Patents

Literature

108results about How to "Reduce shift shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

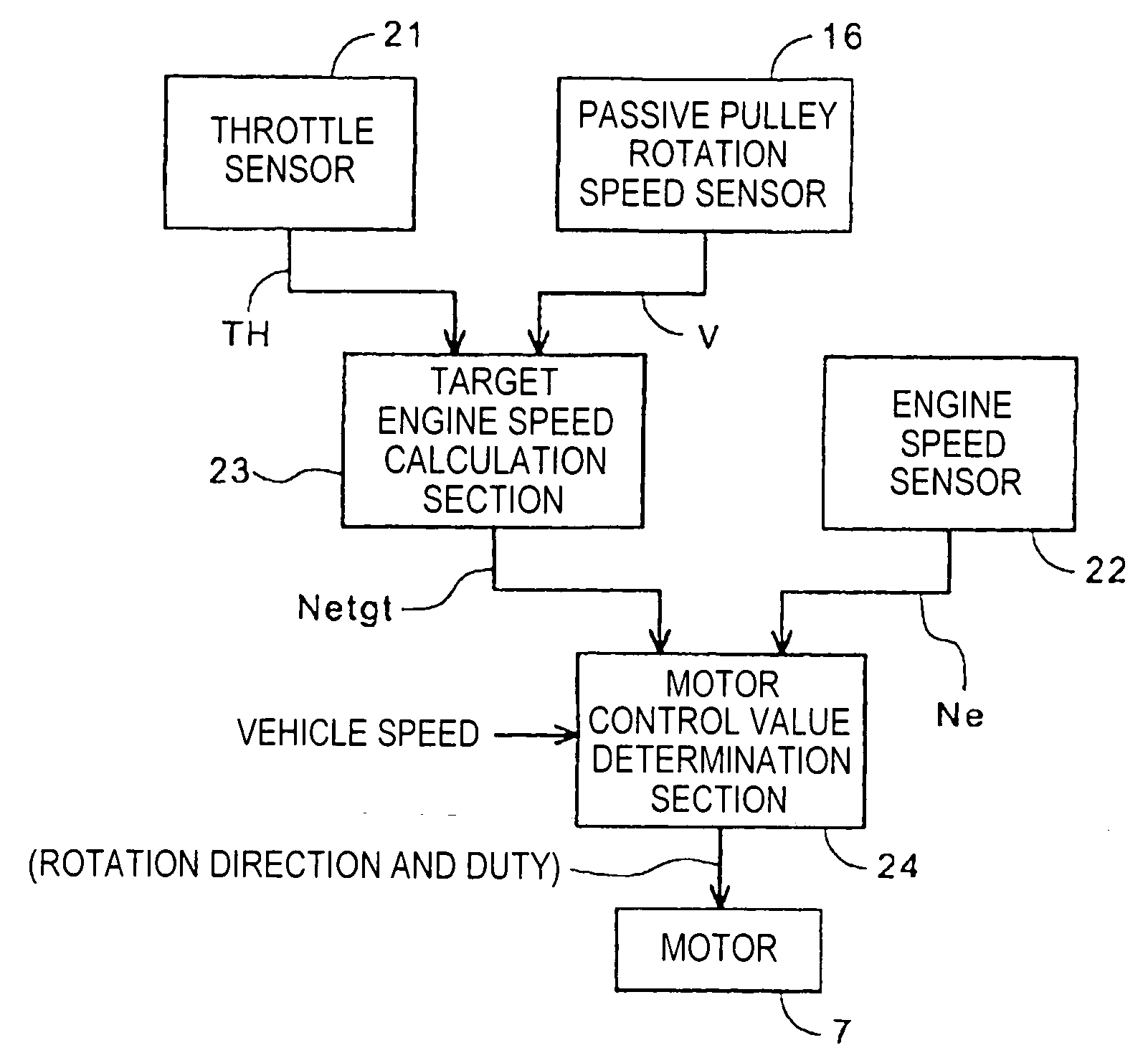

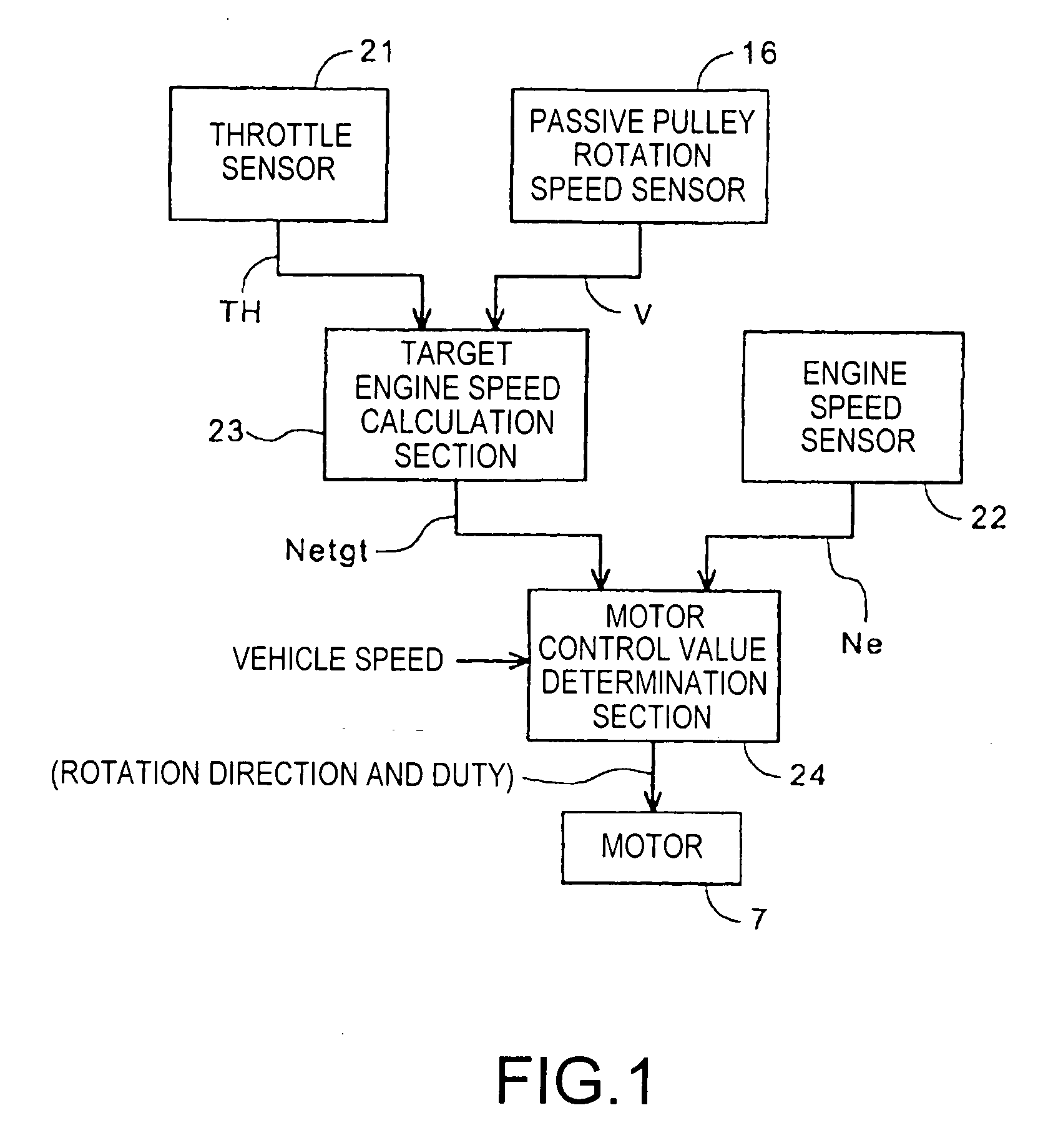

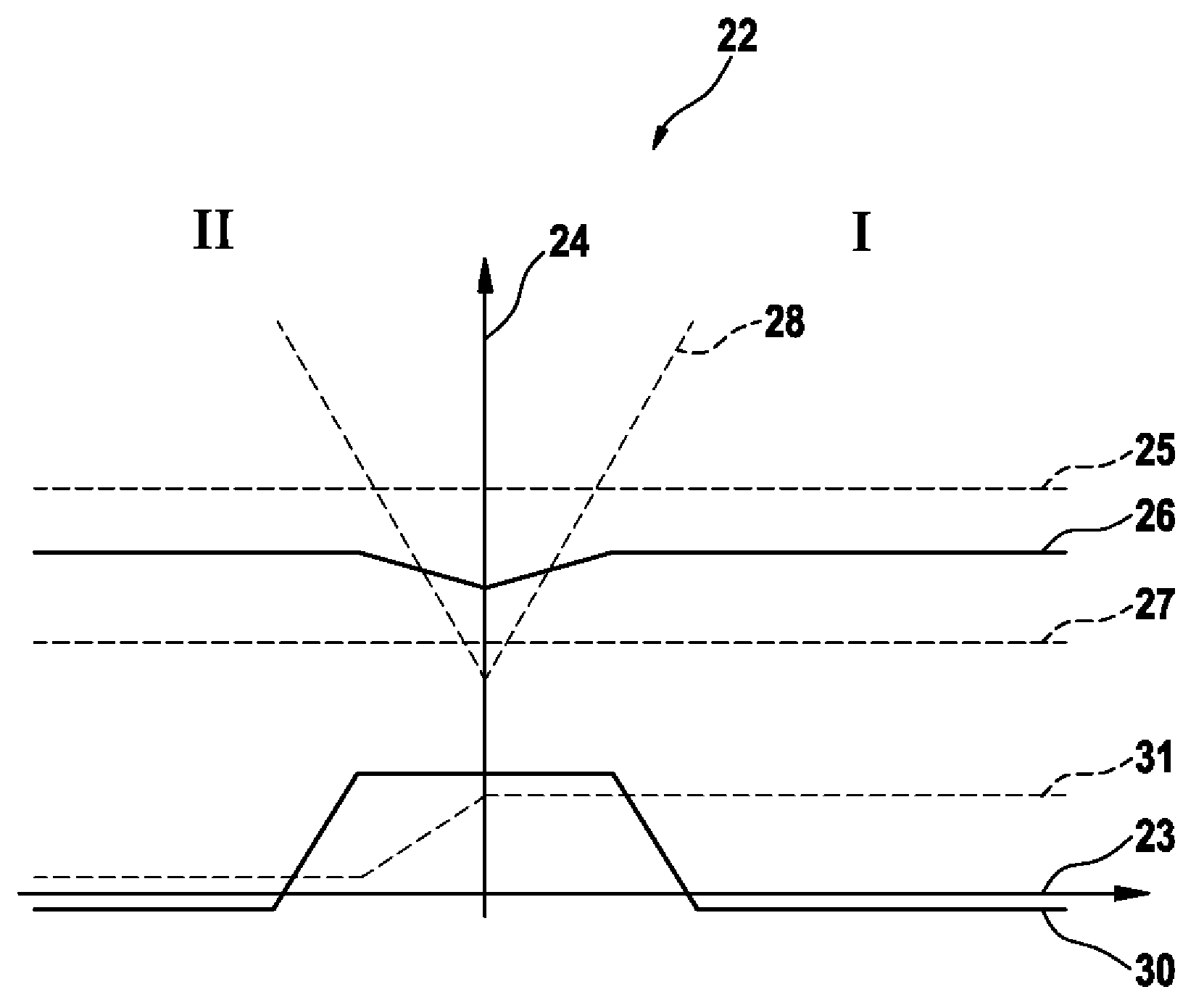

Continuously variable transmission controller

InactiveUS20070004552A1Reduce shift shockReduce update speedDigital data processing detailsGearingThrottle openingControl theory

A continuously variable transmission is mounted on a vehicle capable of selecting plural drive modes and changes a target engine speed between drive modes. A pulley ratio is controlled by a motor. An ECU for transmission control includes a calculation section which outputs a target engine speed as a function of throttle opening and vehicle speed, and a motor control value determination section which outputs a control value for controlling the motor based on the target engine speed and an actual engine speed. In a case where, when a drive mode is selected, the current target engine speed changes by an amount exceeding a predetermined judgment value according to vehicle speed, the motor control value determination section updates the current target engine speed in a stepwise manner. The resulting configuration reduces a shift shock caused by a drive mode change.

Owner:HONDA MOTOR CO LTD

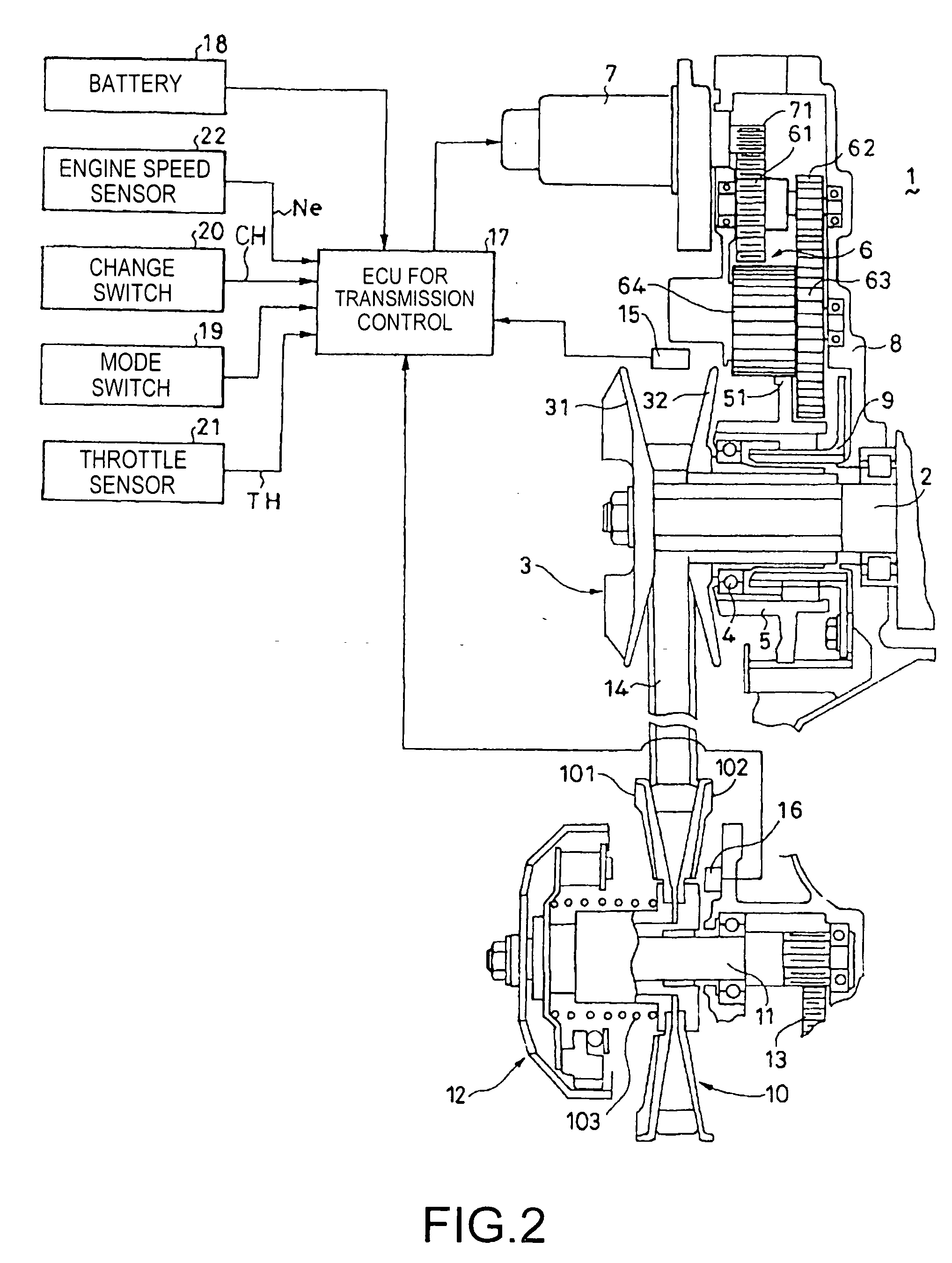

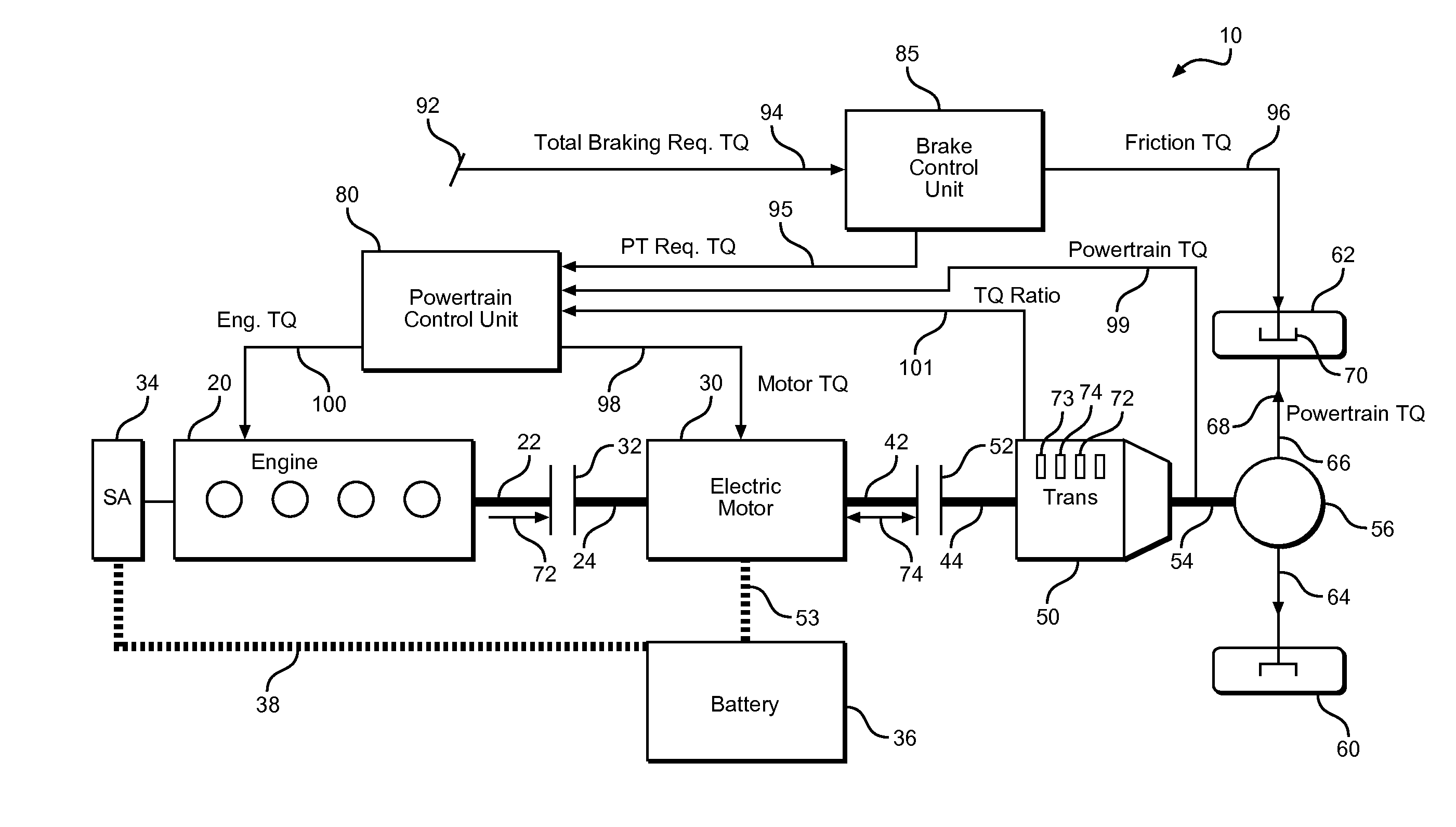

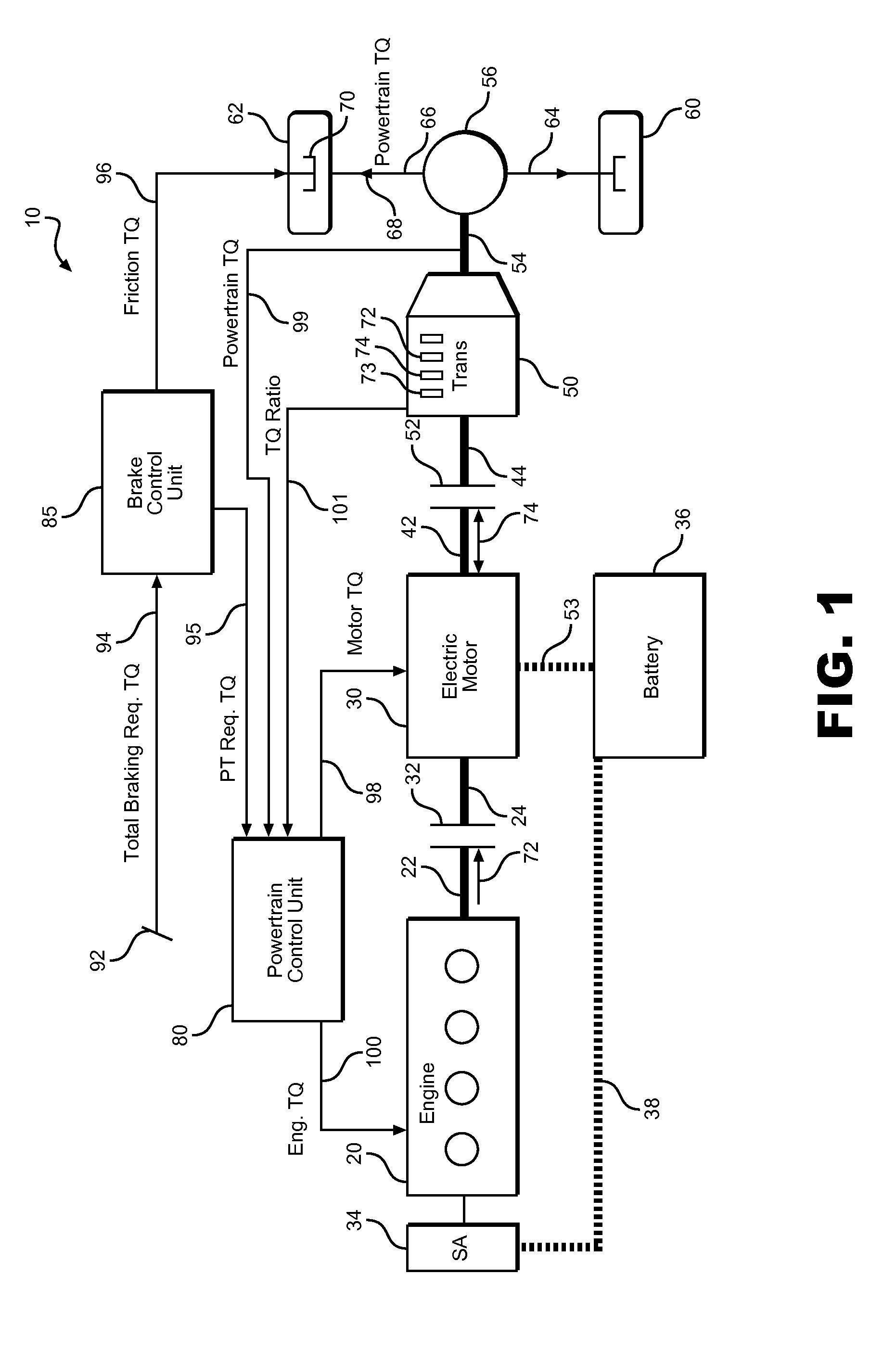

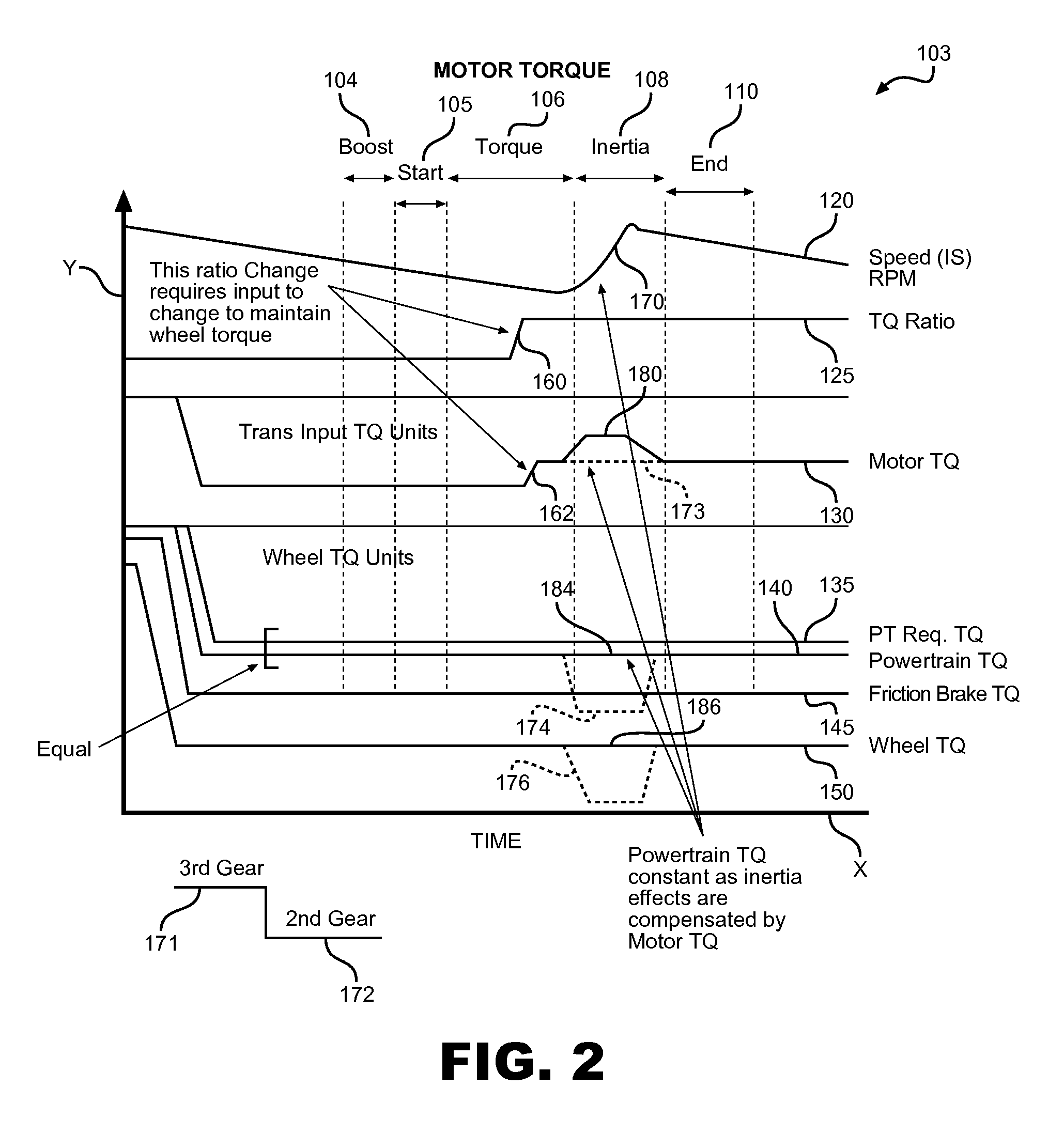

Torque Modulation in a Hybrid Vehicle Downshift During Regenerative Braking

ActiveUS20120265382A1Reduce shift shockReducing shift shockDigital data processing detailsVehicle sub-unit featuresElectric vehicleHybrid vehicle

A controller and a control strategy minimizes shift shock in a hybrid electric vehicle during a downshift conducted while the vehicle is in a regenerative braking mode by maintaining total powertrain torque at a desired target during the downshift. The controller has three preferable modes including modulating just engine torque, modulating just electric motor torque or simultaneously modulating both motor and engine torque.

Owner:FORD GLOBAL TECH LLC

Automatic speed changer

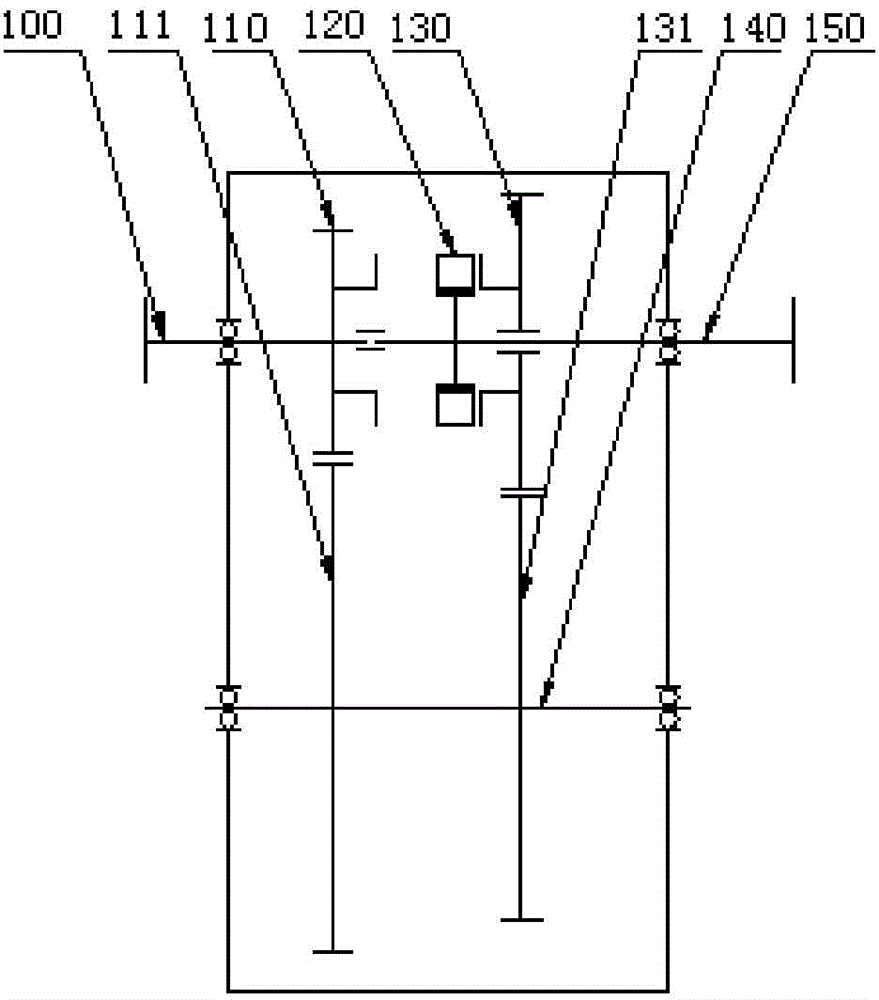

ActiveCN104930137AOptimize layoutImprove reliabilityGearboxesToothed gearingsAutomatic transmissionEngineering

The invention discloses an automatic speed changer. The automatic speed changer comprises a double-end-face tooth combined fluted disc and a two-level speed reduction fixed shaft wheel train. A gear shifting mechanism of the speed changer is the double-end-face tooth combined fluted disc and is provided with double-end-face teeth including the left end face teeth and the right end face teeth. The double-end-face tooth combined fluted disc axially moves on an output shaft of the speed changer, the left end face teeth and the right end face teeth of the double-end-face tooth combined fluted disc are engaged with end face teeth of a one-level speed reduction gear and a two-level speed reduction gear respectively, the two-gear position and the one-gear position are achieved, and when the left end face teeth and the right end face teeth of the double-end-face tooth combined fluted disc are not combined with the end face teeth of the one-level speed reduction gear and the two-level speed reduction gear, the speed changer is at a neutral position. According to the technical scheme, compared with a traditional AMT, a synchronizer is removed, the structure is simple, reliability is high, the gear shifting time is short, the gear shifting impact is small, the production cost is low, and industrialization is easy to achieve. The gear arrangement mode of the speed changer is simple, the axial size is short, the occupied space is small, the weight is low, and the automatic speed changer conforms to the development trend of light weight and energy saving.

