Patents

Literature

2251 results about "Non contact measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non Contact Measurement. Non contact measurement plays an important role for manufacturers in today’s engineering world. Unlike non contact inspection, many traditional contact measurement devices such as, micrometers and vernier callipers touch the surface in order to determine the dimensions of a component.

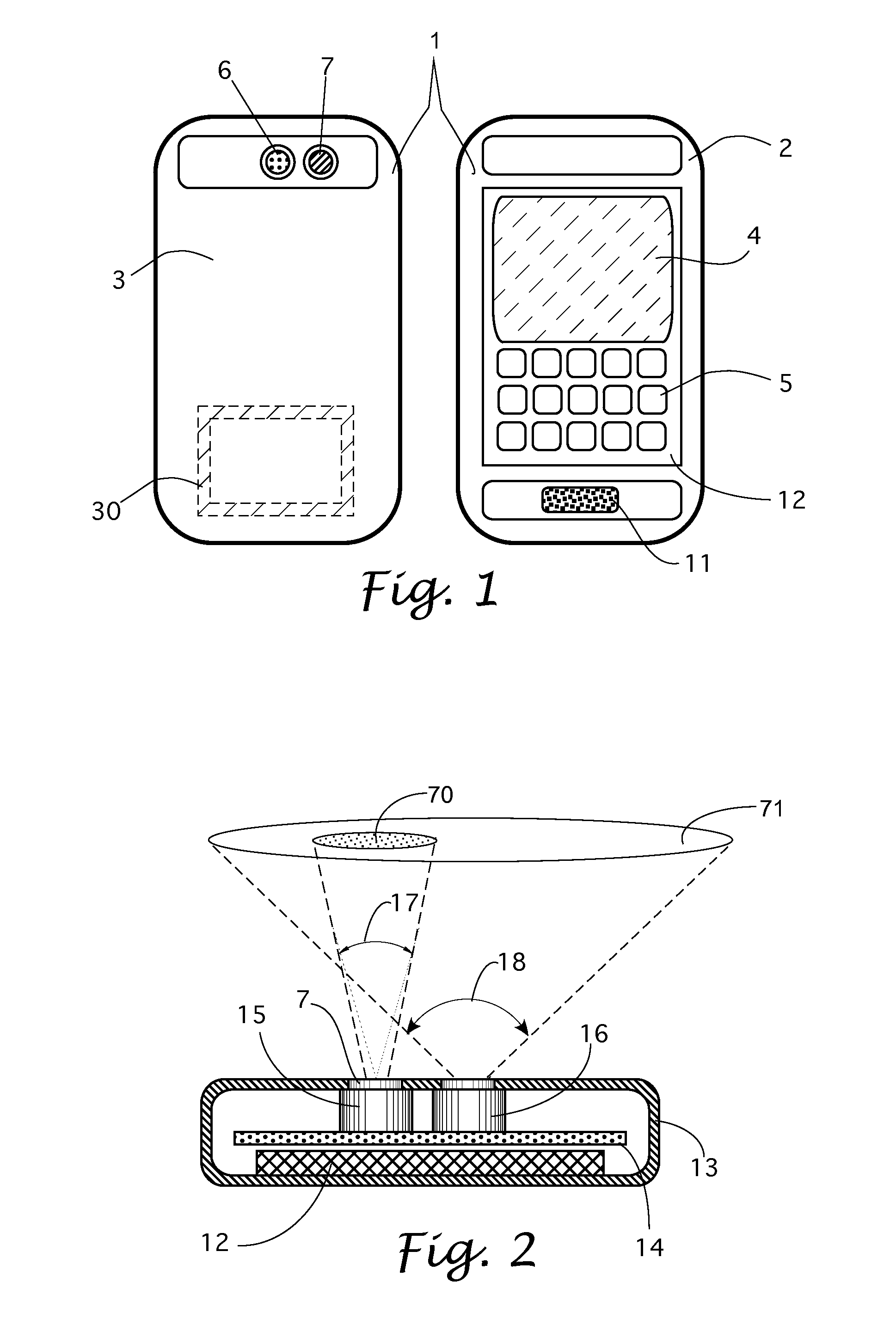

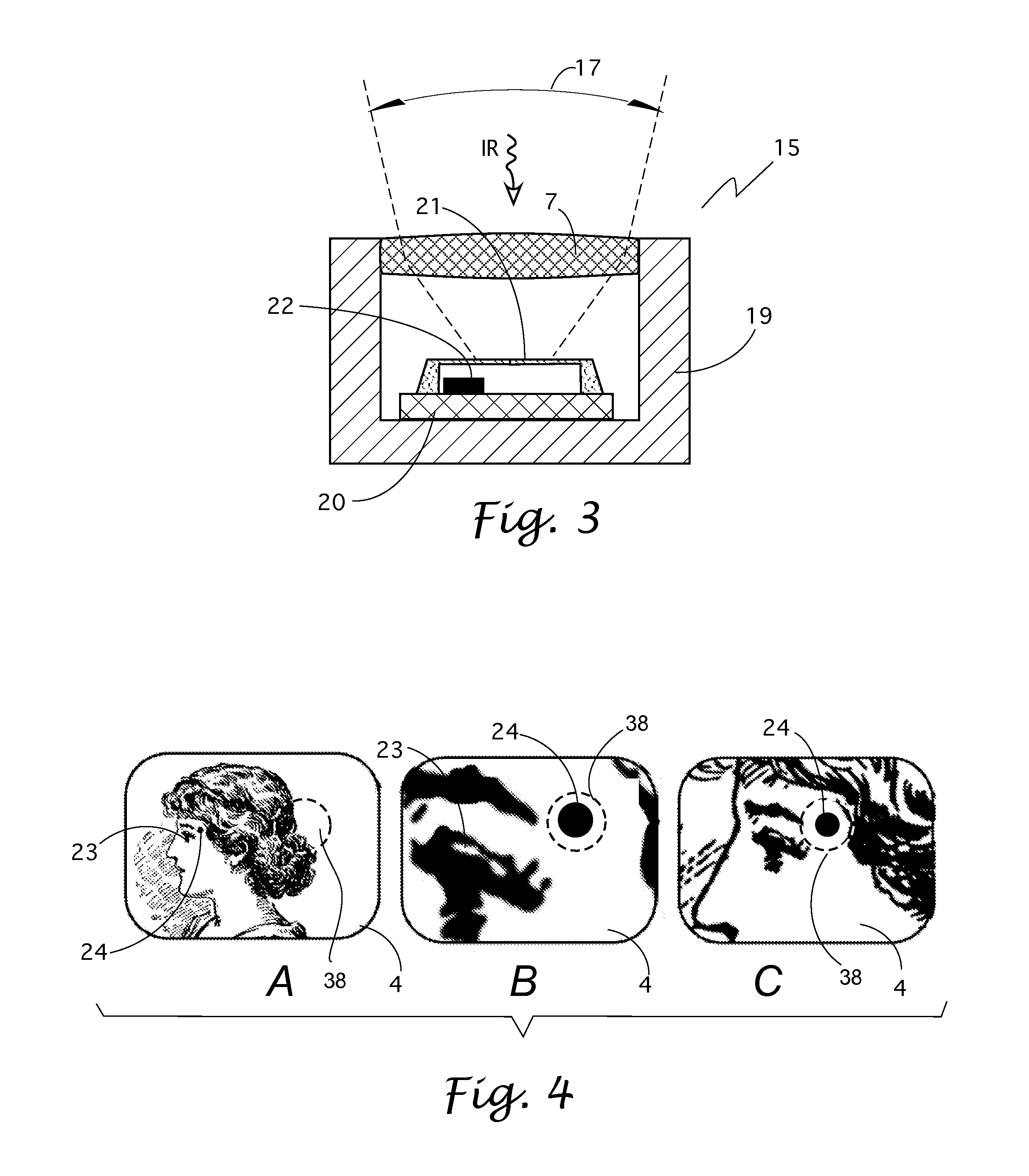

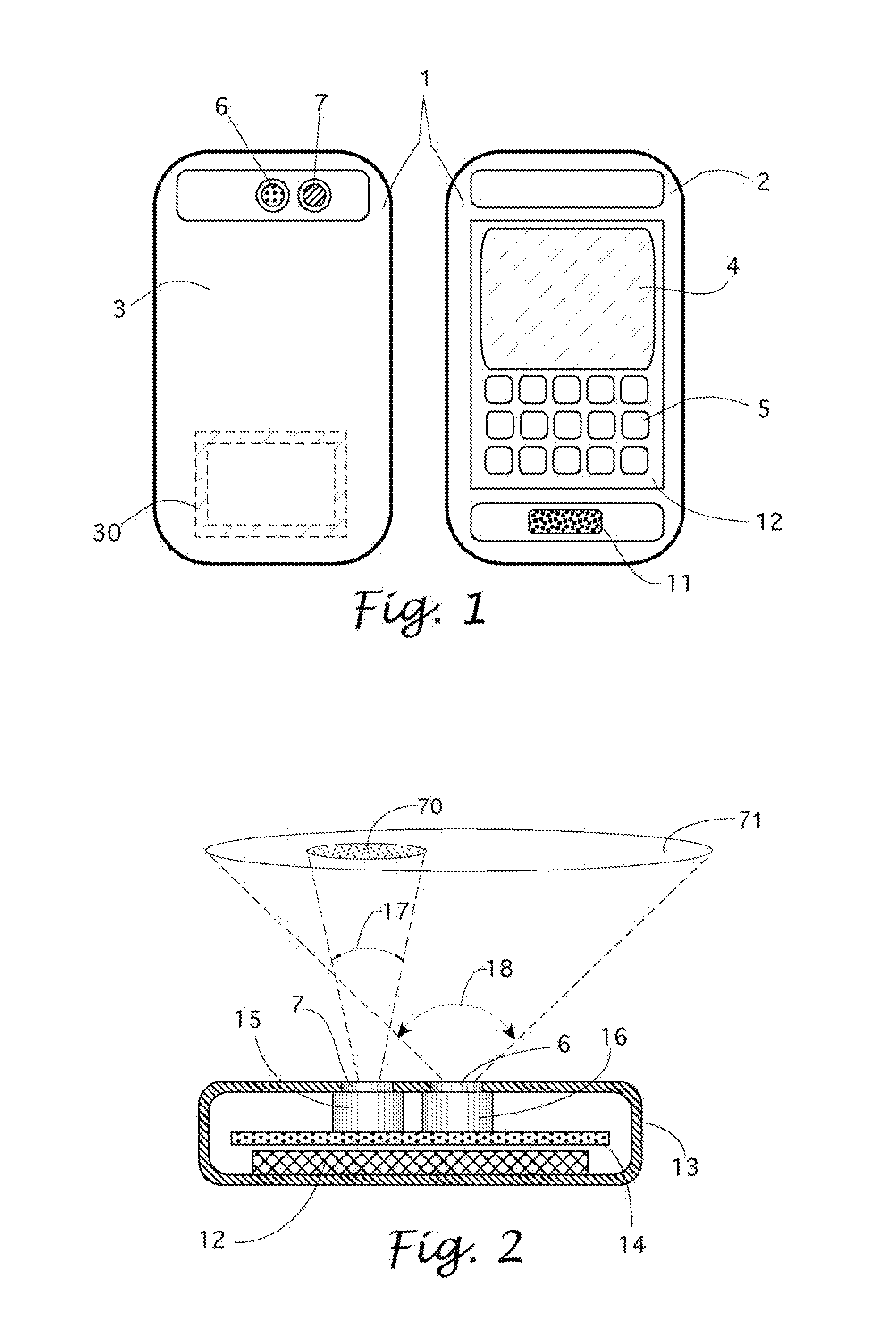

Wireless communication device with integrated electromagnetic radiation sensors

ActiveUS8275413B1Easy to aimDevices with sensorSensing radiation from moving bodiesThermopileHand held

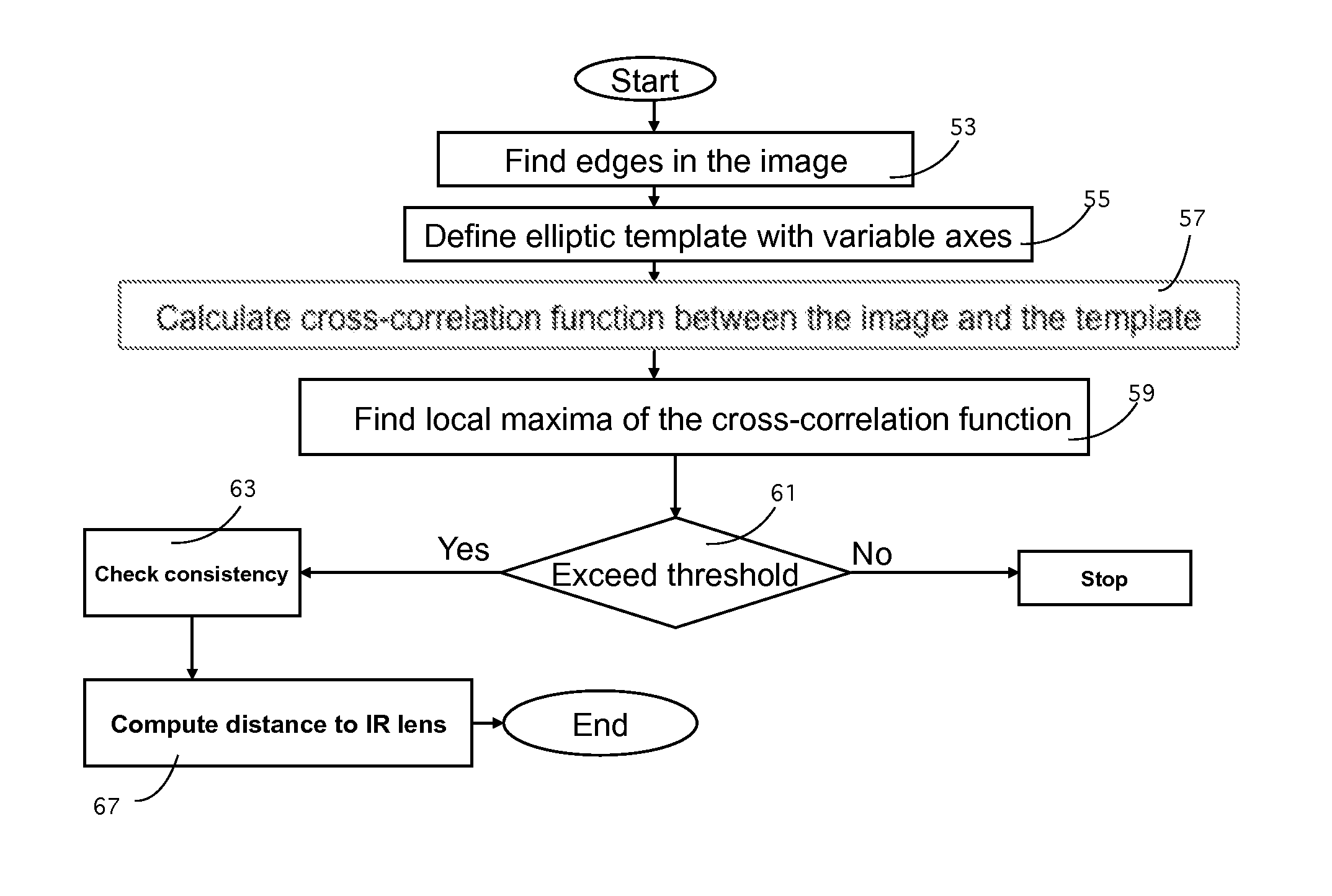

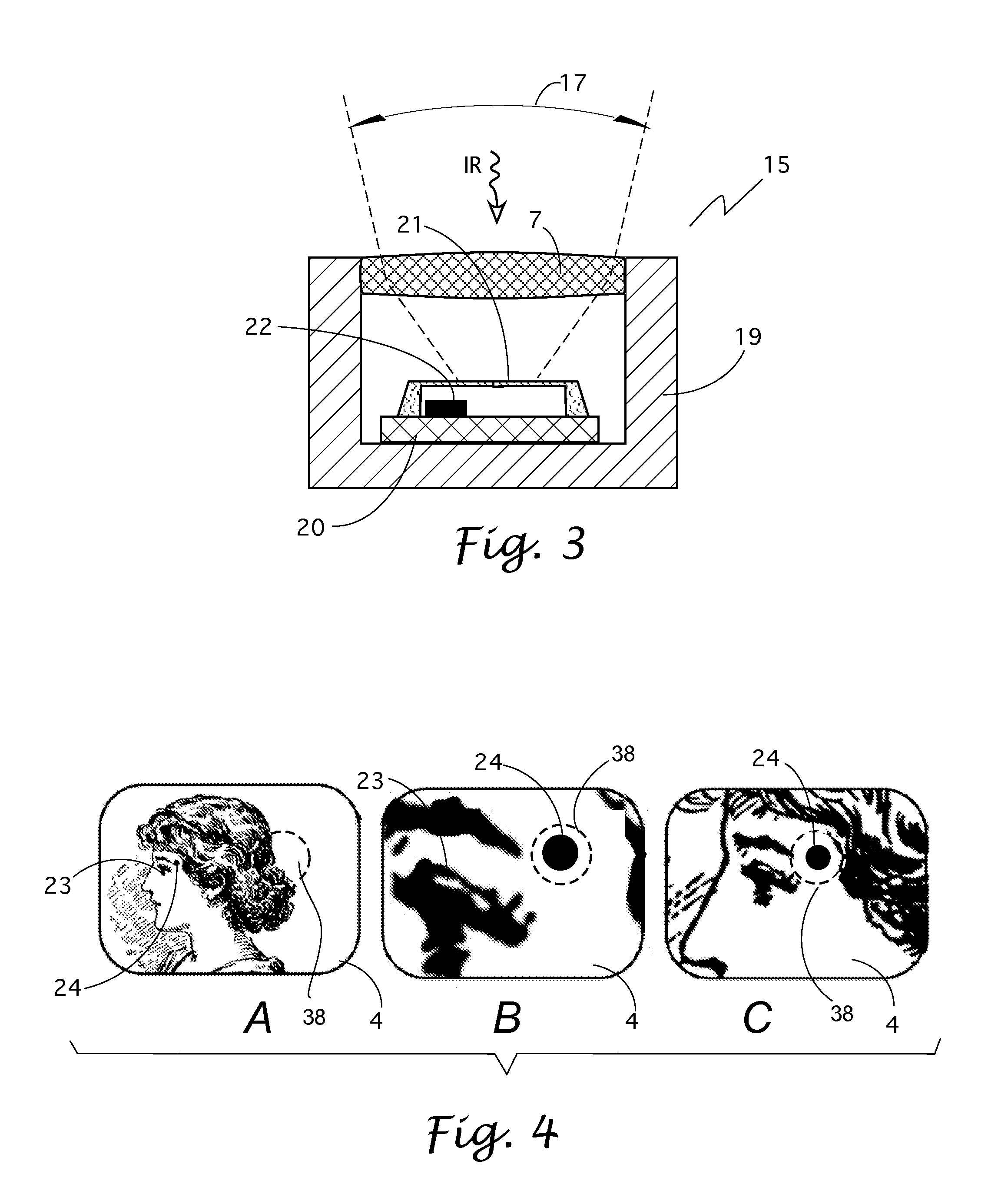

A hand-held mobile communication device, such as smart telephone, incorporating sensors and signal conditioning modules for measuring signals from external sources of electromagnetic radiation (EMR) in the low, radio, ultraviolet, and infrared spectral ranges. These include the detector for receiving and monitoring electromagnetic fields originating from various external sources of radiation that pose potential health hazards or may interfere with various electronic devices. The mobile phone equipped with such sensors could alternate between communication and monitoring functions. Other integrated EMR sensors are a photodiode for the ultraviolet detection to monitor the user's sun exposure and a thermopile for non-contact measurement of temperature of humans or inanimate objects. This infrared sensor in combination with a photographic digital camera and a pattern recognition signal processing allows measuring temperatures at specific locations and from optimal distances to the surface of the object to enhance accuracy of non-contact temperature measurements.

Owner:PATENT ARMORY INC

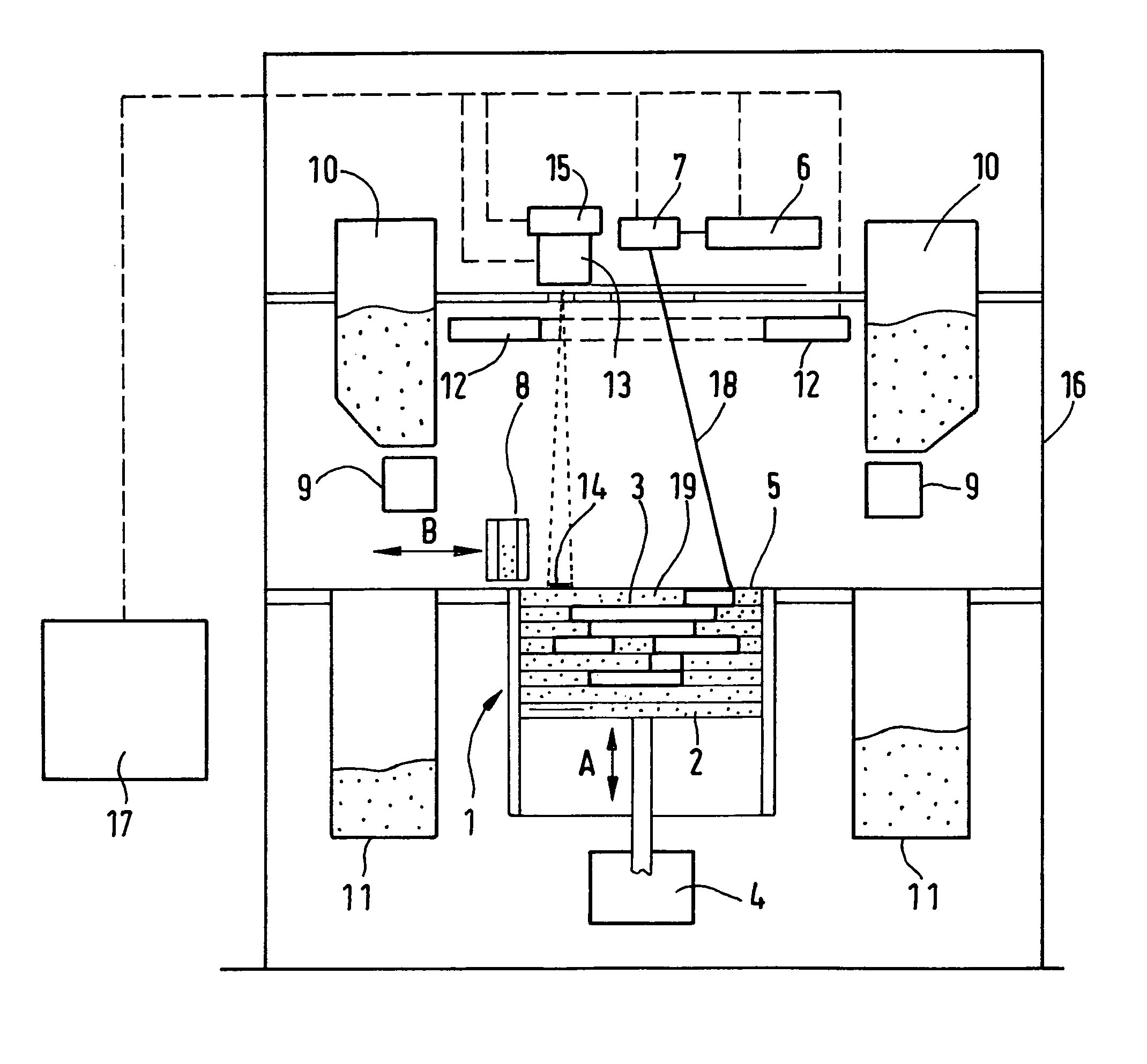

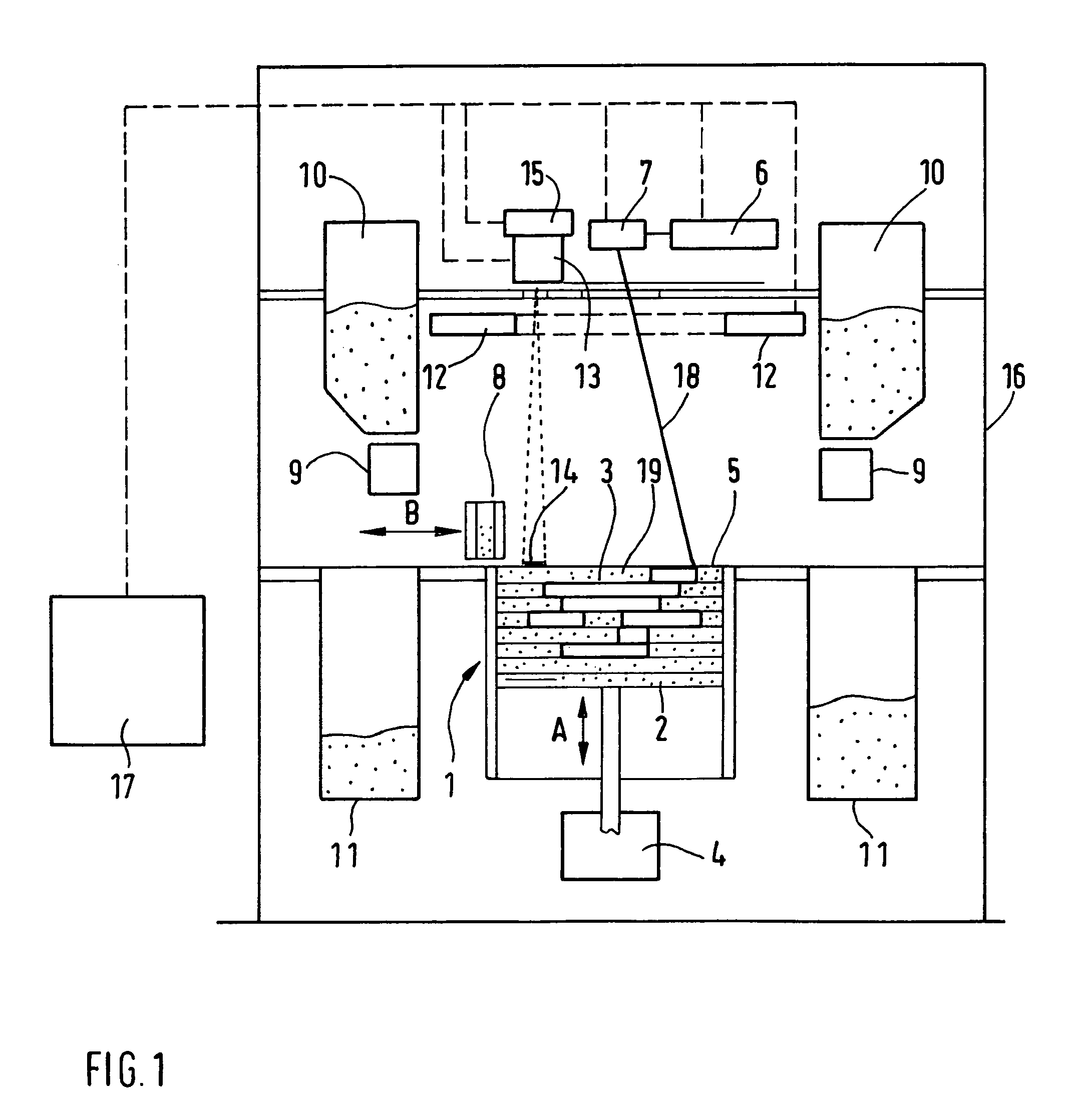

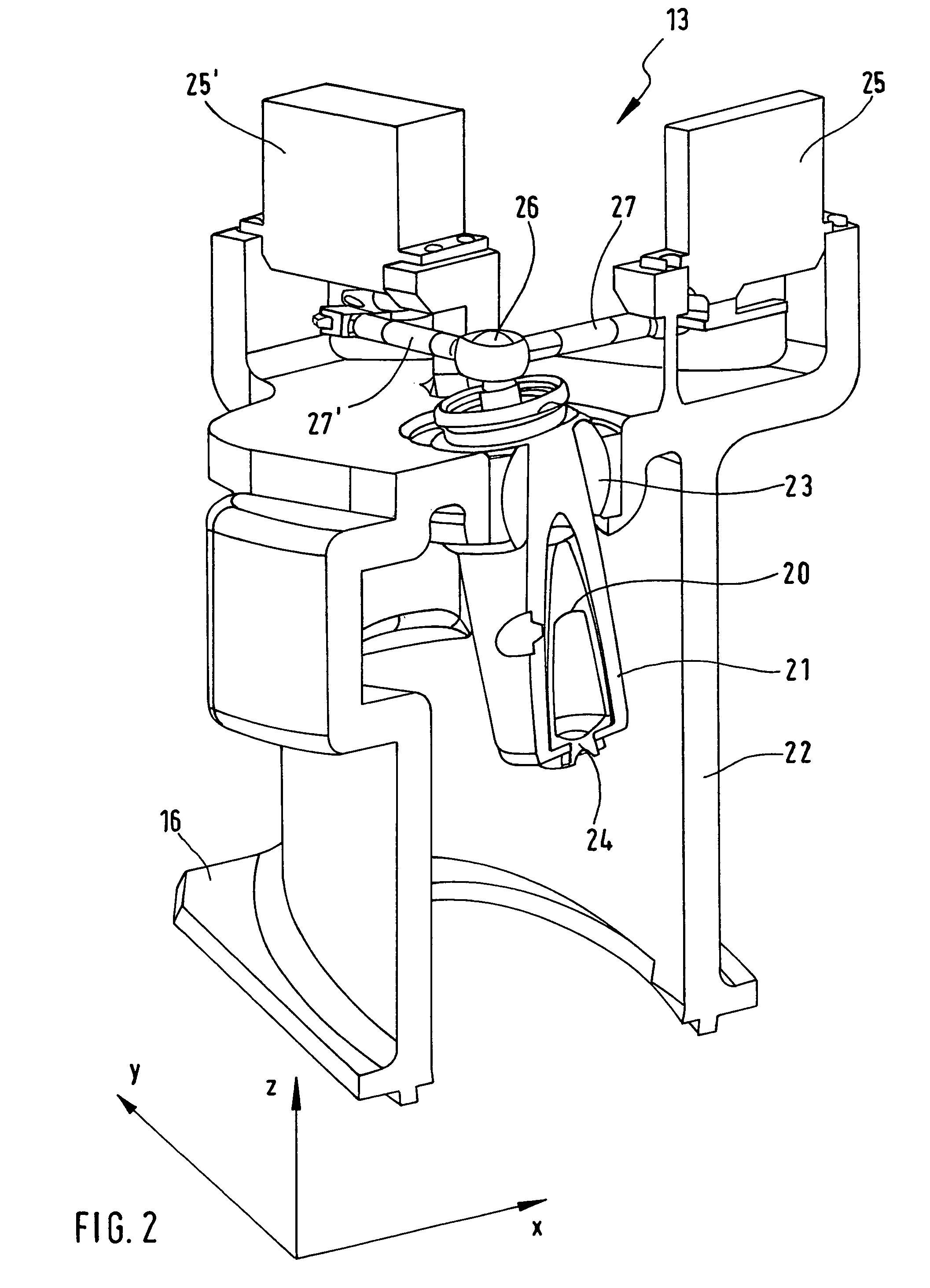

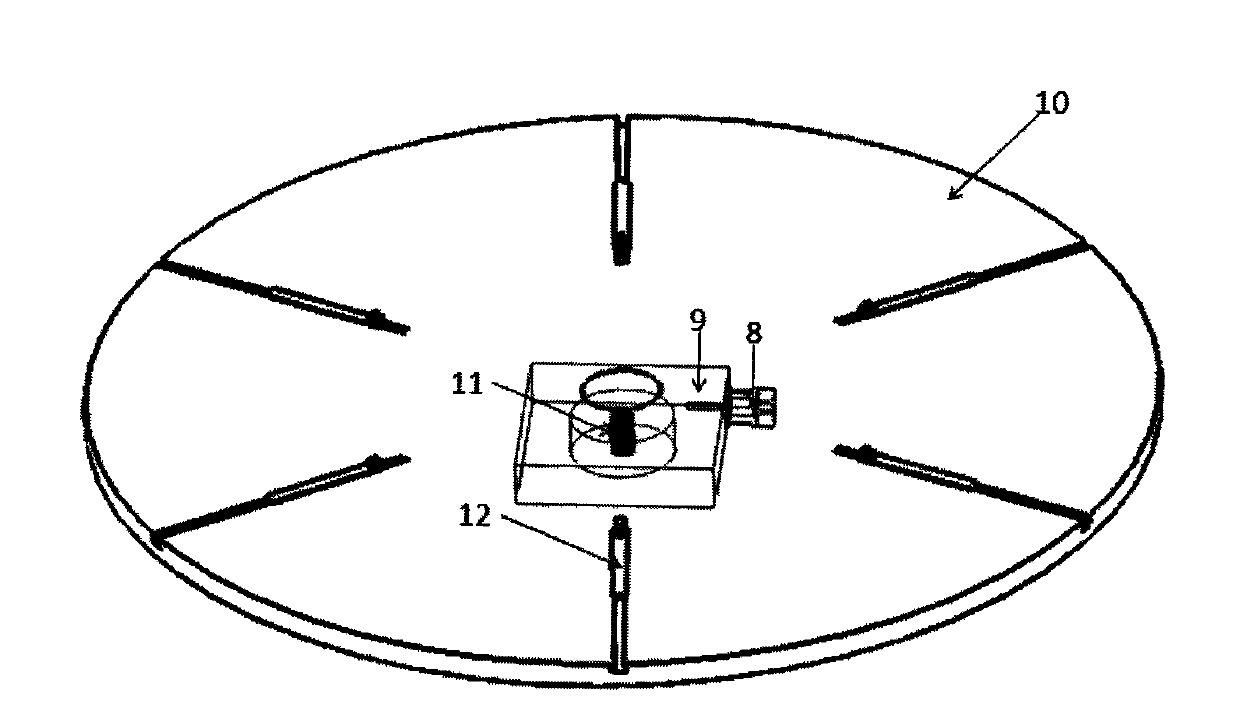

Apparatus and method for the manufacture of a three-dimensional object

InactiveUS8137739B2Reduce risk of damageInvention is simpleAdditive manufacturing apparatusLiquid surface applicatorsBiomedical engineeringRadiation

Provision is made of an apparatus and a method for the manufacture of three-dimensional objects (3) by local solidification of layers of a building material at positions corresponding to the respective cross-section of the object (3), by exposure to electromagnetic or particle radiation. The apparatus comprises a temperature measuring assembly (13) for non-contact measurement of the temperature of the building material in a measurement region (14) which is a partial region of the layer of the building material, and comprises further a position adjustment device (15) for altering the position of the measurement region (14) of the temperature measuring assembly (13) independently of the alteration of the position of the region exposed to the radiation energy. This apparatus can be used to actively access a not exposed region of the surface for measuring the temperature of each layer and to detect a temperature distribution by altering the position of a measurement region (14) in a layer.

