Patents

Literature

36005results about How to "Increase temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

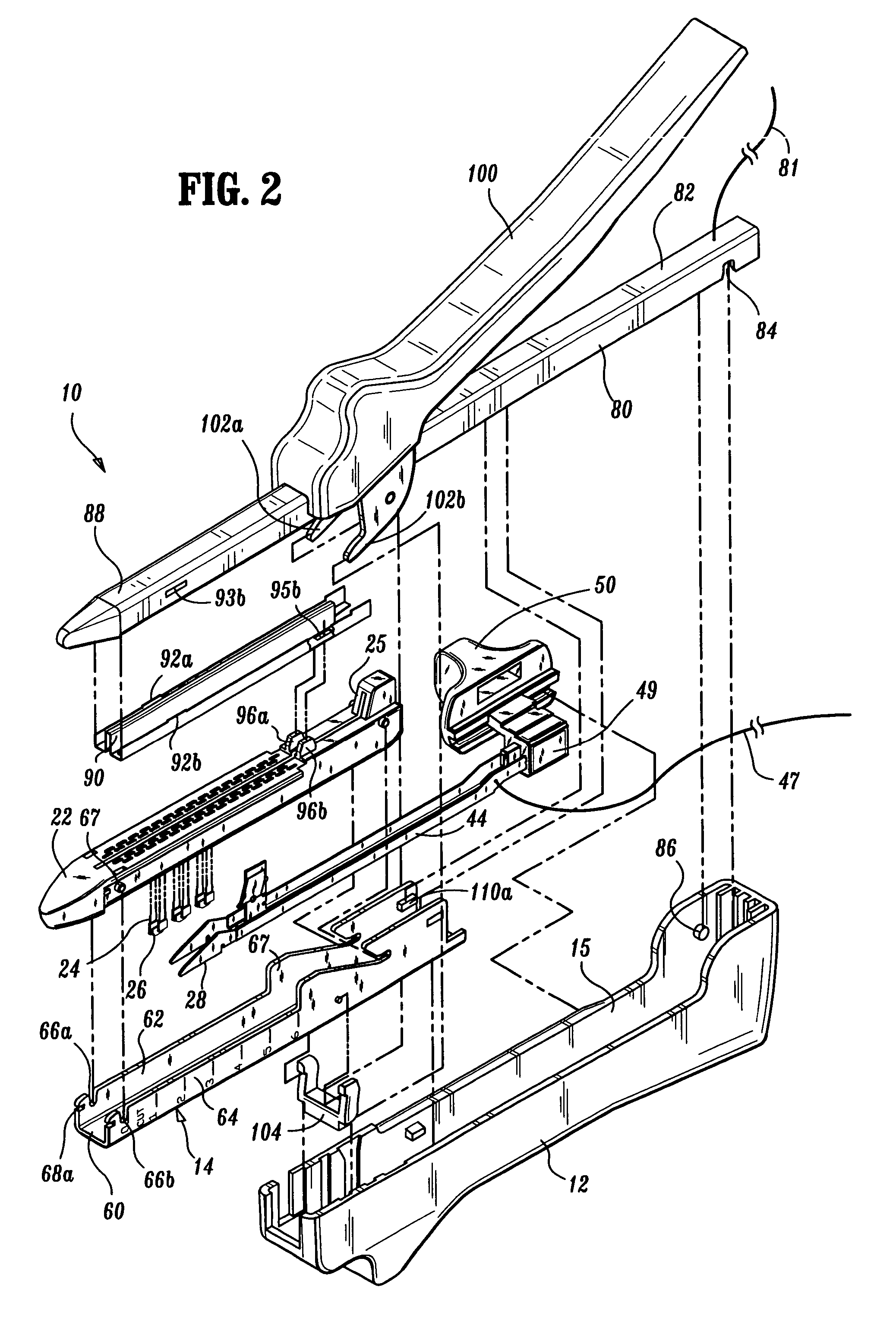

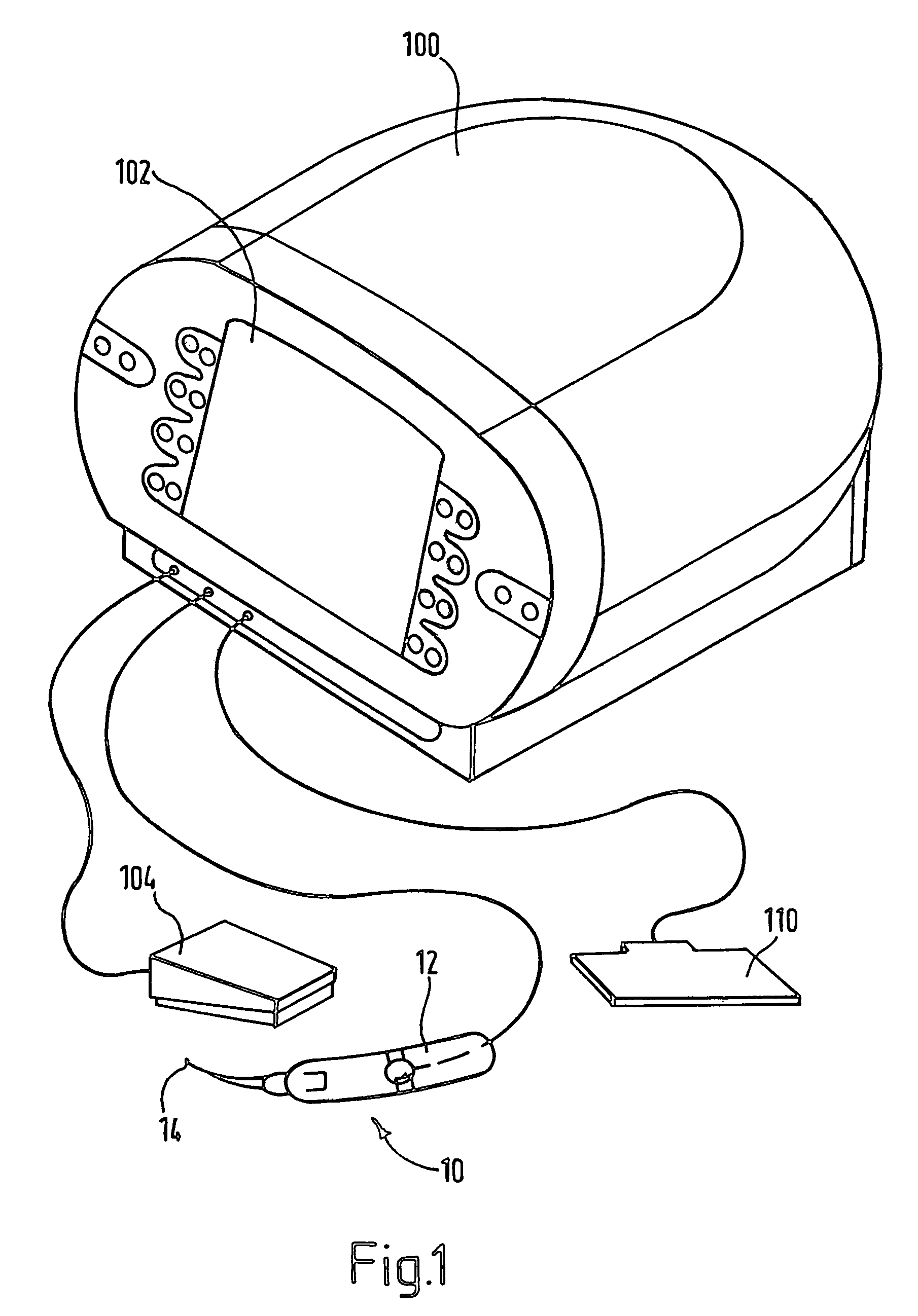

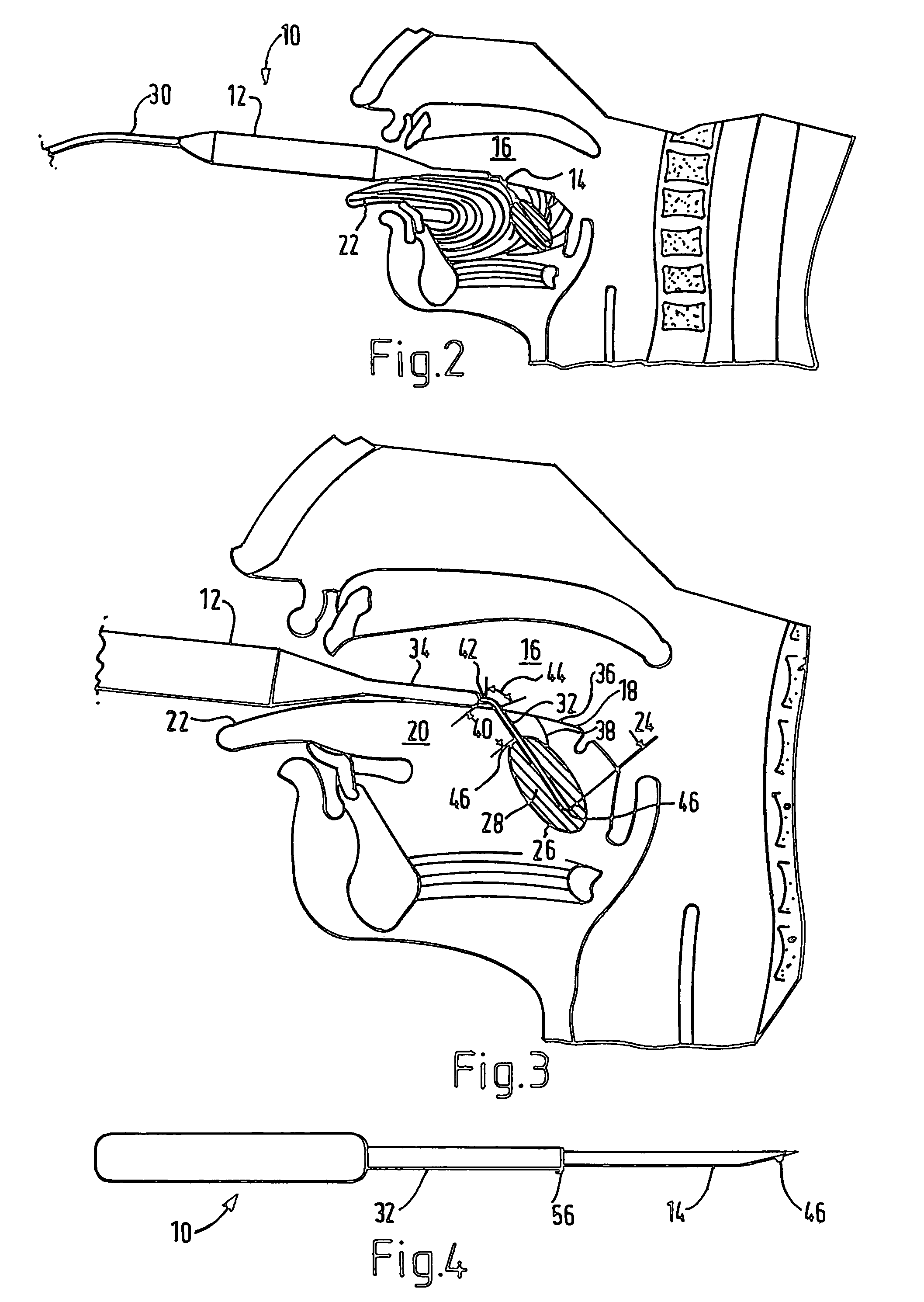

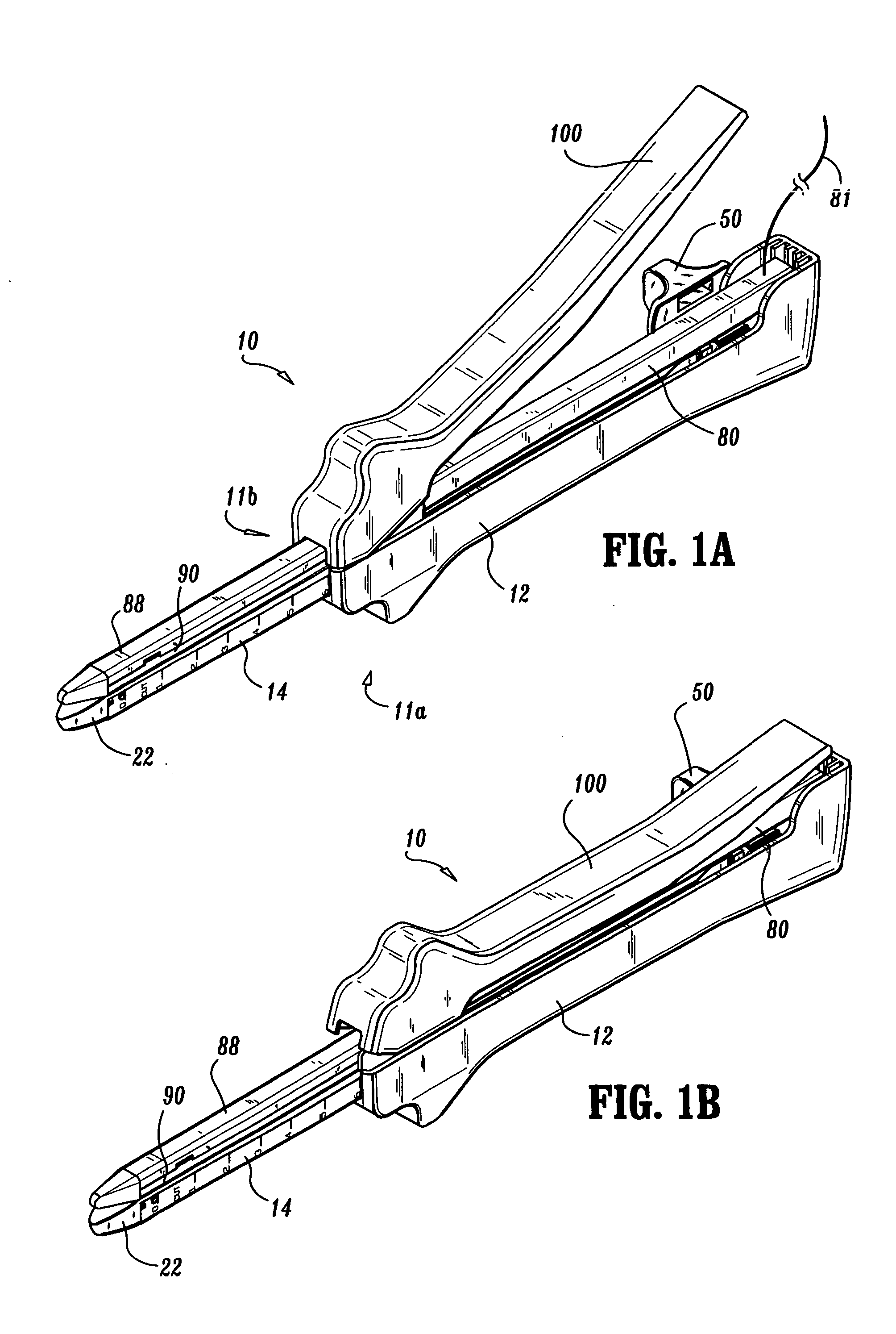

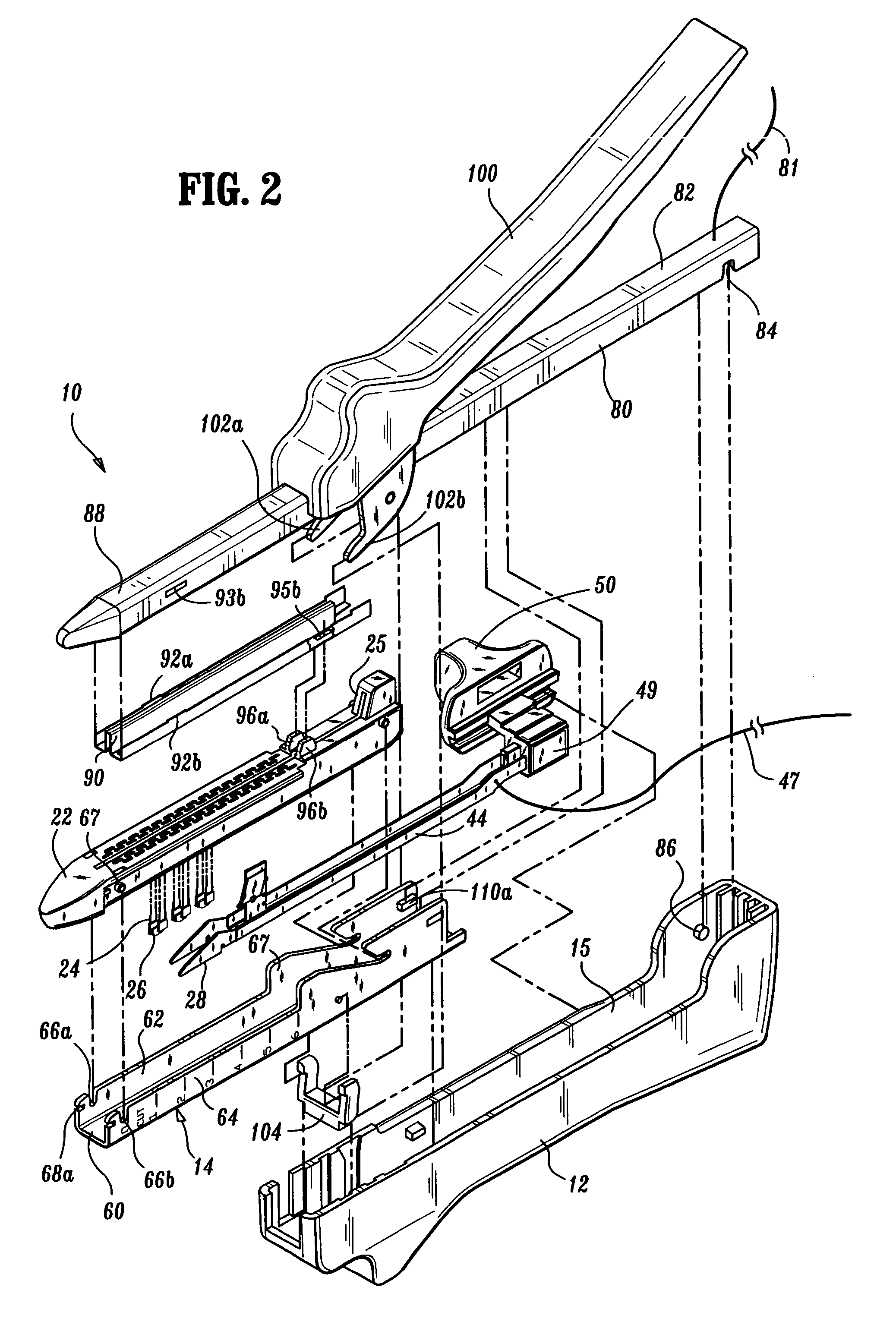

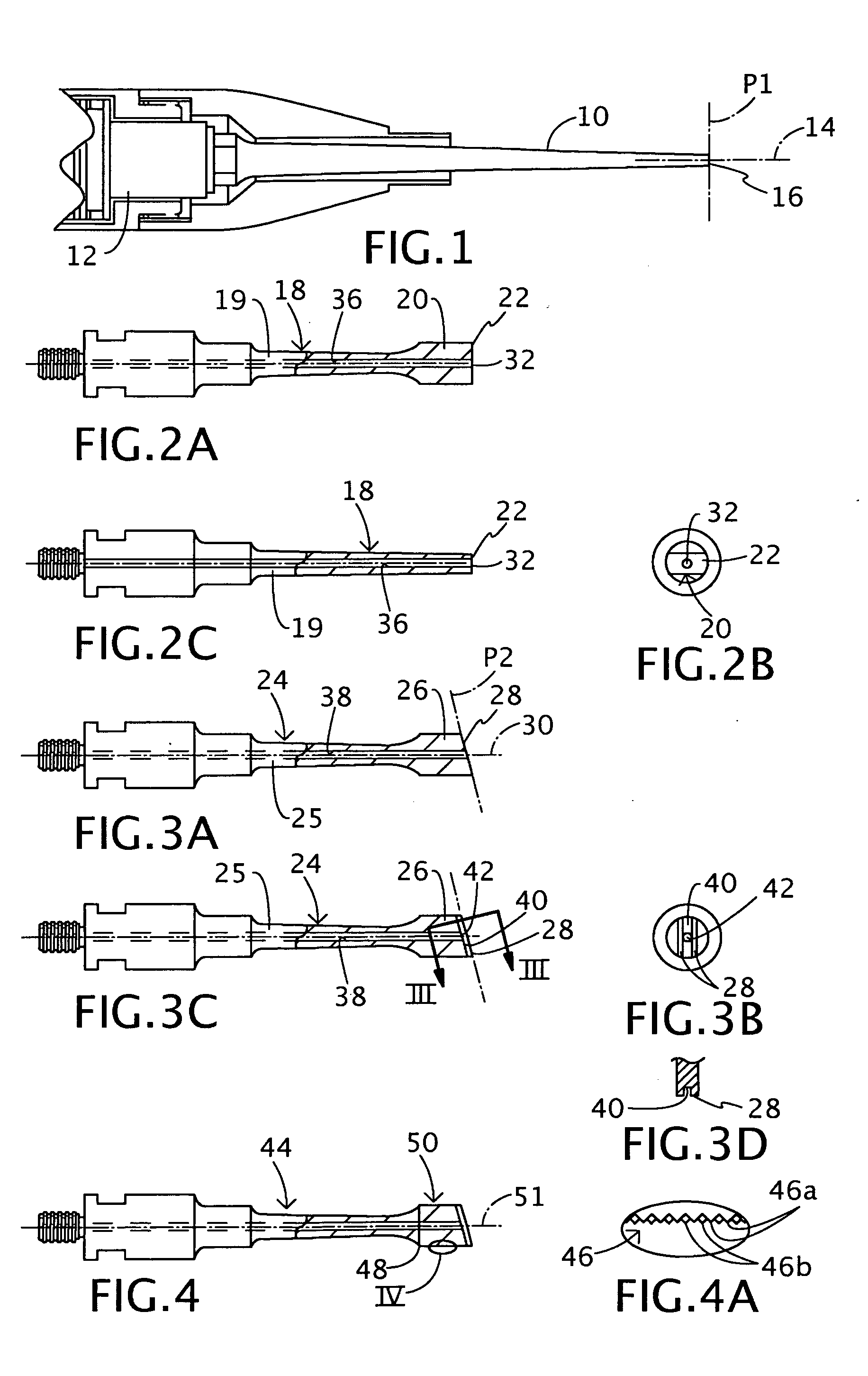

Electrosurgical stapling apparatus

InactiveUS7207471B2Reduces or prevents staple line and cut line bleedingShort and strengthSuture equipmentsStapling toolsStaple lineEngineering

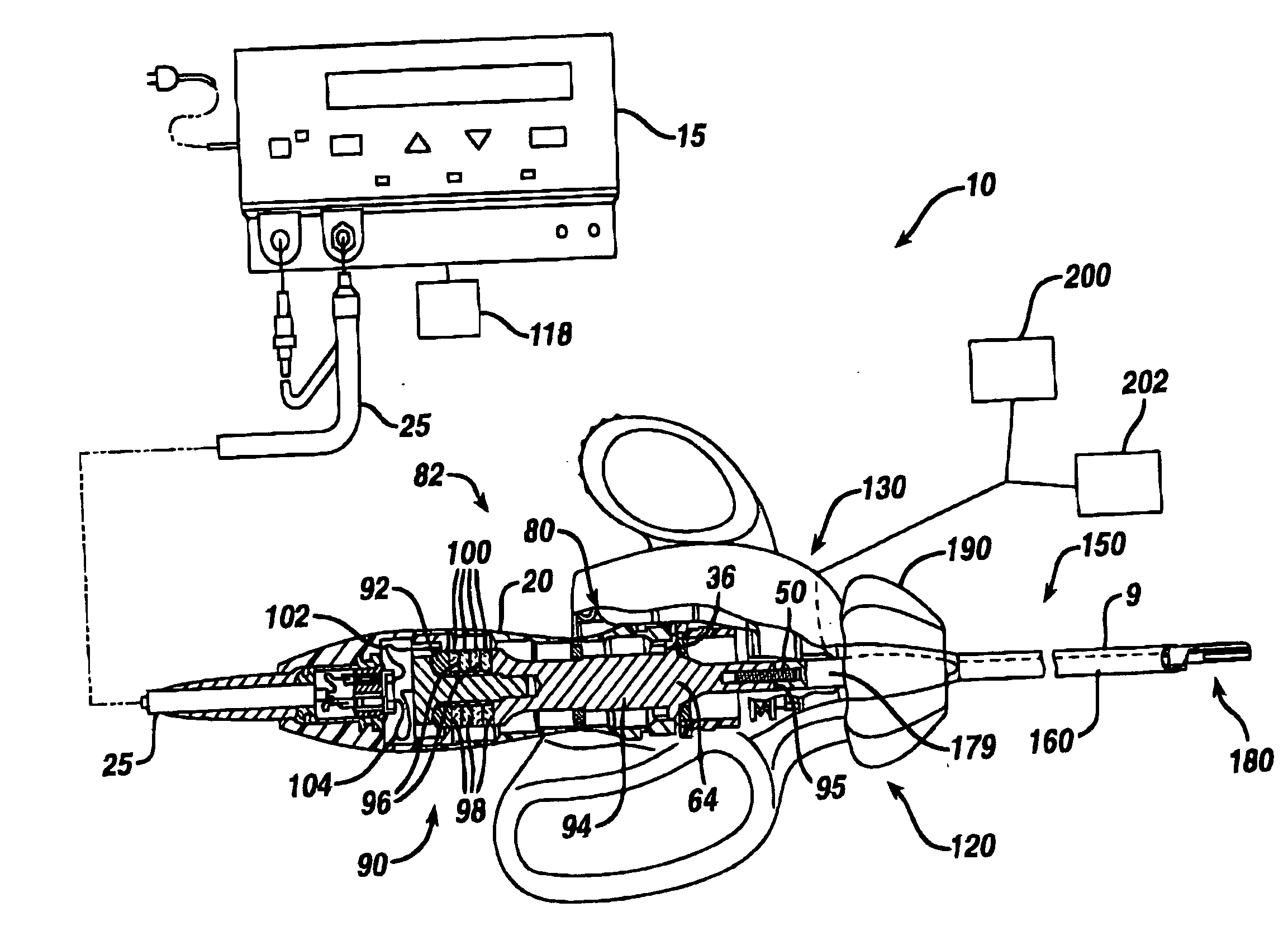

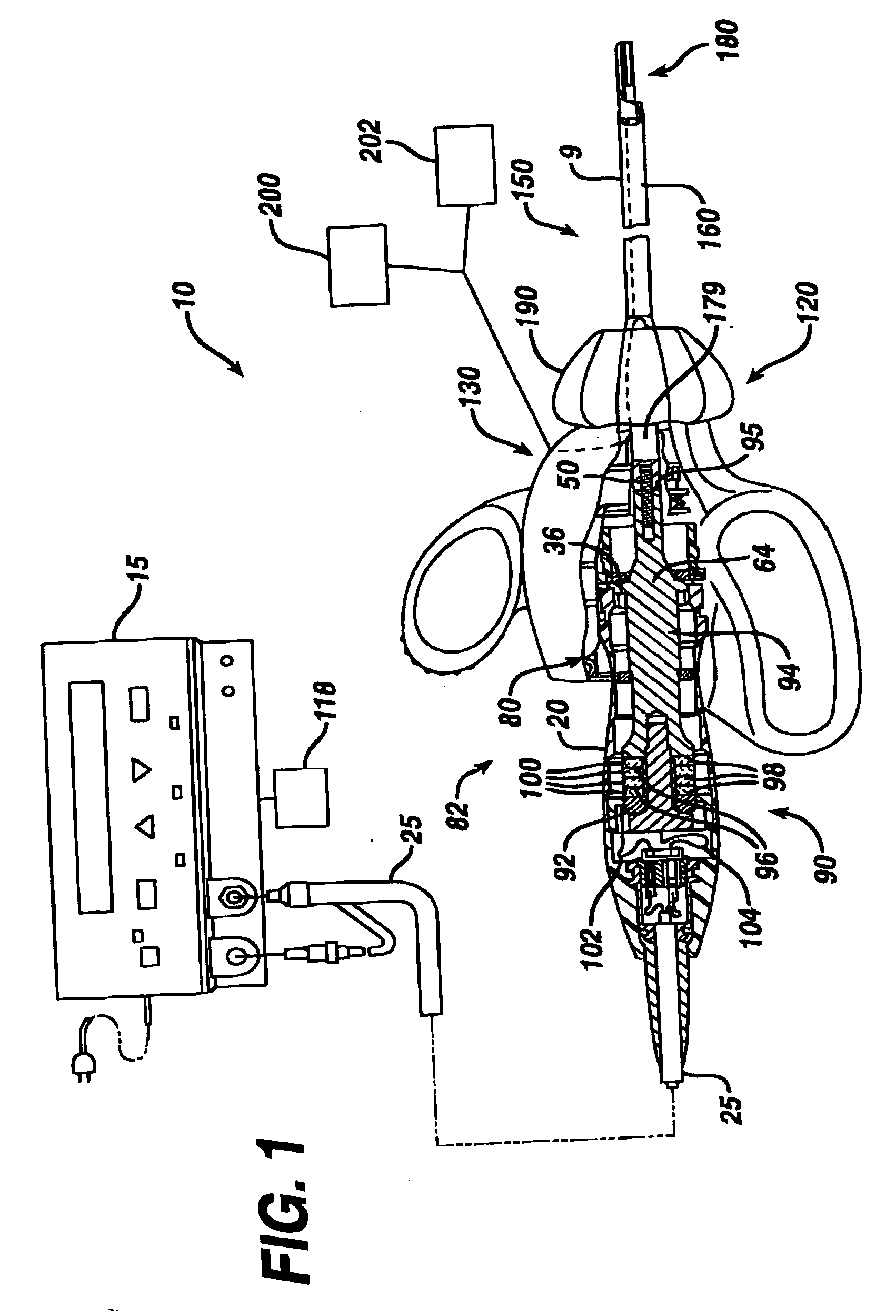

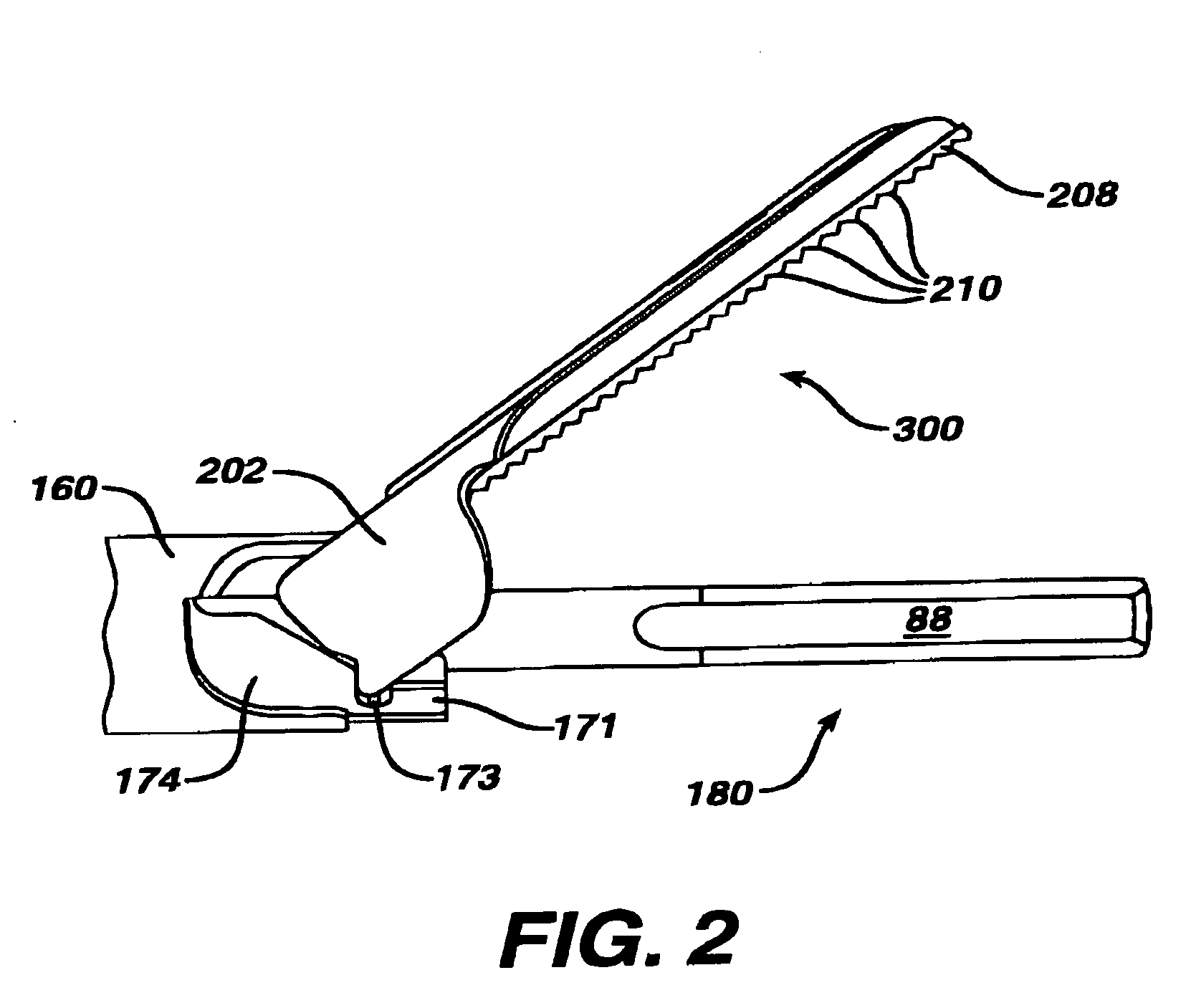

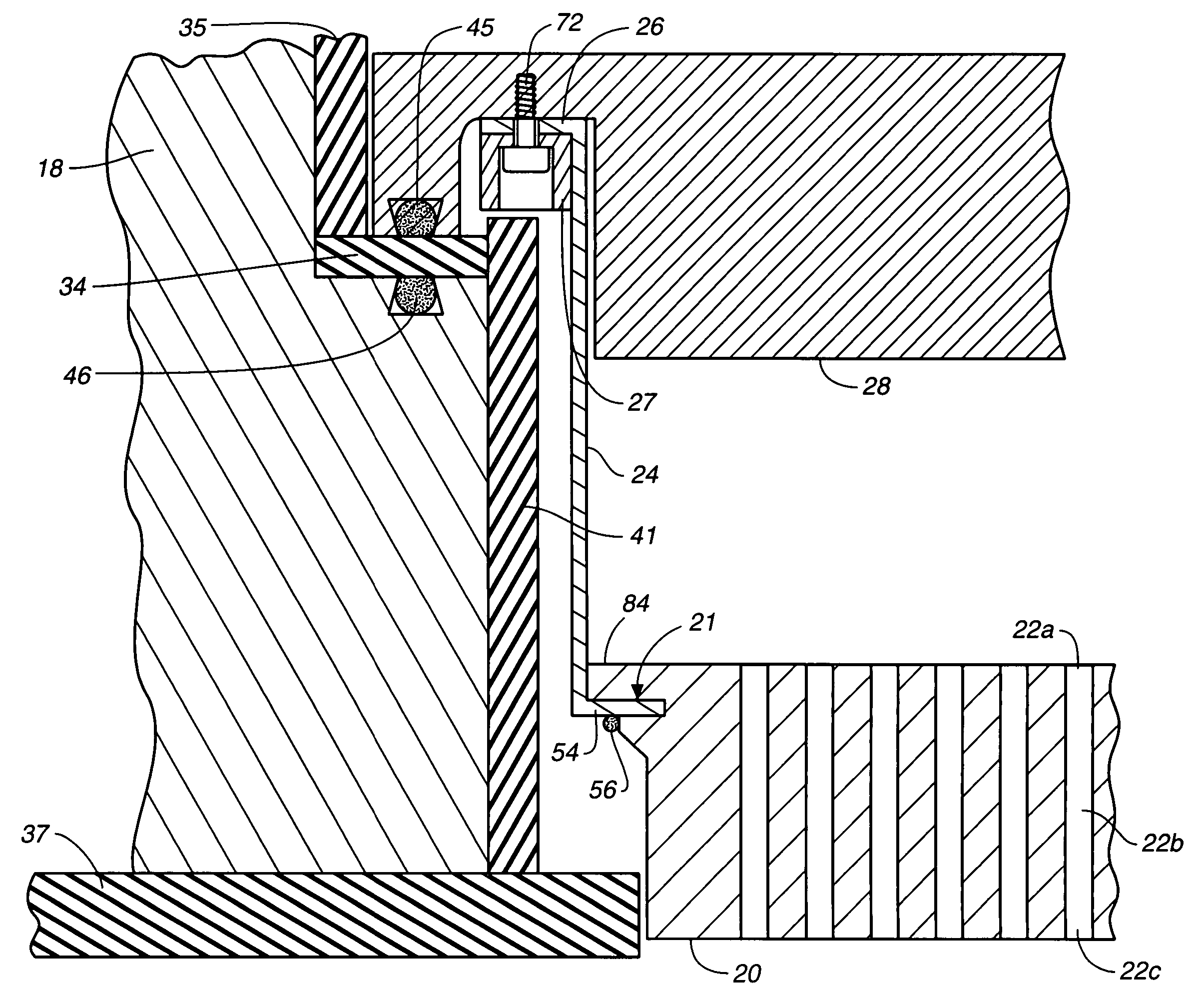

An electrosurgical stapling apparatus is provided which uses thermogenic energy as well as surgical fasteners or staples for strengthening tissue, providing hemostasis, tissue joining or welding. The thermogenic energy also strengthens tissue in proximity to a staple line and knife cut line and provides hemostasis along the staple and cut lines formed by the staples and a knife blade during surgical stapling. The use thermogenic energy provides short-term hemostasis and sealing, and reduces or prevents staple line and cut line bleeding, while the stapling features provide short and long-term tissue strength and hemostasis. The stapling apparatus further substantially reduces or prevents knife cut line bleeding by energizing a knife blade for cauterizing tissue while it is being cut. In one embodiment, energy is applied to the anvil to energize the staples as they make contact with the anvil.

