Patents

Literature

16222results about "Food preservation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

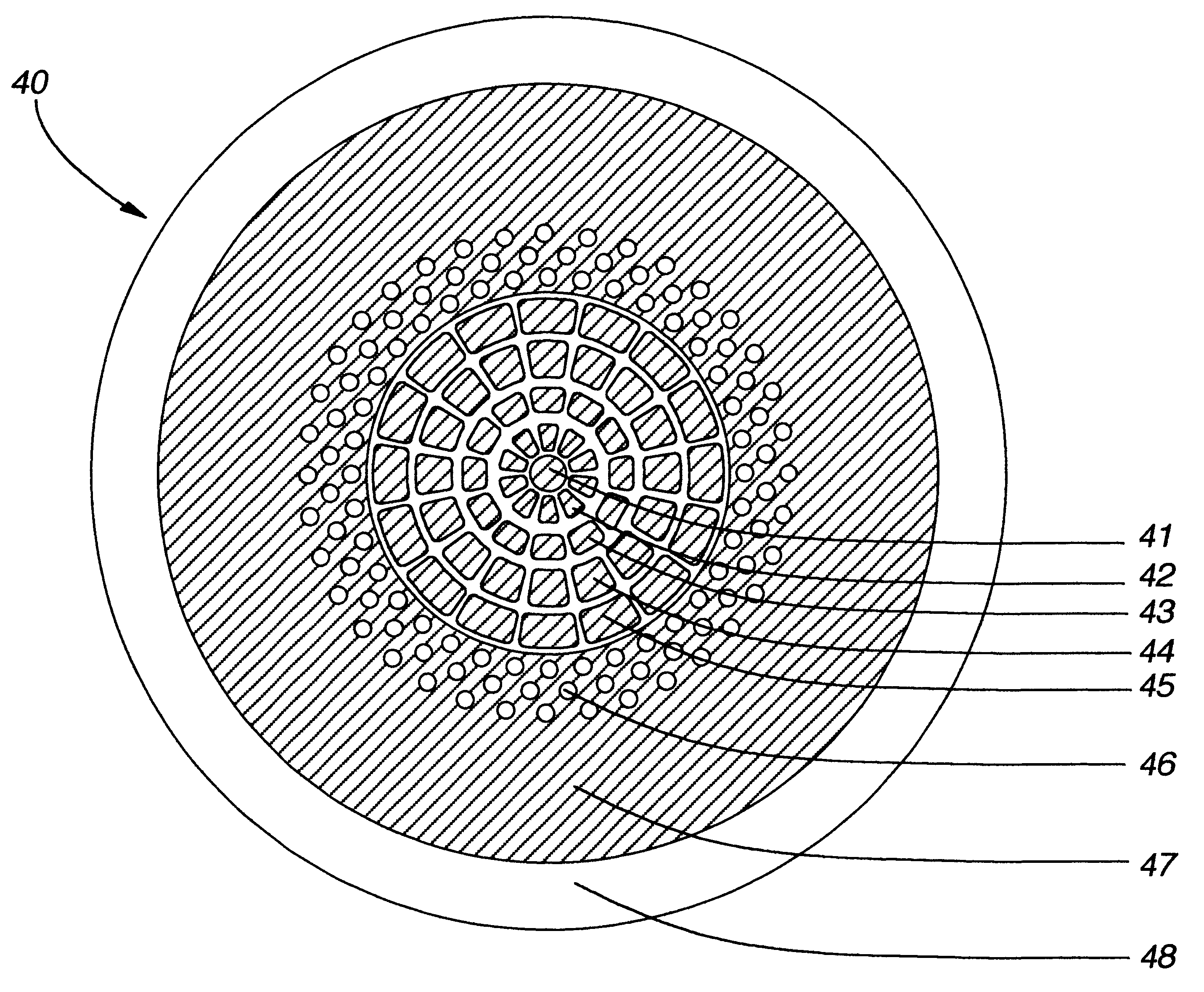

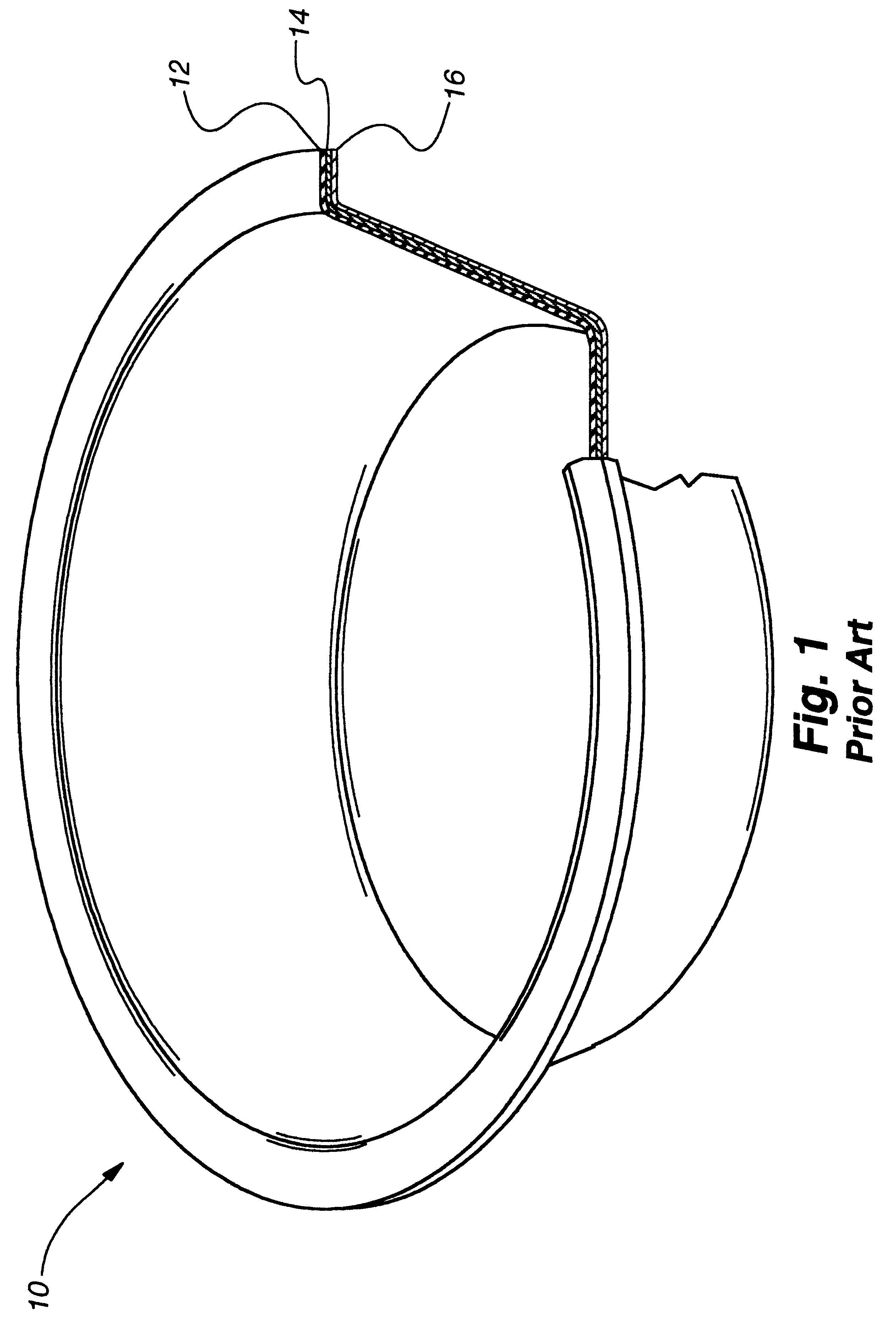

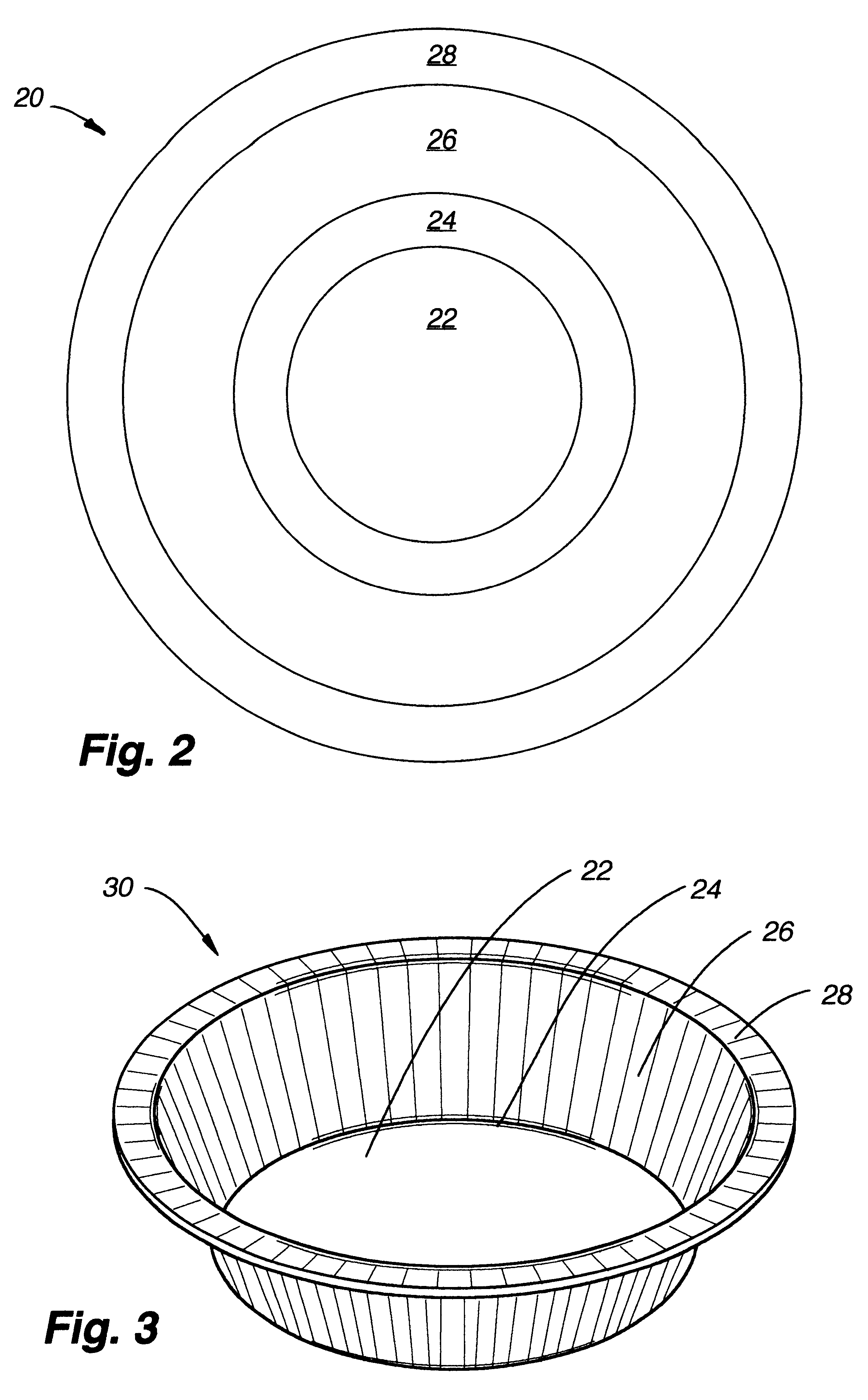

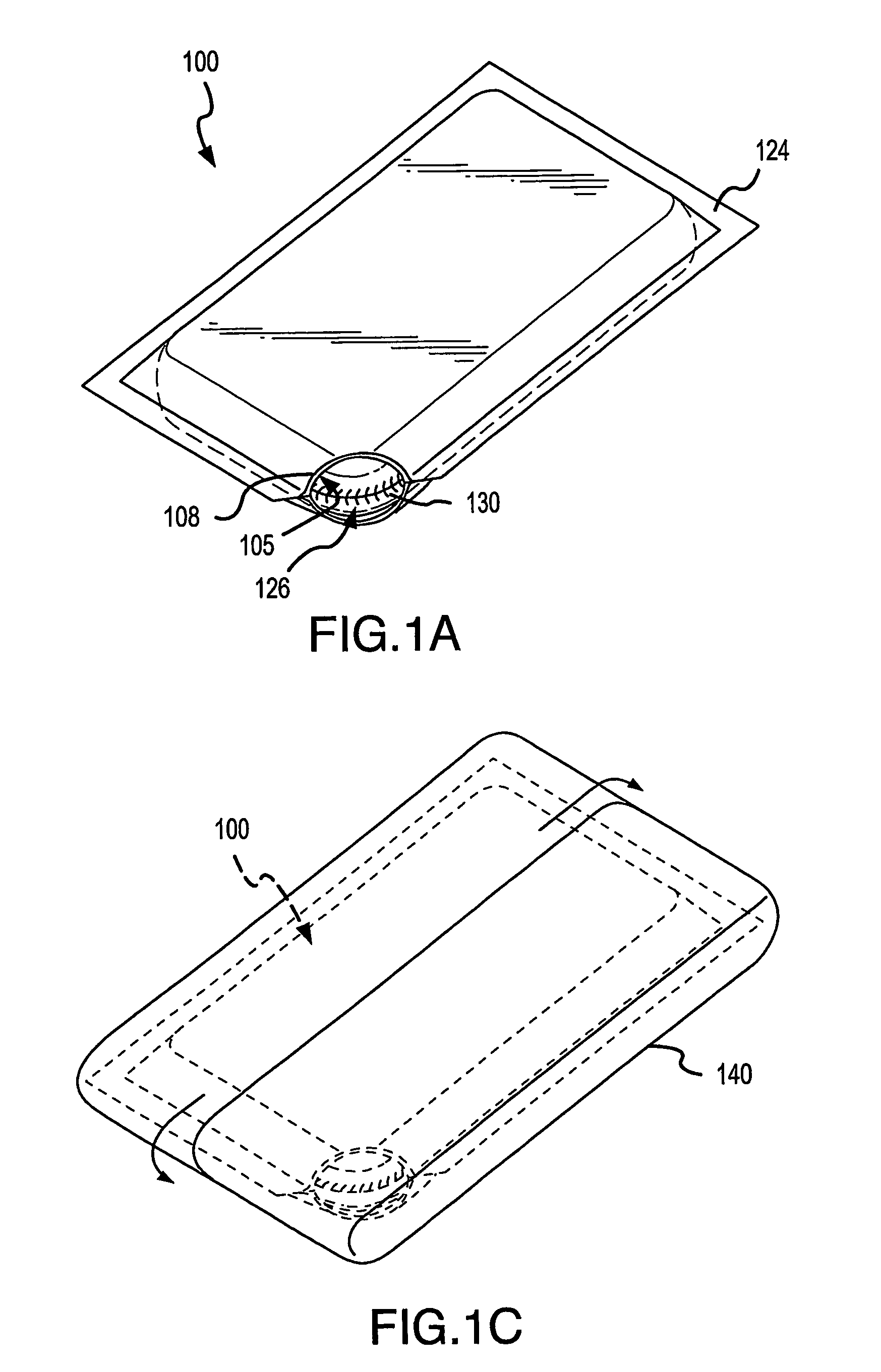

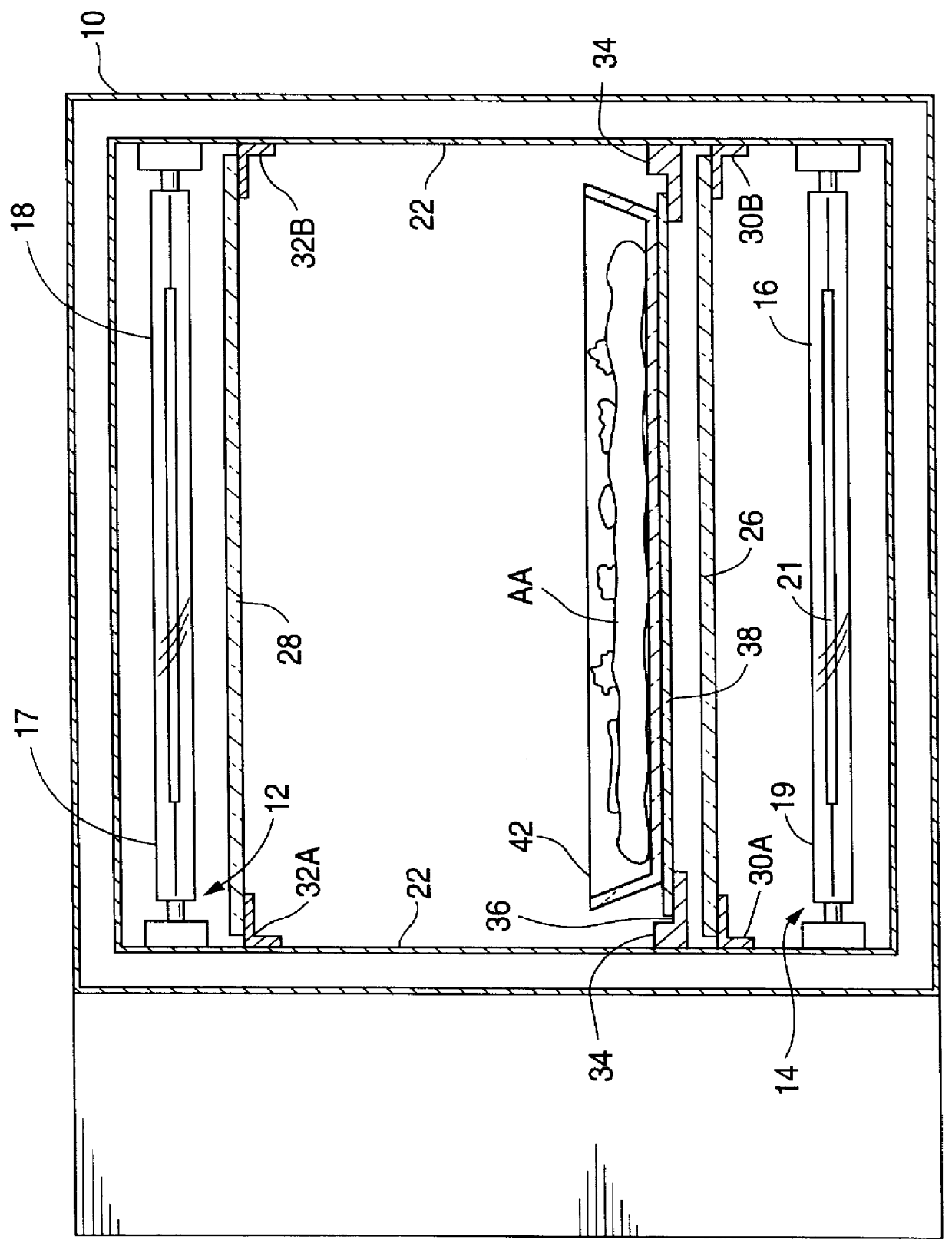

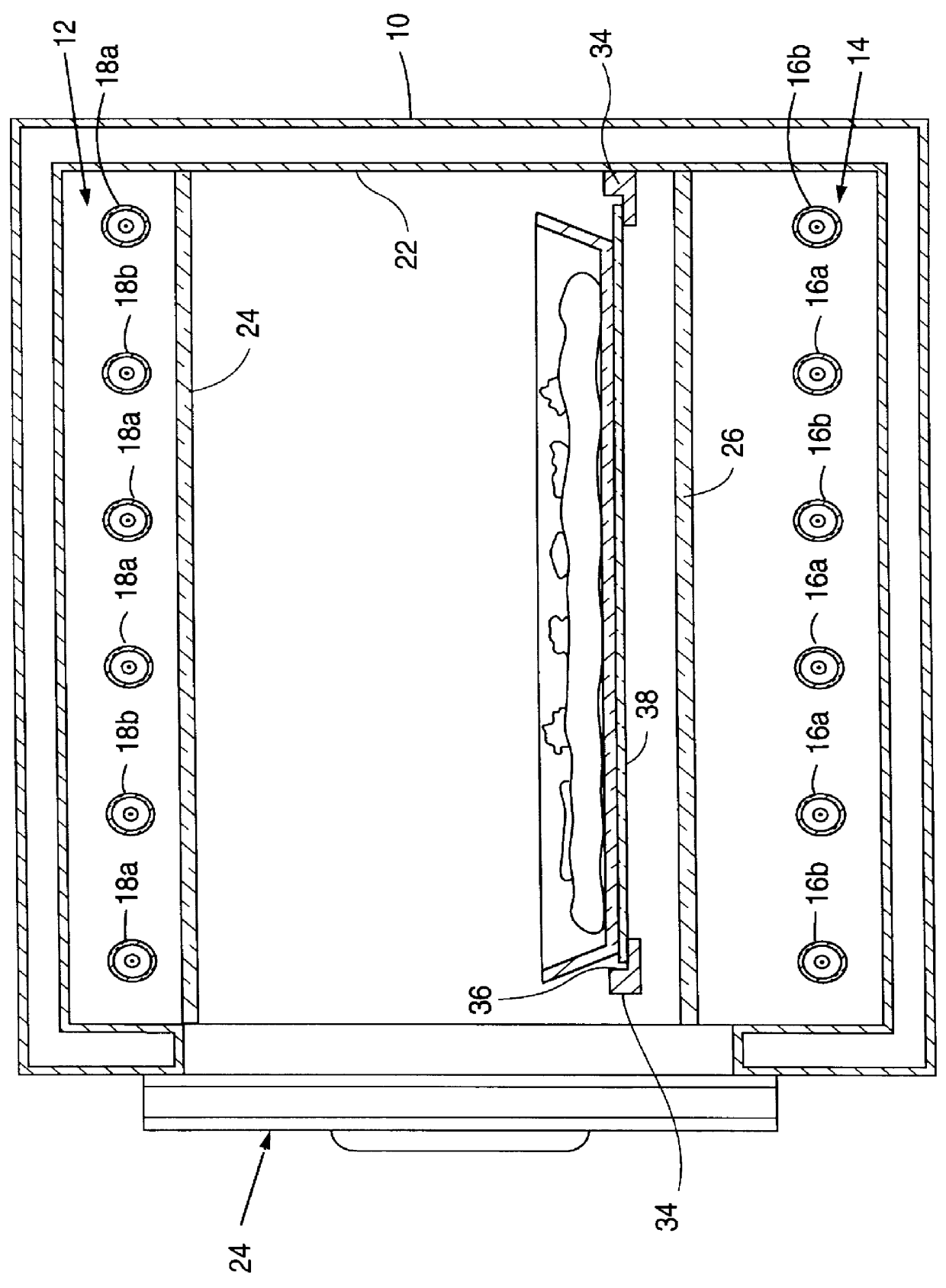

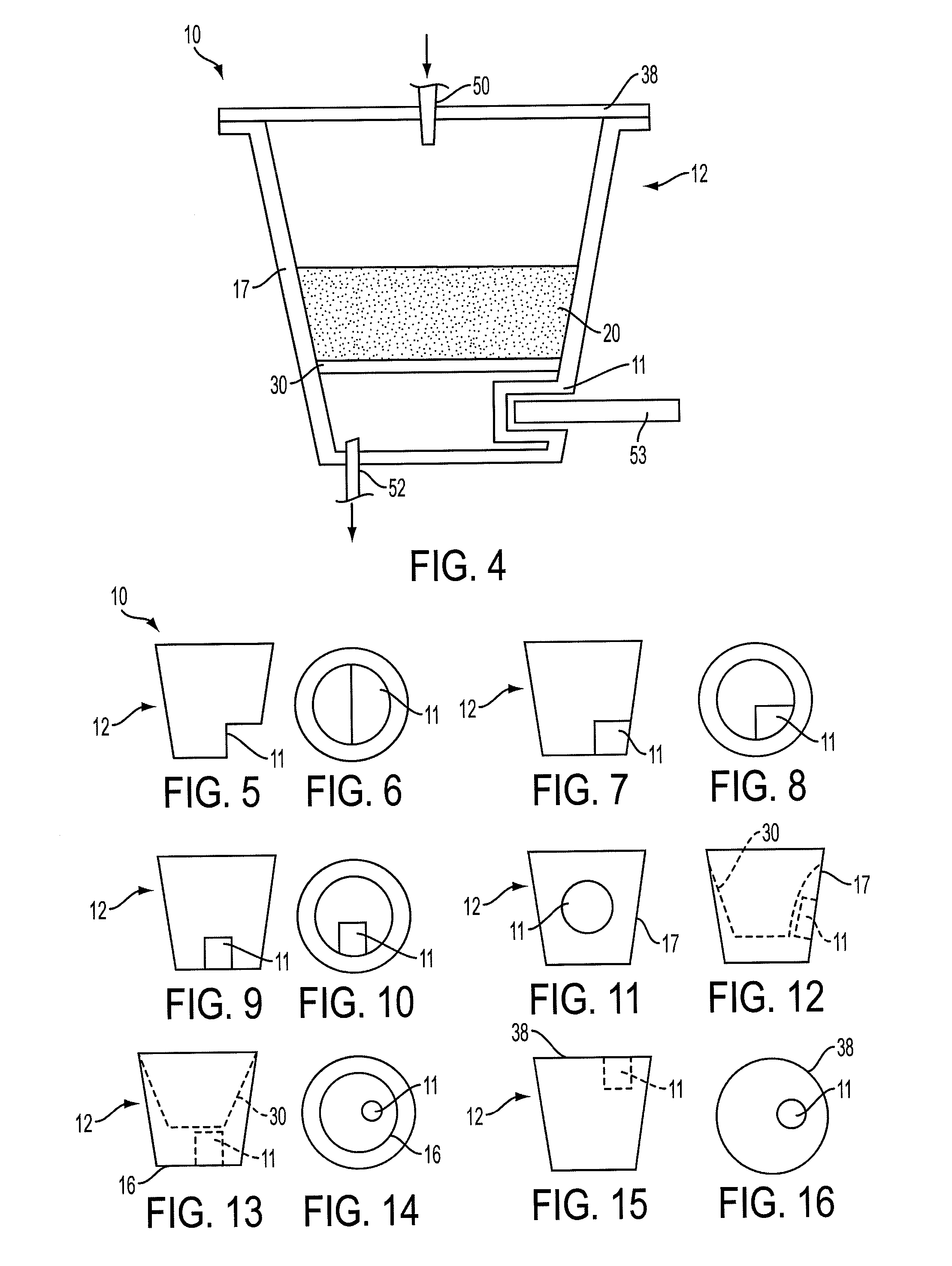

Patterned microwave susceptor element and microwave container incorporating same

A container has a patterned susceptor region in the bottom, a fold region between the bottom and the sidewall of the container, a sidewall region, and a flange region that forms a flange or lip of the container. The patterned susceptor region includes arrangements of microwave-interactive features disposed generally along respective close plane curves, which reduces overheating and increases the filling temperature of the food product. The fold region contains microwave transparent features that minimize de-lamination of the container in the folded region, and also create a generally transmissive area in the vicinity of the heel of the food product to improve the cooking thereof. The sidewall region shields the periphery of the food product so that it is not overcooked while promoting an appropriate degree of pie dough shell browning. The flange area is transmissive to promote an appropriate degree of cooking of the food product crust.

Owner:GRAPHIC PACKAGING INT

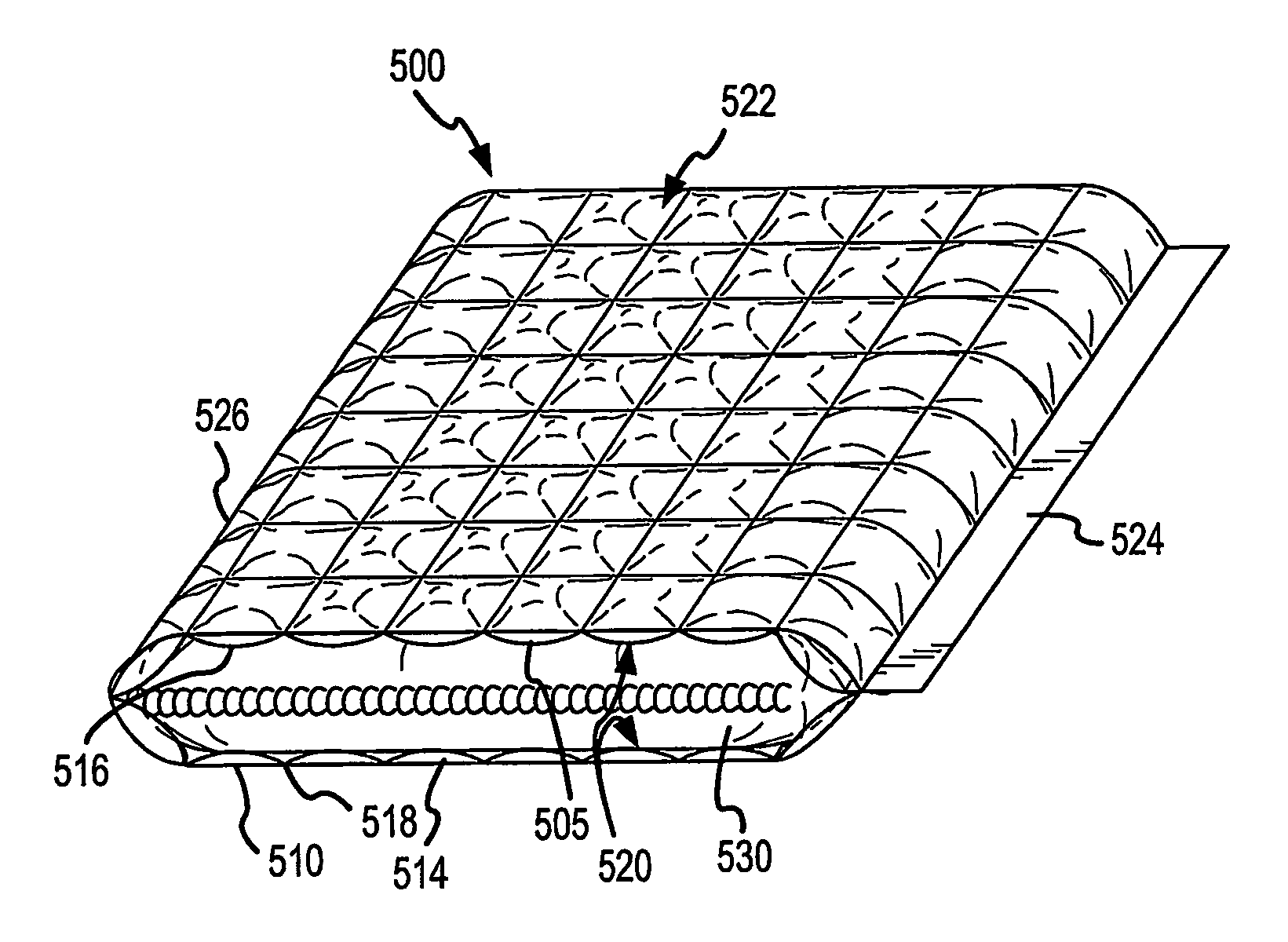

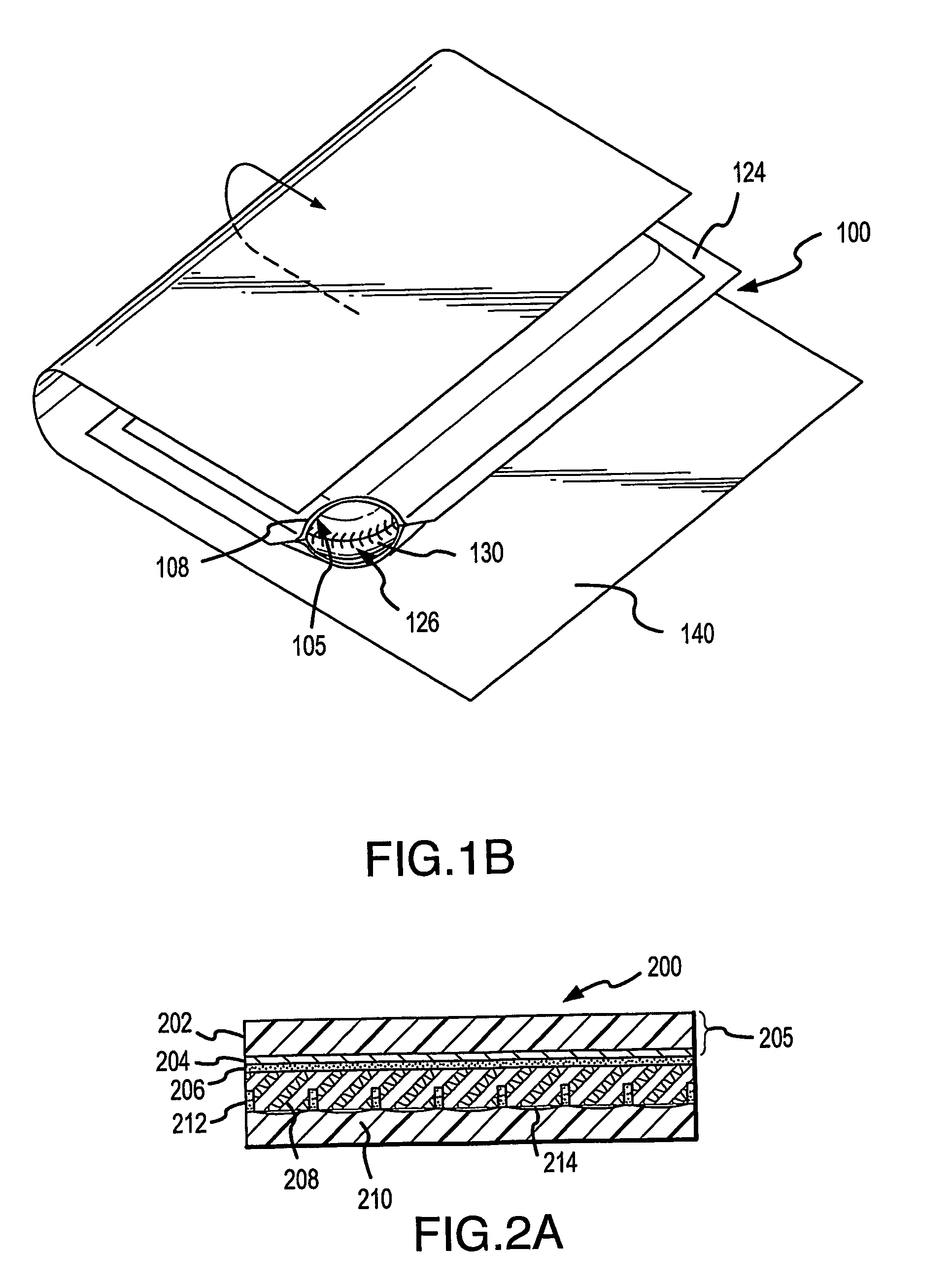

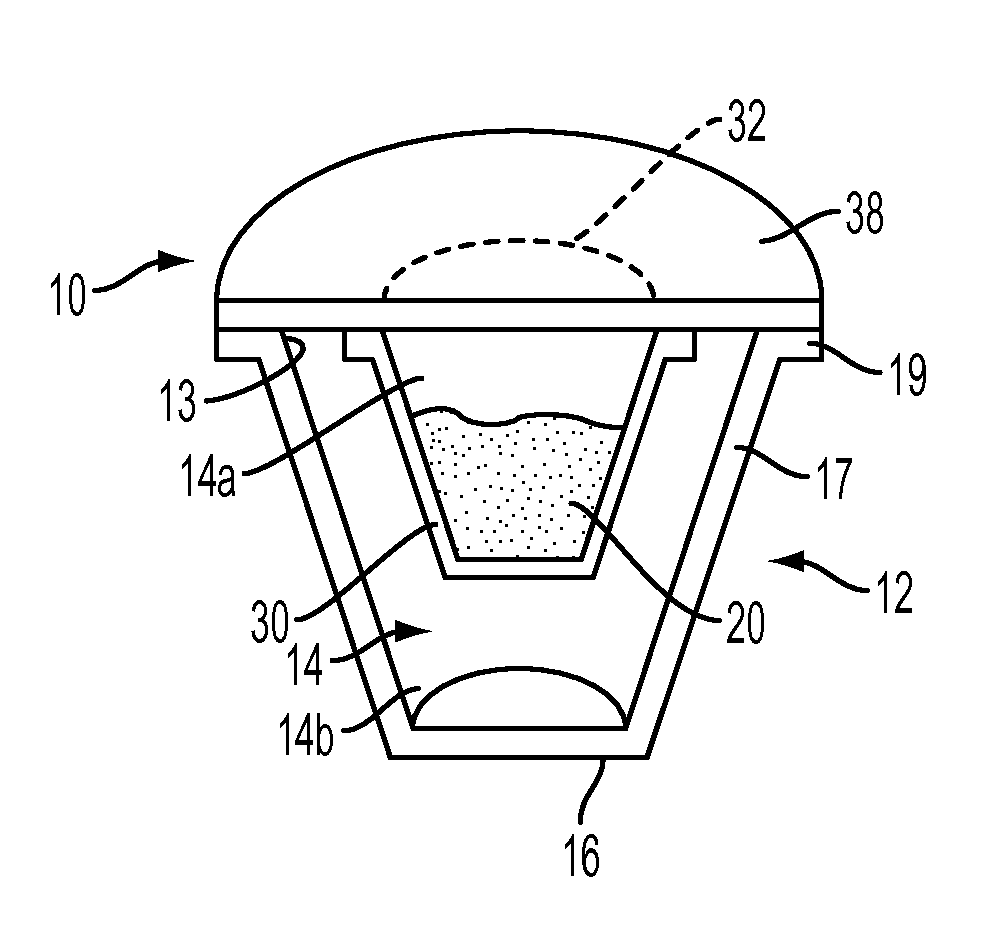

Insulating microwave interactive packaging

InactiveUS7019271B2Improve cooking resultsImprove the heating effectDomestic cooling apparatusLighting and heating apparatusMicrowave ovenEngineering

