures a product which is obtained by means of fine processing in a contact manner. A quality detecting component is used for comparing errors of measured data obtained by the contact type sensor and obtains results of the quality of the product. The non-contact type sensor and the contact type sensor are integrated, an integrated function of 'measuring, processing and detecting' is realized on the same machine tool, manual intervention is omitted in a total process, and processing efficiency and automation degree are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

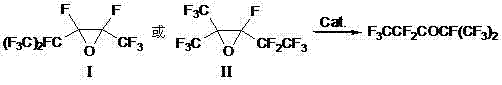

Preparation process of perfluoro-2-methyl-3-pentanone

ActiveCN103787854AHigh selectivityHigh yieldPreparation from heterocyclic compoundsGas phaseReaction rate

The invention discloses a preparation process of perfluoro-2-methyl-3-pentanone, belonging to the technical field of preparation methods of perfluoroketone compounds in the field of organofluorine chemistry. The perfluoro-2-methyl-3-pentanone is obtained by performing an epoxidation reaction and a catalytic isomerization reaction on perfluoro-2-methyl-pentene serving as a raw material in sequence. The preparation process comprises the following steps: I, in a continuous liquid phase epoxidation reaction, mixing a corresponding proportion of aprotic polar solvent into a sodium hypochlorite solution to promote the reaction, increase the raw material conversion ratio and increase the reaction rate at least by 2-3 percent, wherein the step is characterized by easiness and convenience in operation, low equipment requirement and high reaction equipment efficiency; II, performing a continuous gas phase catalytic reaction, wherein the application of a solvent is effectively avoided, the cost and environmental pollution are lowered, the problems of the need of separating the solvent from a product in post-treatment, difficulty in recycling and treating the solvent and a catalyst, and the like are solved, and the product can be refined and purified more easily. The preparation process has the advantages of high process automation degree, easiness and convenience in operation, high product purity and high reaction equipment efficiency, and is suitable for industrial application.

Owner:浙江诺亚氟化工有限公司

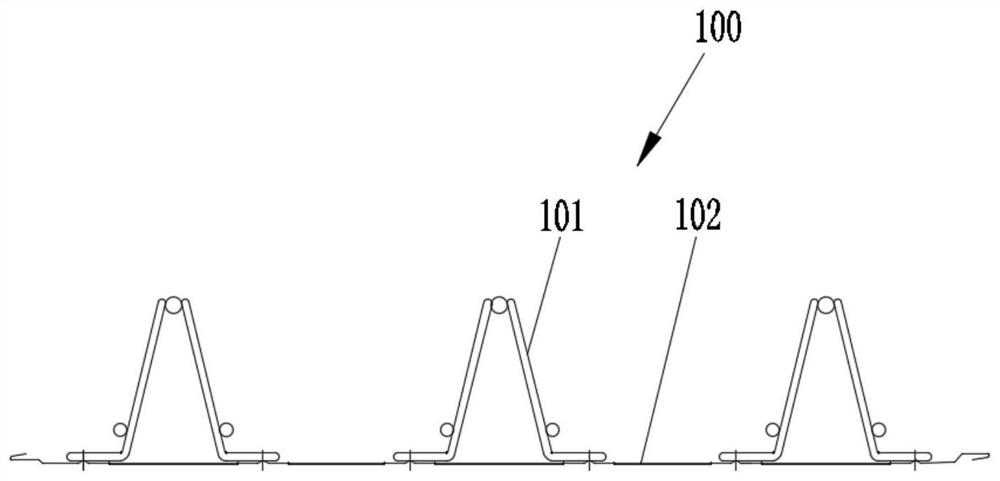

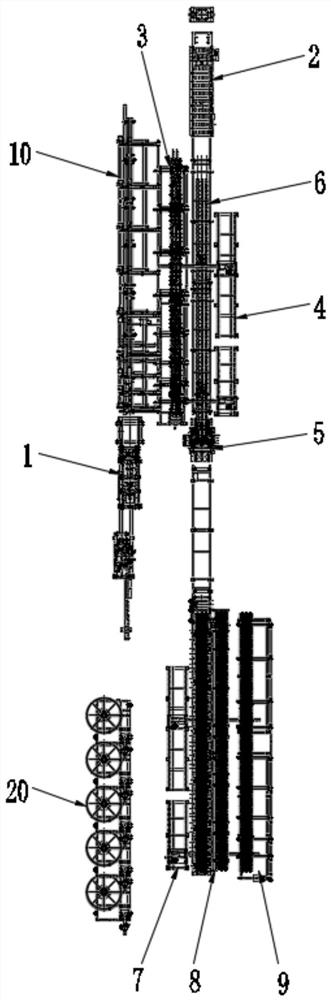

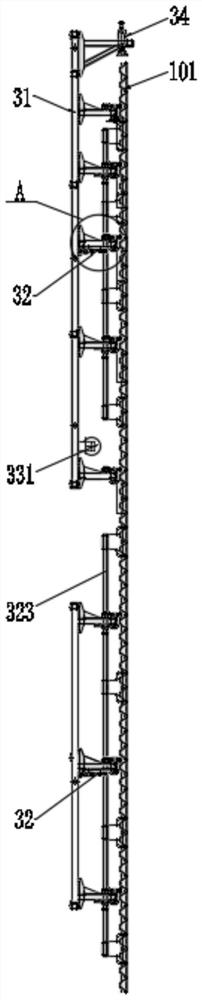

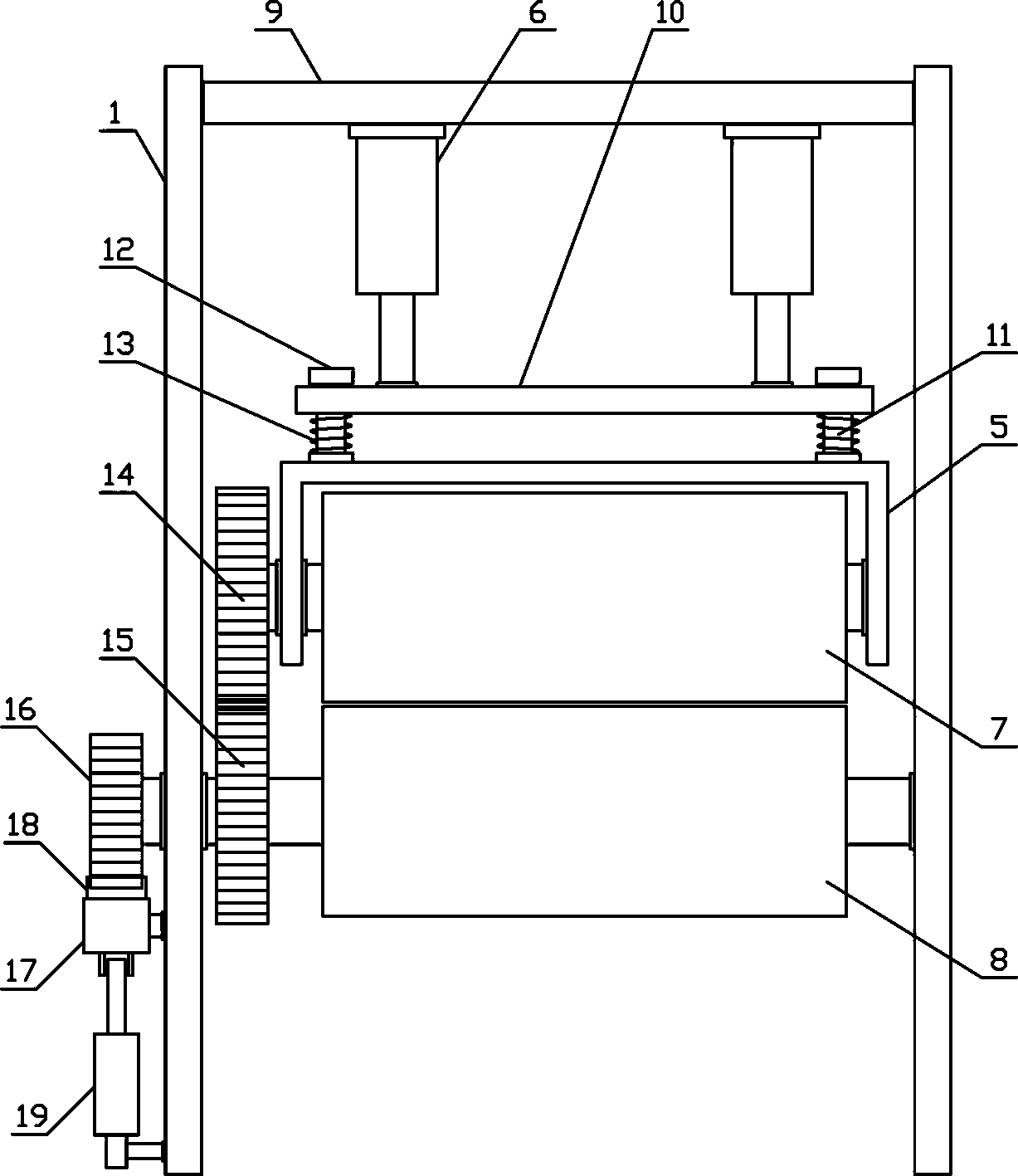

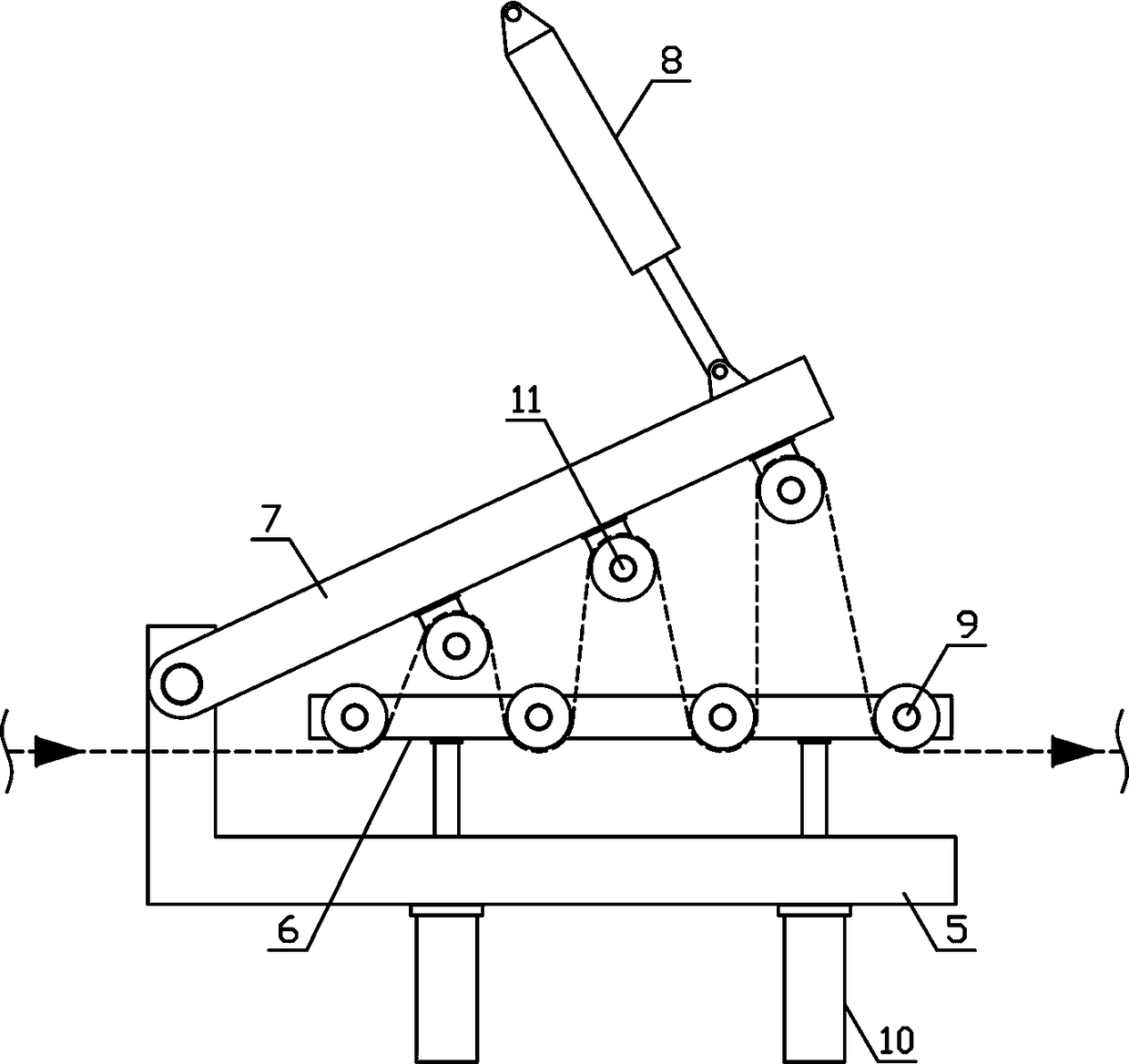

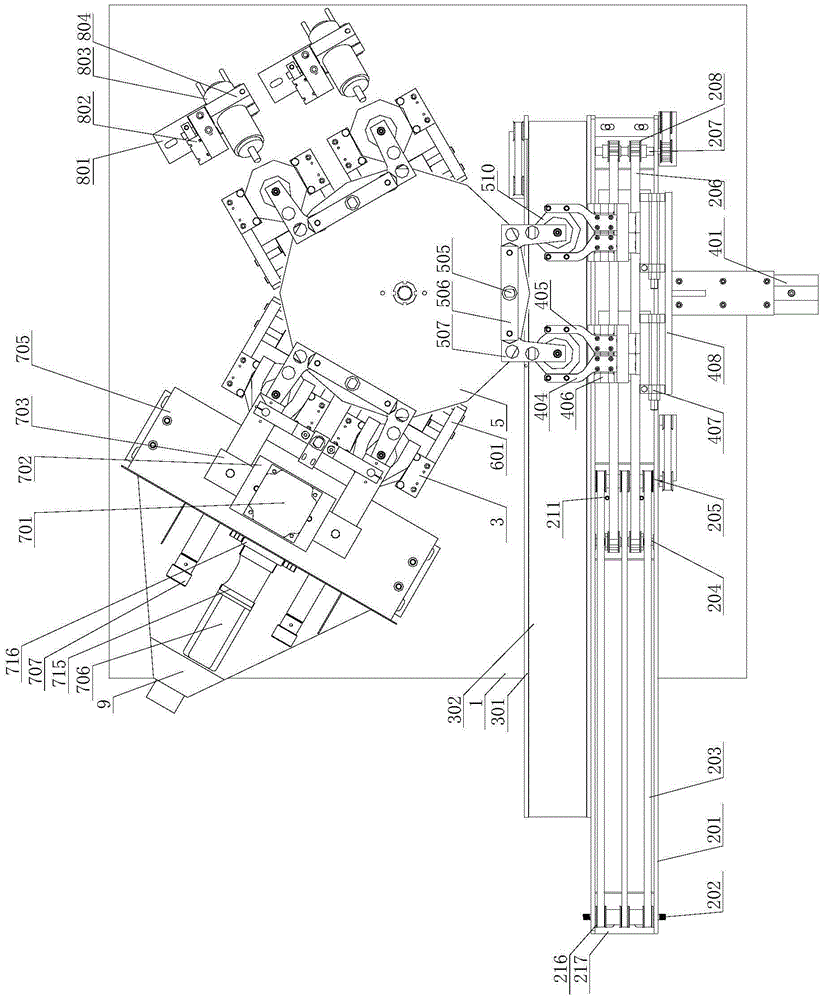

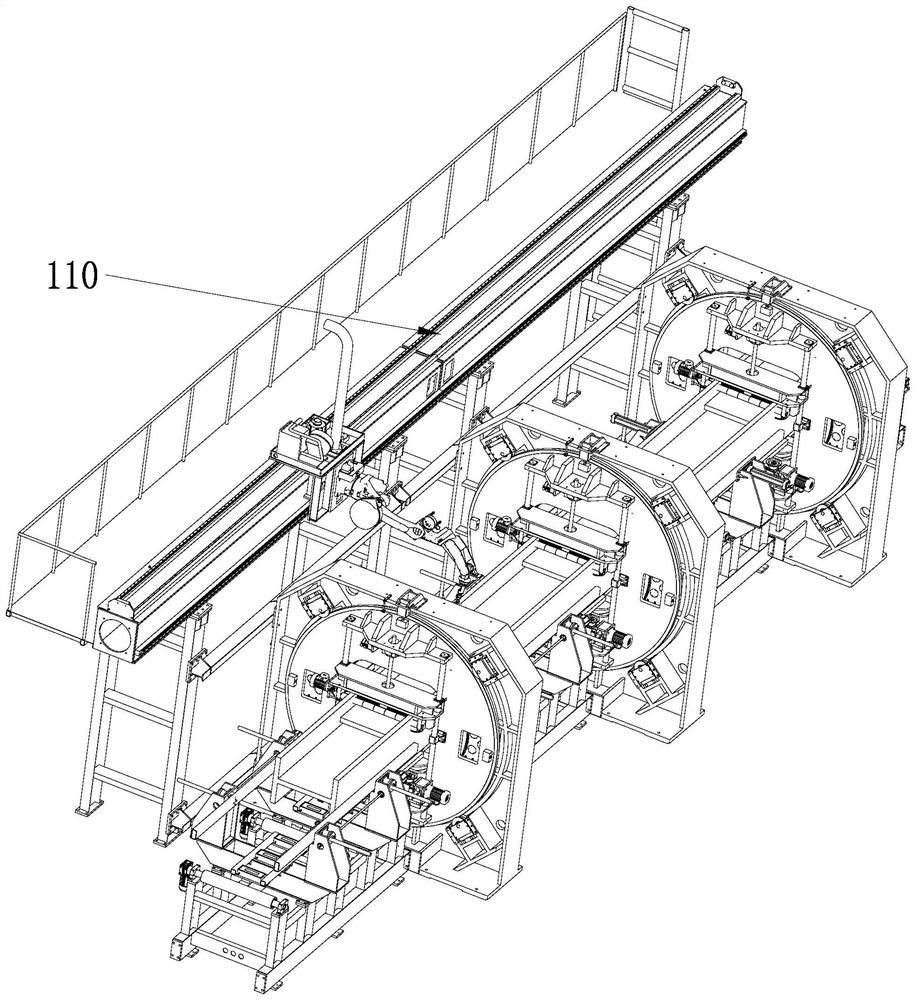

Steel bar truss floor support plate production line

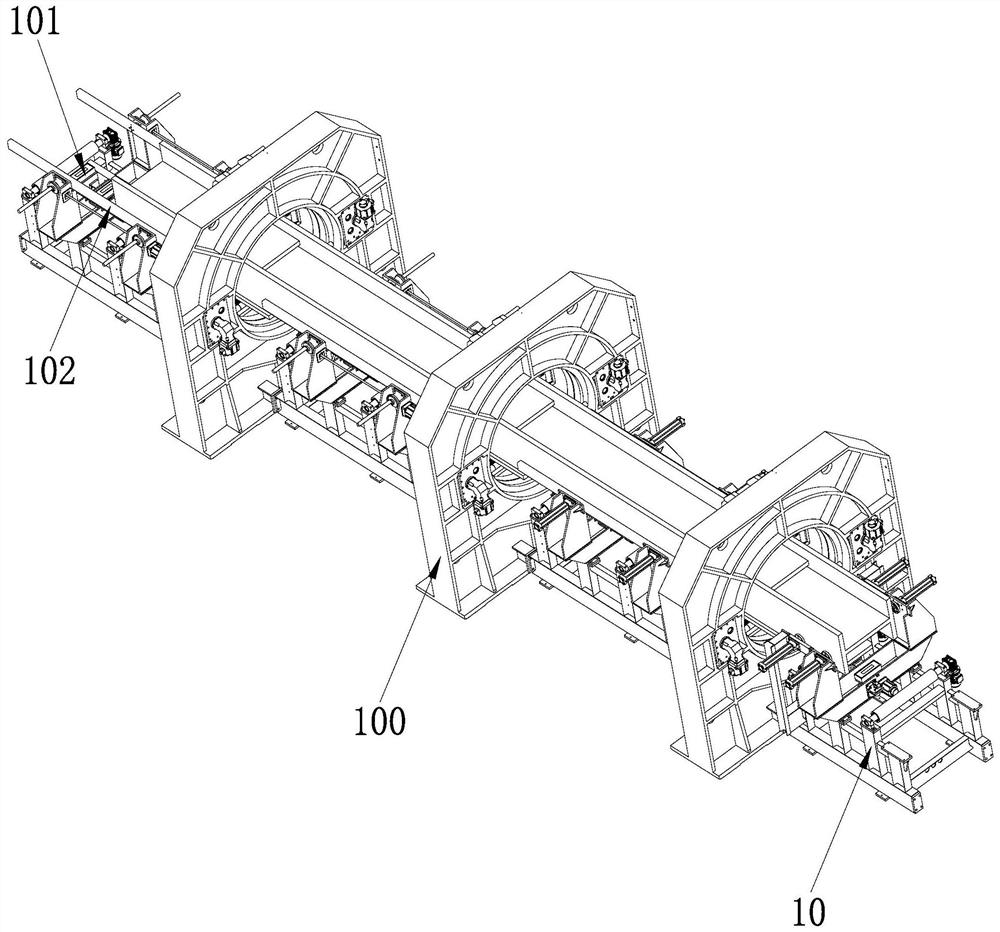

PendingCN112192223ARealize automatic productionReduce manpowerOther manufacturing equipments/toolsRebarManufacturing line

The invention belongs to the technical field of steel bar truss floor support plate production, and discloses a steel bar truss floor support plate production line which comprises a truss machine usedfor producing steel bar trusses, a plate pressing machine used for producing bottom plates, a truss positioning mechanism used for receiving and positioning the steel bar trusses, a truss carrying mechanism used for carrying the steel bar trusses positioned by the truss positioning mechanism to a welding mechanism a bottom plate conveying mechanism used for conveying the bottom plates to the welding mechanism, the welding mechanism used for welding the steel bar trusses and the bottom plates to form steel bar truss floor support plates, and a truss floor support plate carrying mechanism usedfor carrying and stacking the steel bar truss floor support plates. By means of the steel bar truss floor support plate production line, automatic production, carrying and stacking of the steel bar truss floor support plates can be achieved, manpower is reduced, labor intensity and potential safety hazards are reduced, and machining efficiency and the automation degree are improved.