Owner:TYCO HEALTHCARE GRP LP

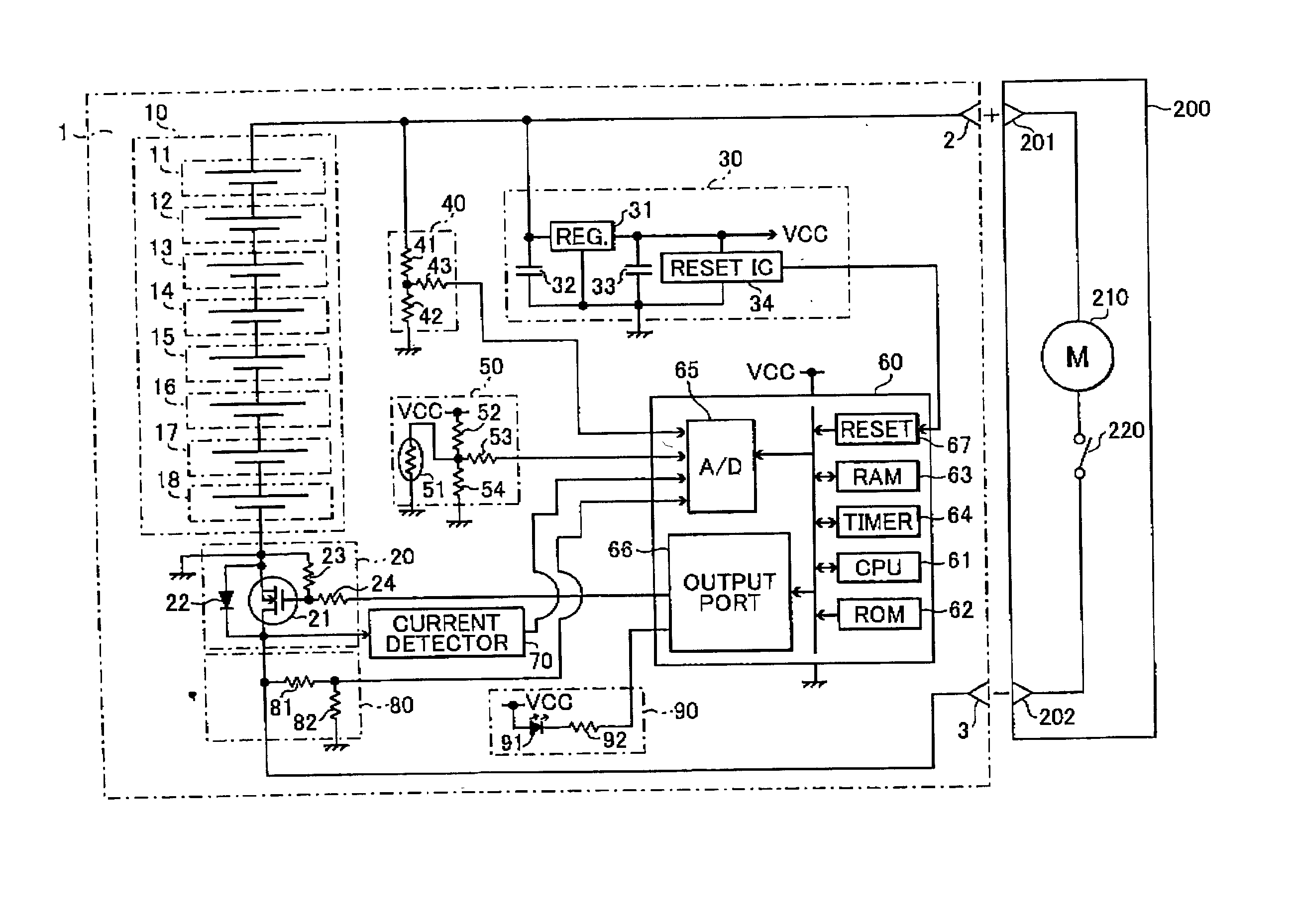

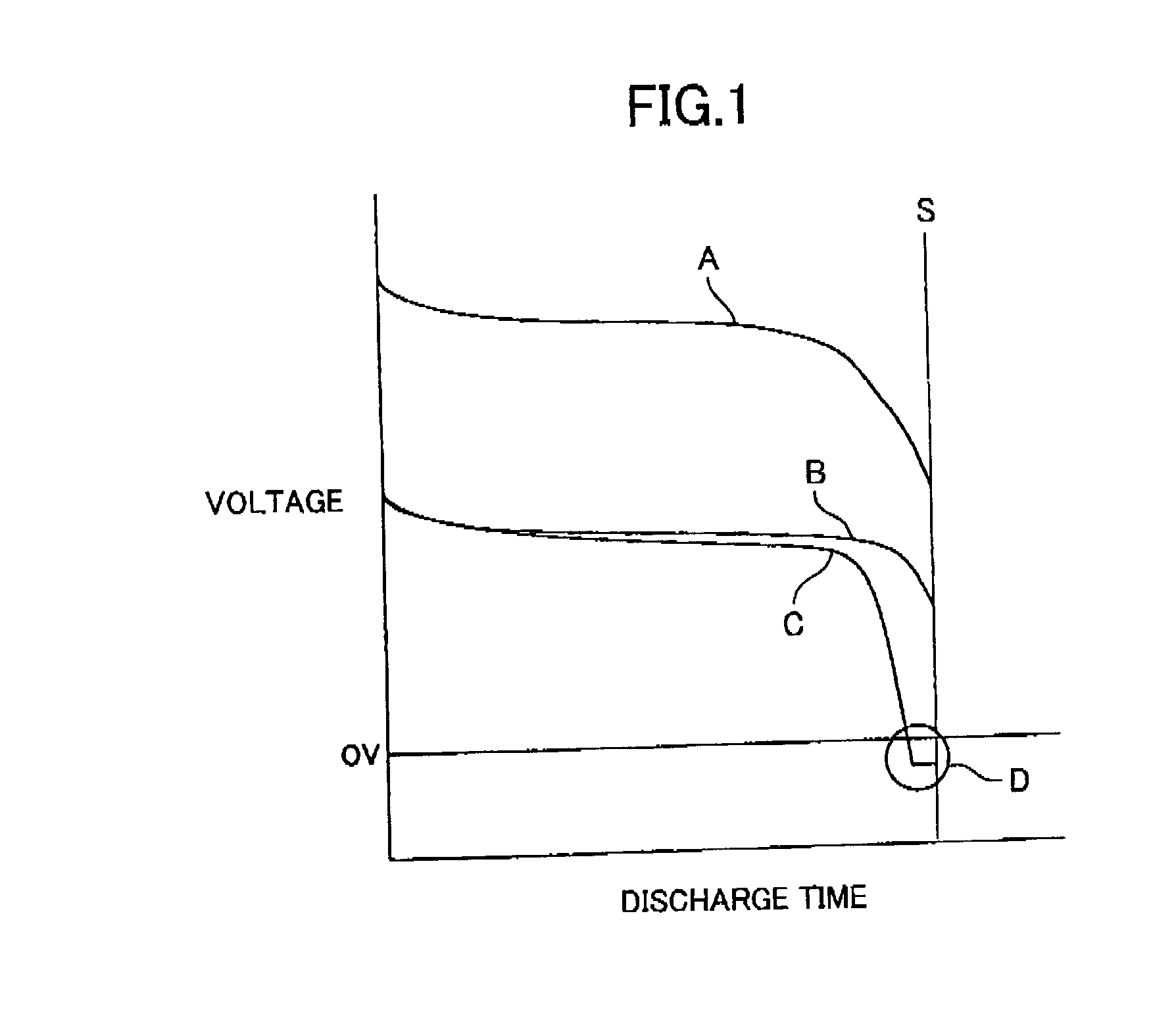

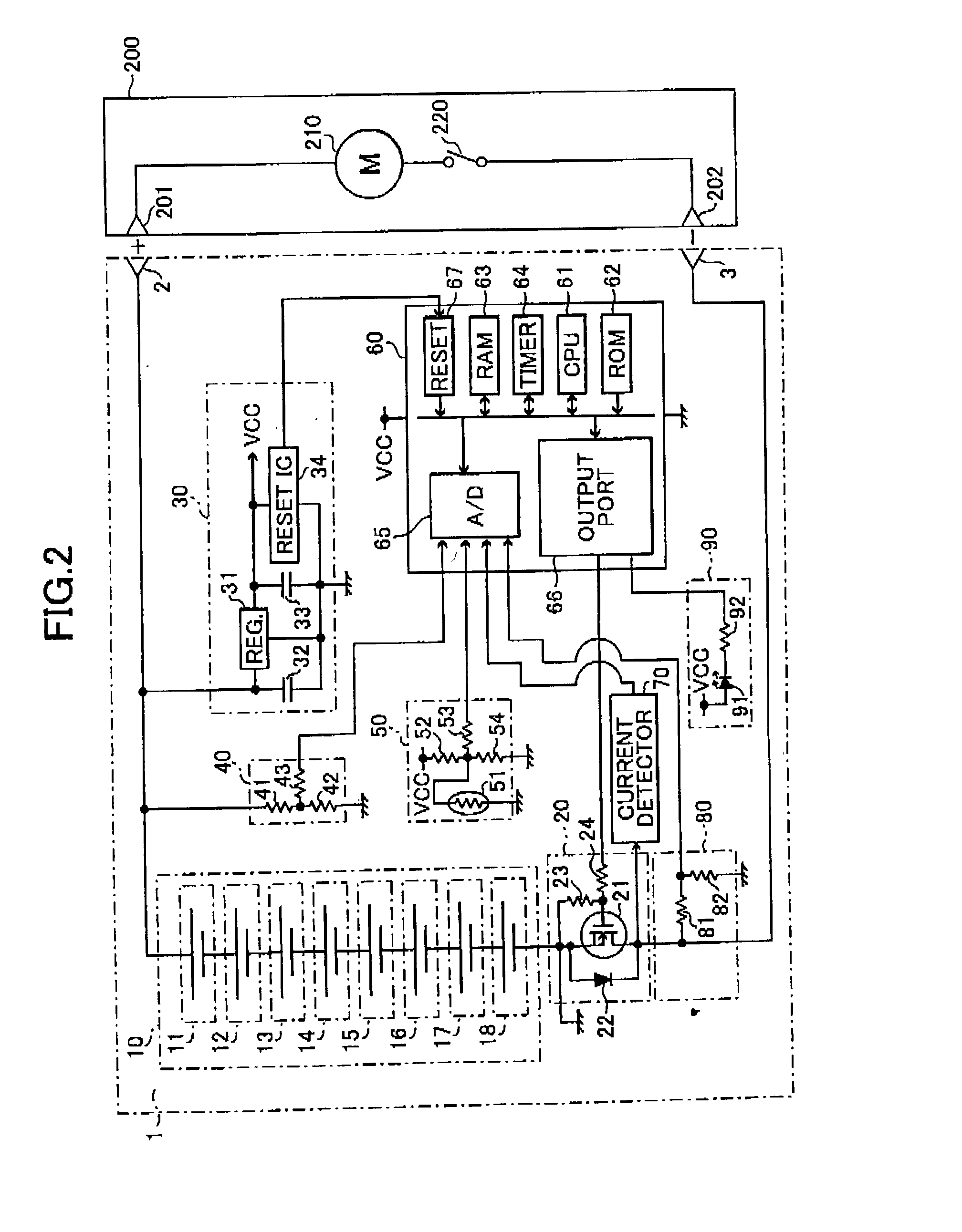

Battery pack and cordless power tool using the same as power source

InactiveUS20030096158A1Shortened battery lifeIncrease temperatureCells with cell condition indicationsSecondary cells charging/dischargingPower toolMicrocomputer

To prevent a battery from being over-discharged and to thus improve a cycle life of the battery, a microcomputer electrically interrupts connection between the battery and a cordless power tool to compulsorily stop driving the tool when the battery voltage has become equal to or fallen below a first predetermined value. Also, to enable an operator to know that the battery is in a near over-discharge condition, the microcomputer performs a switching control of a load current when the battery voltage is above the first predetermined voltage but has become equal to or falls below the second predetermined voltage. As a result, the rotation of the motor of the tool goes abruptly slow down or the motor rotates in an irregular fashion, whereby the operator recognizes that the battery is in a charge-need condition.

Owner:HITACHI KOKI CO LTD

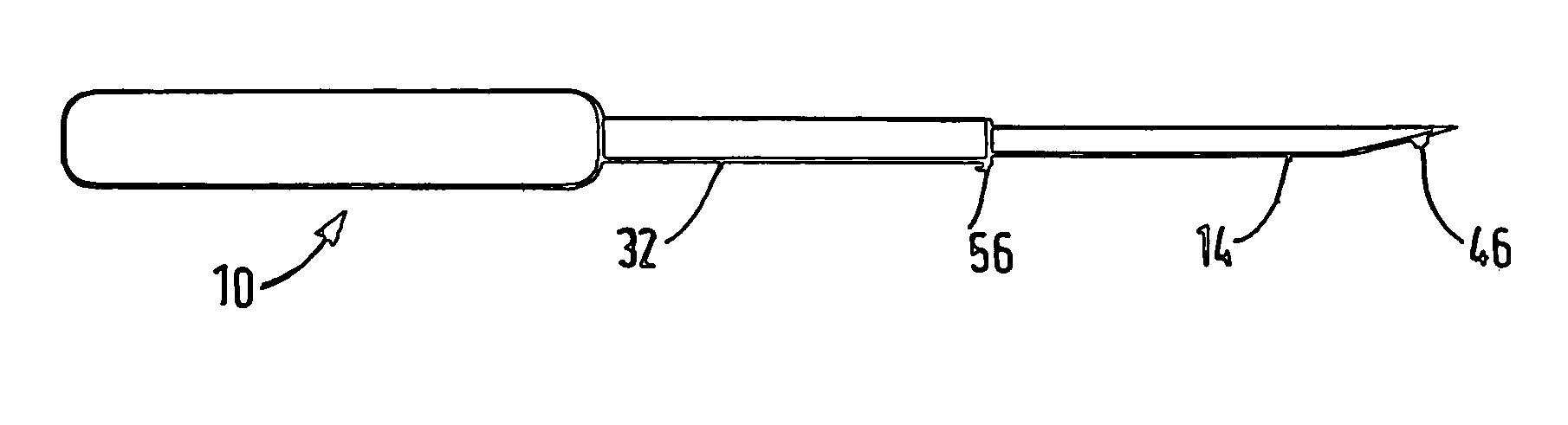

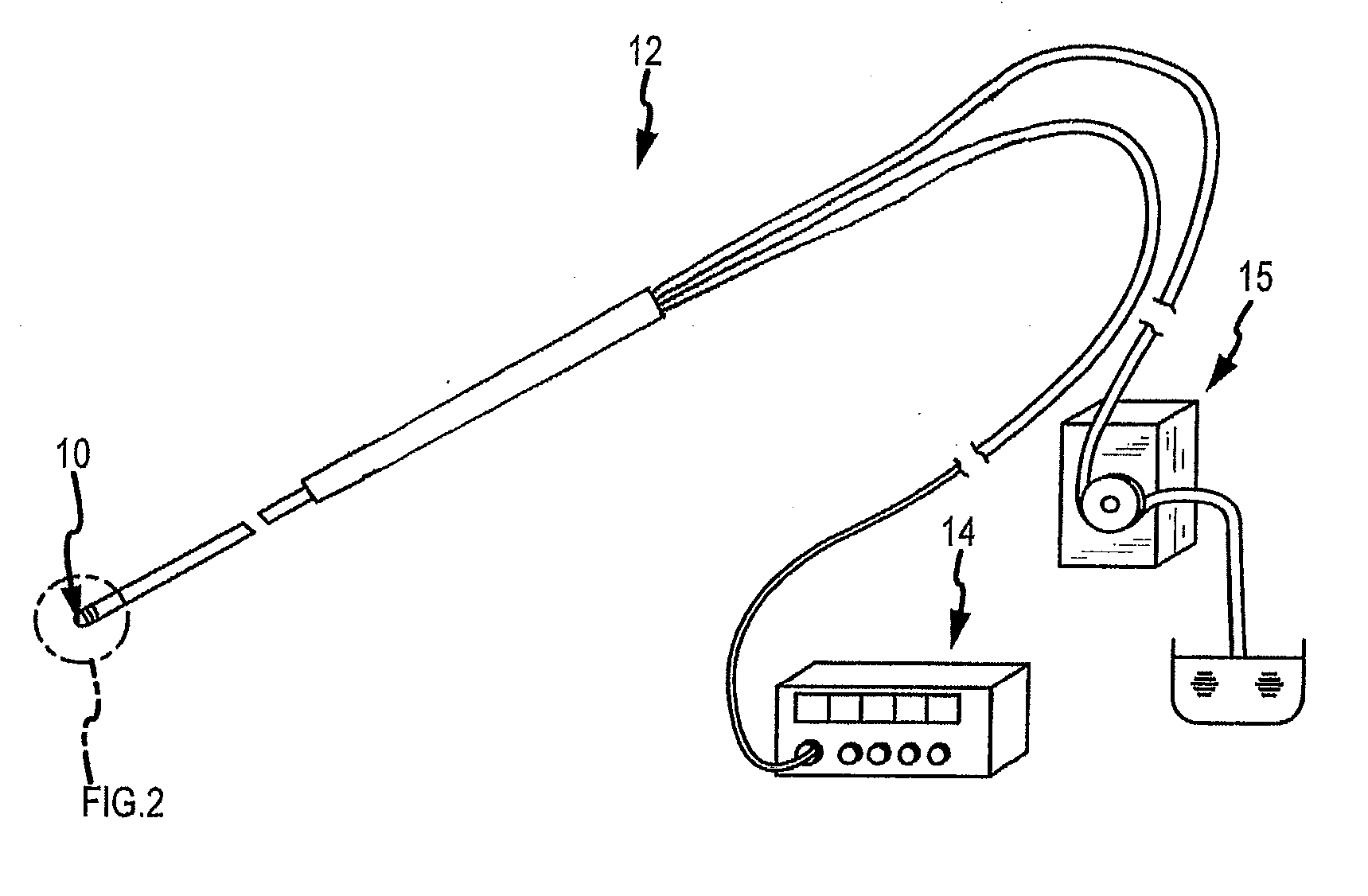

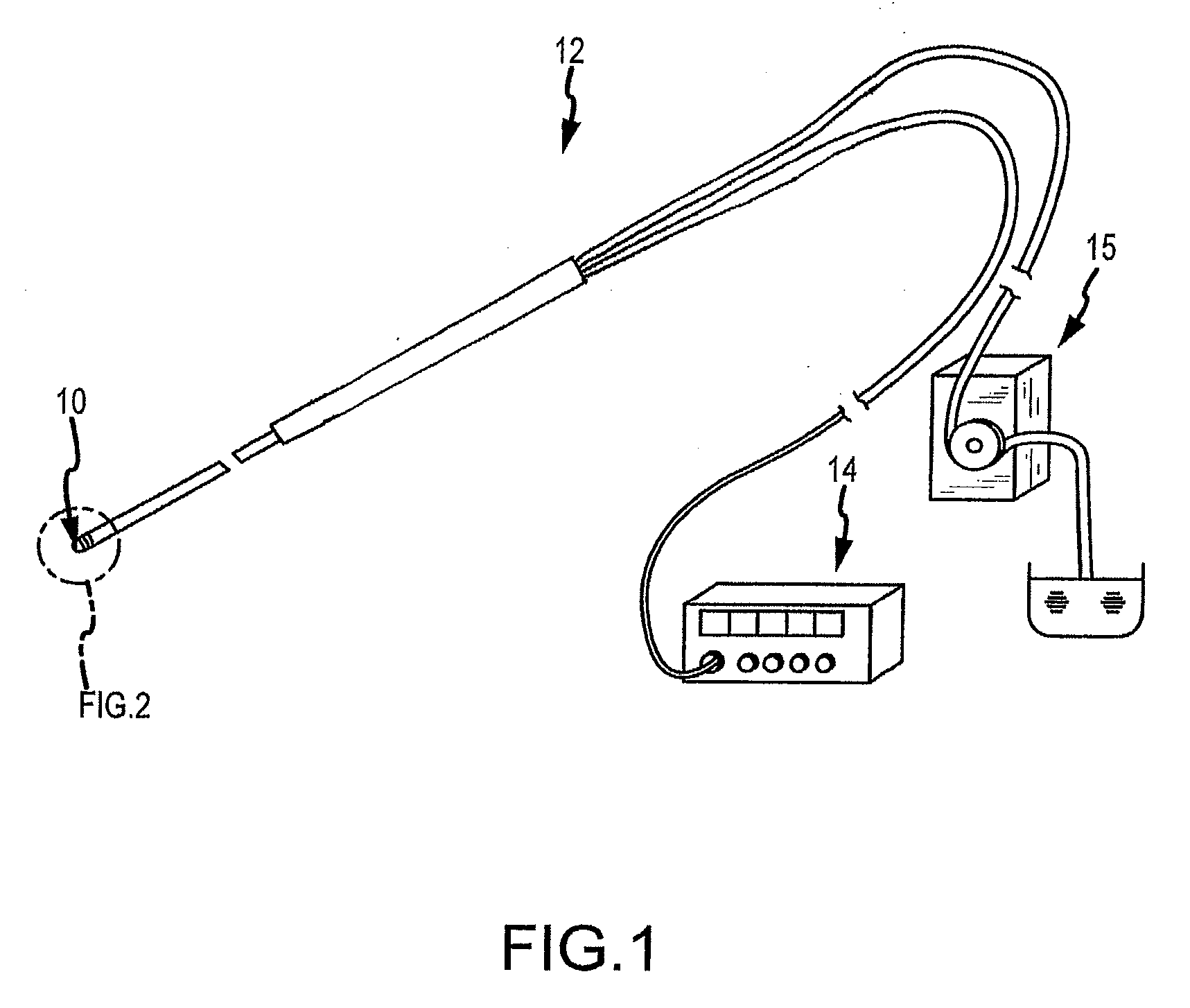

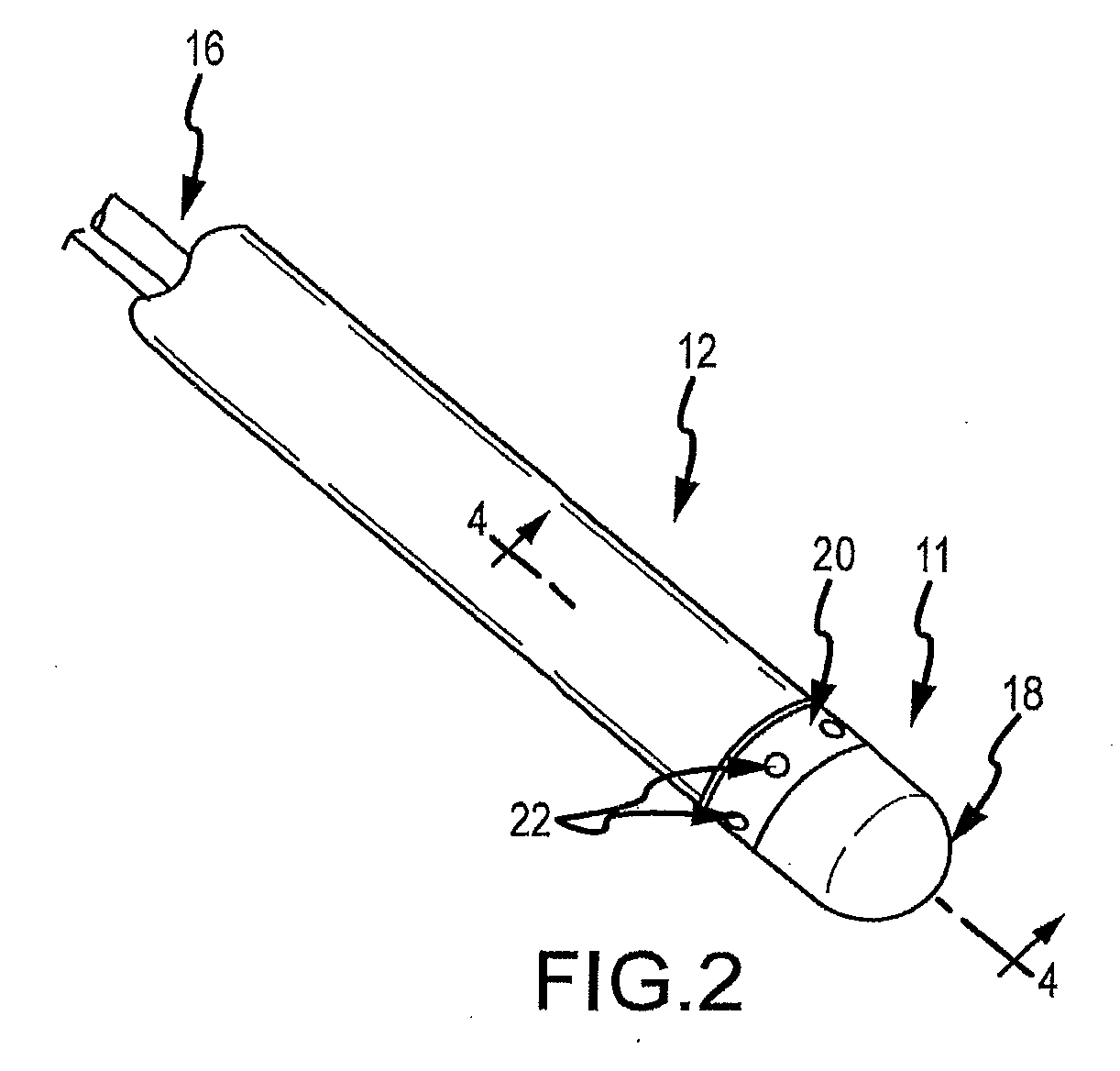

Electrosurgical method and apparatus

ActiveUS7377918B2Compensation delayIncrease temperatureSurgical needlesSurgical instruments for heatingThreshold temperatureRadio frequency

Owner:GYRUS ENT

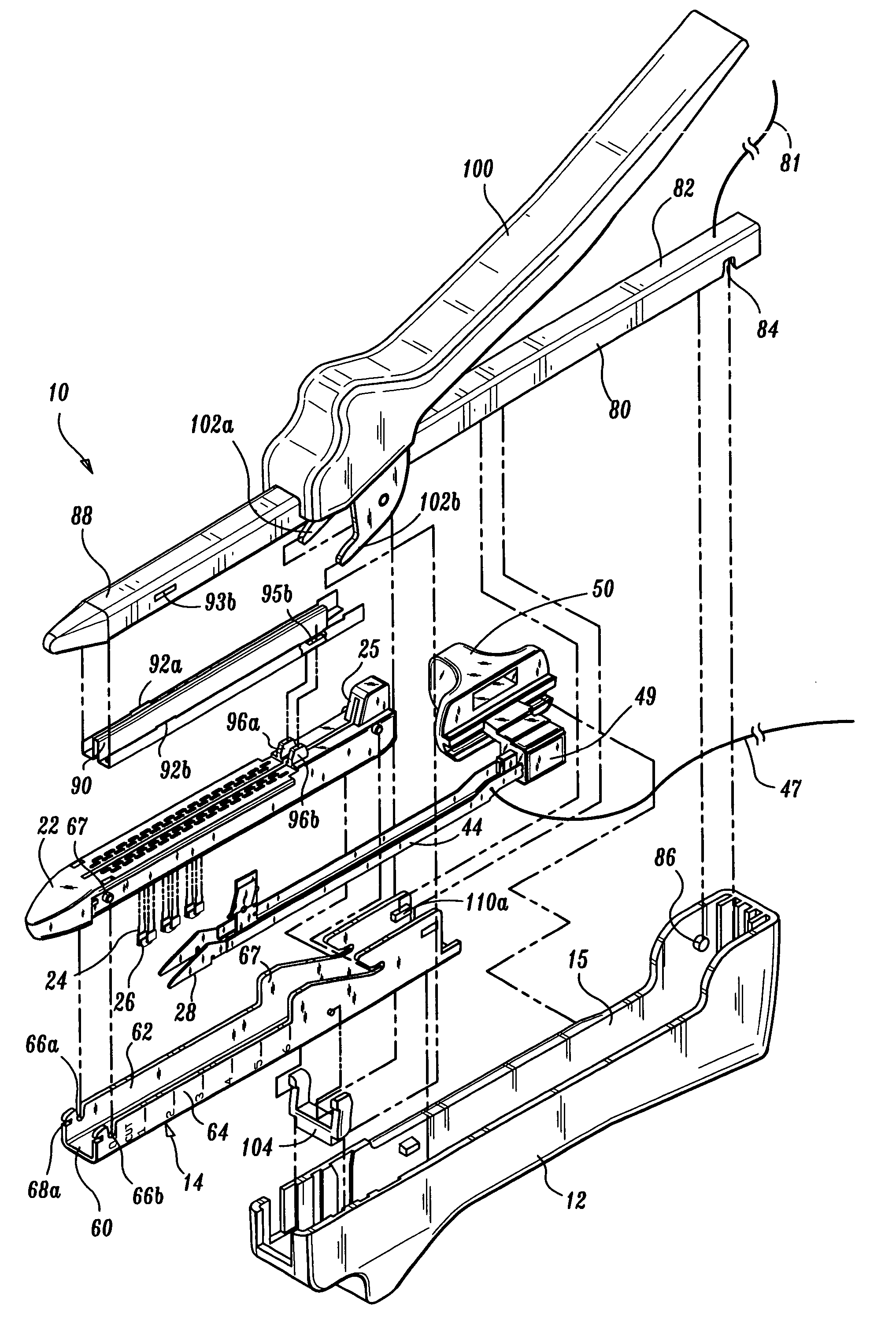

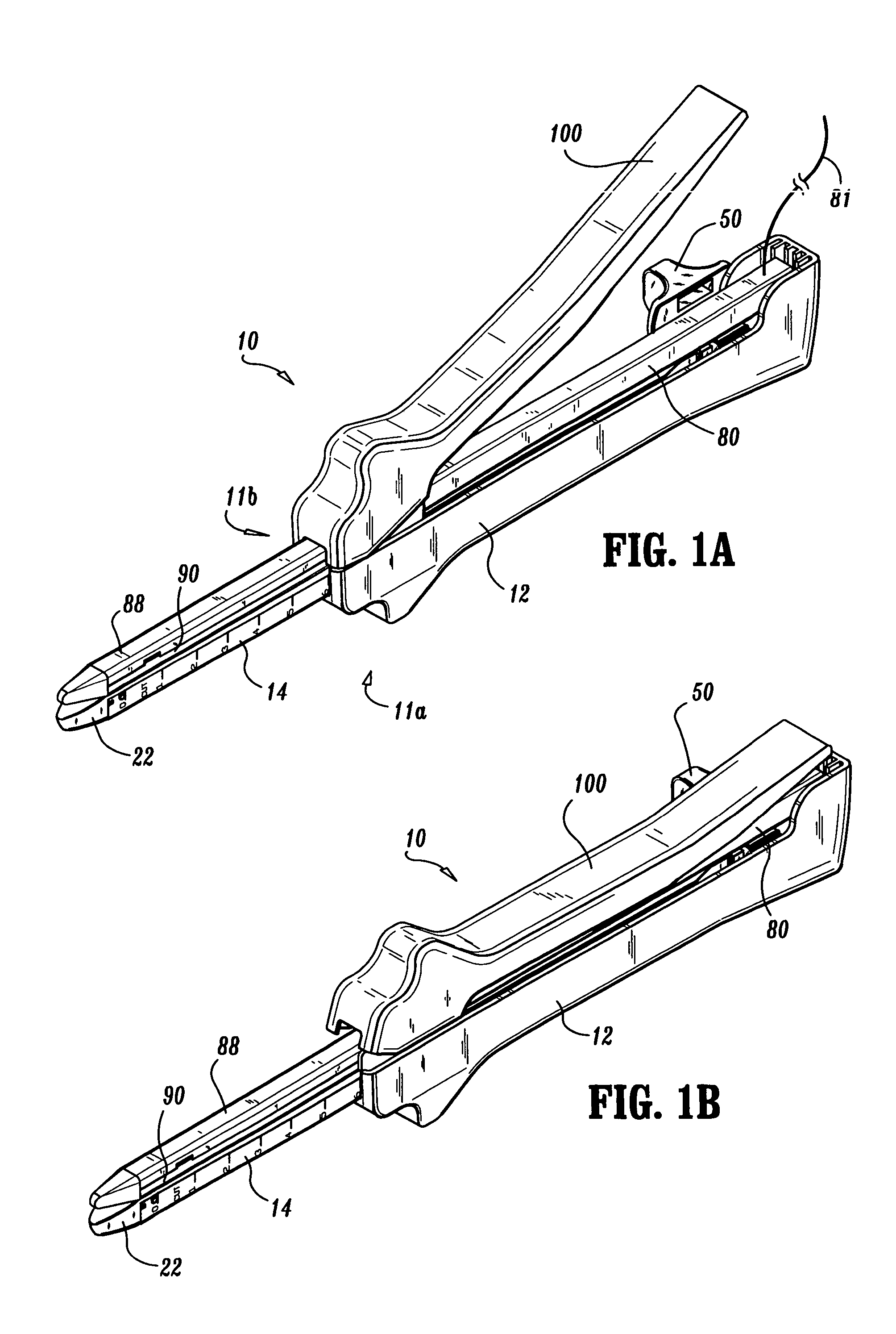

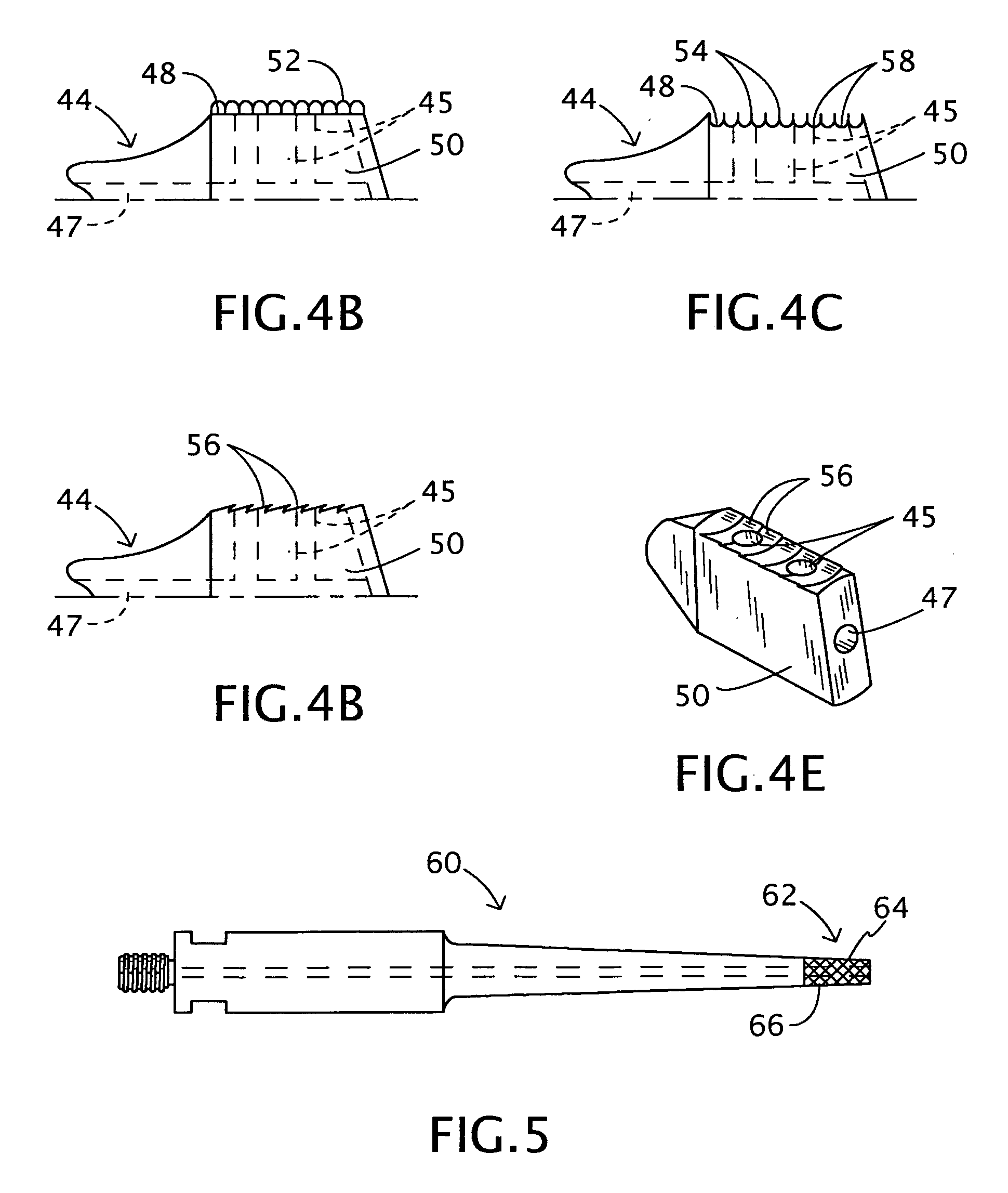

Electrosurgical stapling apparatus

InactiveUS20050159778A1Reduces or prevents staple line and cut line bleedingShort and strengthSuture equipmentsStapling toolsStaple lineEngineering

An electrosurgical stapling apparatus is provided which uses thermogenic energy as well as surgical fasteners or staples for strengthening tissue, providing hemostasis, tissue joining or welding. The thermogenic energy also strengthens tissue in proximity to a staple line and knife cut line and provides hemostasis along the staple and cut lines formed by the staples and a knife blade during surgical stapling. The use thermogenic energy provides short-term hemostasis and sealing, and reduces or prevents staple line and cut line bleeding, while the stapling features provide short and long-term tissue strength and hemostasis. The stapling apparatus further substantially reduces or prevents knife cut line bleeding by energizing a knife blade for cauterizing tissue while it is being cut. In one embodiment, energy is applied to the anvil to energize the staples as they make contact with the anvil.

Owner:TYCO HEALTHCARE GRP LP

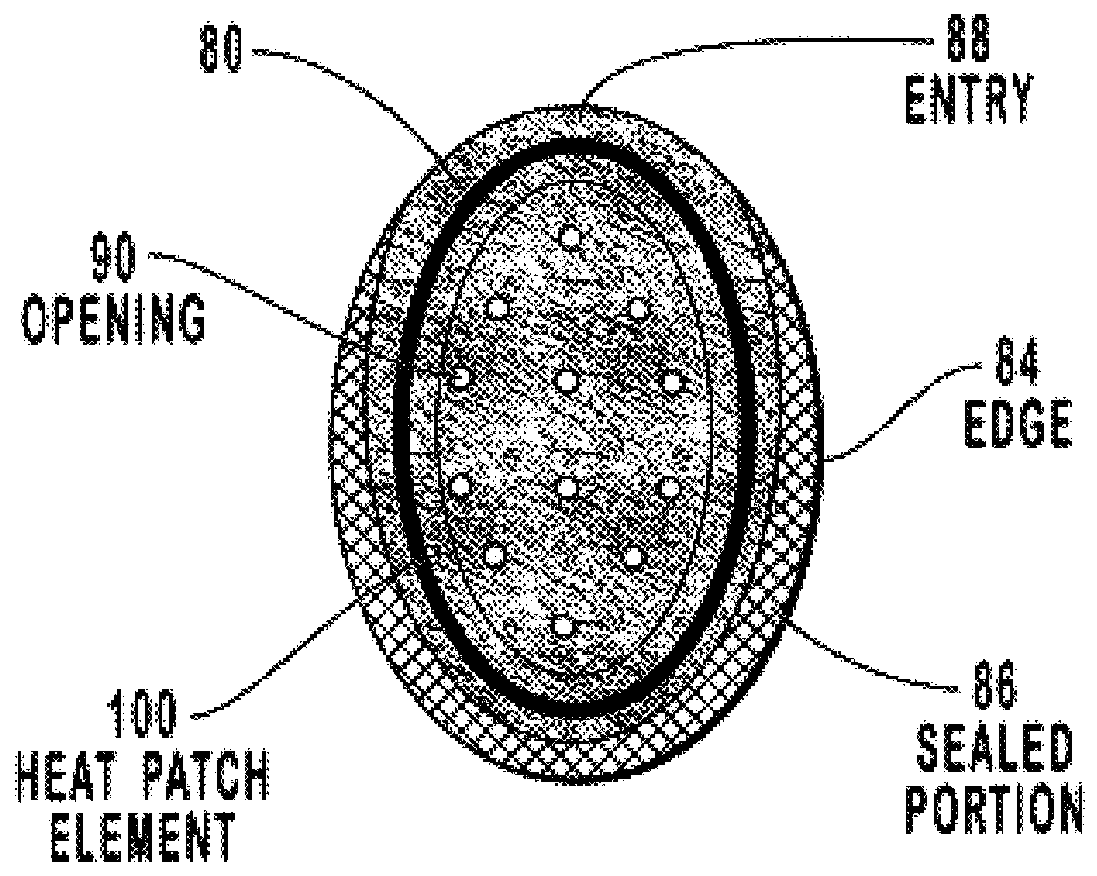

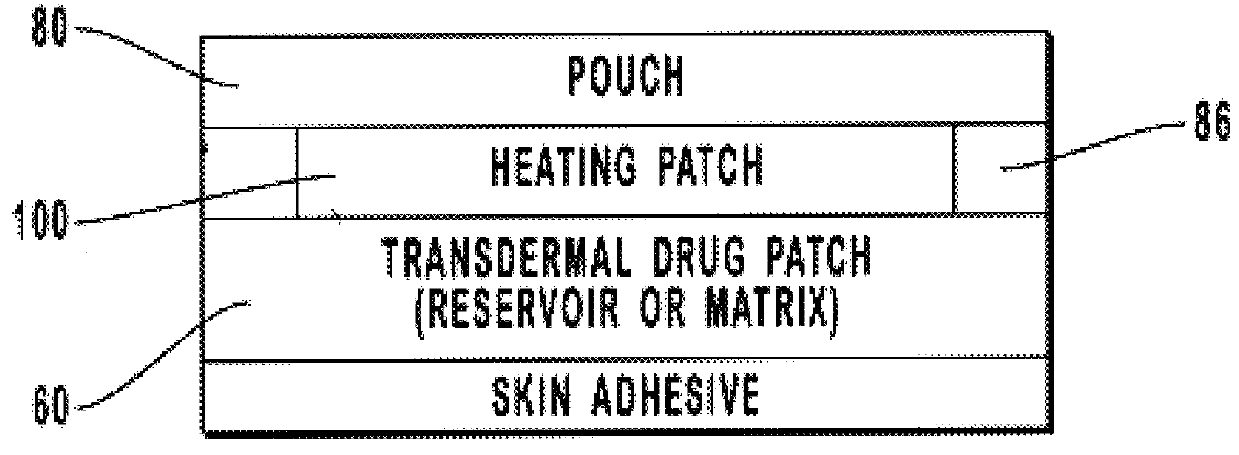

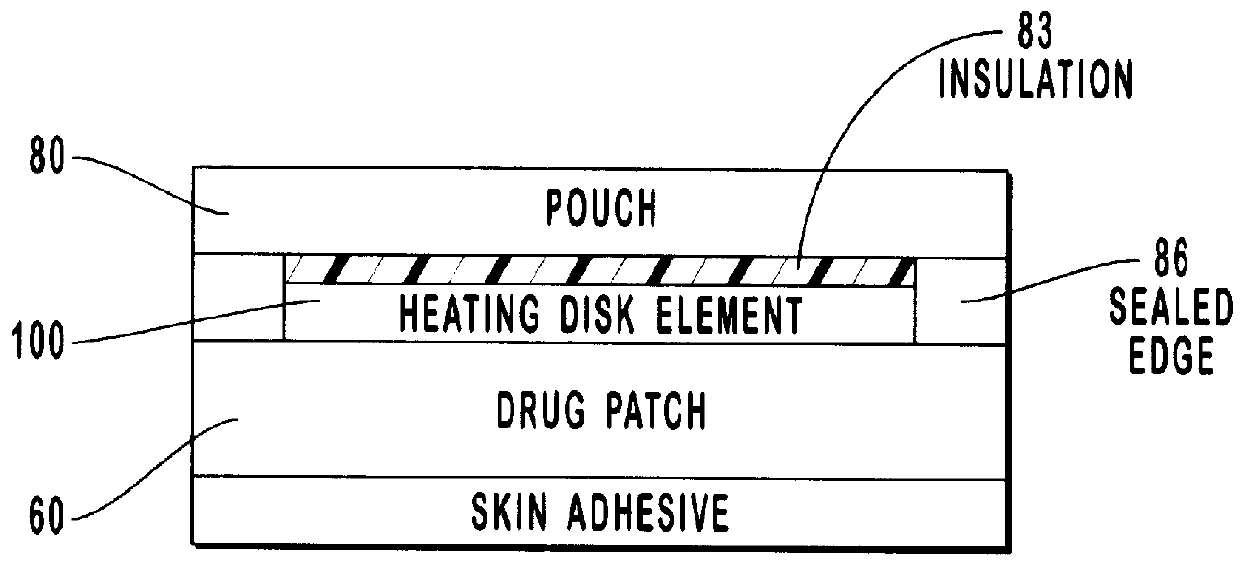

Transdermal drug patch with attached pocket for controlled heating device

InactiveUS6261595B1Shorten the timeEasy to replaceElectrotherapyMedical devicesTransdermal patchDrug administration

The present invention relates to a transdermal drug delivery system comprising a dermal drug delivery patch and a heating element compartment securable to the dermal drug delivery patch. A freely transferrable heating element is securable within the heating element compartment. A drug can be administered transdermally using the present invention by placing the dermal drug delivery patch upon a patient's skin at an administration site. A heating element compartment is secured to the dermal drug delivery patch and a freely transferrable heating element is placed within the heating element compartment. The heating element provides controlled heat to the dermal drug patch and the patient's skin aid thereby improves dermal drug administration.

