Circuit board fault infrared image automatic detection method

An infrared image, automatic detection technology, applied in the field of infrared imaging, can solve the problems of poor image quality, high difficulty, low recognition and positioning accuracy, etc., and achieve the effect of high-precision infrared image registration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

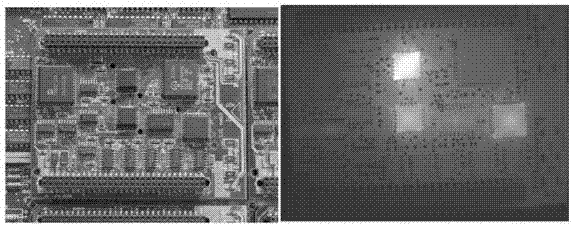

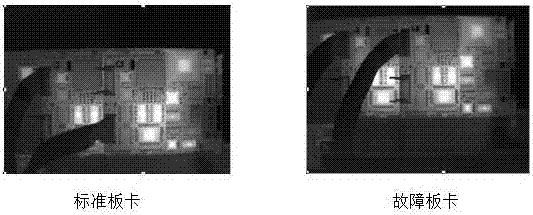

[0105] Check the circuit board of a certain equipment as follows: Figures 17-20 shown.

[0106] Table 1 Temperature analysis of the abnormal working area of the modulator card

[0107] normal board temperature Faulty board temperature Temperature difference area 1 38.6 58.1 19.5 area 2 48.1 41.7 -6.4 area 3 42.0 52.5 10.5

[0108] (1) Area 1 analysis:

[0109] Table 2 Zone 1 temperature analysis

[0110] normal board temperature Faulty board temperature Temperature difference 39.2 56.6 38.3 56.9 38.4 60.8 average 38.6 58.1 19.5

[0111] (2) Area 2 analysis:

[0112] Table 3 Zone 2 temperature analysis

[0113] normal board temperature Faulty board temperature average temperature difference 46.5 41.5 47.3 40.9 49.3 41.6 average 48.1 41.7 -6.4

[0114] (3) Area 3 analysis:

[0115] Table 4 Zone 3 temperature analysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com