Patents

Literature

1306 results about "Hydrocarbon solvents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrocarbon solvent. Benzene, kerosene, xylene, or other petroleum derivative used as an industrial solvent for cleaning or dissolving water-insoluble substances such as greases and oils.

Continuous process for the production of conjugated diene polymers having narrow molecular weight distribution and products therefrom

InactiveUS6897270B2Narrow molecular weight distributionImprove responseHydrocarbon solventsContinuous reactor

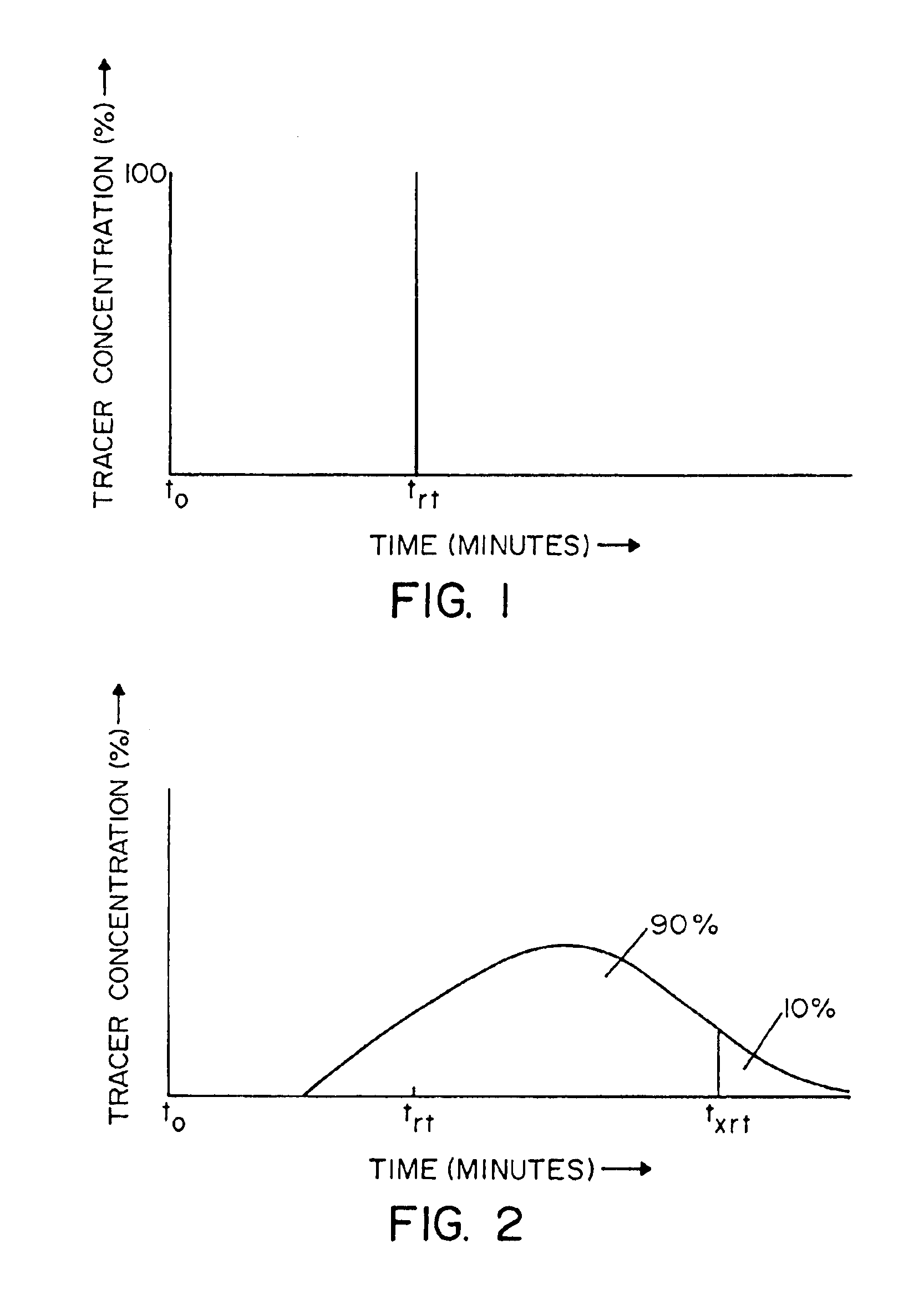

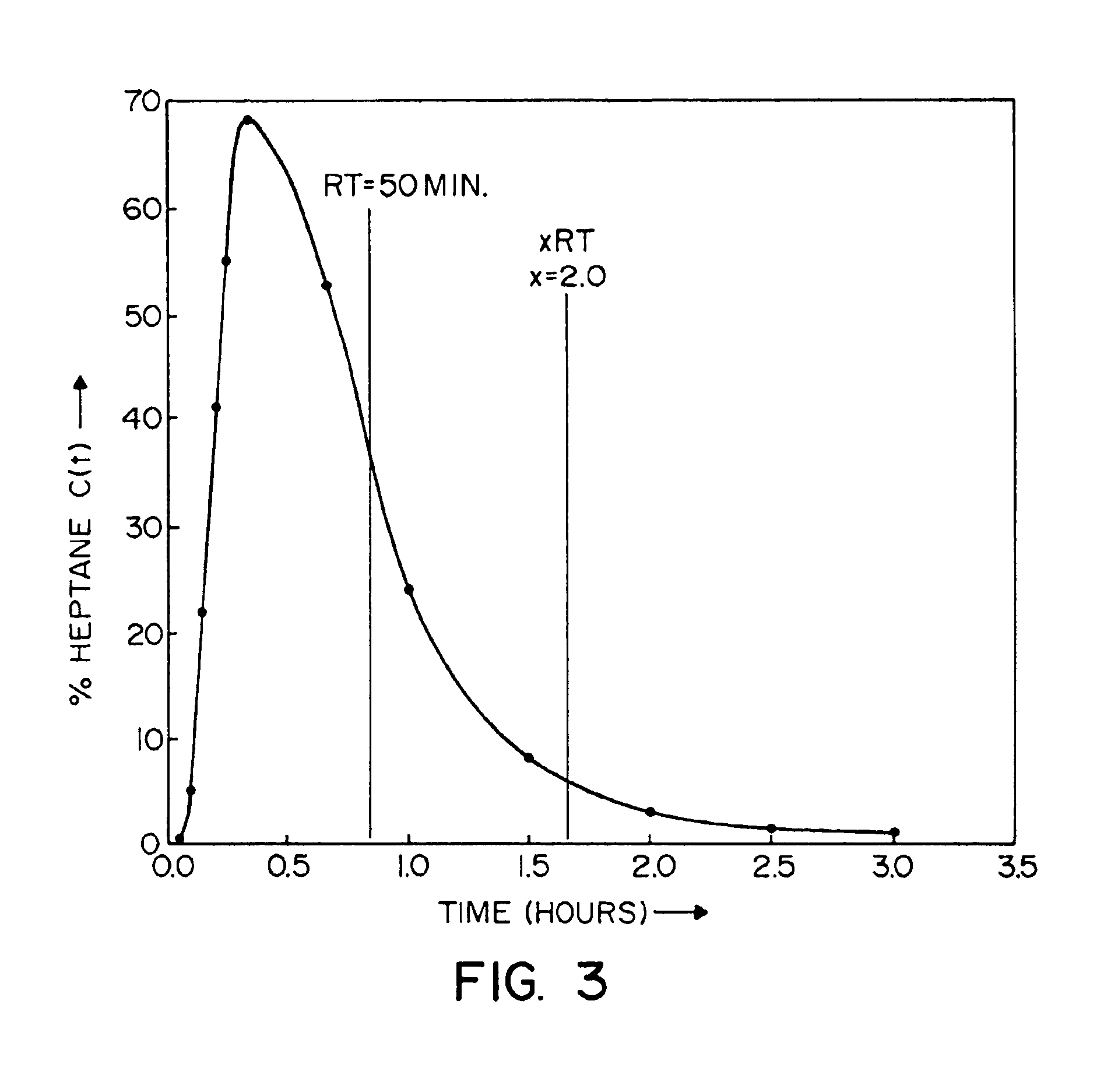

A continuous process for producing conjugated diene polymers comprising the steps of contacting, within an hydrocarbon solvent and within a continuous reactor, conjugated diene monomer and a catalyst composition prepared by combining: (a) a lanthanide compound, (b) an alkylating agent, and (c) a halogen-containing compound, and maintaining a non-ideal flow pattern within the continuous reactor so that 10% of the reagents entering the reactor at a reference time t0 are still present within the continuous reactor at a time t0+xtrt, where trt is the residence time corresponding to ideal flow within the continuous reactor and x is a numeral greater than 1.5.

Owner:BRIDGESTONE CORP

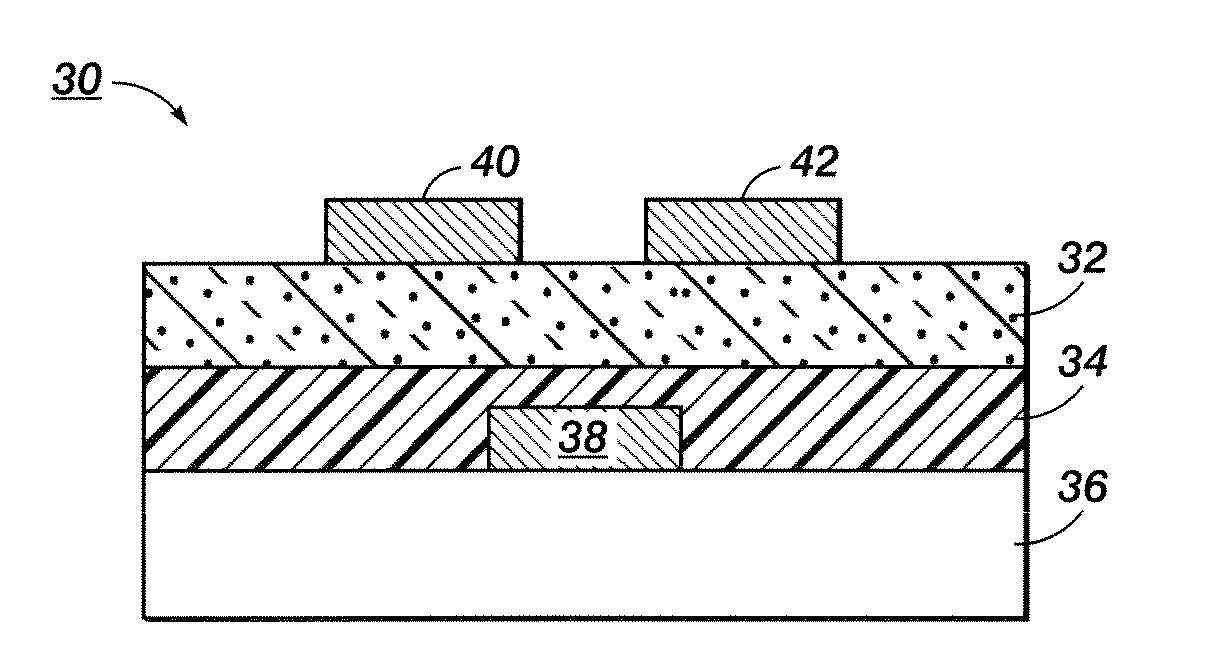

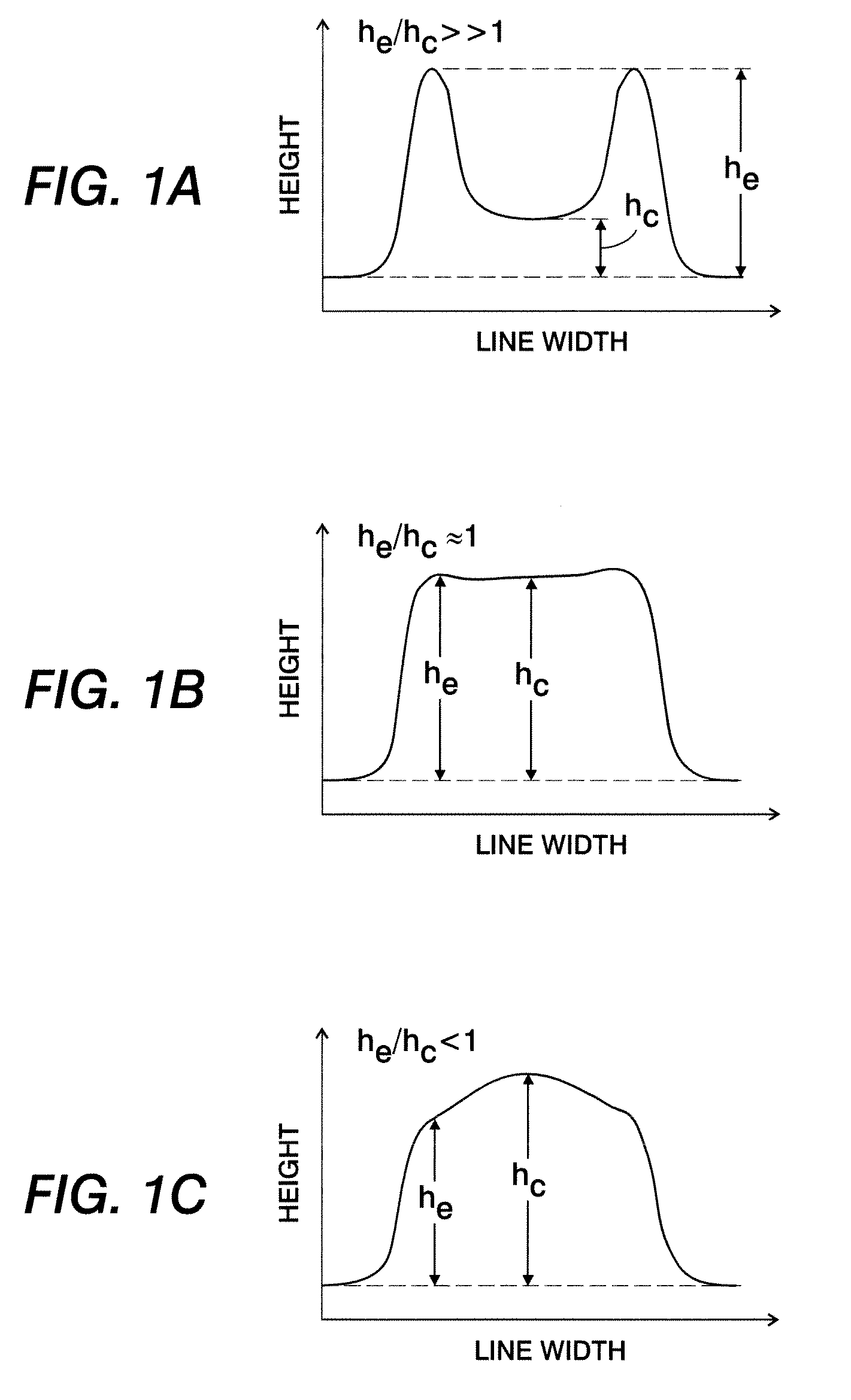

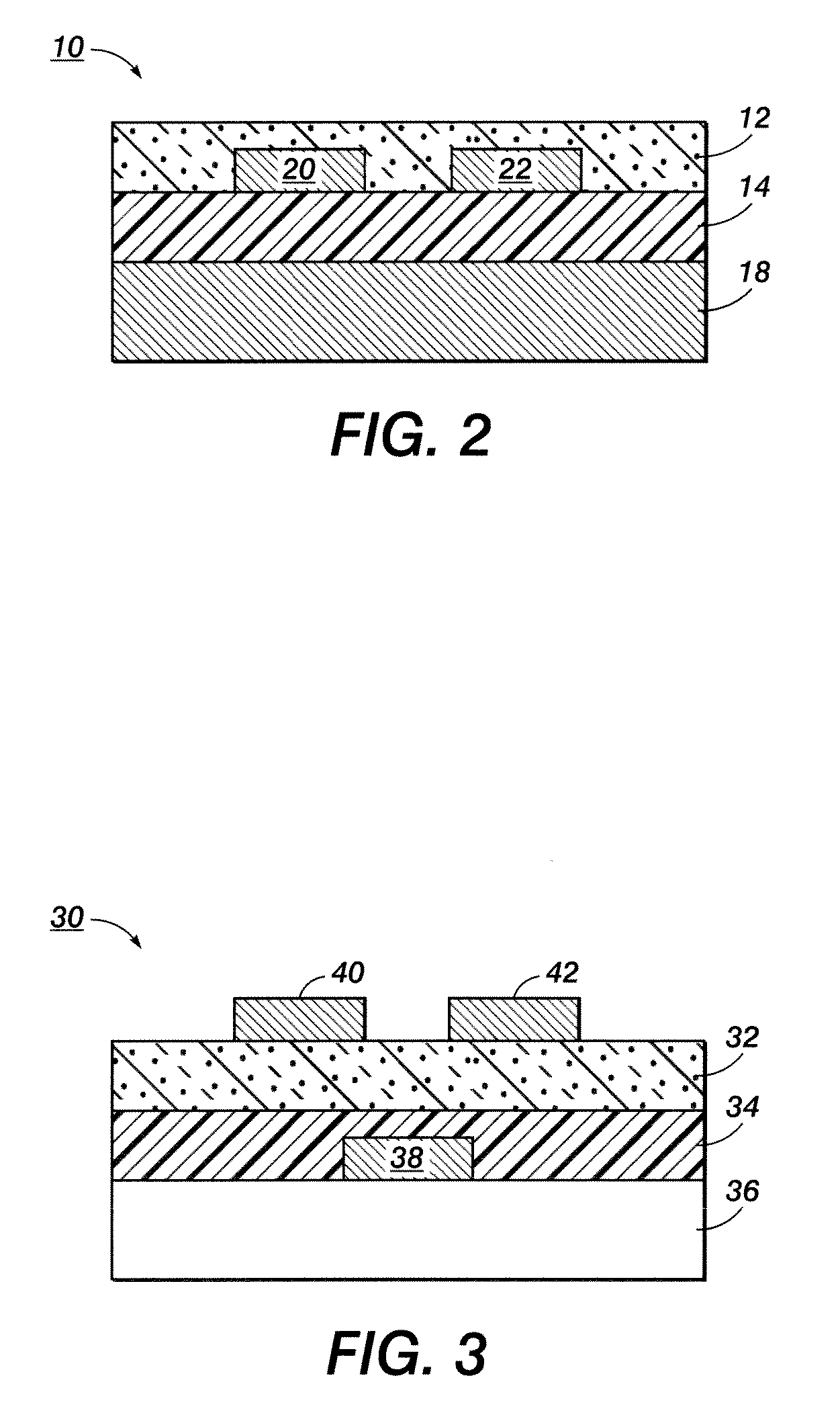

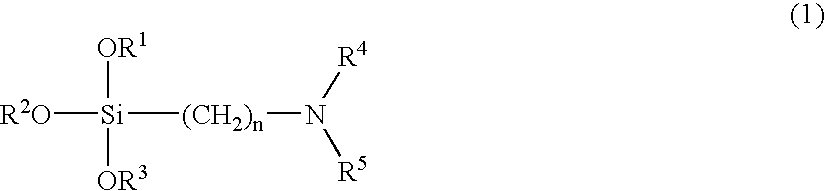

Silver nanoparticle ink composition

An ink composition comprises silver nanoparticles, hydrocarbon solvent, and an alcohol co-solvent. The ink composition is suitable for printing conductive lines that are uniform, smooth, and narrow on various substrate surfaces.

Owner:XEROX CORP

Process for producing modified diene polymer rubber

There is provided a process for producing a modified diene polymer rubber comprising the steps of: (1) polymerizing a conjugated diene monomer or a combination thereof with an aromatic vinyl monomer in a hydrocarbon solvent, in the presence of an alkali metal catalyst, to form an alkali metal end-carrying active polymer, and (2) reacting the alkali metal end-carrying active polymer with a silane compound defined by a specific formula.

Owner:SUMITOMO CHEM CO LTD

Oil-based ink-jet recording ink

InactiveUS6730153B2Maintain good propertiesSatisfactory pigment dispersibilityDuplicating/marking methodsInksParaffin waxVegetable oil

An ink-jet recording oil-based ink which has satisfactory pigment dispersibility both at the beginning of storage and even during long-term storage and provides excellent spouting stability without being influenced by temperature changes in printing circumstances. The ink comprises a pigment; a dispersing agent comprising a reaction product of a polyamine compound and a self condensation product of 12-hydroxystearic acid; a saturated hydrocarbon solvent comprising a liquid paraffin as a main component; and a vegetable oil, the ink having a surface tension of 26 to 30 dyne / cm at 25° C. and a contact angle on a polytetrafluoroethylene plate of 40° to 50° at 25° C., and satisfying the following relationship:wherein WHC is the weight of the saturated hydrocarbon solvent and WVC is the weight of the vegetable oil.

