Patents

Literature

25542results about "Gearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

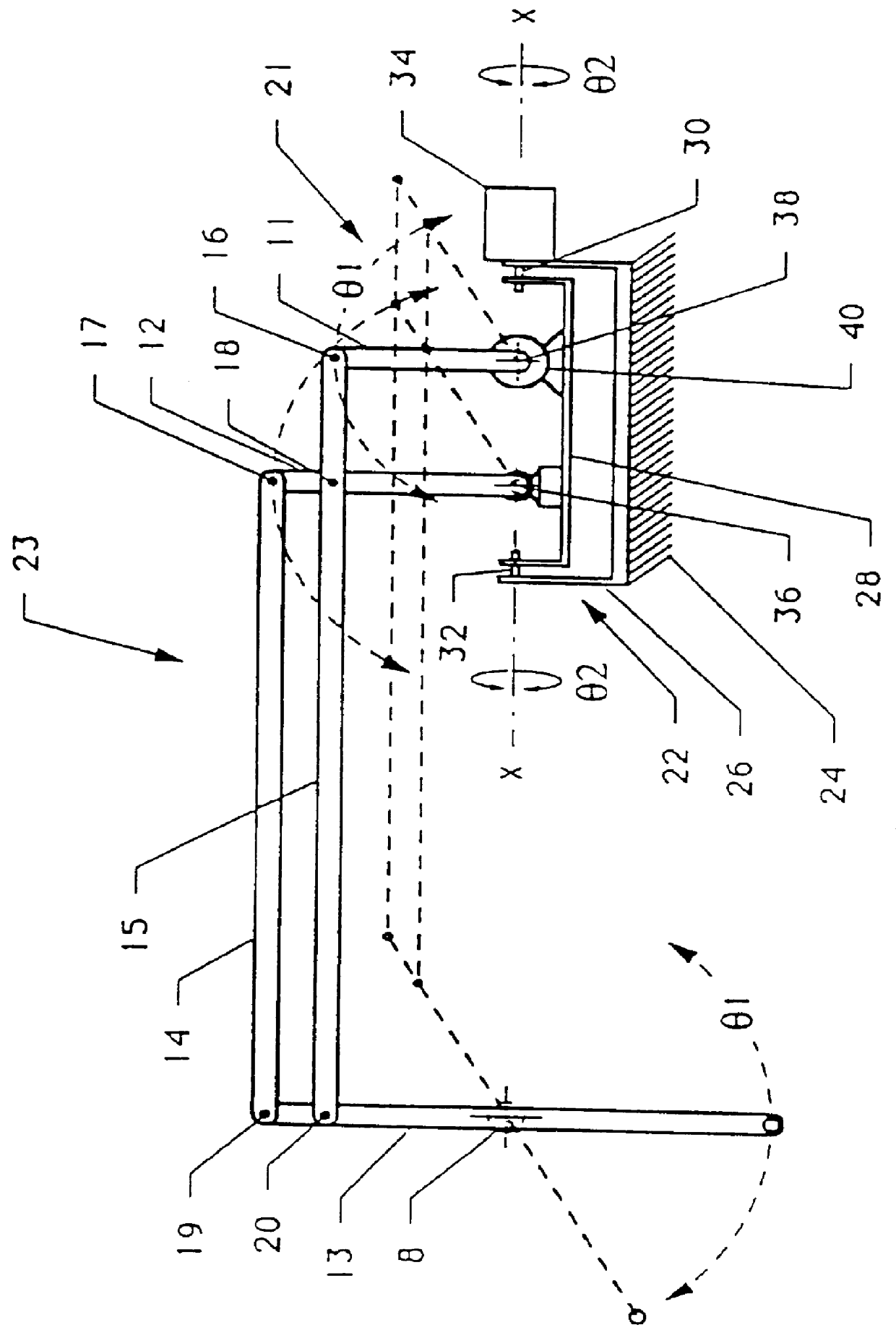

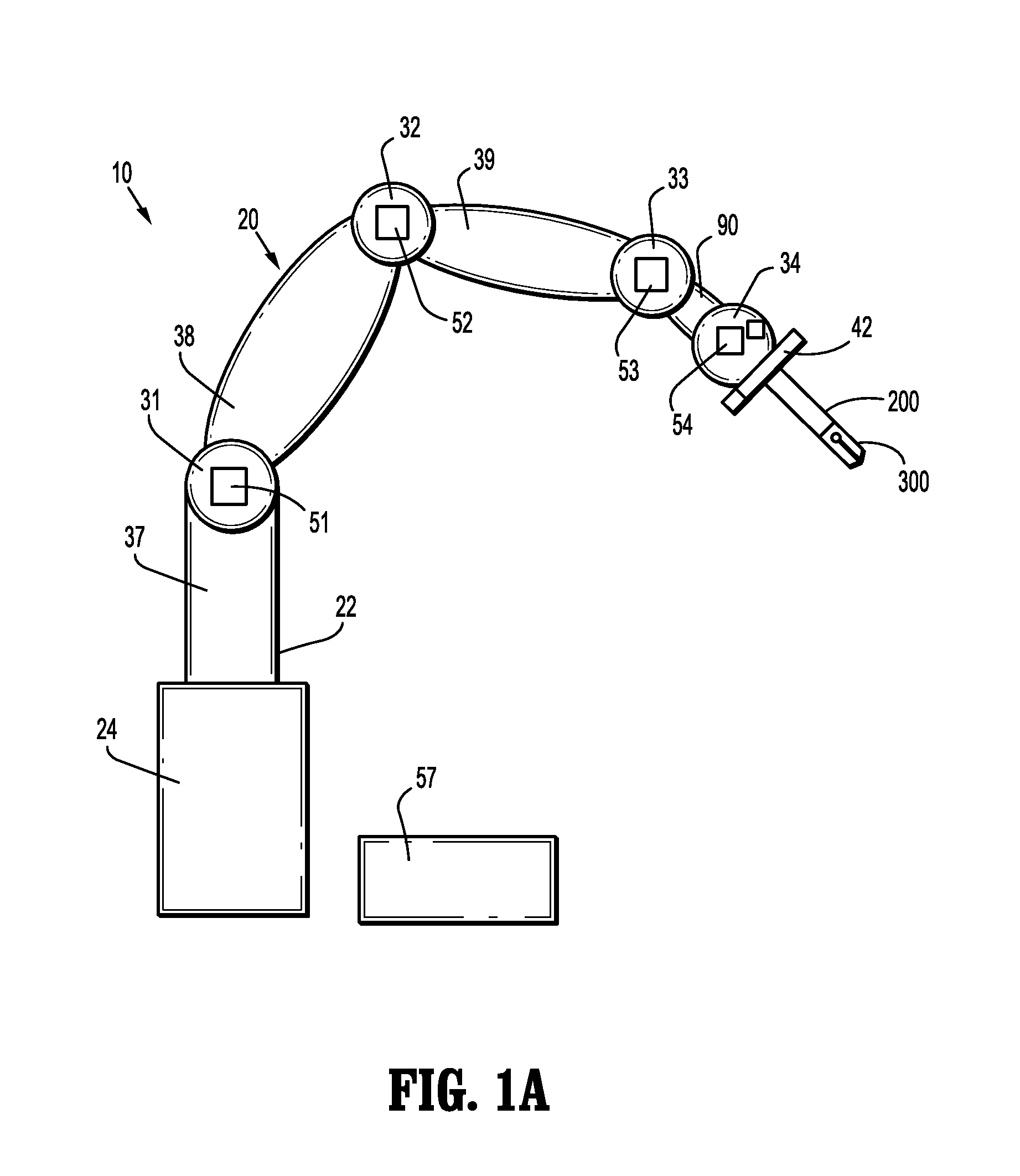

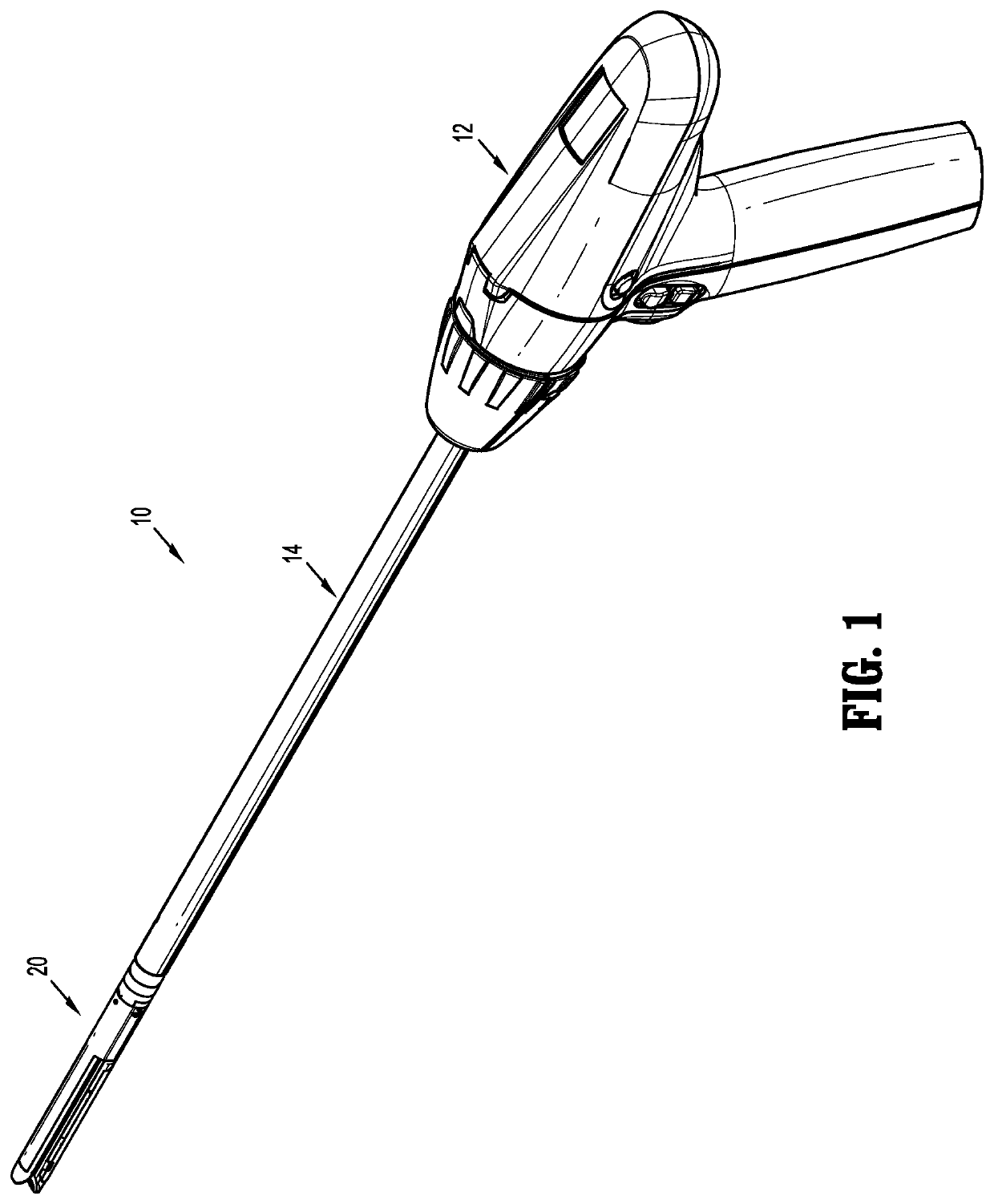

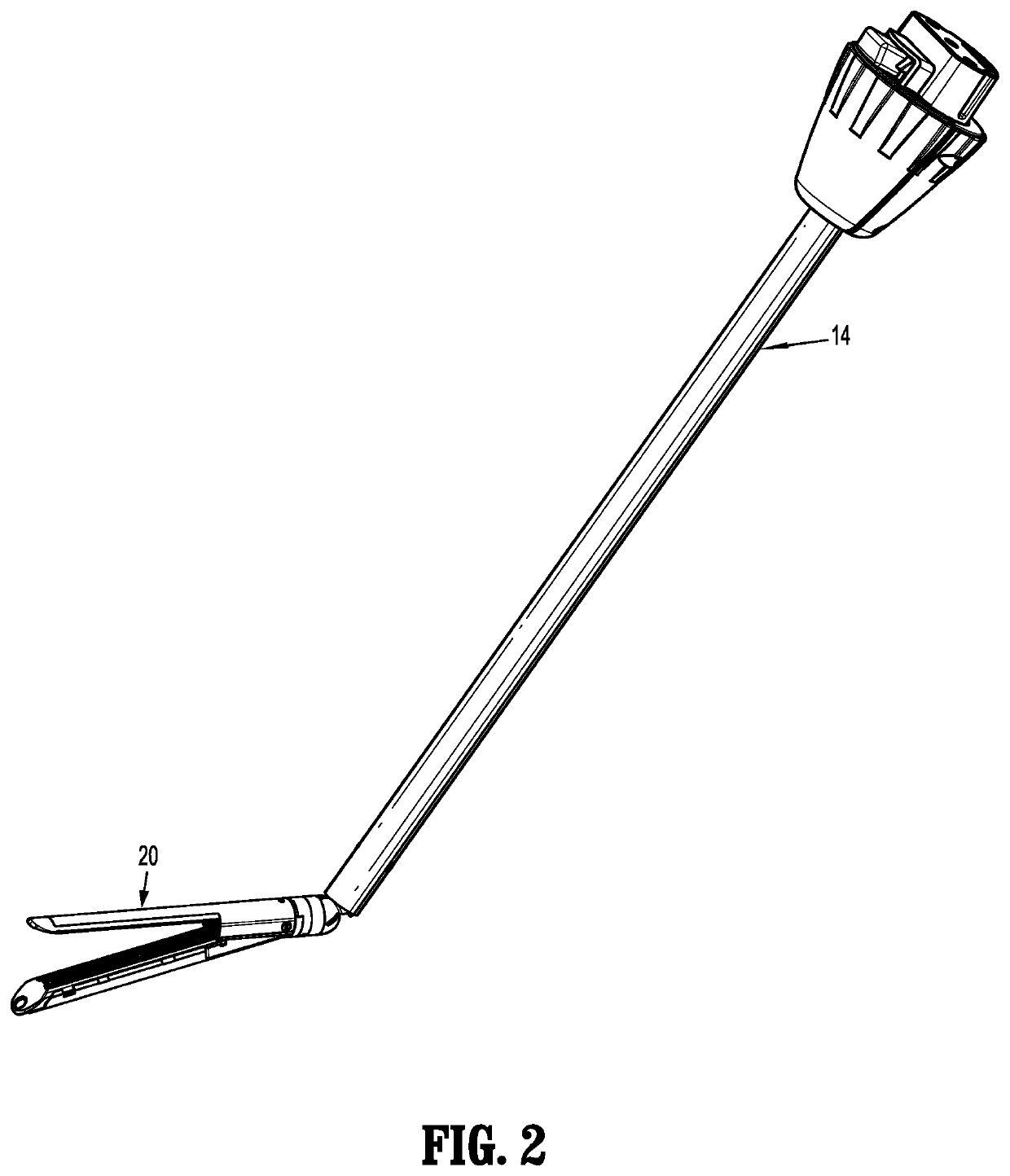

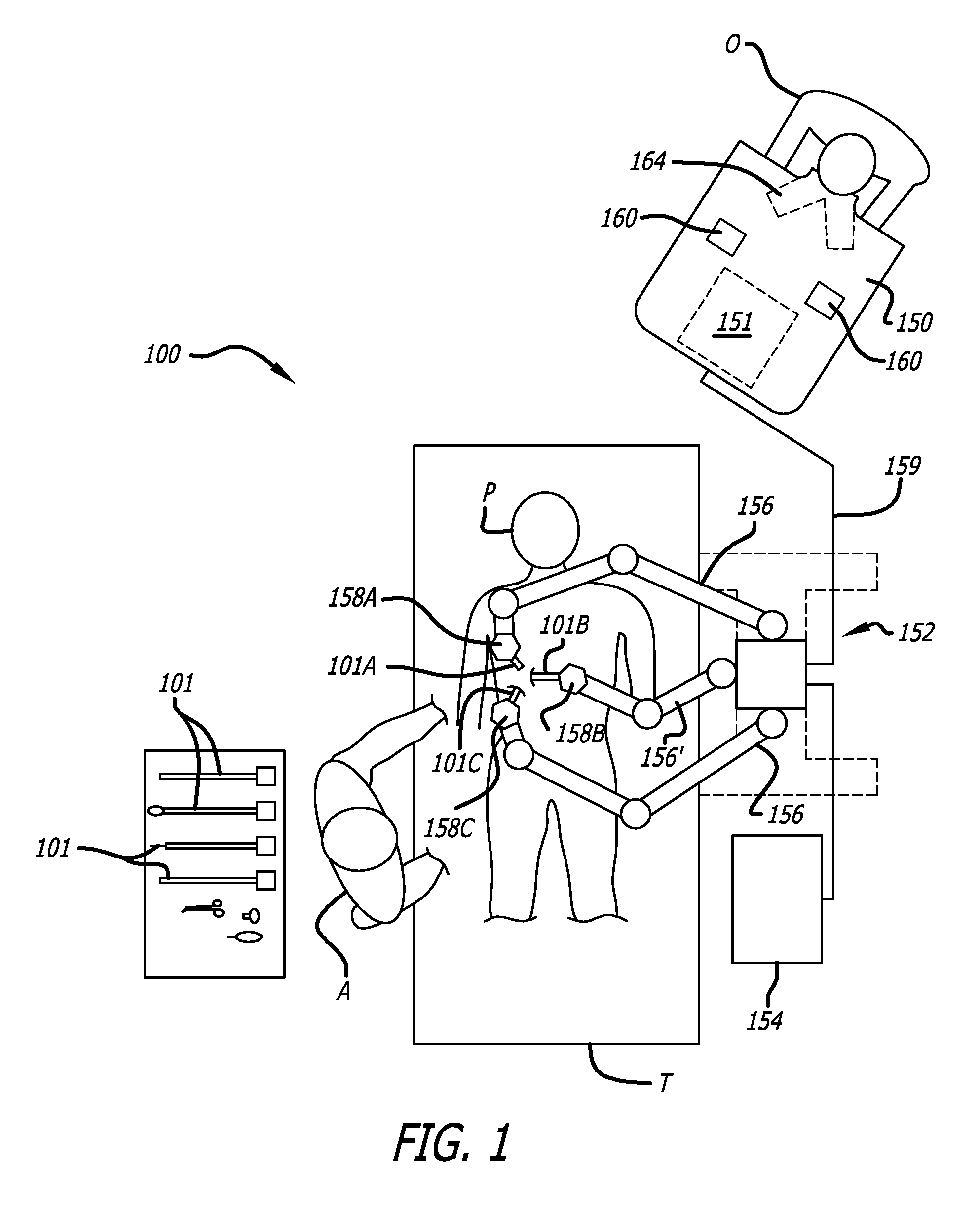

Methods and devices for positioning a surgical instrument at a surgical site

For positioning a surgical instrument at a surgical site, an elongate tubular structure is coupled to the distal portion of a robotic arm. This structure is adapted to be inserted in the body cavity of a patient and is adapted to receive the surgical instrument and serve as a guide for the surgical instrument into the patient's body. The robotic arm may have a parallelogram center of motion linkage and actuators for driving various degrees of freedom of movement of the arm and the surgical instrument. The robotic arm may be remotely controlled by an operator manipulating an input device.

Owner:SRI INTERNATIONAL

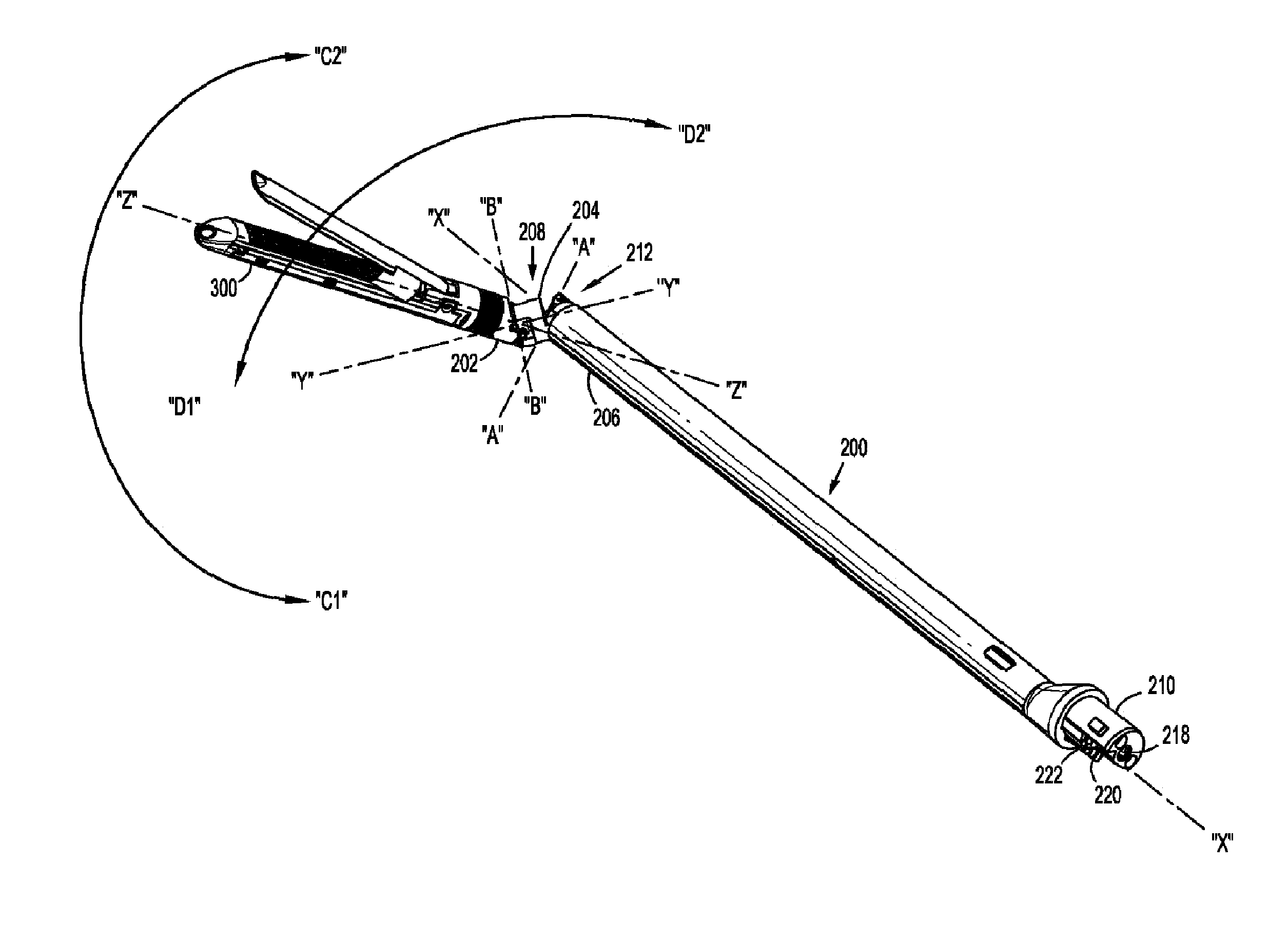

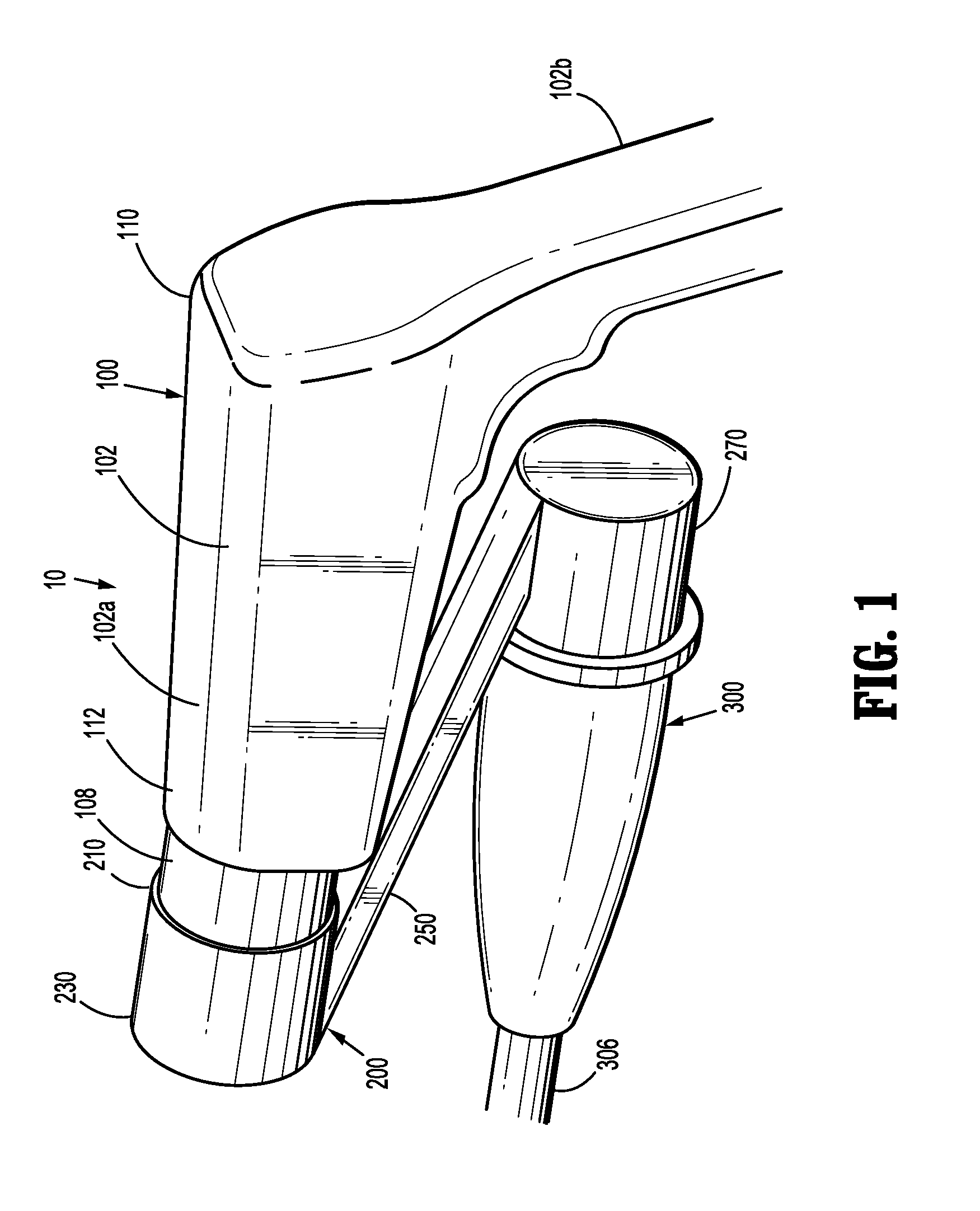

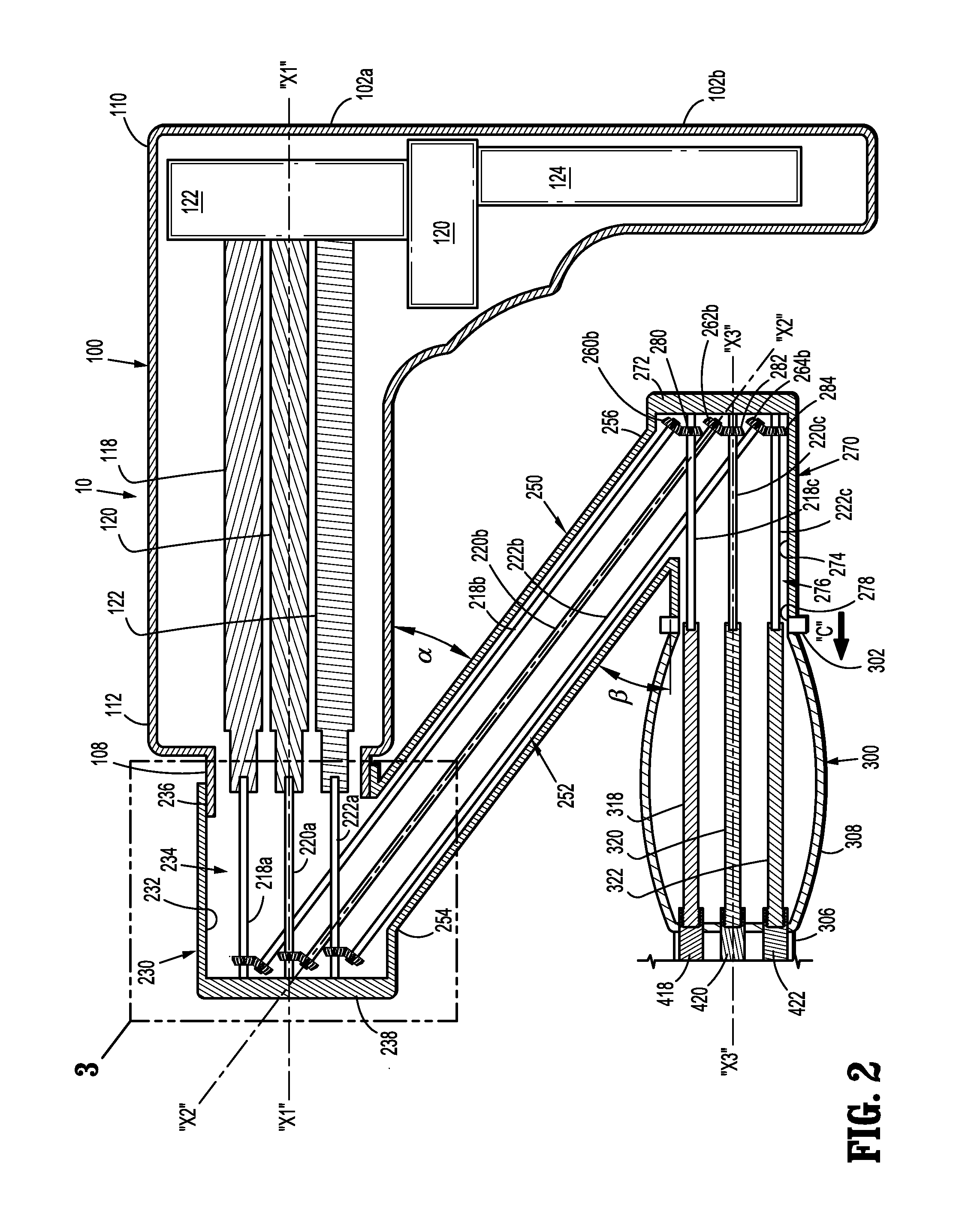

Medical device adapter with wrist mechanism

A surgical device adapter for coupling an end effector to a surgical device includes: a proximal joint housing that is couplable to the surgical device; a middle joint housing that is pivotally coupled to the distal end of the proximal joint housing; and a distal joint housing that is pivotally coupled to the distal end of the middle joint housing. The middle joint housing is pivotable about a first pivot axis defined between the proximal joint housing and the middle joint housing. The distal joint housing is couplable to the end effector and pivotable about a second pivot axis defined between the middle joint housing and the distal joint housing, the second pivot axis being transverse to the first pivot axis.

Owner:TYCO HEALTHCARE GRP LP

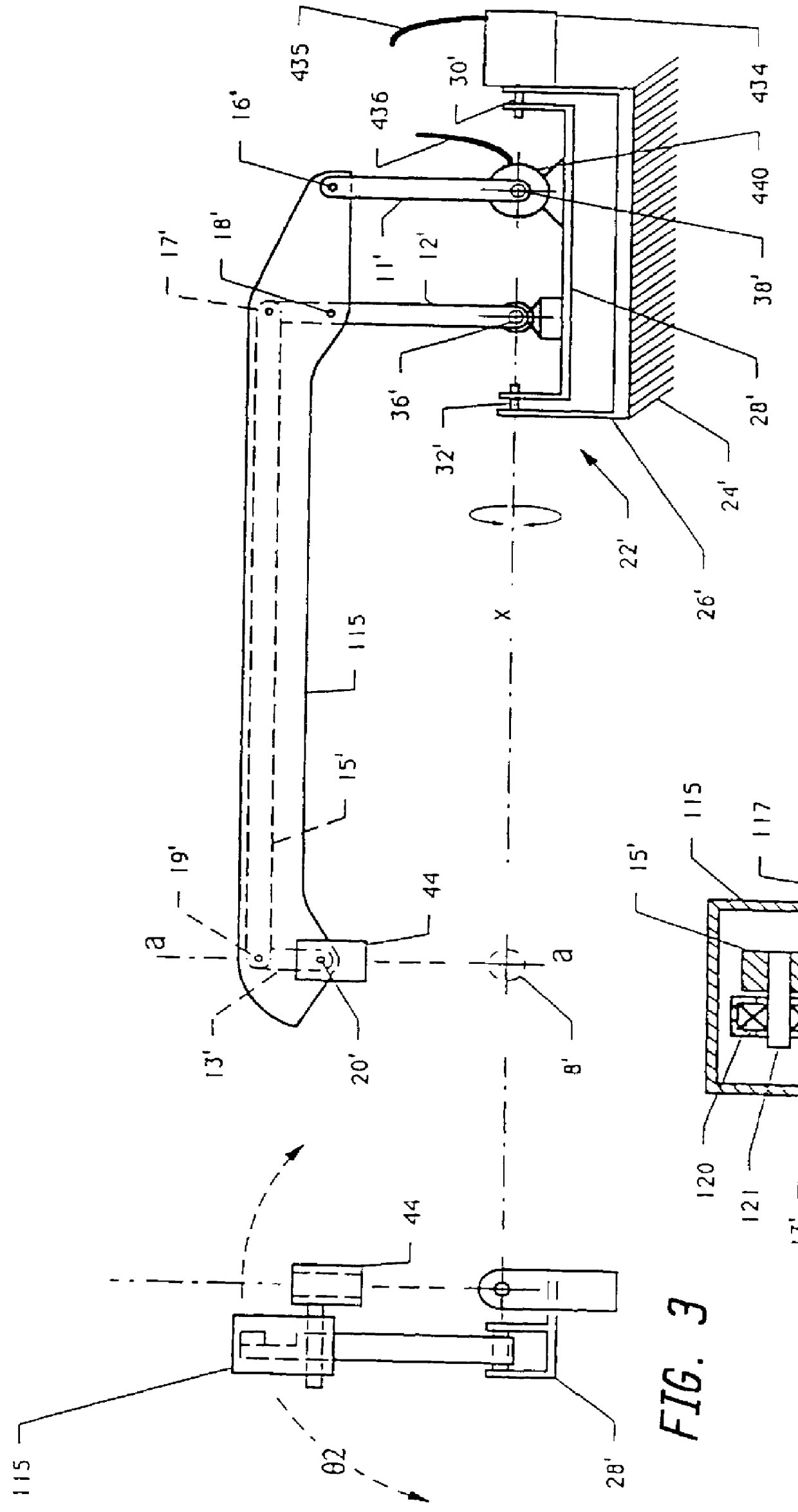

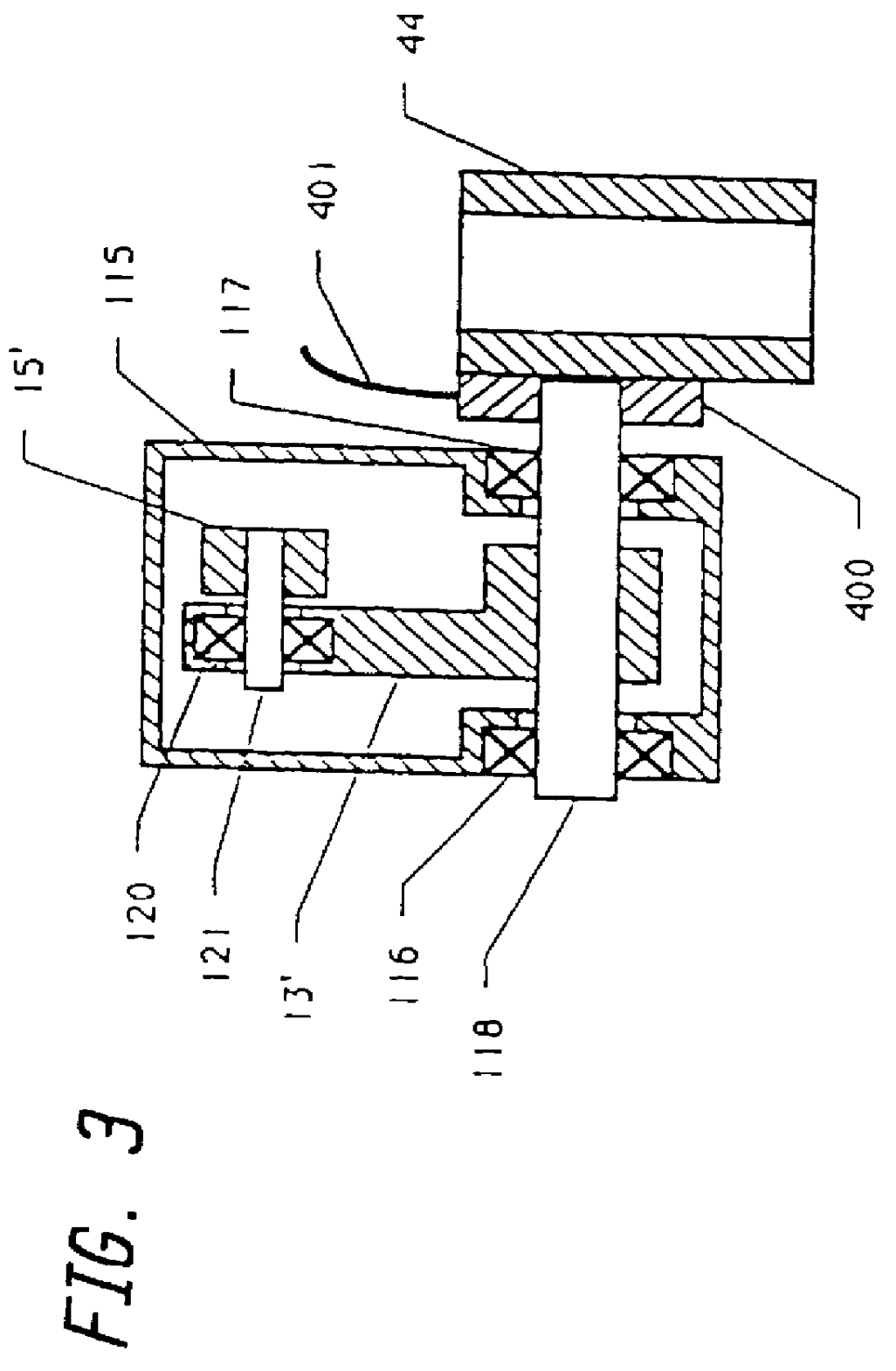

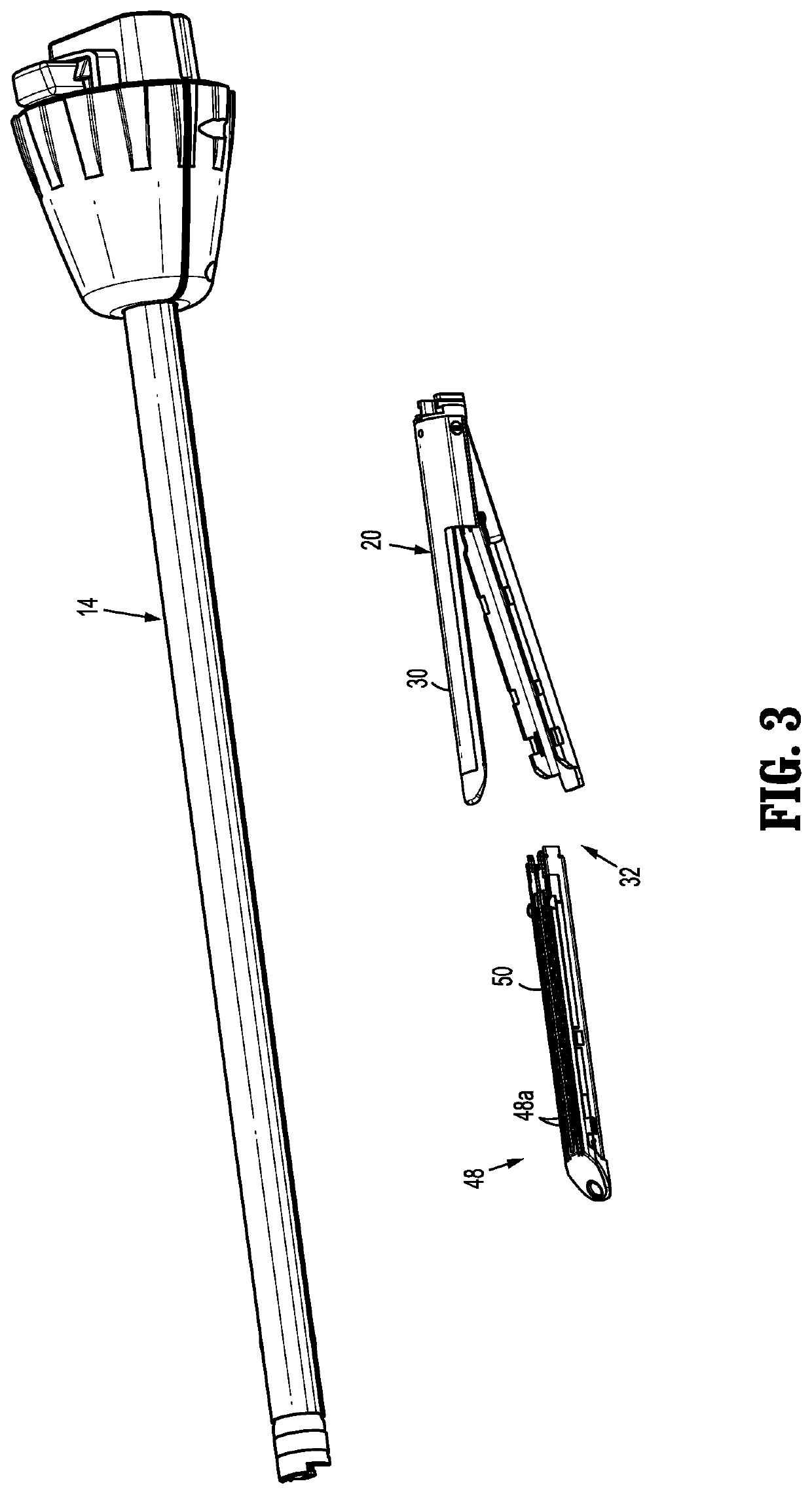

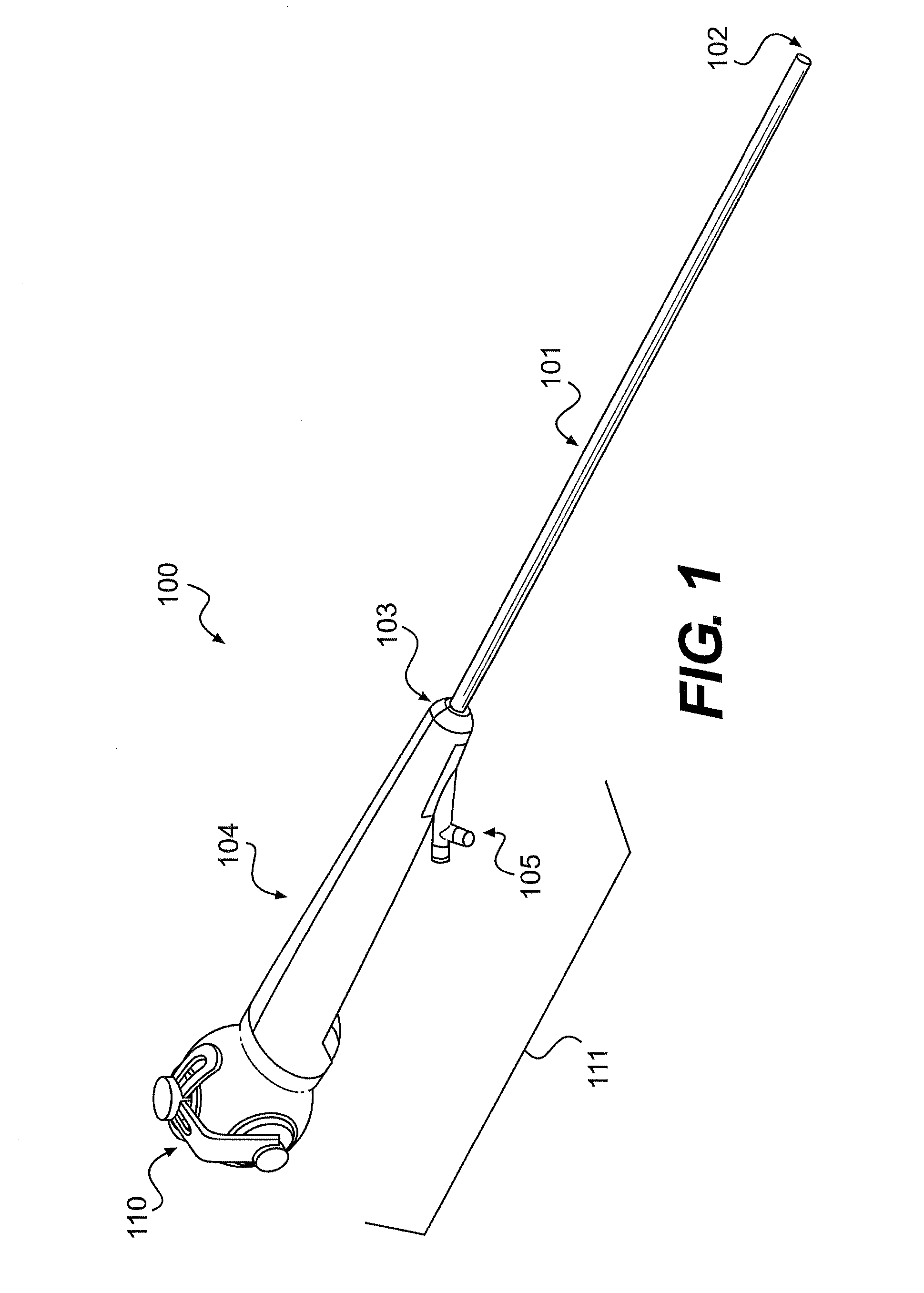

Apparatus for endoscopic procedures

A shaft assembly is provided for interconnecting at least one rotatable drive shaft of a hand-held electromechanical surgical device, and an end effector actuatable by an axial drive force. The shaft assembly includes a flexible drive cable rotatably supported in an outer tube, the flexible drive cable includes a proximal end operatively connected to a respective rotatable drive shaft of the hand-held surgical device. The flexible drive cable being off set a radial distance from a central longitudinal axis of the outer tube. The shaft assembly includes an articulation rod at least partially slidably supported in the outer tube, and an articulation link having a proximal end pivotally connected to the distal end of the articulation rod and a distal end pivotally connected to a distal neck housing. The articulation rod being off set a radial distance from the central longitudinal axis of the outer tube.