Owner:ZARS INC

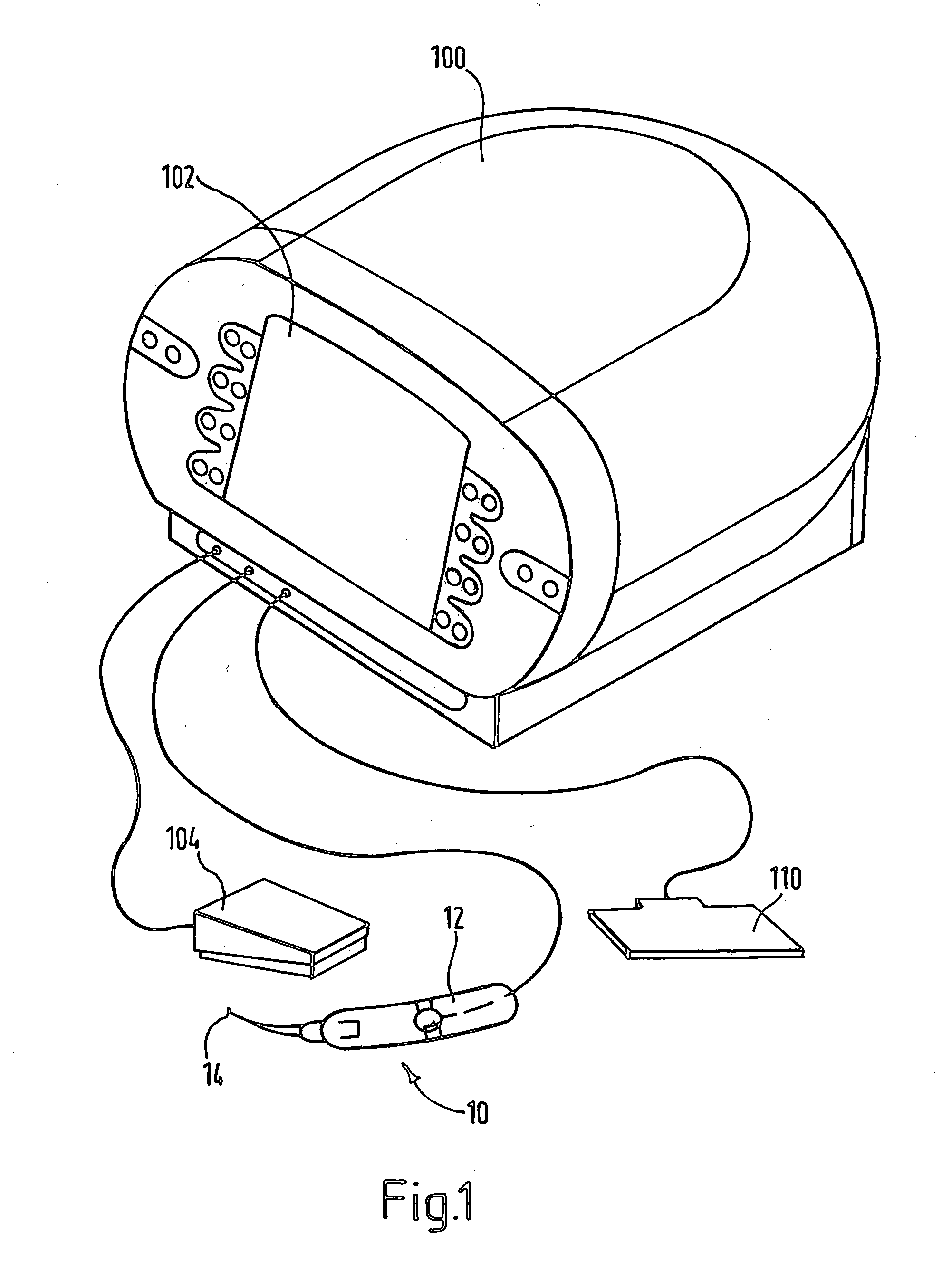

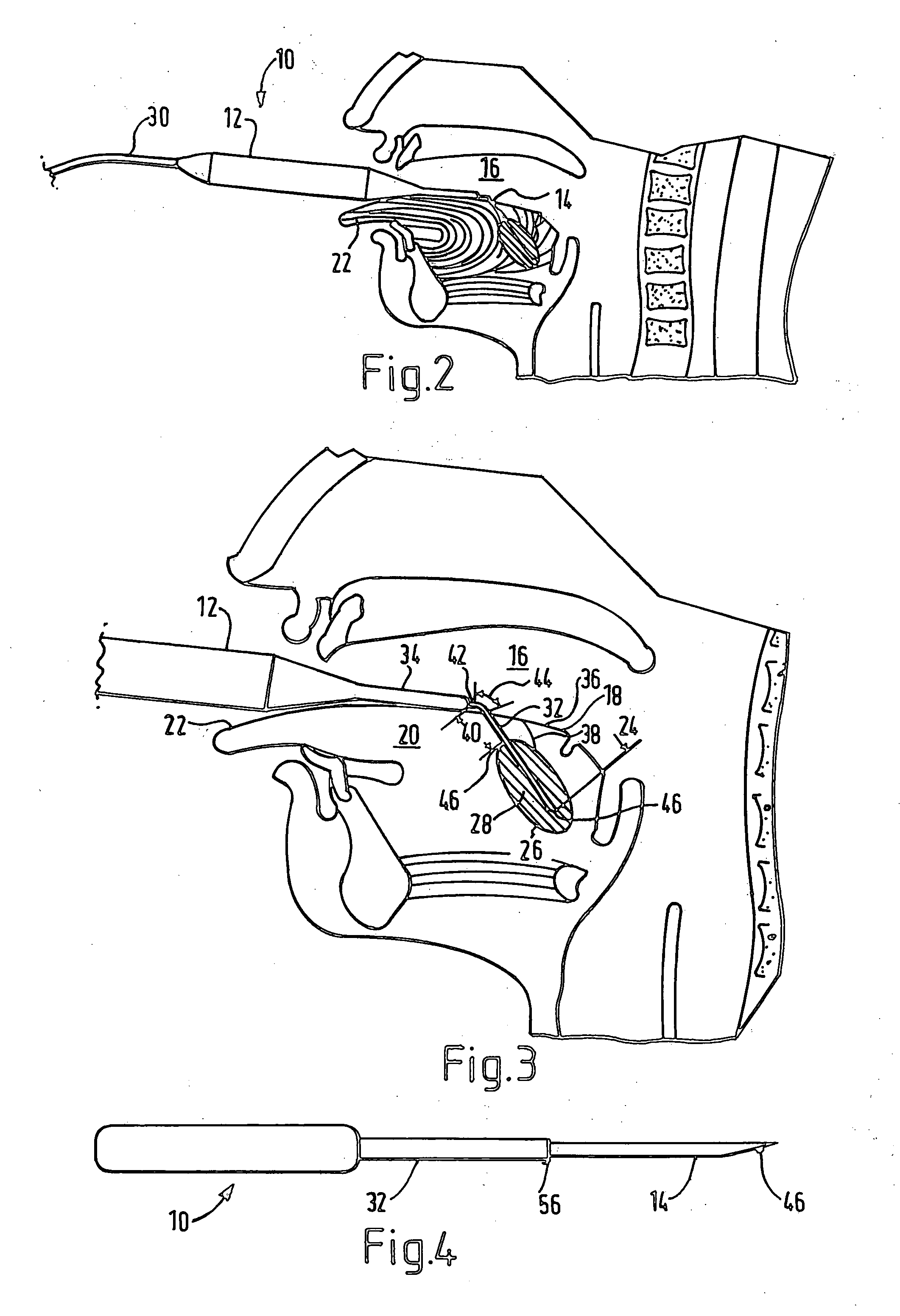

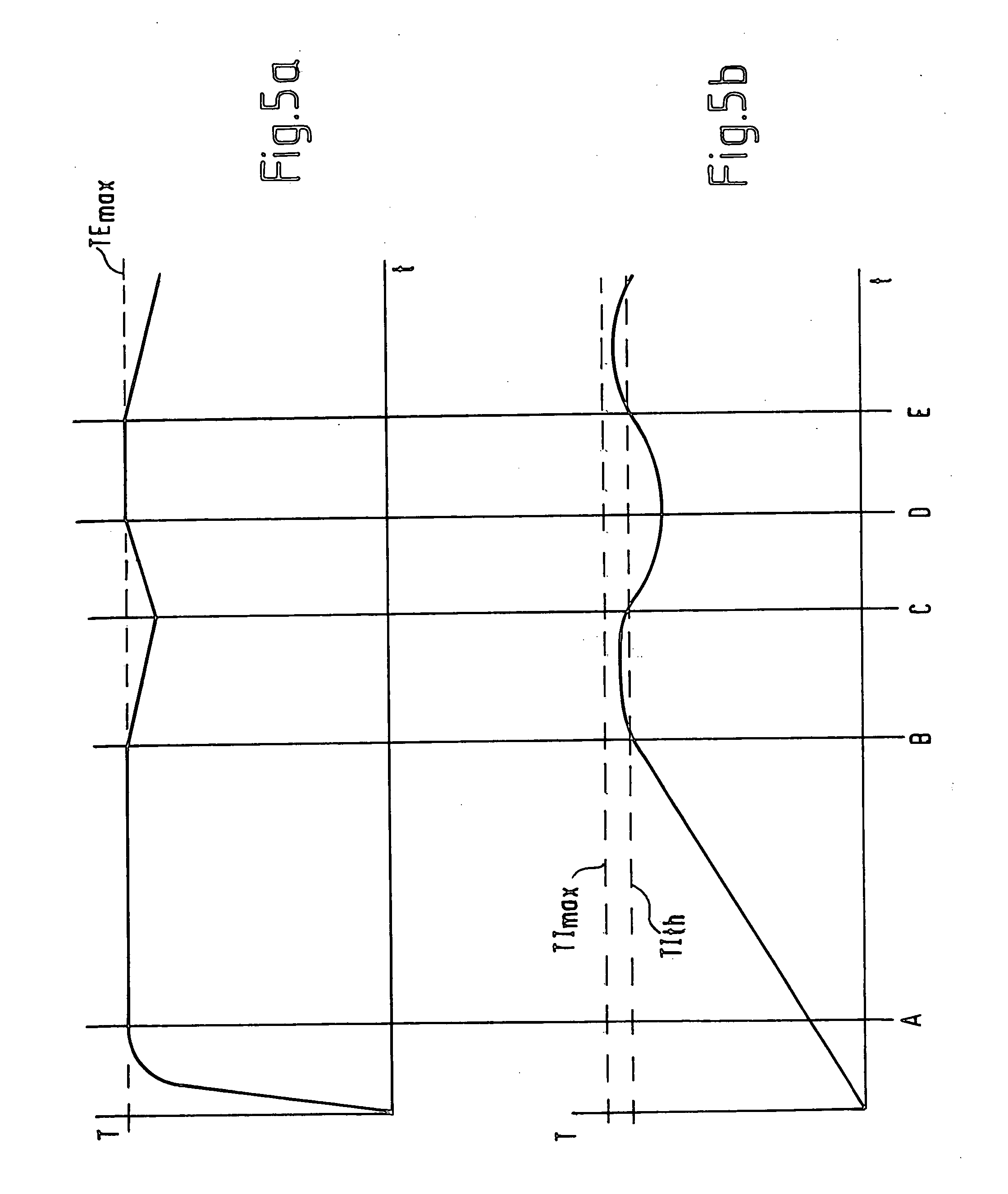

Electrosurgical method and apparatus

ActiveUS20050251128A1Compensation delayIncrease temperatureSurgical needlesSurgical instruments for heatingEngineeringRadio frequency

Apparatus for forming a lesion in body tissue includes a probe having an active region with an electrode for contacting tissue to be treated, and an inactive region including an insulative sleeve around a portion of the electrode. The temperature of the inactive region is monitored using a temperature sensor. A controller supplies radio frequency energy to the electrode and samples signals from the temperature sensor. By performing a calculation using the sampled signals and a predetermined inactive region threshold temperature, and by adjusting the supplied radio frequency power, the inactive region of the probe can be maintained at or below an inactive region maximum temperature whilst the controller continues to supply radio frequency energy to the electrode. The probe has a second temperature sensor, mounted at a distal end of the electrode, the controller being configured to reduce the supplied radio frequency power when the electrode temperature reaches a predetermined maximum electrode temperature.

Owner:GYRUS ENT

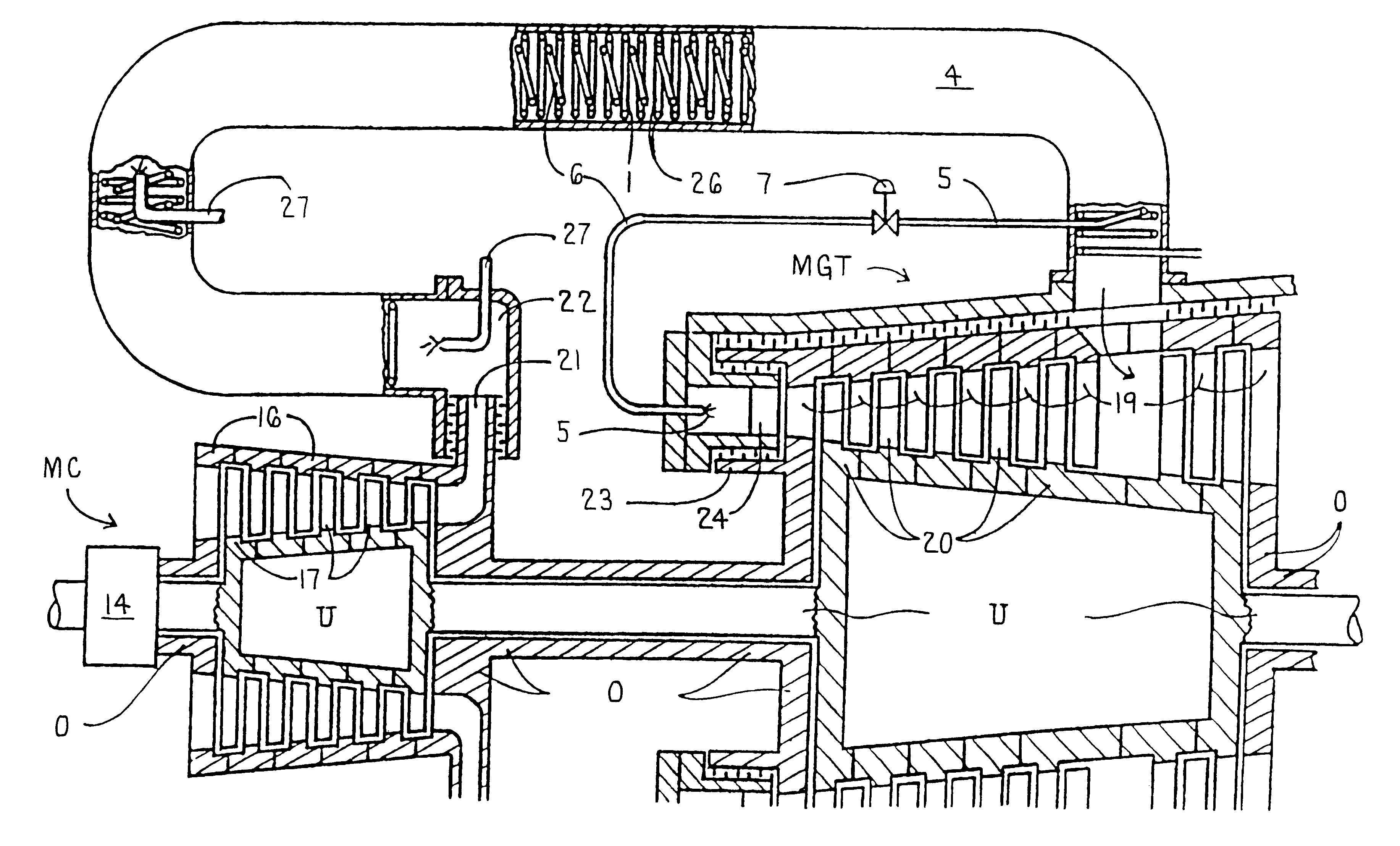

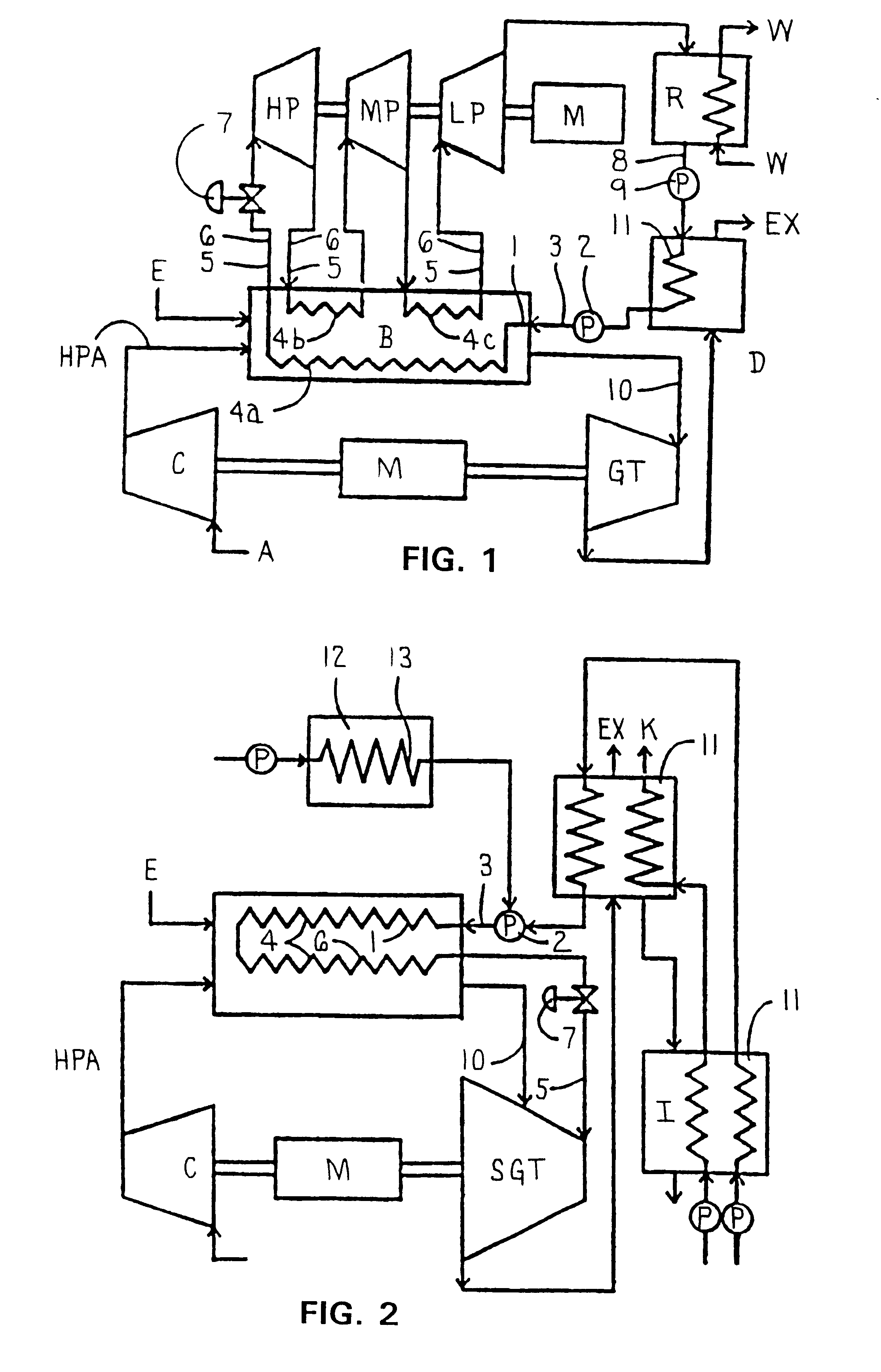

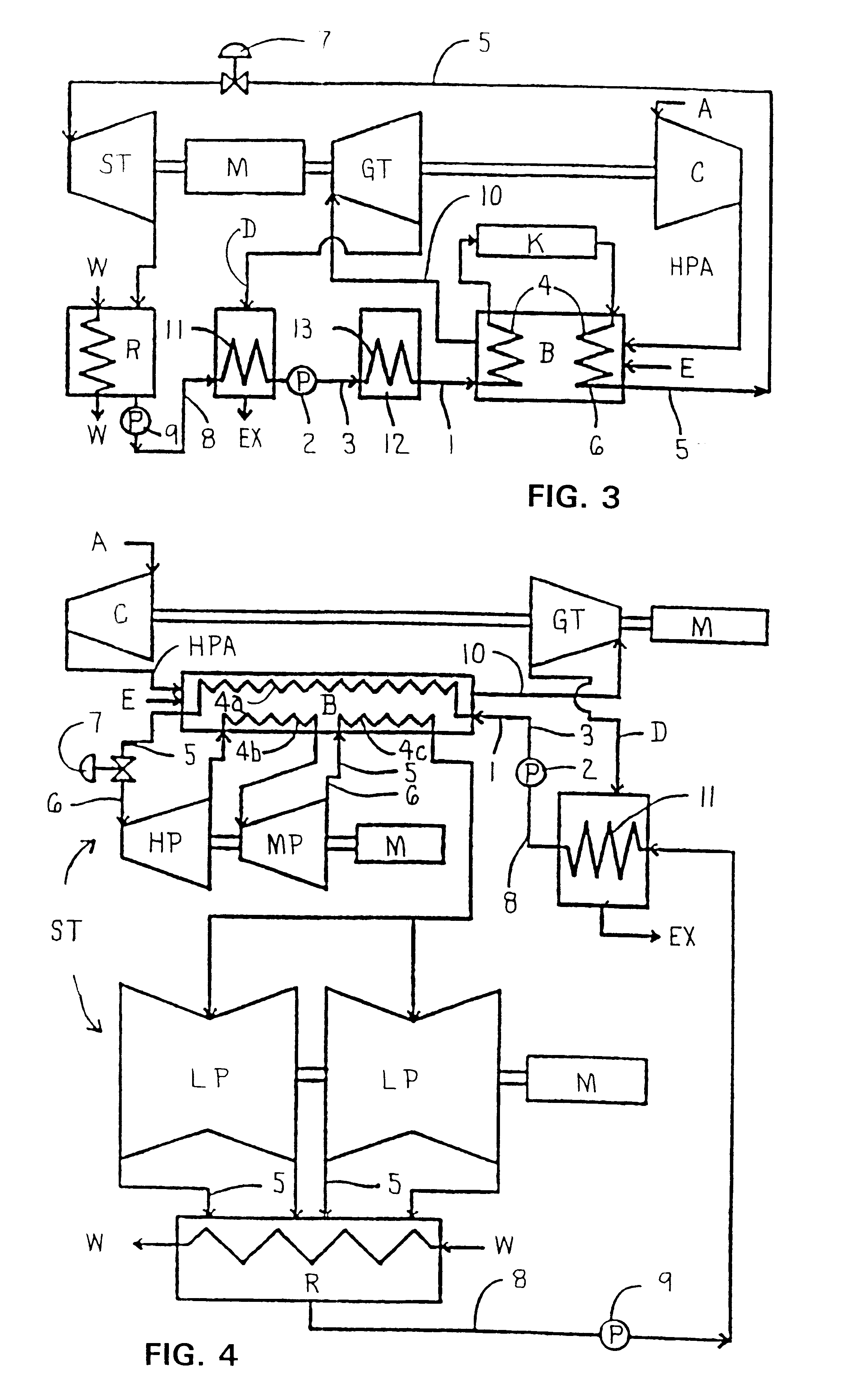

Combined steam and gas turbine engine with magnetic transmission

InactiveUS6263664B1Wide areaImprove system efficiencyContinuous combustion chamberGearingThermal energyCombustion chamber

In a combined steam and gas turbine engine cycle, a combustion chamber is made durable against high pressure and enlarged in length to increase the operation pressure ratio, without exceeding the heat durability temperature of the system while increasing the fuel combustion gas mass flow four times as much as the conventional turbine system and simultaneously for greatly raising the thermal efficiency of the system and specific power of the combined steam and gas turbine engine.Water pipes and steam pipes are arranged inside the combustion chamber so that the combustion chamber can function as a heat exchanger and thereby convert most of the combustion thermal energy into super-critical steam energy for driving a steam turbine and subsequently raising the operation pressure ratio and the thermal efficiencies of the steam turbine cycle and gas turbine cycle. The combustion gas mass flow can be also increased by four times as much as the conventional turbine system (up to the theoretical air to fuel ratio) and the thermal efficiency and the specific power of the gas turbine cycle are considerably increased.Further, the thermal efficiency of the combined system is improved by installing a magnetic friction power transmission system to transmit the power of the system to outer loads.

