Patents

Literature

136results about How to "Process can be minimized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

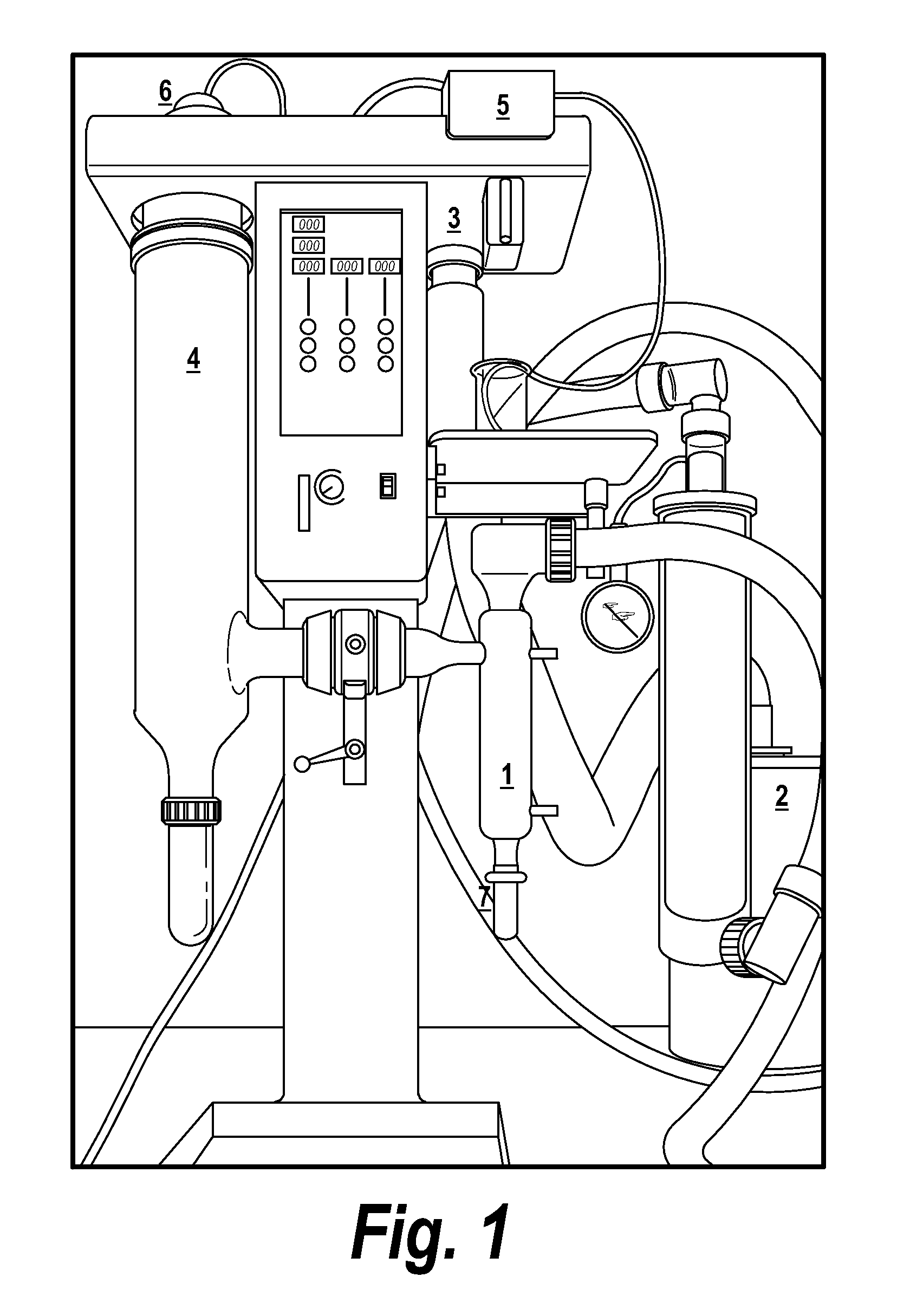

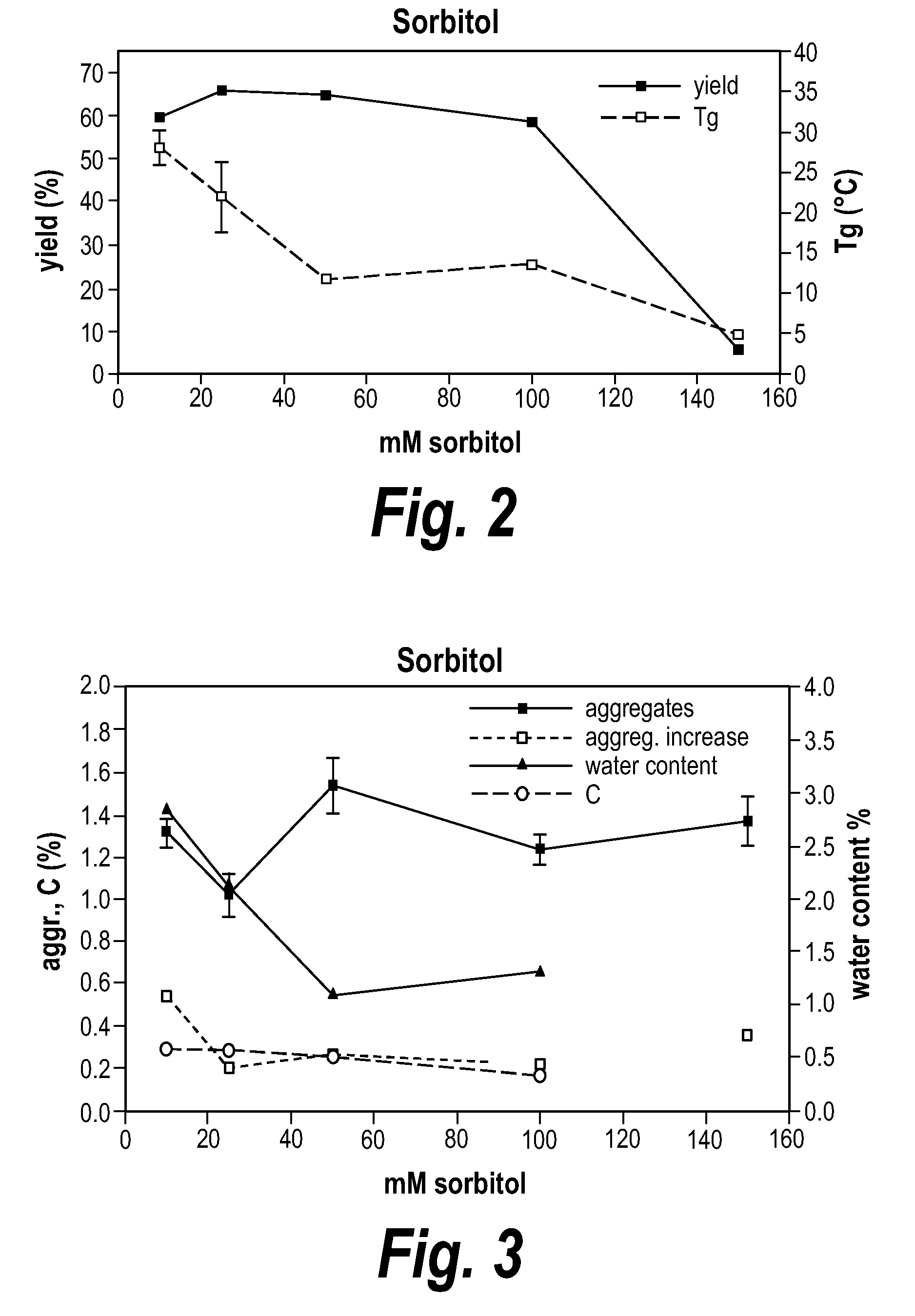

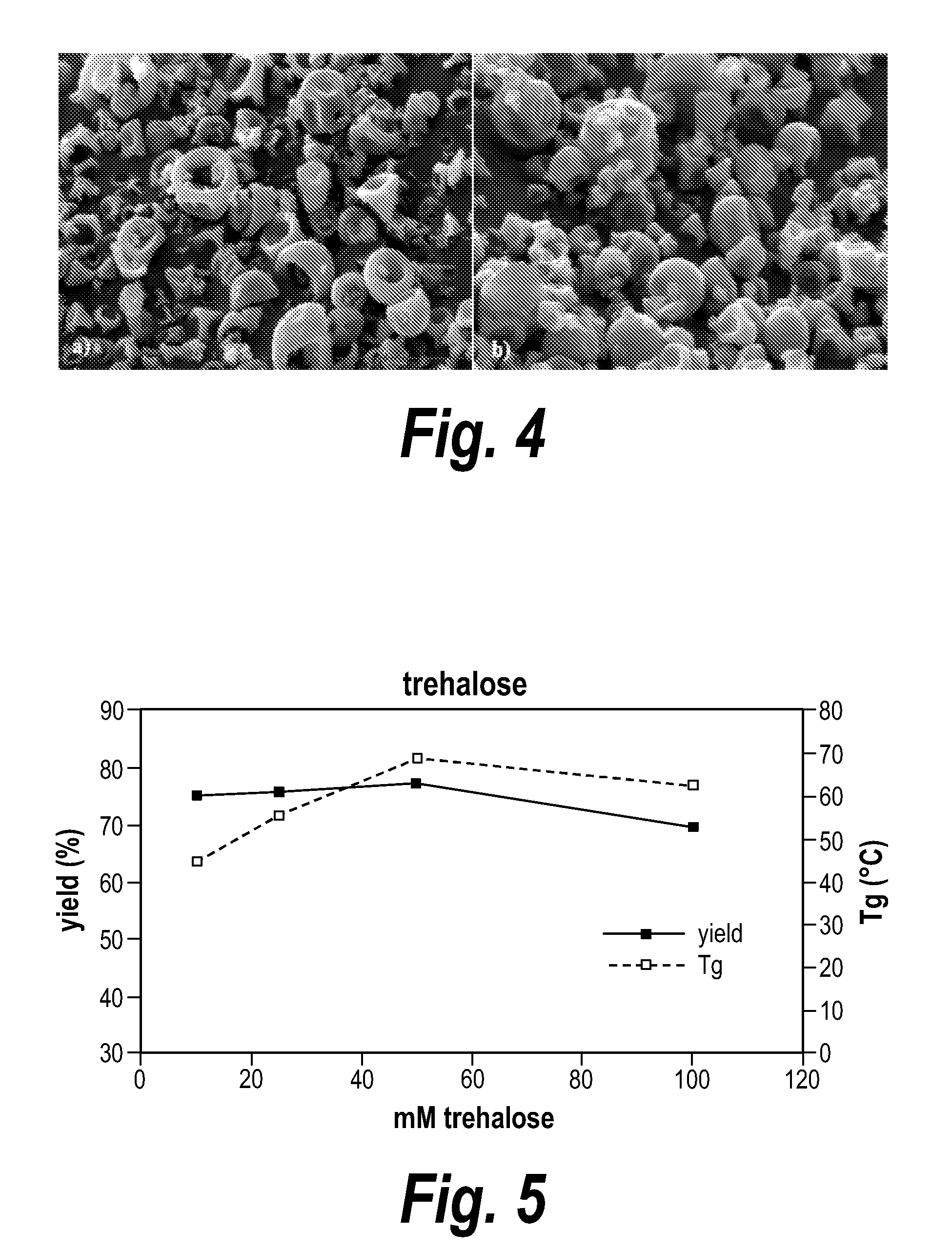

Powdered protein compositions and methods of making same

InactiveUS20090226530A1Easy to moveWide concentration rangeAntibacterial agentsPowder deliveryBiotechnologyProtein composition

Owner:ABBVIE DEUTSHLAND GMBH & CO KG

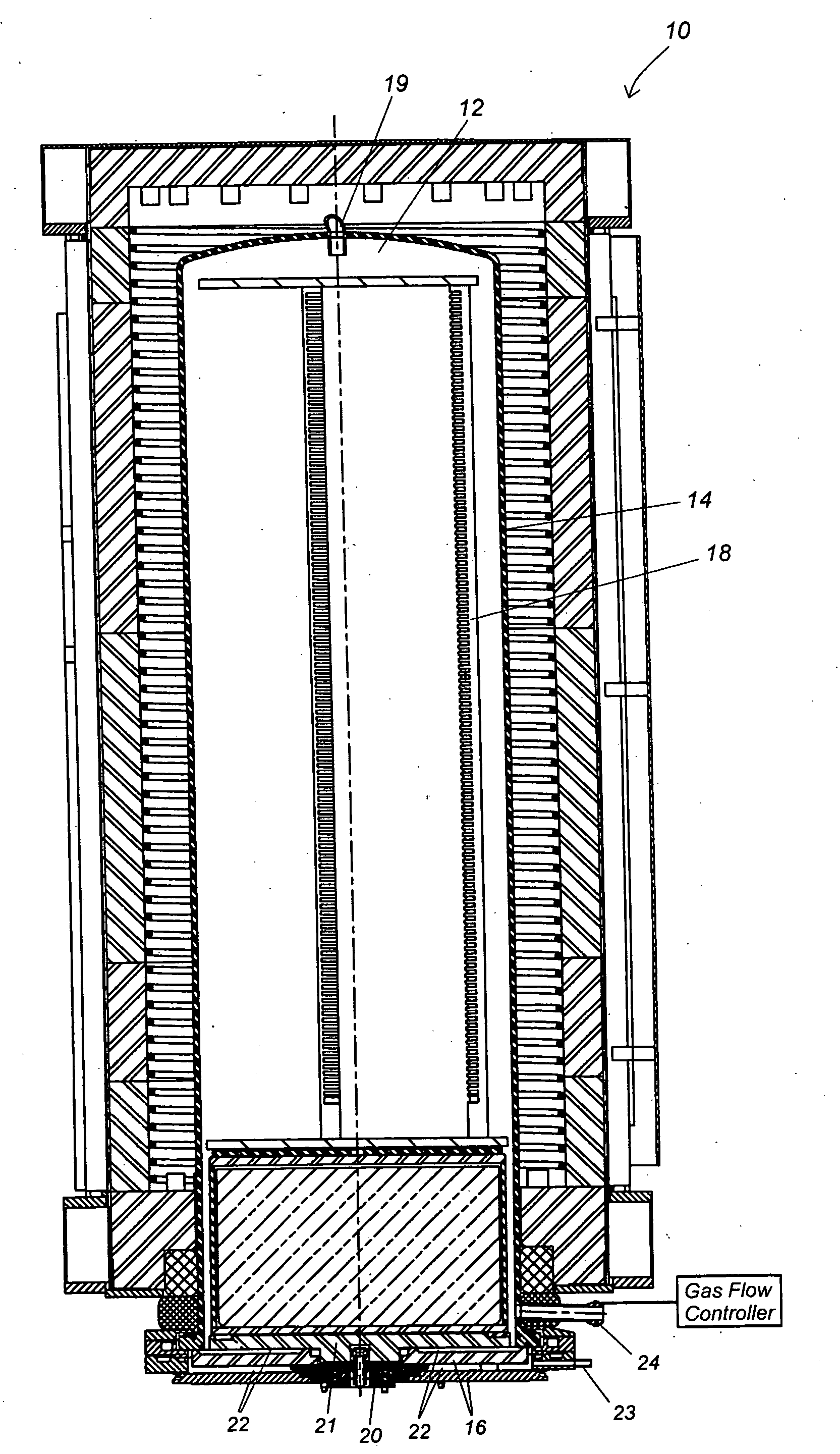

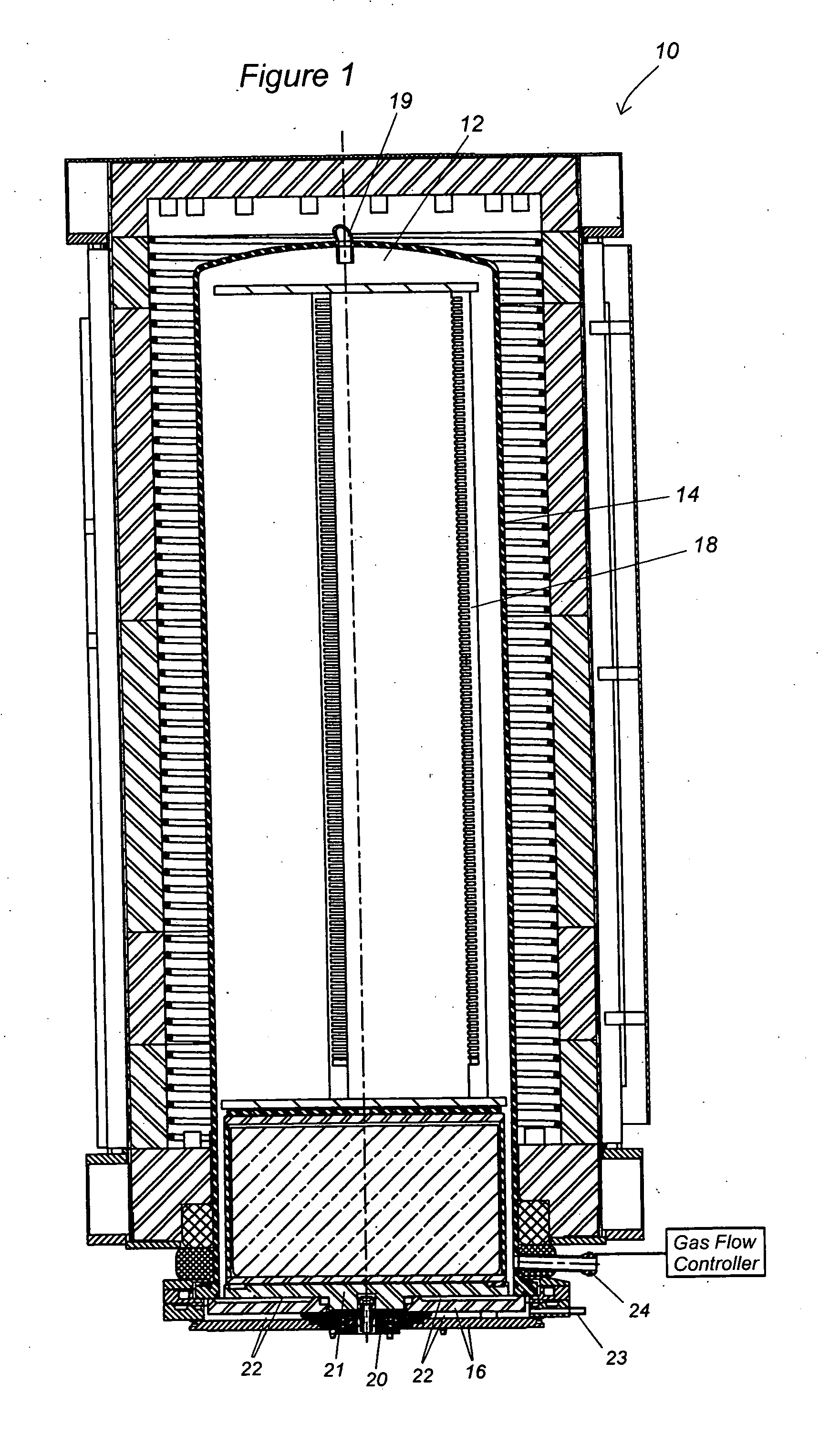

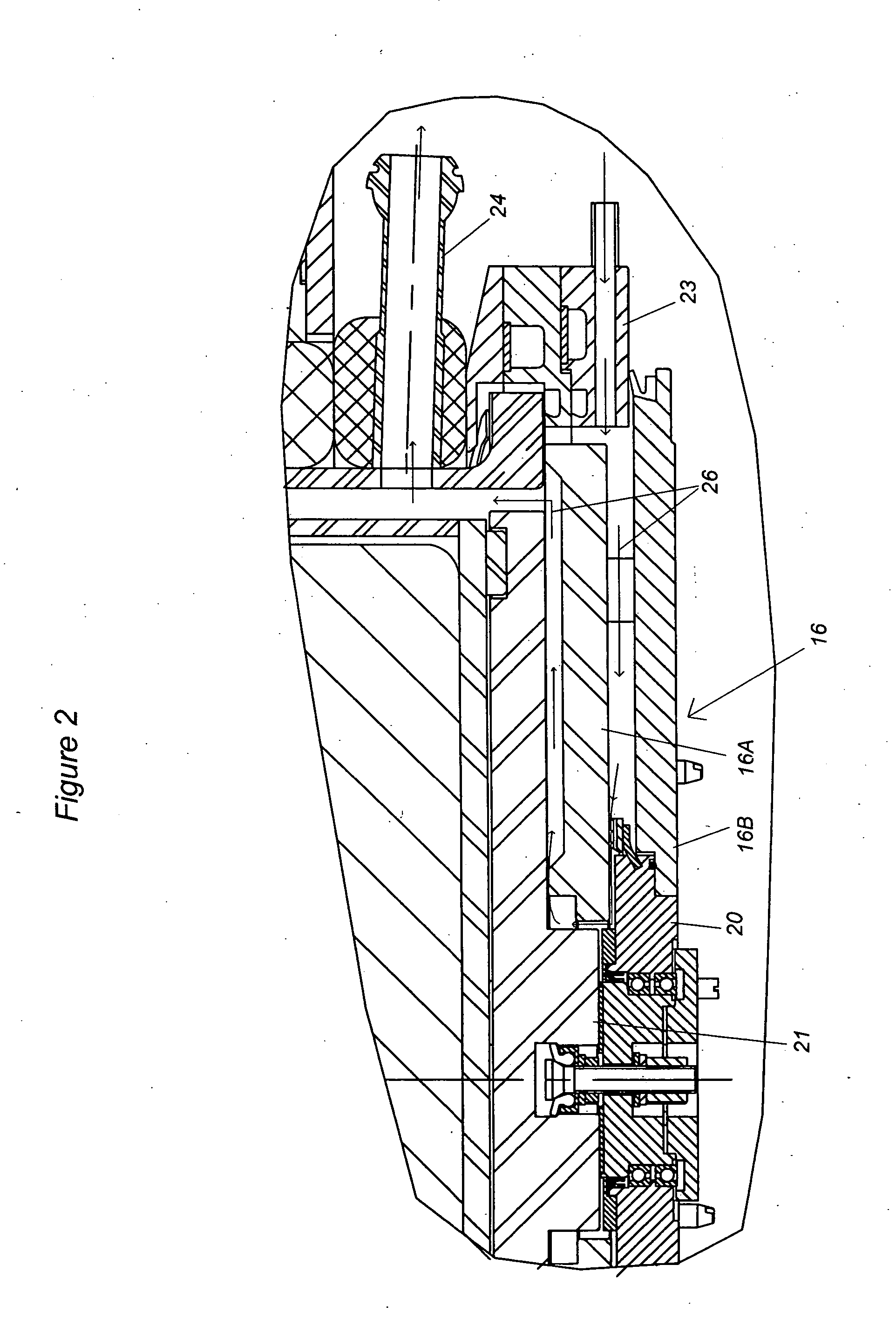

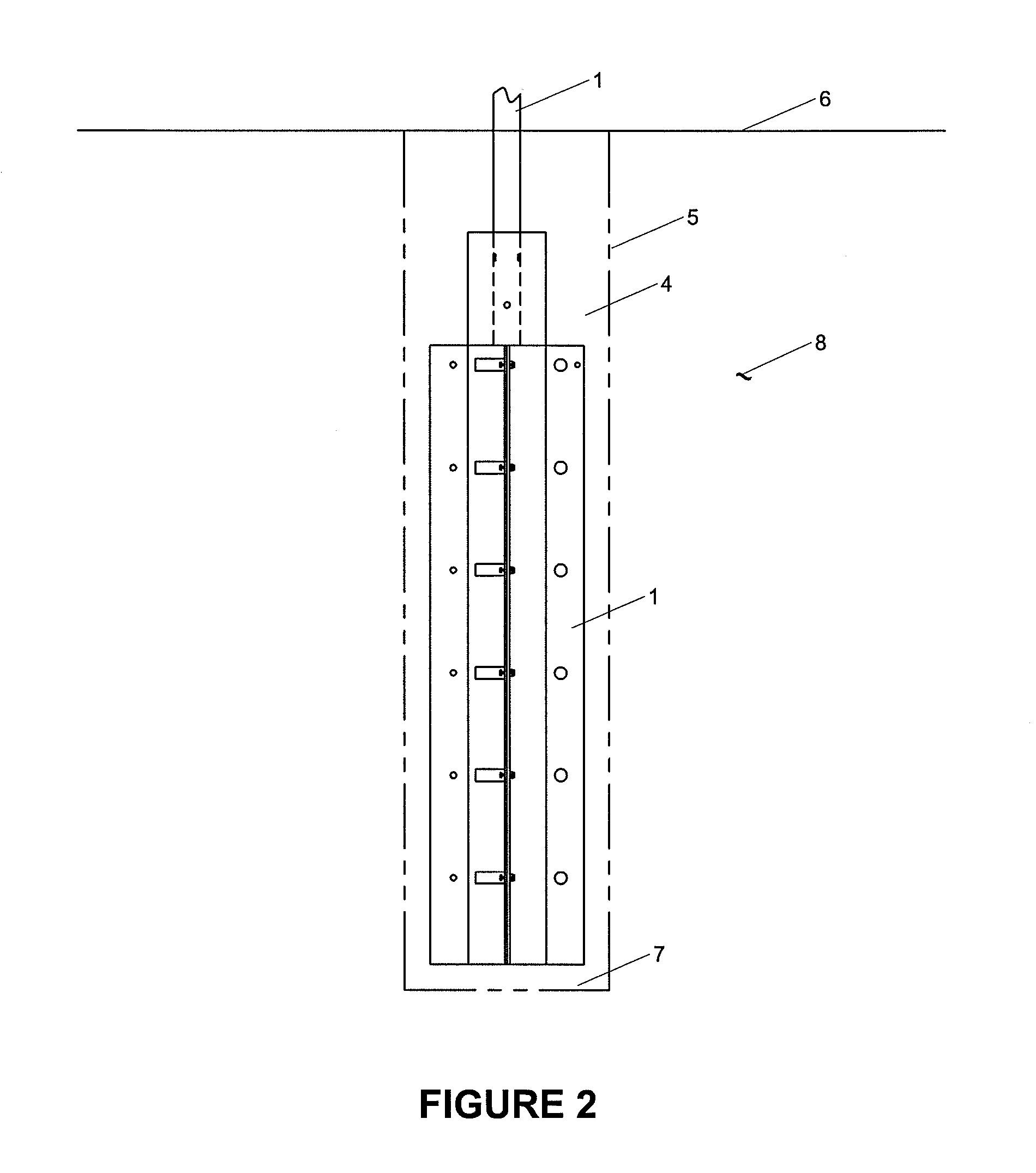

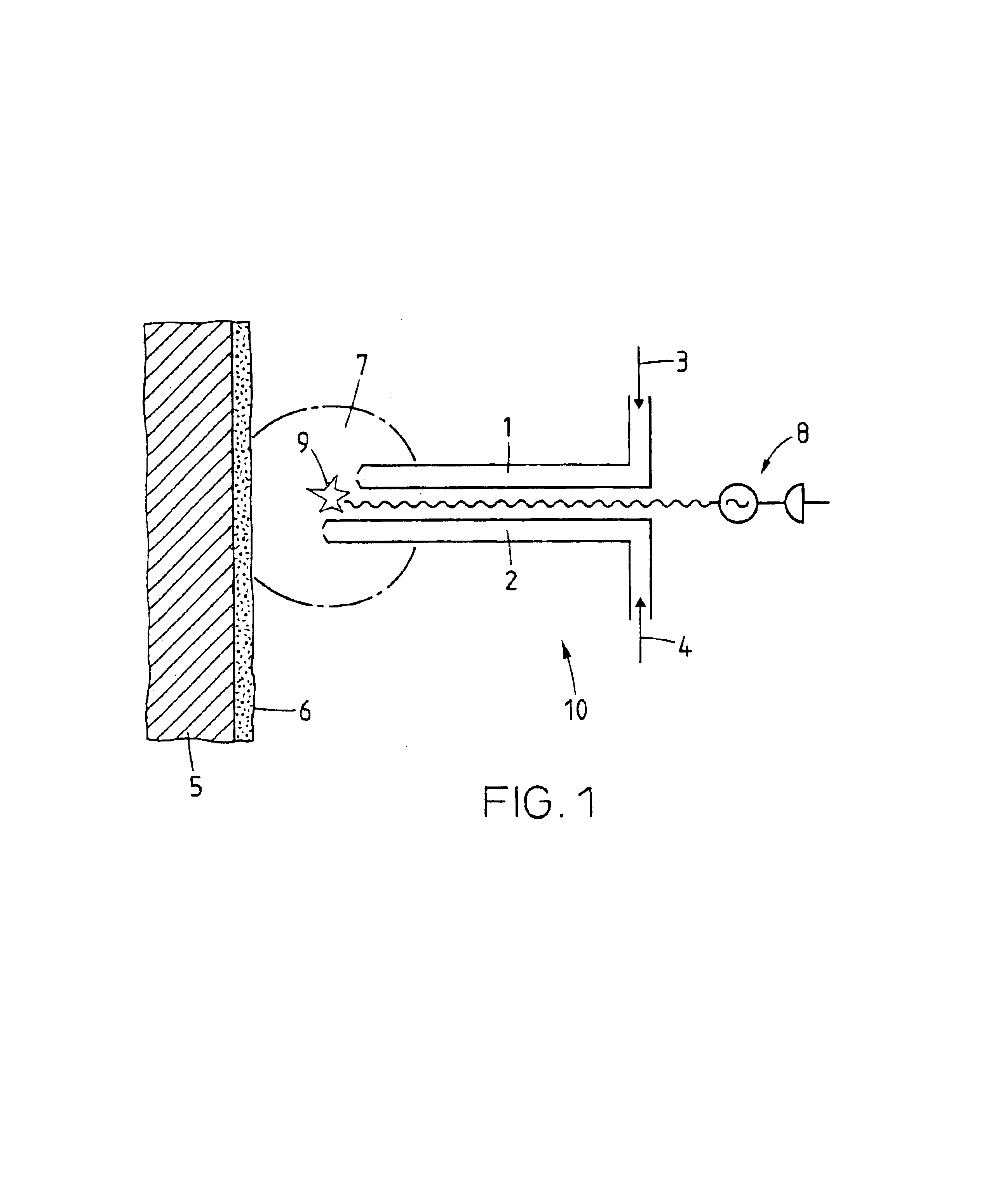

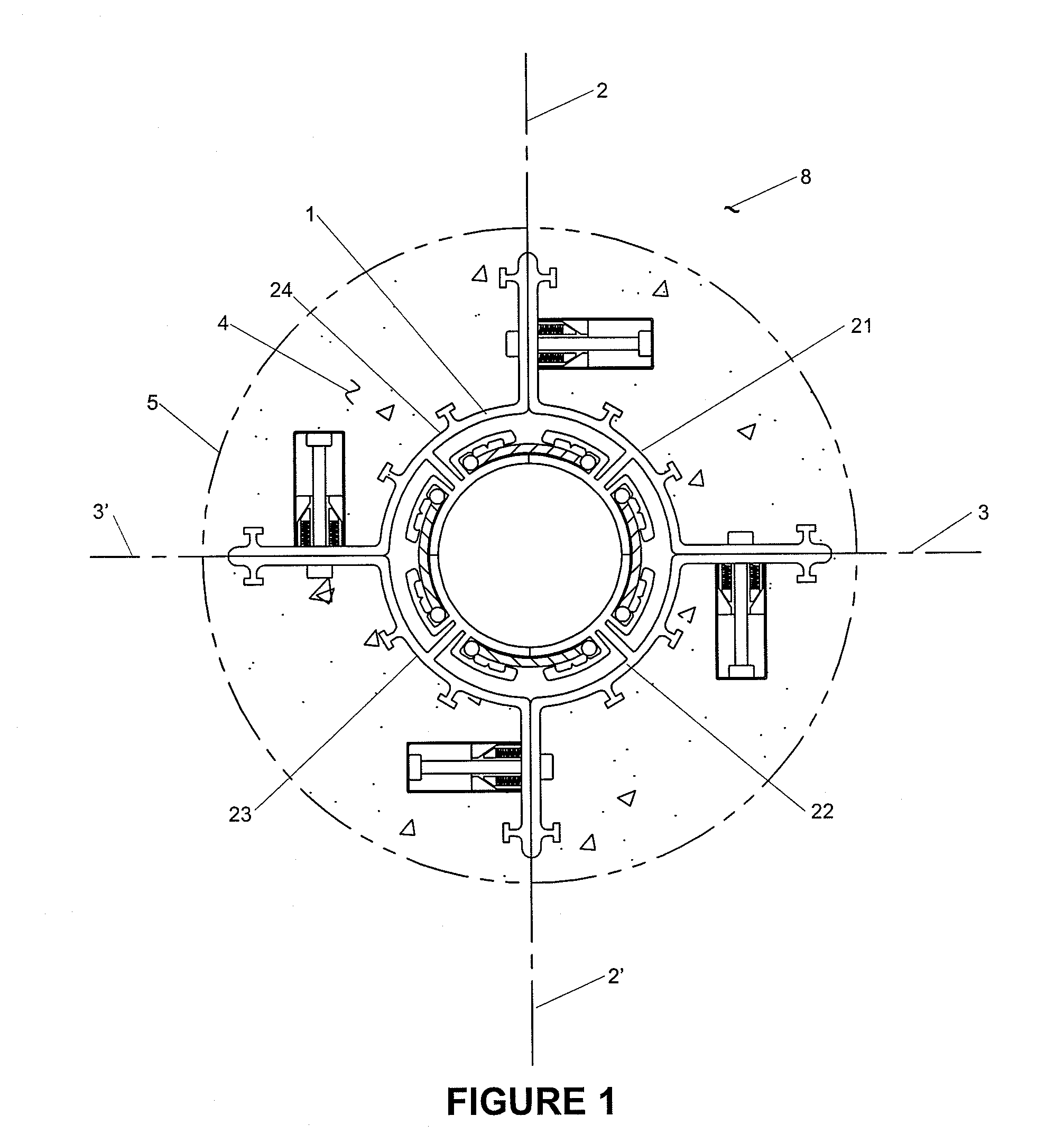

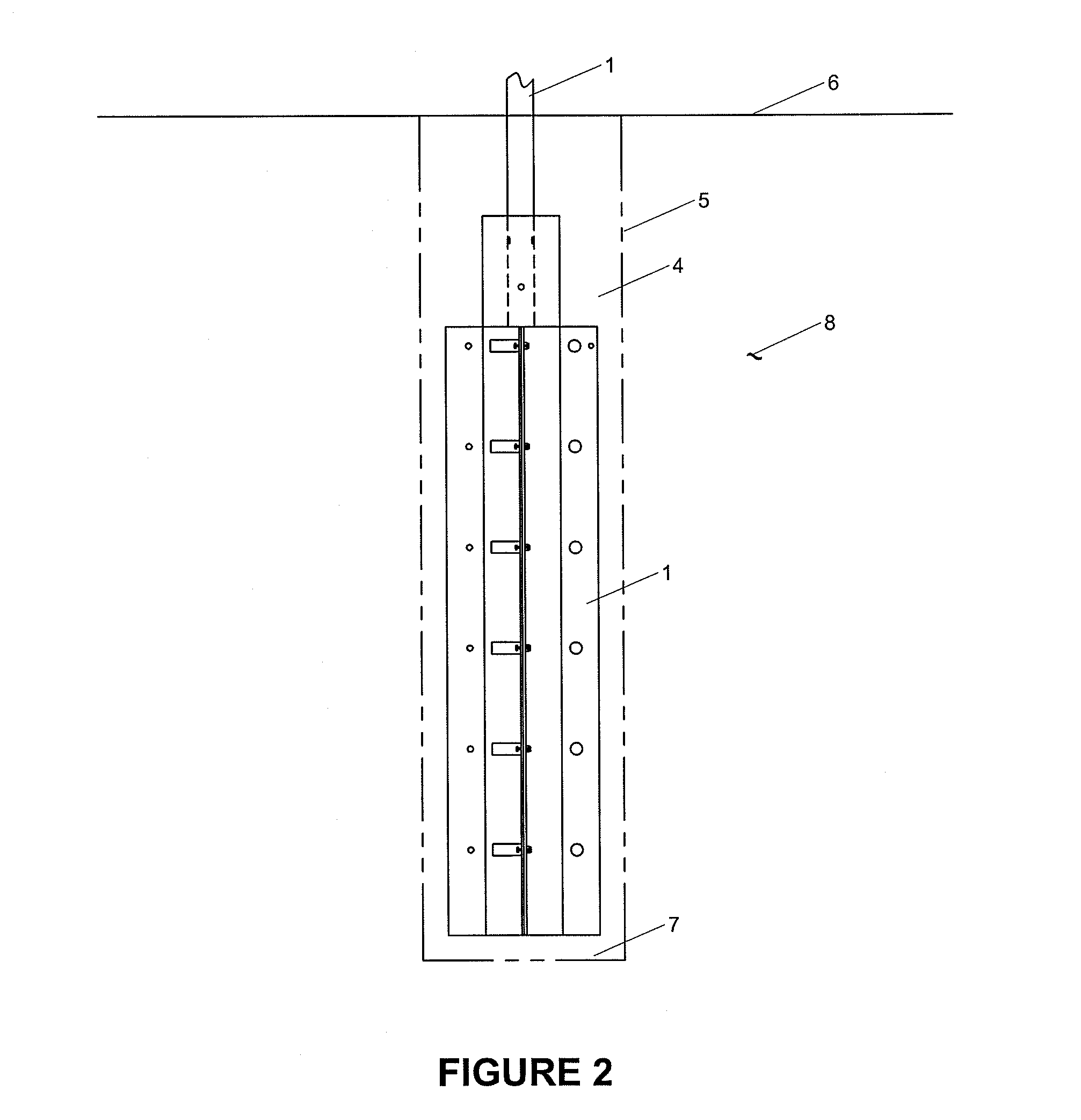

Method and apparatus for purging seals in a thermal reactor

ActiveUS20050170306A1Readily availableProcess can be minimizedDetection of fluid at leakage pointSemiconductor/solid-state device manufacturingProcess engineeringSemiconductor

A semiconductor processing reactor comprises a reaction chamber with a gas exhaust and a mechanical seal at one end of the chamber. The seal seals off the chamber from the ambient environment and is purged with gas to prevent diffusion of ambient gases into the reaction chamber. Because the purge gas can diffuse through the seal into the reaction chamber, the purge gas is chosen based upon the process gas and the location of the seal and exhaust so that the molecular weight of the purge gas causes the purge gas, by the force of gravity or buoyancy, to remain in the portion of the reaction chamber containing the seal and the gas exhaust. Advantageously, keeping the purge gas at the same end of the chamber as the gas exhaust minimizes dilution of the process gas with the purge gas, thereby preventing the purge gas from detrimentally effecting process results.