Owner:SAKATA INX

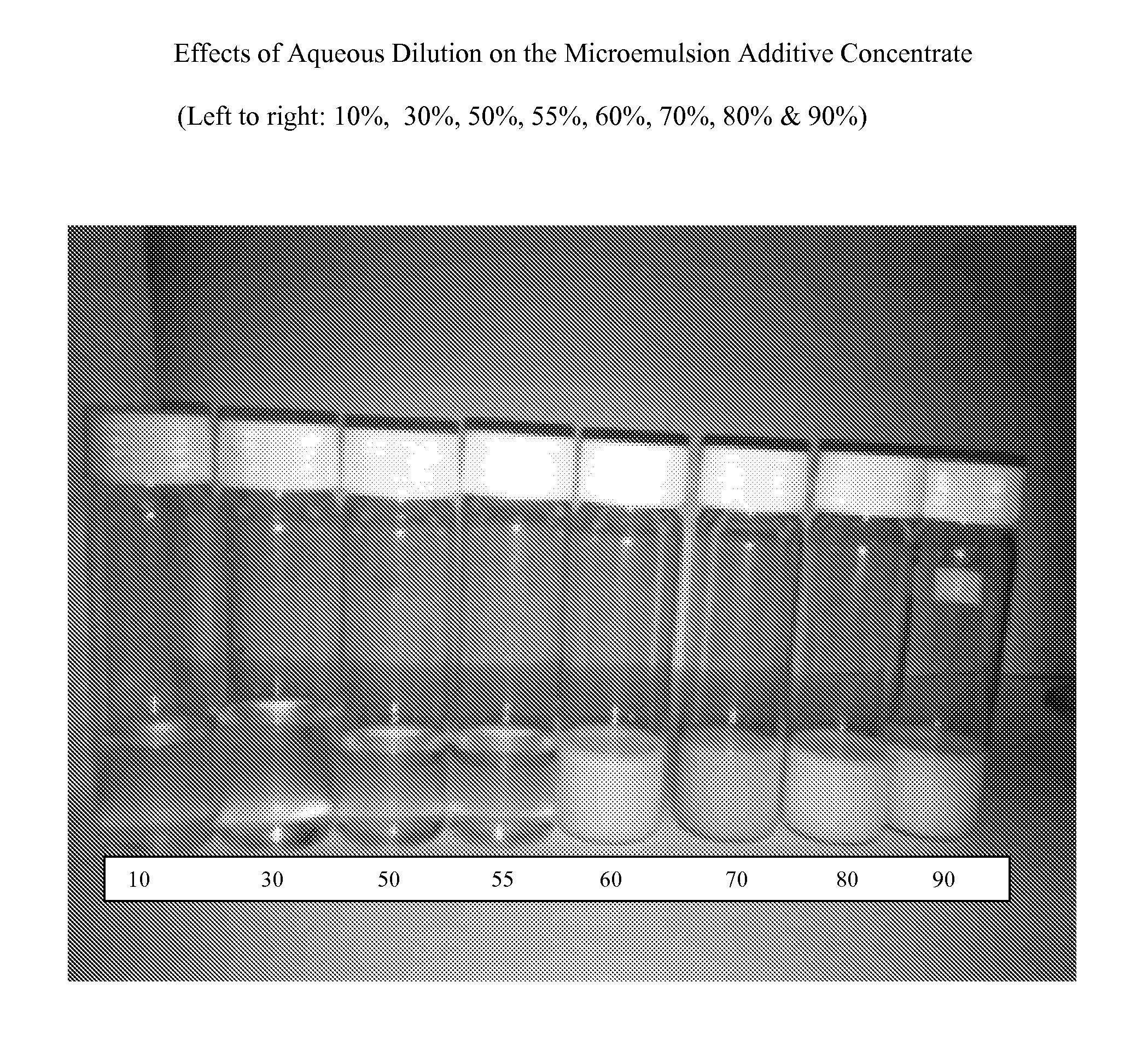

Composition and method of converting a fluid from oil external to water external for cleaning a wellbore

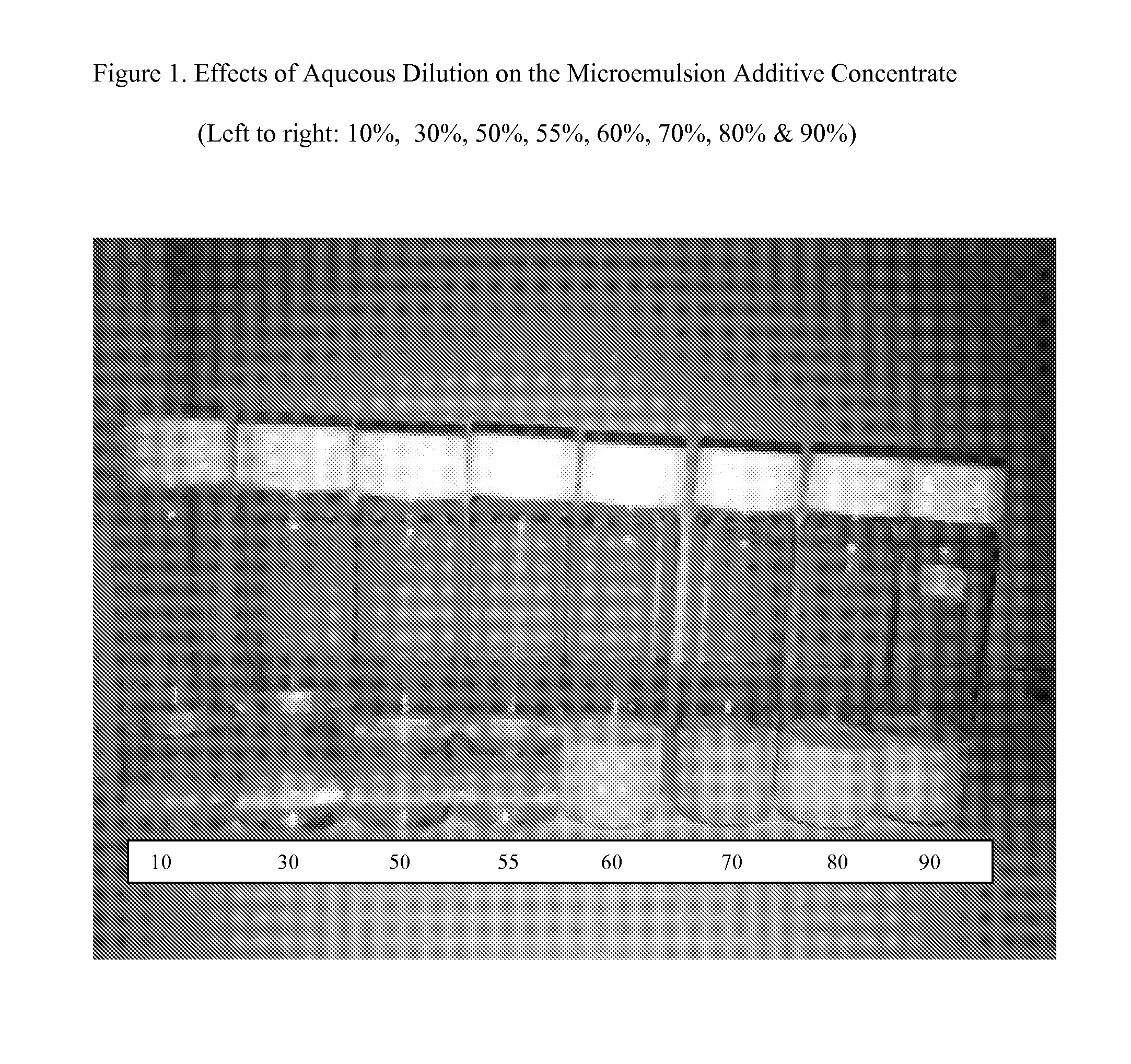

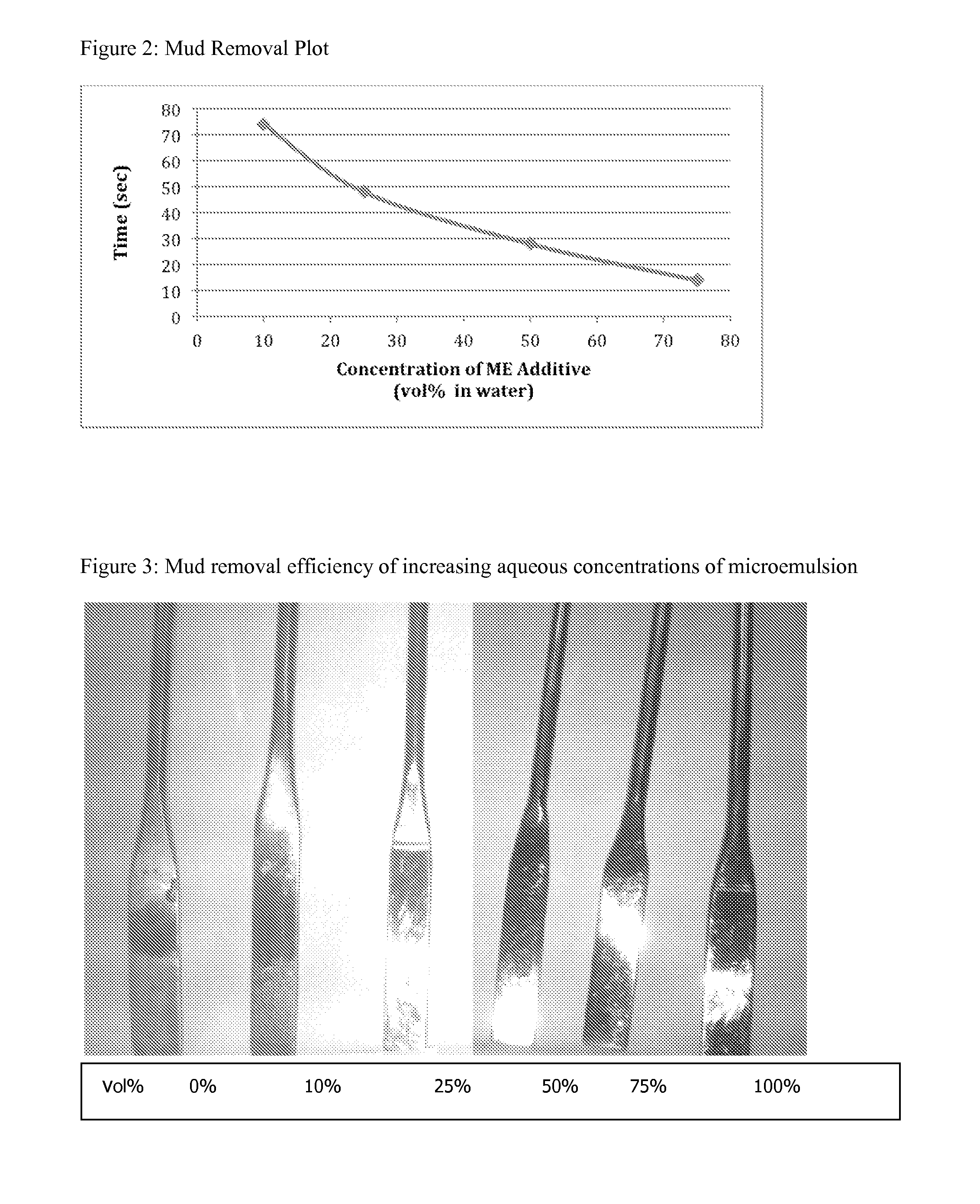

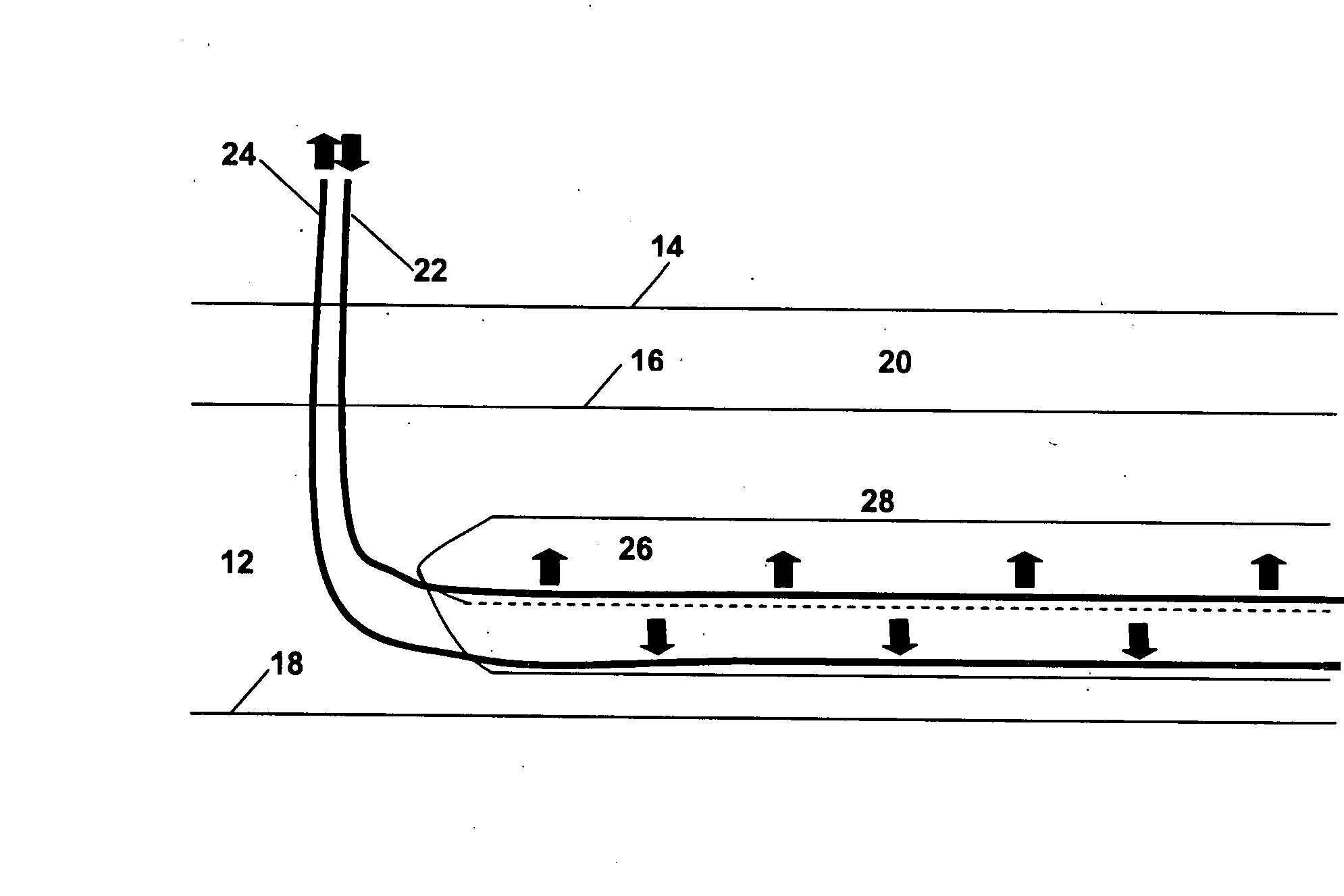

InactiveUS20130244913A1Effective mud removalGood dispersionFlushingDrilling compositionWater basedHydrocarbon solvents

An environmentally acceptable water-in-oil microemulsion composition includes at least one emulsifying surfactant, at least one biodegradable hydrocarbon solvent, at least one co-solvent, at least one hydrocarbon co-surfactant, and water. The microemulsion composition may be used in a method for rendering fluids from oil external to water external. The microemulsion composition may be combined with water or a water based fluid to produce a spacer fluid utilized in removing oil and oil-residues from a surface, particularly that of wellbores in the drilling of oil and gas wells.

