Patents

Literature

398 results about "Continuous reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

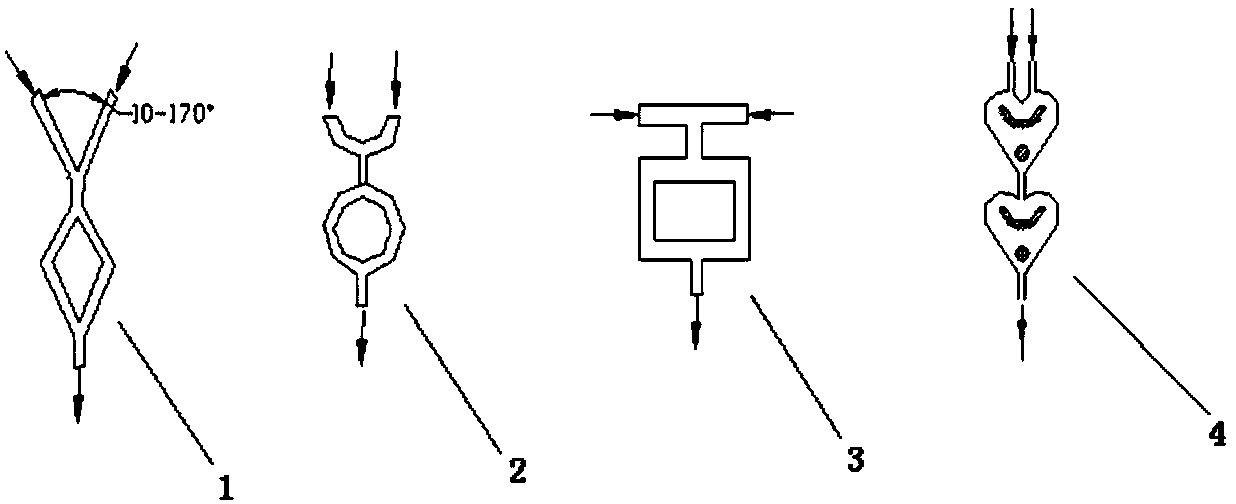

Continuous reactors (alternatively referred to as flow reactors) carry material as a flowing stream. Reactants are continuously fed into the reactor and emerge as continuous stream of product. Continuous reactors are used for a wide variety of chemical and biological processes within the food, chemical and pharmaceutical industries. A survey of the continuous reactor market will throw up a daunting variety of shapes and types of machine. Beneath this variation however lies a relatively small number of key design features which determine the capabilities of the reactor. When classifying continuous reactors, it can be more helpful to look at these design features rather than the whole system.

Continuous process for the production of conjugated diene polymers having narrow molecular weight distribution and products therefrom

InactiveUS6897270B2Narrow molecular weight distributionImprove responseHydrocarbon solventsContinuous reactor

