Free-form surface part processing system based on multi-sensor integrated measurement technology

A curved surface processing and parts processing technology, which is applied in the field of free-form surface parts processing systems, can solve problems such as low processing efficiency, unsatisfactory flexible manufacturing, and inability to inspect product quality, and achieve the effect of improving processing efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

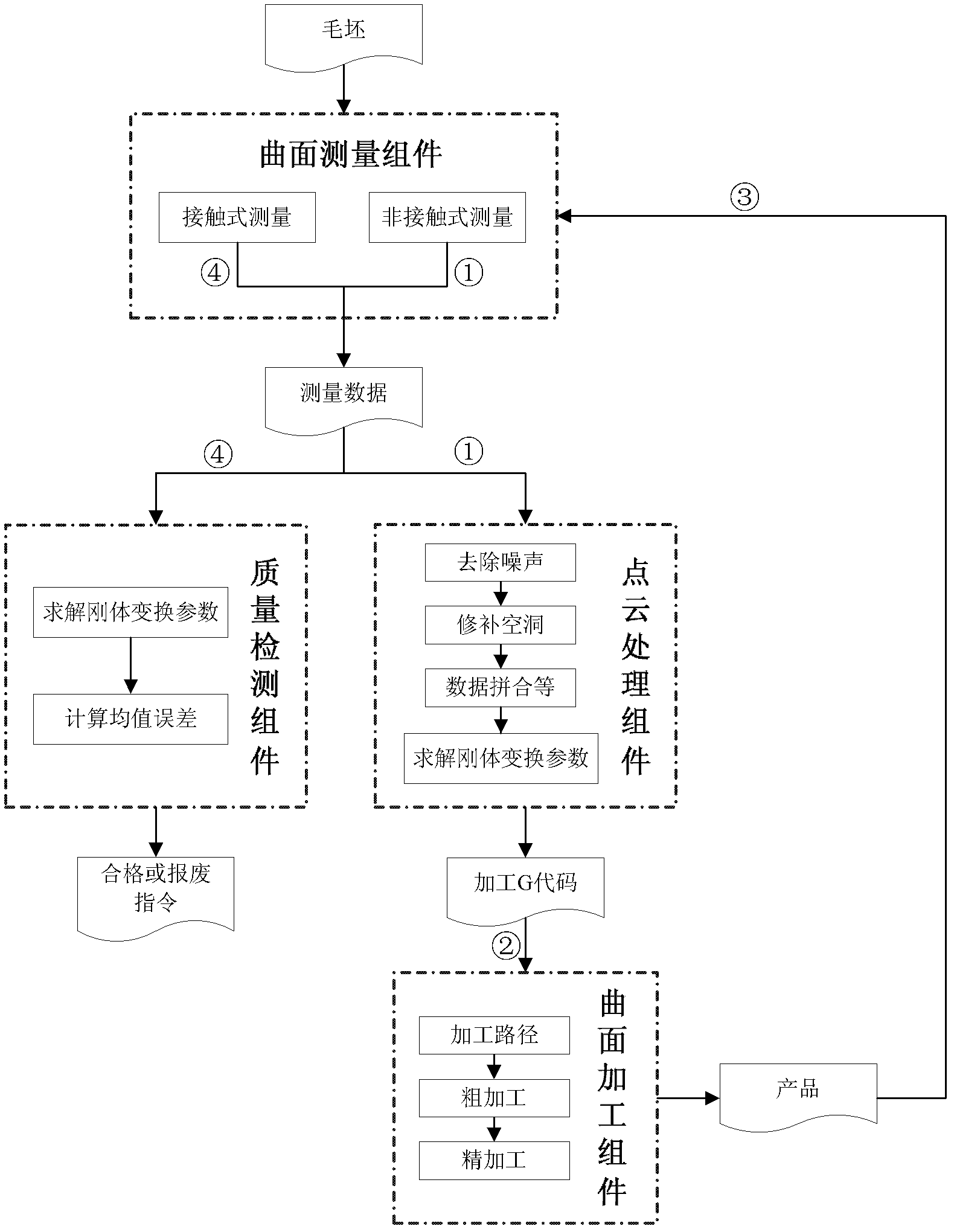

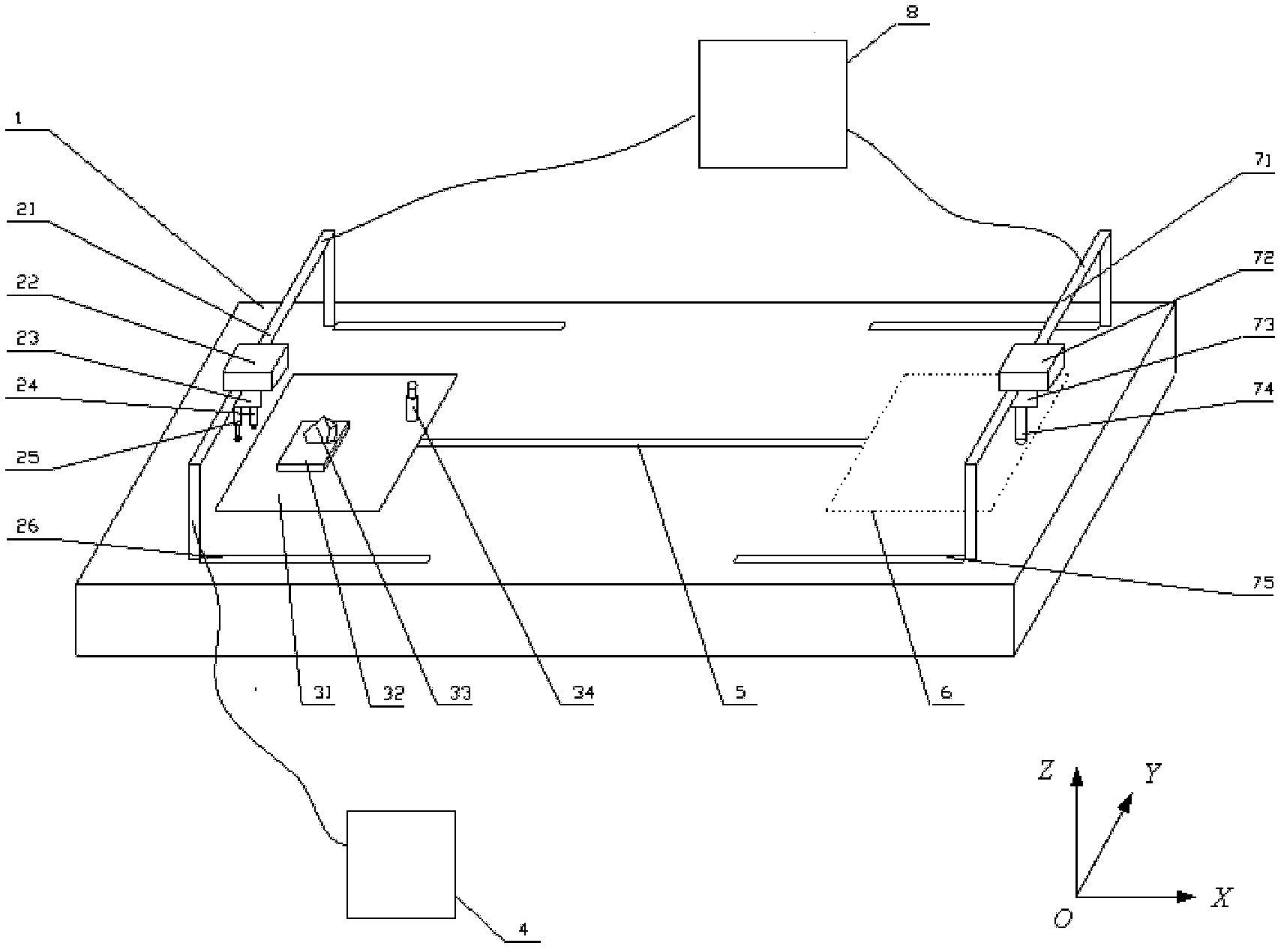

[0019] The invention integrates both non-contact and contact sensors. On the one hand, it uses the characteristics of fast non-contact measurement and large amount of data to quickly calculate the spatial position relationship between the target and the design coordinate system, which is used to generate machining G codes that can be directly applied in the machine tool coordinate system; on the other hand, use With the characteristics of high precision of contact measurement, the quality inspection of processed products is carried out.