Owner:JING JIN ELECTRIC TECH CO LTD +1

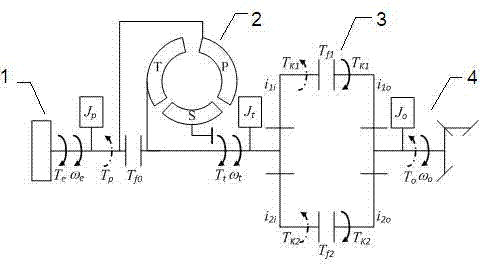

Gear-shifting control method for automatic hydraulic speed changer

ActiveCN103671898AControl torque variationCombined with softGearing controlAutomatic transmissionControl theory

The invention discloses a gear-shifting control method for an automatic hydraulic speed changer. The gear-shifting control method comprises the steps that in the one-time gear shifting process, only one clutch is started, the other clutch is combined, the torque exchanging process is carried out between the two movement clutches, oil pressure is controlled through the combination of the clutch controlling step and the separated clutch controlling step, and the flexible clutch combination is guaranteed by adjusting the K1 and K2 control pressure in the gear shifting process. The engine torque changing is controlled, and easy, efficient and smooth gear shifting controlling of the automatic hydraulic speed changer is achieved. The test carried out under the full accelerator aperture and other limiting conditions such as gear lifting and gear jumping and reducing in a low-gear gear area shows that the control method can meet the requirements for gear shifting quality of forward torque gear lifting, forward torque gear reducing, negative torque gear lifting and negative toque gear reducing.

Owner:SHENGRUI TRANSMISSION

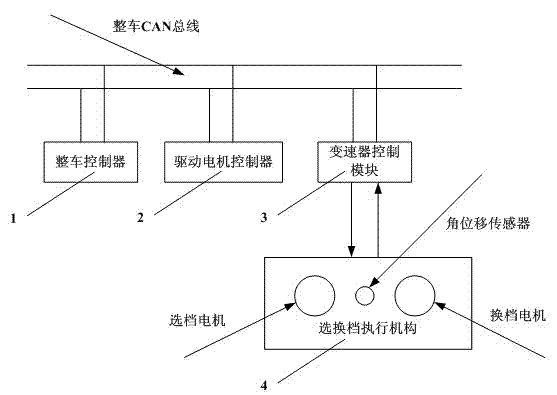

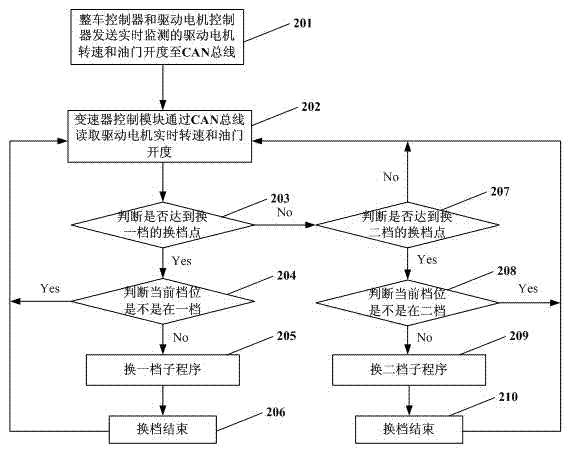

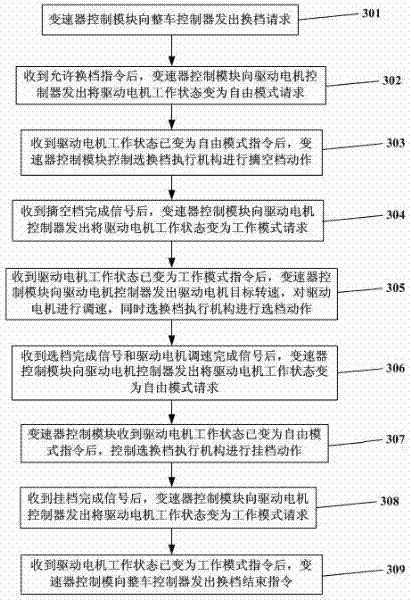

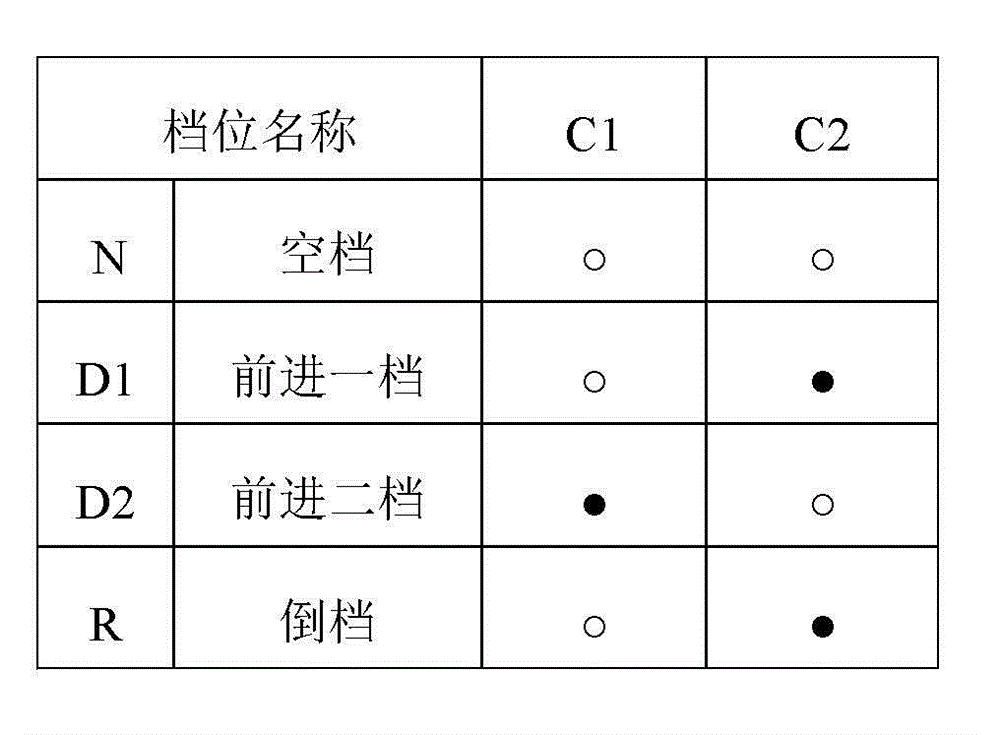

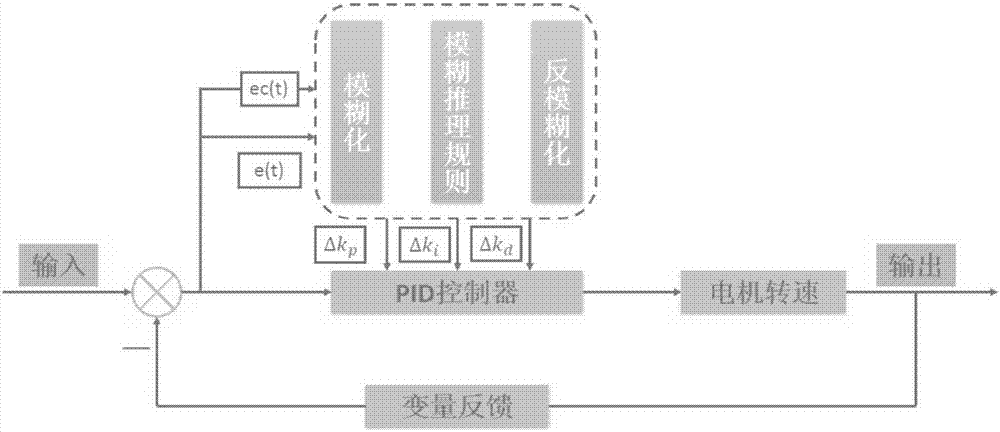

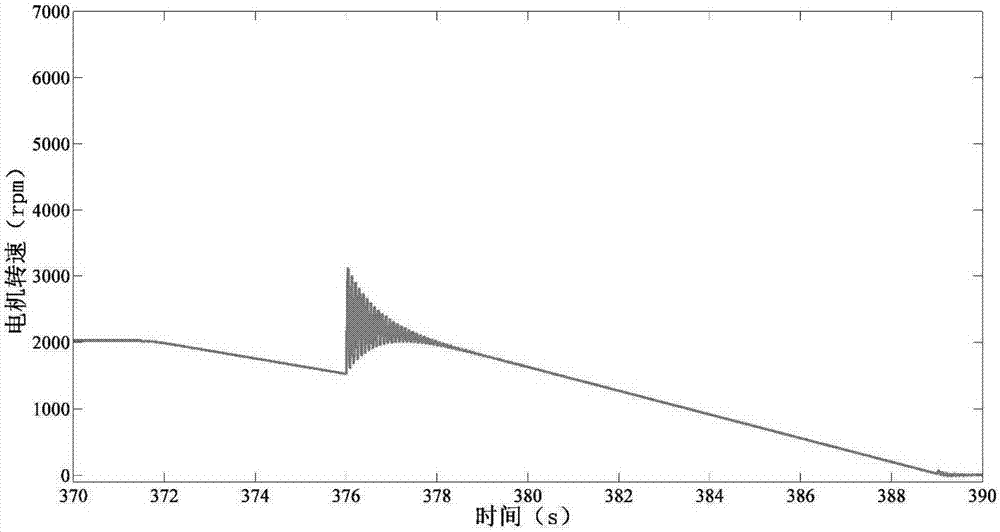

A control system and control method for a two-speed automatic transmission of a pure electric vehicle

The invention discloses a two-speed automatic transmission control system and control method for pure electric vehicles. The control system includes a vehicle controller, a drive motor controller, a transmission control module, and a gear selection actuator. It includes a gear selection motor, a gear shifting motor, a gear position sensor, an angular displacement sensor and a mechanical transmission part. The invention improves the transmission system of the traditional pure electric vehicle. The transmission adopts a two-speed structure, which can improve the performance of the electric vehicle, reduce the requirements on the performance of the motor, make the motor work more in the high-efficiency area, and extend its driving range. During the shifting process, the transmission control module automatically controls the gear selection and shifting actuator to realize automatic shifting and reduce the labor intensity of the operator; during the shifting process, the transmission control module, the vehicle controller and the drive motor controller Through the set control method, the working state of the drive motor is integratedly controlled, the speed of the drive motor is precisely controlled, the impact of shifting is small, and the smoothness of shifting and ride comfort of the vehicle are improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

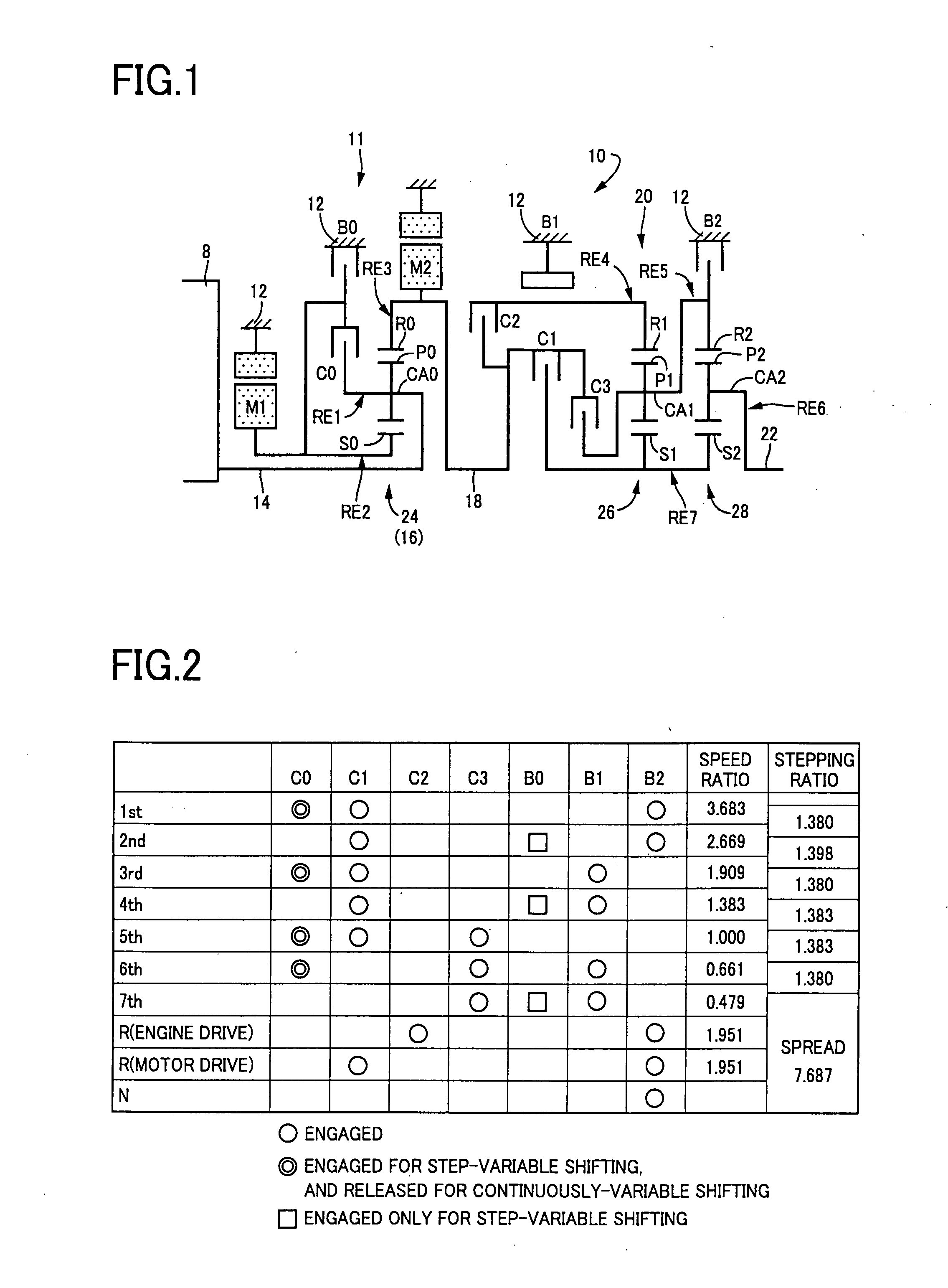

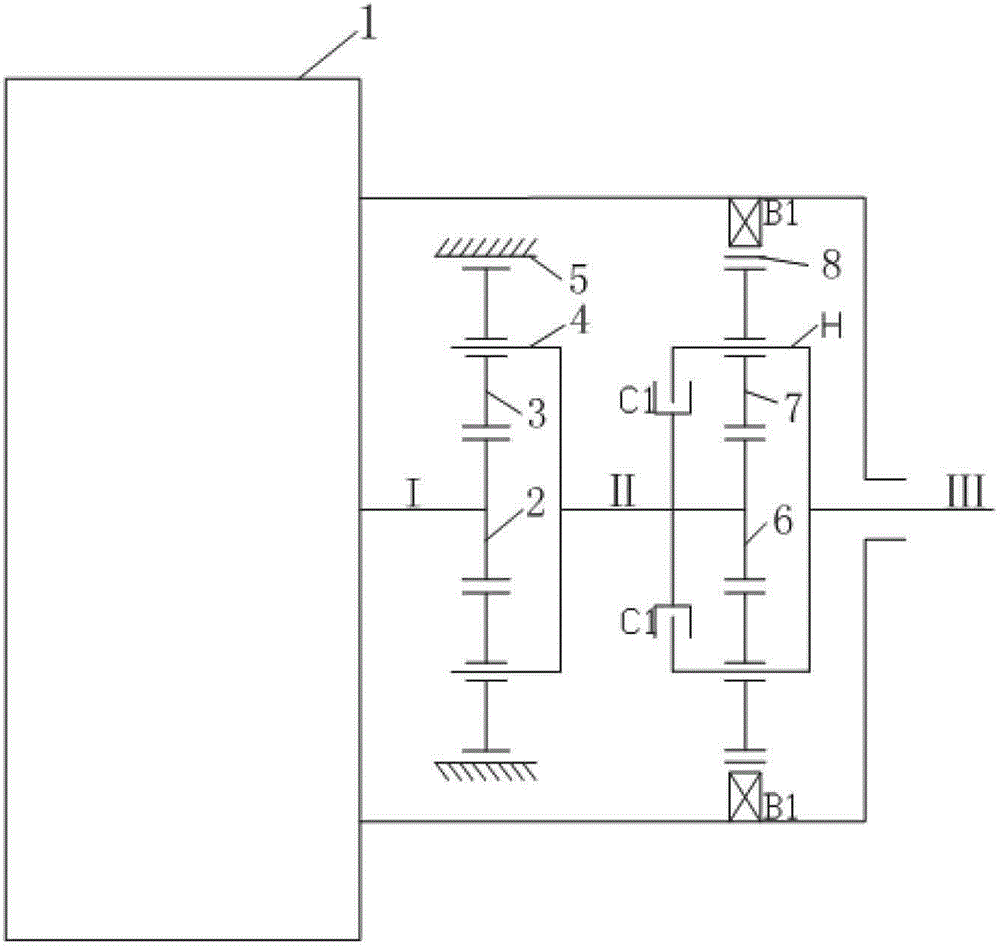

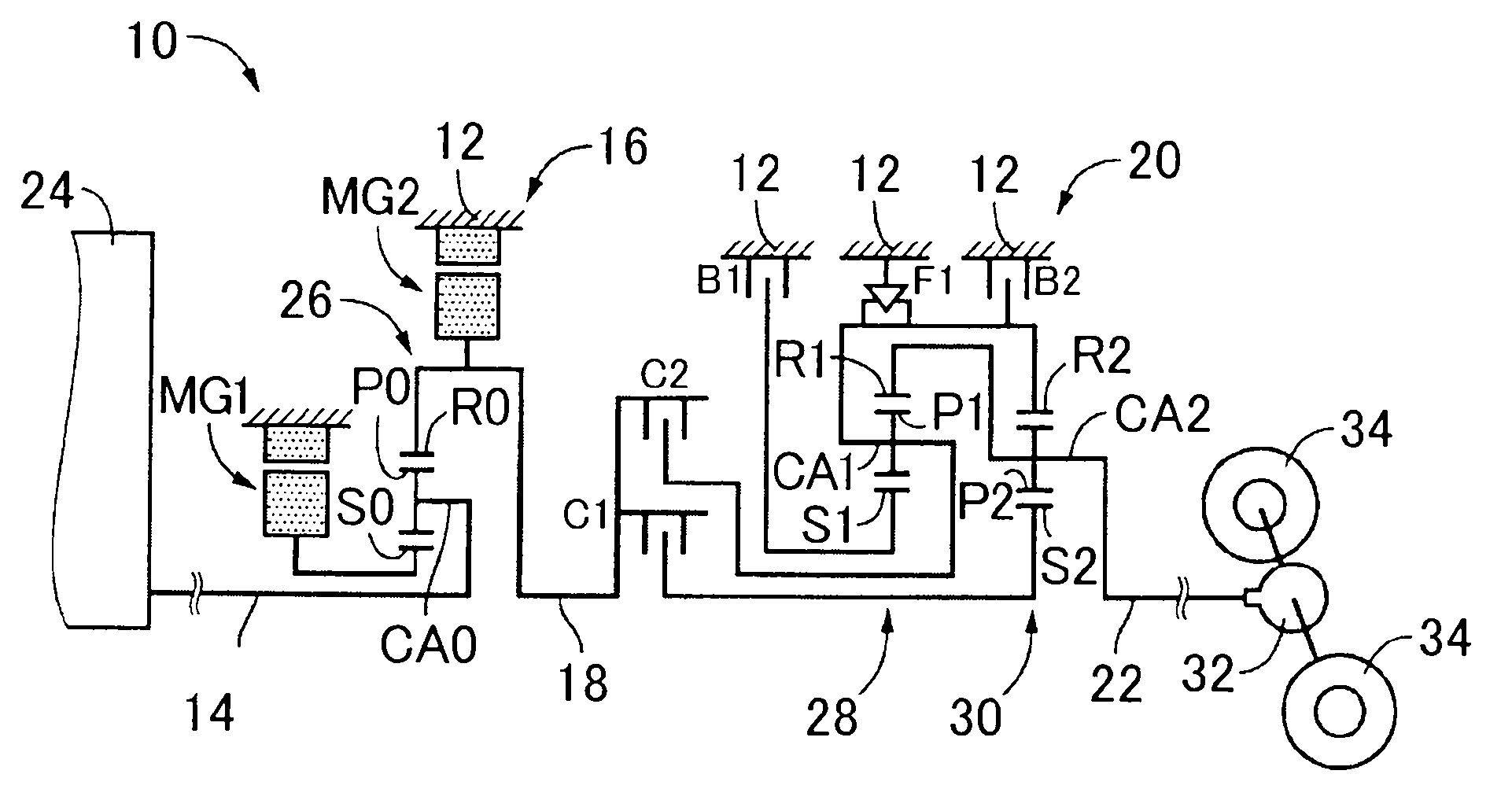

Control apparatus for vehicular drive system

InactiveUS20080153664A1Reduce shift shockReduce total powerHybrid vehiclesDigital data processing detailsVariatorControl equipment

A control apparatus for a vehicular drive system including a first or continuously-variable transmission portion and a second or step-variable transmission portion which are disposed in series with each other, the first transmission portion being switchable between a continuously-variable shifting state and a step-variable shifting state, and the second transmission portion having a plurality of gear positions having respective speed ratios, the control apparatus including a step-variable shifting control portion configured to be operable upon concurrent occurrences of a shift-down action of one of the first and second transmission portions and a shift-up action of the other of the first and second transmission portions, to control the first transmission portion placed in the step-variable shifting state such that the shifting action of the first transmission portion is performed in synchronization with the shifting action of the second transmission portion, or operable upon concurrent occurrences of a switching action of the first transmission portion between the two shifting sates and a shifting action of the second transmission portion, to control the first transmission portion such that the switching action is performed during the shifting action of the second transmission portion.