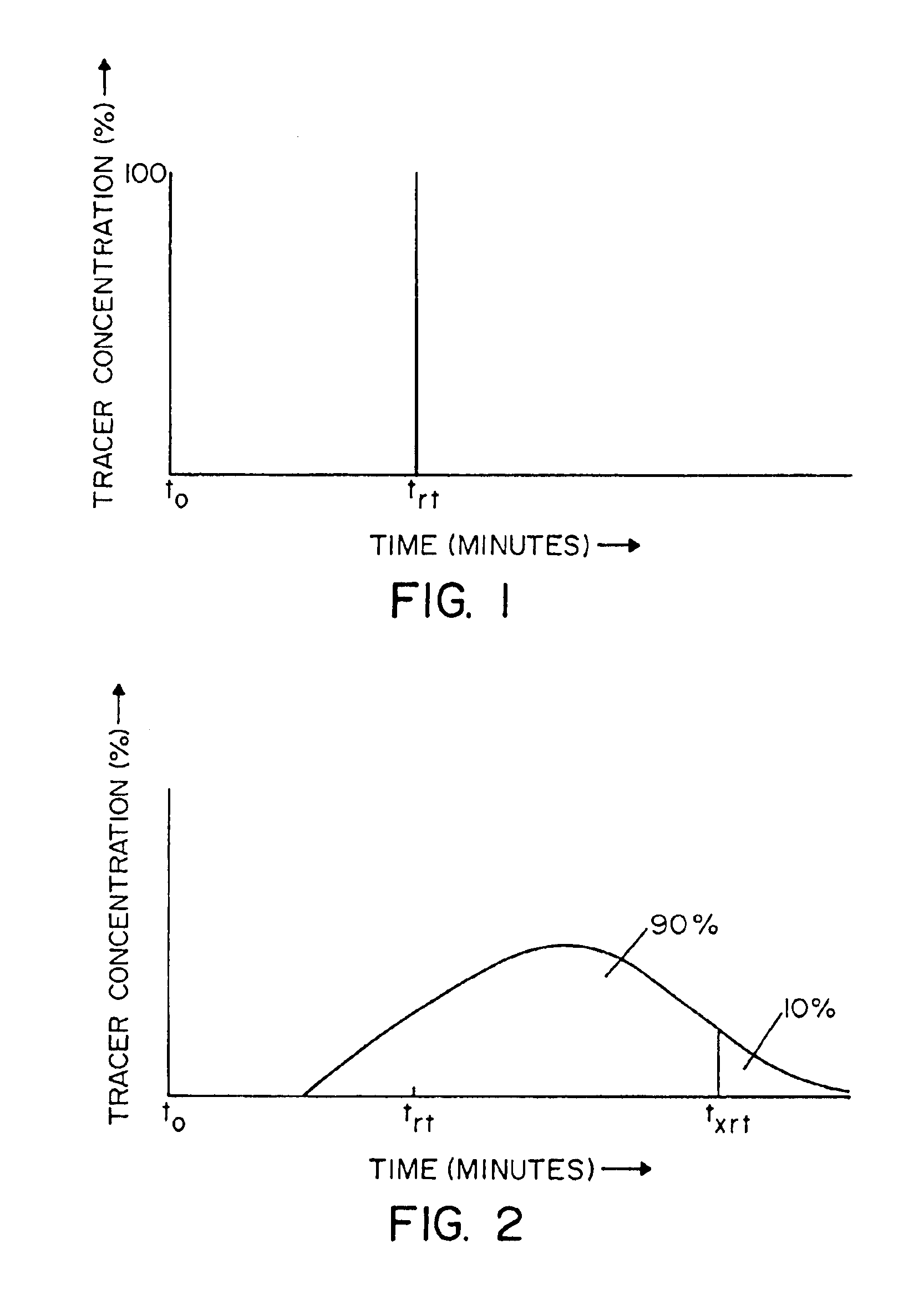

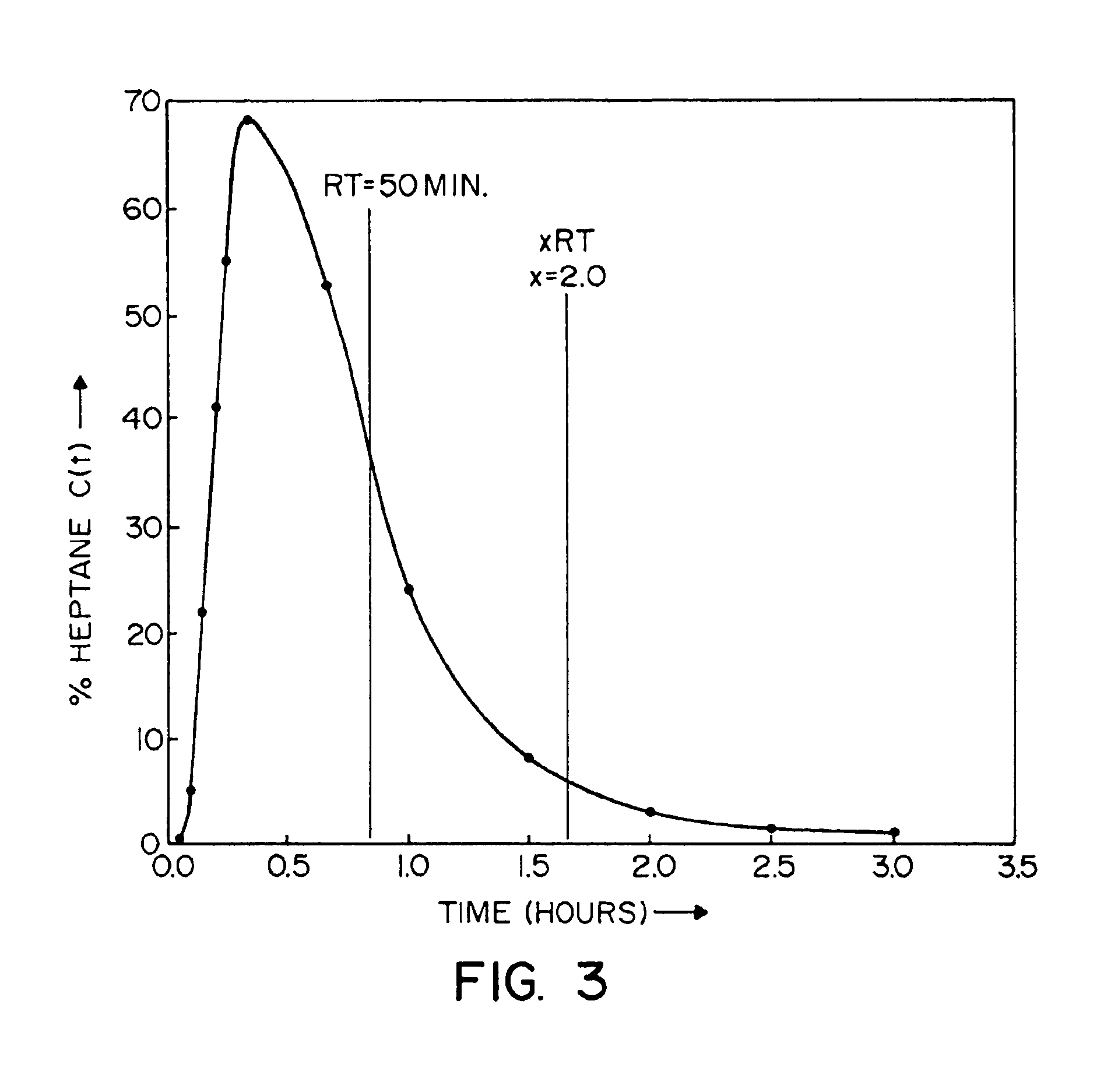

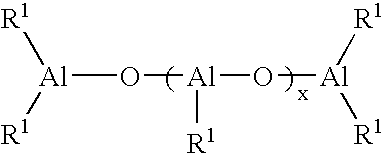

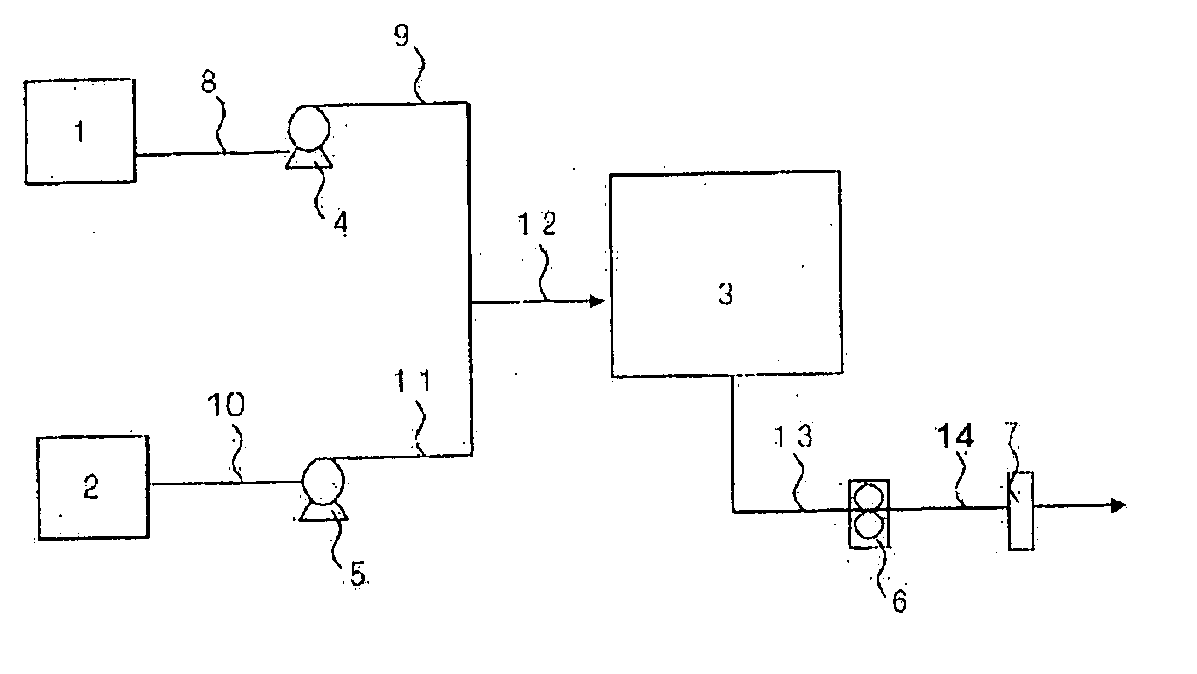

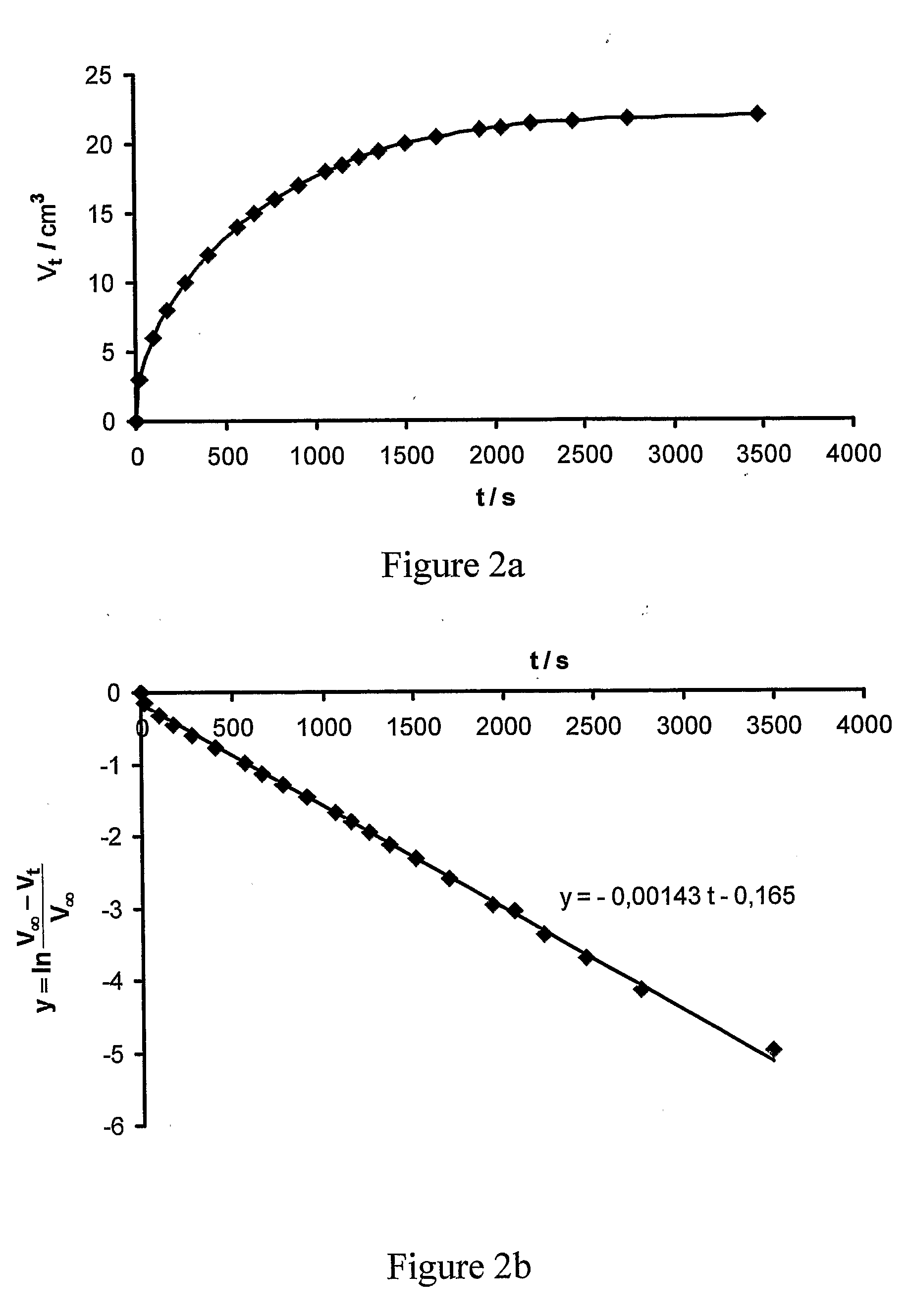

A continuous process for producing conjugated diene polymers comprising the steps of contacting, within an hydrocarbon solvent and within a continuous reactor, conjugated diene monomer and a catalyst composition prepared by combining: (a) a lanthanide compound, (b) an alkylating agent, and (c) a halogen-containing compound, and maintaining a non-ideal flow pattern within the continuous reactor so that 10% of the reagents entering the reactor at a reference time t0 are still present within the continuous reactor at a time t0+xtrt, where trt is the residence time corresponding to ideal flow within the continuous reactor and x is a numeral greater than 1.5.

Owner:BRIDGESTONE CORP

Method for Preparing Adhesive Acrylic Ester Polymer Syrup

InactiveUS20070299226A1Improve performanceThe polymerization process is stableEster polymer adhesivesContinuous reactorProduction rate

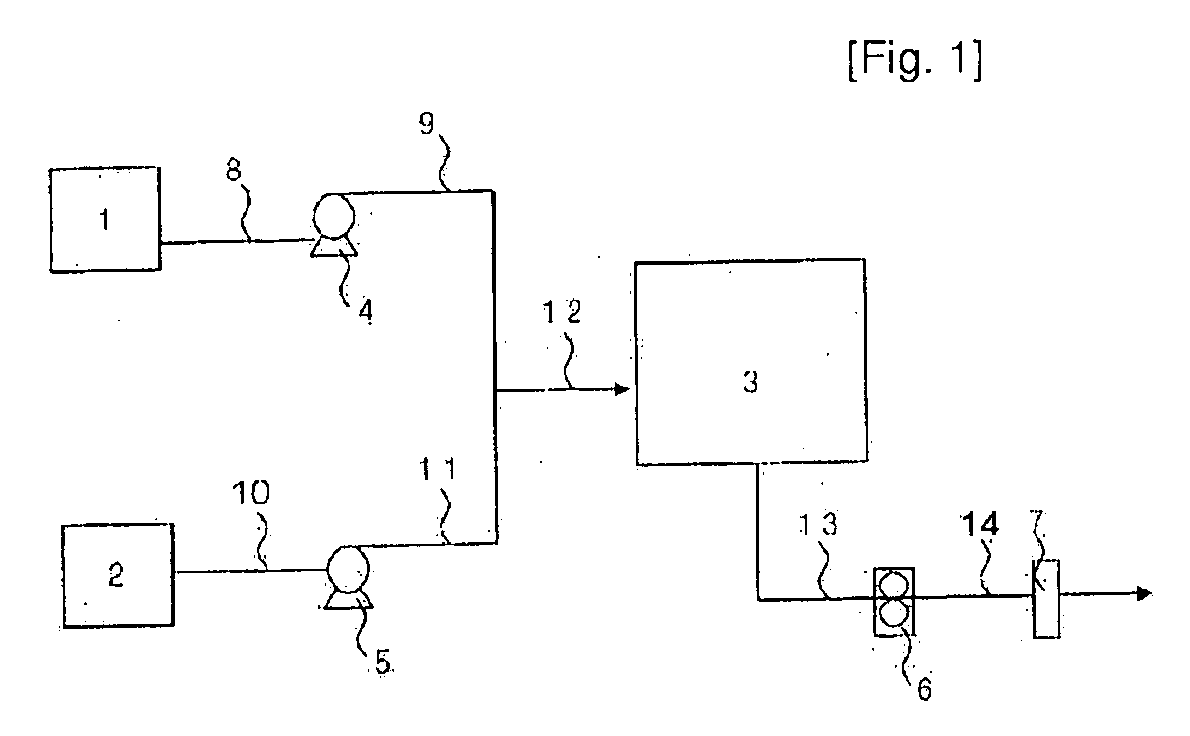

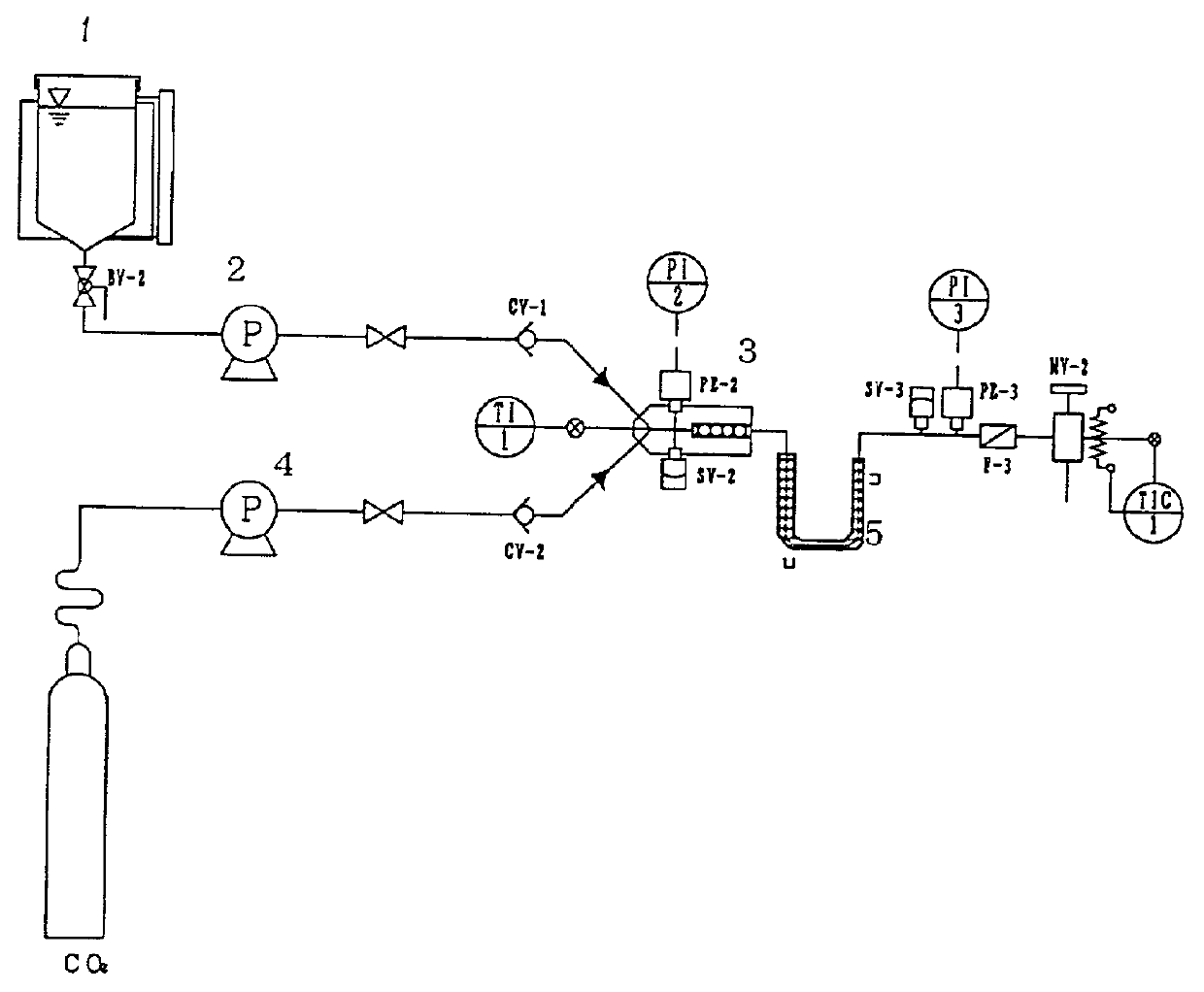

The present invention relates to a method for preparing an acrylic ester polymer syrup by bulk polymerization, and more particularly, to a method for preparing an acrylic ester polymer syrup, which comprises the steps of: supplying a monomer solution and an initiator solution to a monomer solution reservoir and an initiator solution reservoir, respectively; supplying the monomer solution and the initiator solution to a complete-mixing type continuous reactor, while maintaining the dissolved oxygen in the monomer solution reservoir and the initiator solution reservoir at 0.0001 to 3 ppm, separately or after mixing prior to the supply; and performing bulk polymerization continuously while maintaining the solution mixture supplied to the continuous reactor at 70 to 150 ° C. and 1 to 10 atm, with a mean residence time of 30 to 240 minutes. In accordance with the present invention, an acrylic ester polymer syrup can be obtained with a degree of polymerization of 20 to 70% at a low polymerization temperature, even with a small amount of initiator. Productivity can be improved by reducing reaction time with the use of an initiator having a short half-life and polymerization can be performed very stably and continuously without gelation.

Owner:LG CHEM LTD

Process for producing polar polyolefines and modified polyolefines thereof

InactiveUS20050218551A1Increase polarityReduce volatilityCeramic shaping apparatusFlat articlesPolyolefinCompound (substance)

A novel process for modification of polyolefines and their copolymers thereof, enables the production of modified PP with minimal deterioration of molecular weight and low gel content PE and their copolymers and with minimal yellowness. The novel compound is comprised of polyolefin resin or a mixture of resins, unsaturated acidic monomer and organic peroxide, together with low volatility polar acrylic co-monomer and low softening point resin, in a continuous reactive reactor The novel process minimizes sublimation of maleic anhydride and improves distribution of monomers and initiator prior to the melting of the polyolefin.

Owner:POLYRAM RAM ON INDS LP

Two-stage dehydration of sugars

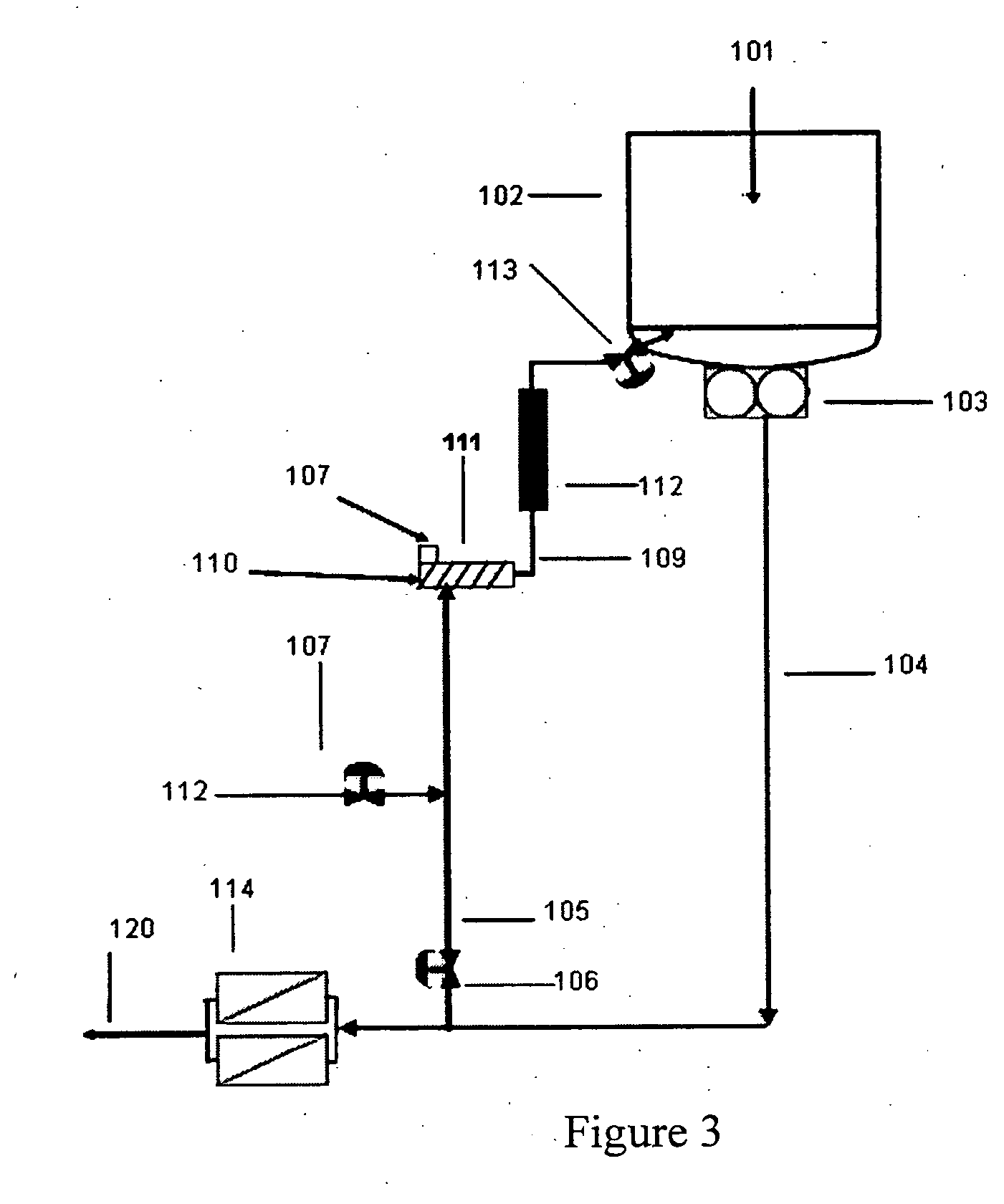

InactiveUS20070173651A1Oxygen-containing compound preparationSugar derivativesContinuous reactorAlcohol

The invention includes methods for producing dianhydrosugar alcohol by providing an acid catalyst within a reactor and passing a starting material through the reactor at a first temperature. At least a portion of the staring material is converted to a monoanhydrosugar isomer during the passing through the column. The monoanhydrosugar is subjected to a second temperature which is greater than the first to produce a dianhydrosugar. The invention includes a method of producing isosorbide. An initial feed stream containing sorbitol is fed into a continuous reactor containing an acid catalyst at a temperature of less than 120° C. The residence time for the reactor is less than or equal to about 30 minutes. Sorbitol converted to 1,4-sorbitan in the continuous reactor is subsequently provided to a second reactor and is dehydrated at a temperature of at least 120° C. to produce isosorbide.

