Patents

Literature

1691results about How to "Easy temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

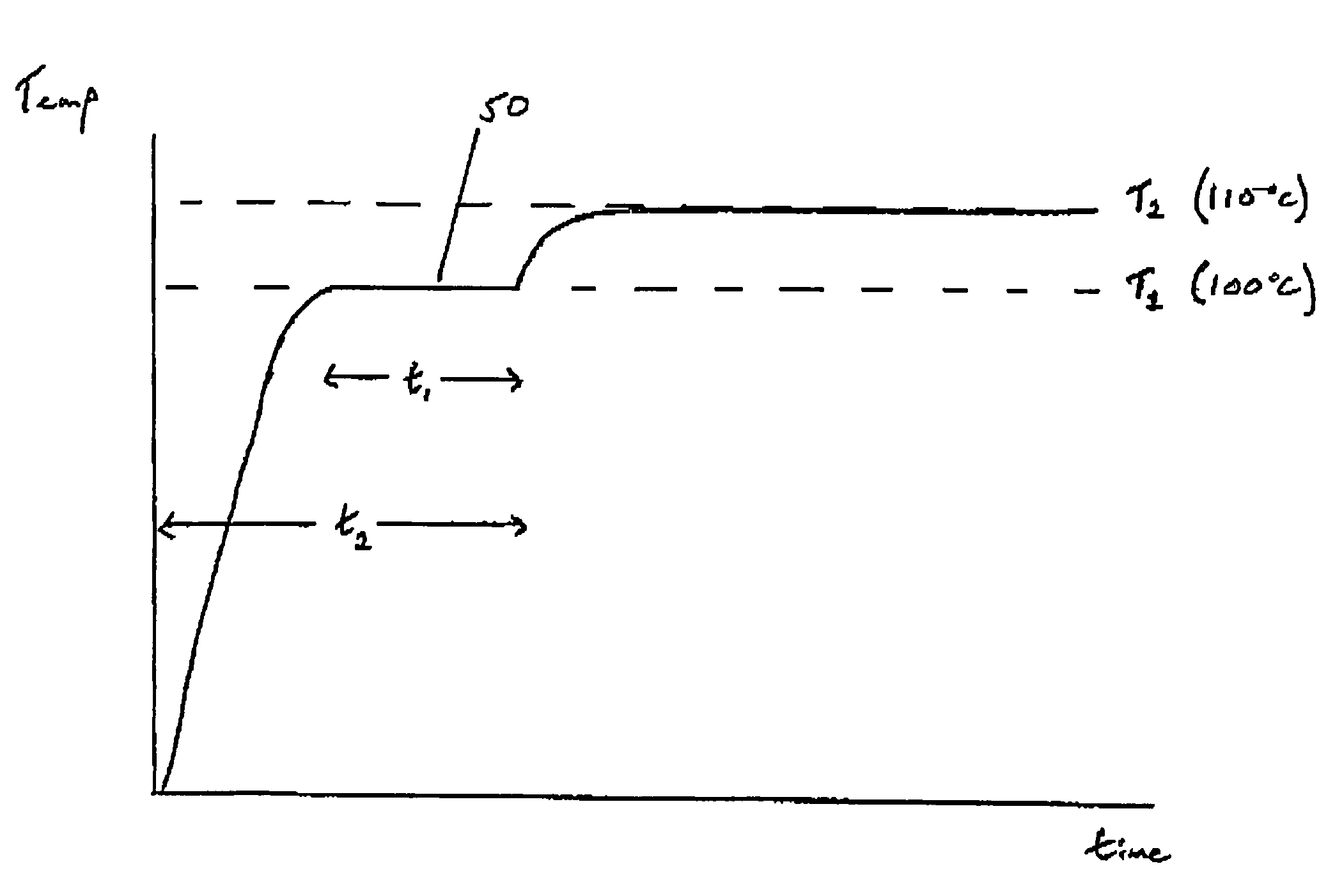

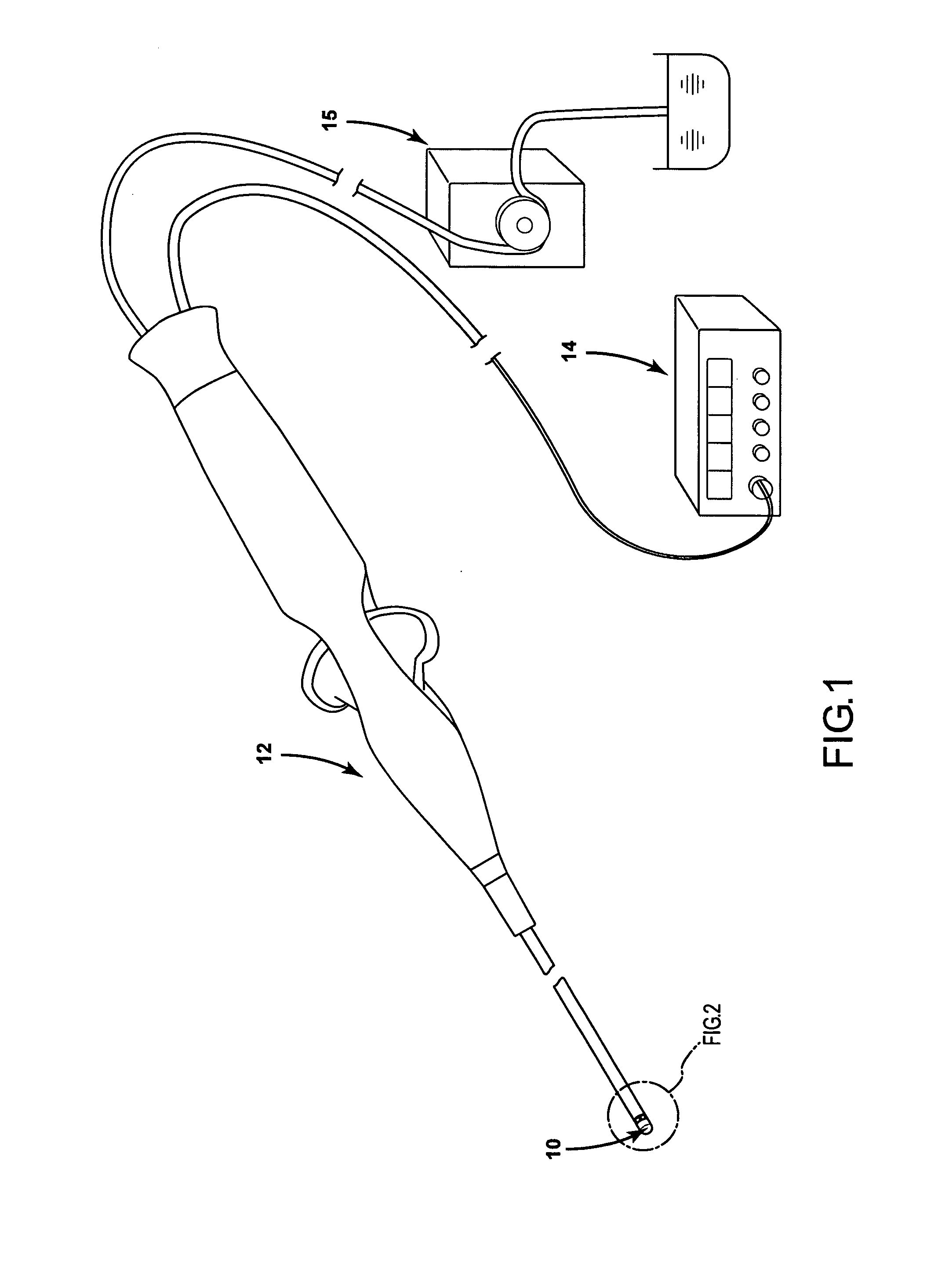

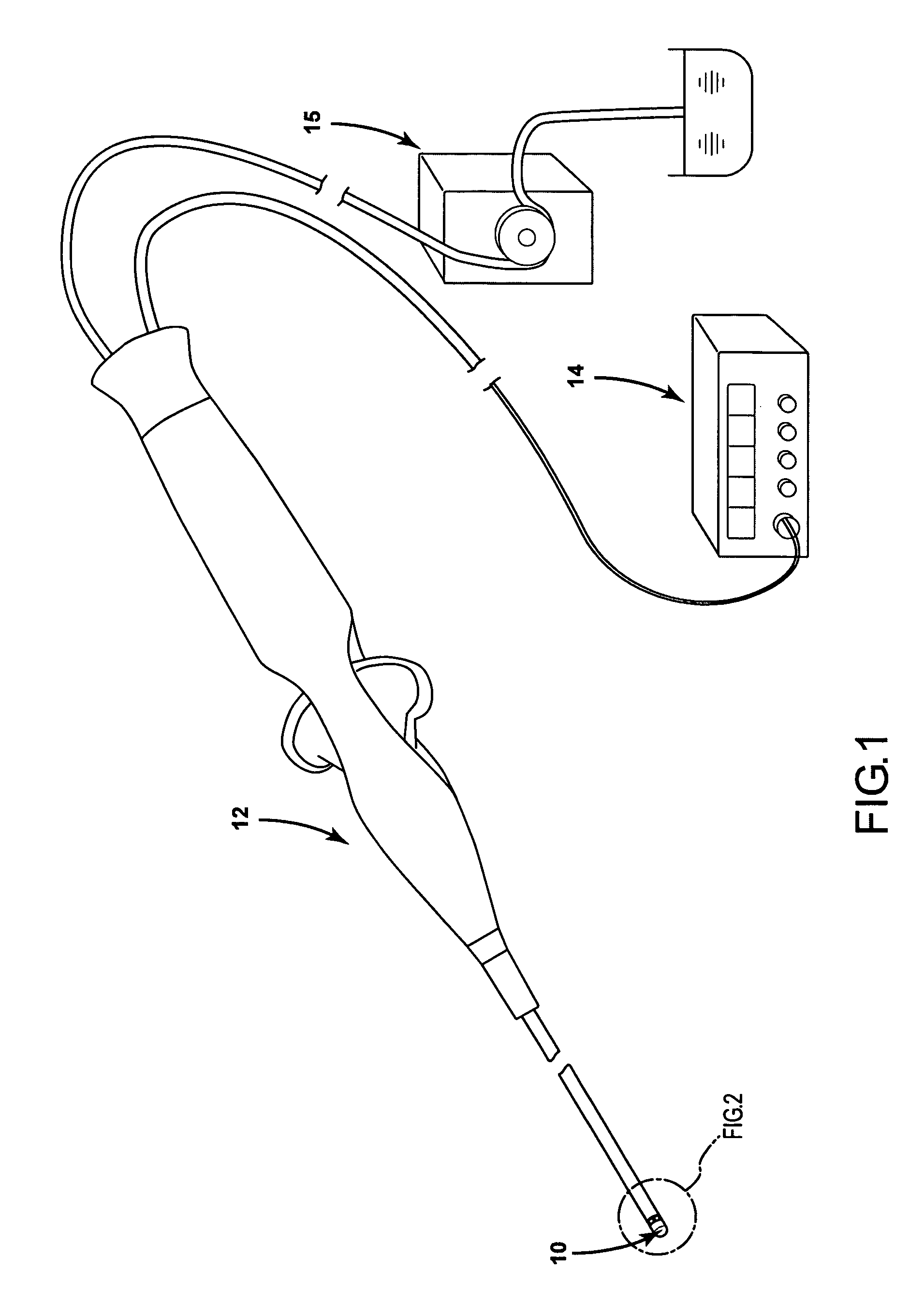

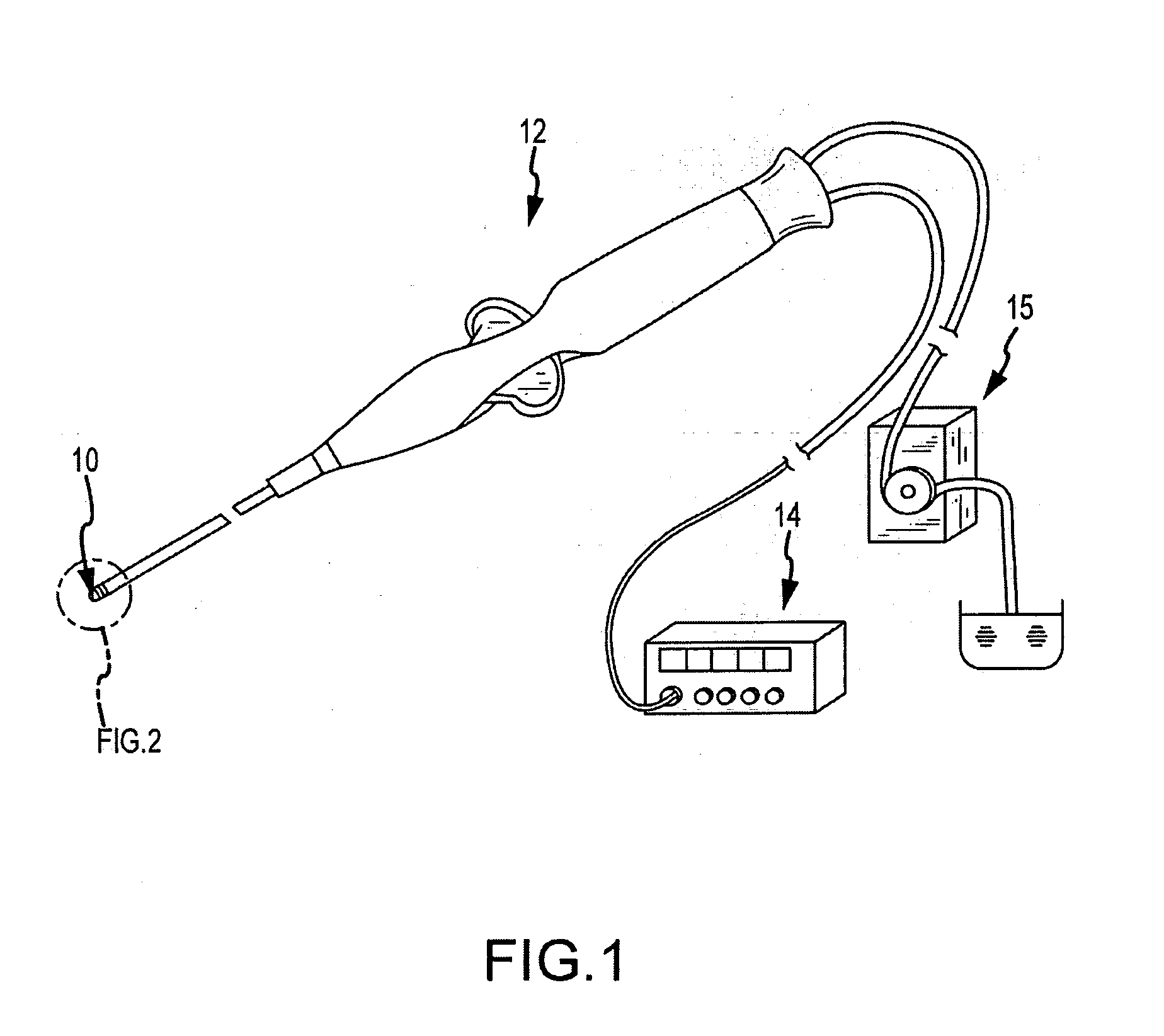

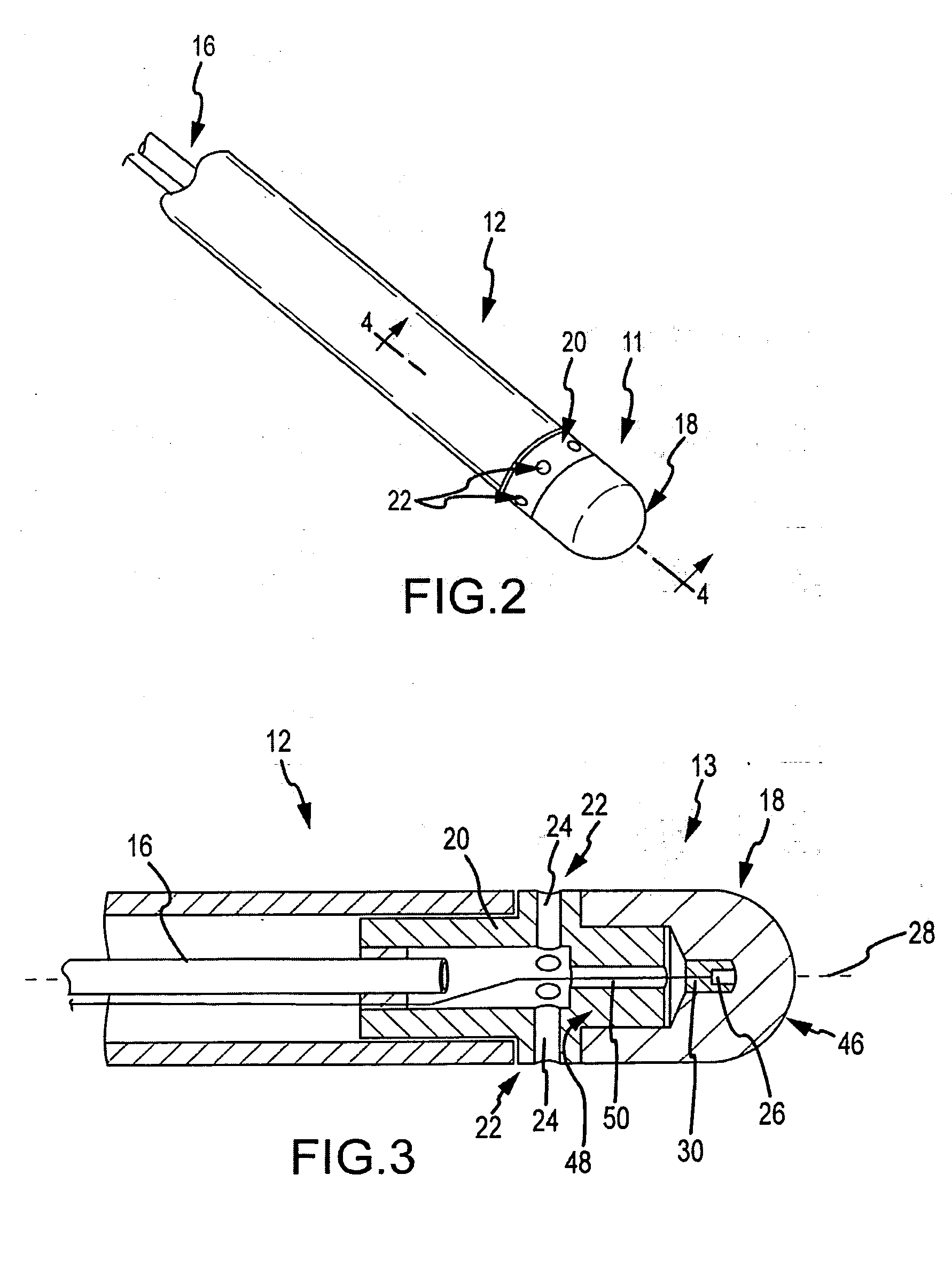

Electrosurgical method and apparatus

ActiveUS7131445B2Effect treatment timeIncrease pointsDiagnosticsSurgical needlesSteady state temperatureEnergy supply

An electrosurgical method and apparatus comprises a probe, at least one temperature sensor, and a controller for generating and controlling electromagnetic energy supplied to the probe. The controller receives signals from the temperature sensor and controls the supply of electromagnetic energy such that the temperature of the probe is ramped up and then maintained at a steady state temperature of between 100° C. and 115° C. In an equilibration phase, between the ramping up and the steady state temperature, the controller holds the temperature of the probe substantially constant for a period of time to allow the temperature of different parts of the probe to equilibrate.

Owner:GYRUS ENT

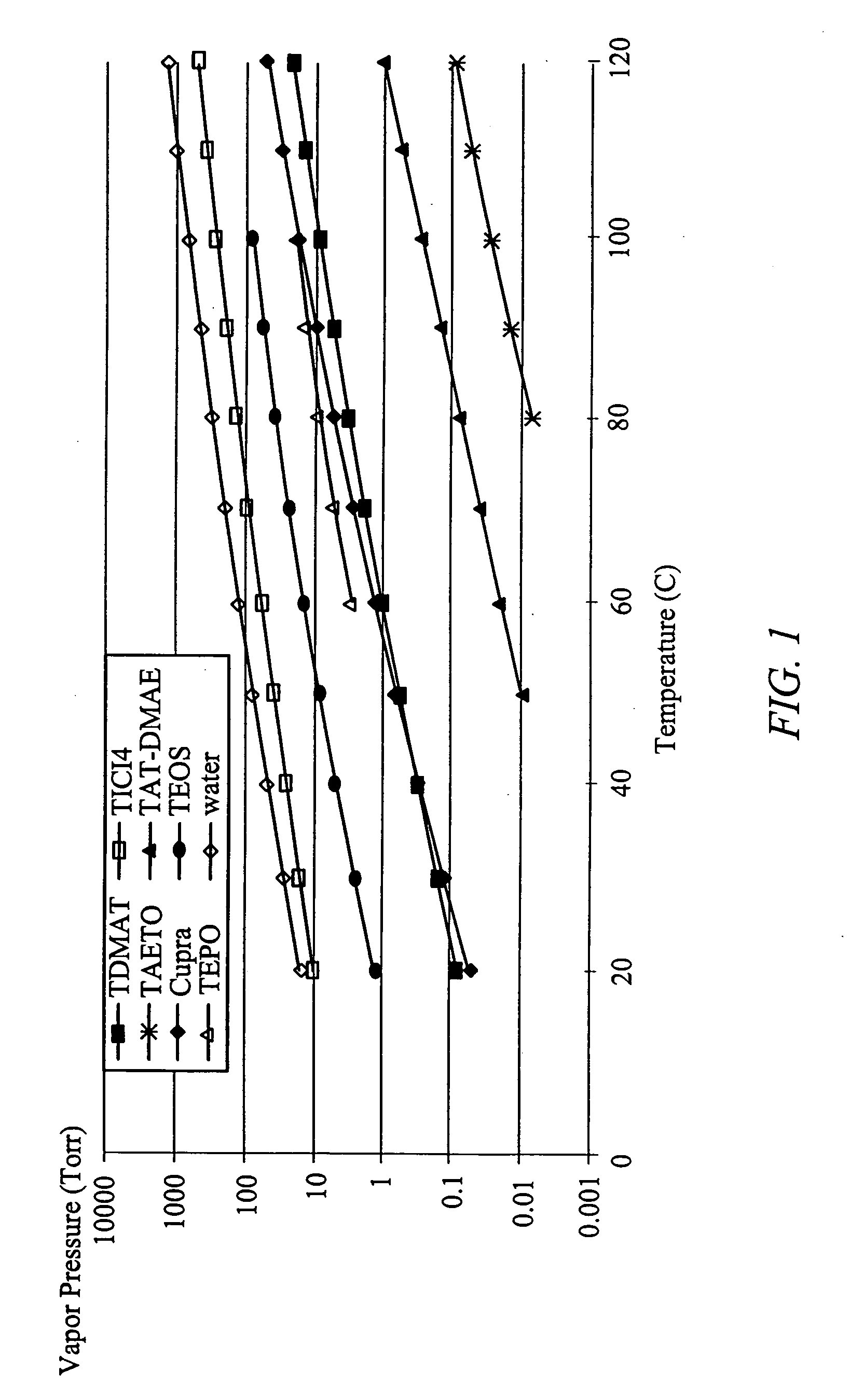

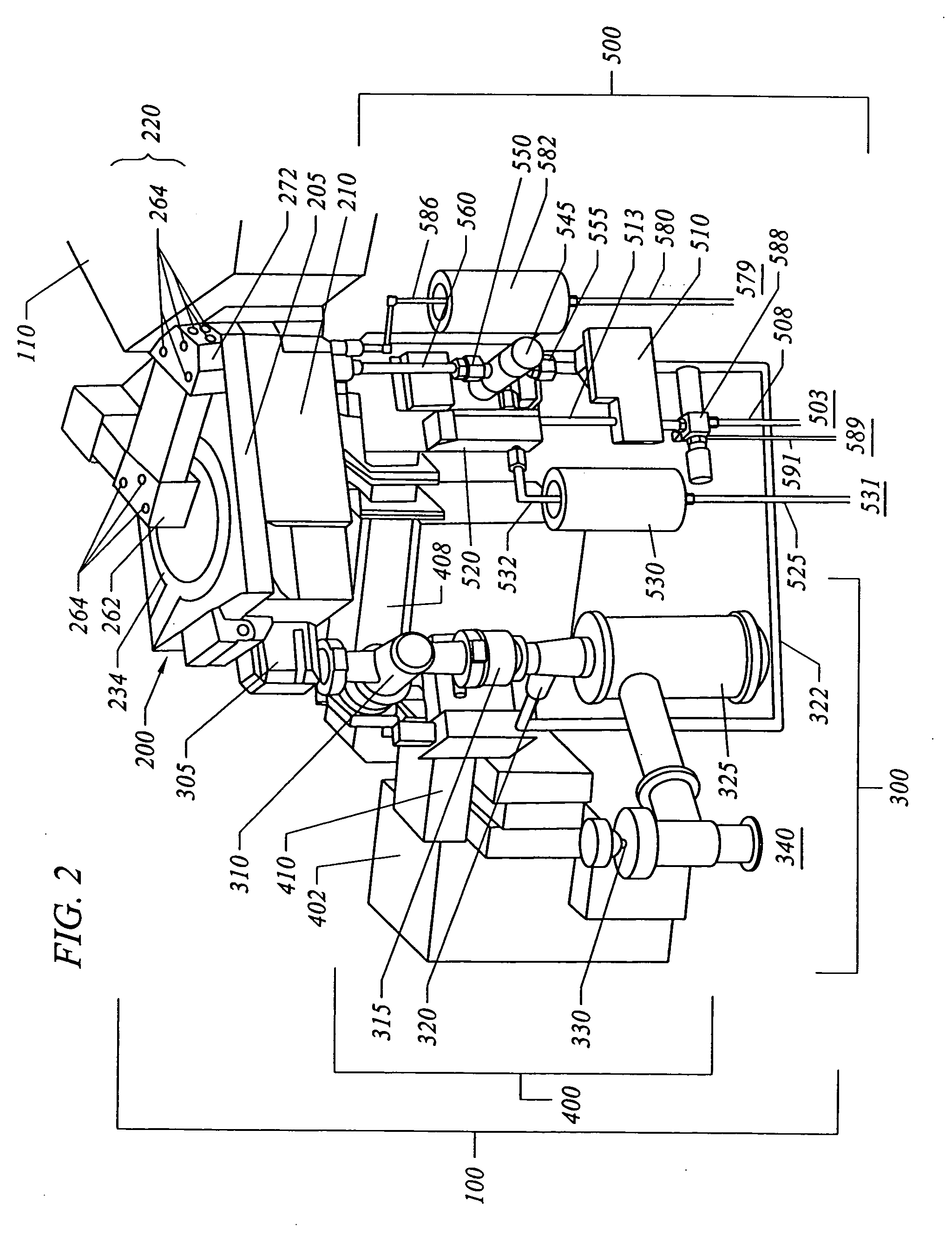

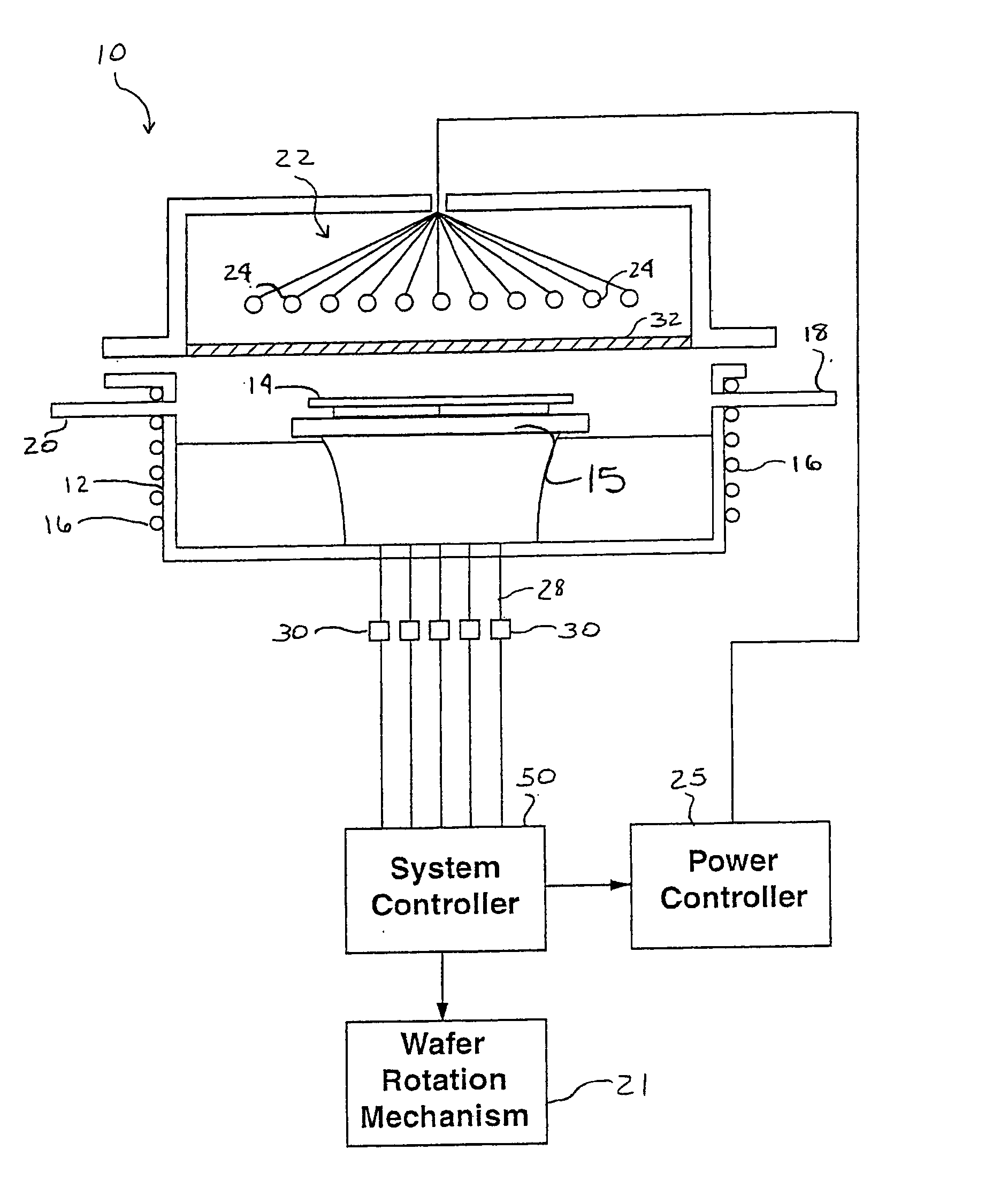

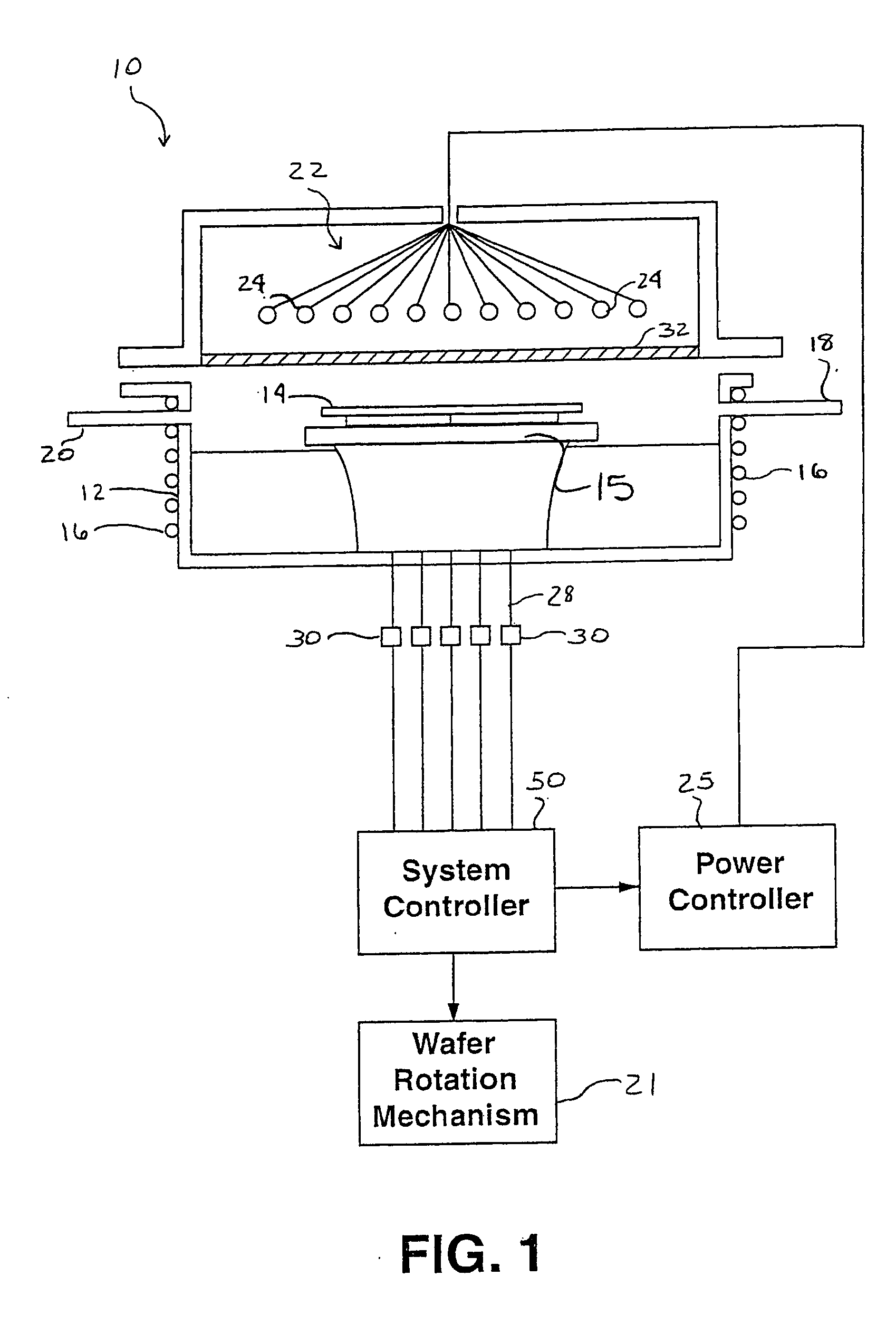

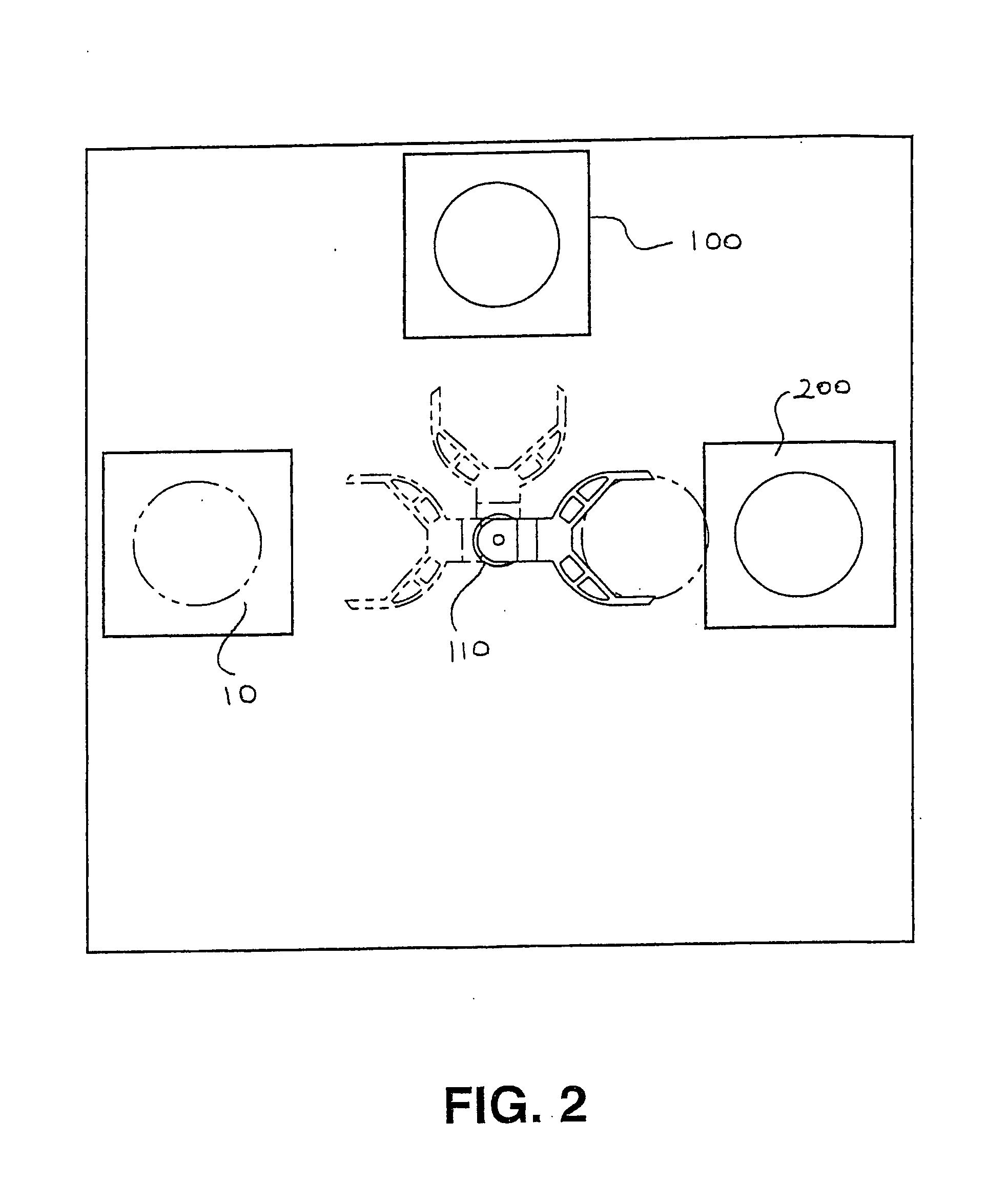

Apparatus for the deposition of high dielectric constant films

InactiveUS20060196421A1Precise temperature controlEasy temperature controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricElectricity

An integrated deposition system is described that is capable of vaporizing low vapor pressure liquid precursors and conveying the vapor to a processing region to fabricate advanced integrated circuits. The integrated deposition system includes a heated exhaust system, a remote plasma generator, a processing chamber, a liquid delivery system, and a computer control module that together create a commercially viable and production worthy system for depositing high capacity dielectric materials from low vapor pressure precursors.