Owner:TJK MACHINERY TIANJIN

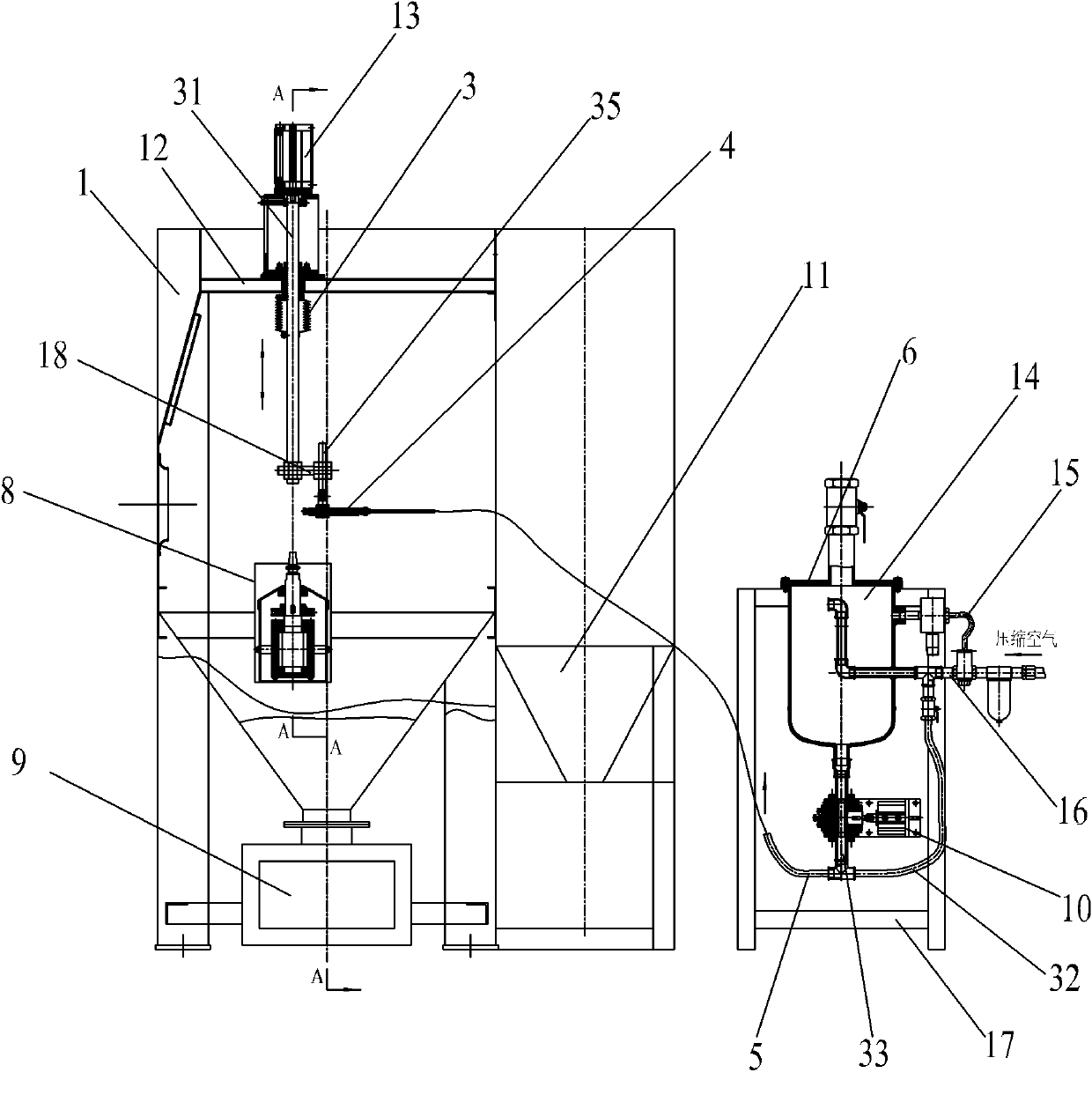

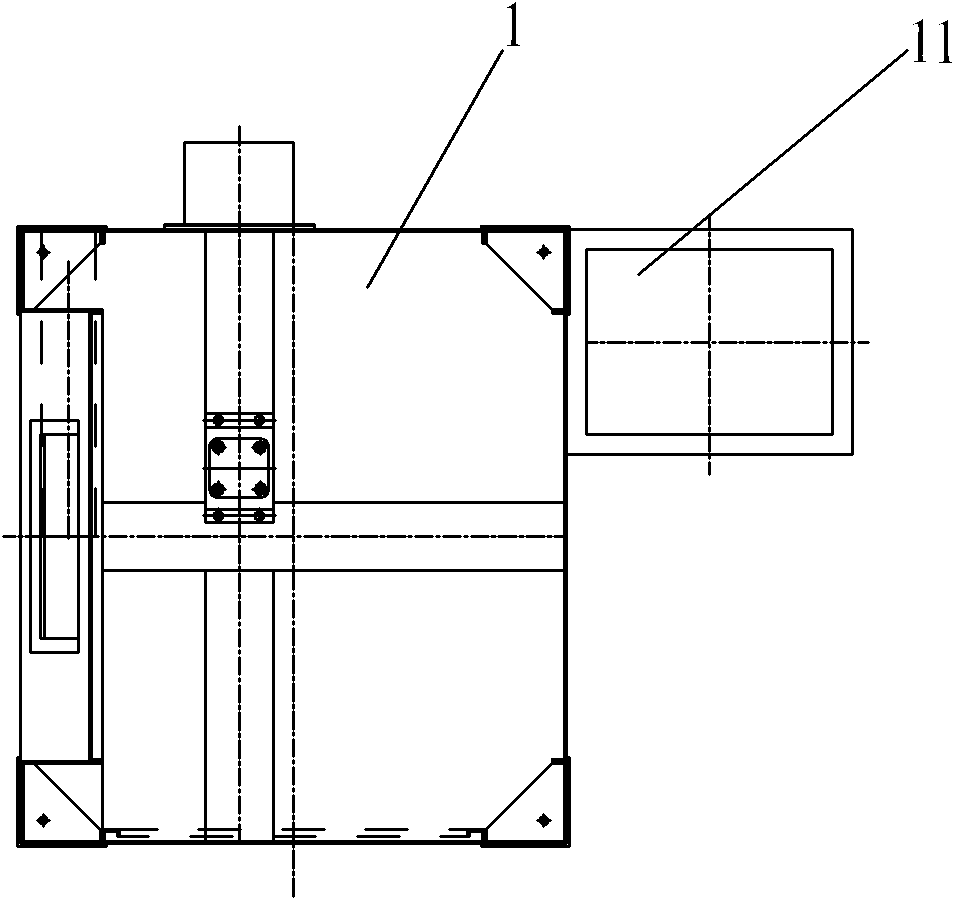

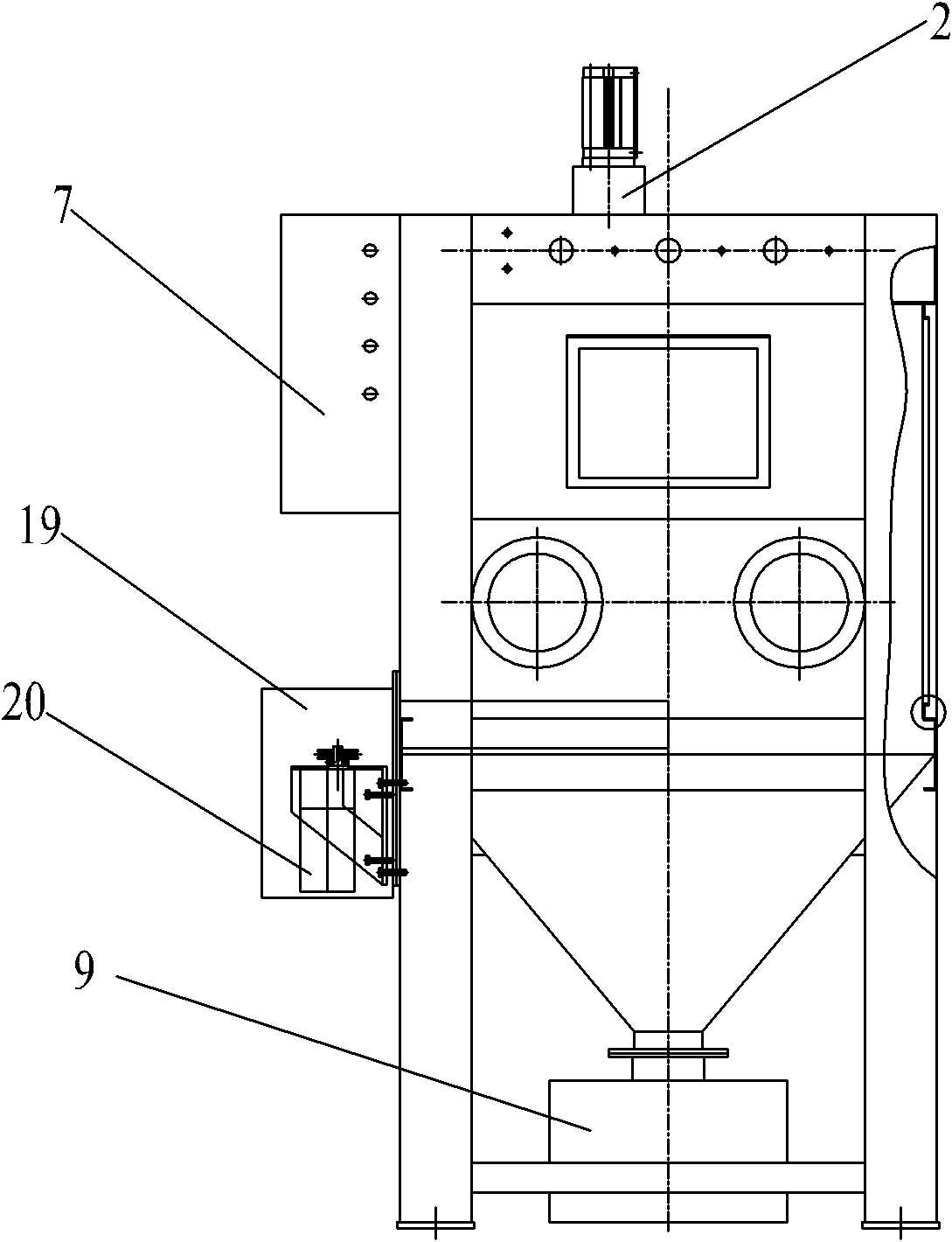

Rotary table type automatic sand-blasting machine

ActiveCN102001046ASatisfy quality blasting requirementsMeet high-quality sandblasting requirementsBlast gunsAbrasive blasting machinesSand blastingPiston rod

The invention relates to a rotary table type automatic sand-blasting machine which comprises a machine body, wherein the top end of the machine body is provided with a lifting mechanism, the lifting mechanism comprises a lifting cylinder; a piston rod of the lifting cylinder is provided with a lifting rod, one end of the lifting rod extends into the machine body and the lifting rod can move relative to a top plate; the lifting rod is provided with a fixedly connected sand-blasting gun corresponding to the other end of the lifting cylinder connected with the piston rod, the sand-blasting gun is connected with a sand-blasting device used for storing and blasting sand through a sand-blasting pipe; a rotating mechanism is arranged below the sand-blasting gun and comprises a rotating shaft, one end of the rotating shaft is arranged in a first shell through a bearing, and the rotating shaft can rotate relative to the first shell; the first shell is fixedly arranged in a second shell which is fixedly connected with a stand; the rotating shaft is correspondingly arranged at the other end of the first shell and penetrates out of the second shell and is close to the sand-blasting gun; and one side of the stand is provided with a speed-reducing motor. The invention can realize fixed-point automatic and precise sand blasting, and meet the requirement for high-quality sand blasting of premise parts.

Owner:WUXI FODOO PRECISION IND

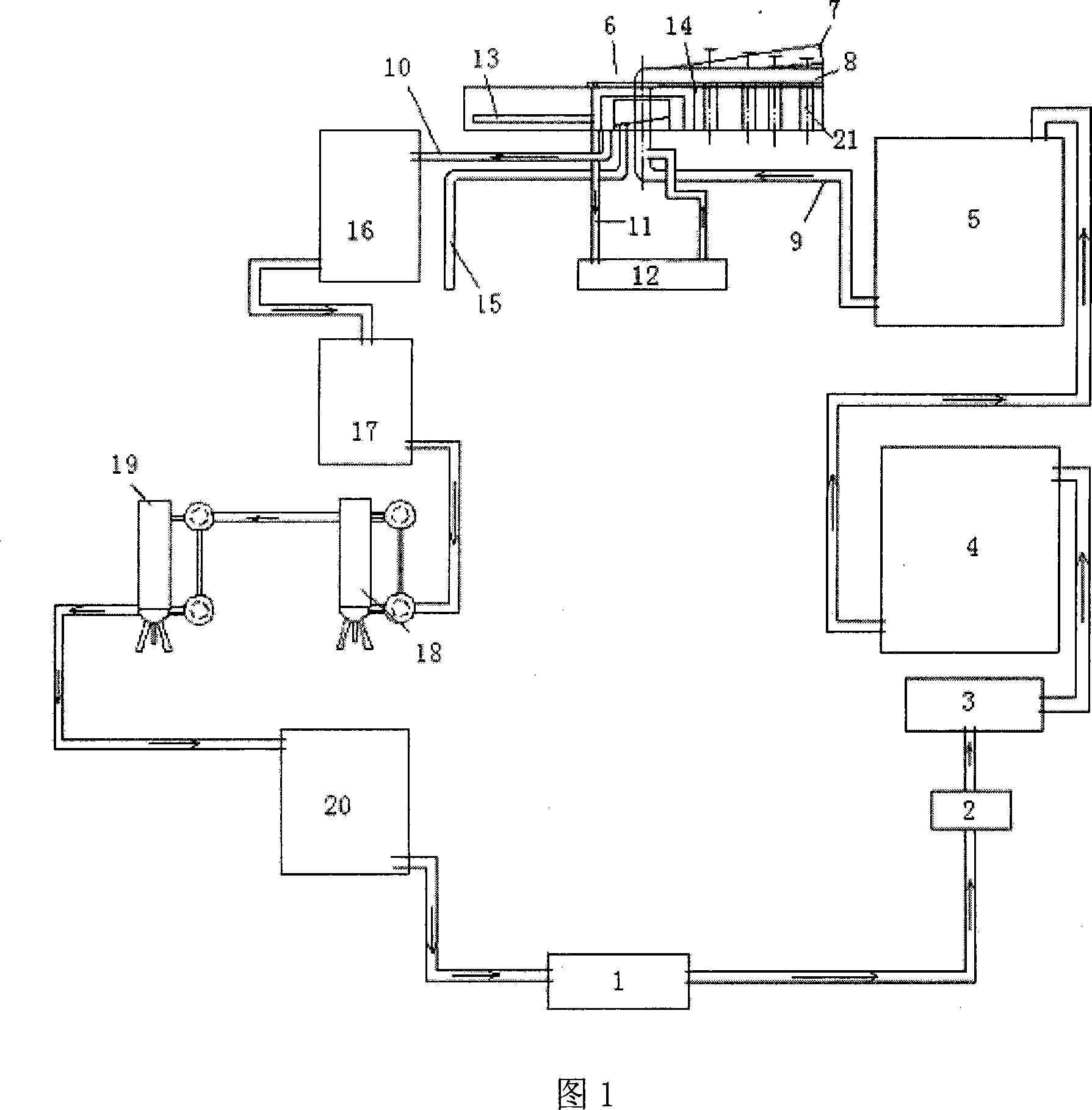

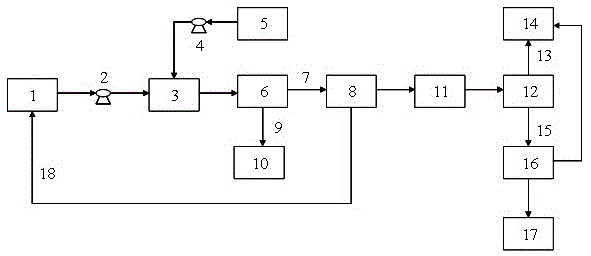

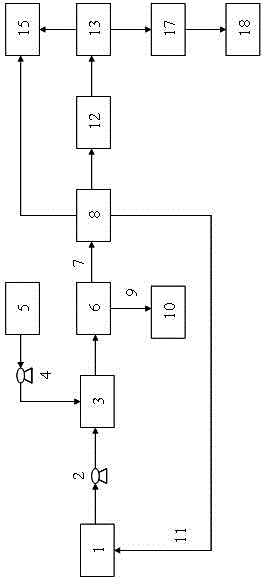

Water treating process and apparatus for cellulose fiber hydro-entangling process

InactiveCN101066814AEfficient removalGuaranteed cleanlinessMultistage water/sewage treatmentWaste water treatment from textile industryWater savingWater quality

The present invention relates to is water treating process and apparatus for cellulose fiber hydro-entangling process. The water treating apparatus includes a high pressure pump, a police filter set between the high pressure pump and the hydro-entangling machine, a vacuum sucker, an efficient superficial air floating tank, a sand filter, a precise tubular filter and a bag filter. During the production, only bactericide is added to the air floating tank and the sewage tank regularly, and no flocculant and coagulant aid are needed. The present invention has high automation, low cost, water saving and short water treating period.

Owner:DONGHUA UNIV +1

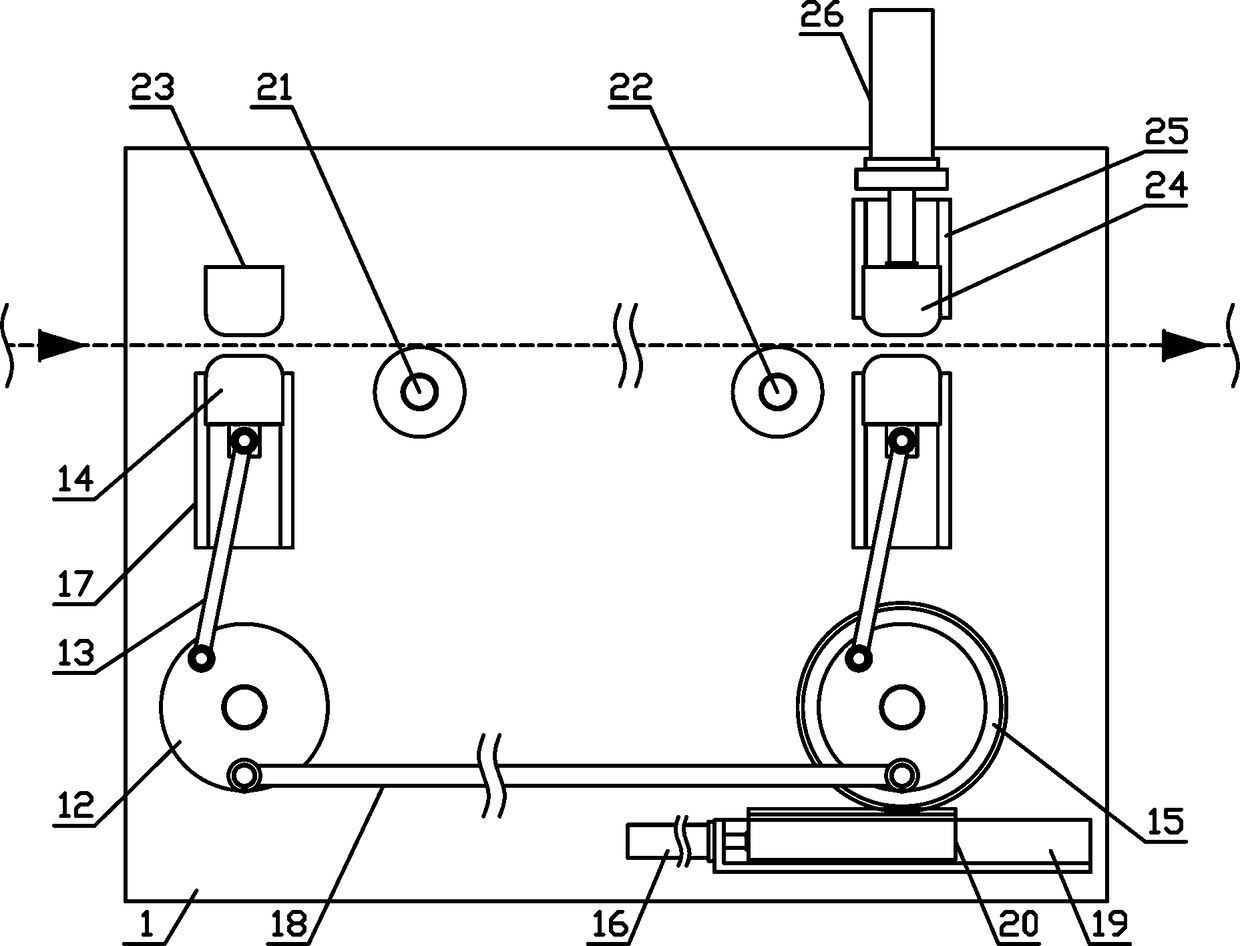

Yarn conveying and pulling mechanism

PendingCN108584532AStable and even stretchingEfficient heatingFilament handlingTextiles and paperYarnHeat conducting

The invention discloses a yarn conveying and pulling mechanism, and belongs to the field of textile processing mechanical equipment. According to the yarn conveying and pulling mechanism, a yarn feeding mechanism, a pulling mechanism and a yarn guide mechanism are arranged on a fixing support in sequence in the horizontal direction. A lower yarn bearing guide roller is connected with the portion,located on the lower side of an upper yarn press guide roller, of the fixing support in a horizontal rotation mode. A shaping rotating drum is connected to the portion, located between a front yarn guide roller and a rear yarn guide roller, of the fixing support in a horizontal rotation mode, and a heat-conducting oil pipe is arranged at the shaft ends of the two sides of the shaping rotating drumin a communicating mode. Pulling guide plates are arranged in pulling guide grooves in a sliding mode in the circular arc direction, and the pulling guide grooves are formed in the two sides of the shaping rotating drum. One end of one pulling rotating roller and the same end of the other pulling rotating roller are connected to the pulling guide plates on the two sides of the fixing support in arotating mode correspondingly. A yarn discharging guide roller is connected to the portion, located on one side of an adjusting support, of the fixing support in a horizontal rotation mode. The yarnconveying and pulling mechanism is reasonable in structural design, can efficiently and accurately convey yarn, and can conduct stable pulling shaping on the yarn section by section in the conveying process, the degree of automation of yarn processing is improved, and the requirements of production and usage are met.