Owner:BATTELLE MEMORIAL INST

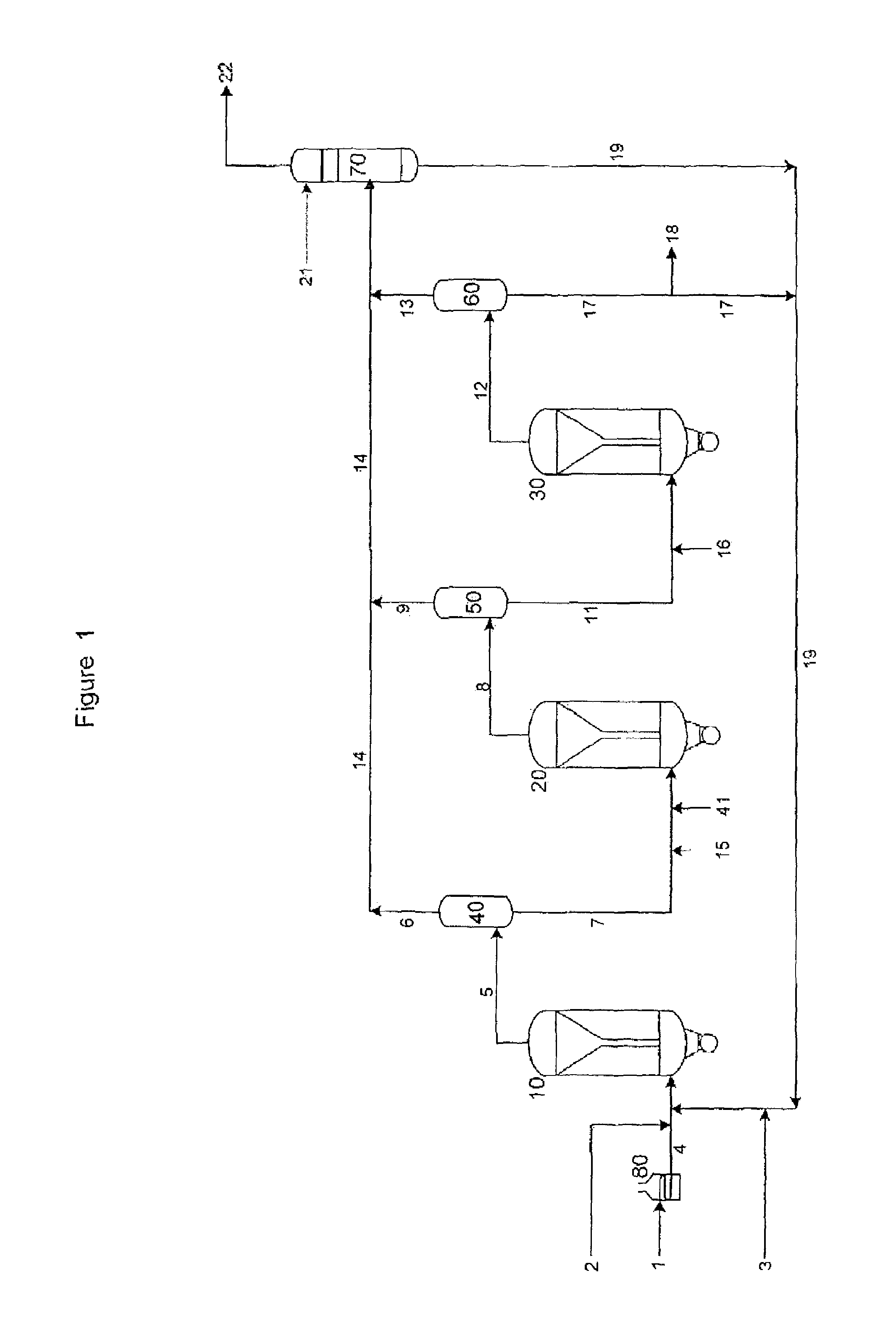

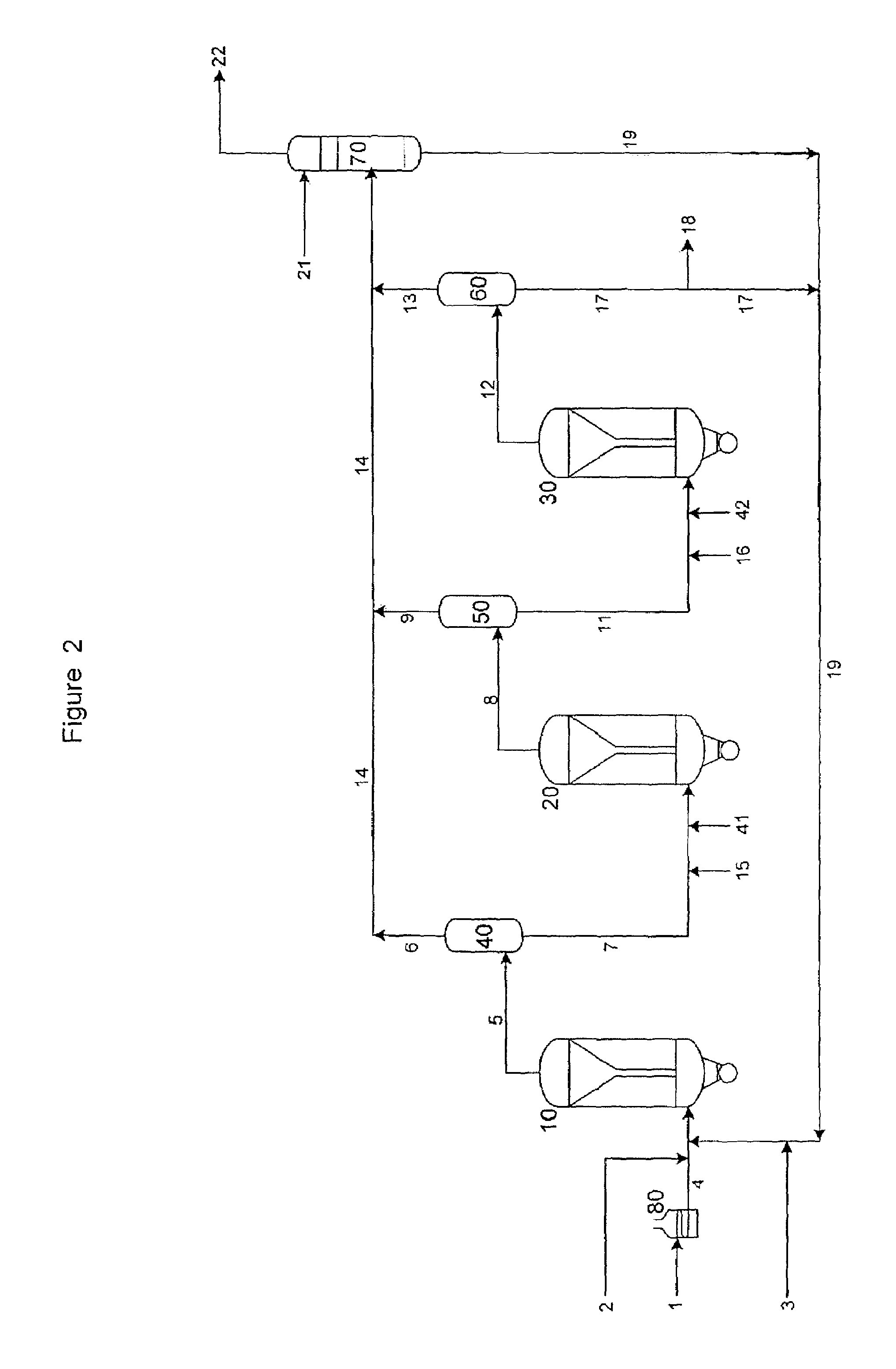

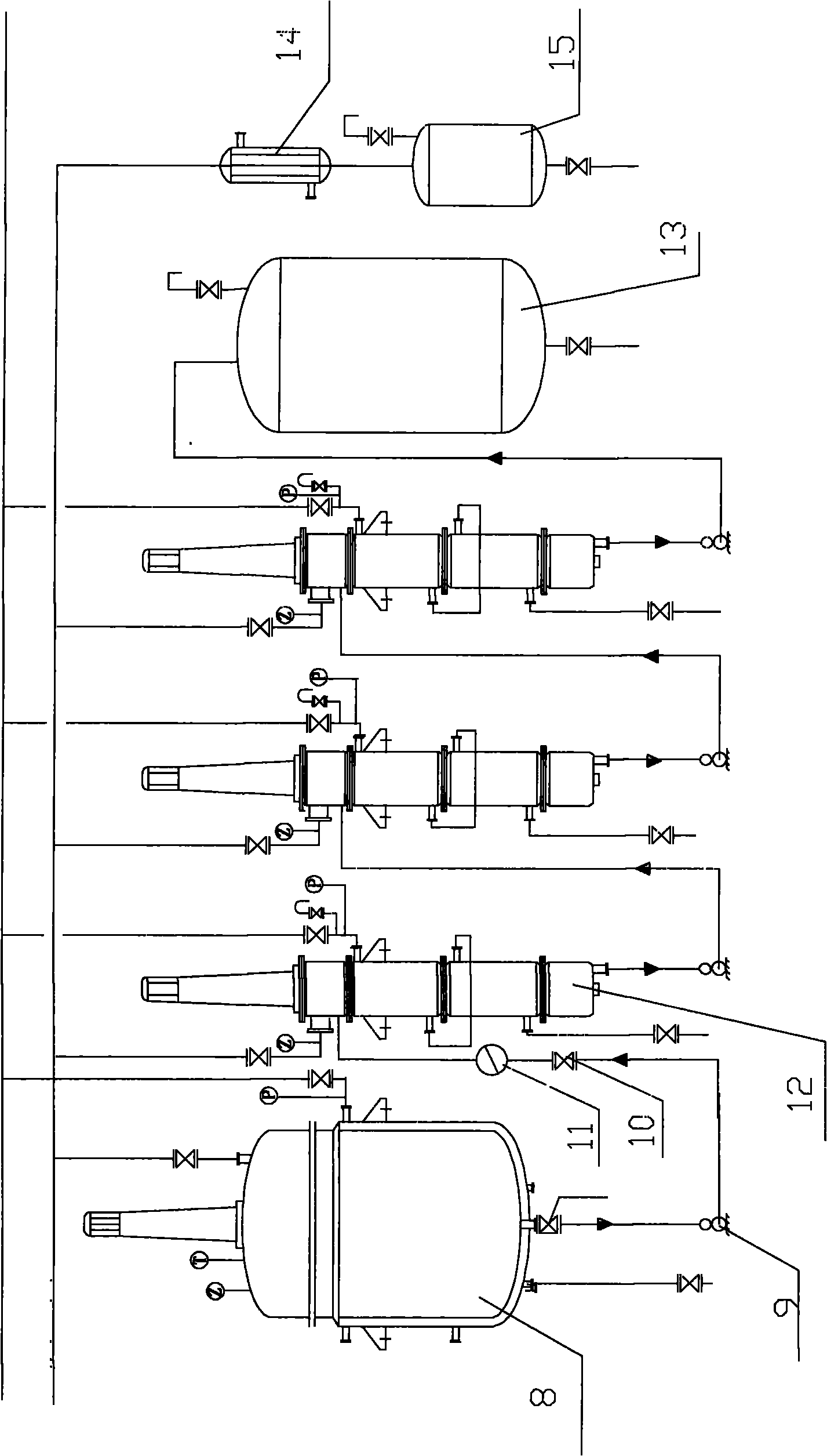

Integrated in-line pretreatment and heavy oil upgrading process

ActiveUS7431831B2Lower capital expenditureImprove product qualityTreatment with plural serial cracking stages onlyTreatment with plural parallel cracking stages onlyContinuous reactorSlurry reactor

A new residuum full hydroconversion slurry reactor system has been developed that allows the catalyst, unconverted oil, products and hydrogen to circulate in a continuous mixture throughout an entire reactor with no confinement of the mixture. The mixture is partially separated in between the reactors to remove only the products and hydrogen while permitting the unconverted oil and the slurry catalyst to continue on into the next sequential reactor. In the next reactor, a portion of the unconverted oil is converted to lower boiling point hydrocarbons, once again creating a mixture of unconverted oil, products, hydrogen and slurry catalyst. Further hydroprocessing may occur in additional reactors, fully converting the oil. The oil may alternately be partially converted, leaving a highly concentrated catalyst in unconverted oil which can be recycled directly to the first reactor. The slurry reactor system is, in this invention, preceded by an in-line pretreating step, such as hydrotreating or deasphalting. Following the slurry reactor system, fully converted oil may be subsequently hydrofinished for the removal of hetoroatoms such as sulfur and nitrogen.