Owner:TANIGAWA HIROYASU +1

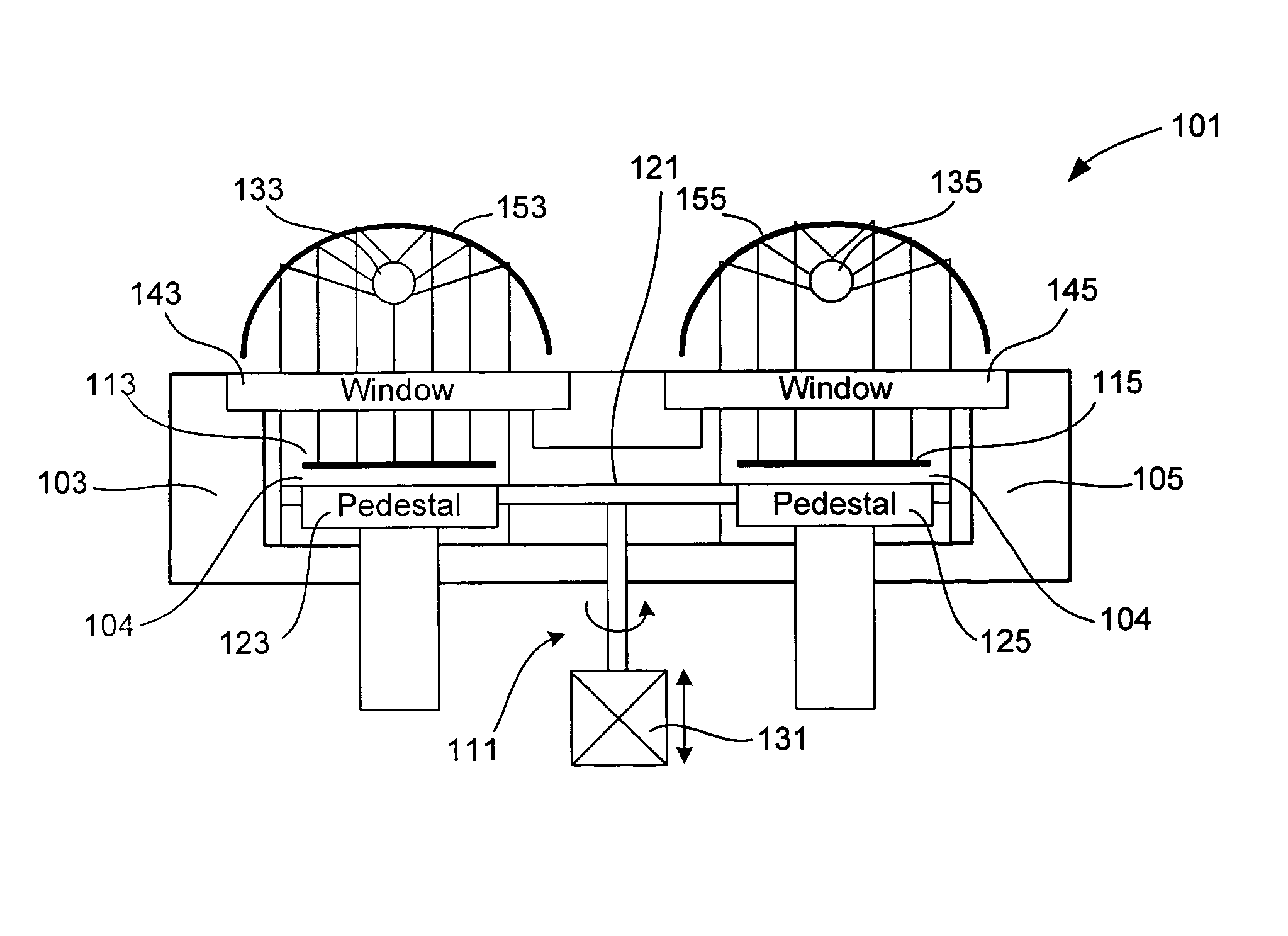

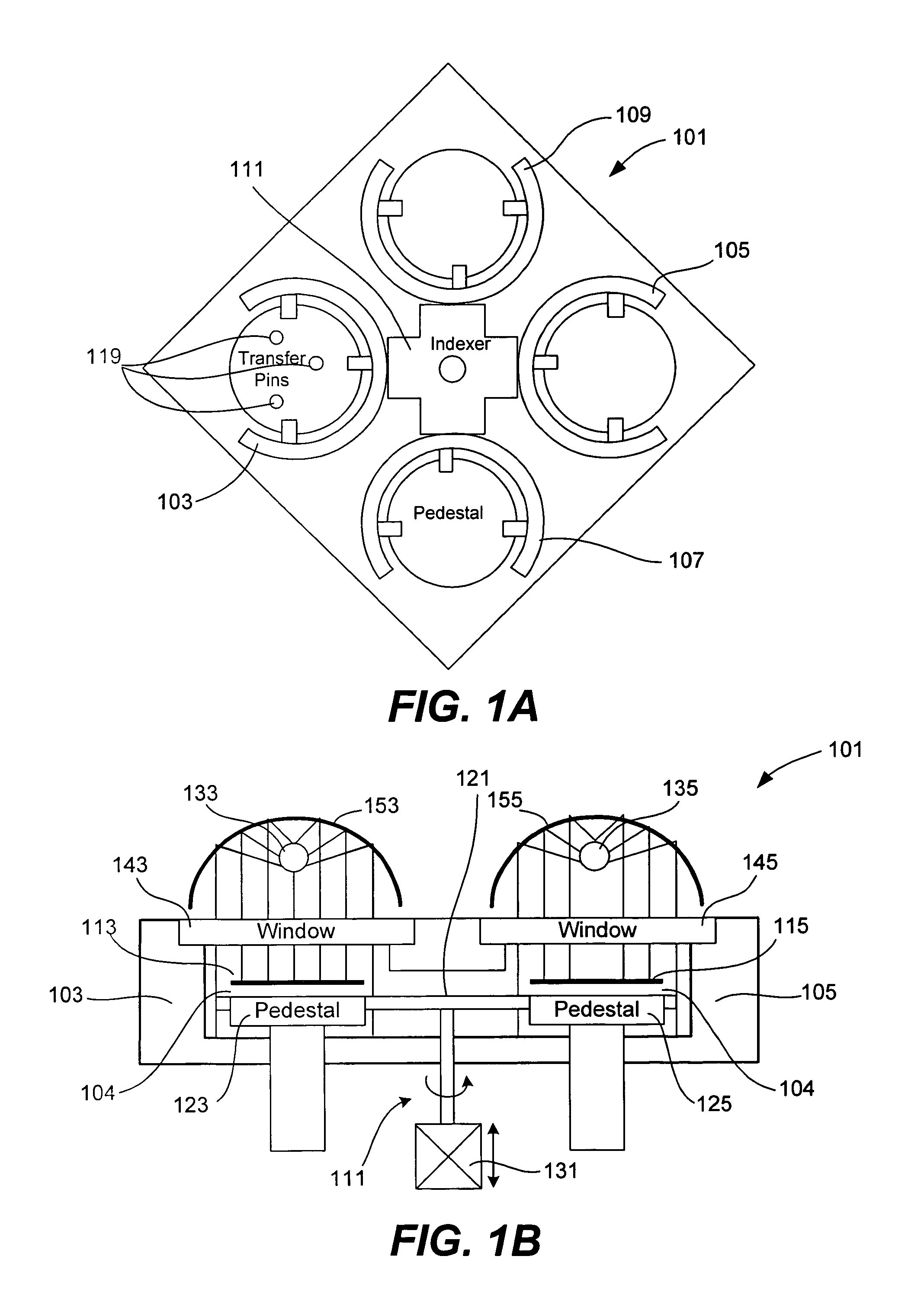

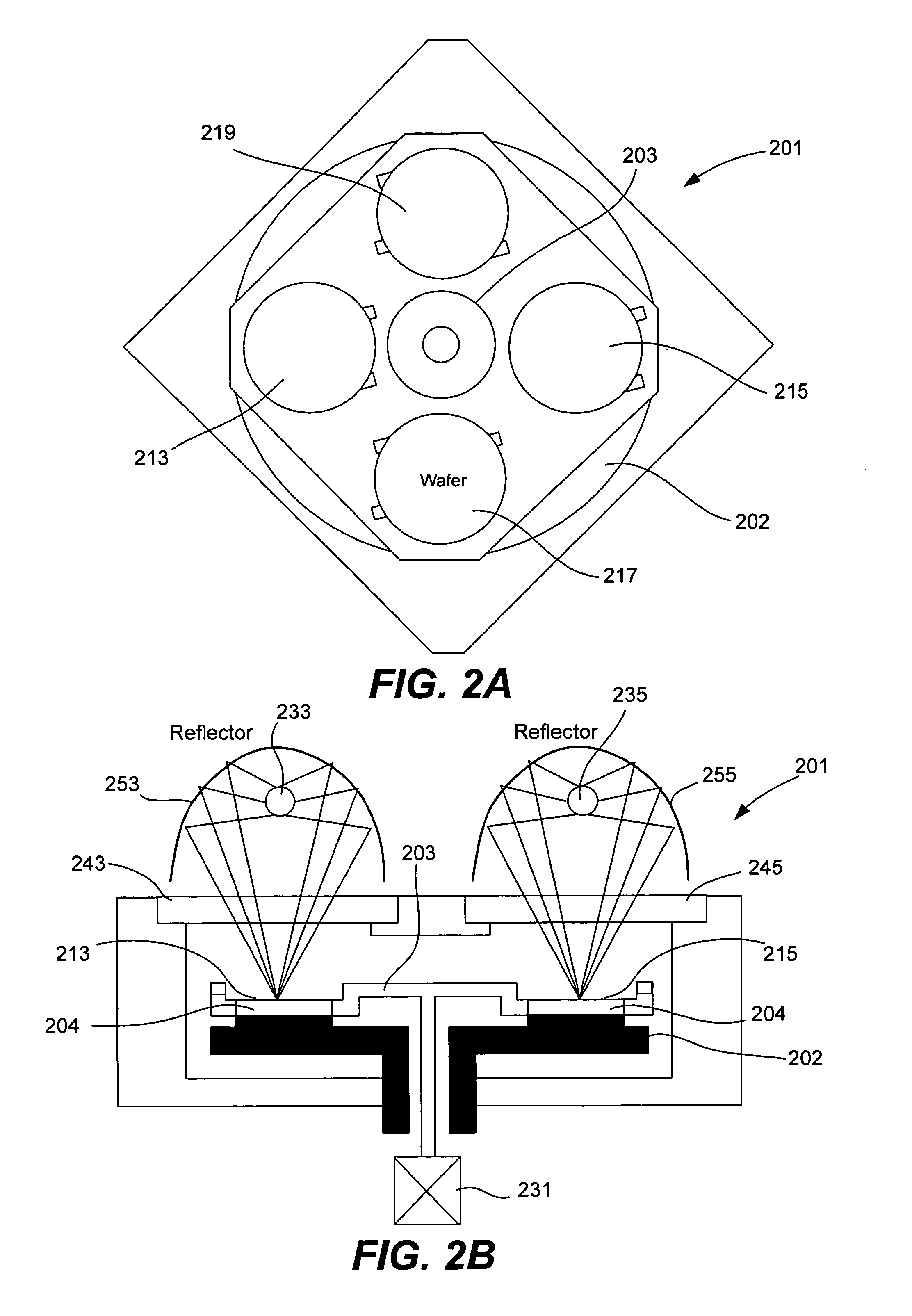

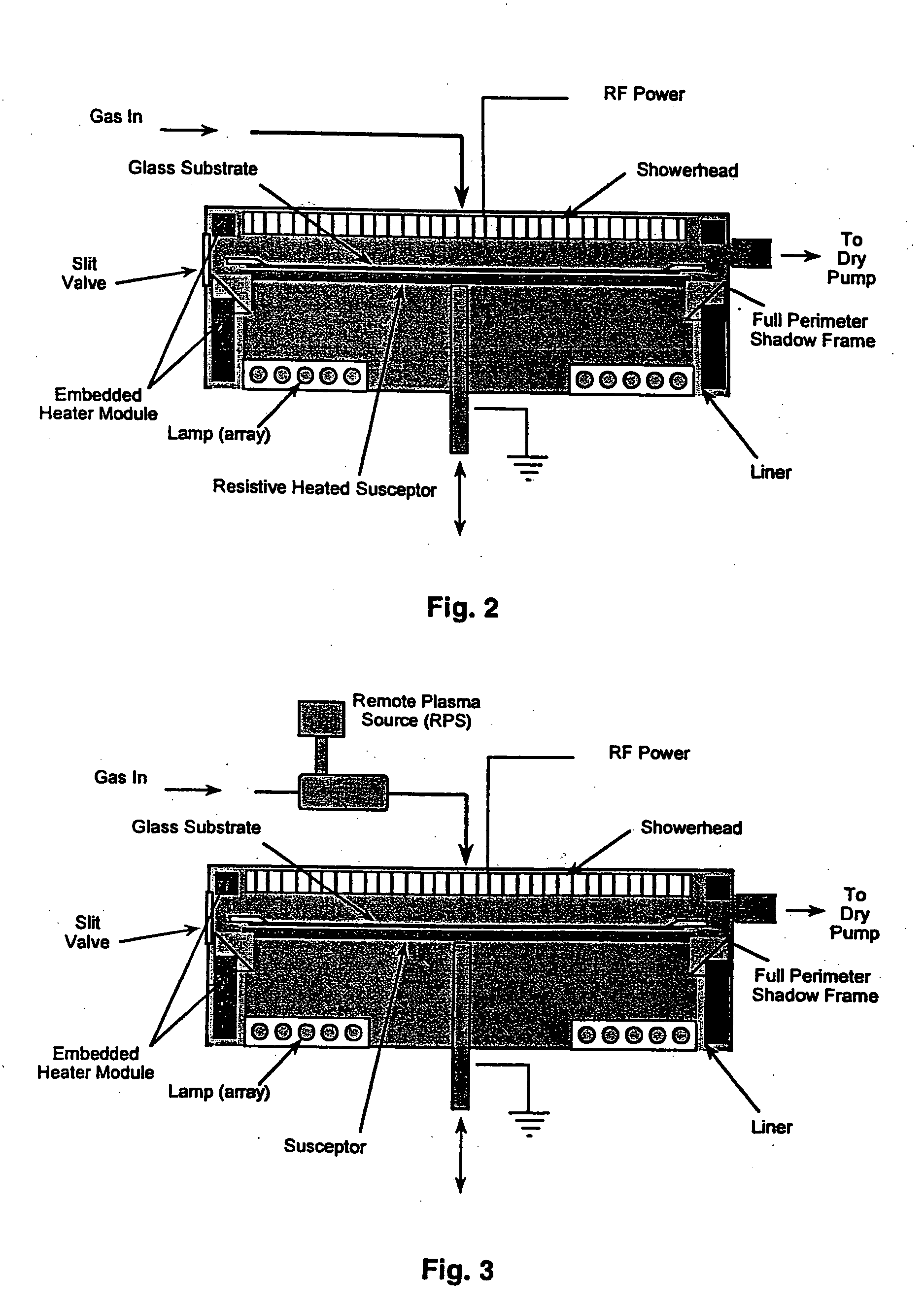

Single-chamber sequential curing of semiconductor wafers

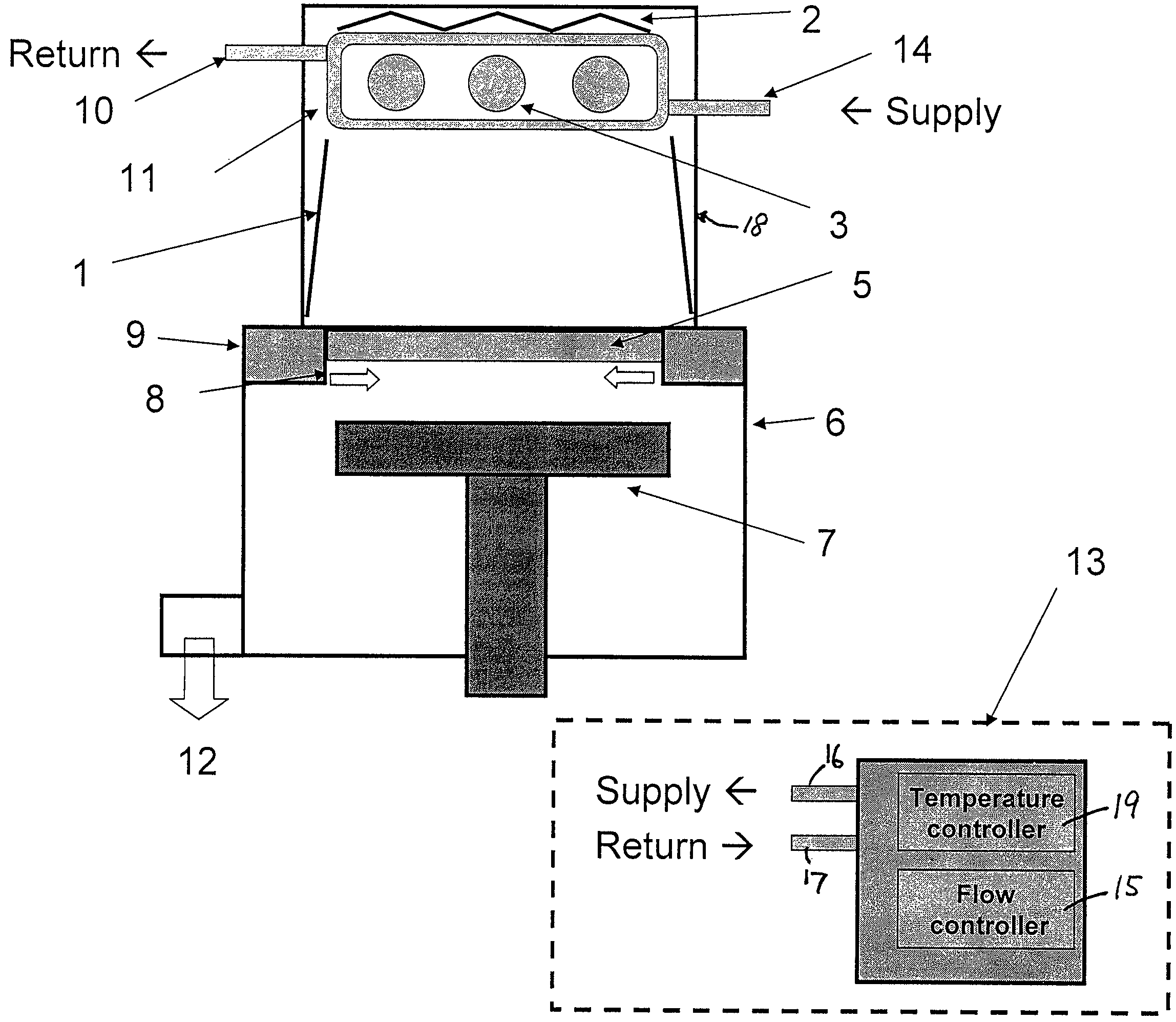

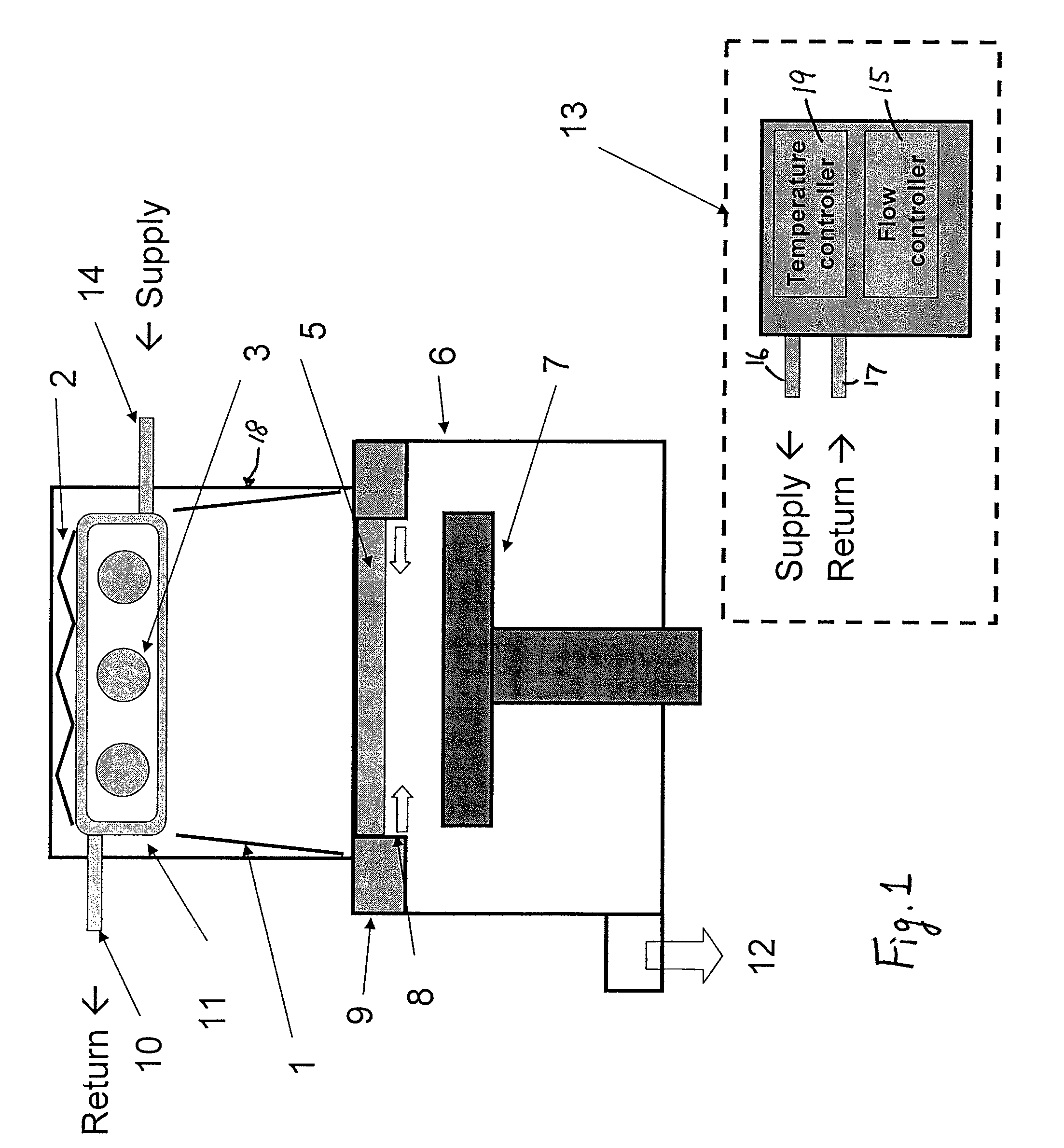

ActiveUS8137465B1Cures waferImprove throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingVolumetric Mass DensitySingle chamber

The present invention relates to curing of semiconductor wafers. More particularly, the invention relates to cure chambers containing multiple cure stations, each featuring one or more UV light sources. The wafers are cured by sequential exposure to the light sources in each station. In some embodiments, the wafers remain stationary with respect to the light source during exposure. In other embodiments, there is relative movement between the light source and the wafer during exposure. The invention also provides chambers that may be used to independently modulate the cross-linking, density and increase in stress of a cured material by providing independent control of the wafer temperature and UV intensity.

Owner:NOVELLUS SYSTEMS

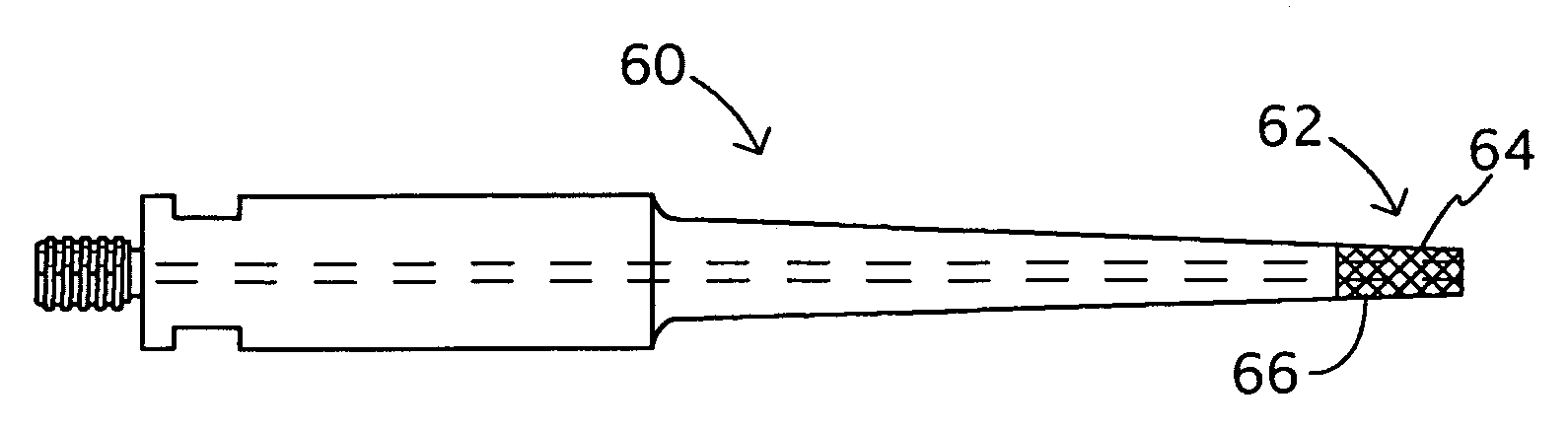

Ultrasonic debrider probe and method of use

InactiveUS20080058775A1Reduce temperature riseAvoid cloggingSurgical instrument detailsBiomedical engineeringMedical treatment

An ultrasonic medical probe has an elongate shaft with a head portion having a distal end face oriented at least partially transversely to a longitudinal axis of the shaft. The head portion has a lateral surface extending substantially parallel to the longitudinal axis, the lateral surface being provided with outwardly or radially extending projections. The shaft of the probe is provided with an internal longitudinal channel or bore and at least one ancillary or tributary channel communicating at an inner end with the longitudinal channel or bore and extending to the lateral surface. The ancillary or tributary channel has an outer end disposed in a region about the projections. The projections may be finely configured and distributed so as to form a knurled surface on the head portion.

Owner:MISONIX INC

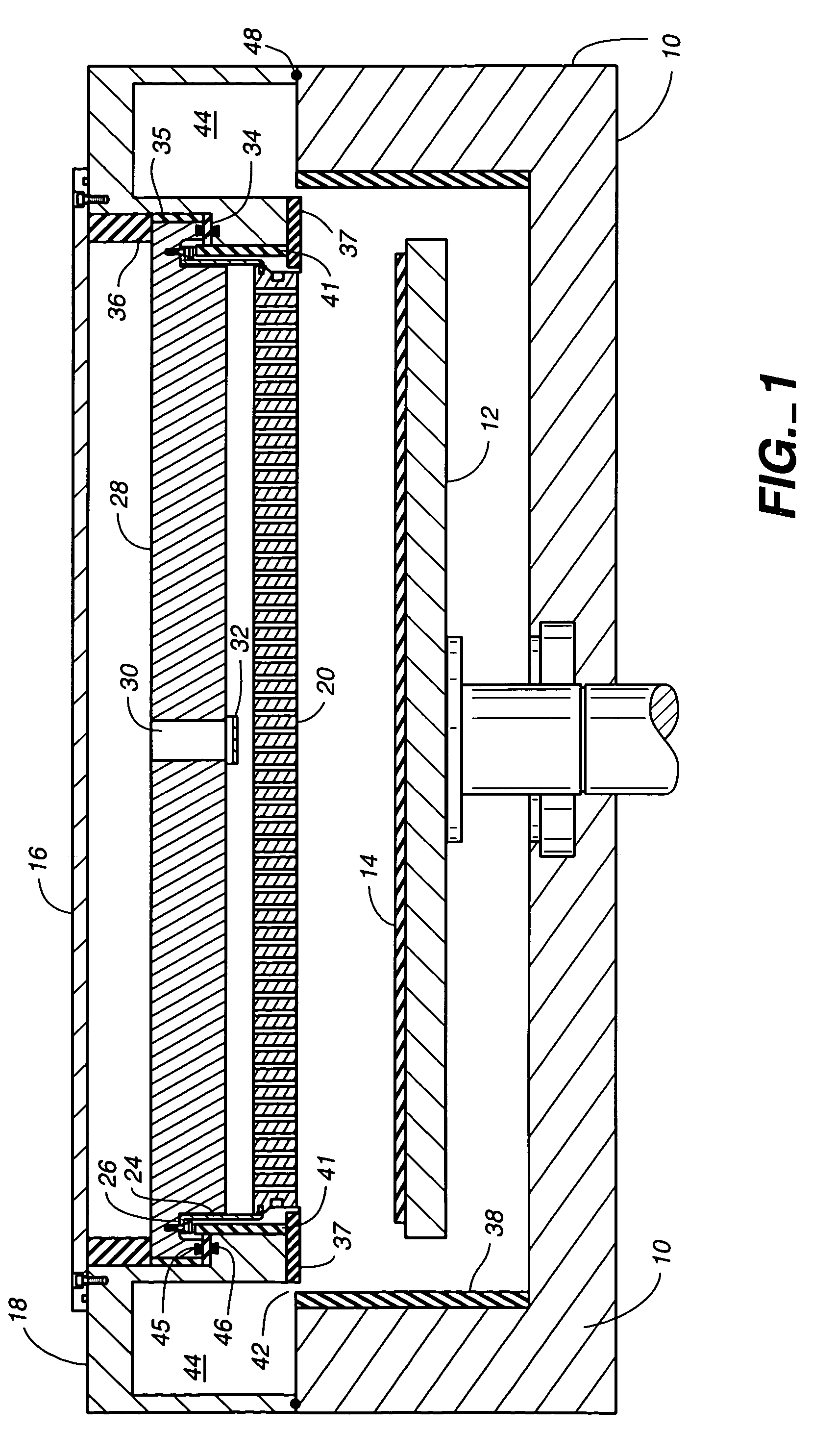

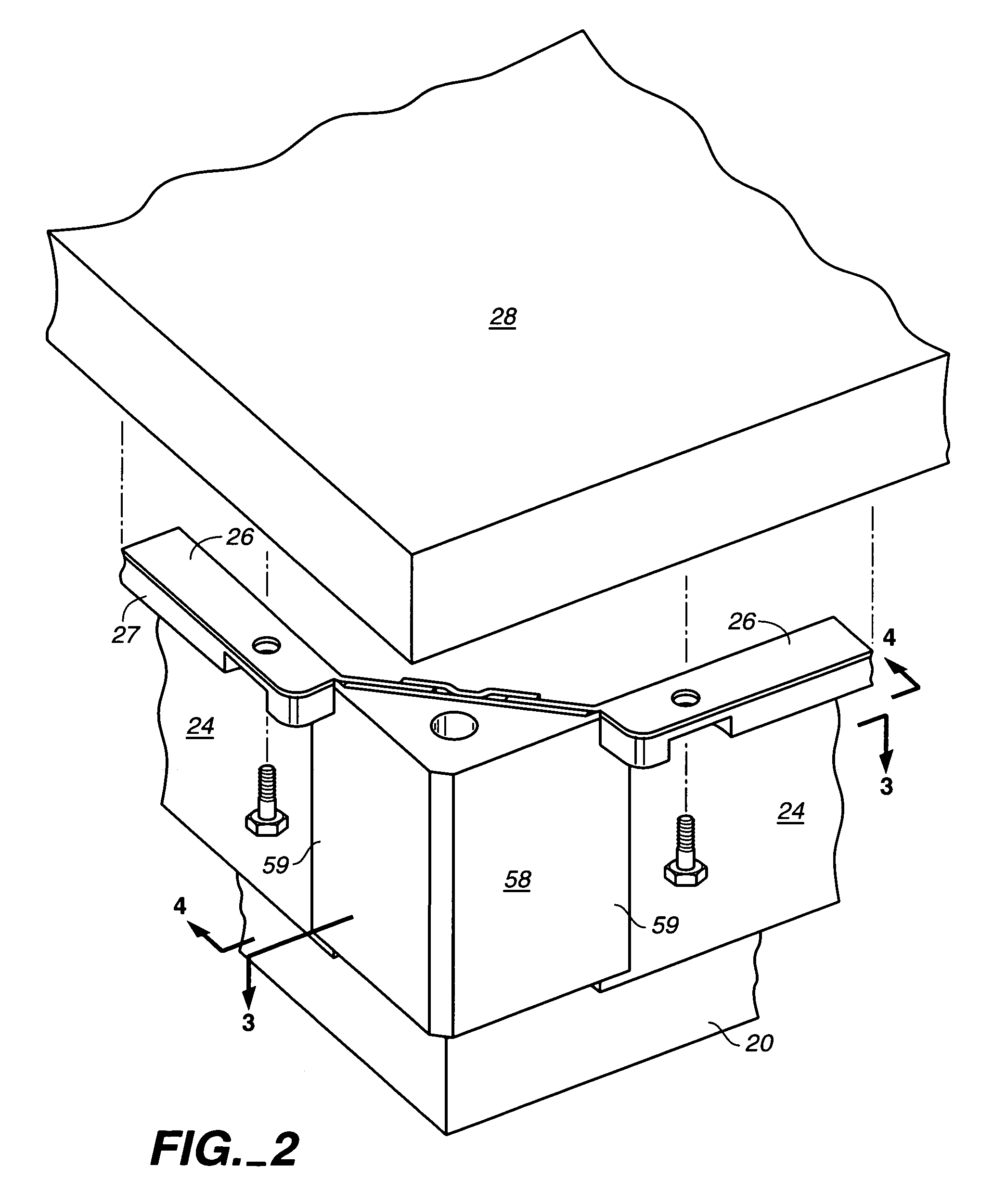

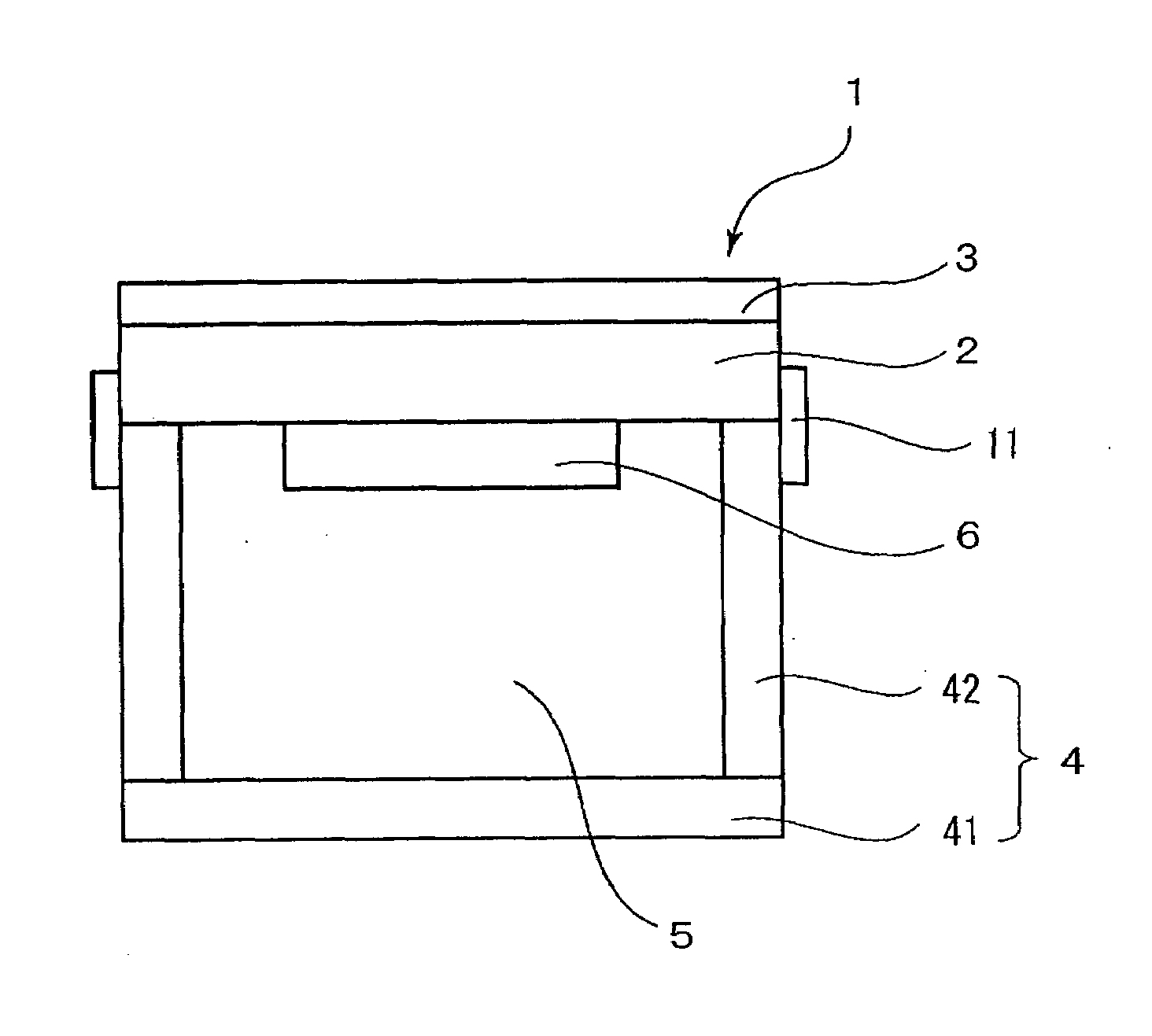

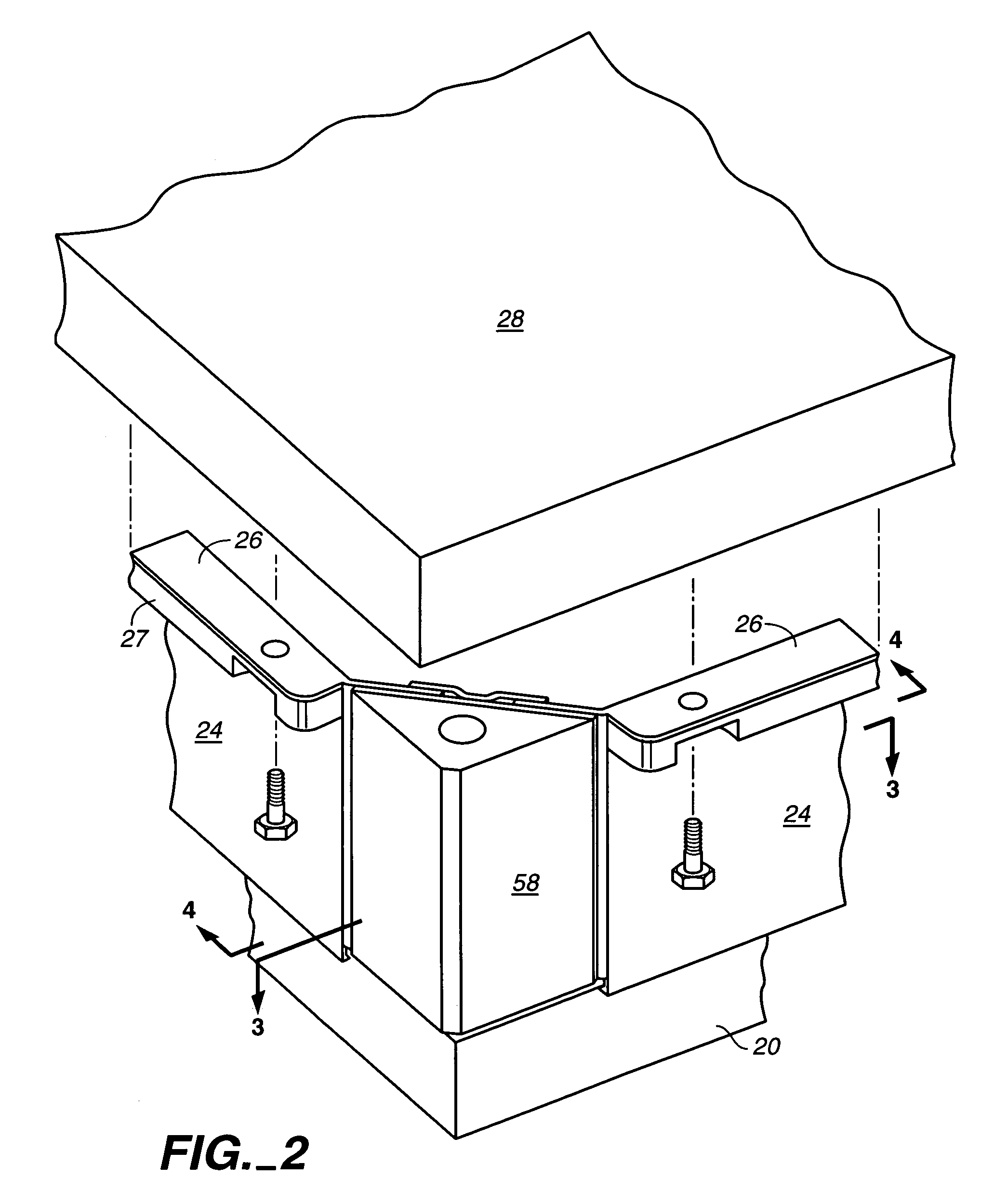

Wafer holder for wafer prober and wafer prober equipped with same

InactiveUS20090045829A1Improve rigidityGood effectHot plates heating arrangementsIndividual semiconductor device testingRoom temperatureEngineering

It is an object of the present invention to provide a wafer prober wafer holder that is highly rigid and increases the heat insulating effect, thereby improving positional accuracy, thermal uniformity, and chip temperature ramp-up and cooling rates, as well as a wafer prober device equipped therewith.A wafer holder of the present invention includes a chuck top that mounts a wafer, and a support member that supports the chuck top, wherein, a restricting member is provided that covers an interface between the chuck top and the support member. By covering the gap between the chuck top and the support member with the restricting member, the heat insulating effect can be increased by preventing the flow of outside air through the gap into the support member, and the cooling rate can be particularly improved if cooling to a temperature below room temperature.

Owner:SUMITOMO ELECTRIC IND LTD

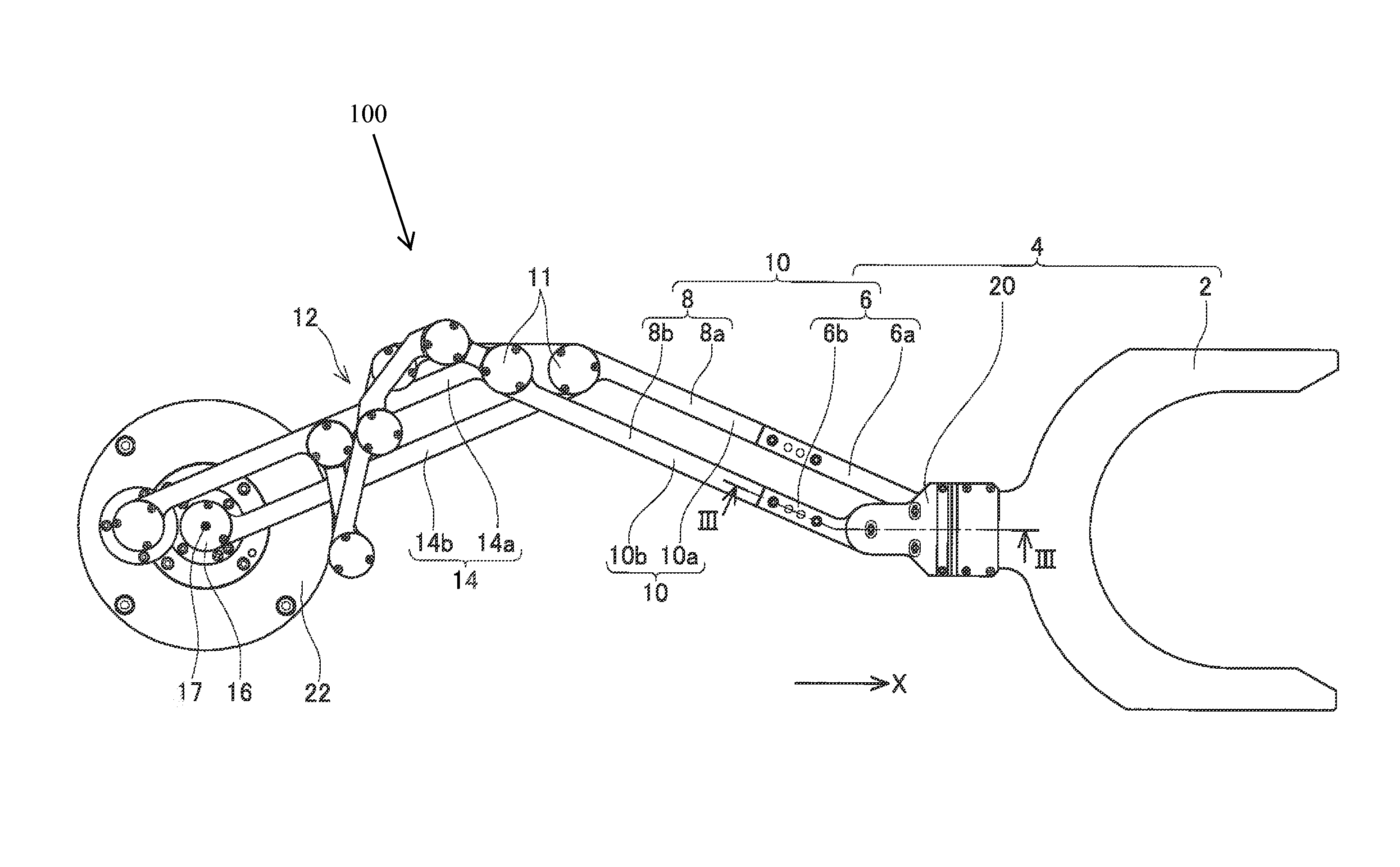

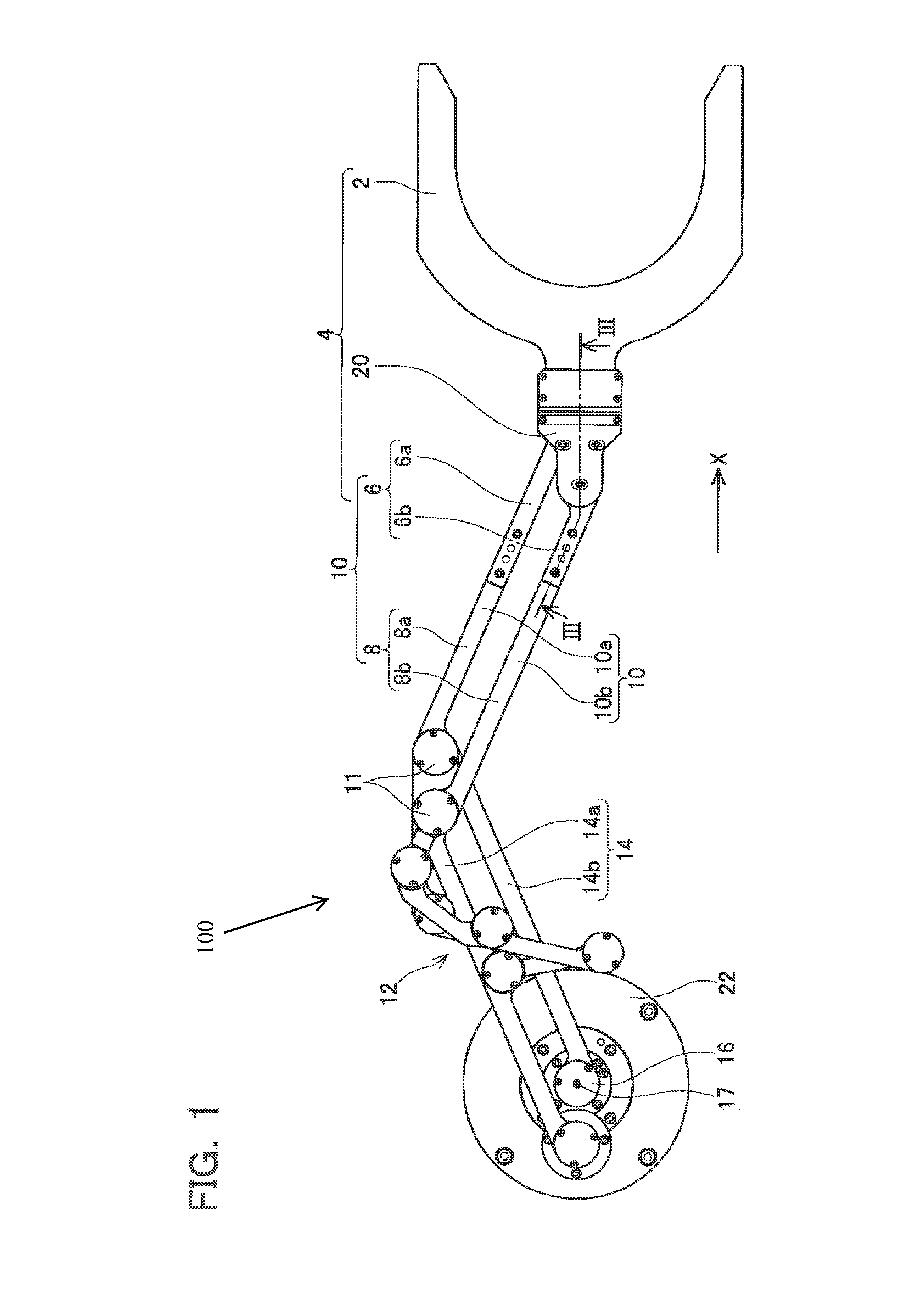

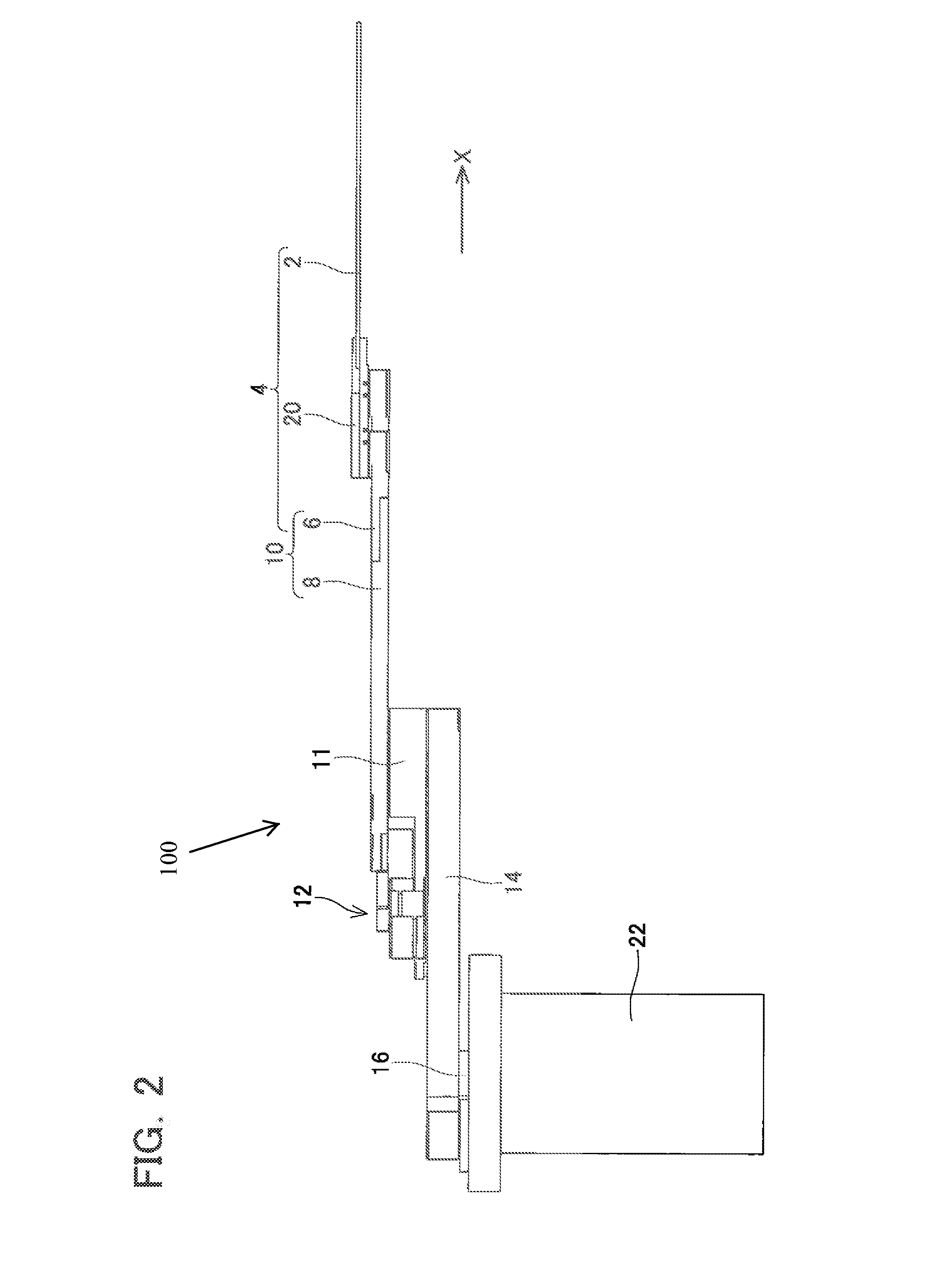

Robot arm

ActiveUS20130084156A1Precise positioningPollution suppressionProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingPhysical medicine and rehabilitationWafering

The robot arm of the present application is a robot arm that transports semiconductor wafers. The robot arm includes a hand, a lower arm link, and an upper arm link. The hand is connected to the lower arm link via a first joint. The upper arm link is connected to the lower arm link via a second joint. In the robot arm of the present application, the lower arm link is capable of being separated at a location between the first joint and the second joint.