Owner:EOS ELECTRO OPTICAL SYST

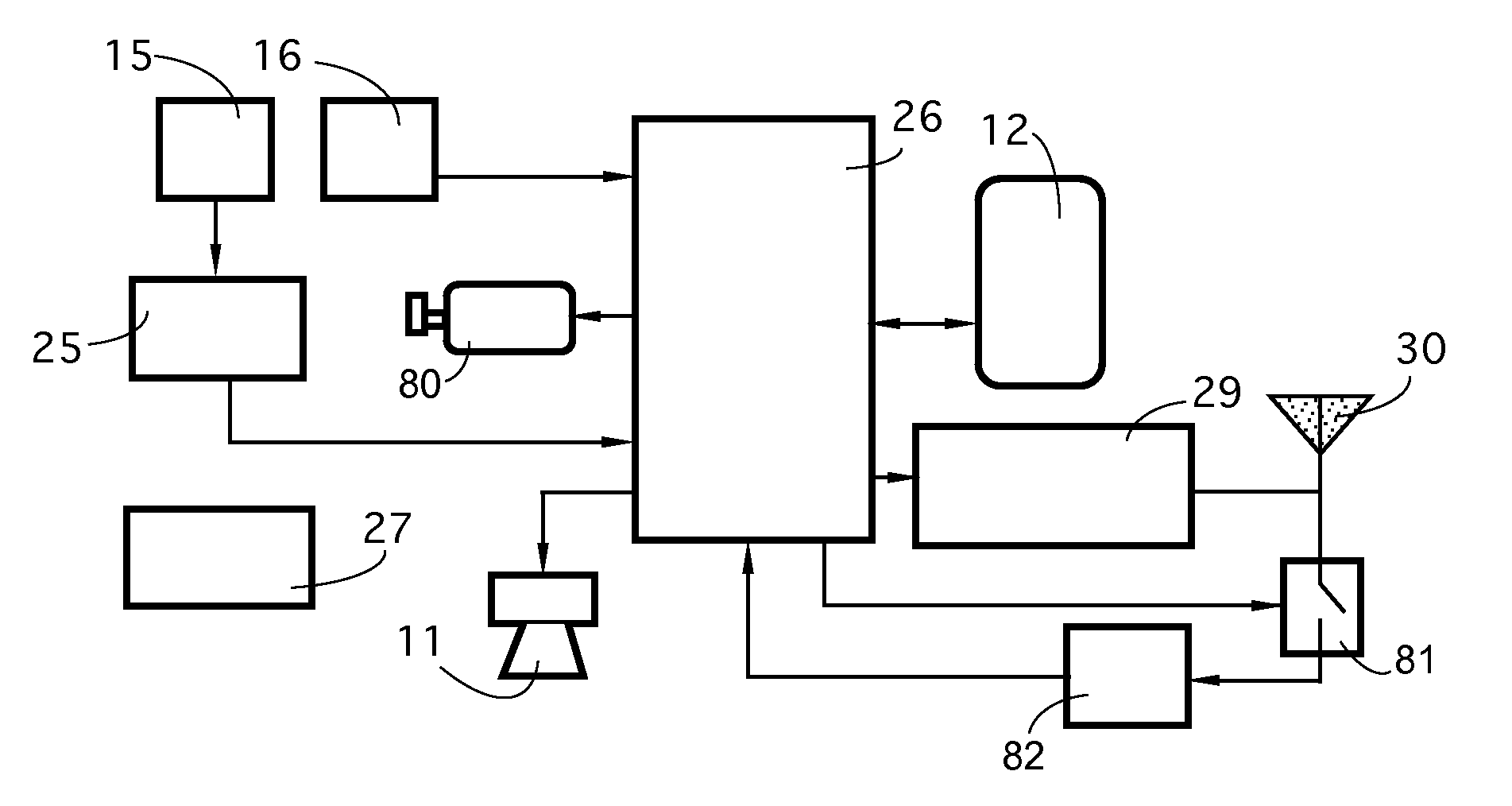

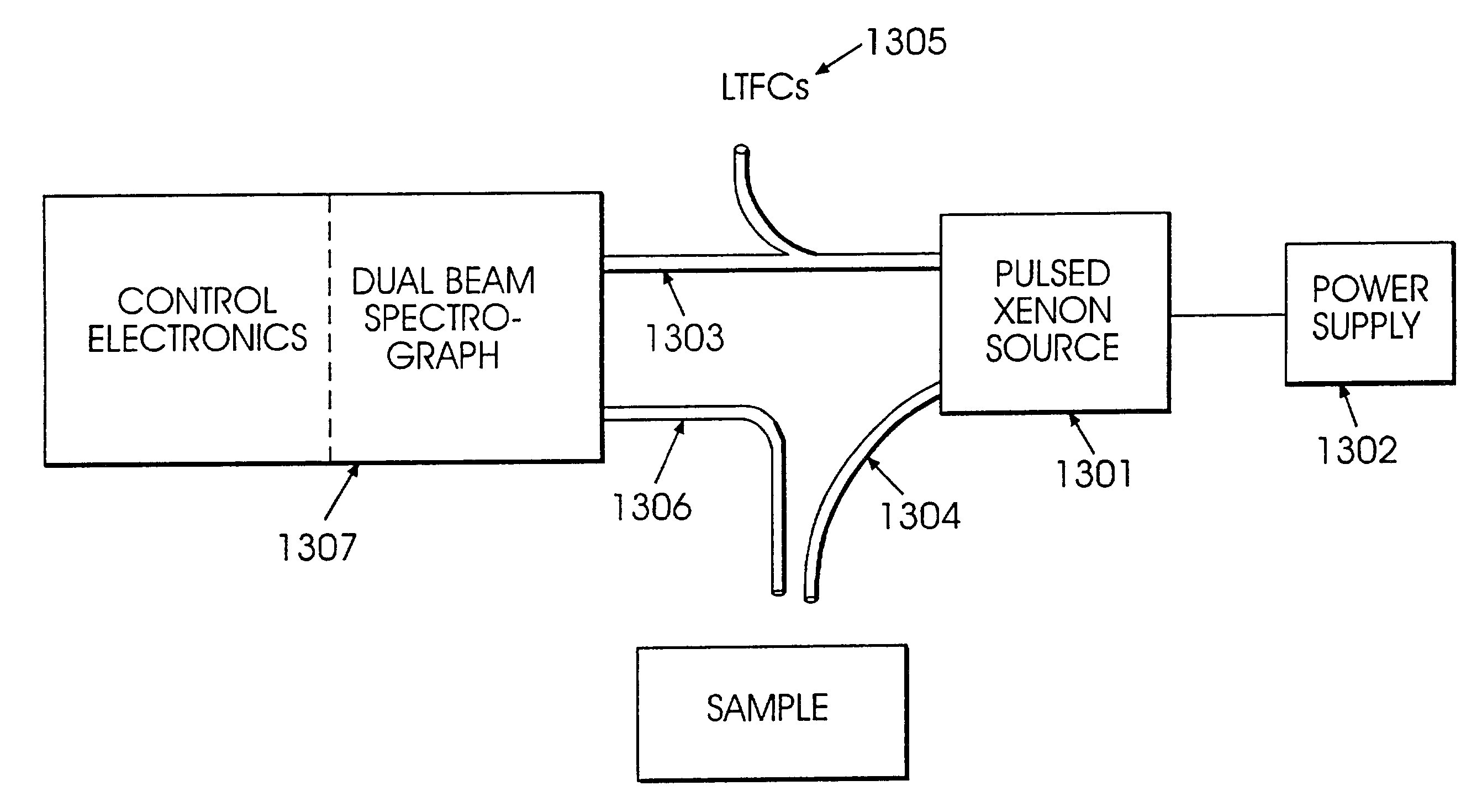

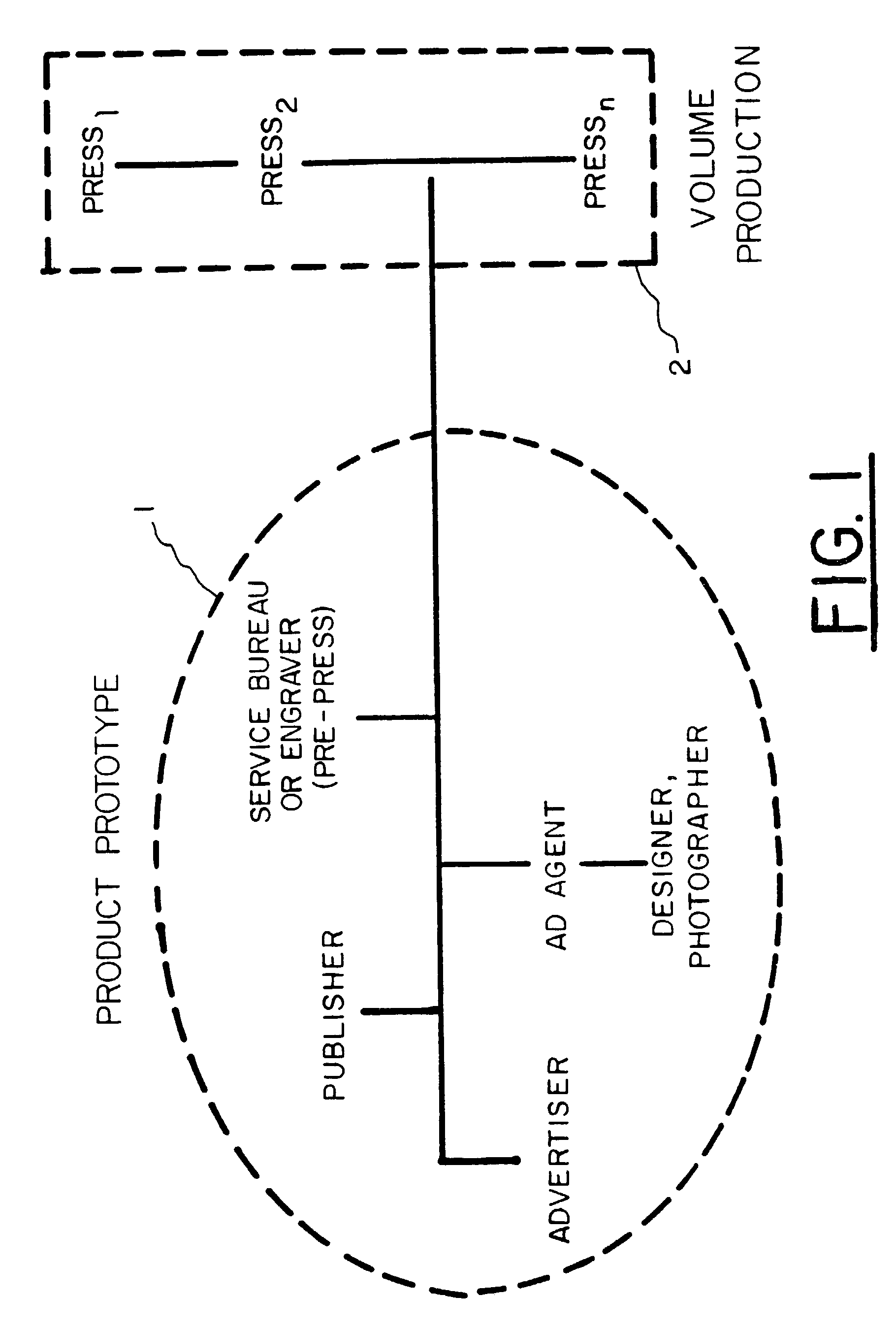

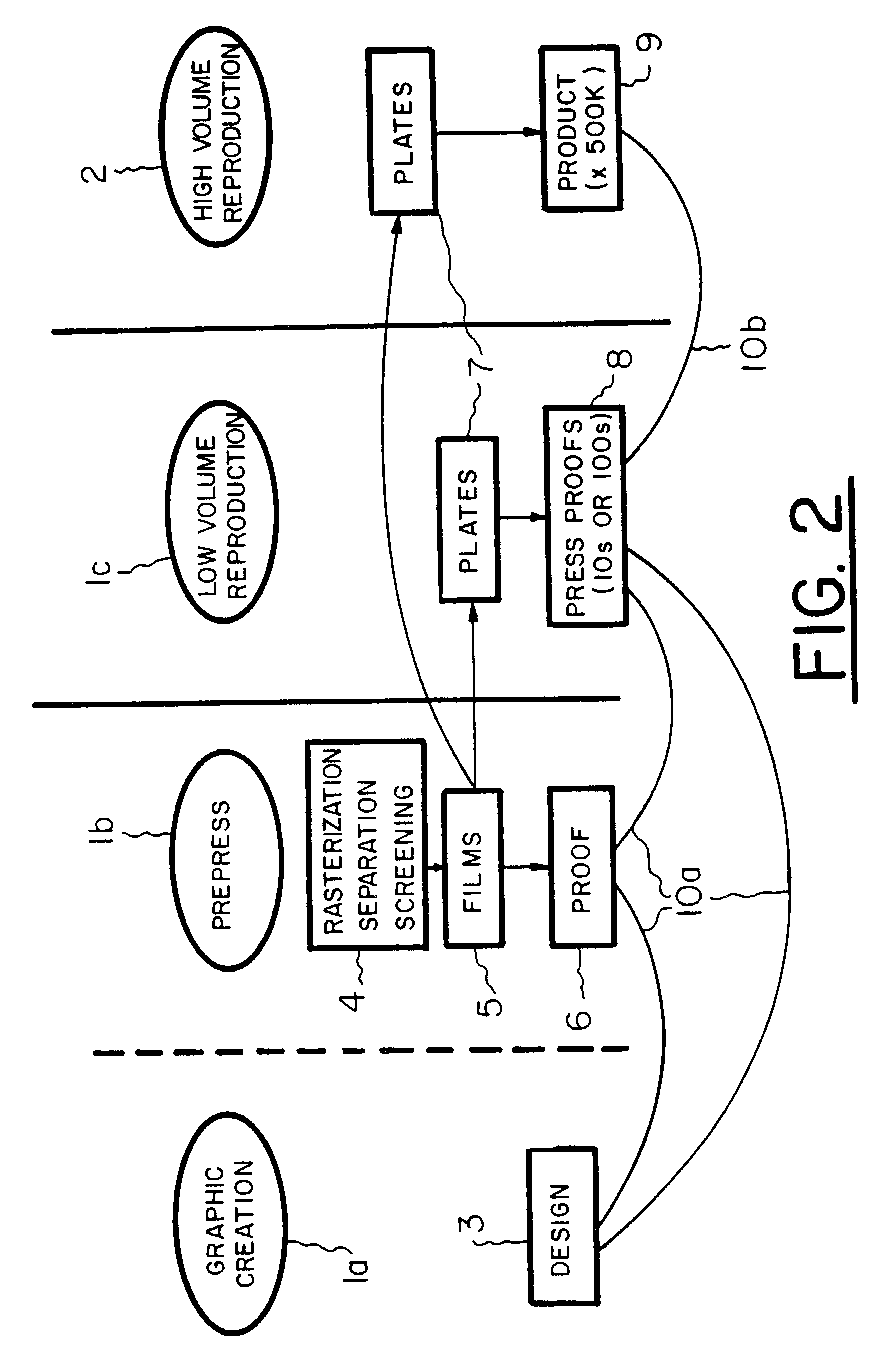

System for distributing and controlling color reproduction at multiple sites

InactiveUS7075643B2Provide accuratelyMinimize involvementImage enhancementRadiation pyrometryMeasuring instrumentSpectrograph

In the color imaging system, multiple rendering devices are provided at different nodes along a network. Each rendering device has a color measurement instrument for calibrating the color presented by the rendering device. A rendering device may represent a color display in which a member surrounds the outer periphery of the screen of the display and a color measuring instrument is coupled to the first member. The color measuring instrument includes a sensor spaced from the screen at an angle with respect to the screen for receiving light from an area of the screen. A rendering device may be a printer in which the measuring of color samples on a sheet rendered by the printer is provided by a sensor coupled to a transport mechanism which moves the sensor and sheet relative to each other, where the sensor provides light from the sample to a spectrograph. The color measuring instruments provide for non-contact measurements of color samples either displayed on a color display, or printed on a sheet, and are self-calibrating by the use of calibration references in the instrument.