Owner:APPLIED MATERIALS INC

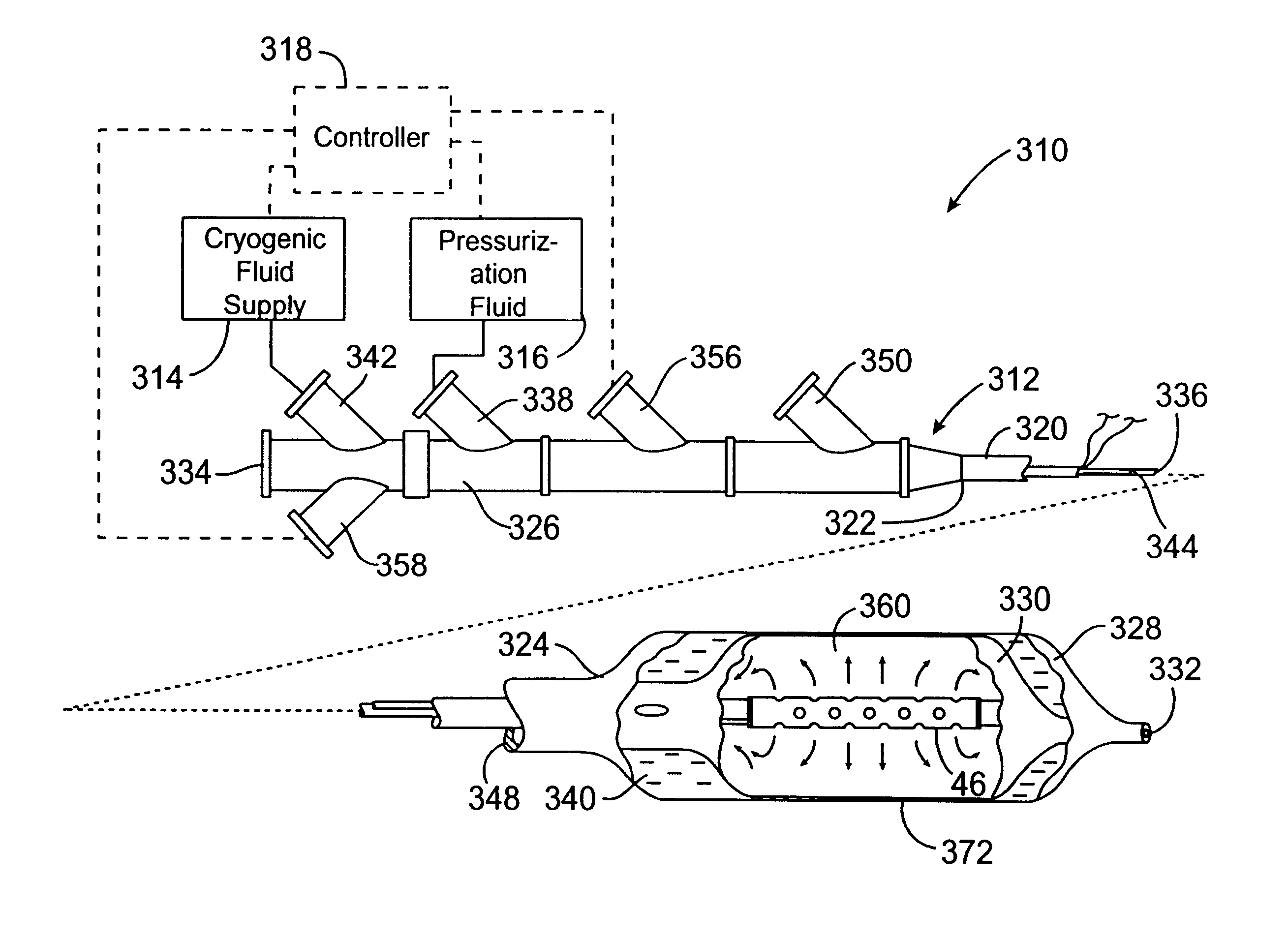

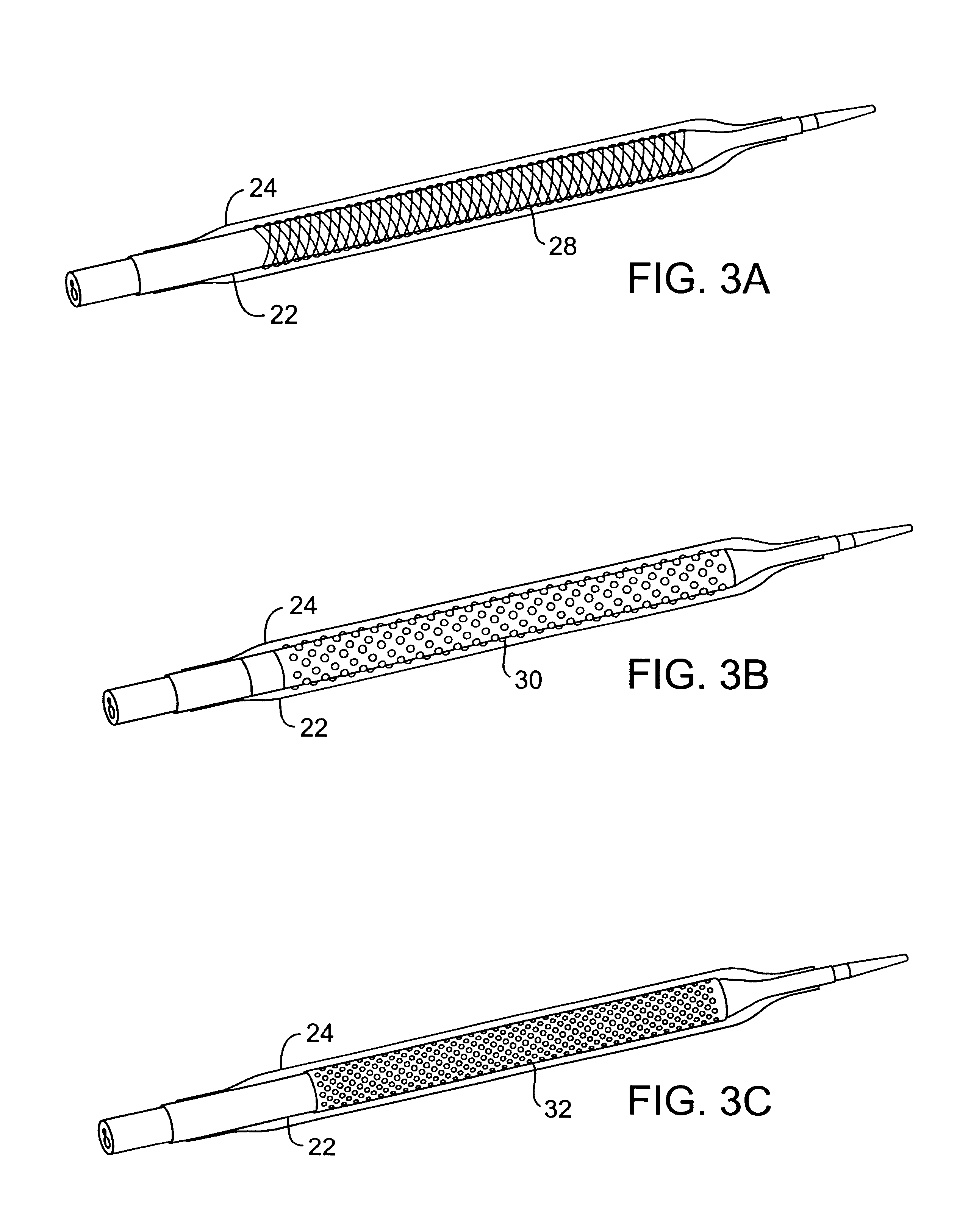

Safety cryotherapy catheter

InactiveUS6514245B1Keep openReduce and/or eliminate any associated hyperplasiaDomestic cooling apparatusLighting and heating apparatusNebulizerTarget tissue

Improved devices, systems, and methods for inhibiting hyperplasia in blood vessels provide controlled and safe cryotherapy treatment of a target portion within a body lumen of a patient. Efficacy of endoluminal cryogenic cooling can be enhanced by limiting cooling of target tissues using a thermal barrier disposed between a dual balloon cryotherapy catheter. Containment of both balloons can be monitored by applying a vacuum within a space between the first and second balloons, and by coupling the vacuum space to a fluid shutoff so as to inhibit flow of cryogenic fluid in response to a change in the vacuum space. Controlled cooling of the vessel can be improved by use of a nebulizer in fluid communication with a cryogenic liquid supply lumen and a gas supply lumen.

Owner:BOSTON SCI SCIMED INC

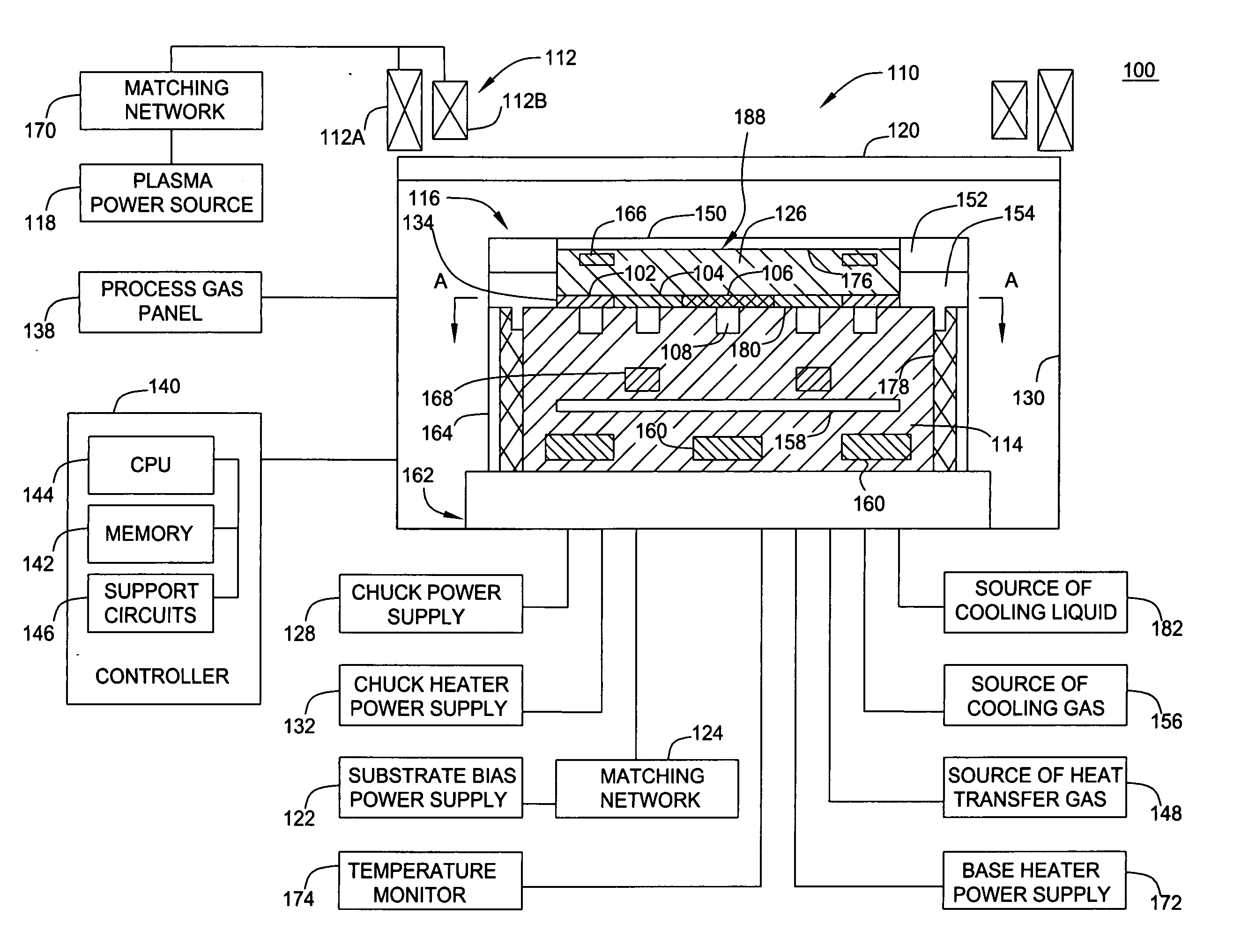

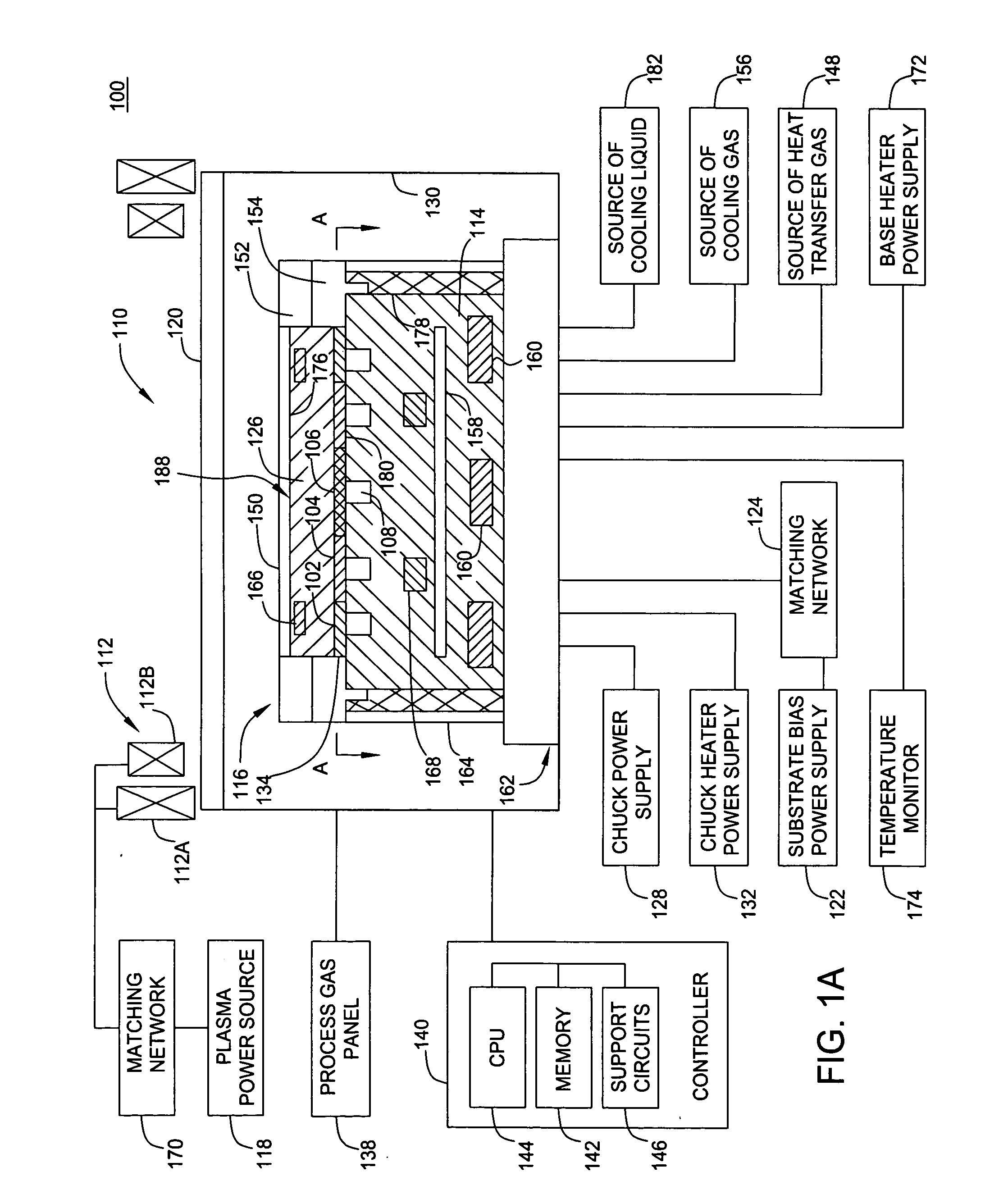

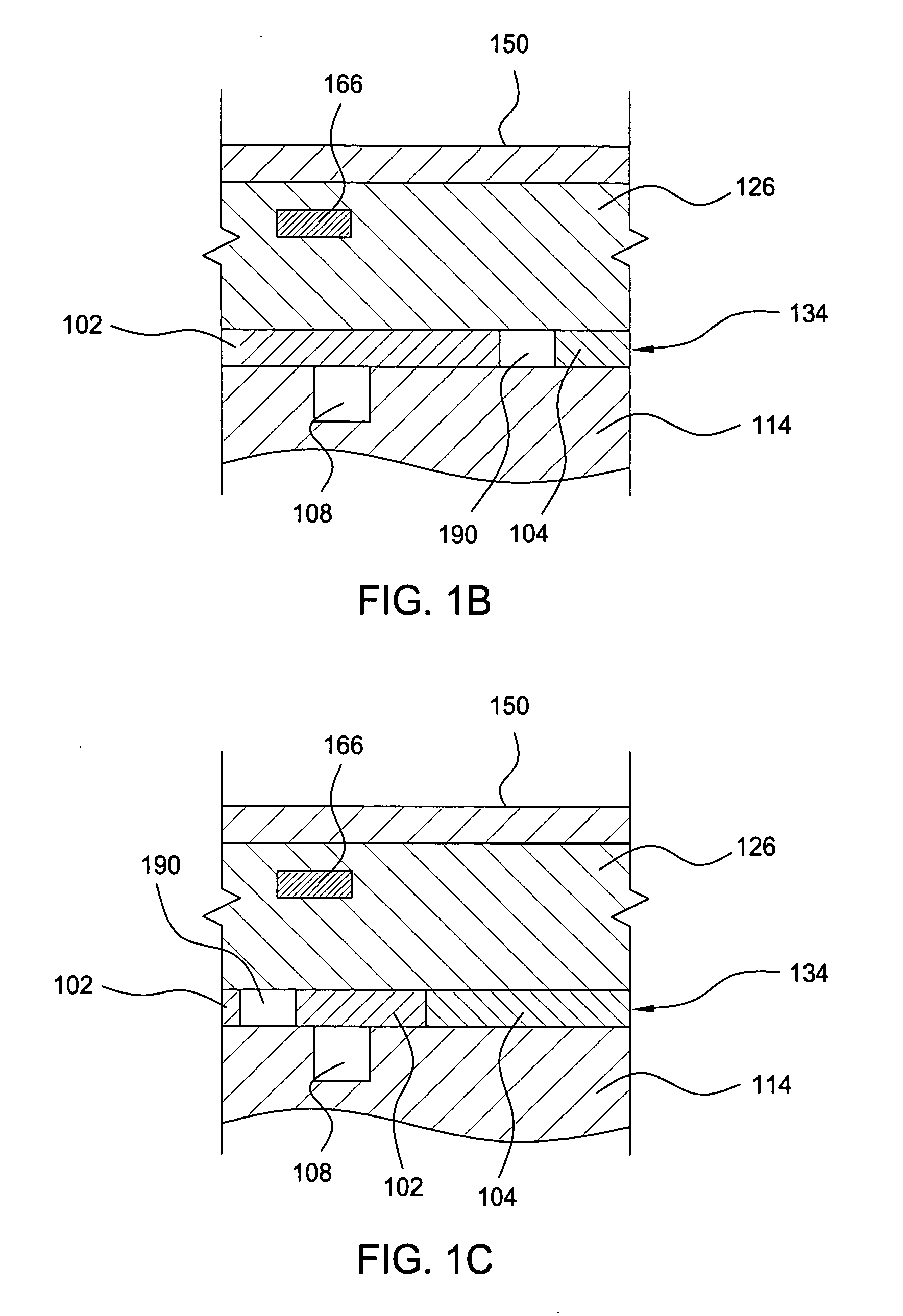

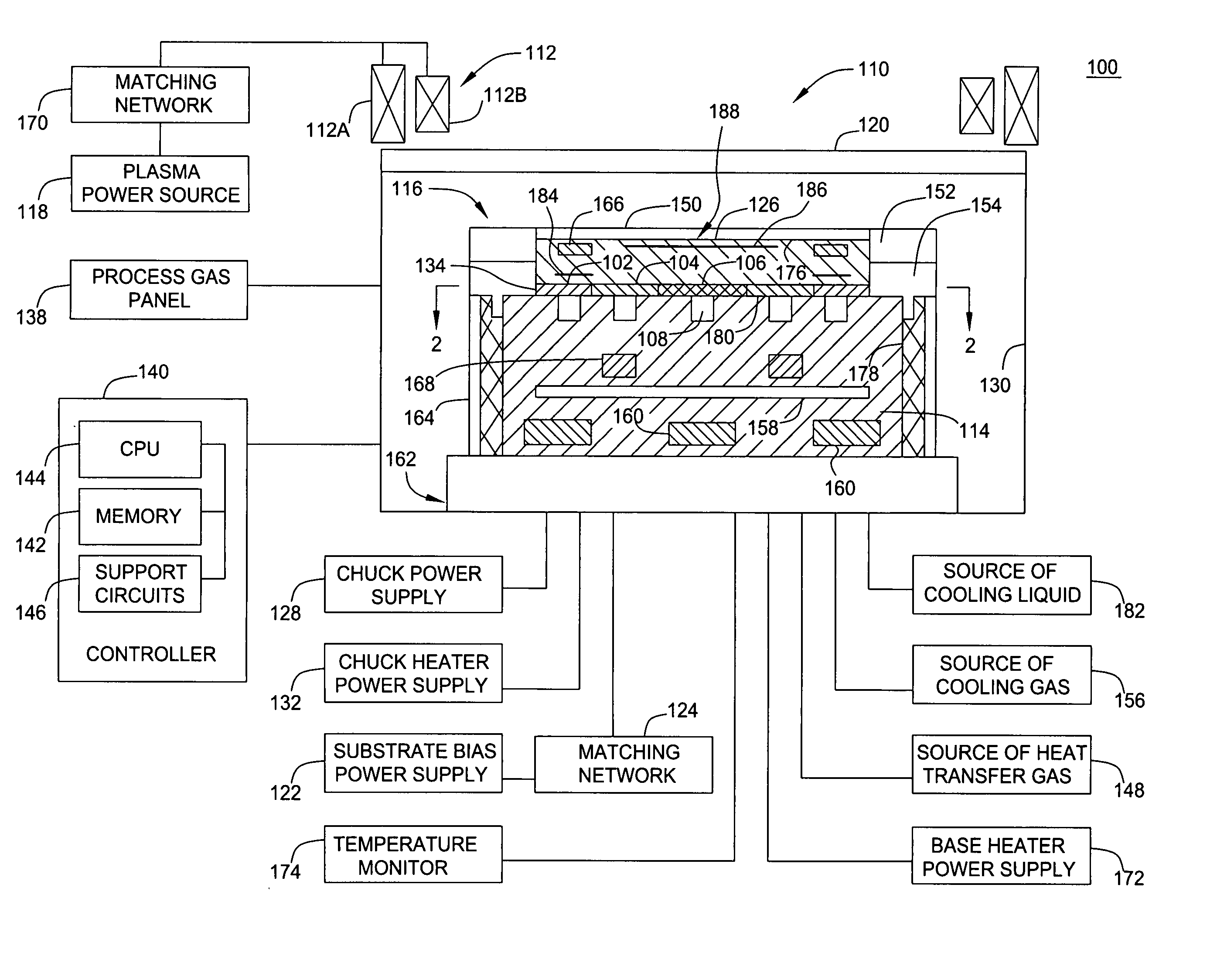

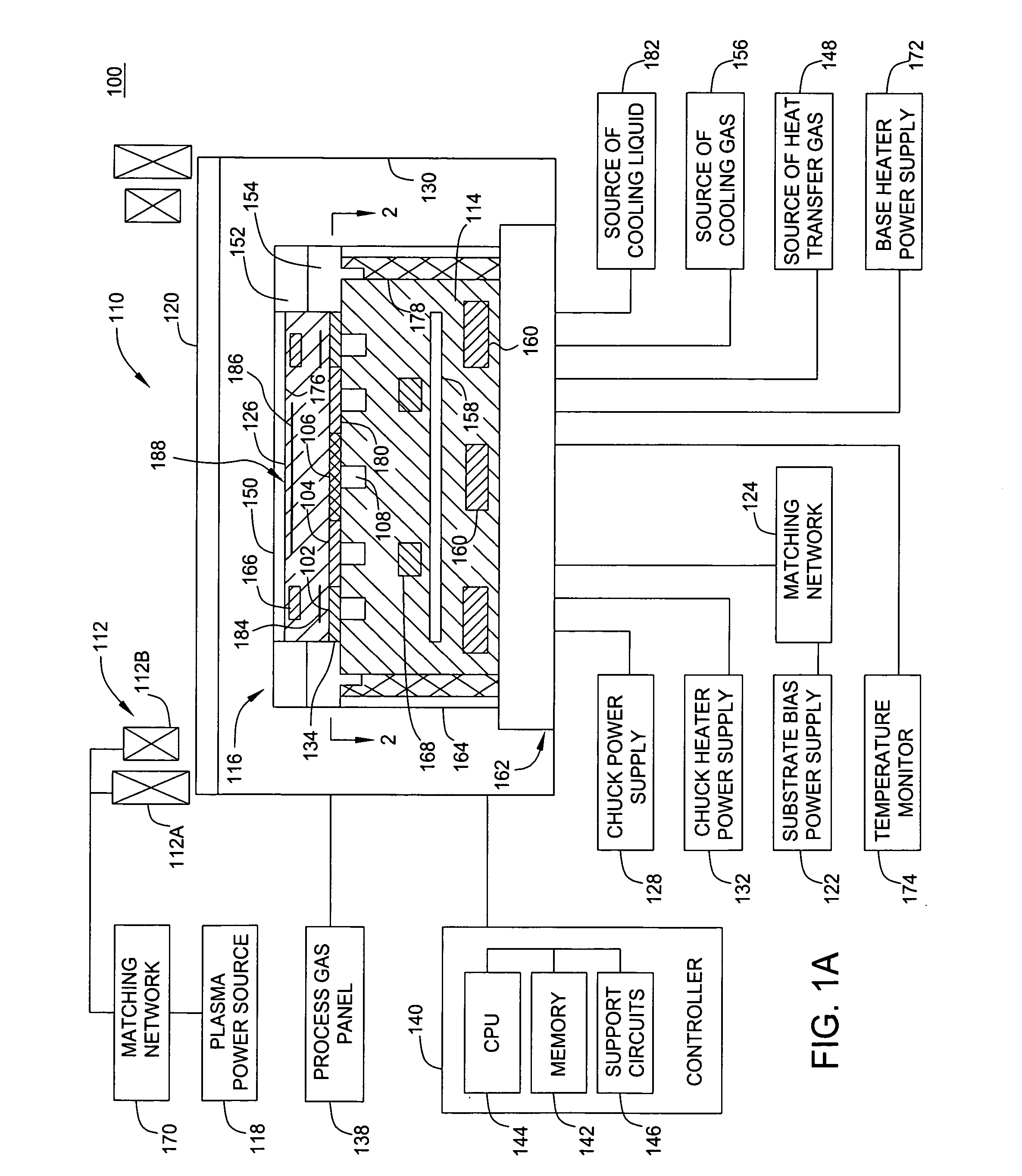

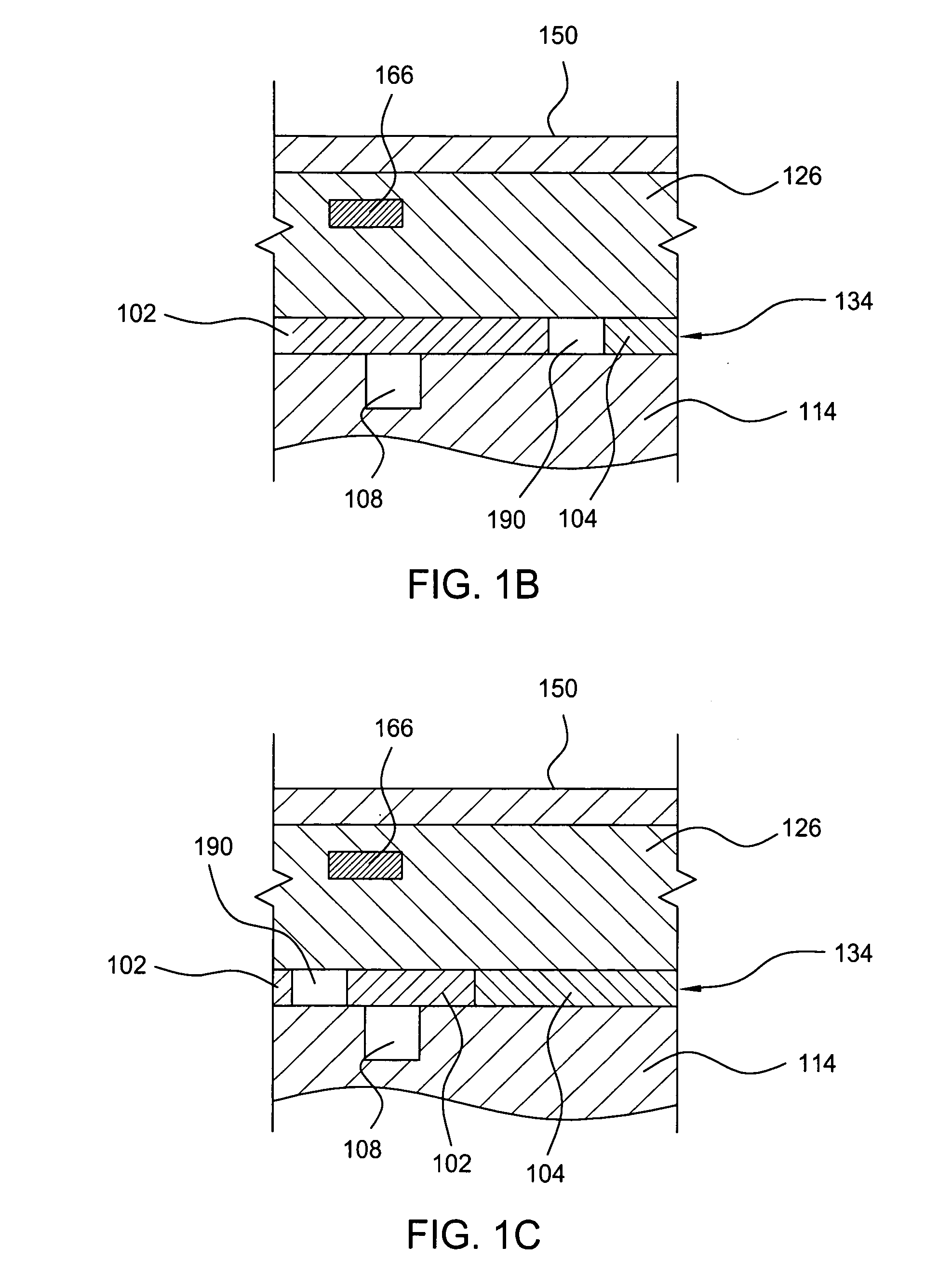

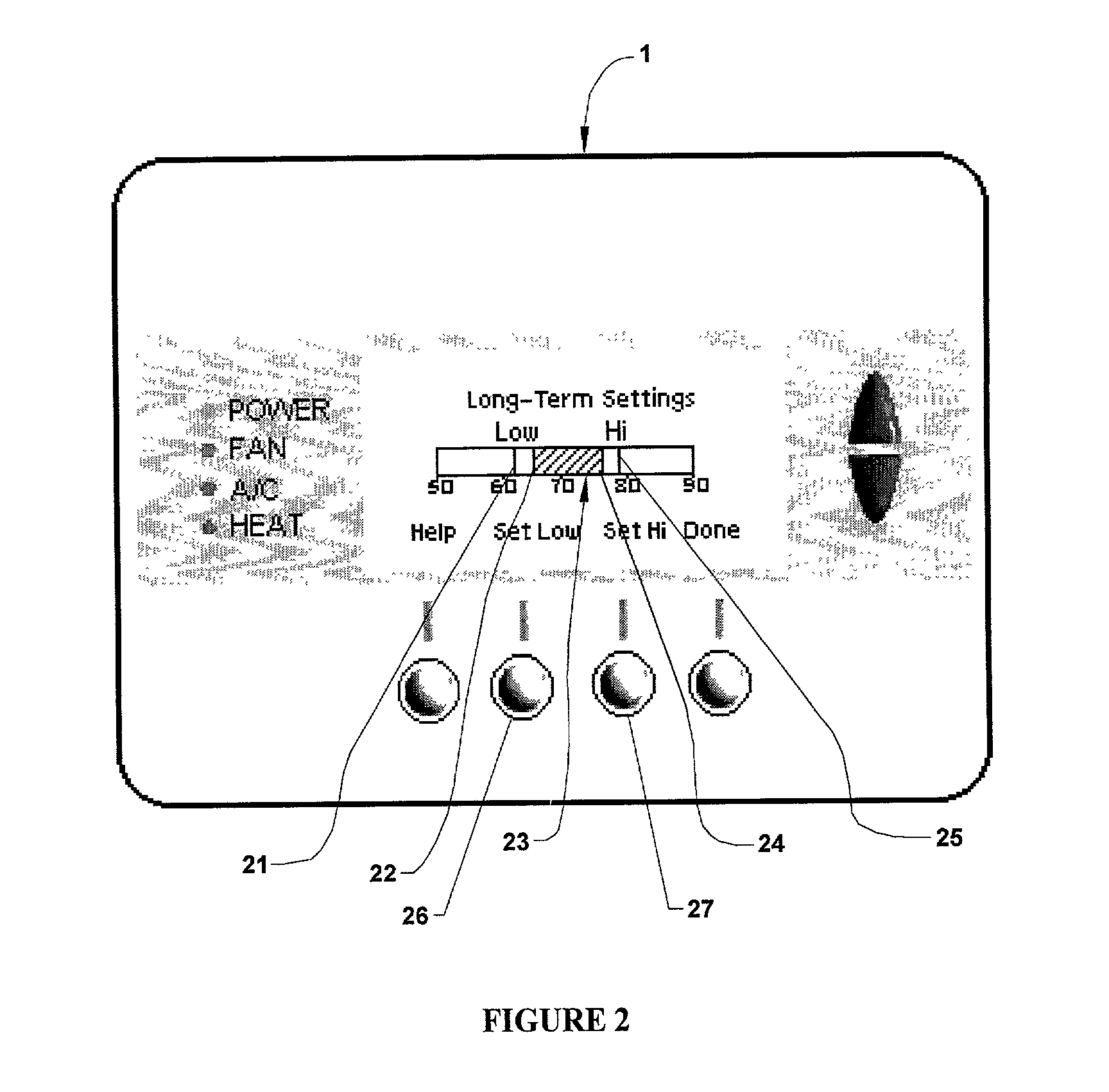

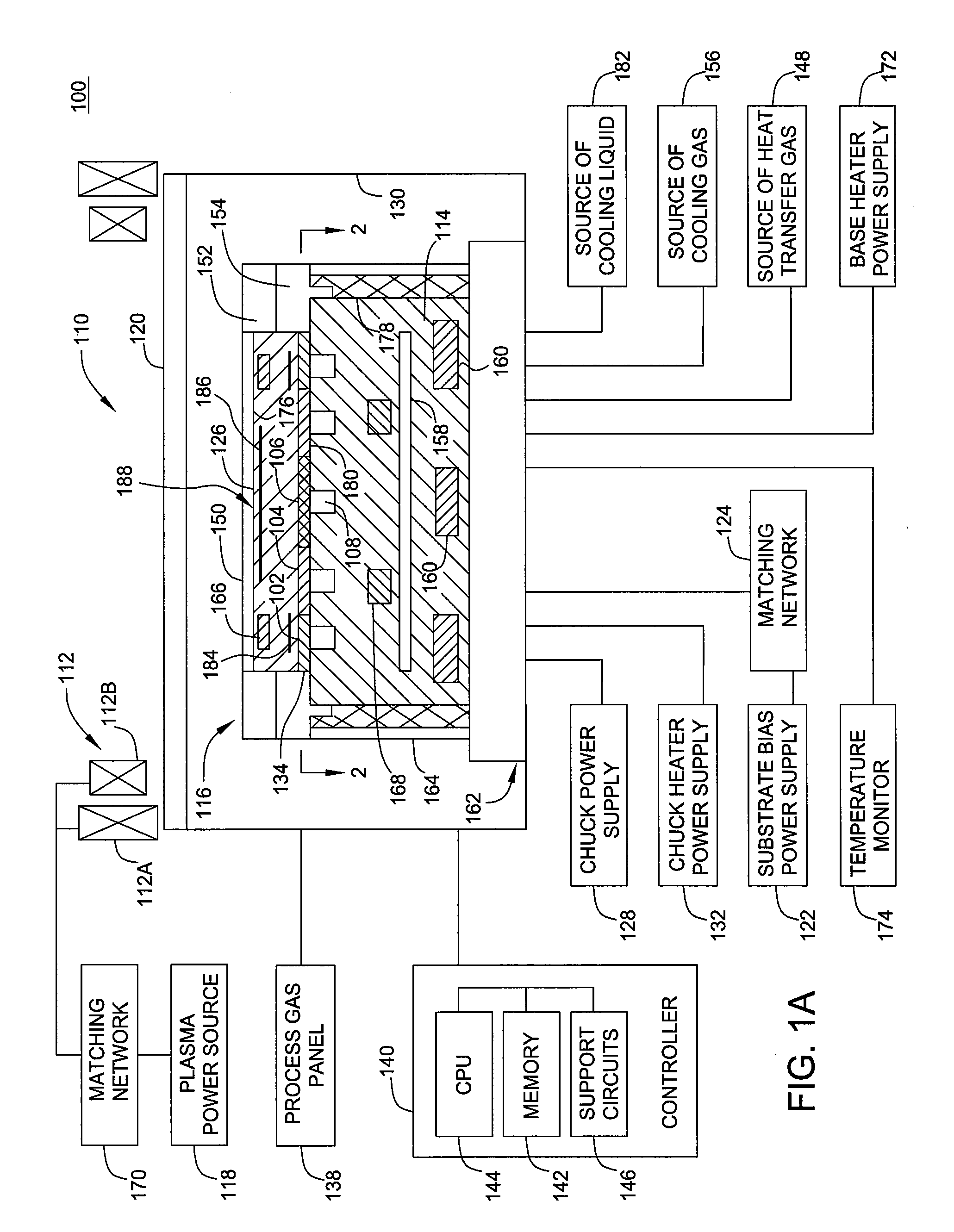

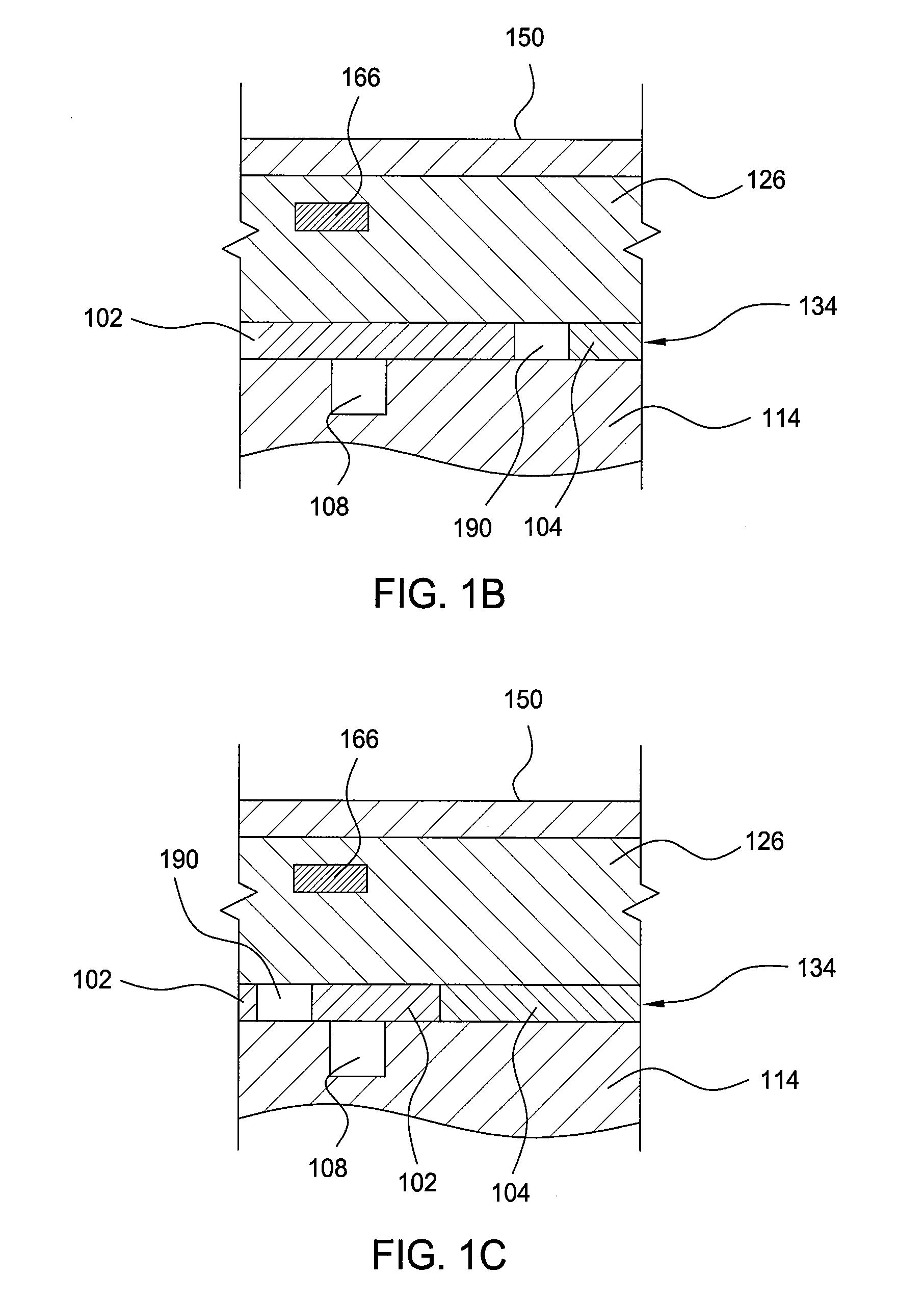

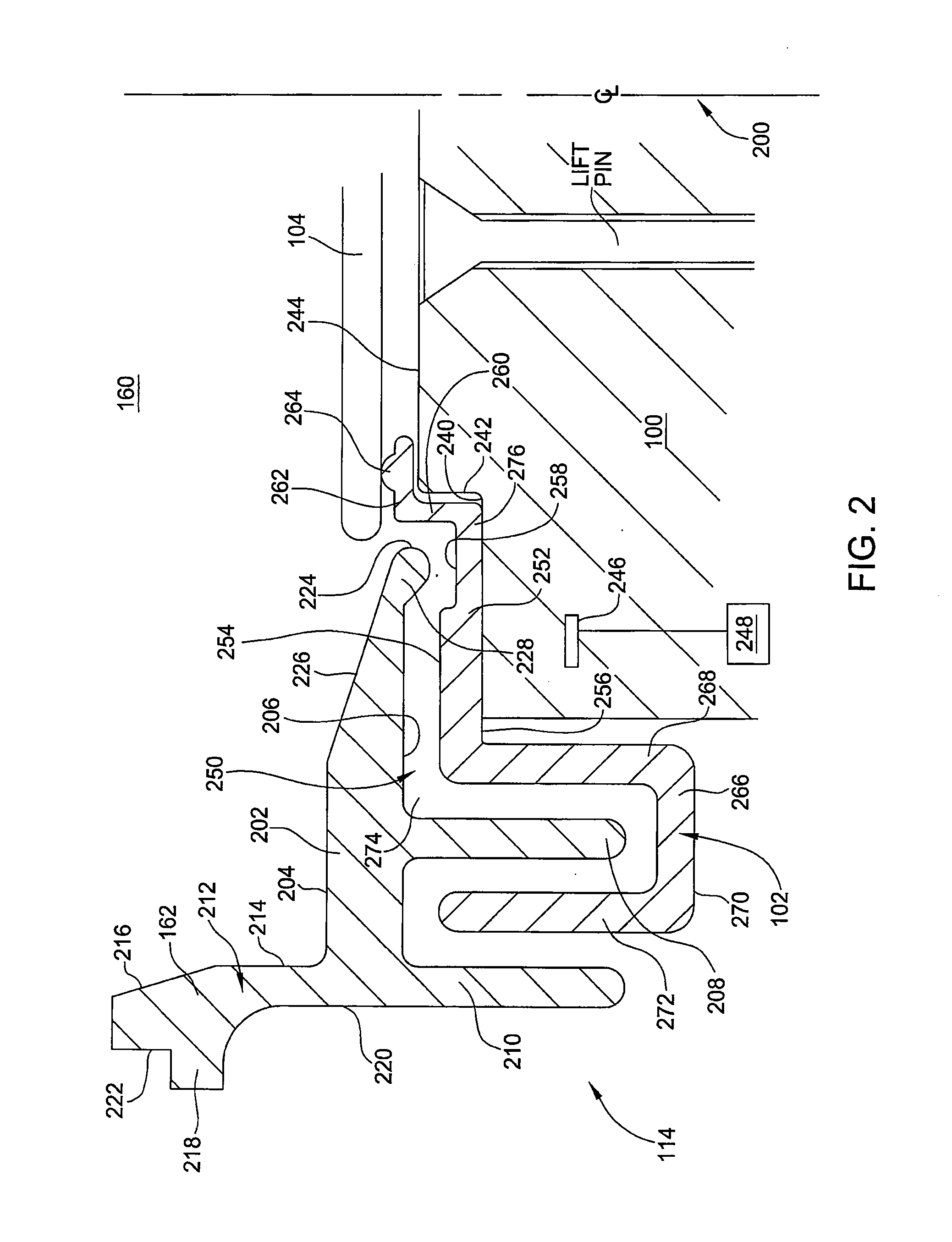

Method and apparatus for controlling temperature of a substrate

InactiveUS20060076108A1Easy temperature controlTemperature controlSleeve/socket jointsDecorative surface effectsEngineeringMechanical engineering

A pedestal assembly and method for controlling temperature of a substrate during processing is provided. In one embodiment, the pedestal assembly includes a support member that is coupled to a base by a material layer. The material layer has at least two regions having different coefficients of thermal conductivity. In another embodiment, the support member is an electrostatic chuck. In further embodiments, a pedestal assembly has channels formed between the base and support member for providing cooling gas in proximity to the material layer to further control heat transfer between the support member and the base, thereby controlling the temperature profile of a substrate disposed on the support member.

