Patents

Literature

2591 results about "Homogenizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A homogenizer is a piece of laboratory or industrial equipment used for the homogenization of various types of material, such as tissue, plant, food, soil, and many others. Many different models have been developed using various physical technologies for disruption. The mortar and pestle, already used for thousands of years, is a standard tool even in modern laboratories. More modern solutions are based on blender type of instruments (also known in the kitchen), bead mills, ultrasonic treatment (also sonication), rotor-stator mechanical, high pressure, and many other physical forces. While there are many application overlaps between methods, each homogenization method has distinct advantages and disadvantages.

Processes to generate submicron particles of water-insoluble compounds

InactiveUS6177103B1Rapid of surface stabilizedRapid attainmentOrganic active ingredientsPowder deliveryWater insolubleChemical compound

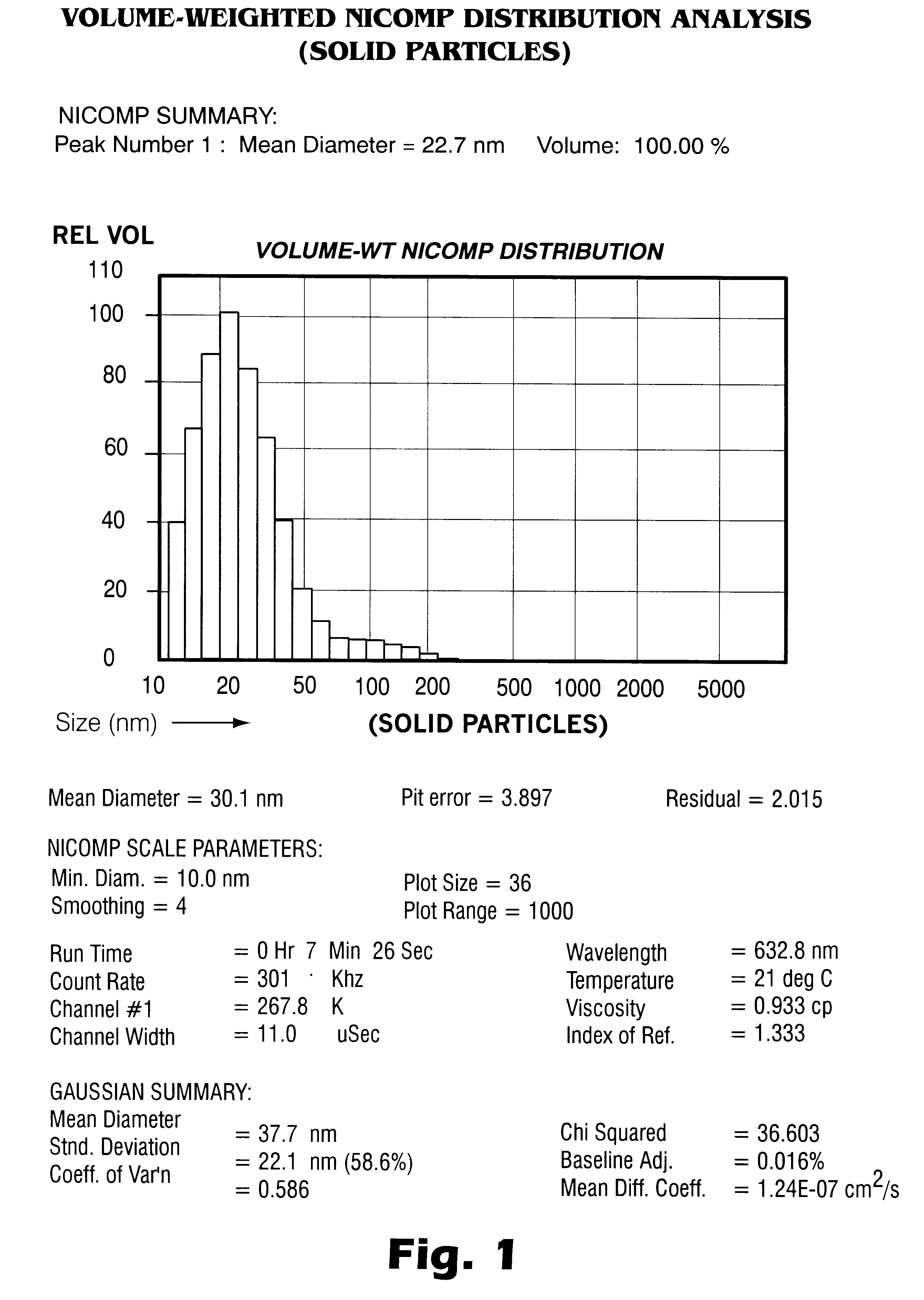

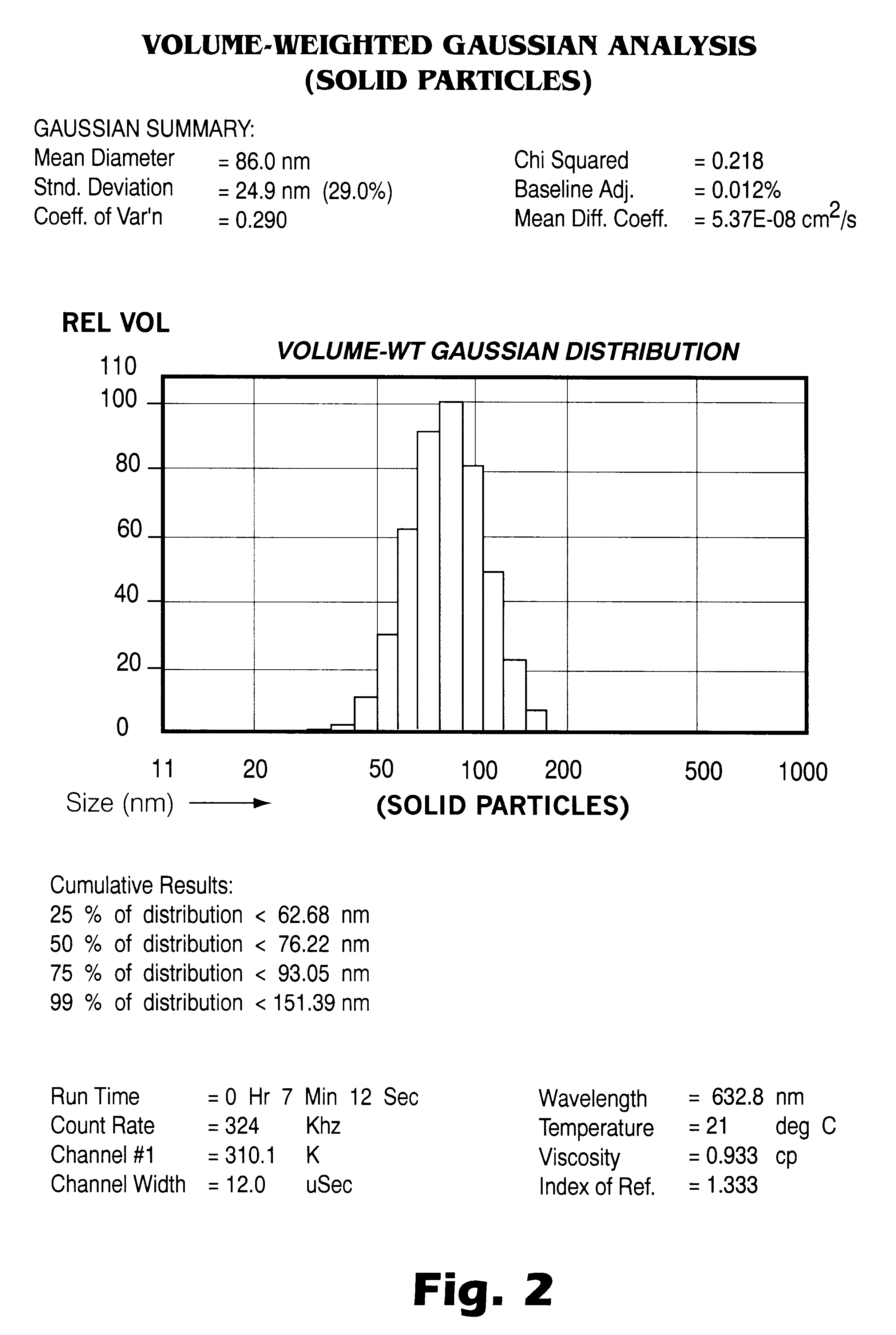

Submicron particles of water-insoluble compounds, particularly drugs, are prepared by simultaneously stabilizing microparticulate suspensions of same with surface modifier molecules by rapid expansion into an aqueous medium from a compressed solution of the compound and surface modifiers in a liquefied gas and optionally homogenizing the aqueous suspension thus formed with a high pressure homogenizer.

Owner:JAGOTEC AG +1

Manufacture of stable low particle size organopolysiloxane emuslion

ActiveUS20070276087A1Rapid emulsificationReduce polymerization timeMaterial nanotechnologyOther chemical processesPolymer scienceEmulsion

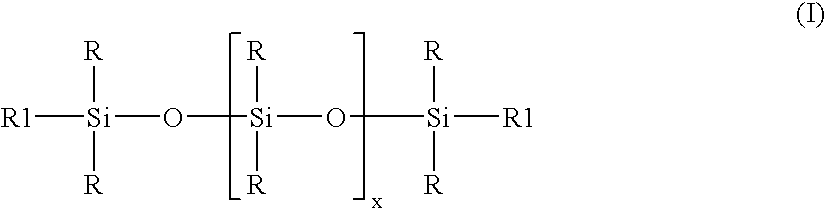

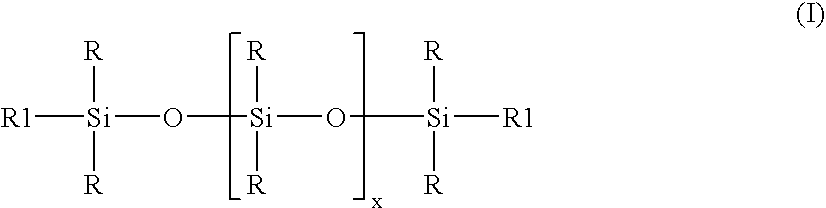

Stable high viscosity organopolysiloxane emulsions with particle sizes up to 150 nanometer may be made in a simple and cost-effective manner employing a standard homogenizer, and optional subsequent polymerization of the organopolysiloxan at controlled temperature. A combination of non-ionic emulsifier together with an at least one anionic emulsifier is employed, having an HLB value 12-15, while maintaining a temperature up to 50° C.

Owner:WACKER CHEM GMBH

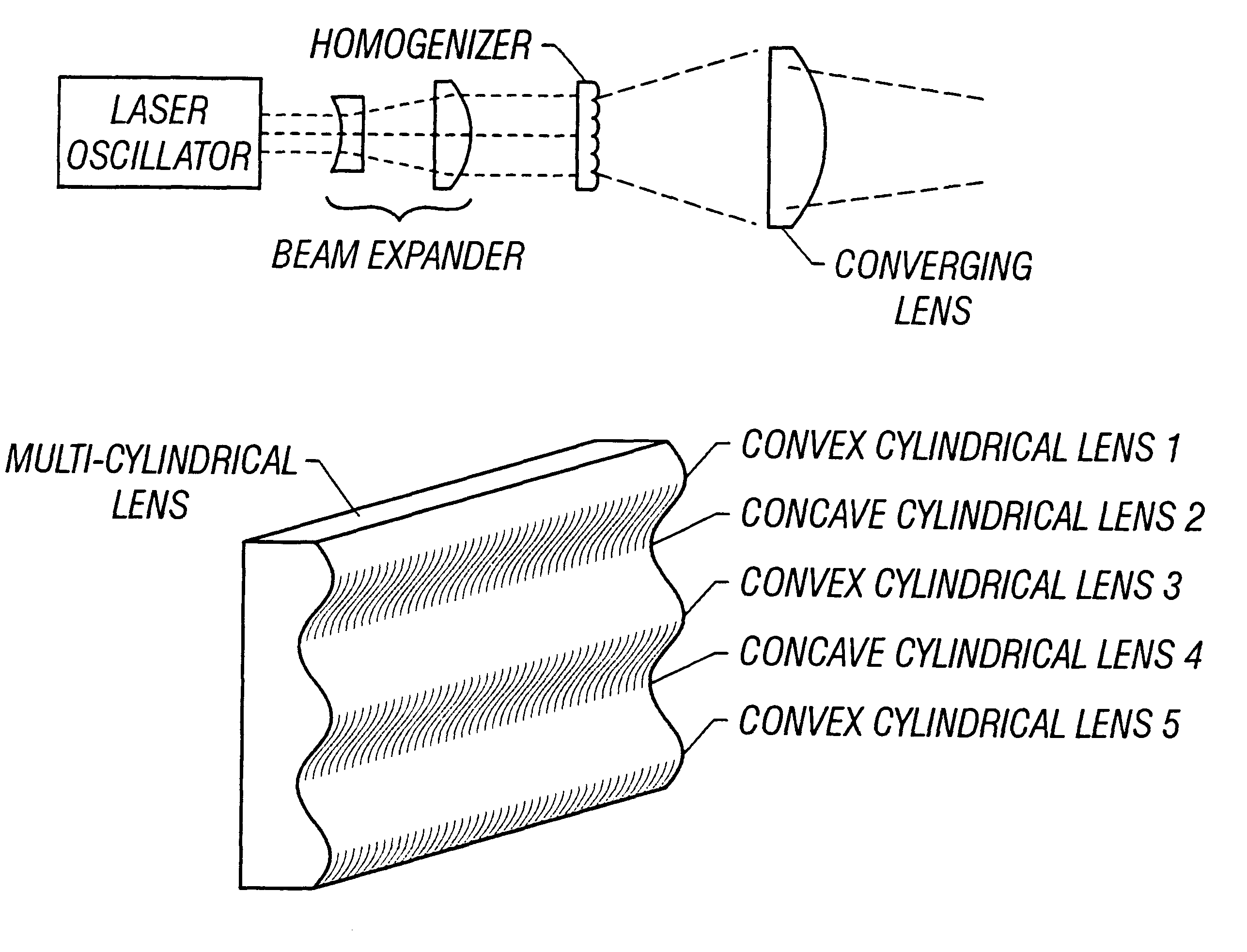

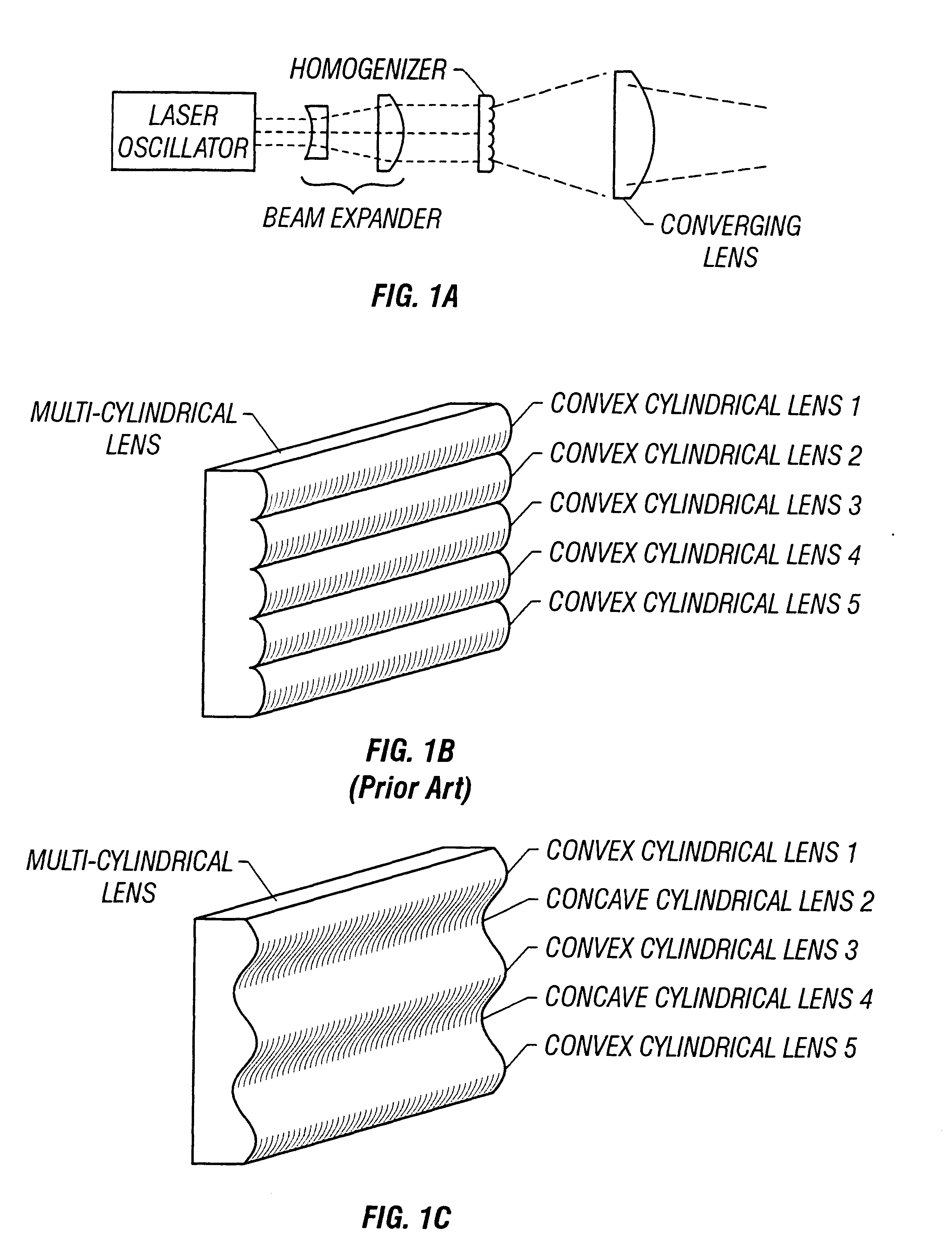

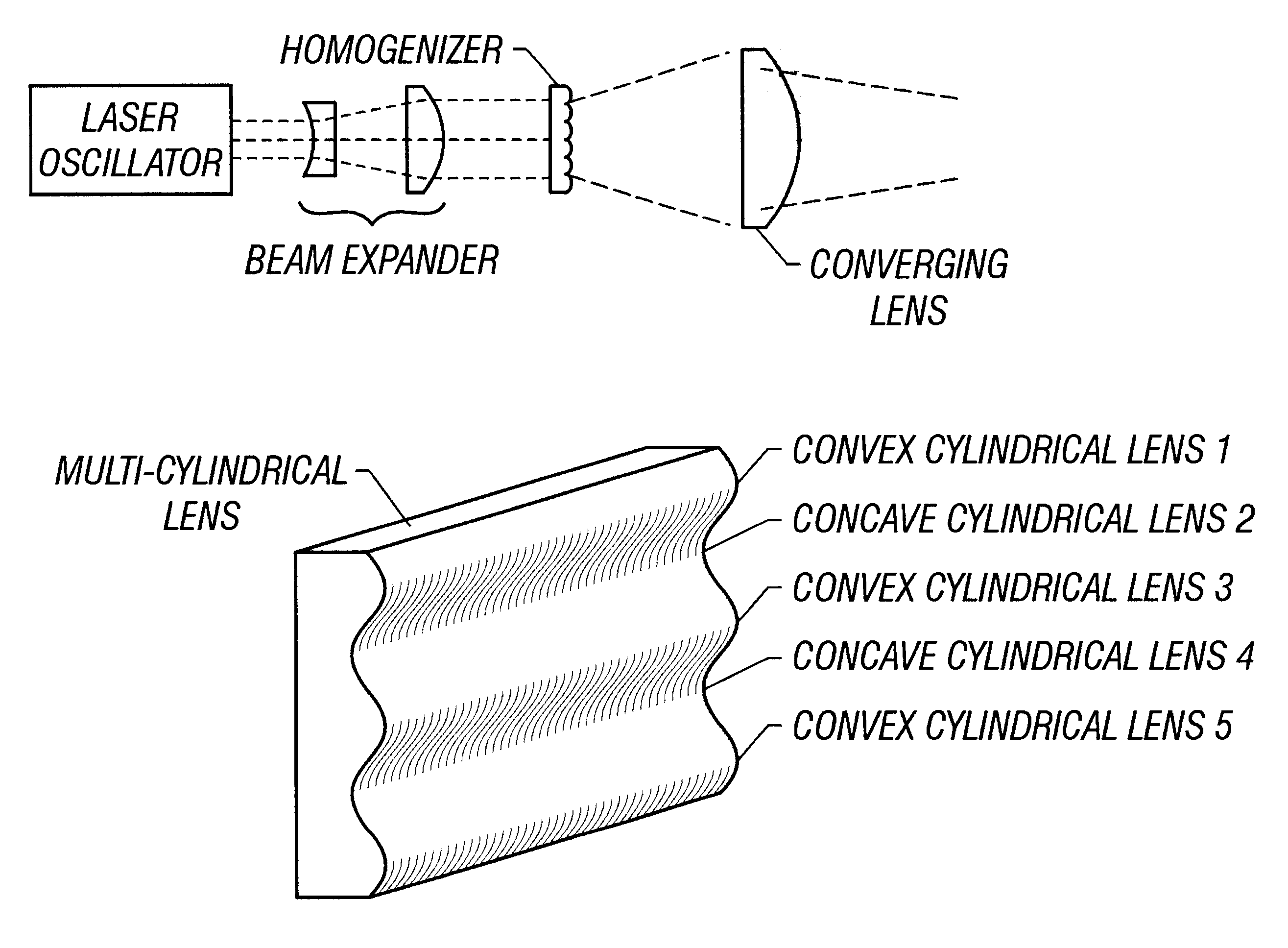

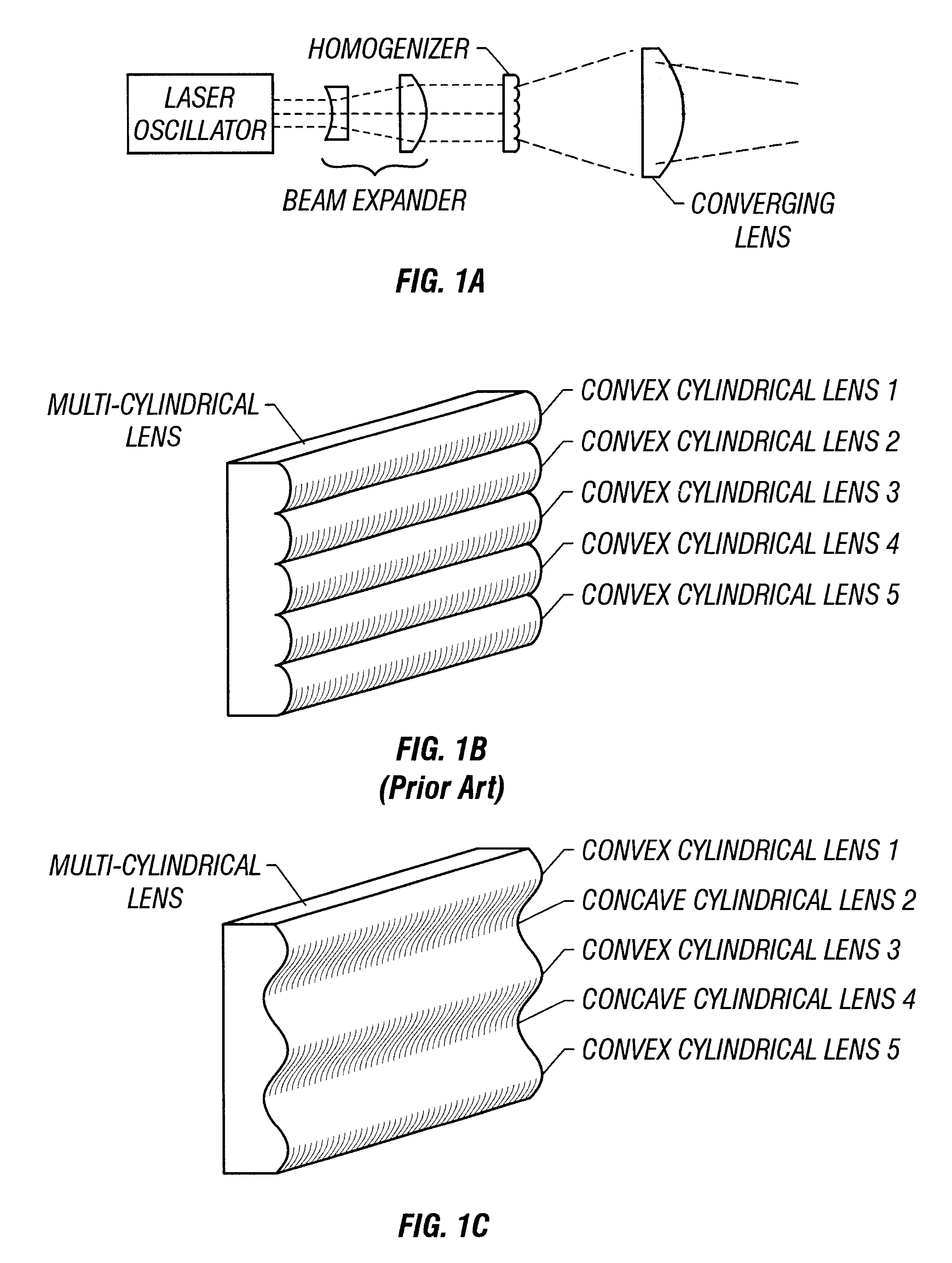

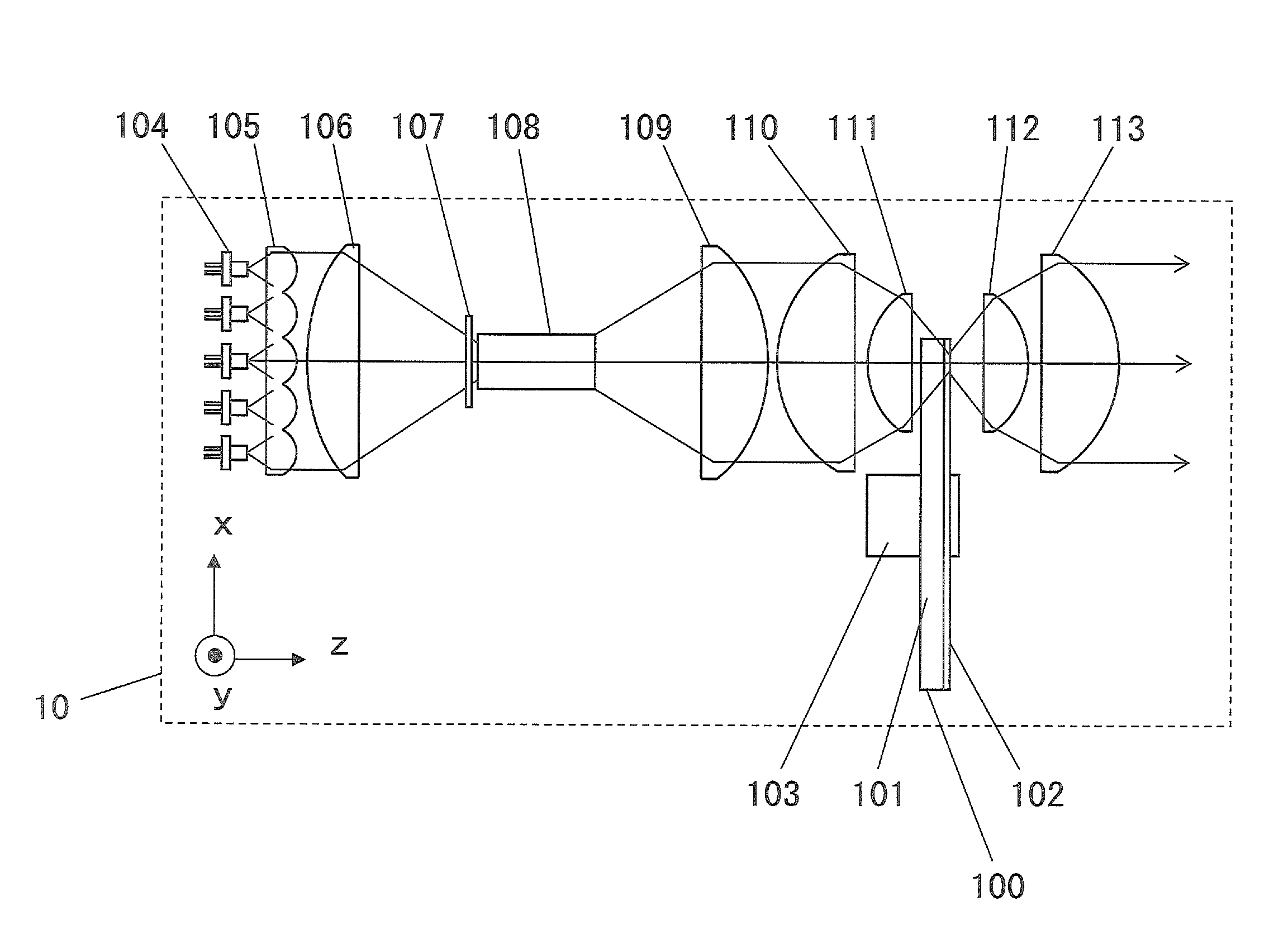

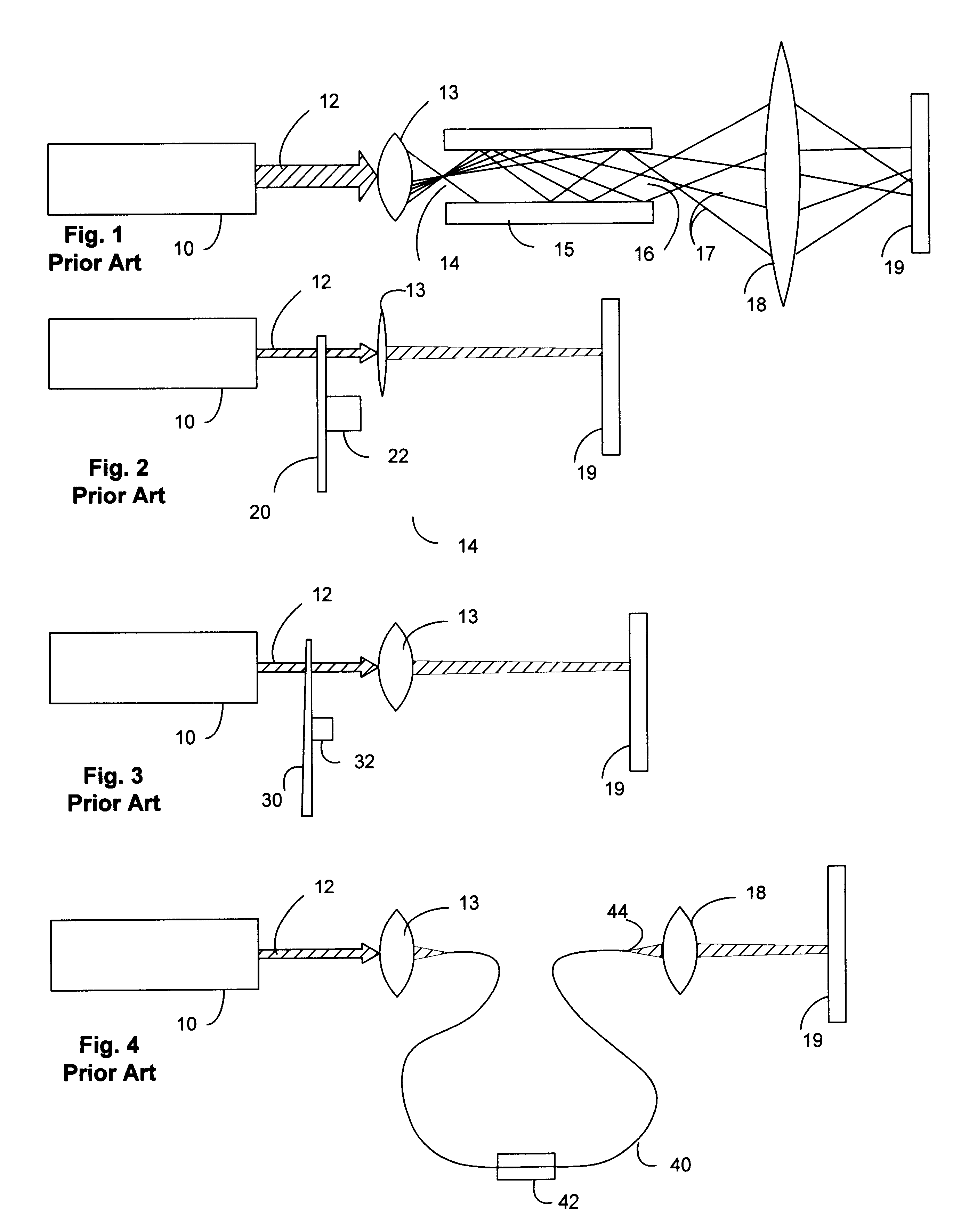

Laser optical apparatus

InactiveUS6212012B1Diffusing elementsSemiconductor/solid-state device manufacturingLight beamUltimate tensile strength

There is provided a structure for reducing optical loss in an optical apparatus (homogenizer) for making the intensity distribution of a laser beam uniform.In a multi-cylindrical lens (a glass substrate having a multiplicity of cylindrical lenses formed thereon) used in a homogenizer, convex cylindrical lenses and concave cylindrical lenses are arranged alternately, and the boundaries between the cylindrical lenses have a smooth structure. This makes it possible to reduce scattering of beams that has occurred at the boundaries between the cylindrical lenses.

