Patents

Literature

102results about How to "Reduce fuel injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

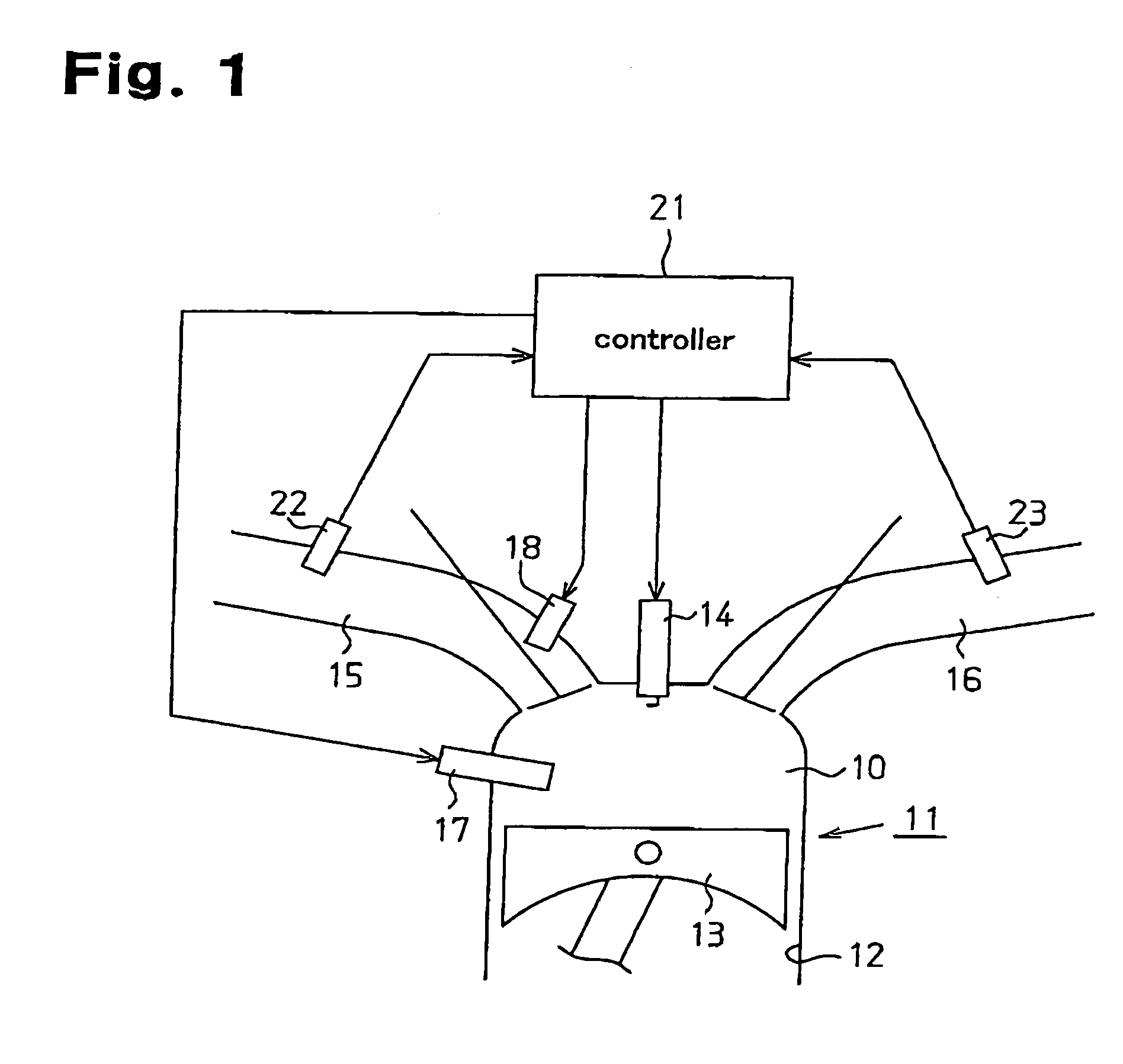

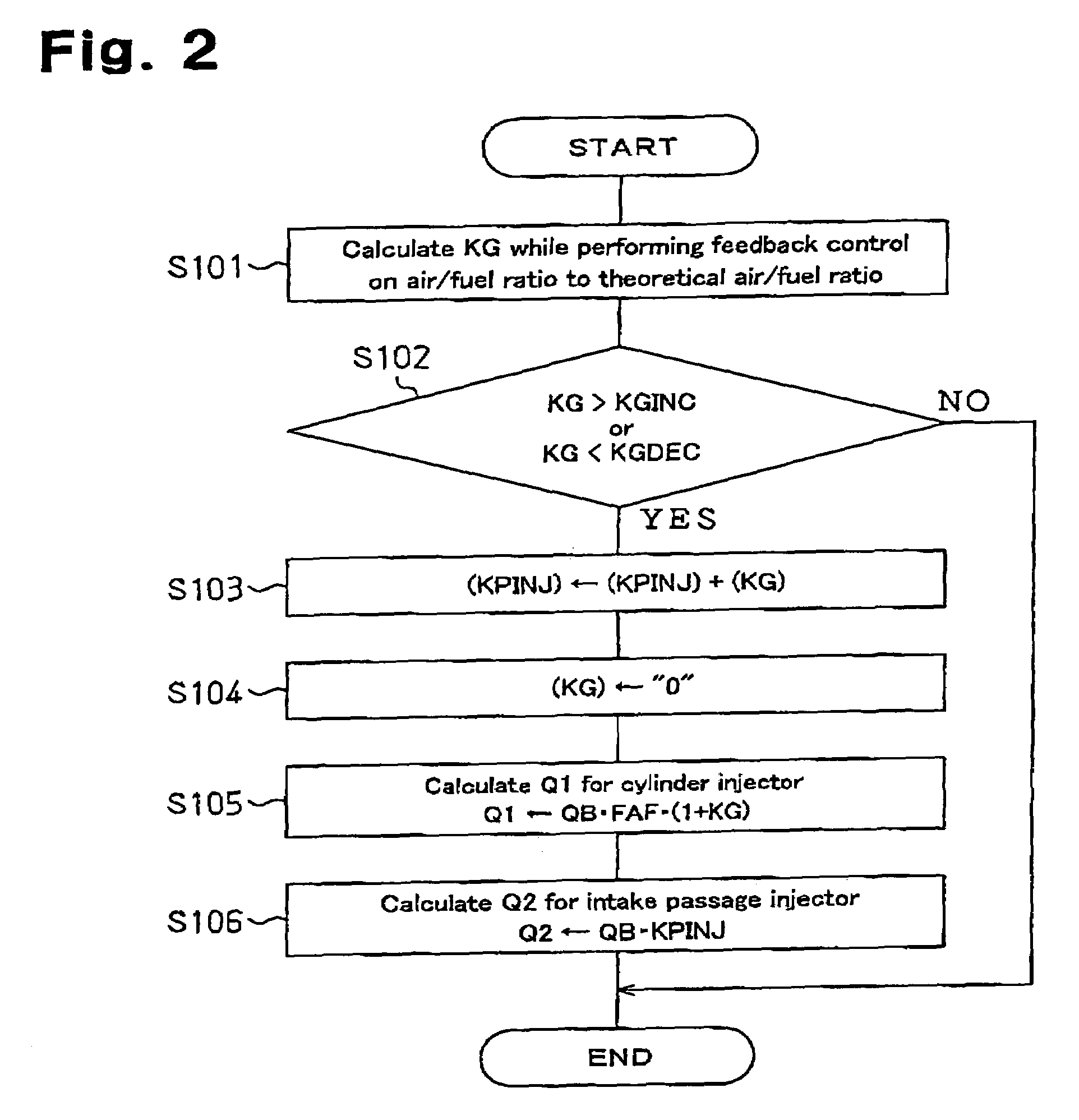

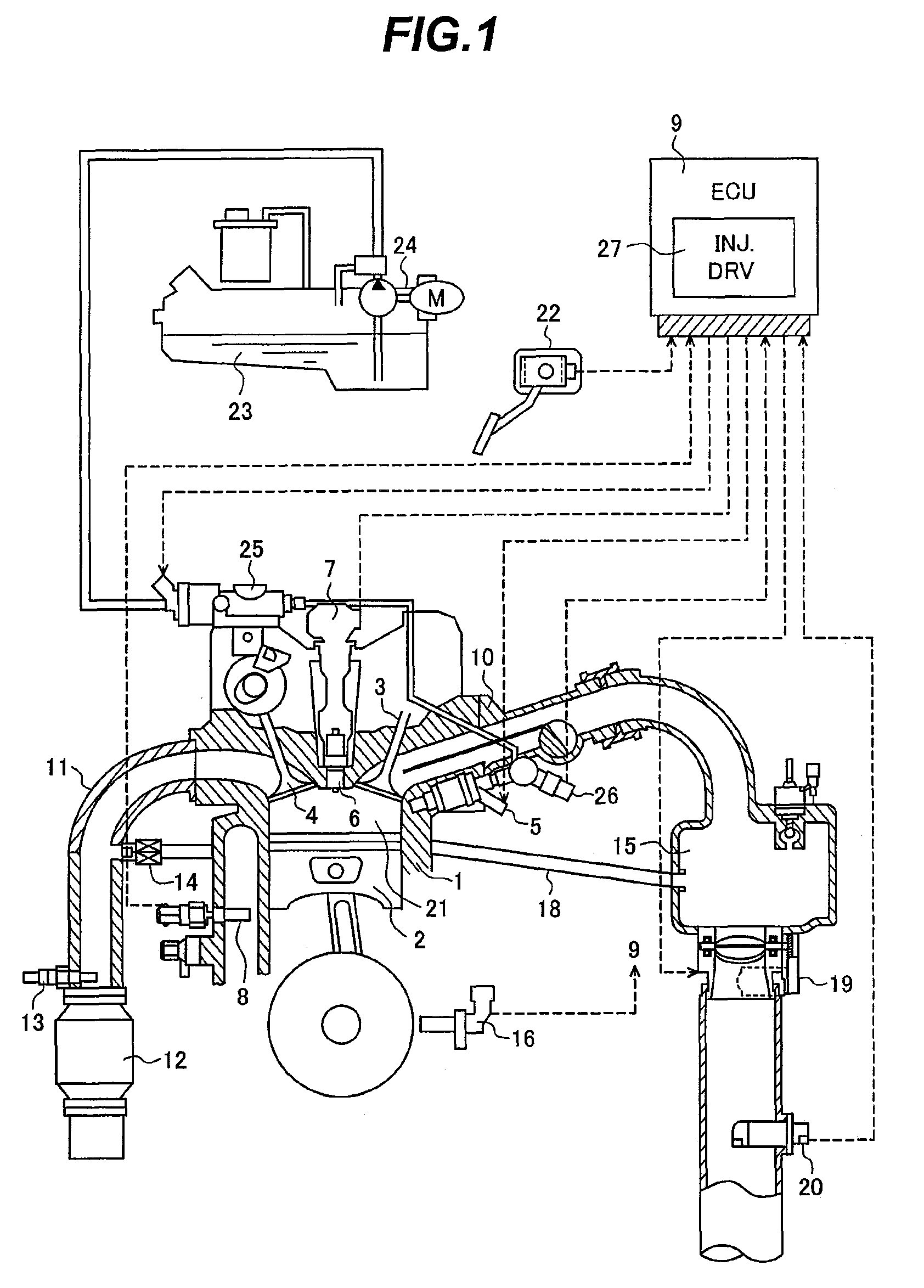

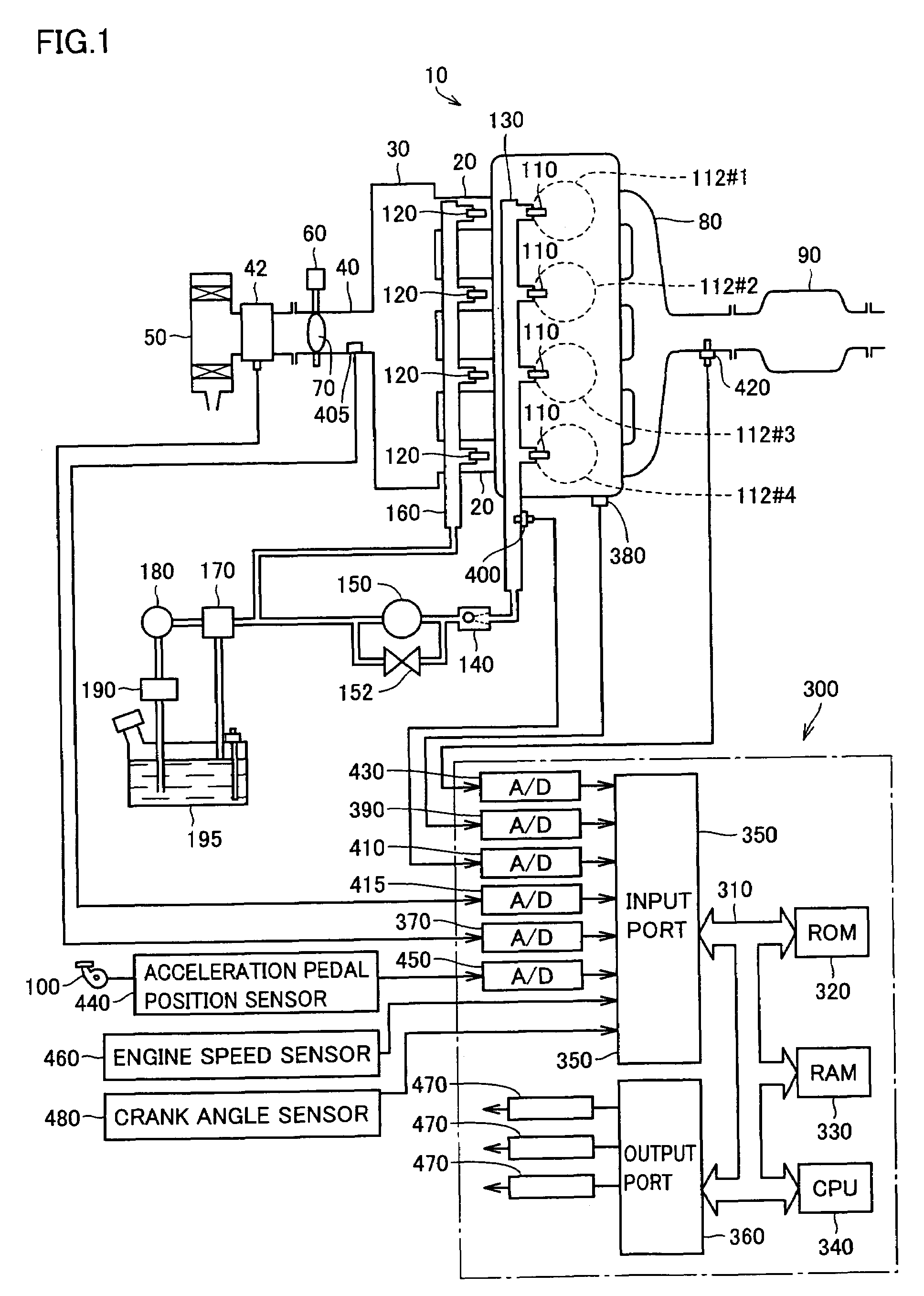

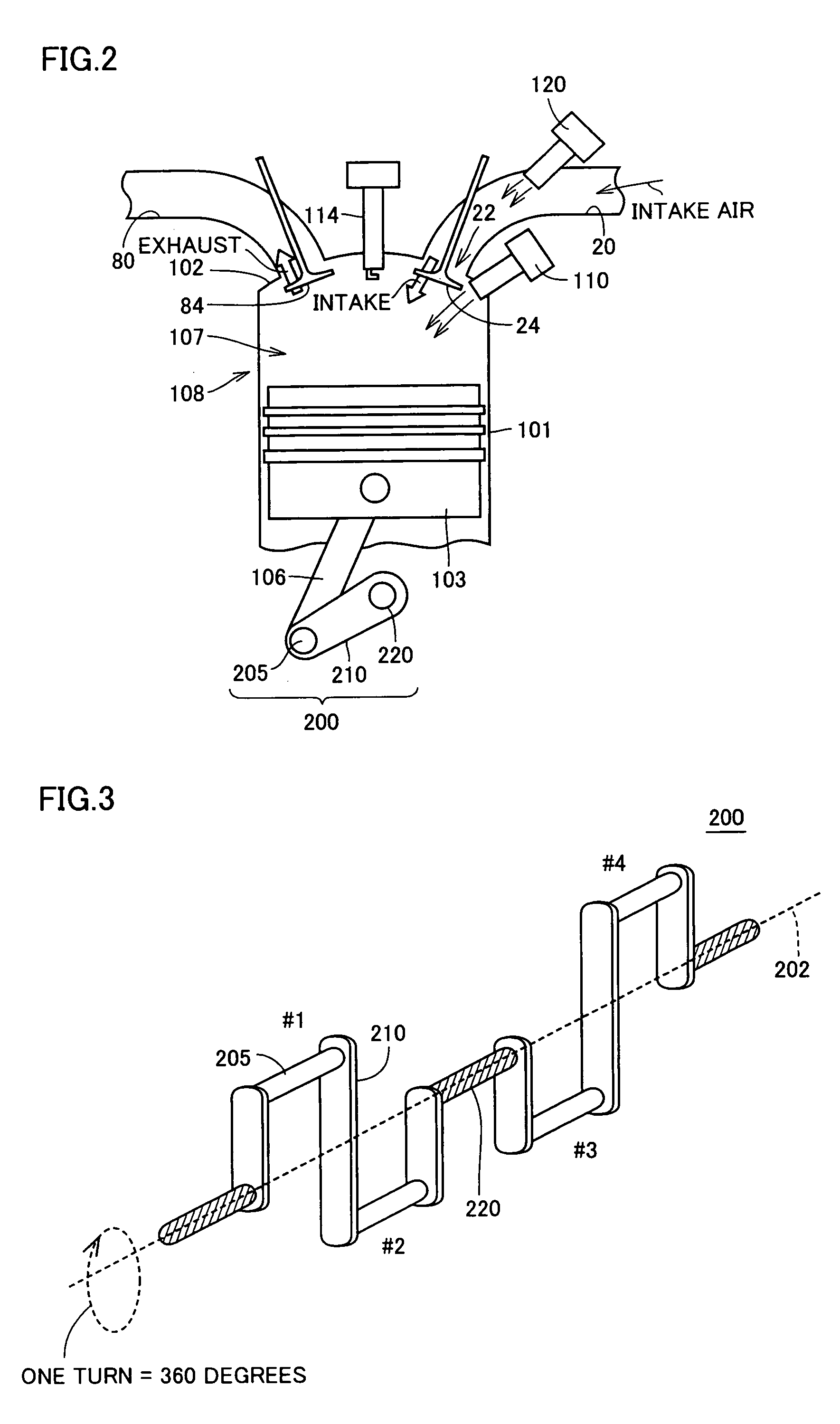

Engine fuel injection control system

InactiveUS20050178360A1Inhibit deteriorationImprove suction efficiencyElectrical controlInternal combustion piston enginesCombustion chamberControl system