Owner:ASM INTERNATIONAL

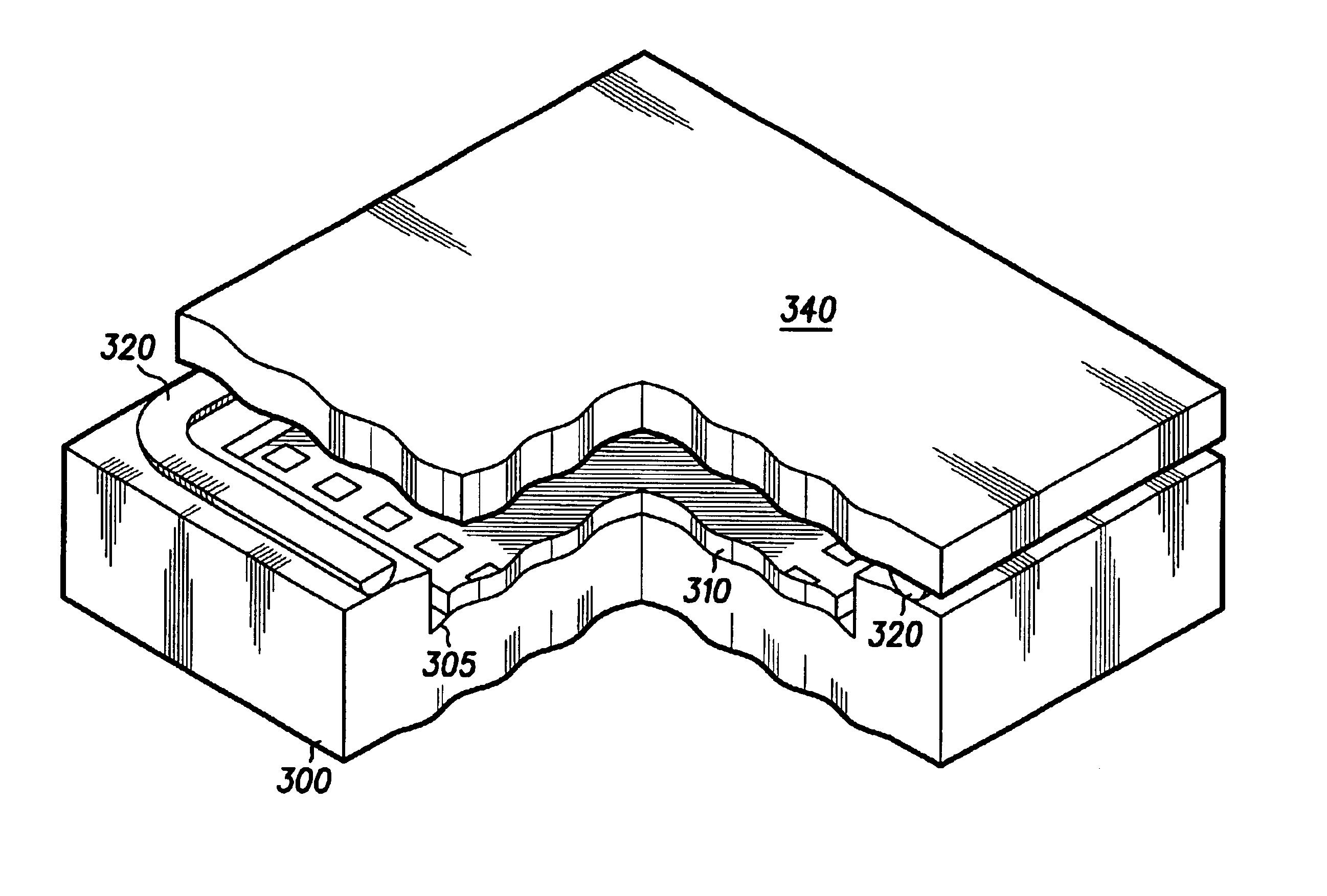

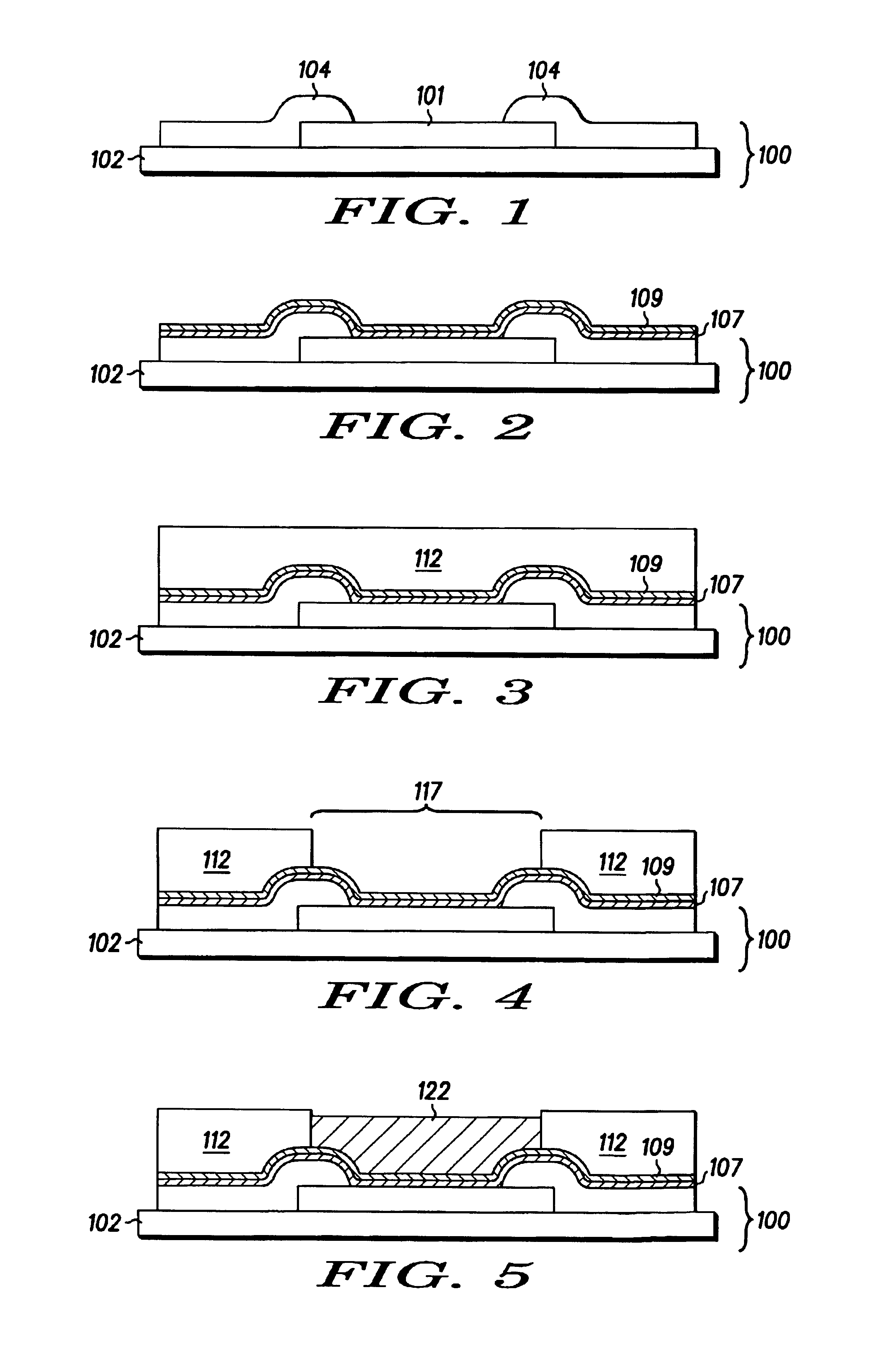

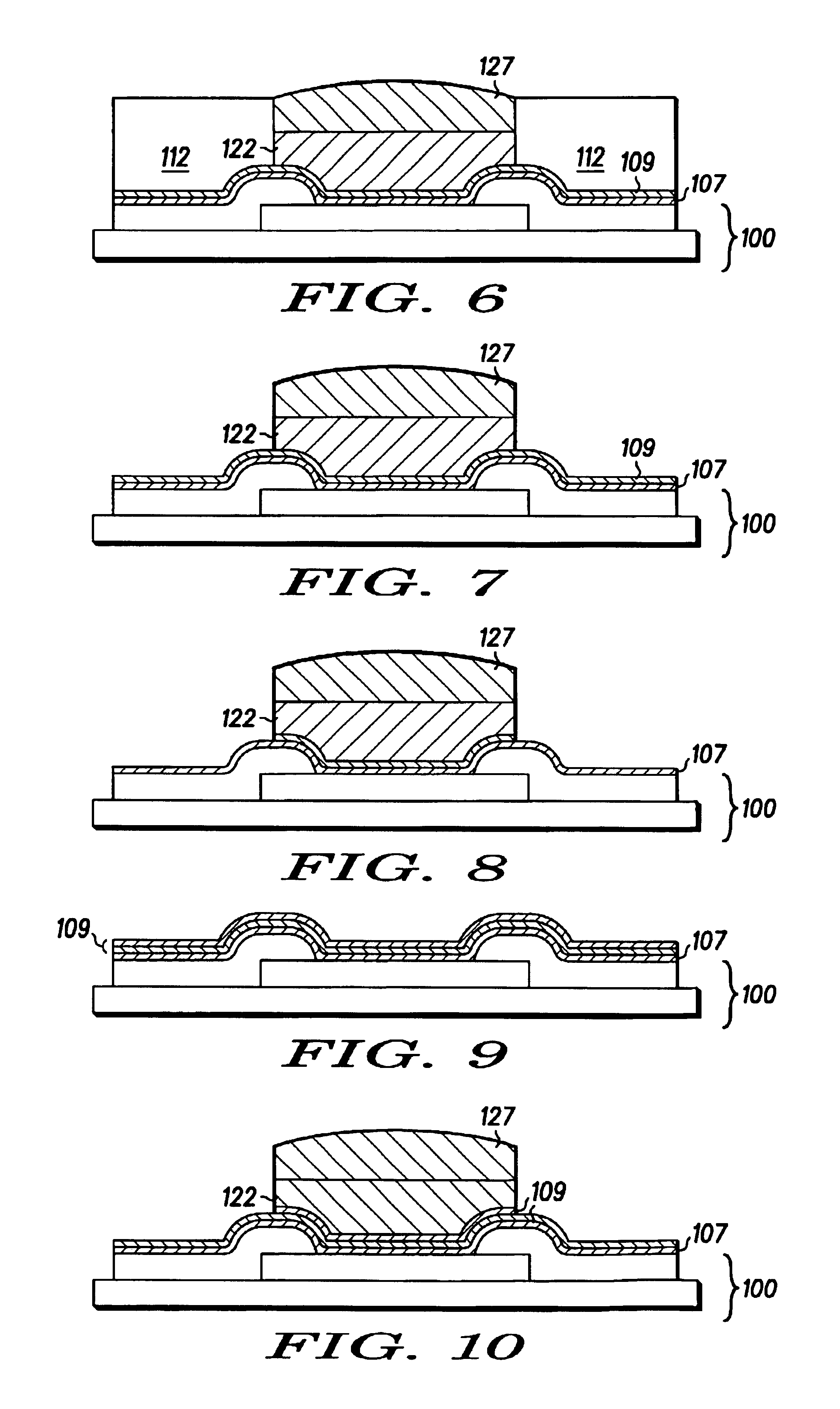

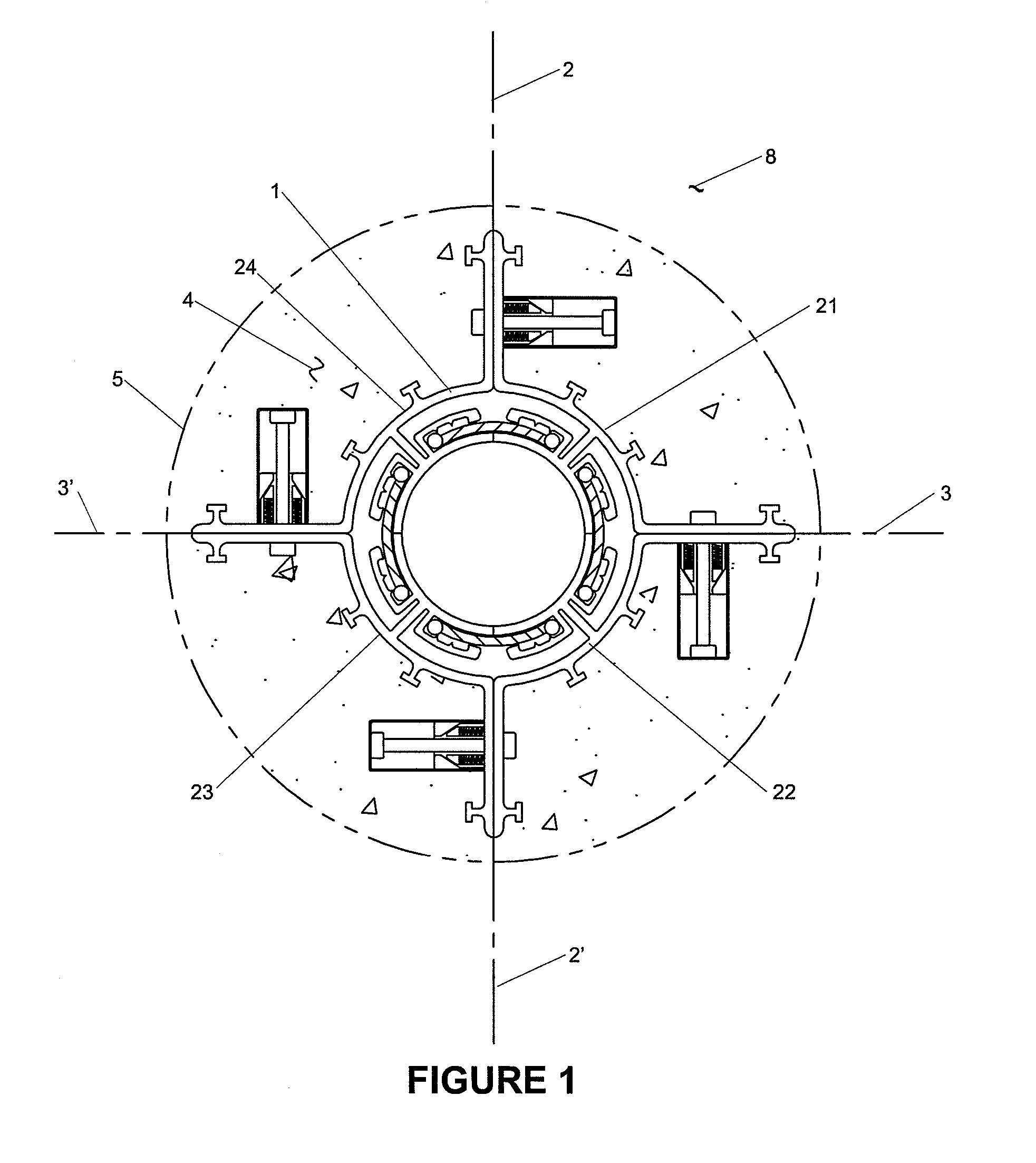

Wafer level MEMS packaging

InactiveUS6953985B2Minimize far processingProcess can be minimizedSemiconductor/solid-state device detailsSolid-state devicesWafer-level packagingEngineering

An exemplary method and apparatus for MEMS device wafer level and / or array packaging comprises inter alia an EM shielding array of dielectric lid elements (340) sealed to a MEMS device die array (300) to produce a sealed MEMS device package array (330). Disclosed features and specifications may be variously controlled, adapted or otherwise optionally modified to improve hermetic sealing and / or EM shielding for any MEMS device. An exemplary embodiment of the present invention representatively provides for wafer level packaging of RF MEMS switches prior to device singulation.

Owner:NORTH STAR INNOVATIONS

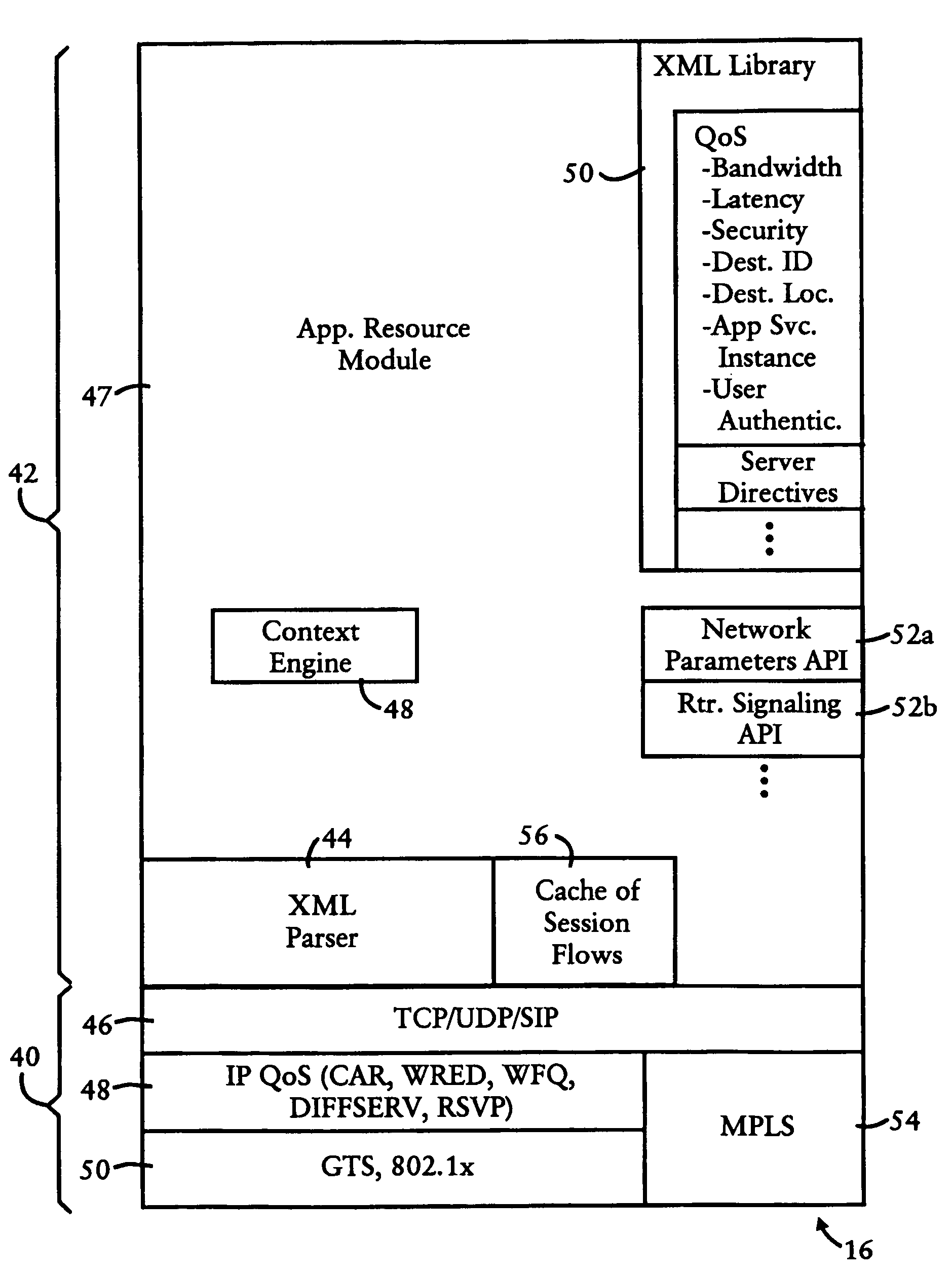

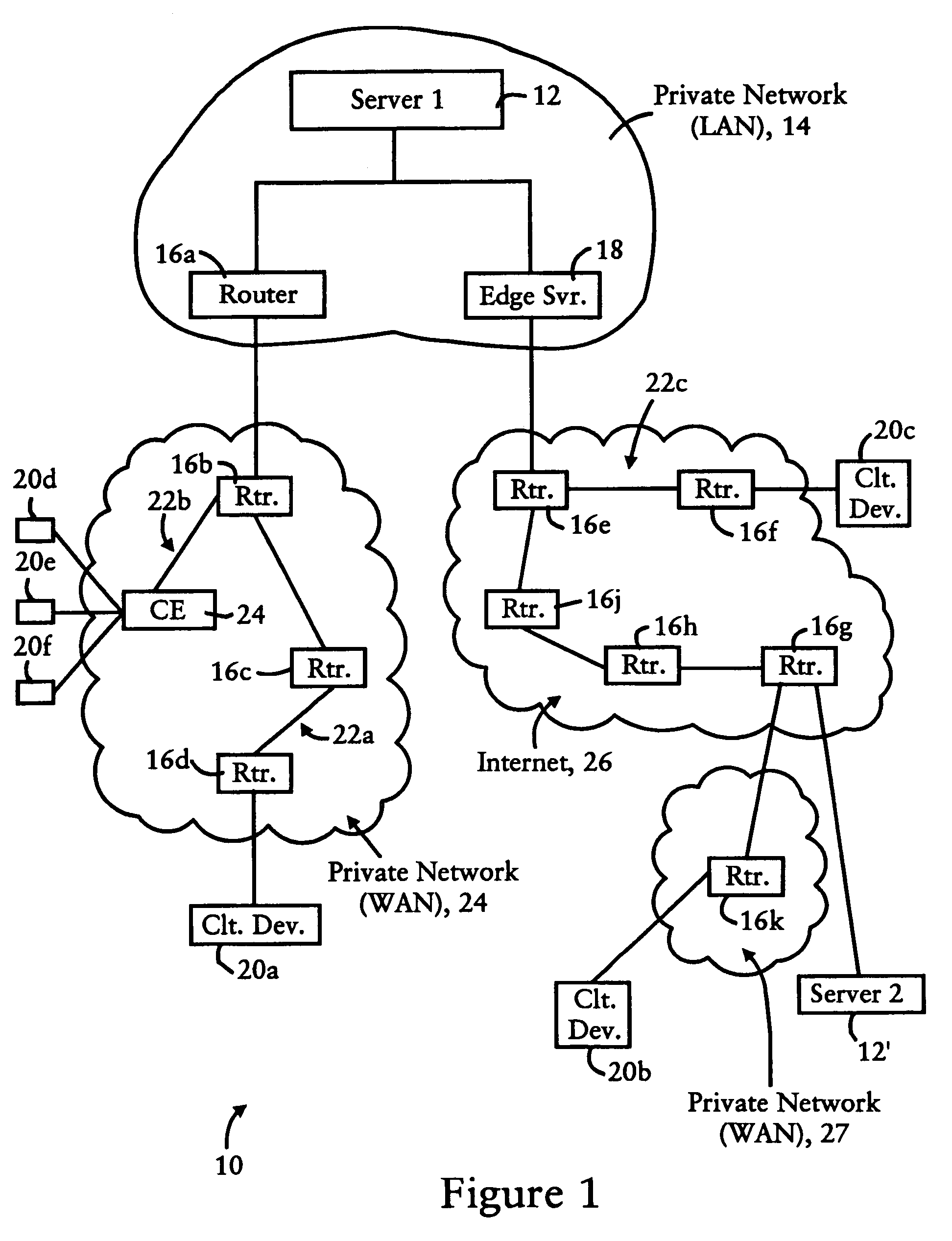

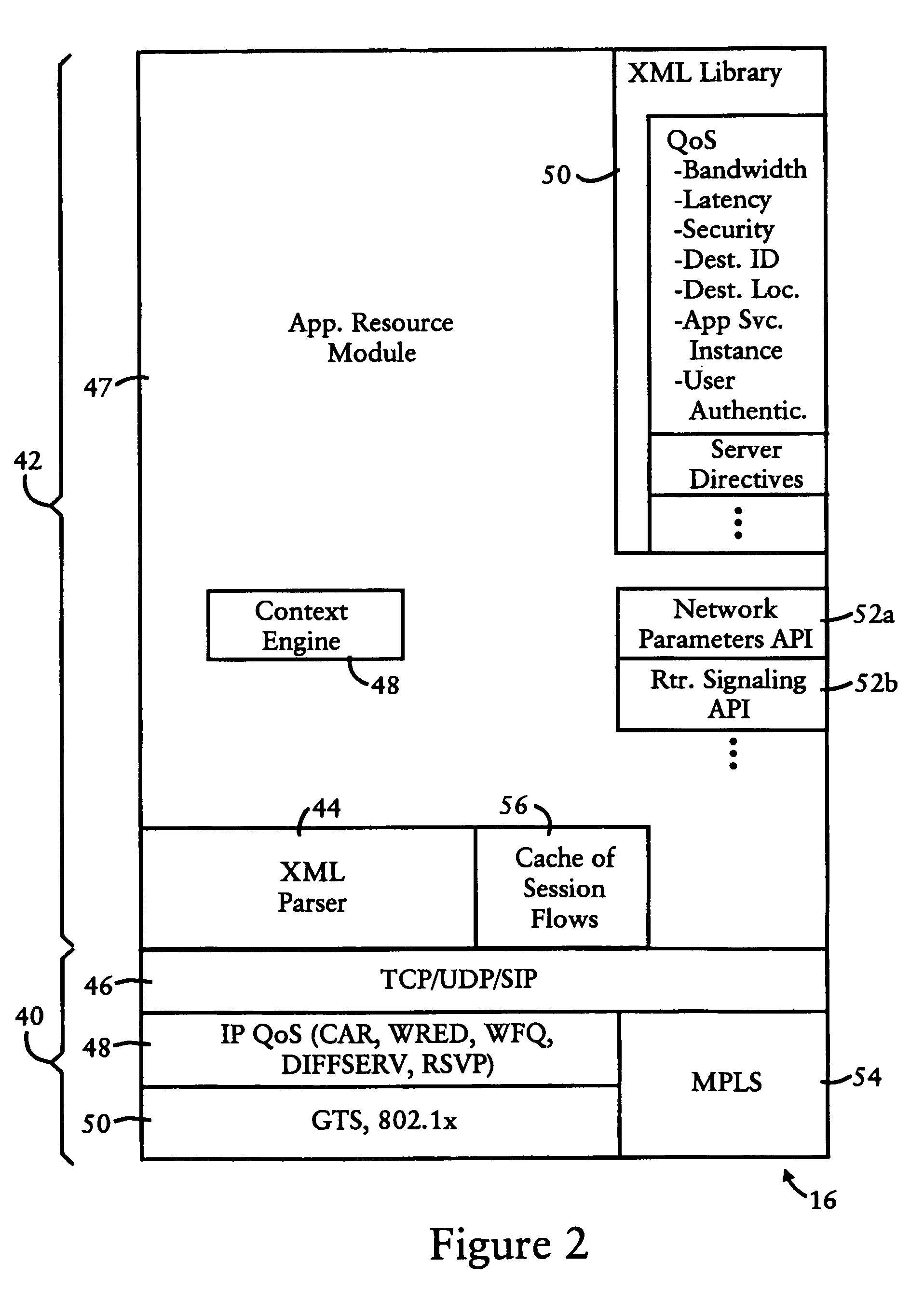

Arrangement for providing content-based quality of service for a service flow based on parsing XML tags detected from a server response to a client request

ActiveUS7516198B1Process can be minimizedData processing applicationsMultiple digital computer combinationsClient-sideApplication server

A network node, for example a router, is configured for assigning network parameters for an identified flow of data packets associated with an application service, based on detecting quality of service parameters specified by XML tags within a message between an application server configured for providing the application service and a destination device configured for receiving the application service. The router includes an XML parser configured for parsing XML tags specifying prescribed user-selectable quality of service attributes for a corresponding application service, and an application resource configured for interpreting the prescribed user-selectable quality of service attributes for the application service. The application resource also is configured for assigning the selected network parameters, for transfer of the identified flow of data packets, based on the interpretation of the prescribed user-selectable quality of service attributes for the specified application service.

Owner:CISCO TECH INC

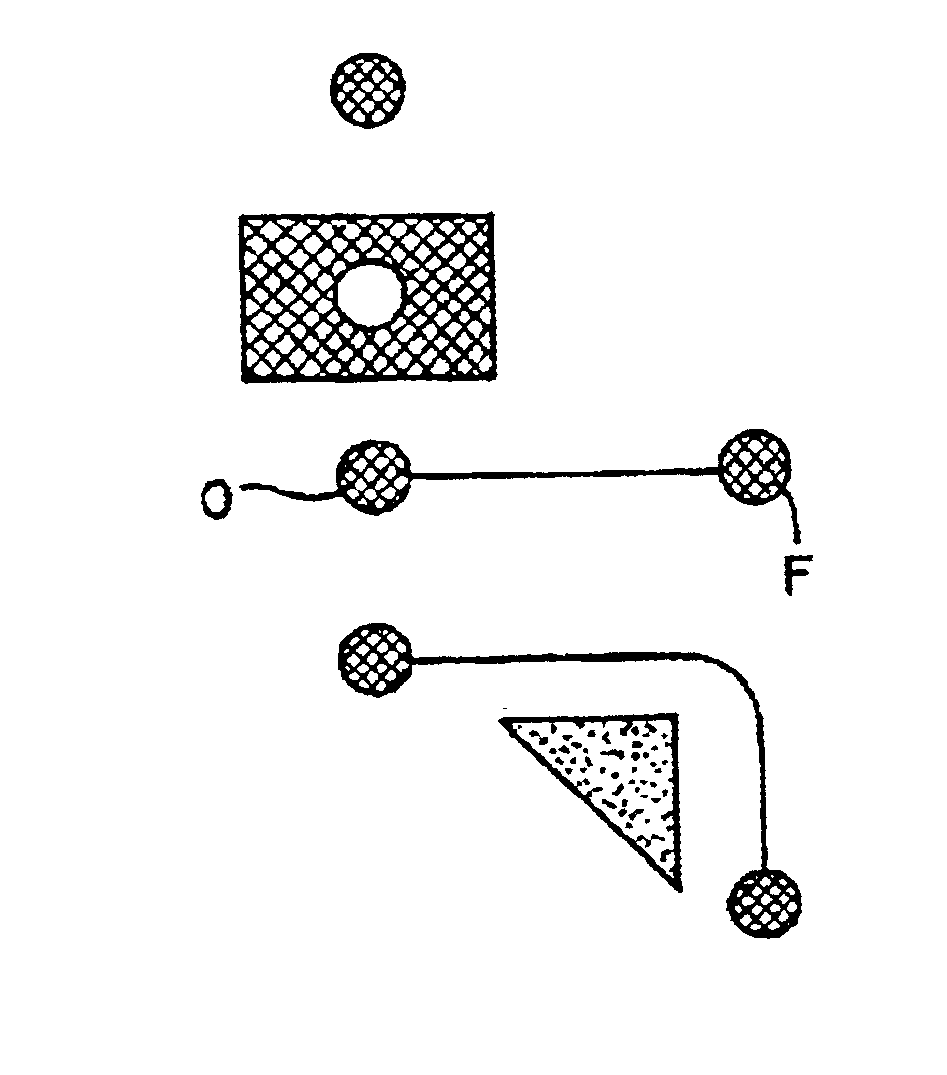

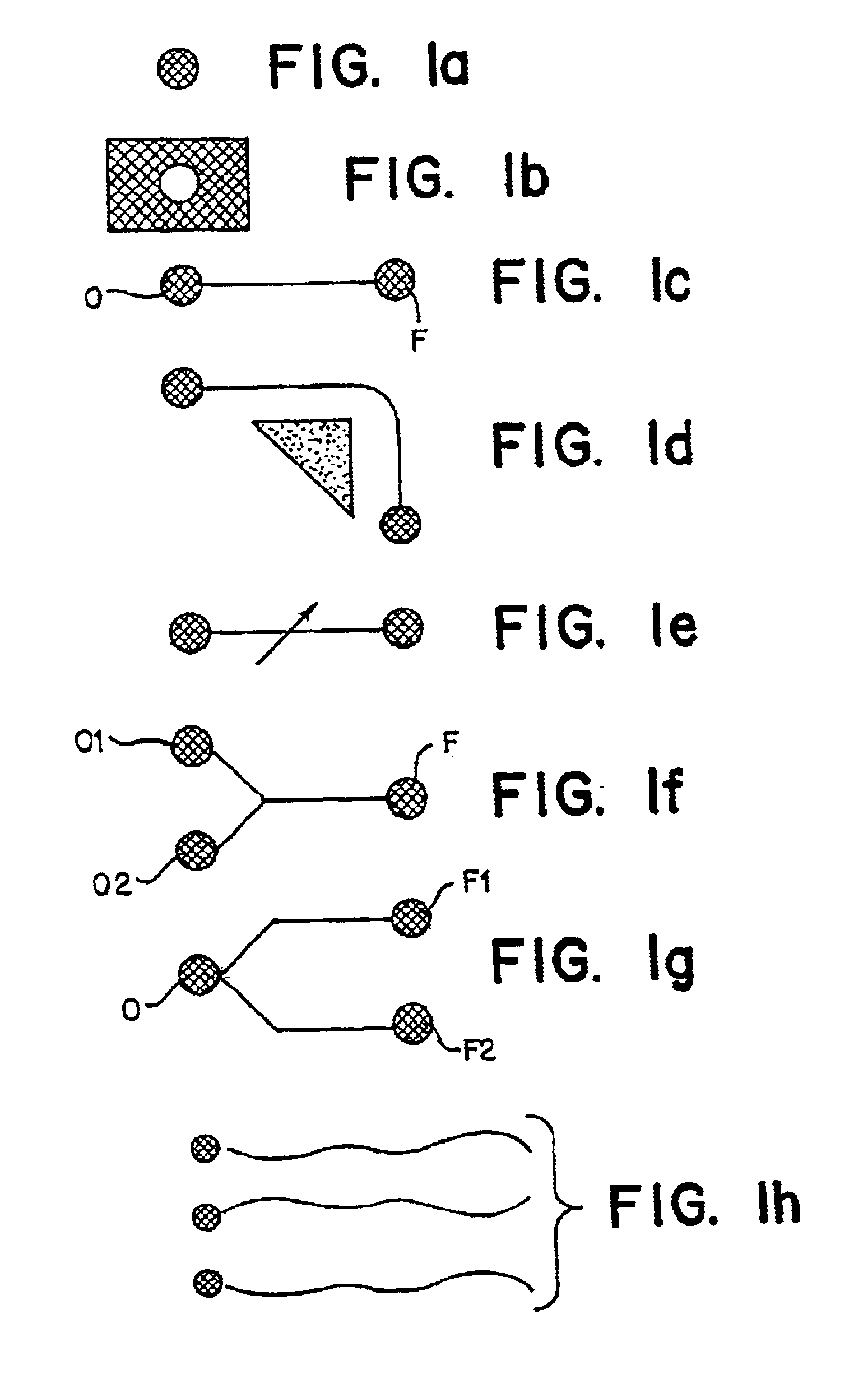

Array cytometry

InactiveUS6958245B2Easy to disassembleMinimize Faradaic processImmobilised enzymesBioreactor/fermenter combinationsParticulatesSilicon oxide

A method and apparatus for the manipulation of colloidal particulates and biomolecules at the interface between an insulating electrode such as silicon oxide and an electrolyte solution. Light-controlled elektrokinetic assembly of particles near surfaces relies on the combination of three functional elements, the AC electric field-induced assembly of planar aggregates; the patterning of the electrolyte / silicon oxide / silicon interface to exert spatial control over the assembly process; and the real-time control of the assembly process via external illumination. The present invention provides a set of fundamental operations enabling interactive control over the creation and placement of planar arrays of several types of particles and biomolecules and the manipulation of array shape and size. The present invention enables sample preparation and handling for diagnostic assays and biochemical analysis in an array format, and the functional integration of these operations. In addition, the present invention provides a procedure for the creation of material surfaces with desired properties and for the fabrication of surface-mounted optical components. This invention is also for a method and apparatus to direct the lateral motion and induce the assembly into planar arrays of cells on semiconductor surfaces in response to temporally and spatially varying electric fields and to projected patterns of illumination.