Owner:SEMICON ENERGY LAB CO LTD

Laser optical apparatus

InactiveUS6239913B1Diffusing elementsSemiconductor/solid-state device manufacturingLight beamUltimate tensile strength

There is provided a structure for reducing optical loss in an optical apparatus (homogenizer) for making the intensity distribution of a laser beam uniform.In a multi-cylindrical lens (a glass substrate having a multiplicity of cylindrical lenses formed thereon) used in a homogenizer, convex cylindrical lenses and concave cylindrical lenses are arranged alternately, and the boundaries between the cylindrical lenses have a smooth structure. This makes it possible to reduce scattering of beams that has occurred at the boundaries between the cylindrical lenses.

Owner:SEMICON ENERGY LAB CO LTD

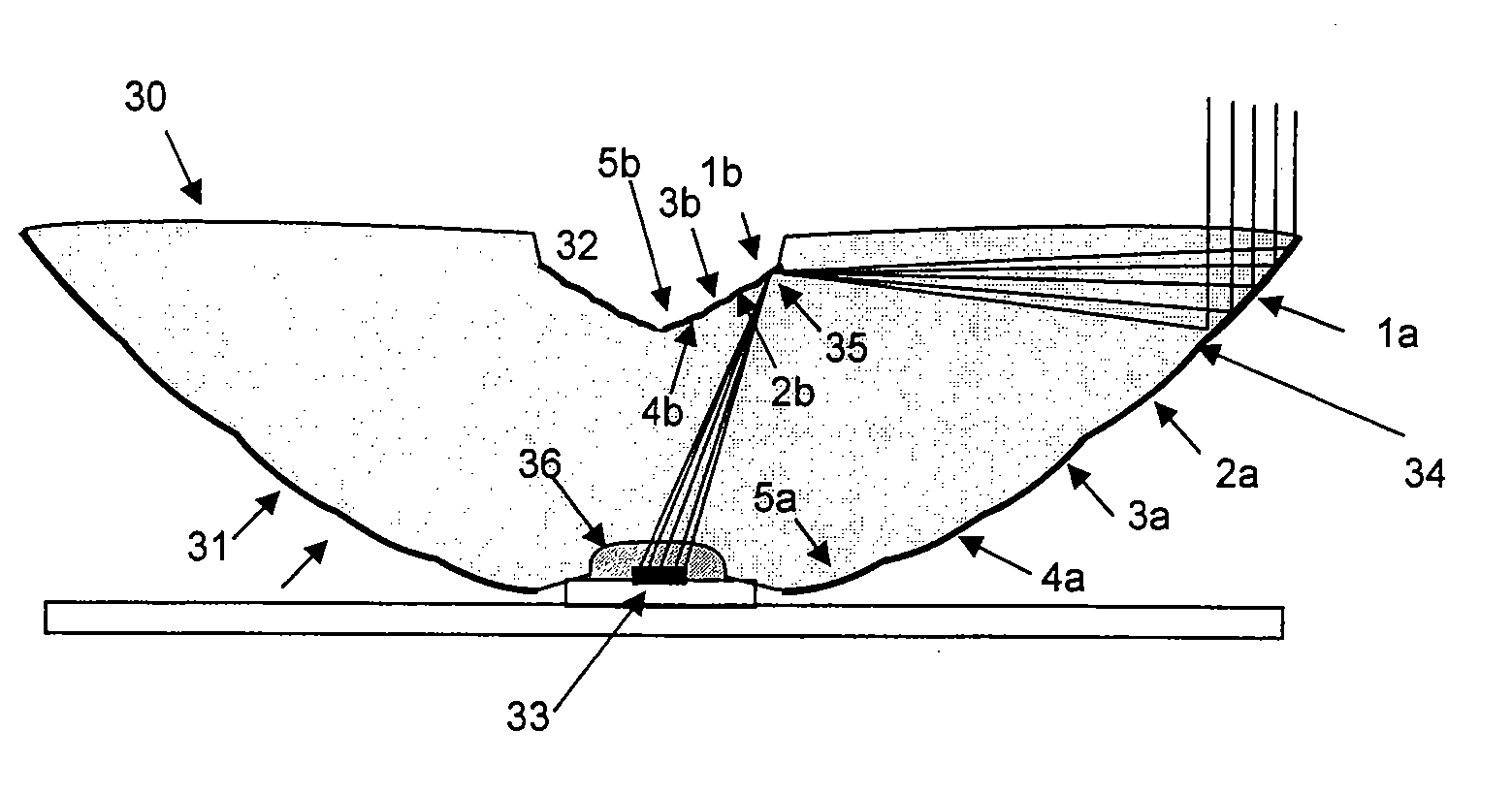

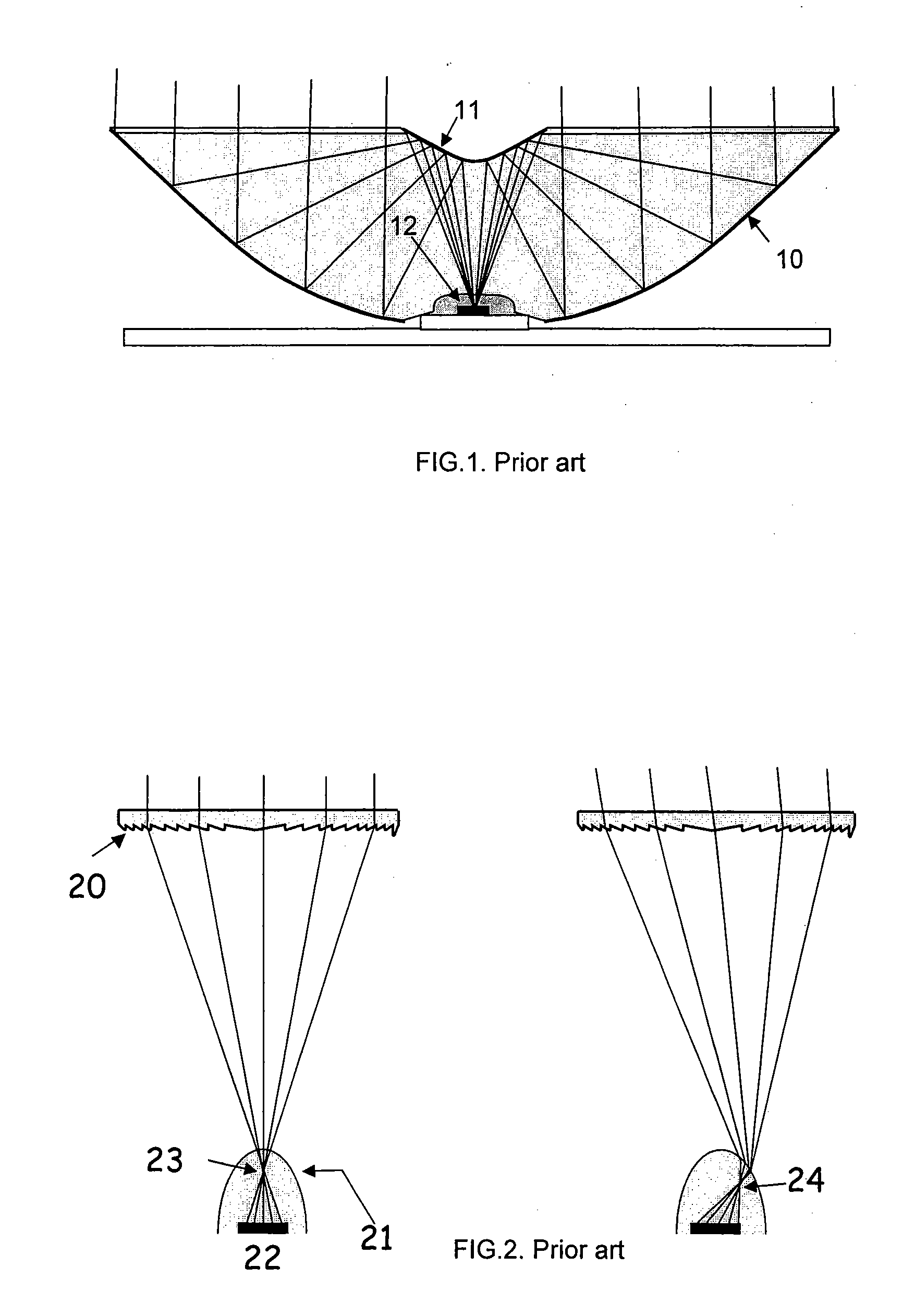

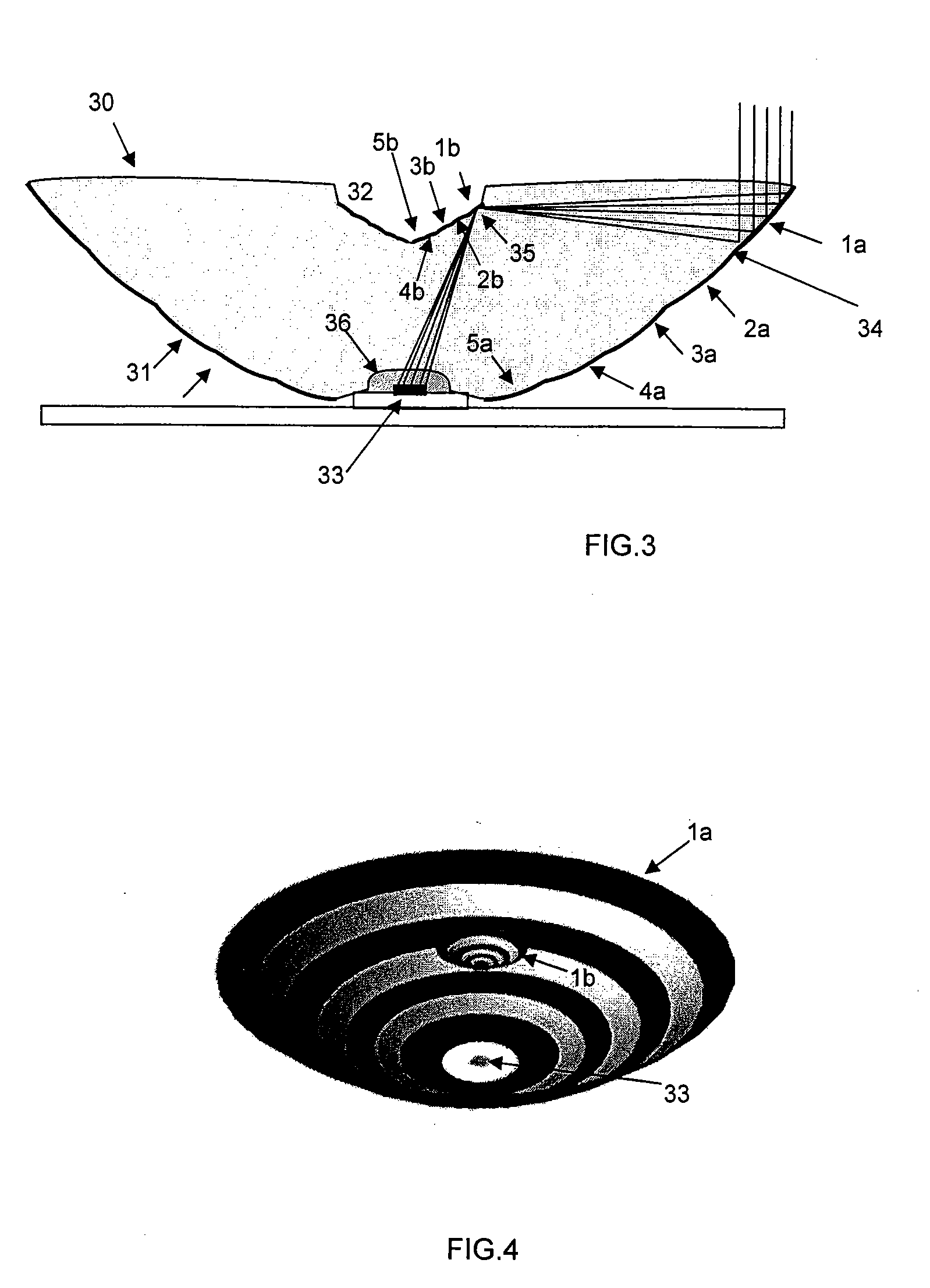

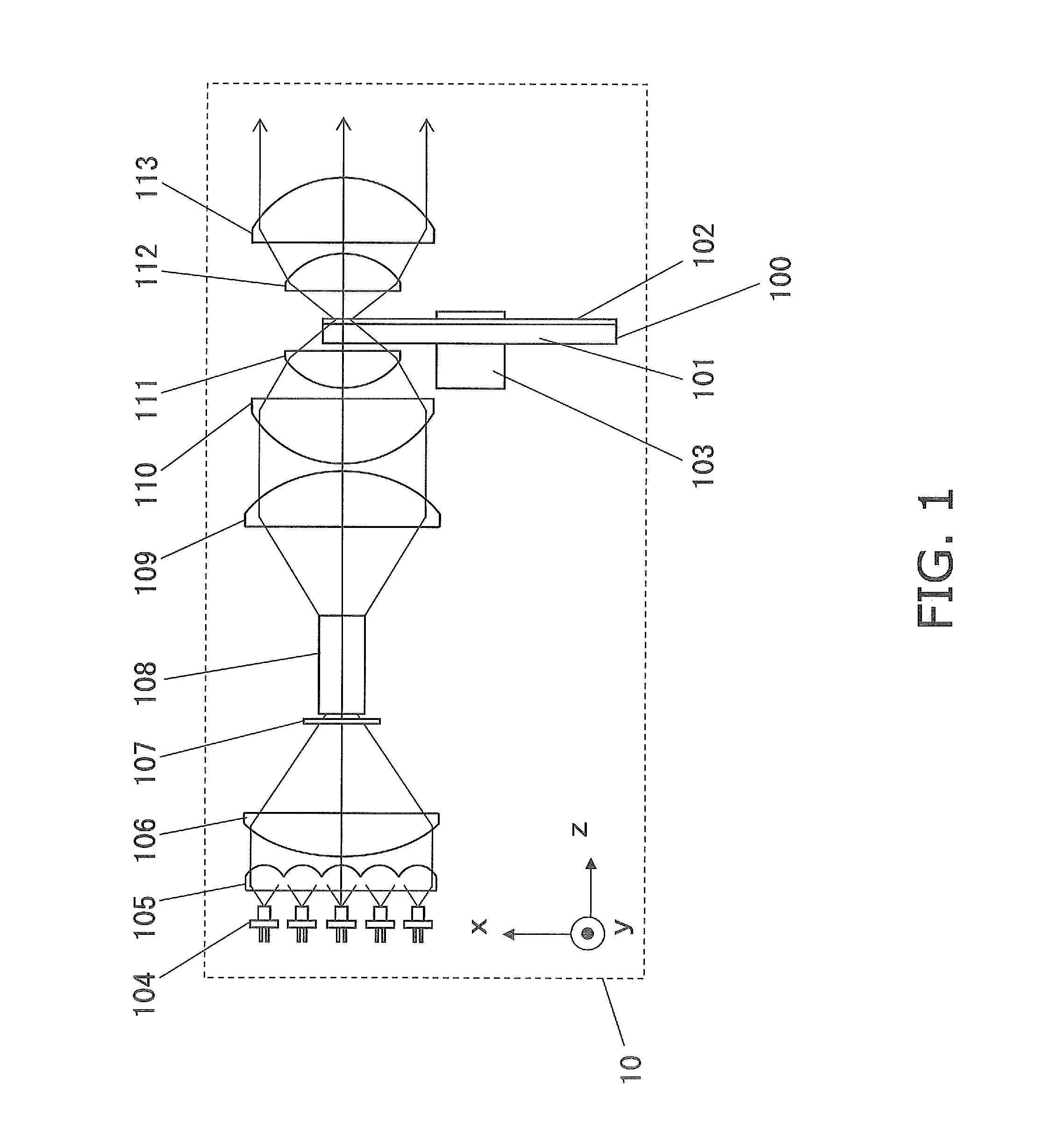

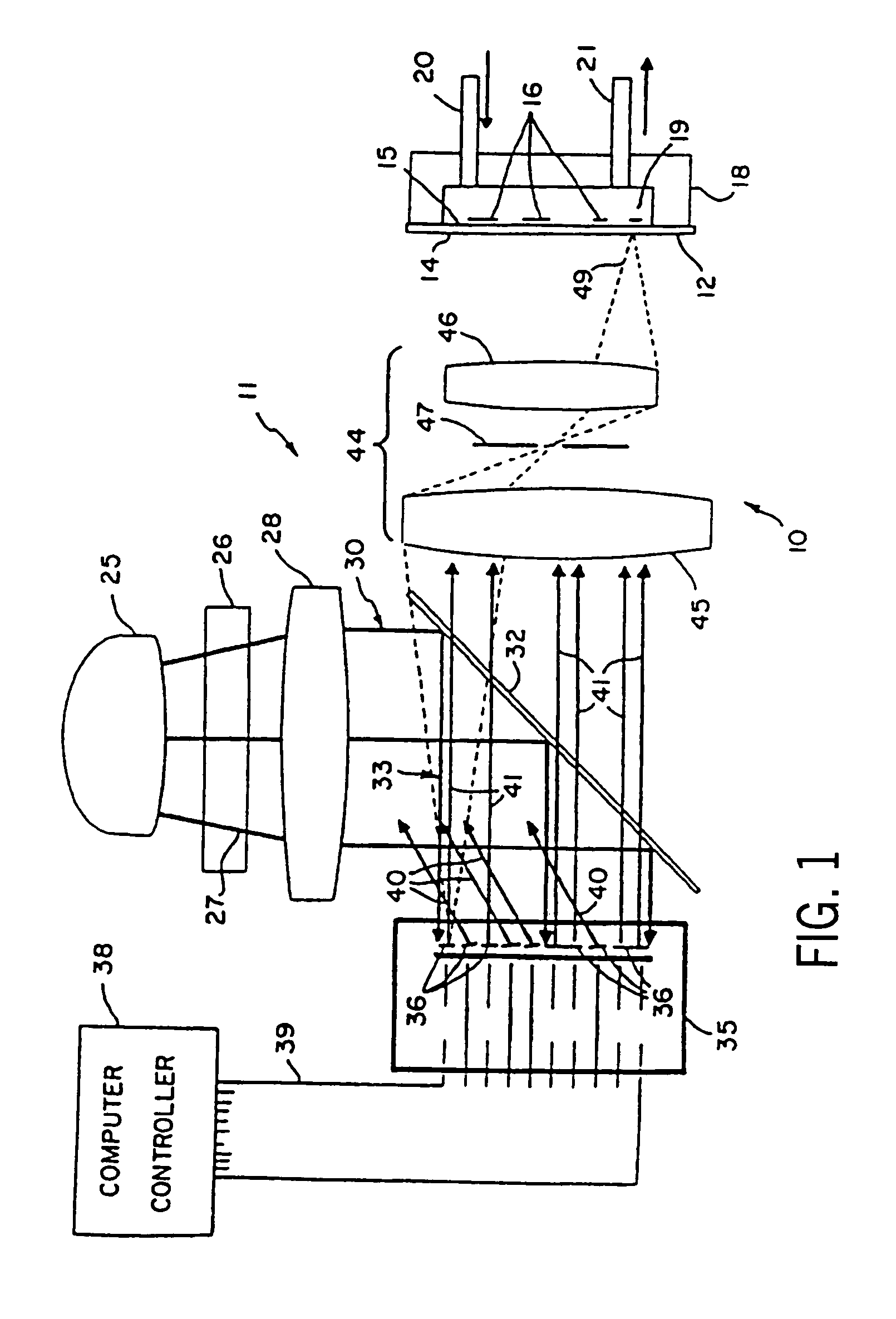

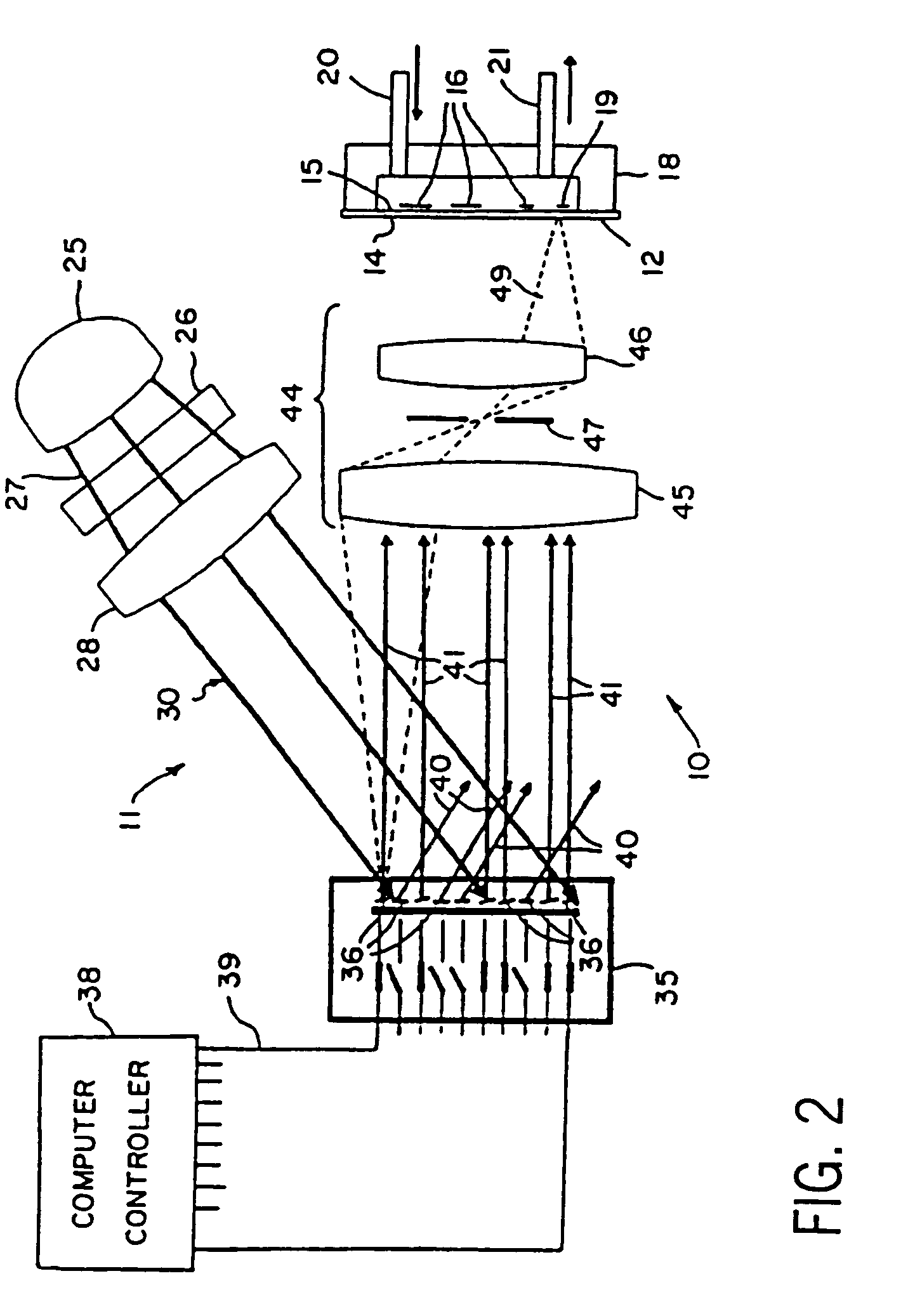

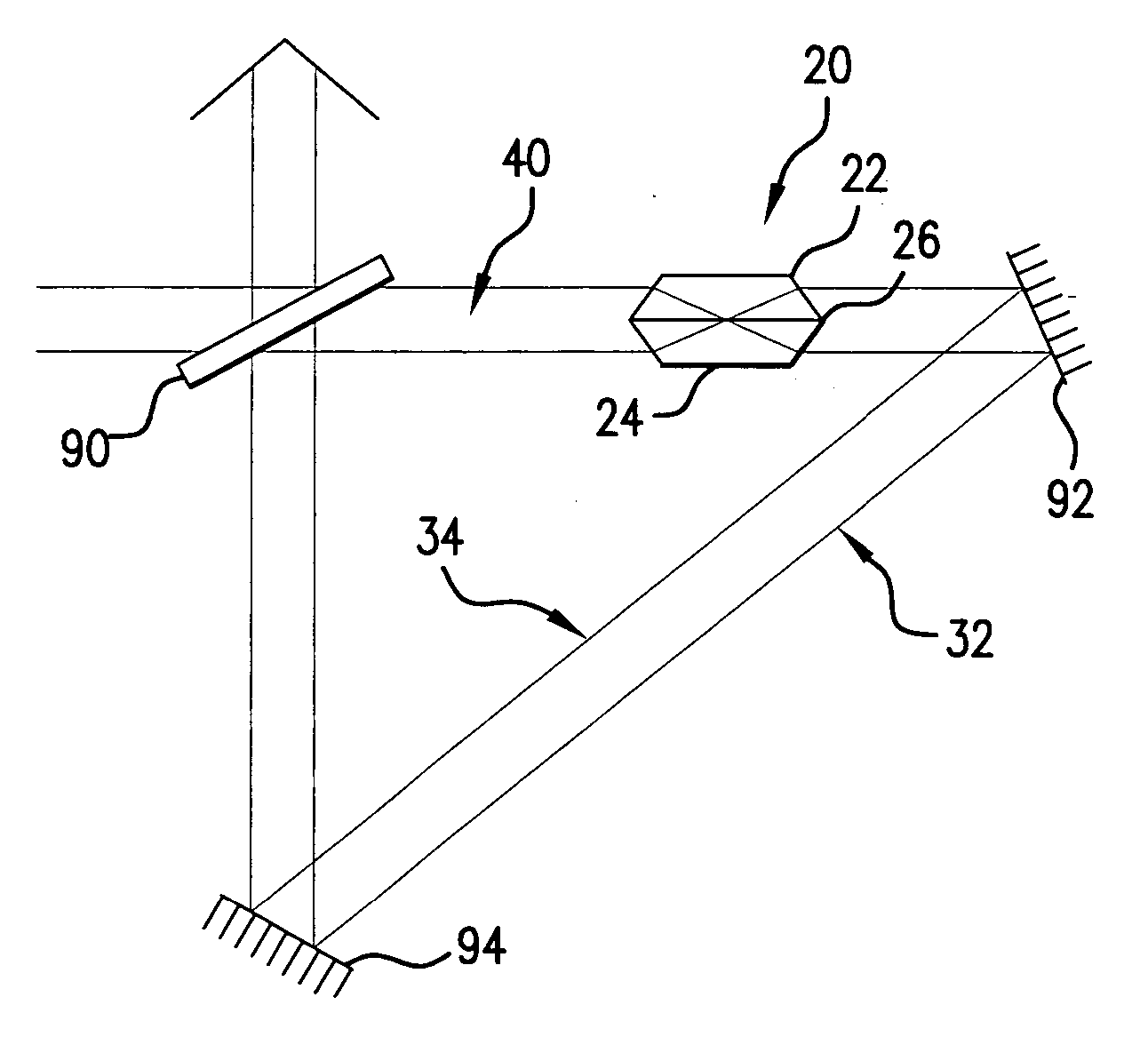

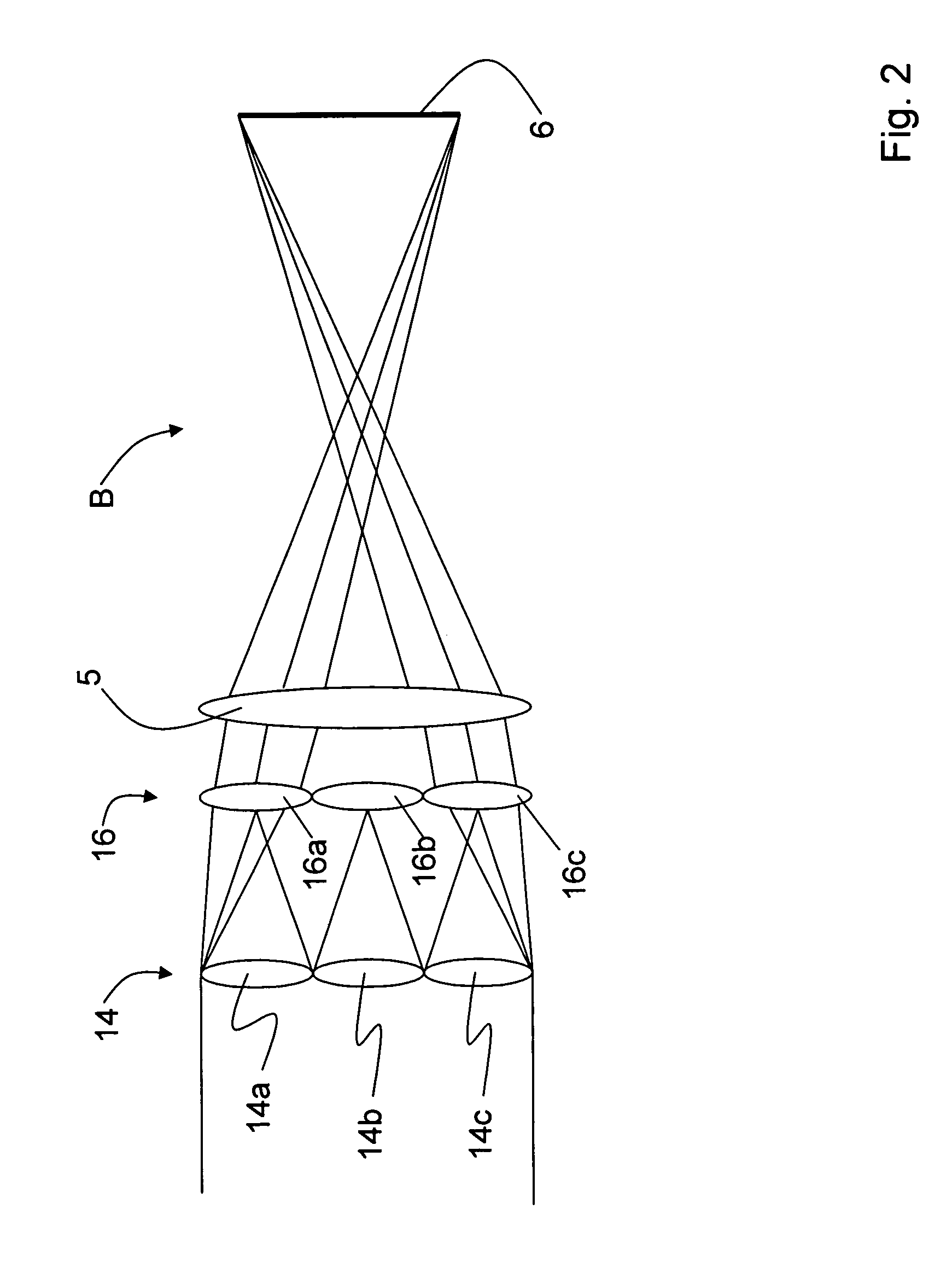

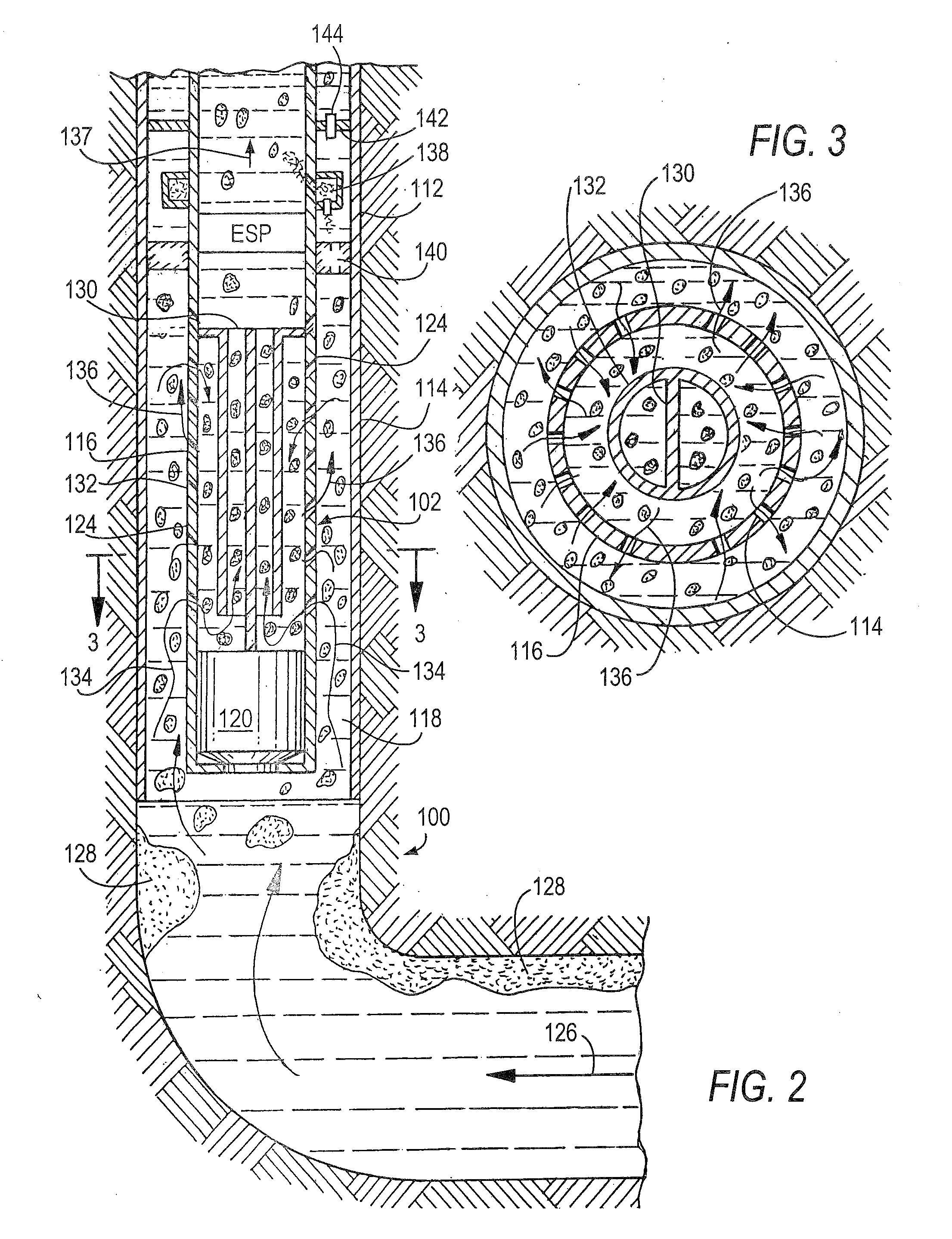

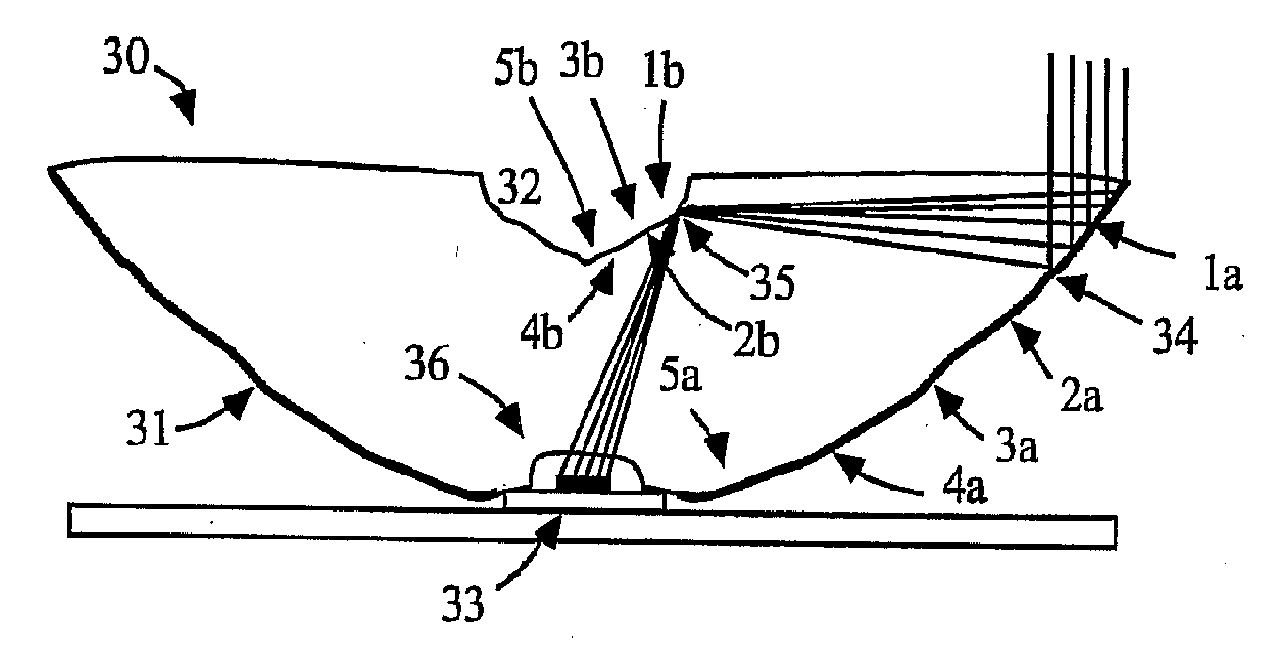

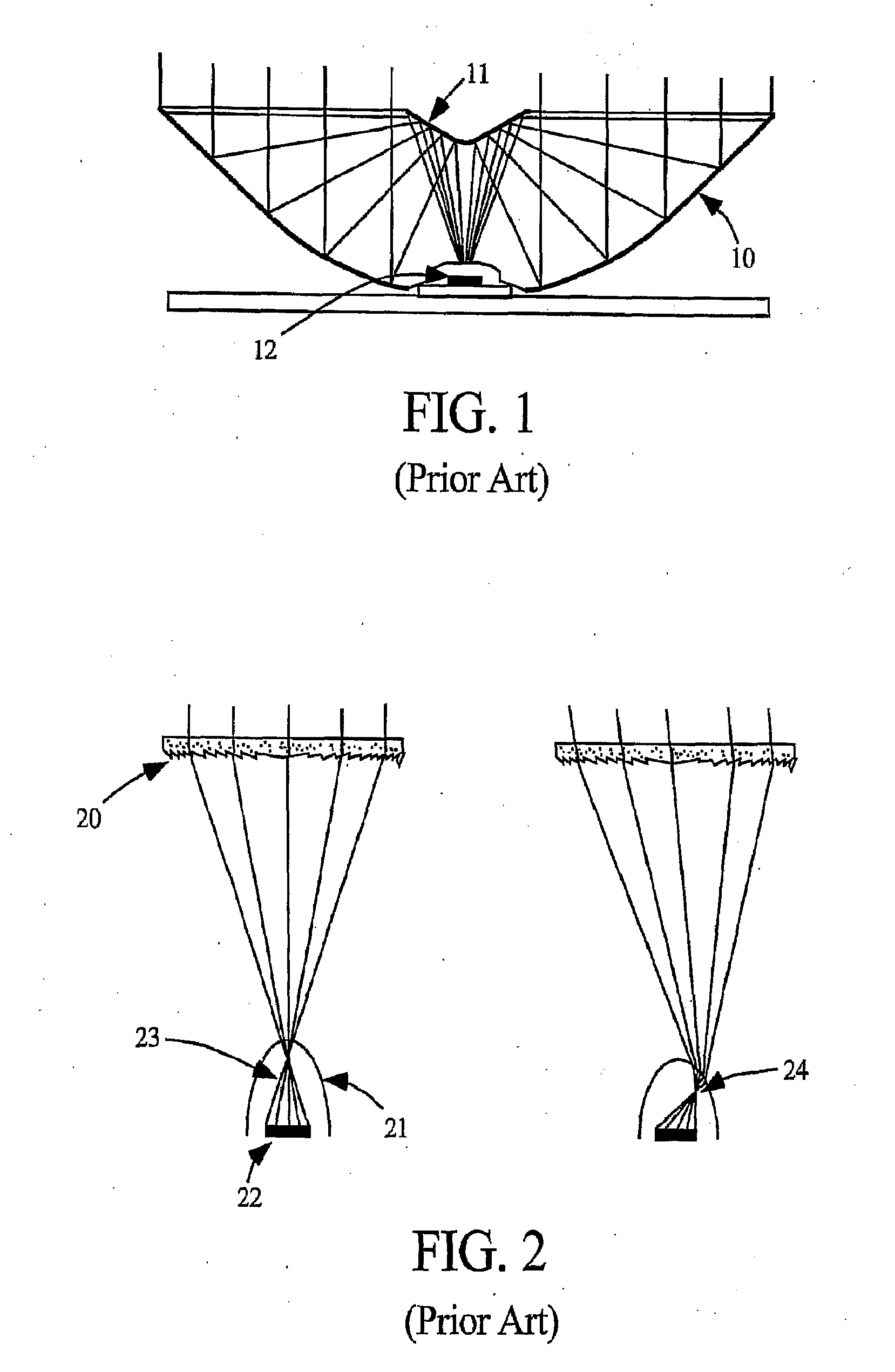

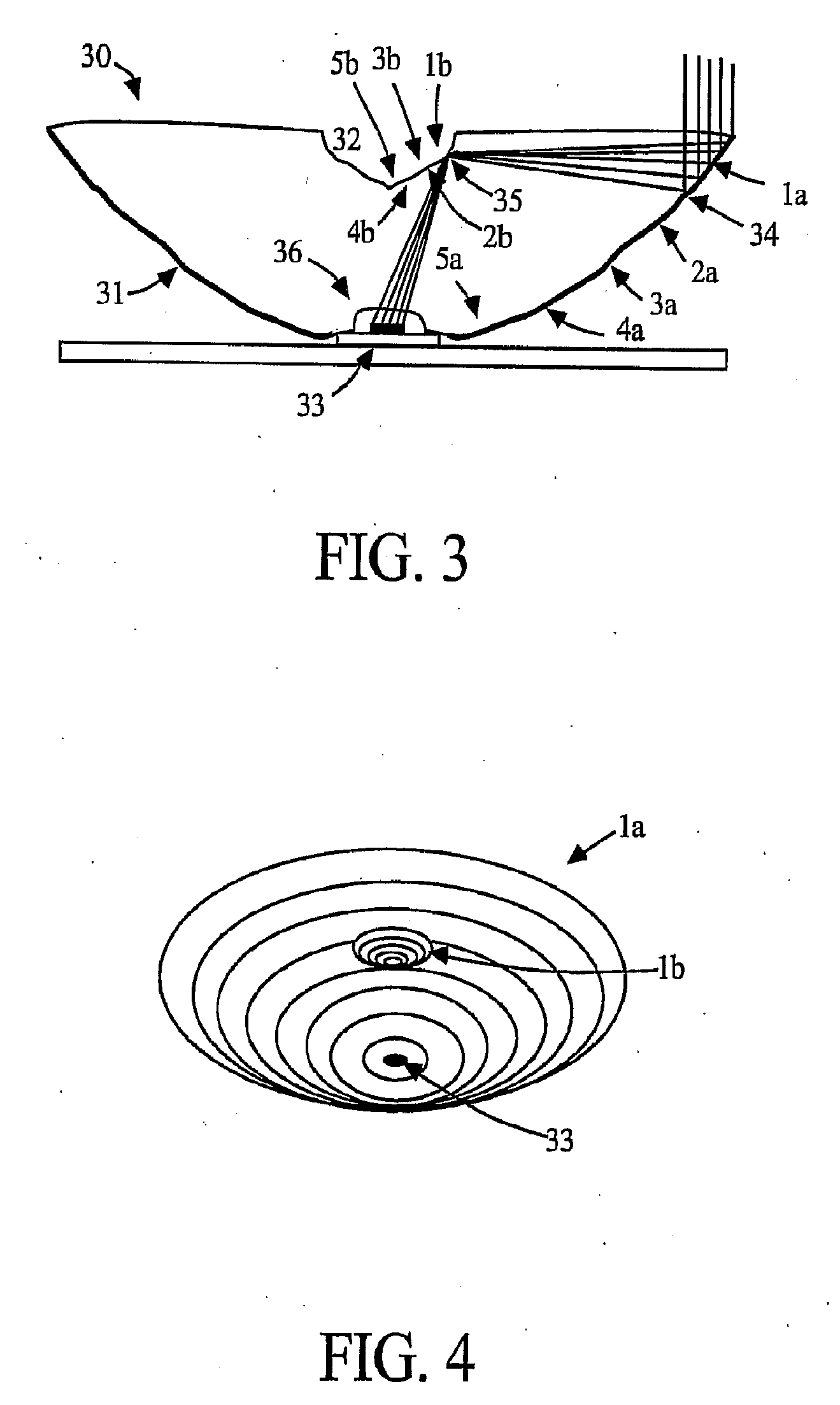

Multi-junction solar cells with a homogenizer system and coupled non-imaging light concentrator

InactiveUS20080047605A1High solar fluxEfficient electrical outputSolar heating energyMirrorsOptic systemMultijunction photovoltaic cell

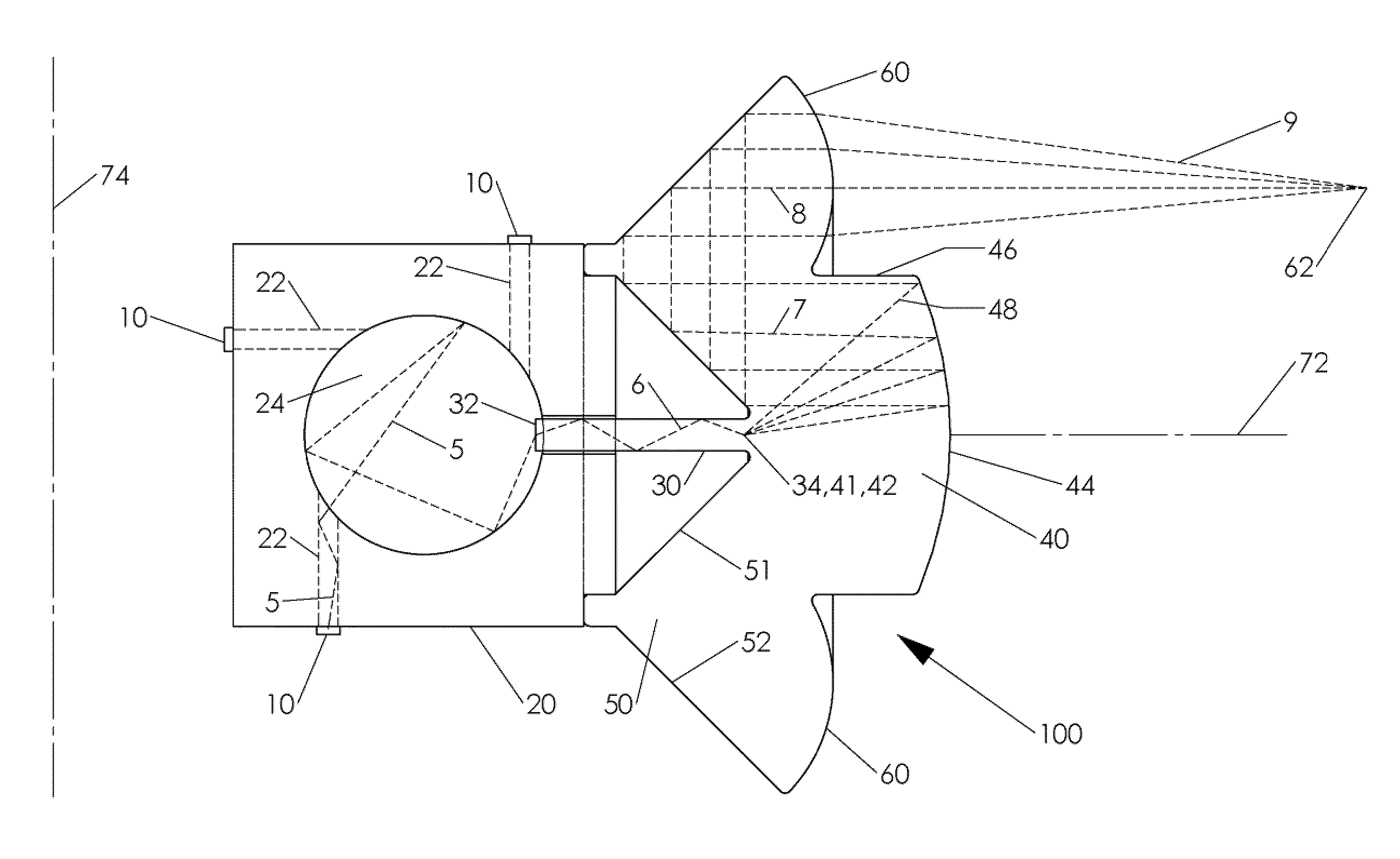

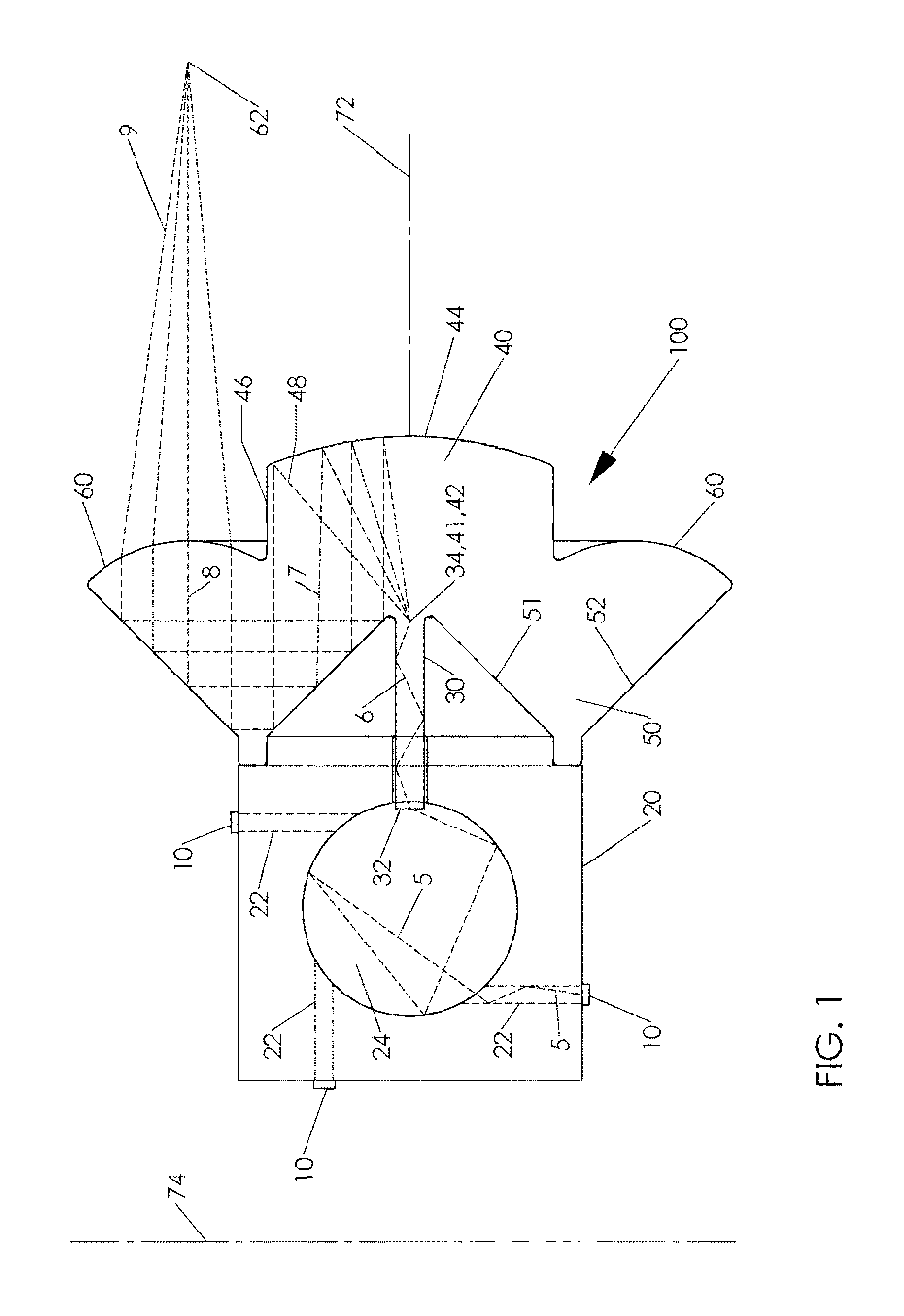