Owner:TYCO HEALTHCARE GRP LP

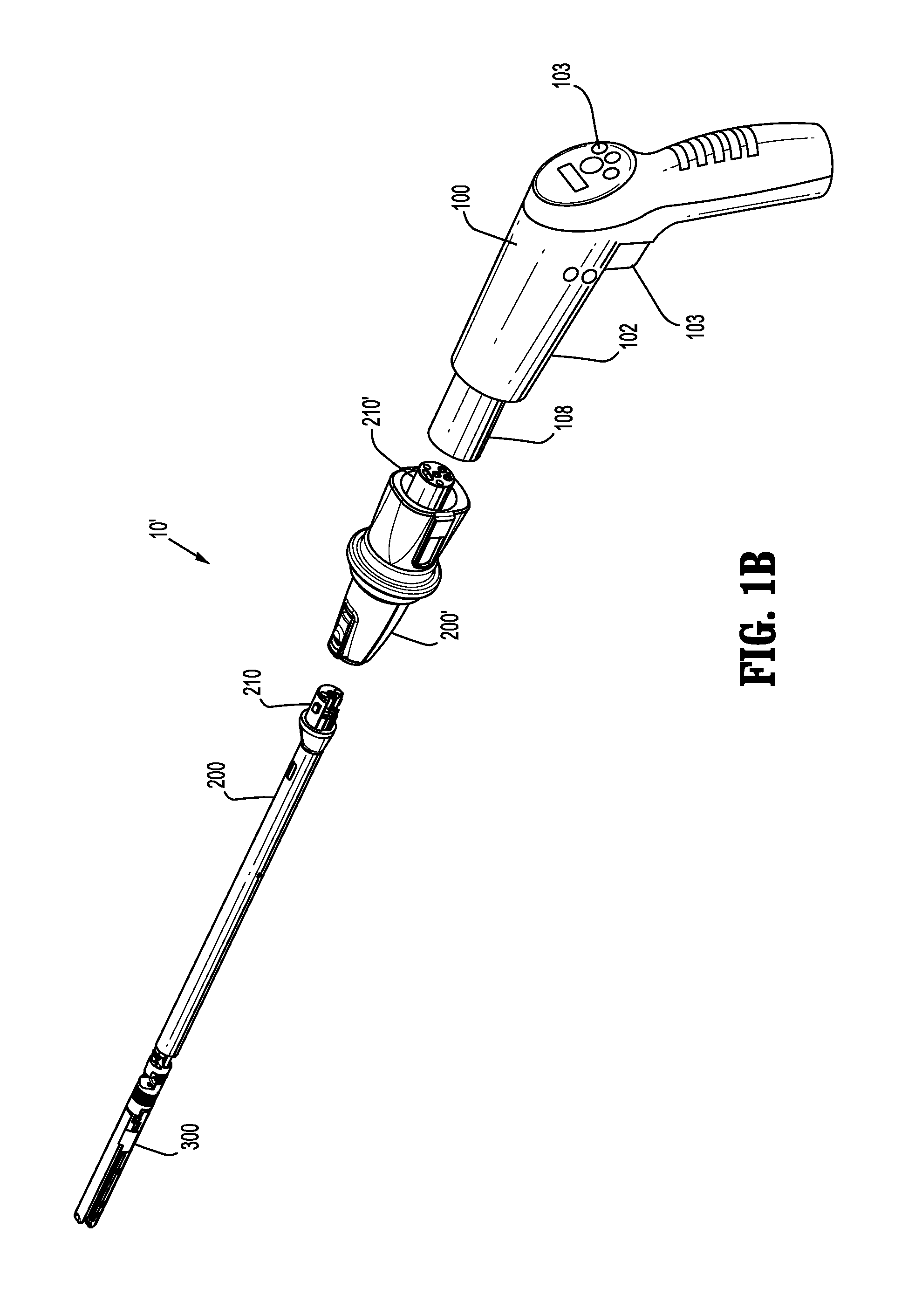

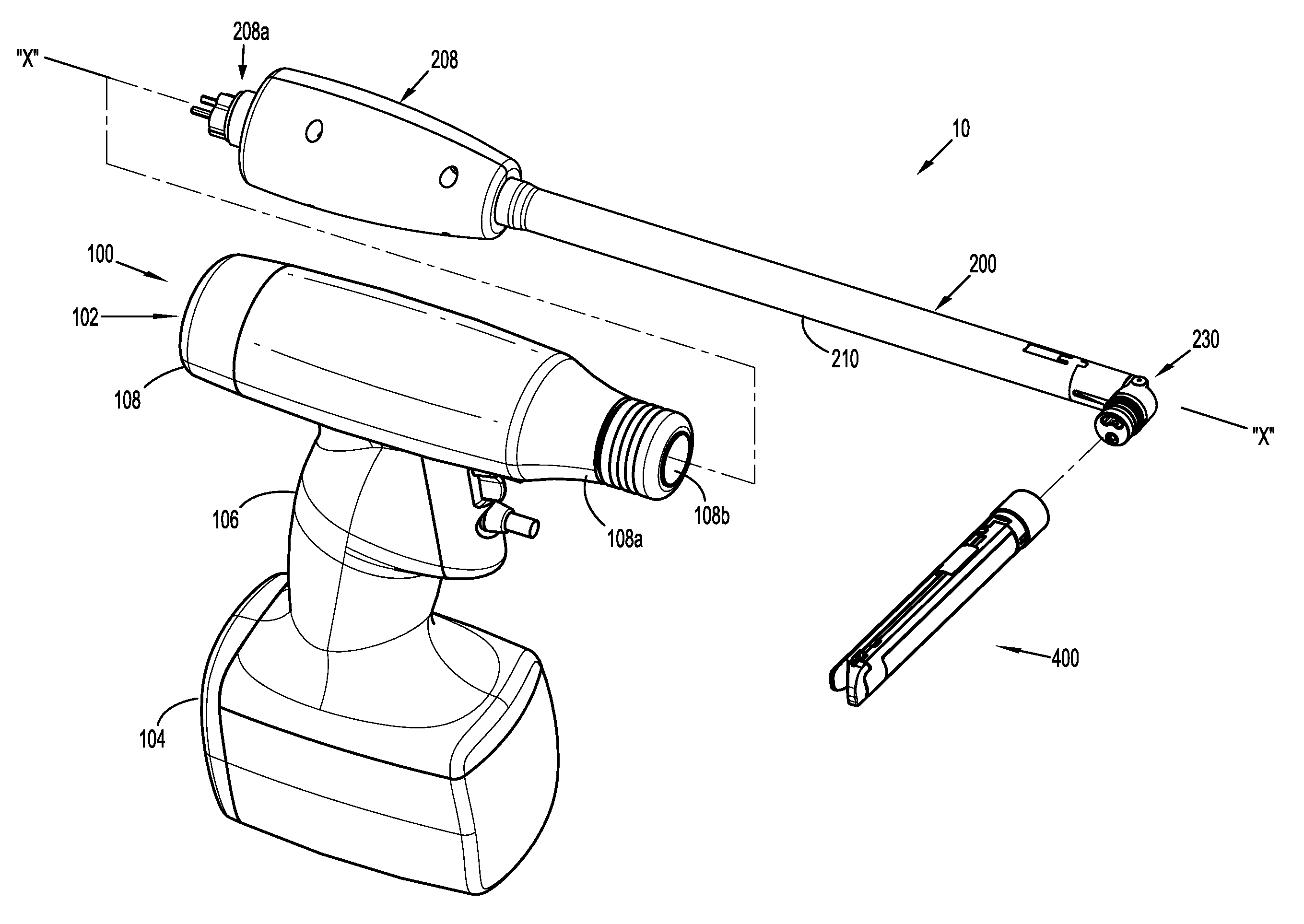

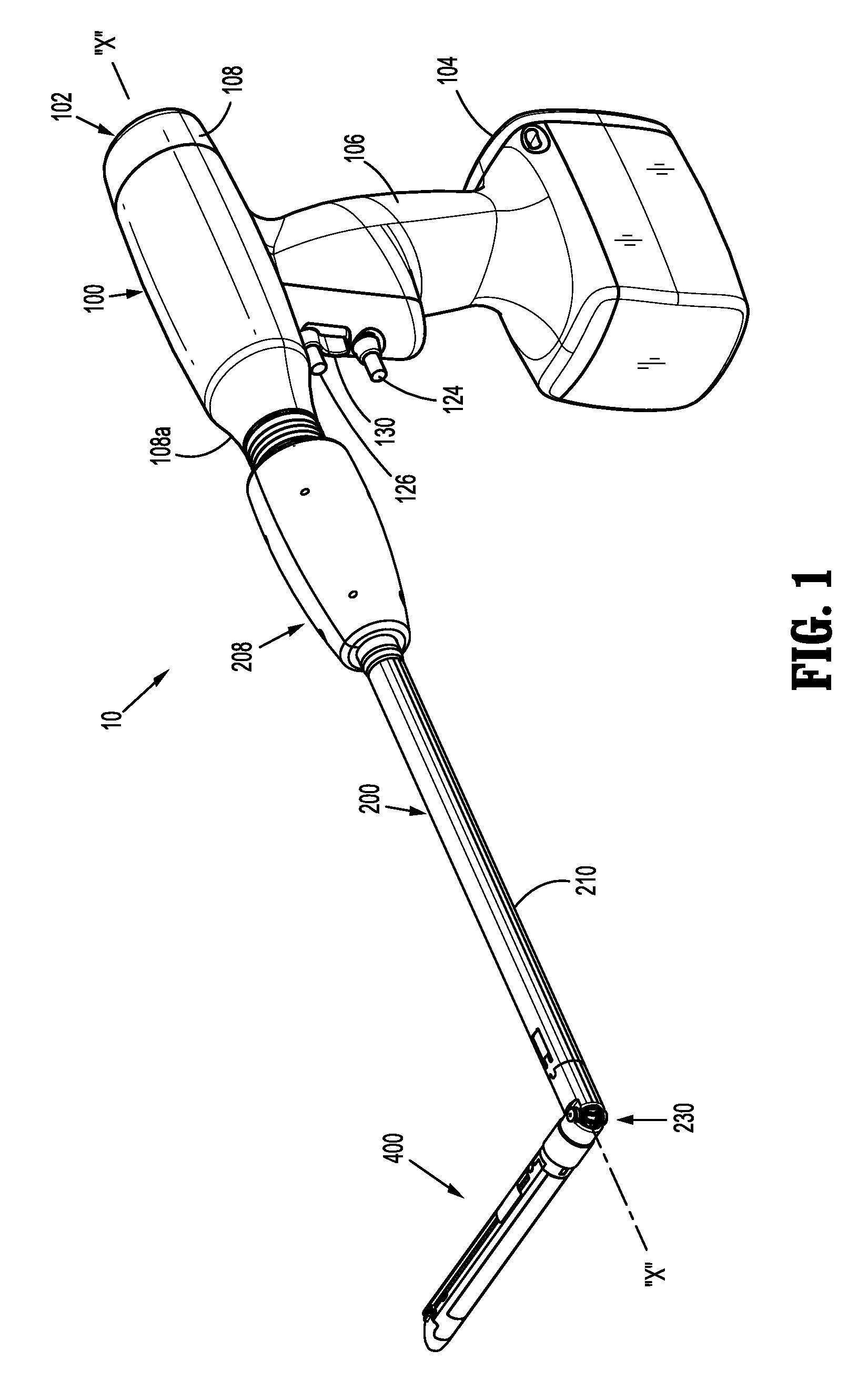

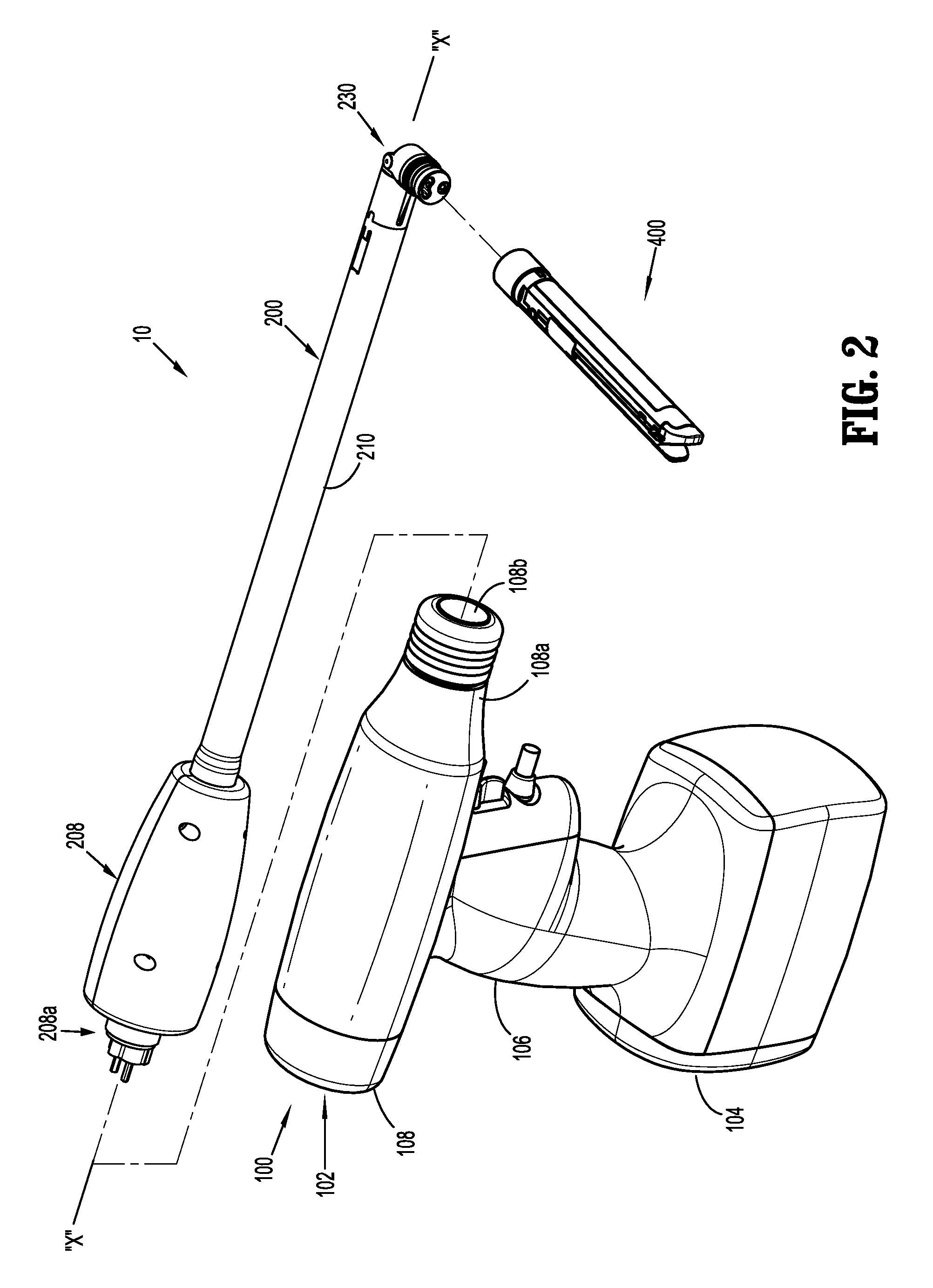

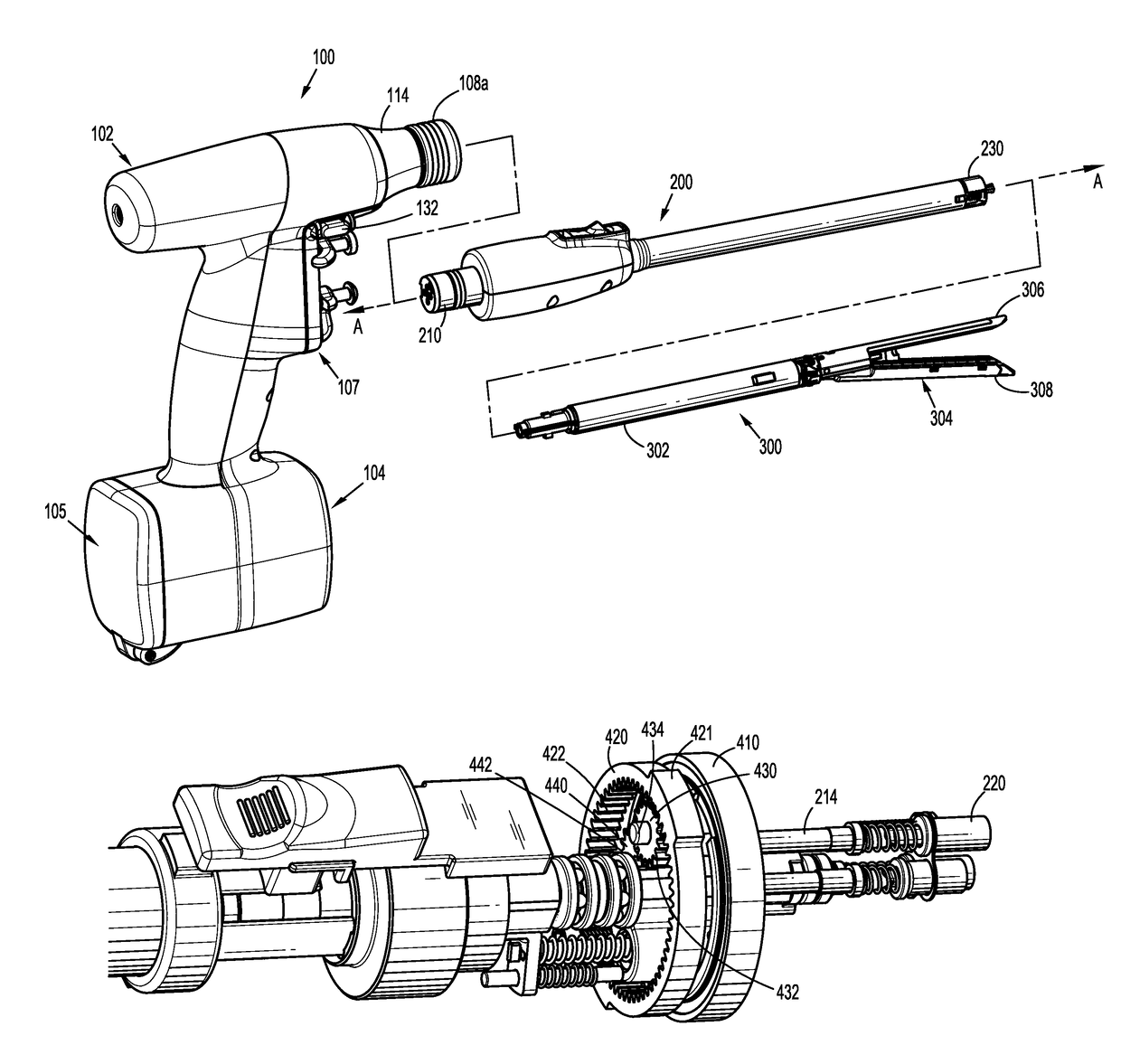

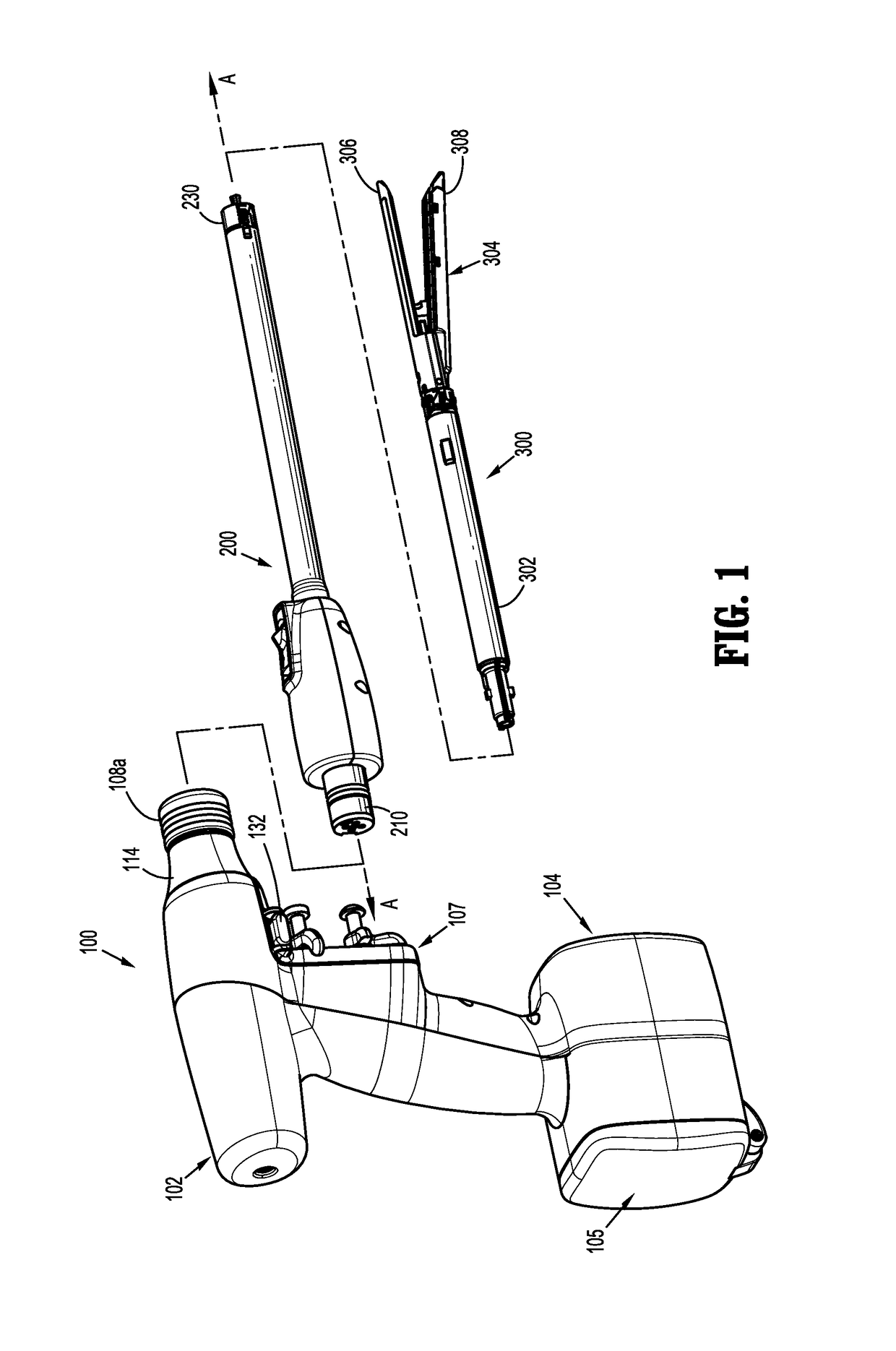

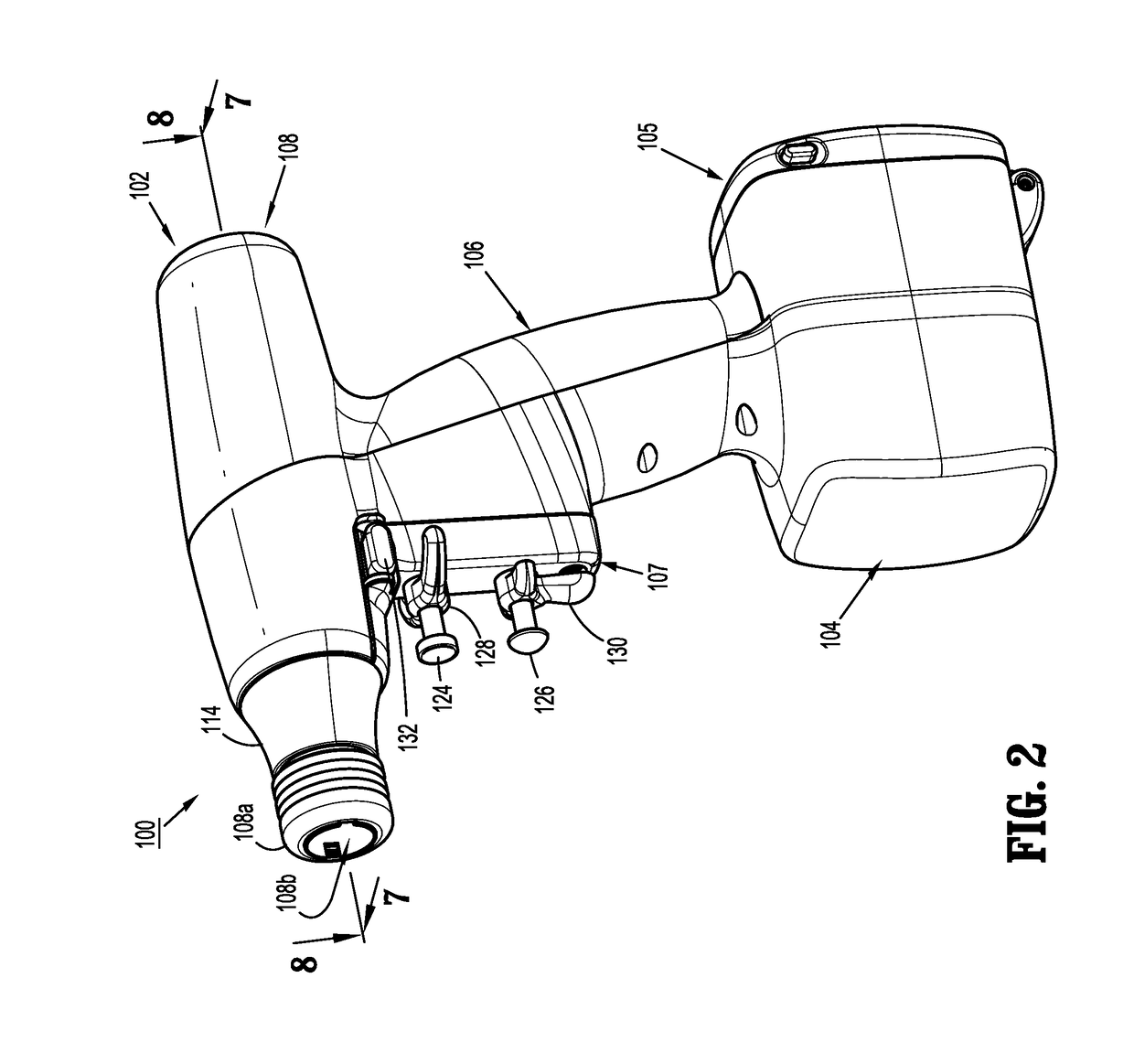

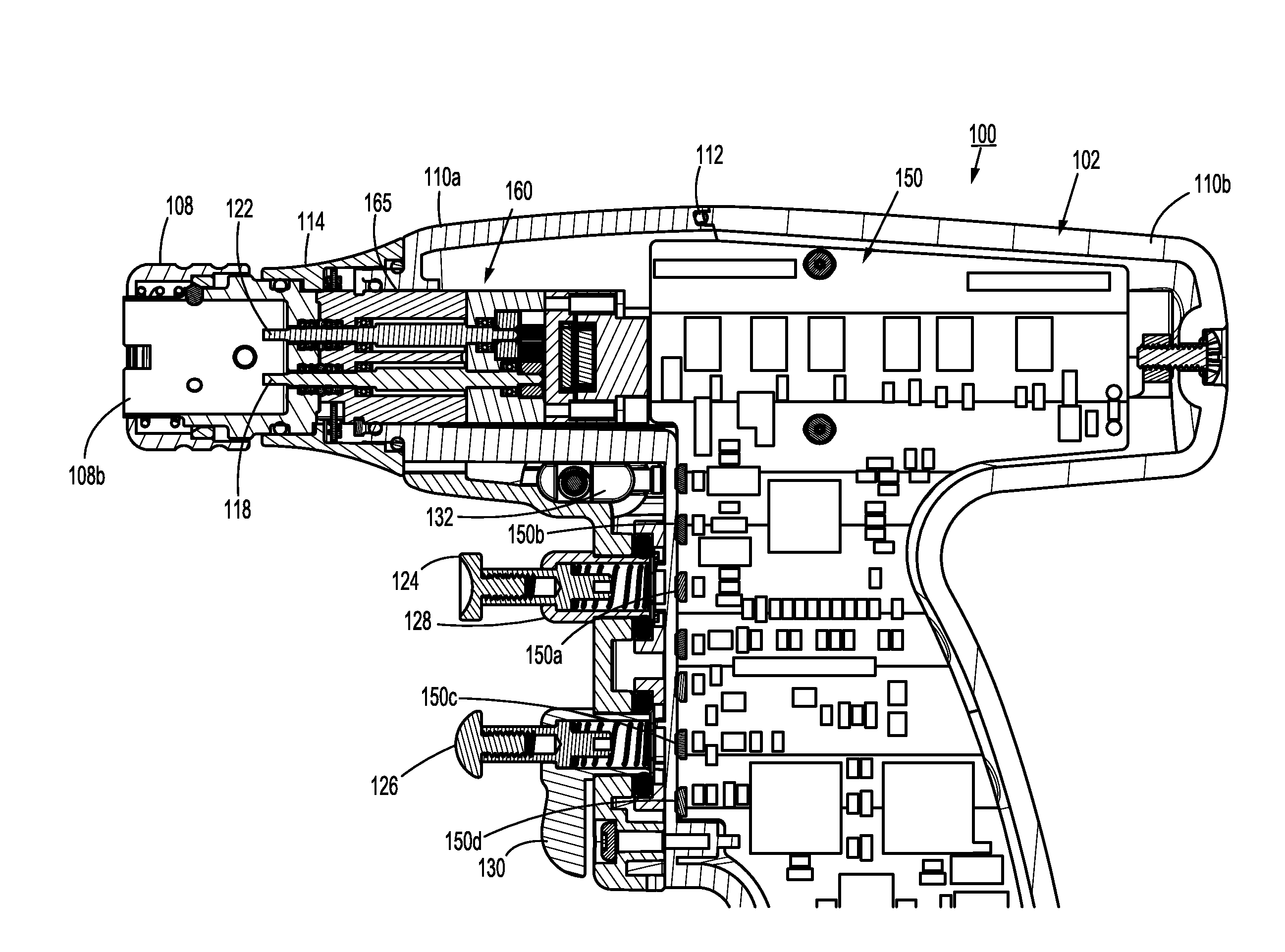

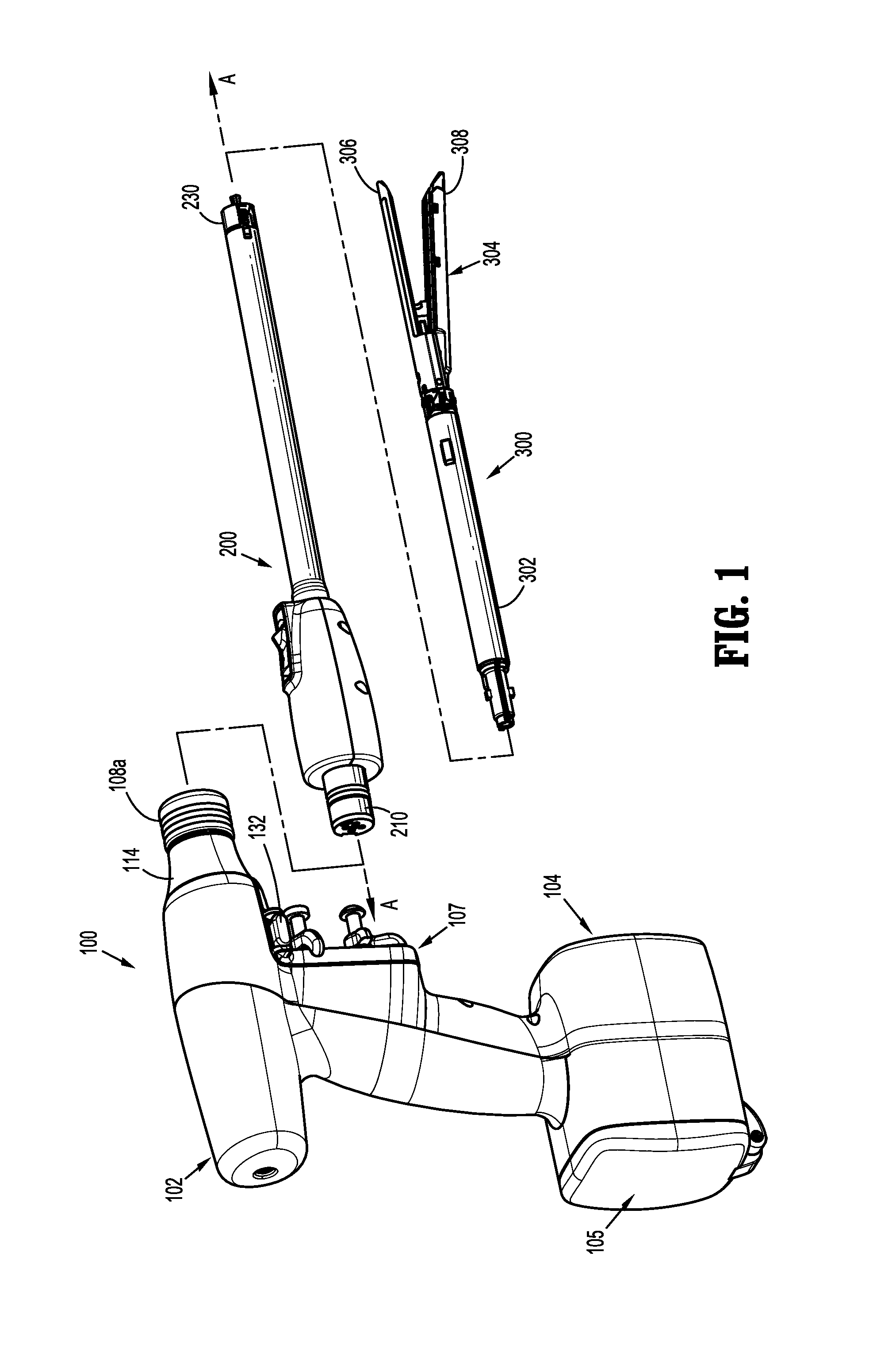

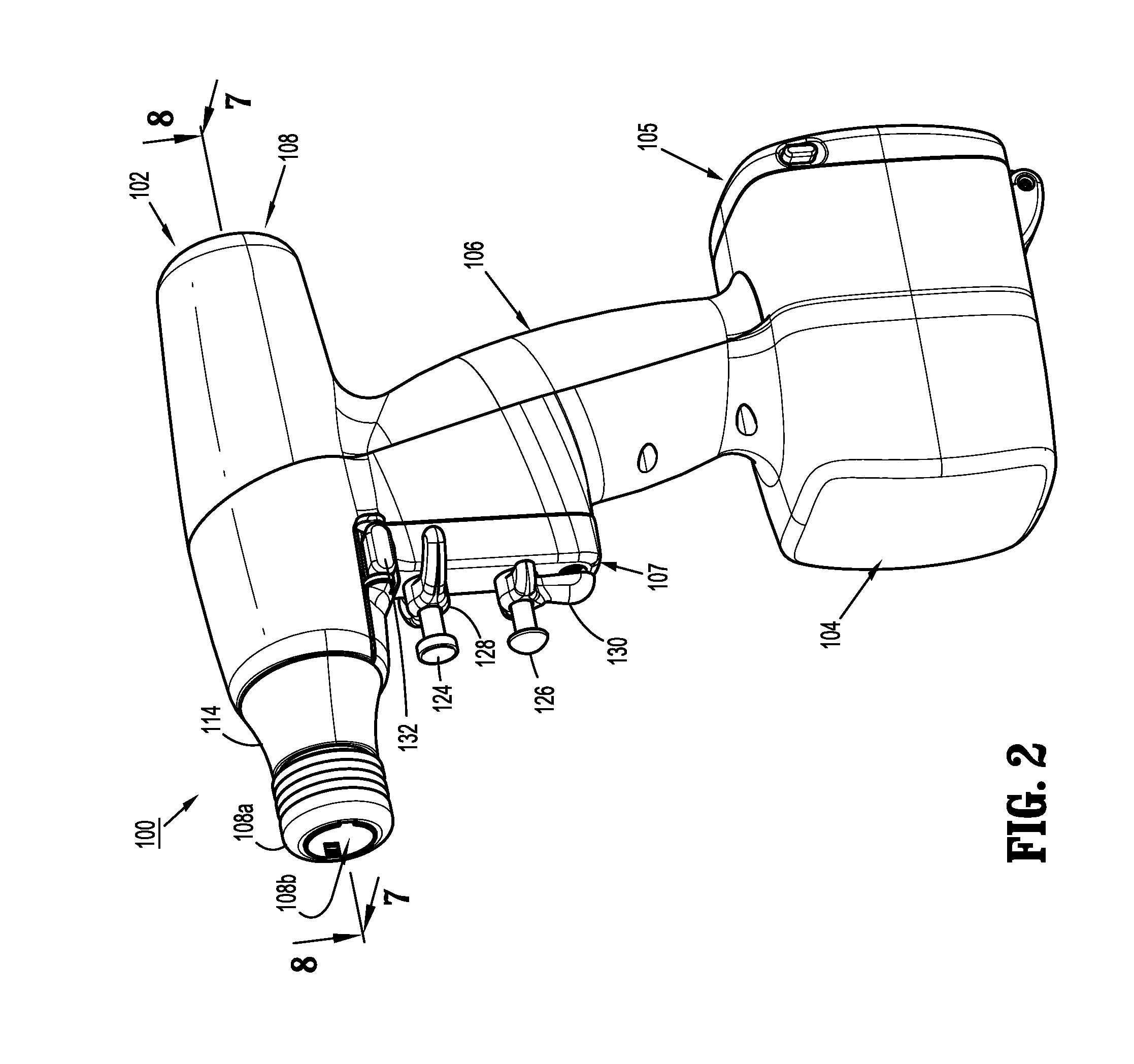

Handheld surgical handle assembly, surgical adapters for use between surgical handle assembly and surgical end effectors, and methods of use

The present disclosure relates to a surgical device including an adapter assembly for selectively interconnecting an end effector and the device housing. The adapter assembly includes at least one drive converter assembly that converts and transmits a rotation of the rotatable drive shaft to an axial translation of at least one axially translatable drive member of the end effector. A first drive converter assembly includes a first drive element, a nut, an articulation sleeve, an articulation bearing, and an articulation link. Rotation of the rotatable drive shaft results in rotation of the first drive element. Rotation of the first drive element results in axial translation of the nut, the articulation sleeve, the articulation bearing, the articulation link, and the at least one axially translatable drive member of the end effector.