Owner:BENCHMARK PERFORMANCE GROUP

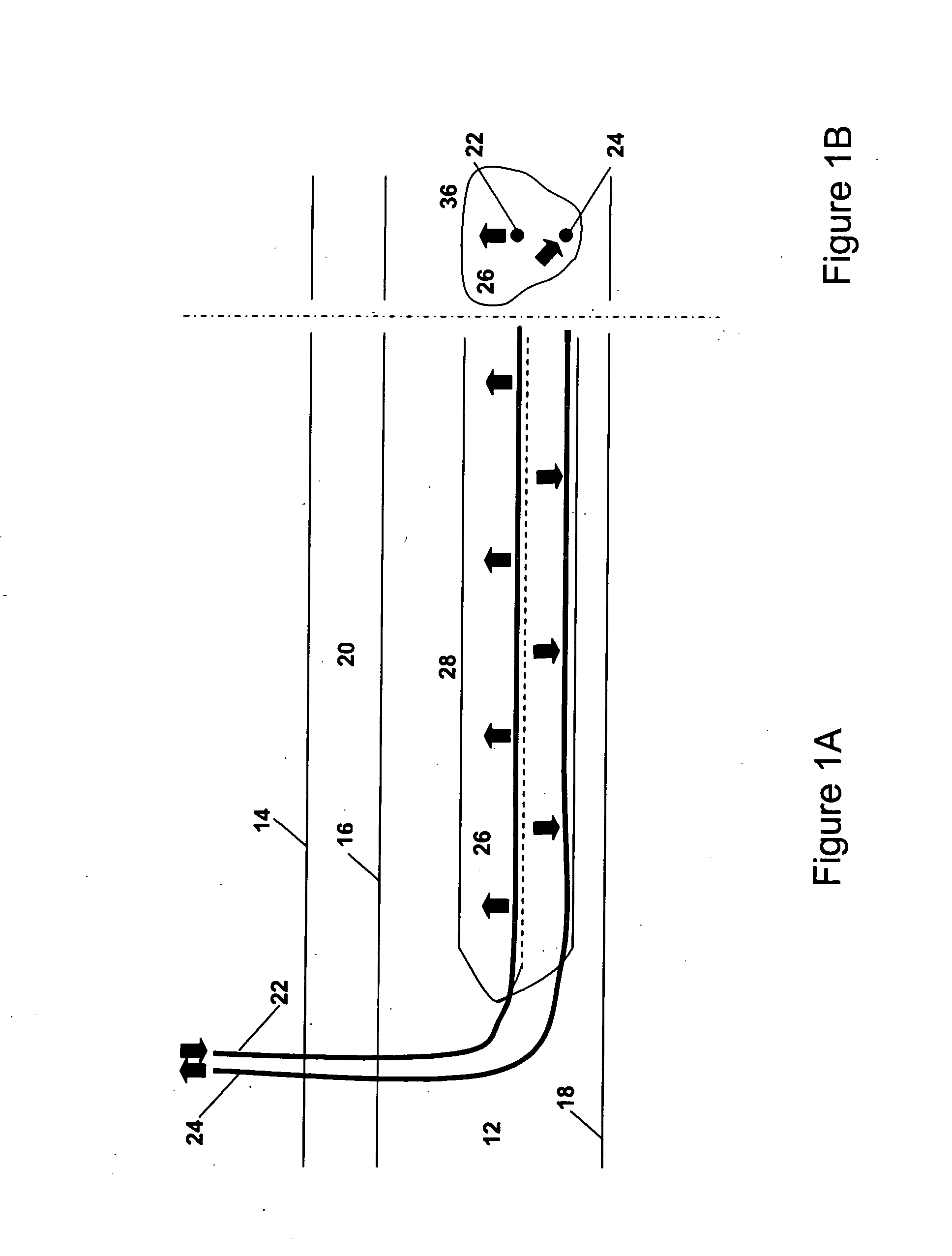

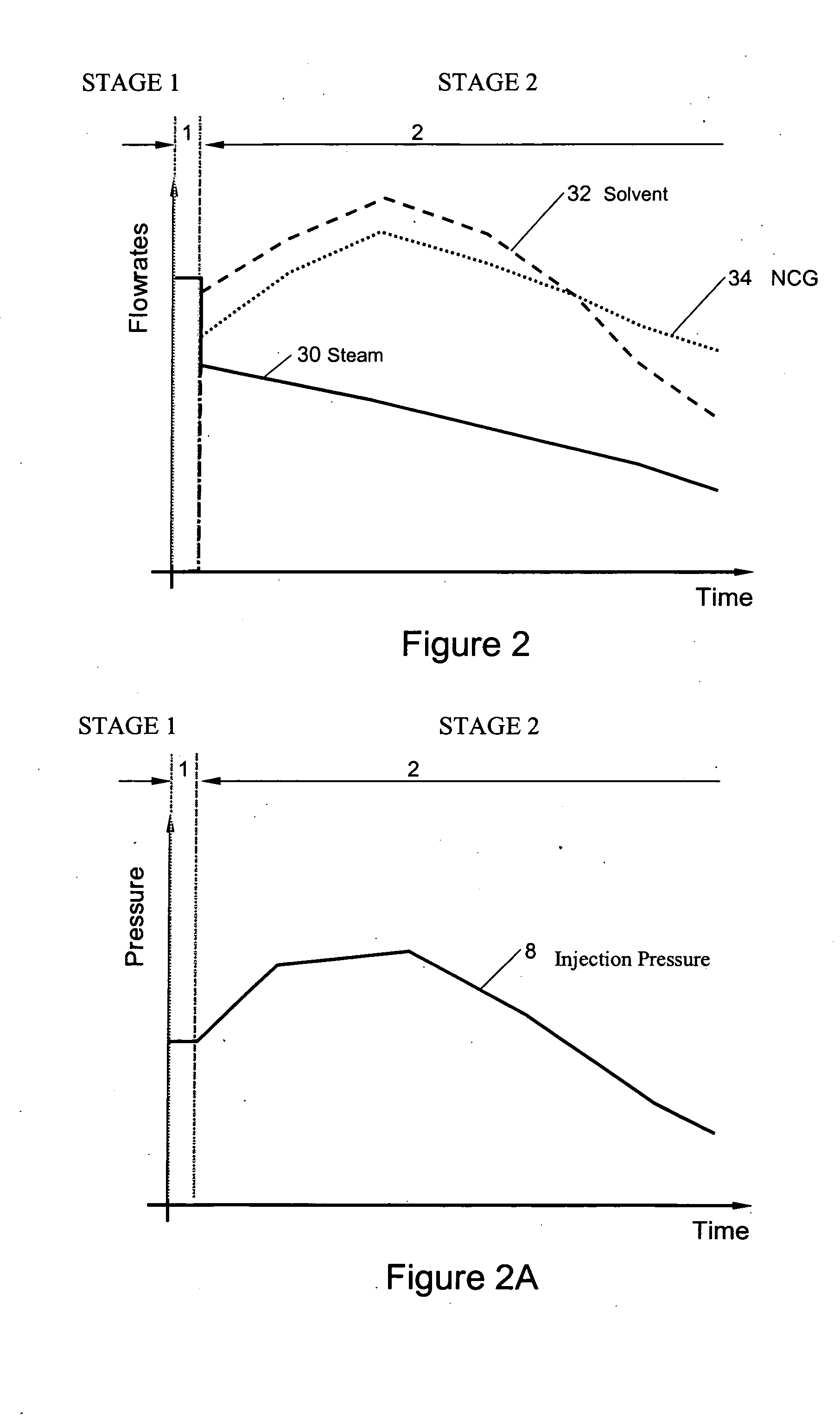

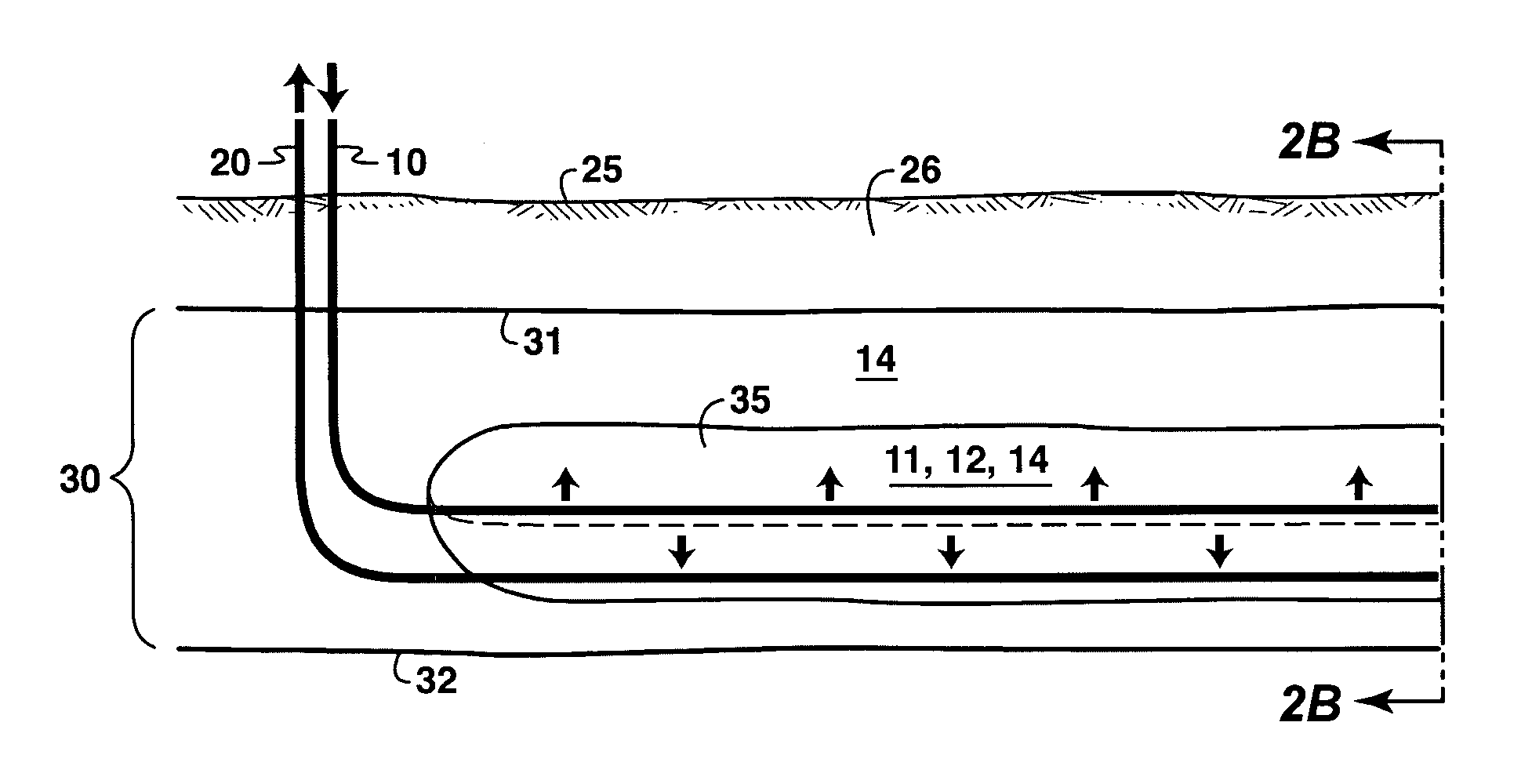

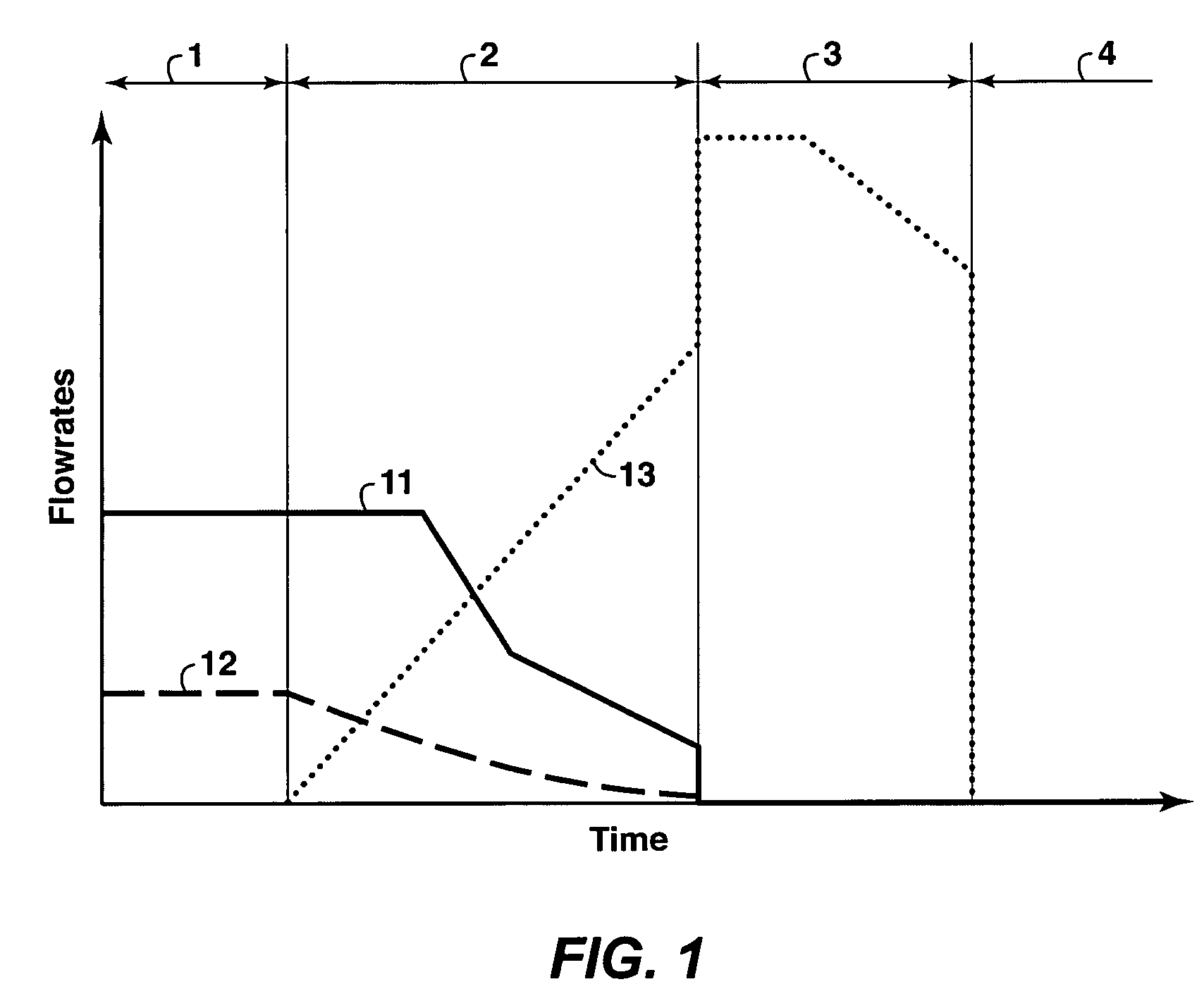

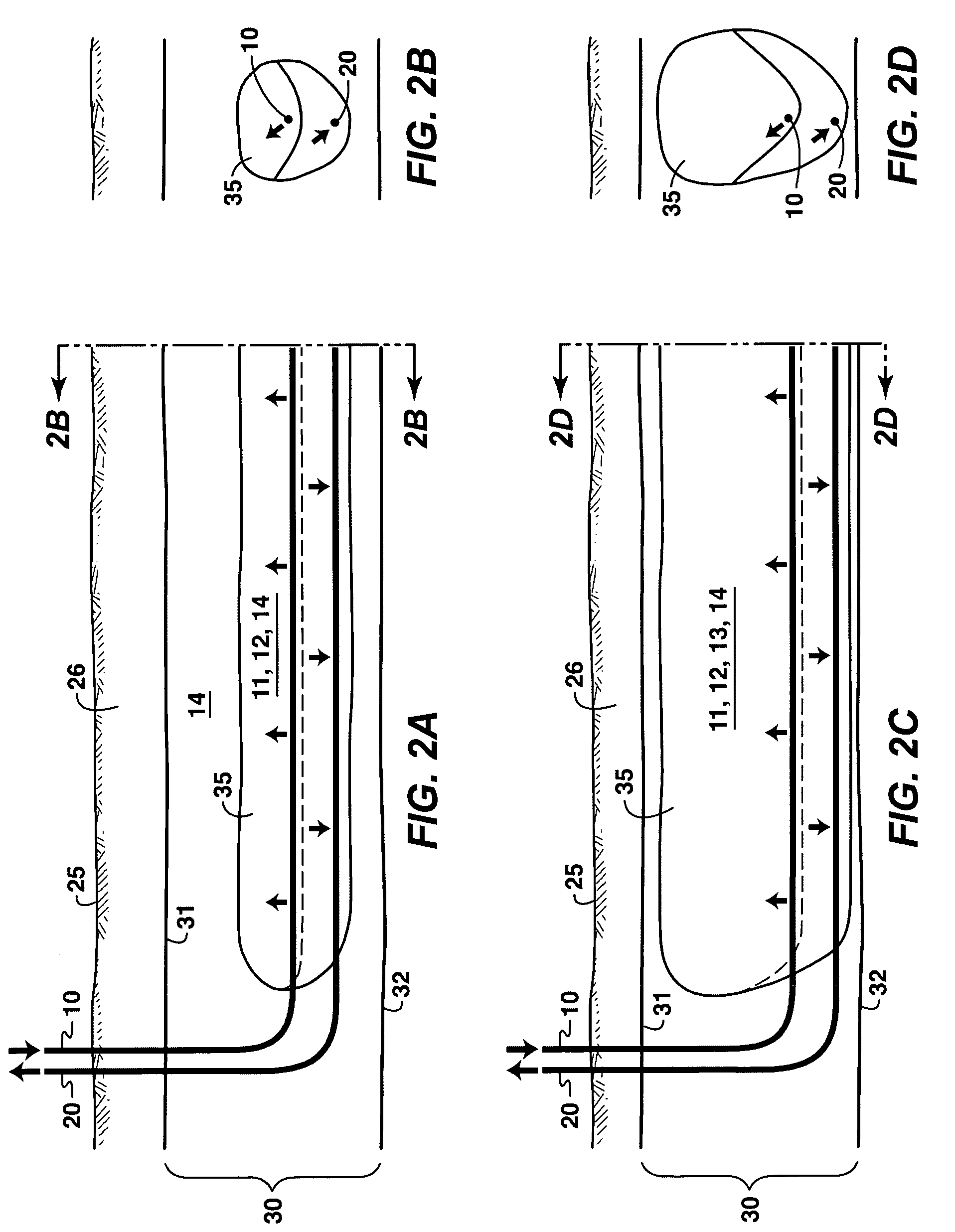

In situ process to recover heavy oil and bitumen

InactiveUS20080017372A1Maximize actionLow viscositySurveyFluid removalHydrocarbon solventsFluid viscosity

An in situ reservoir recovery process consisting of a horizontal injection well and a horizontal production well to extract bitumen or heavy oil from a reservoir. The process consists of a first phase operated at high-pressure in which steam, hydrocarbon solvent and non-condensable gases are injected into the reservoir and a second phase in which the injected fluids are transitioned to a high content of solvent and non-condensable gas and a reduced amount of steam to maintain a warm zone in the neighbourhood of the injection and production wells. The steam injection is sufficient to promote vapor transport of the solvent into the vapor depletion chamber and maintain the process at elevated temperatures in order to maintain low fluid viscosities in the production wellbore and to achieve preferred phase behaviour of the solvent hydrocarbon and the heavy oil or bitumen. The operating pressure of the process is controlled to prevent losses of the solvent hydrocarbon to the formation and to aid in solvent production to the production well in order for future re-cycling.