Owner:嘉兴市华益股份有限公司

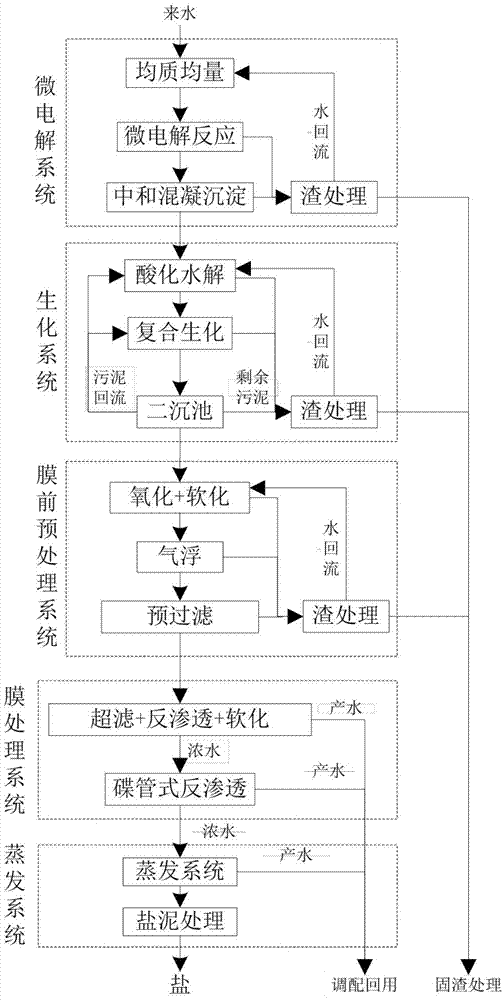

Lignin wastewater recycling technology

ActiveCN105439390AImprove reuse rateReduce pollutionScale removal and water softeningTreatment involving filtrationElectrolysisChemical oxygen demand

The invention relates to a lignin wastewater recycling technology. A micro-electrolysis system, a biodegradation system, a membrane pretreatment system, a membrane treatment system and an evaporation system are adopted in the technology, wherein the micro-electrolysis system at least comprises a micro-electrolysis reaction and coagulating sedimentation, the biodegradation system at least comprises anaerobic and aerobic composite biodegradation, the membrane pretreatment system integrates multiple technologies selected according to effluent quality of the biodegradation system, and the membrane treatment system at least comprises ultrafiltration and reverse osmosis. The biodegradability of high-content lignin wastewater is improved by the micro-electrolysis system, effluent of the micro-electrolysis system enters the biodegradation system for removal of partial COD (chemical oxygen demand), the wastewater enters the membrane treatment system after the hardness, the COD and suspended solids are reduced again by the membrane pretreatment system, produced water of the membrane treatment system is deployed and recycled, and concentrated water enters the evaporation system for evaporative crystallization. The technology treats and recycles the high-content lignin wastewater, the pollution caused by the wastewater to the environment is reduced, and efficient recovery of the water resource is realized.

Owner:NANJING JIUSI HIGH TECH

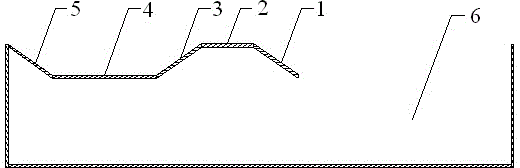

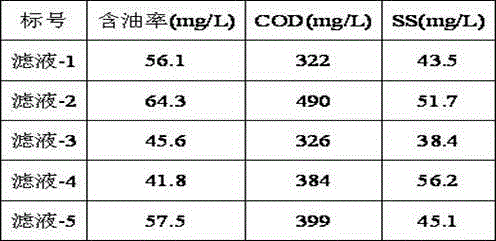

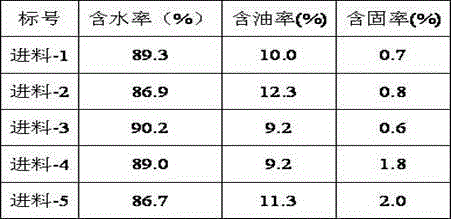

Oily sludge advanced treatment technology

ActiveCN104649563AGood demulsification effectGood biodegradabilitySludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesPetroleumSludge dewatering

The invention discloses an oily sludge advanced treatment technology which comprises the following contents: oily sludge in a raw material storage sludge-tank enters a sludge mixing tank; a demulsifier is added to carry out demulsification treatment; demulsified oily sludge enters screw-type sludge dewatering equipment to undergo solid-liquid separation so as to obtain a filtrate and sludge cake; the filtrate enters a two-phase cyclone to be separated; after two-phase separation, excess sludge at the lower layer flows back to the raw material storage sludge-tank, a mixed liquor at the upper layer is sent into a gas-liquid mixing tank to be mixed with the air and then enters a separation pond to carry out primary separation of sump oil and sewage; sump oil is recovered to a sump oil tank by the use of a sludge scraper; sewage enters a filter to separate suspended particles and residual sump oil in the sewage from water; sump oil separated from the top of the filter is recovered to a sump oil recovery tank; and sewage discharged from the filter is sent to a sewage treatment plant to undergo subsequent processing. By the technology, water content of the oily sludge can be reduced from 80-98% to about 50%, and most crude oil in the oily sludge can be recovered. Thus, sludge subsequent processing difficulty is greatly reduced. The technology provided by the invention has a wide range of application, is especially suitable for processing of oily sludge at the bottom of an oil-tank, dross and activated sludge as well as processing of various oily sludge generated from oil exploitation and storage transportation enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

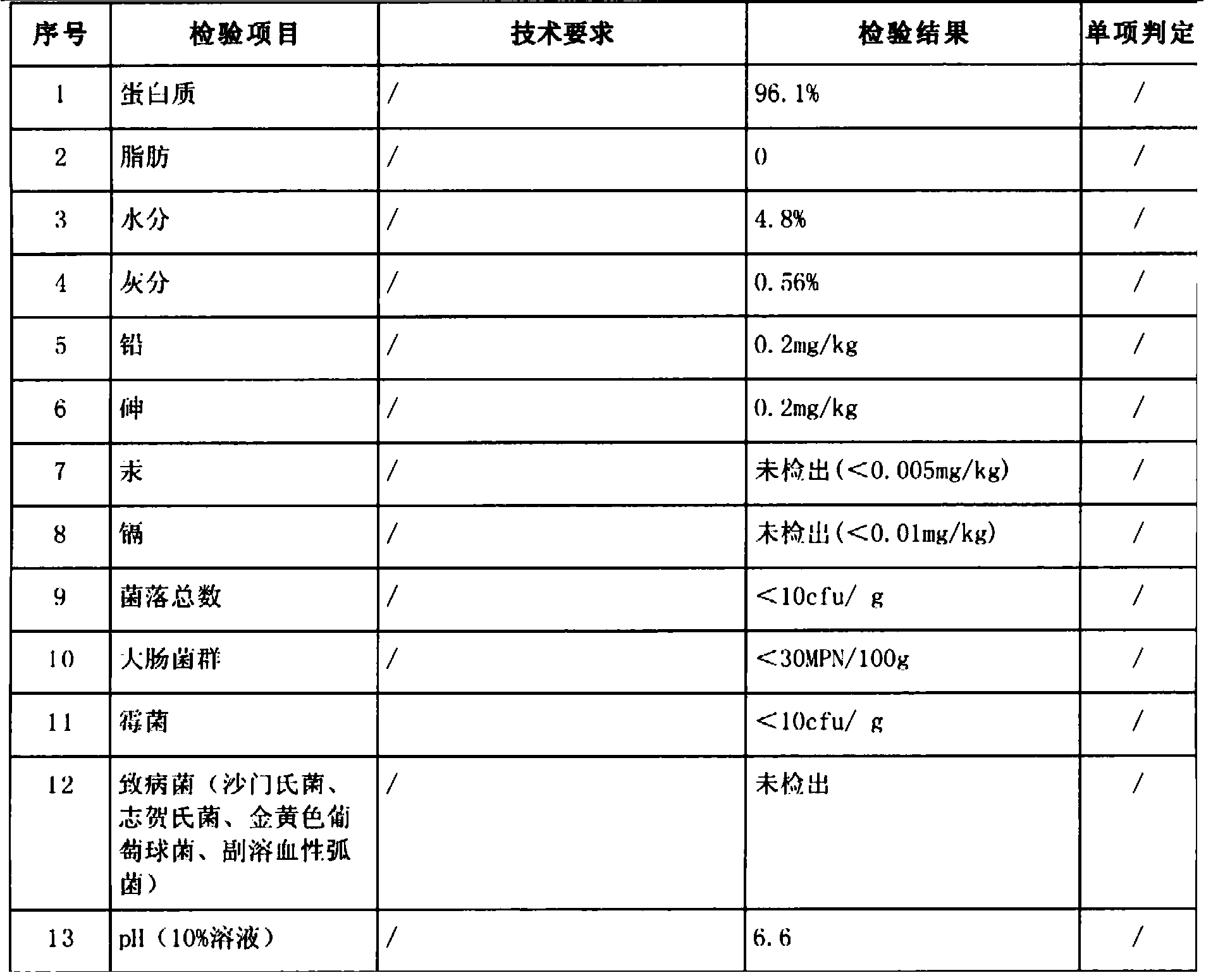

Extraction method of deep-sea fish gelatin

ActiveCN103805071AAvoid it happening againAvoid yield reductionGlue/gelatin preparationCompound organicRoom temperature

The invention discloses an extraction method of deep-sea fish skin gelatin, and the method comprises the following steps of putting cleaned fish skin in conditioning fluid which is prepared from compound organic acid and stirring, cleaning the conditioned fish skin by water at room temperature, putting the cleaned fish skin in weakly acidic water solution at 30-60 DEG C for extraction, combining the extracting solution, filtering the extracting solution by 100-mesh filter cloth, and carrying out concentration and drying to obtain the gelatin. The method provided by the invention is gentler, and the prepared product is high in yield and purity, large in molecular weight, narrow in molecular weight distribution, shallow in color and light in fishy smell.