Owner:TYCO HEALTHCARE GRP LP

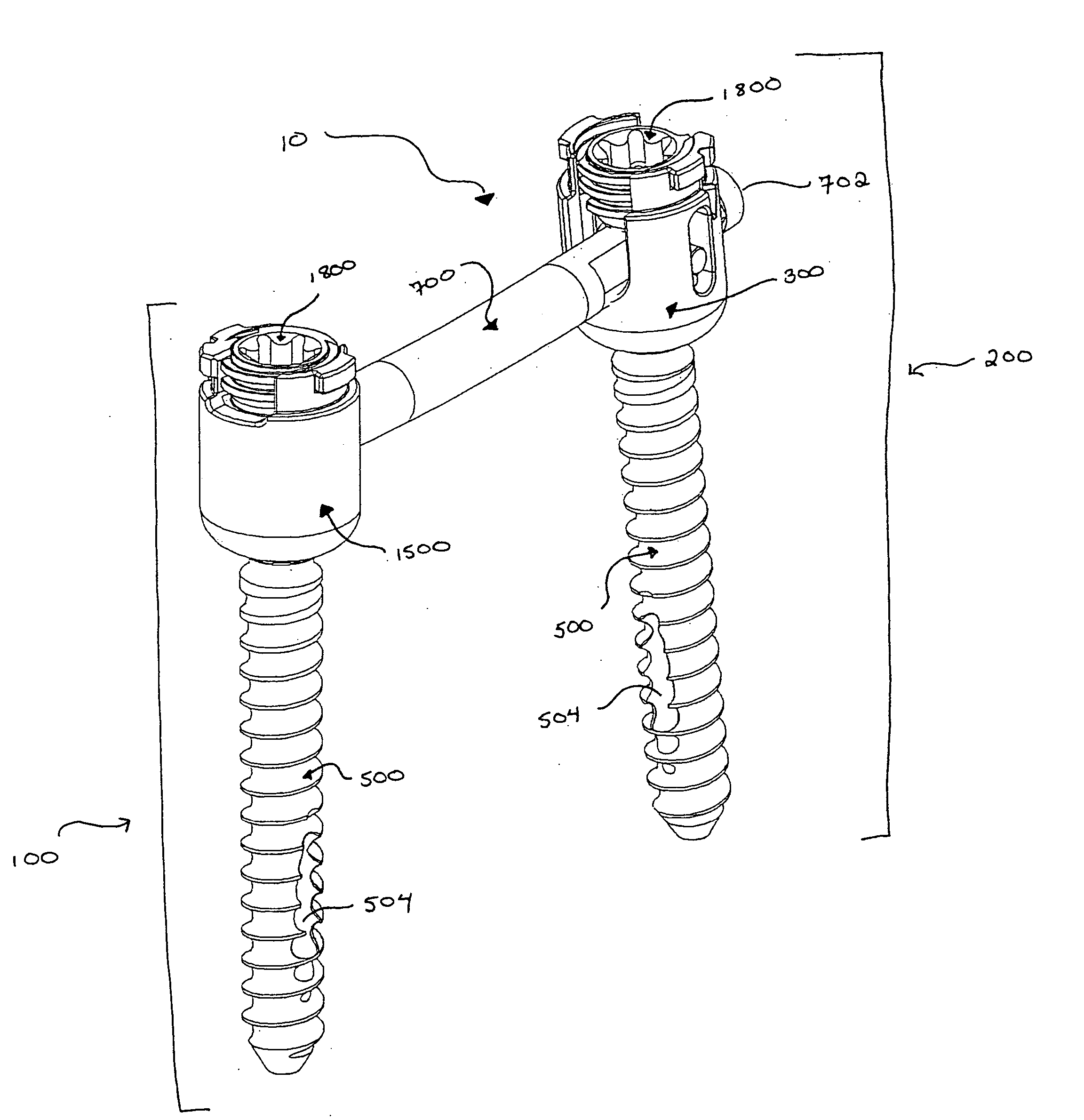

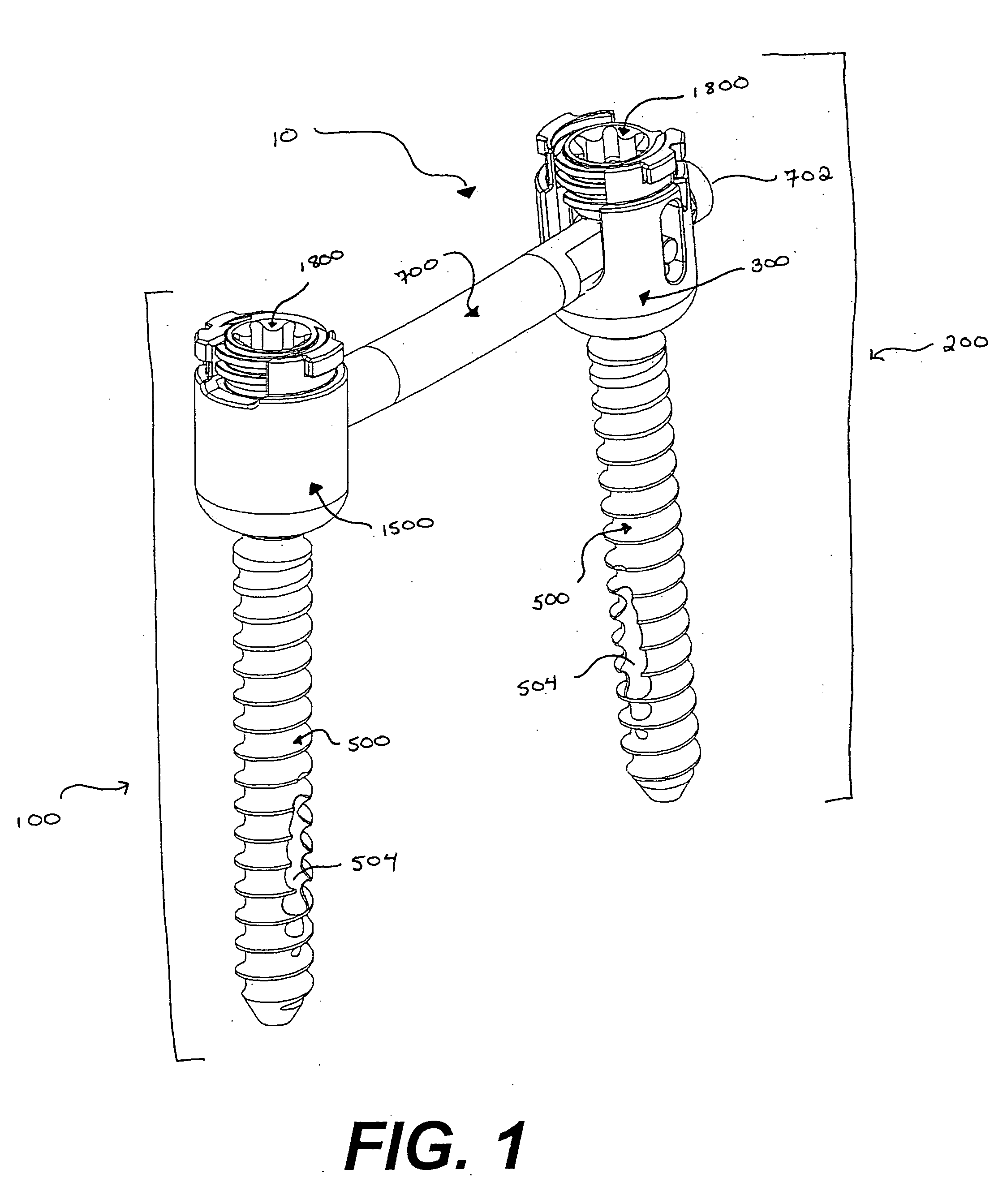

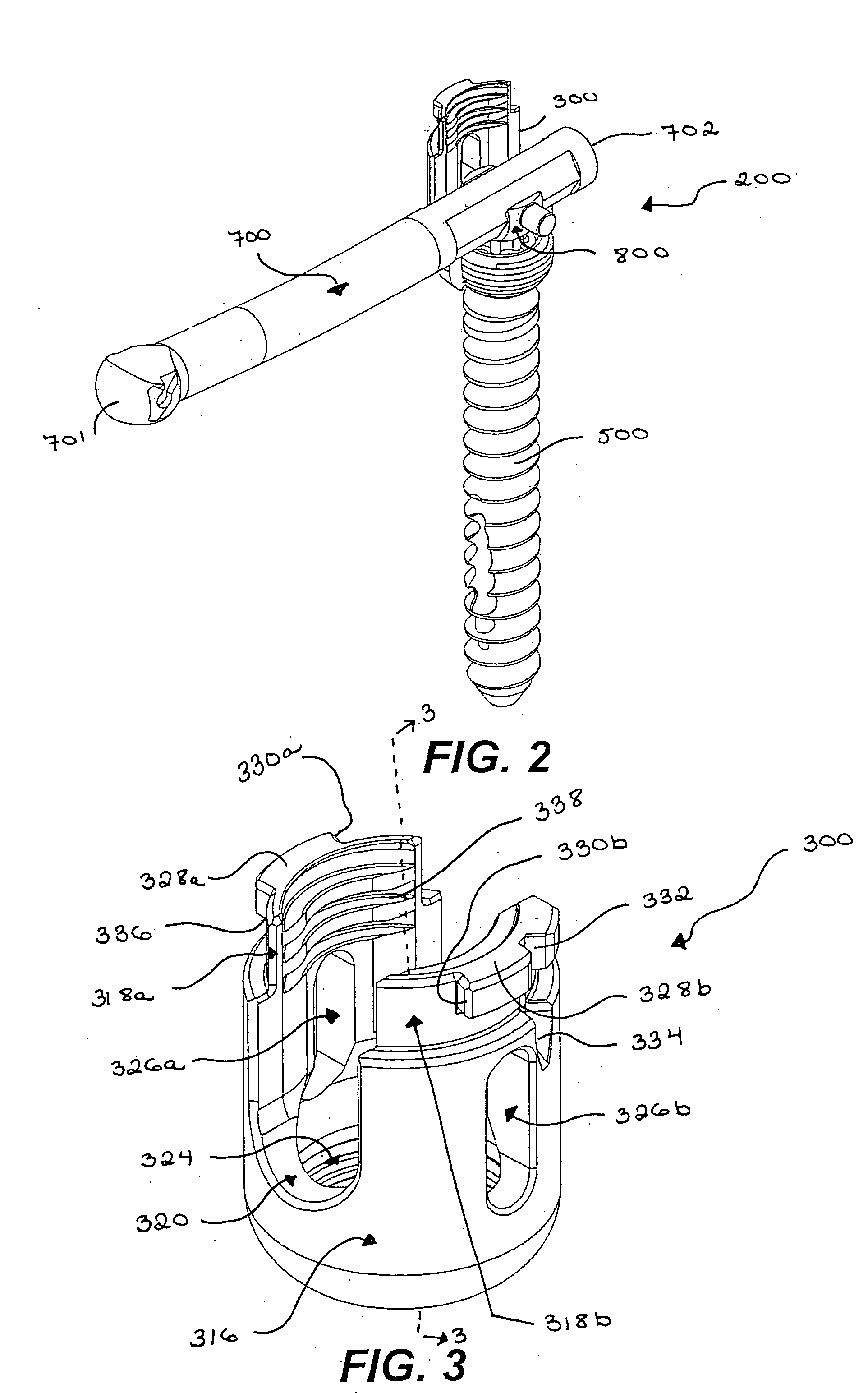

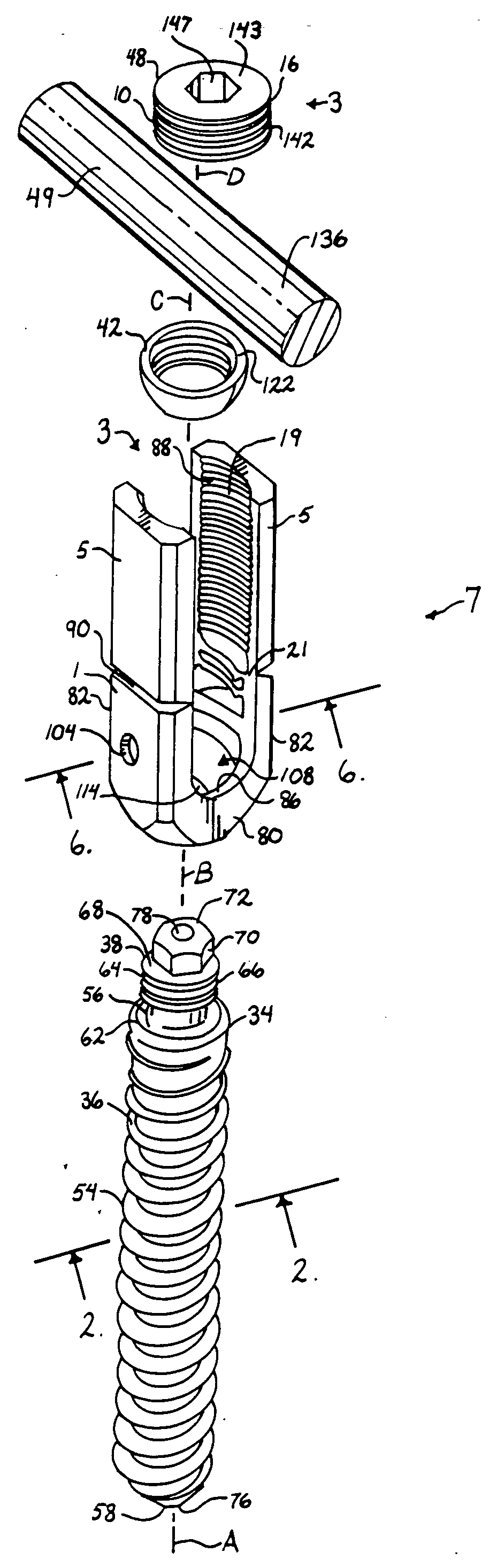

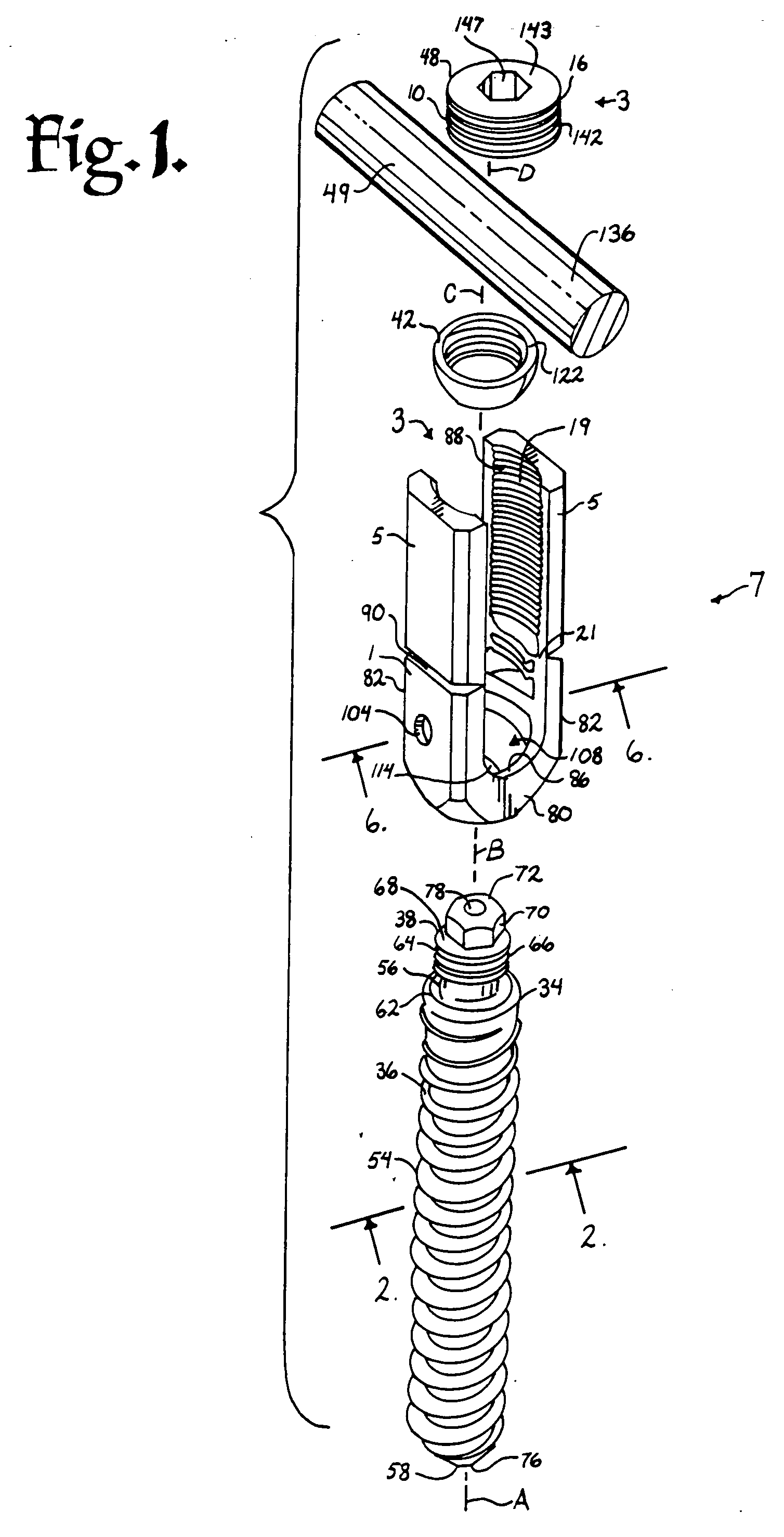

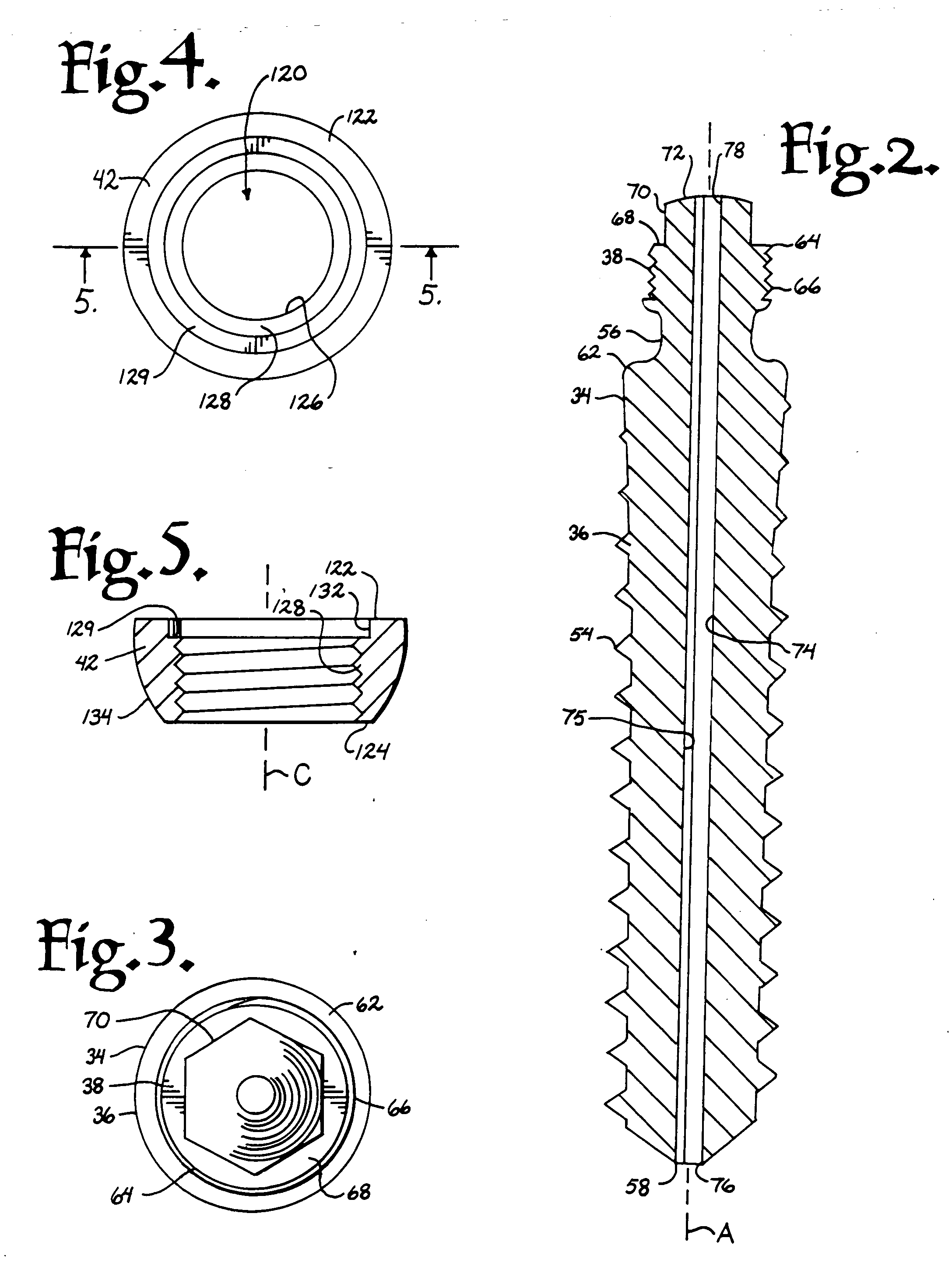

Implant assembly and method for use in an internal structure stabilization system

ActiveUS20060036244A1Prevent slidingEffectively locking out the conical freedom of the anchorSuture equipmentsInternal osteosythesisEngineeringHead parts

A stabilization assembly is described that stabilizes bony structures such as vertebrae. The stabilization assembly is partially formed by a poly-axial assembly which includes an anchor connected to a poly axial connector assembly head, where the poly-axial connector-assembly head includes a slide ring mounted in the head and a connector mounted in the slide ring. The slide ring allows the connector to move between an upright and a horizontal position relative to the poly-axial connector-assembly head. In the upright position the connector engages with a drive mechanism on the anchor for inserting the anchor into a pedicle. In the horizontal position the connector can engage a poly-axial connector capturing assembly which is the second piece included in the stabilization assembly. An end of the connector engages with a poly-axial connector-capturing head which is connected another anchor mounted in a second pedicle. Once the connector is captured by the poly-axial connector-capturing assembly, the stabilization system is made rigid by installing locking caps in the poly-axial heads.

Owner:THEKEN SPINE

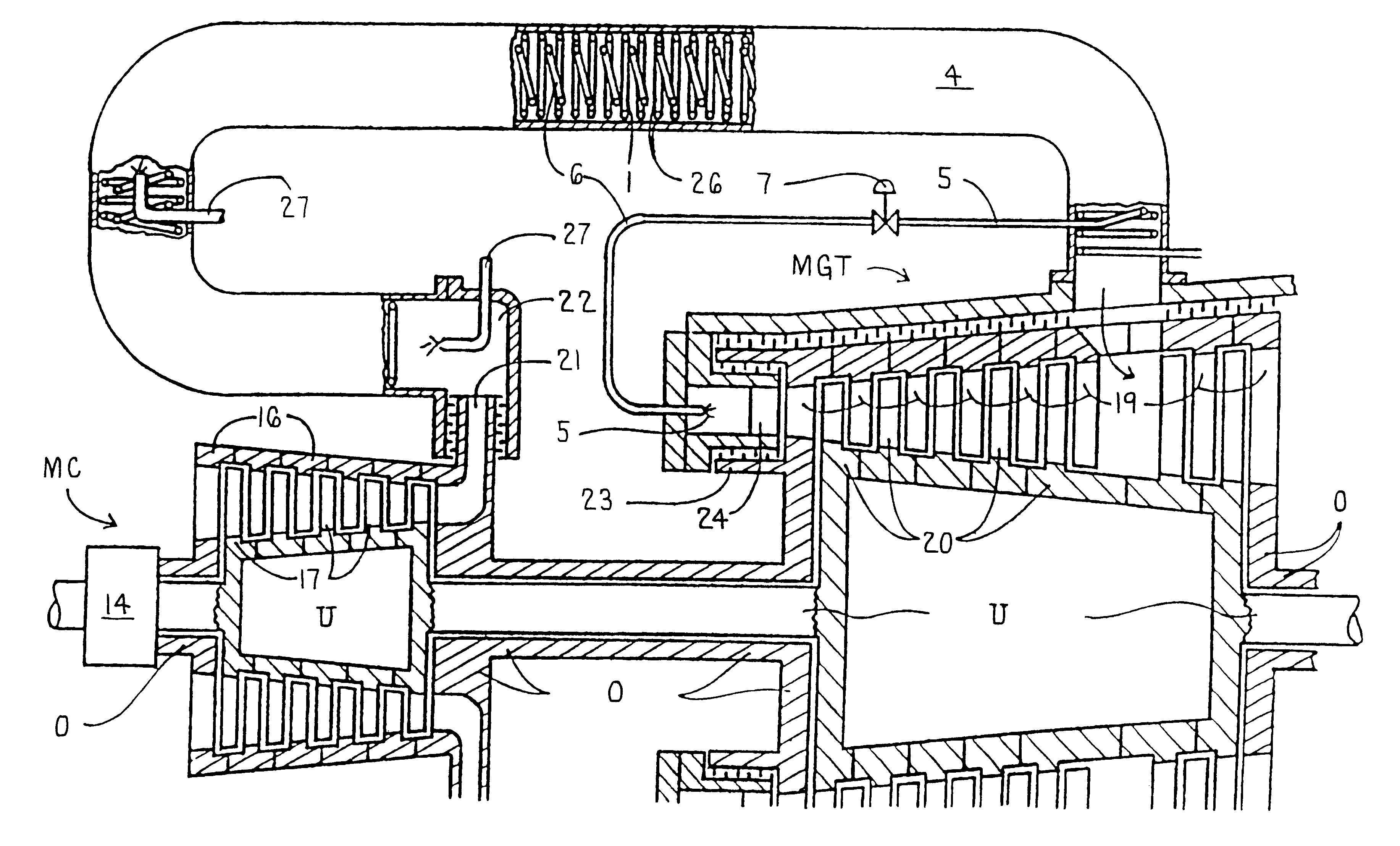

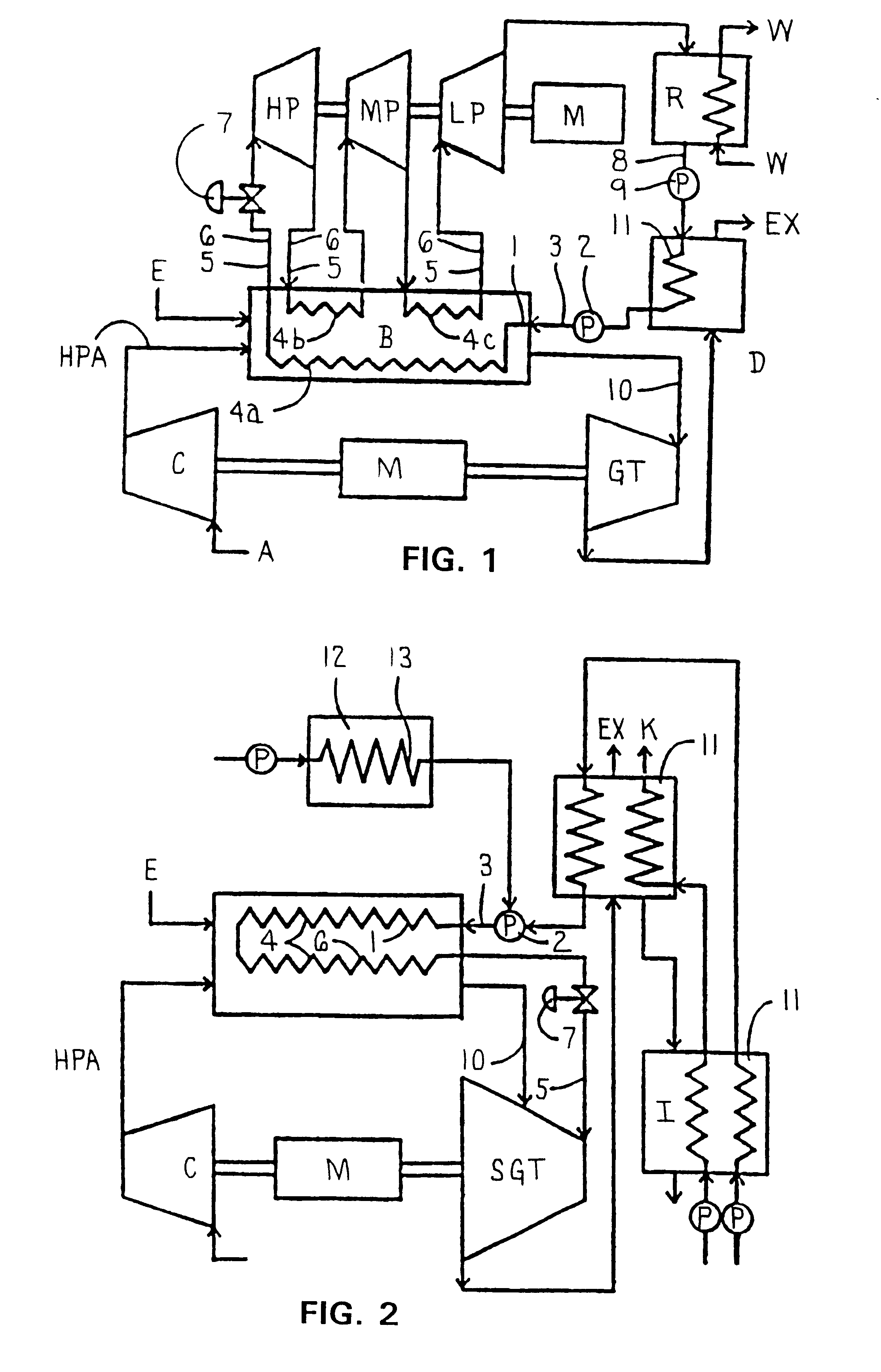

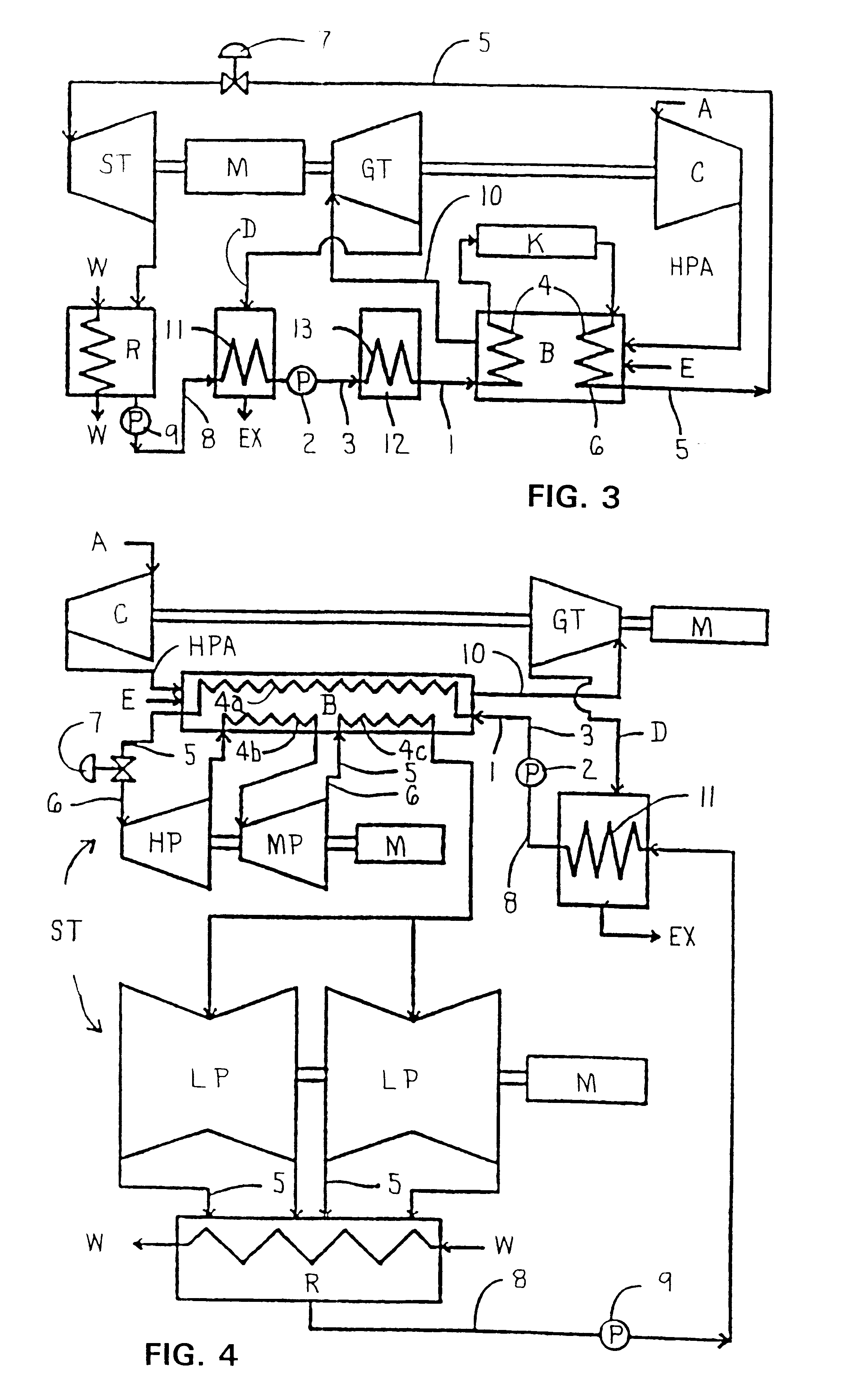

Combined steam and gas turbine engine with magnetic transmission

InactiveUS6263664B1Wide areaImprove system efficiencyContinuous combustion chamberGearingThermal energyCombustion chamber

In a combined steam and gas turbine engine cycle, a combustion chamber is made durable against high pressure and enlarged in length to increase the operation pressure ratio, without exceeding the heat durability temperature of the system while increasing the fuel combustion gas mass flow four times as much as the conventional turbine system and simultaneously for greatly raising the thermal efficiency of the system and specific power of the combined steam and gas turbine engine.Water pipes and steam pipes are arranged inside the combustion chamber so that the combustion chamber can function as a heat exchanger and thereby convert most of the combustion thermal energy into super-critical steam energy for driving a steam turbine and subsequently raising the operation pressure ratio and the thermal efficiencies of the steam turbine cycle and gas turbine cycle. The combustion gas mass flow can be also increased by four times as much as the conventional turbine system (up to the theoretical air to fuel ratio) and the thermal efficiency and the specific power of the gas turbine cycle are considerably increased.Further, the thermal efficiency of the combined system is improved by installing a magnetic friction power transmission system to transmit the power of the system to outer loads.

Owner:TANIGAWA HIROYASU +1

Powered end effector assembly with pivotable channel

Owner:TYCO HEALTHCARE GRP LP

Helical reverse angle guide and advancement structure with break-off extensions

A spinal fixation device combines an anchor member with an open receiver, such as a polyaxial bone screw or a hook, with a rotatable closure that operably clamps a spinal fixation rod to the anchor member. The anchor member has spaced apart arms forming a rod receiving channel. The arms have arm extensions or tabs connected to main portions of the arms by weakened regions to enable the extensions to be broken off or separated after the rod is clamped. The closure and inner surfaces of the arms and tabs have mating helical, anti-splay, reverse angle guide and advancement structure formed thereon that mechanically cooperate to prevent splaying of the arms and the extensions as the closure is advanced into the rod receiving channel. The increased length of the arms with the extensions enables the rod to be captured at a greater distance from the seat of the channel and allows the rod to be urged toward the seat by helical advancement of the closure into the channel, starting between the extensions. Separation of the break-off extensions results in an implant with a desirable low profile.