Owner:PARAMOUNT RESOURCES LTD

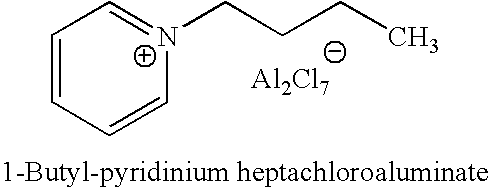

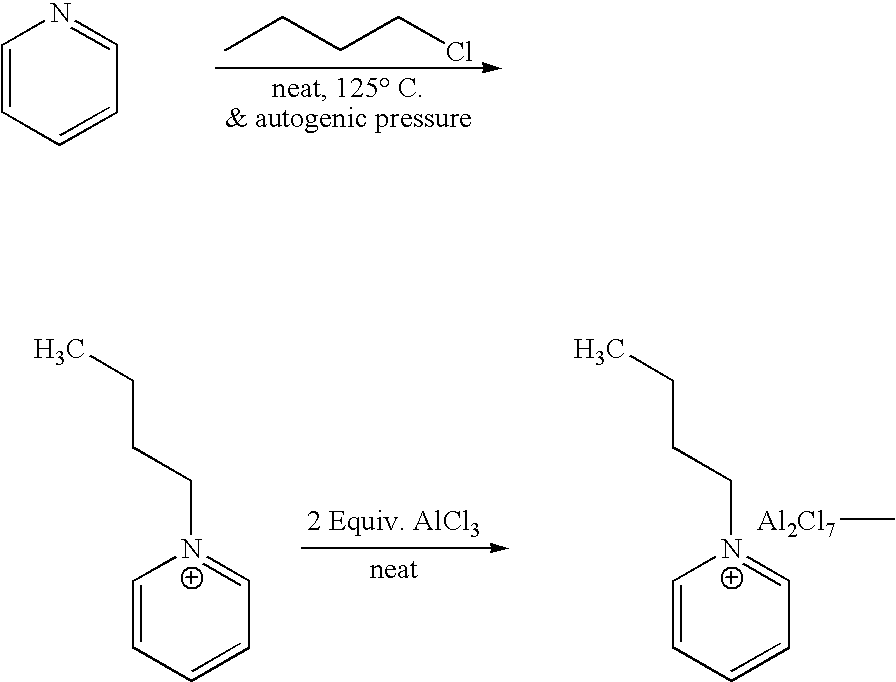

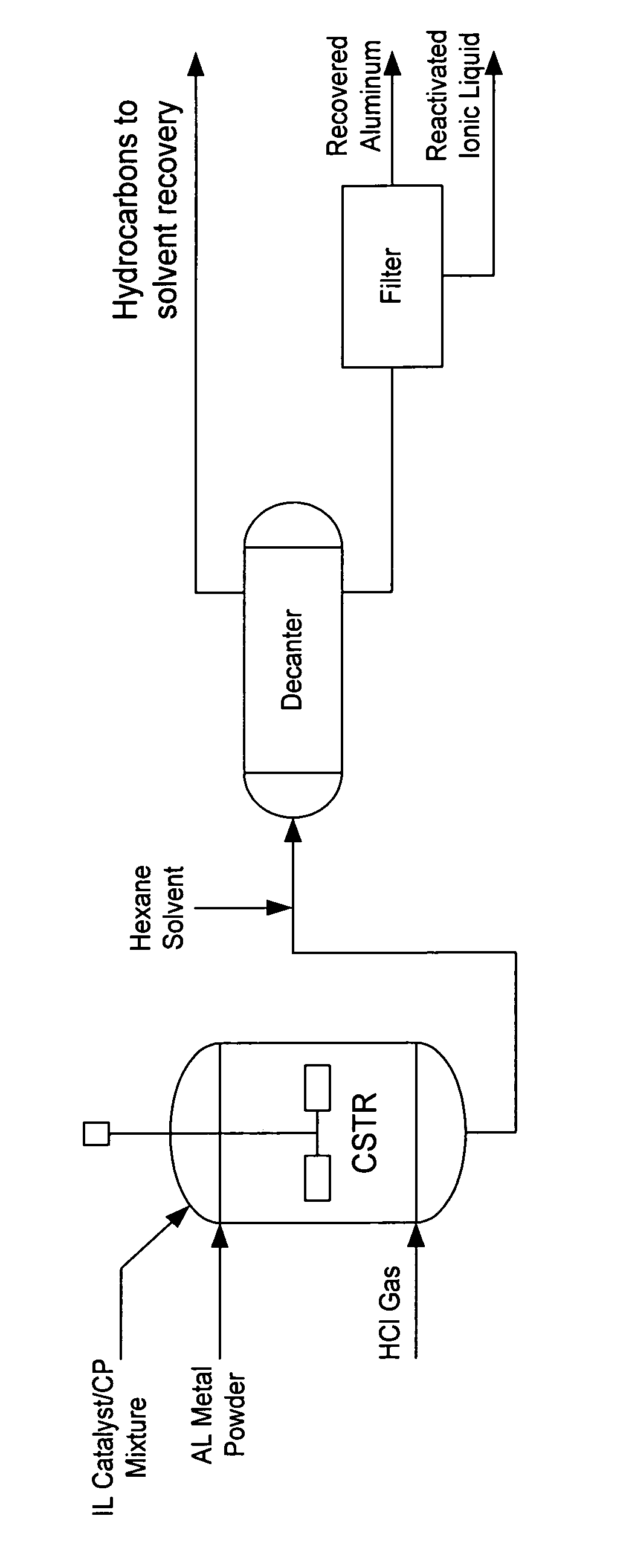

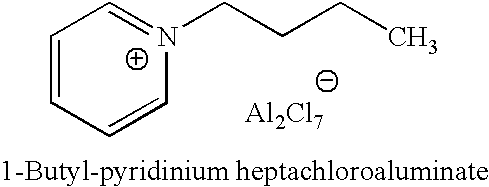

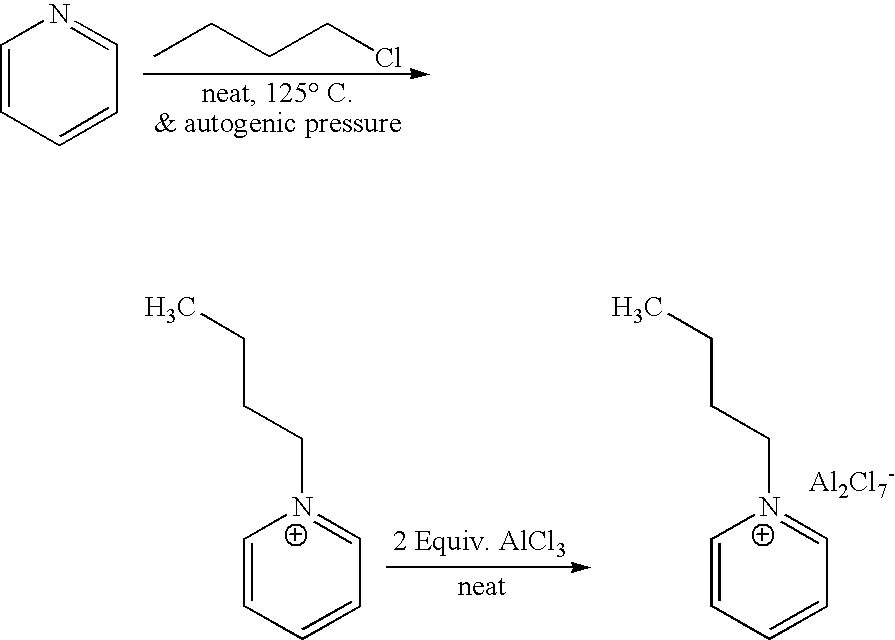

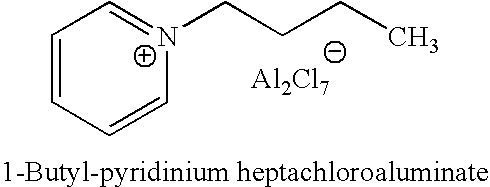

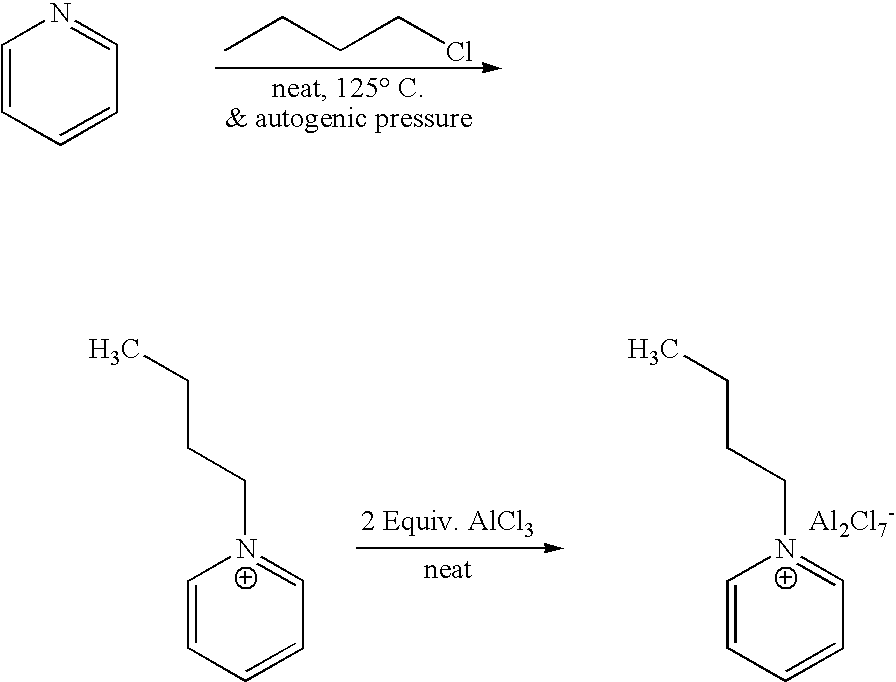

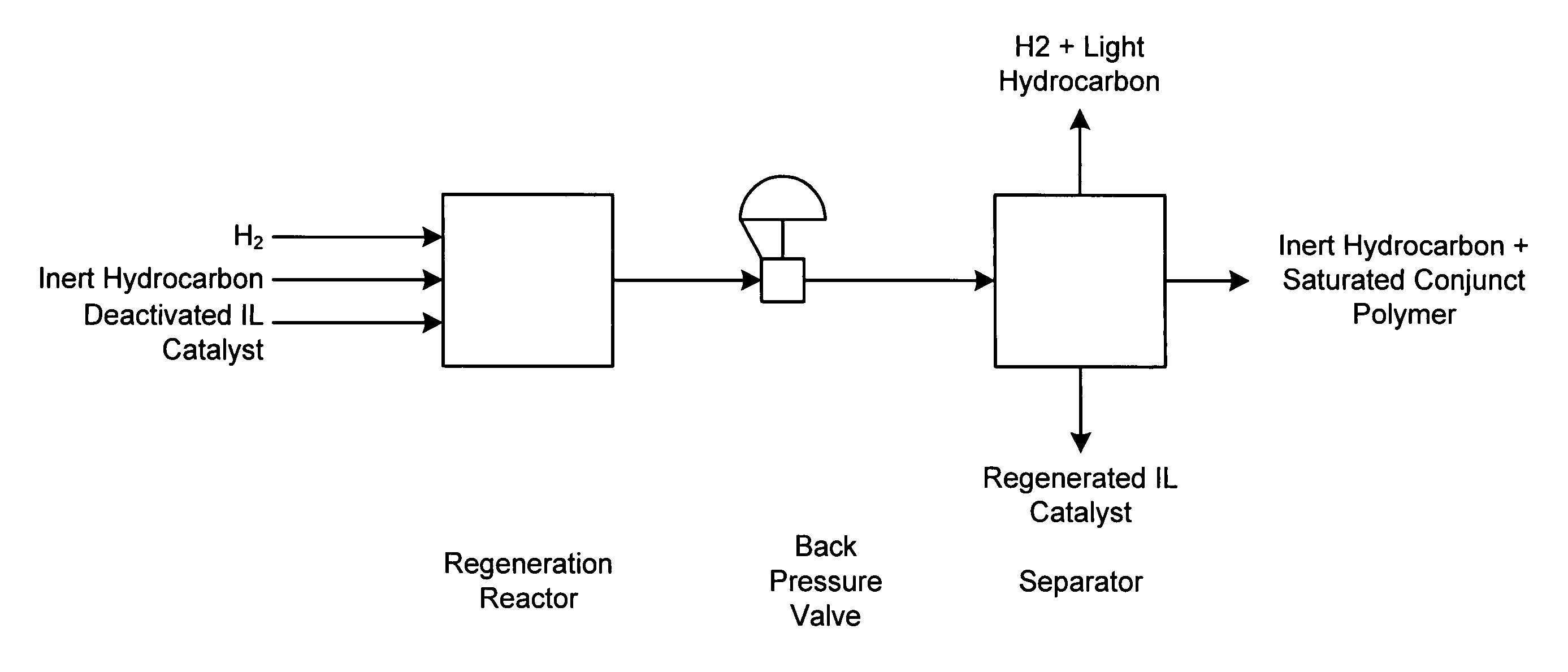

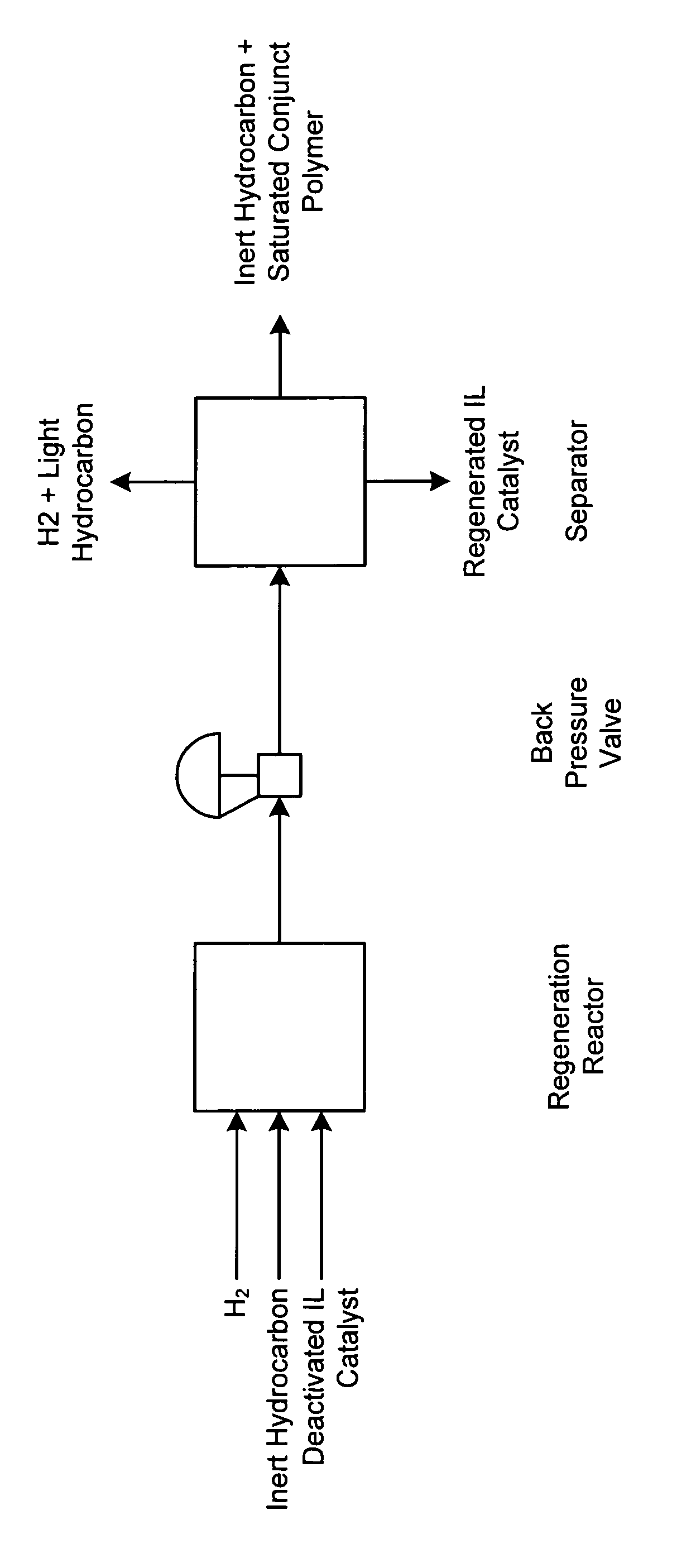

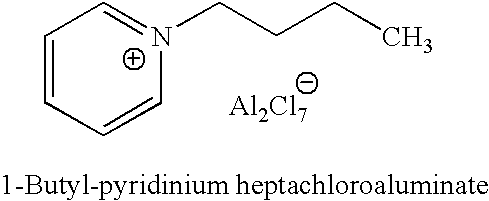

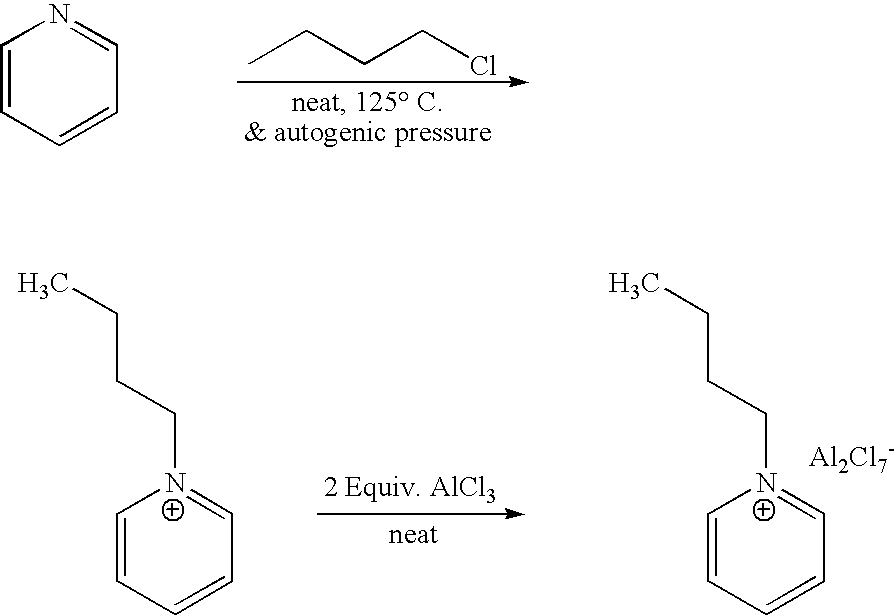

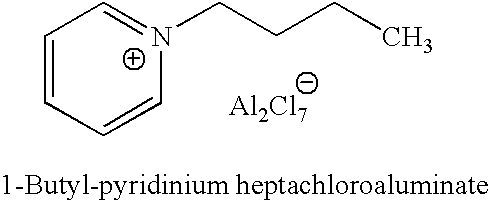

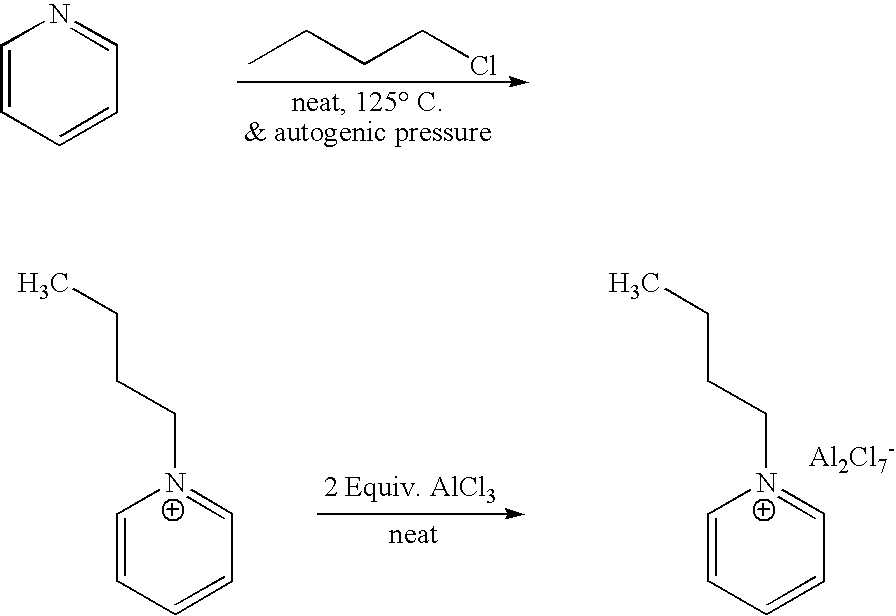

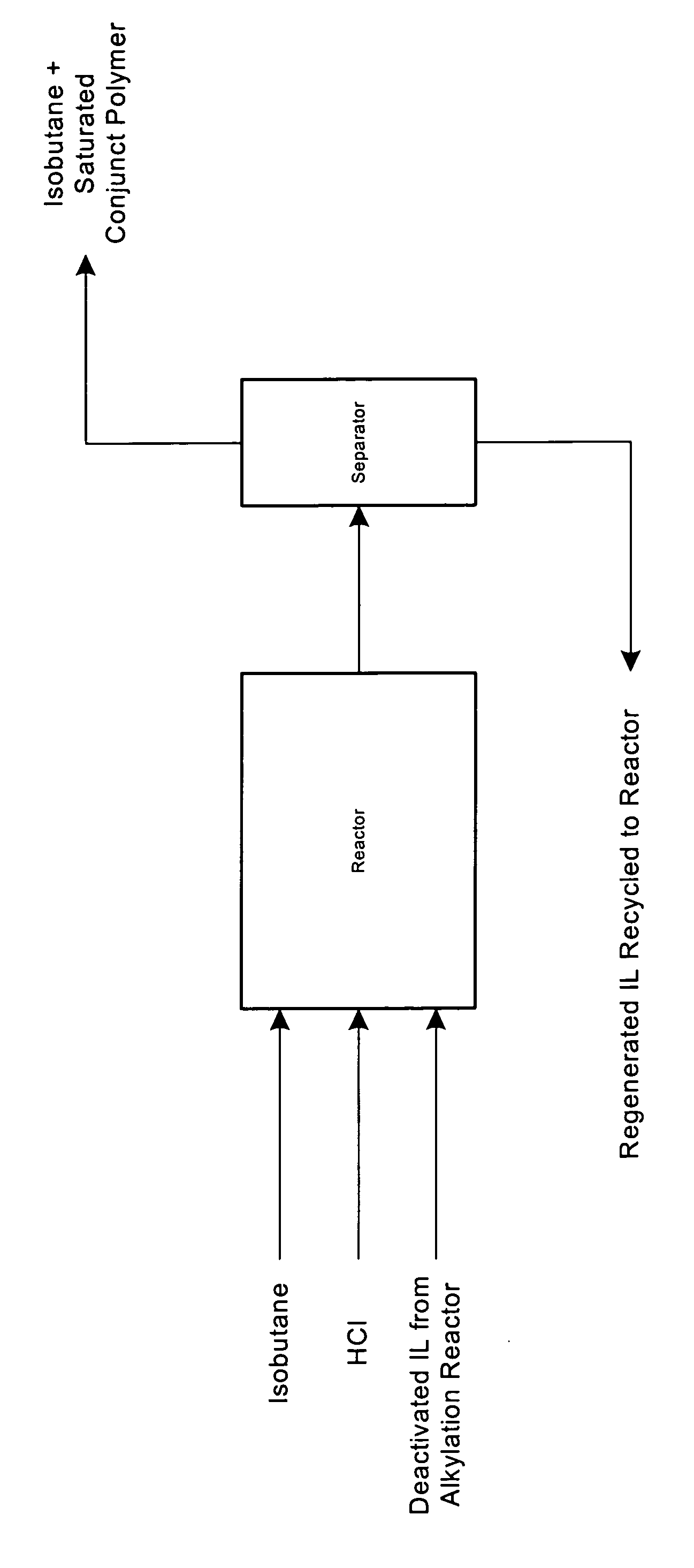

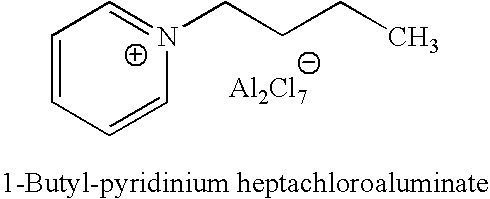

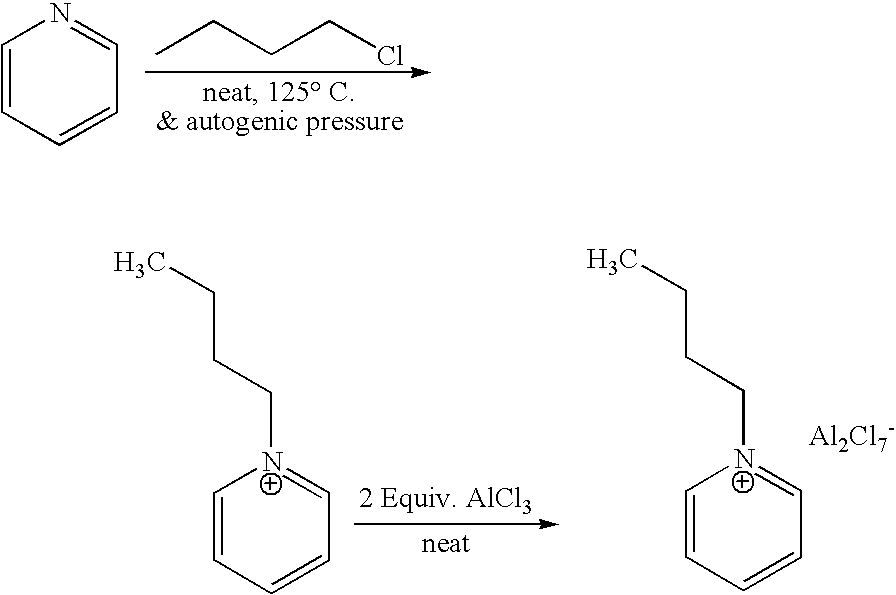

Regeneration of ionic liquid catalyst using a metal in the absence of added hydrogen

ActiveUS20070249485A1High activityMolecular sieve catalystsOther chemical processesHydrocarbon solventsHydrogen

A process for regenerating a used acidic ionic liquid catalyst comprising contacting the used ionic liquid catalyst with at least one metal in a regeneration zone in the absence of added hydrogen under regeneration conditions for a time sufficient to increase the activity of the ionic liquid catalyst is described. In one embodiment, regeneration is conducted in the presence of a hydrocarbon solvent.

Owner:CHEVROU USA INC

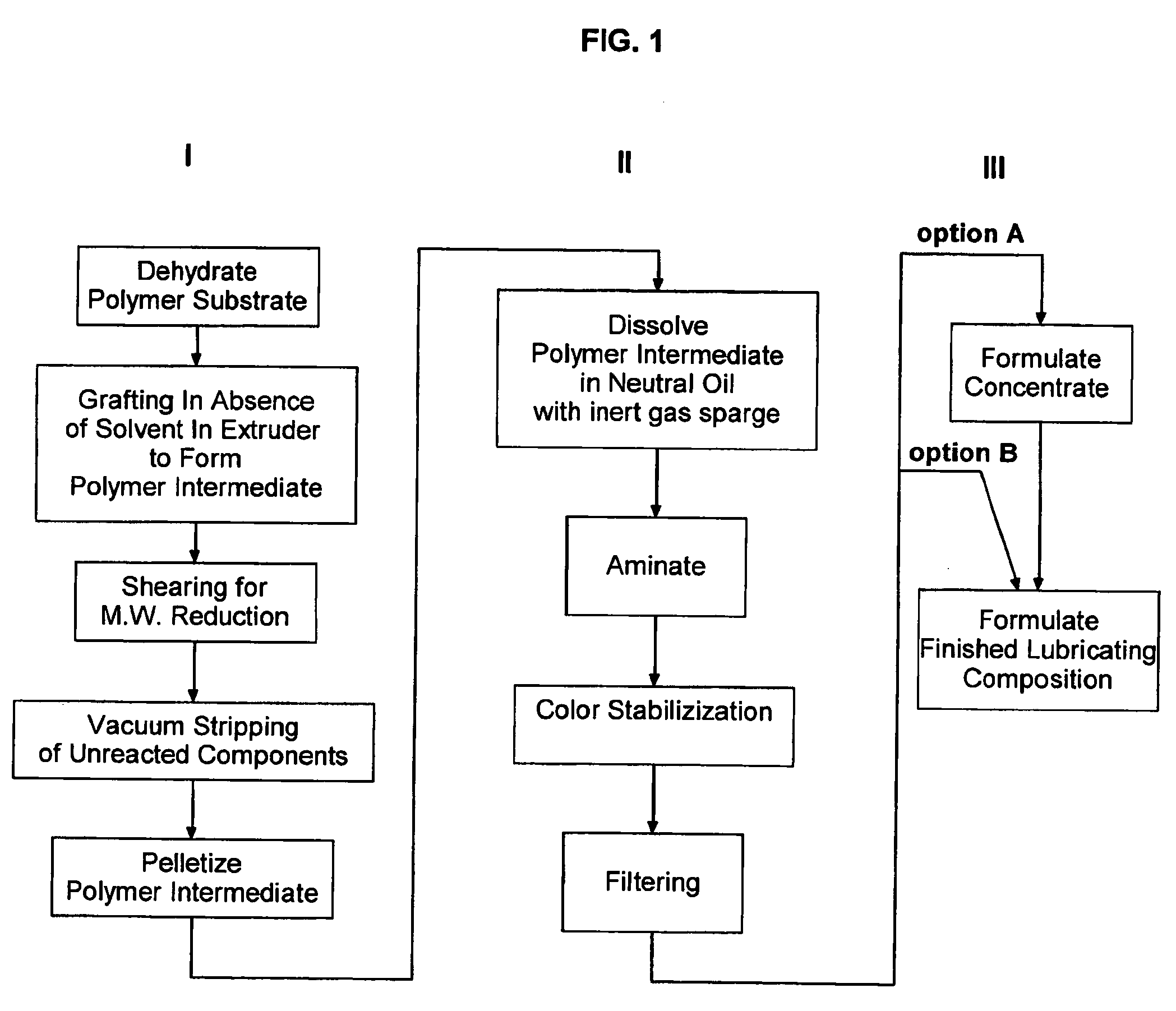

Grafted multi-functional olefin copolymer VI modifiers and uses thereof

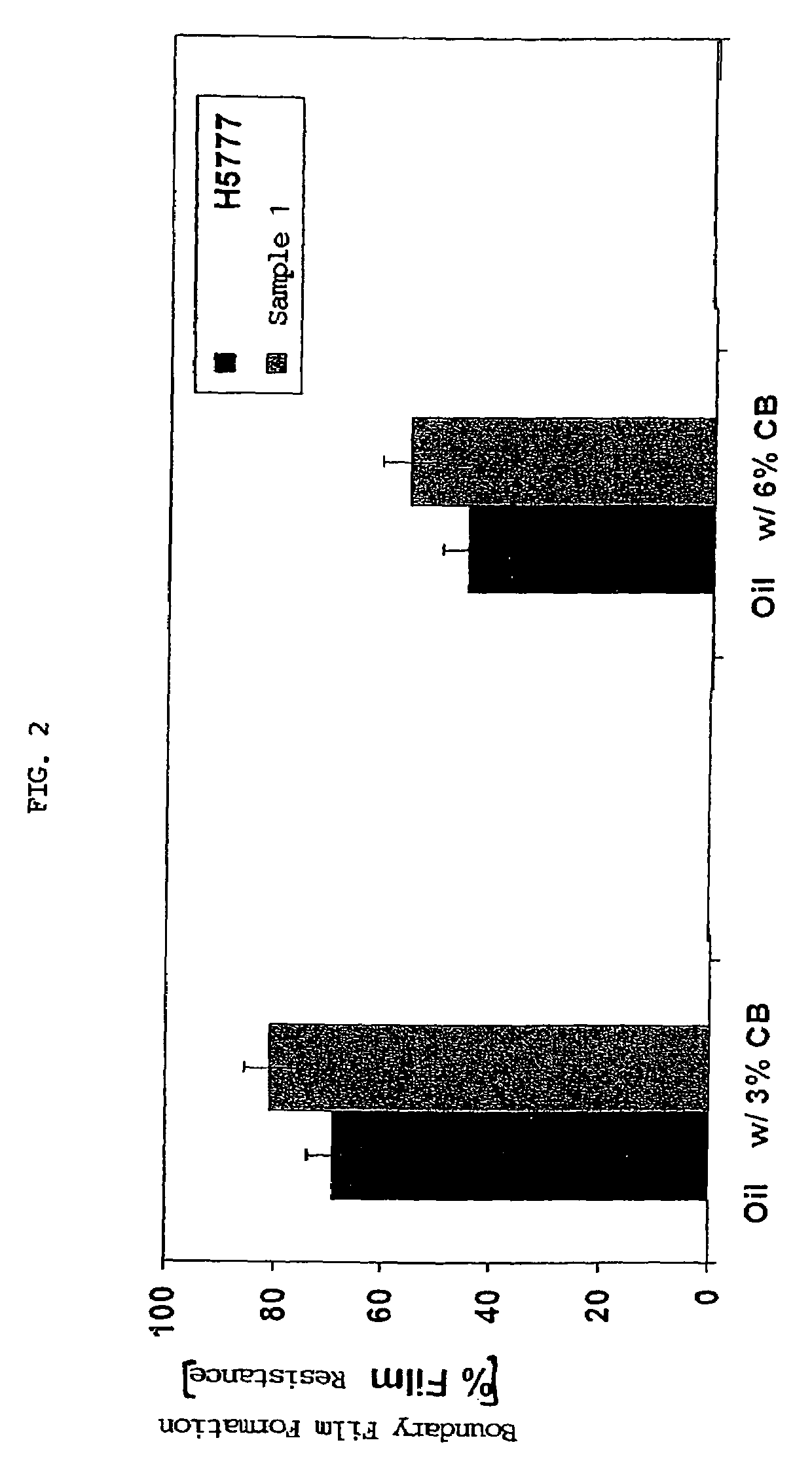

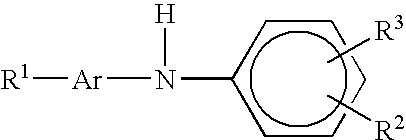

ActiveUS7253231B2High activityImprove functionalityLiquid carbonaceous fuelsAdditivesHydrocarbon solventsCanis lupus familiaris

Owner:ARLANXEO NETHERLANDS +1

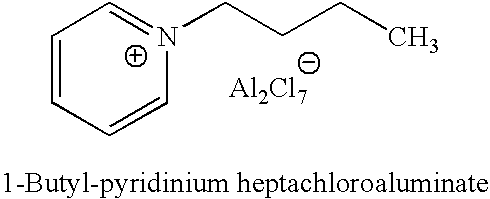

Regeneration of ionic liquid catalyst by hydrogenation using metal and acid

A process for regenerating a used acidic ionic liquid catalyst which has been deactivated by conjunct polymers comprising combining the used catalyst, a metal and a Broensted acid which acts a source of hydrogen in a reaction zone under hydrogenation conditions for a time sufficient to hydrogenate at least a portion of the conjunct polymer is disclosed. An embodiment of a process for regenerating a used acidic ionic liquid catalyst which has been deactivated by conjunct polymers comprising the steps of combining the used ionic liquid catalyst, a metal and HCl in a reaction zone under hydrogenation conditions for a time sufficient to hydrogenate at least a portion of the conjunct polymer; removing reaction product from the reaction zone; mixing the removed reaction product with a hydrocarbon solvent in which the hydrogenated conjunct polymers are soluble; allowing the mixture to separate into two phases, a lighter phase which contains the hydrogenated conjunct polymers and a heavier phase which contains a regenerated ionic liquid catalyst; and recovering at least a portion of the heavier phase is also disclosed.