Owner:BIOARRAY SOLUTIONS

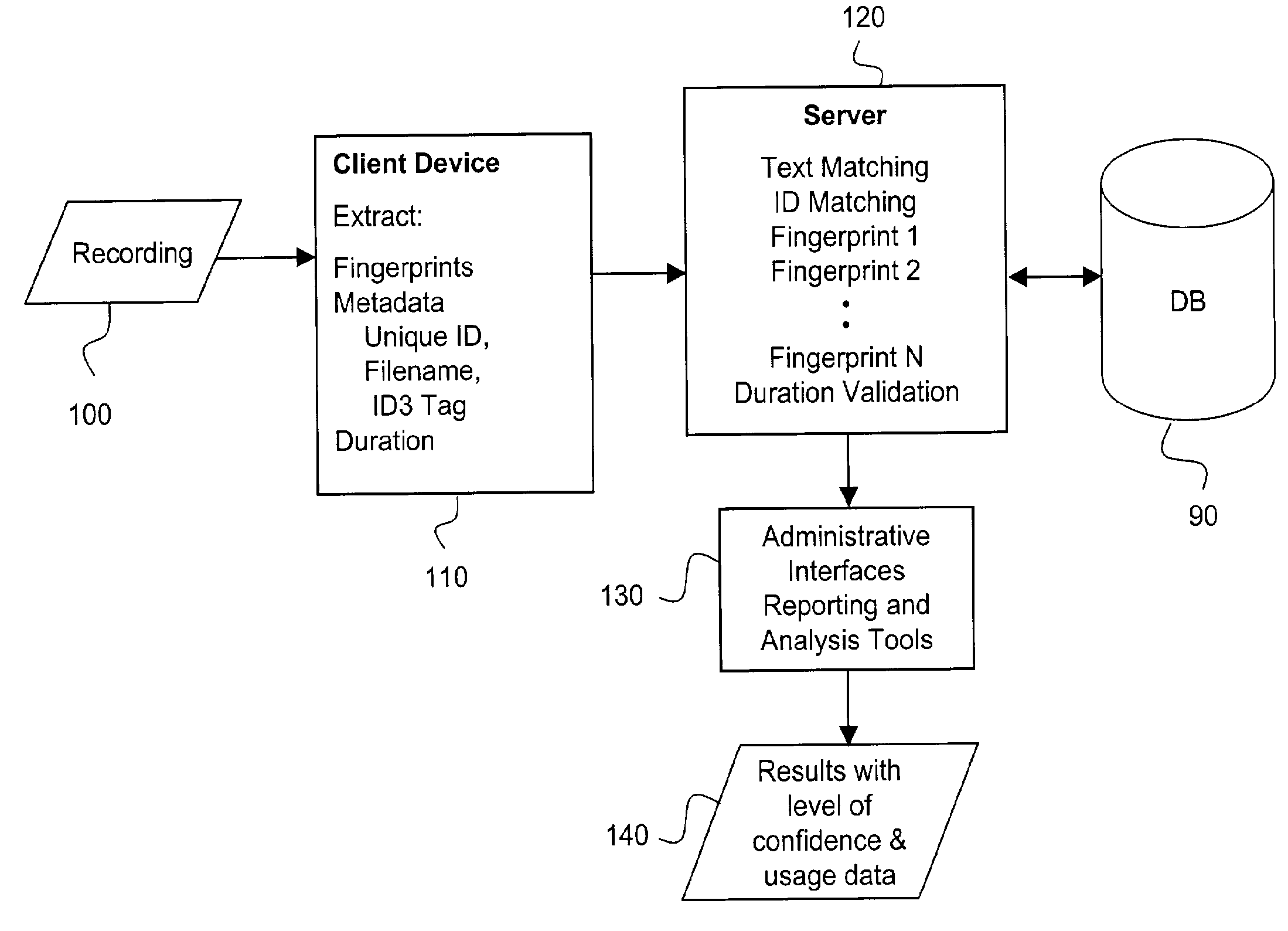

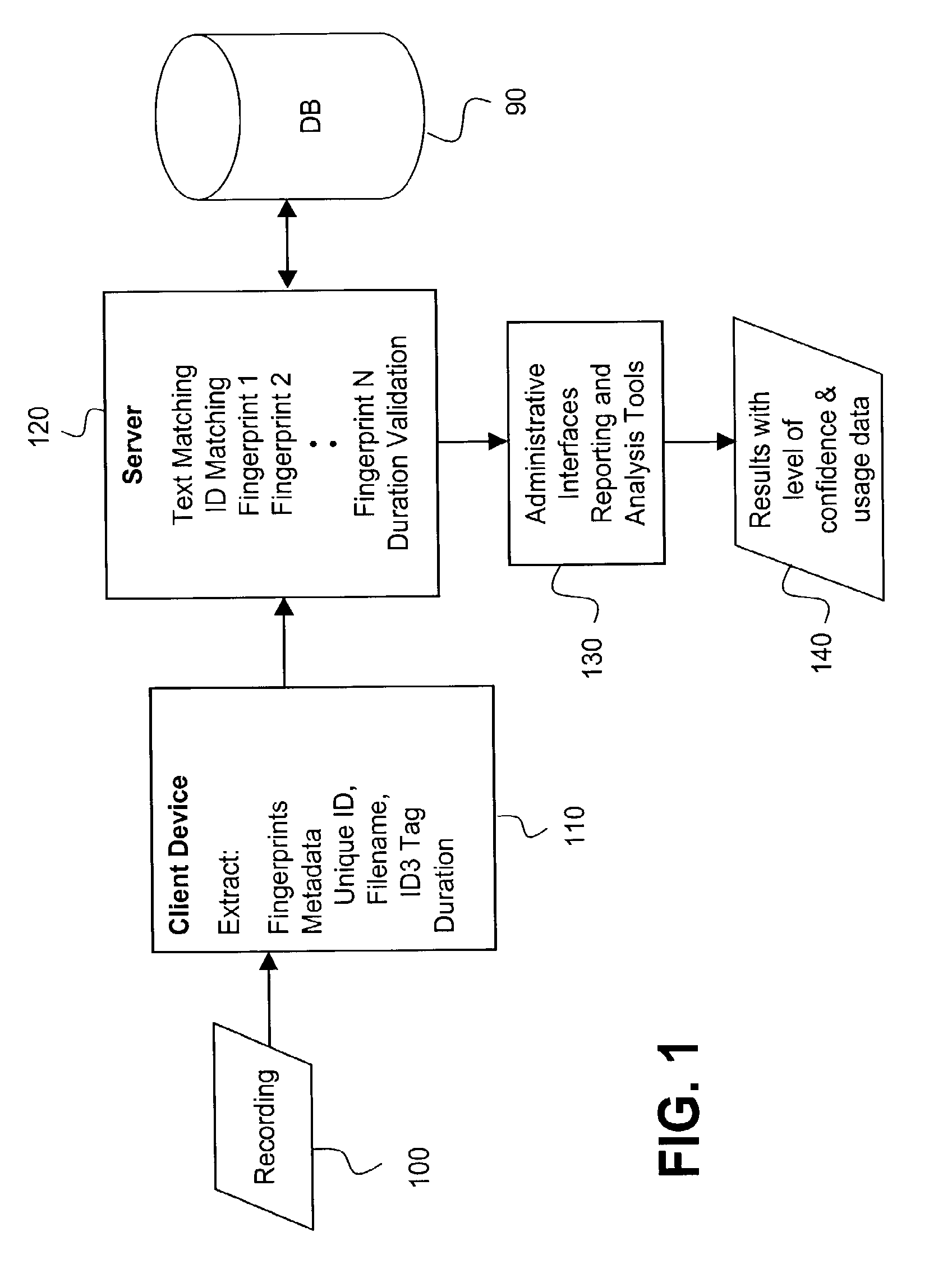

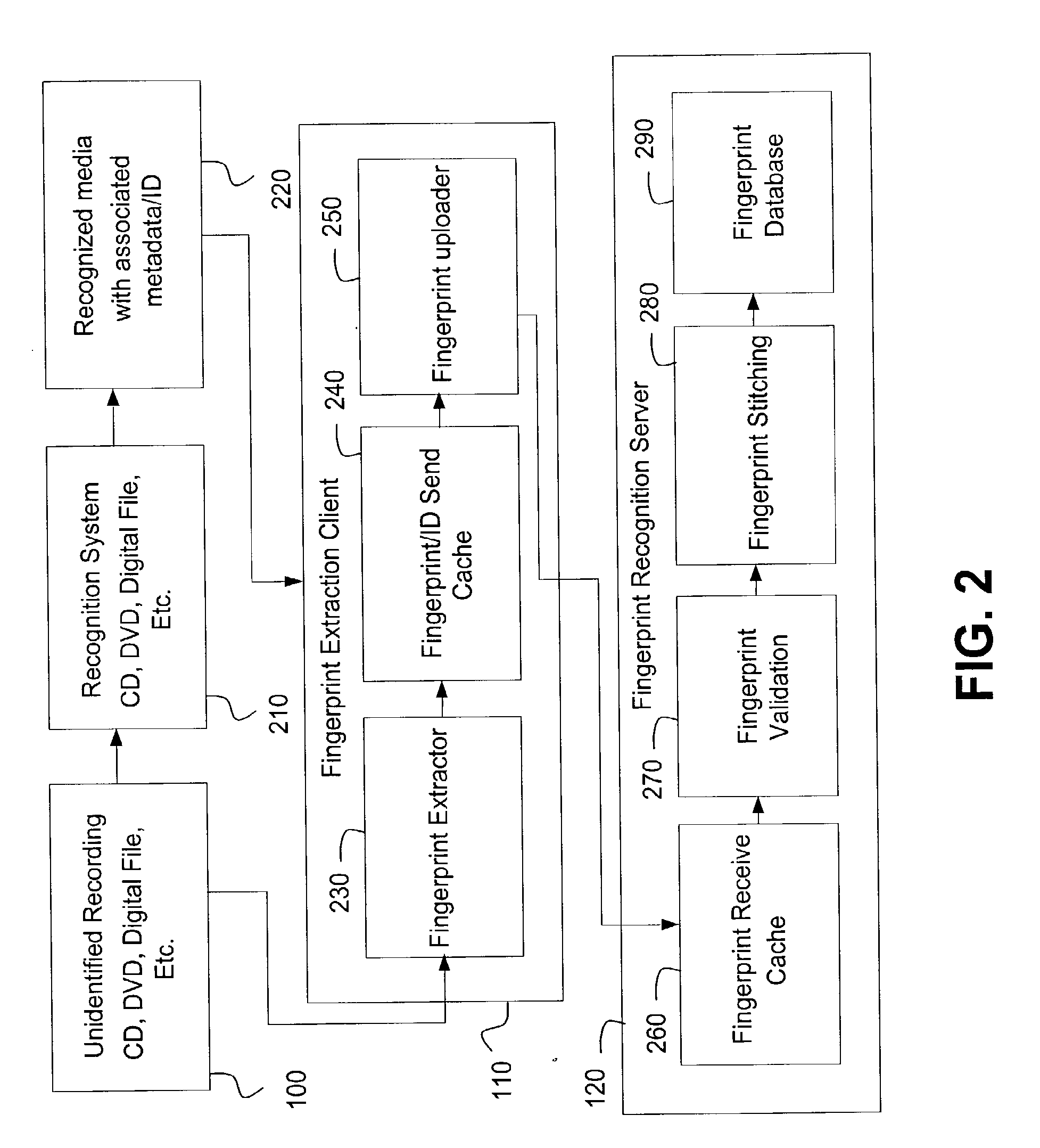

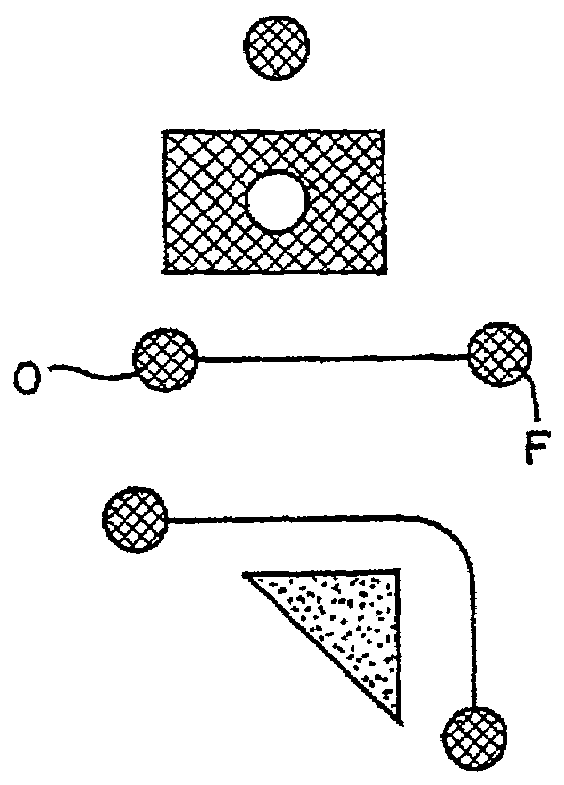

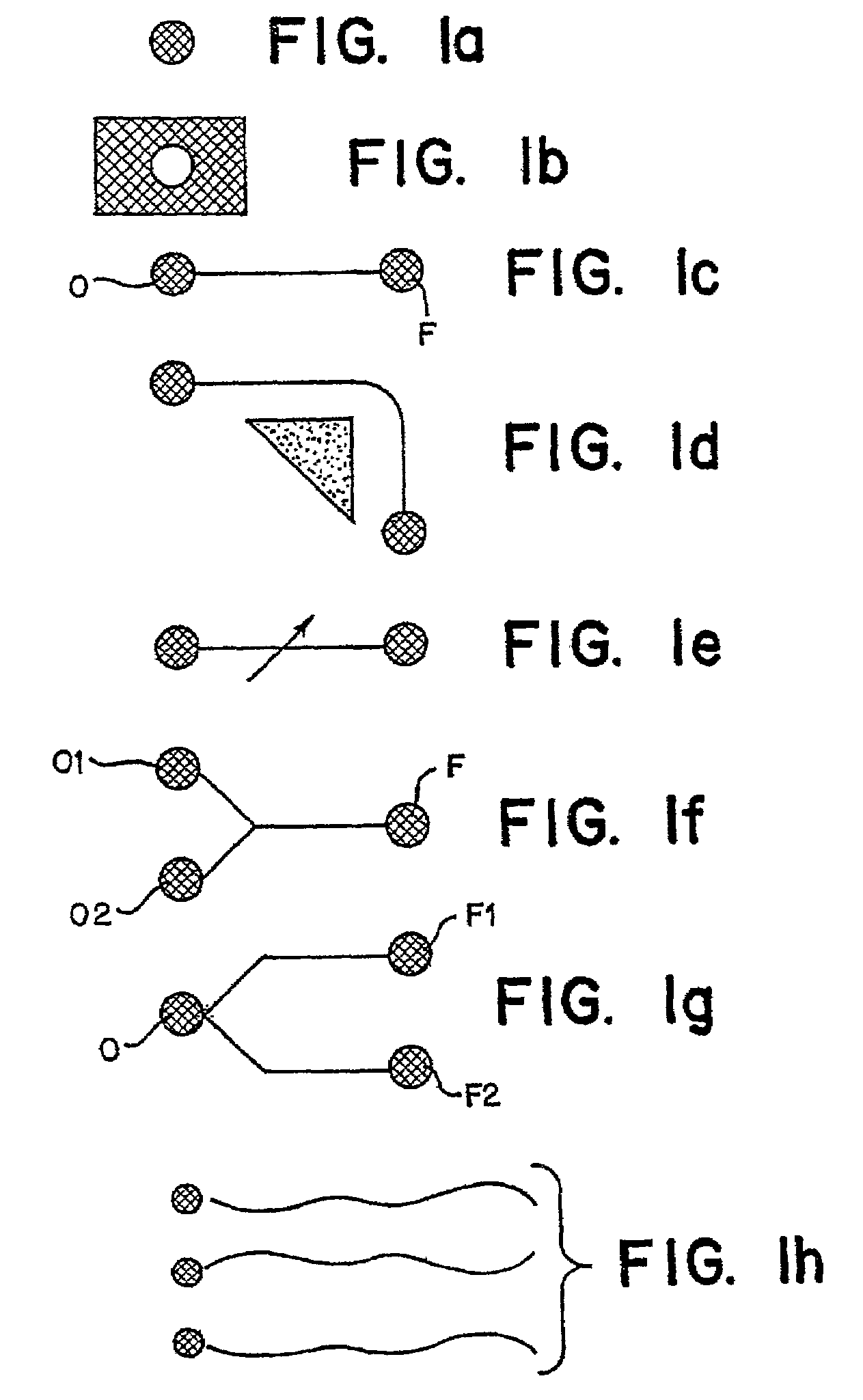

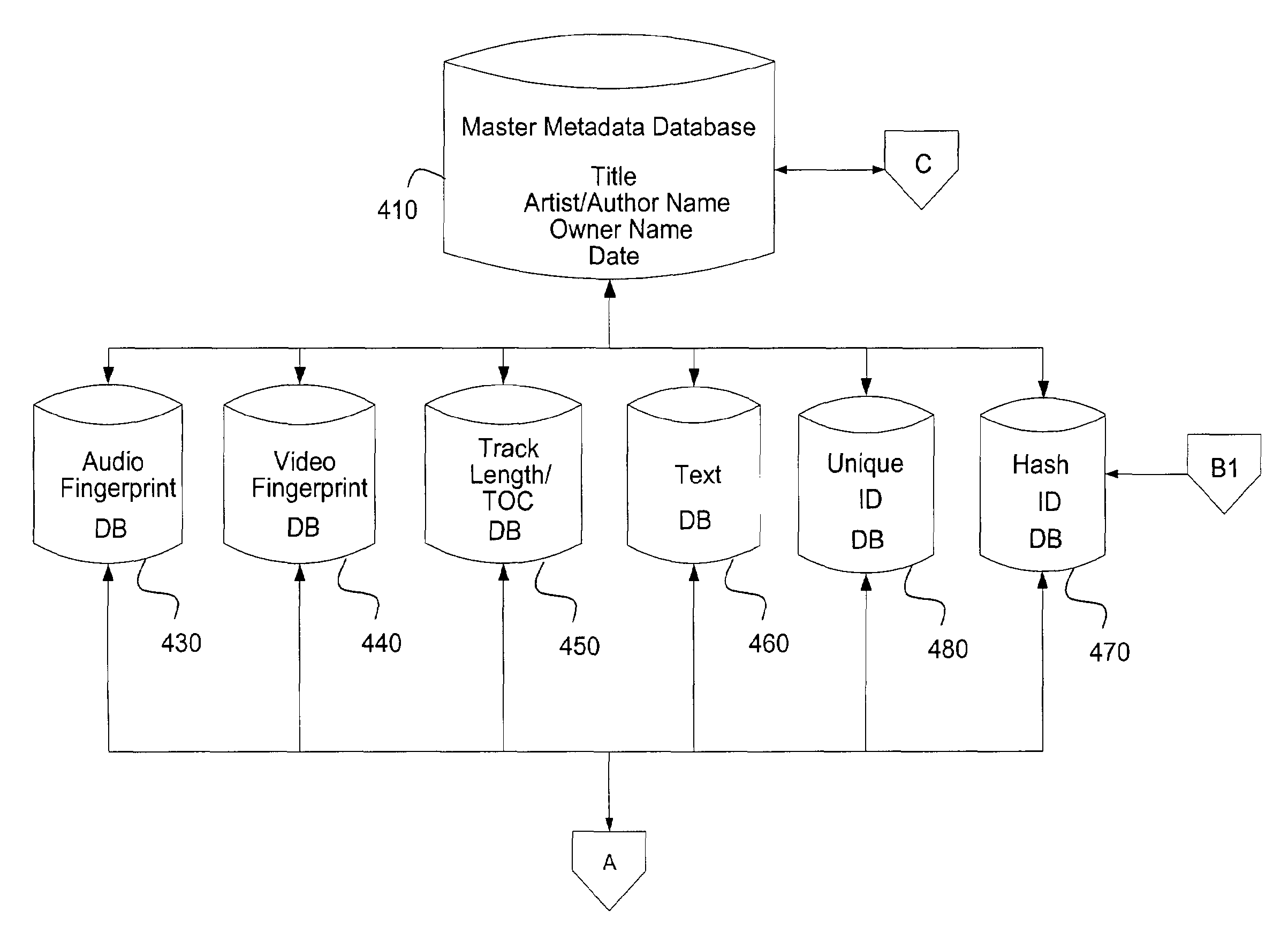

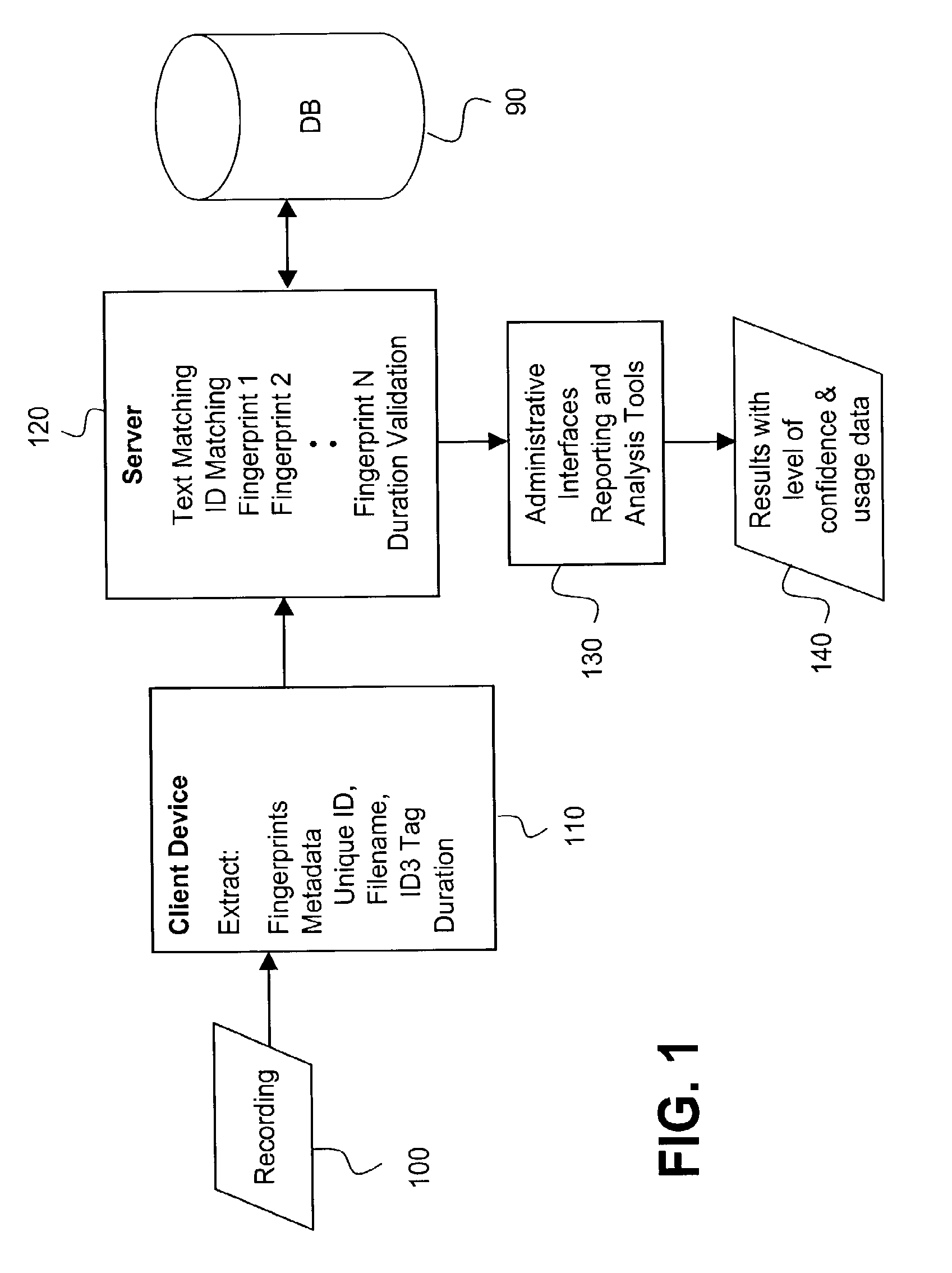

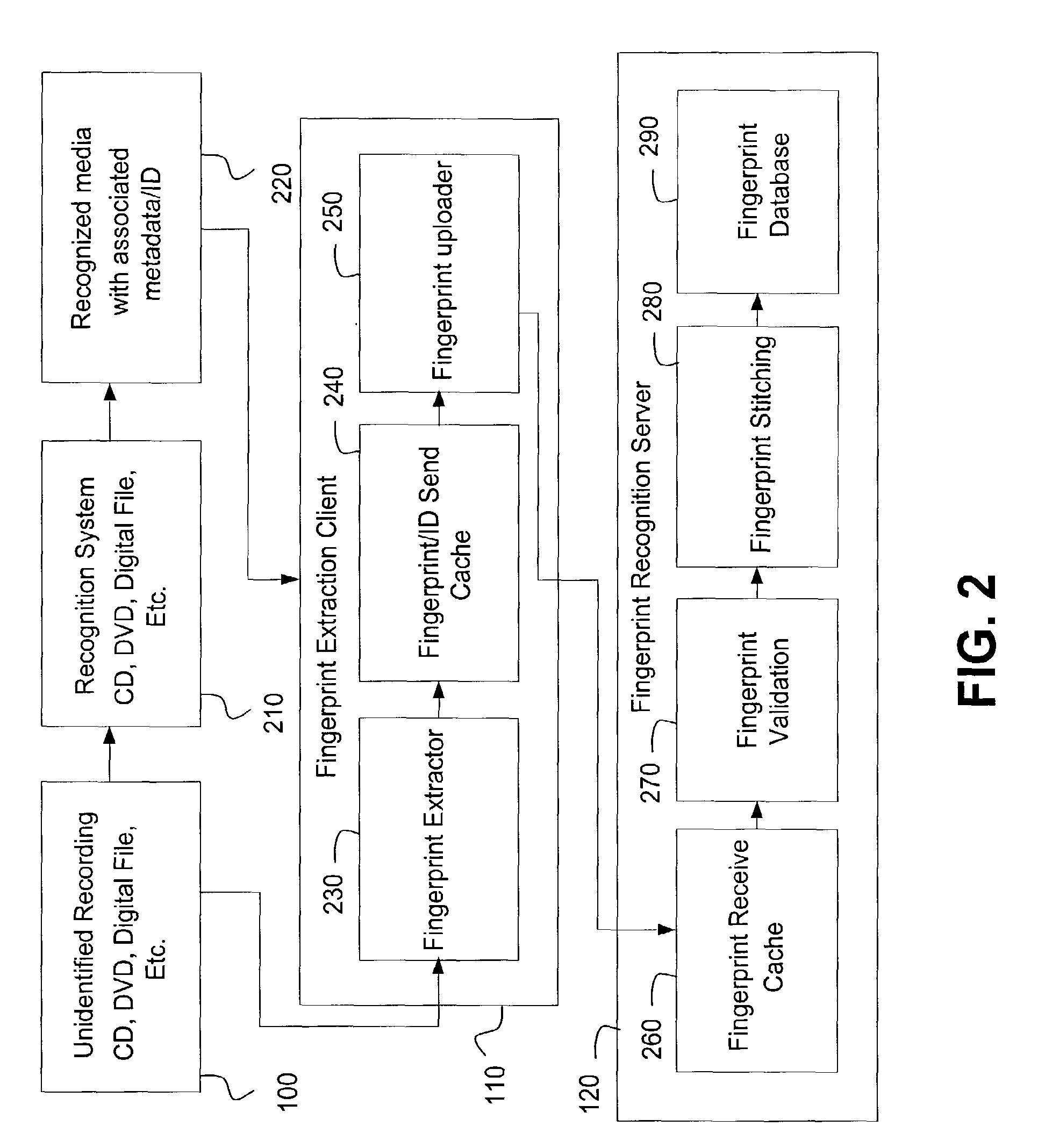

Multiple step identification of recordings

ActiveUS20100158488A1Maximizing identificationUse minimizedTelevision system detailsMetadata video data retrievalCompact discRelevant information

Multiple information is extracted from an unknown recording and information associated therewith. Associated information includes the filename, if the recording is a computer file in, e.g., MP3 format, or table of contents (TOC) data, if the recording is on a removable medium, such as a compact disc. At least one and preferably several algorithmically determined fingerprints are extracted from the recording using one or more fingerprint extraction methods. The information extracted is compared with corresponding information in a database maintained for reference recordings. Identification starts with the most accurate and efficient method available, e.g., using a hash ID, a unique ID or text. Fingerprint matching is used to confirm other matches and validation is performed by comparing the duration of the unknown and a possibly matching reference recording.

Owner:GRACENOTE

Array cytometry

InactiveUS7056746B2Easy to disassembleMinimize Faradaic processSequential/parallel process reactionsOrganic chemistry methodsParticulatesEngineering

A method and apparatus for the manipulation of colloidal particulates and biomolecules at the interface between an insulating electrode such as silicon oxide and an electrolyte solution. Light-controlled electrokinetic assembly of particles near surfaces relies on the combination of three functional elements: the AC electric field-induced assembly of planar aggregates; the patterning of the electrolyte / silicon oxide / silicon interface to exert spatial control over the assembly process; and the real-time control of the assembly process via external illumination. The present invention provides a set of fundamental operations enabling interactive control over the creation and placement of planar arrays of several types of particles and biomolecules and the manipulation of array shape and size. The present invention enables sample preparation and handling for diagnostic assays and biochemical analysis in an array format, and the functional integration of these operations. In addition, the present invention provides a procedure for the creation of material surfaces with desired properties and for the fabrication of surface-mounted optical components. This invention is also for a method and apparatus to direct the lateral motion and induce the assembly into planar arrays of cells on semiconductor surfaces in response to temporally and spatially varying electric fields and to projected patterns of illumination.

Owner:BIOARRAY SOLUTIONS

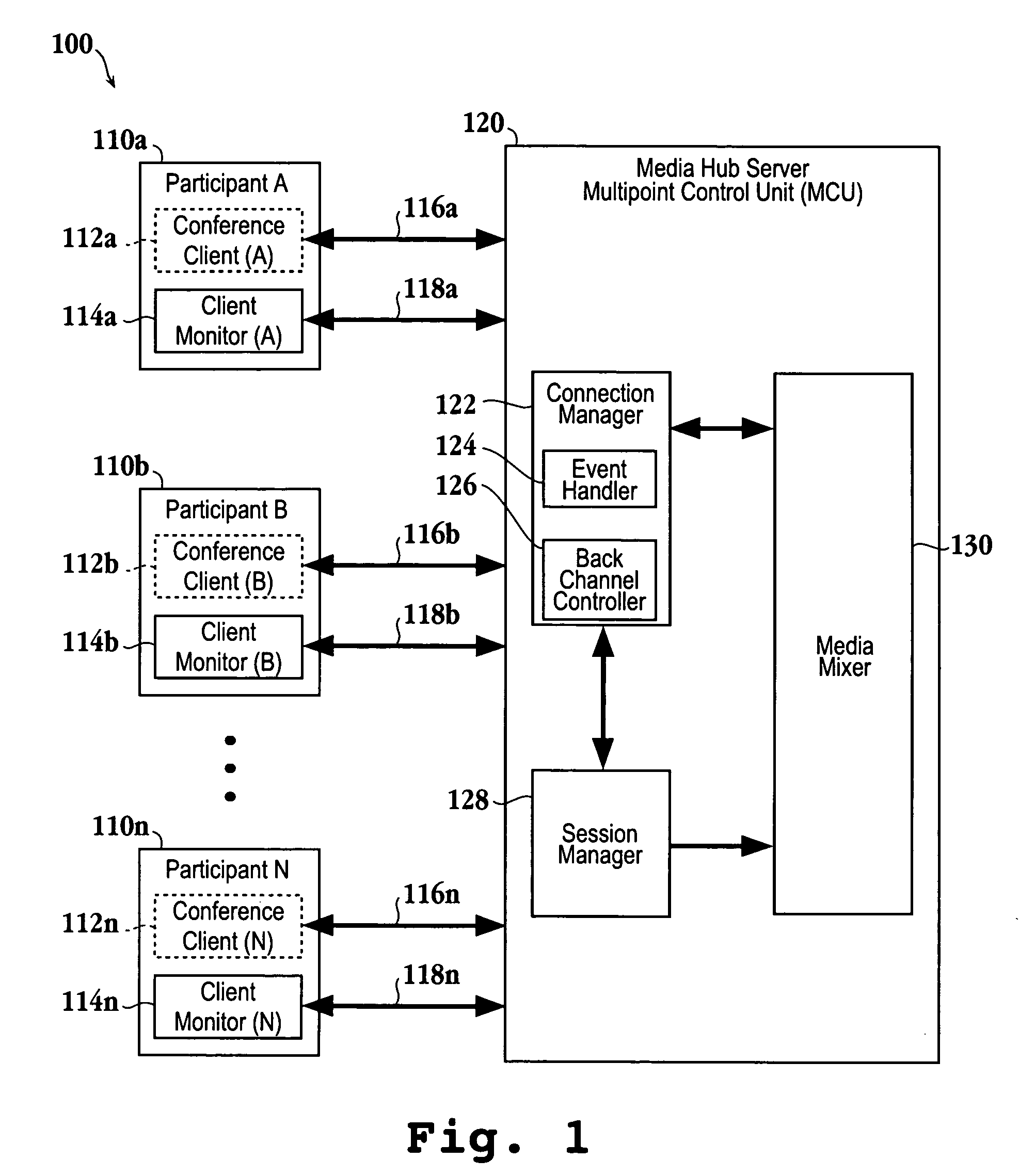

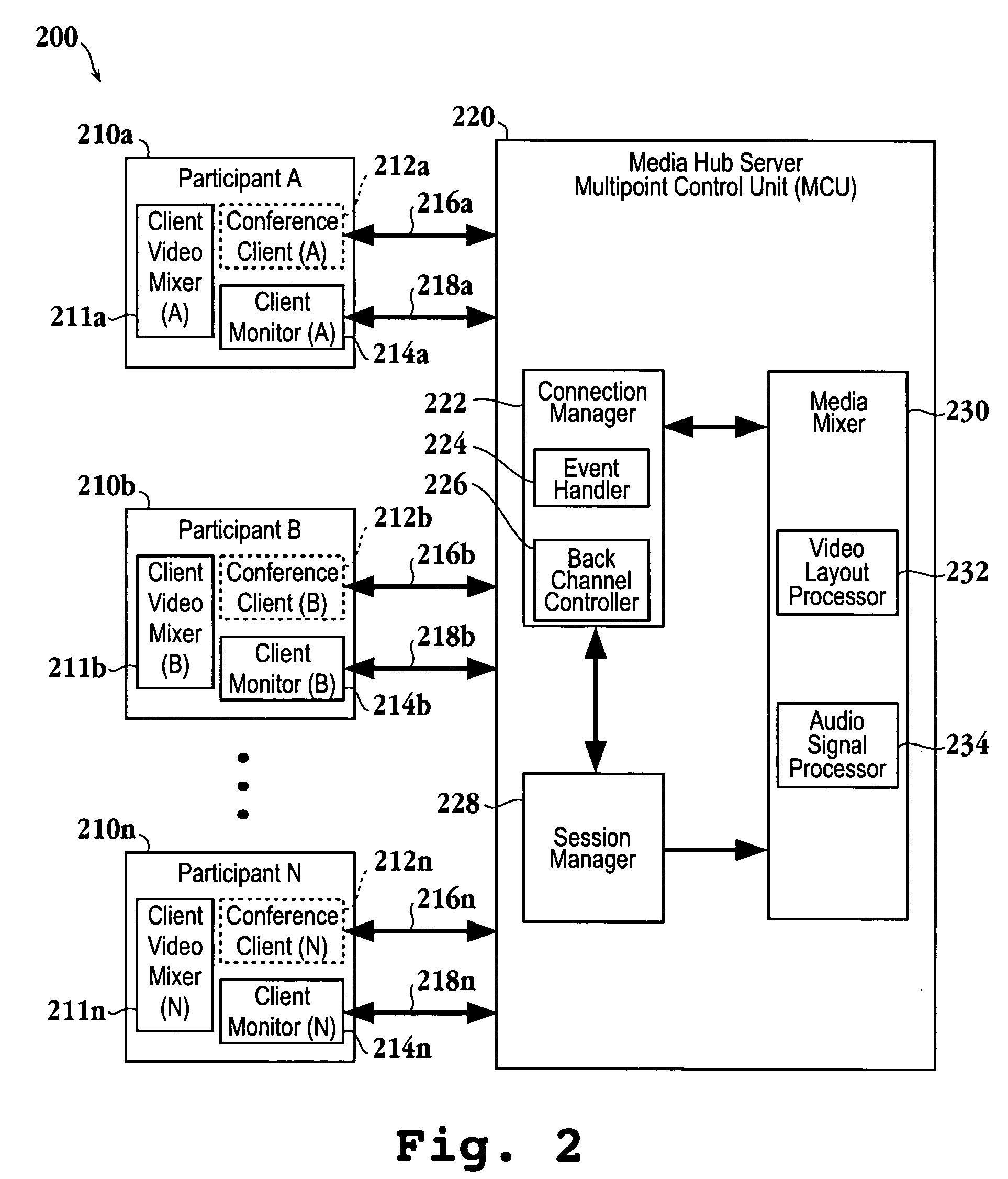

Local video loopback method for a multi-participant conference system using a back-channel video interface

InactiveUS7176957B2Improve image qualityProcess can be minimizedTelevision conference systemsTwo-way working systemsComputer graphics (images)Client-side

