Dual clutch transmission

A dual-clutch transmission and clutch technology, which is applied in the direction of machine/engine, gear transmission, transmission control, etc., can solve the problems of large transmission size, high cost, and increased number of parts, so as to prevent cost increase and reduce replacement. The effect of preventing file impact and preventing size enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

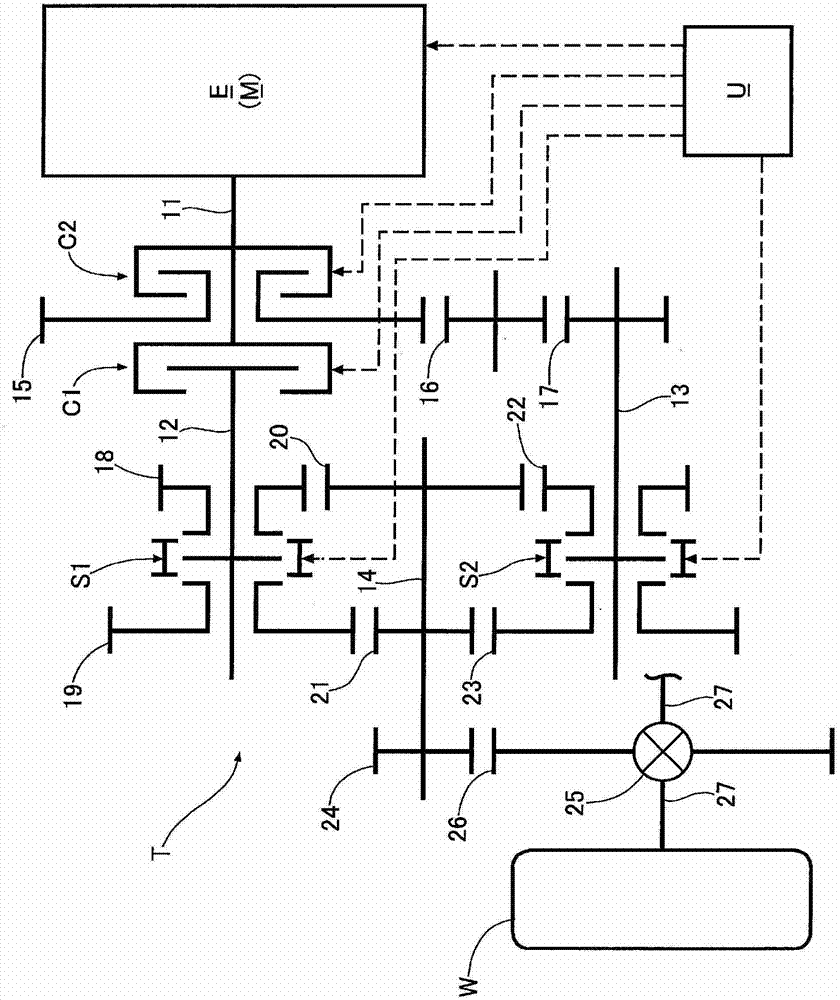

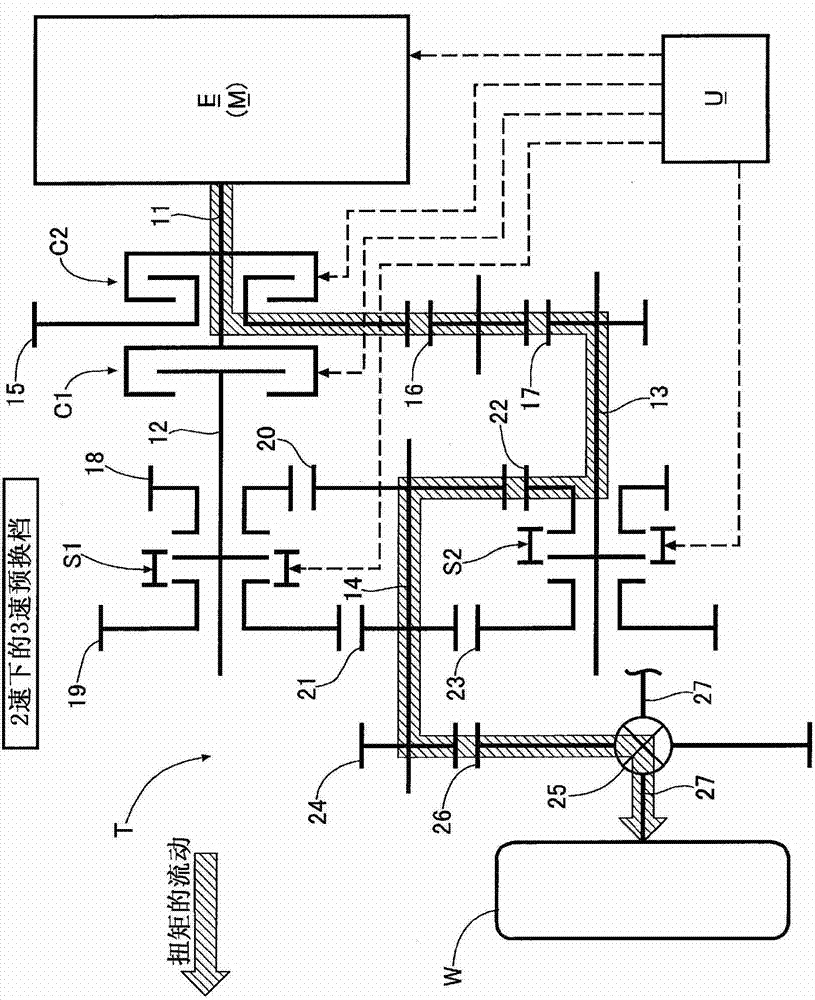

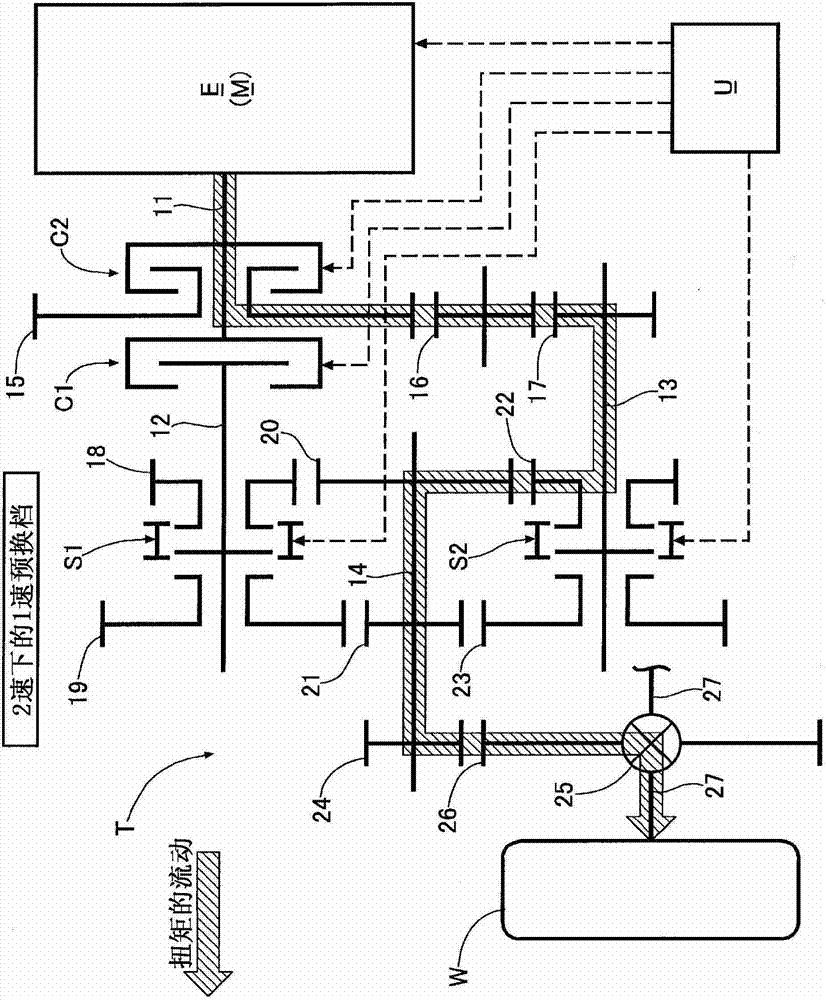

[0031] Such as figure 1 As shown, the dual-clutch transmission T mounted on a vehicle includes: a first input shaft 12 arranged coaxially with a crankshaft 11 of an internal combustion engine E composed of a gasoline engine; a second input shaft 13 parallel to the first input shaft 12 and the output shaft 14 is arranged parallel to the first input shaft 12 and the second input shaft 13 . The driving force of the crankshaft 11 is transmitted to the first input shaft 12 through the first clutch C1, and the driving force of the crankshaft 11 is transmitted to the second input shaft through the second clutch C2, the driving gear 15, the intermediate gear 16, and the driven gear 17. axis 13.

[0032] A first-speed drive gear 18 and a third-speed drive gear 19 are supported on the first input shaft 12 in a relatively rotatable manner. - The 2nd speed driven gear 20 meshes with the 3rd - 4th speed driven gear 21 . In addition, the 2nd speed drive gear 22 and the 4th speed drive ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com