Patents

Literature

2264 results about "Energy distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Distribution of Energy The distribution of a fixed amount of energy among a number of identical particles depends upon the density of available energy states and the probability that a given state will be occupied.

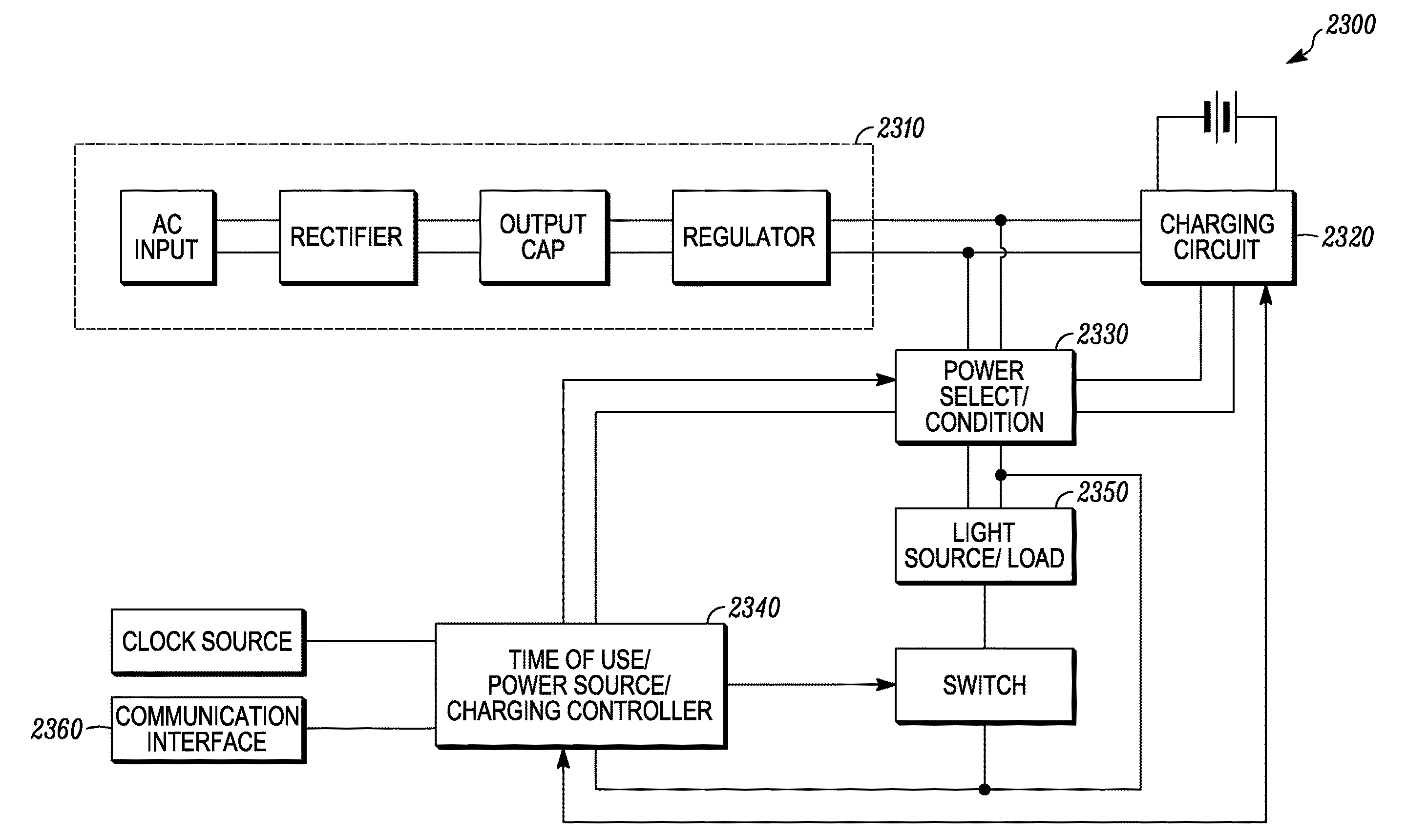

Autonomous grid shifting lighting device

InactiveUS20110133655A1Advantage in easeLow costElectroluminescent light sourcesSemiconductor lamp usageElectricityEffect light

In embodiments of the present invention improved capabilities are described for autonomous shifting of at least a portion of a lighting load off an energy distribution grid, comprising electrically connecting a lighting device to the energy distribution grid; causing the lighting device to interpret information obtained from an information source proximate the lighting device; and causing the lighting device to select from at least two different power sources based on the interpretation, where selecting may include a sharing of the load between the two different power sources, and where one power source may be the energy distribution grid.

Owner:RING LLC

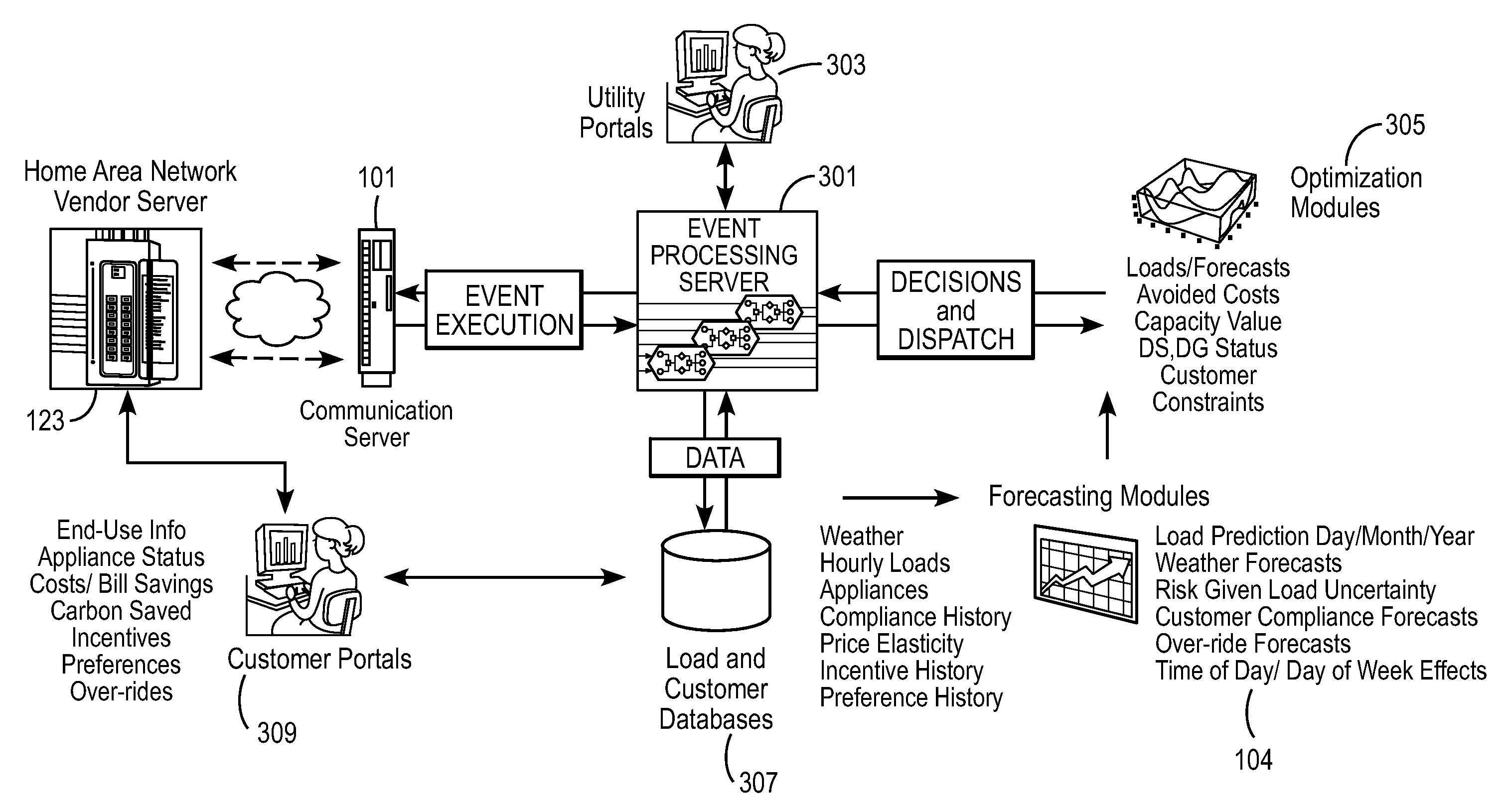

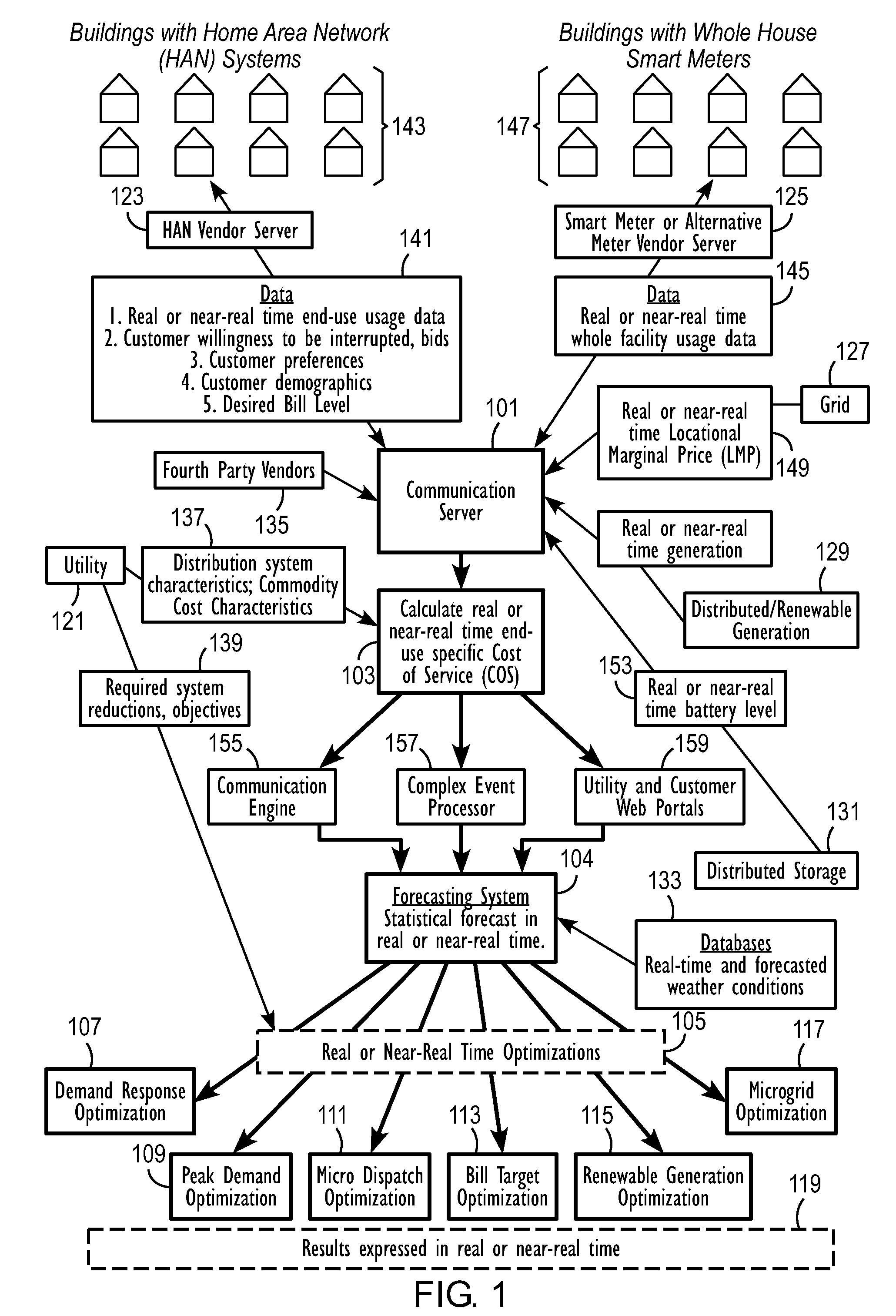

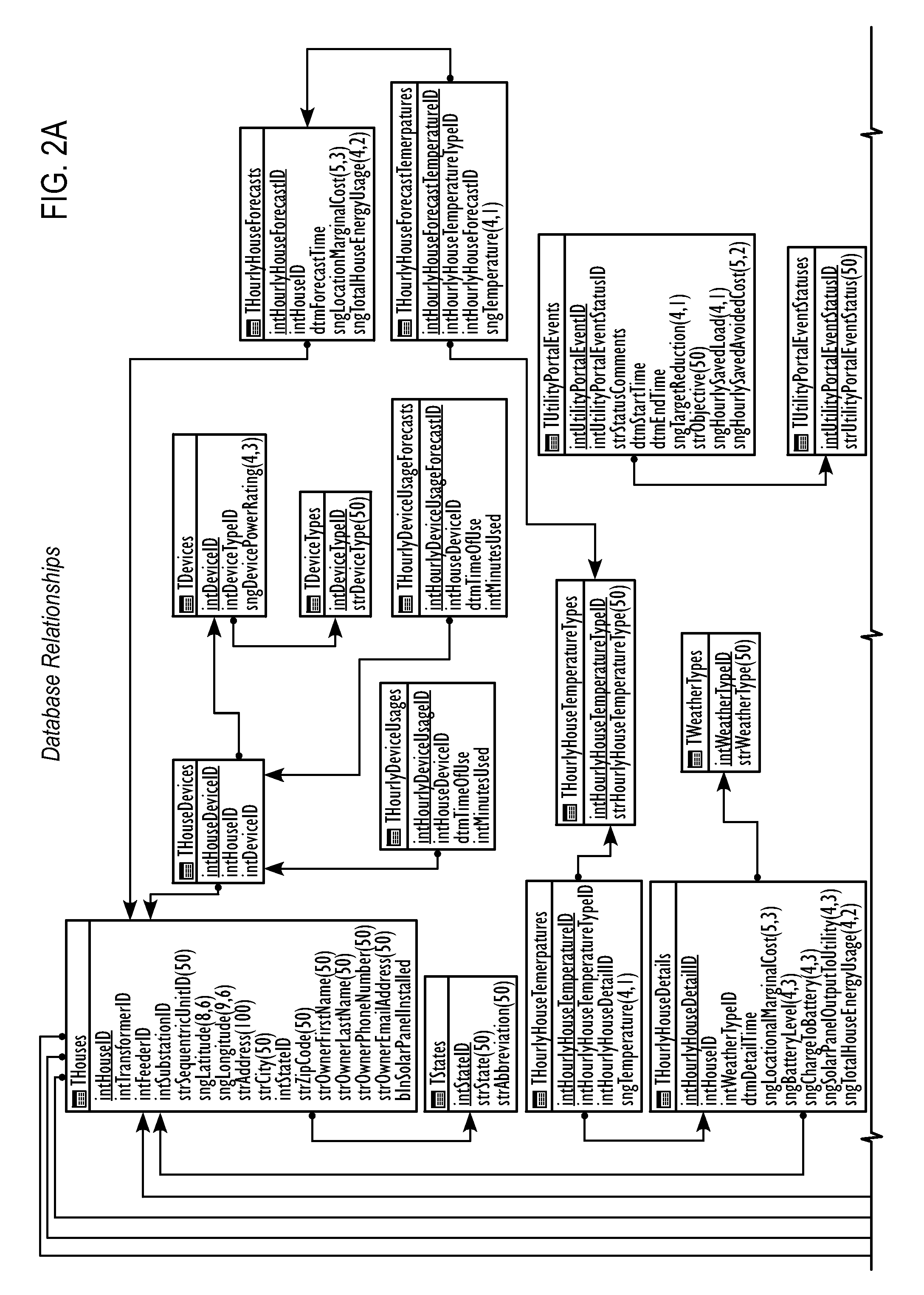

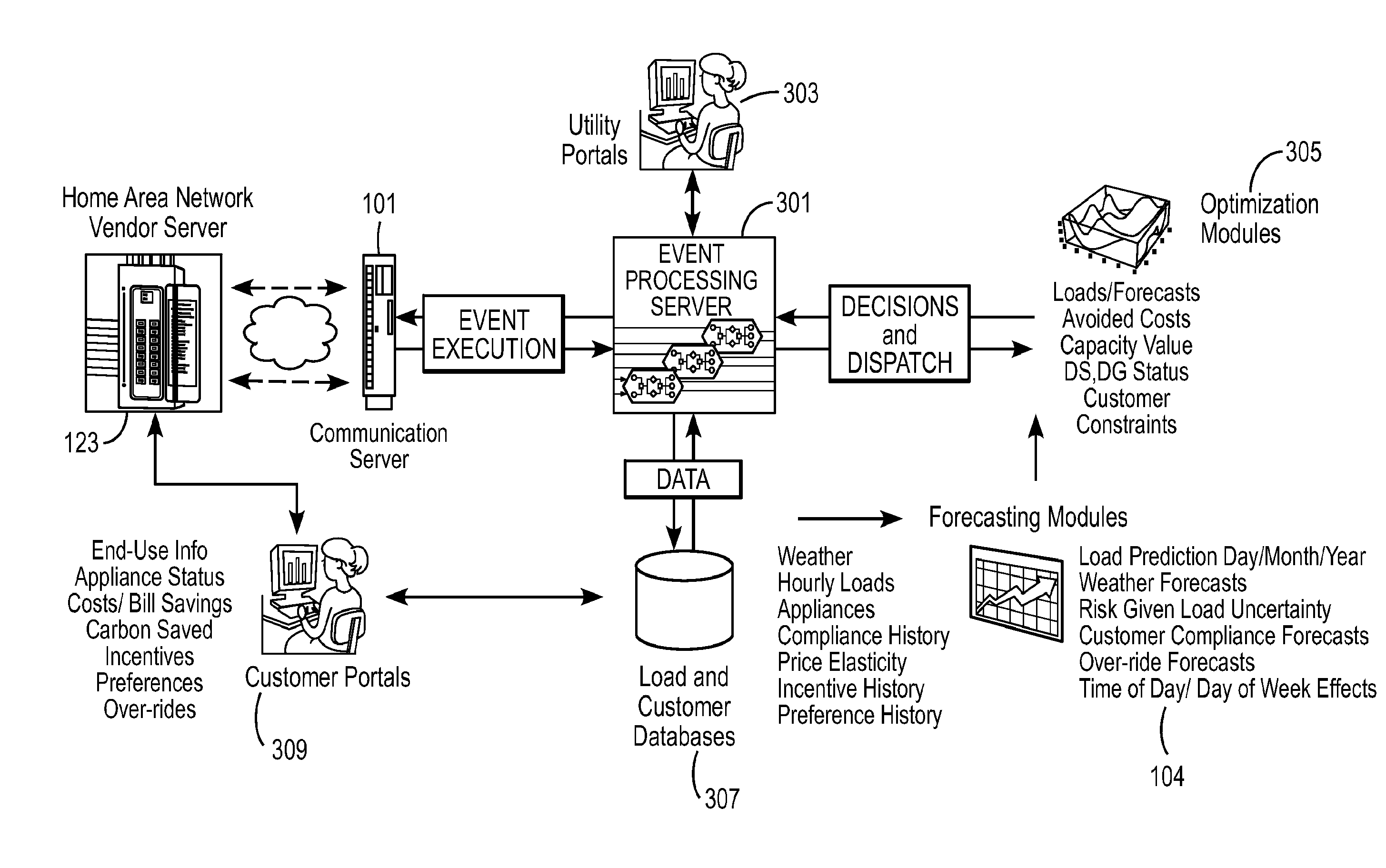

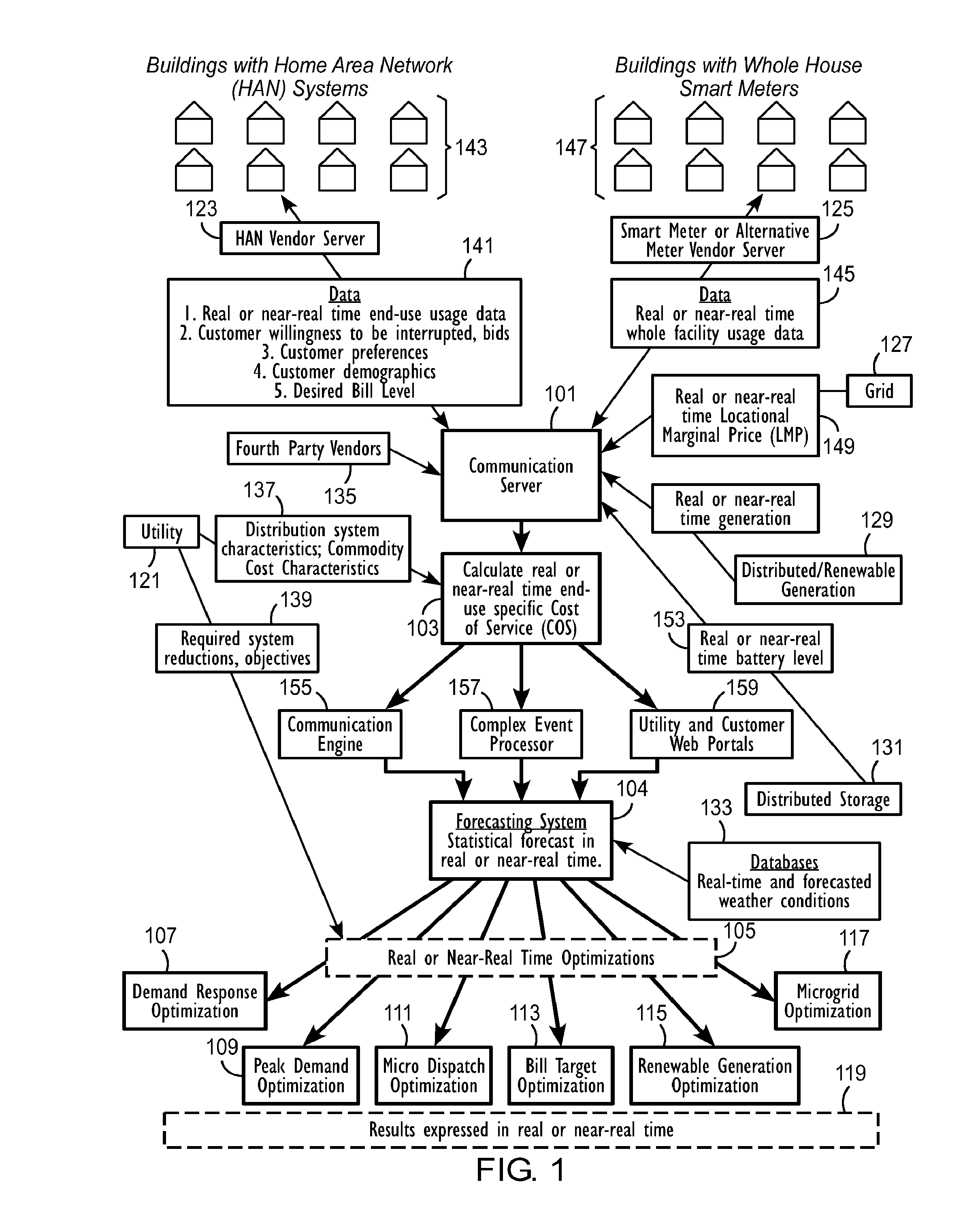

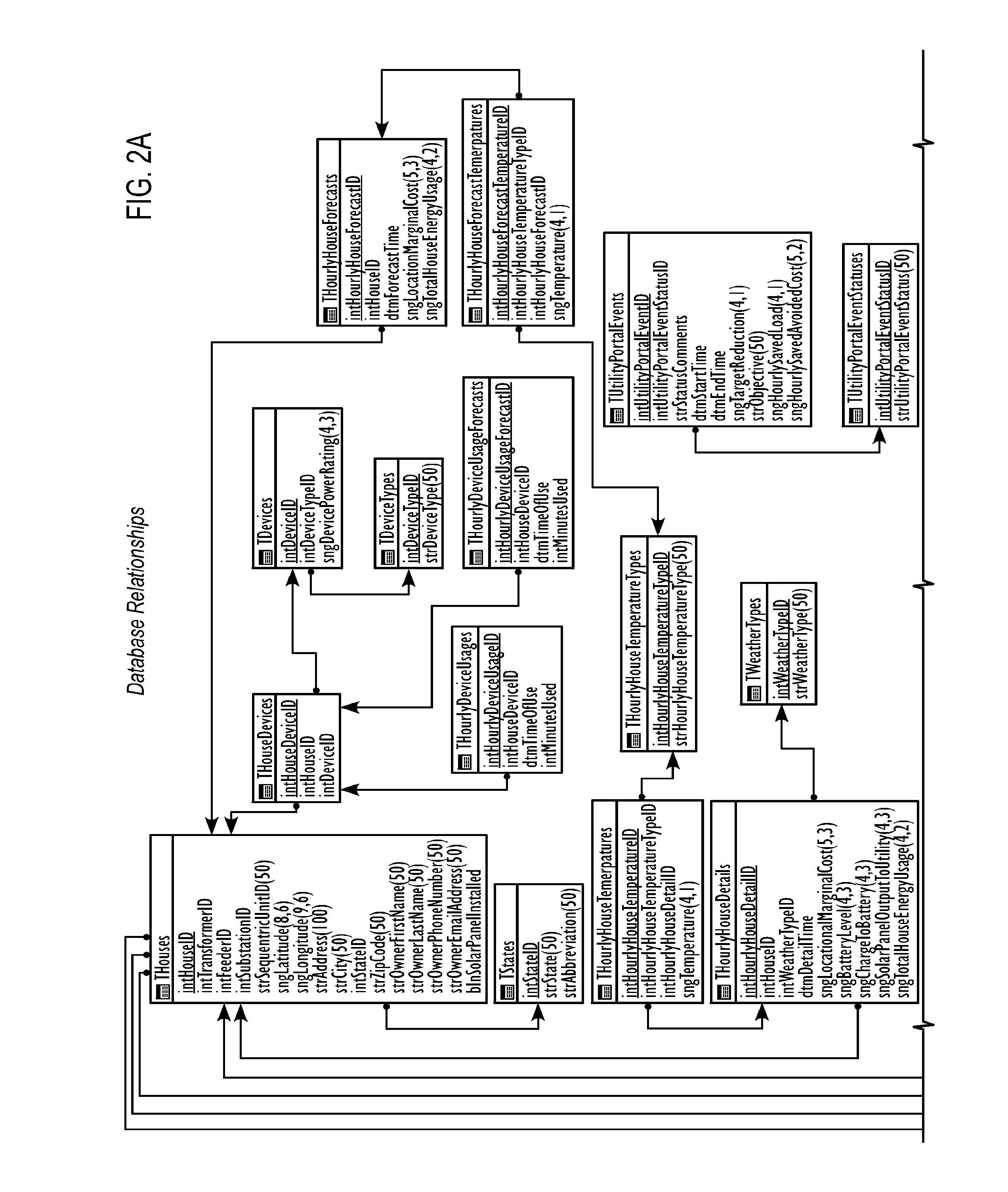

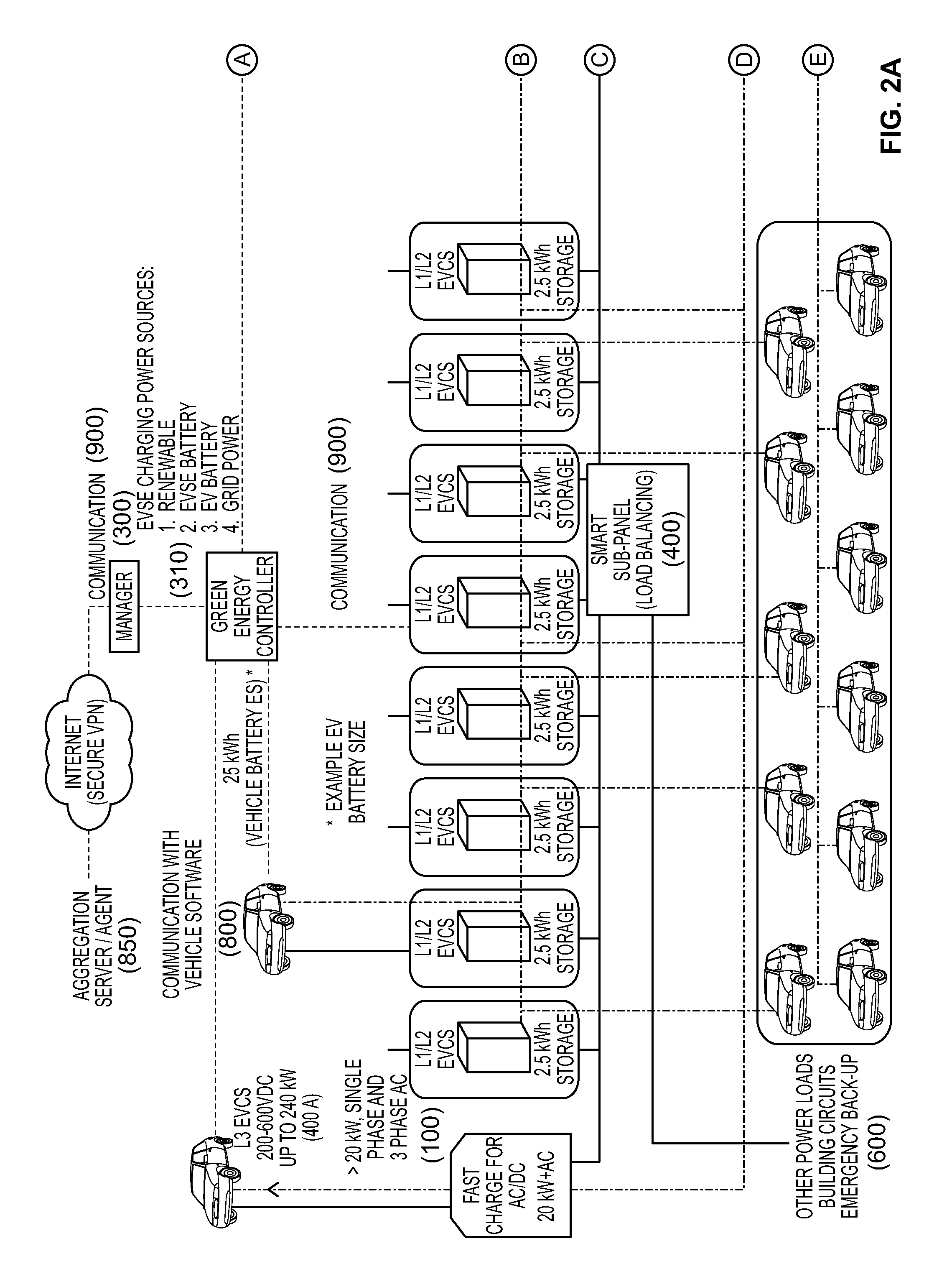

Optimization of microgrid energy use and distribution

ActiveUS20100179704A1Optimize energy distributionOptimize energy useBatteries circuit arrangementsLevel controlPersonalizationMicrogrid

An energy distribution may include a server and one or more databases. The system may communicate with an energy provider to receive energy provider data, at least one information collector to receive information collector data such as individualized energy usage data, customer preferences, and customer or location characteristics, and the one or more databases for receiving data for optimization. The system may calculate a cost of service or avoided cost using at least one of the individualized energy usage data and a system generation cost at a nearest bus. The system may also forecast individualized demand by end-use, individualized demand by location, energy prices, or energy costs. The system may optimize energy distribution, energy use, cost of service, or avoided cost using the forecasted individualized demand by end-use, the forecasted individualized demand by location, the forecasted energy prices, and the forecasted energy costs.