Owner:TOYOTA JIDOSHA KK

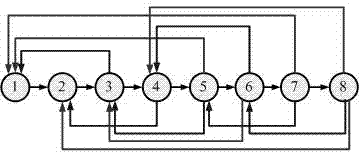

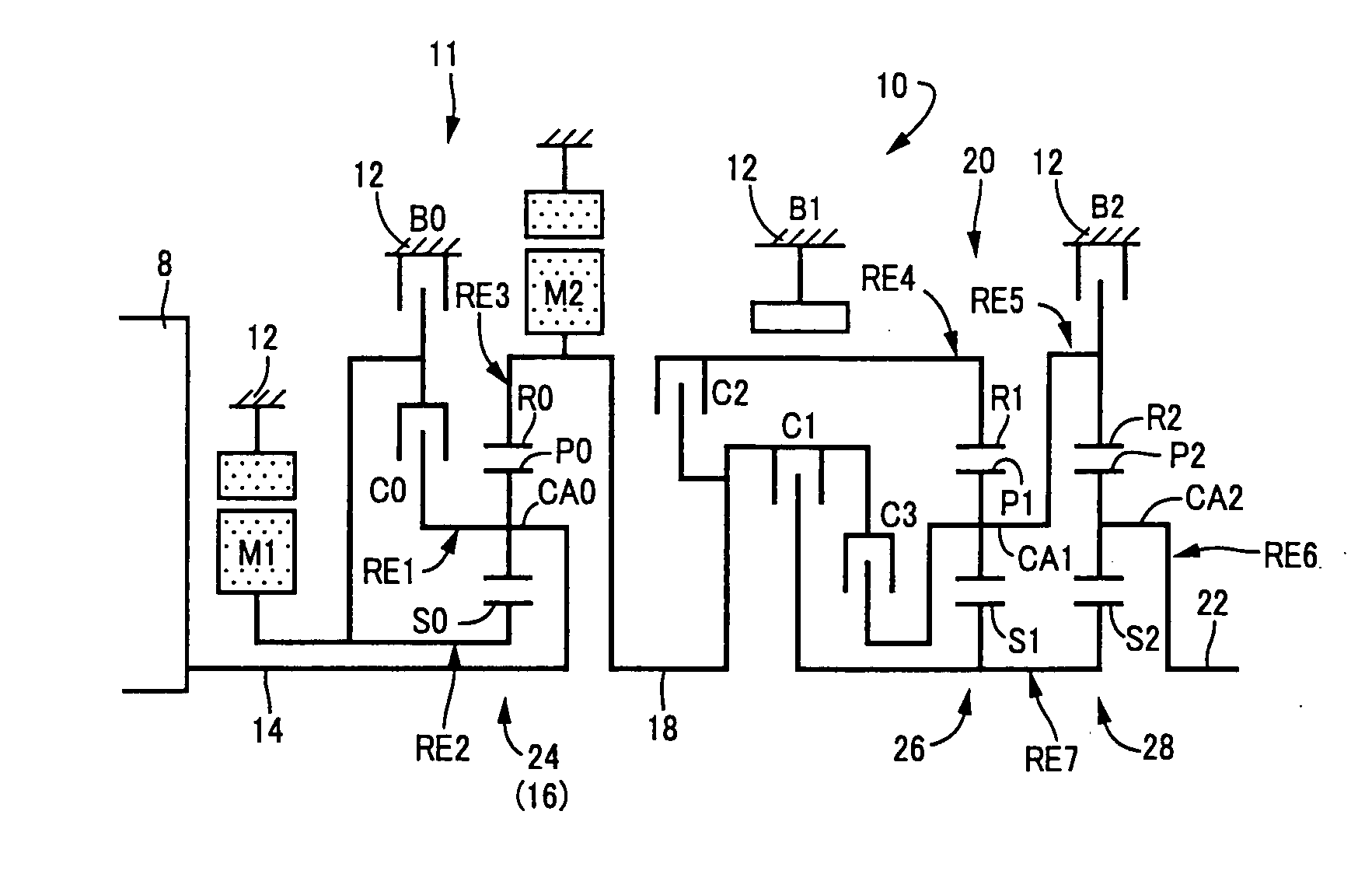

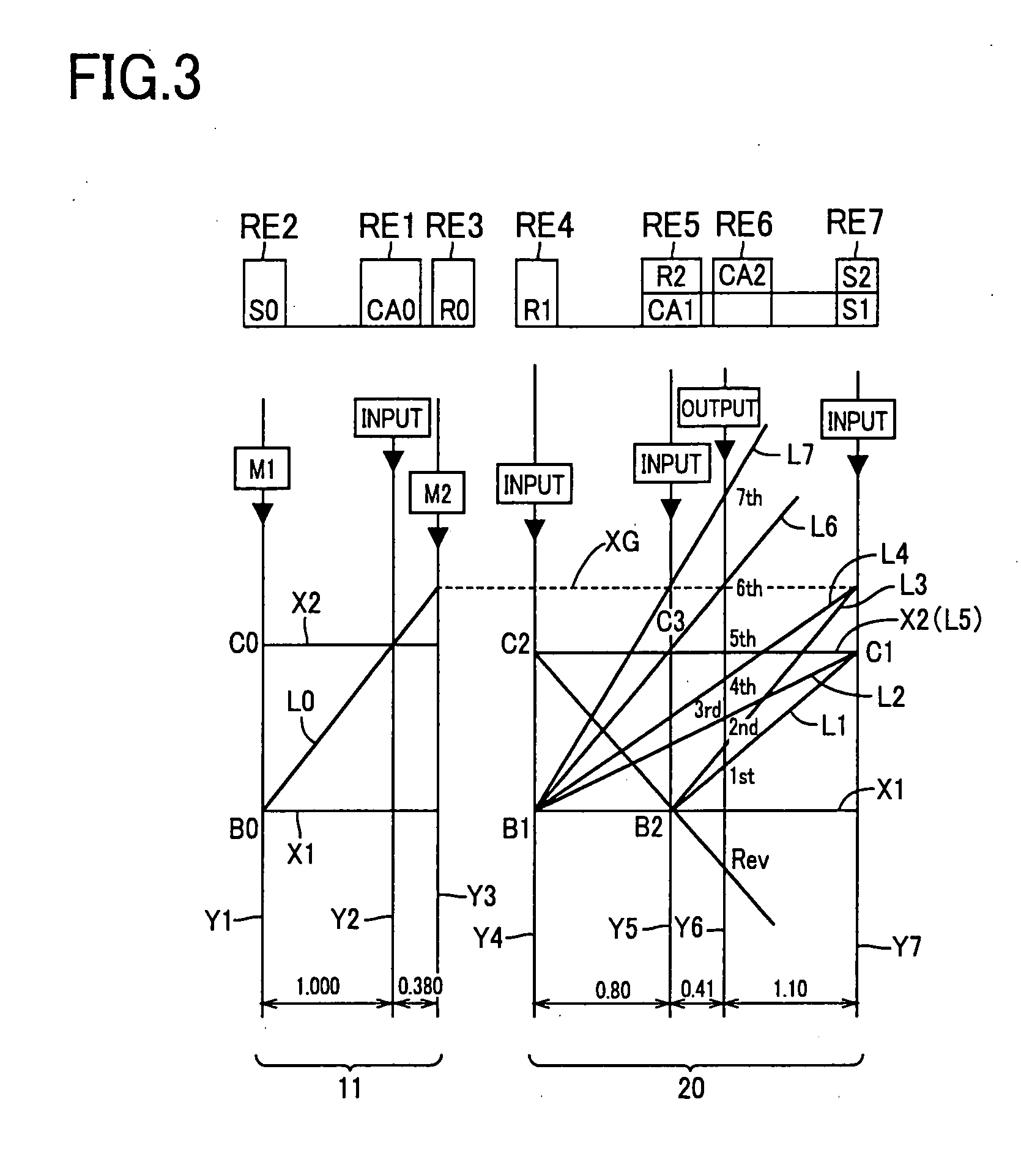

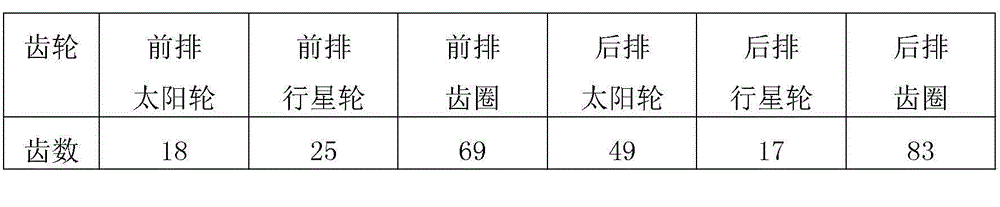

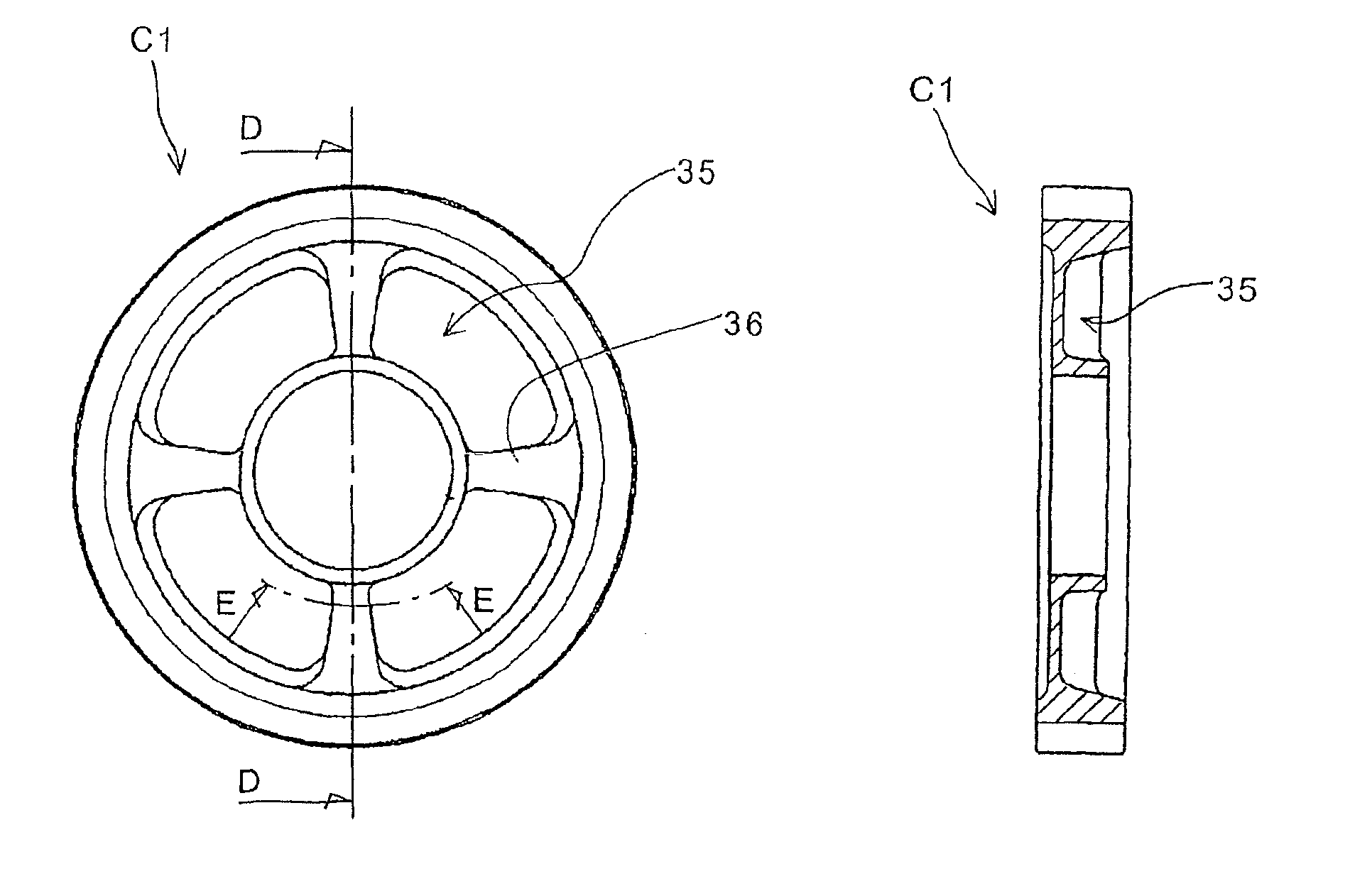

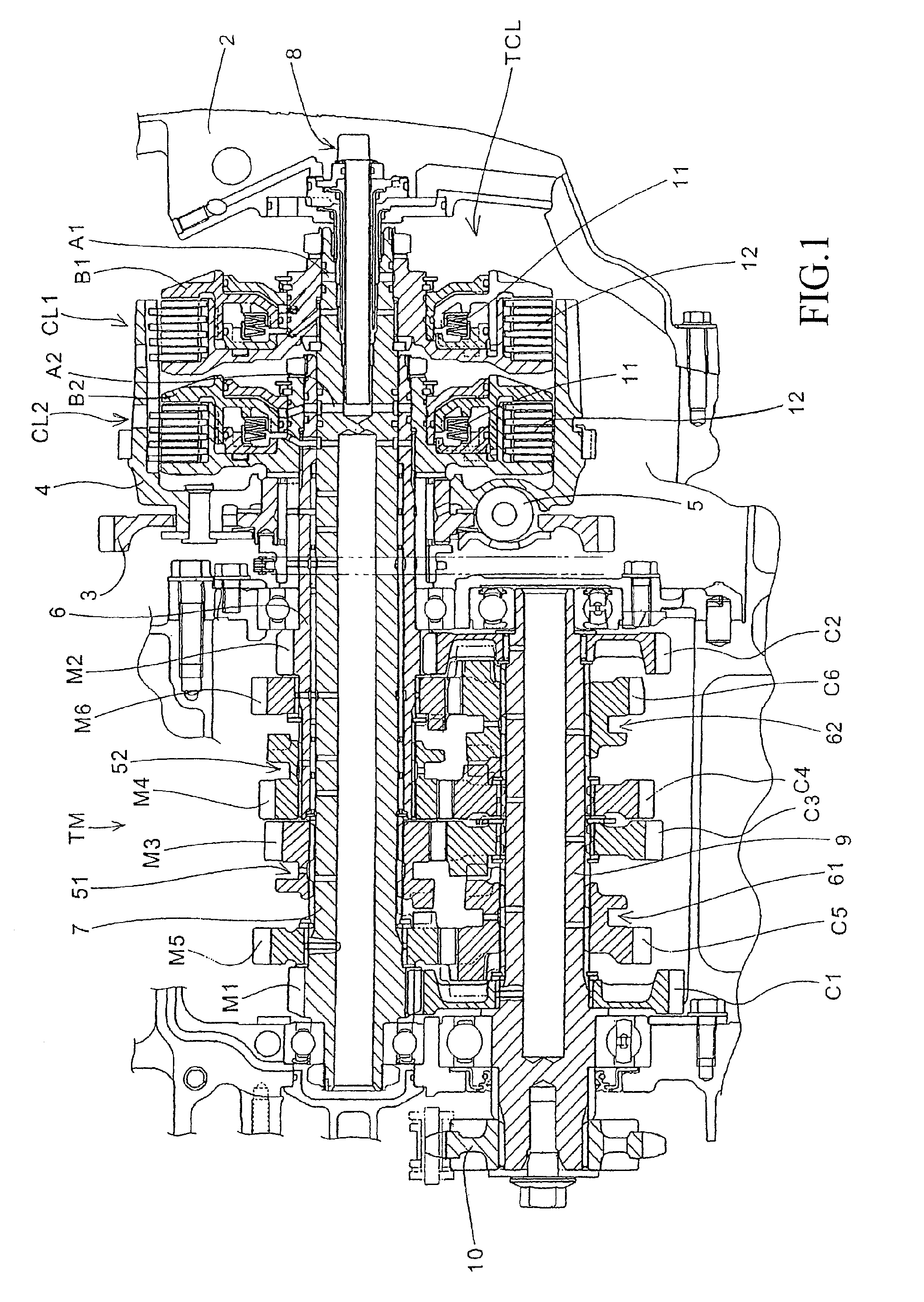

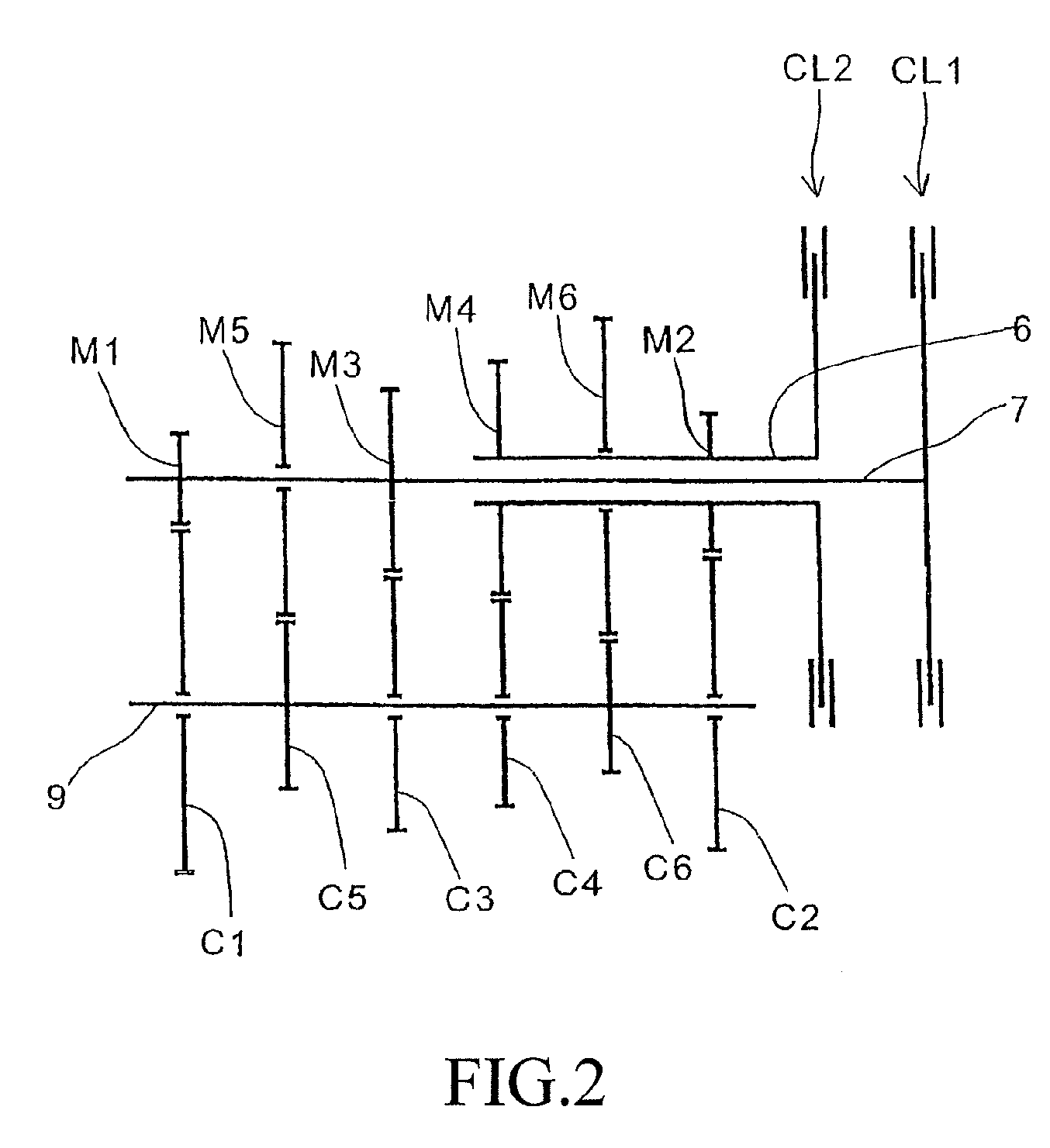

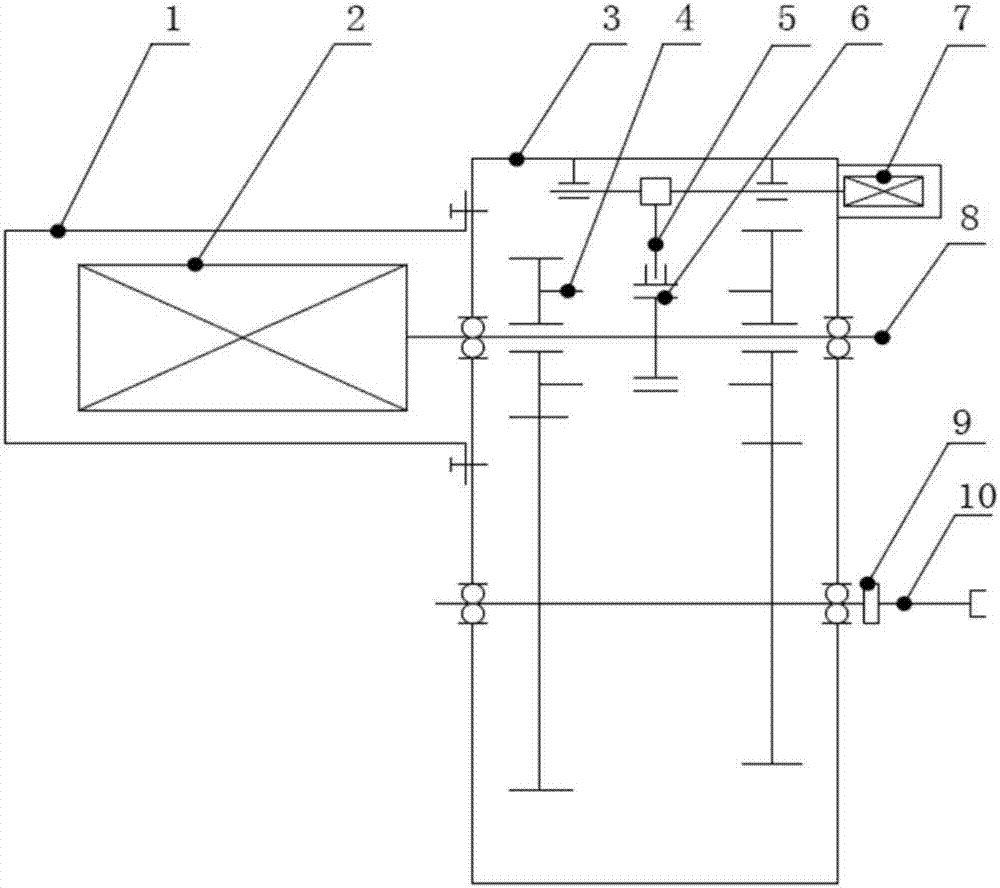

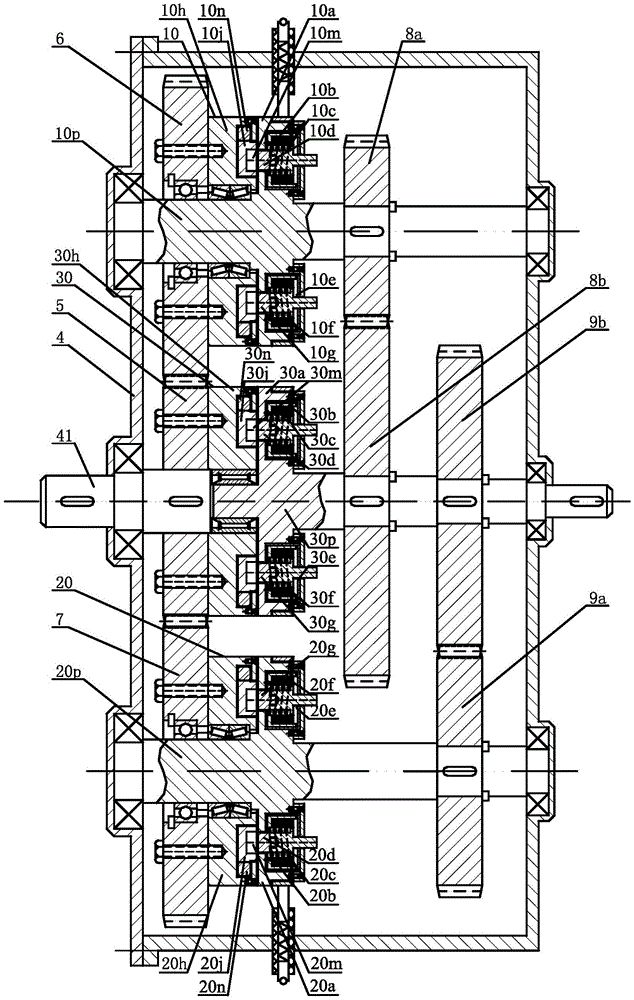

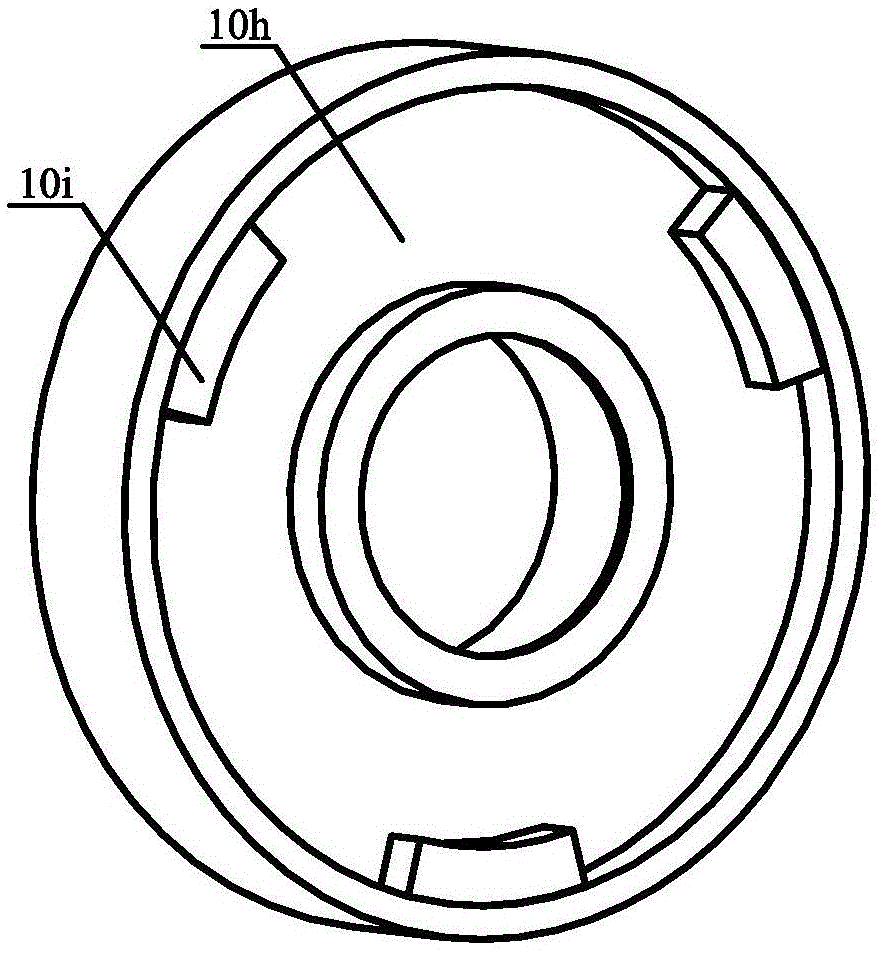

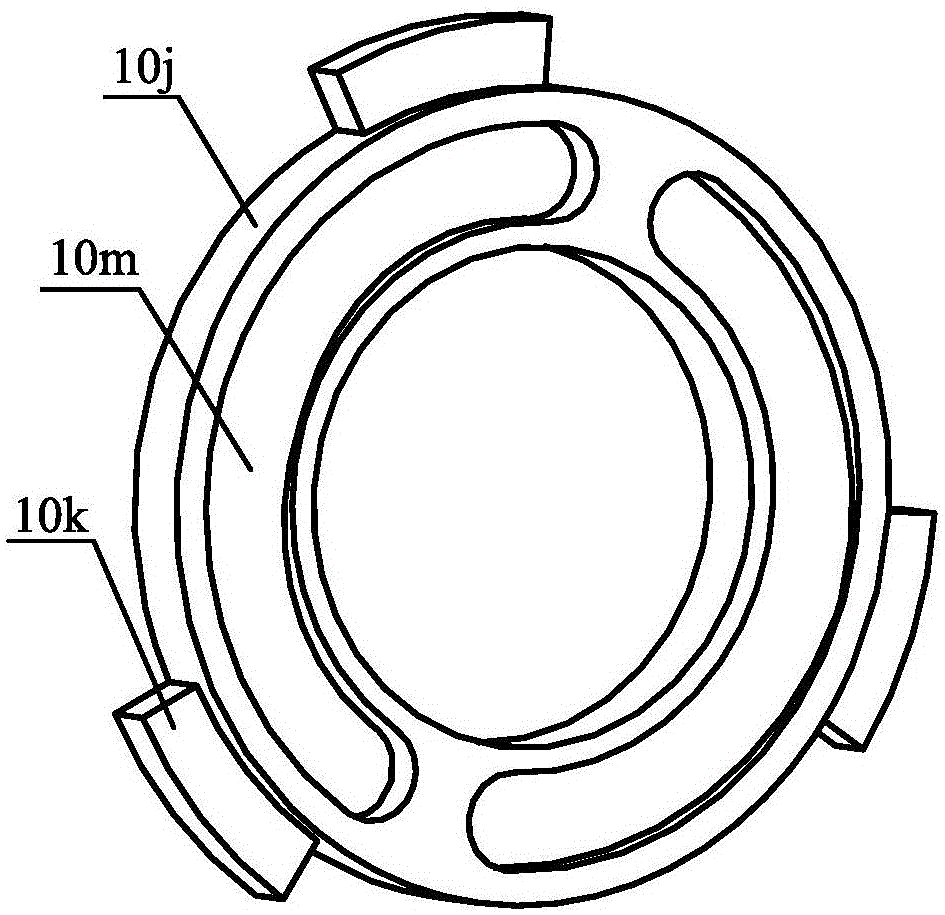

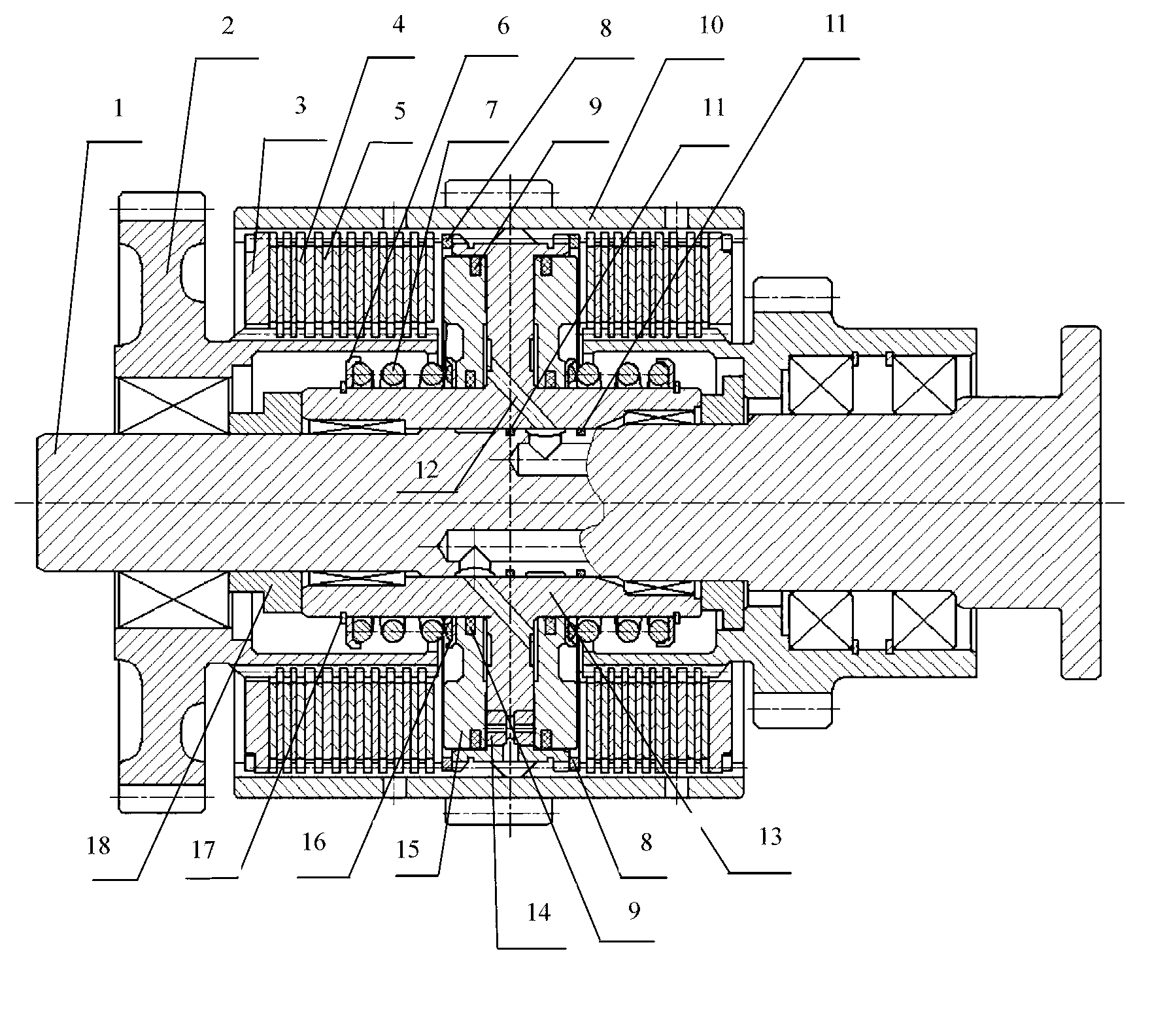

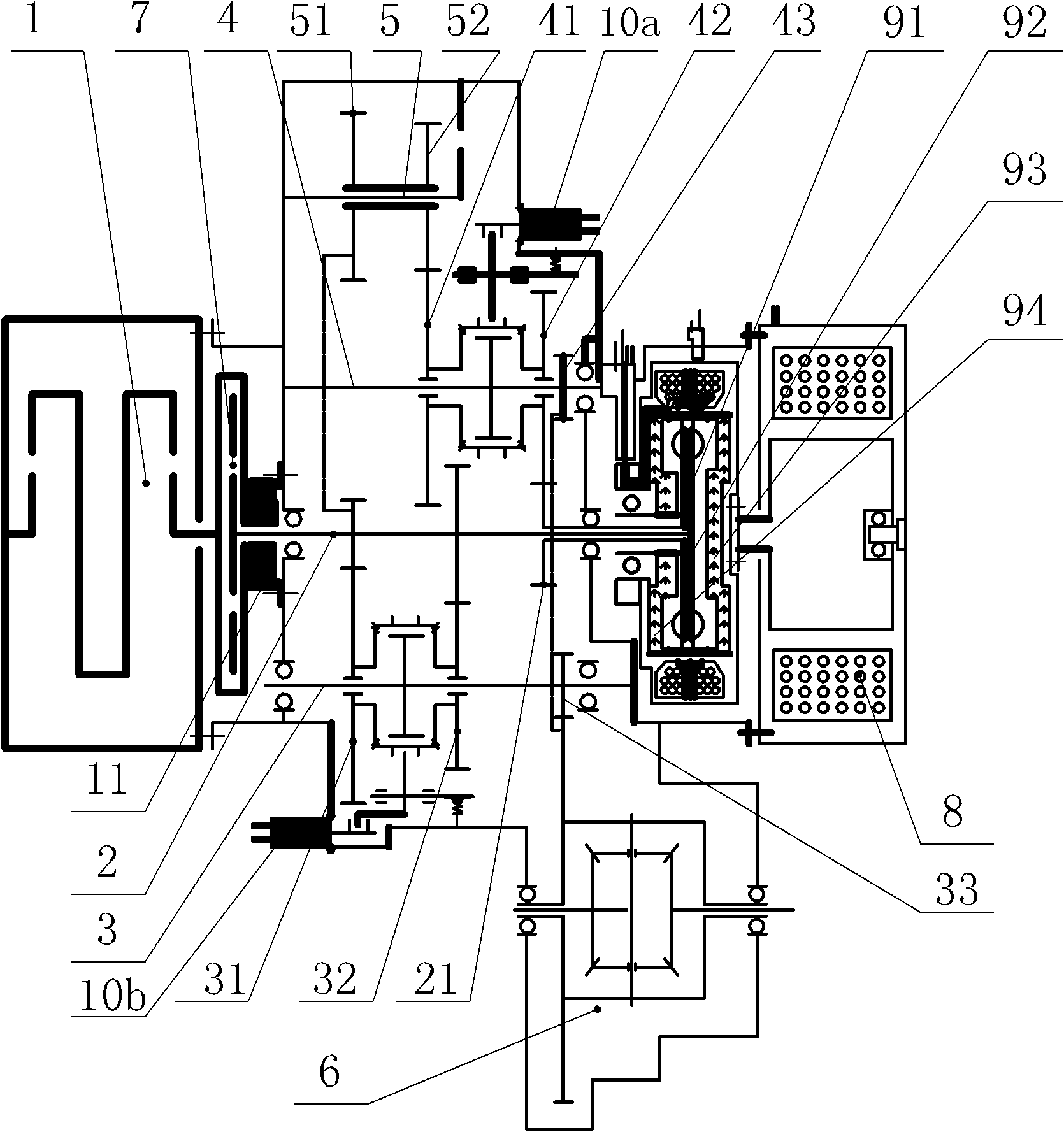

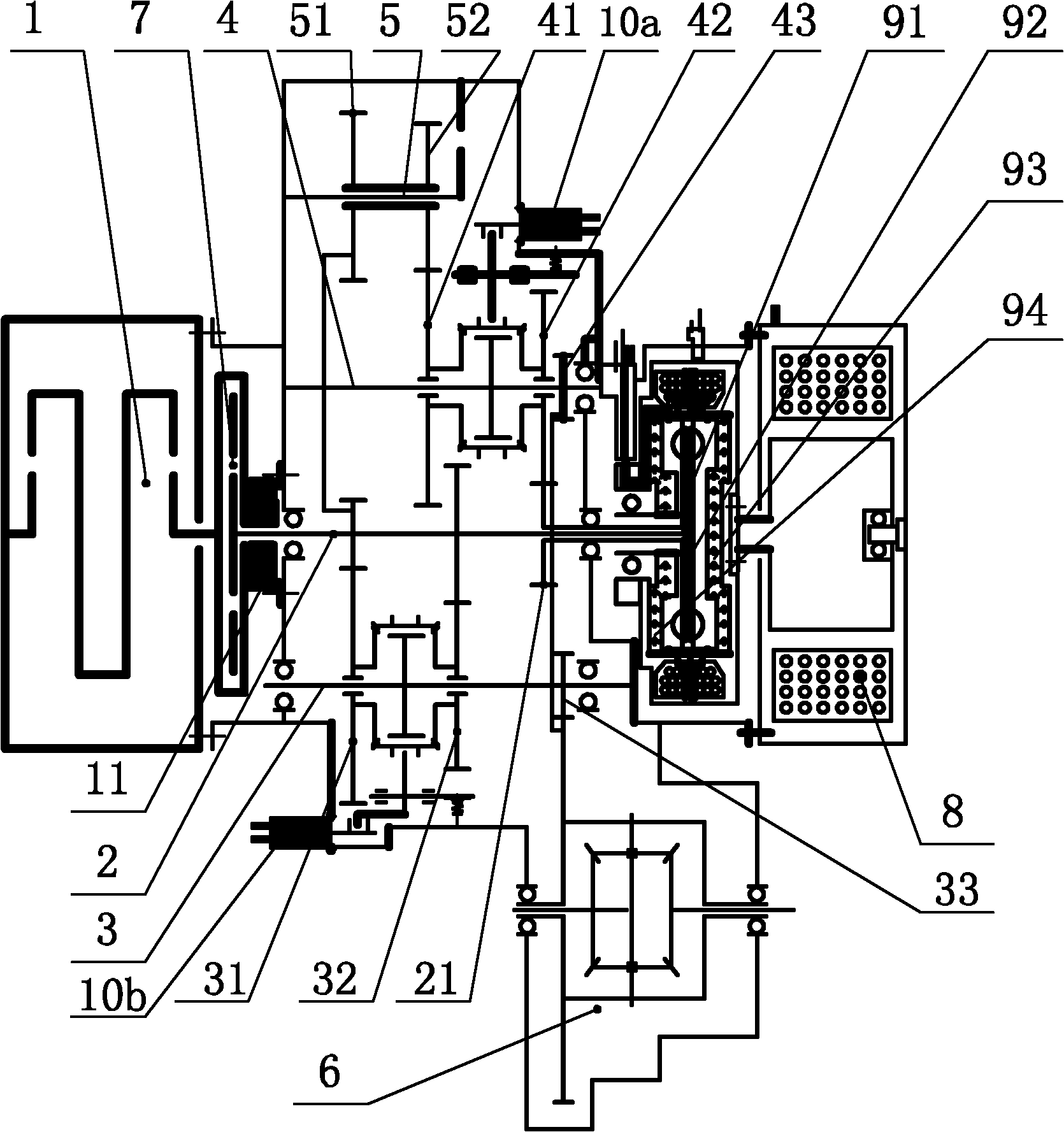

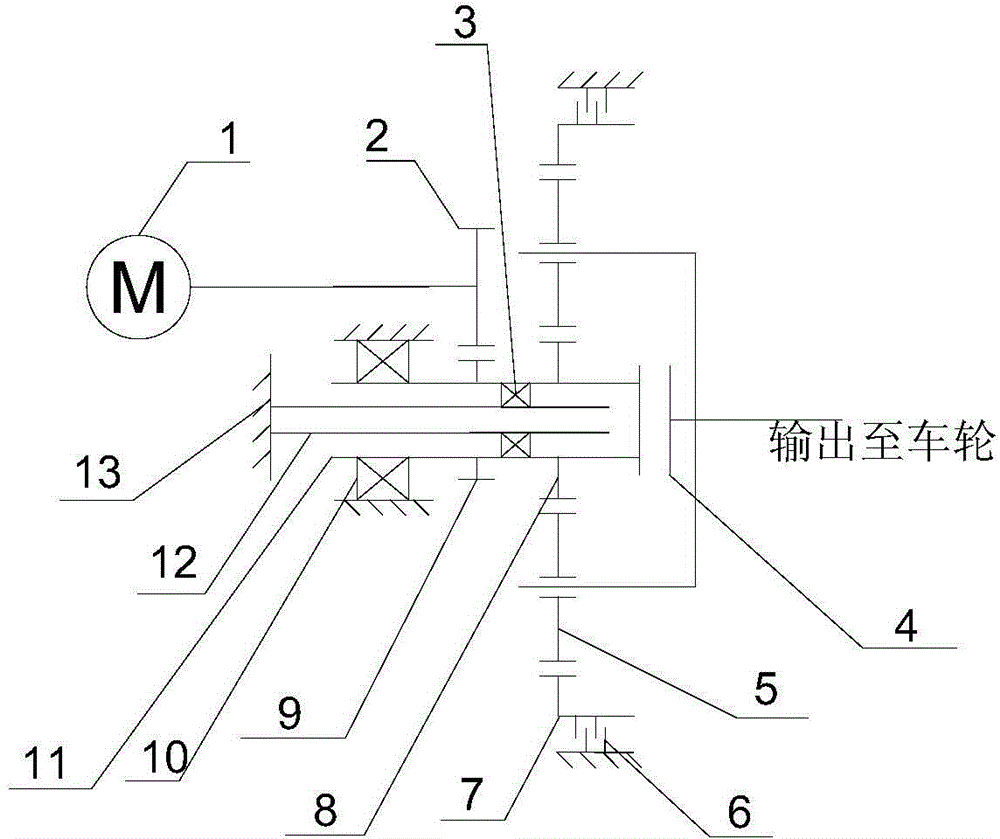

Motor-transmission integral transmission system for electric automobile

ActiveCN102983672AReduce shift actuatorsImprove efficiencyElectric machinesMechanical energy handlingAutomatic transmissionEngineering