Owner:CHEVROU USA INC

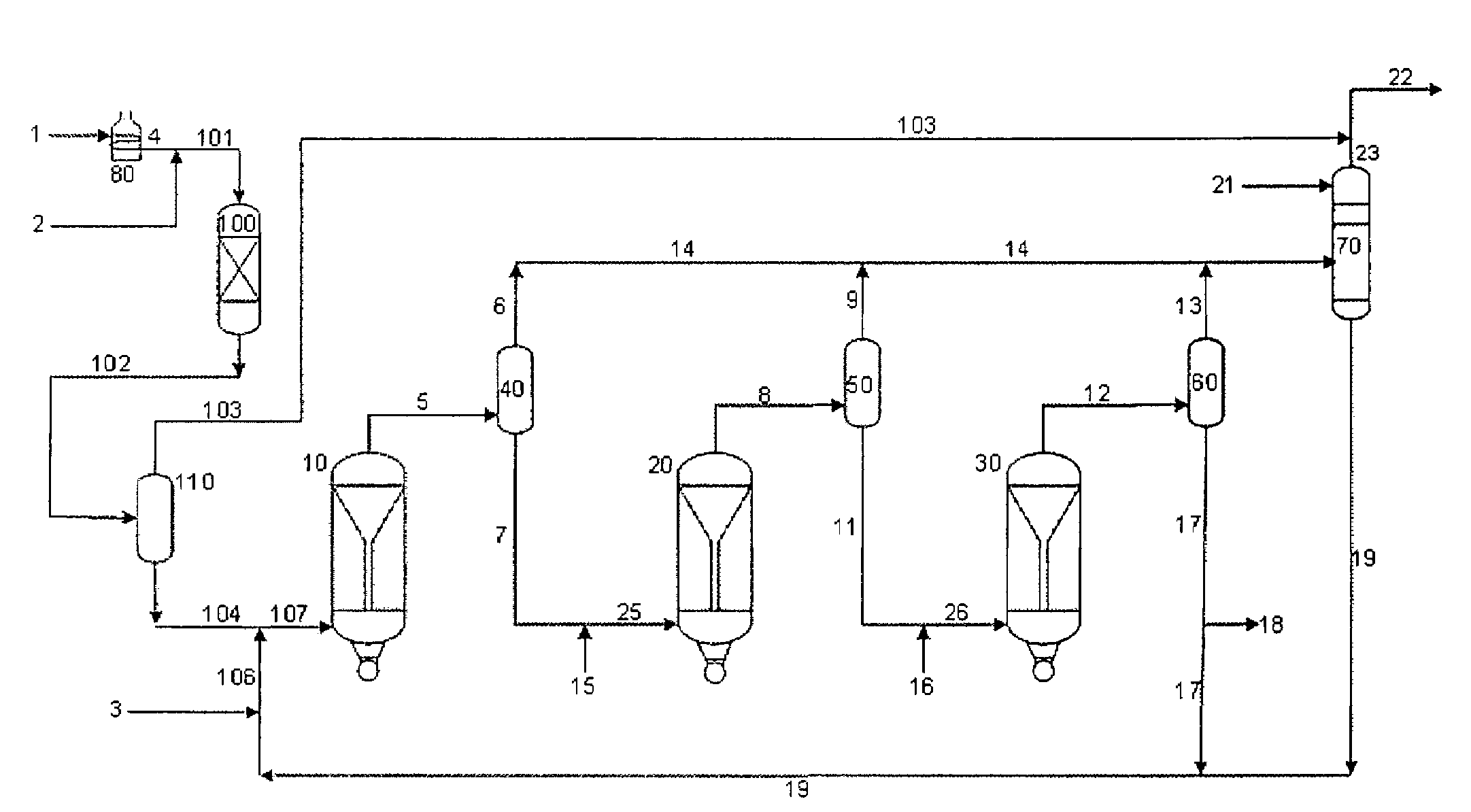

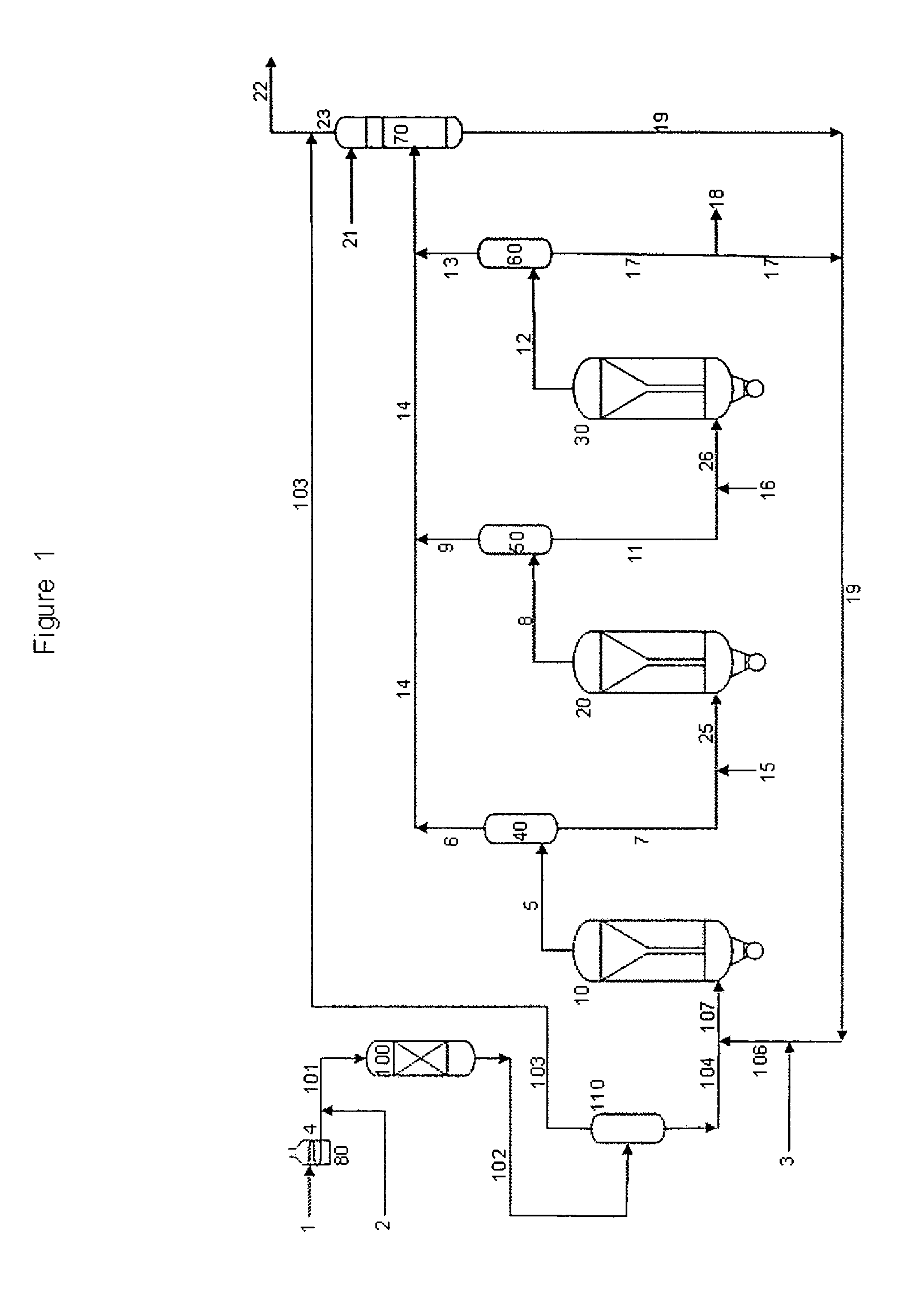

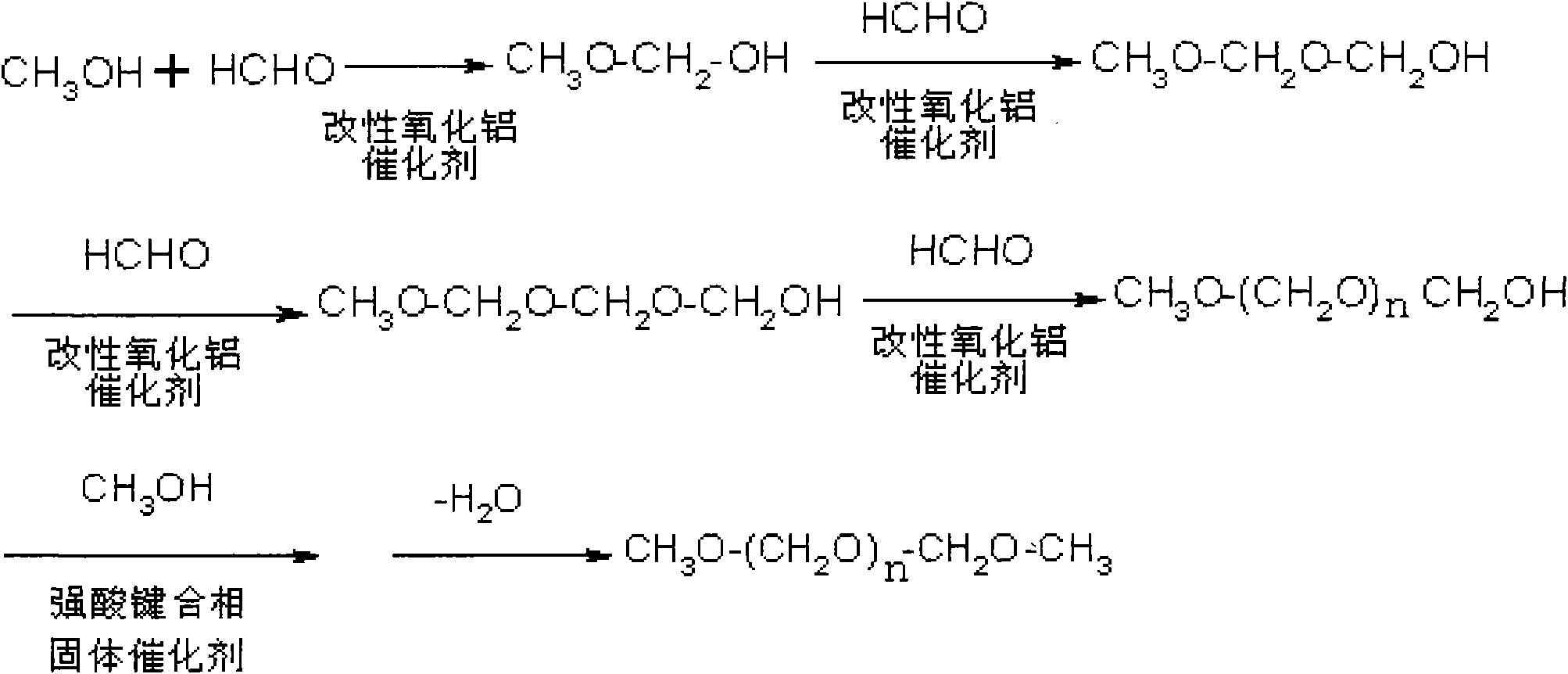

Method for synthesizing polyoxymethylene dimethyl ethers

ActiveCN101898943AImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationSynthesis methodsStrong acids