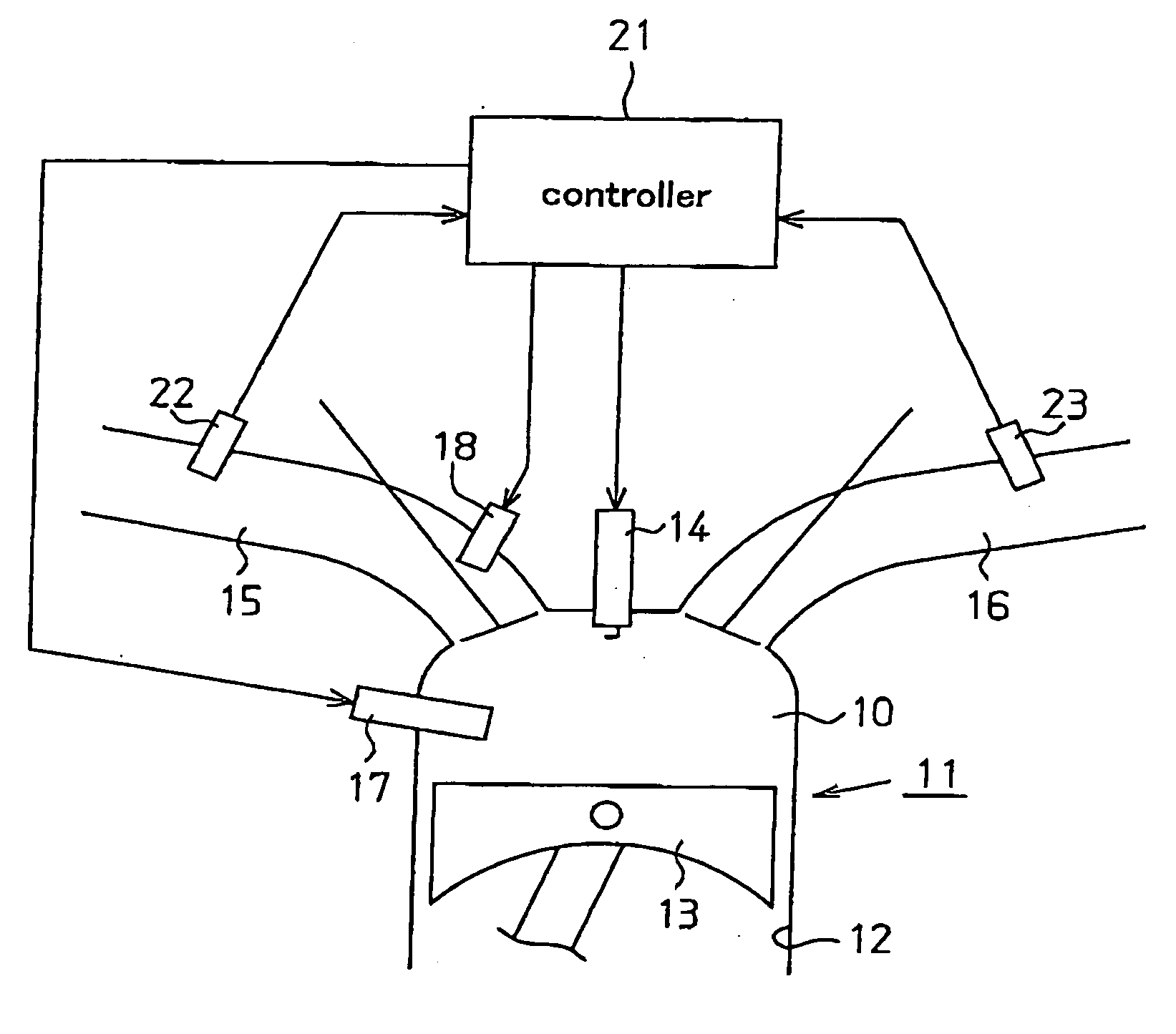

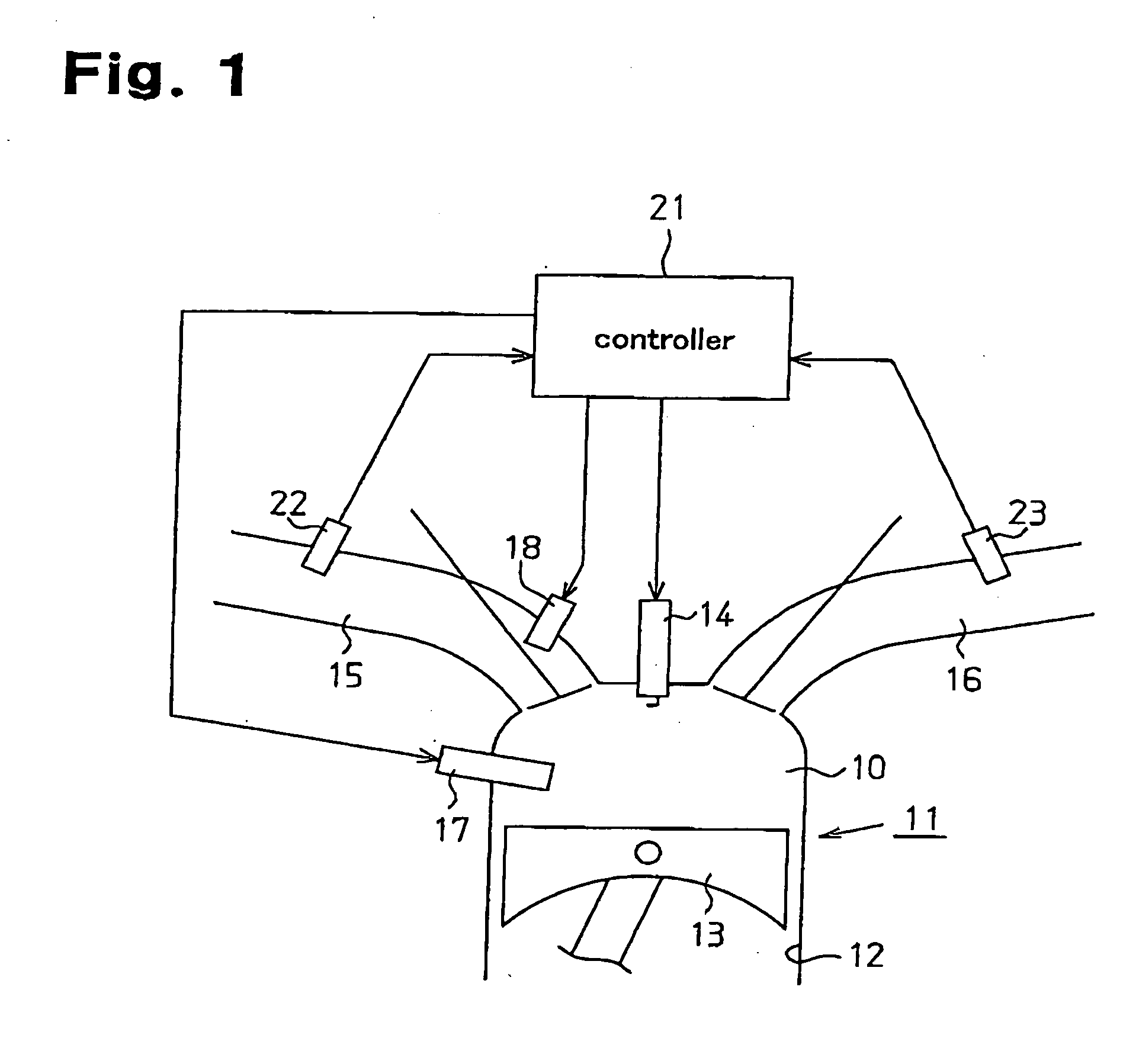

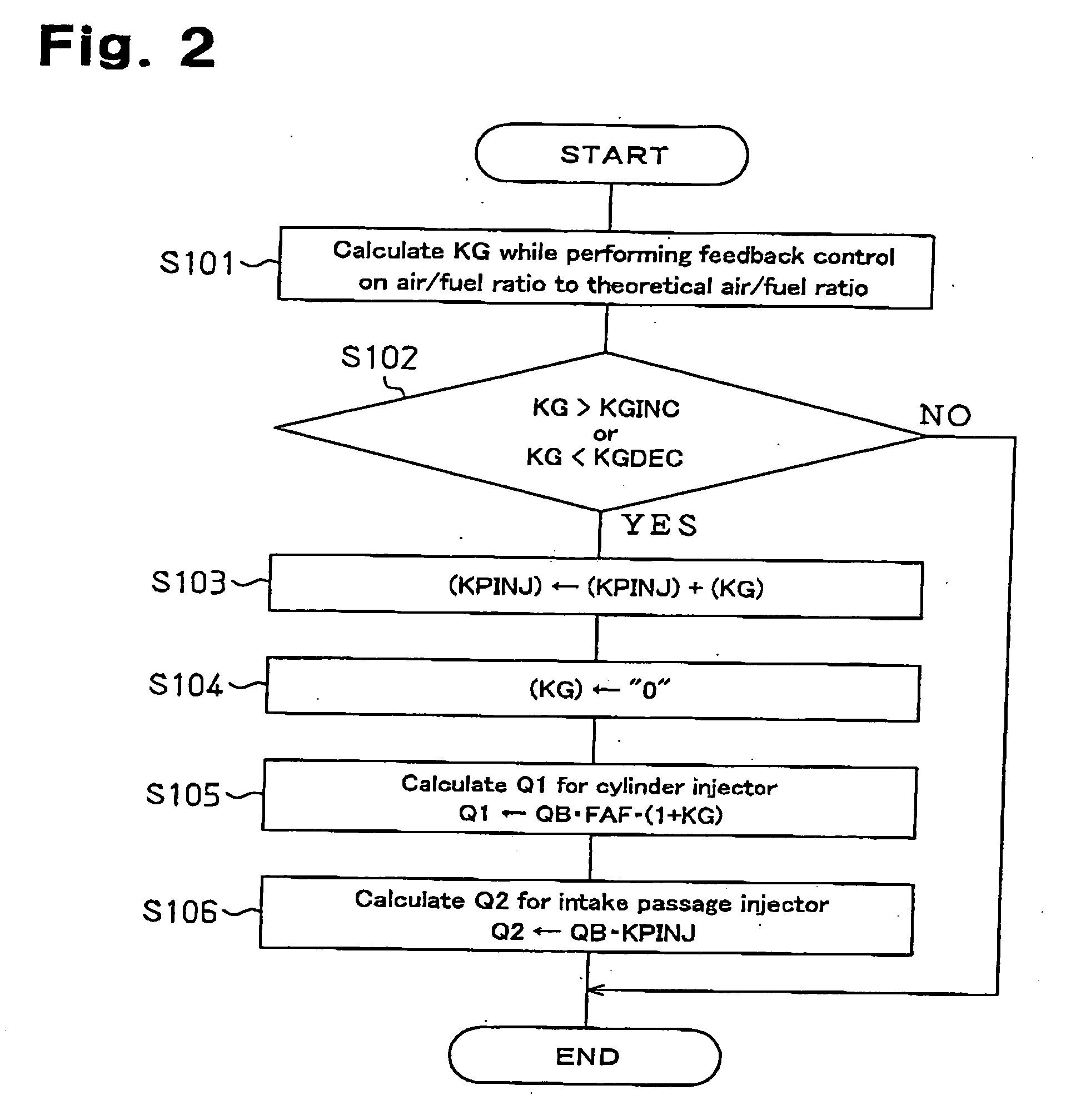

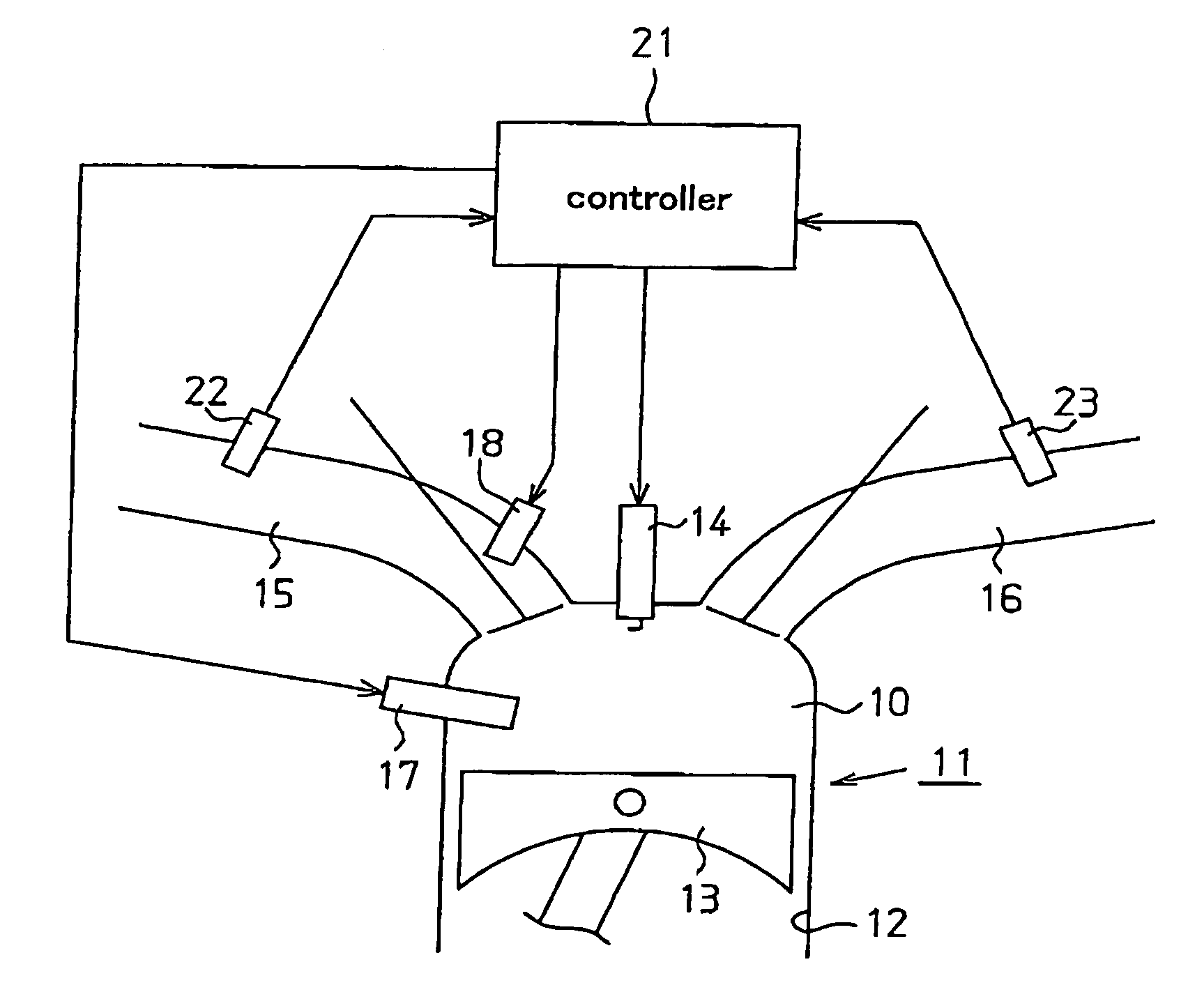

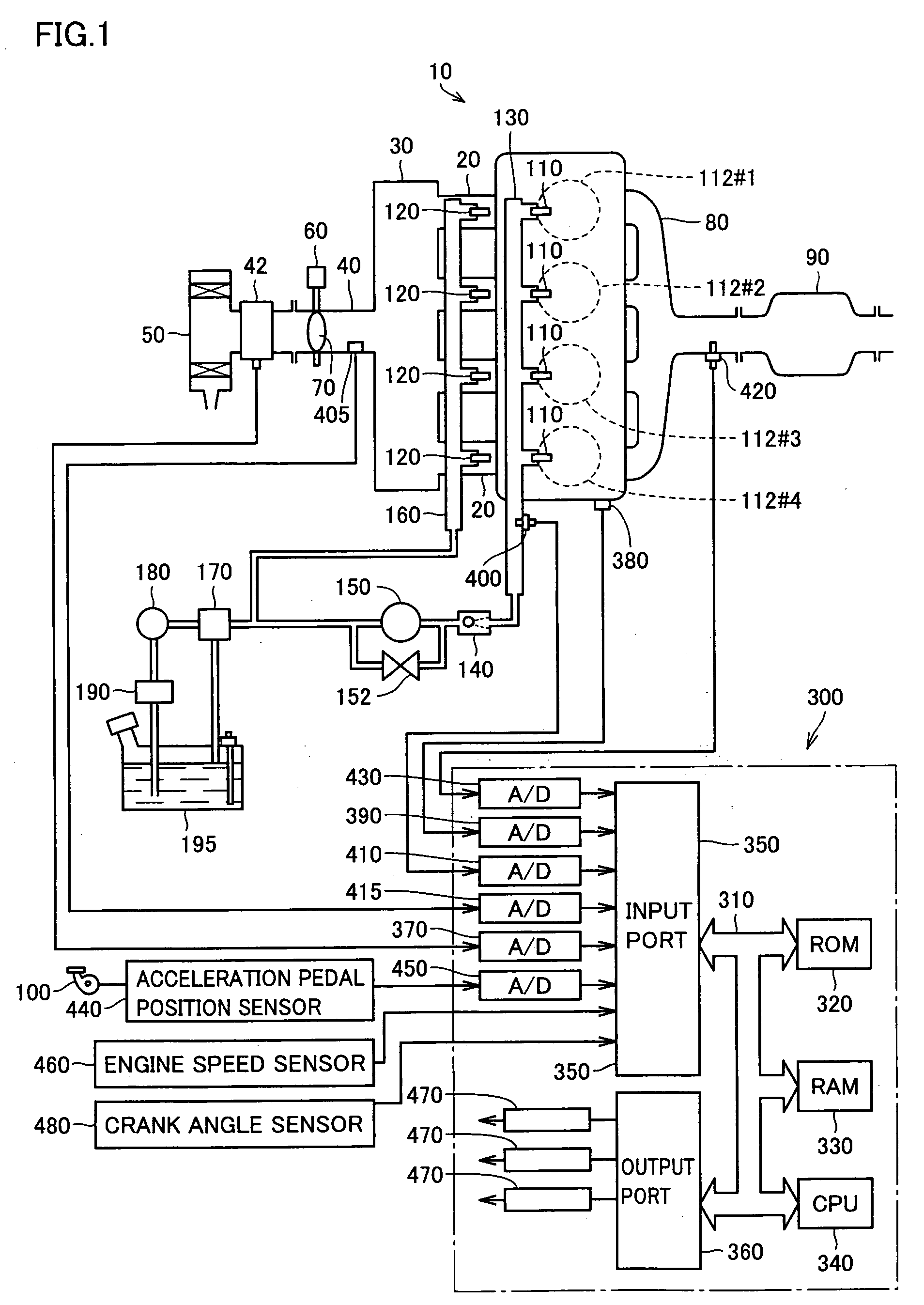

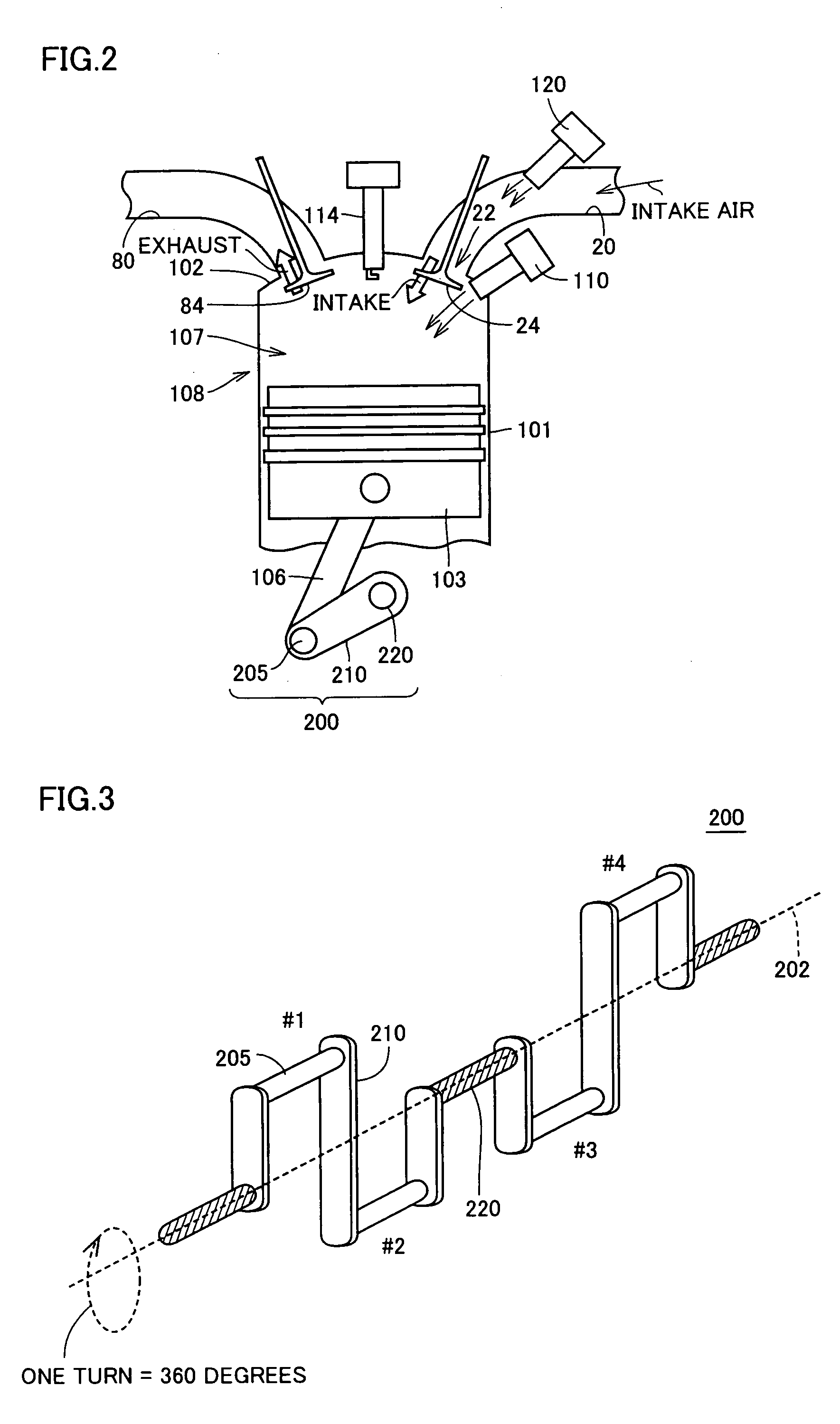

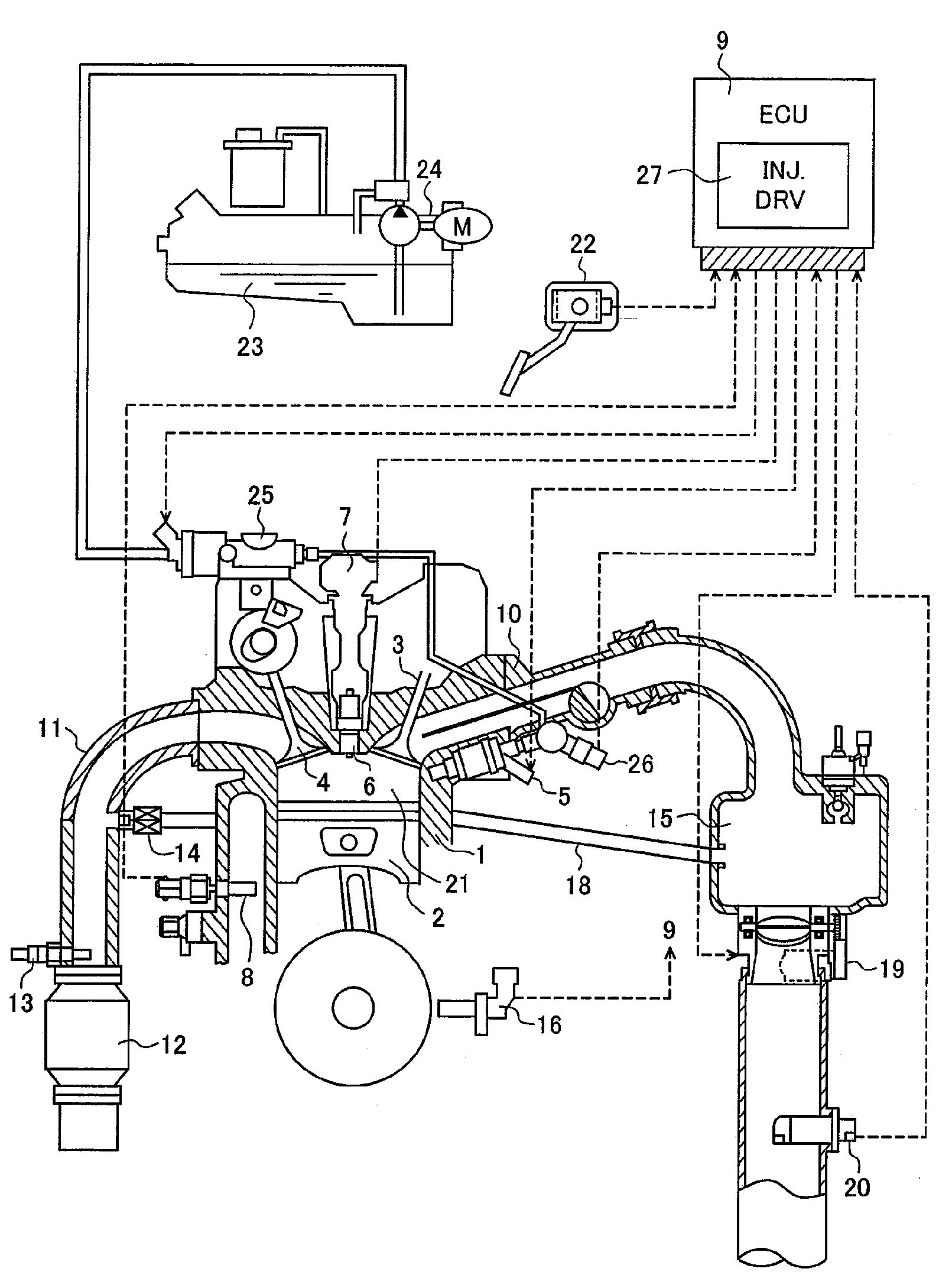

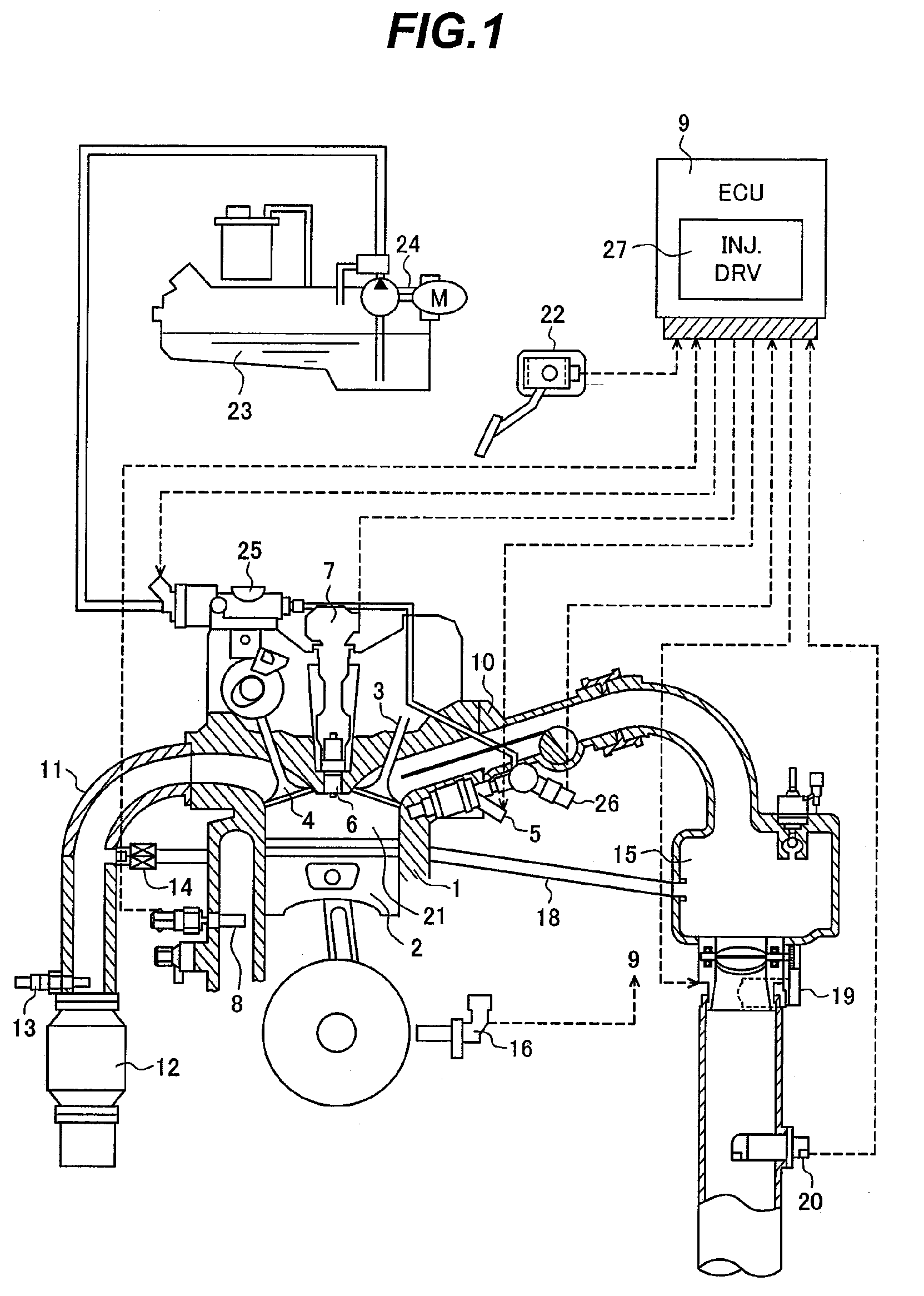

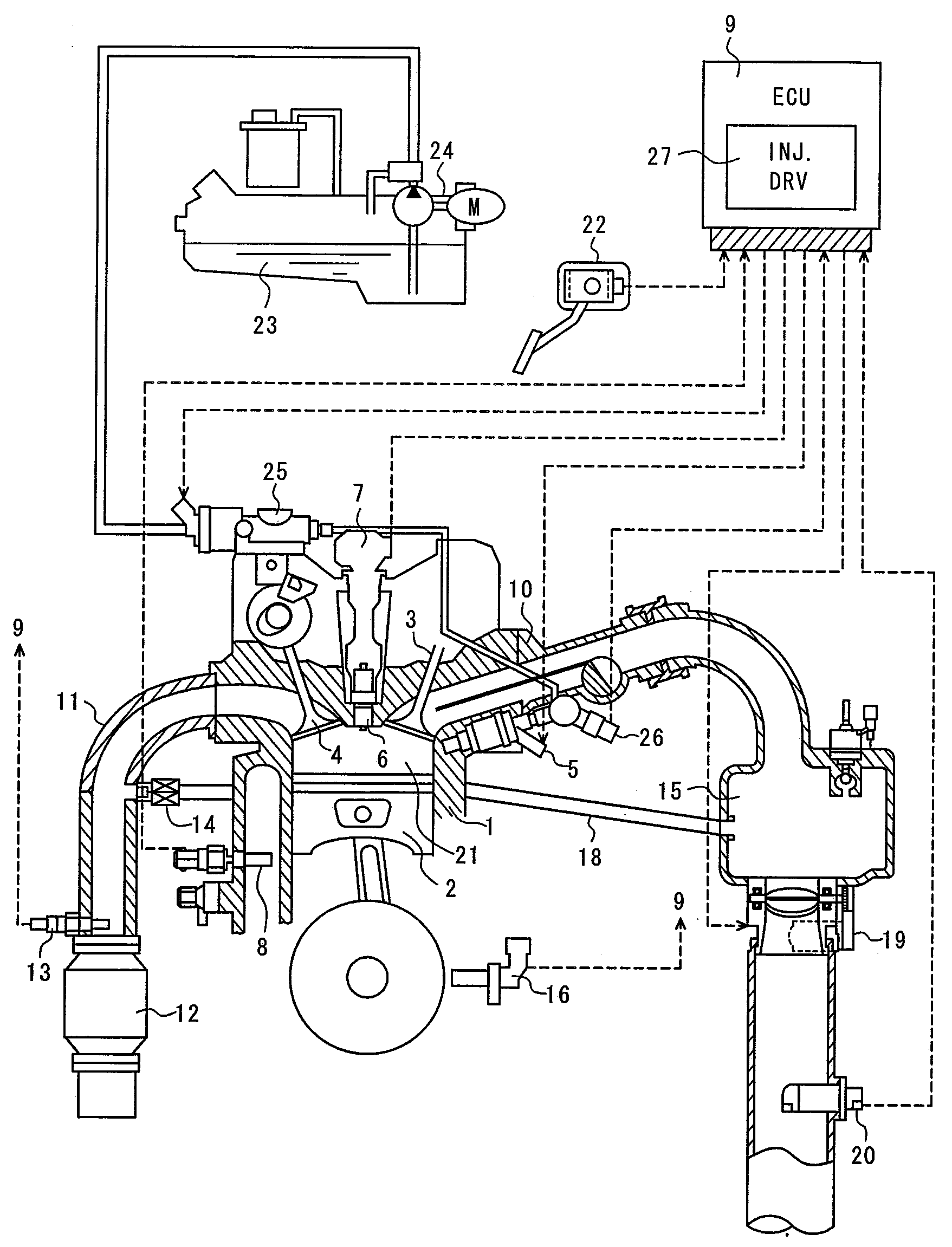

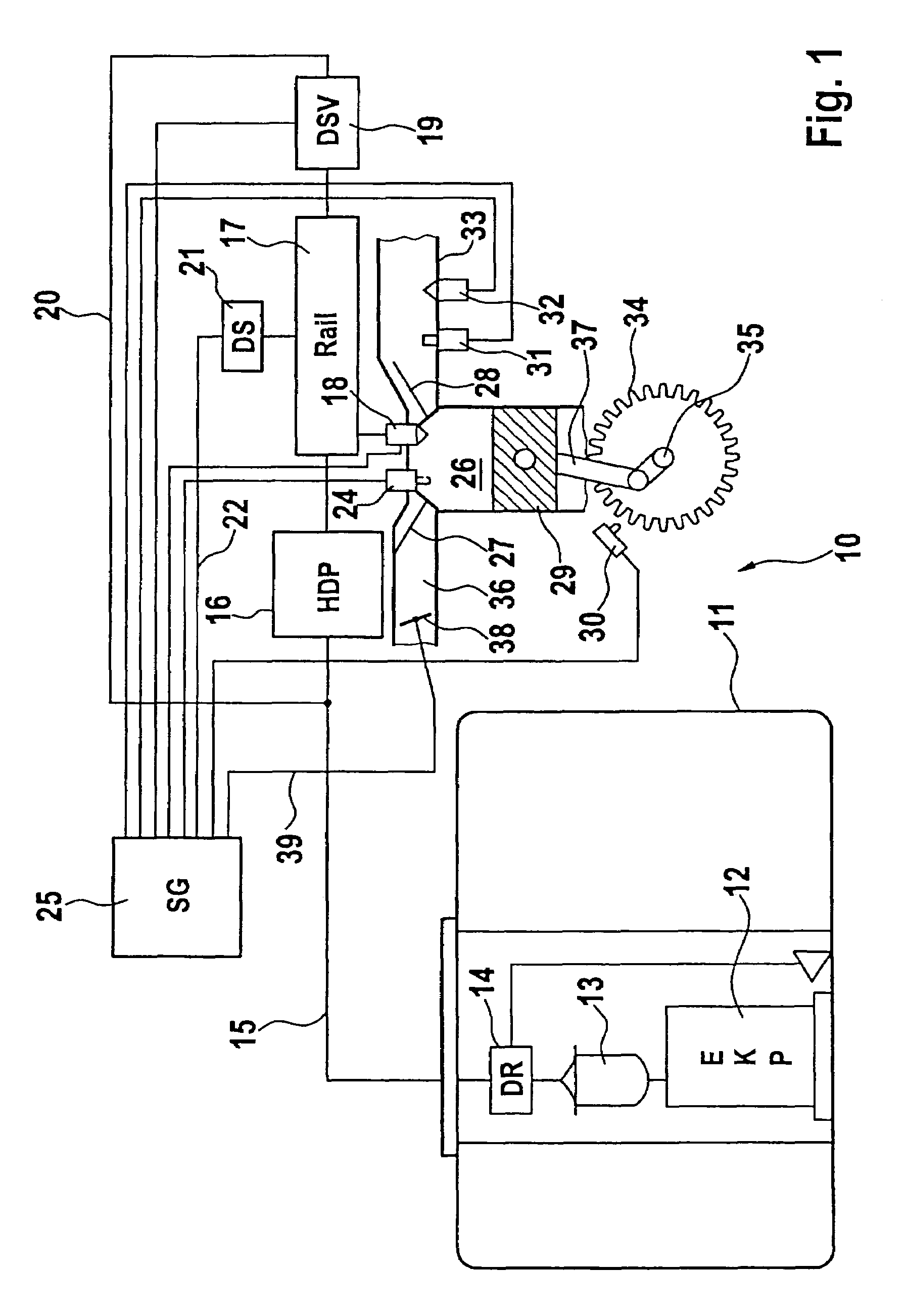

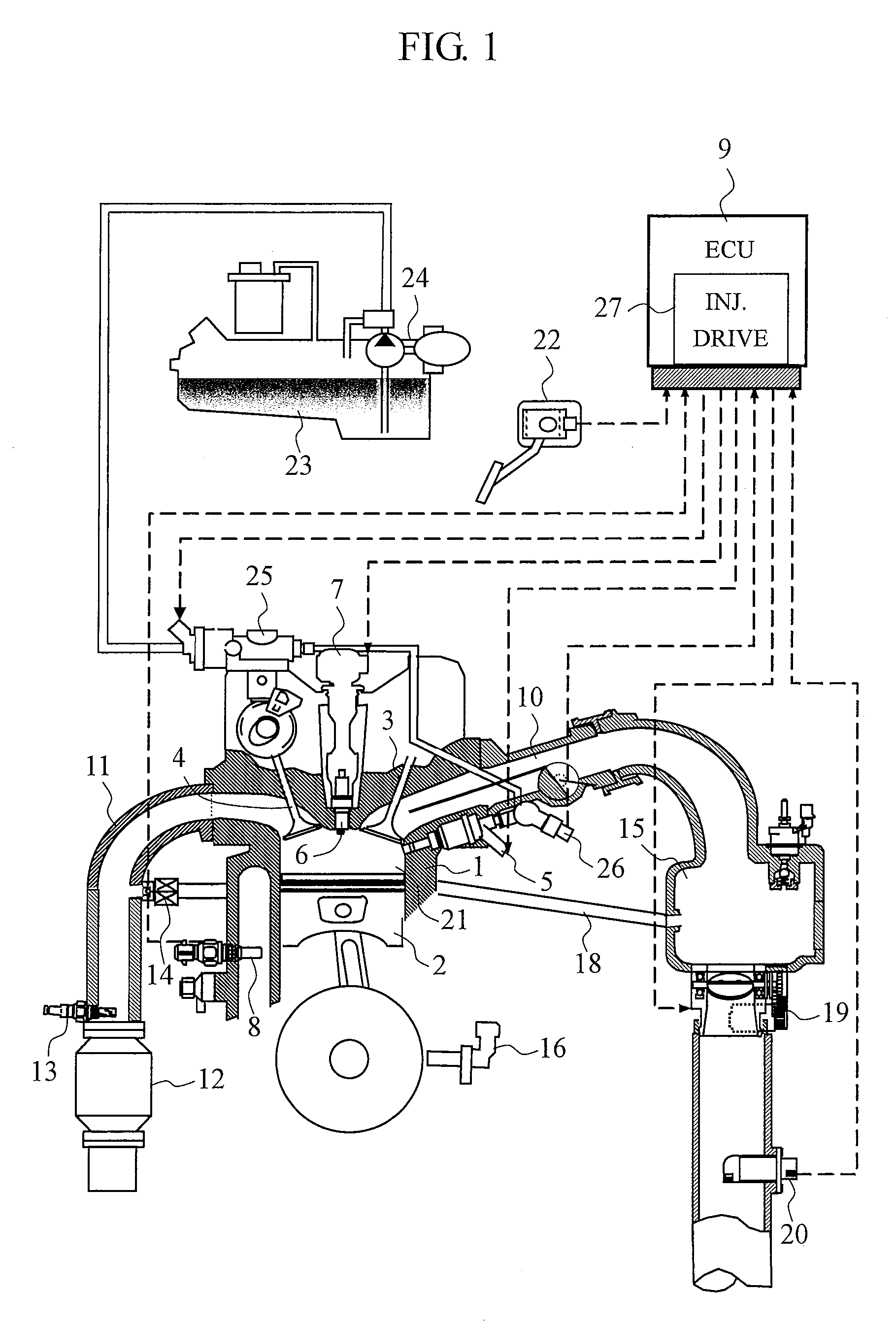

A system for controlling fuel injection in an engine. The engine includes an intake passage, an intake passage injector, a cylinder having a combustion chamber, and a cylinder injector for injecting a target amount of fuel into the combustion chamber. The system includes a controller for controlling the intake passage and cylinder injectors to permit fuel injection, each with an injection ratio, while said engine operates in a condition in which said engine permits fuel injection from said cylinder injector, a sensor for sensing the amount of fuel injected from the cylinder injector, a detector for detecting the difference between the target injection amount and the amount of fuel injected and an adjustor for adjusting the injection ratio based on the result of the detection by the detector so that the intake passage injector performs fuel injection together with the fuel injection performed by the cylinder injector.

Owner:TOYOTA JIDOSHA KK

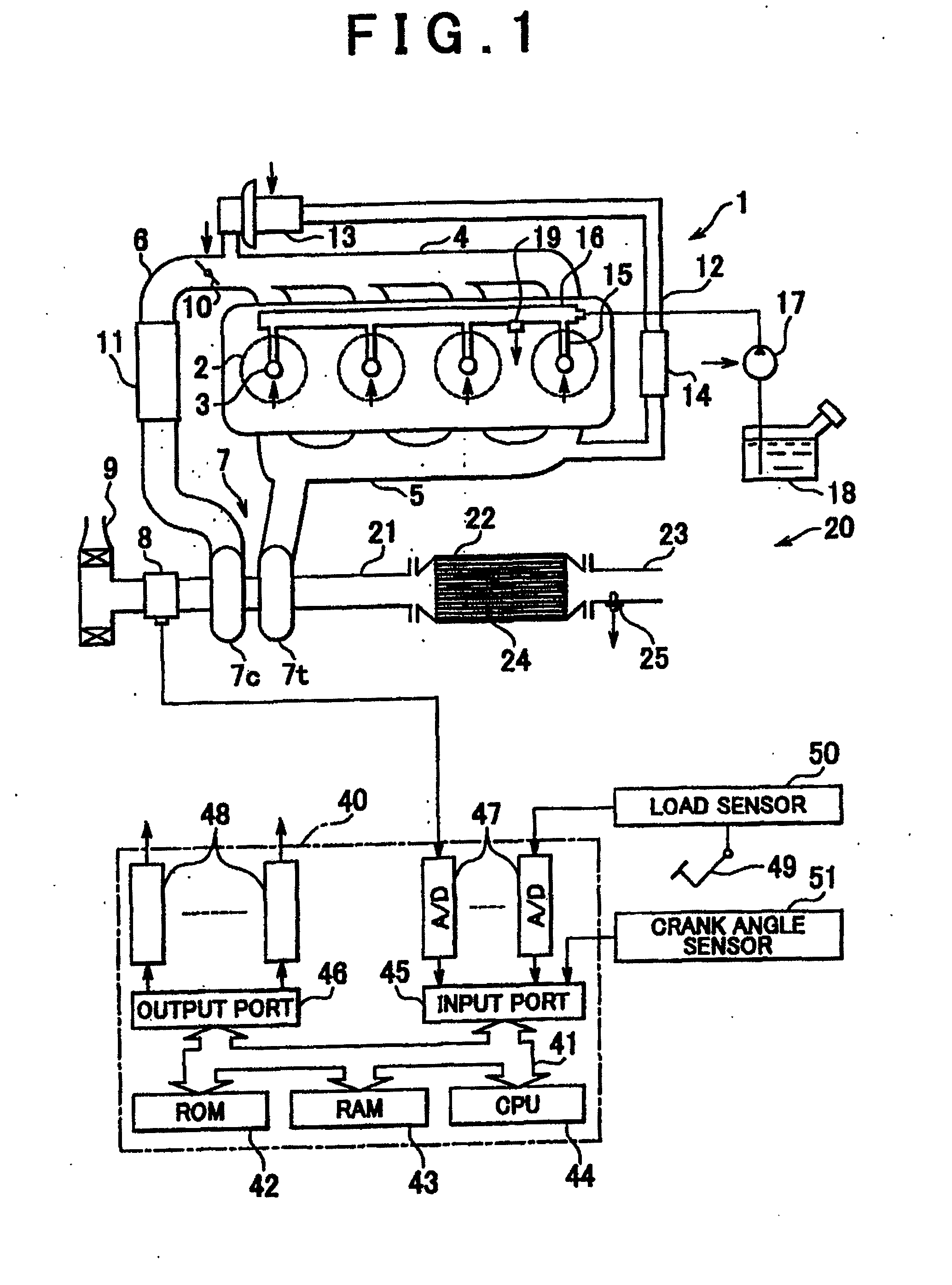

Engine fuel injection control system

InactiveUS6988490B2Reduce fuel injectionSuppress deterioration in combustion stateGrain huskingGrain polishingCombustion chamberControl system

A system for controlling fuel injection in an engine. The engine includes an intake passage, an intake passage injector, a cylinder having a combustion chamber, and a cylinder injector for injecting a target amount of fuel into the combustion chamber. The system includes a controller for controlling the intake passage and cylinder injectors to permit fuel injection, each with an injection ratio, while said engine operates in a condition in which said engine permits fuel injection from said cylinder injector, a sensor for sensing the amount of fuel injected from the cylinder injector, a detector for detecting the difference between the target injection amount and the amount of fuel injected and an adjuster for adjusting the injection ratio based on the result of the detection by the detector so that the intake passage injector performs fuel injection together with the fuel injection performed by the cylinder injector.