Owner:NABLESCO CORP

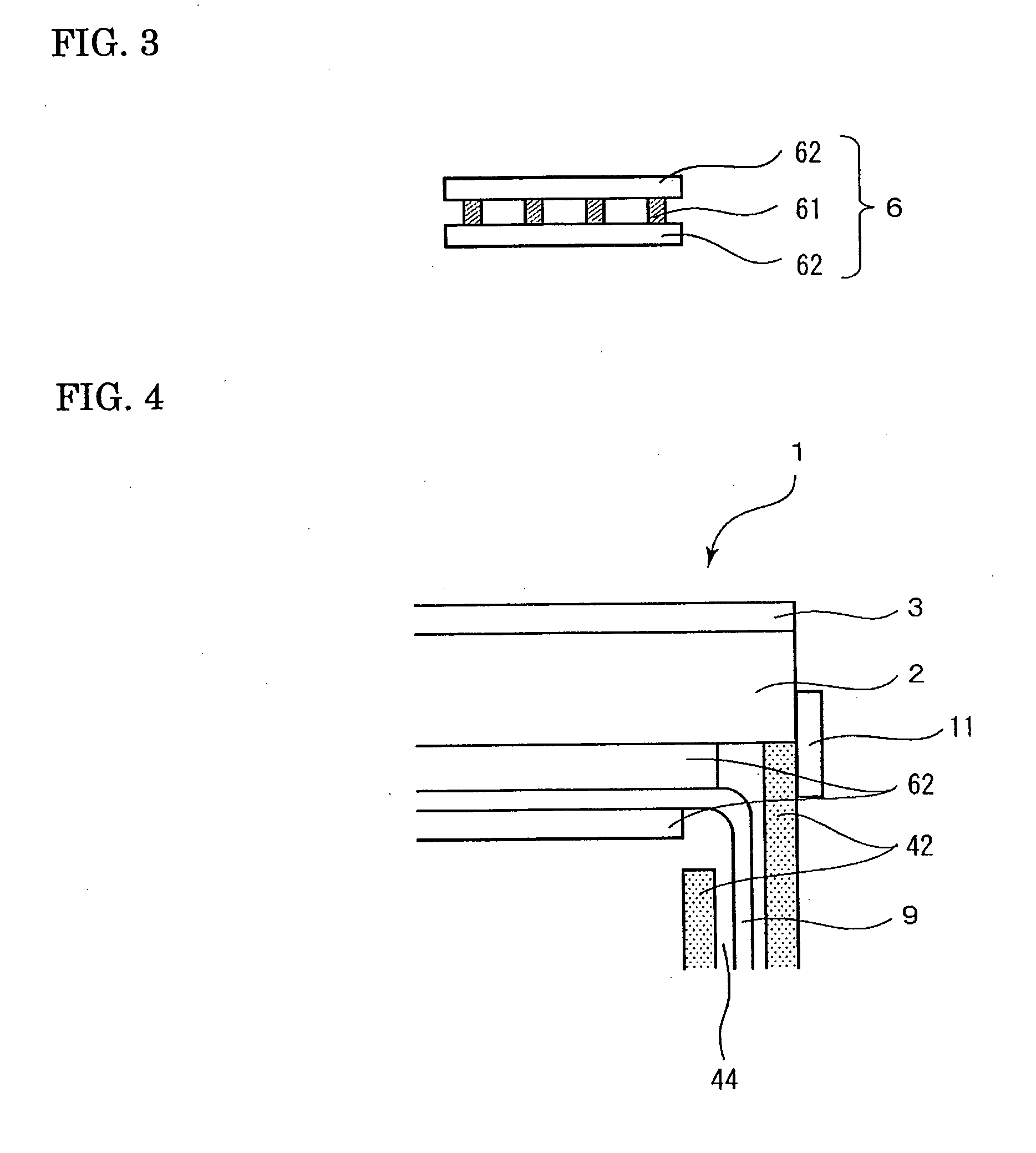

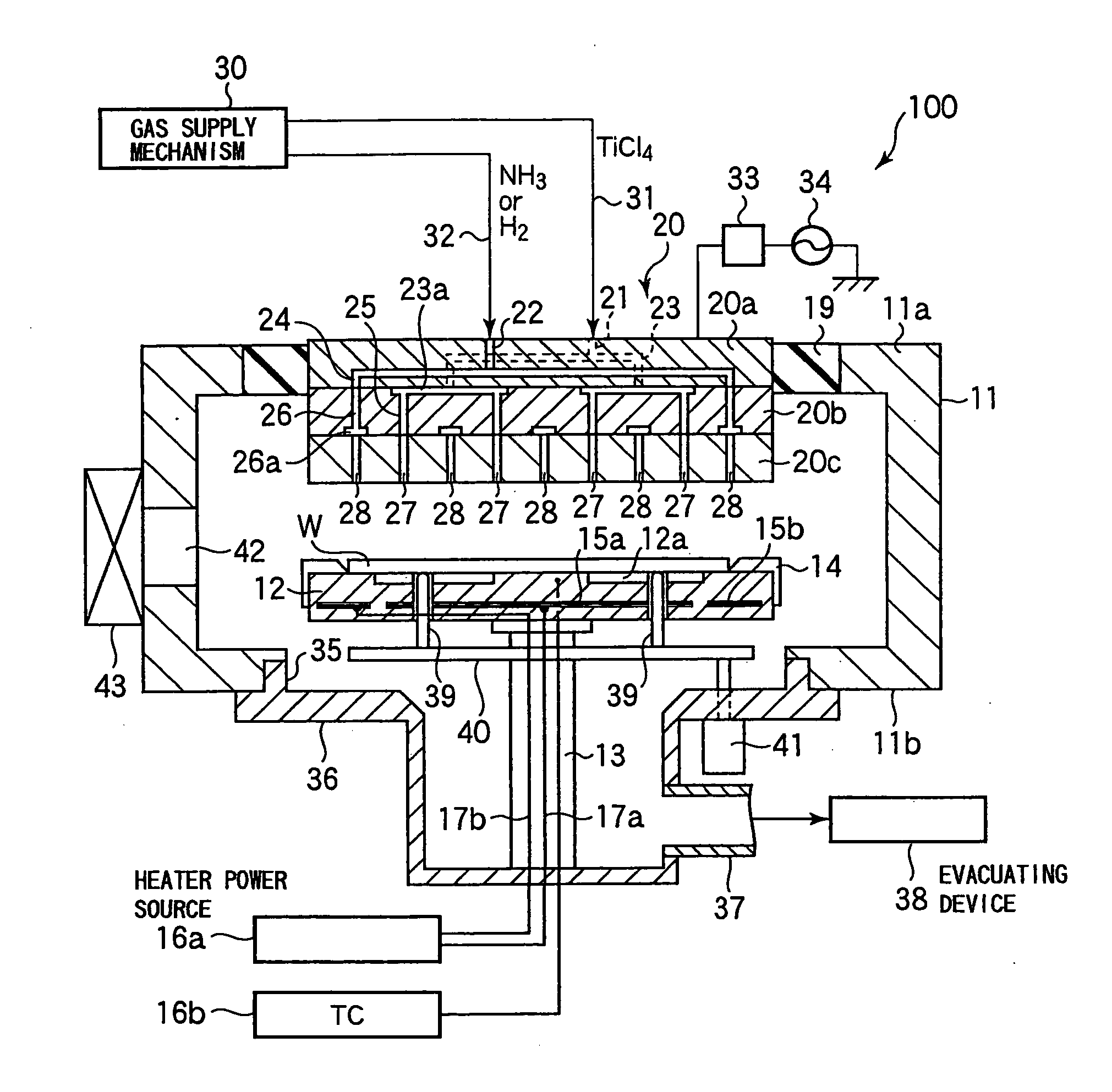

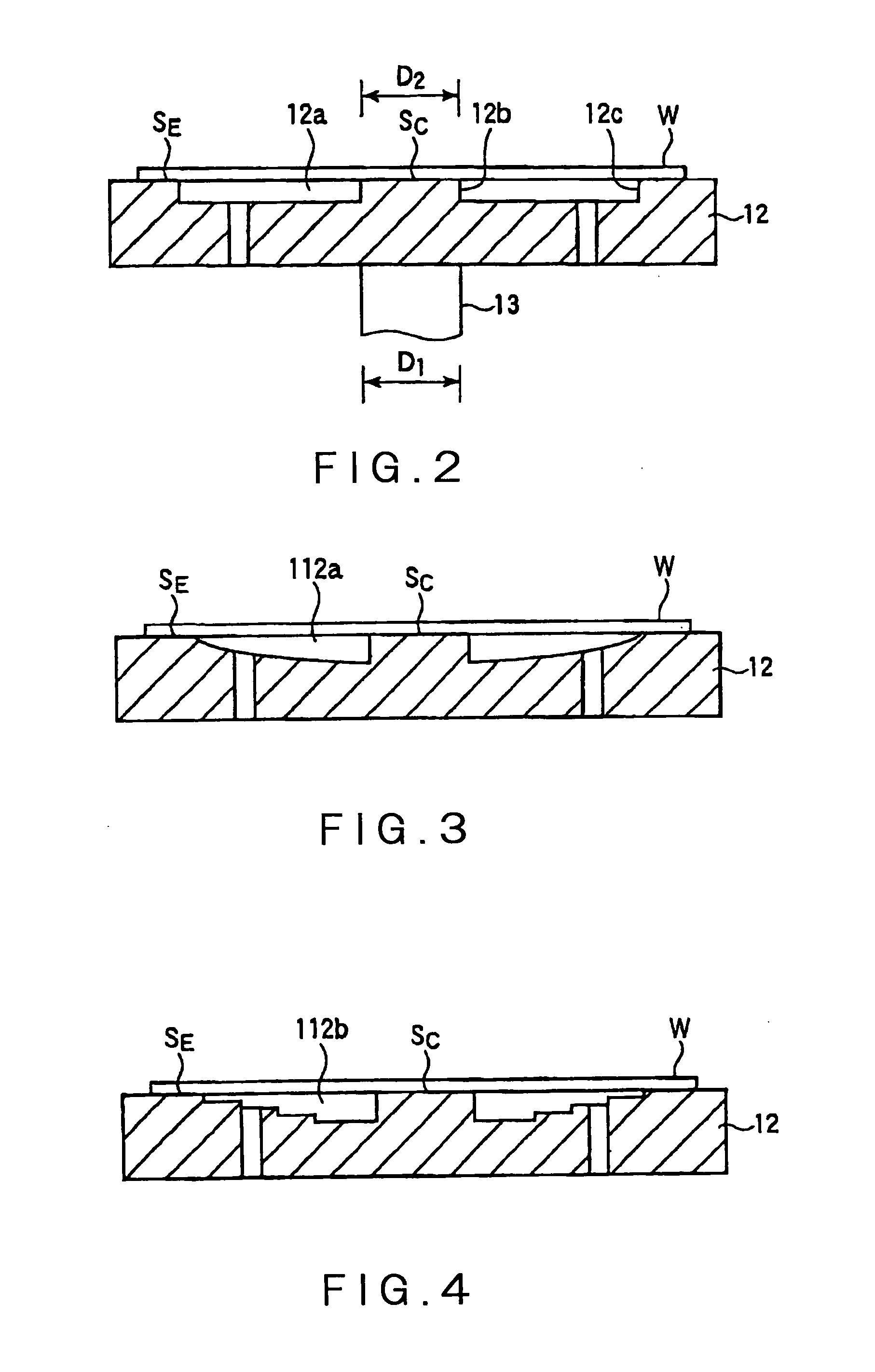

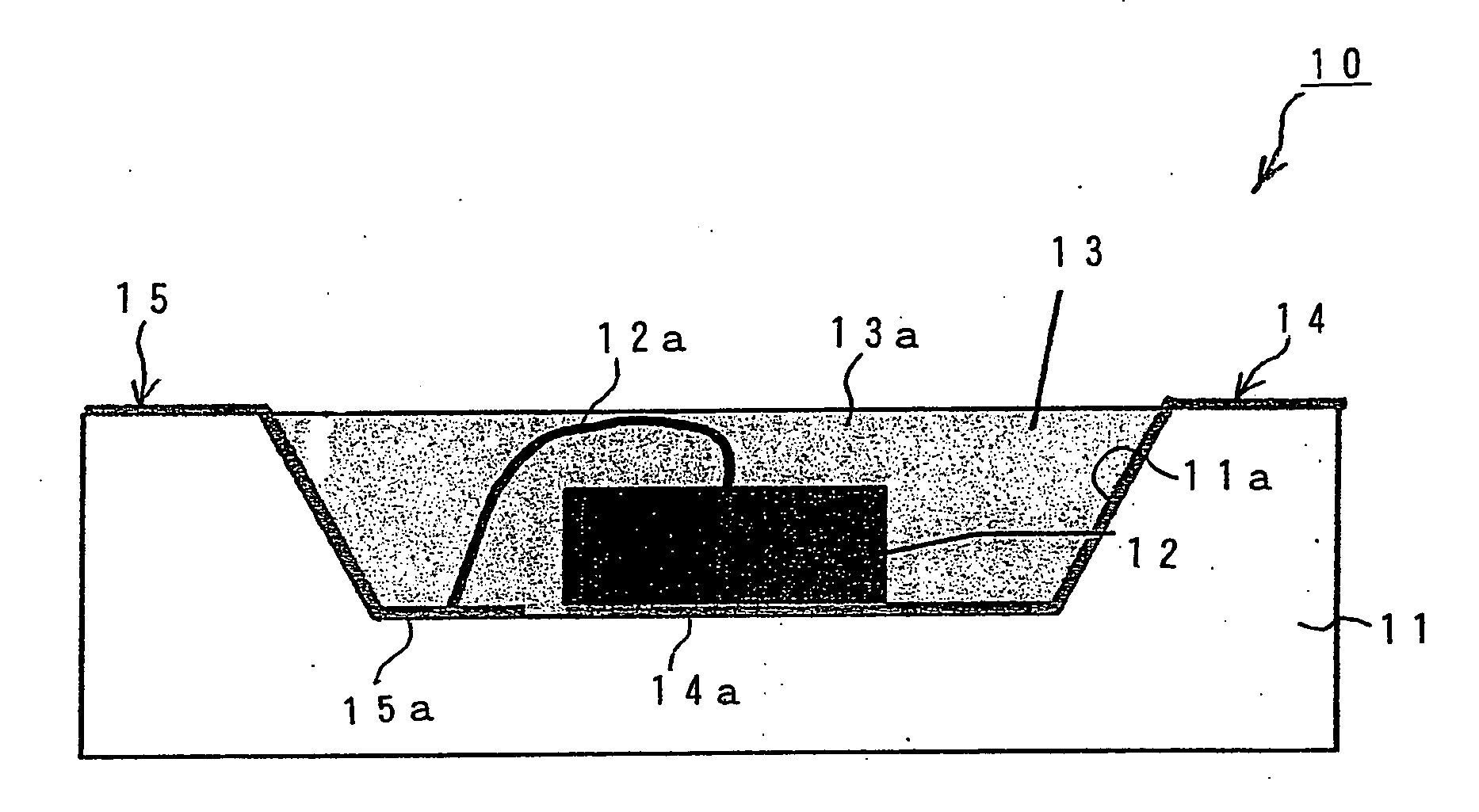

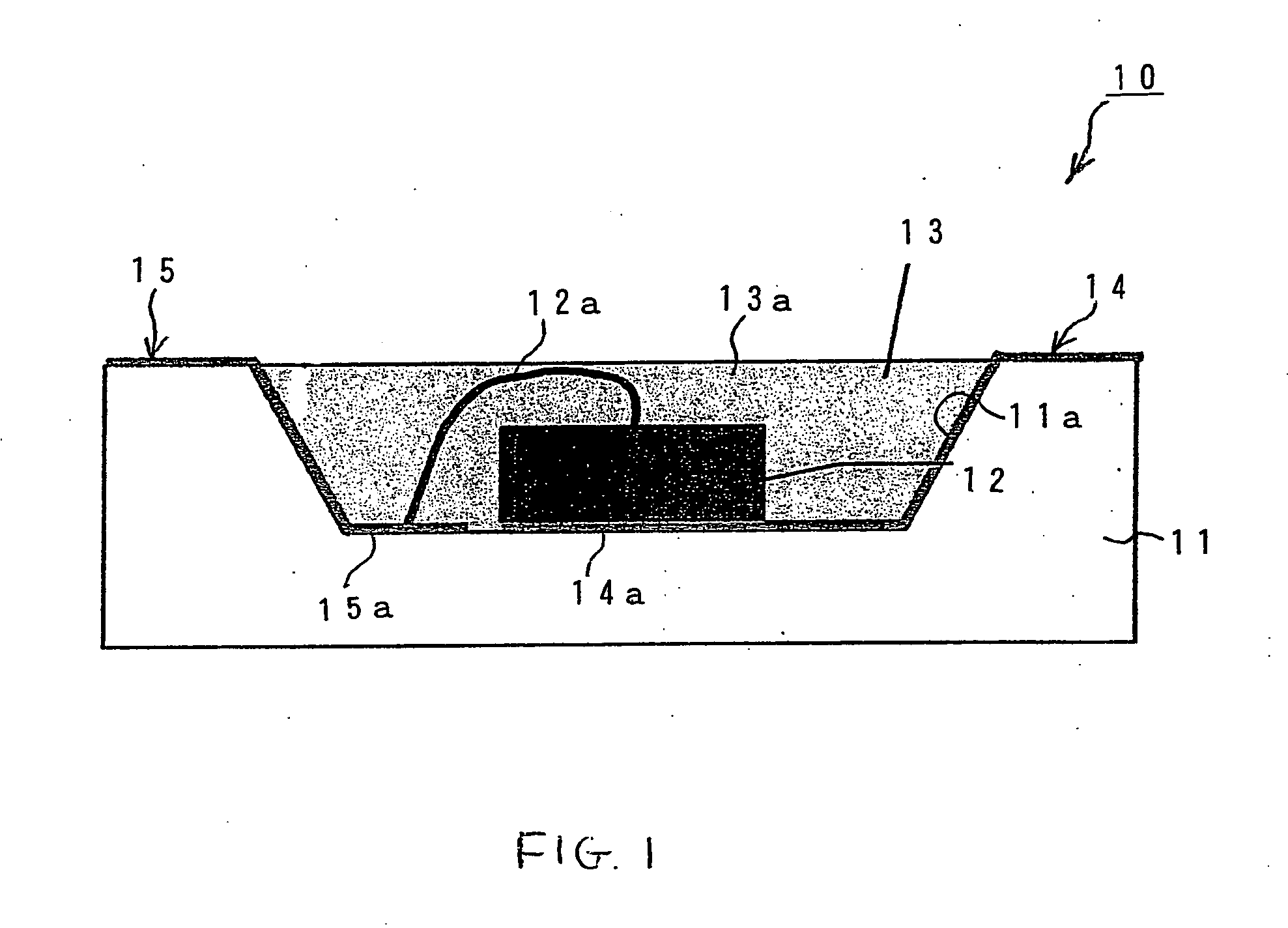

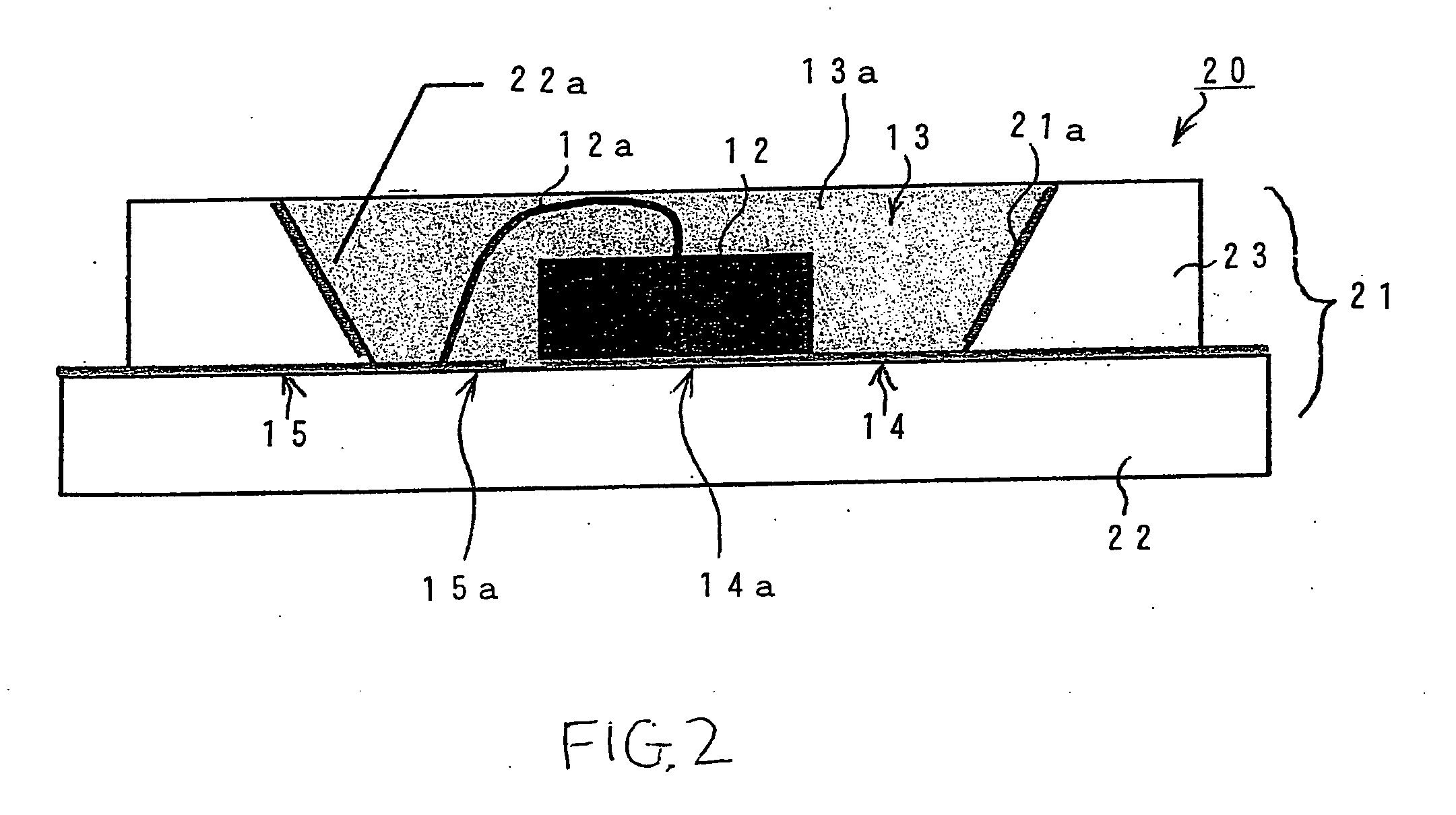

Substrate Processing Apparatus and Substrate Mount Table Used in the Apparatus

InactiveUS20100162956A1Achieving temperature uniformityEliminate the effects ofElectric discharge tubesSemiconductor/solid-state device manufacturingInternal pressureSusceptor

Disclosed is a susceptor which achieves uniform temperature distribution of a wafer placed on the susceptor, and also disclosed is a substrate processing apparatus provided with the susceptor. An annular recess 12a is formed in an intermediate portion between the central portion and the peripheral portion of a wafer support surface of the susceptor 12. Due to the provision of the recess, the substrate heating effect by thermal radiation from the susceptor is suppressed in the intermediate portion. The geometrical dimension of the recess is determined taking the chamber internal pressure into consideration.

Owner:TOKYO ELECTRON LTD

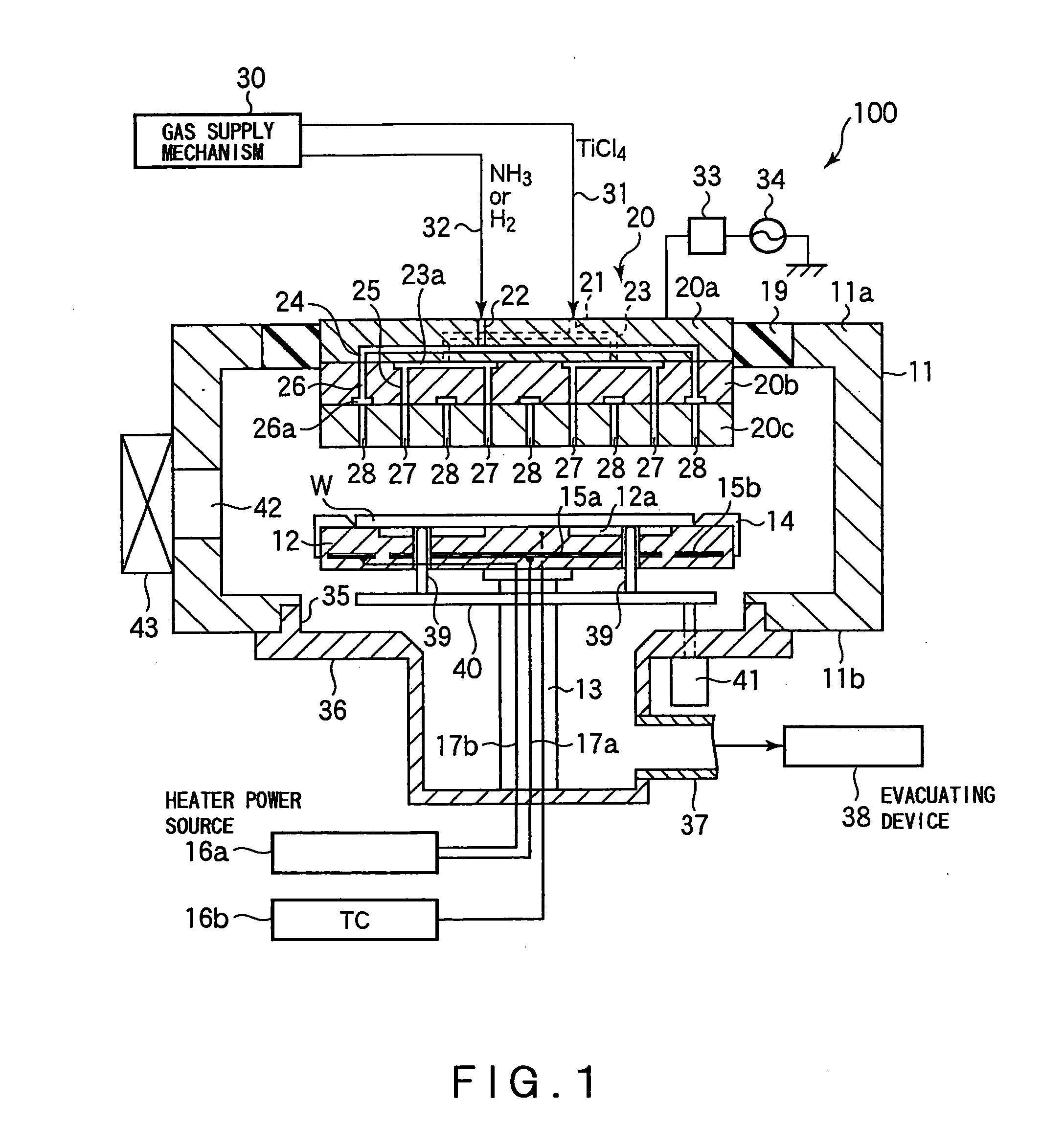

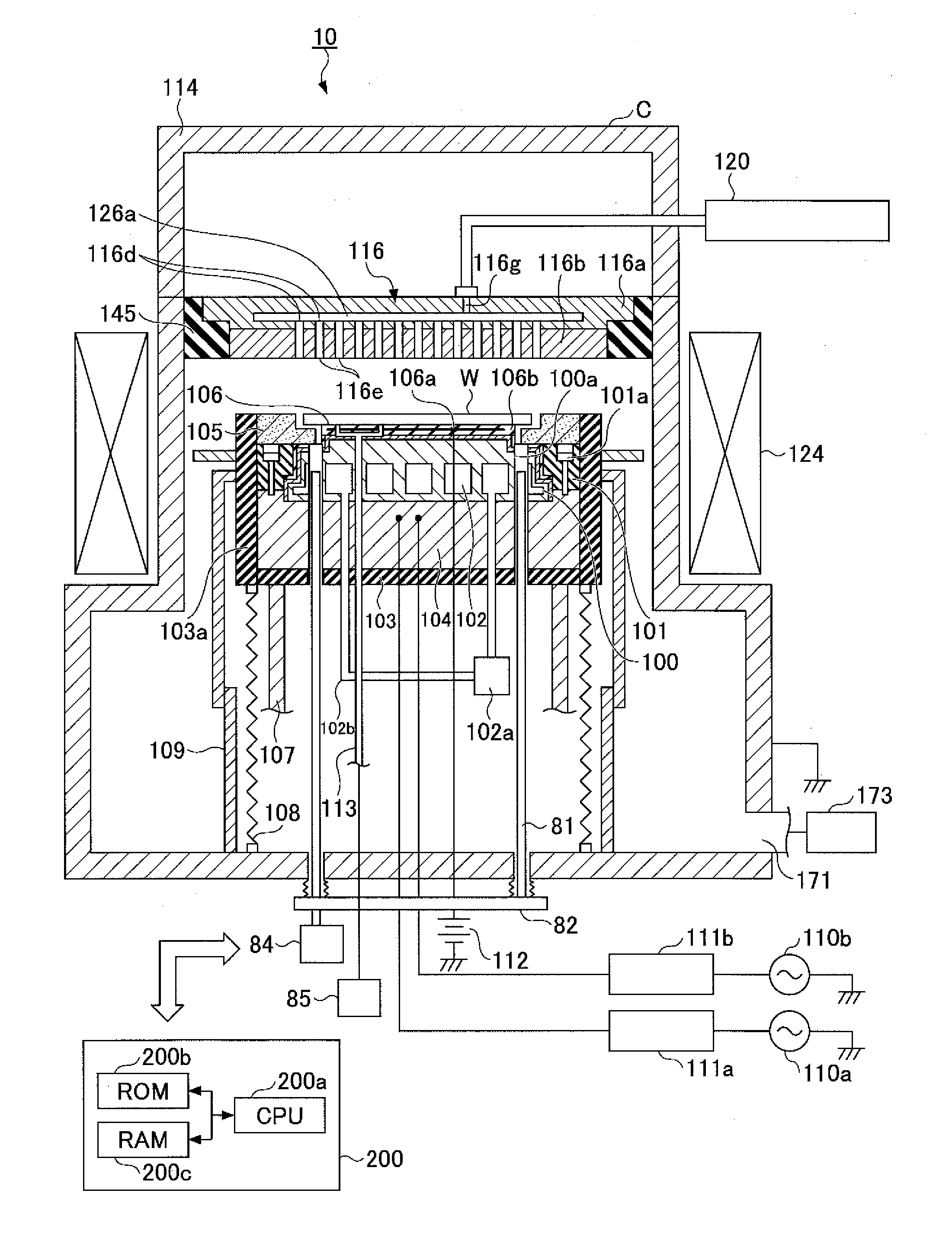

Substrate processing apparatus and susceptor

ActiveUS20140202386A1Increase temperatureLiquid surface applicatorsMolten spray coatingHigh frequency powerSusceptor

A substrate processing apparatus includes a chamber, a susceptor to receive a substrate and provided in the chamber, a gas supply source to supply a predetermined gas into the chamber, and a high frequency power source to treat the substrate by plasma. The susceptor includes a first ceramics base member including a flow passage to let a coolant pass through, a first conductive layer formed on a principal surface and a side surface on a substrate receiving side of the first ceramics base member, and an electrostatic chuck stacked on the first conductive layer and configured to electrostatically attract the wafer received thereon. A volume of the flow passage is equal to or more than a volume of the first ceramics base member. The high frequency power source is configured to supply high frequency power to the first conductive layer.

Owner:TOKYO ELECTRON LTD

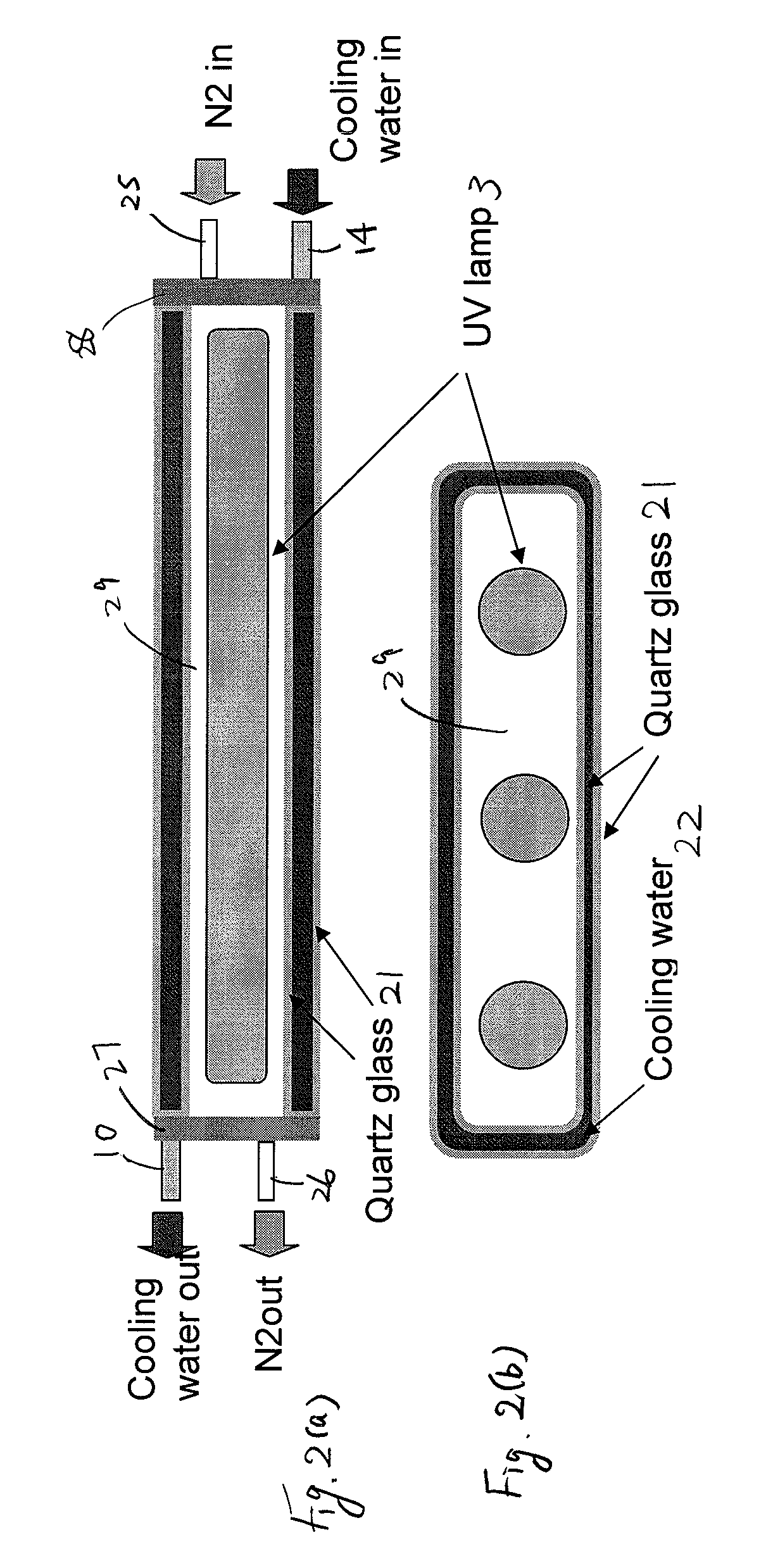

UV light irradiating apparatus with liquid filter

ActiveUS7763869B2High mechanical strengthHigh energyMirrorsOptical filtersLiquid layerLight irradiation

A UV light irradiating apparatus for irradiating a semiconductor substrate with UV light includes: a reactor in which a substrate-supporting table is provided; a UV light irradiation unit connected to the reactor for irradiating a semiconductor substrate placed on the substrate-supporting table with UV light through a light transmission window; and a liquid layer forming channel disposed between the light transmission window and at least one UV lamp for forming a liquid layer through which the UV light is transmitted. The liquid layer is formed by a liquid flowing through the liquid layer forming channel.