Owner:INTEGRAL ANALYTICS

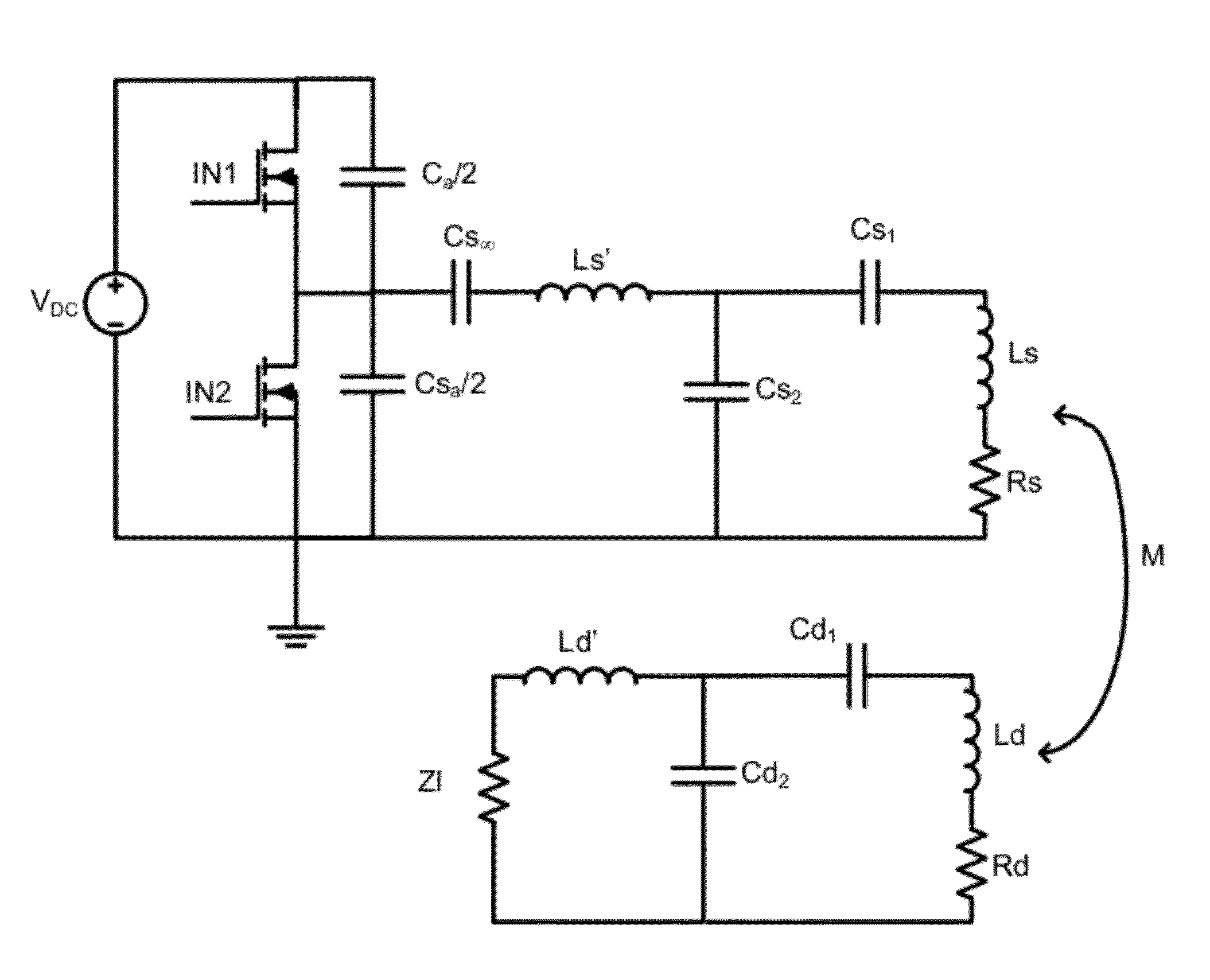

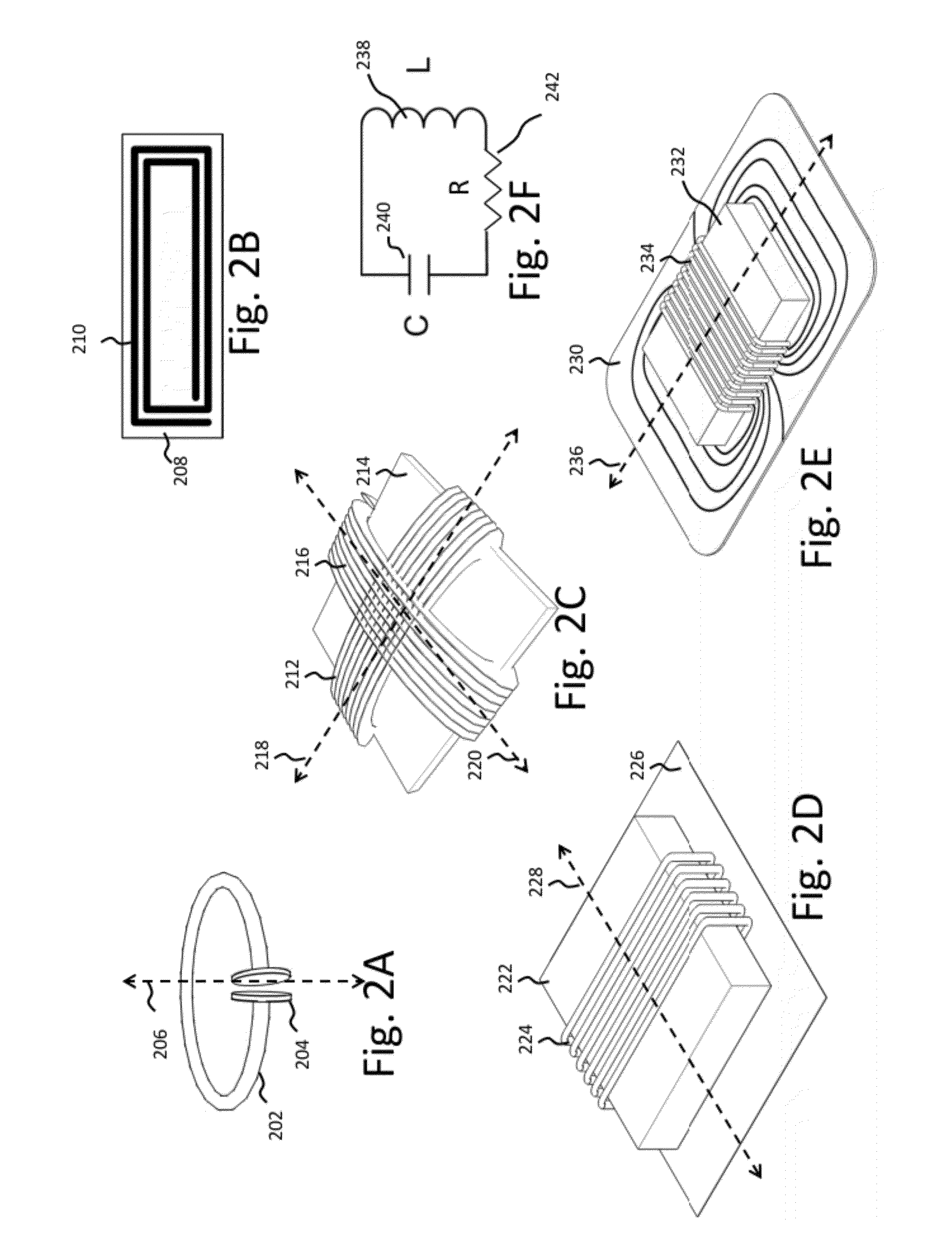

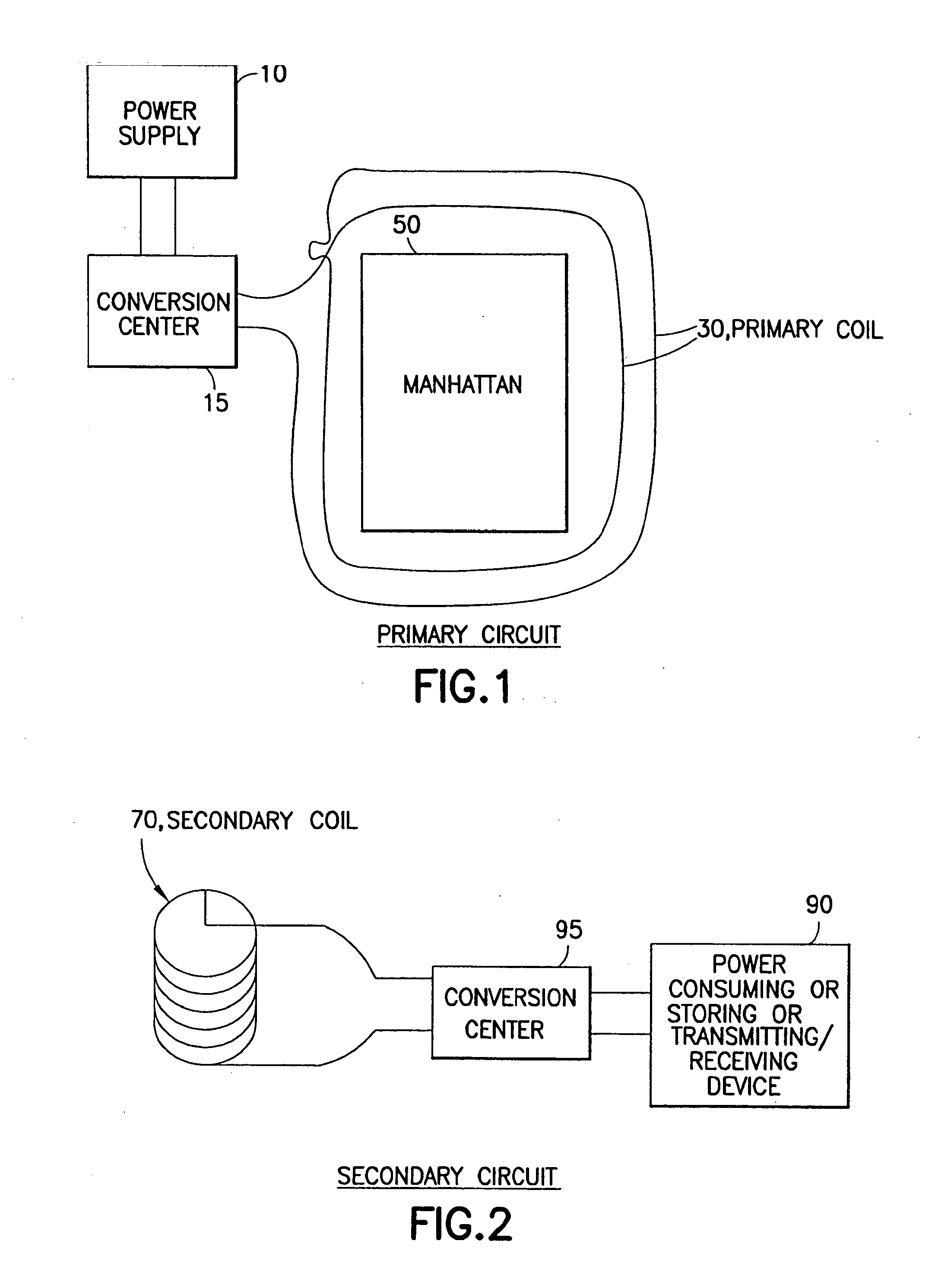

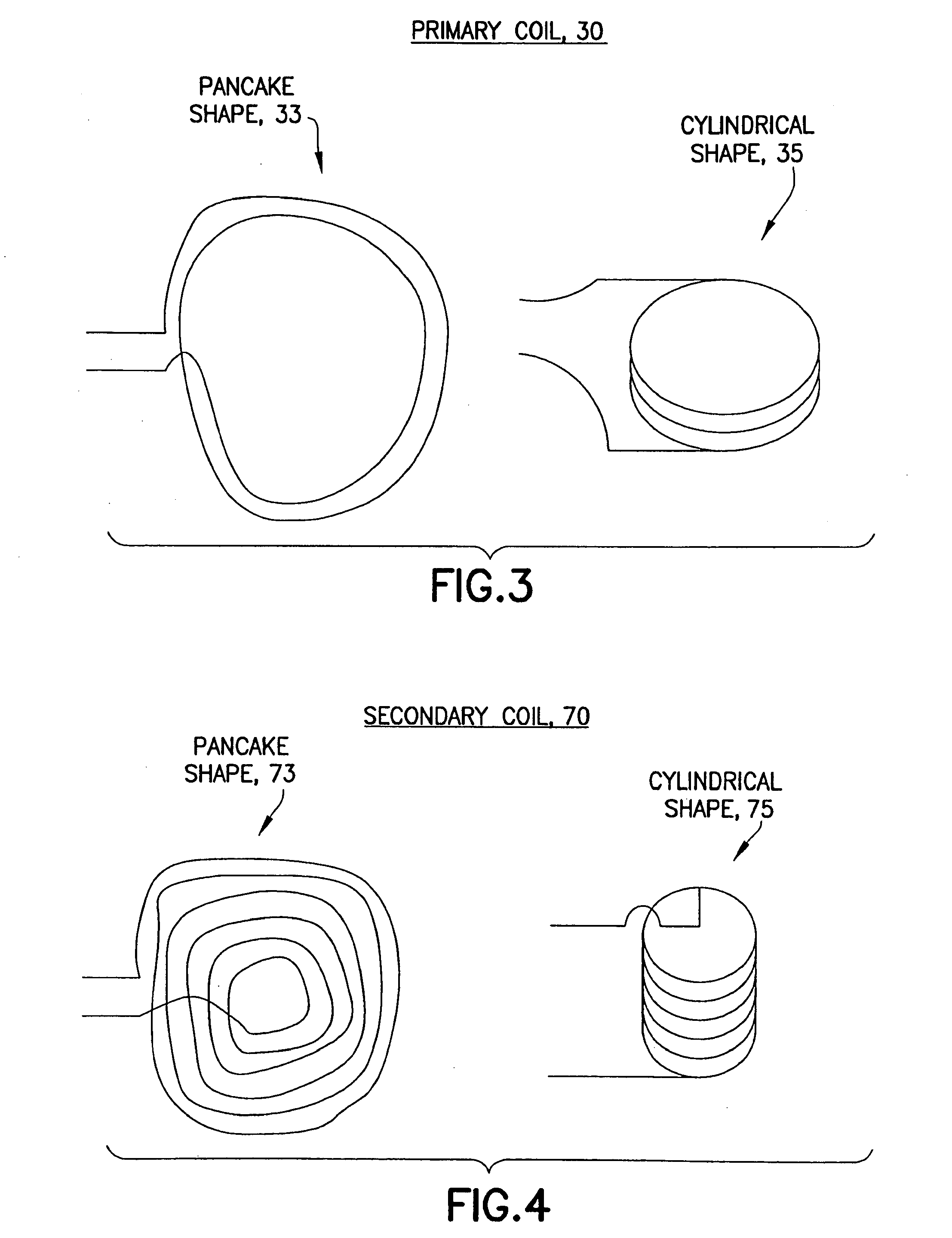

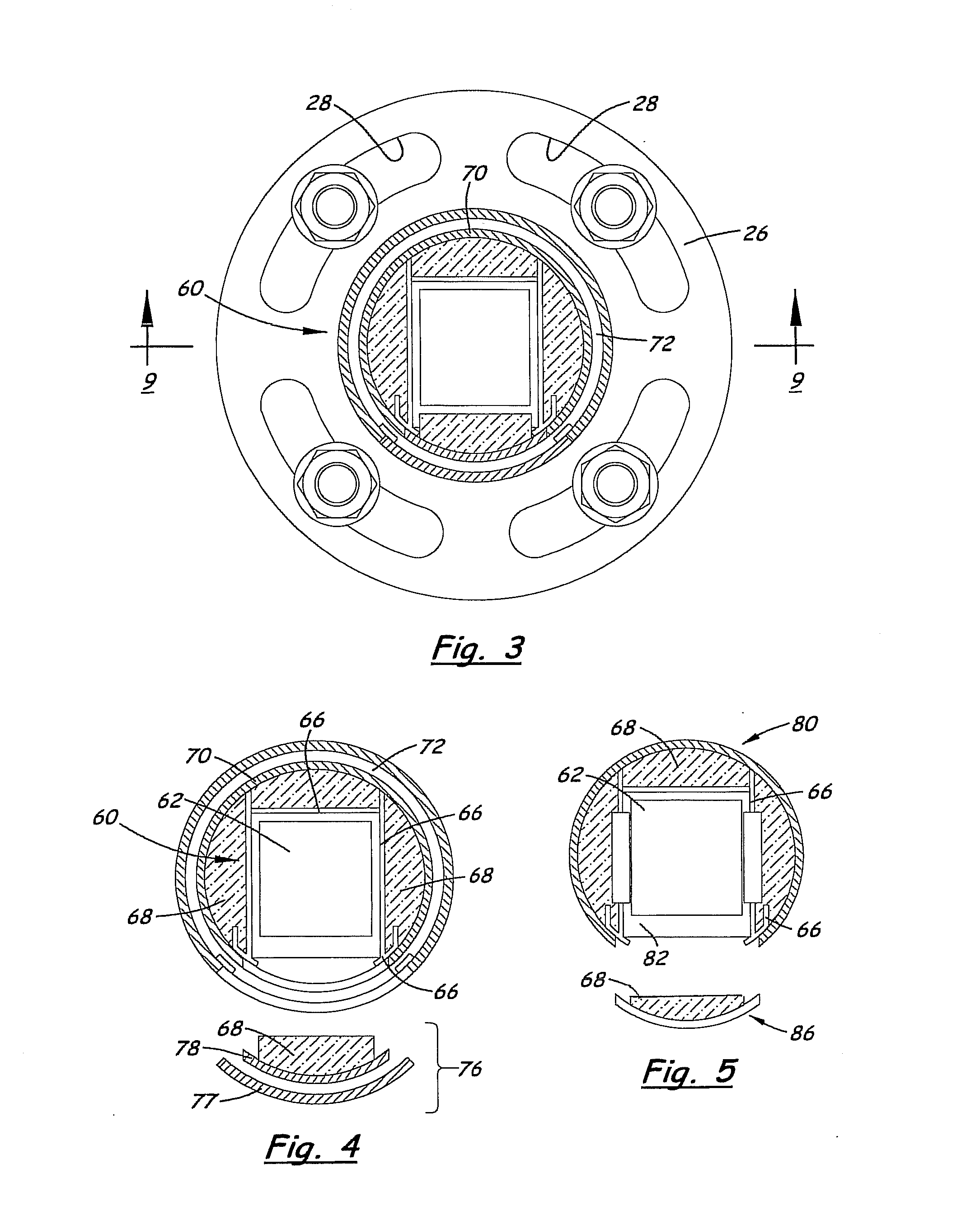

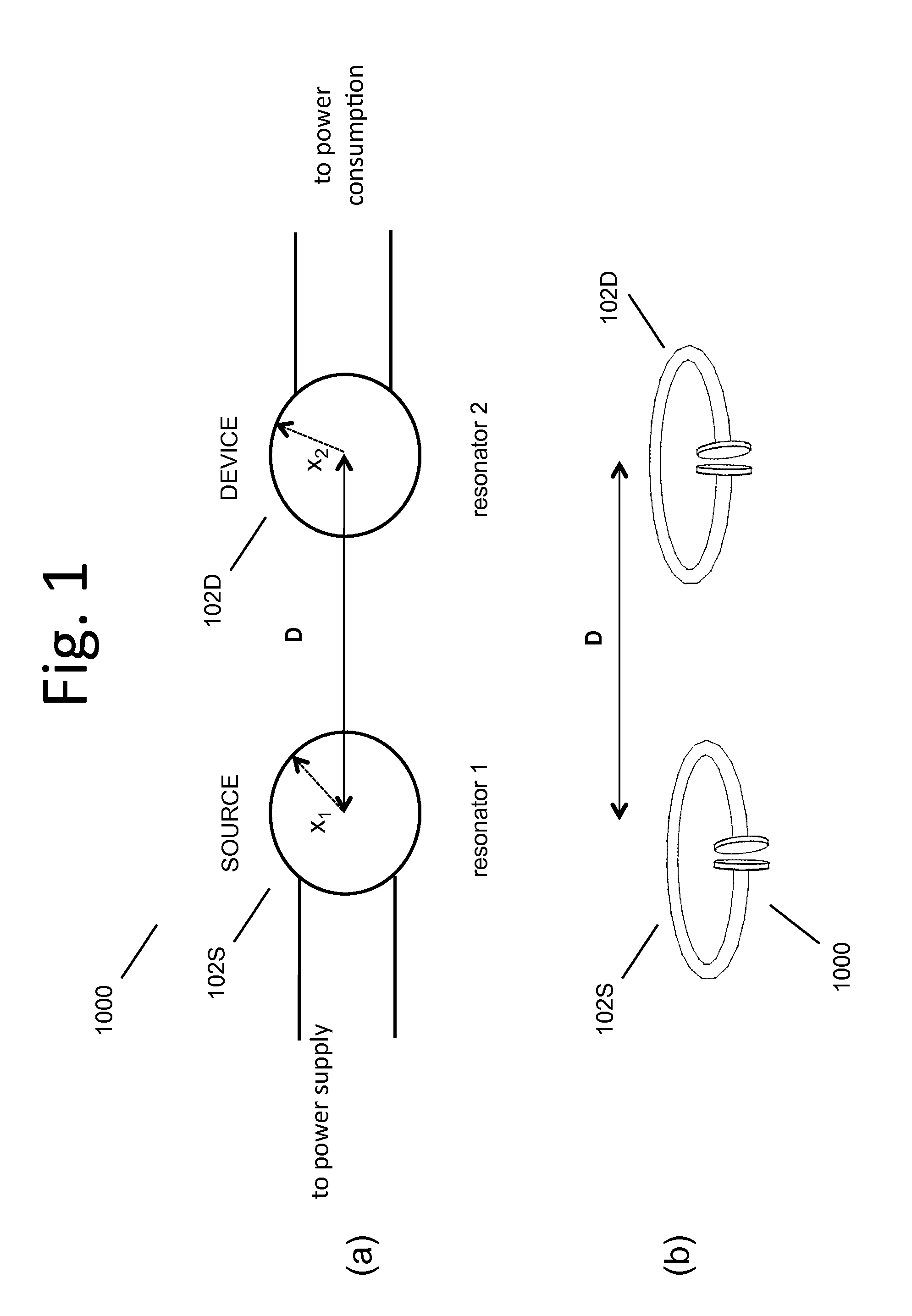

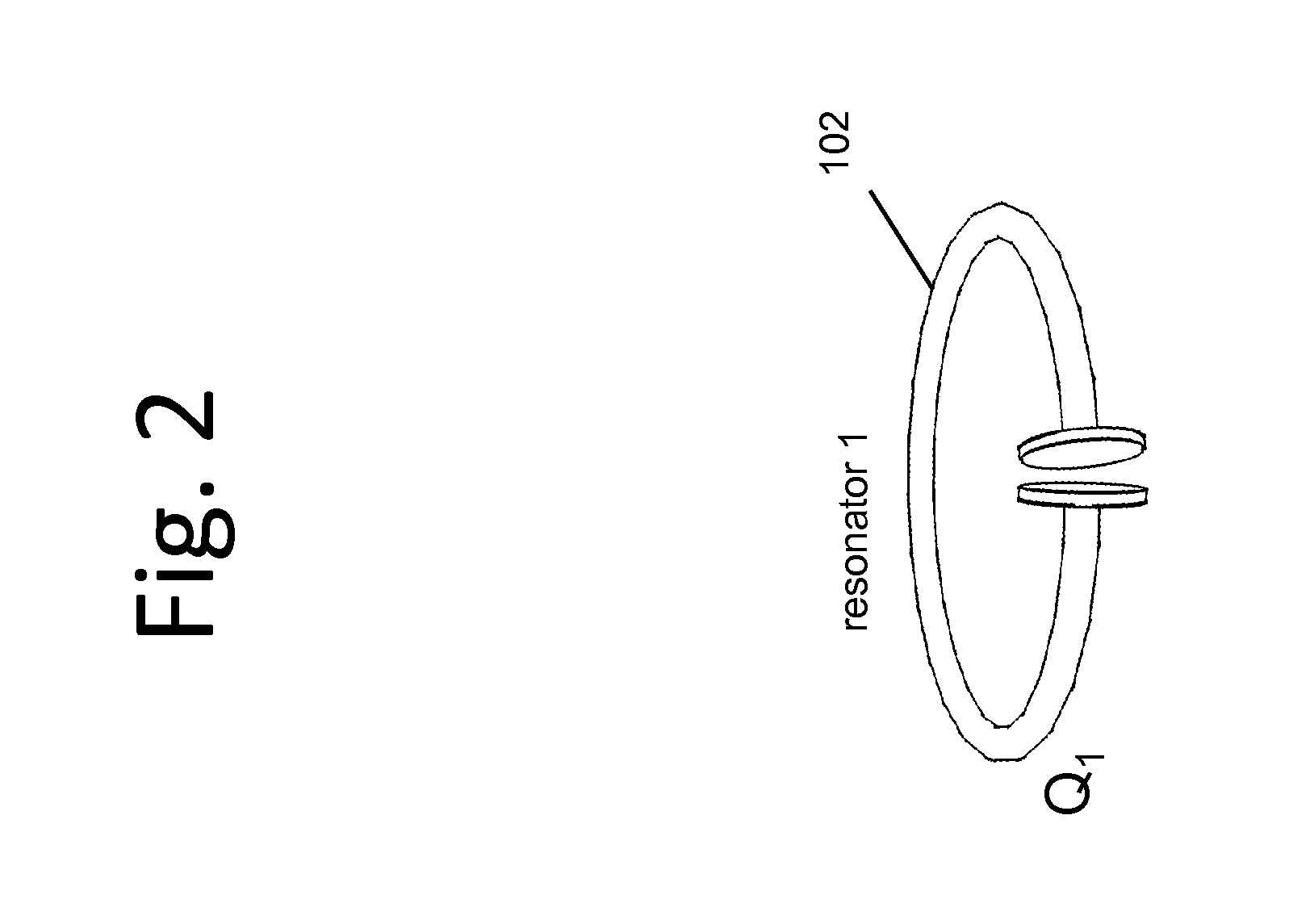

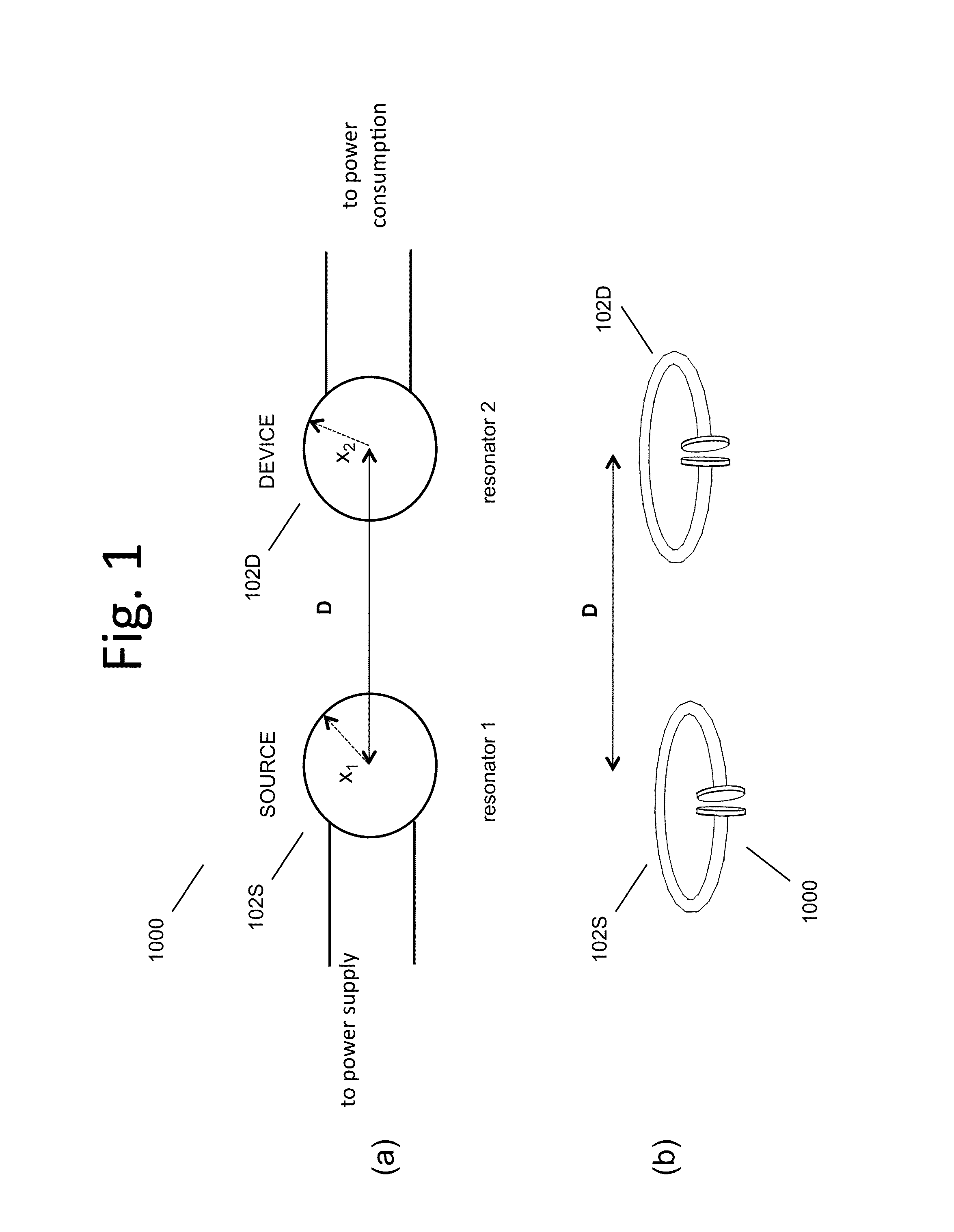

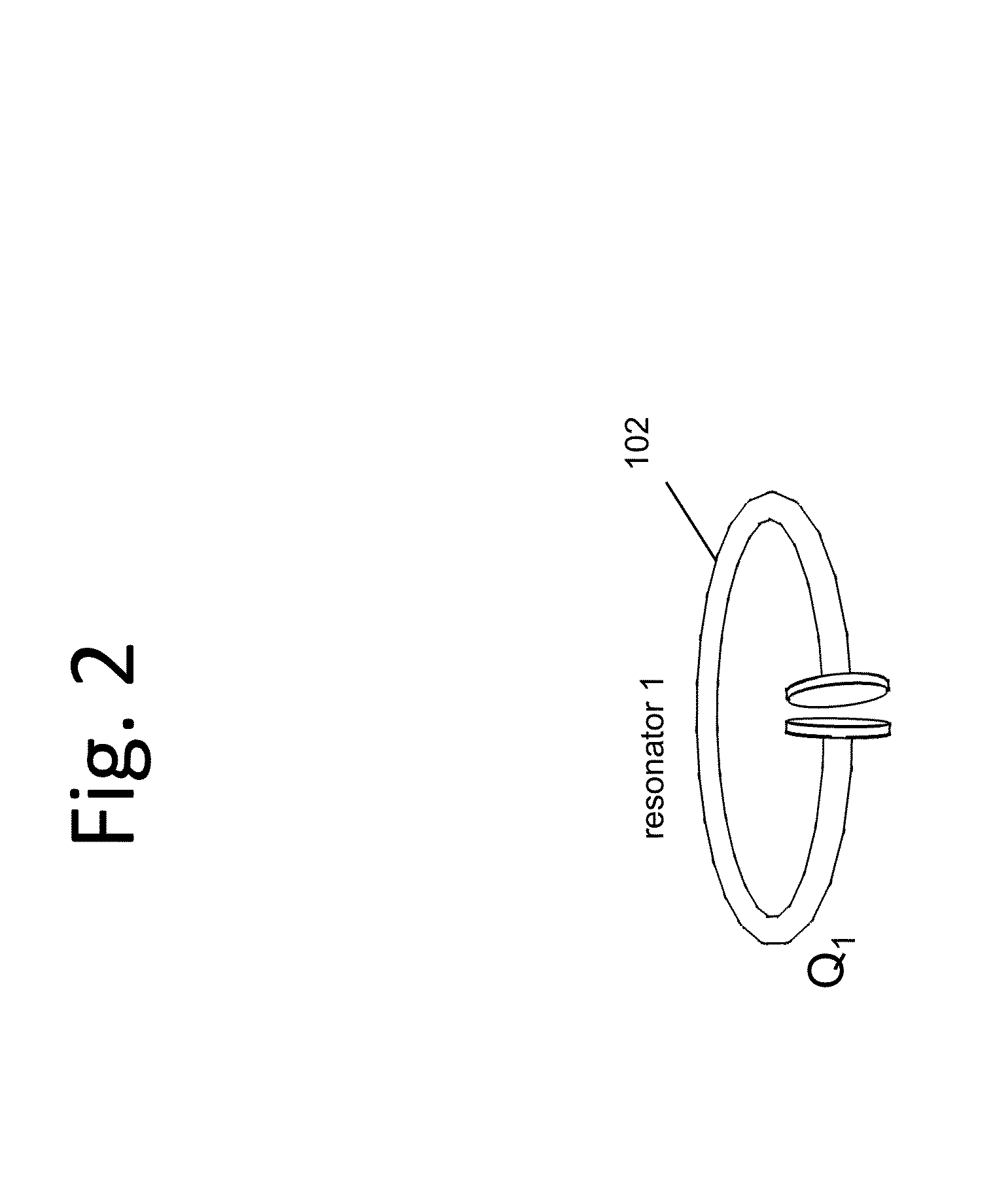

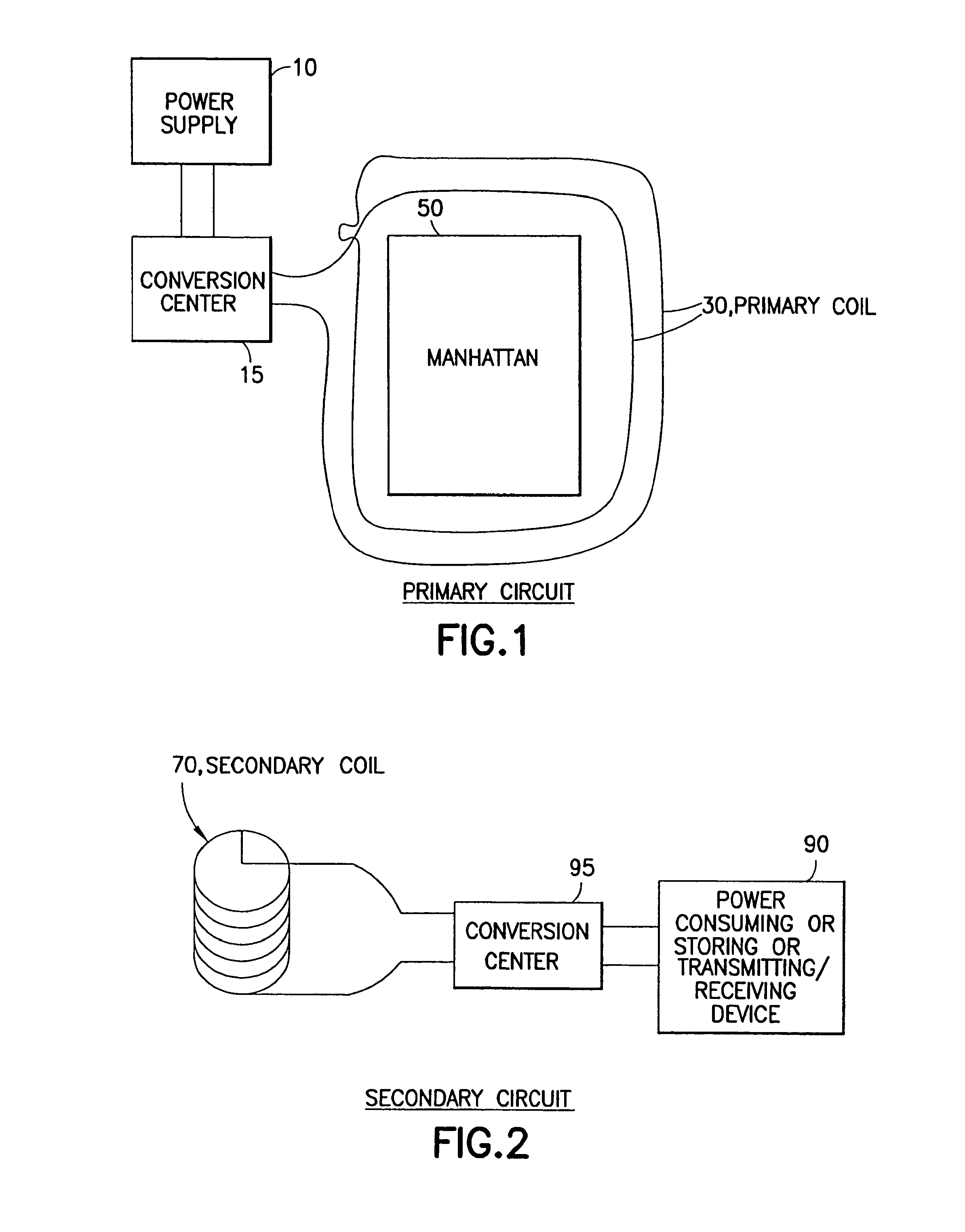

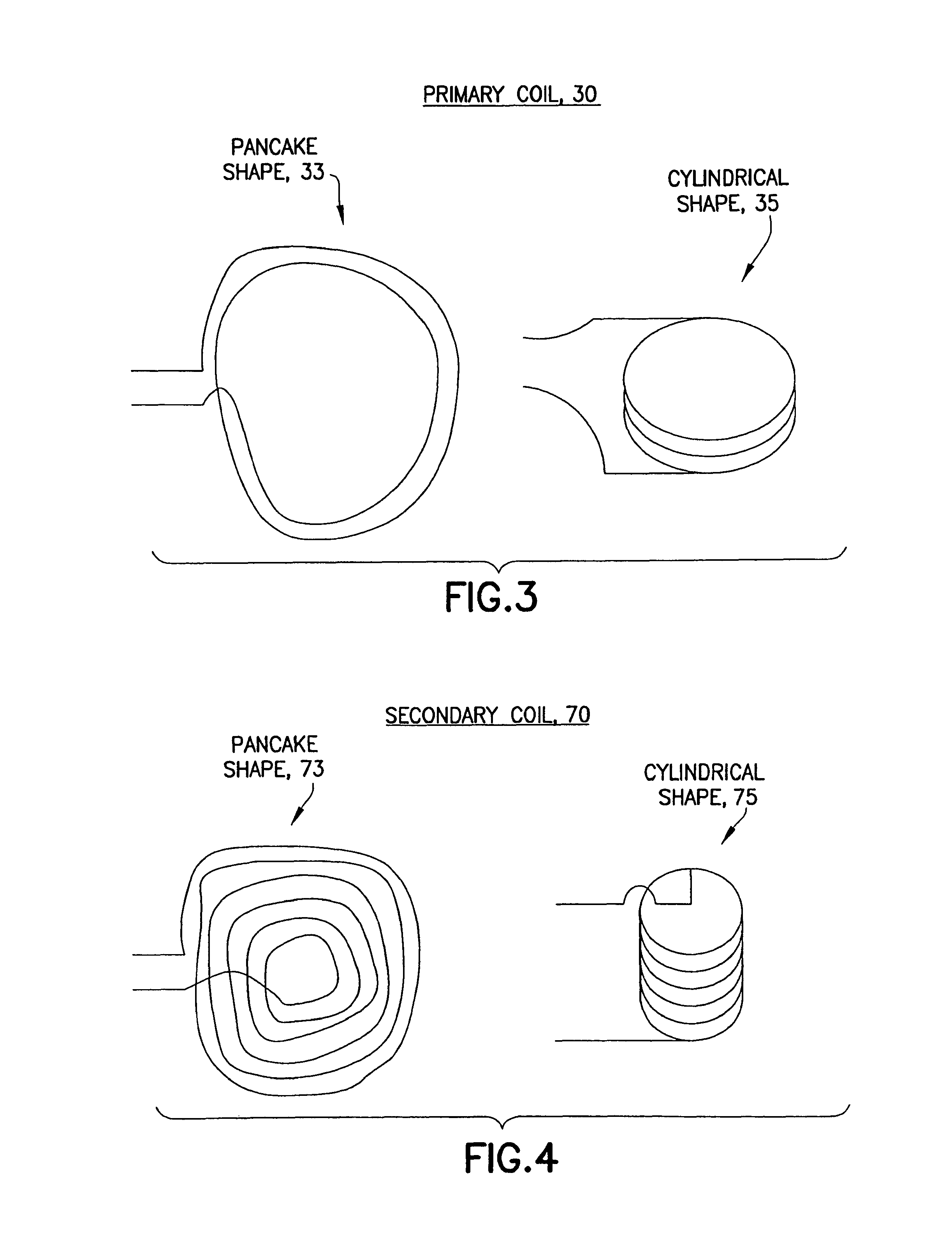

Wireless energy distribution system

ActiveUS20120235500A1Tune performanceMultiple-port networksElectromagnetic wave systemEnergy transferRepeater

Described herein are systems for wireless energy transfer distribution over a defined area. Energy may be distributed over the area via a plurality of repeater, source, and device resonators. The resonators within the area may be tunable and the distribution of energy or magnetic fields within the area may be configured depending on device position and power needs.

Owner:WITRICITY CORP

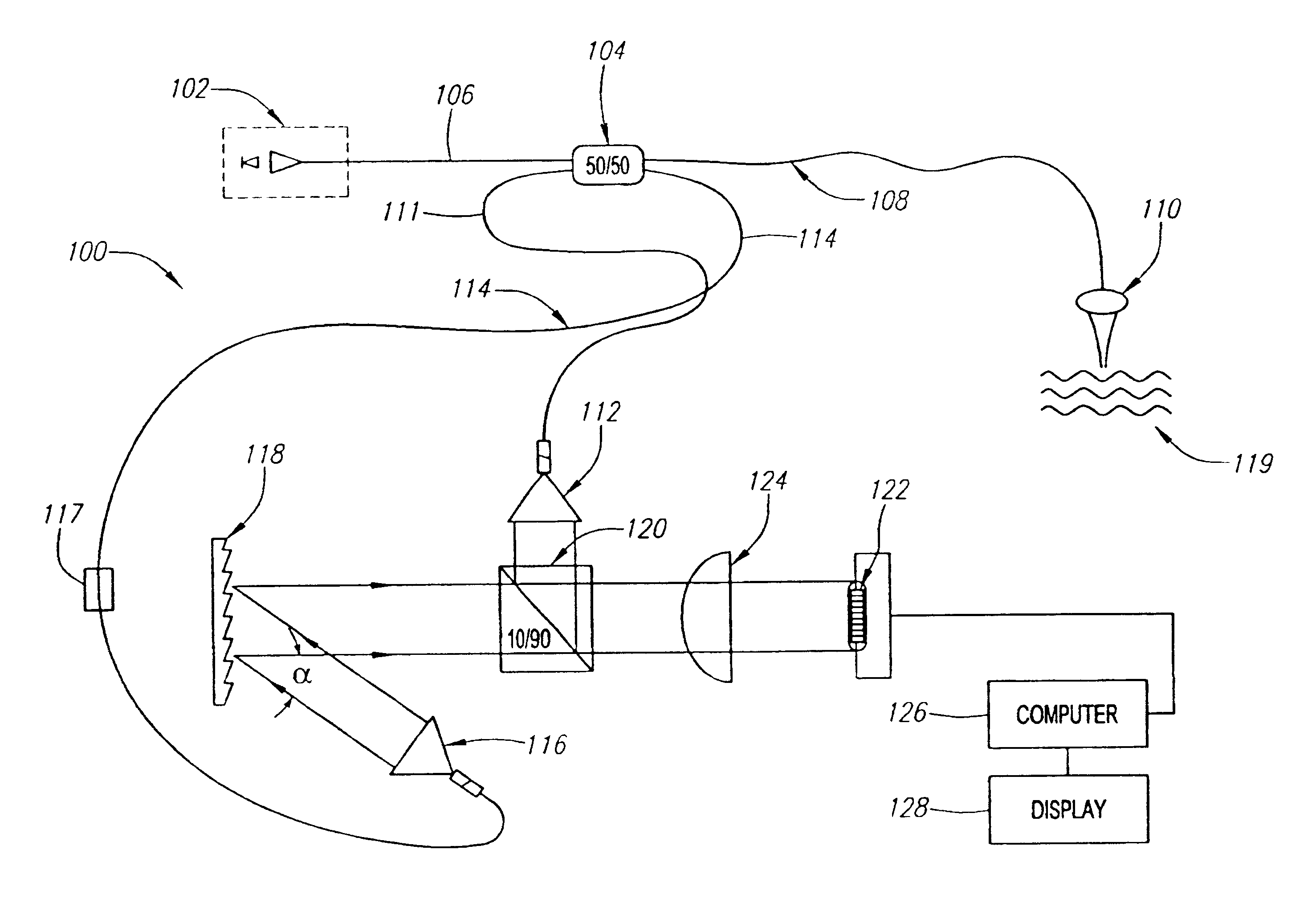

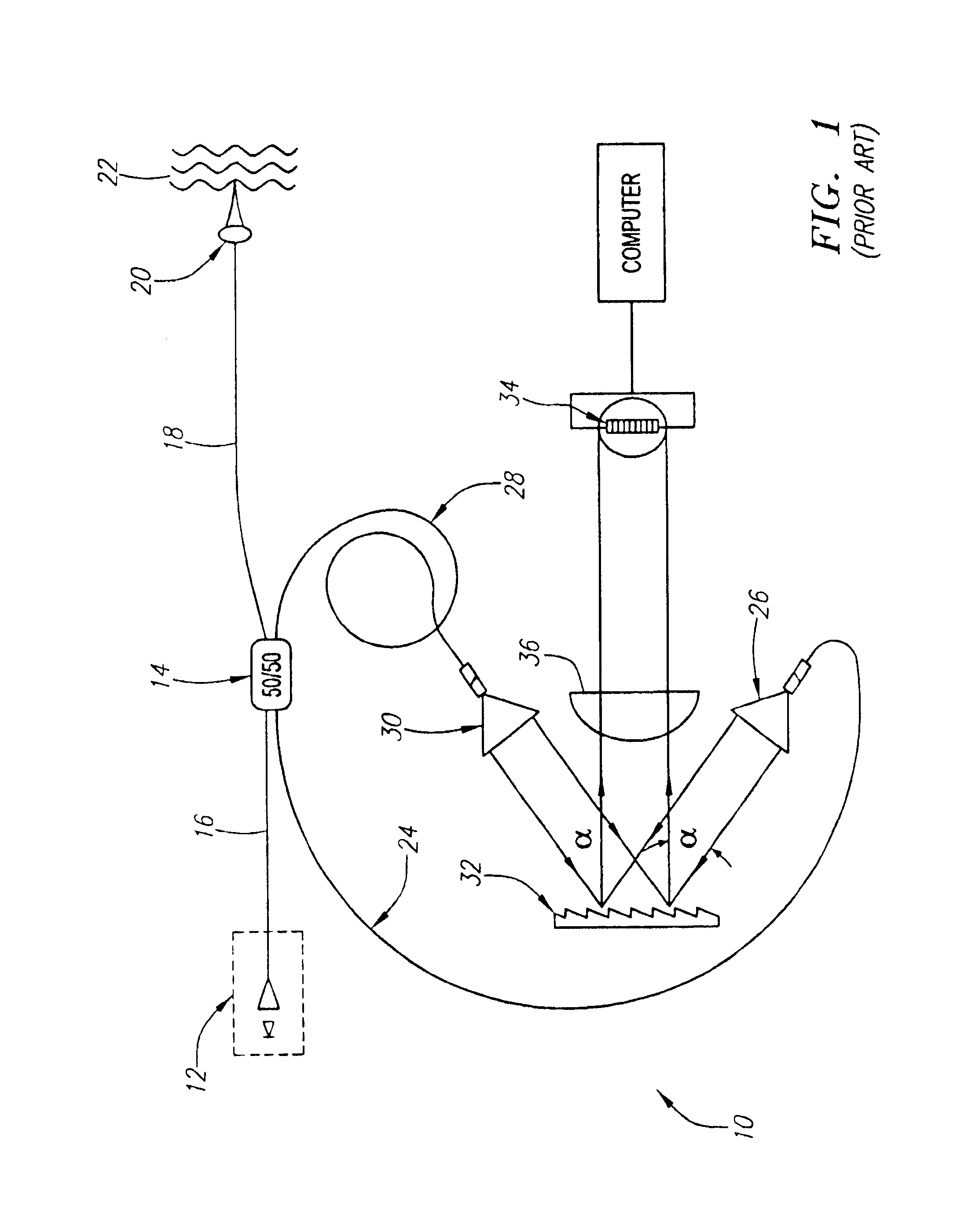

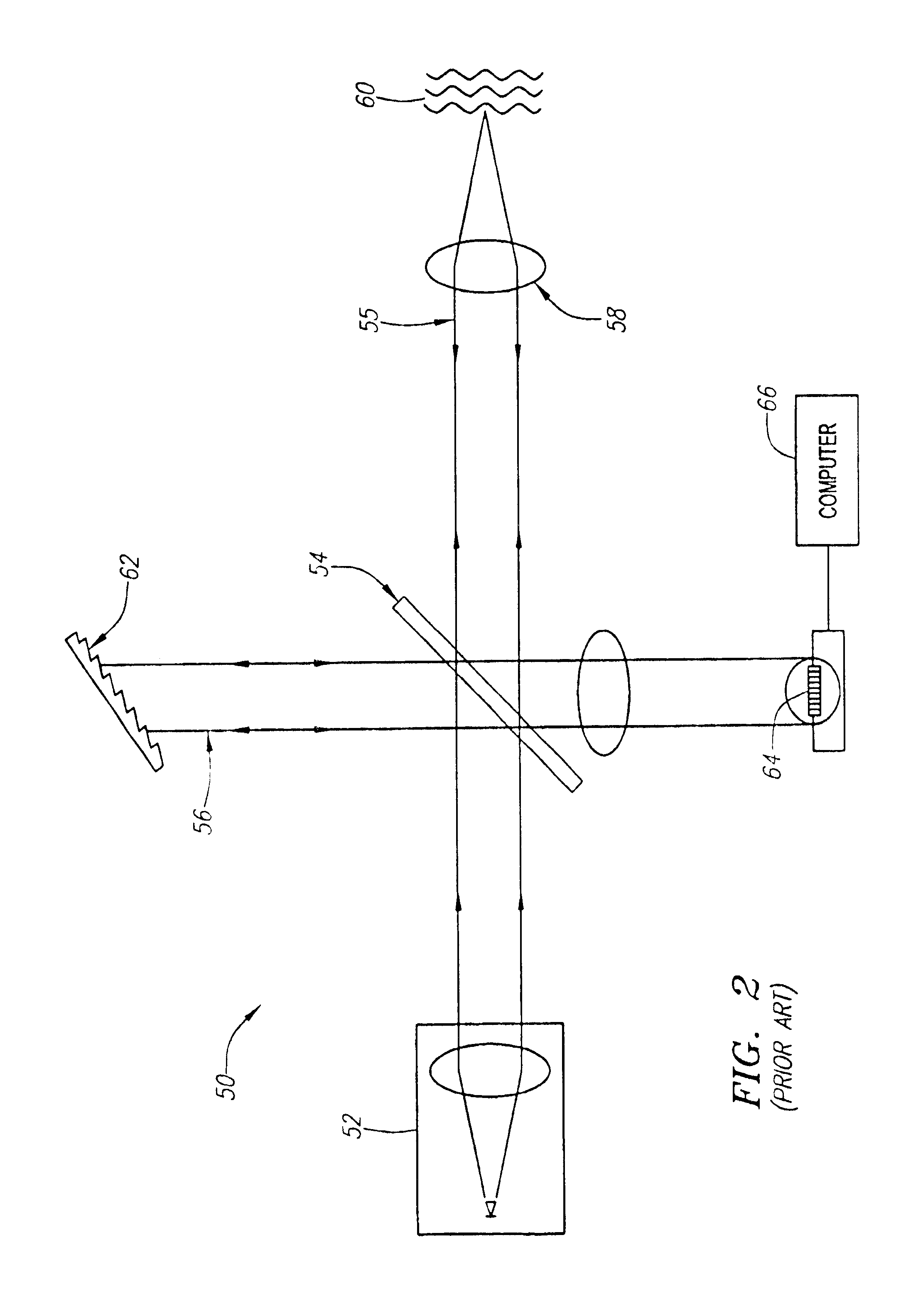

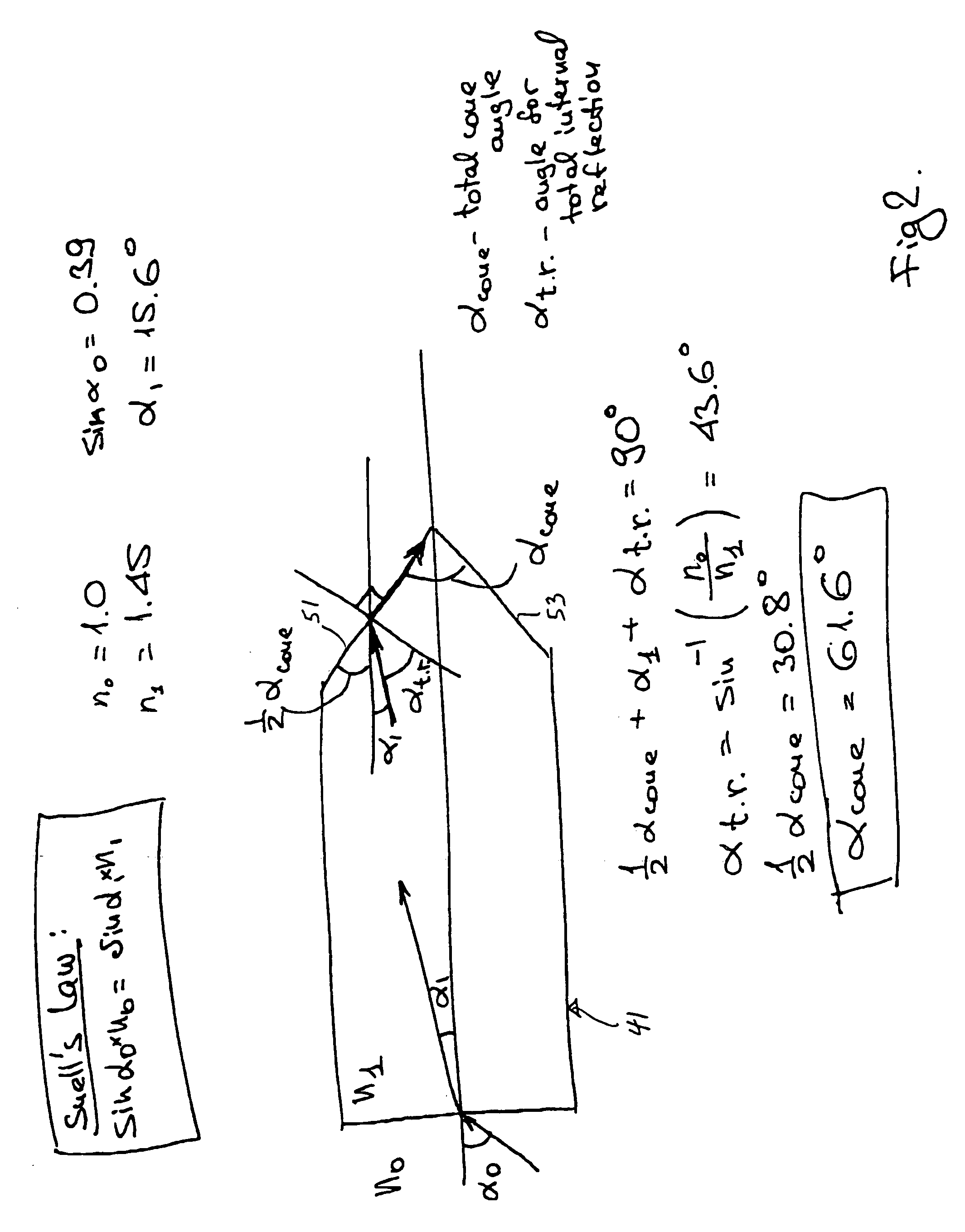

Diffraction grating based interferometric systems and methods

Diffraction grating based fiber optic interferometric systems for use in optical coherence tomography, wherein sample and reference light beams are formed by a first beam splitter and the sample light beam received from a sample and a reference light beam are combined on a second beam splitter. In one embodiment, the first beam splitter is an approximately 50 / 50 beam splitter, and the second beam splitter is a non 50 / 50 beam splitter. More than half of the energy of the sample light beam is directed into the combined beam and less than half of the energy of the reference light beam are directed into the combined beam by the second beam splitter. In another embodiment, the first beam splitter is a non 50 / 50 beam splitter and the second beam splitter is an approximately 50 / 50 beam splitter. An optical circulator is provided to enable the sample light beam to bypass the first beam splitter after interaction with a sample. Two combined beams are formed by the second beam splitter for detection by two respective detectors. More than half of the energy of the light source provided to the first beam splitter is directed into the sample light beam and less than half of the energy is directed into the reference light beam. The energy distribution between the sample and reference light beams can be controlled by selection of the characteristics of the beam splitters.