Owner:JACKSON

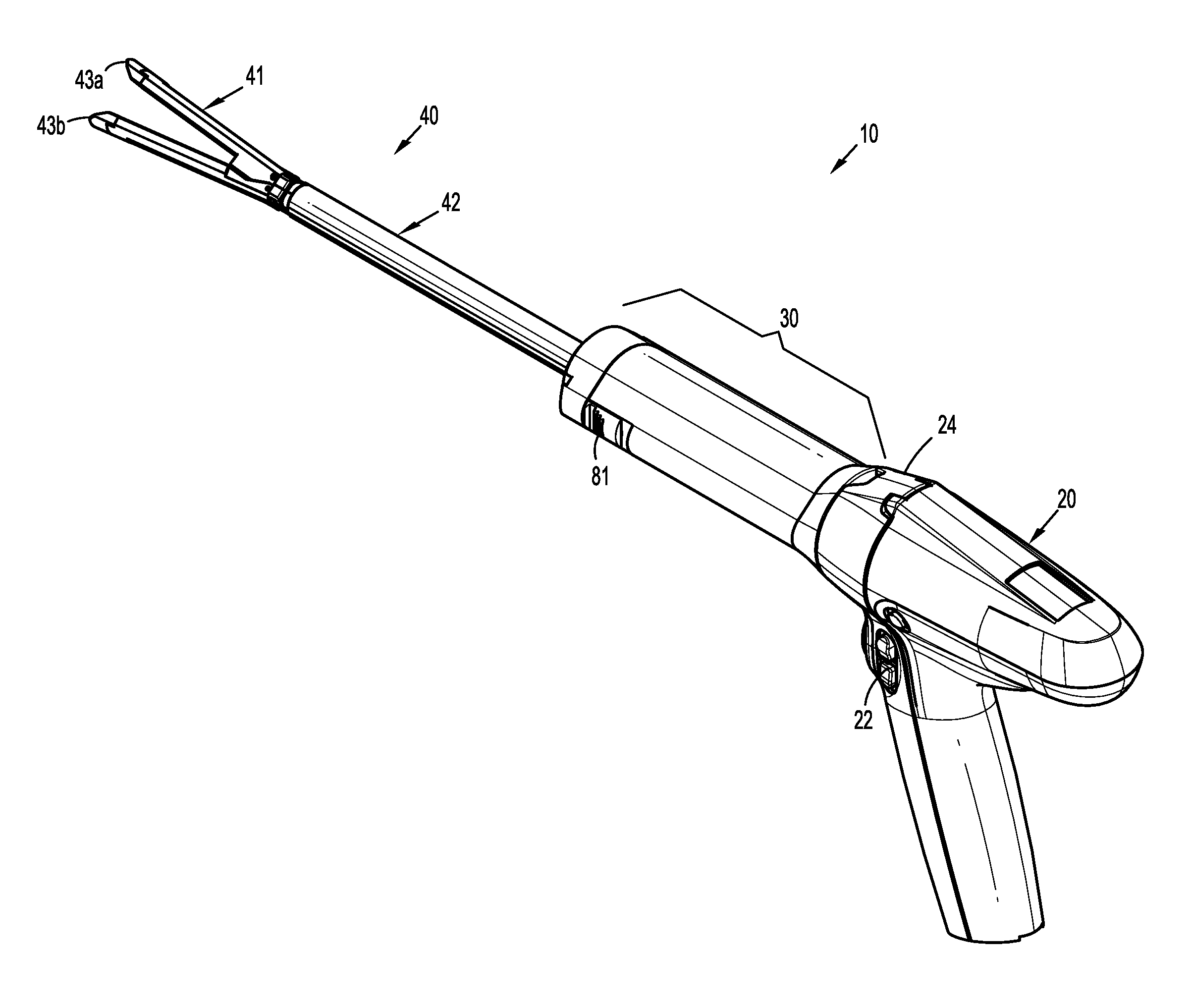

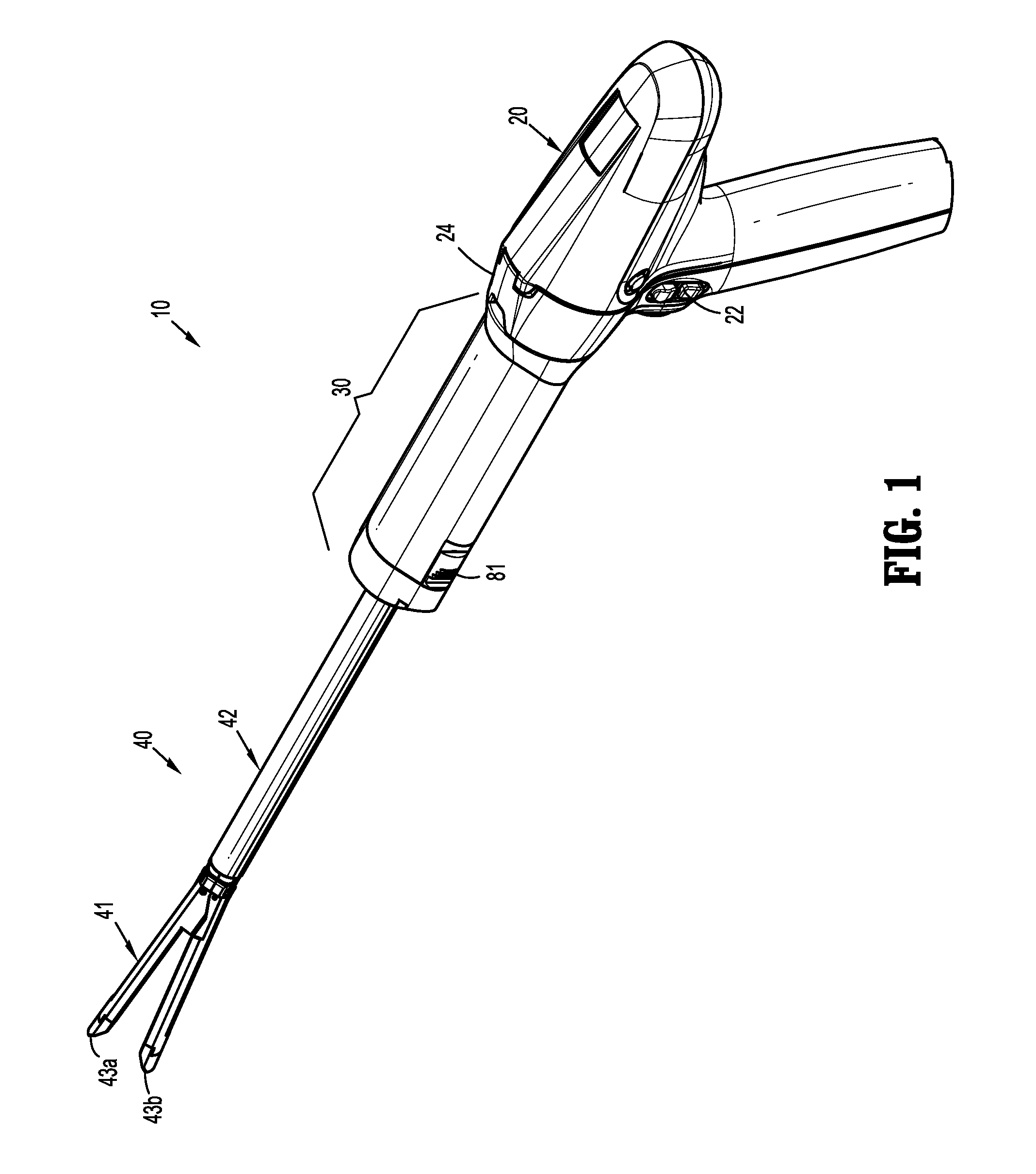

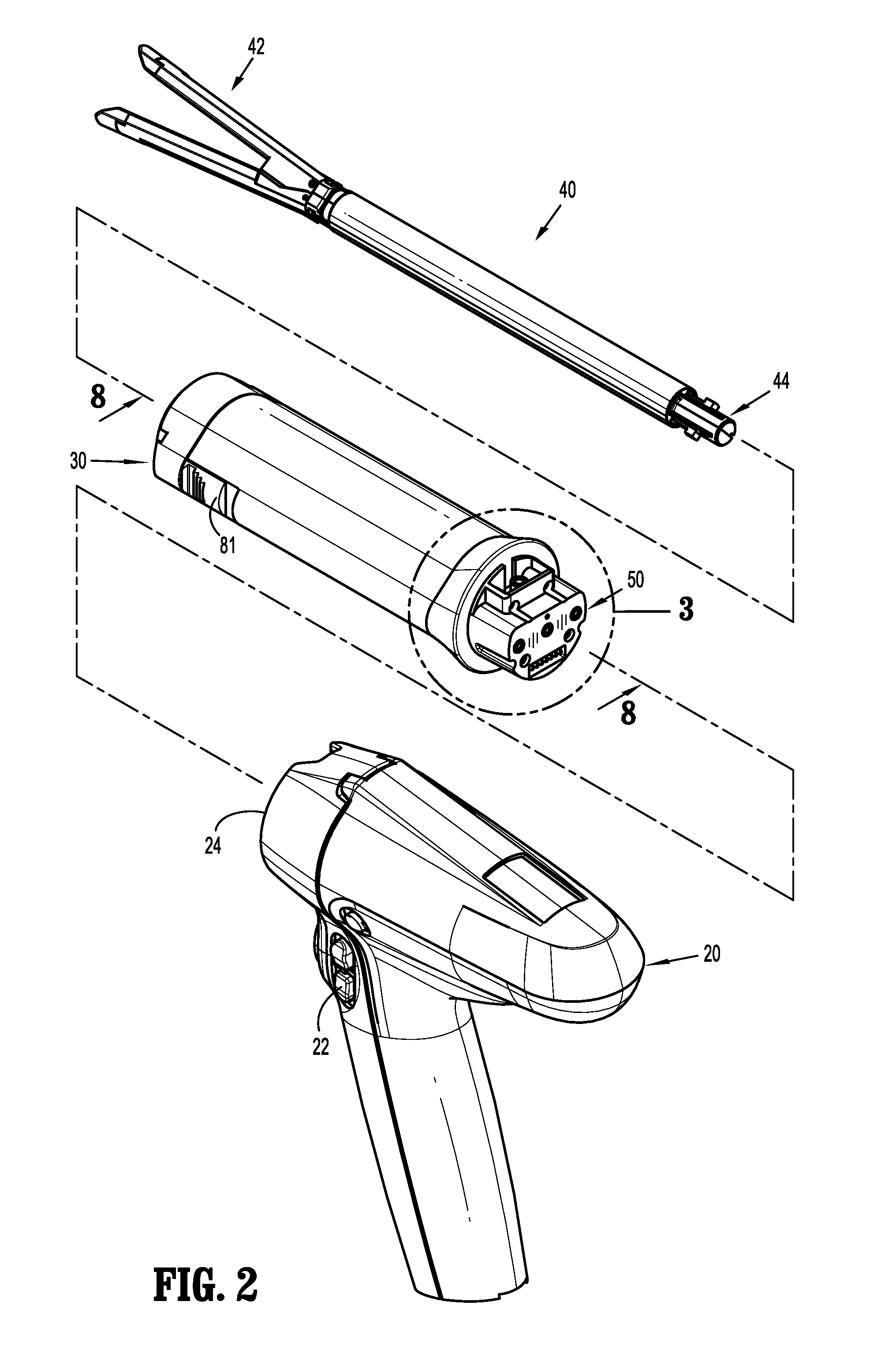

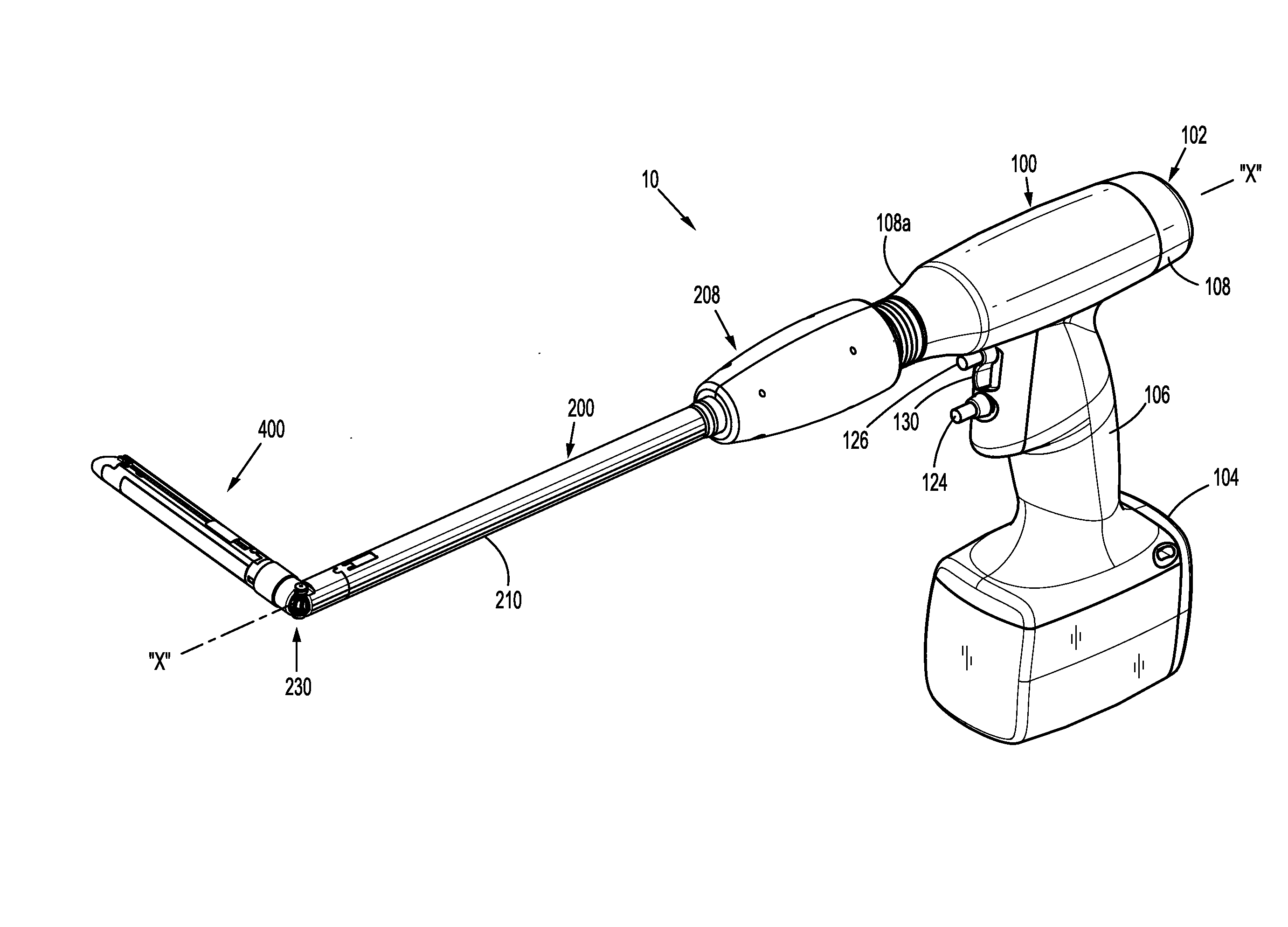

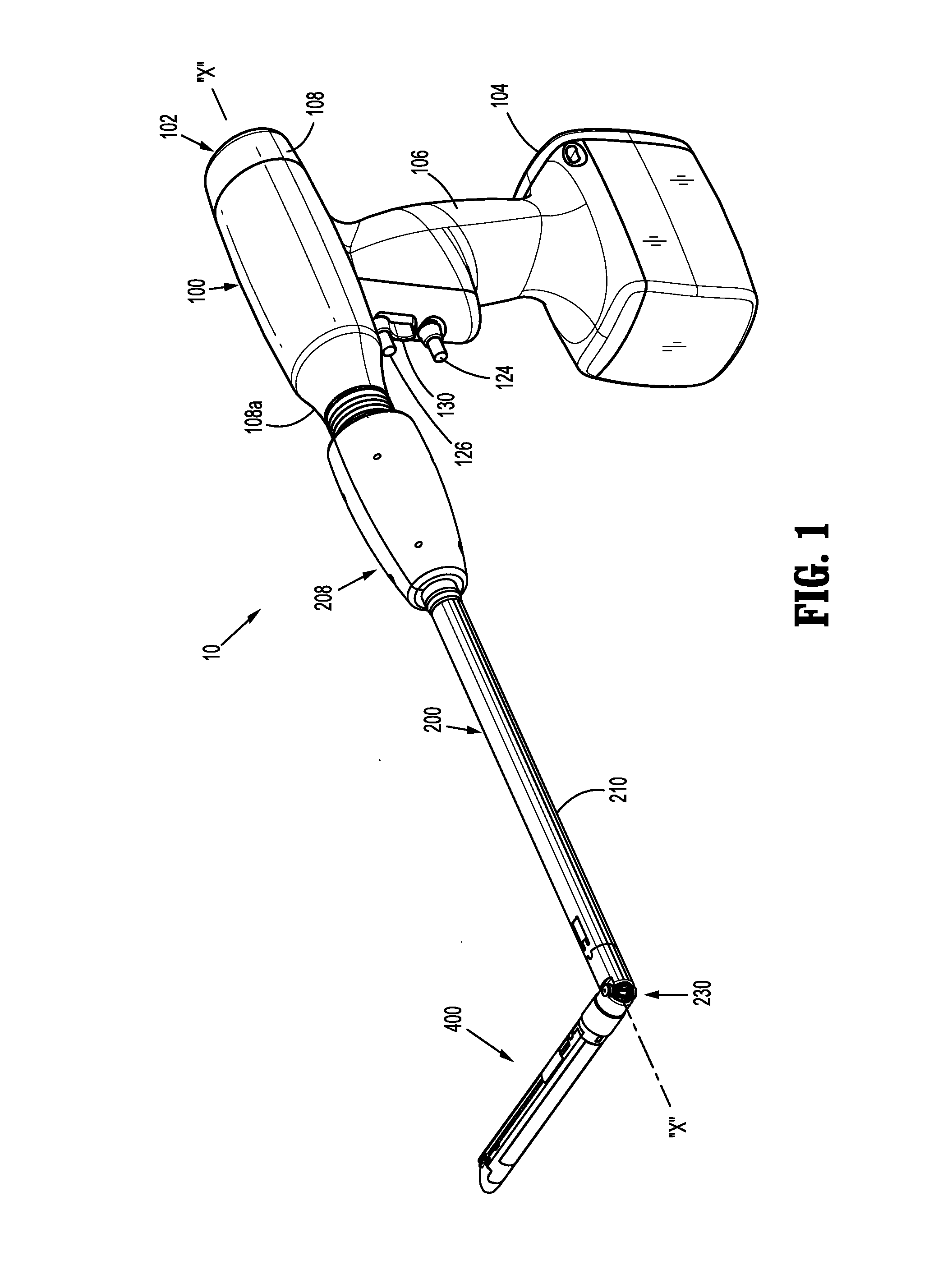

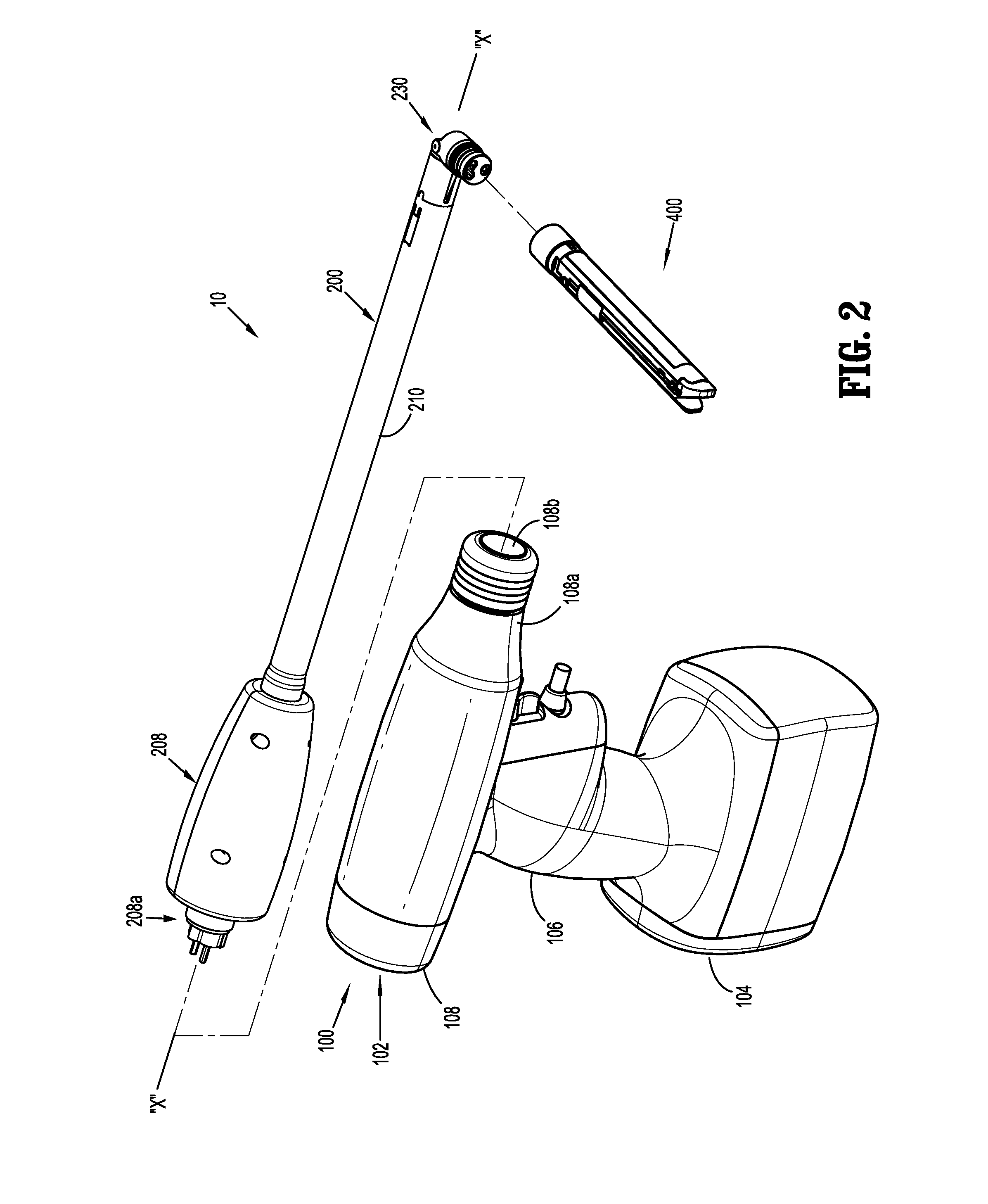

Hand held surgical handle assembly, surgical adapters for use between surgical handle assembly and surgical end effectors, and methods of use

The present disclosure relates to a surgical device including an adapter assembly for selectively interconnecting an end effector and the device housing. The adapter assembly includes at least one drive converter assembly that converts and transmits a rotation of the rotatable drive shaft to an axial translation of at least one axially translatable drive member of the end effector. A first drive converter assembly includes a first drive element, a nut, an articulation sleeve, an articulation bearing, and an articulation link. Rotation of the rotatable drive shaft results in rotation of the first drive element. Rotation of the first drive element results in axial translation of the nut, the articulation sleeve, the articulation bearing, the articulation link, and the at least one axially translatable drive member of the end effector.

Owner:TYCO HEALTHCARE GRP LP

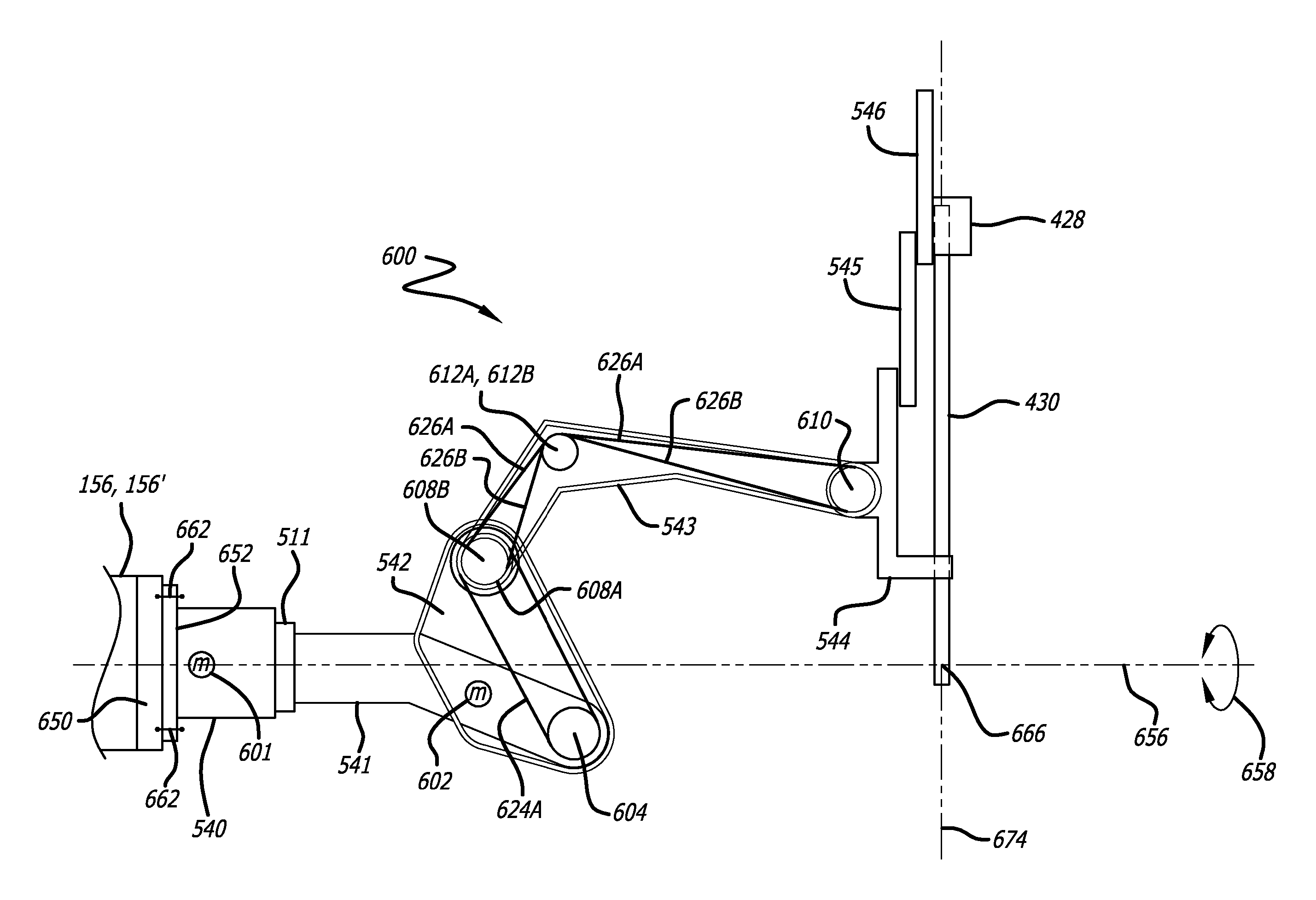

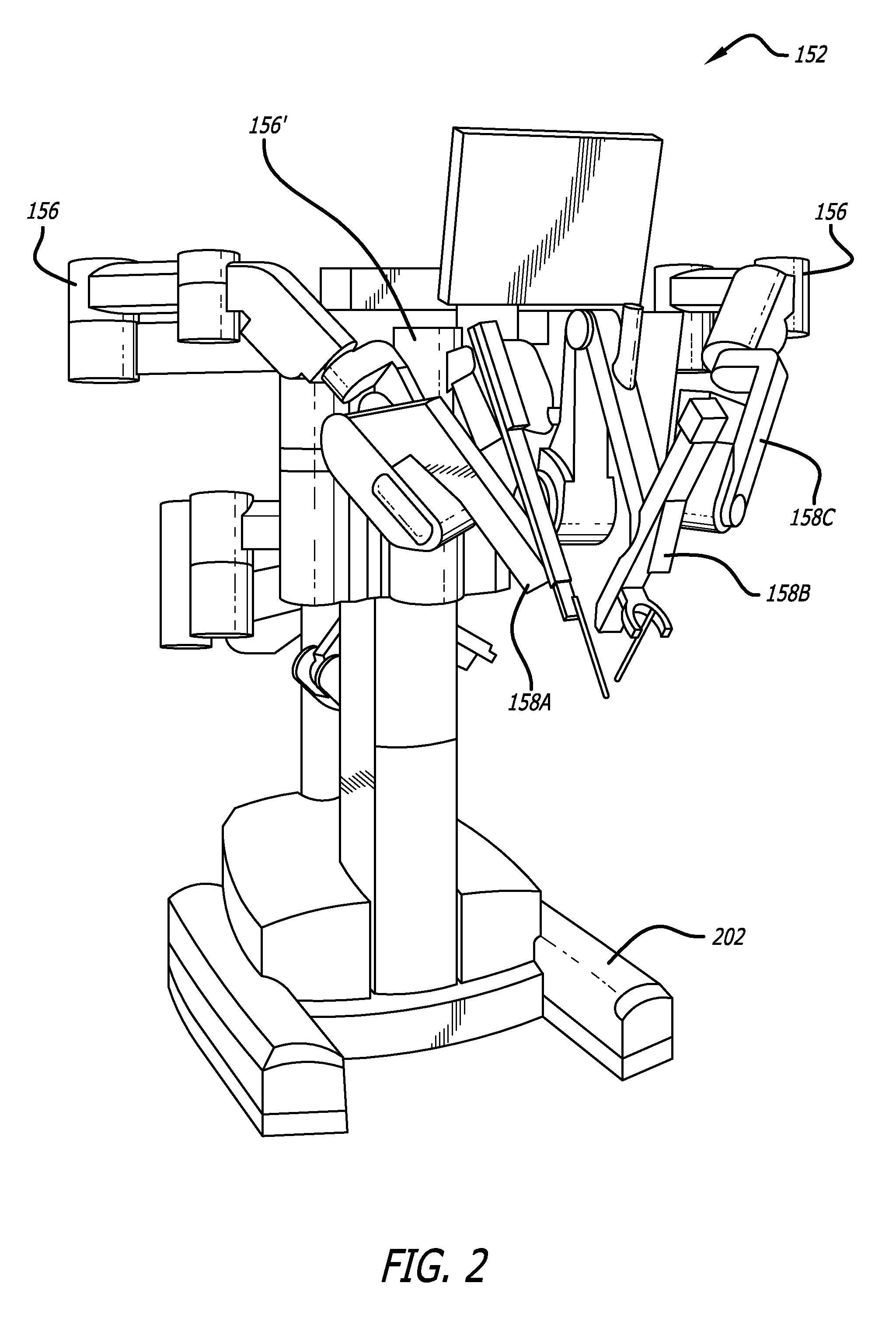

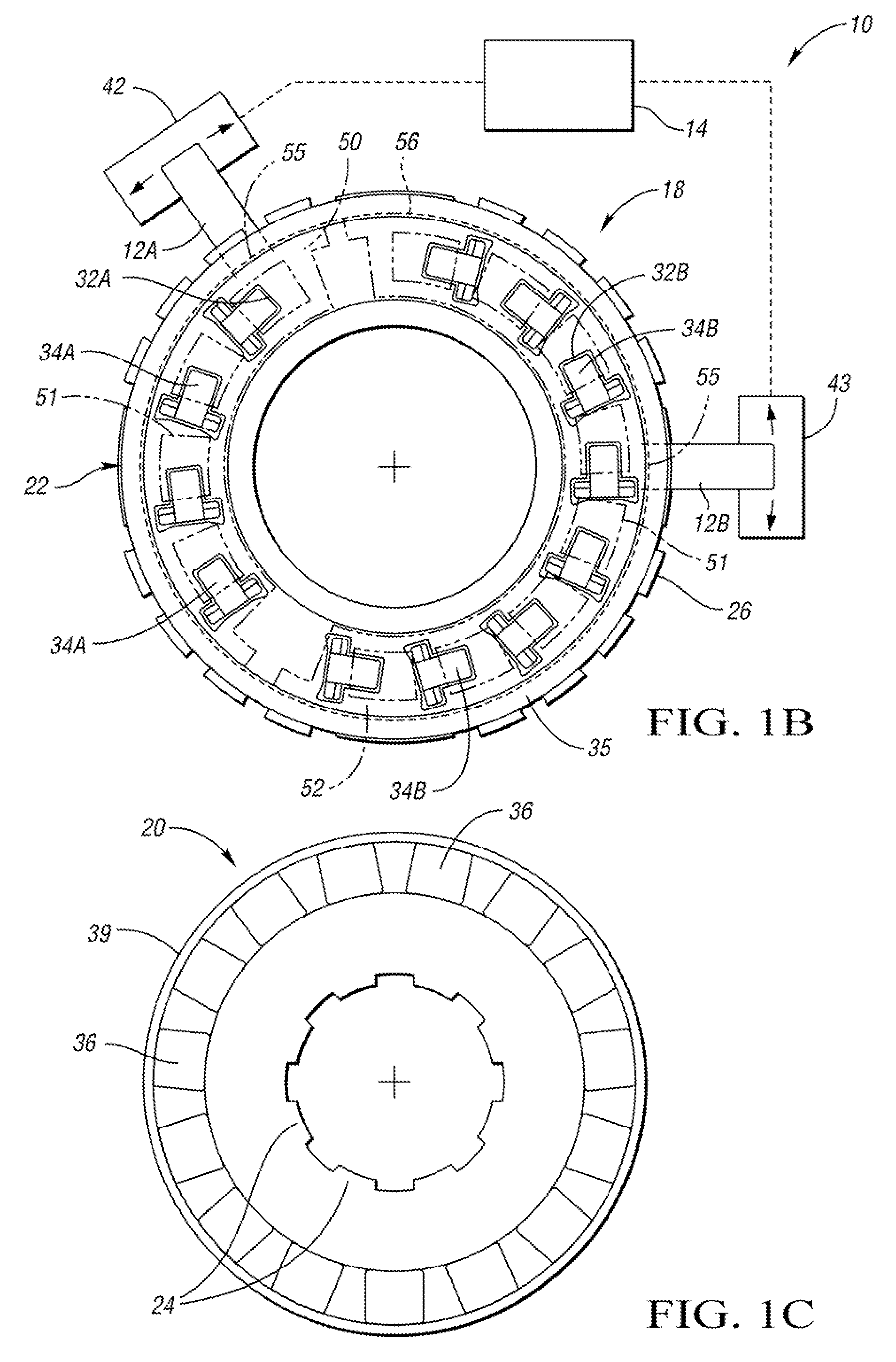

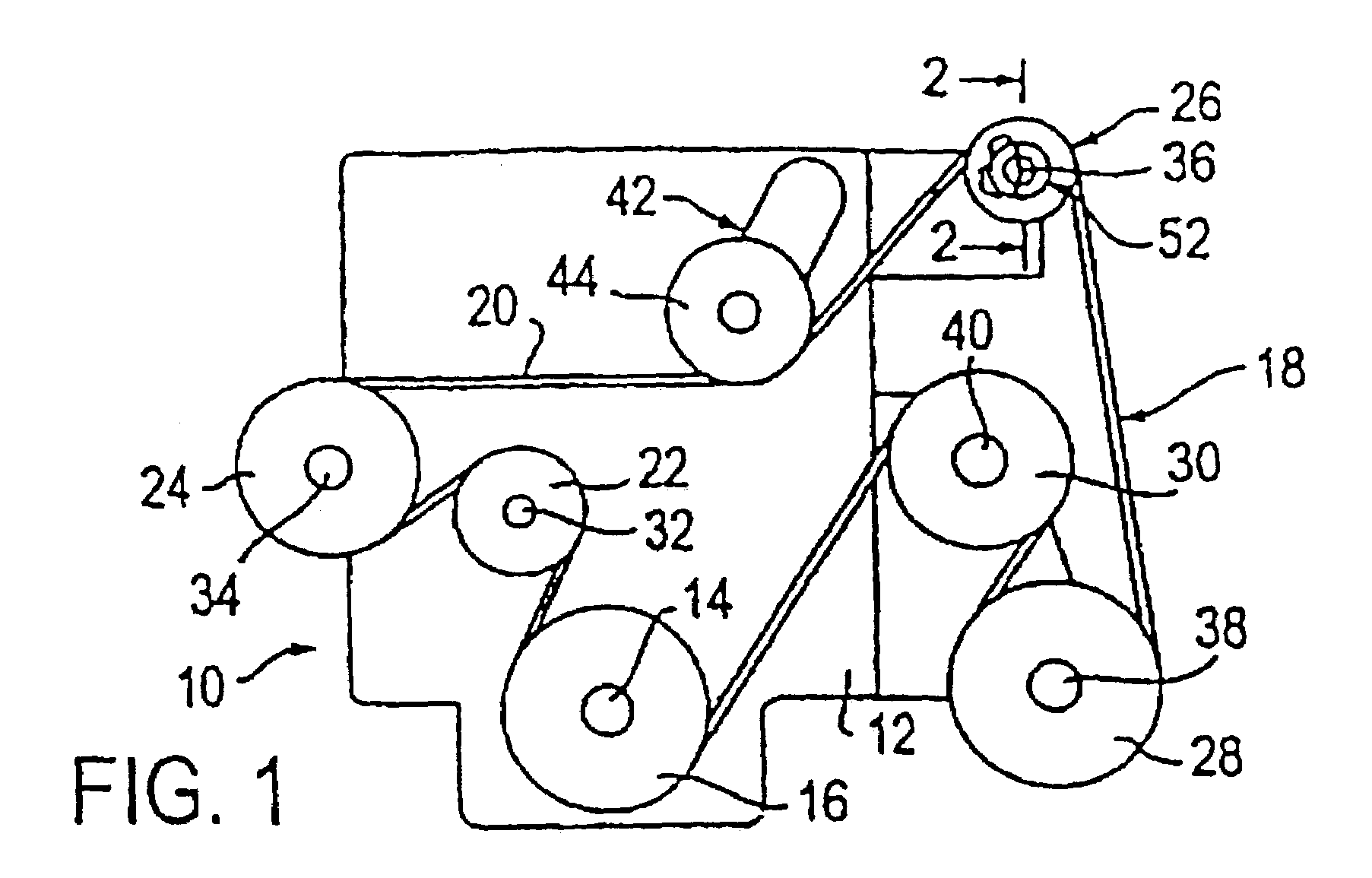

Multi-ply strap drive trains for robotic arms

In one embodiment of the invention, a robotic arm is provided including a linkage assembly and a strap drive train. The linkage assembly includes first, second, third, and fourth links pivotally coupled in series together at first, second, and third joints to define a parallelogram with an insertion axis. The strap drive train includes first and second sets of straps coupled to the linkage assembly. As the linkage assembly is moved about a pitch axis, the first set of straps ensures the third link maintains the same angle relative to the first link, and the first and second set of straps ensures the fourth link maintains the same angle relative to the second link.

Owner:INTUITIVE SURGICAL OPERATIONS INC

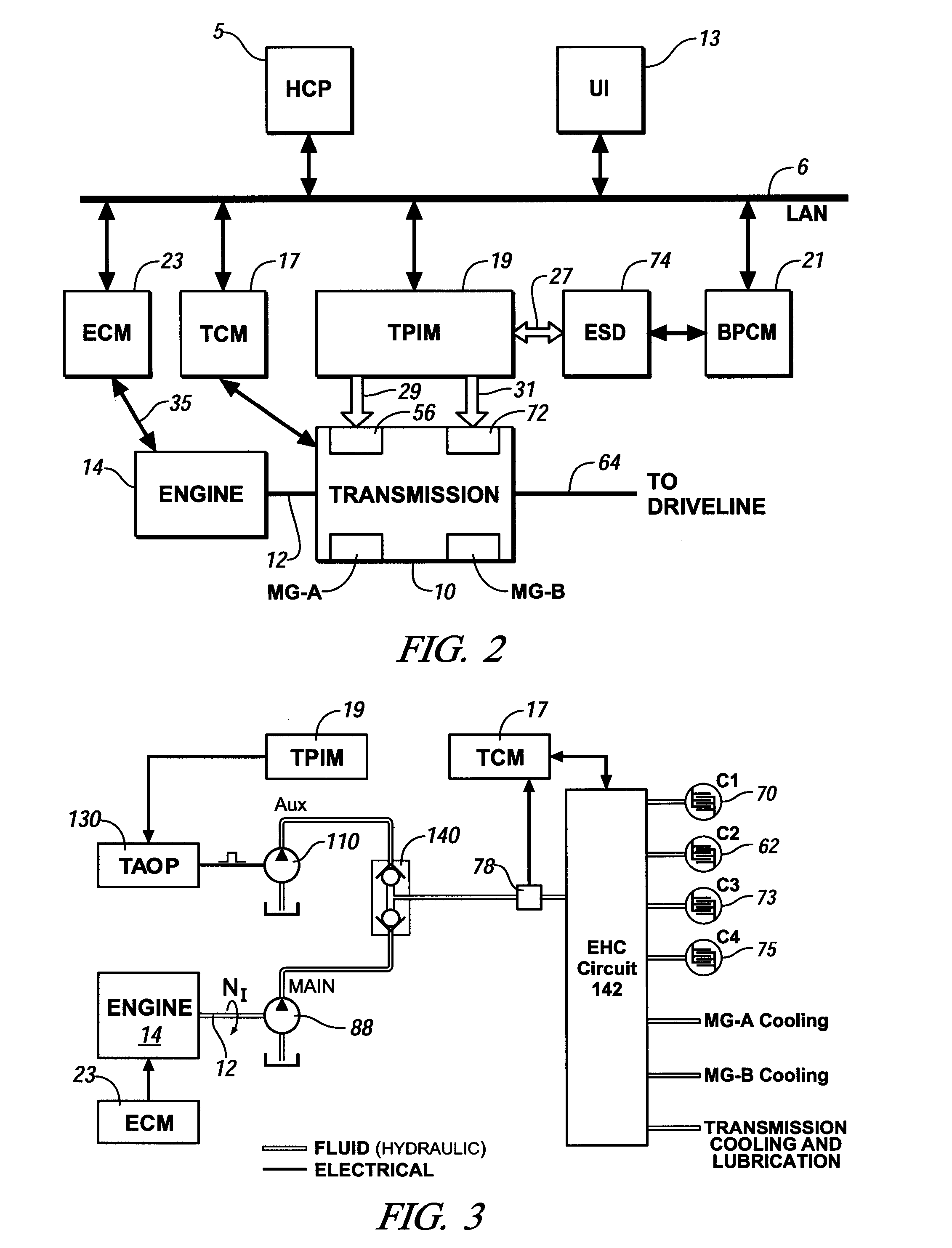

Method and apparatus to monitor operation of an auxiliary hydraulic pump in a transmission

The invention comprises a method and apparatus to monitor operation of an electrically-actuated hydraulic pump selectively operative to supply pressurized fluid to a hydraulic circuit for a transmission device operably connected to an internal combustion engine of a vehicle. It includes monitoring vehicle operation and passively and intrusively monitoring hydraulic circuit pressure. The hydraulic pump is functioning properly when the monitored pressure in the hydraulic circuit exceeds a threshold. A fault related to the hydraulic circuit is identified when the monitored pressure in the hydraulic circuit does not exceed the threshold.

Owner:ELECTRONICS DATA SYST CORP +1

Adaptor for surgical instrument for converting rotary input to linear output

An adaptor for a powered surgical instrument includes a casing, a cam drum, a first linear driver, and a second linear driver. The cam drum defines and is translatable along a longitudinal axis of the adaptor between a retracted position and an advanced position. The cam drum is being supported for rotation about the longitudinal axis. The cam drum defines first and second radial cam grooves about an outer surface thereof. The first cam groove defines a first profile and the second cam groove defines a second profile. The first linear driver includes a first cam follower disposed in the first cam groove and the second linear driver includes a second cam follower disposed in the second cam groove. The first and second linear drivers are supported for movement between advanced and retracted positions in response to rotation of the cam drum.