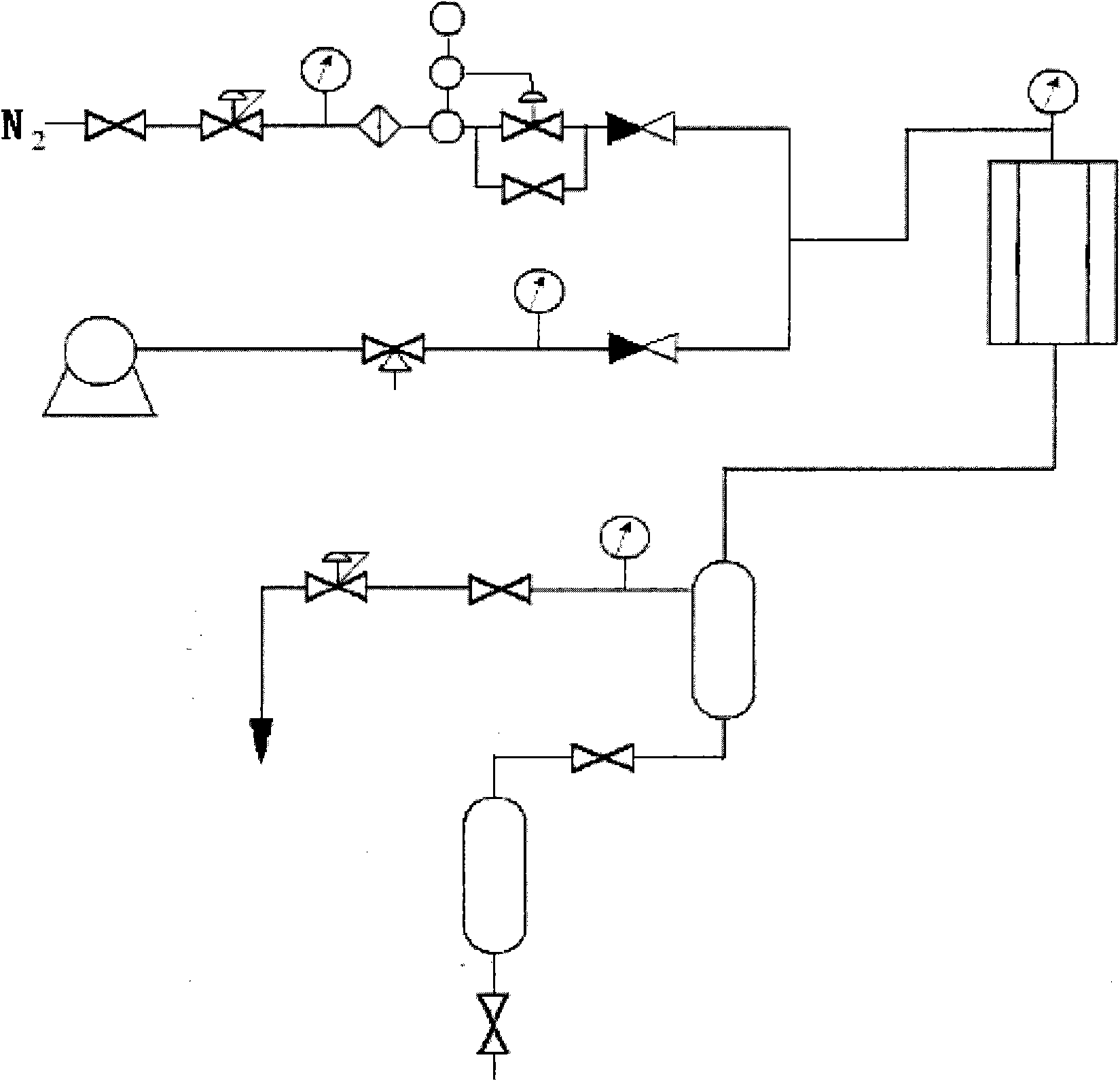

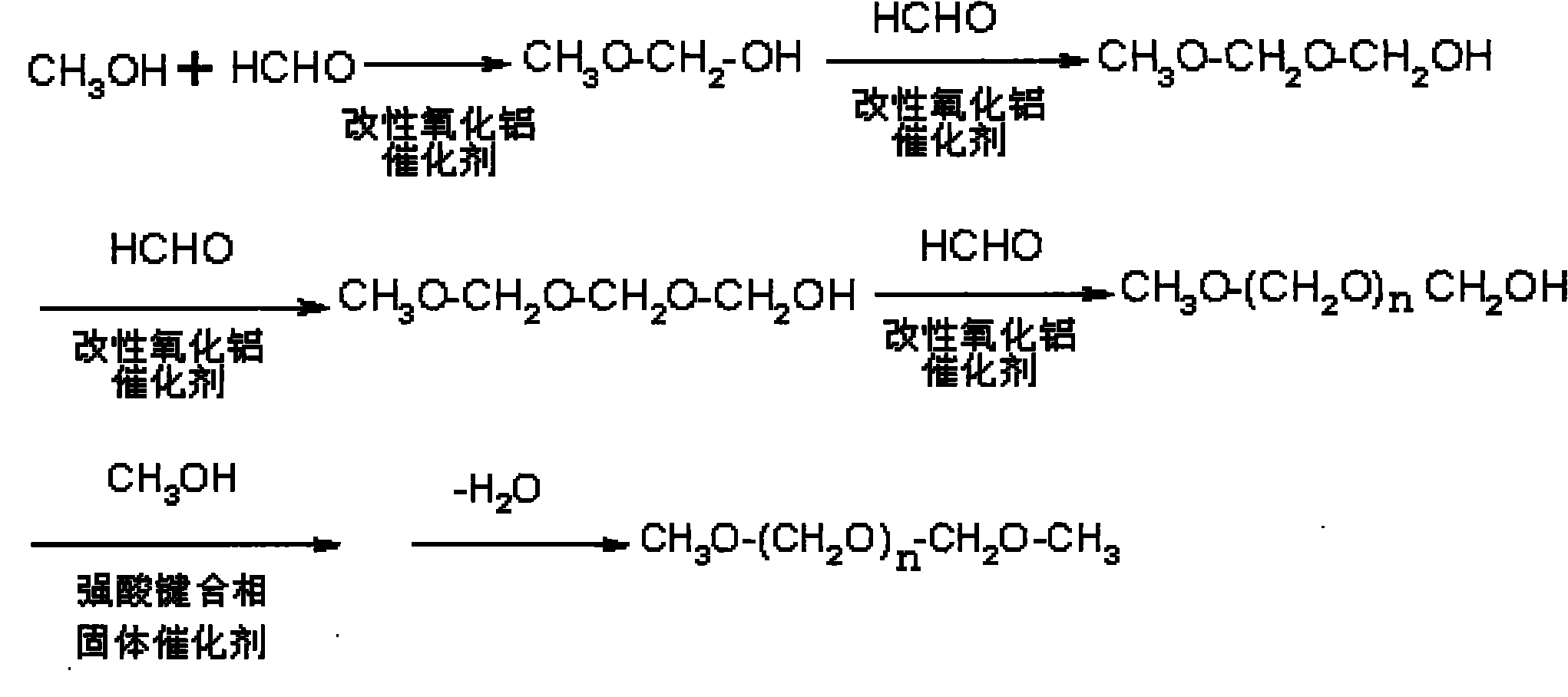

The invention relates to a method for synthesizing polyoxymethylene dimethyl ethers, comprising the following steps: step one, generating hemiacetal by methanol and excessive methanal or paraformaldehyde with low polymerization degree under the existence of a modified alumina catalyst, reacting the hemiacetal with methanal to generate hemiacetal with one more carbon, and successively continuing the above steps to generate poly-hemiacetal with more carbon atoms; and step two, generating the polyoxymethylene dimethyl ethers by the poly-hemiacetal mixture under the existence of methanol and an organic strong acid bonded phase solid catalyst. The invention can achieve the technical targets of improving raw material conversion rate, product selectivity, target product yield and economical efficiency by the two steps of reaction process, adjusts the space velocity by a fixed bed continuous reactor and combines with a catalyst to control the polymerization degree. The synthesis method in the invention has mild reaction conditions and easy control.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

Liquid phase distillate dewaxing

Hydrocarbon feeds can be hydrotreated in a continuous gas-phase environment and then dewaxed in a liquid-continuous reactor. The liquid-continuous reactor can advantageously be operated in a manner that avoids the need for a hydrogen recycle loop. A contaminant gas can be added to the hydrogen input for the liquid-continuous reactor to modify the hydrogen consumption in the reactor.

Owner:EXXON RES & ENG CO

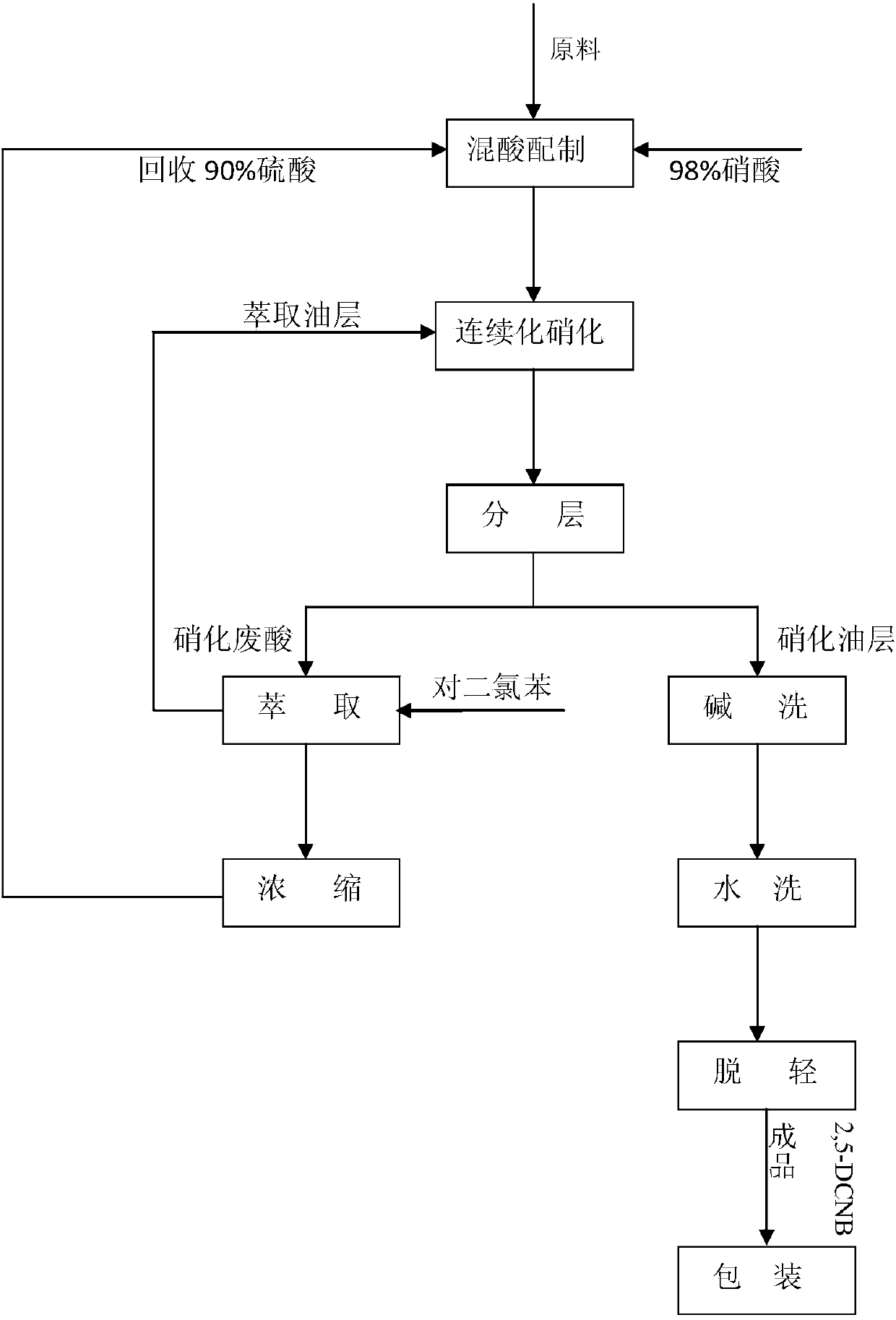

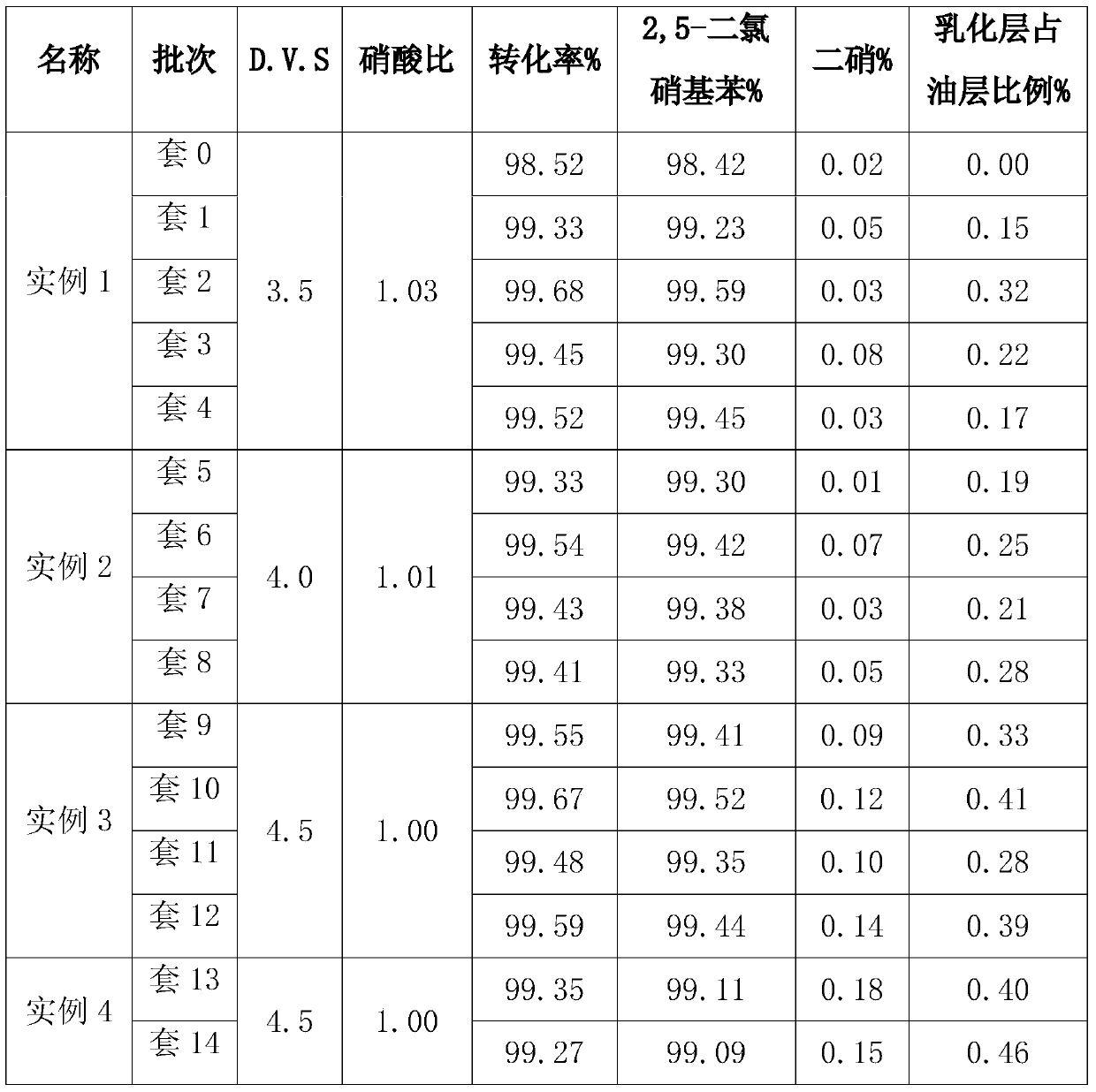

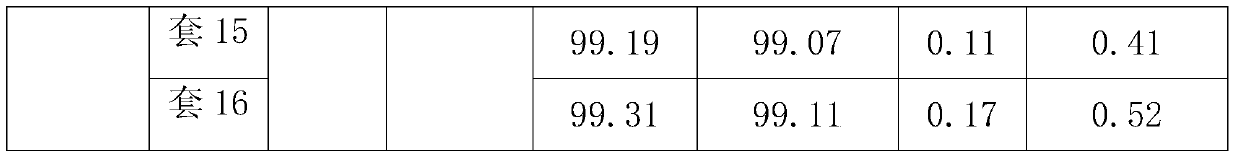

Method capable of recycling acids for preparing 2,5-dichloronitrobenzene (DCNB) through continuous nitration

ActiveCN104649910AReduce labor intensitySimple processNitro compound preparationContinuous reactorEmulsion

The invention relates to a production method for preparing 2,5-dichloronitrobenzene (DCNB) through continuous nitration, which particularly realizes the recycling of waste acids in the preparing process. The invention provides a technological program capable of recycling acids for preparing 2,5-dichloronitrobenzene (DCNB) through the continuous nitration, which is characterized in that sulfuric acid and nitric acid are prepared into a mixed acid, the mixed acid and paradichlorobenzene are simultaneously fed into a three-stages kettle (ring) type continuous reactor to carry out nitration reaction, a nitration reaction solution discharged form the third-stage kettle (ring) type continuous reactor is stood for layering so as to obtain a nitrifying oil layer and a nitrifying waste acid, and the nitrifying oil layer is subjected to alkali cleaning, water washing and light component removal so as to obtain a 2,5-DCNB finished product; paradichlorobenzene is added into the nitrifying waste acid to extract organic matters in the acid layer, residual HNO3 in the acid layer is consumed, after the extraction is completed, the obtained product is layered so as to obtain an extraction oil layer and an extracted residual waste acid, the extraction oil layer is used for next-batch nitrification, the extracted residual waste acid after being concentrated and nitric acid are prepared into the waste acid for next-batch nitrification, a small amount of emulsion layer is produced in the process of recycling, and the emulsion layer after being combined with the nitrifying oil layer is subjected to alkali cleaning and water washing.