Owner:BOSTON SCI SCIMED INC

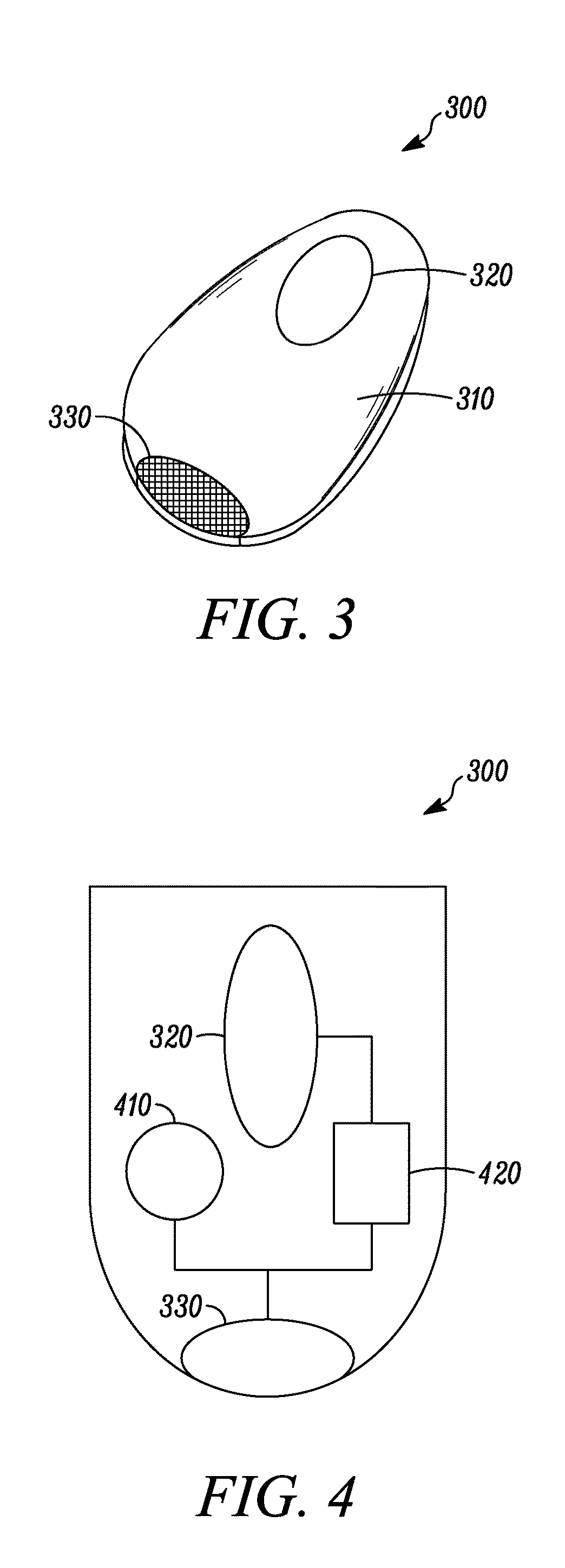

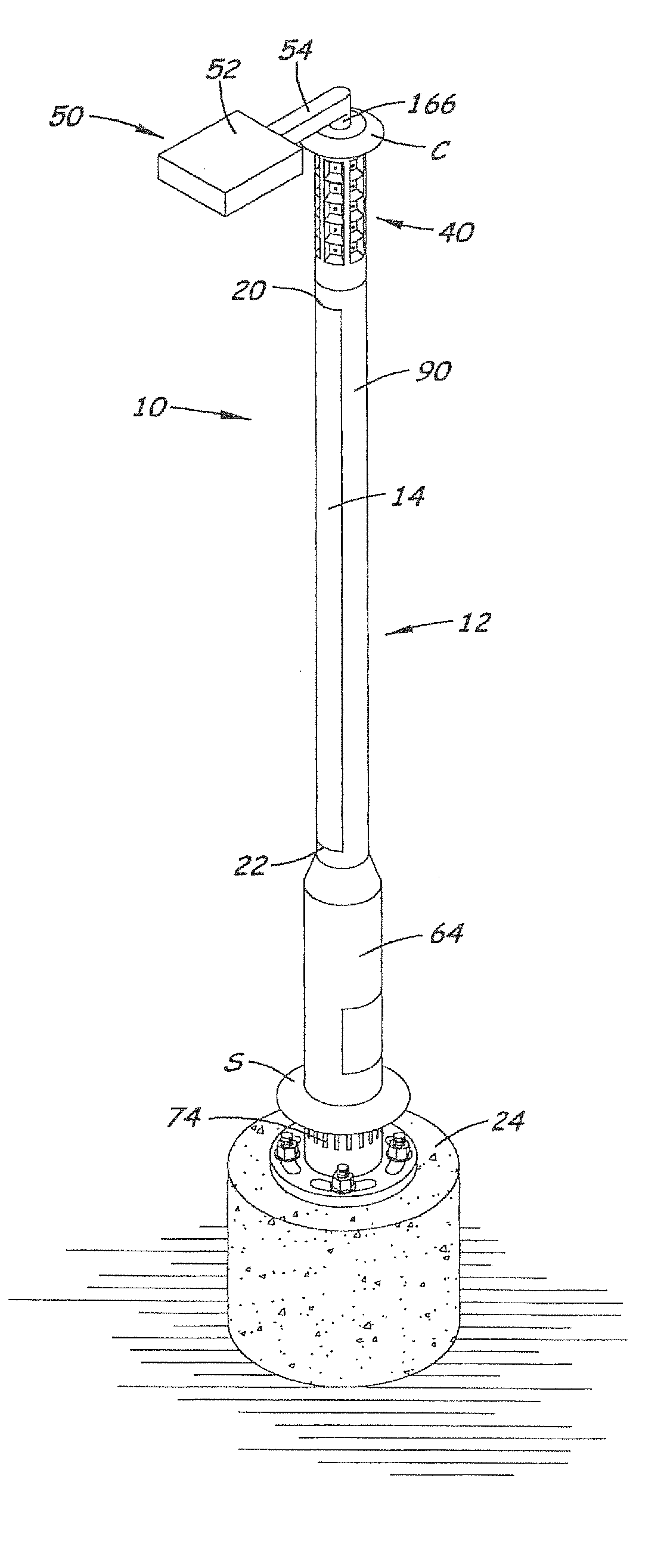

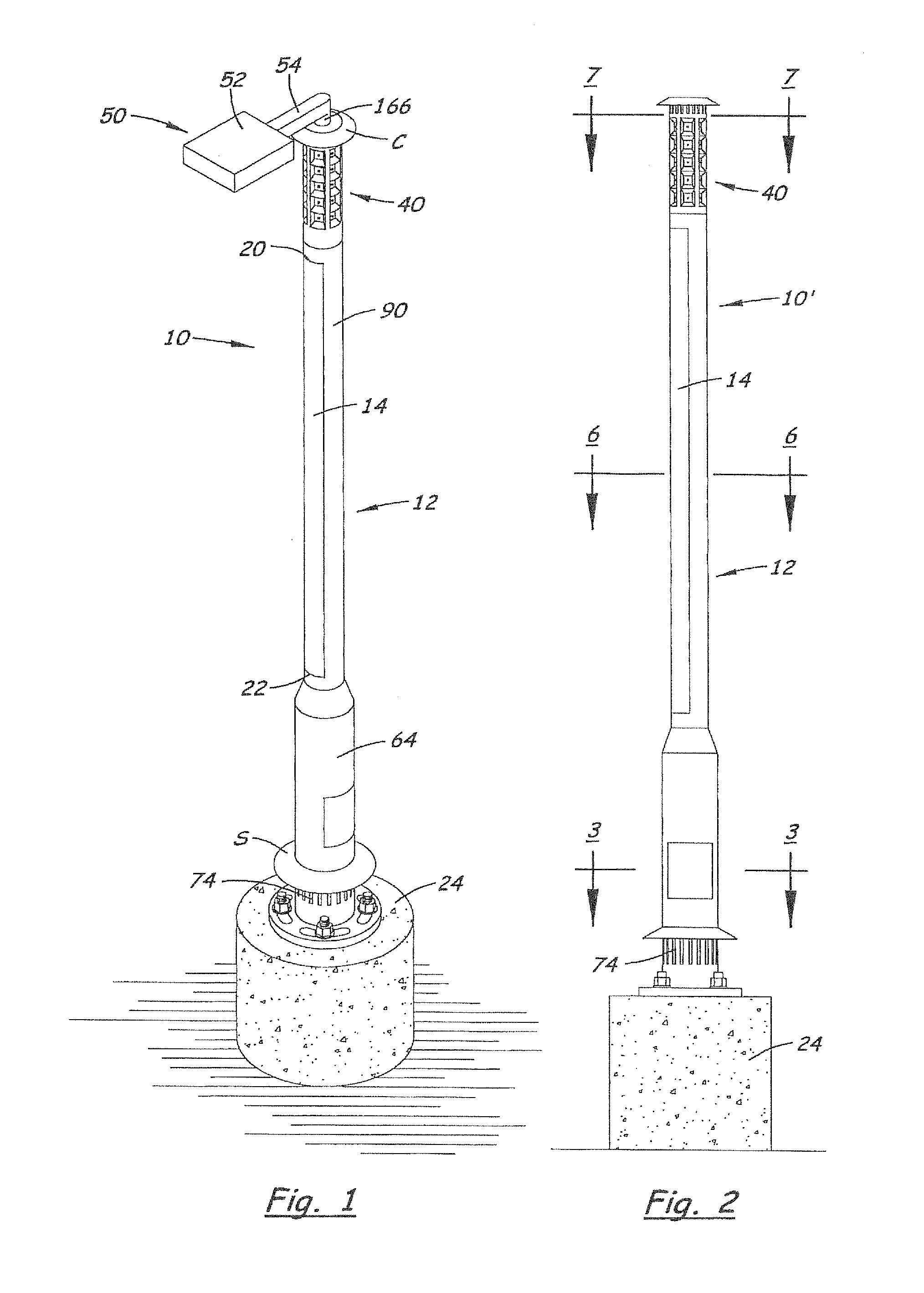

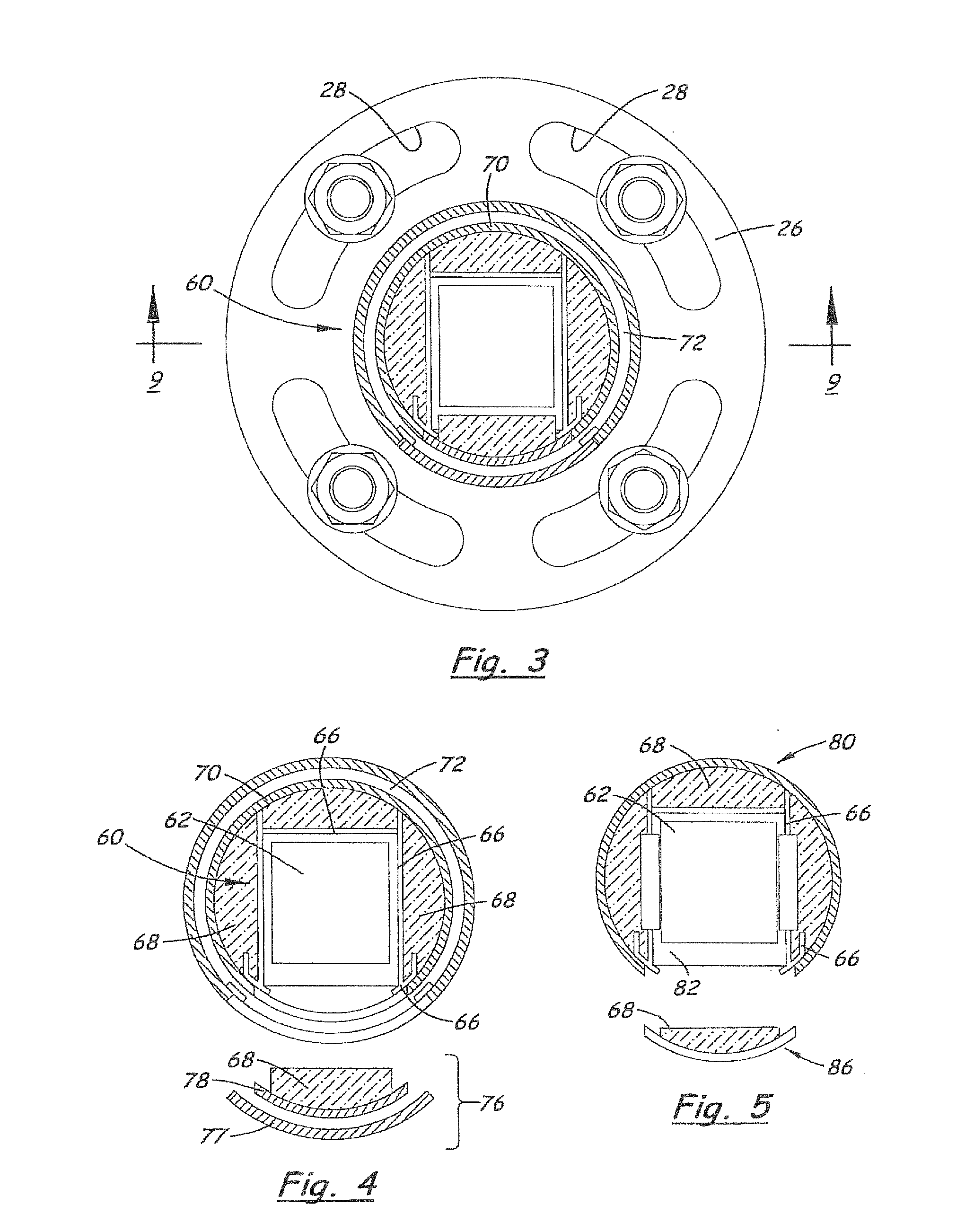

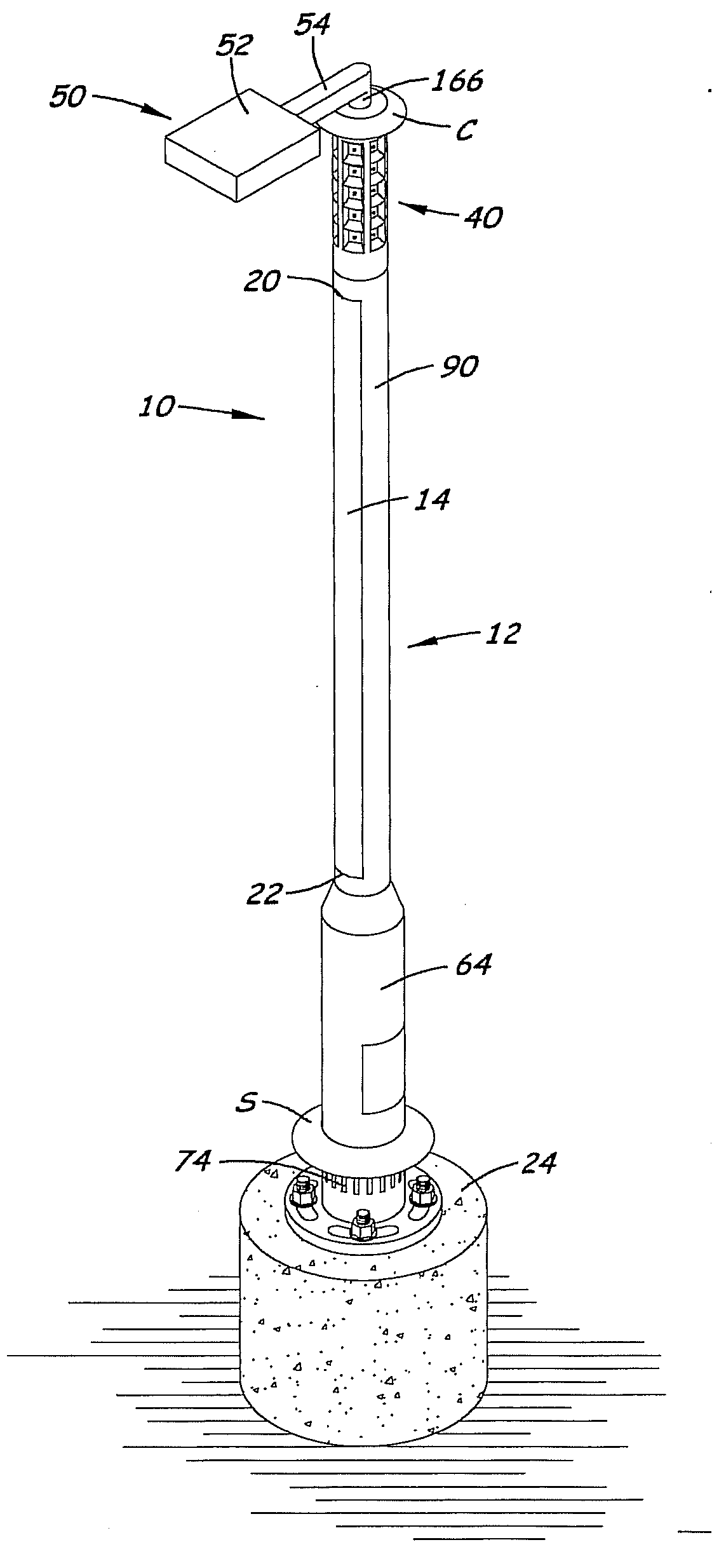

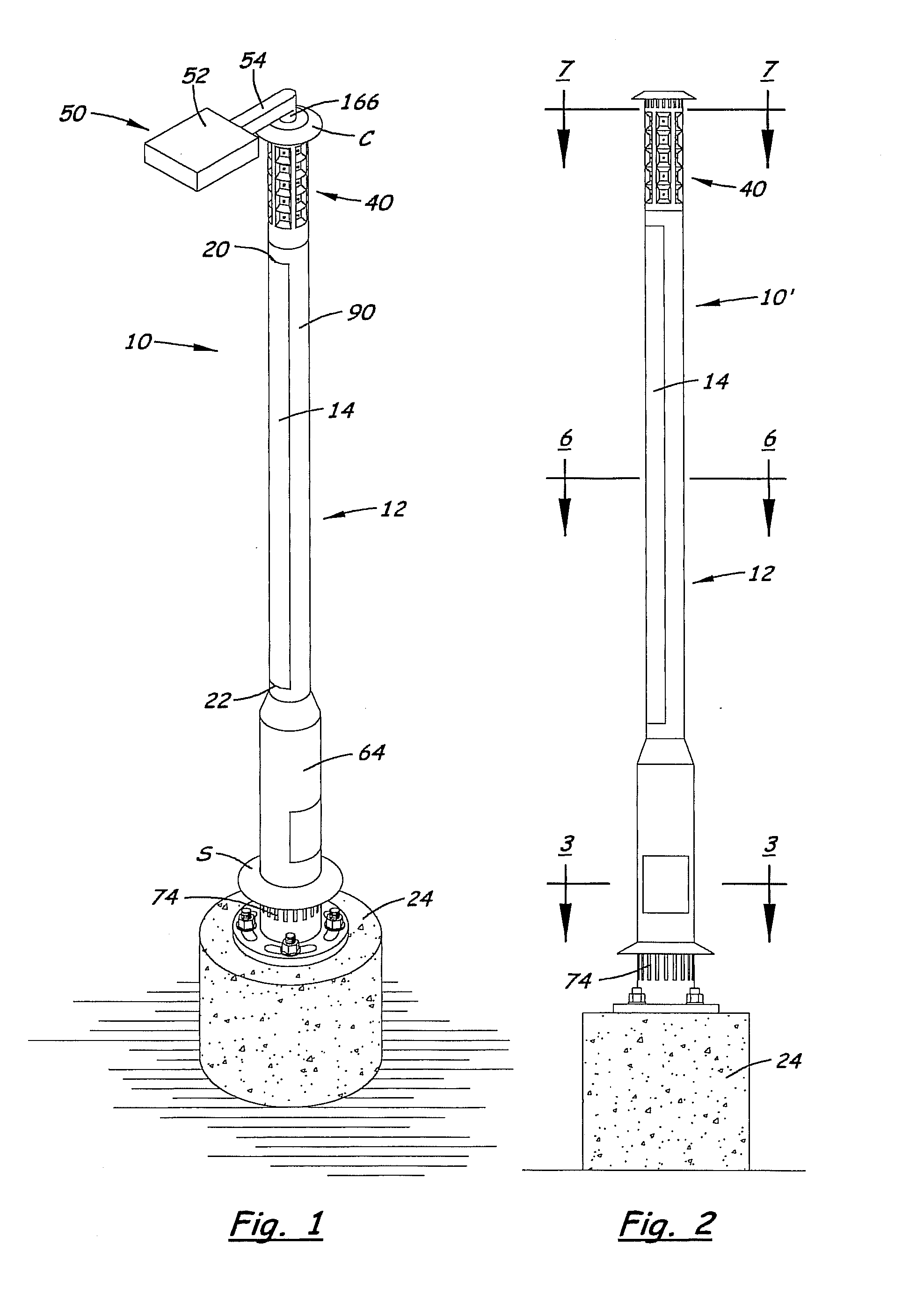

Energy-efficient solar-powered outdoor lighting

InactiveUS20150021990A1Guaranteed uptimeEffectively serveLighting support devicesPoint-like light sourceEffect lightEngineering

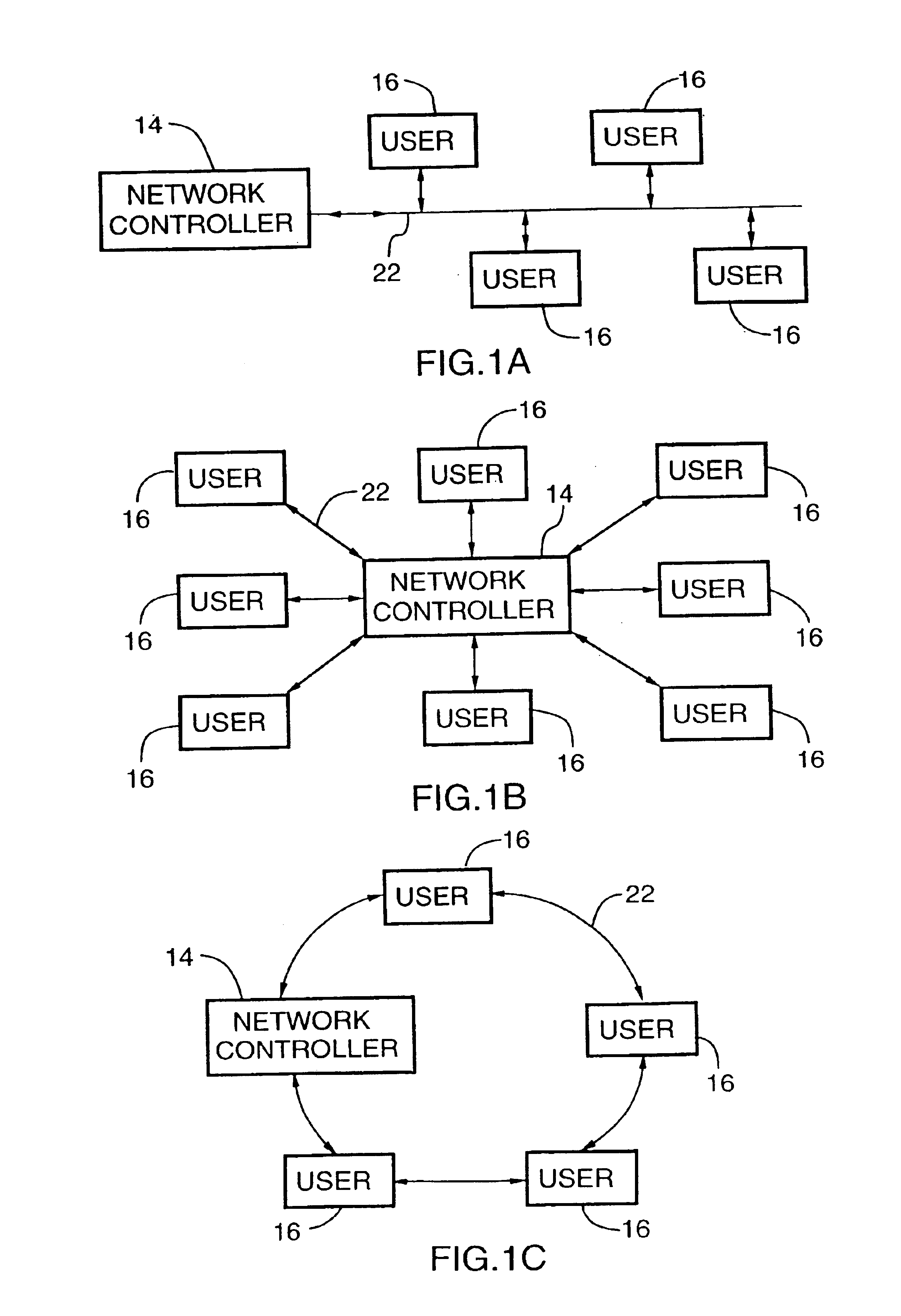

One or more outdoor lights may operate independently with sensing and control processes mainly on-pole, or may communicate as a networked array of poles, wherein a master / coordinating pole / node transmits signals from the networked array to a control station, and receive signals from the control station for the networked array, via call phone and / or satellite. Independent poles and / or the networked array of poles may be adapted for energy-saving processes; cooperation with the grid; renewable power production and storage by means of solar panels and associated batteries; and / or to provide Wi-Fi hot-spots, public safety alarms, information or data-analysis to the public or customers. An energy-saving active control system controls charging of the batteries and distribution of energy from the solar panel and / or the batteries, so that the batteries remain undamaged, and the light(s) remain operation even during the winter or other long periods of clouds and diffuse light. The active control of energy distribution by a load controller function may include dimming during the night, except when sensors detect motion, and, in extreme cloudy or diffuse-light periods, increasing increments of dimming and / or load shedding, to preserve the batteries and operability.

Owner:INOVUS SOLAR

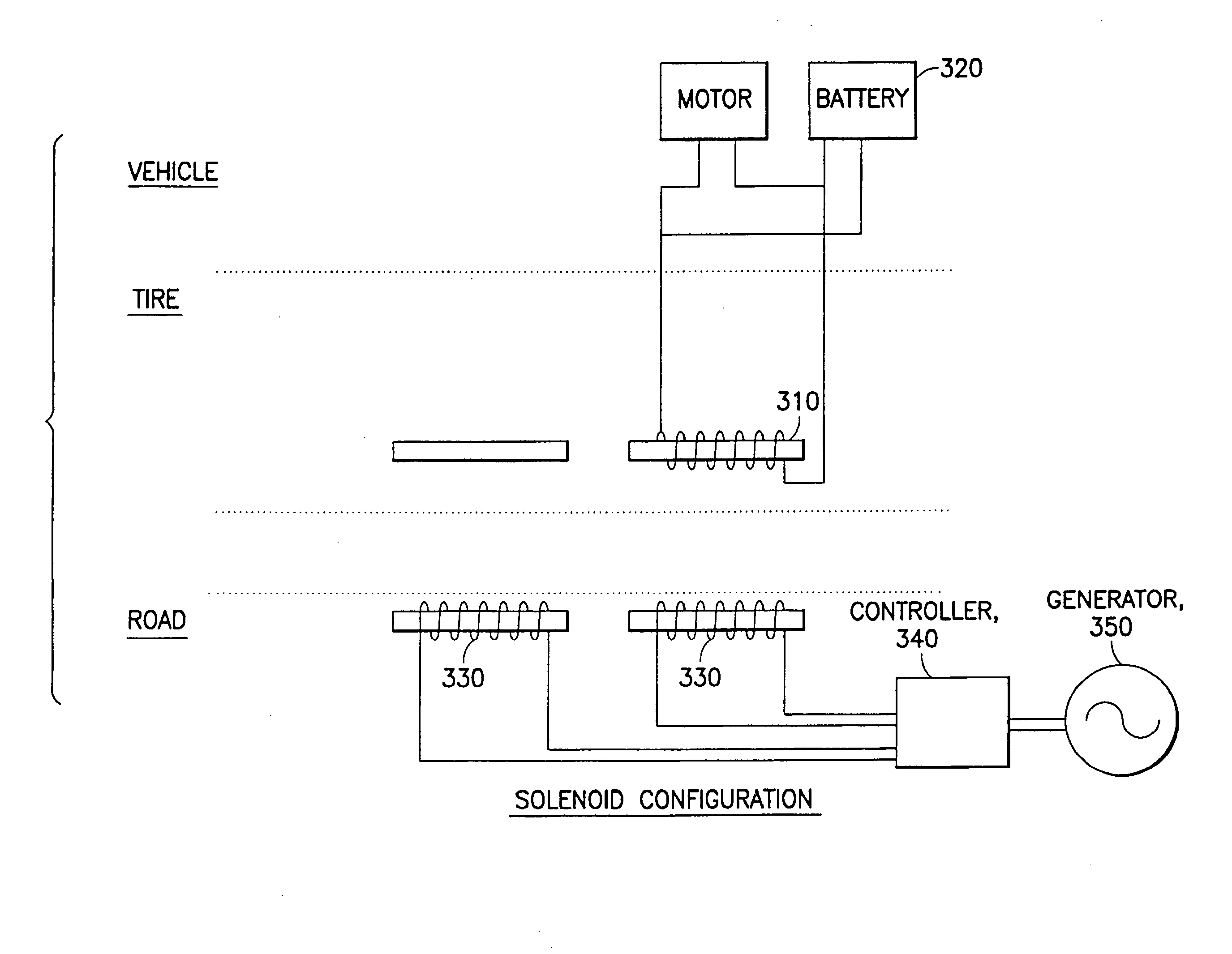

Self-Charging Electric Vehicles and Aircraft, and Wireless Energy Distribution System

InactiveUS20100231163A1Increase rangeImprove transmission efficiencyCharging stationsElectrodynamic brake systemsElectric power systemTransmitted power

A method and system for efficient distribution of power using wireless means, and a system and method for wireless power distribution to provide electric devices, such as vehicles with a way to continuously and wirelessly collect, use and charge their power systems and thereby use the transmitted power for operation. The system and method allows a hybrid, simplified and less costly way to charge devices, such as vehicles so that the devices continuously operate while charging / recharging.