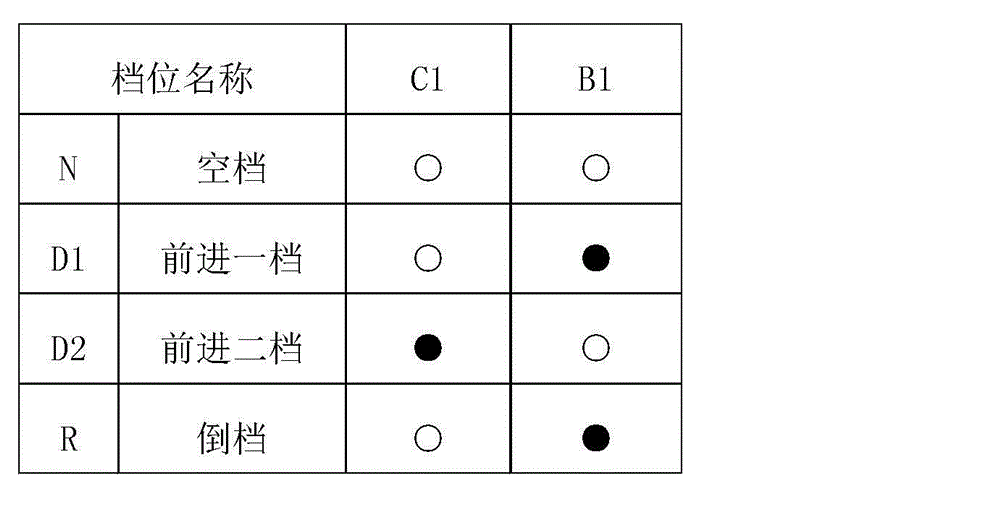

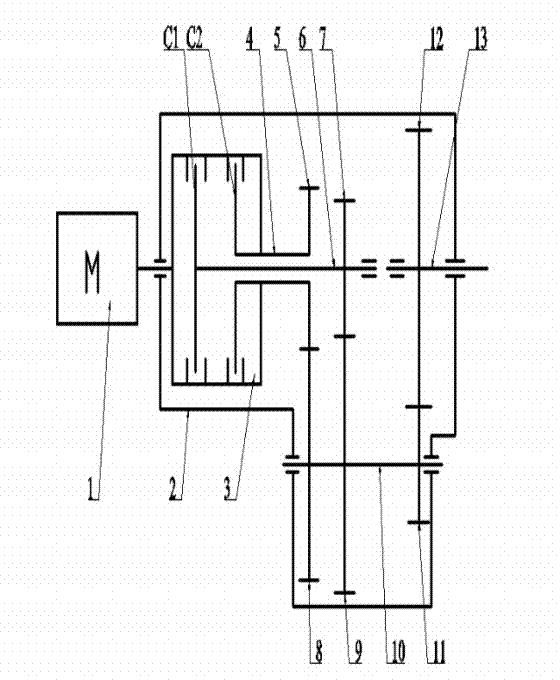

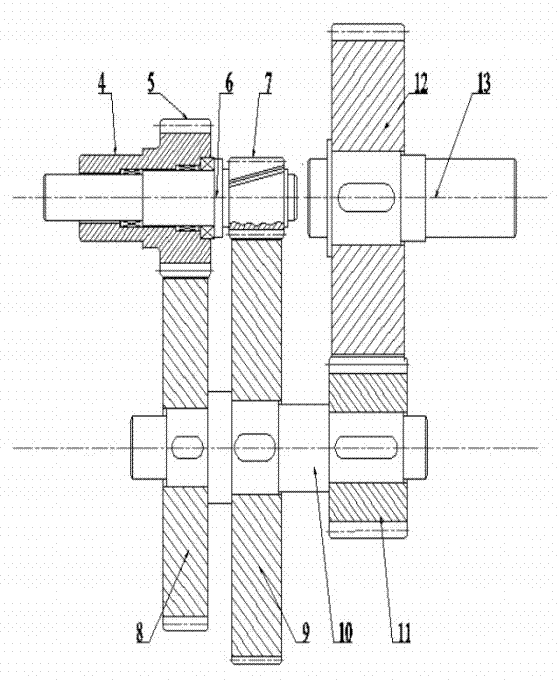

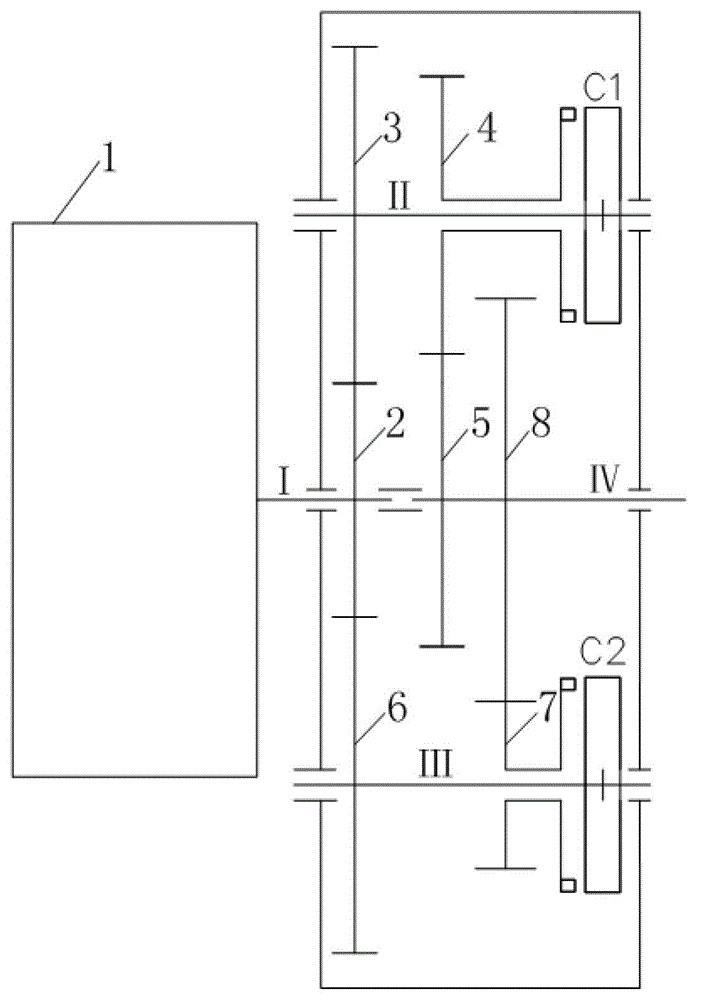

The invention discloses a motor-transmission integral transmission system for an electric automobile and relates to a two-gear automatic gearbox planetary gear mechanism. The mechanism comprises two single-row 2K-H planetary gear transmission systems, a front-row gear ring is fixed in a front-row planetary gear transmission system, and motive power is transmitted from a front-row sun gear to a front-row planet carrier for outputting to complete a first-level deceleration. In a back-row planetary gear transmission system, a clutch C1 achieves combination and separation of a back-row sun gear and a back-row planet carrier, a brake B1 achieves fixation and separation of a back-row gear ring and a tank body, finally the motive power is output by the back-row planet carrier, and shifting of two gears can be completed through different combinations of working of the clutch and the brake. The motor-transmission integral transmission system is simple in mode, compact in structure, small in size and light in weight, and meets principles of automobile light weight.

Owner:HEFEI UNIV OF TECH

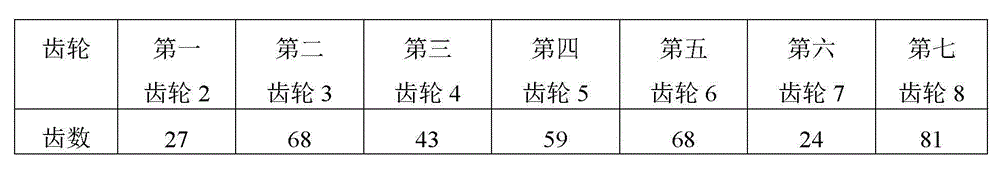

Two-speed dual clutch transmission drive unit for pure electric vehicle

InactiveCN103032526AImprove work efficiencyImprove driving comfort performanceToothed gearingsGearing detailsGear driveReduction drive

The invention relates to a two-speed dual clutch transmission drive unit for a pure electric vehicle. The two-speed dual clutch transmission drive unit comprises a motor, a dual clutch, a transmission box, an inner input gear shaft, an outer input gear shaft, an intermediate shaft and an output shaft. A gear on the inner input gear shaft is a first-gear driving gear; a gear on the outer input gear shaft is a second-gear driving gear; the intermediate shaft is provided with a first-gear driven gear, a second-gear driven gear and a main reducing driving gear; and the output shaft is provided with a main reducing driven gear. Power is delivered from the motor to be input to the dual clutch, and is delivered to a first-gear gear set (a second-gear gear set) through the inner input gear shaft (the outer input gear shaft), and then, a first-gear torsion (a second-gear torsion) is transmitted to the output shaft by a main reducing gear on the intermediate shaft to be output. The two-speed dual clutch transmission drive unit for the pure electric vehicle has the characteristics that 1, by adopting an integrated structure of the transmission and a reducer, the transmission and a main reducer of an electric vehicle are fused together, and thus, the power can be directly output to axletrees; a reducing mechanism is not needed, so that a drive system is more compact in structure, the number of parts is reduced, and the cost is reduced; 2, gears are shifted by adopting the dual clutch, and thus, the requirements of the gear shifting dynamic property and the economic efficiency of a traditional electric vehicle are met; the power of the motor is utilized optimally; and the driving distance of the electric vehicle is extended.

Owner:冯关华

Two-gear automatic transmission for electric automobile

InactiveCN102943846AReduce shift shockReduce manufacturing costToothed gearingsGearing detailsStopped workAutomatic transmission

The invention discloses a two-gear automatic transmission for an electric automobile. The two-gear automatic transmission comprises two electromagnetic clutches and two double-speed-reduction ordinary gear trains which have the same working principle. Power is transmitted to a front pair of gears through a driving motor to achieve primary speed reduction and then transmitted to a rear pair of gears by controlling working of the two electromagnetic clutches to achieve secondary speed reduction. By controlling the two electromagnetic clutches to work or stop working, the shifting of two gears can be achieved. By adopting the two single electromagnetic clutches to serve as gear shifting elements of the two-gear automatic transmission, the two-gear automatic transmission for the electric automobile is small in gear shifting impact, simple in form, compact in structure, small in size, light and capable of according with the efficient and light principle of the automobile.

Owner:HEFEI UNIV OF TECH

Twin clutch speed-change apparatus

A twin clutch speed-change apparatus that can reduce shift shock includes a transmission with multiple gear pairs disposed between a main shaft and a countershaft. A twin clutch is provided on the main shaft, a rotational drive force from an engine being connected / disconnected between the transmission and the engine, a dog clutch is provided between an axially slidably attached slidable gear and an axially non-slidably attached non-slidable gear to select a gear pair, for transmitting a rotational drive force, from the multiple gear pairs. Dog teeth of the dog clutch include steps different in axial height from each other between a portion abutted against a lateral wall surface of a dog hole when the rotational drive force is transmitted by the dog clutch, and a portion abutted against a lateral wall surface of the dog hole when the rotational drive force is not transmitted by the dog clutch.

Owner:HONDA MOTOR CO LTD

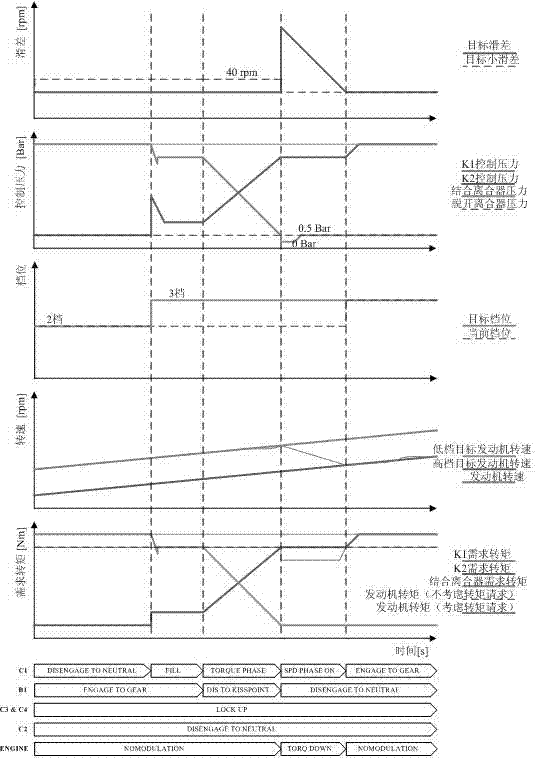

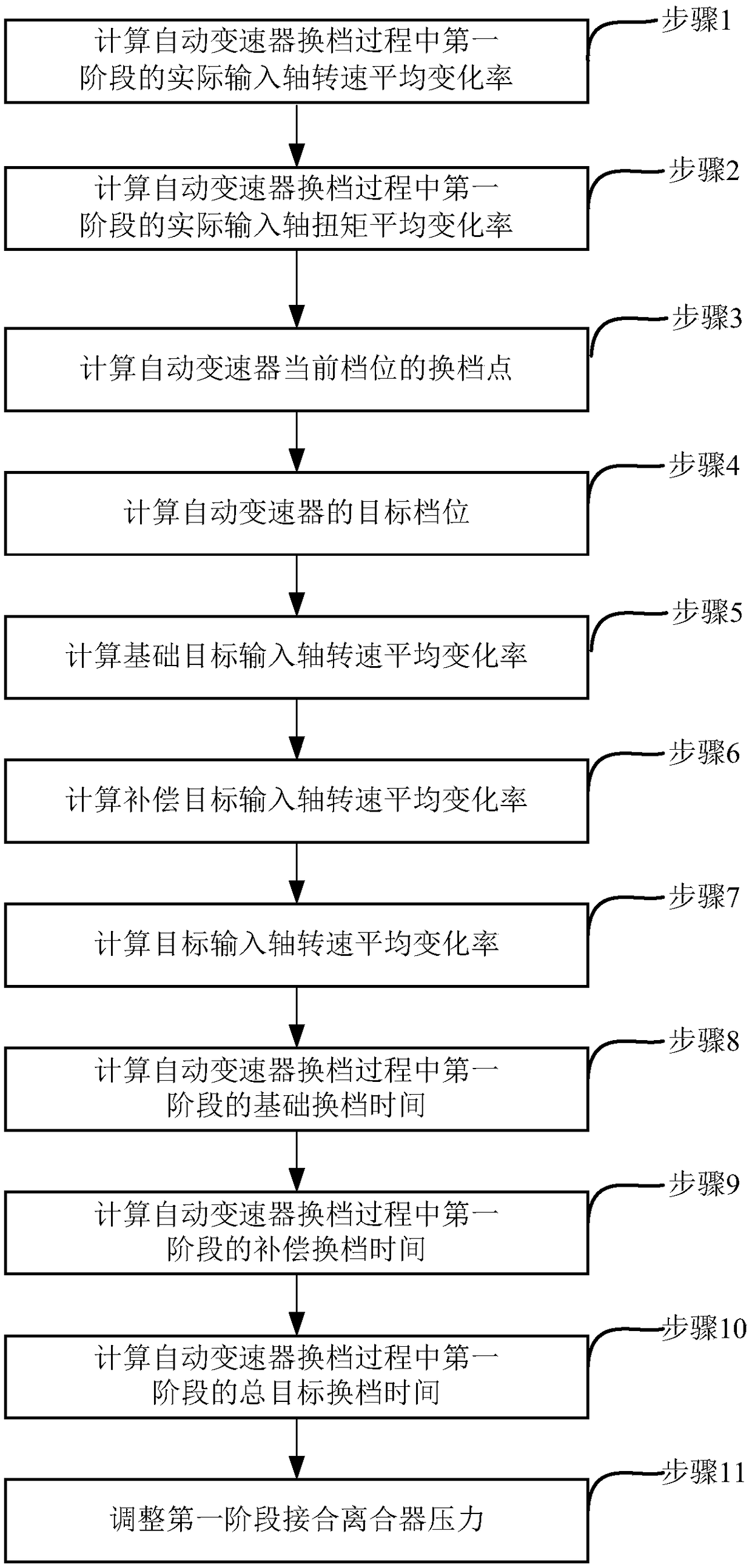

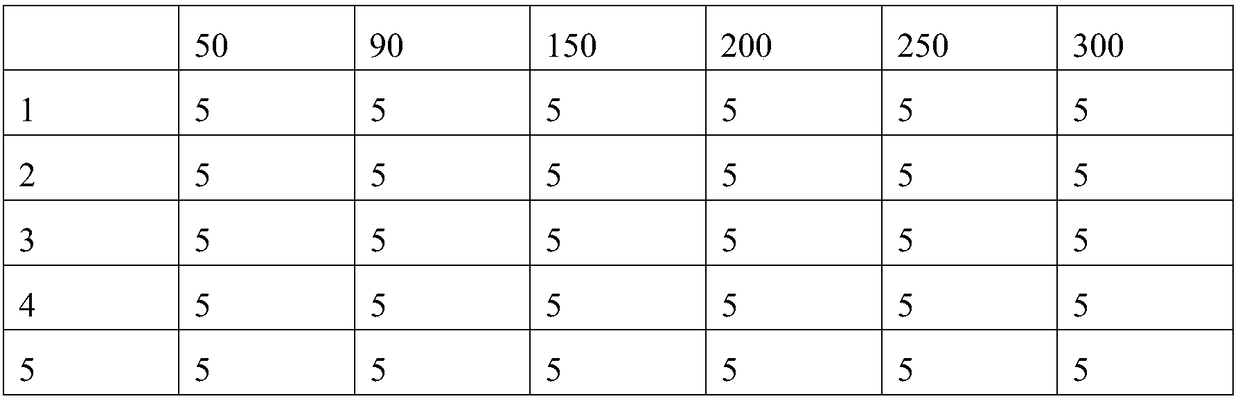

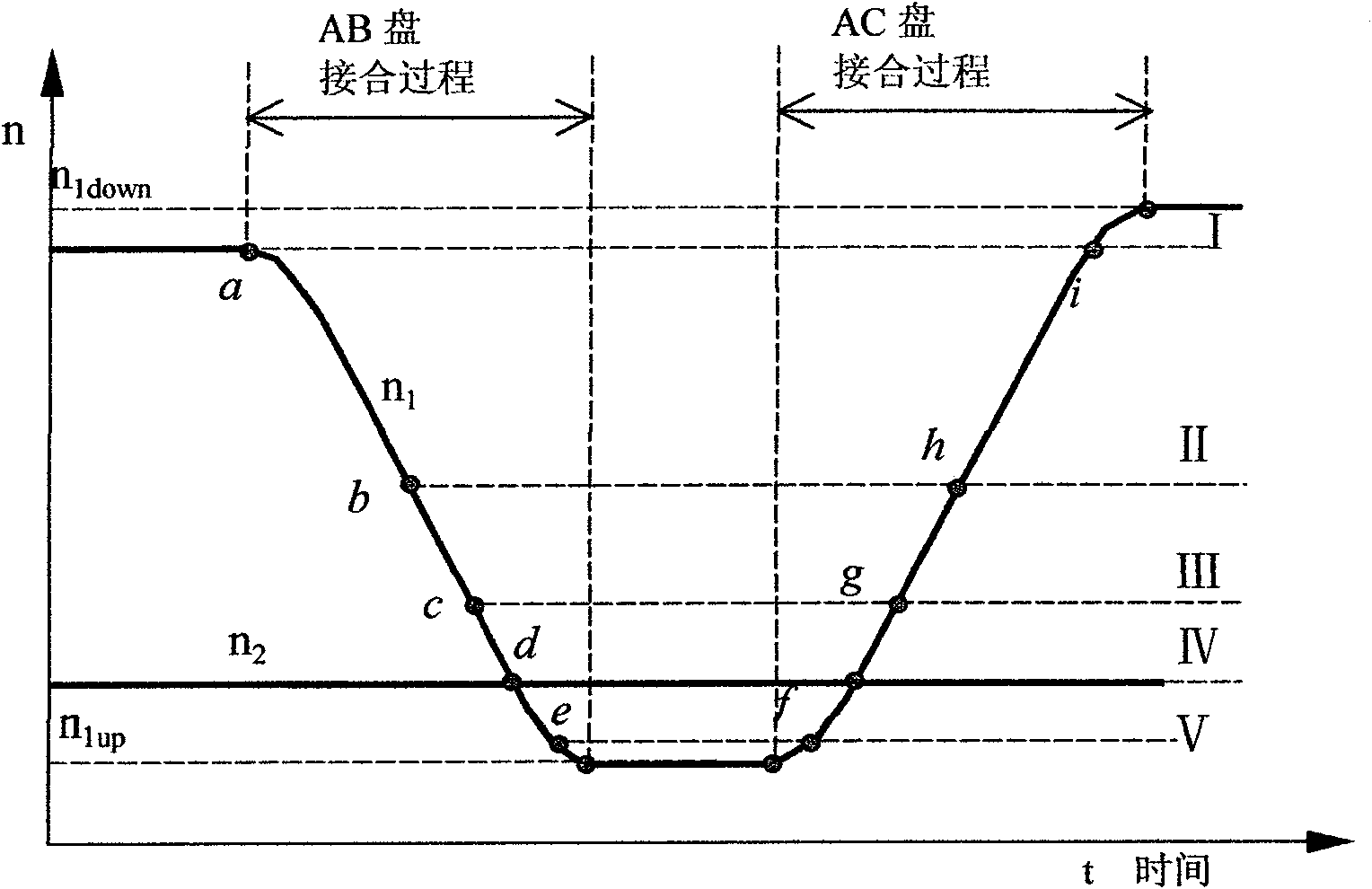

Self-adaptation control method for torque of automatic transmission clutch

ActiveCN109163087AThe rate of change of speed is reducedShift Time GuaranteedGearing controlAutomatic transmissionOptimal control

The invention provides a self-adaptation control method for torque of an automatic transmission clutch. The self-adaptation control method can ensure the optimal control over the torque of the clutchduring the gear shifting process; as for the power upshifting process, the oil filling phase, the torque phase, the speed phase and the locking stage are sequentially performed, according to the inputshaft rotating speed change rate, the gear shifting time, the current gear position and the target gear position in the oil filling phase and the torque phase in the gear shifting process, the engaged clutch pressure correction amount is dynamically adjusted, and therefore on the basis of guaranteeing the gear shifting time, the input shaft rotating speed change rate is reduced, the gear shiftingshock is reduced, and the gear shifting quality is improved.

Owner:FAW JIEFANG AUTOMOTIVE CO

Electric vehicle driving system and control method

InactiveCN107117160AReduce the numberReduce manufacturing costSpeed controllerElectric energy managementGear wheelElectric machine

The embodiment of the invention provides an electric vehicle driving system and a control method. The system comprises a drive motor, a motor controller, an AMT transmission and an AMT transmission controller; the motor controller is connected with the drive motor, and the transmission controller is connected with the transmission; the drive motor comprises a drive motor rotor; the AMT transmission comprises a gear tooth ring, a shifting fork, a joint sleeve, a shifting motor, a transmission input shaft, a rotational speed sensor and a transmission output shaft; the drive motor rotor of the drive motor is connected with the transmission input shaft of the transmission; the gear tooth ring is arranged on the transmission input shaft; the joint sleeve is arranged on the transmission output shaft to be engaged with different dimensions of tooth rings of the gear tooth ring; the drive motor further comprises the shifting motor and the shifting fork; and the shifting motor is connected with the shifting fork so as to control the joint sleeve to be disengaged from the gear tooth ring through the shifting fork to achieve downshift or control the joint sleeve to be engaged with the different tooth rings of the gear tooth ring through the shifting fork to achieve gear engaging.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