Owner:ASM JAPAN

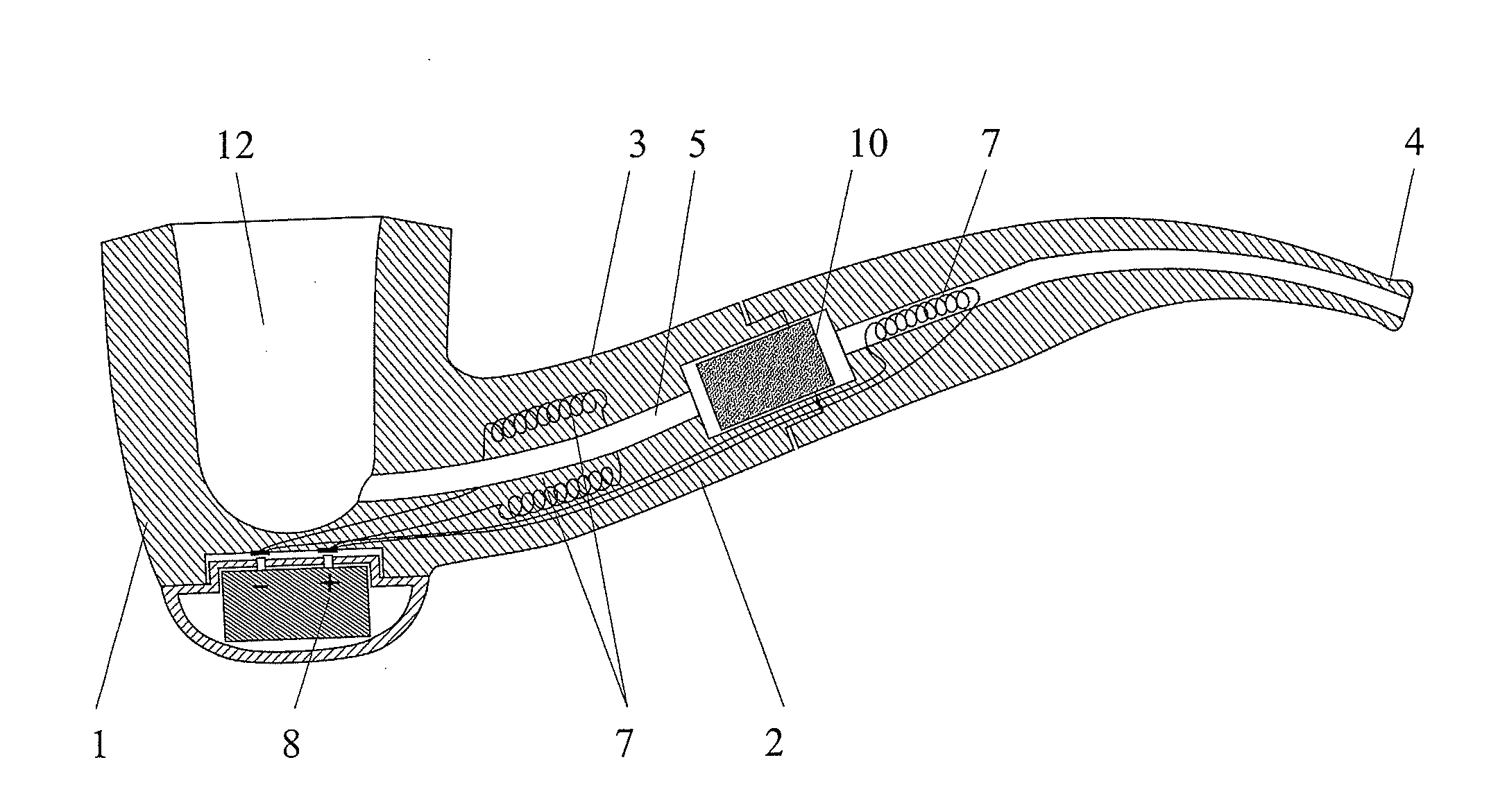

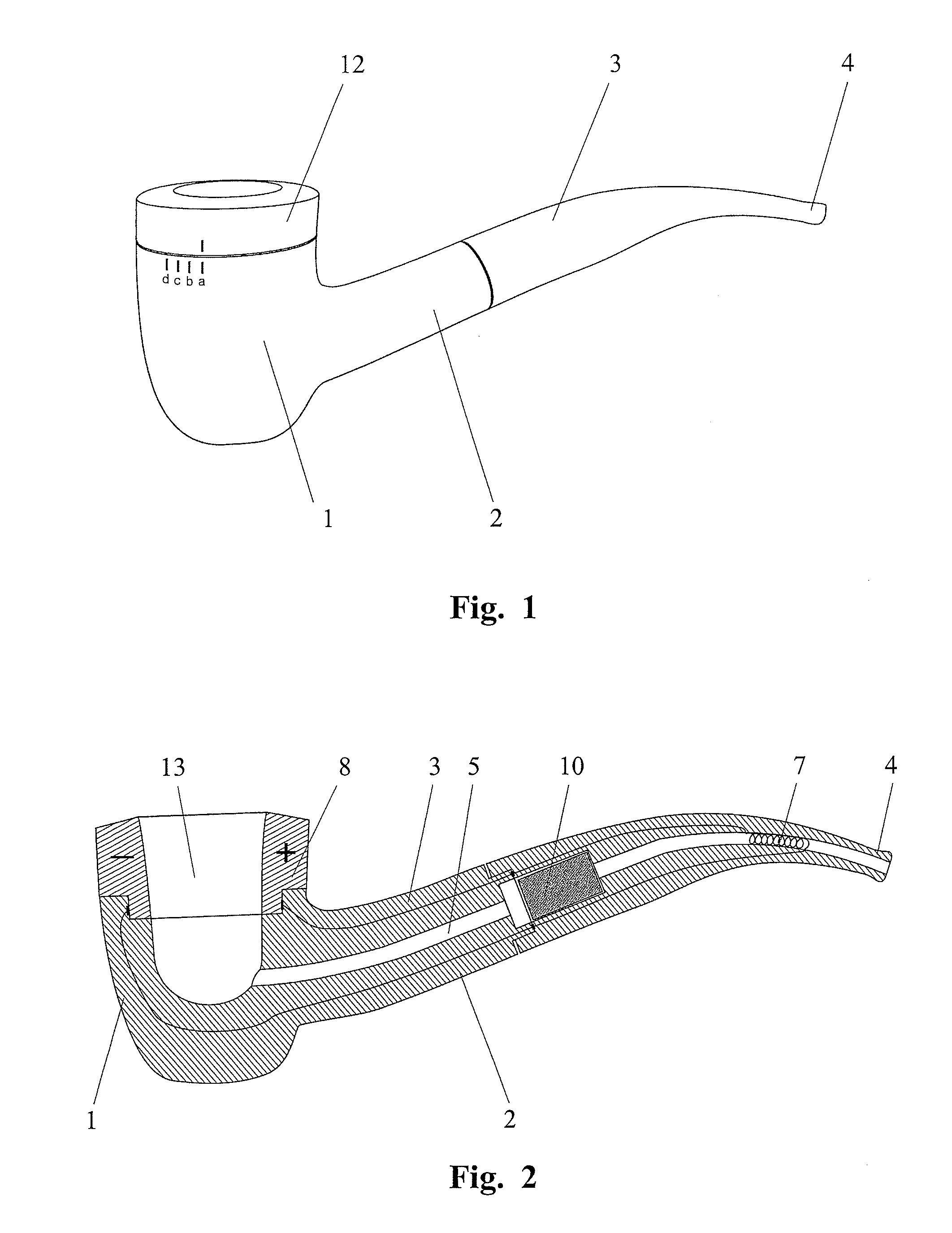

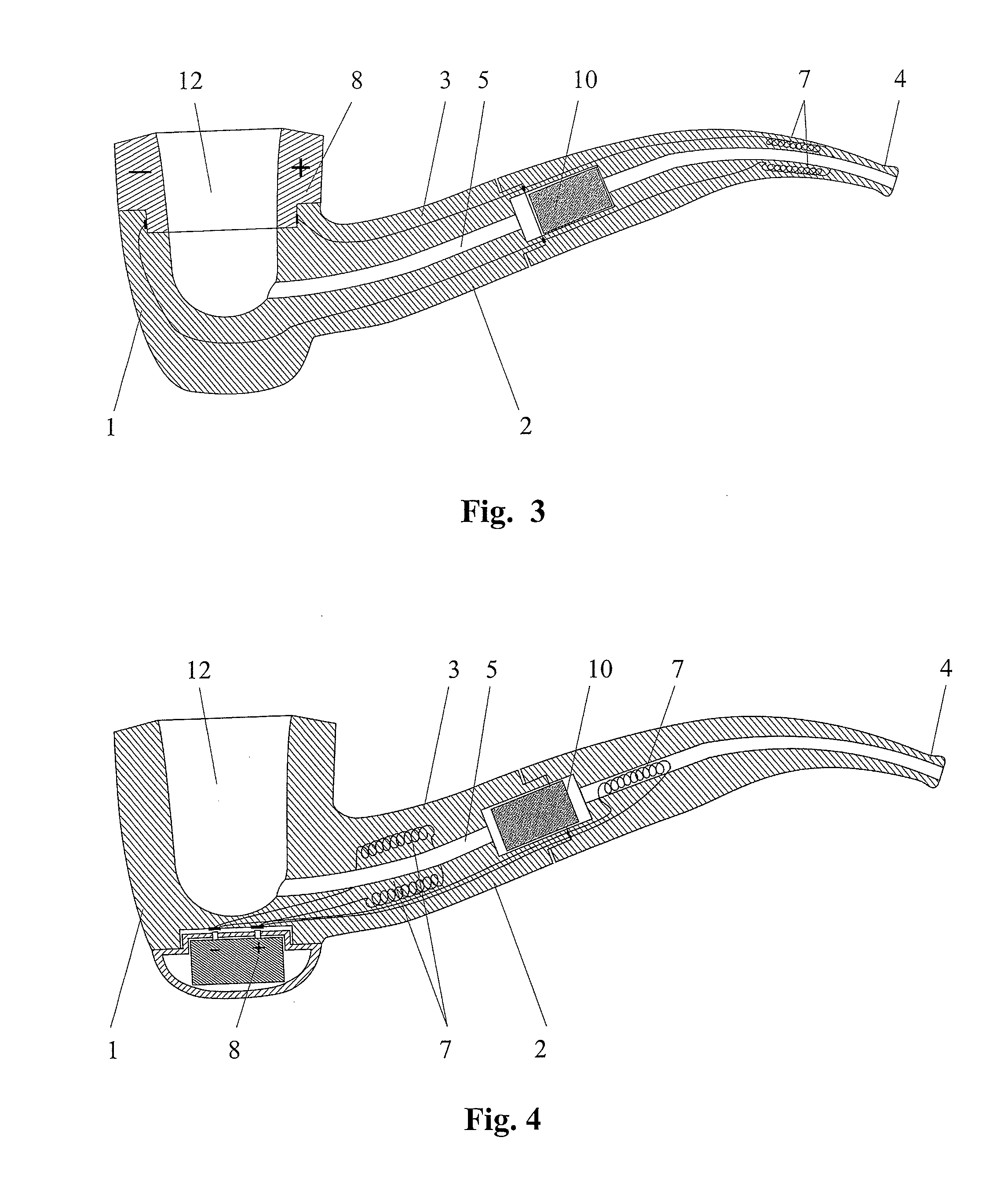

Smokeless pipe

A smokeless pipe comprises a bowl (1), a shank (2), a stem (3) with a bit (4) and an air channel (5) inside of the pipe, which is used for placing a carrier of a nicotine-containing or flavoring agent (10) and a heating unit (7) connected to a power supply (8). According to the invention at least one of elements (7) of a heating unit is arranged in the stem (3) and is shifted to the bit (4). The invention ensures preservation of the health of a pipe smoker while fully simulating the process of smoking.

Owner:URTSEV VLADIMIR NIKOLAEVICH +1

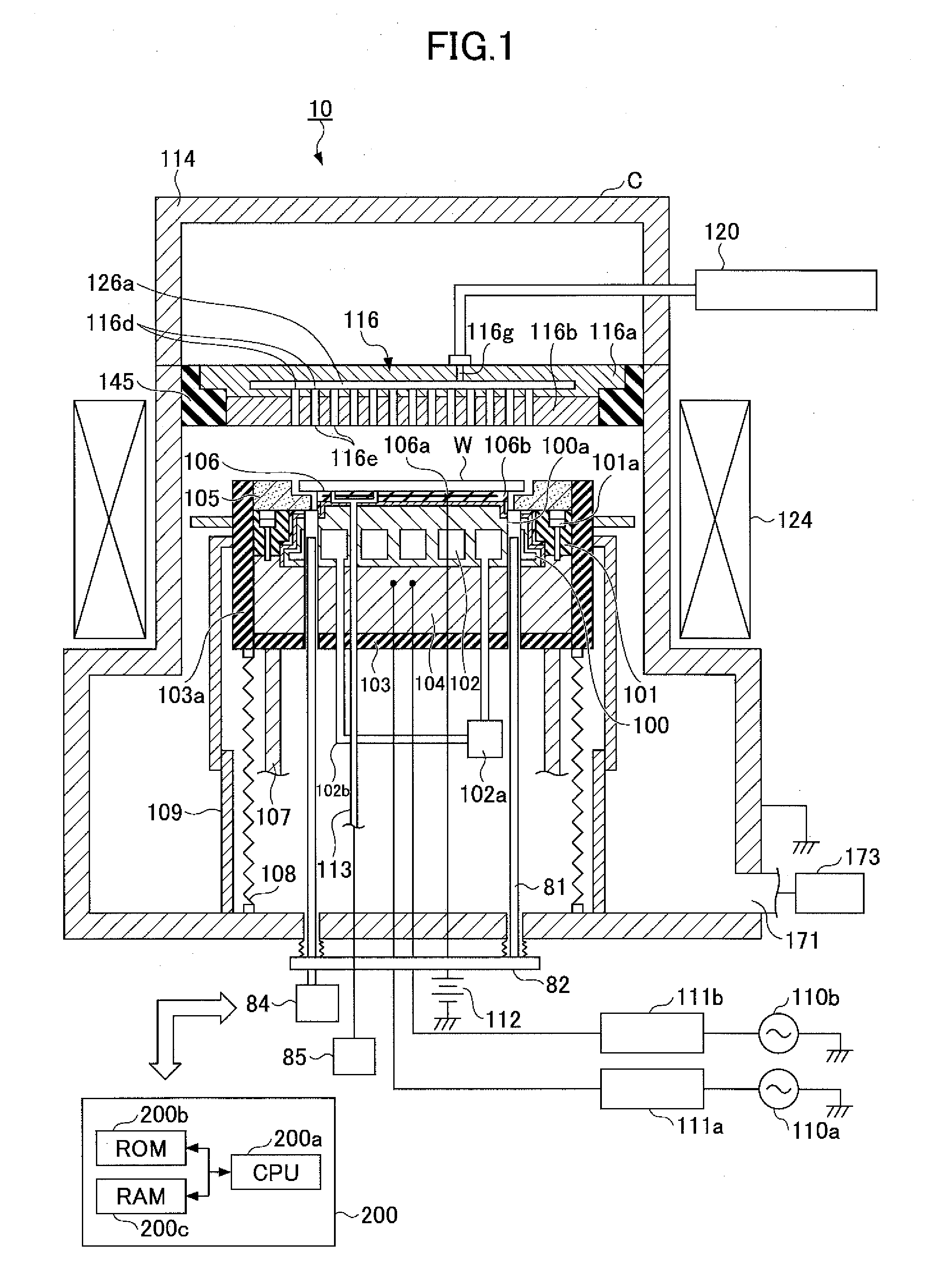

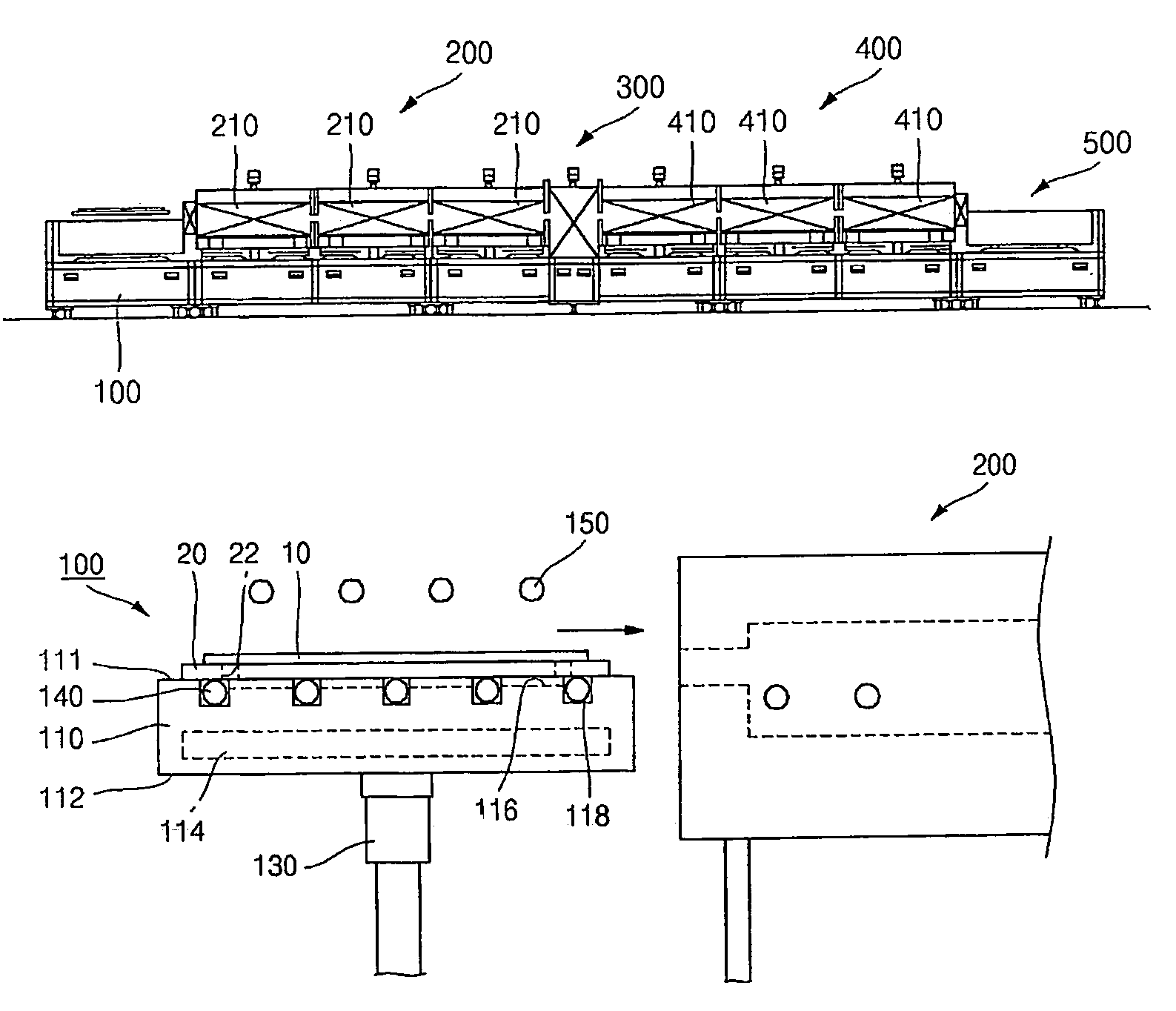

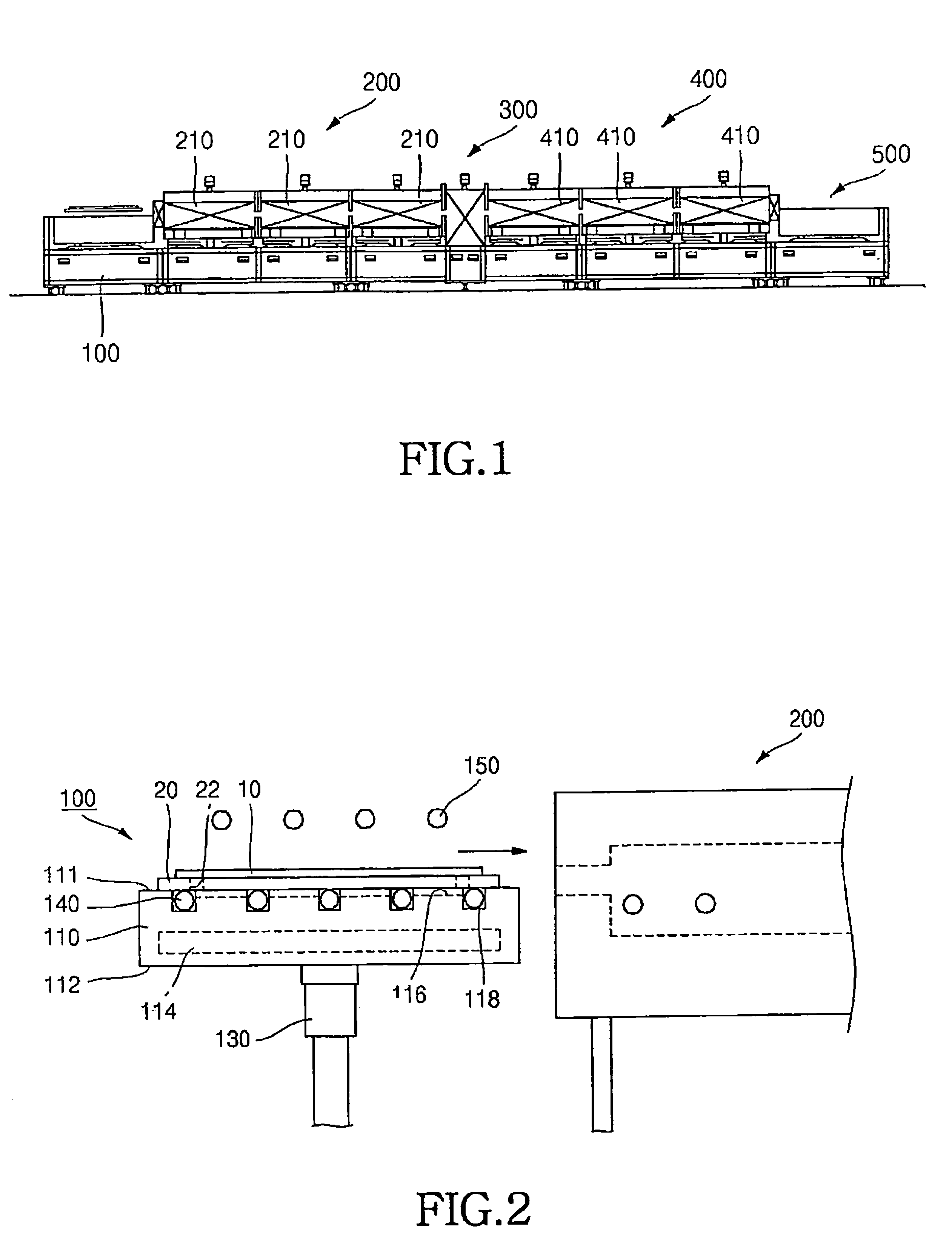

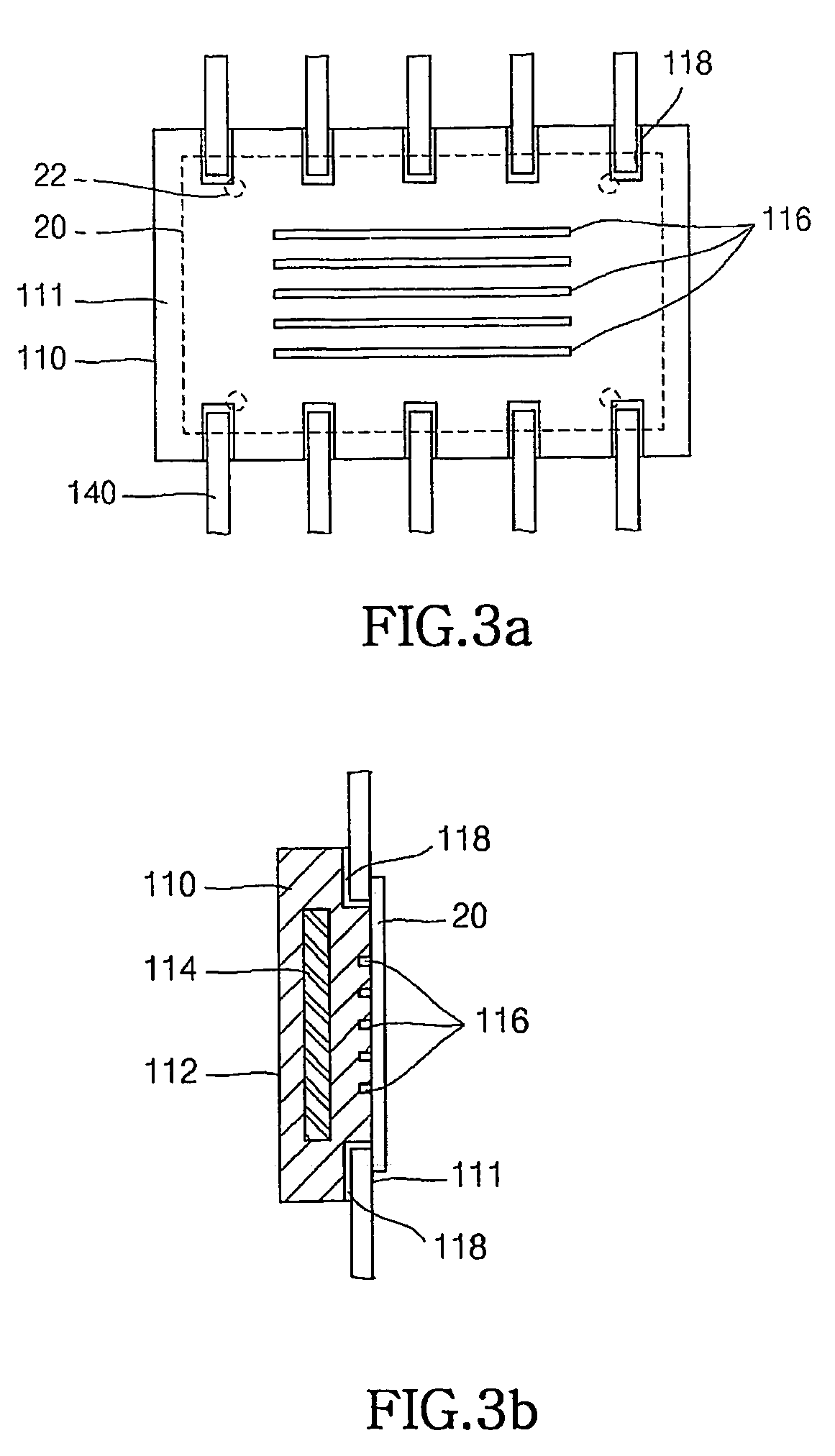

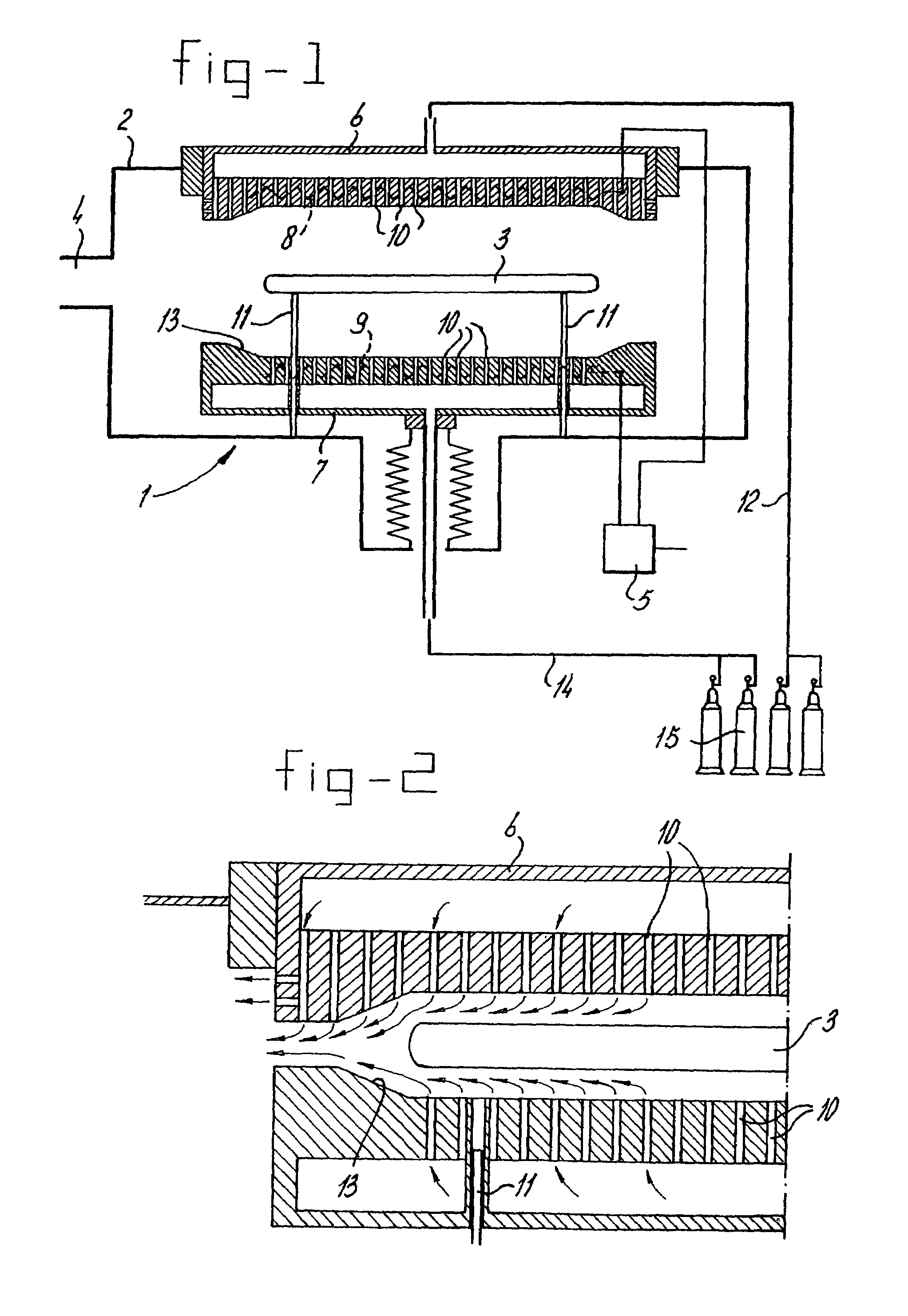

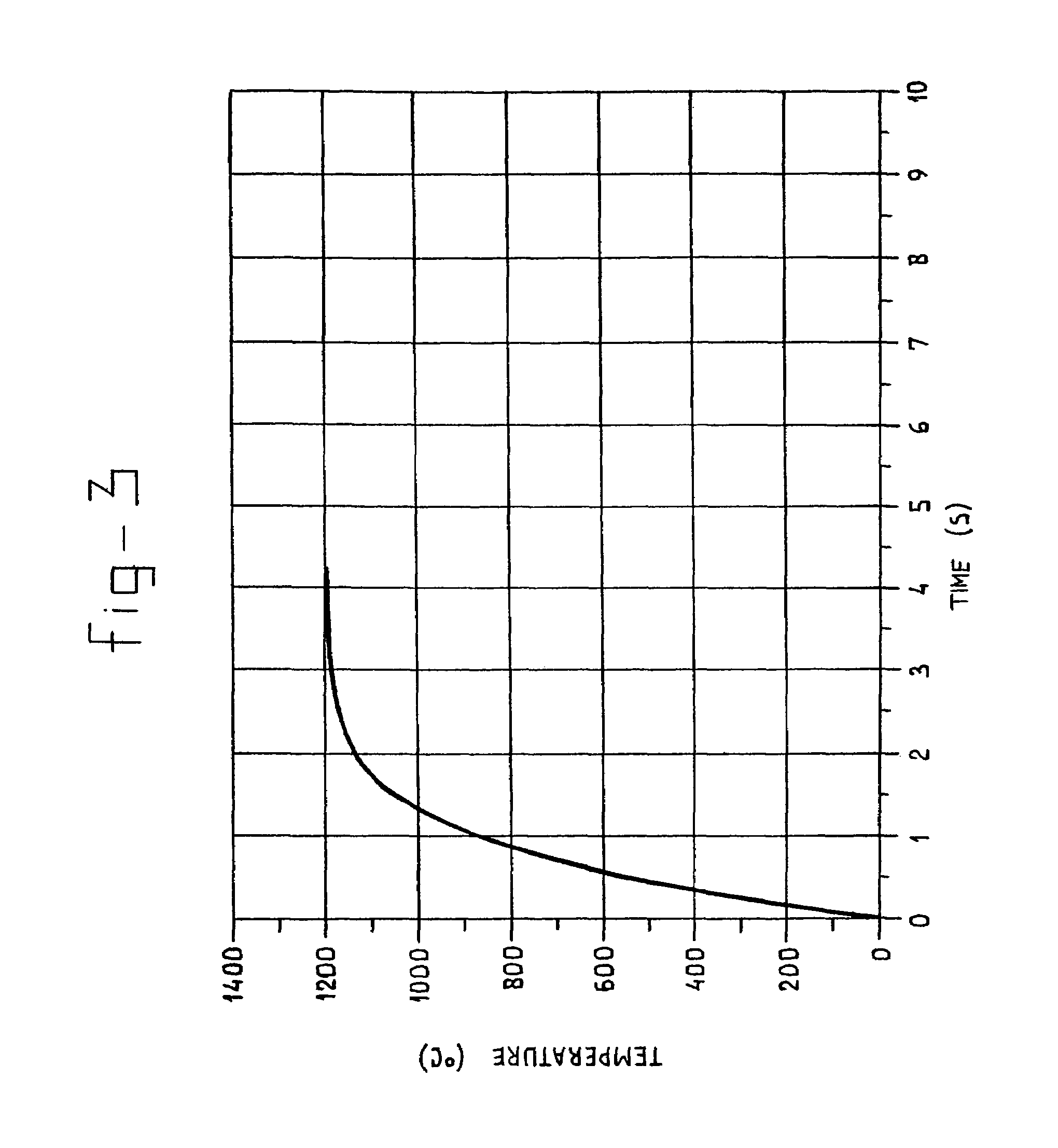

System for heat treatment of semiconductor device

InactiveUS7989736B2Avoid damageIncrease temperatureFurnaces without endless coreSemiconductor/solid-state device manufacturingElectromotive forceSilicon thin film

Disclosed is a heat treatment system for semiconductor devices. The heat treatment system is used in a heat treatment process for semiconductor devices, such as a crystallization process for an amorphous silicon thin film or a dopant activation process for a poly-crystalline silicon thin film formed on a surface of a glass substrate of a flat display panel including a liquid crystal display (LCD) or an organic light emitting device (OLED). The heat treatment system transfers a semiconductor device after uniformly preheating the semiconductor device in order to prevent deformation of the semiconductor device during the heat treatment process, rapidly performs the heat treatment process under the high temperature condition by heating the semiconductor device using a lamp heater and induction heat derived from induced electromotive force, and unloads the semiconductor device after uniformly cooling the semiconductor device such that the semiconductor device is prevented from being deformed when the heat treatment process has been finished. The heat treatment system rapidly performs the heat treatment process while preventing deformation of the semiconductor device by gradually heating or cooling the semiconductor device.

Owner:VIATRON TECH INC

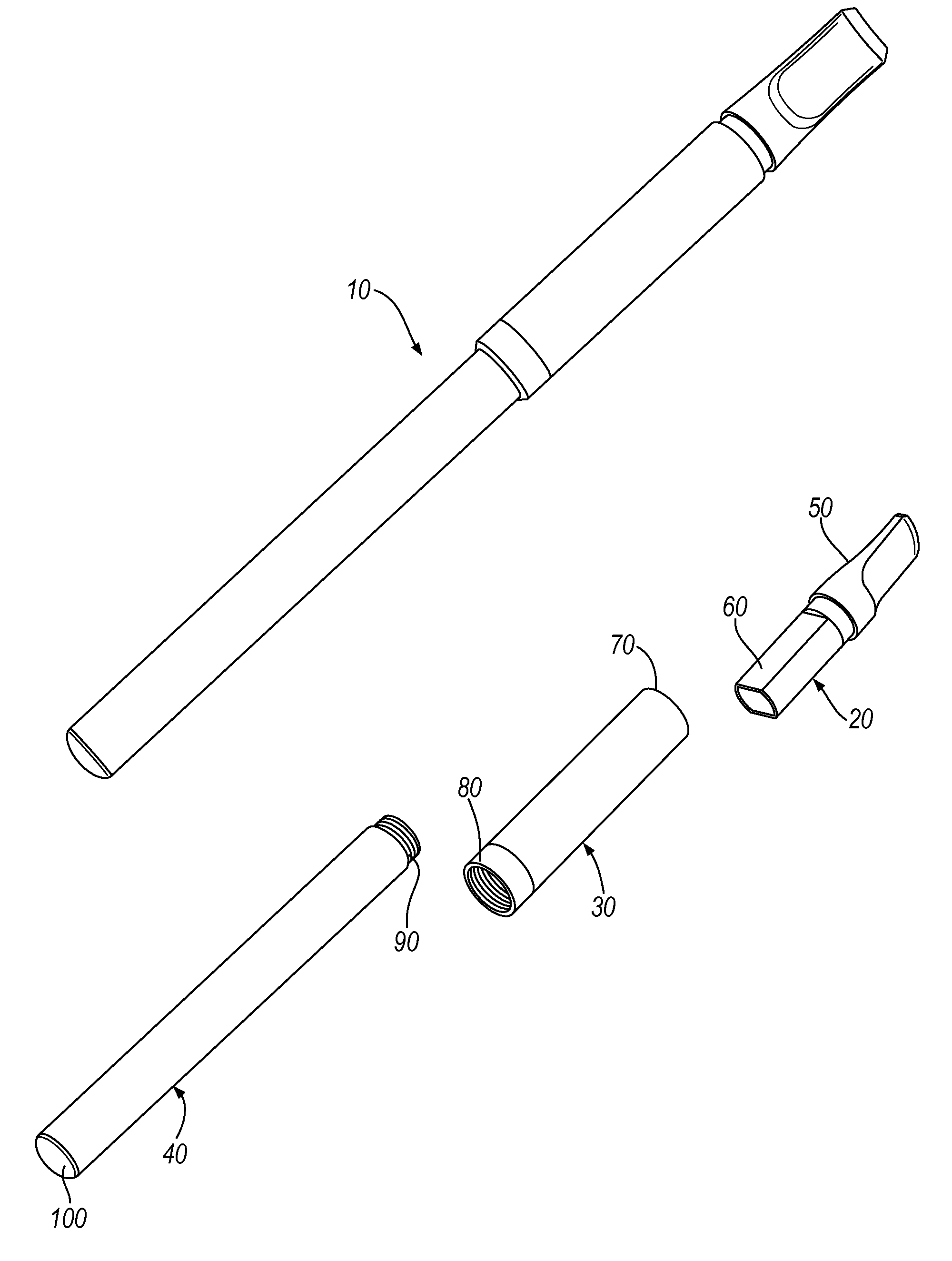

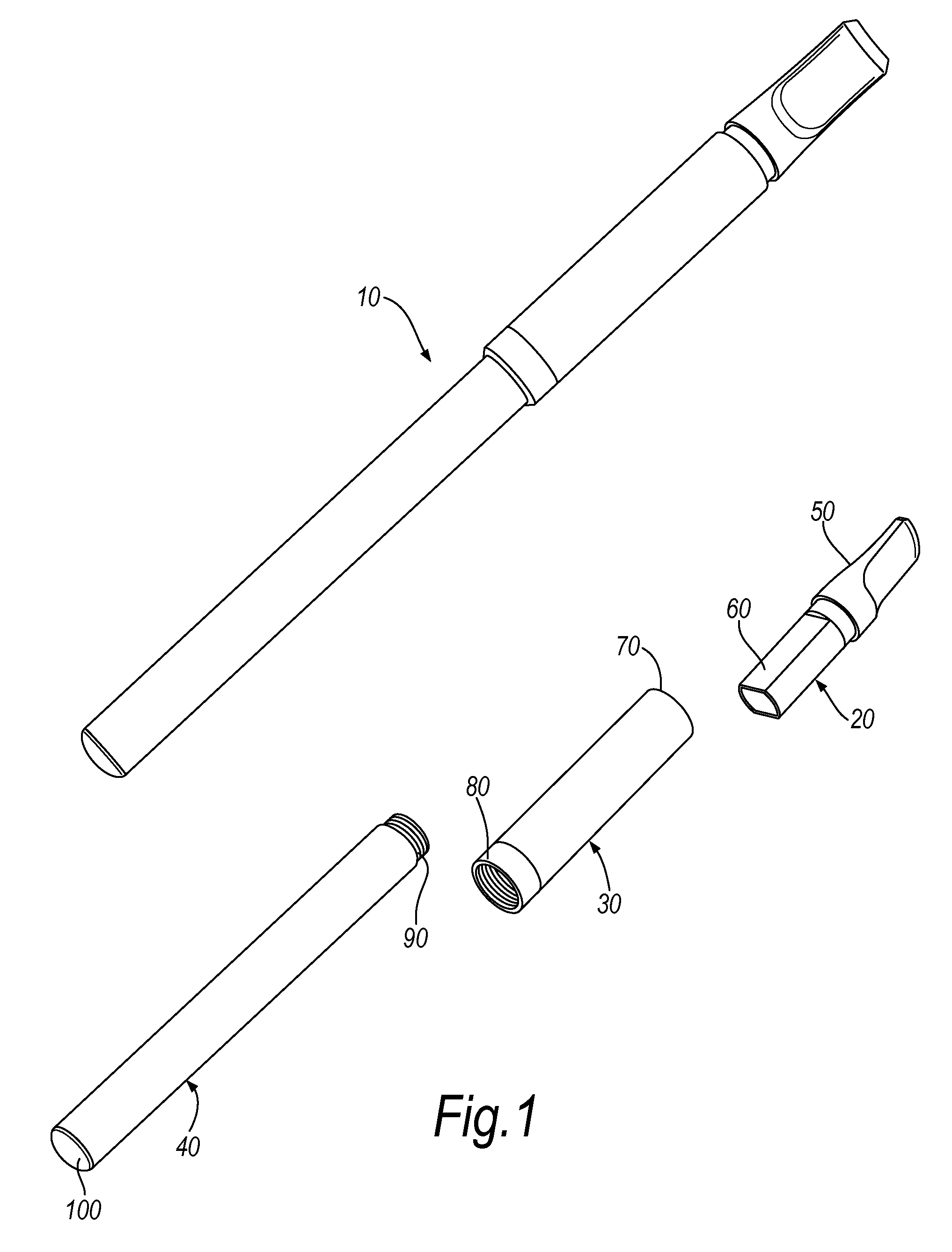

Method and apparatus relating to electronic smoking-substitute devices

InactiveUS20100031968A1Increase the effective areaSmall batteryTobacco devicesEngineeringHeating element

An electronic smoking-substitute device 110 includes a tube containing a reservoir 310 containing a liquid. The liquid includes a substance to be inhaled by the user, for example a nicotine dilution. The device also has a heating element 320, the heating element is a coil and is in direct contact with the reservoir 310. A power source 340 is arranged to power the heating element.