Owner:QINGDAO HUAKE BIOLOGICAL TECH CO LTD

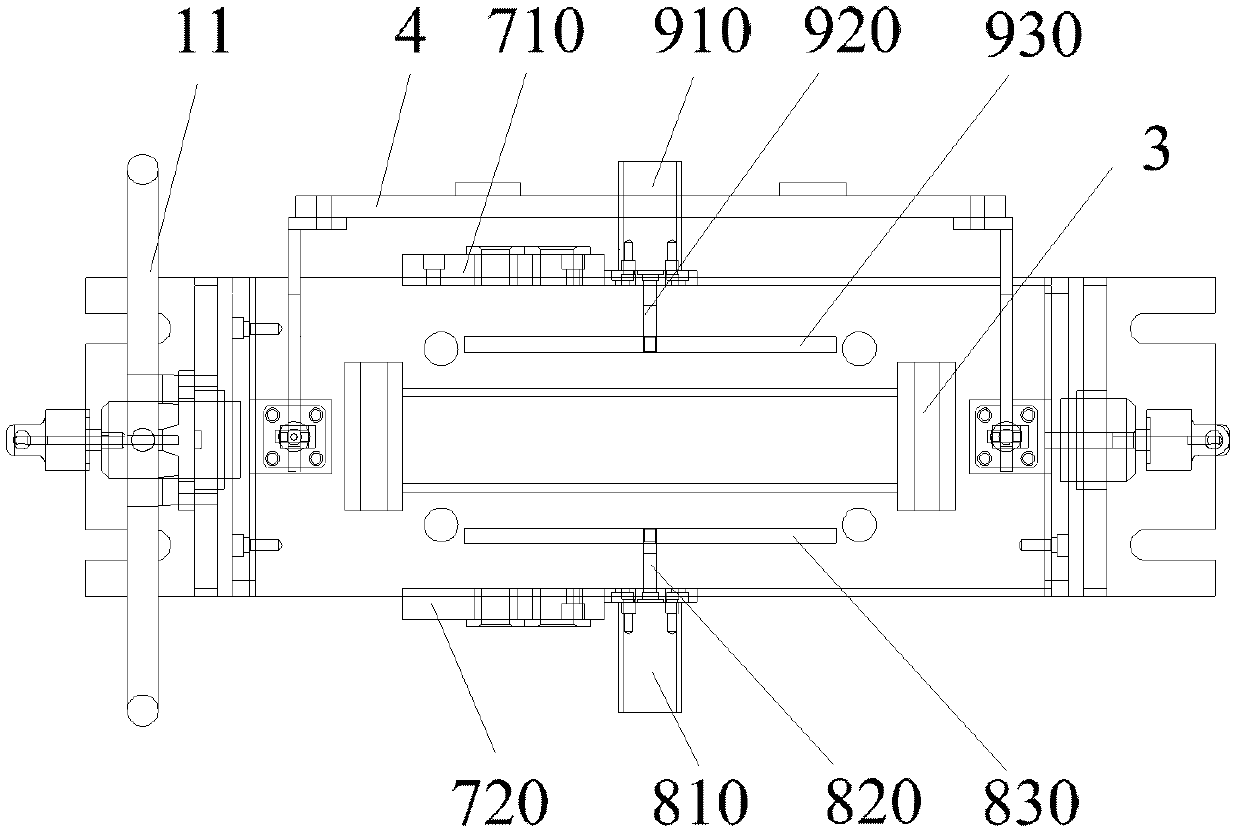

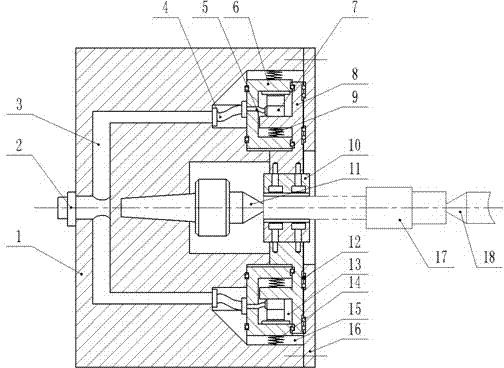

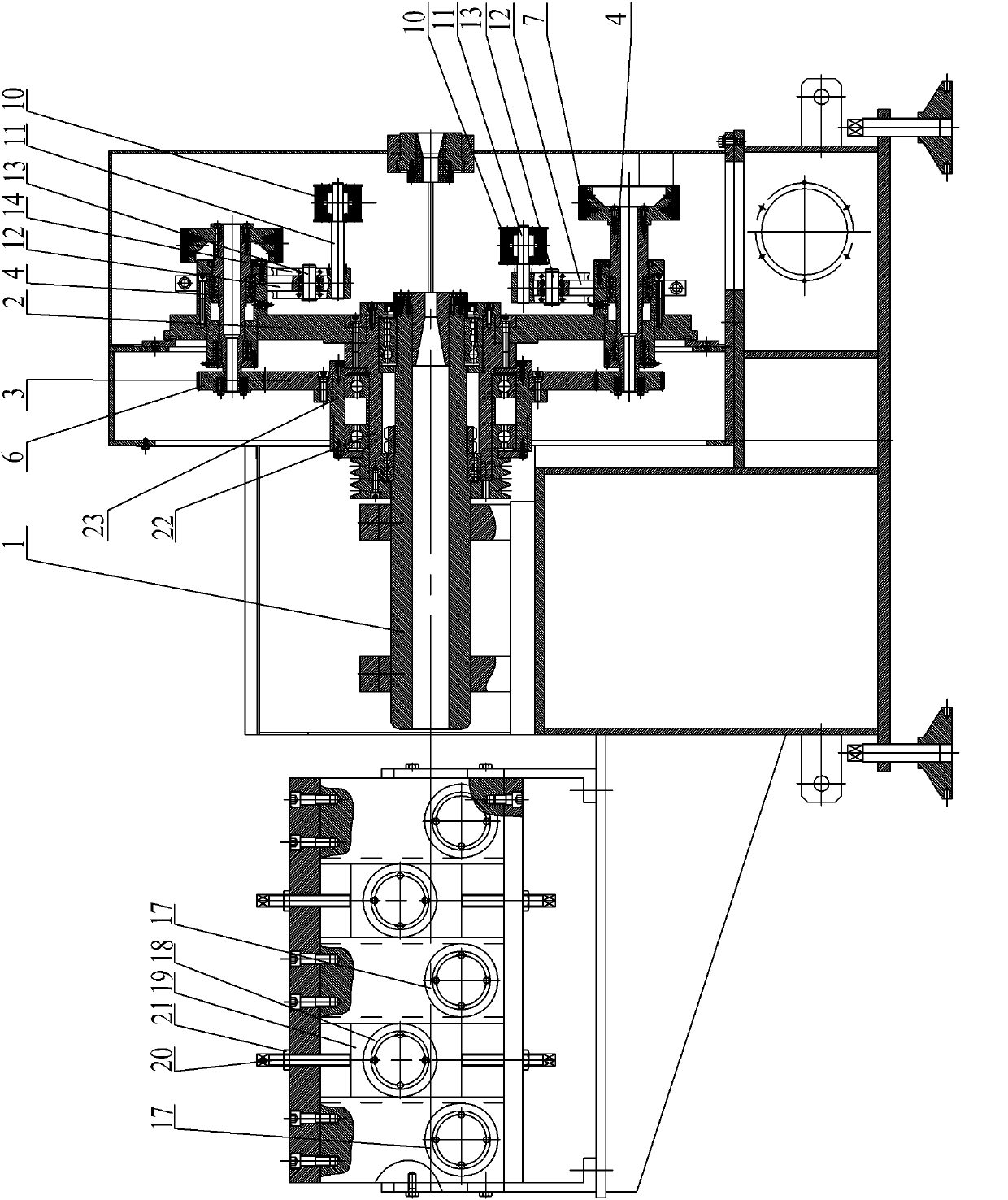

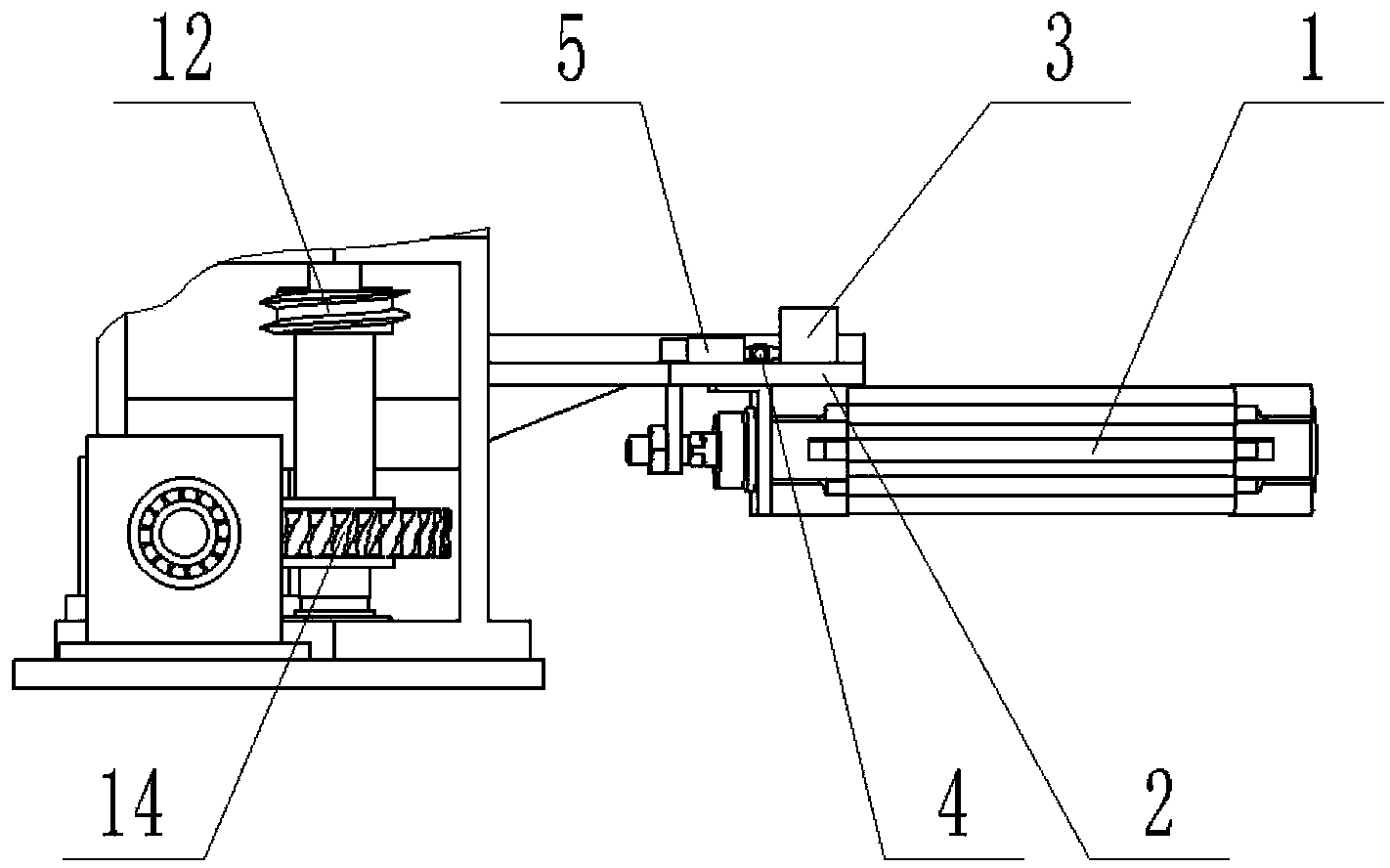

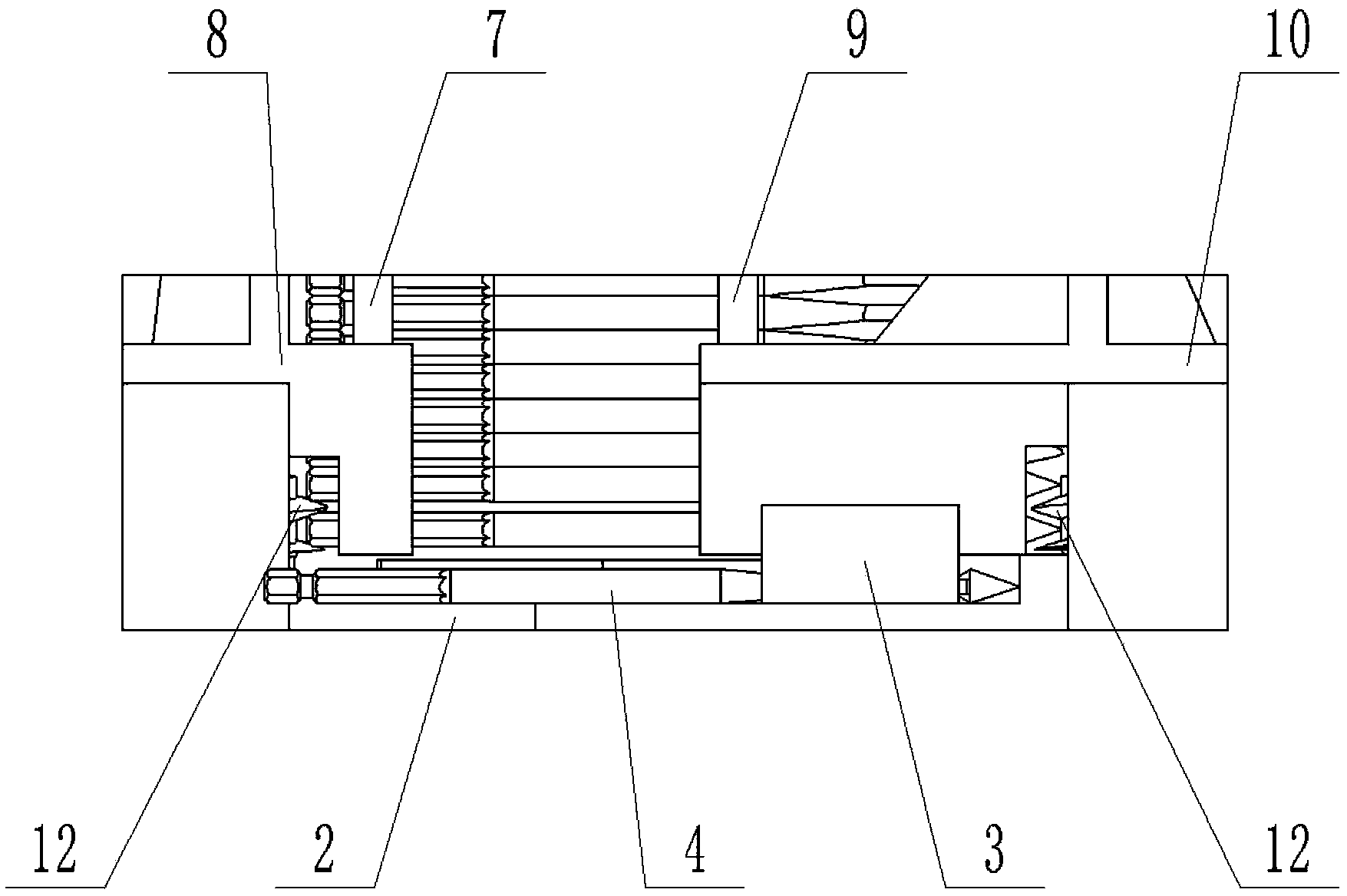

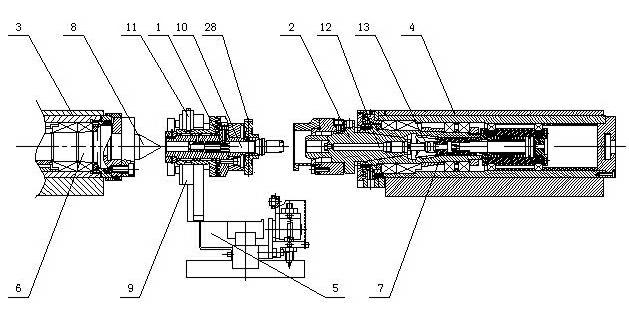

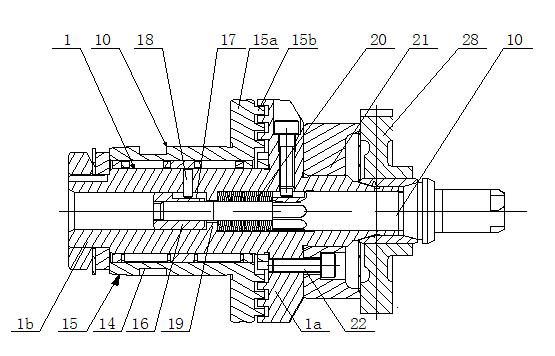

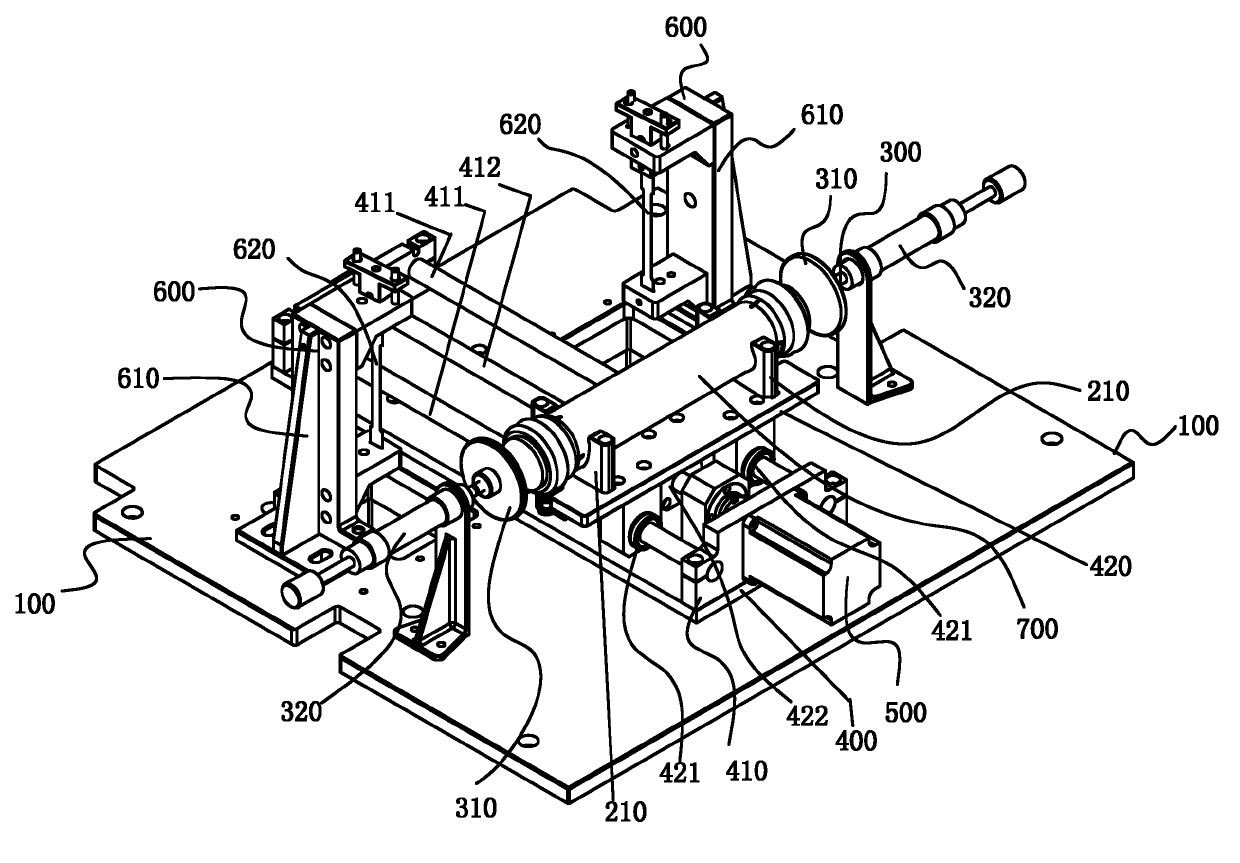

Hydraulic floating centering and clamping transmission device

InactiveCN103878617AOvercome the cumbersome manual clampingIncrease productivityPositioning apparatusMetal-working holdersManipulatorEngineering

The invention discloses a hydraulic floating centering and clamping transmission device. A center is installed in a center hole of a cylindrical chuck body. Symmetrically-arranged semicircular clamping heads are installed in the positions, outside the tip of the center, of the center hole of the chuck body. Rectangular holes are symmetrically formed in the positions, outside the two semicircular clamping heads, of the chuck body. Hydraulic clamping devices which are the same in structure and opposite in installing direction are installed in the corresponding rectangular holes respectively and fixedly connected with the corresponding semicircular clamping heads respectively. An end cover and the outer sides of the two hydraulic clamping devices form a rolling pair. Hydraulic cylinders in the two hydraulic clamping devices are both connected to a center oil port of the chuck body through respective hoses, respective flexible connectors and a hydraulic pipeline on the chuck body respectively. Rotating connectors are connected with the center oil port of the chuck body in a threaded mode. According to the machining characteristics of shaft parts, the shaft parts can be automatically centered and clamped. A mechanical arm and a numerical control machine tool are matched, the shaft parts can be automatically produced, the influence of human factors is reduced, and product quality and production efficiency are improved.

Owner:ZHEJIANG UNIV

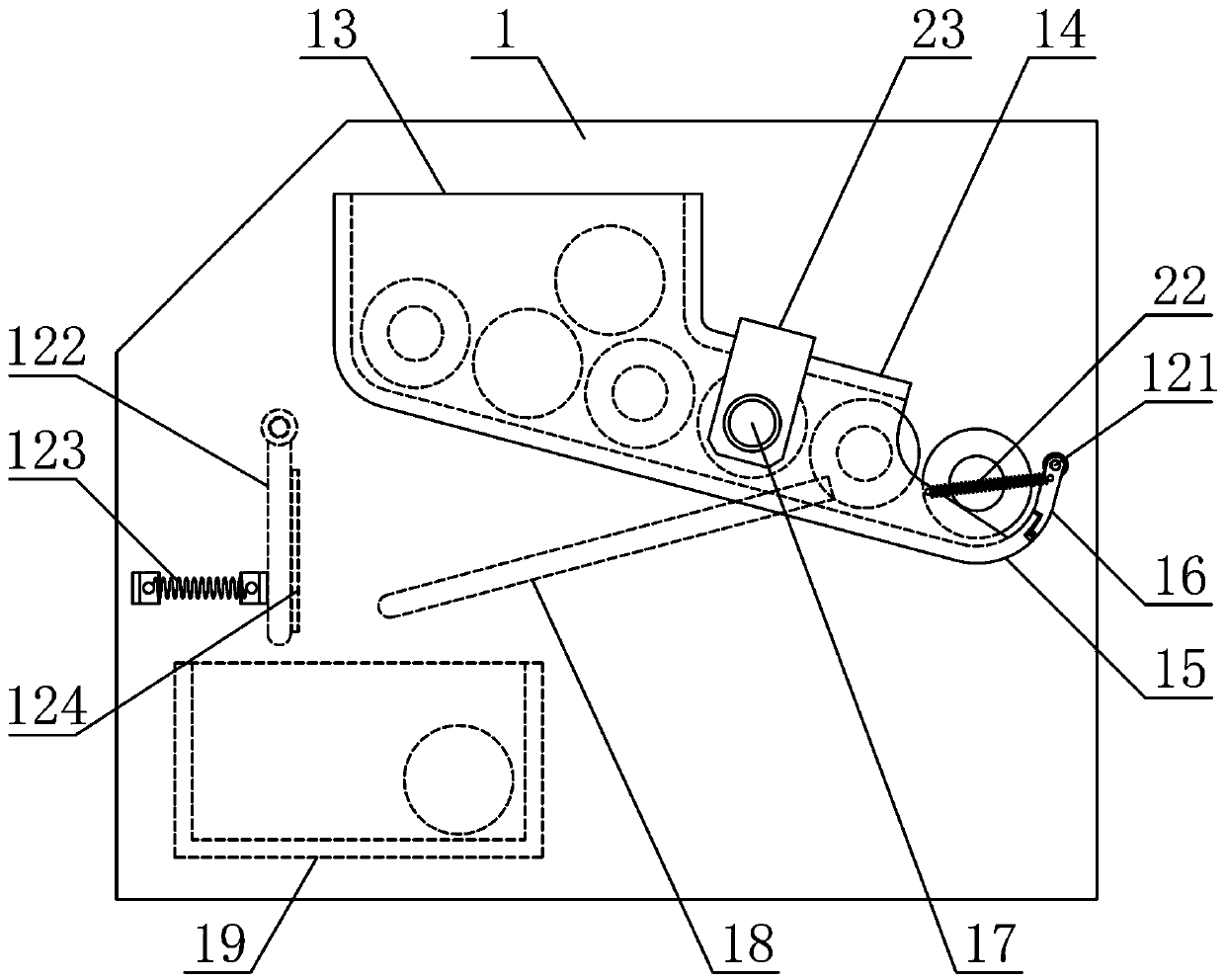

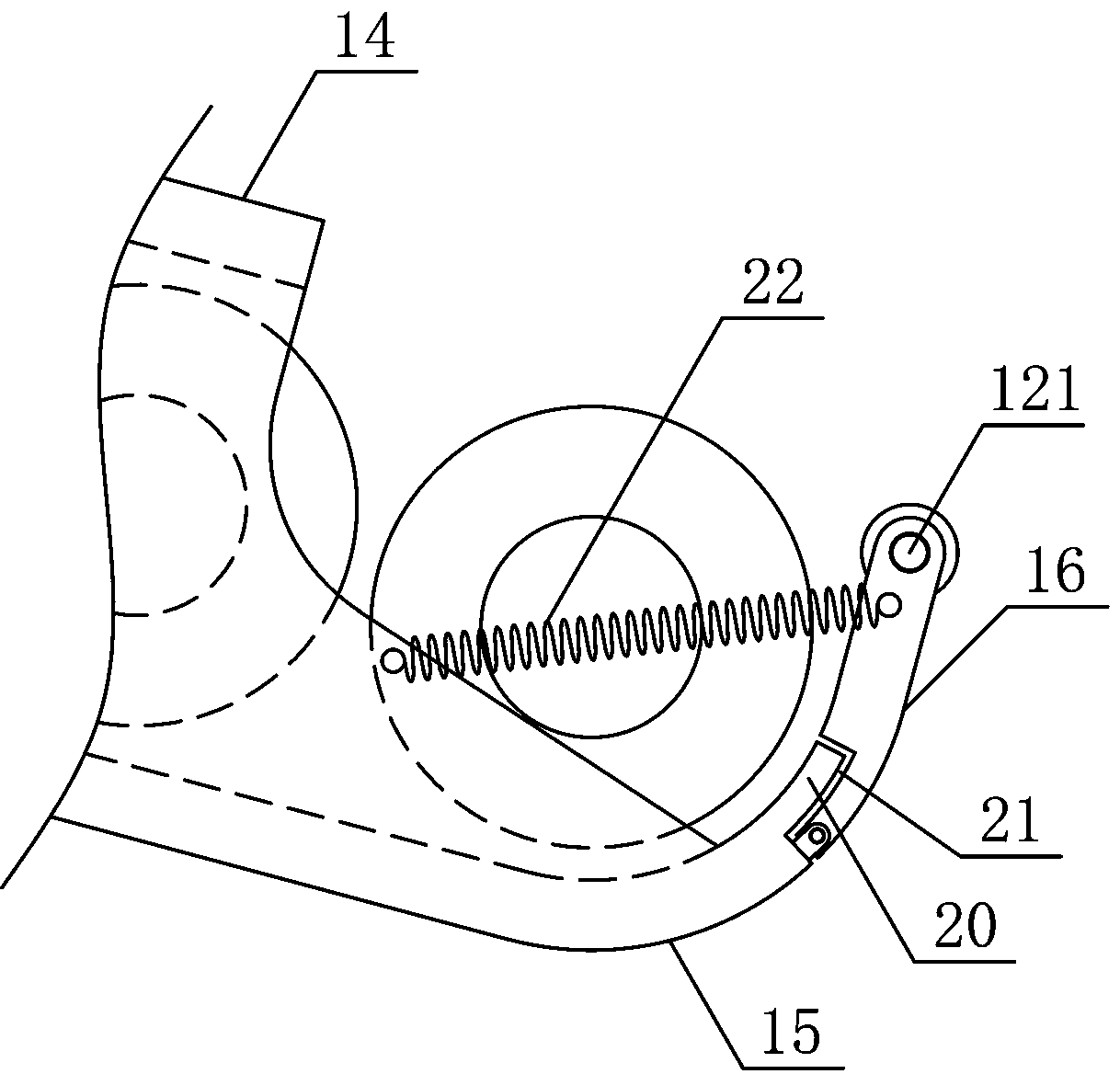

Yarn drafting and rolling mechanism

InactiveCN109230836AHigh degree of processing automationReasonable structural designFilament handlingTextiles and paperYarnMechanical equipment

The invention discloses a yarn drafting and rolling mechanism and belongs to the field of mechanical equipment for yarn conveying processing. Yarn press mechanisms are vertically arranged at the two sides of a drafting mechanism of the yarn drafting and rolling mechanism respectively, a rolling mechanism is arranged on a rolling support of one side of a yarn press mechanism, and multiple draftingrotation rollers are horizontally and rotatably connected to a lifting support of the upper side of a drafting support in the horizontal direction in sequence; multiple rotation rollers are horizontally and rotatably connected to a rotation support in the inclination direction in sequence, yarn press rotation discs are vertically and rotatably connected to rolling supports of the two sides of thelower portion of the drafting mechanism respectively, yarn press connection rods is arranged between lifting yarn press plates and the yarn press rotation discs, and a rolling yarn cylinder slidinglysleeves a rolling rotation roller in the horizontal direction. The yarn drafting and rolling mechanism is reasonable in structural design, the yarn can be stably and evenly drafted and processed segment by segment and can be conveniently and efficiently rolled, the automation degree of yarn processing is improved, and the demands of production and application are met.