Owner:APPLIED MATERIALS INC

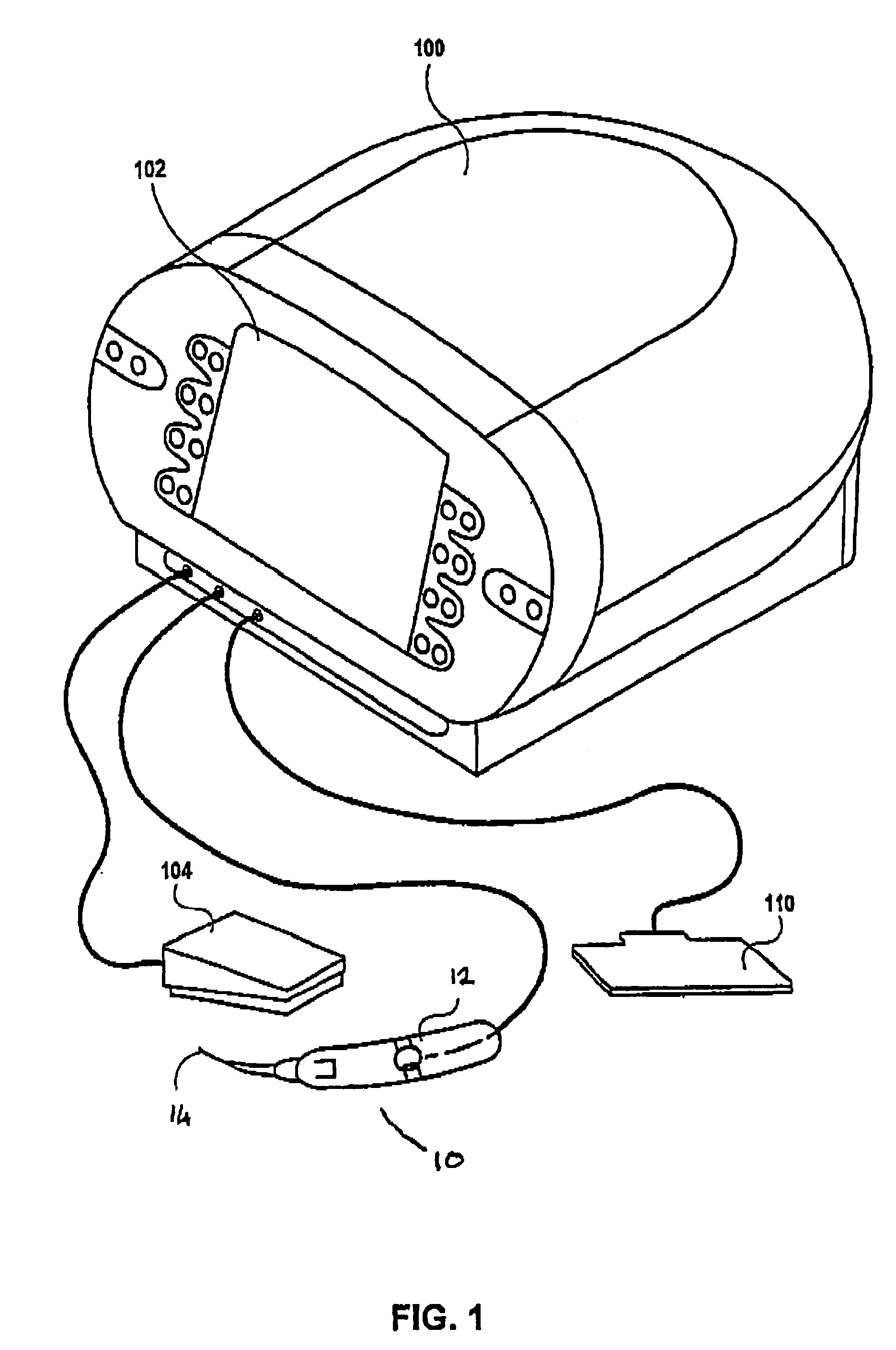

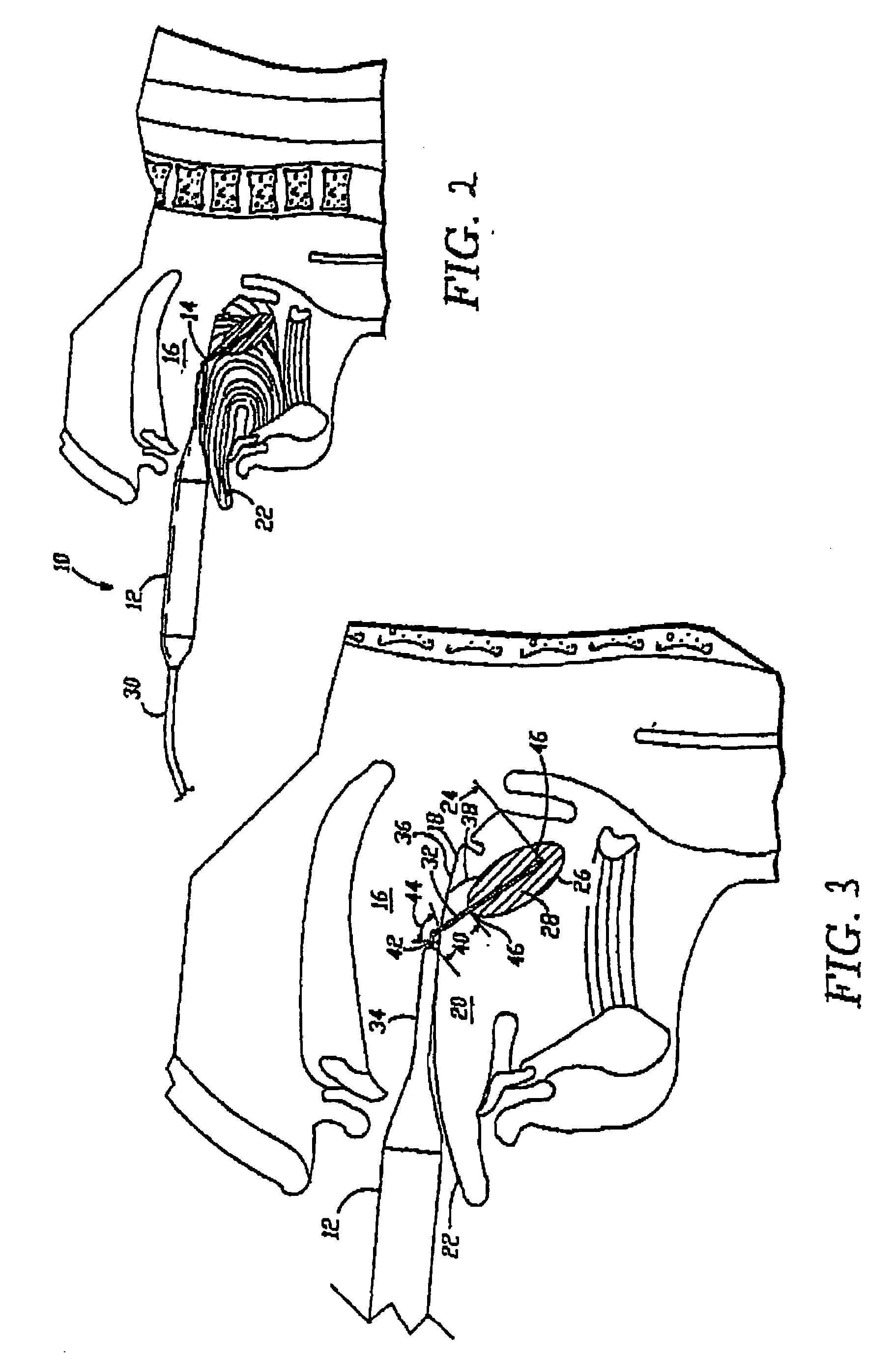

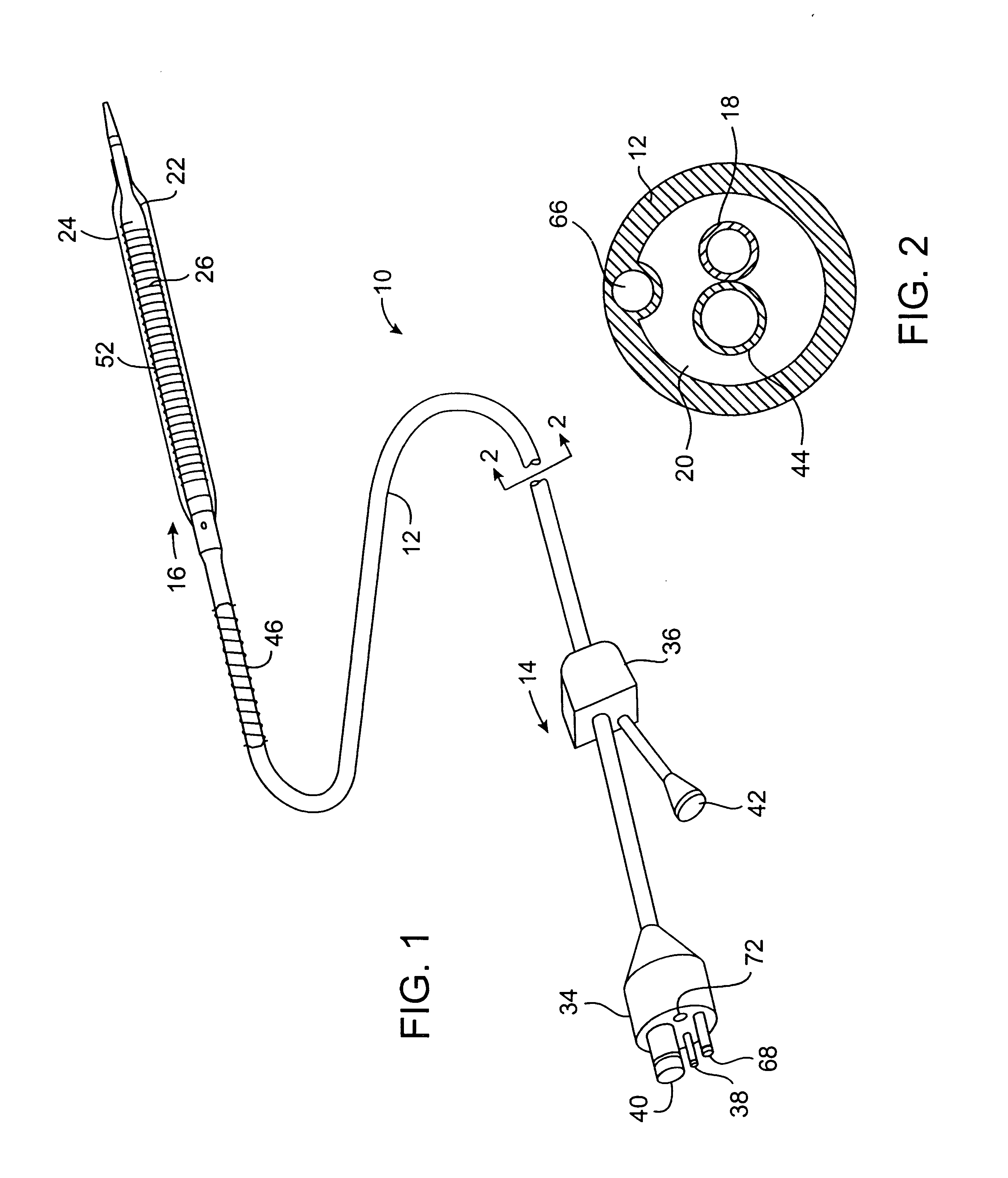

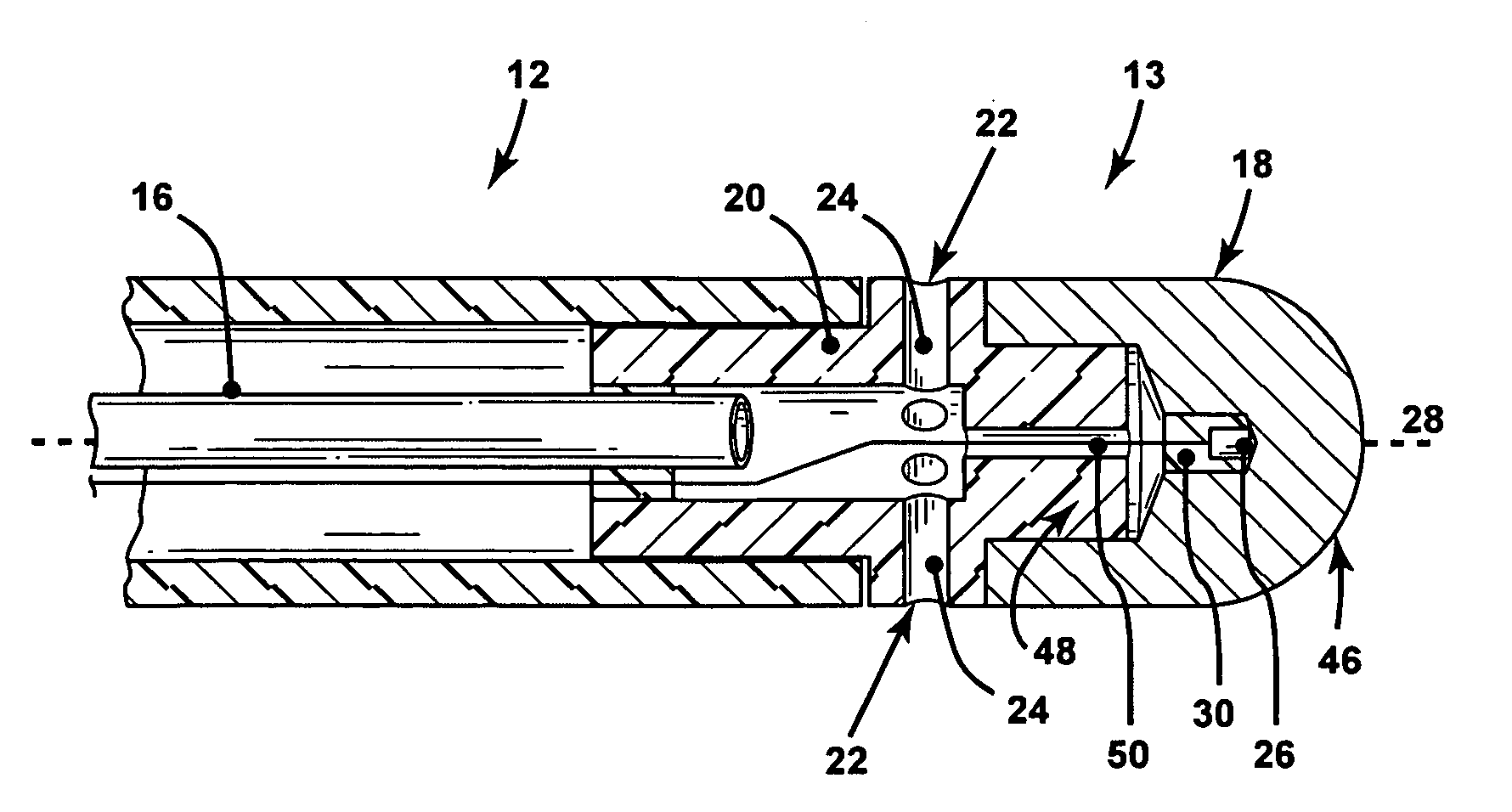

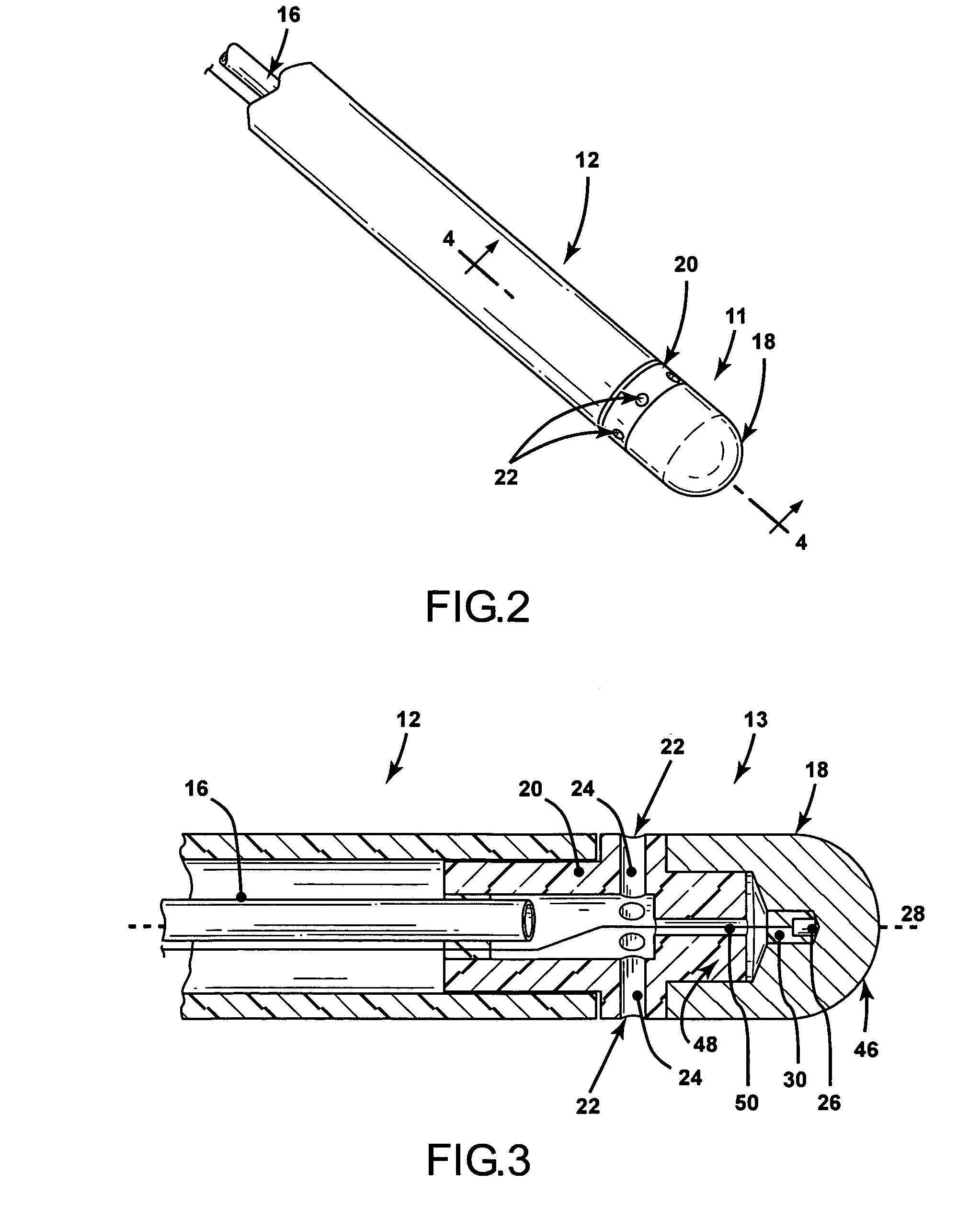

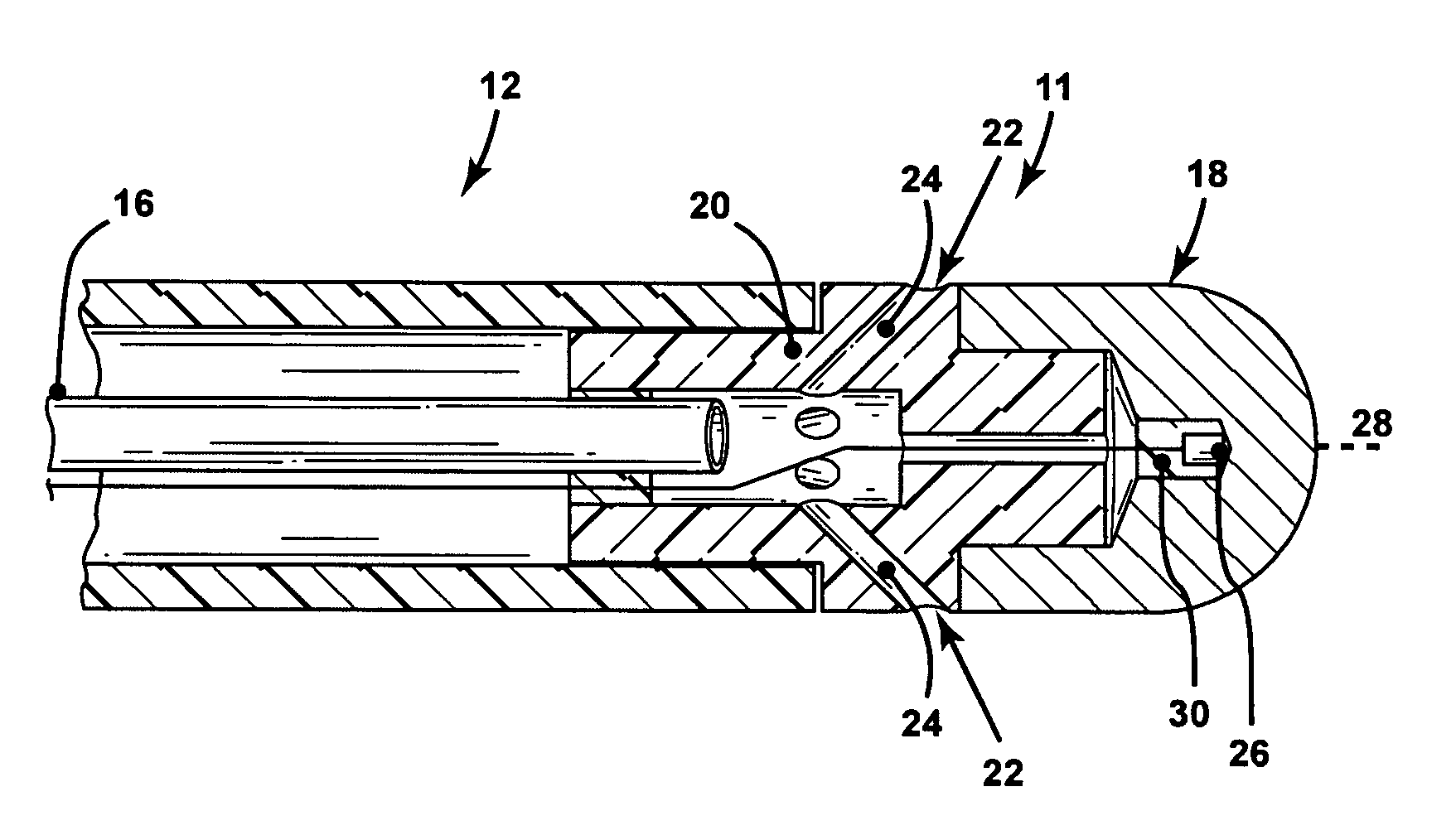

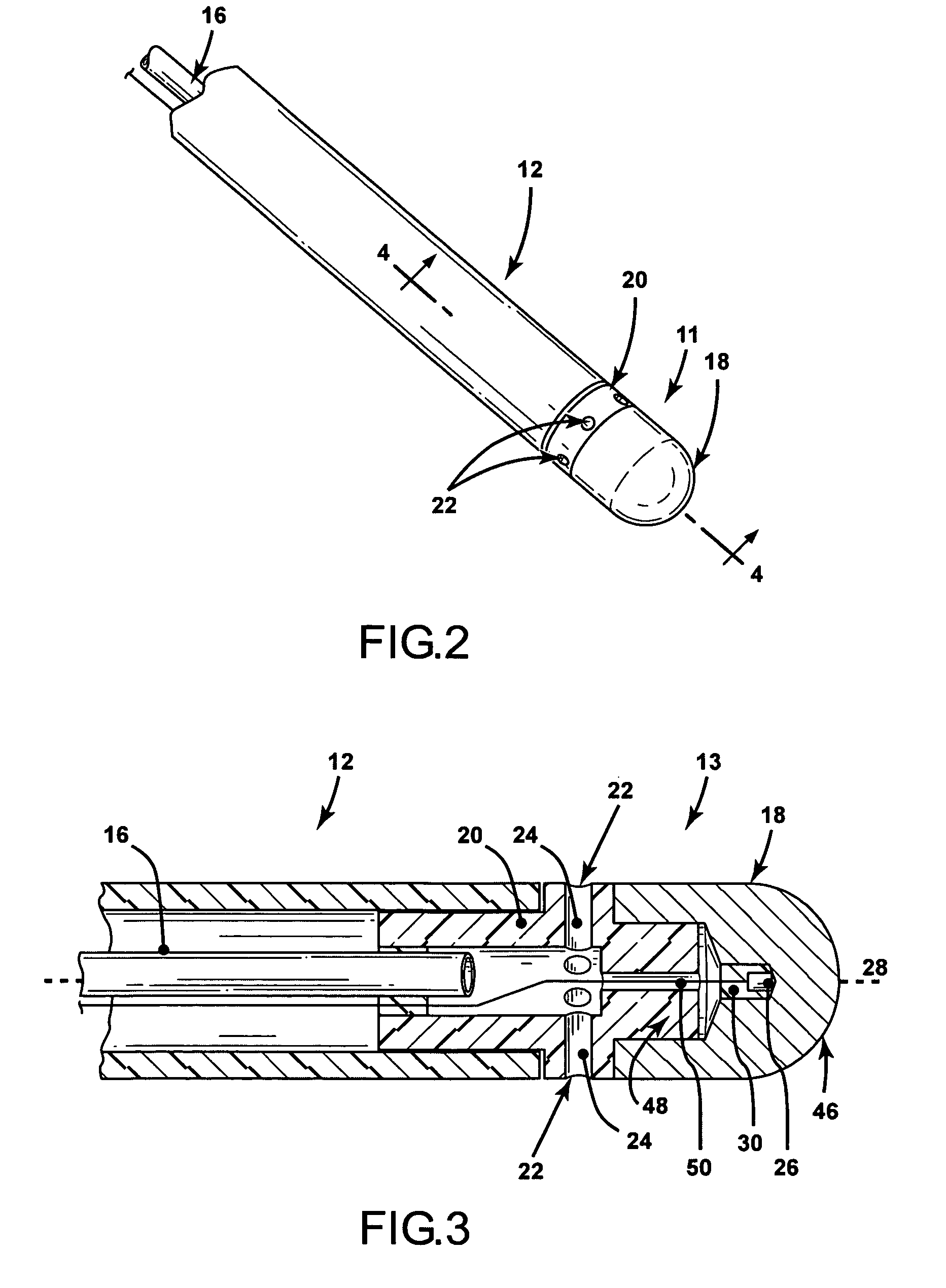

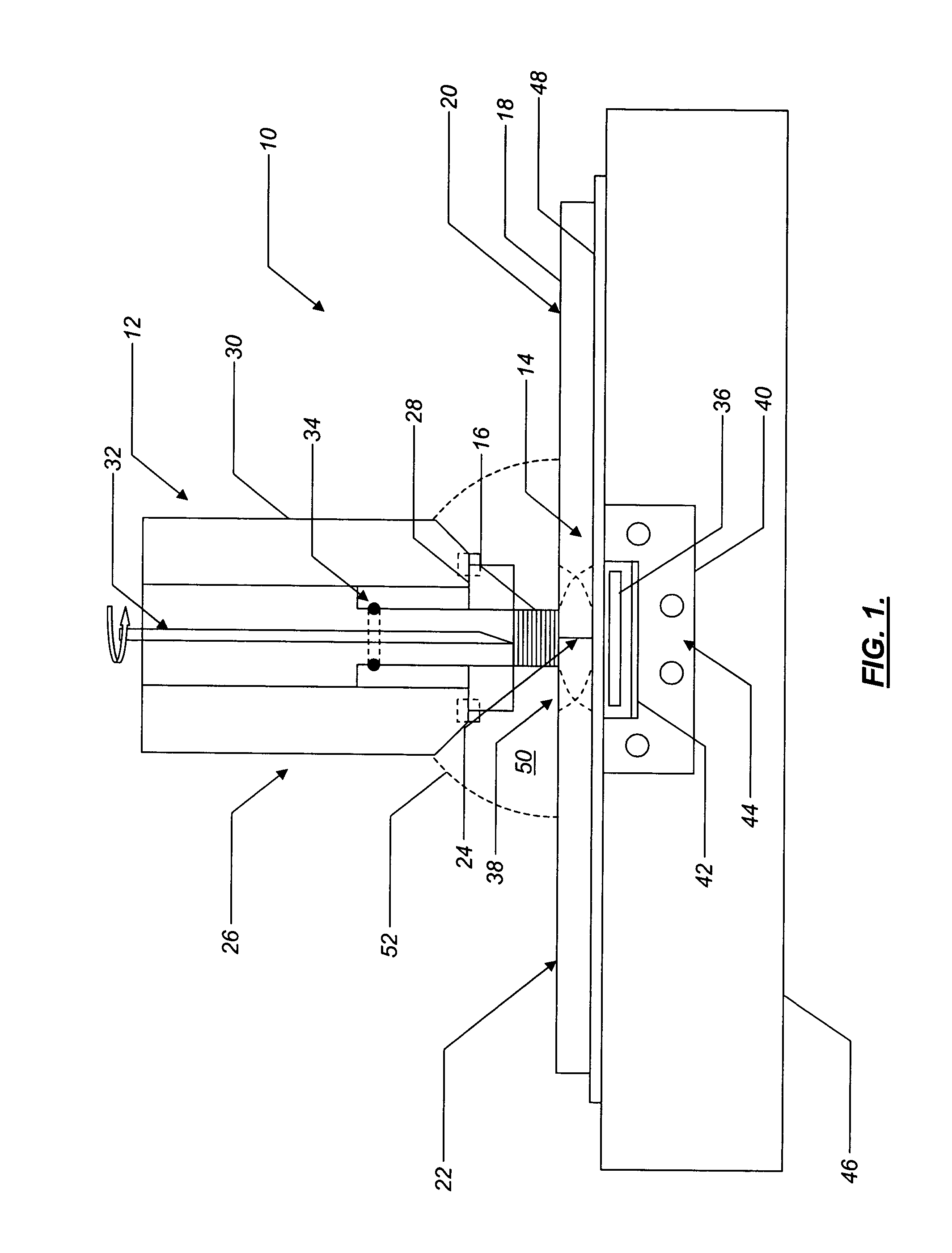

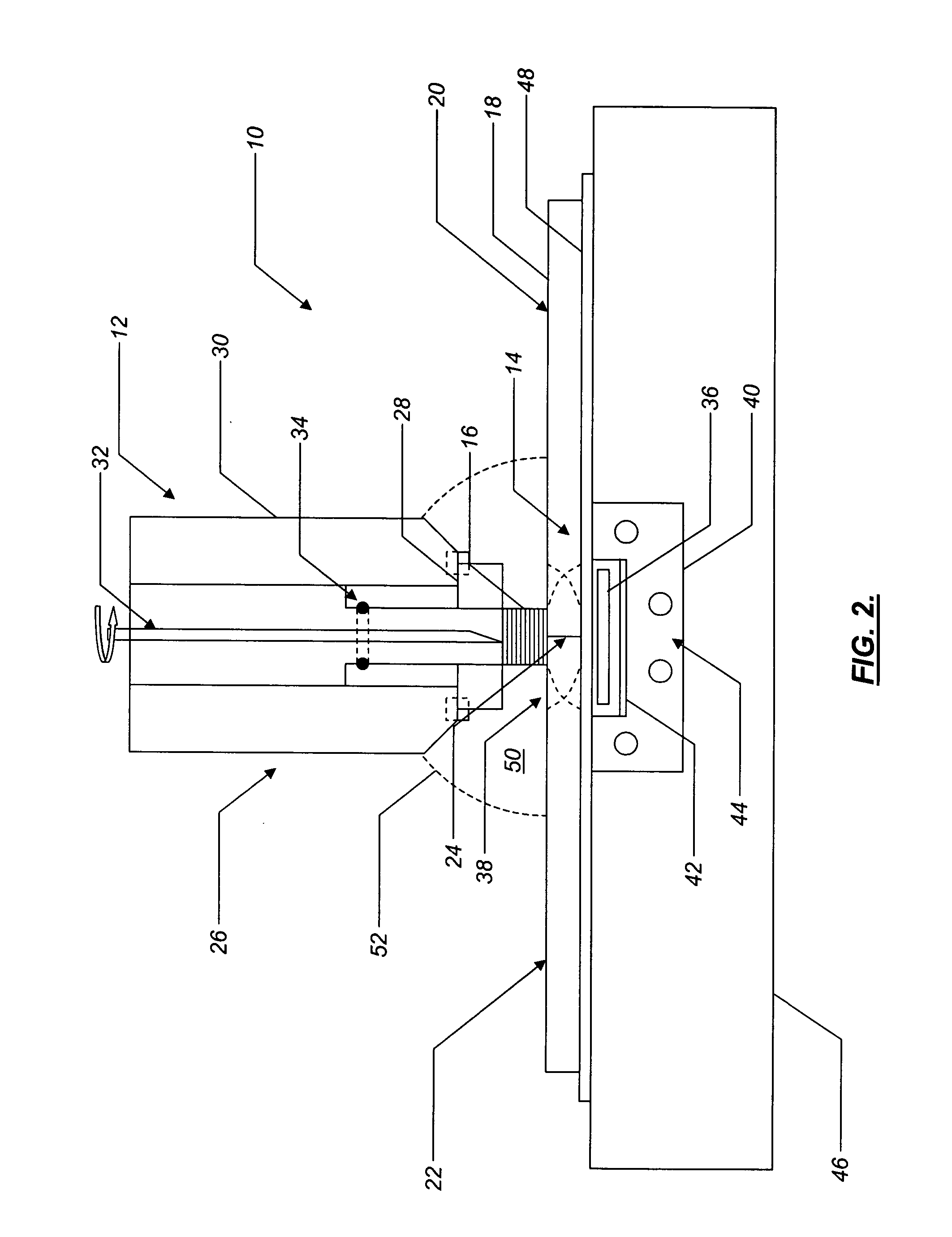

Ablation electrode assembly and methods for improved control of temperature and minimization of coagulation and tissue damage

ActiveUS20070270791A1Easy temperature controlEasy to monitorSurgical instruments for heatingSurgical instruments for irrigation of substancesIrrigation channelTissue damage

The present invention pertains to multiple piece irrigated ablation electrode assemblies wherein the irrigation channels are insulated or separated from at least one temperature sensing mechanism within the distal portion of the electrode assembly. The present invention further pertains to methods for improved assembly and accurate measurement and control of the electrode temperatures while effectively irrigating the device and target areas.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

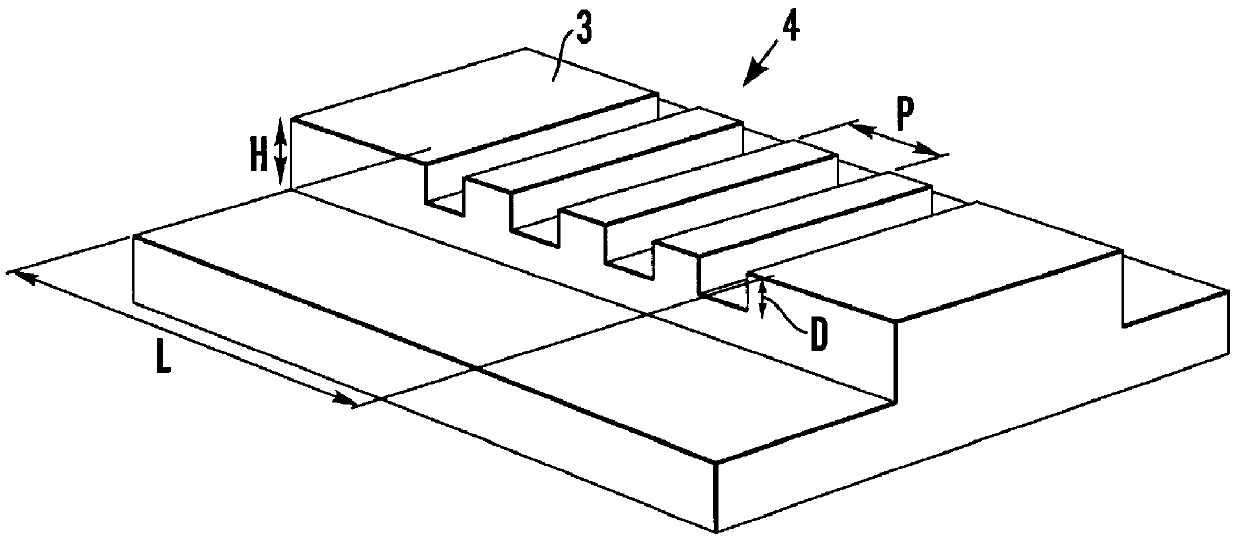

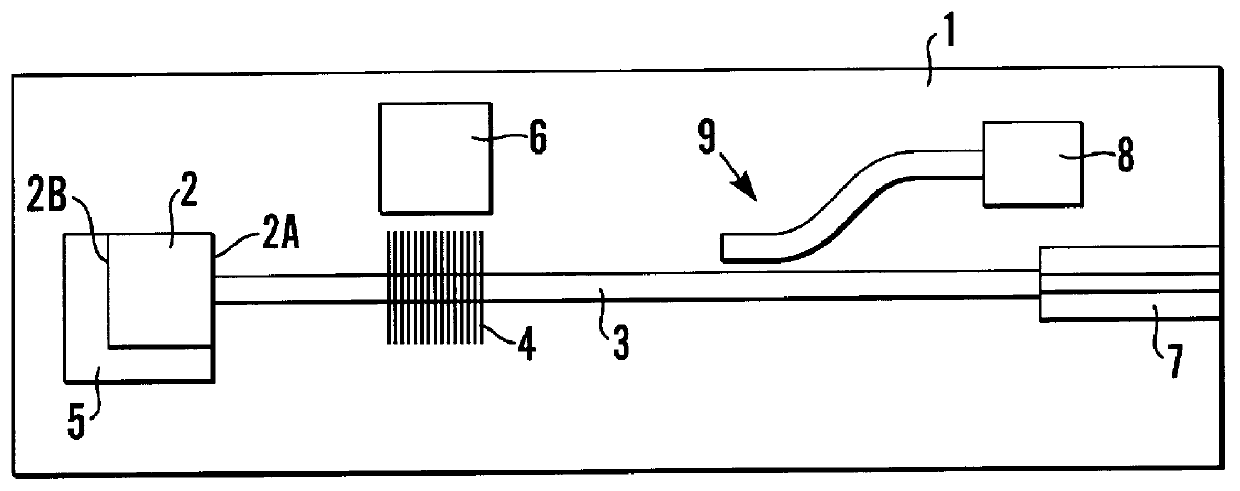

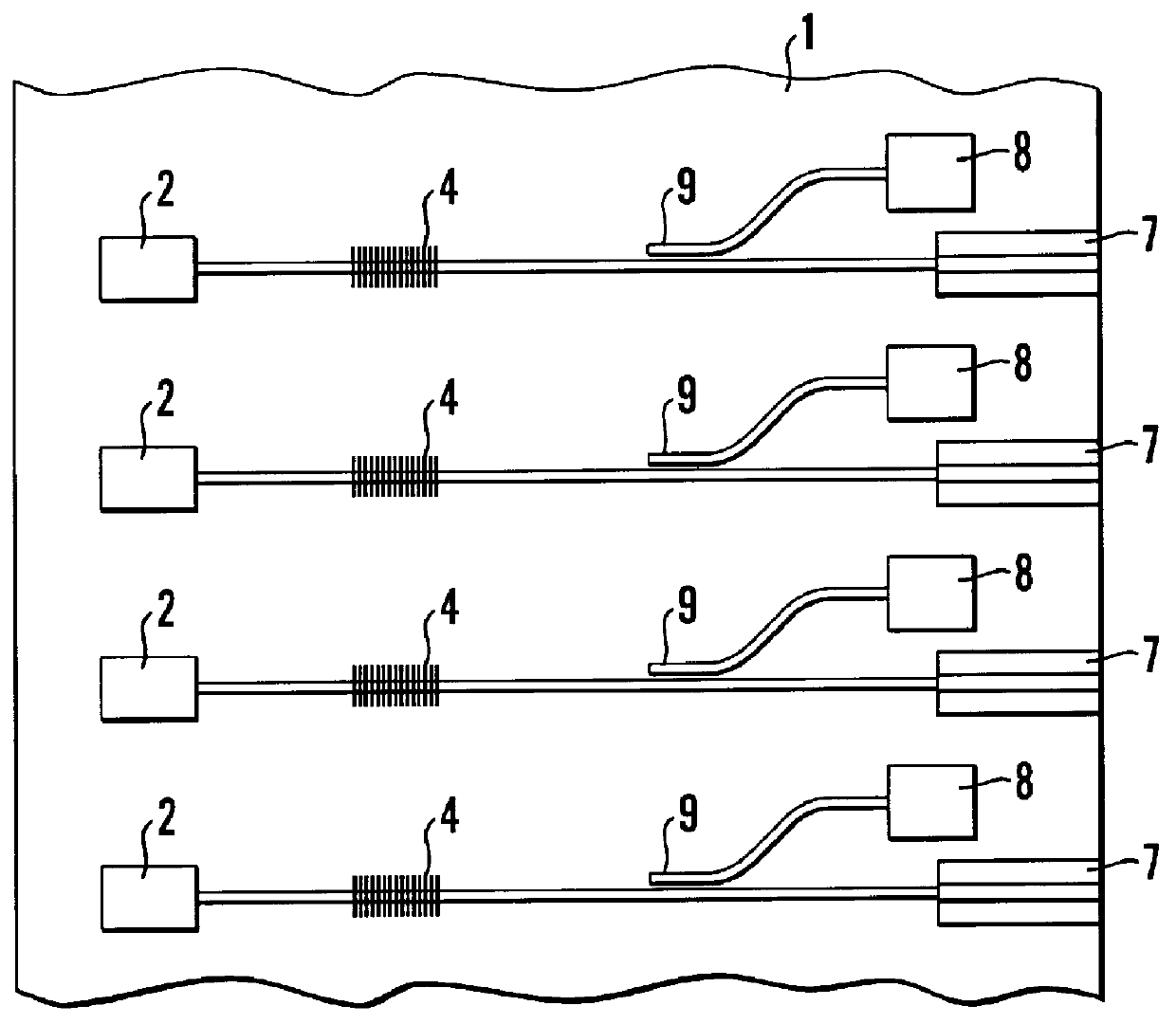

External cavity laser

InactiveUS6101210AAvoid disadvantagesEasy temperature controlLaser optical resonator constructionSemiconductor laser arrangementsTemperature controlGrating

External Cavity Laser An external cavity laser comprising first and second feedback means with an optical gain medium (2) therebetween, one of the feedback means is provided by a grating (4) formed in a silicon waveguide and the other feedback means is provided by a reflective back facet (2B) of the optical gain medium (2). The output wavelength of the laser, at a given temperature, can thus be determined during its manufacture and the laser can be made by mass production techniques. The grating (4) may be thermally isolated to obviate the need for temperature control means (6) to control the temperature of the grating (4). An array of lasers may be provided on a single chip.