Owner:XL DISTRIBUTORS

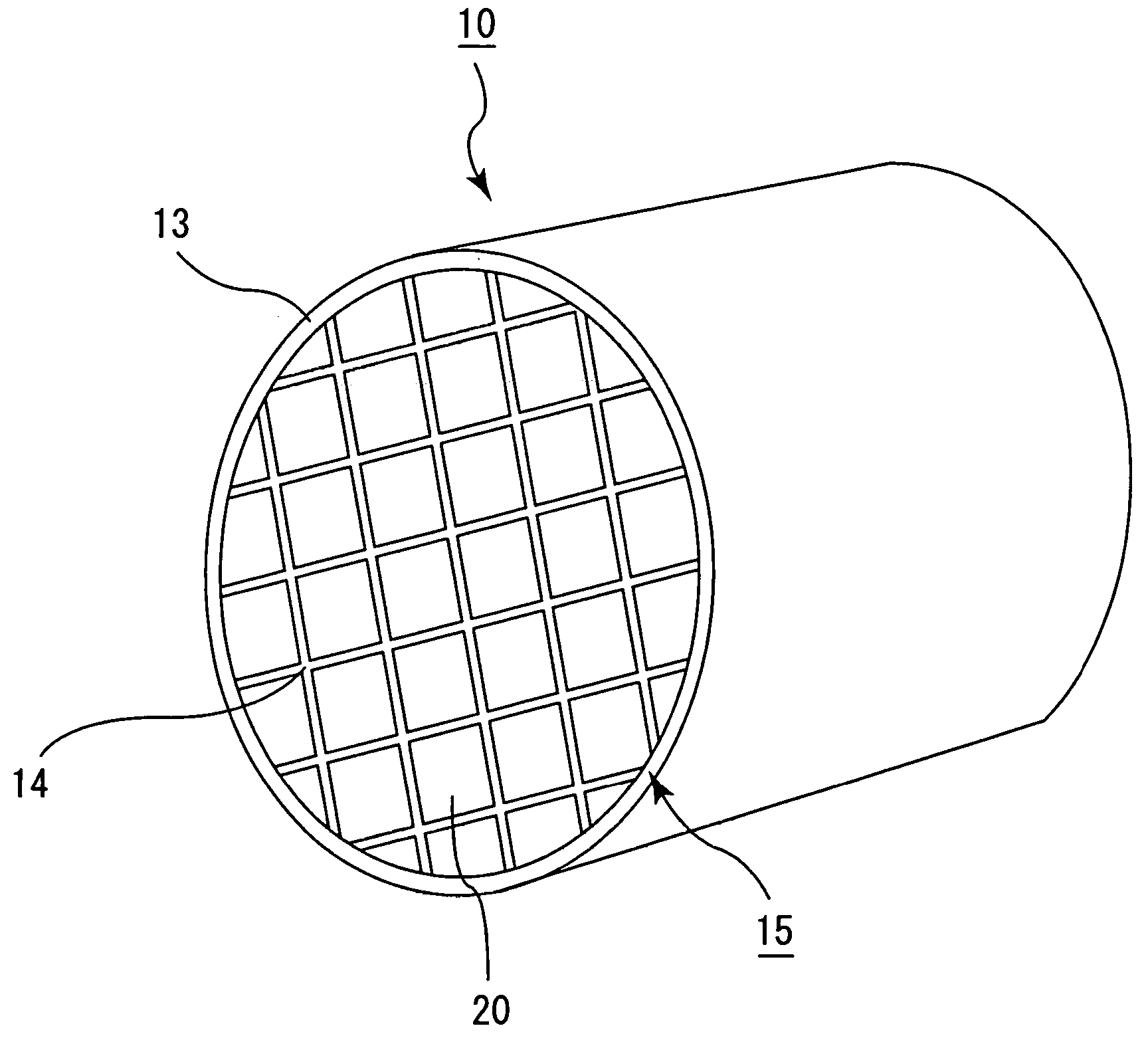

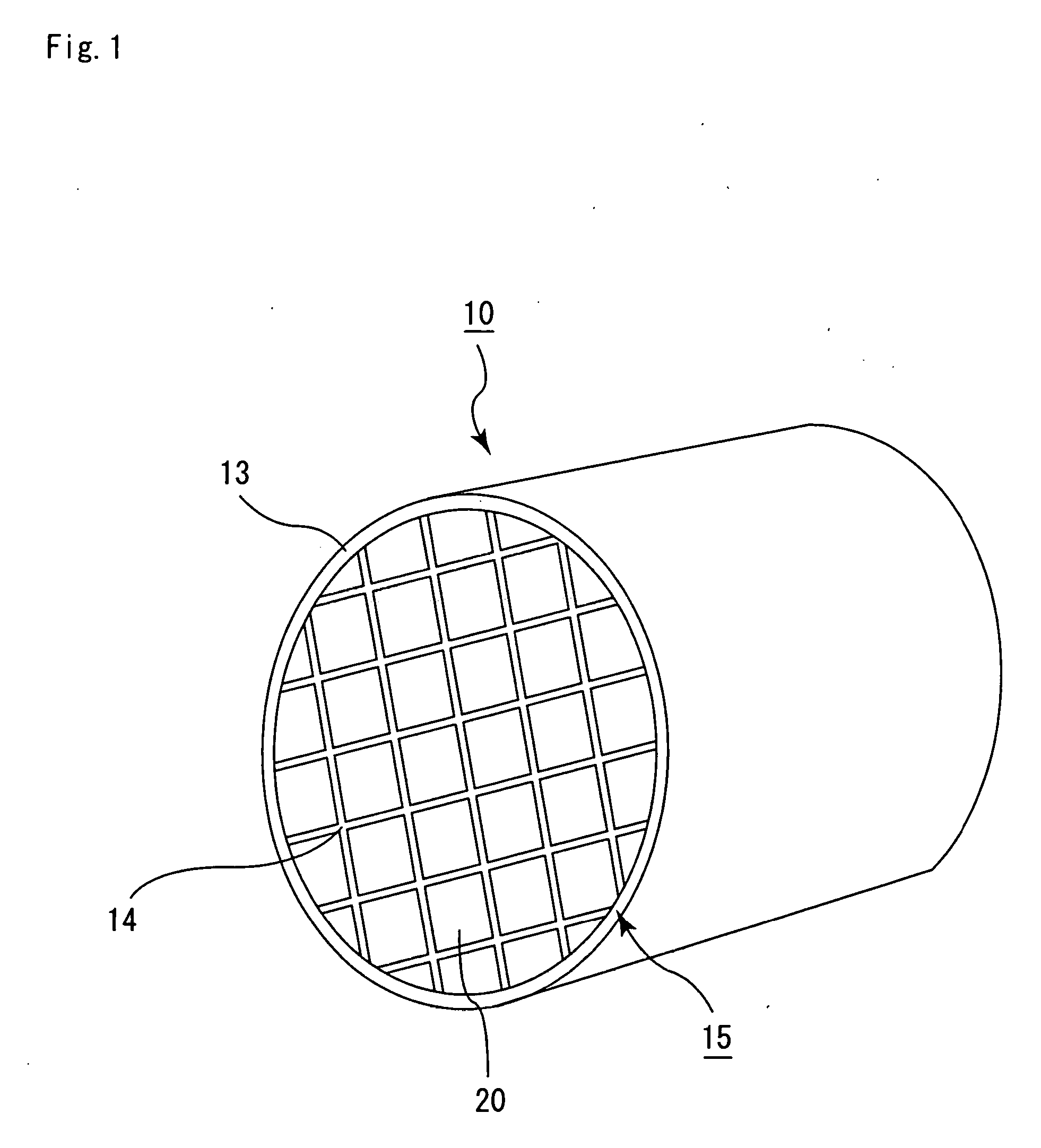

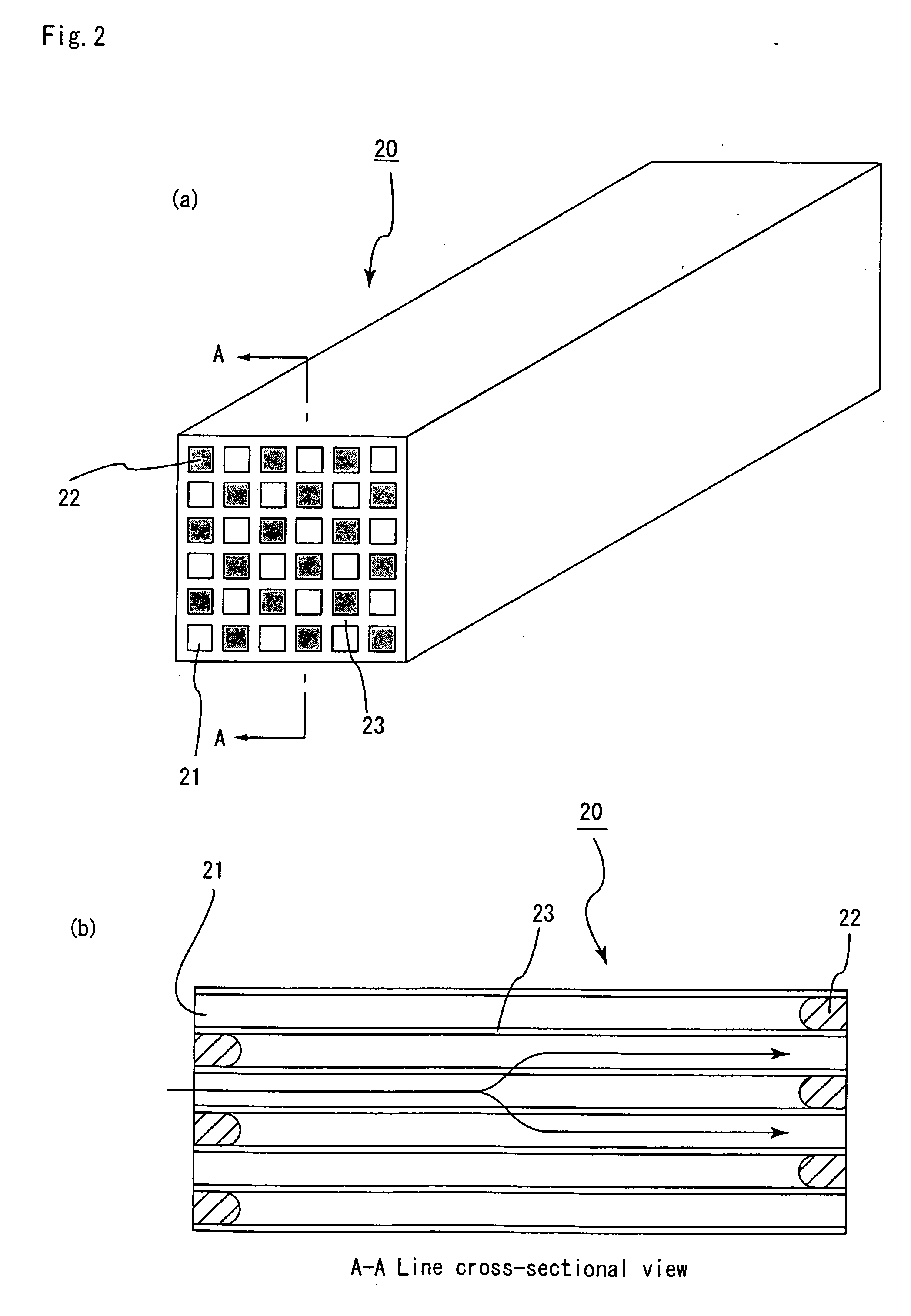

Honeycomb filter for exhaust gas decontamination, adhesive, coating material and process for producing honeycomb filter for exhaust gas decontamination

ActiveUS20050109023A1Reduce thermal stressAlleviating generated thermal stressCombination devicesDispersed particle filtrationParticulatesAdhesive

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change and which is less likely to generate cracks and superior in strength and durability, an adhesive that has a low thermal capacity and is capable of alleviating the thermal stress, a coating material that has a low thermal capacity with a superior heat insulating property and is capable of alleviating the thermal stress, and a manufacturing method of the honeycomb filter for purifying exhaust gases that can improve precision in the outside dimension, and reduce damages in the manufacturing processes. The present invention relates to a honeycomb filter for purifying exhaust gases, having a structure in that a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separate the through holes are allowed to function as a filter for collecting particulates, and in this structure, the thermal expansion coefficient αL of the adhesive layer and the thermal expansion coefficient αF of the porous ceramic member are designed to have the following relationship: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

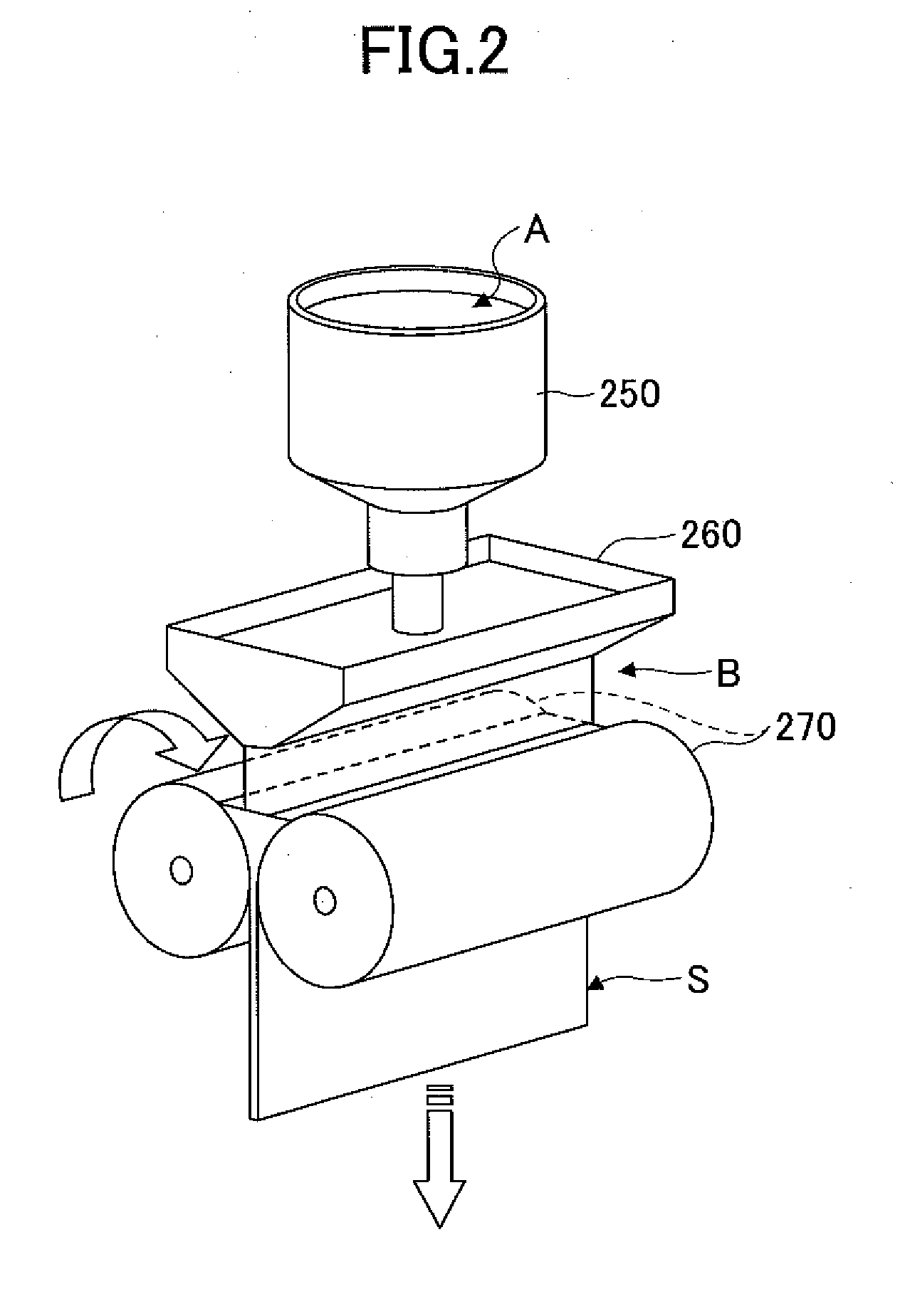

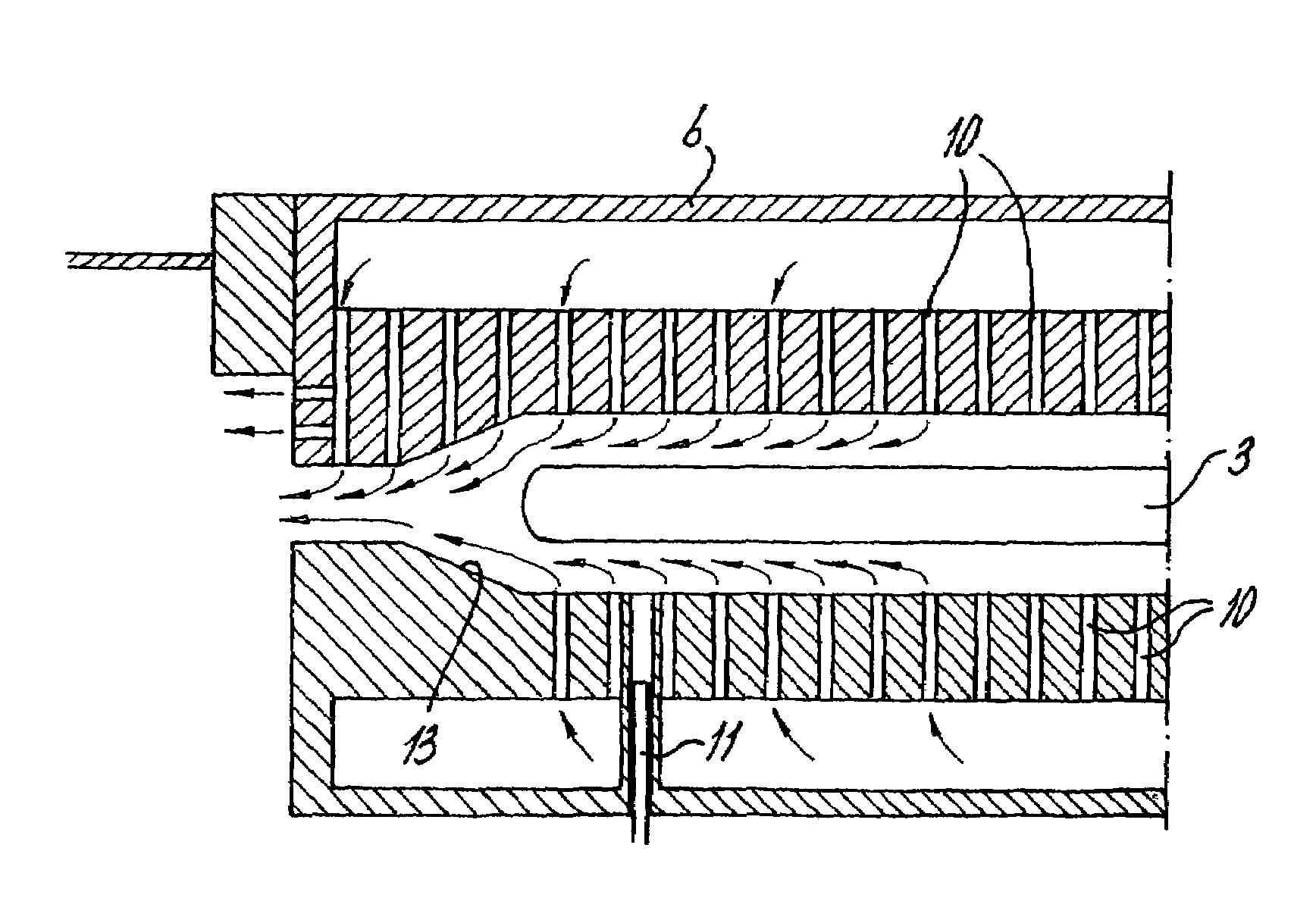

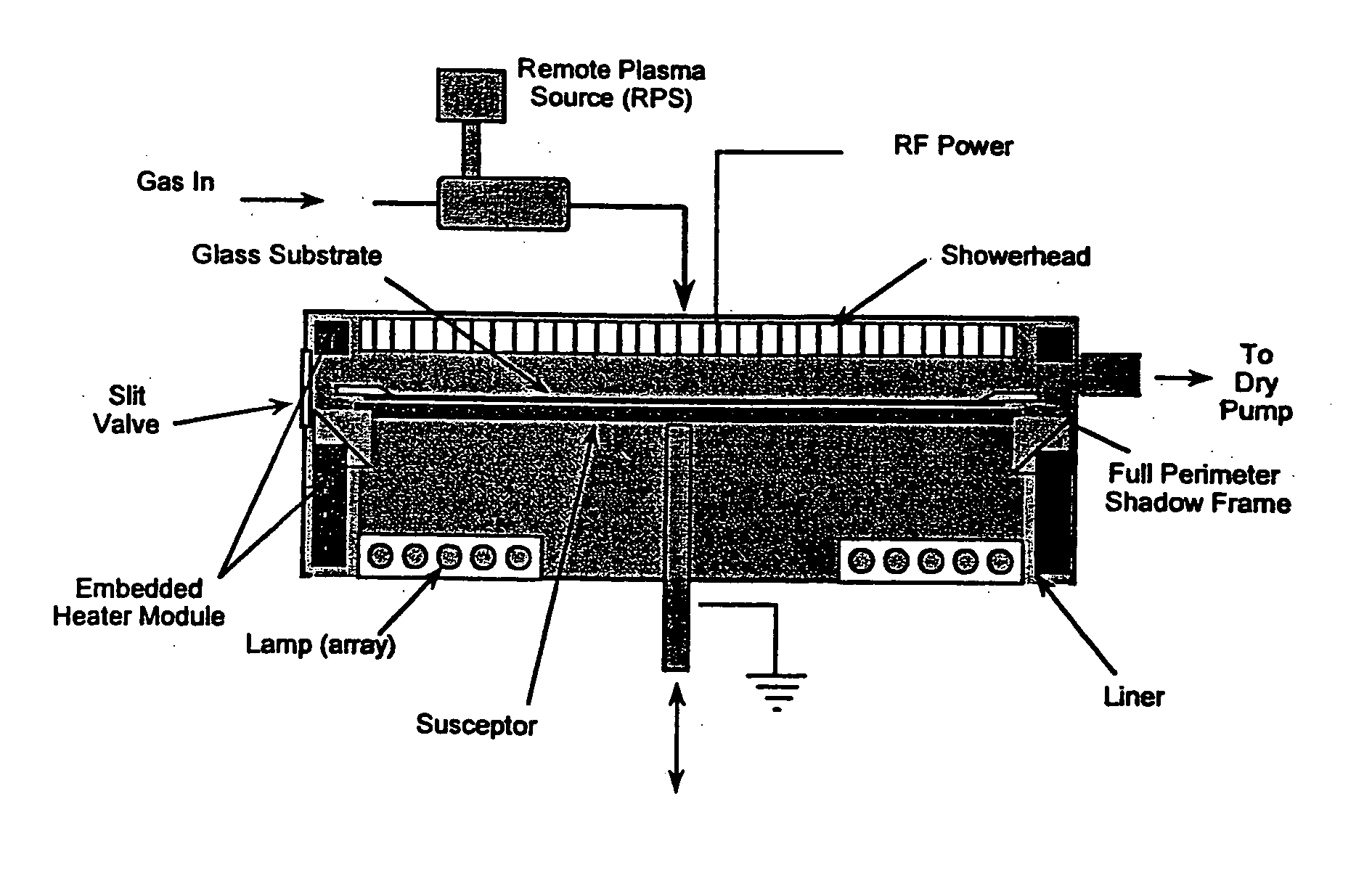

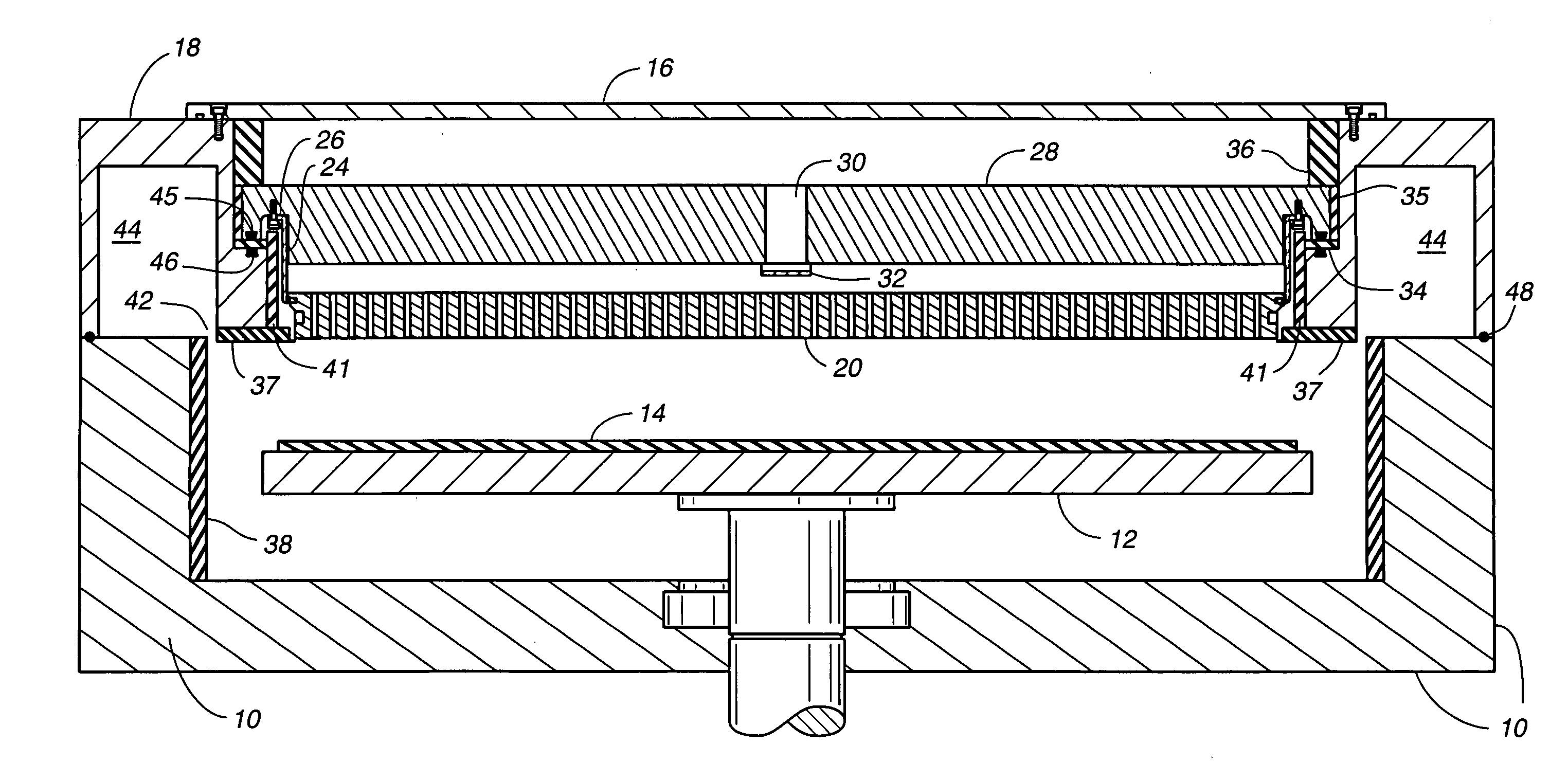

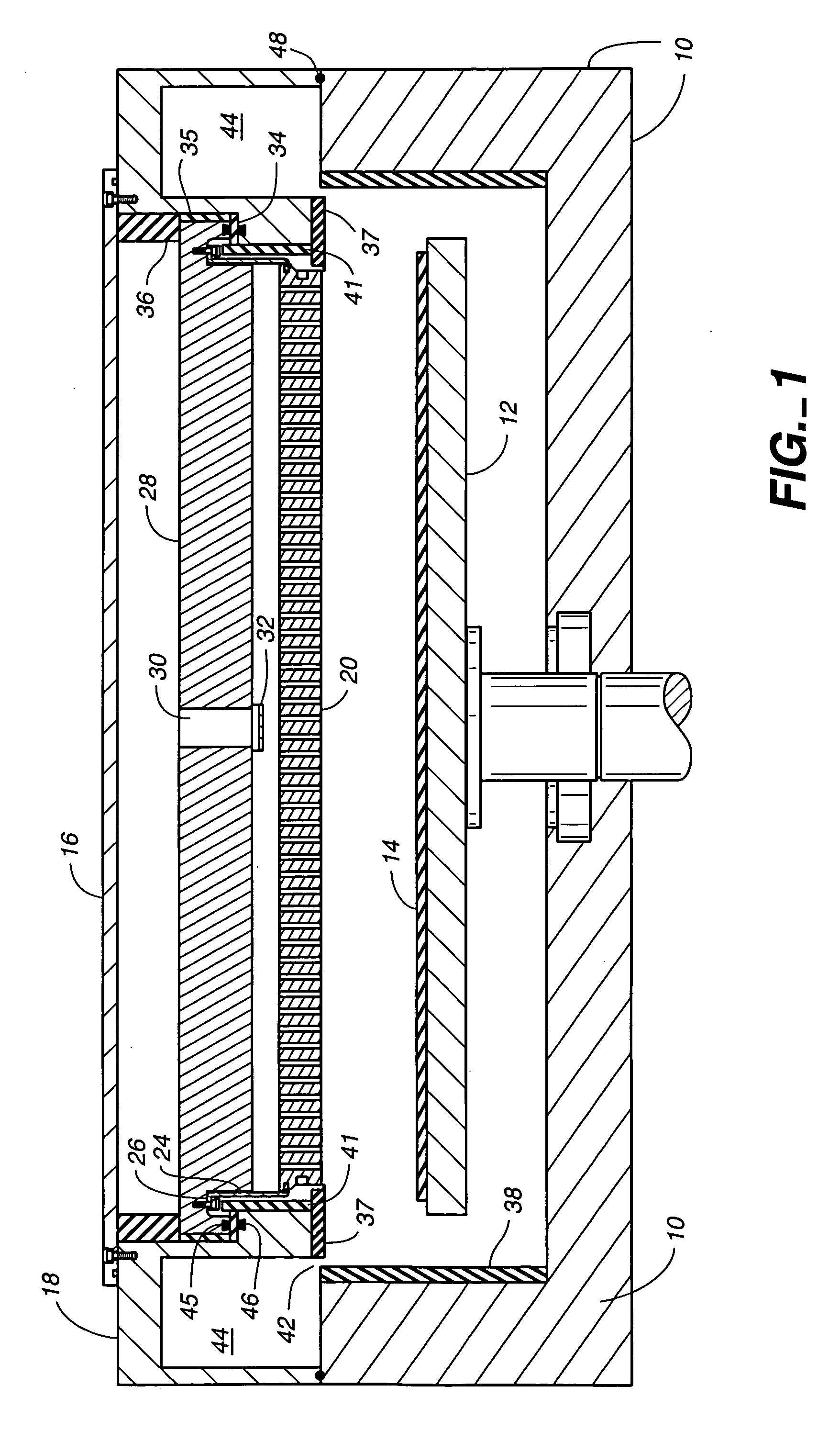

Method and apparatus for supporting a semiconductor wafer during processing

InactiveUS7312156B2Short timeIncrease temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

A semiconductor wafer is processed while being supported without mechanical contact. Instead, the wafer is supported by gas streams emanating from a large number of passages in side sections positioned very close to the upper and lower surface of the wafer. The gas heated by the side sections and the heated side sections themselves quickly heat the wafer to a desired temperature. Process gas directed to the “device side” of the wafer can be kept at a temperature that will not cause deposition on that side section, but yet the desired wafer temperature can be obtained by heating non-process gas from the other side section to the desired temperature. A plurality of passages around the periphery of the wafer on the non-processed side can be employed to provide purge gas flow that prevents process gas from reaching the non-processed side of the wafer and the adjacent area of that side section.

Owner:ASM INTERNATIONAL

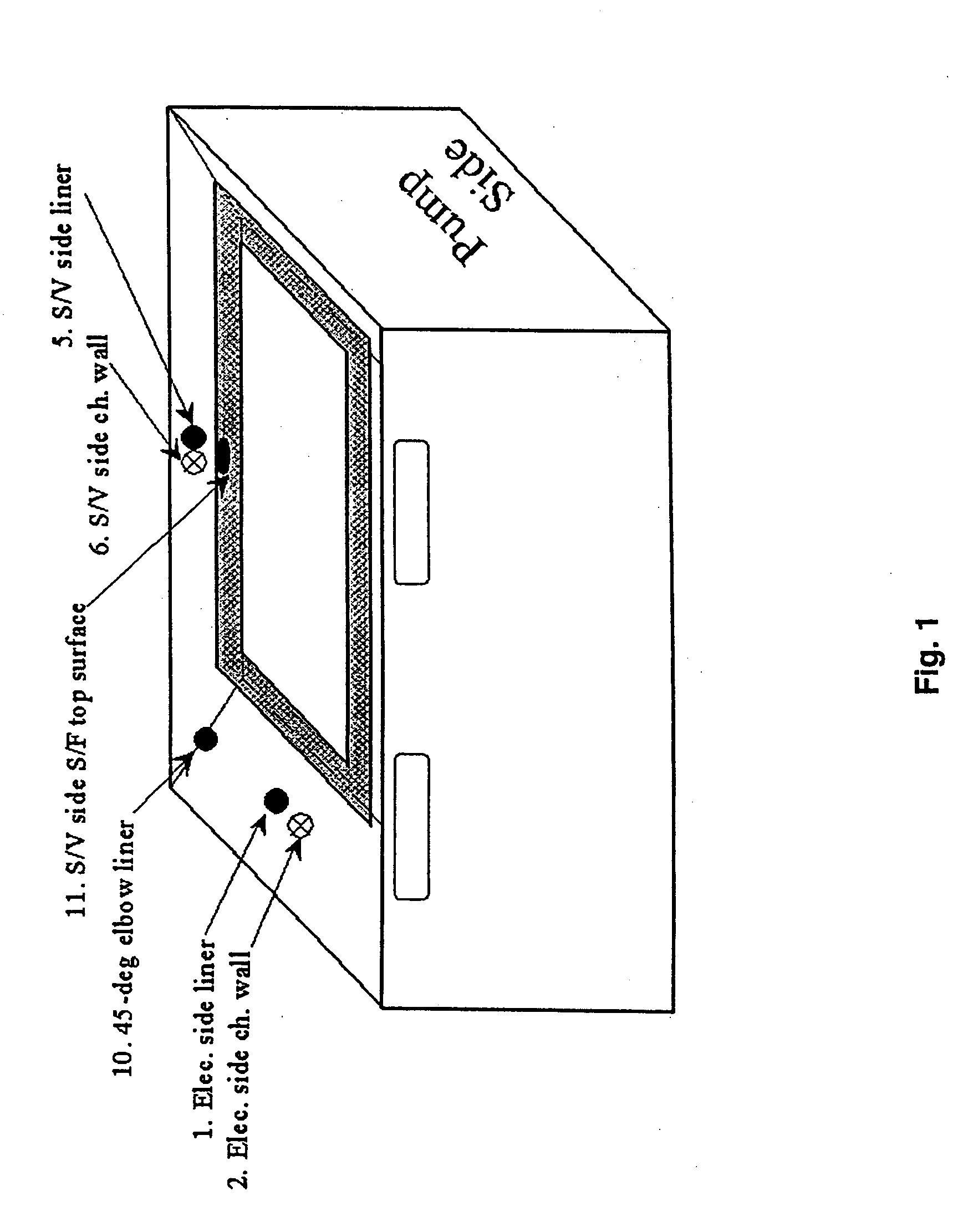

Chamber cleaning via rapid thermal process during a cleaning period

InactiveUS20050109461A1Increase temperatureImprove surface temperature uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringHeat treated

