Food product surface sterilization apparatus and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

French Fried Frozen Potatoes in a Rotary Drum

[0178] Frozen, partially fried, shoestring French fried potato strips are to be surface sterilized prior to being provided to a multiple select scale unit, which is circular from a plan or overhead view. Since this food product is to be introduced to the center of the scale unit, an embodiment of the sterilizer 181 which is supported from above (as in FIG. 7) is selected to facilitate the drum 111 being above the multiple select scale. Assuming the potato strips are frozen, and are being sterilized in an unconditioned ambient atmosphere, the drum 111 may be insulated to prevent condensation on the exterior of the drum, wherein the condensation could drip onto the potato strips on the multiple select scale. The flow rate of the potato strips through the drum 111 is limited by the scale to no more than 50 weighments per minute of 6.5 pounds per weighment, or a flow rate of 325 pounds of potato strips per minute (50 weighments / minute*6.5 lbs...

example 2

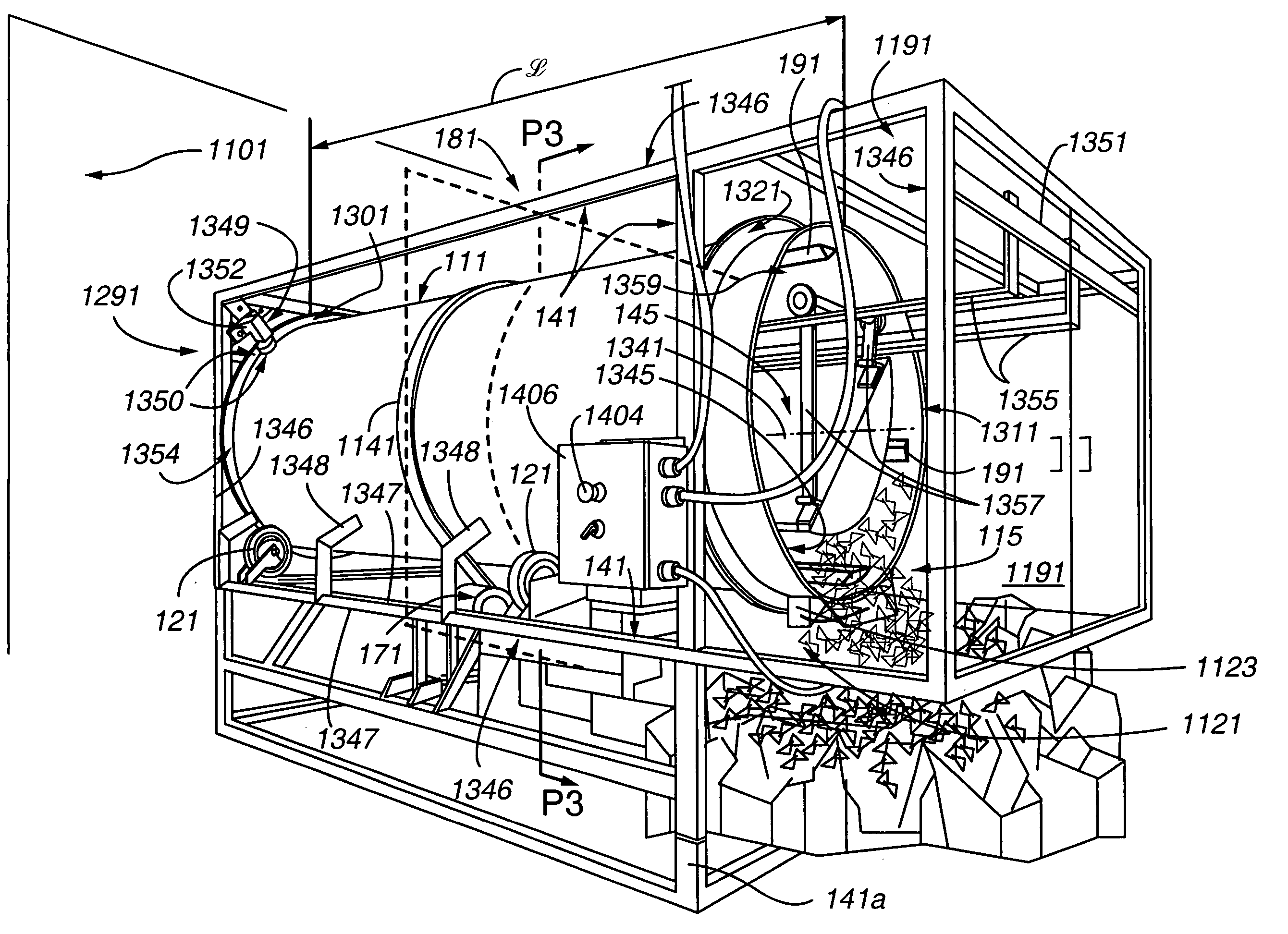

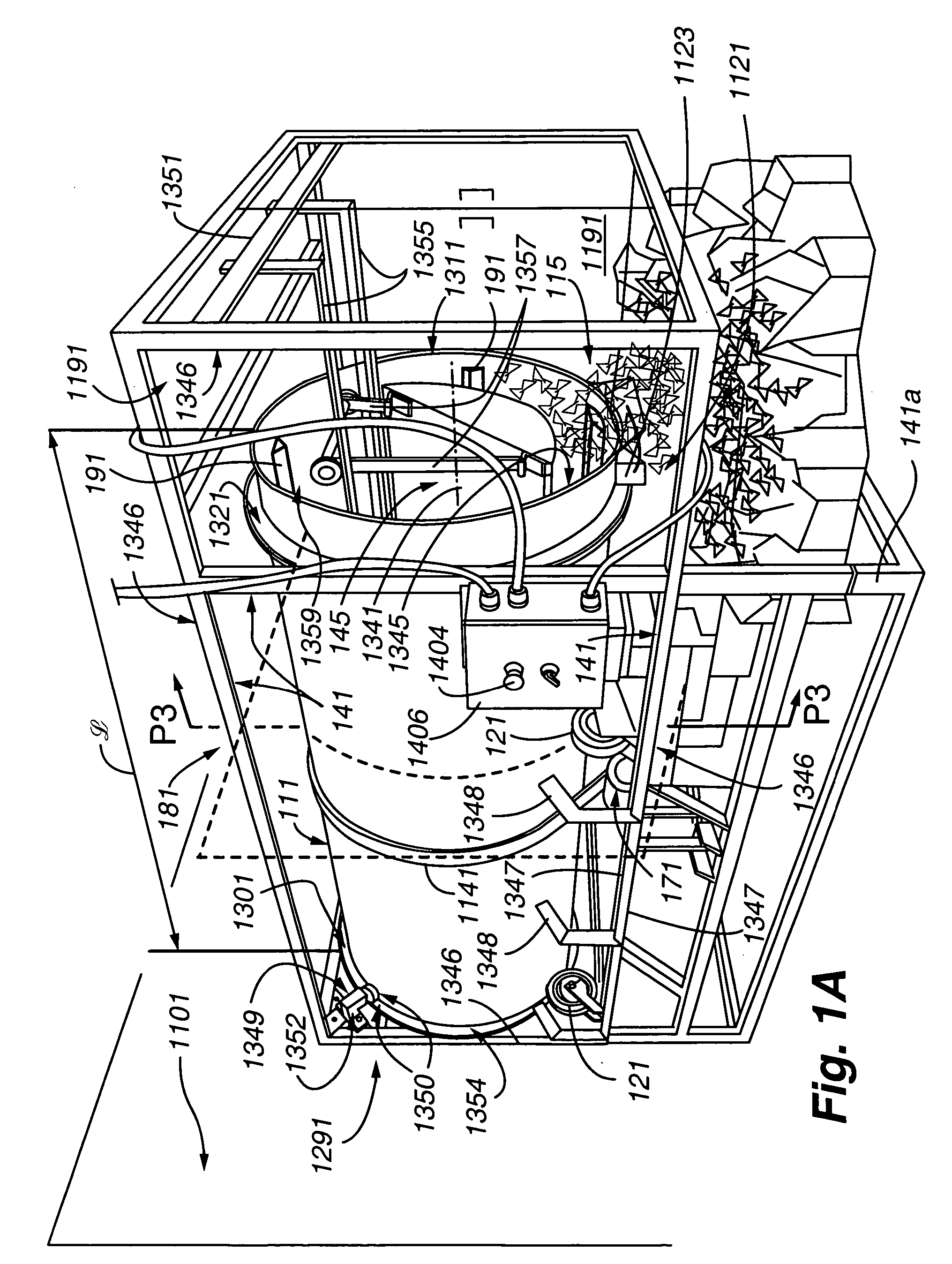

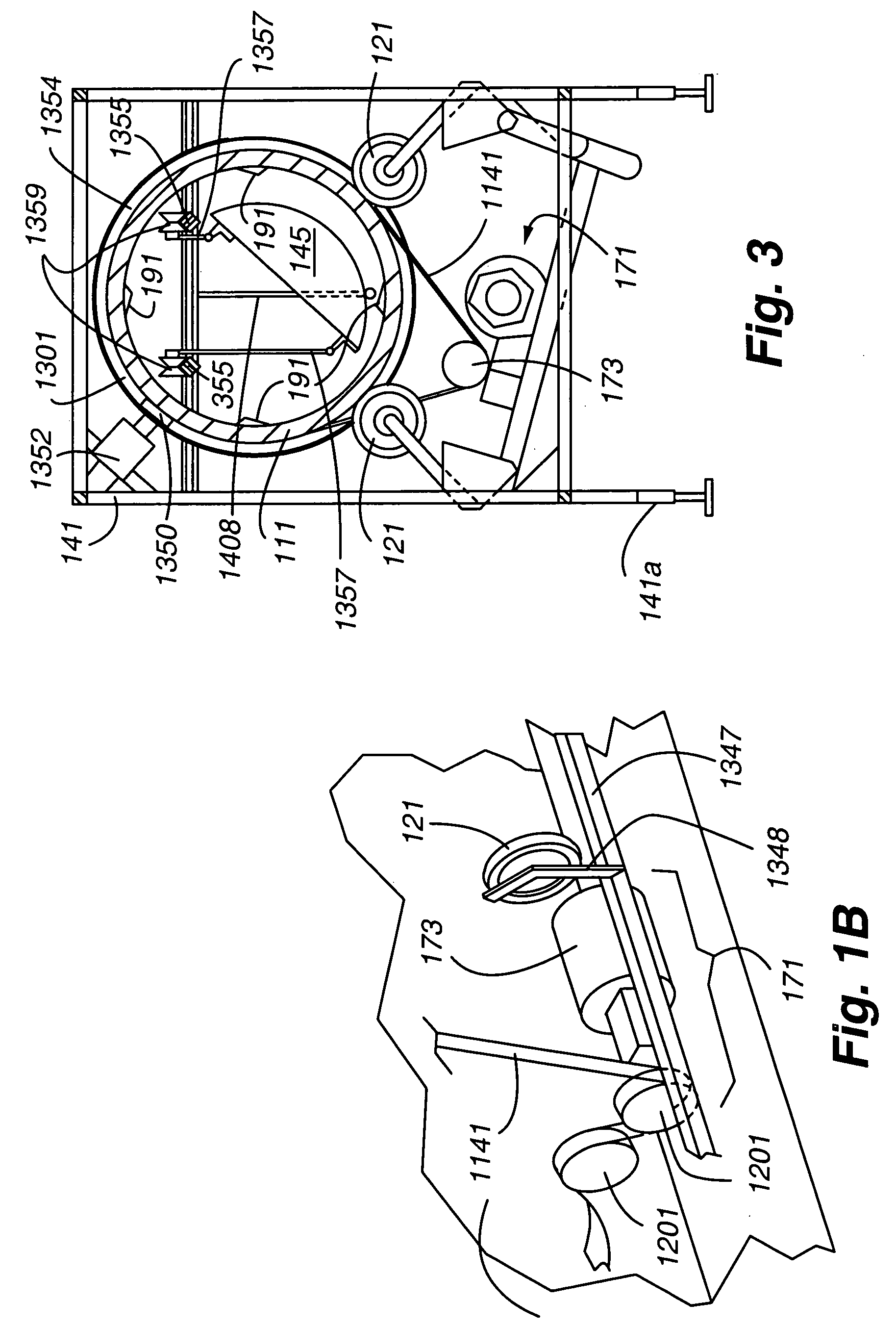

Raw Potatoes to a Potato Storage in a Rotating Drum

[0180] Raw potatoes are to be surface sterilized after being harvested from an agricultural field, and prior to being provided to a storage building. Since the potatoes are delivered with a truck, an embodiment of the sterilizer 181 which is supported from the floor or ground level (as in FIG. 1A) is selected. Since the potatoes are harvested as a root crop from underground in an agricultural field, an embodiment with a perforated drum 111 is selected to separate any loose dirt from the potatoes. Attenuating baffles 1191 are installed around the entire sterilizer 181 to contain the UVC light used with the perforated drum 111. The sterilizer 181 is to be integrated into an existing series of equipment, which receives the potatoes from the transport truck, removes dirt and vines, and conveys the potatoes into a bulk storage building. The potato flow rate for unloading transport trucks into the storage building is limited to no more th...

second embodiment

[0182] the surface sterilizer 181 will now be described with reference to the FIGS. 14 through 16.

[0183] FIG. 14 is a isometric view of a screw conveyor embodiment of the surface sterilizer 181 (denoted herein as screw conveyor sterilizer 1600) having a trough 1604 with an auger assembly 1608 therein. The auger assembly 1608 includes an auger shaft 1612, a plurality of auger flights 1616, and a plurality of lifting tumblers 1620 (that perform substantially the functions within the screw conveyor sterilizer 1600 as the tumblers 191 perform in the drum surface sterilizer 181 embodiments described above). The auger shaft 1612 has a longitudinal extent that traverses substantially the entire length of the trough 1604 (also denoted as a "transport" in, e.g., the Summary section above) from a food product infeed device 1624 to a food product discharge device 1628. Each of the auger flights 1616 spans substantially an entire cross sectional extent of the trough 1604 (such cross sectional e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com