Owner:TOYOTA JIDOSHA KK

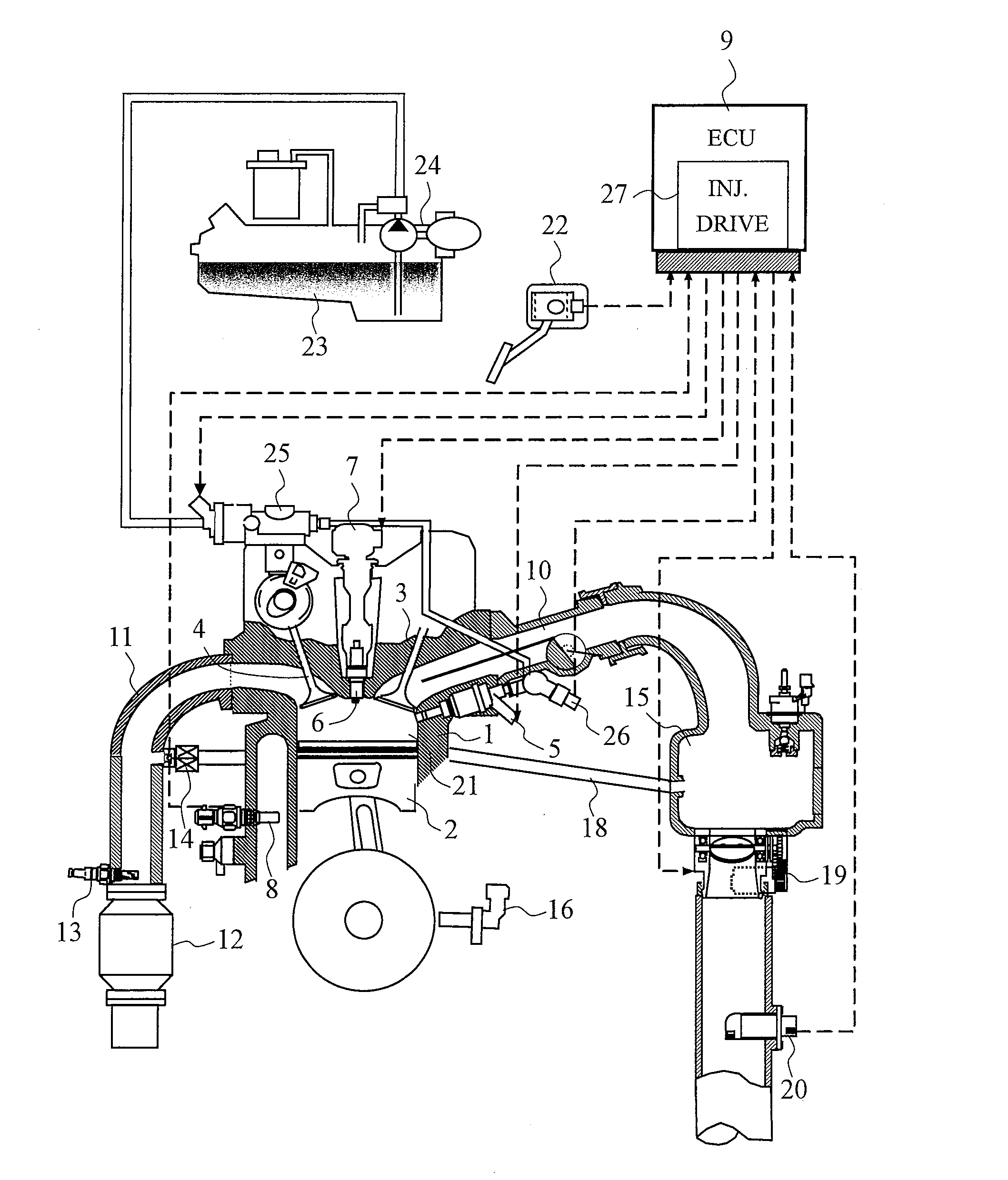

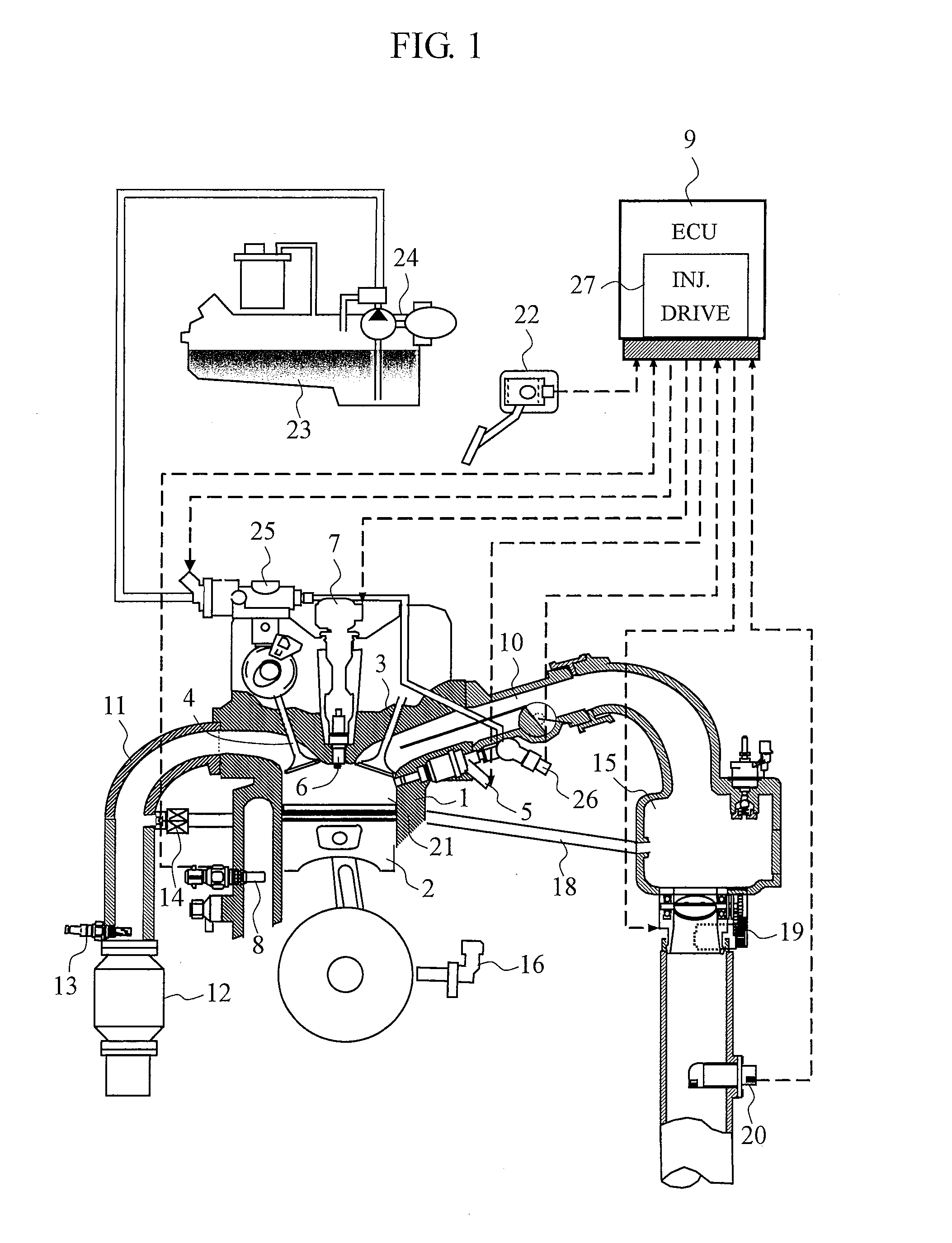

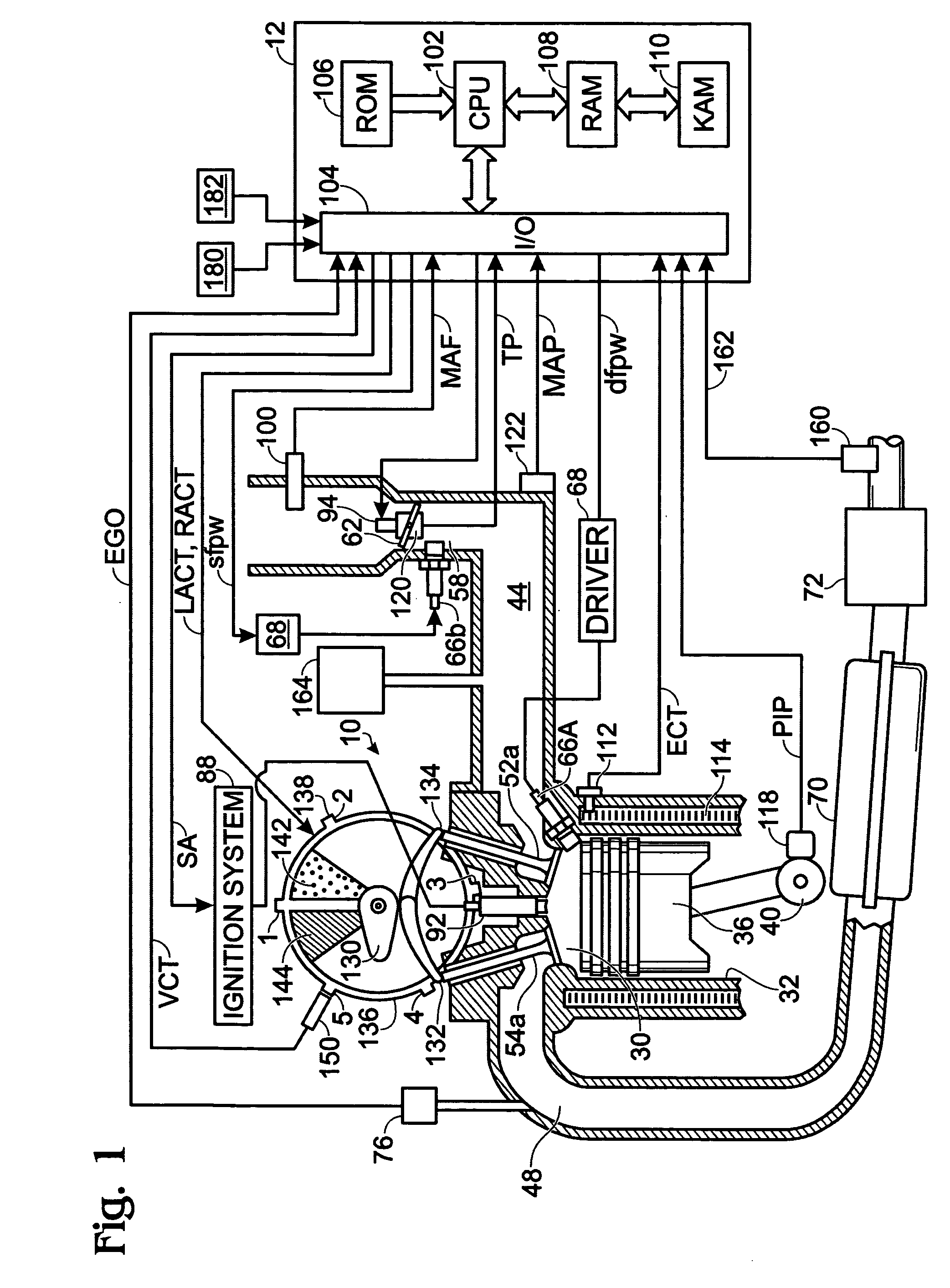

Control Apparatus for Internal Combustion Engine

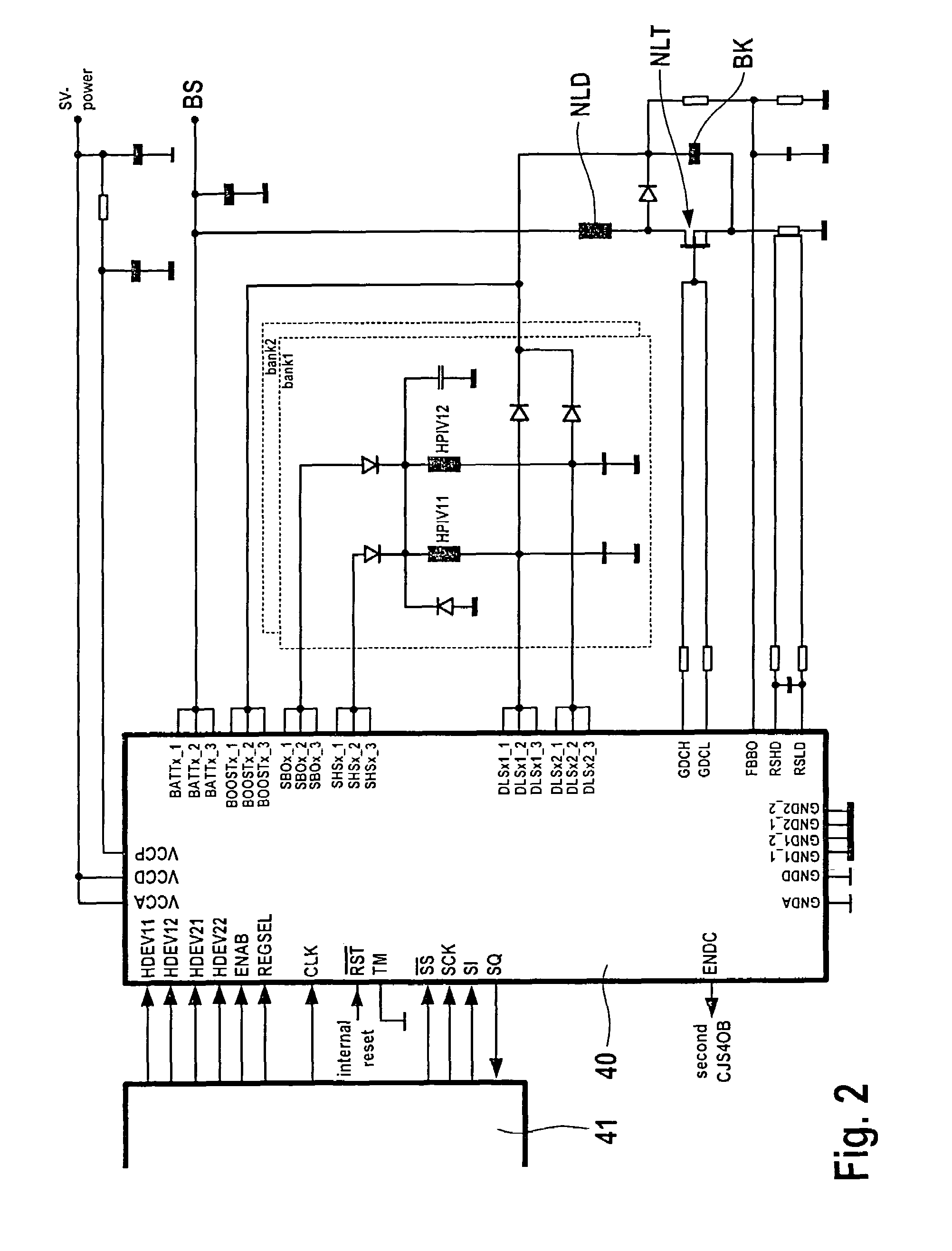

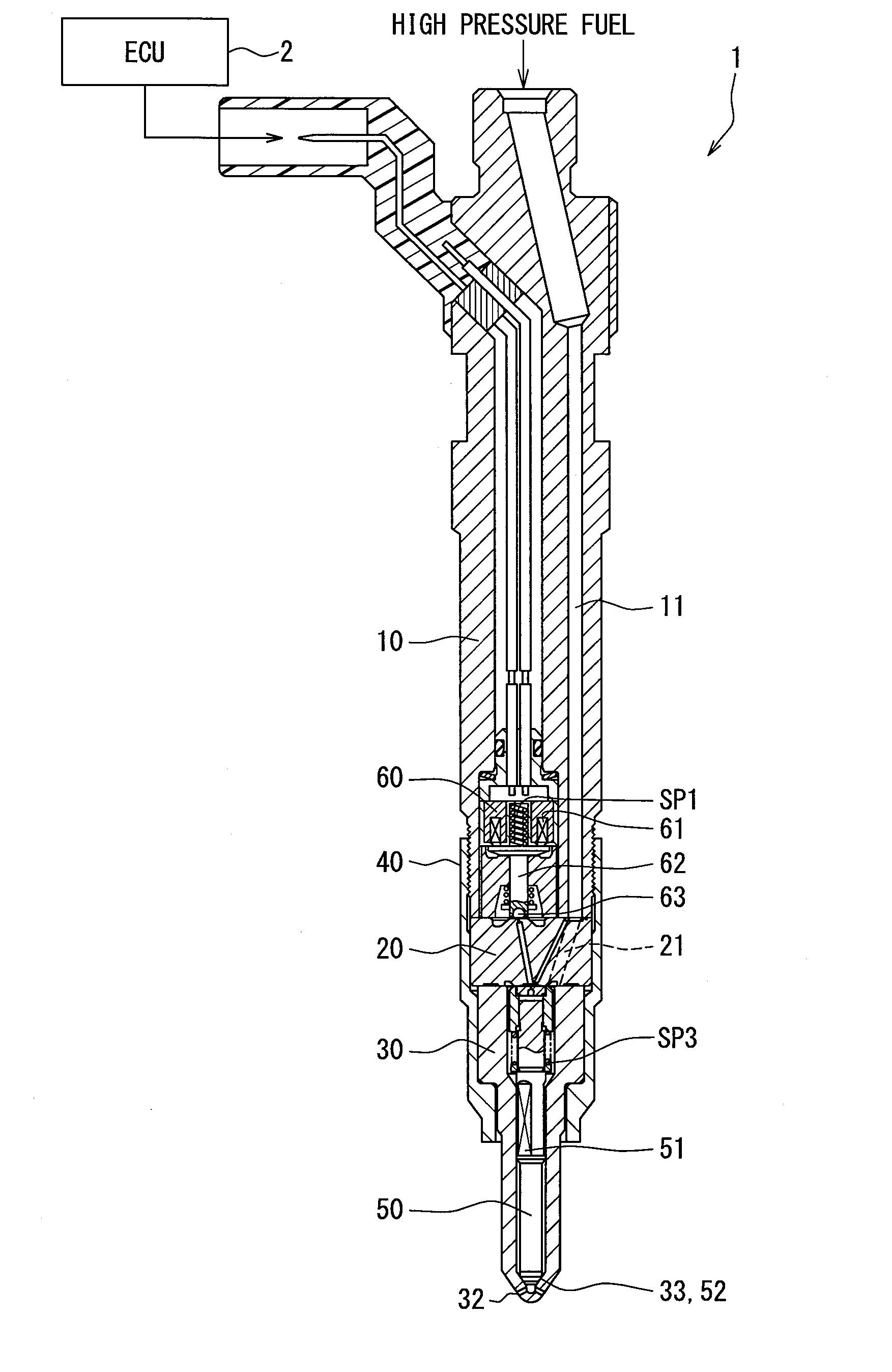

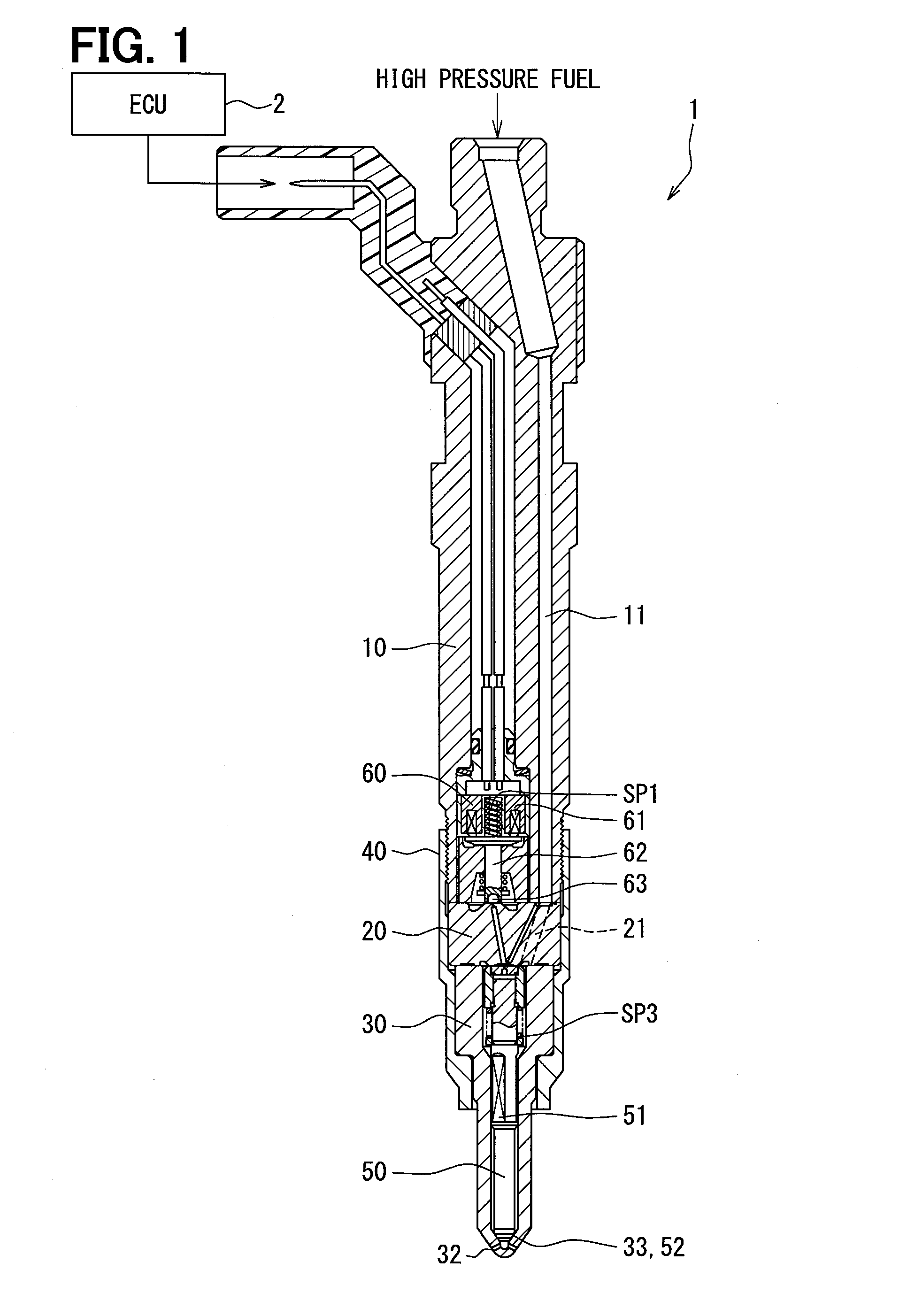

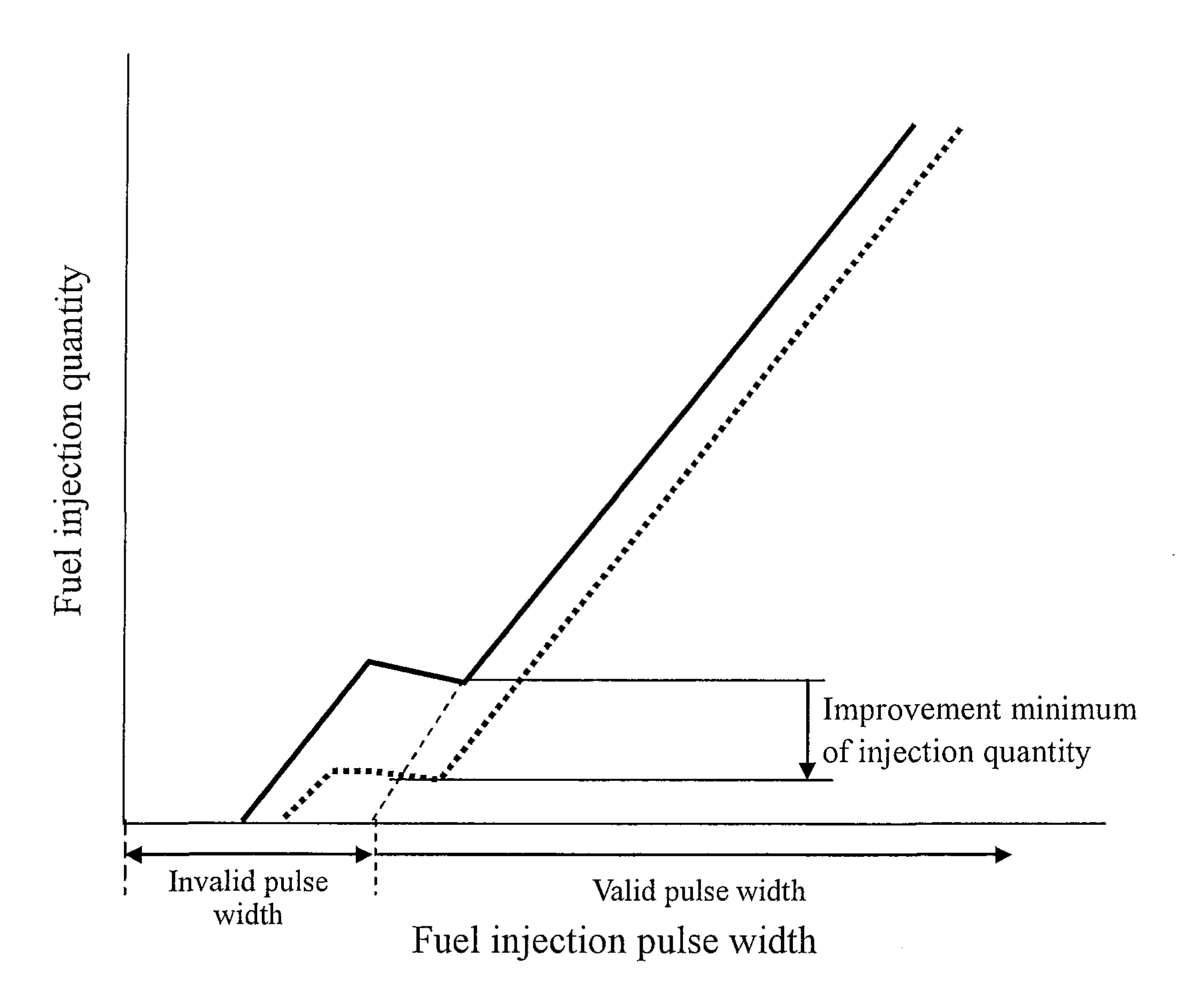

ActiveUS20110100333A1Minimizing amount of fuelImprove performanceElectrical controlInternal combustion piston enginesDriving currentExternal combustion engine

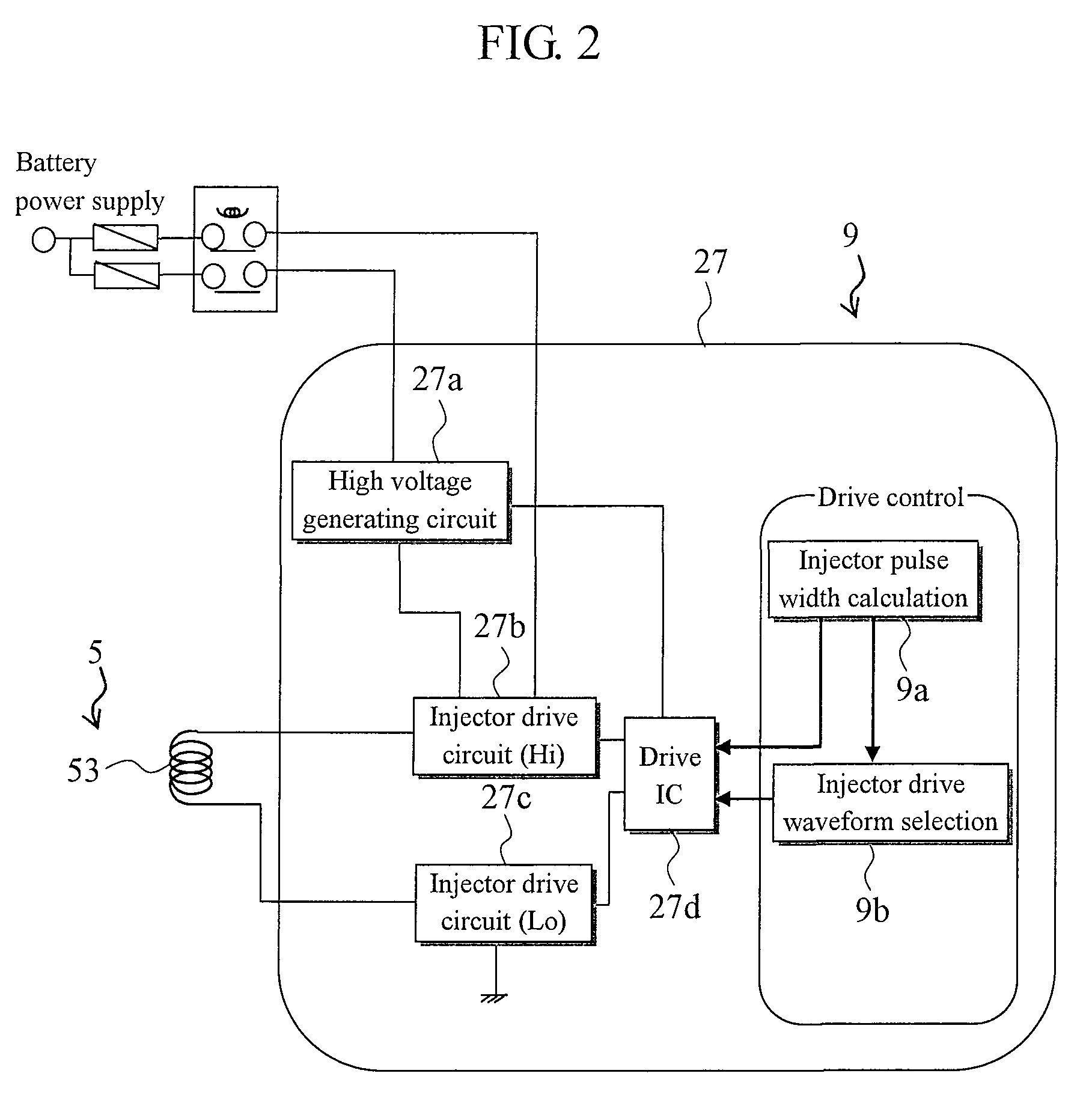

A fuel injection control apparatus for an internal combustion engine which can inject a fuel injection quantity to a fuel injector with accuracy even when the fuel injection quantity is reduced than before is provided. A fuel injection control apparatus of a direct cylinder injection type of internal combustion engine, including a fuel injector which performs fuel injection by supplying a drive current to a solenoid, a fuel pressure sensor which detects fuel pressure supplied to the fuel injector, and operation state detecting means which detects the operation state of the internal combustion engine, comprises current profile changing means 100 which has multiple current profiles of the drive current and changes current profiles based on the operation state and the fuel pressure, valid pulse width calculating means 701 which calculates a valid pulse width for opening and driving the fuel injector, invalid pulse width calculating means 103 which calculates an invalid pulse width, and fuel injector control means which calculates a fuel injection pulse width based on the valid pulse width and the invalid pulse width, and controls the fuel injector based on the fuel injection pulse width, wherein the invalid pulse width calculating means 103 calculates an invalid pulse width corresponding to the current profiles to be changed before the current profiles are changed.

Owner:HITACHI ASTEMO LTD

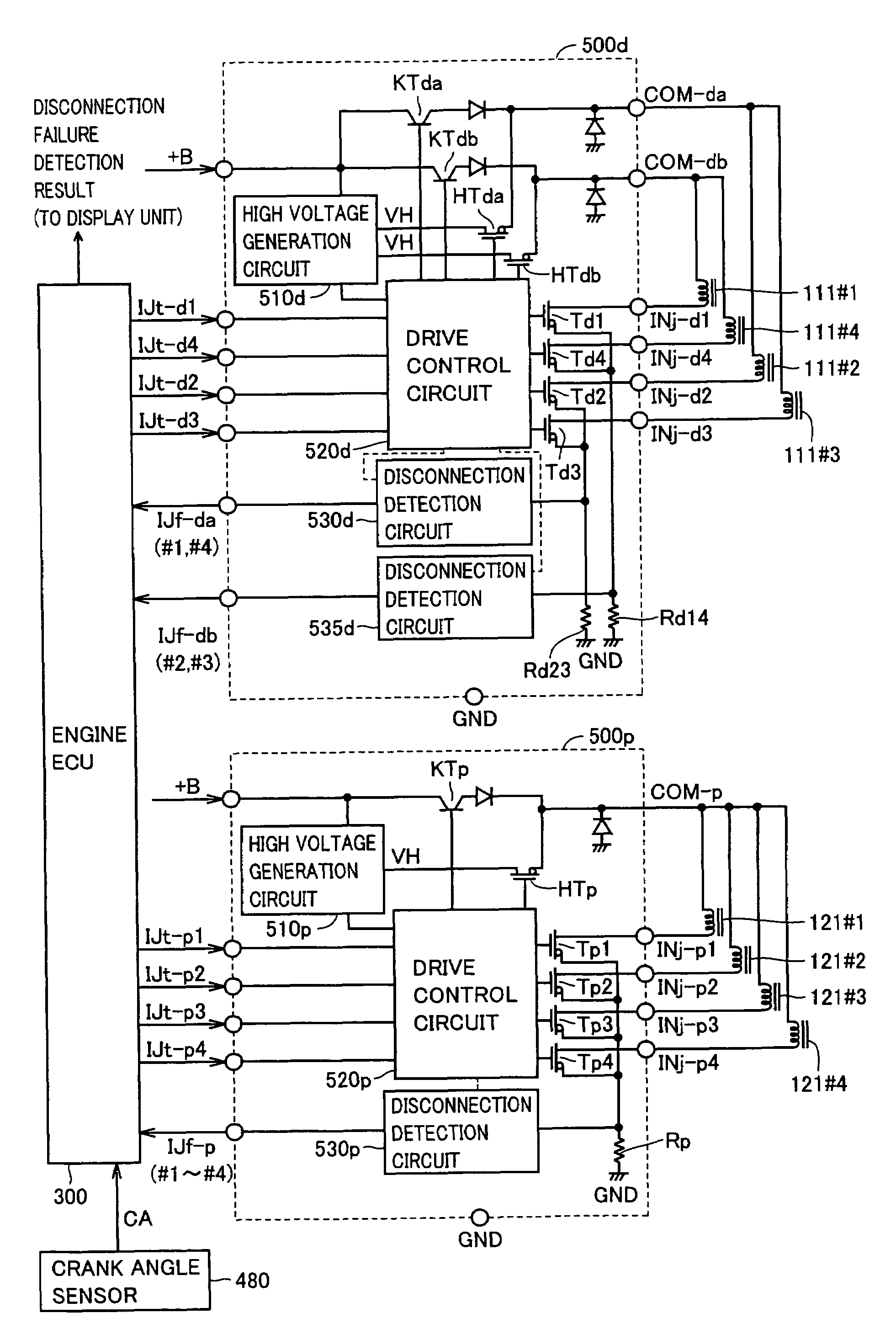

Control apparatus for internal combustion engine

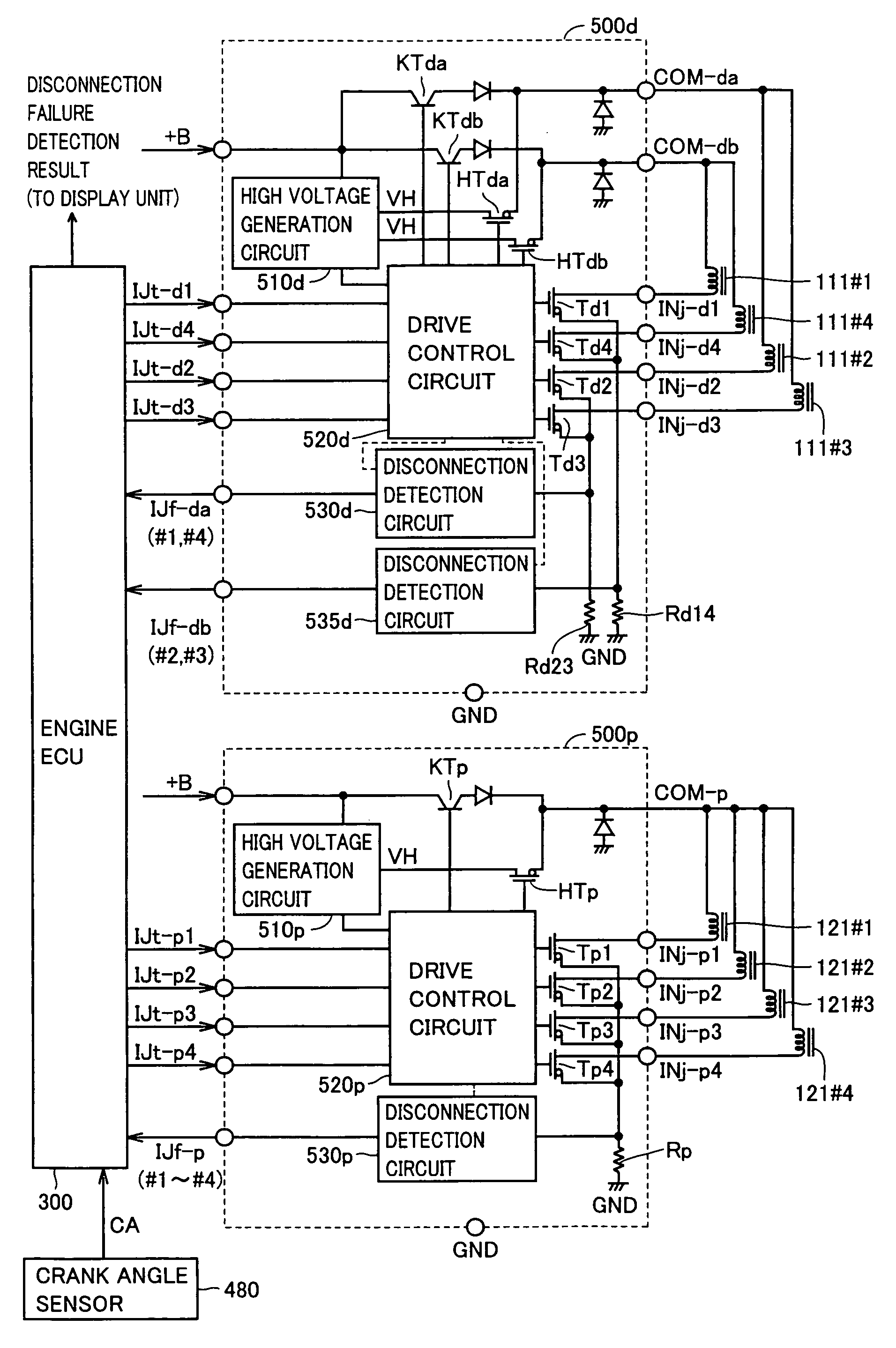

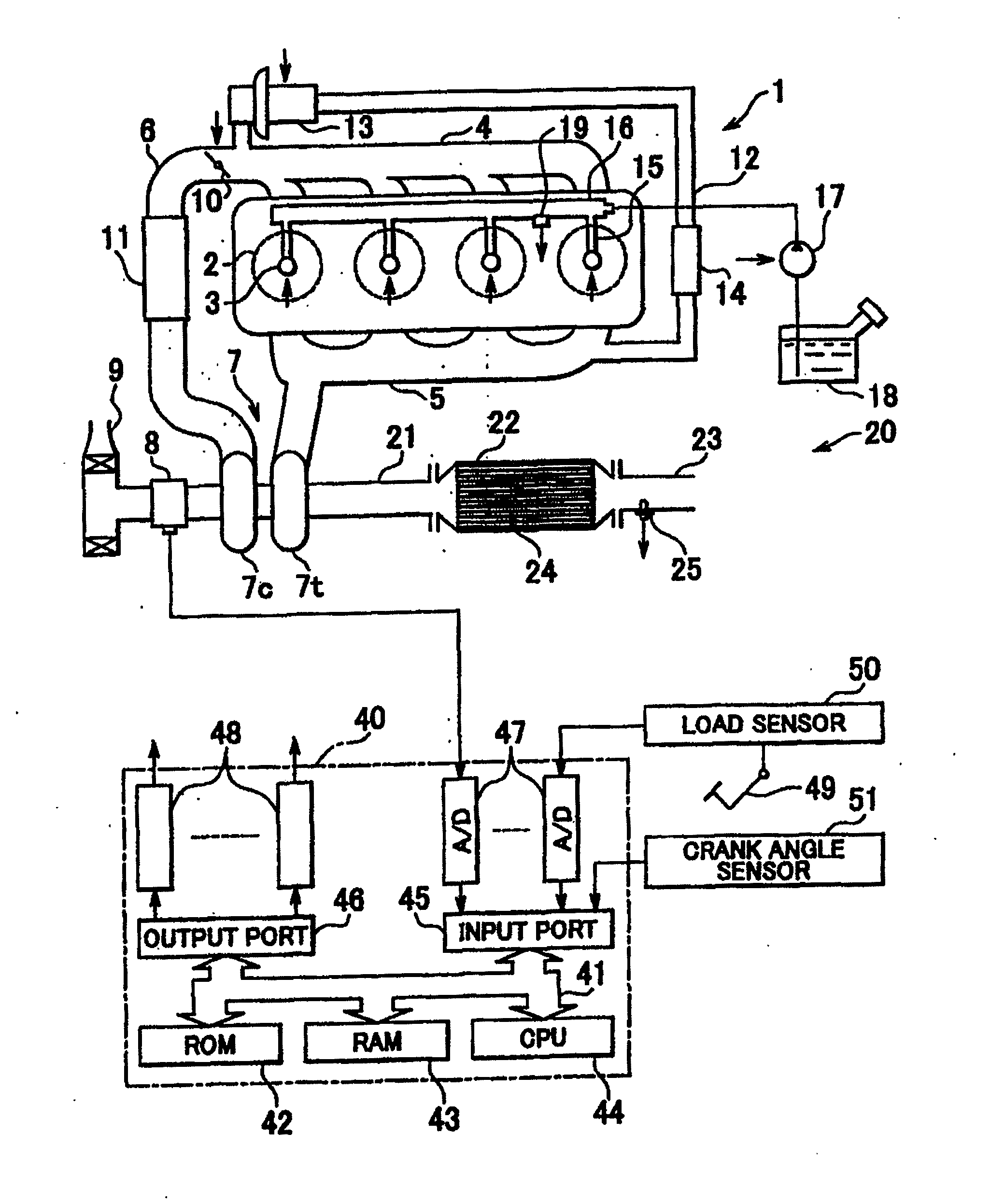

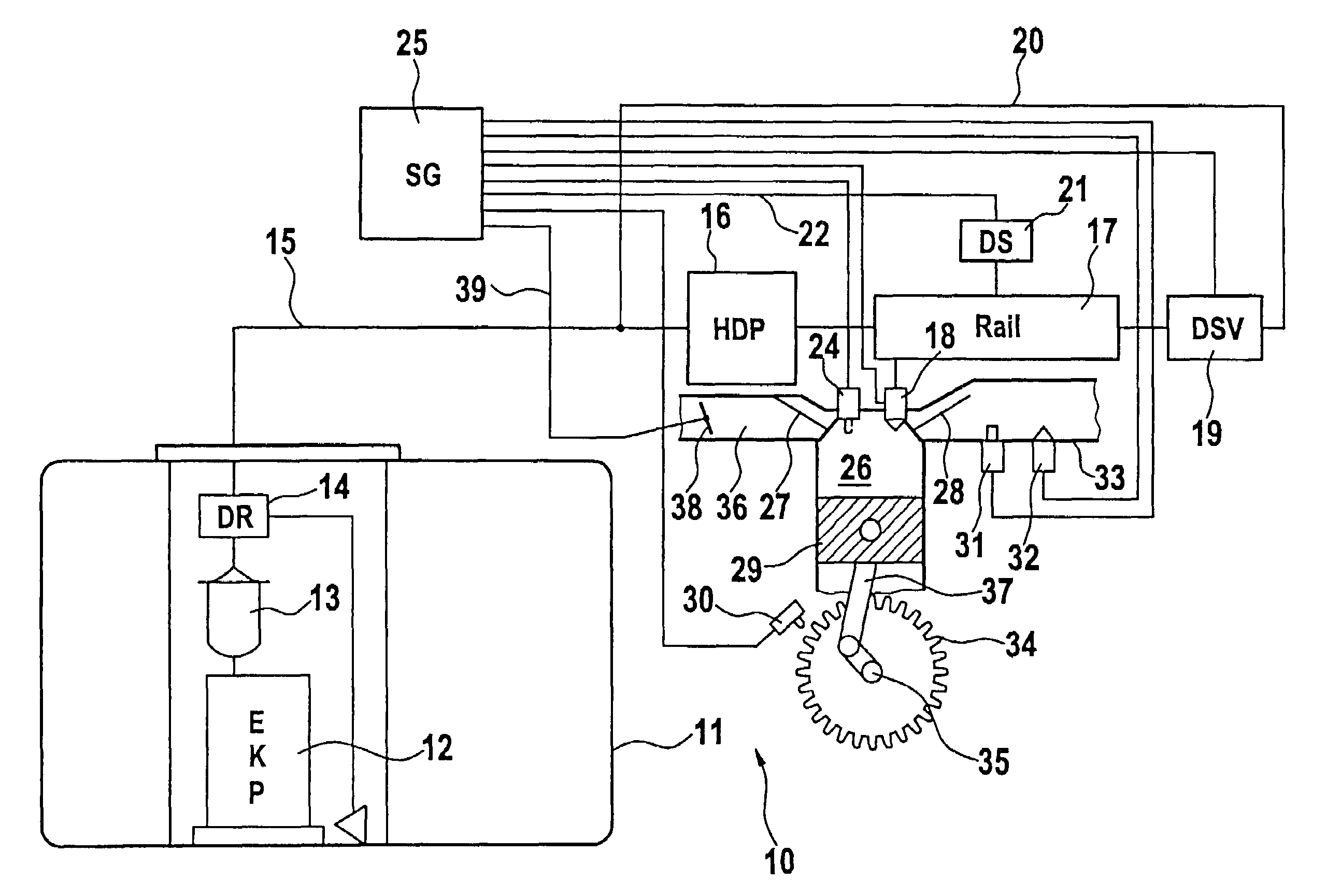

InactiveUS20060207564A1Efficient detectionReduce manufacturing costElectrical controlCombustion enginesDriver/operatorInjector

A drive control circuit supplies power to a solenoid coil in an in-cylinder injector of a cylinder in response to a fuel injection signal. A failure detection circuit to detect disconnection failure at an in-cylinder injector is arranged to be shared among cylinders whose phase of each stroke differs 360 degrees in crank angle. An engine ECU detects failure including identification of the injector with disconnection failure based on a failure detection signal from the failure detection circuit, and a crank angle detected by a crank angle sensor. The driver is notified of the failure detection result through the engine ECU.