Owner:TYCO HEALTHCARE GRP LP

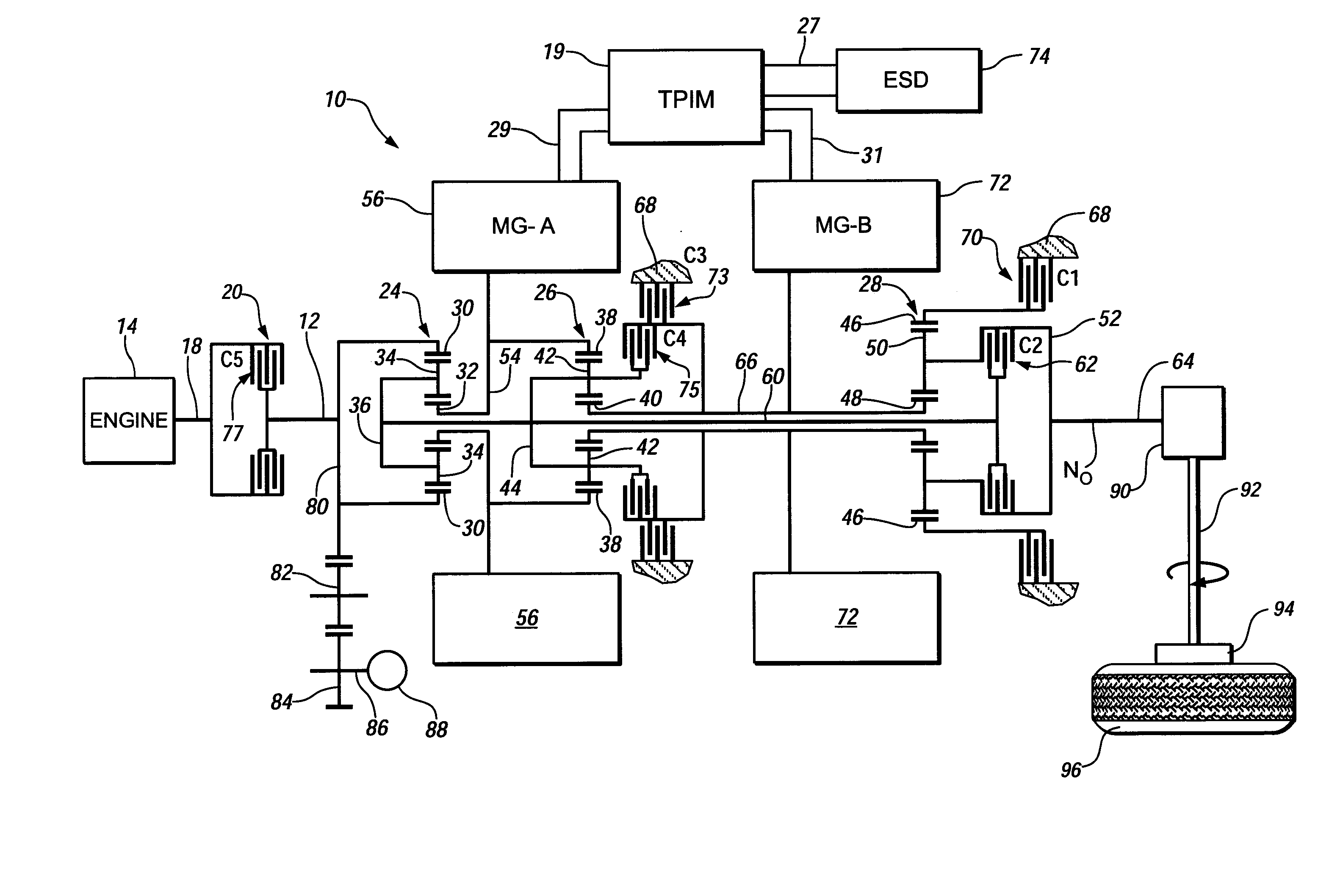

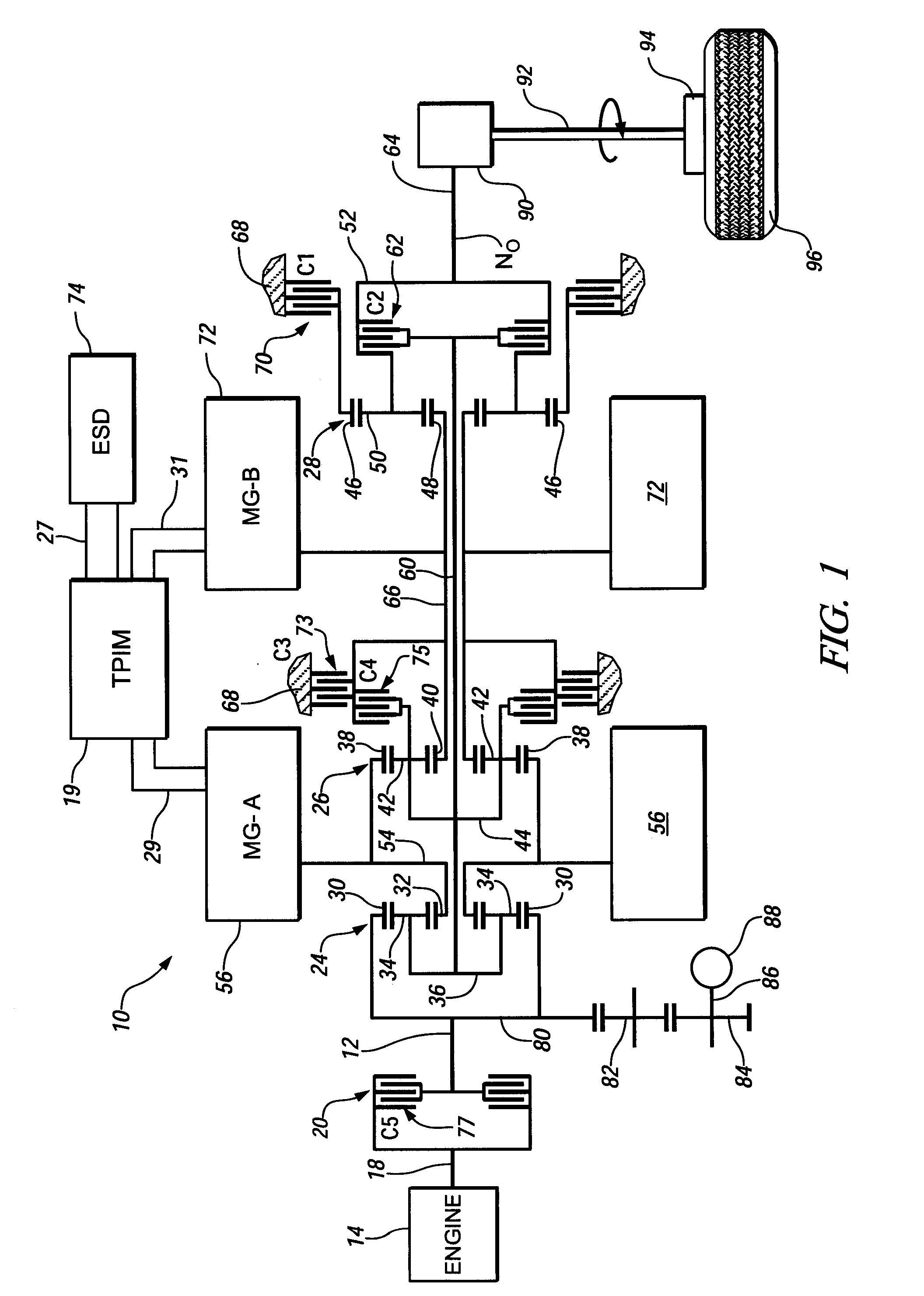

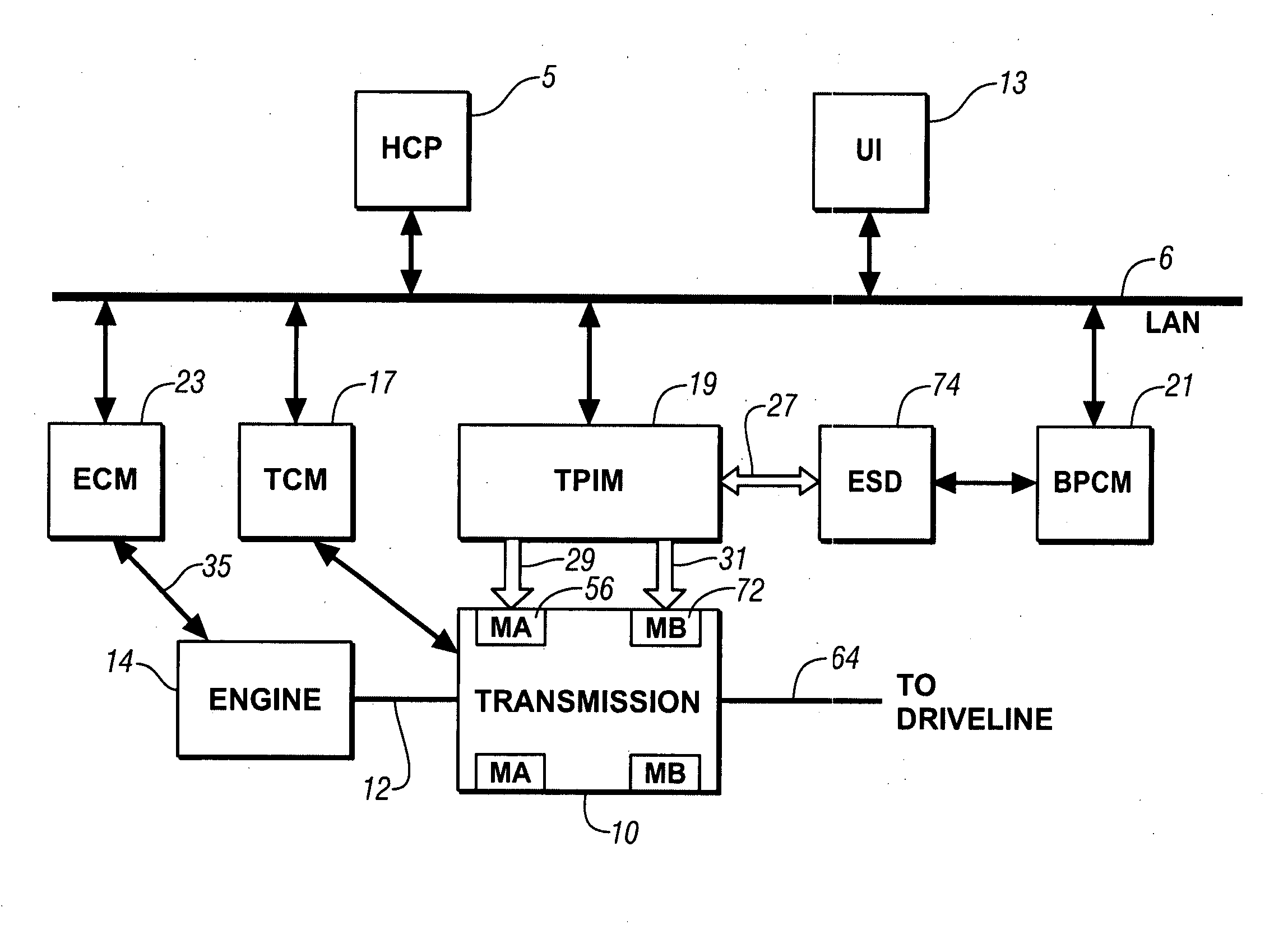

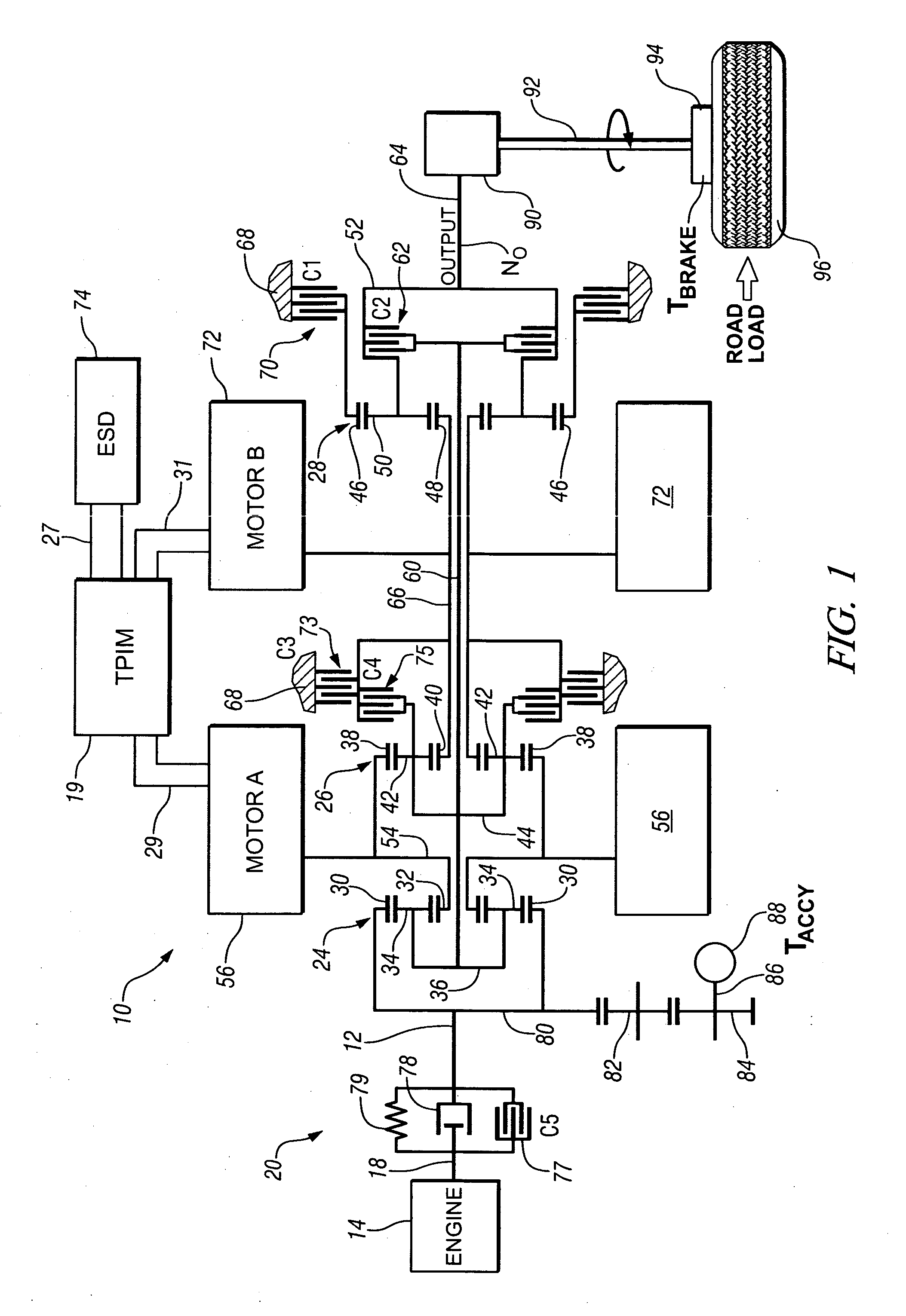

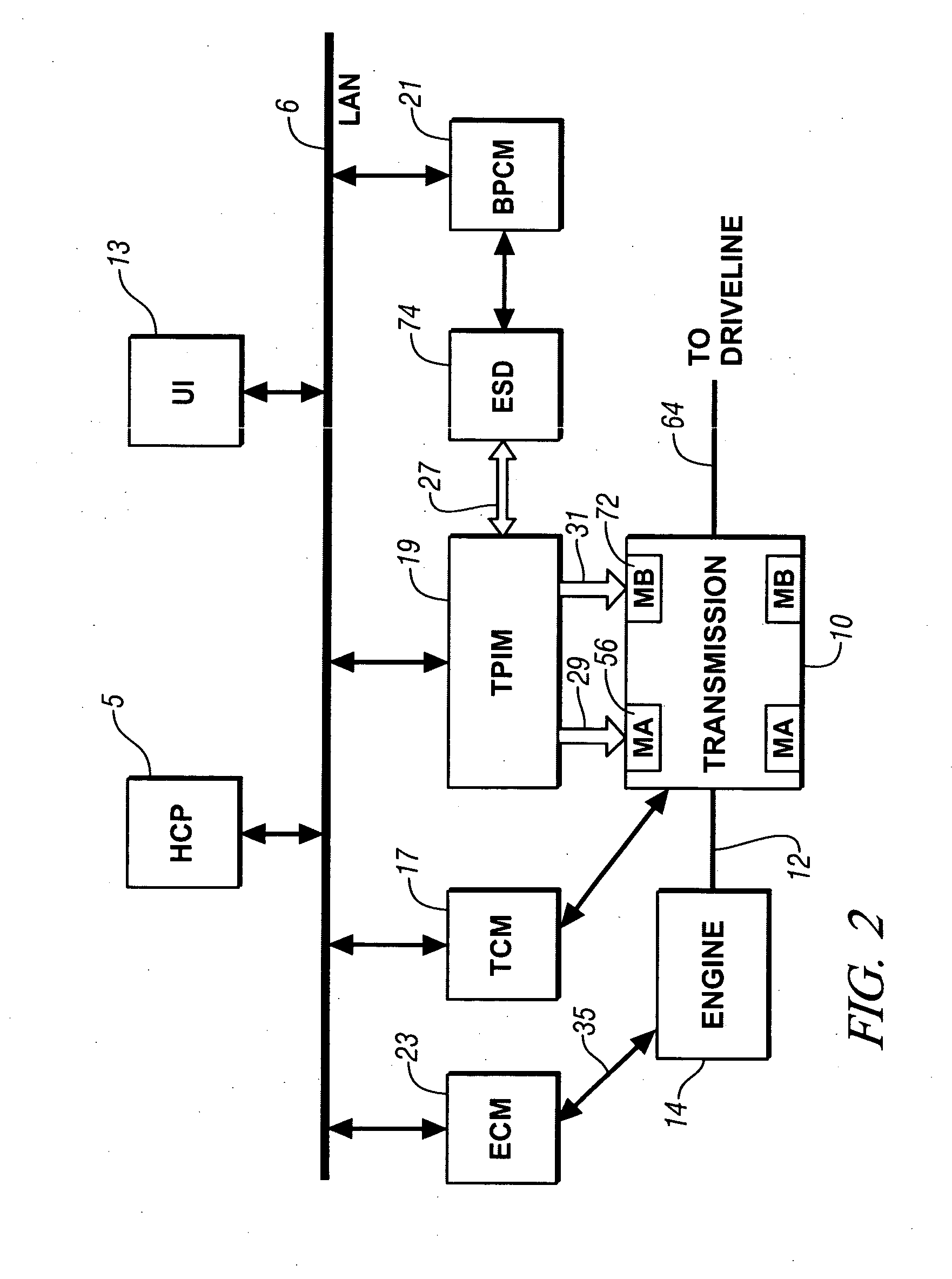

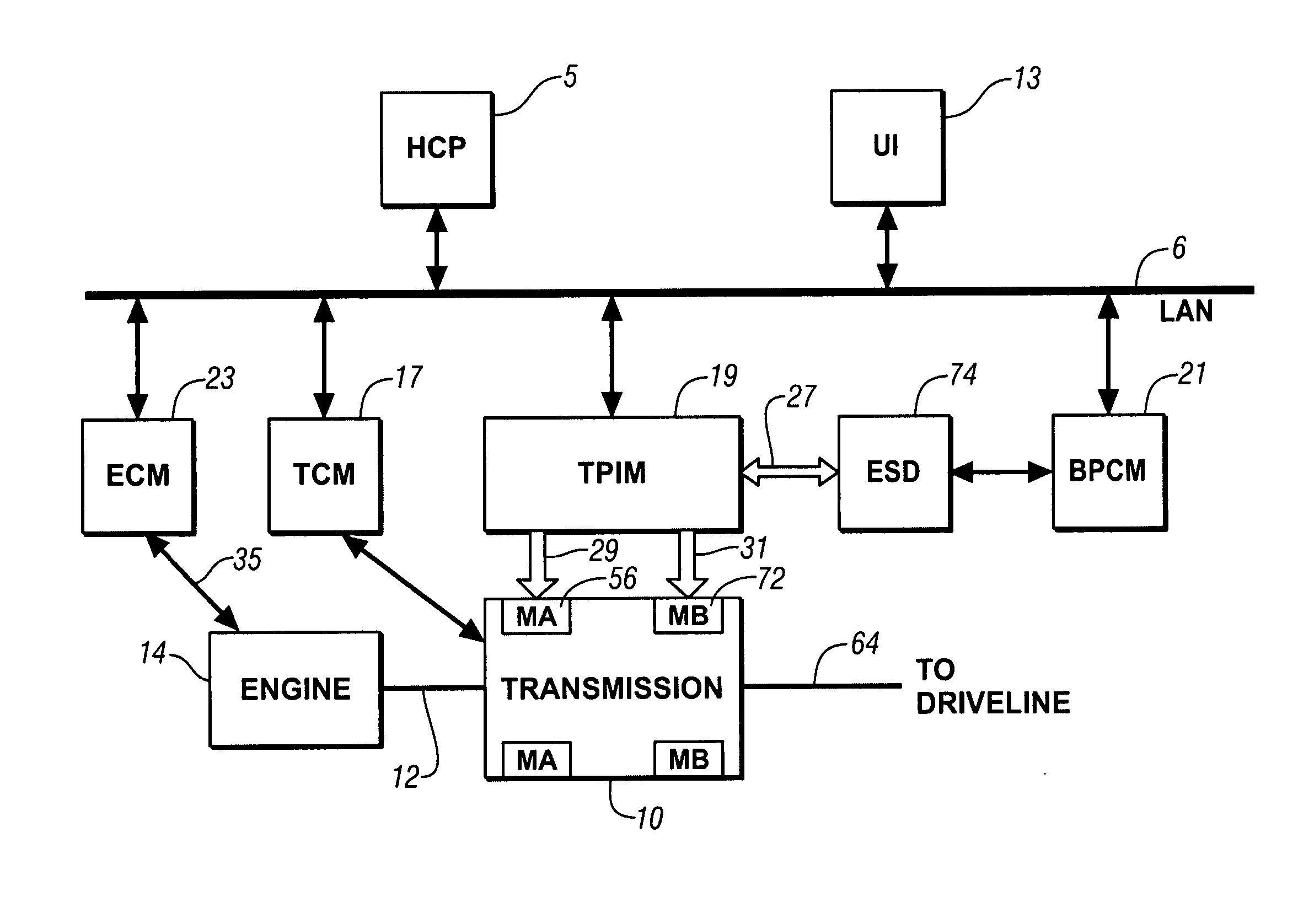

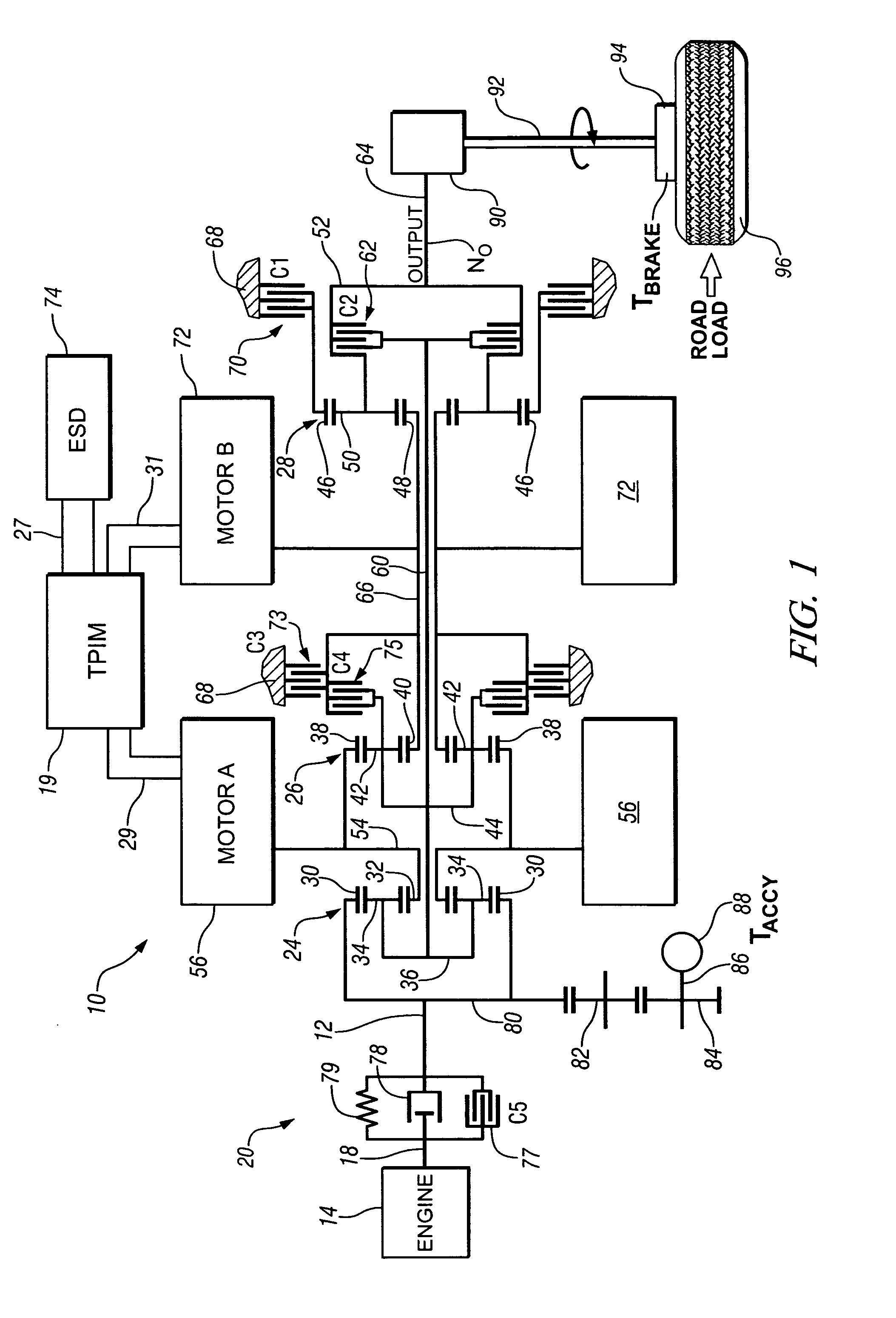

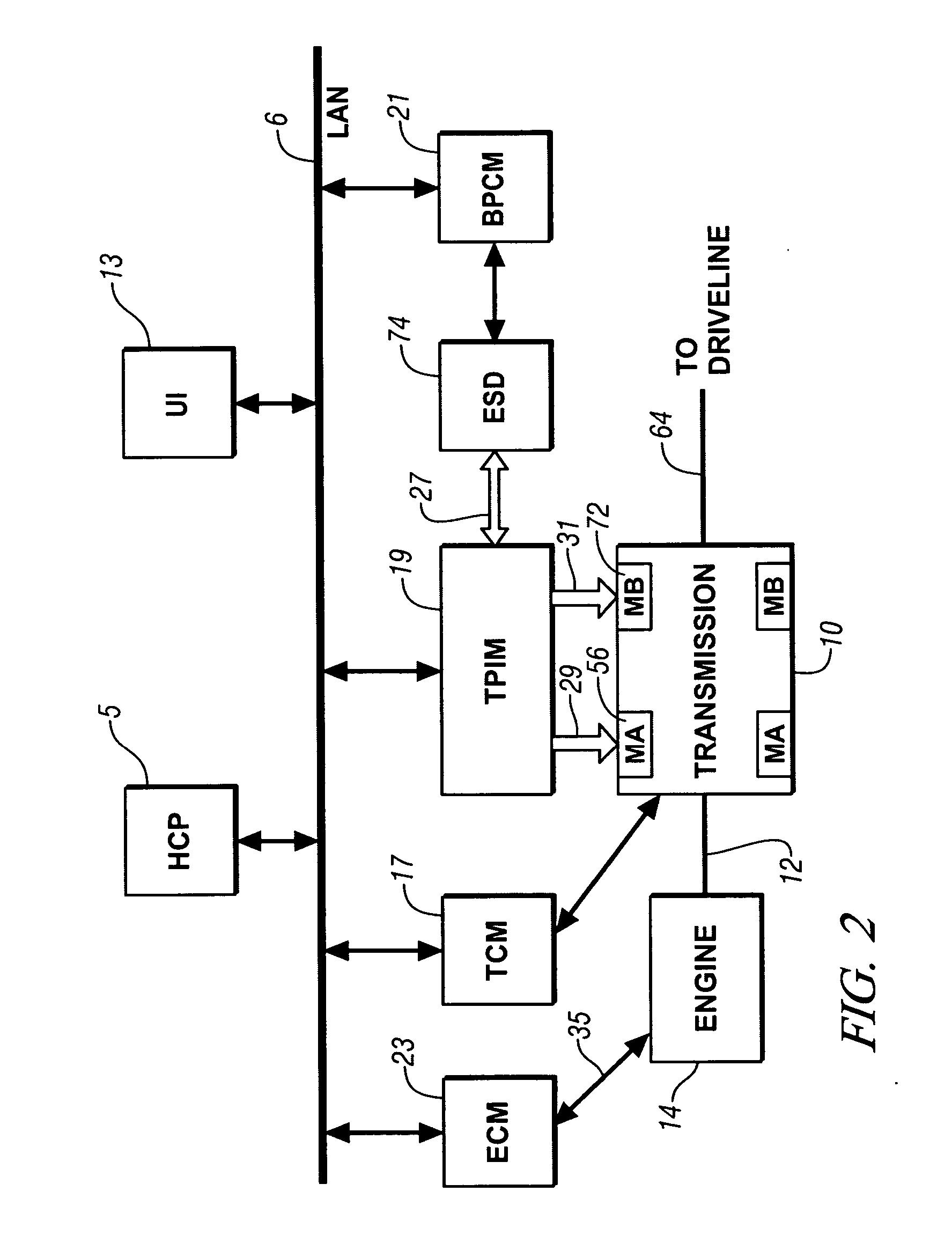

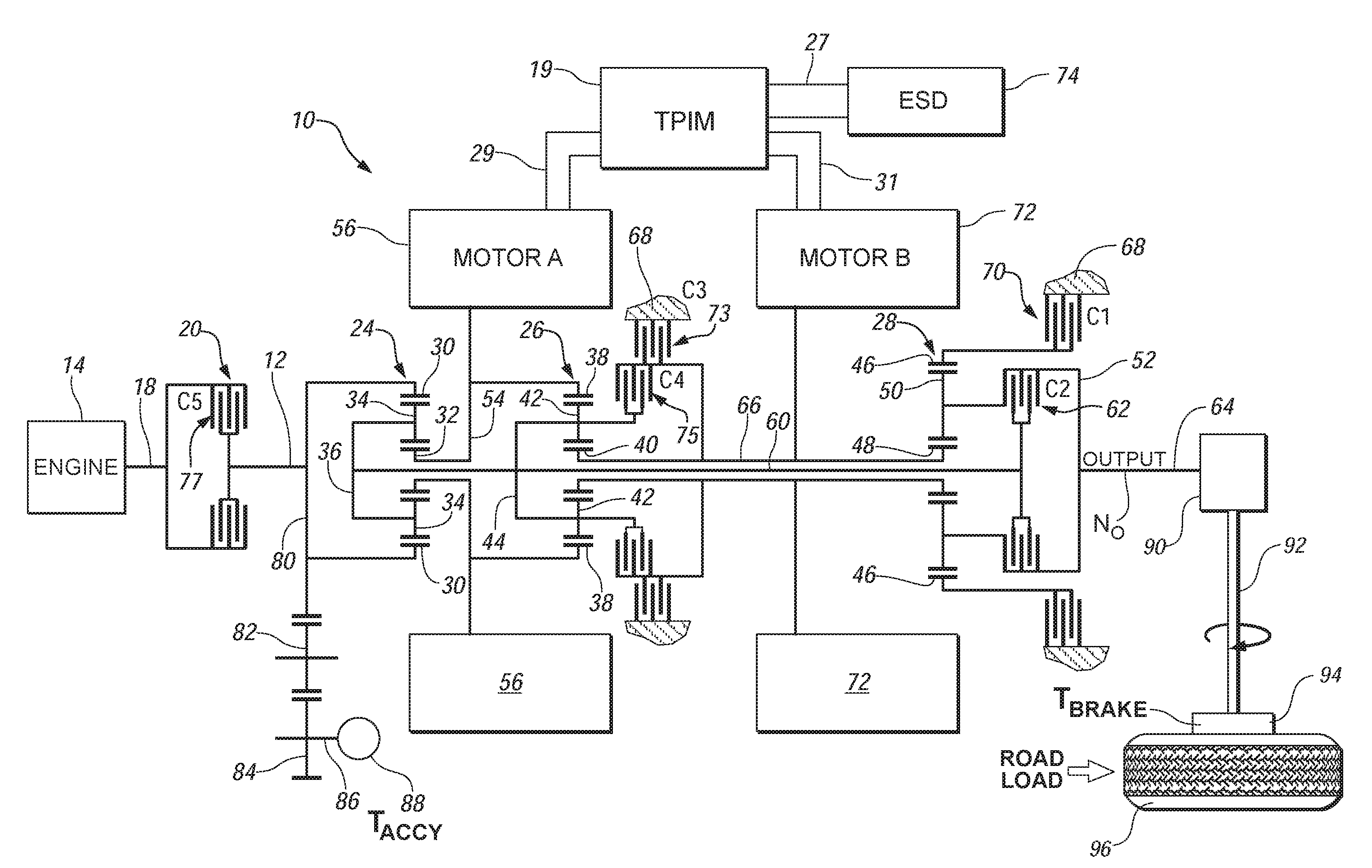

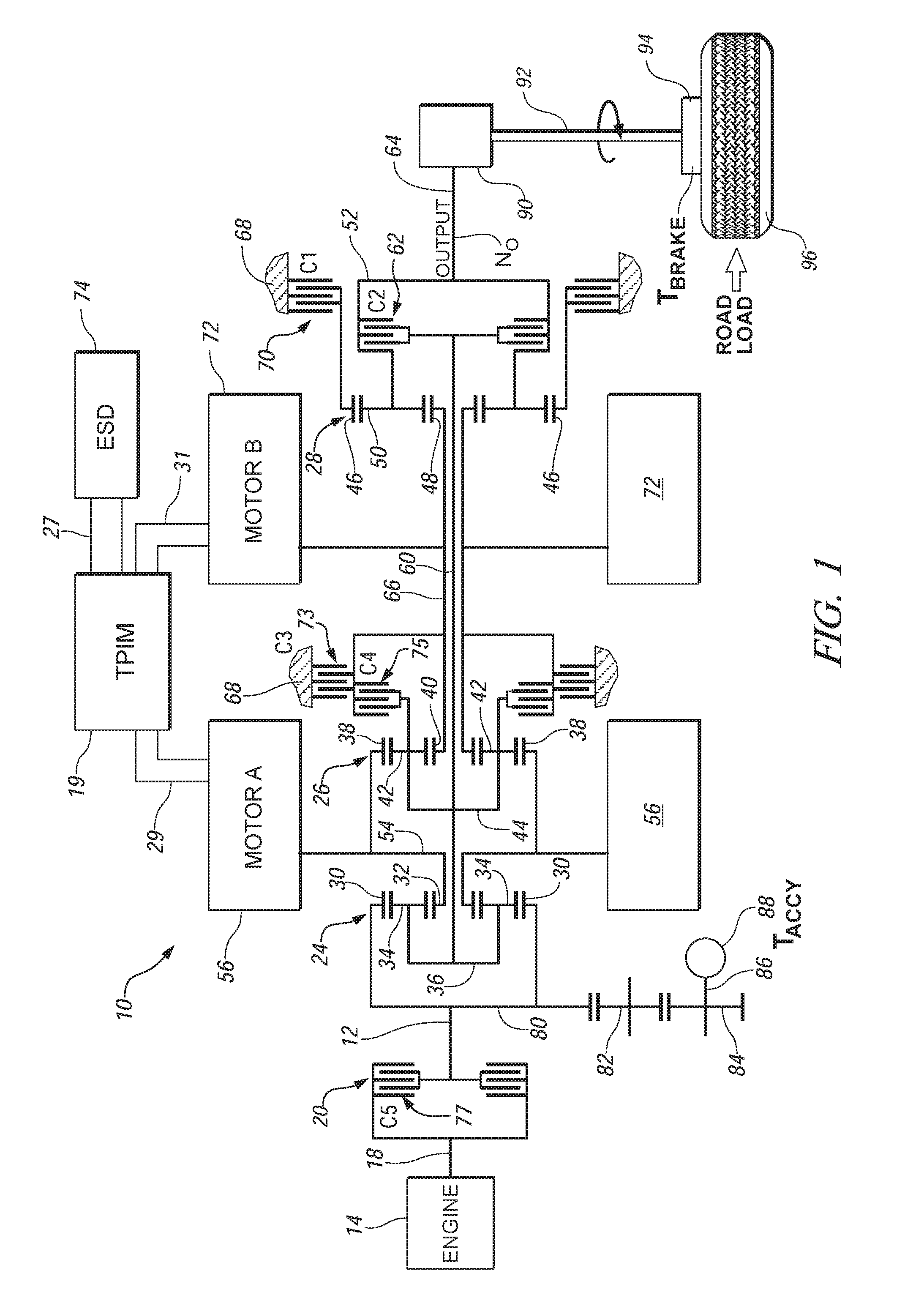

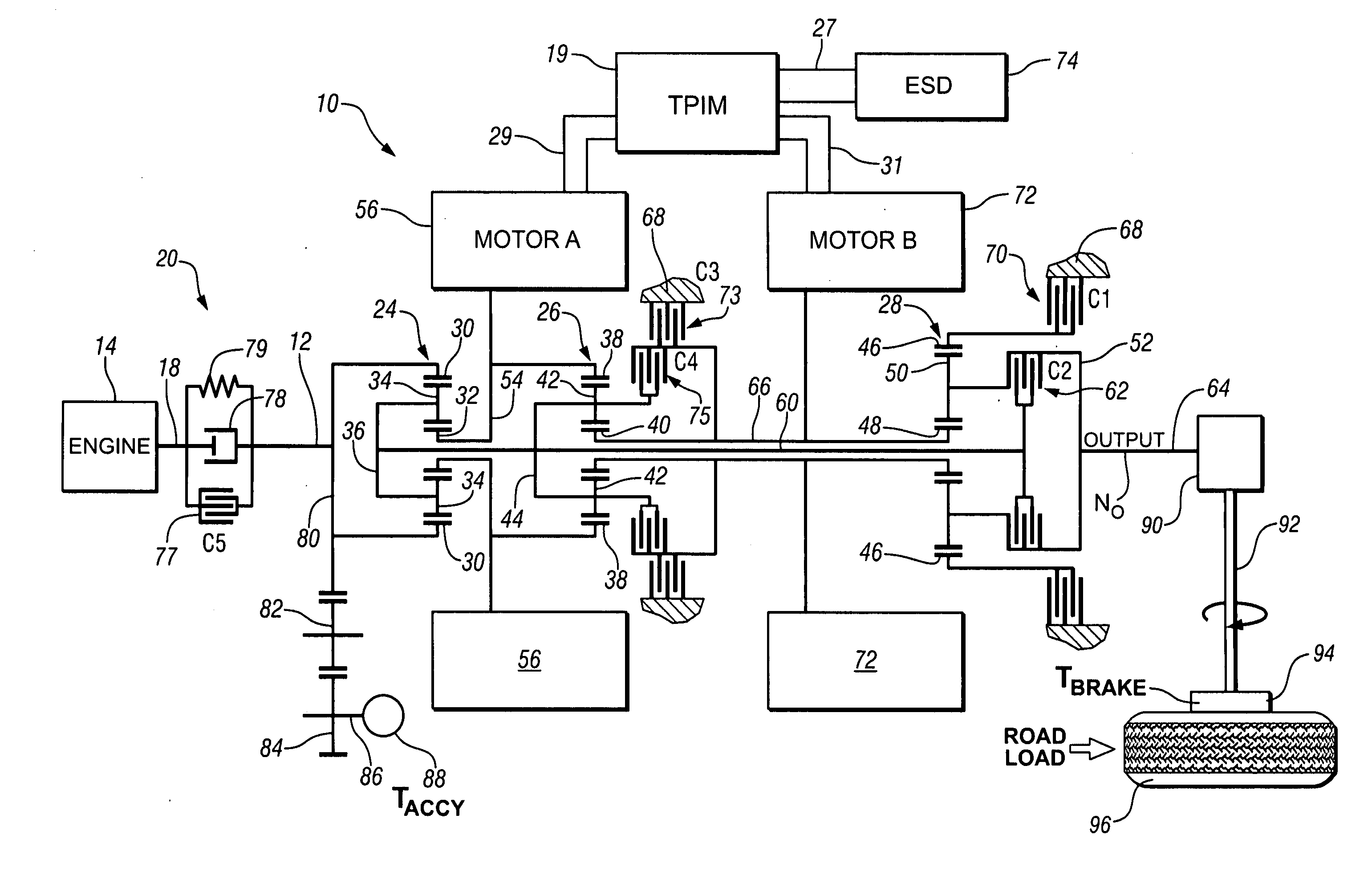

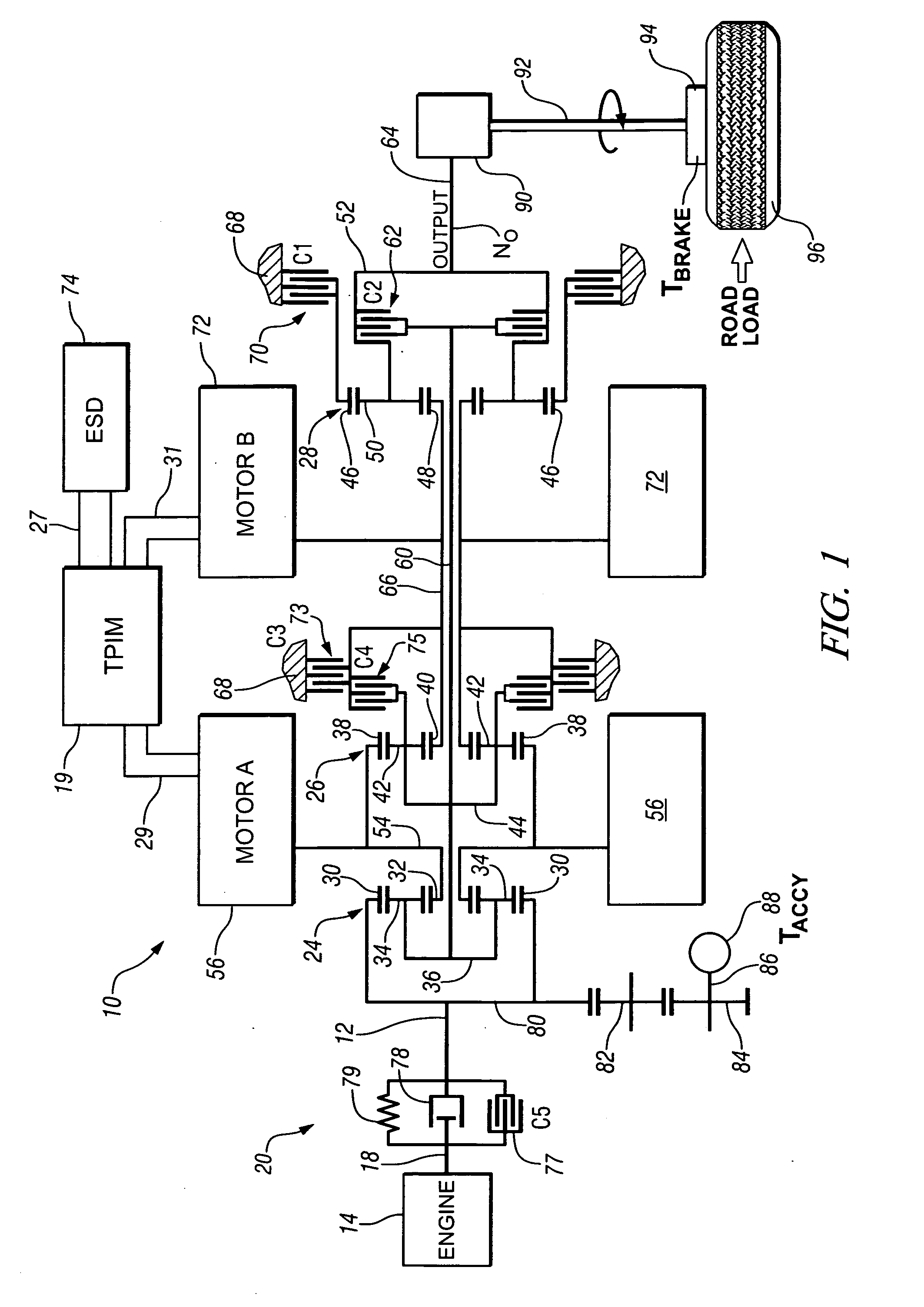

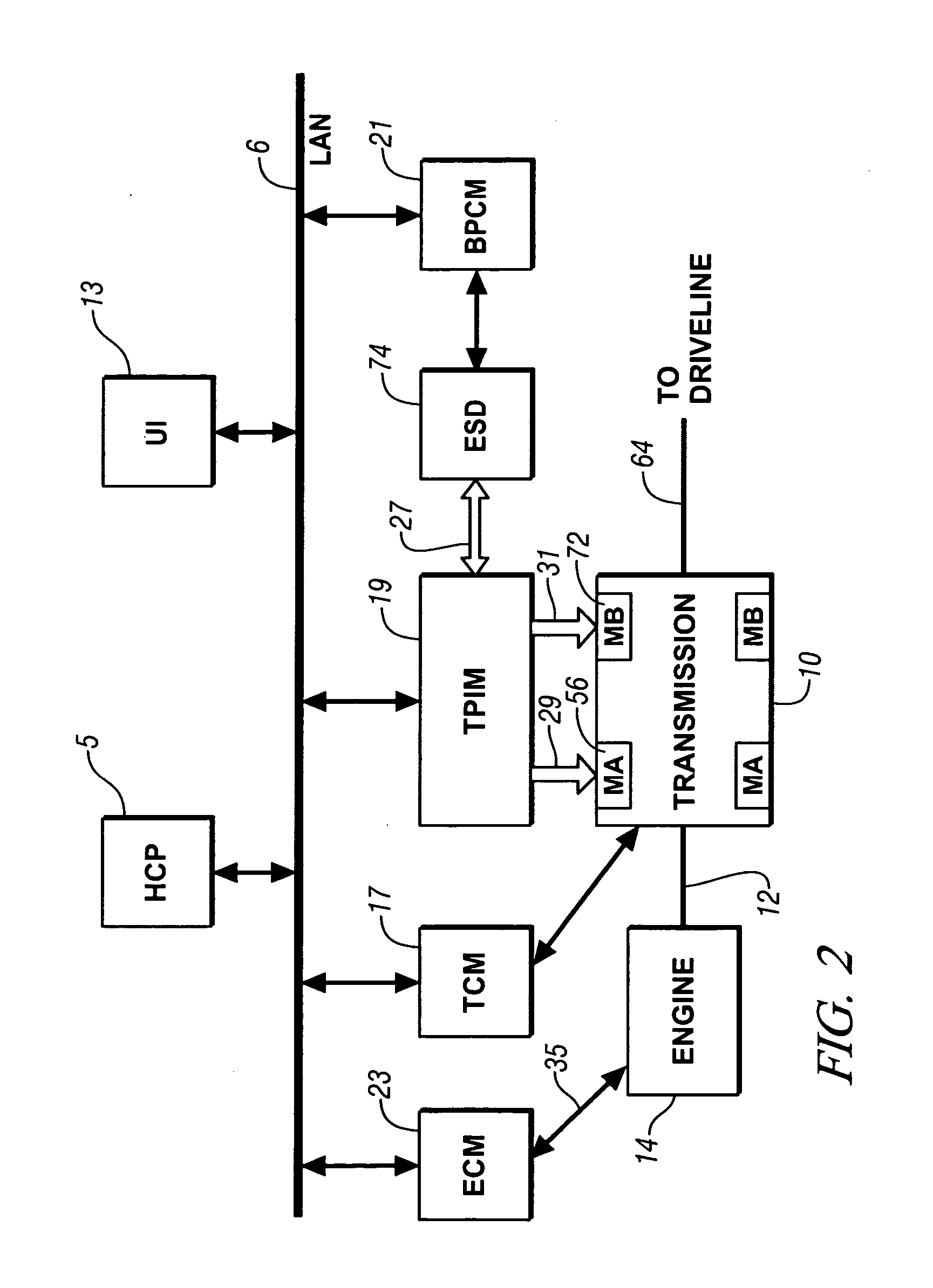

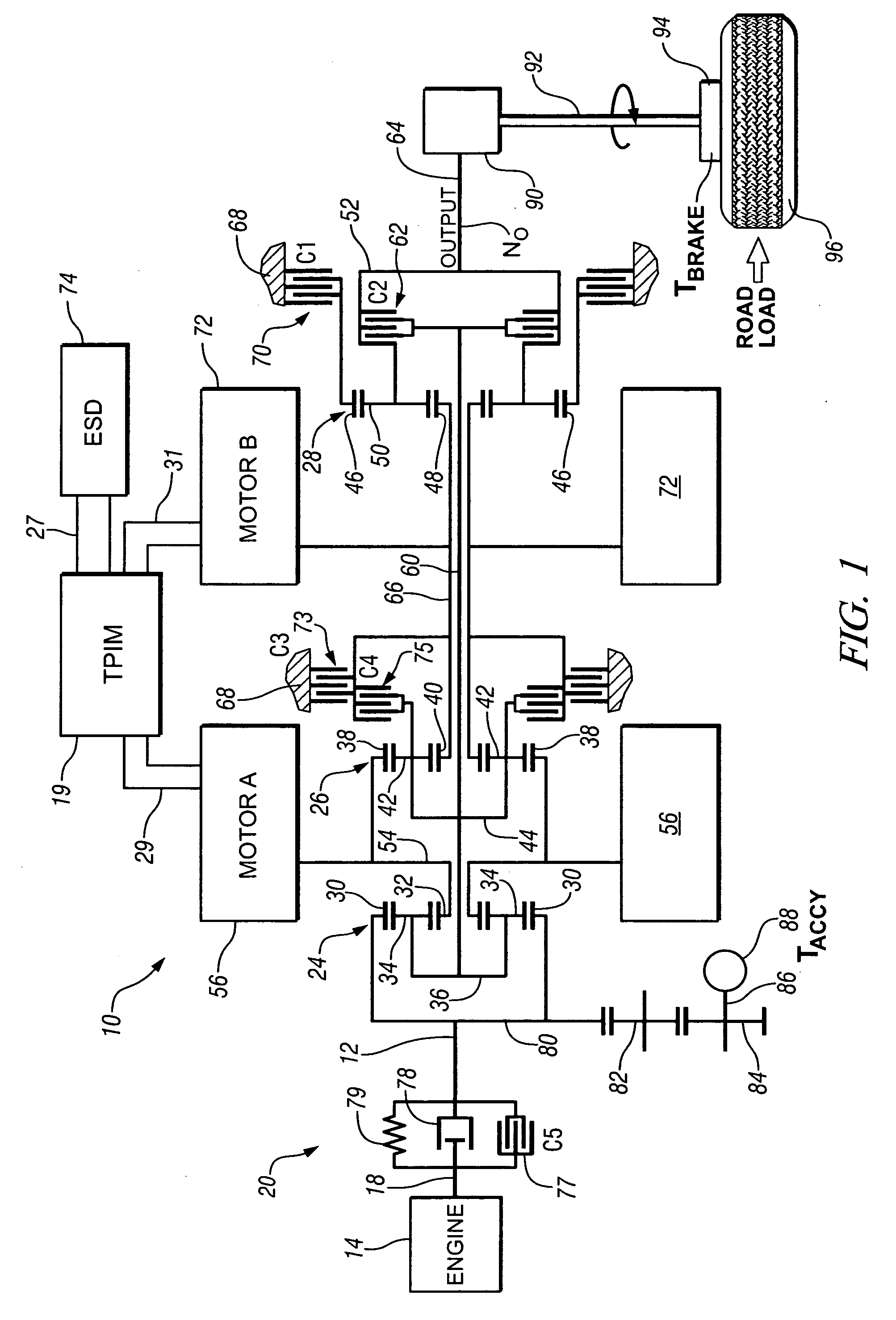

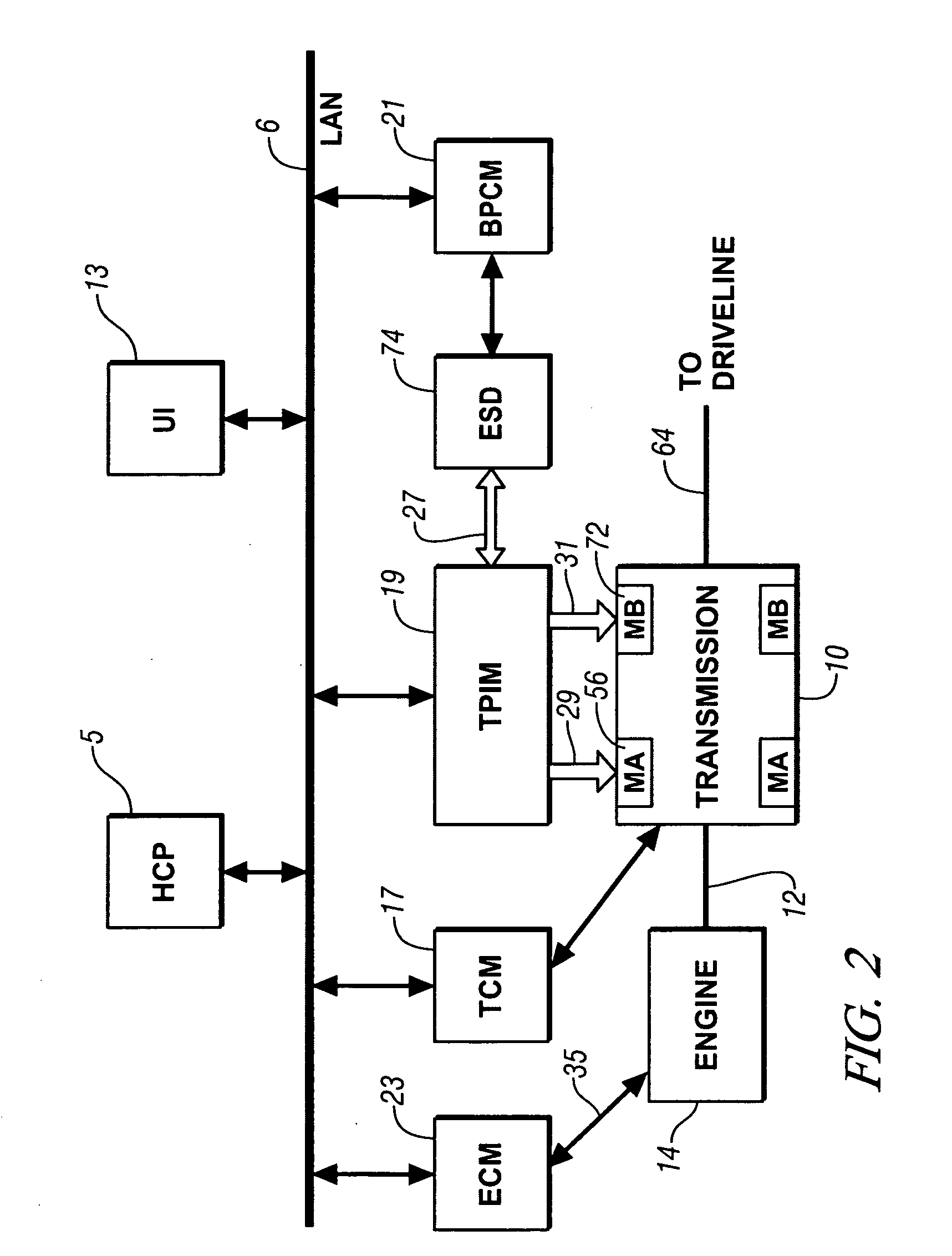

Driveline lash estimation and clunk management using multivariable active driveline damping

ActiveUS20070225888A1Minimize impactHybrid vehiclesDigital data processing detailsDrivetrainEngineering

Driveline lash and clunk are controlled in a powertrain system having multiple torque-generative and torque control devices using a multivariable feedback control approach to provide active driveline damping. Control parameters used by a state estimator are different, depending on whether the driveline lash is taken up or is currently slack. When the estimated driveline axle torque is not substantially zero, the nominal parameters for transmission mode or gear are used in the state estimator. When the estimated axle torque is substantially zero, the parameters are switched to neutral parameters, the lash estimator indicates neutral lash state, and angle of lash is tracked until it accumulates an expected amount of lash in the driveline. During a lash transition time, active damping controls the driveline component speeds so that the effect of lash take-up is minimized. After lash take-up occurs, desired axle torque is used by the system.