Optical systems and methods that concentrate light from a distant source, such as the sun, onto a target device, such as a solar cell. Light impinging from the distant source, is focused or imaged by a plurality of primary reflective segments of a primary mirror element onto a plurality of corresponding secondary reflective segments. The secondary mirror segments image the corresponding primary segments onto an exit aperture such that the exit aperture is uniformly illuminated. A target cell may be located proximal to the exit aperture, or an entry aperture of a non-imaging concentrator may be positioned proximal the exit aperture, wherein the concentrator concentrates the reflected light onto the target cell.

Owner:RGT UNIV OF CALIFORNIA +1

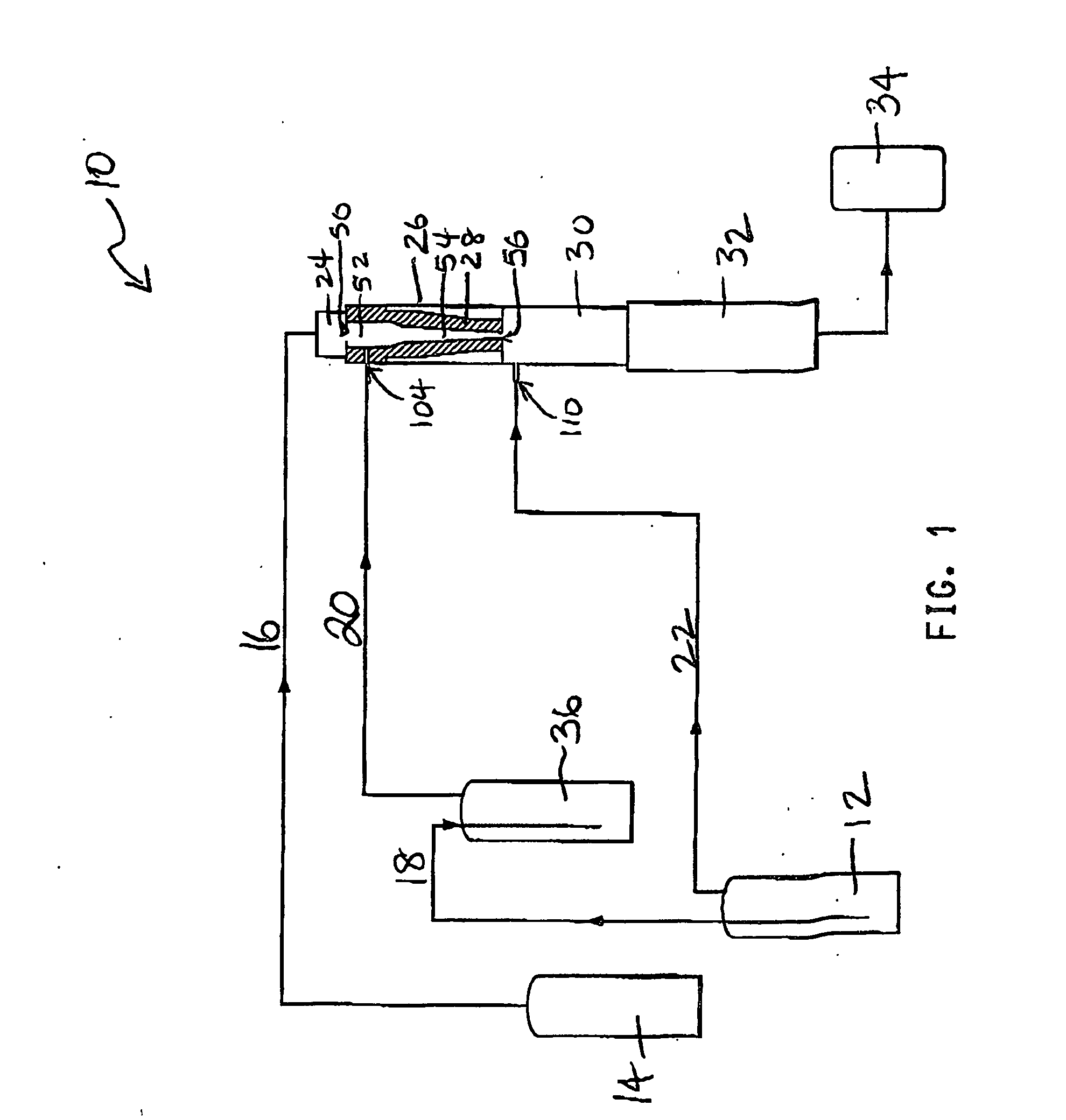

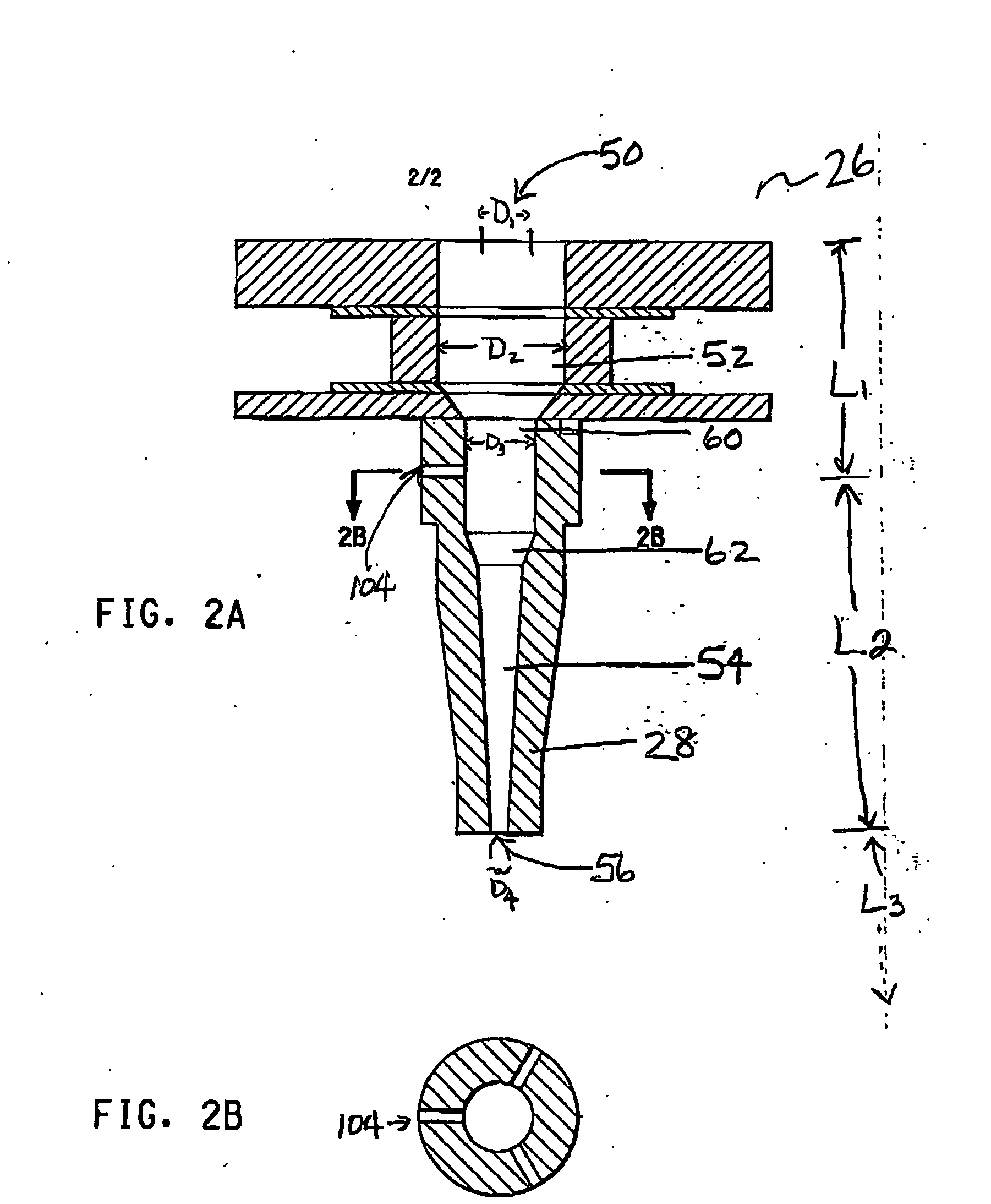

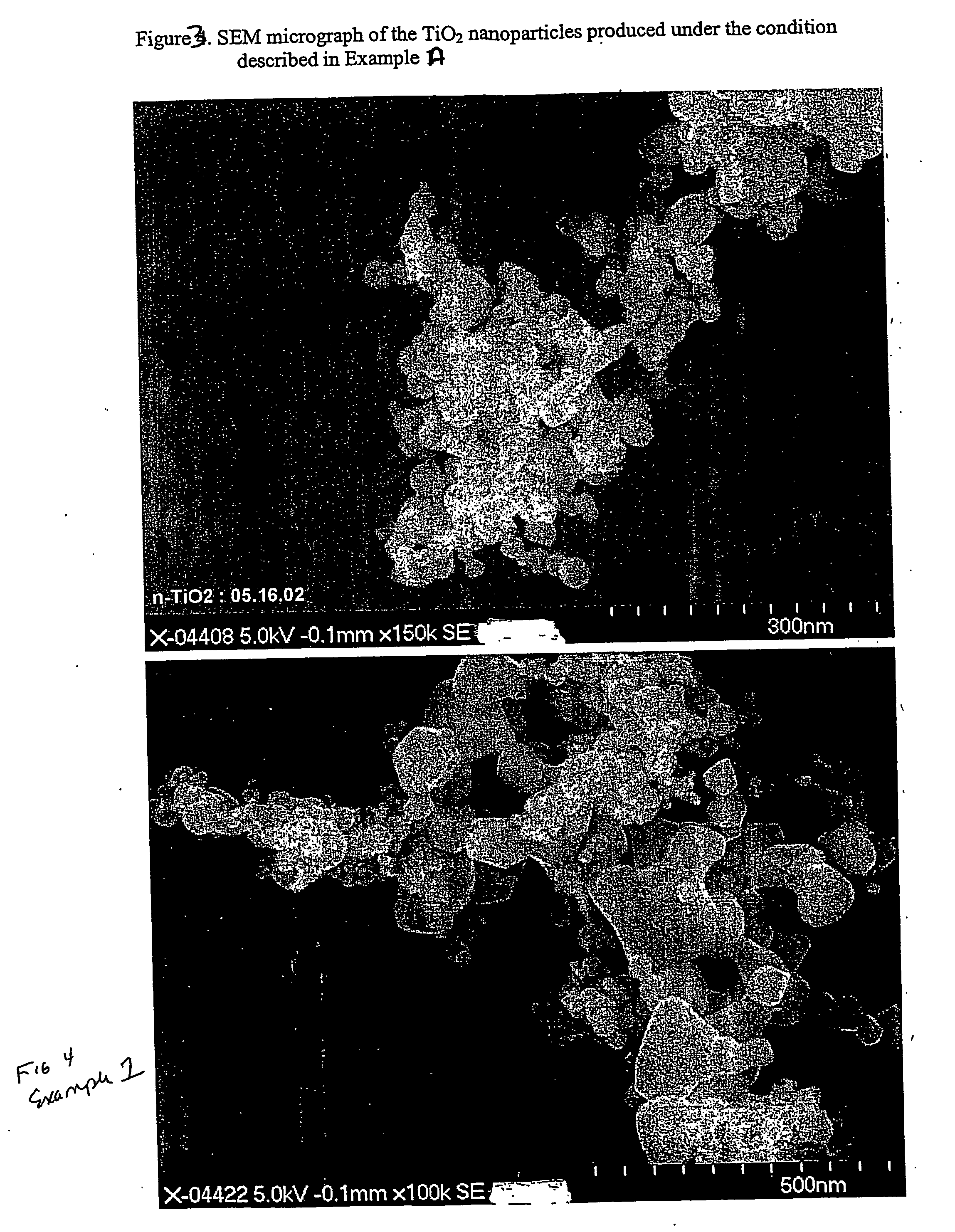

Method of producing nanoparticles using a evaporation-condensation process with a reaction chamber plasma reactor system

InactiveUS20060159596A1Reduce the temperatureMaterial nanotechnologyNanostructure manufactureNanoparticleReaction zone

The present invention provides a method and apparatus for the controlled synthesis of nanoparticles using a high temperature process. The reactor chamber includes a high temperature gas heated by means such as a plasma torch, and a reaction chamber. The homogenizer includes a region between the reactant inlets and the plasma (the spacer zone) to ensure that feeds from the reactant inlets are downstream of the recirculation zone induced by the high temperature gas. It also includes a region downstream of the reactant inlets that provides a nearly I dimensional (varying only in the axial direction) flow and concentration profile in the reaction zone to produce nanoparticles with narrow size distribution.