Owner:GRAPHIC PACKAGING INT +1

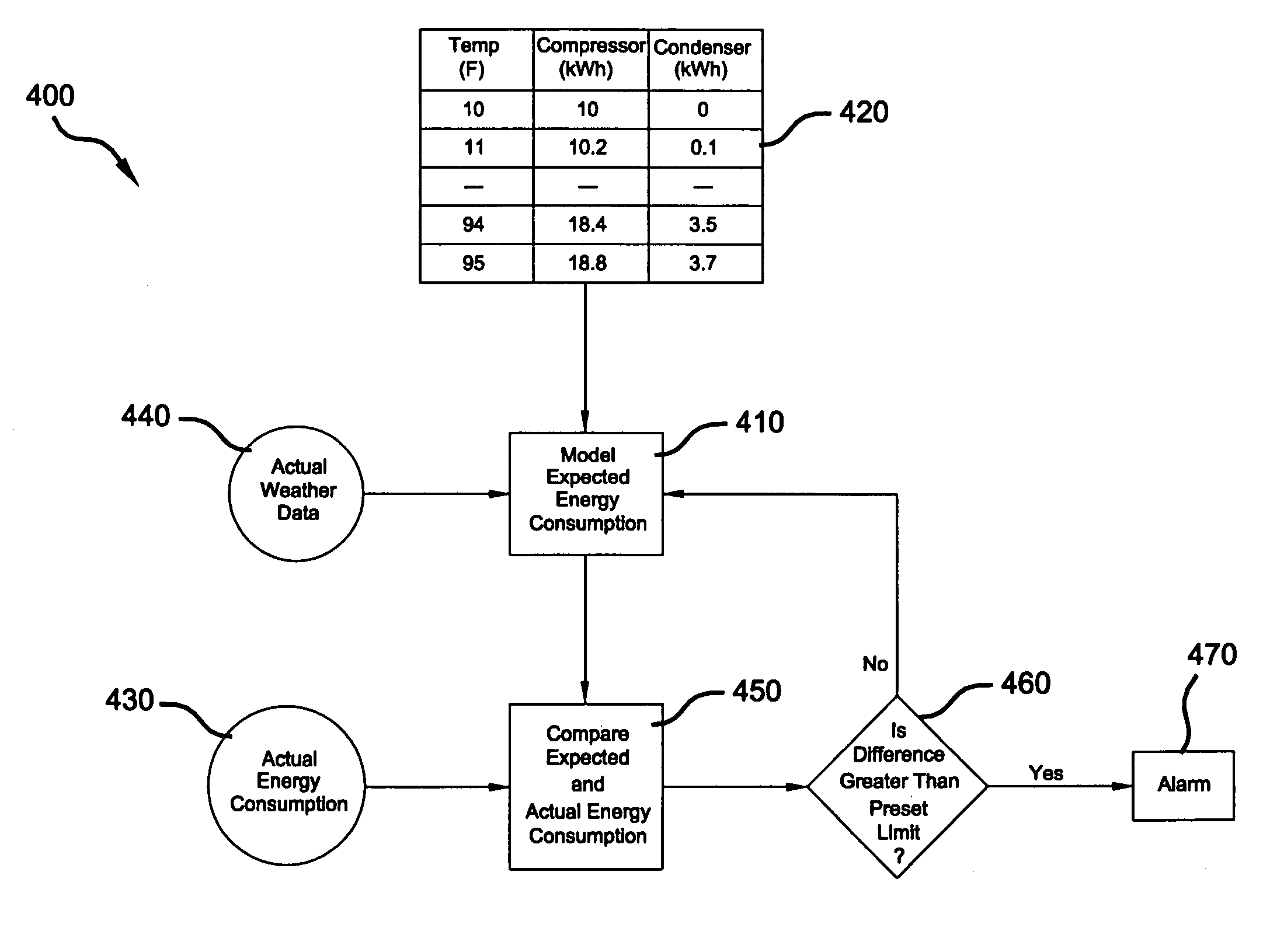

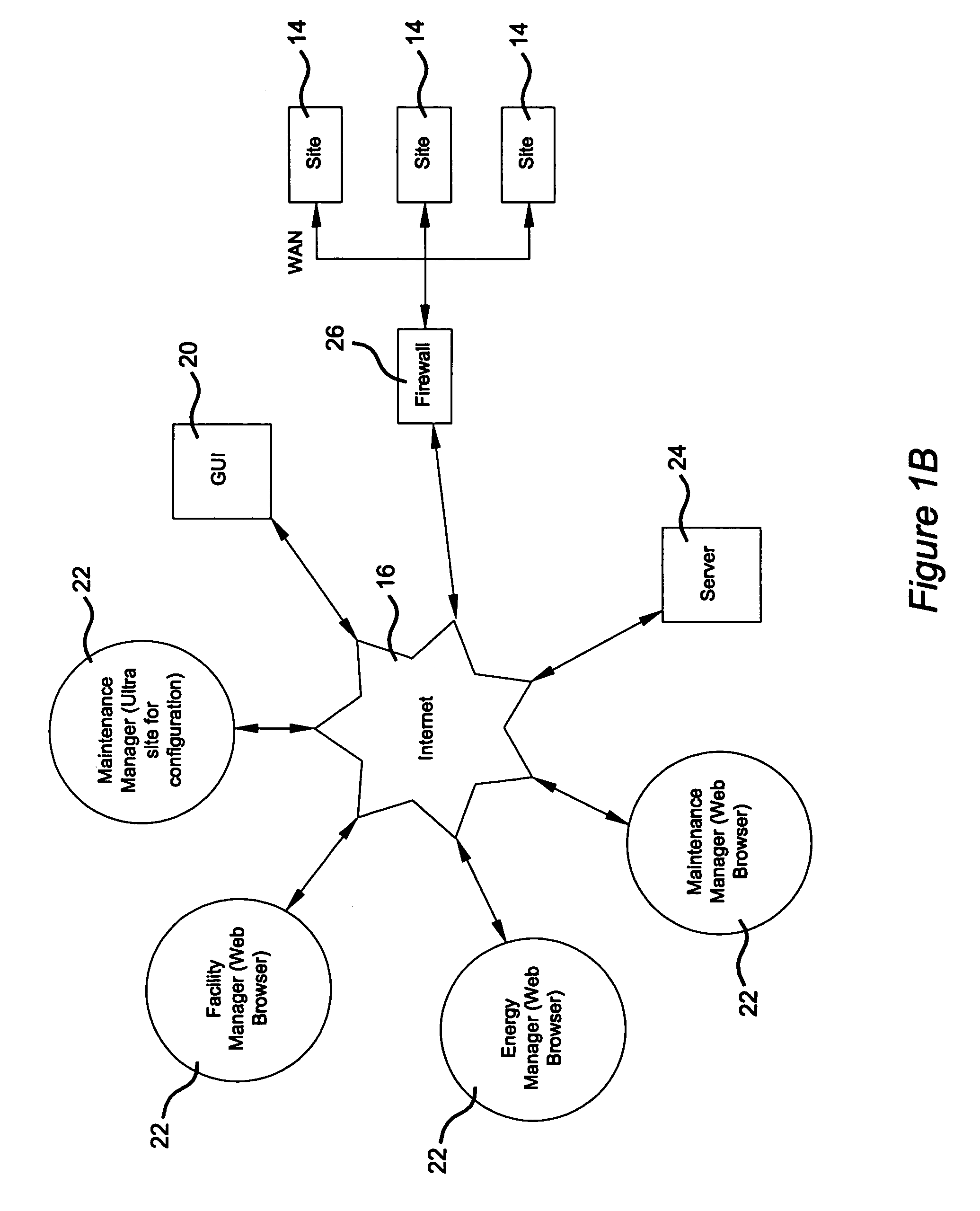

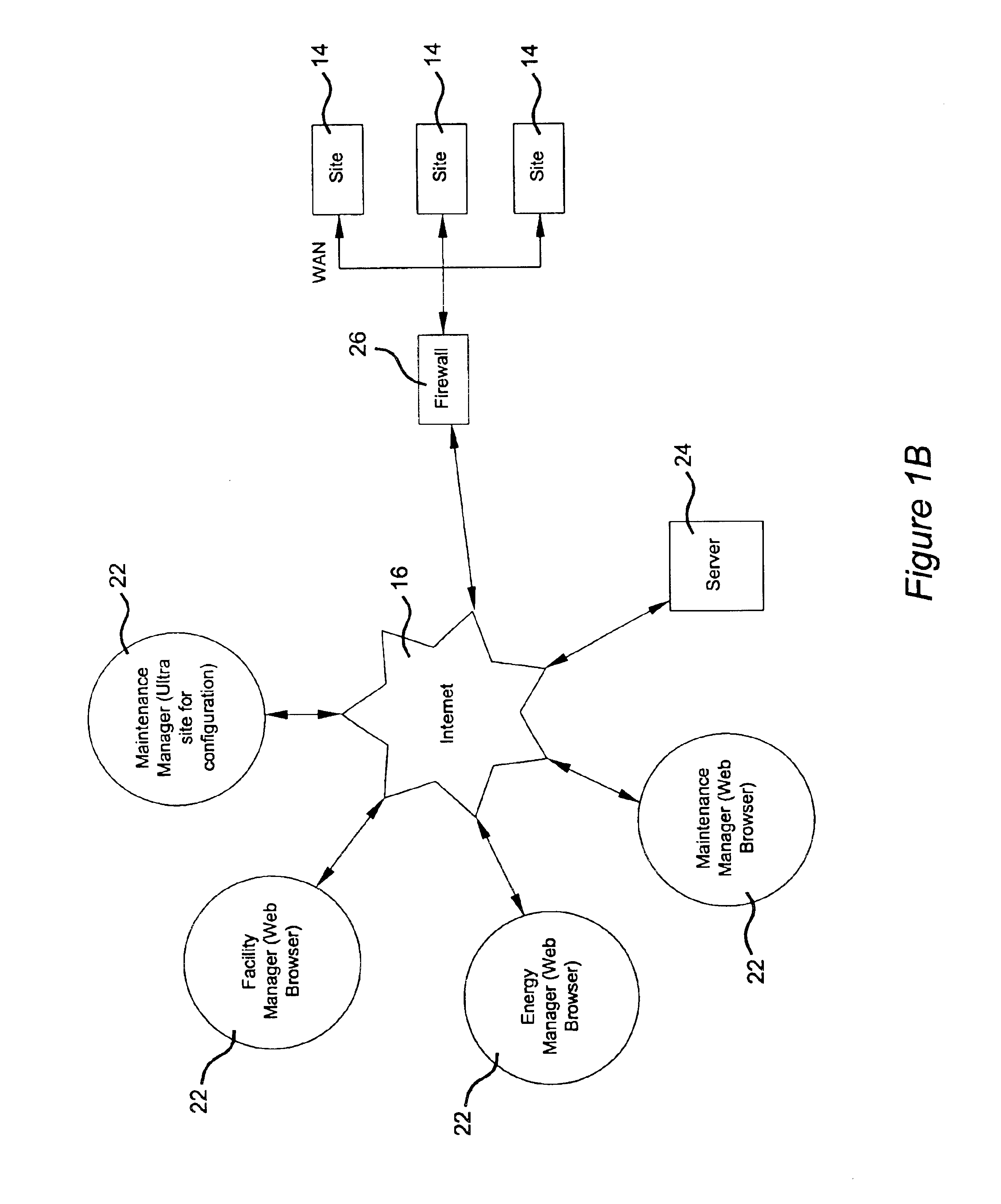

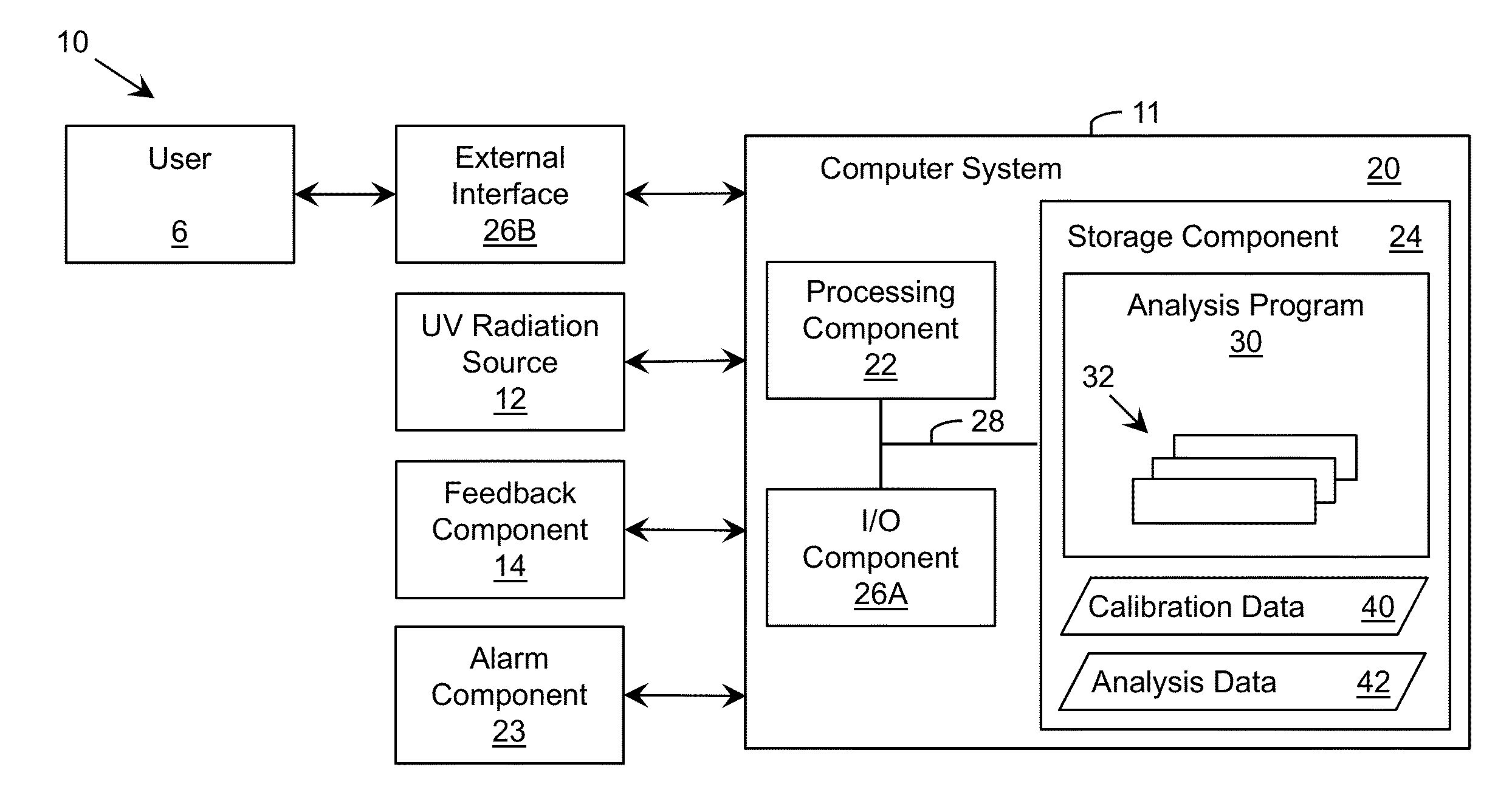

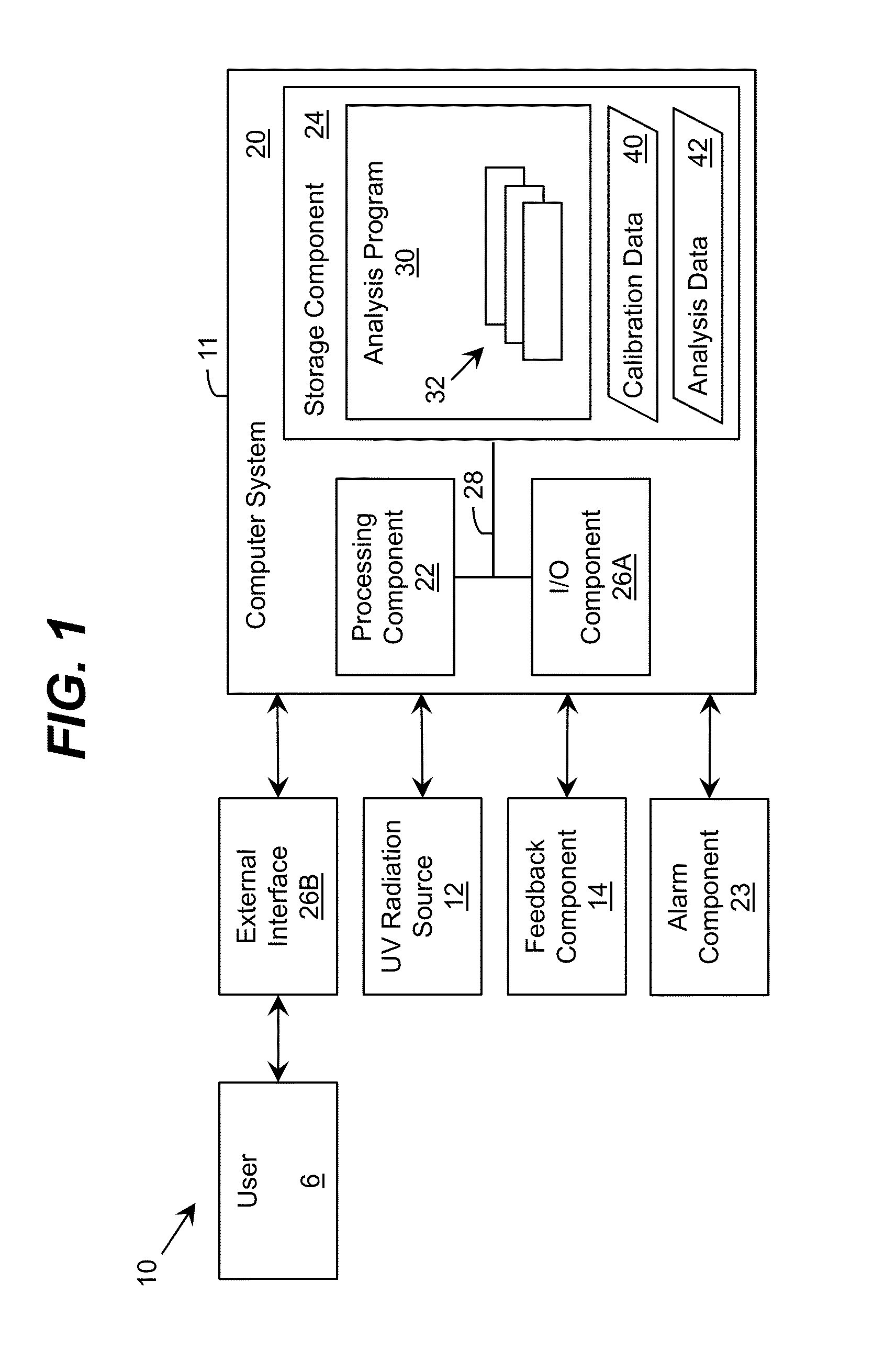

Model-based alarming

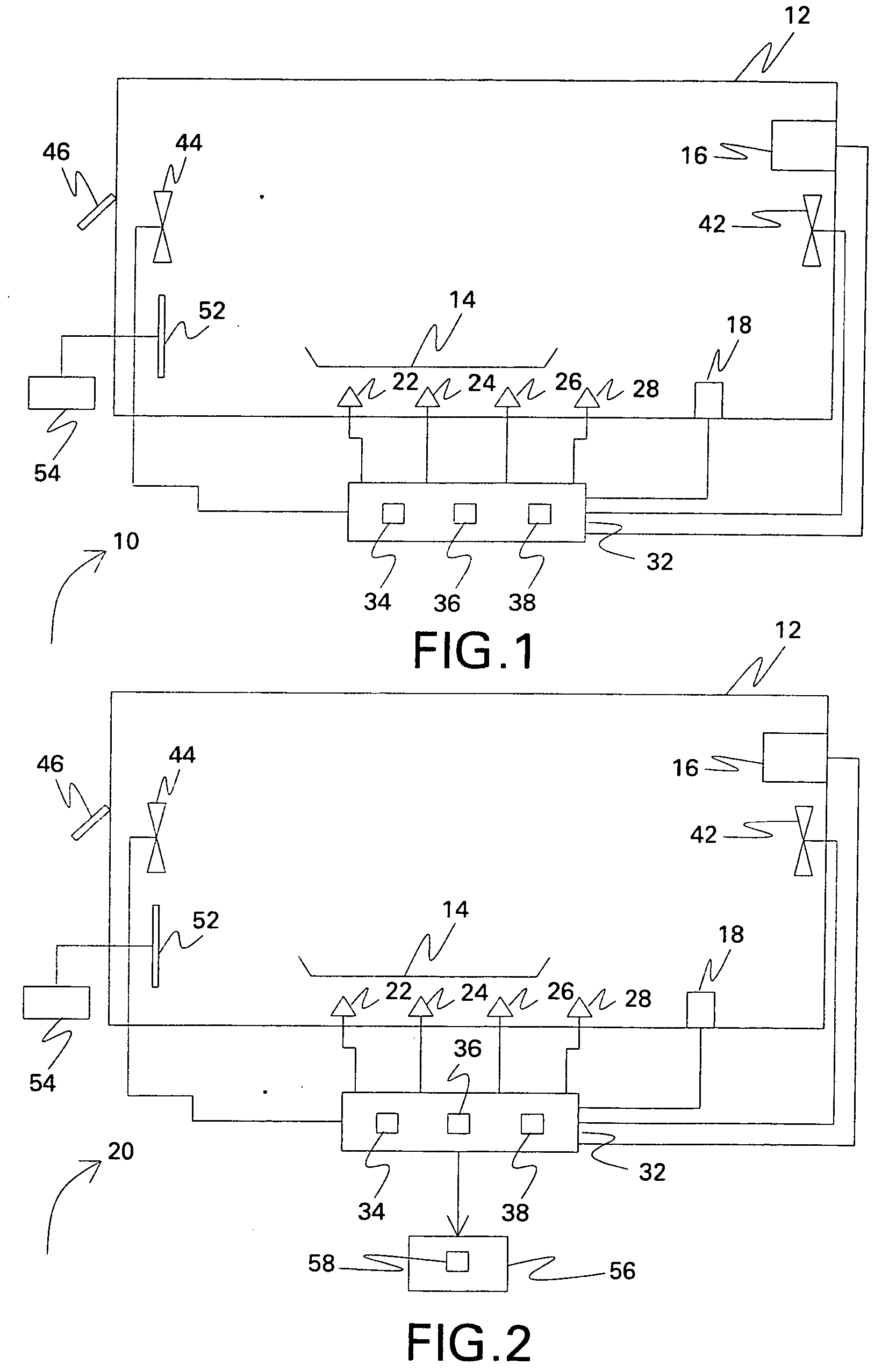

A system and method for managing energy consumption of a building system includes a source of actual energy consumption data, a source of actual weather data, and a database correlating discrete weather data values with expected energy consumption values for at least one component of the building system. A computer accesses the actual weather data, actual energy consumption data and database, wherein the computer compares the expected energy consumption values with actual energy consumption data and generates an output based on the comparison. The expected energy consumption values are generated for the discrete weather data values using an energy consumption model that functionally relates discrete weather data values and design information for the building system component.

Owner:EMERSON DIGITAL COLD CHAIN INC

Hypochlorite Technology

This invention generally relates to compositions and method of producing diluted hypohalous acid and hypohalous acid vapor. These compositions can be used to treat allergen containing surfaces, hard surfaces, food contact surfaces, hospital surfaces, food surfaces, kitchen surfaces, bathroom surfaces, human surfaces, animal surfaces, children's items, outdoor surfaces, soft surfaces, and medical instruments. These compositions can be converted to solid particulate or granular compositions. These compositions can be put into a variety of containers which preserve the stability. These compositions can be used to treat allergens and molds and as part of a mold detection system. These compositions can be dispersed into the air to enable microbiological control.

Owner:BROMBERG STEVEN E +29

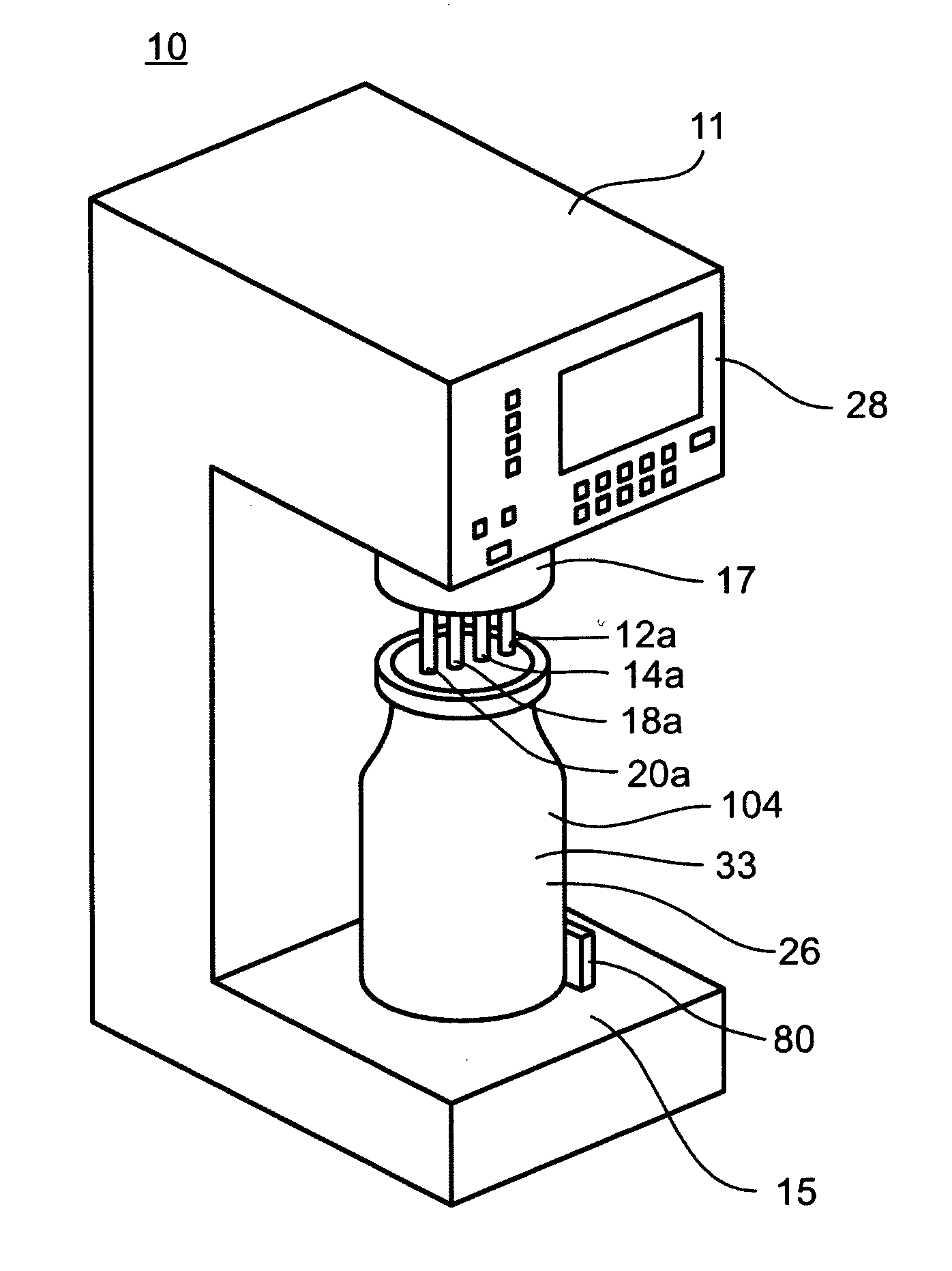

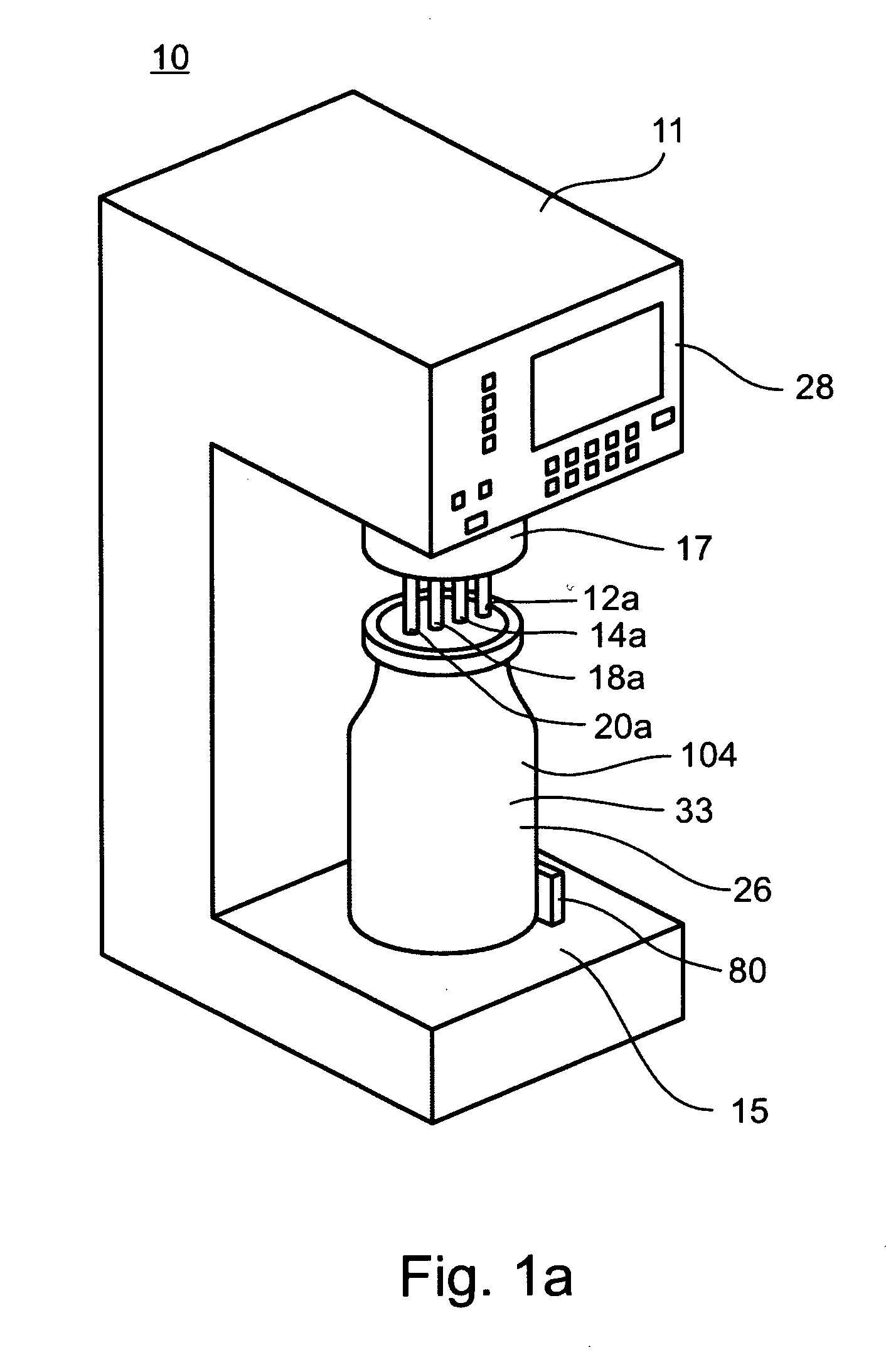

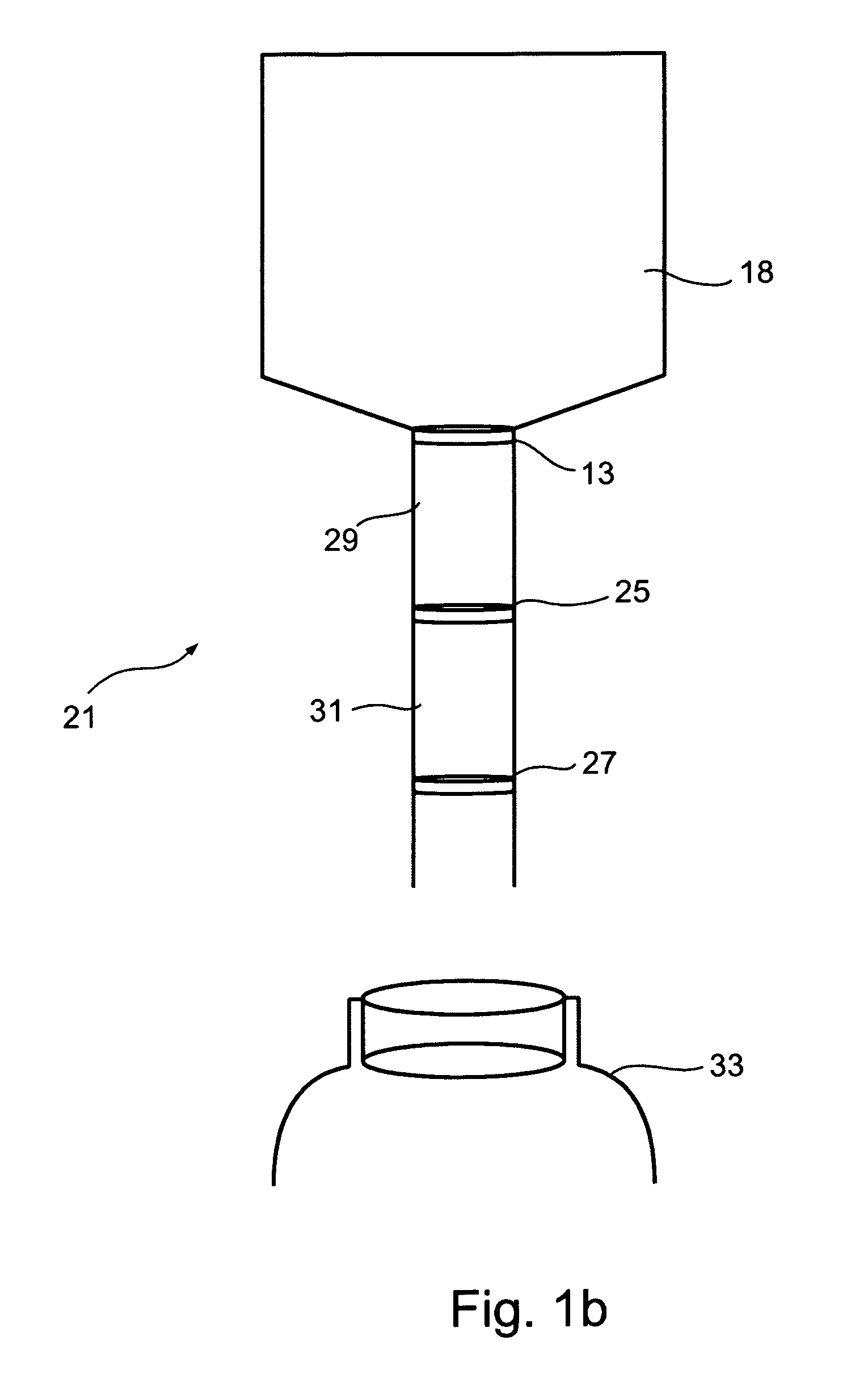

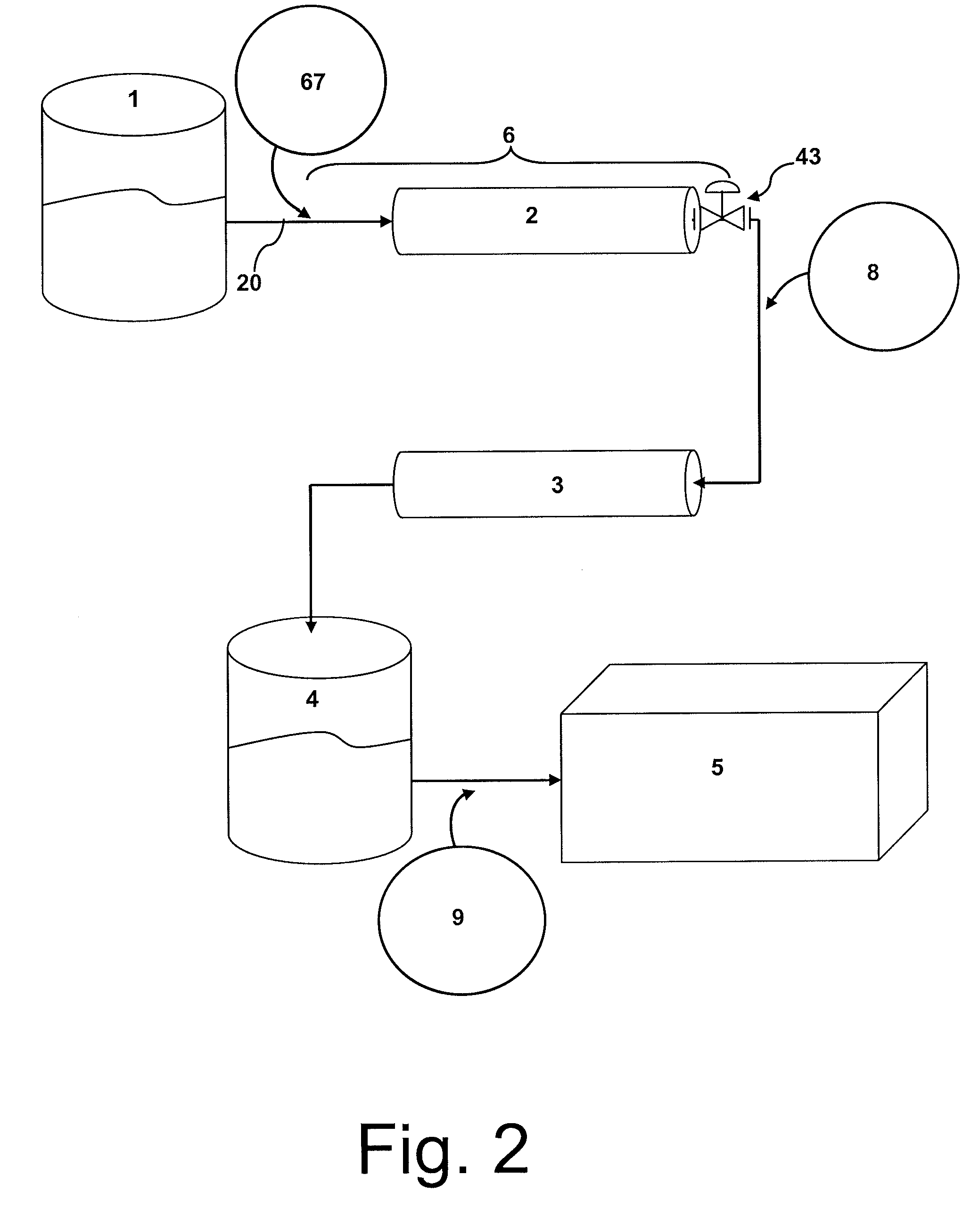

Feeding formula appliance

A device for preparing a fluid food at a desired consumption temperature on demand, comprising two reservoirs of water, a container containing a formula, a data processor and a controller for dispensing water of the correct temperature from each of the reservoirs and the formula from the container into a vessel. Also provided are methods for preparing specialized foods at desired consumption temperatures on demand, and methods for marketing both foods and food-preparation devices.