Owner:JIANGSU YANGNONG CHEM GROUP +2

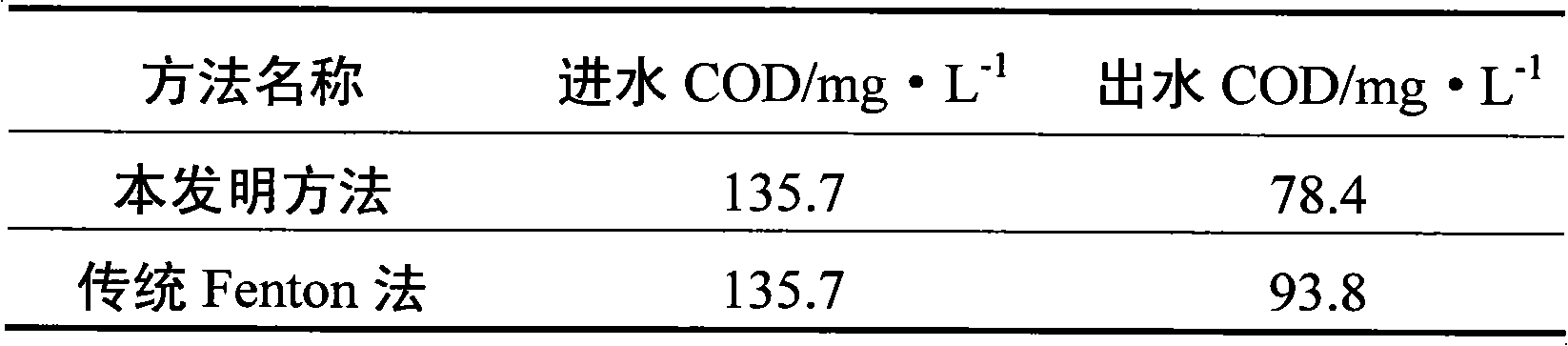

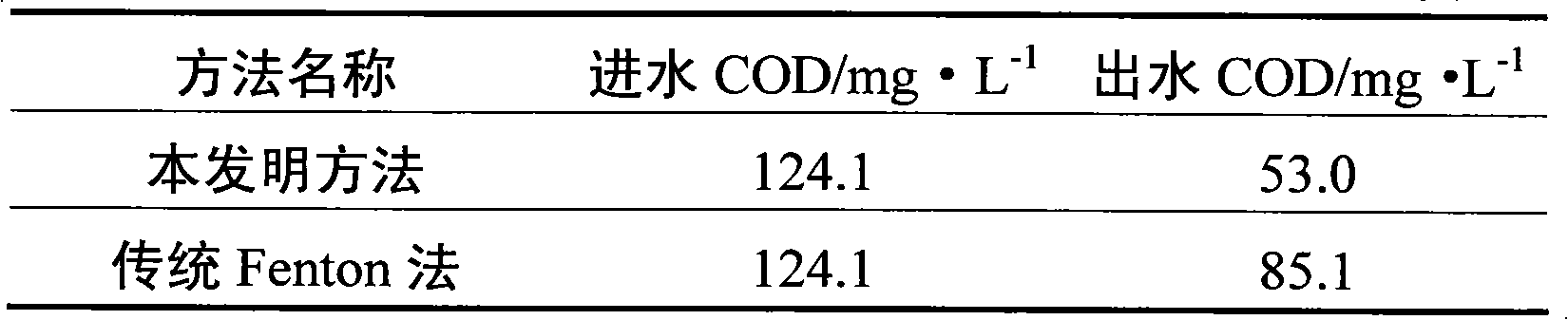

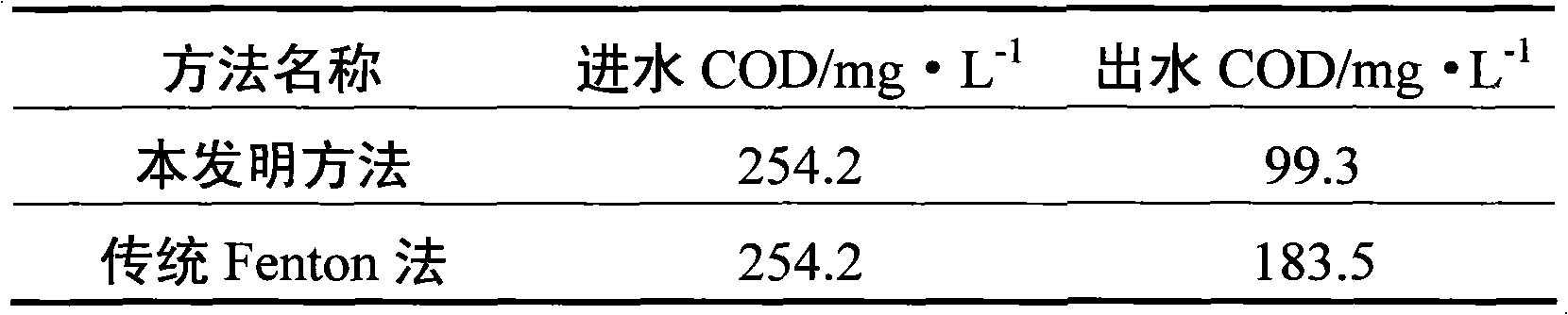

Method for treating sewage by Fenton process

ActiveCN101659467AReduce dosageReduce processing costsWater/sewage treatment by oxidationContinuous reactorTreatment effect

The invention provides a method for treating sewage by Fenton process, which comprises: adopting a multistage serial reactor or a single-stage continuous reactor; adding a catalyst in the initial stage of a reaction; adjusting the pH value to 1.5 to 6.5; sequentially adding an oxidizer in the multistage serial reactor or adding the oxidizer at a plurality of points along water flow direction in the single-stage continuous reactor; and controlling the total additive amount of the oxidizer calculated by mg / L to be smaller than sewage COD value calculated by mg / L. Compared with the conventional method using a single-stage Fenton process, the method requires a greatly reduced amount of the oxidizer and the catalyst for achieving the same treatment effect and reduces treatment cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