Owner:KOTURA

Method and apparatus for controlling temperature of a substrate

InactiveUS20060076109A1Easy to controlEasy temperature controlSleeve/socket jointsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A pedestal assembly and method for controlling temperature of a substrate during processing is provided. In one embodiment, the pedestal assembly includes an electrostatic chuck coupled to a metallic base. The electrostatic chuck includes at least one chucking electrode and metallic base includes at least two fluidly isolated conduit loops disposed therein. In another embodiment, the pedestal assembly includes a support member that is coupled to a base by a material layer. The material layer has at least two regions having different coefficients of thermal conductivity. In another embodiment, the support member is an electrostatic chuck. In further embodiments, a pedestal assembly has channels formed between the base and support member for providing cooling gas in proximity to the material layer to further control heat transfer between the support member and the base, thereby controlling the temperature profile of a substrate disposed on the support member.

Owner:APPLIED MATERIALS INC

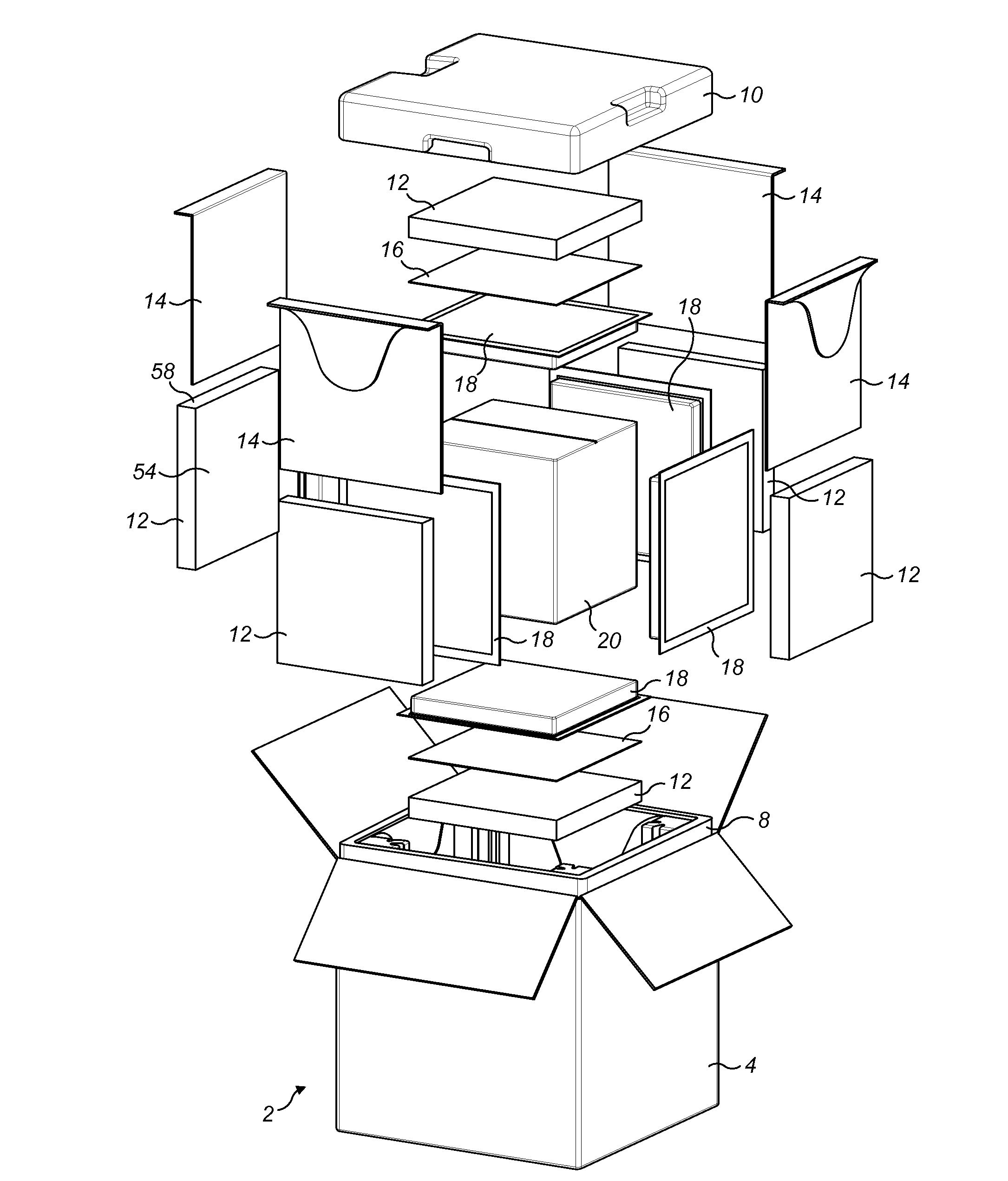

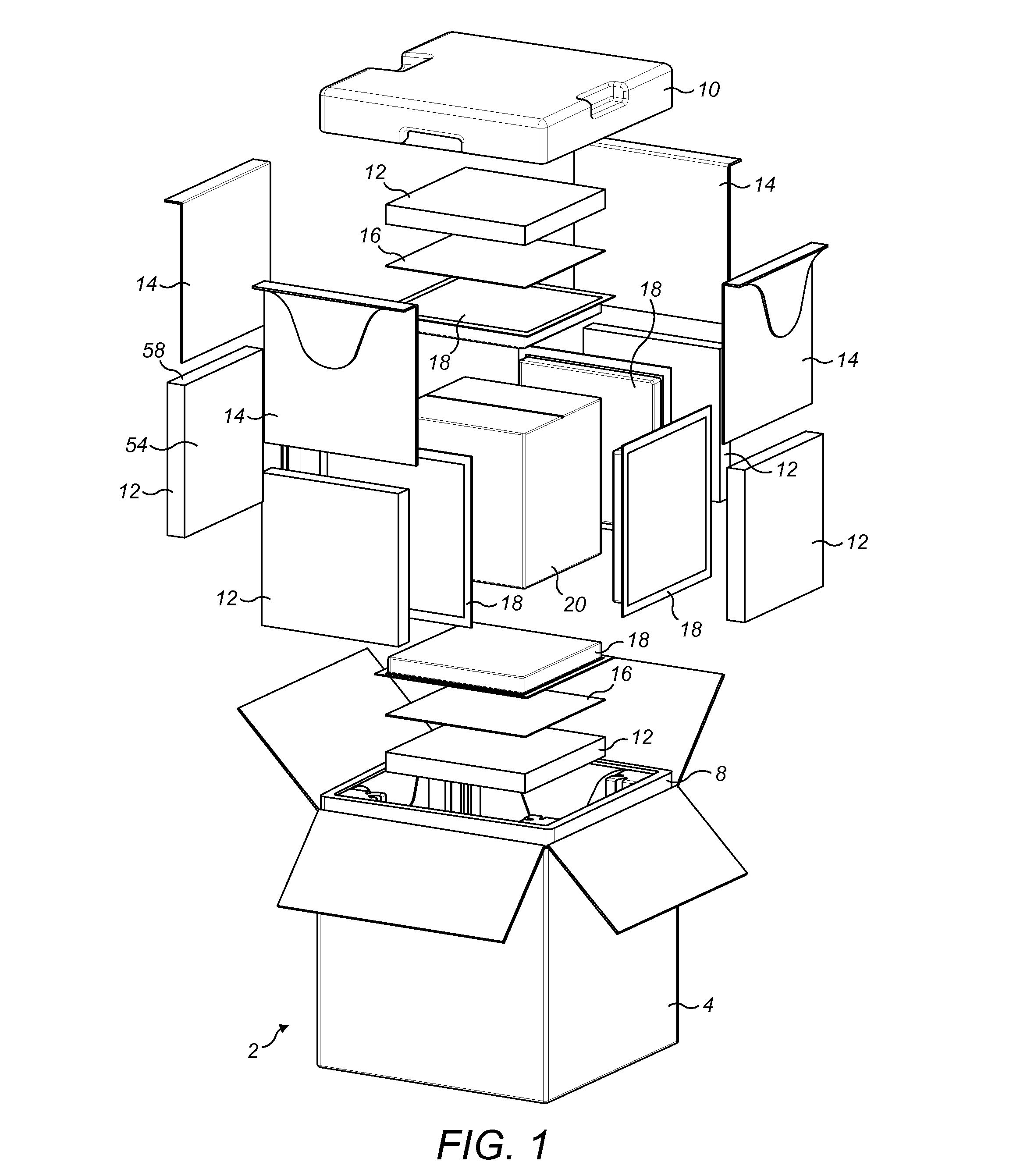

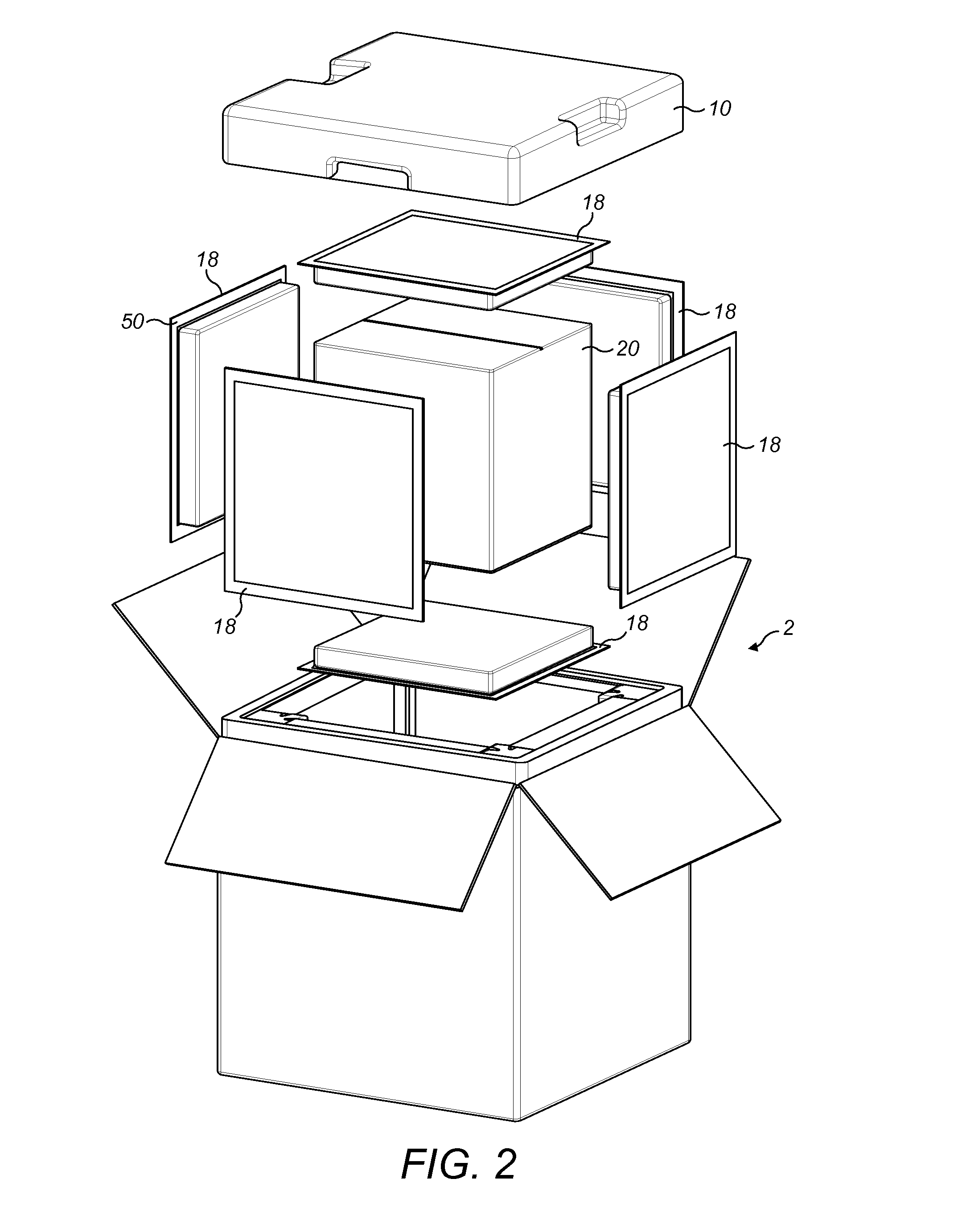

Thermally insulated package

ActiveUS20150166244A1Easy temperature controlLess expensiveLighting and heating apparatusBox making operationsEngineeringPhase-change material

A thermally insulating package comprises an outer shell (6) formed from a foam insulating material, a plurality of vacuum insulated panels (12) removably received on the walls of the outer shell (6) and a plurality of phase change material panels (18) arranged within the vacuum insulated panels (12) to define a payload space.

Owner:PELI BIOTHERMAL LLC (N D GES D STAATES DELAWARE)

Ablation electrode assembly and methods for improved control of temperature and minimization of coagulation and tissue damage

ActiveUS7857810B2Easy to monitorEasy temperature controlSurgical instruments for heatingSurgical instruments for irrigation of substancesTemperature controlDistal portion

The present invention pertains to multiple piece irrigated ablation electrode assemblies wherein the irrigation channels are insulated or separated from at least one temperature sensing mechanism within the distal portion of the electrode assembly. The present invention further pertains to methods for improved assembly and accurate measurement and control of the electrode temperatures while effectively irrigating the device and target areas.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Apparatus for depositing an organic layer and method for controlling a heating unit thereof

InactiveUS20070077358A1Improve heating efficiencyMinimize timeVacuum evaporation coatingSputtering coatingCrucibleEvaporation

An apparatus for depositing an organic layer and a method for controlling the heating unit thereof are provided. The apparatus includes a crucible positioned in a deposition chamber and containing materials for evaporation. The apparatus also includes a heating unit having first and second heat sources for heating the crucible. A housing isolates the heat emitted from the heating unit and an outer wall anchors the crucible. A nozzle sprays the materials evaporated from the crucible. The first and second heat sources are positioned on first and second sides of the crucible, respectively, and are independently controlled to minimize the time required to stabilize the deposition rate.

Owner:SAMSUNG DISPLAY CO LTD

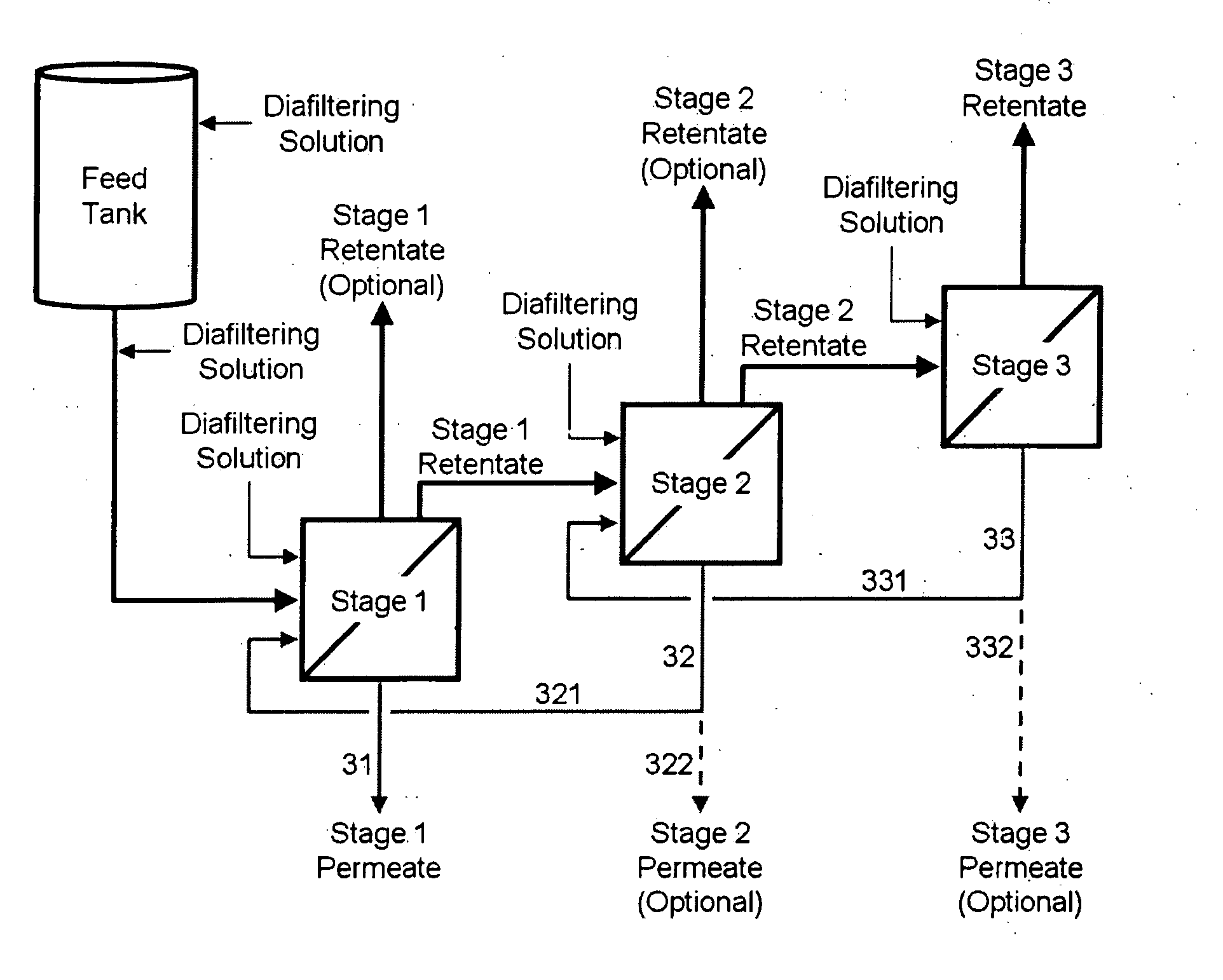

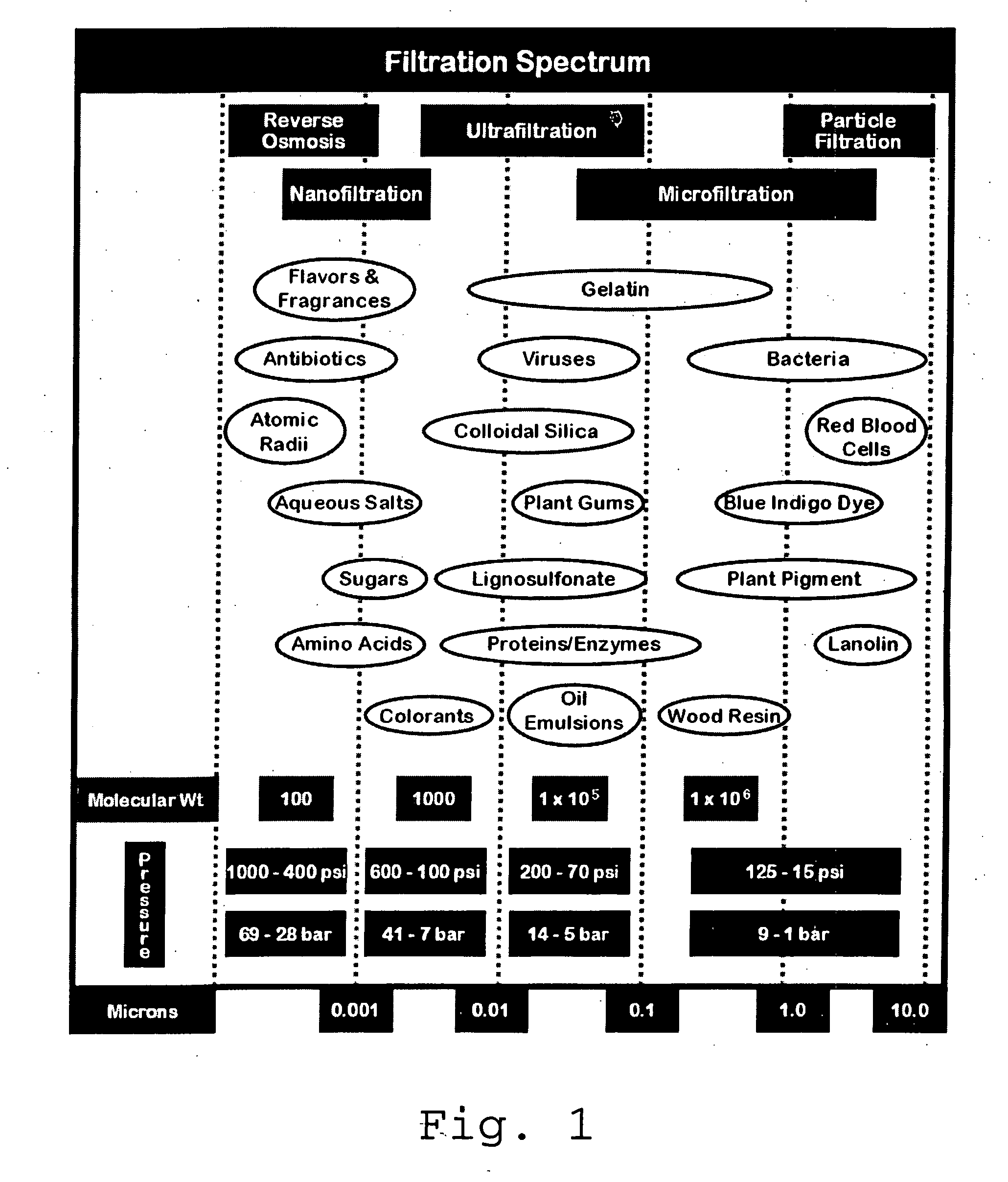

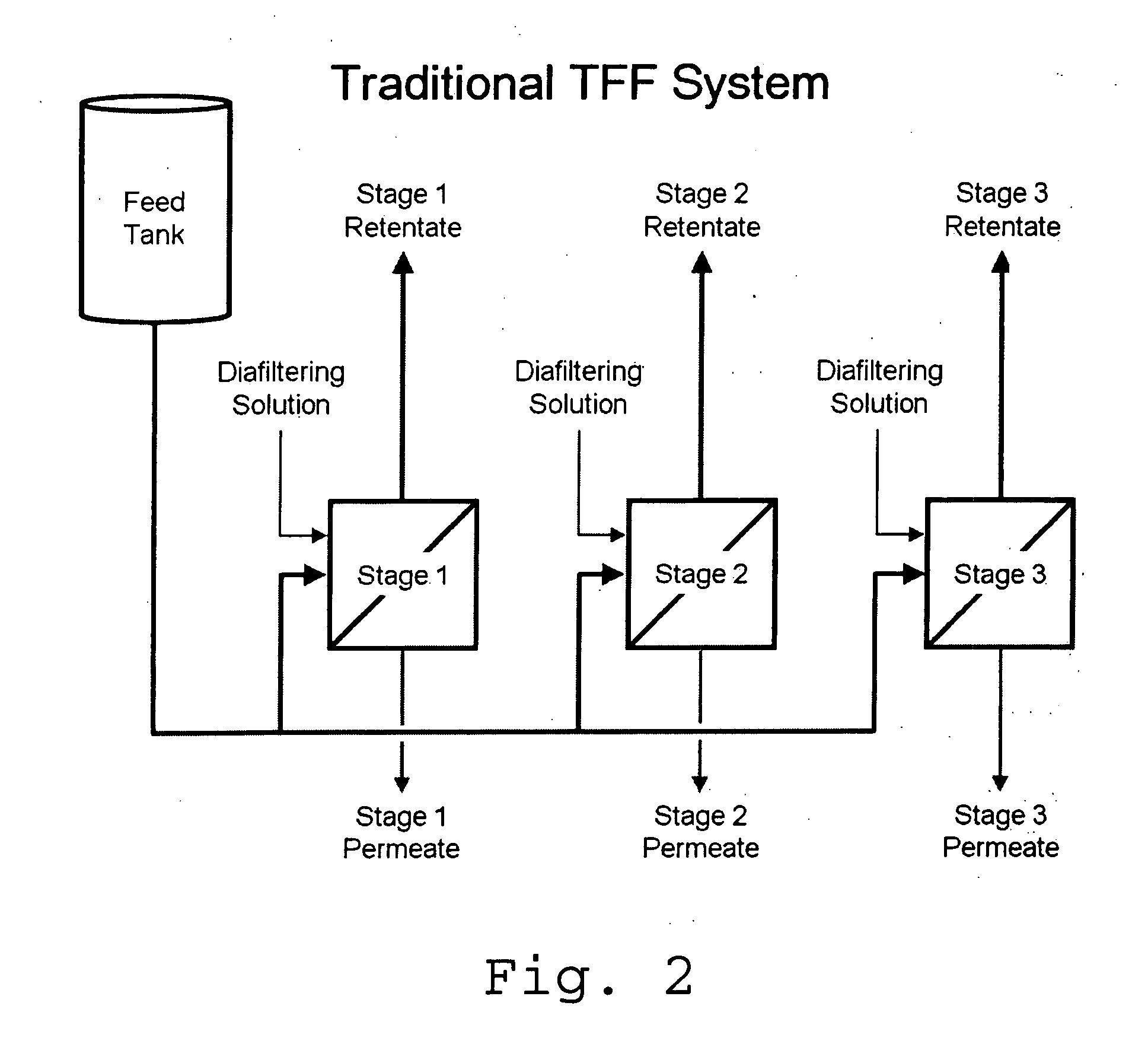

Tangential flow filtration apparatuses, systems, and processes for the separation of compounds

InactiveUS20070246406A1Precise and predictable control of process parameter and product qualityConstantMembranesUltrafiltrationYeastFiltration

The invention relates to apparatuses, machines, systems and methods for the recovery and purification of proteins, peptides, nucleic acids, biologically produced polymers and other compounds from aqueous fluids. The aqueous fluids can comprise enzyme concentrates and or a fermentation broth with or without cells or other starting material. The fermentation broth can be produced by fermentations of fungal, yeast, bacterial, mammalian, insect or plant cells.

Owner:GENENCOR INT INC

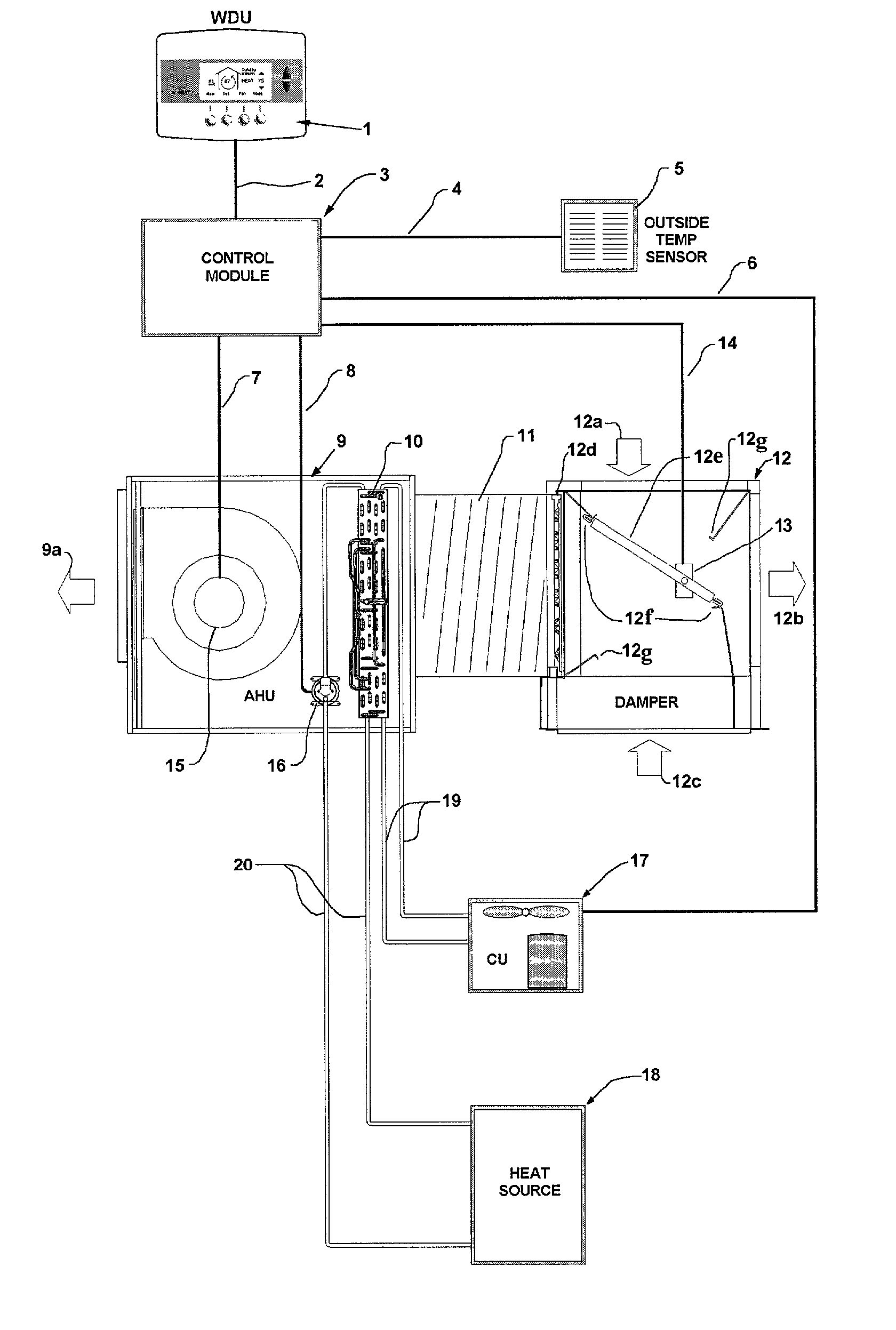

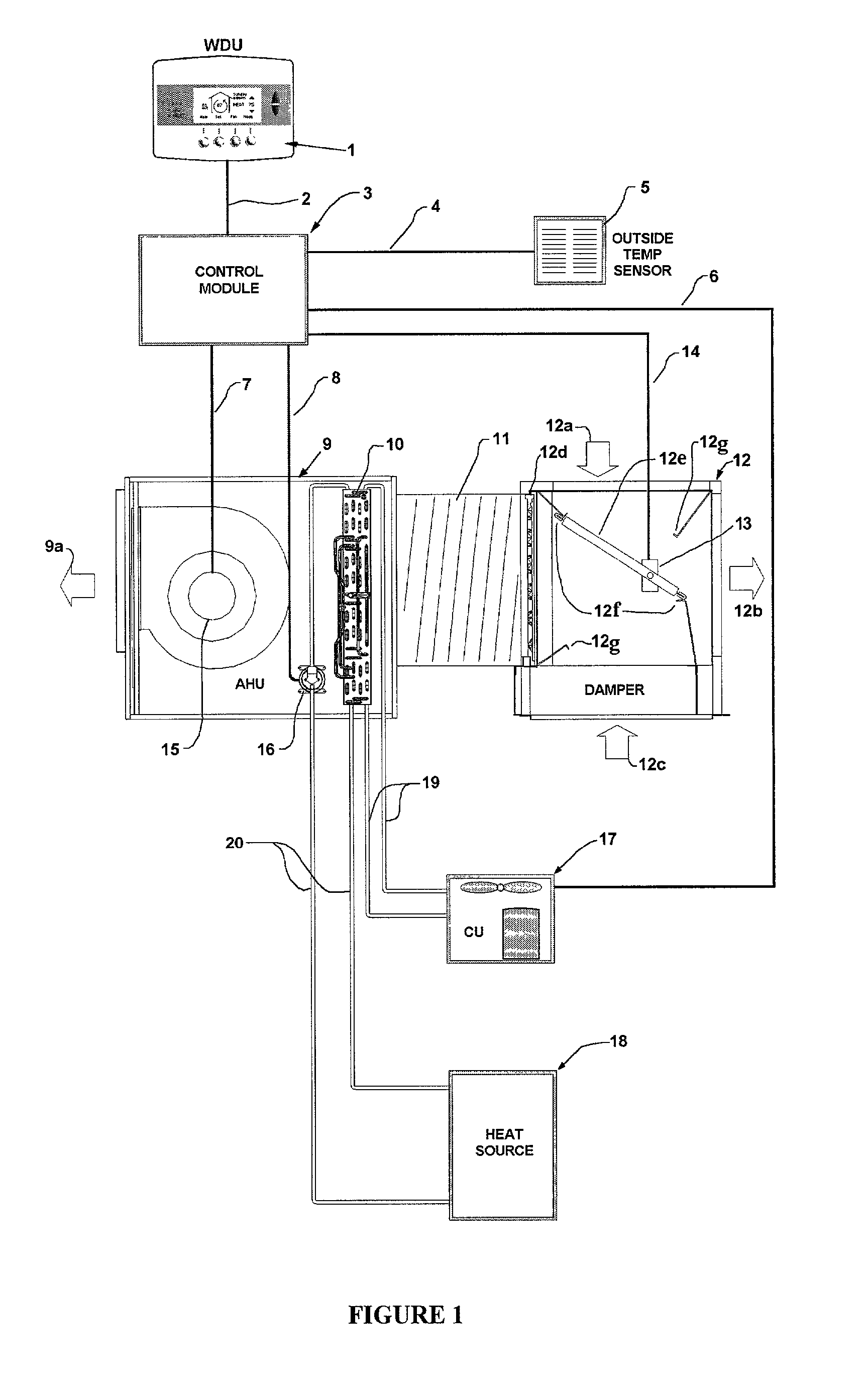

Integrated ventilation cooling system

InactiveUS20020124992A1Reduce energy useEasy temperature controlDucting arrangementsMechanical apparatusIndoor air qualityAir handler

A system and method for cooling and heating of buildings consisting of an integrated assembly of devices, including a variable speed air handler, hot water heating coil, outside air damper, controller, and optional compressor-based air conditioner. During summer the system utilizes nighttime outside air for cooling and uses air temperature predictions to provide information about optimal control settings and to maintain comfort. During winter the system varies airflow with heating demand and ventilates with outside air to maintain indoor air quality.

Owner:NIGHTBREEZE

Method and apparatus for controlling temperature of a substrate

InactiveUS20070139856A1Easy temperature controlTemperature controlSemiconductor/solid-state device manufacturingMechanical engineeringMetal

A pedestal assembly and method for controlling temperature of a substrate during processing is provided. In one embodiment, the pedestal assembly includes an electrostatic chuck coupled to a metallic base. The electrostatic chuck includes at least one chucking electrode and metallic base includes at least two fluidly isolated conduit loops disposed therein. In another embodiment, the pedestal assembly includes a support member that is coupled to a base by a material layer. The material layer has at least two regions having different coefficients of thermal conductivity. In another embodiment, the support member is an electrostatic chuck. In further embodiments, a pedestal assembly has channels formed between the base and support member for providing cooling gas in proximity to the material layer to further control heat transfer between the support member and the base, thereby controlling the temperature profile of a substrate disposed on the support member.