Owner:GM GLOBAL TECH OPERATIONS LLC

Coupling assembly for interconnecting an adapter assembly and a surgical device, and surgical systems thereof

A coupling assembly selectively interconnects a surgical device with an adapter assembly. The adapter assembly is configured for connection with a surgical attachment. The coupling assembly includes a first connector, a second connector and an outer tube. The first connector is configured for mating engagement with a surgical device. The second connector is configured for mating engagement with an adapter assembly. The outer tube extends between and has a first end and a second end defining a longitudinal axis therebetween. The first end of the outer tube supports the first connector. The second end of the outer tube supports the second connector. The longitudinal axis of the outer tube extends transversely relative to a longitudinal axis defined by a surgical device.

Owner:TYCO HEALTHCARE GRP LP

Parameter state estimation

InactiveUS20070225886A1Easy to implementIncrease signal levelHybrid vehiclesDigital data processing detailsPowertrainOperating speed

The state estimator provides parametric estimates for operating states not readily measurable with production powertrain and driveline hardware, such as real-time torque values of axles and dampers. This facilitates implementation of torque oscillation damping control schemes which use multivariable feedback. A control parameter is estimated for a powertrain system having multiple torque-generative devices operably connected to a transmission device having a torque output to a driveline. This includes establishing a plurality of equations operable to estimate the control parameter and other operating parameters based upon torque inputs. The operating parameters comprise operating speeds of the powertrain system and driveline. The operating parameters that comprise operating speeds of the powertrain system and driveline are determined. Coefficients of the plurality of equations are adjusted based upon the operating speeds of the powertrain system.

Owner:GM GLOBAL TECH OPERATIONS LLC

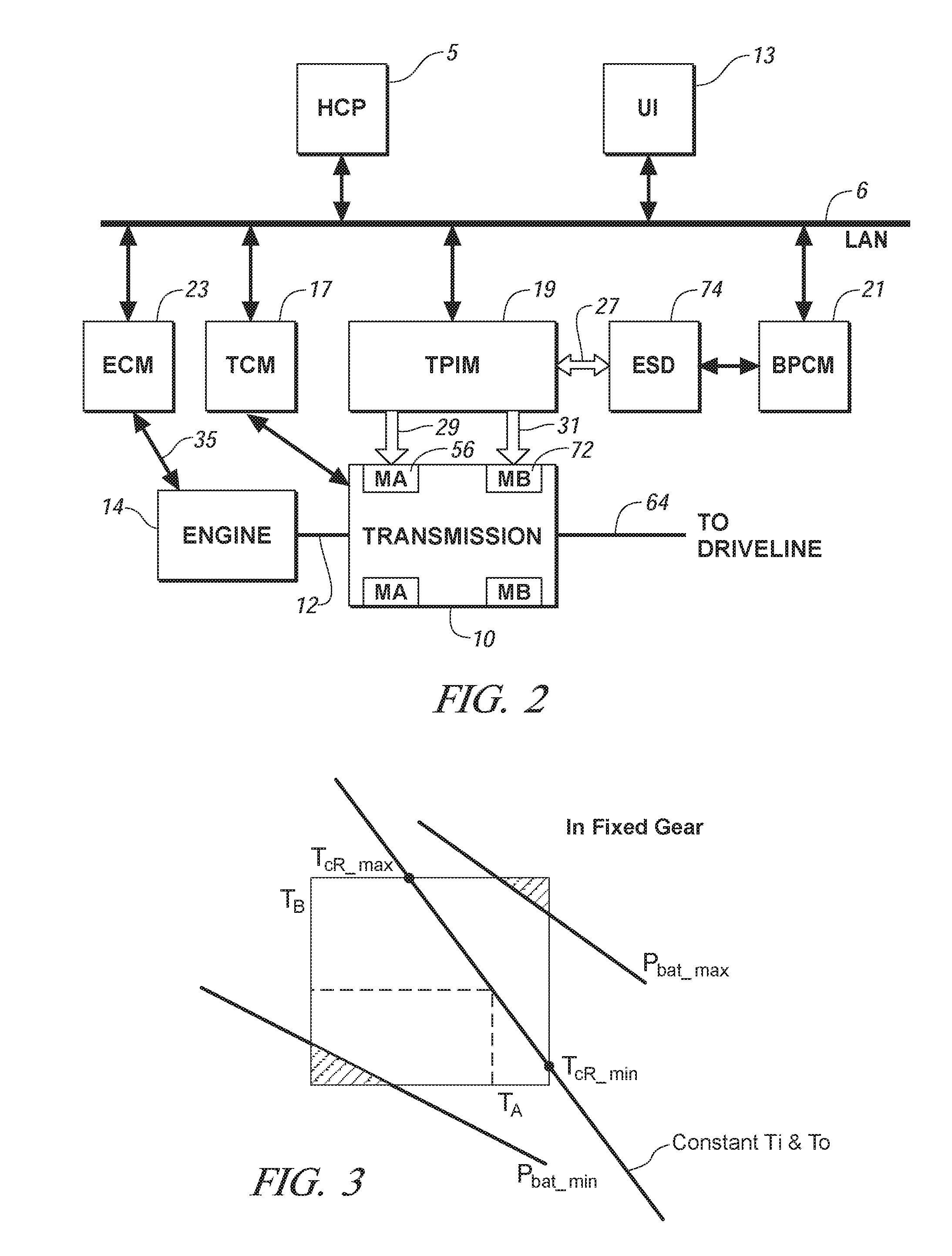

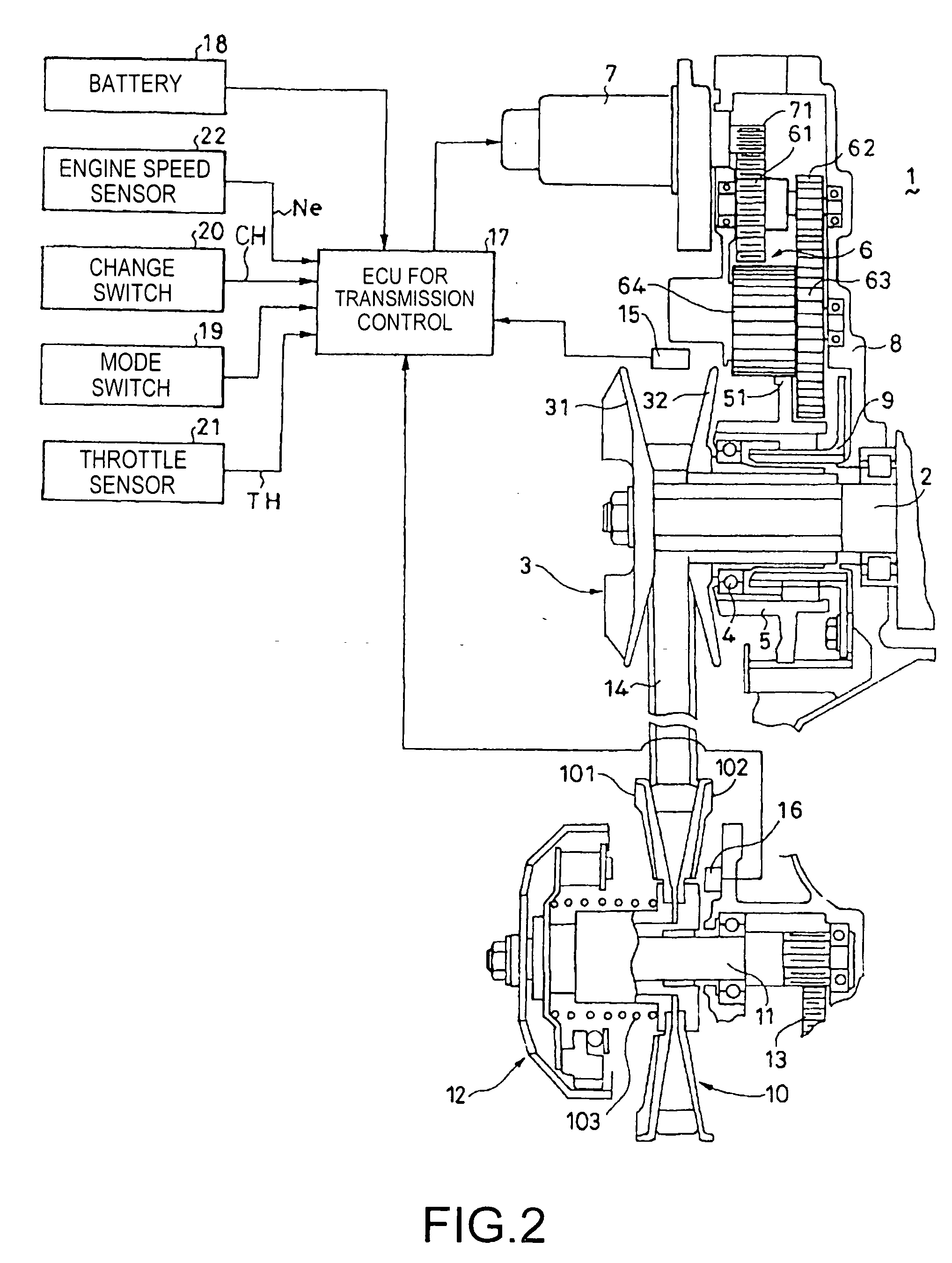

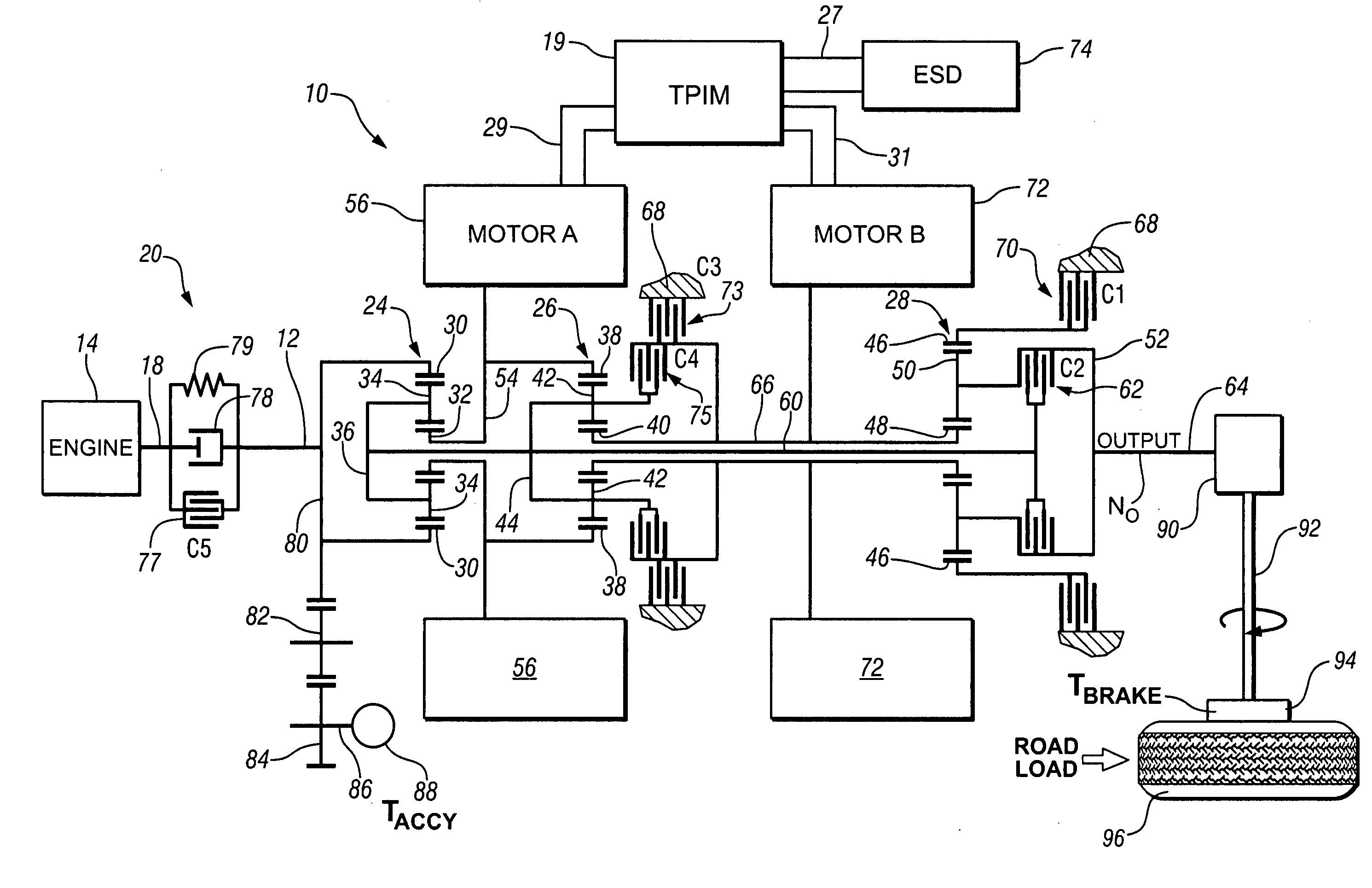

Clutch control for hybrid transmission

A method and system to off-load motive torque from a clutch to execute a transmission shift is provided. The powertrain includes torque-generative devices operably connected to a two-mode, compound-split, hybrid electro-mechanical transmission. The method includes determining a commanded output torque, and a shift command. A first torque is transmitted by electrical motors, and is limited by their torque capacities. A supplemental motive torque is transmitted from an oncoming clutch. The supplemental motive torque is limited by a torque capacity of the oncoming clutch. Output torque of an internal combustion engine to the transmission is adjusted by an amount substantially equal to a difference between the commanded output torque and the first and the supplemental motive torques.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and apparatus for multivariate active driveline damping

A multivariate control method and system to control torque output from a powertrain system to a driveline is provided, to reduce driveline oscillations. The powertrain preferably comprises hybrid powertrain having a plurality of torque-generative devices connected to a transmission. Desired powertrain and driveline operating states are determined, as are a plurality of operating state errors. Each torque-generative device is controlled, based upon the operating state errors, and operating mode of the transmission. A damping torque command, additive to a commanded torque, is determined for one or more of the torque-generative devices based upon the determined transmission operating mode. Determined operating states include operator input, and powertrain / driveline including driveline torque; transmission input torque, rotational speed of the torque-generative devices; road load; and, accessory load.

Owner:GM GLOBAL TECH OPERATIONS LLC

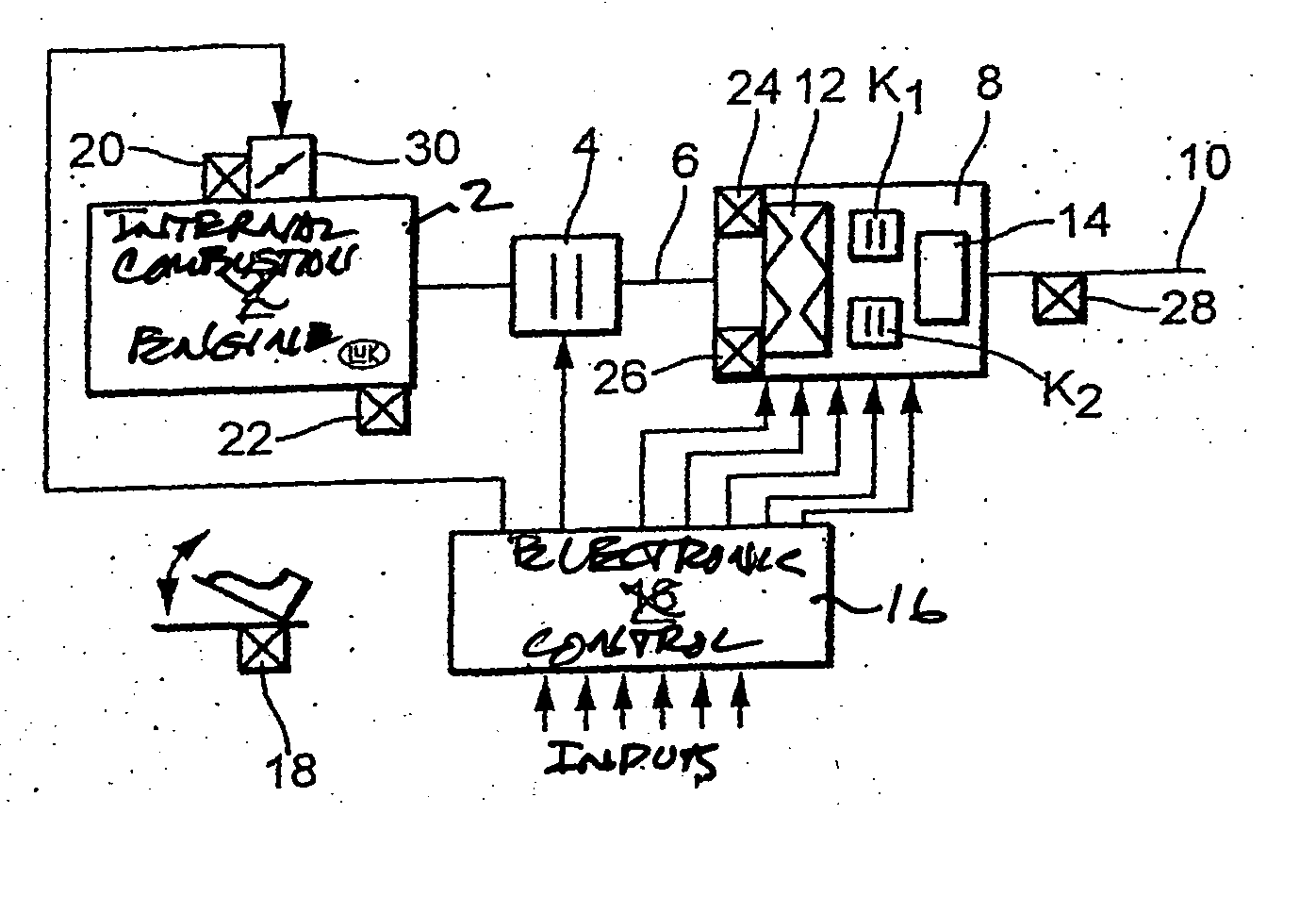

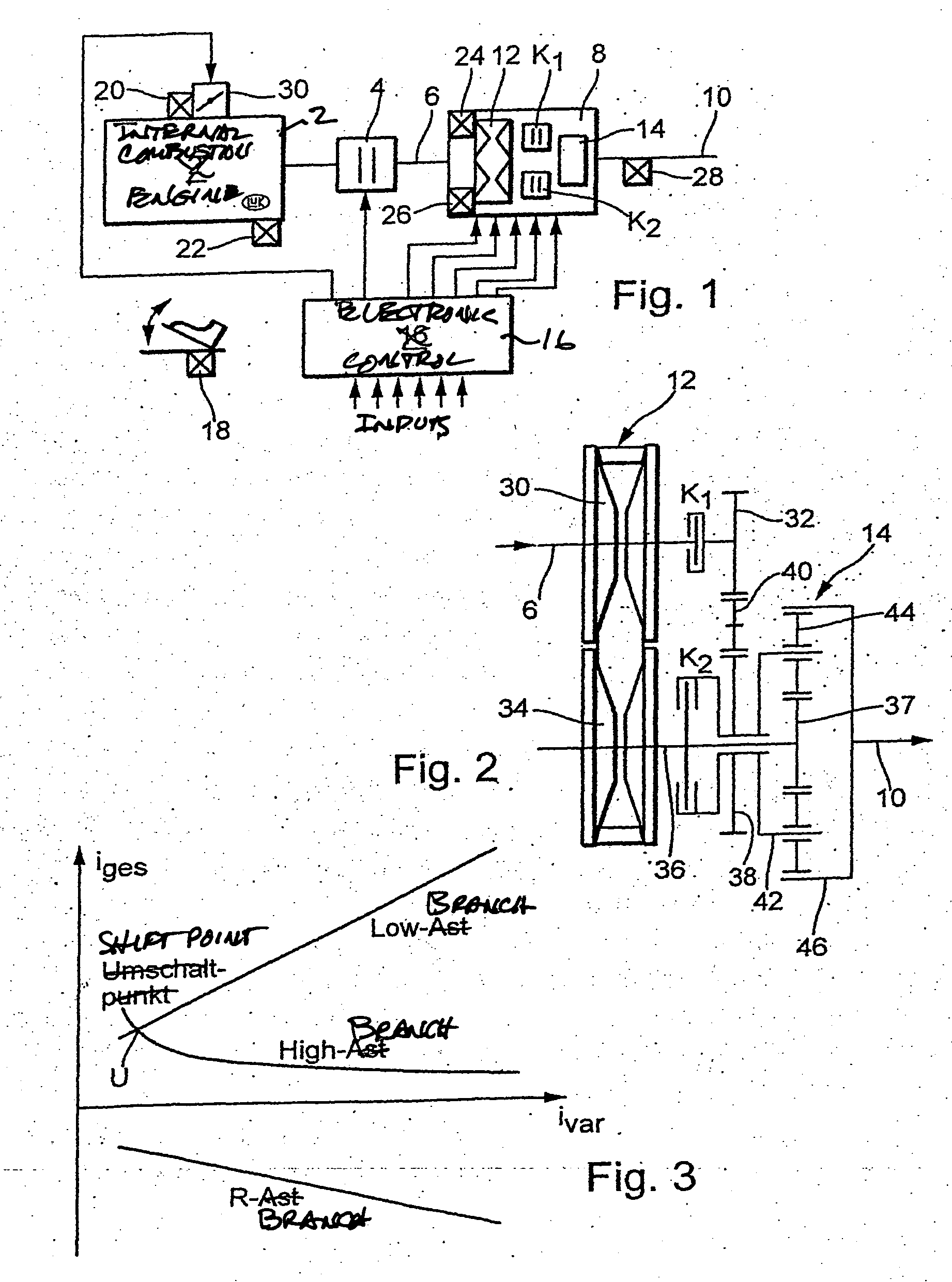

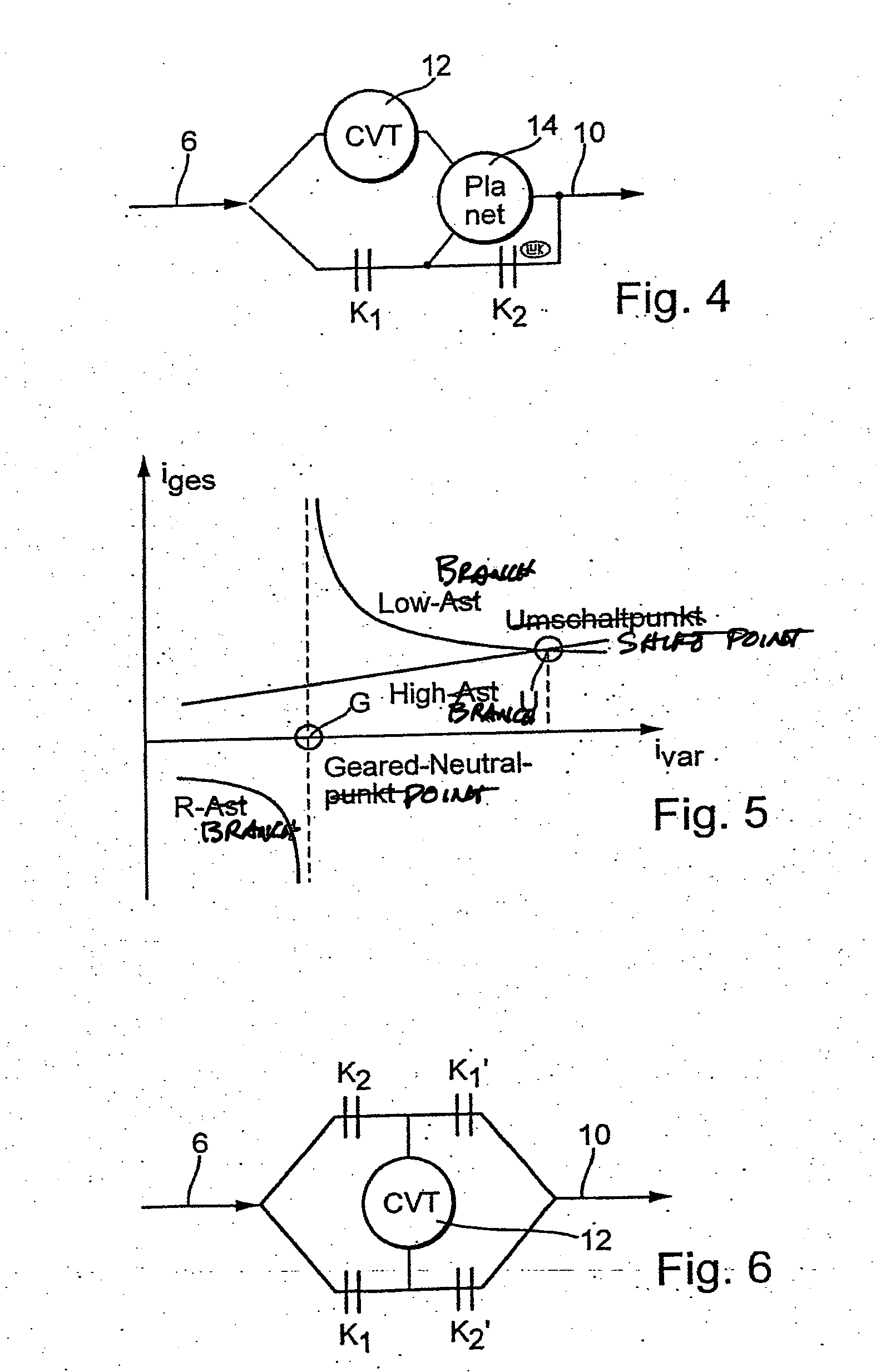

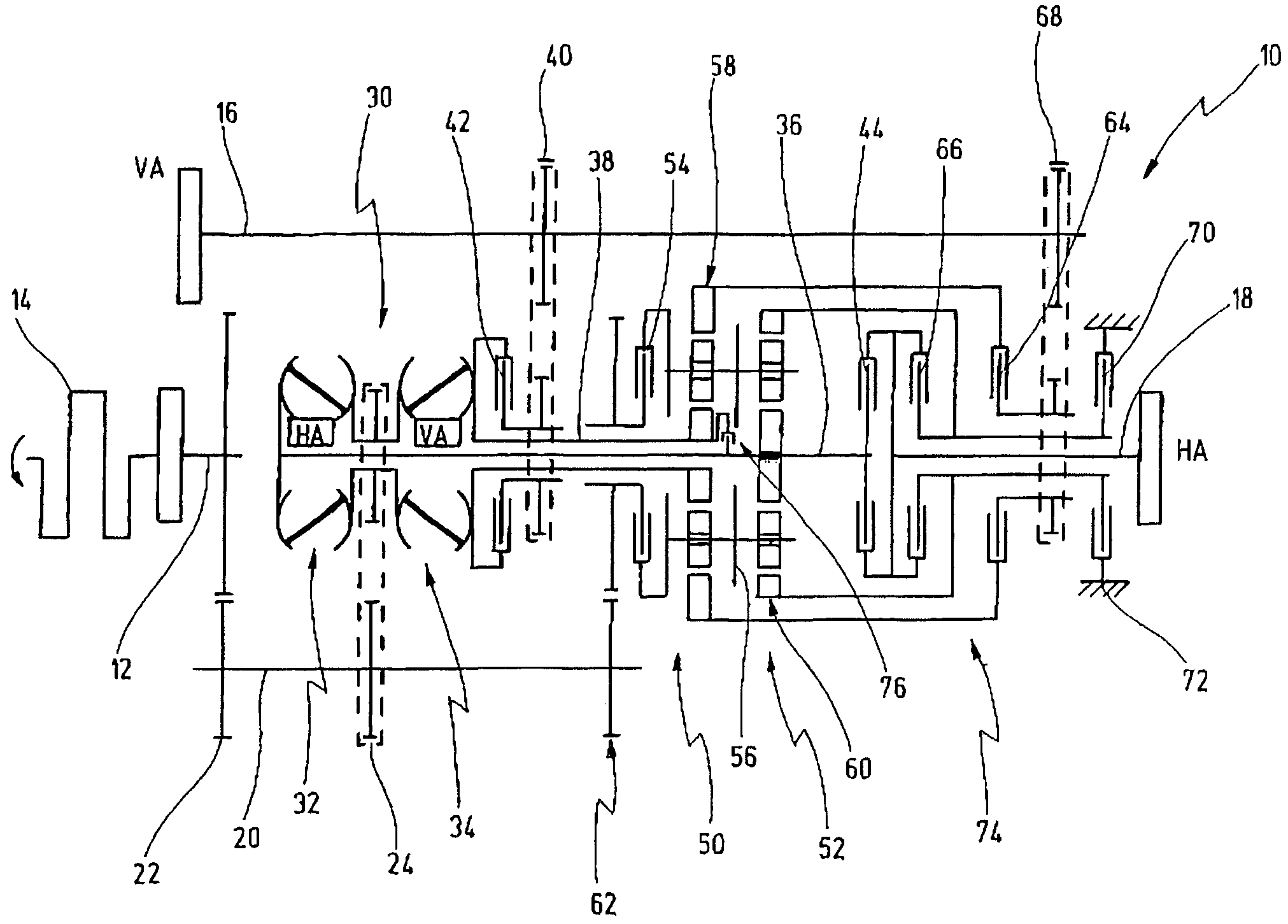

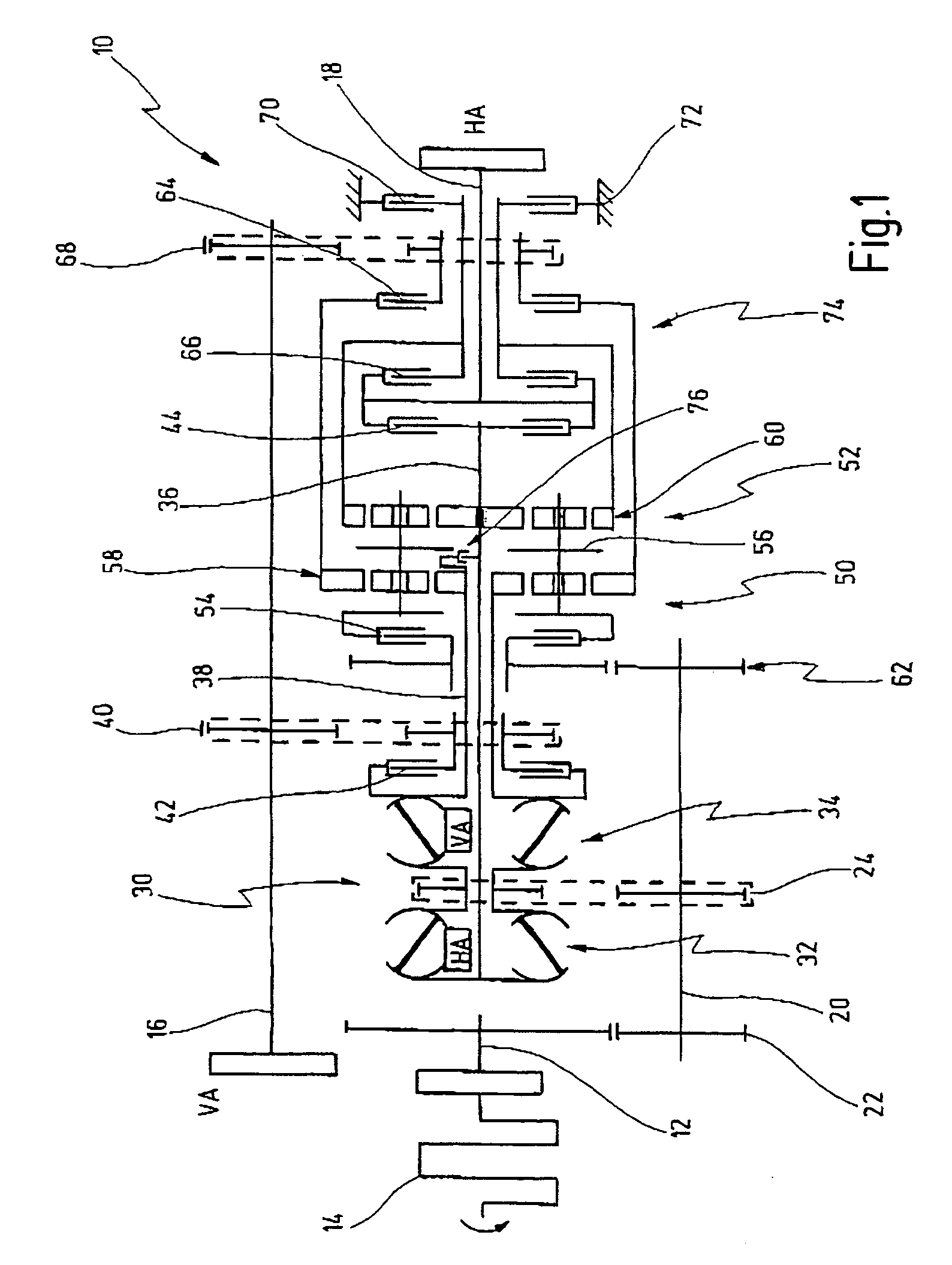

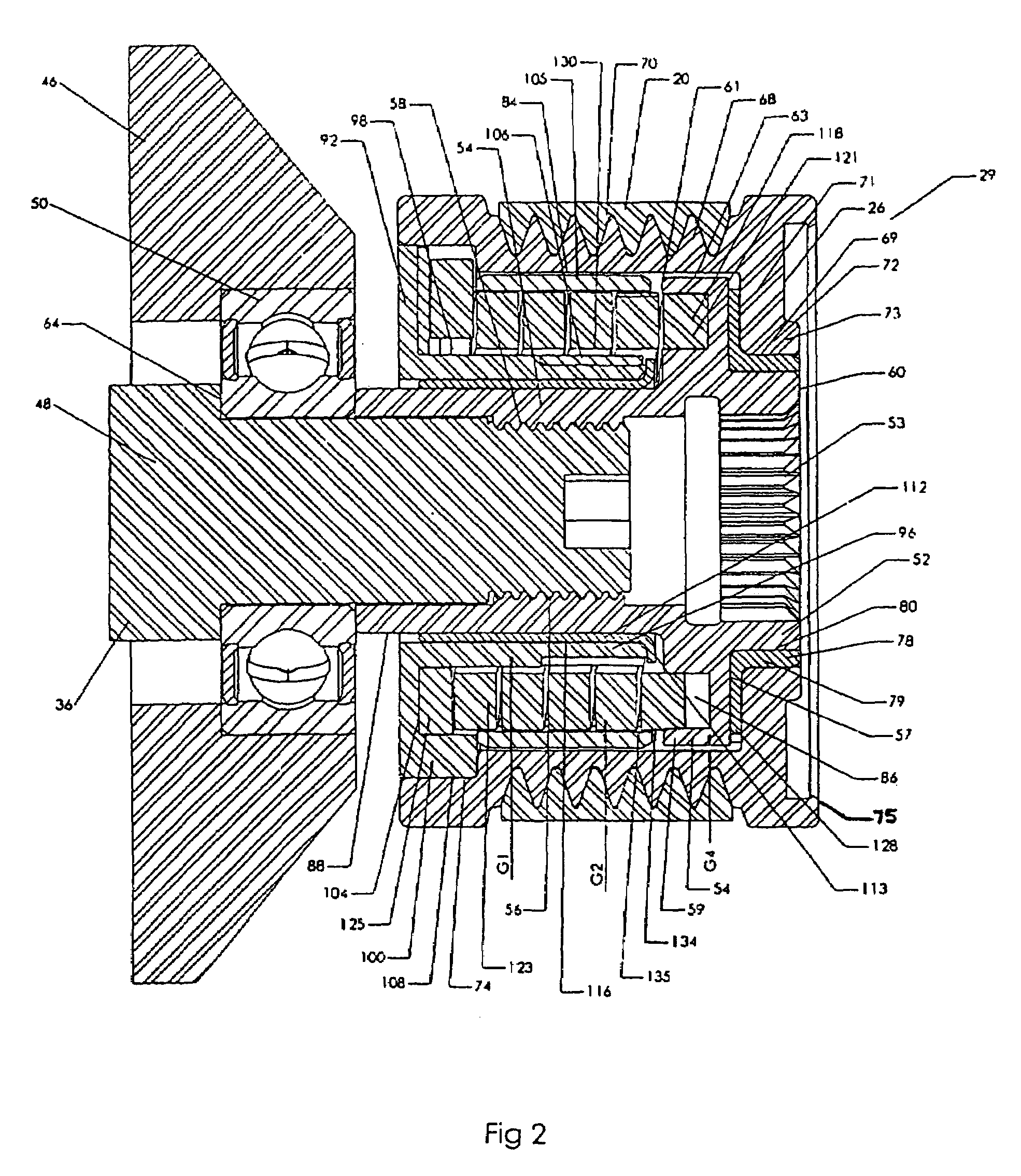

Methods for regulating the gear ratio of an automatic power-branched transmission, and automatic power-branched transmission

A method for regulating or controlling the transmission ratio of an automatic power-branched transmission. Power is transmitted through a shaft driven by an engine, a variable speed drive, a gear transmission, a driven shaft, and at least two control clutches. The variable speed drive and the gear transmission are connected to each other in such a way that the regulating range of the variable speed drive is traversed in one direction within a first range of transmission ratios, and is traversed in the opposite direction within a second range of transmission ratios during traversing of the entire range of transmission ratios. The shifting strategies result in reduced wear of the endless belt device and allow for comfortable changing between the transmission ratio ranges.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

Systems and methods employing a rotary track for machining and manufacturing

InactiveUS6196081B1Low thermal expansionOptimization rangePortable framesJointsThree-dimensional spaceEngineering

The systems and methods described herein include hexapod systems, Stewart platform systems and other mechanical movement systems, in which a set of independently moveable trucks support legs that couple to a working surface capable of holding a machine tool or other end-effector, and preferably wherein the trucks travel across a reference surface, such as around the circumference of a circle or along some other pre-defined geometrical pattern or track. For example, as described herein, the systems include Stewart platform machines that have six supportive legs each of which connects to a truck that can travel independently along a track. By coordinating the movement of these six trucks, the working surface can be moved in three dimensional space and can be oriented about three axes, providing control of roll, pitch and yaw.

Owner:HEXEL CORP

Apparatus for Endoscopic Procedures

A shaft assembly is provided for interconnecting at least one rotatable drive shaft of a hand-held electromechanical surgical device, and an end effector actuatable by an axial drive force. The shaft assembly includes a flexible drive cable rotatably supported in an outer tube, the flexible drive cable includes a proximal end operatively connected to a respective rotatable drive shaft of the hand-held surgical device. The flexible drive cable being off set a radial distance from a central longitudinal axis of the outer tube. The shaft assembly includes an articulation rod at least partially slidably supported in the outer tube, and an articulation link having a proximal end pivotally connected to the distal end of the articulation rod and a distal end pivotally connected to a distal neck housing. The articulation rod being off set a radial distance from the central longitudinal axis of the outer tube.