Owner:TOYOTA JIDOSHA KK

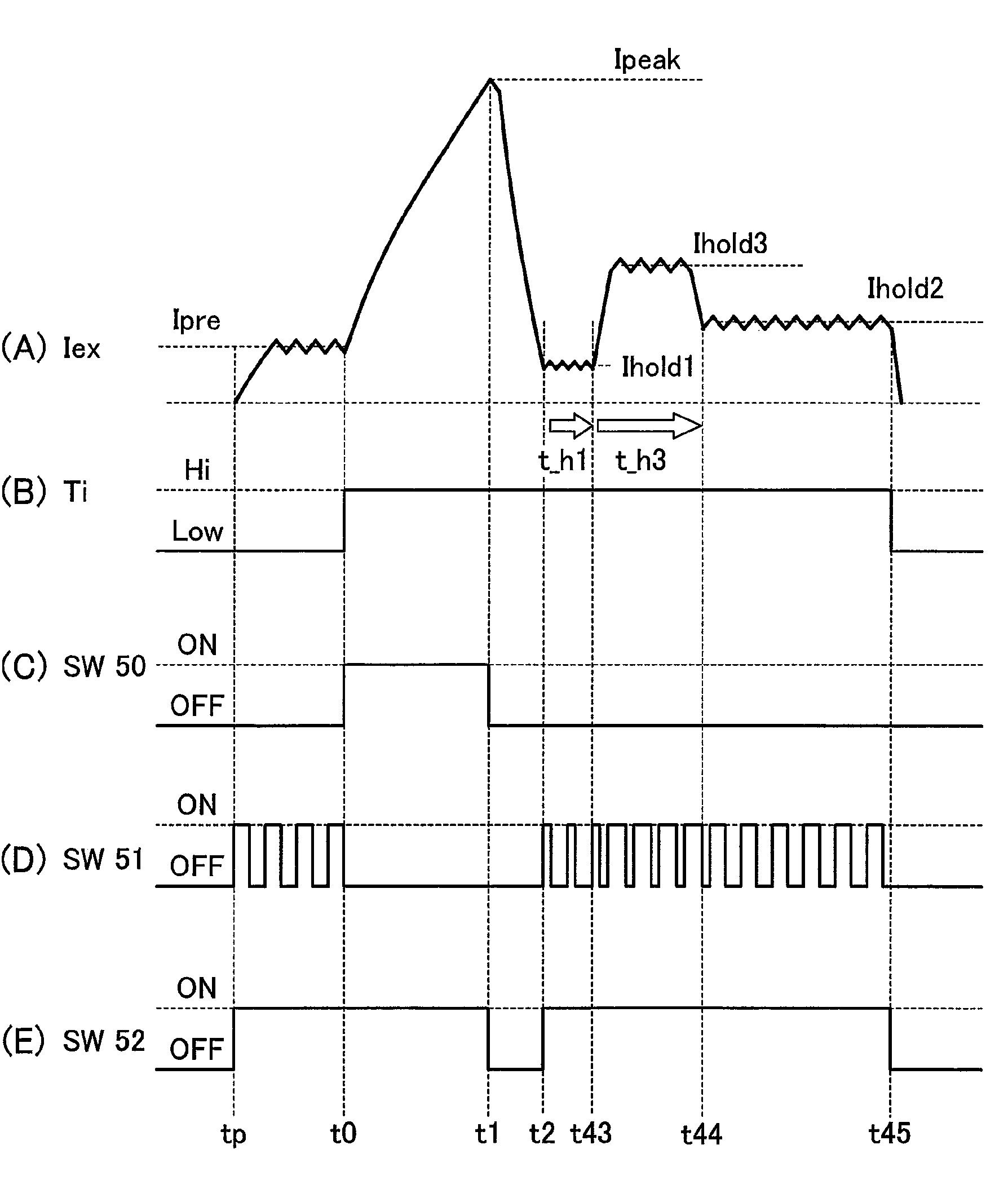

Fuel injection control apparatus

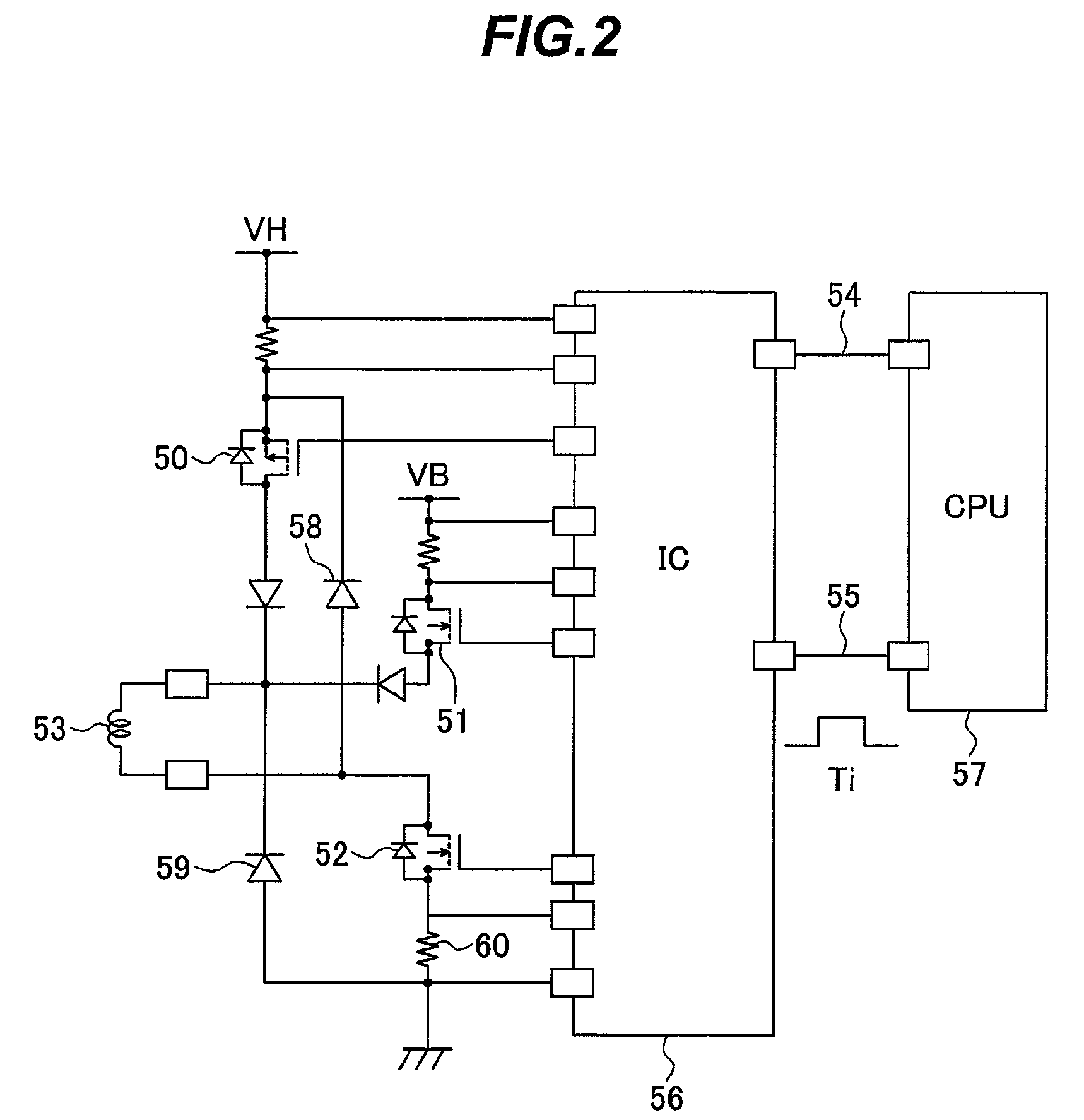

ActiveUS20090177369A1Reduce fuel consumptionImprove performanceElectrical controlDigital data processing detailsMicrocomputerLow voltage

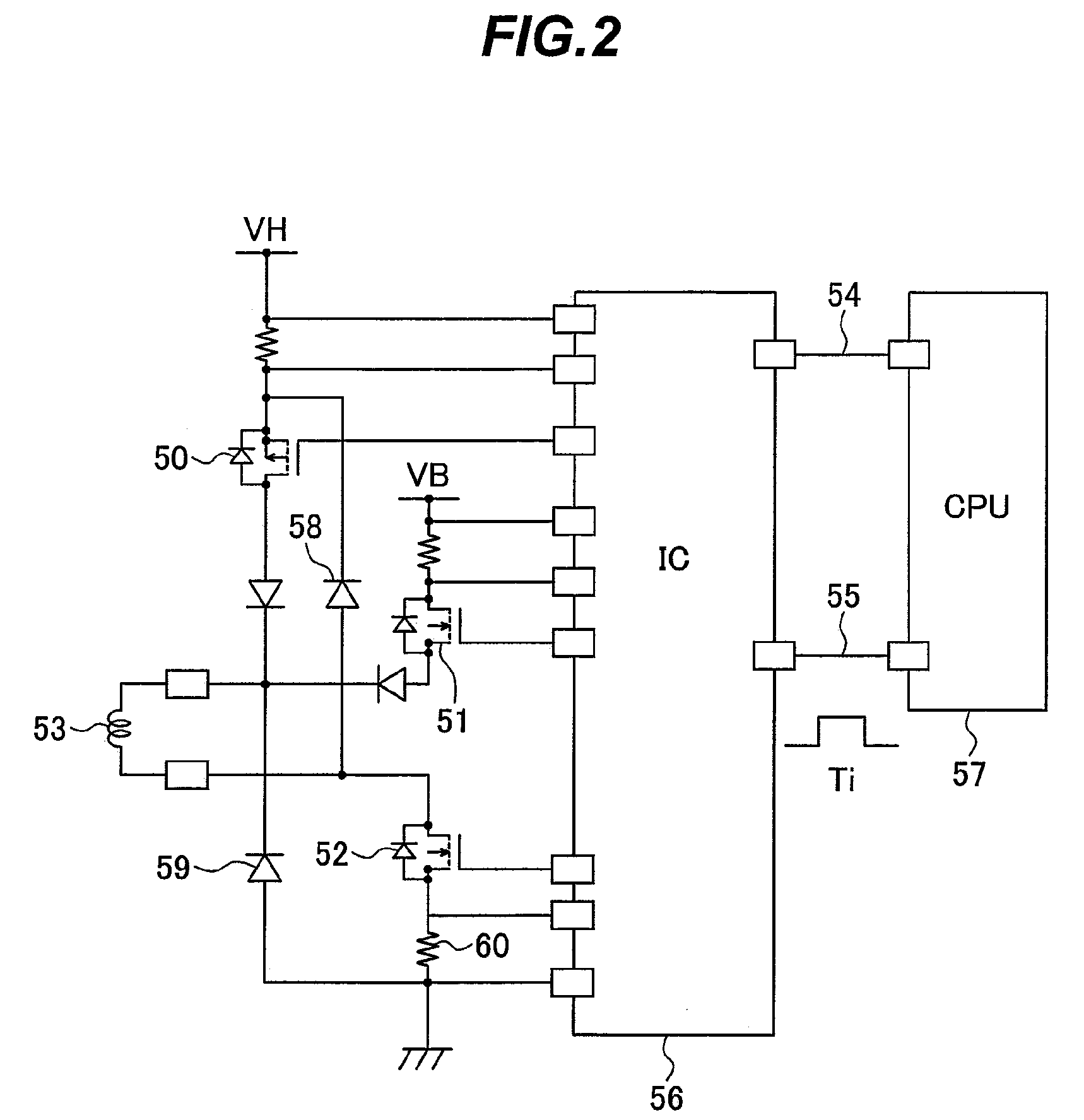

To provide a fuel injection control apparatus capable of reducing the minimum quantity of fuel injection without reducing the maximum quantity of injection.For fuel injector valve opening, a driving circuit 56 supplies an electric current from a high-voltage power supply VH to the fuel injector 53, then after valve opening, switches the high-voltage power supply VH to a low-voltage power supply LV, and retains the open state of the valve. A microcomputer 57 is adapted such that for opening the valve of the fuel injector, the microcomputer, after supplying the current from the high-voltage power supply to the injector 53, discharges the current rapidly for a decrease below a first current level Ihold1 at which the open state of the valve cannot be retained, and then controls the supply current to the injector 53 so as to supply a current of a second current level Ihold2 at which the open state of the valve can be retained.

Owner:HITACHI ASTEMO LTD

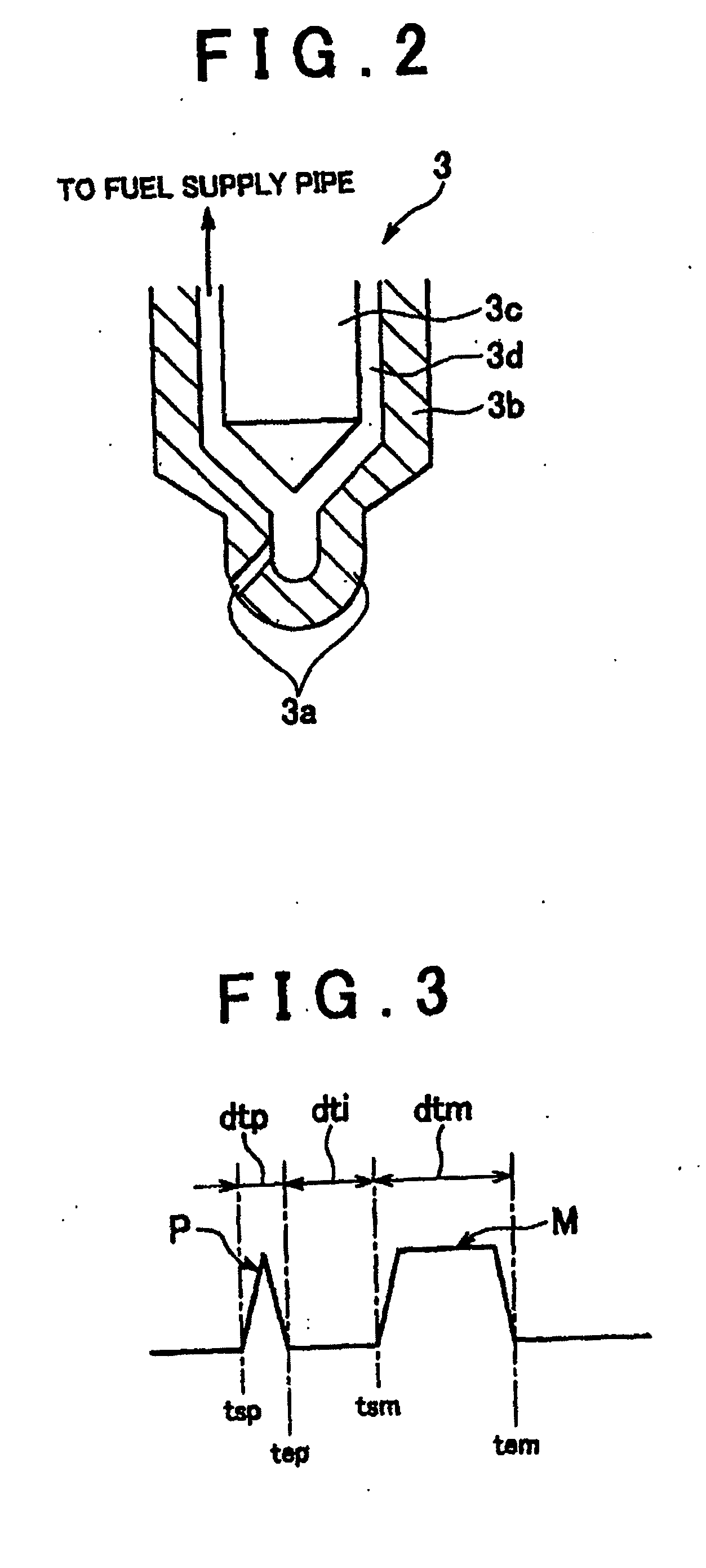

Fuel injection control apparatus and fuel injection control method for internal combustion engine

InactiveUS20100116243A1Reduce fuel injectionEnsure accuracyElectrical controlInternal combustion piston enginesEngineeringExternal combustion engine

A fuel injection valve coupled to a common rail is provided. When fuel injection is carried out, the fuel pressure in the fuel injection valve pulsates. An interval between a pilot injection and a main injection is set so that the main injection is carried out at a zero gradient timing as a timing when the gradient of the fuel pressure in the fuel injection valve after the pilot injection is approximately equal to zero. Owing to a fuel injection control apparatus and a fuel injection control method for an internal combustion engine that perform the above-mentioned control, the fuel injection amount for the subsequent fuel injection following the preceding fuel injection can be reliably held equal to a normal amount.

Owner:TOYOTA JIDOSHA KK

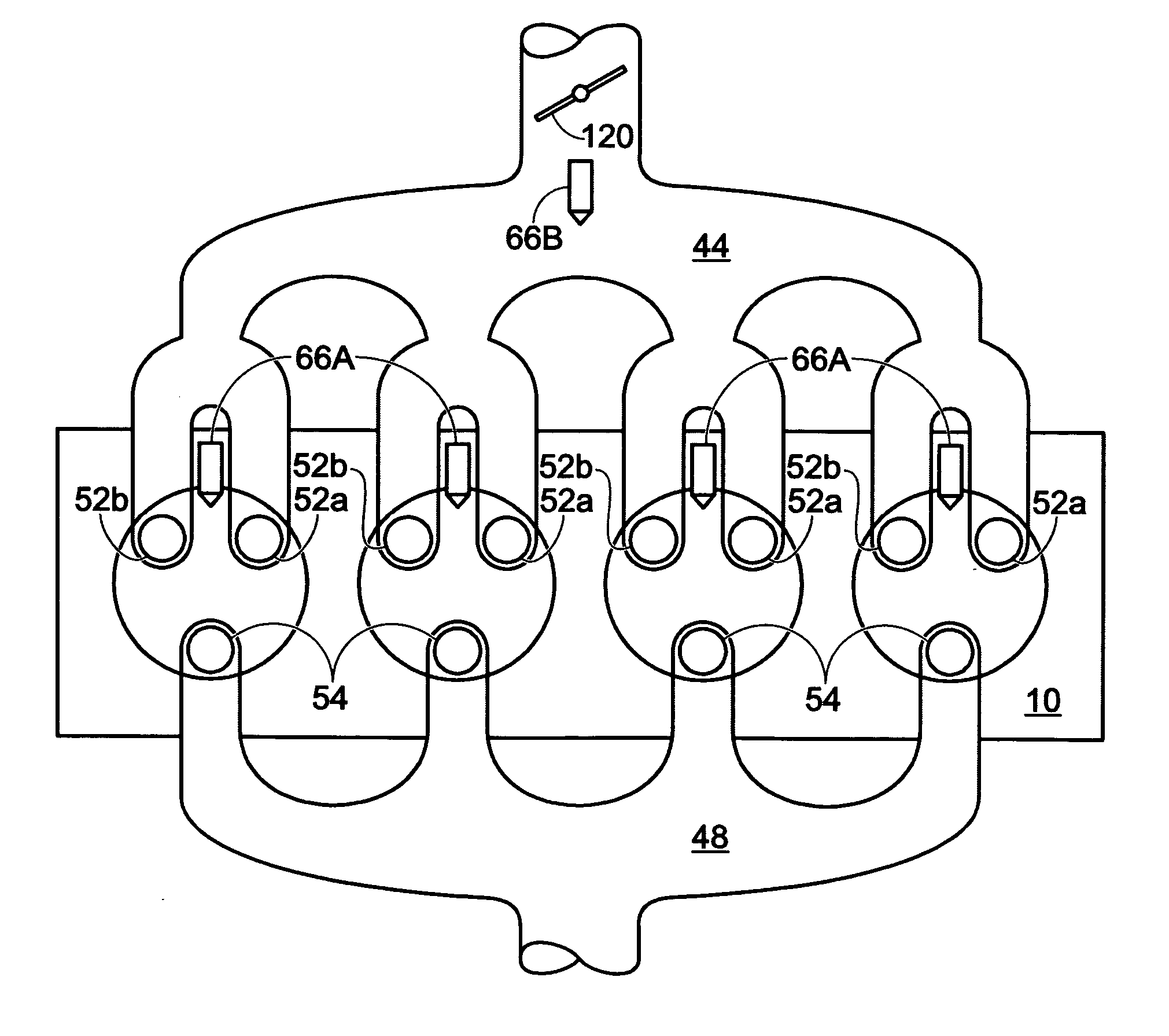

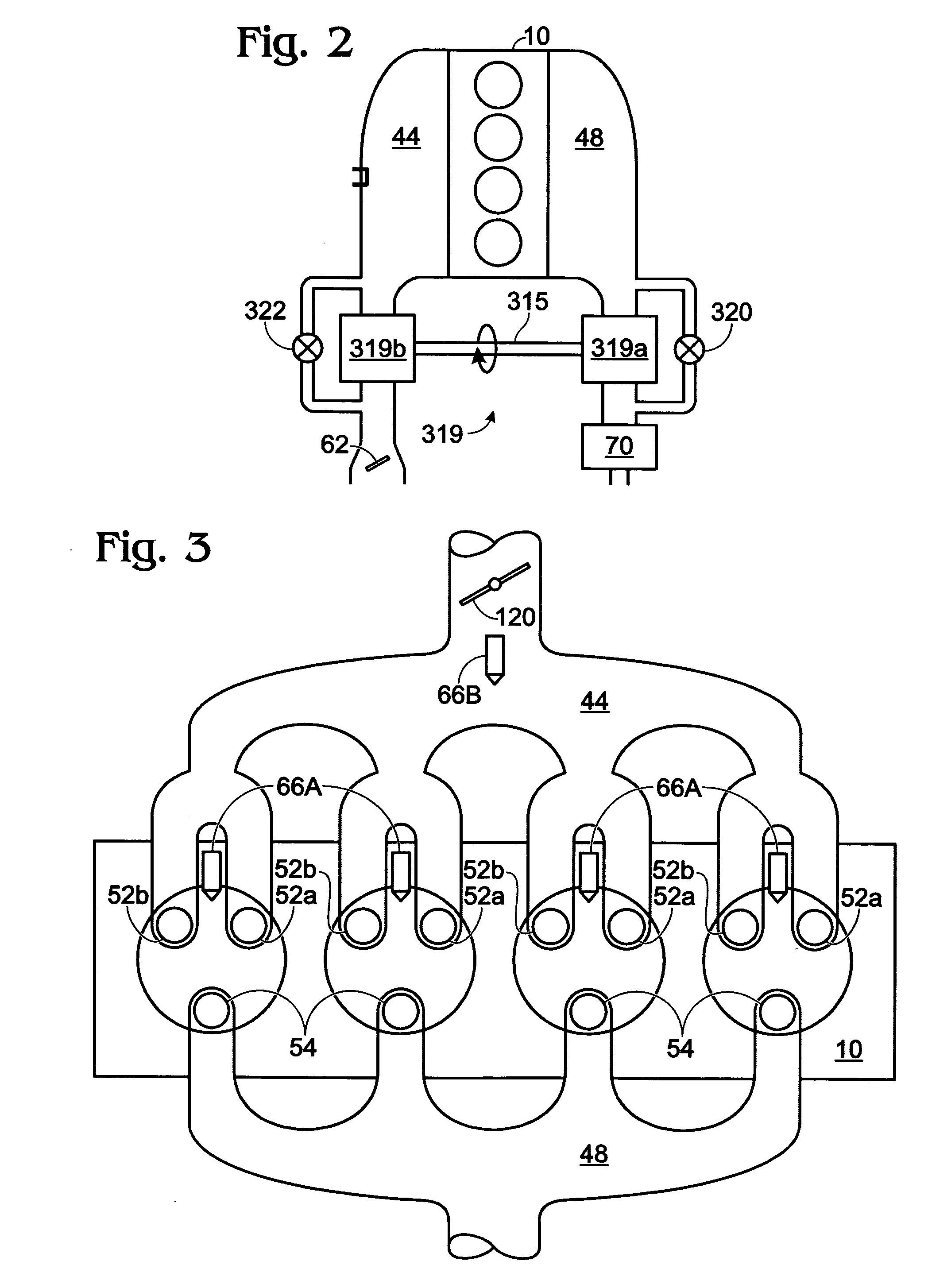

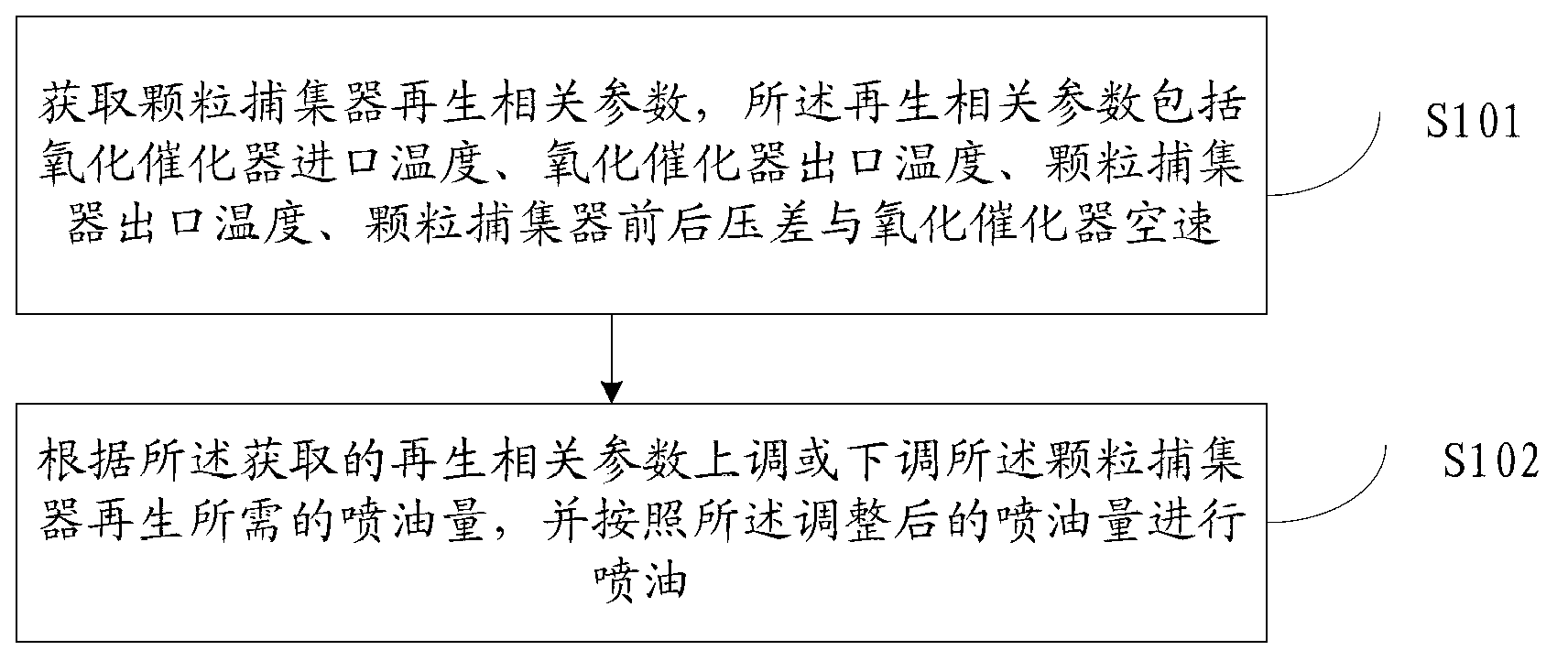

Engine having multiple injector locations

InactiveUS20070215112A1Maintain ratio controlReduce fuel injectionElectrical controlInternal combustion piston enginesEngineeringInjector

A method for controlling a first and second injector of an engine, the first injector located in a first cylinder of the engine and the second injector located upstream of, and configured to inject fuel into, the first and a second cylinder of the engine, the method comprising of decreasing total injection from the first and second injectors when decreasing injection from the second injector, and increasing total injection from the first and second injectors when increasing injection of the second injector.

Owner:FORD GLOBAL TECH LLC

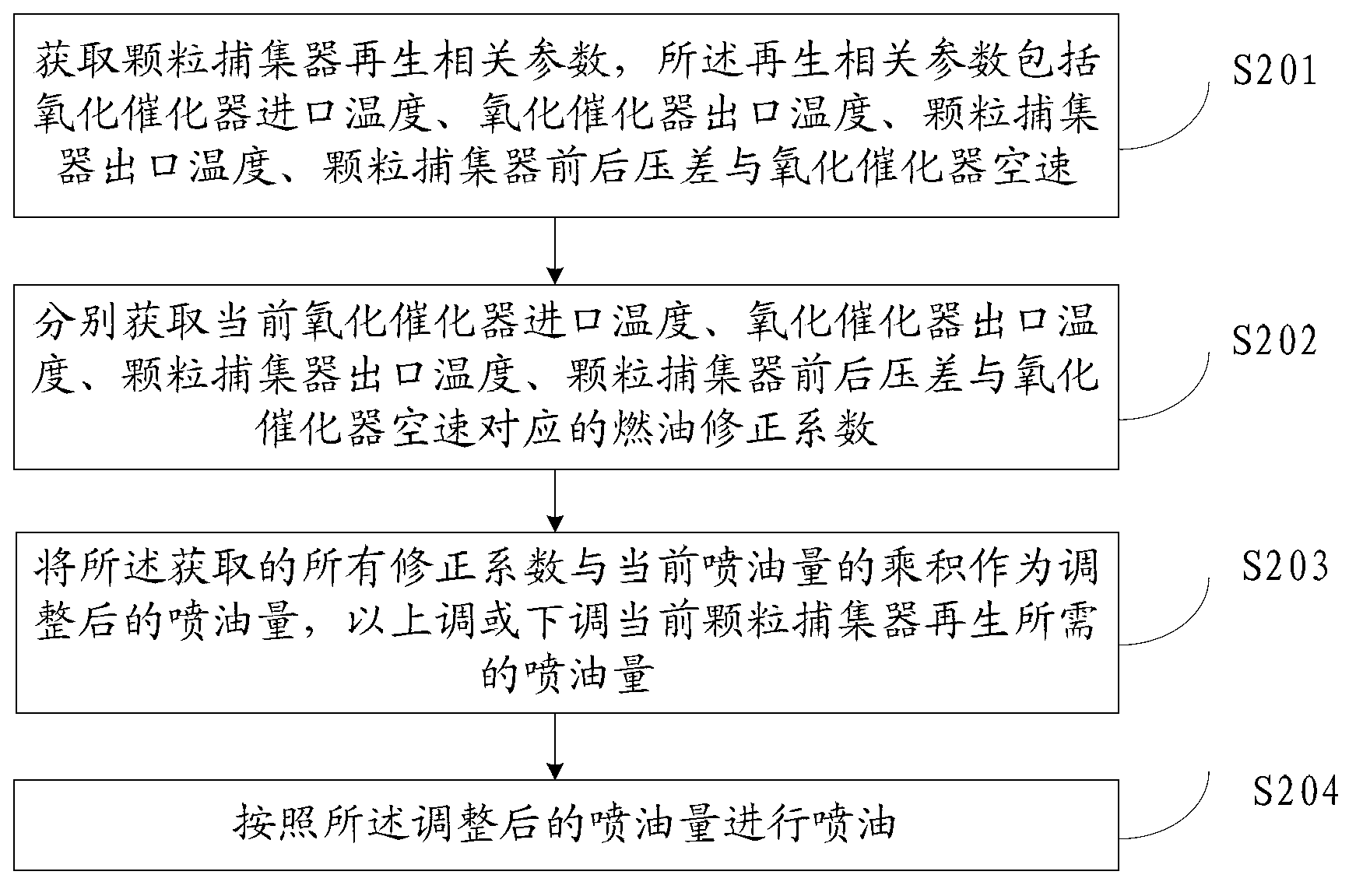

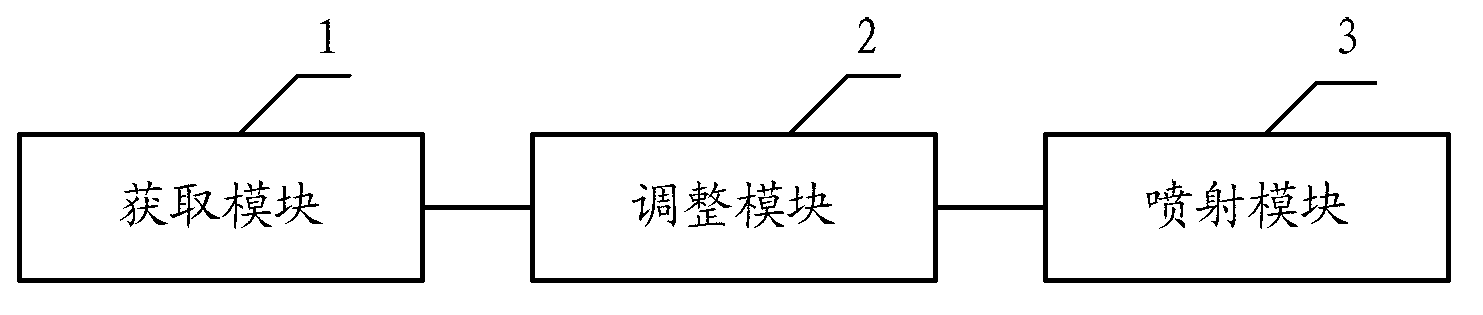

Control method and device for preventing regeneration and sintering of particle catcher

ActiveCN103016118AReduce fuel injectionIncrease fuel injectionInternal combustion piston enginesExhaust apparatusEngineeringPressure difference

The invention discloses a control method for preventing regeneration and sintering of a particle catcher. The method comprises the following steps: acquiring regeneration related parameters of the particle catcher, wherein the regeneration related parameters comprise inlet temperature of an oxidation catalyst, outlet temperature of the oxidation catalyst, outlet temperature of the particle catcher, pressure difference of the particle catcher and air speed of the oxidation catalyst; increasing or decreasing the fuel injection quantity required by regeneration of the particle catcher according to the acquired regeneration related parameters; and injecting fuel according to the adjusted fuel injection quantity. The invention further discloses a control device for preventing regeneration and sintering of the particle catcher.