Owner:EI DU PONT DE NEMOURS & CO

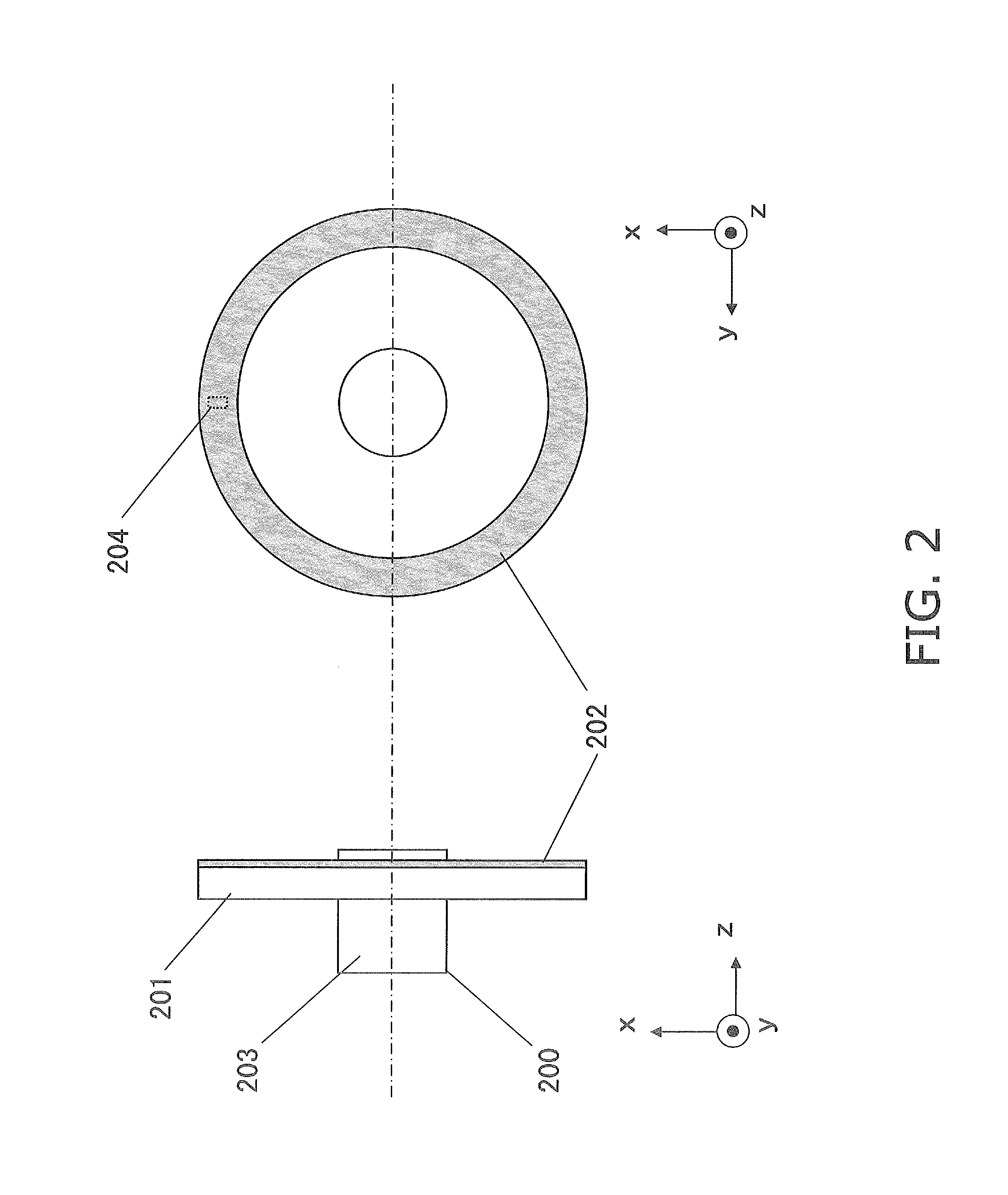

Light source device and image display device

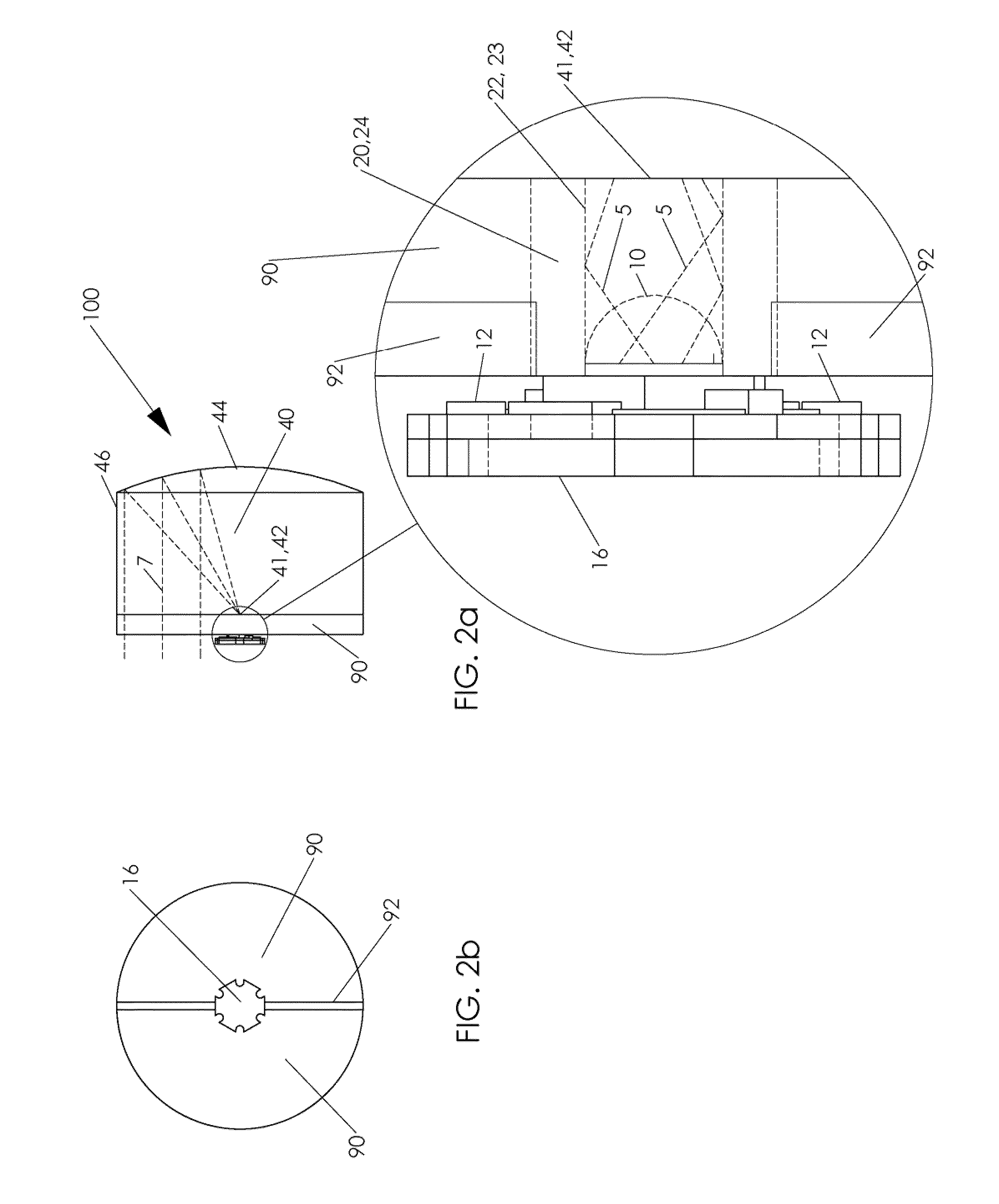

ActiveUS20130088471A1Long life-timeImprove efficiencyElectric circuit arrangementsProjectorsIlluminancePhosphor

The light source device includes a first light source component, a fluorescent component, a first illuminance homogenizer, and a relay optical system. The first light source component emits laser light. The fluorescent component has a phosphor. The phosphor is excited by laser light. The first illuminance homogenizer converts the laser light into laser light showing a spatially uniform light intensity distribution. The first illuminance homogenizer is disposed between the first light source component and the fluorescent component. The relay optical system guides laser light emitted from the first illuminance homogenizer to the fluorescent component. The relay optical system is disposed between the first illuminance homogenizer and the fluorescent component.

Owner:PANASONIC CORP

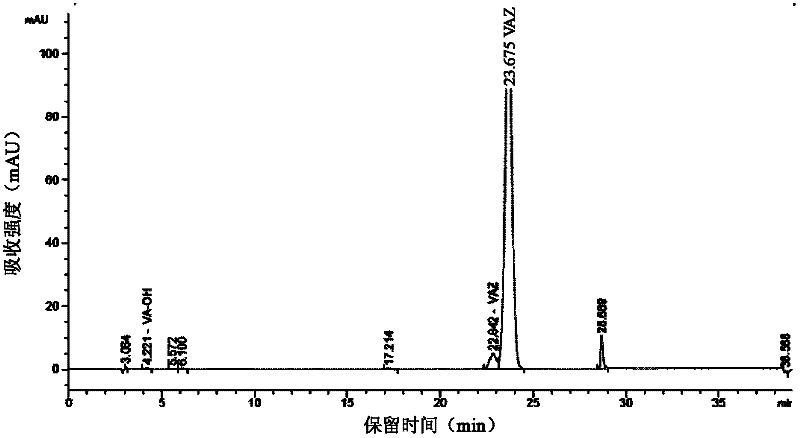

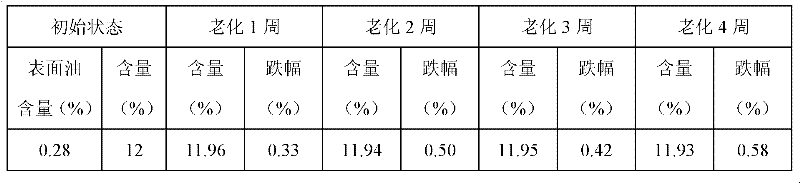

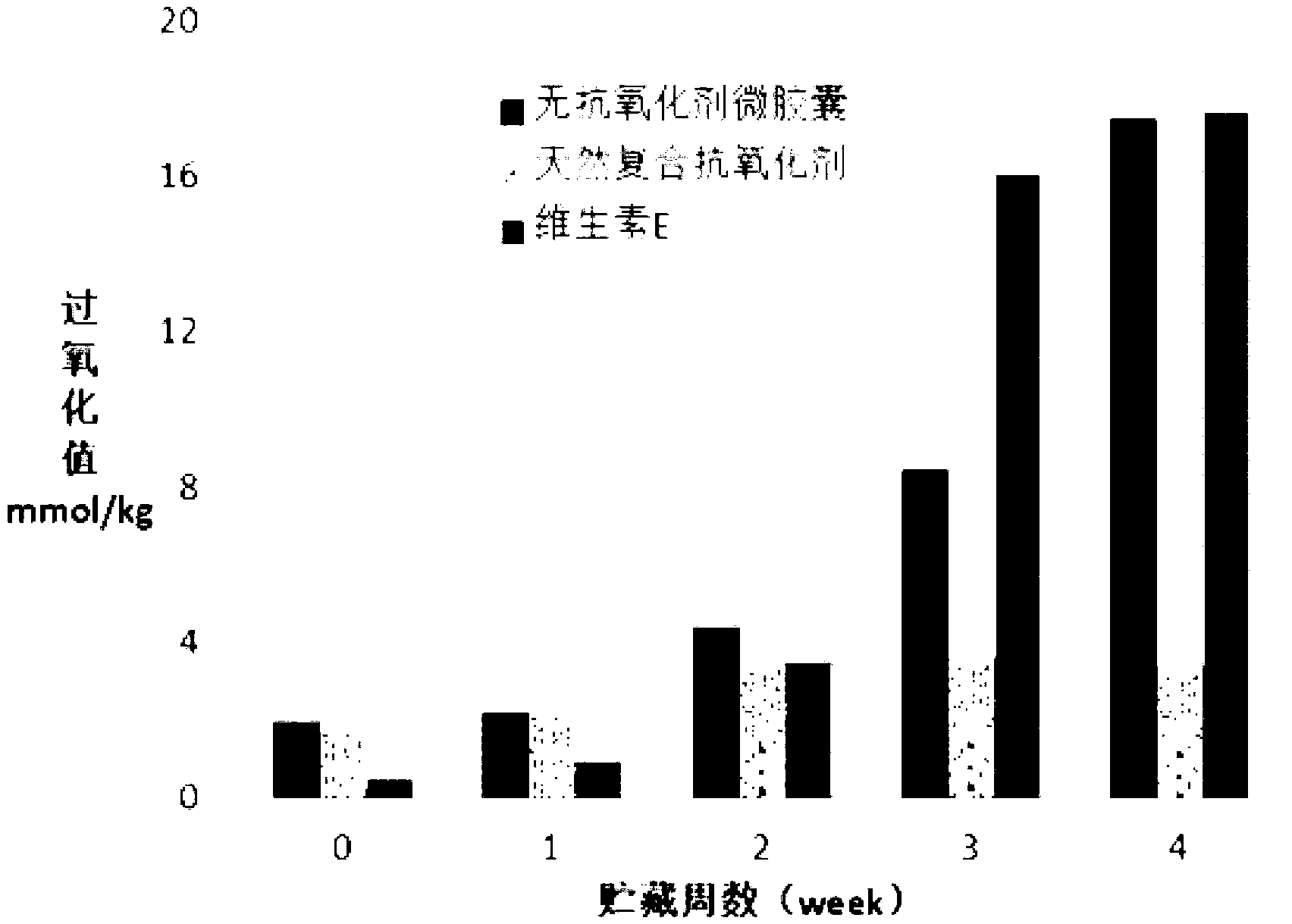

Functional oil microencapsulation and manufacturing method thereof

ActiveCN102550817AGood water solubilityImprove antioxidant capacityMetabolism disorderAlgae medical ingredientsOil and greaseWater baths

The invention provides a functional oil microencapsulation and a manufacturing method thereof and relates to a microencapsulation, and the functional oil microencapsulation has the advantages of high stability and immobilized proteinaceous pellicle. The oil microencapsulation is prepared from the following raw materials: functional oil, plant oil, an antioxidant, aqueous-phase main-wall materials, aqueous-phase auxiliary-wall materials, bio-enzyme protein and water. The plant oil serving as a carrier is mixed with the functional oil, then the antioxidant is added, and then the materials are heated and dissolved in water bath, thus obtaining an oil-phase core material solution; the aqueous-phase main-wall materials and the aqueous-phase auxiliary-wall materials are added into deionized water, and then the materials are heated and dissolved in water bath, thus obtaining an aqueous-phase wall material solution; the oil-phase core material solution is added in the aqueous-phase wall material solution, the mixture is sheared and emulsified by a shearing machine, and then is homogenized by a homogenizer, thus obtaining a nanometer-level solution with uniform oil drop diameter; and bio-enzyme is added into the nanometer-level solution, the mixture is placed in hot-water bath for heating and stirring reaction, temperature is raised after the reaction so as to enable the bio-enzyme to be inactivated, and drying is carried out, thus obtaining the functional oil microencapsulation.

Owner:XIAMEN KINGDOMWAY BIOTECH CO LTD +1

Method for the preparation of an aerated frozen product

Using an homogenizer operating at higher pressures (ca. 2000 bar) than those conventionally used in ice cream manufacturing, it is possible to generate smaller oil droplet sizes (ca. 0.3 mum) in an ice cream premix. It allows stabilization of a larger air:water interface, leading to smaller discrete gas cells which in turn modify the organoleptic quality of the ice cream.

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

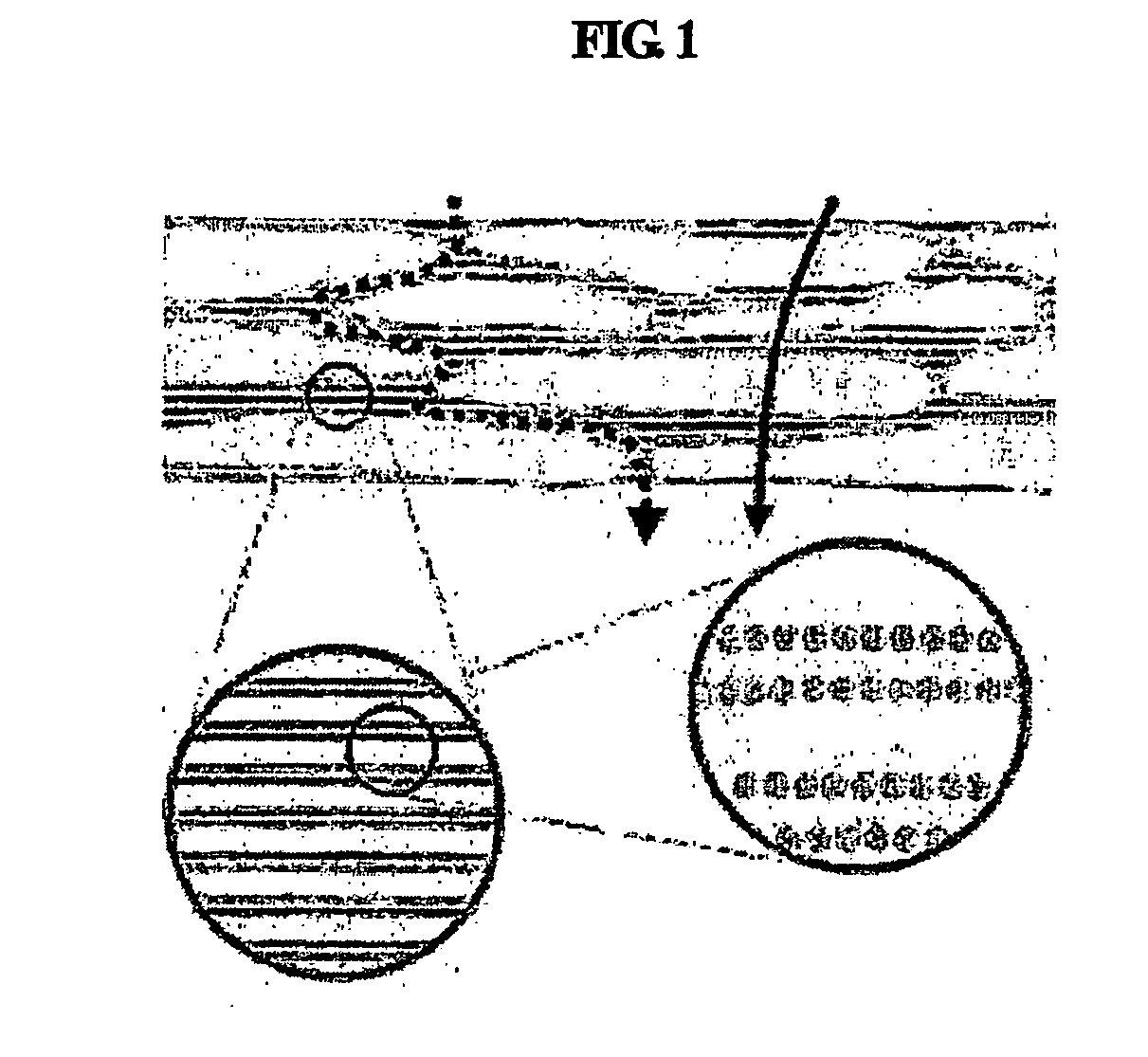

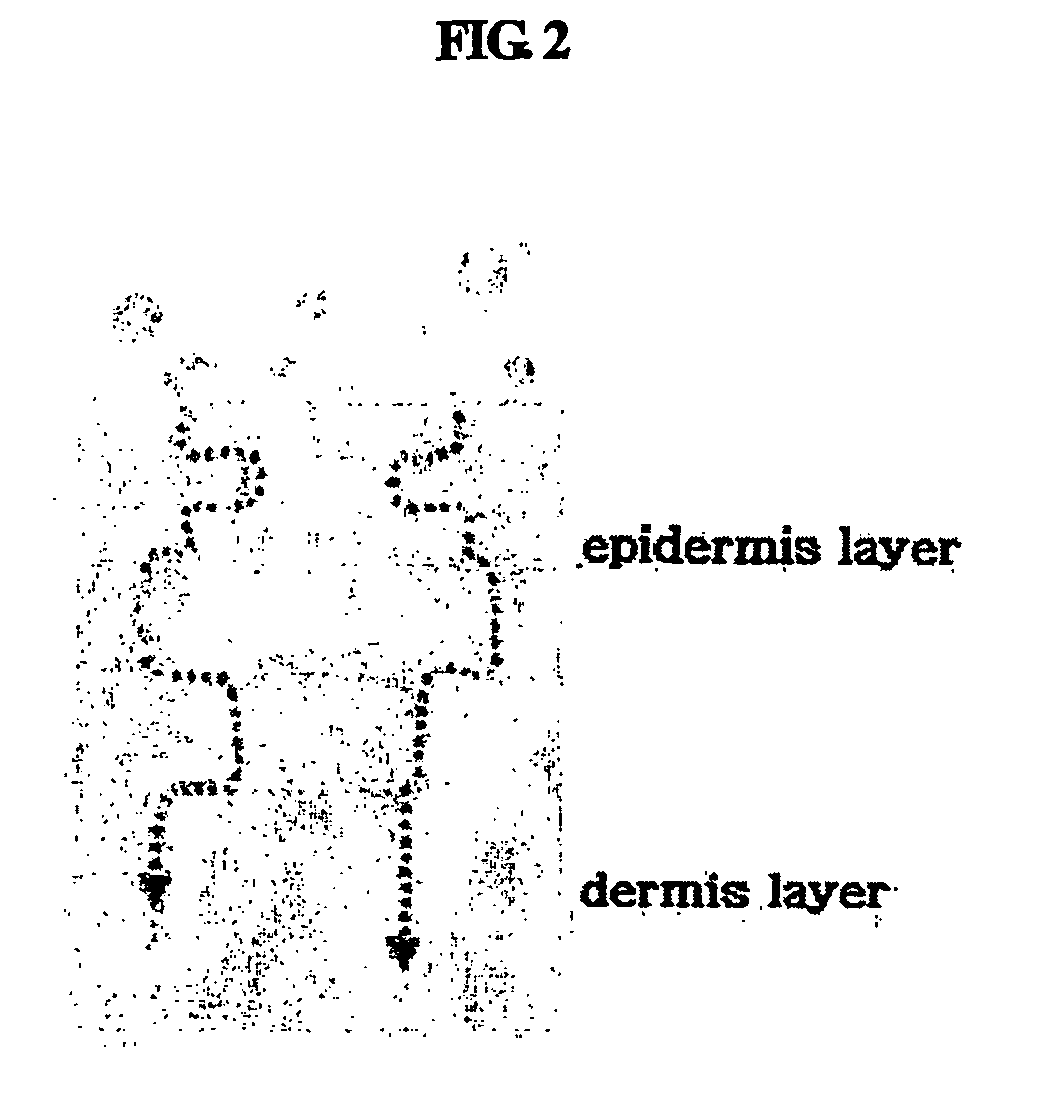

Multiple-layered liposome and preparation method thereof

InactiveUS20070082042A1Good skin permeabilityImprove stabilityDermatological disorderLiposomal deliverySterolIntercellular space

Disclosed are multilayered liposomes for transdermal absorption and a method of preparing the liposomes. The multilayered liposomes are prepared using a mixture of oil-phase components comprising squalane, sterols, ceramides, neutral lipids or oils, fatty acids and lecithins, is 200 to 5000 nm in particle size, and is capable of entrapping a physiologically active substance. The multilayered liposomes entrap a larger amount of a physiologically active substance and are structurally stable when encapsulating the physiologically active substance, compared to unilamellar liposomes. Also, they are prepared by a simple and cost-effective process not using a high-pressure homogenizer but using a general homo mixer. Further, since the multilayered liposomes are prepared in a larger size than the intercellular spaces in the stratum corneum, they overcome the tension of surrounding cells when passing through the intercellular spaces and are thus able to penetrate into the dermal layer, compared to nano-sized unilamellar liposomes. Thus, the multilayered liposomes are useful for enhancing the transdermal absorption of physiologically active substances.

Owner:BIOSPECTRUM

Achromatic Homogenizer and Collimator for LEDs

A lens arrangement with an achromatic homogenizer and collimator for multiple LEDs. The lens arrangement combines the hemispherical emittance profiles from one or more LEDS into a collimated beam without chromatic aberration. The lens arrangement has one or more LEDs, a homogenizer, a solid lightpipe, an internal parabolic reflector, a retroreflector, and a refractor. The emittance profiles of the LEDs are distributed evenly over space and angle by multiple reflections inside a diffusely reflecting cavity of the homogenizer. The internal reflector has a numerical aperture of 1.0, which defines a hemispherical solid angle of collection within air. The retroreflector directs rays away from the LEDs. The retroreflection permits space for the electronics of high radiance LEDs. The refractor converts the retroreflector rays in a plurality of shapes. The lens is optimally designed for applications with high standards for color mixing, uniformity, and efficient conversion of electrical power into light.