Owner:RAH COLOR TECH

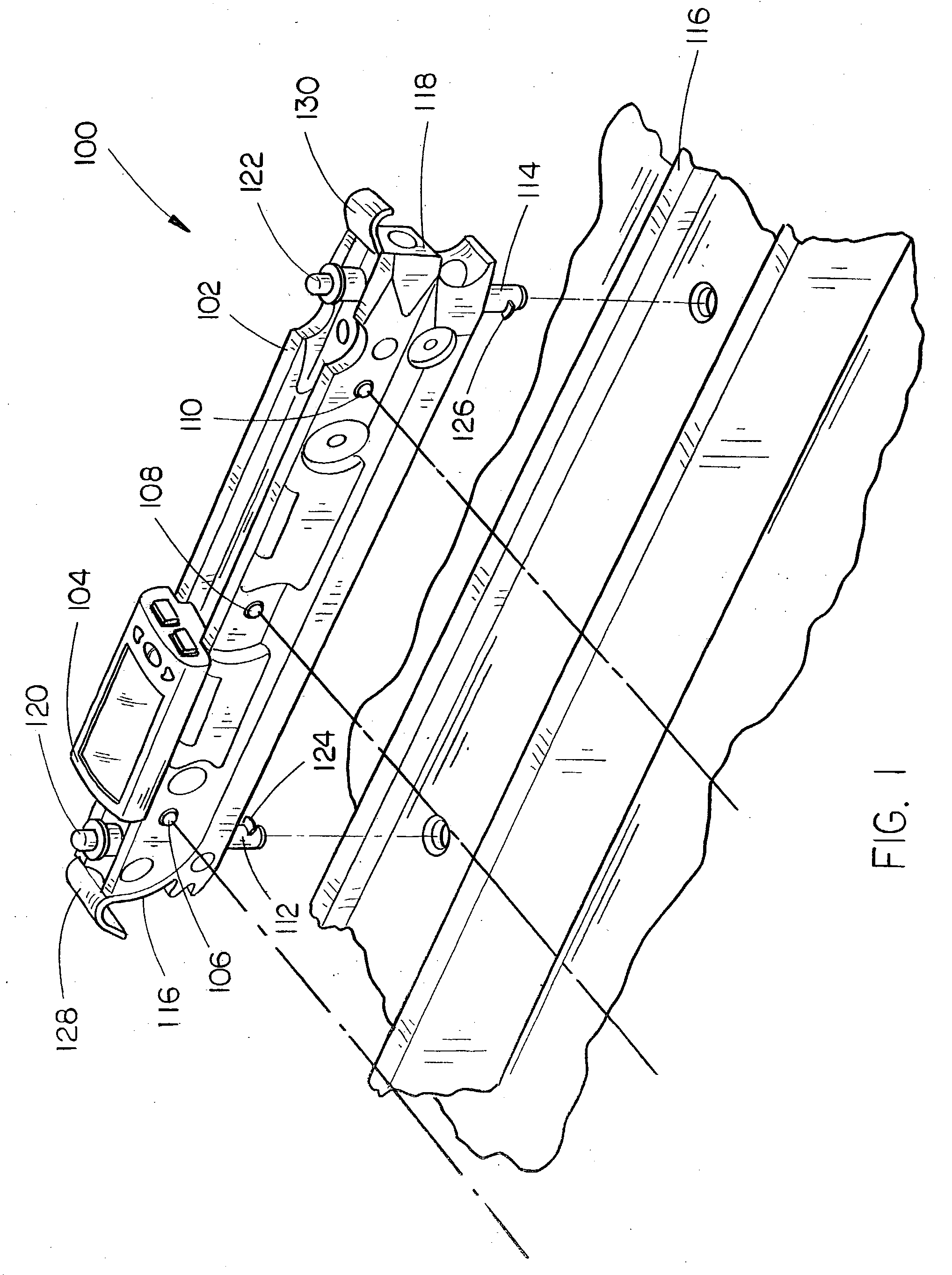

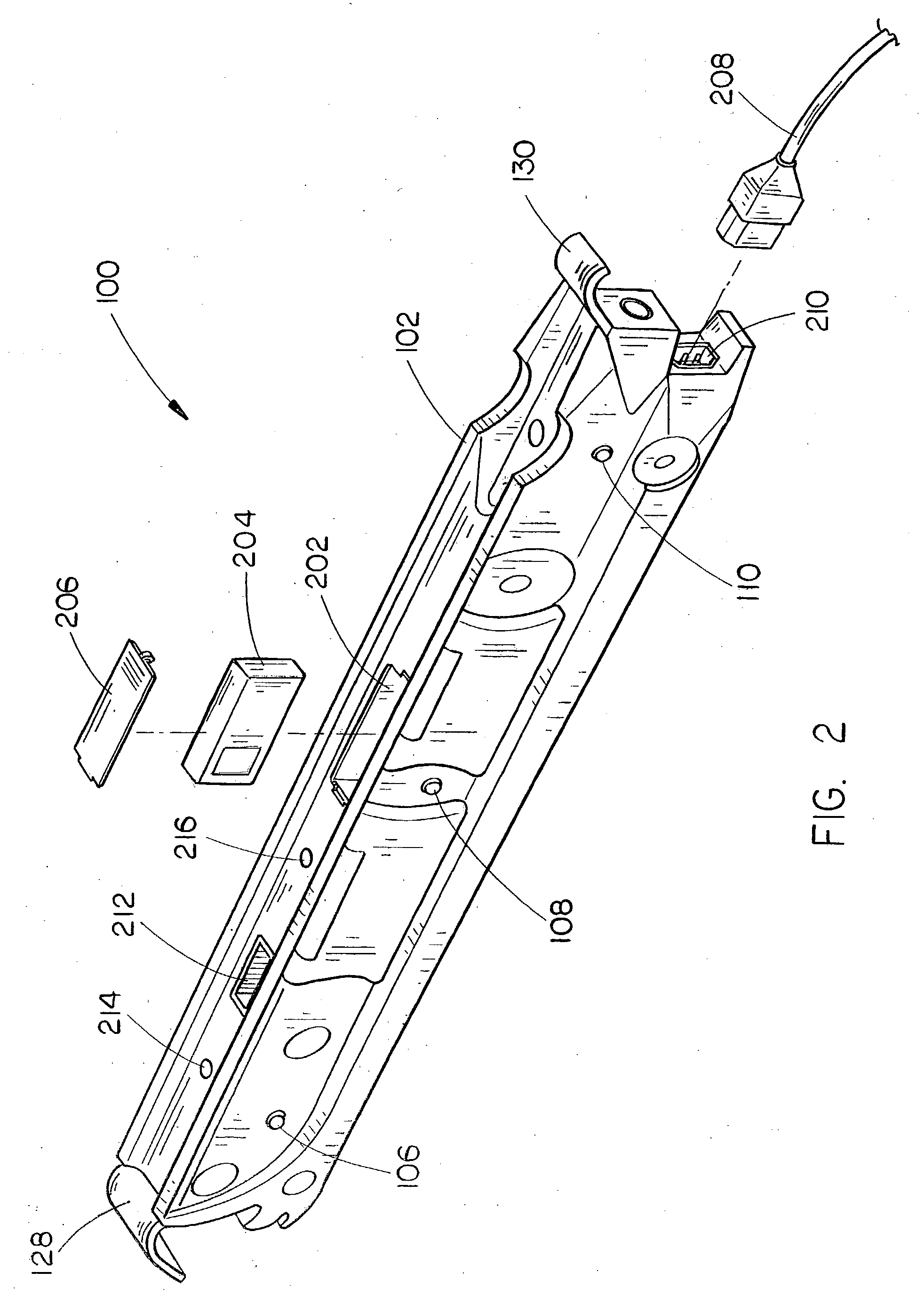

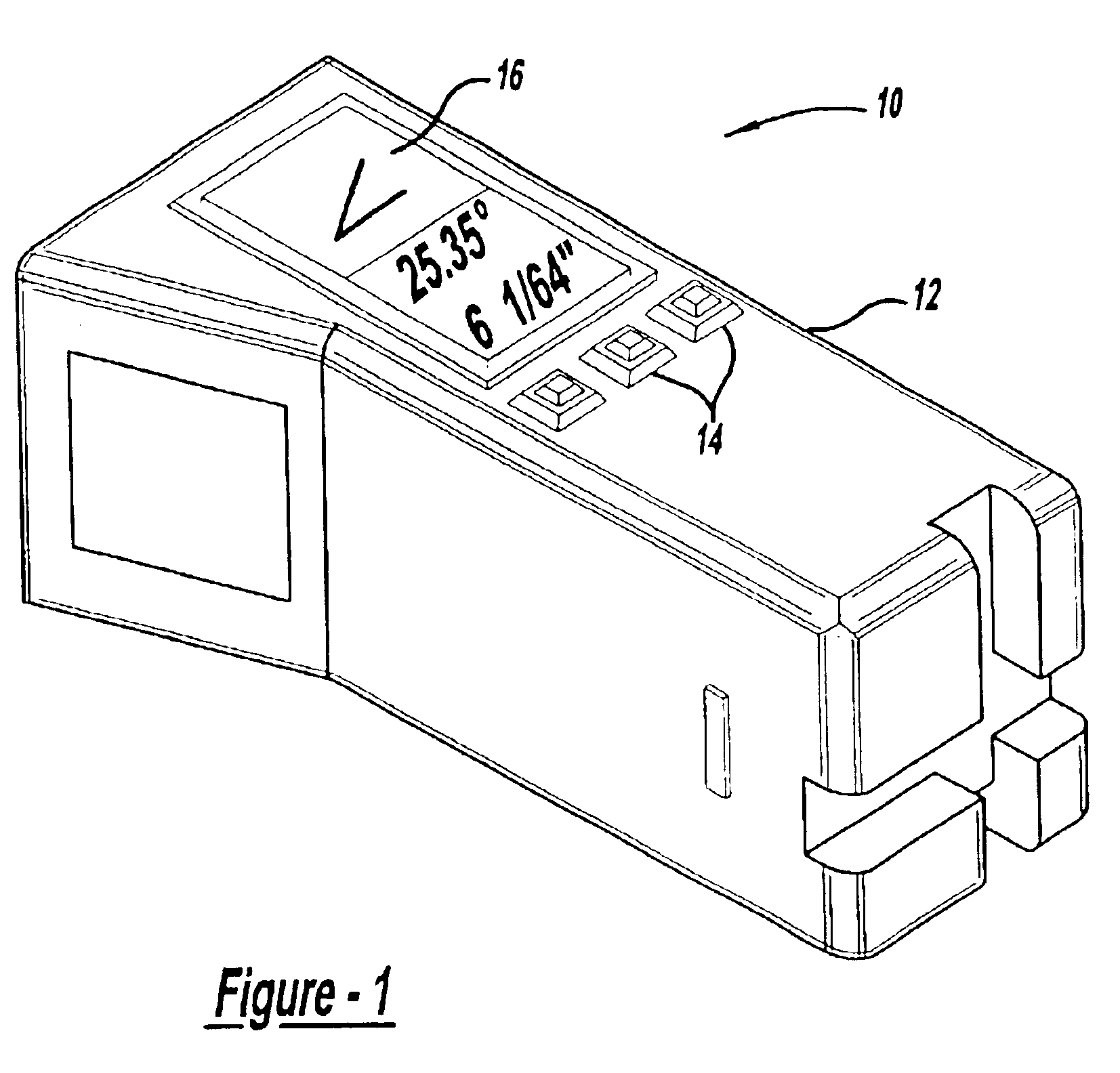

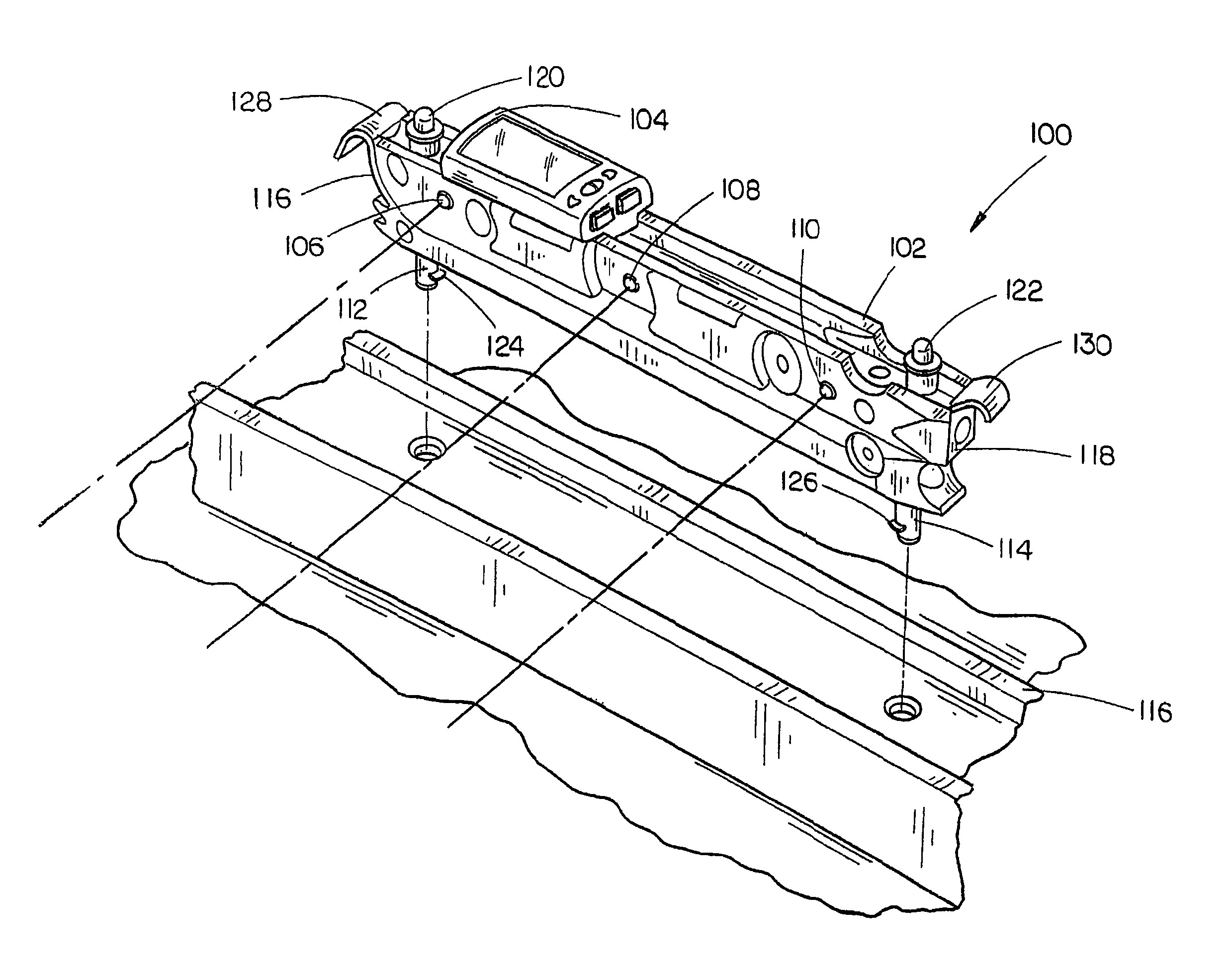

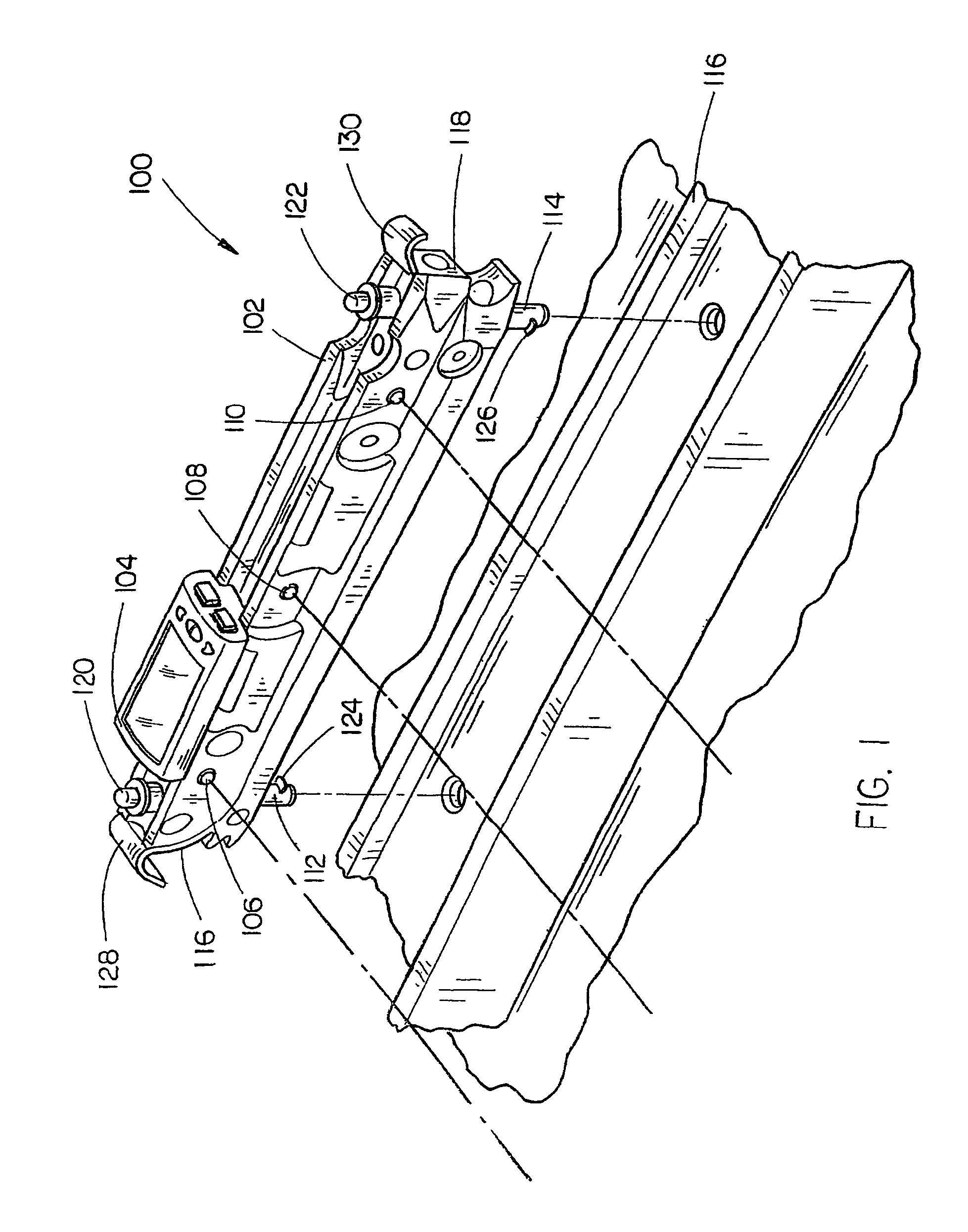

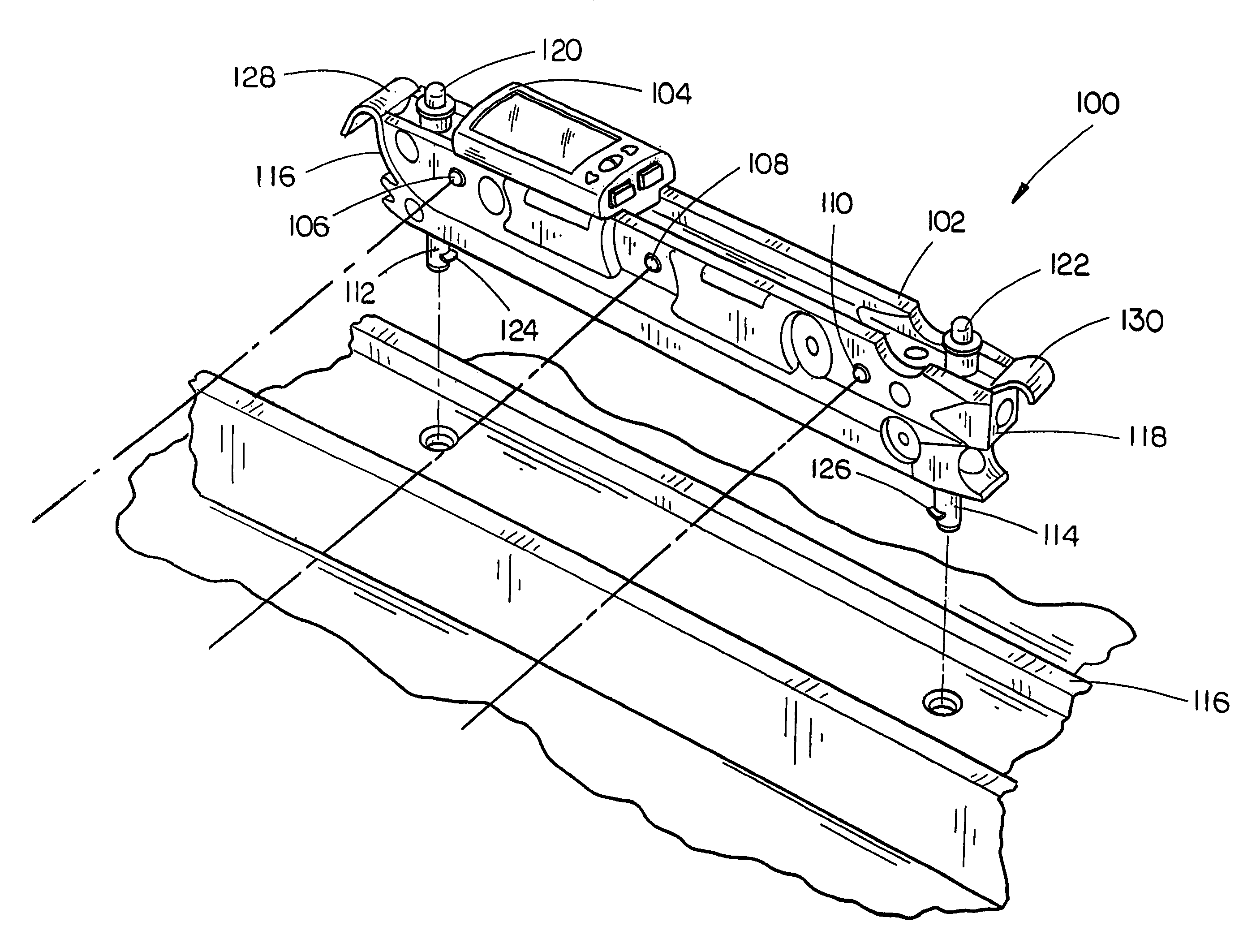

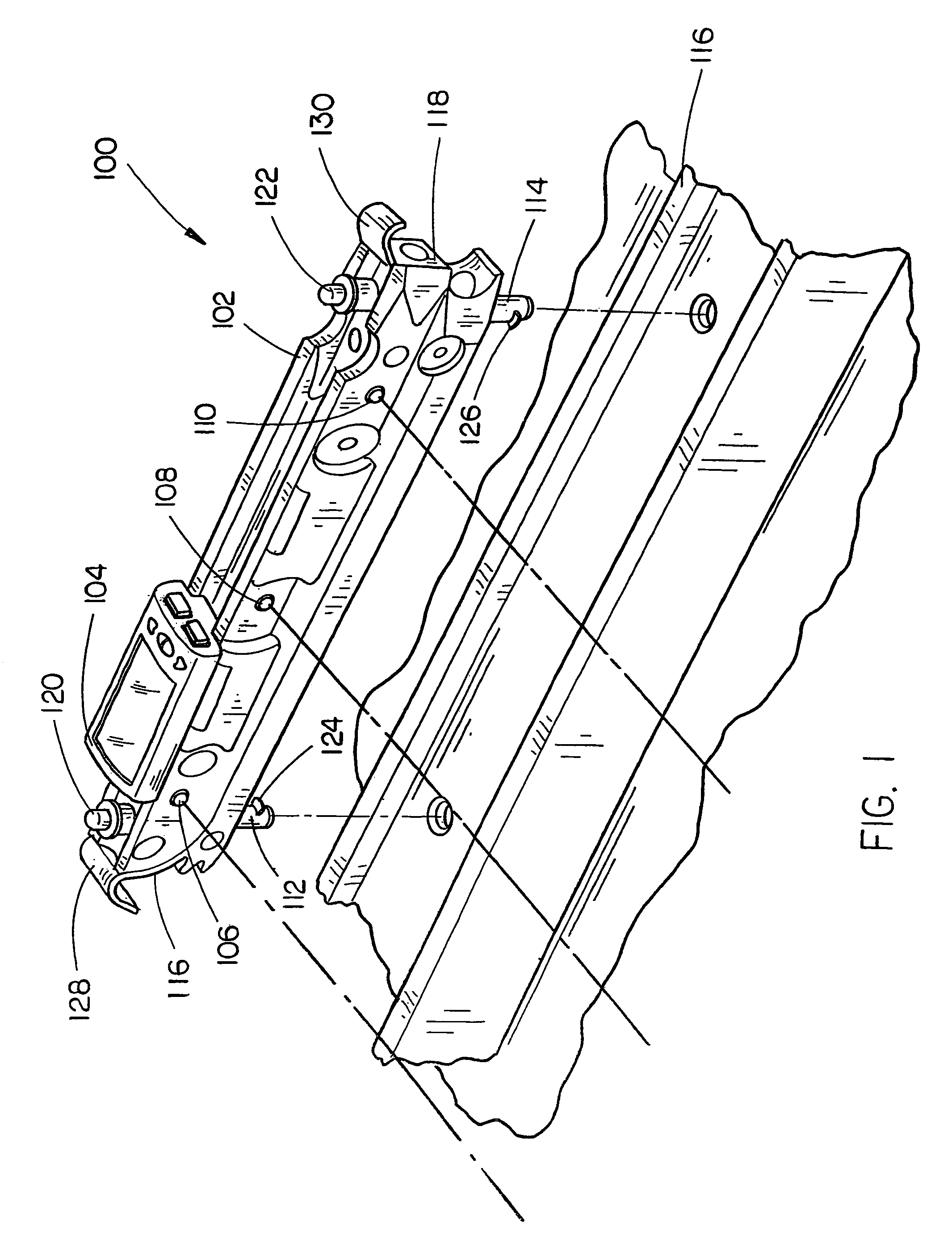

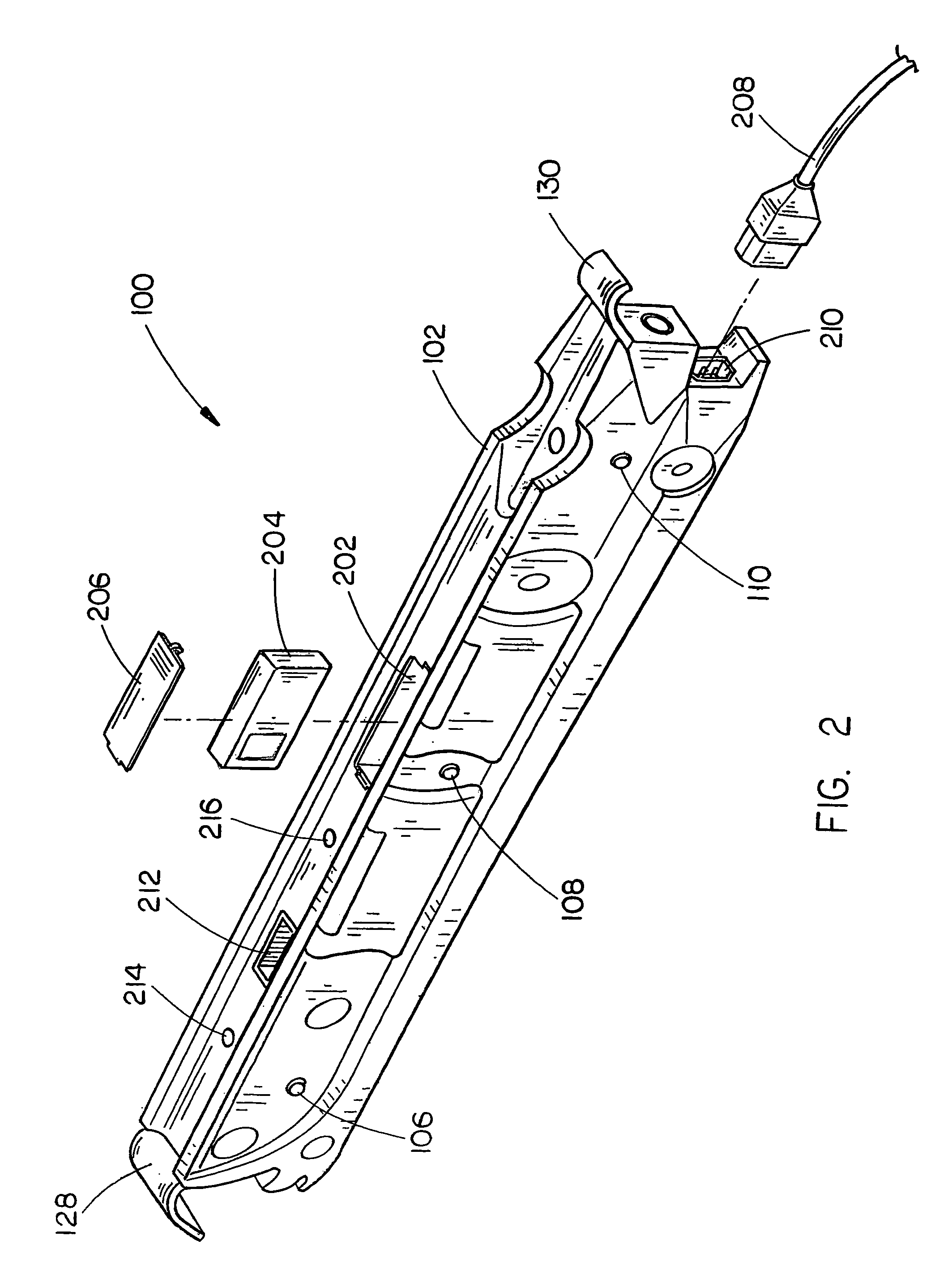

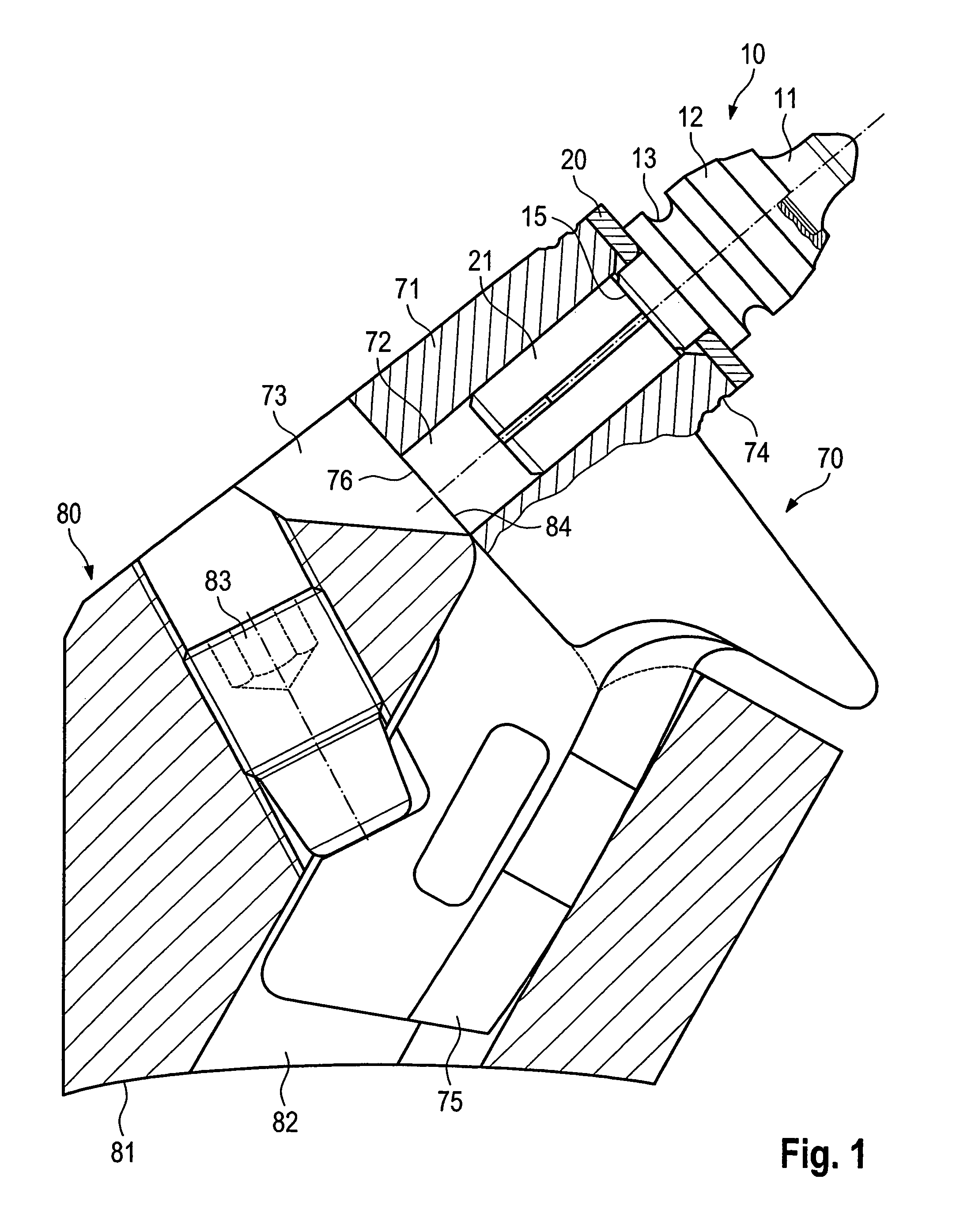

Power tool control system

InactiveUS20060076385A1Quality improvementWell formedStapling toolsDrilling/boring measurement devicesUser needsGraphics

A power tool control system allows a user to operate a power tool through a graphical user interface communicatively coupled with a non-contact measurement and alignment device. The graphical user interface correlates user engageable selectors with a logically related menu of power tool setting options displayed on a display screen in a high quality and easily readable format. The non-contact measurement and alignment device uses one or more lasers to determine power tool settings and establish proper alignment based on user needs. The power tool control system further enables stud detection and visual indication of stud location.

Owner:BLACK & DECKER INC

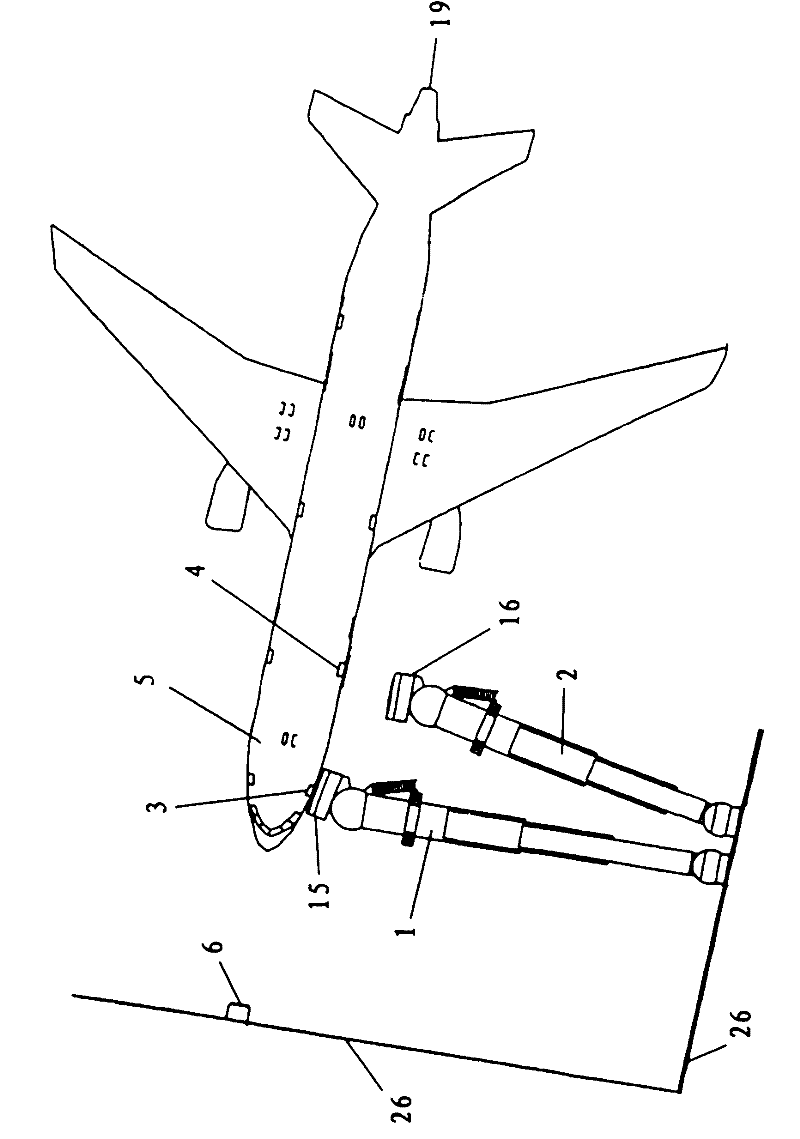

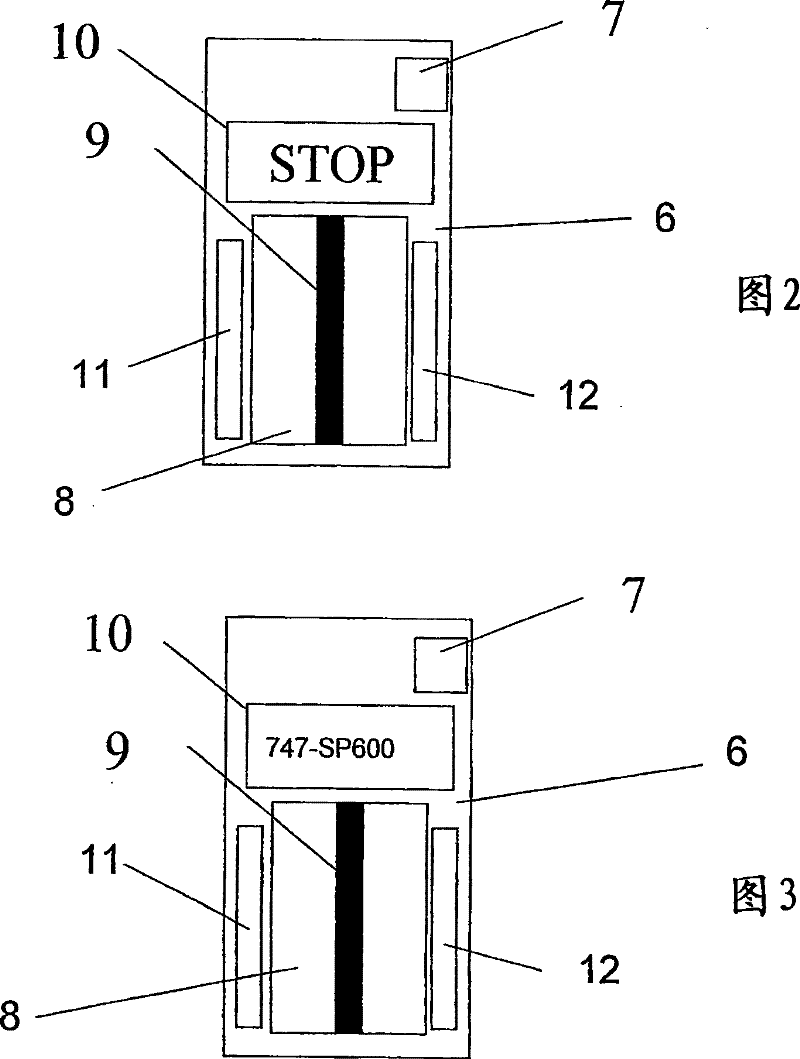

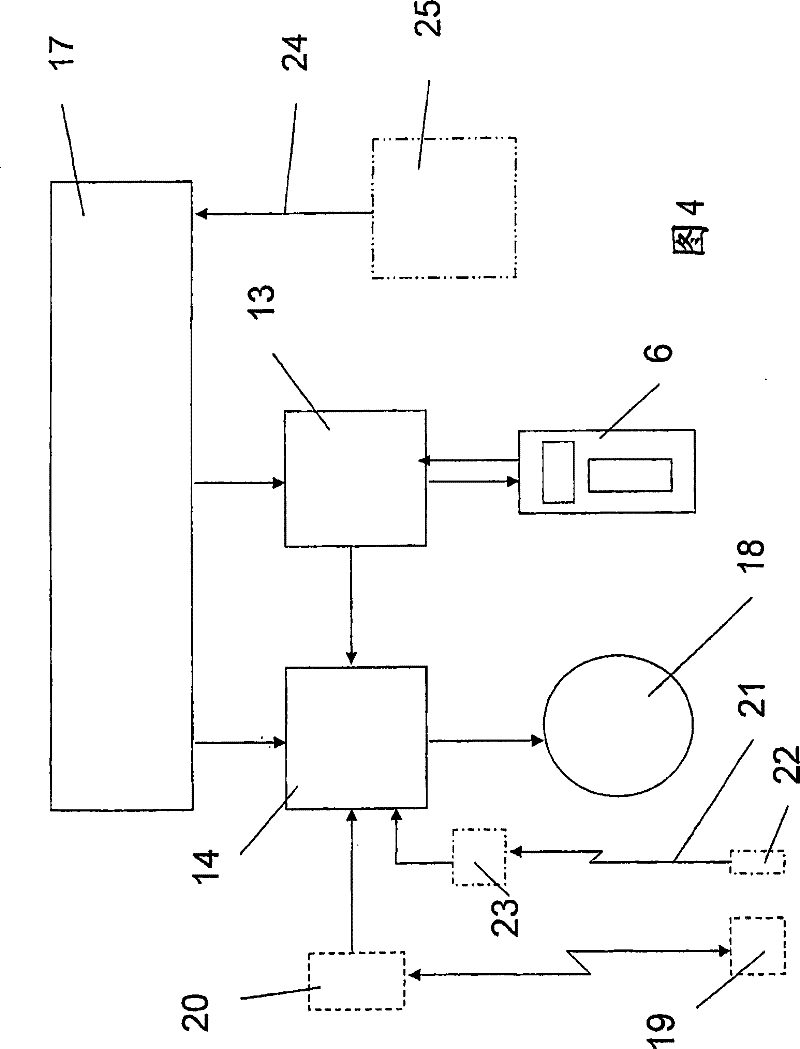

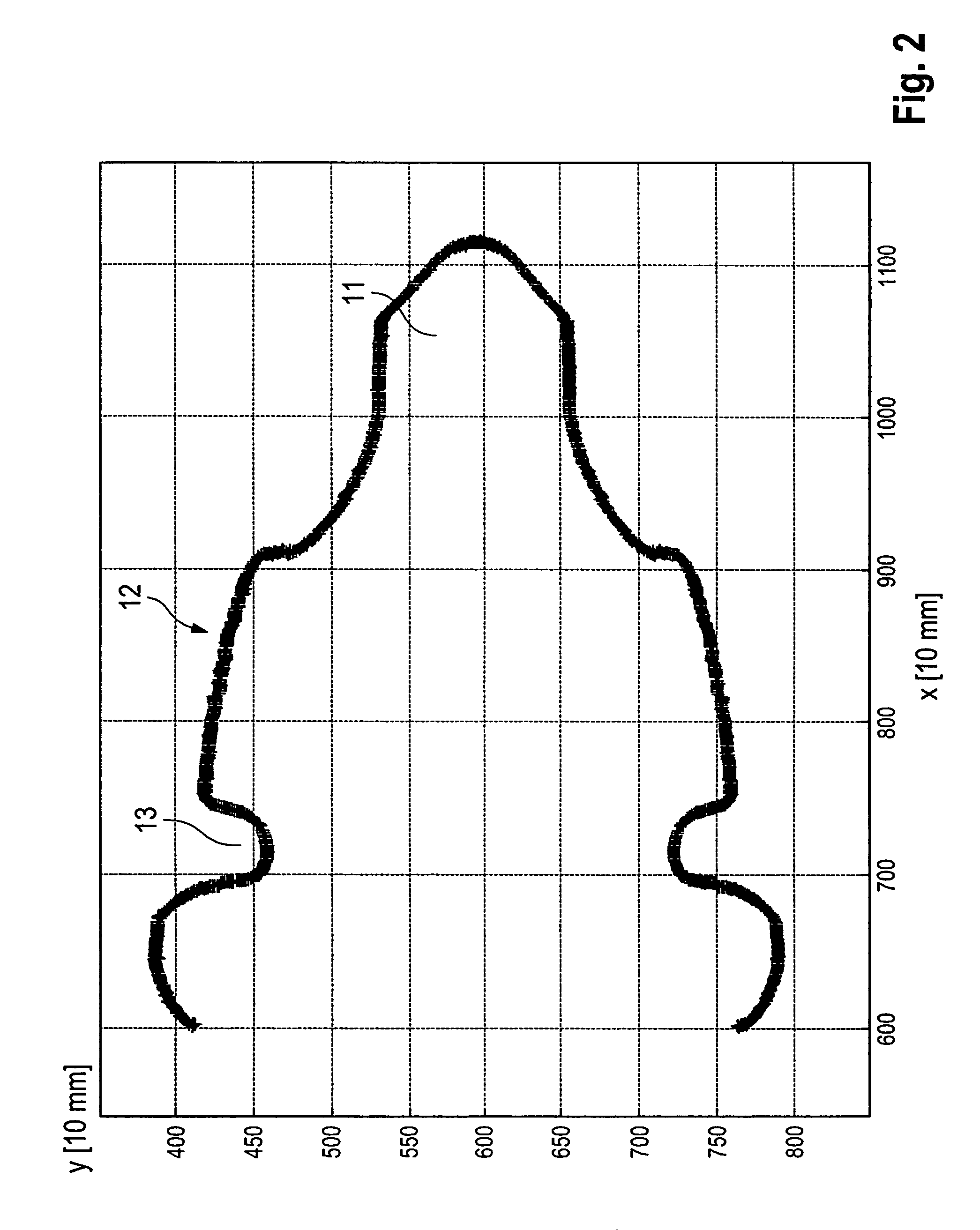

Method for automatic docking of a boarding bridge or cargo handling bridge to a door of an aircraft

A method of automatically docking a boarding bridge (1, 2) to a door (3, 4) of an aircraft (5) at an airport boarding gate, wherein the aircraft is detected by non-contact measurement of its distance from a fixed point Taken to and parked at a predetermined location, and where a control computer (14) is used to control the movement of the boarding bridge, and the person is required to give a start signal (24) after establishing the correct type of aircraft and the correct pattern for that type of aircraft , so that the control computer prompts the boarding bridge to move and dock.

Owner:FMT INT TRADE

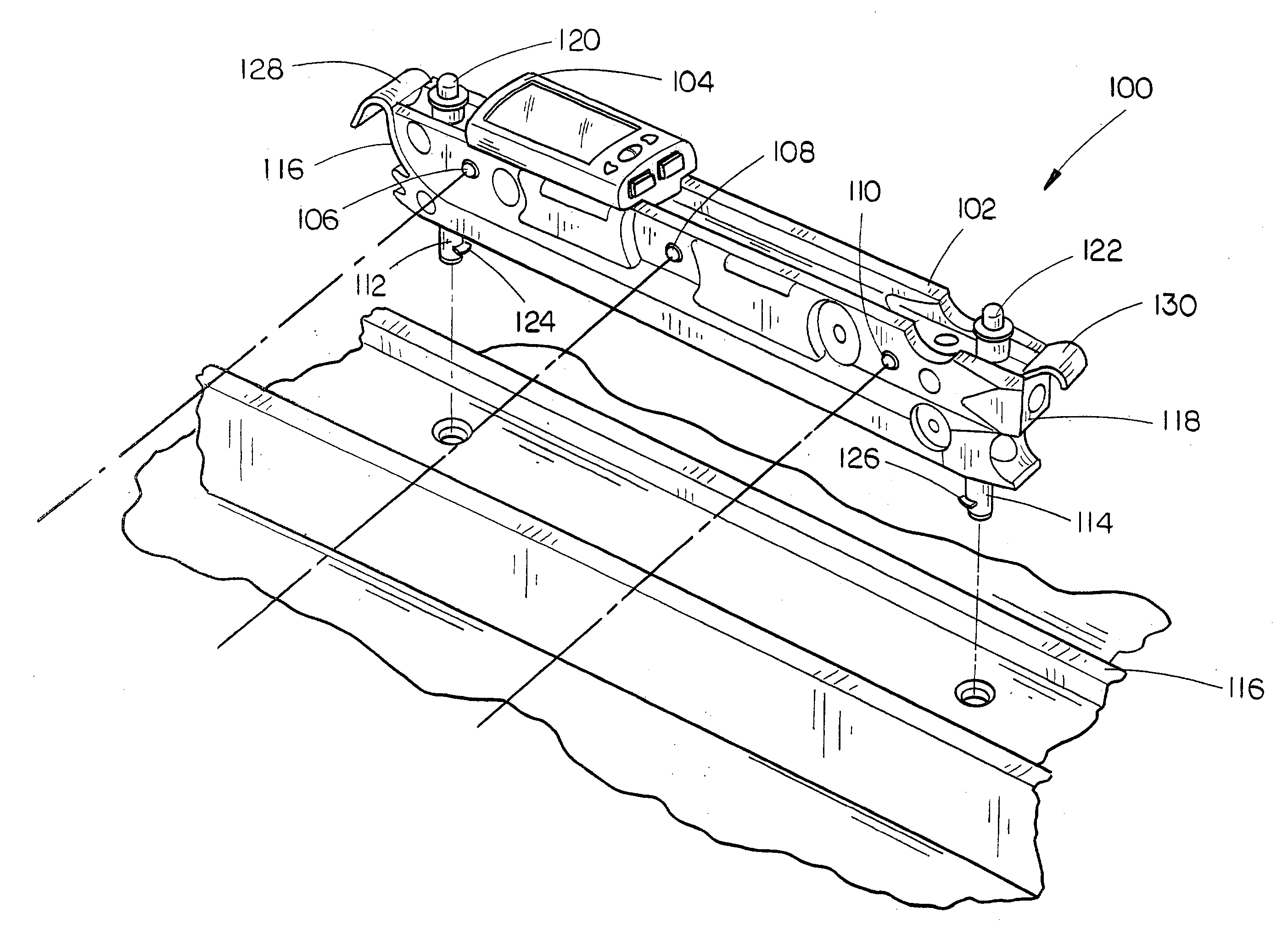

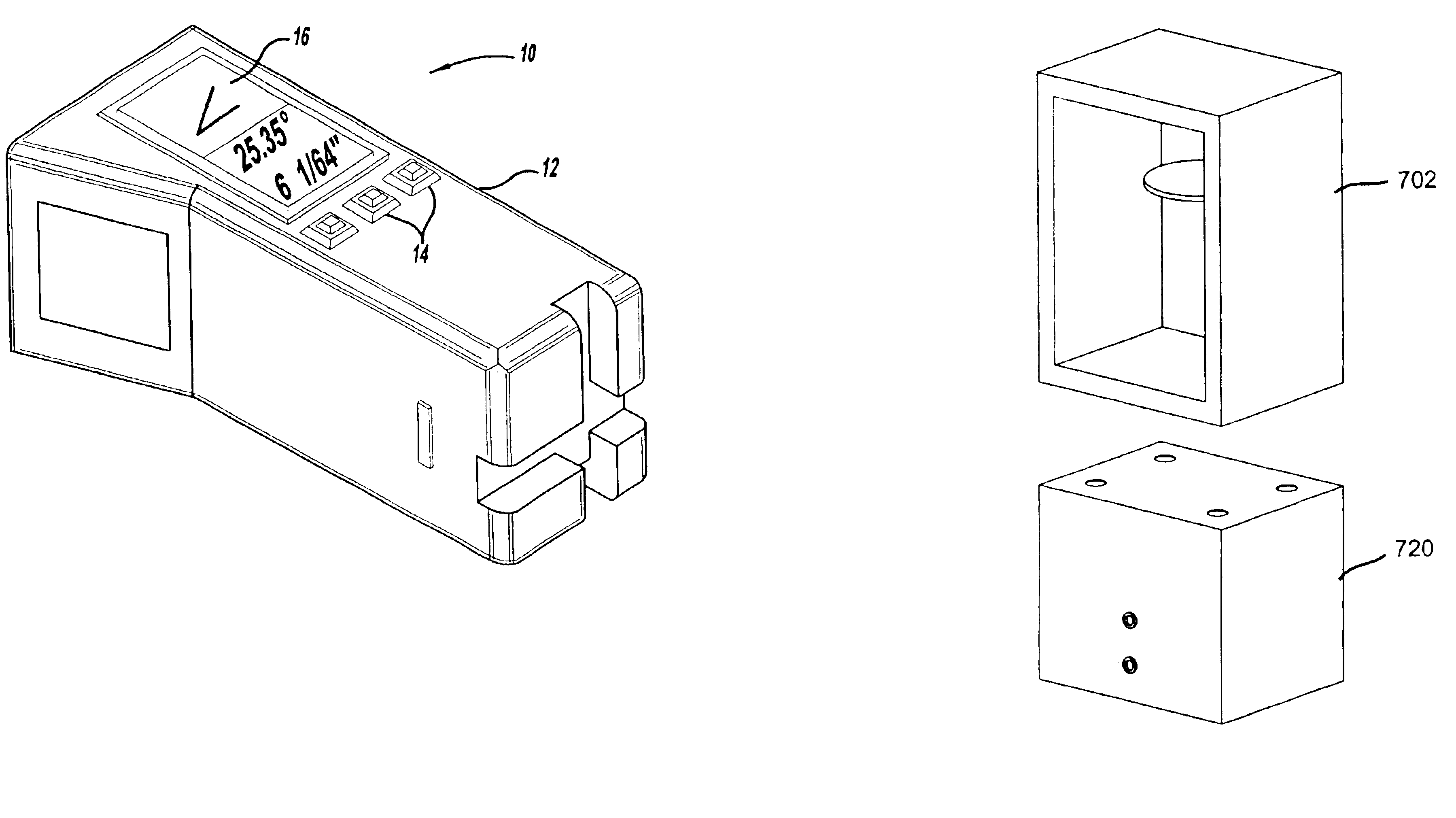

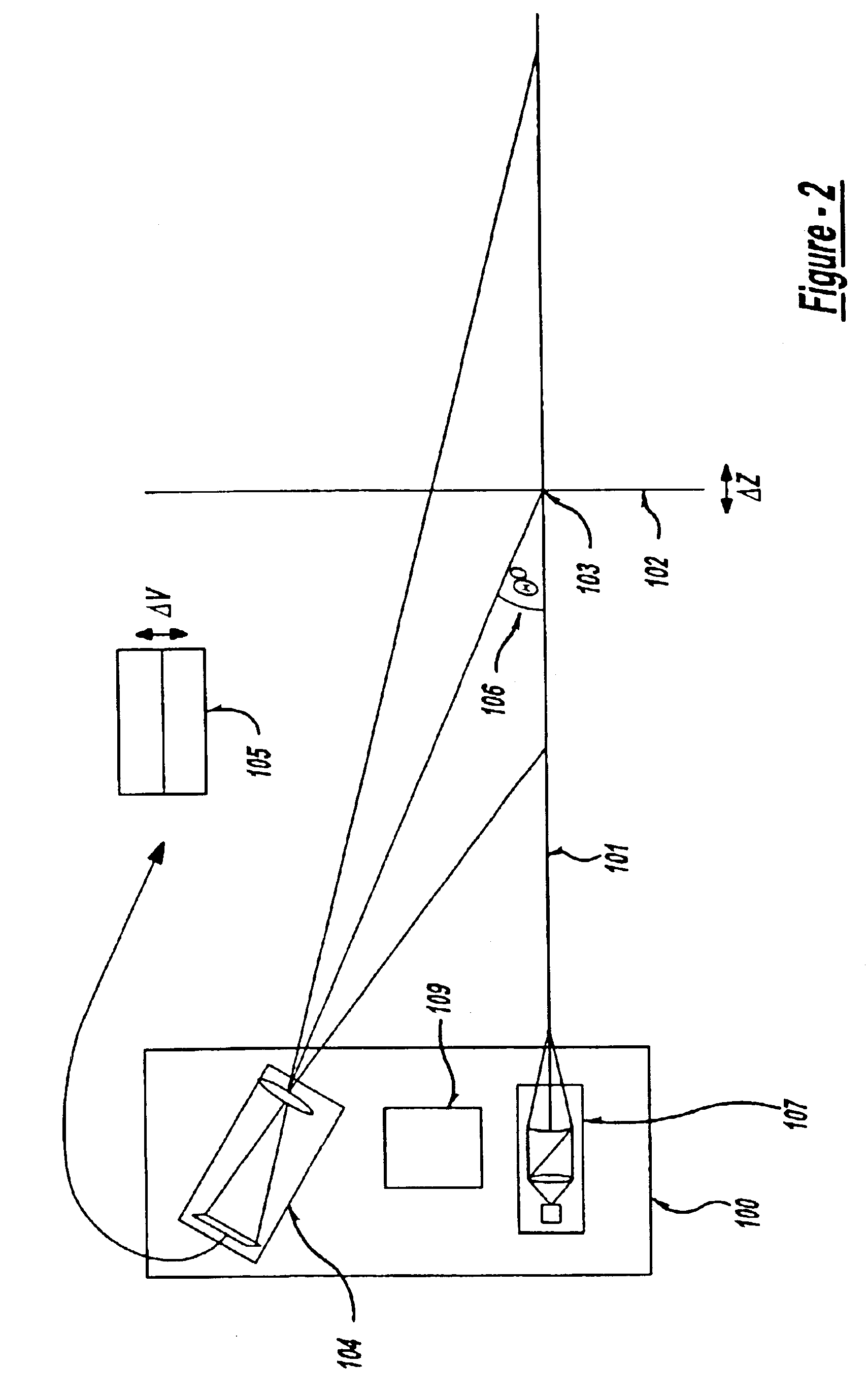

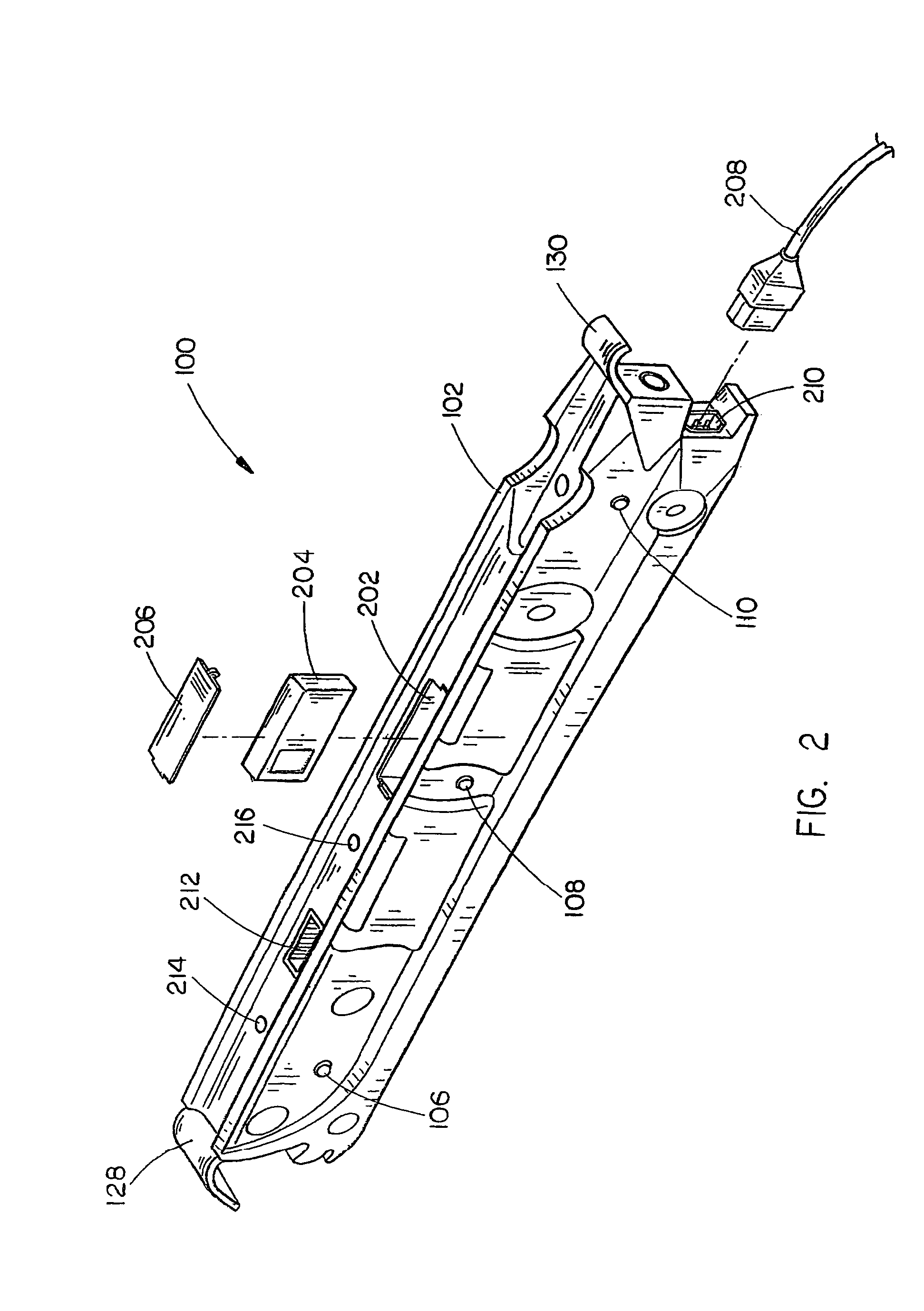

Modular non-contact measurement device for quickly and accurately obtaining dimensional measurement data

InactiveUS6858857B2Quickly and accurately performingRemove most human judgement of measurement resultsImage analysisMetal sawing accessoriesMeasurement deviceDimension measurement

A modular measurement device is provided for quickly and accurately performing non-contact measurements of various objects at different locations within a commercial or residential work area. The modular measurement device generally includes a laser base that is operable to project light onto a measured object; and a portable measurement module adapted to receive light reflected from a surface of the measured object and operable to determine dimensional measurement data for the measured object, where the portable measurement module is configured to releasably couple to the laser base. The operational components of the measurement device are partitioned between the portable measurement module and the laser base. In this way, a single portable measurement module having more expensive operational components may be used with different, less expensive laser bases, where each laser base may be adapted for a different application.