Owner:WEICHAI POWER CO LTD

Fuel injection control apparatus for internal combustion engine

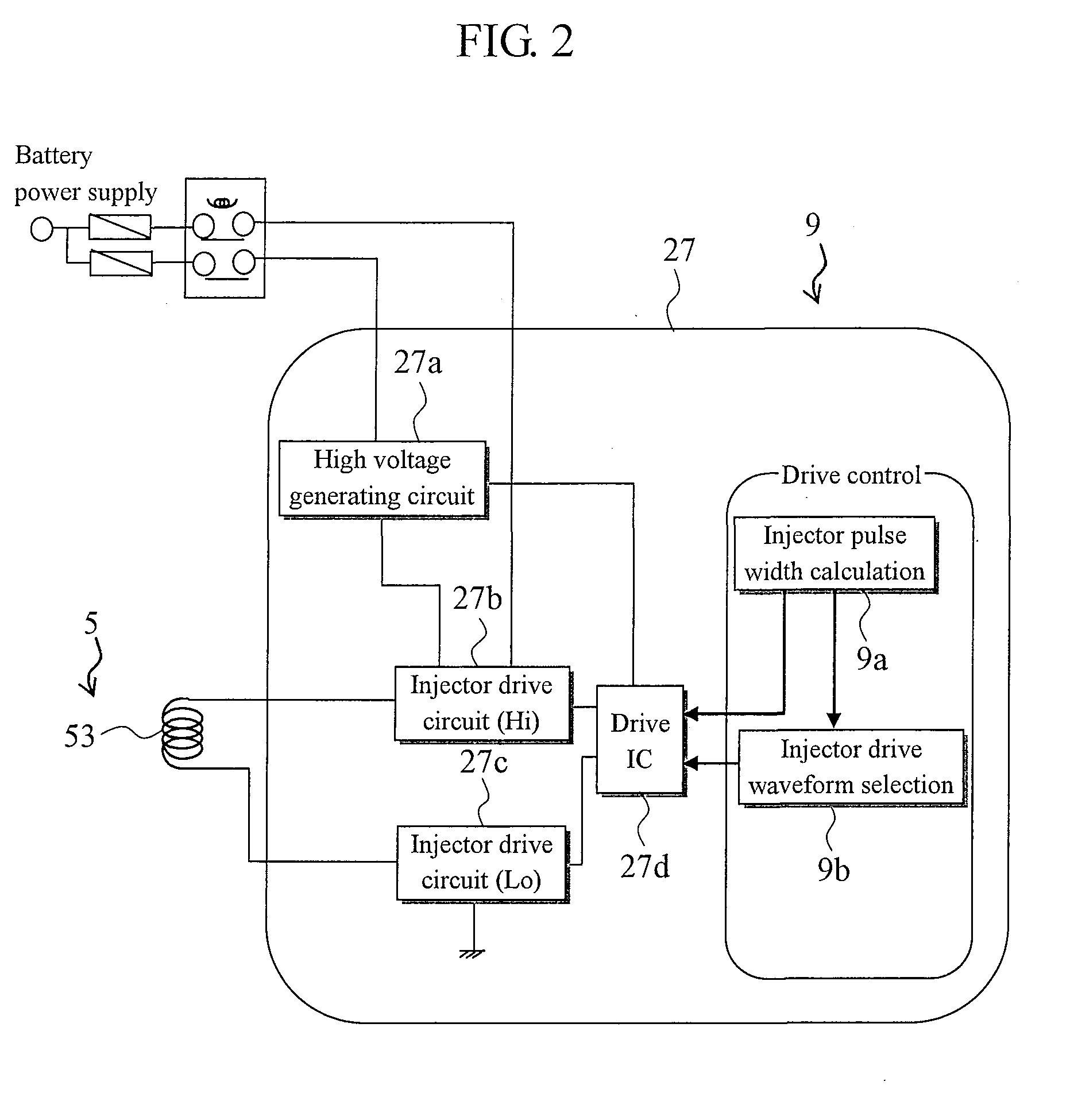

InactiveUS20090177367A1Open and close accuratelyImprove performanceElectrical controlDigital data processing detailsInjectorPulse duration

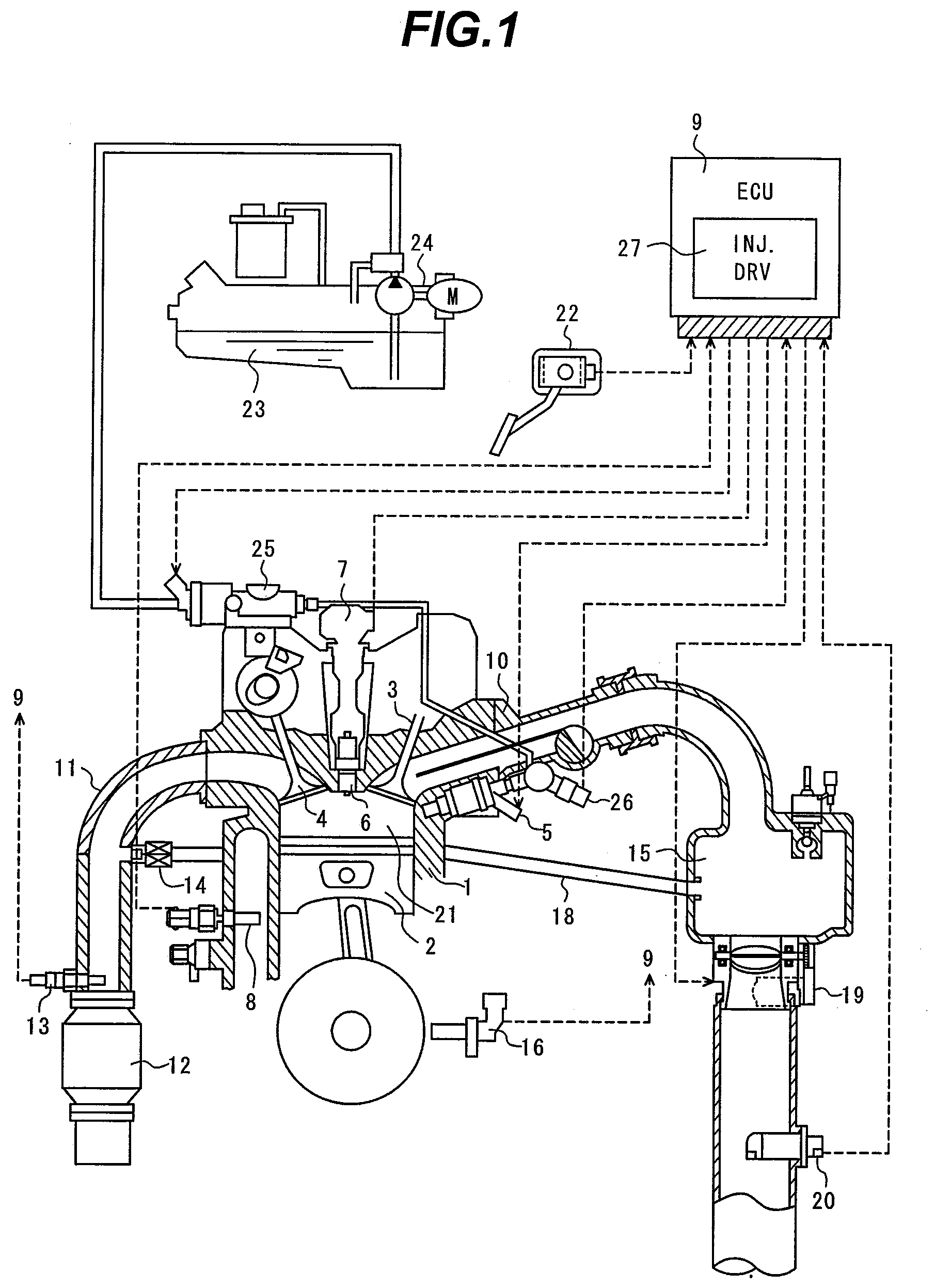

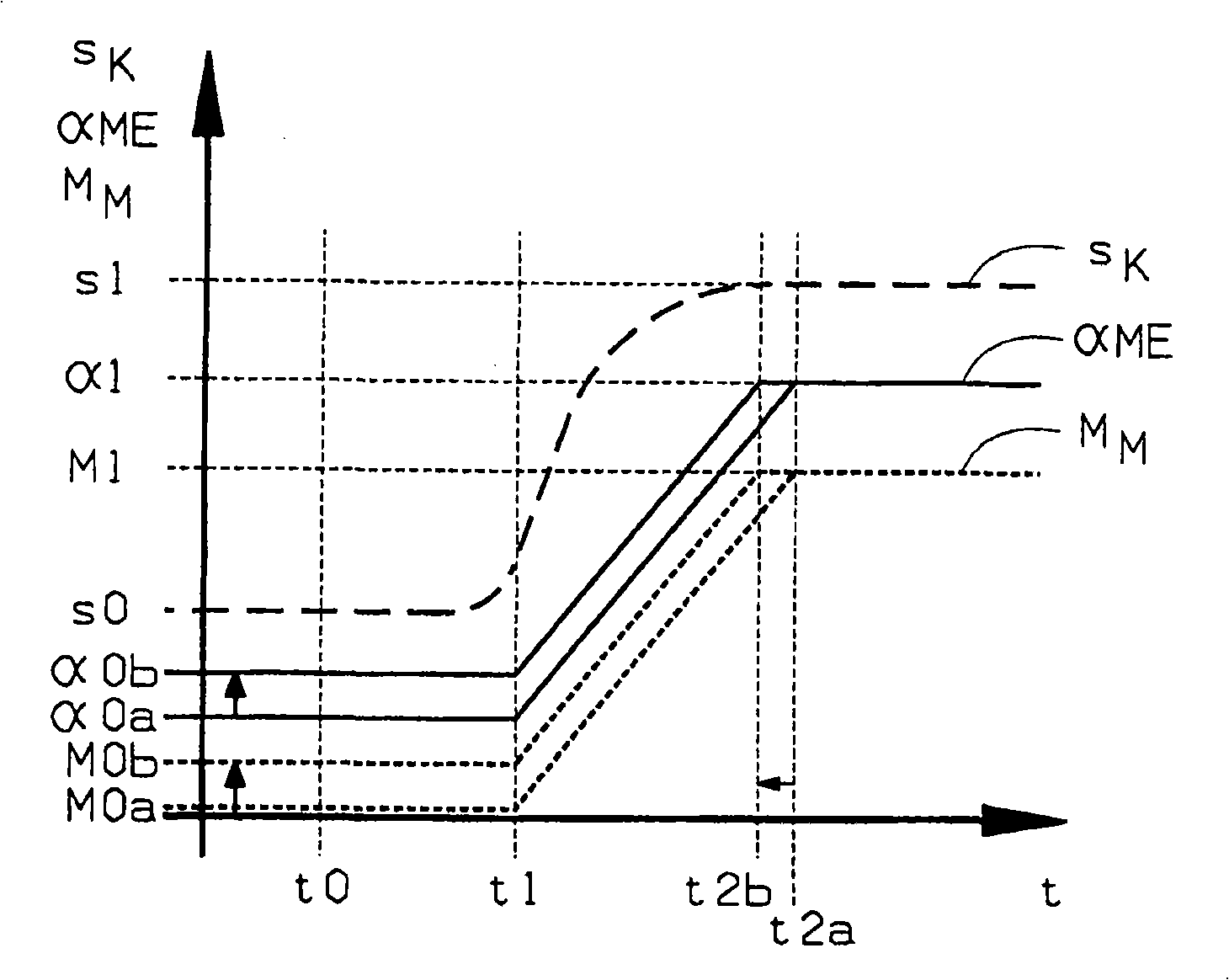

Disclosed herein is a fuel injection control apparatus for an internal combustion engine, capable of opening and closing accurately a valve of the fuel injector even when the quantity of injection required is small and a pulse duration of a driving pulse signal to the fuel injector is short.A fuel injector pulse width computing unit 9a calculates, from the operational state of the internal combustion engine and the fuel pressure detected by a fuel pressure sensor, pulse width of a pulse signal which drives the valve of the fuel injector. After an valve-opening command has turned on and a high valve-opening current for opening the fuel injector valve has been supplied from a high-voltage source to the fuel injector, a fuel injector driving signal waveform command unit 9b discharges the current and supplies from a low-voltage source a small hold current Ih2 that allows the fuel injector to maintain the valve-open state. Also, during the time from supply of the valve-opening current to an arrival at the value of the hold current Ih2, after the elapse of a previously assigned rapid-discharge starting time Tsy from the turn-on of the valve-opening command, the fuel injector driving signal waveform command unit 9b rapidly discharges the current until the hold current Ih2 has been reached.

Owner:HITACHI LTD

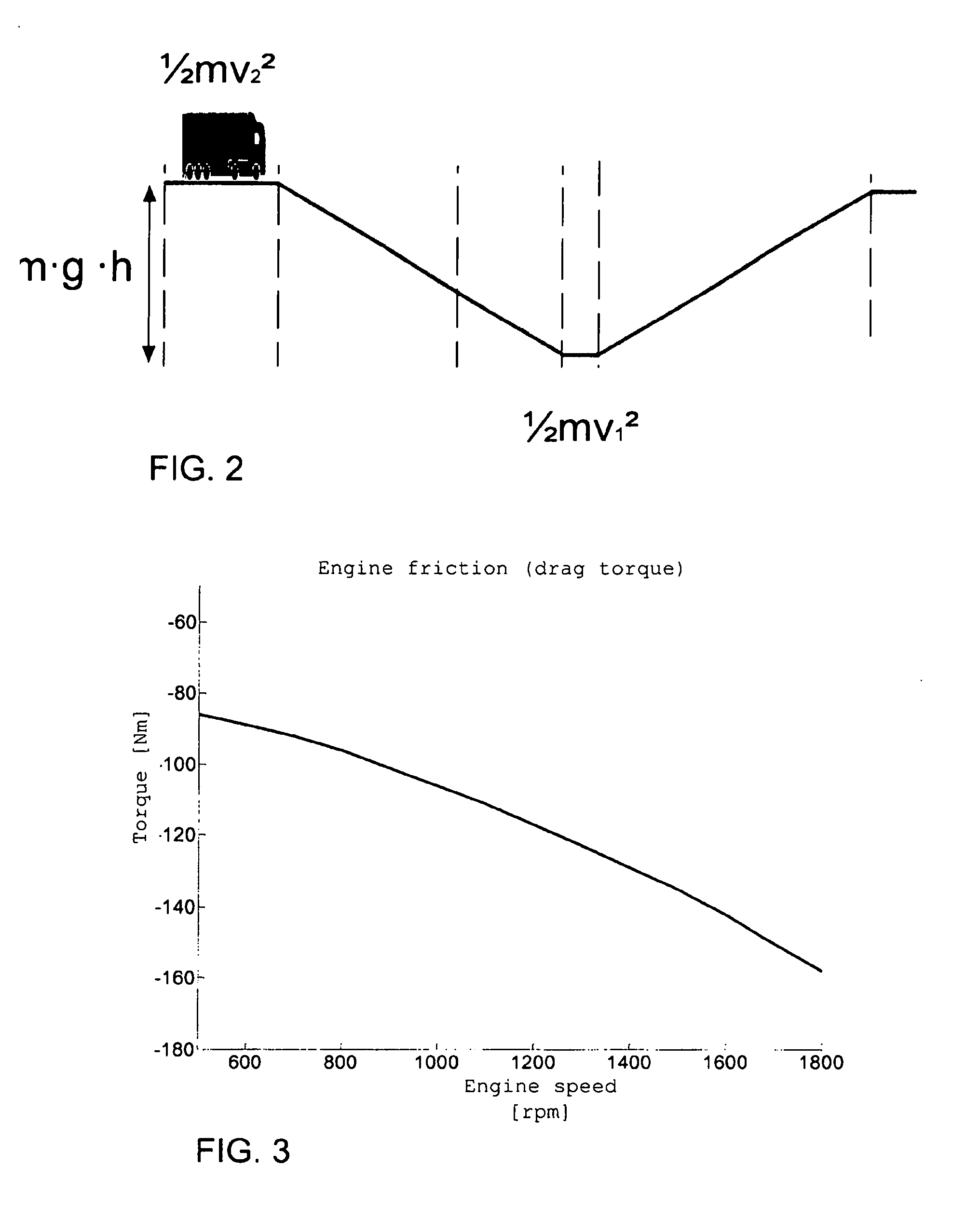

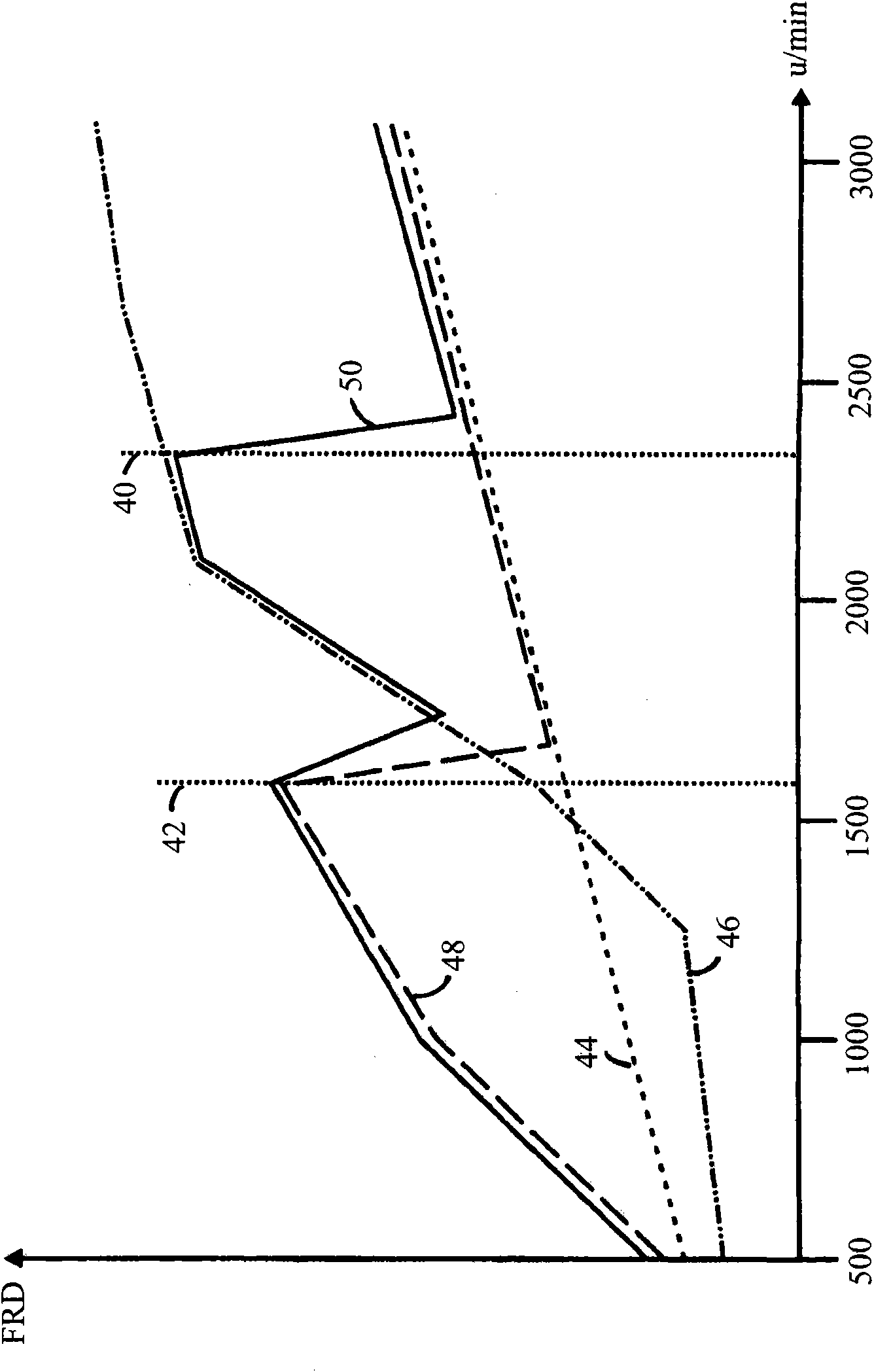

Shift control method for an automatic gearbox

InactiveCN101321943AReduce wearReduce and increase fuel injection volumeElectrical controlGearing controlAutomatic transmissionLoad torque

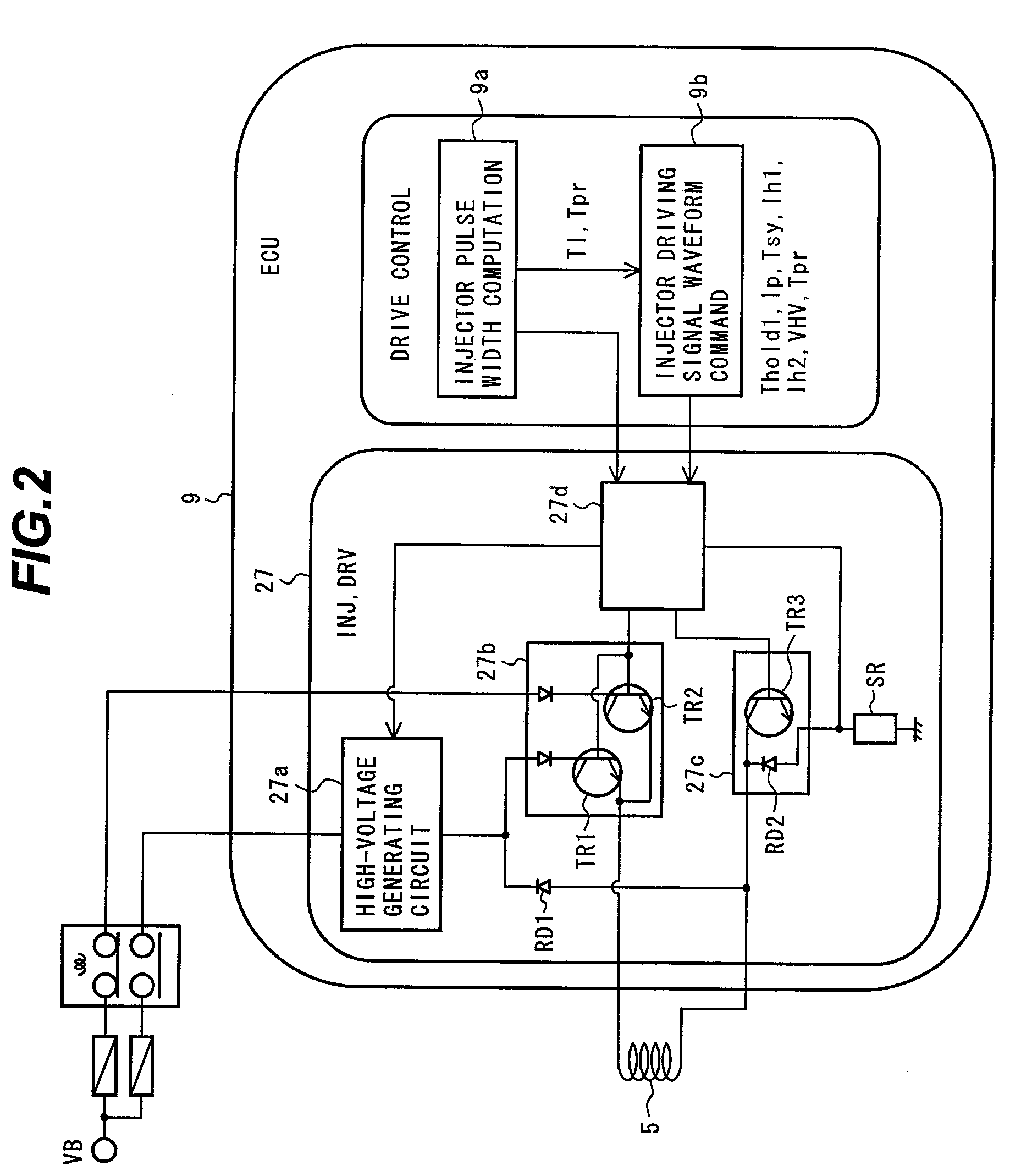

During a gear shift from a gear under load to a target gear, the torque MM of the driving engine is set to an idling torque by a modification of the injection quantity aME before the gear under load is disengaged and to a load torque by a reverse modification of the injection quantity before the target gear is engaged. To allow the process to be better adapted to the respective operating conditions, at least one operating parameter that characterises the current operating condition of the motor vehicle and / or a shift parameter that characterises the designated gear shift is detected and evaluated at the start of the gear shift, and the injection quantity a0a of the driving motor that is assigned to the idling torque is variably adapted to the operating condition of the motor vehicle and / or the gear shift in accordance with the evaluated result.

Owner:ZF FRIEDRICHSHAFEN AG

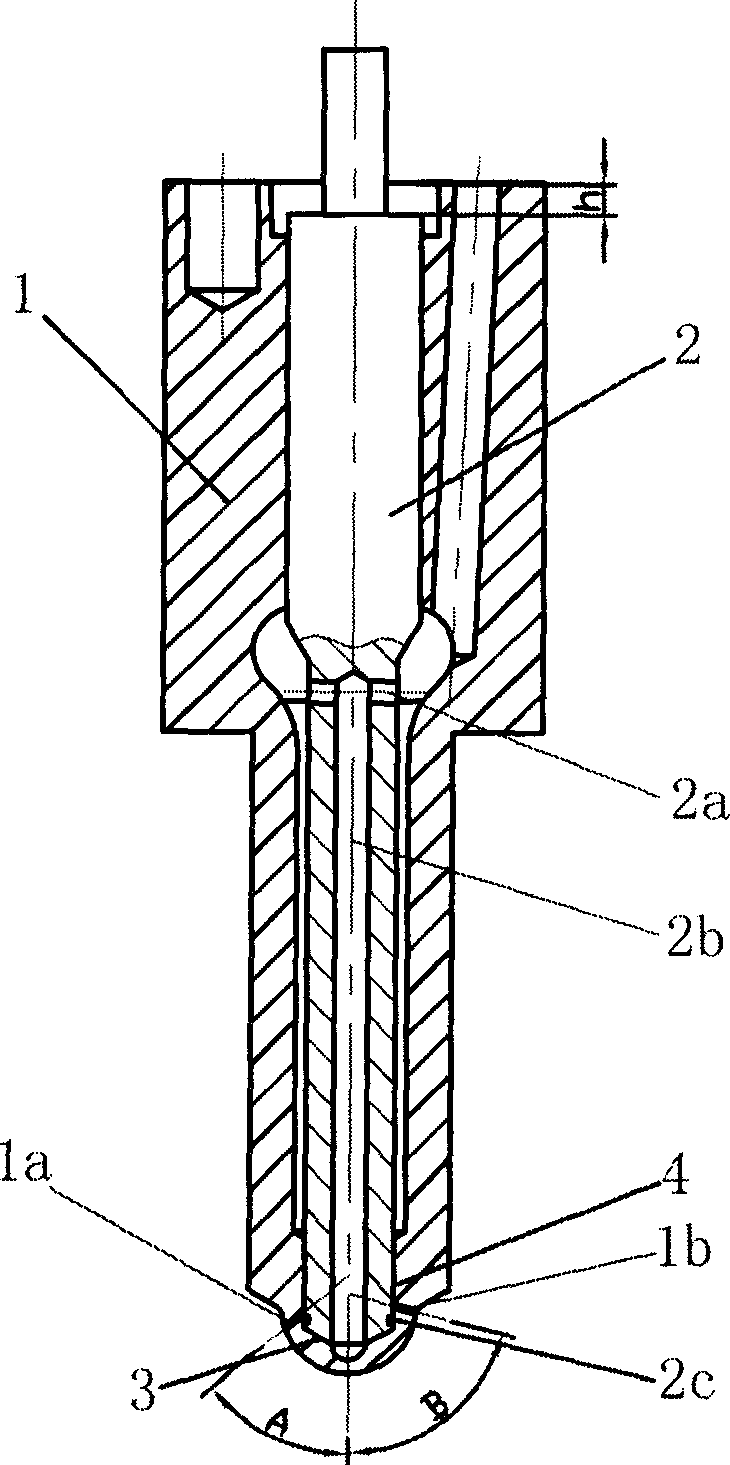

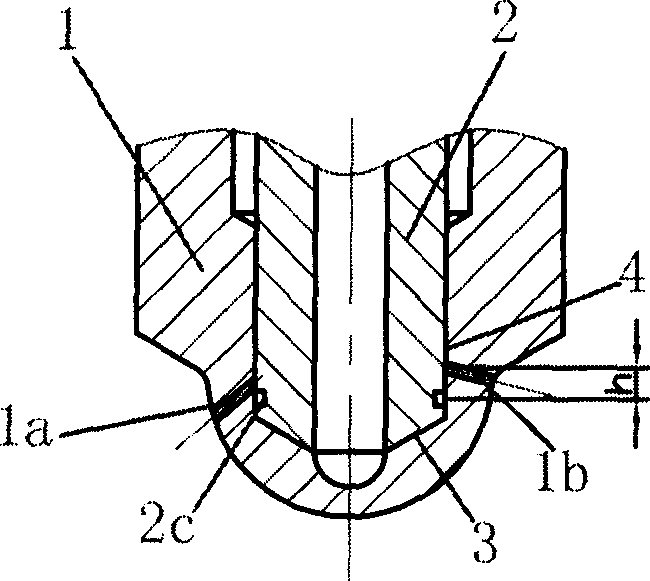

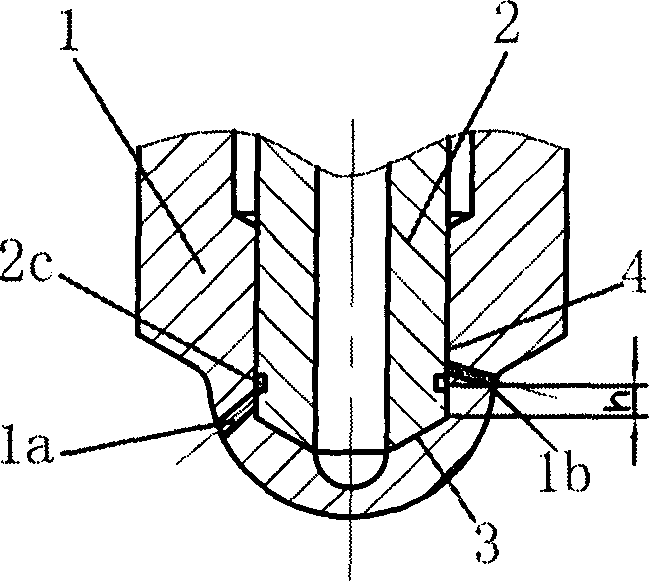

Fuel injection nozzle

InactiveCN1651755AAvoid mutual interferenceIncrease disturbanceFuel injection apparatusMachines/enginesMultiple injectionCombustion system

The present invention relates to a fuel nozzle capable of implementing multiple injection. It belongs to an injection device of fuel combustion system of internal combustion engine. Said fuel nozzle is characterized by that the lower end portion of needle valve of said fuel nozzle is equipped with a circumferential ring groove and on the internal cylindrical surface of said needle valve body a fuel guide groove is set. Said invention also provides the working principle of saod fuel nozzle, it can make the combustion of engine fuel and complete, and can improve noise and starting performance of internal combustion engine. Said fuel nozzle also can be used in direct injection ignited engine.