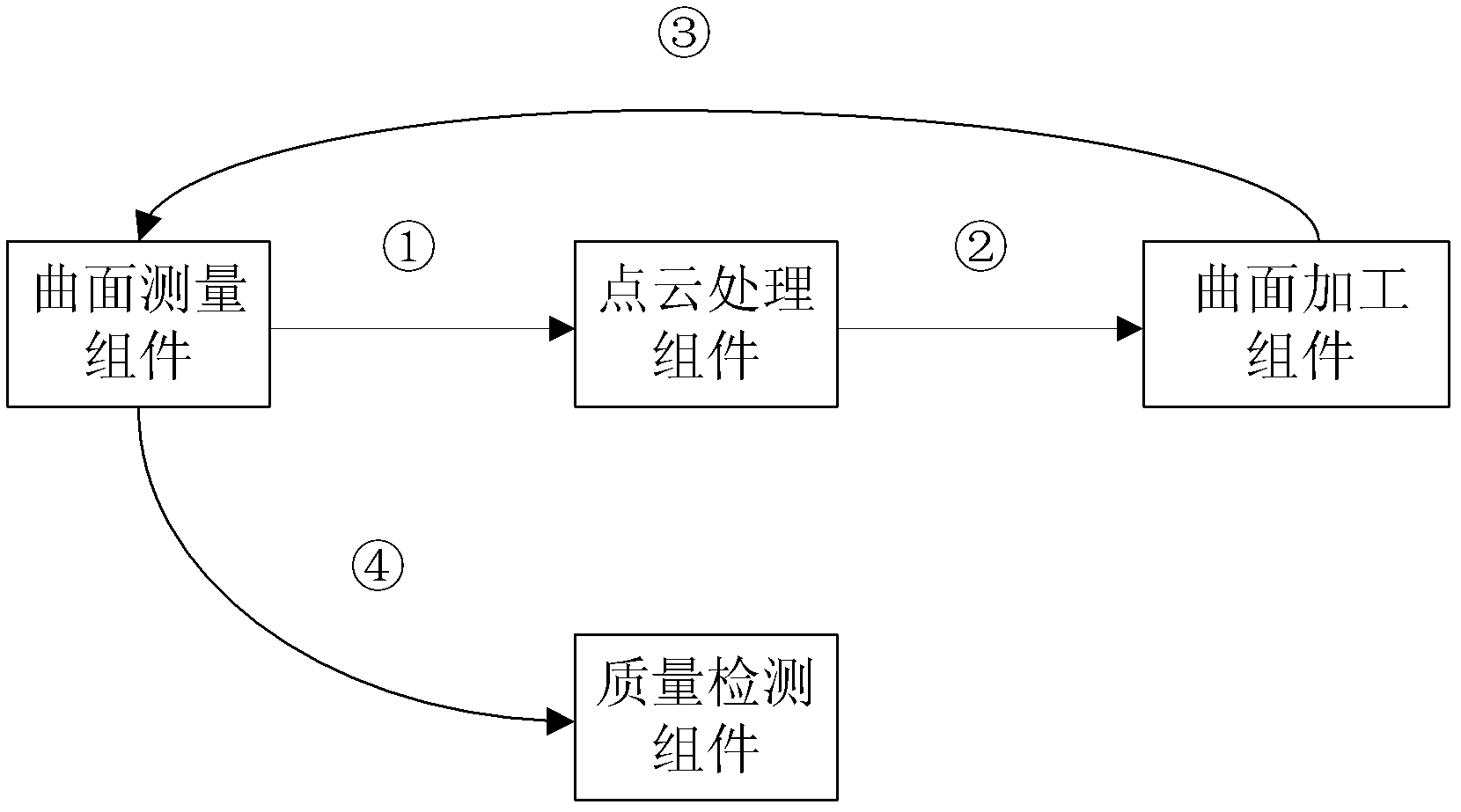

[0020] Such as figure 1 As shown, the free-form surface part processing system based on multi-sensor integrated measurement includes four working components: surface measurement component, point cloud processing component, surface processing component and quality inspection component.

[0021] The surface measurement component integrates both non-contact and contact sensors for discrete measurement of the target to be measured. The surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com