Owner:BIDERMAN EYTAN

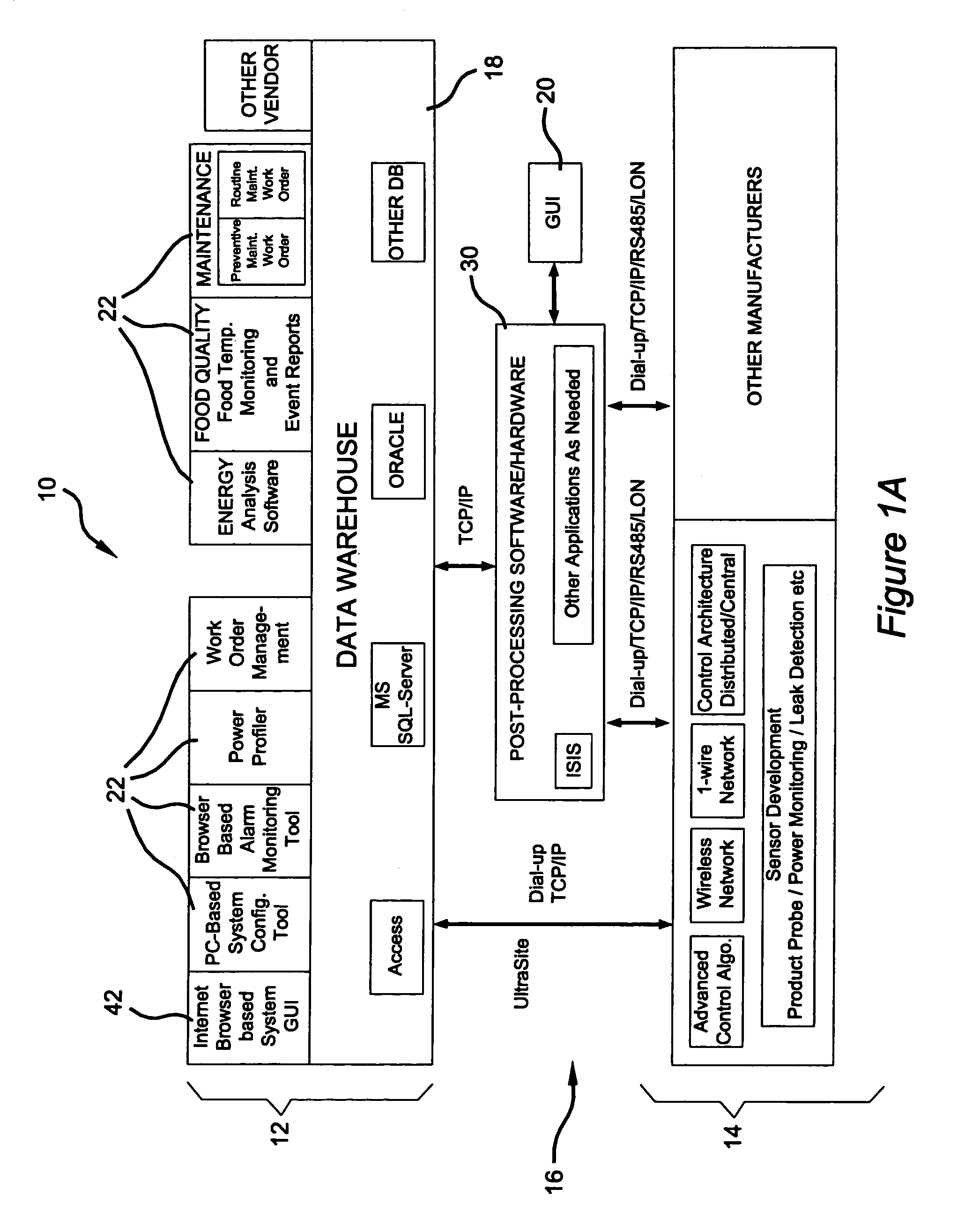

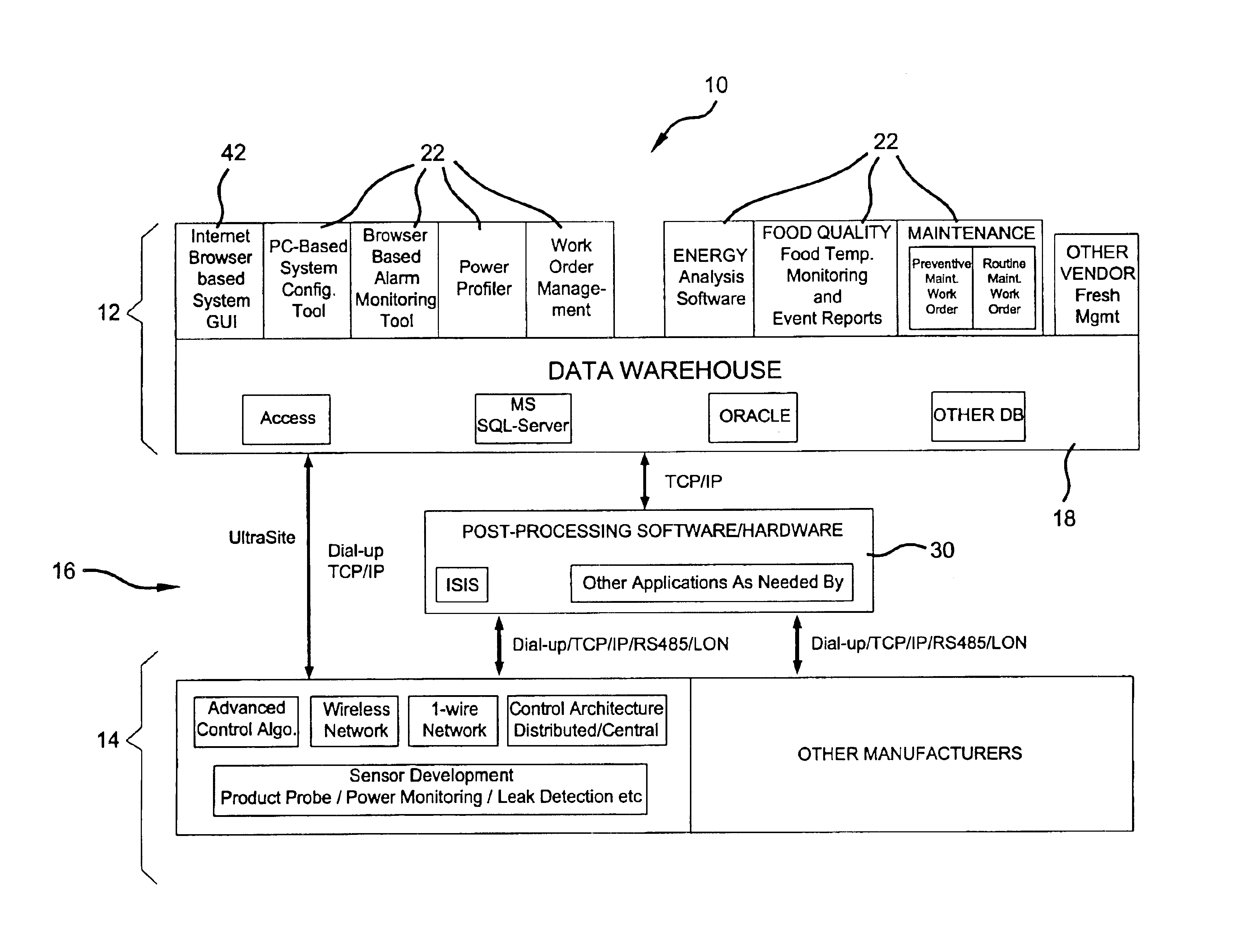

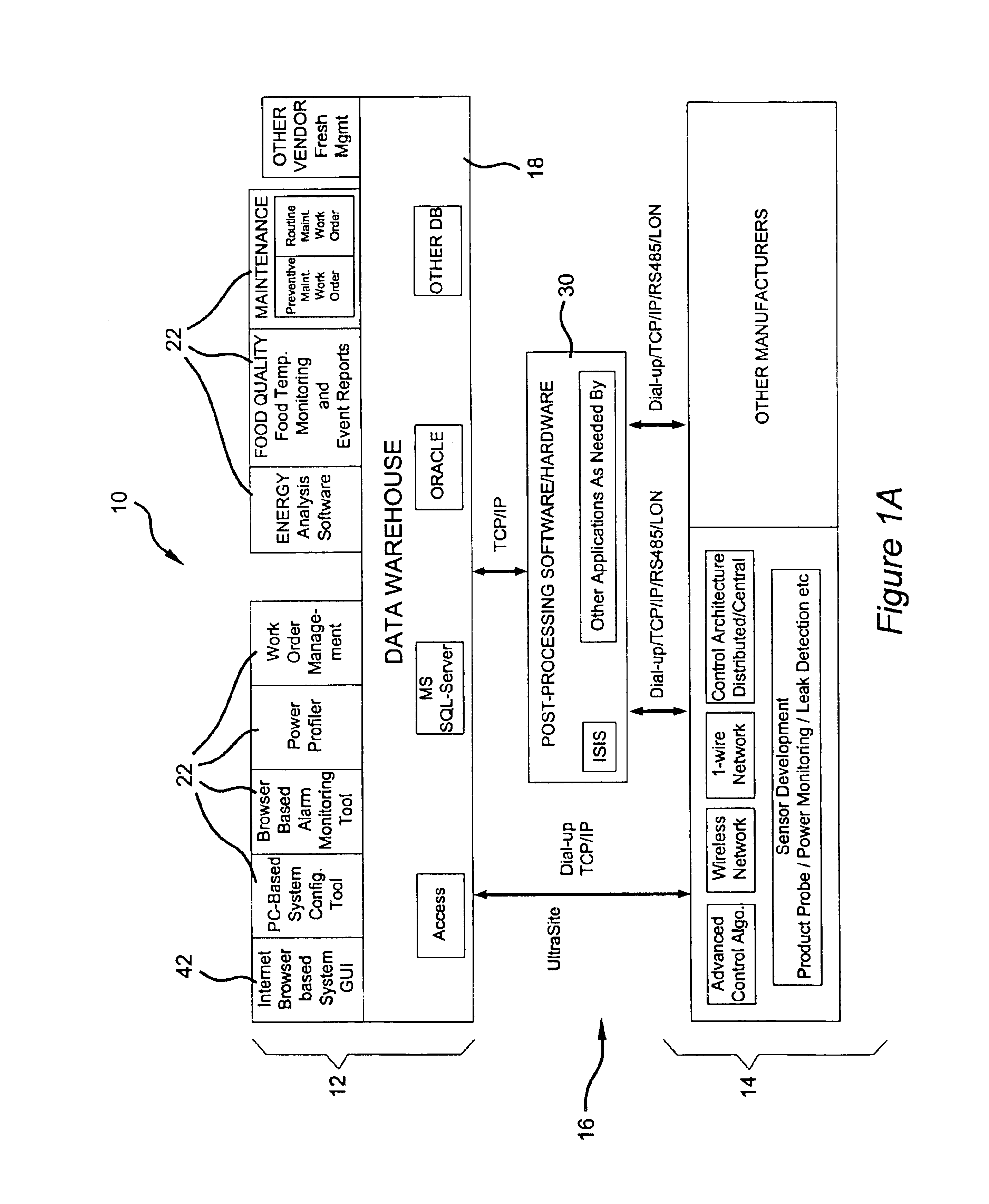

System for remote refrigeration monitoring and diagnostics

A system and method for monitoring the food product and refrigeration system performance of a remote location includes a management center in communication with a remote location through a communication network. The management center receives performance information of the refrigeration system at a remote location. The management center employs software modules to analyze the performance information, diagnose system conditions, and provide alarms for food safety and quality issues, refrigeration system component failure, and indicate maintenance conditions.

Owner:COPELAND COLD CHAIN LP

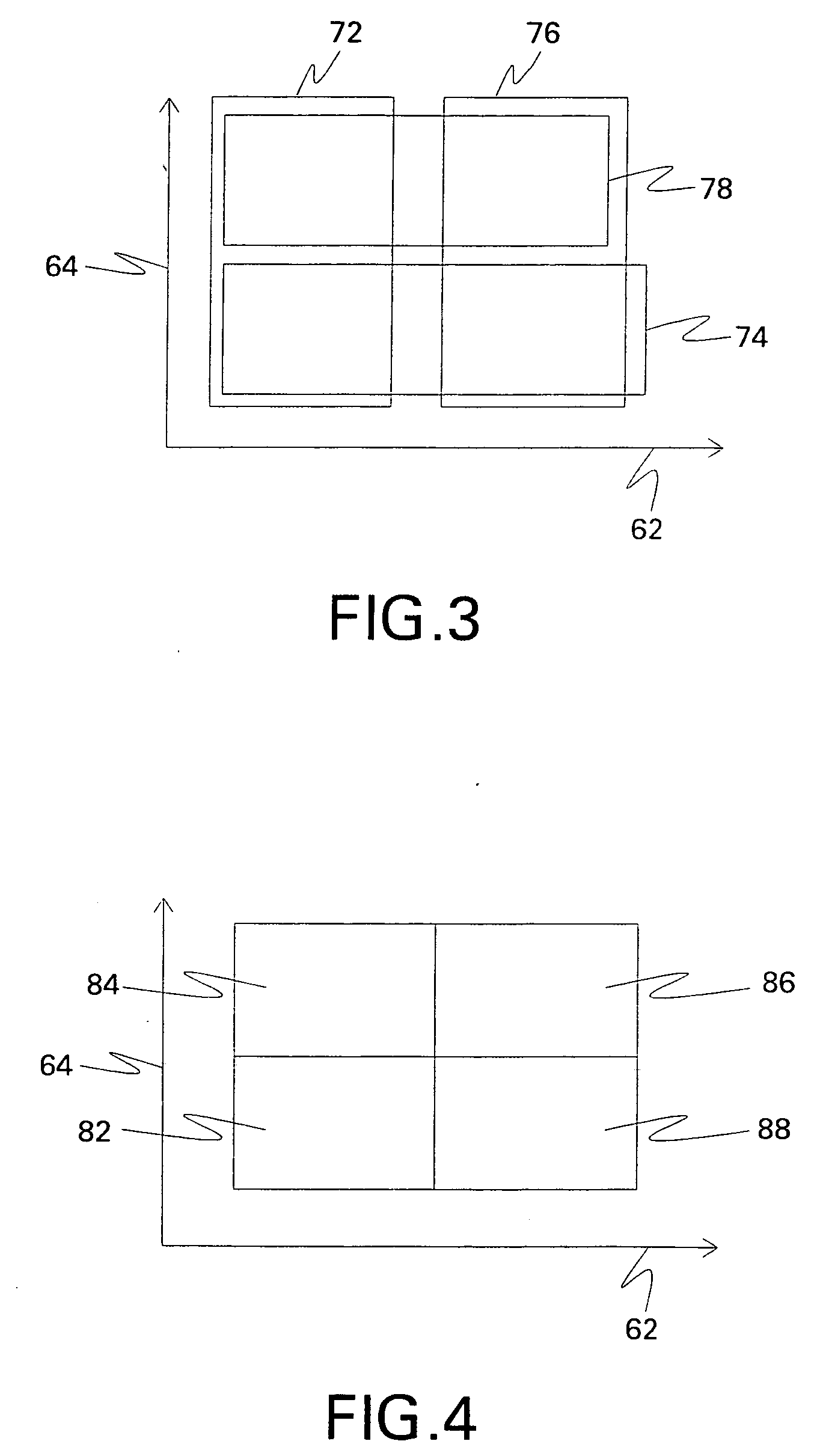

Food preparation

ActiveUS20090236335A1Improve efficiencyIncrease net powerContainer decorationsLevel indicationsEngineeringIngested food

Owner:JOLIET 2010 LTD

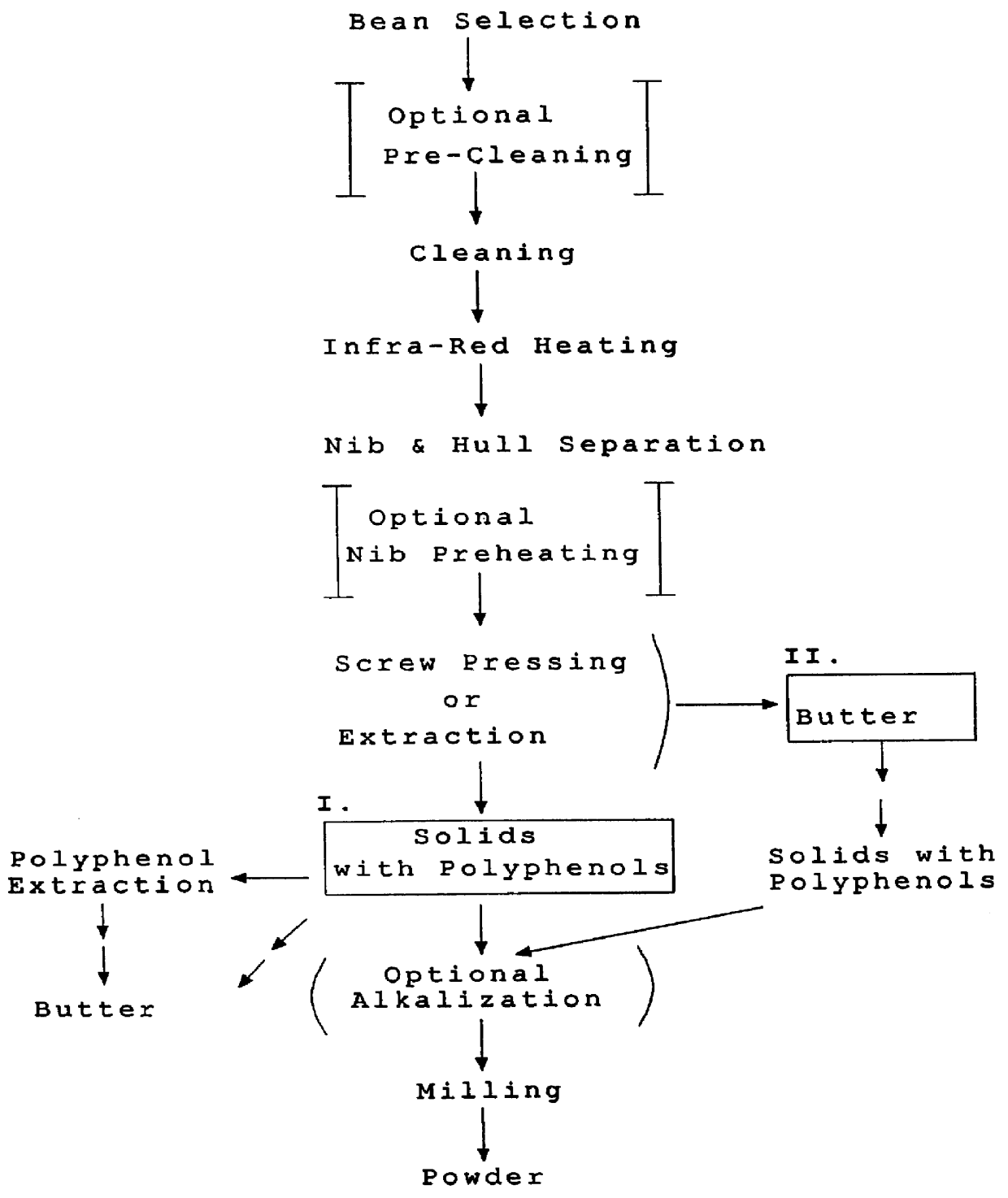

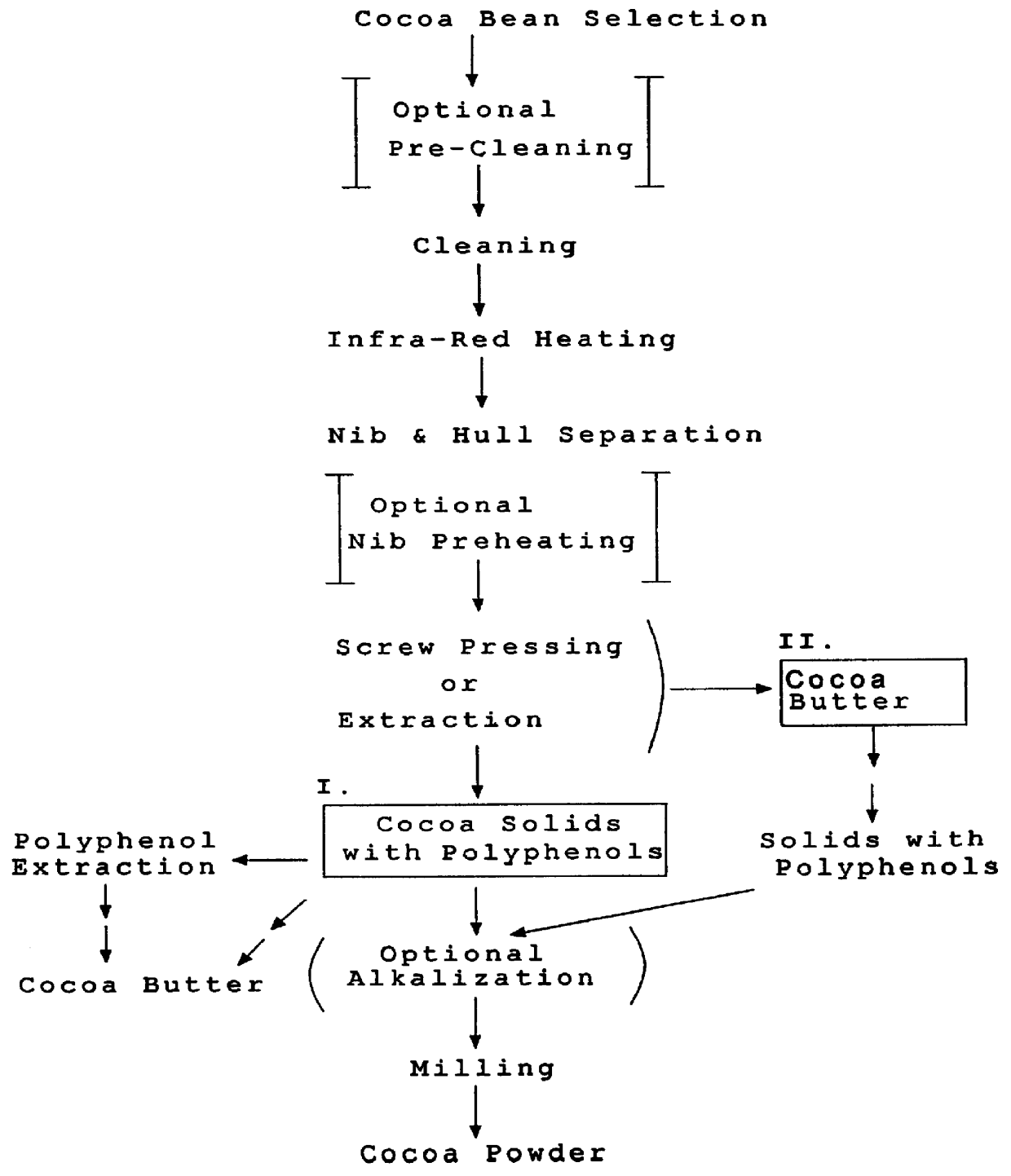

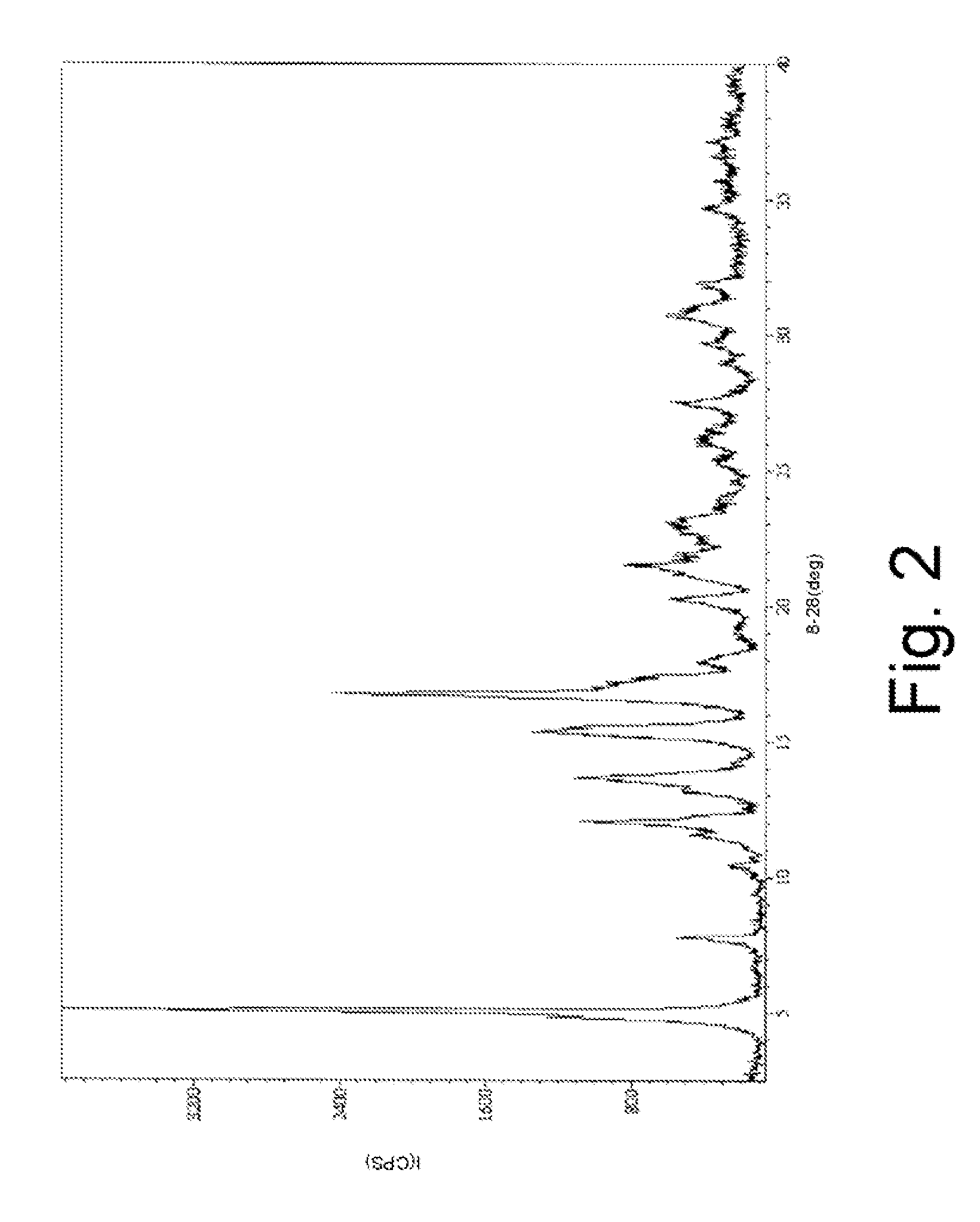

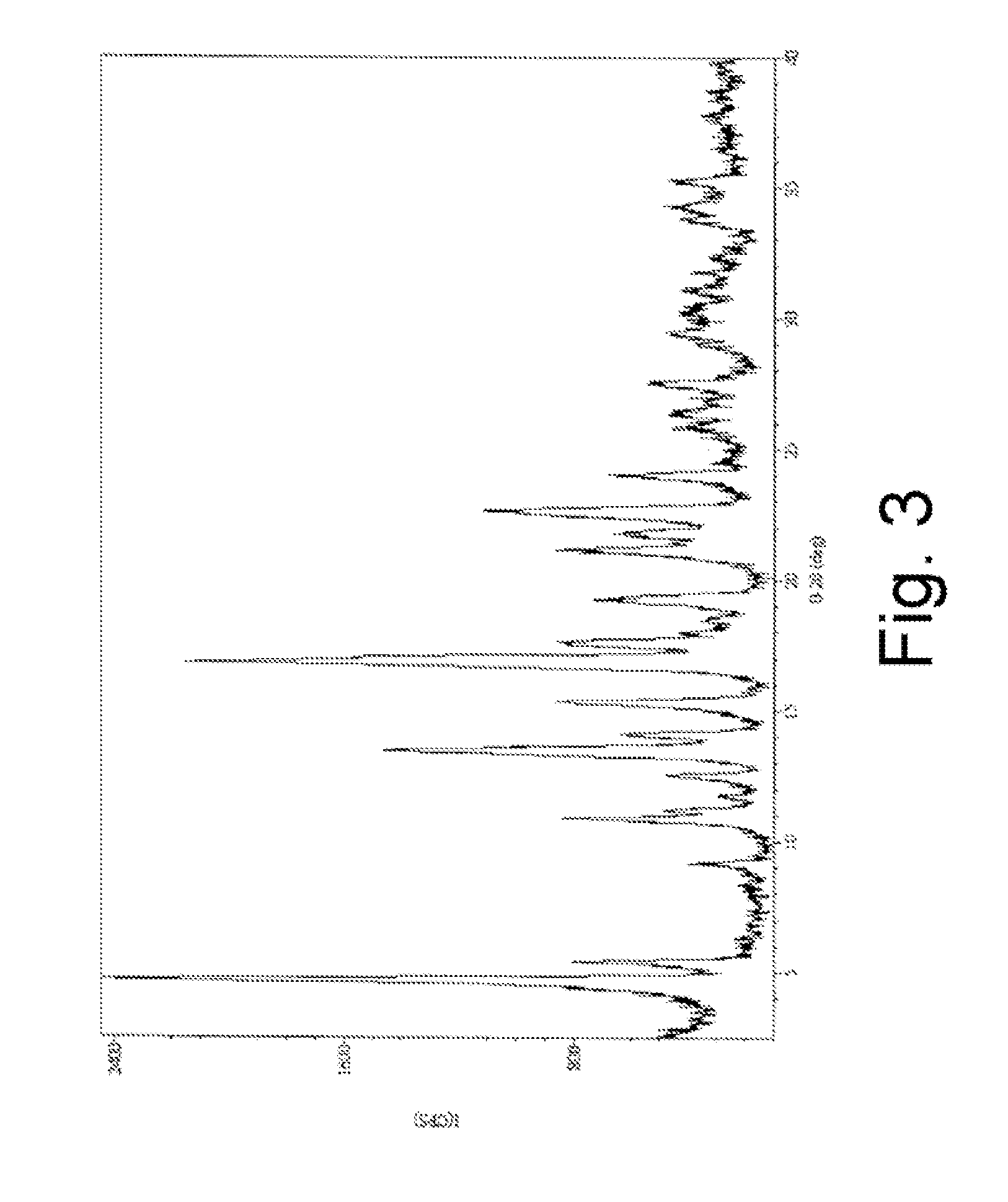

Method for producing fat and/or solids from cocoa beans

InactiveUS6015913AHighly conserved levelReduce moisture contentBiocideDough treatmentPolyphenolCOCOA BEAN

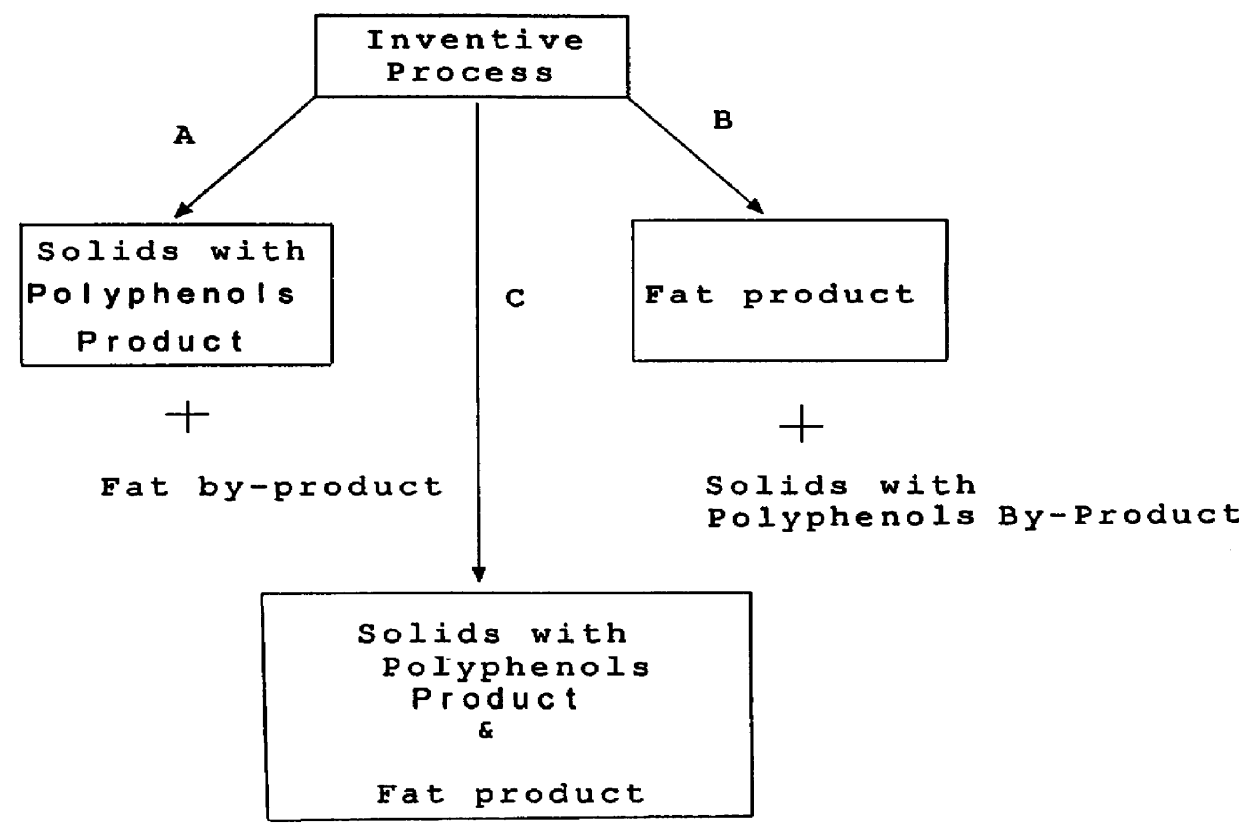

The present invention is directed to a method of processing a fat-containing bean, e.g., cocoa beans, for producing solids comprising active polyphenols and / or fat-containing products, comprising extracting the fat to produce solids and fat-containing products. Additionally, the inventive method also provides cocoa compositions comprising at least one active polyphenol, wherein the concentration of the polyphenol(s) with respect to the nonfat solids is conserved with respect to the concentration of the active polyphenol(s) in the bean from which the compositions are derived.