Owner:SEWARD GEORGE H

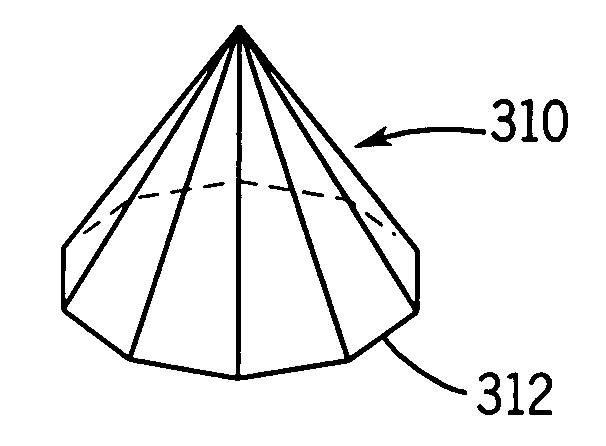

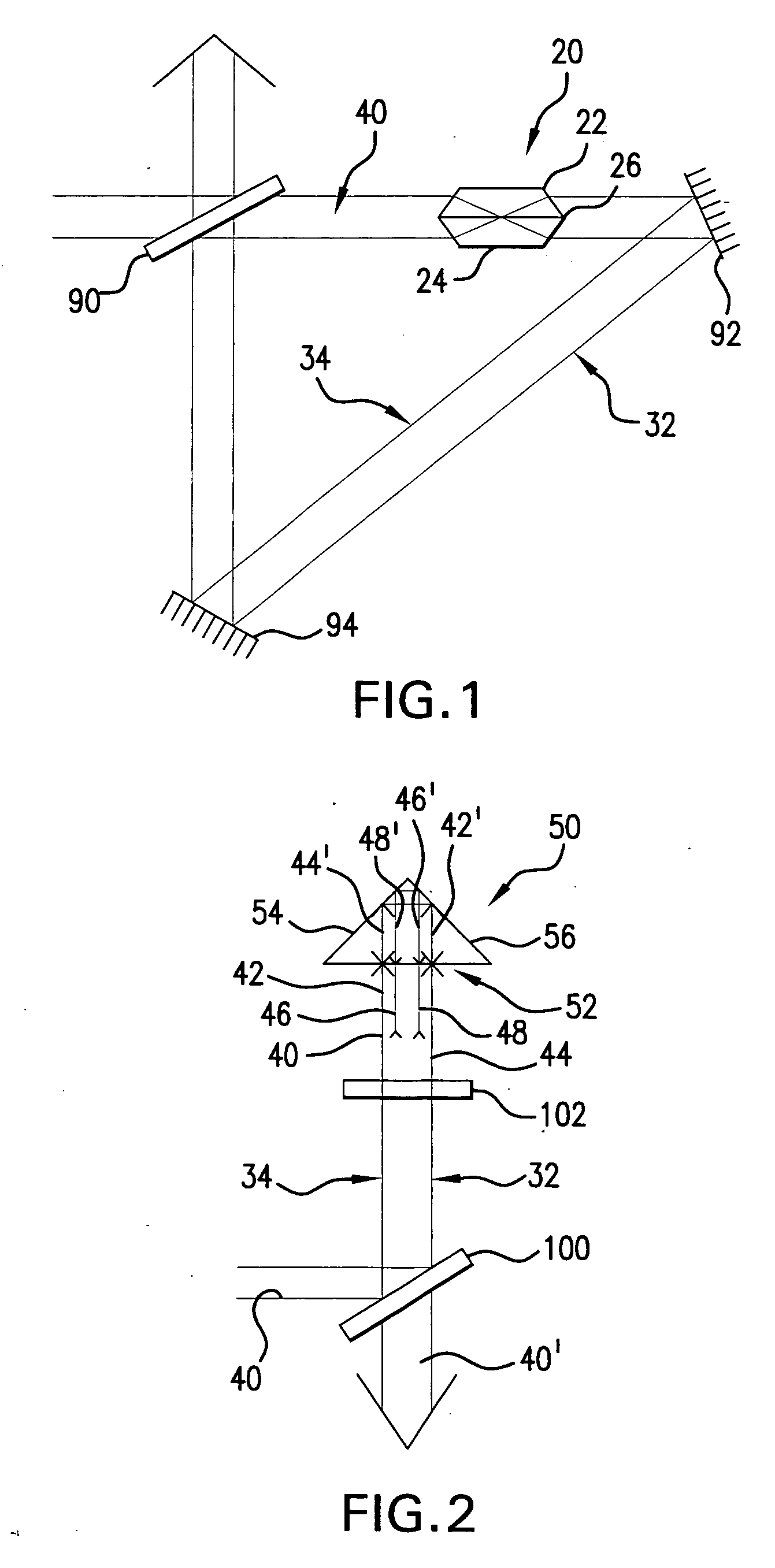

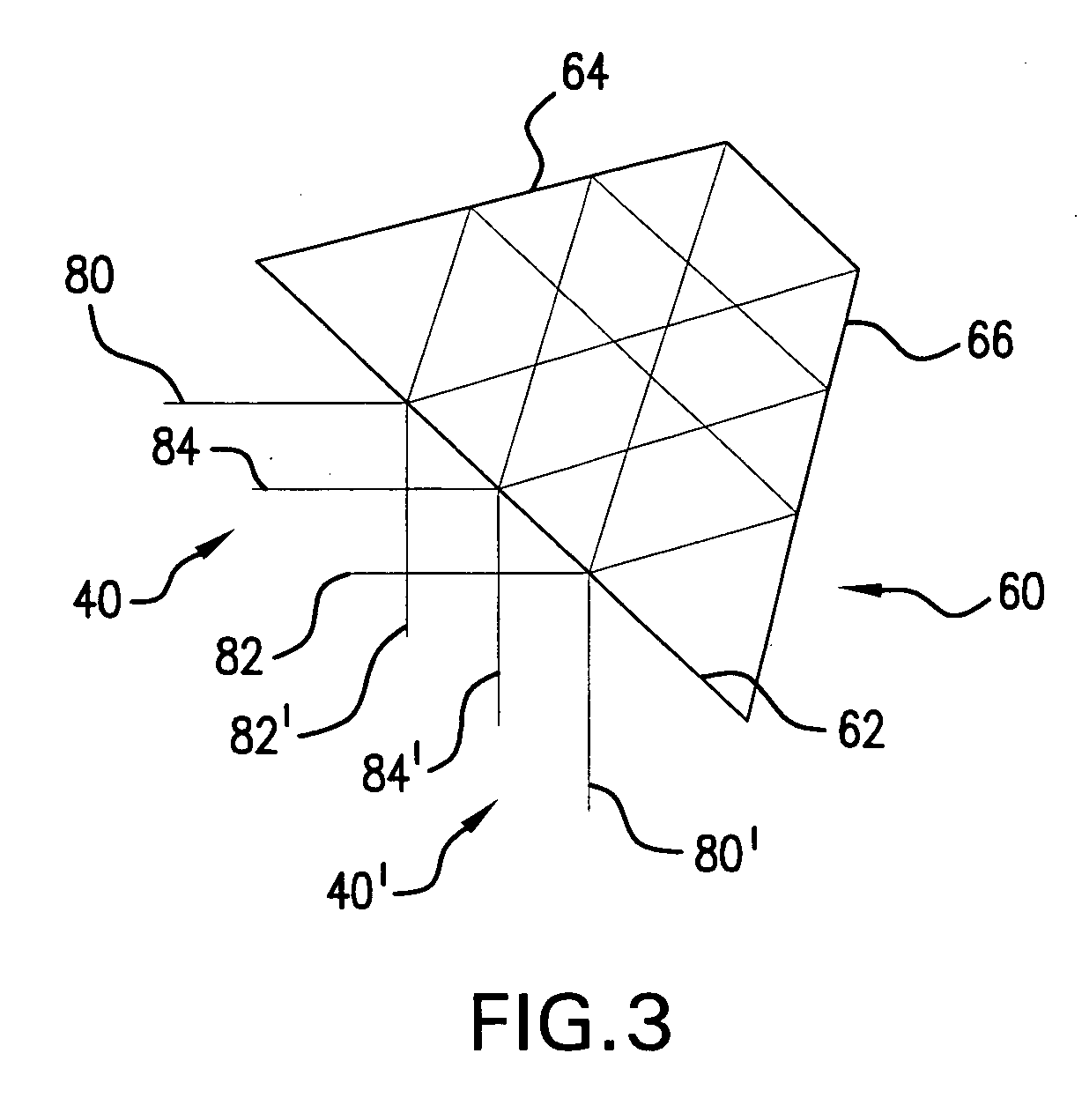

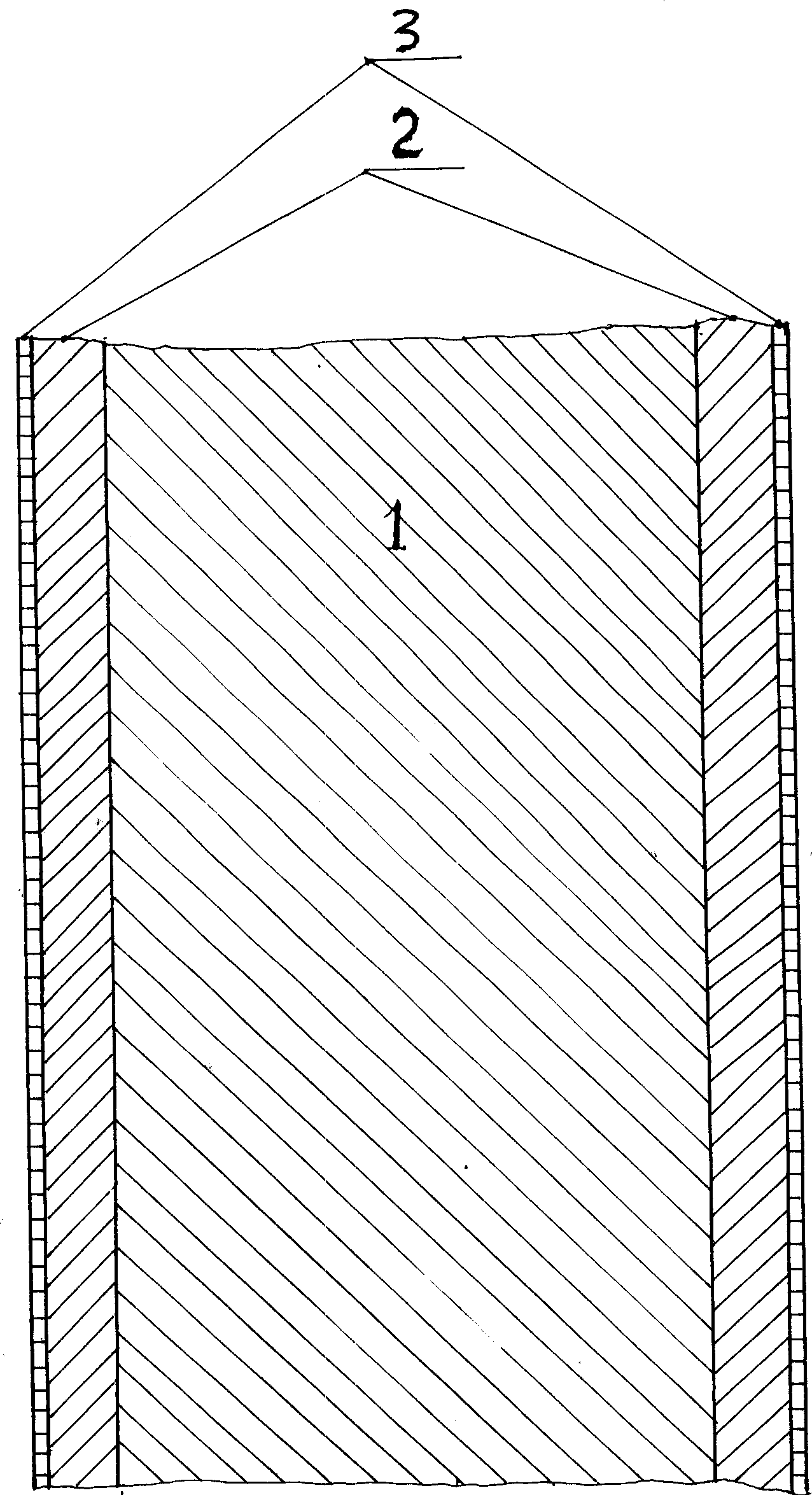

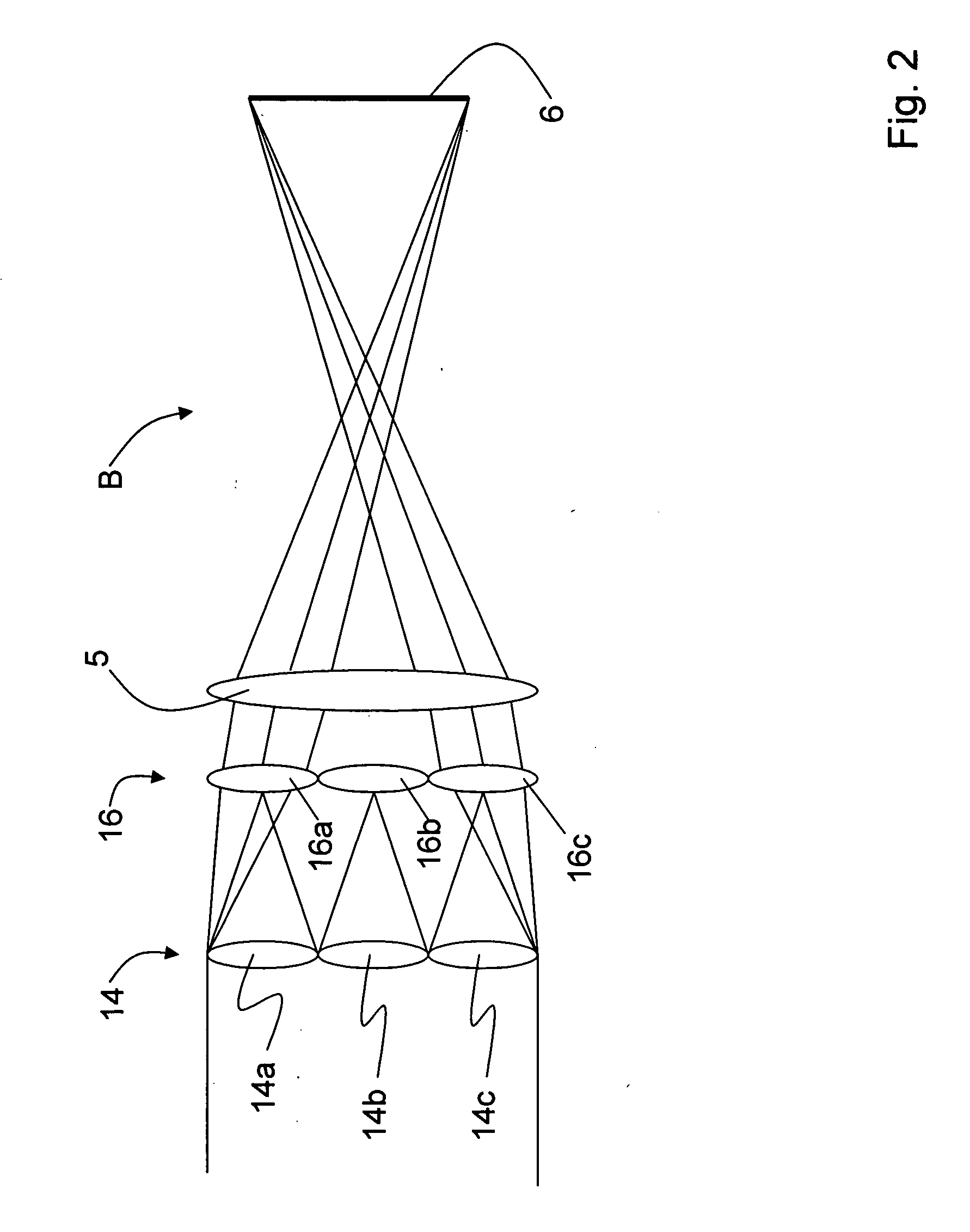

Apparatus for constructing DNA probes having a prismatic and kaleidoscopic light homogenizer

InactiveUS7037659B2Improve evenlyImprove uniformityBioreactor/fermenter combinationsMaterial nanotechnologyLight beamPrism

The present invention provides an apparatus for constructing arrays of DNA sequences using the image of a micromirror array projected on a reaction site using a highly uniform beam of light produced by a homogenizer formed of a prismatic refractive element followed by a kaleidoscopic element.

Owner:NIMBLEGEN SYST

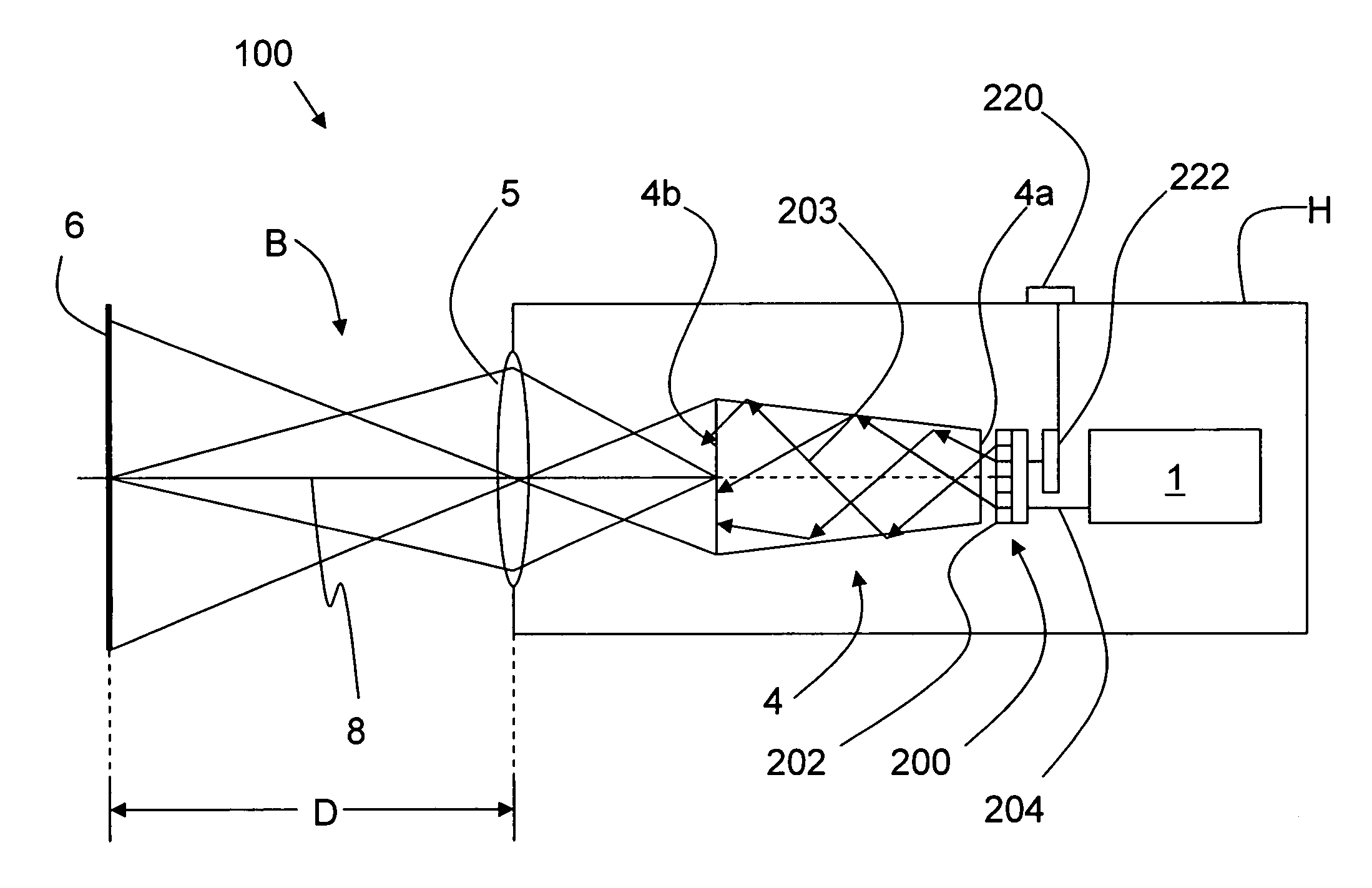

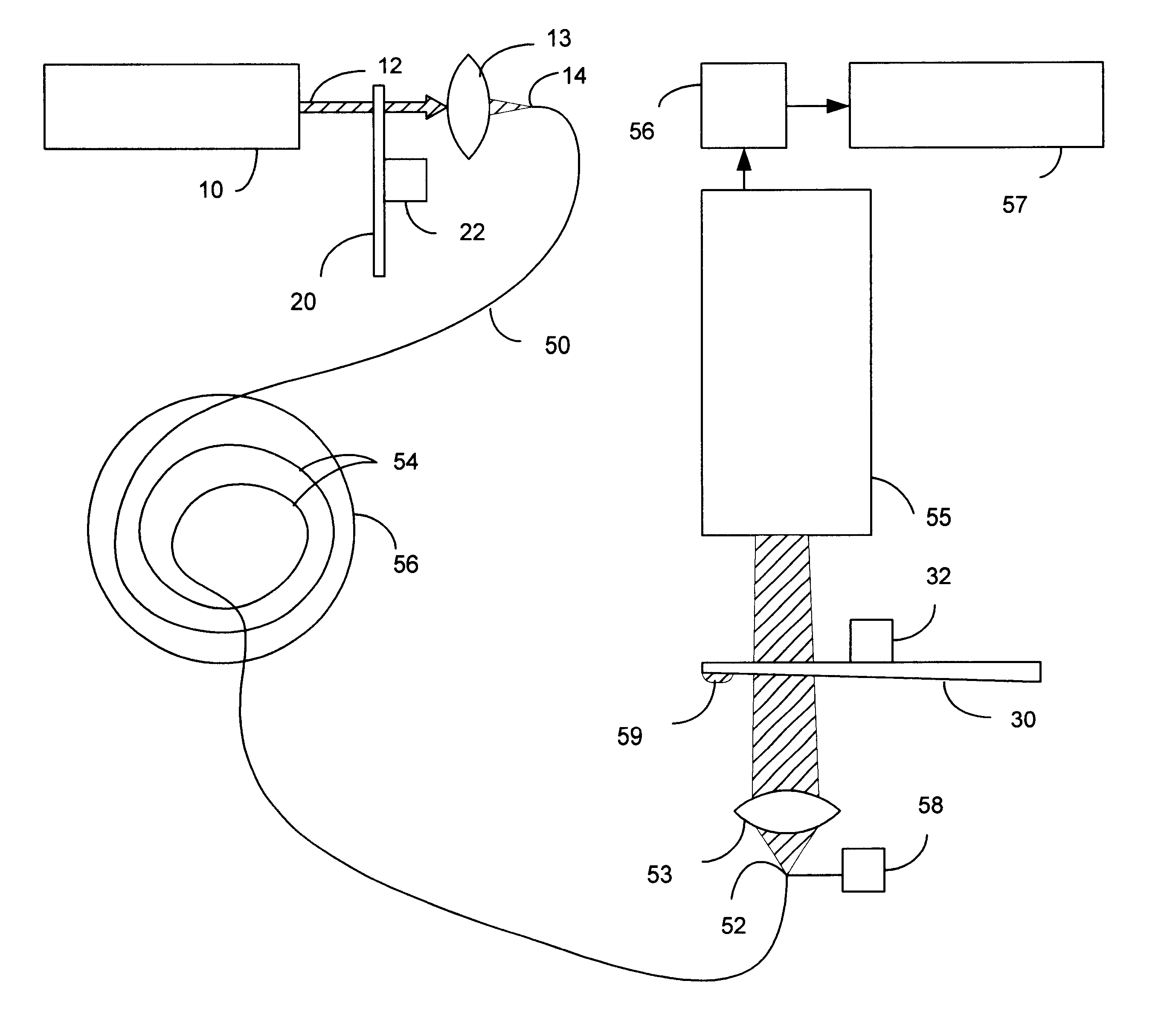

Method and apparatus for gas discharge laser output light coherency reduction

A method and apparatus for producing with a gas discharge laser an output laser beam comprising output laser light pulses, for delivery as a light source to a utilizing tool is disclosed which may comprise a beam path and a beam homogenizer in the beam path. The beam homogenizer may comprise at least one beam image inverter or spatial rotator, which may comprise a spatial coherency cell position shifter. The homogenizer may comprise a delay path which is longer than, but approximately the same delay as the temporal coherence length of the source beam. The homogenizer may comprise a pair of conjoined dove prisms having a partially reflective coating at the conjoined surfaces of each, a right triangle prism comprising a hypotenuse face facing the source beam and fully reflective adjoining side faces or an isosceles triangle prism having a face facing the source beam and fully reflective adjoining side faces or combinations of these, which may serve as a source beam multiple alternating inverted image creating mechanism. The beam path may be part of a bandwidth measuring the bandwidths of an output laser beam comprising output laser light in the range of below 500 femtometers at accuracies within tens of femtometers. The homogenizer may comprise a rotating diffuser which may be a ground glass diffuser which may also be etched. The wavemeter may also comprise a collimator in the beam path collimating the diffused light; a confocal etalon creating an output based upon the collimated light entering the confocal etalon; and a detector detecting the output of the confocal etalon and may also comprise a scanning mechanism scanning the angle of incidence of the collimated light entering the confocal etalon which may scan the collimated light across the confocal etalon or scan the etalon across the collimated light, and may comprise an acousto-optical scanner. The confocal etalon may have a free spectral range approximately equal to the E95 width of the beam being measured. The detector may comprise a photomultiplier detecting an intensity pattern of the output of the confocal etalon.

Owner:CYMER INC

Interface paint with high hydrophobicity, heat conductivity and adhesion

A high-hydrophobicity, heat conductivity and adhesivity pigment of interface is prepared by taking methyl chloroform and butanone as medium, liquid-phase treating ordinary carbon black by silicone oil to hydrophobic activate, forming coating into dense methyl surface by polyester modified dimethylsilicone and agitation dispersing by supersonic homogenizer. The formed coating (2) is three-dimensional cross-linking network of cured polyphenylene methyl resin, which contains nanometer carbon black and silicon dioxide, and it forms dense methyl thin layer (3) on coating surface. It can be used to treat heat exchanger surface (1) of indoor apparatus and outer tube fin of household air conditioner. It has good hardness and is non- toxic.

Owner:李跃

Multifunctional compound fertilizer capable of killing pests, preventing diseases and increasing yield

InactiveCN101792353AImprove insecticidal efficiencyImprove sterilization efficiencyFertilizer mixturesSide effectPolyethylene glycol

The invention relates to a multifunctional compound fertilizer capable of killing pests, preventing diseases and increasing yield. The preparation method of the multifunctional compound fertilizer comprises the following steps: firstly, respectively preparing a component A, a component B and a component C, wherein the component A is a vegetable insecticide, thecomponent B is a vegetable bactericide, and the component C is a vegetable growth promoting and yield increasing agent; after the three components are prepared, adding the finished product of the component C into a synthesis kettle for heating; then, sequentially adding the liquid medicine of the component A and the liquid medicine of the component B for continuously stirring, and keeping constant temperature; adding a penetrating agent JFC and polyethylene glycol into the synthesis kettle for stirring; and finally, adding a buffering agent for stirring and mixing uniformly, and homogenizing the mixture by a high-pressure homogenizer to obtain the finished product of the multifunctional compound fertilizer. The multifunctional compound fertilizer of the invention has very high insecticidal and bactericidal efficiencies, smaller toxic side effects and safety to people and livestock, promotes the growth and the development of plants, increases the chlorophyll content, and greatly improves the crop yield.