Owner:DALIAN UNIV OF TECH

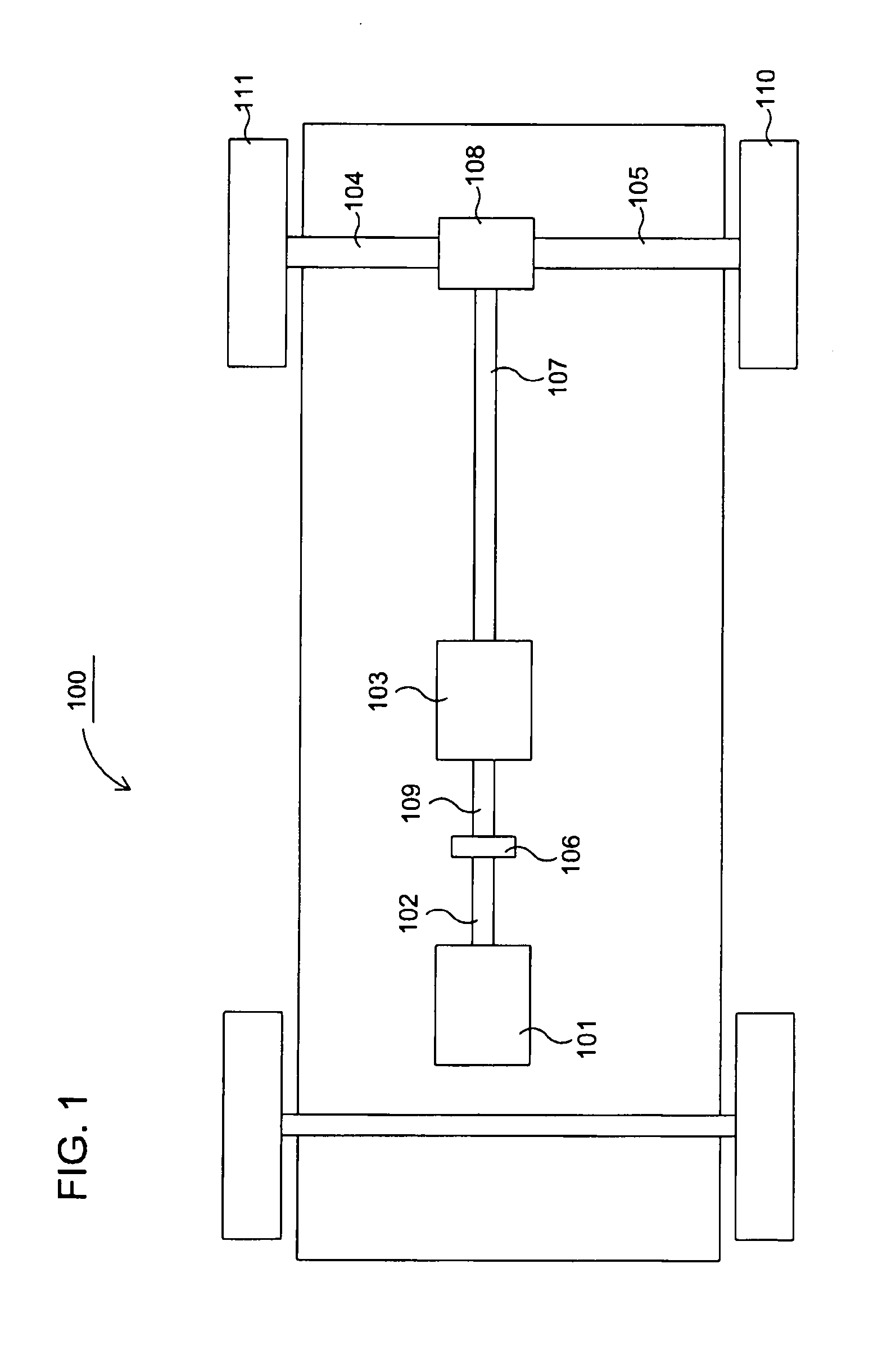

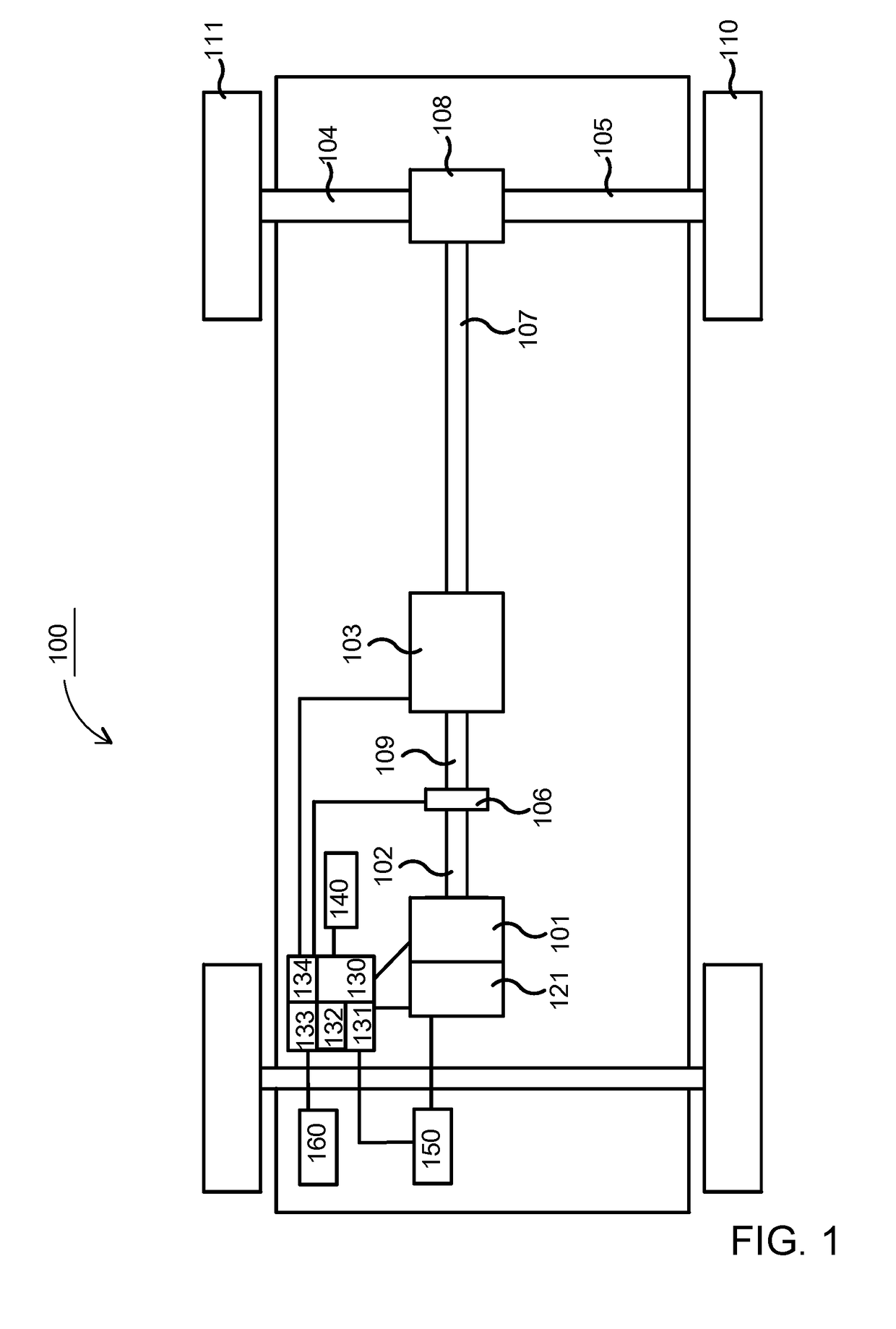

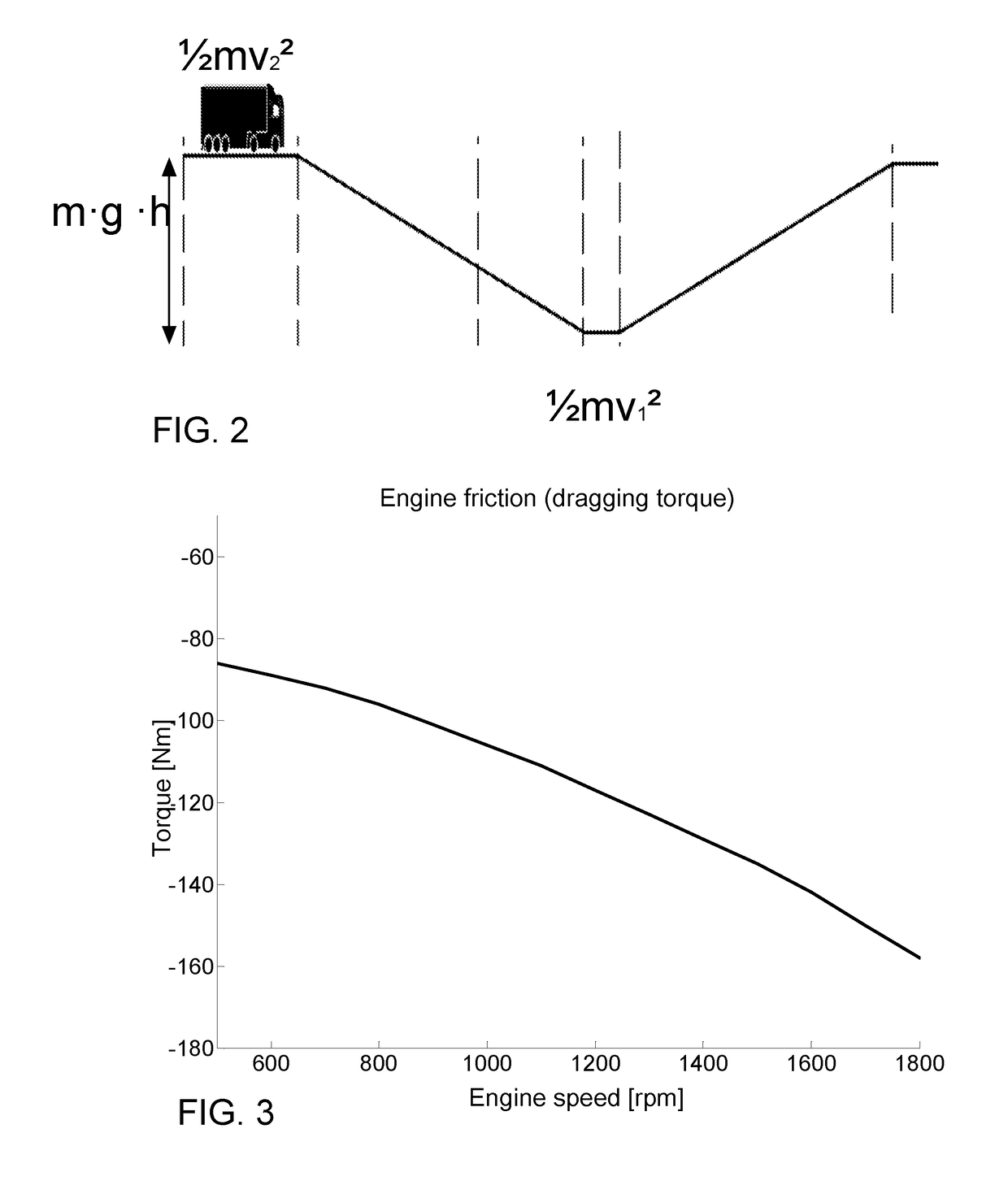

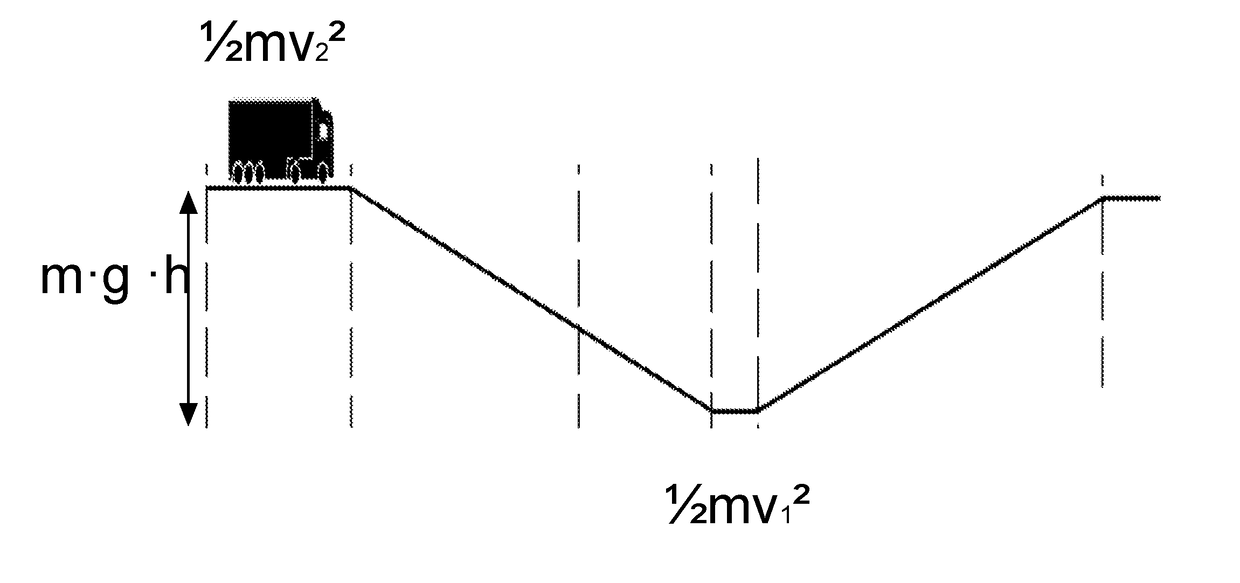

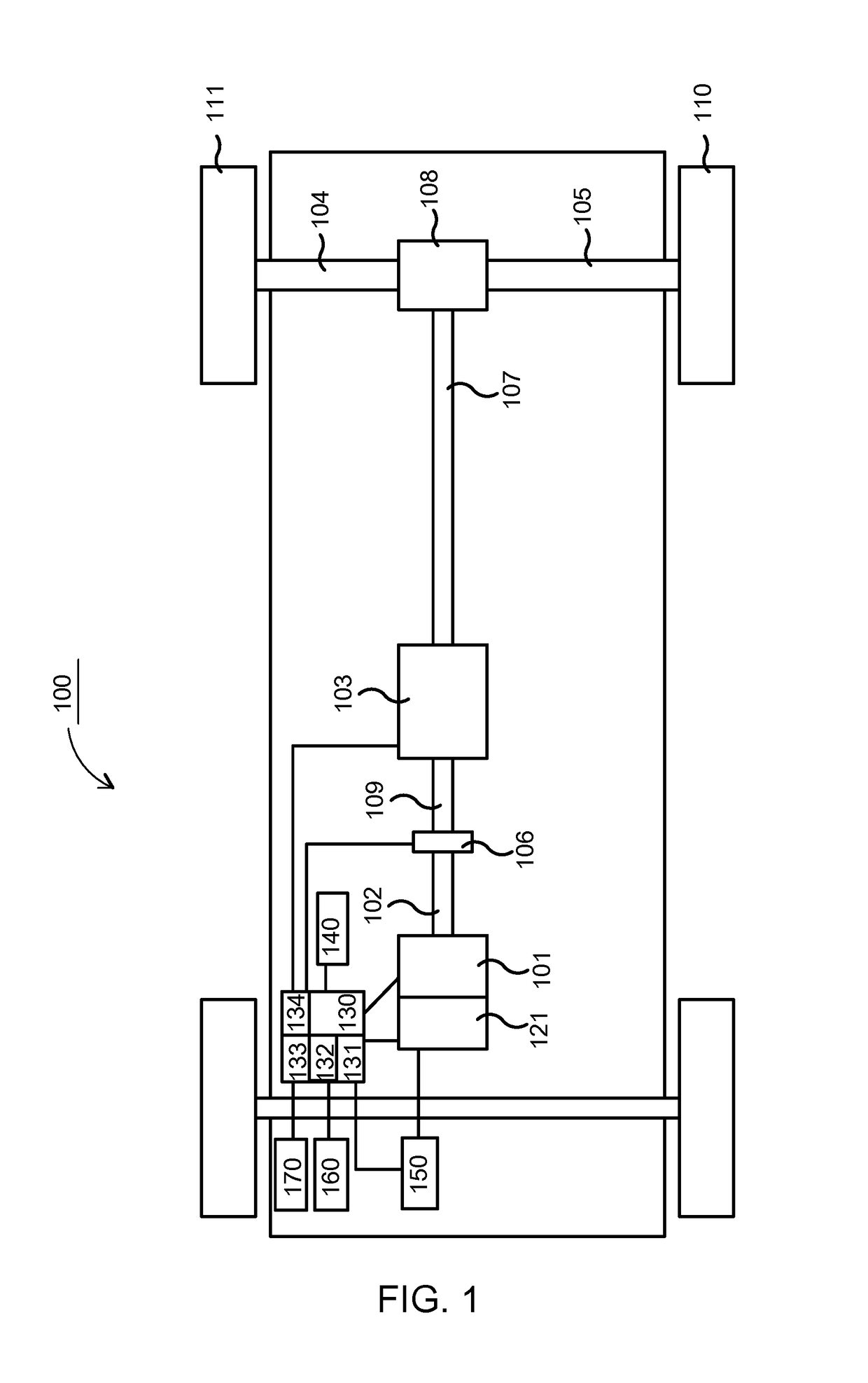

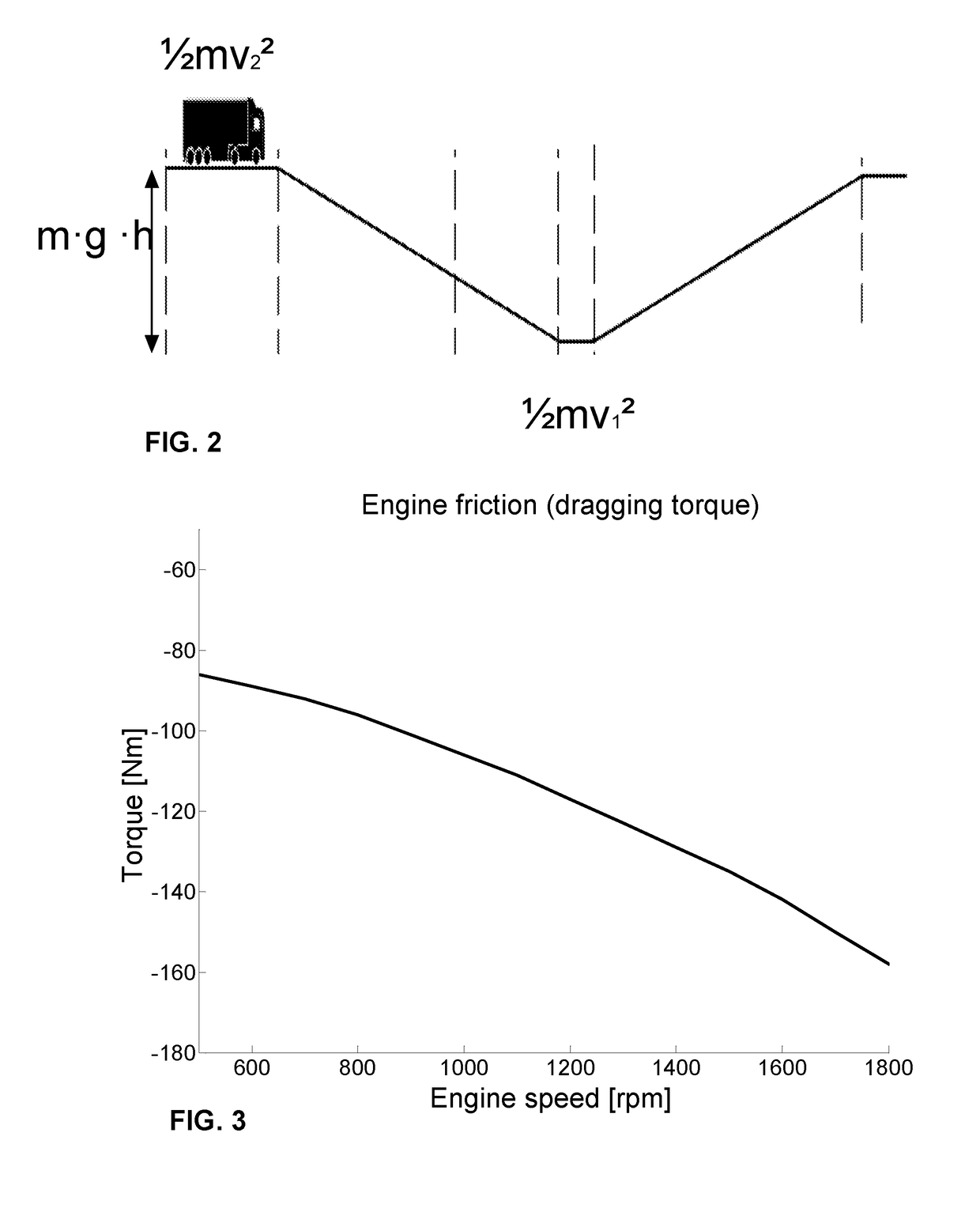

Predictive vehicle pulse and glide control

ActiveUS20160214606A1Reduce fuel consumptionLow possible engine speedInternal combustion piston enginesGearing controlControl systemSimulation

Disclosed are a method and a control system adapted to making it possible to use, or prolong a use of, a higher transmission mode in a vehicle. The control system comprises a simulation unit configured for simulating at least one future speed profile for an actual speed for the vehicle along a section of road ahead of the vehicle, which simulation is conducted at a time when the section of road is still ahead of the vehicle, and is based on information related to a gradient of the section of road. The system further comprises an evaluation unit configured for evaluating whether a raising of an actual speed for the vehicle is appropriate to achieving the making possible or prolongation, which evaluation is based on the simulation of at least one future speed profile, and a use unit configured for using the evaluation during control of the actual speed.

Owner:SCANIA CV AB

Fuel injection control apparatus

ActiveUS7789073B2Improve performanceReduce idle speedElectrical controlDigital data processing detailsMicrocomputerDriver circuit

A fuel injection control apparatus is capable of reducing a minimum quantity of fuel injection without reducing a maximum quantity of injection. To open a fuel injector valve, a driving circuit supplies an electric current from a high-voltage power supply to the fuel injector. Then, after valve opening, the high-voltage power supply is switched to a low-voltage power supply, and an open state of the valve is retained. For opening the valve of the fuel injector, a microcomputer, after supplying current from the high-voltage power supply to the injector, discharges the current rapidly for a decrease below a first current level at which the open state of the valve cannot be retained. The microcomputer then controls the supply current to the injector so as to supply a current at a second current level at which the open state of the valve can be retained.

Owner:HITACHI ASTEMO LTD

Method for operating an internal combustion engine

InactiveUS7497206B2High strengthIncrease cracking pressureElectrical controlFuel injection apparatusExternal combustion engineInternal combustion engine

Owner:ROBERT BOSCH GMBH

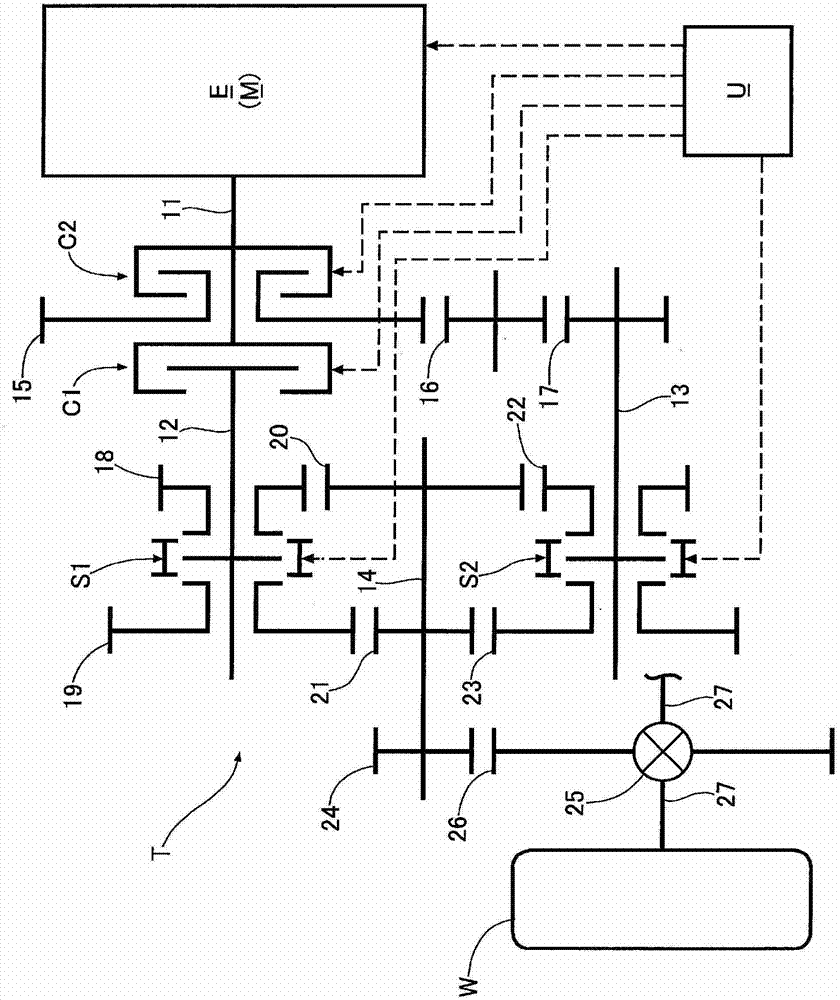

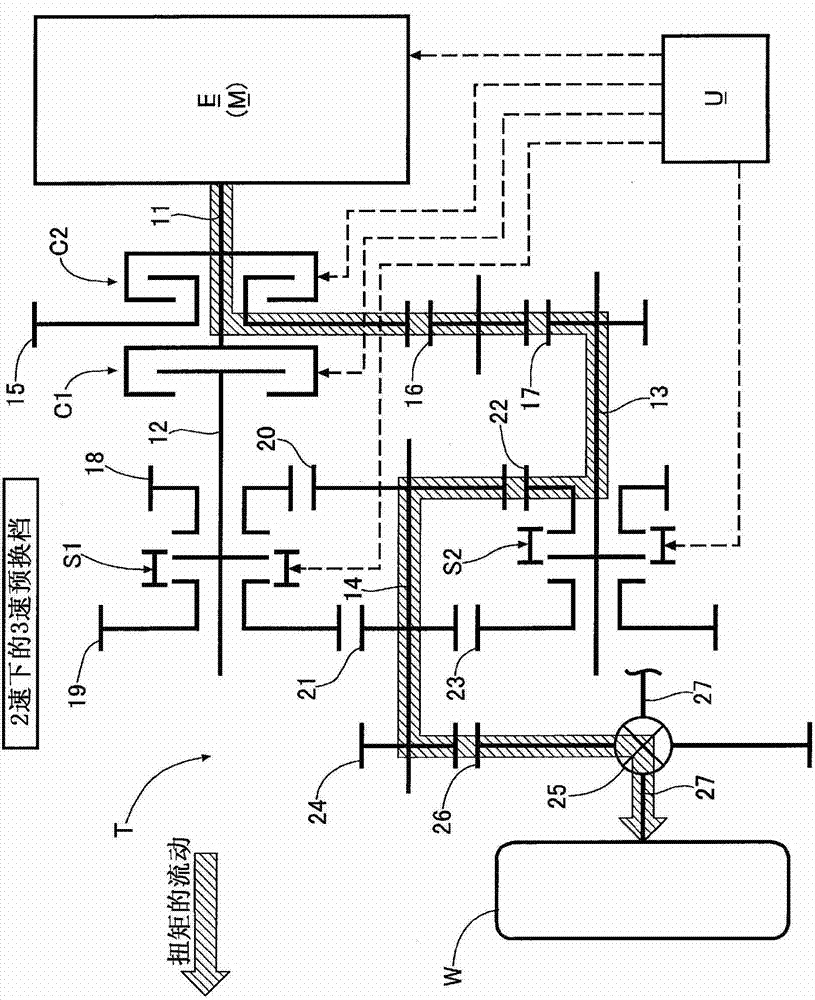

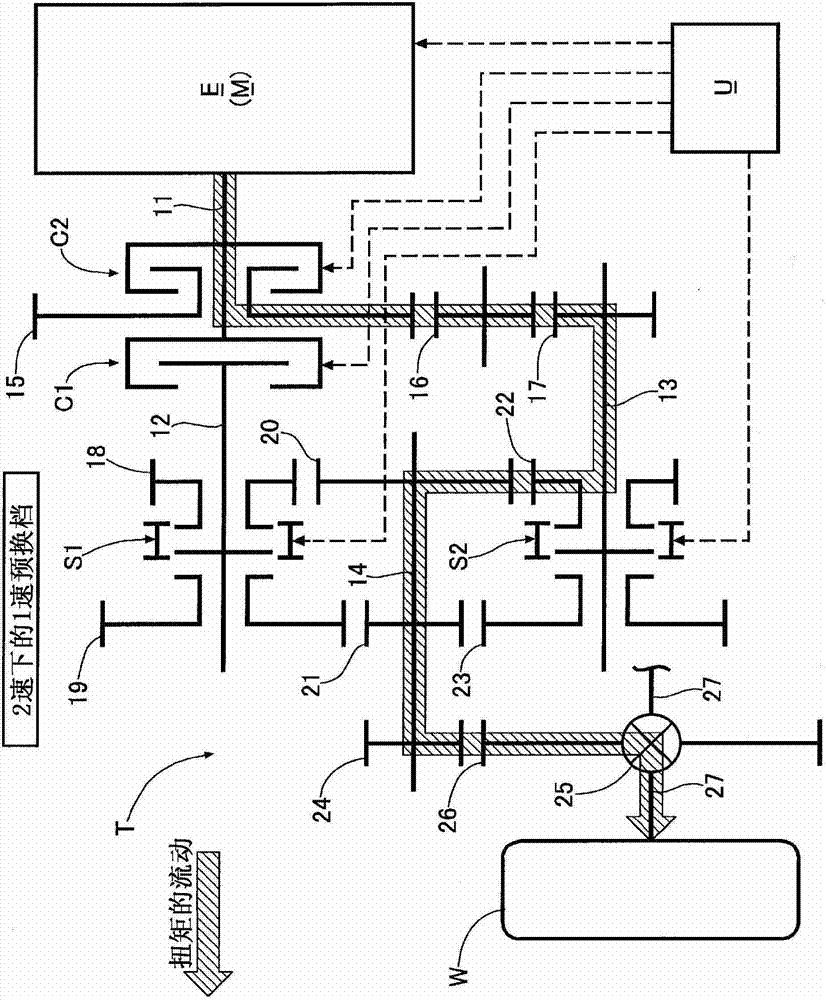

Dual clutch transmission

ActiveCN102959210ASuppress changesReduce shift shockElectrical controlToothed gearingsExternal combustion engineEngineering

Disclosed is a dual clutch transmission wherein, during a pre-shifting operation wherein, when a vehicle is driven using either a first or a second drive force transmission path extending from first and second input shafts (12, 13) to an output shaft (14), a synchronizer (S1, S2) of the other drive force transmission path is operated, the drive force of an internal combustion engine (E) is changed by a command from an electronic control unit (U), and accordingly, even when a drive force or a braking force is generated by inertia, due to a change in the number of rotations of the first and second input shafts (12, 13) in conjunction with the pre-shifting operation, the drive force or the braking force generated by inertia can be compensated by a change in the drive force of the internal combustion engine (E), to reduce shift-shock. Furthermore, the shift-shock can be reduced by only changing the drive force of the internal combustion engine (E) without adding any special structures to the dual clutch transmission (T), and accordingly, the cost and size of the dual clutch transmission (T) can be prevented from increasing.

Owner:HONDA MOTOR CO LTD

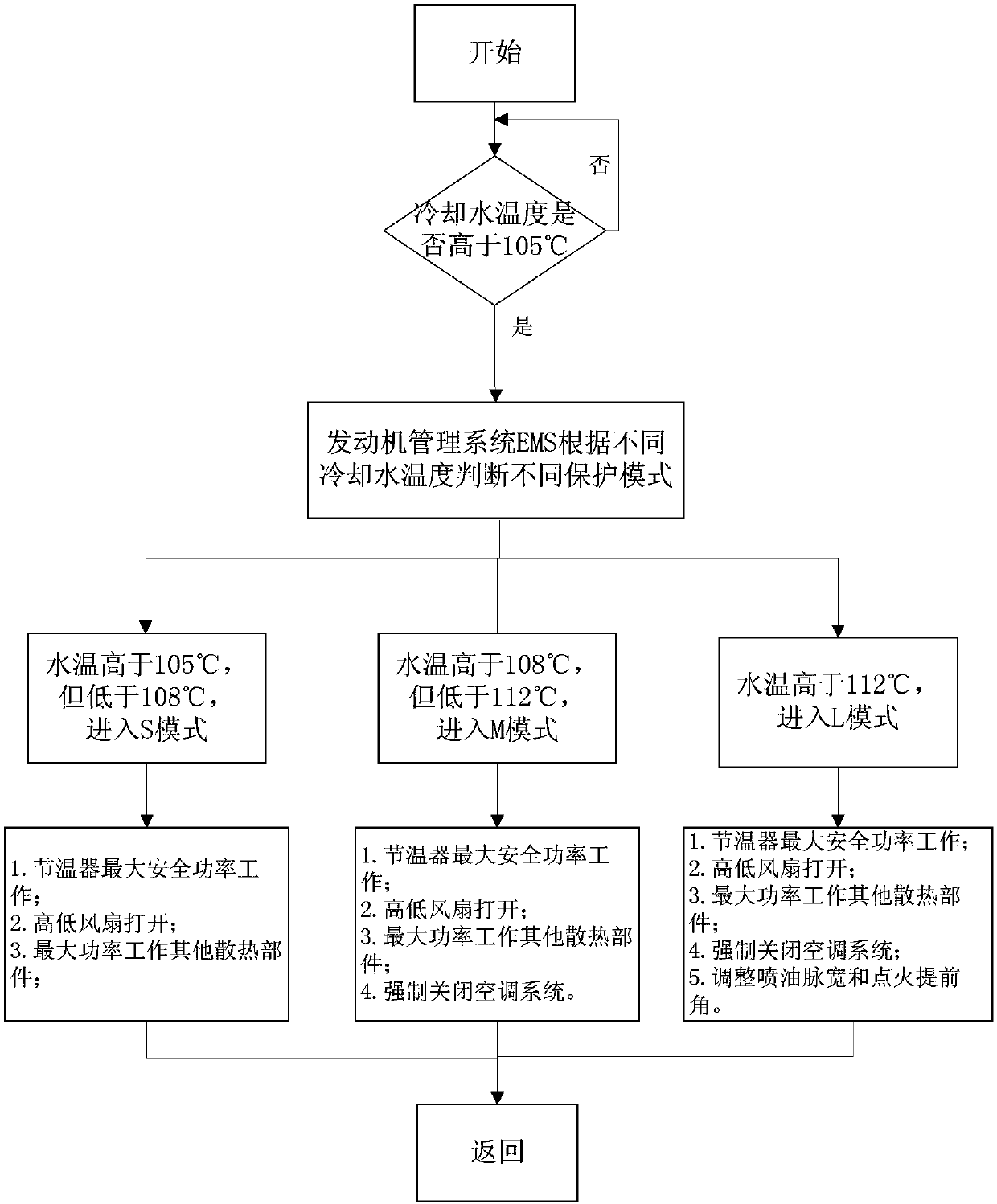

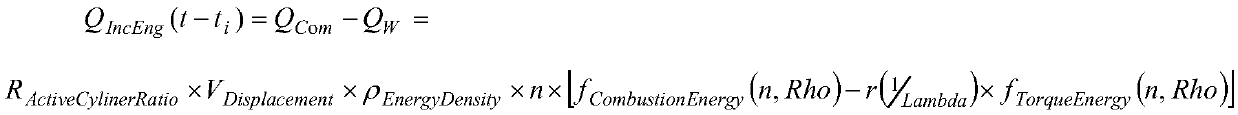

Cooling water high-temperature protection system of gasoline engine and control method thereof

ActiveCN107654284AReduce feverRapid coolingAir-treating devicesElectrical controlDetonationThermostat

The invention discloses a cooling water high-temperature protection system of a gasoline engine and a control method thereof. The cooling water high-temperature protection system comprises an engine management system, a cooling water temperature sensor, a vehicle speed sensor, an air inlet temperature sensor and an air pressure sensor, wherein the signal output ends of the cooling water temperature sensor, the vehicle speed sensor, the air inlet temperature sensor and the air pressure sensor are respectively connected with the engine management system, and the signal output end of the engine management system is respectively connected with the execution ends of an air conditioner control system, a thermostat, a cooling fan, a radiator and an electric control injection and ignition system through control units. According to the cooling water high-temperature protection system, when the temperature of cooling water is high, heat can be dissipated to the maximum, and the heat of an engineis reduced, so that the cooling water is quickly cooled, the engine system can be protected in time before an alarm is given, hidden danger of an oil supply system and an ignition system is reduced,and metamorphic engine oil and detonation are avoided.

Owner:DONGFENG MOTOR CORP HUBEI

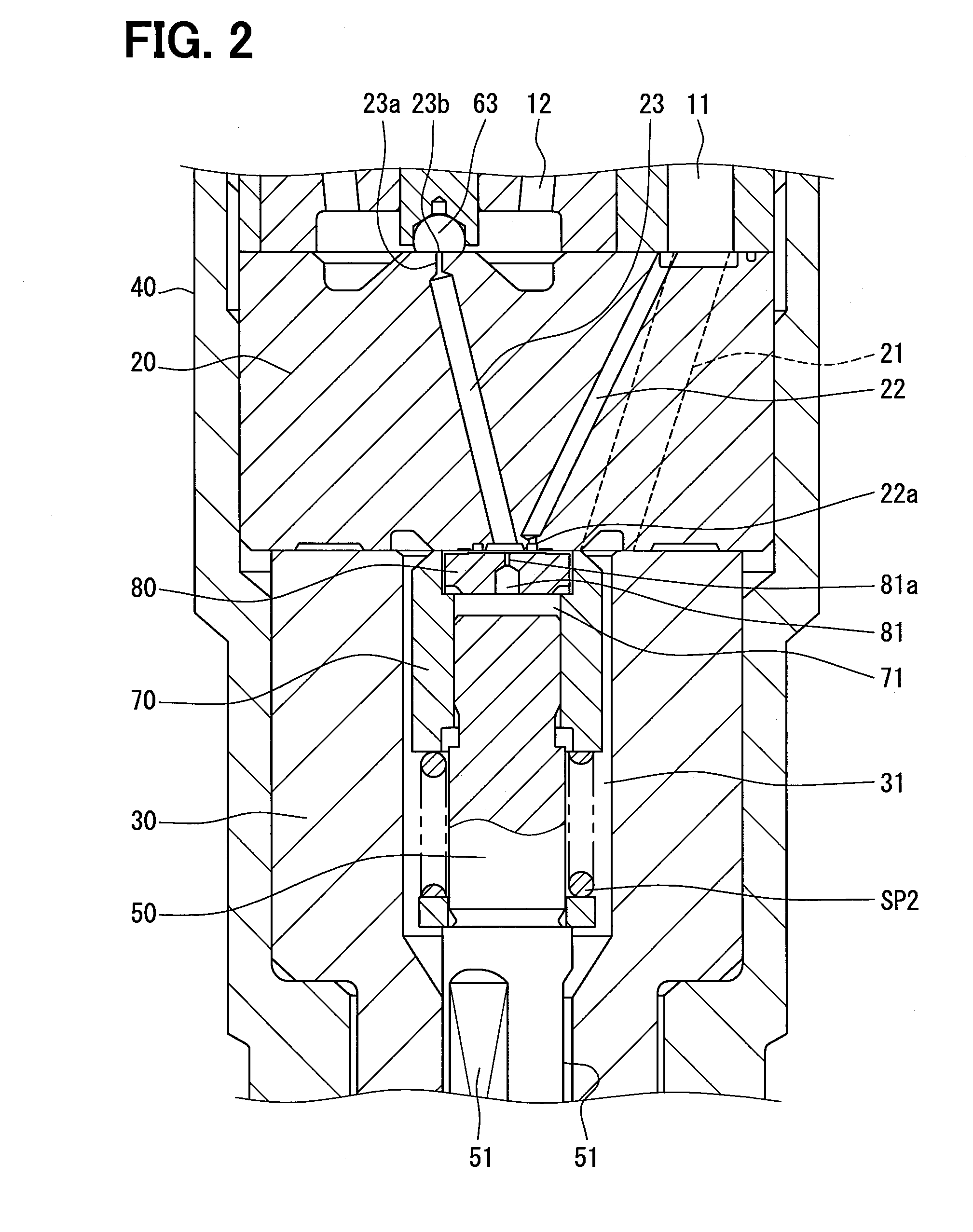

Fuel injection valve

ActiveUS20140174405A1Decrease control-chamber pressureProcess stabilityFluid pressure injection controlMachines/enginesNormal controlEngineering

A sub out-orifice and an in-orifice are respectively formed in a low pressure passage and a high pressure passage of a fixed plate. A control valve is provided at an outlet port of the low pressure passage. In a normal control, the control valve starts its control-valve opening operation when a movable plate is in contact with the fixed plate. In an interval-shortening control, the control valve starts the control-valve opening operation at an earlier timing than that in the normal control, namely during a course in which a valve body is still in its valve-body closing operation.

Owner:DENSO CORP

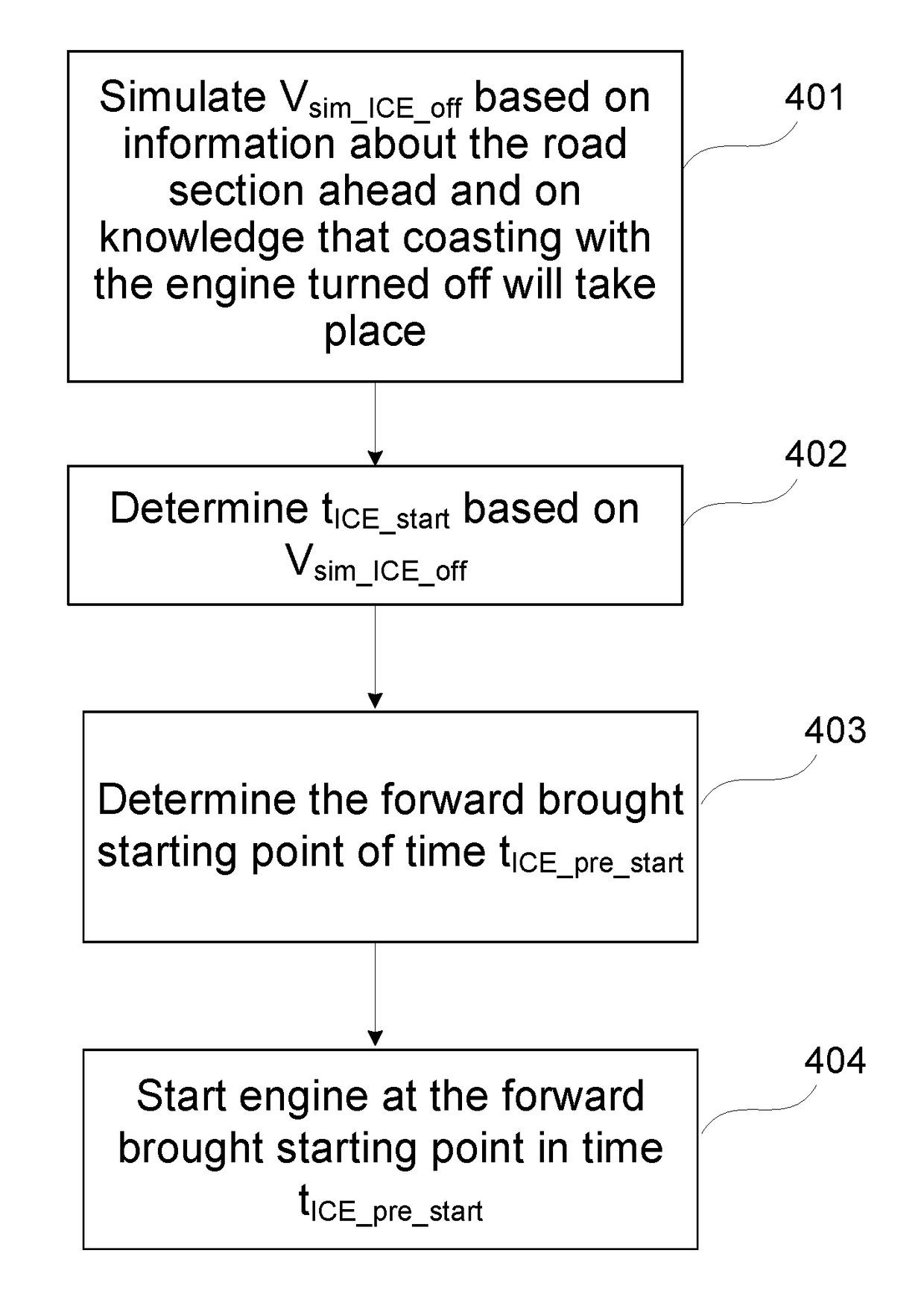

Control of an internal combustion engine in a vehicle

ActiveUS20170198655A1Reduce fuel consumptionSave fuelElectrical controlRoad transportCombustionInternal combustion engine

Methods and systems are provided for control of a combustion engine in a vehicle. In operation, at least one future speed profile for an actual speed of the vehicle is simulated during a road section ahead based on information about the road section and on knowledge that coasting with the combustion engine shut down will be applied during the road section. Subsequently, based on the future speed profile, a starting point in time is determined, when the combustion engine will need to be started for forward driving the vehicle and / or to brake the vehicle. Subsequently, a starting point brought forward in time is determined based on the need for a forward driving or braking force arising, where the starting point brought forward in time precedes the starting point in time. Subsequently, the combustion engine is controlled to be started at the starting point brought forward in time.

Owner:SCANIA CV AB

Control of an combustion engine in a vehicle

ActiveUS20170158204A1Save fuelReduced request of positive engine torqueHybrid vehiclesInternal combustion piston enginesCombustionInternal combustion engine

Methods, systems, and computer program products are provided for control of a combustion engine in a vehicle. At least one future speed profile for an actual speed of the vehicle during a road section is simulated based on information about the road section, and that coasting will be applied during the road section. An applicability for coasting during the road section is evaluated. Subsequently, it is evaluated whether the combustion engine may be shut down during a coasting for at least a part of the road section. The evaluation of the shutdown of the combustion engine is based on whether one or several system conditions for engine shutdown have been met, on one or several properties for one or several brake systems in the vehicle, and on a shutdown period, when the combustion engine could be shut down. The combustion engine is then controlled based on this evaluation.