Owner:MARS INC +1

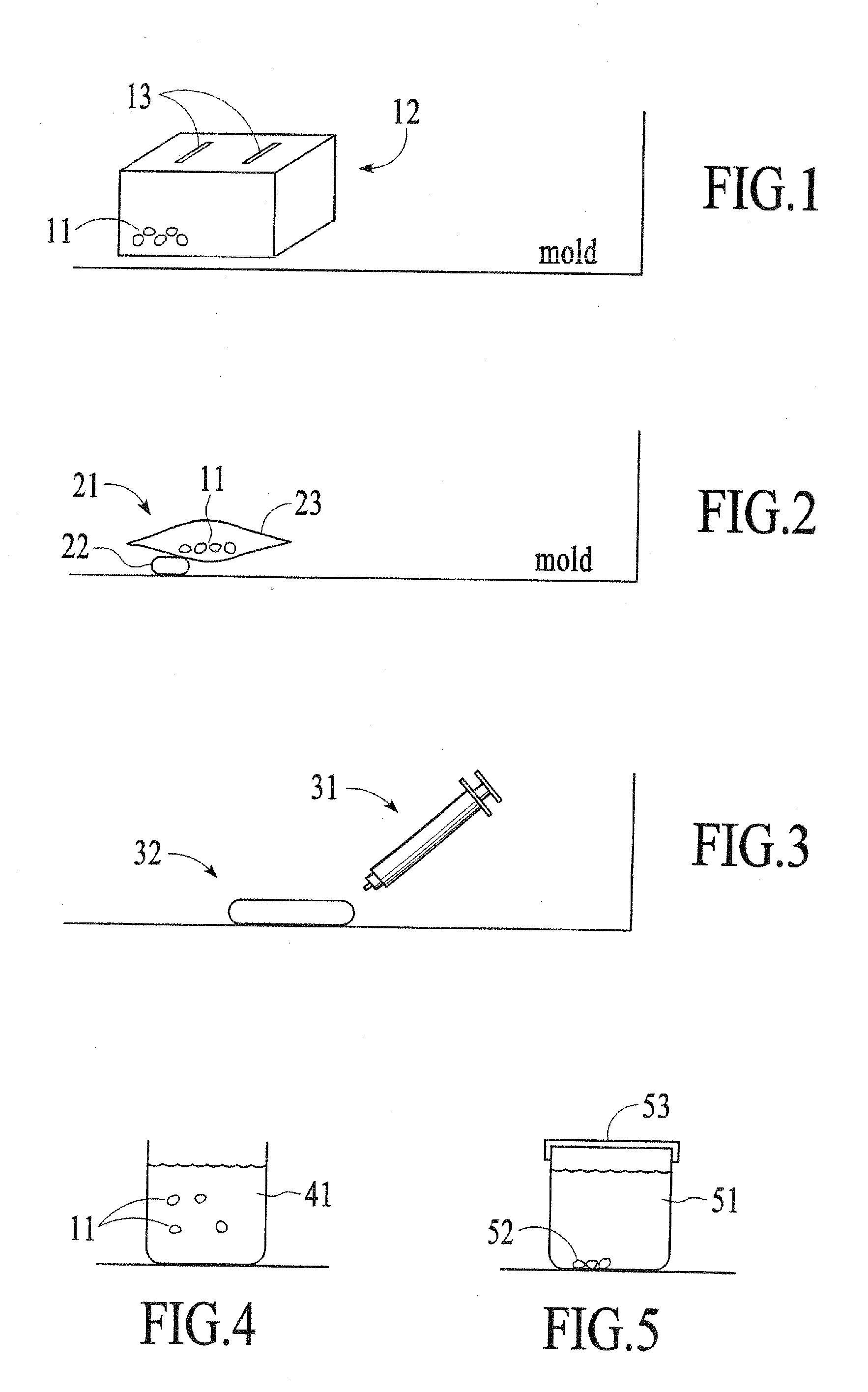

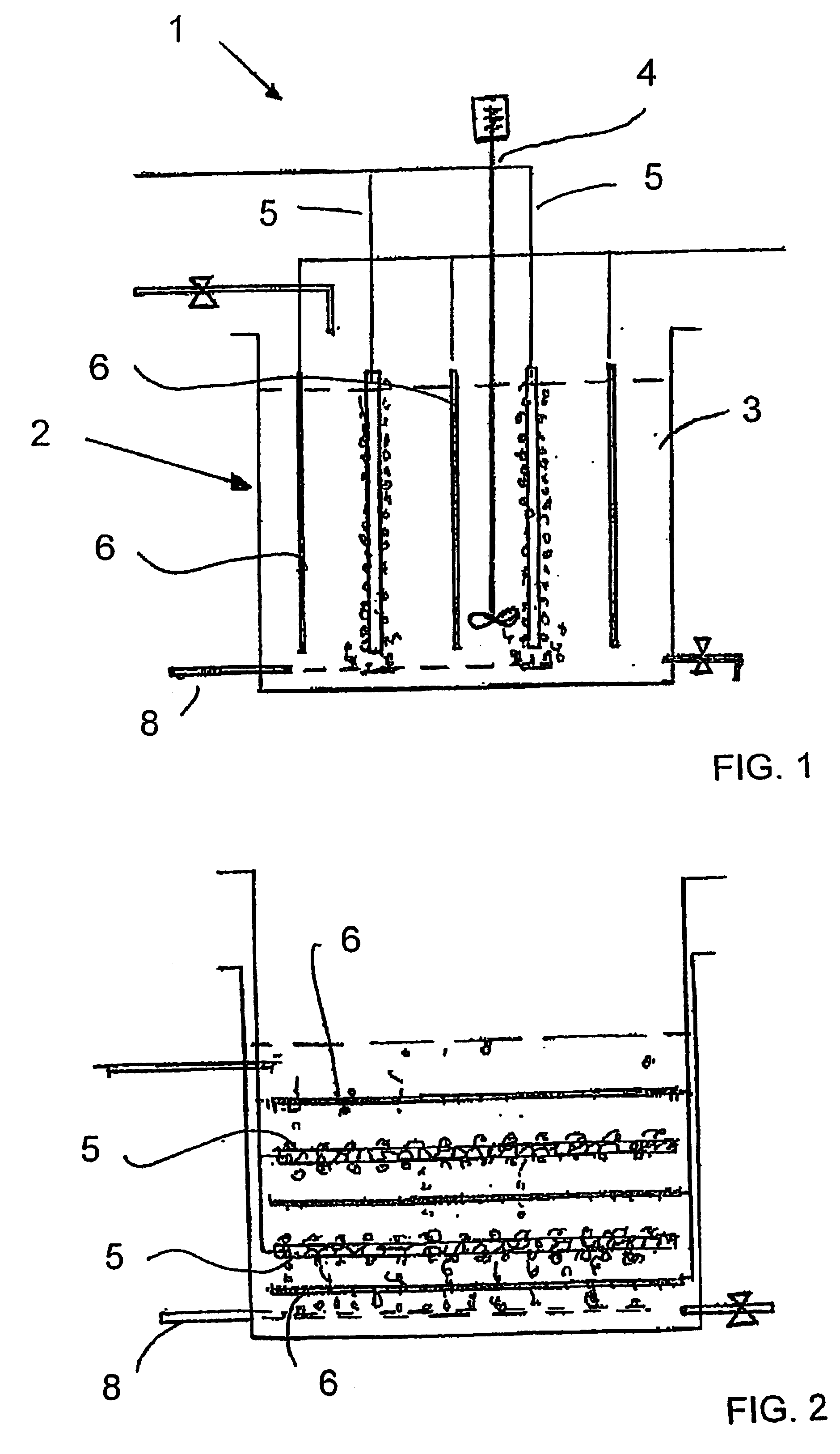

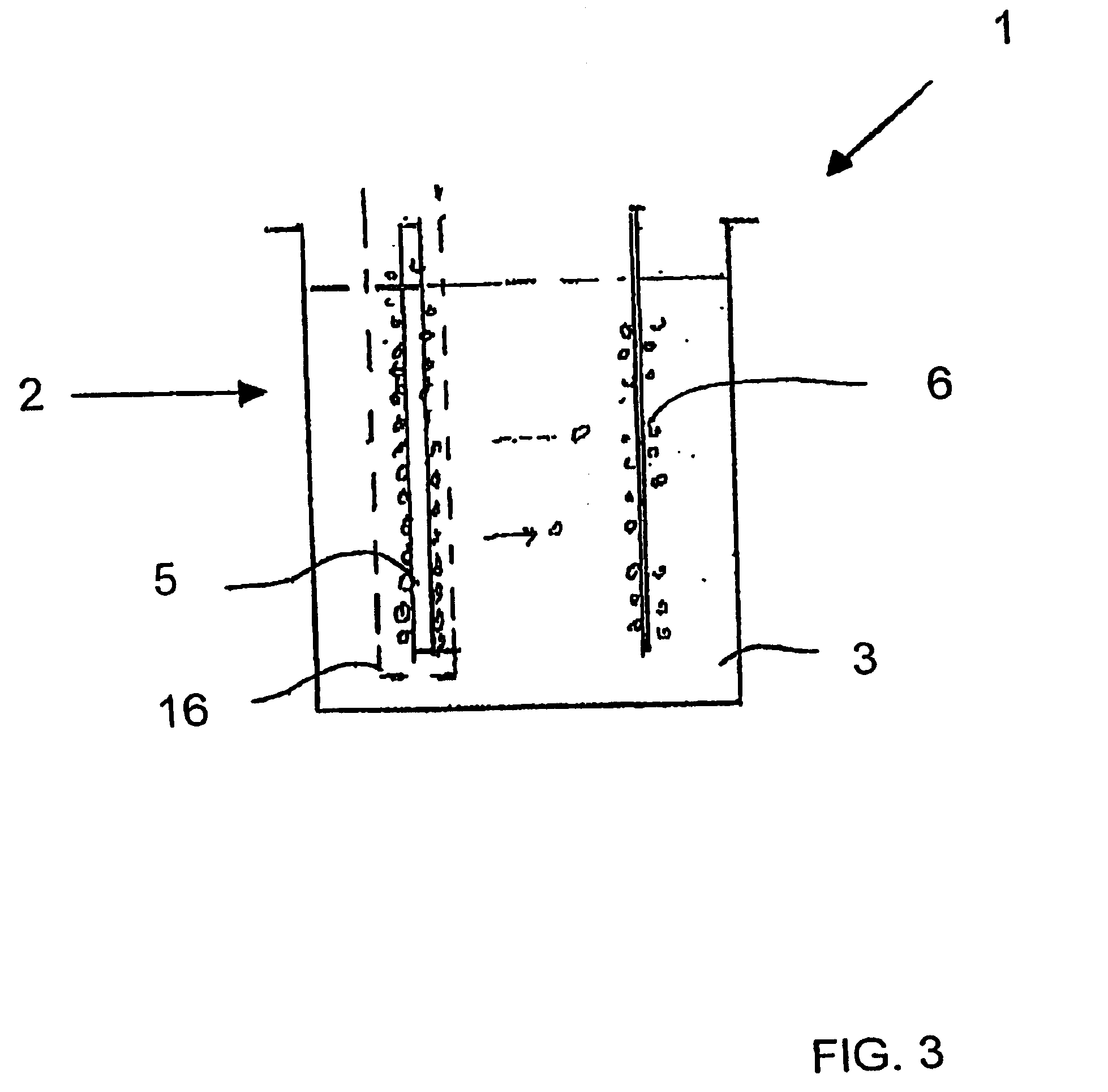

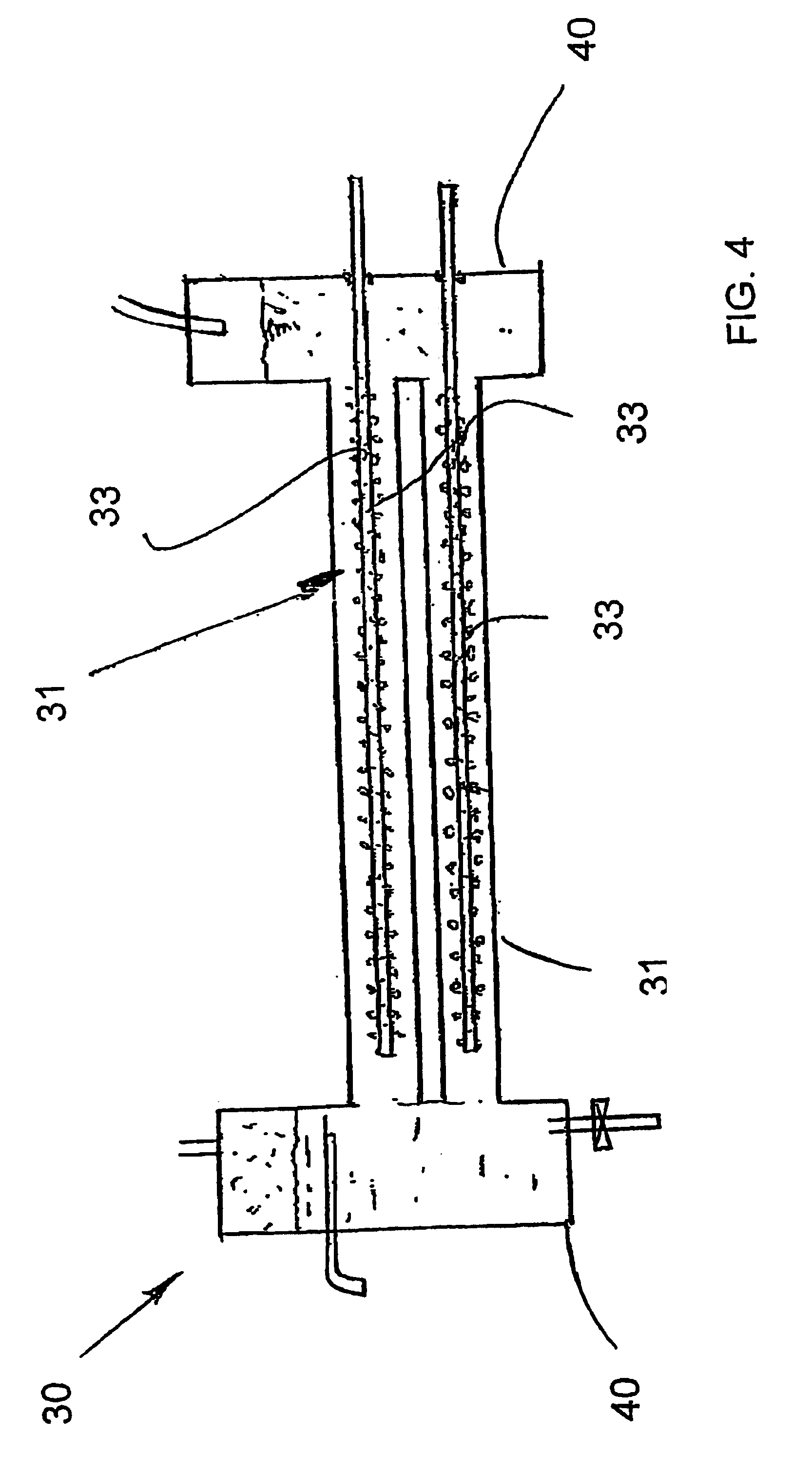

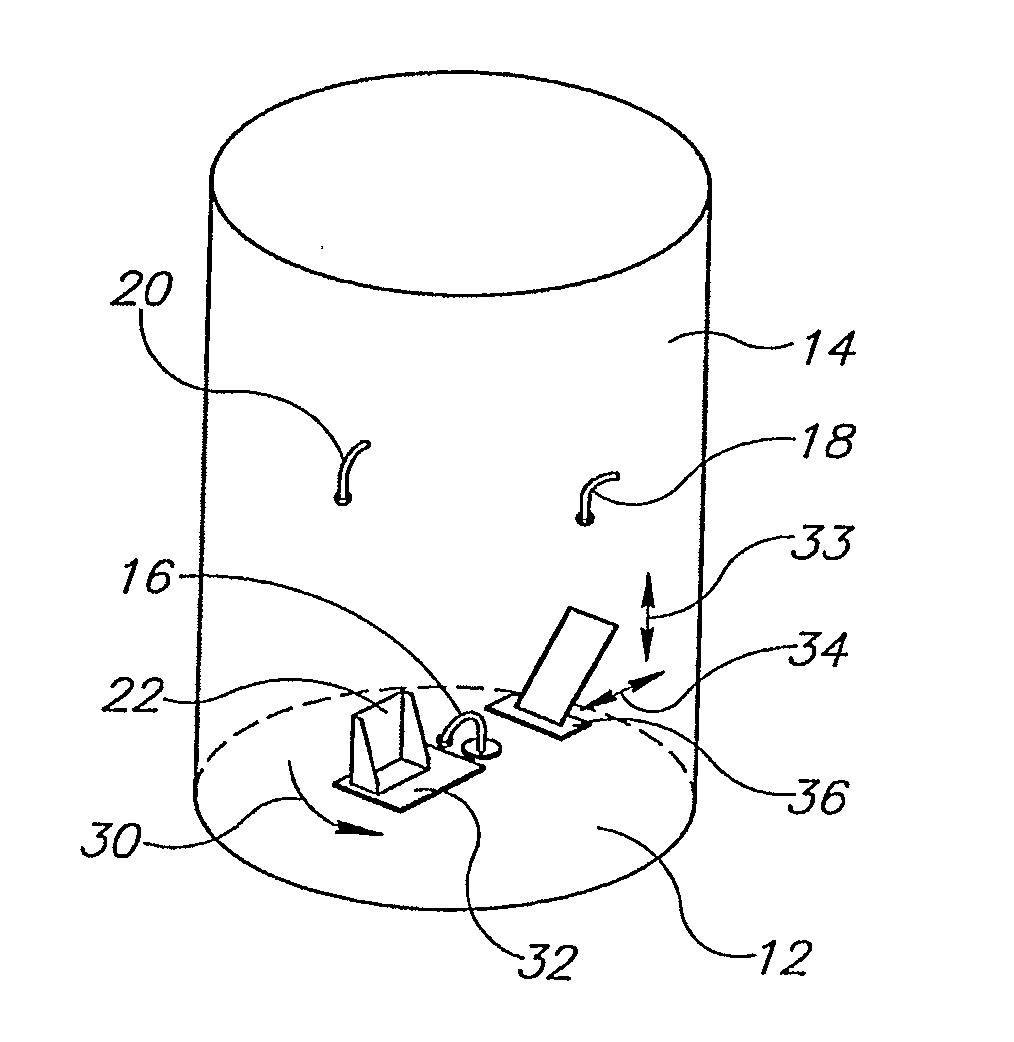

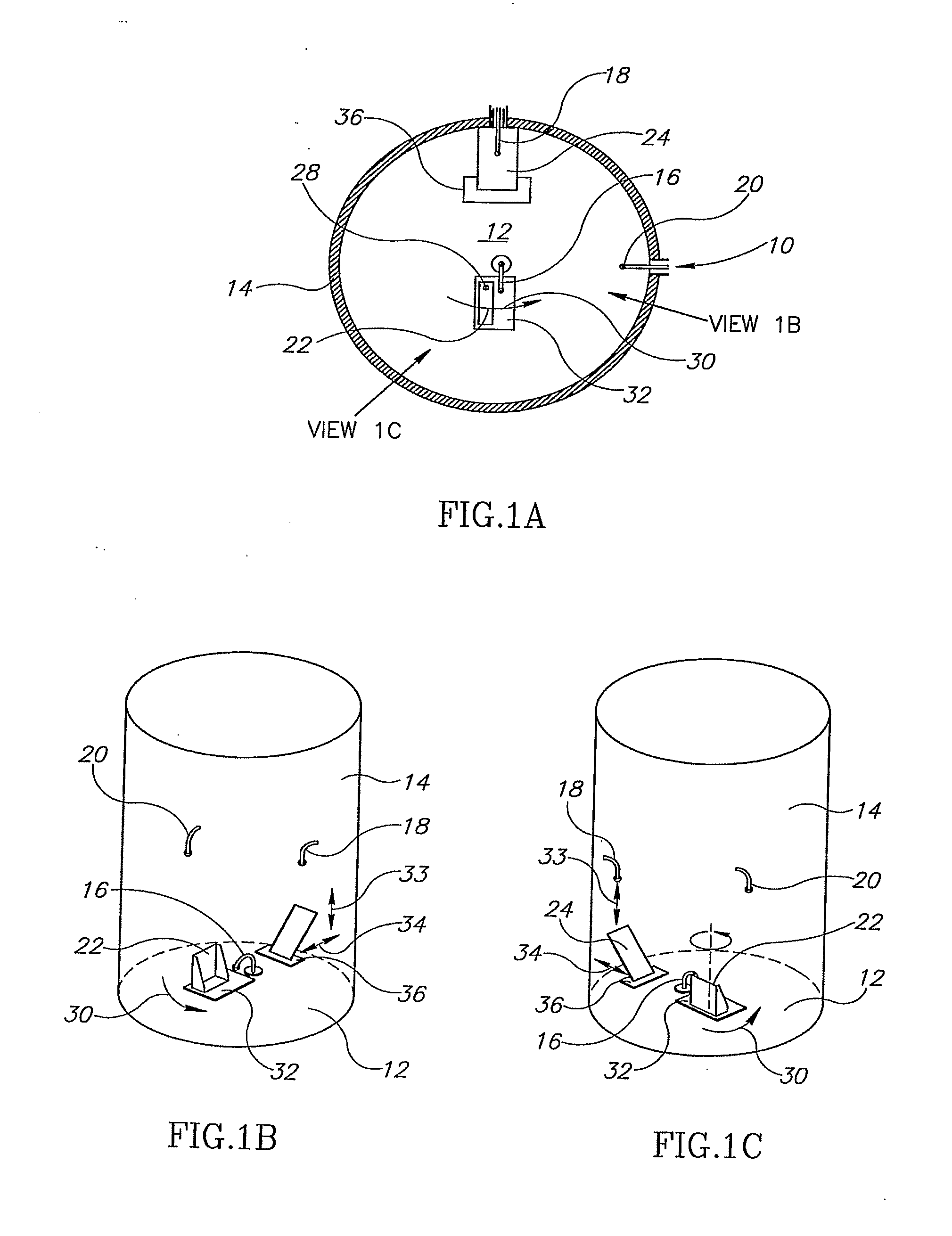

Plasma formed in a fluid

InactiveUS20060060464A1BuildEfficient electrolysisHydrogenWater/sewage treatment by irradiationElectrolysisPotential difference

A method and apparatus for generating plasma in a fluid. The fluid (3) is placed in a bath (2) having a pair of spaced electrodes (4, 6) forming a cathode and an anode. A stream of bubbles is introduced or generated within the fluid adjacent to the cathode. A potential difference is applied across the cathode and anode such that a glow discharge is formed in the bubble region and a plasma of ionized gas molecules is formed within the bubbles. The plasma may then be used in electrolysis, gas production, effluent treatment or sterilization, mineral extraction, production of nanoparticles or material enhancement. The method can be carried out at atmospheric pressure and room temperature. The electrodes may carry means to trap the bubbles in close proximity. Partitions may be present between the electrodes.

Owner:CHANG CHAK MAN THOMAS

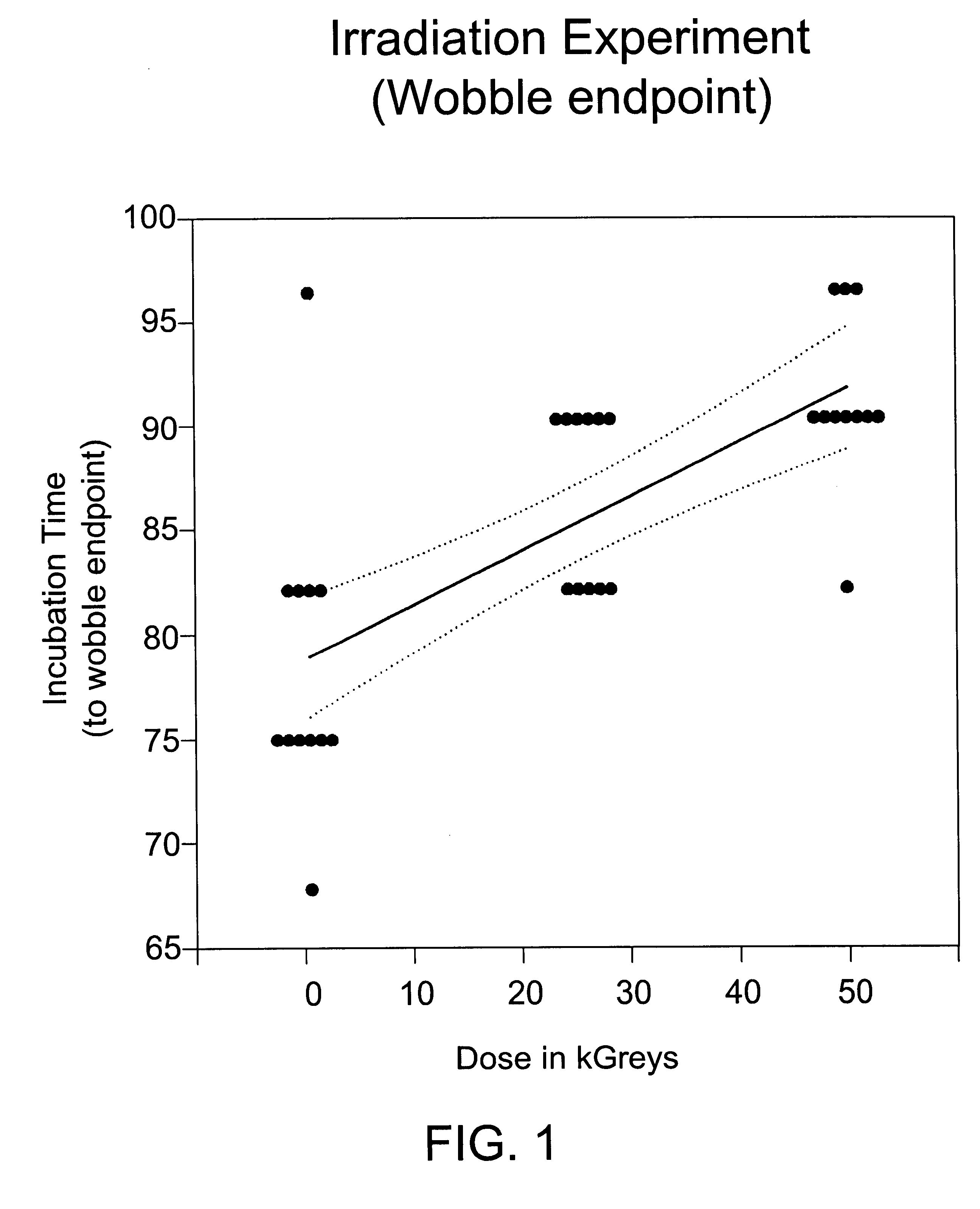

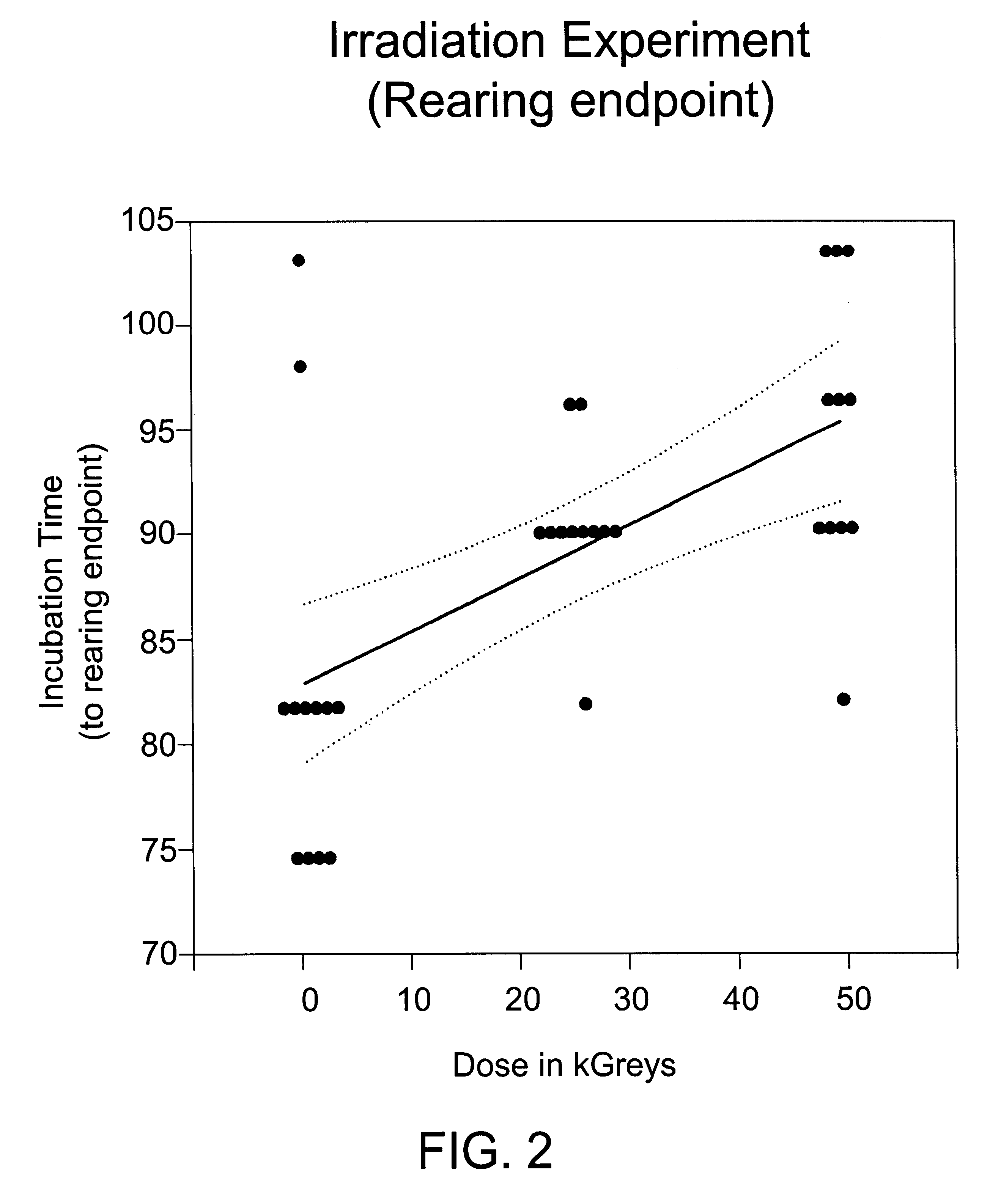

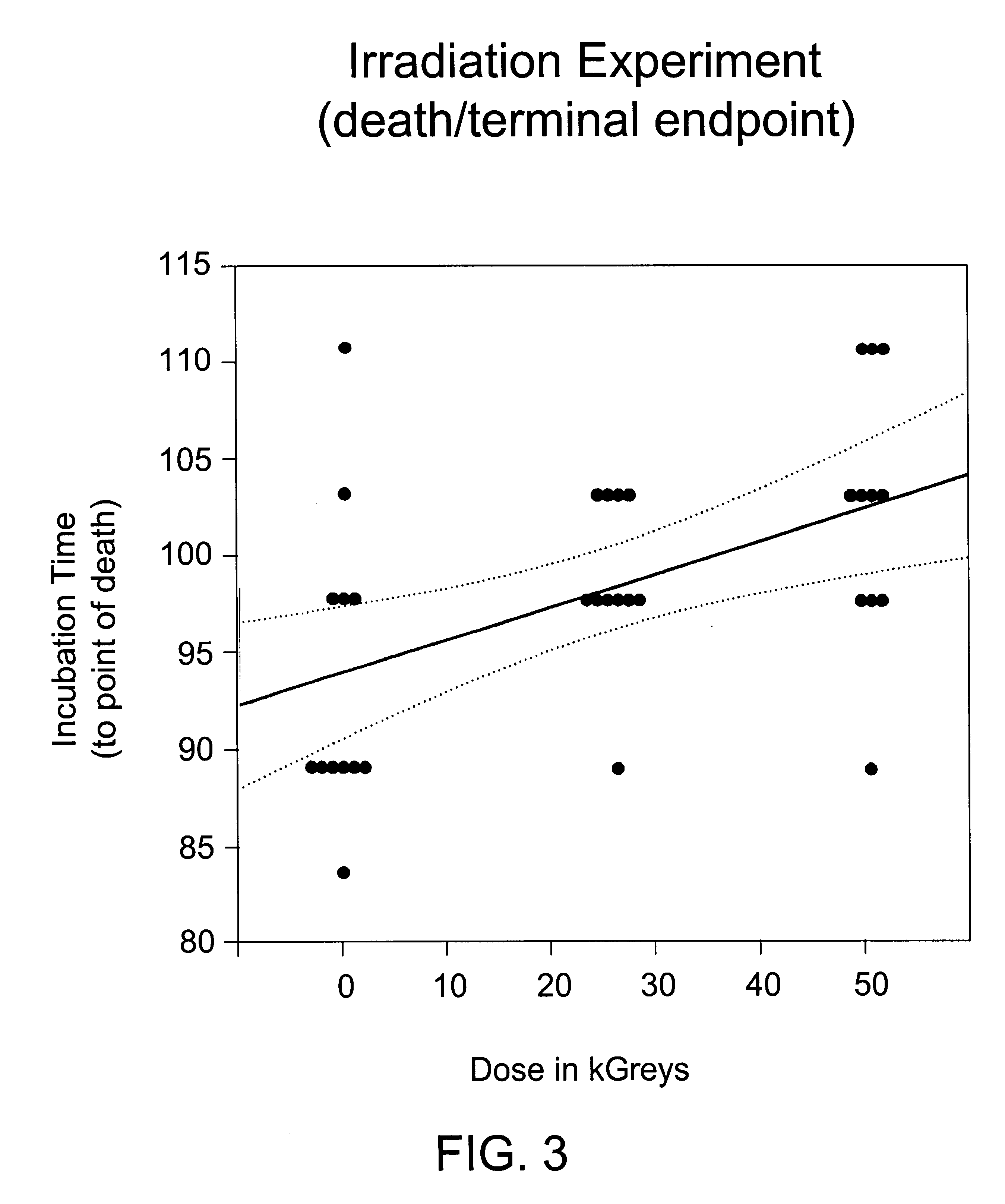

Methods for sterilizing biological materials

InactiveUS6946098B2Lowered residual solventReduce the temperatureOther blood circulation devicesFood preservationBiochemistryBiological materials

Methods are disclosed for sterilizing biological materials to reduce the level therein of one or more biological contaminants or pathogens, such as prions, responsible for the disease states known as transmissible spongiform encephalopathies (TSEs) in mammals. These methods involve sterilizing biological materials with irradiation.