Owner:桐乡市澳得利纤维股份有限公司

Wire rod husking sander

The invention relates to a wire rod husking sander, comprising a main shaft fixed on a frame, wherein a through hole is arranged in the axis direction of the main shaft; a main turntable and a driving gear are rotatably arranged on the main shaft; a plurality of driving rotation shafts are rotatably arranged on the main turntable and each driving rotation shaft is provided with a driven belt pulley mounting shaft; drive gears and driving belt pulleys are fixedly arranged on the driving rotation shafts, and the drive gears are meshed with the driving gear; driven belt pulleys are rotatably arranged on the driven belt pulley mounting shafts; the driving belt pulleys and the driven belt pulleys are provided with grinding abrasive belts, and equipped with tension pulleys with tension shafts; the distances from the driving belt pulleys, the driven belt pulleys and the tension pulleys to the main turntable are the same; and the difference between the distances from any two driving belt pulleys to the main turntable is longer than the width of the grinding abrasive belts. By using the wire rod husking sander of the invention, the mill scale and the corrosion on the surface of a processed wire rod are removed, the defects on the surface of the wire rod are removed, the surface finish of the wire rod is increased, and the mechanical and physical performance of the wire rod is improved.

Owner:WUXI FODOO PRECISION IND

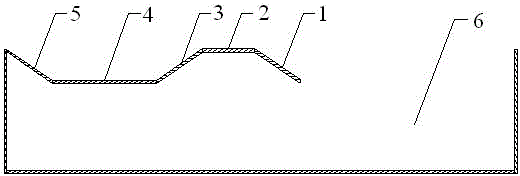

Curved surface forming and processing device

InactiveCN107473573AImprove yield rateImprove processing stabilityGlass reforming apparatusGlass productionEngineeringIntegrated processing

The invention relates to the technique field of a curved surface hot-pressing device, in particular to a curved surface forming and processing device. The device comprises a work table, wherein a processing box and a vacuum feeding device are mounted on the work table; the vacuum feeding device is connected with the processing box; a heating device, a hot-pressing device and cooling shaping devices are sequentially mounted on the processing box; the heating device comprises two staggered heating coils, the hot-pressing device comprises a pressing assembly, and the pressing assembly comprises a first pressing mechanism used for pressing the middle of a forming mold and a second pressing mechanism used for pressing the periphery of the forming mold; each cooling shaping device comprises an upper shaping part and a cooling table corresponding to the upper shaping part, and a material transfer device used for transferring materials to the next procedure is mounted on the processing box. The integrated processing device for curved screens is provided, the processing efficiency and the automation degree of the device are further improved, and the yield and the processing stability of the curved screens are advantageously improved.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

Treatment process for oily sludge

ActiveCN104556595AImprove surface activityLess irritatingSludge treatment by de-watering/drying/thickeningEmulsionProcess engineering

The invention discloses a treatment process for oily sludge. The treatment process comprises the following steps: putting the oily sludge in a raw material storage sludge basin into a sludge mixing tank, adding an emulsion breaker for emulsion breaking, putting the oily sludge subjected to emulsion breaking into a stacked type sludge dewatering machine for solid-liquid separation to obtain filtrate and mud cakes, putting the filtrate into a settling tank for settling separation, recycling waste oil discharged from the top of the settling tank, conveying the sludge at the bottom of the settling tank into the raw material storage sludge basin, feeding middle-layer mixed liquid into an air-liquid mixing tank for mixing with air to obtain a mixture, enabling the mixture to enter a separation basin for oil-water separation, recycling separated waste oil, putting sewage into a biochemical device for treatment, and discharging the sewage after the sewage meets the standard. According to the process, three-phase separation and treatment on oil, water and sludge of the oily sludge can be effectively realized, and most raw oil in the oily sludge can be further recycled; after being treated, the sewage meeting the standard can be discharged.

Owner:CHINA PETROLEUM & CHEM CORP +1

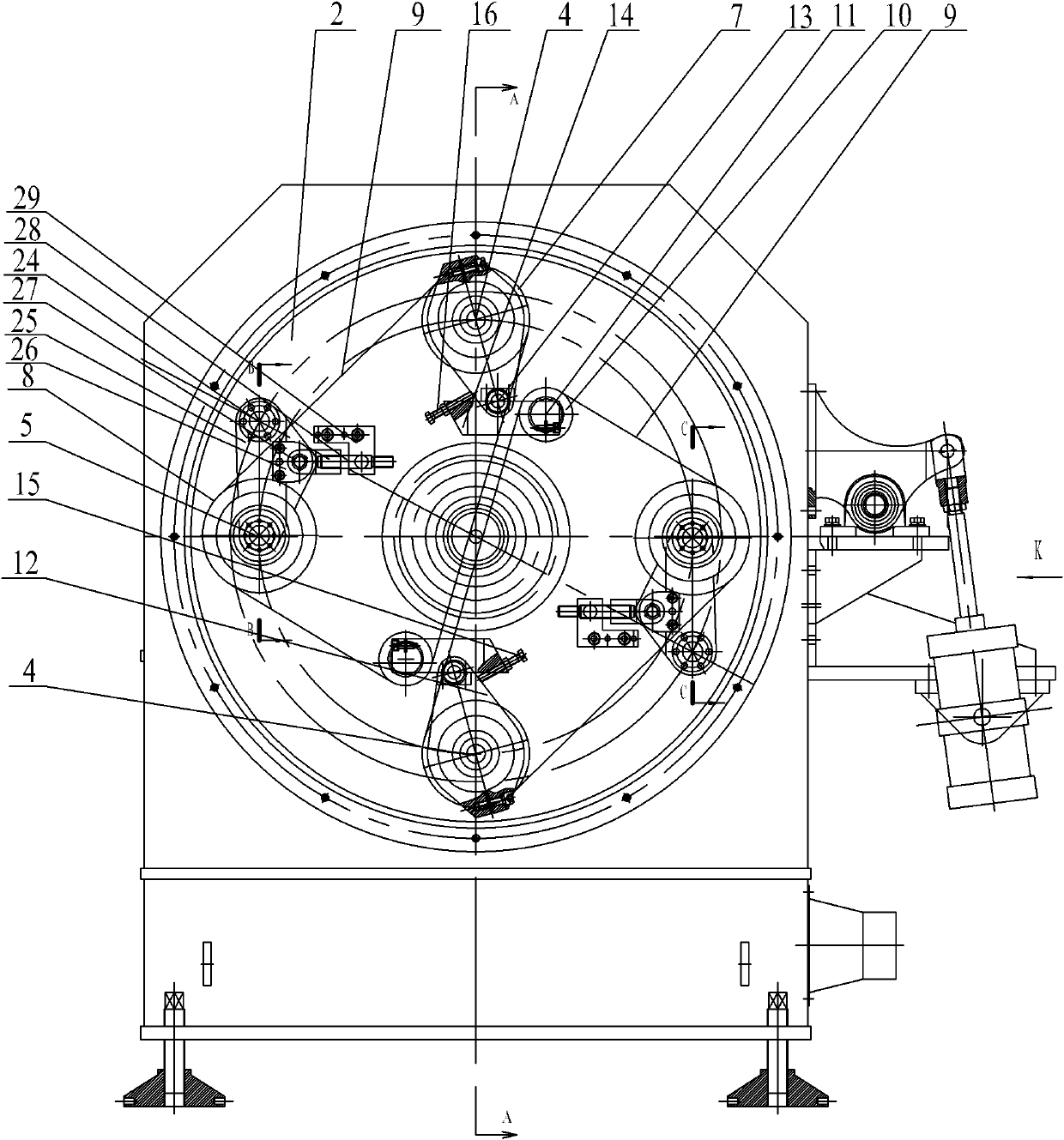

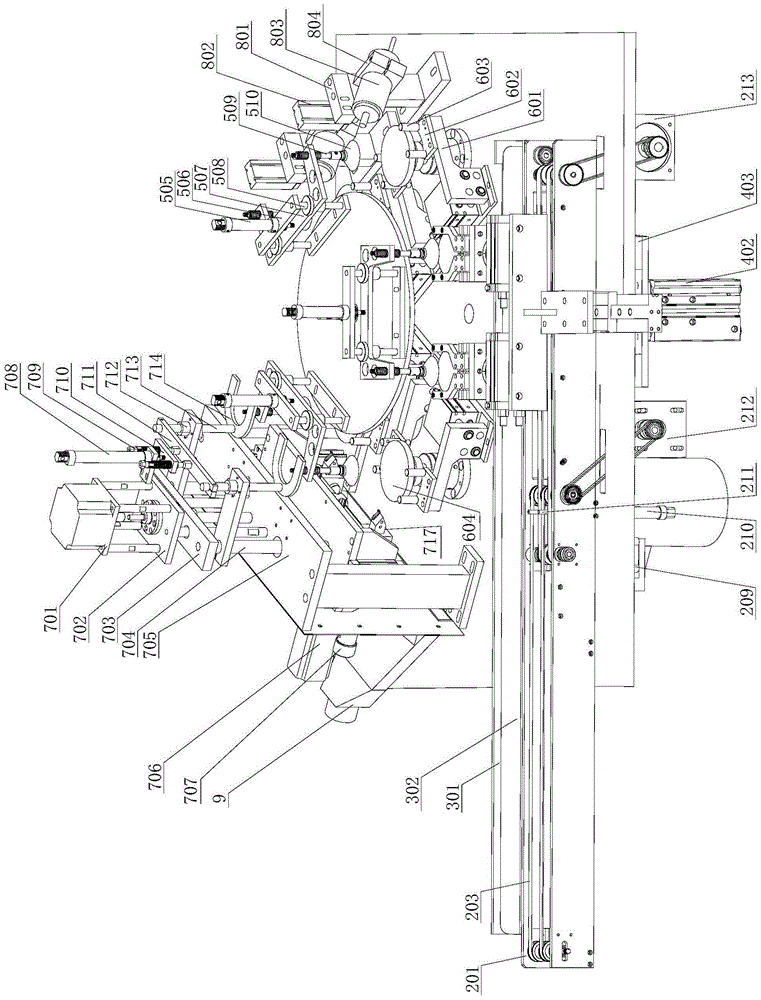

Rotating disc type lens edging and chamfering machine

ActiveCN105196057AImprove processing efficiencyHigh degree of processing automationOther manufacturing equipments/toolsMetal working apparatusAutomatic controlControl system

The invention discloses a rotating disc type lens edging and chamfering machine. The rotating disc type lens edging and chamfering machine comprises a working platform, an automatic control system as well as a lens conveying device, a lens taking device, a station rotating disc, an edging processing device and a chamfering processing device which are arranged on the working platform. Feeding and blanking, edging processing and chamfering processing procedures are carried out in steps by virtue of the station rotating disc at the center, and pipelined automation of the whole edging and chamfering processing of a lens is realized by virtue of the automatic control system, so that the processing efficiency and the automation degree are greatly improved, and workers are liberated.