Owner:TYCO HEALTHCARE GRP LP

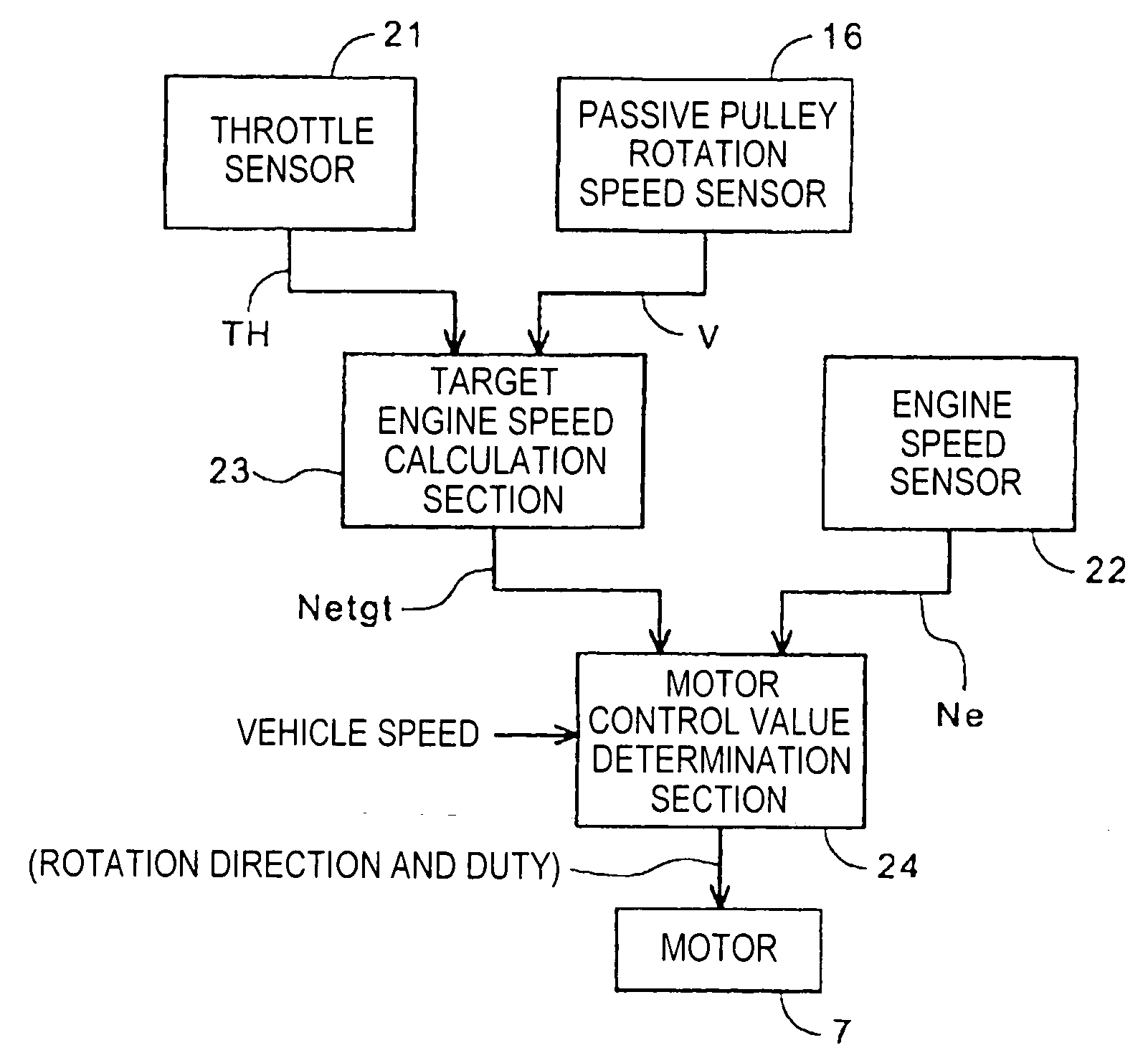

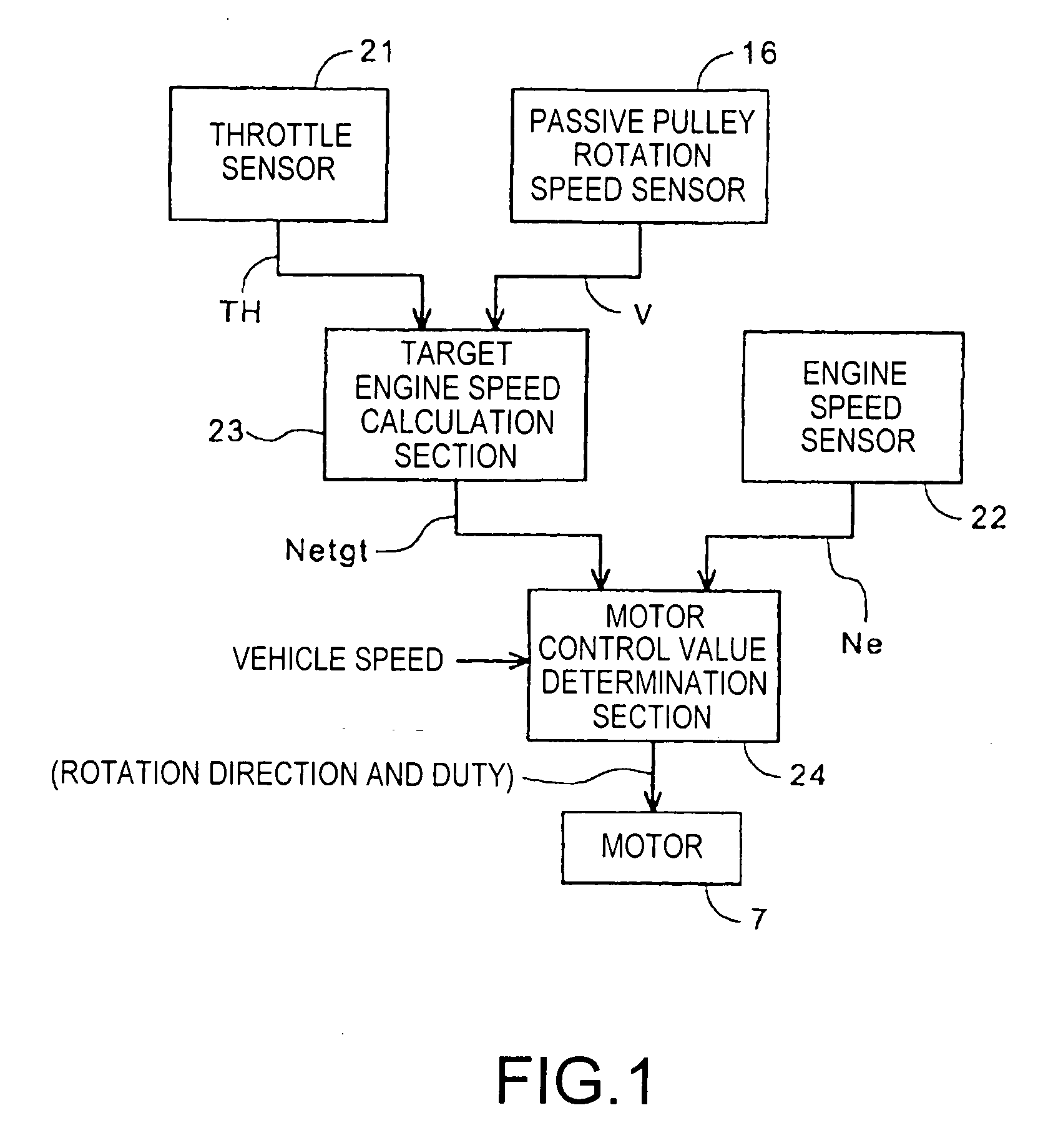

Continuously variable transmission controller

InactiveUS20070004552A1Reduce shift shockReduce update speedDigital data processing detailsGearingThrottle openingControl theory

A continuously variable transmission is mounted on a vehicle capable of selecting plural drive modes and changes a target engine speed between drive modes. A pulley ratio is controlled by a motor. An ECU for transmission control includes a calculation section which outputs a target engine speed as a function of throttle opening and vehicle speed, and a motor control value determination section which outputs a control value for controlling the motor based on the target engine speed and an actual engine speed. In a case where, when a drive mode is selected, the current target engine speed changes by an amount exceeding a predetermined judgment value according to vehicle speed, the motor control value determination section updates the current target engine speed in a stepwise manner. The resulting configuration reduces a shift shock caused by a drive mode change.

Owner:HONDA MOTOR CO LTD

Jerk management using multivariable active driveline damping

ActiveUS20070225889A1Actively dampen magnitudeMinimize impactHybrid vehiclesDigital data processing detailsDrive wheelEngineering

A multivariable feedback control approach to actively dampen magnitude of jerks in a powertrain system using multiple torque-control devices is offered. To manage jerks, a desired axle torque is restricted when a torque reversal occurs. When the vehicle operator or the system executes a command that requires change in direction of torque, the desired axle torque is limited to a low level until the lash estimate has changed accordingly. During this transition time, active damping controls driveline component speeds so that the effect of lash take-up is minimized. After lash take-up occurs, the desired axle torque proceeds without restriction. The invention includes determining a desired axle torque, an output speed of the transmission, and an output speed of a driven wheel of the driveline. One of the devices is controlled based upon a time-rate change in the desired axle torque.

Owner:GM GLOBAL TECH OPERATIONS LLC

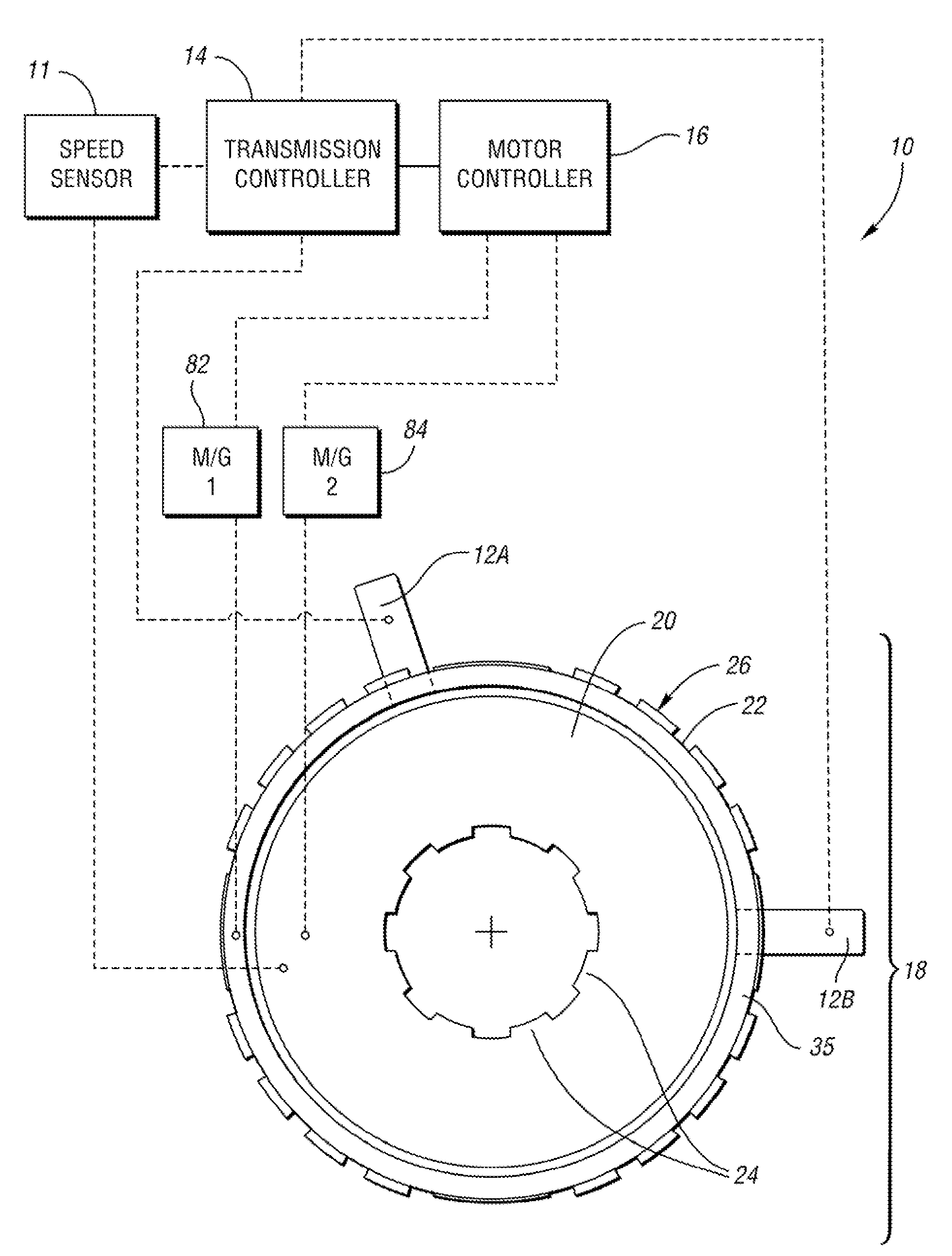

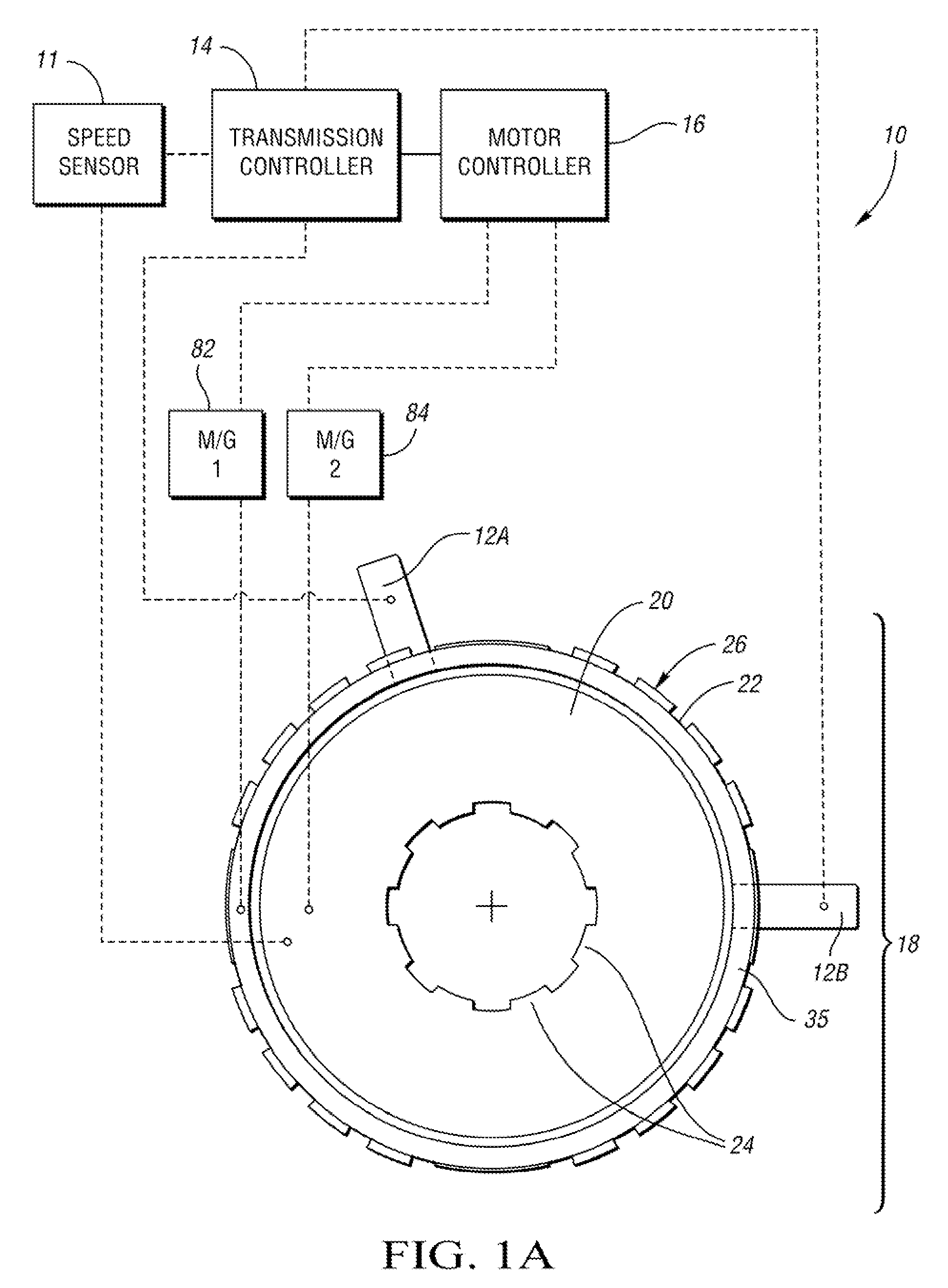

Selectable one-way clutch

A controllable selectable one-way clutch is provided for use within a hybrid transmission. The clutch comprises an outer and inner race, and a first and second selector plate. A transmission motor controller synchronizes the speeds of the races to facilitate application and release of the clutch, and a transmission controller communicates a signal to the clutch for re-positioning of the plates to apply and release the clutch. The clutch has three operational modes, including freewheeling and holding torque in one direction or both directions. A method is also provided for applying a selectable one-way clutch in a vehicle having a hybrid transmission with a motor controller and a transmission controller, including synchronizing the clutch speed using the motor controller, detecting the direction of the race speed difference, communicating the race speed difference to the transmission controller, and selecting between the clutch operational modes in response to the detected speed difference.

Owner:GM GLOBAL TECH OPERATIONS LLC

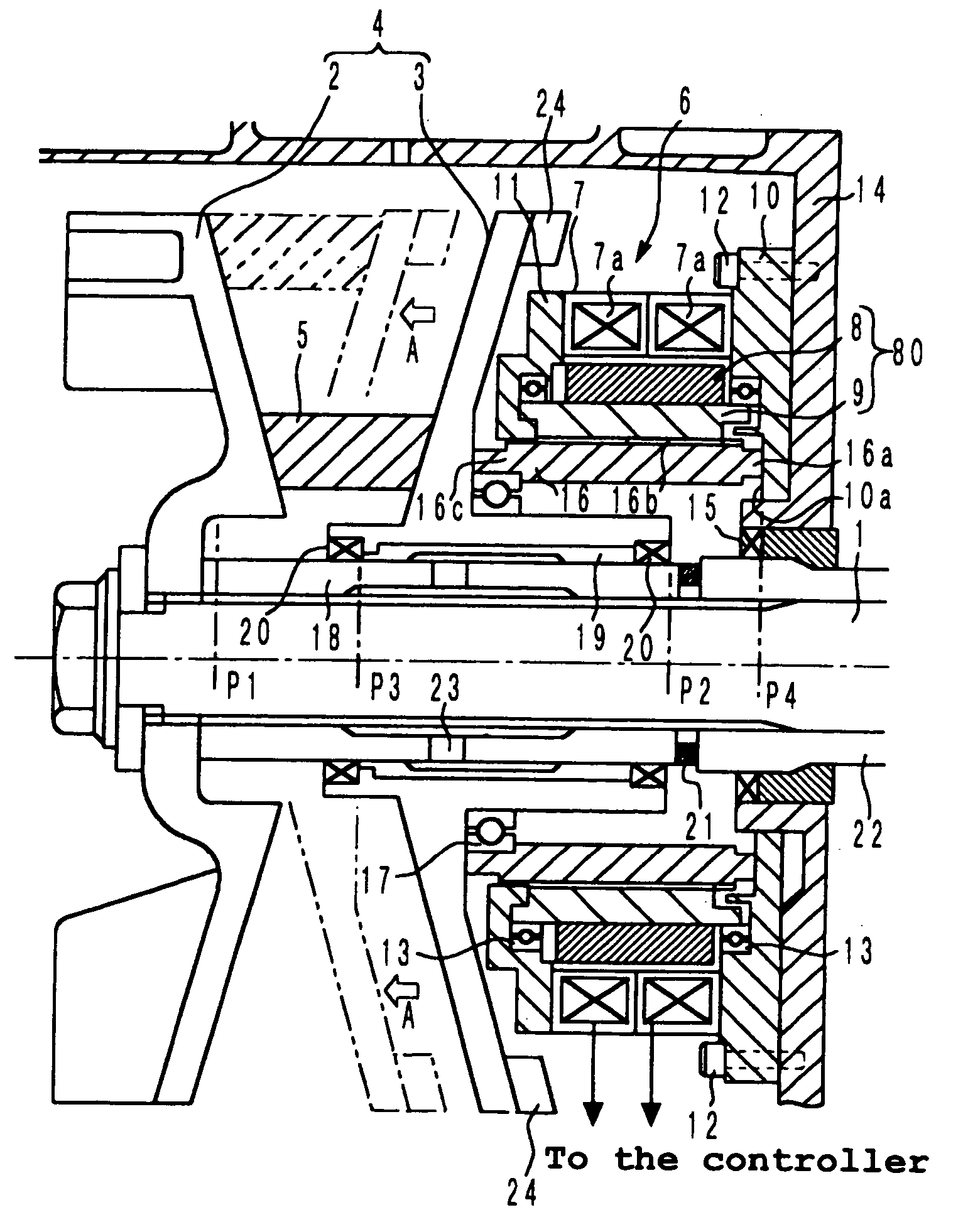

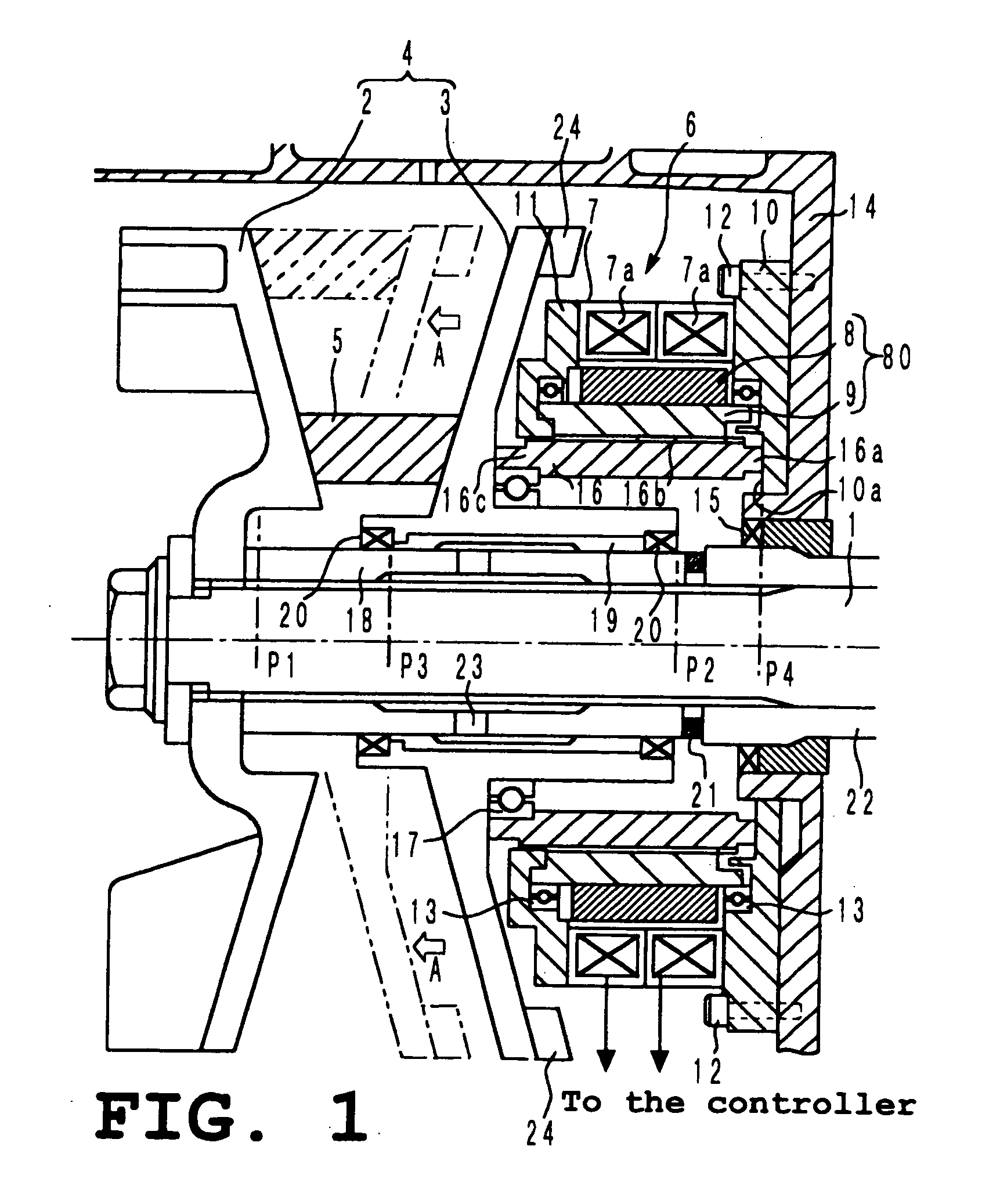

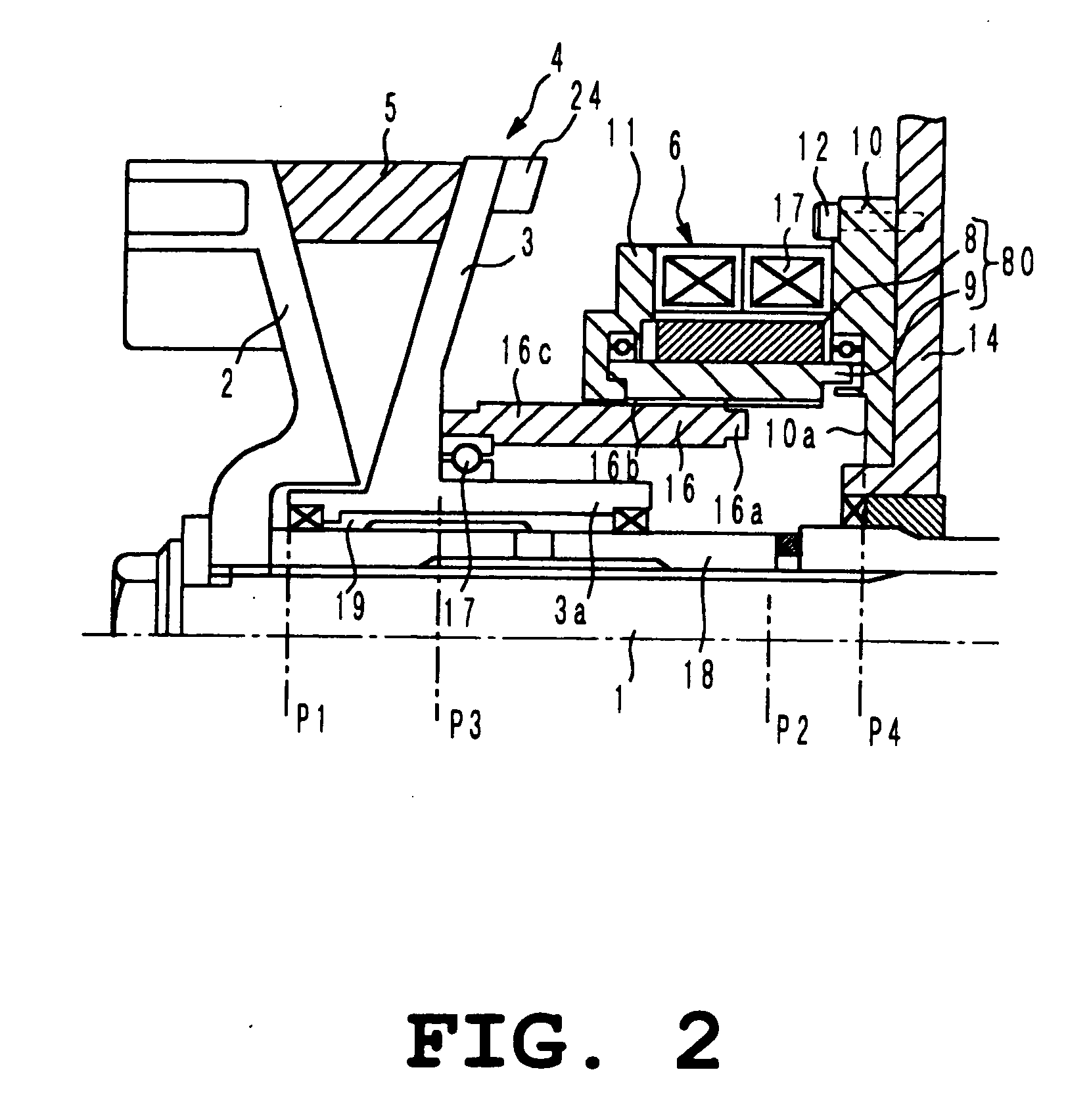

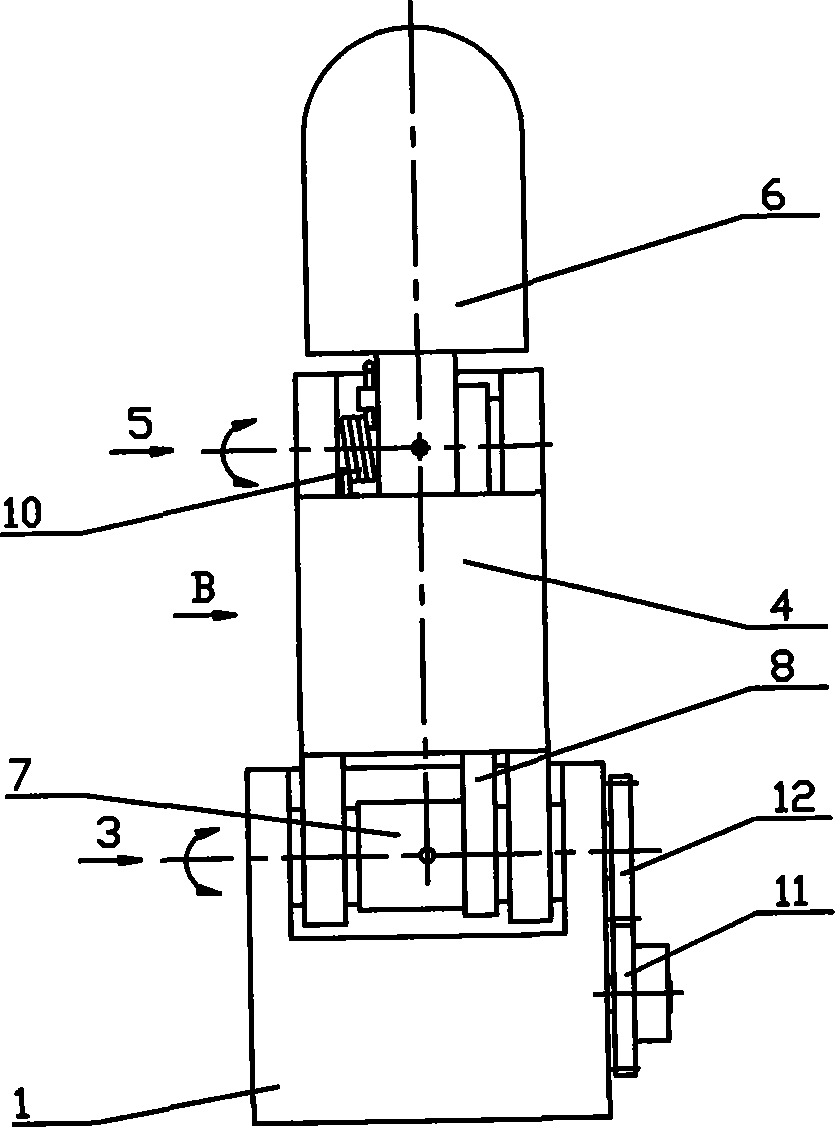

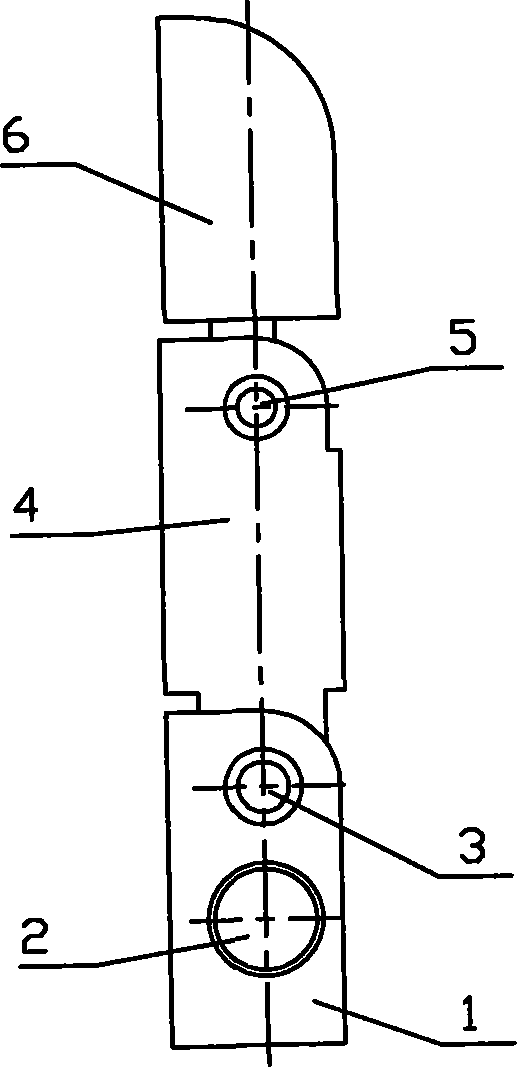

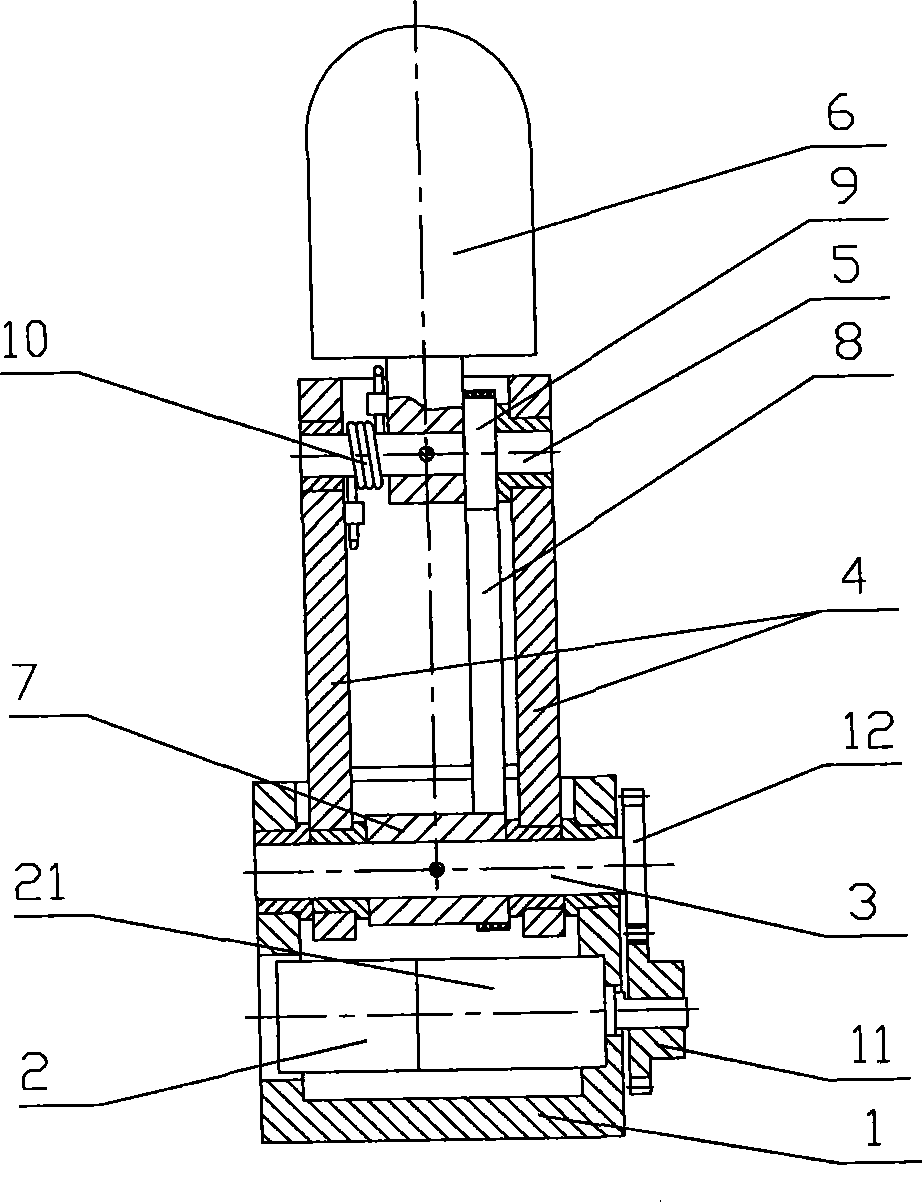

Continuously variable transmission and method of controlling it

InactiveUS20050037876A1Shorten the axial lengthReduce widthGearingGearing controlRotational axisControl theory

To provide a continuously variable transmission and a control method thereof, allowing for control of the axial position of a movable sheave without a sensor for measuring the axial position of the movable sheave on a rotational shaft and for stable control with the movable sheave being held in position, without the increase in the size of mechanisms and power consumption. A continuously variable transmission in which, on a rotational shaft 1 thereof are mounted a fixed sheave 2 positioned in the axial direction and a movable sheave 3 slidable axially, so as to face each other, a motor is provided for driving the movable sheave, and a slide driving means 16 is provided for sliding the movable sheave 3 axially by the rotation of the motor, characterized in that: the motor is a step motor 6, and the step motor 6 and the slide drive means 16 are mounted coaxially with the rotational shaft 1.

Owner:YAMAHA MOTOR CO LTD

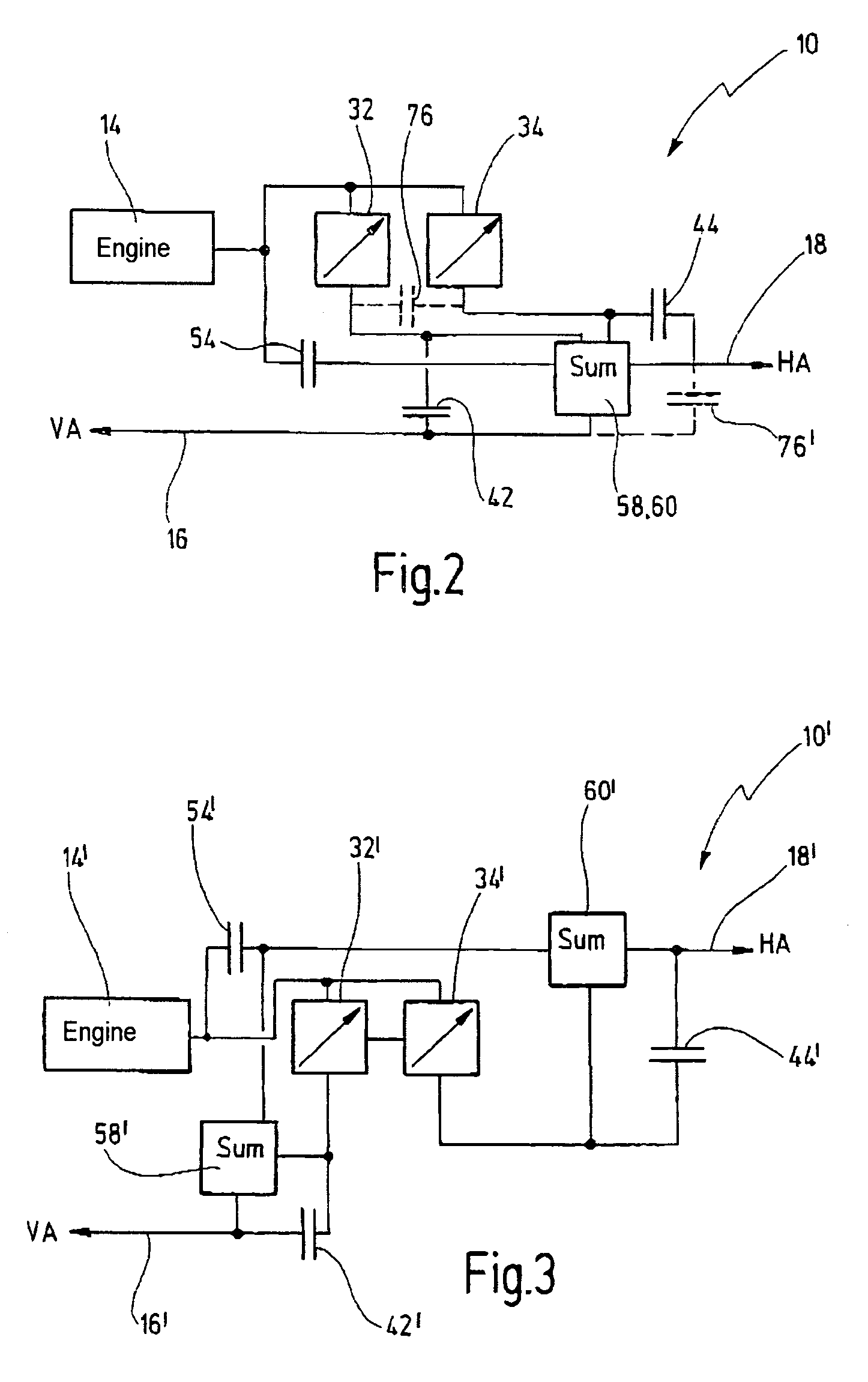

Toroidal transmission

A toroidal transmission, especially for motor vehicles, comprising an input shaft which can be connected to an engine, a first toroidal variator and a second toroidal variator which are connected to the input shaft on the input side. A first output shaft can be connected to the output of the first toroidal variator, and a second output shaft can be connected to the output of the second toroidal variator. The toroidal transmission comprises a first power range shifter for the first toroidal variator and a second power range shifter for the second toroidal variator. The first power range shifter and the second power range shifter have a common clutch.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