Owner:CLEARANT

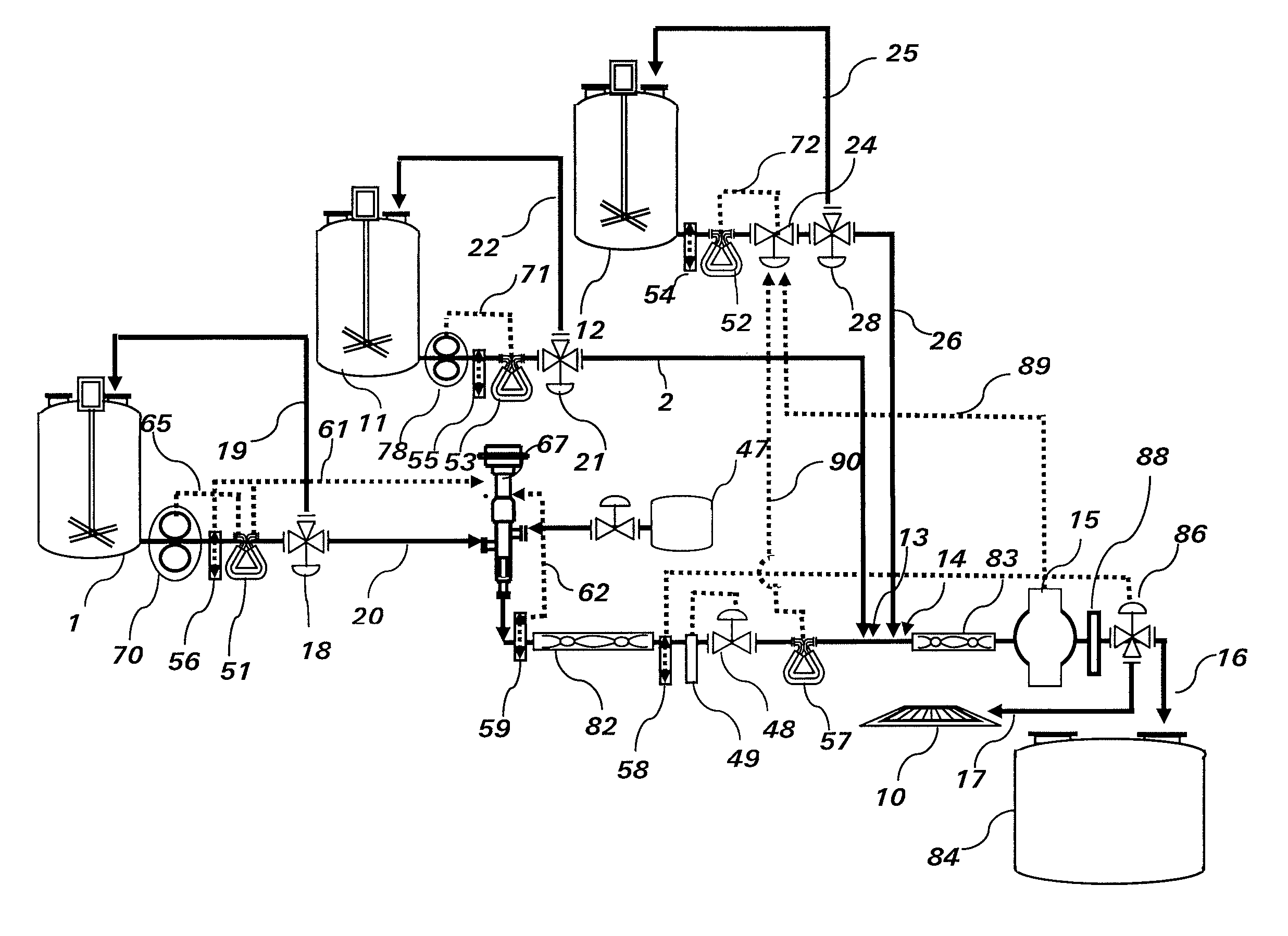

Sterilization of Flowable Food Products

InactiveUS20080160149A1Prevent degradationExtend heating timeCombination devicesAuxillary pretreatmentSporeAlicyclobacillus acidoterrestris

Methods of beverage and flowable food product production using steam injection are provided to efficiently destroy microorganisms able to withstand normal pasteurization temperatures. Microorganisms such as Alicyclobacillus acidoterrestris and its spores may be eliminated from fruit juices and the like while minimizing organoleptic degradation due to heating. The apparatus is capable of pasteurizing, blending and controlling the product specifications of a finished beverage in a continuous matter.

Owner:KRAFT FOODS GLOBAL BRANDS LLC

Protein beverage and protein beverage concentrate and methods of making the same

An improved protein beverage which may provide a relatively high protein content, ranging from about 0.01% by weight to about 15% by weight, while optionally employing a carbonation concentration between about 0.1 volumes of carbonation (per volume of liquid drink) to about 6 volumes of carbonation. Preferably the protein is a protein, such preferably as whey protein, or others. The protein beverage may contain juice and / or an additive which provides energy generation enhancement. The protein beverage may be heat treated to inactivate pathogenic microbes in the presence of the carbonation which may be used to provide taste and mouth feel for the drink. Typically, the treatment for pathogenic microbe inactivation is carried out in the individual package used for storage and handling of the protein drink. The protein beverage may be prepared from a protein beverage concentrate, which may be in the form of a syrup concentrate or a powder concentrate.

Owner:DAVINAS LLC

Food preparation

ActiveUS20090236333A1Improve efficiencyIncrease net powerContainer decorationsLevel indicationsEngineeringIngested food

Owner:JOLIET 2010 LTD

Microbial decontamination of food

InactiveUS6165526AShorten treatment timeEliminate areaMilk preparationDough treatmentMicroorganismEngineering

PCT No. PCT / GB98 / 02840 Sec. 371 Date Jul. 14, 1999 Sec. 102(e) Date Jul. 14, 1999 PCT Filed Sep. 18, 1998 PCT Pub. No. WO99 / 13741 PCT Pub. Date Mar. 25, 1999Food is rendered sterile by UV irradiation, preferably with UV at 265+ / -15 nm. A sterilization unit may include UV sources (90, 100, 110, 120) and a heat source, which may be a broad band UV source, a source of IR or microwave radiation. A combined microwave / UV unit can be used to defrost frozen food and simultaneously sterilize it or maintain sterility. Heating prior to UV irradiation can enhance the sterilization, as can rapid cooling after irradiation. Irradiation can also be enhanced by displacing the food during irradiation e.g. by supporting it on a rotatable support (135) and / or by displacing it relative to the support surface.

Owner:NEWMAN PAUL BERNARD

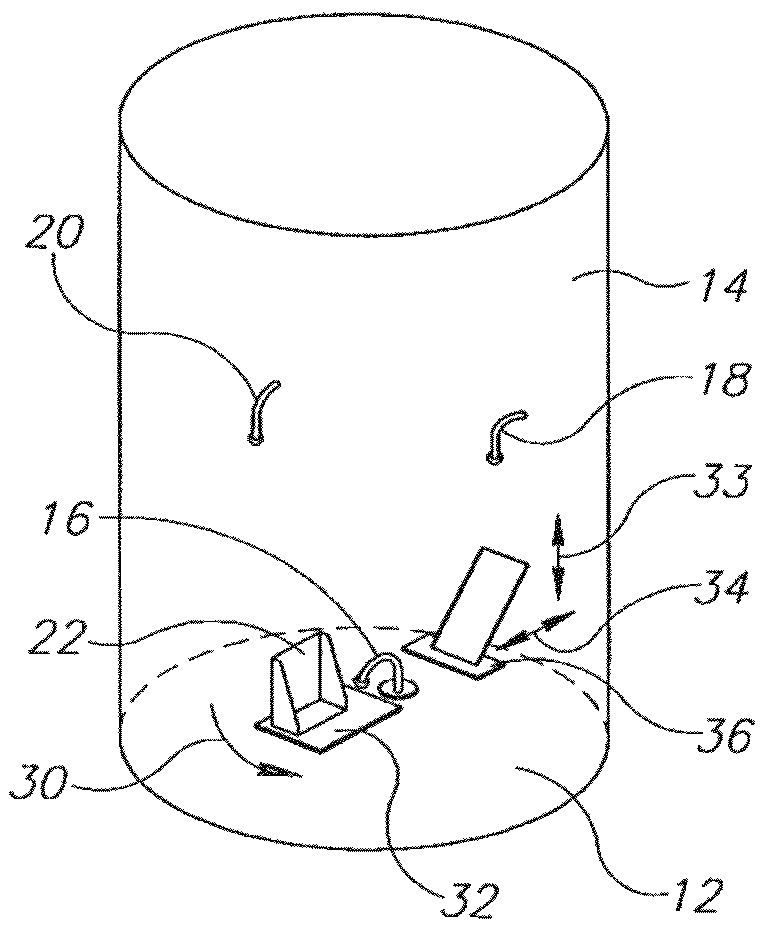

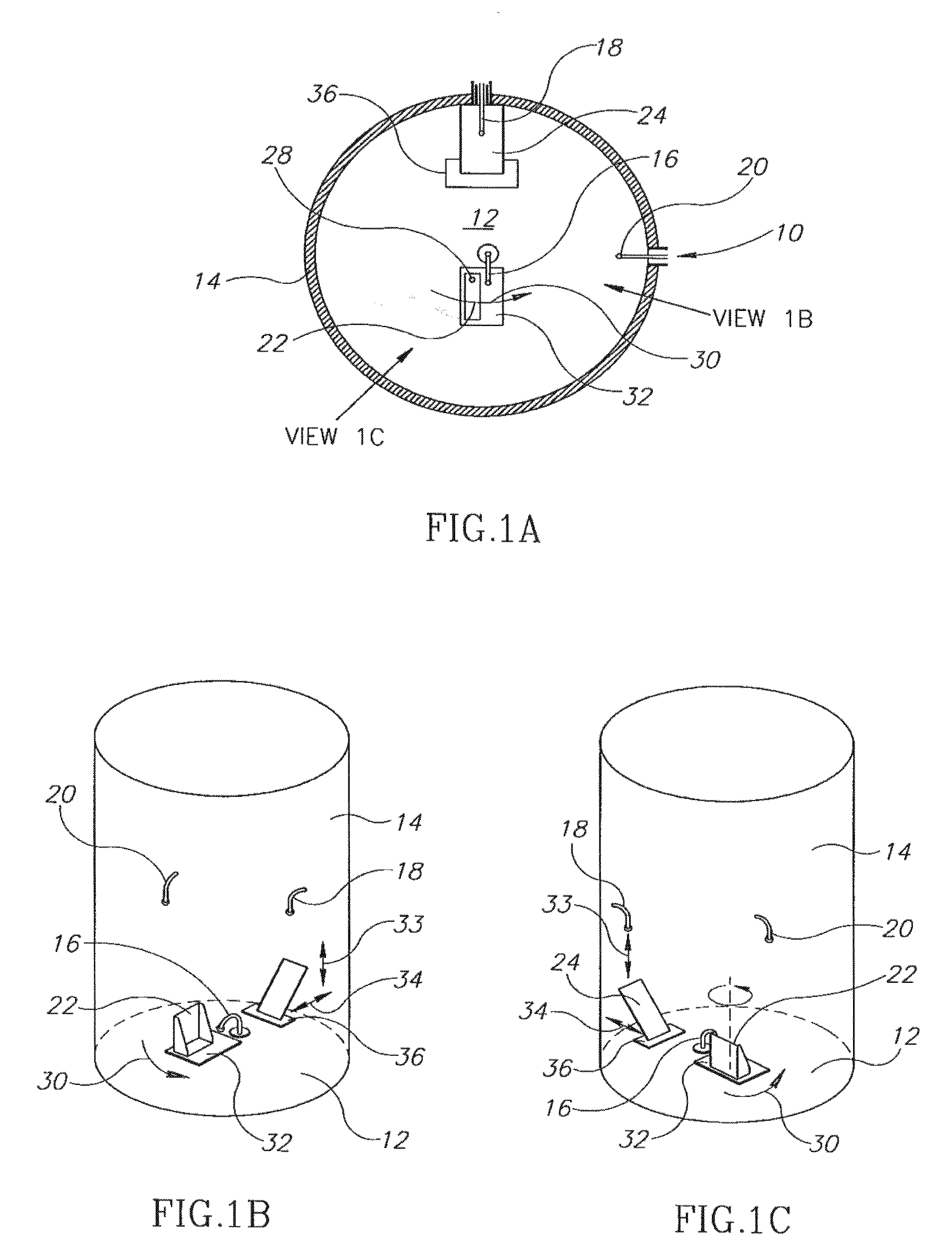

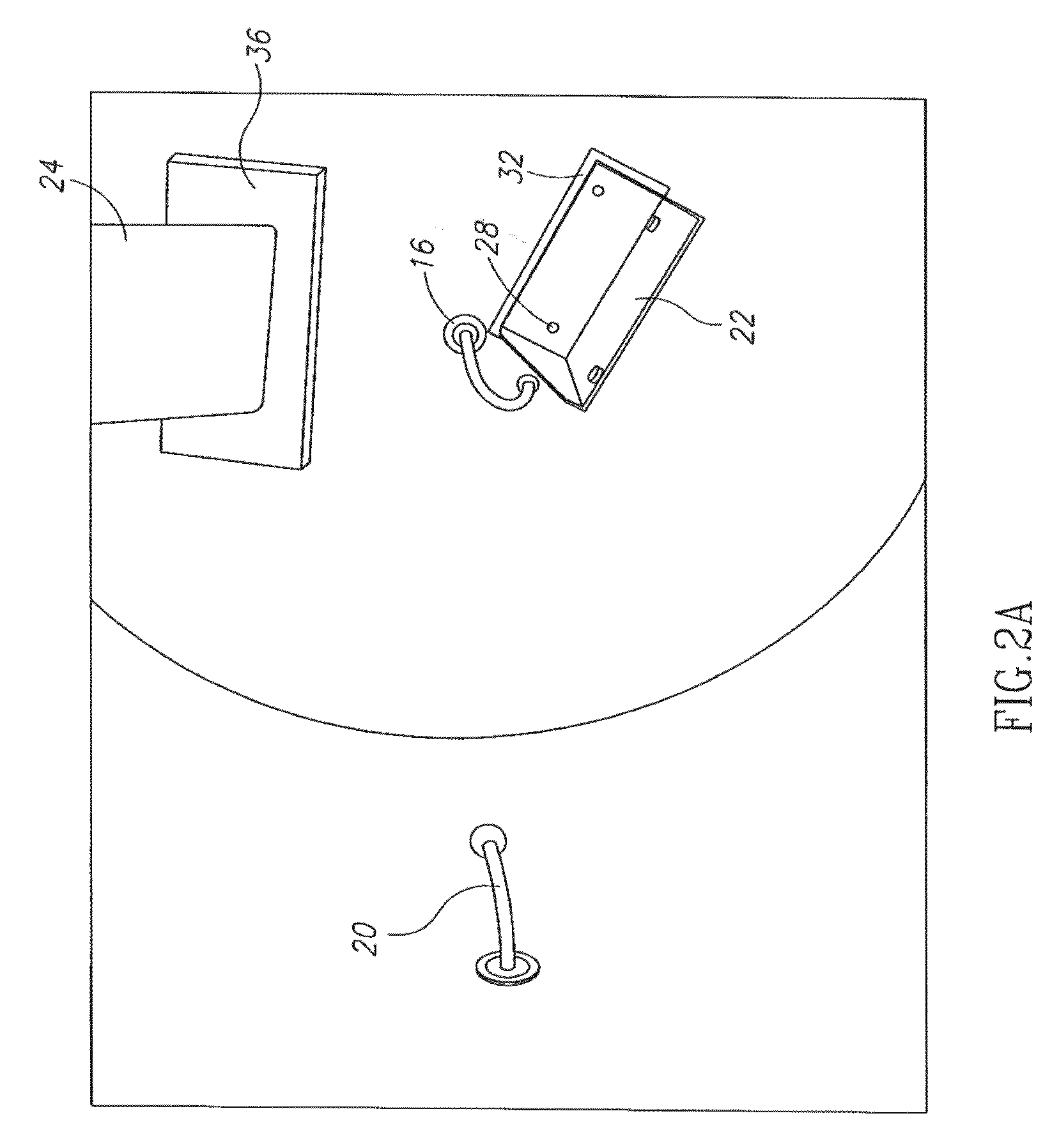

System and method for preserving food

System and method for preserving food. Embodiments of the system include a food compartment to store food and a user interface configured to receive user input relating to the preservation of the food stored. The system also includes a humidity sensor configured to sense a humidity level, an ozone generator configured to generate ozone gas, an ozone sensor configured to sense an ozone level and a gas sensor configured to sense a level of residual gases inside the food compartment. The system further includes a controller, responsive to the user interface, the humidity sensor, the ozone sensor and the gas sensor. In one embodiment, the controller preserves the food stored in the food compartment as a function of the user input, the humidity level, the ozone level, the residual gas level and as a function of a type of the food stored in the food compartment.

Owner:HAIER US APPLIANCE SOLUTIONS INC

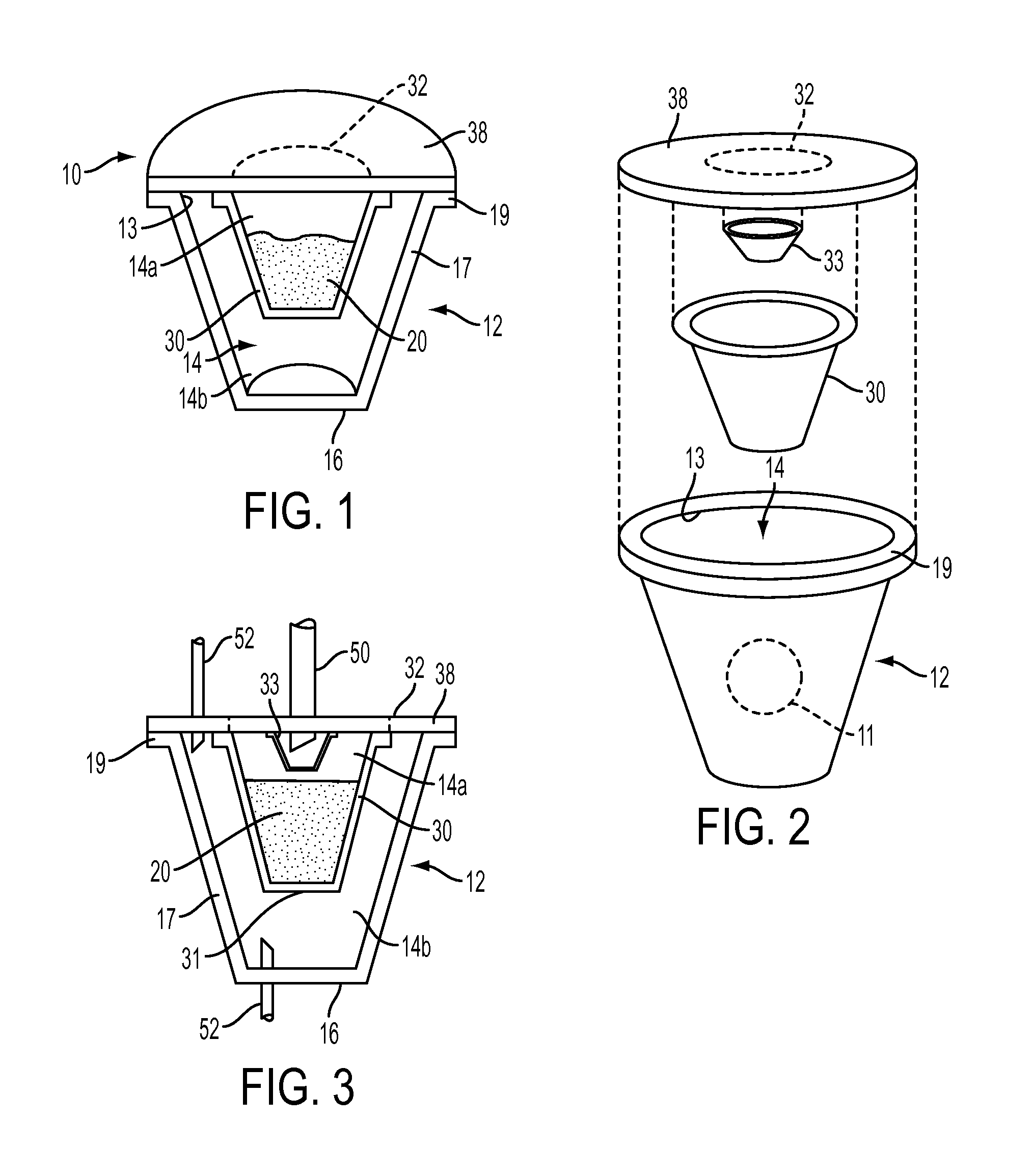

Beverage formation apparatus and method using vibratory energy

ActiveUS20120308688A1Uniform strengthQuick mixDough treatmentShaking/oscillating/vibrating mixersInterior spaceEngineering

Apparatus and method for forming beverages using a beverage cartridge and sonic energy. A cartridge may include a sonic receiver, such as a feature that extends into an interior space of the cartridge and is arranged to receive a sonic emitter that introduces sonic energy into the interior space. The sonic receiver may be excited by sonic energy, which causes the sonic receiver to itself introduce sonic energy into the cartridge.

Owner:KEURIG GREEN MOUNTAIN INC

Process of reducing fouling during heat processing of foods and beverages

InactiveUS20060240159A1Reduce dirtFood preservationPackaging protectionMethyl cellulosePasteurization

A pasteurization or sterilization process reduces fouling of a food or beverage composition containing protein during the heat treatment. An antifouling agent is added to the food or beverage composition that is selected from hydroxypropylcellulose (HPC) with a hydroxypropyl molar substitution of greater than 3.0 and a weight average molecular weight (Mw) as measured by SEC of greater than 350,000 Dalton, methylhydroxypropylcellulose (MHPC) with a methoxyl content of greater than 17% and a hydroxypropyl content of greater than 3%, methylcellulose (MC) with a methoxyl content greater than 17% and a viscosity in water at ambient temperatures and a concentration of 2% of greater than 1,000 cps, or mixtures thereof, This food or beverage composition is then heated in a first heat exchanger at a temperature between 50 and 100° C. for a time of from about 2 seconds to 30 minutes for pasteurization or it is further heated to sterilization temperatures before being packaged out or further processed. The improvements of this process is that the heat exchangers are fouled at least 10% by weight less or run-time increased at least 10% as compared to when heat-treating a similar food or beverage composition without the antifouling agent.

Owner:HERCULES INC

High-Potency Sweetener Composition With Preservative and Compositions Sweetened Therewith

ActiveUS20080108710A1Improve flavor profileImproving temporal profile profileBiocideDough treatmentPreservativeSweetness

The present invention relates generally to sweetener compositions comprising non-caloric or low-caloric high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different sweetener compositions comprising at least one non-caloric or low-caloric natural and / or synthetic high-potency sweetener, at least one sweet taste improving composition, and at least one preservative. The present invention also relates to sweetener compositions and methods that can improve the tastes of non-caloric or low-caloric natural and / or synthetic, high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the sweetener compositions and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

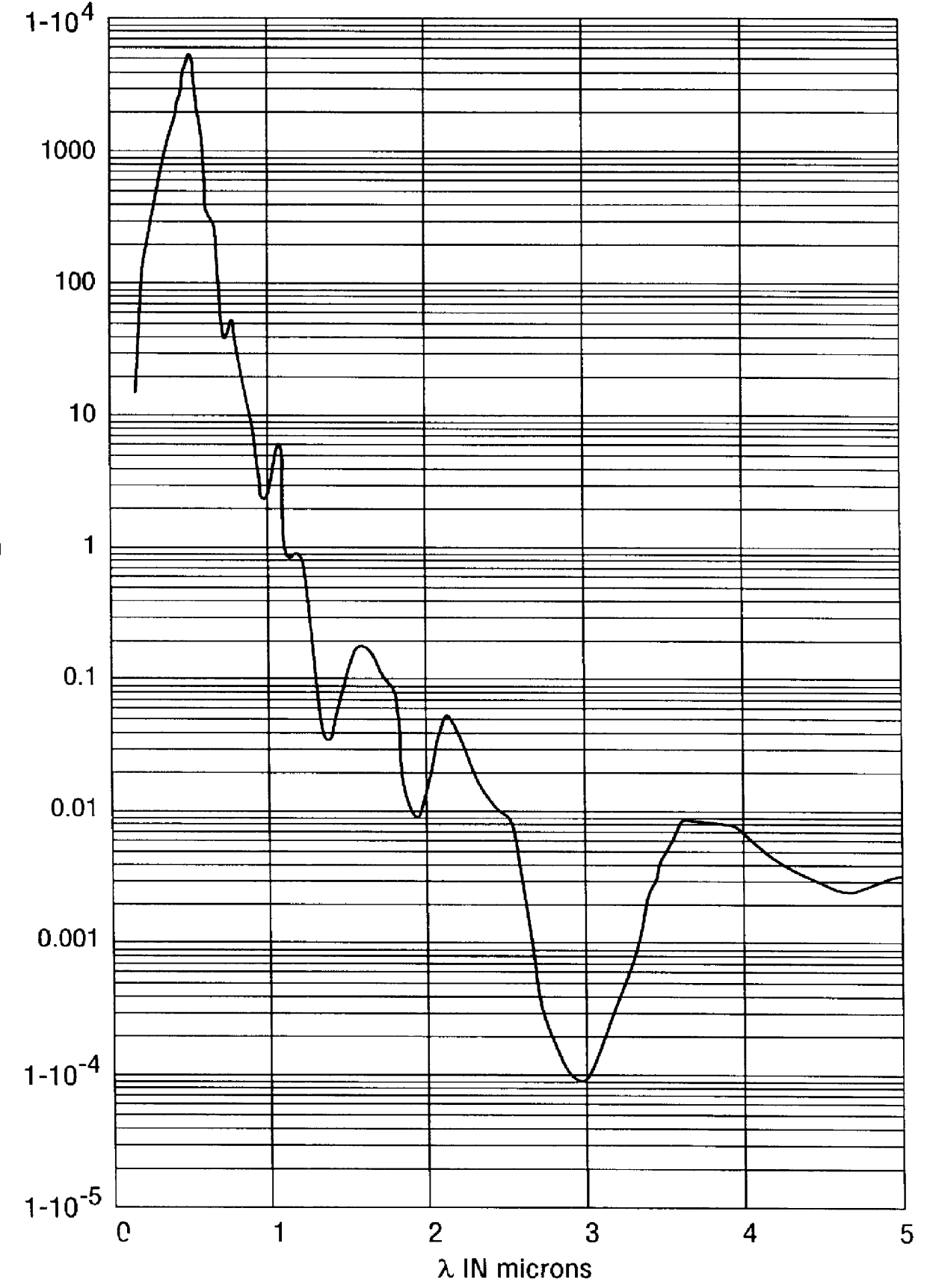

Apparatus and method for cooking food with a controlled spectrum

InactiveUS6069345AHigh strengthIncrease temperatureMilk preparationDomestic stoves or rangesLight energyEngineering

A lightwave oven for cooking with light having wavelengths in the visible, near visible, and infra-red spectral ranges uses one or more quartz halogen tungsten lamps or quartz arc bulbs positioned above and below the food item and delivers light energy in select ranges of the electromagnetic spectrum during select portions of the cooking cycle.

Owner:HAIER US APPLIANCE SOLUTIONS INC

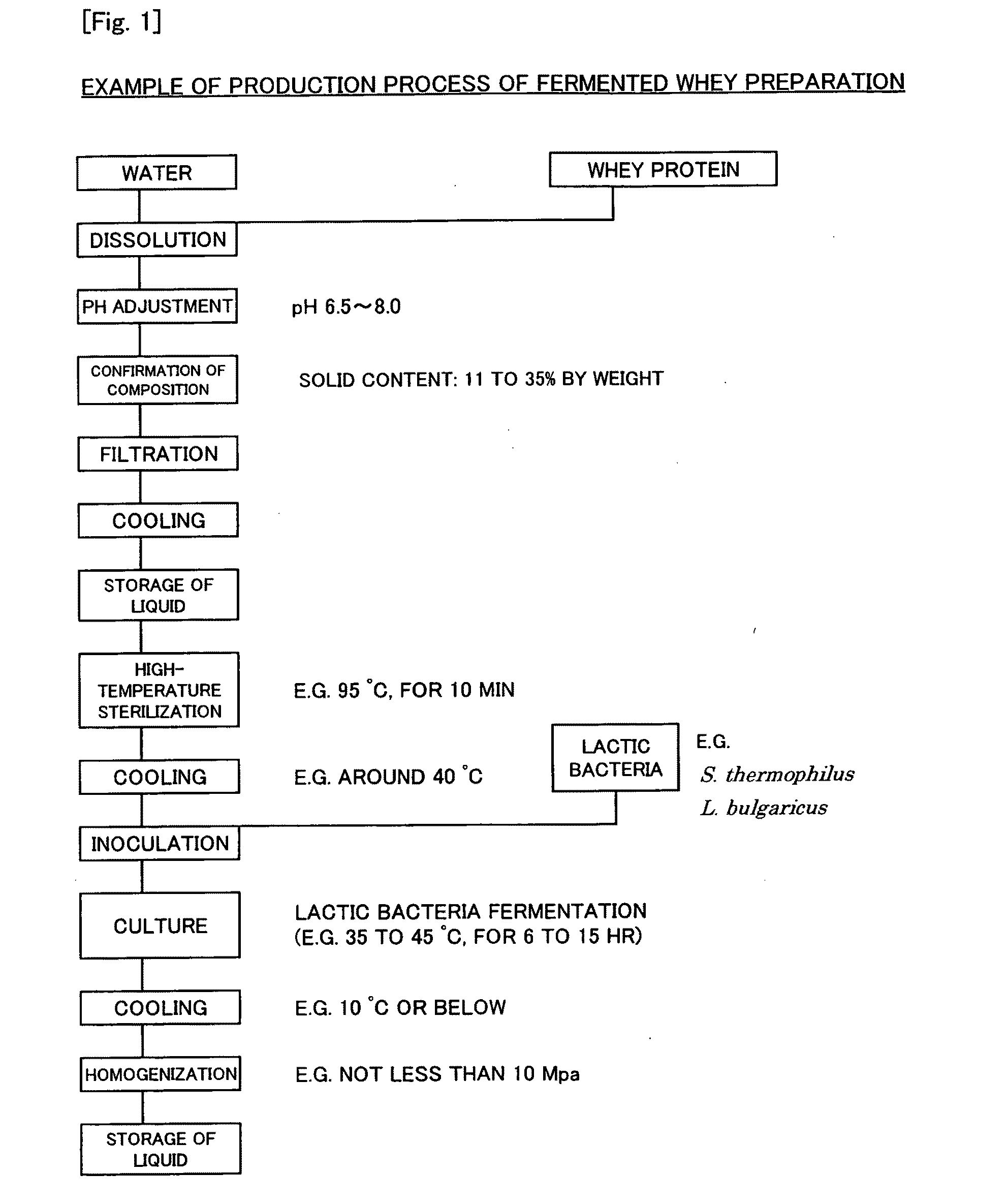

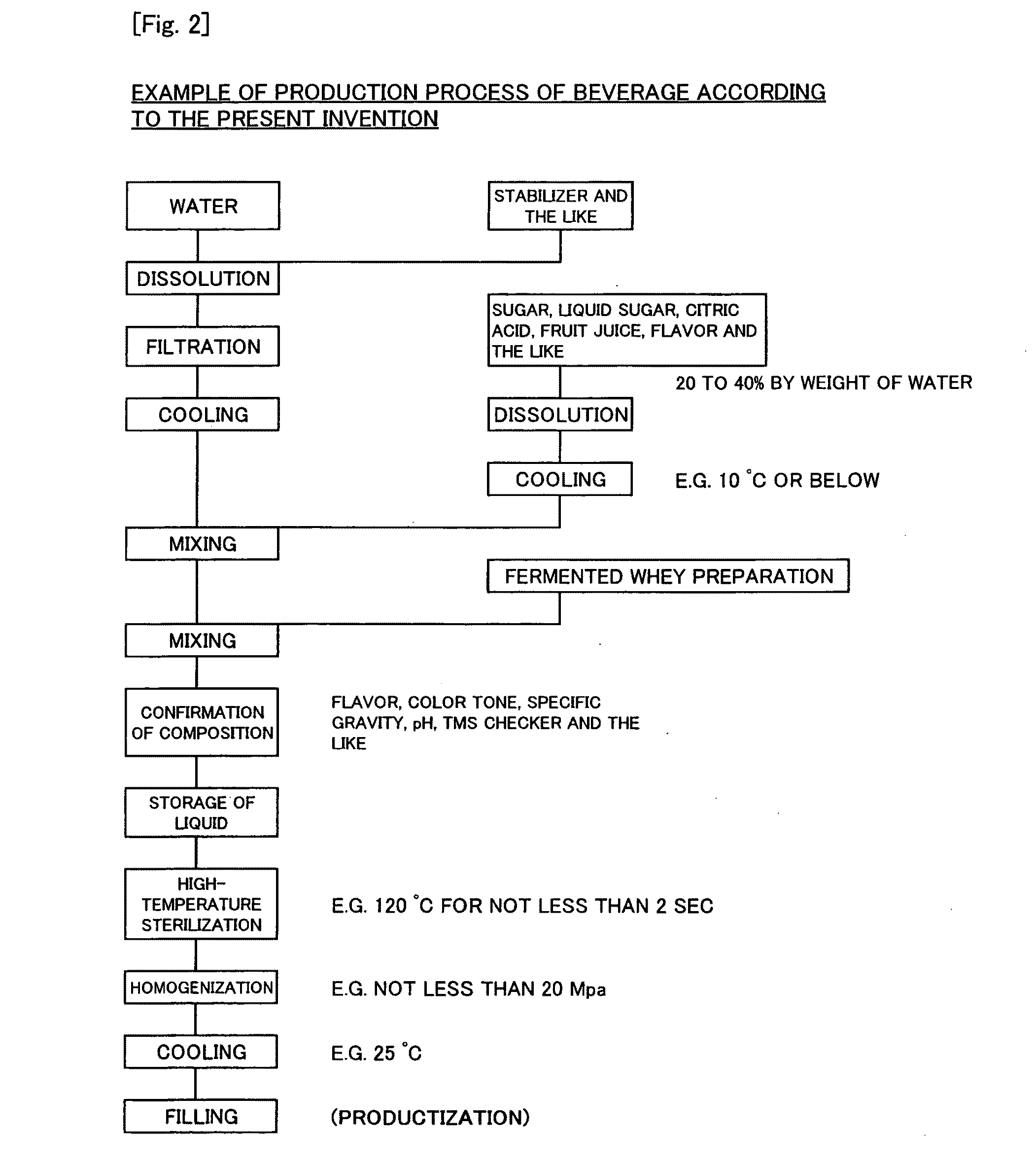

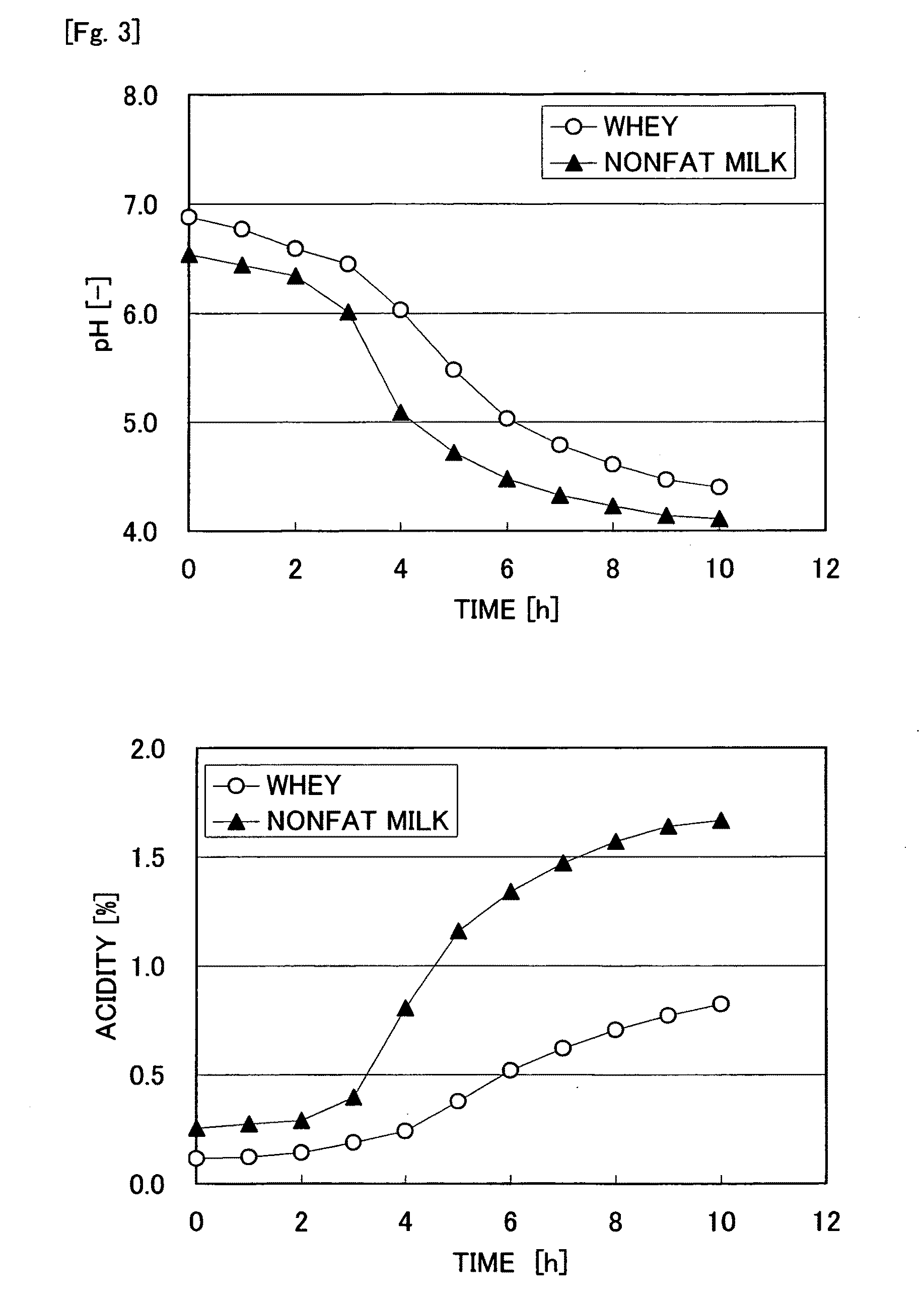

Fermented whey prepration and method for producing the same

InactiveUS20100136203A1Improve securityGreat tasteMilk preservationFood preservationWhey proteinVelvety texture

Disclosed is a fermented whey preparation produced by carrying out high-temperature sterilization of an aqueous whey protein solution having a solid content of 11 to 35% by weight and a pH value adjusted to 6.5 to 8.0, then subjecting the aqueous whey protein solution to lactic acid fermentation, and homogenizing the resultant fermentation liquor as such. The fermented whey preparation has a fermentation-derived unique and good flavor and, at the same time, has a refreshed and invigorating flavor and further has a velvety texture. The fermented whey preparation is also excellent in thermal stability and safety.