Owner:SCANIA CV AB

Control apparatus for internal combustion engine

ActiveUS8280613B2Minimizing amount of fuelImprove performanceElectrical controlInternal combustion piston enginesDriving currentExternal combustion engine

A fuel injection control apparatus for an internal combustion engine which can inject a fuel injection quantity to a fuel injector with accuracy even when the fuel injection quantity is reduced than before is provided. A fuel injection control apparatus of a direct cylinder injection type of internal combustion engine, including a fuel injector which performs fuel injection by supplying a drive current to a solenoid, a fuel pressure sensor which detects fuel pressure supplied to the fuel injector, and operation state detecting means which detects the operation state of the internal combustion engine, comprises current profile changing means 100 which has multiple current profiles of the drive current and changes current profiles based on the operation state and the fuel pressure, valid pulse width calculating means 701 which calculates a valid pulse width for opening and driving the fuel injector, invalid pulse width calculating means 103 which calculates an invalid pulse width, and fuel injector control means which calculates a fuel injection pulse width based on the valid pulse width and the invalid pulse width, and controls the fuel injector based on the fuel injection pulse width, wherein the invalid pulse width calculating means 103 calculates an invalid pulse width corresponding to the current profiles to be changed before the current profiles are changed.

Owner:HITACHI ASTEMO LTD

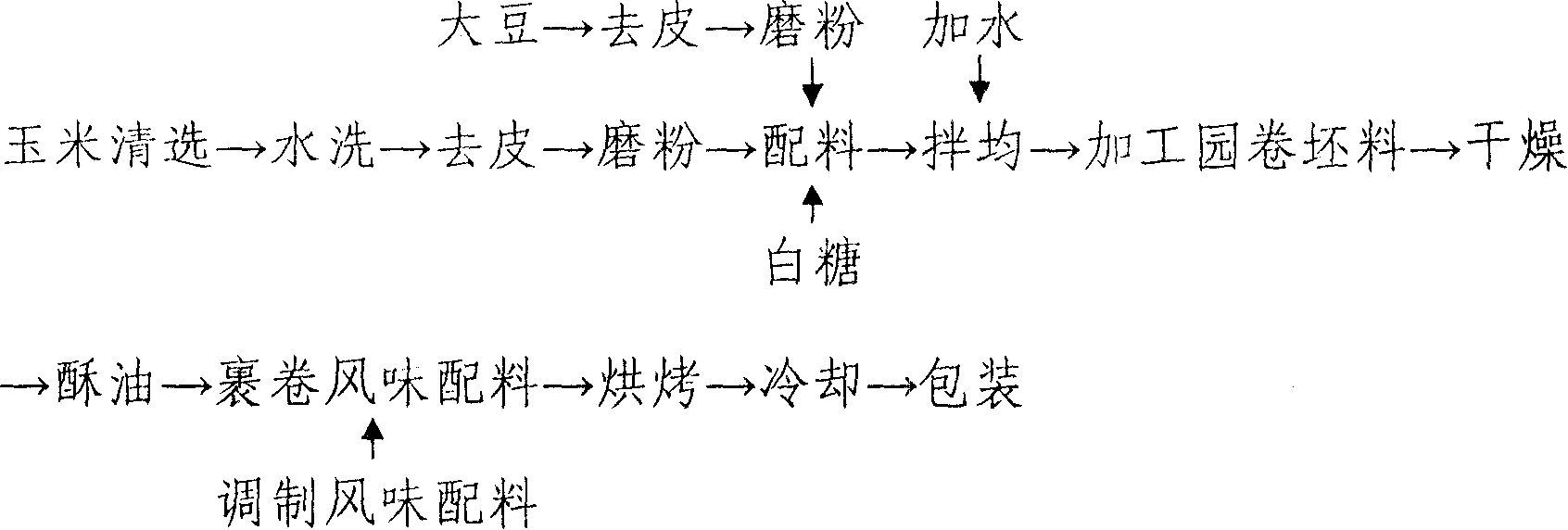

Fragrant curled food, its derivative food and its production

The invention is concerned with a kind of xiangmijuan food and its derivative and these produce method, and the associated expanding and soft roller machine and multi-function heating and warm revolving pan. The xiangmijuan food and its derivative take corn as main material and they fit for corn, and the foods of grain, wheat and amylum. The xiangmijuan food and its derivative are expanding and loosen shape with multi-hole and multi-clearance, its outer roll is a kind of hollow and long cylinder in round roll shape. The inner roll is regular, shapely, expanding and loosening, and there are netlike small eyelets or small clearances on the body of roll equably in color with golden yellowness. The whole roll body is sweet and crisp, the outer roll is the warping layer with flavor stuff adhering to the surface of inner roll tightly in 3 mm thickness. It has pure color for different tastes and obvious individuation.

Owner:王训勇

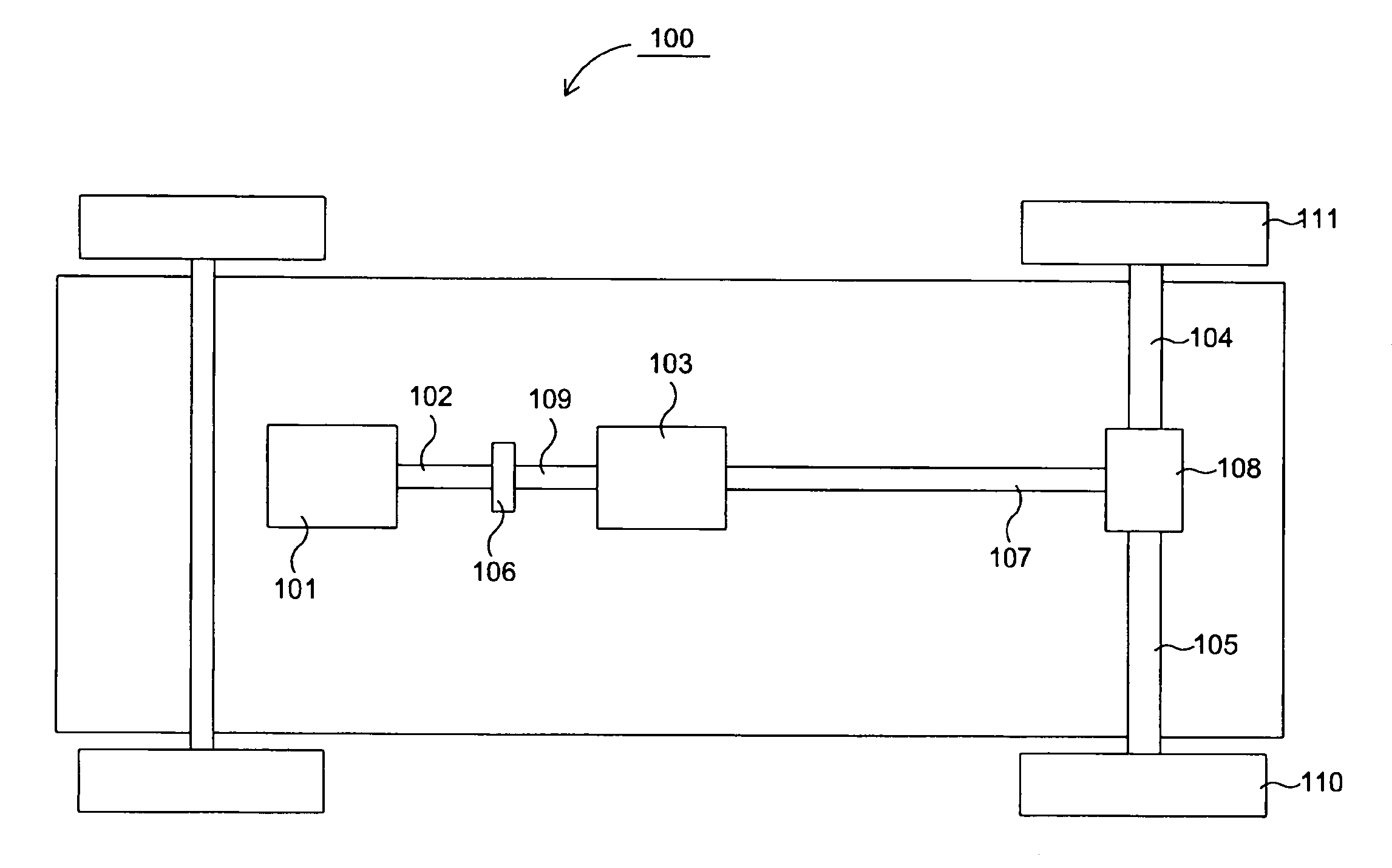

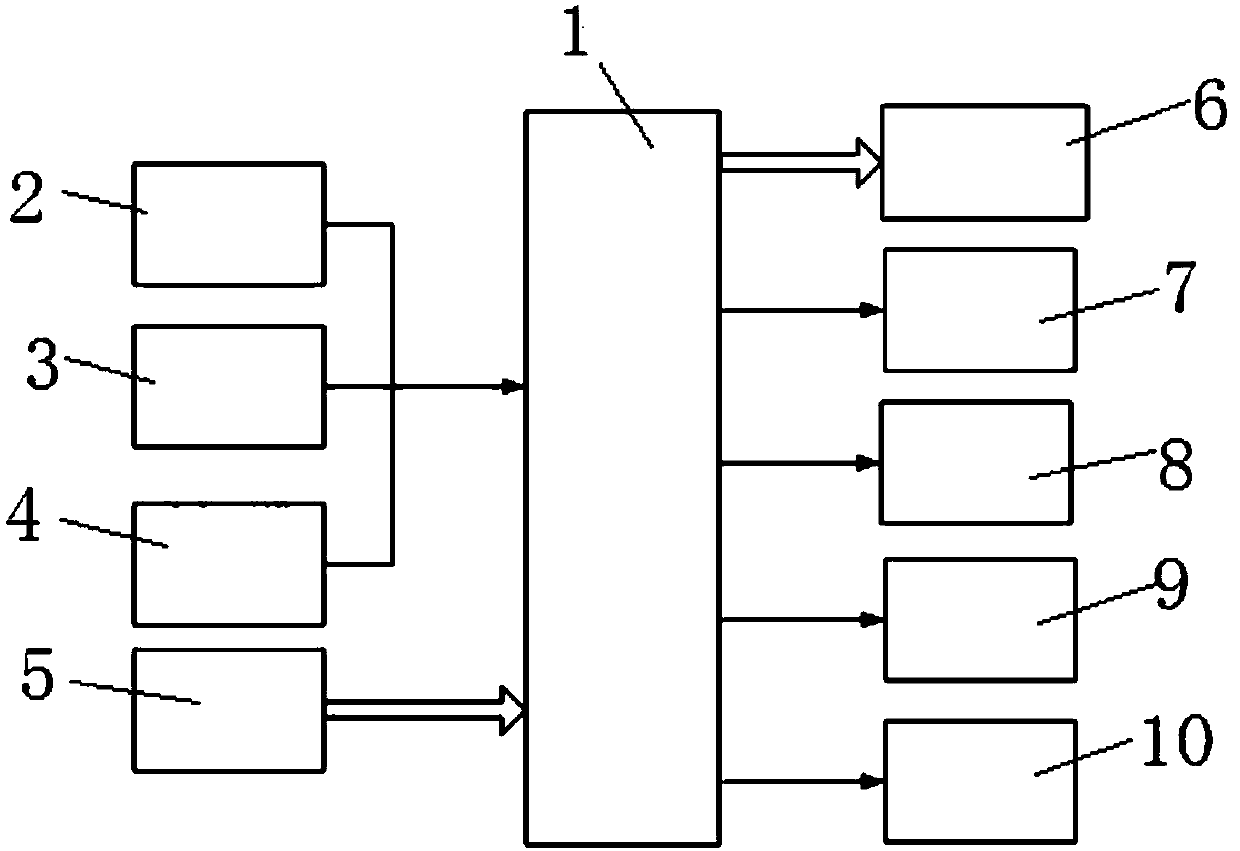

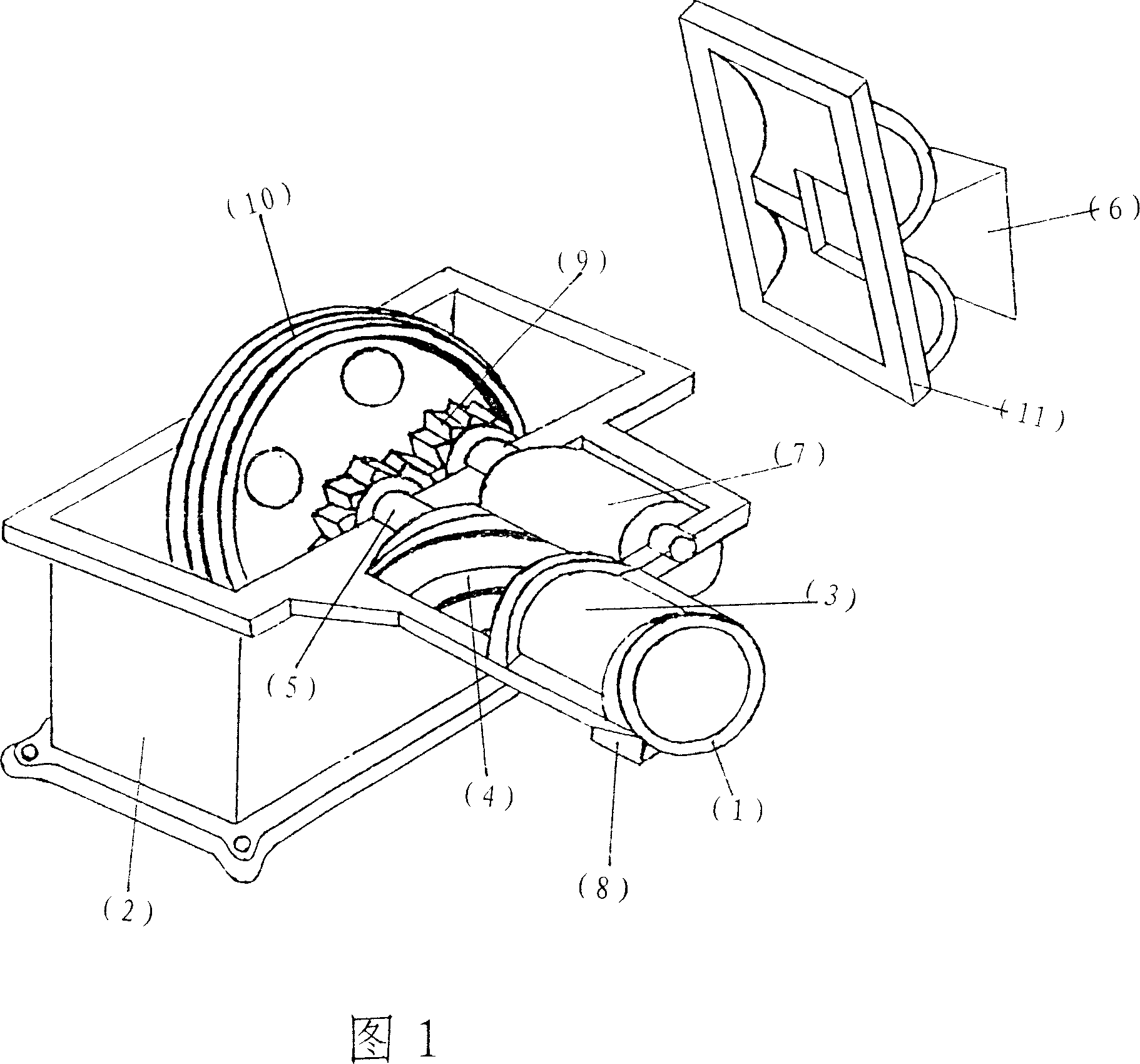

Method and device for cleaning up carbon deposited in automobile engine

InactiveCN102808693AImprove fuel atomizationFine atomizationMachines/enginesEngine componentsVIT signalsClean-up

The invention relates to the technical field of automobile electronics, specifically to a method and a device for cleaning up carbon deposited in an automobile engine, wherein the device comprises a sensor, a controller and a pulse generator, wherein the controller is composed of a power circuit, a signal input circuit, a processor and a signal output interface, wherein the signal input circuit, the processor and the signal output interface are orderly connected; the pulse generator is composed of a condition indicator, a pulse circuit and a signal output circuit, wherein the pulse circuit and the signal output circuit are connected with each other; the sensor is connected with the signal input circuit of the controller; and the pulse generator is connected with the signal output interface of the controller. The method and the device provided by the invention can transmit a pulse signal timely according to an operation condition of the engine so as to clean up original deposited carbon of the engine, prevent newly deposited carbon from being generated, ensure a combustion condition is optimal under various conditions, and improve overall performance of entire automobile.

Owner:威海中创国际贸易有限公司

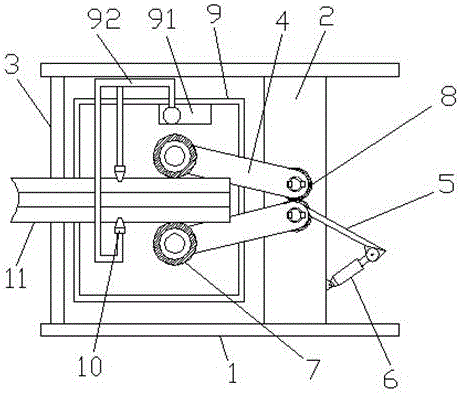

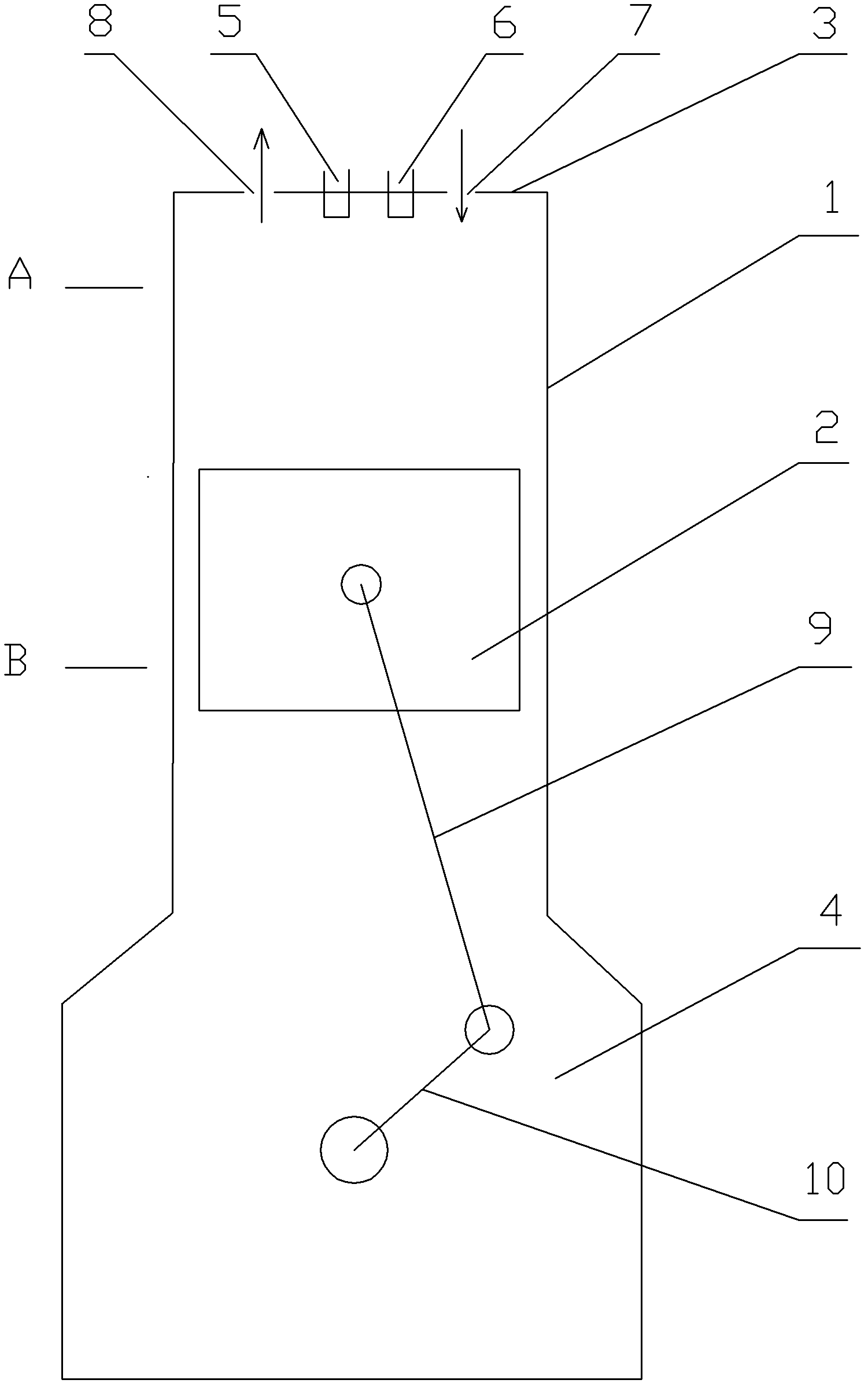

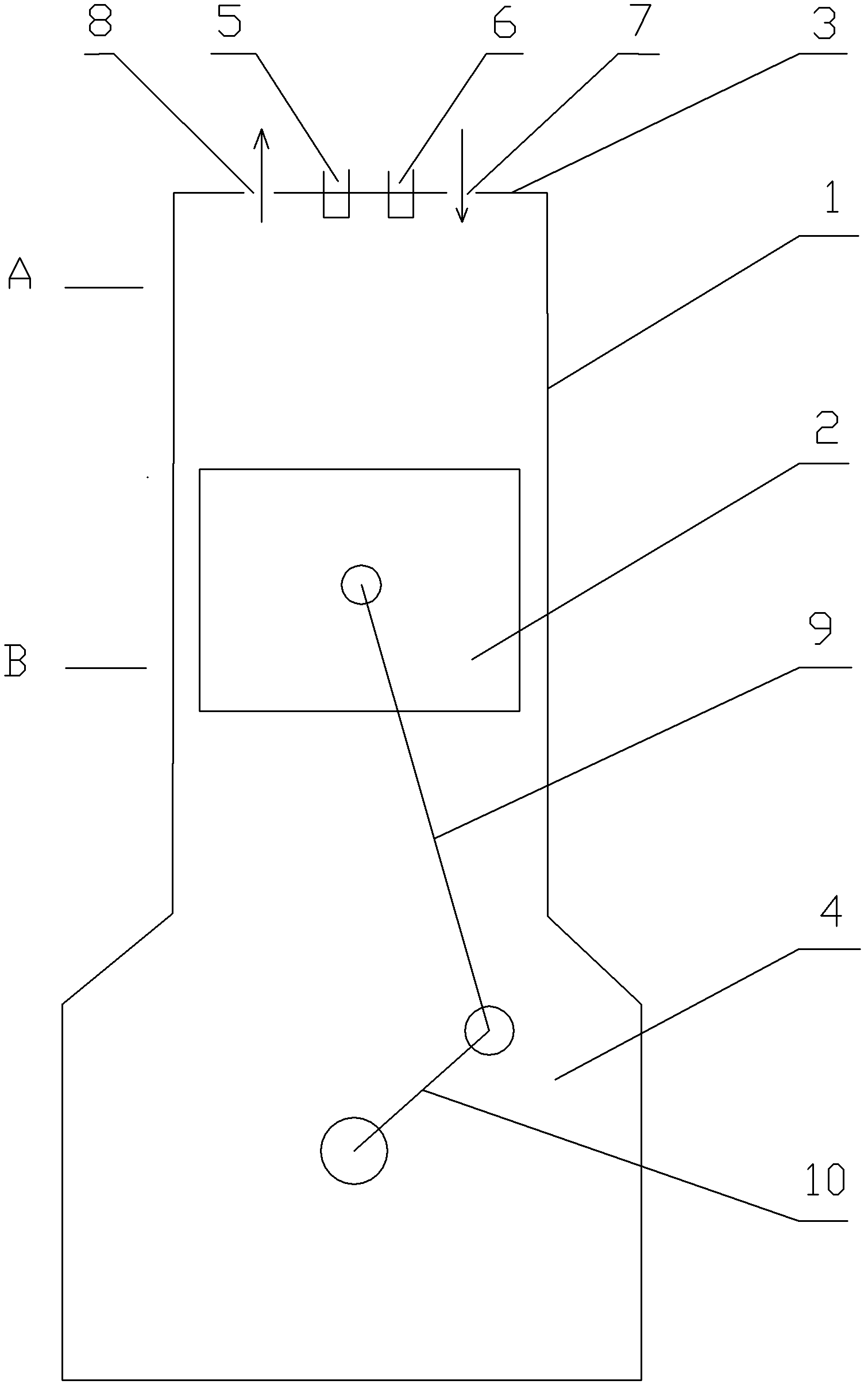

Mist spray covering device for oil film on side face of elevator guide rail

The invention discloses a mist spray covering device for an oil film on the side face of an elevator guide rail. The mist spray covering device comprises a base support and a plurality of rollers. The rollers are arranged on the base support at intervals. The T-shaped guide rail is conveyed forwards on the rollers. The base support is provided with a supporting plate, and the supporting plate is symmetrically provided with swing arms located at the two sides of the T-shaped guide rail. Oil suction rollers are arranged at the front ends of the swing arms separately. The base support is provided with an oil receiving tank located below the oil suction rollers. The oil receiving tank is provided with an oil pump. The output end of the oil pump is provided with bends extending to the two sides of the T-shaped guide rail. According to the mist spray covering device for the oil film on the side face of the elevator guide rail, by the adoption of the mode, anti-rust oil in the oil receiving tank can be atomized to be sprayed onto the two side faces of the T-shaped guide rail through an atomizing spray head, and then the two side faces of the T-shaped guide rail are clamped through the oil suction rollers, so that oil droplets are evenly smeared, and redundant anti-rust oil can be adsorbed and recycled.

Owner:张家港奥斯卡电梯部件有限公司

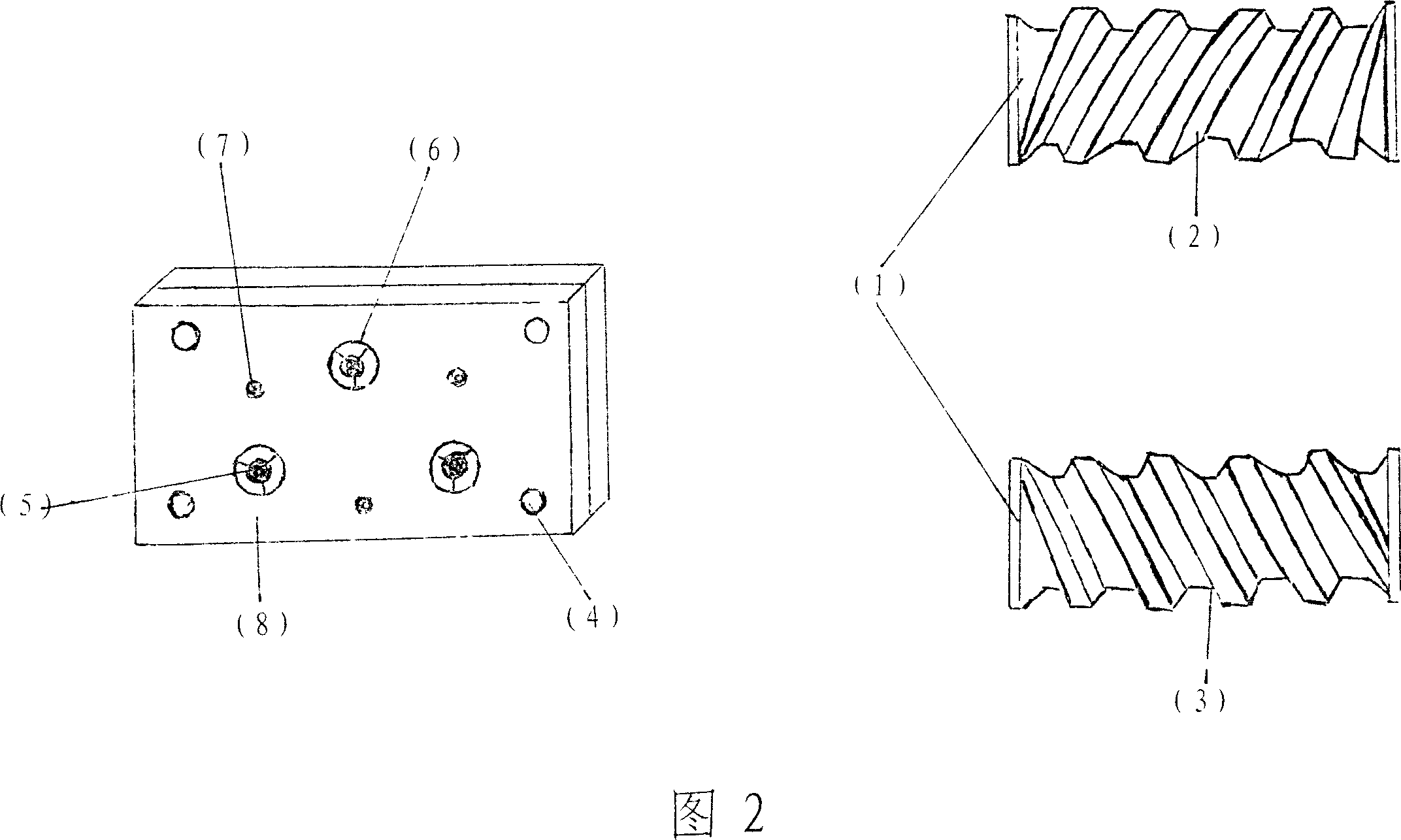

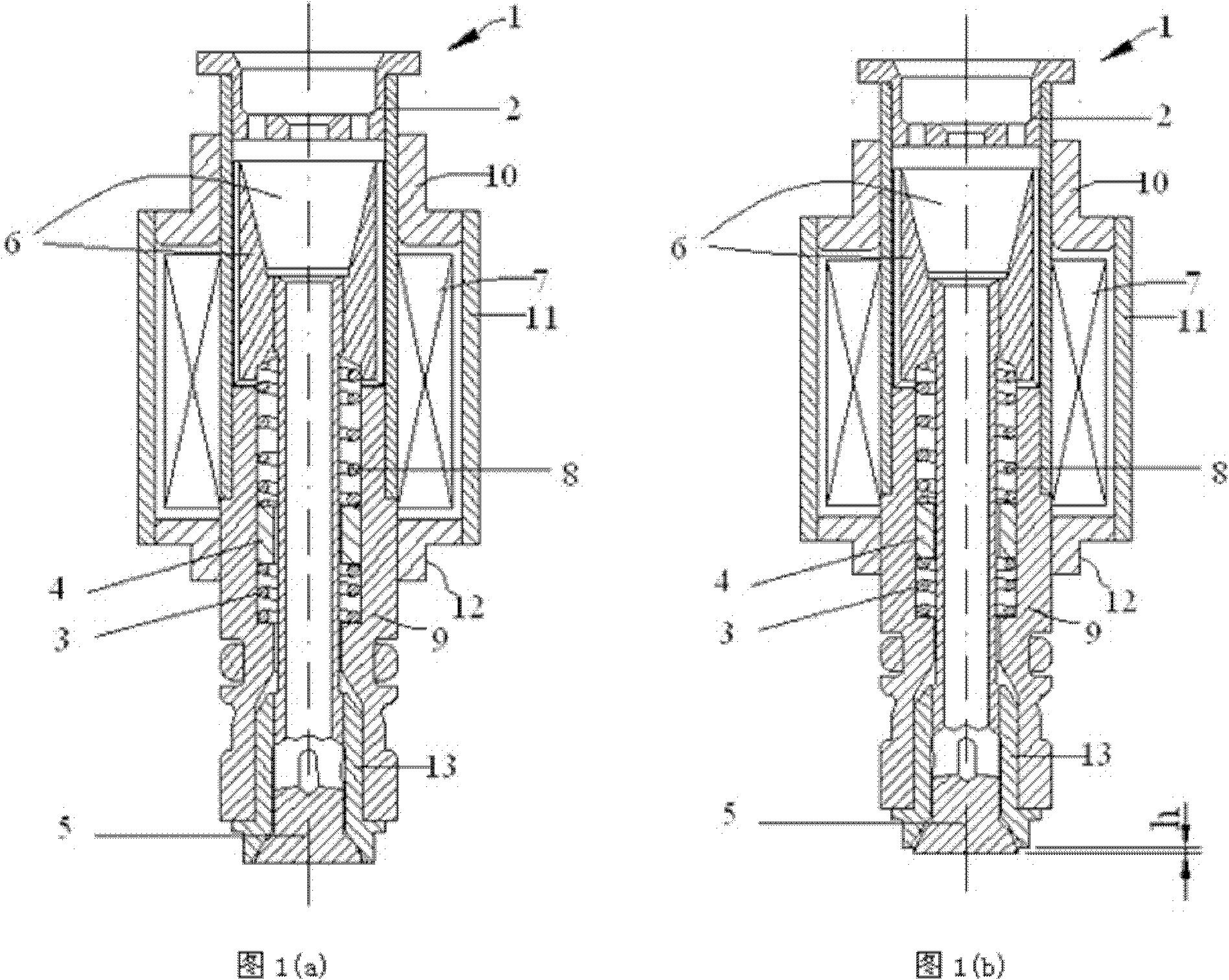

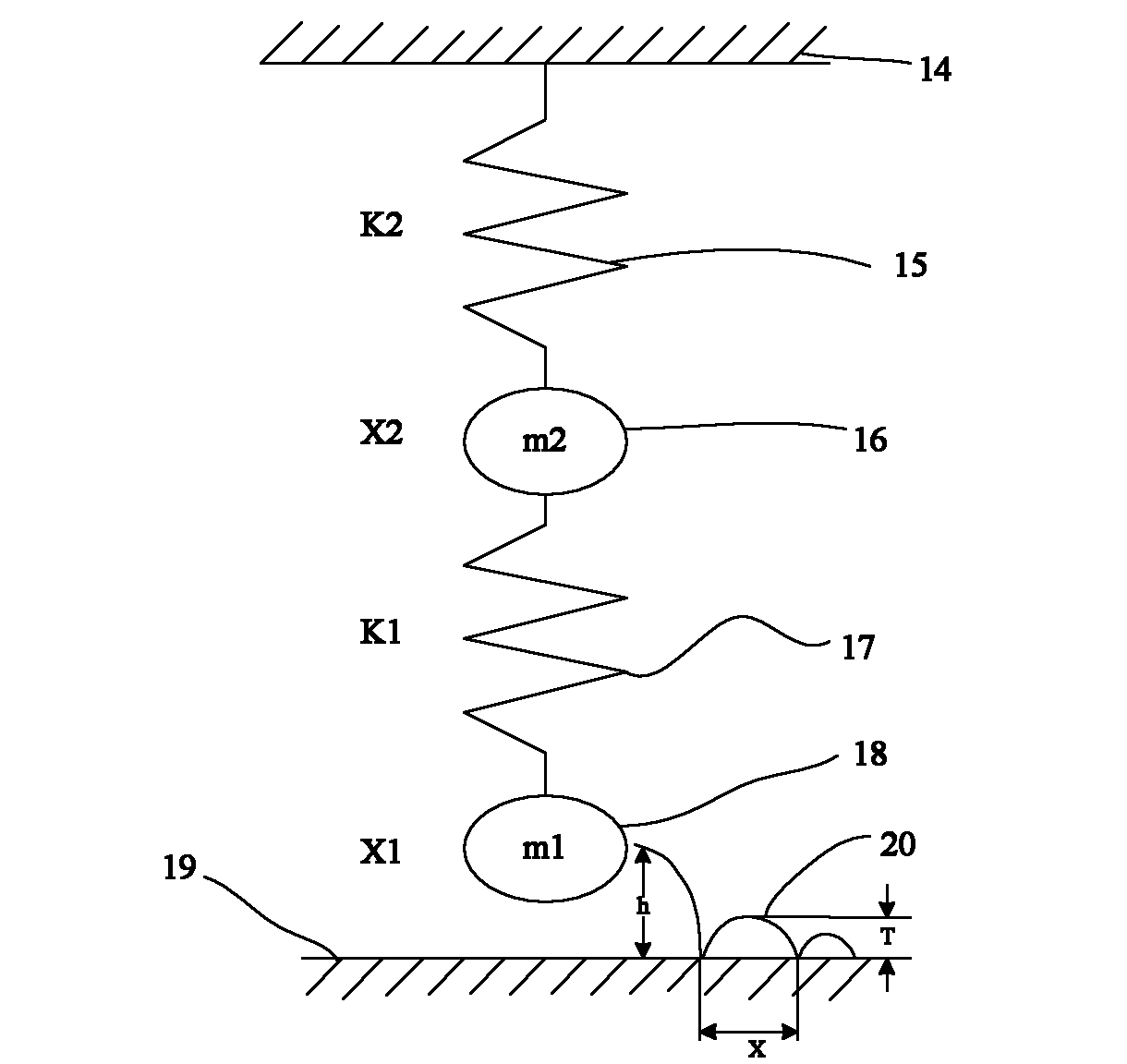

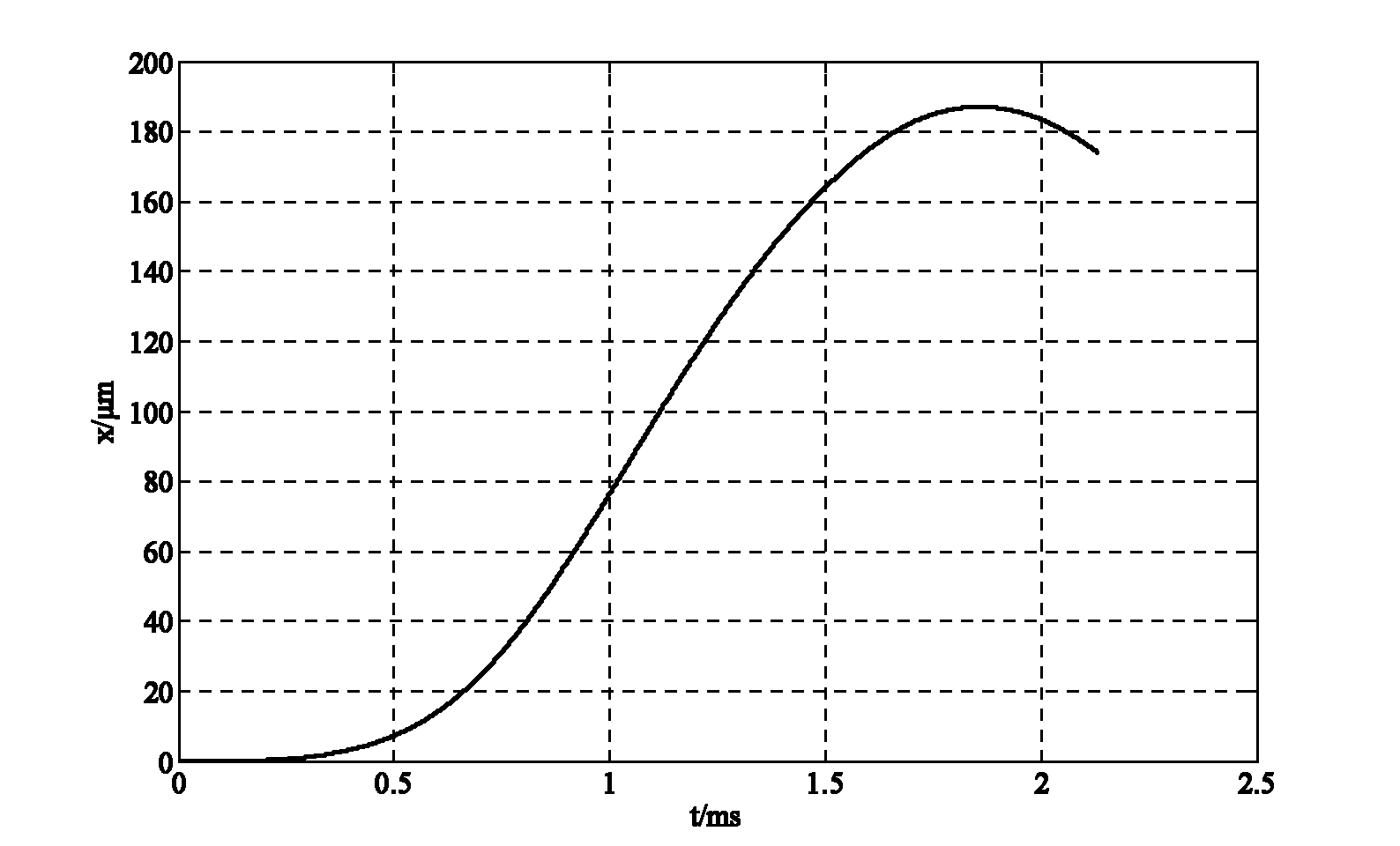

High revolving speed fuel oil magnetic valve and method for measuring closing and starting points thereof