Owner:齐绍春

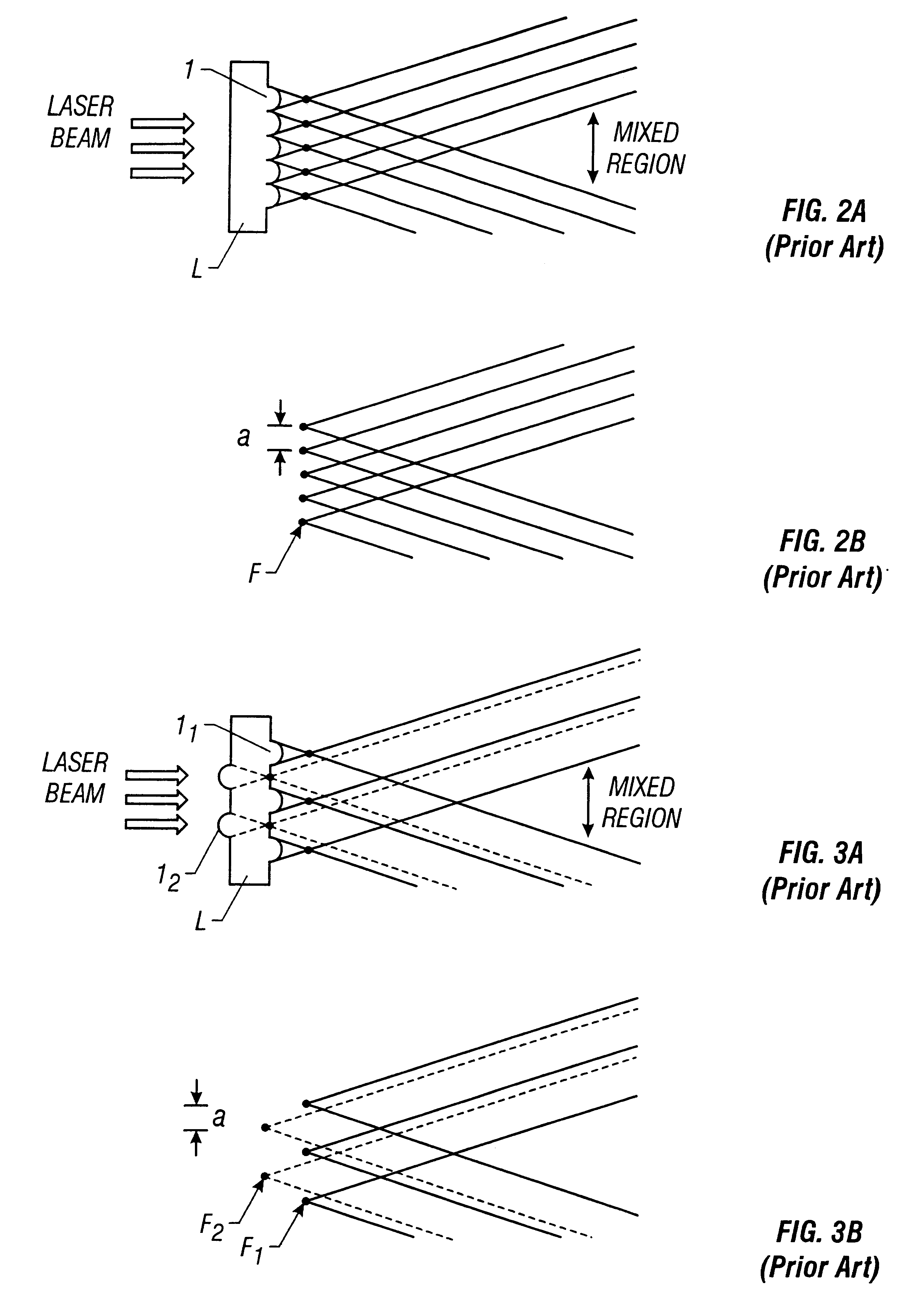

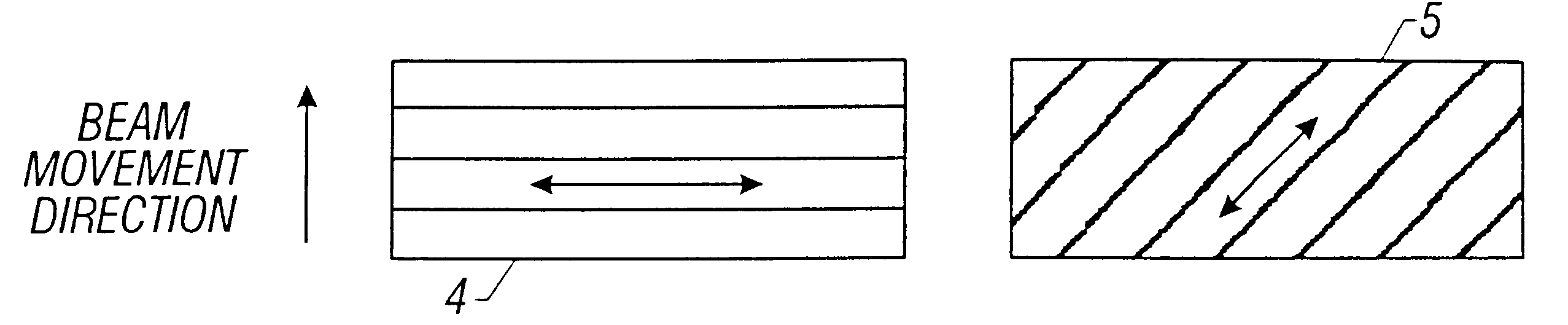

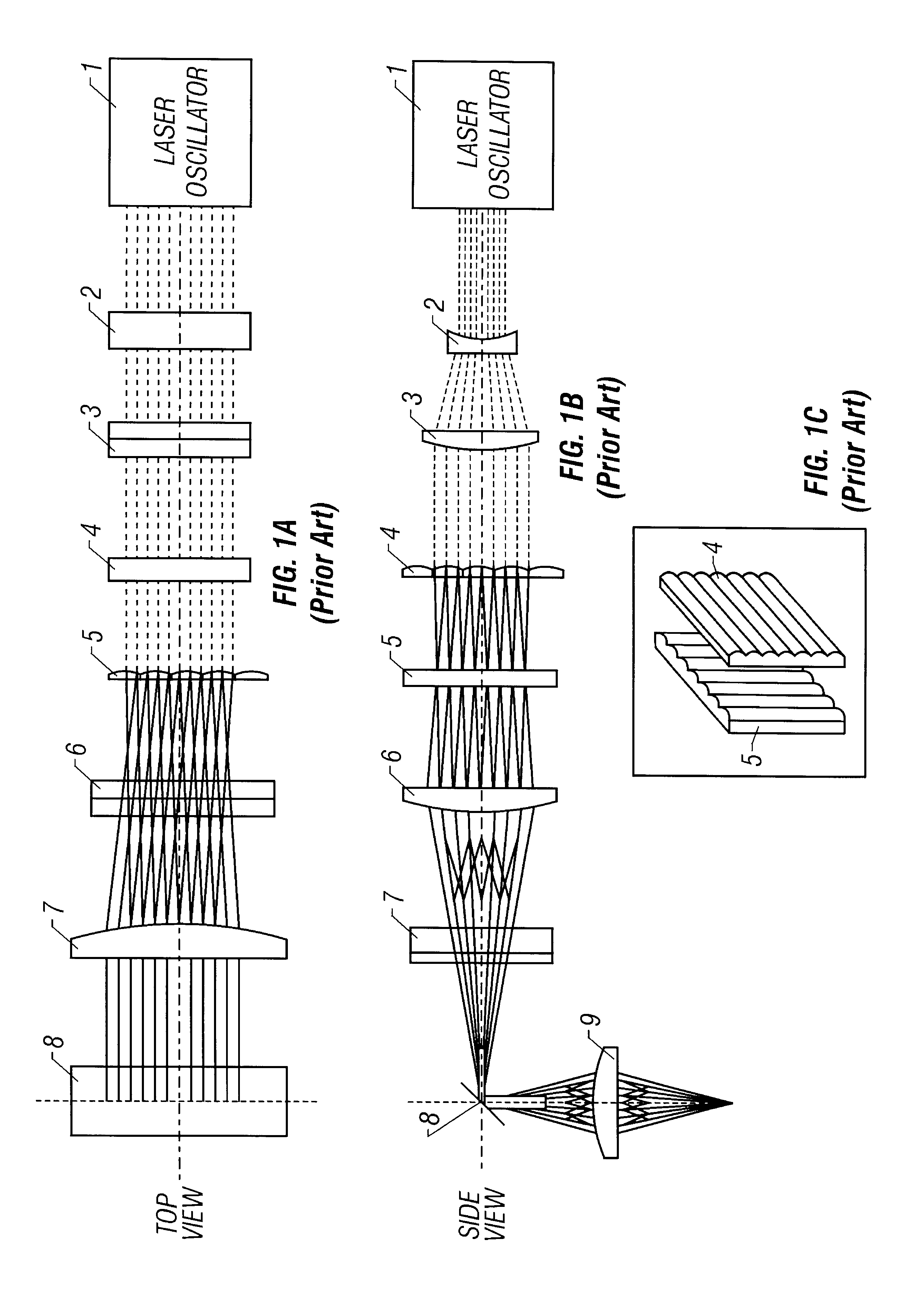

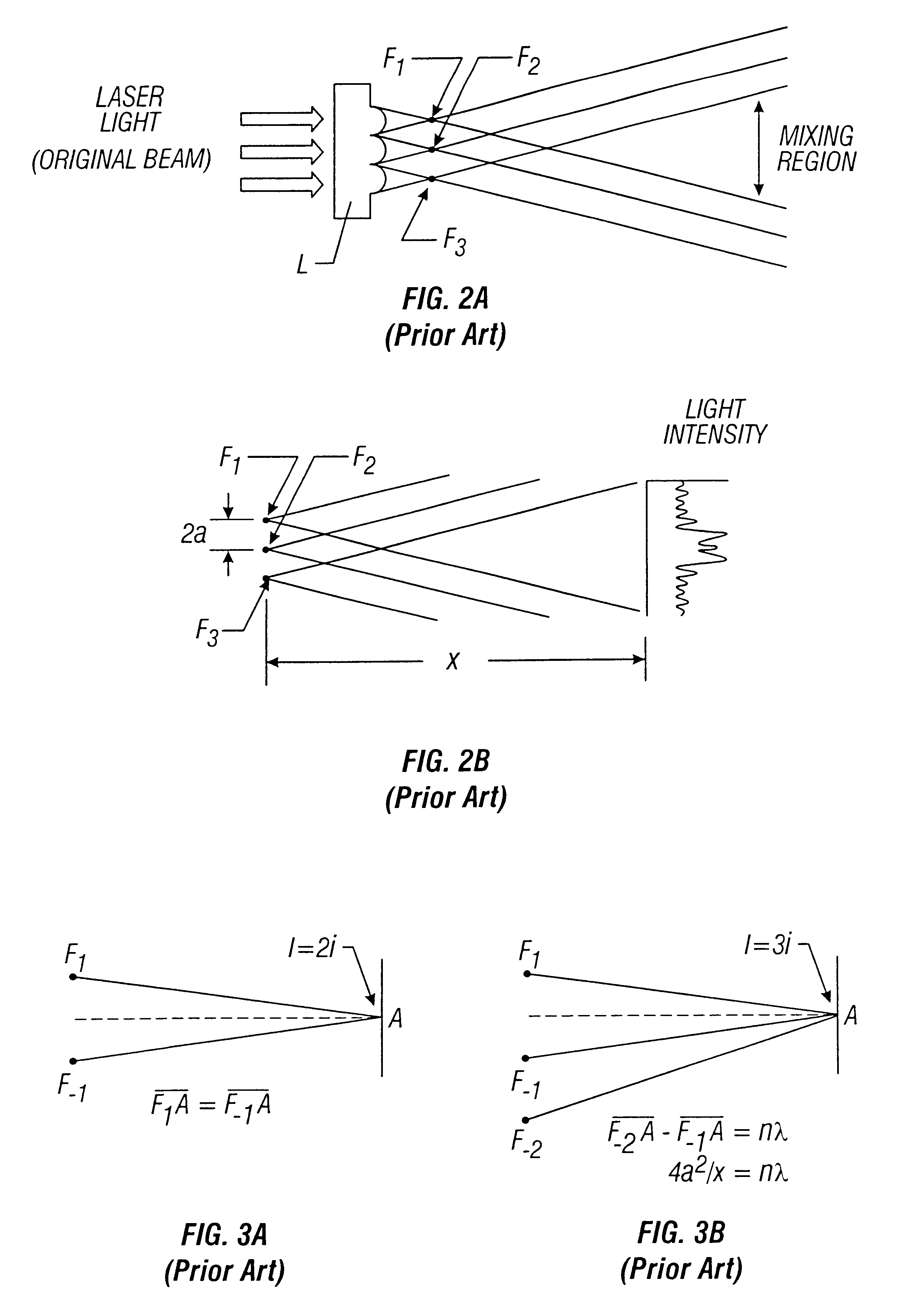

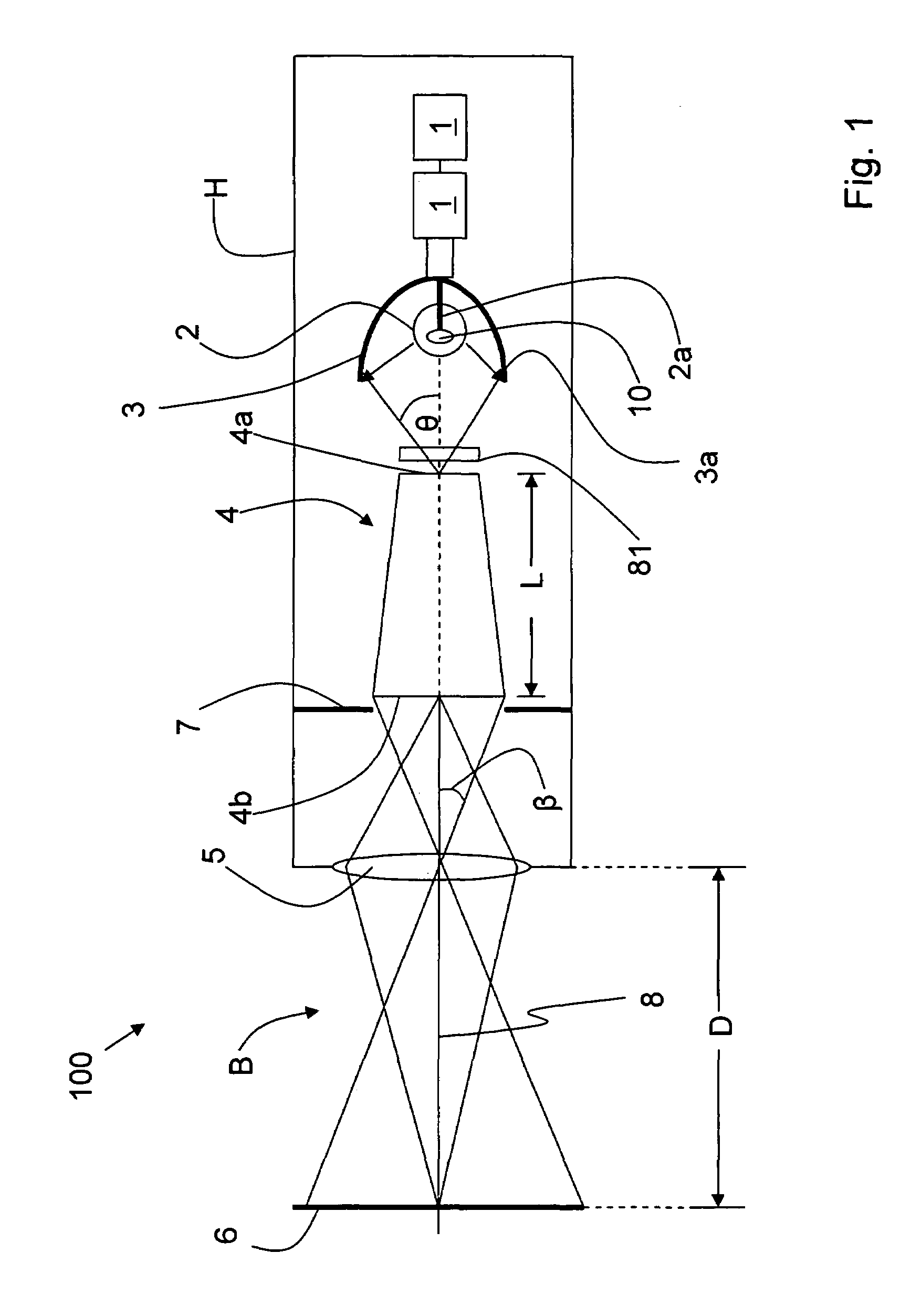

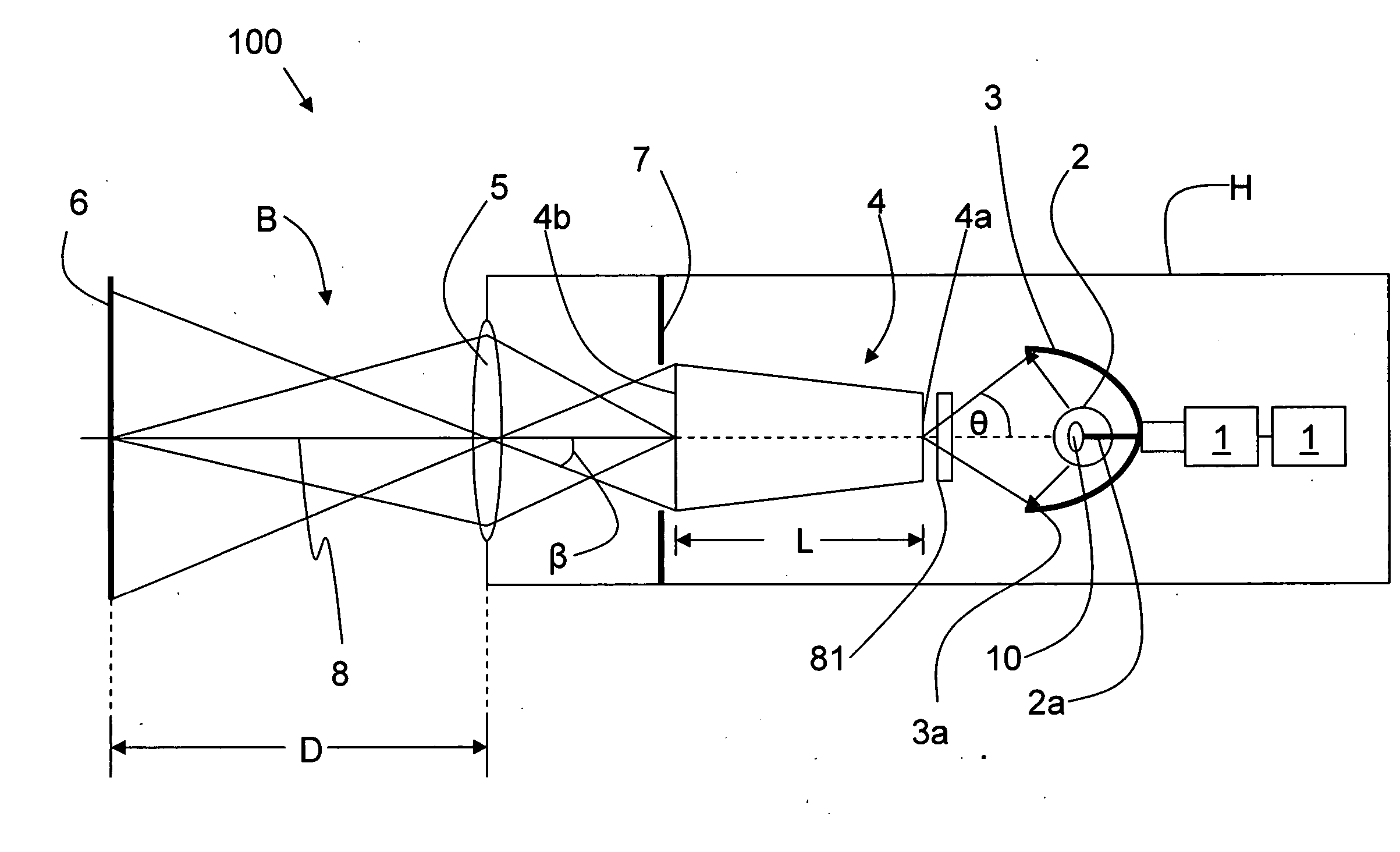

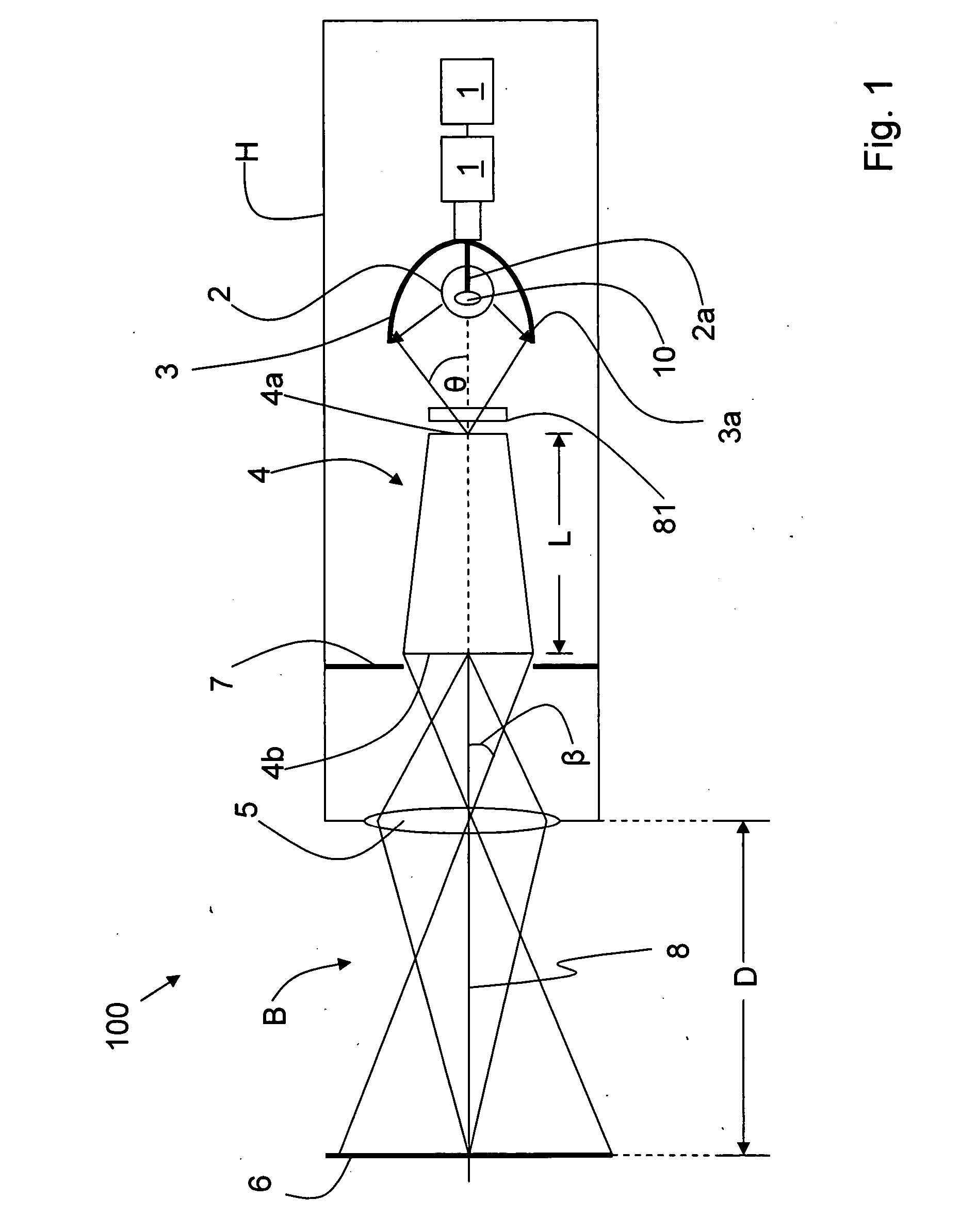

Laser irradiation apparatus

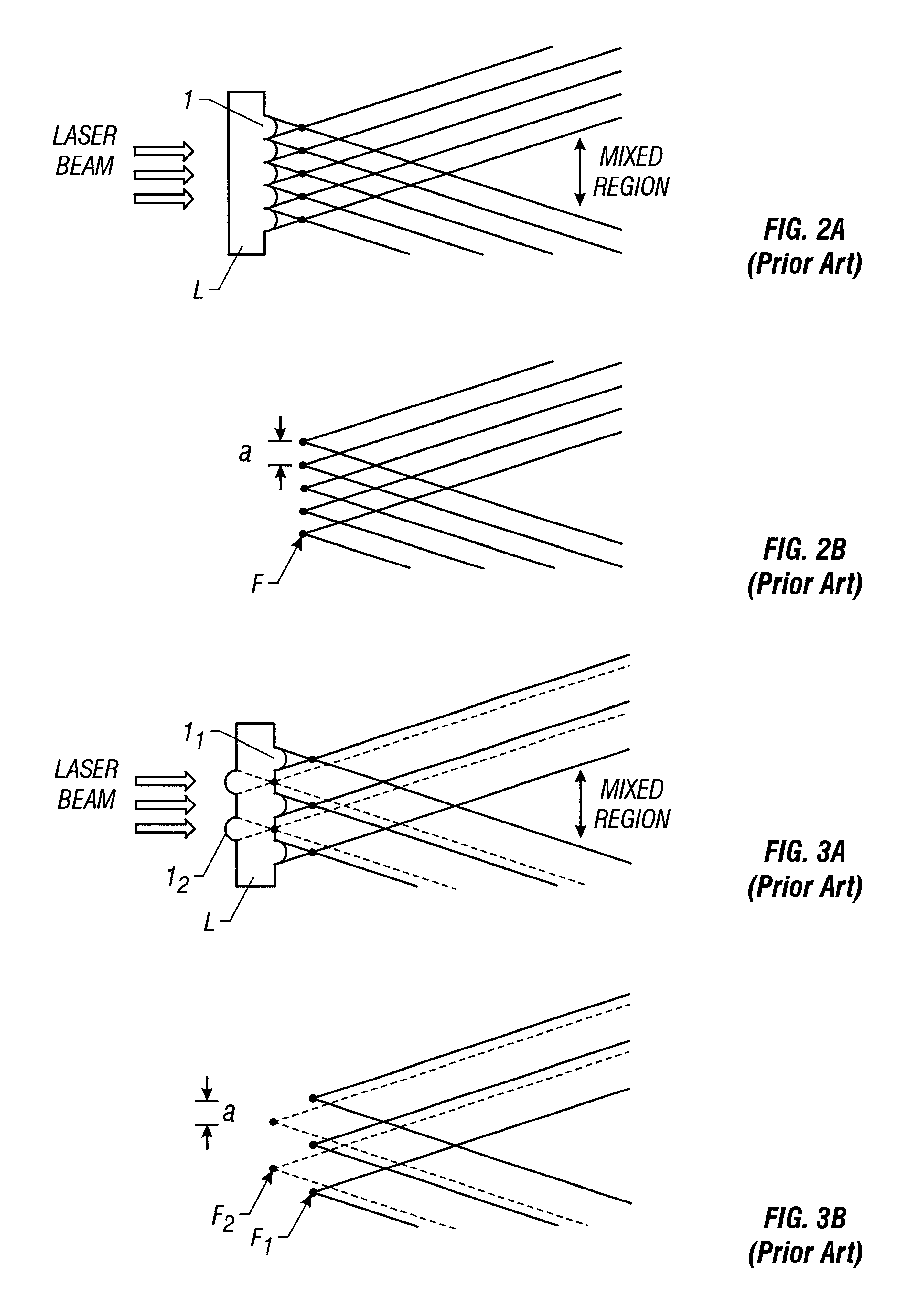

InactiveUS6249385B1Improve uniformitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLight beamOptoelectronics

An apparatus for irradiating an irradiation surface with a laser light having a linear or rectangular shape. A homogenizer operates on the principle that variations in the light intensity profile of an original beam as emitted from a laser device are dispersed by passing the original beam through two multi-cylindrical lenses. The directions of the respective multi-cylindrical lenses are set so as not to be parallel with the beam movement direction. Thus, an uniformity of annealing by irradiating with a laser light is improved.

Owner:SEMICON ENERGY LAB CO LTD

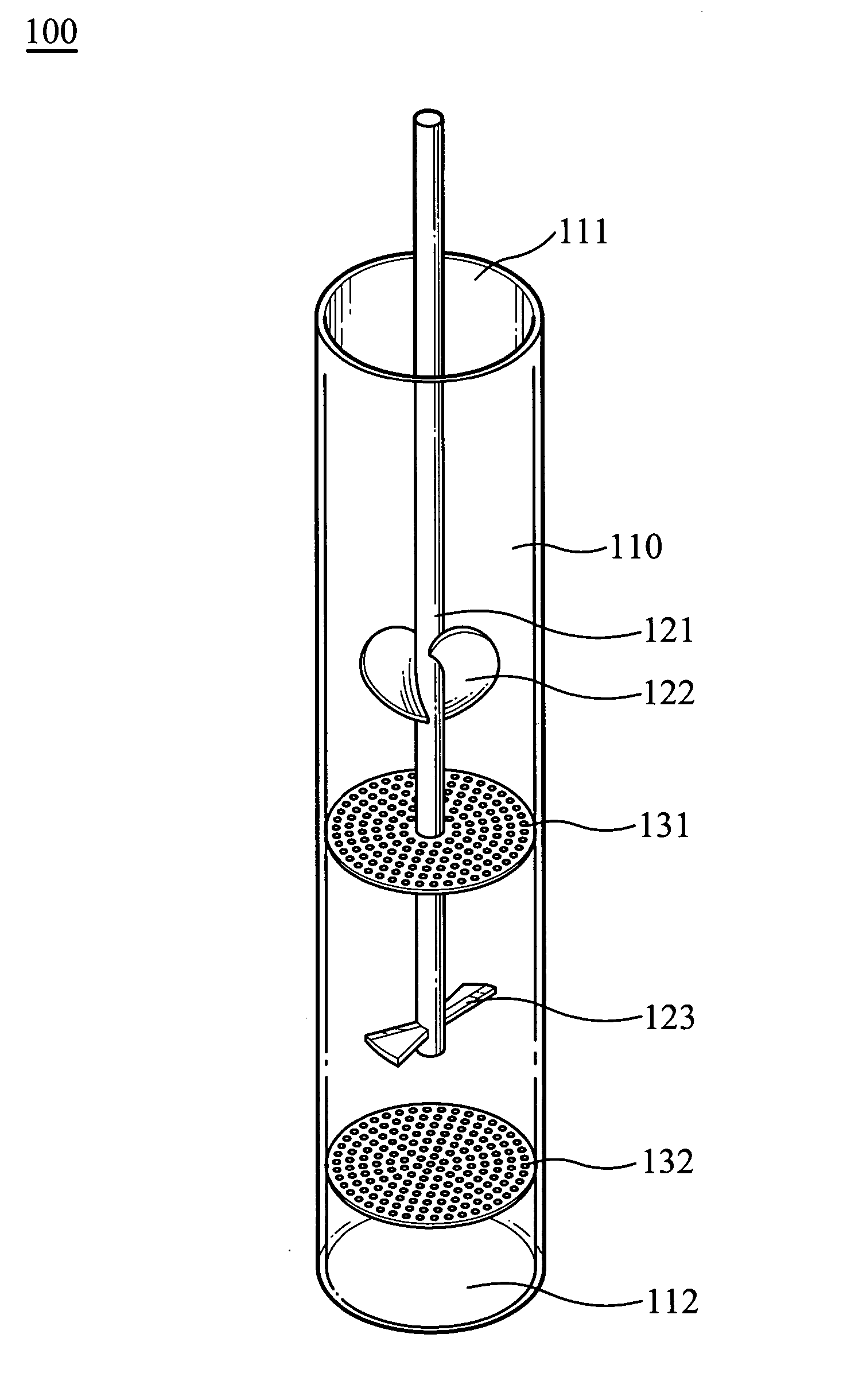

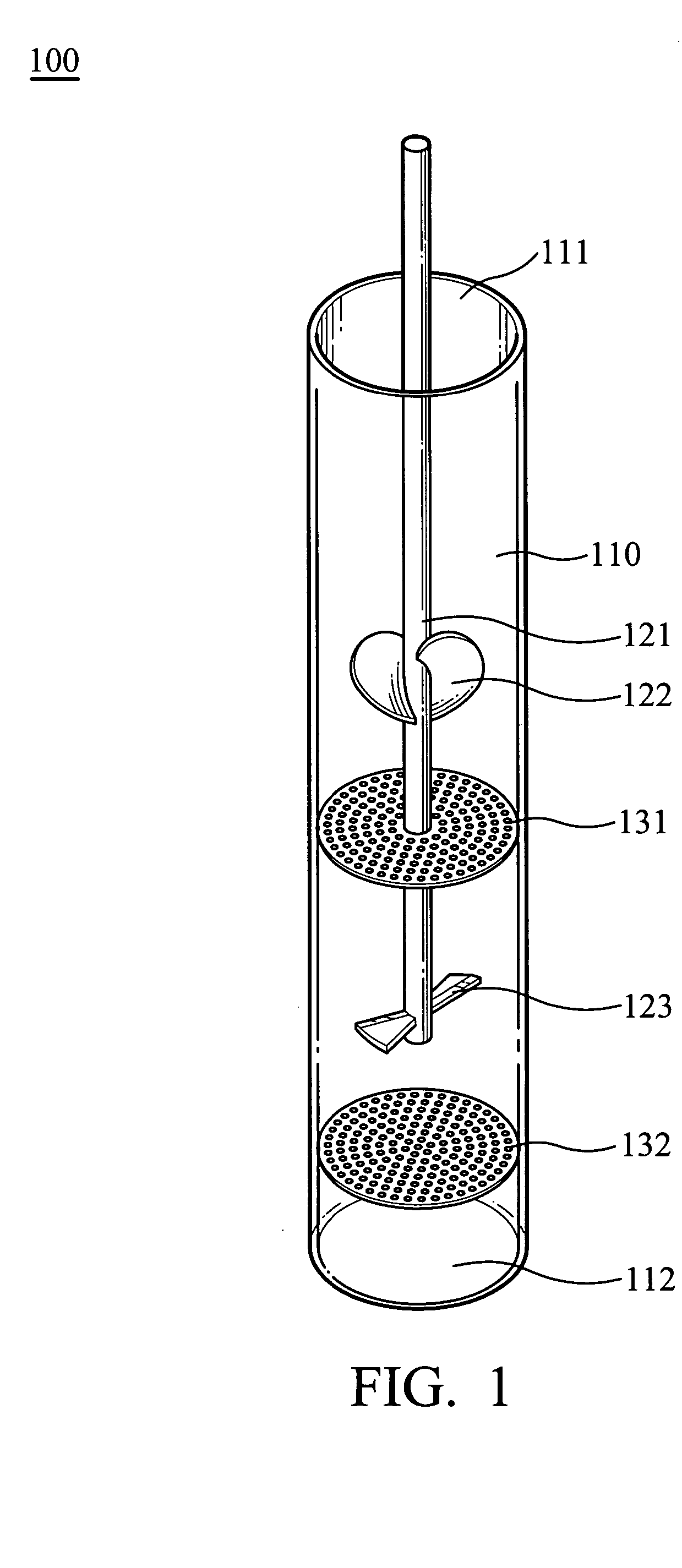

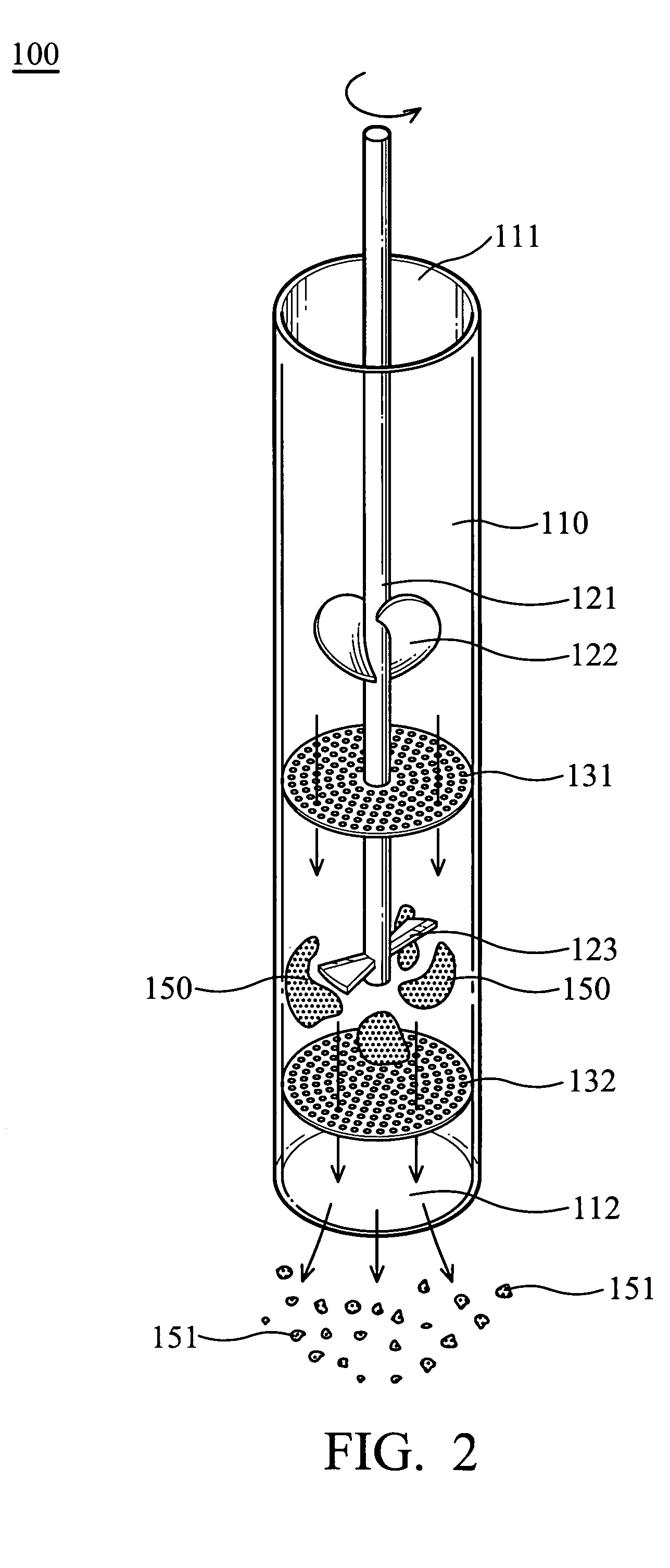

Tissue homogenizer

ActiveUS20050139704A1Low costShort timeBiological substance pretreatmentsSamplingKnife bladesBiomedical engineering

A tissue homogenizer. The tissue homogenizer comprises a first chamber, a pair of blades, a first filter and a second filter. The first chamber has a first opening and a second opening. The blades are disposed in the first chamber. The first filter is disposed in the first chamber between the first opening and the blades. The second filter is disposed in the first chamber between the second opening and the blades. A tissue piece is placed between the first filter and the second filter cut by the blade, and moved by a fluid through the second filter to generate homogenized tissue pieces.