Owner:COPAL CO LTD +1

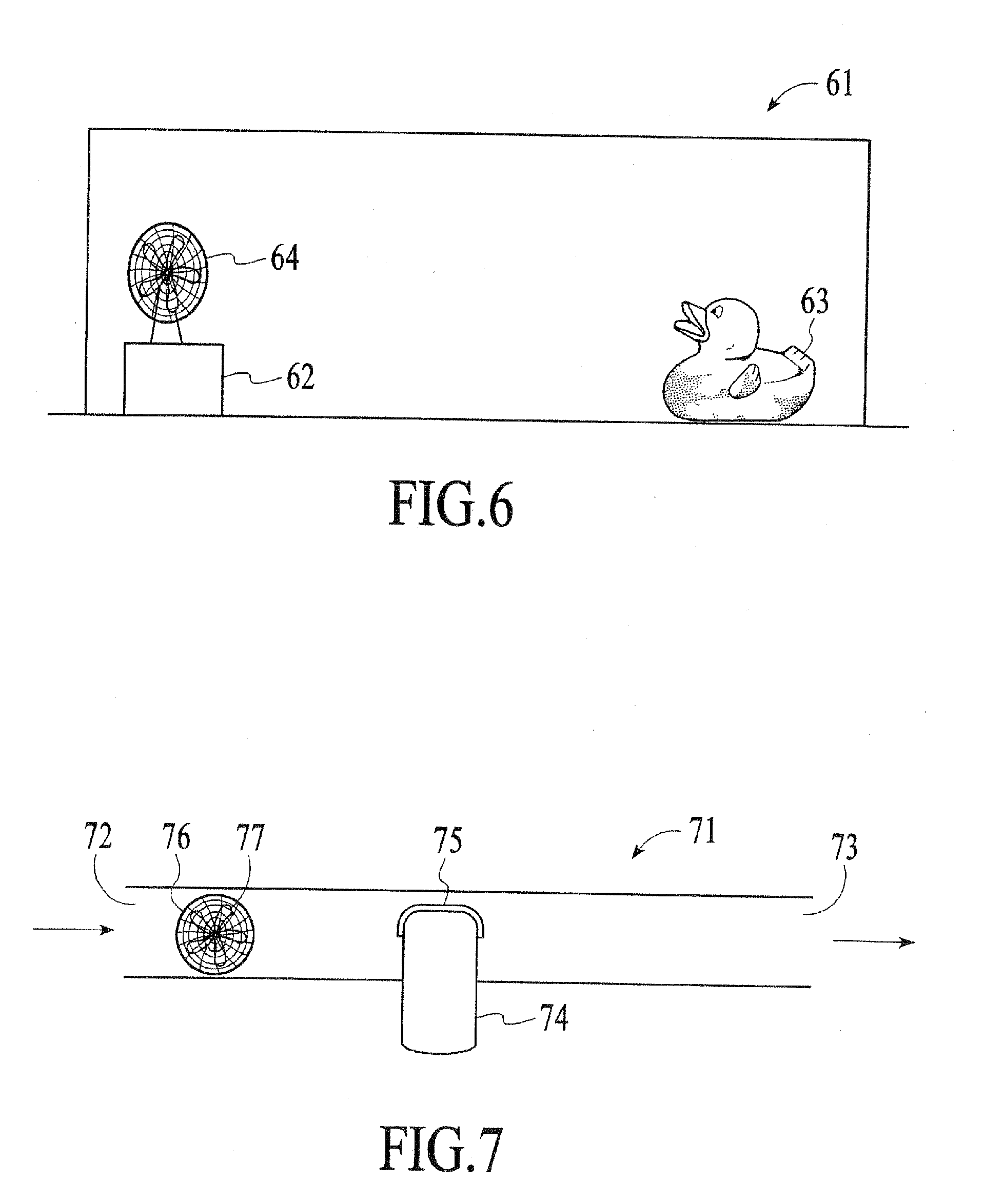

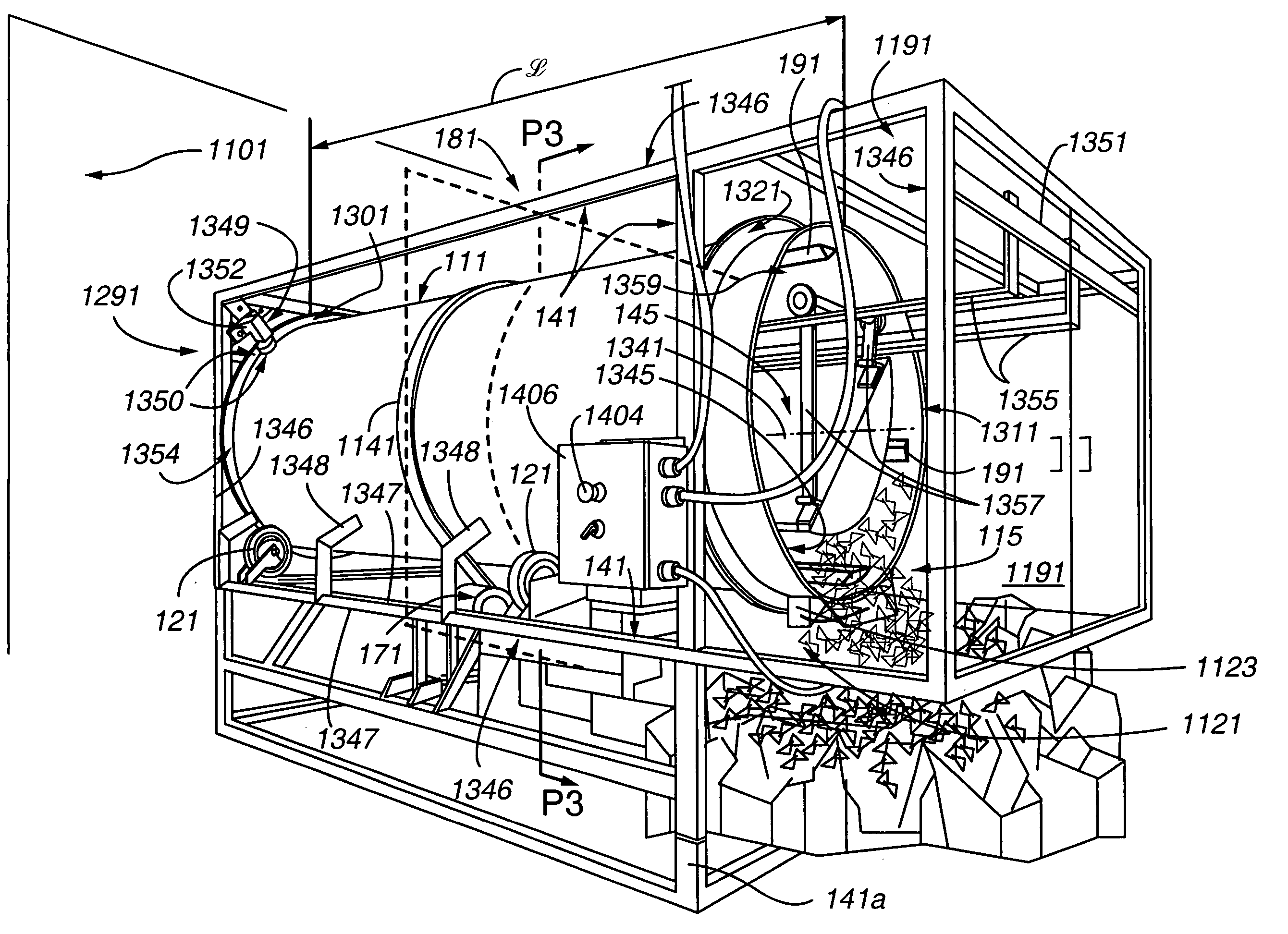

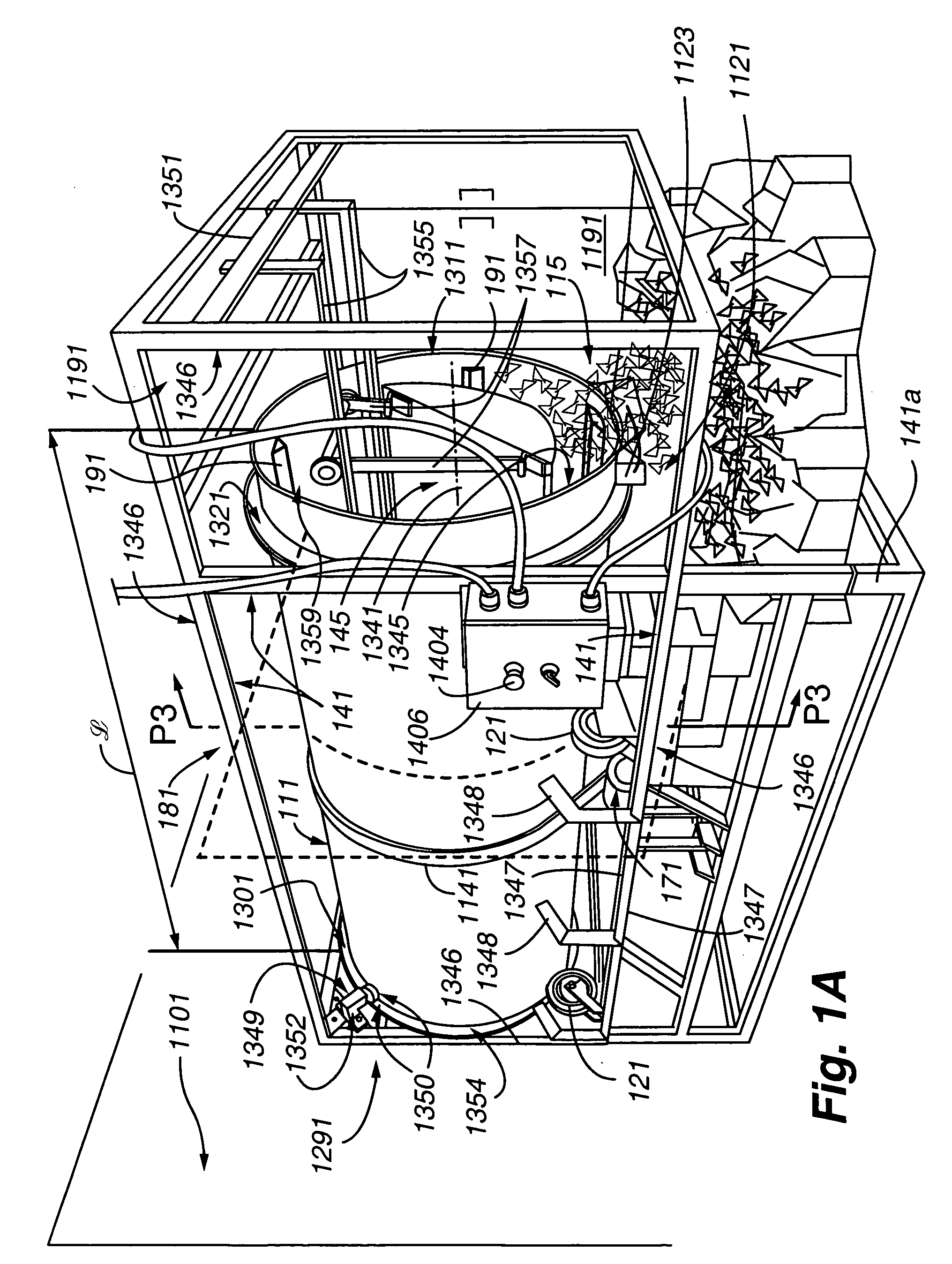

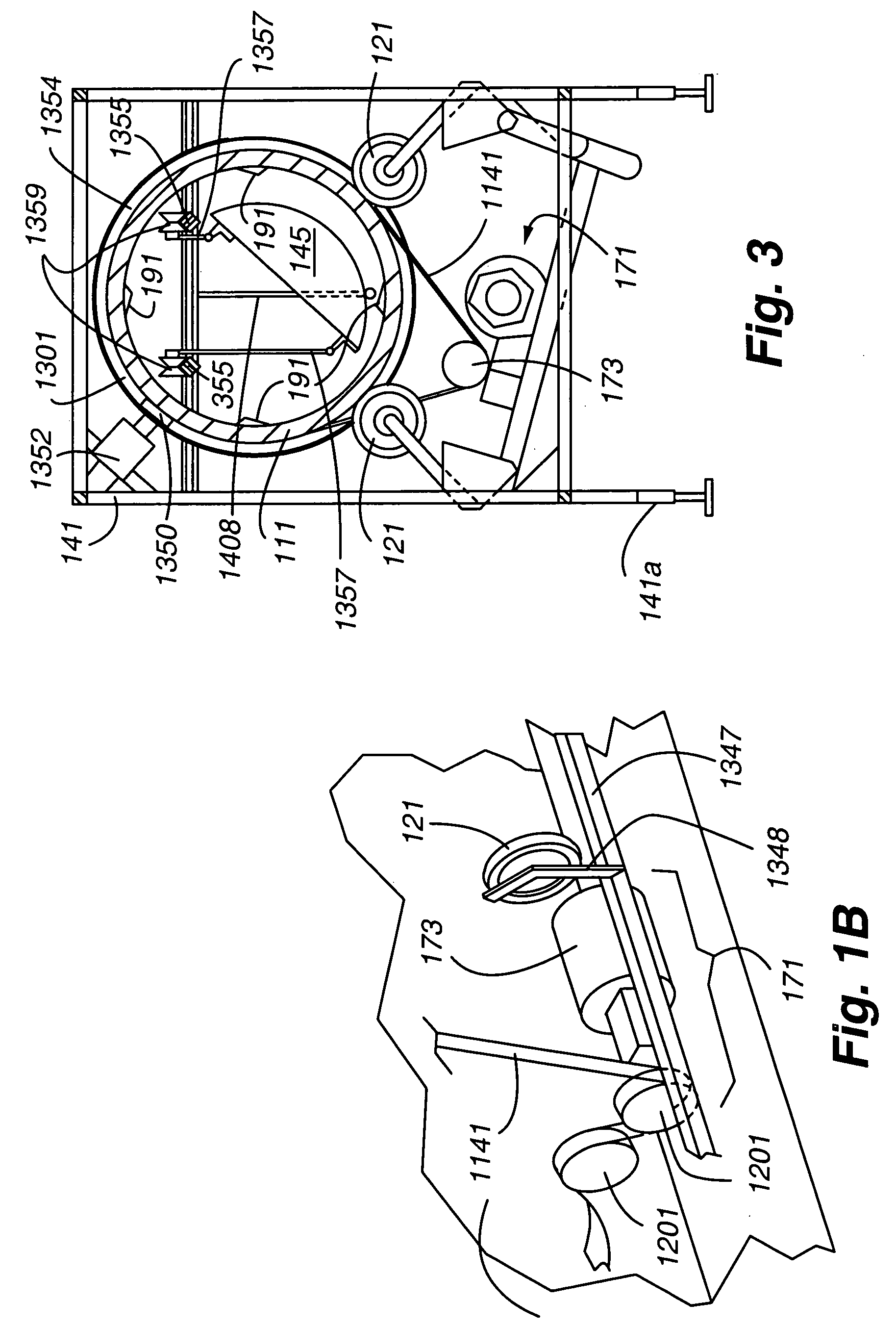

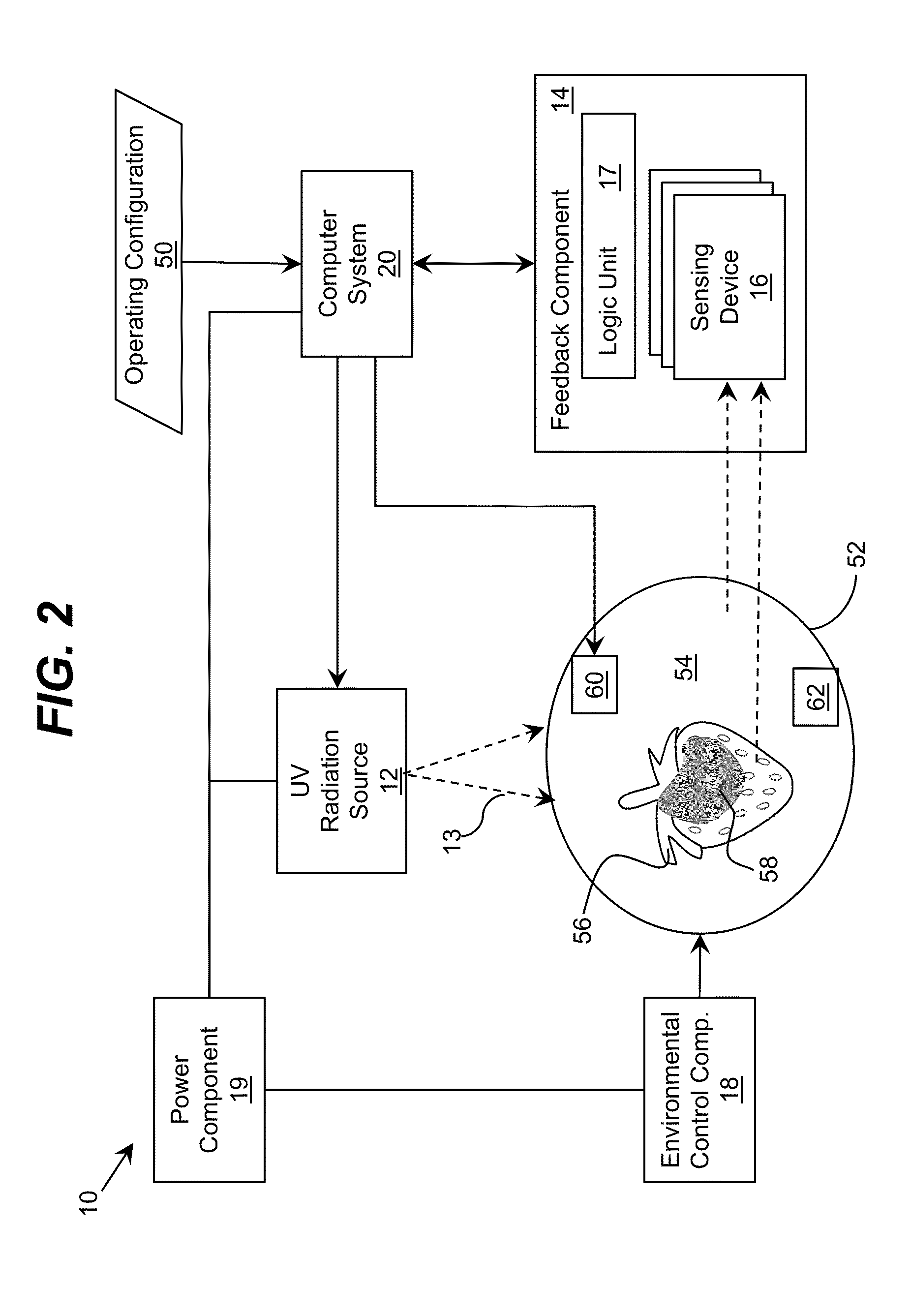

Food product surface sterilization apparatus and method

InactiveUS20040052702A1Increase temperatureReduce food product temperature changeFood preservationIndirect heat exchangersUnsafe conditionUltraviolet

An apparatus is disclosed for the micro-organism surface sterilization of foods using, a "germicidal" such as light waves (e.g., ultraviolet), and in some cases in combination with (or replaced by) one or more of sound waves and ozone. The surface sterilizer apparatus may include a plurality of germicidal (e.g., ultraviolet) emitters for surface sterilization of foods that are, e.g., rotated in a drum or rotated via a screw auger. Assemblies of emitters for the germicidal may be constructed to be watertight (i.e., withstand a high pressure, heated water spray), and movable relative to the drum or screw conveyor for easy cleaning and maintenance. The apparatus may also include a controller (e.g., programmable logic controller) for controlling the sterilization process so that the apparatus does not endanger personnel nearby, and so that the food is properly sterilized. The controller may vary the amount of germicidal used, the rate that food traverses the apparatus, the inclination of the apparatus, and terminate sterilization processing when an unsafe condition is detected. The apparatus may be used in-line with other food processing equipment for the real-time sterilization of food. The controller may also communicate with food processing components upstream of the apparatus for controlling the flow of food to the surface sterilizer

Owner:C & S EQUIP COMPANY

Ultraviolet Gradient Sterilization, Disinfection, and Storage System

ActiveUS20140060104A1Milk preservationLighting and heating apparatusUltraviolet radiationUltraviolet

Ultraviolet radiation is directed within an area. The storage area is scanned and monitored for the presence of biological activity within designated zones. Once biological activity is identified, ultraviolet radiation is directed to sterilize and disinfect designated zones within the storage area.

Owner:SENSOR ELECTRONICS TECH

Applications of microencapsulated essential oils

Owner:BOTANOCAP LTD

Beverage formation apparatus and method using sonic energy

ActiveUS20110151075A1Uniform strengthImproving wetting of the beverage mediumMilk preservationDough treatmentInterior spaceAcoustic energy

Apparatus and method for forming beverages using a beverage cartridge and sonic energy. A cartridge may include a sonic receiver, such as a feature that extends into an interior space of the cartridge and is arranged to receive a sonic emitter that introduces sonic energy into the interior space. The sonic receiver may be excited by sonic energy, which causes the sonic receiver to itself introduce sonic energy into the cartridge.

Owner:KEURIG GREEN MOUNTAIN INC

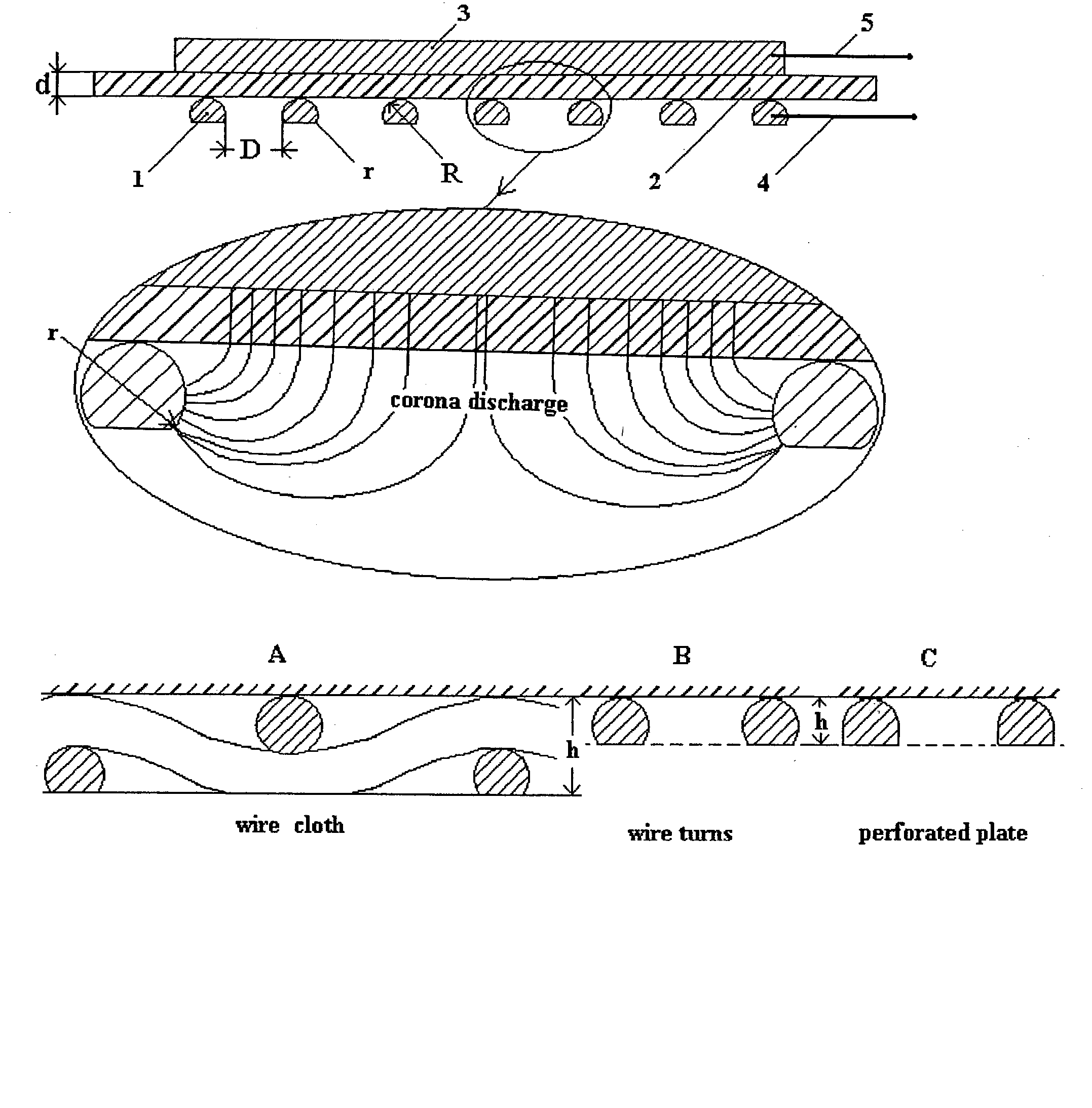

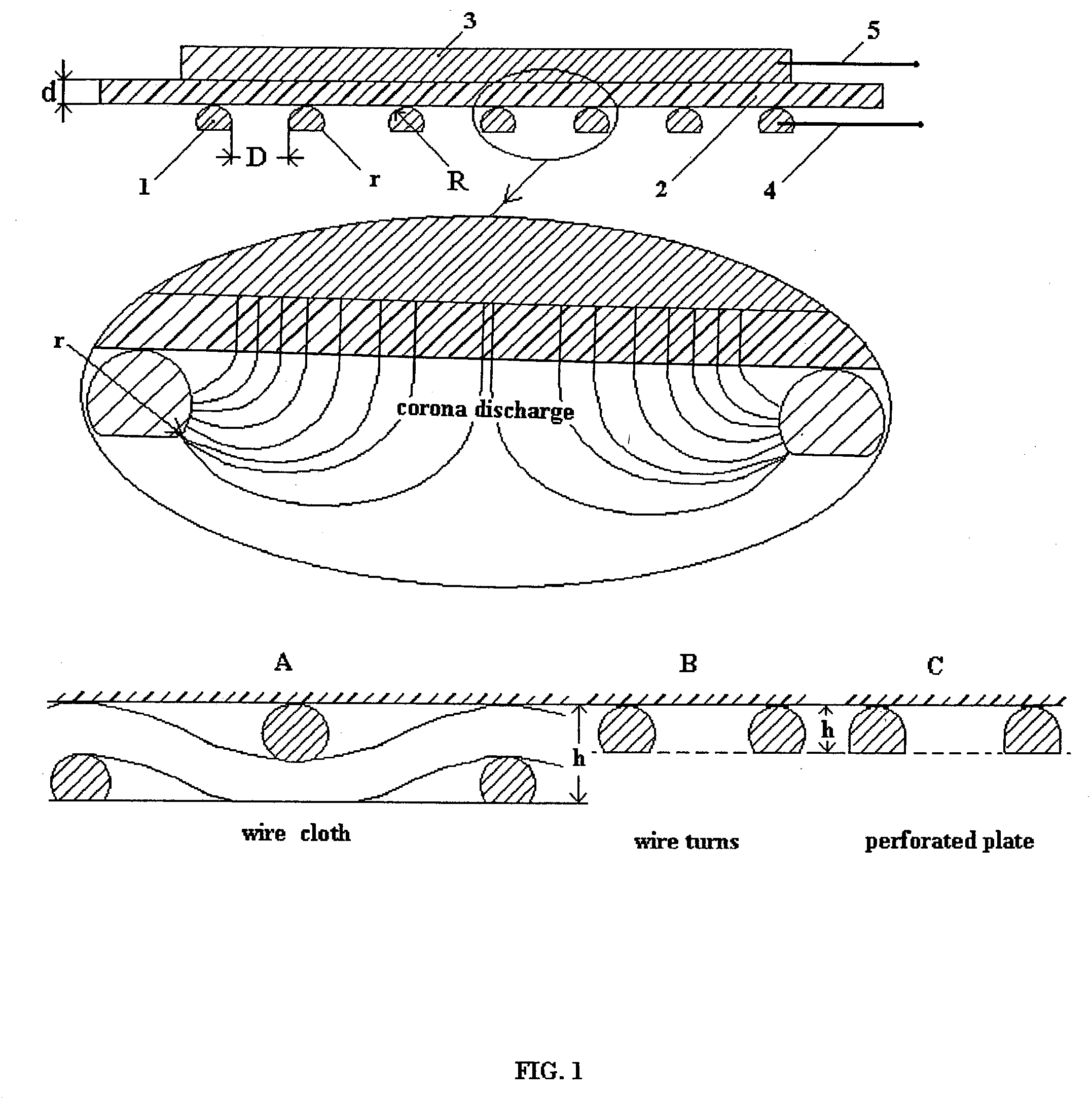

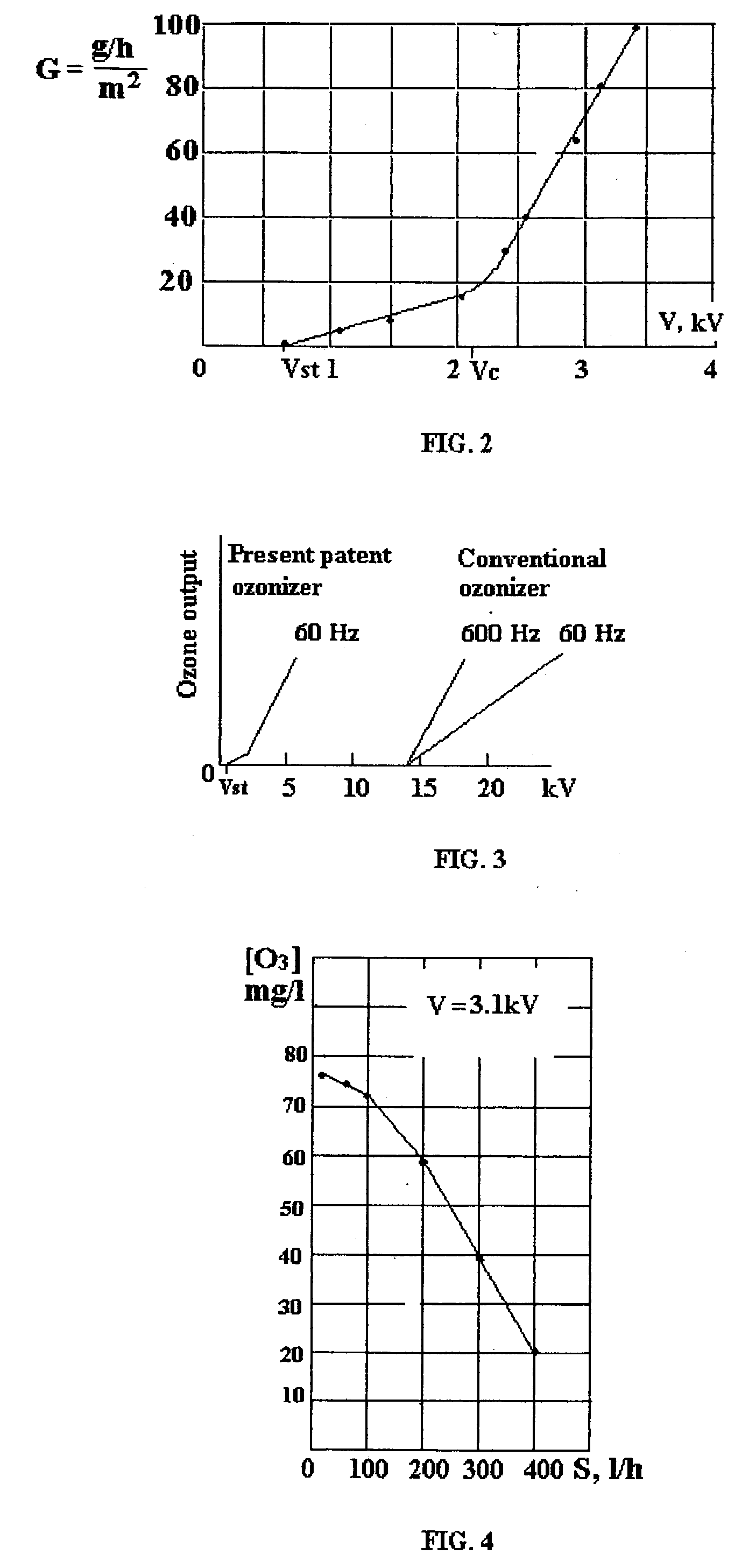

Method for surface corona/ozone making, devices utilizing the same and methods for corona and ozone applications

A method for making surface corona discharge, which produces ozone gas and apparatus for producing the same are disclosed, in which a dielectric spacer / film having a specific capacity C' equal to or more than 200 nanofarad per square meter positioned between the base electrode and the net electrode. Said net electrode is a wire net or a perforated metal or a wire winding having an open area not less than about 70%, and a size of hole D equals to or less than about 0.7V / P, where V is a voltage in kilovolts and P is pressure of an ambient air or an oxygen in atmospheres. Net electrode has radius R of wire or radius of an edge of openings in the perforated metal equal to or more than about 1.6d, where d is the thickness of the said dielectric spacer / film, which is determined by a fundamental formula d=9k / C', where d is in millimeters, C' is in nF / m2, and k is dimensionless dielectric constant k of given material. Under disclosed parameters said surface corona is safe for human contact if said net electrode is grounded. Start voltage Vst of ozone production is determined by experimental formula Vst=0.7+60 / C', kV, here C' in nF / m2. The even and high intensity corona surface and high ozone output takes place if the operating voltage is more than about 3Vst. AC power supply is applied to produce ozone gas at "home" voltage 0.7-1.0 kV and produces ozone gas more effectively at 2,5-3.6 kV. A method for disinfection and decontamination of objects by using the direct corona contact and apparatus for making the same is disclosed, in which safe corona surface is placed on said object and is acting by ozone, ultraviolet and ion bombing simultaneously in the unique environment, which takes place inside of the safe corona. A method for ozone disinfection and decontamination and devices for making the same is disclosed, in which said ozone generating element is placed in a closed container / room with or without treated objects and produce a high ozone concentration due to effective ozone dispersion from corona surface without blowing of air / oxygen through said container / room.