Owner:LINHAI CITY RAUL MACHINE

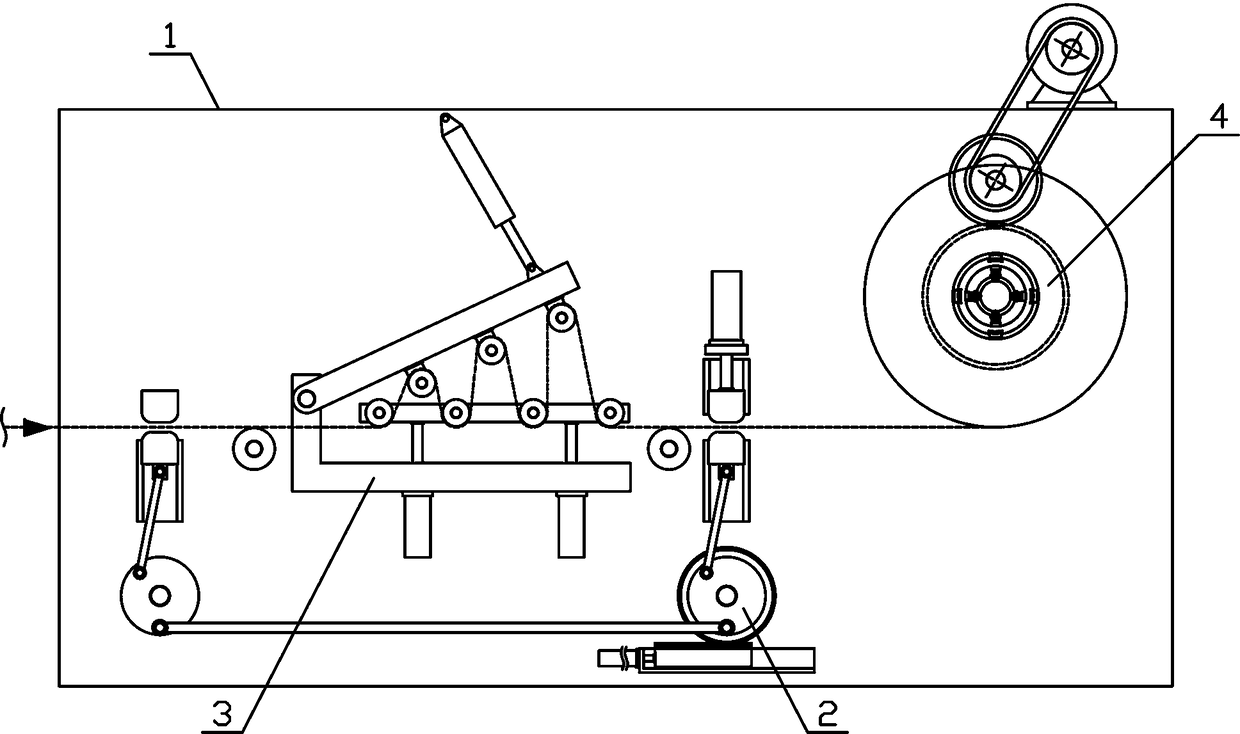

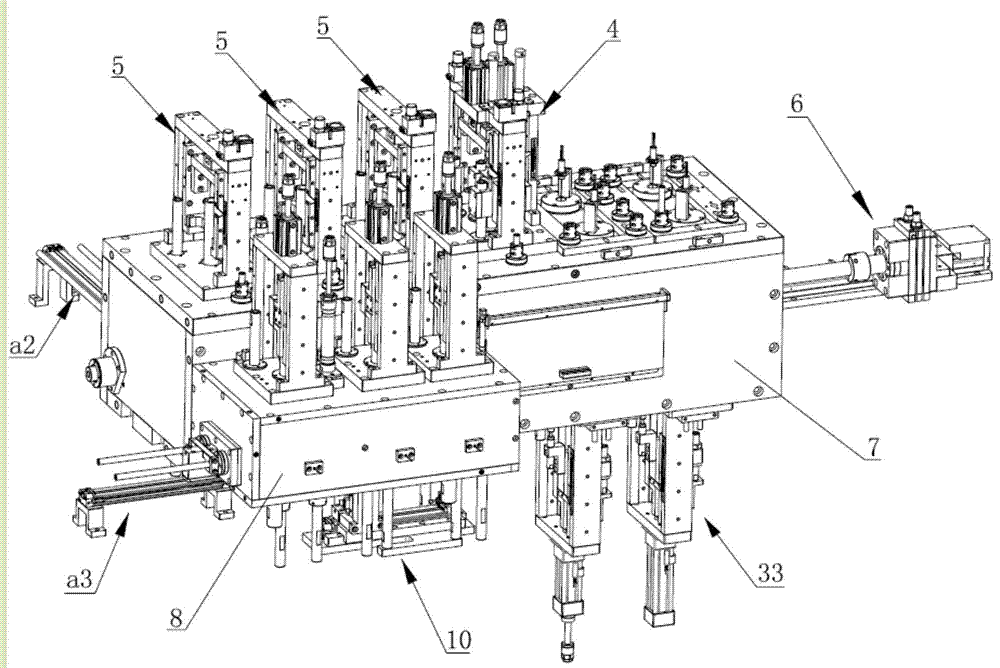

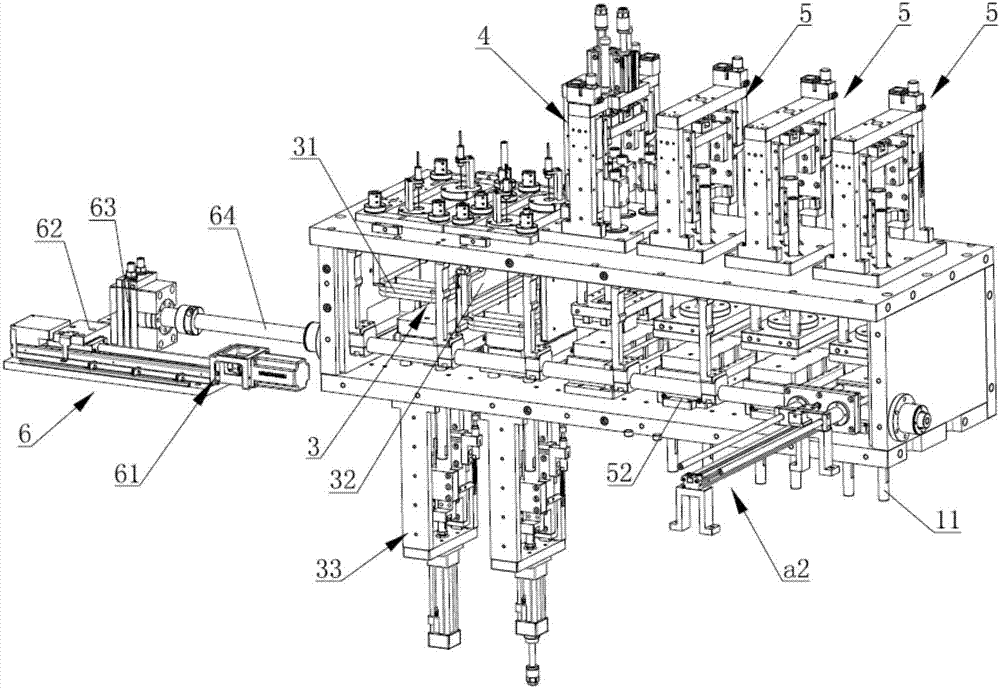

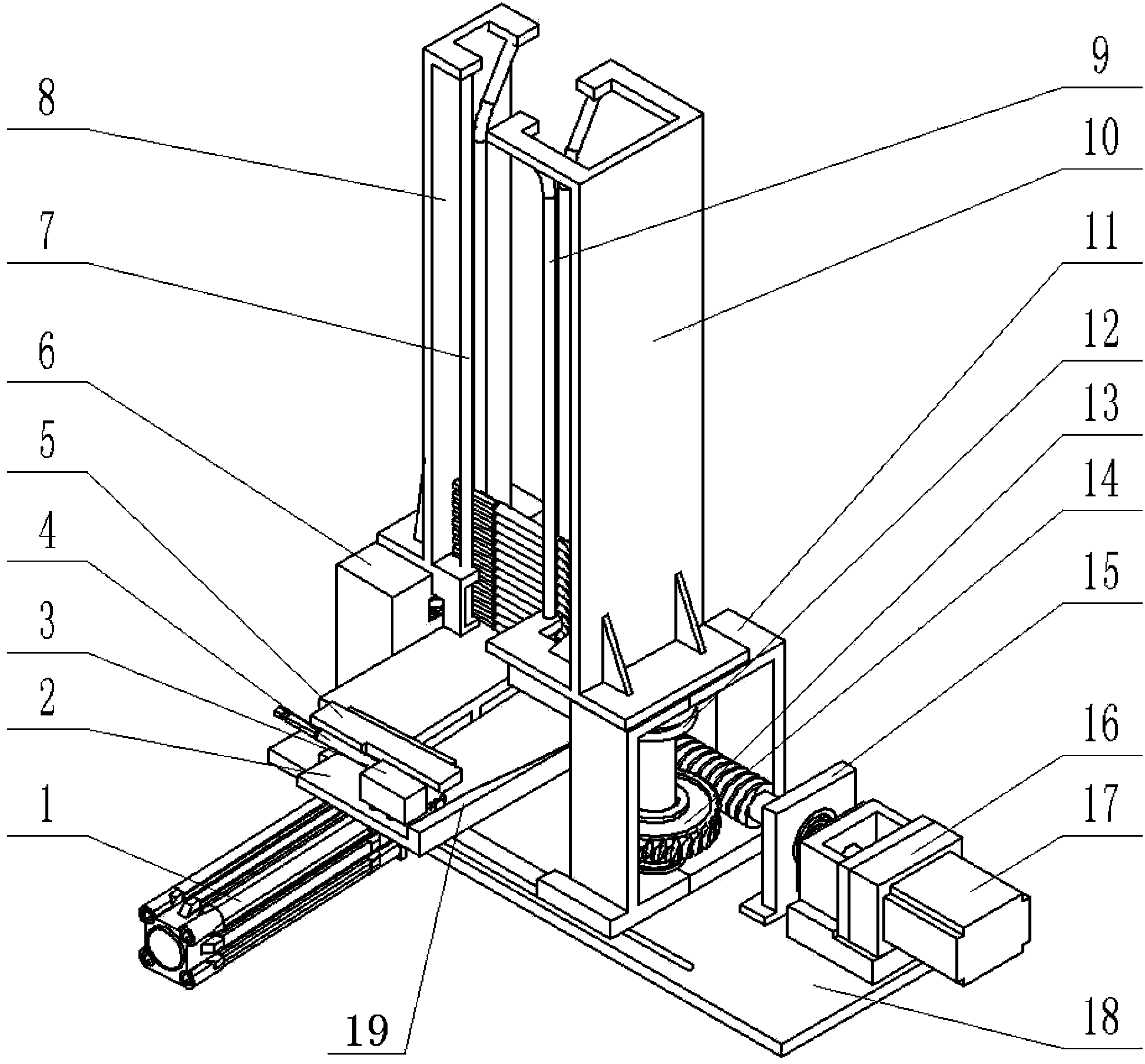

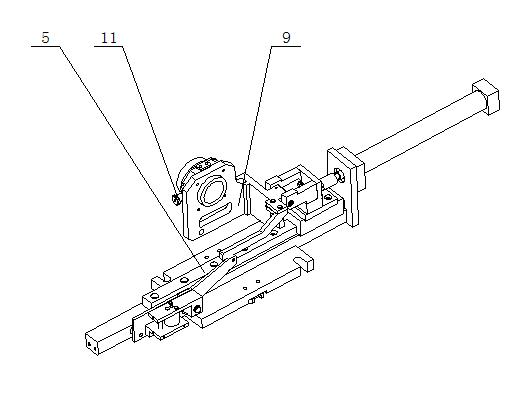

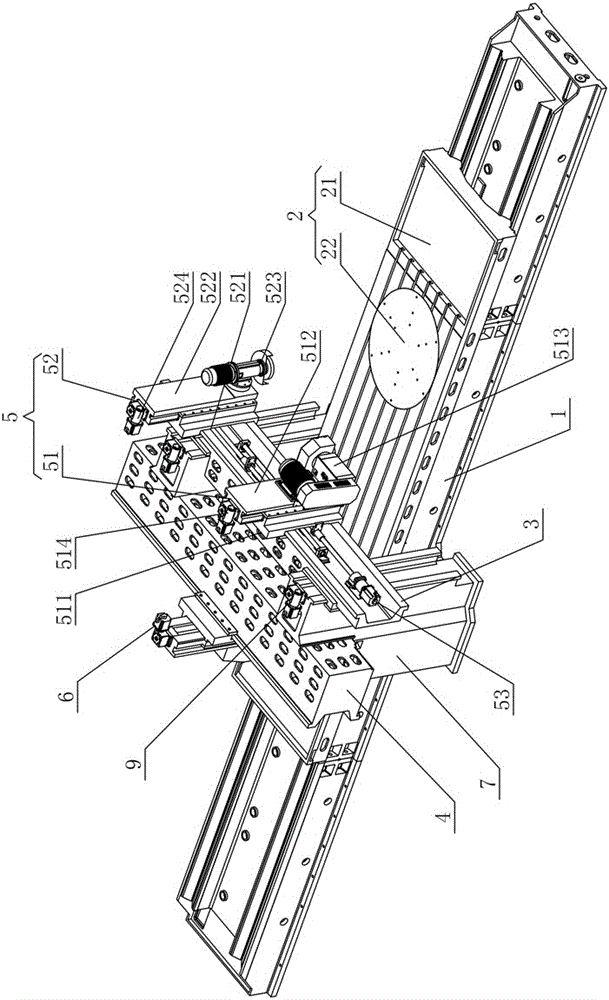

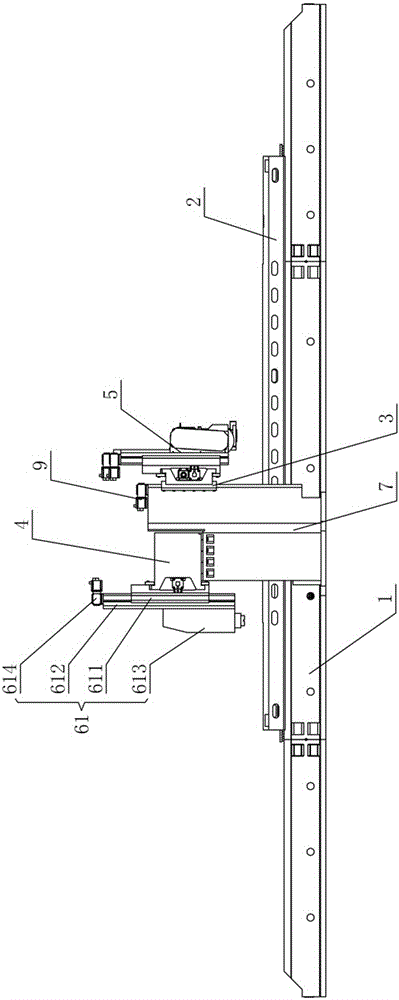

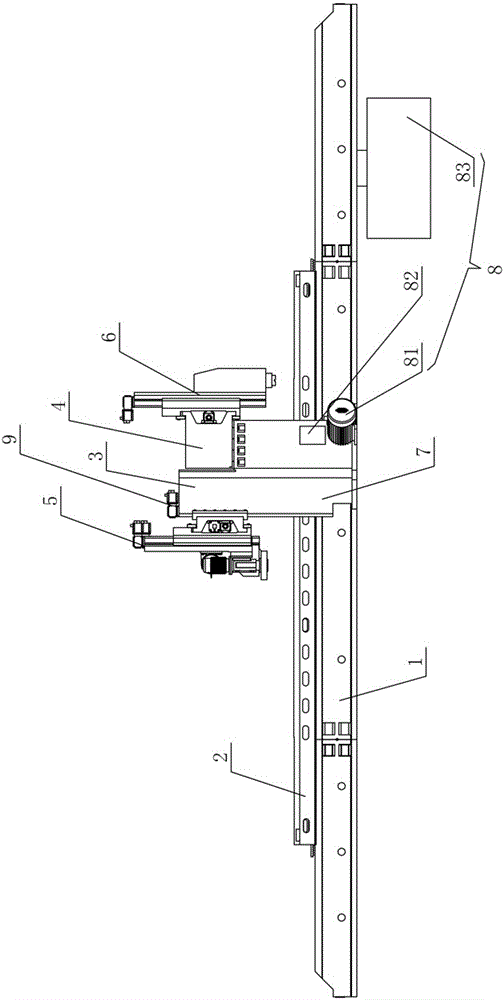

Flexible automatic distribution device for deformed bar materials

ActiveCN103358166AHigh degree of processing automationEasy to operateMetal working apparatusNumerical controlRobot hand

The invention relates to a bar material distribution device, in particular to a flexible automatic distribution device for deformed bar materials. The device comprises a flexible material storage mechanism, a servo distribution mechanism and a pneumatic material pushing mechanism which are used for storing, distributing and pushing the deformed bar materials respectively. Starting from a mechanical-electrical integration design idea, the distribution automation of the deformed bar materials is achieved by a flexible design method according to the characteristics of the deformed bar materials; after the device works with a special mechanical hand and a numerical control special machine, the automatic distributing, feeding and processing of the deformed bar materials can be achieved; the device is simple and reliable to use; the processing automation level of the deformed bar materials is effectively increased; the labor intensity is reduced; the influences caused by human factors are reduced; good cost performance is achieved.

Owner:SUZHOU ZIJINGANG INTELLIGENT MFG EQUIP

Automatic reinforcing steel bar thread machining production line

ActiveCN105690100AOccupy less laborSmall footprintOther manufacturing equipments/toolsProduction lineEngineering

The invention belongs to the field of building material processing machinery, and in particular relates to an automatic reinforcing steel bar thread machining production line which comprises a conveying mechanism and a plurality of moving mechanisms, wherein the moving directions of the moving mechanisms are perpendicular to the conveying direction of the conveying mechanism; a plurality of lifting clamping devices are arranged on the moving parts of the moving mechanisms; clamping openings of the lifting clamping devices face reinforcing steel bars on the conveying mechanism; machining equipment is arranged at two ends of the moving mechanisms; a limiting block is rotationally connected with one side of a reinforcing steel bar machined by each machining equipment on the conveying mechanism; rotation limiting positions of the limiting blocks are all above the conveying surface of the conveying mechanism; the other rotation limiting positions are below the conveying surface of the conveying mechanism. The automatic reinforcing steel bar thread machining production line has the beneficial effects that the reinforcing steel bars do not need to be moved and loaded and unloaded manually, so that the labor can be saved, and the machining efficiency can be improved; the occupied area is small; the reinforcing steel bars can roll under the action of gravity of self, so that the energy can be saved and the emission can be reduced; the automation degree is high, and the labor intensity is low; a baffle can be aligned with the reinforcing steel bars, a gradually shrunk channel has a guide function, and good thread machining quality can be achieved.

Owner:无锡天盈建筑科技有限公司

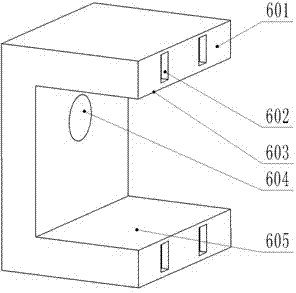

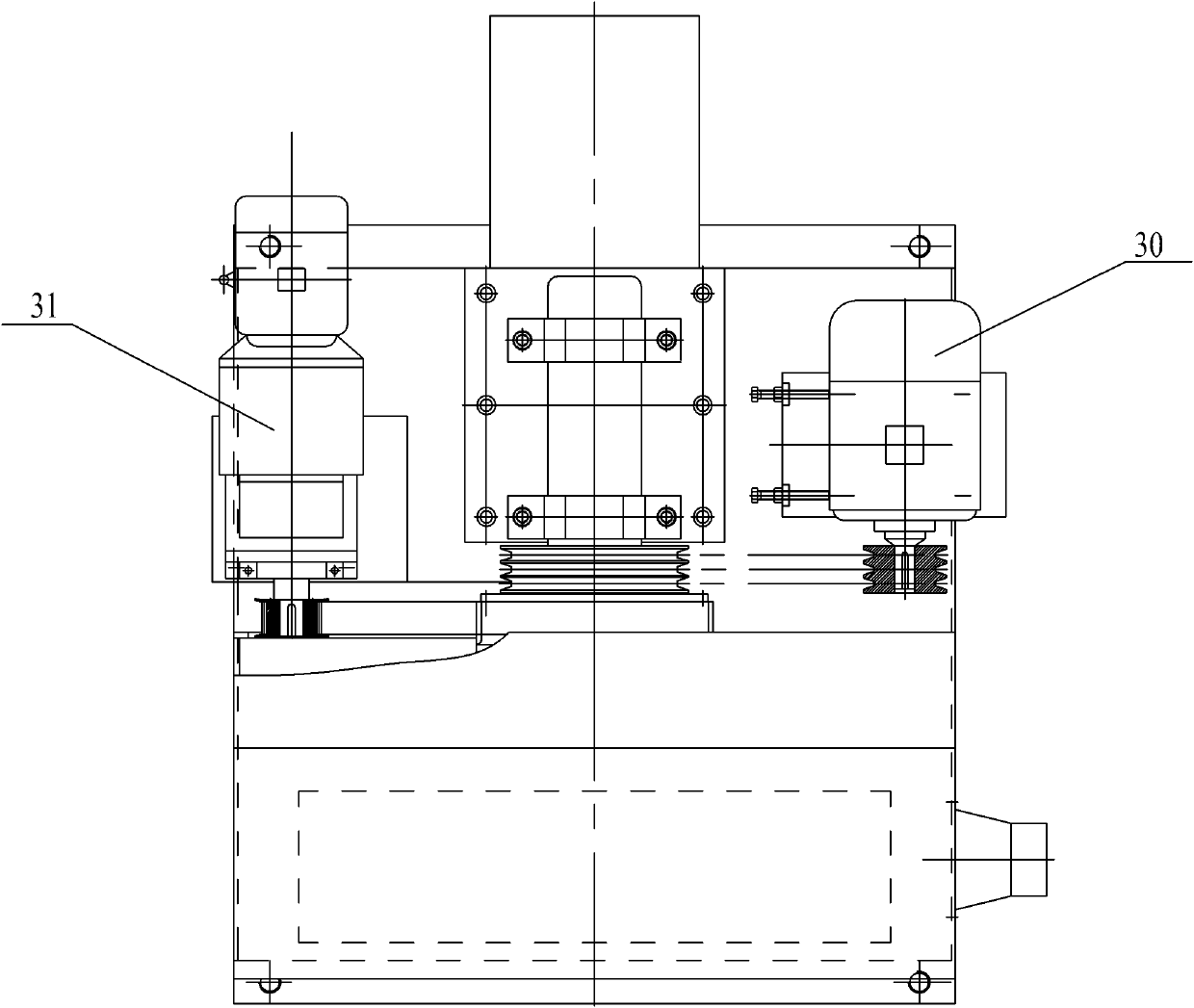

Automatic quick change device for workpiece fixtures for gear shaving machine

ActiveCN102554368AThe heart-to-heart process is fastImprove processing efficiencyGear-cutting machinesGear teethEngineeringMachine tool

The invention discloses an automatic quick change device for workpiece fixtures for a gear shaving machine. The right end of a first rotating shaft (6) is tightly abutted to a first fixture (1) through a centre, the first fixture (1) penetrates into a positioning hole of a quick change bracket (9) for the fixtures, the quick change bracket (9) for the fixtures is rotatably connected onto a feeding mechanism (5), a first pull rod (10) penetrates into the first fixture (1), the right end of the first pull rod (10) extends into a central hole of the second fixture (2), the right end of the second fixture (2) is matched with a second rotating shaft (7) through a conical surface, a second pull rod (12) penetrates into the central hole of the second fixture (2), and the right end of the second pull rod (12) is connected with an openable and closable pull claw (13) in the second rotating shaft (7). By the aid of the automatic quick change device, centering time in fixture change is shortened, fixture change frequency is decreased, and the machining efficiency and the automation degree of a machine tool are improved. Besides, the automatic quick change device has the advantages of ingenious design, high reliability and the like.

Owner:CHONGQING MACHINE TOOL GROUP

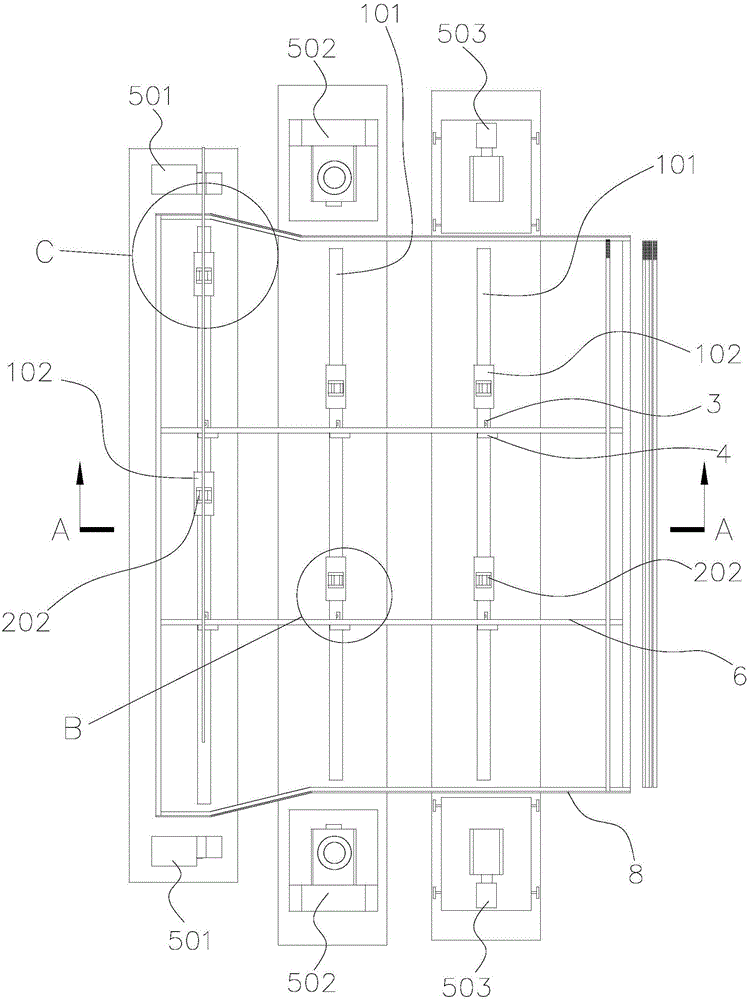

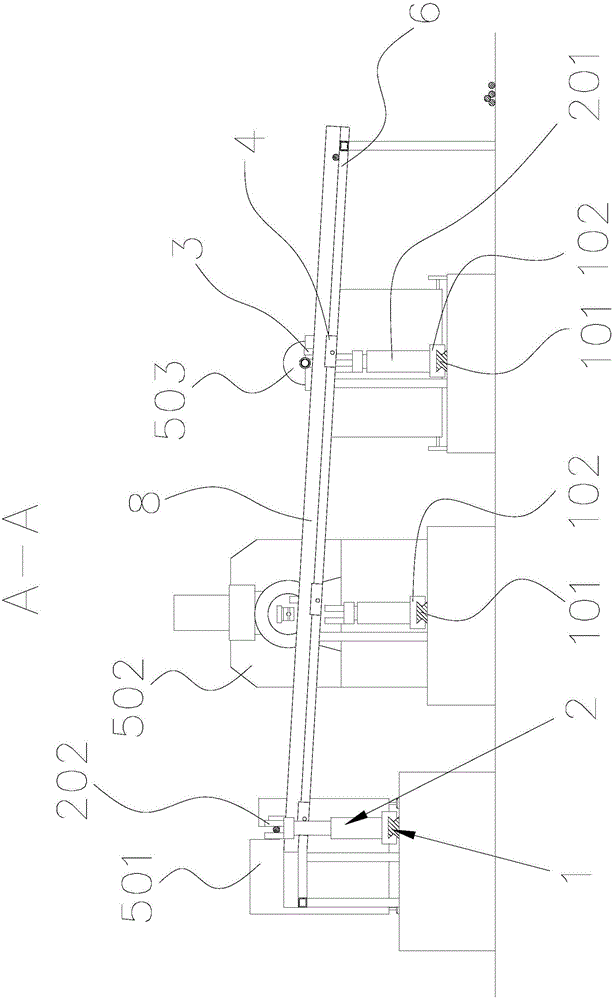

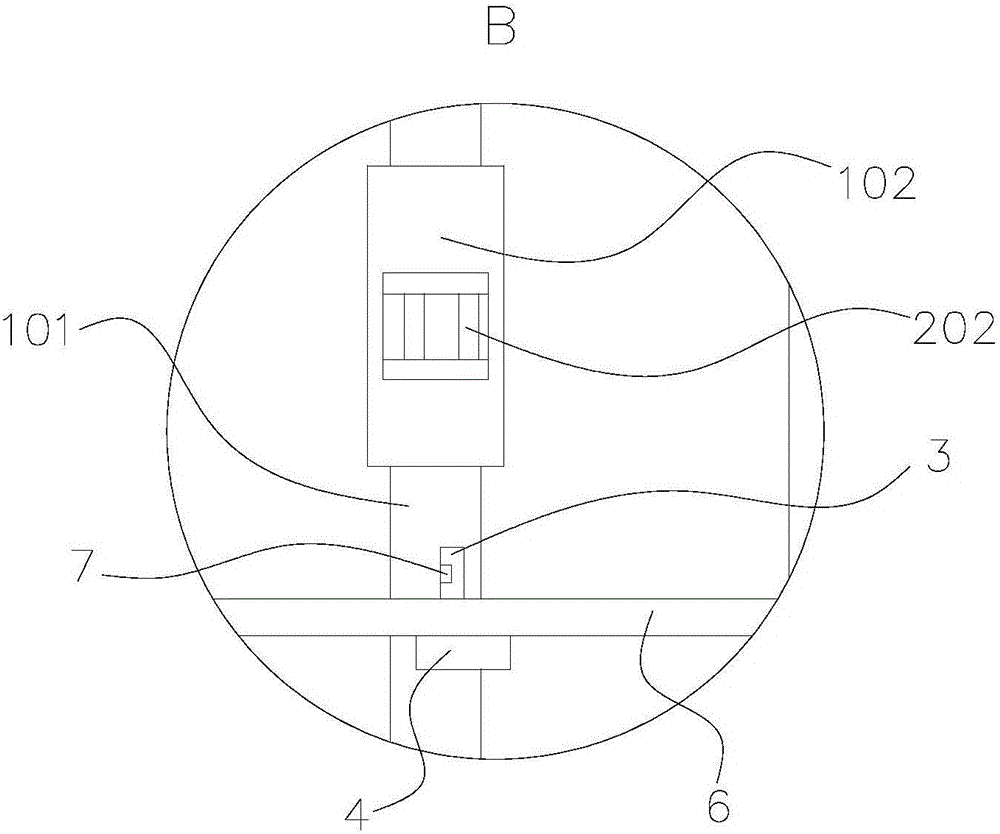

H-shaped steel overturning, welding and forming device

ActiveCN112059456AImprove assembly accuracyImprove processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention relates to an H-shaped steel overturning, welding and forming device. The H-shaped steel overturning, welding and forming device comprises a welding robot moving mechanism, a steel plateconveying mechanism, and a plurality of clamping and overturning mechanisms arranged in the length direction of the steel plate conveying mechanism, wherein a web jacking mechanism and a wing plate jacking mechanism are further arranged on the steel plate conveying mechanism. The H-shaped steel overturning, welding and forming device is simple in structure, ingenious in design and suitable for welding of H-shaped steel components of various types, and ensures the welding quality and the welding precision; spot welding is performed through an electric welding machine; and the assembling precision, machining efficiency and automation degree of the H-shaped steel are greatly improved; the H-shaped steel can be directly assembled through the H-shaped steel overturning, welding and forming device with no need for a traveling crane and a large amount of auxiliary manual work; and the the H-shaped steel overturning, welding and forming device has high assembling operation efficiency, saves labor force and operation time, is safe and convenient, and improves the production efficiency of products.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