Owner:PERCEPTRON

Non-contact measuring method for leaf apex radial clearance of engine rotor

InactiveCN102175135AImprove assembly qualityReduce disassemblyEngine testingUsing electrical meansCapacitanceFailure rate

The invention relates to a non-contact measuring method for a leaf apex radial clearance of an engine rotor, and the method comprises the following steps: 1) assembling a measuring system, calibrating a sensor and determining the relation between the radial clearance and voltage of a leaf apex; 2) preparing before measuring; and 3) measuring the leaf apex radial clearance of the engine rotor. In the measuring method provided by the invention, a measurement technique based on a capacitance method is adopted; the measuring course and the assembling are synchronously carried out; the once cartridge disassembly and assembly is reduced; the measuring time is shortened; the production efficiency is improved; and the measuring accuracy is improved, thereby improving the assembly quality of an engine and reducing the failure rate of the engine. The non-contact measuring method provided by the invention is mainly used for measuring the leaf apex radial clearance of the rotors of parts such as an engine, a high-pressure compressor, a low-pressure compressor, a high-pressure turbine, a low-pressure turbine and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Power tool control system

InactiveUS8004664B2Quality improvementWell formedStapling toolsDrilling/boring measurement devicesGraphical user interfaceControl system

A power tool control system includes a non-contact measurement and alignment device operative with the power tool and enabled to establish various readings, such as power tool settings. A graphical user interface communicatively coupled with the non-contact measurement and alignment device enables user control over and display of the readings from the non-contact measurement and alignment device.

Owner:CHANG TYPE INDAL

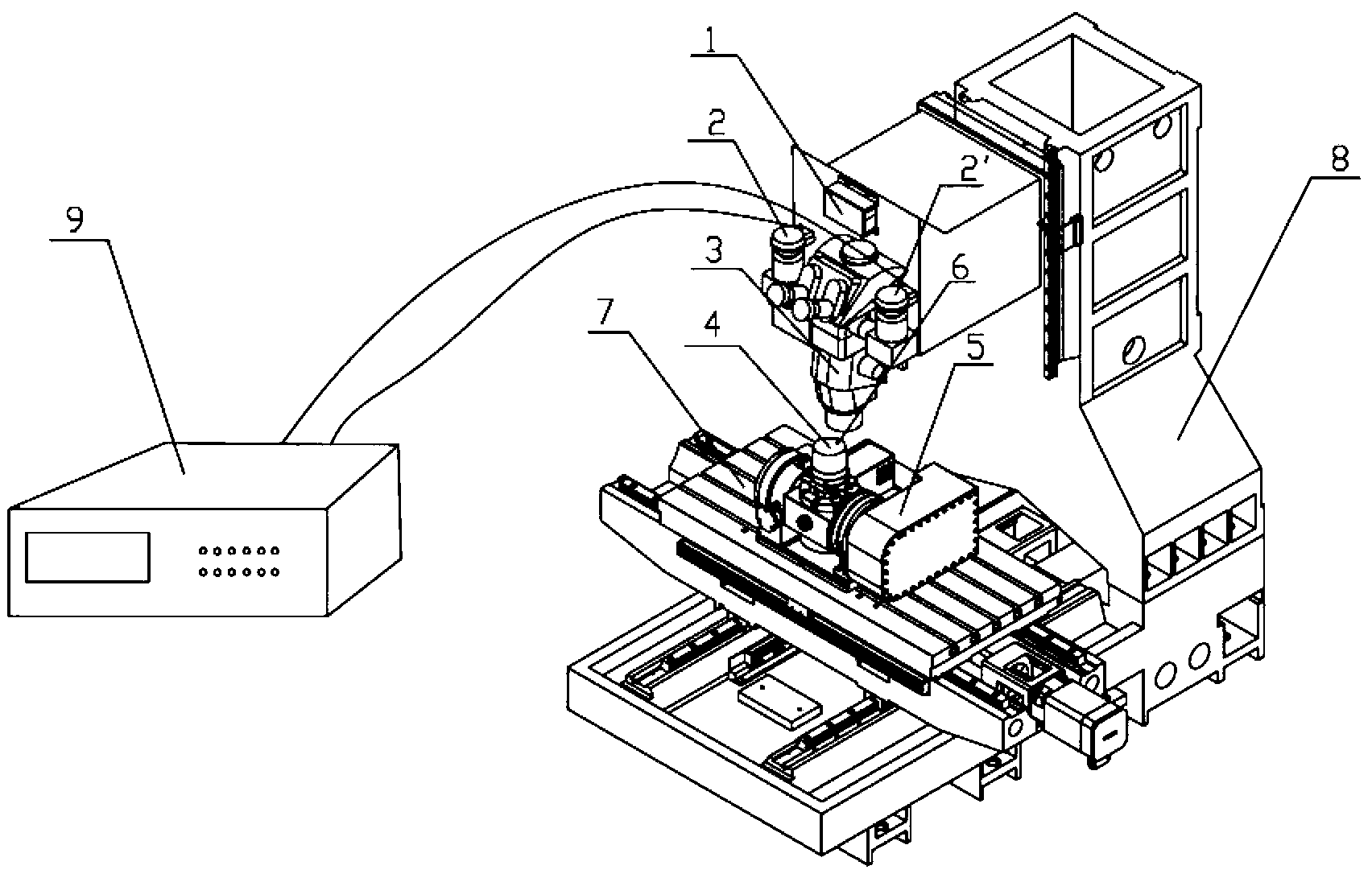

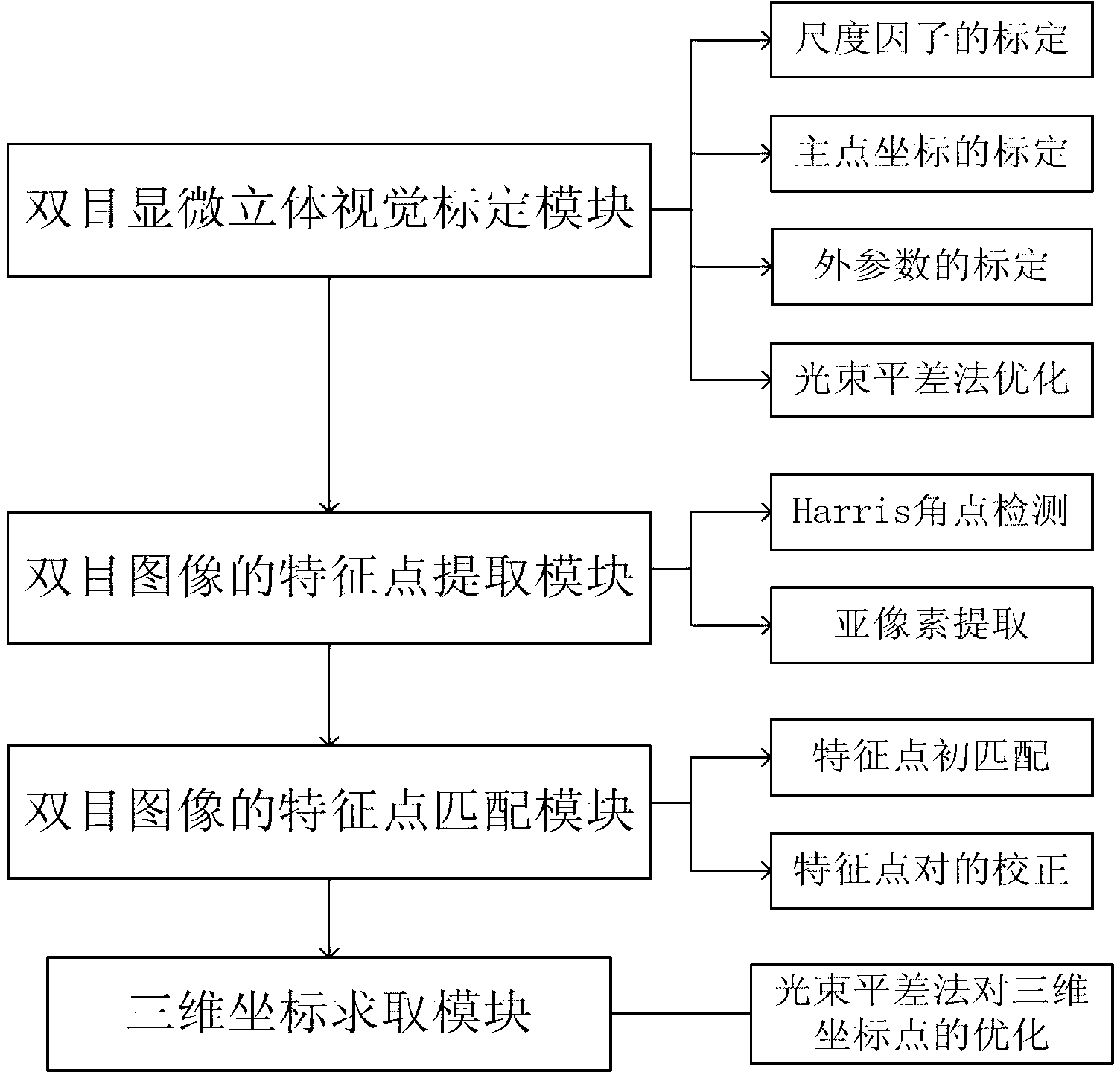

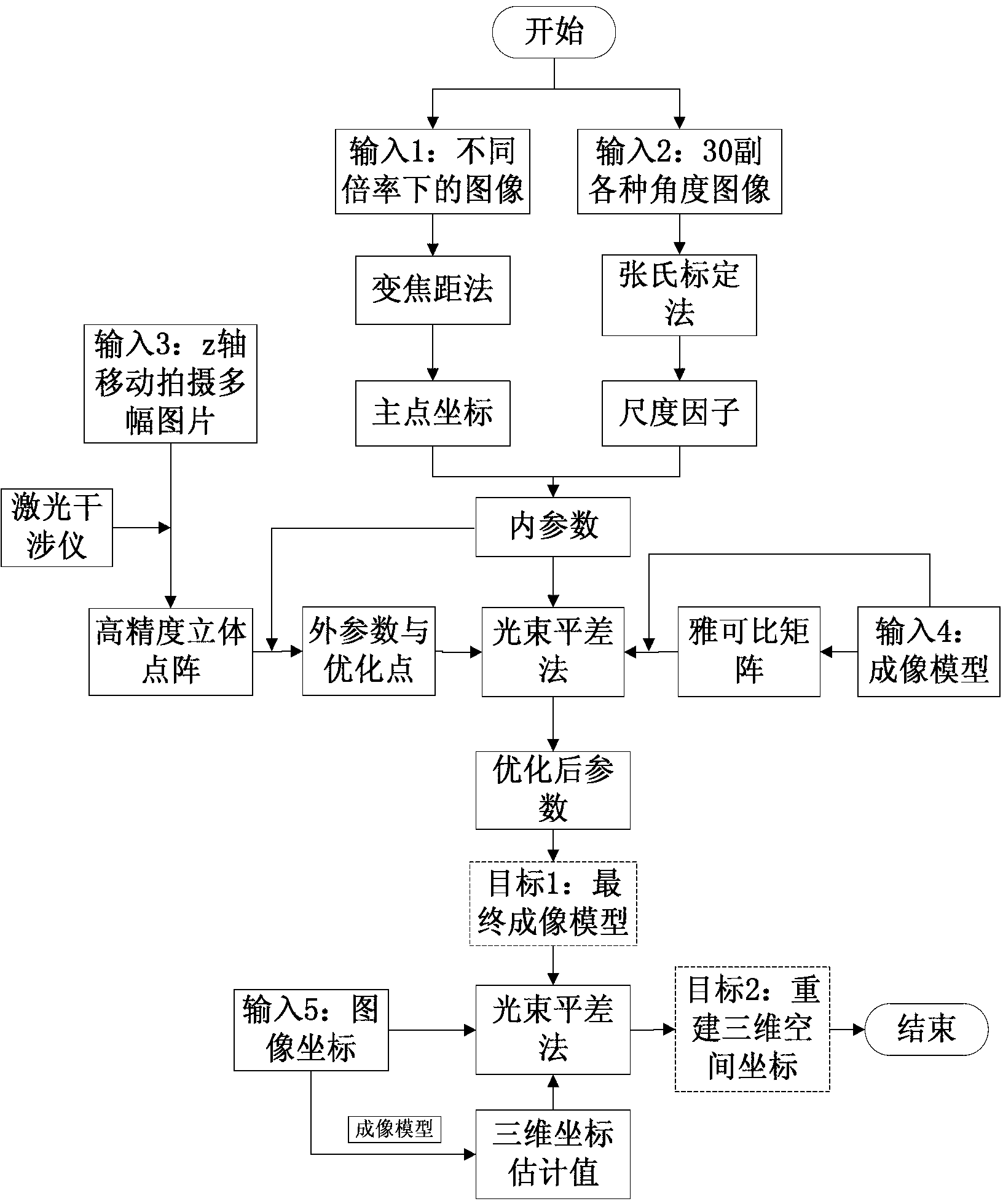

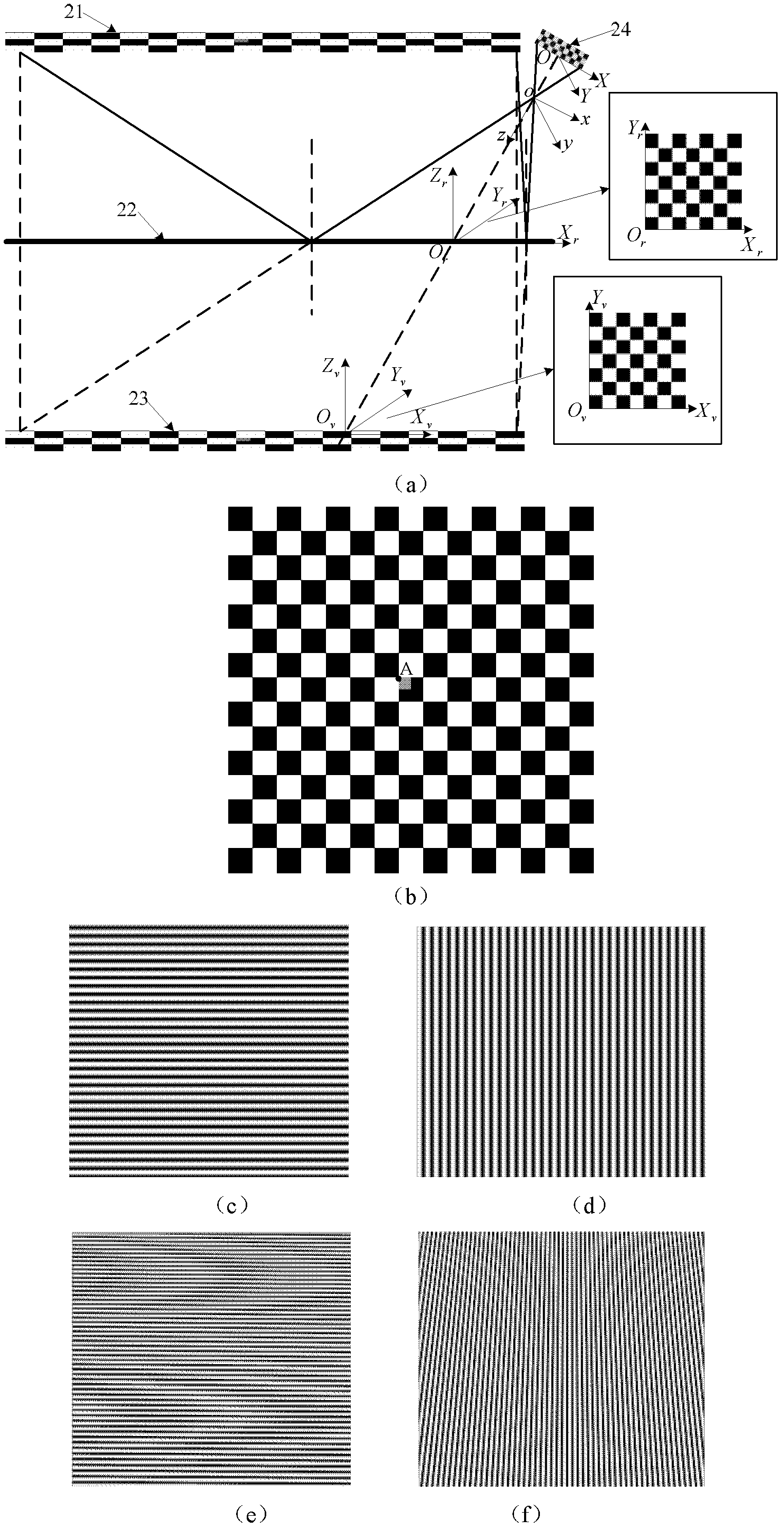

Accurate part positioning method based on binocular microscopy stereo vision

The invention discloses an accurate part positioning method based on binocular microscopy stereo vision, which belongs to the technical field of computer visual measuring and relates to an accurate precision part positioning method based on the binocular microscopy stereo vision. A binocular microscopy stereo vision system is adopted, two CCD (charge coupled device) cameras are adopted to acquire the images of the measured parts, the image information in the to-be-measured area on the measured part is amplified by a stereo microscope, a checkerboard calibrating board is adopted to calibrate the two CCD cameras, and a Harris corner point detecting algorithm and a sub-pixel extracting algorithm are adopted to extract feature points. The extracted feature points are subjected to the primary matching and correcting of matching point pairs, and the feature point image coordinates are inputted to a calibrated system to obtain the space actual coordinates of the feature points. The accurate part positioning method based on the binocular microscopy stereo vision solves the measuring difficult problems generated by the small size of the to-be-measured area, high positioning demand, non-contact and the like. The accurate positioning of the precision part is well finished by adopting the non-contact measuring method of the binocular microscopy stereo vision.

Owner:DALIAN UNIV OF TECH

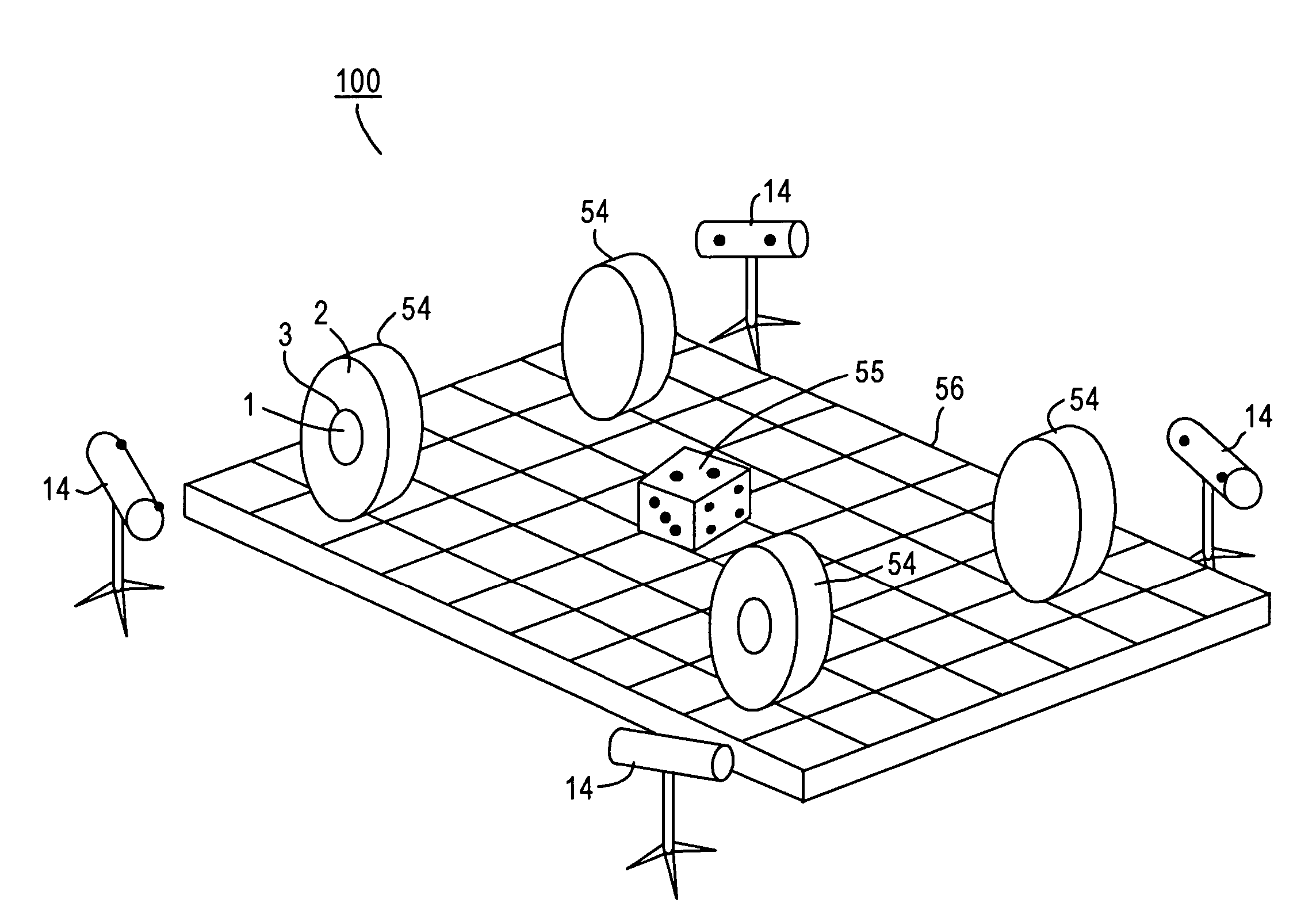

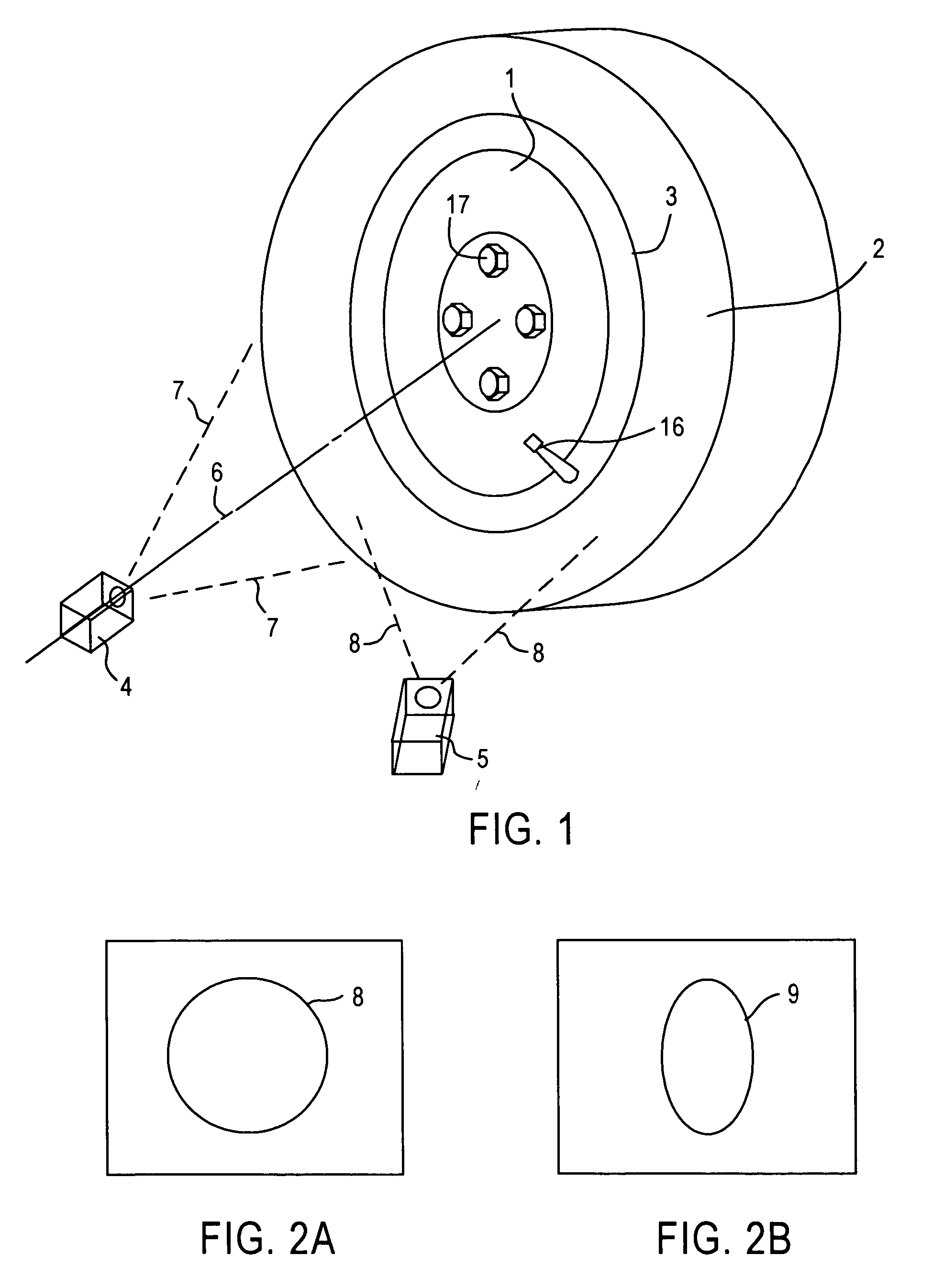

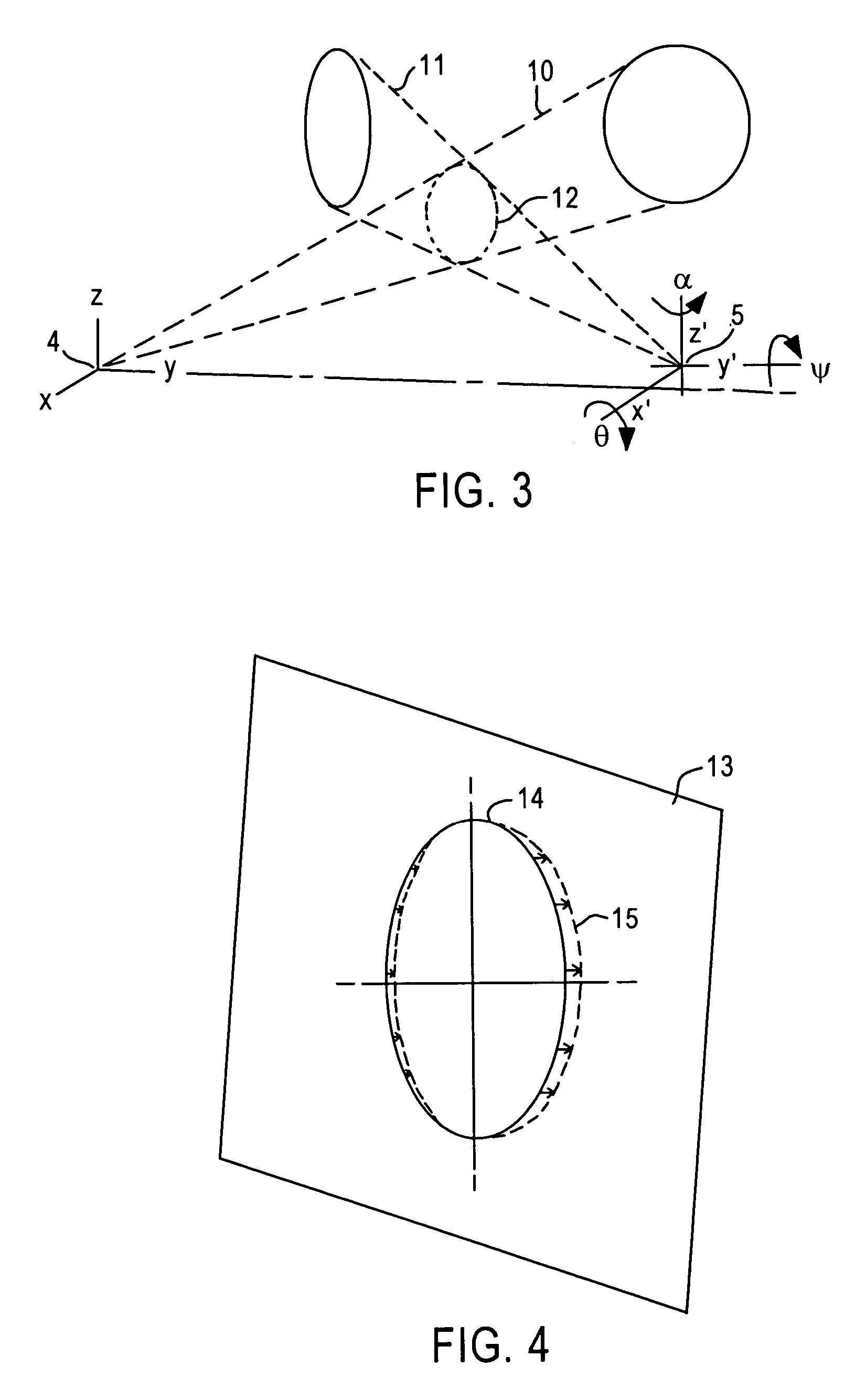

Non-contact vehicle measurement method and system

InactiveUS20060152711A1Readily apparentAngle measurementUsing optical meansData processing systemImage based

An image-based, non-contact measurement method and system for determining spatial characteristics and parameters of an object under measurement. Image capturing devices, such as cameras, are used to capture images of an object under measurement from different viewing angles. A data processing system performs computations of spatial characteristics of the object under measurement based on the captured images.

Owner:SNAP ON INC

Measurement and alignment device including a display system

InactiveUS7359762B2Quality improvementWell formedProgramme controlMetal working apparatusGraphicsGraphical user interface

A graphical user interface communicatively coupled with a non-contact measurement and alignment device enables user control over and display of the readings from the non-contact measurement and alignment device. In operation with a power tool, the graphical user interface provides a user with selectable control over the power tool through the computation and display of multiple power tool settings.

Owner:CHANG TYPE INDAL

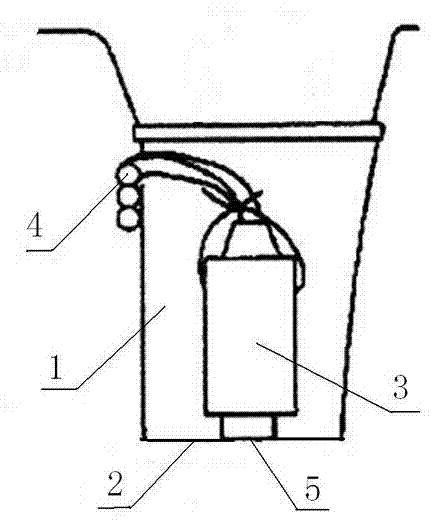

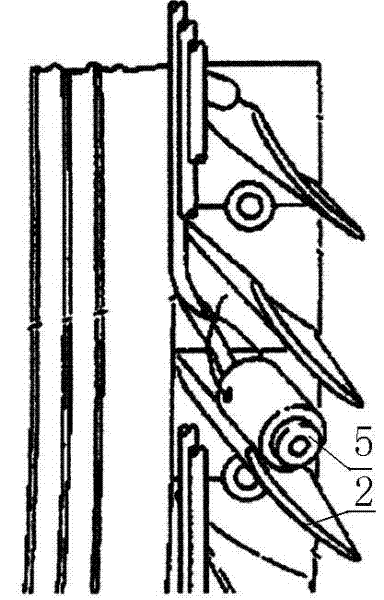

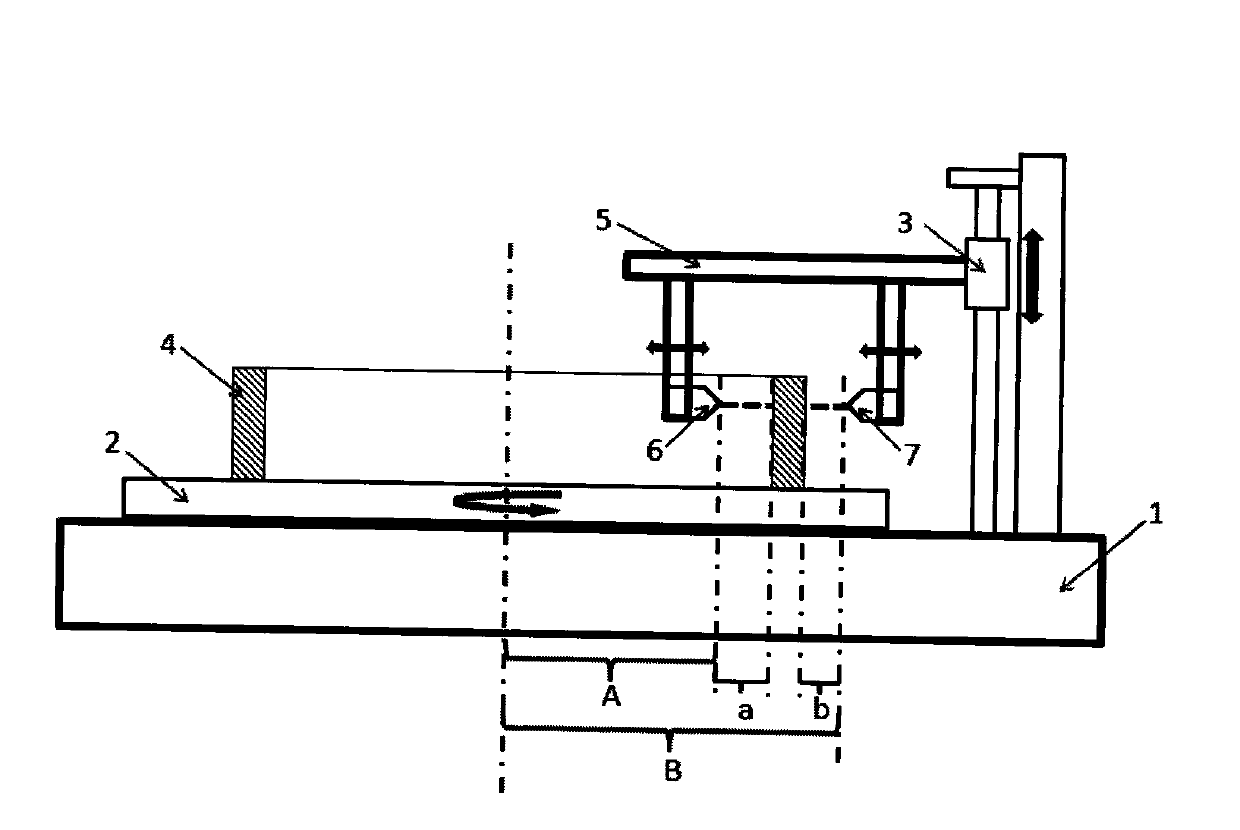

Non-contact measurement apparatus of inner and outer diameters of large-diameter circular ring type component

InactiveCN104180763AEasy to placeEnables automated non-contact measurementsUsing optical meansPhysicsNon contact measurement

The invention, which belongs to the technical field of industrial measurement, discloses a non-contact measurement apparatus of inner and outer diameters of a large-diameter circular ring type component. According to the apparatus, a rotation platform (2) drives to-be-measured circular ring type components to make rotation; a non-contact laser displacement sensor is used for measuring the inner diameters and the outer diameters of the to-be-measured circular ring type components (4); and measurement of the to-be-measured circular ring type components (4) with different dimensions can be realized based on fine tuning of a lifting platform (3) and an inner-outer diameter adjusting rack (5). With the apparatus, automatic non-contact measurement of the inner diameter, outer diameter, thickness, and ovality of a circular ring type component can be realized; the measurement error is small; the operation is simple and convenient; the measurement speed is fast; and the work efficiency is high. The provided measurement apparatus is suitable for bath detection occasions of large-diameter circular ring type component production and processing enterprises.

