High-efficiency internal-combustion engine

An internal combustion engine, high-efficiency technology, applied in the direction of internal combustion piston engines, combustion engines, engine components, etc., to increase output power, improve air density, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

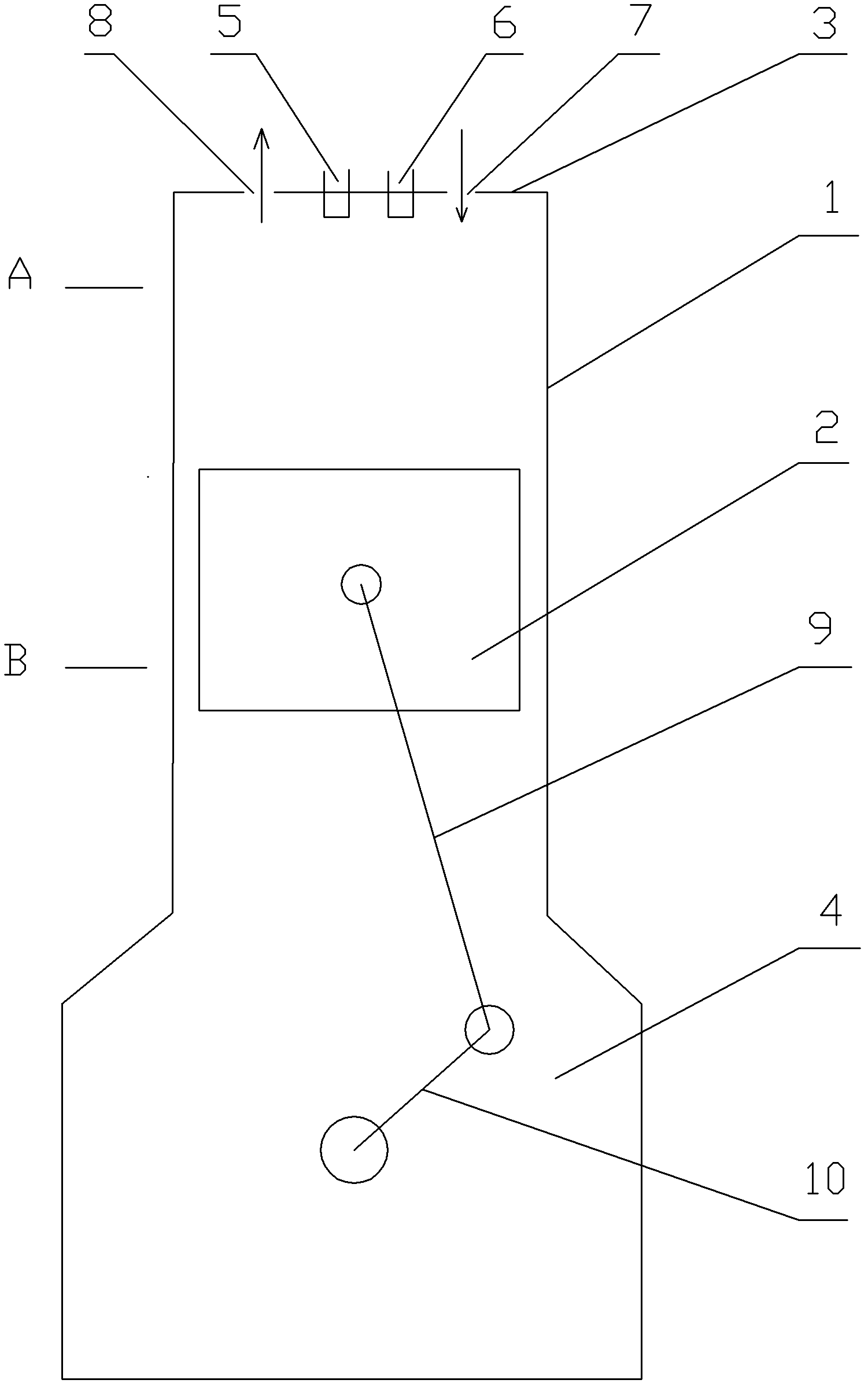

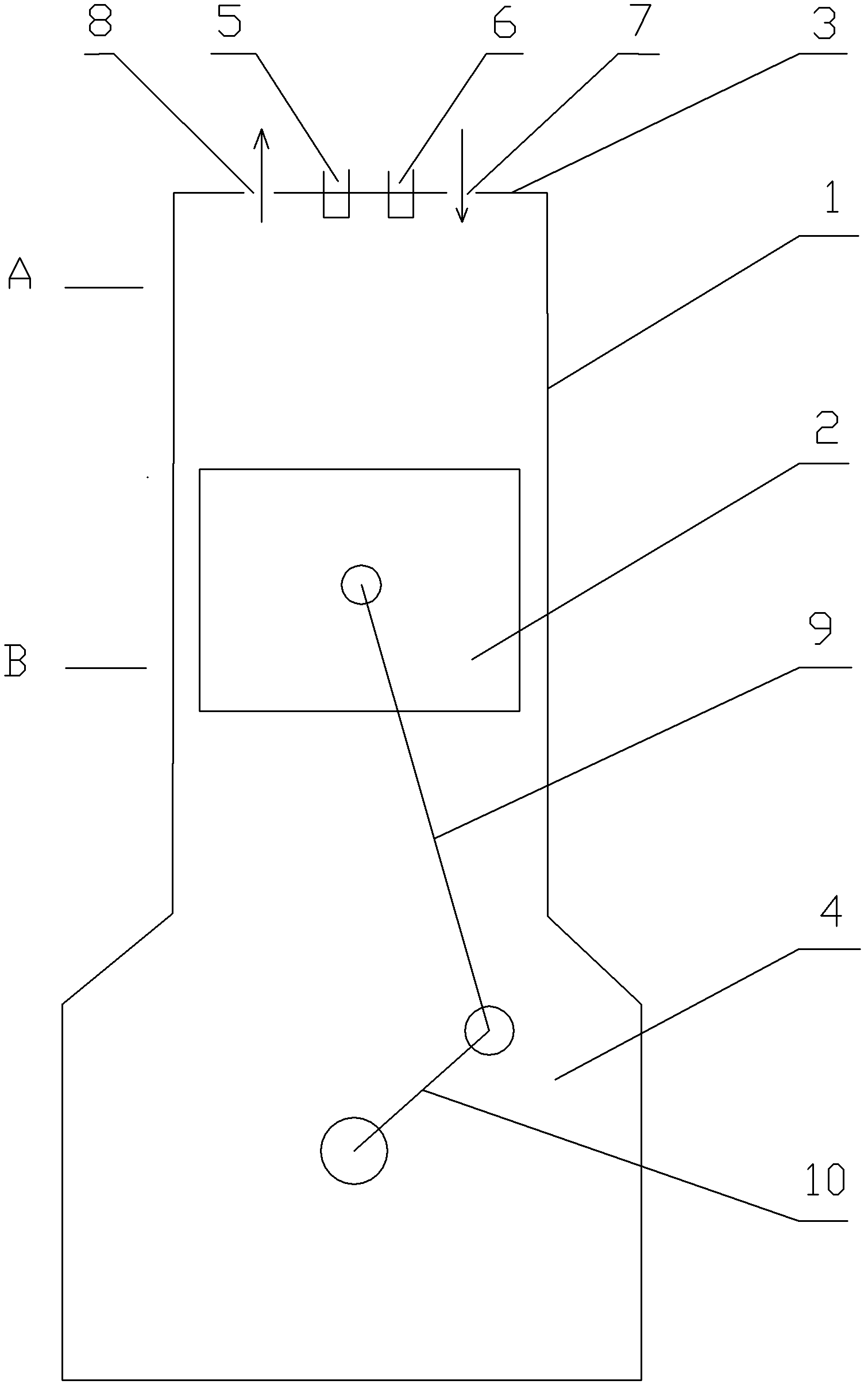

[0024] figure 1 Shown is one embodiment of the invention, a gasoline engine having four cylinders, each cylinder having a volume of 0.25 liters, for a total engine volume of 1 liter.

[0025] exist figure 1 In the shown embodiment, the upper opening of the cylinder body 1 is sealed by the cylinder head 3, and the fuel injection nozzle 5 of the fuel injection device is arranged in the center of the cylinder head 3, and the high-pressure water spray device is also arranged on the cylinder head 3 next to the fuel injection nozzle 5. The water nozzle 6, the opening and closing of the water spraying device and the adjustment of the water spray volume are controlled by the control device, which also controls the opening and closing of the fuel injection device and the adjustment of the fuel injection volume. The air port 8 is opened on the cylinder head 3; the lower port of the cylinder body 1 is connected to the crankcase 4, and the crankcase 4 is provided with a crank connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com