Owner:SEIKO EPSON CORP

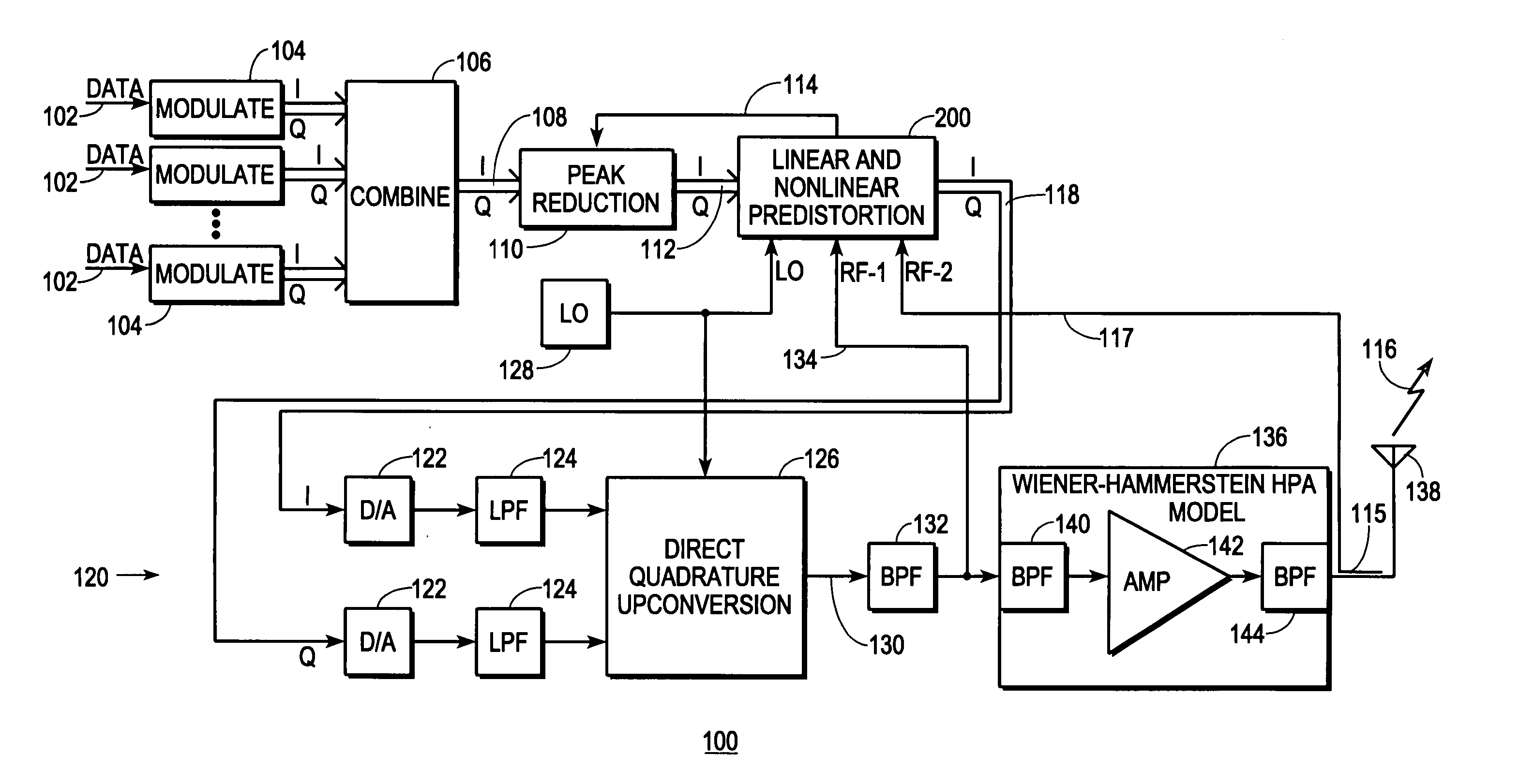

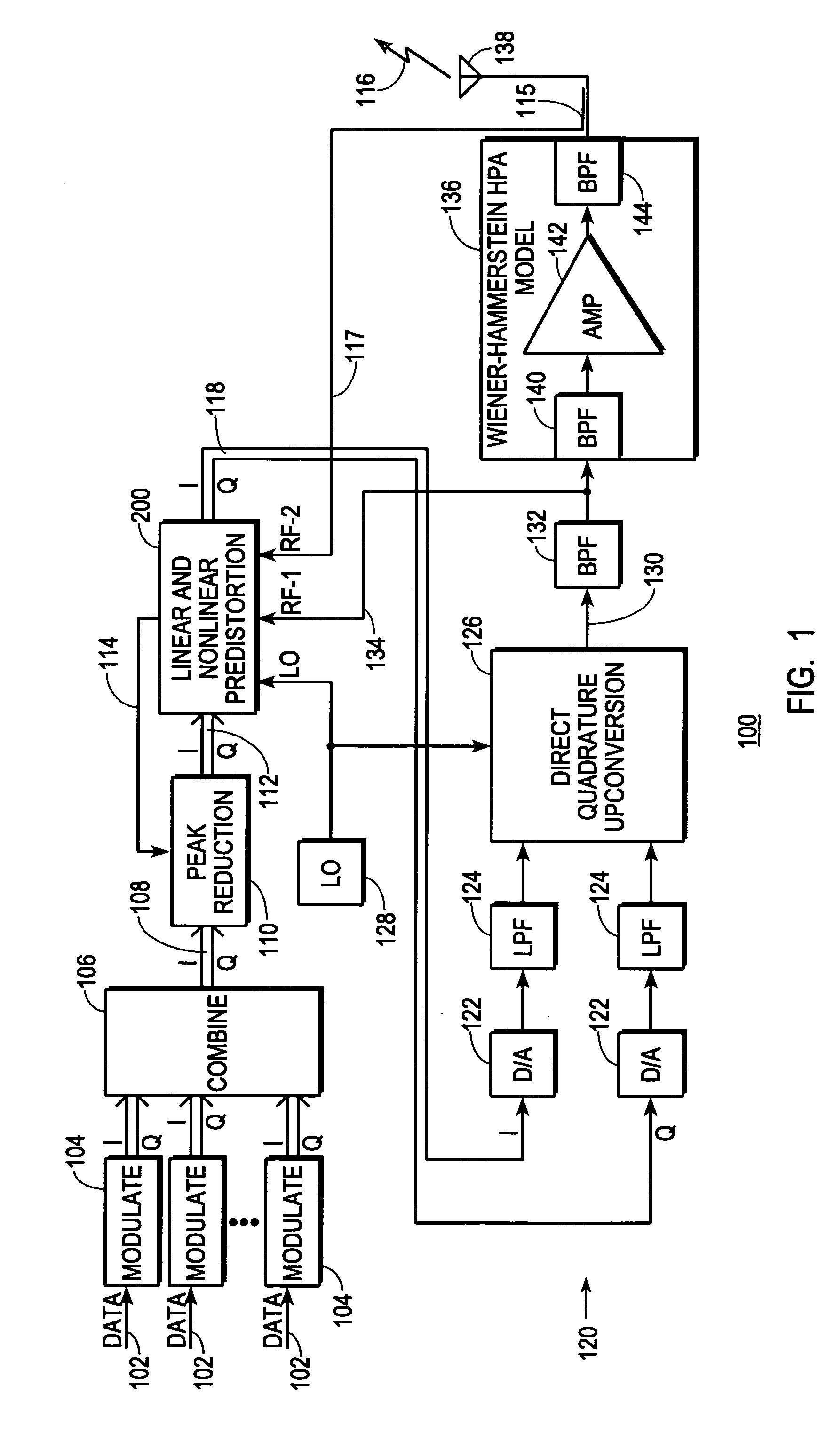

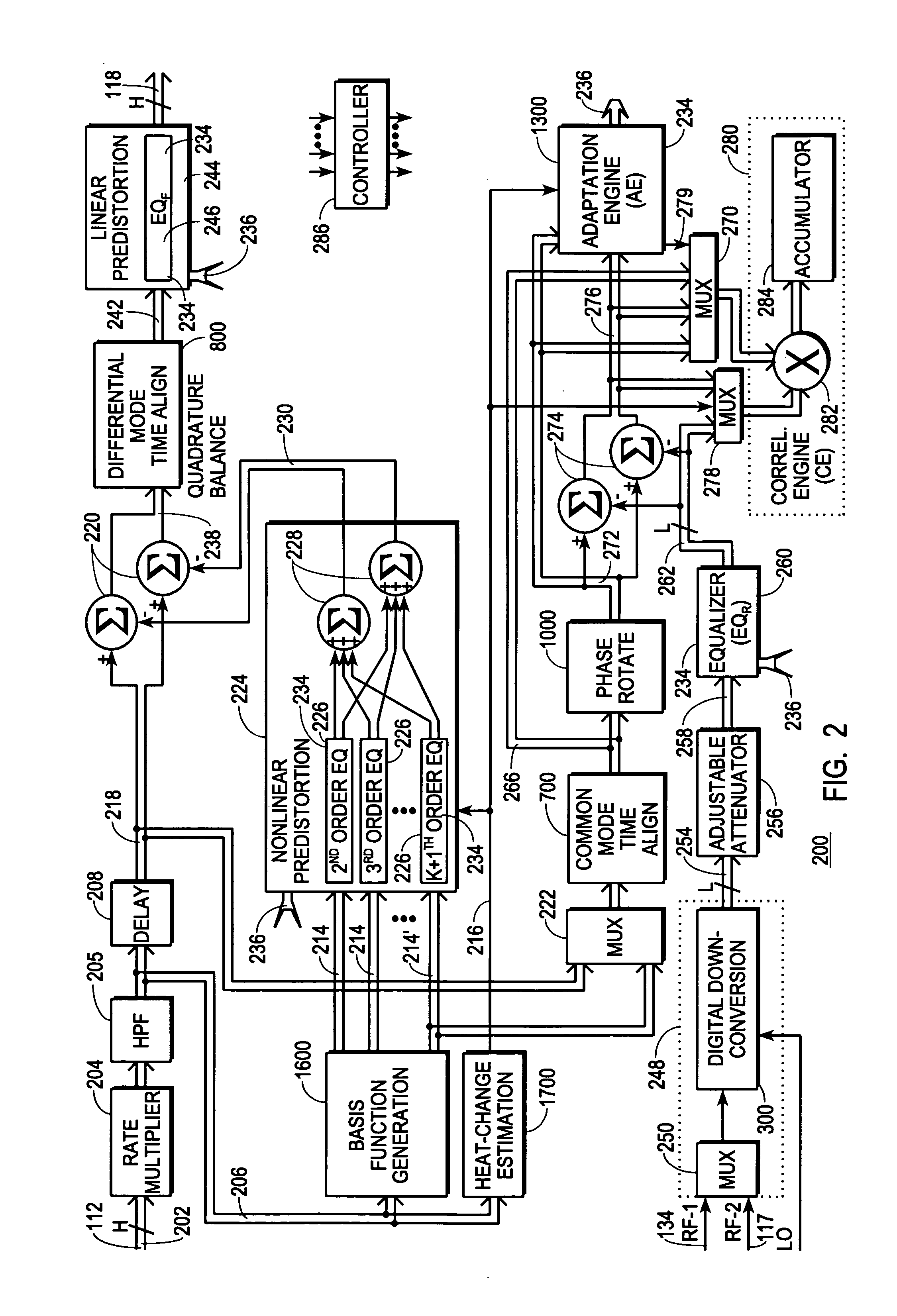

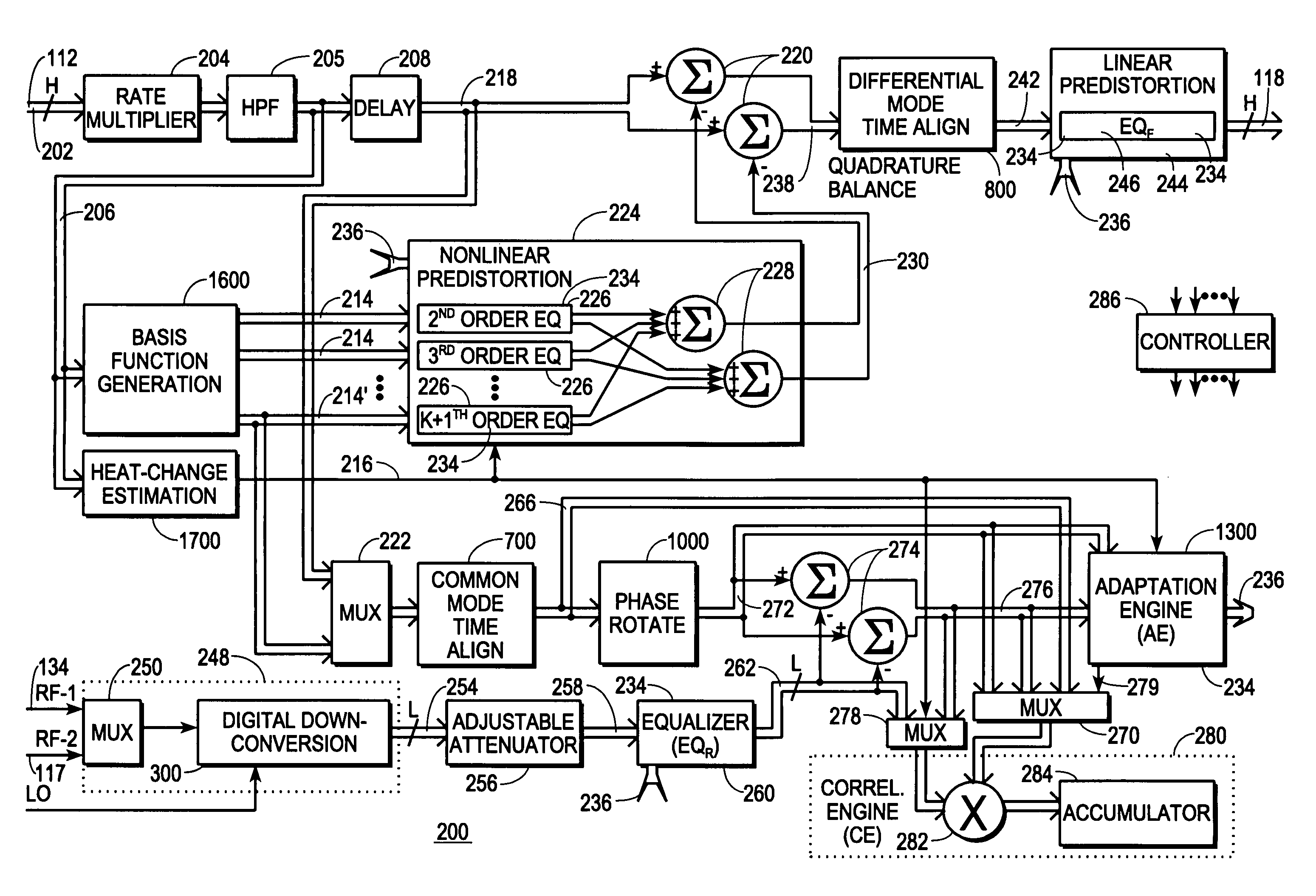

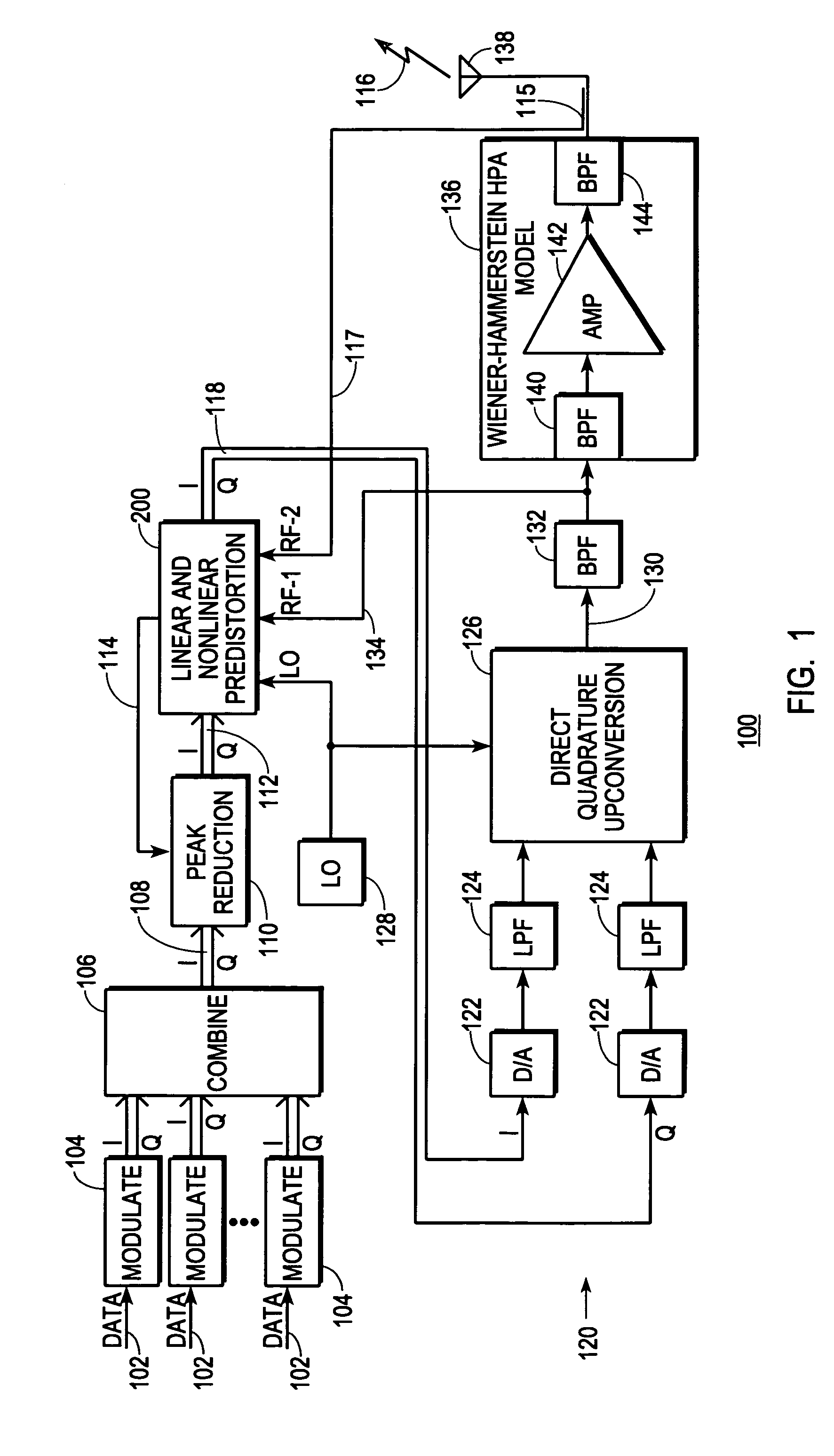

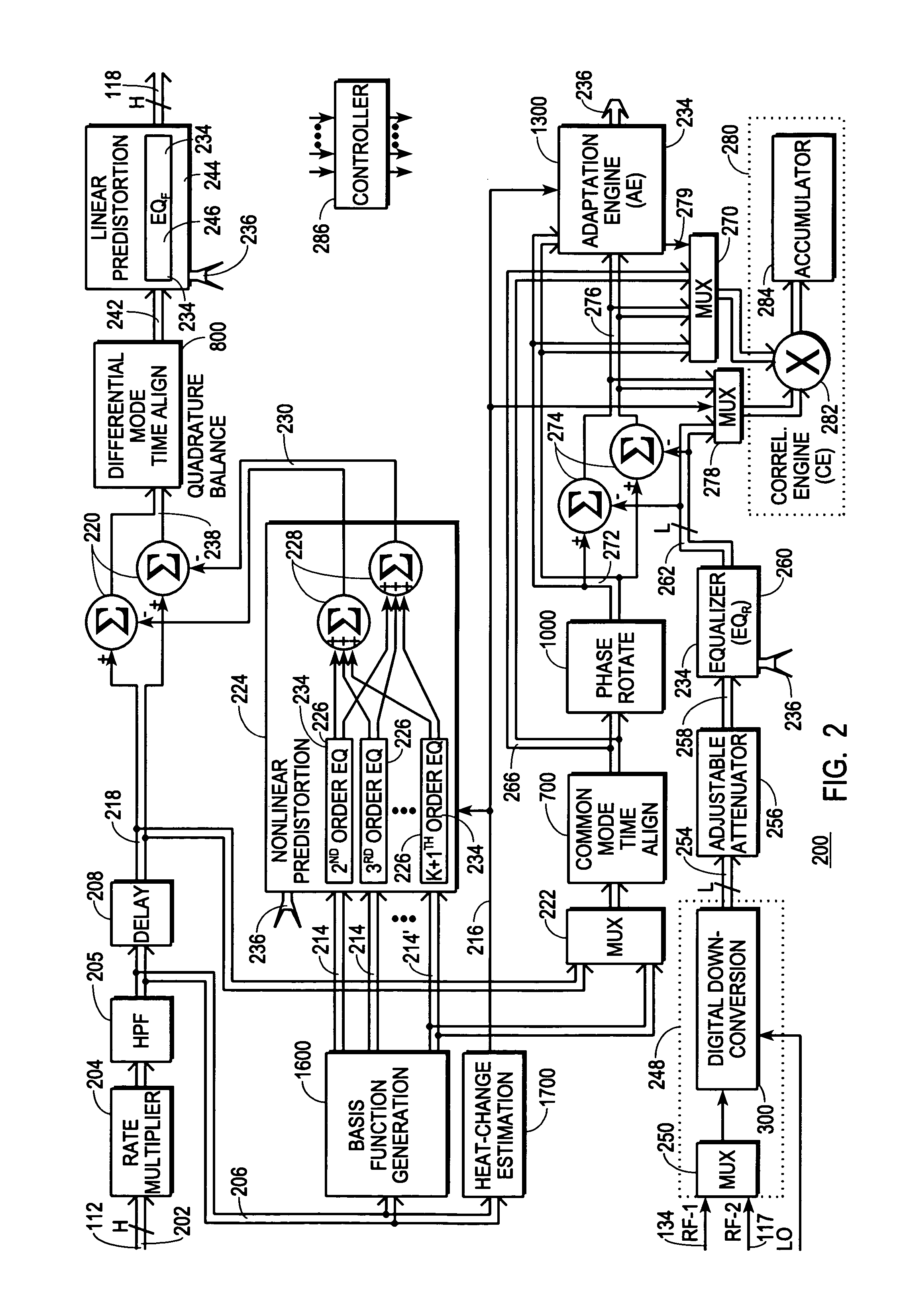

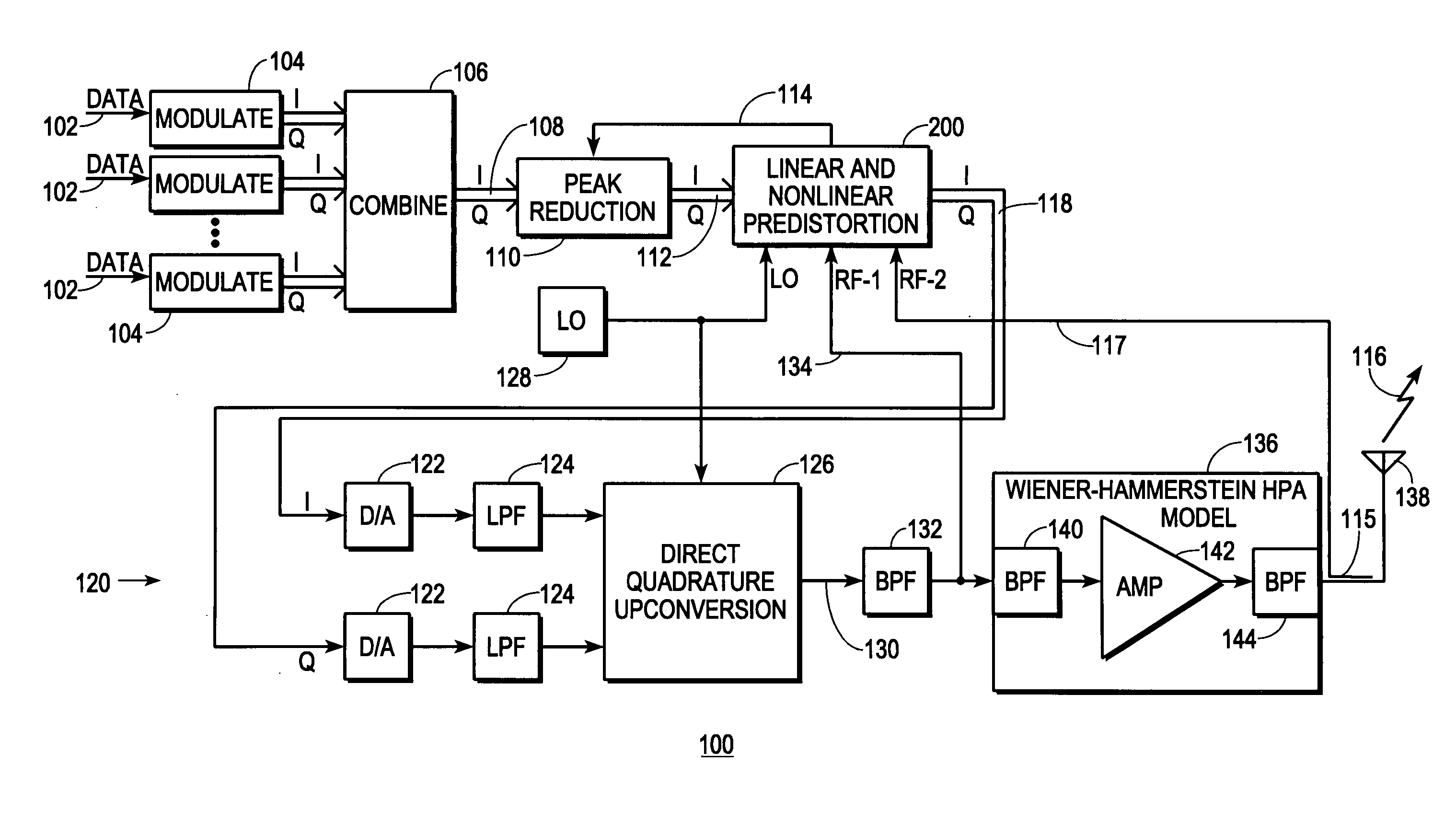

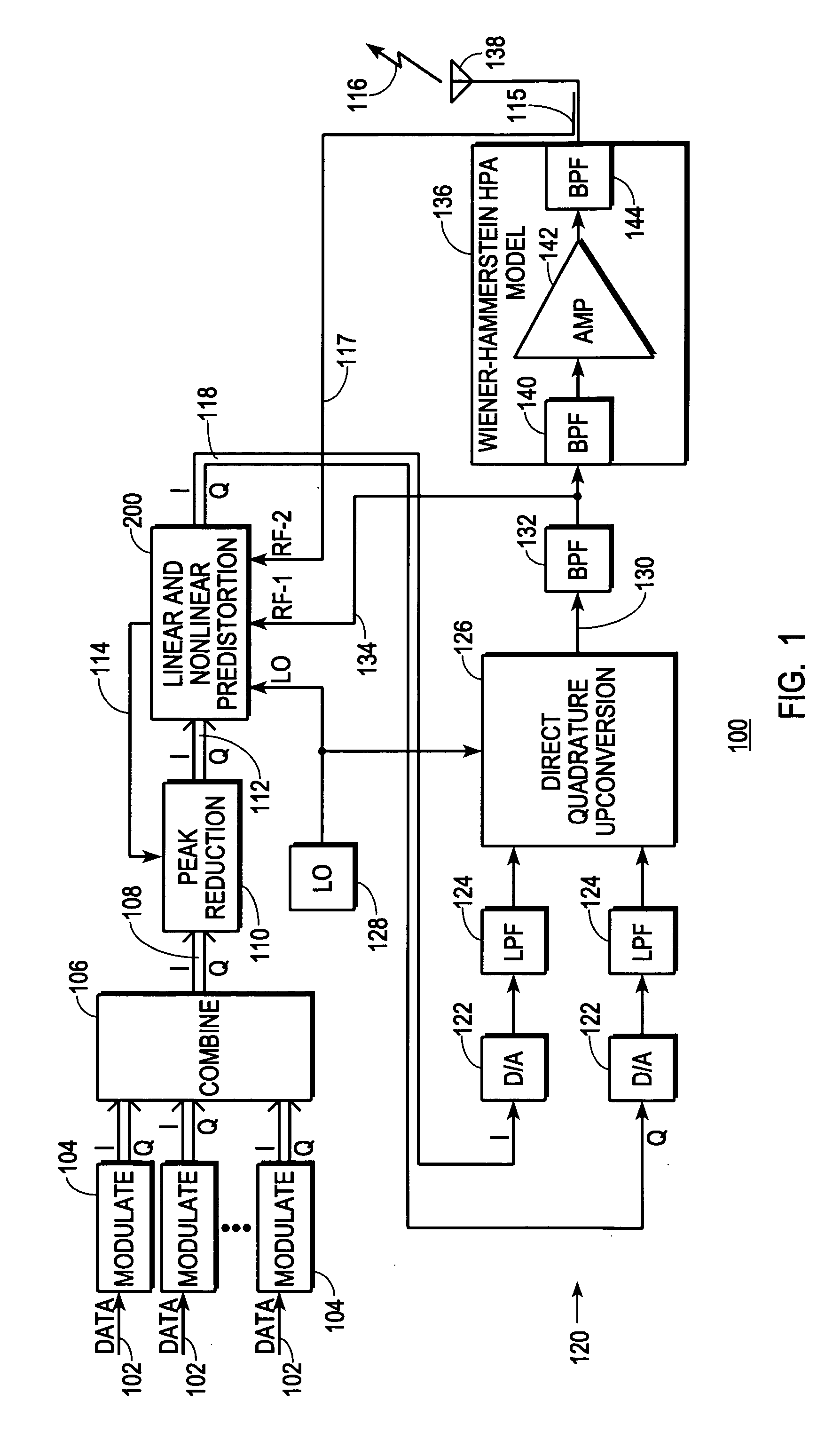

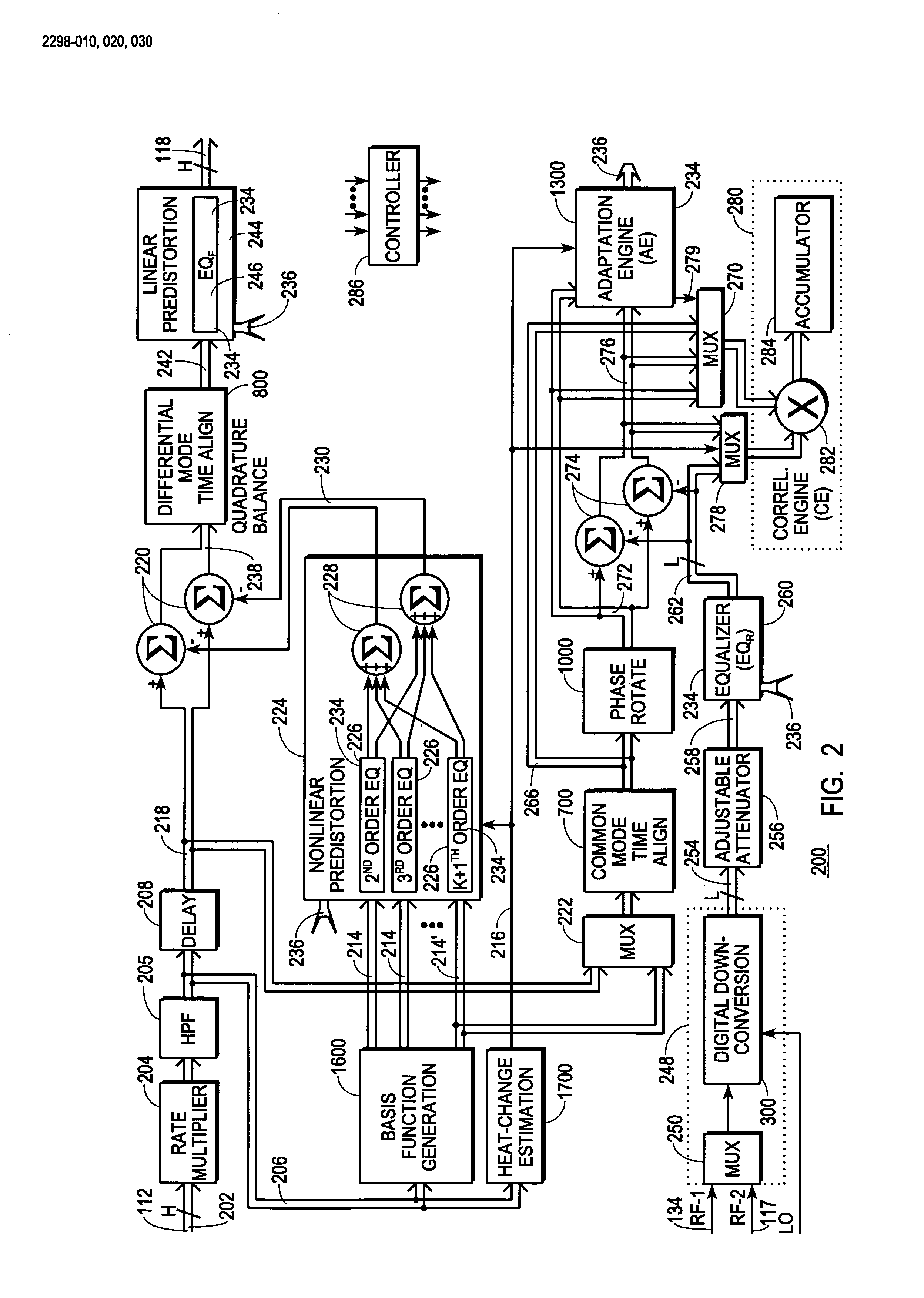

Distortion-managed digital RF communications transmitter and method therefor

ActiveUS20050163250A1Improved distortion-managedImprove accuracySimultaneous amplitude and angle modulationAmplifier modifications to reduce non-linear distortionNonlinear distortionData stream

A digital communications transmitter (100) includes a digital linear-and-nonlinear predistortion section (200) to compensate for linear and nonlinear distortion introduced by transmitter-analog components (120). A direct-digital-downconversion section (300) generates a complex digital return-data stream (254) from the analog components (120) without introducing quadrature imbalance. A relatively low resolution exhibited by the return-data stream (254) is effectively increased through arithmetic processing. Linear distortion is first compensated using adaptive techniques with an equalizer (246) positioned in the forward-data stream (112). Nonlinear distortion is then compensated using adaptive techniques with a plurality of equalizers (226) that filter a plurality of orthogonal, higher-ordered-basis functions (214) generated from the forward-data stream (112). The filtered-basis functions are combined together and subtracted from the forward-data stream (112).

Owner:CRESTCOM INC

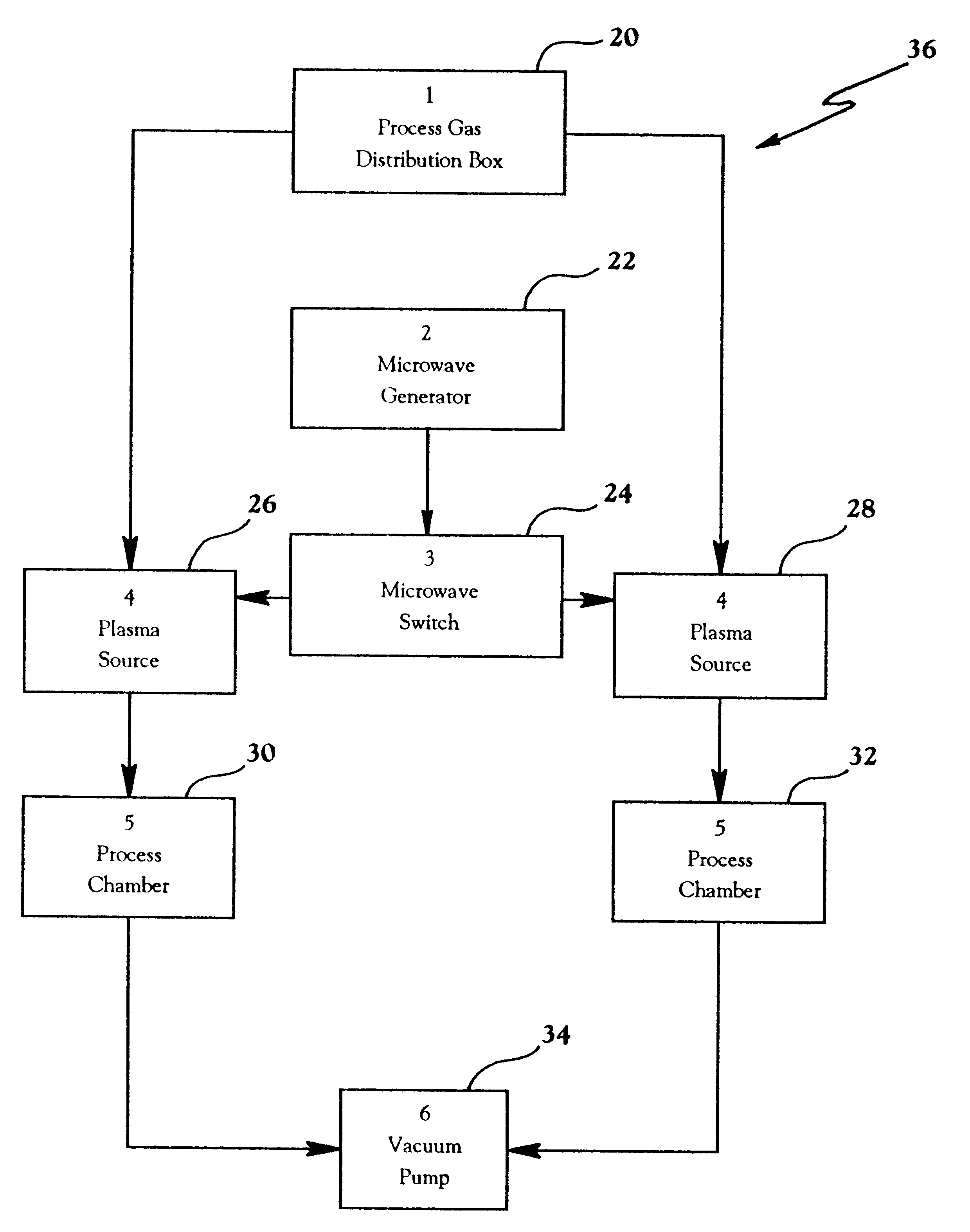

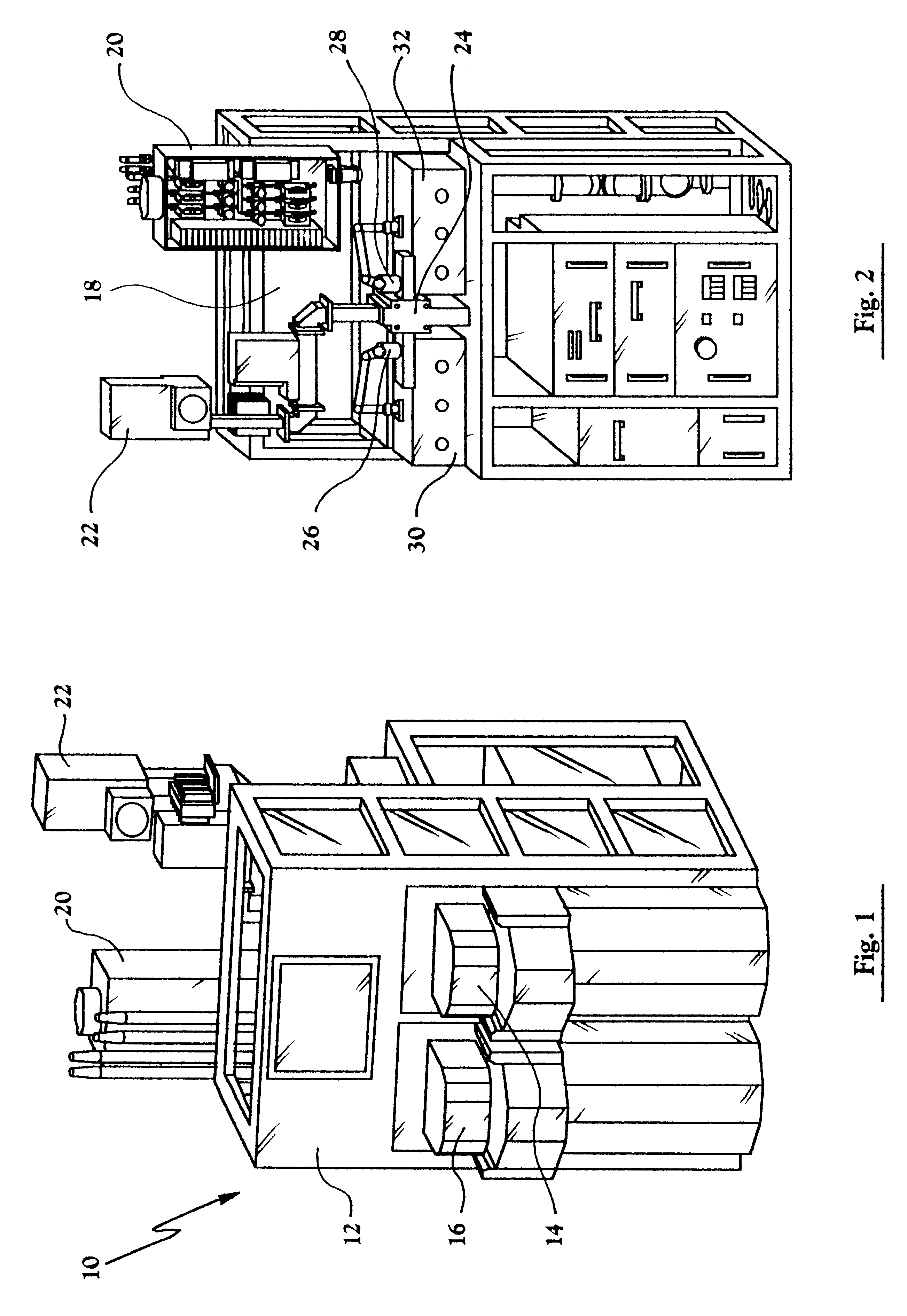

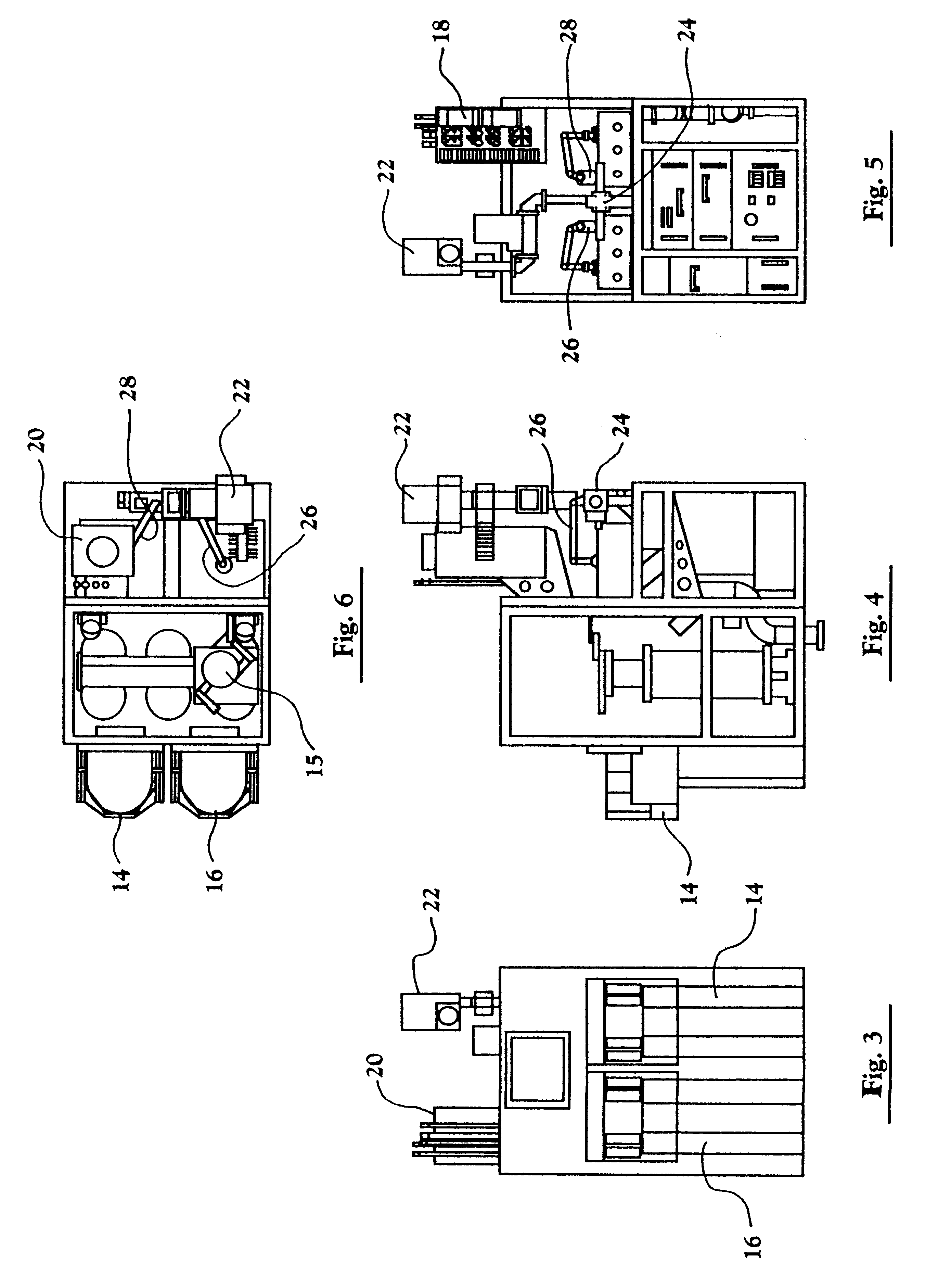

Synchronous multiplexed near zero overhead architecture for vacuum processes

InactiveUS6228773B1Redundant partImprove throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingAtmospheric airMicrowave power

Workpieces, such as, semiconductor wafers, are continuously manufactured by repetitively alternately switching a common radio frequency power source between a plurality of downstream or in-chamber processing reactors and actively processing one workpiece in a vacuum in an operating one of the processing chambers while simultaneously executing with a robot at atmospheric pressure the overhead tasks relative to next processing another workpiece in the other processing chamber. The active processing of the workpieces in alternate chambers does not overlap, and the robot starts and completes all of its preparatory tasks during the active processing step during the time when a chamber's door is closed thereby providing virtual zero overhead. System architecture allows eliminating all redundant components other than the dual chambers which operate in parallel. For a modest cost increase for the second chamber throughput is trebled and overall costs significantly reduced. Preferred modes include switching a common microwave power source between the pair of processing chambers, pumping down with a common vacuum pump, and stabilizing the chamber pressure with a common throttle valve.

Owner:LAM RES CORP

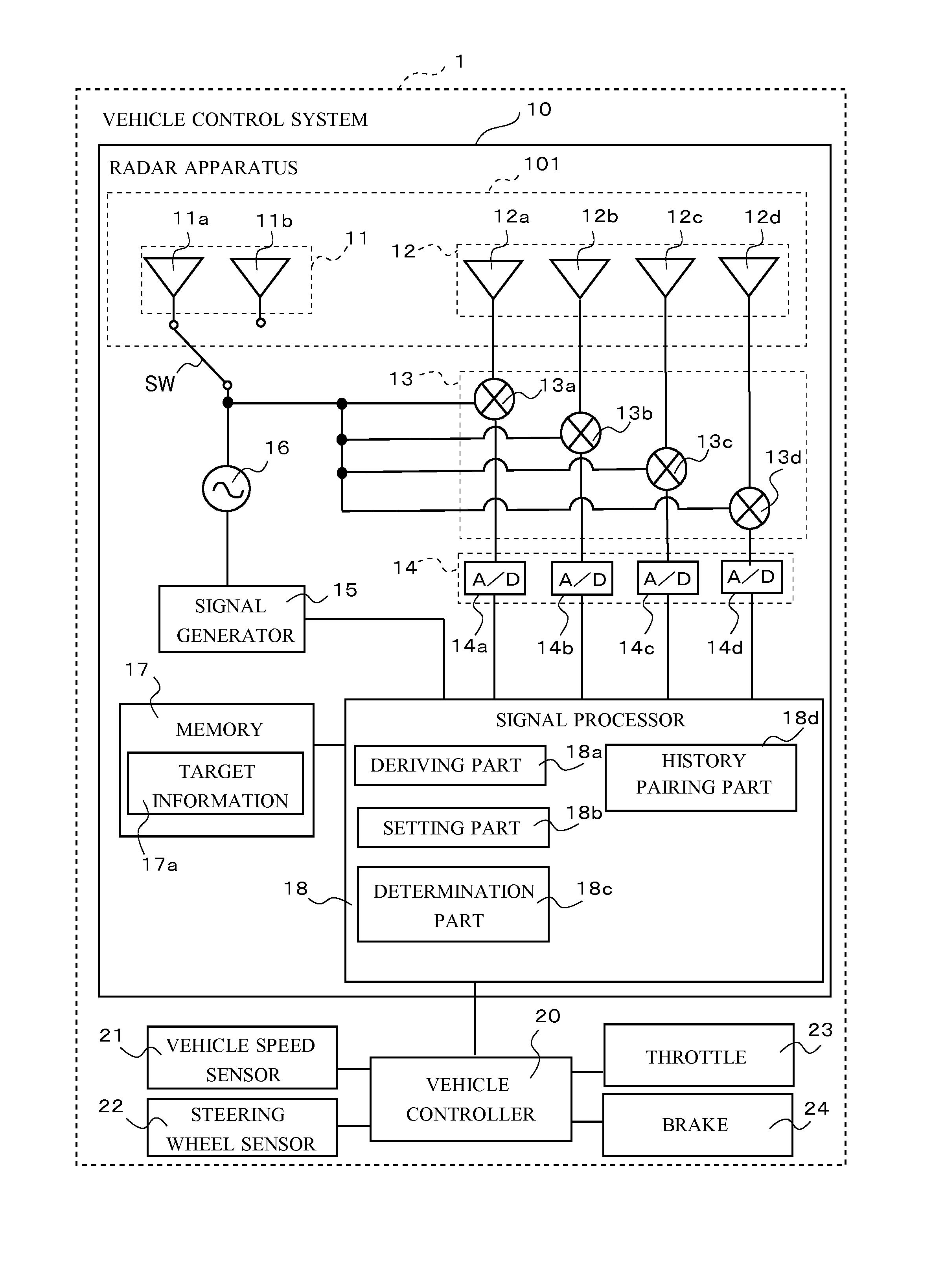

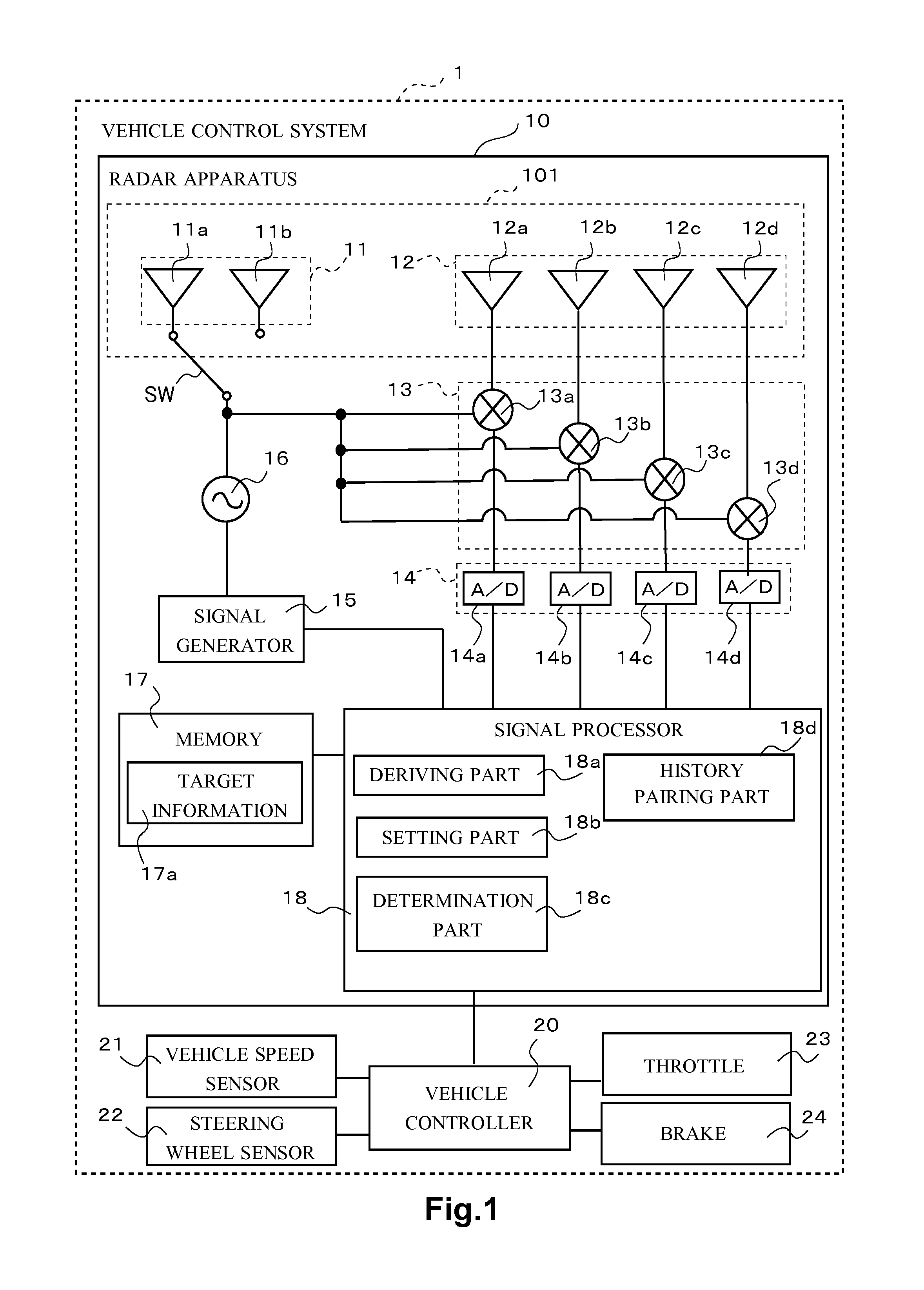

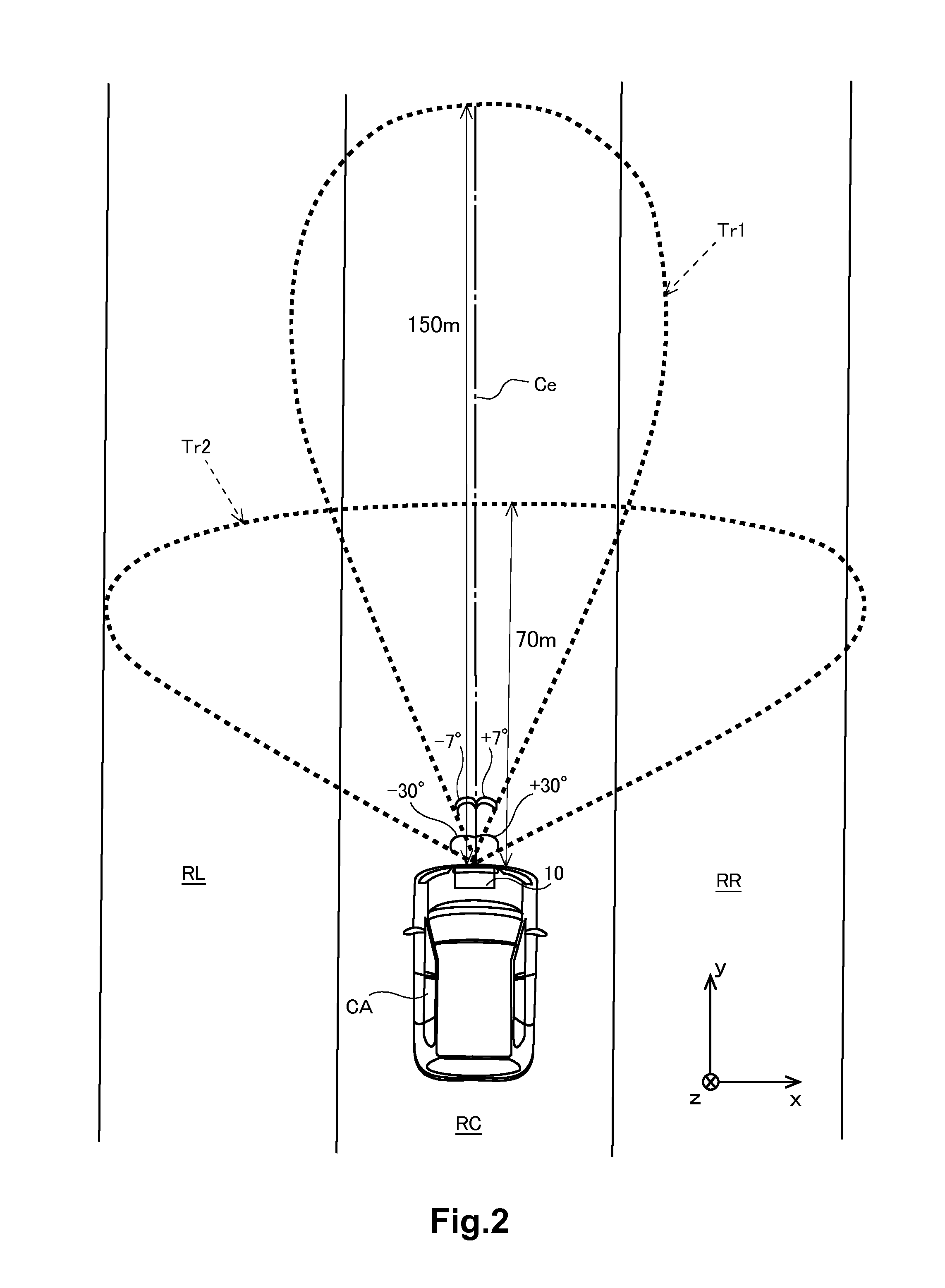

Radar apparatus

InactiveUS20150204971A1Reduce usageReduce processing loadRadio wave reradiation/reflectionPaired DataData set

A radar apparatus includes a signal processor configured to: (i) in a case where a first angle peak signal closest to a prediction position in an up period and a second angle peak signal closest to the prediction position in a down period satisfy a pairing condition, finalize a combination of the first angle peak signal and the second angle peak signal as a pair data set; and (ii) in a case where the combination of the first angle peak signal and the second angle peak signal does not satisfy the pairing condition, where the plurality of angle peak signals exist in the prediction region in at least one of the up period and the down period and where a different combination from the combination of the first angle peak signal and the second angle peak signal satisfies a re-pairing condition, finalize the different combination as the pair data set.