Owner:APPLIED MATERIALS INC

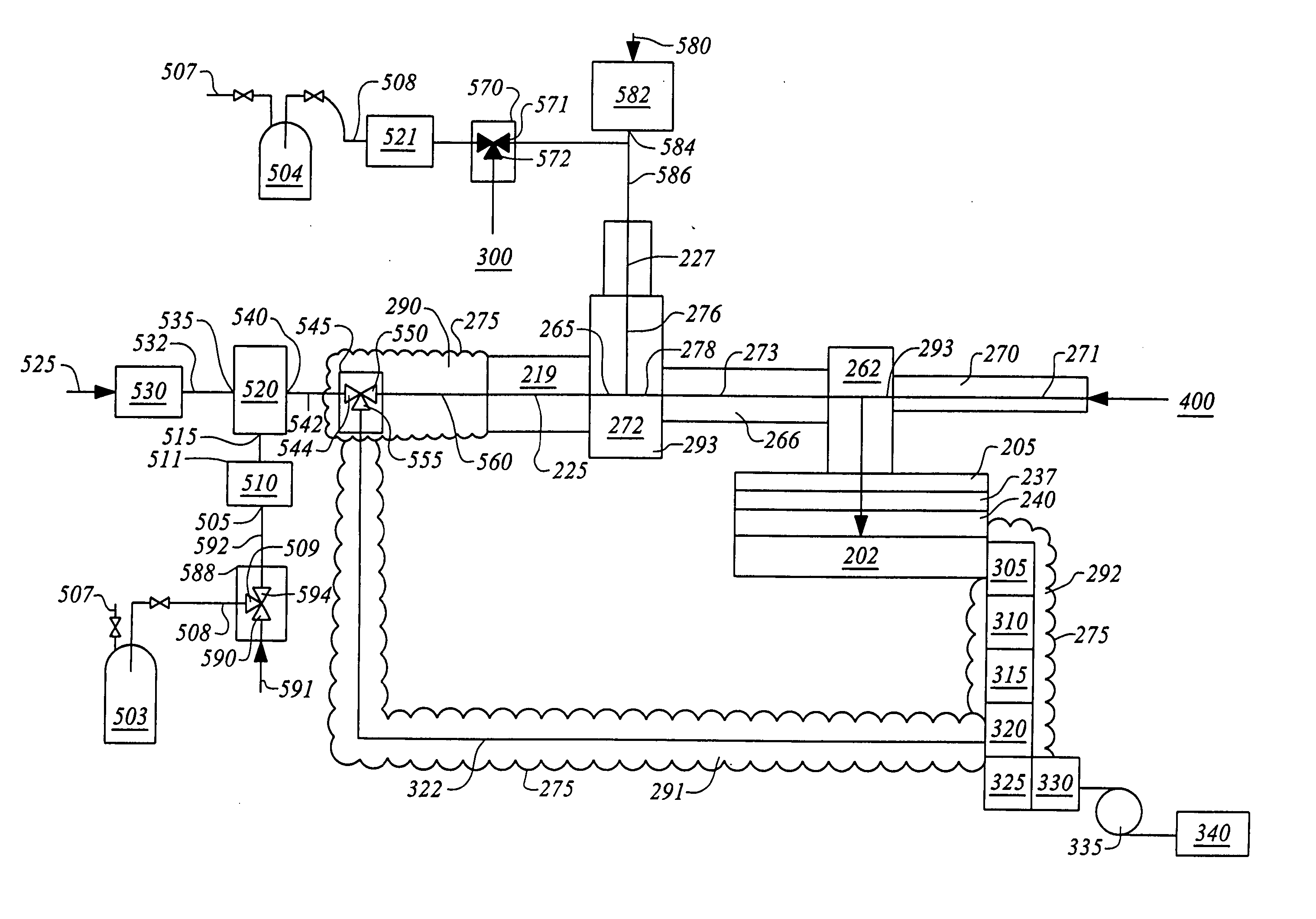

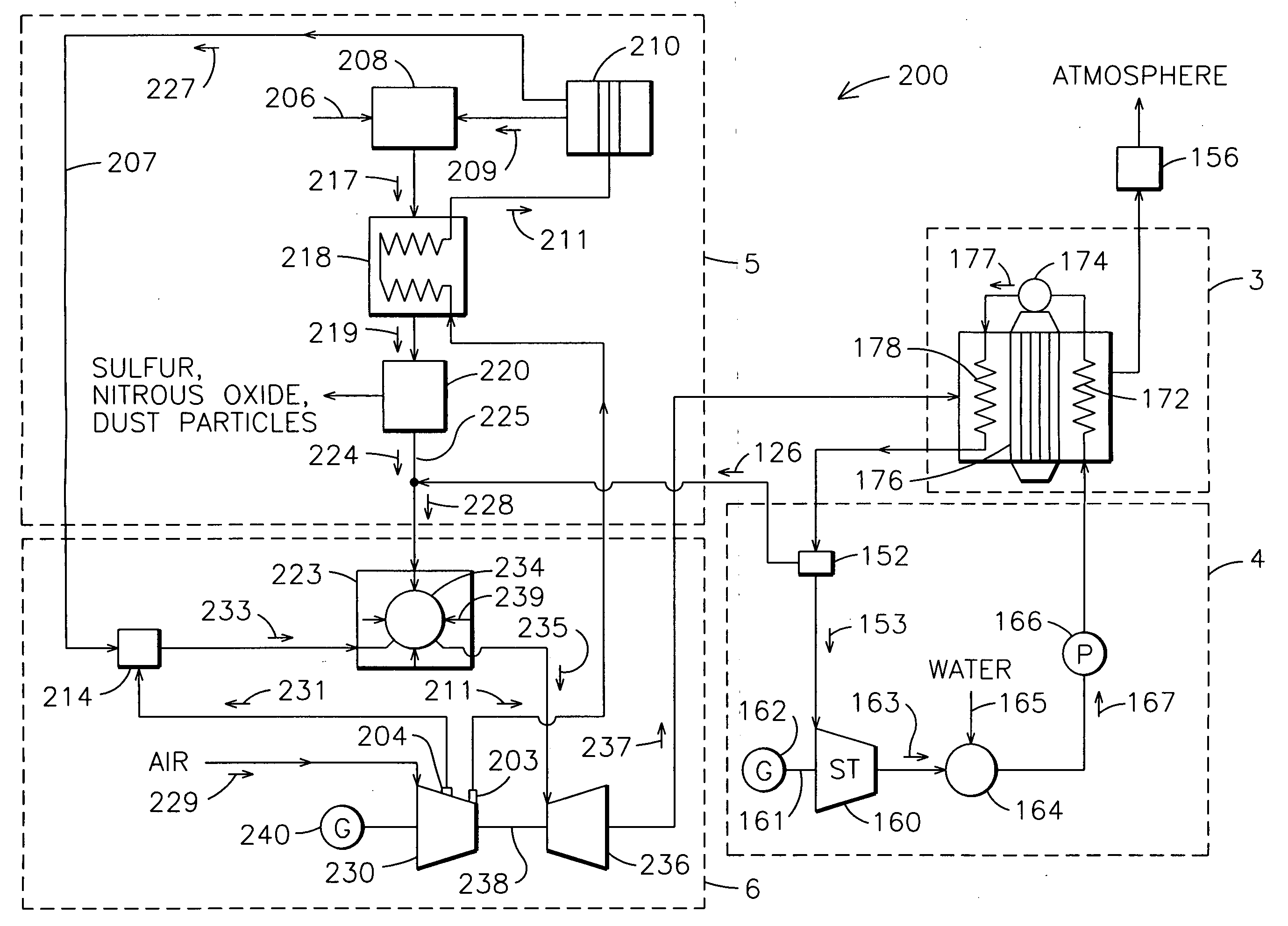

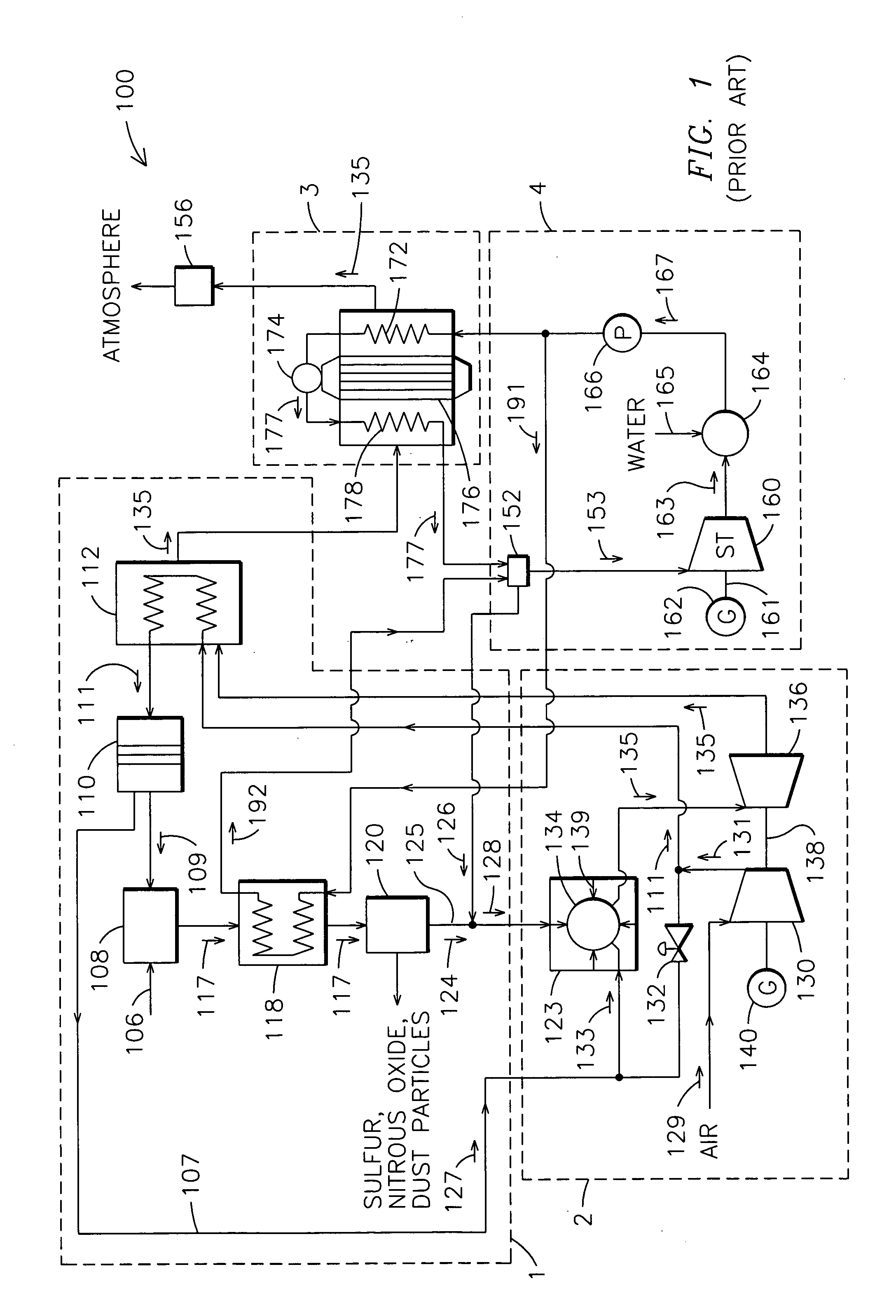

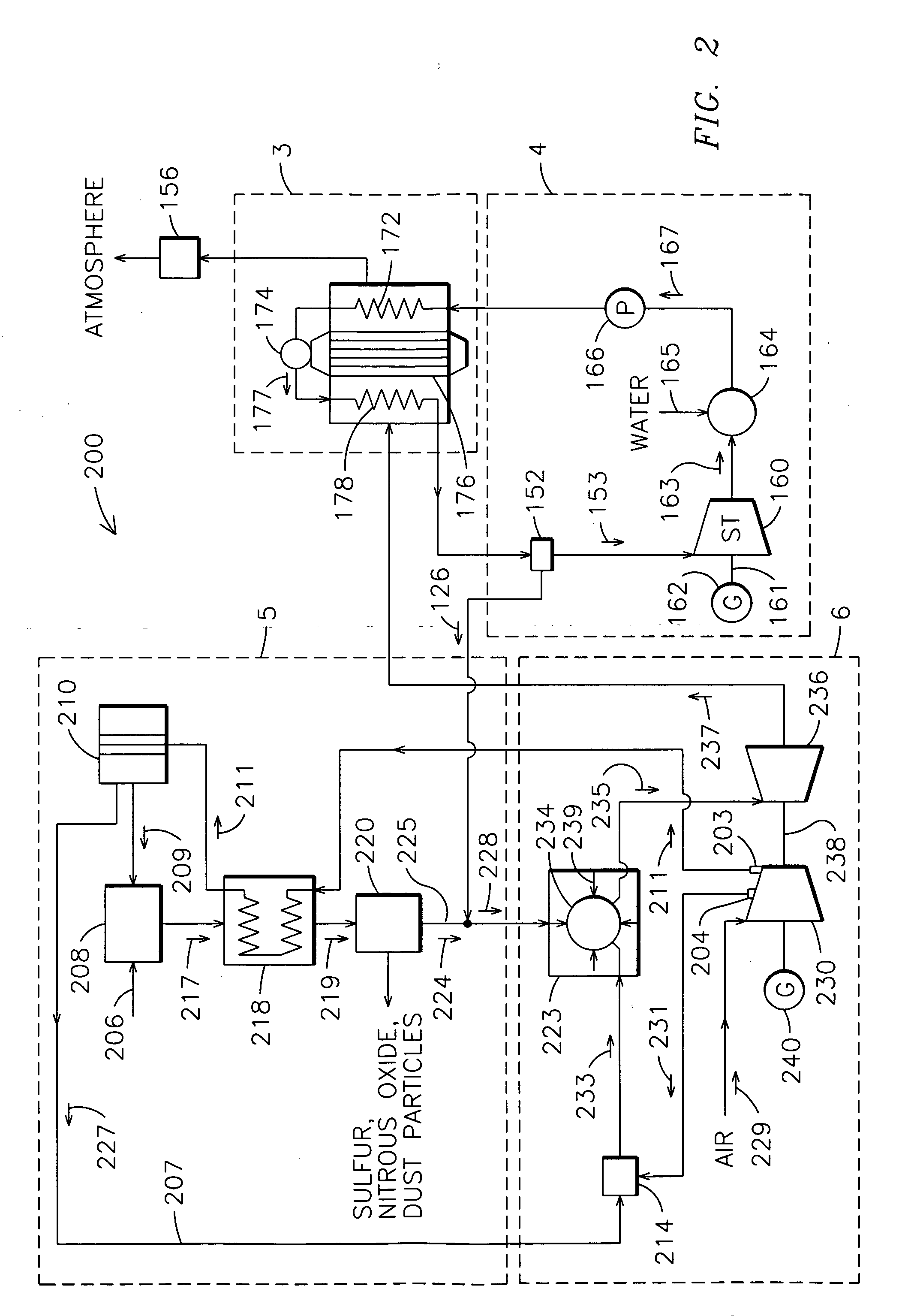

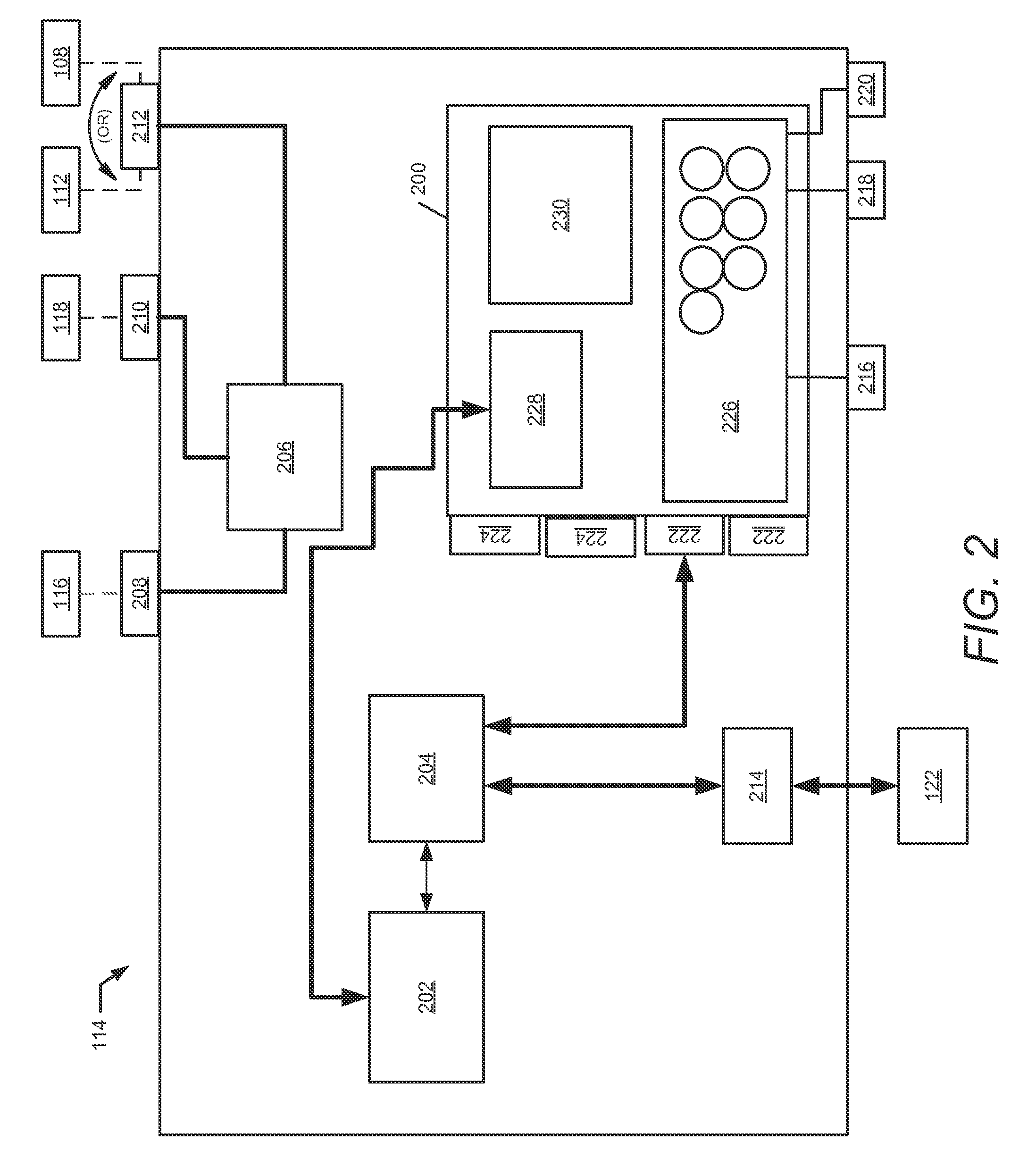

System and method for generation of high pressure air in an integrated gasification combined cycle system

InactiveUS20080115478A1Reduces capital equipment cost and operational costEasy temperature controlMuffle furnacesCombustion enginesAir separationProcess engineering

An integrated gasification combined cycle system. In one embodiment (FIG. 2) a system (200) includes an ion transport membrane air separation unit (210) for producing oxygen-enriched gas (209) and oxygen-depleted air (227), a gasification system (5) for generating syngas with the oxygen-enriched gas (209), a gas combustor (234) for reacting the syngas (224), and a subsystem configured to provide a first stream of air to the combustor (234) at a first pressure and to provide a second stream of air to the air separation unit (210) at a second pressure greater than the first pressure. The subsystem includes a compressor (230) having multi-pressure outlets (203, 204).

Owner:SIEMENS ENERGY INC

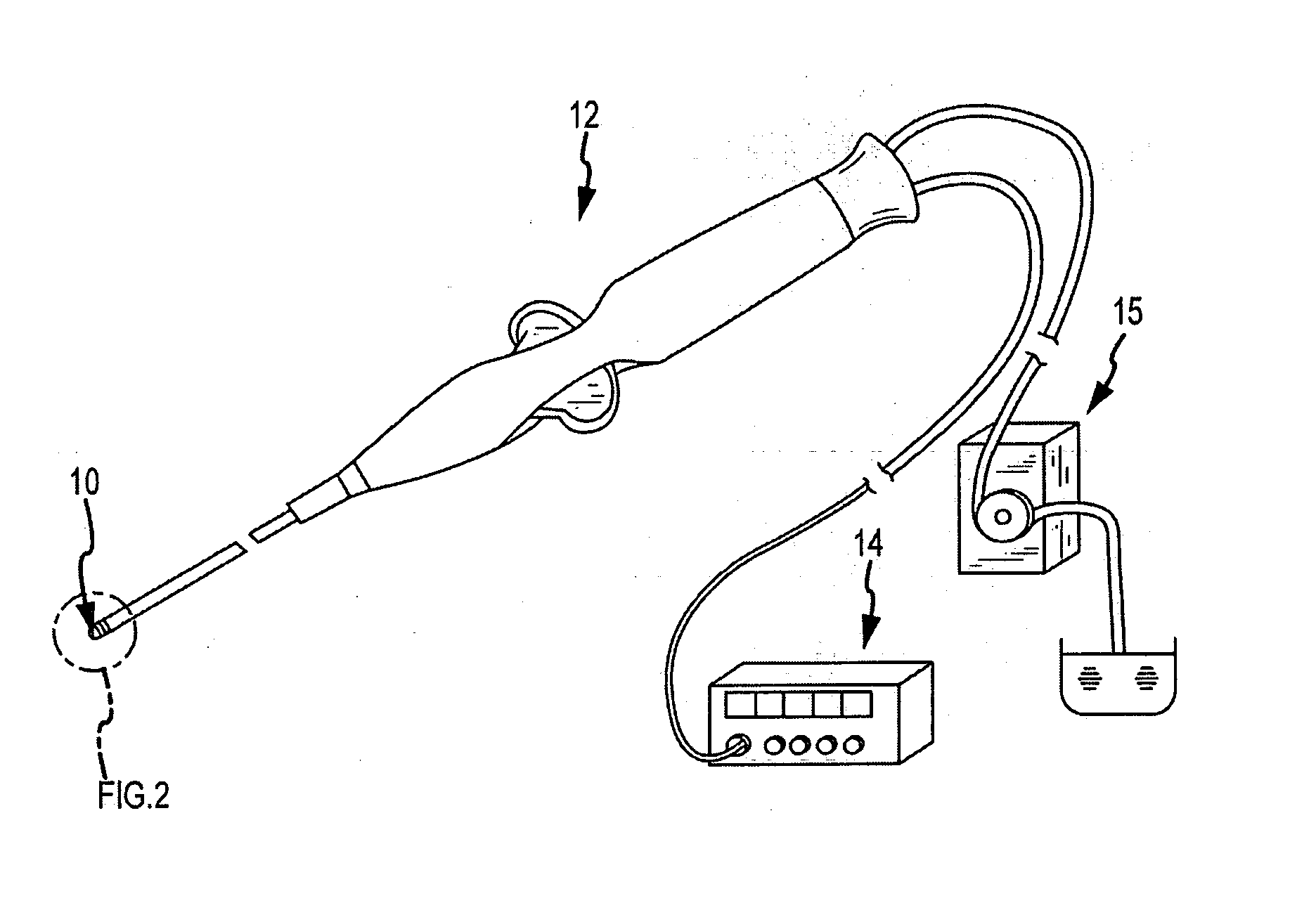

Irrigated ablation electrode assembly and method for control of temperature

ActiveUS20080071267A1Easy temperature controlEasy to monitorSurgical instruments for heatingSurgical instruments for irrigation of substancesMedicineCatheter

Embodiments of the present invention provide an irrigated catheter having irrigation fluid directed at target areas where coagulation is more likely to occur so as to minimize blood coagulation and the associated problems. In one embodiment, an irrigated ablation electrode assembly for use with an irrigated catheter device comprises a proximal member having at least one passageway for a fluid with an outlet disposed at an external surface of the proximal member; and a distal member connected with the proximal member and having an external surface. The distal member includes an electrode. The external surface of the proximal member and the external surface of the distal member meet at an intersection. The at least one passageway of the proximal member is configured to direct a fluid flow through the outlet toward a region adjacent the intersection.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

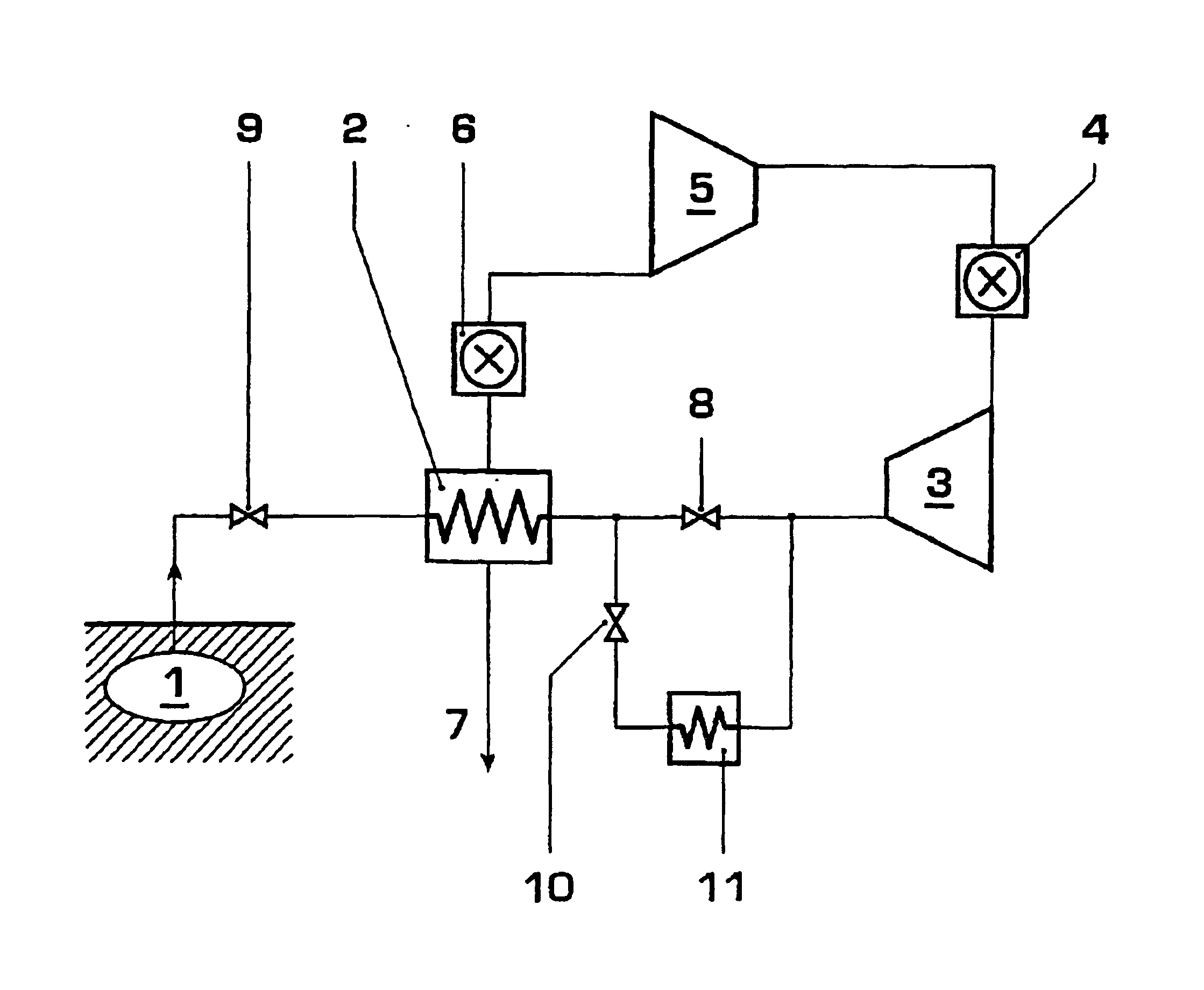

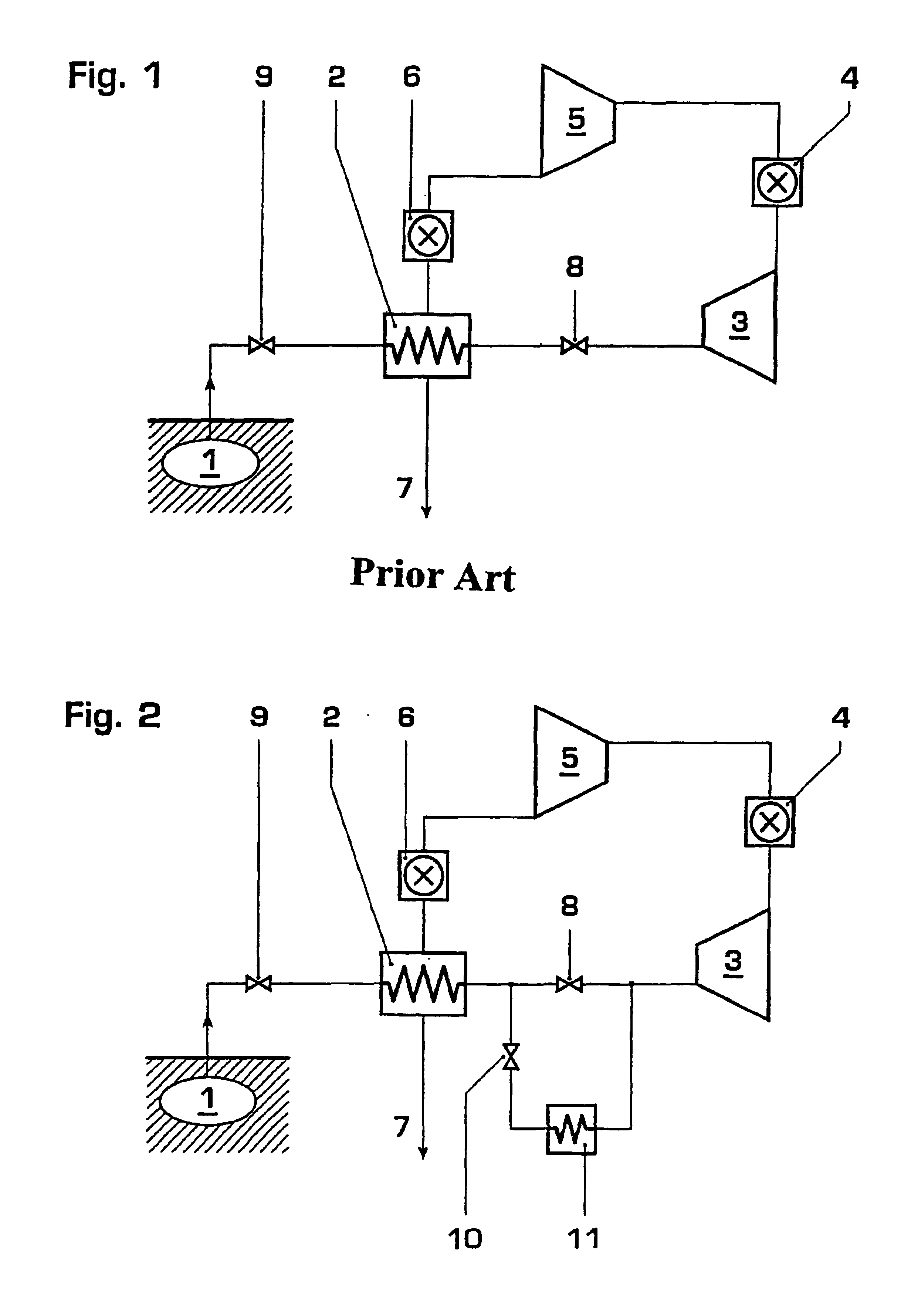

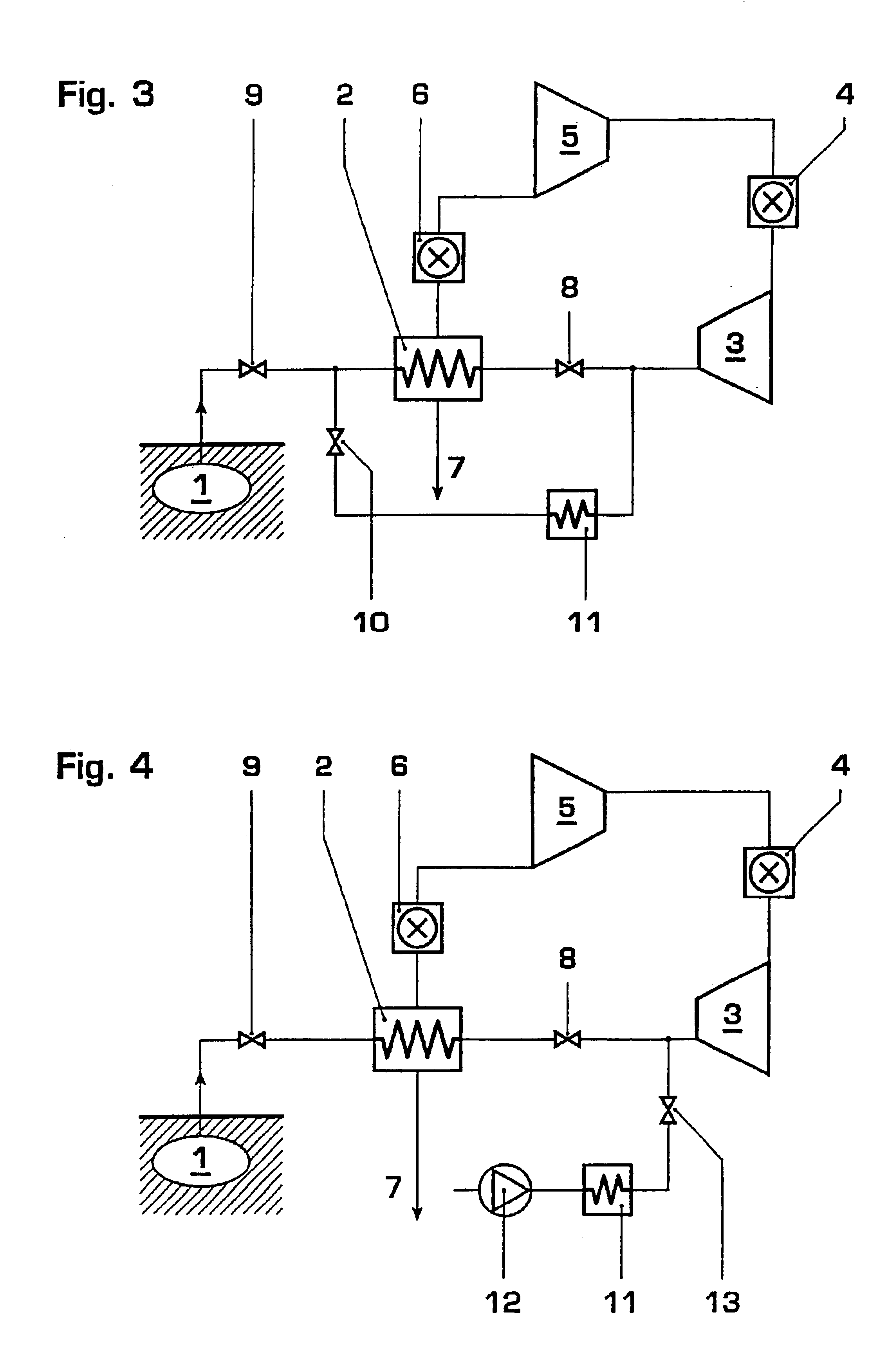

Compressed air energy storage system having a standby warm keeping system including an electric air heater

InactiveUS6848259B2Reduce thermal stressEasy temperature controlGas turbine plantsJet propulsion plantsTemperature controlCombustor

A compressed air energy storage system comprises a cavern (1) for stored compressed air and a system for providing the compressed air to a power train (3, 5), this system including a recuperator (7) and a first valve arrangement (8) that controls the flow of the compressed air from the recuperator and to the power train (3, 5). A system for warm-keeping of the power train (3, 5) during stand-by operation of the compressed air energy storage system comprises the recuperator (2) and / or an auxiliary electrical air heater (11) and a second valve arrangement (10, 13) for controlling the airflow for warm-keeping. The system for warm-keeping of the power train allows improved temperature control and avoids disadvantages associated with a warm-keeping system having a combustor.