Owner:NANKAI UNIV

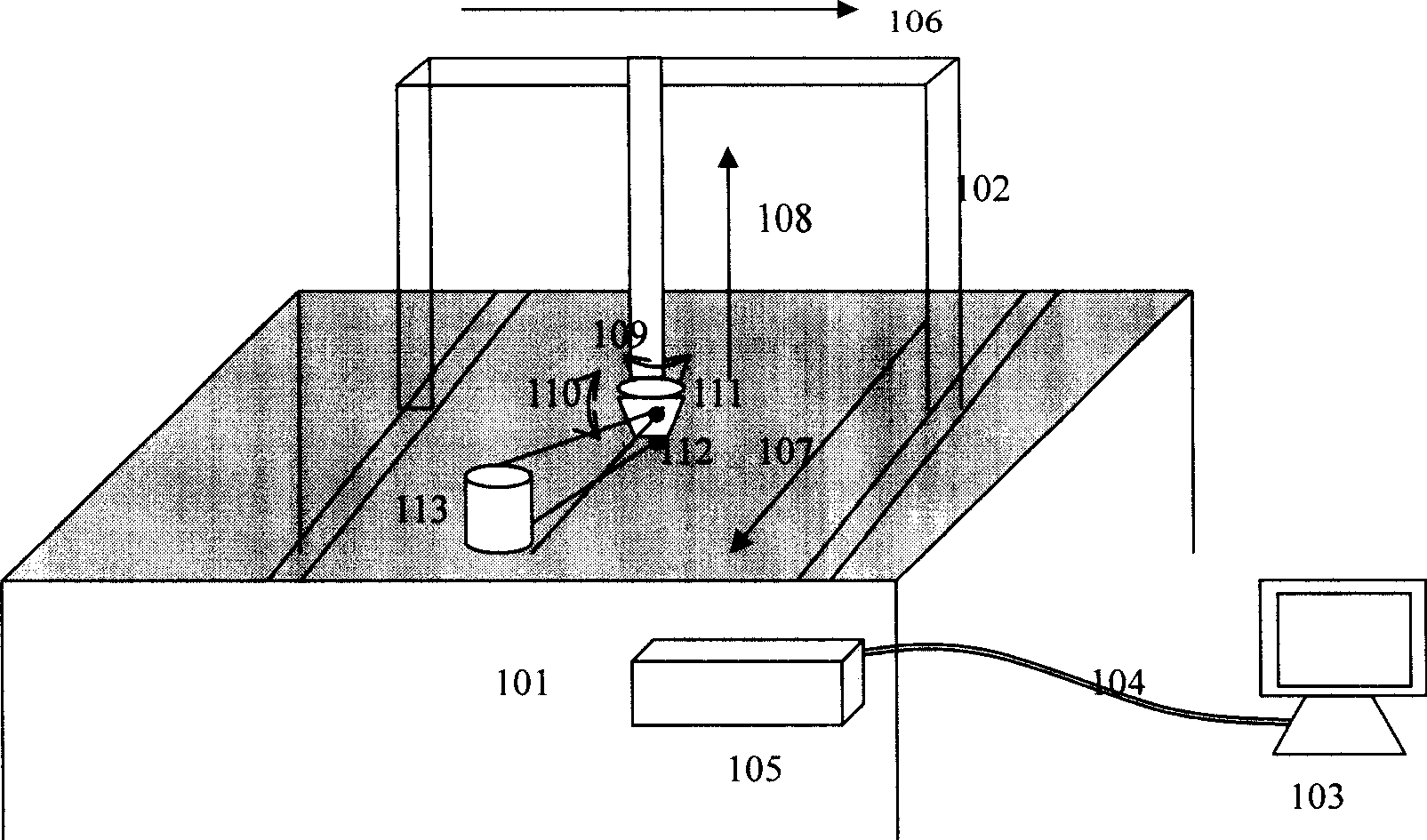

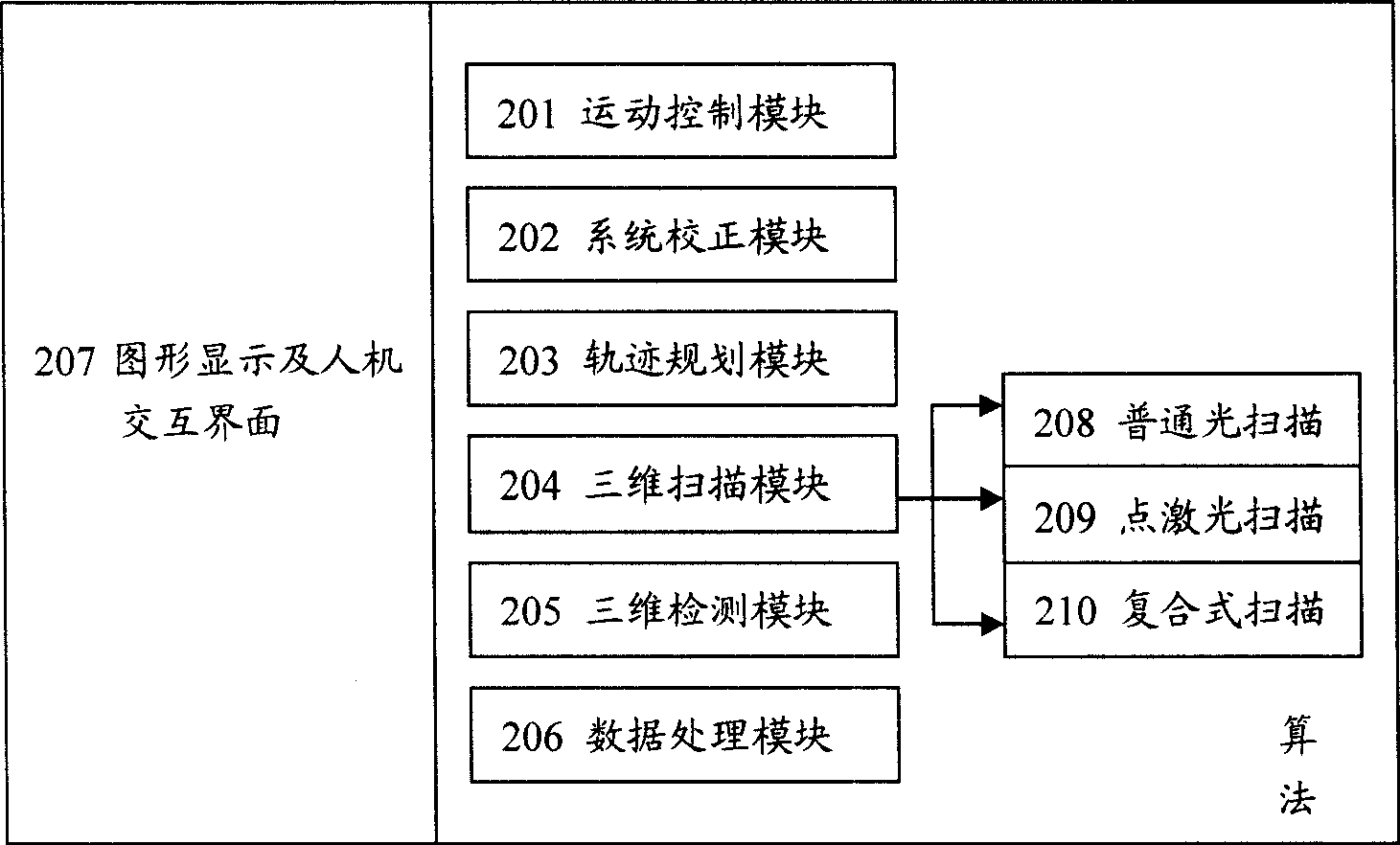

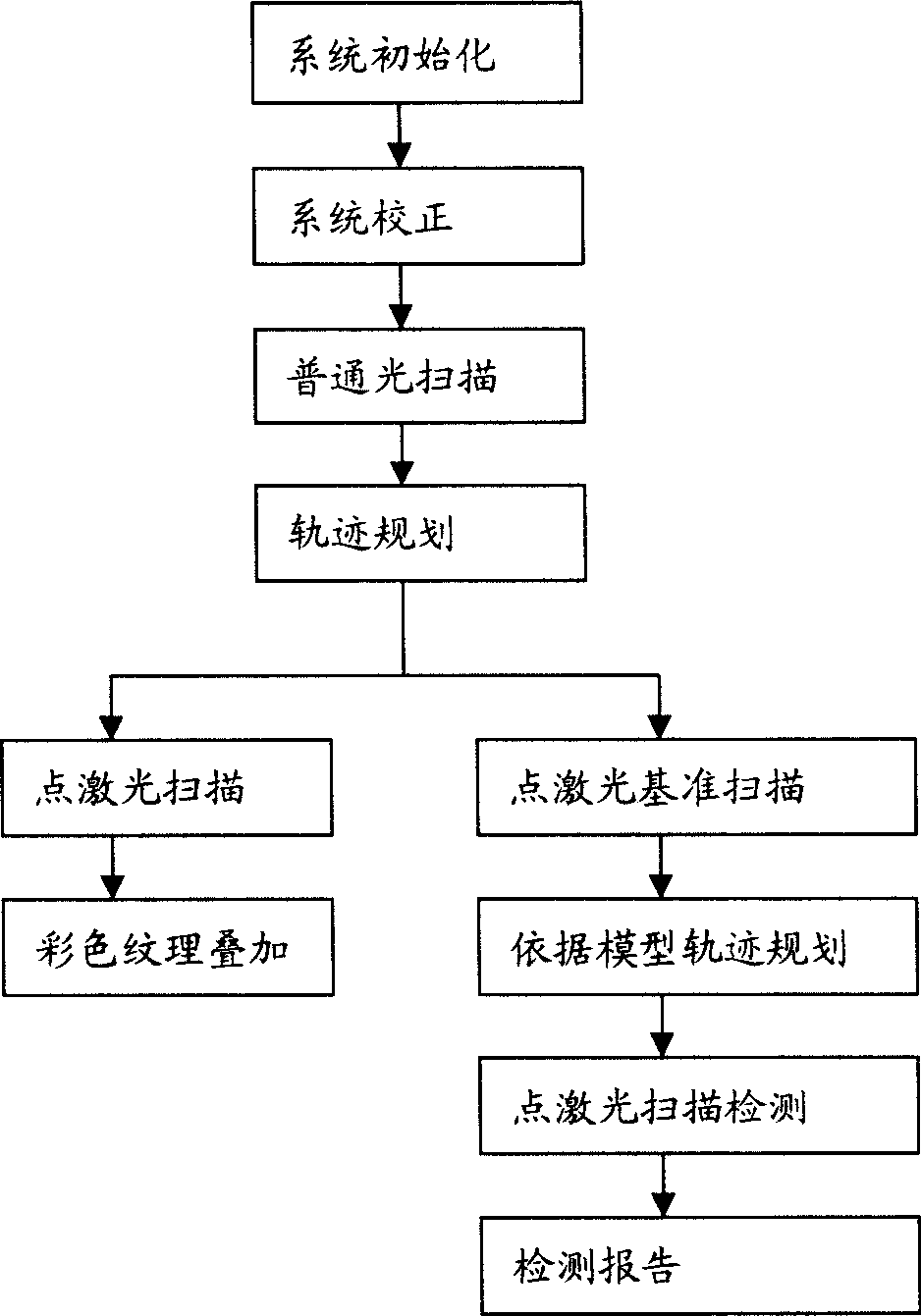

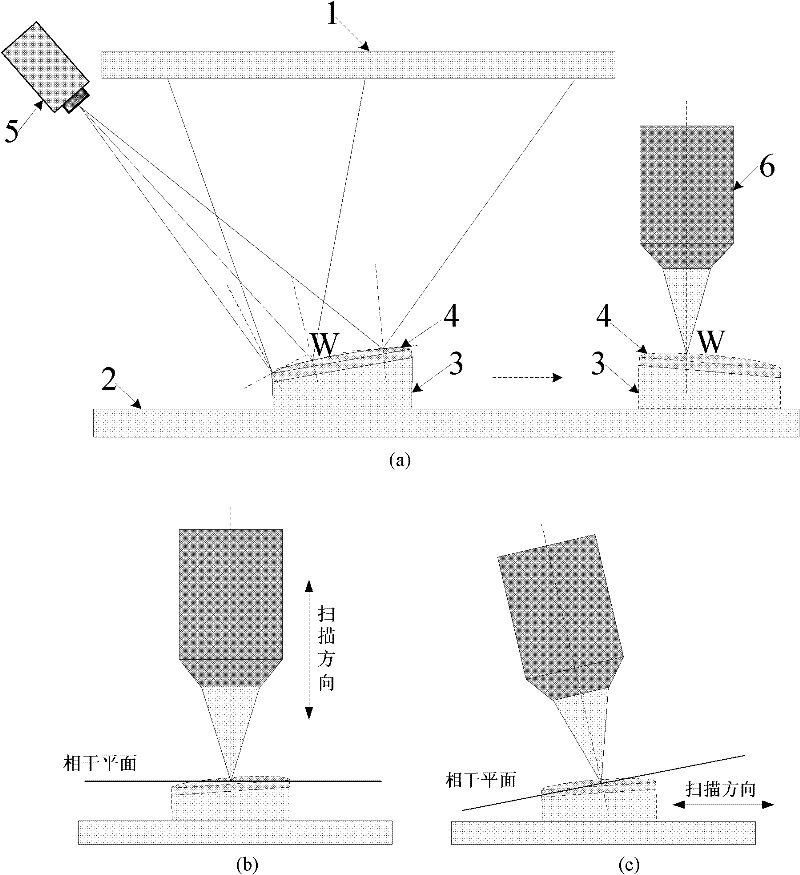

Composite three-dimensional laser measurement system and measurement method

InactiveCN101520319ARealize automated high-speed measurementAdjust light outputPhotogrammetry/videogrammetryUsing optical meansPoint cloudLaser probe

The invention provides a composite three-dimensional point laser measurement system and a measurement method, comprising three-dimensional scanning and three-dimensional detection. Normal optical scanning is adopted so as to obtain the profile information of the article quickly and establish a three-dimensional model; motion trajectory planning is carried out by the profile data; and a point laser probe is guided to carry out more precise measurement so as to obtain the three-dimensional point cloud data of higher precision and higher quality. The three-dimensional non-contact detection to the characteristic position, appointed section line and integer of the workpiece is obtained further on the basis of comparing the point cloud and model data. The system and the method have the advantages that the non-contact measurement can obtain the point cloud of good quality and high precision, the article can be positioned freely, precise clamping devices are not needed, the measurement speed is quick, the process is automatic and the measured article has wide applicable range.

Owner:深圳市精易迅科技有限公司

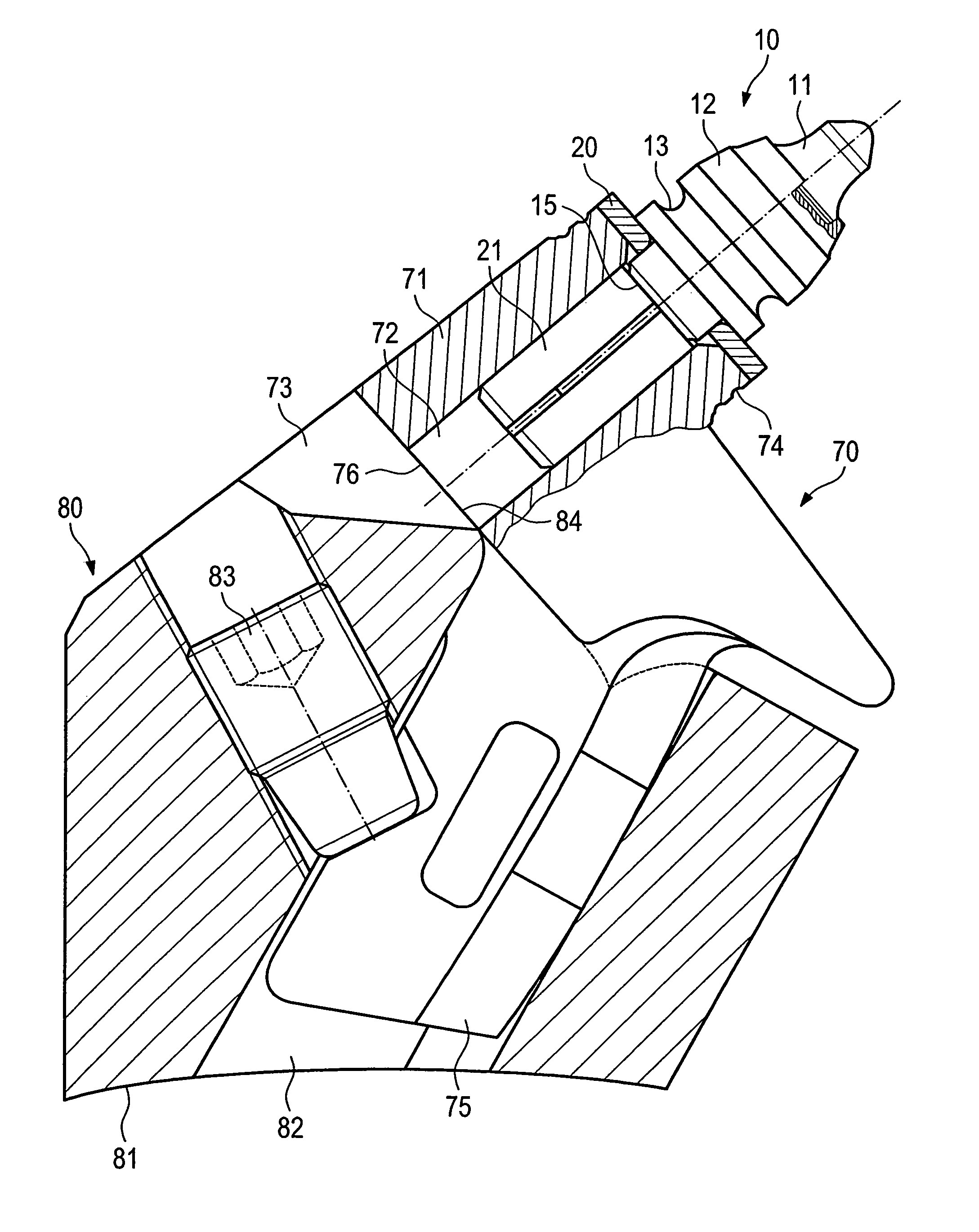

Method for determining the wear state

This invention relates to a method for determining a wear state of a chisel, a chisel holder, and / or a chisel holder replacement system equipped with a chisel and chisel holder. For this method to give the user qualitative and quantitative information about the wear, according to one embodiment of this invention, a position of at least one point of the chisel and / or the chisel holder is determined by a contactless measurement method and a corresponding measurement result is compared in a switching unit to a reference value stored in a memory device.

Owner:WIRTGEN GMBH

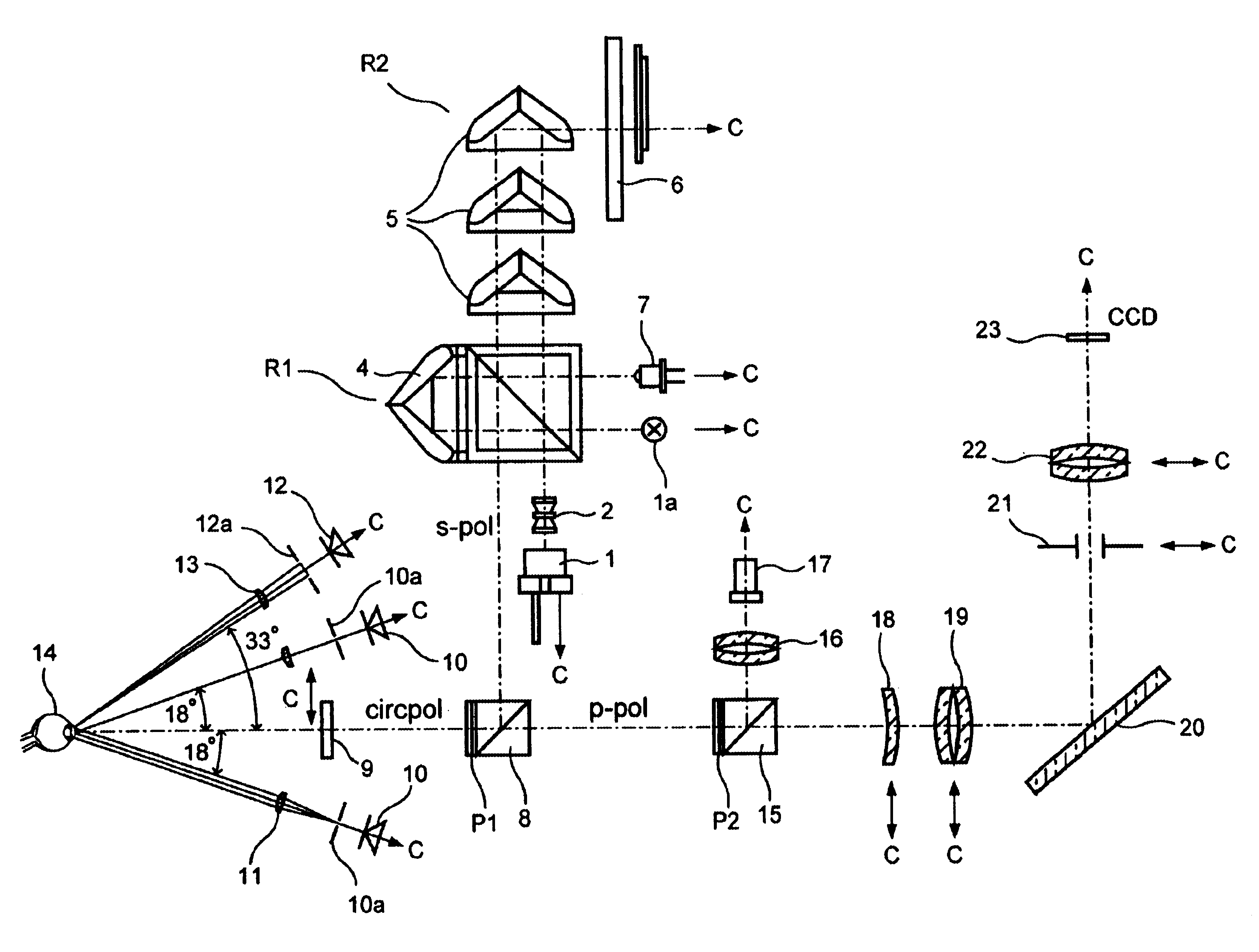

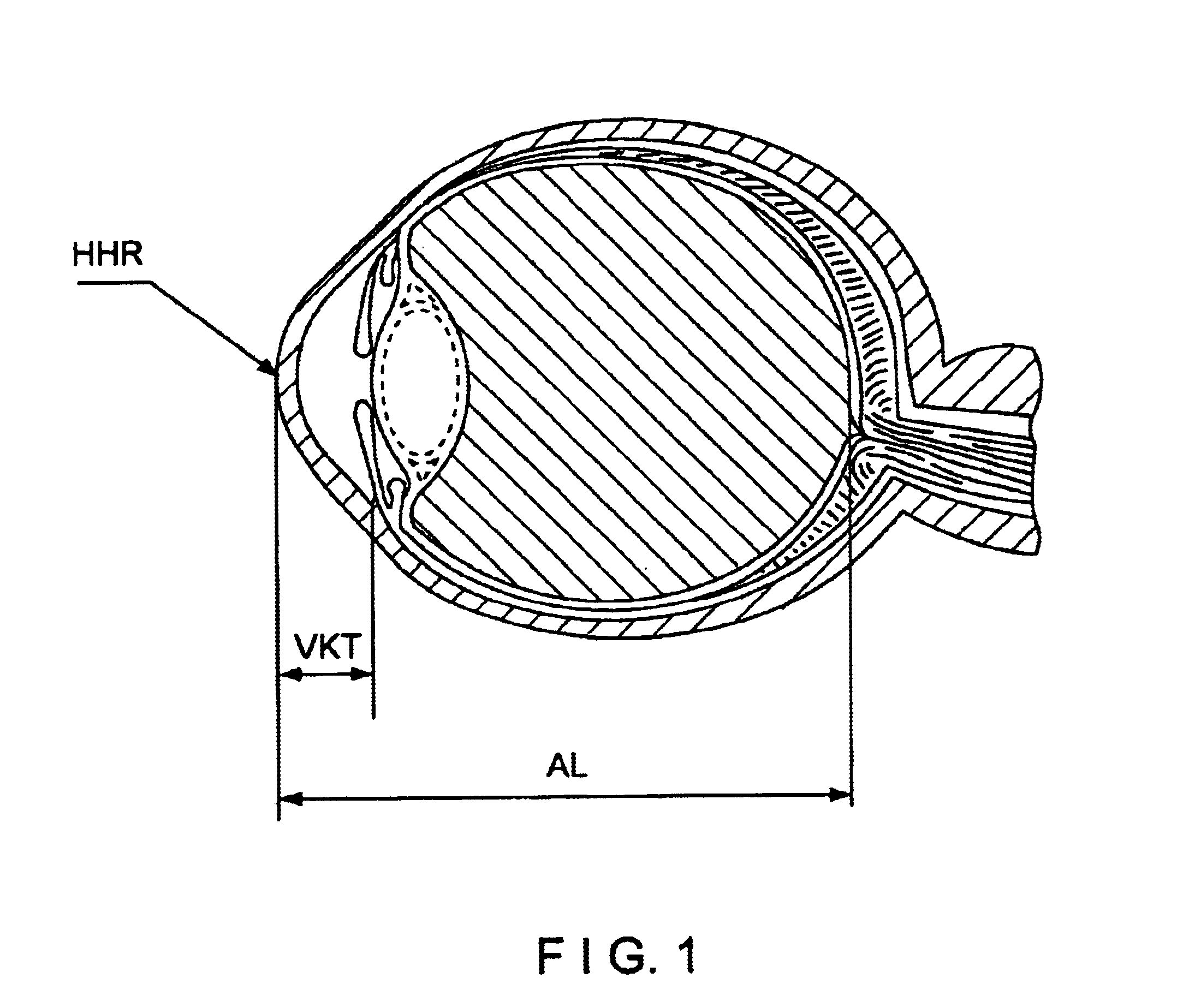

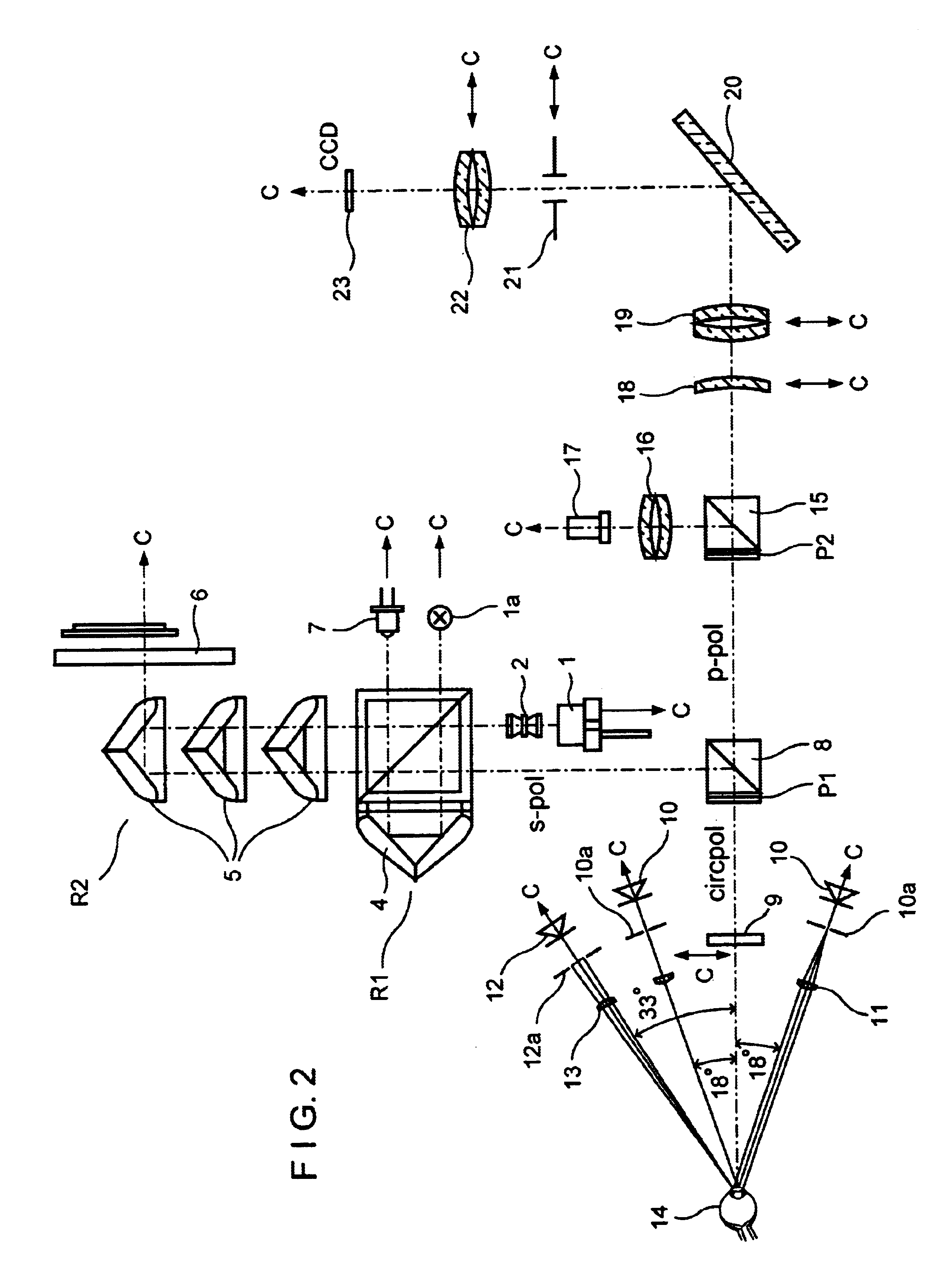

System and method for non-contacting measurement of the eye

InactiveUS6779891B1Reduce device-dependent measurement errorReduce measurement errorEye inspectionGonioscopesCorneal curvatureIntraocular lens

Combined equipment for non-contacting determination of axial length (AL), anterior chamber depth (VKT) and corneal curvature (HHK) of the eye are also important for the selection of the intraocular lens IOL to be implanted, particularly the selection of an intraocular lens IOL to be implanted, preferably with fixation of the eye by means of a fixating lamp and / or illumination through light sources grouped eccentrically about the observation axis.