Owner:GOVERNING DYNAMICS INVESTMENT +1

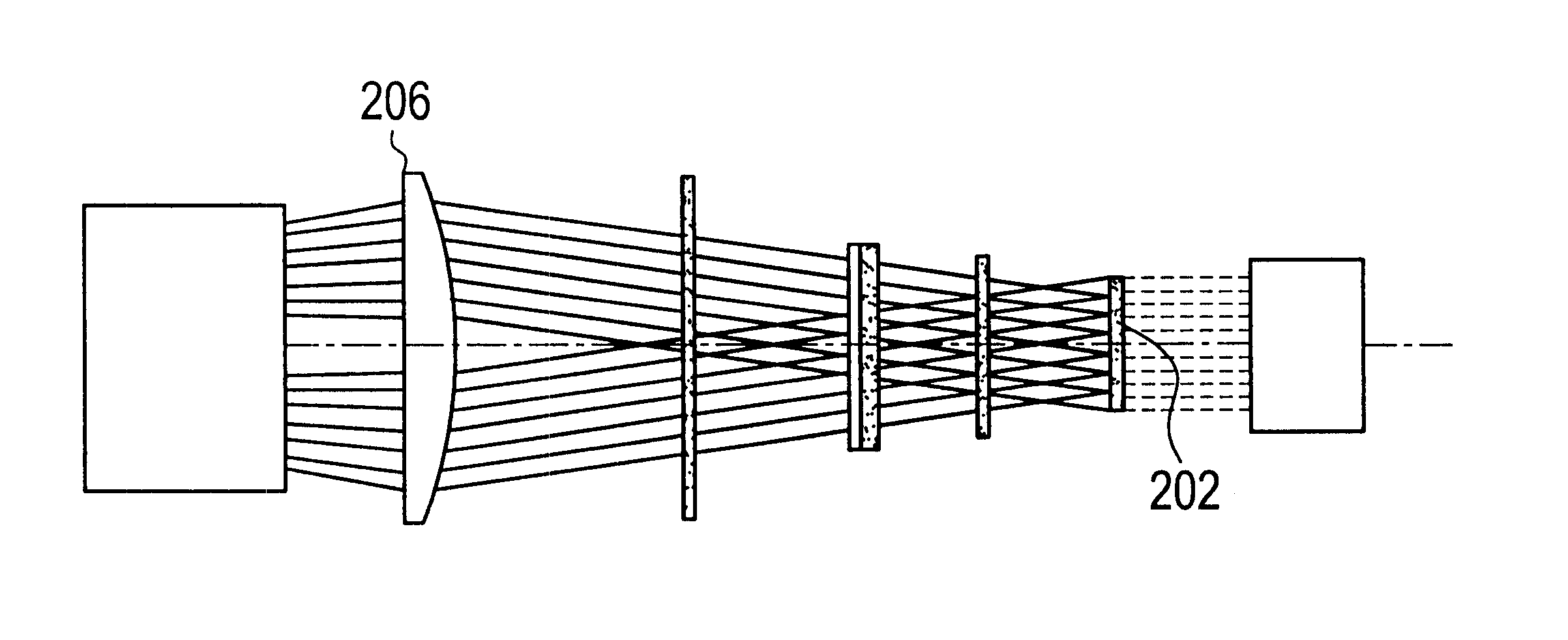

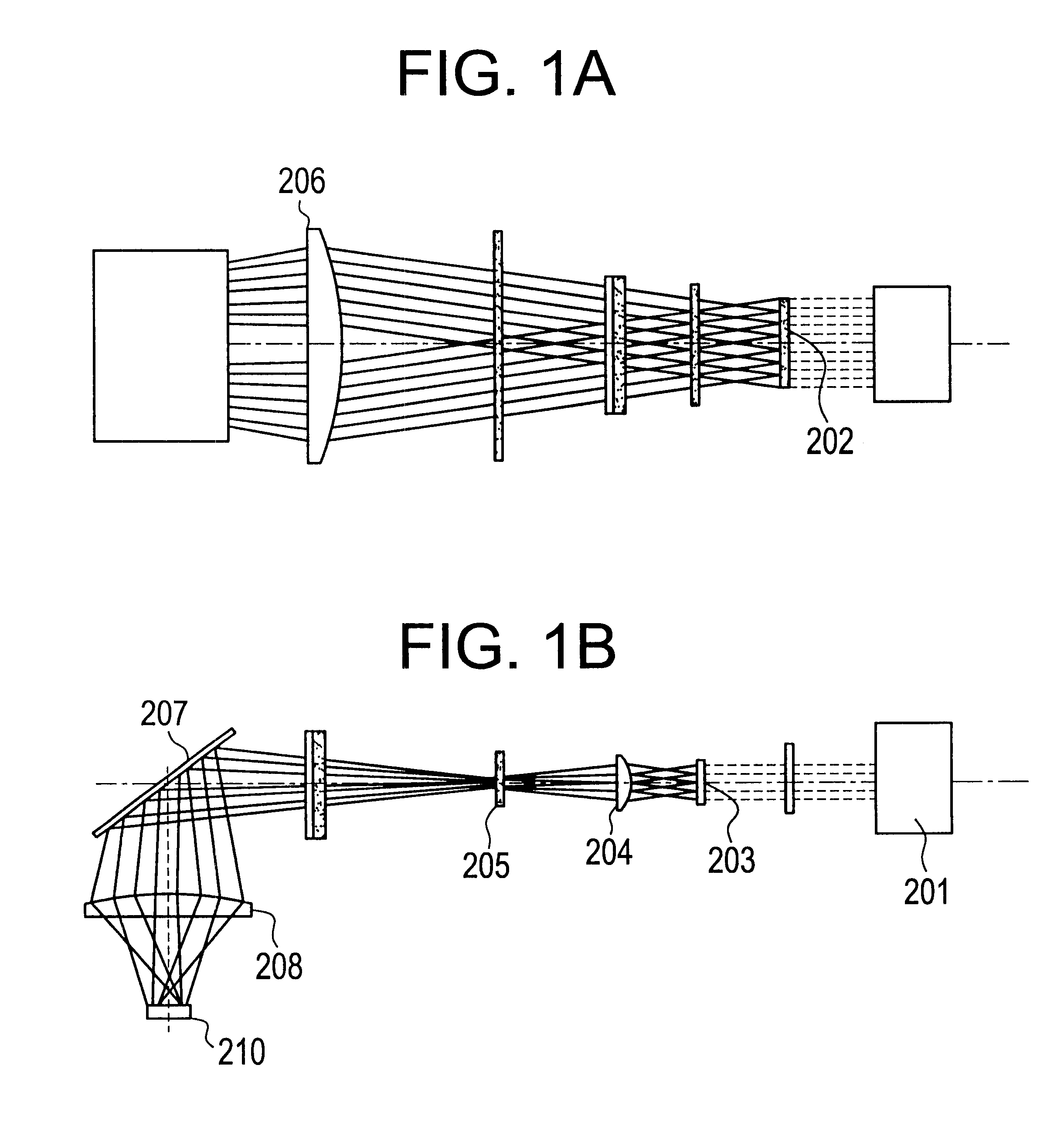

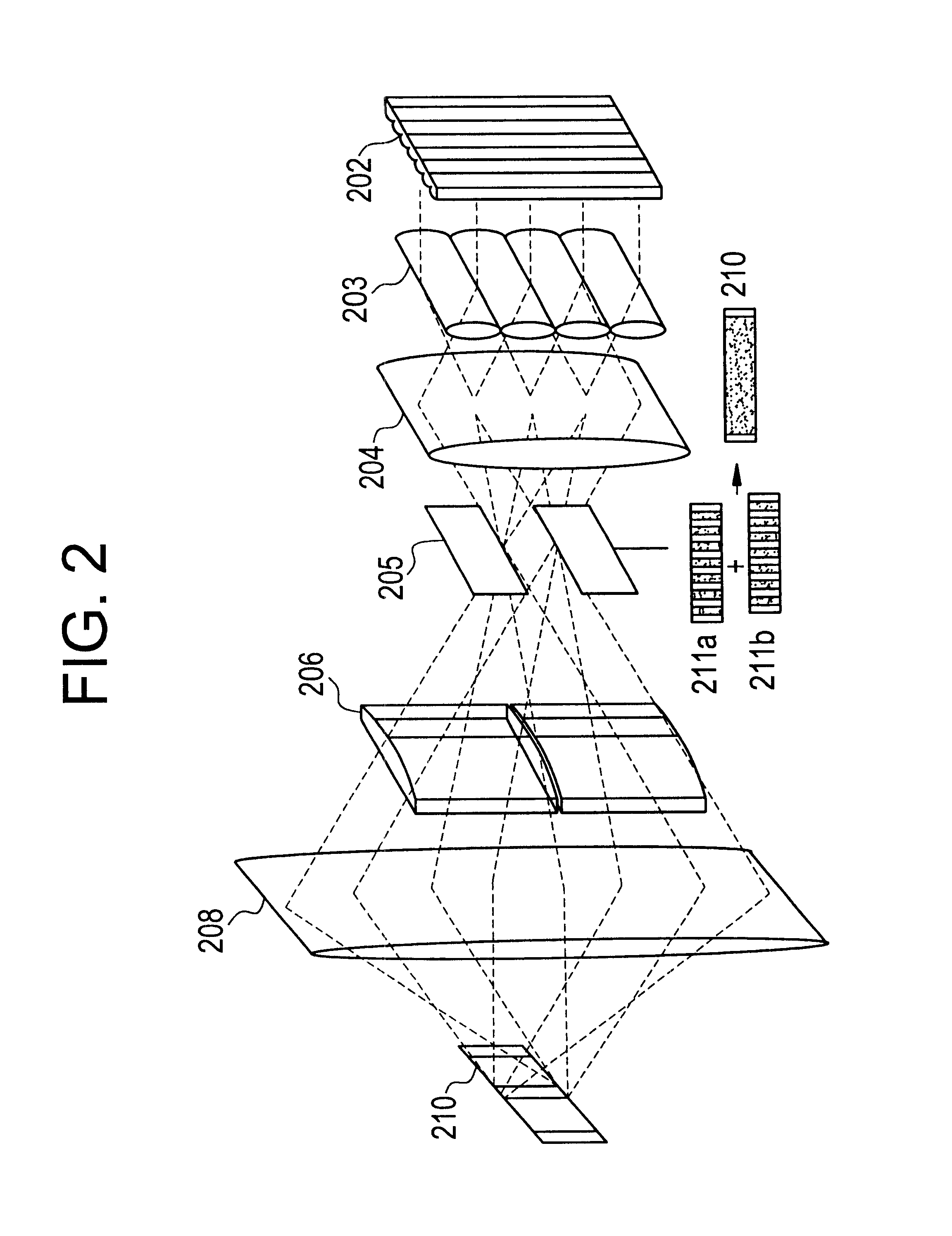

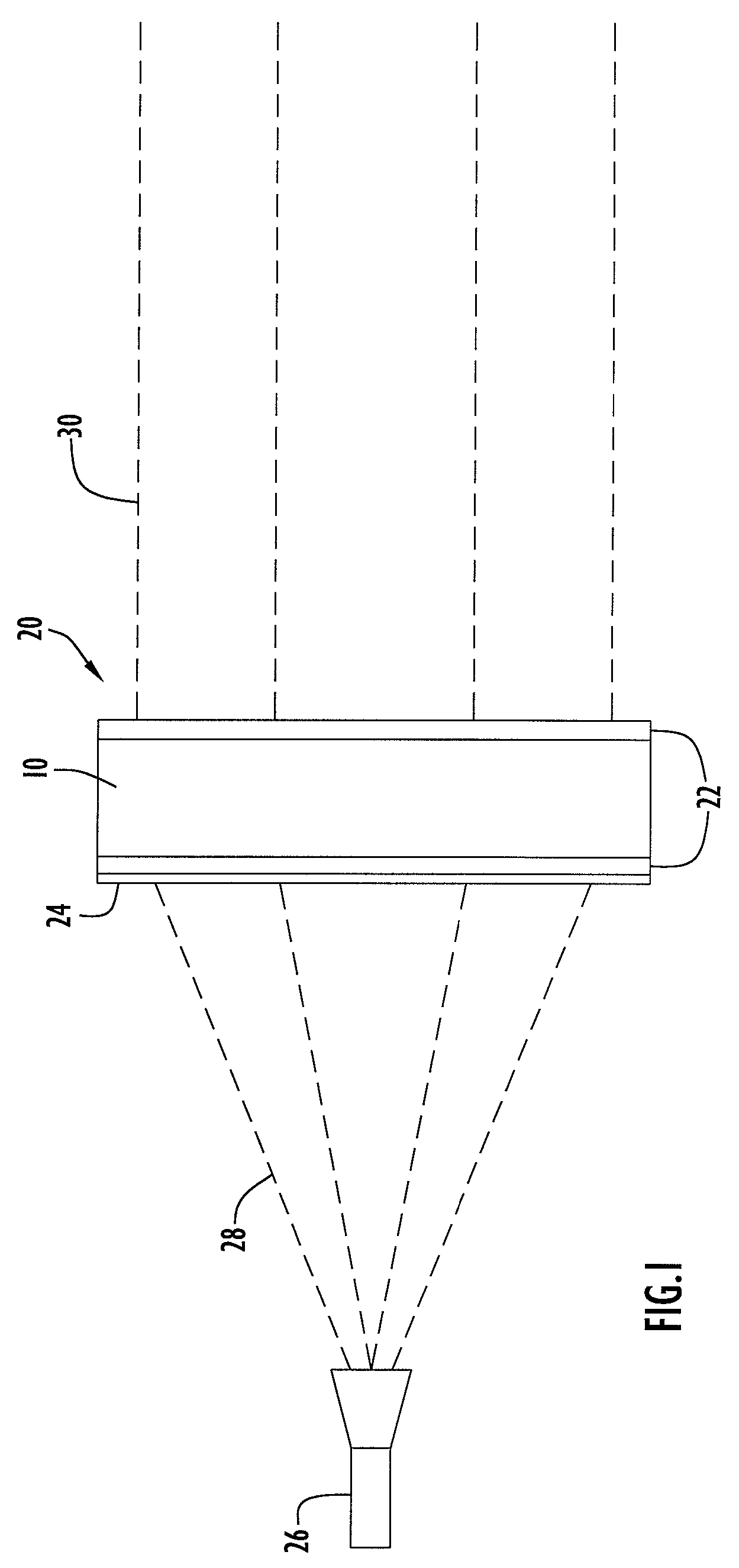

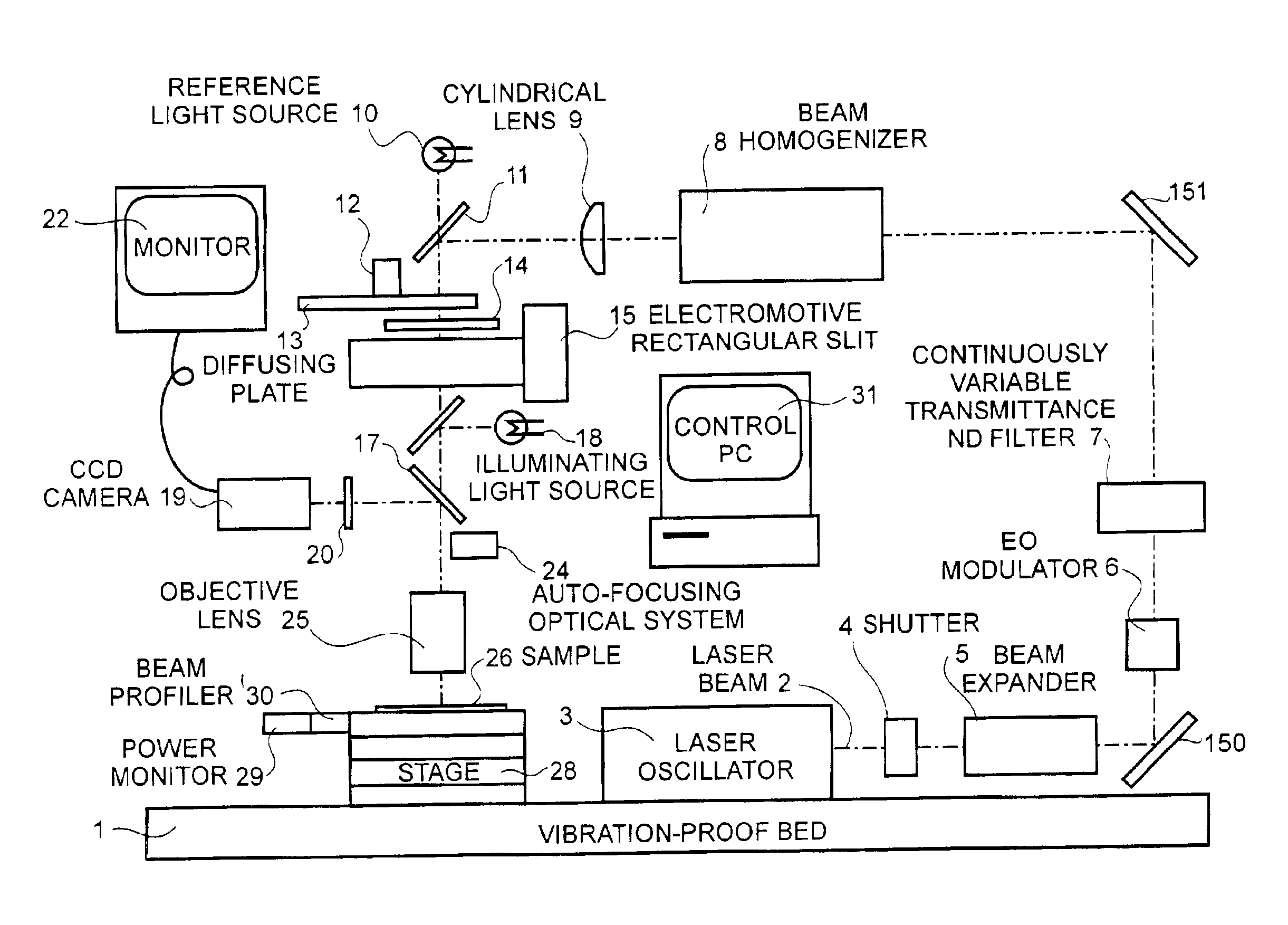

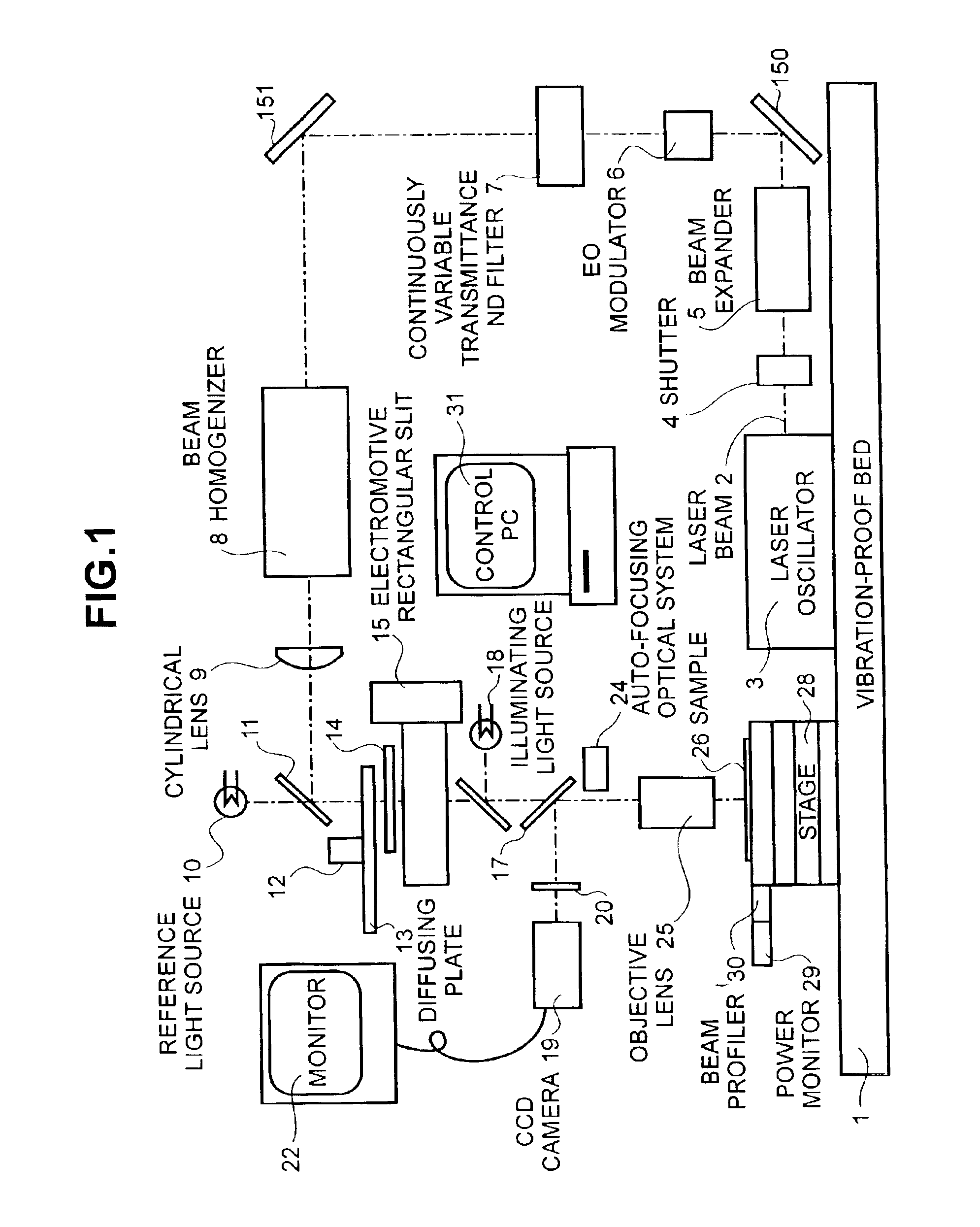

Beam homogenizer and laser irradiation apparatus

InactiveUS6393042B1Semiconductor/solid-state device manufacturingOptical resonator shape and constructionLight beamOptoelectronics

There is provided a beam homogenizer which can unify the energy distribution of a linear laser beam in a longitudinal direction. In the beam homogenizer including cylindrical lens groups for dividing a beam, and a cylindrical lens and a cylindrical lens group for condensing the divided beams, the phases, in the longitudinal direction, of linear beams passing through individual cylindrical lenses of the cylindrical lens group for condensing the divided beams are shifted, and then, the beams are synthesized, so that the intensity of interference fringes of the linear beam on a surface to be irradiated is made uniform.

Owner:SEMICON ENERGY LAB CO LTD

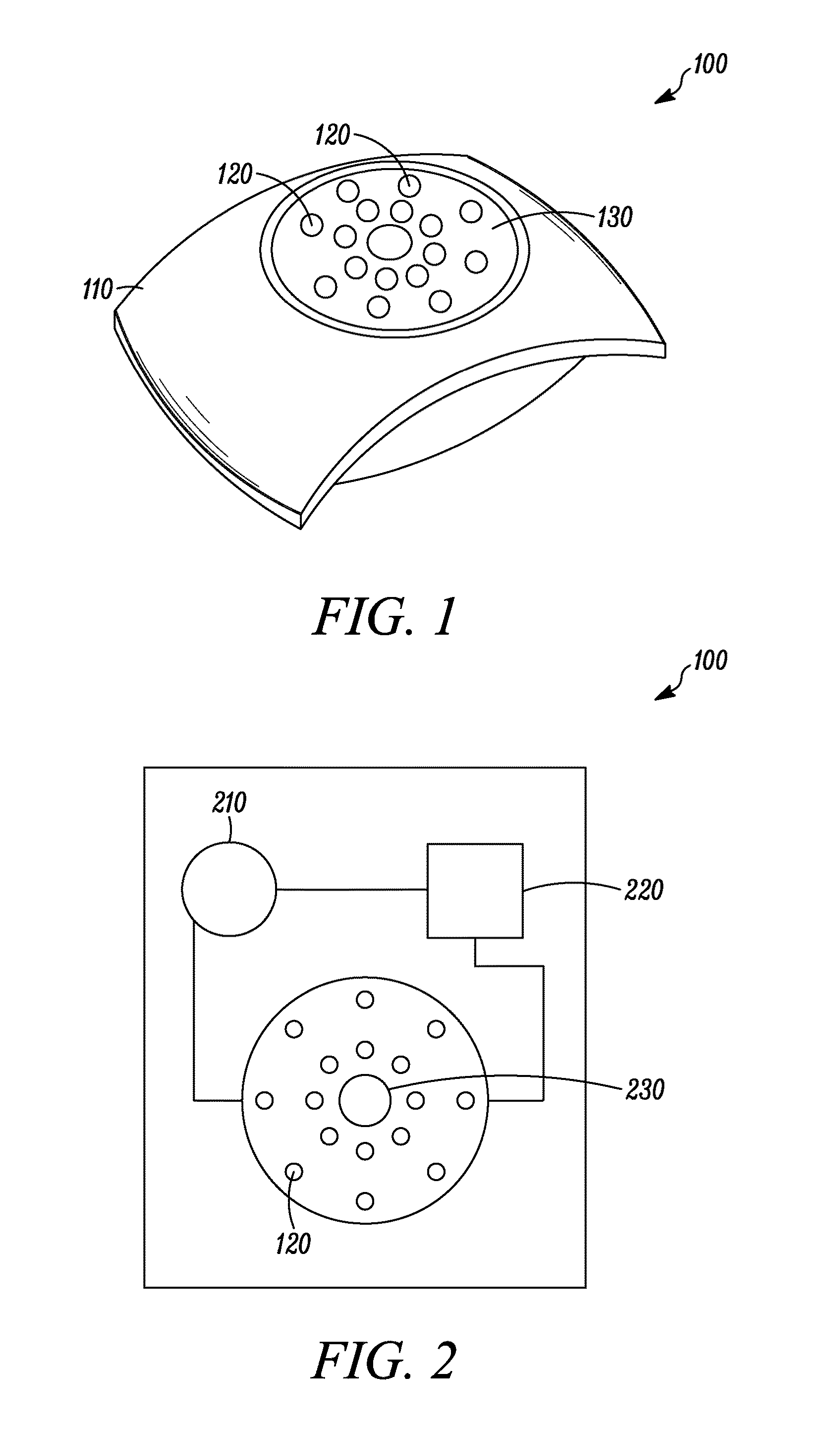

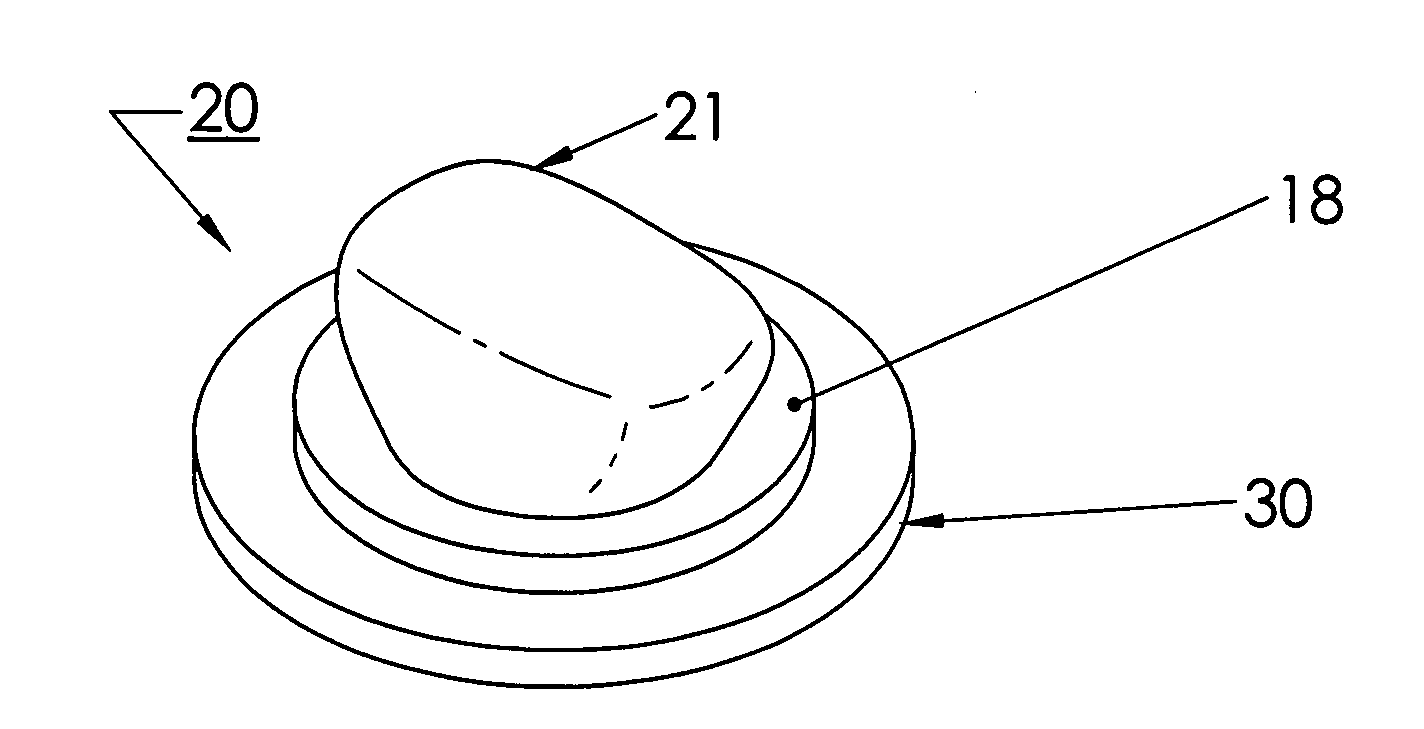

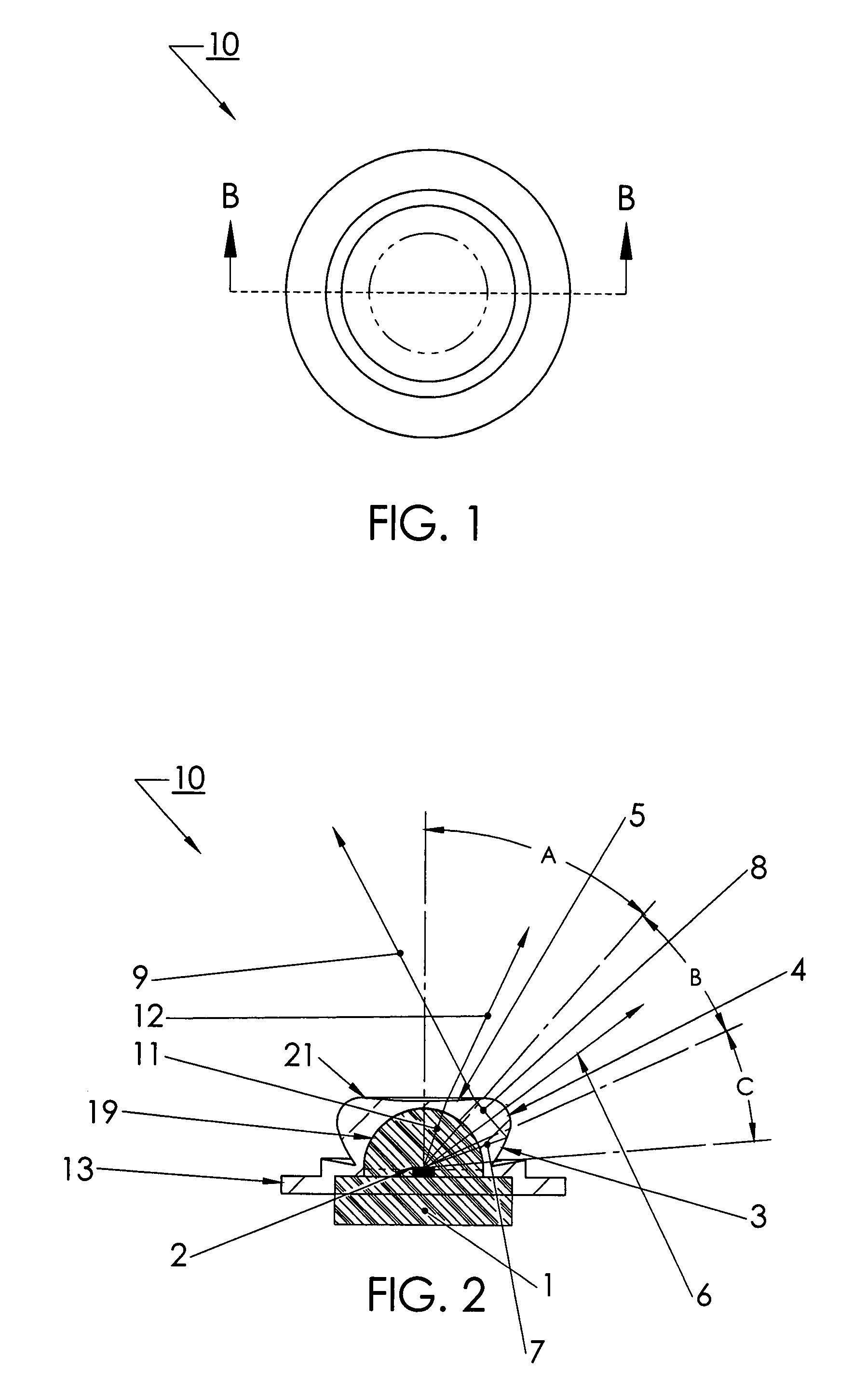

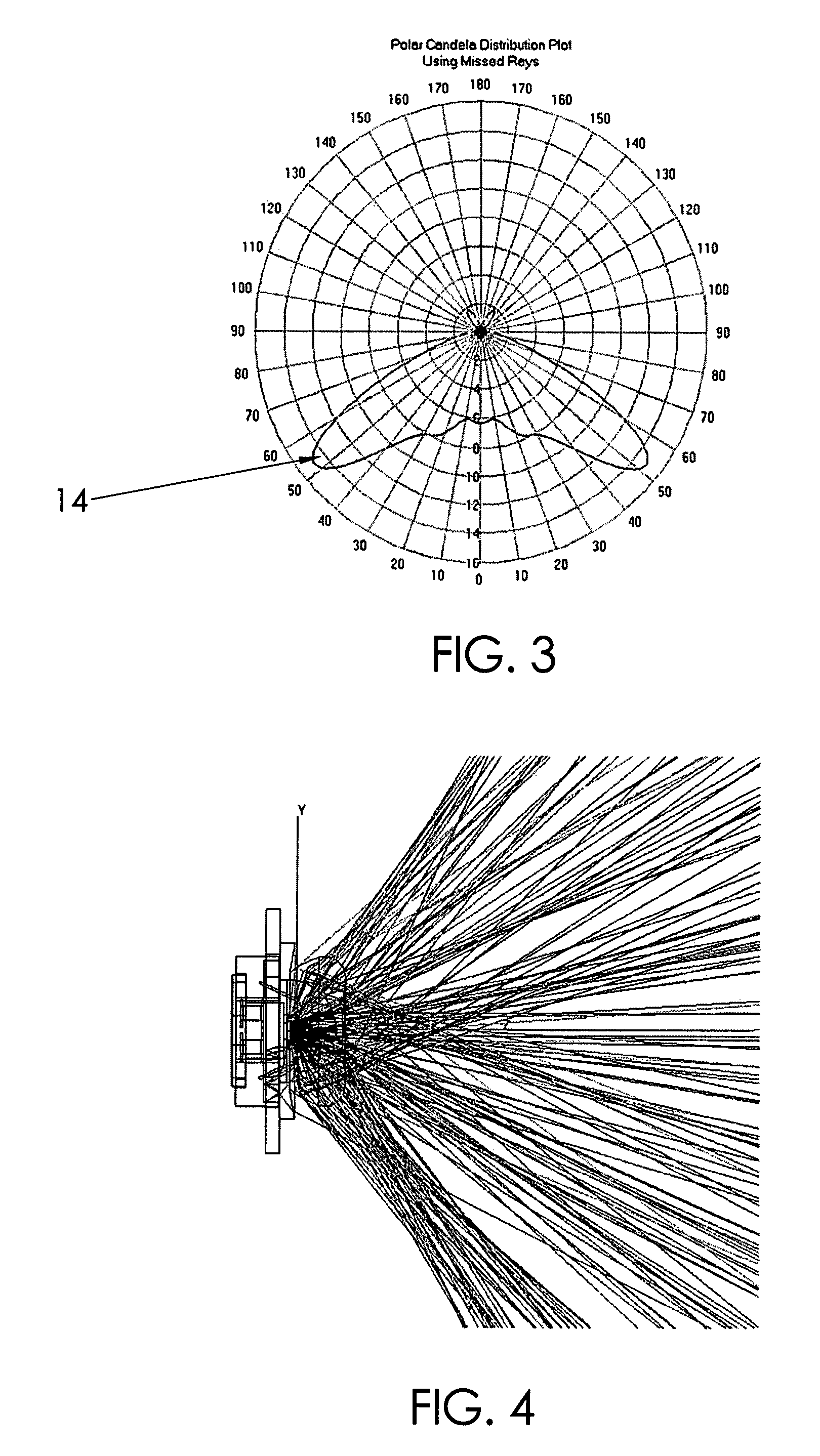

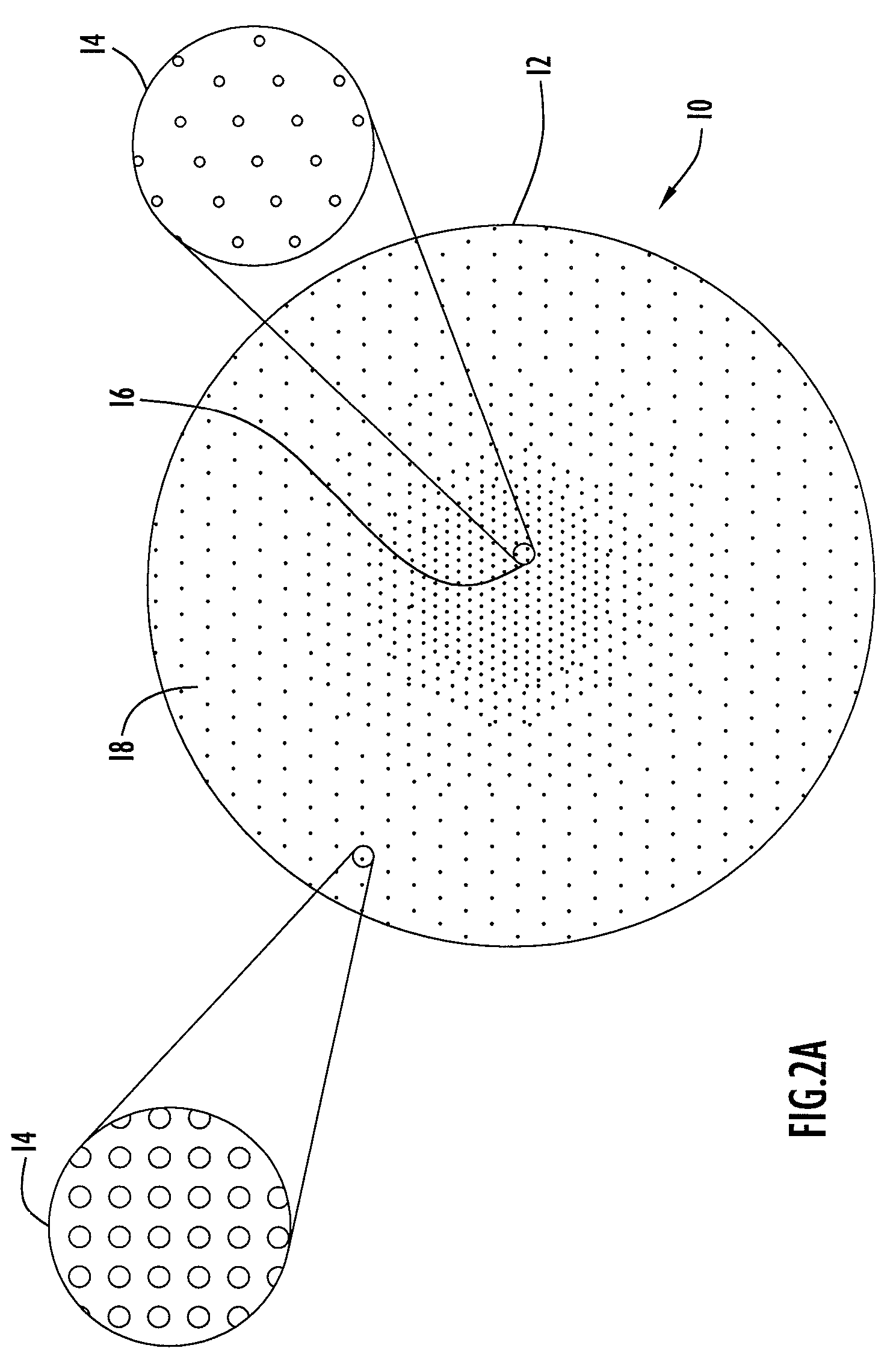

LED device for wide beam generation

ActiveUS7674018B2Easy to combineReduce discontinuityPlanar light sourcesMechanical apparatusSurface patternWide beam

An apparatus and method is characterized by providing an optical transfer function between a predetermined illuminated surface pattern, such as a street light pattern, and a predetermined energy distribution pattern of a light source, such as that from an LED. A lens is formed having a shape defined by the optical transfer function. The optical transfer function is derived by generating an energy distribution pattern using the predetermined energy distribution pattern of the light source. Then the projection of the energy distribution pattern onto the illuminated surface is generated. The projection is then compared to the predetermined illuminated surface pattern to determine if it acceptably matches. The process continues reiteratively until an acceptable match is achieved. Alternatively, the lens shape is numerically or analytically determined by a functional relationship between the shape and the predetermined illuminated surface pattern and predetermined energy distribution pattern of a light source as inputs.

Owner:SIGNIFY HLDG BV

Energy-efficient solar-powered outdoor lighting

InactiveUS20120020060A1Guaranteed uptimeEffectively serveLighting support devicesPoint-like light sourceElectrical batteryOperability

One or more outdoor lights may operate independently with sensing and control processes mainly on-pole, or may communicate as a networked array of poles, wherein a master / coordinating pole / node transmits signals from the networked array to a control station, and receive signals from the control station for the networked array, via call phone and / or satellite. Independent poles and / or the networked array of poles may be adapted for energy-saving processes; cooperation with the grid; renewable power production and storage by means of solar panels and associated batteries; and / or to provide Wi-Fi hot-spots, public safety alarms, information or data-analysis to the public or customers. An energy-saving active control system controls charging of the batteries and distribution of energy from the solar panel and / or the batteries, so that the batteries remain undamaged, and the light(s) remain operation even during the winter or other long periods of clouds and diffuse light. The active control of energy distribution by a load controller function may include dimming during the night, except when sensors detect motion, and, in extreme cloudy or diffuse-light periods, increasing increments of dimming and / or load shedding, to preserve the batteries and operability.

Owner:INOVUS SOLAR

Mechanically removable wireless power vehicle seat assembly

ActiveUS20130221744A1Efficient deliveryEfficient energy transferMultiple-port networksCircuit monitoring/indicationHigh conductivityElectric power

Described herein are improved capabilities for a system and method for wireless energy distribution to a mechanically removable vehicle seat, comprising a source resonator coupled to an energy source of a vehicle, the source resonator positioned proximate to the mechanically removable vehicle seat, the source resonator generating an oscillating magnetic field with a resonant frequency and comprising a high-conductivity material adapted and located between the source resonator and a vehicle surface to direct the oscillating magnetic field away from the vehicle surface, and a receiving resonator integrated into the mechanically removable vehicle seat, the receiving resonator having a resonant frequency similar to that of the source resonator, and receiving wireless energy from the source resonator, and providing power to electrical components integrated with the mechanically removable vehicle seat.

Owner:WITRICITY CORP

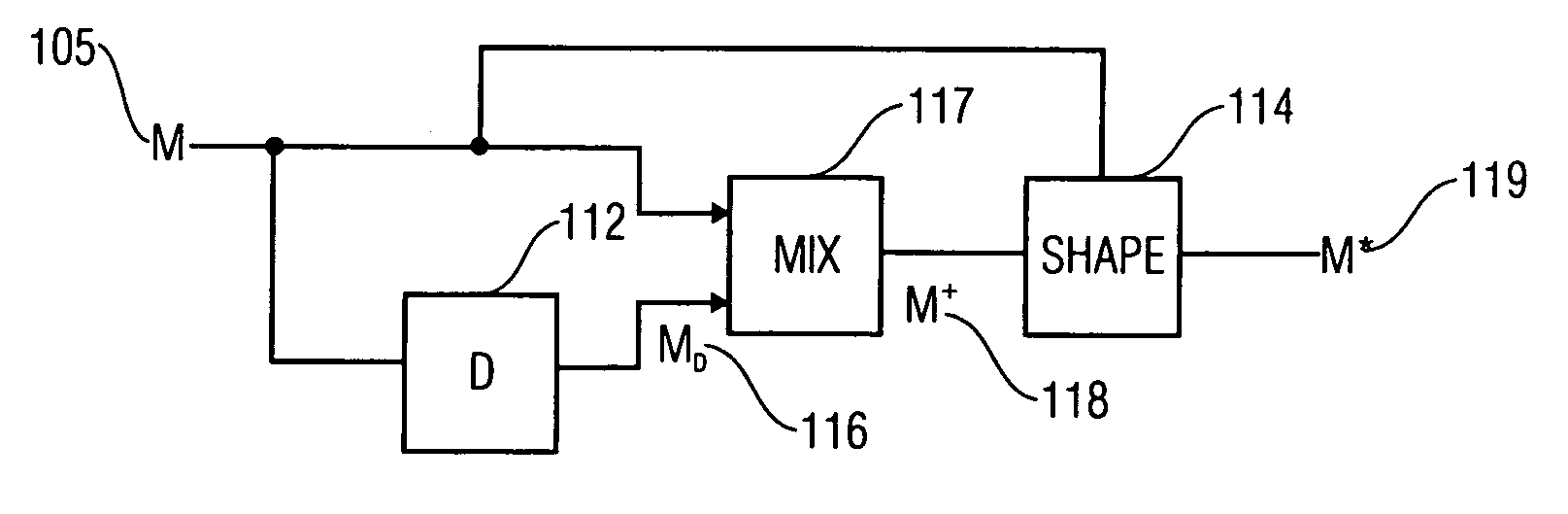

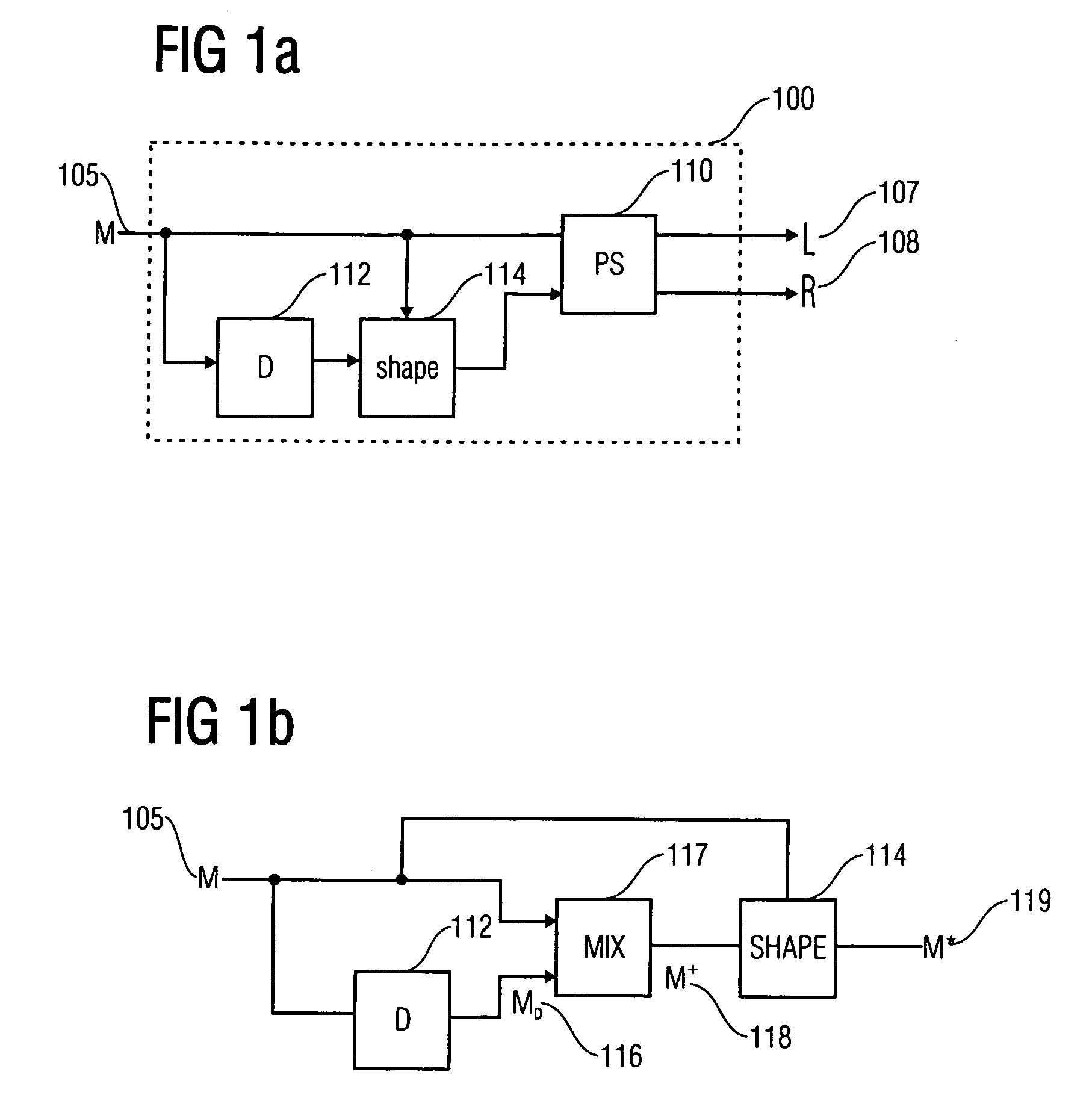

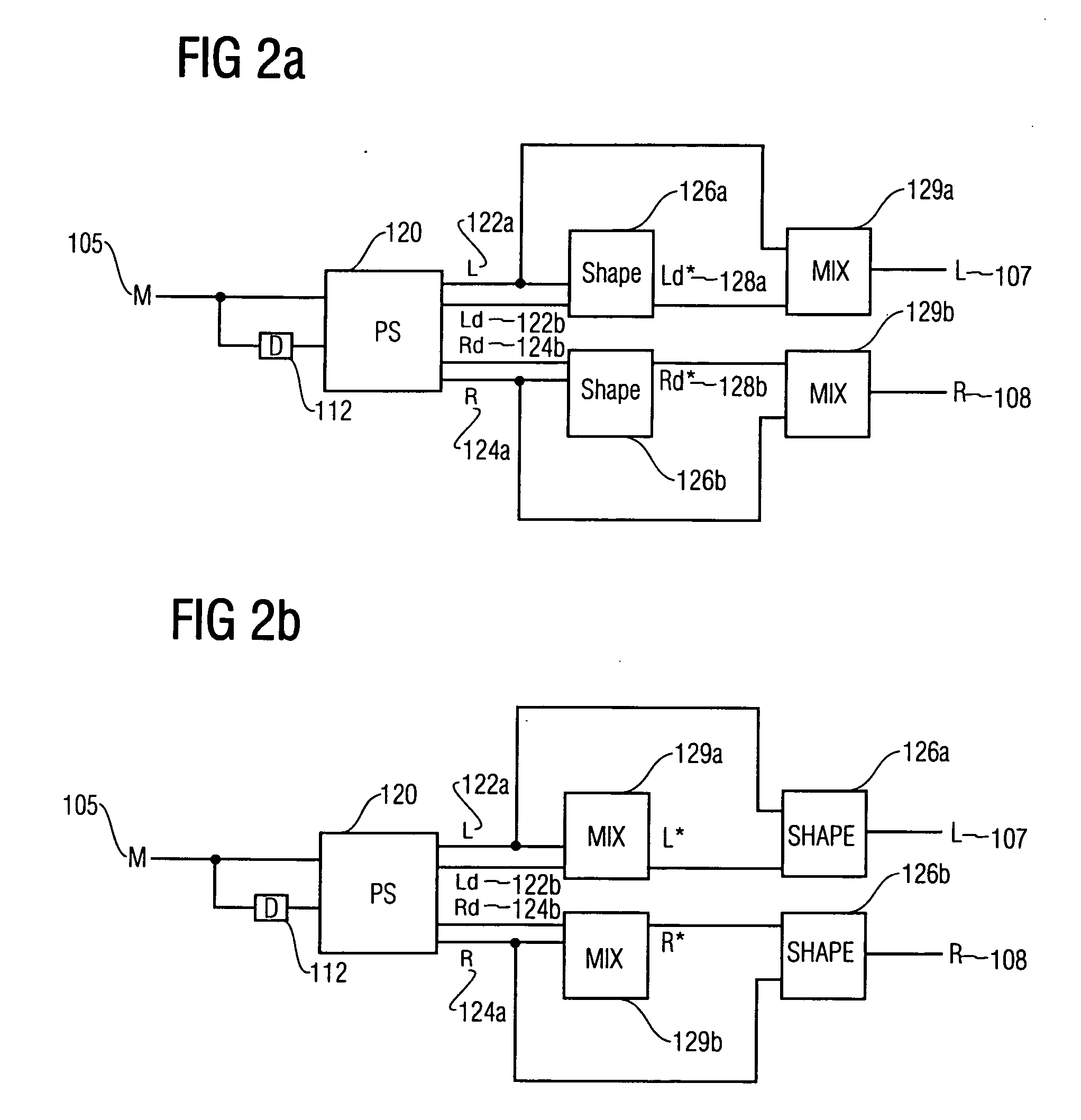

Envelope shaping of decorrelated signals

ActiveUS20060239473A1Avoid introducingEffective shapingSpeech analysisPseudo-stereo systemsFrequency spectrumDistortion

The envelope of a decorrelated signal derived from an original signal can be shaped without introducing additional distortion, when a spectral flattener is used to spectrally flatten the spectrum of the decorrelated signal and the original signal prior to using the flattened spectra for deriving a gain factor describing the energy distribution between the flattened spectra, and when the so derived gain factor is used by an envelope shaper to timely shape the envelope of the decorrelated signal.