Owner:FUJITSU GENERAL LTD

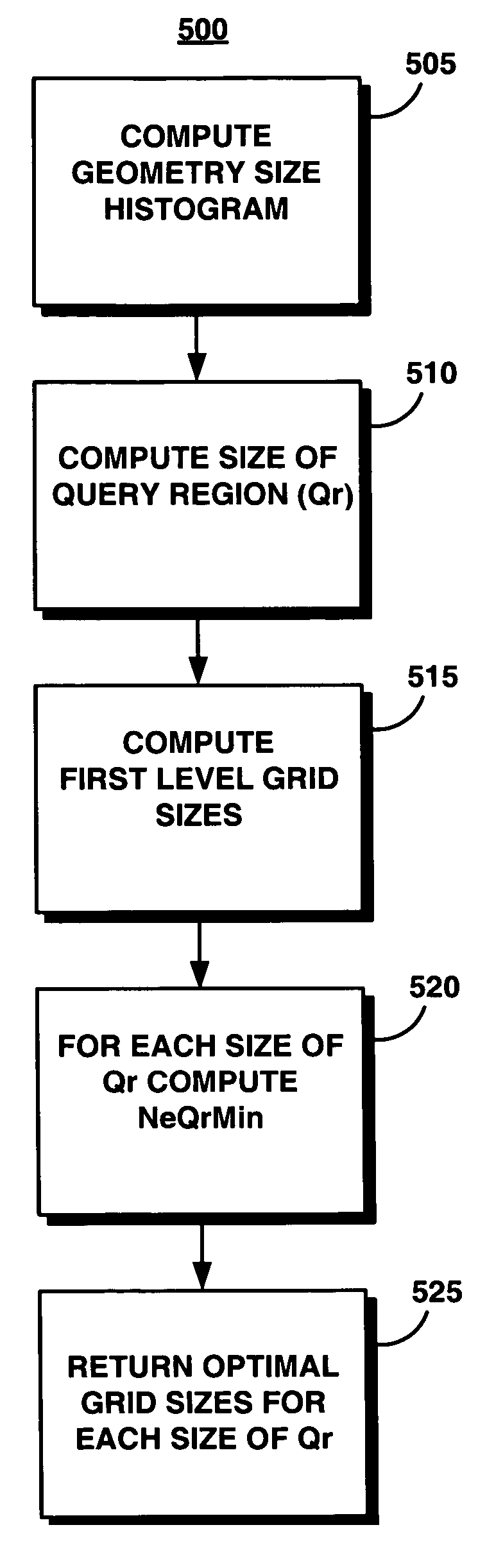

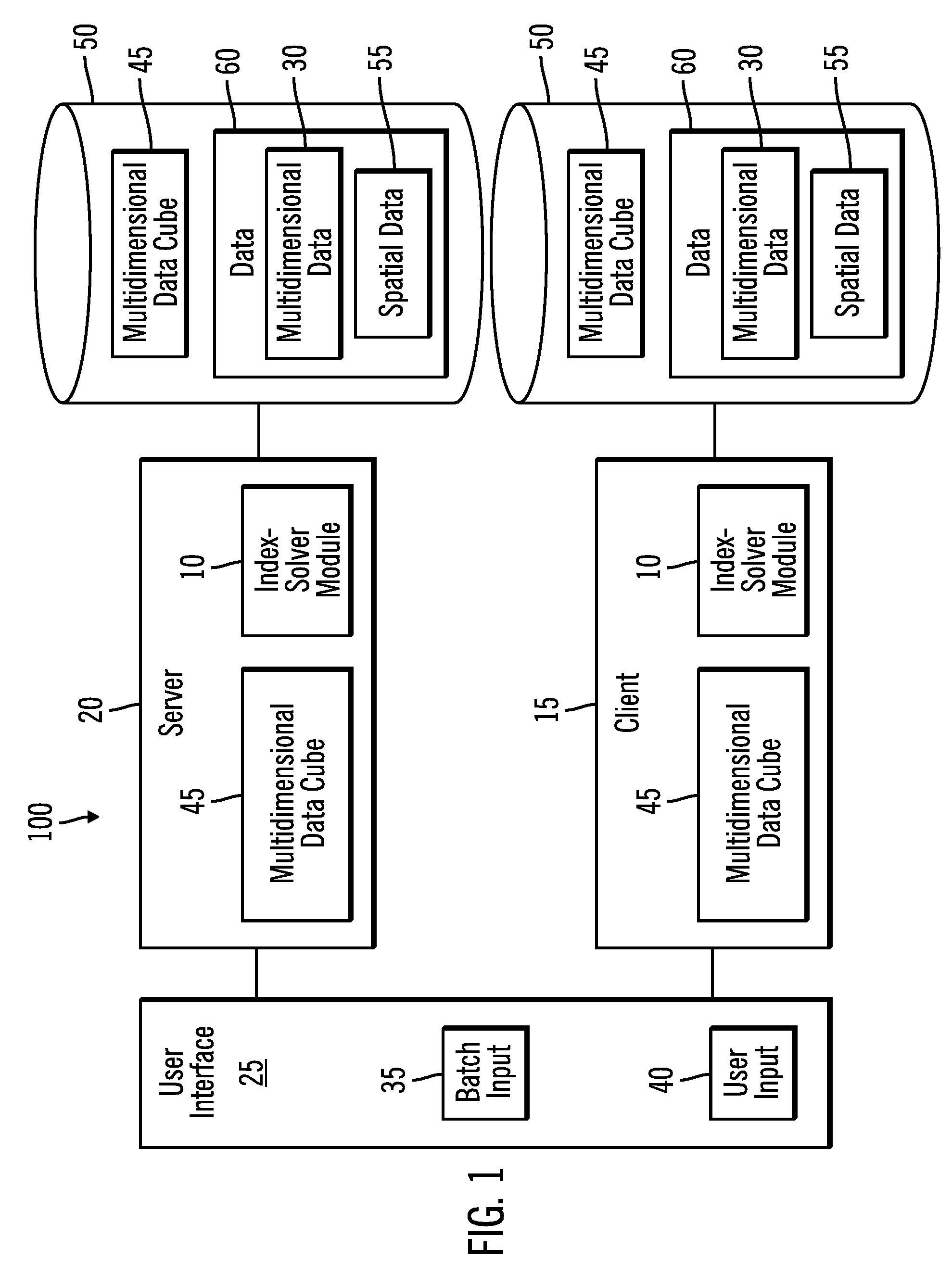

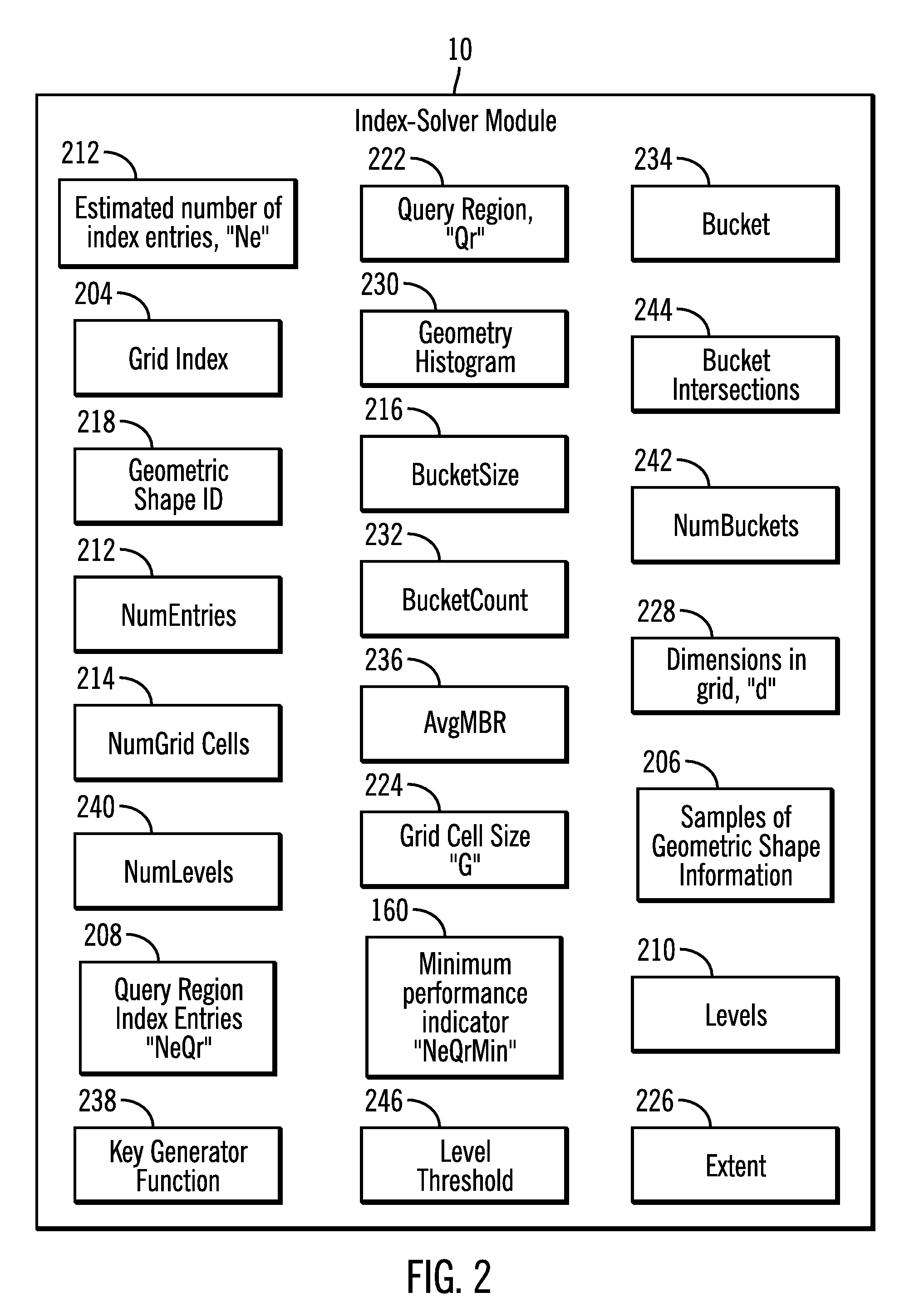

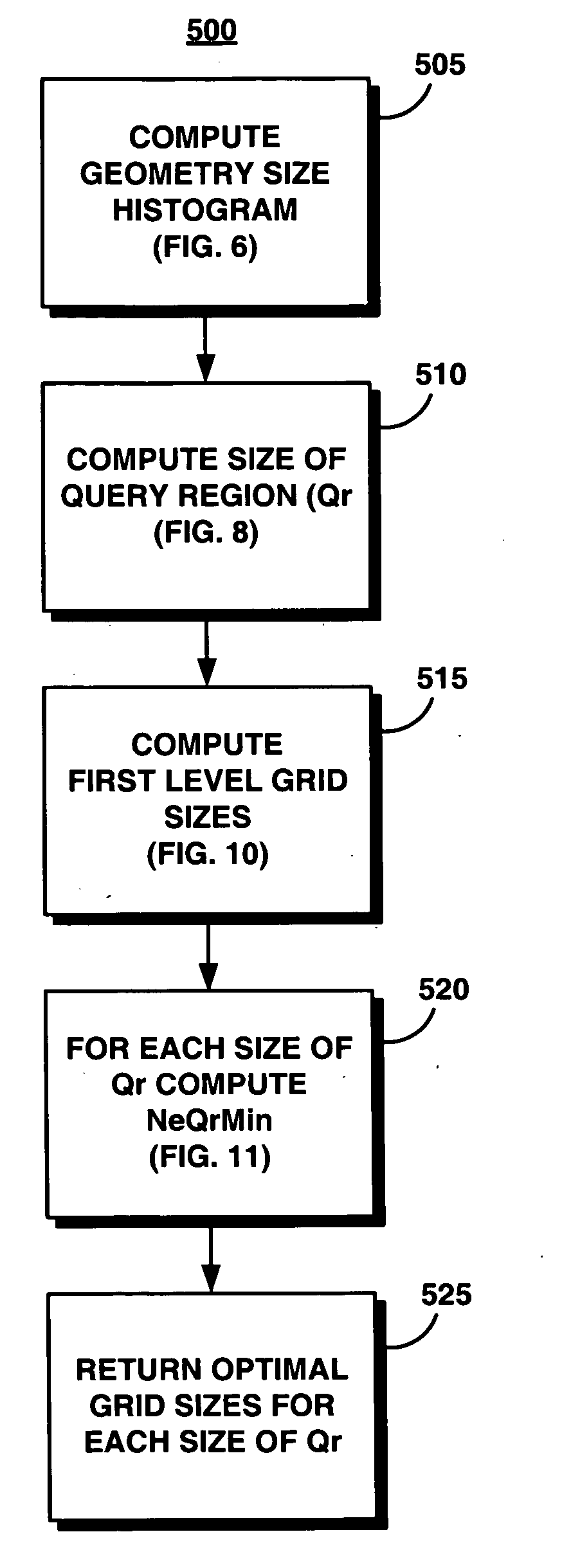

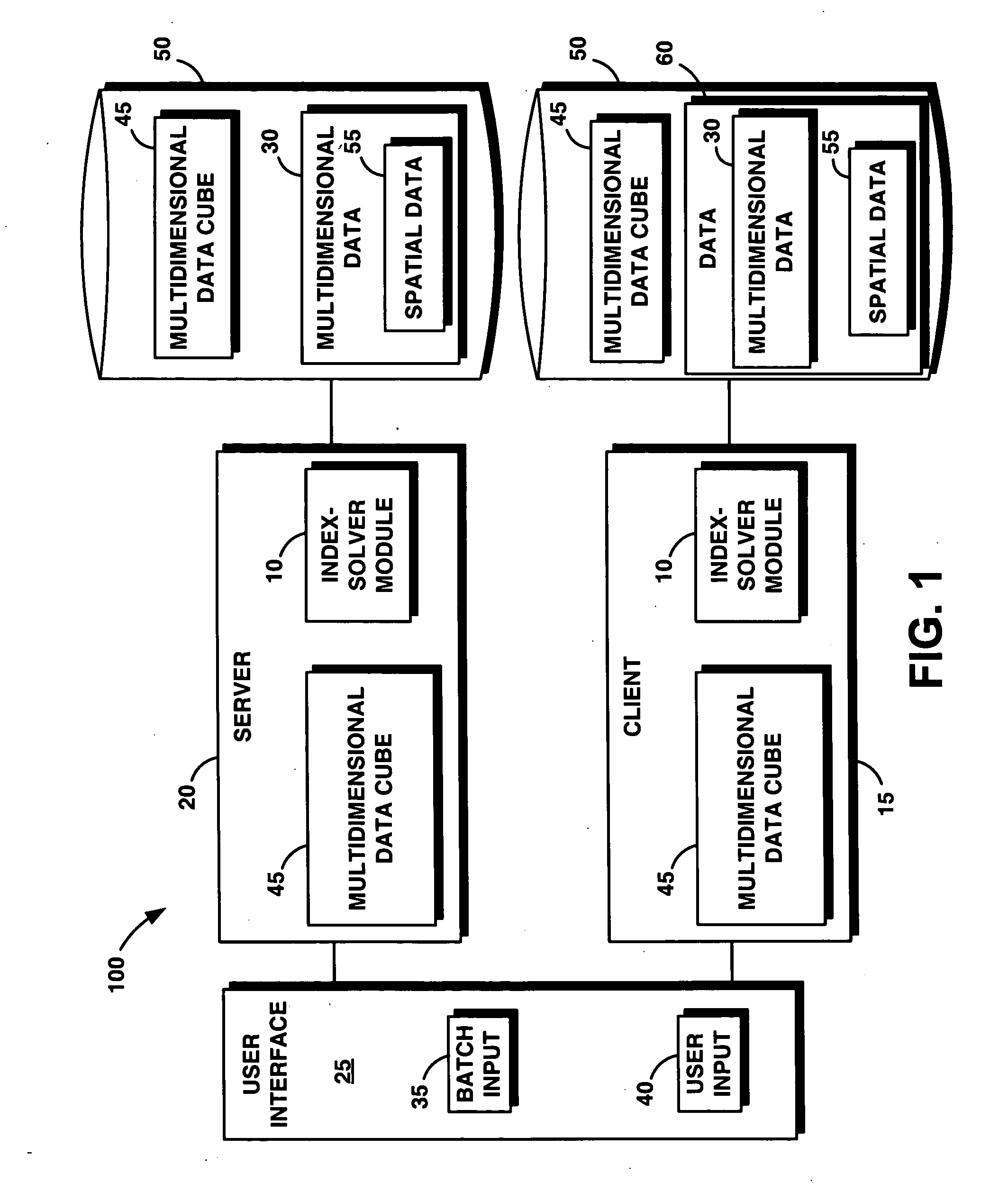

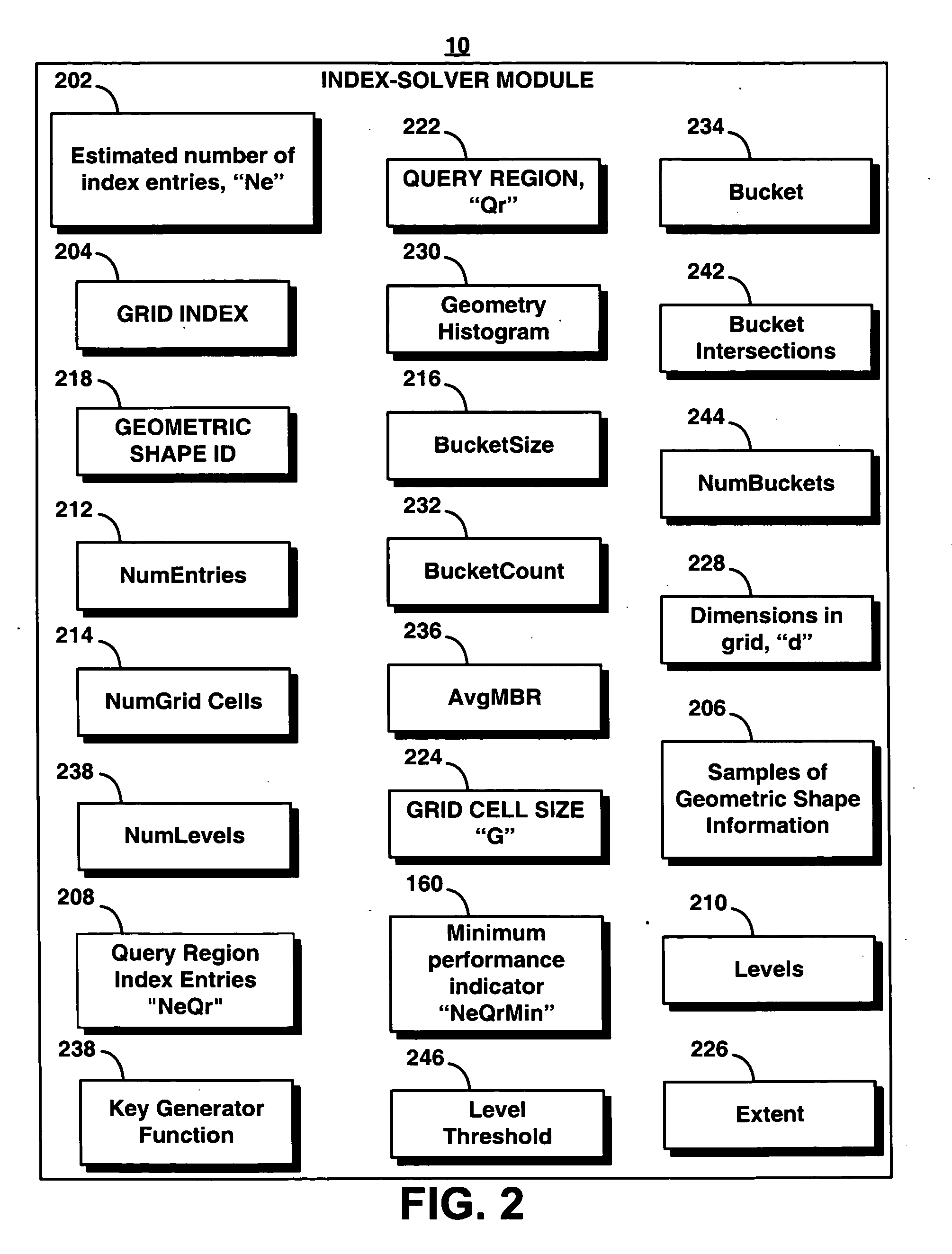

Method for determining an optimal grid index specification for multidimensional data

InactiveUS7389283B2Simple technologyProcess can be minimizedData processing applicationsRoad vehicles traffic controlData setNumber times

A system, method, and associated computer product improve the search of multidimensional databases. The present system determines a near-optimal grid index that is used to locate a geometric shape in a spatial database. More particularly, the present system improves the technique of sampling data for defining the grid cell size in a grid for a given data set, minimizing the number times the data set needs to be sampled, thereby reducing the time to compute the cost of alternative grid index parameters.

Owner:INT BUSINESS MASCH CORP

Distortion-managed digital RF communications transmitter and method therefor

ActiveUS7099399B2Improved distortion-managedImprove accuracySimultaneous amplitude and angle modulationAmplifier modifications to reduce non-linear distortionNonlinear distortionData stream

A digital communications transmitter (100) includes a digital linear-and-nonlinear predistortion section (200) to compensate for linear and nonlinear distortion introduced by transmitter-analog components (120). A direct-digital-downconversion section (300) generates a complex digital return-data stream (254) from the analog components (120) without introducing quadrature imbalance. A relatively low resolution exhibited by the return-data stream (254) is effectively increased through arithmetic processing. Linear distortion is first compensated using adaptive techniques with an equalizer (246) positioned in the forward-data stream (112). Nonlinear distortion is then compensated using adaptive techniques with a plurality of equalizers (226) that filter a plurality of orthogonal, higher-ordered-basis functions (214) generated from the forward-data stream (112). The filtered-basis functions are combined together and subtracted from the forward-data stream (112).

Owner:CRESTCOM INC

Multiple step identification of recordings

ActiveUS8468357B2Maximizing identificationUse minimizedDigital data processing detailsUser identity/authority verificationCompact discRelevant information

Multiple information is extracted from an unknown recording and information associated therewith. Associated information includes the filename, if the recording is a computer file in, e.g., MP3 format, or table of contents (TOC) data, if the recording is on a removable medium, such as a compact disc. At least one and preferably several algorithmically determined fingerprints are extracted from the recording using one or more fingerprint extraction methods. The information extracted is compared with corresponding information in a database maintained for reference recordings. Identification starts with the most accurate and efficient method available, e.g., using a hash ID, a unique ID or text. Fingerprint matching is used to confirm other matches and validation is performed by comparing the duration of the unknown and a possibly matching reference recording.

Owner:GRACENOTE

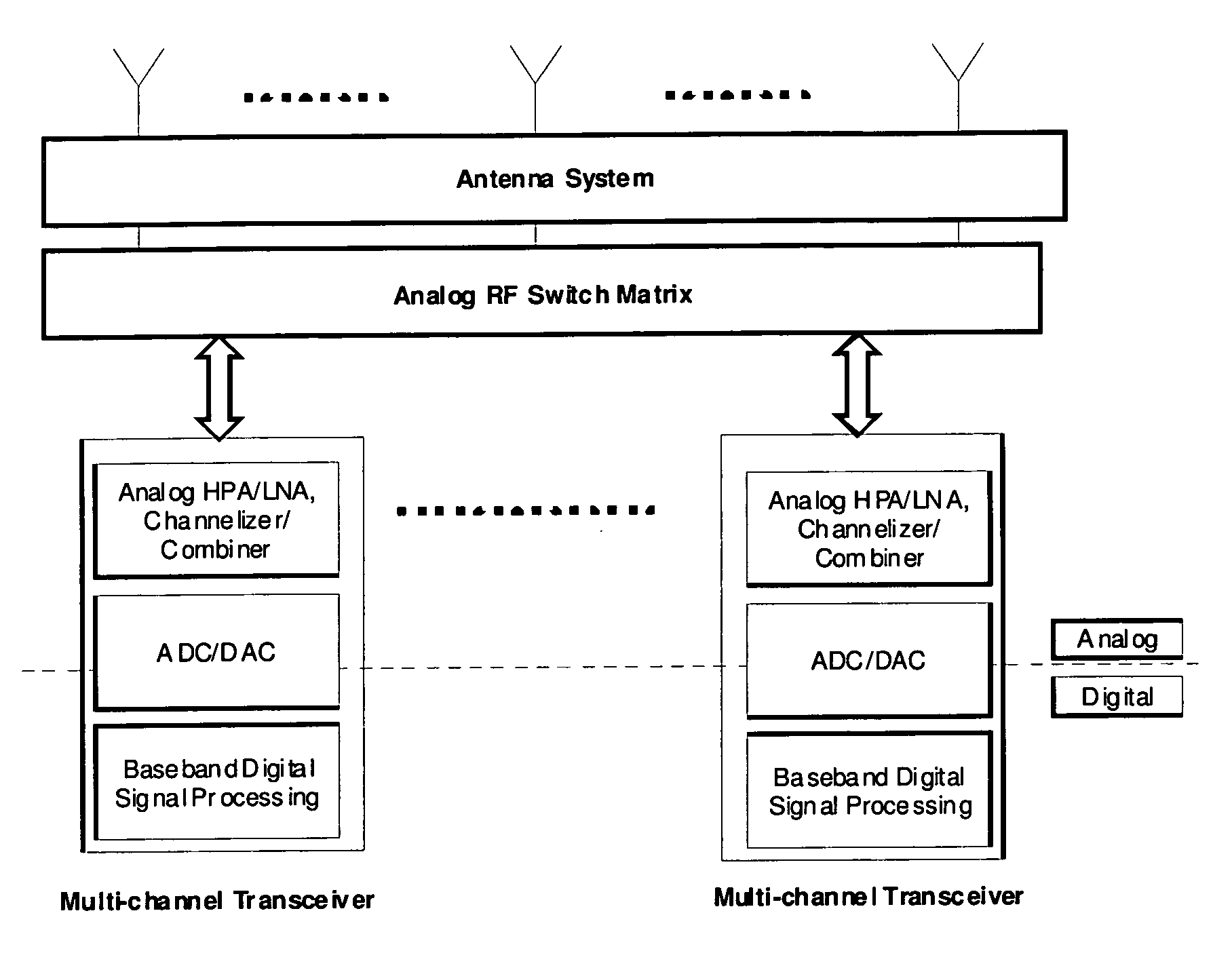

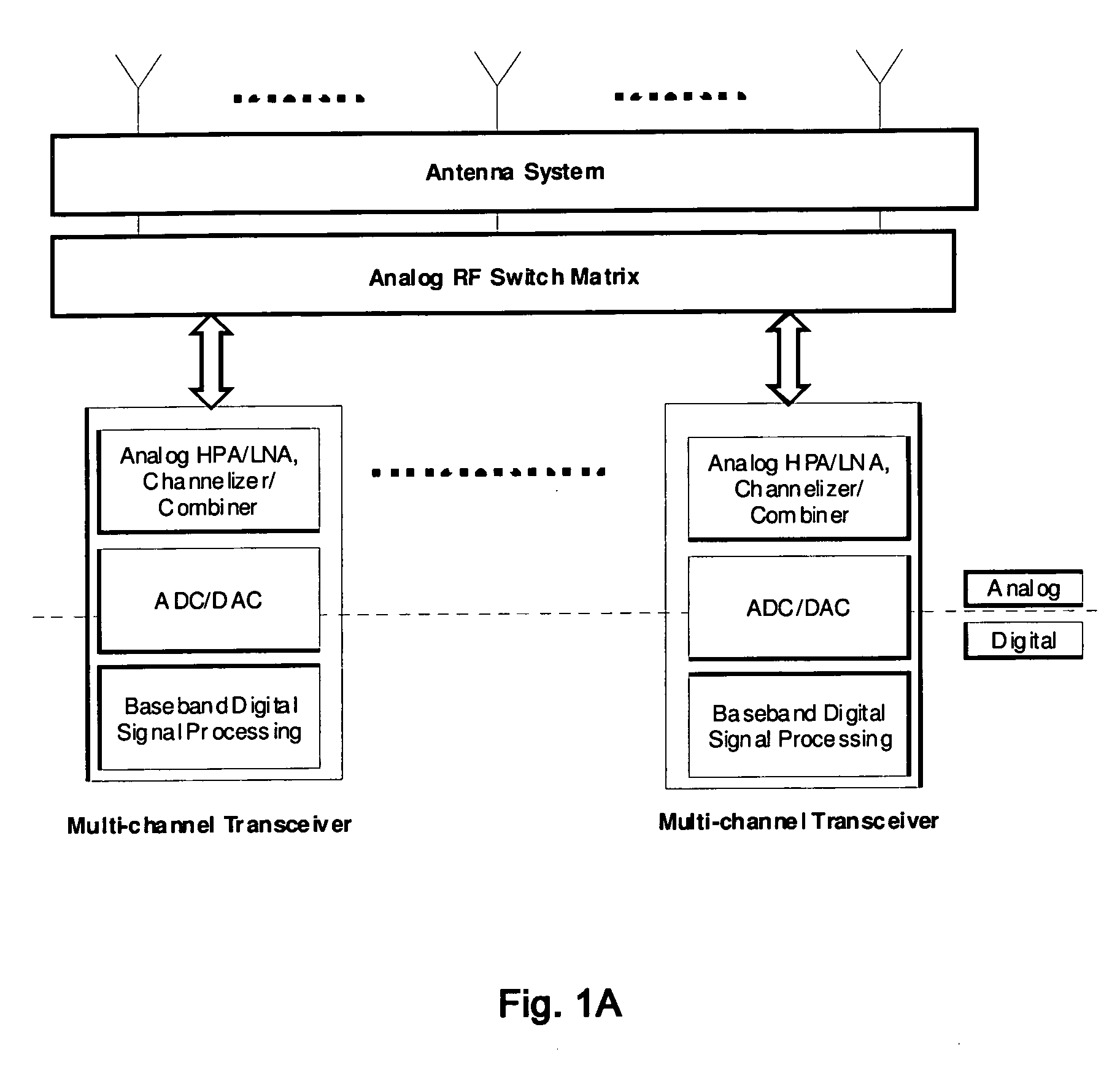

Oversampling digital receiver for radio-frequency signals

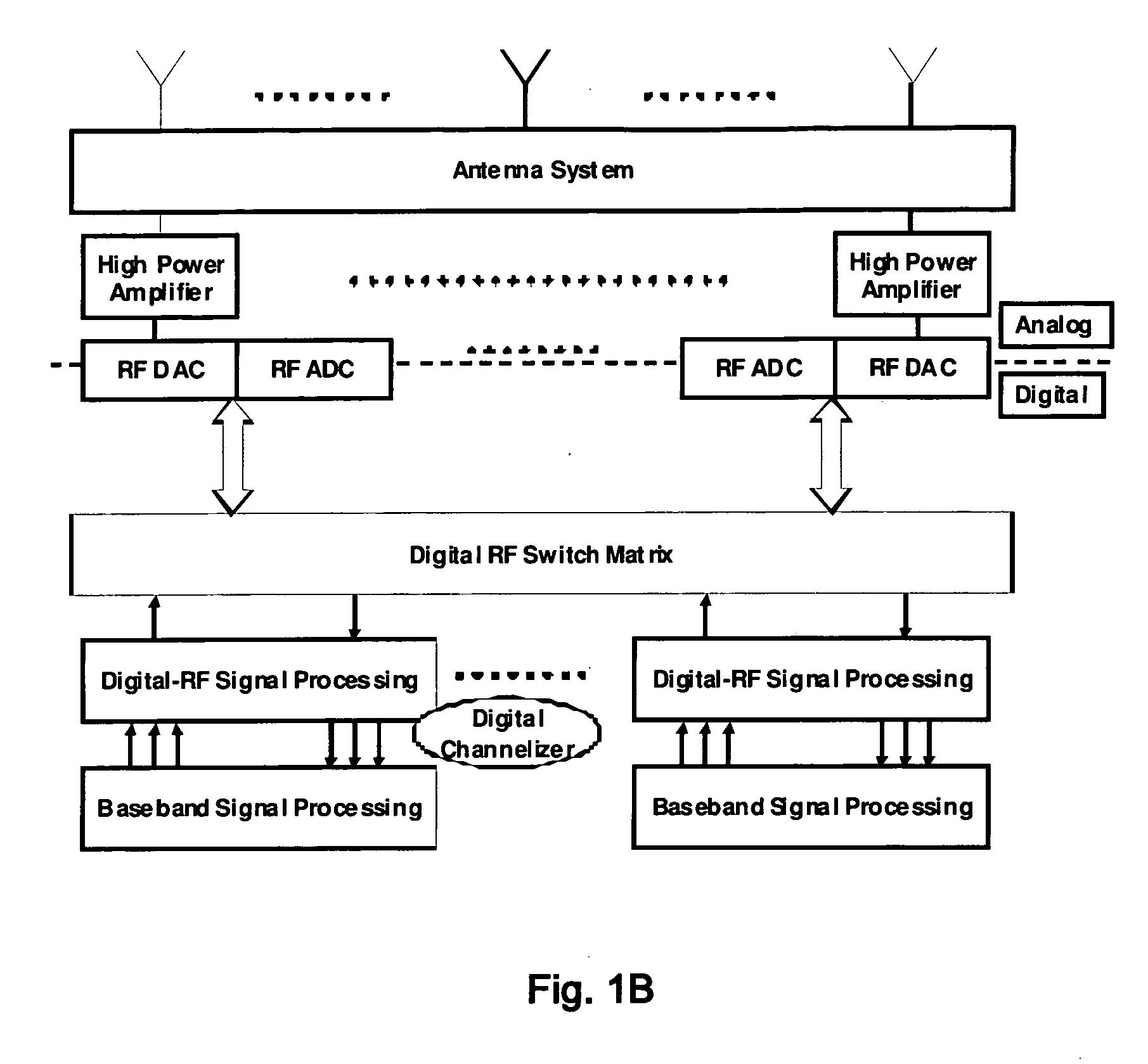

ActiveUS20080101503A1Efficient executionPrecise processingPolarisation/directional diversityLine-faulsts/interference reductionAutomatic controlDigital clock

A system and method for receiving a radio frequency signal, comprising a device for digitizing, without prior alteration of frequency, an analog radio frequency representation of each of a plurality of radio frequency signals to produce a respective plurality of digital radio frequency signals having a respective associated radio frequency digital clock, the plurality of digital radio frequency signals having a sufficiently high respective associated clock rate to preserve an information content of an information communication present in the analog radio frequency representation; a switch matrix adapted to concurrently switch the plurality of digital radio frequency signals and associated digital radio frequency clock to ones of a plurality of digital signal processors; and a control adapted to selectively automatically control the concurrent switching of a plurality of digital signals and associated digital clock to the respective plurality of digital signal processors; wherein the digital signal processors produce processed representations of information contained in respective analog radio frequency representations.