Owner:CHEVROU USA INC

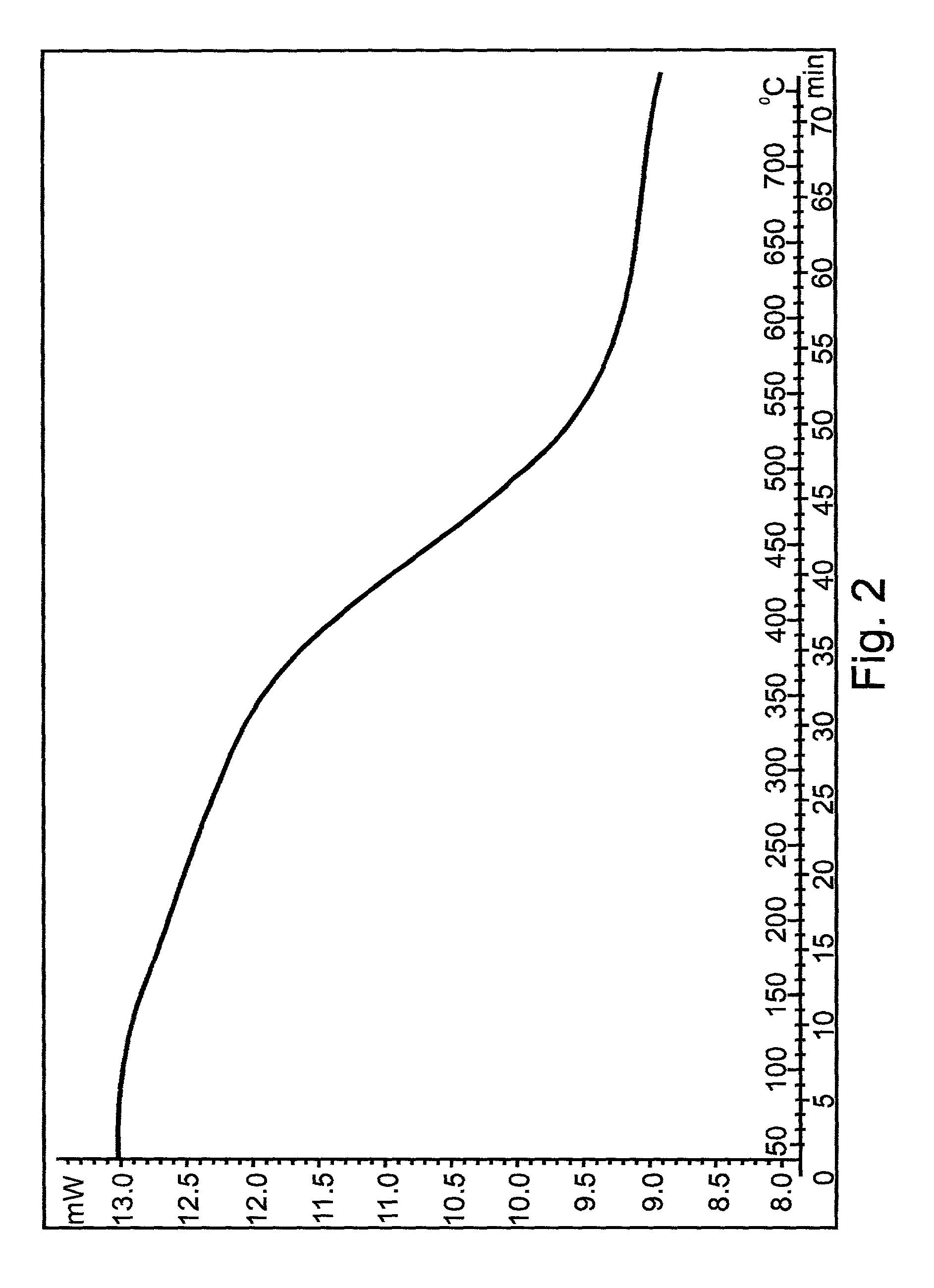

Nanoscale metal particles and method of preparing same

A process of preparing individually-isolated, carbon-coated nanoscale metal particles is disclosed. The process is effected by sonicating a mixture of a metal carbonyl and a hydrocarbon solvent that is selected so as to polymerize during sonication. Air-stable and aqueous solution-stable, carbon-coated nanoscale metal particles and a process of preparing same are also disclosed.