Owner:DOLBY INT AB +1

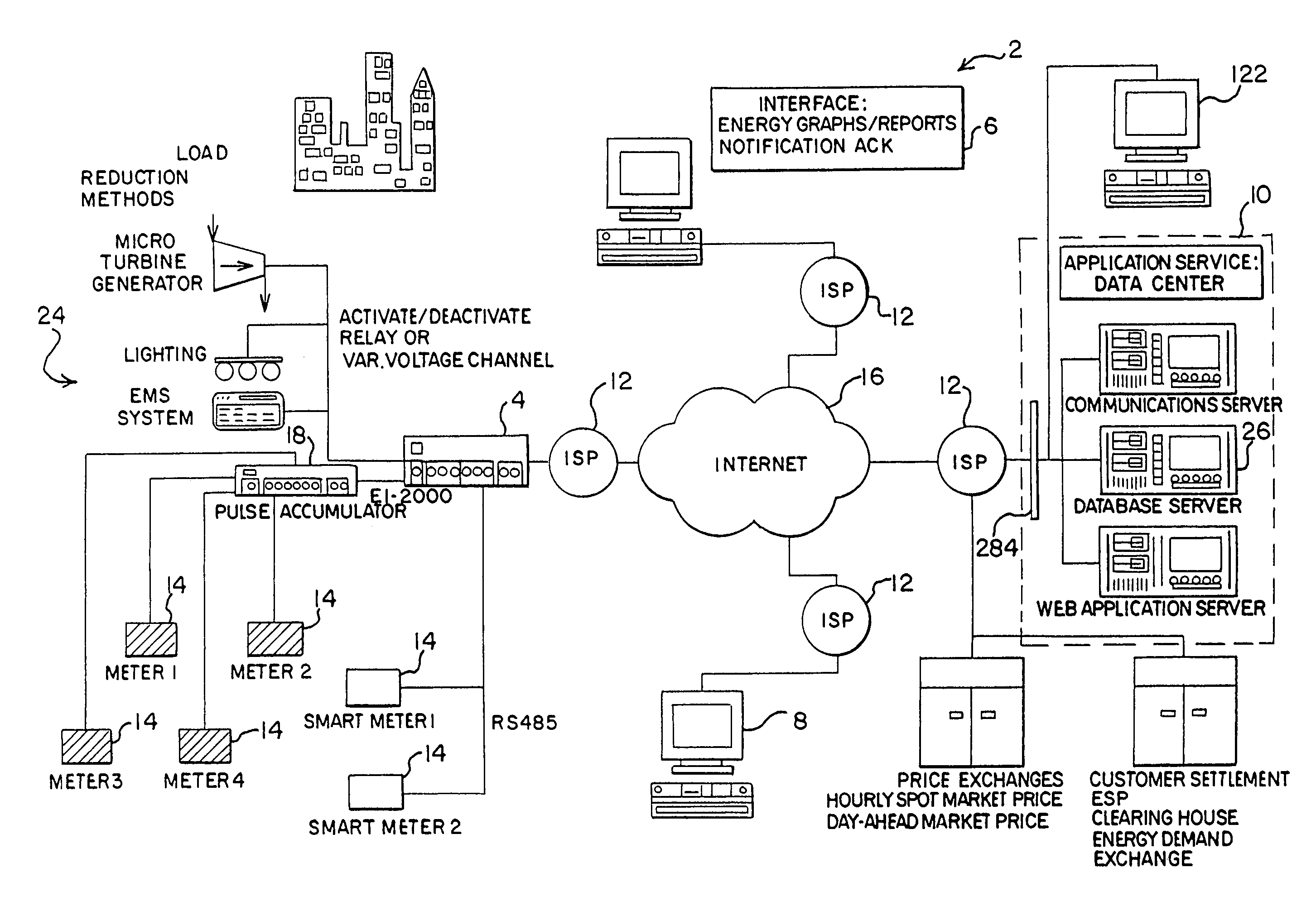

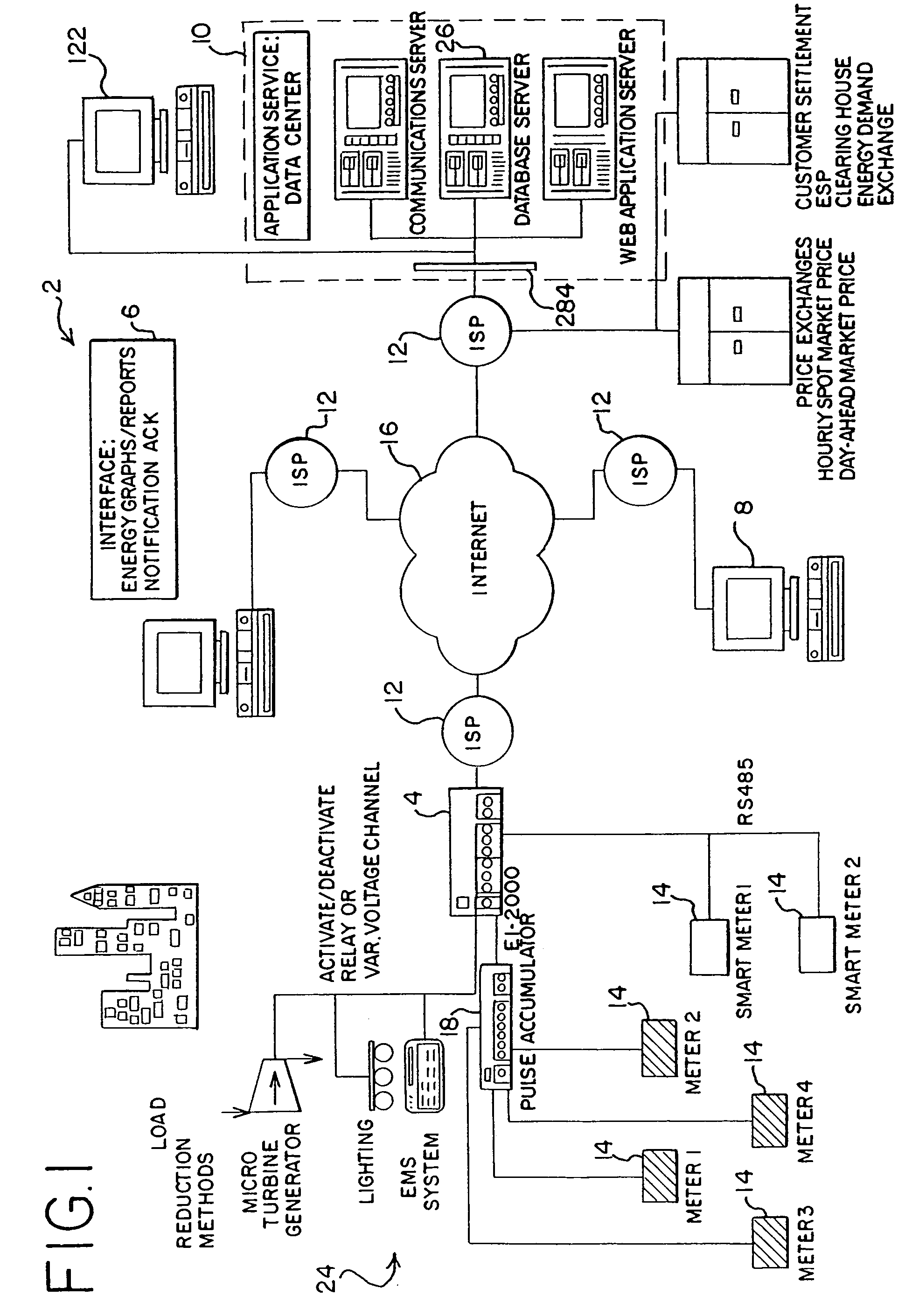

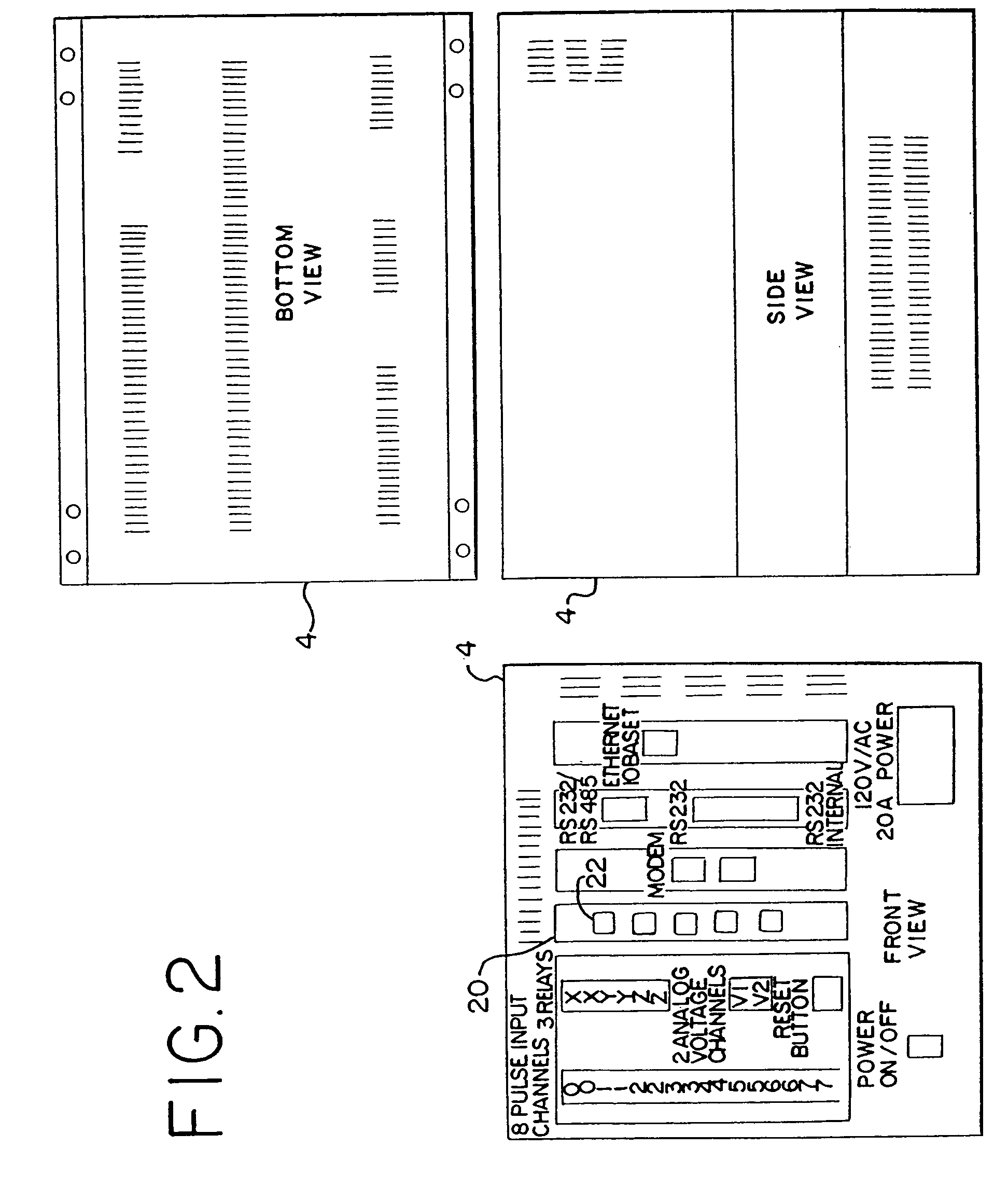

System and method for monitoring and controlling energy distribution

InactiveUS7088014B2Dc network circuit arrangementsData processing applicationsService provisionSystems management

Systems that monitor and control energy distribution manage energy distribution or use for Energy Service Providers and end-users. A system includes a publicly or privately accessible distributed network, a network access device, and a management device. The network access device communicates with the management device through the distributed network to control loads at a remote location. The method of monitoring and controlling energy distribution receives data at an on-line Site, processes an application program that evaluates load and market supply data, and initiates power curtailment requests or power curtailment events.

Owner:STONEWATER CONTROL SYST

Optimization of microgrid energy use and distribution

ActiveUS20110035073A1Low costCostBatteries circuit arrangementsLevel controlPersonalizationMicrogrid

Owner:INTEGRAL ANALYTICS

Radio frequency lens and method of suppressing side-lobes

ActiveUS7777690B2Weaken energyImproves Structural IntegrityAntennasPhotonic crystal structureCrystal structure

An RF lens according to the present invention embodiments collimates an RF beam by refracting the beam into a beam profile that is diffraction-limited. The lens is constructed of a lightweight mechanical arrangement of two or more materials, where the materials are arranged to form a photonic crystal structure (e.g., a series of holes defined within a parent material). The lens includes impedance matching layers, while an absorptive or apodizing mask is applied to the lens to create a specific energy profile across the lens. The impedance matching layers and apodizing mask similarly include a photonic crystal structure. The energy profile function across the lens aperture is continuous, while the derivatives of the energy distribution function are similarly continuous. This lens arrangement produces a substantial reduction in the amount of energy that is transmitted in the side-lobes of an RF system.

Owner:HARRIS CORP

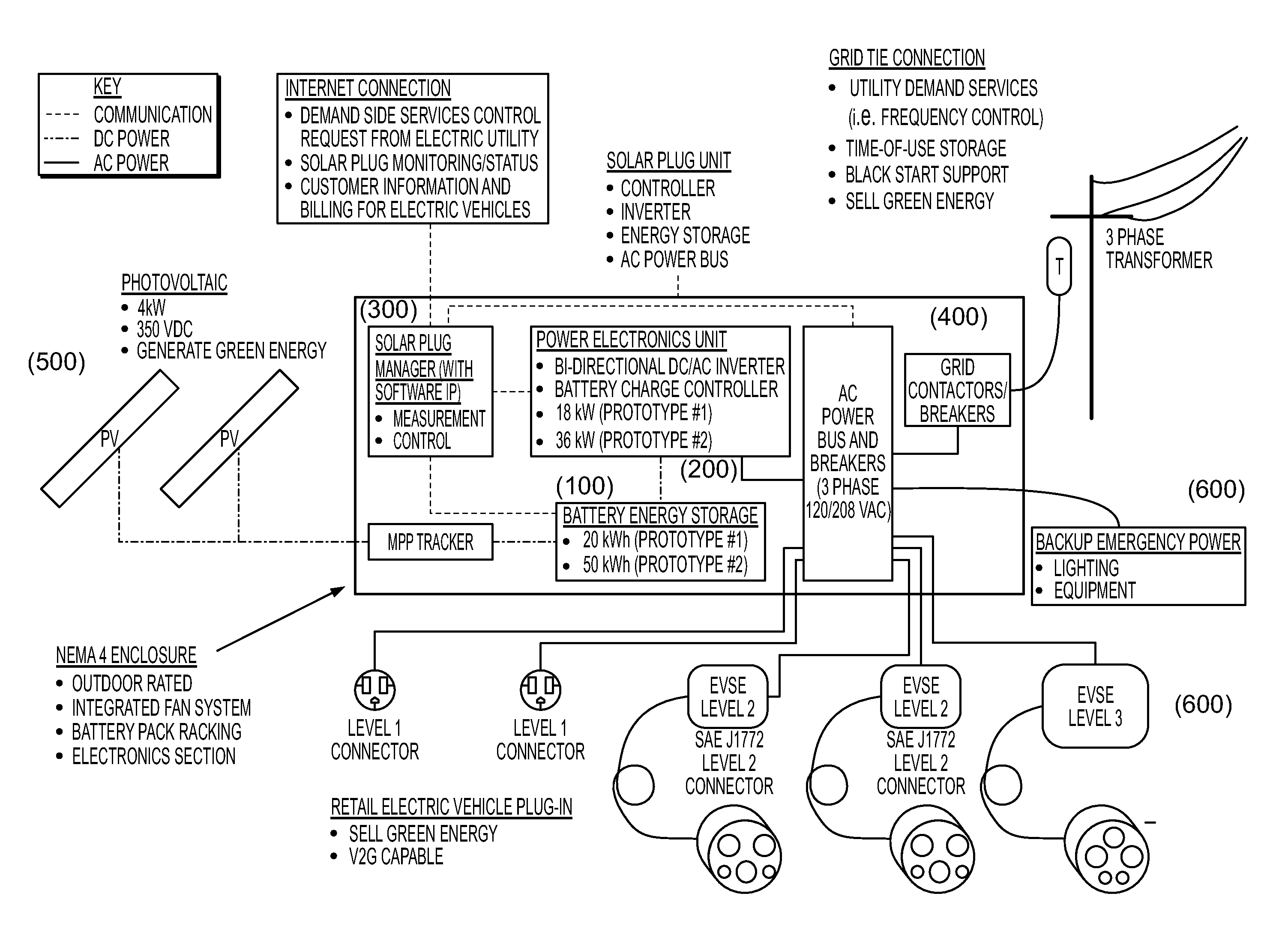

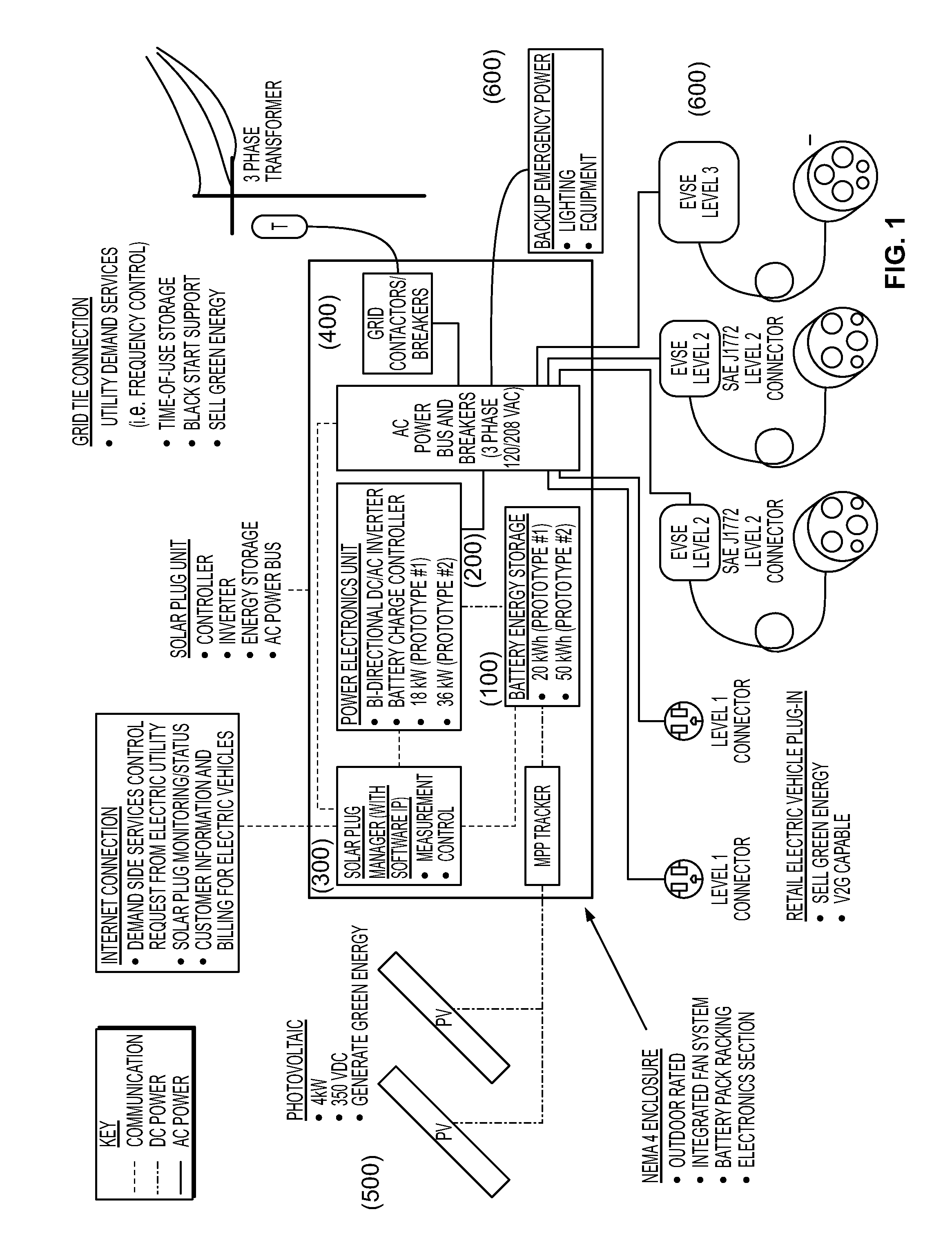

System and method for energy management

InactiveUS20110276194A1Meet charging requirementsLevel controlVehicular energy storageEnergy storageElectric power

The present invention provides for multiple energy pooling stations to combine renewable energy, utility energy and back-up power services in the form of Green and Black Energy with energy storage to create a multi-income stream. An energy pooling station is an advanced part of an evolving “energy network” in which multiple energy pooling stations are communicating with each other to share energy credit, bank energy, and distribute the energy to customers.

Owner:ENERGY INVESTMENT FUND

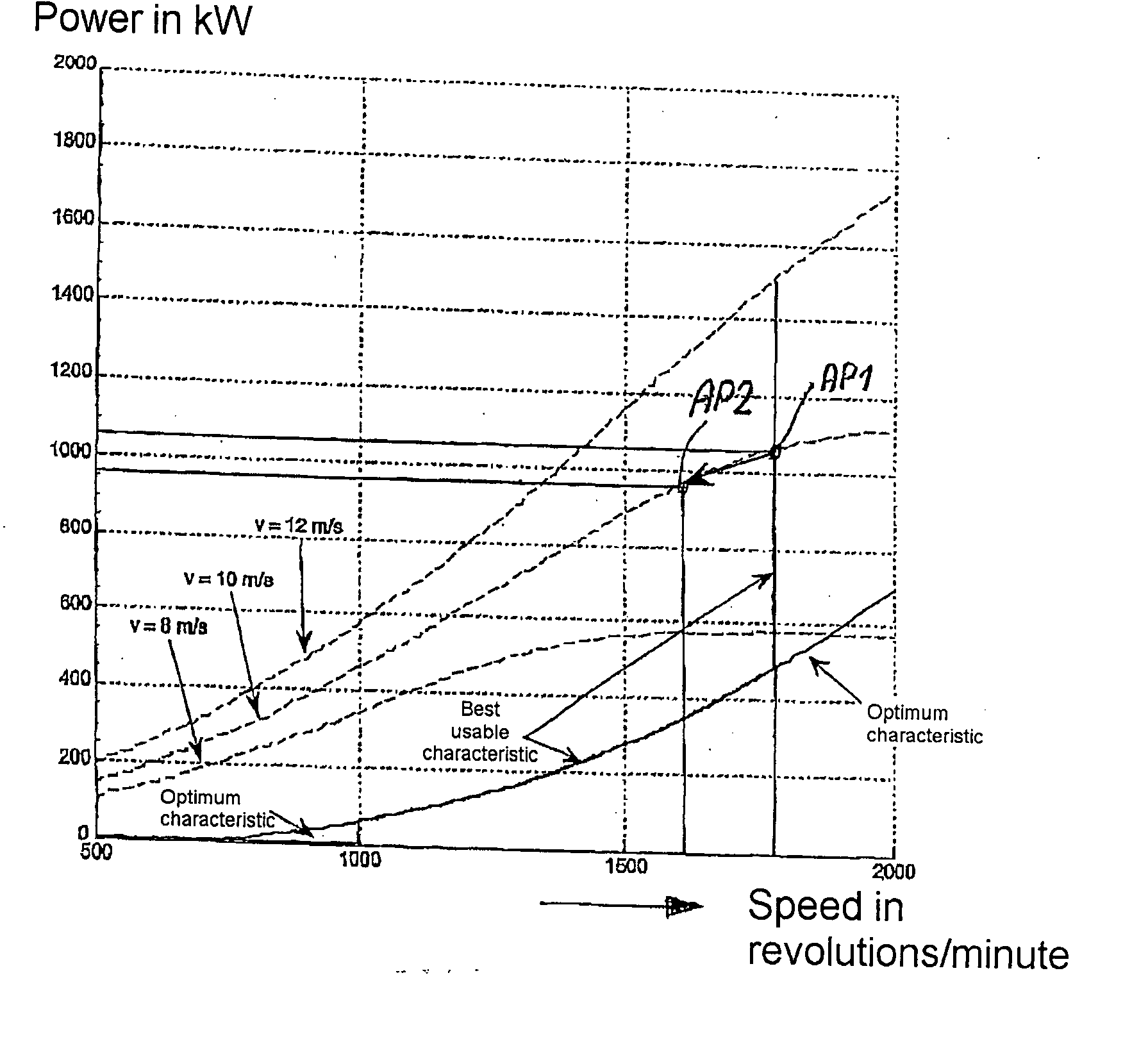

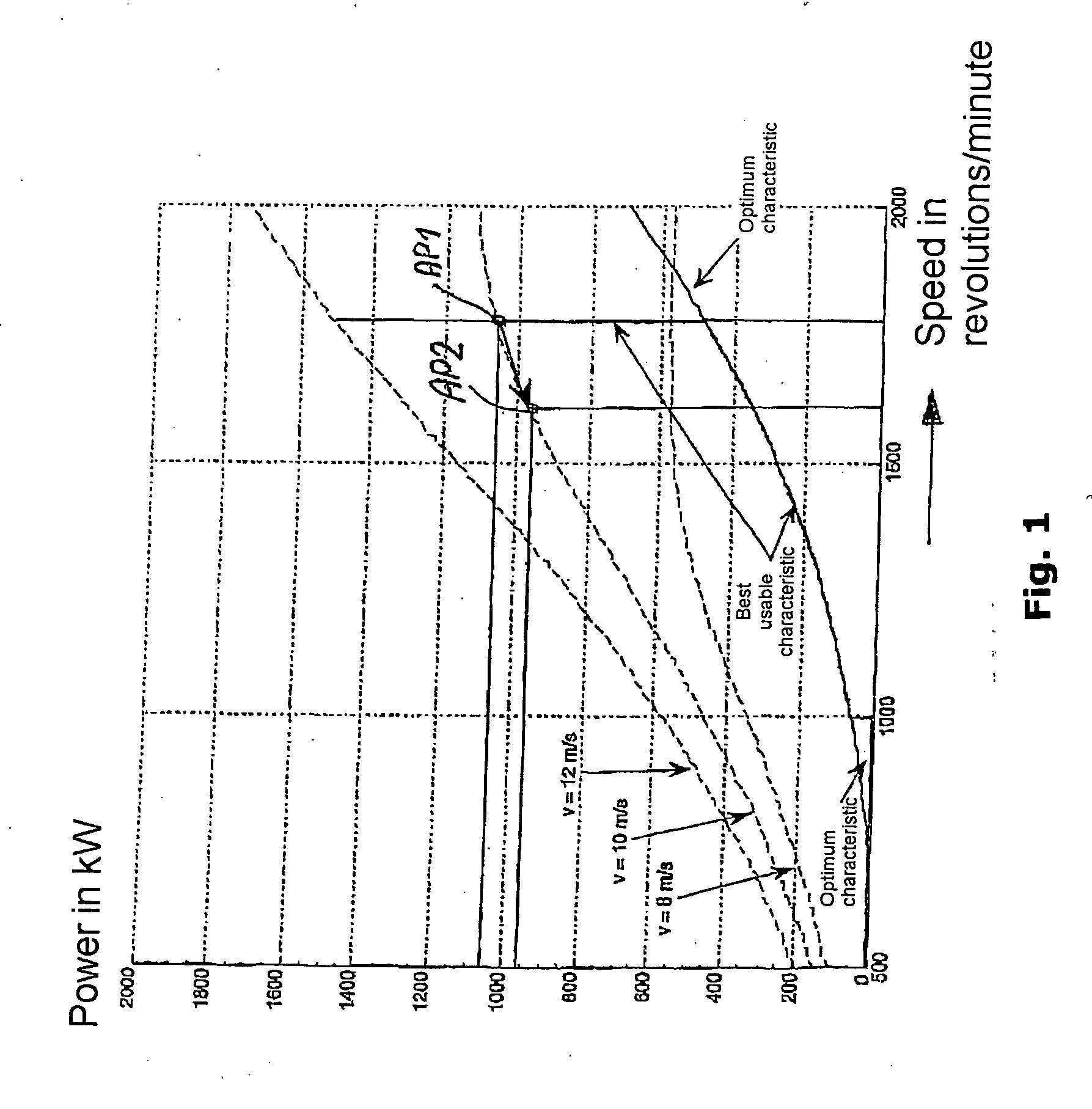

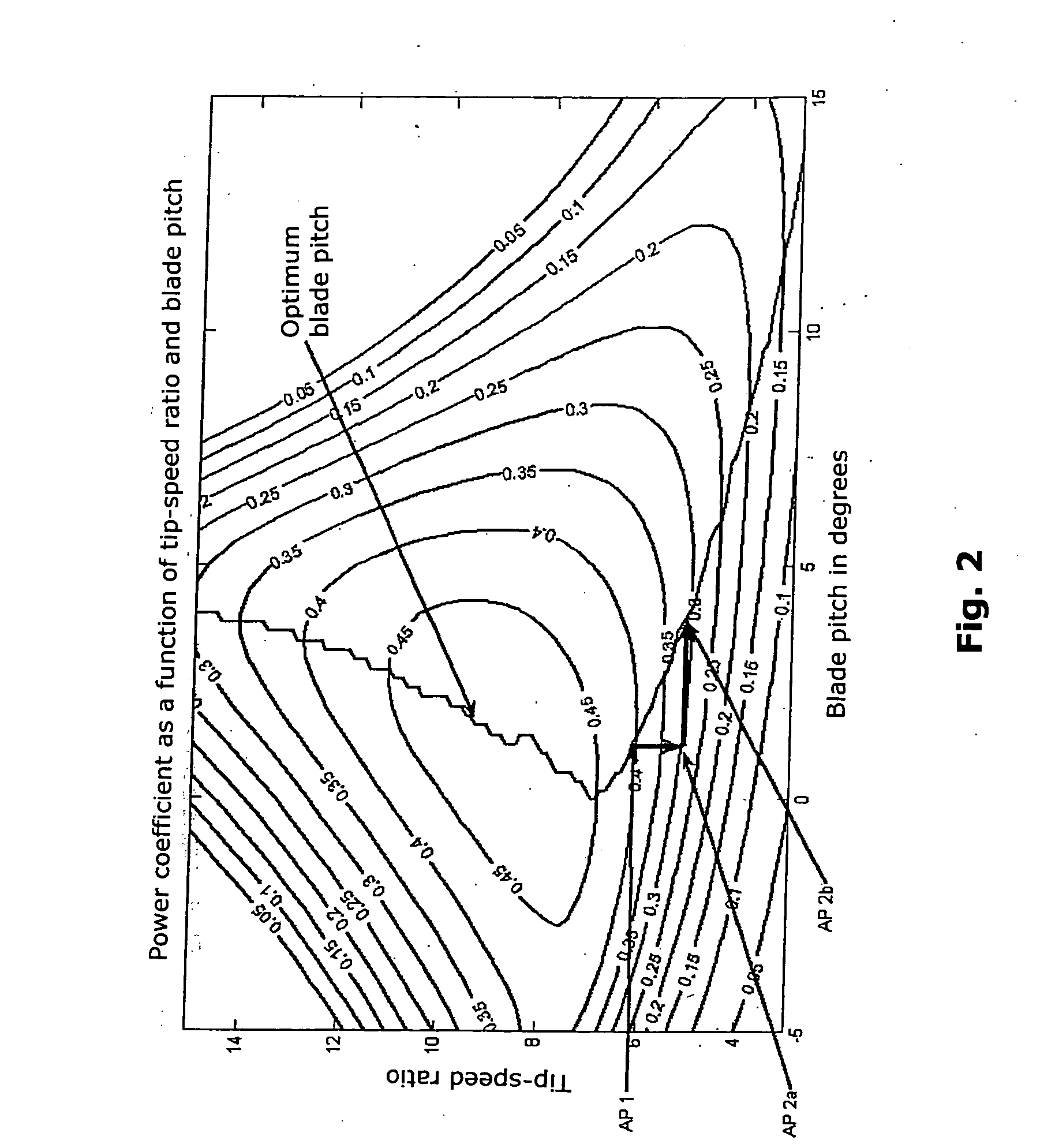

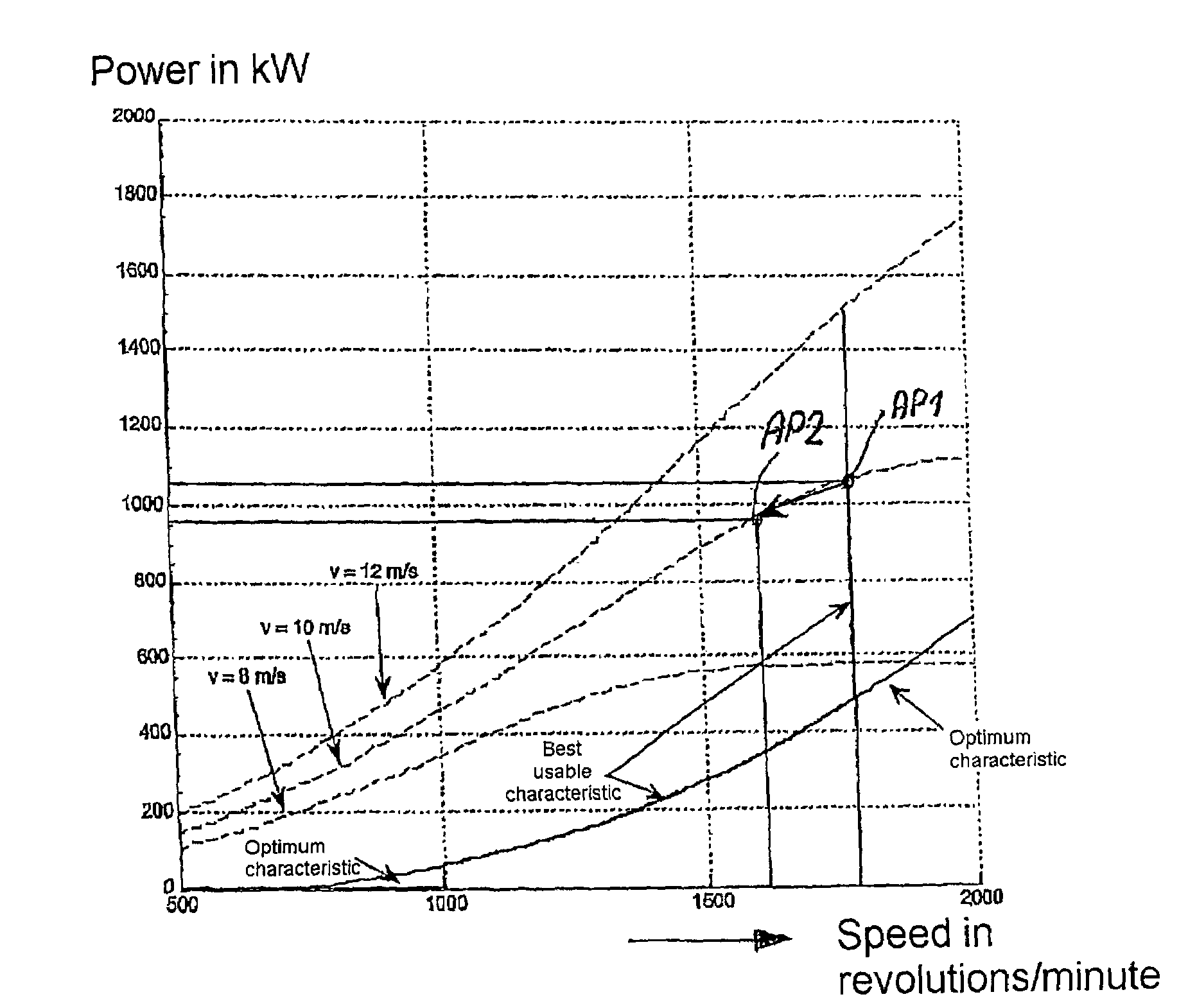

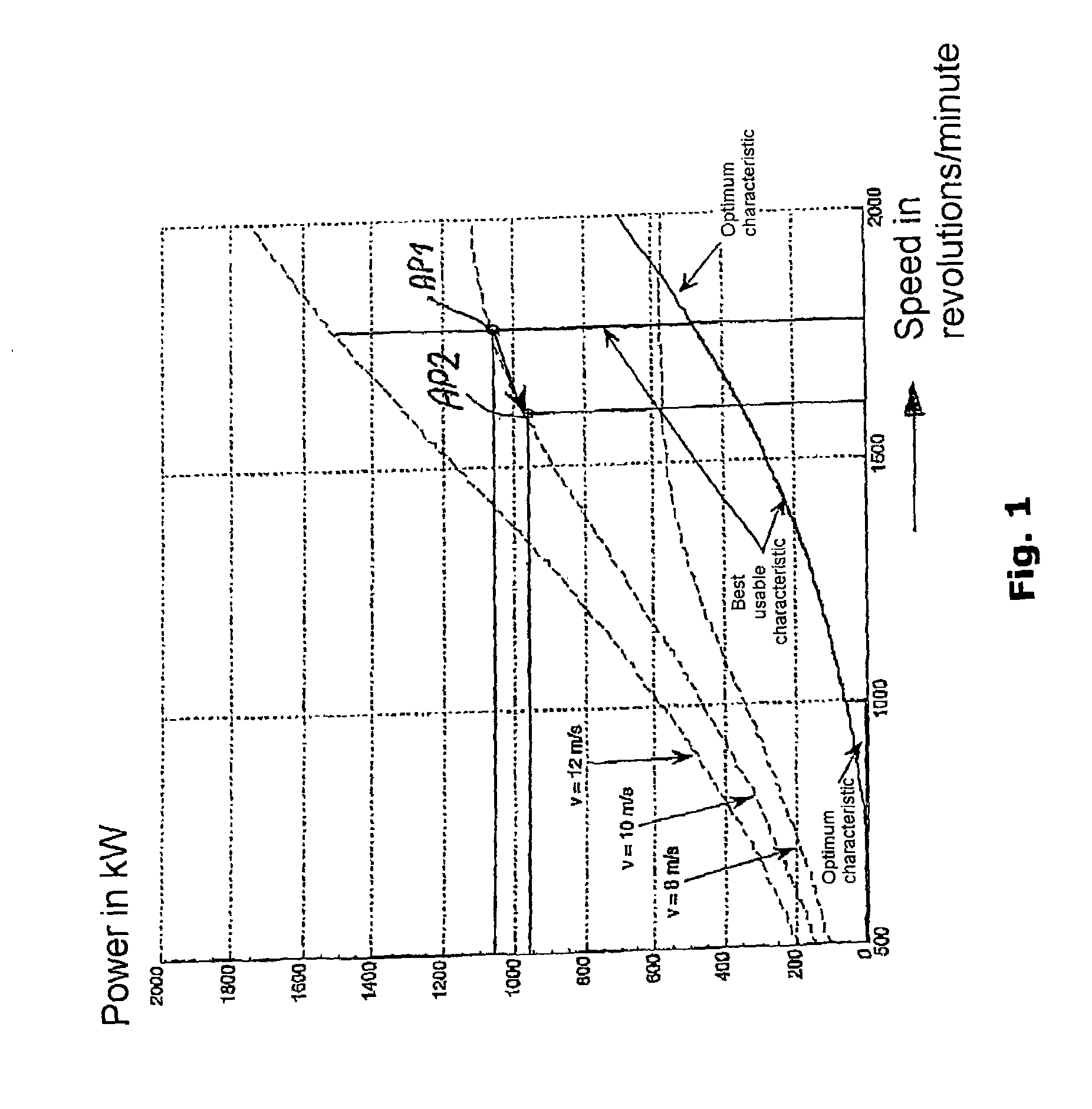

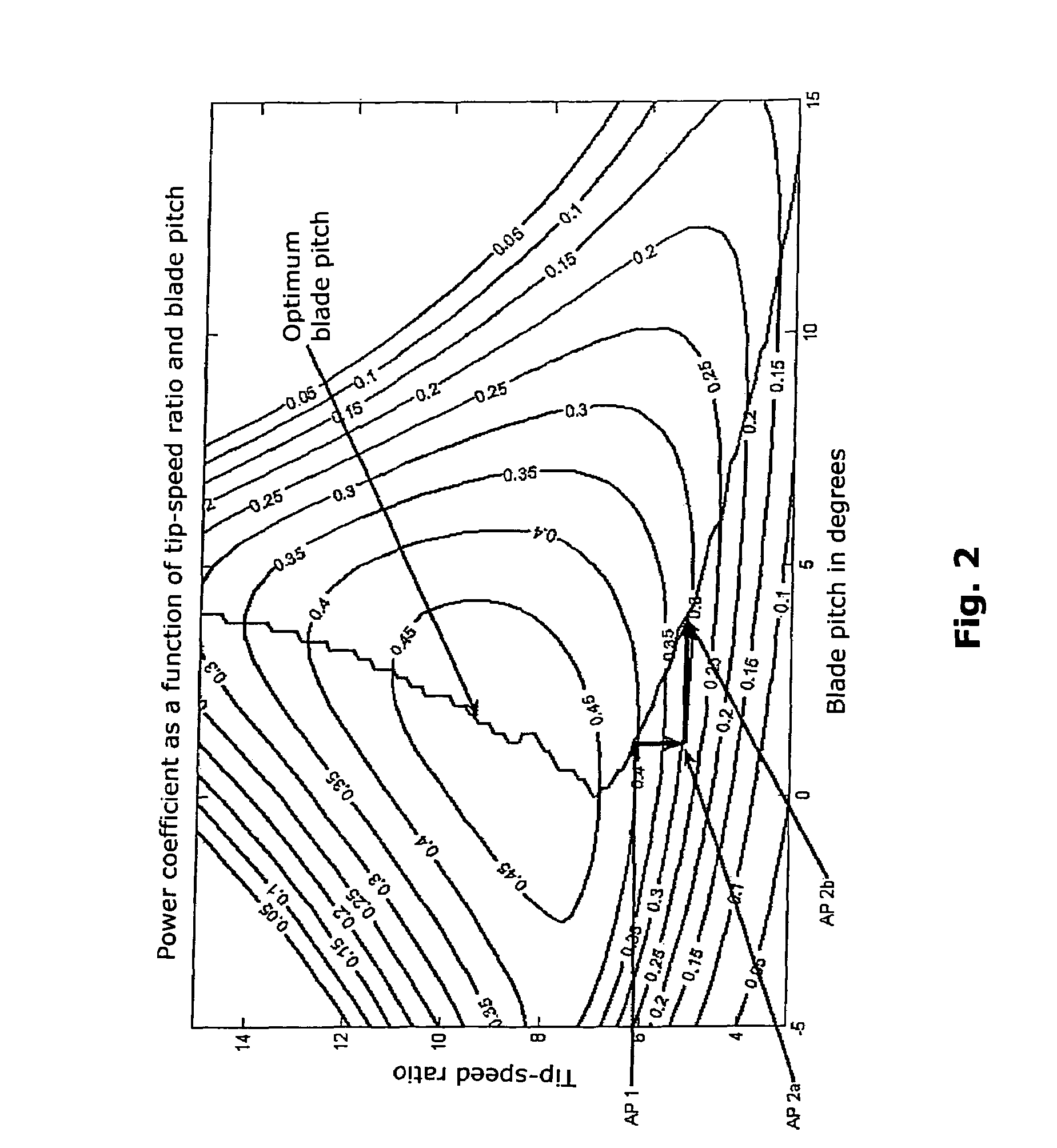

Method for operating or controlling a wind turbine and method for providing primary control power by means of wind turbines