Owner:IND TECH RES INST

Led-based flashlight

A flashlight that utilizes an array of one or more light-emitting diodes (LEDs) as a light source, and a light pipe as a light homogenizer to generate a light beam capable of forming a uniformized light distribution at a given distance from the flashlight is disclosed. The LEDs may be all the same color, or some or all may be different colors. A switch, coupled to switching electronics coupled to the LED array, is used to change the state of the LED array to create a variety of different types of light beams, each of which provides relatively uniform and bright illumination at a given distance from the flashlight, wherein the given distance is selectable by adjusting an adjustable imaging lens.

Owner:OPTICS 1

Laser beam homogenizer

InactiveUS6672739B1Improve efficiencyReduce Image ArtifactsNanotechCosmonautic condition simulationsWide fieldLaser beams

An apparatus, system, and method for illuminating a lithographic mask or an object in a microscope is presented, whereby the output of a laser beam homogenizer is imaged on to a field such as the object plane for lithographic application or on to the rear focal plane of an epi illuminating objective lens as a source for wide field illumination at an object plane in a microscope (for application to magnified imaging of weak phase objects)., and the image of the output is dithered with respect to the field

Owner:IBM CORP

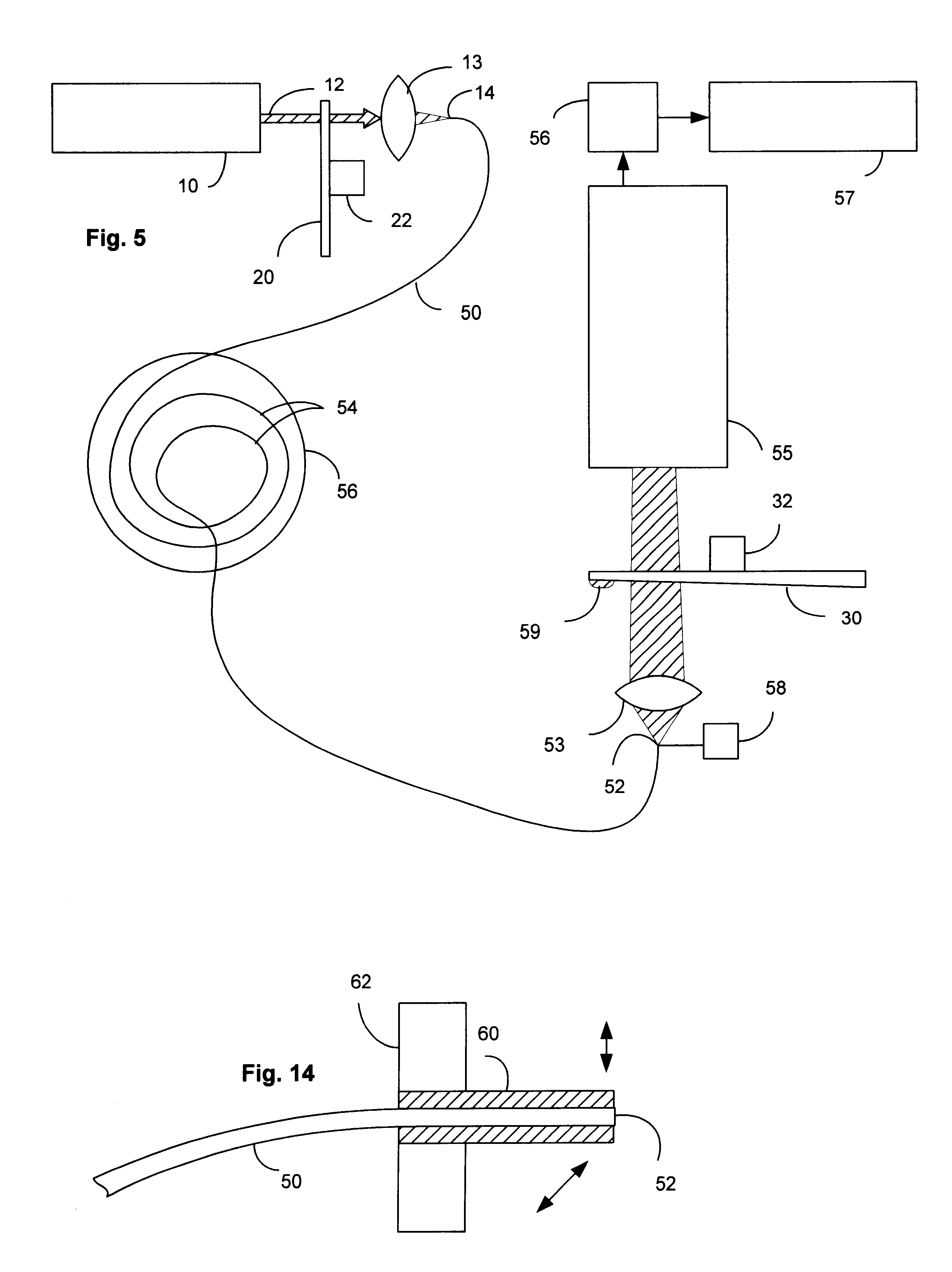

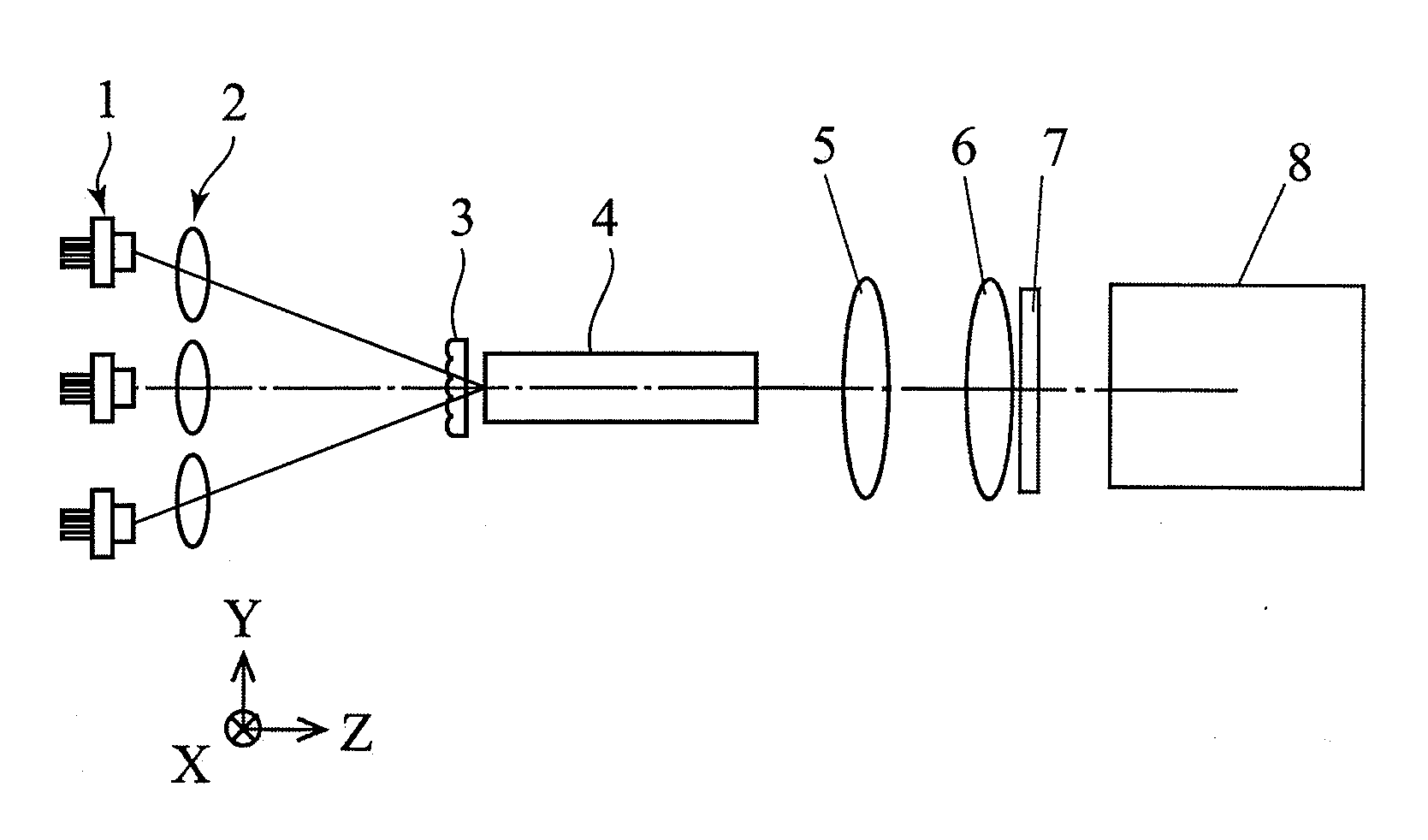

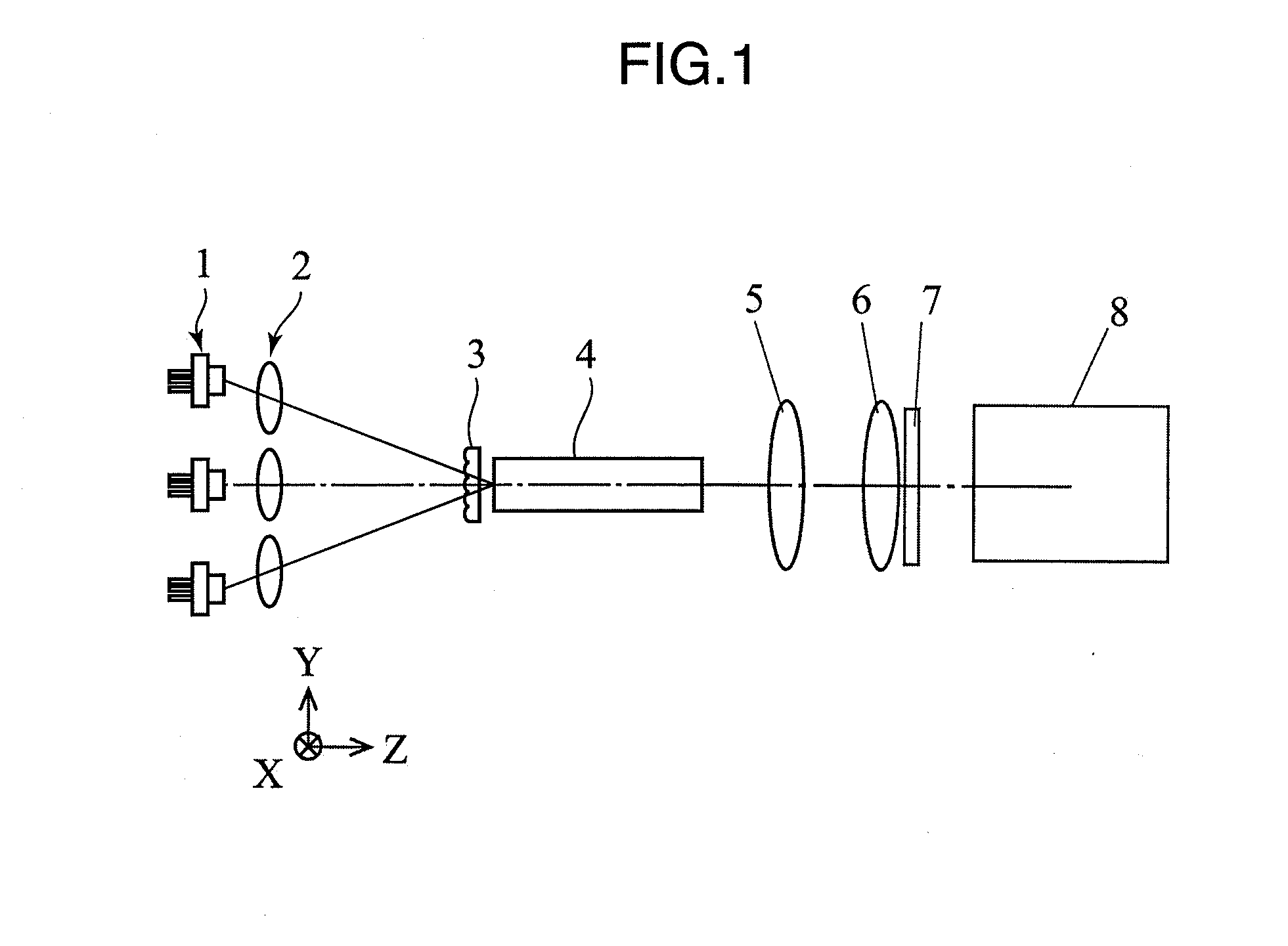

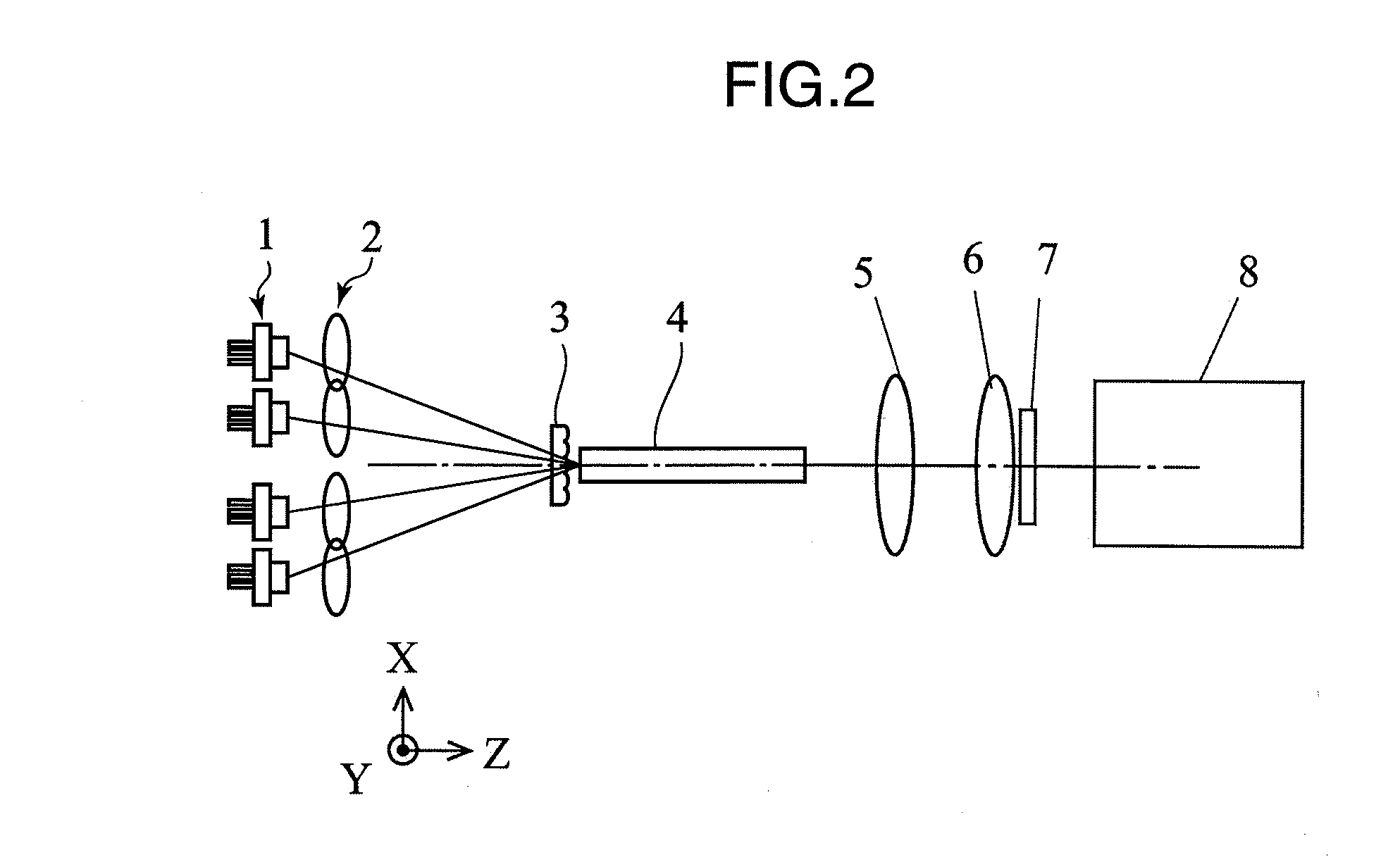

Projection type display device and light source device

ActiveUS20100231862A1Complicated constructionMiniaturizationProjectorsColor television detailsIntegratorDisplay device

Miniaturization is realized and high-output lights are obtained by optimizing the arrangement of a laser light source unit and a homogenizer.A laser light source unit 1 has a light emission region for emitting an elliptical laser light. A focusing lens unit 2 focuses the laser light emitted from the laser light source unit 1. A rod integrator 4 has a rectangular incident surface on luminous flux focused by the focusing lens unit 2. A spatial light modulation element 7 modulates the laser light emitted from the rod integrator 4. A projection lens 8 projects the laser light modulated by the spatial light modulation element 7. The incident surface of the rod integrator 4 has a rectangular shape, and the laser light source unit 1 is arranged such that a longer axis direction of the light emission region and a longer side direction of the incident surface of the rod integrator are parallel.

Owner:PANASONIC CORP

Compact work light with high illumination uniformity

A compact work light that generates a light beam having high brightness and high illumination uniformity is disclosed. The work light includes a housing that houses a light source, a light homogenizer and an imaging lens in an operational relationship. The housing is attached to an adjustable mount, which can be attached to a fixed region such as wall, or to a movable support member such as a lamp base. The light source generates light that is uniformized by the light homogenizer. The homogenized light is then imaged by the imaging lens as a highly uniform, bright beam spot having a sharp boundary. The beam spot is formed at a selectable distance from the work light by varying the imaging lens and / or the adjustable mount. The work light is useful for a variety of industrial, professional and personal applications, including but not limited to a reading light, a dentist light, a head lamp, a head light and an optical projector.

Owner:OPTICS 1

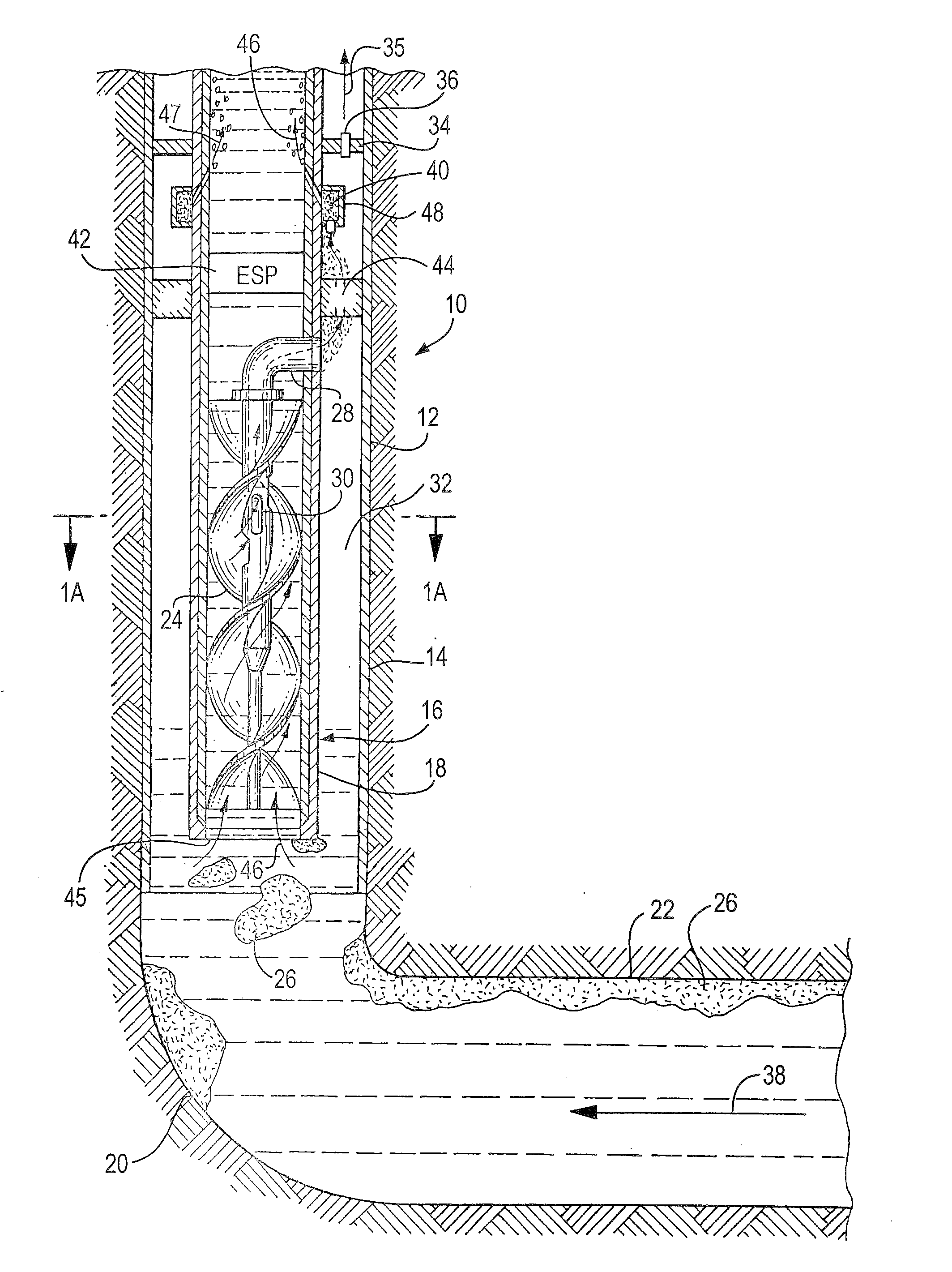

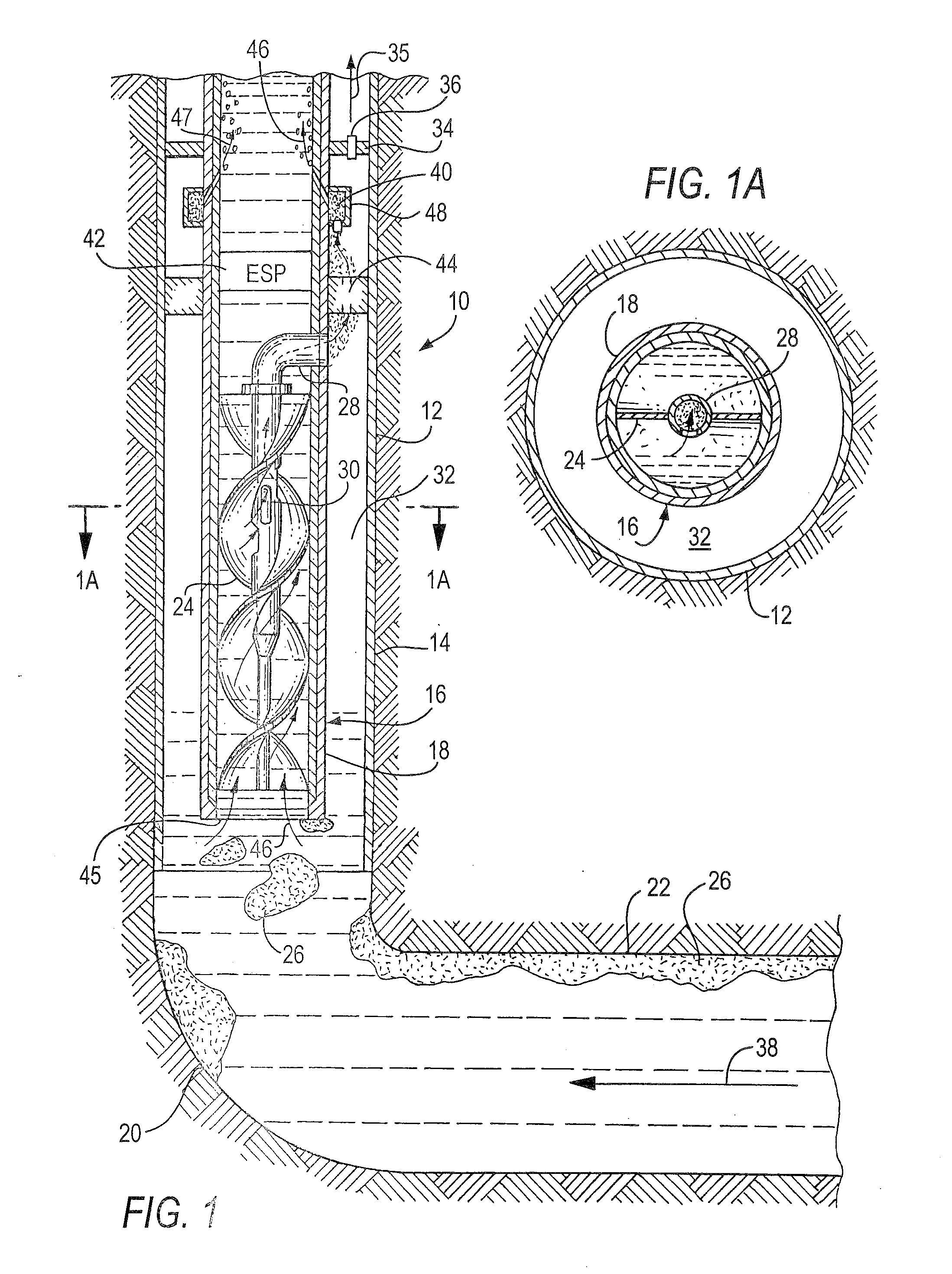

Fluid homogenizer system for gas segregated liquid hydrocarbon wells and method of homogenizing liquids produced by such wells

ActiveUS20150233228A1Improve flow characteristicsImproving homogeneity and flow characteristicLiquid degasificationFlow mixersLiquid productStream flow

A system and method for improving the flow characteristics of gaseous slug-laden liquid hydrocarbon wells, particularly from horizontal, of similar boreholes. The invention provides a system and method which essentially homogenizes the liquid and the gas, utilizing a unique flow tube arrangement and a sequence of steps by first breaking up and separating the slugged gas from the liquid at a first location, and then gathering it into holding location—i.e., an annulus section—where it is re-introduced in controlled amounts into the liquid downstream of the first location. The gas is re-introduced into the liquid flow in such pre-determined and controlled quantities as to promote better pressure and flow characteristics of the hydrocarbon liquid product. Various alternative gas / liquid separation devices are incorporated into the system of the invention, which devices may be located either in a vertical wellbore or a horizontal wellbore, depending upon the particular well characteristics. Optionally, an electric submersible pump may be incorporated where needed to assist the mixed production flow toward surface. A compressor may optionally be provided in the gaseous holding location, where needed. An apparatus for homogenizing production fluid from an oil well having one or more horizontal bores is also disclosed.