Owner:ANDREEV SERGEY I +1

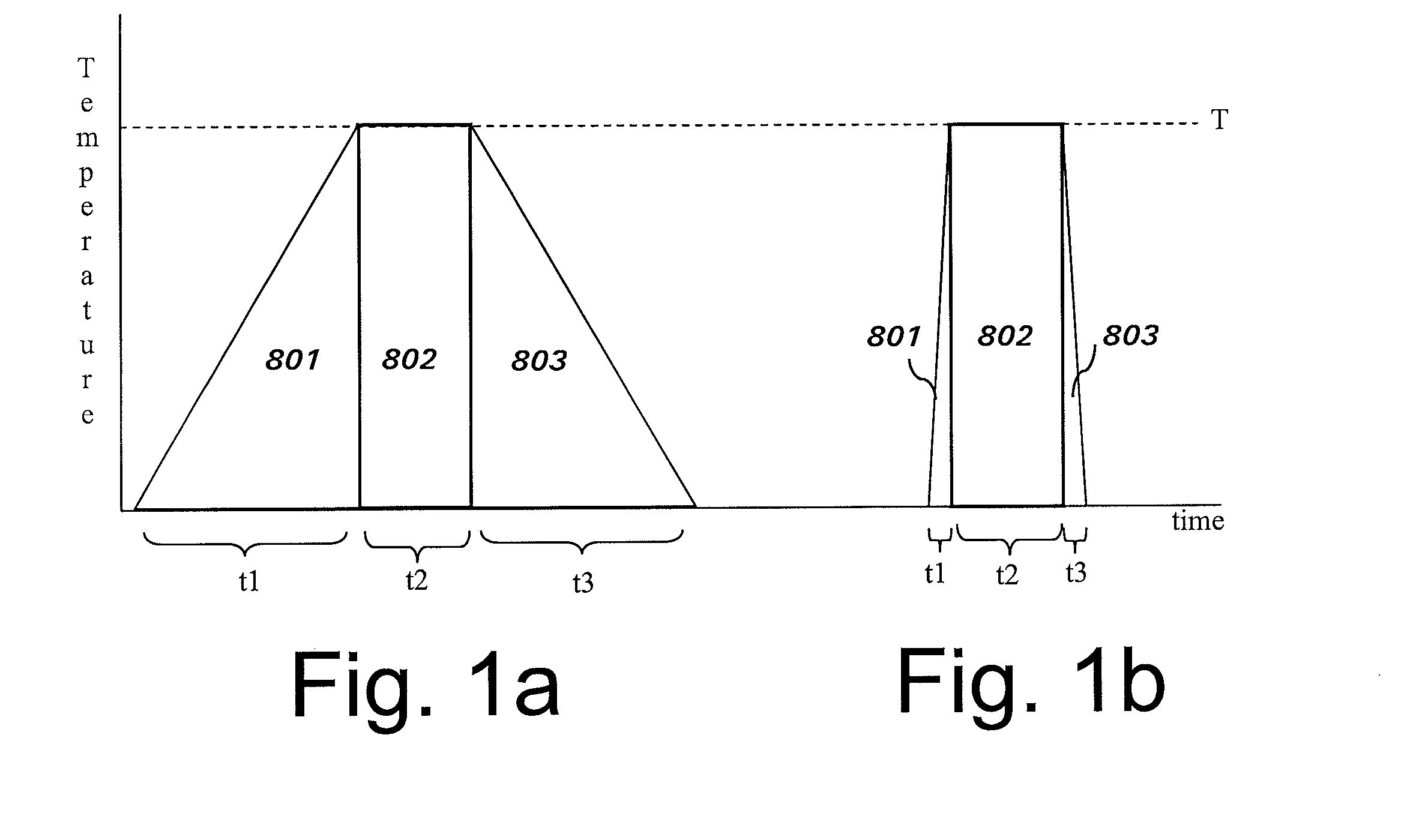

Food preparation

ActiveUS20110031236A1Improve uniformityAvoid heat damageContainer decorationsLevel indicationsElectrical and Electronics engineeringFood preparation

Owner:JOLIET 2010 LTD

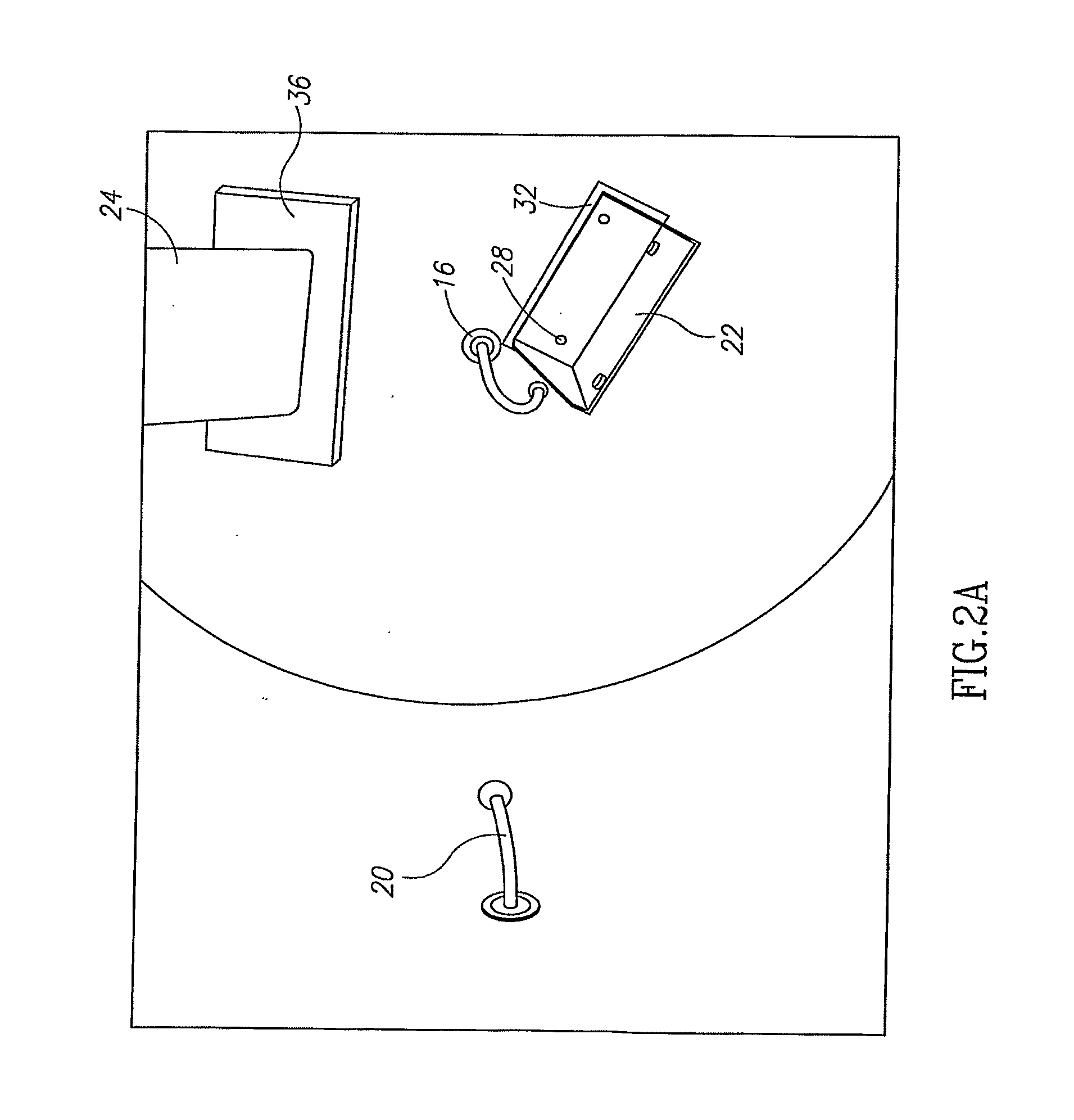

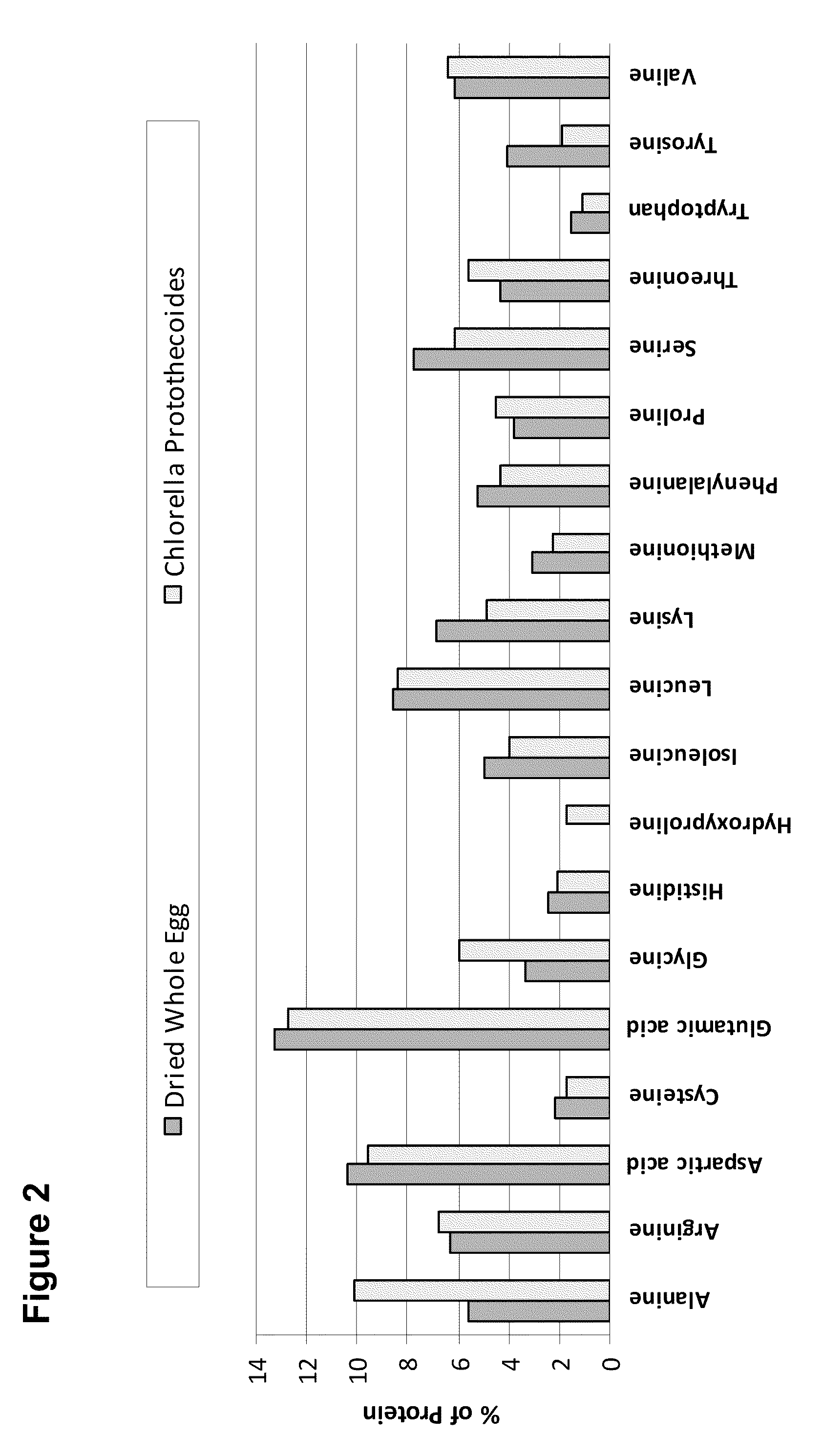

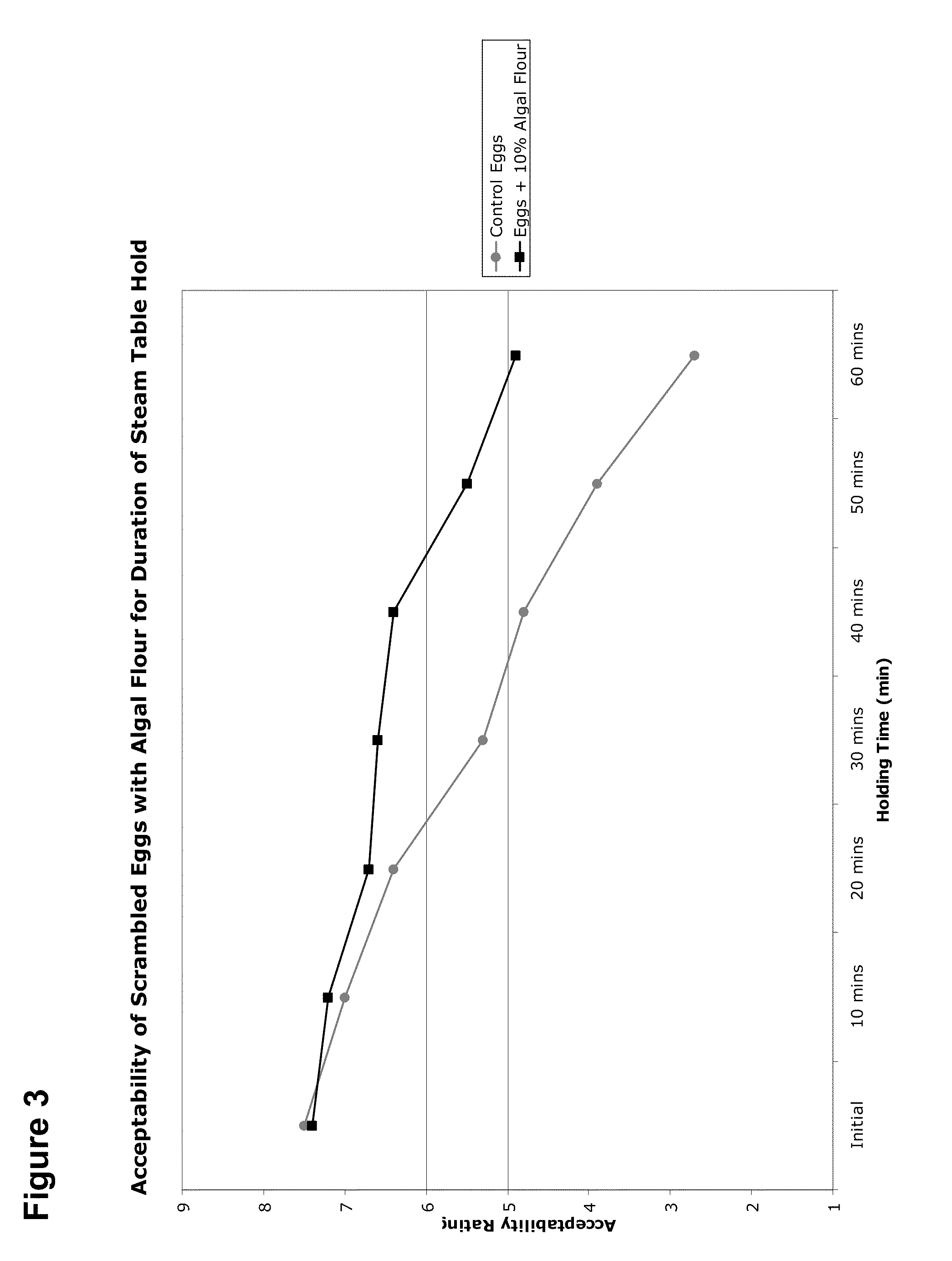

Microalgae-Based Beverages

InactiveUS20100297295A1Great tasteLower levelMilk preparationDough treatmentEmulsionAdditive ingredient

The invention provides novel beverages and raw materials for the manufacture thereof, such beverage and raw materials containing microalgae of various species with varying components. Attributes of the microalgal biomass used in the invention include nutrition-providing materials such as carotenoids, dietary fiber, tocotrienols and tocopherols, and varying lipid compositions, particularly low levels of saturated lipids. Attributes of the microalgal biomass used in the invention include structural attributes such as improved mouth feel compared to alternative milk products such as soy milk and rice milk. The novel beverages provide delivery systems for high nutrition materials found in microalgae. The invention provides a new category of finished beverages based on microalgae (such as refrigerated and shelf stable liquids and emulsions) as well as compositions for augmenting properties of current beverages through inclusion of novel microalgae-based materials as ingredients.