Owner:CARL ZEISS JENA GMBH

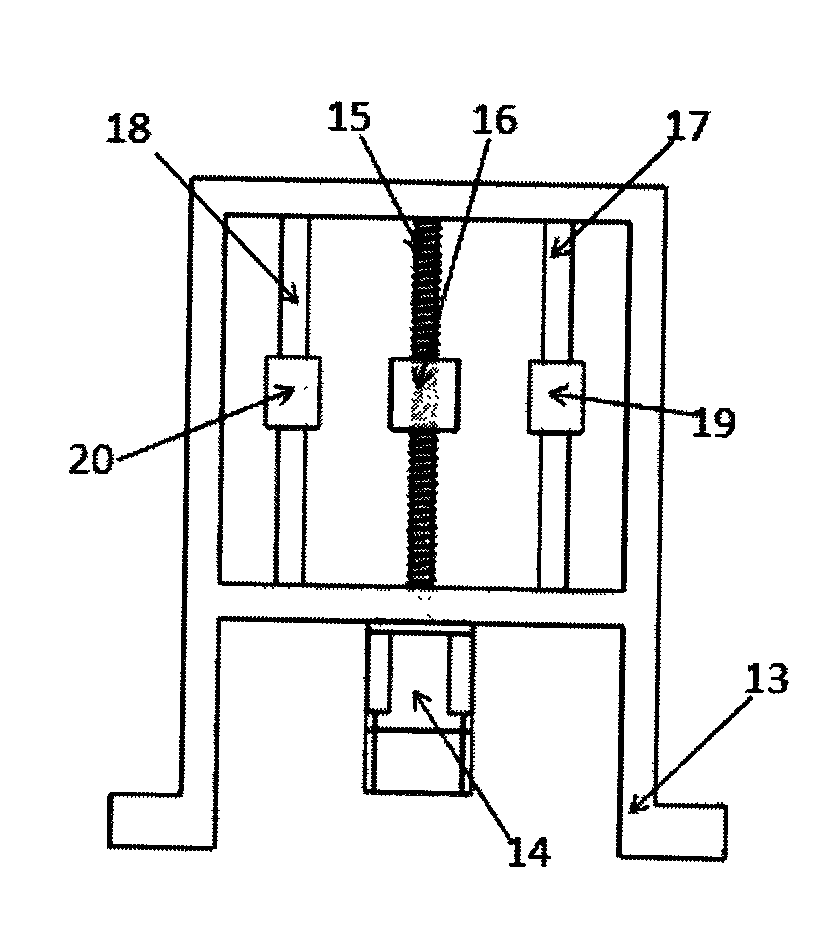

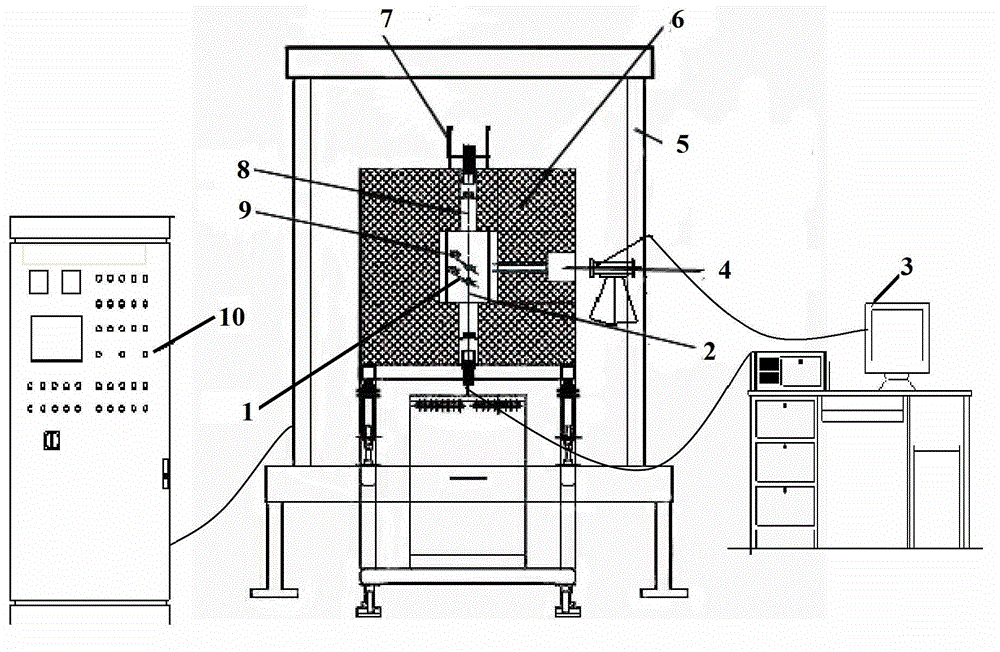

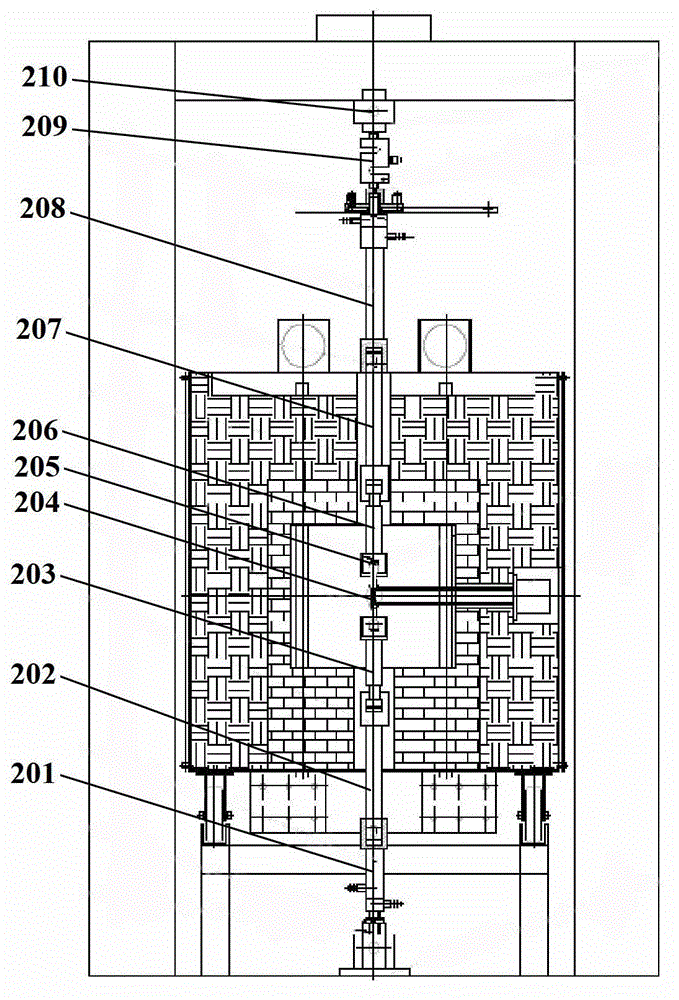

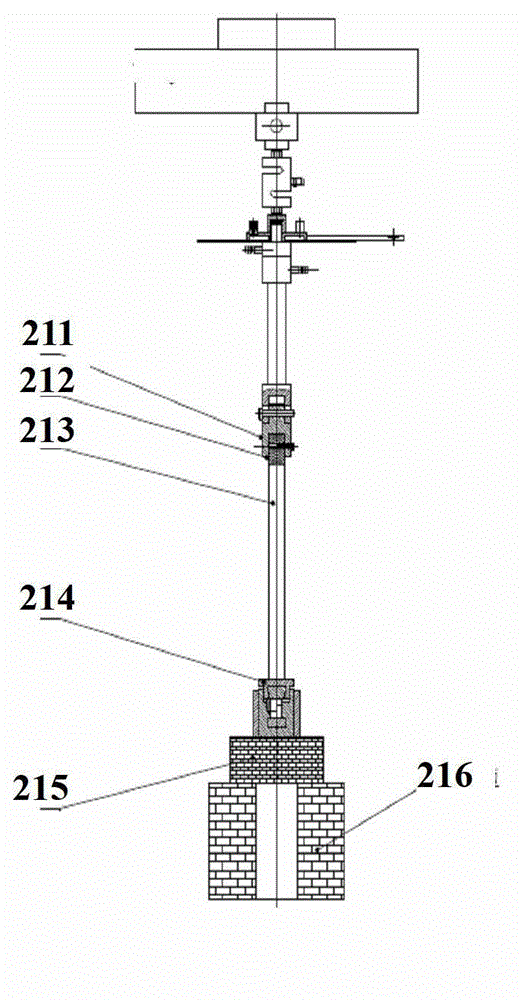

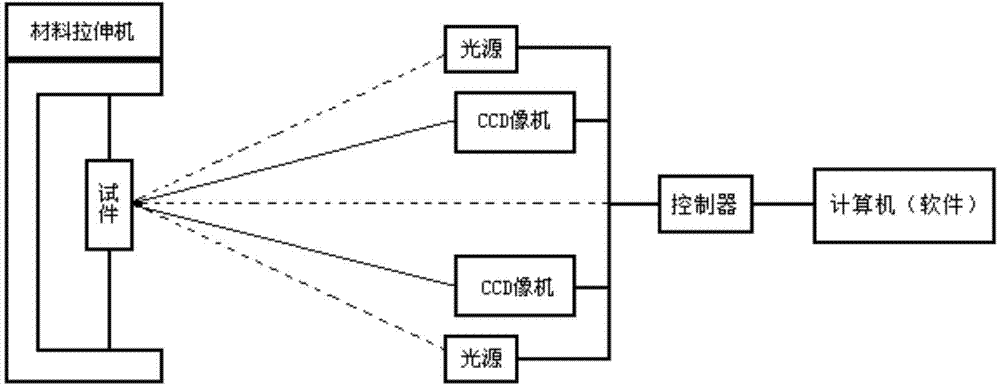

Device and method for testing mechanical property in ultrahigh temperature oxidation environment

ActiveCN102944466AMeasuring Tensile StrengthMeasuring Compressive StrengthMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectric controlMeasurement precision

The invention provides a device and a method for testing mechanical properties such as stretching, compression, bending, fracture toughness, shear strength and deformation of a high-temperature material in an ultrahigh temperature oxidation atmosphere in a temperature range from normal temperature to 1,800 DEG C. The experimental device is formed by assembling an electric control cabinet, a loading clamp, a load control and deformation sensing measurement system, a furnace body, a non-contact deformation measurement system, a display recording system and the like. According to the method, a furnace oxidation environment is uniformly and stably heated and kept through a heating body, so that the mechanical properties can be tested at temperature range from the room temperature to 1,800 DEG C, and mechanical property parameters such as stretching, compression, bending, shear strength and strain are captured by utilizing the contact sensing system and the non-contact measurement system. The device has the greatest characteristics of multiple testing parameters, high data measurement precision and high experimental repeatability.

Owner:PEKING UNIV +2

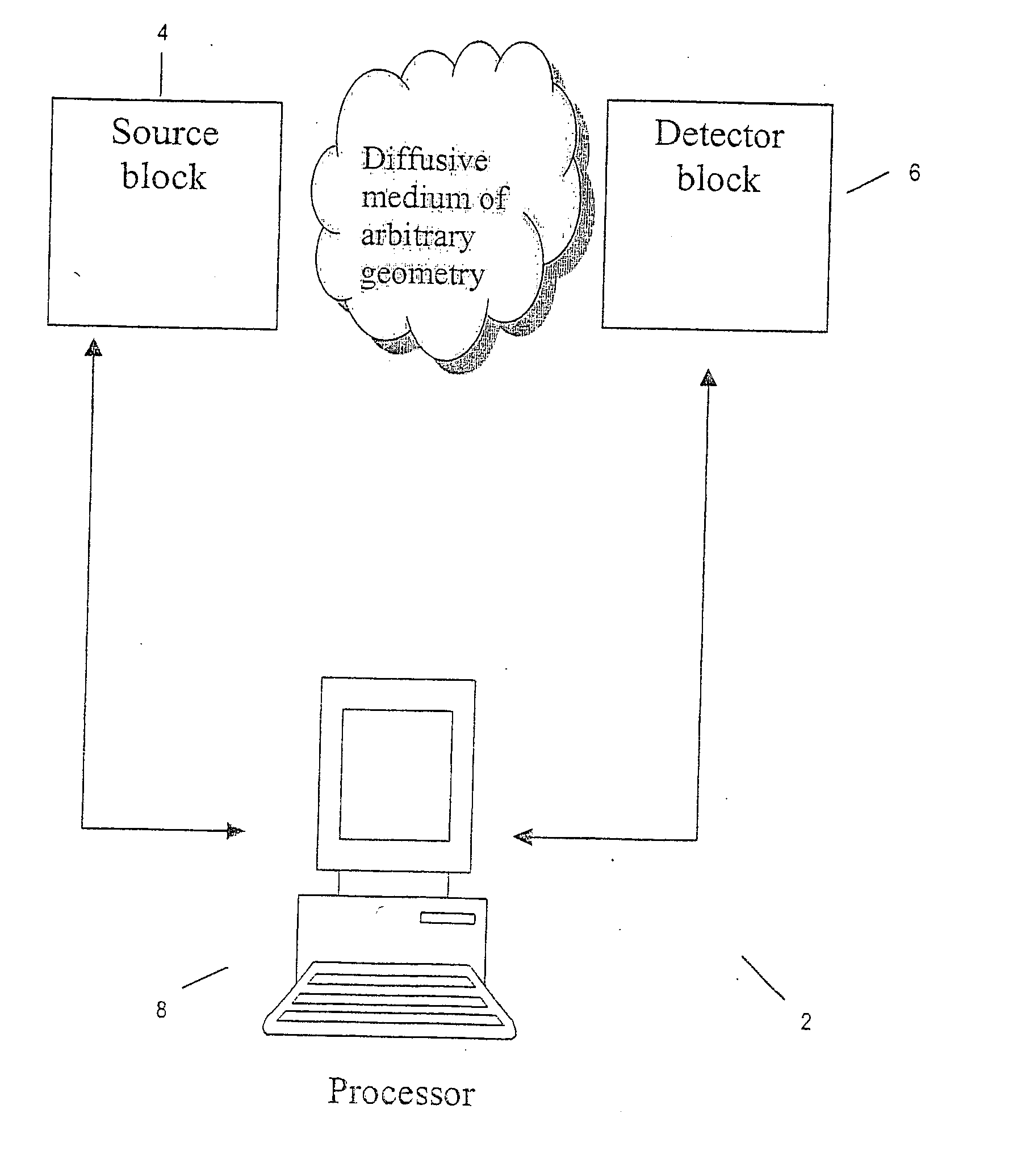

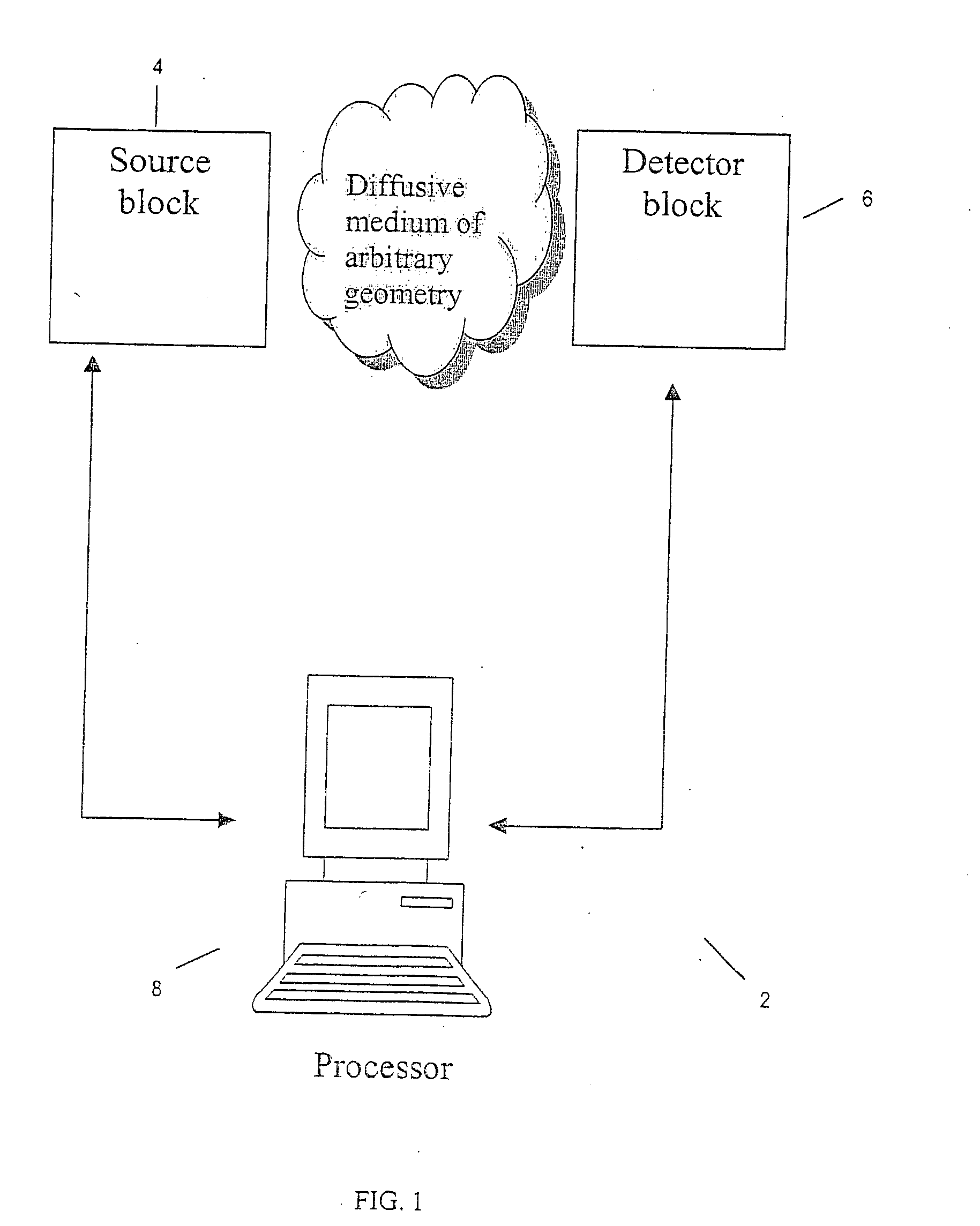

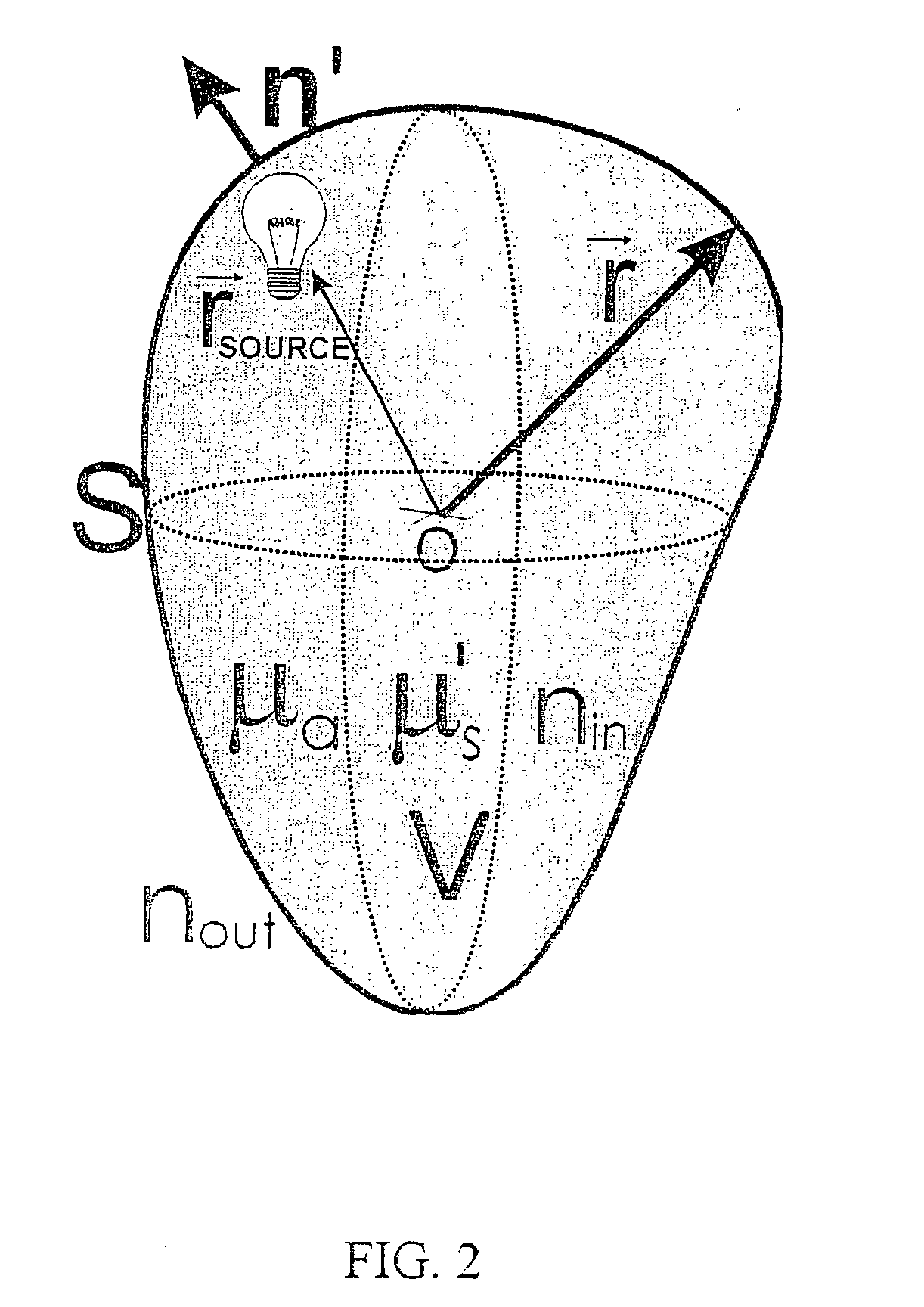

Imaging volumes with arbitrary geometries in contact and non-contact tomography

InactiveUS20050283071A1Attain computational simplicity and efficiencyRetaining accuracyDiagnostics using lightScattering properties measurementsDecompositionTomography

A method for tomographic imaging of diffuse medium includes directing waves into a diffusive medium, solving a surface-bounded inversion problem by forward field calculations through decomposition of contributions from the multiple reflections from an arbitrary surface within the diffusive medium or outside the diffusive medium into a sum of different orders of reflection up to an arbitrary order, and using contact or non-contact measurements of waves outside said diffusive medium to generate a tomographic image.

Owner:VISEN MEDICAL INC

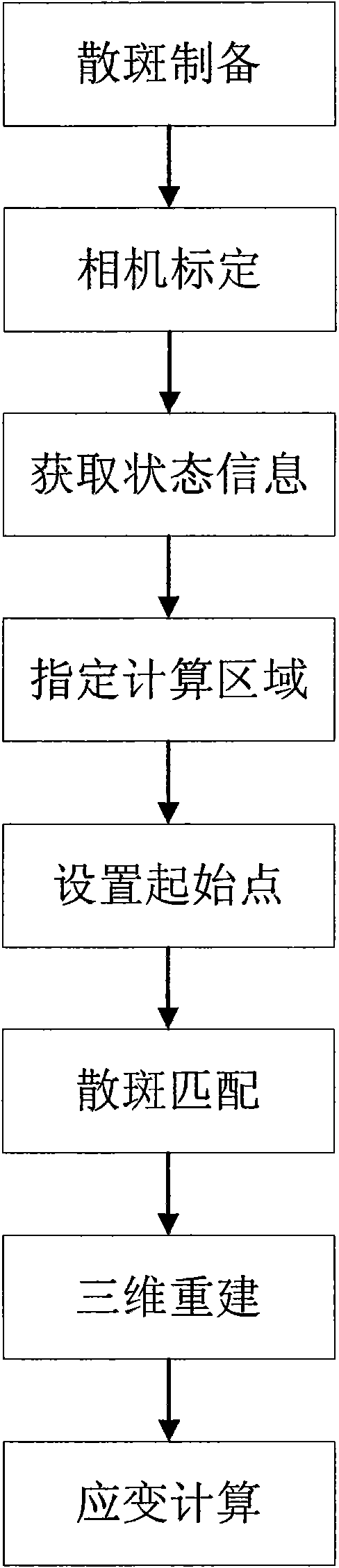

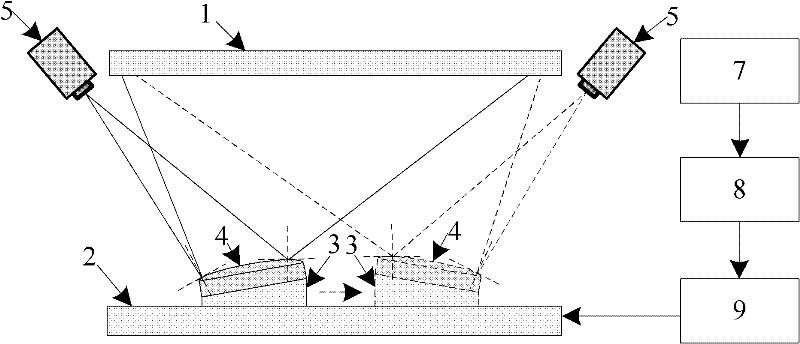

Three-dimensional speckle strain measurement device and measurement method thereof

ActiveCN101655352AHigh measurement accuracySimplify requirementsUsing optical meansVibration measurementFracture mechanics

The invention discloses a three-dimensional speckle strain measurement method, comprising: (1) speckle preparation; (2) camera calibration; (3) state information acquisition; (4) computational domaindesignation; (5) initial point setting; (6) speckle matching; (7) three-dimensional reconstruction; and (8) strain computation. By the above operation steps, the invention provides a three-dimensionalspeckle strain measurement method, which can effectively obtain high preciseness measurement results in measurements of material characteristic parameters such as full-field vibration measurement, dynamic strain measurement, high speed deformation measurement, fracture mechanics, impact excitation and dynamic material experiments. The invention has the characteristics of convenient measurement operation, high automation degree, exact and reliable results, high efficiency and non-contact measurement.

Owner:XI AN JIAOTONG UNIV

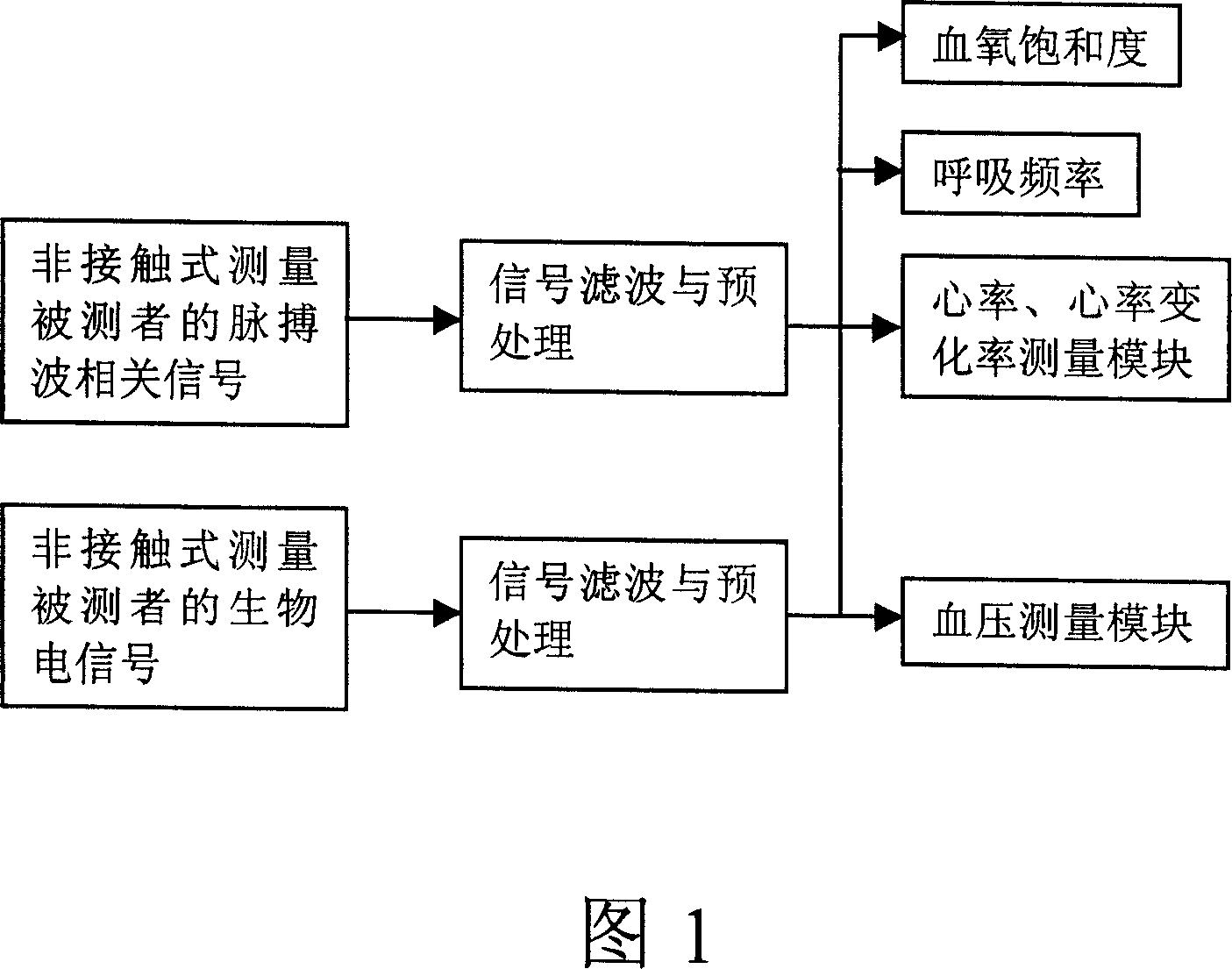

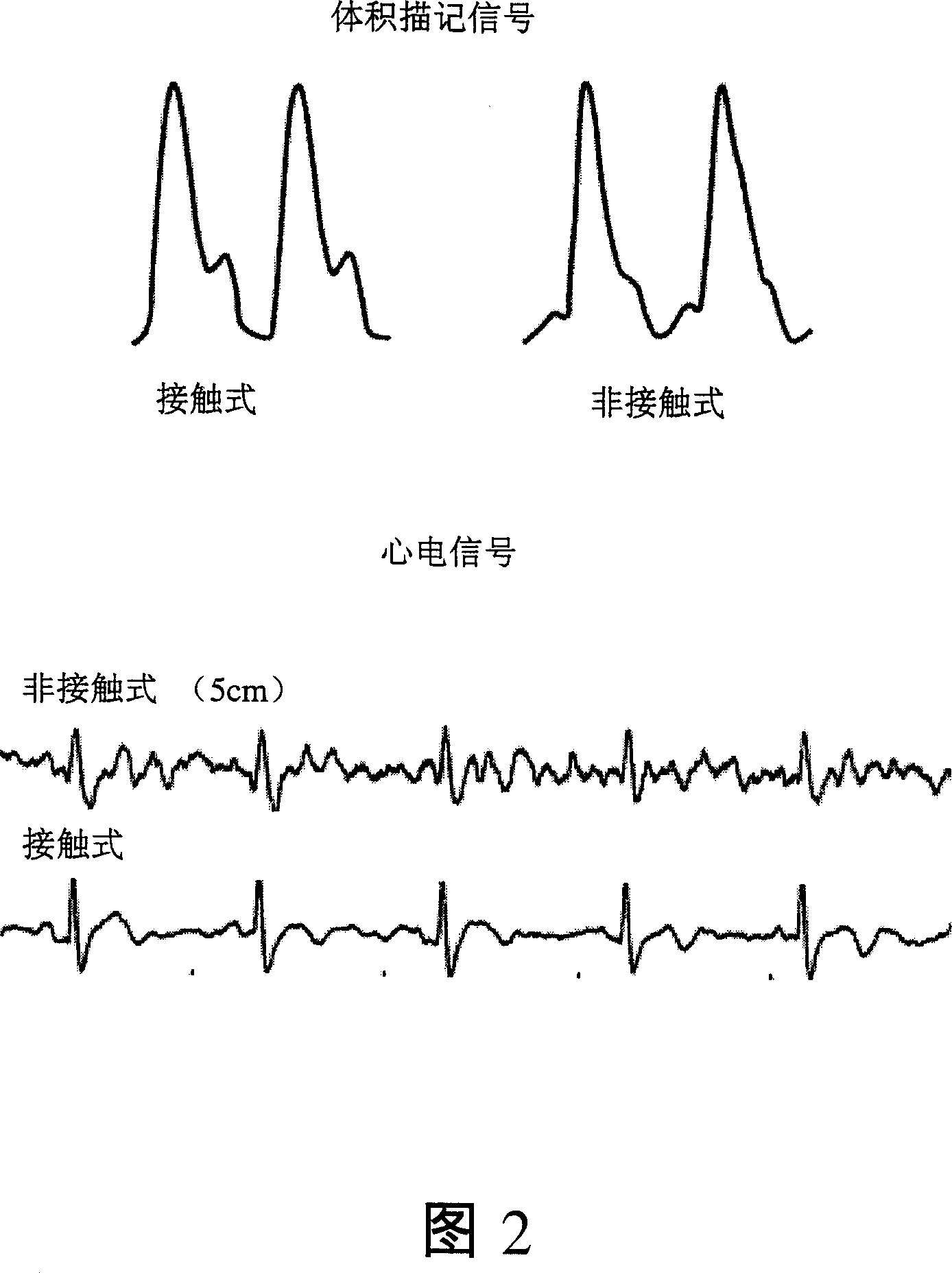

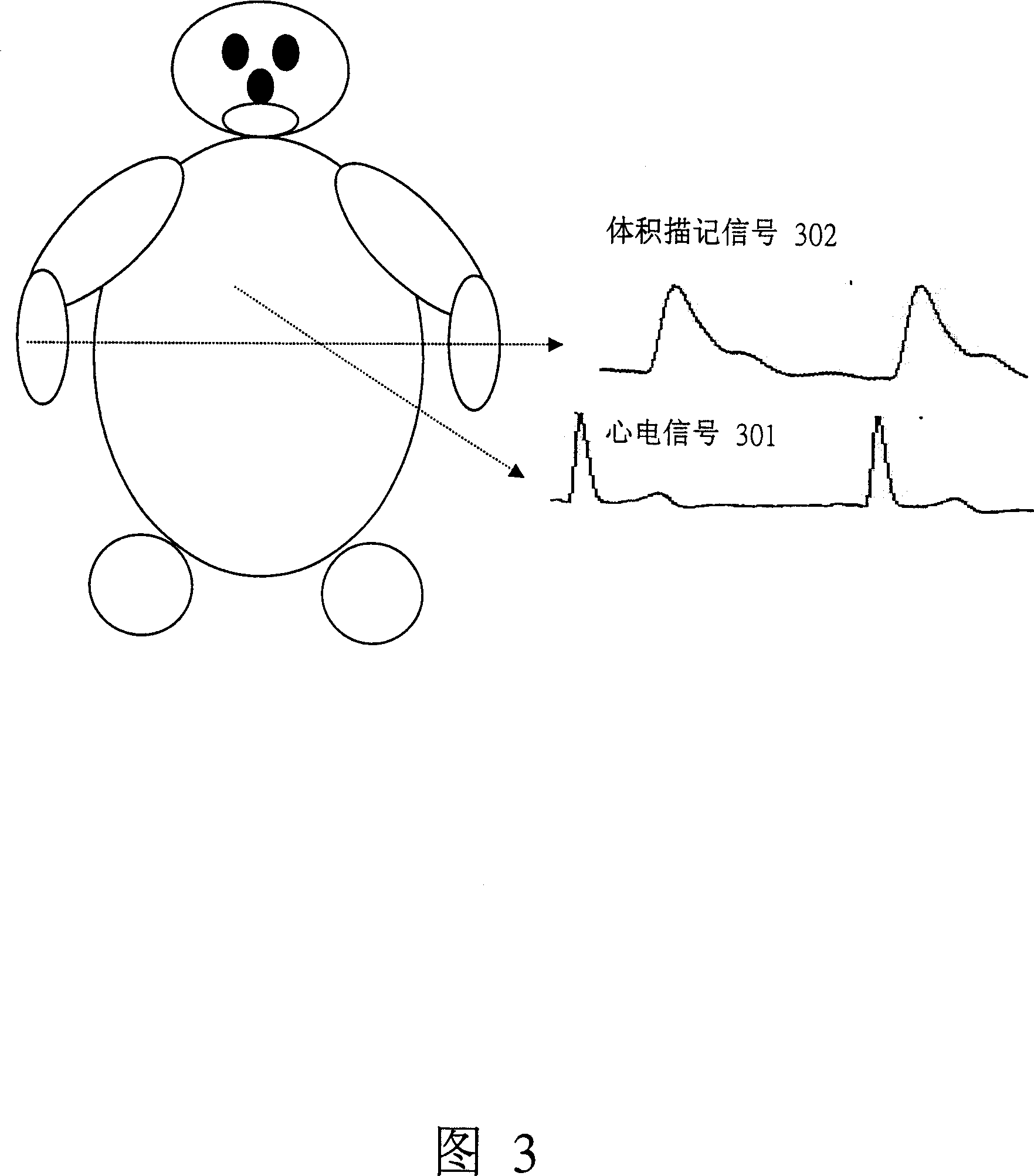

Non-contact measurement method of key physiological parameters

InactiveCN101006915AReduce volumeEasy to operateSensorsMeasuring/recording heart/pulse rateHuman bodyMedicine

The invention relates to a method for measuring key physiological parameters in noncontact manner, such as blood pressure and its change rate, electrocardiogram, blood oxygen saturation, respiratory frequency, and heart rate and its change rate. The key physiological parameters can be measured by analyzing plethysmographic signals and bioelectric signals collected by a sensor or a probe without contacting human body. The device adopted in the method has wider application scope than the conventional contact measurements, can be applied in particular environments such as mobile ambulance or battle field treatment, and can also be integrated in auxiliary facilities such as bathtub, bed and coach in everyday life. The device has the advantages of simple and easy operation, no affect to users' activities during measurements of physiological parameters, and no requirement of active intervention of users, and can provide safe, economical and practical, nondestructive real time continuous monitoring of physiological parameters for users.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