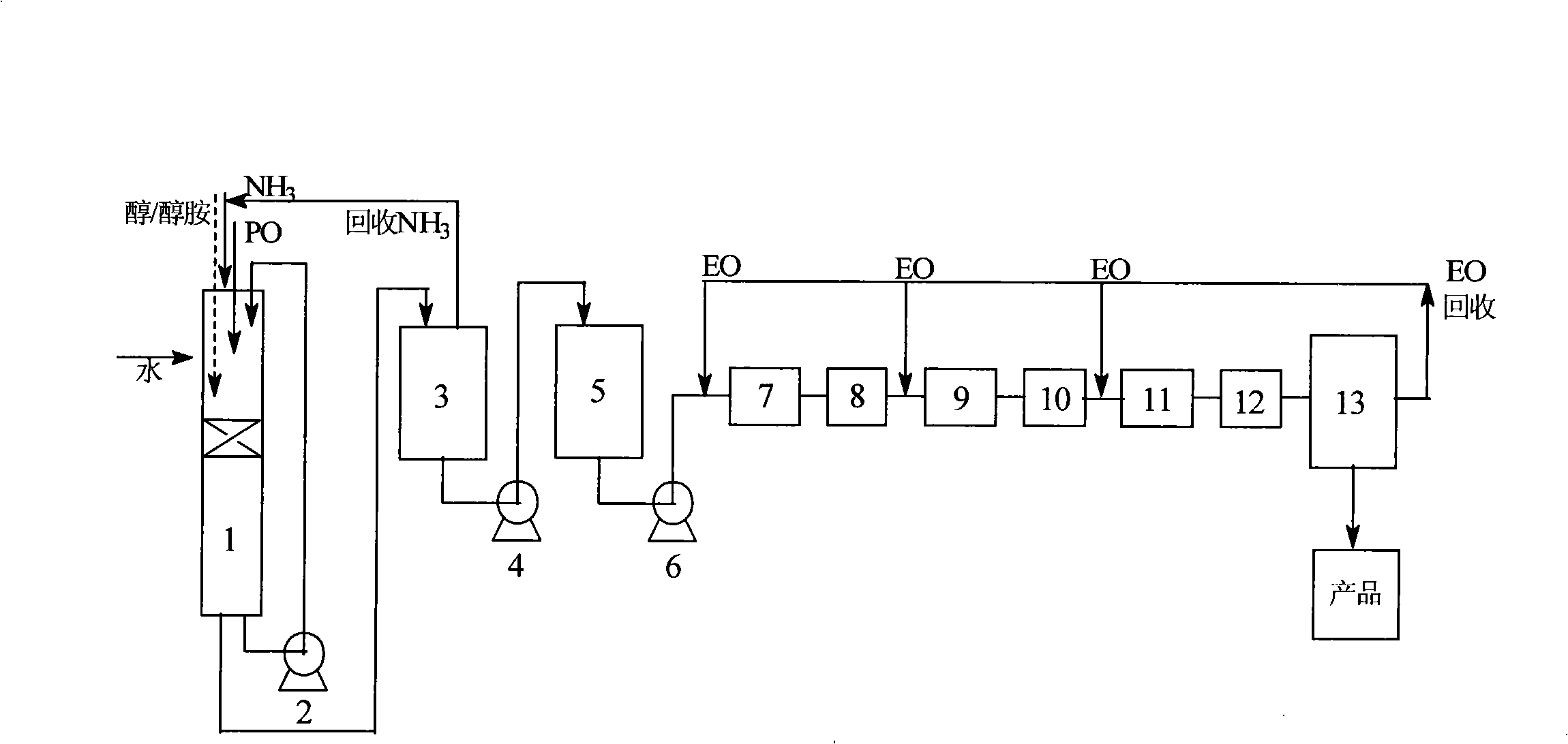

Method for continuously producing high-efficiency concrete grinding aid

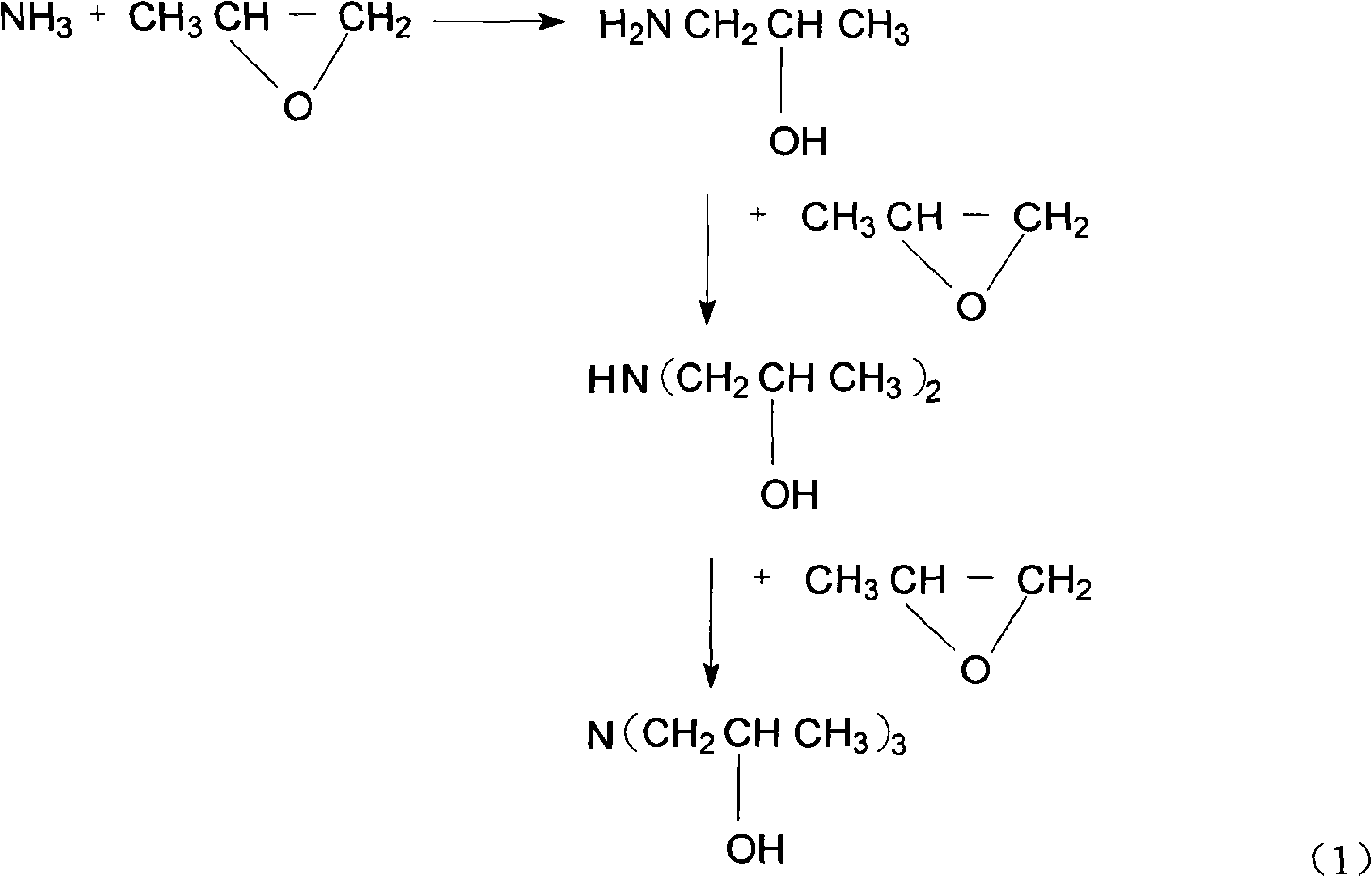

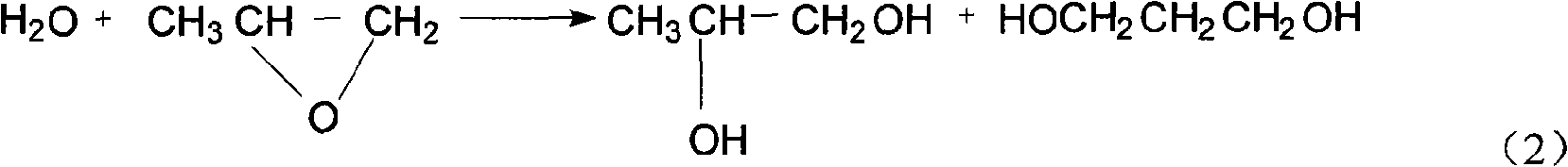

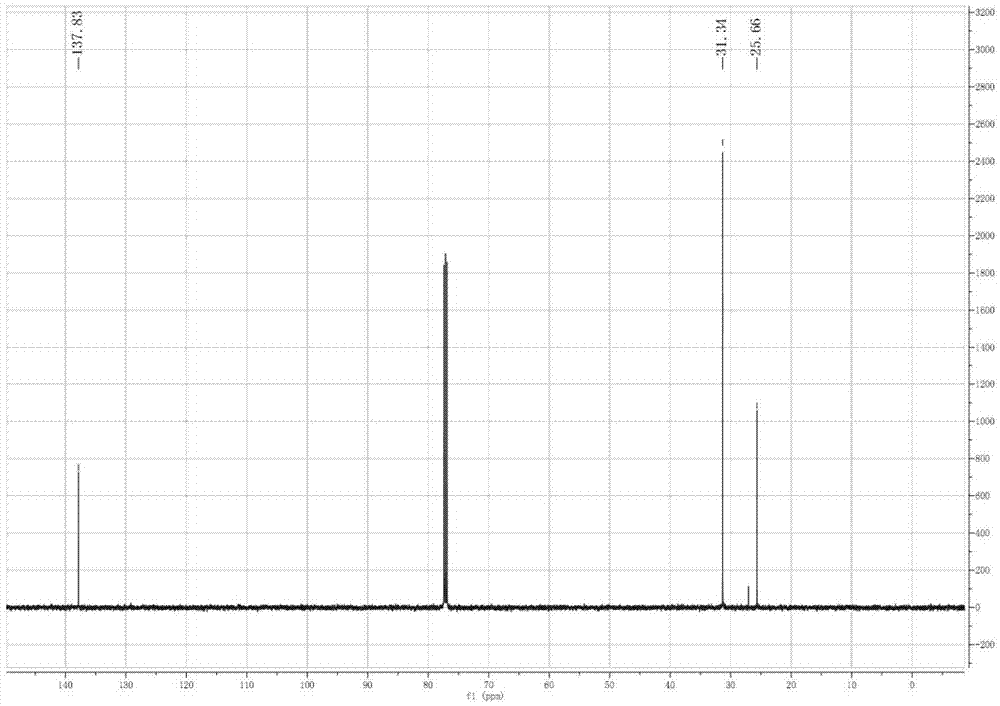

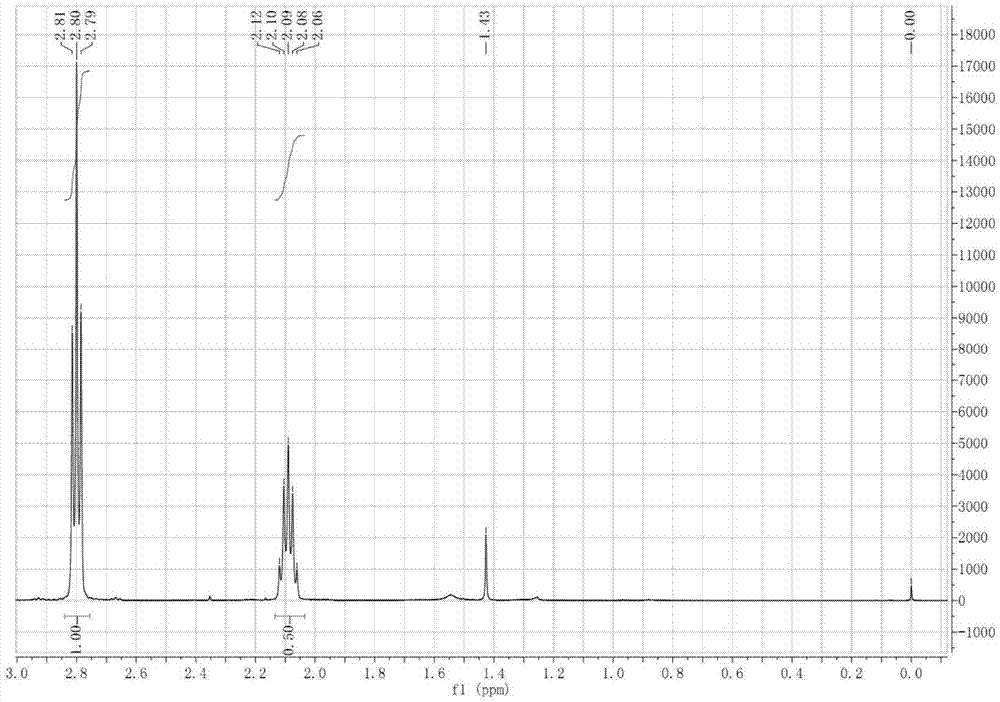

InactiveCN101314533AReduce production energy consumptionReduce manufacturing costCement productionContinuous reactorMonoisopropanolamine

The invention provides a method for realizing simple and direct preparing of high-efficiency cement rubber additive. The method, which has lower cost and takes ammonia, propylene oxide (PO) and ethylene oxide (EO) as raw materials, comprises the following steps that: superfluous ammonia stream and PO stream are fed into a continuous reactor so as to continuously form a mixture containing isopropanolamine, diisopropanolamine and triisopropanolamine; liquid level inside the continuous reactor is maintained to ensure that the stream in the reactor undergoes outer circulation spraying through a circulating pump from the bottom to the top of the continuous reactor, and part of the stream is continuously fed into a flash tower so as to remove unreacted ammonia; then, the stream with ammonia removed is reacted with EO stream so as to continuously generate products. The method ensures that products do not need rectification separation and greatly reduce production energy consumption, thereby reducing the production cost of products.

Owner:HONGBAOLI GRP CO LTD

Preparation method of high-density liquid hydrocarbon fuel

InactiveCN106867565AThe synthetic route is simpleEfficient synthetic routeLiquid hydrocarbon mixture productionBio-feedstockCarbon numberAlkane

The invention relates to a preparation method of high-density liquid hydrocarbon fuel. The method totally comprises two parts: (1) on a first catalyst bed layer of a fixed bed continuous reactor, cyclopentanone (furfural water phase selective hydrogenation products) takes a self aldol condensation (and hydrogenation) reaction under the catalysis effect of acid / alkali catalysts or metal doping solid alkali to obtain oxygen-containing organic compounds with the carbon number being 15 and 10; (2) on a second catalyst bed layer of the fixed bed continuous reactor, the products generated on the first catalyst bed layer take a further hydrodeoxygenation reaction under the conditions of low temperature and no solvent under the catalysis effect of load metal A / X type bifunctional catalysts to obtain polycyclic hydrocarbon fuel with the carbon number being 15 and 10. The high-density liquid fuel (C15 tri-cycloalkane: 0.917 g / cm<3>; C10 bi-cycloalkane: 0.866g / cm<3>) has the advantages that the energy carried by an aircraft can be effectively improved; the engine oil consumption rate is reduced; the requirements of high flight speed, great load and long emitting range can be met.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

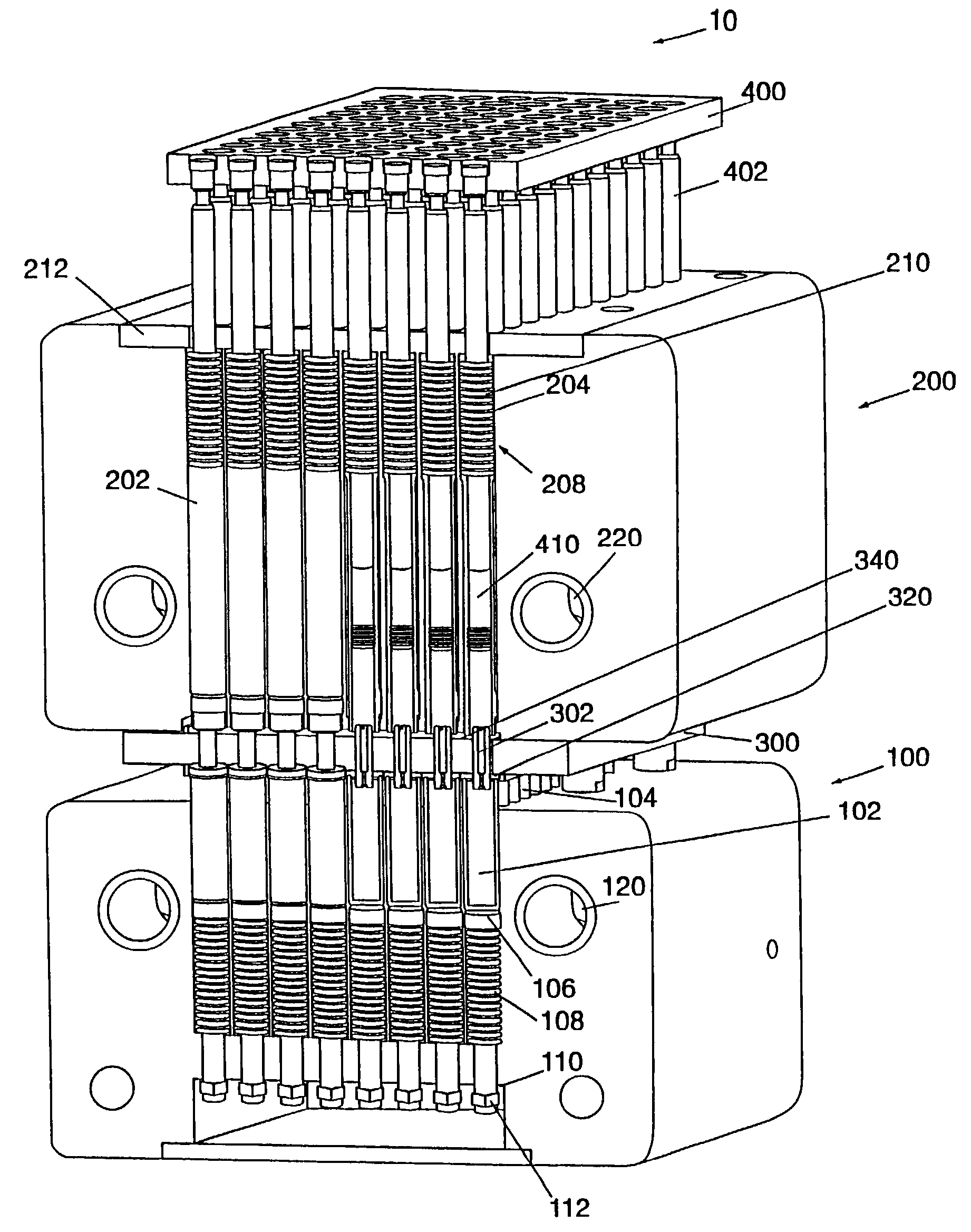

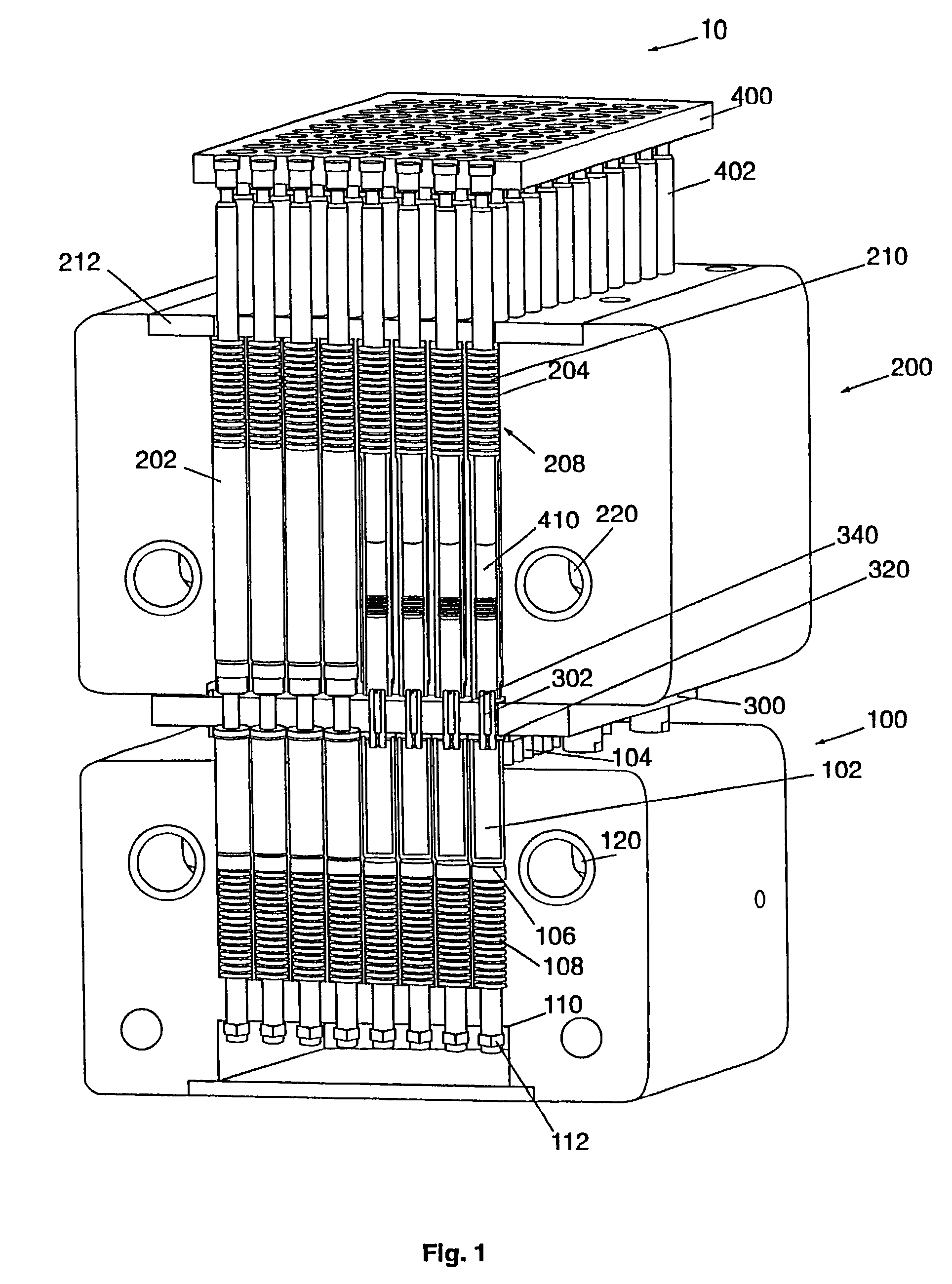

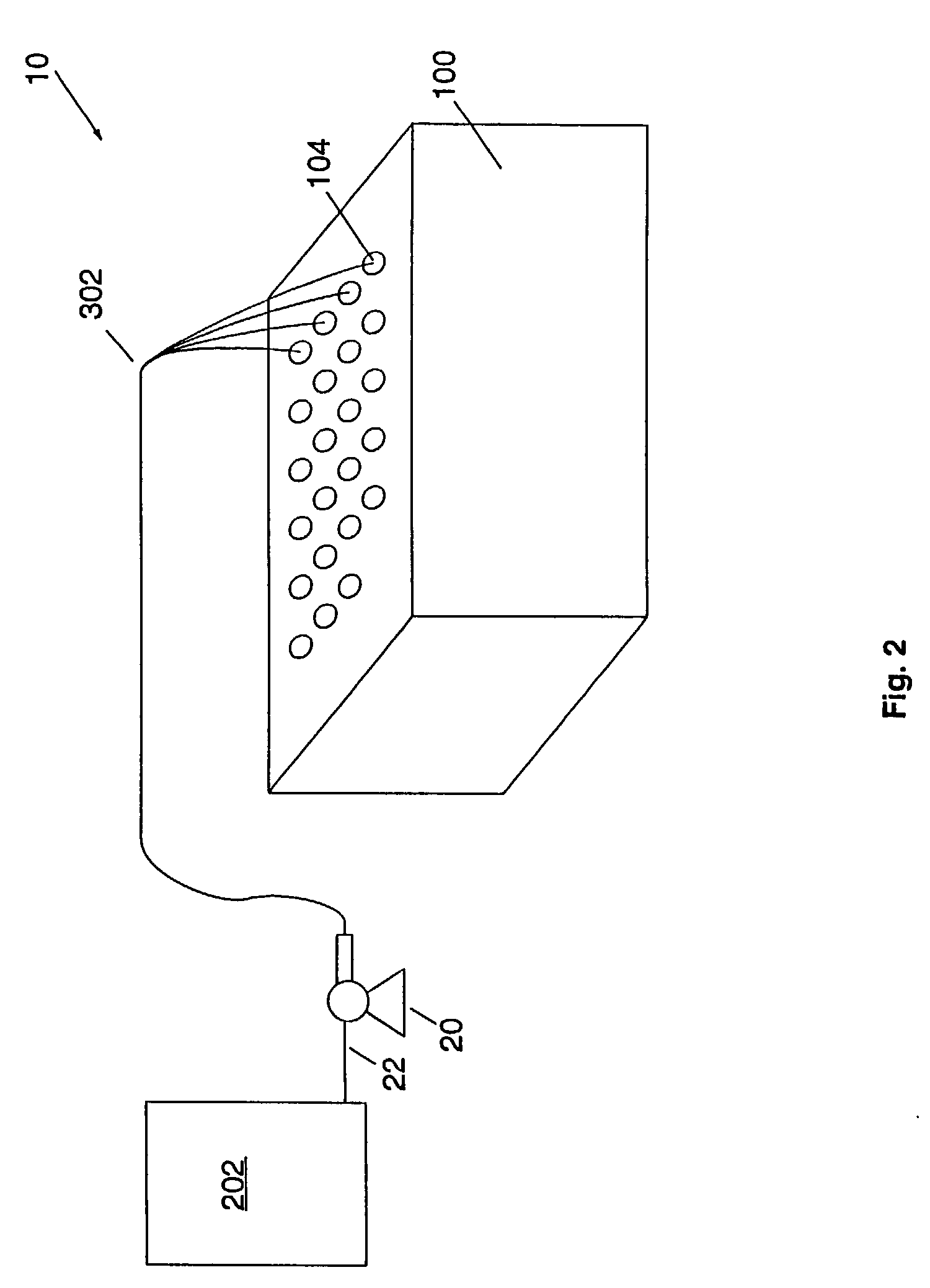

Parallel semi-continuous or continuous reactor system

InactiveUS7115234B2Prevent undesired mixingReduce entrapmentGaseous chemical processesSequential/parallel process reactionsContinuous reactorProcess engineering