ActiveUS20070085343A1Reduce yield lossImprove power transmissionWind motor controlSingle network parallel feeding arrangementsElectric forcePower station

A method for operating at least one wind turbine with a rotor and an electric generator coupled to the rotor for delivering electrical power into an energy distribution system with the aid of a control device ensures that the wind turbine operates within its operating range. The wind turbine is controlled in response to the change of a system operating parameter and for a period of time, in such a manner that a higher power is fed into the system than belongs to the operating range of the steady-state operation. The same conditions also apply to a method for providing control power or primary control power for an electric energy generator and distributor system to which a multiplicity of power stations including wind turbines is connected, and to a wind turbine.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

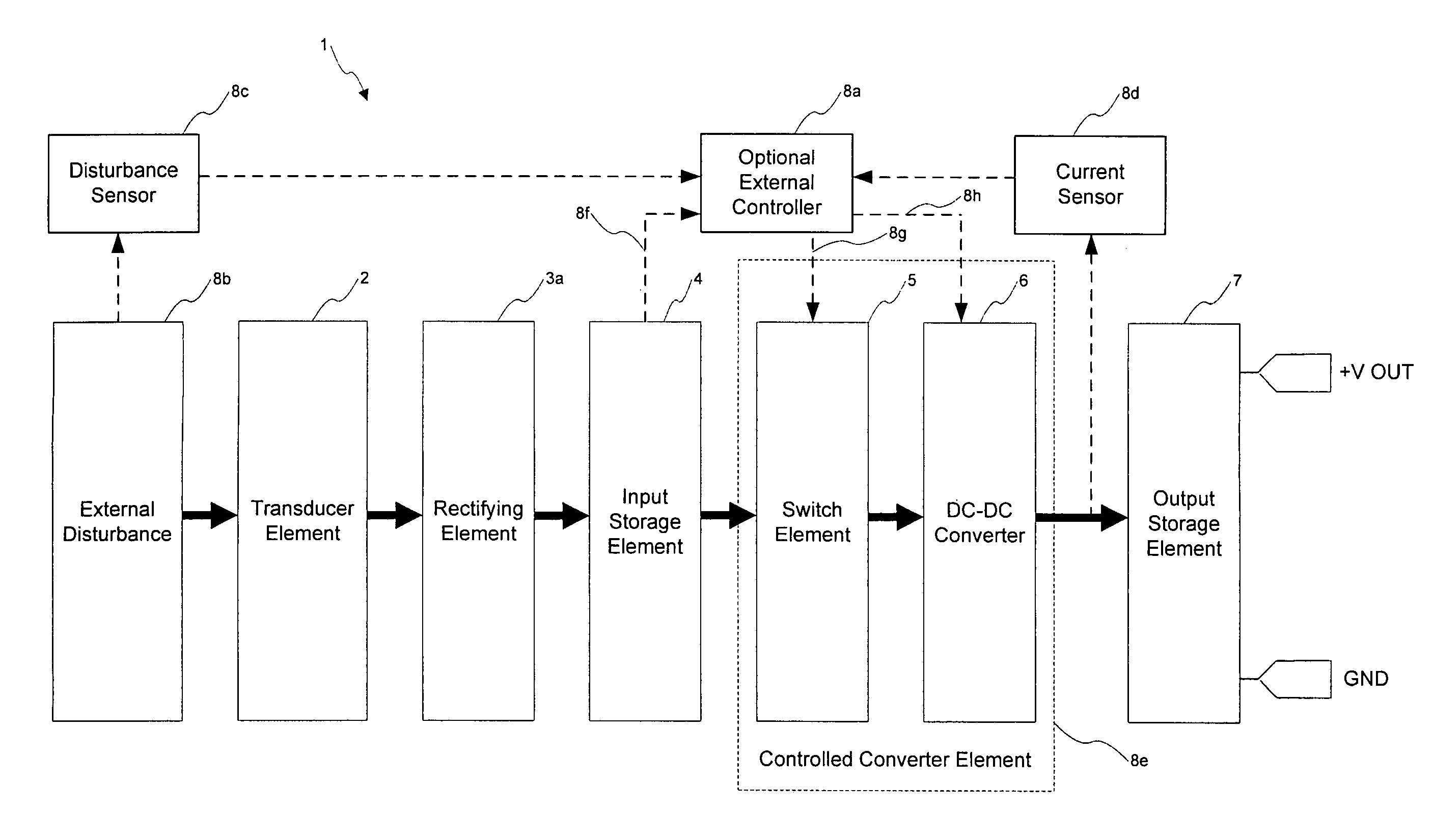

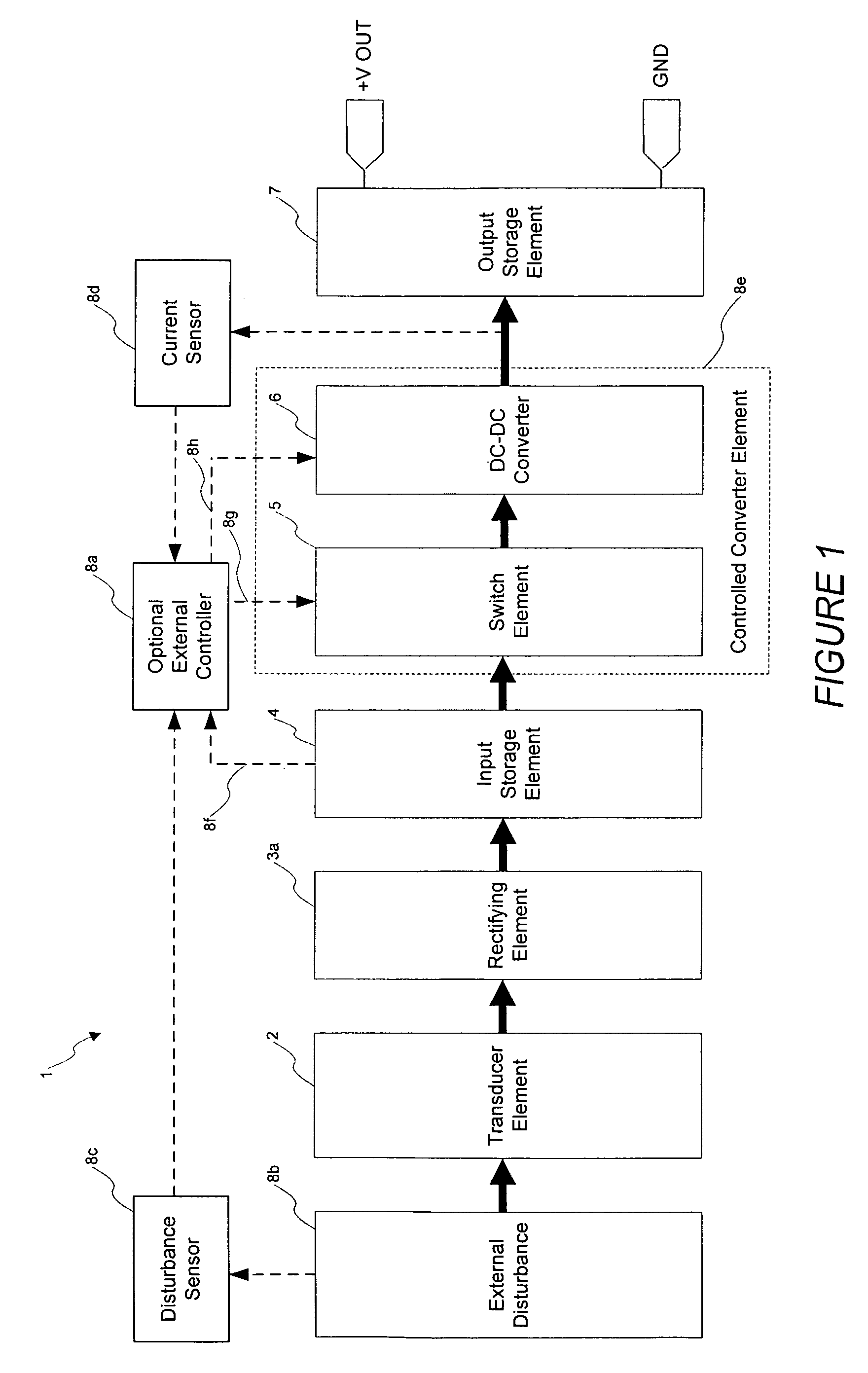

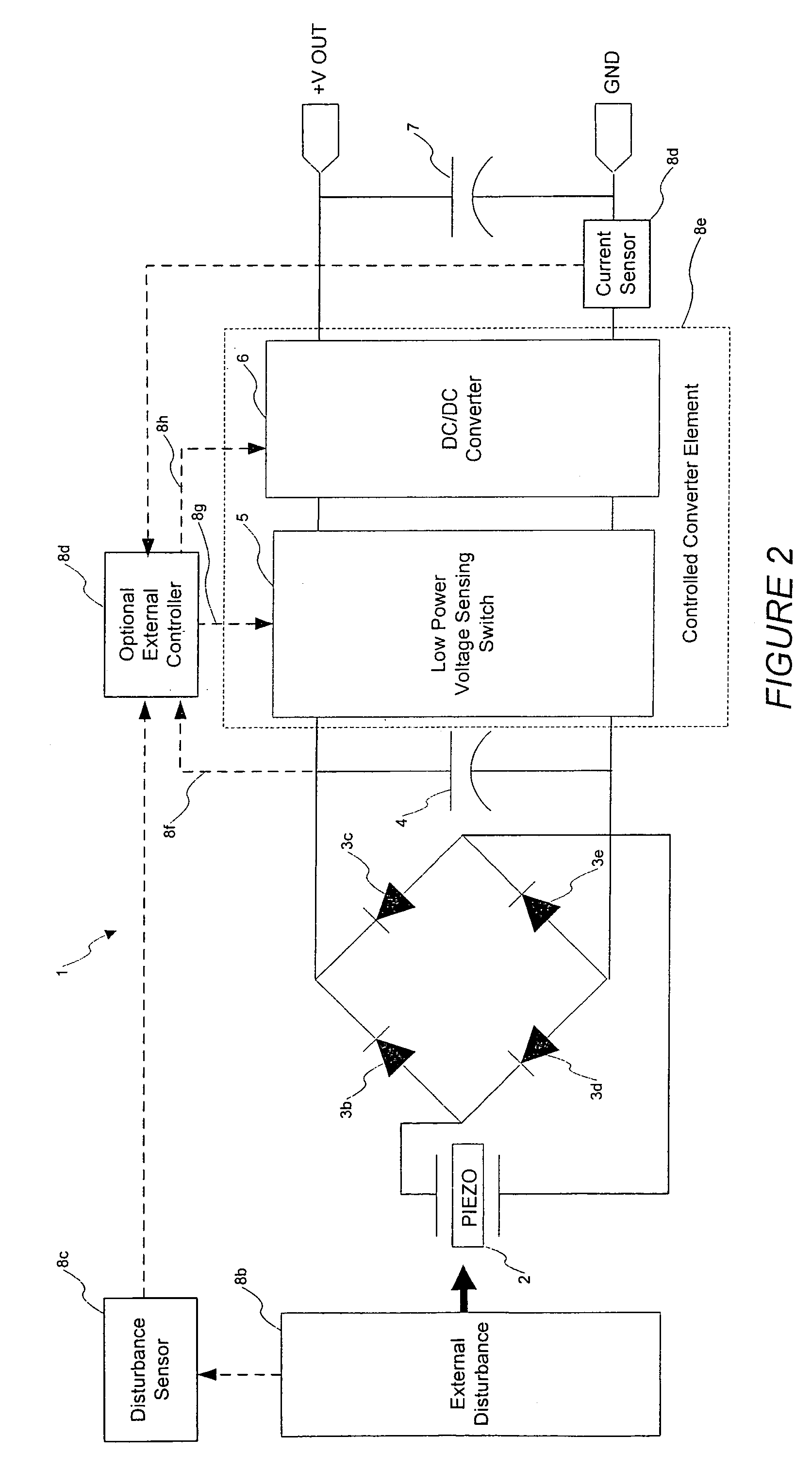

System for optimal energy harvesting and storage from an electromechanical transducer

ActiveUS7105982B1Efficient HarvestingEfficient storagePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesStored energyMechanical energy

A device for collection of energy from mechanical disturbances and distribution of that energy to an electrical load. A transducer converts mechanical energy in the form of forces and displacements into electrical energy in the form of charge pulses. The charge pulses are rectified into a Direct Current (DC) power signal and accumulated and stored in an input storage element. A controlled conversion circuit assures that the voltage on the storage element is maintained within a predetermined optimal range for energy harvesting from the transducer, avoiding the application of peak voltages. The controlled conversion circuit can be hard wired and / or controllably adjustable to match a given disturbance characteristic. Only when the voltage is within the optimal range for a given type of disturbance will the controlled conversion circuit enable a DC / DC converter to further convert the stored energy to a voltage that is coupled to an output storage element. This technique optimizes power conversion by controlling the high voltage to low version conversion process by, for example, sensing the disturbance with external sensor or internal voltage of the system, and then using this information about the disturbance to control how and when the electrical conversion process will occur.

Owner:POLATIS PHOTONICS INC

Series relayed wireless power transfer in a vehicle

InactiveUS20140265555A1Efficient deliveryEfficient energy transferElectromagnetic wave systemRailway vehiclesElectric power transmissionEnergy transfer

Described herein are improved capabilities for a system and method for wireless energy distribution across a vehicle compartment of defined area, comprising a source resonator coupled to an energy source of a vehicle and generating an oscillating magnetic field with a frequency, and at least one repeater resonator positioned along the vehicle compartment, the at least one repeater resonator positioned in proximity to the source resonator, the at least one repeater resonator having a resonant frequency and comprising a high-conductivity material adapted and located between the at least one repeater resonator and a vehicle surface to direct the oscillating magnetic field away from the vehicle surface, wherein the at least one repeater resonator provides an effective wireless energy transfer area within the defined area.

Owner:WITRICITY CORP

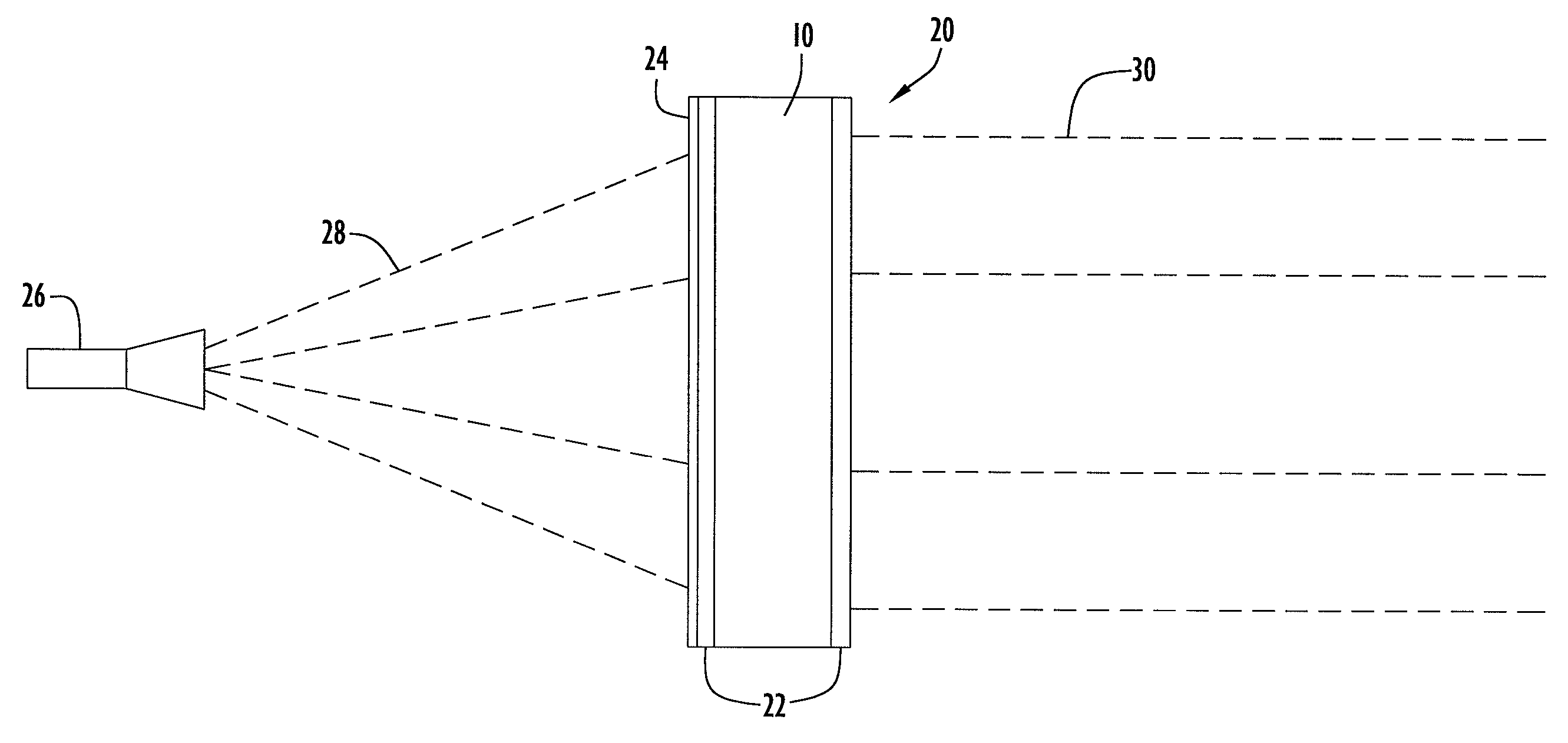

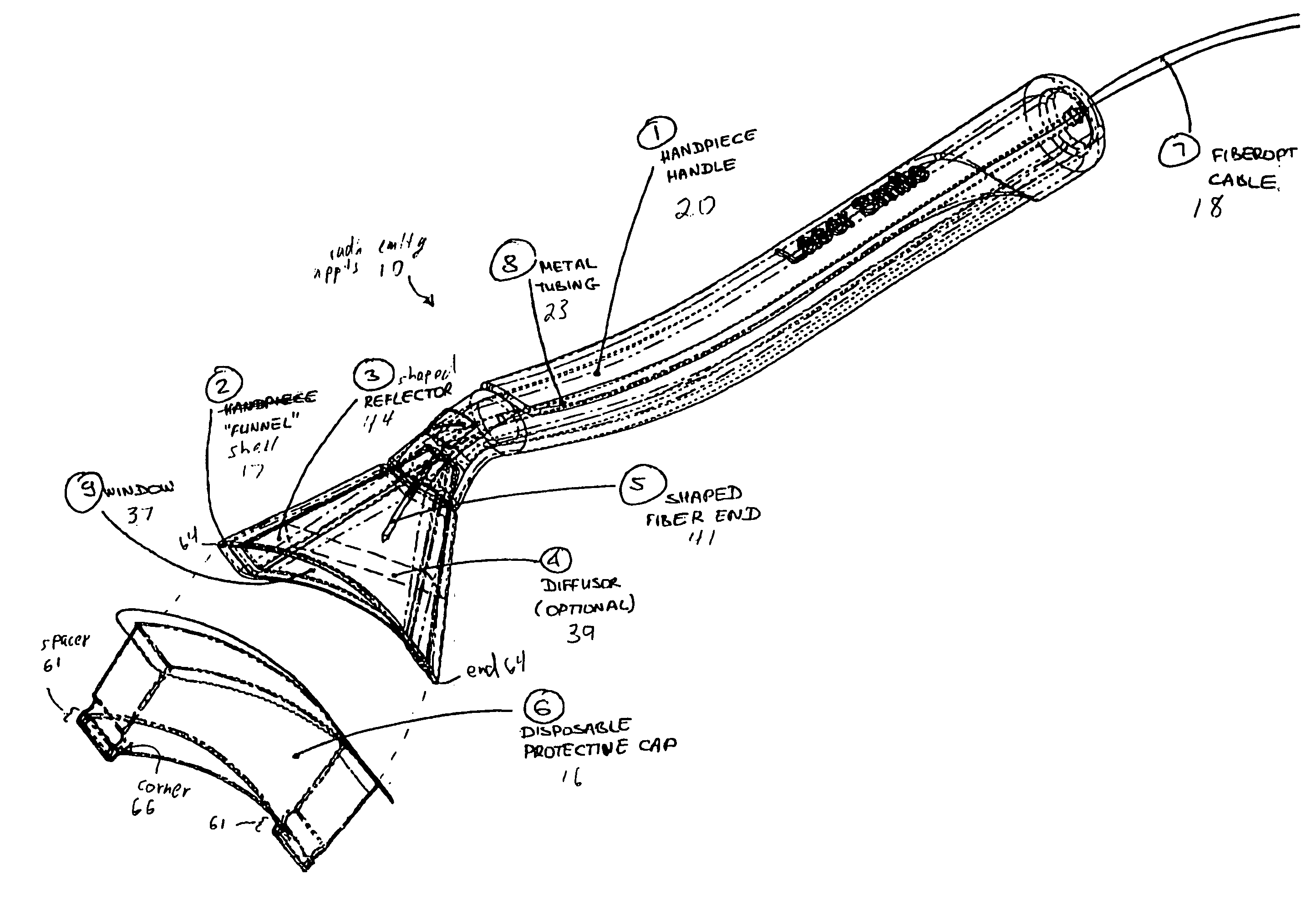

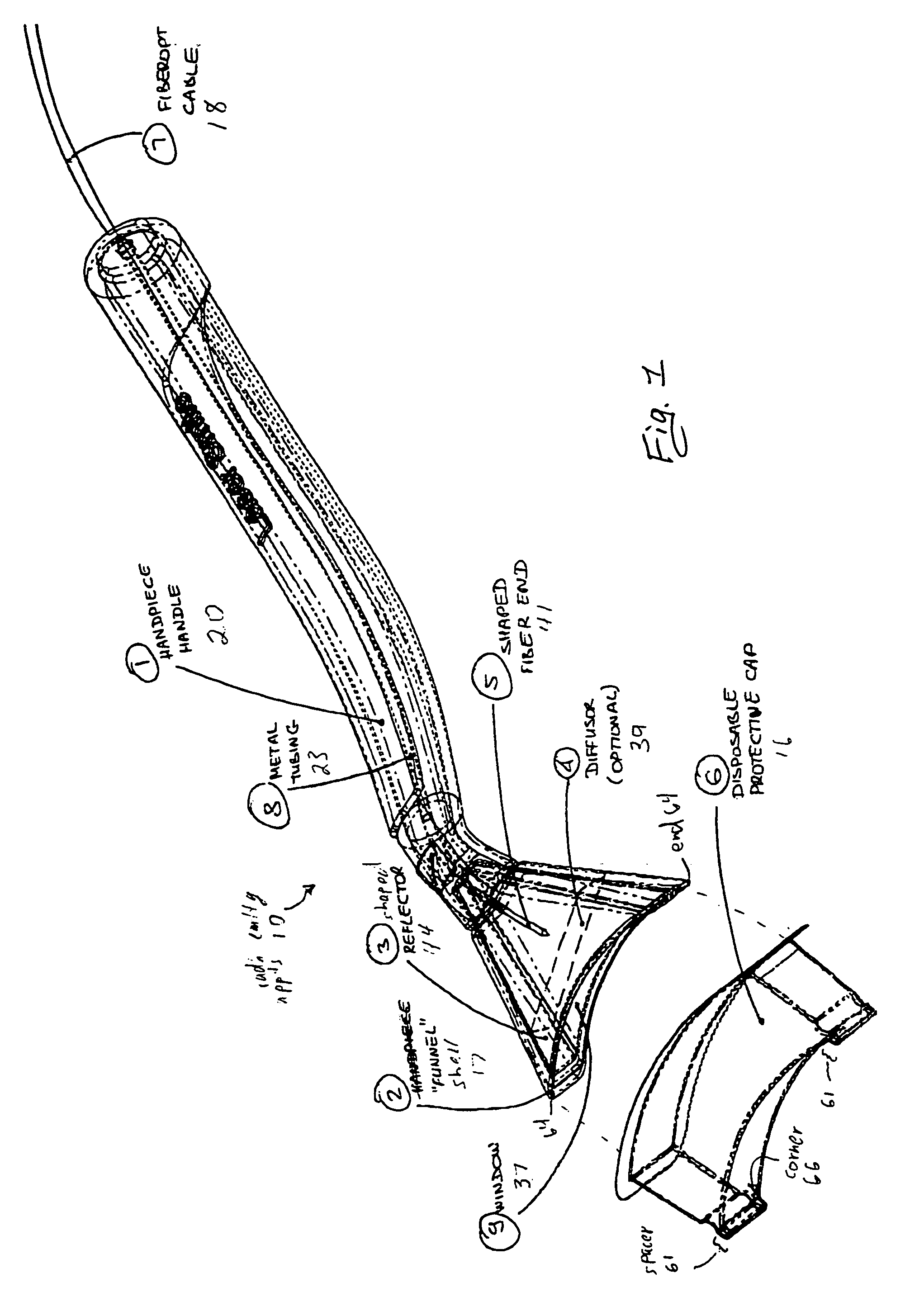

Radiation emitting apparatus with spatially controllable output energy distributions

InactiveUS6942658B1Loss of optical powerEvenly distributedSurgical instrument detailsCoupling light guidesFiberOptoelectronics

A laser handpiece is disclosed, including a fiber optic end having a non-cylindrical shape and further including a reflector surrounding a portion of the fiber optic end. The reflector is shaped to direct laser energy emitted from the fiber optic end in a direction away from the laser handpiece and toward a treatment site.

Owner:BIOLASE TECH INC

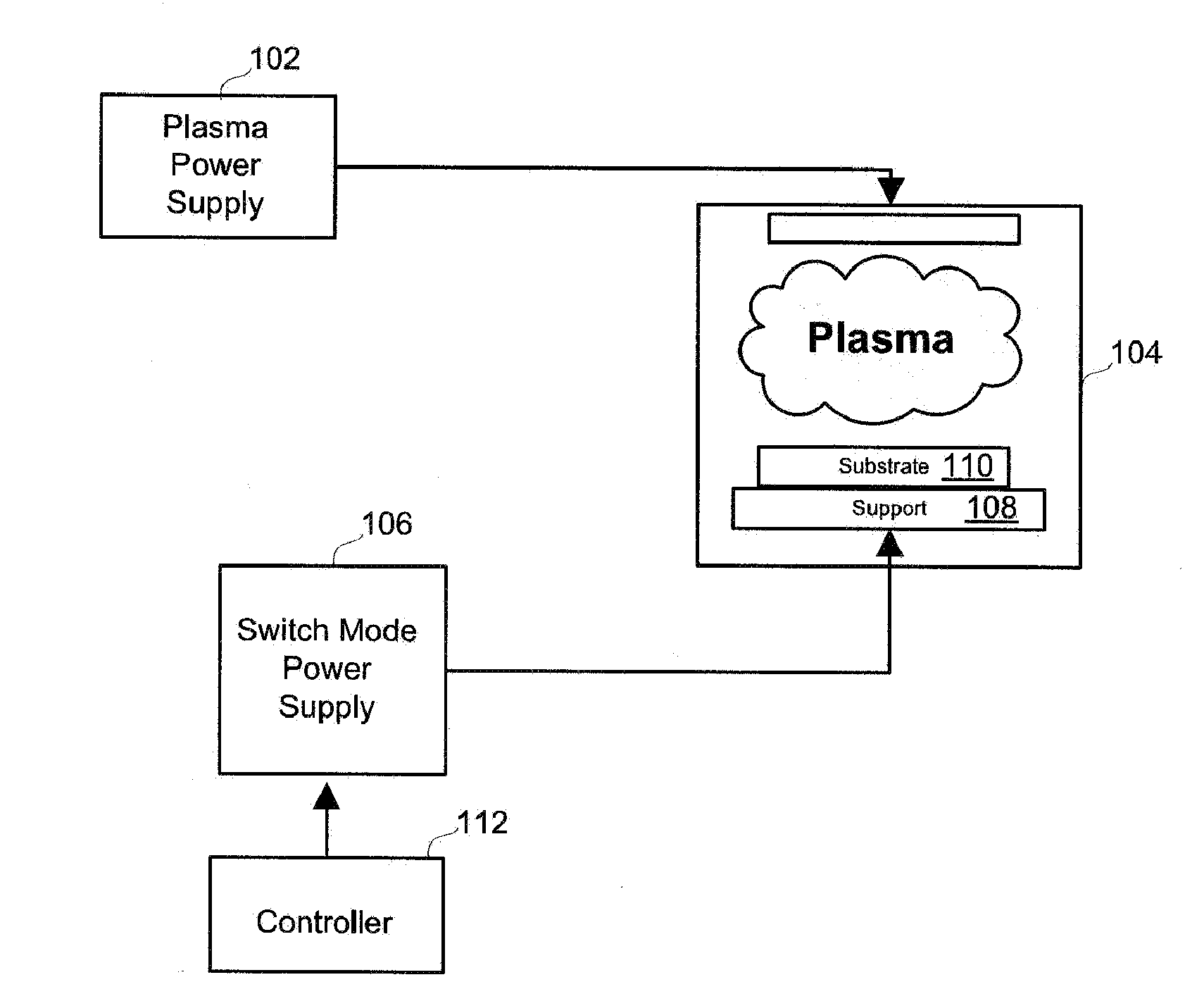

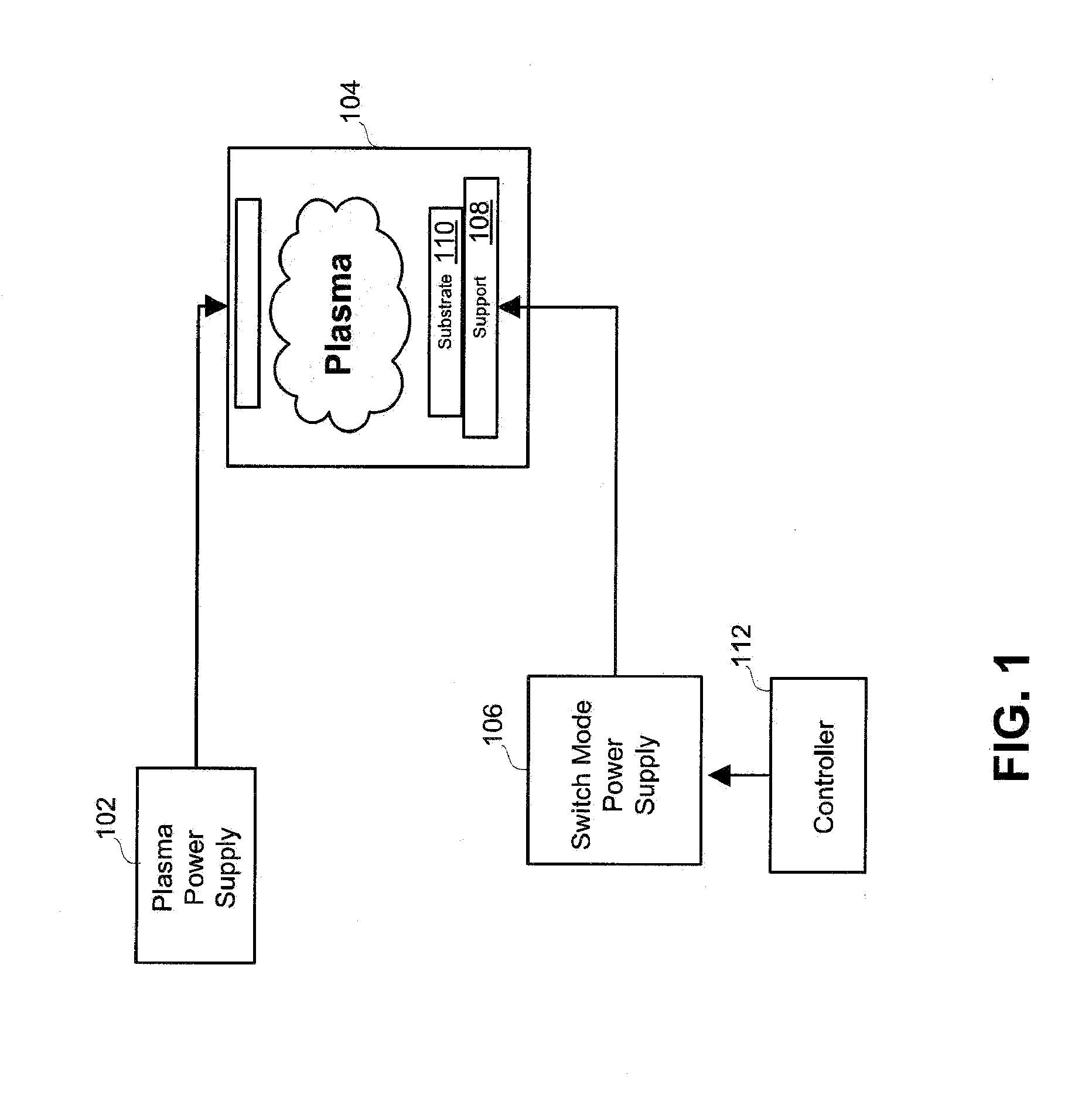

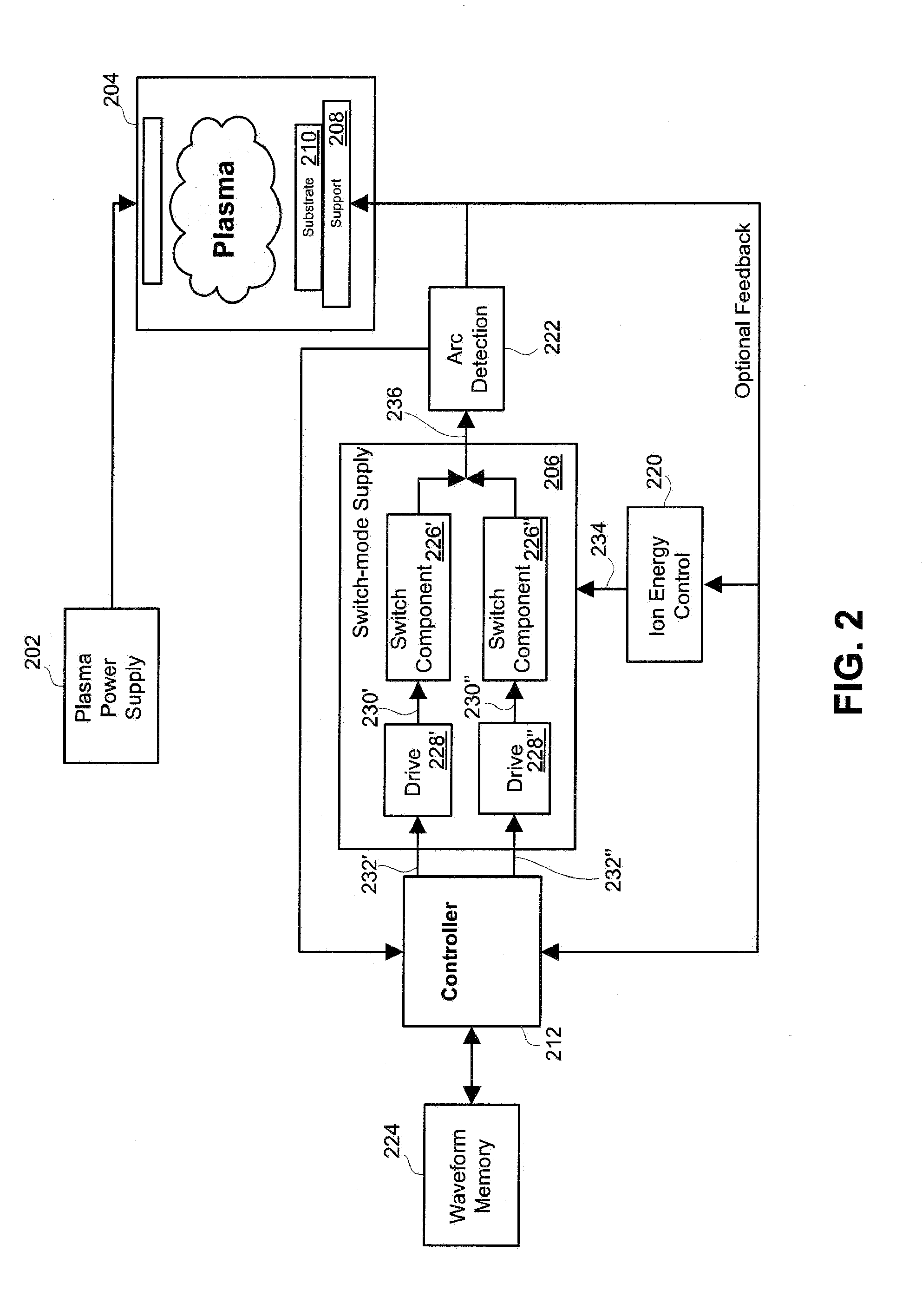

Systems and methods for calibrating a switched mode ion energy distribution system

Systems, methods and apparatus for regulating ion energies and ion energy distributions along with calibrating a bias source and a plasma processing chamber are disclosed. An exemplary method includes applying a periodic voltage function to a load emulator, which emulates electrical characteristics of a plasma load and associated electronics such as an e-chuck. The load emulator can be measured for various electrical parameters and compared to expected parameters generated by the bias source. Differences between measured and expected values can be used to identify and correct faults and abnormalities in the bias supply, the chamber, or a power source used to ignite and sustain the plasma. Once the bias supply is calibrated, the chamber can be calibrated by measuring and calculating an effective capacitance comprising a series and parallel capacitance of the substrate support and optionally the substrate.