Owner:HYPRES

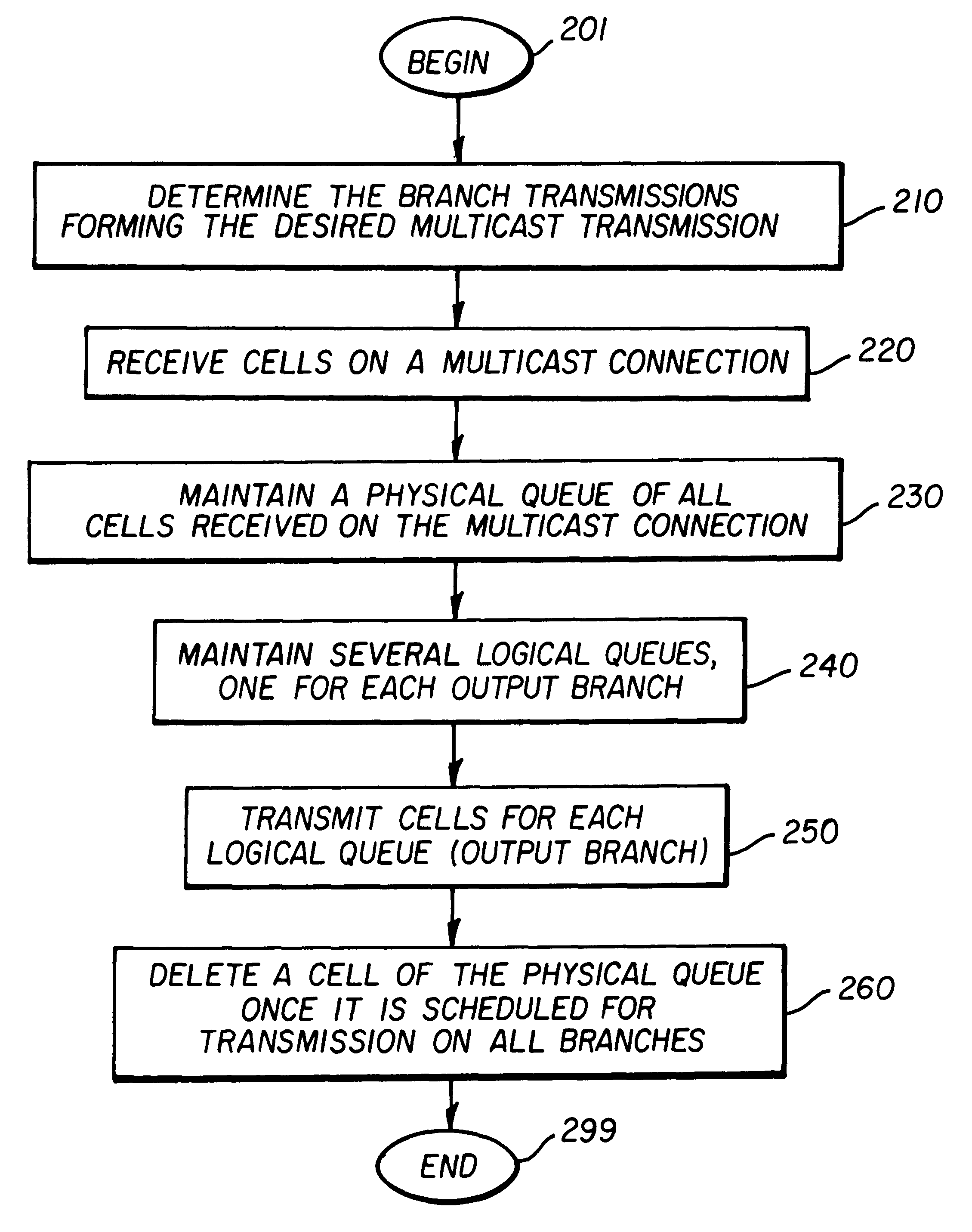

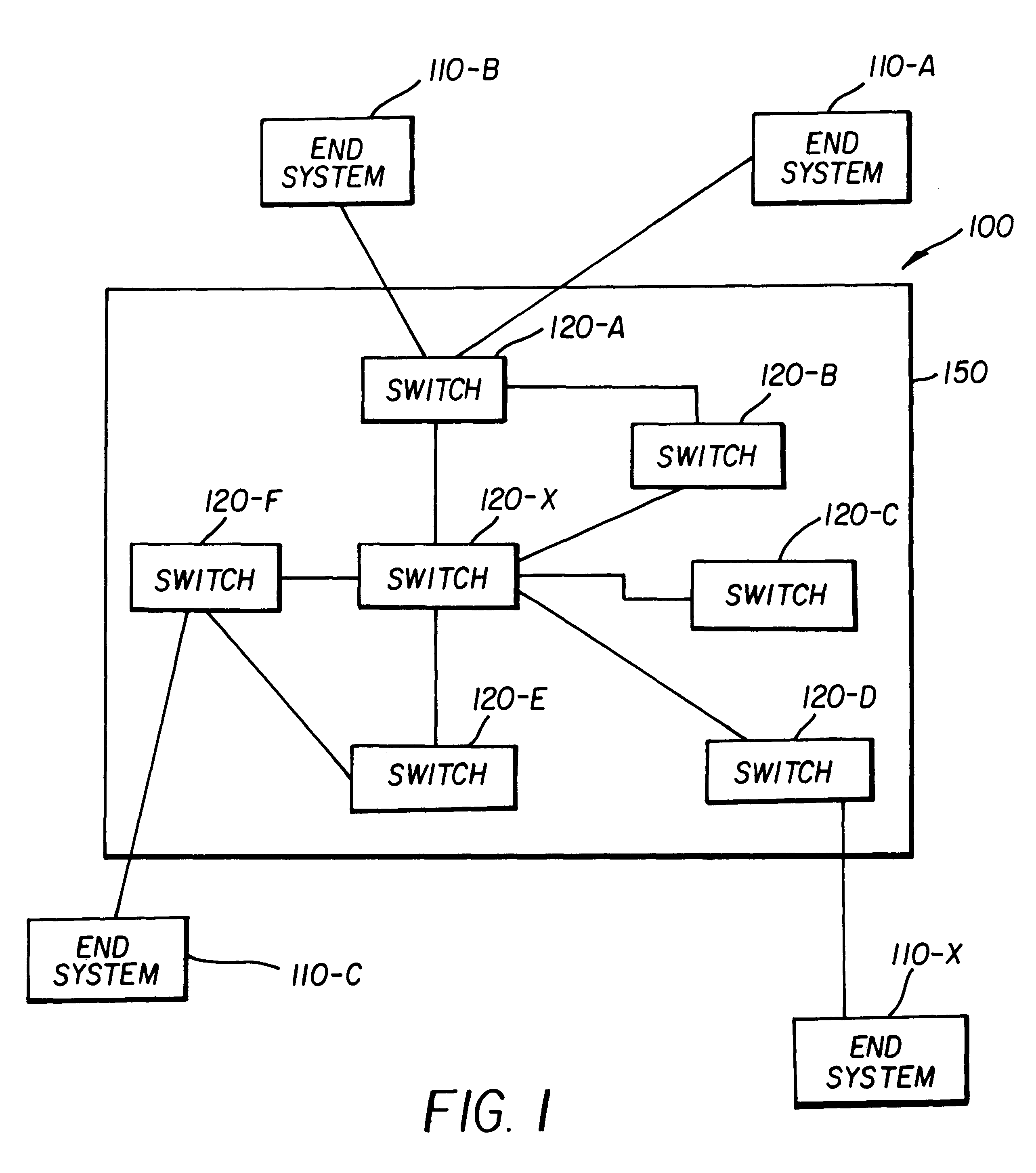

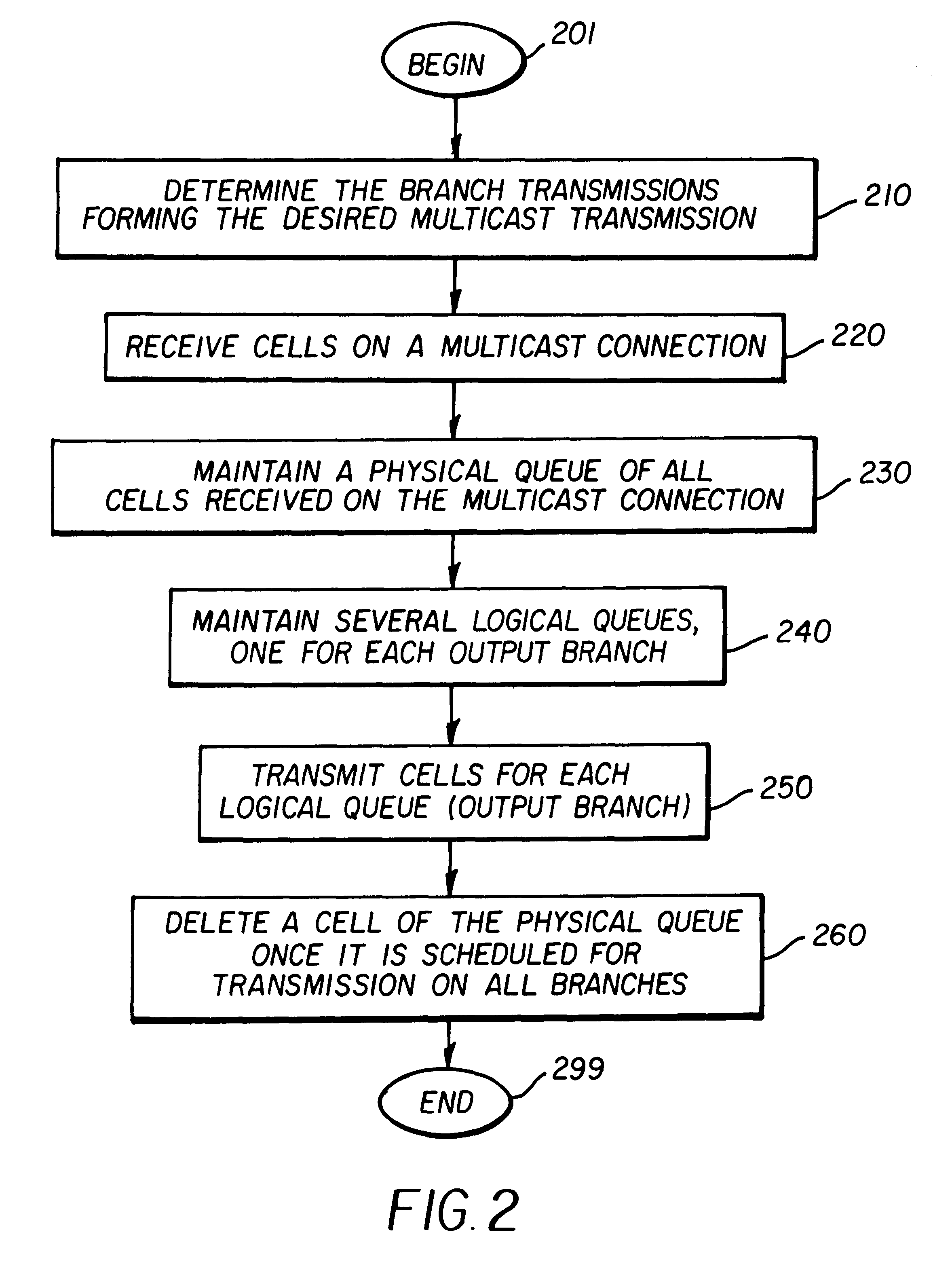

Queue management with support for multicasts in an asynchronous transfer mode (ATM) switch

InactiveUS6219352B1Quantity minimizationImprove throughput performanceSpecial service provision for substationTime-division multiplexQueue management systemAsynchronous Transfer Mode

An ATM switch supporting multicast transmissions and efficient transmission of frames. A cell is received on a multicast connection and transmitted on several branches / ports. Instead of copying a multicast cell several times for each output branch, only one copy of each multicast cell is maintained. The cell order and the stored cell data form a physical queue. Several logical queues are maintained, one for each output branch. In one embodiment, linked lists are used to maintain the queues. A cell in the physical queue is deleted after all logical queues traverse that cell. A shared tail pointer is used for all the logical queues to minimize additional processing and memory requirements due to the usage of logical queues. The queues enable cells forming a frame to be buffered until the end of frame cell is received, which provides for efficient handling of frames.

Owner:RIVERSTONE NETWORKS

System and method for determining an optimal grid index specification for multidimensional data

InactiveUS20060129529A1Simple technologyProcess can be minimizedRoad vehicles traffic controlNavigation instrumentsData setNumber times

A system, method, and associated computer product improve the search of multidimensional databases. The present system determines a near-optimal grid index that is used to locate a geometric shape in a spatial database. More particularly, the present system improves the technique of sampling data for defining the grid cell size in a grid for a given data set, minimizing the number times the data set needs to be sampled, thereby reducing the time to compute the cost of alternative grid index parameters.

Owner:IBM CORP

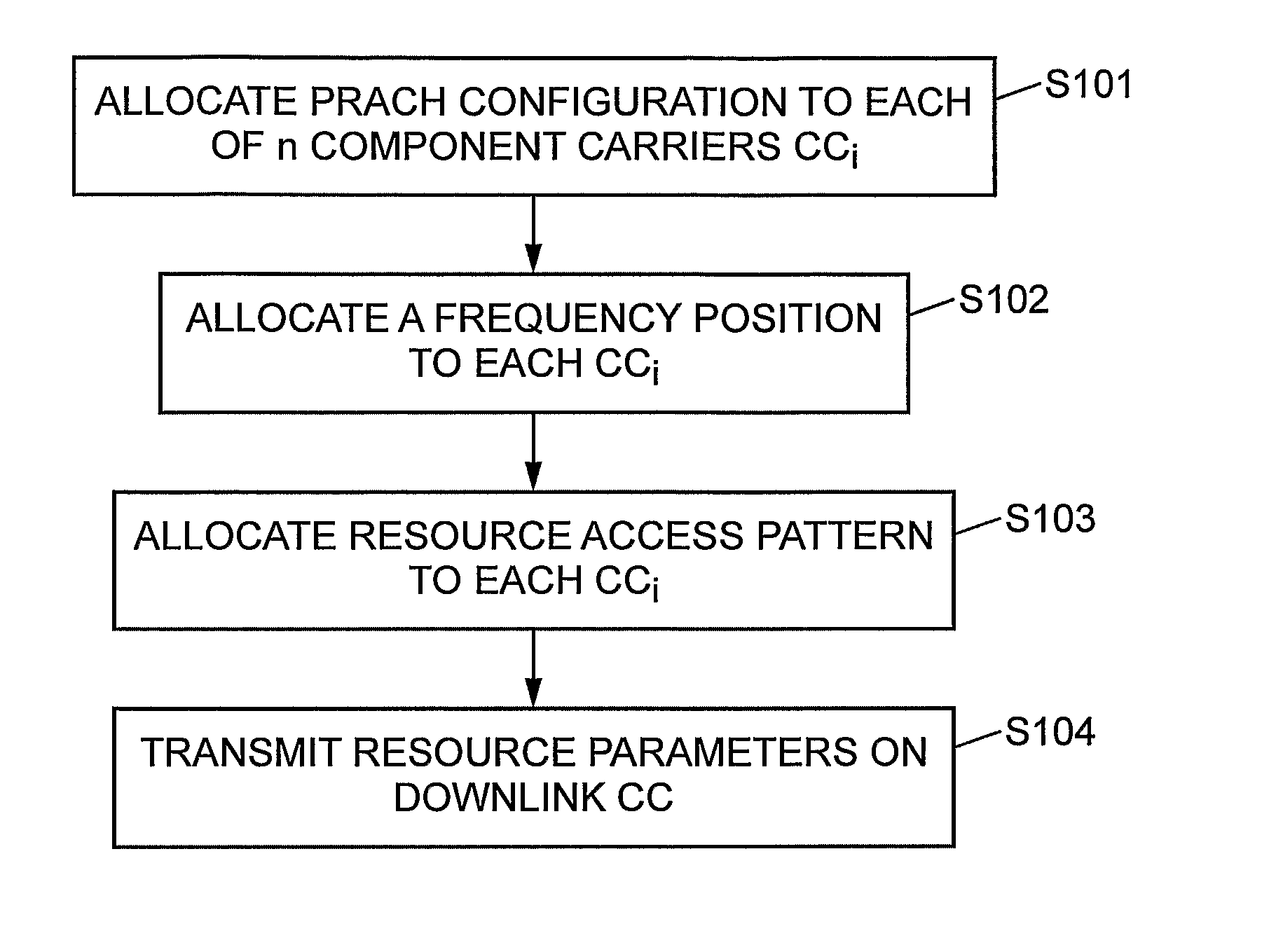

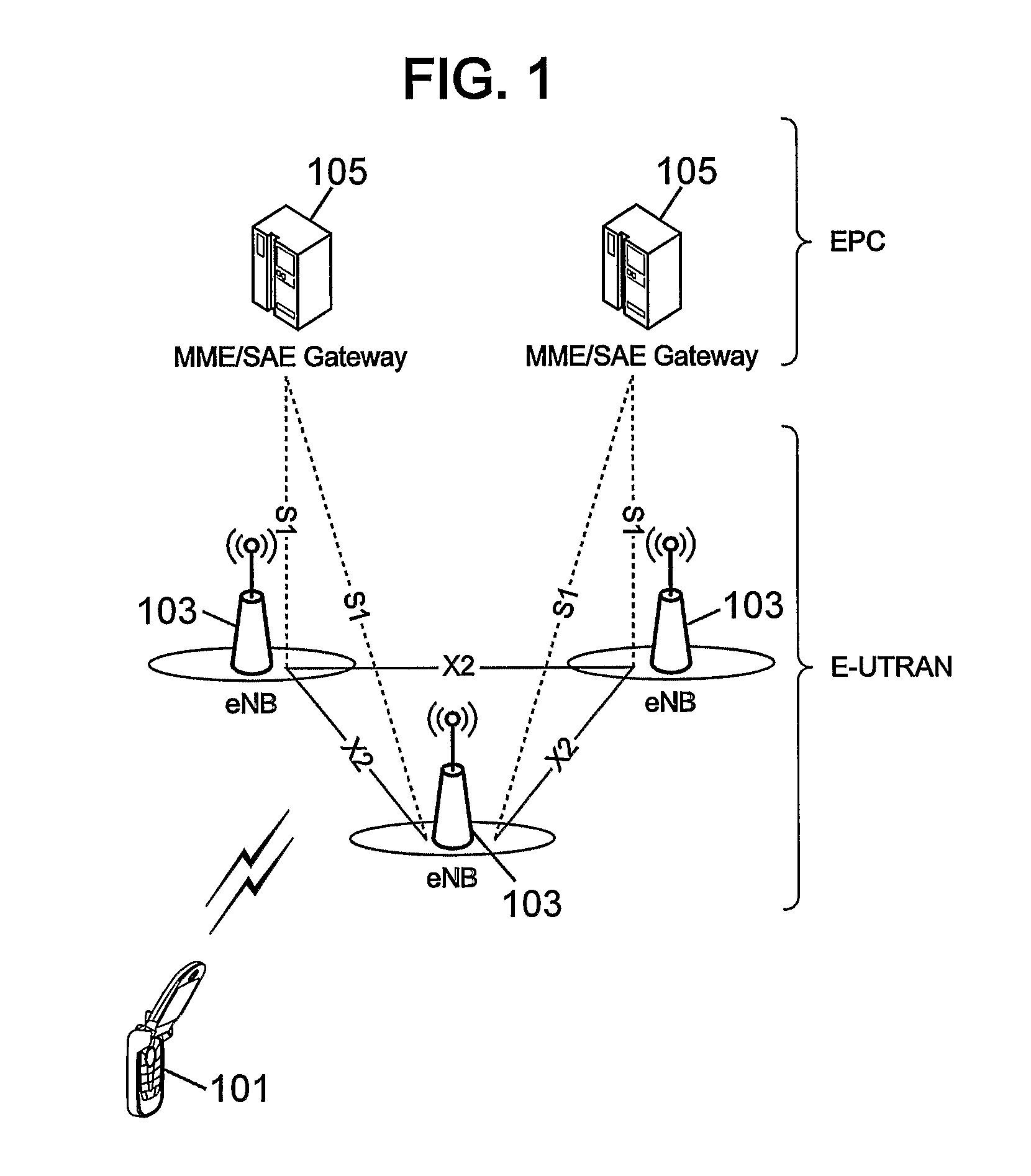

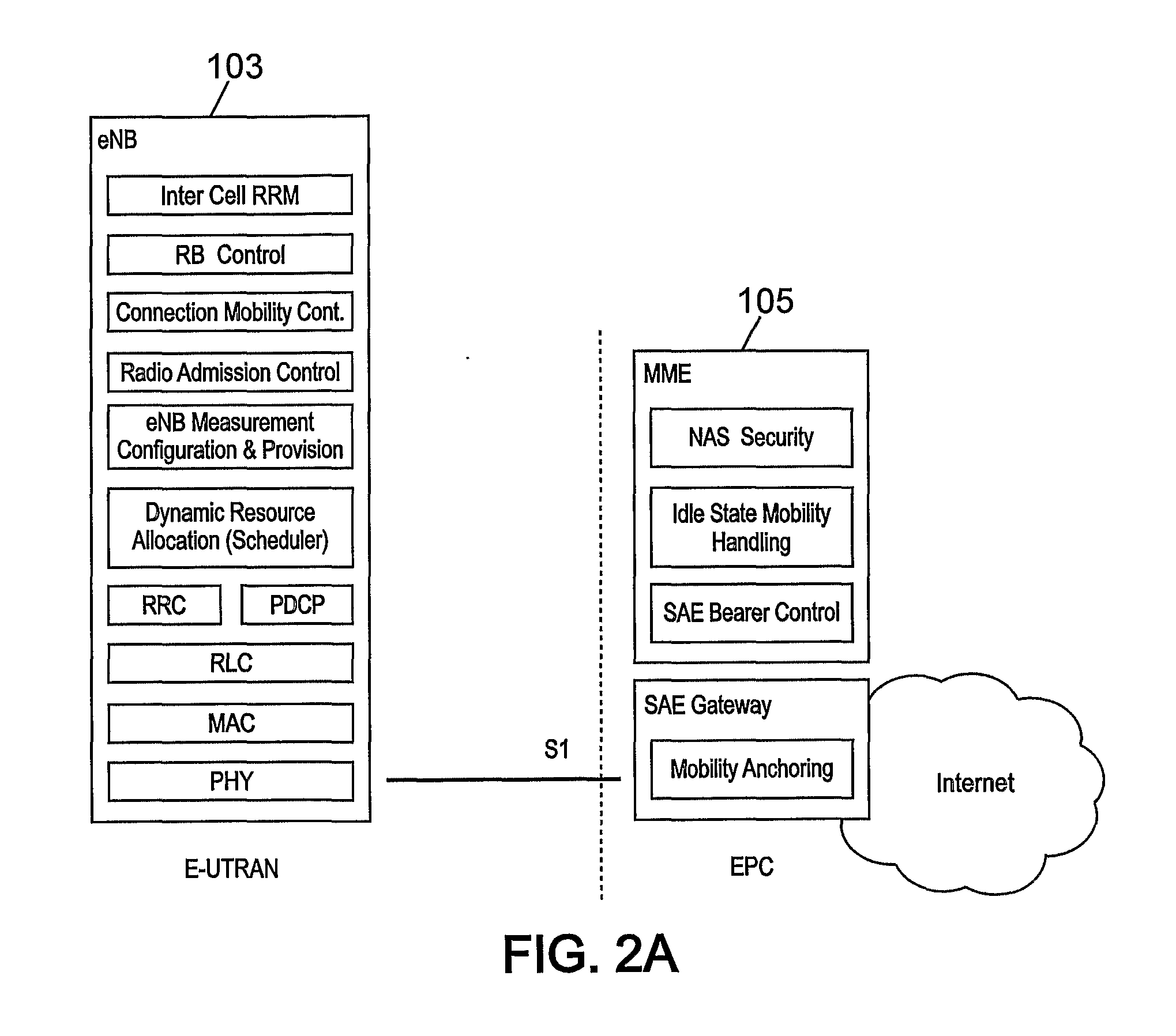

Random access resource configuration

ActiveUS20120008575A1Process can be minimizedSignal allocationWireless commuication servicesCarrier signalUser equipment

The invention relates to a method of configuration of random access resources in the case of carrier aggregation wherein one or more uplink and downlink component carriers can be configured by the network, the method comprising the resolution of carrier ambiguity in case of downlink and uplink asymmetric component carrier (CC) configuration by allowing the network to determine on which downlink component carrier the UE camps on. The invention further relates to a method of random access and a network entity and a user equipment for implementing the methods.