Owner:SUN SHENG

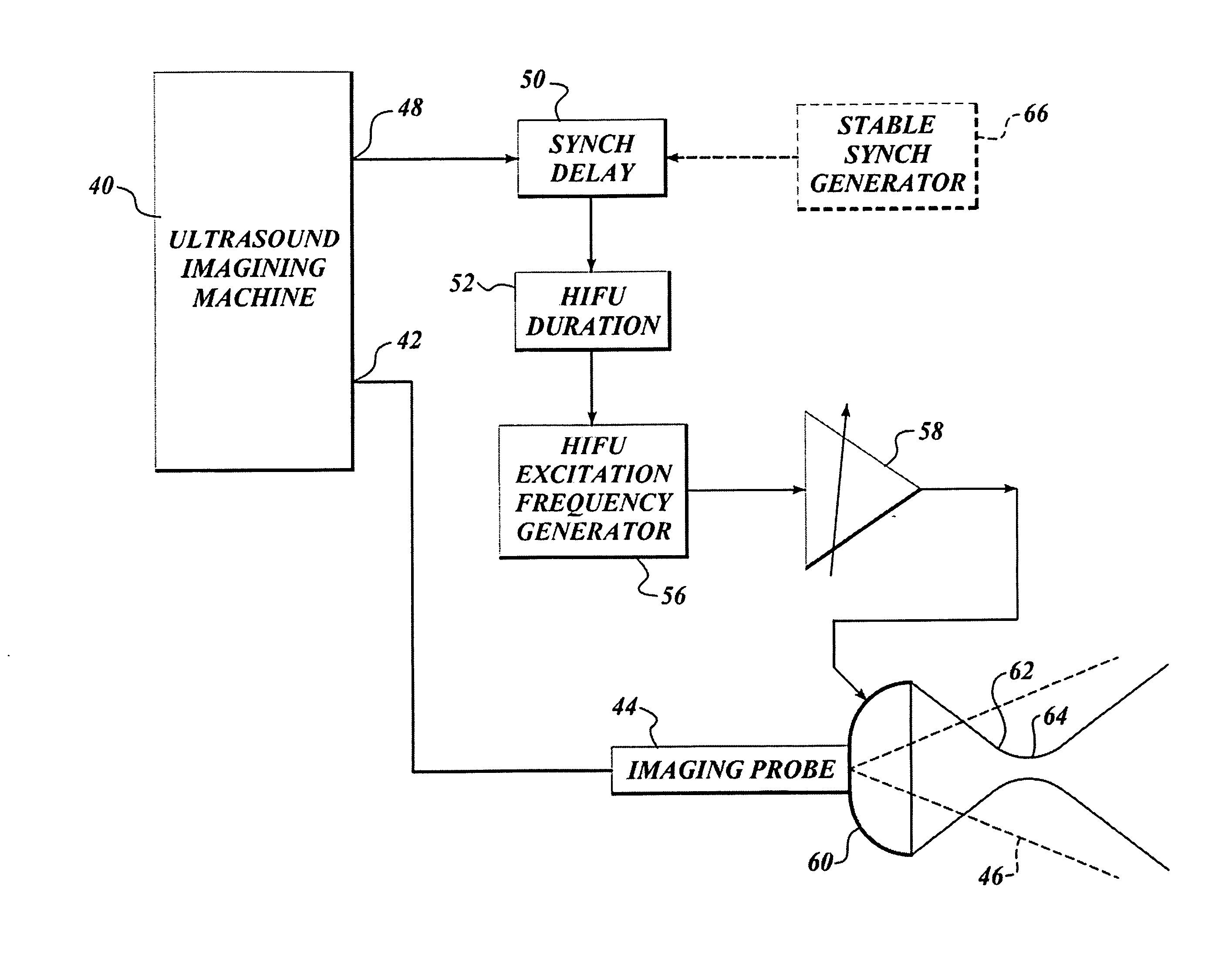

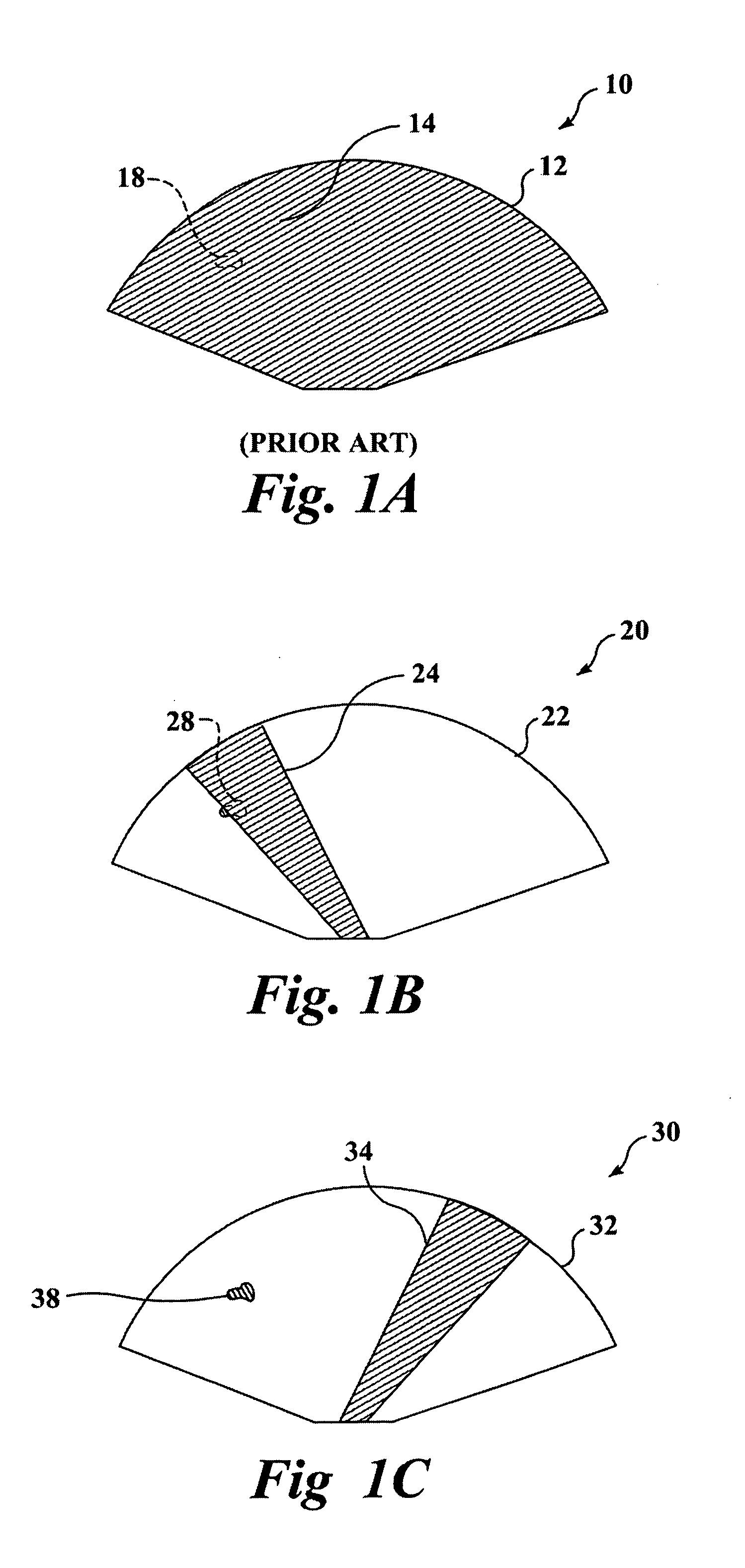

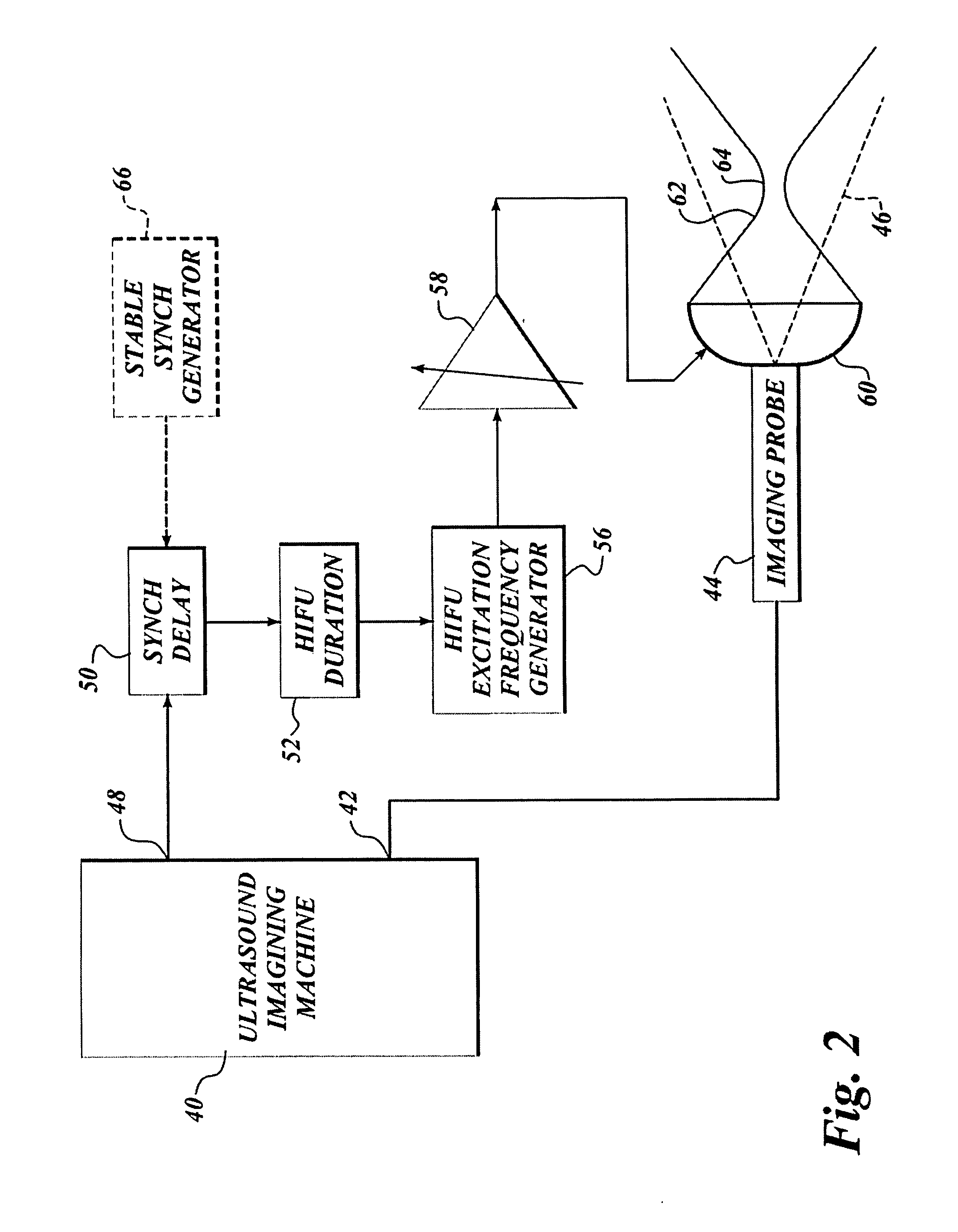

Use of contrast agents to increase the effectiveness of high intensity focused ultrasound therapy

InactiveUS20050038340A1Easy to useGood choiceUltrasound therapyBlood flow measurement devicesCavitationUltrasound contrast media

Ultrasound contrast agents are used to enhance imaging and facilitate HIFU therapy in four different ways. A contrast agent is used: (1) before therapy to locate specific vascular structures for treatment; (2) to determine the focal point of a HIFU therapy transducer while the HIFU therapy transducer is operated at a relatively low power level, so that non-target tissue is not damaged as the HIFU is transducer is properly focused at the target location; (3) to provide a positive feedback mechanism by causing cavitation that generates heat, reducing the level of HIFU energy administered for therapy compared to that required when a contrast agent is not used; and, (4) to shield non-target tissue from damage, by blocking the HIFU energy. Various combinations of these techniques can also be employed in a single therapeutic implementation.

Owner:UNIV OF WASHINGTON

Irrigated ablation catheter having magnetic tip for magnetic field control and guidance

InactiveUS20080091193A1Electrode surface coolingPrecise processDiagnosticsSurgical instruments for heatingGuidance controlIrrigation fluids

Embodiments of the present invention provide an irrigated ablation electrode assembly for use with an irrigated catheter device comprises at least one passageway for a fluid with an outlet disposed at an external surface of the electrode assembly; a permanent magnet; a shield separating the permanent magnet from the at least one passageway and from an exterior, the shield being substantially less oxidizable than the permanent magnet; and an electrode having an external electrode surface. A catheter guidance control and imaging system drives the permanent magnet to guide and control the catheter tip. In specific embodiments, the irrigation fluid flow paths through the electrode assembly are thermally insulated from the electrode and temperature sensor. The irrigation fluid is directed at target areas where coagulation is more likely to occur. One or more monitoring electrodes are provided for mapping or other monitoring functions.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

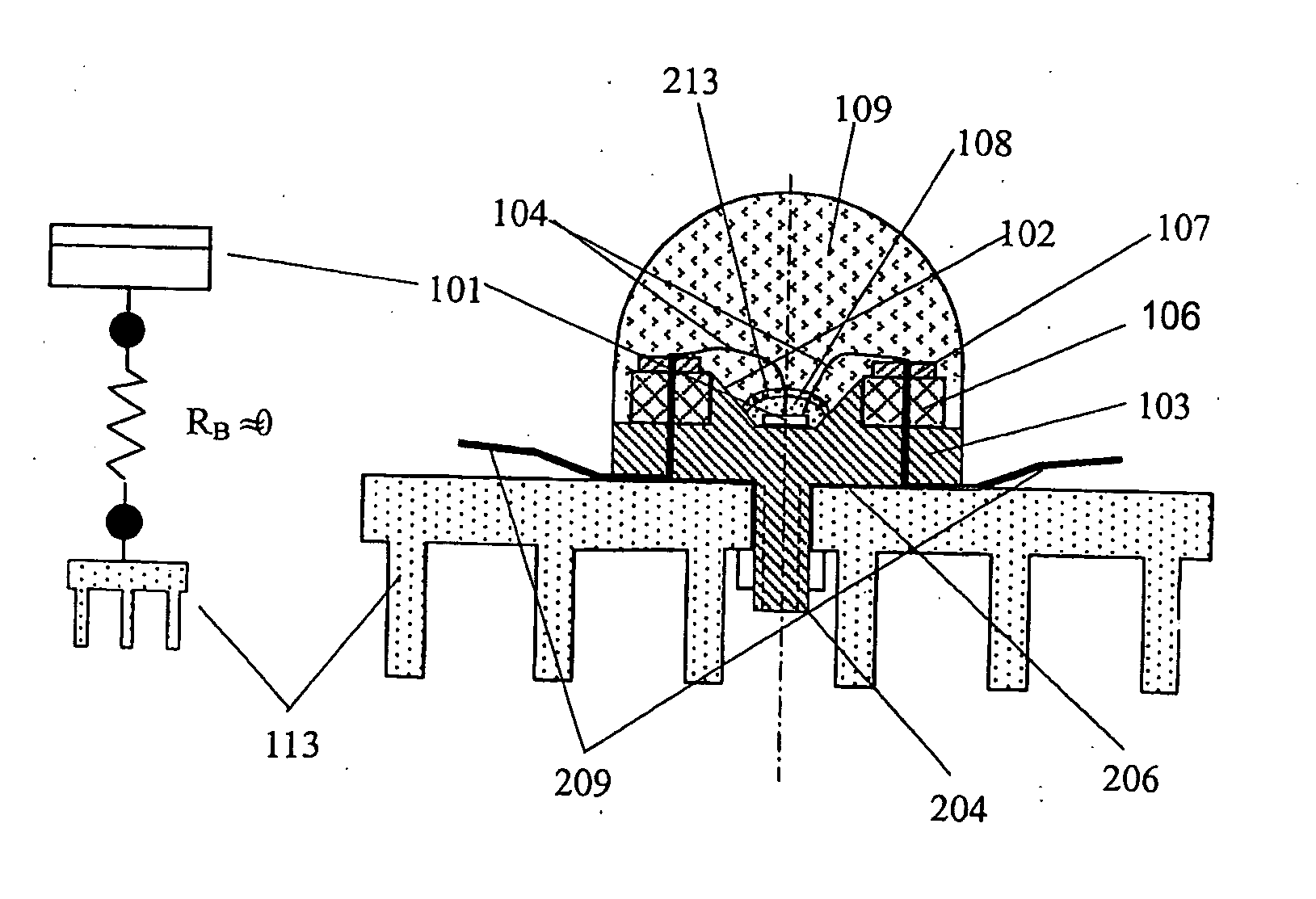

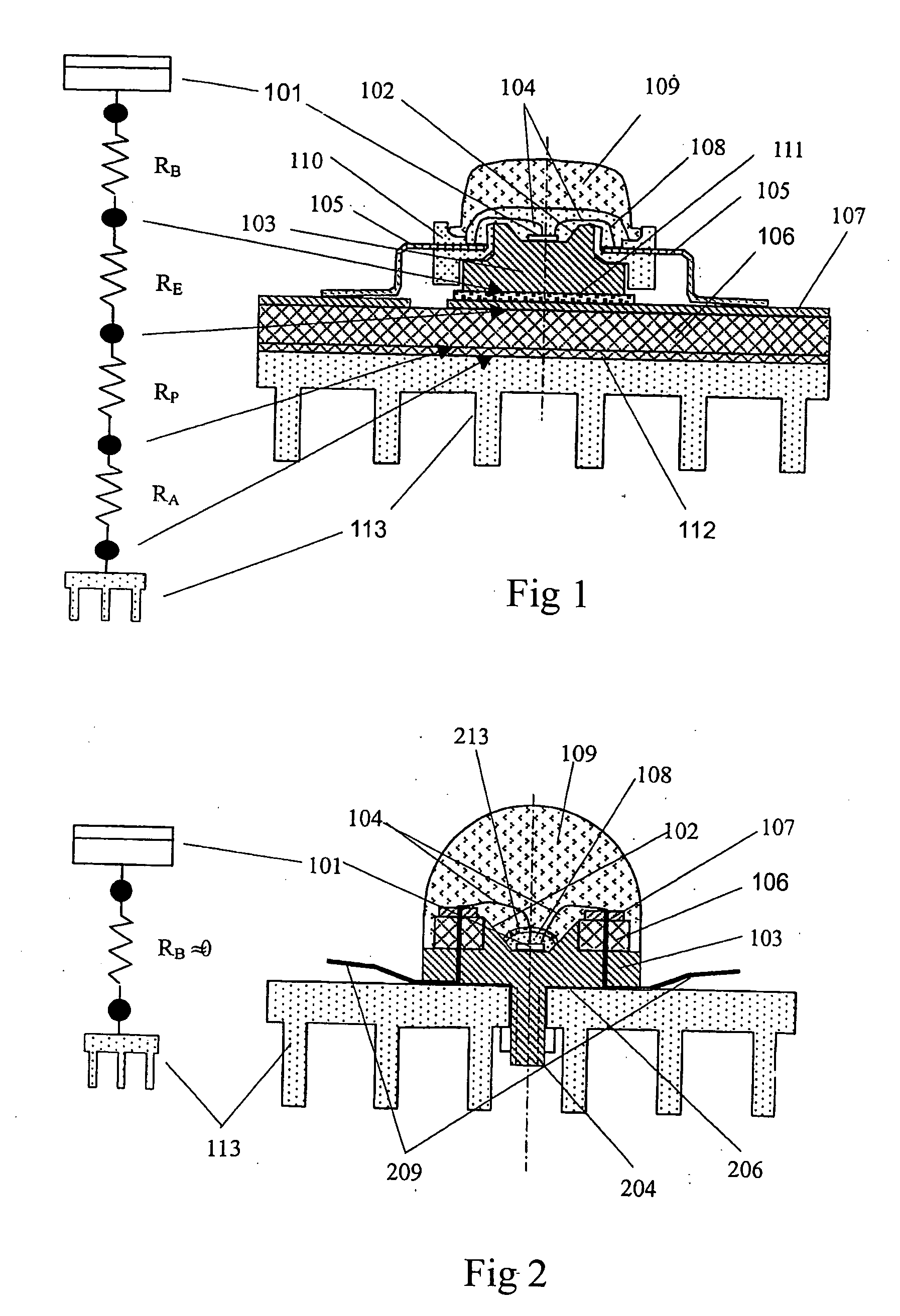

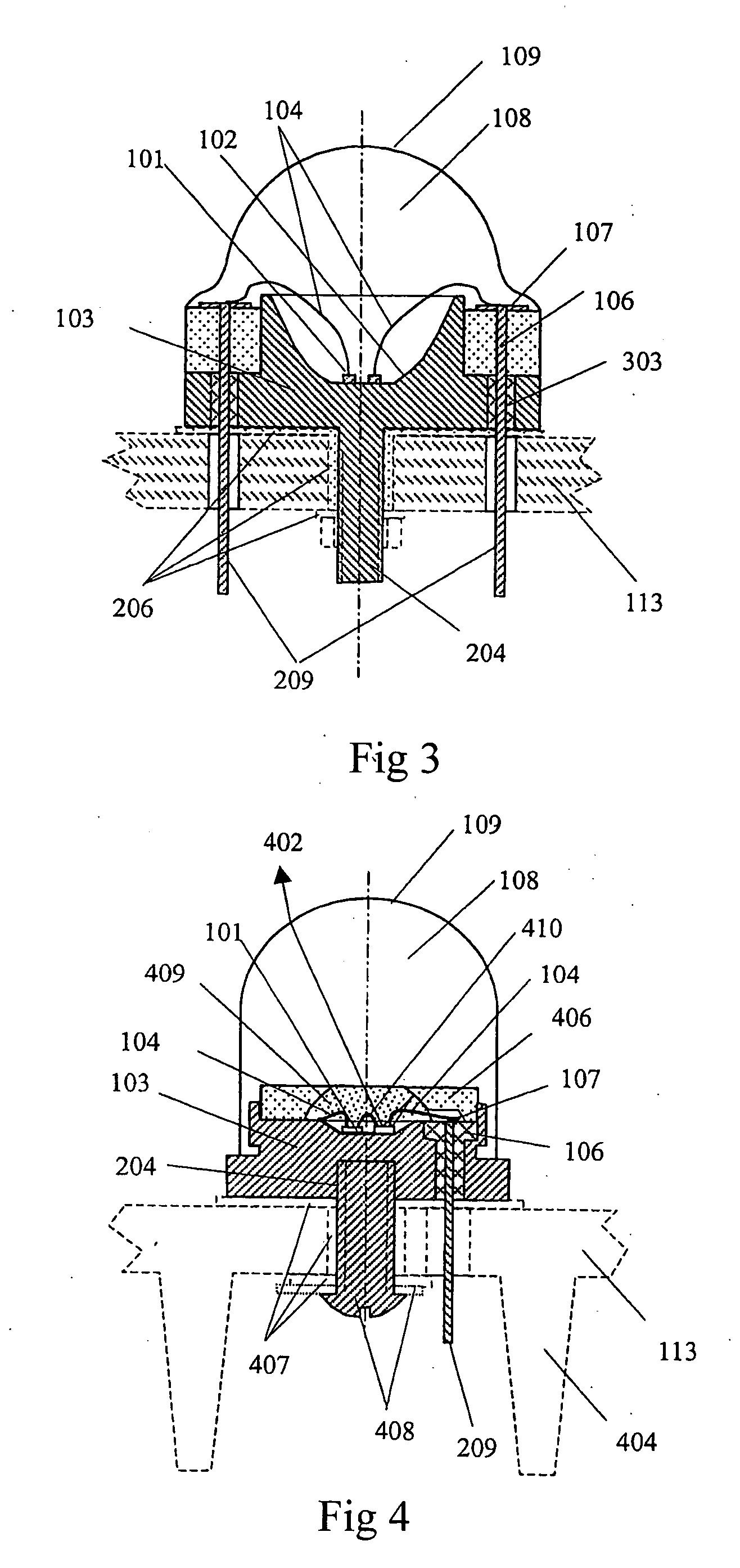

Led and led lamp

InactiveUS20050068776A1Great disadvantageIncrease temperatureMechanical apparatusLight source combinationsLight reflectionEngineering

This invention relates to a light emitting diode (LED) and a LED lamp consisted of LEDs. The LED comprises at least one LED chip. The LED is mounted on a high heat conductivity base and is connected to an applied power supply through a circuit board. The LED chip also has a transparent medium layer on it. The base top surface acts as a light reflective surface, or a light reflective surface is provided around the base, the LED comprises a screw extended downwards from the base bottom or a screw hole in the base bottom to connect the LED to a heat sink mechanically. The LED is electrically connected to a driving circuit through its outgoing wires. The driving circuit is in turn electrically connected to an electrical connector through its housing. A LED lamp can be fabricated after the LED is enclosed in a transparent bulb housing. The LED has high efficiency, high power and long lifetime and can be used to fabricate LED traffic lamps, LED plane light sources, etc.

Owner:LOU MANE

Suspended gas distribution plate

InactiveUS7017269B2Avoid distortionAvoid crackingElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationEngineering

A gas inlet manifold for a plasma chamber having a perforated gas distribution plate suspended by flexible side walls. The flexible suspension minimizes mechanical stress due to thermal expansion of the gas distribution plate. In another aspect, the suspension provides thermal isolation between the gas distribution plate and other components of the chamber.

Owner:APPLIED MATERIALS INC

Led and fabrication method of same

InactiveUS20060001055A1Easily and compactly configuredEasy to installTransistorSolid-state devicesEngineeringAnisotropic etching

An LED can include a silicon substrate and a pair of electrodes formed inside a horn that is formed on the silicon substrate by anisotropic etching. The LED can include an LED chip mounted inside the horn, the LED chip being electrically connected to the pair of electrodes. A resin mold made of a resin material can be filled in the horn.

Owner:STANLEY ELECTRIC CO LTD

Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators

InactiveUS6465551B1Exceptional nucleation efficacyExcellent calcium stearate compatibilityOrganic chemistryOrganic compound preparationChemistryPolyolefin

Compounds and compositions comprising specific metal salts of bicyclo[2.2.1 ]heptane dicarboxylate salts in order to provide highly desirable properties within polyolefin articles are provided. The inventive salts and derivatives thereof are useful as nucleating and / or clarifying agents for such polyolefin, provide excellent crystallization temperatures, stiffness, and calcium stearate compatibility within target polyolefin. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Polyolefin additive compositions and methods of producing polyolefin with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

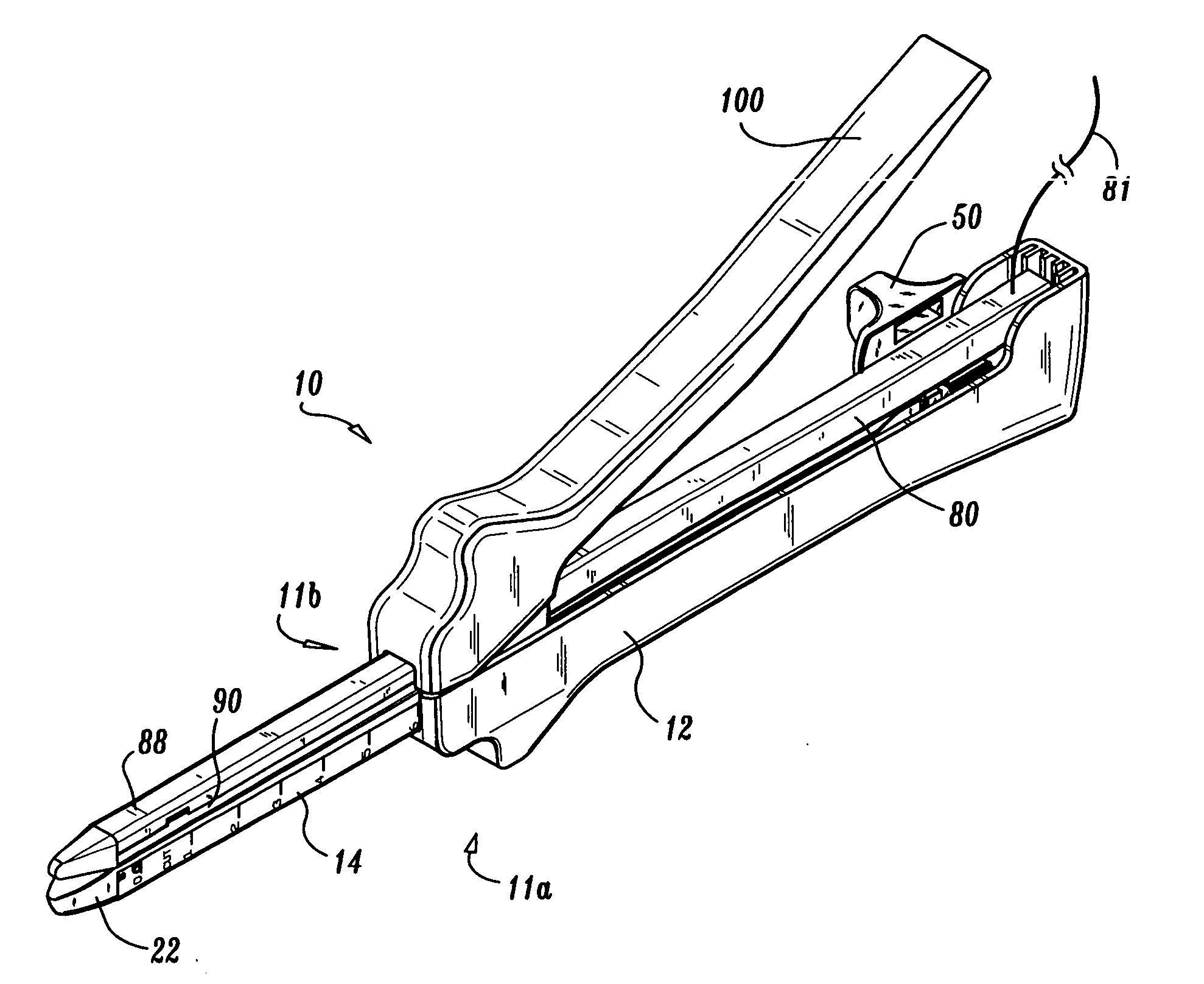

Ultrasonic surgical instrument incorporating fluid management

ActiveUS20050049546A1Load minimizationEfficient removalDiaphragm valvesEngine diaphragmsSurgical bladeSonification

Disclosed is an ultrasonic surgical device having a distally / proximally movable fluid management system consisting of single lumen or multiple lumens. The invention provides for the delivery of irrigation fluid or the removal of fluid, debris or vapor from the tissue-effecting portion of the blade while minimizing the loading on the blade. The blades of the surgical device, when excited at a natural blade system frequency, will have modal shapes characterized by longitudinal, transverse and / or torsional motion and will have nodal locations for these motions at positions along the tissue effecting length of the blade. The instrument is designed to allow for the fluid management system to be positioned at one or more motion nodes to facilitate efficient removal of tissue or fluid, which tends to accumulate at such nodes of the ultrasonic surgical blades.

Owner:ETHICON ENDO SURGERY INC

Suspended gas distribution manifold for plasma chamber

InactiveUS7484473B2Avoiding distortion and crackingImprove spatial uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationProduct gas

Owner:APPLIED MATERIALS INC

Non-aqueous electrolyte battery separator

InactiveUS6447958B1Improve securityHigh short-circuit temperatureFinal product manufactureLi-accumulatorsNitrogenPolymer

A non-aqueous electrolyte battery separator comprising a heat-resistant nitrogen-containing aromatic polymer and a ceramic powder.

Owner:SUMITOMO CHEM CO LTD

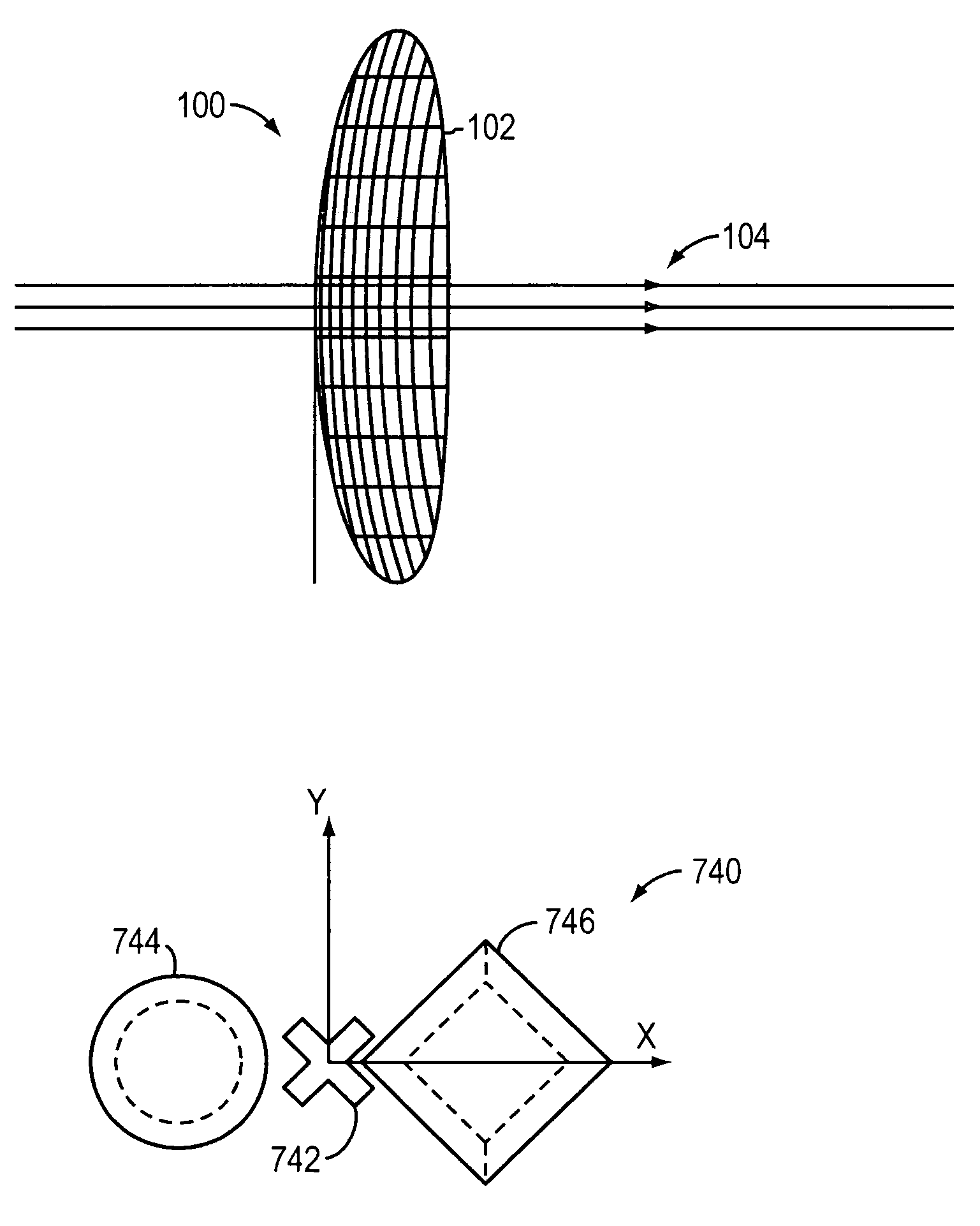

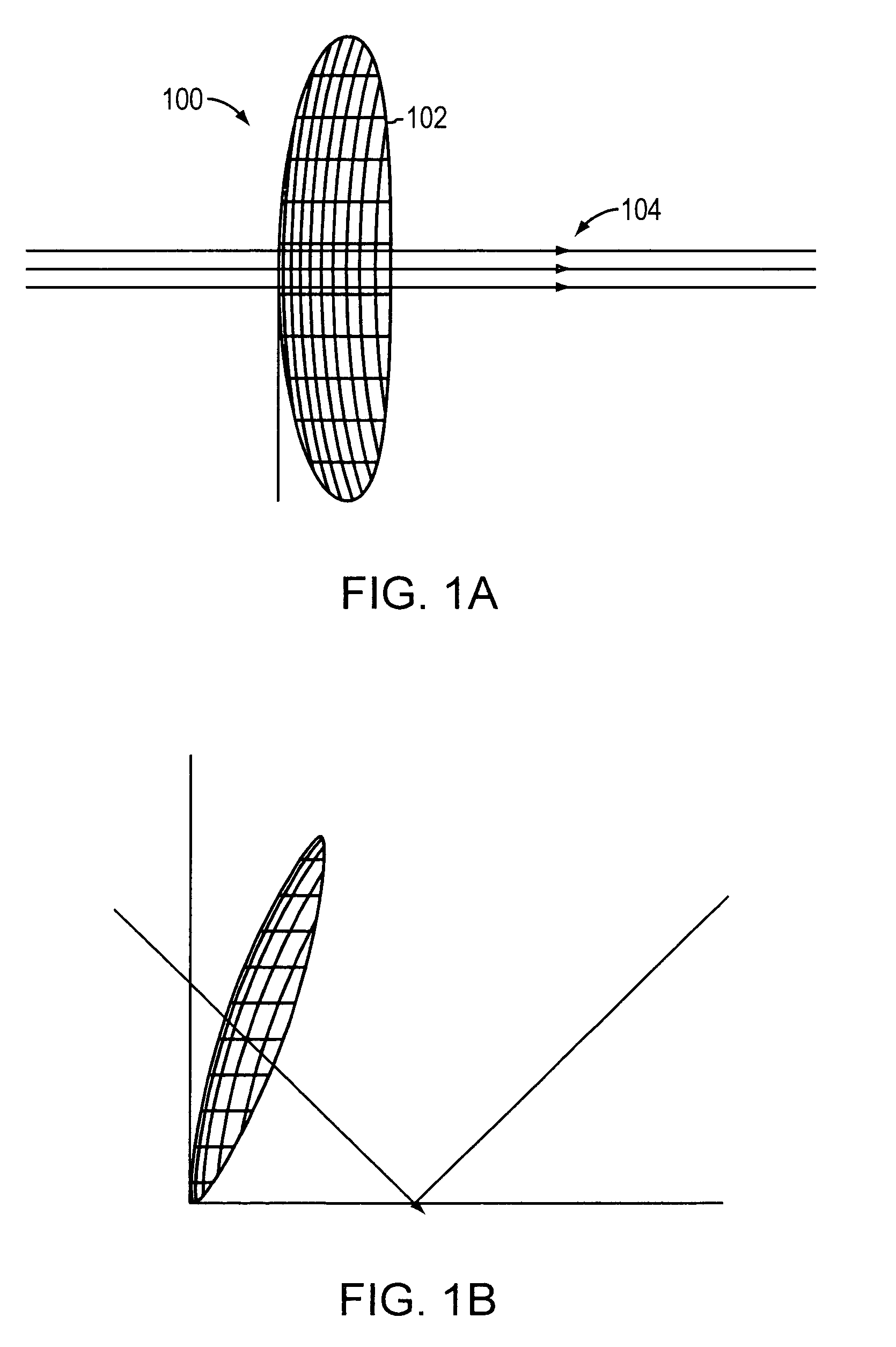

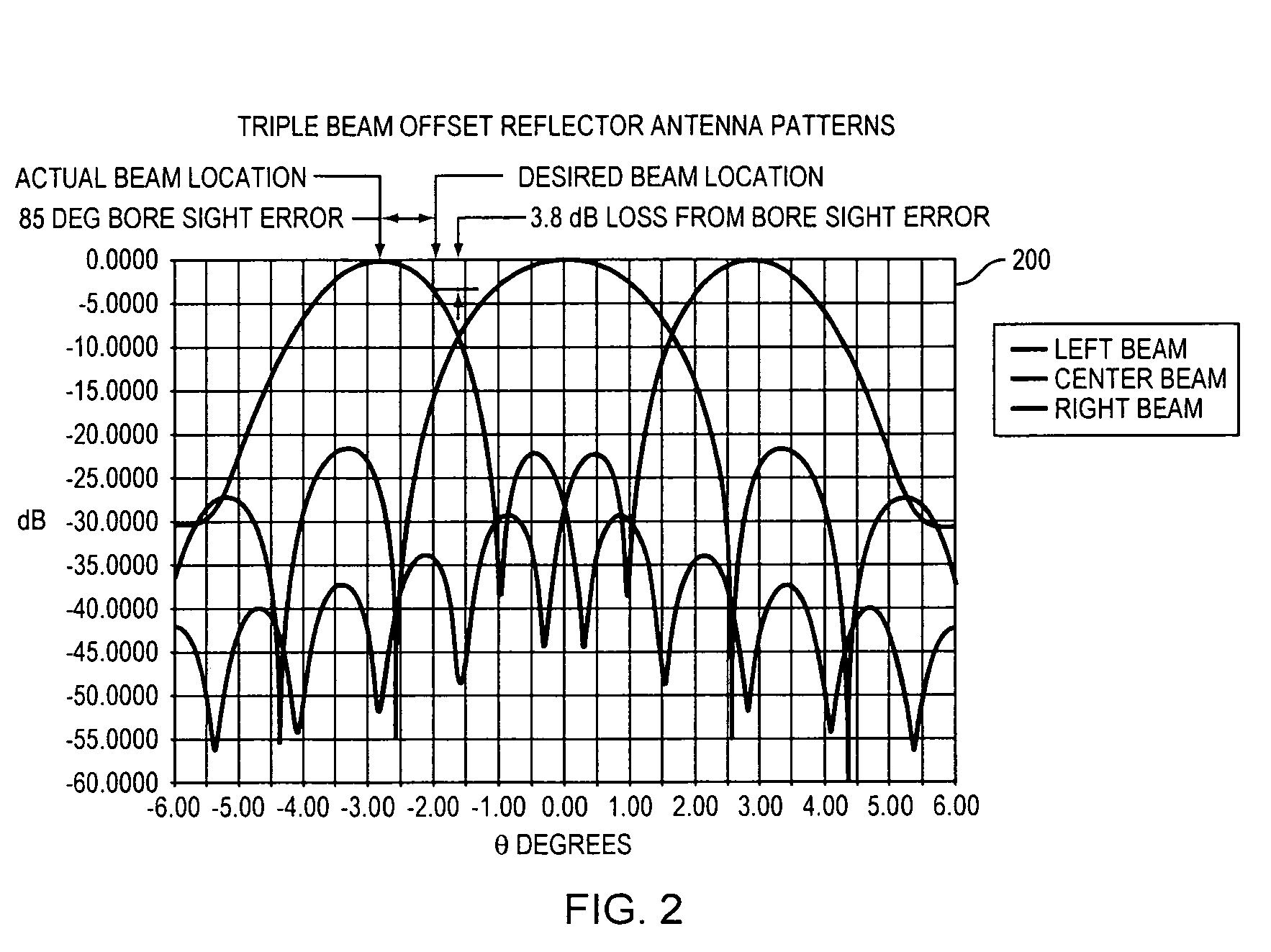

Small wave-guide radiators for closely spaced feeds on multi-beam antennas

Owner:PRO BRAND INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators](https://images-eureka.patsnap.com/patent_img/7d258cb1-9493-44a8-9f4d-3c287732759f/US06465551-20021015-C00001.png)

![Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators](https://images-eureka.patsnap.com/patent_img/7d258cb1-9493-44a8-9f4d-3c287732759f/US06465551-20021015-C00002.png)

![Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators](https://images-eureka.patsnap.com/patent_img/7d258cb1-9493-44a8-9f4d-3c287732759f/US06465551-20021015-C00003.png)