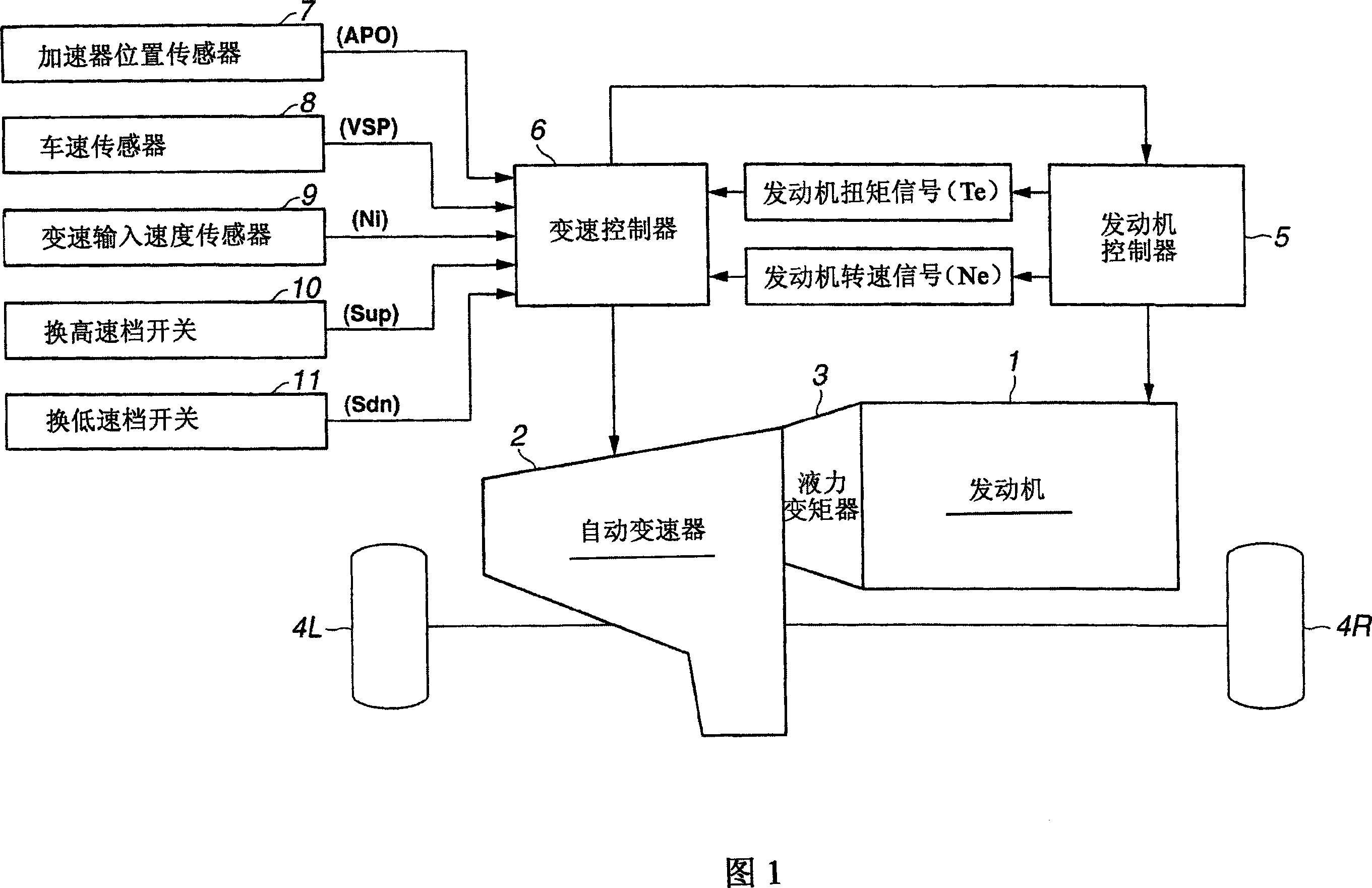

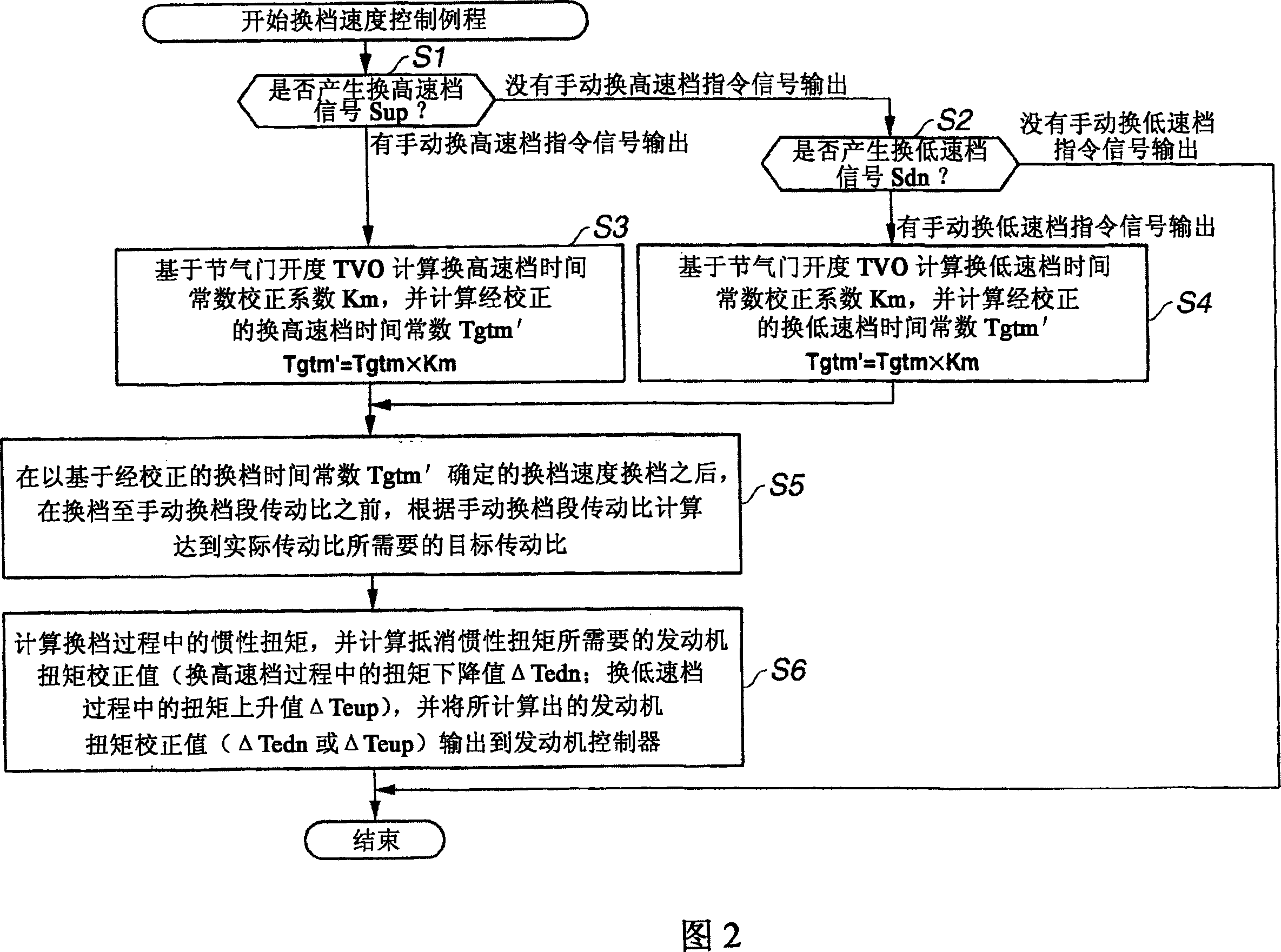

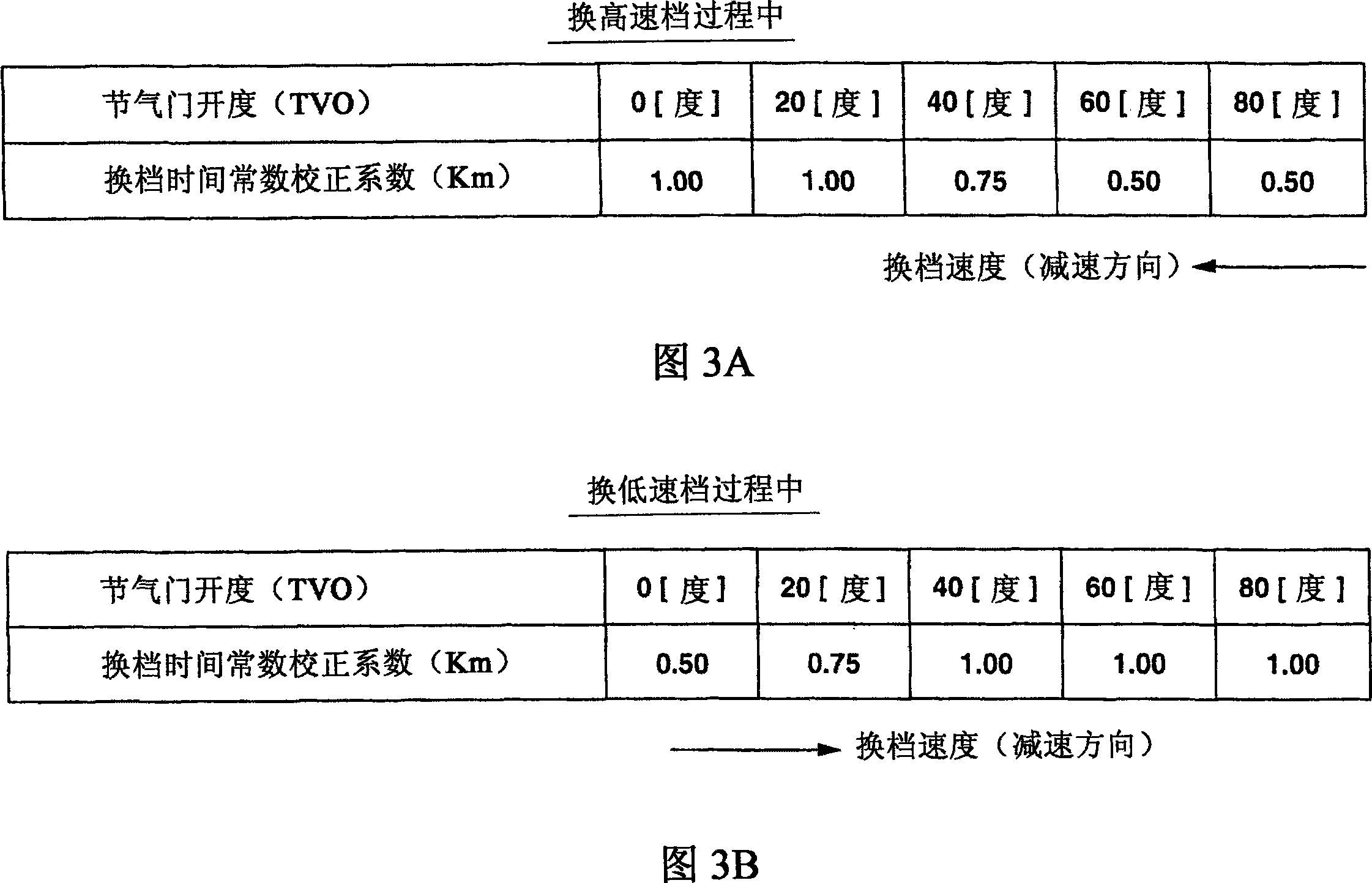

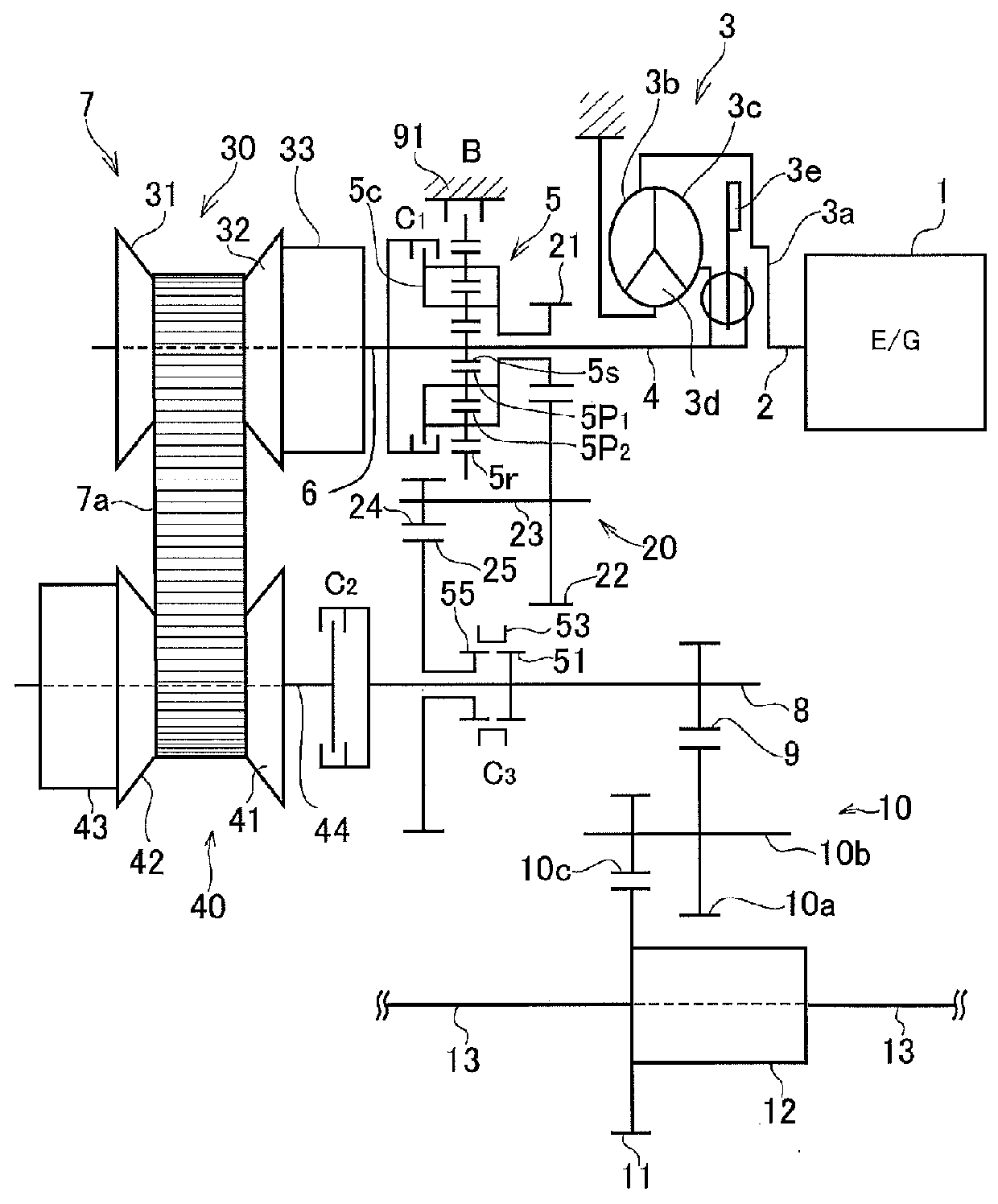

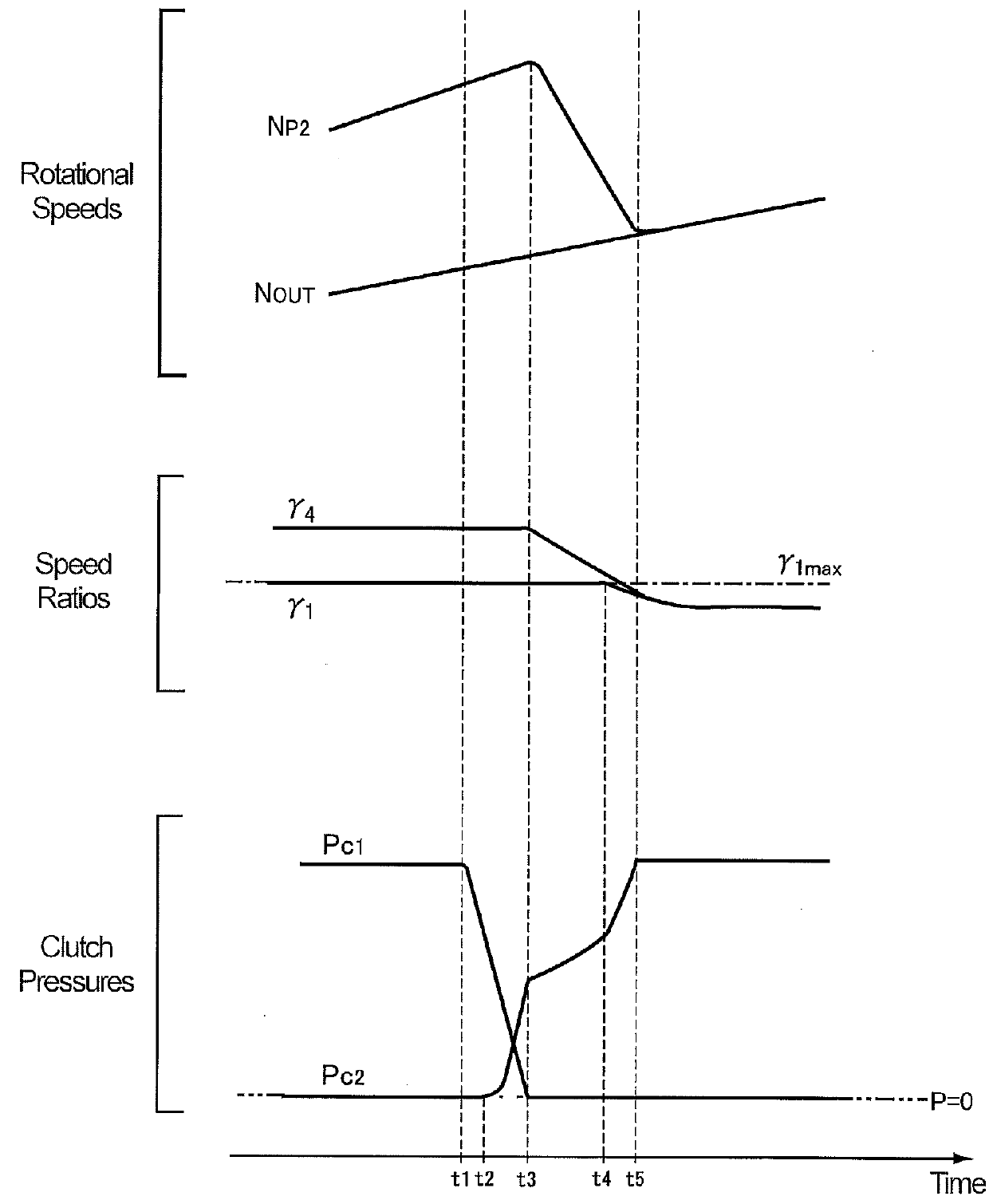

Shift-shock reducing apparatus of power train

InactiveCN101086295AReduce shift shockGearing controlEngine controllersAutomatic transmissionEngineering

In a shift-shock reducing apparatus of a power train employing an engine (1) and an automatic transmission (2), an engine controller (5) executes engine-torque correction for canceling an inertia torque generated owing to a change in transmission input speed (Ni) during a shift, for shift-shock reduction. A transmission controller (6) includes a shift-speed correction circuit (S3-S4) for compensating for a shift speed of the automatic transmission (2) depending on engine load (TVO), so as to effectively suppress the generated inertia torque, thereby aimfully reducing or suppressing shift shocks.

Owner:NISSAN MOTOR CO LTD +1

Vehicle control system and vehicle control method

ActiveUS20160052522A1Reduce shift shockLess discomfortGearingPortable liftingControl systemTorque transmission

Vehicle control system and method provided to change speed ratio smoothly when switching a power transmission route from a route including a geared transmission to a route including a continuously variable transmission. Vehicle control system applied to a vehicle comprising: continuously variable transmission for changing speed ratio continuously is disposed between input shaft and output shaft; geared transmission is disposed parallel to the continuously variable transmission, and is adapted to establish speed ratio that cannot be established by continuously variable transmission; and friction clutch is brought into engagement to switch torque transmission route from a route including the geared transmission to a route including the continuously variable transmission. Vehicle control system configured to start speed change operation of continuously variable transmission before the friction clutch is brought into engagement completely when switching torque transmission route from the route including the geared transmission to the route including the continuously variable transmission.

Owner:TOYOTA JIDOSHA KK

Electric finger pin joint device type three-gear automatic transmission for electric vehicle

The invention discloses an electric finger pin joint device type three-gear automatic transmission for electric vehicle. An input gear is mounted on an input shaft of a transmission, and is normally engaged with a first-gear input gear and a second-gear input gear; the first-gear input gear, the second-gear input gear and the input gear are fixedly connected with output discs of first-gear, second-gear and third-gear electric finger pin joint devices; and the gear shifting control of the electric finger pin joint device type three-gear automatic transmission is realized through controlling the joint and the separation of the first-gear, second-gear and third-gear electric finger pin joint devices. When electric finger pin valves of the electric finger pin joint devices are not electrified, the output discs are in a separation state under the effect of return springs; and when the electric finger pin valves are electrified, electric finger pins overcome elastic force to move to the direction of the output discs under the effect of electromagnetic force, and slide into arc annular grooves in a rotating state, the output discs are pushed to synchronously rotate, and the joint devices are joined. The electric finger pin joint device type three-gear electric vehicle automatic transmission has such advantages as compact structure, capability of shifting gears through power and no mechanic or hydraulic gear shifting parts.

Owner:SHANDONG UNIV OF TECH

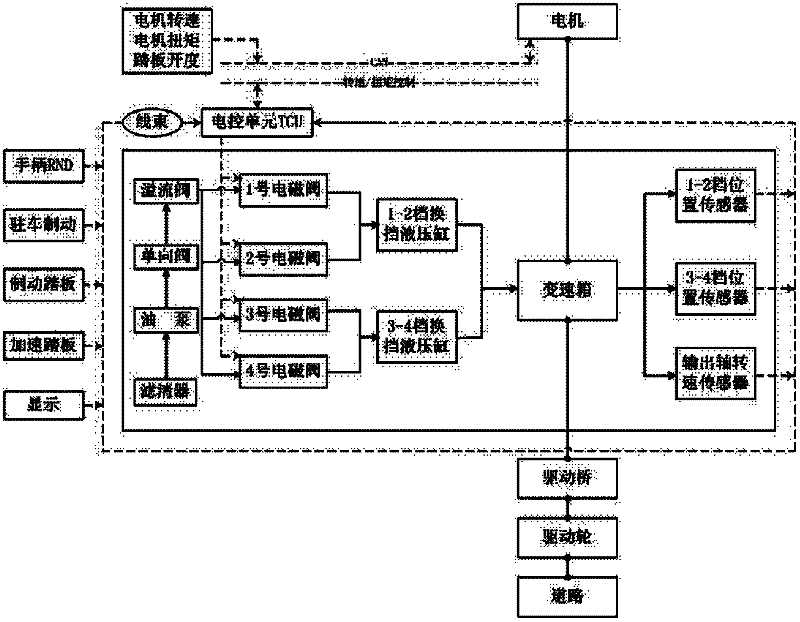

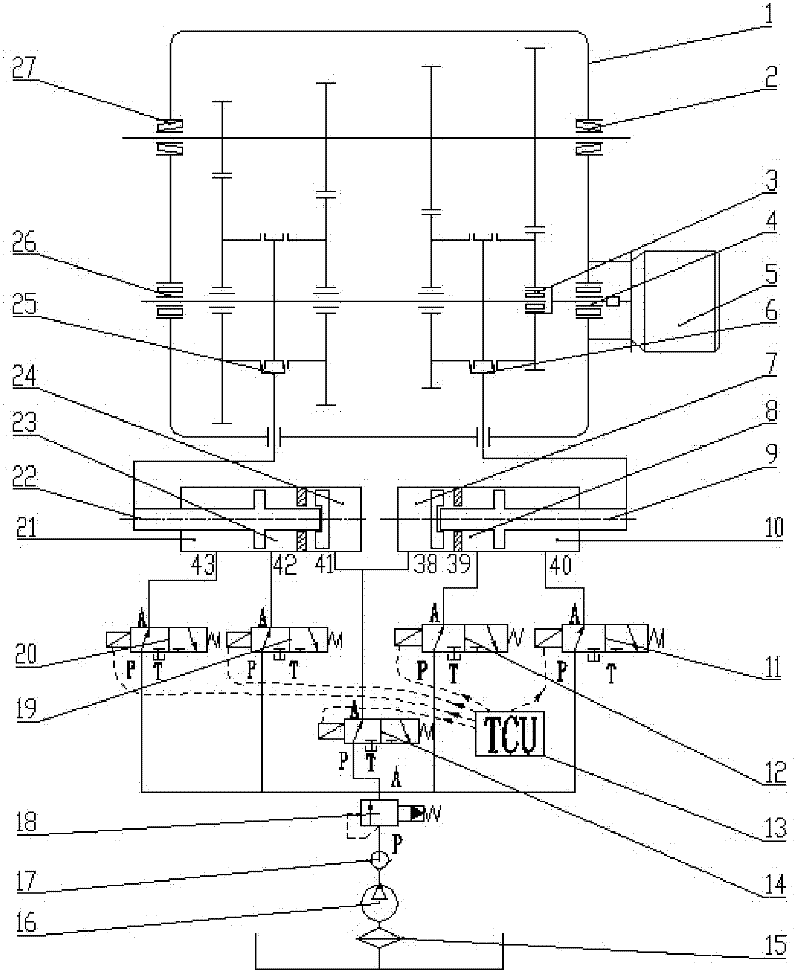

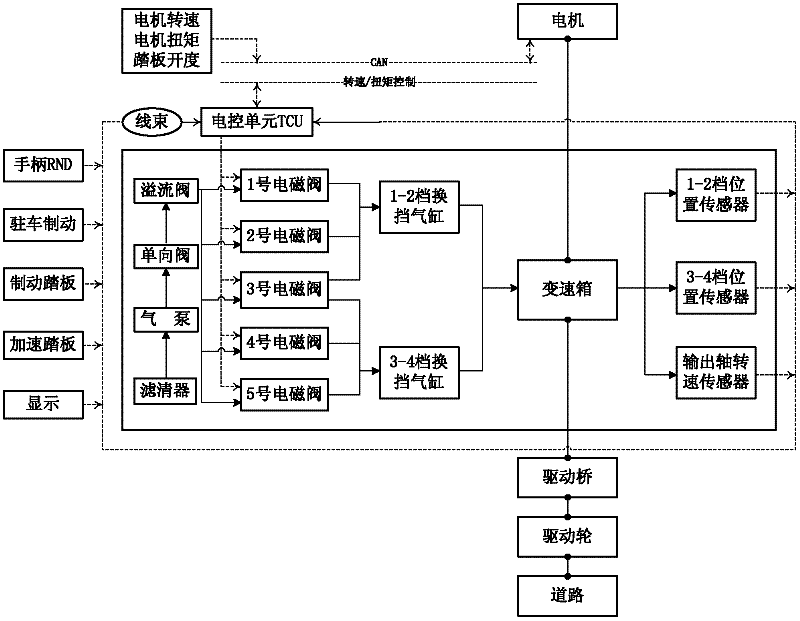

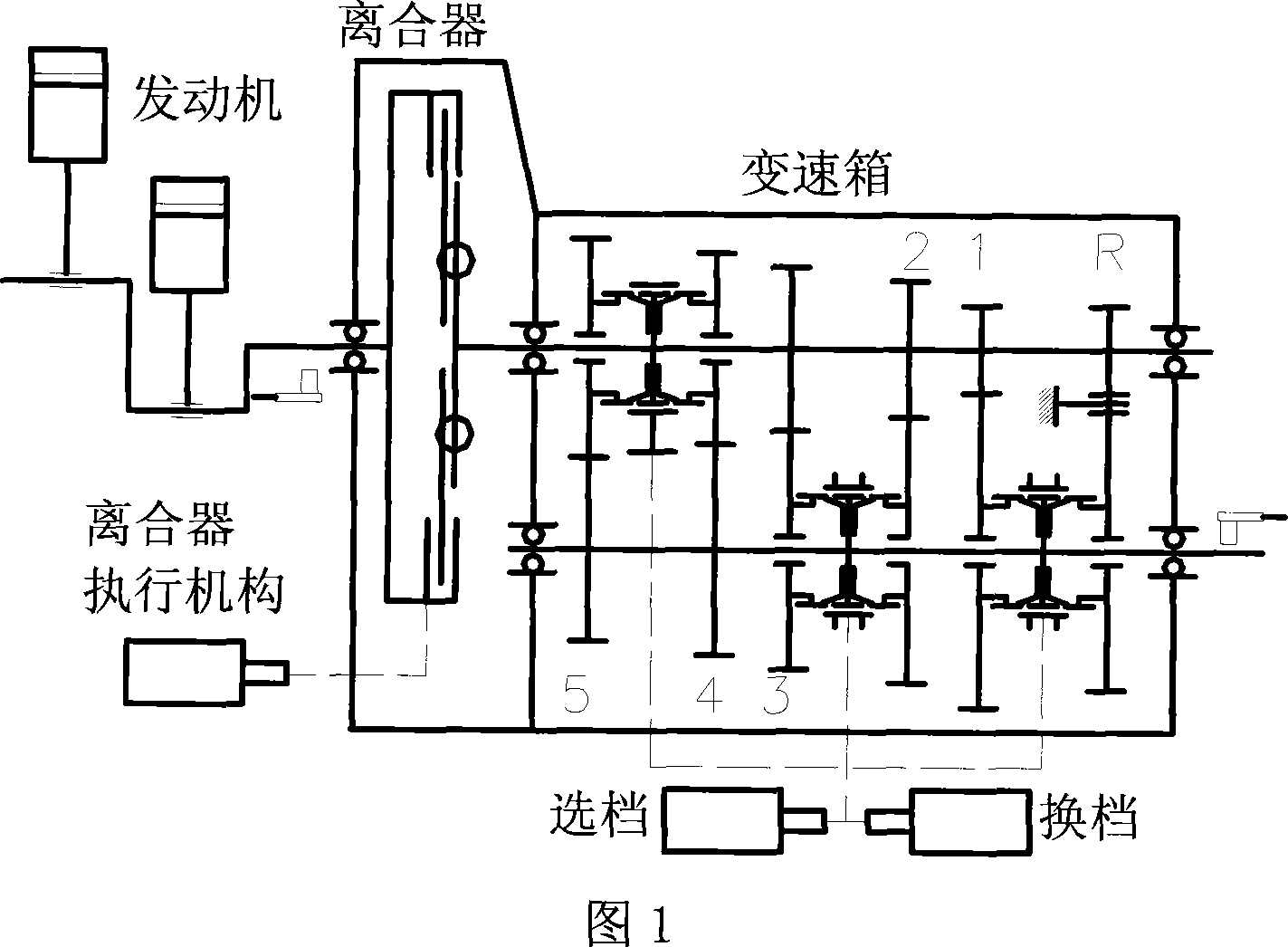

Electronic control hydraulic drive mechanical type automatic gear shift system

InactiveCN102518788ATake advantage ofSimple structureControlled membersGearing controlHydraulic cylinderSolenoid valve

The invention discloses an electronic control hydraulic drive mechanical type automatic gear shift system, which comprises a parallel axis type gearbox, a drive motor and a gear selection and shift mechanism, wherein the gear selection and shift mechanism comprises a gear 1 and gear 2 shift mechanism, a gear 3 and gear 4 shift mechanism, a filter, a hydraulic pump, a check valve and an overflow valve. The gear 1 and gear 2 shift mechanism and the gear 3 and gear 4 shift mechanism comprise a gear 1 and gear 2 shift fork, a gear 3 and gear 4 shift fork, a gear 1 and gear 2 shift hydraulic cylinder, a gear 3 and gear 4 shift hydraulic cylinder and solenoid valves No.1 to No.4. An oil tank, the filter, the hydraulic pump and a port P of the overflow valve are sequentially connected through pipelines, a port A of the overflow valve is connected with ports P of the solenoid valves No.1 to No.4 through pipelines, ports A of the solenoid valves No.1 to No.4 are connected with oil ports on the gear 1 and gear 2 shift hydraulic cylinder and the gear 3 and gear 4 shift hydraulic cylinder through pipelines, and the gear 3 and gear 4 shift fork and the gear 1 and gear 2 shift fork are connected with a gear 3 and gear 4 meshing sleeve and a gear 1 and gear 2 meshing sleeve in the parallel axis type gearbox in a contact mode.

Owner:JILIN UNIV

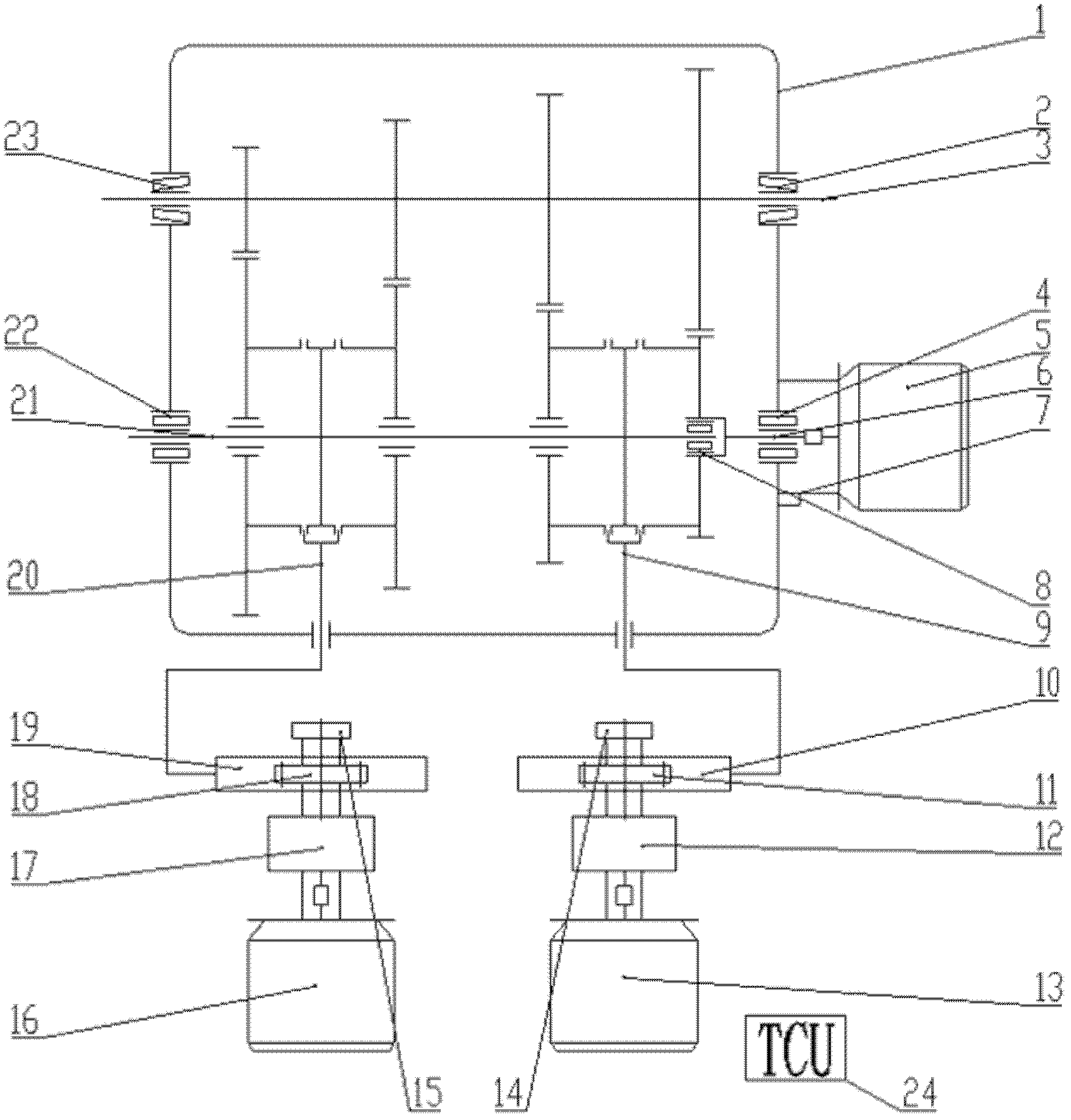

Electrically controlled electromechanical automatic shift system

InactiveCN102506165ASimple control structureReduce weightGearing controlFriction gearingsCouplingEngineering

The invention discloses an electrically controlled electromechanical automatic shift system, which consists of a parallel shaft type speed change box, a selection and shift mechanism and an electric control unit, wherein the selection and shift mechanism comprises a first shift rack, a first shift gear, a second motor, a third motor, a second shift gear and a second shift rack; the output end of the second motor is connected with a coupler at the input end of a first speed reducer; the output end of the first speed reducer is in keyed joint with the first shift gear; the first shift gear is engaged with the first shift rack; the first shift rack is fixedly connected with a first shirt fork; a second sensor is fixedly connected with the first speed reducer; the output end of the third motor is connected with a coupler at the input end of a second speed reducer; the output end of the second speed reducer is in keyed joint with the second shift gear; the second shift gear is engaged with the second shift rack; the second shift rack is fixedly connected with a second shift fork; a third sensor is fixedly connected with the second speed reducer; and the second sensor and the wiring end of the third sensor are connected with the electric control unit through wires.