Owner:LG ELECTRONICS INC

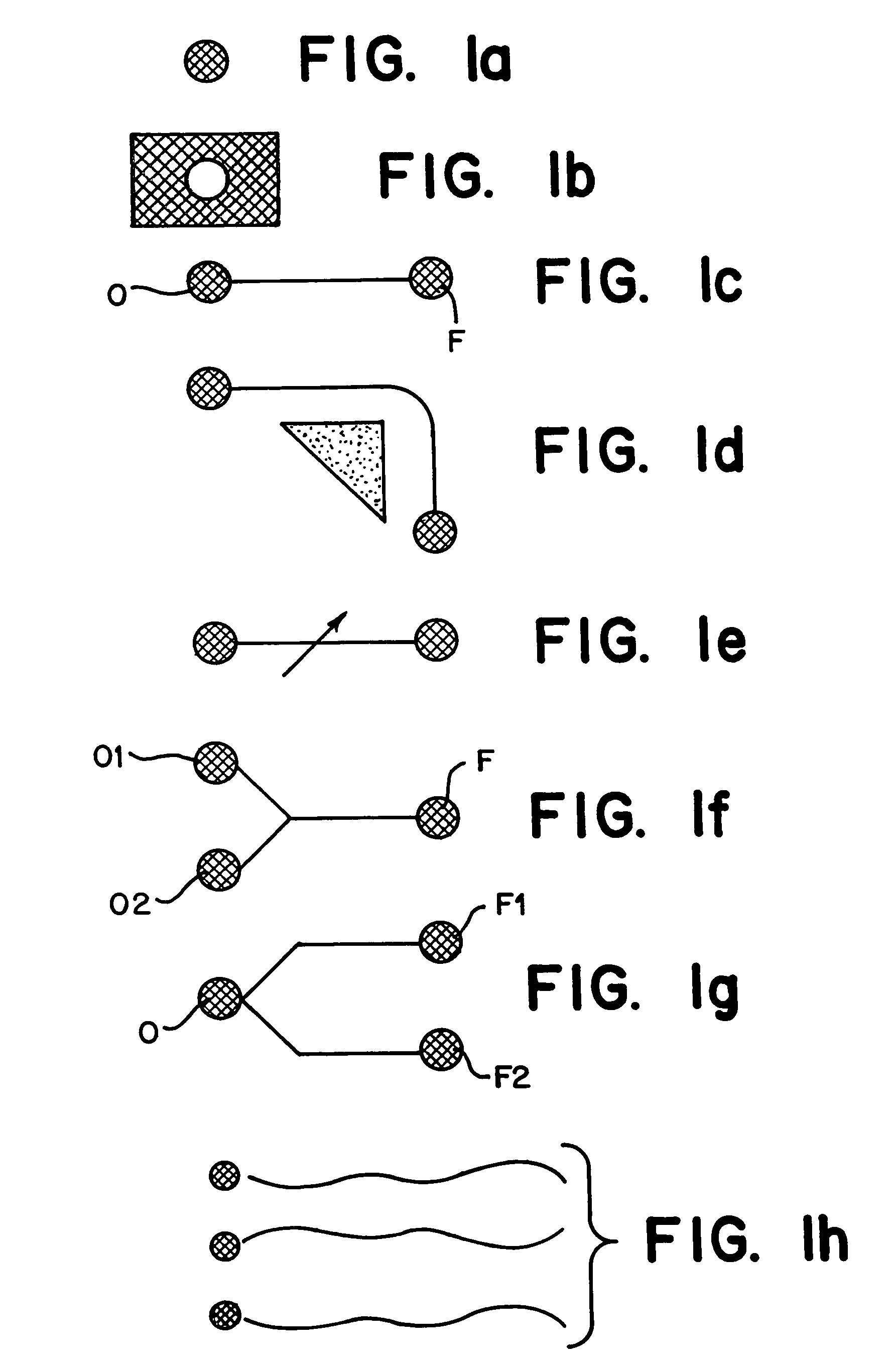

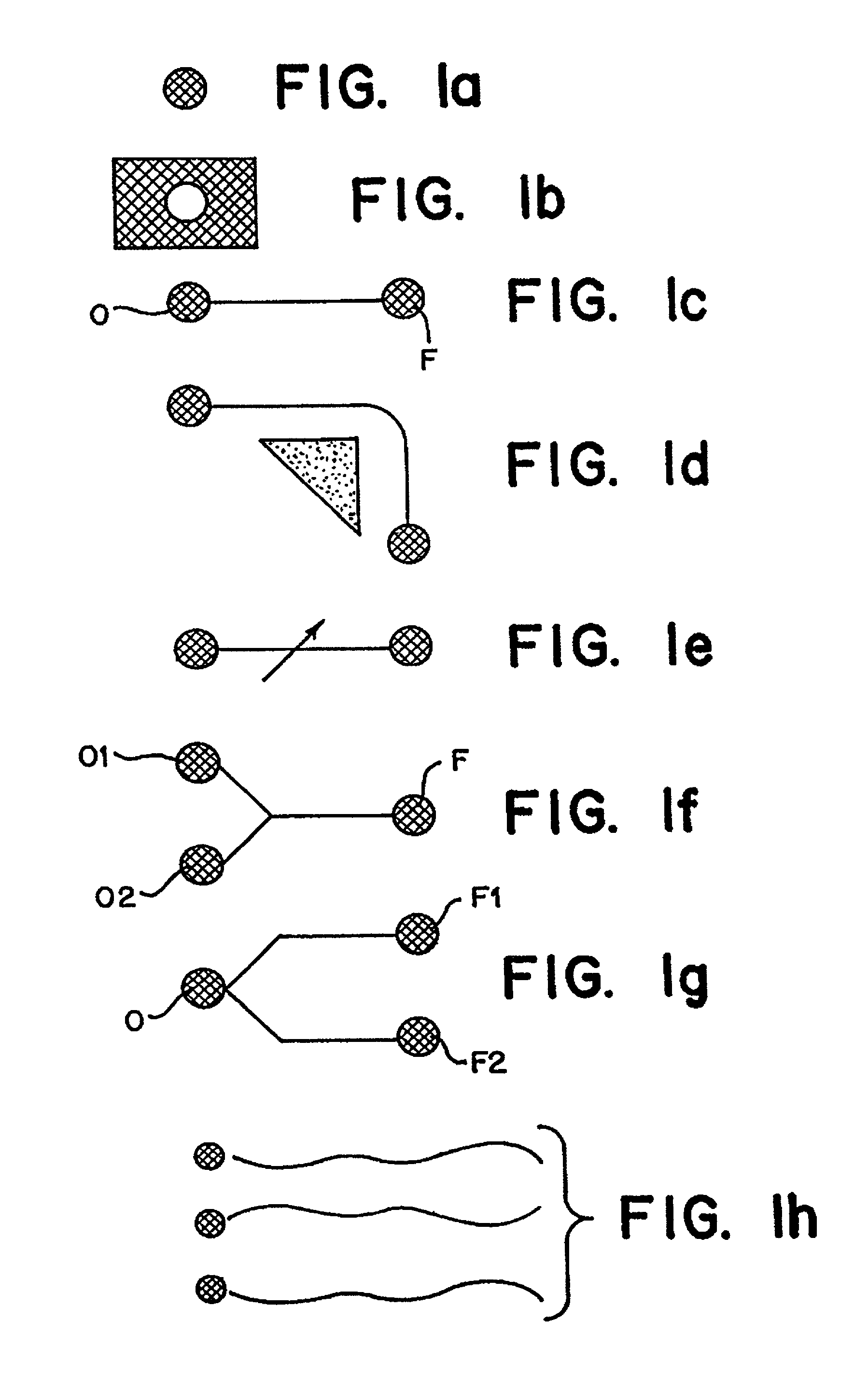

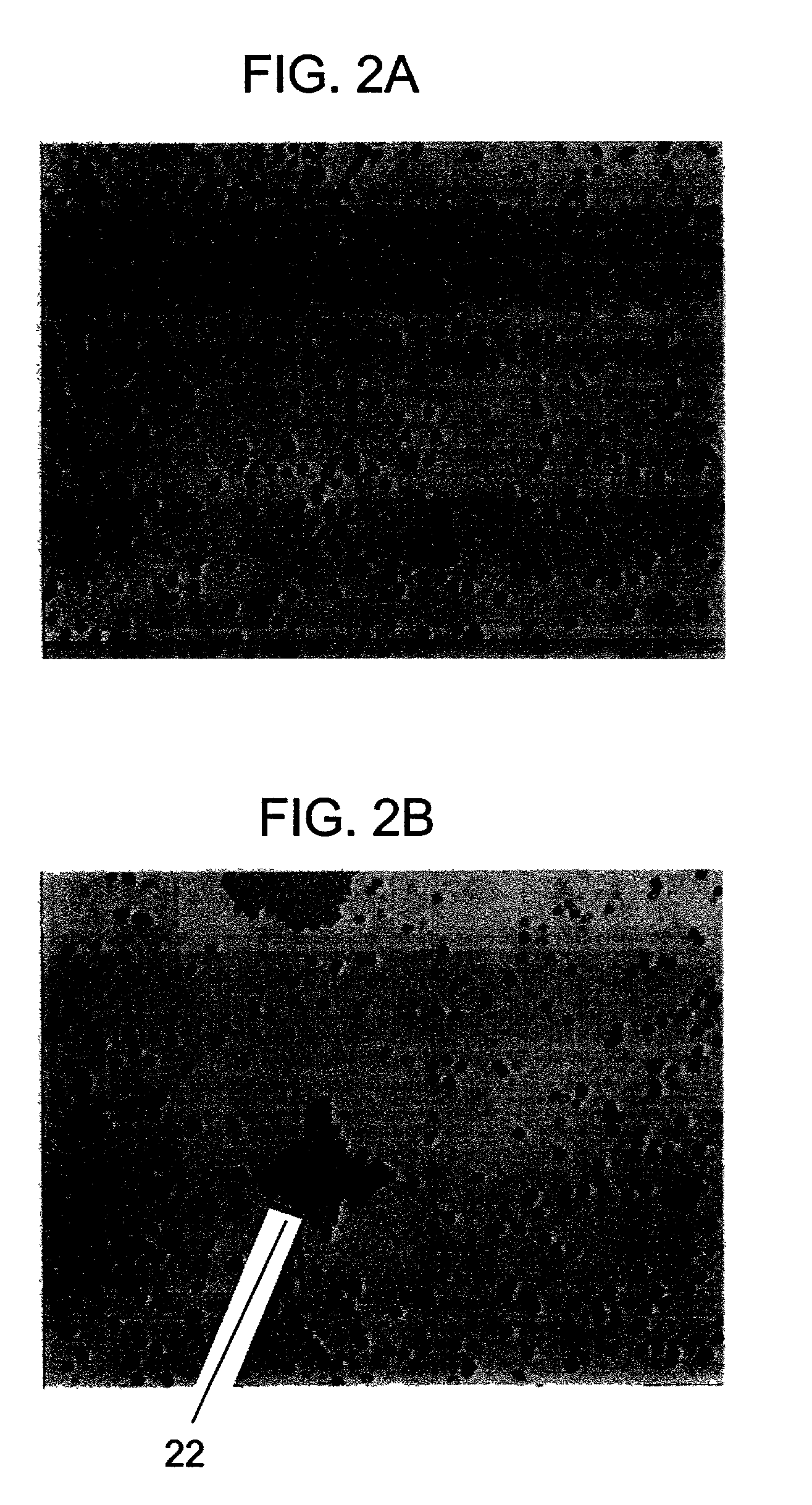

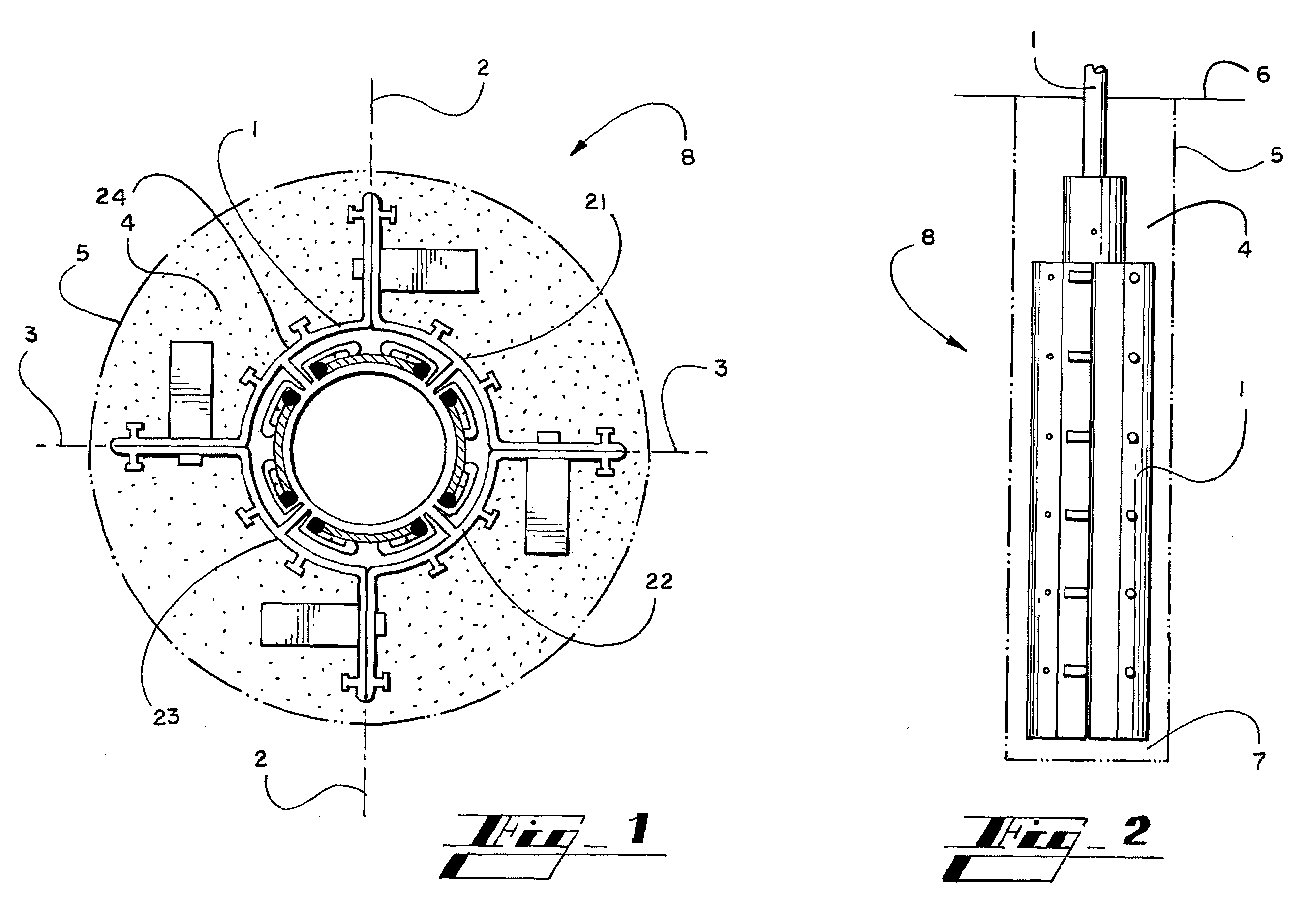

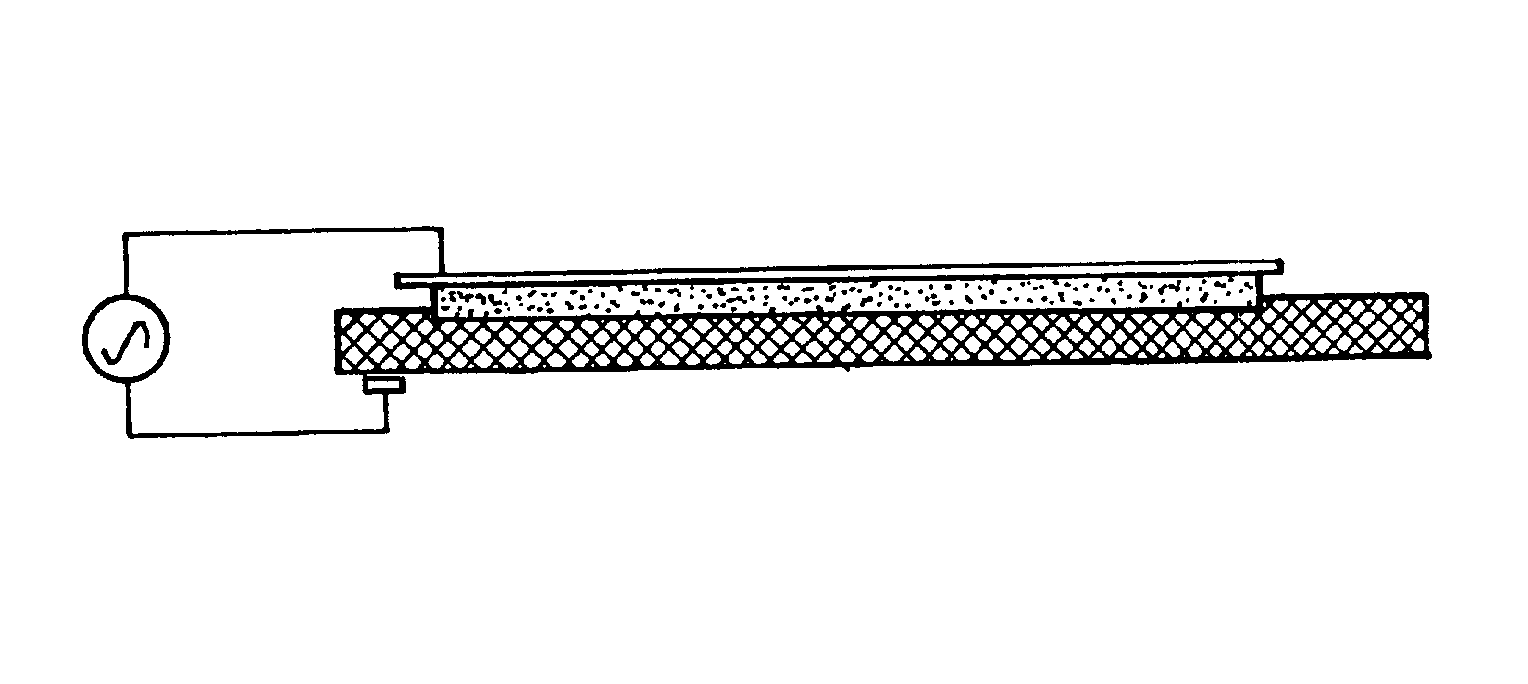

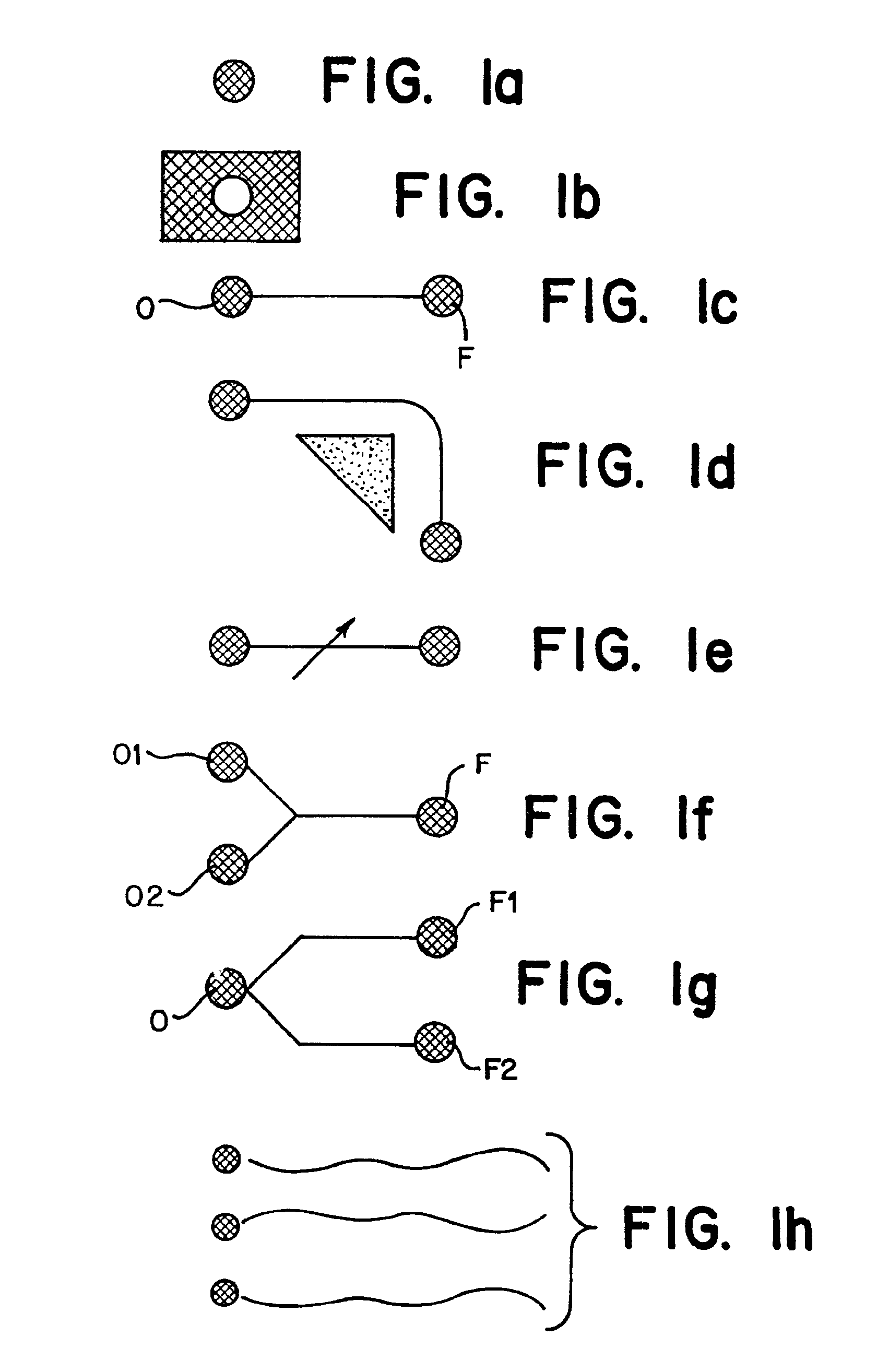

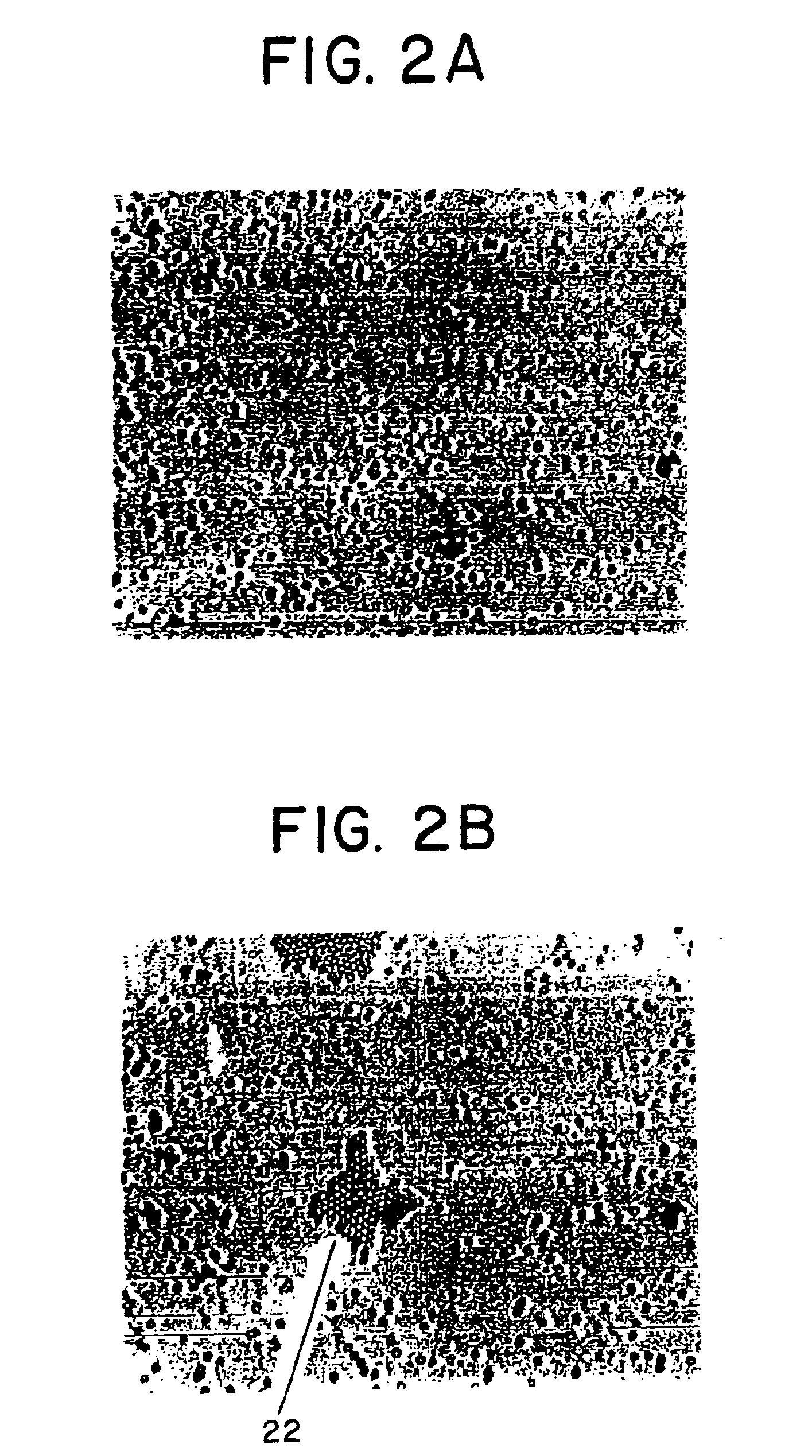

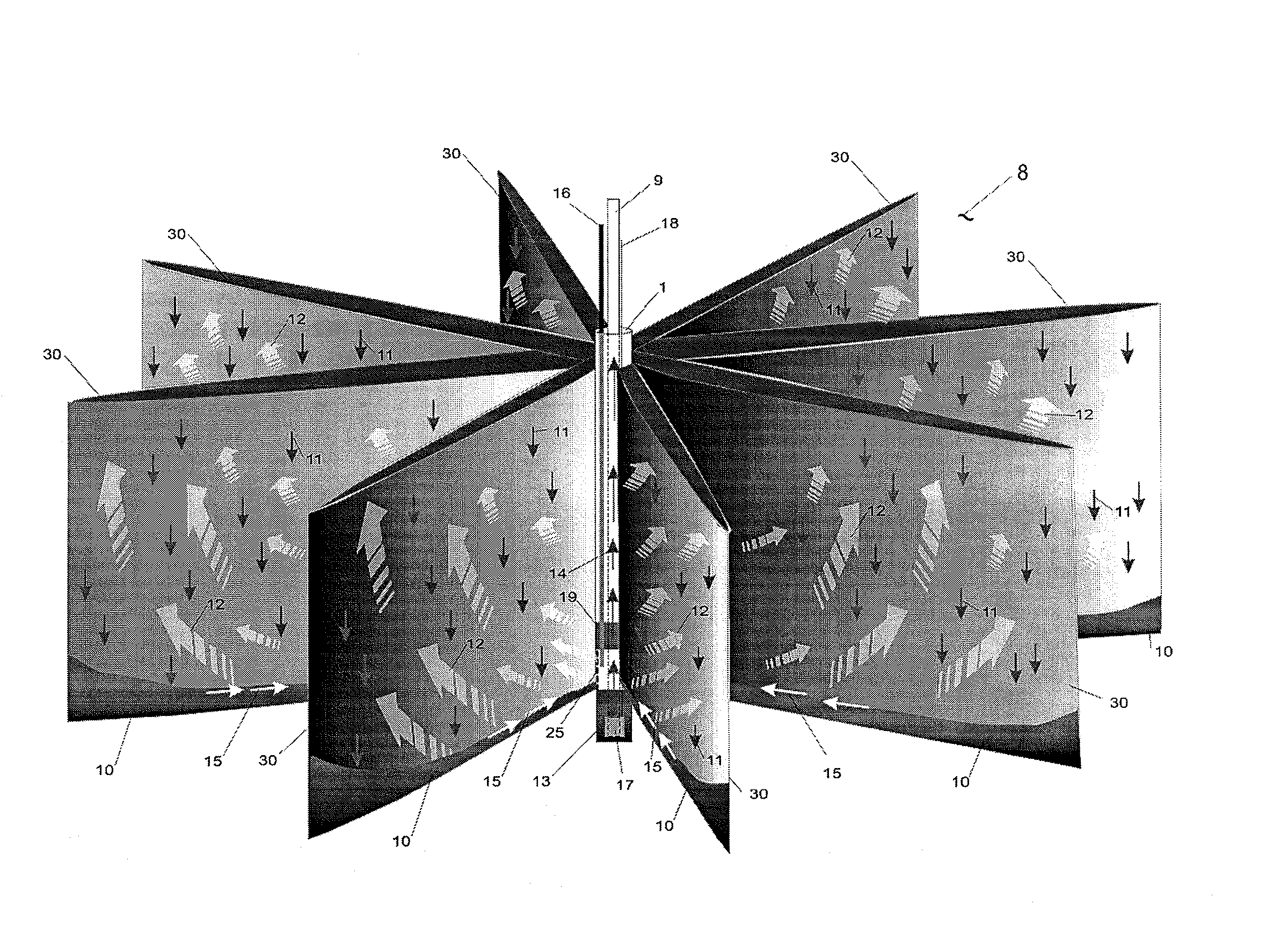

Light-controlled electrokinetic assembly of particles near surfaces

InactiveUS6991941B1Easy to disassembleProcess can be minimizedSequential/parallel process reactionsElectrostatic separatorsParticulatesMicroparticle

A method and apparatus for the manipulation of colloidal particulates and biomolecules at the interface between an insulating electrode such as silicon oxide and an electrolyte solution. Light-controlled electrokinetic assembly of particles near surfaces relies on the combination of three functional elements: the AC electric field-induced assembly of planar aggregates; the patterning of the electrolyte / silicon oxide / silicon interface to exert spatial control over the assembly process; and the real-time control of the assembly process via external illumination. The present invention provides a set of fundamental operations enabling interactive control over the creation and placement of planar arrays of several types of particles and biomolecules and the manipulation of array shape and size. The present invention enables sample preparation and handling for diagnostic assays and biochemical analysis in an array format, and the functional integration of these operations. In addition, the present invention provides a procedure for the creation of material surfaces with desired properties and for the fabrication of surface-mounted optical components.

Owner:BIOARRAY SOLUTIONS

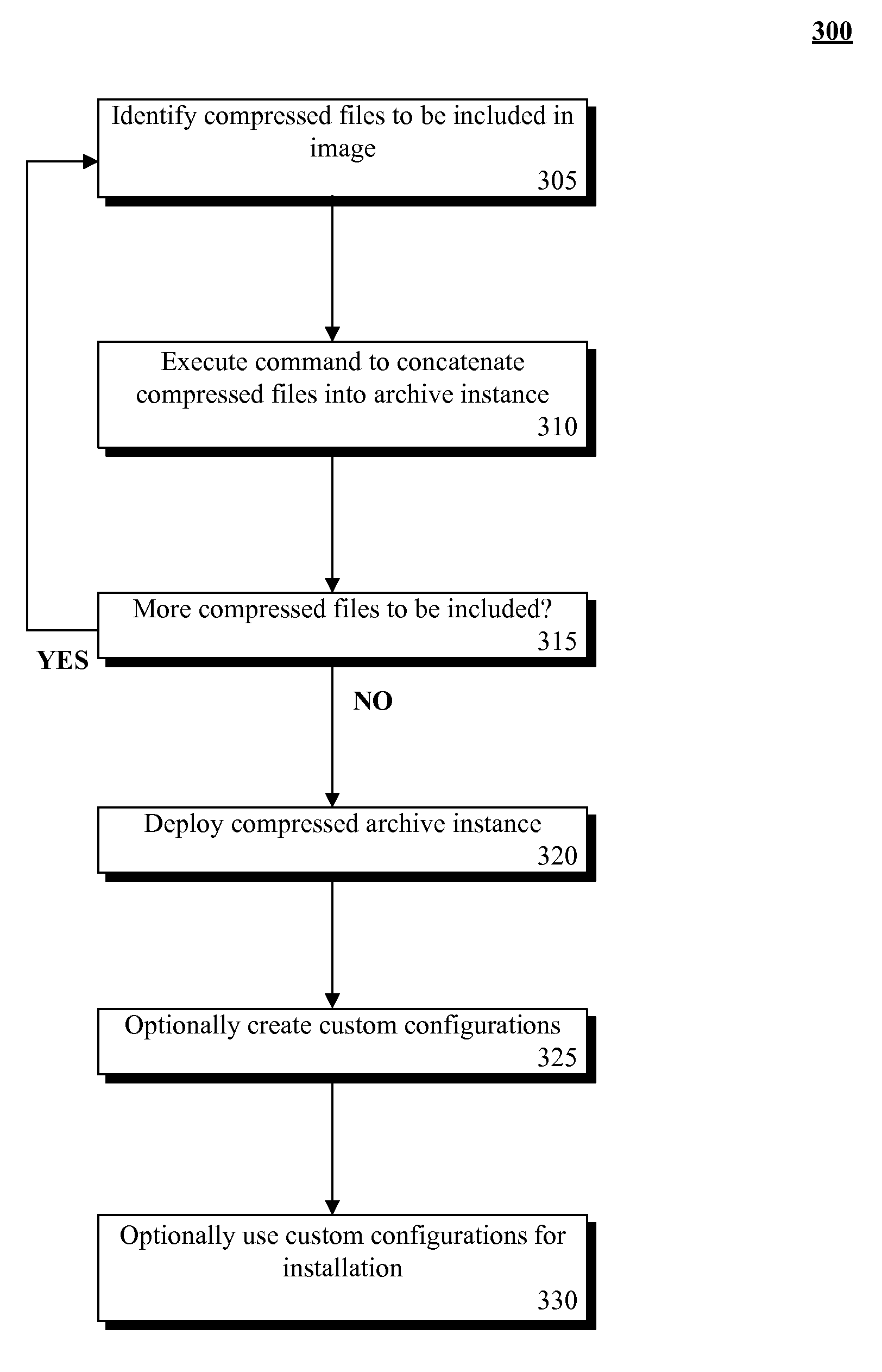

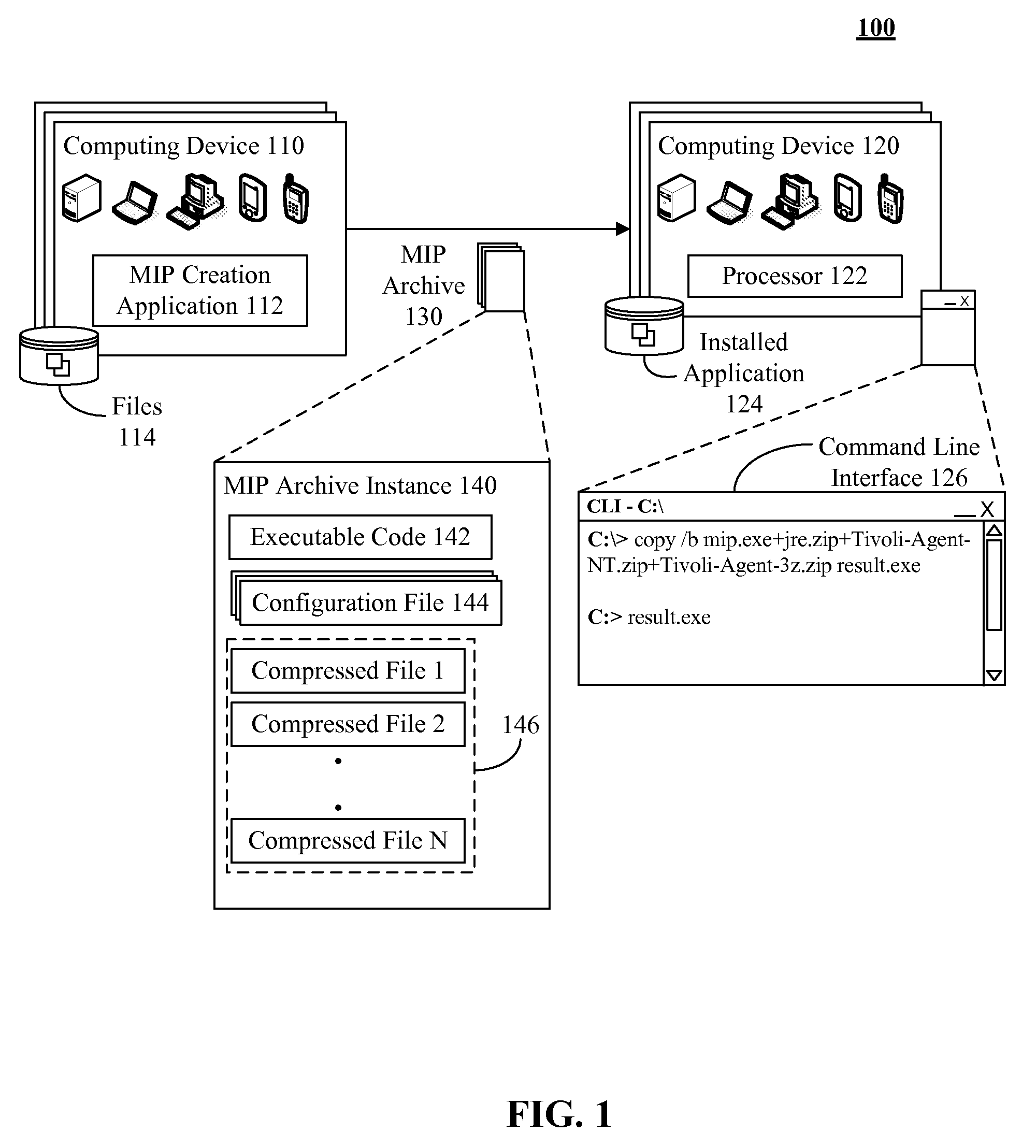

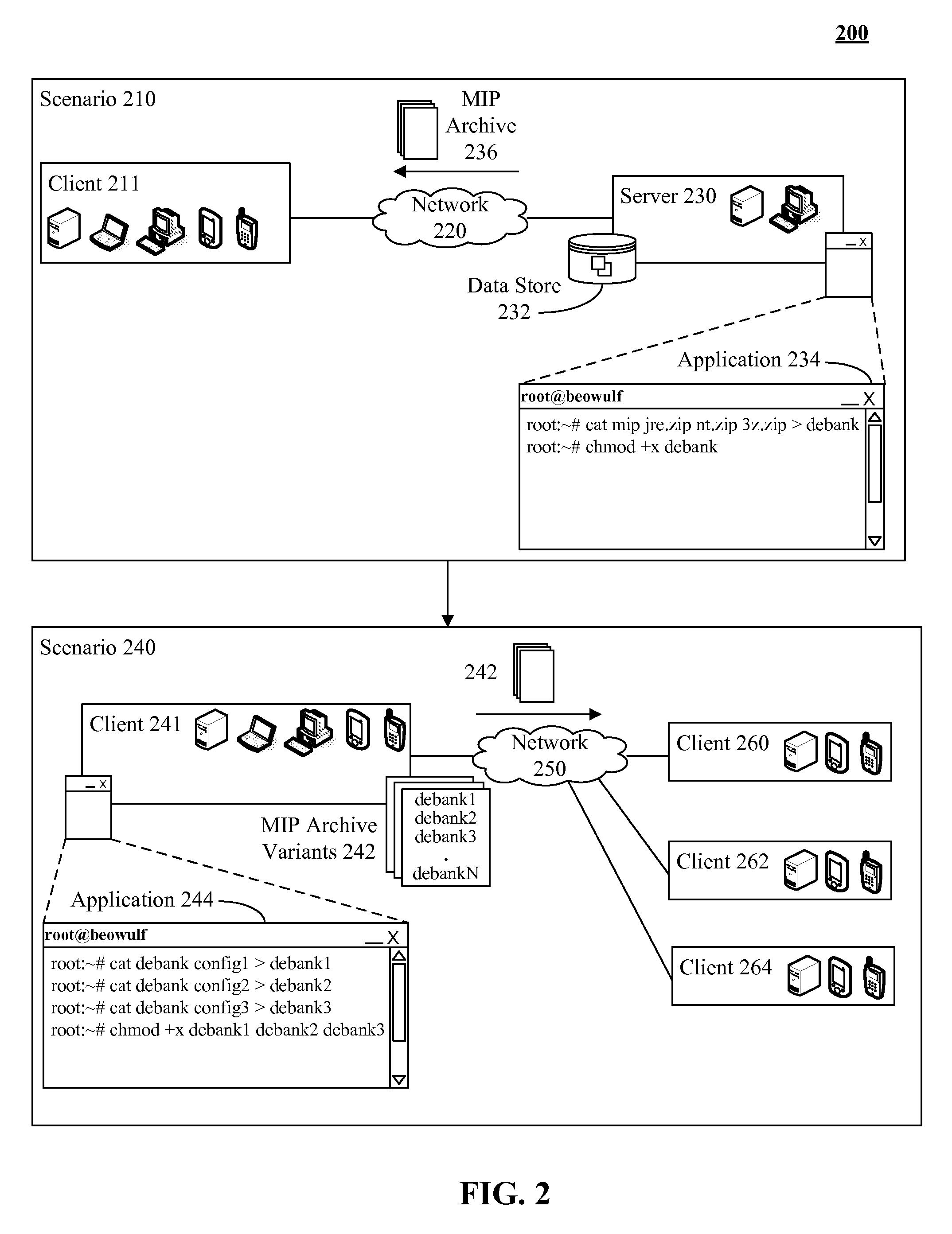

Micro installation process for software packaging and distribution

InactiveUS20090119660A1Consume resourcesEasy to deployProgram loading/initiatingMemory systemsSoftware engineeringWeb transport

The present invention discloses a software program that includes a first set of one or more compressed files and an executable file. The executable file can include a second set of one or more compressed files. The software program can be a self-executing program stored in a machine readable medium. Executing the software program can result in an automatic extraction of files contained within the first set and the second set of compressed files. In one embodiment, the software program can be an installation program, which includes a configuration file specifying settings to be applied during an installation process. The installation program can be dynamically constructed at a time an installation file is requested. The installation program can be a network lean file containing only those necessary components for a customized installation, which minimizes an amount of time and bandwidth expended when transferring the installation program over a network.

Owner:IBM CORP +1

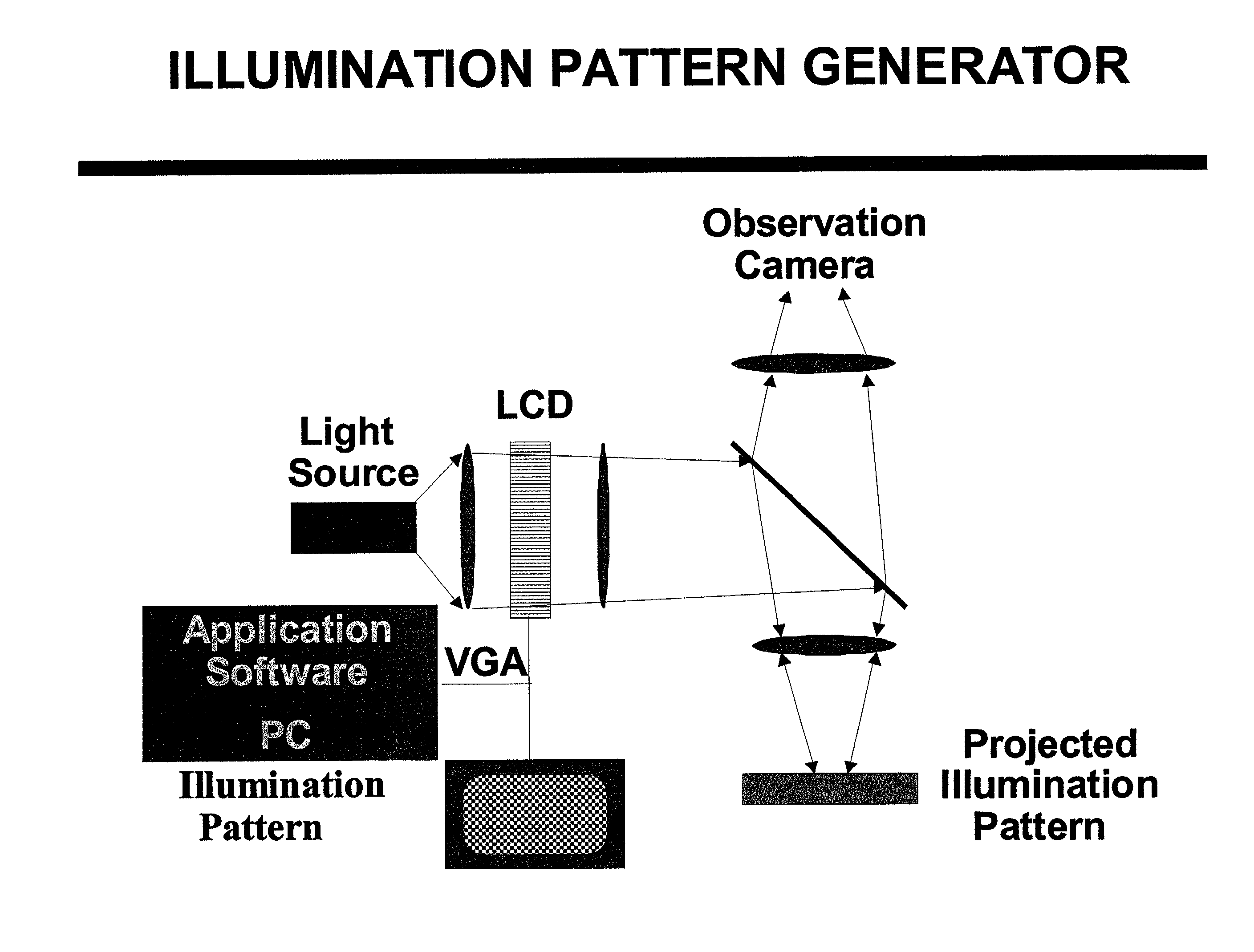

System and method for programmable illumination pattern generation

InactiveUS7144119B2Easy to disassembleProcess can be minimizedSequential/parallel process reactionsRadiation/particle handlingParticulatesEngineering

An apparatus providing programmable illumination pattern generation for the manipulation of colloidal particulates and biomolecules in suspension between electrodes, is disclosed. The apparatus implements LEAPS (Light-controlled electrokinetic assembly of particles near surfaces), which relies on: AC electric field-induced assembly of particles the patterning of the electrolyte / silicon oxide / silicon interface to exert spatial control over the assembly process; and the real-time control of the assembly process via external illumination. The apparatus generates patterns of illumination and projects then onto planar surfaces, i.e., a LEAPS electrode. This enables the creation of patterns using graphical design or drawing software on a personal computer and the projection or said patterns, or sequences of patterns (“time-varying patterns”), onto the interface using a liquid crystal display (LCD) panel and an optical design which images the LCD panel onto the surface of interest, to provide for arrangements and assembly of particles in such patterns.

Owner:BIOARRAY SOLUTIONS

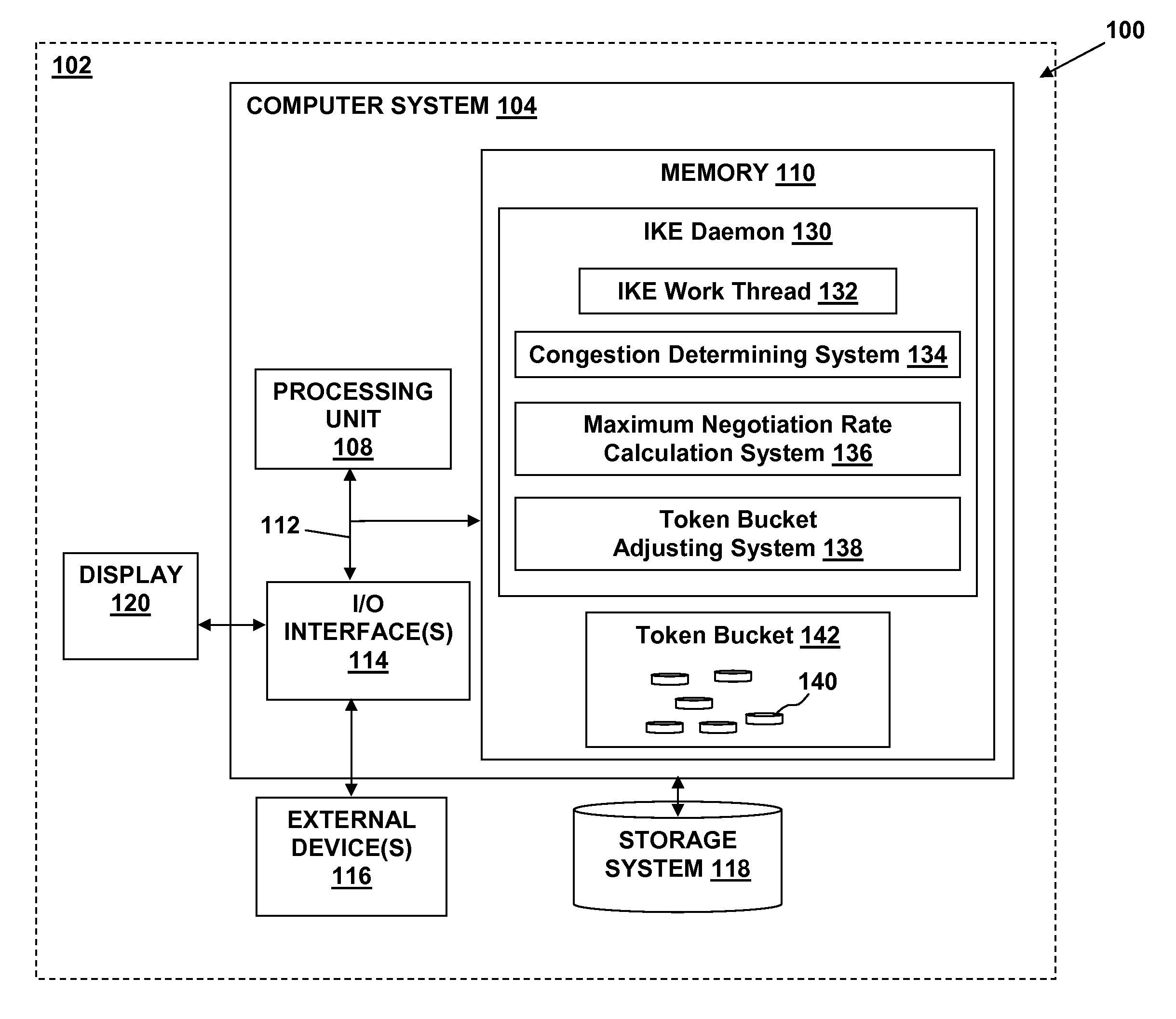

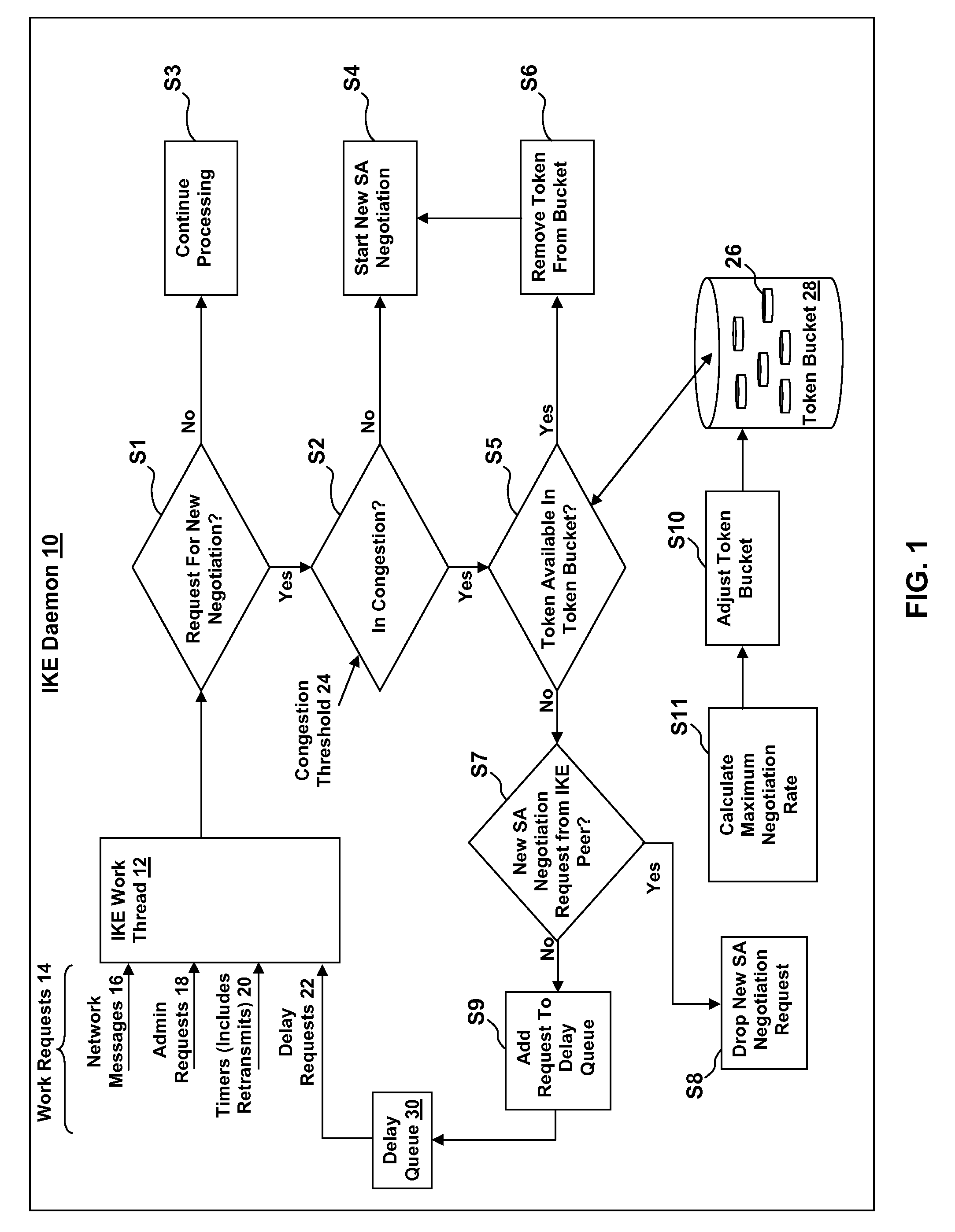

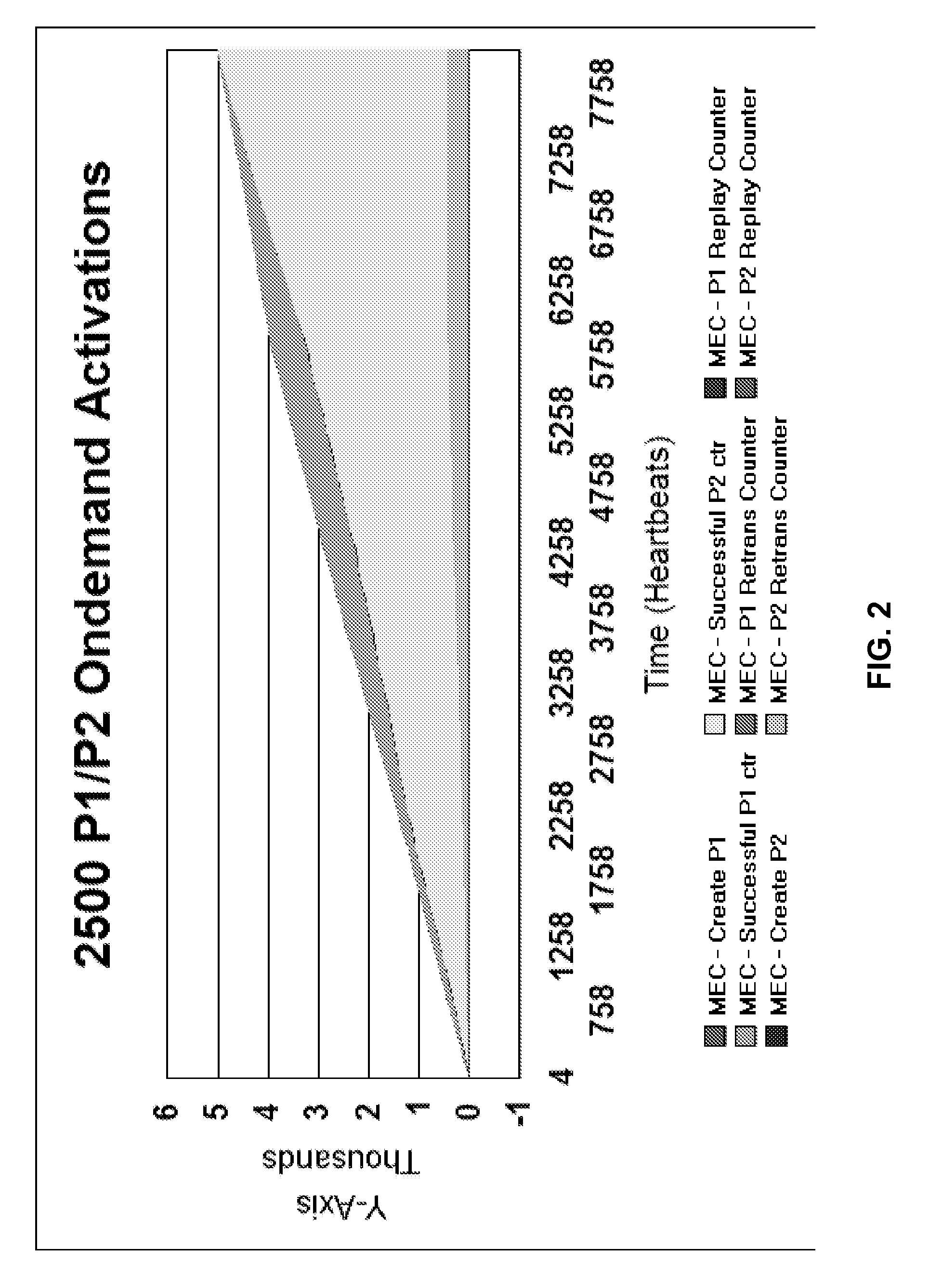

Ike daemon self-adjusting negotiation throttle

InactiveUS20070277232A1Minimizing retransmission processingMaximizing numberDigital data processing detailsUser identity/authority verificationComputer networkInternet Key Exchange

The present invention provides an Internet Key Exchange (IKE) daemon self-adjusting negotiation throttle for minimizing retransmission processing during Security Association (SA) negotiation requests. A method in accordance with an embodiment of the present invention includes: receiving a request for a new negotiation to be performed by a negotiation system; determining if the negotiation system is in congestion; and if the negotiation system is determined to be in congestion: determining if a token is available in a token bucket; and if a token is available in the token bucket, removing the token from the token bucket; and performing the new negotiation.