Owner:BAR ILAN UNIV

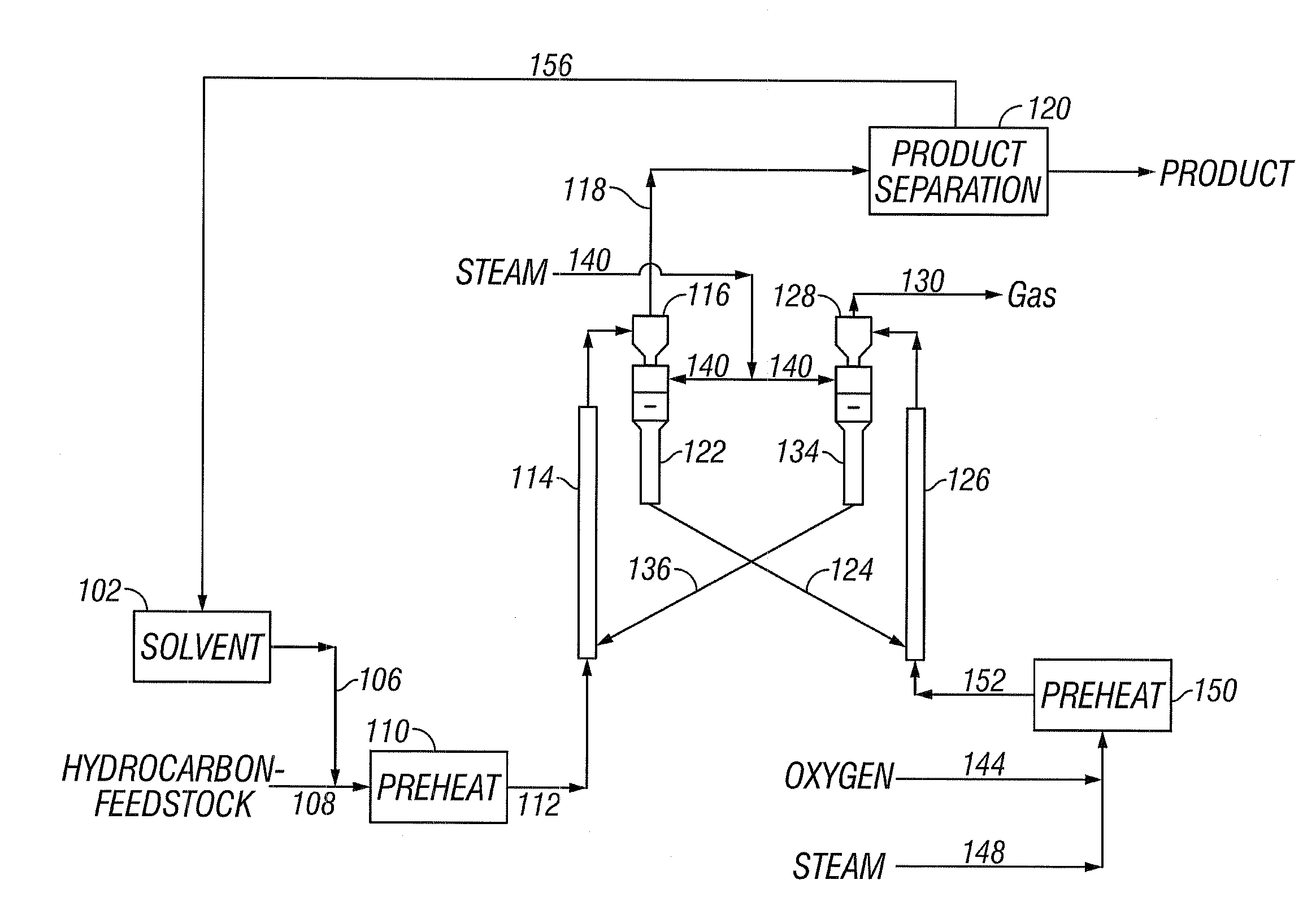

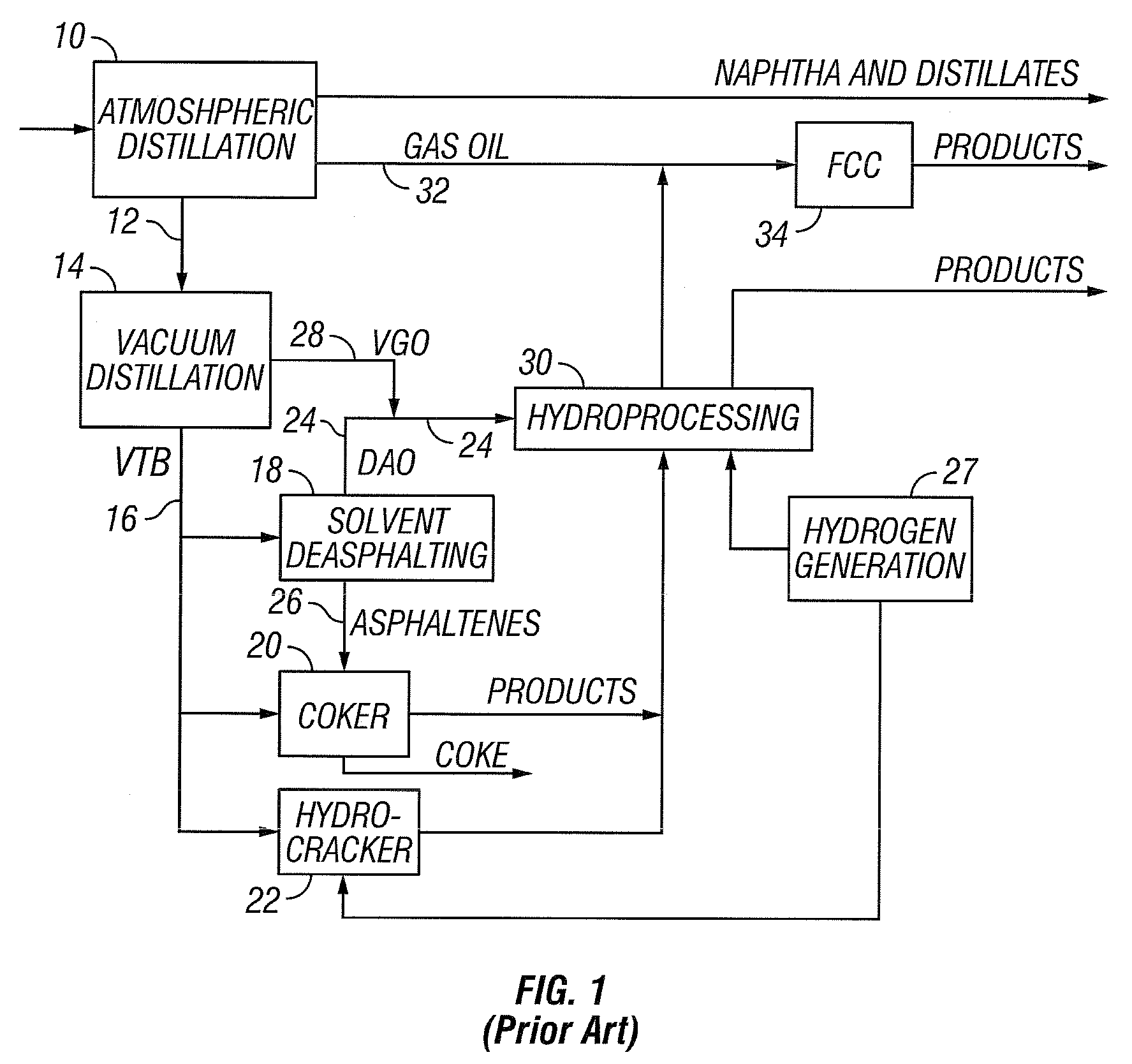

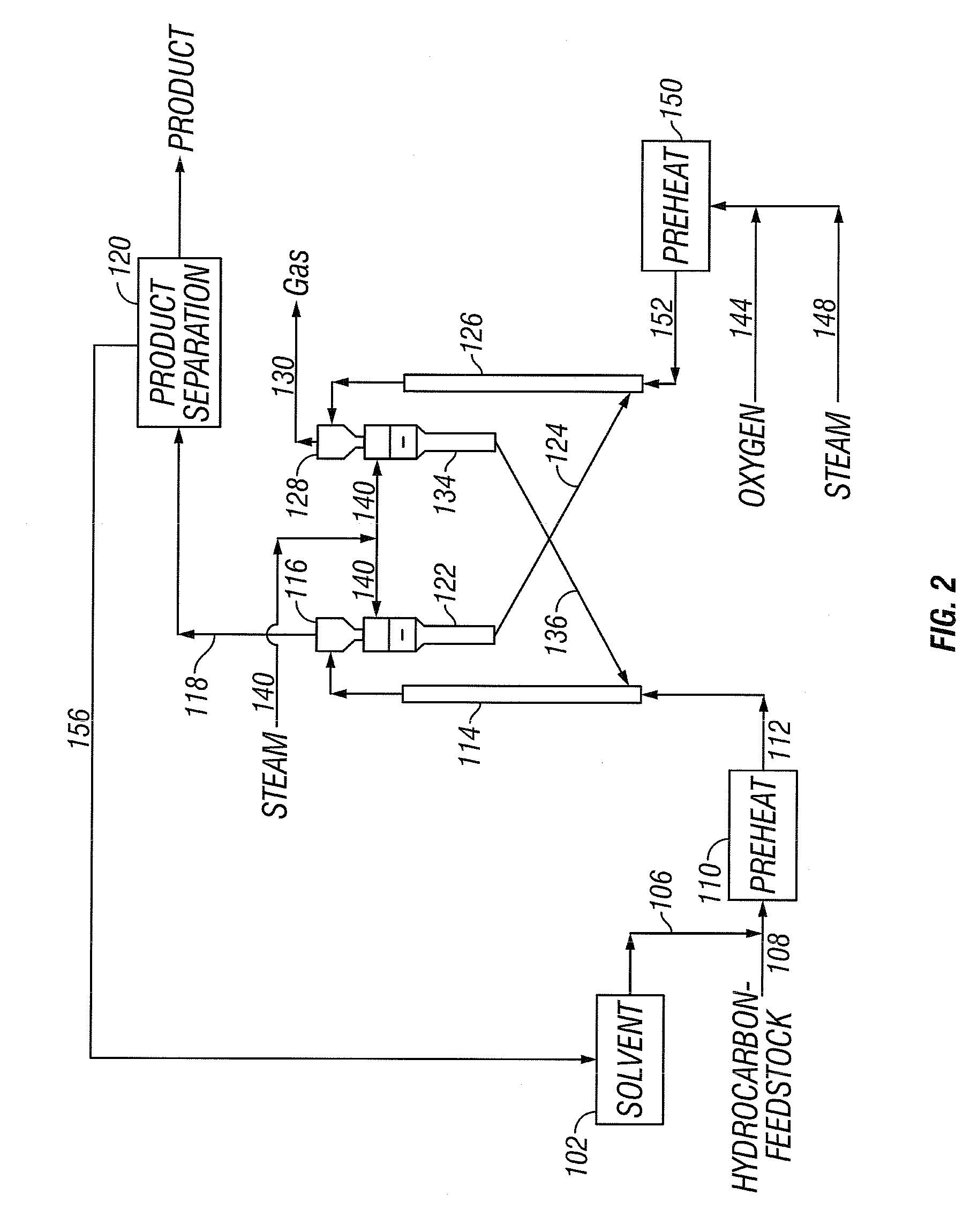

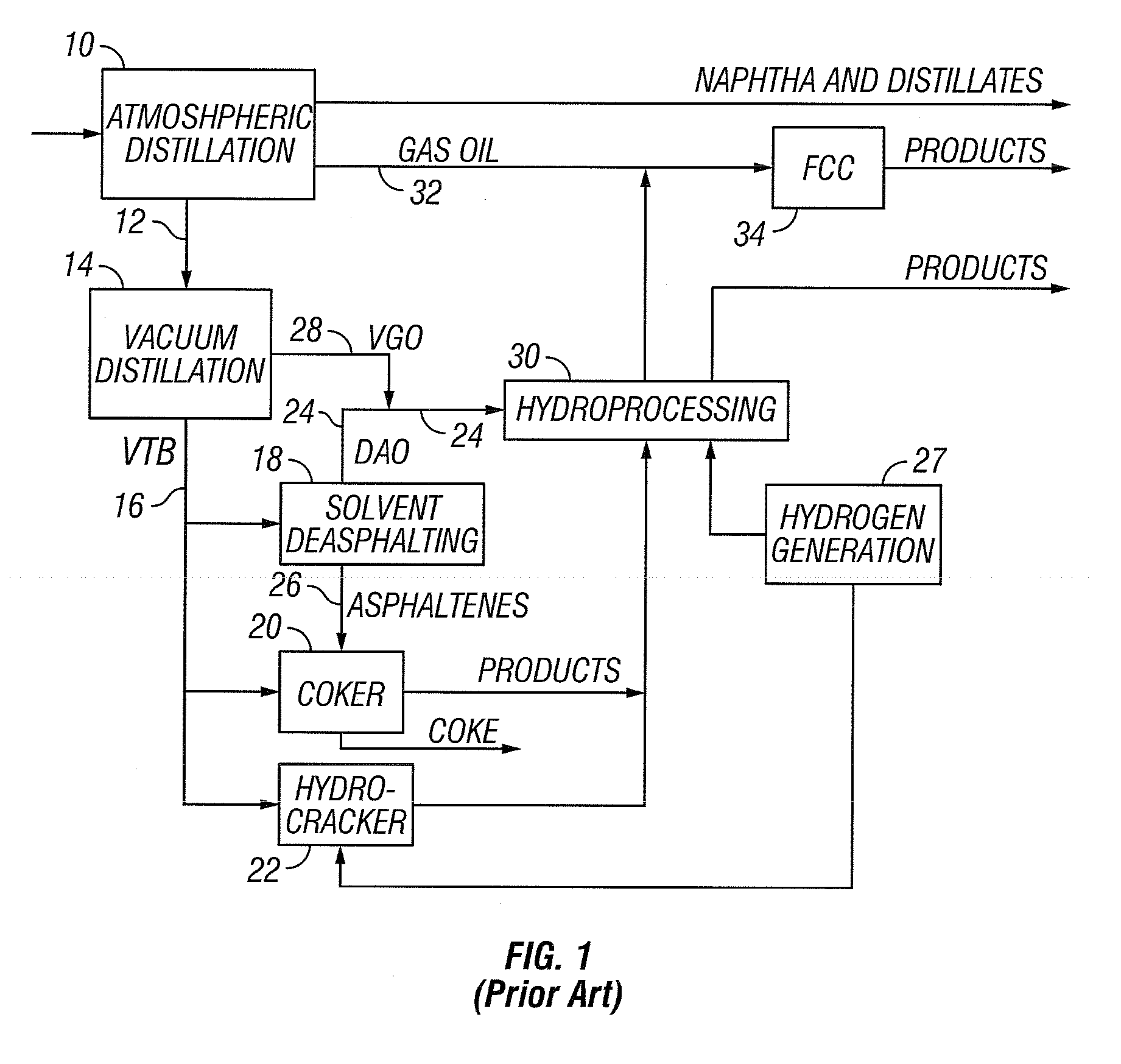

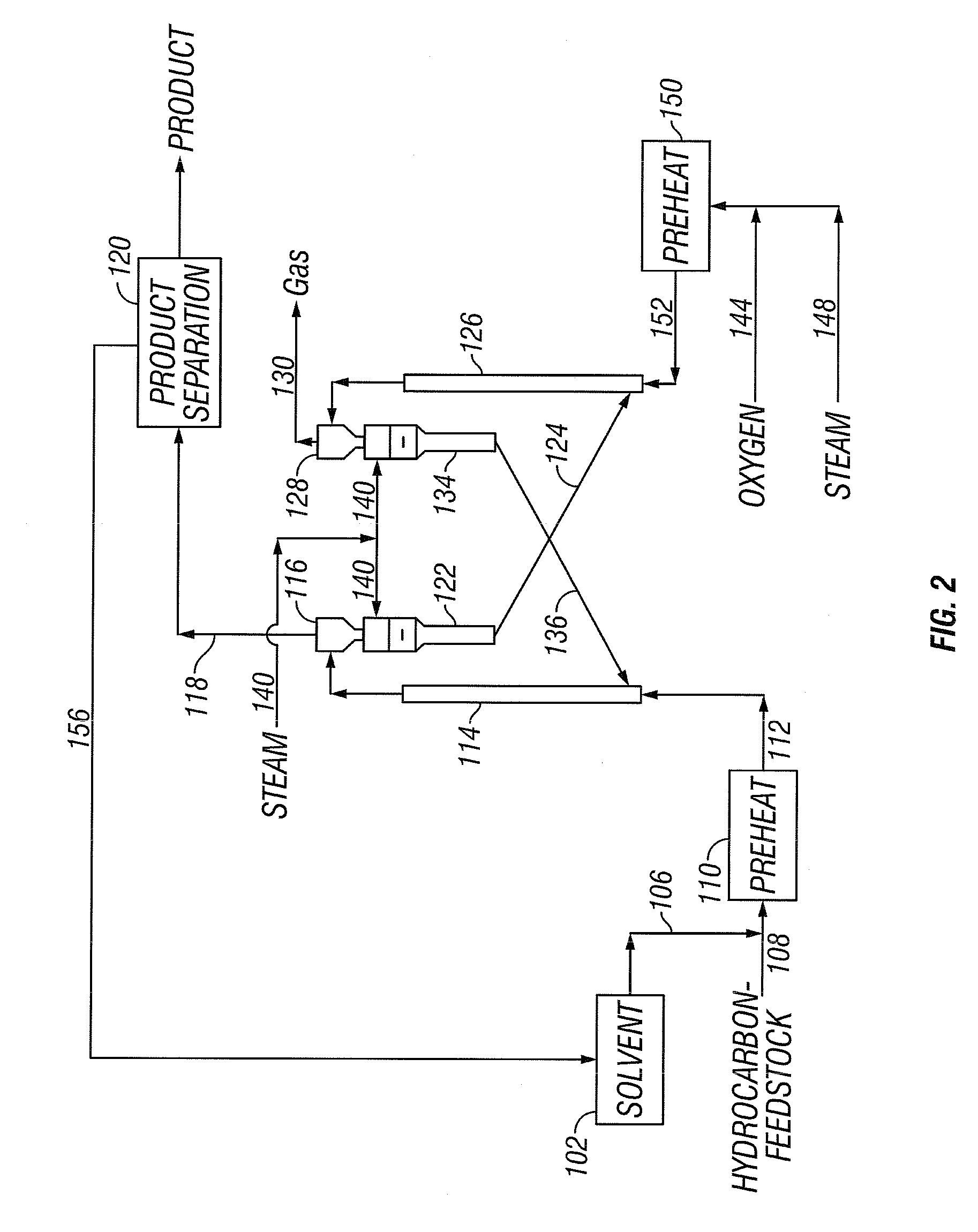

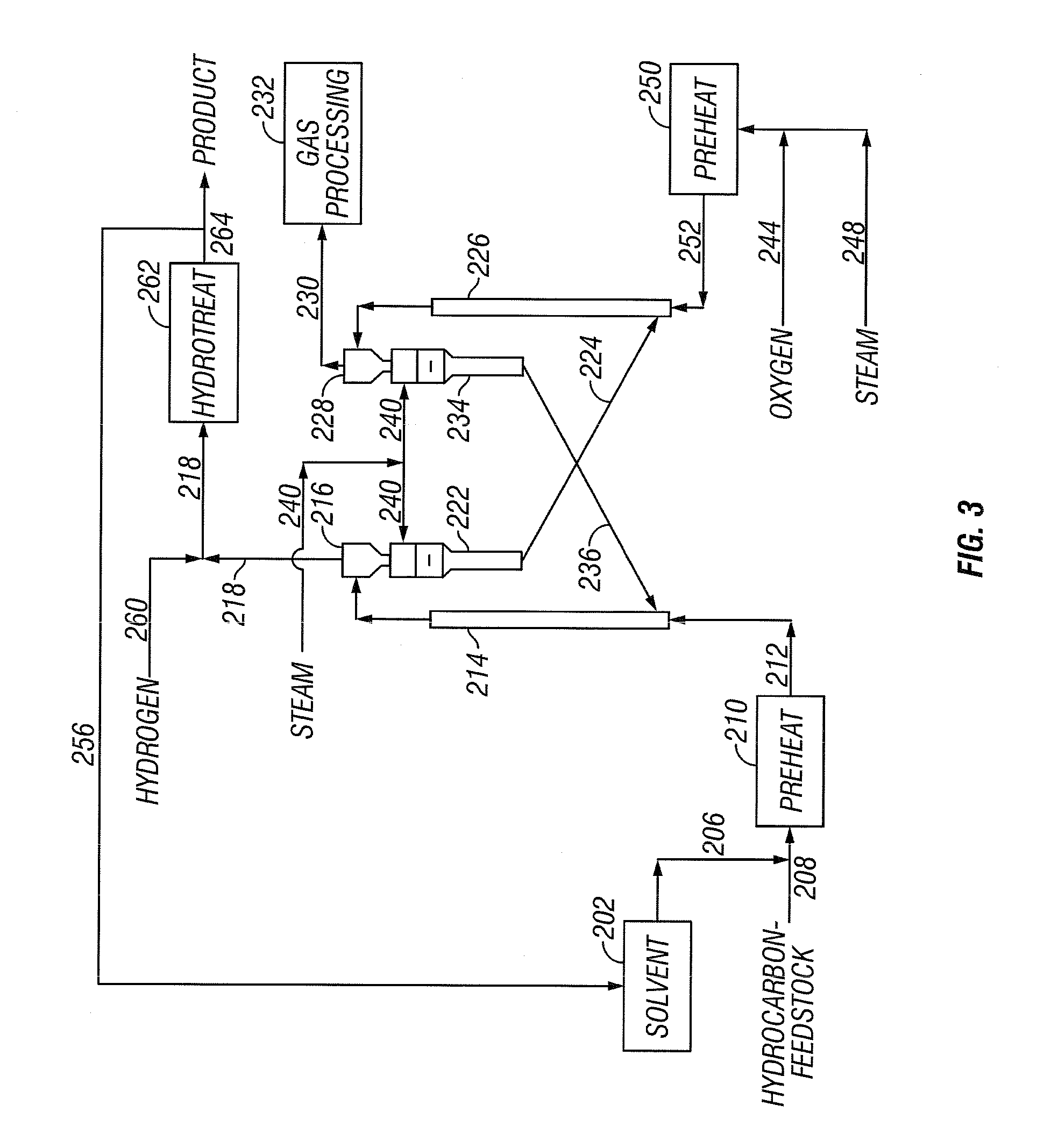

Supercritical hydrocarbon conversion process

ActiveUS7144498B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

Regeneration of ionic liquid catalyst using a metal in the absence of added hydrogen

ActiveUS7674739B2High activityMolecular sieve catalystsOther chemical processesHydrocarbon solventsSufficient time