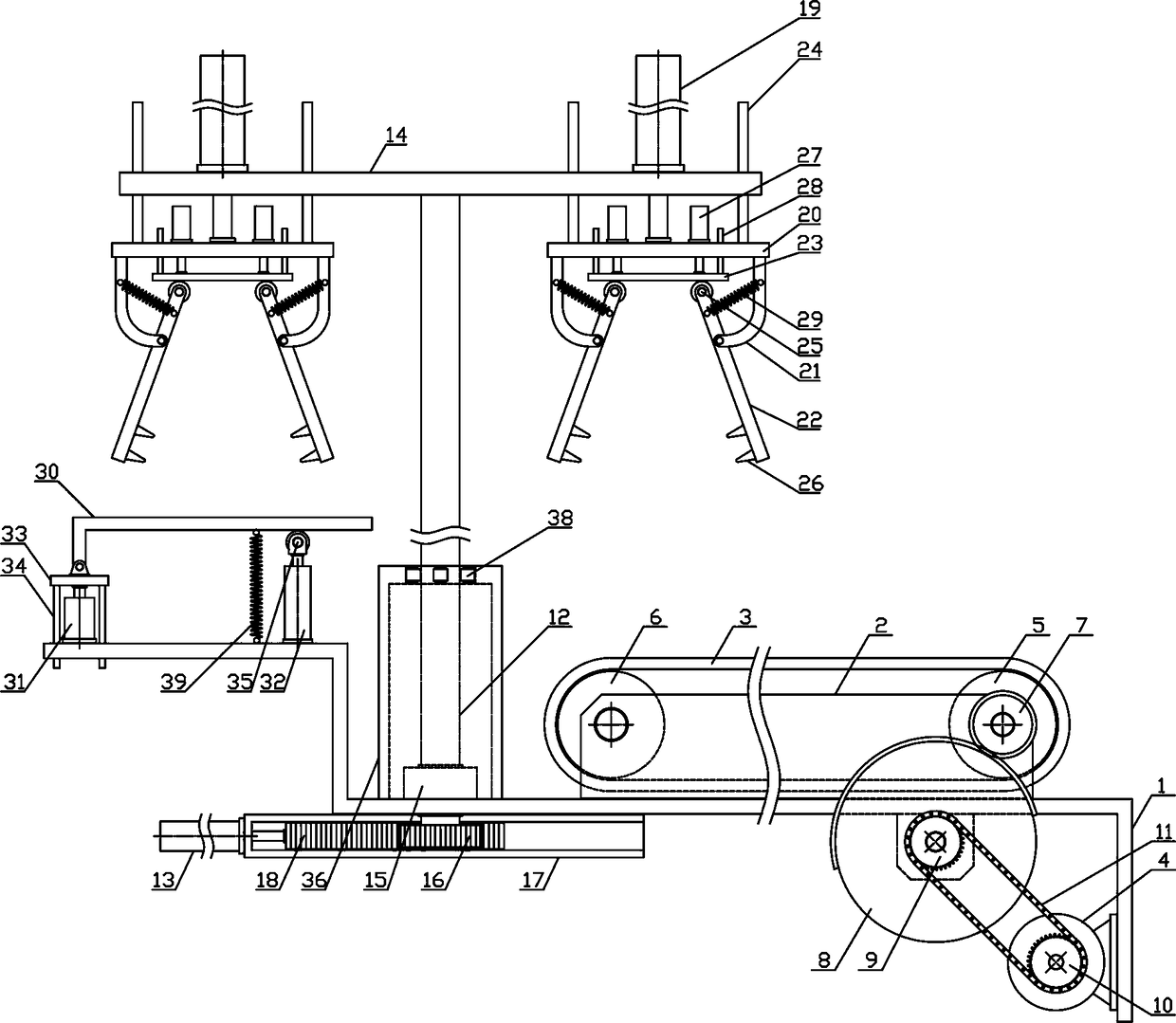

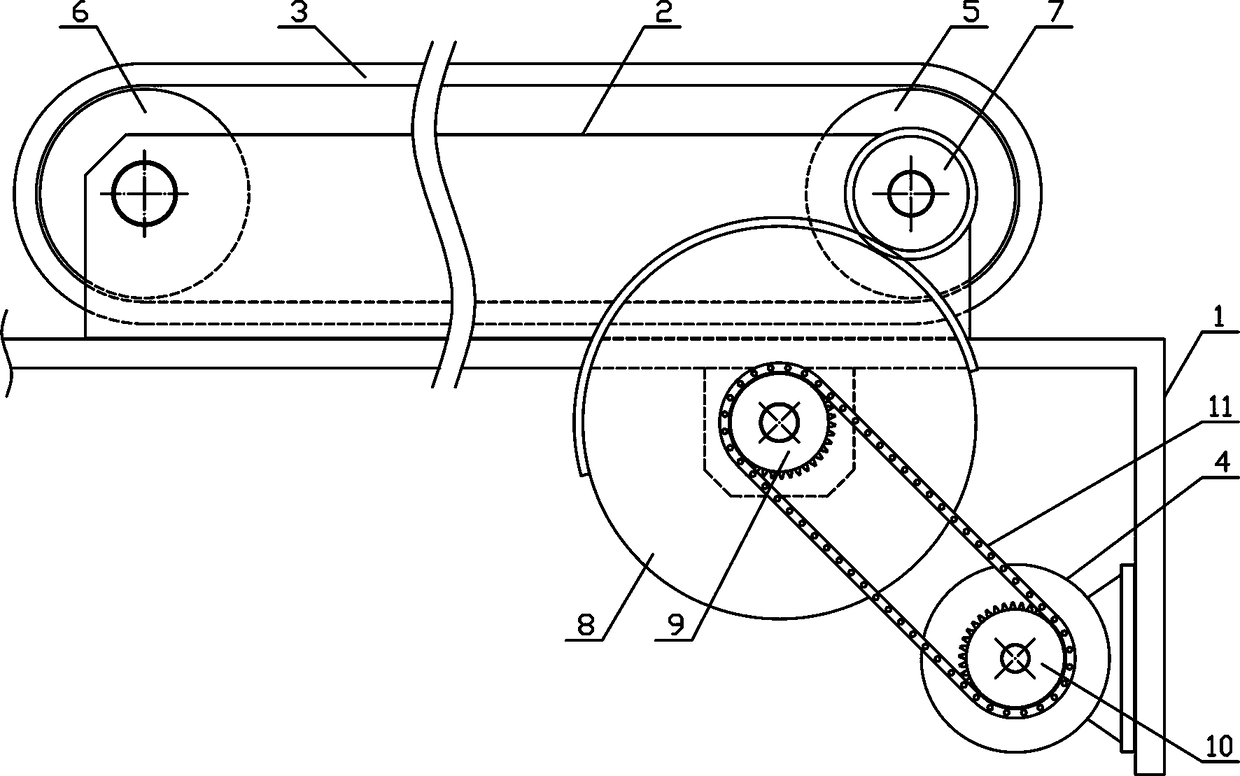

Flax coil continuous loading mechanism

InactiveCN108946035AReasonable structural designHigh degree of automationMechanical conveyorsMaterial transferLeather belt

The invention discloses a flax coil continuous loading mechanism and belongs to the field of textile processing machinery equipment. A material transferring mechanism and a bearing carrying mechanismare horizontally arranged on the two sides of the lower side of the loading mechanism respectively; the two sides of a material conveying belt are connected to a main conveying roll and an auxiliary conveying roll which are on the two sides of a fixed bracket in a coiling manner respectively; a drive gear which is adapted to a conveying gear is vertically and rotationally connected to the fixed bracket on the lower side of the conveying gear; a loading rotary shaft is vertically and rotationally connected to the middle part of a rotation truncated cone; a rotation disc is horizontally arrangedat the upper end of the loading rotary shaft; the two sides of the rotation disc are vertically and symmetrically provided with coil clamping mechanism in a radial direction of the rotation disc; oneend of a bearing carrying rotary plate is hinged to the middle part of the supper side of a carrying plate bracket; and a push plate rotary wheel is vertically and rotationally connected to the output ends of a push plate cylinder on the two sides of the lower side of one end of the material carrying rotary plate. The flax coil continuous loading mechanism provided by the invention is reasonablein structure design, can rapidly, efficiently, continuously and smoothly perform conveying and loading on a flax coil, increases the processing automation degree of the flax coil and meets the demandof production use.

Owner:戴杰

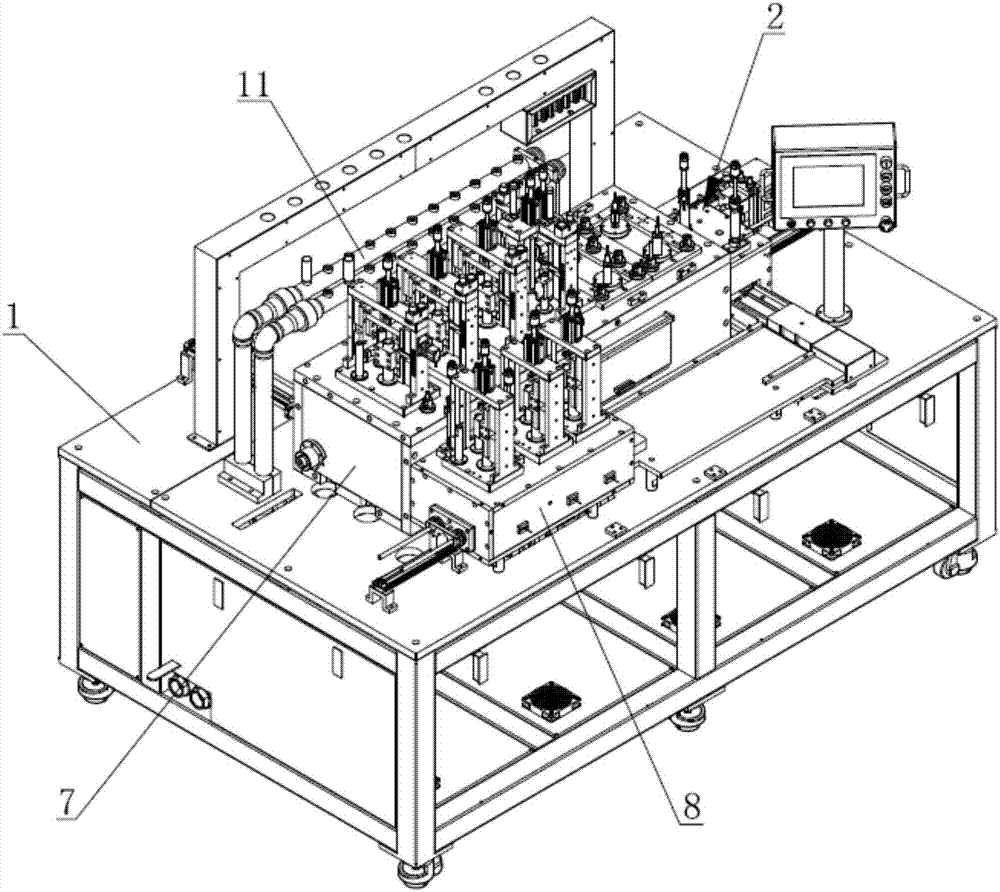

Continuous press fitting equipment for tubular workpieces

ActiveCN111230458AFalling steadilyEfficient and smooth flip adjustmentMetal working apparatusElectric machineryMechanical equipment

The invention discloses continuous press fitting equipment for tubular workpieces, and belongs to the field of workpiece production and processing mechanical equipment. A workpiece conveying belt is arranged on the lower side of a workpiece conveying support, the two sides of the workpiece conveying belt are wound and connected with workpiece conveying rotating rollers on the two sides of the workpiece conveying support respectively, and a workpiece conveying motor is in transmission connection with the workpiece conveying rotating rollers through a workpiece conveying chain. A workpiece guidemechanism, a workpiece transfer mechanism and a workpiece turnover mechanism are sequentially arranged on the workpiece conveying support on the upper side of the workpiece conveying belt in the conveying direction of the workpiece conveying belt. A workpiece push mechanism and a workpiece press fitting mechanism are arranged on the workpiece conveying support on the two sides of the ends in theconveying direction of the workpiece conveying belt respectively. The continuous press fitting equipment is reasonable in structural design, can guide and transfer the tubular workpieces one by one conveniently and smoothly, can realize successive and continuous press fitting processing of multiple assemblies in the transfer process of the tubular workpieces, improves the automation degree of workpiece processing and meets the needs of production and use.

Owner:SUZHOU ZHIYUN CHUANGYU INFORMATION TECH CO LTD

Heat-sheet membrane sealing machine and membrane sealing process of dialyser

InactiveCN101991886AImprove product qualityHigh degree of processing automationDialysis systemsThermodynamicsFixed frame

The invention discloses a heat-sheet membrane sealing machine and a membrane sealing process of a dialyser. The heat-sheet membrane sealing machine is provided with a frame body, a clamping device, calibration devices, a mobile device, a drive device, a heat-sealing device and a control device, wherein the clamping device is fixed on the mobile device; the mobile device is connected with the drive device; the calibration devices are arranged at the two sides of the clamping device; the mobile device is provided with a fixed frame and a mobile frame; the clamping device is designed to be a U-shaped support; the calibration device is provided with a calibration plate and a calibration air cylinder; and the heat-sealing device is provided with a heat-sealing frame and a strip-shaped heat sheet. The membrane sealing process of the dialyser comprises the following steps of: placing the dialyser on the clamping device; adjusting the end part of the dialyser by the calibration device; driving the mobile device to move by the drive device and transporting the dialyser to the heat-sealing device; driving the mobile device to move by the drive device so that the dialyser gradually passes through the heat-sealing device; and returning to an initial position. The membrane-sealed product has the advantages of stable quality and high automation degree, and is suitable for batch production.

Owner:贝恩医疗设备(广州)有限公司

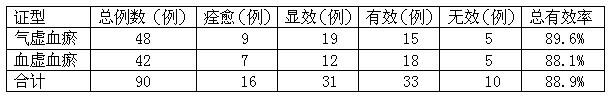

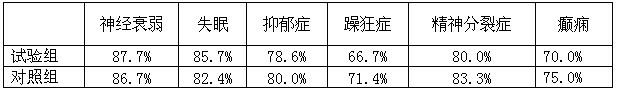

Preparation process of blood activating capsule

ActiveCN101773571AQuality improvementEasy to takeNervous disorderCapsule deliveryCitrus aurantium extractCyclodextrin

The invention discloses a preparation process of a blood activating capsule, which comprises the following steps that: first, angelica and citrus aurantium extract the fat-soluble effective ingredient groups through a supercritical CO2 extraction process, the fat-soluble effective ingredient groups are included by Beta-cyclodextrin to prepare inclusion volatile oil, herb residue and astragalus, peach kernel, safflower and other six Chinese medicines are decocted, the filtrate is concentrated into clear cream A, ethanol is added in so that the ethanol content is 65 percent, supernatant is taken out and the ethanol is recovered, and clear cream B is prepared by concentration; and finally clear cream C is purified by macroporous resin enrichment, the clear cream C is heated, sterilized, dried by microwave to prepare dry cream, and the dry cream is mixed with rhizoma ligustici wallichii fine powder and the included volatile oil and starch, boiled and granulated, and the capsule is filled. The preparation process of the blood activating capsule has the advantages that the blood activating capsule prepared has safe and reliable therapeutic effect and stable and controllable quality, abandons the ineffective and harmful ingredients in the Chinese medicine raw material, improves the medicine purity and reduces the dose of a patient.

Owner:西安大唐制药集团有限公司

Flexible and automatic distributing device for shaft sleeve workpieces

InactiveCN103878628AOvercome stuckHigh degree of processing automationMetal working apparatusProcess engineeringManipulator

The invention discloses a flexible and automatic distributing device for shaft sleeve workpieces. The device comprises a flexible storage mechanism, a servo distribution mechanism and a pneumatic pushing mechanism arranged under the servo distribution mechanism. The three mechanisms achieve storage, distribution and pushing of the shaft sleeve workpieces respectively. According to characteristics of the shaft sleeve workpieces and by the adoption of a flexible design method, automation of distribution of the shaft sleeve workpieces is achieved, operation is easy, the number of workers is effectively reduced, and recruitment and management difficulty is eased. In specific application, an operator only needs to place a preset number of the shaft sleeve workpieces in the flexible storage mechanism, and other distribution work is finished through the servo distribution mechanism and the pneumatic pushing mechanism automatically. With the combination of a simple manipulator and a numerical control machine tool, automatic distribution, feeding and machining of the shaft sleeve workpieces are achieved, and accordingly influences of human factors are reduced and product quality and production efficiency are improved.