Owner:AES GLOBAL HLDG PTE LTD

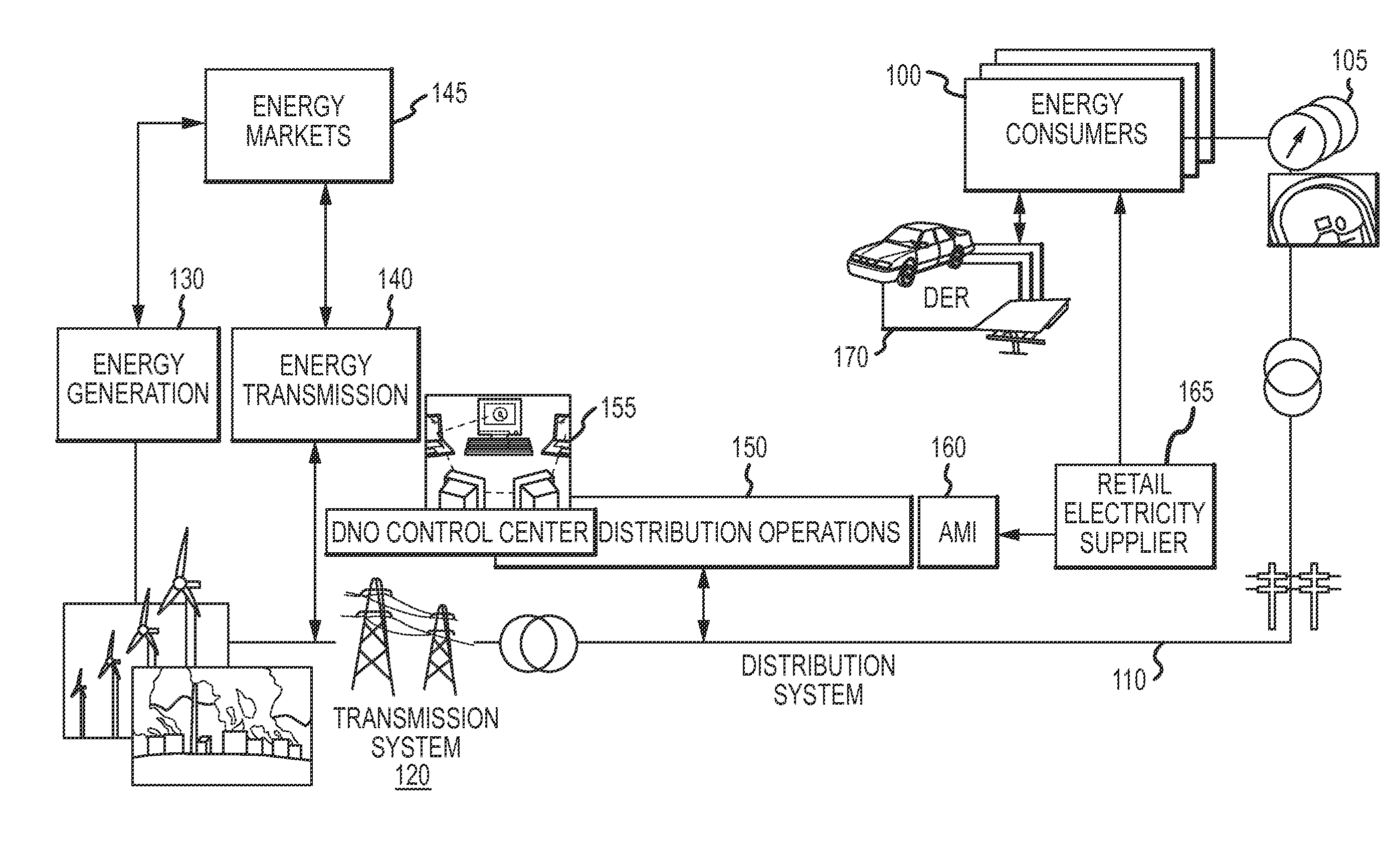

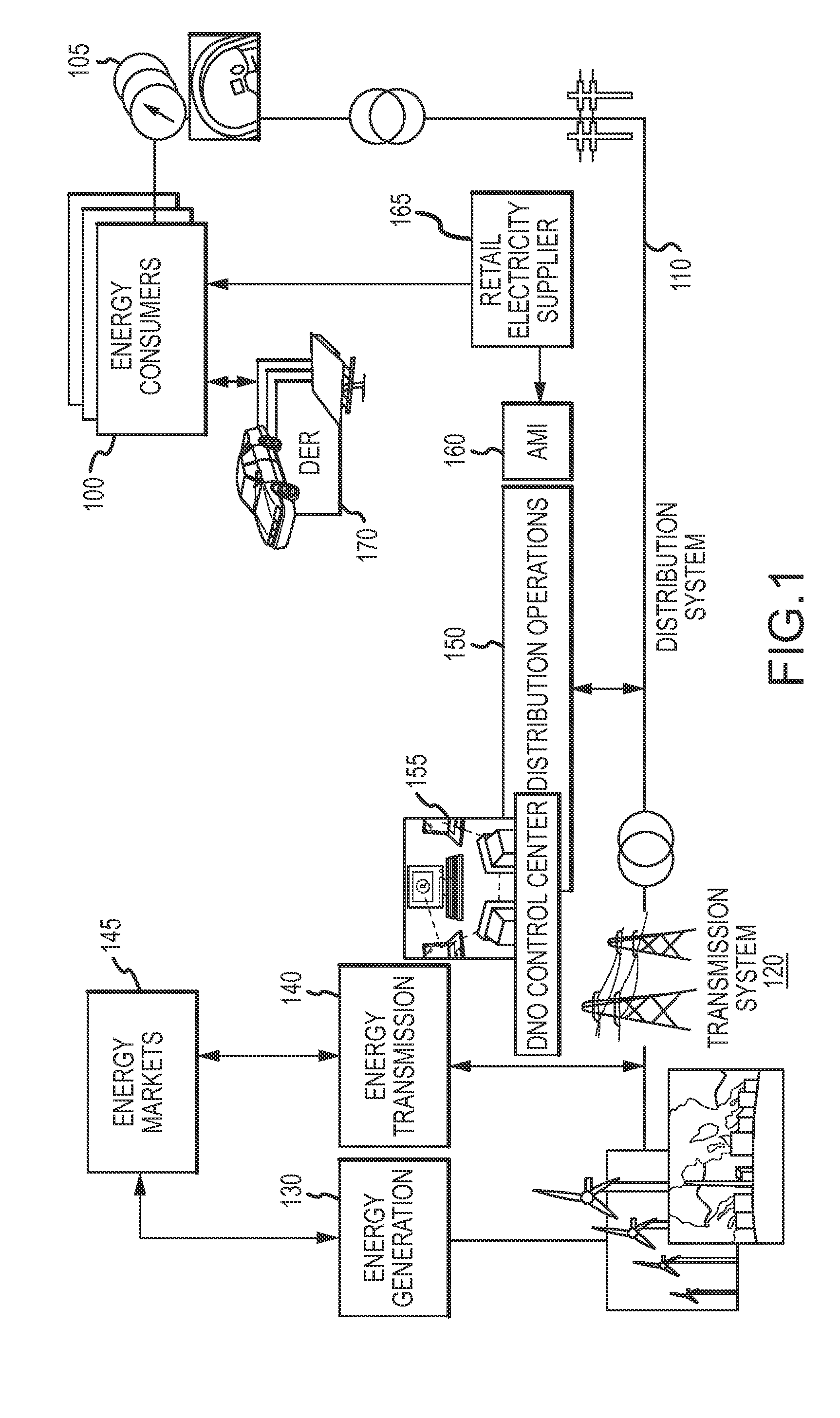

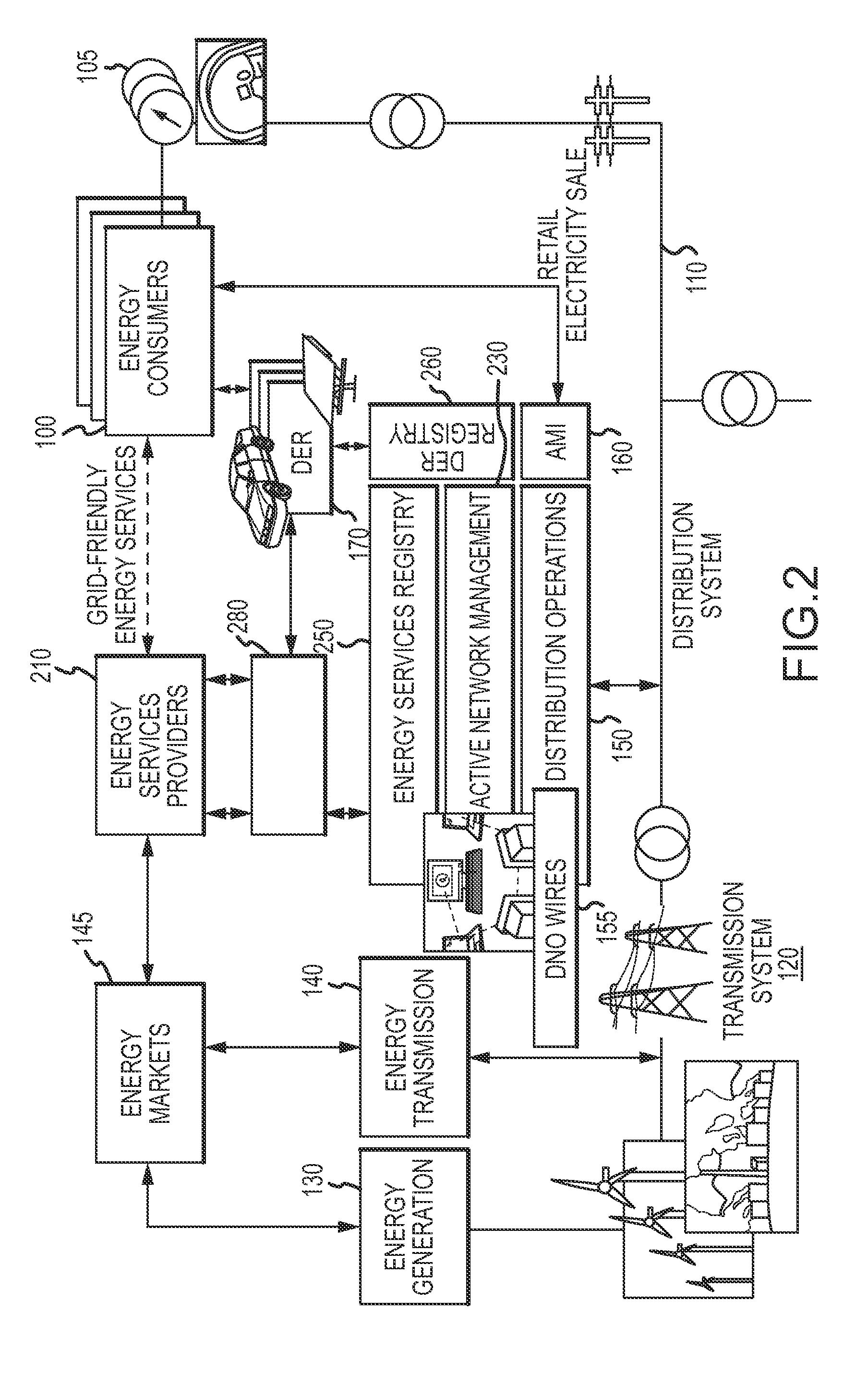

Energy Services Interface

ActiveUS20130054036A1Avoid energyLow efficiencyMechanical power/torque controlLevel controlTime informationService Interface for Real Time Information

An energy services bridge interposed between one or more energy service providers and an energy distribution network operator manages a plurality of diversified energy consumer service plans so as to be compliant with the physical and technical constraints of the transmission / distribution gird. The energy services bridge further conveys real-time information regarding the state of the transmission / distribution grid to the plurality of energy service providers enabling active management of the service plans and correspondingly active management of the transmission / distribution grid.

Owner:AVISTA DEV

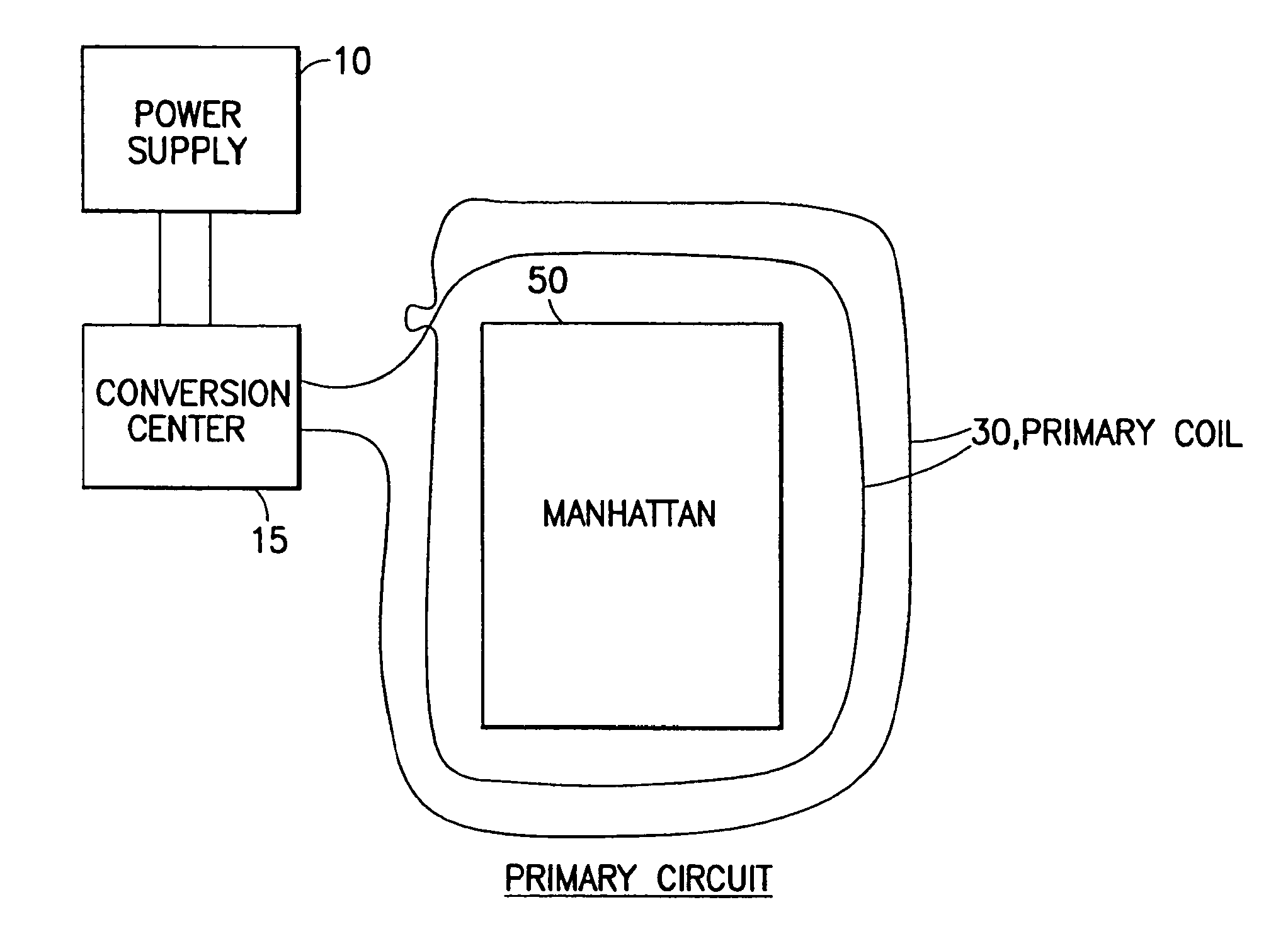

Self-charging electric vehicles and aircraft, and wireless energy distribution system

InactiveUS8890472B2Rapid collection and storageIncrease rangeMobile unit charging stationsPropulsion by batteries/cellsElectric power systemTransmitted power

A method and system for efficient distribution of power using wireless means, and a system and method for wireless power distribution to provide electric devices, such as vehicles with a way to continuously and wirelessly collect, use and charge their power systems and thereby use the transmitted power for operation. The system and method allows a hybrid, simplified and less costly way to charge devices, such as vehicles so that the devices continuously operate while charging / recharging.

Owner:GOVERNING DYNAMICS INVESTMENT +1

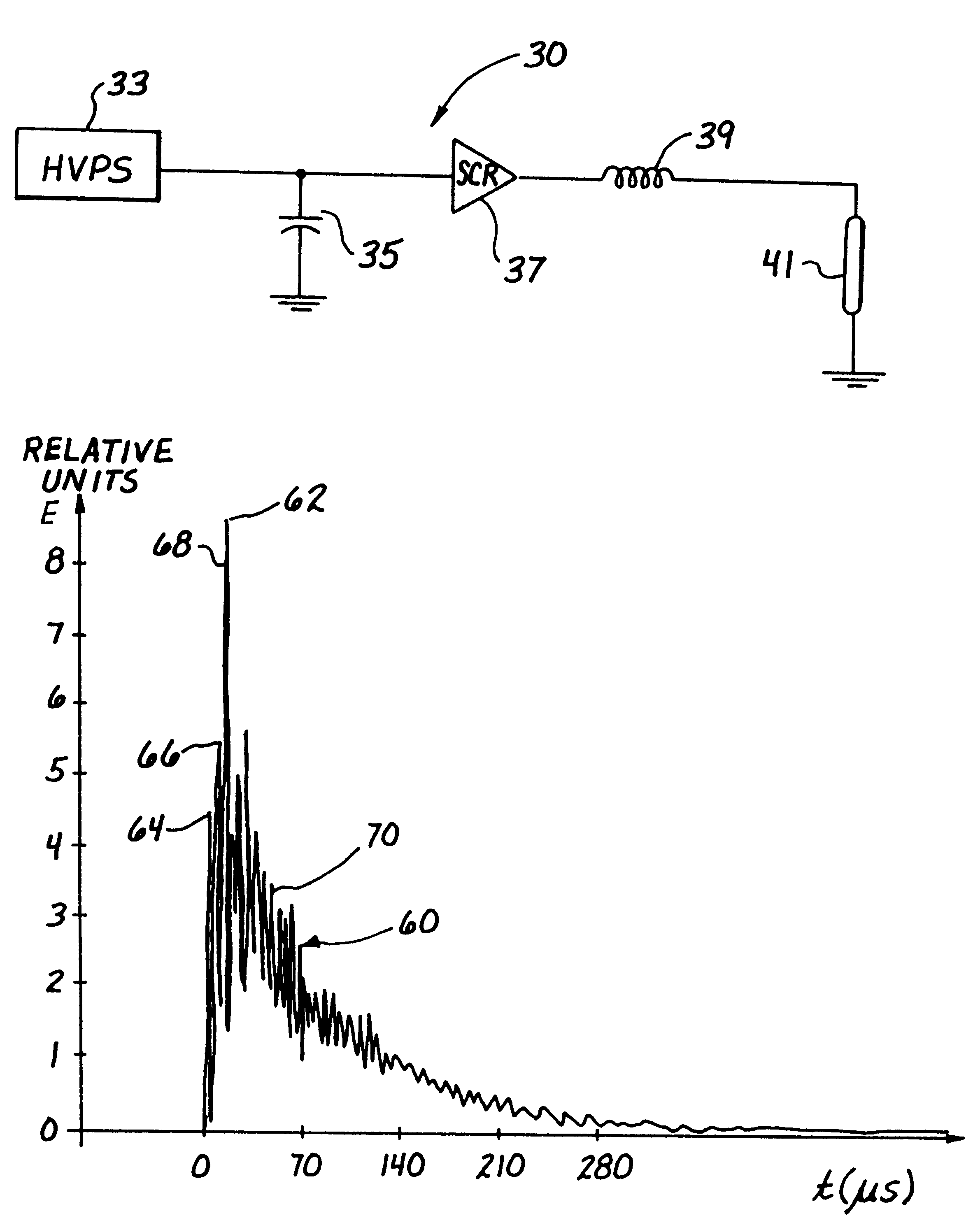

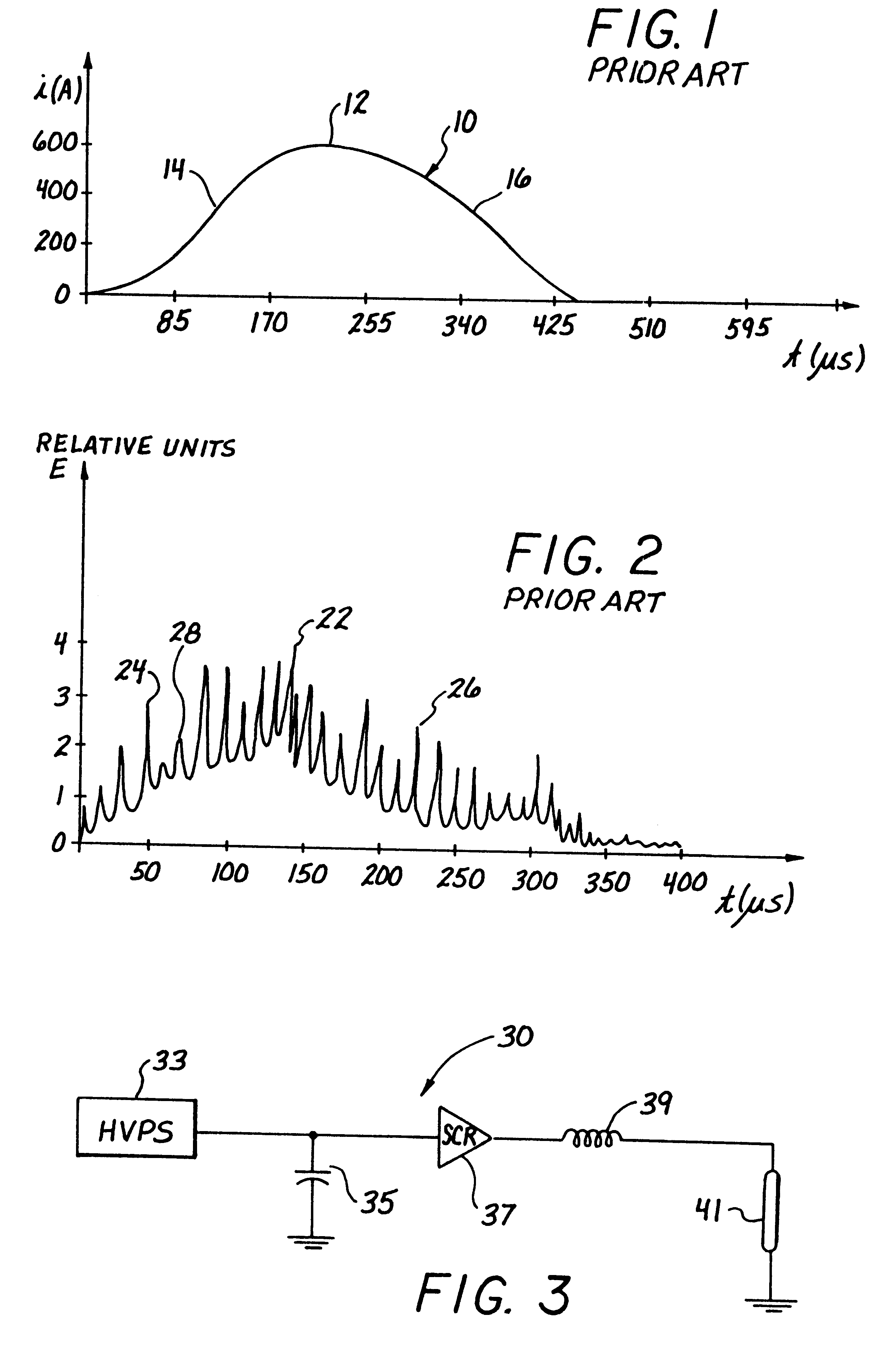

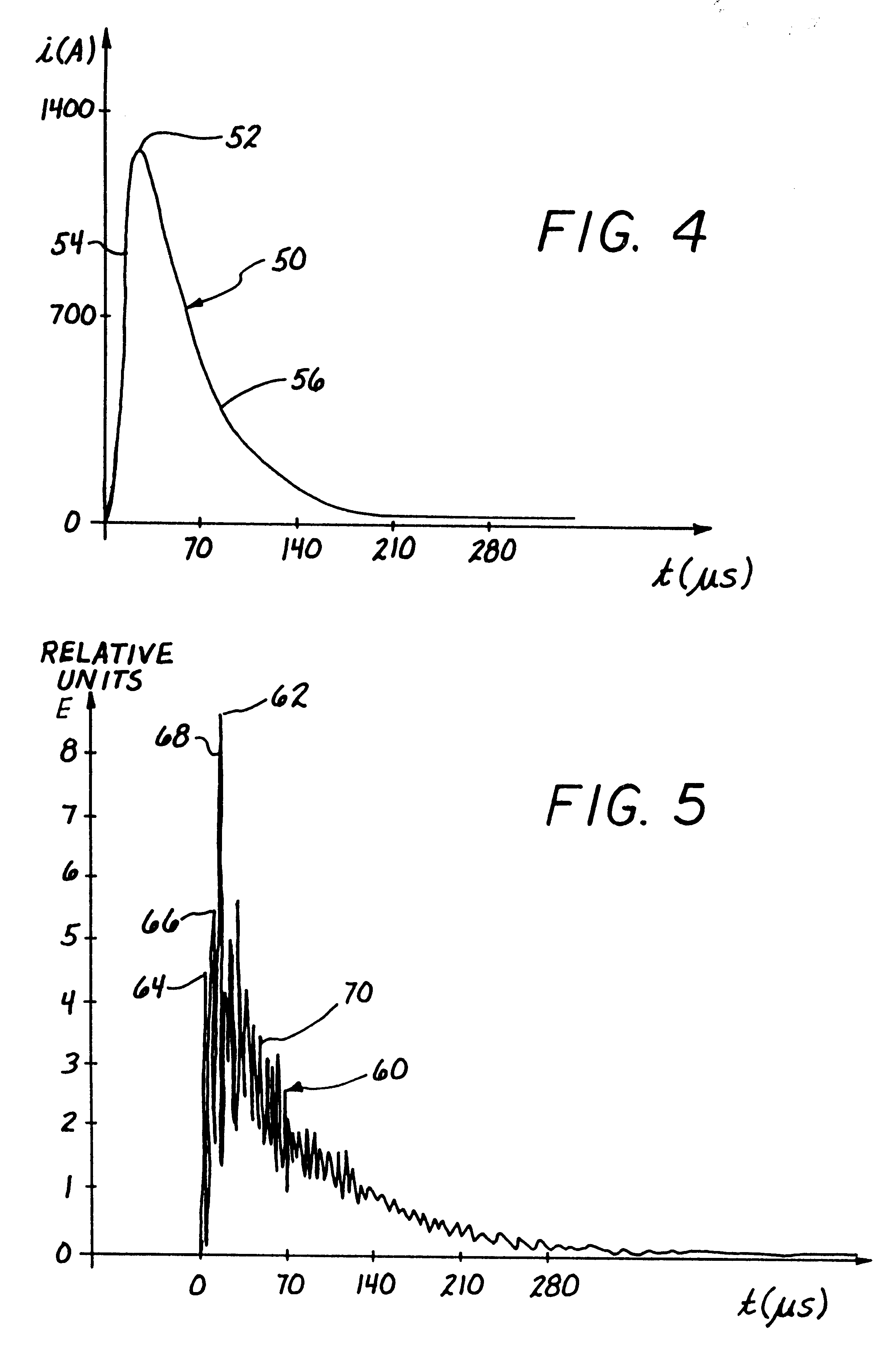

Electromagnetic energy distributions for electromagnetically induced mechanical cutting

Output optical energy pulses including relatively high energy magnitudes at the beginning of each pulse are disclosed. As a result of the relatively high energy magnitudes which lead each pulse, the leading edge of each pulse includes a relatively large slope. This slope is preferably greater than or equal to 5. Additionally, the full-width half-max value of the output optical energy distributions are between 0.025 and 250 microseconds and, more preferably, are about 70 microseconds. A flashlamp is used to drive the laser system, and a current is used to drive the flashlamp. A flashlamp current generating circuit includes a solid core inductor which has an inductance of 50 microhenries and a capacitor which has a capacitance of 50 microfarads.

Owner:BIOLASE TECH INC

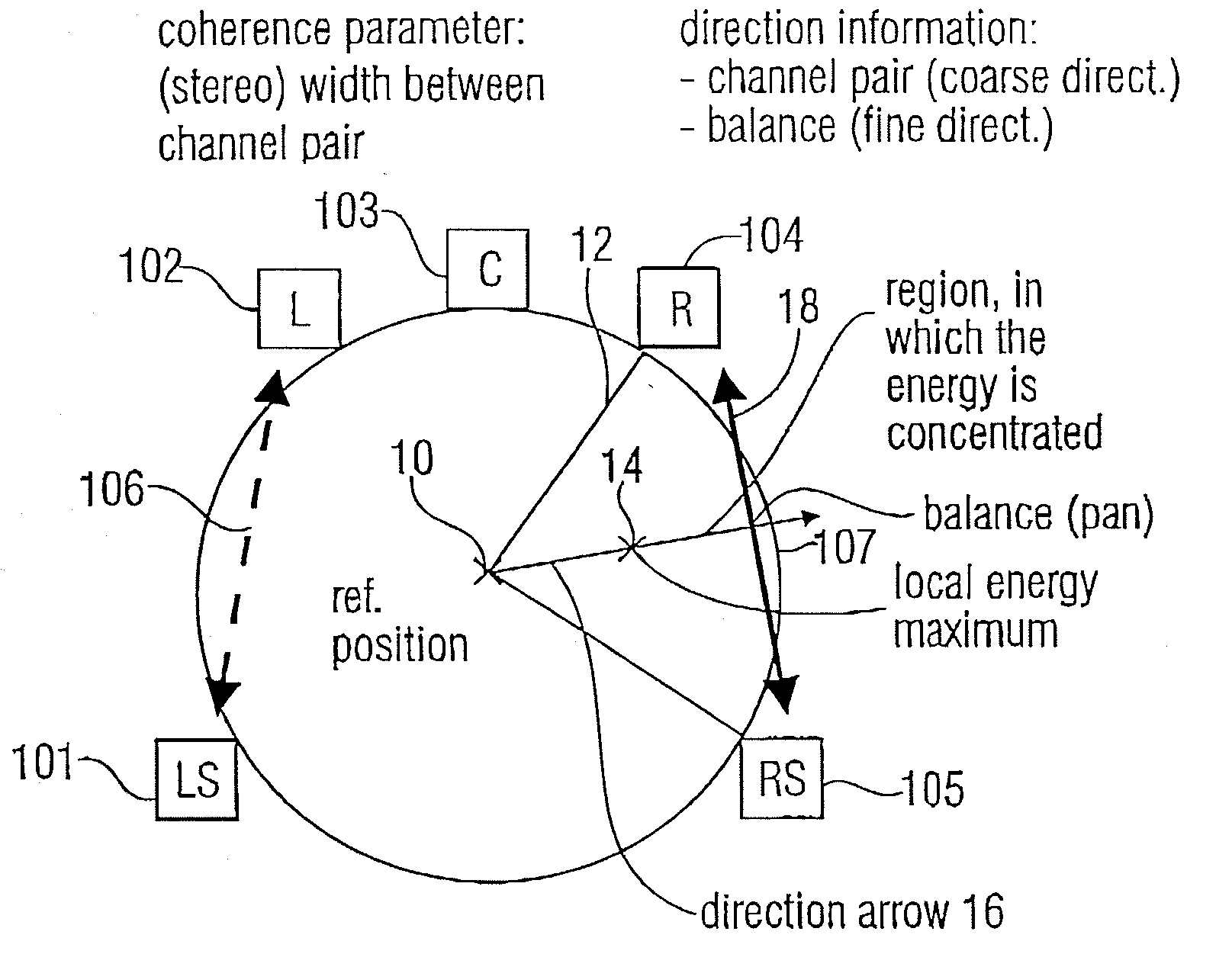

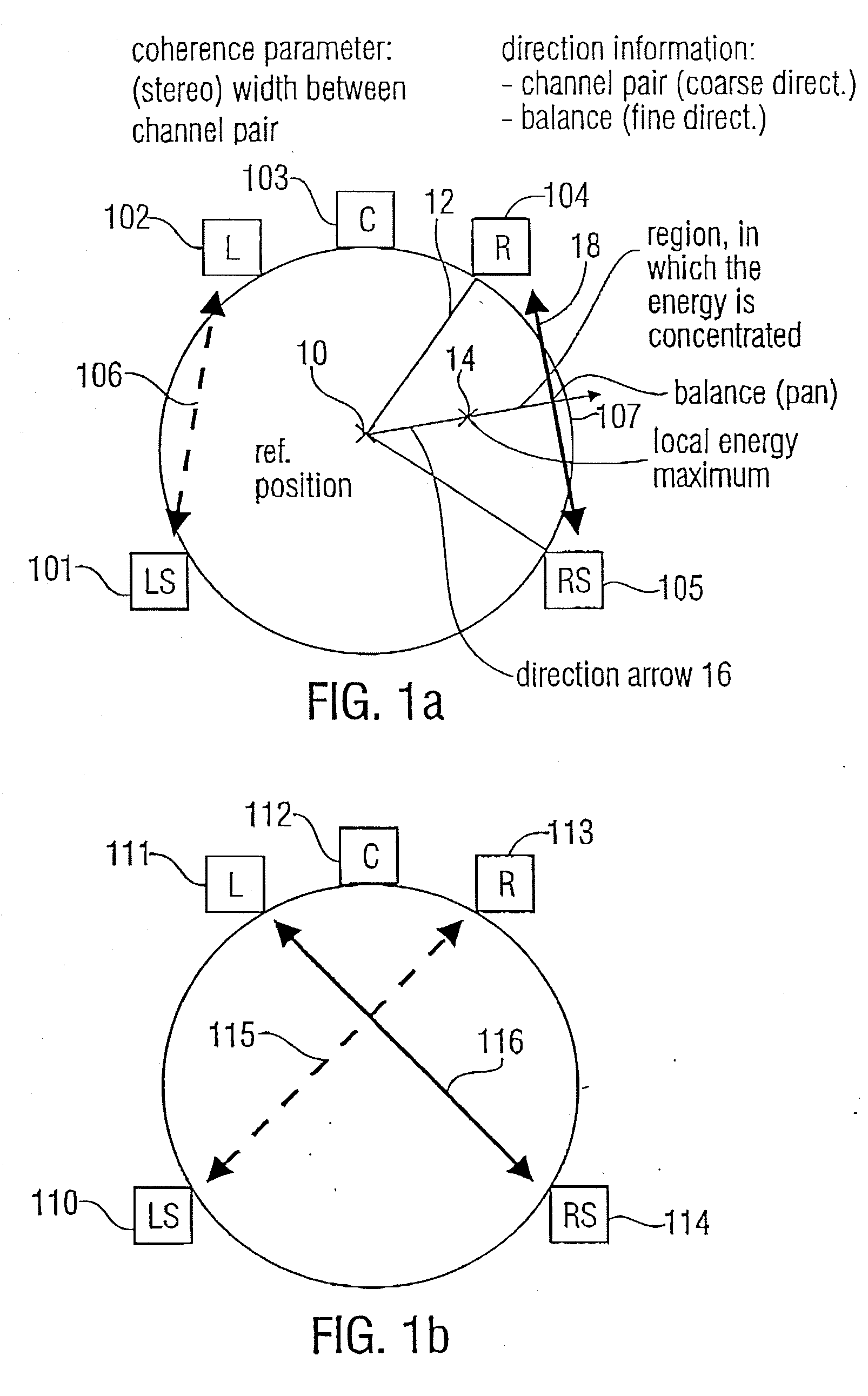

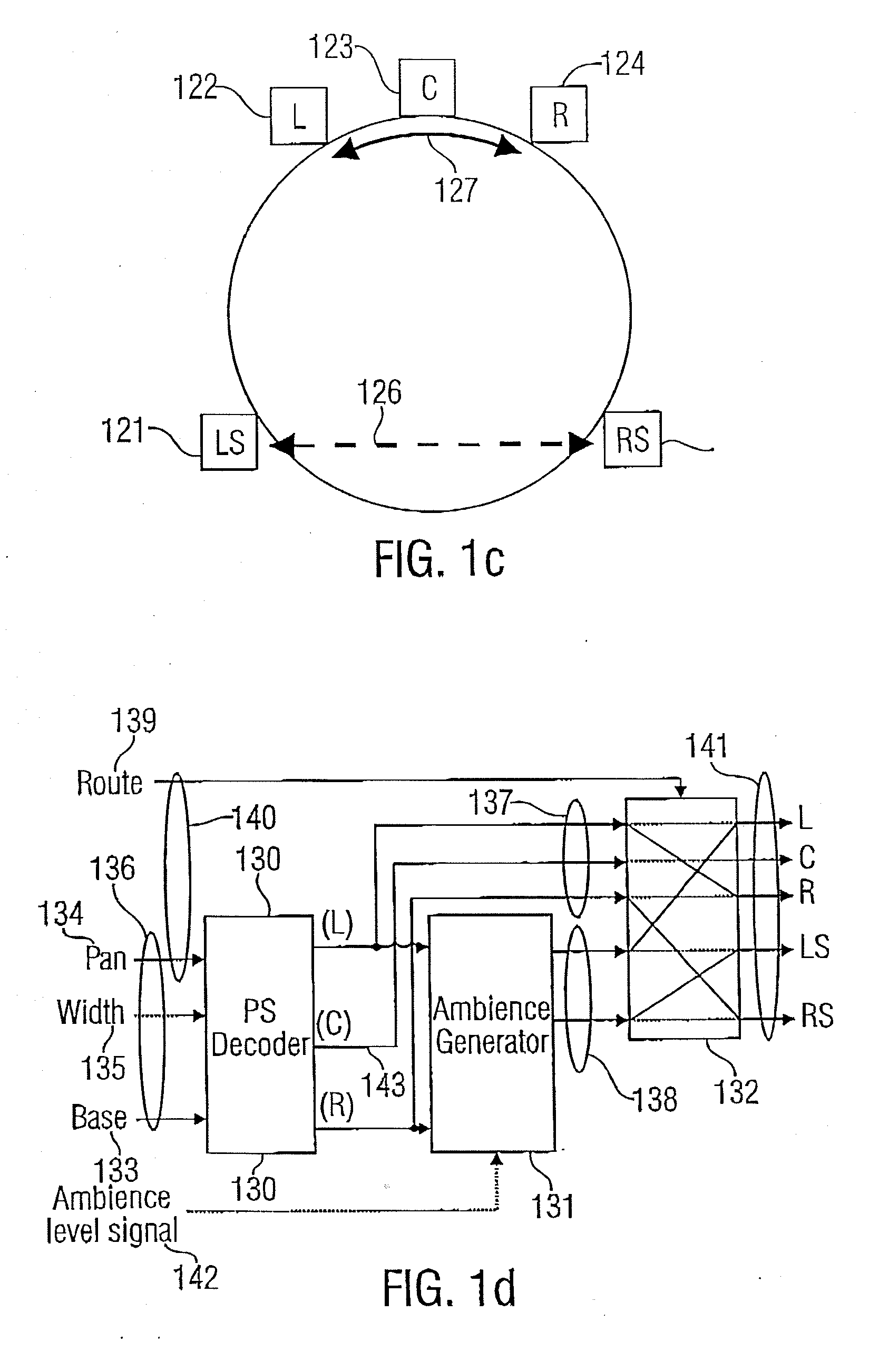

Scheme for Generating a Parametric Representation for Low-Bit Rate Applications

ActiveUS20070127733A1Little informationSpeech analysisBroadcast circuit arrangementsSound energyComputer science

For generating a parametric representation of a multi-channel signal especially suitable for low-bit rate applications, only the location of the maximum of the sound energy within a replay setup is encoded and transmitted using direction parameter information. For multi-channel reconstruction, the energy distribution of the output channels identified by the direction parameter information is controlled by the direction parameter information, while the energy distribution in the remaining ambience channels is not controlled by the direction parameter information.