Owner:GENERAL ELECTRIC TECH GMBH

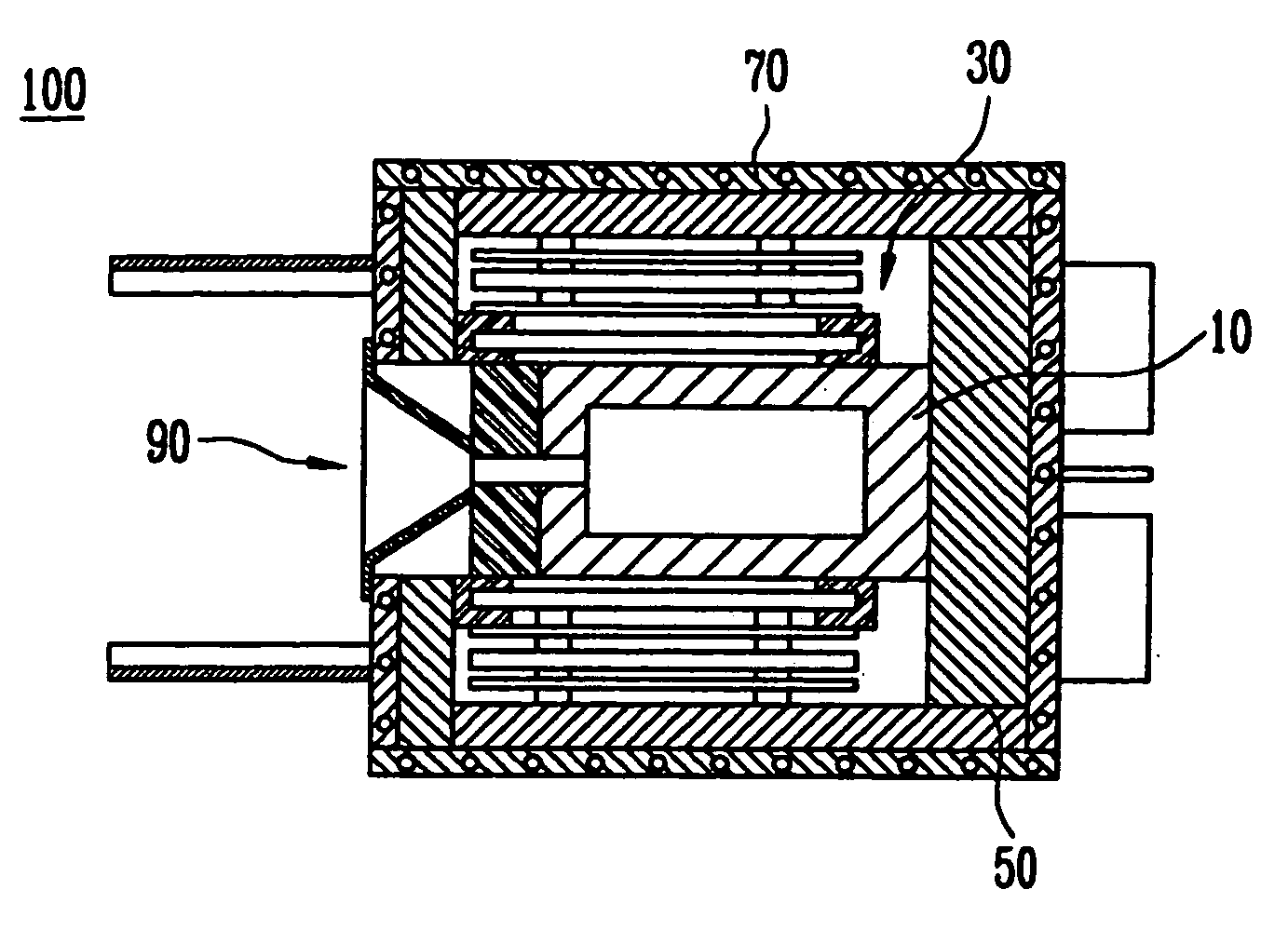

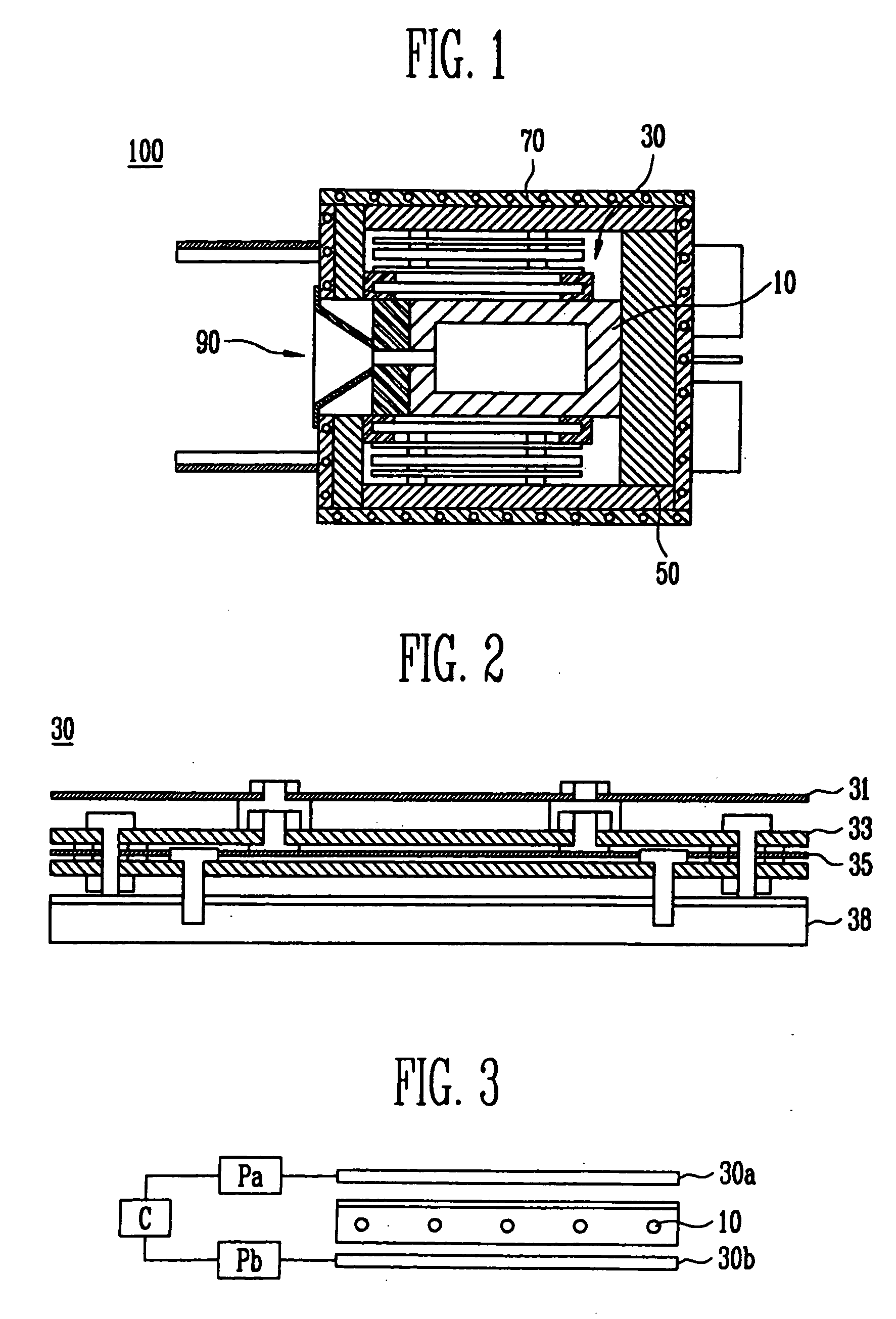

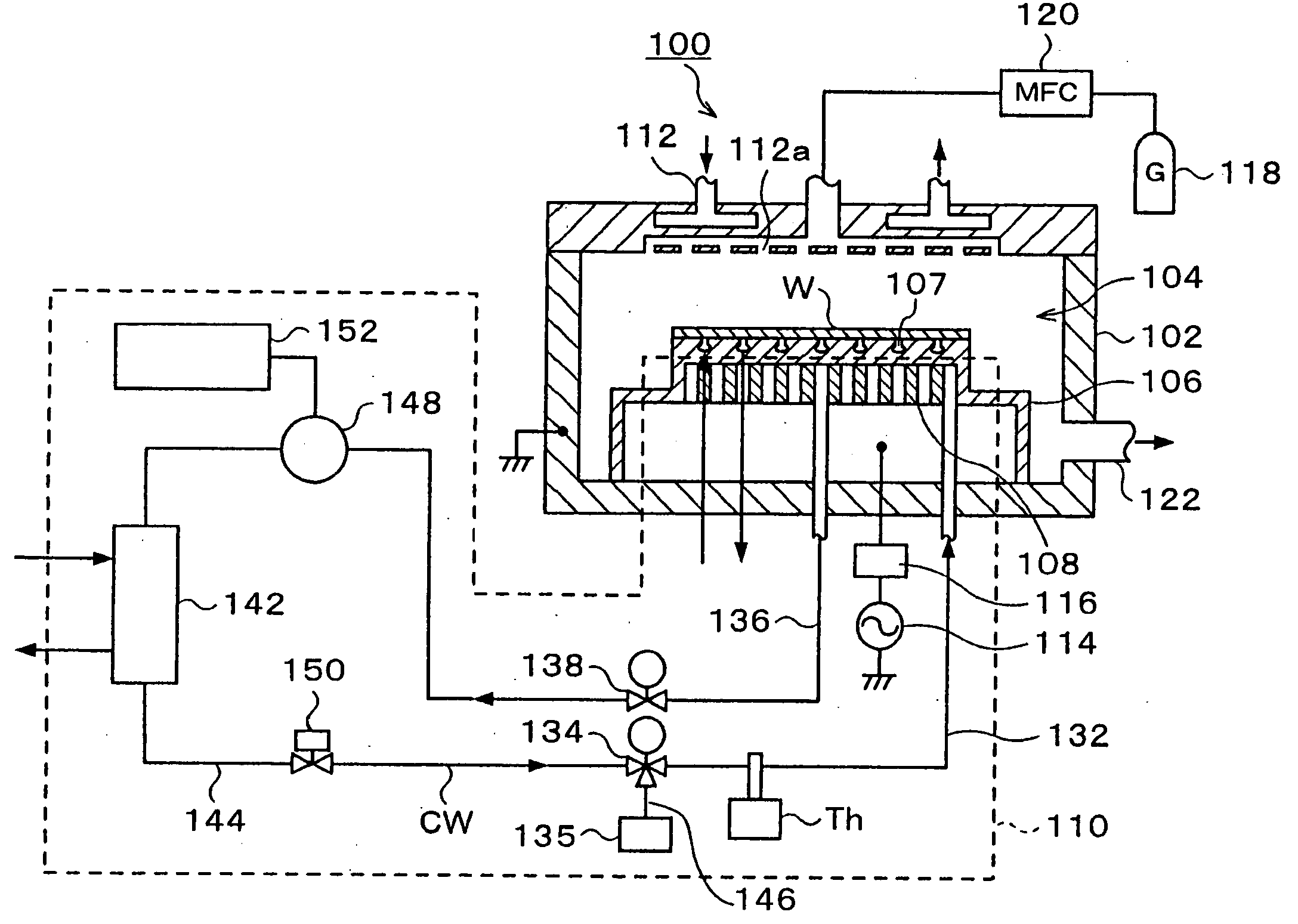

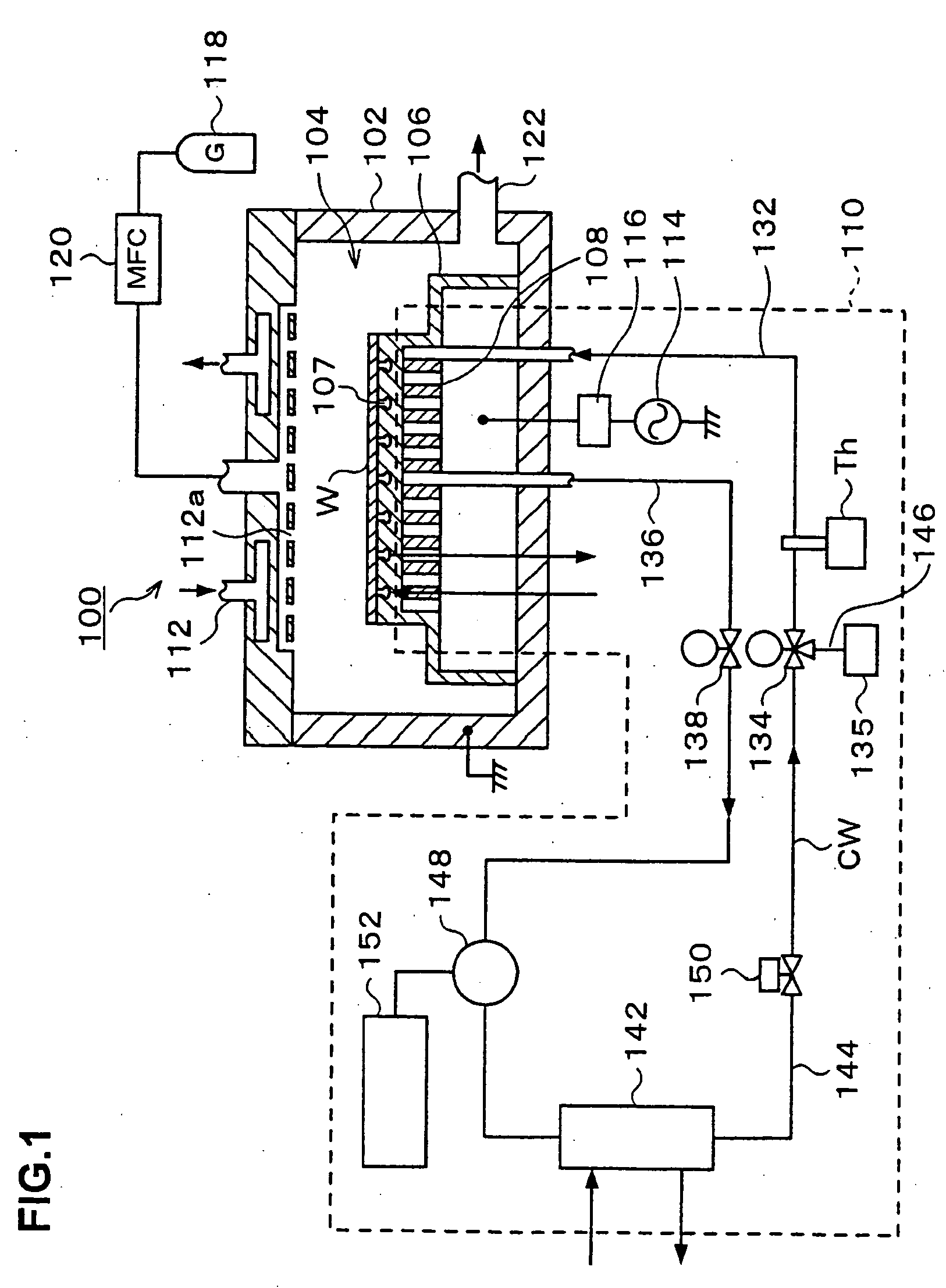

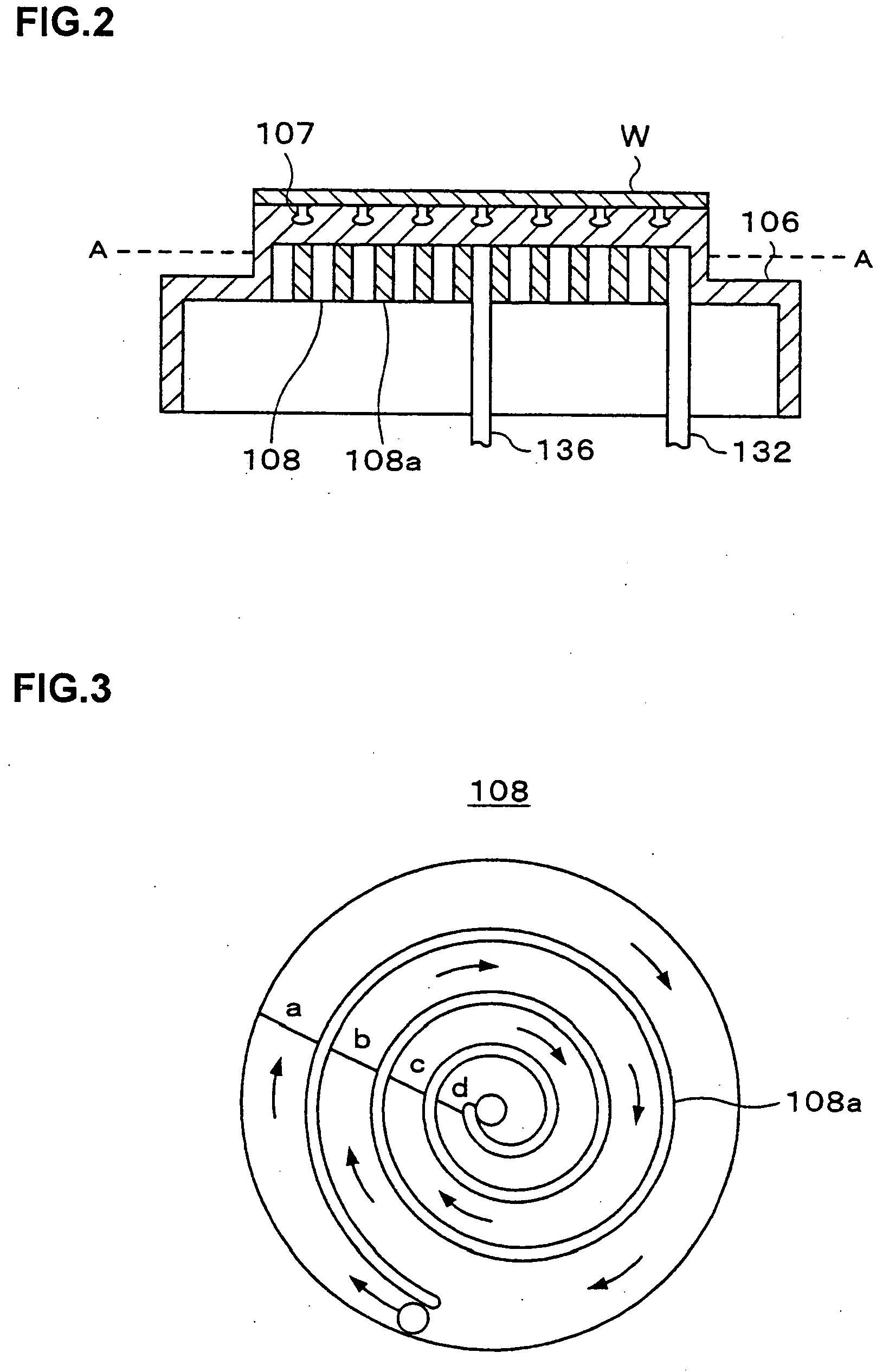

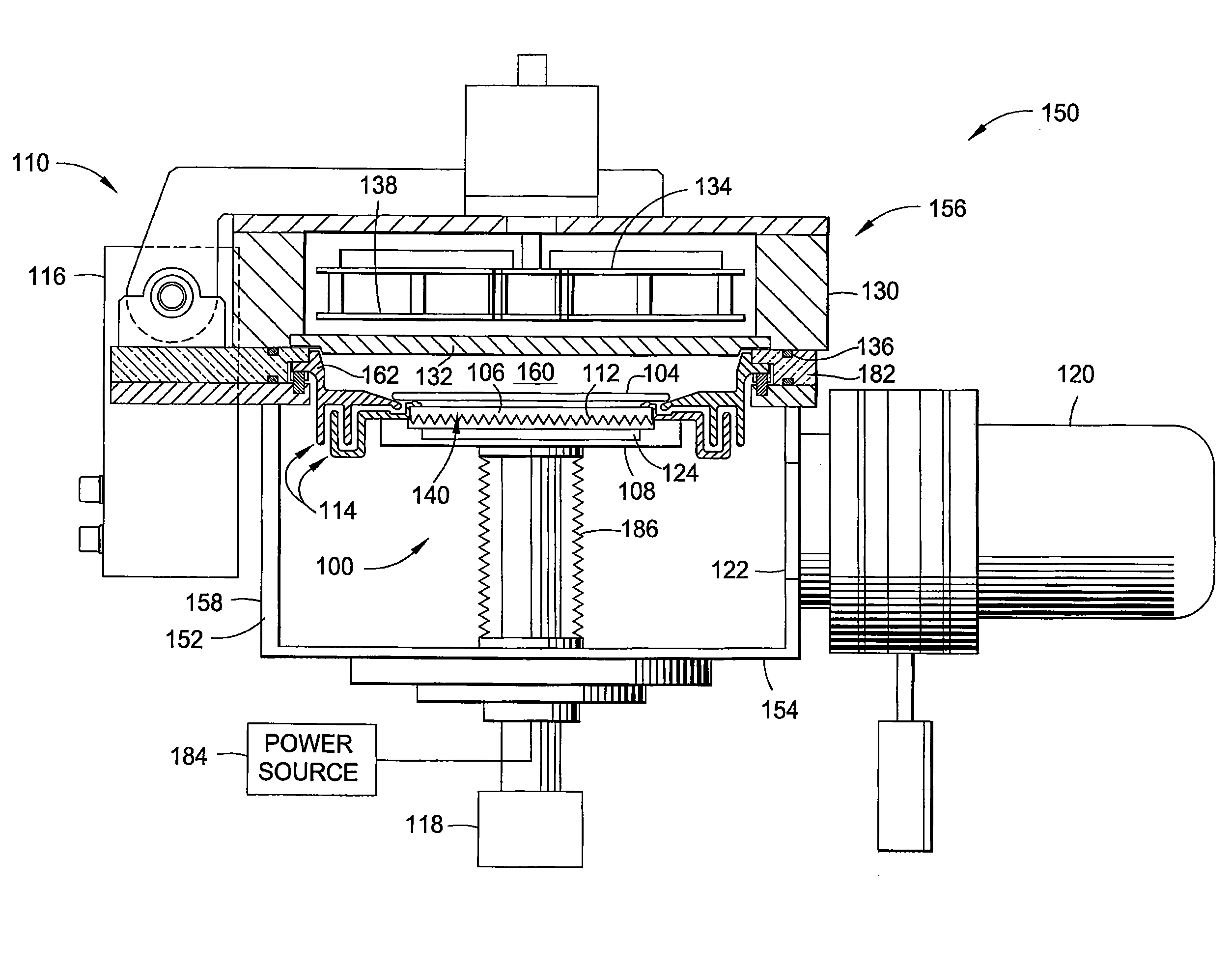

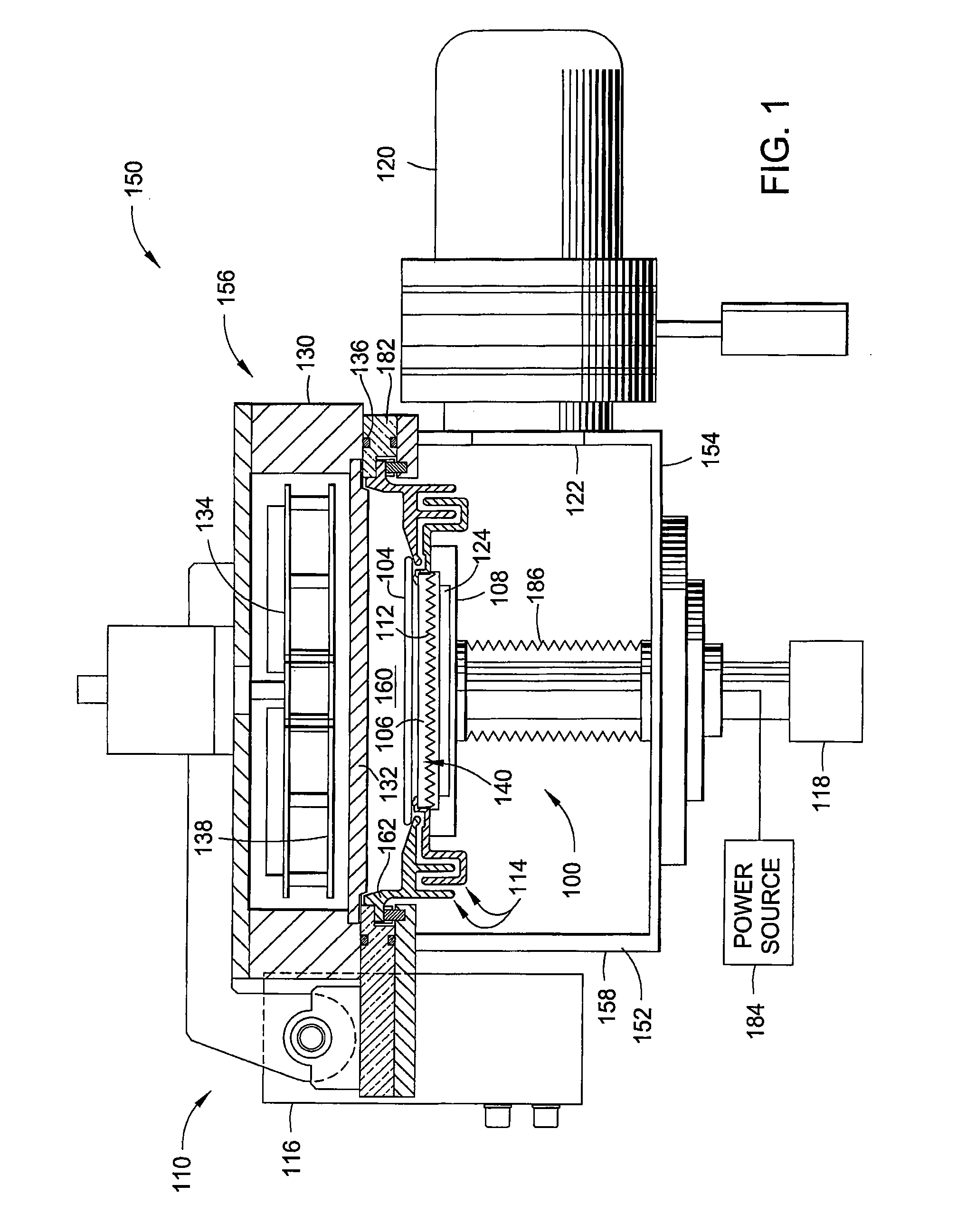

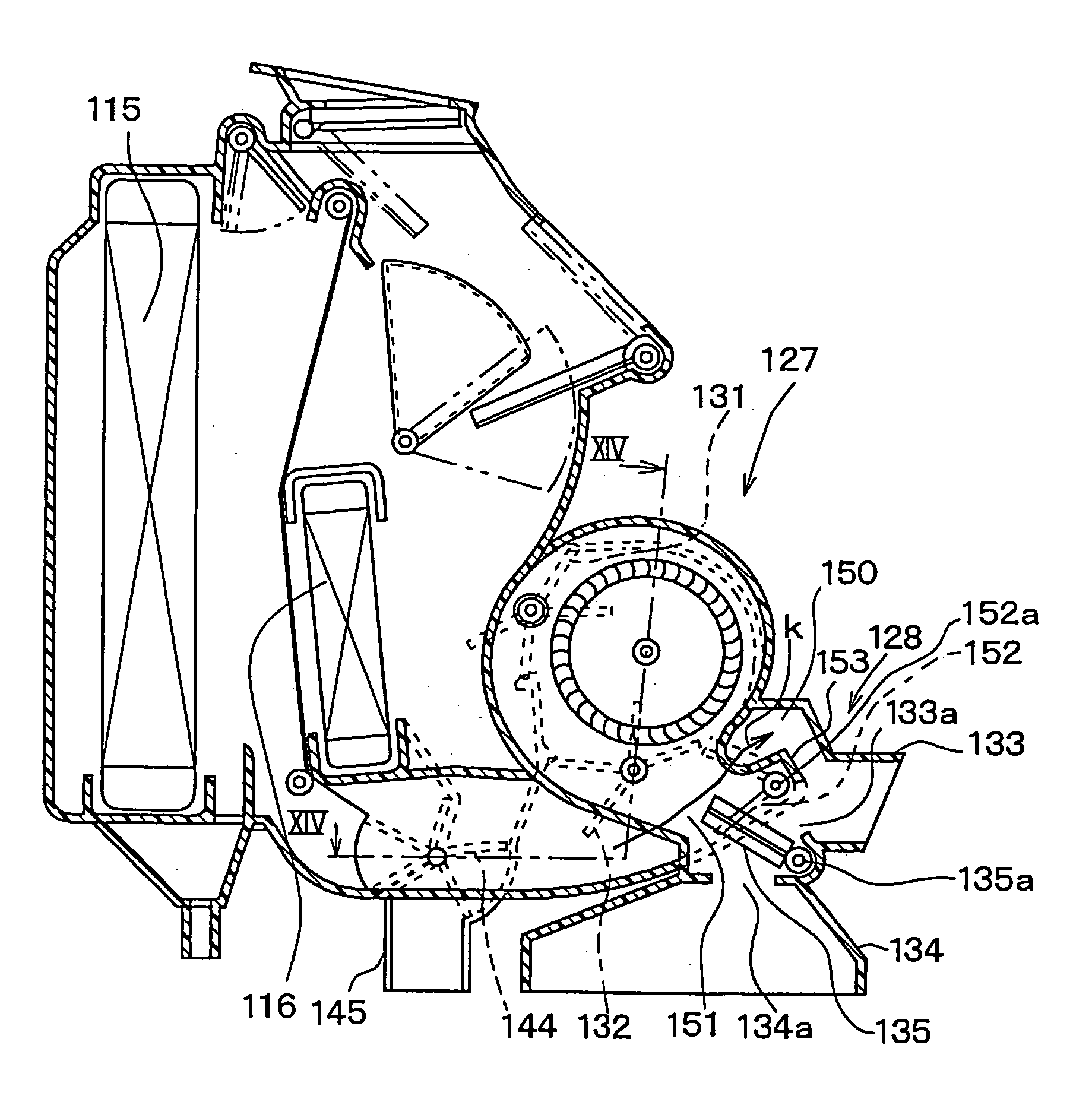

Processing apparatus and processing apparatus maintenance method

InactiveUS20050155373A1Reduced installation areaSave energyElectric discharge tubesCompression machines with non-reversible cycleTemperature controlEngineering

The electrode temperature control device in a processing apparatus 100 includes a freezing circuit 110 comprising a compressor 148, a condenser 142, an expansion valve 150 and an evaporator 108 with the evaporator disposed inside a lower electrode 106. This electrode temperature control device does not require components such as a coolant tank for storing the coolant, a pump for supplying the coolant to the processing apparatus, a heater for adjusting the temperature of the coolant and a heat exchanger for exchanging heat between a primary coolant and a secondary coolant. Thus, the production cost can be lowered, a reduction in installation area through miniaturization of the apparatus is achieved and more efficient use of energy is achieved as well. In addition, by using CO2 as the coolant, the GWP value can be reduced to approximately {fraction (1 / 8000)} to {fraction (1 / 7000)} that of Freon.

Owner:TOKYO ELECTRON LTD

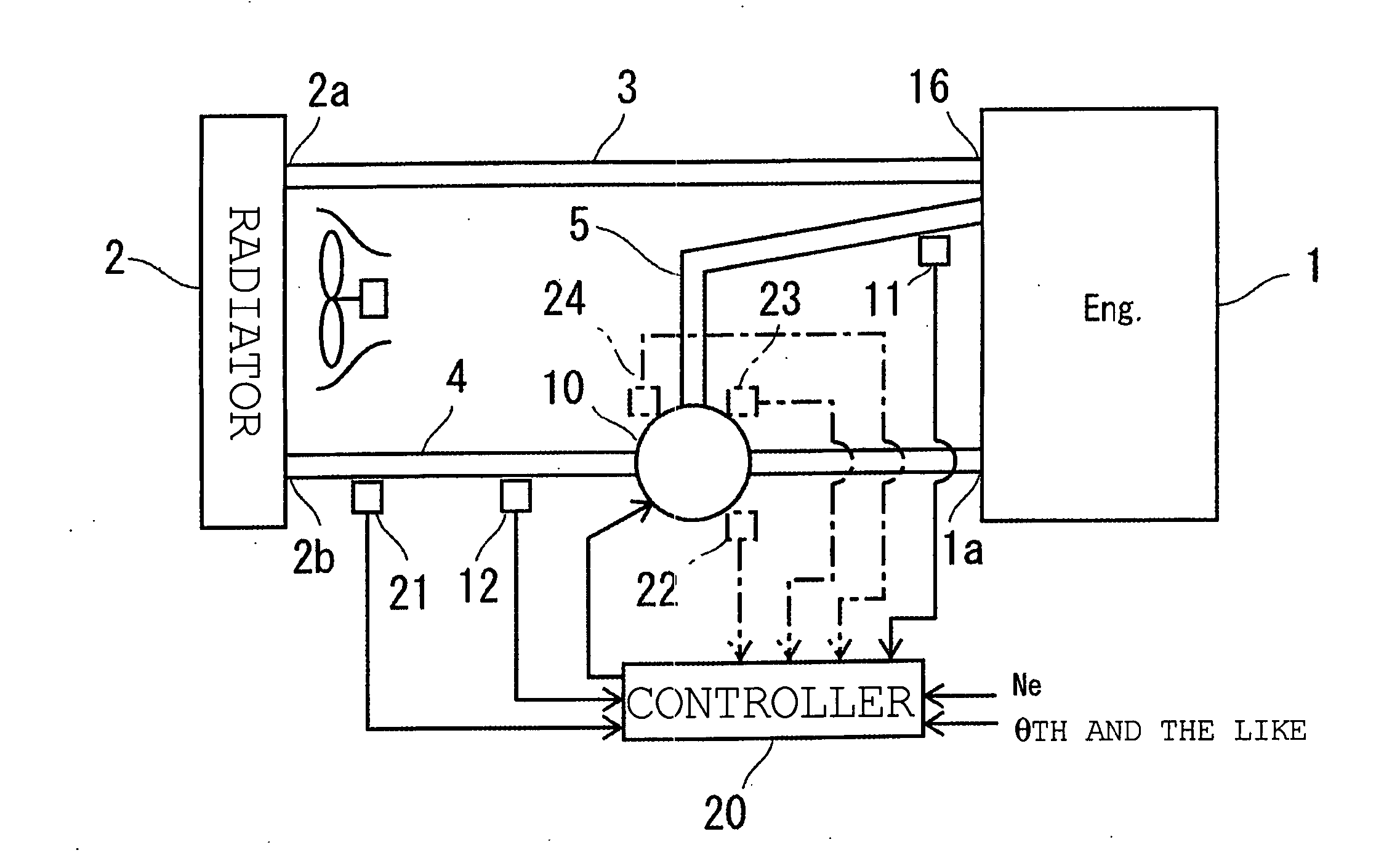

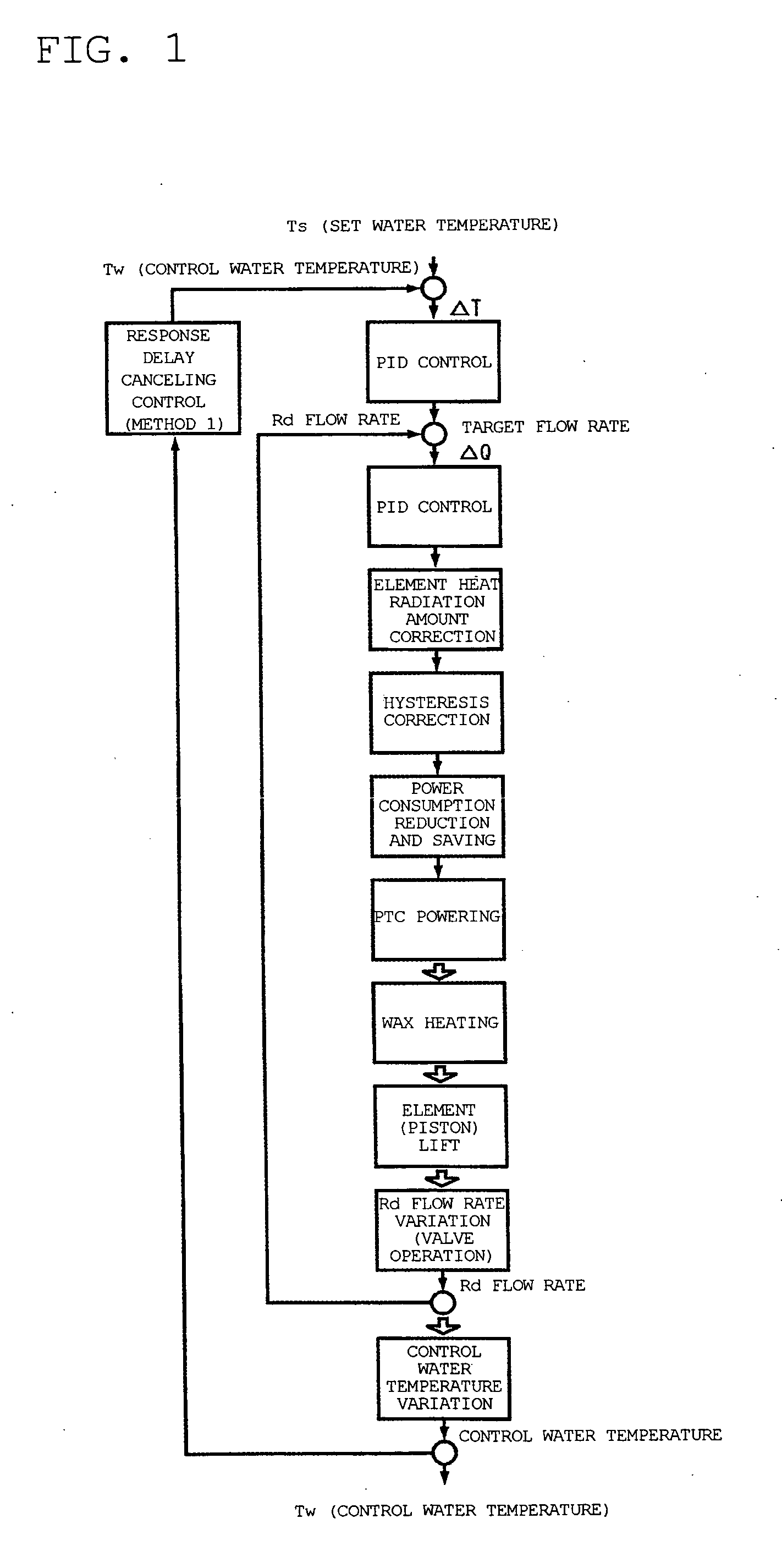

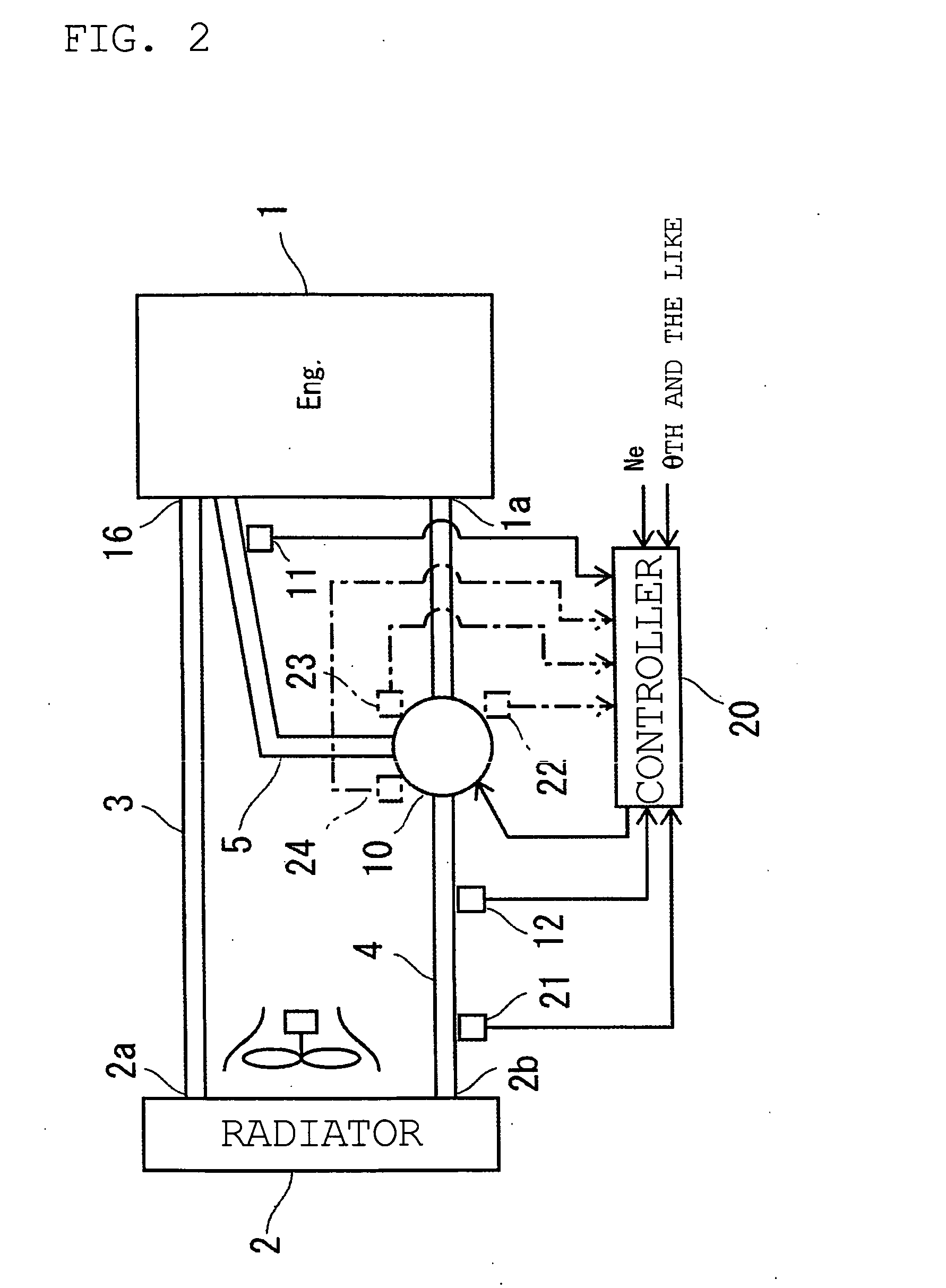

Method of controlling electronic controlled thermostat

ActiveUS20050006487A1Reliable improvement in fuel consumptionPoor temperature controlTemperature control without auxillary powerElectrical controlResponse delayEngineering

An electronically controlled thermostat control method is obtained which makes it possible to eliminate the response delay from the time that the required cooling water temperature is set to the time that the actual cooling water temperature reaches the set water temperature by controlling the flow rate, and to realize high cooling water temperature tracking characteristics with a high degree of precision at a low cost. The method of the present invention is characterized in that in an electronically controlled thermostat which is used to control the cooling water temperature of an engine, and which comprises an actuator that can arbitrarily vary the degree of valve opening without depending only on the actual cooling water temperature, the actuator is controlled by the control controller, which has means for calculating the elapsed time from the powering of the actuator to the variation of the water temperature for predicting the water temperature after the elapsed time when the cooling water temperature is controlled to an arbitrarily set water temperature, and the actuator is controlled in advance in accordance with the above-described predicted water temperature.

Owner:NIPPON THERMOSTAT CO LTD

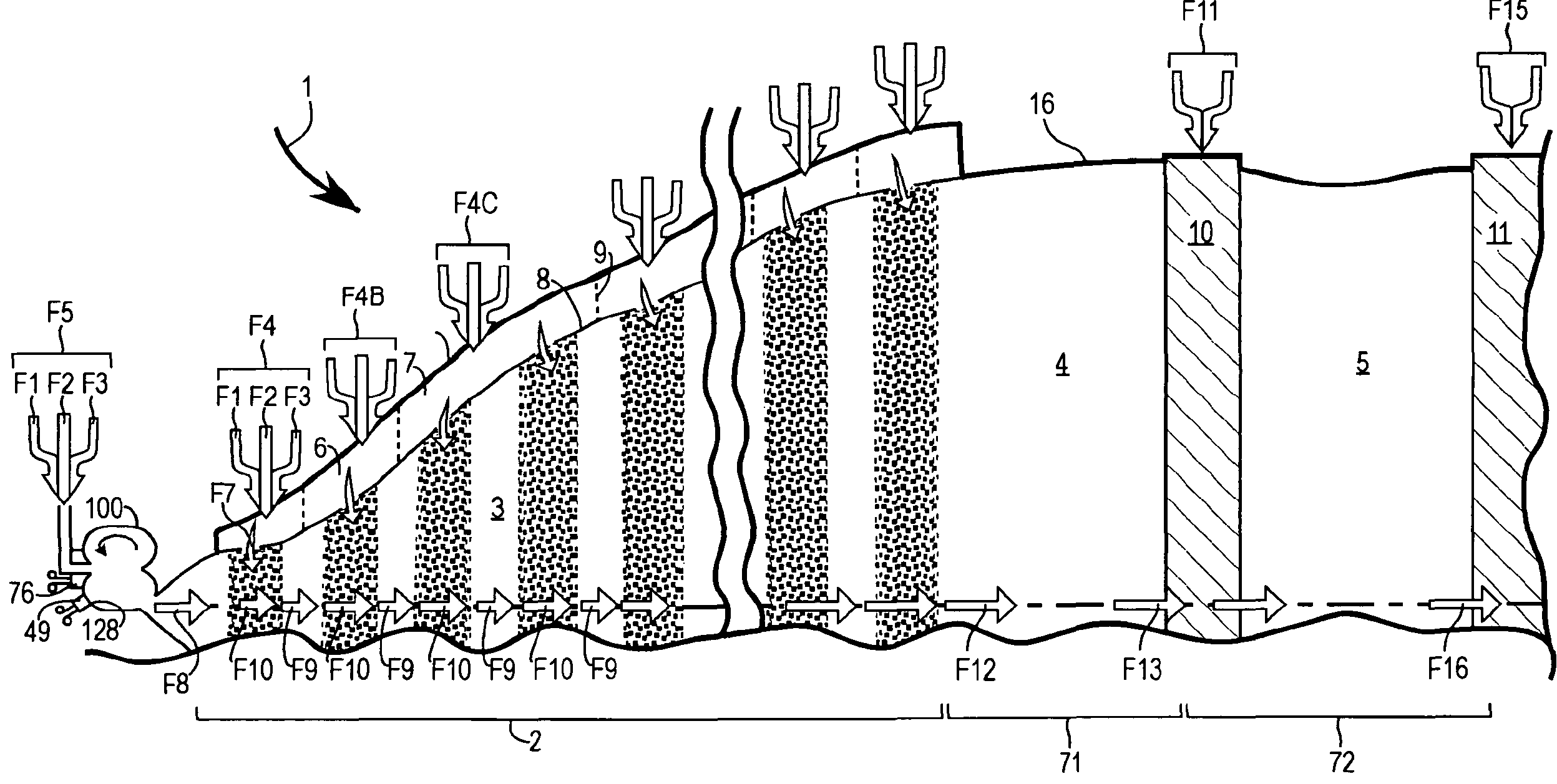

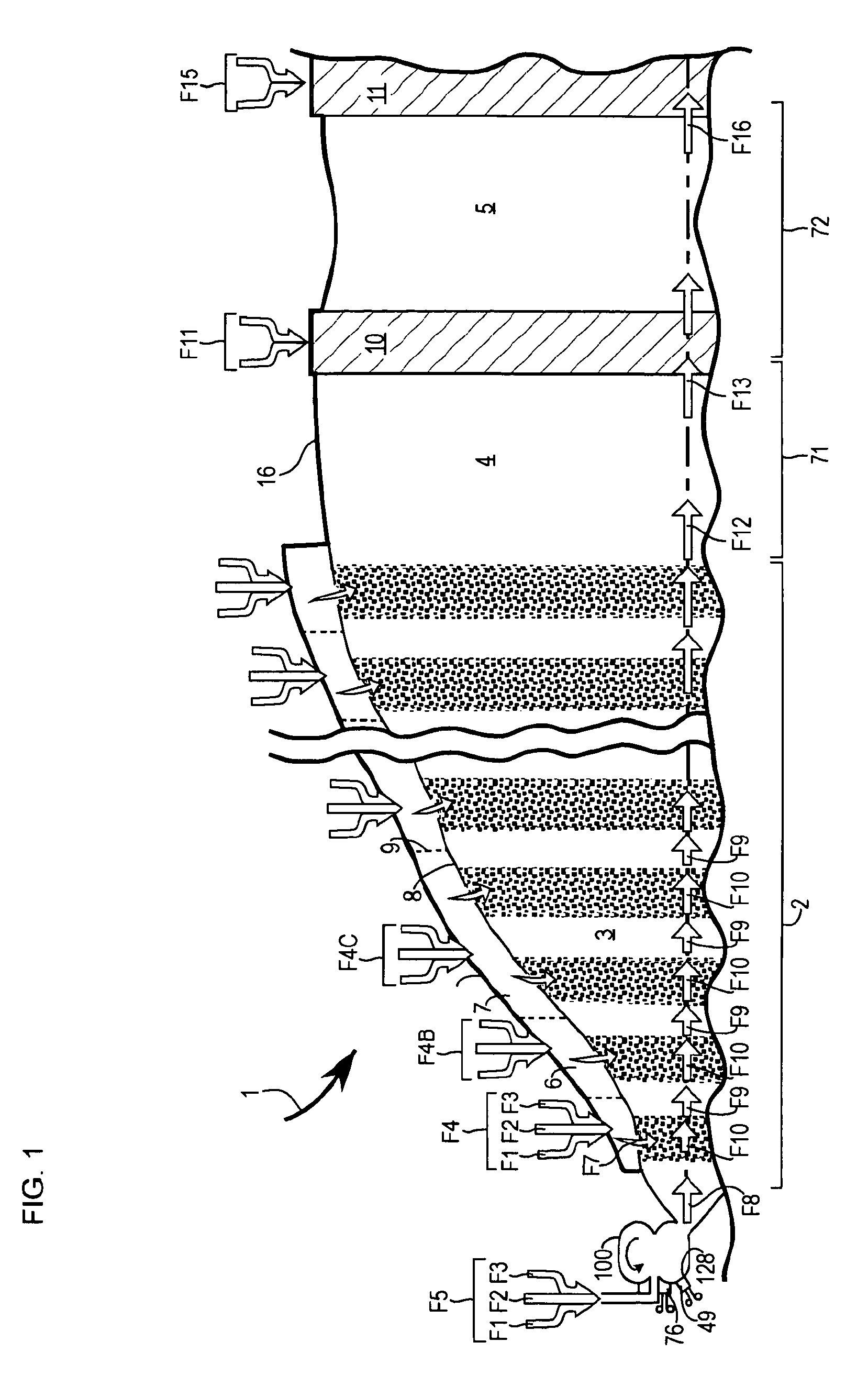

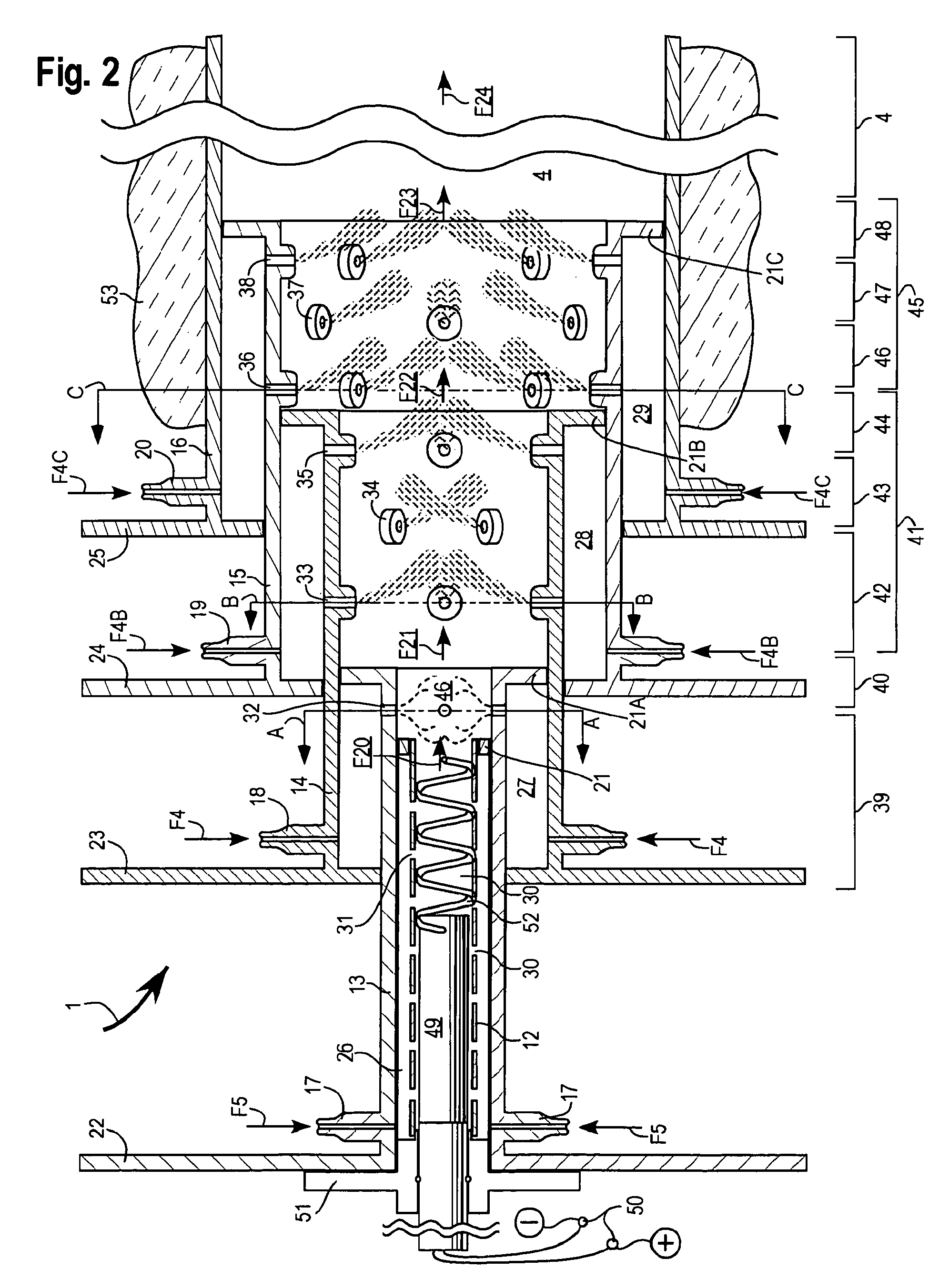

Low emissions combustion apparatus and method

ActiveUS7788897B2Well mixedImprove stabilityGas turbine plantsIndirect carbon-dioxide mitigationCombustionDiluent

Clean combustion and equilibration equipment and methods are provided to progressively deliver, combust and equilibrate mixtures of fuel, oxidant and aqueous diluent in a plurality of combustion regions and in one or more equilibration regions to further progress oxidation of products of incomplete combustion, in a manner that sustains combustion while controlling temperatures and residence times sufficiently to reduce CO and NOx emissions to below 25 ppmvd, and preferably to below 3 ppmvd at 15% O2.