InactiveCN102182597AReduce the amplitude of bounce vibrationReduce fuel injectionEngine testingFuel injection apparatusMagnetic valveEngineering

The invention discloses a high revolving speed fuel oil magnetic valve and a method for measuring closing and starting points thereof. The high revolving speed fuel oil magnetic valve comprises a valve body, wherein two ends of the valve body are respectively provided with a valve end cover and a valve seat; the inner cavity of the valve body is provided with a valve core which is arranged close to the valve end cover; a valve close piece is matched in the inner cavity of the valve seat; the inner cavity of the valve body is provided with a magnetic coil; the valve core is supported on a bulge arranged in the inner cavity of the valve body through a secondary oscillating unit; the secondary oscillating unit comprises a moving block, and an upper spring and a lower spring which are respectively connected with two ends of the moving block; and the lower spring is installed on the bulge in the inner cavity of the valve body, and the upper spring is connected with the valve core. According to the invention, the amplitude value of the original system rebound vibration is reduced effectively; and through the accurate estimation of the closing and starting points of the magnetic valve, the exchanging time of the loading voltage and the retaining voltage can be determined accurately, the response speed of the magnetic valve is improved, and simultaneously the settling speed of the magnetic valve is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-efficiency internal-combustion engine

InactiveCN102192049AReduce the temperatureIncrease profitNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberReciprocating motion

The invention discloses a high-efficiency internal-combustion engine. The engine comprises a cylinder body, an air inlet device, a fuel injection device and a piston, wherein the air inlet device and the fuel injection device, which are communicated with a cavity of the cylinder body, are arranged on the cylinder body; and the piston does reciprocating motion in the cylinder body. The high-efficiency internal-combustion engine is characterized by also at least comprising a water injection device and a control device; the water injection device can atomize water and import the atomized water into the cavity of the cylinder body; and the control device controls the open and close of the water injection device, adjusts the water injection quantity, and controls the water injection device to spray the atomized water when the piston does inhaling movement. By adopting the measure of spraying the atomized water to a combustion chamber for cooling, the high-efficiency internal-combustion engine can effectively prevent the early deflagration, the compression ratio of the engine is increased and the atomized water is increased, so the power output of the engine is improved.

Owner:麦镇荣 +2

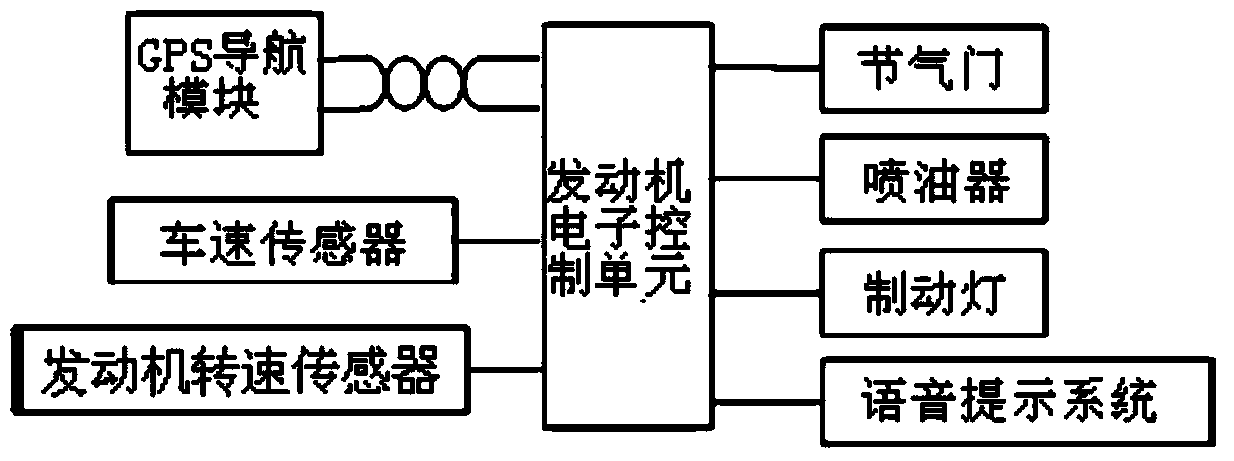

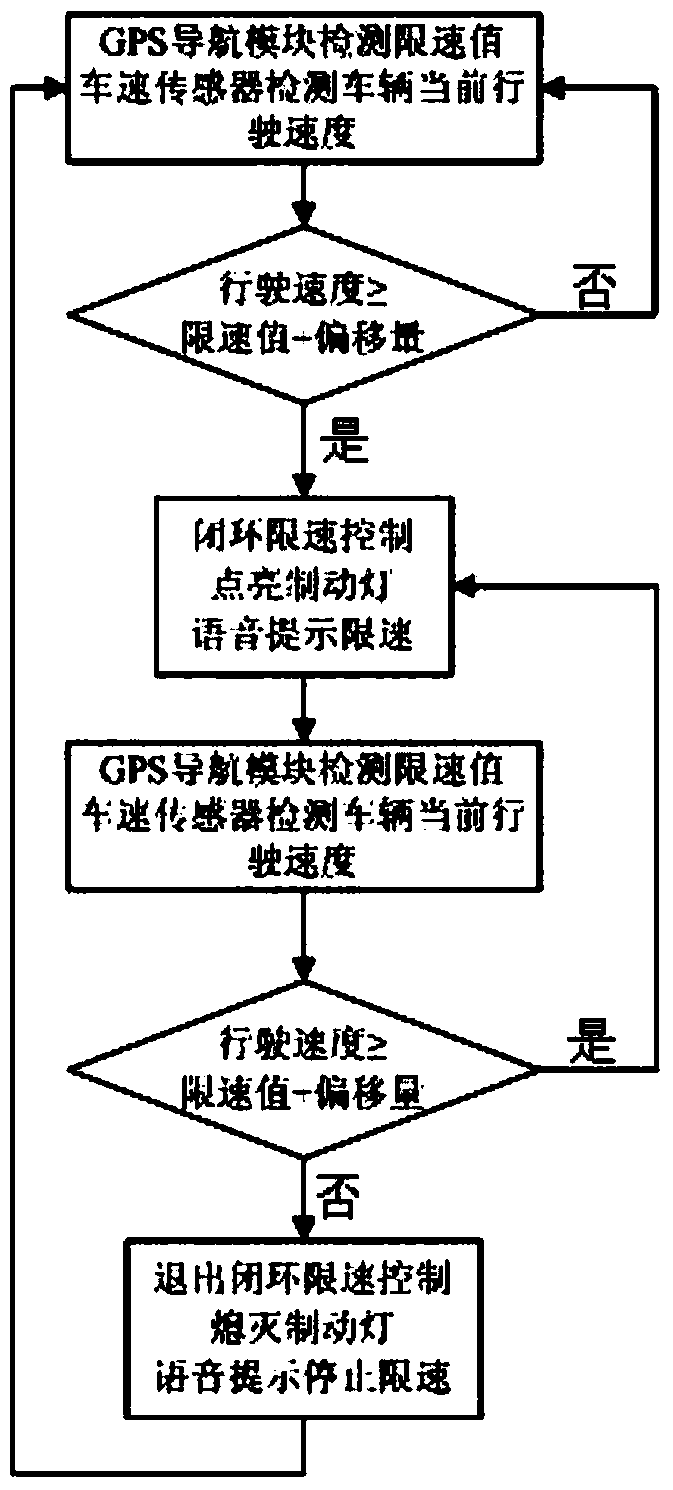

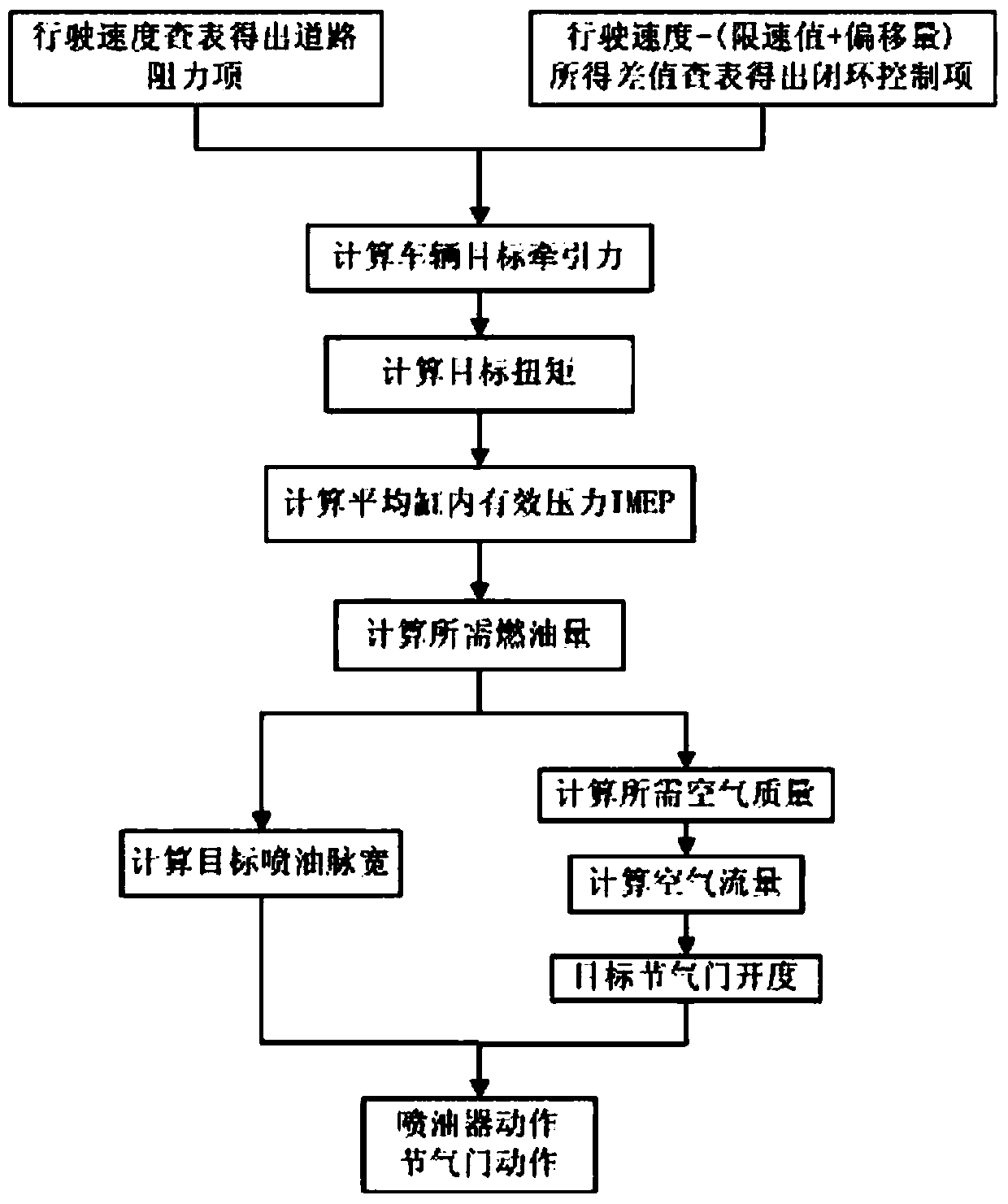

Vehicle intelligent speed limit system and method

InactiveCN103742279AImprove securityReduce work stressElectrical controlMachines/enginesDriver/operatorClosed loop

The invention discloses a vehicle intelligent speed limit system and method. A GPS (Global Positioning System) navigation module detects a highest speed limit value of a road in which a vehicle is located currently; a vehicle speed sensor detects the vehicle driving speed; an engine electronic control unit limits the vehicle speed within a regulated speed range through a closed loop speed limit control and regulate throttle valve and an oil atomizer according to the differences between the current vehicle speed and the highest speed limit value; meanwhile the engine electronic control unit lights a brake lamp when performs speed limit motions to warn other vehicles and guarantee safety; a warning is sent to a driver of the vehicle through a voice prompt system to enable the driver to know speed limit conditions. The vehicle intelligent speed limit system and method has the advantages of monitoring the road section in which the vehicle is arranged and the current vehicle speed in real time, improving the vehicle driving safety due to the fact that the electronic control unit initiatively limit the vehicle speed intelligently according to the requirements and meanwhile reducing the working pressure of traffic management departments to some extent.

Owner:DONGFENG MOTOR CORP HUBEI

Control apparatus for internal combustion engine

InactiveUS7318420B2Efficient detectionReduce manufacturing costElectrical controlCombustion enginesInternal combustion engineControl circuit

A drive control circuit supplies power to a solenoid coil in an in-cylinder injector of a cylinder in response to a fuel injection signal. A failure detection circuit to detect disconnection failure at an in-cylinder injector is arranged to be shared among cylinders whose phase of each stroke differs 360 degrees in crank angle. An engine ECU detects failure including identification of the injector with disconnection failure based on a failure detection signal from the failure detection circuit, and a crank angle detected by a crank angle sensor. The driver is notified of the failure detection result through the engine ECU.

Owner:TOYOTA JIDOSHA KK

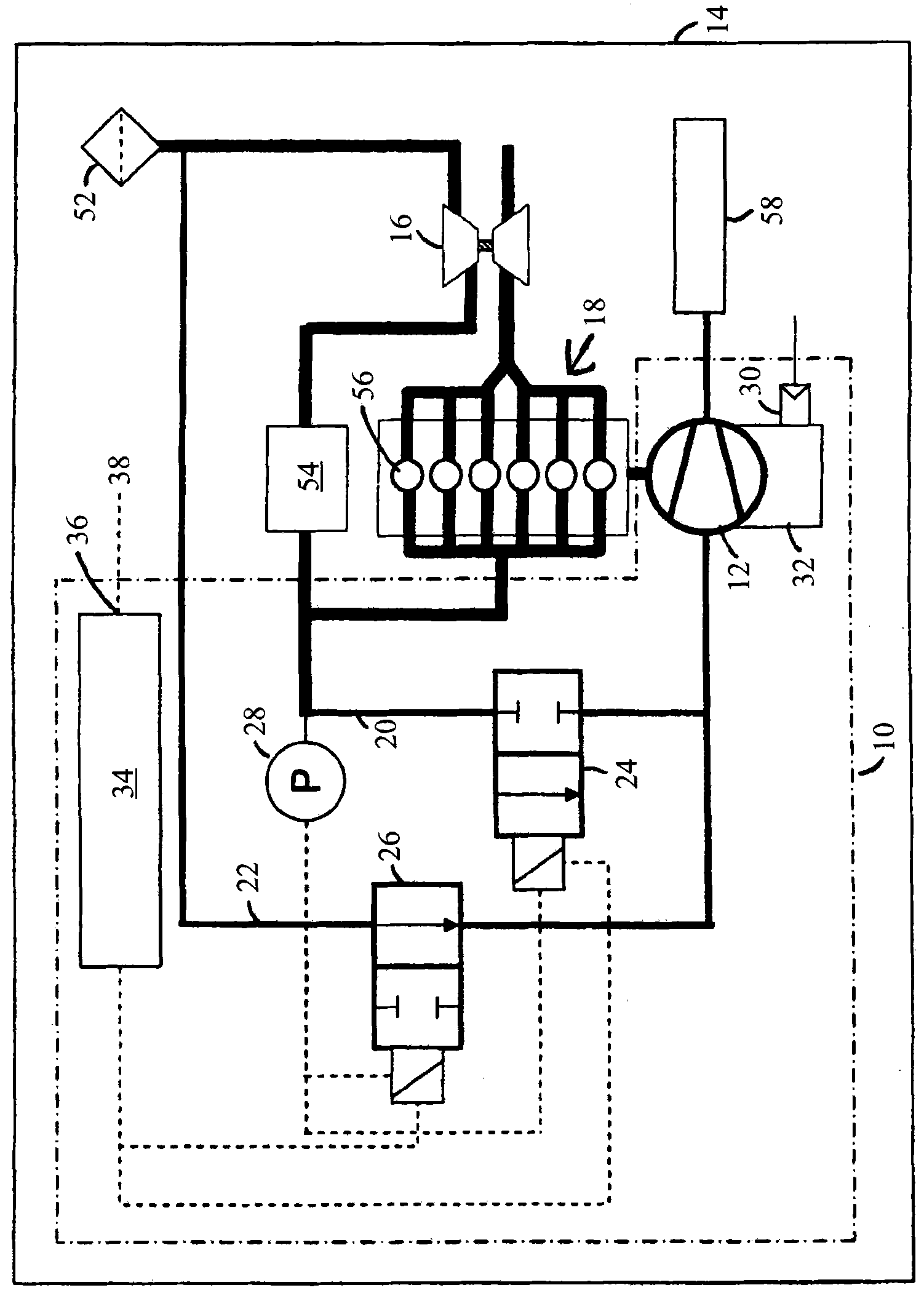

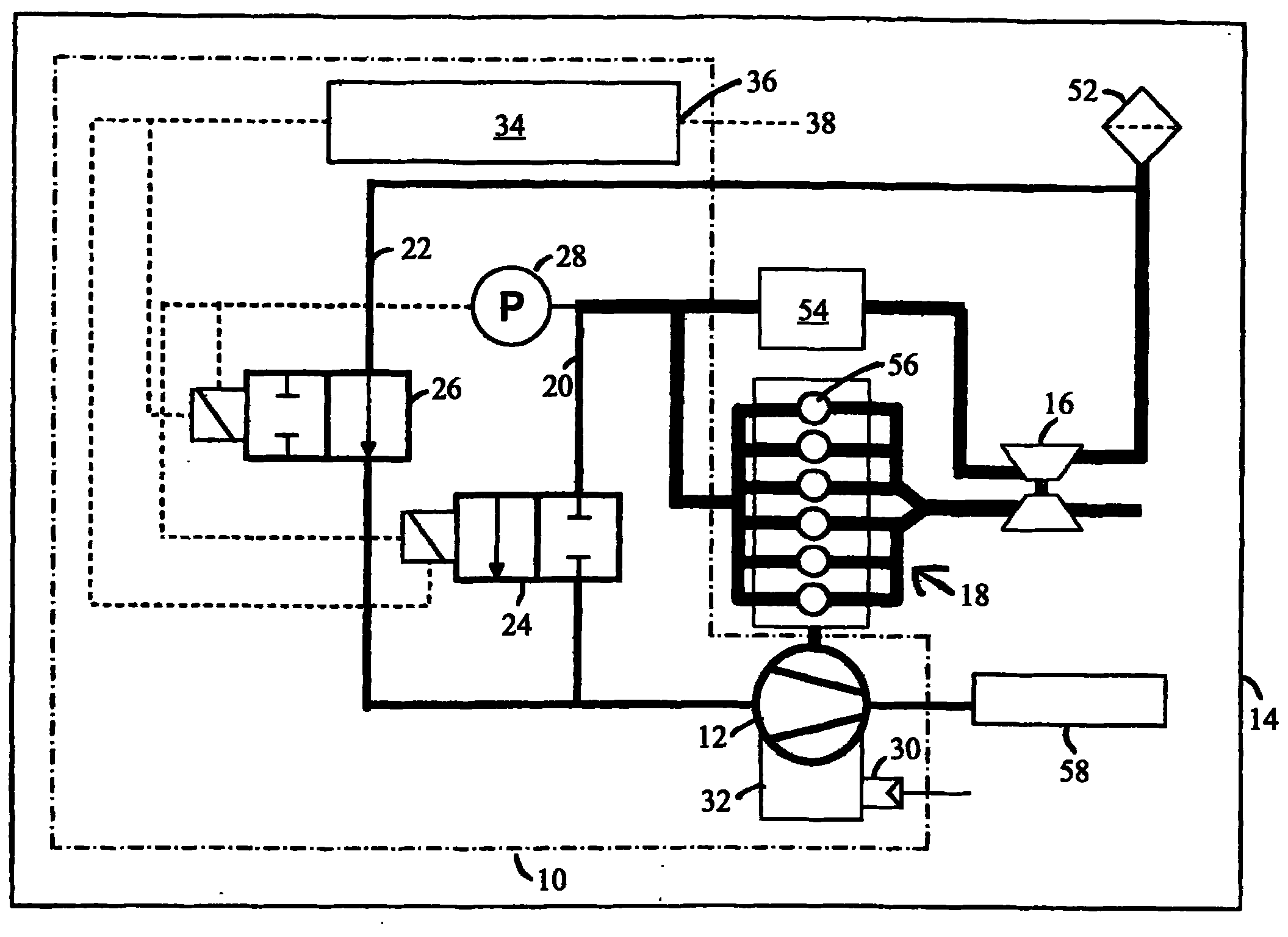

Compressor system, and method for the operation of a compressor system

InactiveCN101959729AIncrease air volumeNot overloadedPump controlApplication and release valvesTurbochargerAmbient air

The invention relates to a compressor system (10) comprising a compressor (12) for supplying compressed air to a utility vehicle (14) that has a driving engine (18) with a turbocharger (16). Air that is pre-compressed by the turbocharger (16) can be sucked in by the compressor (12) via a first air supply pipe (20). According to the invention, ambient air that is not pre-compressed can be sucked in by the compressor (12) via a second air supply pipe (12). The invention further relates to a method for controlling a compressor system (10) comprising a compressor (12) for supplying compressed air to a utility vehicle (14) that has a driving engine (18) with a turbocharger (16).

Owner:KNORR BREMSE SYST FUER NUTZFAHRZEUGE GMBH

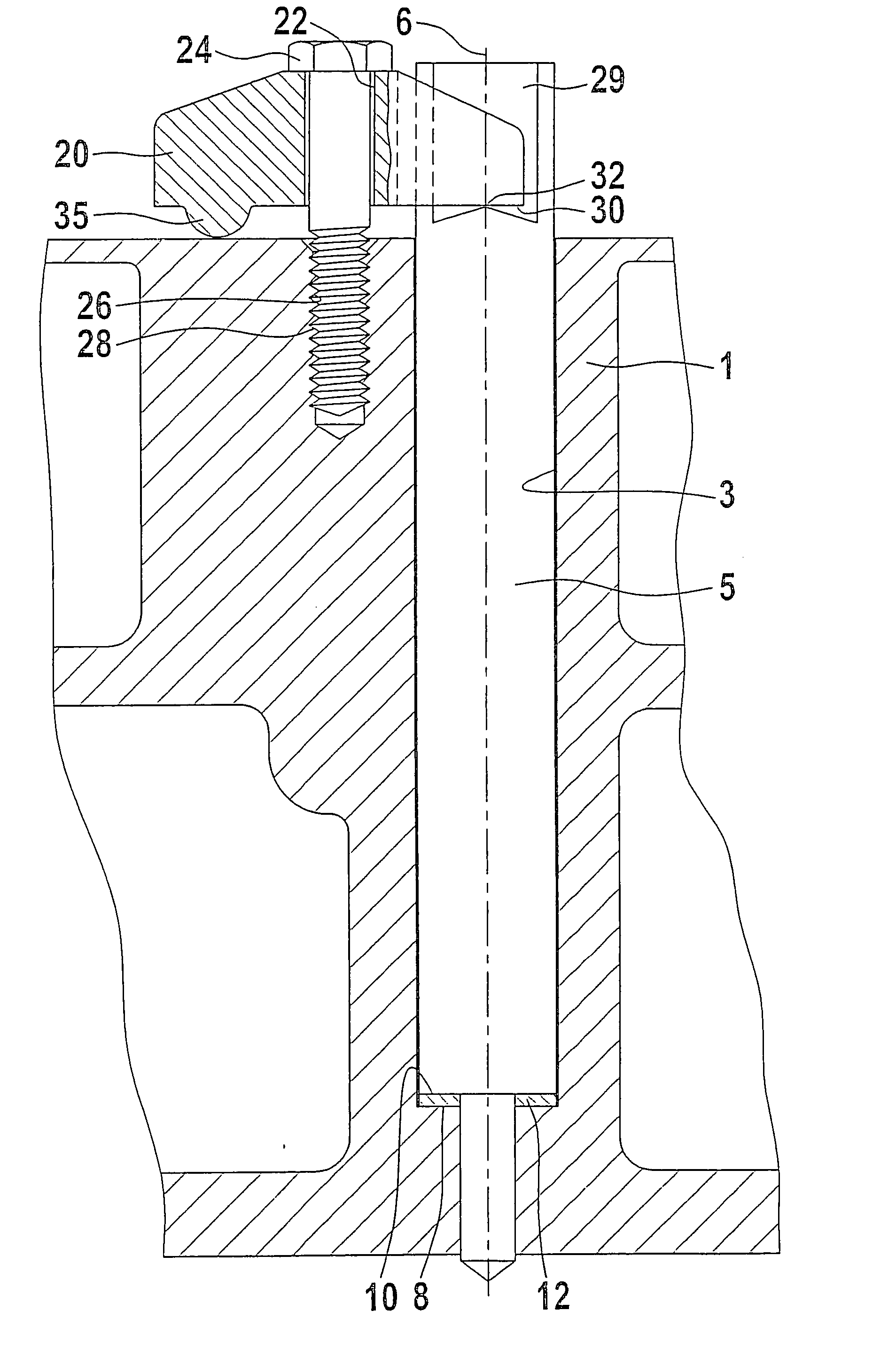

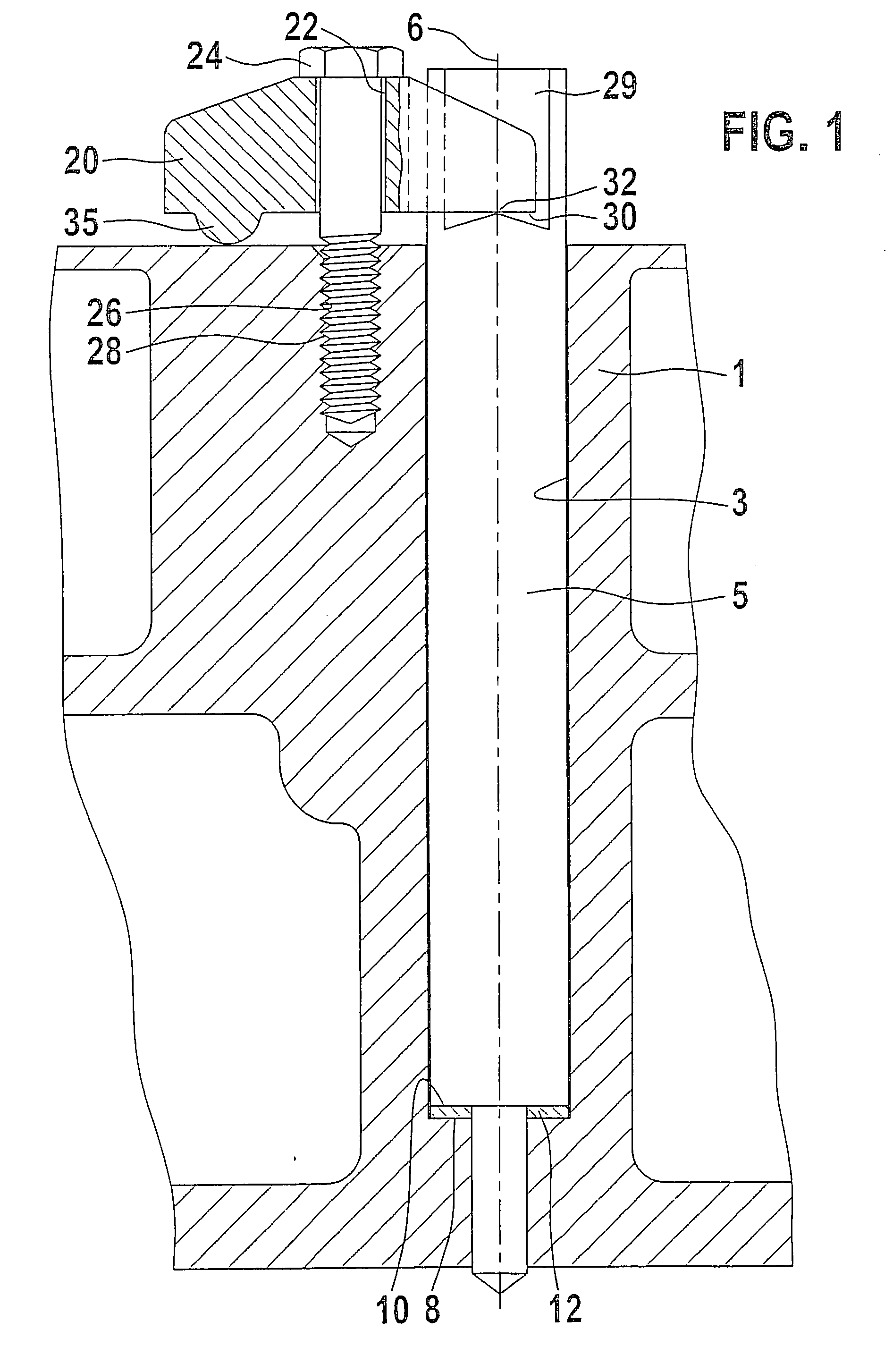

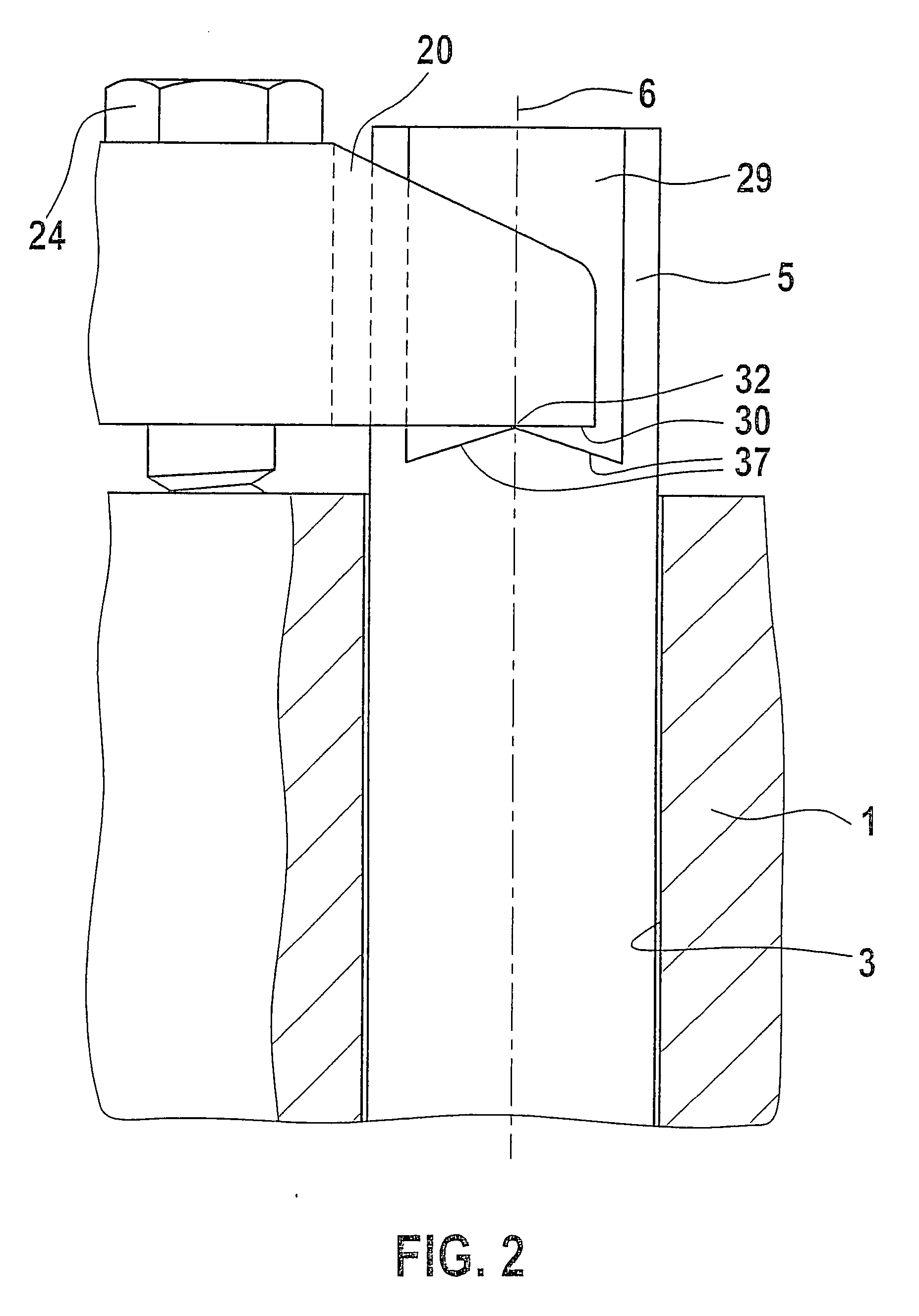

Fixing device for a fuel injection valve

InactiveUS20040040542A1Easy to makeReduce fuel injectionFuel injection apparatusMachines/enginesCylinder headEngineering

A fastening device for a fuel injection valve (5) in a bore (3) in the cylinder head of an internal combustion engine, in which the fuel injection valve (5) has a longitudinal axis (6). A clamping jaw (20) is acted upon by a fastening force, and the clamping jaw (20) rests with at least one support face (30) on a support point (32) of the fuel injection valve (5), so that the clamping jaw (20) is pressed with its support face (30) against the support point (32). The support point (32) on the fuel injection valve (5) is embodied linearly, and the line is straight and in its imaginary extension intersects the longitudinal axis (6) of the fuel injection valve (5)

Owner:VODAFONE GRP PLC +1

Power consumption control method for vehicle air conditioning

InactiveCN101311513APrecise control of air-fuel ratioReduce fuel injectionAir-treating devicesVehicle heating/cooling devicesAutomobile air conditioningEngine management

The invention relates to a power consumption control method of a vehicle air conditioning; wherein, the dynamic load change for the running of a vehicle air conditioning system is transferred to an engine management system ECU by a pressure sensor; the engine management system ECU corrects the air inlet amount of the engine and reduces the oil spray amount according to the load change of the air conditioning system, thereby achieving the goal of precisely controlling the output power of the engine and an air-fuel ratio.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com