Owner:DOLBY INT AB

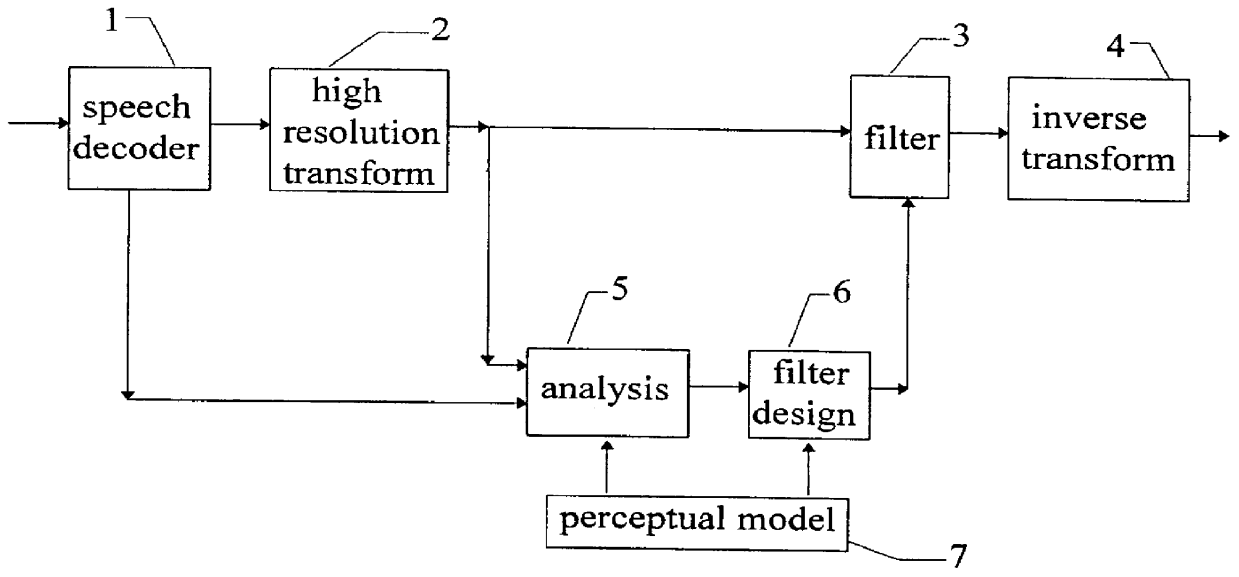

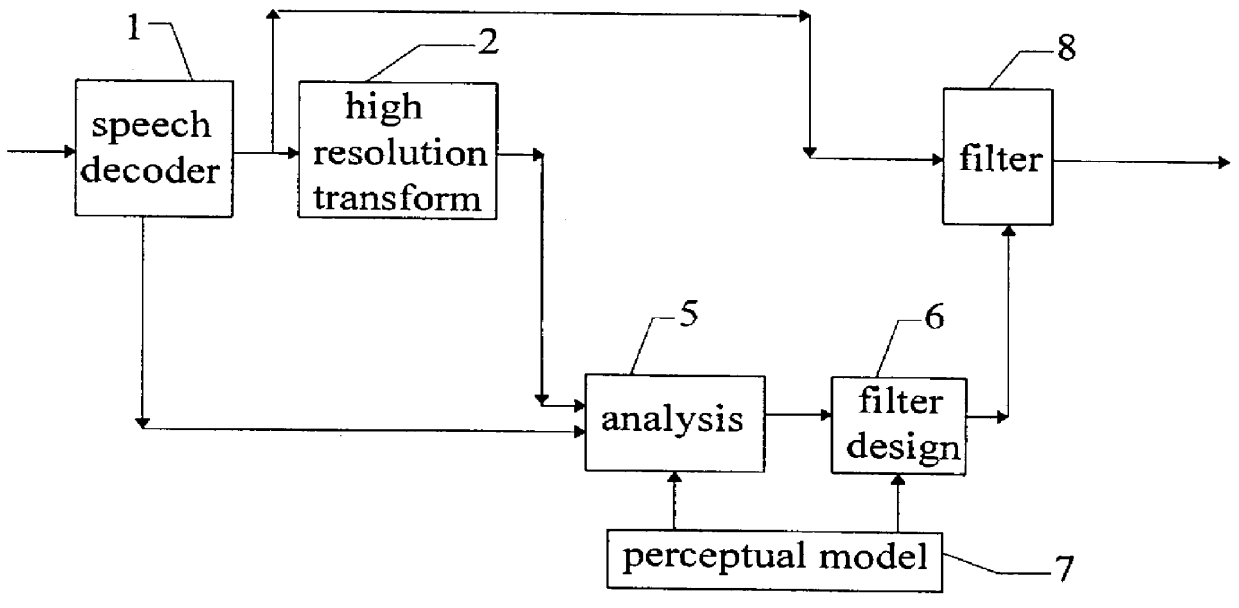

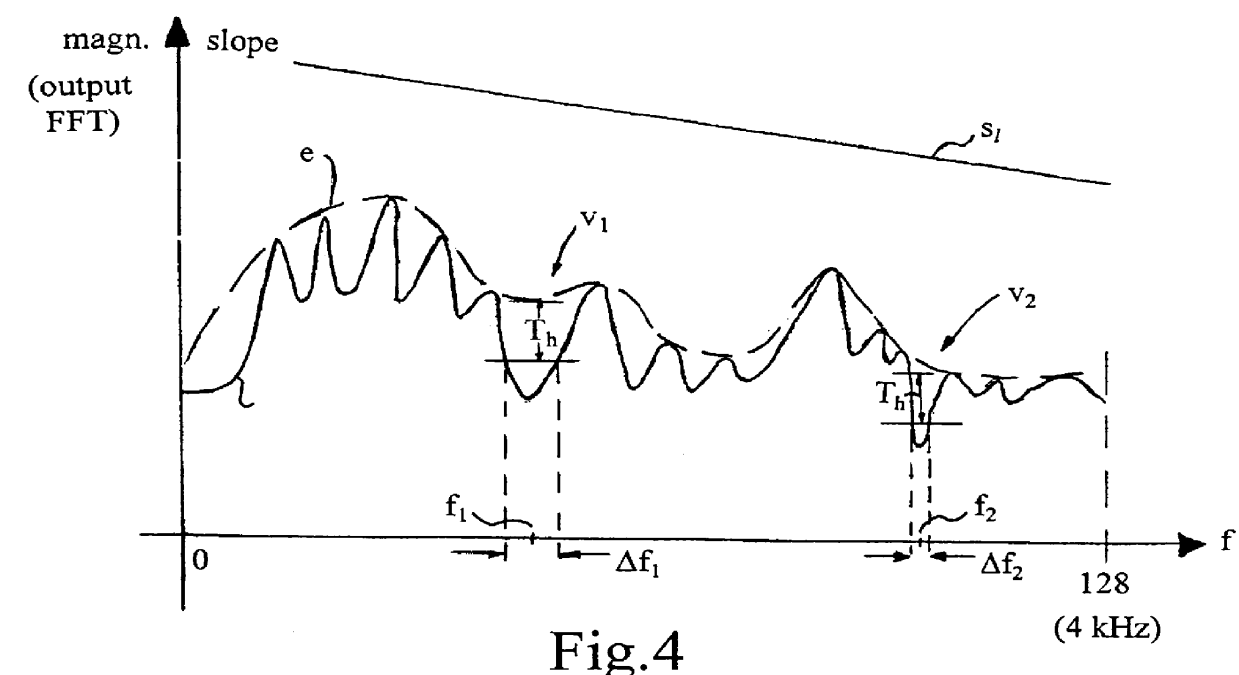

High resolution post processing method for a speech decoder

InactiveUS6138093AImprove perceived qualityReduce noiseCode conversionTransmissionTime domainFrequency spectrum

A post-processing method for a speech decoder which outputs a decoded speech signal in the time domain provides high frequency resolution based on a frequency spectrum having non-harmonic and noise deficiencies. This is obtained by transforming the decoded time domain signal to a frequency domain signal by using a high frequency resolution transform (FFT). Then an analysis of the energy distribution of the frequency domain signal is made throughout its frequency area (4 kHz) to find the disturbing frequency components and to prioritize such frequency components which are situated in the higher part of the frequency spectrum. Next, the suppression degree for the disturbing frequency components is found based on prioritizing. Finally the steps of controlling a post-filtering of the transform in dependence of the finding, and inverse transforming the post-filtered transform in order to obtain a post-filtered decoded speech signal in the time domain are performed.

Owner:TELEFON AB LM ERICSSON (PUBL)

Method for operating or controlling a wind turbine and method for providing primary control power by means of wind turbines

ActiveUS7528496B2Improve power transmissionHigh yieldWind motor controlSingle network parallel feeding arrangementsEngineeringDistributor

A method for operating at least one wind turbine with a rotor and an electric generator coupled to the rotor for delivering electrical power into an energy distribution system with the aid of a control device ensures that the wind turbine operates within its operating range. The wind turbine is controlled in response to the change of a system operating parameter and for a period of time, in such a manner that a higher power is fed into the system than belongs to the operating range of the steady-state operation. The same conditions also apply to a method for providing control power or primary control power for an electric energy generator and distributor system to which a multiplicity of power stations including wind turbines is connected, and to a wind turbine.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

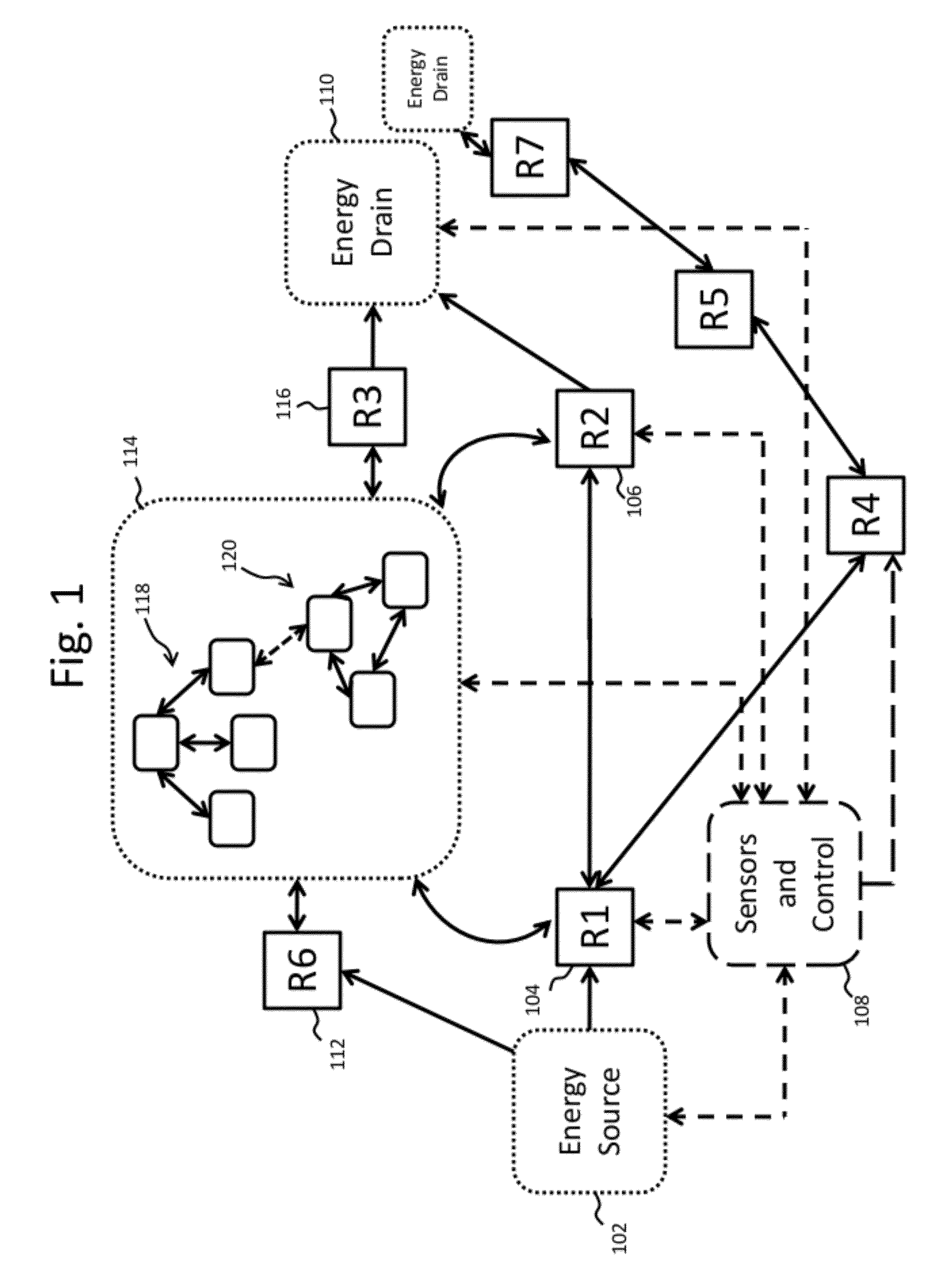

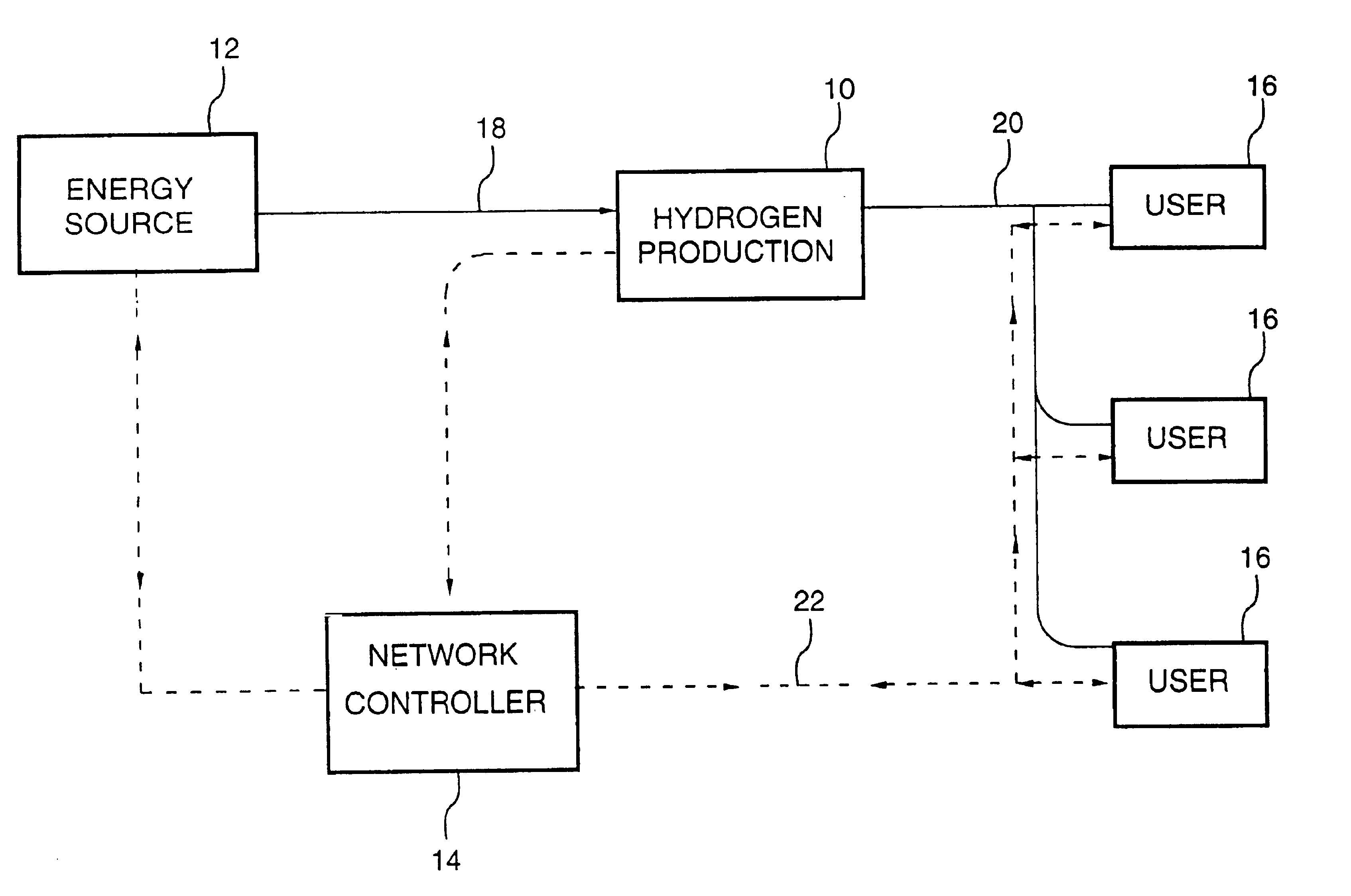

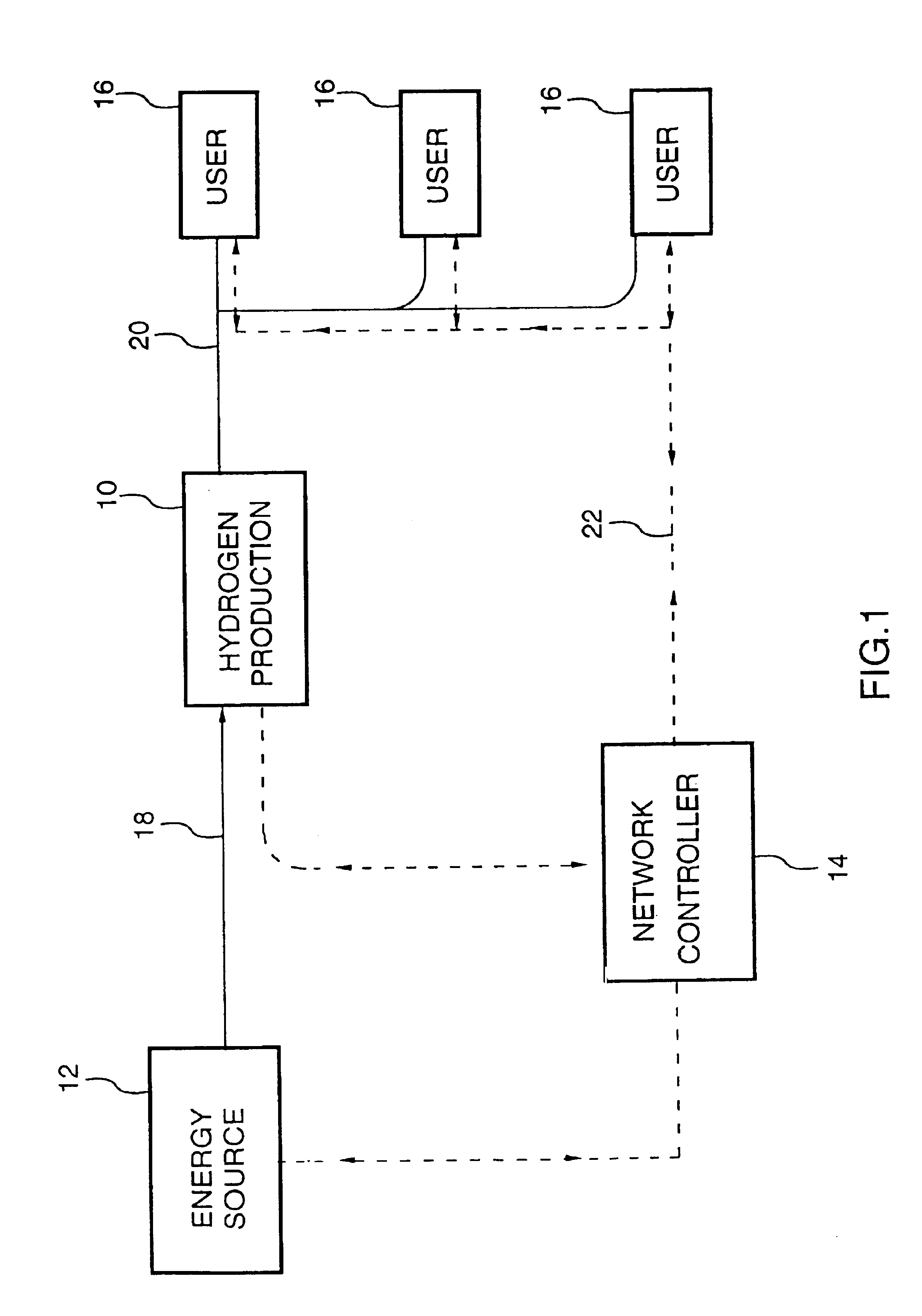

Energy distribution network

InactiveUS6745105B1Good decisionEasy to useElectricity cogenerationElectrolysis componentsProcess engineeringEnergy source

An energy distribution network is provided including an energy source; a hydrogen production facility connected to the energy source; a recipient for hydrogen from the hydrogen production facility; and a controller. The controller controls the production of hydrogen by the hydrogen production facility based on inputs including energy resource availability.

Owner:HYDROGENICS CORP

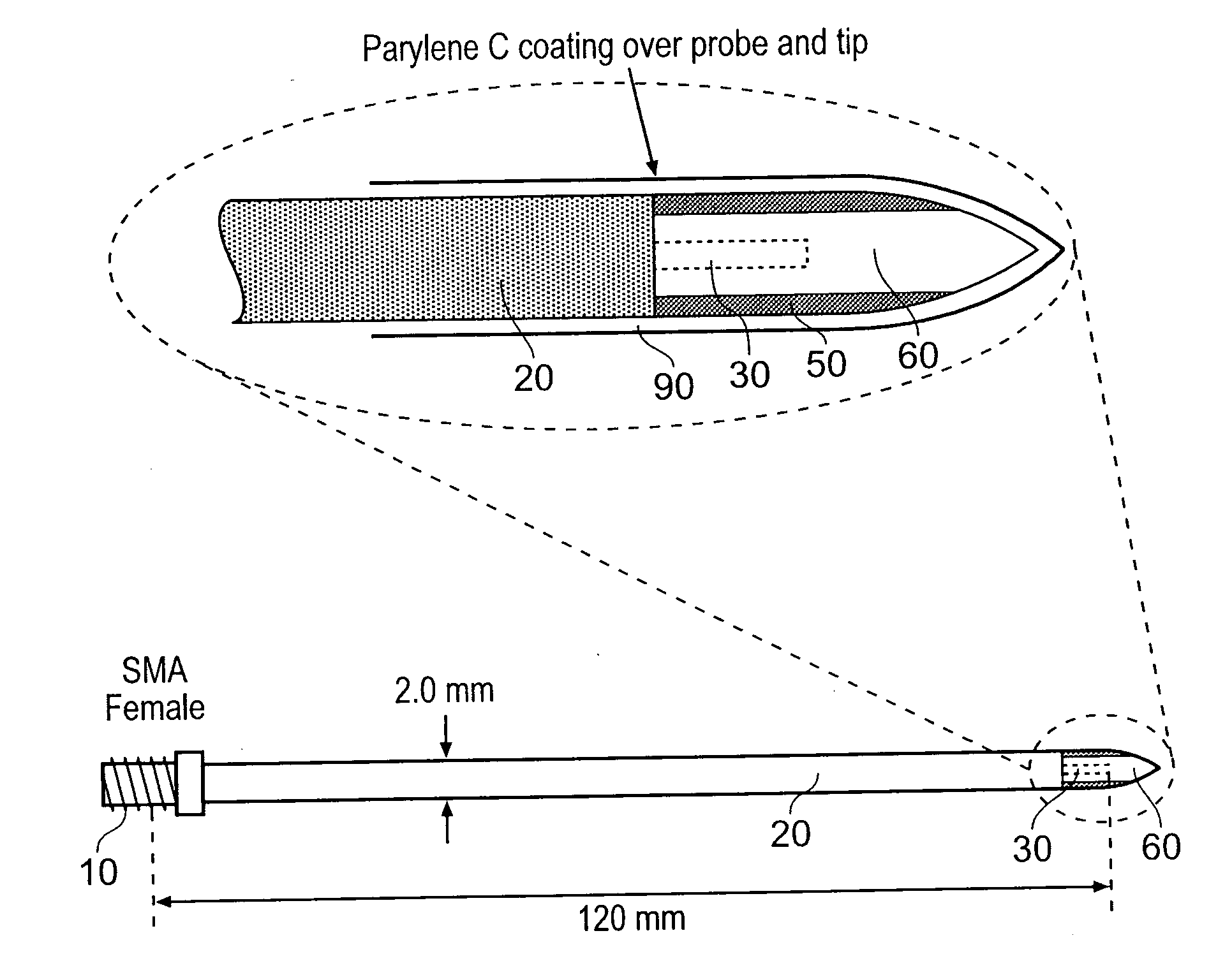

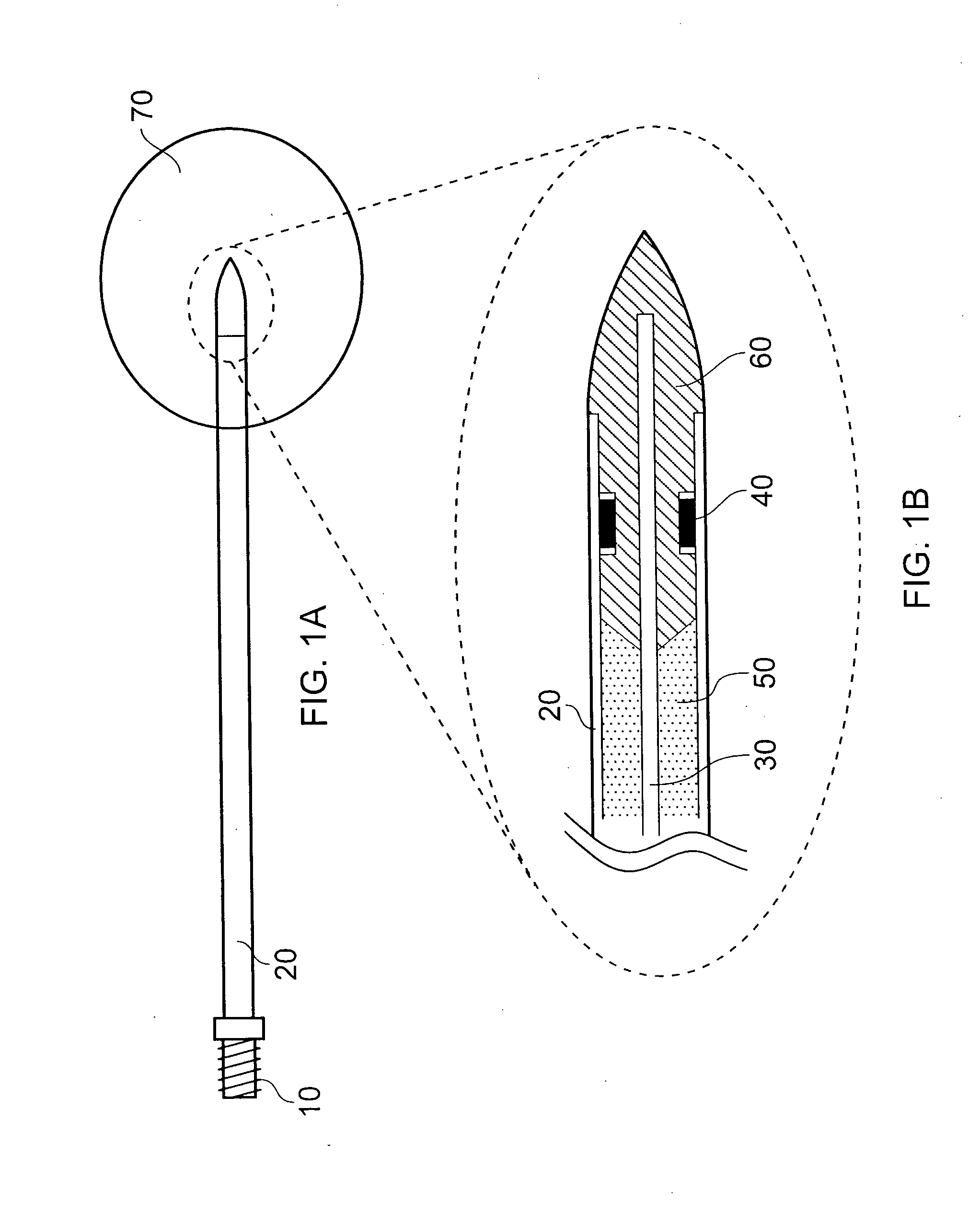

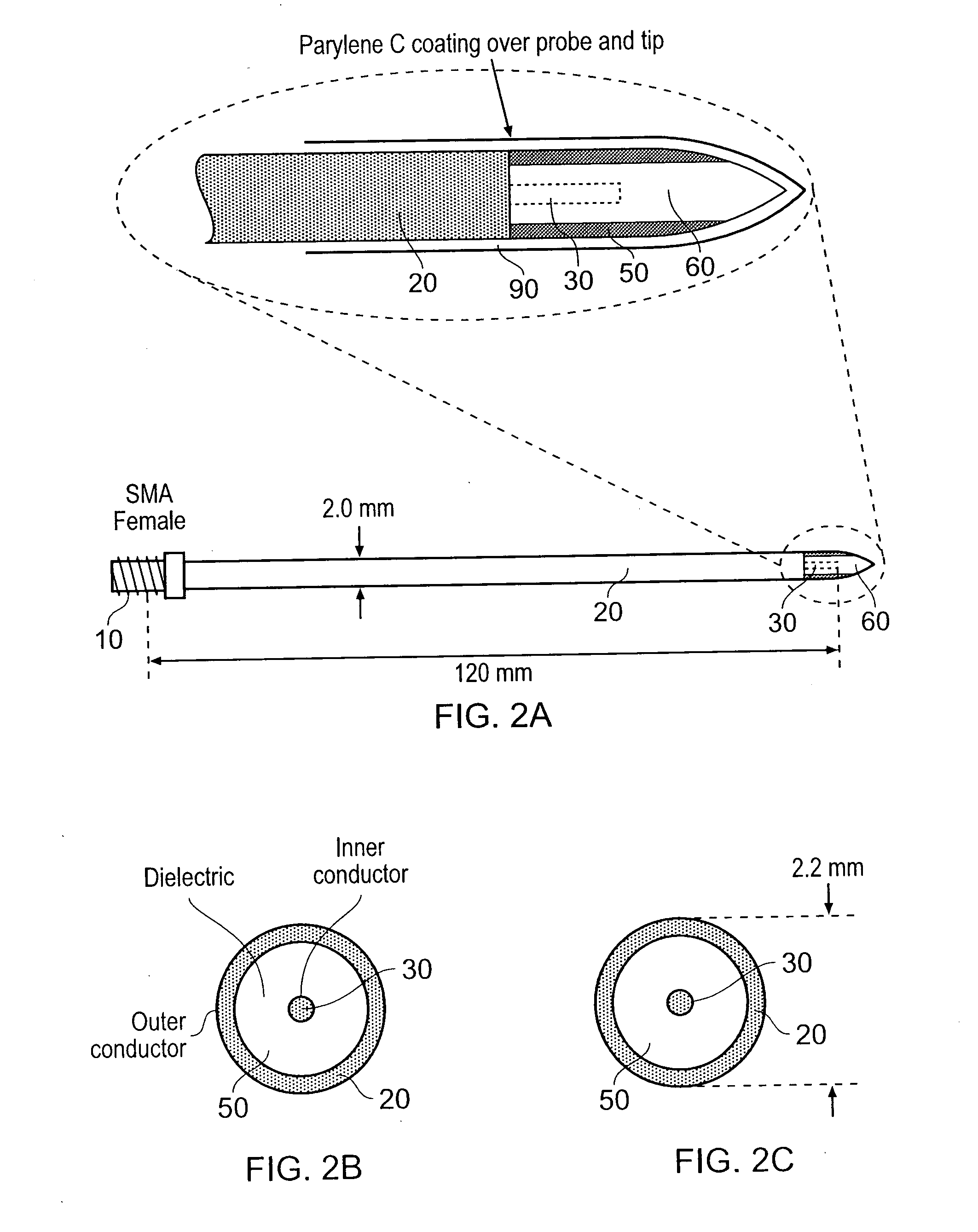

Tissue measurement and ablation antenna

InactiveUS20100228244A1Easy to operateImproving Impedance MatchingSurgical instruments for heatingSurgical instruments using microwavesElectrical conductorMicrowave

A surgical antenna for radiating microwave energy (e.g. frequency 500 MHz to 60 GHz) from a e.g. ceramic insertion tip (60) into biological tissue is disclosed. The tip is provided at the end of an elongate body which delivers the microwave energy to the tip via an inner conductor (30), an outer conductor (20) surrounding the inner conductor and a dielectric material (50) therebetween. The impedance of the insertion tip (60) is selected to improve impedance matching with the complex conjugate of the complex impedance of the tissue at a treatment frequency. For example the insertion tip may act as or include at least one quarter wavelength impedance transformer. By closely matching the antenna's impedance to the tissue, dynamic tuning (if used) can be performed much more efficiently. Impedance matching at the tip can also focus the radiated energy distribution.

Owner:MEDICAL DEVICE INNOVATIONS

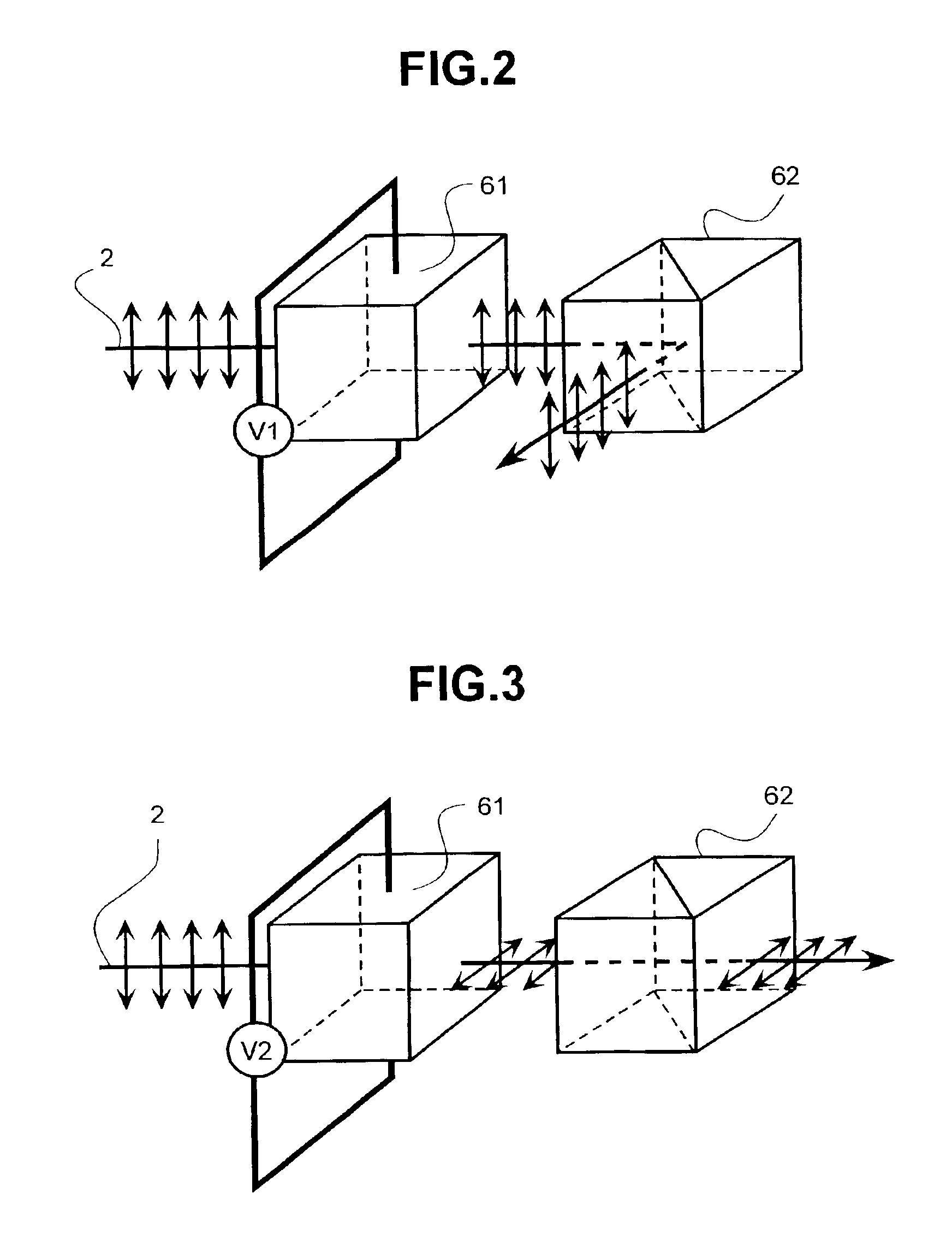

Laser annealing apparatus, TFT device and annealing method of the same

InactiveUS6943086B2Reducing and eliminating influenceTransistorSolid-state devicesEnergy variationSingle crystal

A laser beam is concentrated using an objective lens and radiated on a amorphous silicon film or polycrystalline silicon film having a grain size of one micron or less, the laser beam being processed from a continuous wave laser beam (1) to be pulsed using an EO modulator and to have arbitrary temporal energy change while pulsing ; (2) to have an arbitrary spatial energy distribution using a beam-homogenizer, filter having an arbitrary transmittance distribution, and rectangular slit; and (3) to eliminate coherency thereof using a high-speed rotating diffuser. In this manner, it is possible to realize a liquid crystal display device in which a driving circuit comprising a polycrystalline silicon film having substantially the same properties as a single crystal is incorporated in a TFT panel device.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

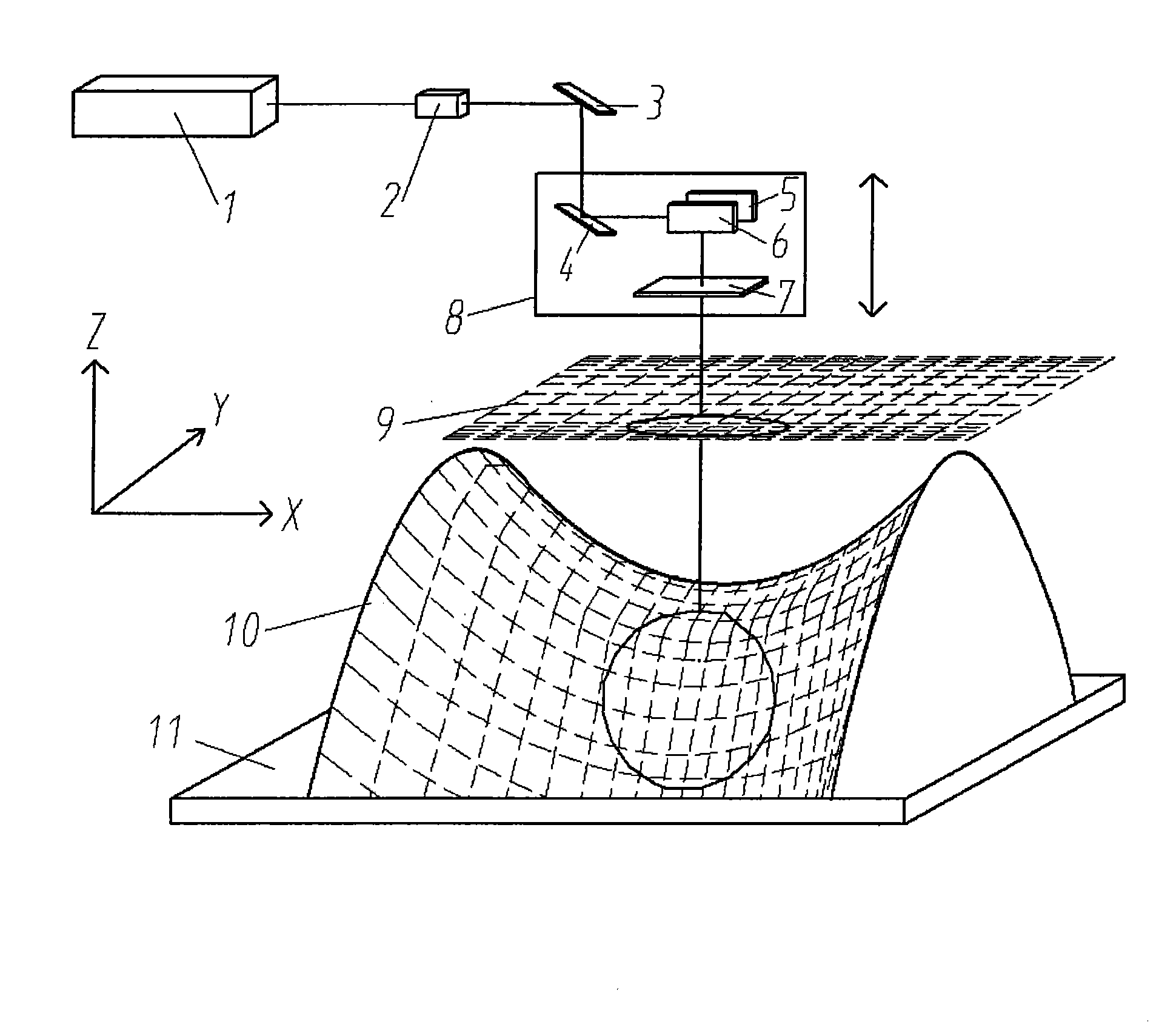

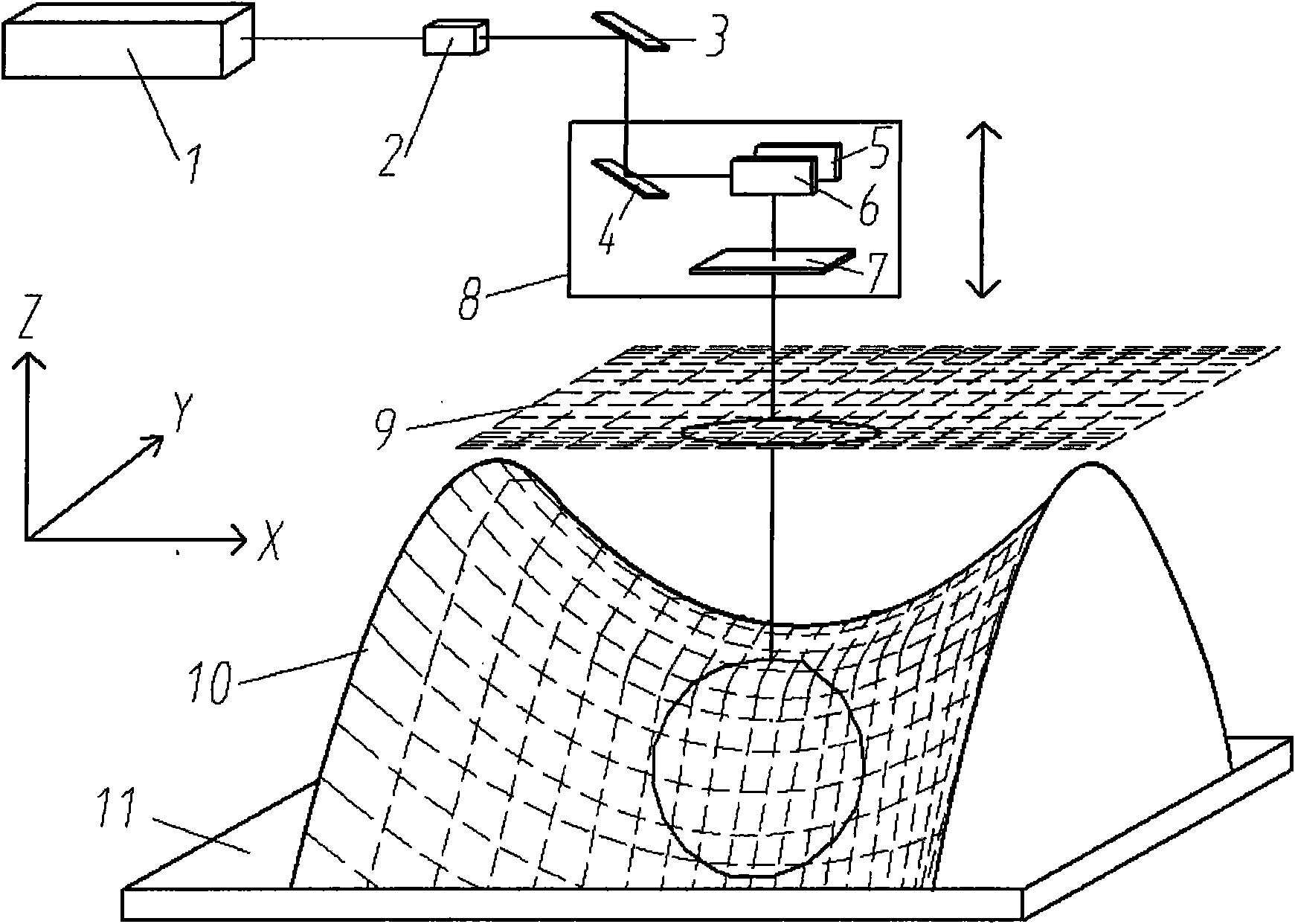

Method for projection-type laser etching on free curved surface

ActiveCN101786200AImprove efficiencySimple processLaser beam welding apparatusLaser etchingLaser processing

The invention discloses a method for projection-type laser etching on a free curved surface. By combining a laser galvanometer as well as a triaxial coordinate positioning technology and adopting the principles of partitioned parallel projection as well as height mapping, the invention directly conducts precise surface laser etching on the basis of a discrete point cloud model of a free curved surface part. The method has the characteristic that the laser etching properties such as the shape and size of a spot and the energy distribution remain unchanged within the focal depth range of a focusing lens, so that the free curved surface is converted into a plurality of plane subblocks for processing, and the high-precision processing efficiency of the free curved surface can be improved even by adopting the existing laser etching technology. The diameter of the focusing spot of a laser beam can reach tens of microns and is much smaller than the size of the part processed by a traditional knife tool; and the processing precision of nearly 10 microns can be realized by controlling the laser energy property. Under the premise of meeting the demands for high precision and high efficiency of pattern etching on the free curved surface, the method can realize high reliability and high flexibility in the processing of the free curved surface.

Owner:武汉飞能达激光技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com