Owner:IBM CORP

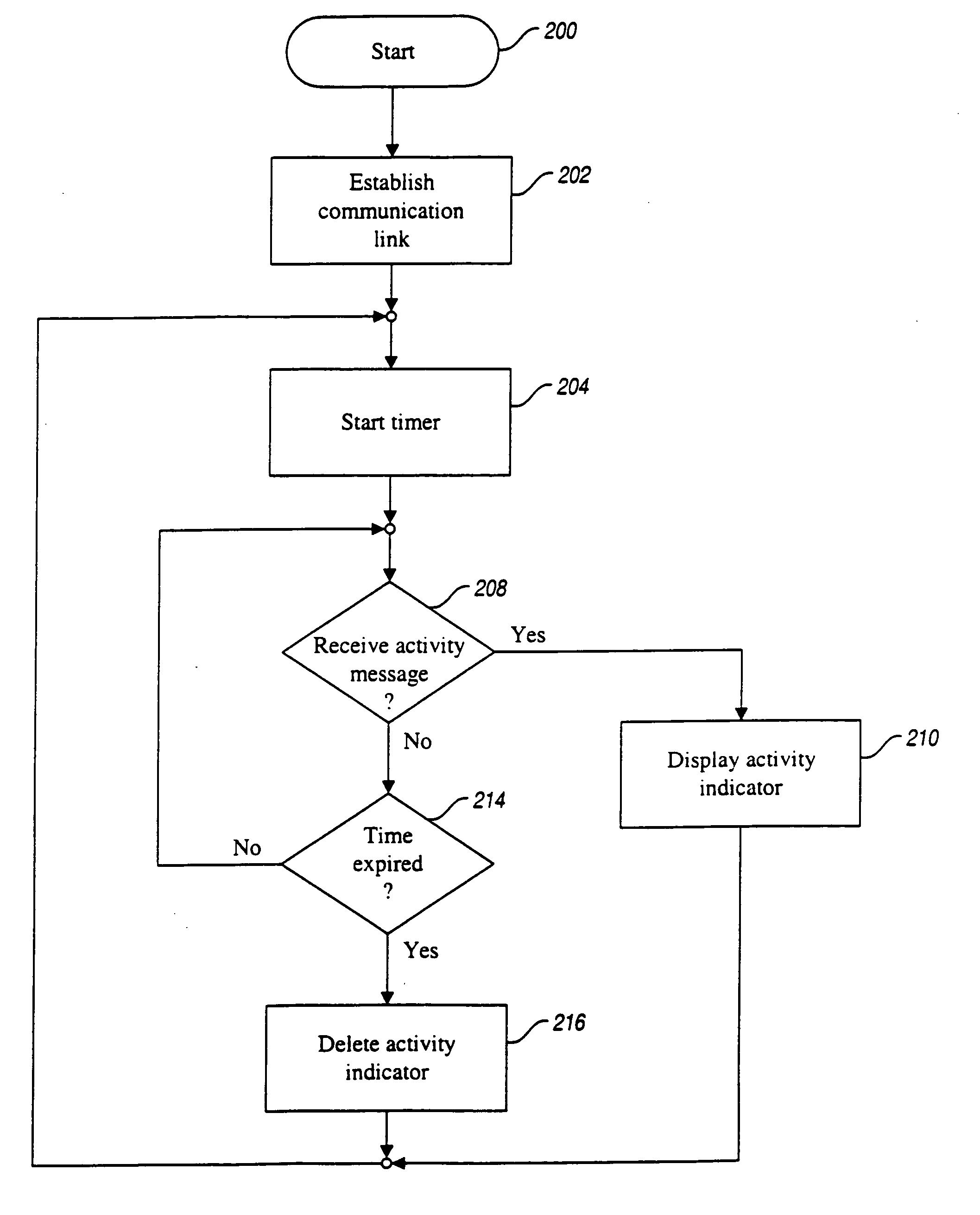

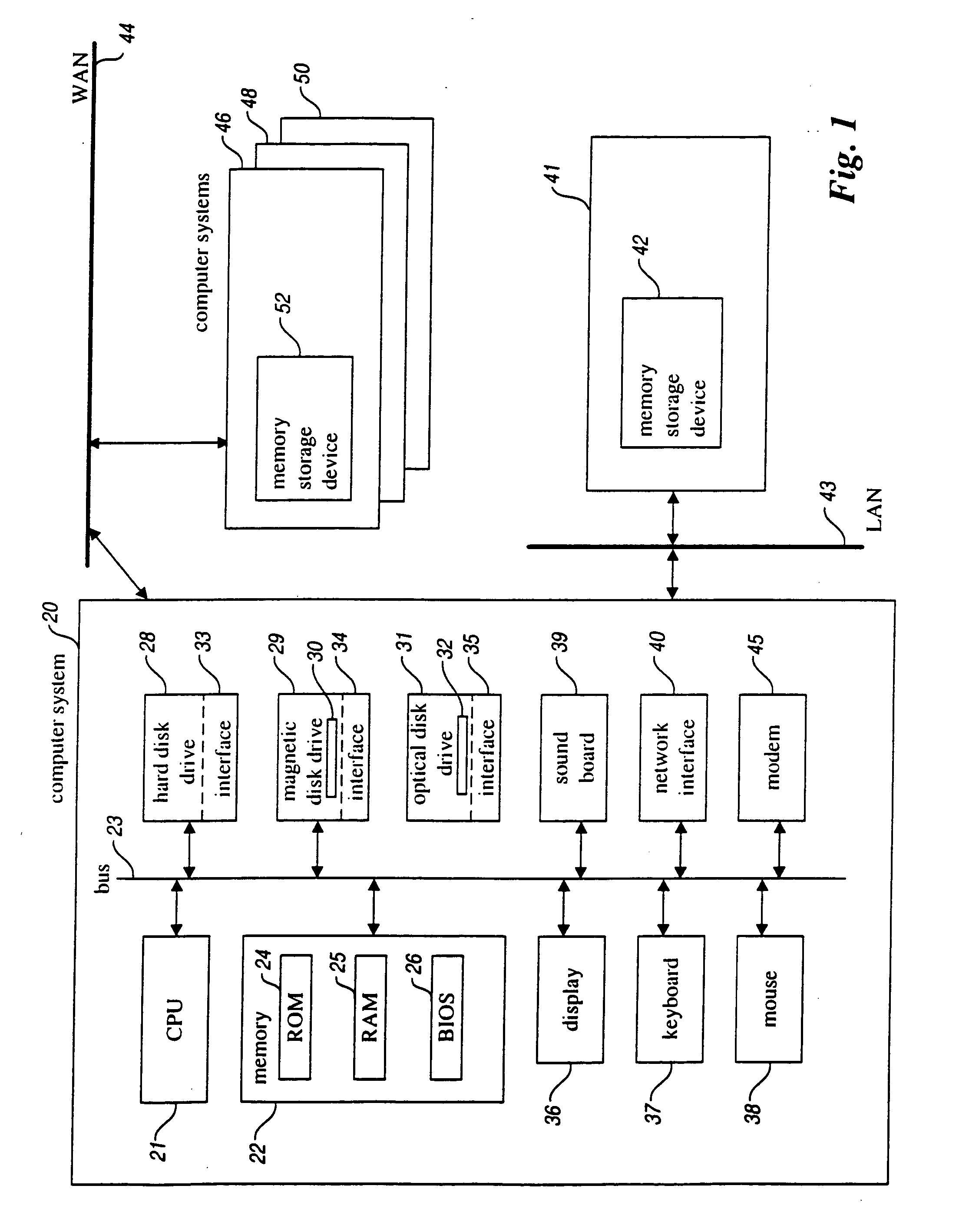

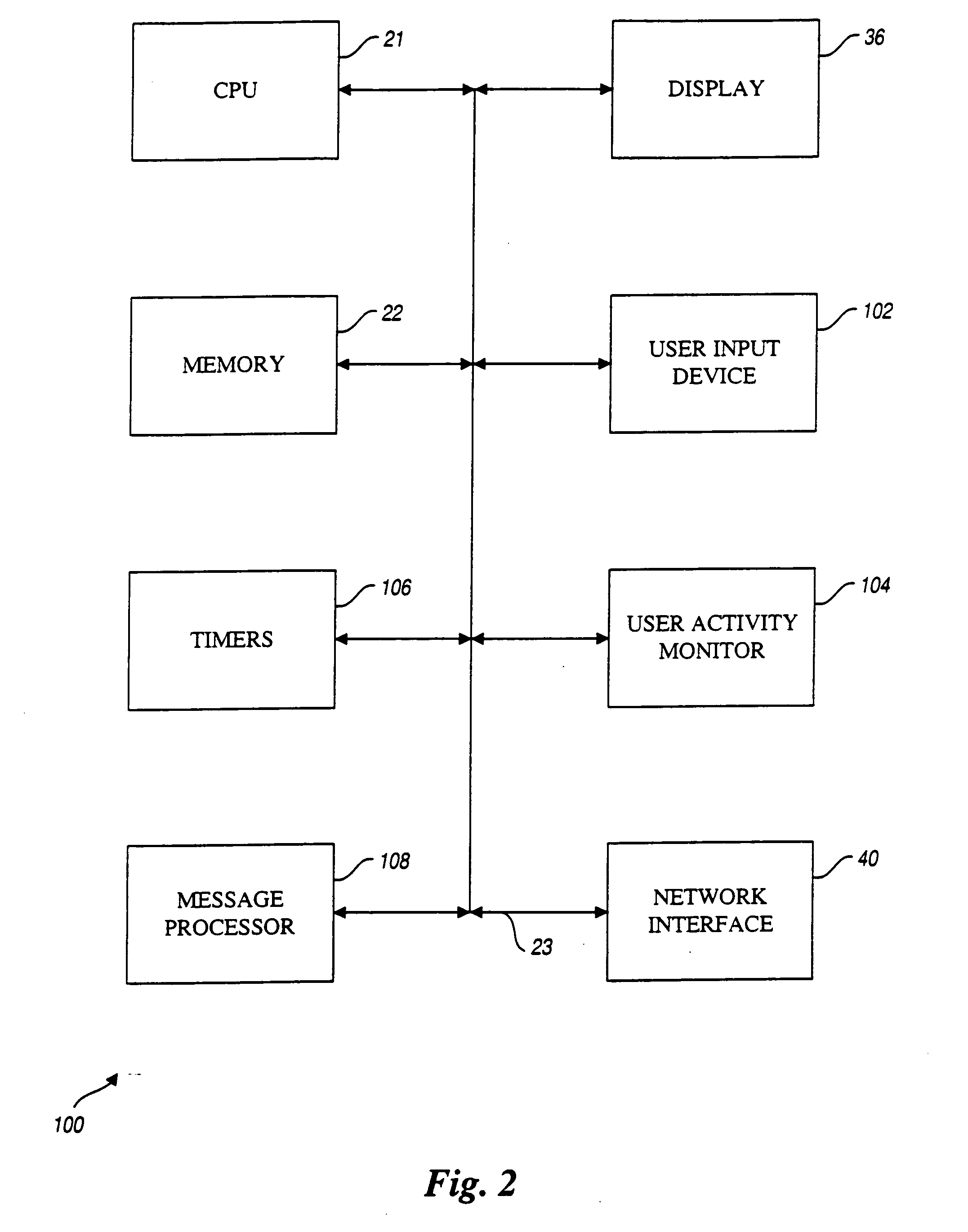

System and method for activity monitoring and reporting in a computer network

InactiveUS20050108392A1Process can be minimizedDigital computer detailsSecuring communicationDisplay deviceActivity monitoring

Owner:MICROSOFT TECH LICENSING LLC

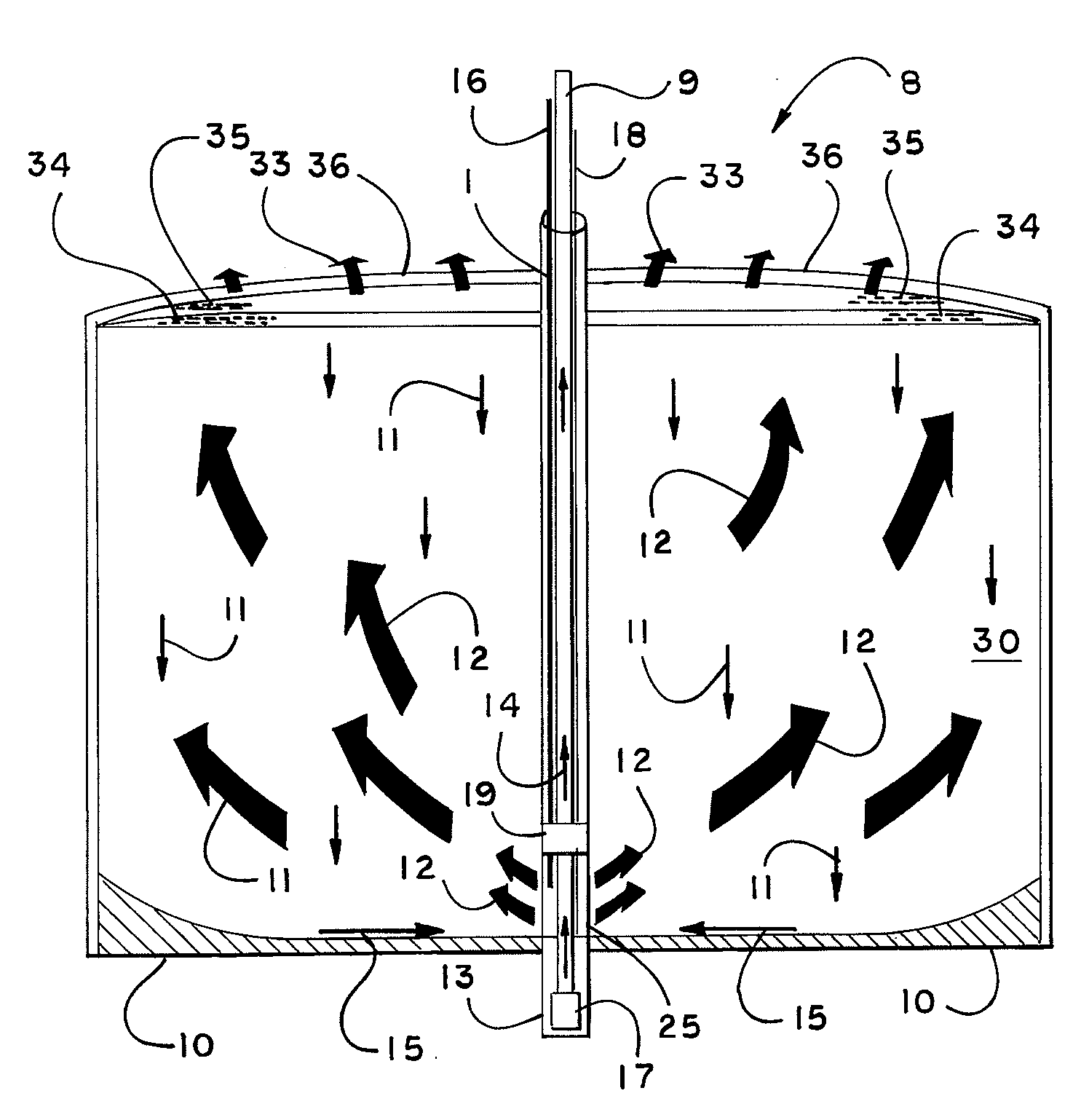

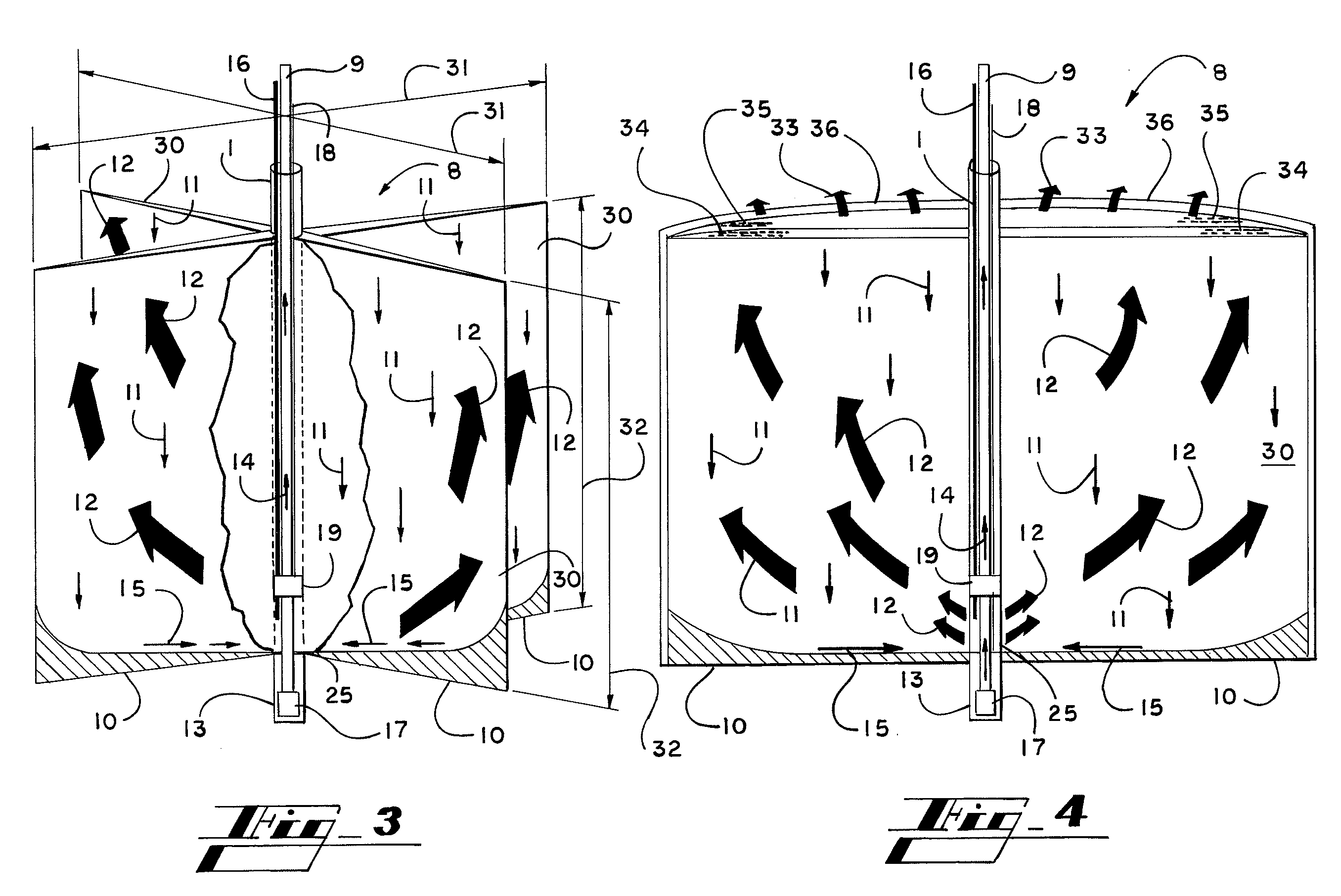

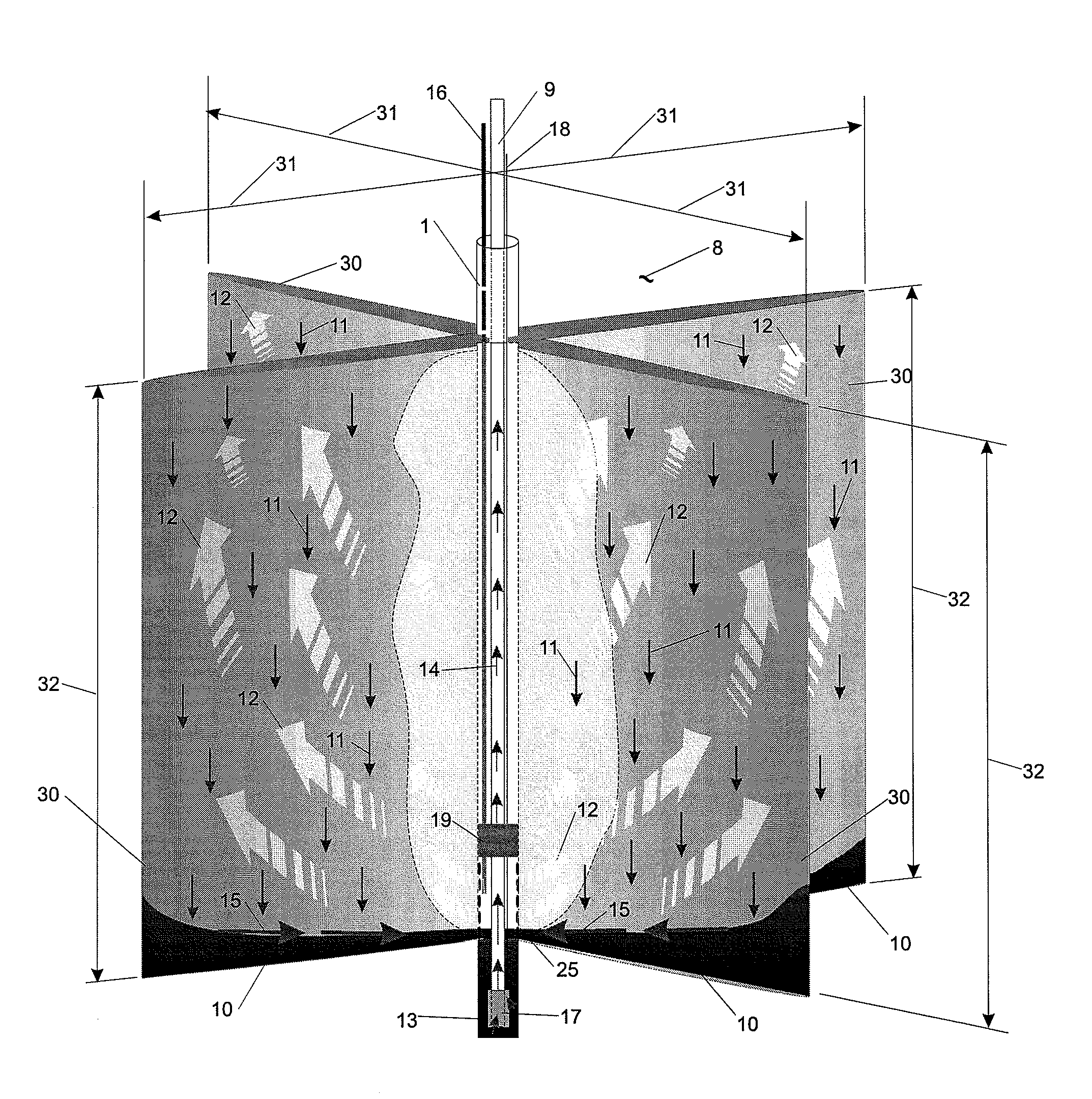

Enhanced Hydrocarbon Recovery By Steam Injection of Oil Sand Formations

InactiveUS20070199698A1Promote recoveryIncrease productionSurveyInsulationHydrocarbon solventsFuel oil

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by injection of a steam and hydrocarbon vaporized solvent in contact with the oil sand formation and the heavy oil and bitumen in situ. Multiple propped hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a highly permeable proppant. Steam, a hydrocarbon solvent, and a non-condensing diluent gas are injected into the well bore and the propped fractures. The injected gas flows upwards and outwards in the propped fractures contacting the oil sands and in situ bitumen on the vertical faces of the propped fractures. The steam condenses on the cool bitumen and thus heats the bitumen by conduction, while the hydrocarbon solvent vapors diffuse into the bitumen from the vertical faces of the propped fractures. The bitumen softens and flows by gravity to the well bore, exposing fresh surface of bitumen for the process to progressively soften and mobilize the bitumen in a predominantly circumferential, i.e. orthogonal to the propped fracture, diffusion direction at a nearly uniform rate into the oil sand deposit. The produced product of oil and dissolved solvent is pumped to the surface where the solvent can be recycled for further injection.

Owner:GEOSIERRA

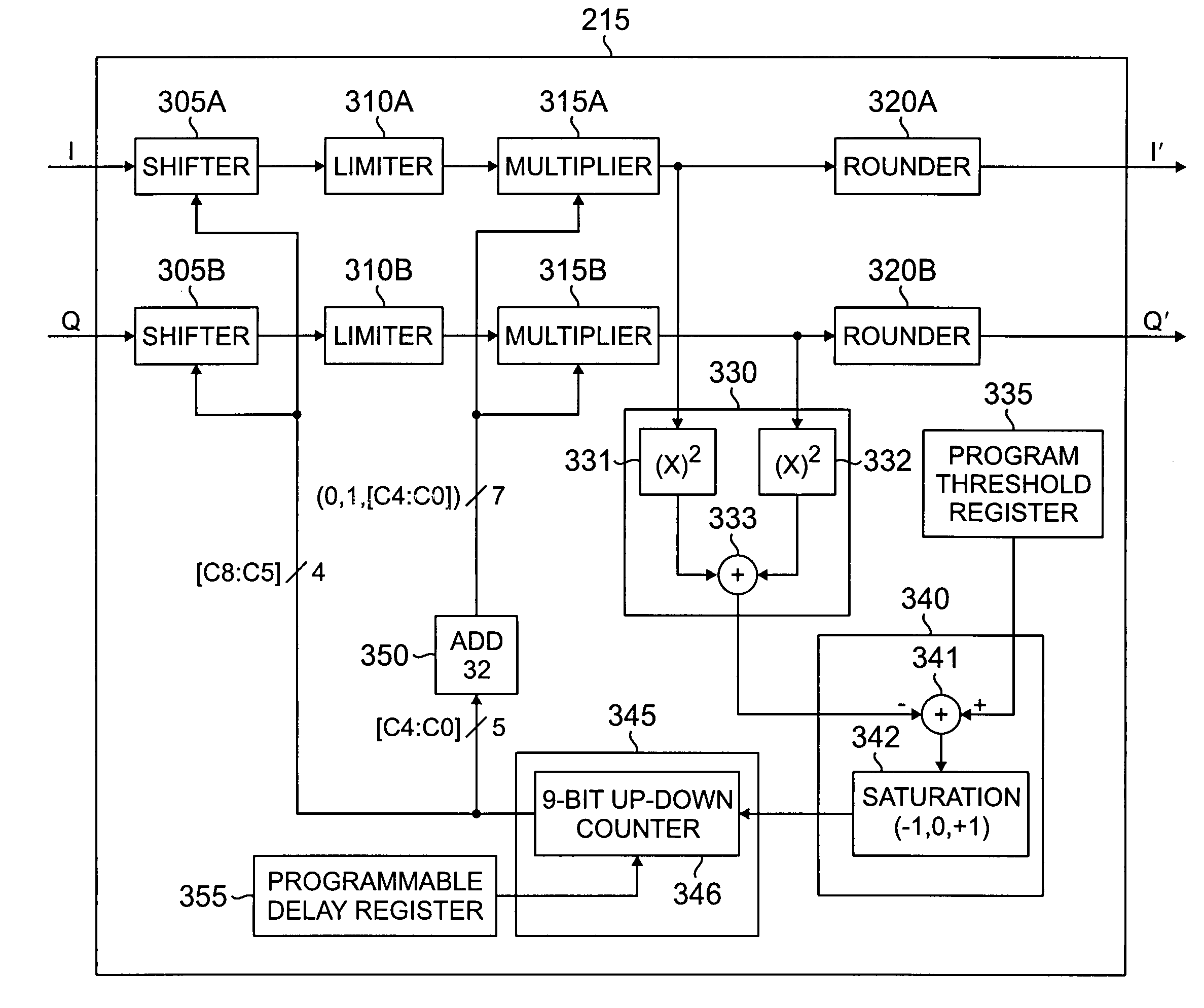

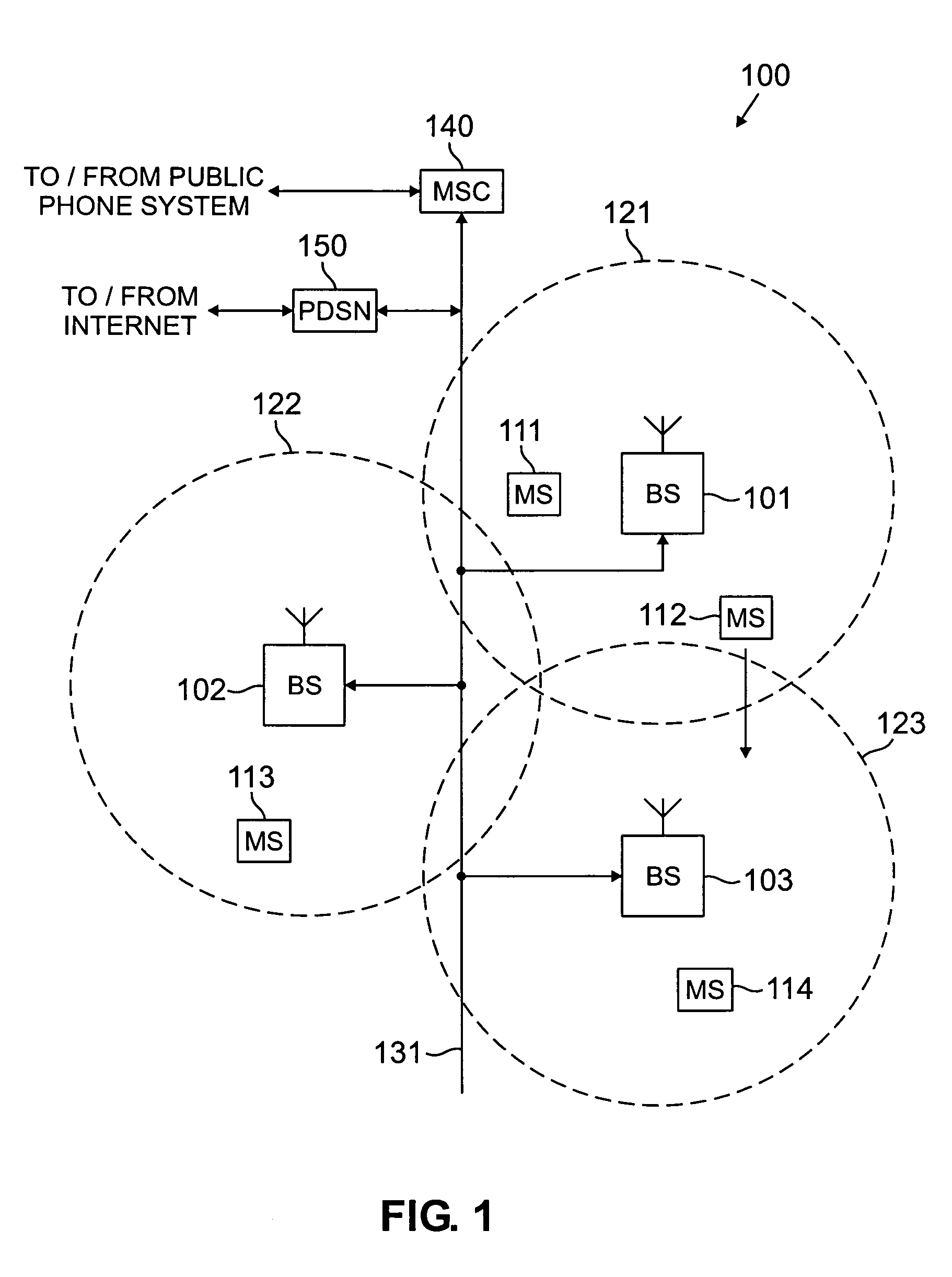

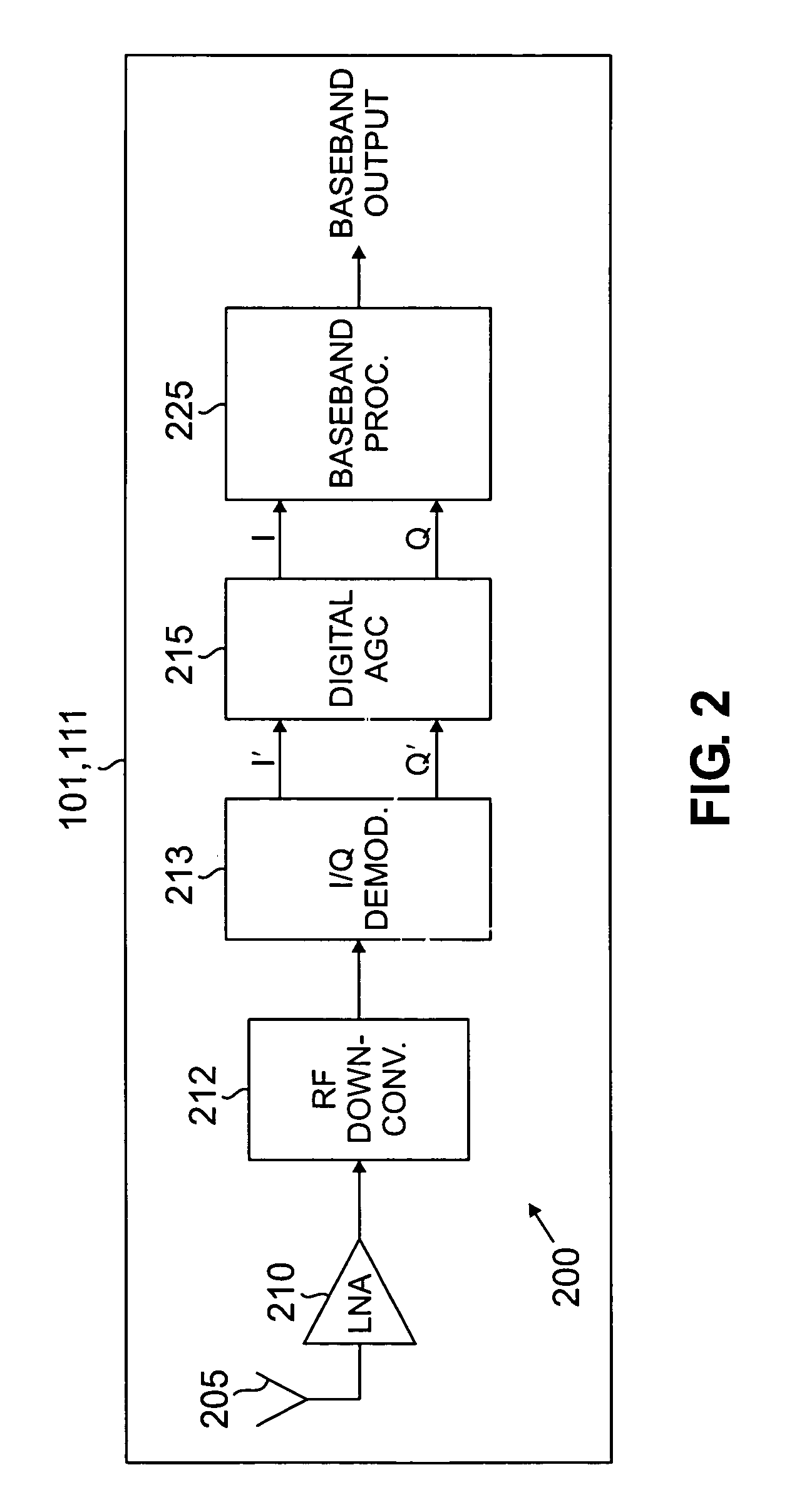

Fully digital AGC circuit with wide dynamic range and method of operation

InactiveUS7031409B2MinimizesEasy to implementAmplitude-modulated carrier systemsRadio transmissionBinary multiplierEngineering

A digital automatic gain control (AGC) circuit for use in a radio frequency (RF) receiver. The AGC circuit comprises: 1) a first shifter for receiving an in-phase signal as a first series of X-bit samples and left-shifting each X-bit sample by a number of bits determined by a coarse scaling factor; 2) a first limiter for receiving the D most significant bits of the output of the first shifter and outputting a subset of the D most significant bits of the first shifter output; 3) a first multiplier for multiplying the subset of the D most significant bits of the first shifter output by a fine scaling factor to produce a first M-bit product; and 4) a gain adjustment circuit for comparing a power signal derived from the first M-bit product to a maximum threshold value and generating the coarse scaling factor and the fine scaling factor.

Owner:SAMSUNG ELECTRONICS CO LTD

Enhanced hydrocarbon recovery by steam injection of oil sand formations

InactiveUS20070199697A1Promote recoveryIncrease productionSurveyInsulationHydrocarbon solventsFuel oil

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by injection of a steam and hydrocarbon vaporized solvent in contact with the oil sand formation and the heavy oil and bitumen in situ. Multiple propped hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a highly permeable proppant. Steam, a hydrocarbon solvent, and a non-condensing diluent gas are injected into the well bore and the propped fractures. The injected gas flows upwards and outwards in the propped fractures contacting the oil sands and in situ bitumen on the vertical faces of the propped fractures. The steam condenses on the cool bitumen and thus heats the bitumen by conduction, while the hydrocarbon solvent vapors diffuse into the bitumen from the vertical faces of the propped fractures. The bitumen softens and flows by gravity to the well bore, exposing fresh surface of bitumen for the process to progressively soften and mobilize the bitumen in a predominantly circumferential, i.e. orthogonal to the propped fracture, diffusion direction at a nearly uniform rate into the oil sand deposit. The produced product of oil and dissolved solvent is pumped to the surface where the solvent can be recycled for further injection.

Owner:GEOSIERRA

Predistortion circuit and method for compensating linear distortion in a digital RF communications transmitter

InactiveUS20050163249A1Simple methodImprove accuracyAdaptive networkDelay line applicationsNonlinear distortionData stream

A digital communications transmitter (100) includes a digital linear-and-nonlinear predistortion section (200) to compensate for linear and nonlinear distortion introduced by transmitter-analog components (120). A direct-digital-downconversion section (300) generates a complex digital return-data stream (254) from the analog components (120) without introducing quadrature imbalance. A relatively low resolution exhibited by the return-data stream (254) is effectively increased through arithmetic processing. Linear distortion is first compensated using adaptive techniques with an equalizer (246) positioned in the forward-data stream (112). Nonlinear distortion is then compensated using adaptive techniques with a plurality of equalizers (226) that filter a plurality of orthogonal, higher-ordered-basis functions (214) generated from the forward-data stream (112). The filtered-basis functions are combined together and subtracted from the forward-data stream (112).

Owner:CRESTCOM INC

Light-controlled electrokinetic assembly of particles near surfaces

InactiveUS6955751B1Easy to disassembleMinimize Faradaic processSequential/parallel process reactionsOrganic chemistry methodsParticulatesMicroparticle

A method and apparatus for the manipulation of colloidal particulates and biomolecules at the interface between an insulating electrode such as silicon oxide and an electrolyte solution. Light-controlled electrokinetic assembly of particles near surfaces relies on the combination of three functional elements: the AC electric field-induced assembly of planar aggregates; the patterning of the electrolyte / silicon oxide / silicon interface to exert spatial control over the assembly process; and the real-time control of the assembly process via external illumination. The present invention provides a set of fundamental operations enabling interactive control over the creation and placement of planar arrays of several types of particles and biomolecules and the manipulation of array shape and size. The present invention enables sample preparation and handling for diagnostic assays and biochemical analysis in an array format, and the functional integration of these operations. In addition, the present invention provides a procedure for the creation of material surfaces with desired properties and far the fabrication of surface-mounted optical components.

Owner:BIOARRAY SOLUTIONS

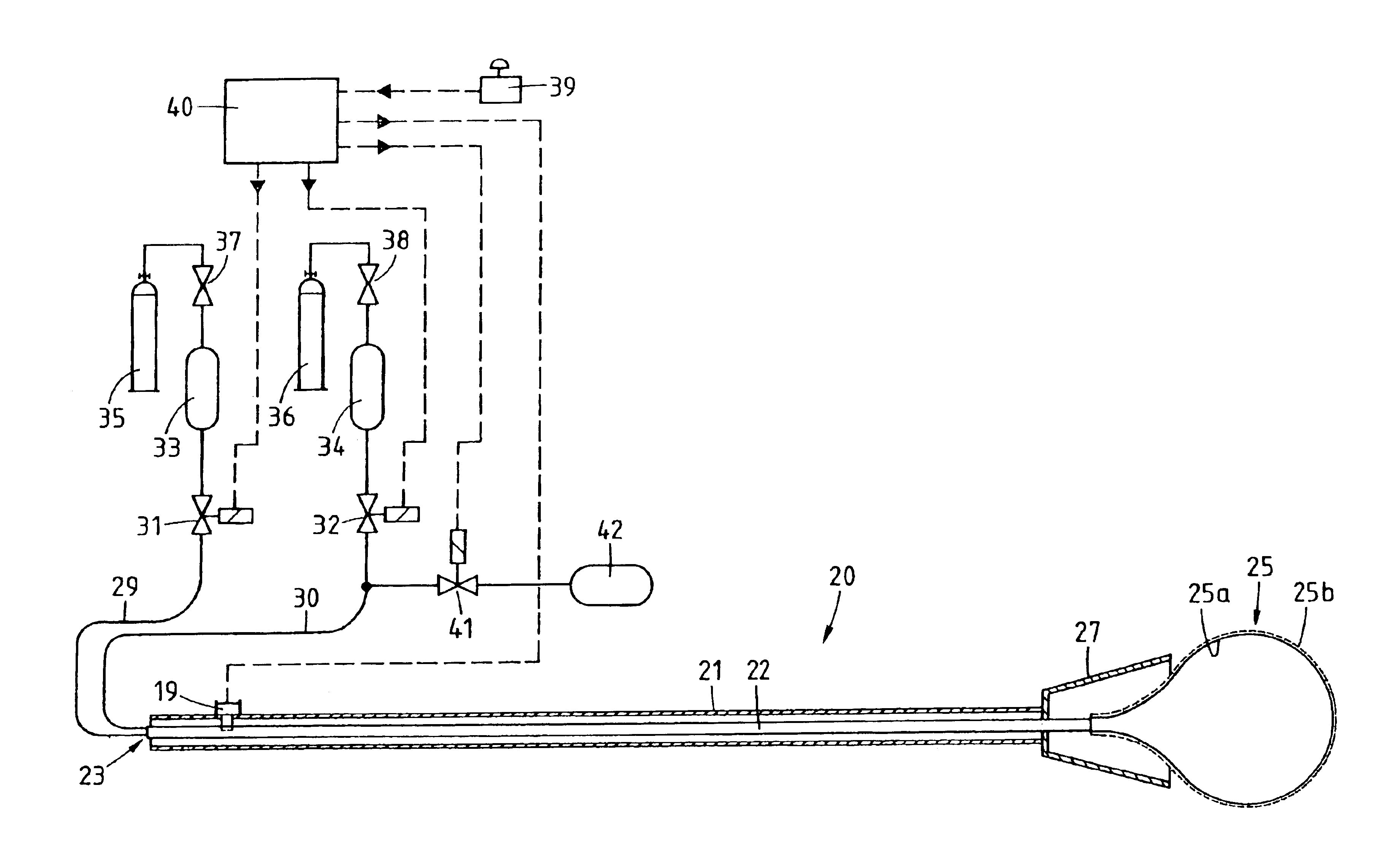

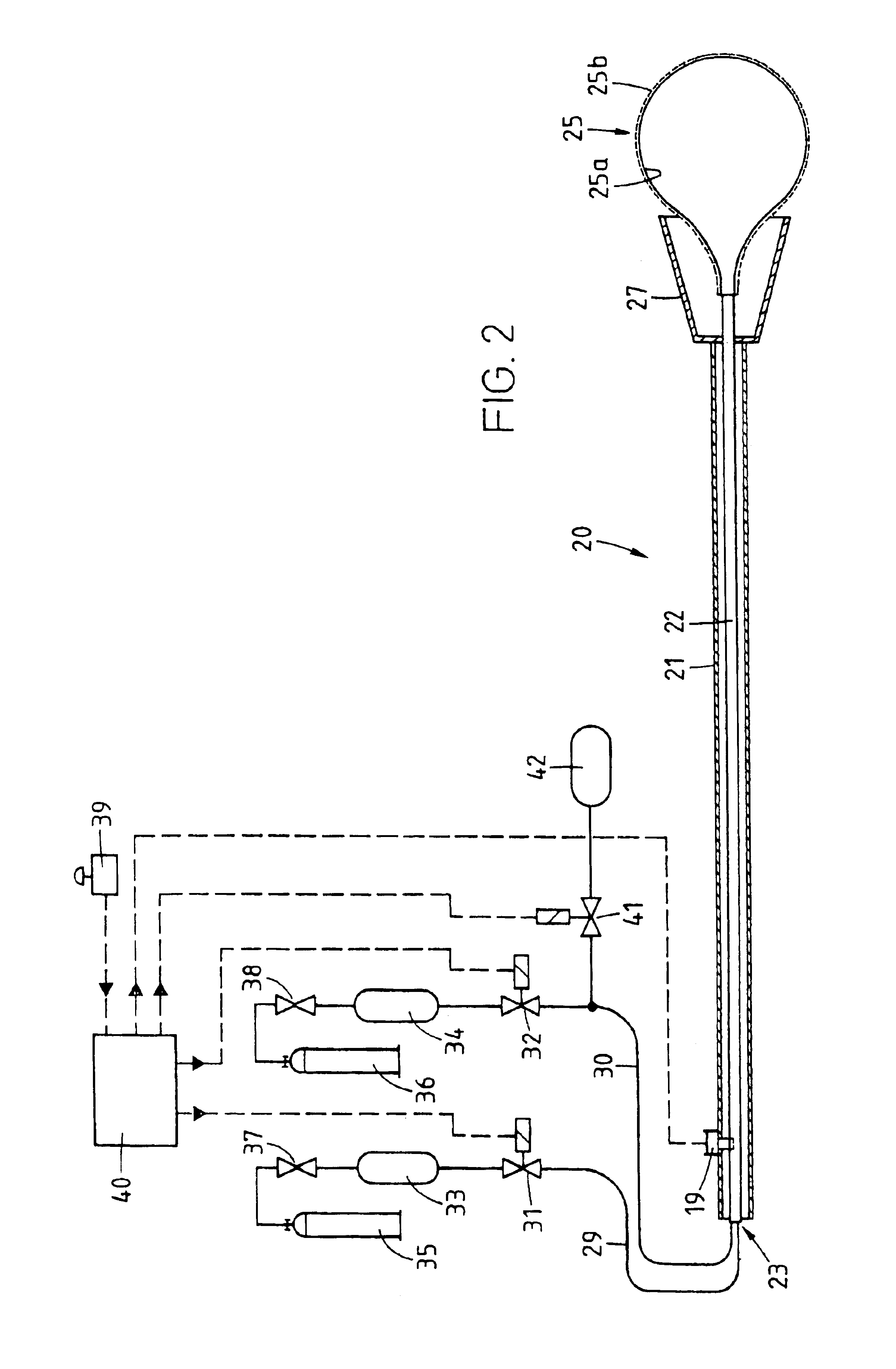

Method for cleaning combustion devices

InactiveUS6935281B2Short timeProcess can be minimizedLinings repairBoiler cleaning apparatusCombustionSlag

An on-line method and a device for cleaning of contamination such as caking or slag deposits from surfaces in vessels and combustion installations by means of blasting technology. An explosive gas mixture is made to detonate in the proximity of the deposits and thereby clean the deposits from the surfaces.

Owner:BANG & CLEAN

Enhanced hydrocarbon recovery by steam injection of oil sand formations

InactiveUS20070199712A1Promote recoveryLimit upward growthInsulationFluid removalHydrocarbon solventsFuel oil

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by injection of a steam and hydrocarbon vaporized solvent in contact with the oil sand formation and the heavy oil and bitumen in situ. Multiple propped hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a highly permeable proppant. Steam, a hydrocarbon solvent, and a non-condensing diluent gas are injected into the well bore and the propped fractures. The injected gas flows upwards and outwards in the propped fractures contacting the oil sands and in situ bitumen on the vertical faces of the propped fractures. The steam condenses on the cool bitumen and thus heats the bitumen by conduction, while the hydrocarbon solvent vapors diffuse into the bitumen from the vertical faces of the propped fractures. The bitumen softens and flows by gravity to the well bore, exposing fresh surface of bitumen for the process to progressively soften and mobilize the bitumen in a predominantly circumferential, i.e. orthogonal to the propped fracture, diffusion direction at a nearly uniform rate into the oil sand deposit. The produced product of oil and dissolved solvent is pumped to the surface where the solvent can be recycled for further injection.

Owner:GEOSIERRA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com