Owner:CHEVROU USA INC

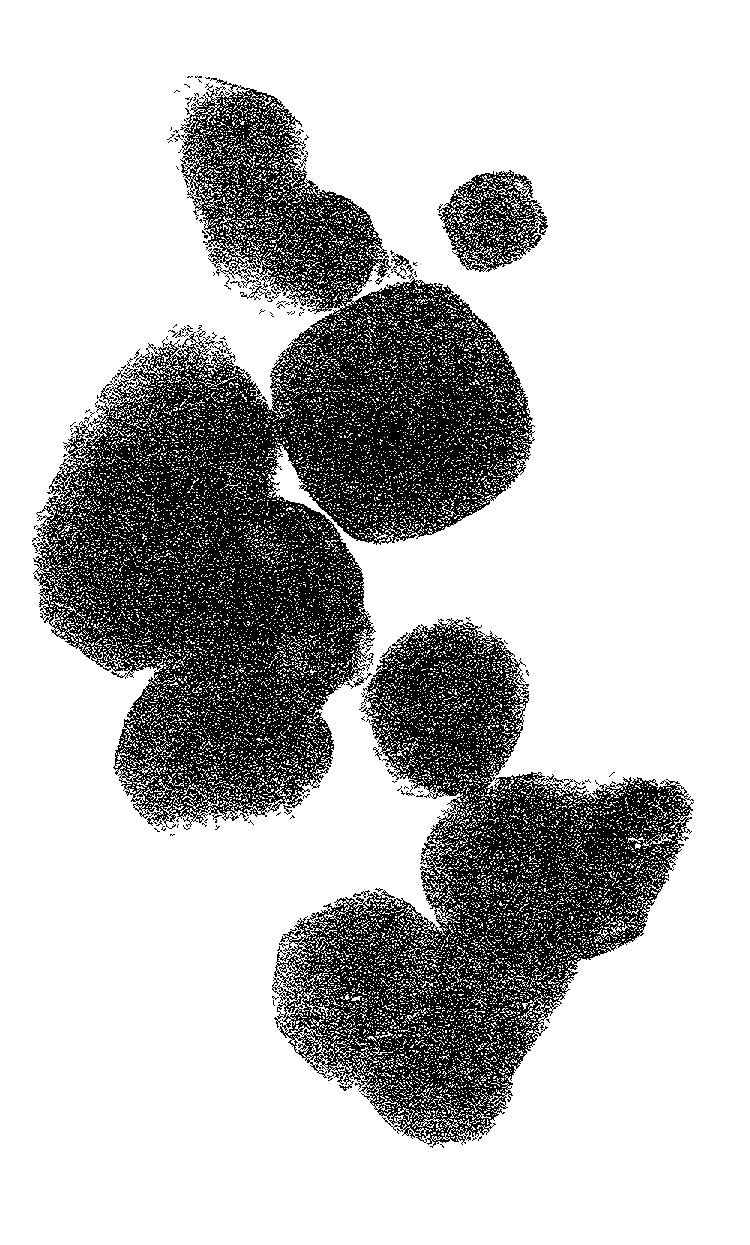

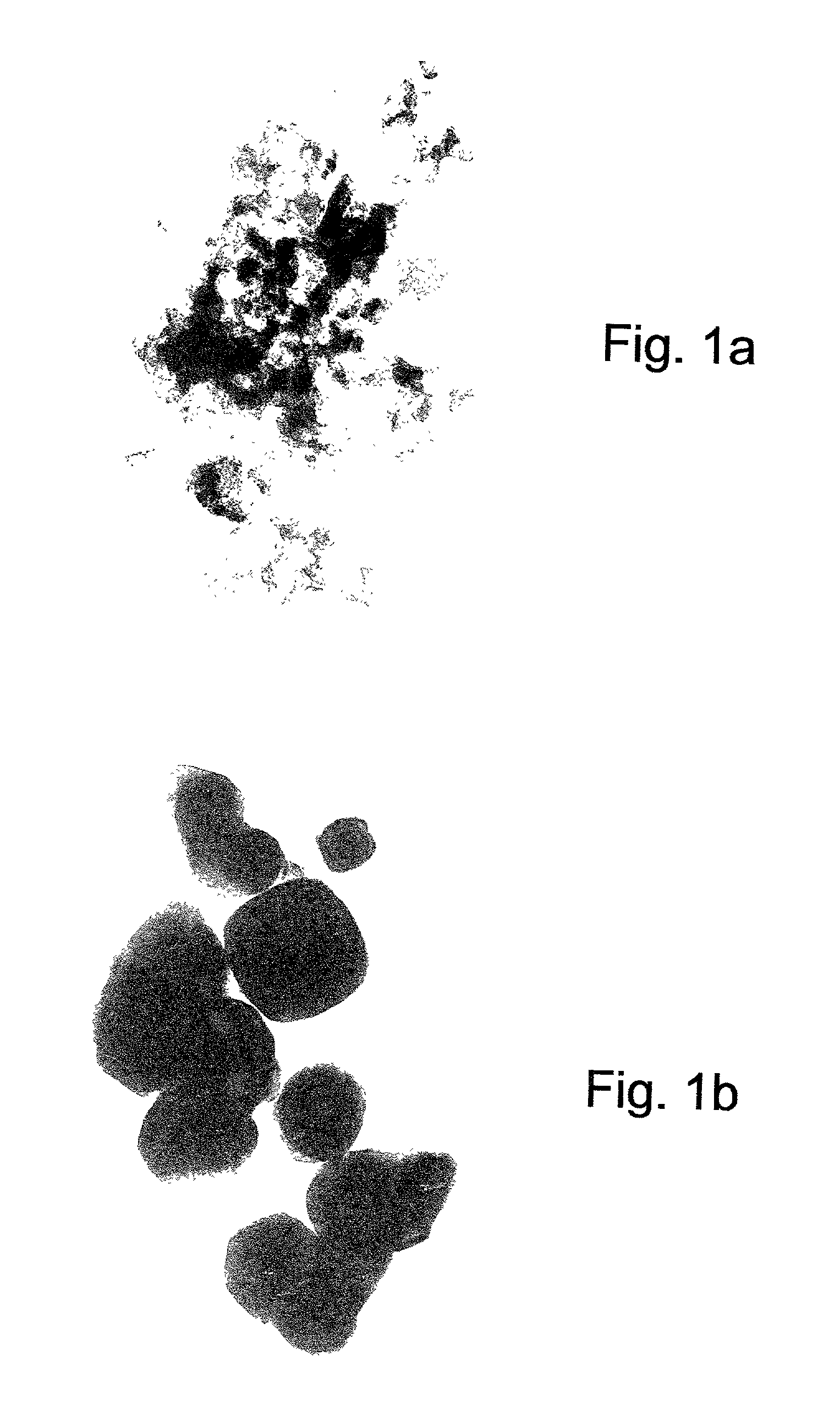

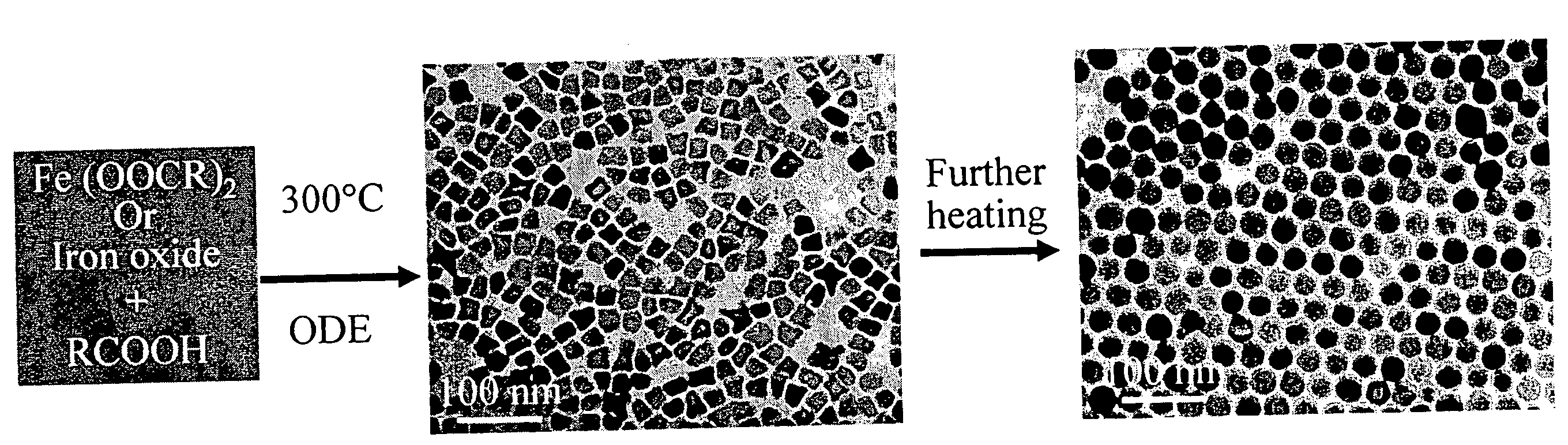

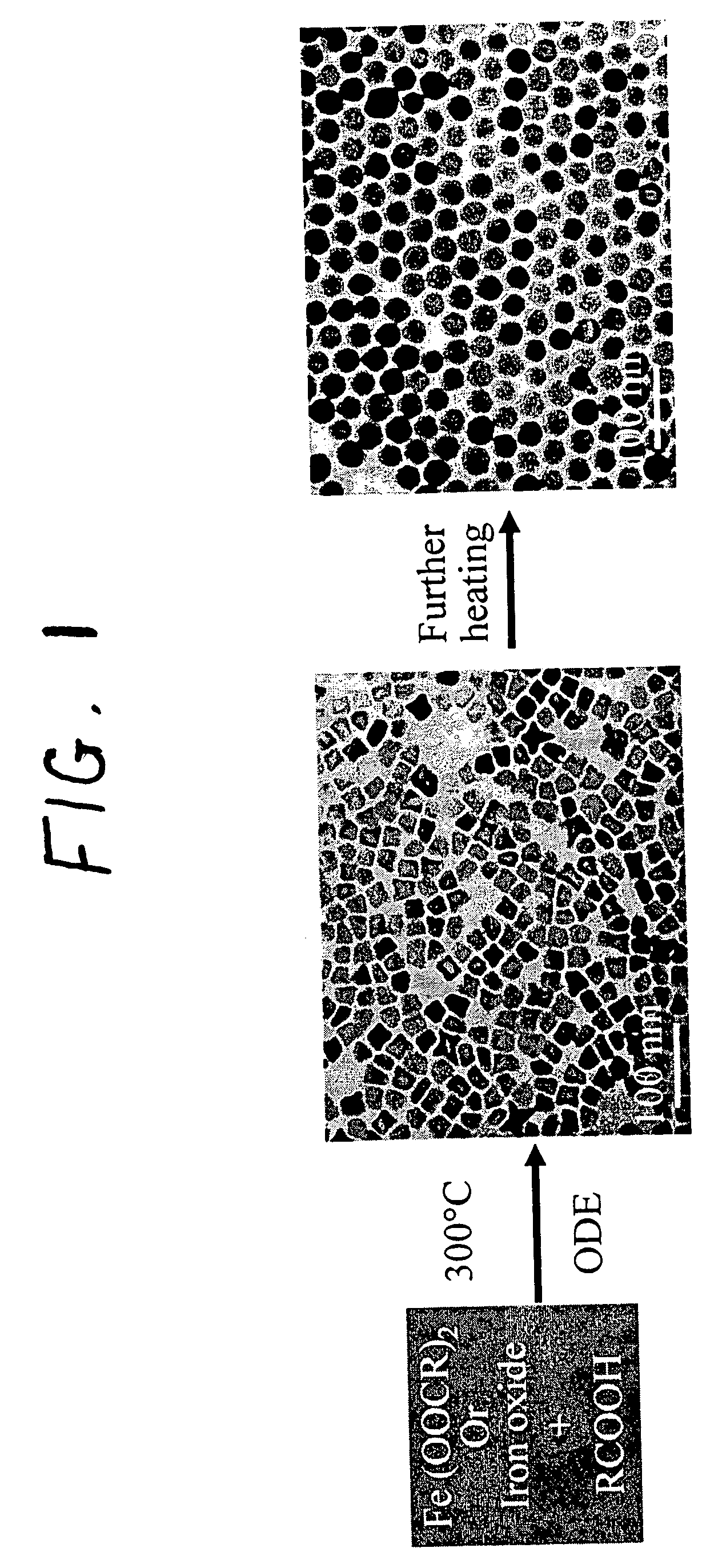

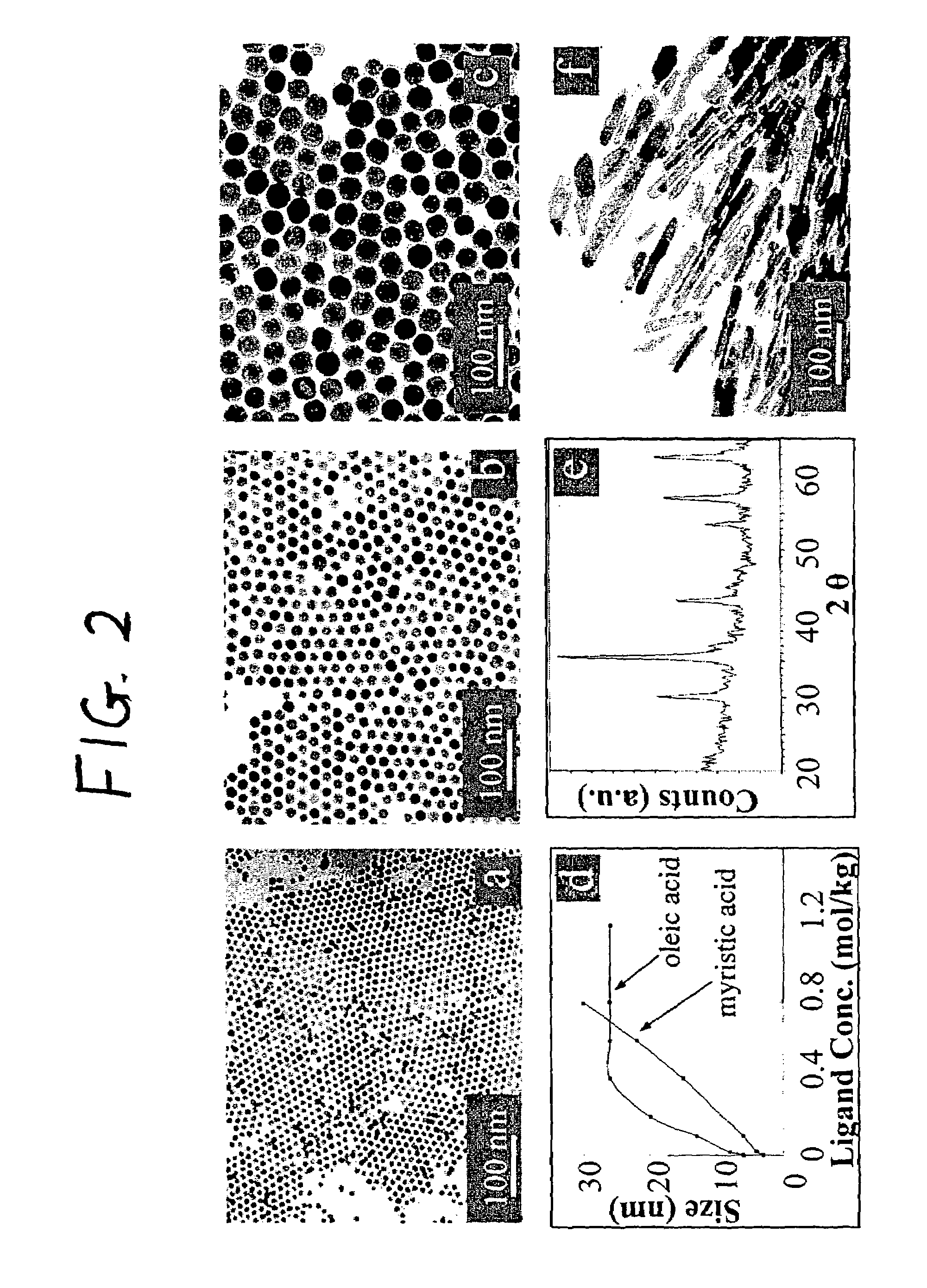

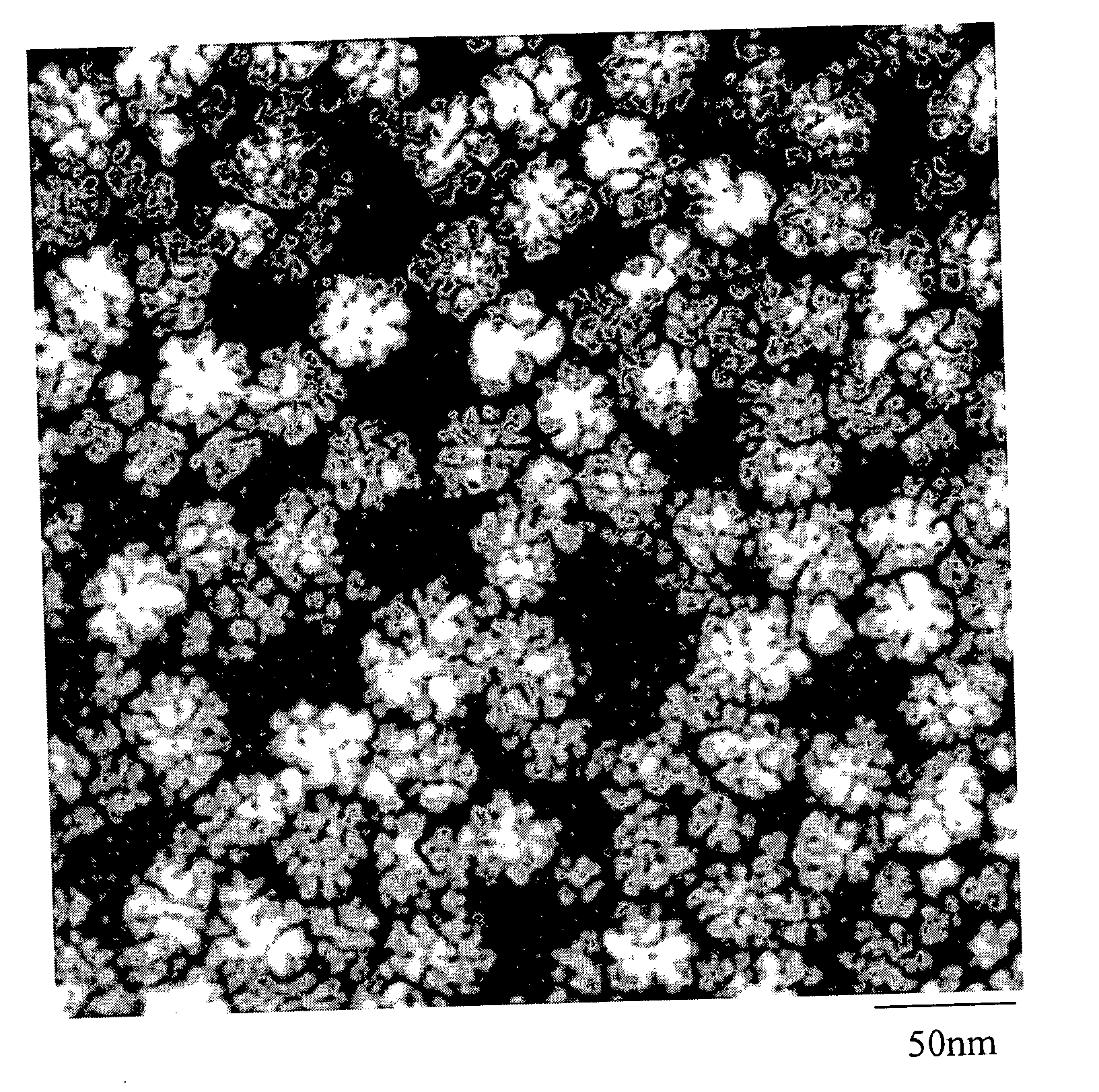

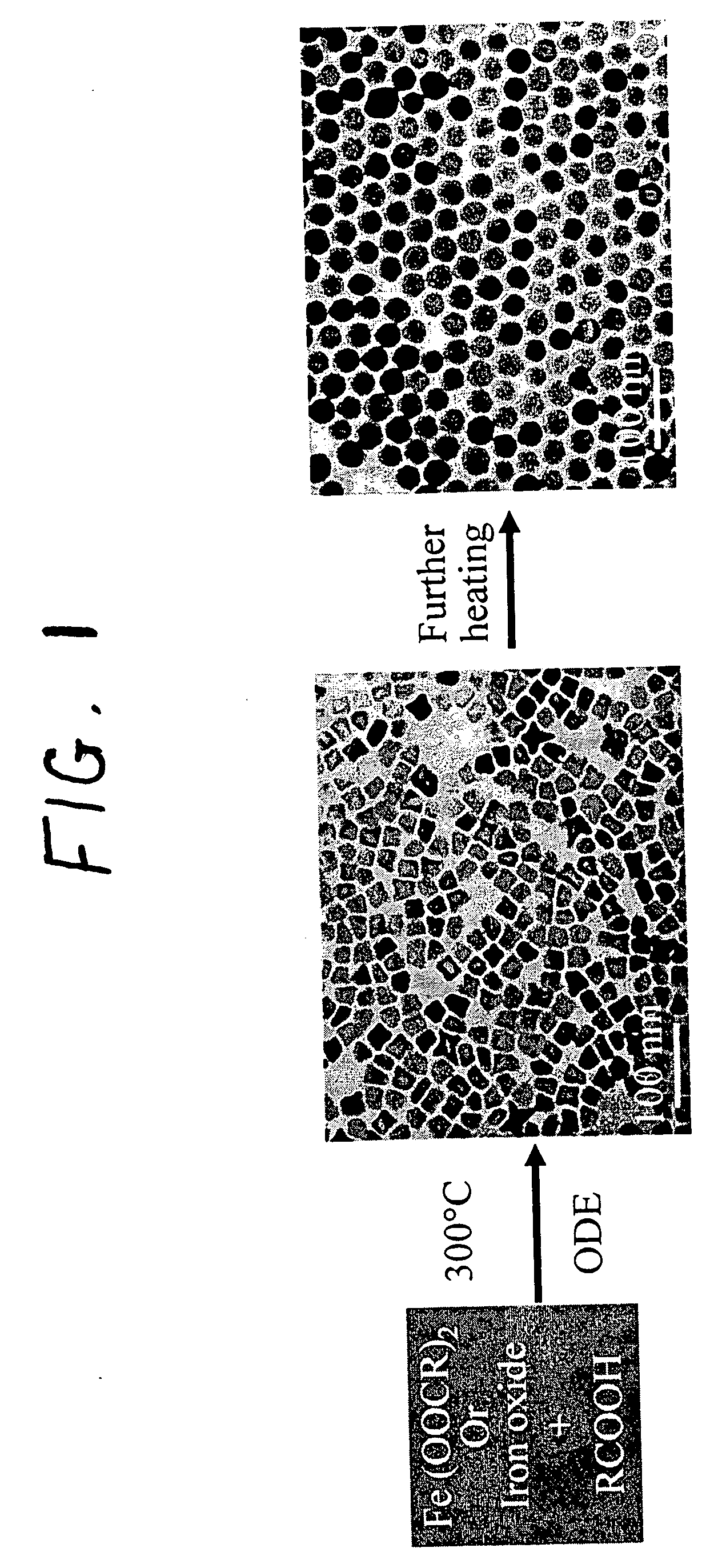

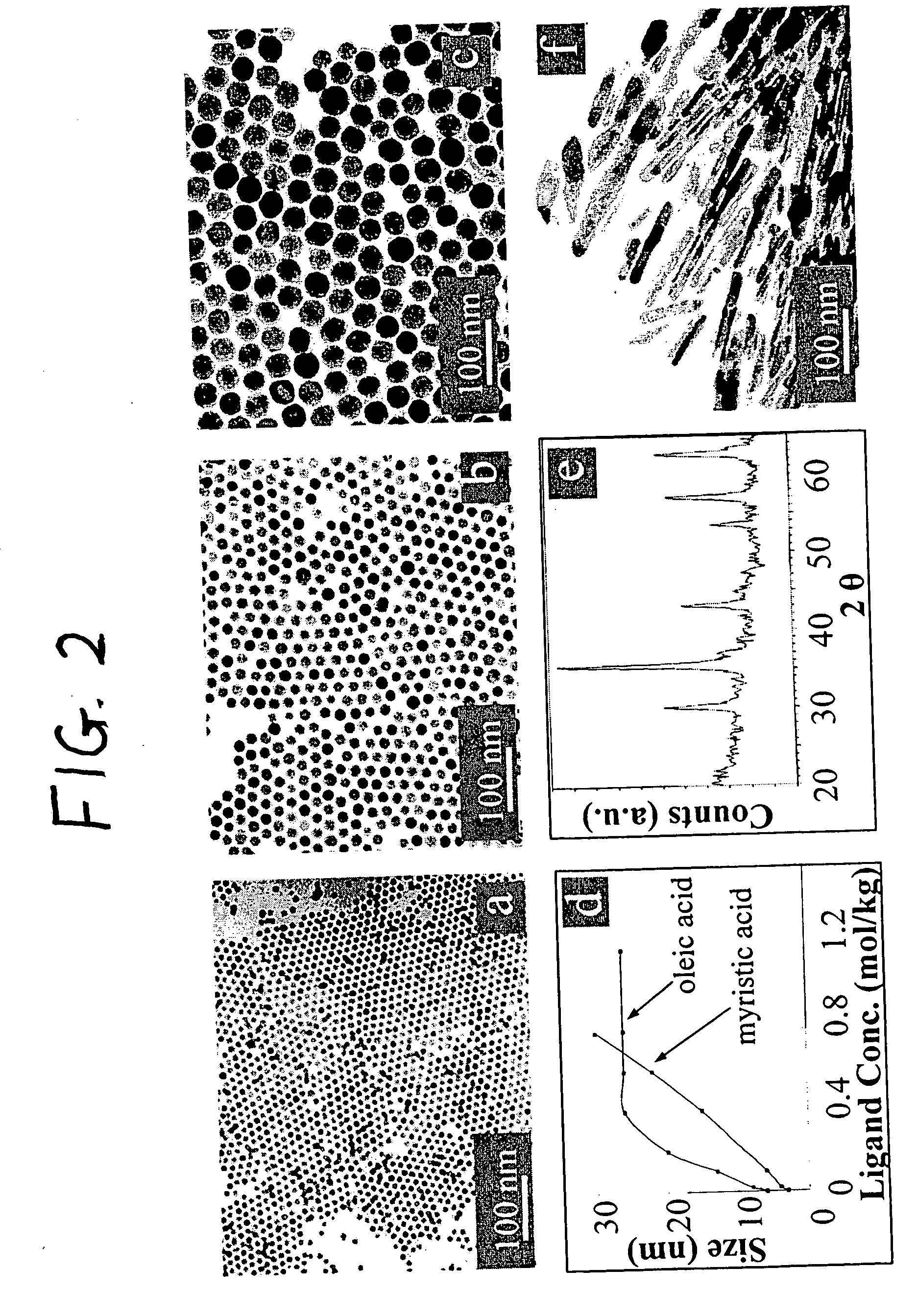

Synthetic control of metal oxide nanocrystal sizes and shapes

A general, reproducible, and simple synthetic method that employs readily available chemicals permits control of the size, shape, and size distribution of metal oxide nanocrystals. The synthesis entails reacting a metal fatty acid salt, the corresponding fatty acid, and a hydrocarbon solvent, with the reaction product being pyrolyzed to the metal oxide. Nearly monodisperse oxide nanocrystals of Fe3O4, Cr2O3, MnO, Co3O4, NiO, ZnO, SnO2, and In2O3, in a large size range (3-50 nm), are described. Size and shape control of the nanocrystals is achieved by varying the reactivity and concentration of the precursors.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Regeneration of ionic liquid catalyst by hydrogenation using a metal or metal alloy catalyst

ActiveUS7651970B2High activityMolecular sieve catalystsOther chemical processesHydrocarbon solventsHydrogen

A process for regenerating a used acidic ionic liquid catalyst which has, been deactivated comprising the steps of contacting the used chloroaluminate ionic liquid catalyst and hydrogen with a metal hydrogenation catalyst in a reaction zone under hydrogenation conditions for a time sufficient to increase the activity of the ionic liquid catalyst is described. In one embodiment, hydrogenation is conducted in the presence of a hydrocarbon solvent.

Owner:CHEVROU USA INC

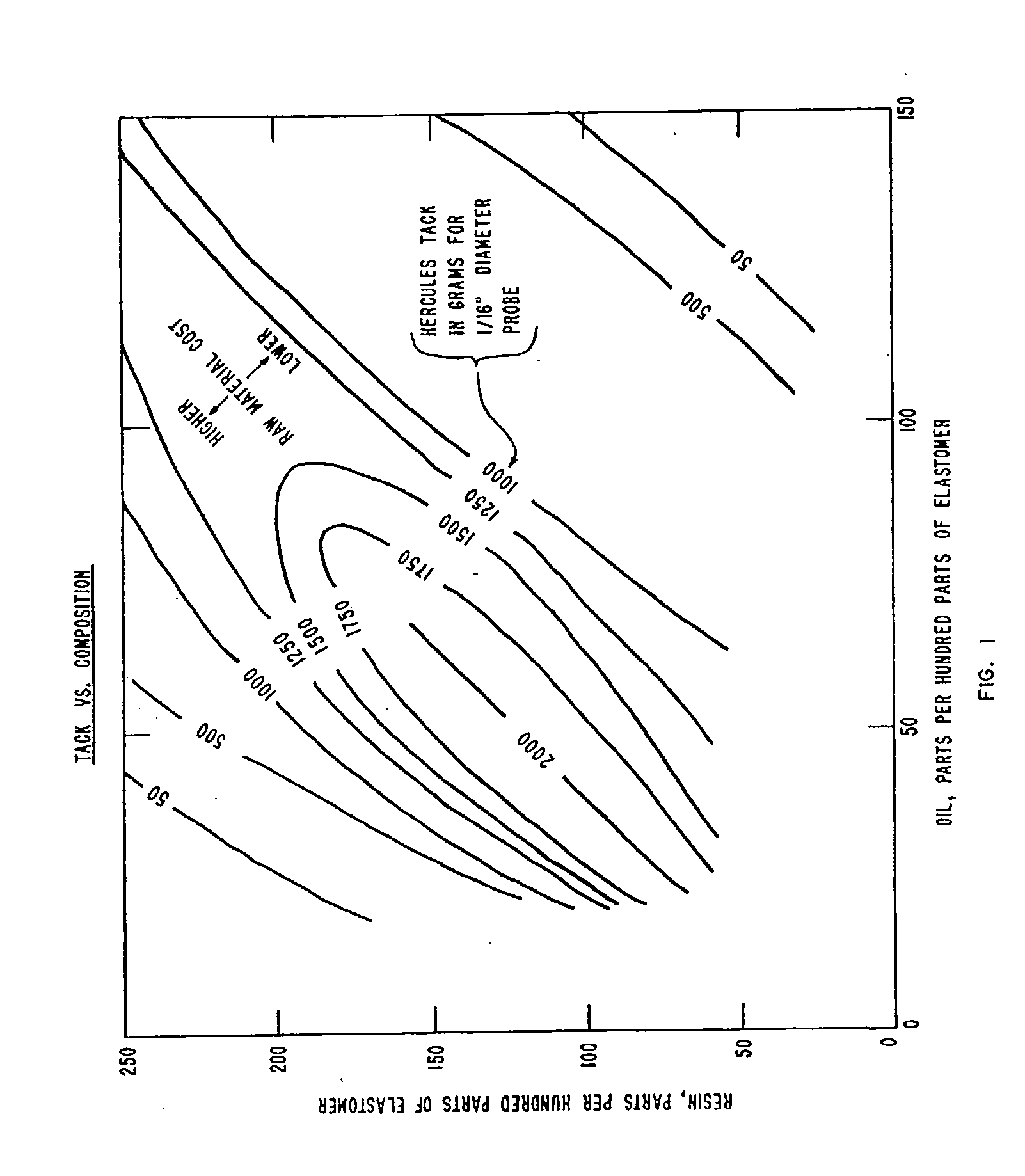

Solvent based, elastomeric coatings with lower VOC

The present invention relates to solvent based coatings which have a low level of volatile organics compounds (VOC) meeting California VOC regulations and which can be spray applied as a coating on a variety of surfaces. The coating formulation comprises a hydrogenated styrene / butadiene triblock copolymer, a hydrogenated styrene / butadiene diblock copolymer, at least one hydrocarbon solvent, at least one VOC exempt solvent, a midblock tackifying resin, and a pigment or filler. The relative amounts of solvent, tackifying resin and pigment are adjusted to obtain a solvent based, elastomeric coating having a VOC content of no more than 250 grams per liter and a viscosity no higher than 2,000 centipoise @ 25° C. as measured according to ASTM D2196.

Owner:ST CLAIR DAVID JOHN

Process for liquid phase hydrogenation

A process for the liquid phase selective hydrogenation of alkynes to alkenes with high selectivity to alkenes relative to alkanes, high alkyne conversion, and sustained catalytic activity comprising a reactant comprising an alkyne and a non-hydrocarbon solvent / absorbent, contacting the reactant stream with a hydrogen-containing stream in the presence of a supported, promoted, Group VIII catalyst, removing the solvent / absorbent, and recovering the alkene product.

Owner:SYNFUELS INT

Oil well cleaning compositions

InactiveUS20120234548A1Increase output flowEasy to useCleaning apparatusFluid removalDemulsifierHydrocarbon solvents

A method for cleaning oil wells to increase the flow of oil thereof by use of a unique cleaning emulsion comprising of water, hydrocarbon solvent, terpene hydrocarbon material, demulsifier, detergent, and optionally an acid. This one step method provides for the simultaneously cleaning / removal of asphaltene and / or paraffin and scale at a wide range of temperatures. This method can be used alone or with the assistance of a wash tool which is a combination pressure and surge wash tool having a nipple assembly, or a hydro self-rotating nozzle wash tool.

Owner:DYER RICHARD J

Silica containing rubber composition

InactiveUS7307121B2Great tractionReduce rolling resistanceSpecial tyresPretreated surfacesElastomerHysteresis

This invention discloses a method for preparing rubber compositions that exhibit unique combinations of properties that are desirable for tire tread applications for enhanced snow / ice and wet traction, low rolling resistance and increased treadwear performance in comparison with conventional silica compounds. Specifically, a high reactively silane coupling agent, such as a mercaptosilane, is used in combination with a silane coupling typically used for silica tread compounds such as bis(triethoxylsilylpropyl)disulfide to treat silica pellets in a hydrocarbon solvent at elevated temperatures. The treated silica is then blended with solution elastomer cement in a hydrocarbon solvent. The deposited reactive silanes partially react with the elastomer molecules forming a layer of polymer grafted on the silica surfaced. This structure significantly improves the silica retention during the steam stripping operation. Almost 100% (99+%) silica retention has been achieved by this invention. After solvent removal from steam stripping, the treated silica / elastomer mixer is dewatered and dried using conventional equipment such as shaker screens, expellers and expanders to form a well-dispersed silica masterbatch. This technique results in silica compounds with excellent silica dispersion and increased filler-polymer interaction, hence enhanced compound performance such as better physical properties, more desirable dynamic properties (low hysteresis at high temperatures and high hysteresis at low temperatures) and increased abrasion resistance.

Owner:THE GOODYEAR TIRE & RUBBER CO

Regeneration of ionic liquid catalyst using a regeneration metal in the presence of added hydrogen

ActiveUS20070249486A1High activityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon solventsHydrogen

A process for regenerating a used acidic ionic liquid catalyst comprising contacting the used ionic liquid catalyst with at least one ‘regeneration’ metal in a regeneration zone in the presence of added hydrogen under regeneration conditions for a time sufficient to increase the activity of the ionic liquid catalyst is described. In one embodiment, regeneration is conducted in the presence of a hydrocarbon solvent.

Owner:CHEVROU USA INC

Process for in situ recovery of bitumen and heavy oil

A process is described for in situ recovery of bitumen or heavy oil from a reservoir having a horizontal injection well and a horizontal production well. The process includes a first phase in which steam and a heavy hydrocarbon solvent are injected into the reservoir, a second phase in which the steam and heavy hydrocarbon injections are transitioned to a light hydrocarbon solvent injection, and a third phase in which a light hydrocarbon solvent is injected without further steam or heavy hydrocarbon injection. A displacement gas may be added during any of the phases, and production of hydrocarbons continues throughout all phases. The process employs a high-production start-up phase, followed by lower cost phases which progress a depletion chamber within the reservoir.

Owner:EXXONMOBIL UPSTREAM RES CO

Emulsifying and viscosity-decreasing method of thick oil

ActiveCN101768462AStrong resistance to mineral saltLow viscosityFluid removalDrilling compositionHydrocarbon solventsViscosity

The invention relates to an emulsifying and viscosity-decreasing method of thick oil. The method comprises the following steps: mixing oil-soluble component with hydrocarbon solvent to prepare an agent A; mixing nonionic-anionic surfactant, straight chain or branched chain macromolecular compound containing hydrophilic groups with water to prepare an agent B; firstly mixing the agent A with thickoil, secondly adding the agent B in the mixture of the agent A and thick oil and mixing to form an oil-in-water emulsion. The method can be used for the emulsifying and viscosity-decreasing of thick oil and especially for the emulsifying and viscosity-decreasing of thick oil under the condition of ultrahigh rock salt formation.

Owner:CHINA PETROLEUM & CHEM CORP +1

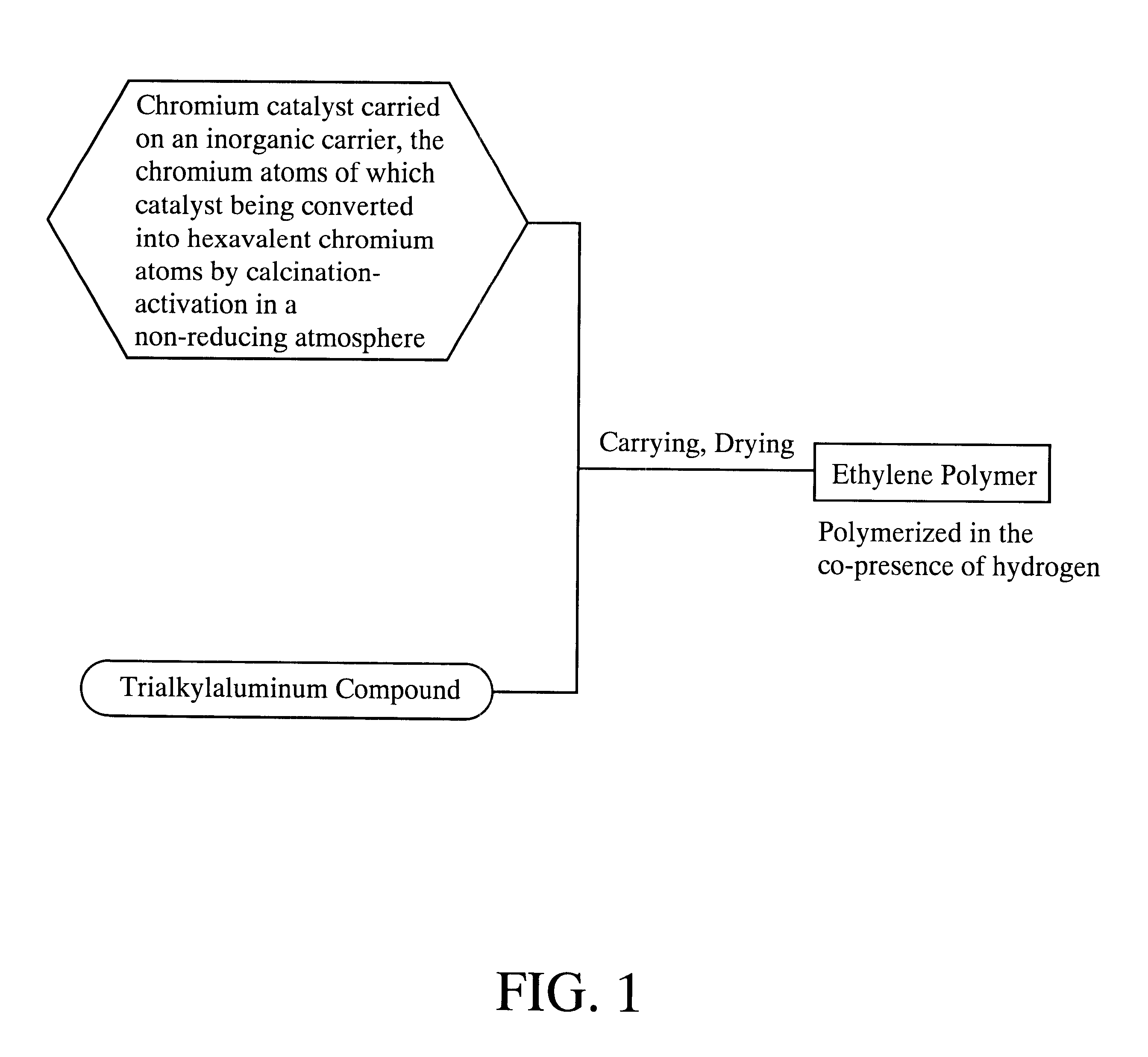

Ethylene polymers and method for producing the same

InactiveUS6646069B2Improve impact resistanceImprove balanceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChromium CompoundsCrack resistance

The invention relates to a method for producing an ethylene polymer, comprising performing polymerization of ethylene in co-presence of hydrogen using a trialkylaluminum compound-carried chromium catalyst, wherein the chromium catalyst is obtained by calcination-activating a chromium compound that is carried on an inorganic oxide carrier in a non-reducing atmosphere to convert chromium atoms in the chromium compound into hexavalent chromium atoms for at least a portion thereof, and treating with a trialkylaluminum compound in an inert hydrocarbon solvent to carry thereon and removing to dry the solvent so that the chromium atoms are not over-reduced by the trialkylaluminum compound, and to an ethylene polymer suitable for blow molded articles obtained by the production method. The ethylene polymer of the invention have improved environment stress crack resistance (ESCR) and impact resistance in a good balance and are suitable for molded blow articles, in particular large size blow molded articles.