Owner:JILIN UNIV

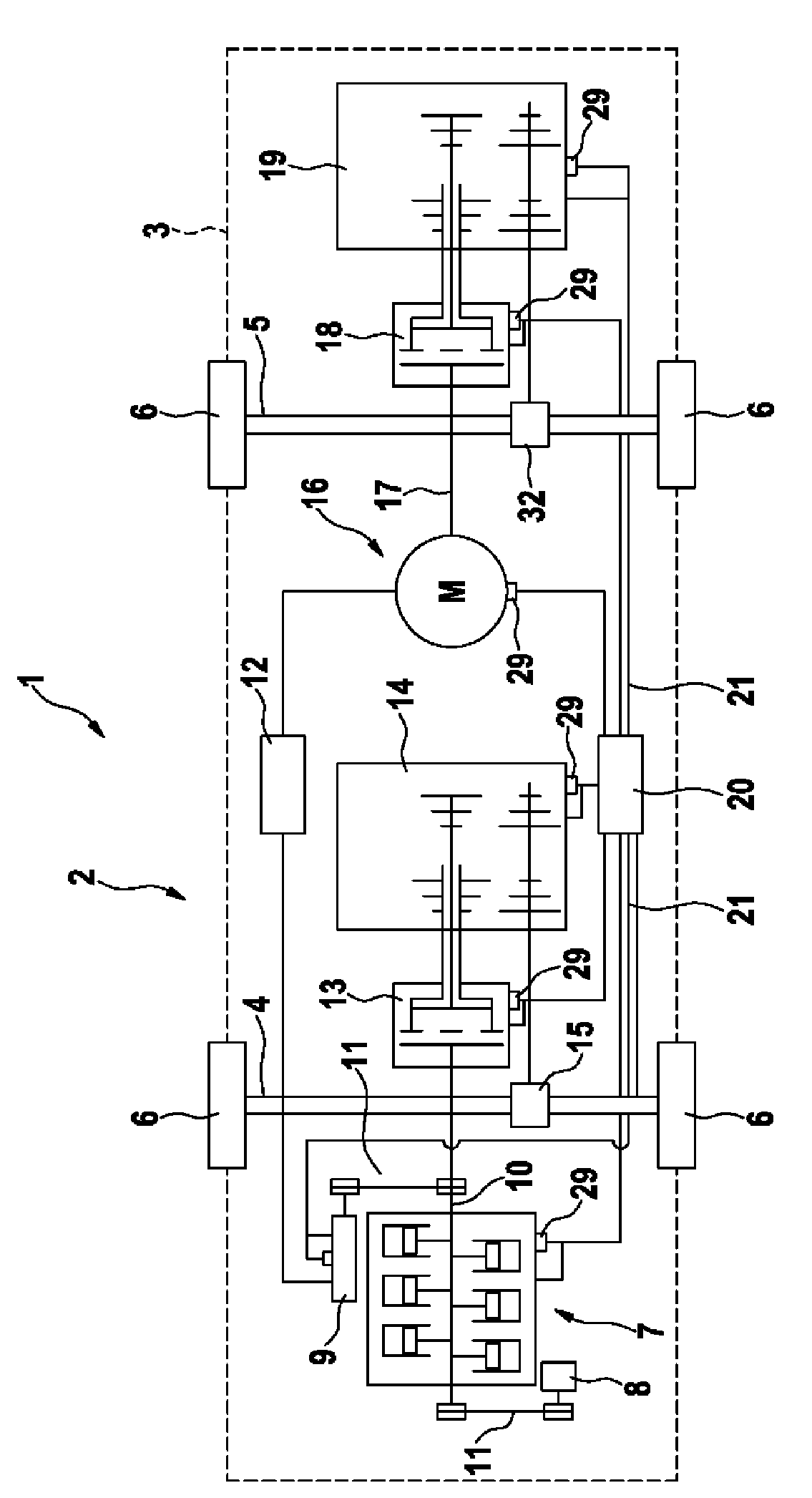

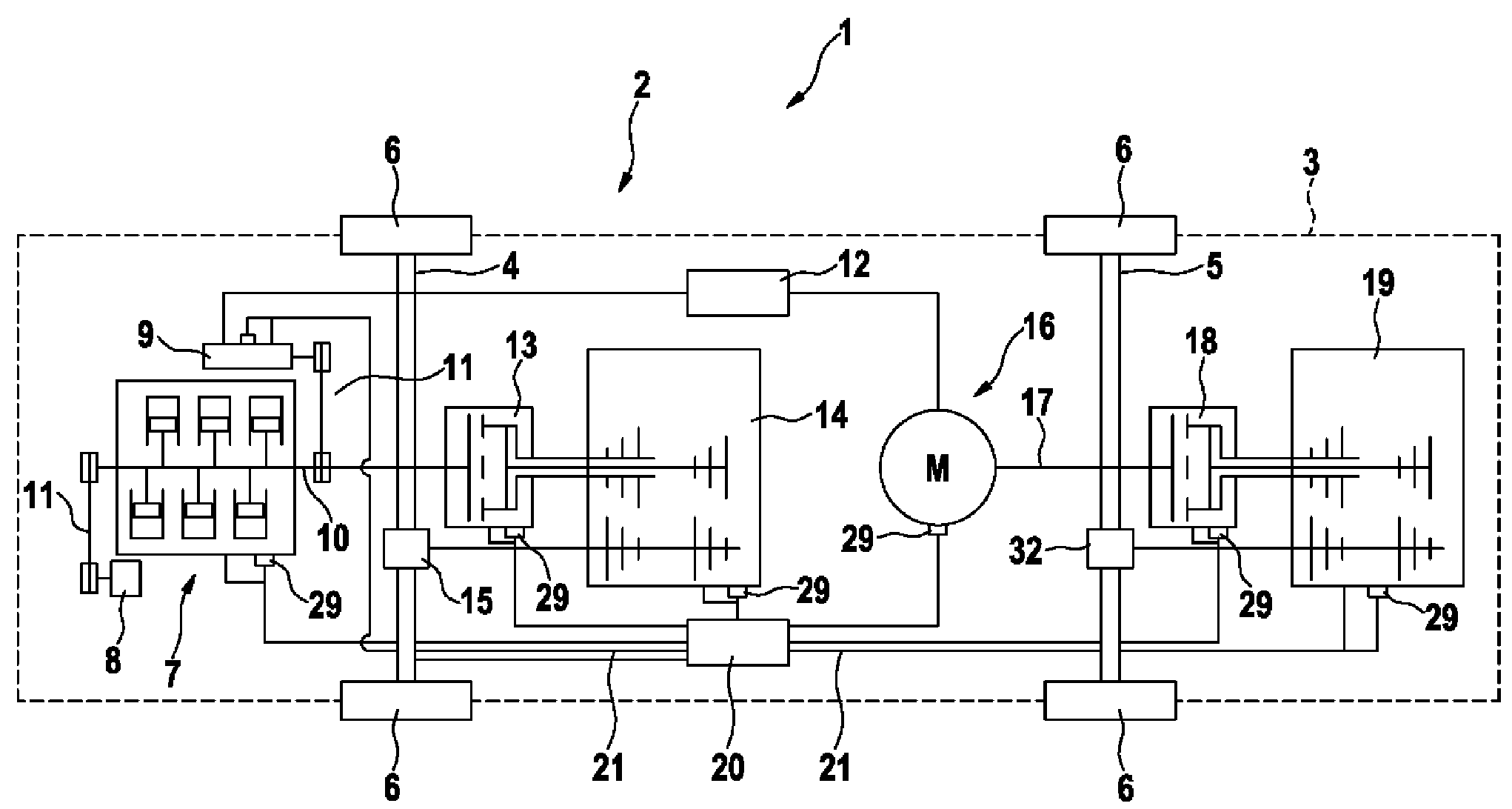

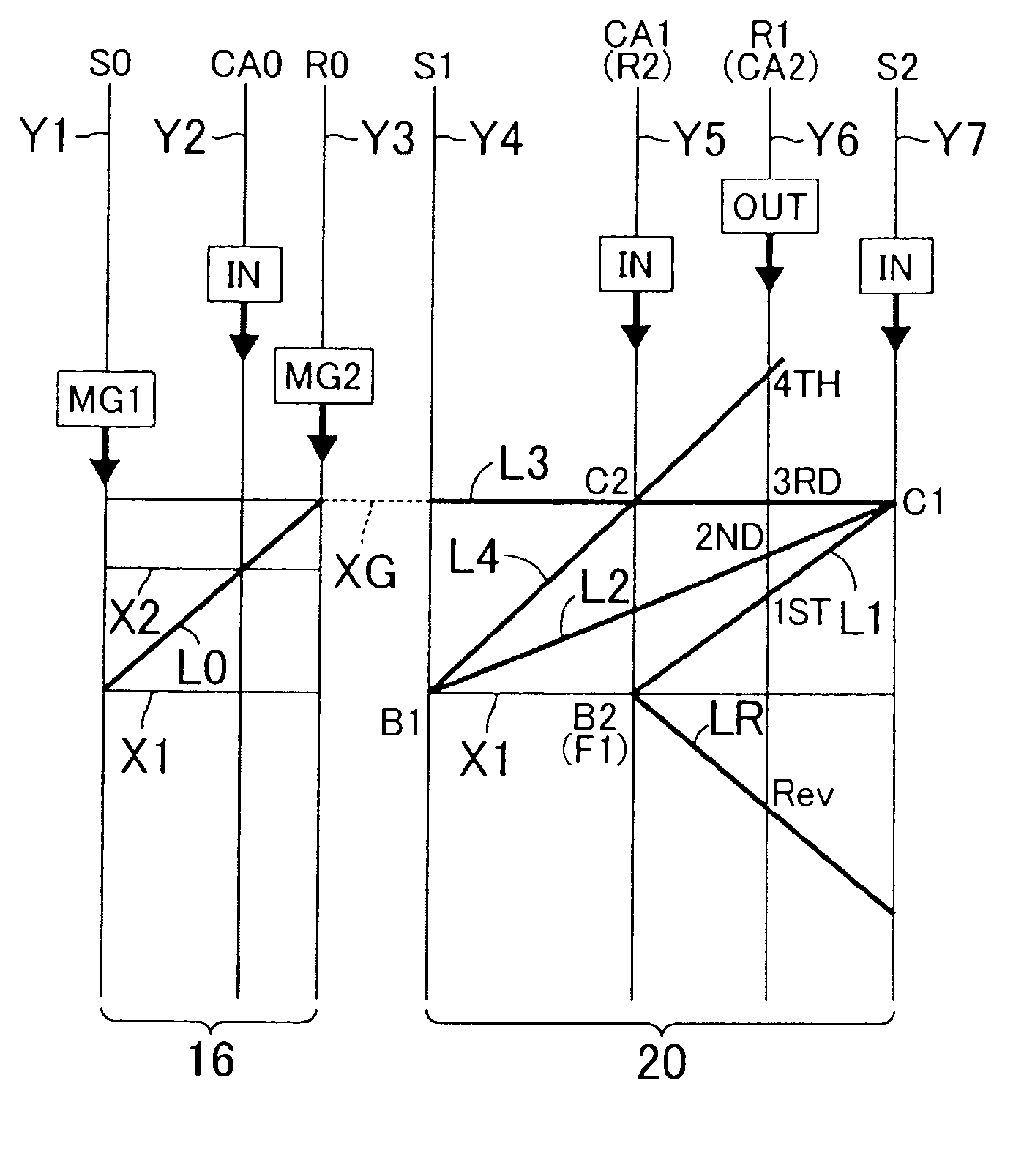

Hybrid drive system

InactiveCN102149558AReduce consumptionImprove driving comfort performanceSpeed controllerElectric devicesControl theoryMotronic

The invention relates to a hybrid drive system (2) for a motor vehicle (1), comprising an internal combustion engine (7) and an electric motor (16) which respectively drives the wheels (6) of the motor vehicle (1). Said internal combustion engine (7) is coupled to the corresponding wheels (6) by means of a first multi-speed gearbox (14). Said electric motor (16) is coupled to the corresponding wheels (6) by means of a second multi-speed gearbox (19).

Owner:ROBERT BOSCH GMBH

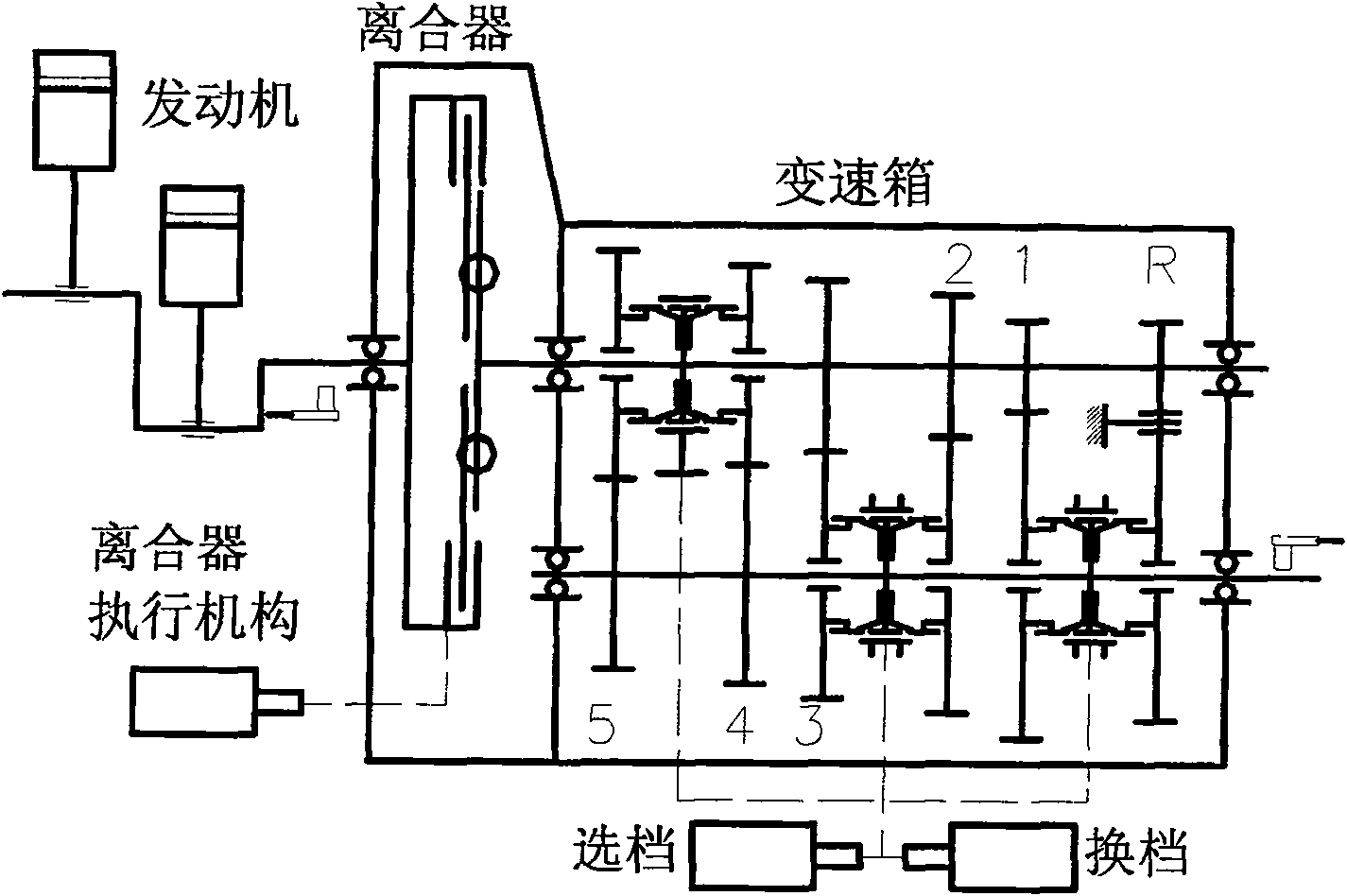

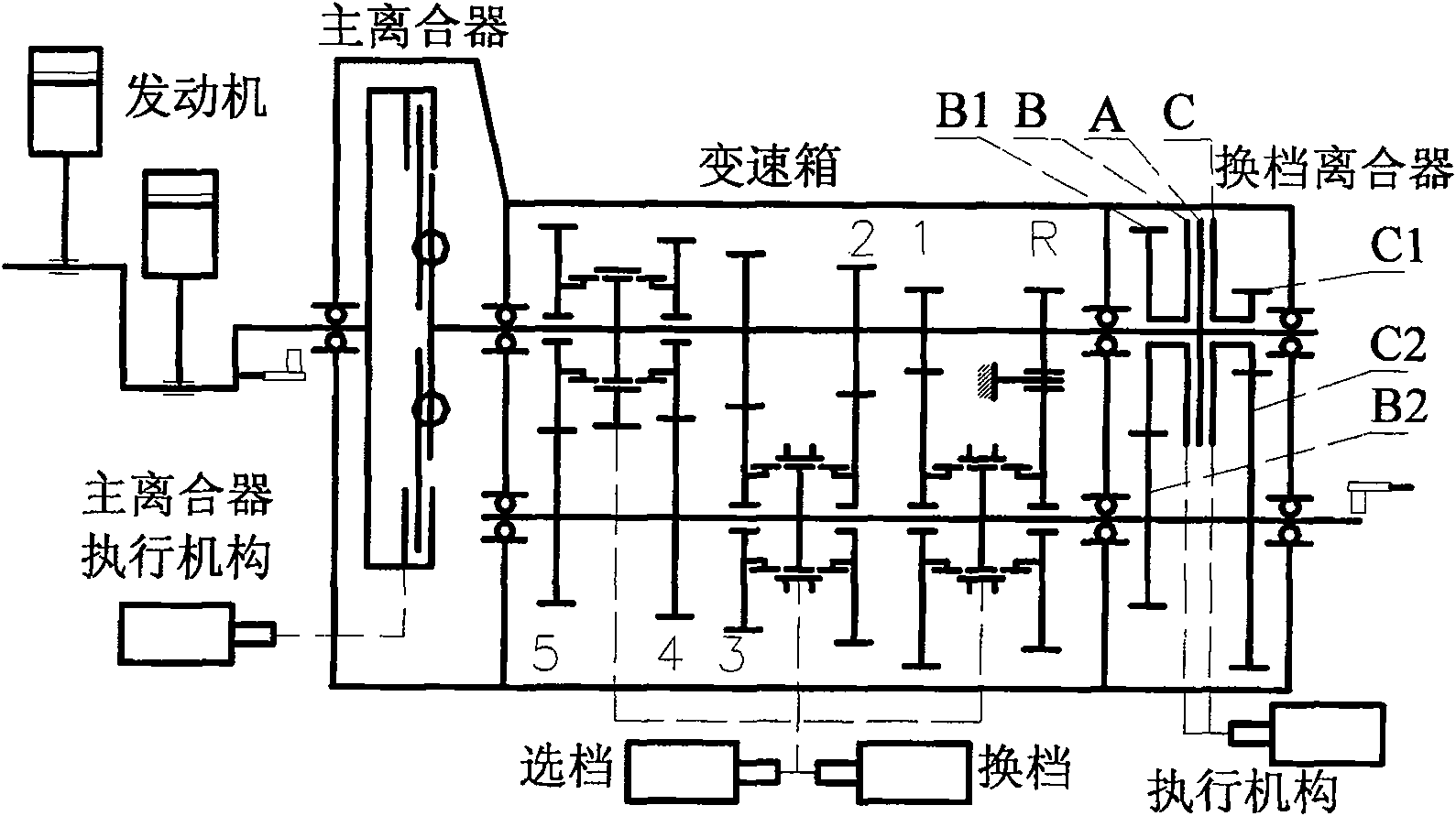

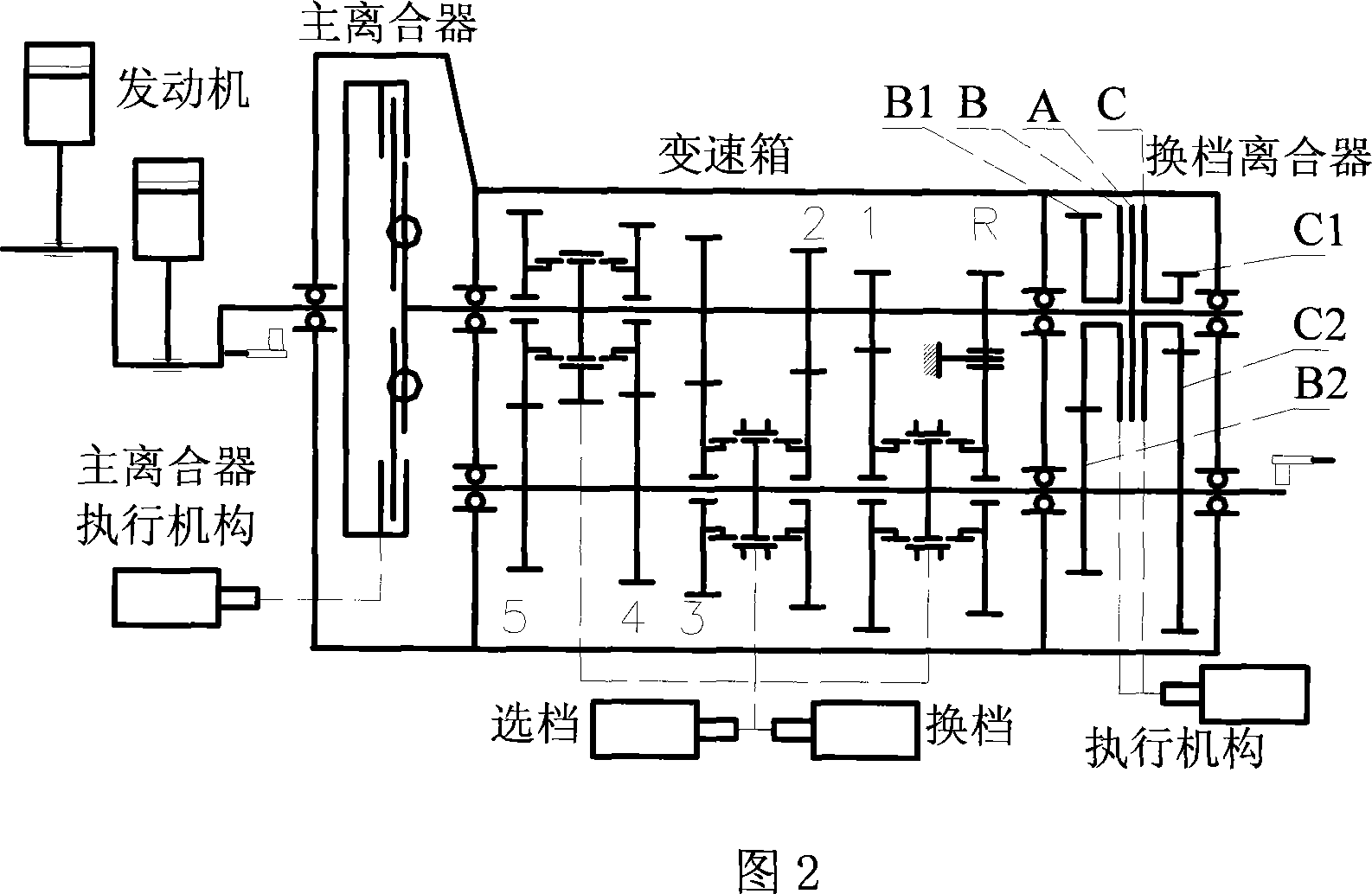

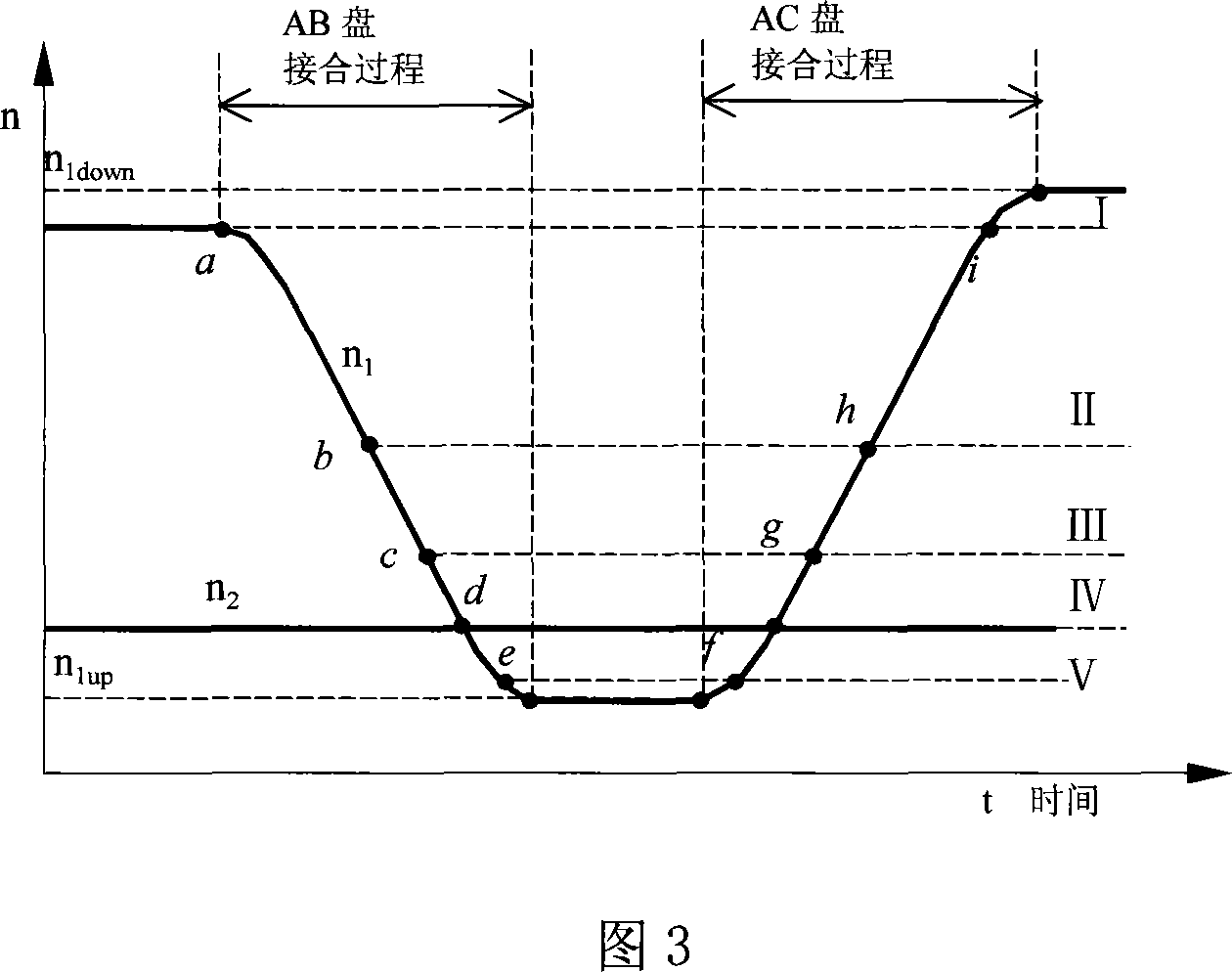

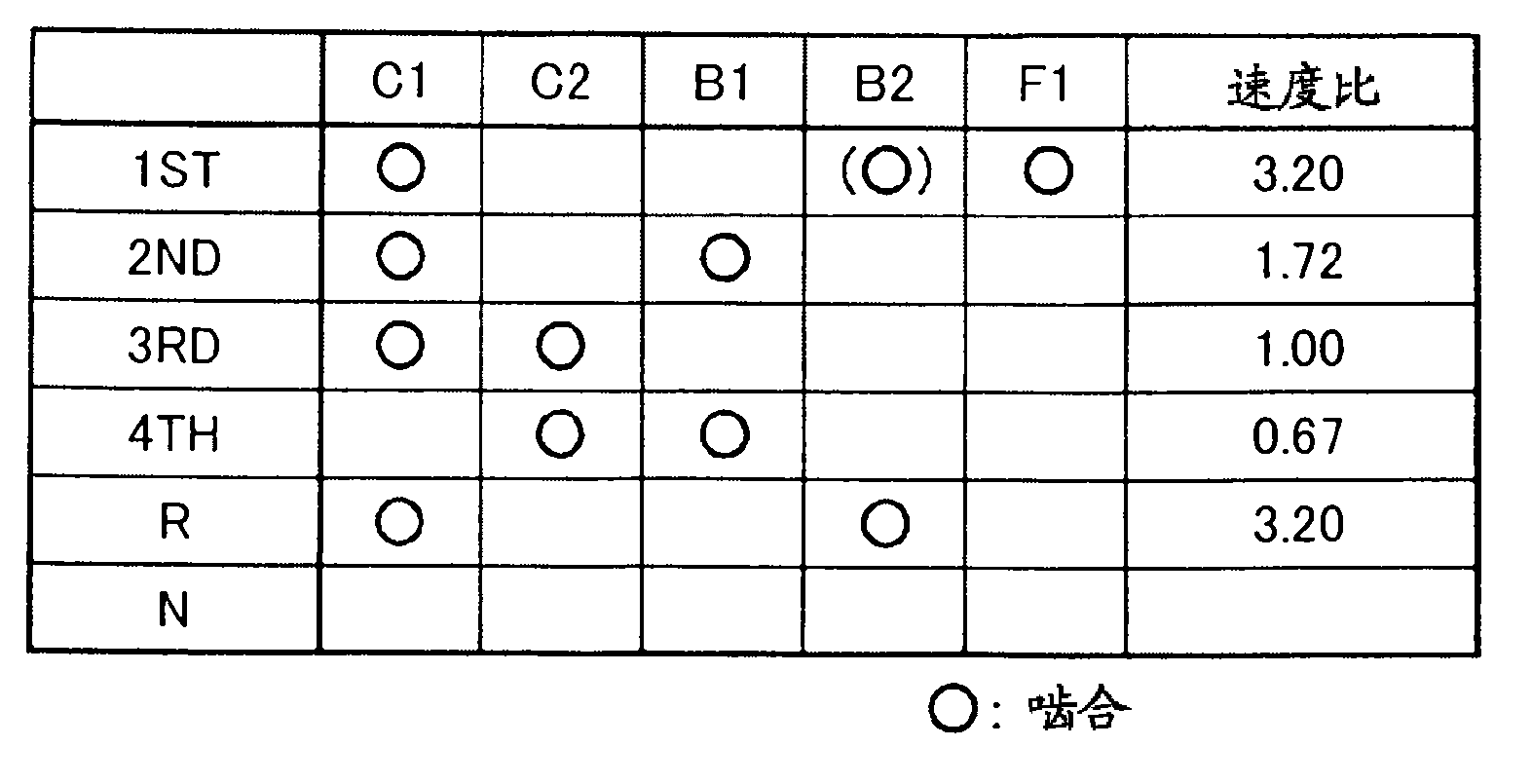

Automatic gearbox without synchronizer and not interrupt power shifting gear

An automatic gearbox of synchronizer-free and gearshift without power interruption type is prepared for applying two-shaft mode with five-gear variable speed, adding double-surface gearshift clutch, fixing fixed plate of gearshift clutch on a shaft of gearbox and arranging two float plates at two sides of said fixed plate.