Owner:ZHEJIANG UNIV

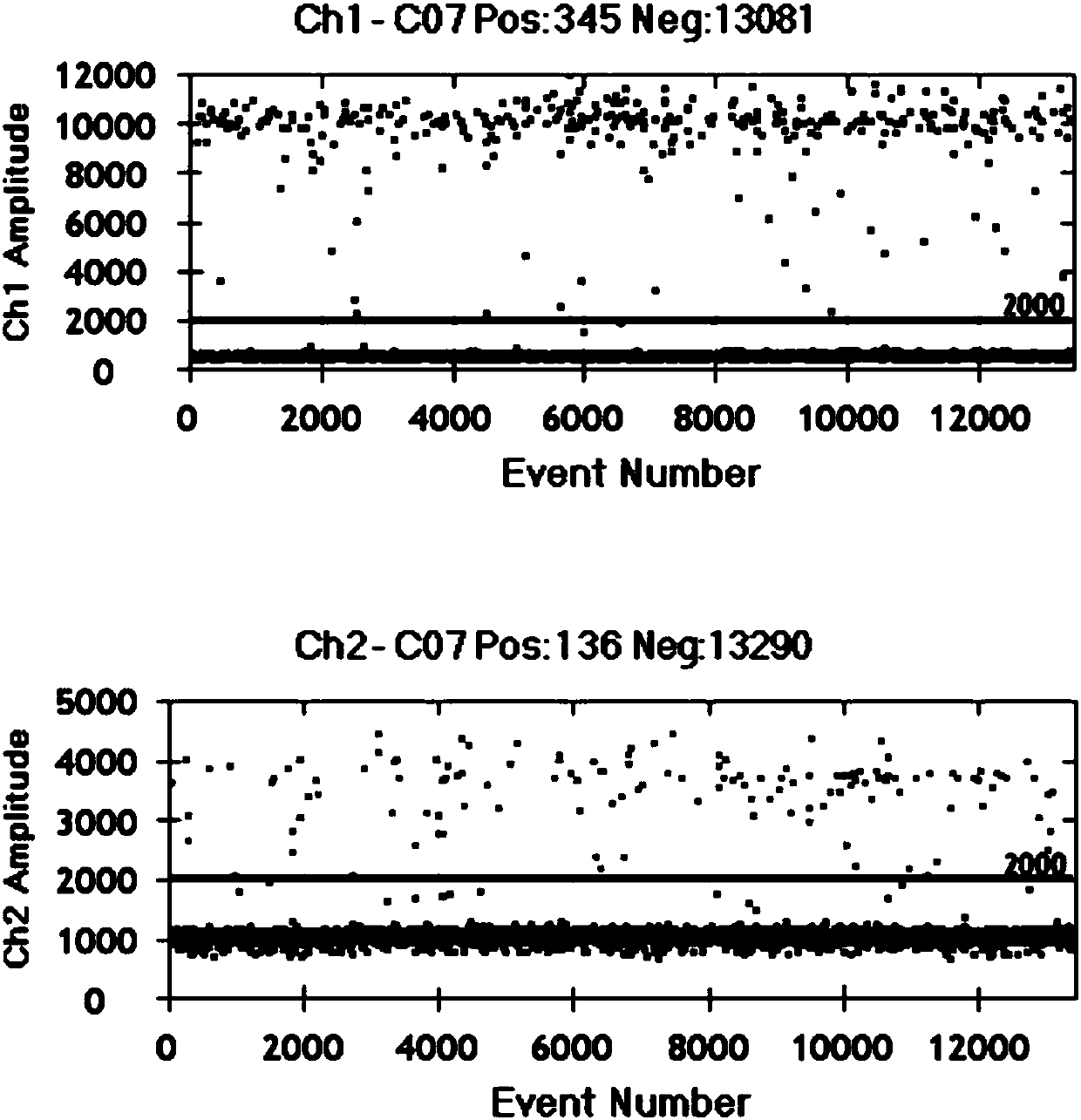

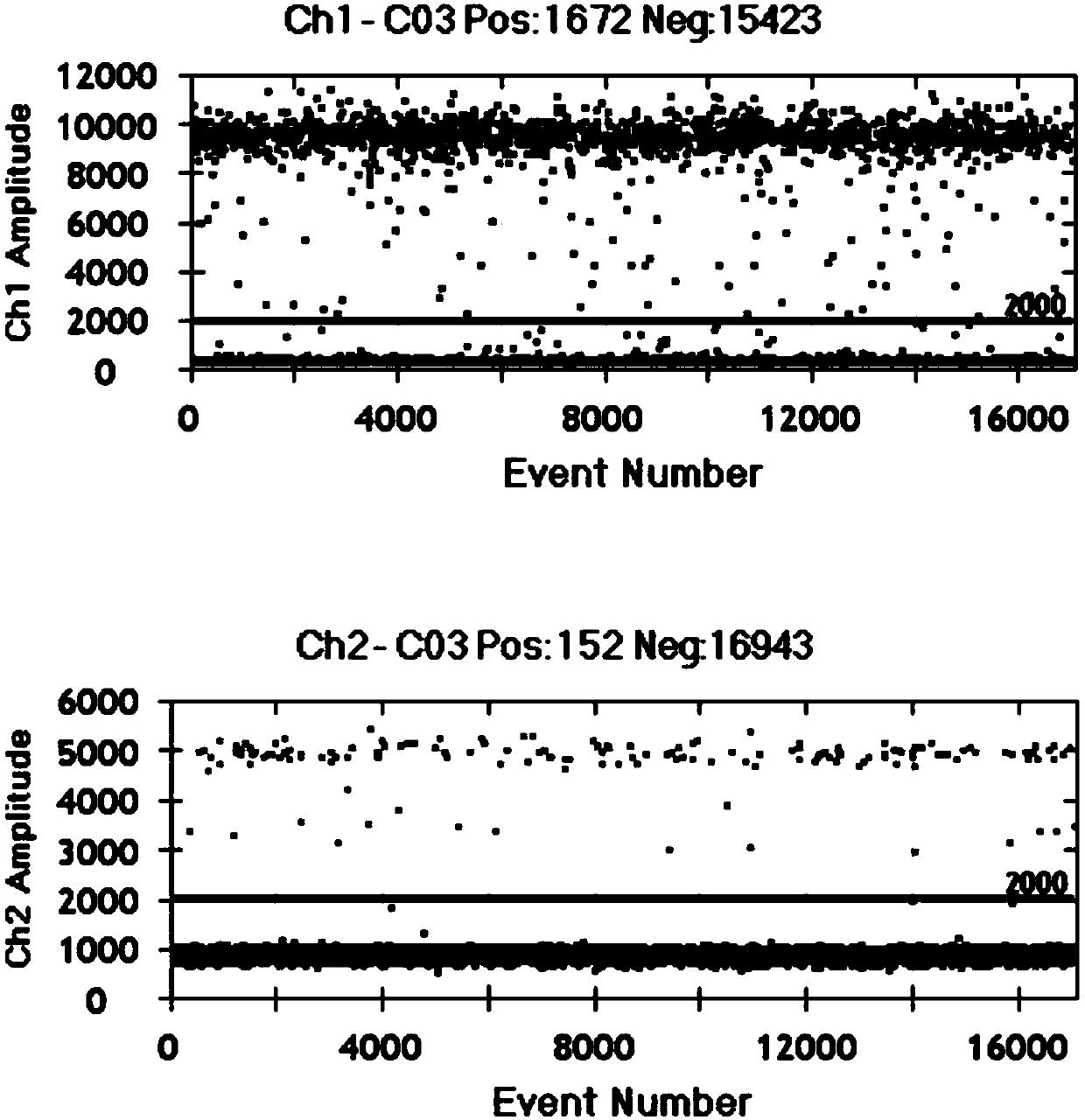

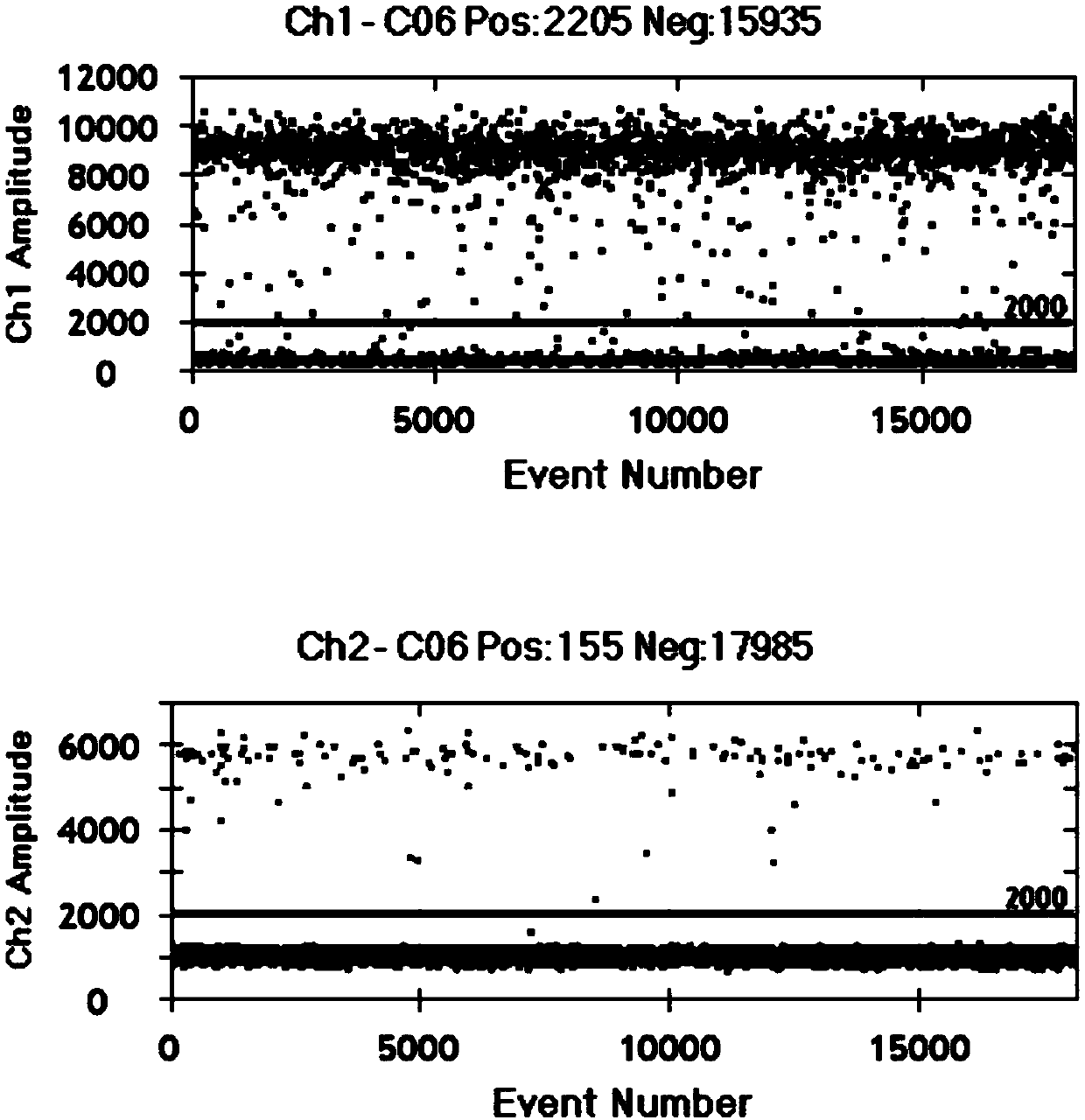

Nucleotide sequence and kit for HER-2 gene copy number amplification detection, and application of kit

ActiveCN107739760AThe result is accurateLow costMicrobiological testing/measurementDNA/RNA fragmentationMolecular diagnostic techniquesNucleic acid sequencing

The invention discloses a nucleotide sequence and a kit for detecting a human epidermal growth factor receptor-2 (HER-2), which belong to the technical field of molecular diagnosis. A primer and a probe for detecting the HER-2 provided by the invention can be used for specifically amplifying and detecting amplification of an HER-2 gene. The invention also discloses the detection kit for detectingthe HER-2 gene based on a microdroplet type PCR (Polymerase Chain Reaction) system, so that the amplification of the HER-2 gene can be quickly, sensitively and accurately detected. The nucleotide sequence and the kit provided by the invention have the advantages of simplicity and convenience in operation, high specificity, high sensibility, low cost, high throughput and the like, can be used for quickly detecting clinic HER-2 gene amplification, and provide references for diagnosis and treatment of the clinic human epidermal growth factor receptor-2.

Owner:昆山迪安医学检验实验室有限公司

Gantry type milling processing center

InactiveCN106239165AFunction increaseEliminate setup errorsOther manufacturing equipments/toolsEngineeringPentahedron

The invention discloses a gantry type milling processing center. The milling processing center comprises a bed body, a worktable, a movable beam, a fixed beam, a grinding component, an all-purpose pentahedron milling component and two uprights, wherein the worktable is installed on the bed body, the two uprights are respectively arranged at two sides of the bed body and located at two sides of the worktable, the movable beam is arranged at one sides of the two uprights and capable of lifting along the uprights, and the fixed beam is fixedly arranged at the other sides of the two uprights; the grinding component is arranged on the movable beam and capable of transversely moving along the movable beam, and the all-purpose pentahedron milling component is arranged on the fixed beam and capable of transversely moving along the fixed beam; and the worktable comprises a linear movement platform and a rotary platform, the linear movement platform is arranged on the bed body, the rotary platform is embedded on the linear movement platform, the uprights are provided with driving components for driving the linear movement platform and the rotary platform to operate. The processing center disclosed by the invention has the advantages of being suitable for large complex part processing, high in processing precision, and capable of improving the processing efficiency and the automation degree.

Owner:XIANGTAN SANFENG CNC MACHINE TOOL

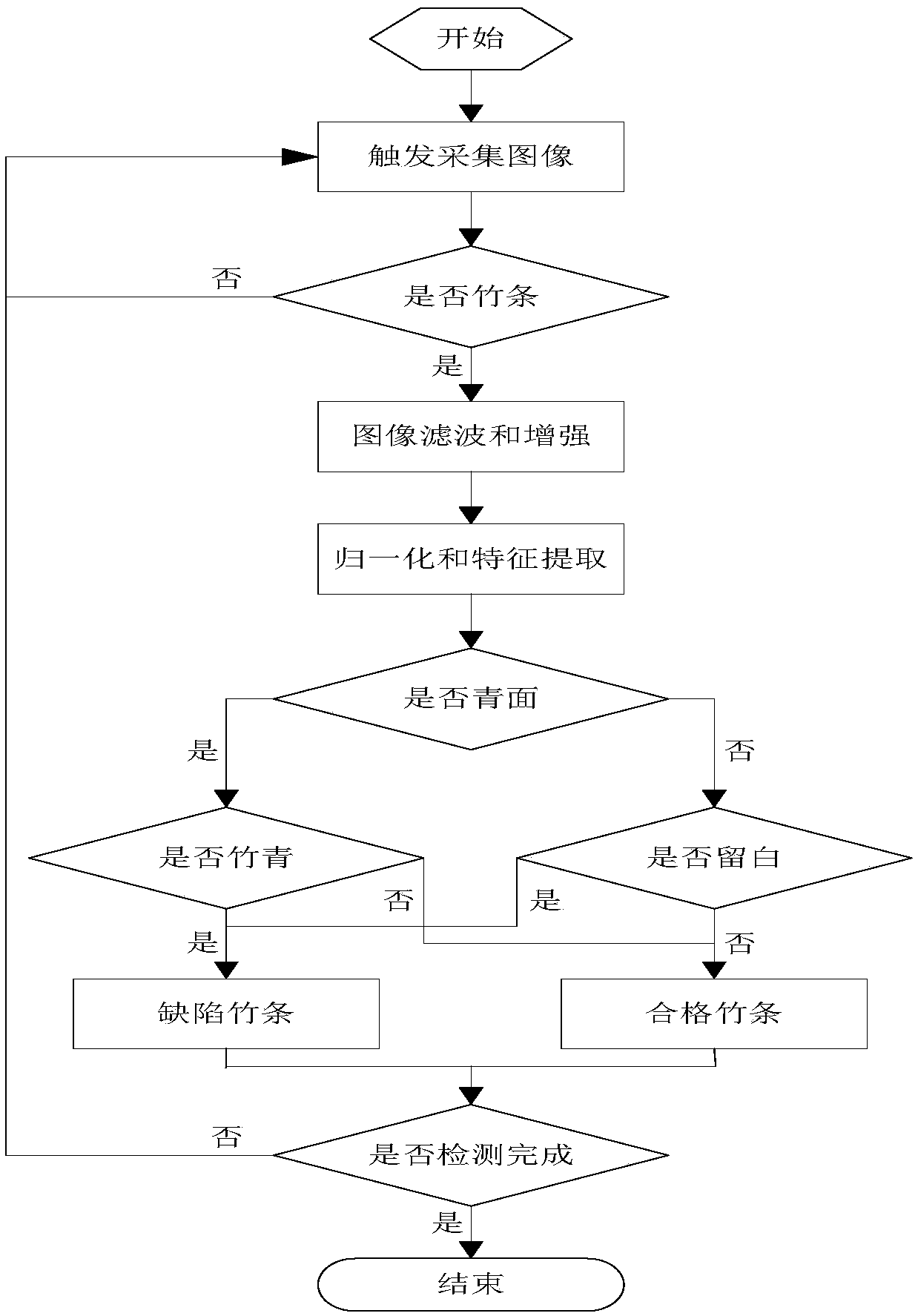

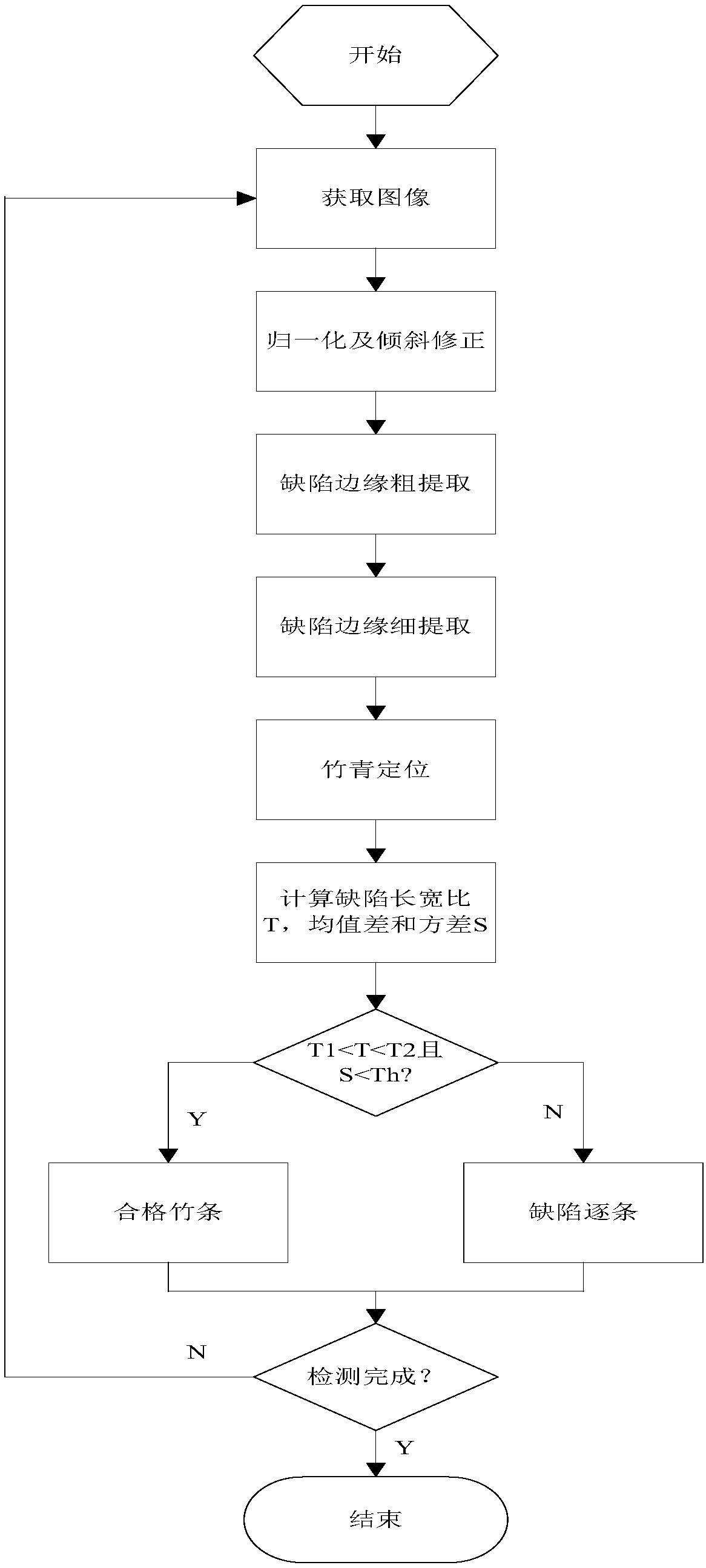

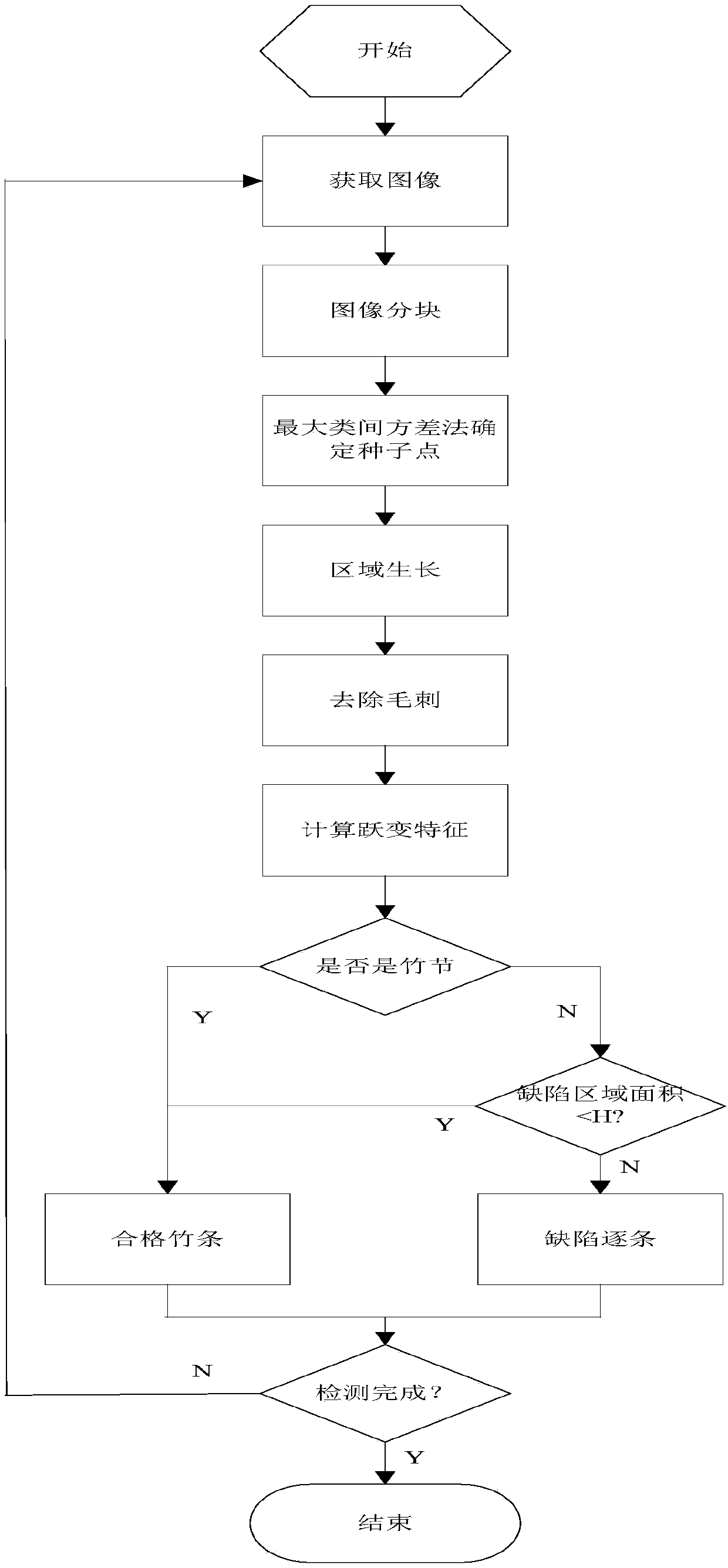

Machine vision based bamboo strip defect detection method

ActiveCN108181316AAvoid slow recognitionQuick classificationImage enhancementInvestigation of vegetal materialFeature extractionMachine vision

The invention provides a machine vision based bamboo strip defect detection method which comprises the following steps of S1, establishing a neural network structure used for bamboo strip recognitionto obtain a recognition model used for recognizing the yellow-green face of a bamboo strip; S2, collecting an original image of the bamboo strip to be detected; S3, performing normalized processing onthe original image of the bamboo strip to be detected; S4, performing feature extraction on image data after normalized processing; and S5, inputting features extracted in the step S4 into the recognition model in the step S1, judging the condition of the yellow-green face of the bamboo strip image, and performing defect detection of bamboo greenness and left blank according to a judgment resultrespectively. The invention provides the machine vision based bamboo strip defect detection method which can rapidly recognize and classify the bamboo strip. The machine vision based bamboo strip defect detection method is simple and feasible, can relatively rapidly realize effective detection of the bamboo strip under the condition of invariable illumination condition, increases the automation degree of bamboo product processing and improves the industrial production efficiency.

Owner:GUANGXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com