Isolator for alternator pulley

Owner:LITENS AUTOMOTIVE INC

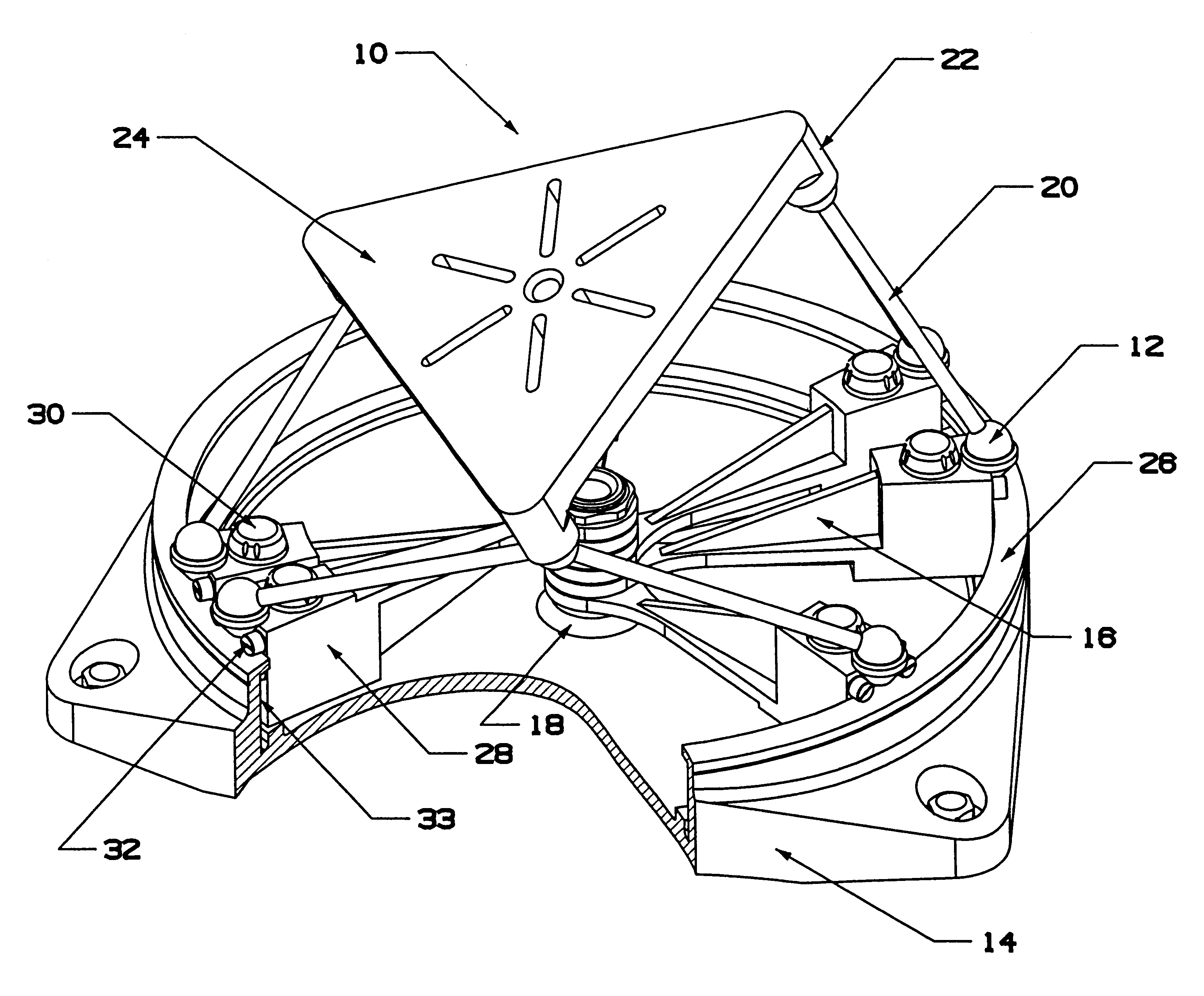

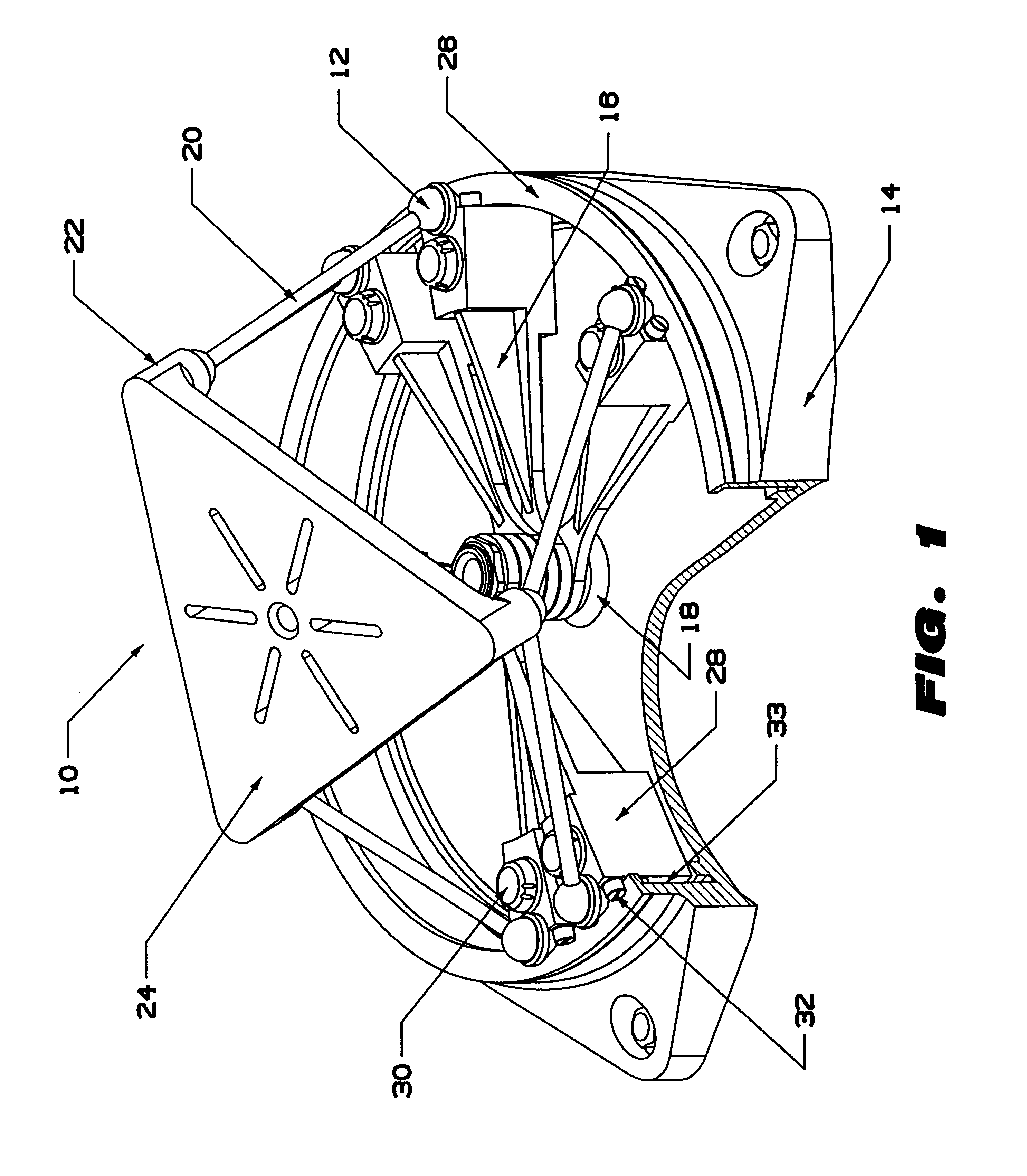

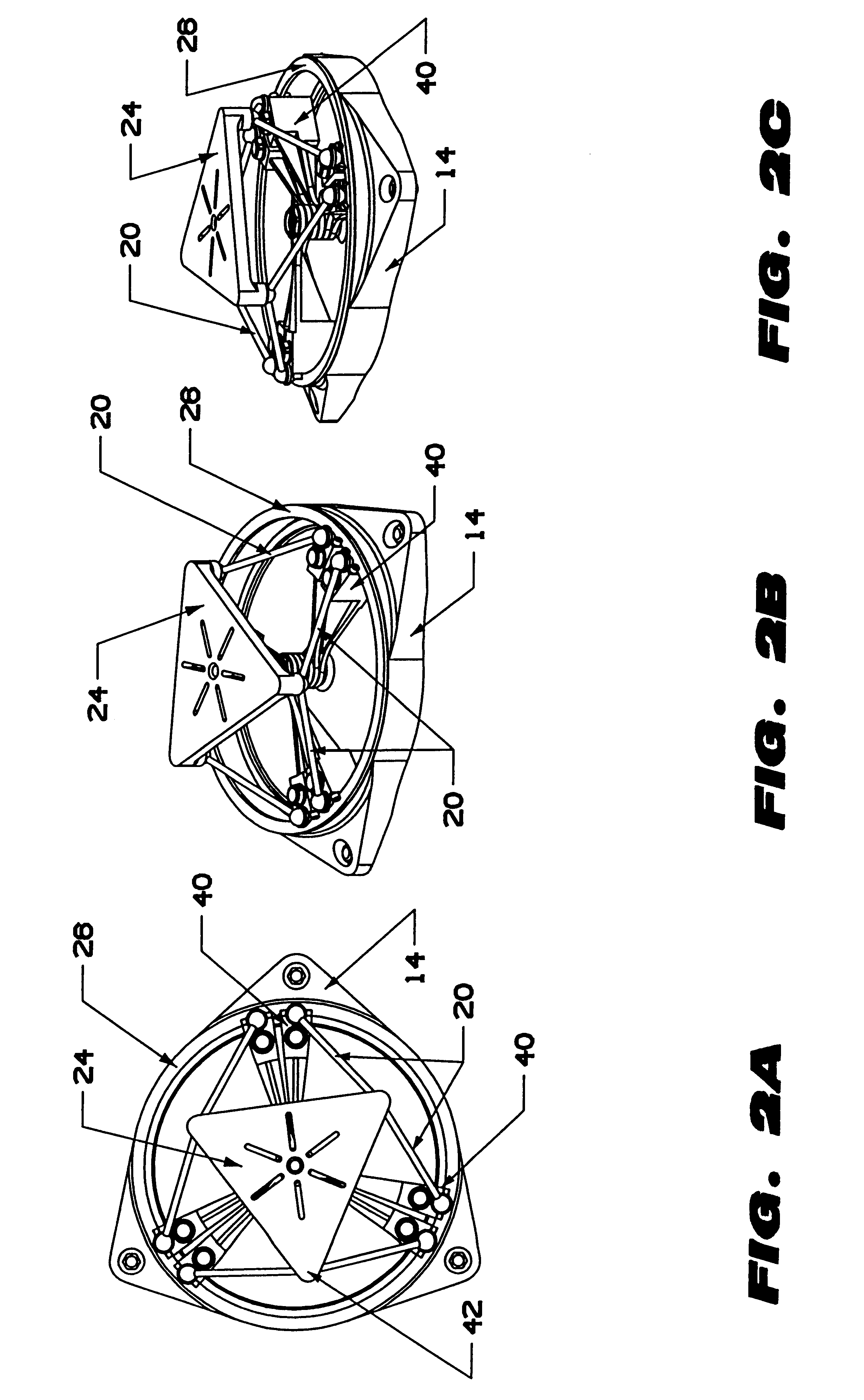

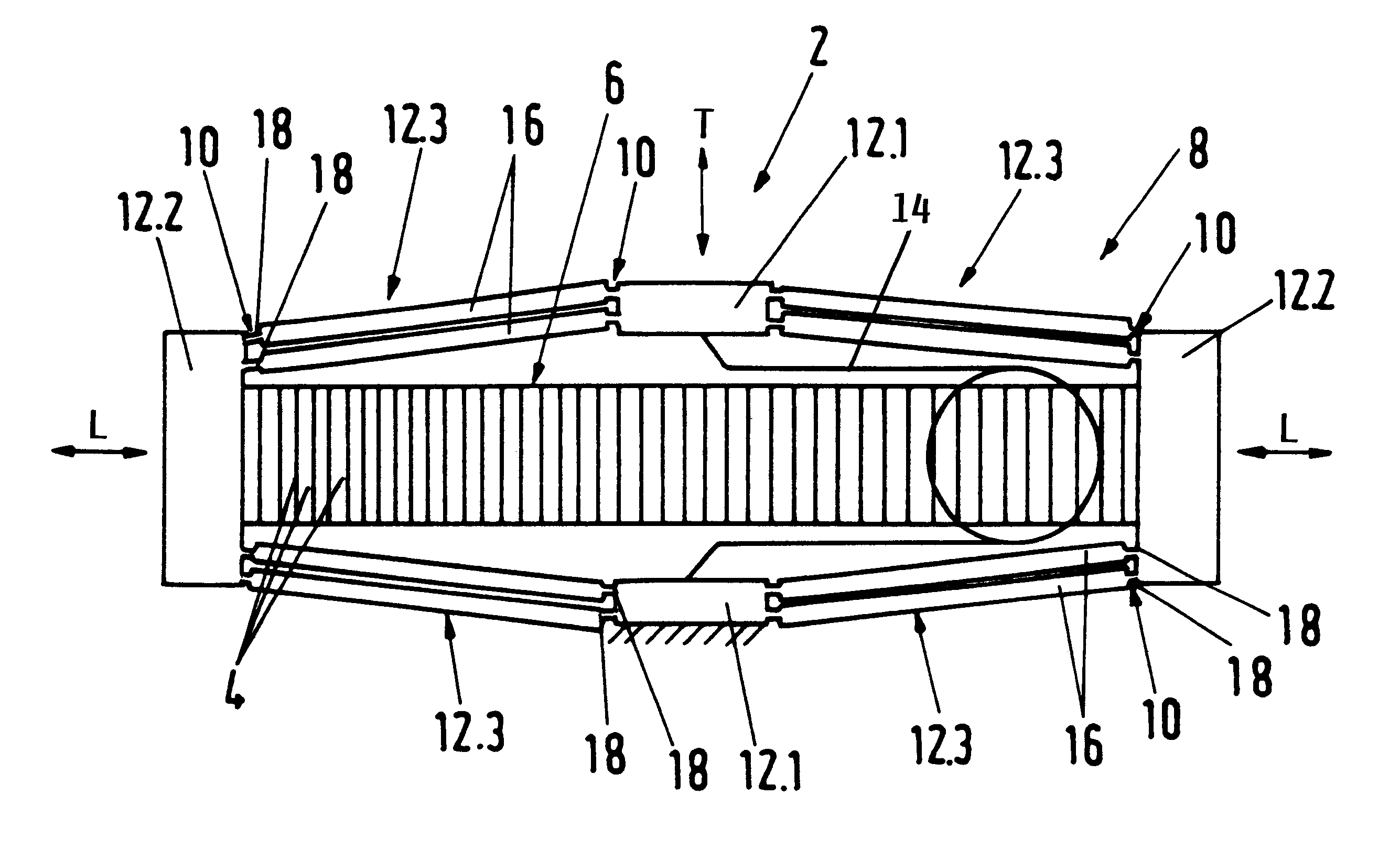

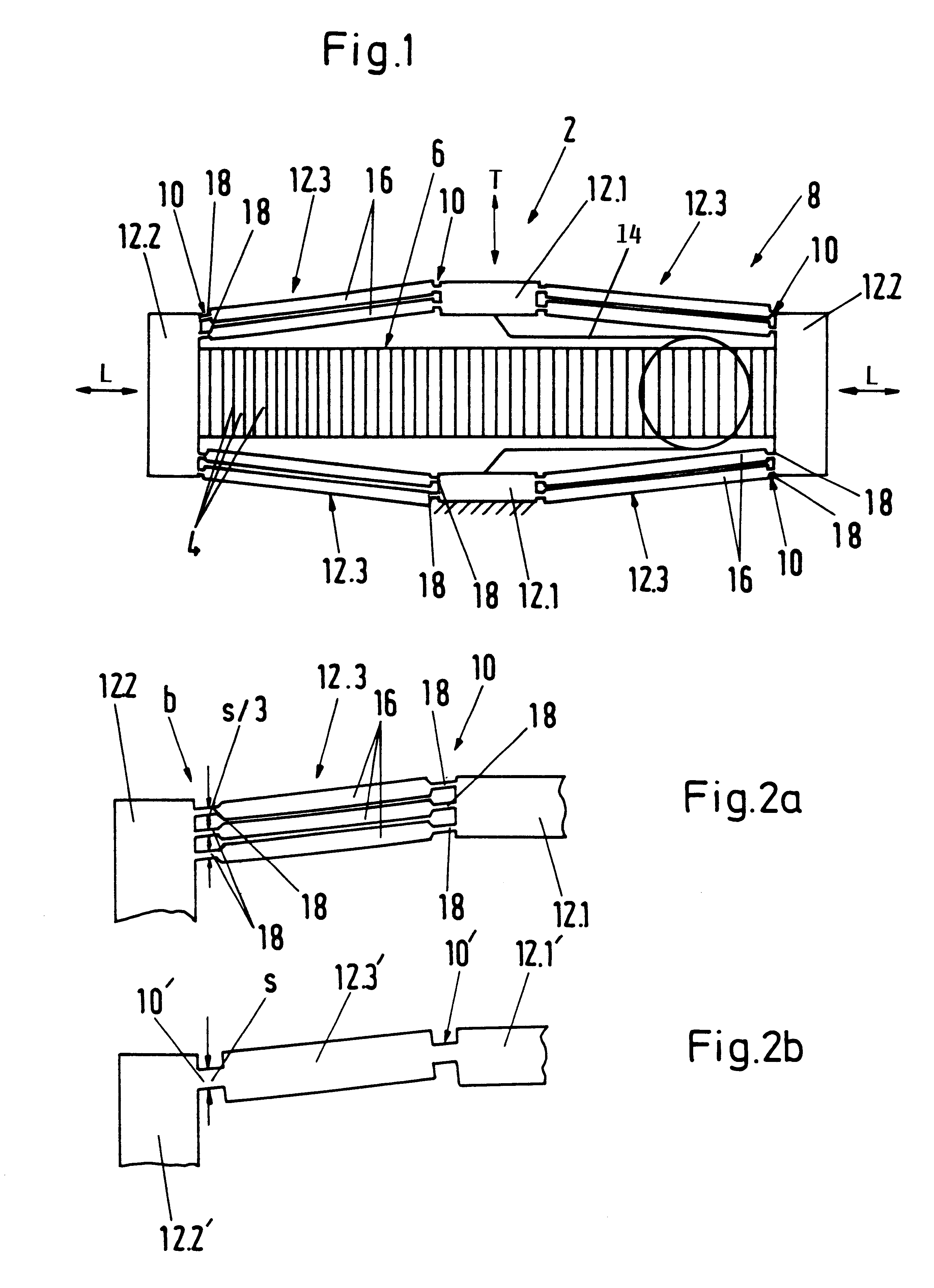

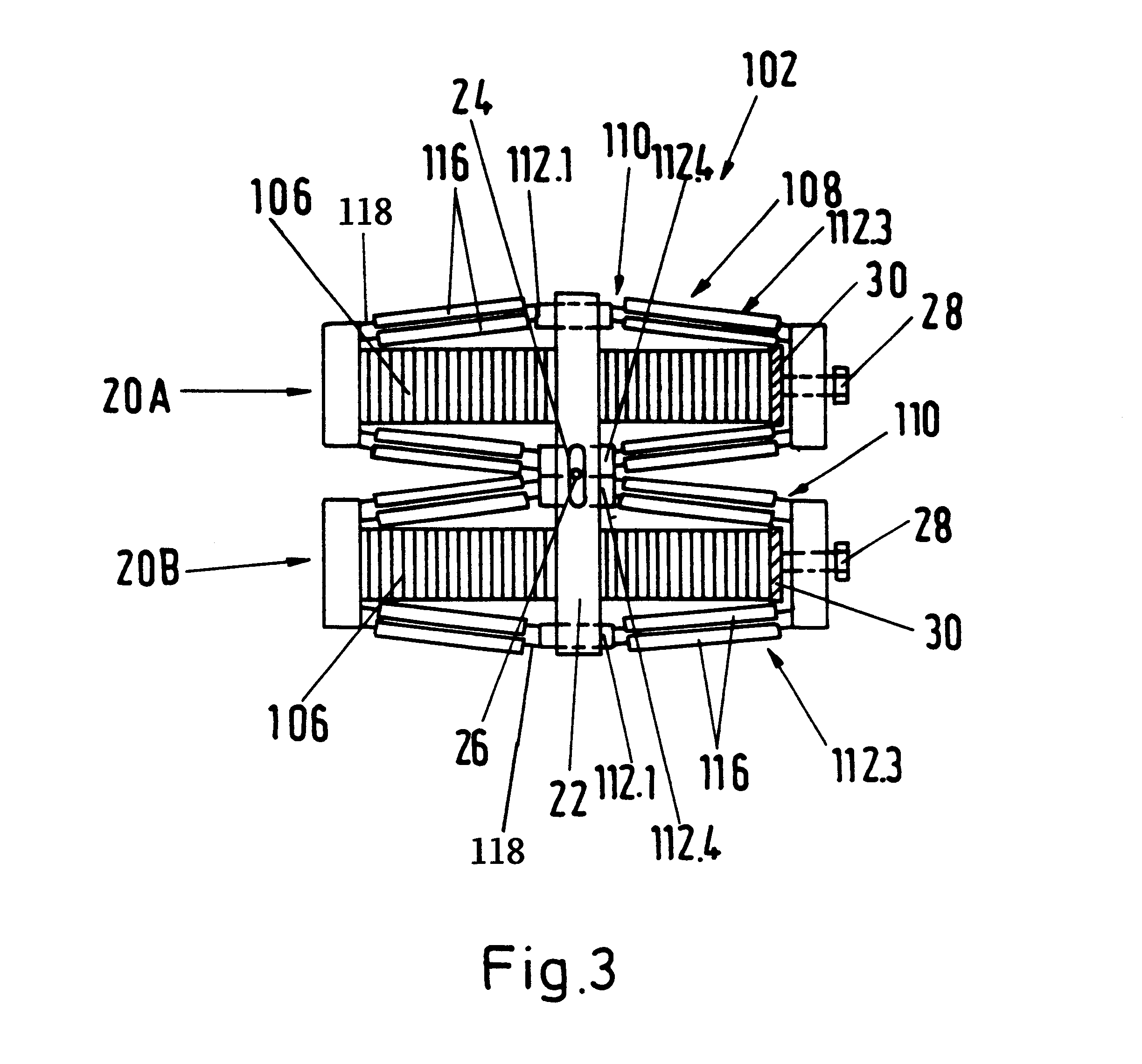

Electrostrictive or piezoelectric actuator device with a stroke amplifying transmission mechanism

InactiveUS6294859B1Low bending stiffnessReduce joint stiffnessPiezoelectric/electrostriction/magnetostriction machinesGearingFiber strainPiezoelectric actuators

An actuator device (2) includes a piezoelectric or electro-strictive solid state actuator element (6) that is elongated upon application of an electric voltage thereto, and a transmission mechanism (8) that amplifies the stroke displacement of the actuator element. The transmission mechanism (8) includes a plurality of rigid frame members (12), including unitary frame members (12.1, 12.2) and divided frame members (12.3), and elastically flexible joints (10) that respectively interconnect the frame members. Each one of the divided frame members (12.3) is made up of a plurality of separate parallel link rods (16). Each flexible joint (10) is made up of a plurality of individual parallel hinge members (18) that respectively connect an end of each one of the link rods (16) to the adjacent unitary frame member (12.1, 12.2). By this division of the flexible joints and of the divided frame members into parallel sub-components, the cross-sectional thickness of each individual hinge member is reduced, and thereby the bending stiffness and the outer fiber strain of the material of the hinge members is significantly reduced while providing the same total tensile strength and tensile stiffness. The link rods of each divided frame member effectively form a parallelogram linkage for moving and guiding the output members (12.1) in a parallel manner.

Owner:EADS DEUT GMBH

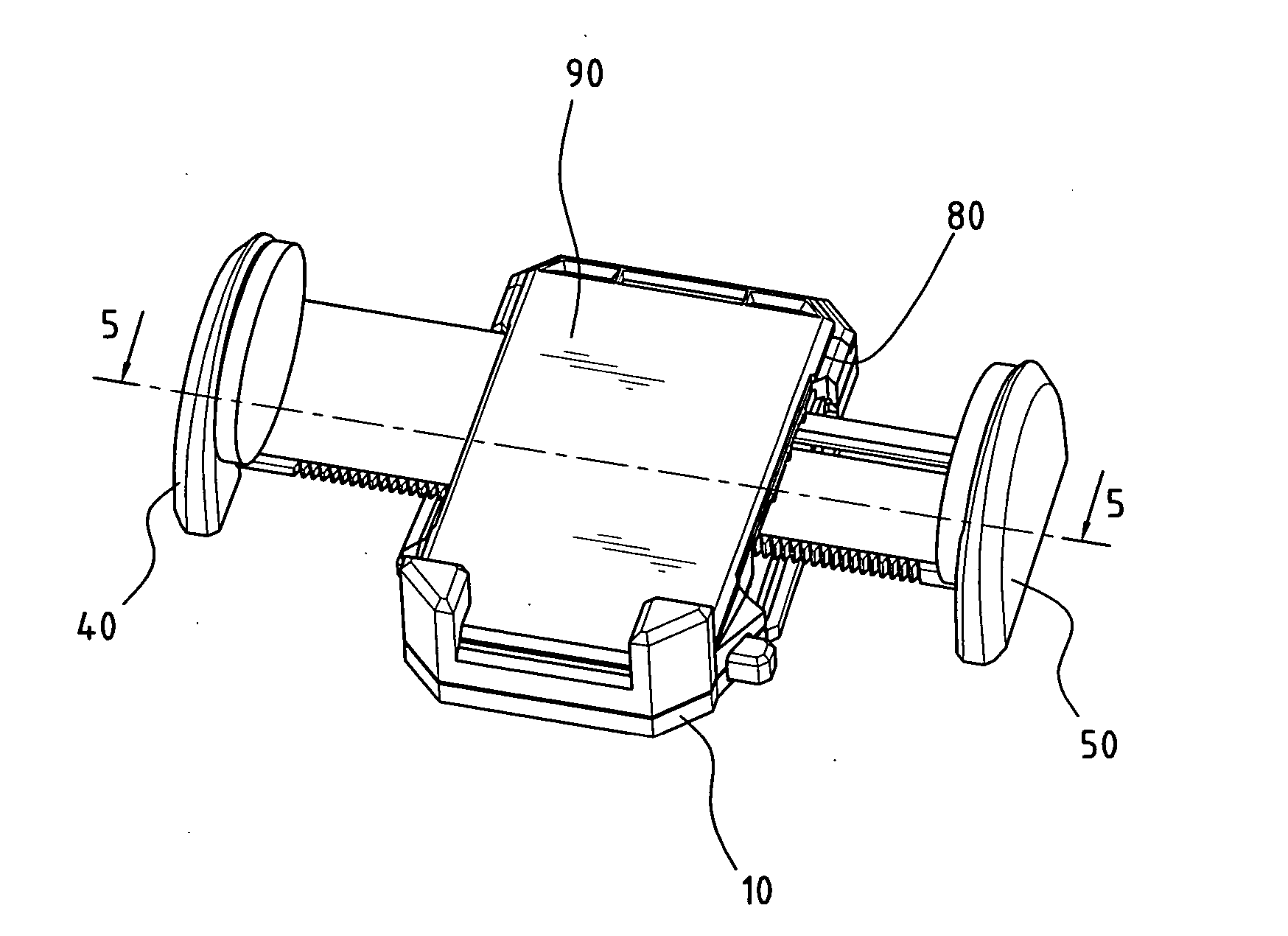

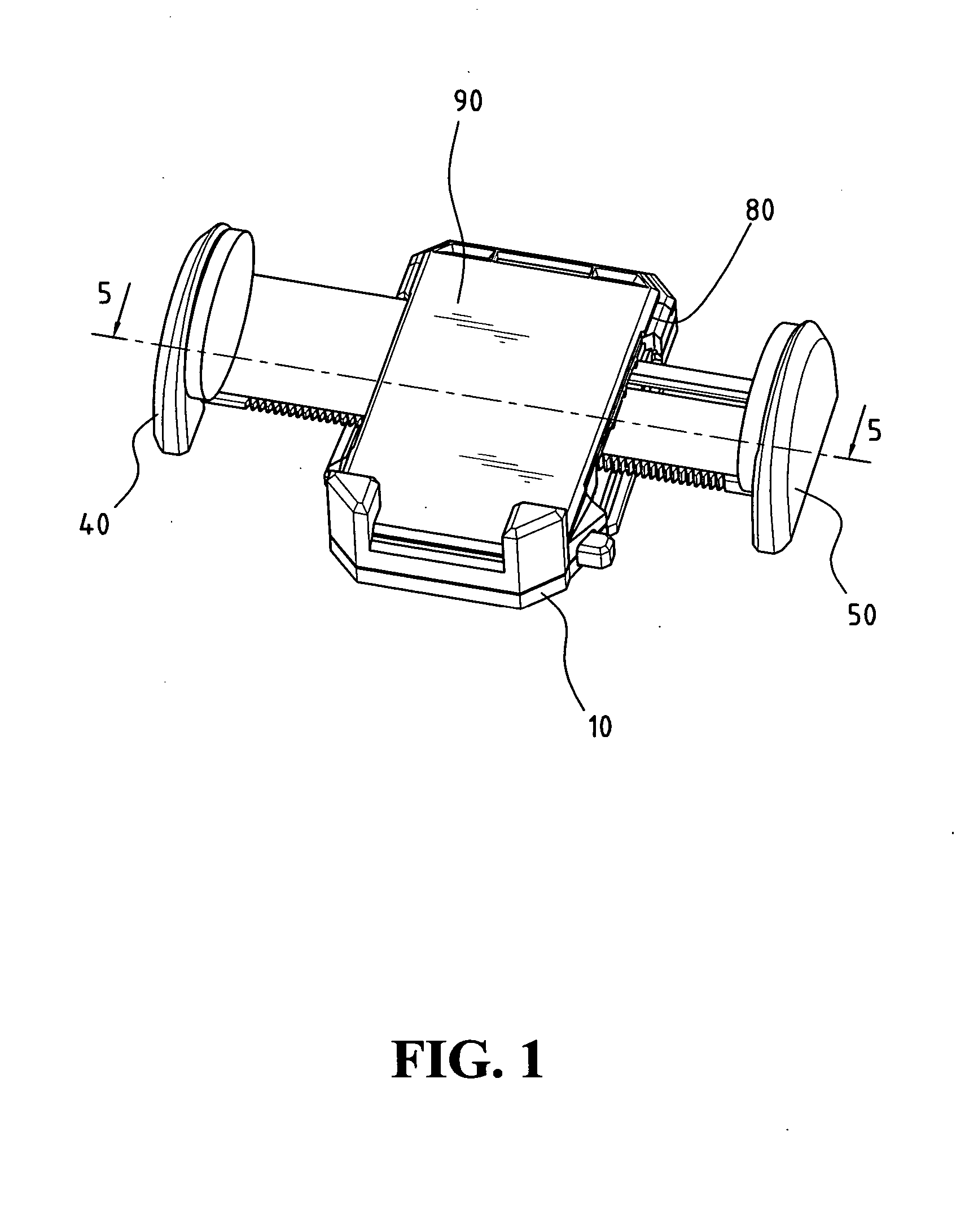

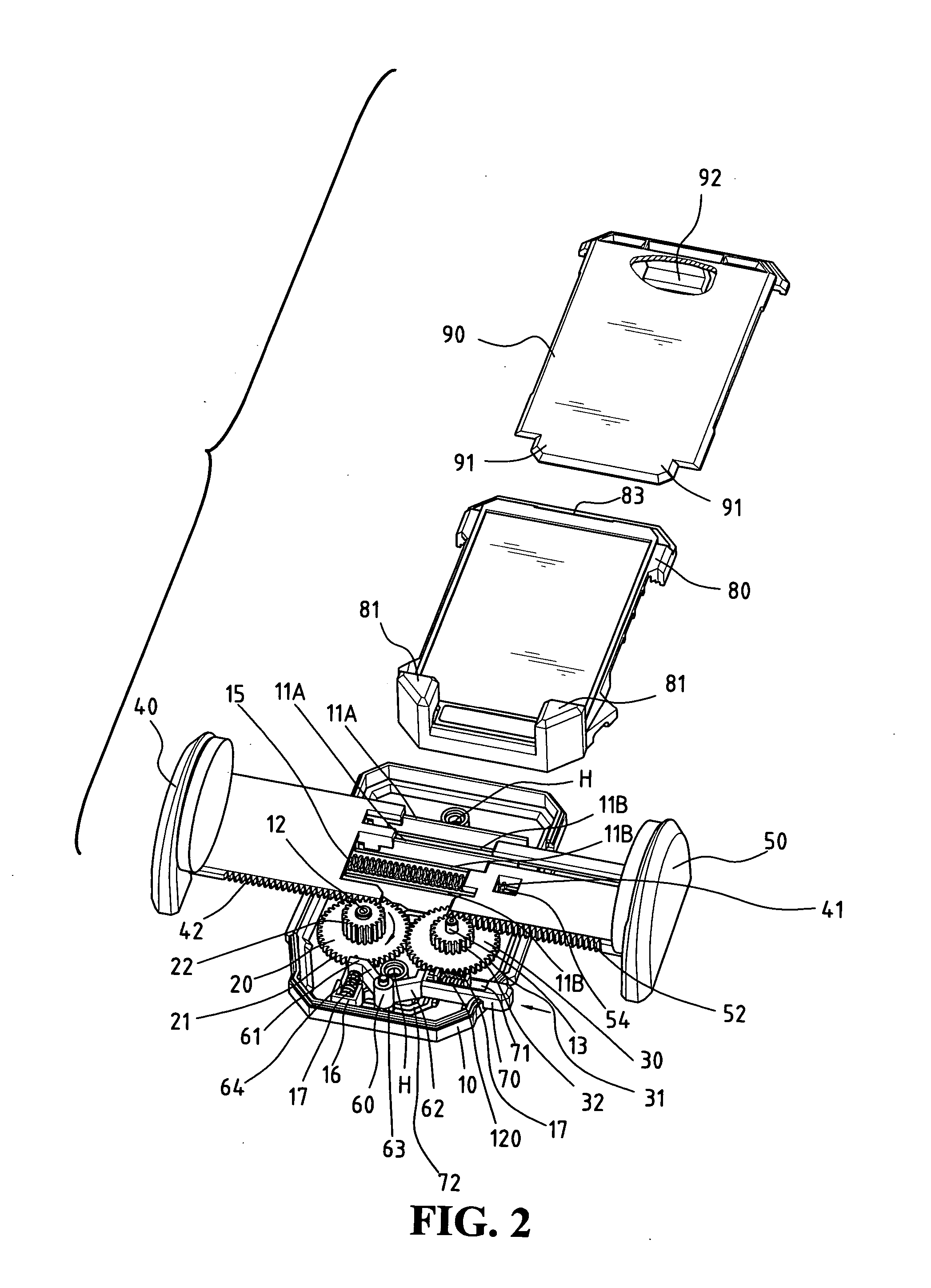

Belt wheel under-driven robot finger device

The invention provides a wheel driving robot finger device, belonging to a robot technical field which comprises a base, a motor, a reducer, a first gear, a second gear, a close joint shaft, a middle part finger, a far joint shaft and a terminal finger section as well as a driver, a transmission part, a driven wheel, a spring part. The middle part finger is sleeved on the close joint shaft. Two terminals of the spring part are respectively connected with the middle and the terminal finger sections. The device uses a pair of wheel mechanisms to sleeve a plurality of active middle part fingers with the decoupling effect of the spring part comprehensively to realize the special effect that the double joints drive the finger to bend so as to catch the objects. With simple structure, reliability, low cost, convenient installation and maintenance, small volume and light weight, the wheel driving robot finger device similar to human fingers is especially suitable for being used as a thumb of the hand of the humanoid robot or a part of other fingers that uses fewer drivers to drive more rotation joints to automatically adjust to catch the objects of different shapes and sizes.

Owner:TSINGHUA UNIV

Electronic appliance holding device

Owner:FAN EAGLE

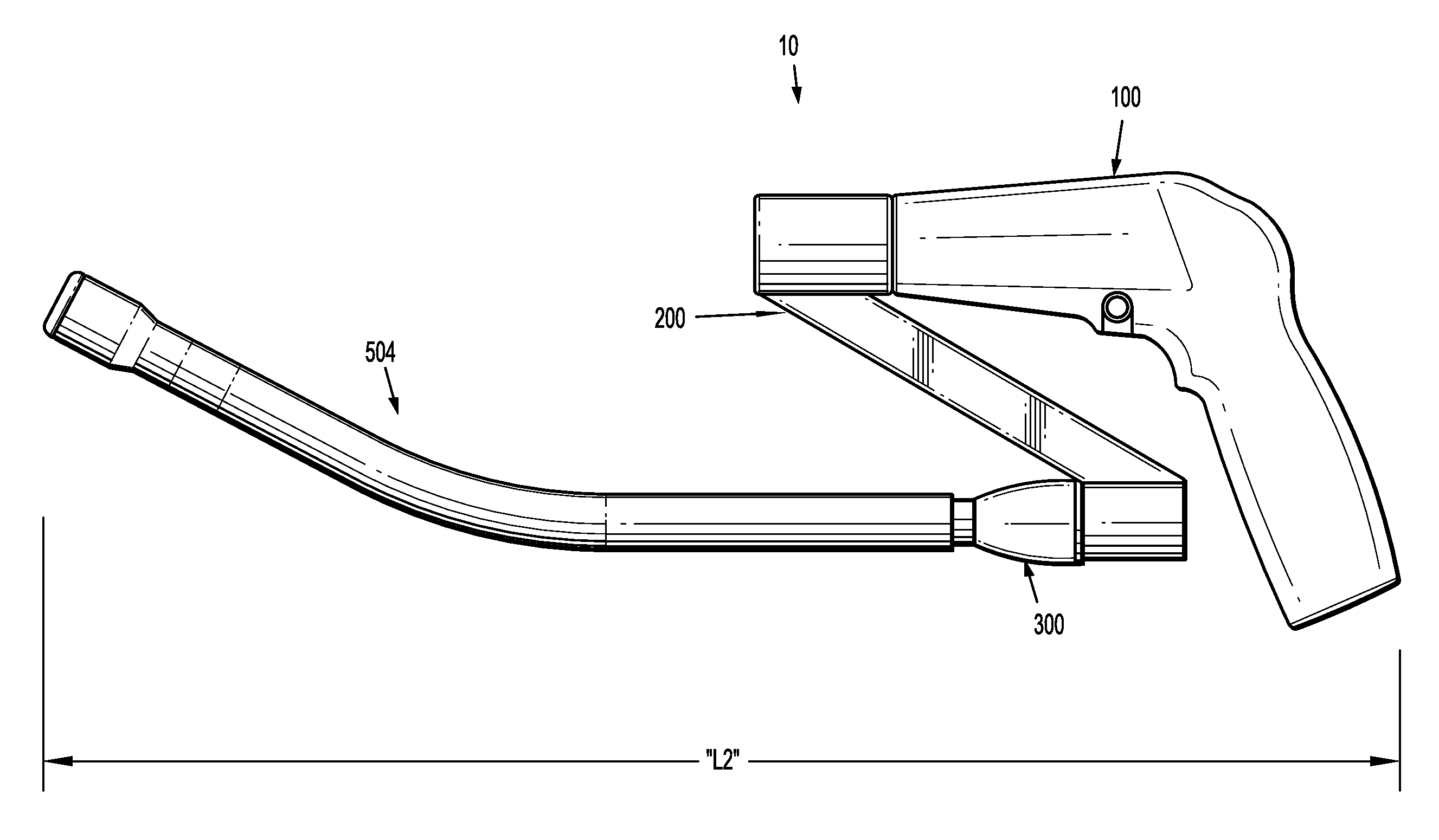

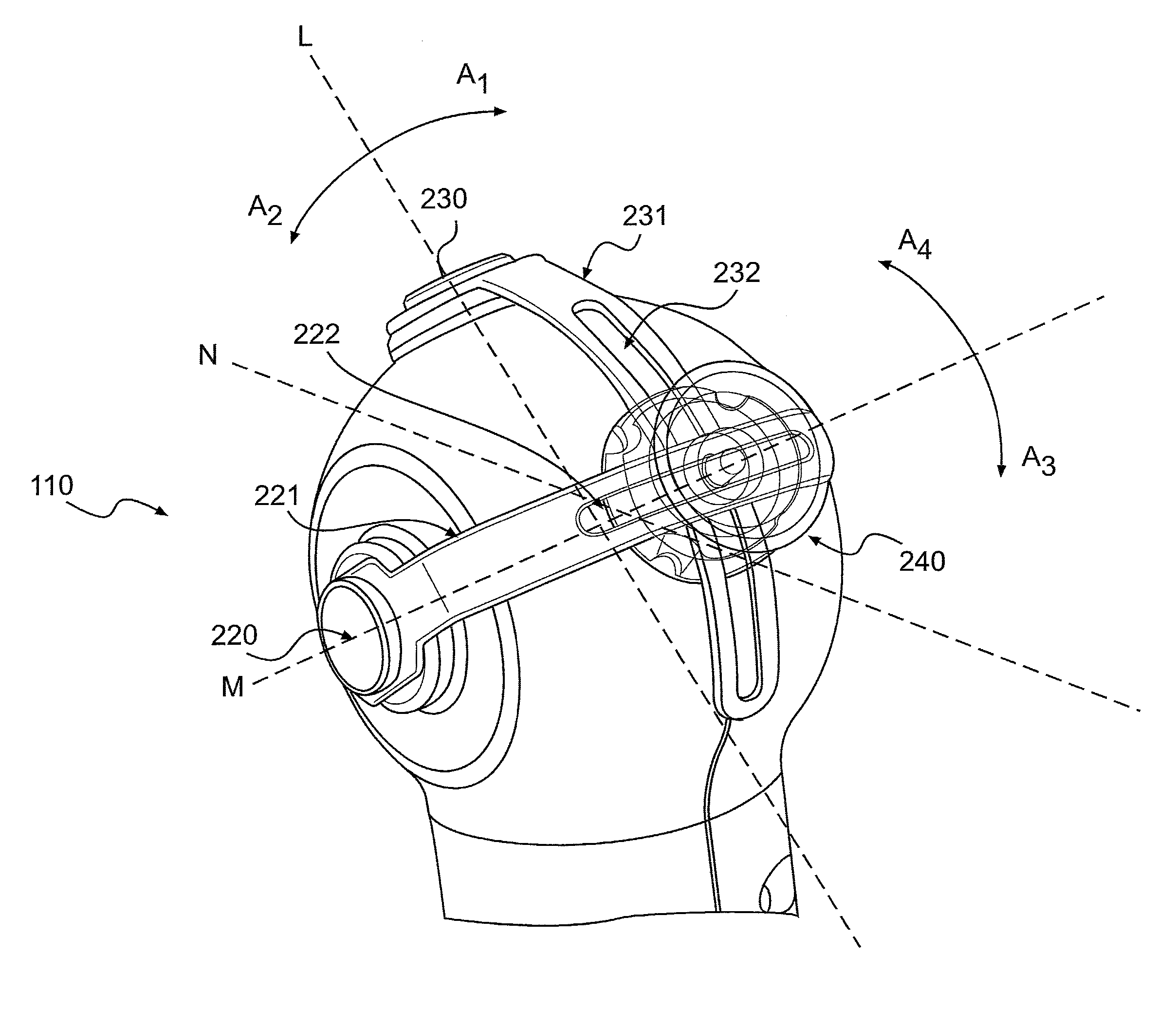

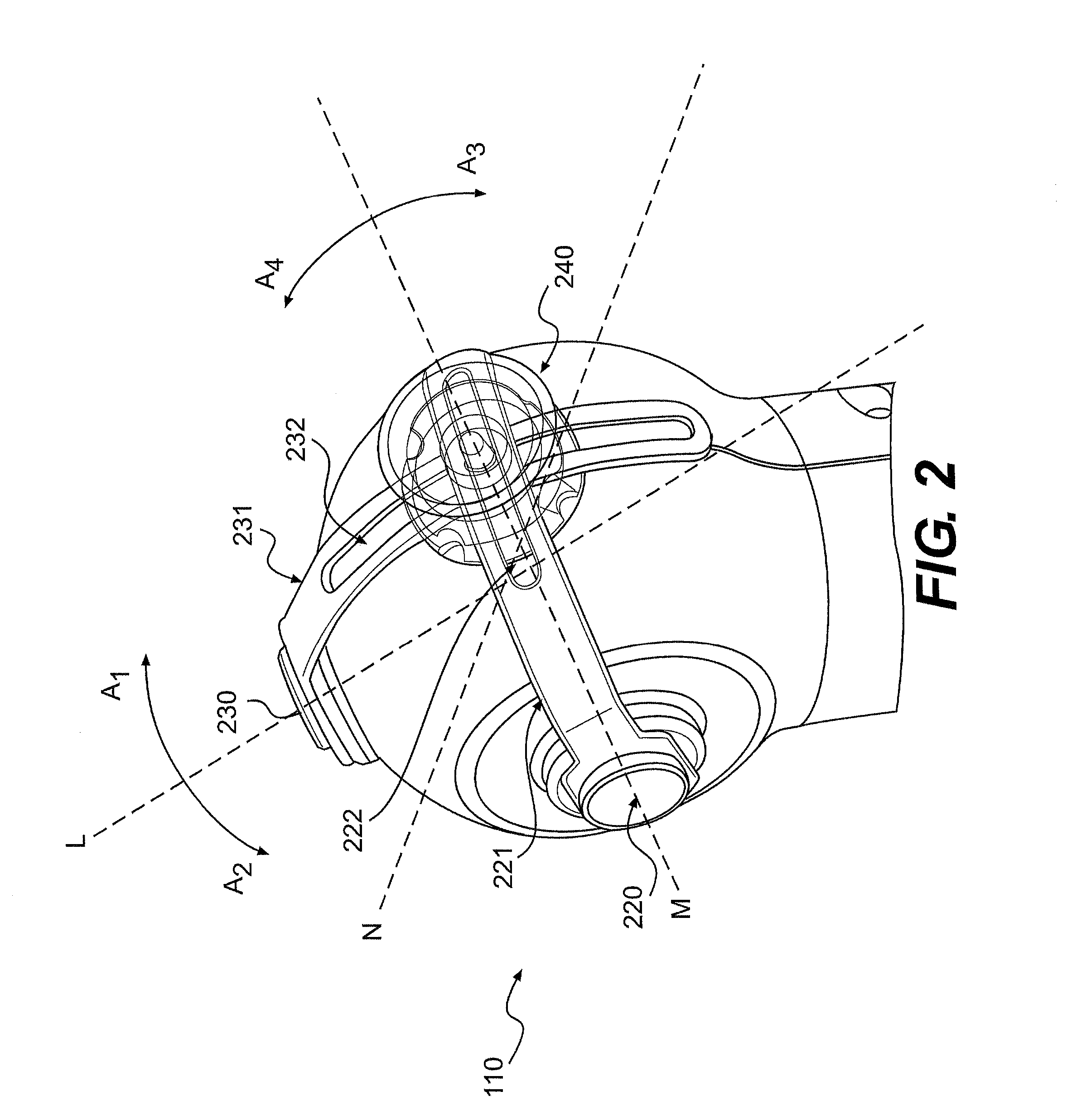

Deflection mechanism

A steering mechanism may comprise an actuation system for one-fingered operation by a user, the system configured to move at least a distal portion of the medical device such that 360 degree articulation is achievable, and a housing coupled to the system, the housing having proximal and distal ends. The system may comprise a first lever rotatable about a first axis, the first lever coupled to a first cam and configured to move the first cam from a first position to a second position when rotated about the first axis to deflect the distal portion; and a second lever rotatable about a second axis, the second lever coupled to a second cam and configured to move the second cam from a first position to a second position when rotated about the second axis to deflect the distal portion, wherein the first lever is coupled to the second lever.

Owner:BOSTON SCI SCIMED INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com