Owner:JAPAN POLYOLEFINS CO LTD

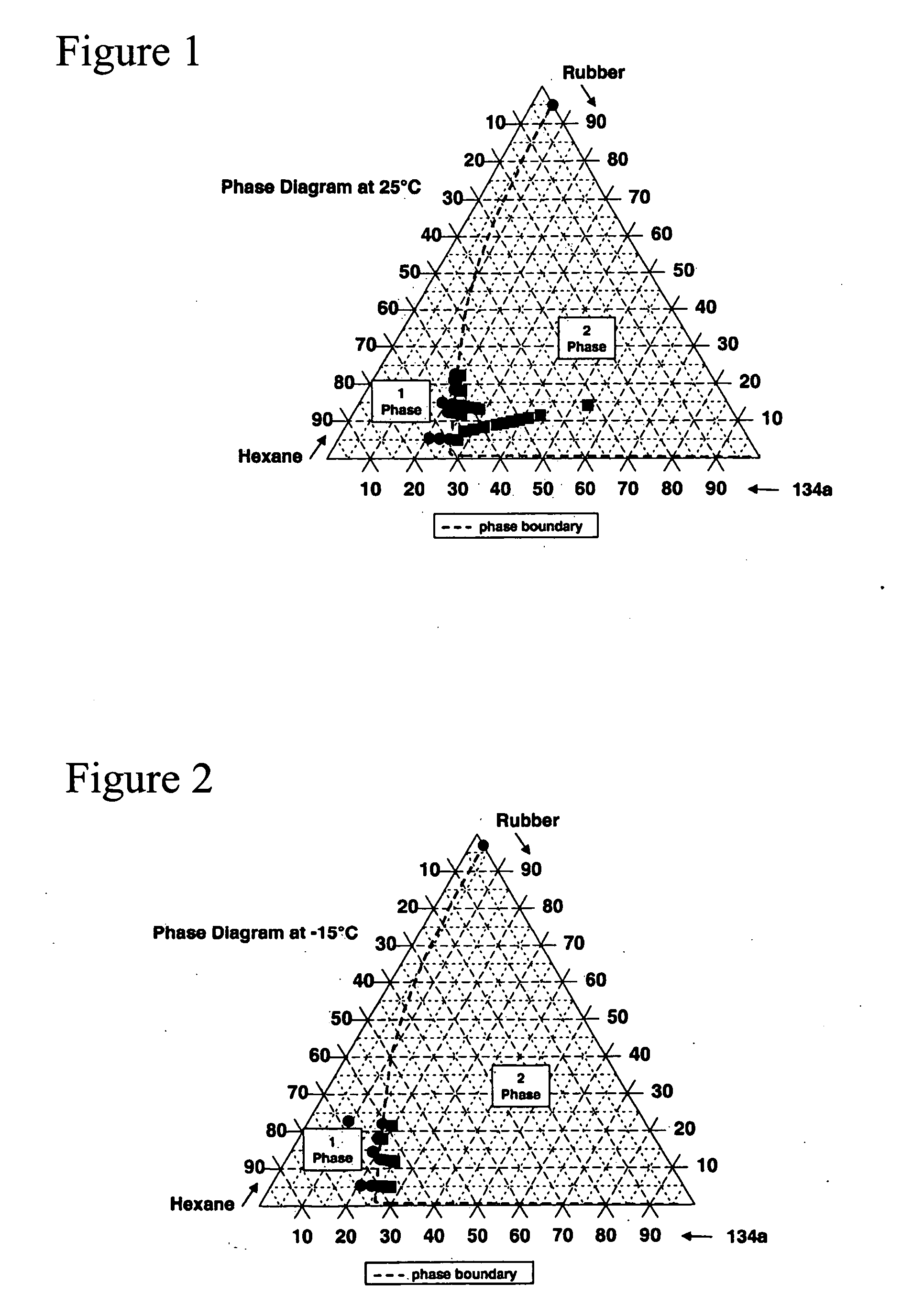

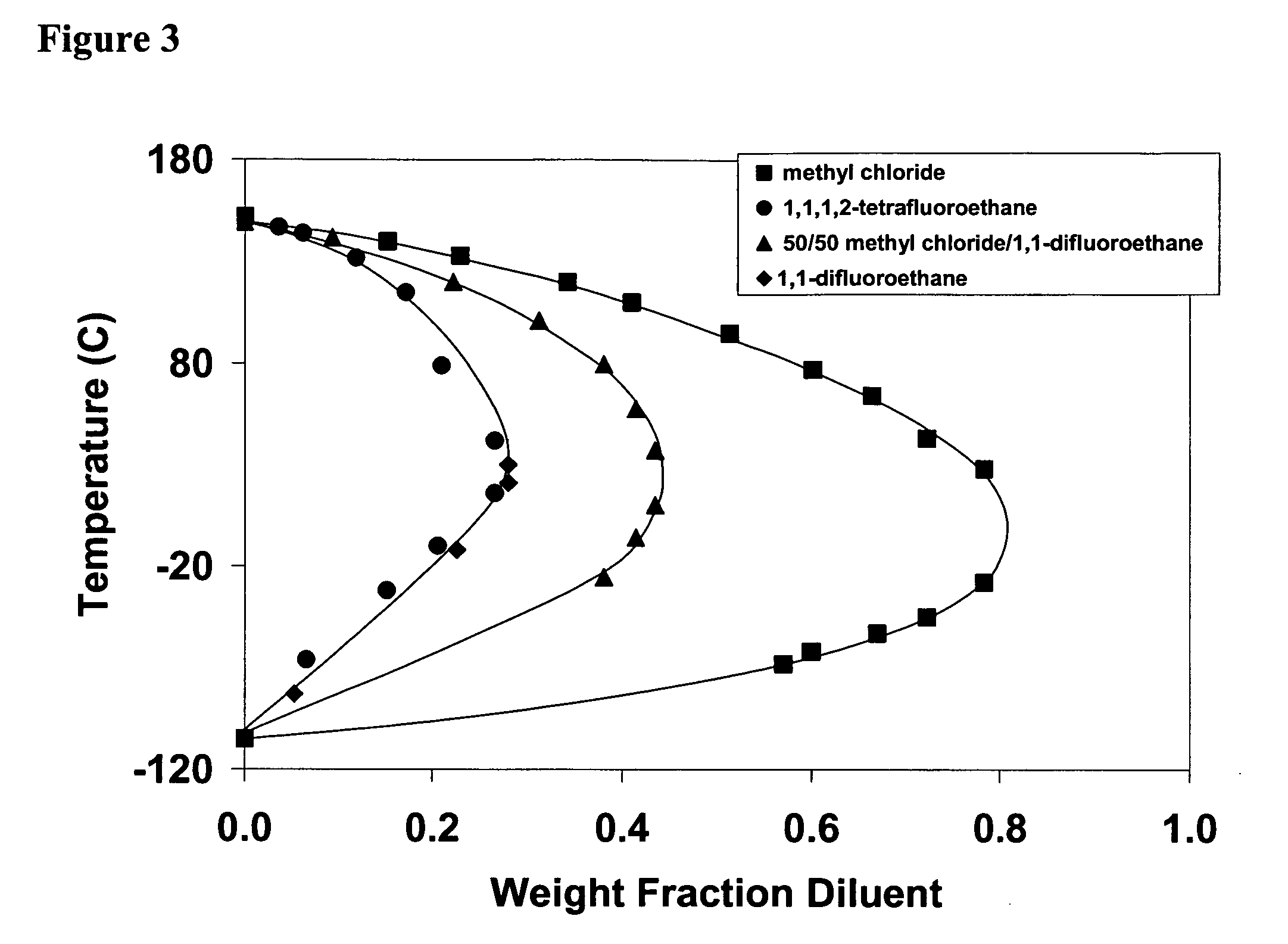

Phase separation process utilizing a hydrofluorocarbon

ActiveUS20070299161A1Easy to appreciateSpecial tyresMultistage water/sewage treatmentHydrocarbon solventsPhase separation process

Provided for herein is a process for separating a hydrocarbon-rubber from a hydrofluorocarbon diluent comprising contacting a polymer slurry comprising the hydrocarbon-rubber dispersed within the hydrofluorocarbon diluent with a hydrocarbon solvent capable of dissolving the hydrocarbon-rubber, to produce a first liquid phase and a second liquid phase, and separating the first liquid phase from the second liquid phase.

Owner:EXXONMOBIL CHEM PAT INC

Regeneration of ionic liquid catalyst using a regeneration metal in the presence of added hydrogen

ActiveUS7825055B2Other chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon solventsHydrogen

A process for regenerating a used acidic ionic liquid catalyst comprising contacting the used ionic liquid catalyst with at least one ‘regeneration’ metal in a regeneration zone in the presence of added hydrogen under regeneration conditions for a time sufficient to increase the activity of the ionic liquid catalyst is described. In one embodiment, regeneration is conducted in the presence of a hydrocarbon solvent.

Owner:CHEVROU USA INC

Supercritical Hydrocarbon Conversion Process

ActiveUS20050167333A1Reduce molecular weightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

Synthetic control of metal oxide nanocrystal sizes and shapes

A general, reproducible, and simple synthetic method that employs readily available chemicals permits control of the size, shape, and size distribution of metal oxide nanocrystals. The synthesis entails reacting a metal fatty acid salt, the corresponding fatty acid, and a hydrocarbon solvent, with the reaction product being pyrolyzed to the metal oxide. Nearly monodisperse oxide nanocrystals of Fe3O4, Cr2O3, MnO, Co3O4, NiO, ZnO, SnO2, and In2O3, in a large size range (3-50 nm), are described. Size and shape control of the nanocrystals is achieved by varying the reactivity and concentration of the precursors.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Screen printable curable conductive material composition

InactiveUS6204303B1Uniform transferEasy to touchOrganic chemistrySemiconductor/solid-state device detailsHydrocarbon solventsConductive materials

The present invention provides a novel UV curable composition for forming thermally conductive interface and a method of using the same. The composition is used to promote the transfer of heat from a source of heat such as an electronic device to a heat dissipation device such as a heat sink. The composition comprises by weight from about 35% to about 75% of a UV curable acrylate material, from about 0.5% to about 15% catalyst, from about 10% to about 30% hydrocarbon solvent and from about 20% to about 70% conductive filler.

Owner:FERRO CORP

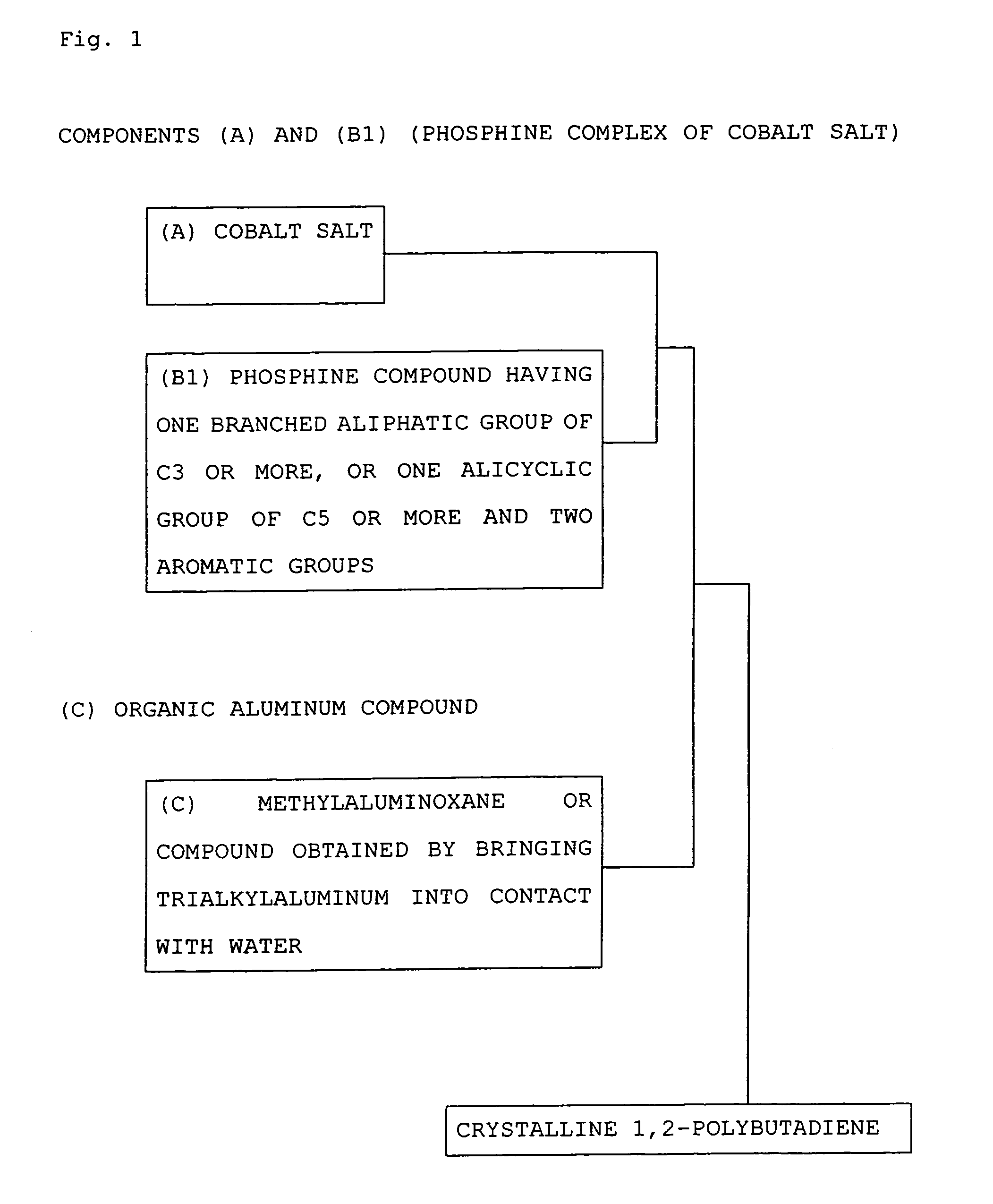

Process for producing crystalline 1,2-polybutadiene

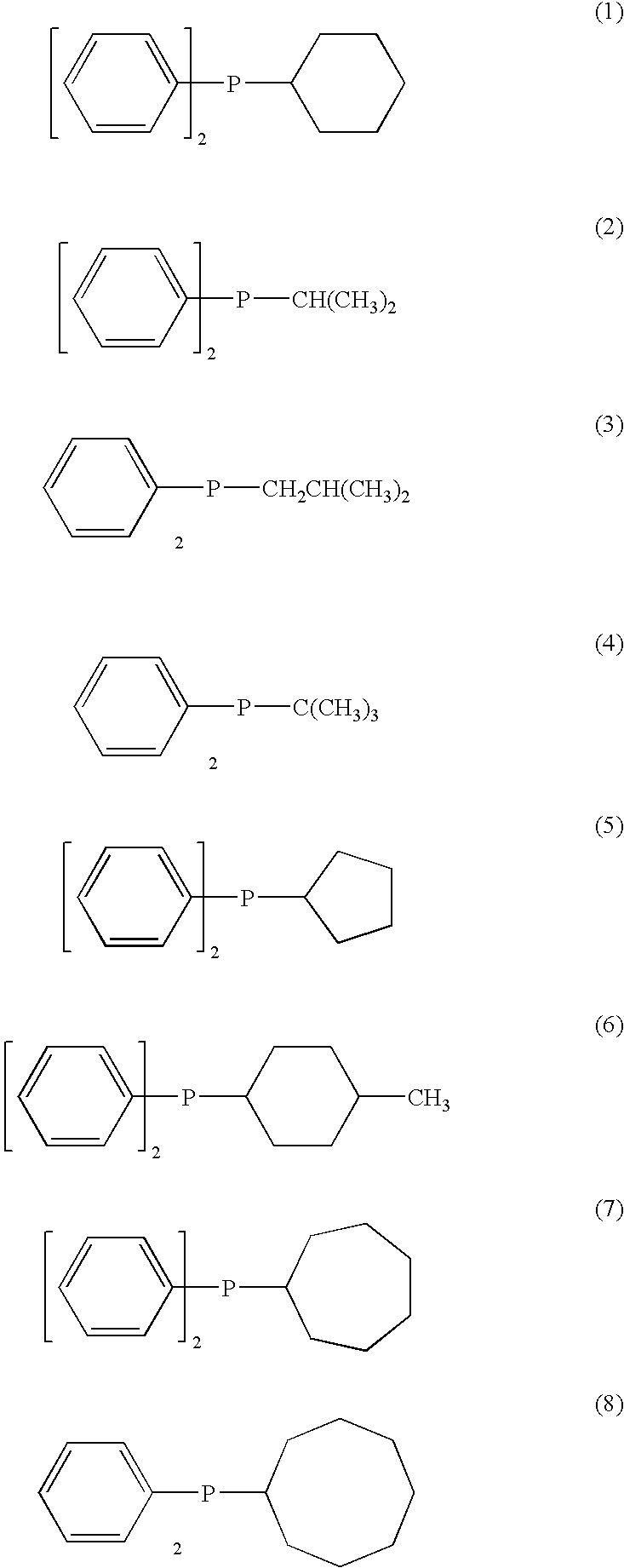

1,3-Butadiene is polymerized in a hydrocarbon solvent using a catalyst system containing (A) a cobalt salt, (B1) a phosphine compound having one branched aliphatic group of 3 or more carbon atoms or one alicyclic group of 5 or more carbon atoms and two aromatic groups, and (C) an organic aluminum compound, or a catalyst system containing (A) a cobalt salt, (B) (B1) a phosphine compound having one branched aliphatic group of 3 or more carbon atoms or one alicyclic group of 5 or more carbon atoms and two aromatic groups and / or (B2) a triarylphosphine compound having three aromatic groups, (C) an organic aluminum compound and (D) an active halogen-containing compound, thereby obtaining crystalline 1,2-polybutadiene.

Owner:ENEOS MATERIALS CORP

Regeneration of ionic liquid catalysts

ActiveUS20070142216A1High activityMolecular sieve catalystsOther chemical processesAlkyl transferHydrocarbon solvents

A process for regenerating a used acidic ionic liquid catalyst comprising contacting the used ionic liquid catalyst with an isoparaffin-containing stream and Broensted acid in a reaction zone under alkylation conditions for a time sufficient to increase the activity of the ionic liquid catalyst is disclosed. An embodiment of a process for regenerating a used acidic ionic liquid catalyst comprising the steps of contacting the used ionic liquid catalyst with an isoparaffin-containing stream and Broensted acid in a reaction zone under alkylation conditions for a time sufficient to increase the activity of the ionic liquid catalyst; removing reaction product from the reaction zone; mixing the removed reaction product with a hydrocarbon solvent; allowing the mixture to separate into two phases; and recovering at least a portion of the heavier phase which contains a regenerated ionic liquid catalyst having greater activity than the used ionic liquid catalyst is also disclosed.

Owner:CHEVROU USA INC

Conjugated diene polymer, conjugated diene polymer composition, and method for producing conjugated diene polymer

InactiveCN101659731AImprove fuel economyGrip (good grip)Rolling resistance optimizationHydrocarbon solventsPolymer science

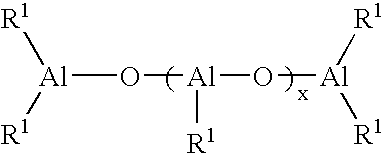

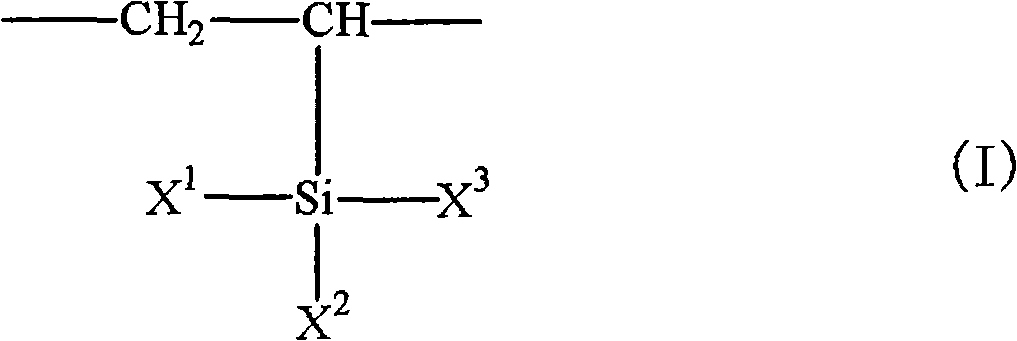

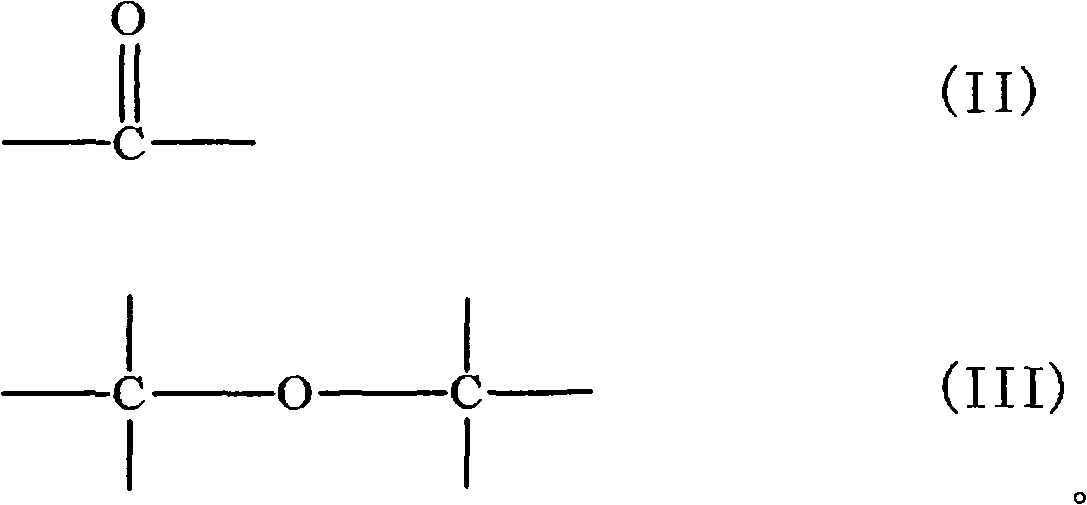

The invention provides a conjugated diene polymer that comprises a conjugated diene-based constituent unit and a constituent unit of formula (I) below, at least one terminus of the polymer being modified by a silicon compound having a linkage of formula (II) below and / or a linkage of formula (III) below. The invention provides a conjugated diene composition, containing conjugated diene polymer andstuffing. The invention also provides a manufacturing method of conjugated diene polymer, which includes the following process A and process B. The process A is a process for using alkali metal catalyst in the hydrocarbon solvent to polymerize the conjugated diene and the monomer of the vinyl compound of the formula (V), to obtain a polymer having alkali metal come from the catalyst on at least one terminus of the polymer chain containing the conjugated diene-based monomeric unit and the monomeric unit based on the vinyl compound of the formula (V). The process B is a process for reacting thepolymer obtained from theprocess A and the silicon compound having a linkage of formula (II) below and / or a linkage of formula (III) below.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com