Owner:VAST HLDG LLC

Active night vision cooling system

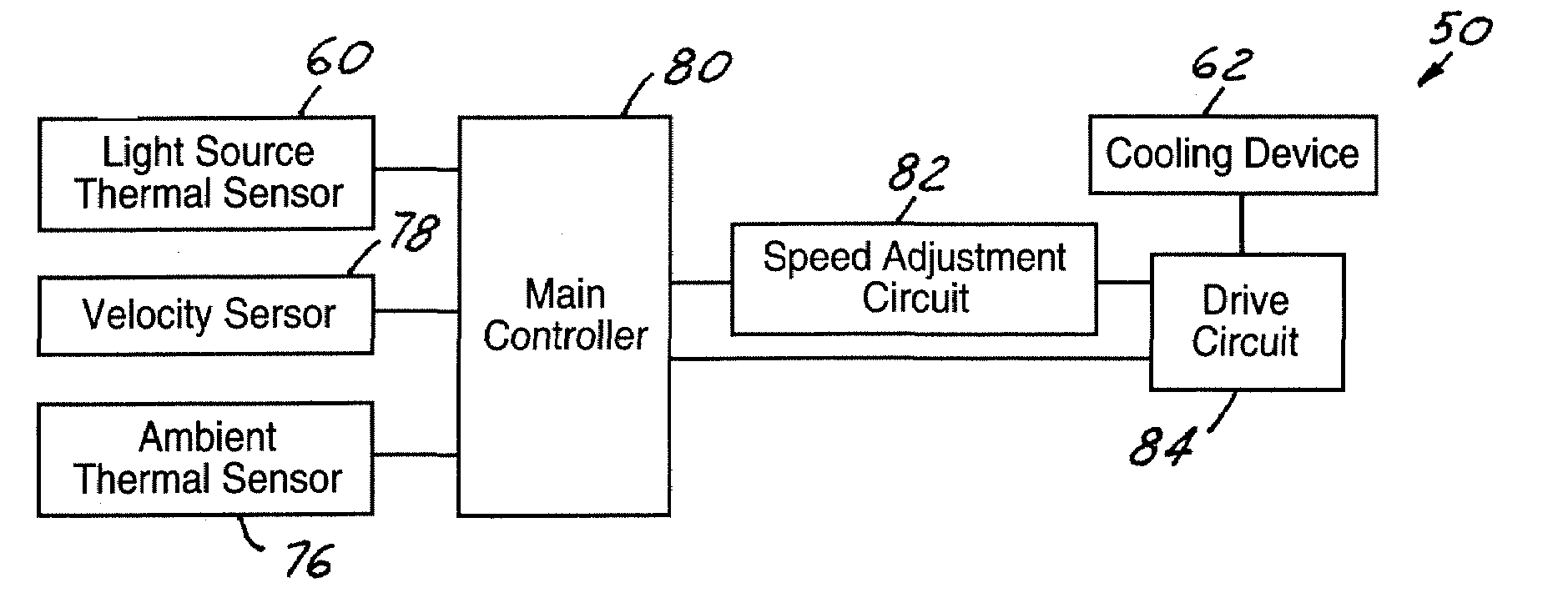

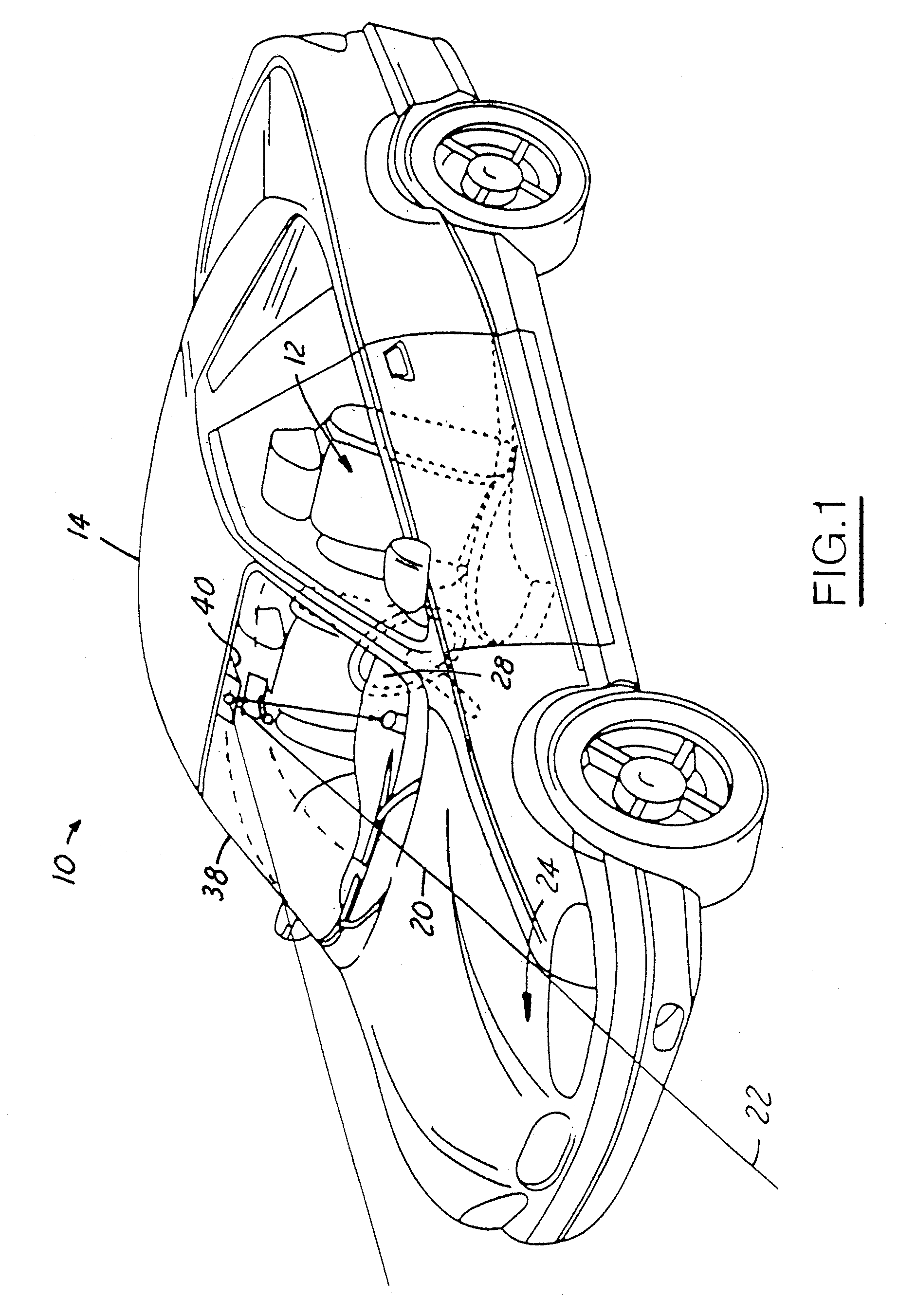

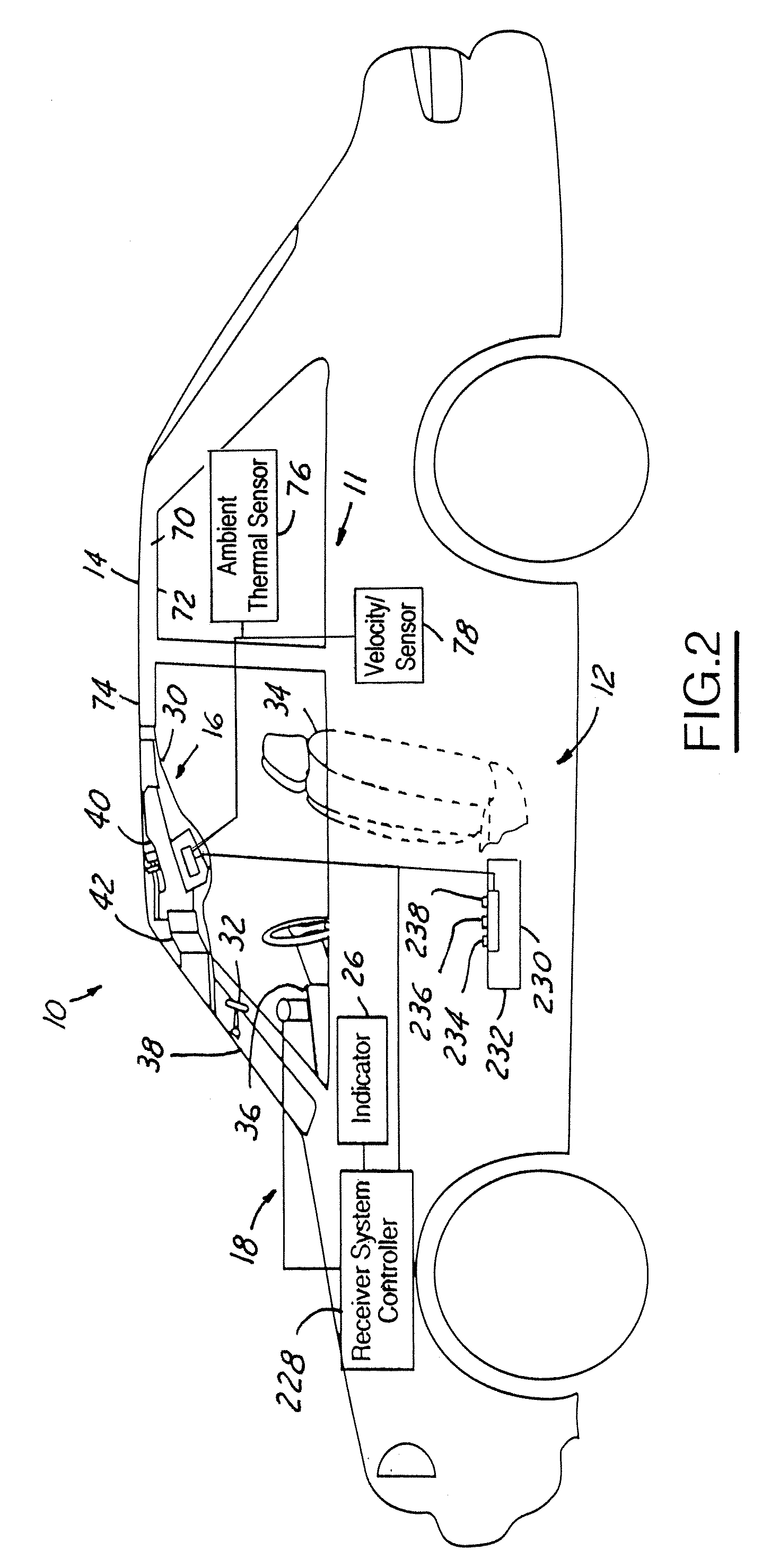

InactiveUS7015470B2Efficiently adjusts temperatureNoise minimizationLighting heating/cooling arrangementsSighting devicesNight visionEngineering

A thermal control system (11) for a light source (46) of a vision system (10) includes a cooling assembly (61) that has a cooling device (62) and is thermally coupled to the light source (46). A thermal sensor (60) is thermally coupled to the light source (46) and generates a light source temperature signal. A control circuit (50) is coupled to the cooling assembly (61) and to the thermal sensor (60) and operates the cooling device (62) when the light source temperature signal is above a minimum temperature limit.

Owner:LEAR CORP

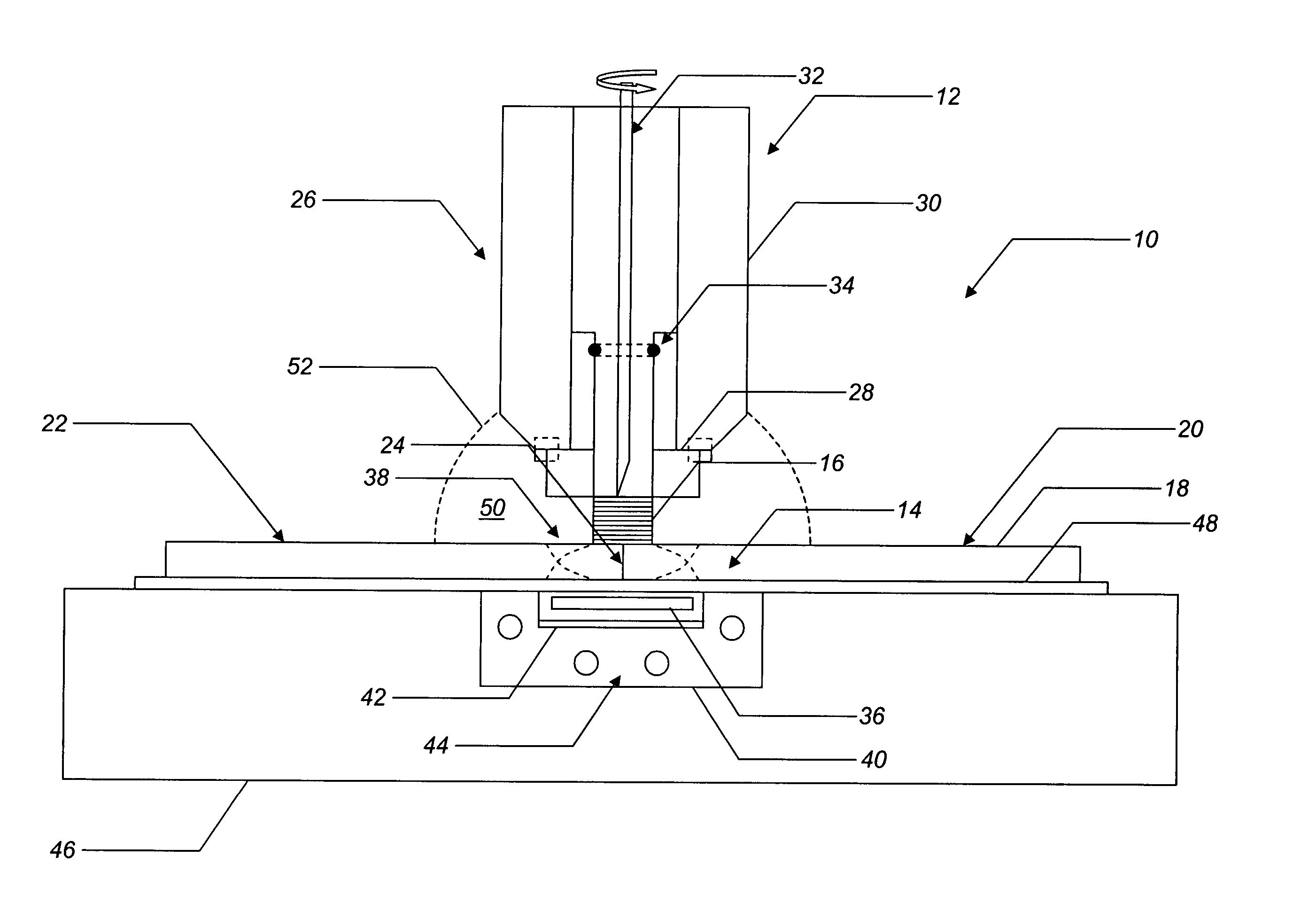

Friction stir welding apparatus and associated thermal management systems and methods

ActiveUS20050045694A1Good mechanical integrityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThermal management system

The present invention provides a friction stir welding apparatus and associated thermal management systems and methods for joining one or more similar or dissimilar materials forming a workpiece along a joint to be welded. The friction stir welding apparatus includes a pin tool apparatus selectively disposed adjacent to and in direct contact with a first surface of the workpiece along the joint to be welded and a heating member disposed adjacent to a second surface of the workpiece along the joint to be welded, the heating member operable for controllably heating at least a portion of the workpiece adjacent to the joint to be welded. The friction stir welding apparatus also includes an annular spindle having an interior portion and an axis, the interior portion of the annular spindle at least partially defining one or more cooling channels, the one or more cooling channels operable for containing a cooling fluid. The friction stir welding apparatus further includes a shoulder disposed adjacent to the annular spindle and substantially aligned with the axis of the annular spindle and a pin tool disposed adjacent to the shoulder and substantially aligned with the axis of the annular spindle. The cooling fluid is operable for cooling at least one of the shoulder and the pin tool.

Owner:GENERAL ELECTRIC CO

Non-contact process kit

ActiveUS20080141942A1Excellent and predictable temperature controlProcess can be minimizedCellsVacuum evaporation coatingEngineeringPhysical vapor deposition

A process kit for use in a physical vapor deposition (PVD) chamber, along with a PVD chamber having a non-contact process kit are provided. In one embodiment, a process kit includes a generally cylindrical shield that has a substantially flat cylindrical body, at least one elongated cylindrical ring extending downward from the body, and a mounting portion extending upwards from an upper surface of the body. In another embodiment, a process kit includes a generally cylindrical deposition ring. The deposition ring includes a substantially flat cylindrical body, at least one downwardly extending u-channel coupled to an outer portion of the body, an inner wall extending upward from an upper surface of an inner region of the body, and a substrate support ledge extending radially inward from the inner wall.

Owner:APPLIED MATERIALS INC

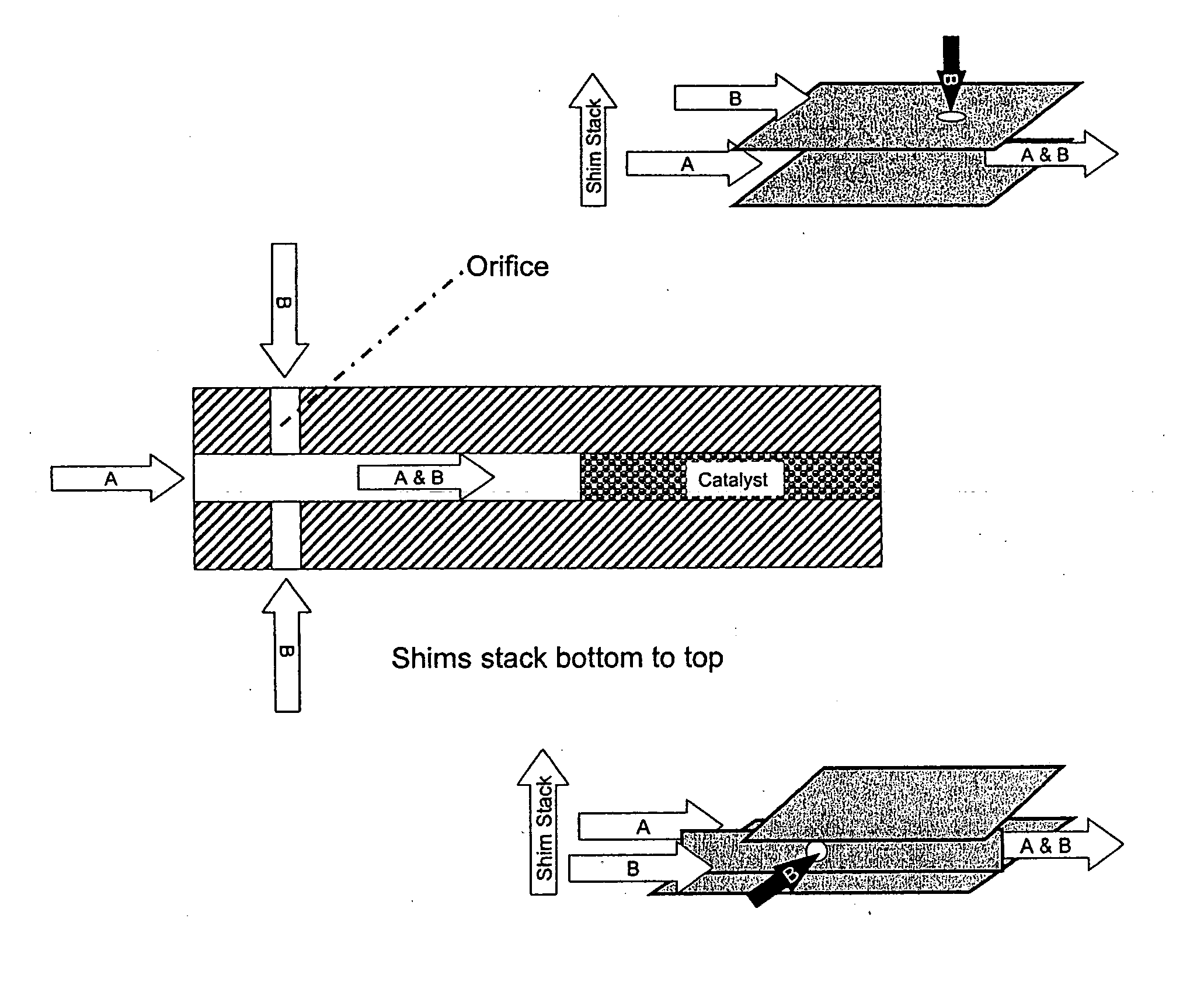

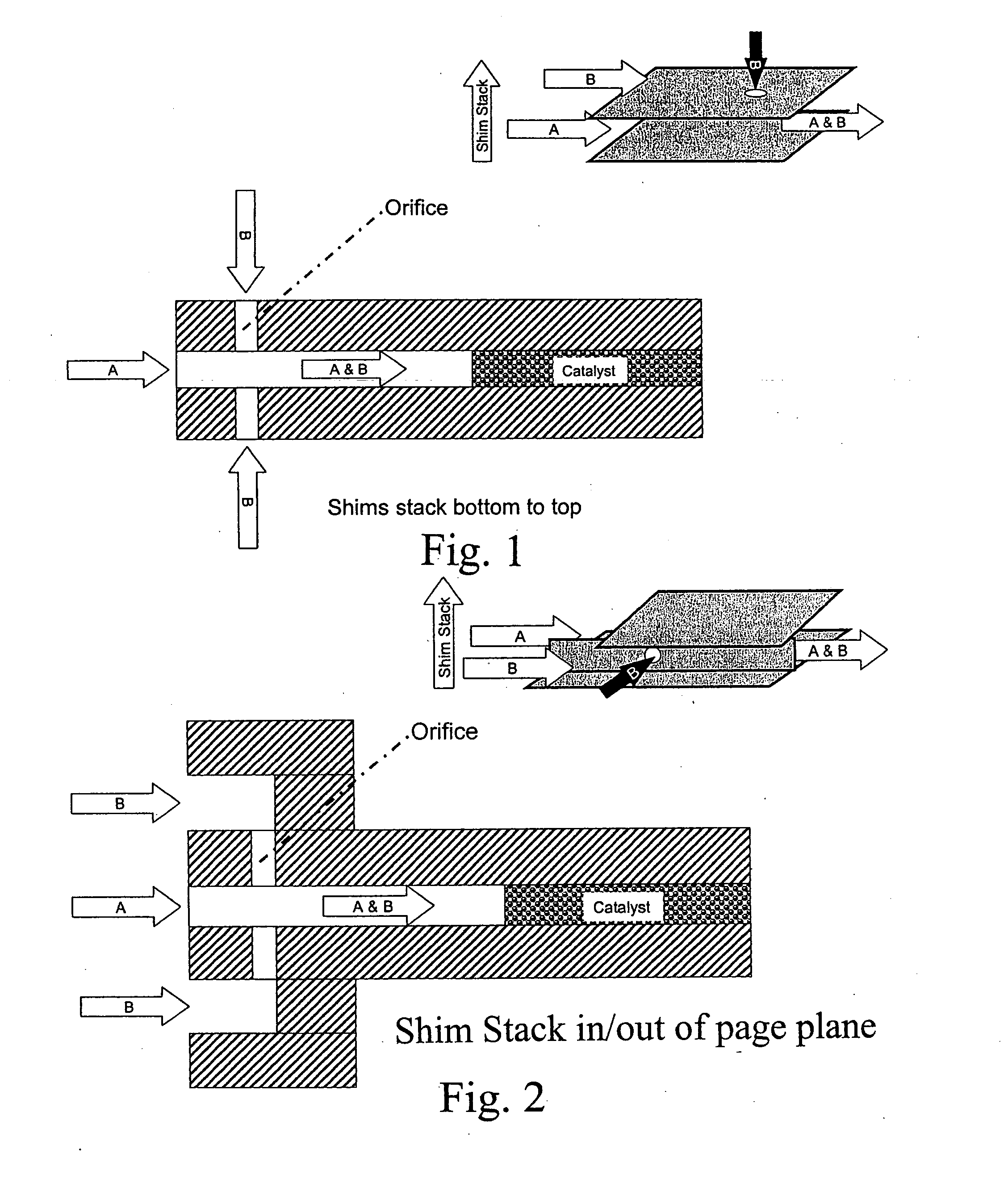

In situ mixing in microchannels

InactiveUS20050133457A1Reduce flammabilityImprove thermal conductivityPhysical/chemical process catalystsFlow mixersEngineering

Owner:VELOCYS CORPORATION

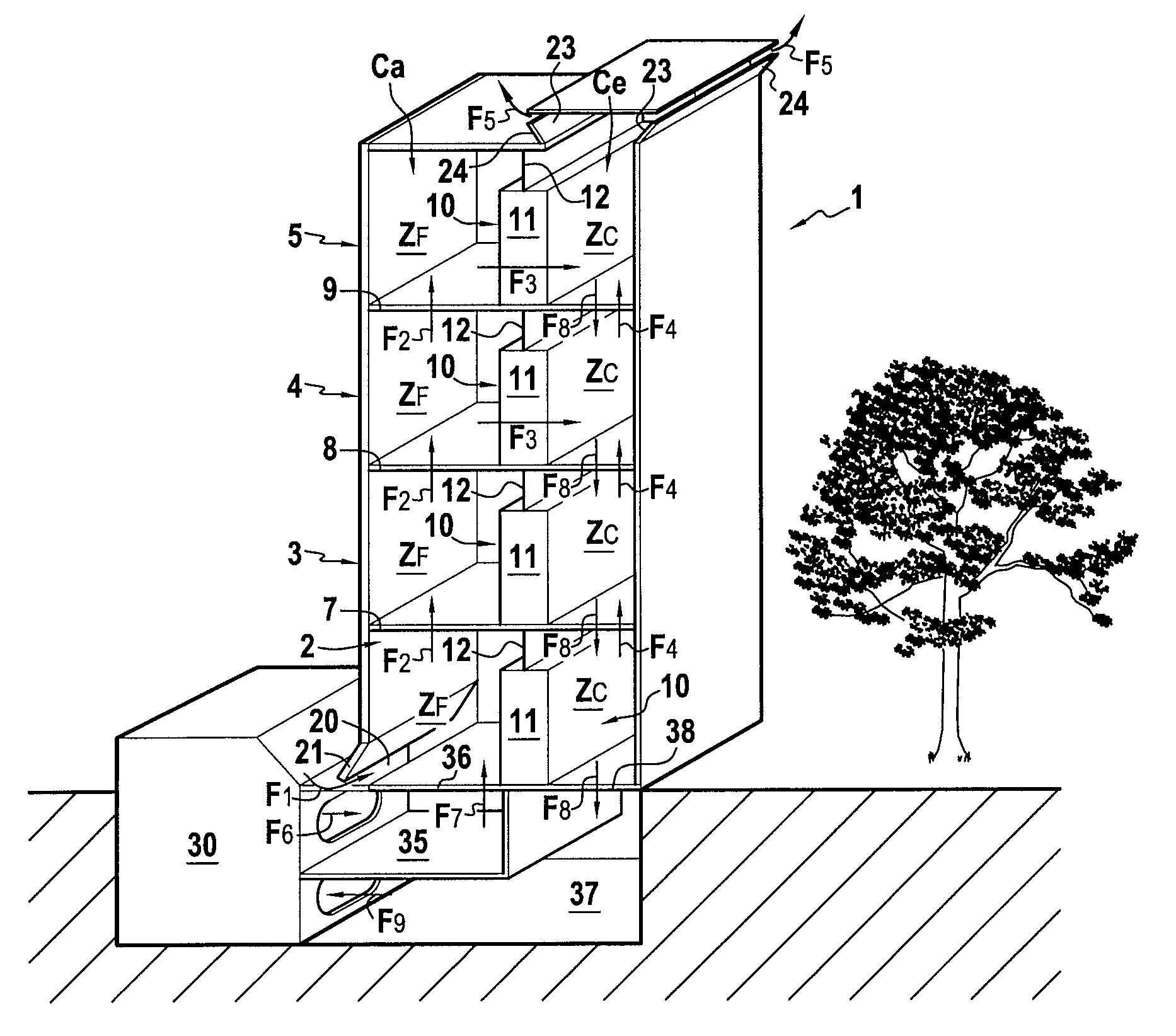

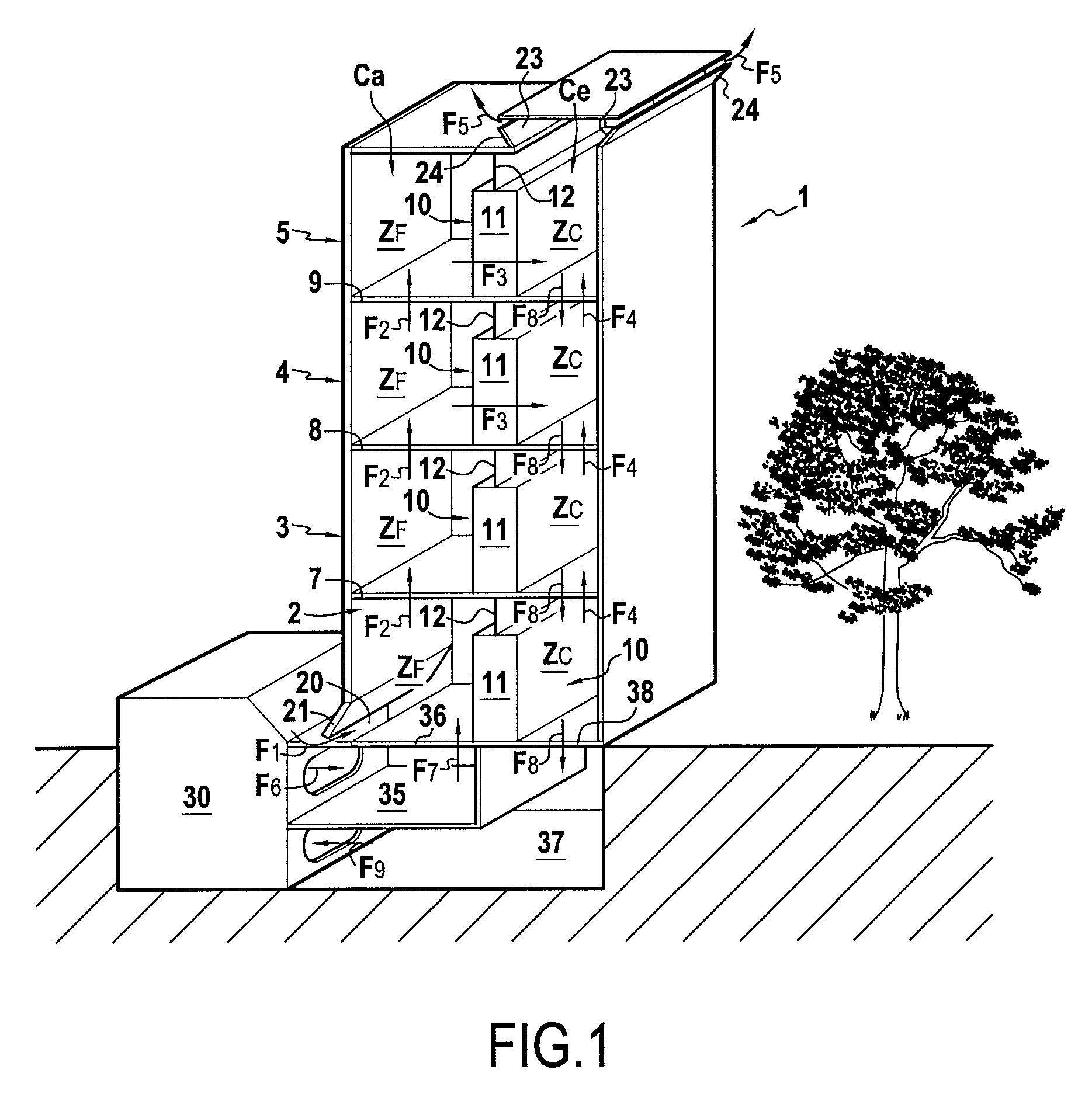

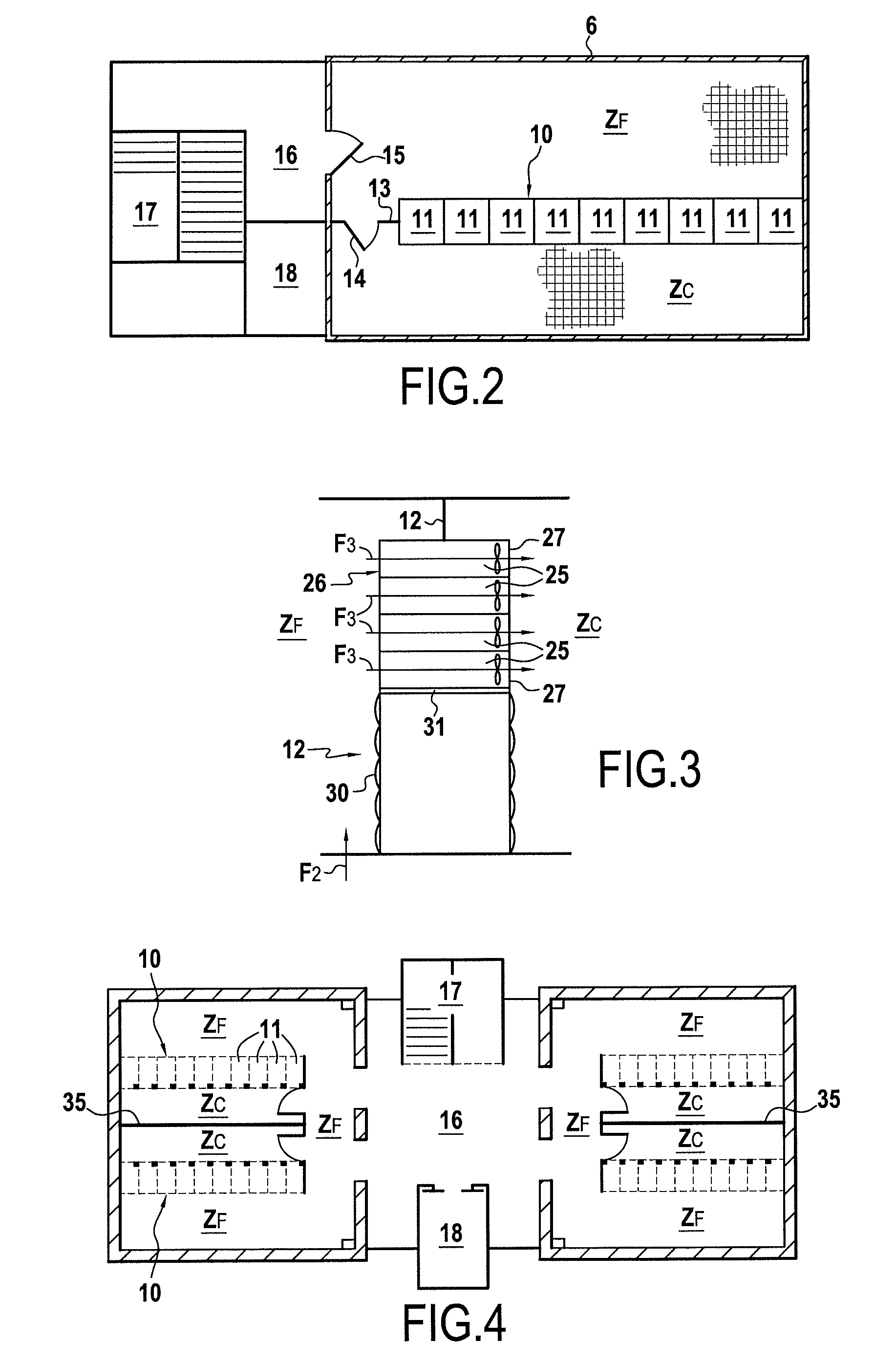

Superimposed Computer Room Building and Process for Cooling this Building

InactiveUS20110138708A1Easy temperature controlLower overall pressure dropTemperature control without auxillary powerRoof covering using slabs/sheetsHot zoneEngineering

Building comprising at least two vertically superimposed computer rooms 2, 3, 4, 5 each limited by a peripheral wall 6 and separated from each other by an intermediate floor 7 and which each contain computer cabinets 11 for computer or electronic equipment 25. The building is characterised in that: each computer room 2, 3, 4, 5 comprises at least one interior wall 10 formed in part or less by the computer cabinets 11 and which separates the interior volume of each computer room into a hot zone Zc and a cold zone Zf, since the air cannot flow between the hot zone Zc and the cold zone Zf without passing through the computer cabinets 11; each intermediate floor 7, 8, 9 is perforated to allow free circulation of air, all cold zones Zf are superimposed and forming a supply column of fresh air Ca and all the hot spots are superimposed forming an exhaust column of hot air Ce; the floors 7, 8, 9, the perimeter walls 6 and interior walls 10 are adapted to prevent a direct flow of air between the supply column Ca and the exhaust column Ce, and the building comprises fresh air means 20, 30 in the supply column Ca and means for evacuating 23, 30 hot air from the exhaust column Ce.