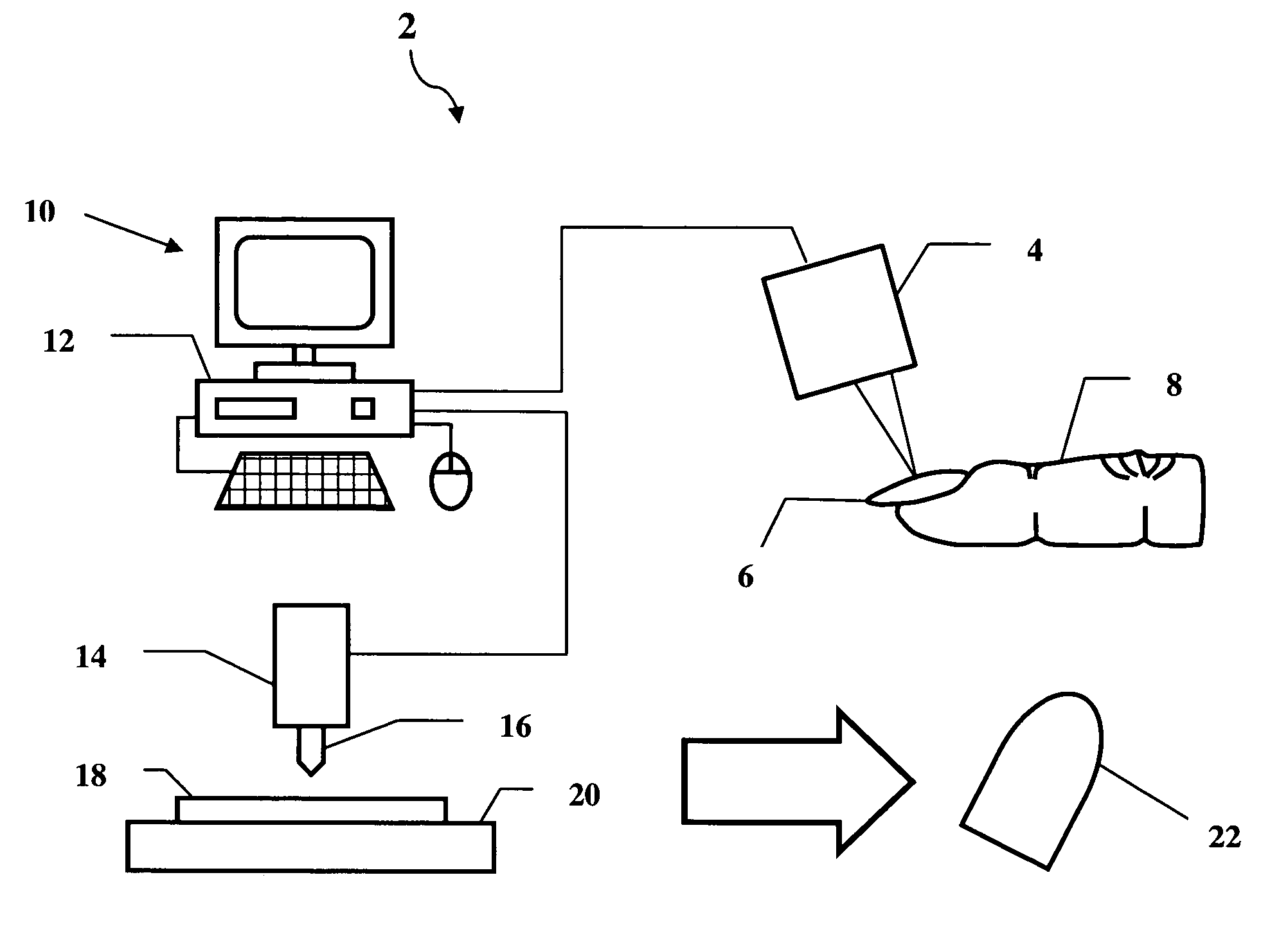

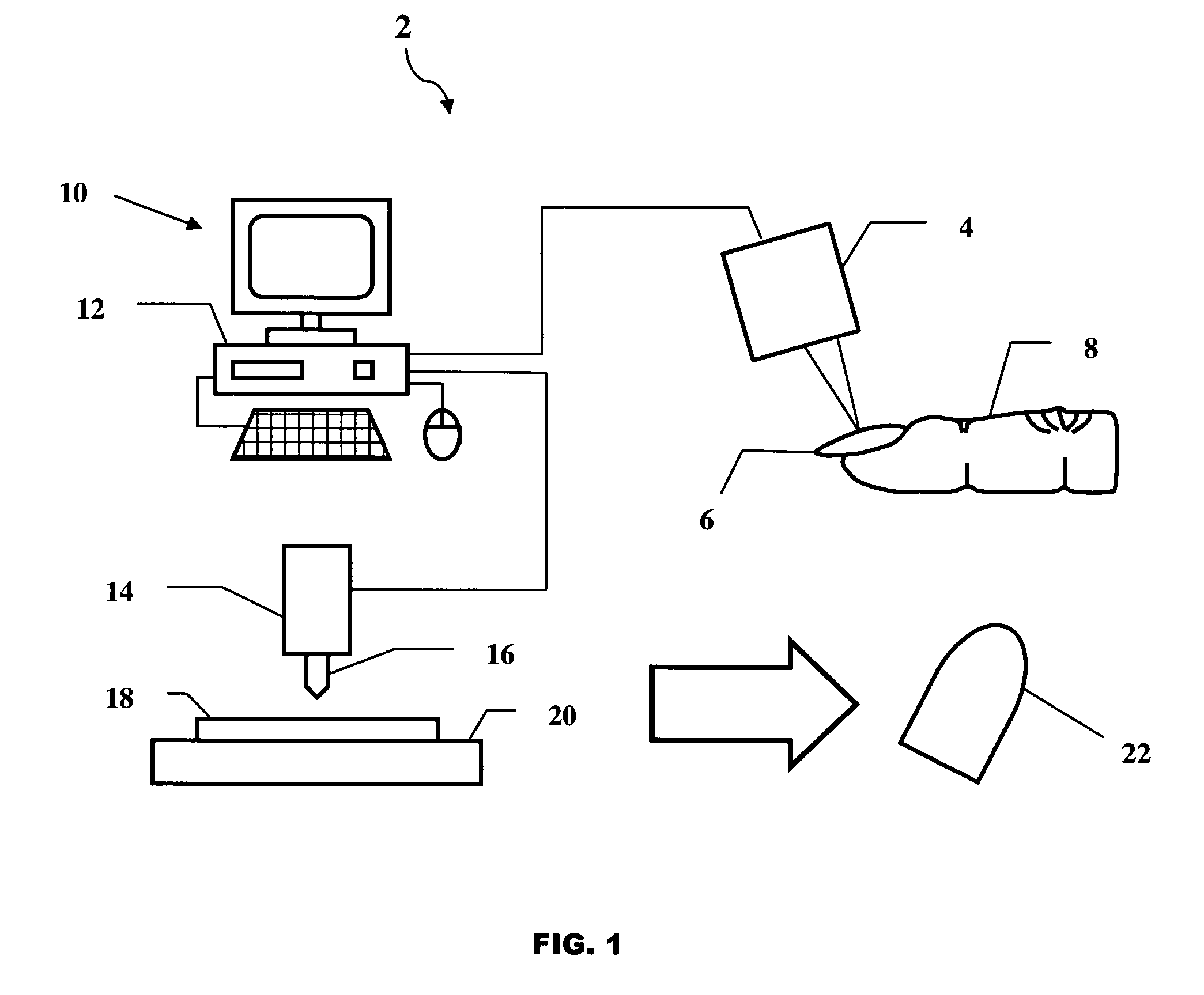

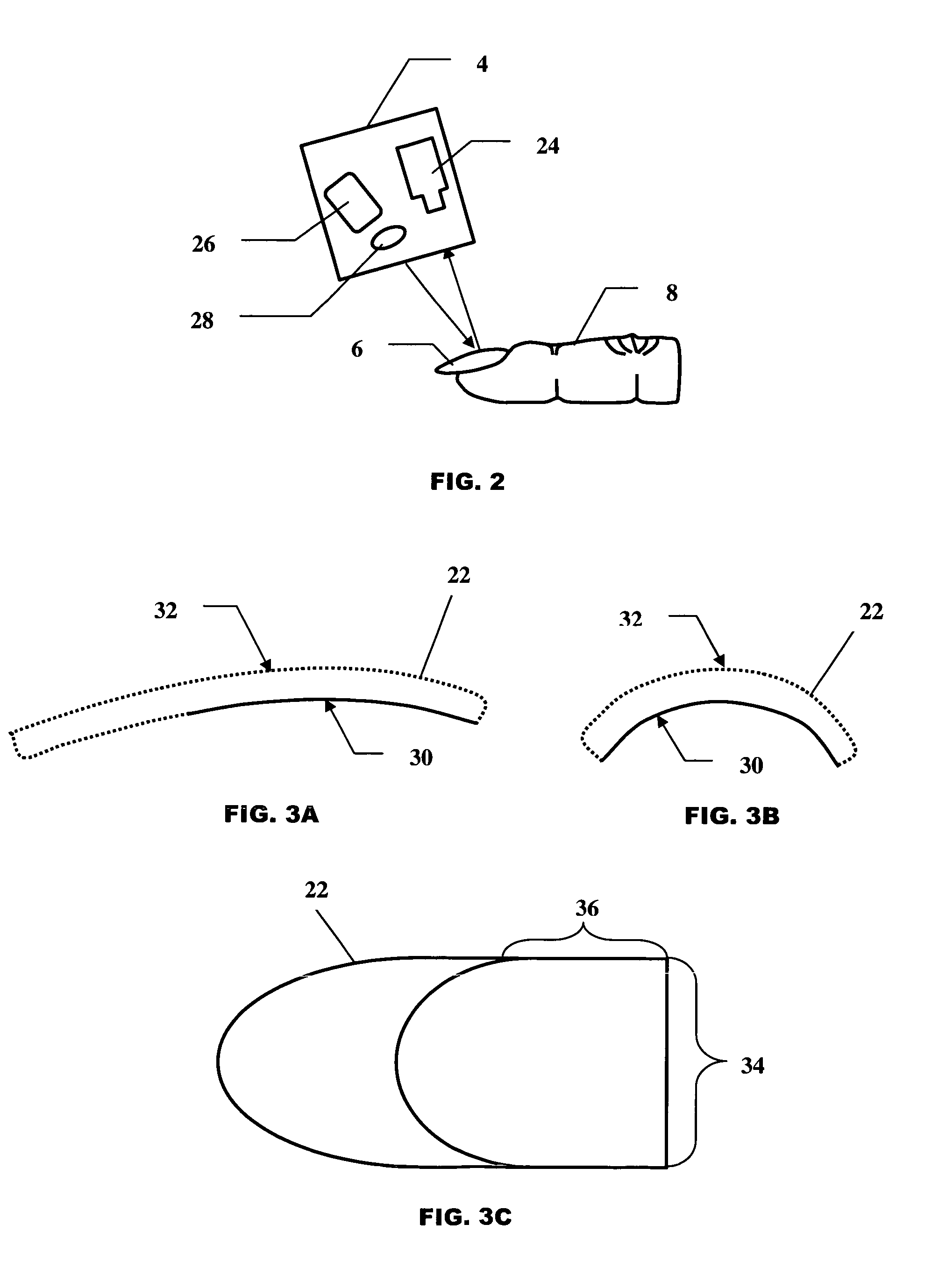

System and process for creating custom fit artificial fingernails using a non-contact optical measuring device

InactiveUS7123983B2Safe and convenient and accurate and rapidManicure/pedicureSpecial data processing applicationsThree dimensional shapeEngineering

A system and process for creating custom fit artificial fingernails using a non-contact measuring device is disclosed. A fingernail is measured for its topographical configuration by an optical non-contact measuring device. The measured topography of the fingernail is then used to direct a machining device to create an artificial fingernail. Also disclosed is a method to digitally design an artificial fingernail, which has a portion of its under surface fitted to the natural fingernail by using a special computer program. The three-dimensional shape information of the digitally designed artificial fingernail is then converted into machine codes to drive a computer numerical controllable device, which will then cut the artificial fingernail from a piece of raw material. Finally, the user selected nail art can be printed onto the artificial fingernail by using a nail art printing device.

Owner:MIIC AMERICA

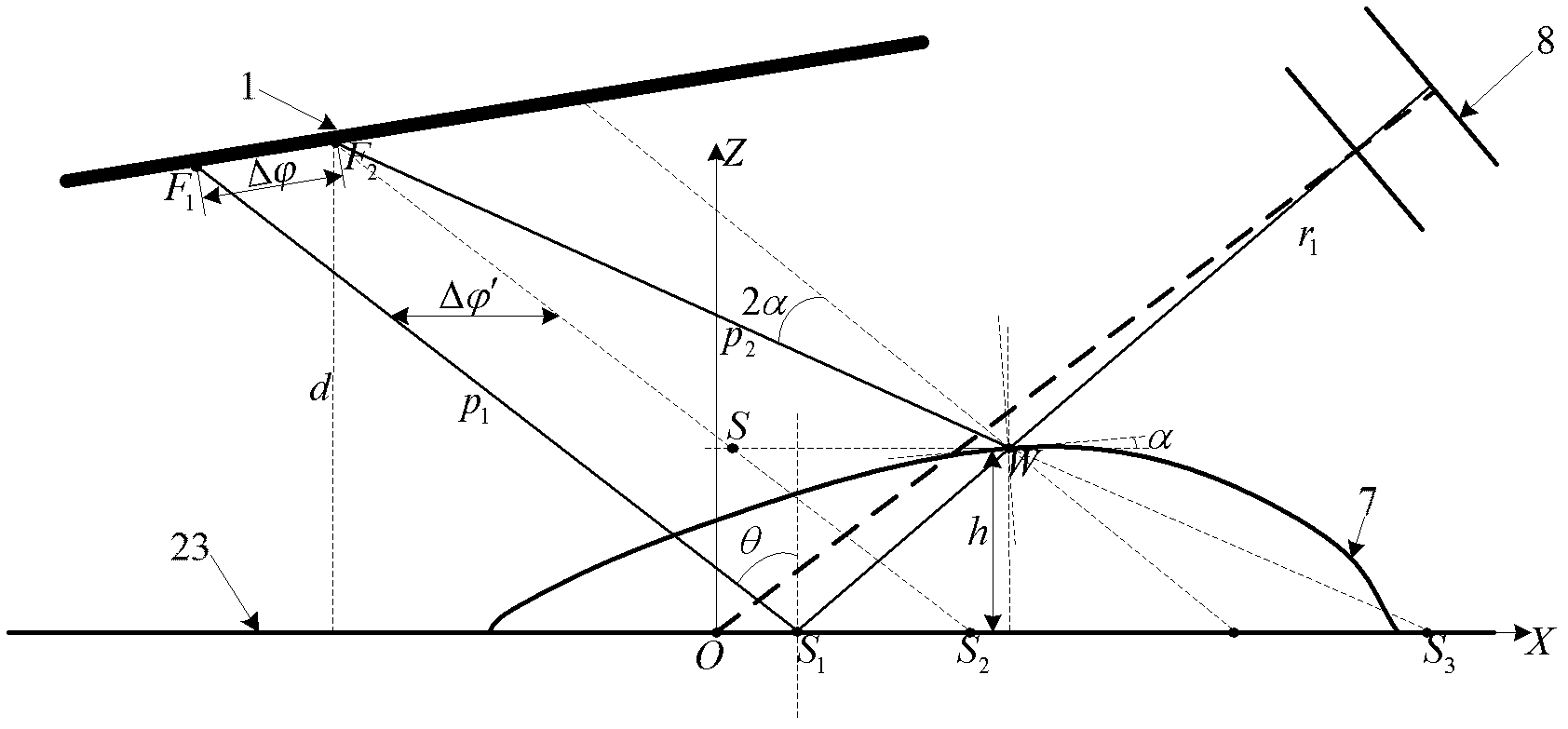

High-precision non-contact measurement method and device for three-dimensional profile of optical freeform curved surface

InactiveCN102305601AImprove detection accuracyImprove resolutionUsing optical meansGratingError separation

The invention relates to high-precision in-situ detection for complicated curved-surface parts with high-curvature surface form. In order to provide non-contact for the parts and detection for the surfaces of the parts, the invention provides the following technical scheme, namely a high-precision non-contact measurement method and a high-precision non-contact measurement device for a three-dimensional profile of an optical freeform curved surface. A grating projection device is used for projecting a sine grating stripe onto the surface of a measured object; an image acquisition device acquires a deformed stripe pattern modulated by the surface of the measured object and sends the deformed stripe pattern into a computer to recover the three-dimensional profile of the surface of the measured object; a white light scanning interference measuring head is used for scanning and measuring local characteristics of the measured object in nano-scale precision; a white light scanning image acquisition device acquires an interfered stripe pattern and sends the interfered stripe pattern into the computer to acquire data of the three-dimensional profile of a measurement region; and a result can be obtained according to data obtained by measurement of a grating projection vision detection unit and a white light scanning interference measurement unit through a multi-sensor massive data combination algorithm and corresponding error separation and compensation measures. The invention is mainly applied to the high-precision in-situ detection of the parts.

Owner:TIANJIN UNIV

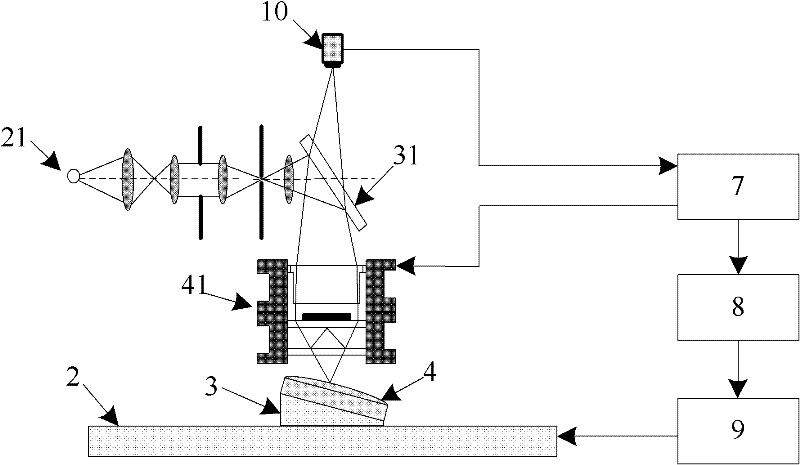

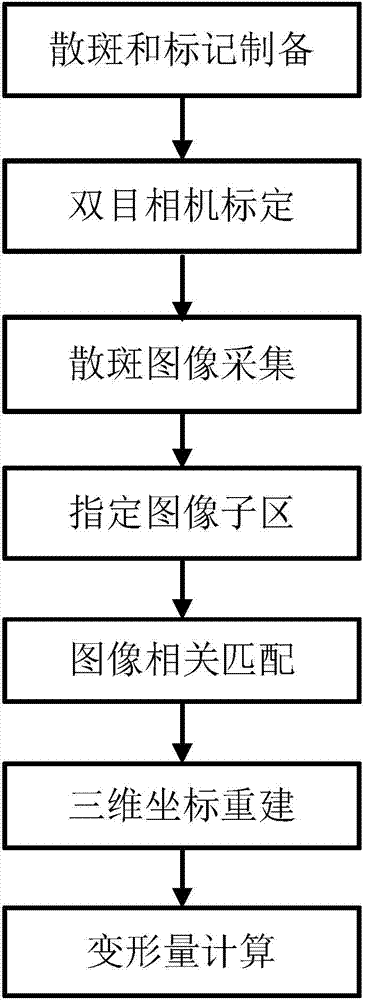

Vision extensometer implementation method based on digital speckles

ActiveCN103575227ASimple spraying workImprove measurement efficiencyUsing optical meansVisual perceptionImage acquisition

The invention discloses a vision extensometer implementation method based on digital speckles. The method includes the first step of speckle and mark making, the second step of binocular camera calibration, the third step of speckle image acquisition, the fourth step of image subarea specifying, the fifth step of image correlation matching, the sixth step of three-dimensional coordinate reconstruction and the seventh step of deformation calculation. Through the operating steps, the vision extensometer implementation method based on the digital speckles can be used for accurately measuring the deformation of materials in the tensile experiment process and has the advantages of being convenient to operate, capable of achieving non-contact measurement, accurate and reliable in measuring result and the like.

Owner:新拓三维技术(西安)有限公司

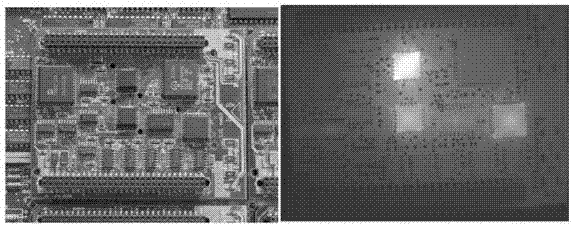

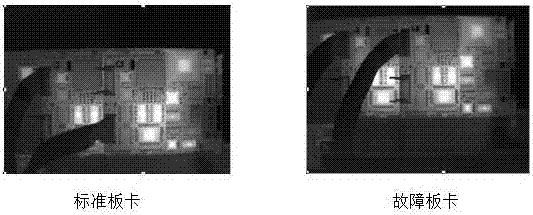

Circuit board fault infrared image automatic detection method

InactiveCN107025648AQuick registrationEffective registrationImage enhancementImage analysisThermal insulationPetrochemical

Disclosed is a circuit board fault infrared image automatic detection method. The image information of the working state of a circuit board is obtained by collecting a visible light image and an infrared image simultaneously. First, a visible light image and an infrared image of a circuit board working normally are collected and stored in a database. During detection of the circuit board which malfunctions, circuit board images (including a visible light image and an infrared image) taken are compared with the images under a normal state in the database, and a computer processes the images to find an area and a specific position where a component or line with abnormal temperature is located and automatically make a mark on the visible light image. Thus, automatic detection of a possible faulty component of the circuit board is completed. The technology can be applied to fields such as circuit board maintenance and equipment fault monitoring, and can also be applied to power equipment fault repair, petrochemical pipeline coke plugging, thermal insulation layer fall-off check, railway locomotive axle condition monitoring, fire prevention, flood control, disease prevention and other temperature change related non-contact measurement fields.

Owner:AIR FORCE UNIV PLA

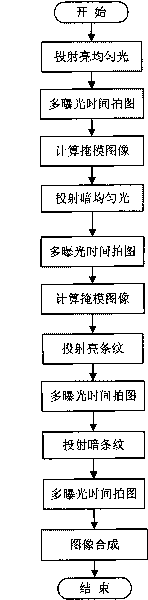

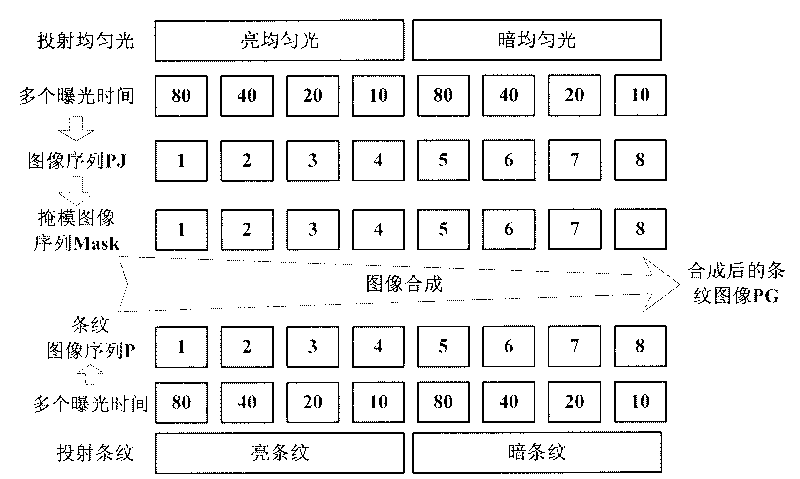

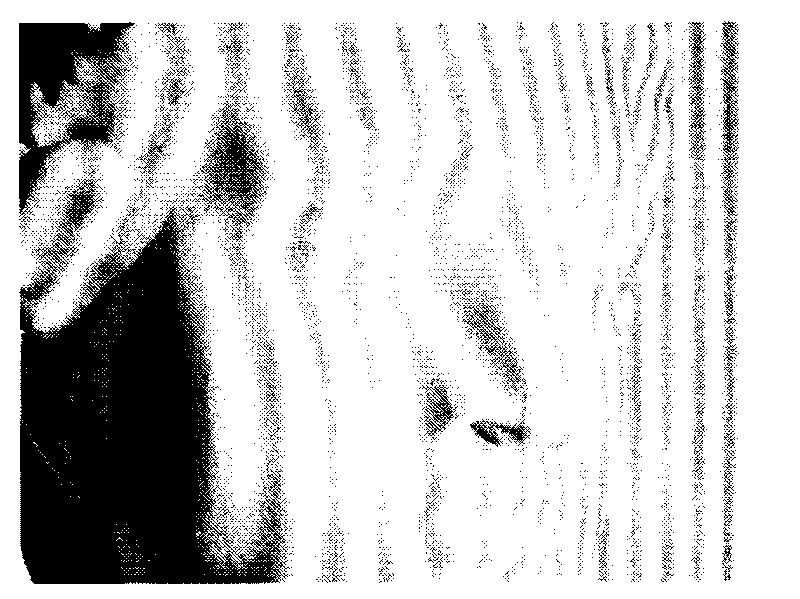

Stereoscopic vision detecting method for measuring three-dimensional morphology on strong reflection surface

InactiveCN101694375AGuaranteed measurement accuracySimple methodUsing optical meansThree dimensional morphologyStereo matching

A stereoscopic vision detecting method for measuring three-dimensional morphology on a strong reflection surface is provided. A traditional stereoscopic vision detecting method based on the sine stripe projection comprises steps of stripe projection, image collection, phase resolving, stereoscopic matching and three-dimensional recurrence, and the invention adds new technologies, such as bright-dark stripe projection, image collection in long exposure time, image synthesis within high dynamic range and the like in the steps of the strip projection and the image collection, which overcomes saturated or darker stripe images caused by the strong reflection surface, and can realize the non-contact optical measurement of three-dimensional morphology on the strong reflection surface such as metal. The detecting method has the characteristics of simpleness, flexibility and excellent reliability, and can be used for the optical non-contact measurement of three-dimensional morphology on the strong reflection surface such as metal.

Owner:BEIHANG UNIV

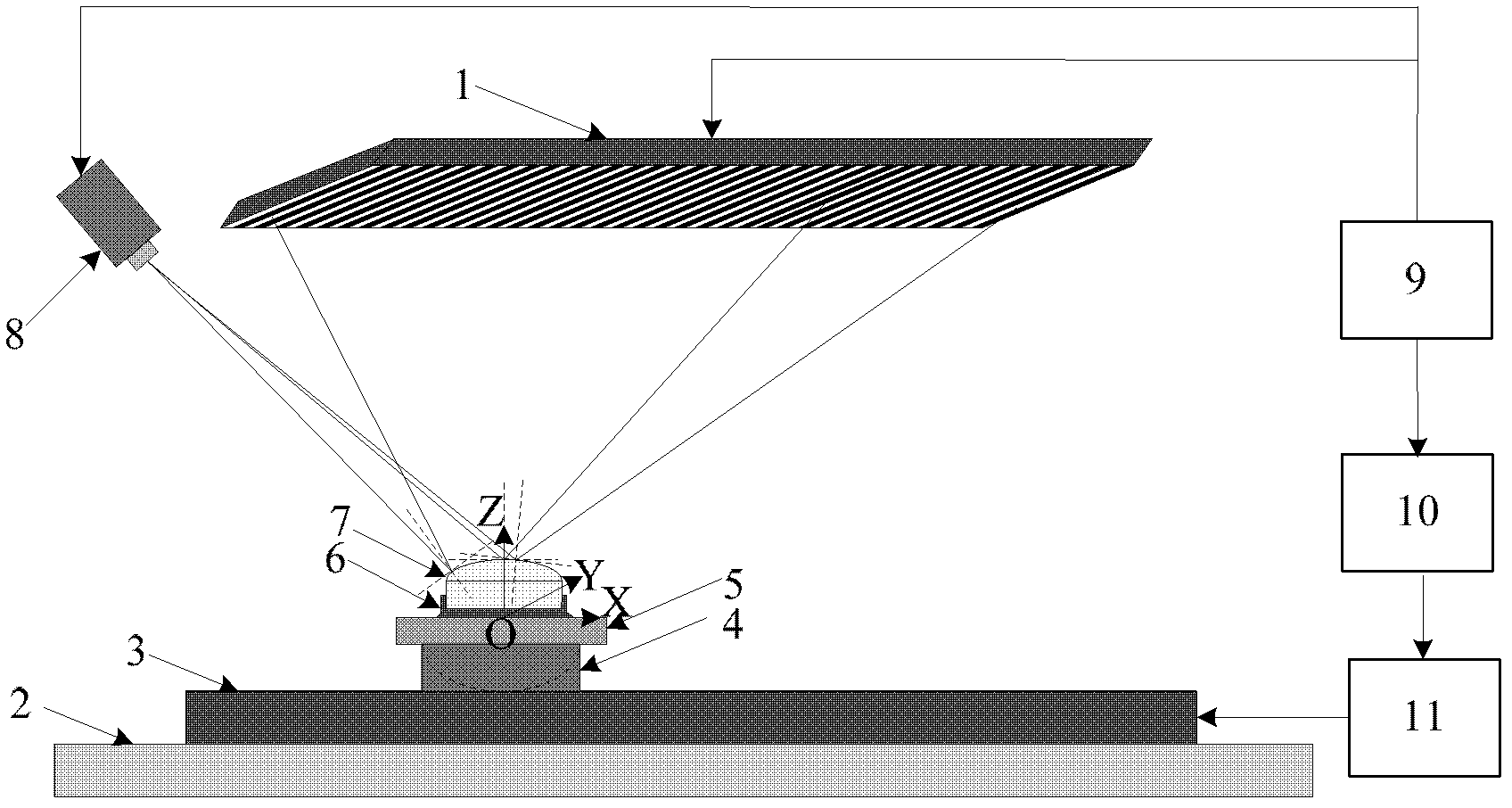

Grating projection rapid non-contact measurement method and device for high-reflectance free-form curved-surface parts

The invention relates to high-precision detection of complex optical curved-surface parts with large-curvature surface shapes, and aims to provide a high-precision detection method for the complex curved-surface parts with large curvature surface shapes, such as optical curved-surface parts, which has the advantages of rapidity, non-contact and no damage to part surfaces and surface layers. The technical scheme adopted by the invention is that the invention provides a grating projection rapid non-contact measurement method and device for high-reflectance free-form curved-surface parts, and the method comprises the following steps that: three degree-of-freedom motion of a measured object is realized with the help of a precision motion control system; coded grating fringes are projected onto the surface of the measured object by using a grating projection device; phase distribution information of the surface of the measured object is obtained from a deformed fringe pattern by using a digital phase shifting technology and a phase unwrapping algorithm; reference phase distribution information is obtained by using a virtual reference surface technology; and three-dimensional morphological information of a measuring area of the surface of the measured object is recovered according to a corresponding relation between phase deviation information and the gradient of the surface of the measured object. The grating projection rapid non-contact measurement method and device are mainly applied to the measurement of the optical curved-surface parts.

Owner:TIANJIN UNIV

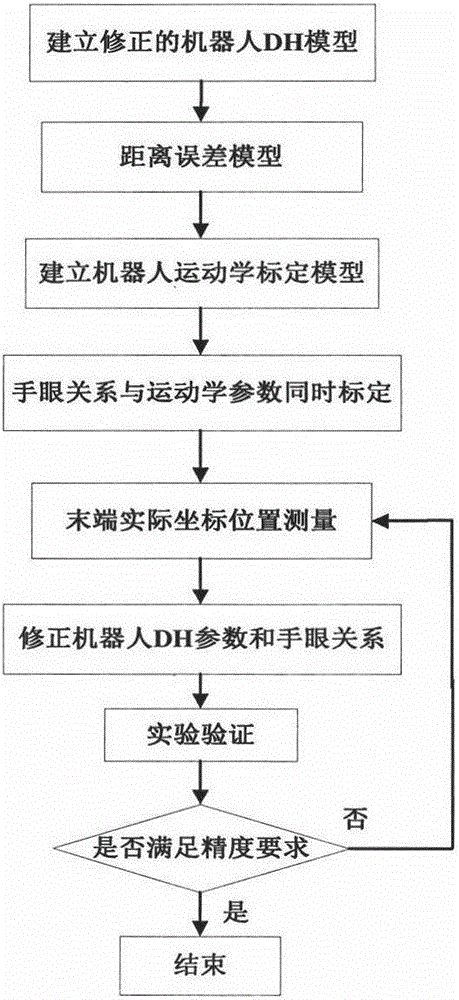

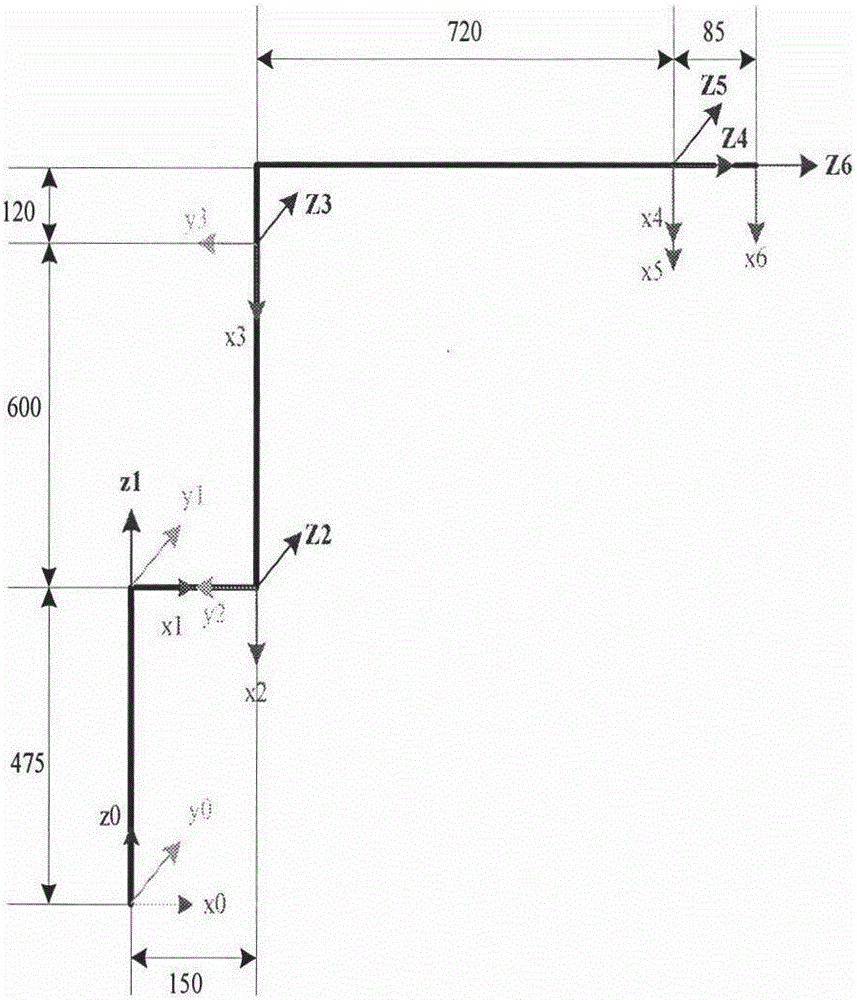

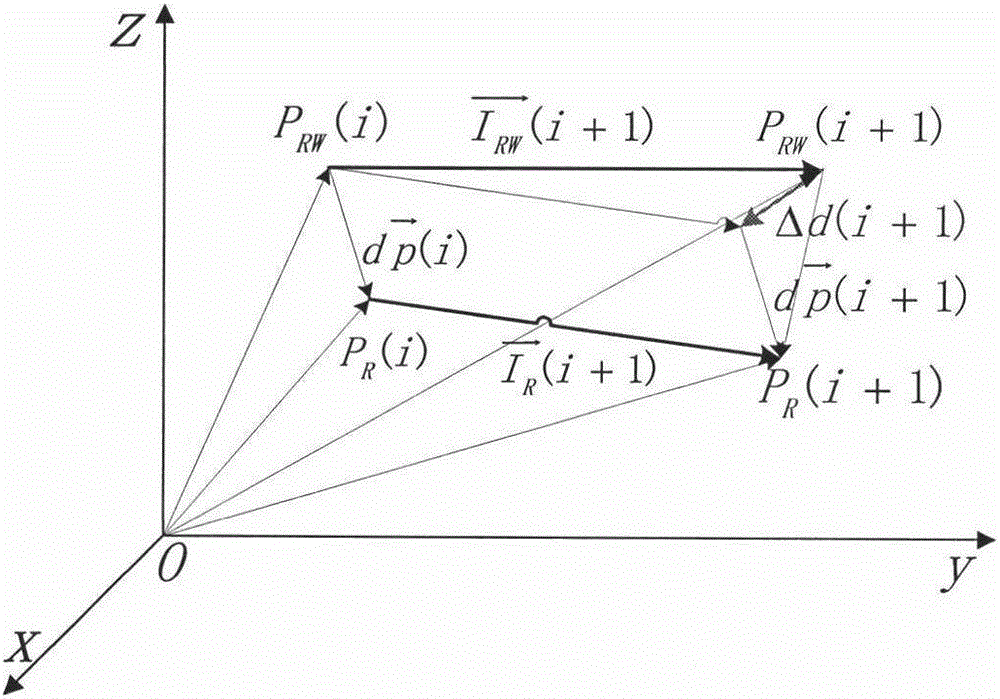

Robot kinematics calibration method based on vision measurement and distance error model

InactiveCN105773609ASimple kinematic calibration methodKinematic calibration method is practicalProgramme-controlled manipulatorKinematicsSimulation

The invention discloses a robot kinematics calibration method based on vision measurement and a distance error model. The method includes the steps that a corrected robot D-H model is established; the distance error model is established; a robot kinematics calibration model is established; simultaneous calibration of a hand-eye relation and kinematics parameters is performed; measurement of an actual coordinate position of a tail end is performed; robot D-H parameters are corrected; and experimental verification is conducted. The robot kinematics calibration method based on vision measurement and the distance error model and provided by the invention has the advantages of being simple, efficient and fast; a non-contact measurement mode of vision detection is adopted; meanwhile, repetitive errors of hand-eye calibration are considered, and the calibration model is simplified through a mode of an equidistance model; and accordingly, the positioning precision and distance precision of an industrial robot can be greatly improved, the robot kinematics calibration method is universally suitable for series connection joint-type robots, and certain practical significance is achieved.