Owner:BEIJING JIAOTONG UNIV

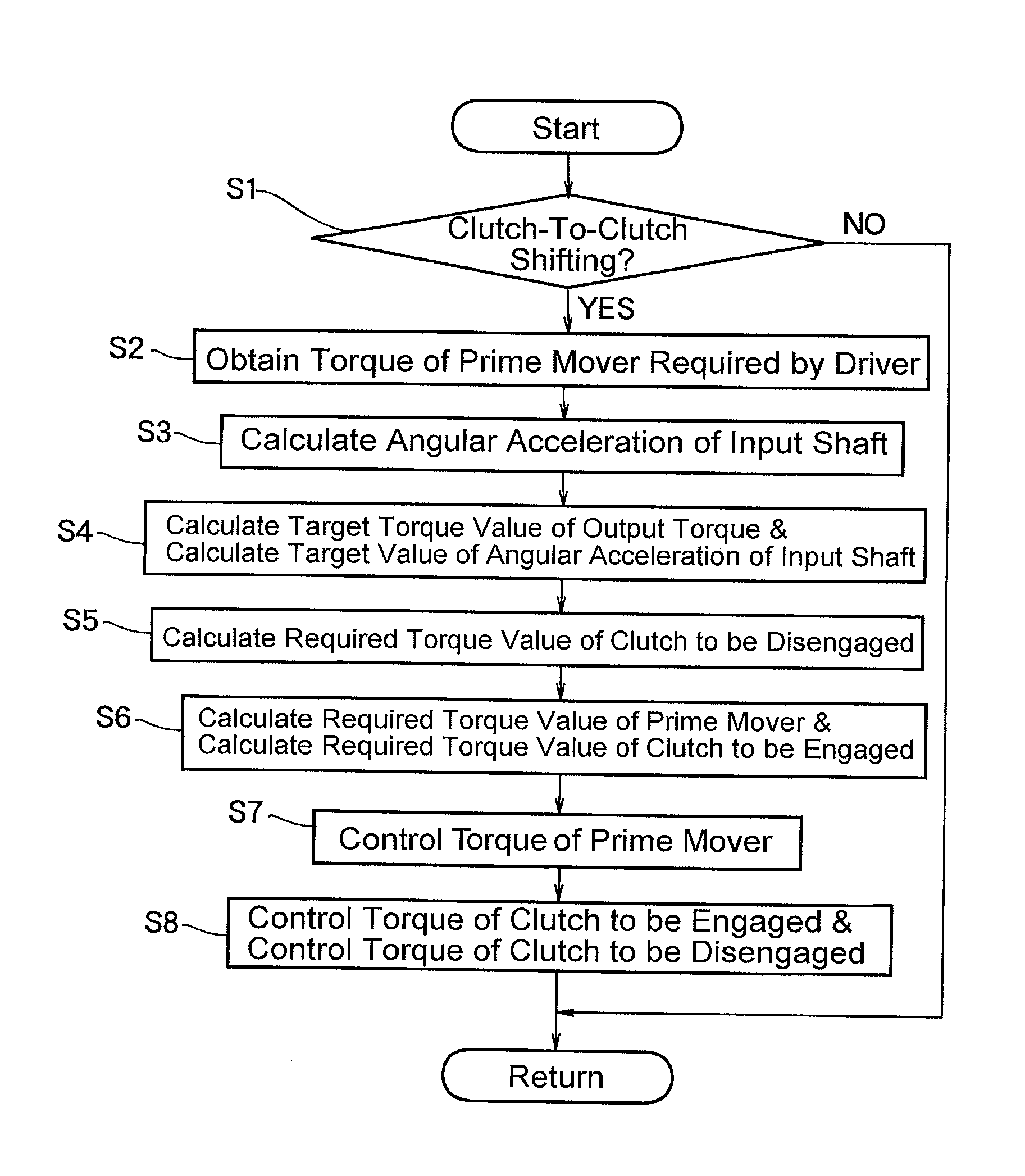

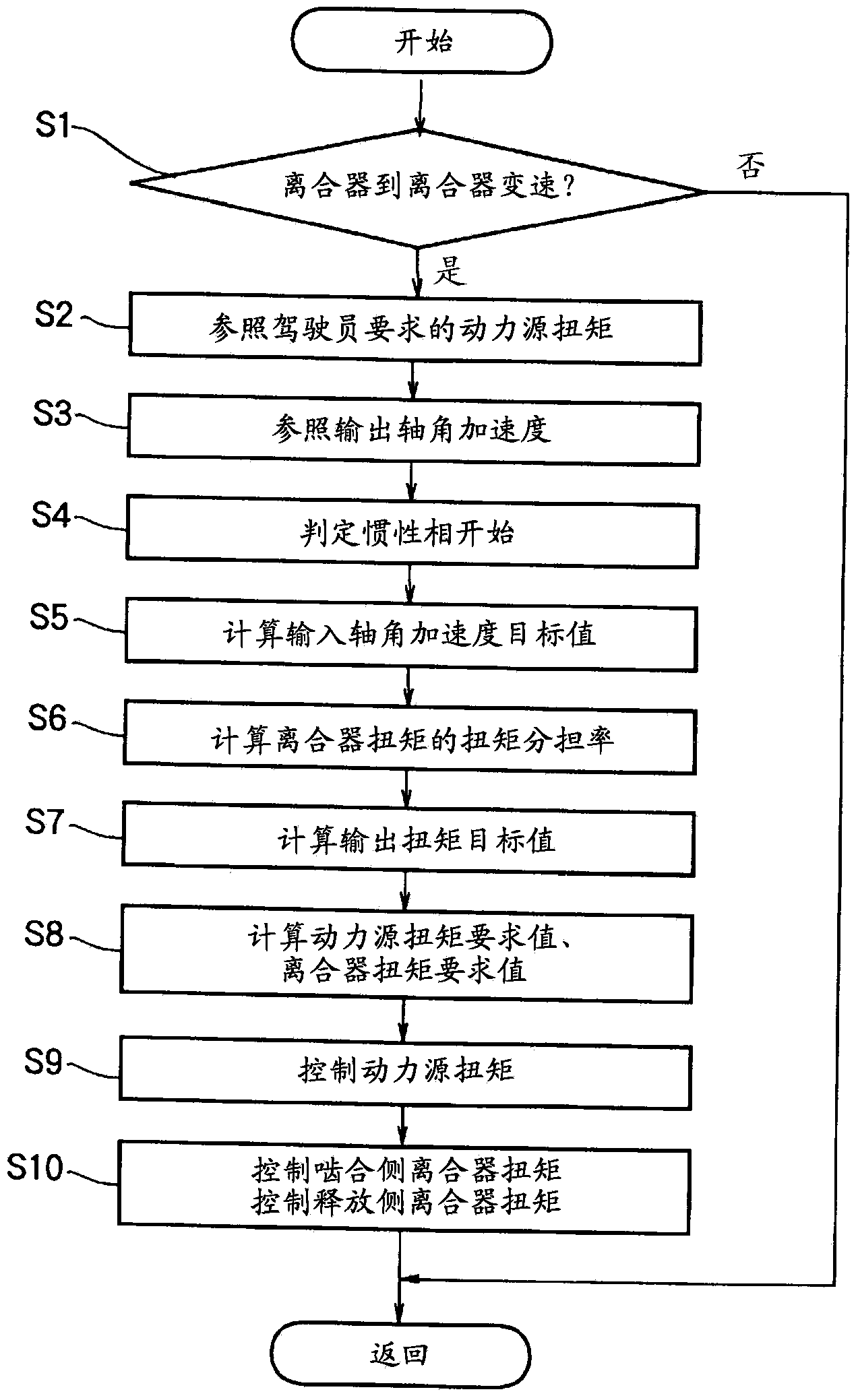

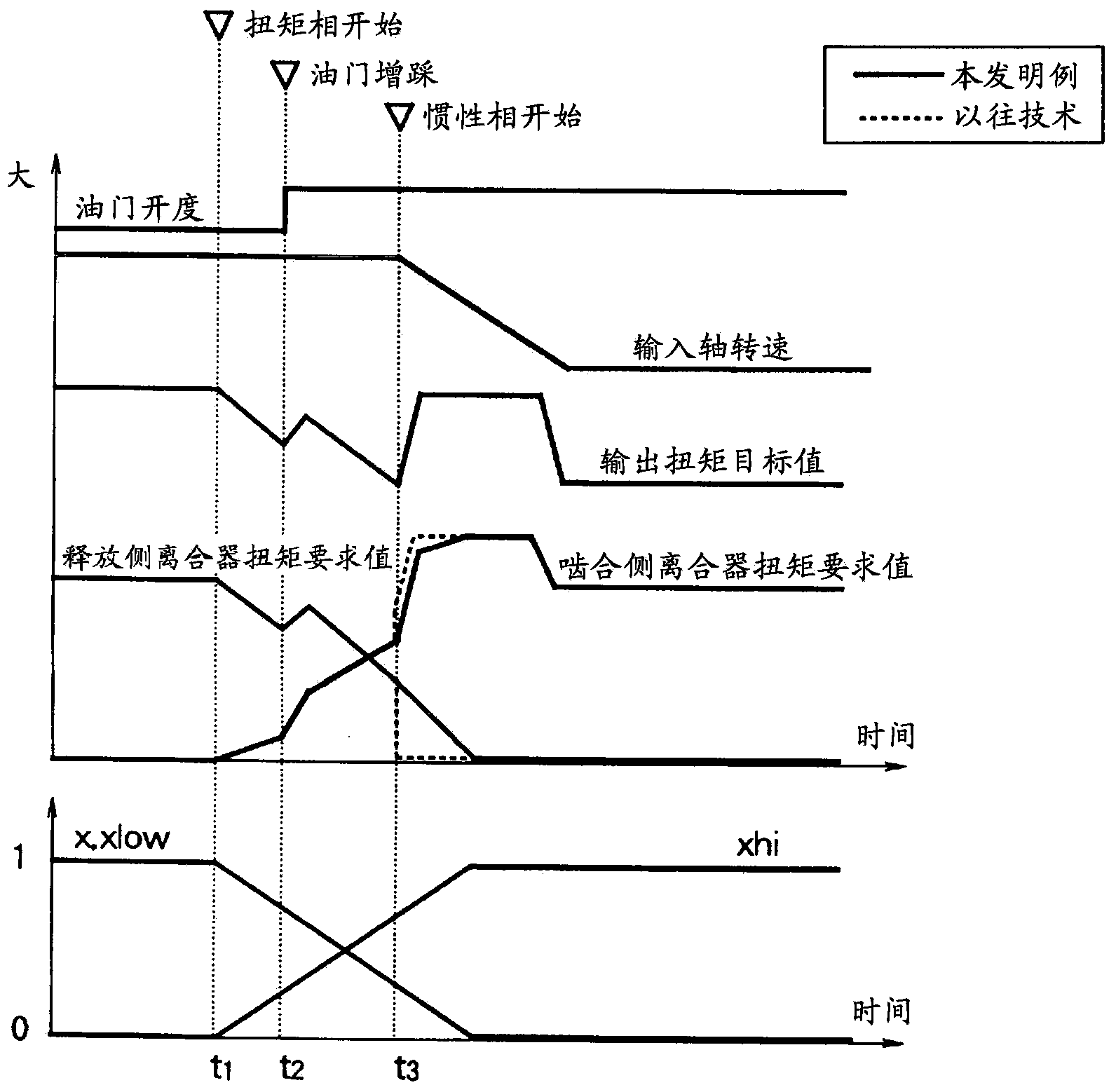

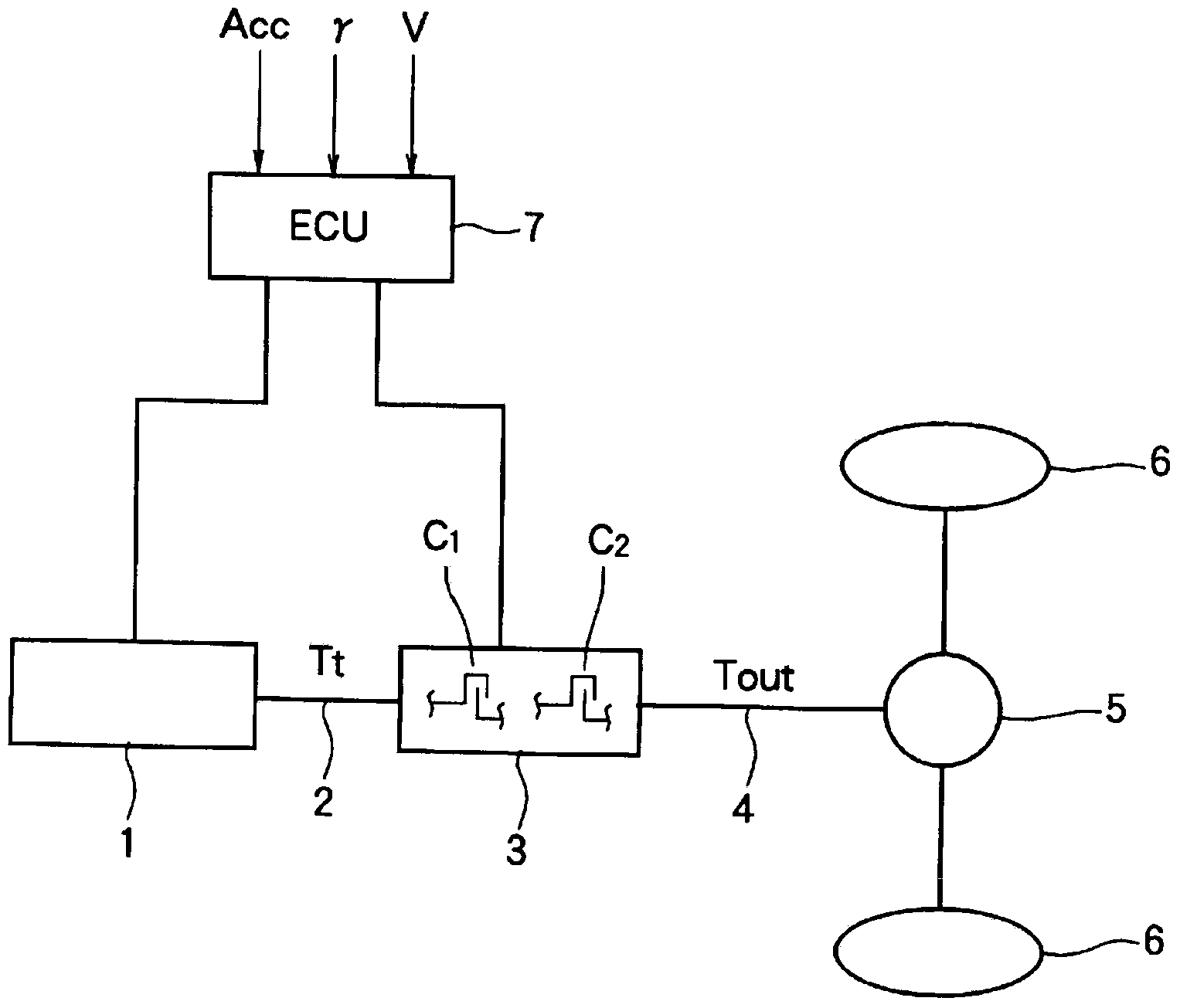

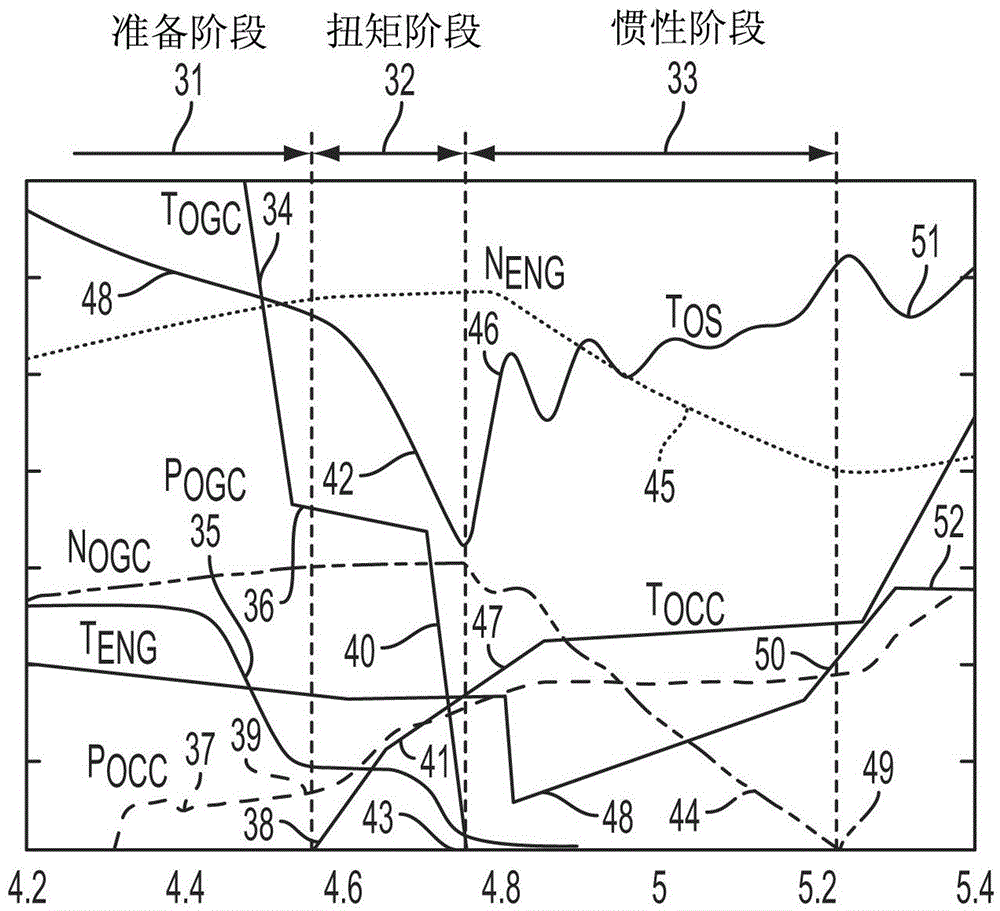

Speed change control system for vehicles

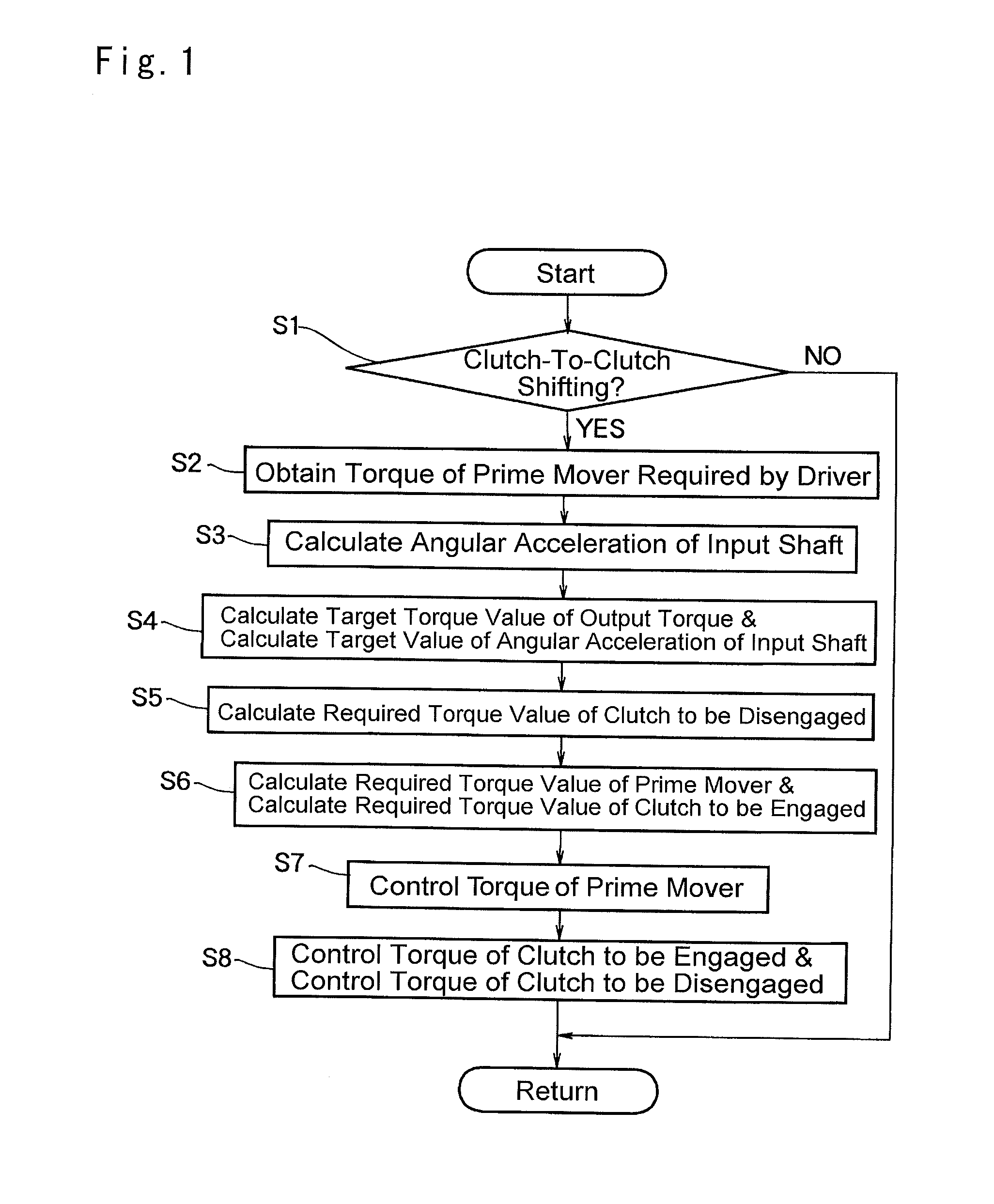

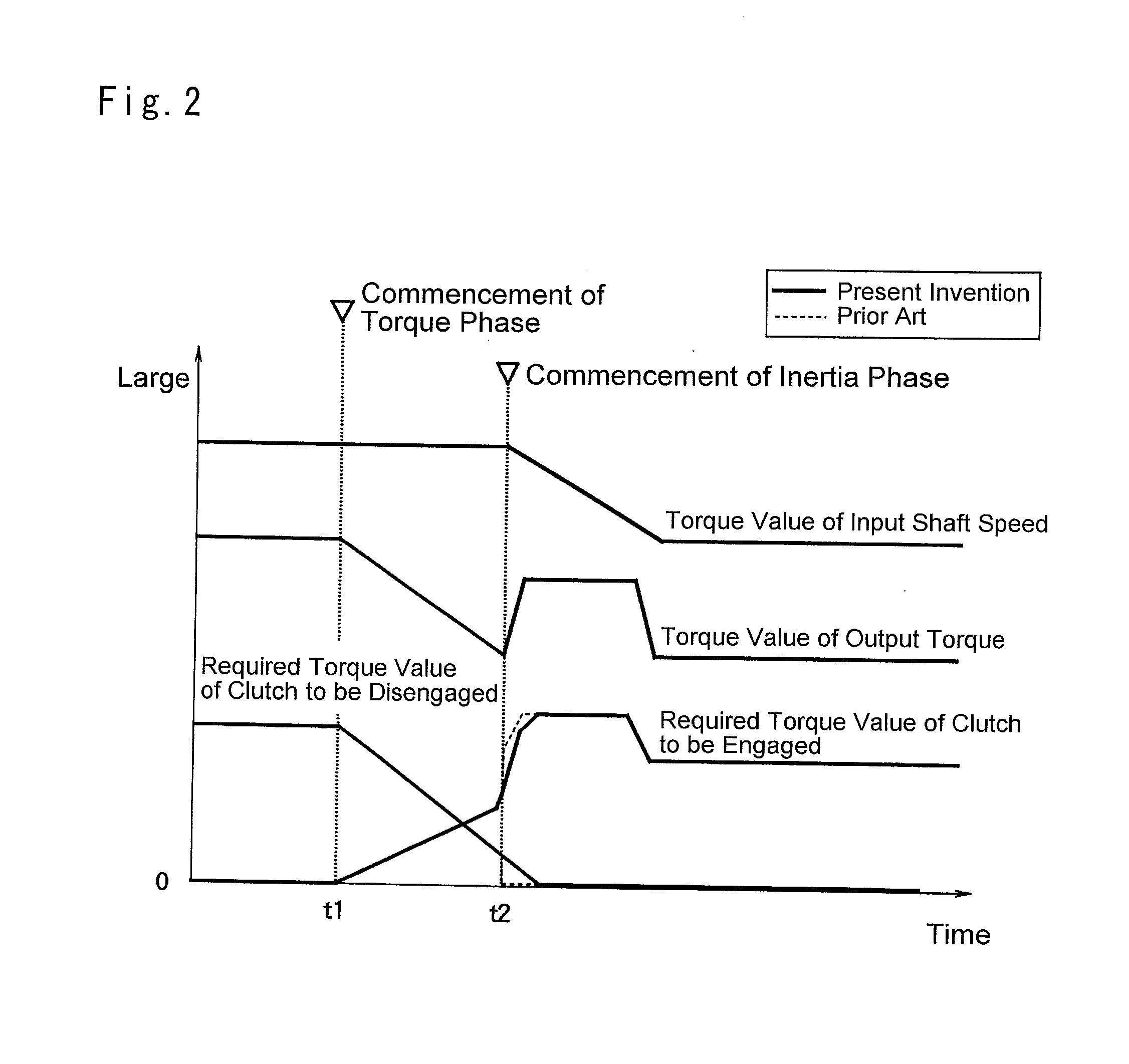

ActiveUS20150120154A1Reduce resultReduce shift shockDigital data processing detailsGearing controlControl systemChange control

A speed change control system for reducing shift shocks of clutch-to-clutch shifting is provided. The control system is applied to a vehicle in which a transmission having a plurality of engagement devices is connected to an output side of a prime mover, and in which a gear stage of the transmission is shifted among a plurality of stages by changing engagement states of the engagement devices. The speed change control system is configured to carry out a clutch-to-clutch shifting of the gear stage from a predetermined gear stage to another gear stage by gradually reducing a torque capacity of the predetermined engagement device to be disengaged while gradually increasing a torque capacity of another engagement device to be engaged. The speed change control system is comprised of a torque calculation means that calculates a target torque capacity of the engagement device to be engaged during a torque phase and an inertia phase under the clutch-to-clutch shifting, based on a target input angular acceleration of the transmission, a target output angular acceleration of the transmission, a target torque capacity of the engagement device to be disengaged, and a target output torque, and configured to change the target torque capacity of the engagement device to be disengaged continuously from the torque phase to the inertia phase under the clutch-to-clutch shifting.

Owner:TOYOTA JIDOSHA KK

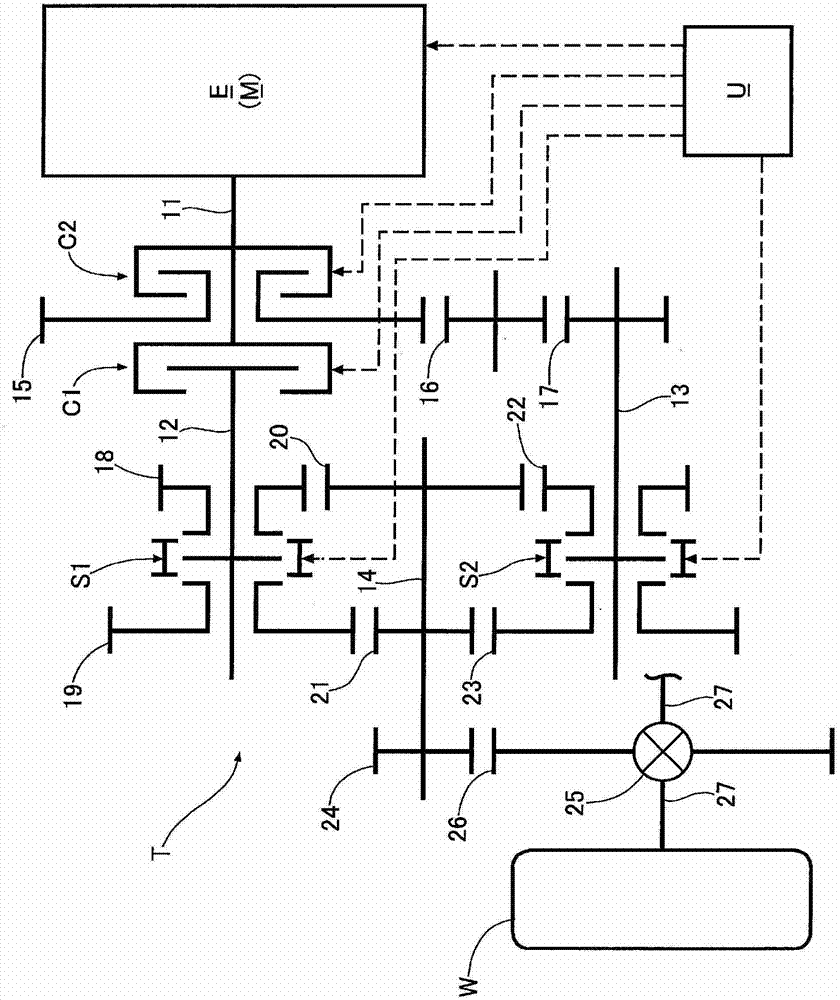

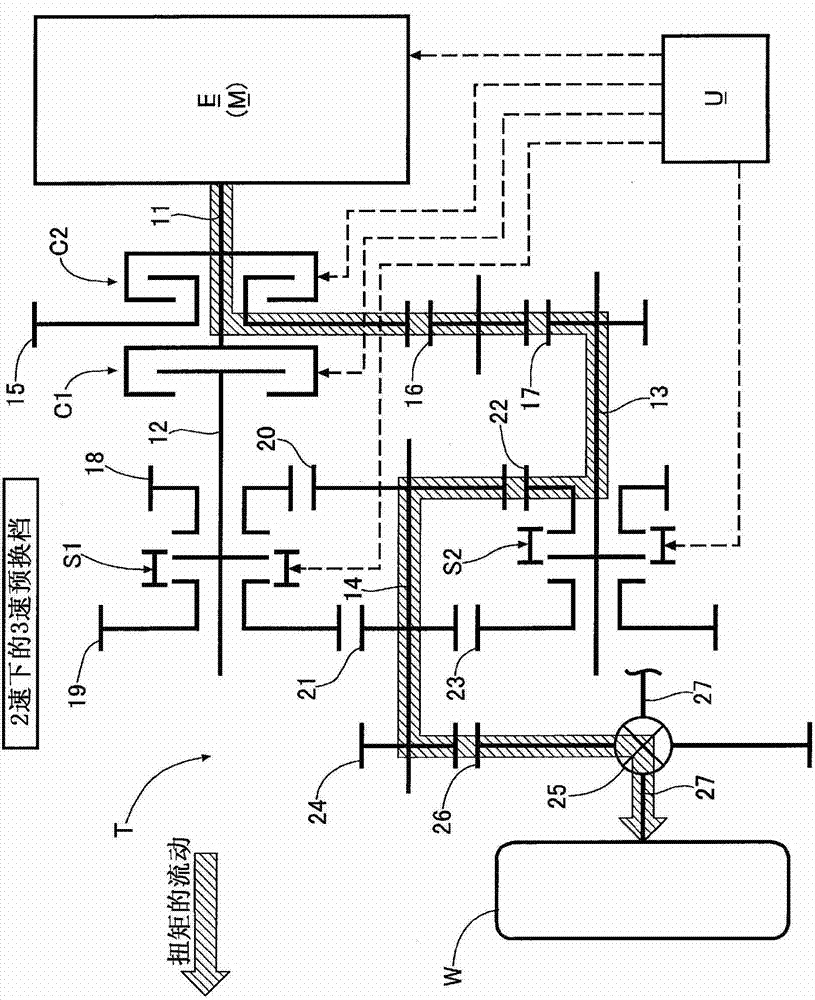

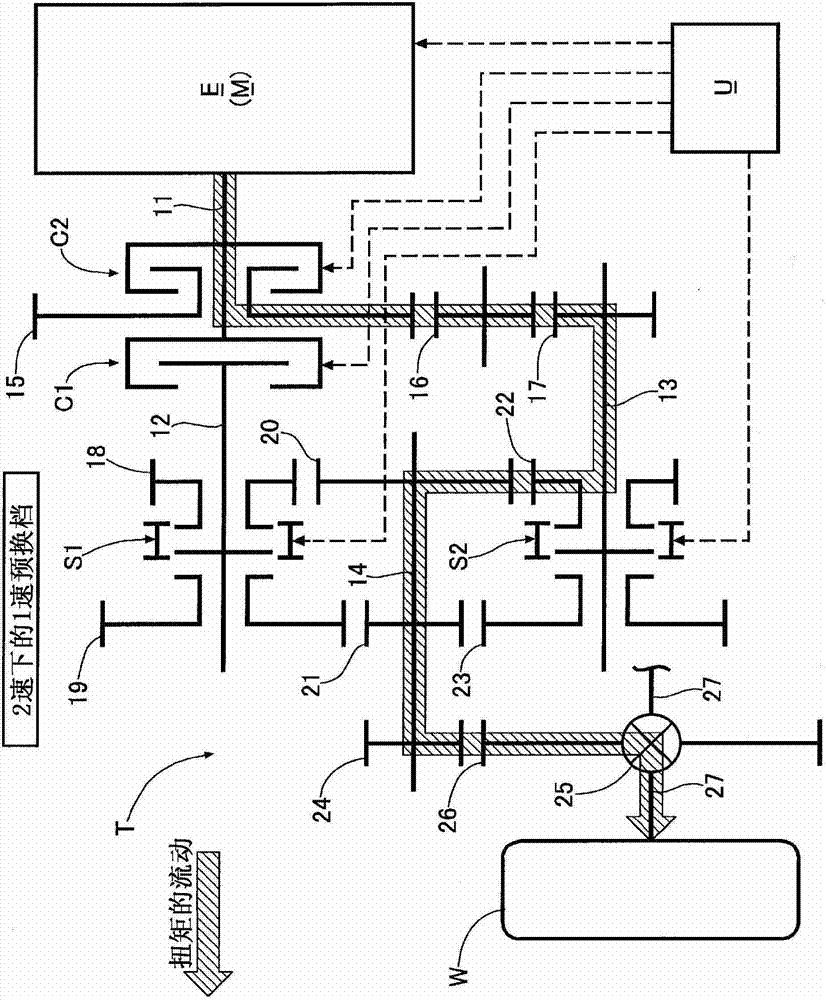

Dual clutch transmission

ActiveCN102959210ASuppress changesReduce shift shockElectrical controlToothed gearingsExternal combustion engineEngineering

Disclosed is a dual clutch transmission wherein, during a pre-shifting operation wherein, when a vehicle is driven using either a first or a second drive force transmission path extending from first and second input shafts (12, 13) to an output shaft (14), a synchronizer (S1, S2) of the other drive force transmission path is operated, the drive force of an internal combustion engine (E) is changed by a command from an electronic control unit (U), and accordingly, even when a drive force or a braking force is generated by inertia, due to a change in the number of rotations of the first and second input shafts (12, 13) in conjunction with the pre-shifting operation, the drive force or the braking force generated by inertia can be compensated by a change in the drive force of the internal combustion engine (E), to reduce shift-shock. Furthermore, the shift-shock can be reduced by only changing the drive force of the internal combustion engine (E) without adding any special structures to the dual clutch transmission (T), and accordingly, the cost and size of the dual clutch transmission (T) can be prevented from increasing.