Owner:ENIA ARCHITECTES +1

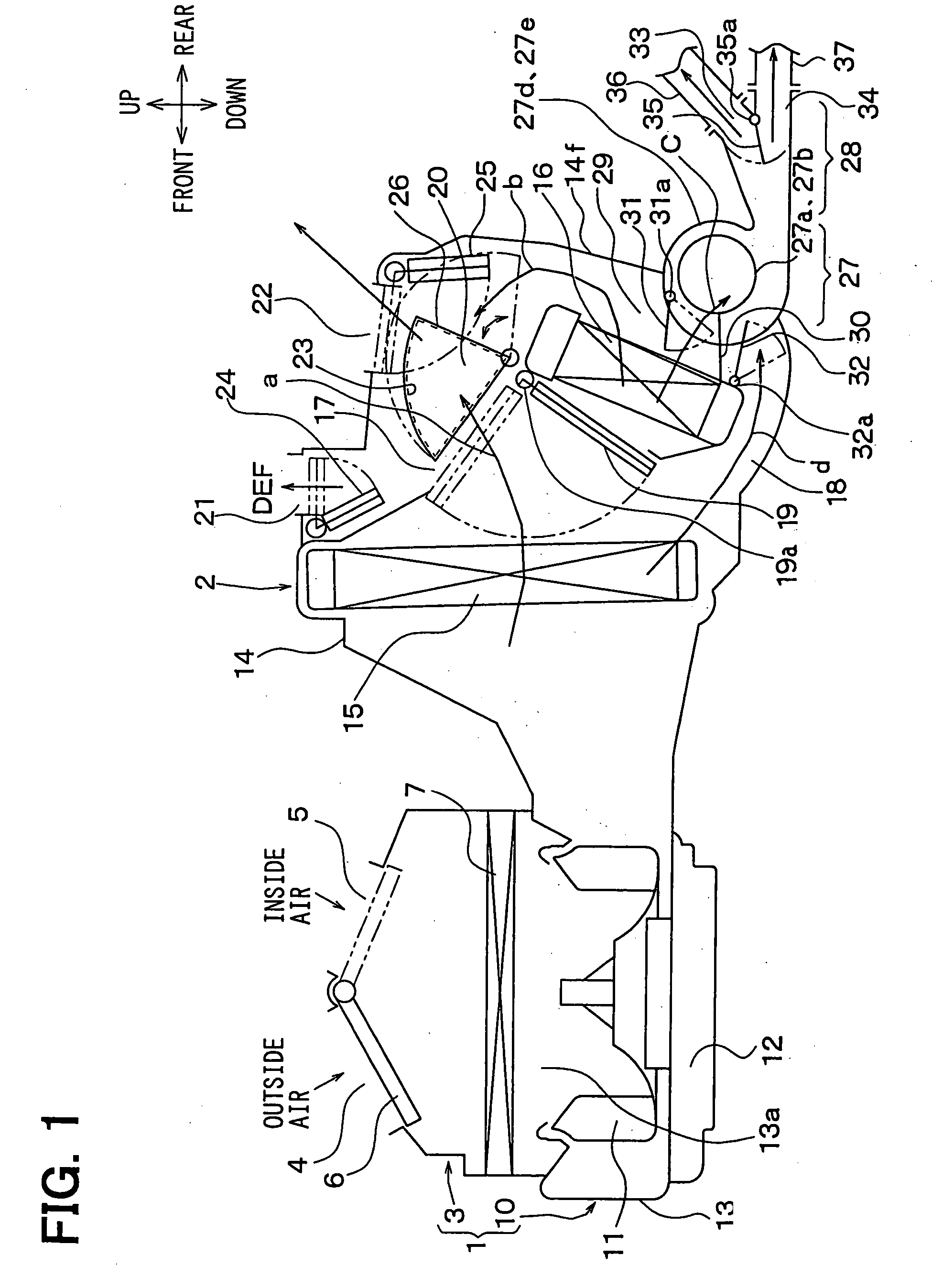

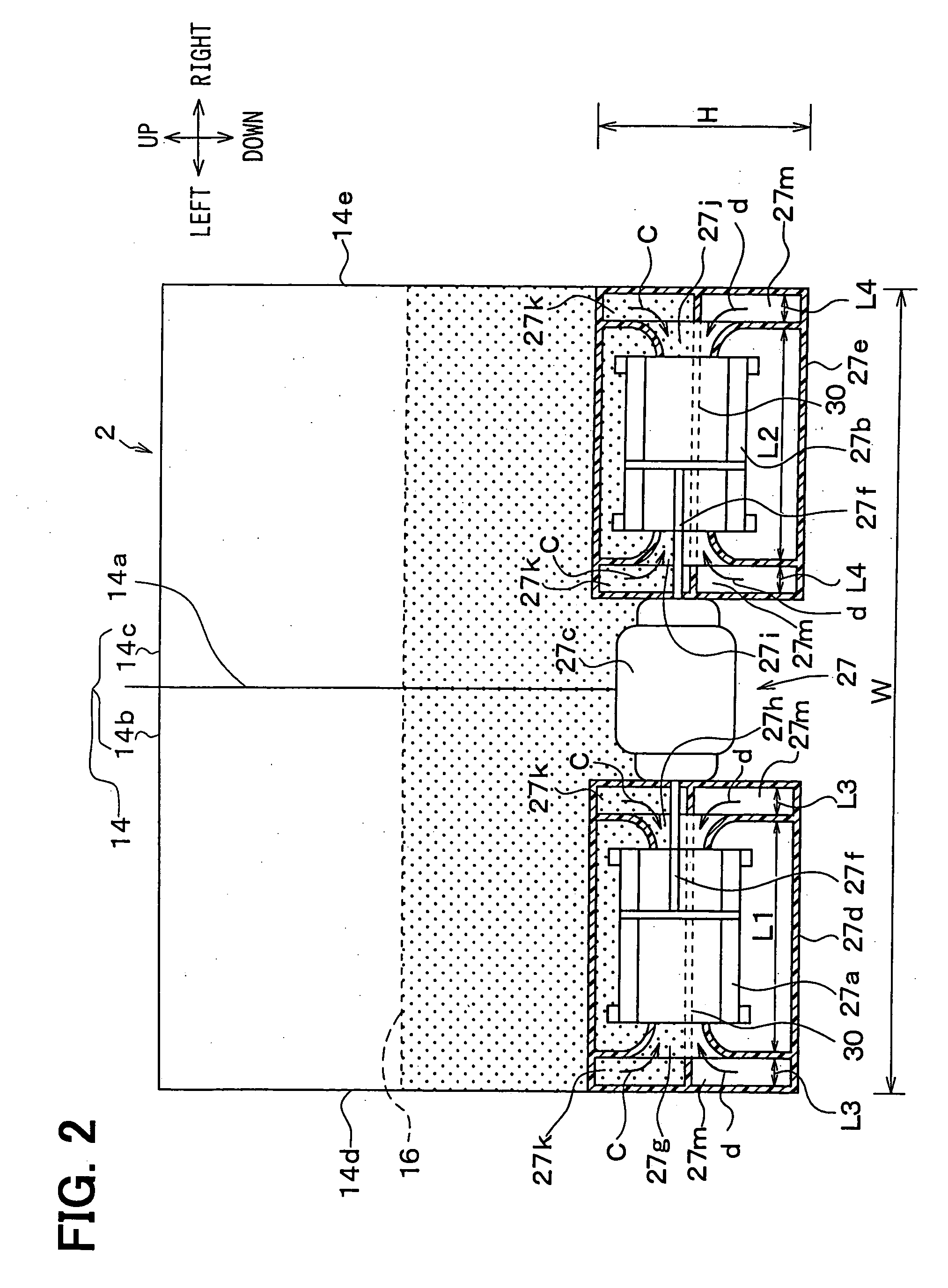

Vehicle air conditioner with main blower and sub-blower

InactiveUS20040093885A1Increase air pressureLarge resistanceAir-treating devicesRailway heating/coolingAir conditioningEconomic shortage

A vehicle air conditioner includes a main blower and a sub-blower for blowing air into a passenger compartment. A heat exchange unit for performing a heat exchange with air blown by the main blower is disposed in a case, and the case is provided with a front air passage and a rear air passage. A rear air duct through which air in the rear air passage is introduced to a rear area in the passenger compartment is connected to the case, so that an air flow resistance in the rear air passage becomes larger as compared with the air flow resistance in the front air passage. Further, the sub-blower is disposed integrally with the case for blowing air in the rear air passage to the rear area in the passenger compartment. Accordingly, it can effectively prevent a shortage of an air conditioning capacity in the rear area of the passenger compartment.

Owner:DENSO CORP

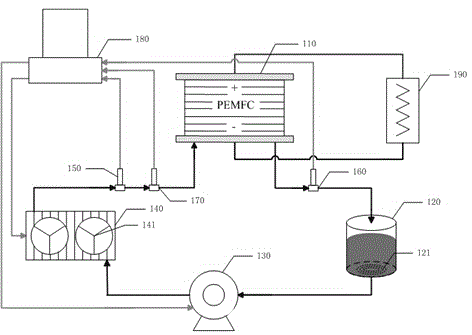

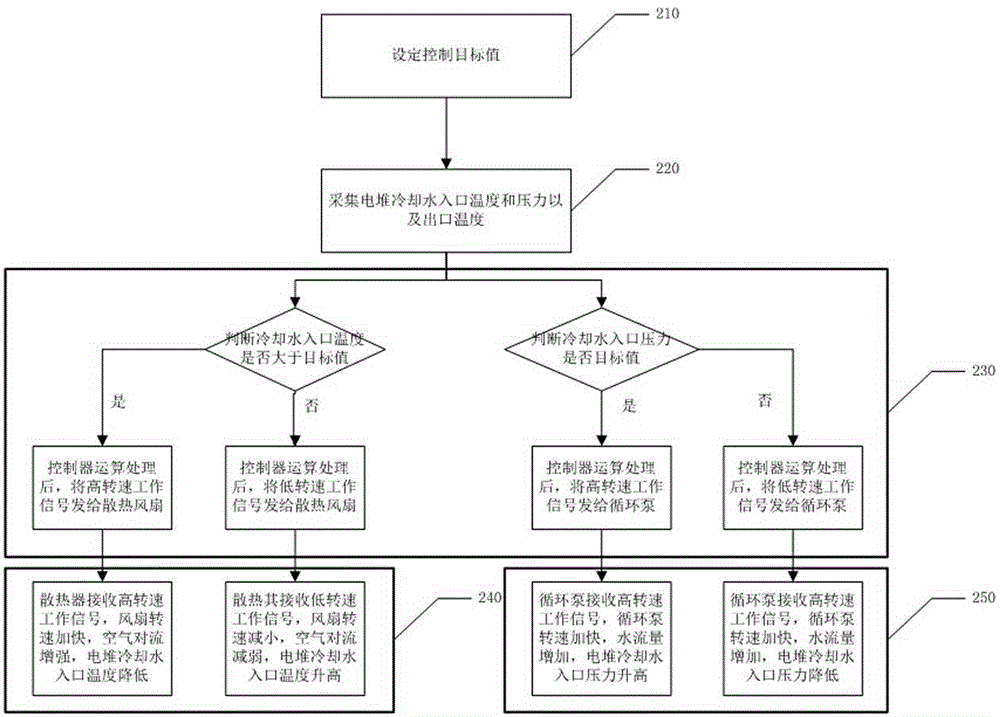

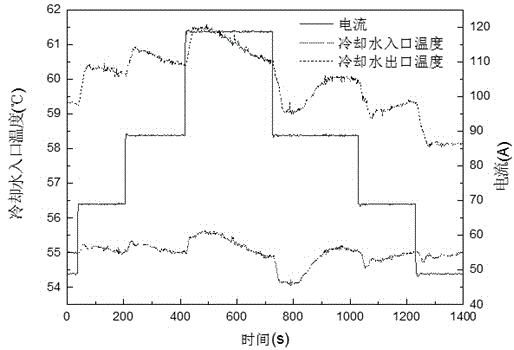

Thermal management system of water-cooling proton exchange membrane fuel cell and control method of thermal management system

ActiveCN104934619AReduce poisonEasy temperature controlFuel cell auxillariesThermal management systemEngineering

The invention provides a simple and effective thermal management system of a water-cooling proton exchange membrane fuel cell and a control method of the thermal management system. The thermal management system mainly comprises an electric pile, a water tank provided with a heating device, a cooling water circulating pump, a radiator, a cooling water pile inlet temperature sensor, a cooling water pile outlet temperature sensor, a cooling water pile inlet pressure sensor and a controller of the thermal management system. The control method following pressure change is provided to overcome the defects of lag, great overshooting, system coupling and the like caused by temperature change tracking in the traditional control strategy. The radiator is mainly used for controlling the cooling water inlet temperature of the pile and mainly controls the rotating speed of a radiator fan according to the cooling water inlet temperature of the pile of the fuel cell; and the cooling water circulating pump is mainly used for controlling the cooling water flow in the whole thermal management system and mainly controls the rotating speed of the circulating pump according to the cooling water inlet pressure of the pile of the fuel cell.

Owner:SOUTHWEST JIAOTONG UNIV

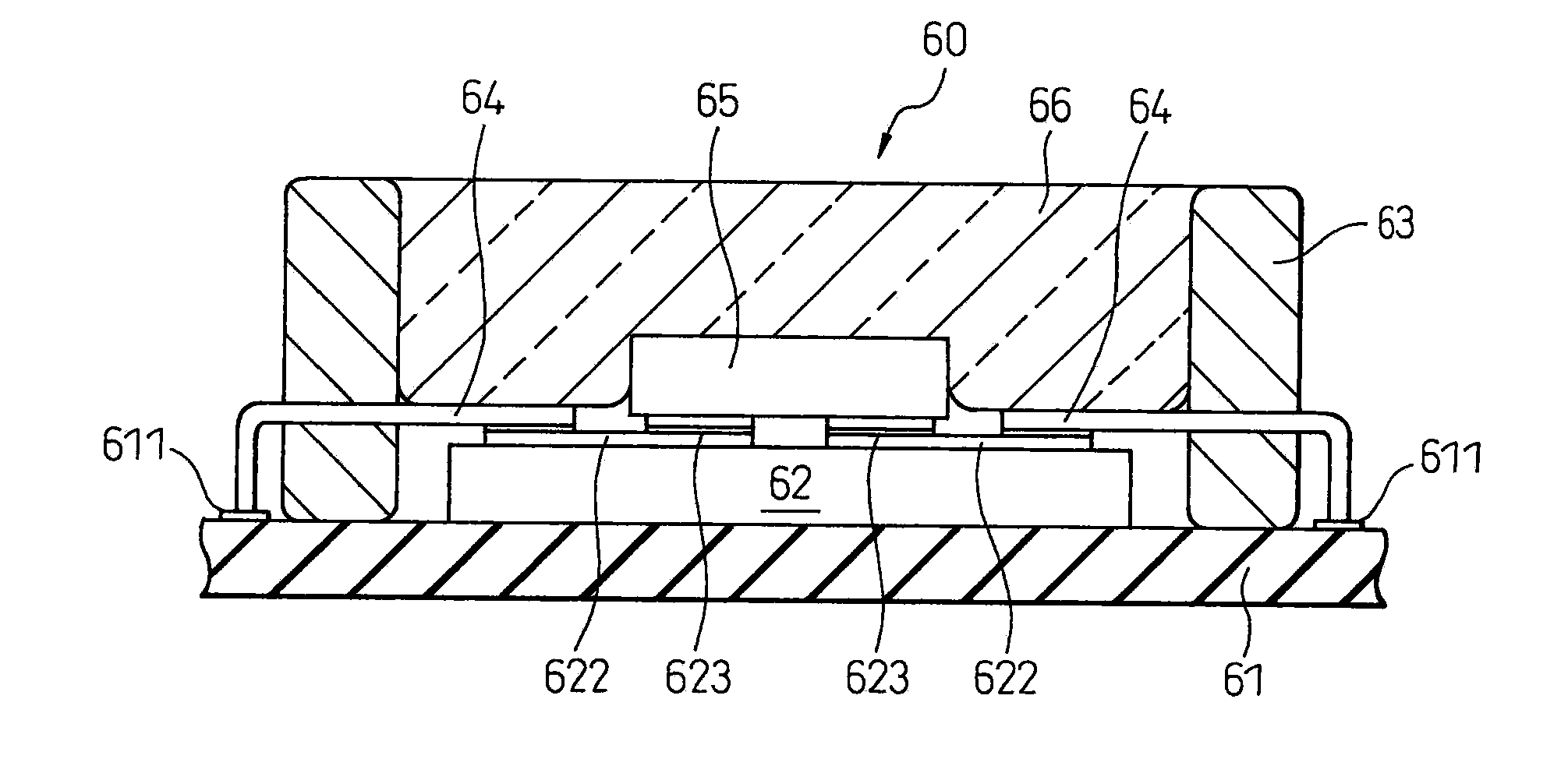

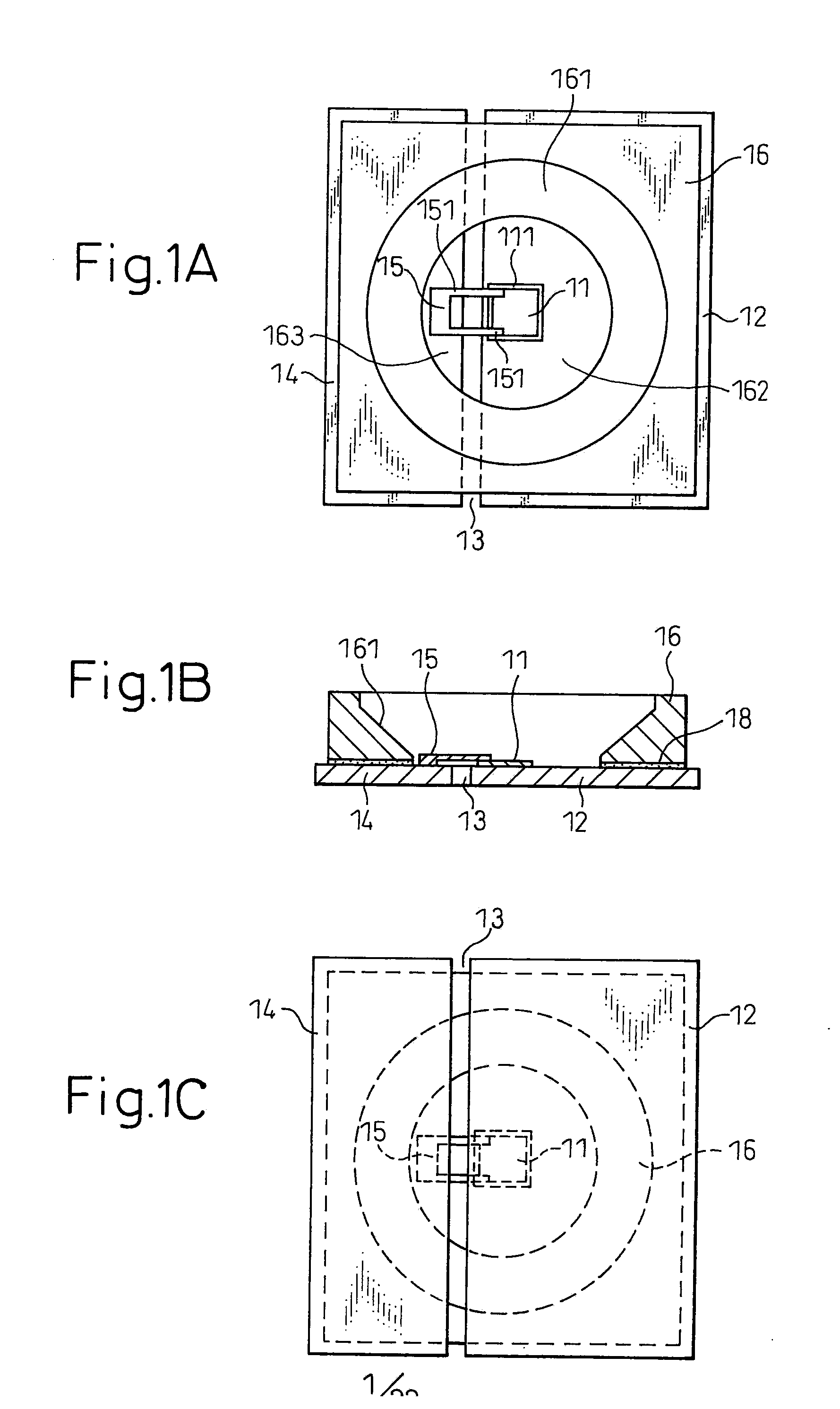

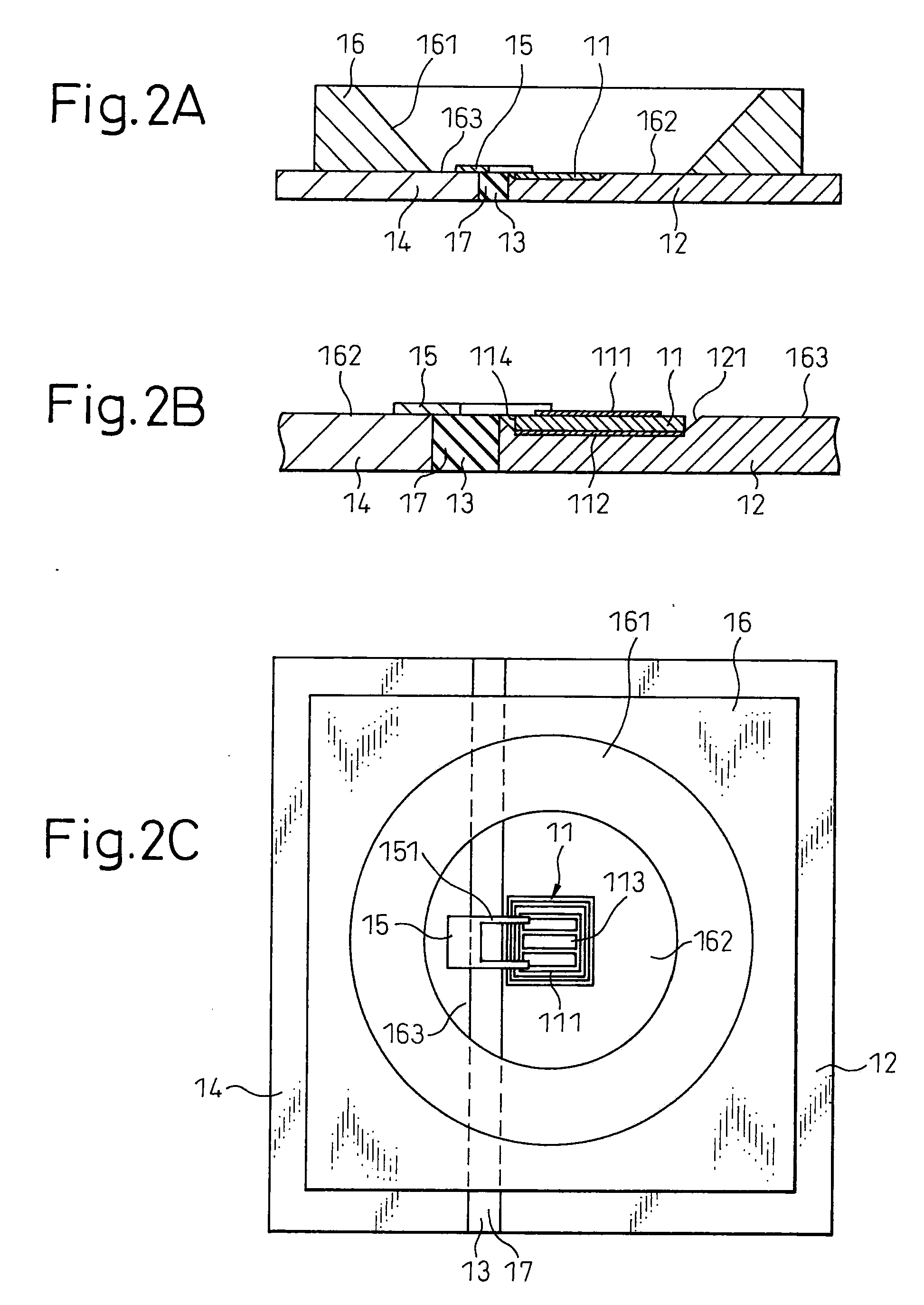

Vertical geometry light emitting diode package aggregate and production method of light emitting device using the same

InactiveUS20100187546A1High strengthEasy temperature controlSolid-state devicesSemiconductor/solid-state device manufacturingMetal sheetLight emitting device

There are provided a vertical geometry light emitting diode package aggregate useful for the production of a light emitting device having a vertical geometry light emitting diode as the light source, the light emitting device satisfying requirements in terms of current capacity flowed for light emission, dissipation of heat generated due to flow of a large current, resistance to thermal stress, strength of device and light emission efficiency, and a method for producing a light emitting device having a vertical geometry light emitting diode as the light source by using the package aggregate. The vertical geometry light emitting diode package comprises a metal sheet having formed thereon a number of vertical geometry light emitting diode package units, each package unit comprising two or more substrate portions as a part of the metal sheet, which are separated by a slit, and a reflector having a penetrating opening and being adhered to the two or more substrate portions to cover parts of the slit such that the vertical geometry light emitting diode-mounting position is exposed in the inner side of the opening and at the same time, the end part of the slit is exposed in the outer side of the reflector.

Owner:CI KASEI COMPANY

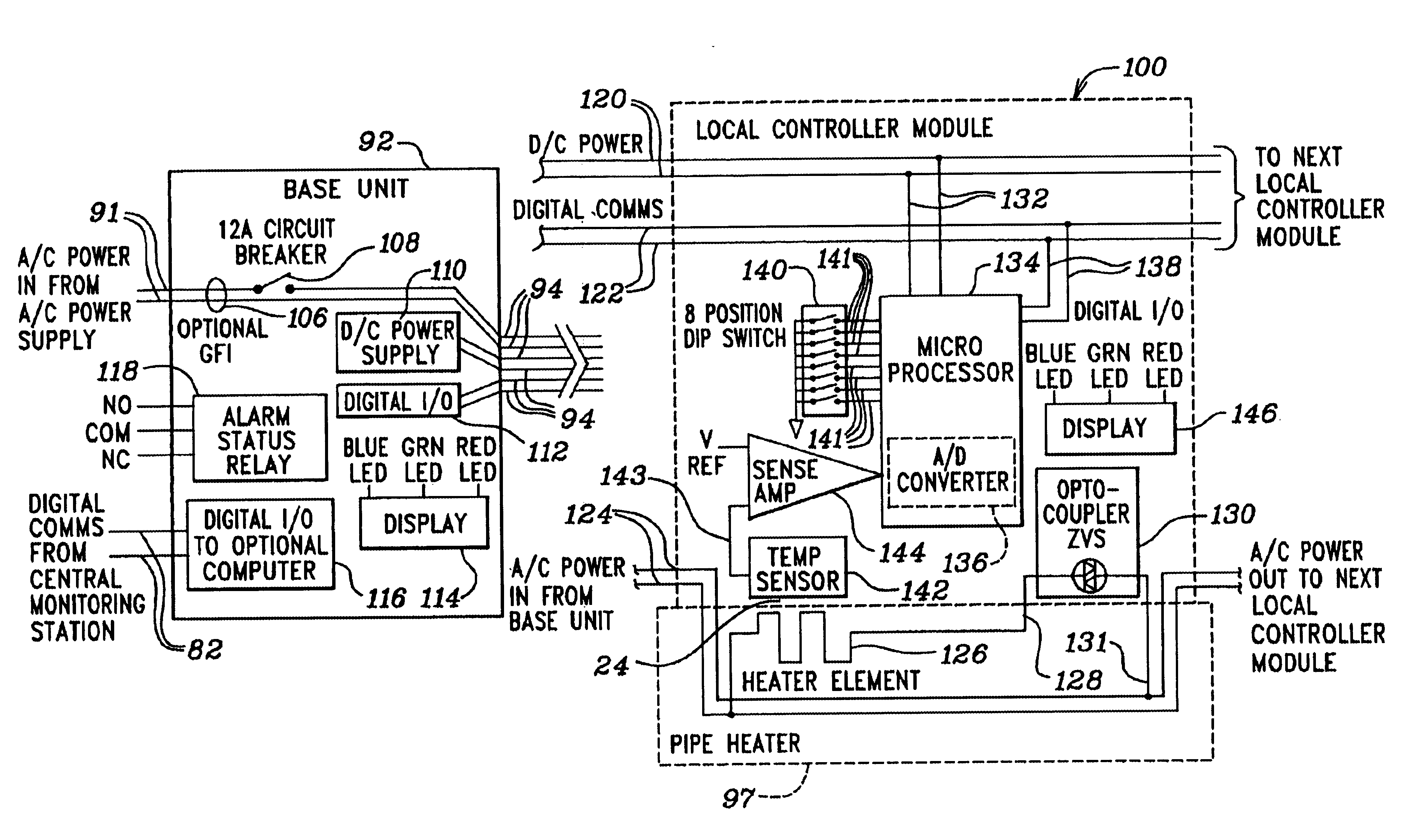

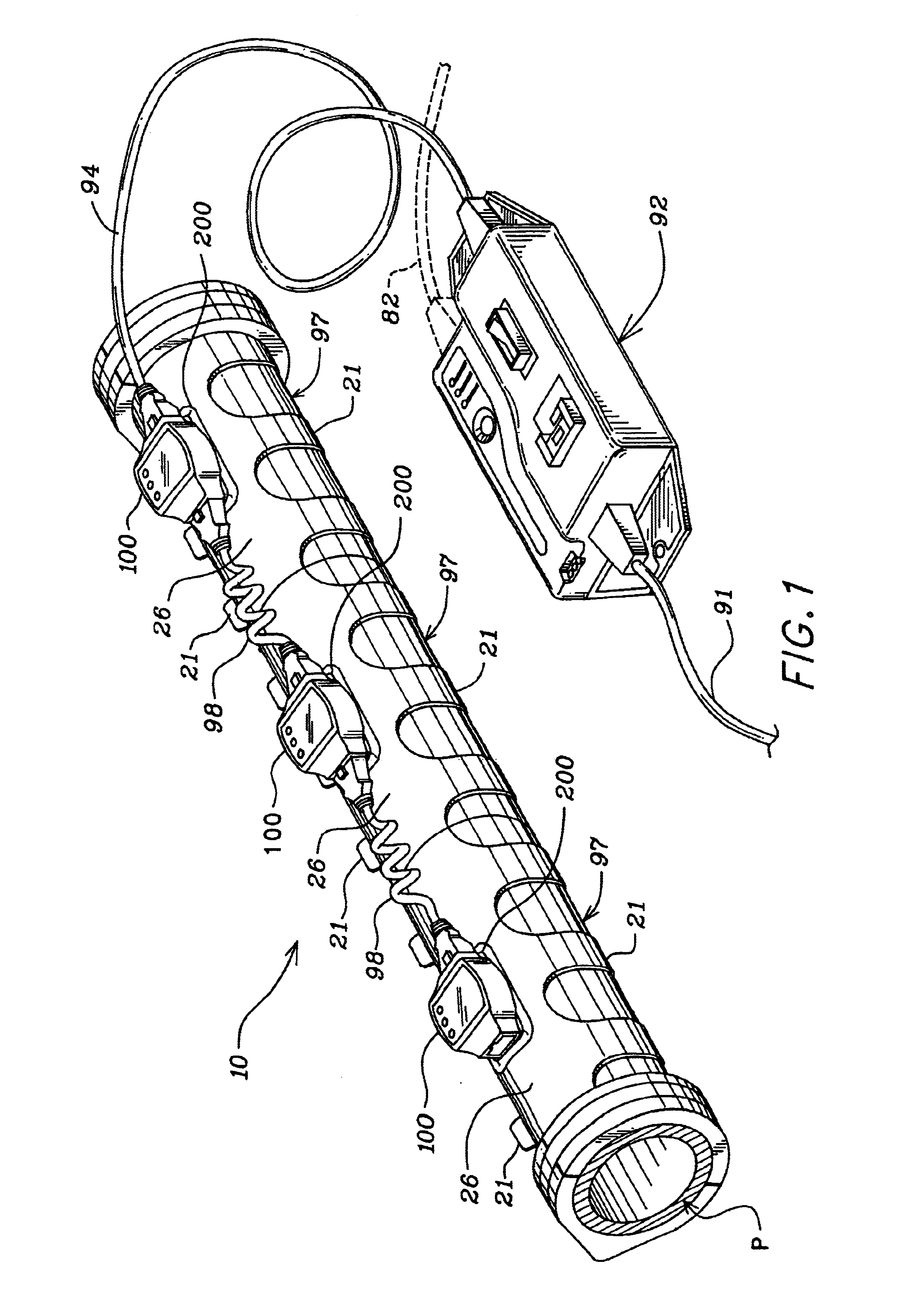

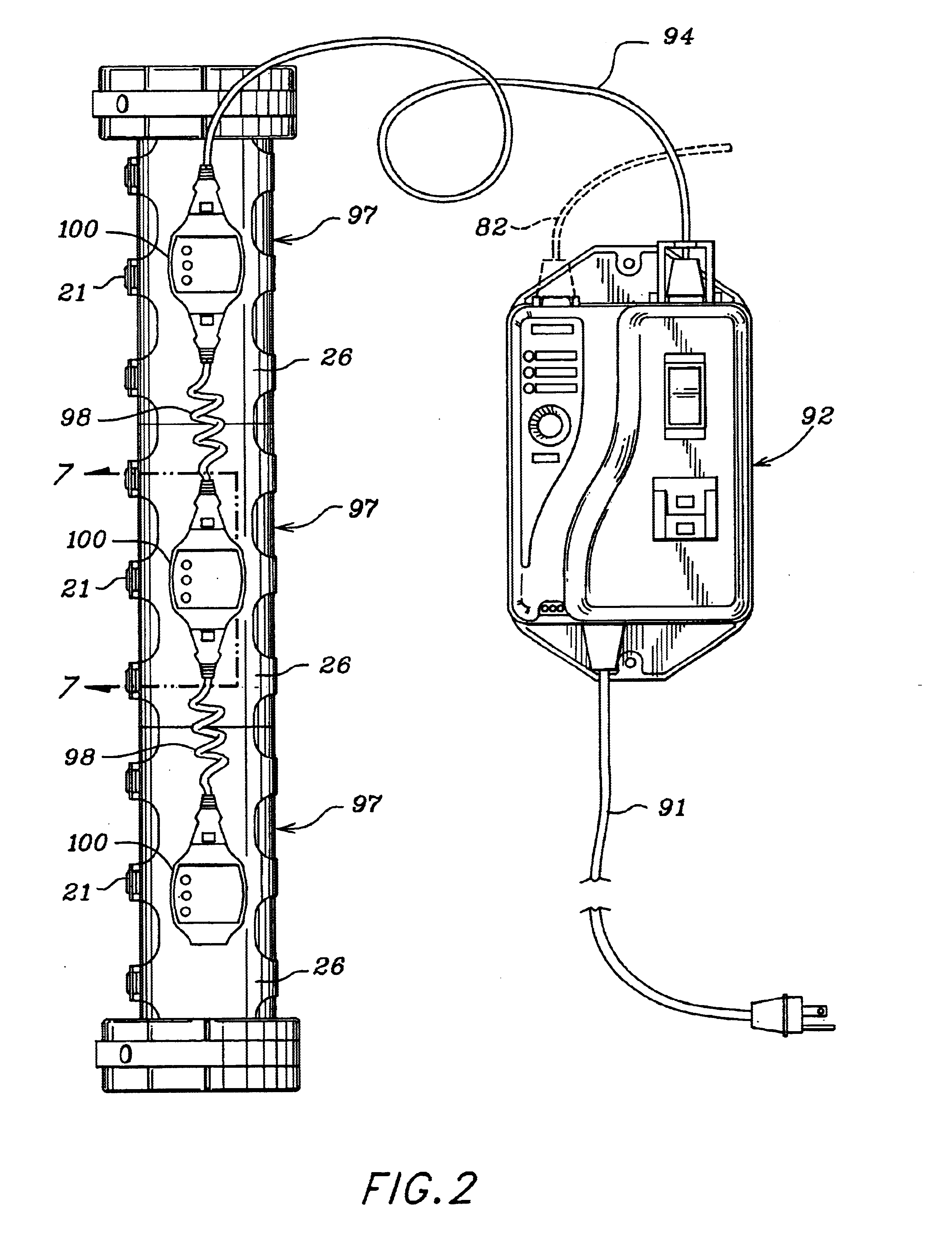

Heater control system with combination modular and daisy chained connectivity and optimum allocation of functions between base unit and local controller modules

InactiveUS6894254B2Increase heightMinimizing physical sizeDc network circuit arrangementsOhmic-resistance heating detailsTemperature controlRemote conditioning

A heater control system that utilizes electronic temperature control at each of a number of interconnected heaters is provided for monitoring and operating heaters within a narrow temperature range. In one embodiment, a heater control system is provided that is adapted for controlling a number of heaters positioned on pipe and components of a piping system from a remote location. The heater control system includes satellite controllers mounted on each heater connected daisy chain fashion and includes a monitoring station with a user interface for allowing a user to monitor and to remotely control the operating status or temperature of each heater in the heater control system. To satisfy the user's space requirements, the size of each controller is maintained at a small form factor and a single cord is used to provide power and communications lines to and between the controllers. Each controller integrates power supply and control with electronic temperature control to minimize the use of mechanical switching and to increase the accuracy of temperature control. The temperature set point is adjustable at each controller and, in one embodiment, the temperature set point is remotely adjustable from a remote monitoring station. The operating status of each controller is displayed on the exterior of the controller's housing and in one embodiment, the operating status, such as temperature, is displayed at a base station for each line of controllers and heaters and on a user interface monitor at a monitoring station.

Owner:MKS INSTR INC

Method and system for determining optical properties of semiconductor wafers

ActiveUS20070020784A1Precise heatingImprove accuracyRadiation pyrometrySemiconductor/solid-state device testing/measurementOptical propertyEmissivity

A method and system are disclosed for determining at least one optical characteristic of a substrate, such as a semiconductor wafer. Once the optical characteristic is determined, at least one parameter in a processing chamber may be controlled for improving the process. For example, in one embodiment, the reflectivity of one surface of the substrate may first be determined at or near ambient temperature. From this information, the reflectance and / or emittance of the wafer during high temperature processing may be accurately estimated. The emittance can be used to correct temperature measurements using a pyrometer during wafer processing. In addition to making more accurate temperature measurements, the optical characteristics of the substrate can also be used to better optimize the heating cycle.

Owner:MATTSON TECHNOLOGY +1

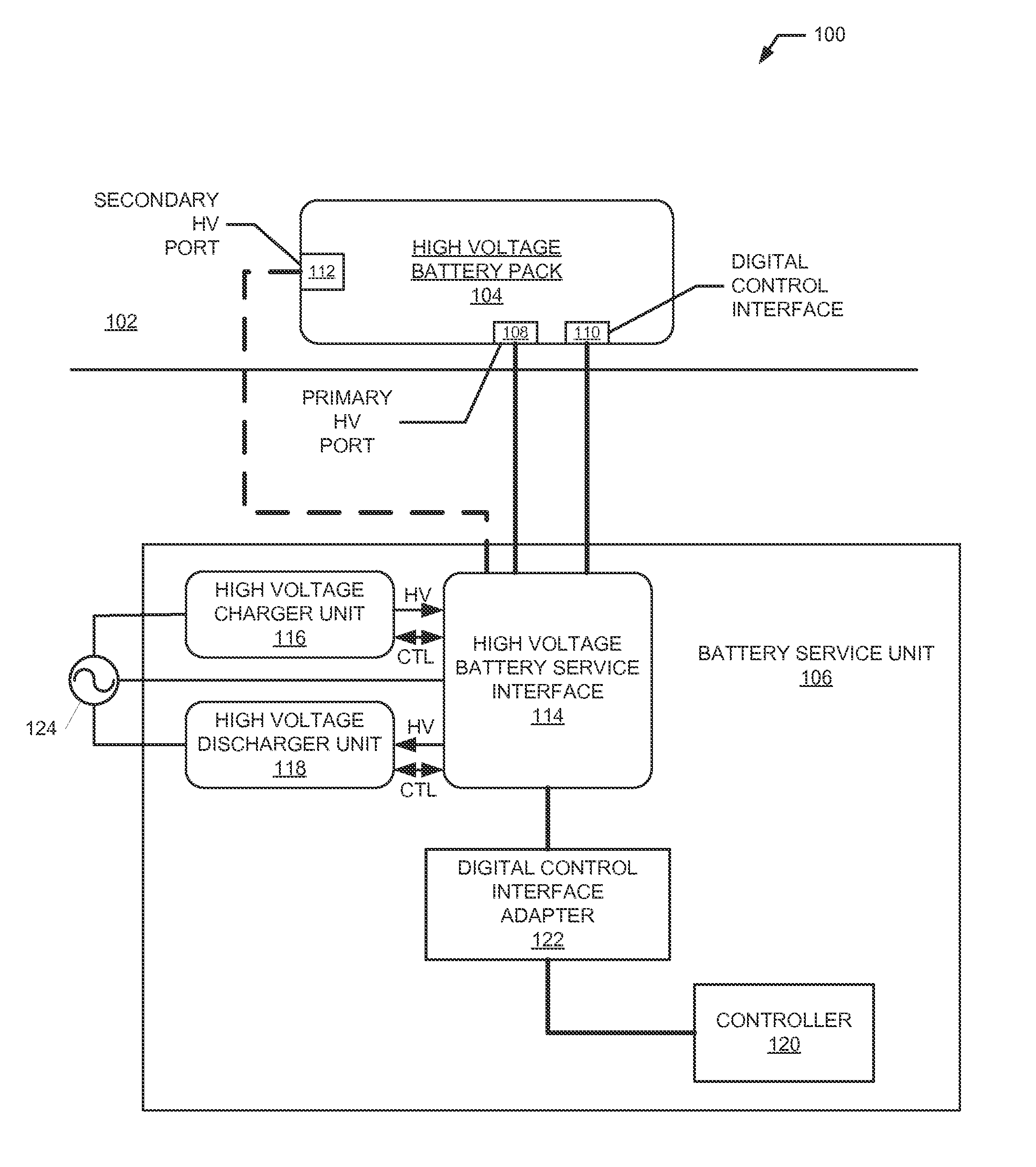

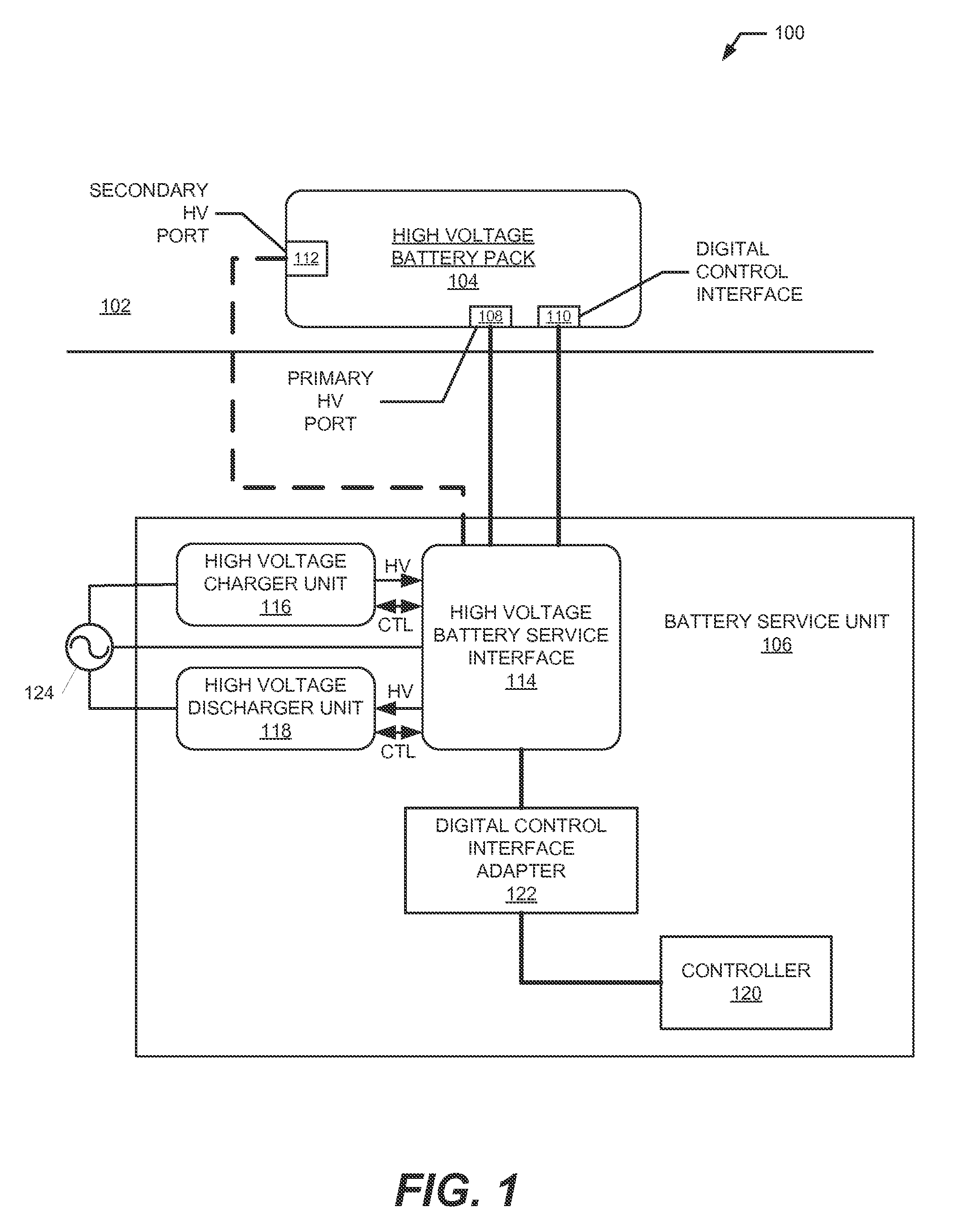

Self-discharge for high voltage battery packs

ActiveUS20130307480A1Increase discharge rateImproved temperature controlCharging stationsElectric devicesHigh energyEnergy management

A system and method for providing energy management and maintenance of a high energy battery pack through use self-discharge features and processes. A battery pack is configured with self-discharger enabled-components that selectively discharge energy from the battery pack without the battery pack providing operational power.

Owner:TESLA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com