Owner:TERRAVIA HLDG INC

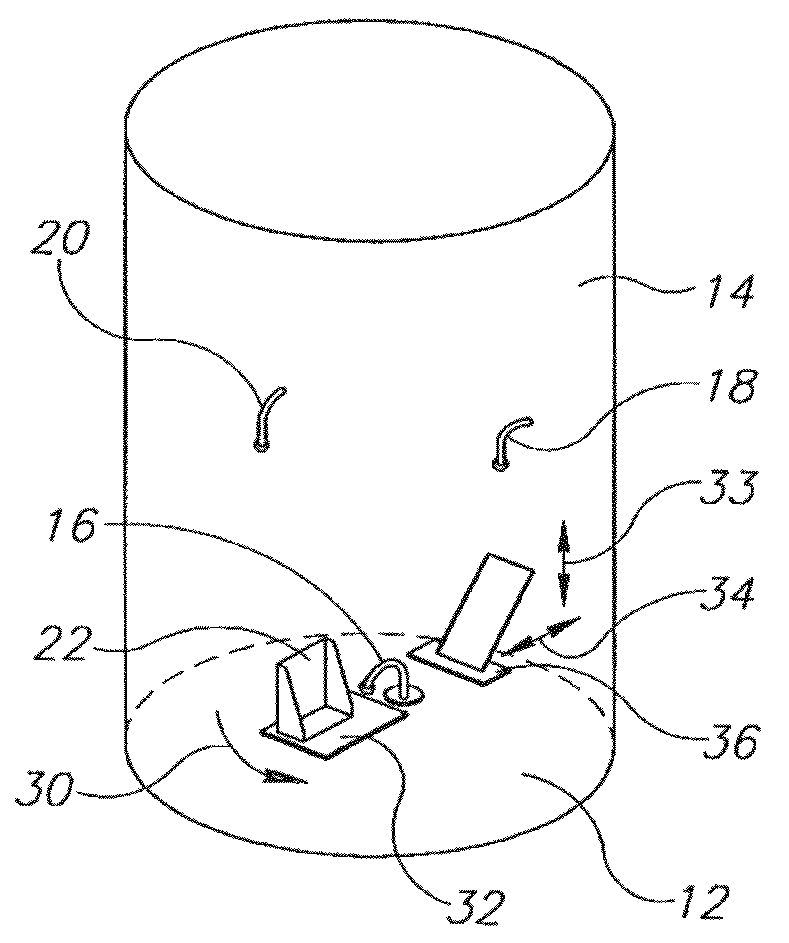

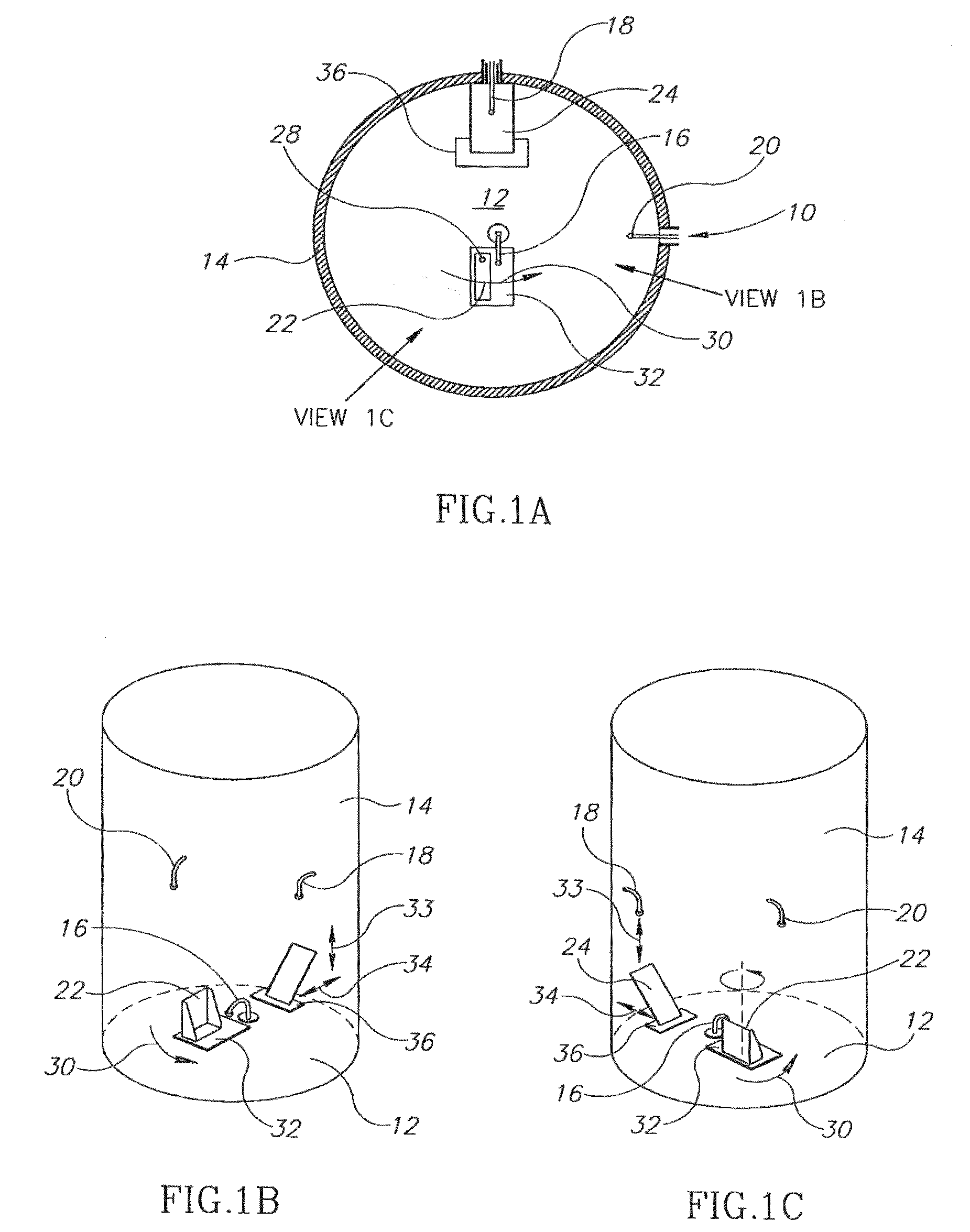

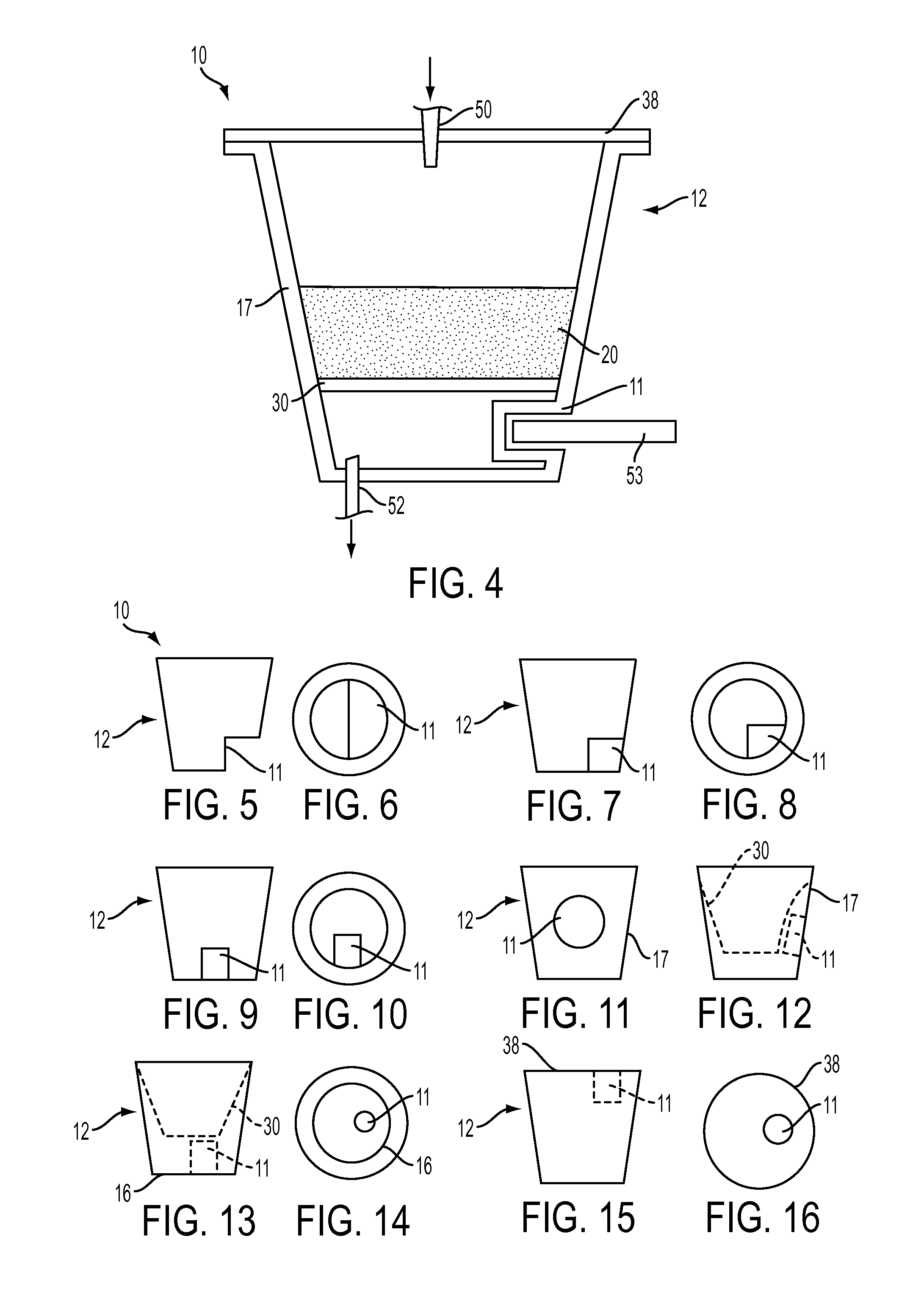

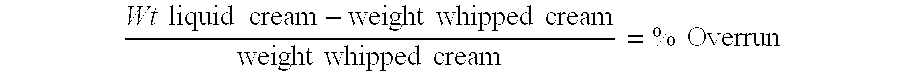

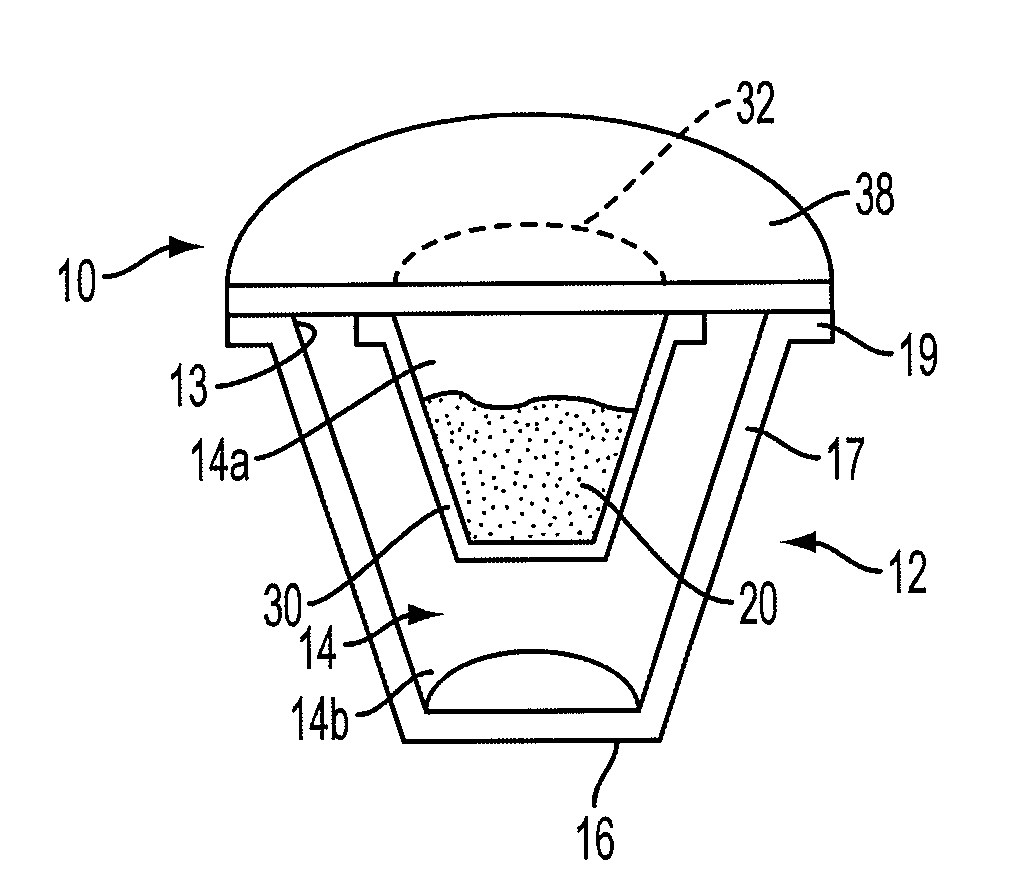

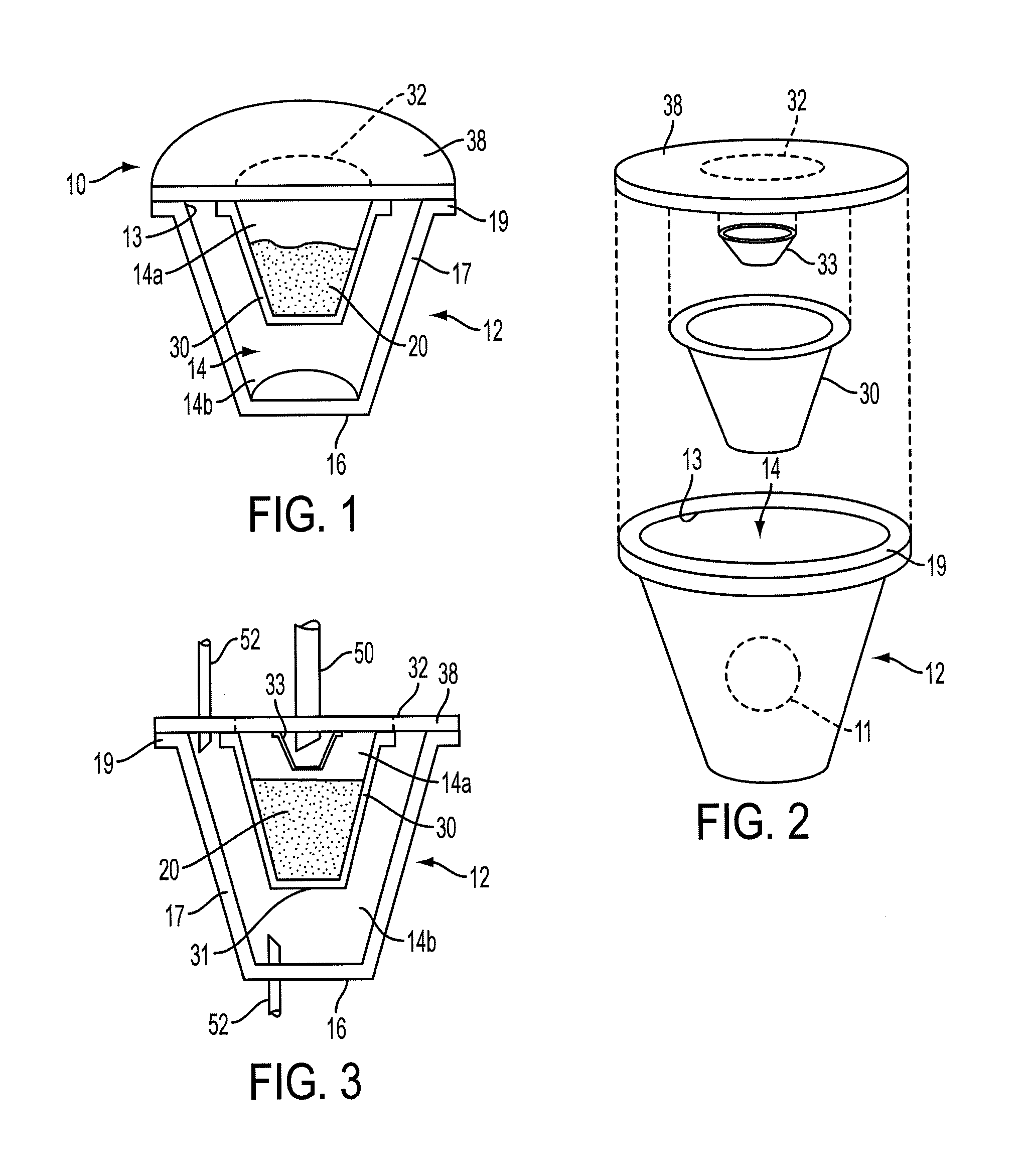

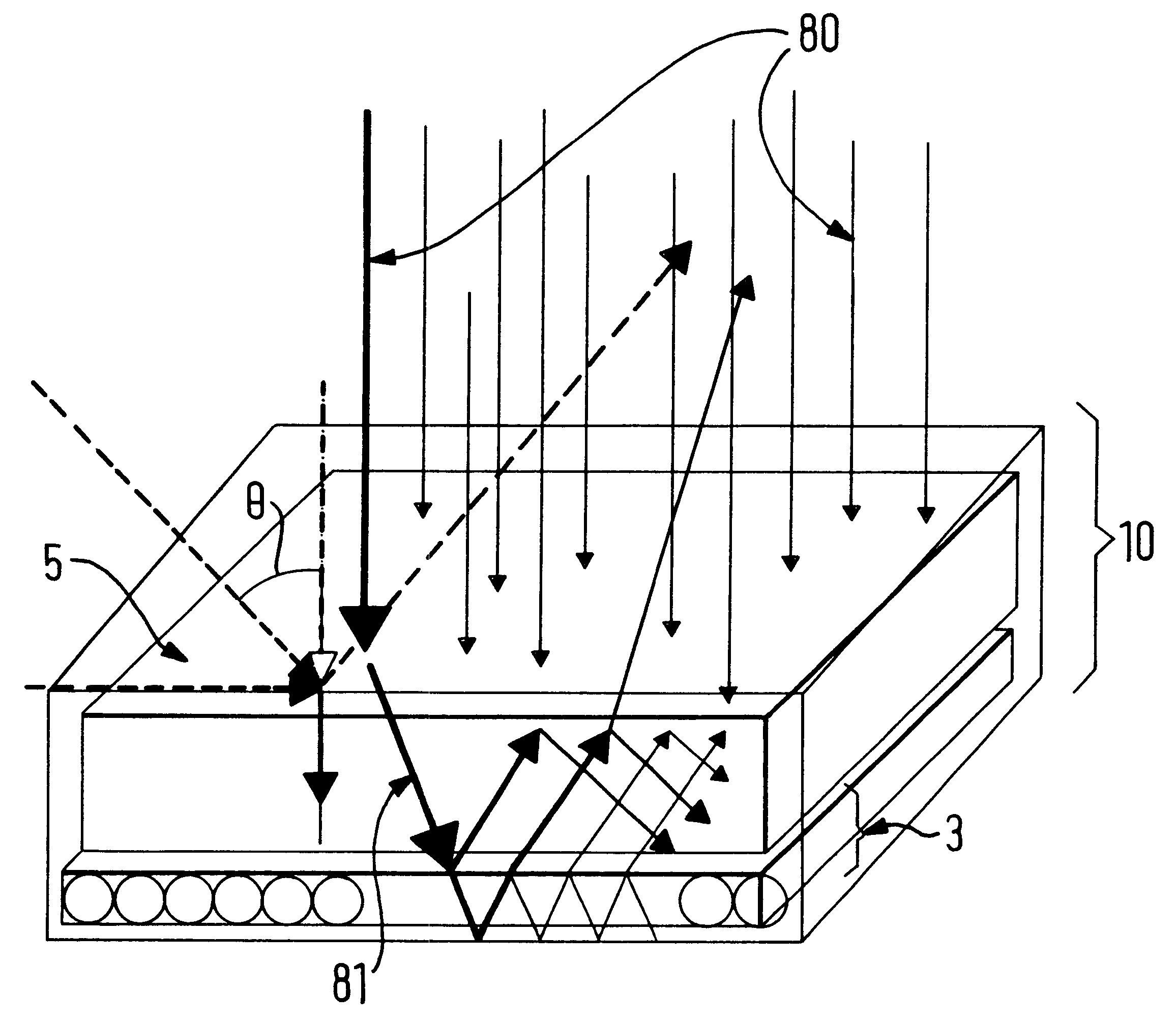

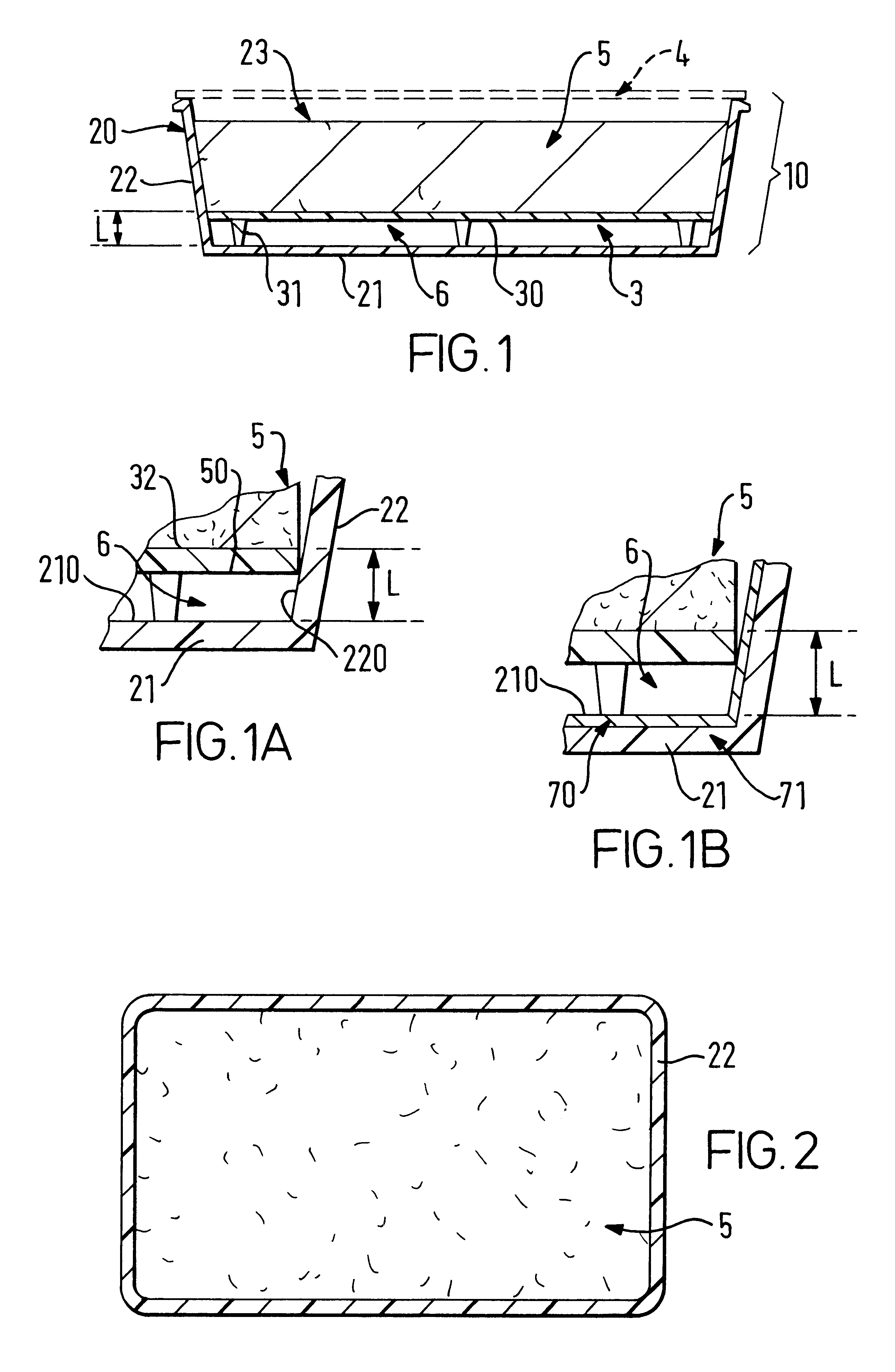

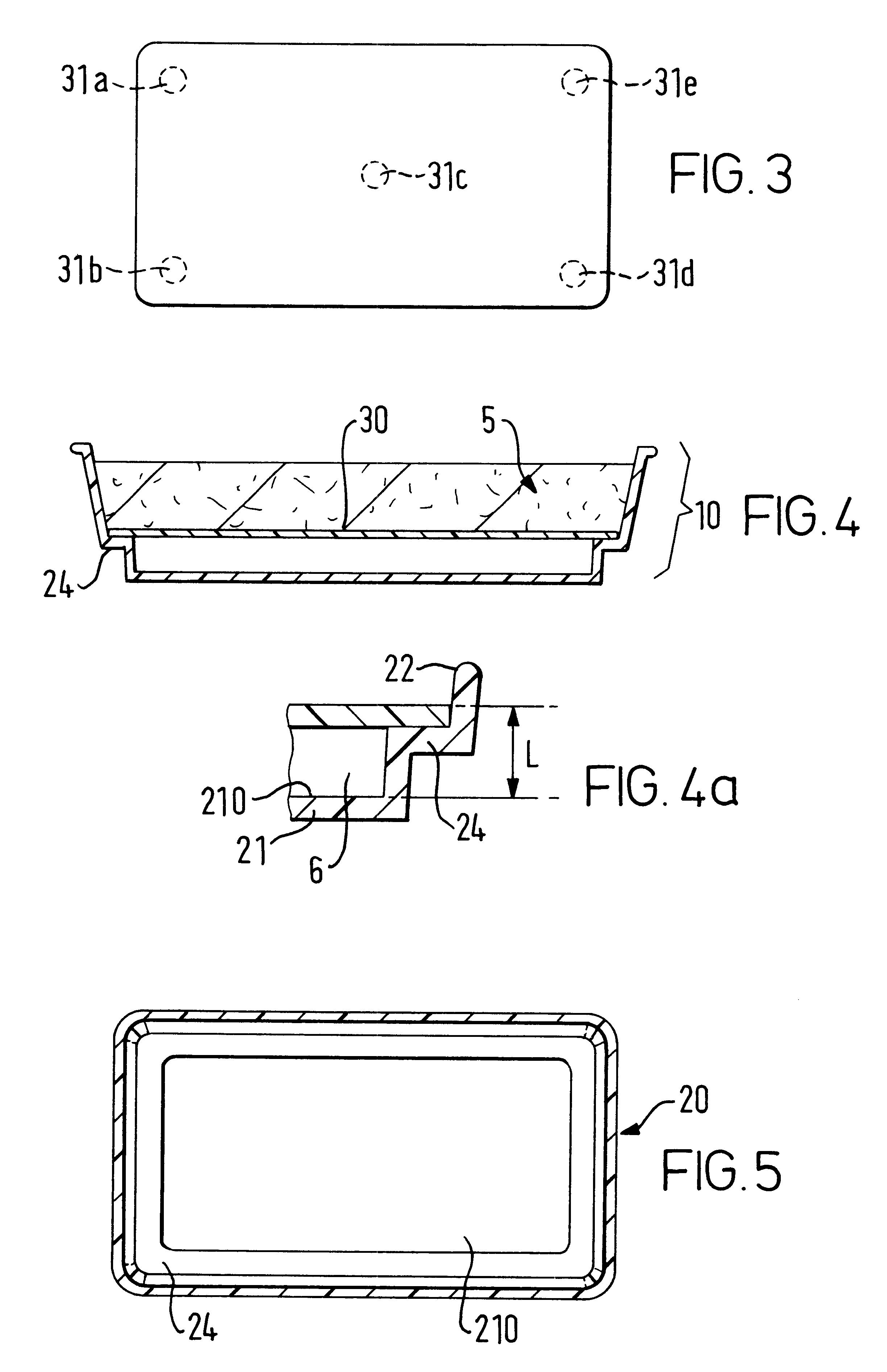

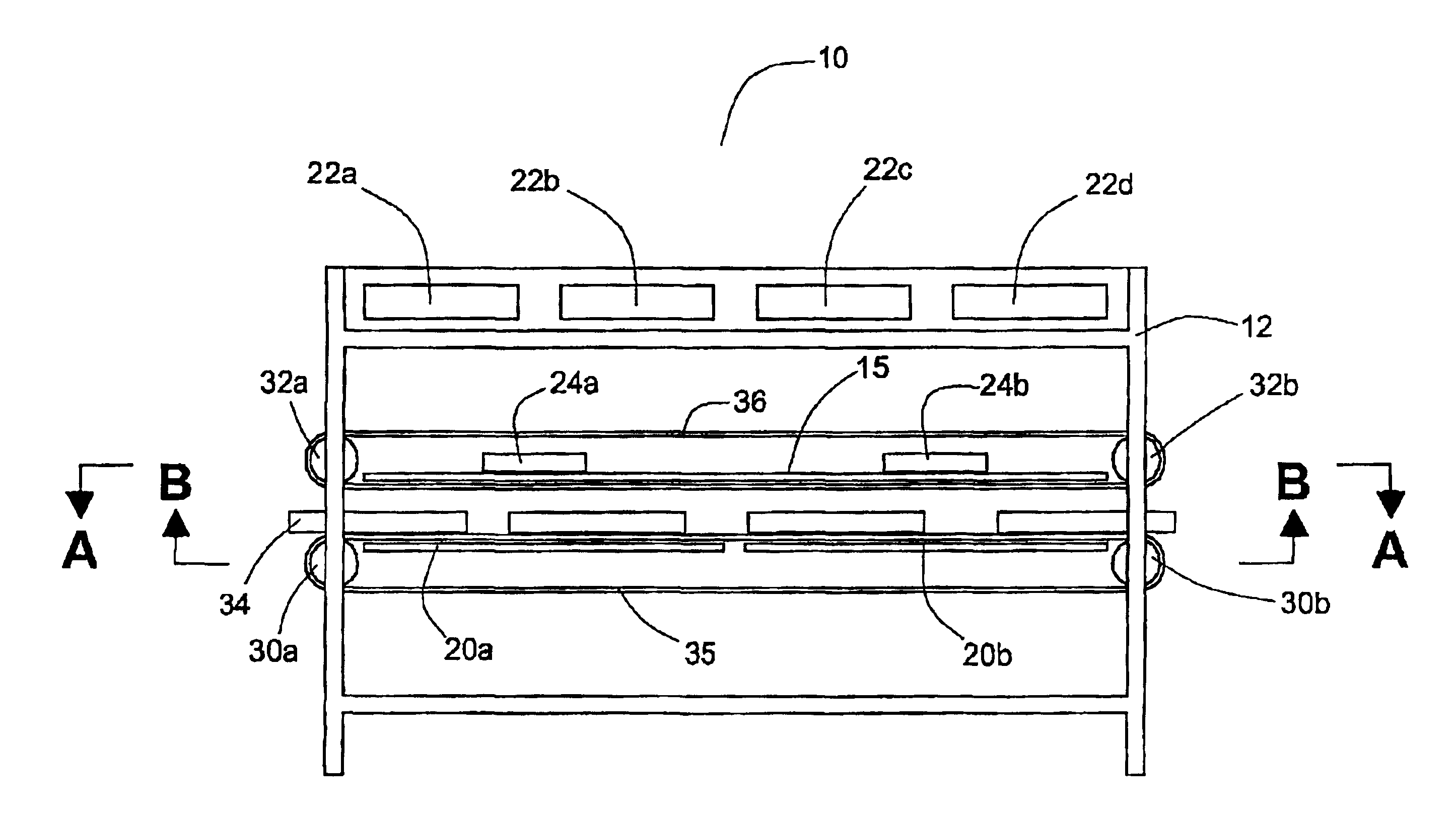

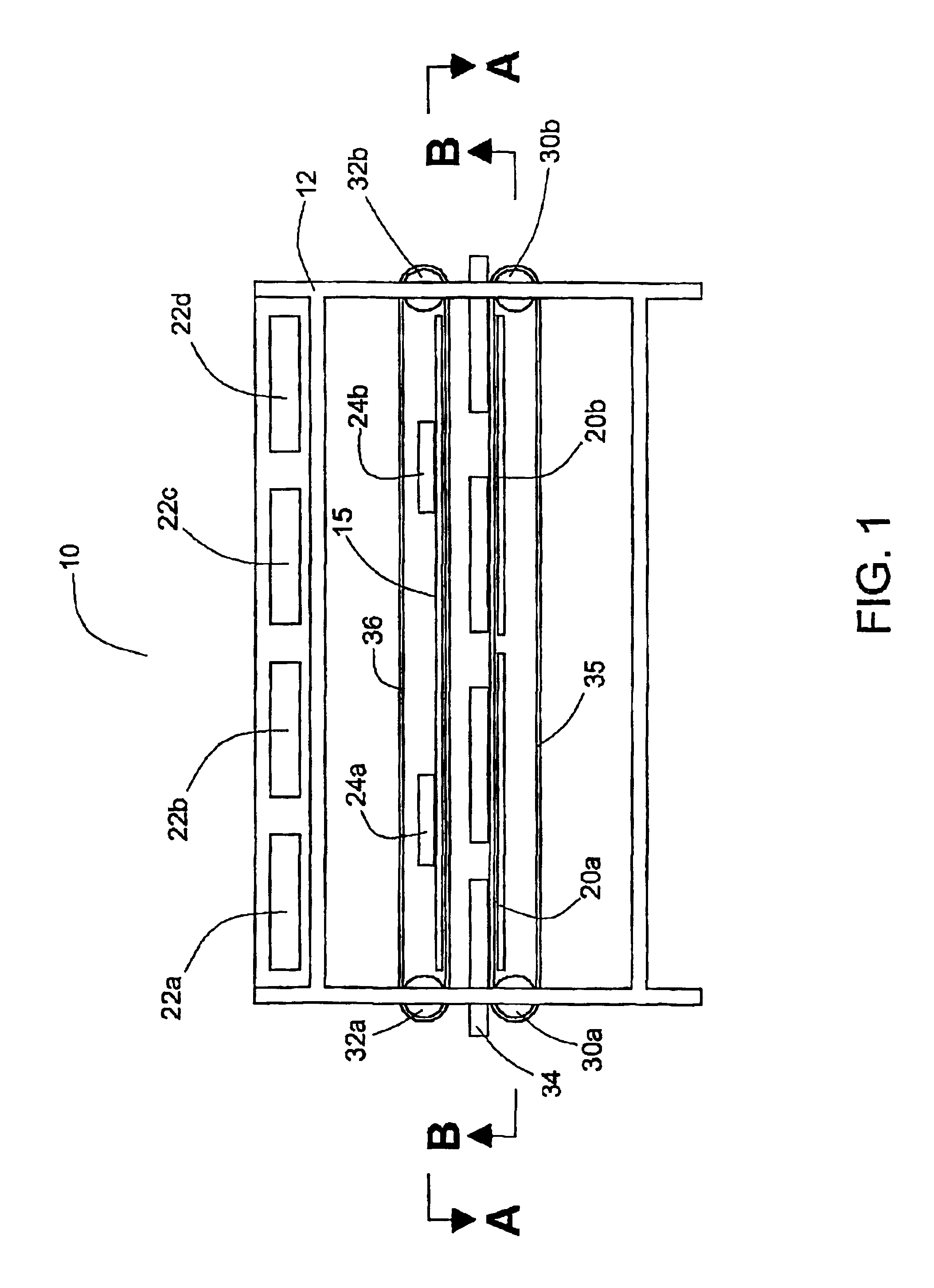

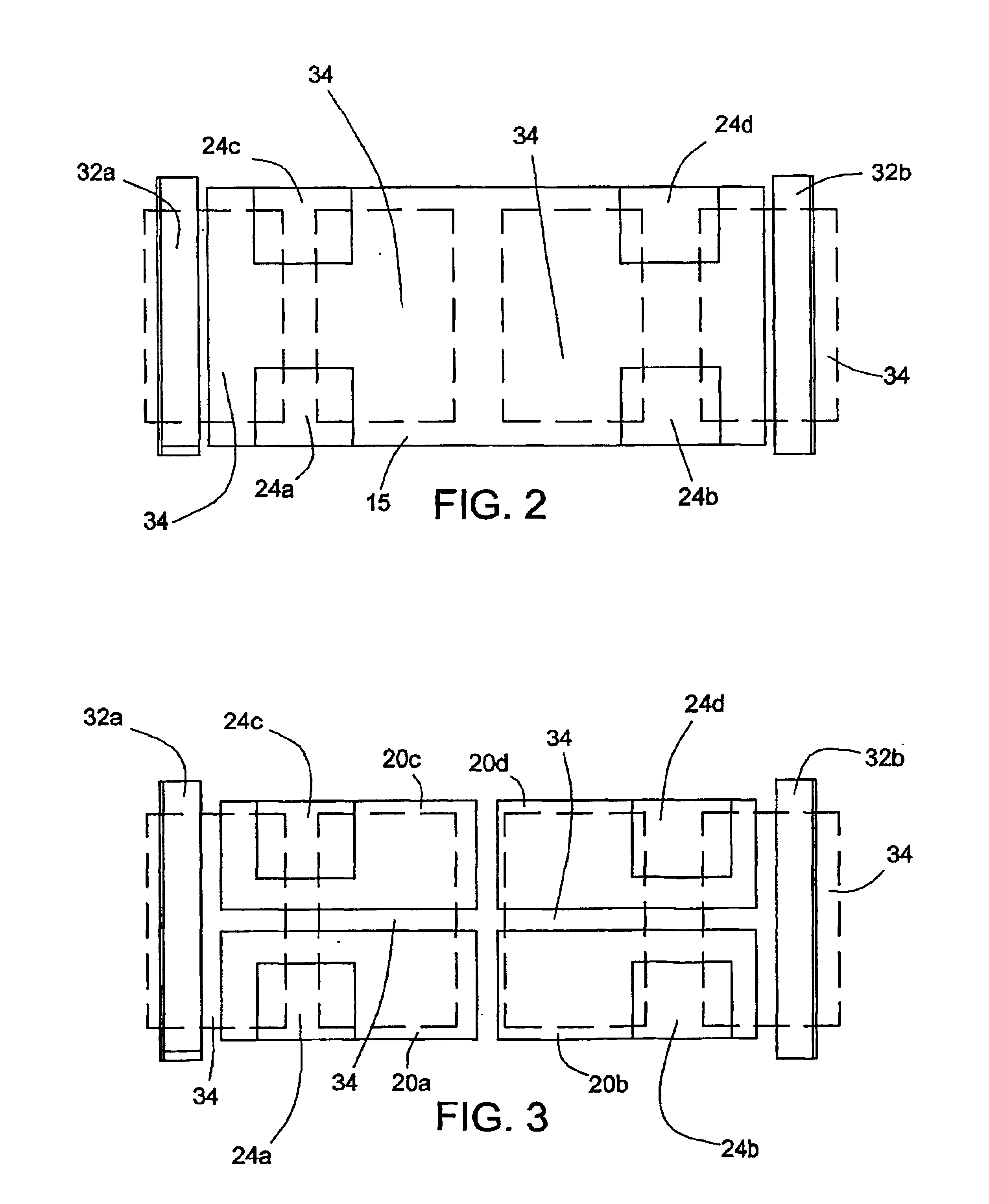

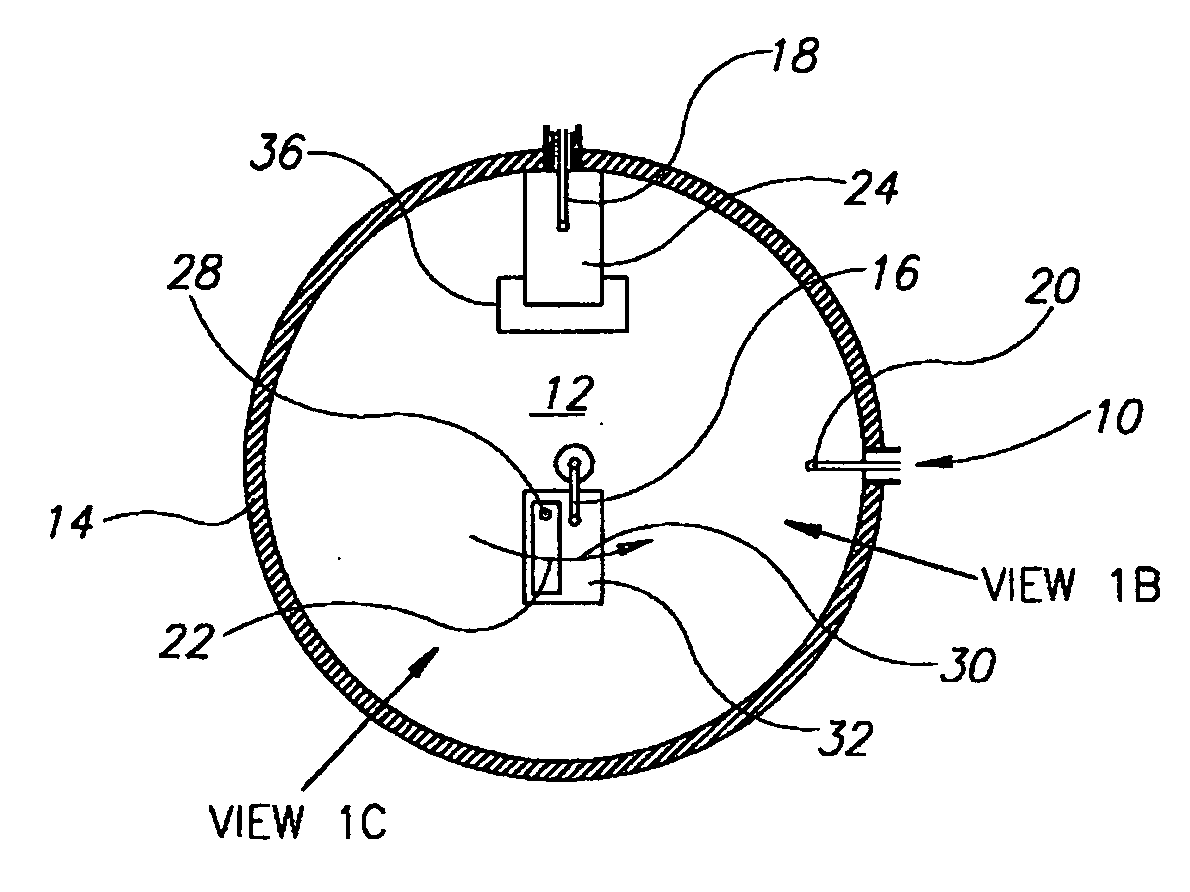

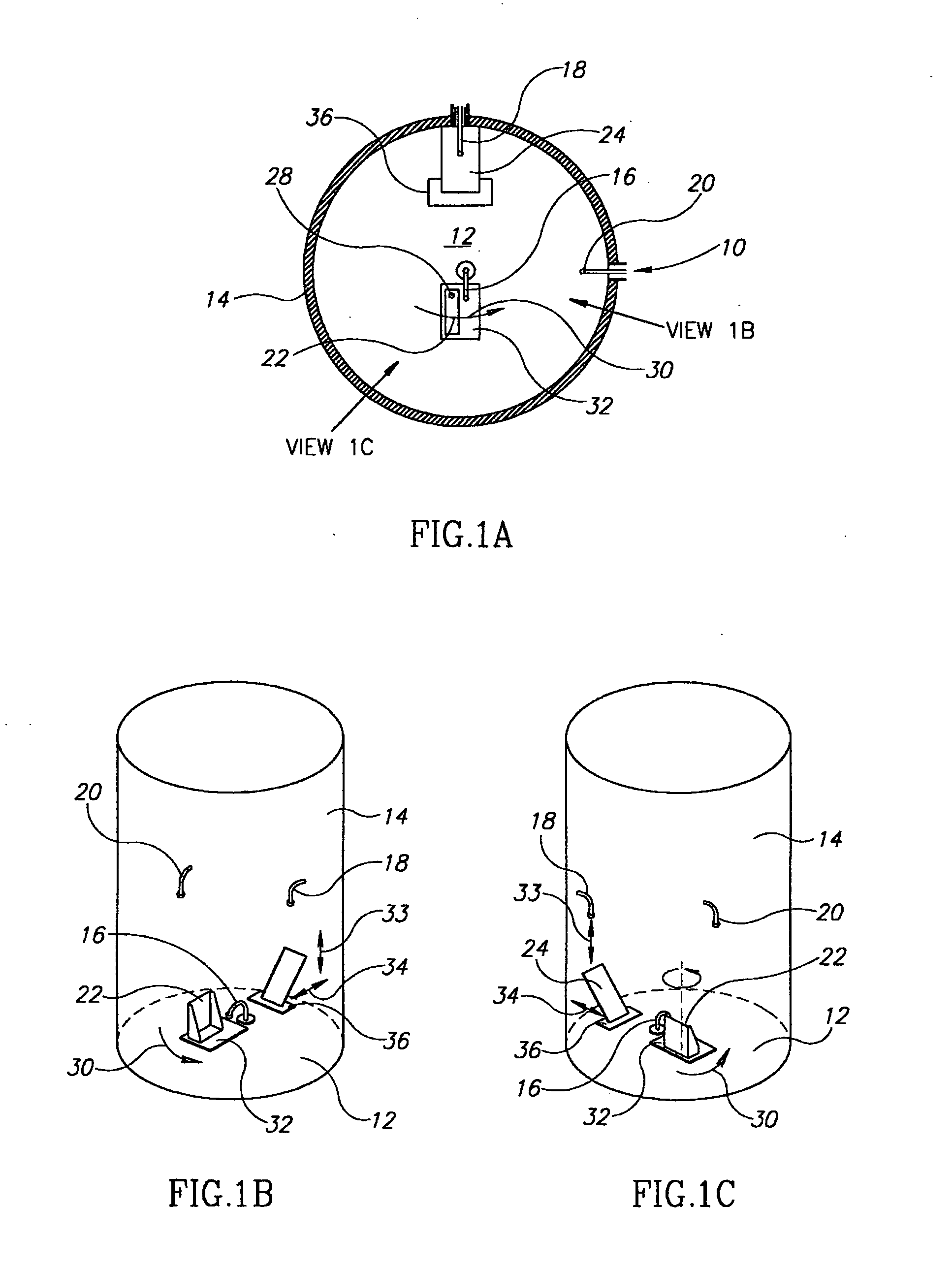

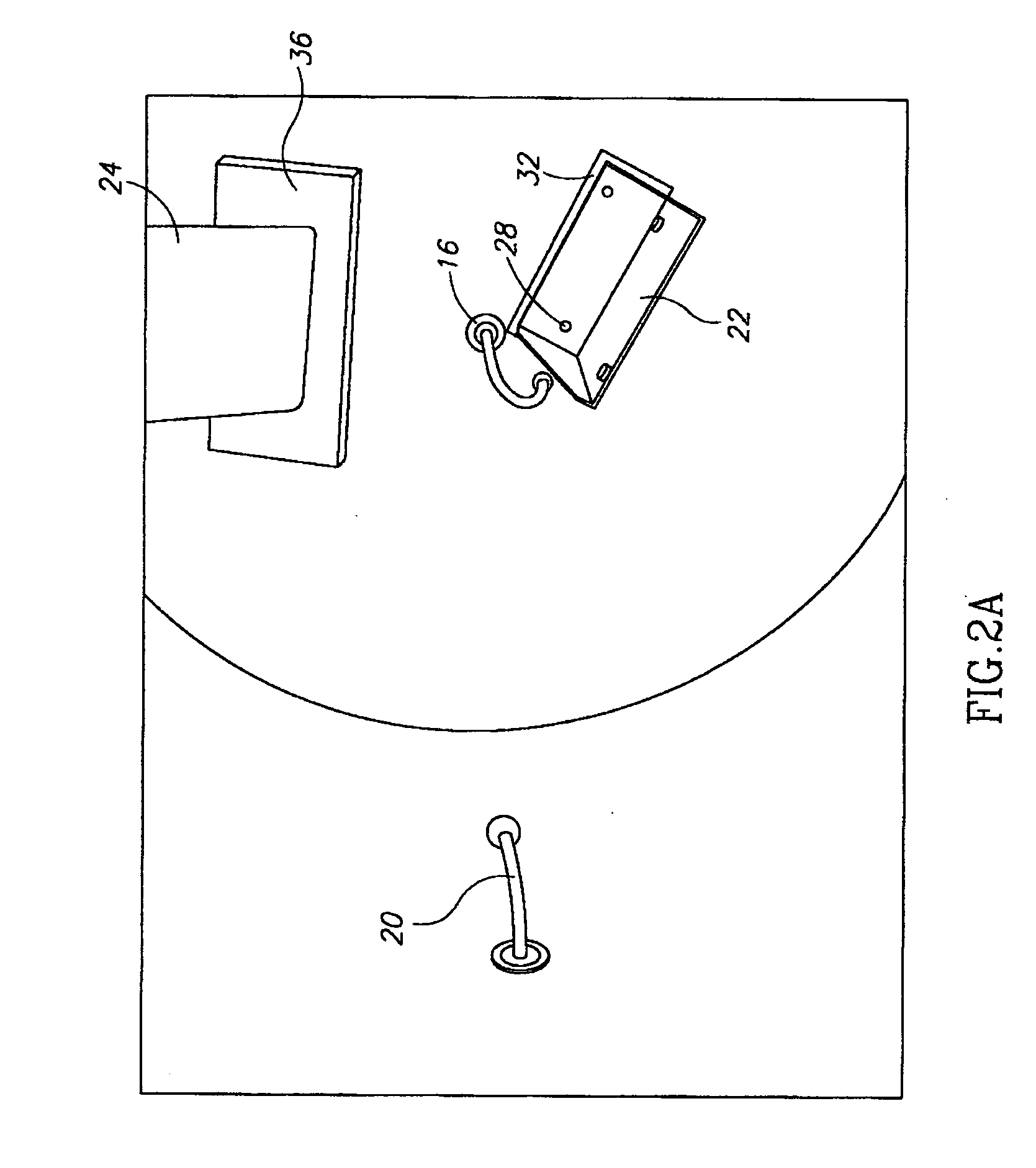

Container for heating rapidly and evenly frozen foods in a microwave oven

The present invention relates to a container for cooking food in a microwave oven. The container includes a tray having a bottom wall and a side wall that is attached to the bottom wall and extends upwardly from the bottom wall to define an interior cavity and a support means to provide support for a food product and elevate the food product with respect to the bottom wall. A continuous shielding layer is provided in the bottom wall and the side wall of the tray. The bottom wall and side wall of the tray along with the bottom of the food product define a free space under the food product that totally reflects microwave beams that pass through the food product back in the direction of the food product. The container of the invention reduces the formation of temperature gradients in the food product when it is heated and accelerates the microwave reheating of the food product. The container is particularly useful for reheating large blocks of frozen food.

Owner:NESTEC SA

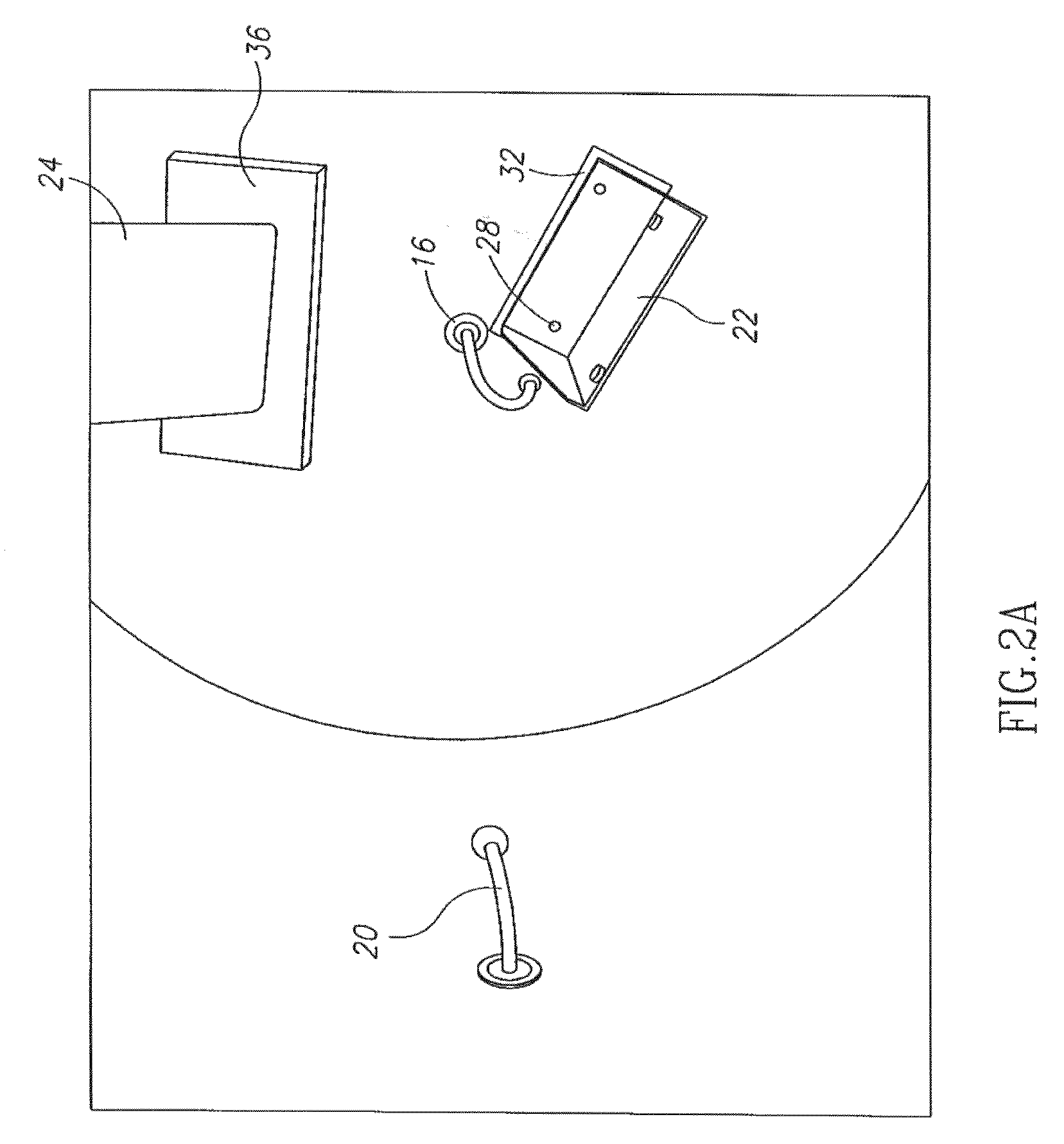

Oven for heating a product with RF energy

RF energy provided by electrodes positioned between a product is used to heat a product that exhibits a variable impedance during the heating process. As the product's impedance changes during the heating process, RF heating system impedance can be maintained constant by adjusting the distance between the electrodes, adjusting the impedance of a variable impedance device connected between the RF power source and an electrode, or a combination of electrode distance adjustment and impedance adjustment of the variable impedance device. The system is particularly applicable to the heating or pasteurization of bulk food products with multiple heating zones.

Owner:XP POWER LLC

Electromagnetic heating

ActiveUS20080290087A1Improve efficiencyIncrease net powerLighting and heating apparatusFood preservationElectromagnetic heatingFast scanning

Owner:JOLIET 2010 LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com