Owner:HONDA MOTOR CO LTD

Shift control device for vehicle

ActiveCN104285083AReduce shift shockPrevent shifting shockGearing controlEngine controllersAngular accelerationControl theory

Owner:TOYOTA JIDOSHA KK

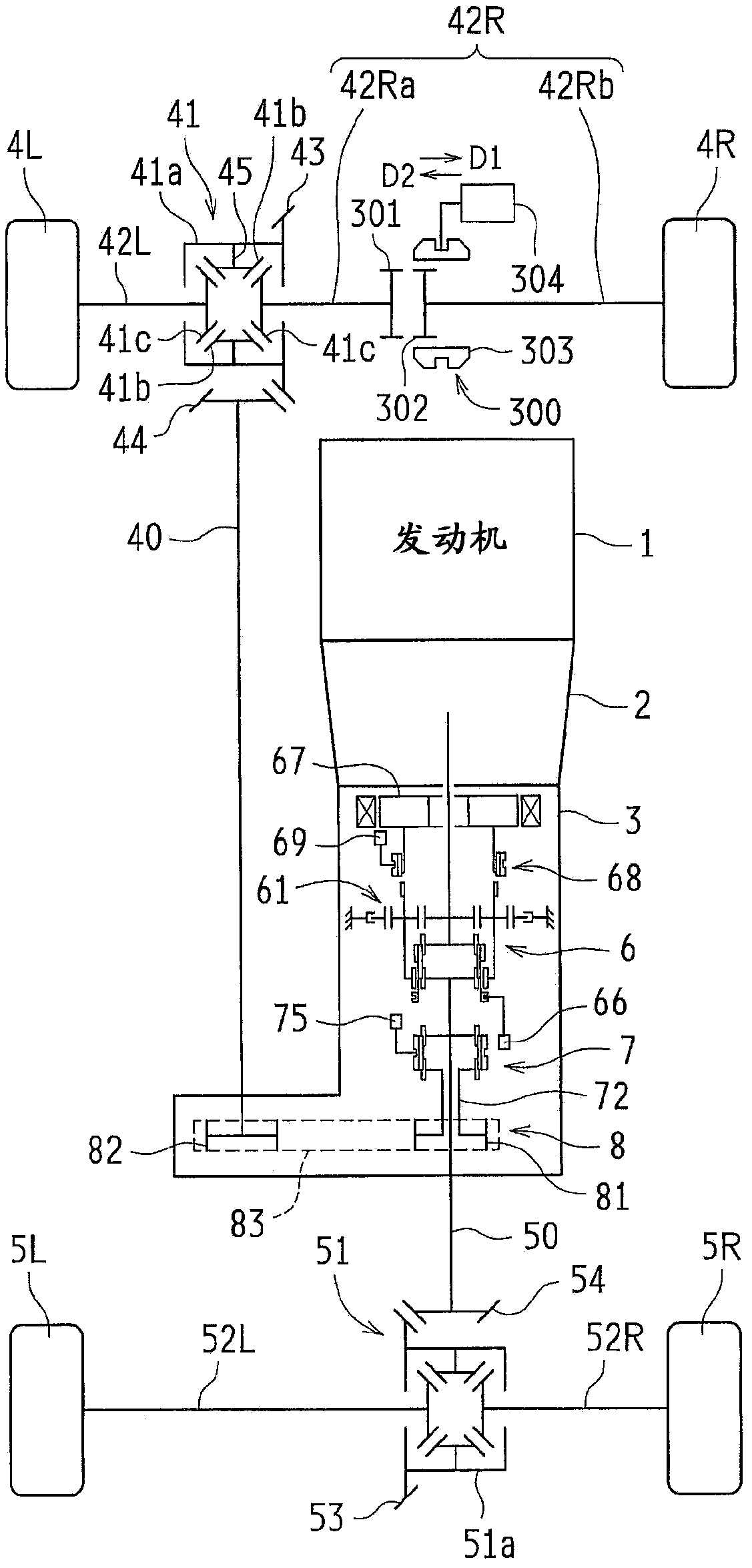

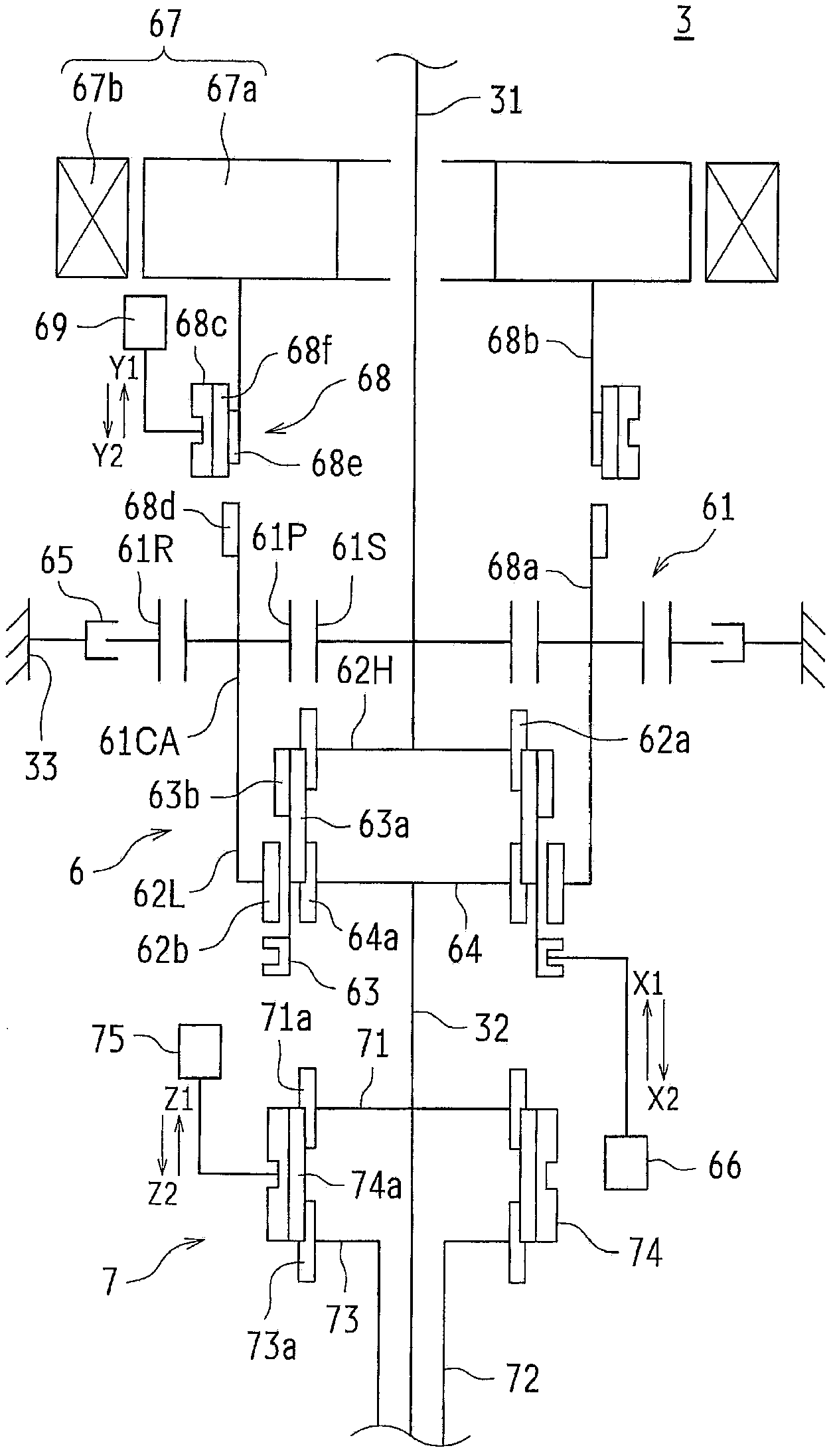

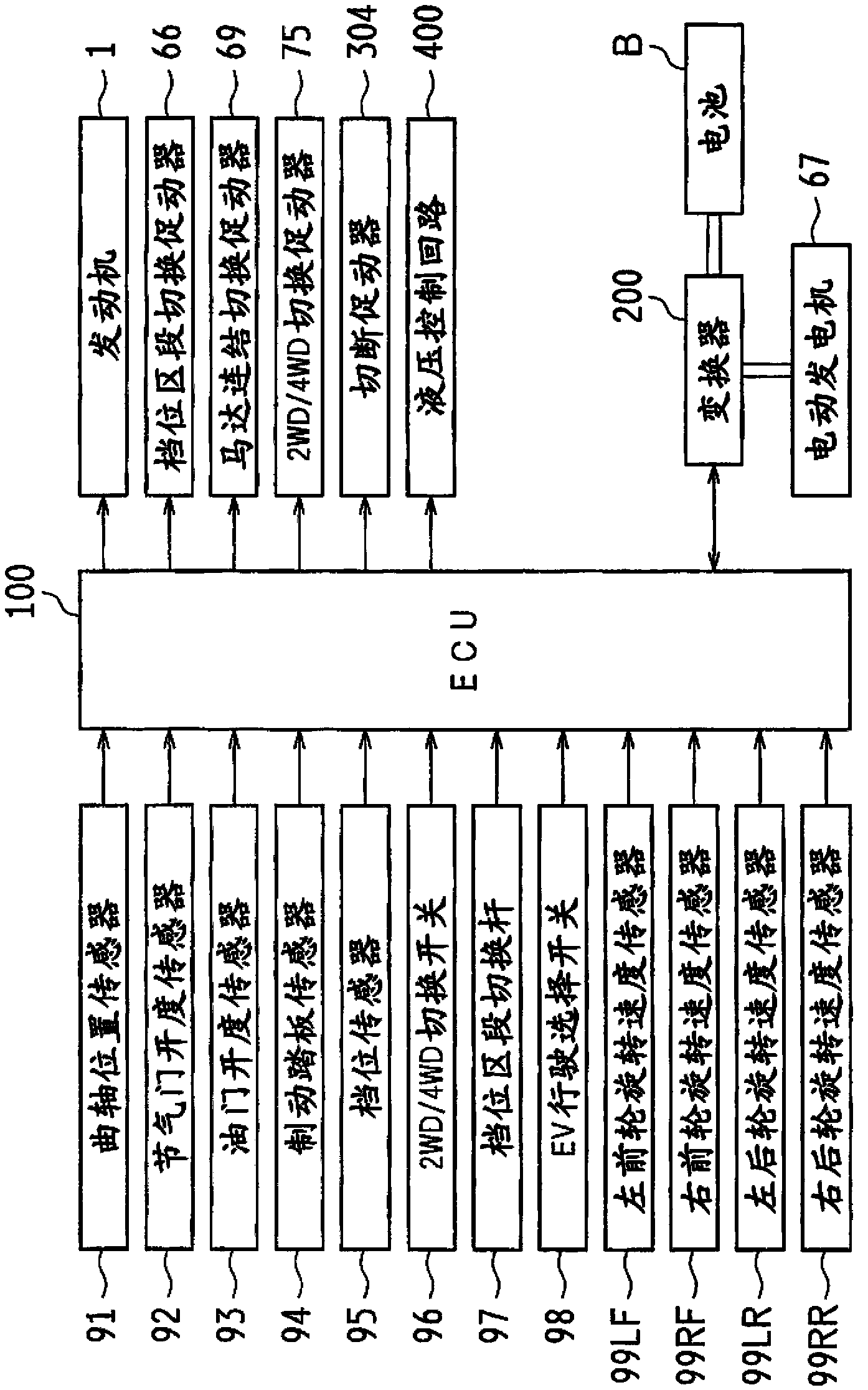

Vehicle power transmission system

ActiveCN103998828AIncrease rotation speedShift downToothed gearingsPropulsion using engine-driven generatorsElectric power transmissionLow speed

A motor generator (67) is connected to carriers (61CA) of an auxiliary transmission mechanism (6) capable of switching between a high-speed range and a low-speed range, in a manner that enables power to be transmitted to a vehicle provided with said auxiliary transmission mechanism (6). When switching from the high-speed range to the low-speed range, the rotational speed of the carriers (61CA) is increased by the motor generator (67) so as to synchronize the rotational speed of low-speed range pieces (62L) with the rotational speed of an input shaft (31). When switching from the low-speed range to the high-speed range, the rotational speed of the carriers (61CA) is increased by the motor generator (67) so as to synchronize the rotational speed of an output shaft (32) with the rotational speed of the input shaft (31). Thus, range switching can be performed while reducing transmission shocks, even while the vehicle is moving.

Owner:TOYOTA JIDOSHA KK

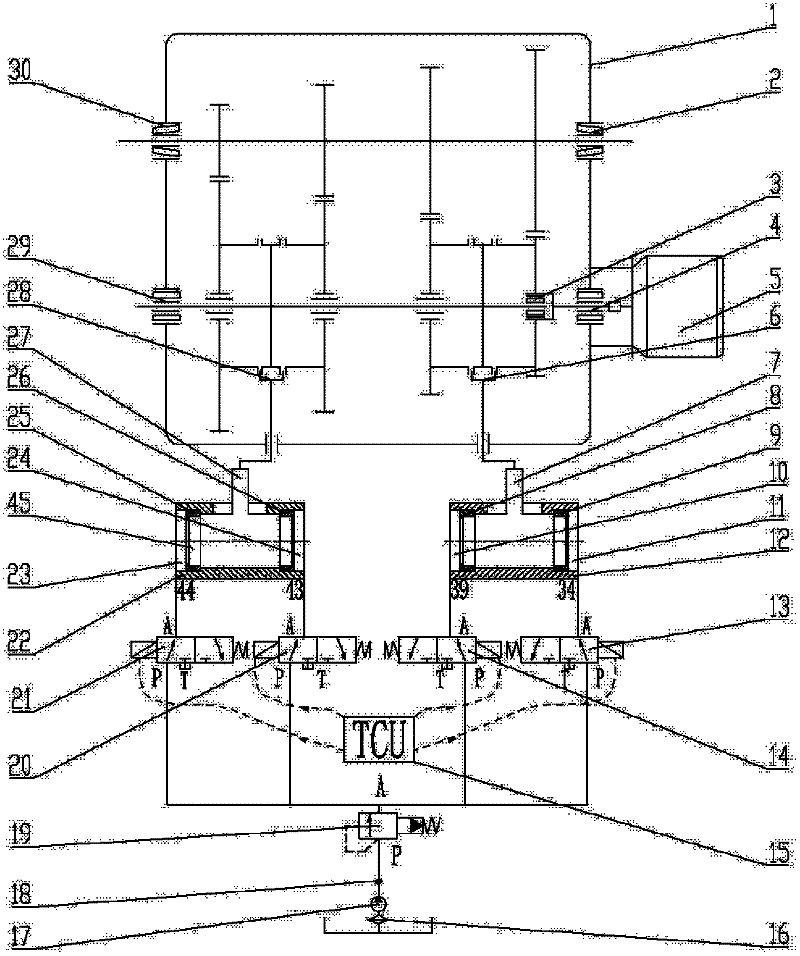

Electric control pneumatic mechanical automatic shift system

The invention discloses an electric control pneumatic mechanical automatic shift system which comprises a transmission case (1), a motor (5), a pneumatic control system and an electric control unit(13), wherein the pneumatic control system comprises a 3-gear and 4-gear shift air cylinder (9), a No 5 electromagnetic valve (11), a No 4 electromagnetic valve (12), a No 3 electromagnetic valve (14), a No 2 electromagnetic valve (19), a No 1 electromagnetic valve (20), and a 1-gear and 2-gear shift air cylinder (22); the No 2 piston of the 1-gear and 2-gear shift air cylinder (22) is connected with a 1-gear and 2-gear shifting yoke of the transmission case (1), and the No 2 piston (32) of the 3-gear and 4-gear shift air cylinder (9) is connected with a 3-gear and 4-gear shifting yoke of the transmission case (1); the motor(5) is fixedly connected with the transmission case (1), and the spline pair of the input shaft of the transmission case (1) is connected with the output end of the motor (5); and the terminals of electromagnetic coils from the No 1 electromagnetic valve (20) to the No 5 electromagnetic valve (11) are connected with a wire of the electric control unit (13).

Owner:JILIN UNIV

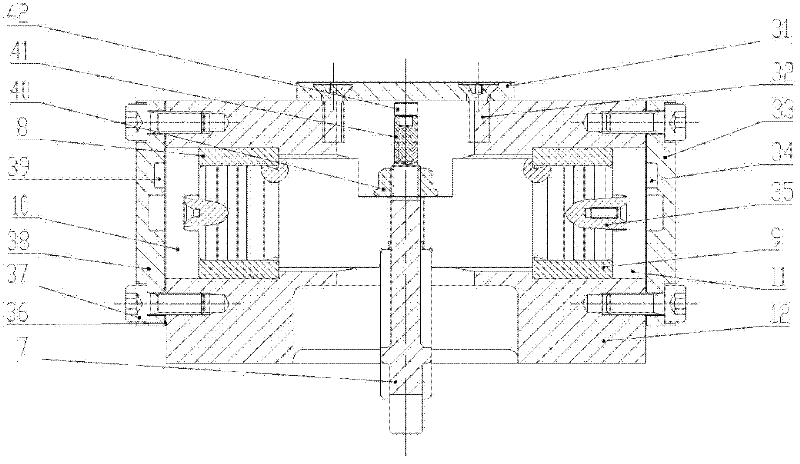

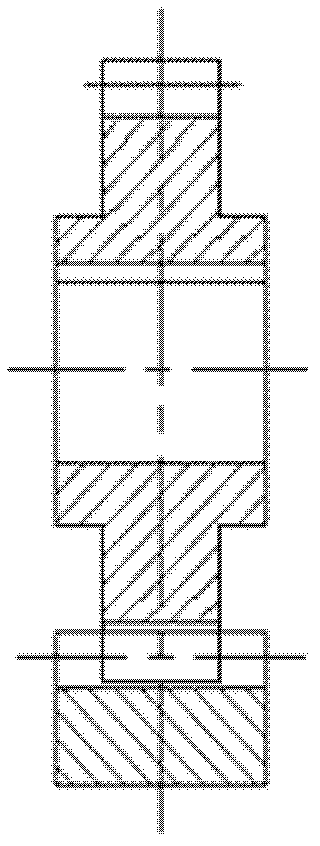

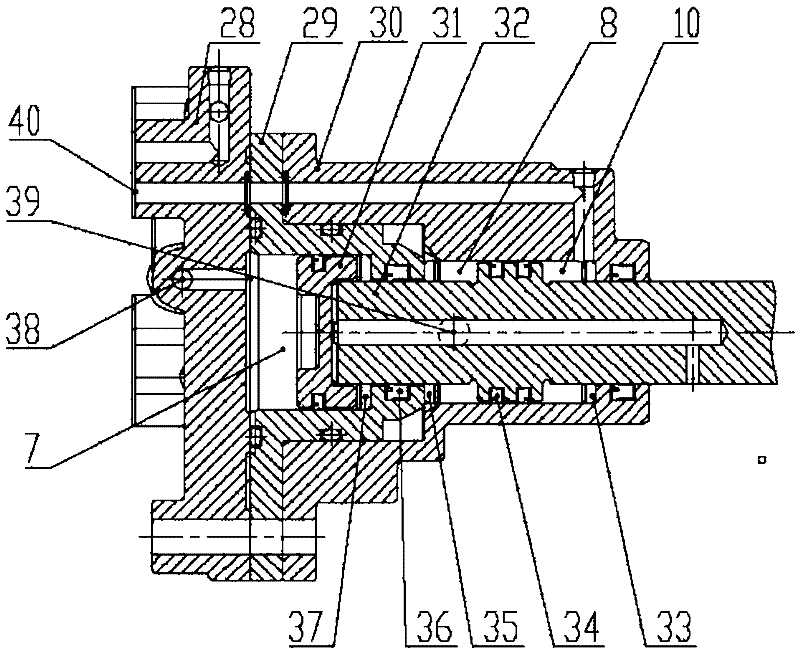

Integrated structure clutch applied to gearbox

InactiveCN103062241AReduce noiseReduce weightFluid actuated clutchesGearing detailsPistonTransmission system

The invention relates to an integrated structure clutch applied to a gearbox of a wheel type engineering machinery transmission system. The clutch comprises a main shaft, a gear, a hydraulic system, a power transmission system, a returning system and a casing, wherein the main shaft is fixed on a box body of the gearbox, the gear is positioned on the main shaft through an abrasion bearing pad, one end of the power transmission system is connected with the gear, the other end of the power transmission system is connected with the casing and connected with the hydraulic system through the return system simultaneously, the hydraulic system comprises a piston, a piston seat and an oil relief valve, the piston is fixed on the piston seat through a snapping ring A, the piston and the piston seat are sealed through a seal ring A, the oil relief valve is arranged at one end of the piston seat, the piston seat is fixed on the casing through the snapping ring A, the piston, the piston seat, the oil relief valve and the seal ring A form a closed oil chamber, and an oil way is arranged between the gearbox matched with the clutch and the closed oil chamber. By means of the integrated structure clutch, gear shift impact is reduced, transmission efficiency is improved, transmission accuracy of a gear pair is improved, and noises of the gearbox are reduced.

Owner:SHANTUI CONSTR MASCH CO LTD

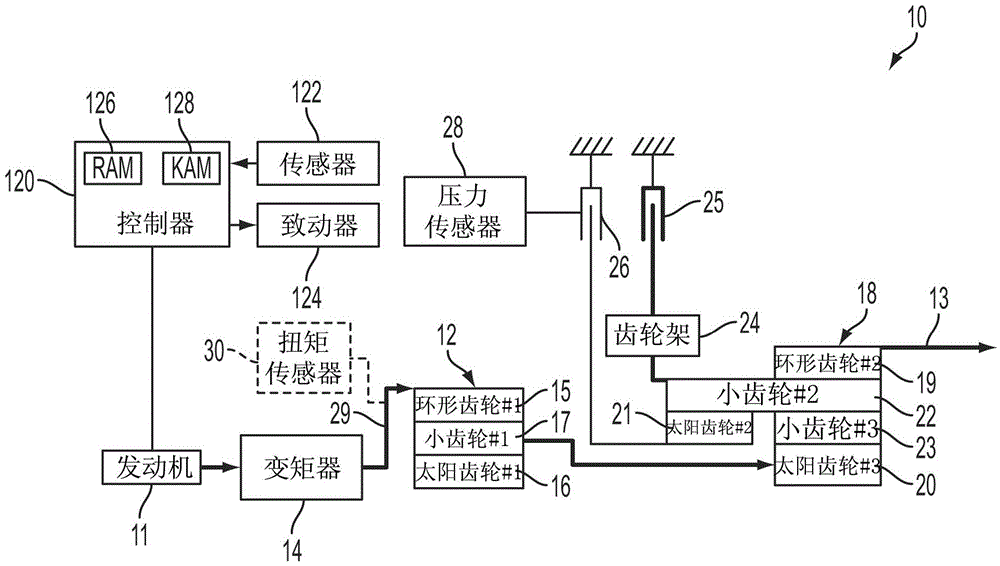

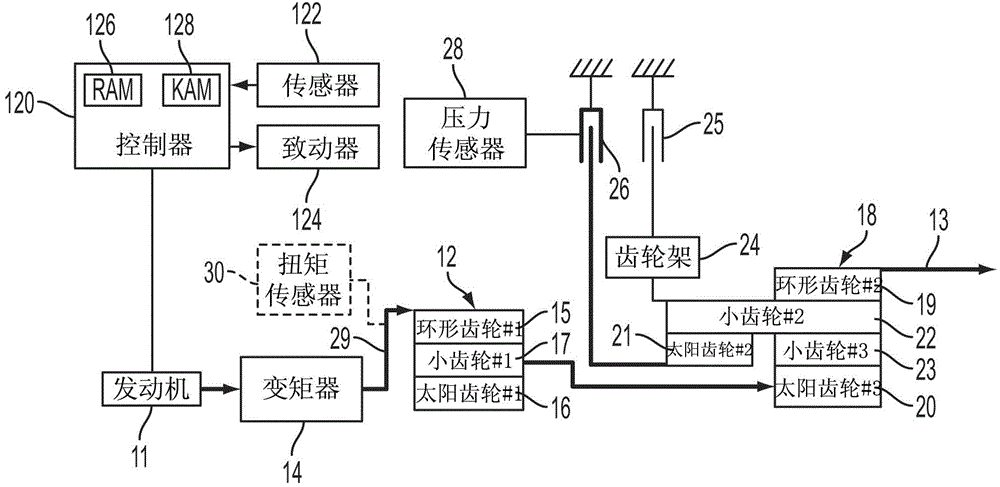

Automatic transmission shift control based on transmission input shaft torque signal

ActiveCN104048031AReduce shift shockReduce torque disturbanceInternal combustion piston enginesGearing controlAutomatic transmissionMagneto elastic

The invention relates to automatic transmission shift control based on a transmission input shaft torque signal, and a system and a method for minimizing torque disturbances during a shift event for an automatic transmission control actual transmission input shaft torque using a transmission input shaft signal produced by an input shaft torque sensor. The torque sensor provides a signal to a controller that monitors the measured transmission input torque. The torque sensor may be implemented by a strain gauge, a piezoelectric load cell, or a magneto-elastic torque sensor. The system may include a vehicle powertrain having an engine, a transmission coupled to the engine via a torque converter, an input torque sensor coupled to the input shaft of the transmission and a controller configured to control engine torque to cause the measured transmission input shaft torque to achieve a target transmission input shaft torque during the shift event.

Owner:CHANGAN FORD AUTOMOBILE CO LTD

Three-gear magnetic particle type double-clutch speed changer for hybrid power

ActiveCN102155530AReduce energy conversion lossesReduce shift shockGearboxesToothed gearingsEngineeringHybrid vehicle

The invention provides a three-gear magnetic particle type double-clutch speed changer for hybrid power, belonging to the technical field of automobiles. The speed changer solves the problem that a driving system of an existing hybrid vehicle has high shifting impact performance. The three-gear magnetic particle type double-clutch speed changer for hybrid power comprises an engine, an input shaft, a first output shaft, a second output shaft, a reverse gear shaft and a differential mechanism and a commutator controlling the changing-over of gears; an output shaft of the engine is provided witha single clutch; one end of the input shaft is connected with the single clutch; the other end of the input shaft is provided with a magnetic particle type double-clutch; and the double-clutch is connected with an electric motor which is connected with a storage battery. The speed changer has advantages of compact structure, small shifting impact, less energy conversion loss and the like.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Automatic gearbox without synchronizer and not interrupt power shifting gear

An automatic gearbox of synchronizer-free and gearshift without power interruption type is prepared for applying two-shaft mode with five-gear variable speed, adding double-surface gearshift clutch, fixing fixed plate of gearshift clutch on a shaft of gearbox and arranging two float plates at two sides of said fixed plate.

Owner:BEIJING JIAOTONG UNIV

Control apparatus and control method for vehicular automatic transmission

ActiveCN103089984AShift downPrevent drive force reductionHybrid vehiclesGearing controlAutomatic transmissionEngineering

In a downshift of an automatic transmission in a state where an accelerator pedal is depressed, one of a clutch-to-clutch shift in which the shift is carried out by gradually reducing an engagement pressure of a clutch or a brake to be disengaged in the shift and a rotation synchronization shift in which the shift is carried out by reducing the engagement pressure of the clutch or the brake more quickly than in the clutch-to-clutch shift is selected based on an output shaft torque of the automatic transmission, a region where the rotation synchronization shift is selected is lower in output shaft torque than a region where the clutch-to-clutch shift is selected, and hence it is possible to appropriately selectively execute a shift placing emphasis on a shock and a shift placing emphasis on a shift speed in accordance with the output shaft torque.

Owner:TOYOTA JIDOSHA KK +1

Single planet-row two-shift automatic transmission for electric automobile

InactiveCN104930140AIncrease mileageReduce shift shockToothed gearingsTransmission elementsAutomatic transmissionElectromagnetic clutch

The invention discloses a single planet-row two-shift automatic transmission for an electric automobile. The automatic transmission comprises a casing. The casing is internally provided with a driving gear connected to a driving motor, a driven gear engaged with the driving gear, and an intermediate shaft fixedly connected to the driven gear. The intermediate shaft is provided with a planetary gear mechanism. The planetary gear mechanism comprises a sun gear fixedly connected to the intermediate shaft, a planetary gear engaged with the sun gear, a planetary gear holder, and a gear ring engaged with the planetary gear. The planetary gear holder is provided with an output shaft, and a clutch is arranged between the output shaft and the sun gear or the intermediate shaft. The casing is also provided with a brake used for braking the tooth ring. According to the invention, the electromagnetic brake and the electromagnetic clutch are employed in the single planet-row two-shift automatic transmission, so that demands on the performance of the driving motor are reduced, the operation efficiency of the motor is improved, and the driving range of the electric automobile is increased.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com