Owner:SAUDI ARABIAN OIL CO

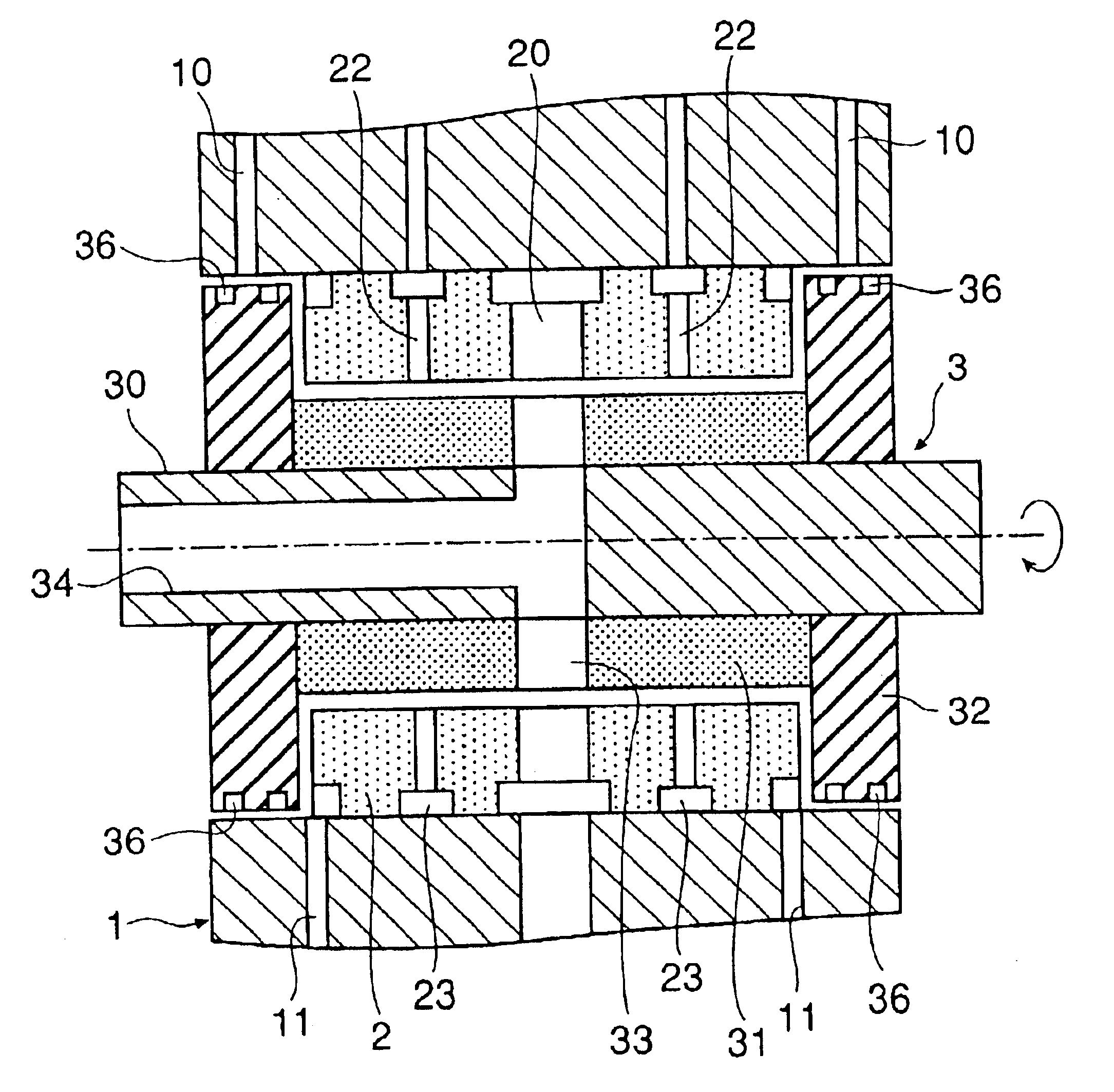

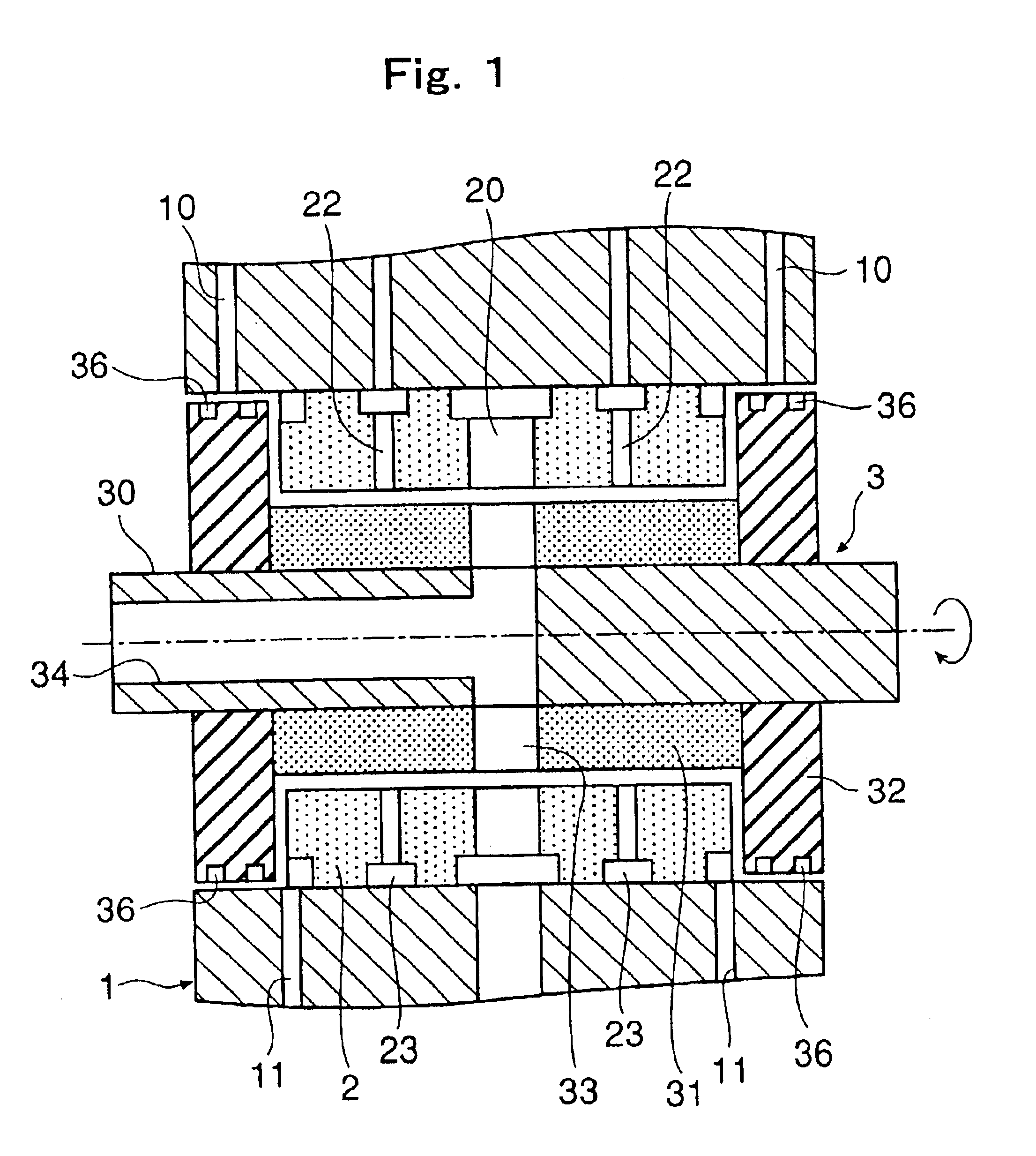

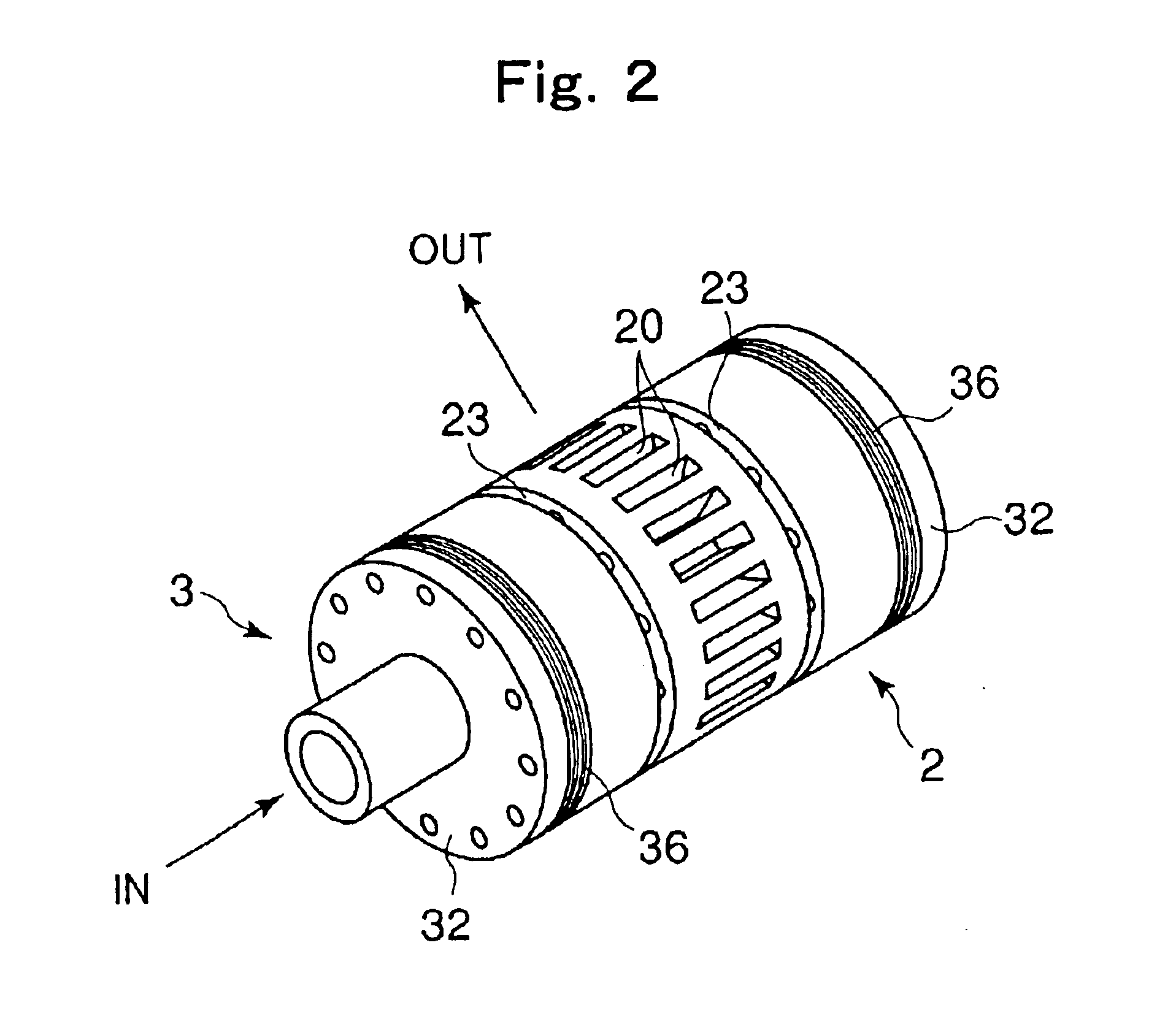

Rotor/stator type homogenizer

InactiveUS6869212B2Increase rotation speedEfficient homogenizerFlow mixersRotary stirring mixersEngineeringMechanical engineering

Disclosed is a rotor / stator type homogenizer which allows the gap between the rotor and the stator to be set to a very small dimension and which does not involve generation of abrasion particles or the like even if the rotor is rotated at high speed, making it possible to efficiently homogenize a plurality of liquids having no mutual compatibility. The inner peripheral surface of the stator and the outer peripheral surface of the rotor are opposed to each other through a predetermined gap and a portion of the solutions is introduced into the gap to form a hydrodynamic bearing, thereby supporting rotation of the rotor with respect to the stator.

Owner:THK CO LTD

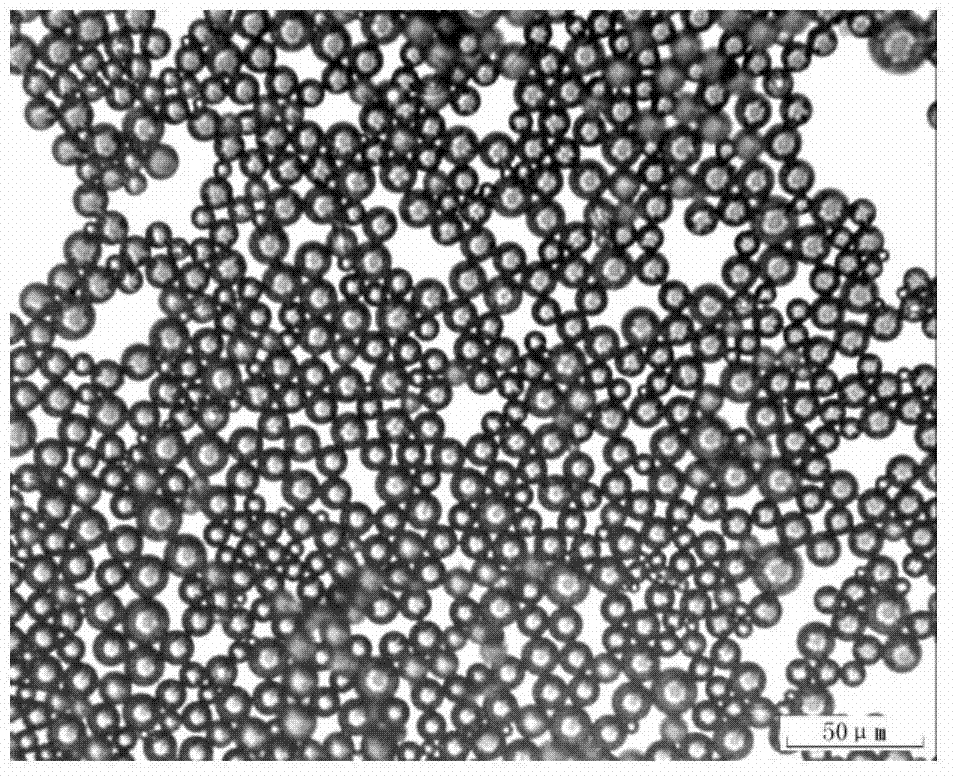

Urea-formaldehyde resin coated epoxy acrylic resin microcapsule for resin-base self-repair coating and preparation method thereof

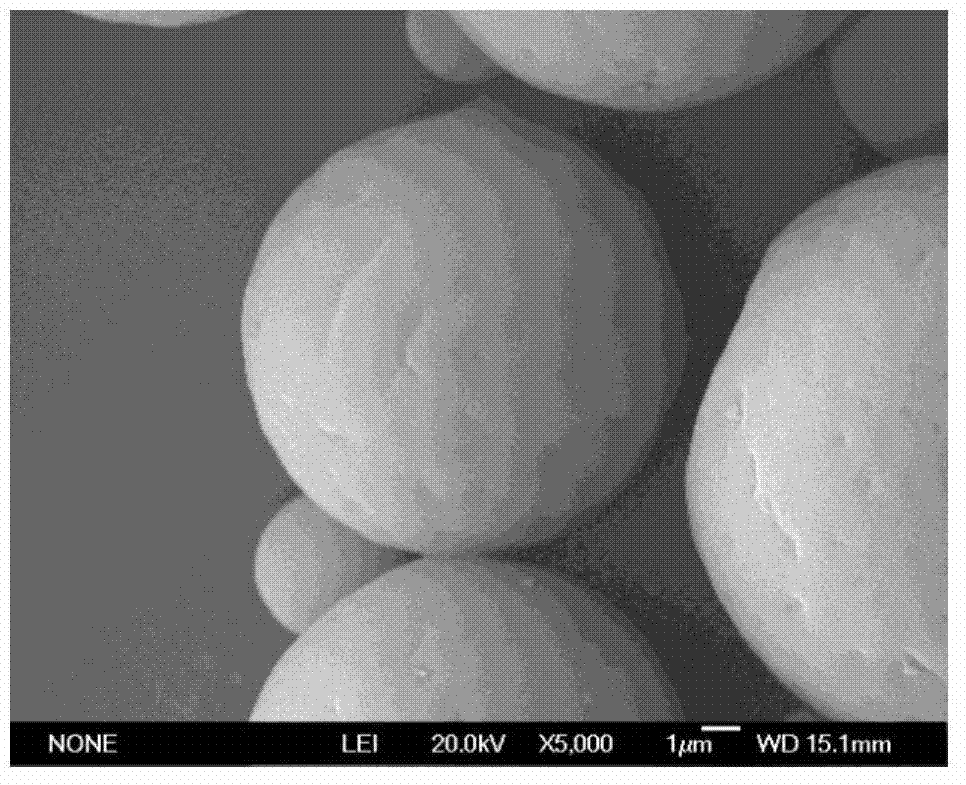

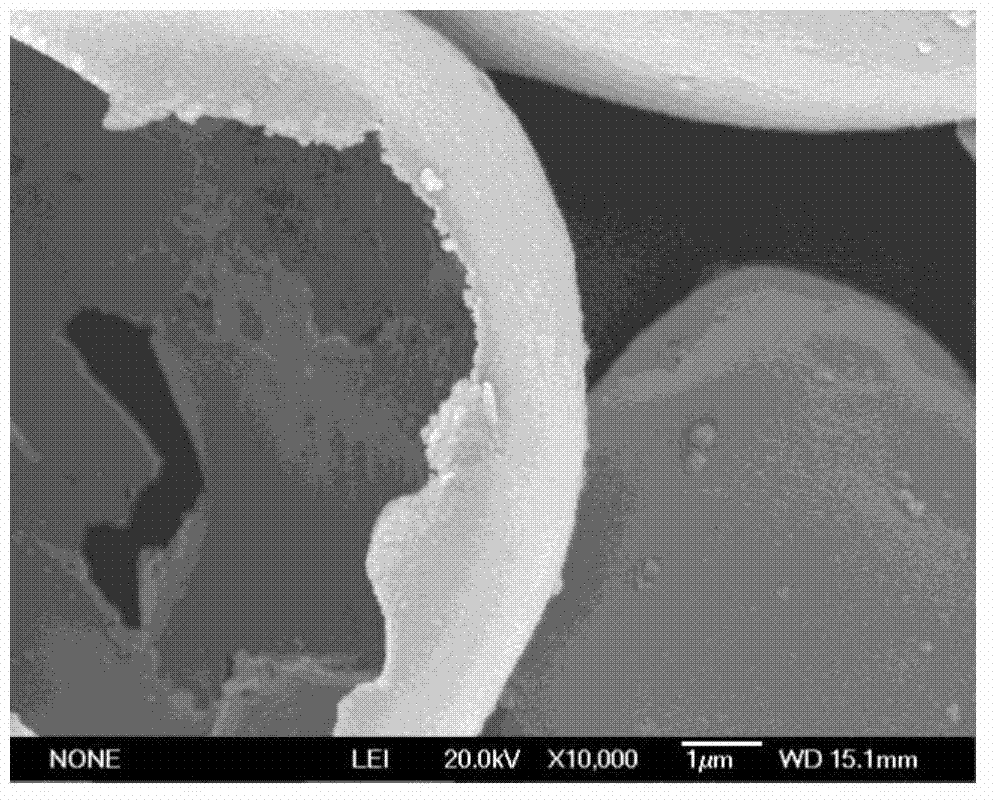

ActiveCN102773053AHigh speedSphericity RulesMicroballoon preparationMicrocapsule preparationAcrylic resinResin coating

The invention relates to a urea-formaldehyde resin coated epoxy acrylic resin microcapsule for a resin-base self-repair coating and a preparation method thereof. The preparation method is characterized by comprising the following steps: adding capsule core raw materials epoxy acrylic resin and acrylate reactive diluent into a water solution containing an emulsifier and a defoaming agent, dispersing the capsule core with a homogenizer or emulsifying machine to form a stable emulsion; regulating the pH value of the stable emulsion system to 2-3, adding capsule wall raw materials urea, formaldehyde and crosslinking agent, stirring until the capsule is formed, and after the reaction finishes, regulating the pH value of the system to neutral; and repeatedly washing with hot water and acetone, centrifuging, and carrying out vacuum drying to obtain the epoxy acrylic resin microcapsule. The capsule provided by the invention has the advantages of favorable sealability, regular sphericity, controllable grain size and controllable capsule wall thickness, and can be widely used for self-repair of a UV-cured acrylic resin coating or epoxy resin coating at low temperature and room temperature, thereby prolonging the service life of the coating material and widening the application range of the resin-base coating.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

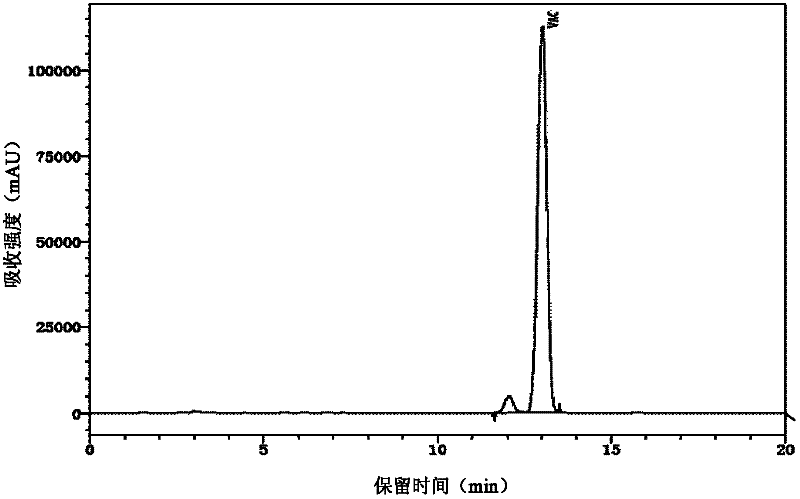

Separation and extraction method of microbial oil

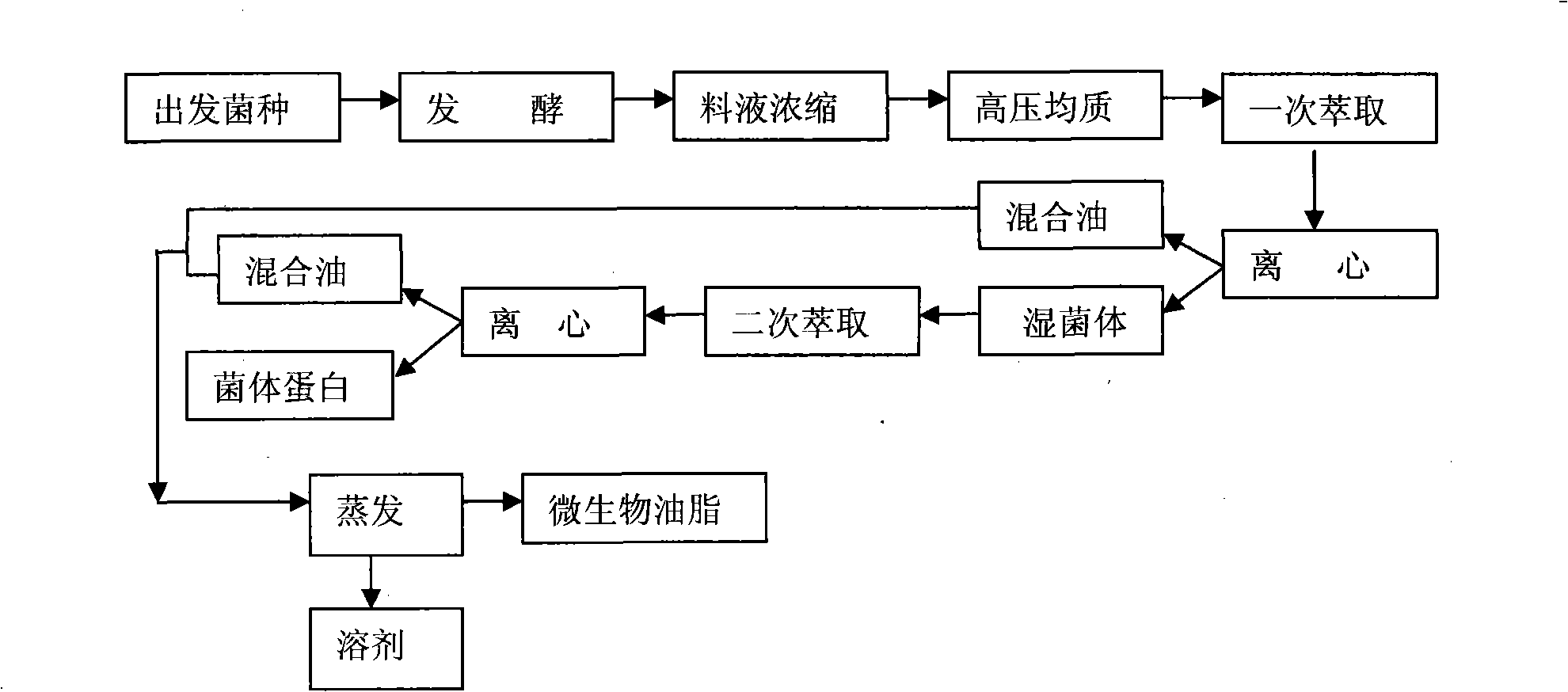

InactiveCN101323865AHigh yieldSimple and fast operationMicroorganism based processesFermentationMicrobial oilOrganic solvent

A method for separating and extracting microbial oil comprises the following steps: (1) microbial strains are inoculated for fermentation; (2) the obtained fermentation liquor is concentrated to remove 45 percent to 55 percent of water in the fermentation liquor so as to obtain the concentrated fermentaton liquor; (3) the concentrated fermentation liquor is fed into a high pressure homogenizer with the pressure of 70 to 130MPa to carry out cell-crushing; (4) an extractive solvent is added, and after two times of extraction, the upper layer organic solution phase is separated and collected to obtain mixed oil; and (5) at last, the solvent in the mixed oil is vaporized and recycled to obtain the microbial oil. The method combines the fermented solution concentration with the high pressure homogenization technology to carry out cell crushing, and then adopts the two-time extraction to collect the contained oil and obtain bacterial protein accordingly. The process improves the original method which needs the steps, such as the separation of strains, drying, grinding and granulation, etc., thus greatly simplifying the technology, improving efficiency and reducing production cost. The method homogenizes the fermented solution under high pressure after concentration, which promotes the utilization rate of facilities, and reduces energy consumption.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

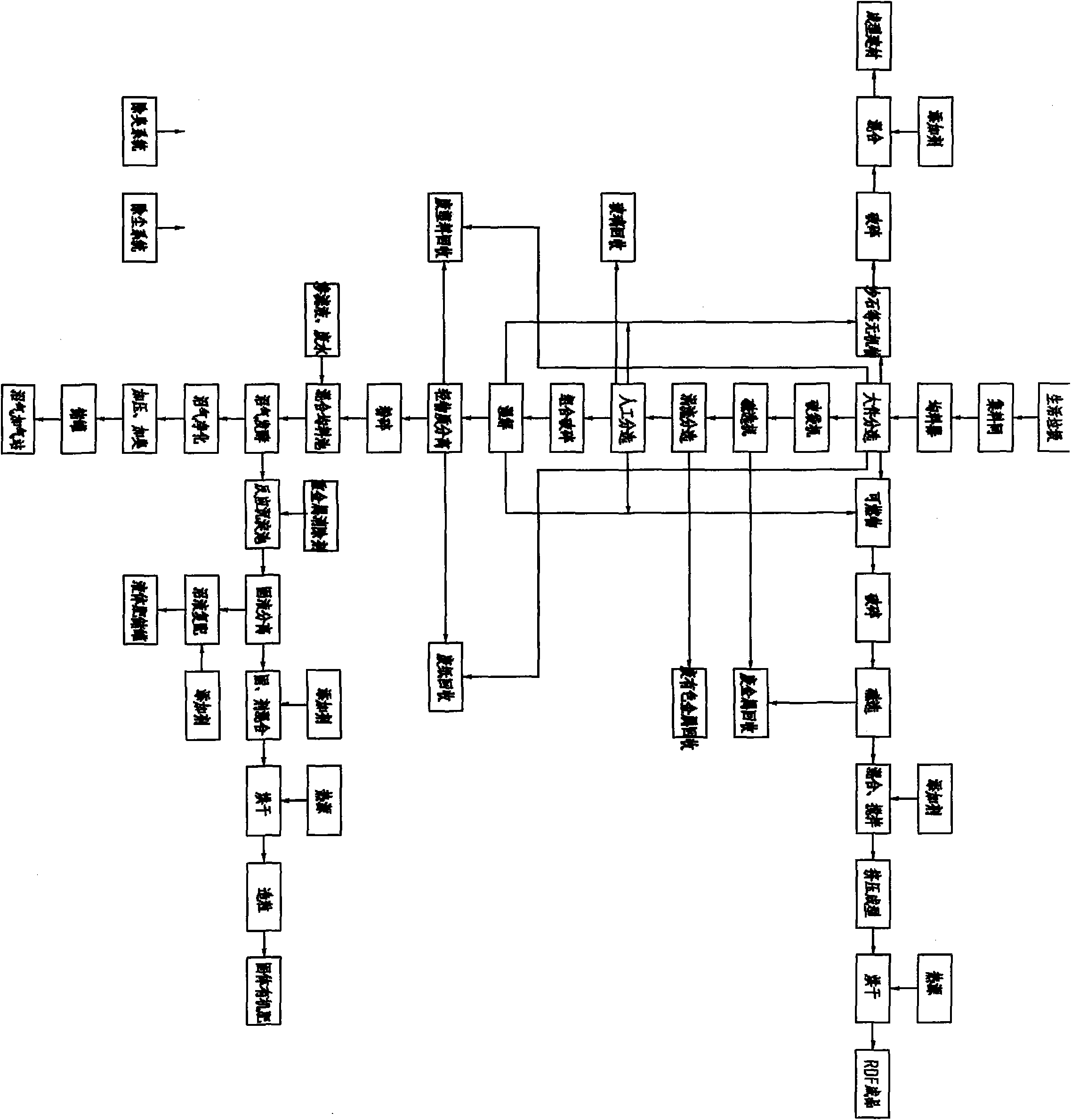

Technology for full classification recycling treatment on household waste

InactiveCN102728601ASolve problems in the treatment processRealize recycling of resourcesBio-organic fraction processingSolid waste disposalRefuse-derived fuelPlastic packaging

The invention discloses a technology for full classification recycling treatment on household waste and relates to the field of recycling integrated utilization of household waste. A main process route of the technology comprises that household waste is homogenized by a homogenizer, is subjected to large object sorting (wherein large objects comprise large combustibles and inorganic matters), is treated by a bag breaking device (for scratching a plastic packaging bag), is treated by a magnetic separator (for separating out magnetic materials), is treated by an eddy sorting machine (for separating out nonferrous metals), is subjected to artificial sorting, then is broken, is fed into a hydrothermal degradation tank, is treated by a light material separator (for separating out papers and plastics), and then is crushed; then mixed organic matters and percolate are mixed and then are subjected to methane fermentation so that methane is produced; and methane residues and a methane liquid are prepared into an organic fertilizer and inorganic matters are prepared into a building material and the combustibles are prepared into a refuse derived fuel (RDF). The technology really realizes reduction, harmlessness and recycling of waste.

Owner:张希曾 +1

Method for extracting DHA from cells of algae and fungi by breaking cell walls

ActiveCN101817738AOvercome residualLow costCarboxylic compound separation/purificationDocosahexaenoic acidAntioxidant

The invention provides a method for extracting DHA from cells of algae and fungi by breaking cell walls and relates to a method for extracting active ingredients from microorganisms. The method provided by the invention avoids the assistance from any organic solvent and chemical medicaments, breaks the walls of the cells of the algae and the fungi by using a physical method and extracts a grease product DHA (docosahexaenoic acid) from the cells and is suitable for large-scale production at low cost. The method comprises: after fermentation is finished, introducing fermentation liquor of microalgae or fungi to a separation system for separating and collecting the cells, adjusting the pH value of bacterial sludge with an acid to 2.0 to 4.0, keeping the temperature of the bacterial sludge between 10 and 20 DEG C, adding antioxidant into the bacterial sludge, and performing high-pressure homogenization and wall breaking by using a high-pressure homogenizer; and adding water into the bacterial sludge subjected to wall breaking, stirring the bacterial sludge, and separating feed liquor in a three-phase separator to obtain DHA grease. In the invention, physical wall breaking and the physical extracting method are used, the process is simple, the cell breaking is high efficient, the low-temperature treatment and antioxidant treatment of the bacterial sludge can effectively protect thebioactivities of the matters in the cells of the algae and the fungi, and the product is green, nontoxic and free from residues.

Owner:XIAMEN HUISON BIOTECH

Multi-junction solar cells with a homogenizer system and coupled non-imaging light concentrator

The present embodiments provide methods and systems to homogenize illumination on a target. Some embodiments provide rotational symmetric dual-reflector solar concentrators that include a concave primary reflector with an aim-direction directed toward the sun to receive optical radiation in a far-field angle within an angle of acceptance and redirect radiation upward and centrally generating flux concentration, a secondary reflector positioned coaxial with said primary reflector to receive said redirected radiation and redirect radiation downward and centrally generating flux concentration solar rays, and a central target zone receiving said concentrated solar rays, where cross sections of said primary and secondary reflectors both further comprise a multiplicity of segments that establish a correspondence between pairs of segments, each of said segments of said primary reflector such as to image said angle of acceptance onto said corresponding segment of said secondary reflector to image onto said target zone.

Owner:LIGHT PRESCRIPTIONS INNOVATORS

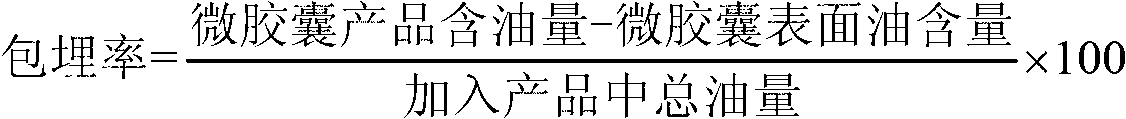

Flaxseed oil microcapsule and production method thereof

ActiveCN102934703AFit for consumptionImprove stabilityFood shapingEdible oils/fatsSodium CaseinateOil phase

The invention discloses a flaxseed oil microcapsule and a production method thereof. The core material of the flaxseed oil microcapsule is flaxseed oil, and the wall material is made of modified starch, maltodextrin and sodium caseinate. The production method comprises steps of adding the modified starch, the maltodextrin and the sodium caseinate to hot water with high-speed stirring until the the modified starch, the maltodextrin and the sodium caseinate are dissolved completely and forming a water phase; weighing and taking the flaxseed oil, adding vitamin E, rosemary and tea polyphenol step by step, stirring the mixture until the mixture is dissolved completely and forming an oil phase; conducting high-speed cutting for the obtained water phase by using a cutting machine, adding the obtained oil phase slowly and obtaining an emulsion; homogenizing the emulsion by using a high-pressure homogenizer; sterilizing the emulsion which is homogenized by using an ultra high-temperature sterilizing machine; and spraying and drying the sterilized and obtaining the flaxseed oil microcapsule. The embedding rate of the flaxseed oil microcapsule is more than 90%, the capacity of the flaxseed oil can reach 45%, the process is simple, the taste is special, the scent is obvious and the shelf life is long.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD +3

Cherry fruity ice cream and its preparation method

The invention discloses a cherry fruity ice cream and its preparation method. The cherry fruity ice cream is made from the following raw materials of: by weight, 40-60 parts of a cherry juice, 8-15 parts of a strawberry juice, 8-15 parts of a watermelon juice, 40-60 parts of whole milk, 10-20 parts of white sugar, 5-10 parts of cream and 30-50 parts of water. The preparation method comprises the following steps of: 1) uniformly mixing each raw material to obtain a mixture; 2) sterilizing the mixture; 3) putting the mixture into a homogenizer for homogenization; 4) rapidly cooling the mixture to minus 2-4 DEG C, and aging at the temperature; and 5) filling the aged mixture into a stirring barrel of a freezing machine, freezing at the stirring state, taking out, packaging, and quick-freezing and hardening to obtain the ice cream. The ice cream provided by the invention has a simple preparation method, contains no chemical additive, and has health-care effects of whitening, beautifying, clearing away summer heat, strengthening physique and the like.

Owner:张小钰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com