Owner:NANJING UNIV OF TECH

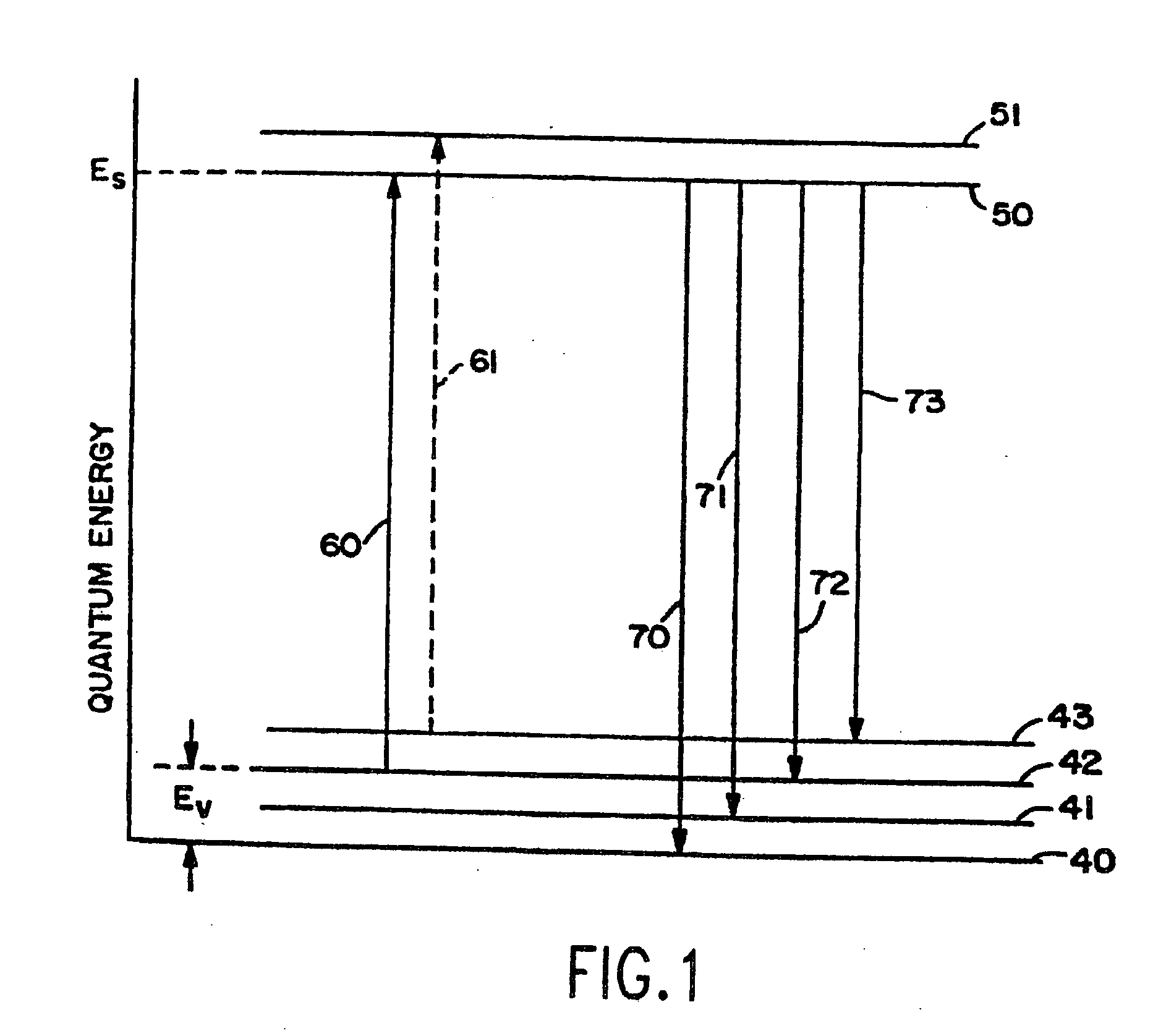

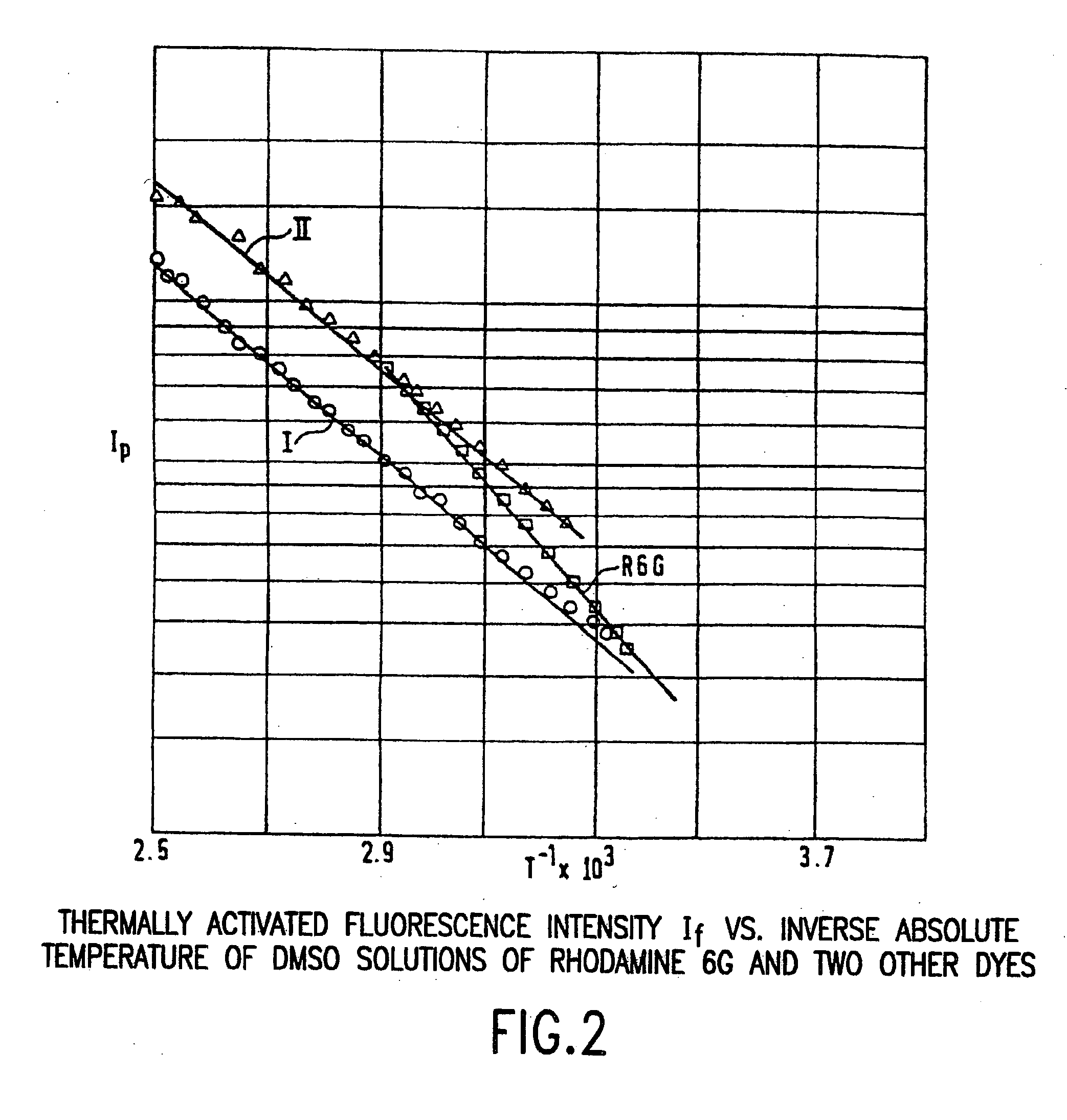

Optical detectors for infrared, sub-millimeter and high energy radiation

InactiveUS20060214113A1Reduce the total massSimpler and less-costlyRadiation pyrometryPhotometryHigh energyGram

Optical methods and devices for the thermal detection and imaging of infrared, sub-millimeter, millimeter and high energy radiation, wherein the thermal mass of the detector is minimized by the use of microscopic photoluminescent temperature probes having a weight mass which can be of the order of 10−11 grams or smaller. Used for detection of high energy radiation, including quantum calorimetry, said temperature probes allow non-contact measurements free of electrical sources of noise like Johnson noise or Joule heating.

Owner:KLEINERMAN MARCOS Y

Mobile communication device with electromagnetic radiation sensors

InactiveUS8825112B1Easy to aimTelevision system detailsTelevision system scanning detailsHand heldUltraviolet

A hand-held mobile communication device, such as smart telephone, alone or in protective case, incorporating sensors and signal conditioning modules for measuring signals from external sources of electromagnetic radiation (EMR) in different spectral ranges. These include detector monitoring EMR that pose potential health hazards or may interfere with various electronic devices. Other integrated EMR sensor is a photodiode for the ultraviolet detection to monitor the user's sun exposure and a thermal infrared detector for non-contact measurement of temperature of humans or inanimate objects. This detector in combination with a digital camera and a pattern recognition signal processing allows accurate non-contact measuring temperatures at specific location.

Owner:PATENT ARMORY INC

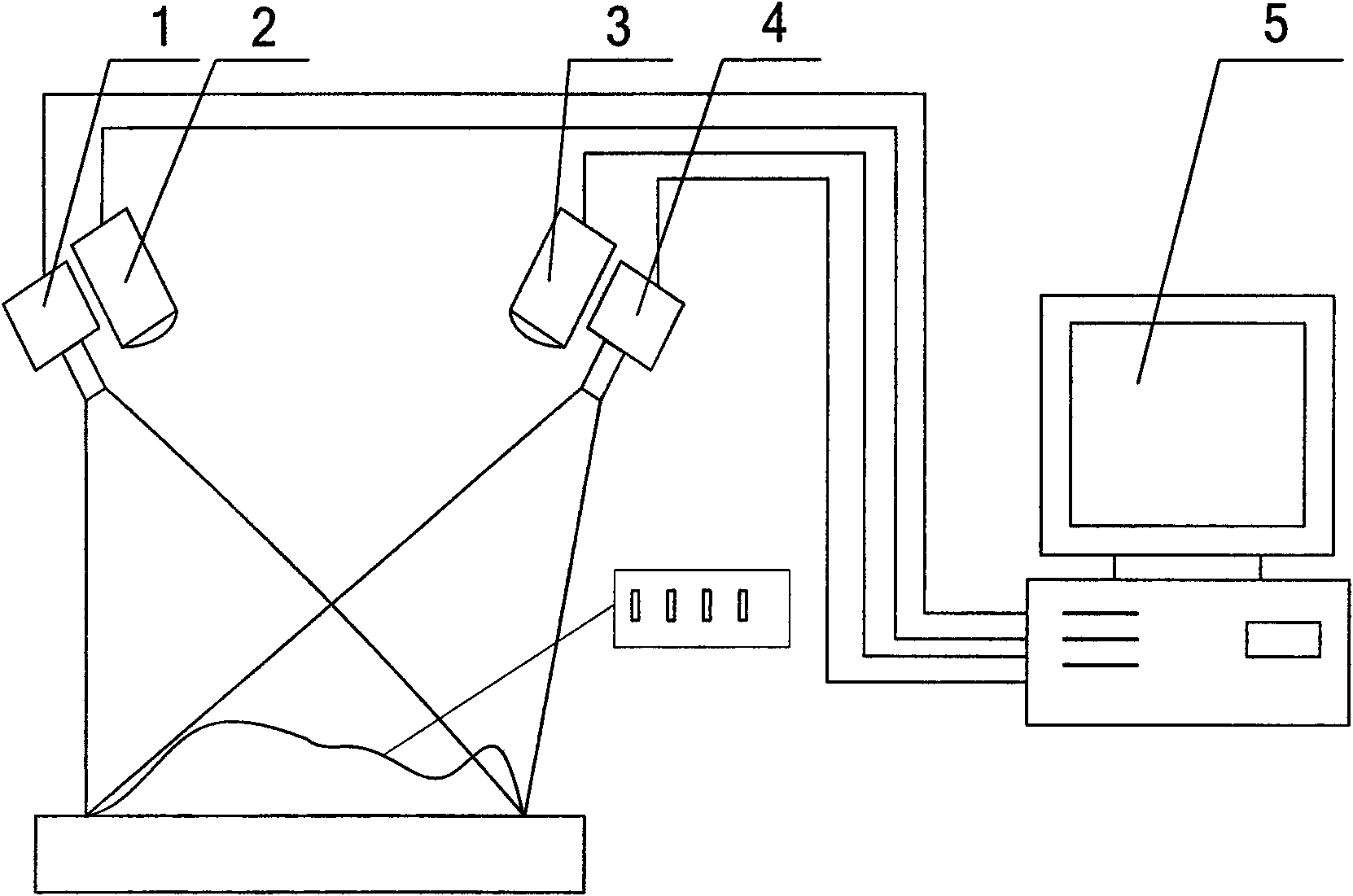

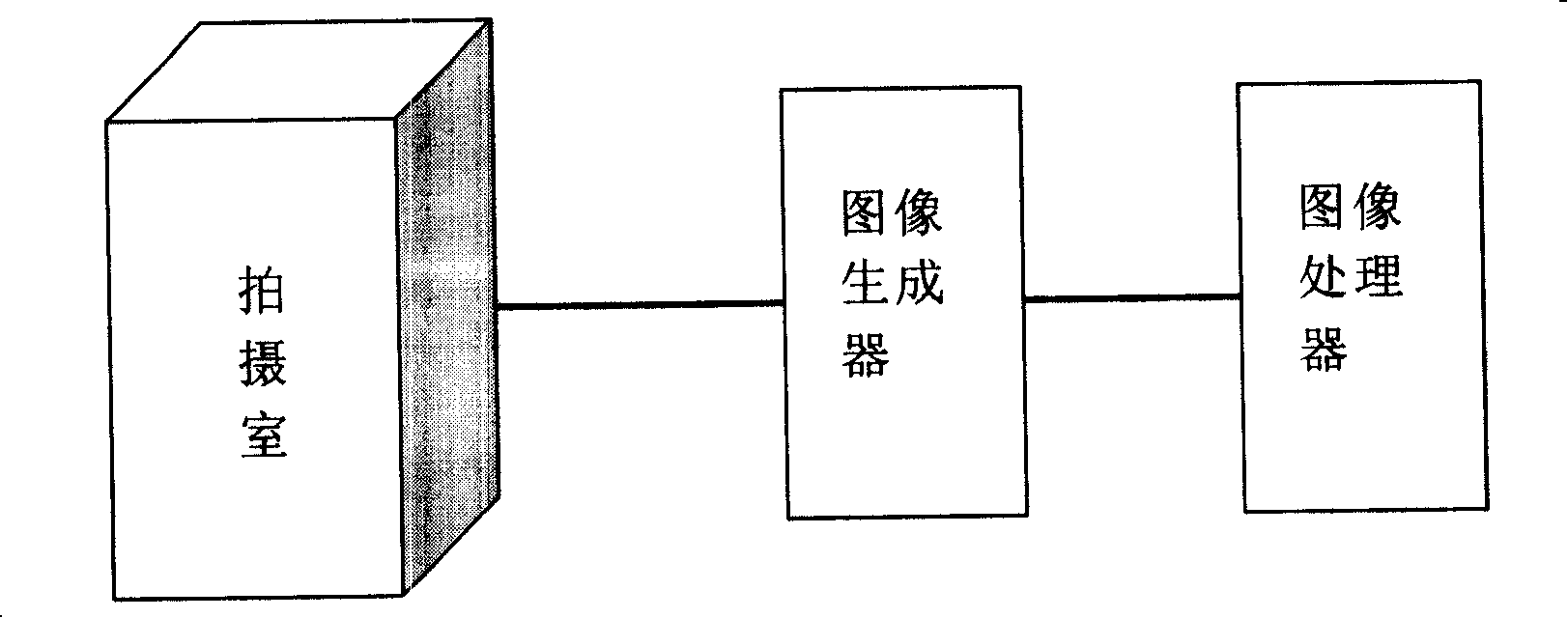

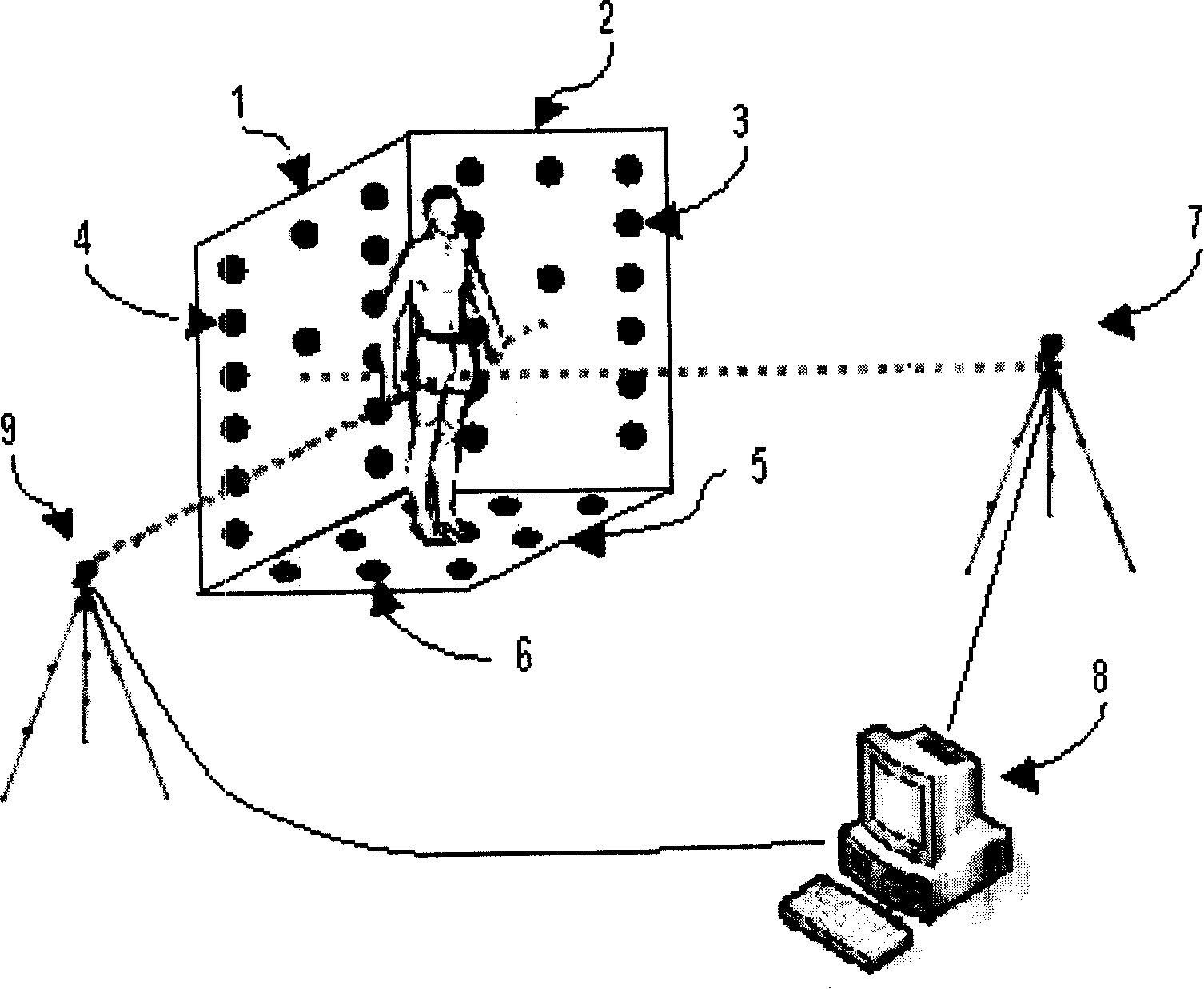

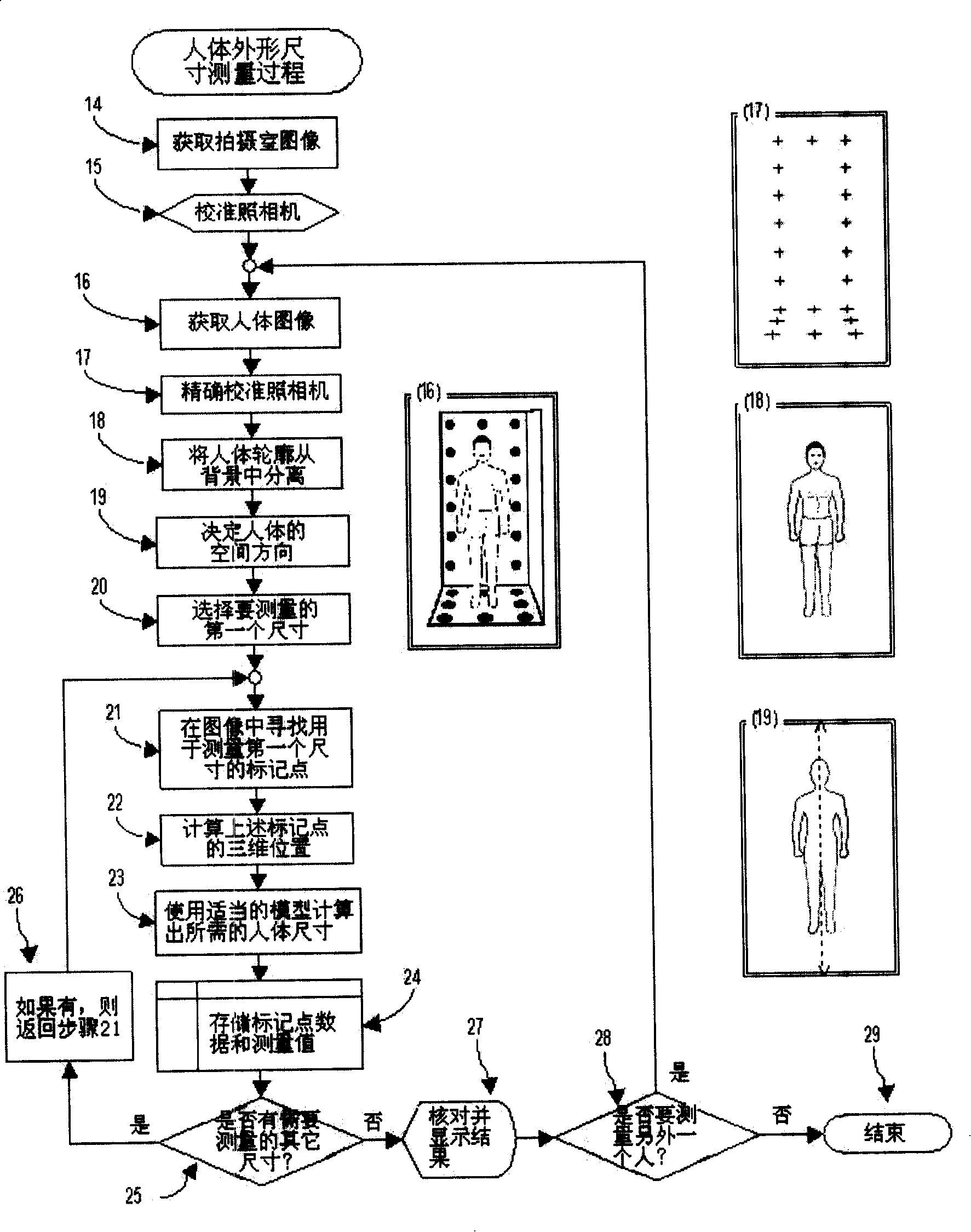

Non-contact measurement method and system for human outside measurement

InactiveCN101228973AAvoid the hassle of separate processingReduce complexityDiagnostic recording/measuringSensorsHuman bodyState of art

The invention provides a measurement method of automatically acquiring outline dimension of human body by shooting human body image with an image acquisition device and analyzing the image through specific algorithm, and relates to a measurement system for implementing the non-contact measuring method. In the invention, a human body is in a shooting room, a two-dimensional image of the human body is acquired by an image generator, and the image generator processes the two-dimensional image, generates three-dimensional characteristic points of the human body and eventually calculates the needed human body figure data according to the three-dimensional characteristic points of the human body. Compared with the prior art, the invention directly arranges the marking points for calibrating on a background wall, processes specific algorithm by means of designing a large amount of images and provides a technical proposal that can realize fully automatic physical measurement of the human body, thereby significantly simplifying complicacy of the device and the operation and increasing the consistency and accuracy of the measurement.

Owner:因美吉智能科技(济南)有限公司

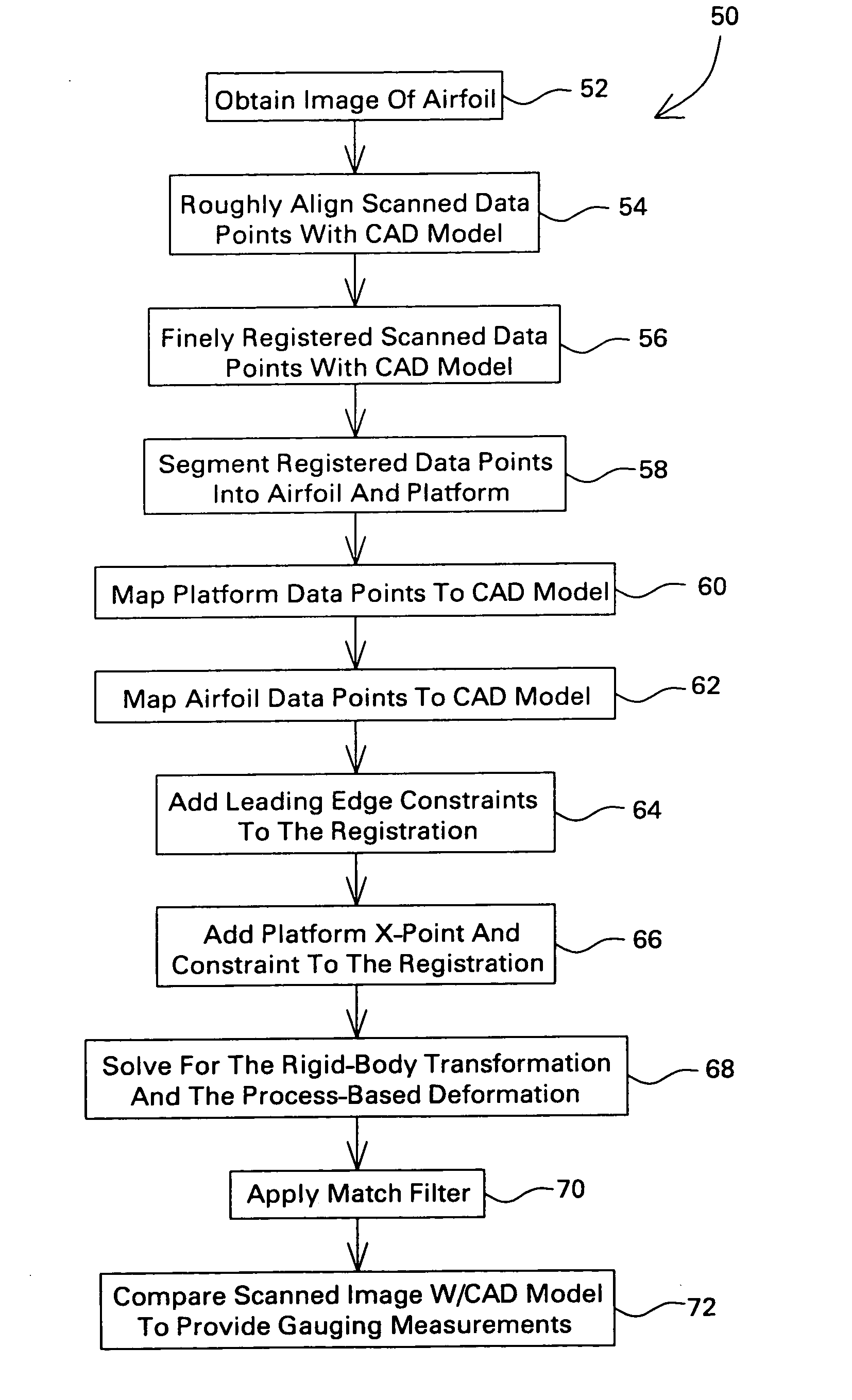

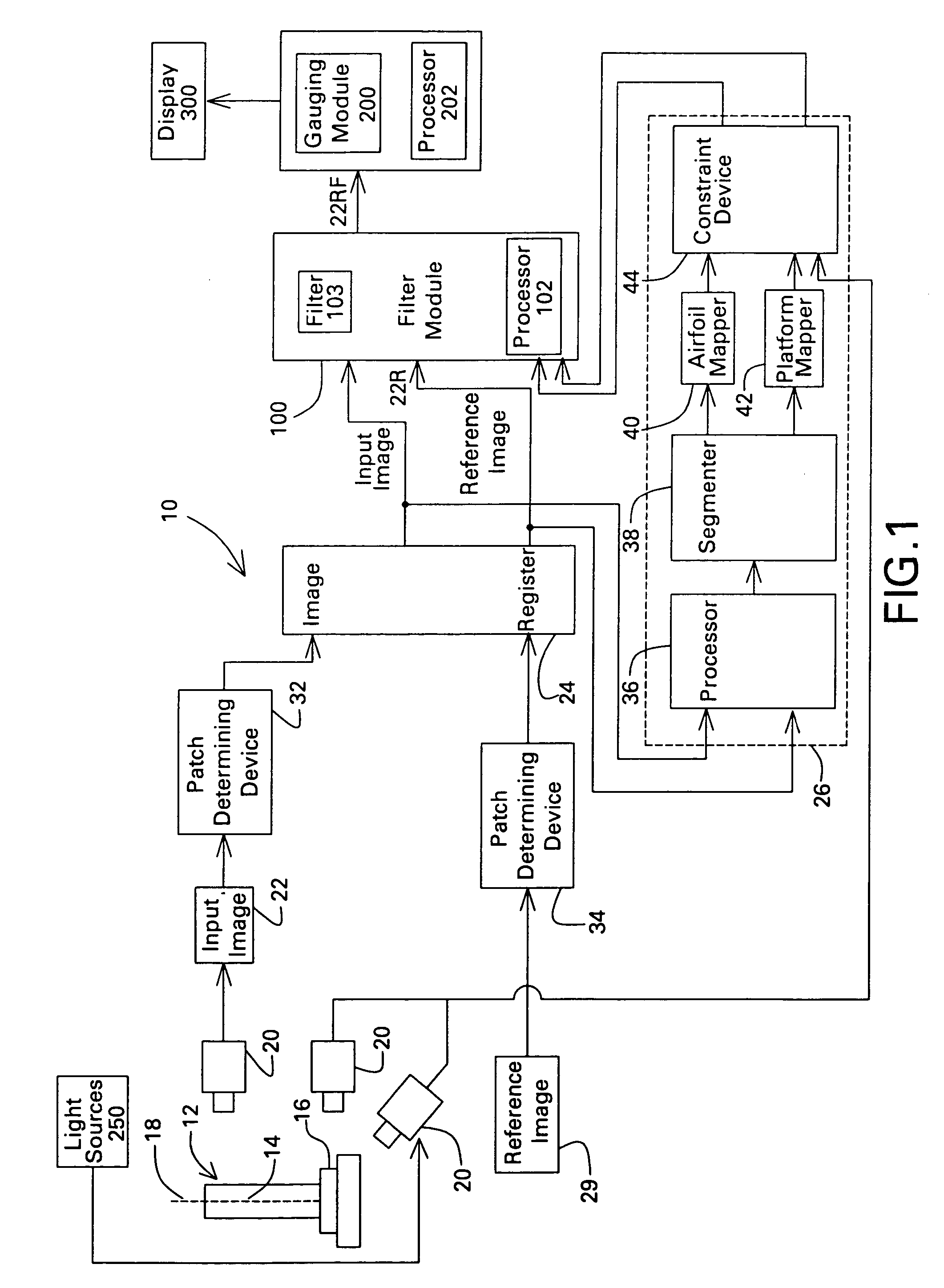

Non-contact measurement method and apparatus

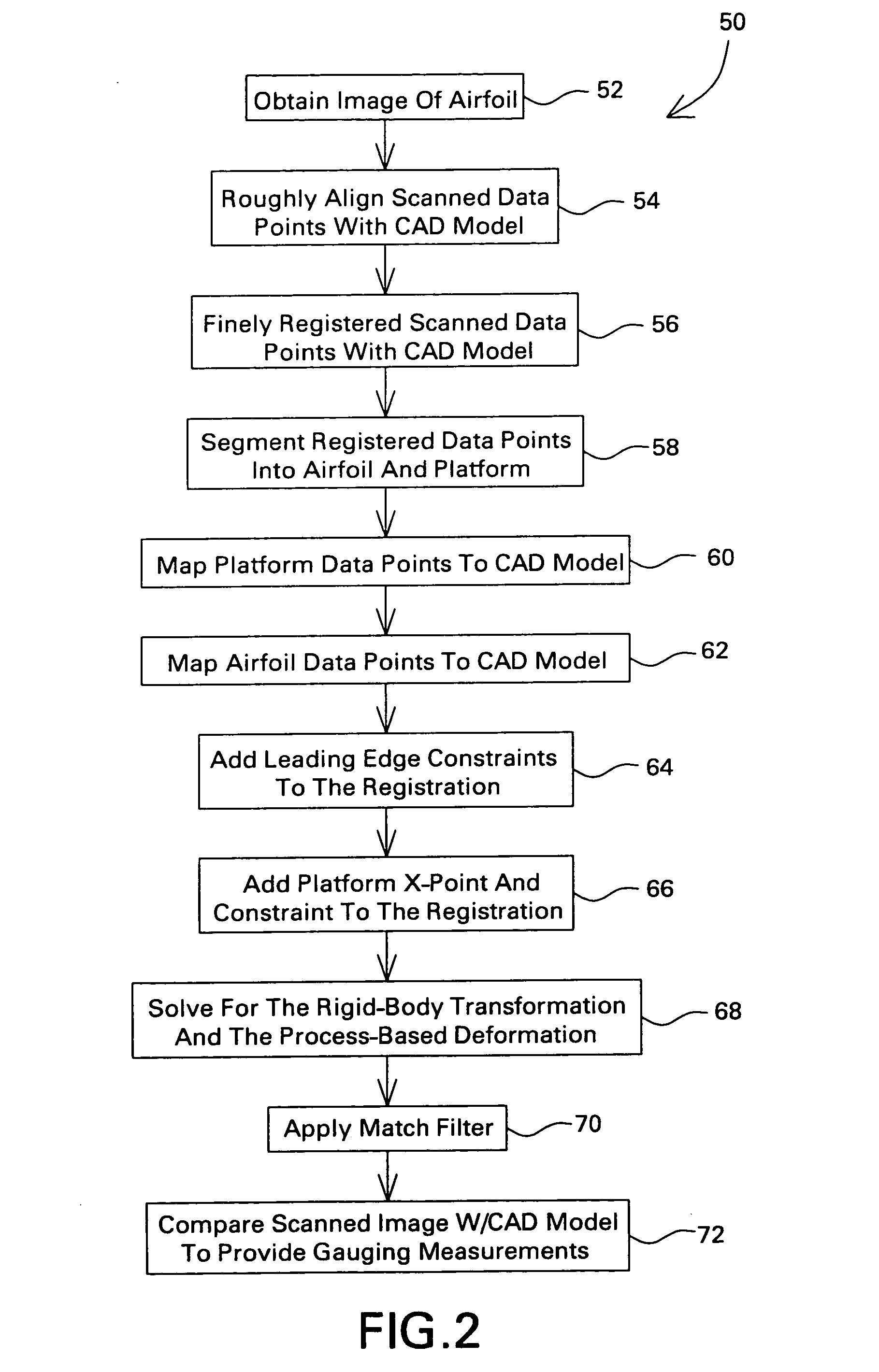

InactiveUS20050201611A1Reduce noiseImprove accuracyImage enhancementBlade accessoriesPrior informationReference image

A non-contact imaging apparatus for examining an object having complex surfaces or shape deformations. The imaging apparatus includes at least one imaging device for obtaining a scanned image of the exterior surfaces of the object being examined. A predetermined reference image) of an ideal model for the object is stored in a memory. An image register is coupled to the imaging device and to the memory containing the reference image of the ideal model for the object. A transformation estimator compares the scanned image to the reference image and provides a transform which maps the scanned image to the reference image and provides a set of registered object data points. One or more filter modules process the registered object data points with a priori information to reduce noise and to further enhance the accuracy and precision of the registration. A gauge estimator is coupled to the filter module. The gauge estimator utilizes the processed and registered object data to determine deformation parameters of the object, which are then displayed to an operator as gauging information.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com