A method and apparatus for reacting a plurality of different mixtures in parallel in a semi-batch or continuous mode is provided. Each reaction is contained within a reactor vessel, the reactor vessels combined into a reactor block. Reactant(s) to be added during the reaction are kept in a header barrel, which has a plunger to feed reactant(s) from the header barrel through a transfer line into the reactor vessel. The plunger is moved using a drive system. The header barrels are optionally combined in a header block. The header block is sealed to a plate containing the transfer lines, which in turn is sealed to the reactor block. A latch mechanism is provided for easy sealing of the reactor and header blocks to the plate. The entire apparatus may be placed on a rocker or rotating plate for mixture as the reaction is proceeding.

Owner:FREESLATE

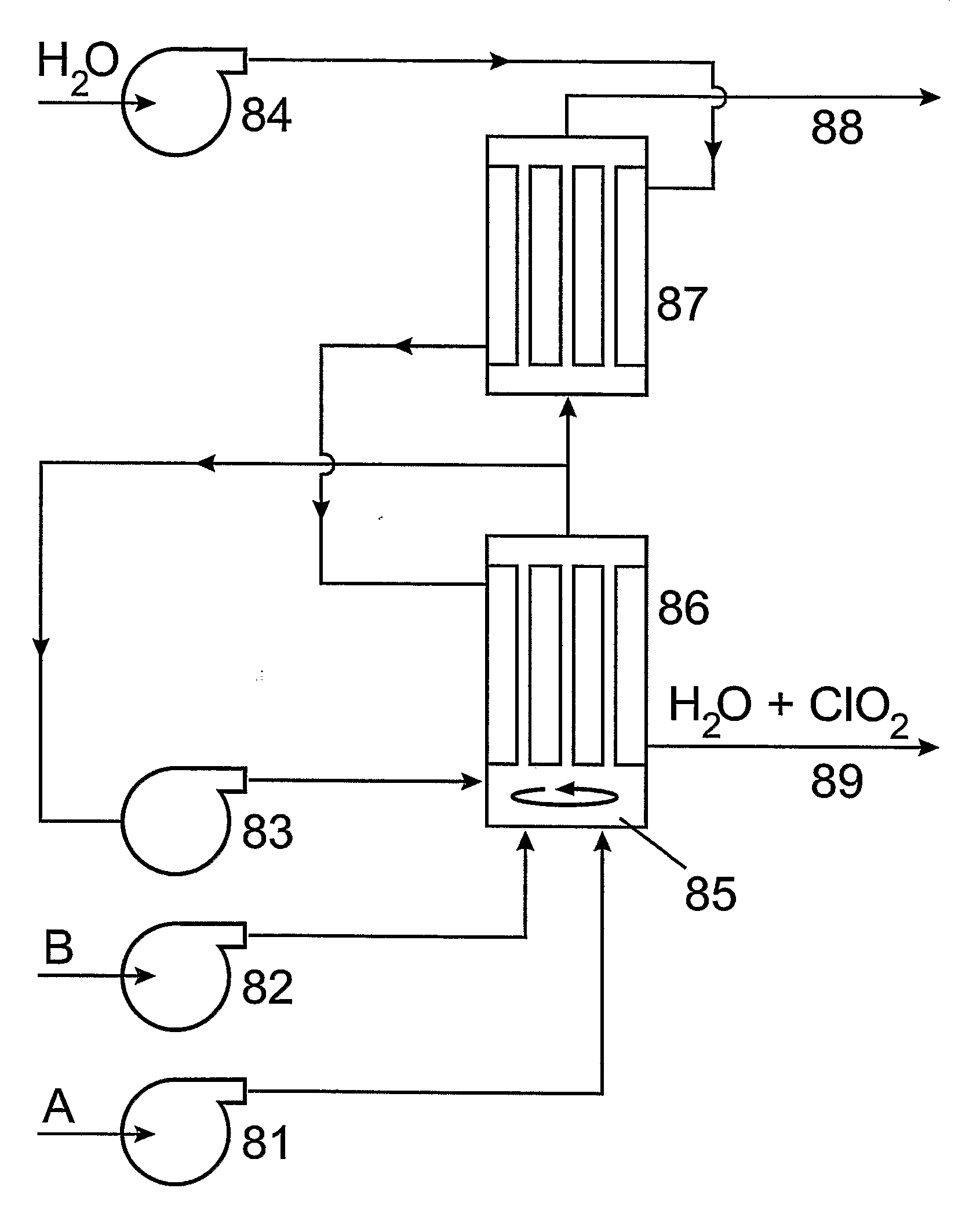

Permeation method and apparatus for preparing fluids containing high purity chlorine dioxide

ActiveUS20100189631A1Simple equipmentEasy constructionSemi-permeable membranesMembranesContinuous reactorChlorine dioxide

Method to prepare fluids (liquids and gases) containing pure chlorine dioxide which is not contaminated by the starting materials or the byproducts of the chlorine dioxide synthesis or to deliver pure chlorine dioxide into any medium capable of dissolving chlorine dioxide, wherein the chlorine dioxide generated in the process is transported across a pore free polymeric membrane via selective permeation into the target medium. Apparatus to realize the said method, wherein the generation of chlorine dioxide is carried out in such a reactor where some or all walls comprising the reactor, or the walls of a permeator unit attached to the reactor, are made of the said pore free polymer, characteristically some kind of silicone rubber, which is highly permeable to chlorine dioxide, but which is practically impermeable for the acidic and corrosive reagents used for the chlorine dioxide synthesis, its permeability being at least 3 orders of magnitude lower for these contaminating components compared to that of chlorine dioxide. The invention can be realized both by batch and by continuous reactors.

Owner:NOSZTICZIUS ZOLTAN

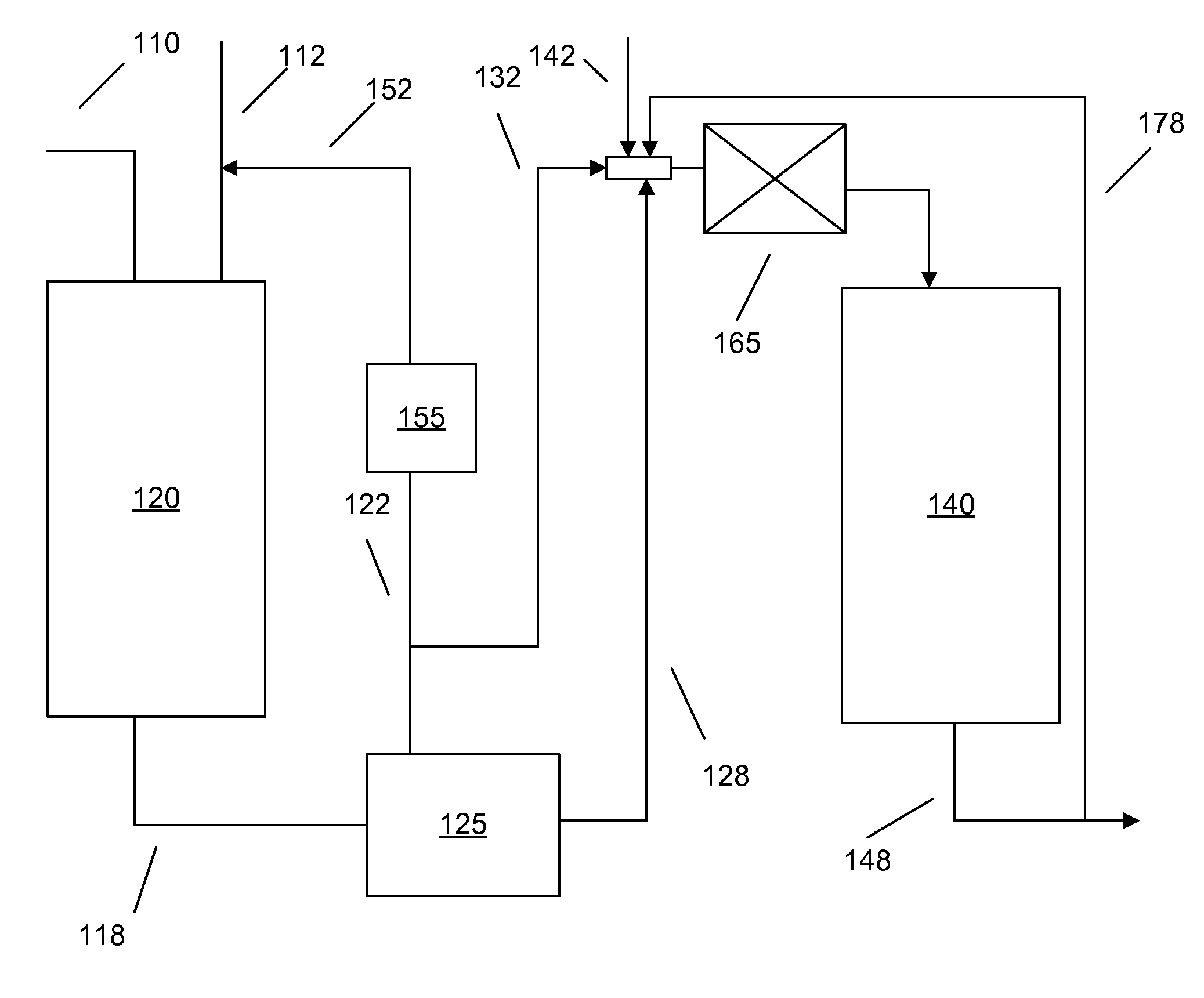

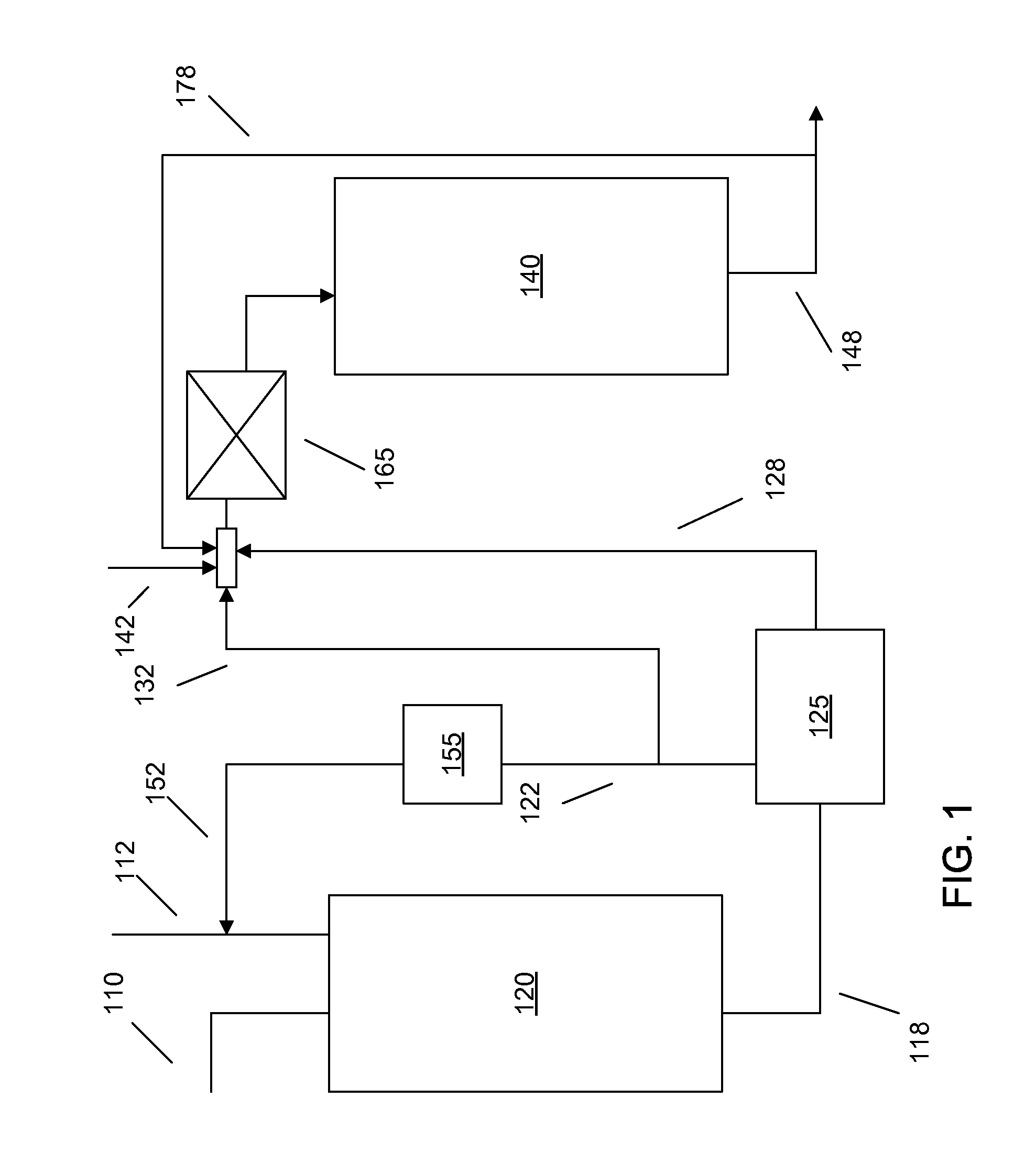

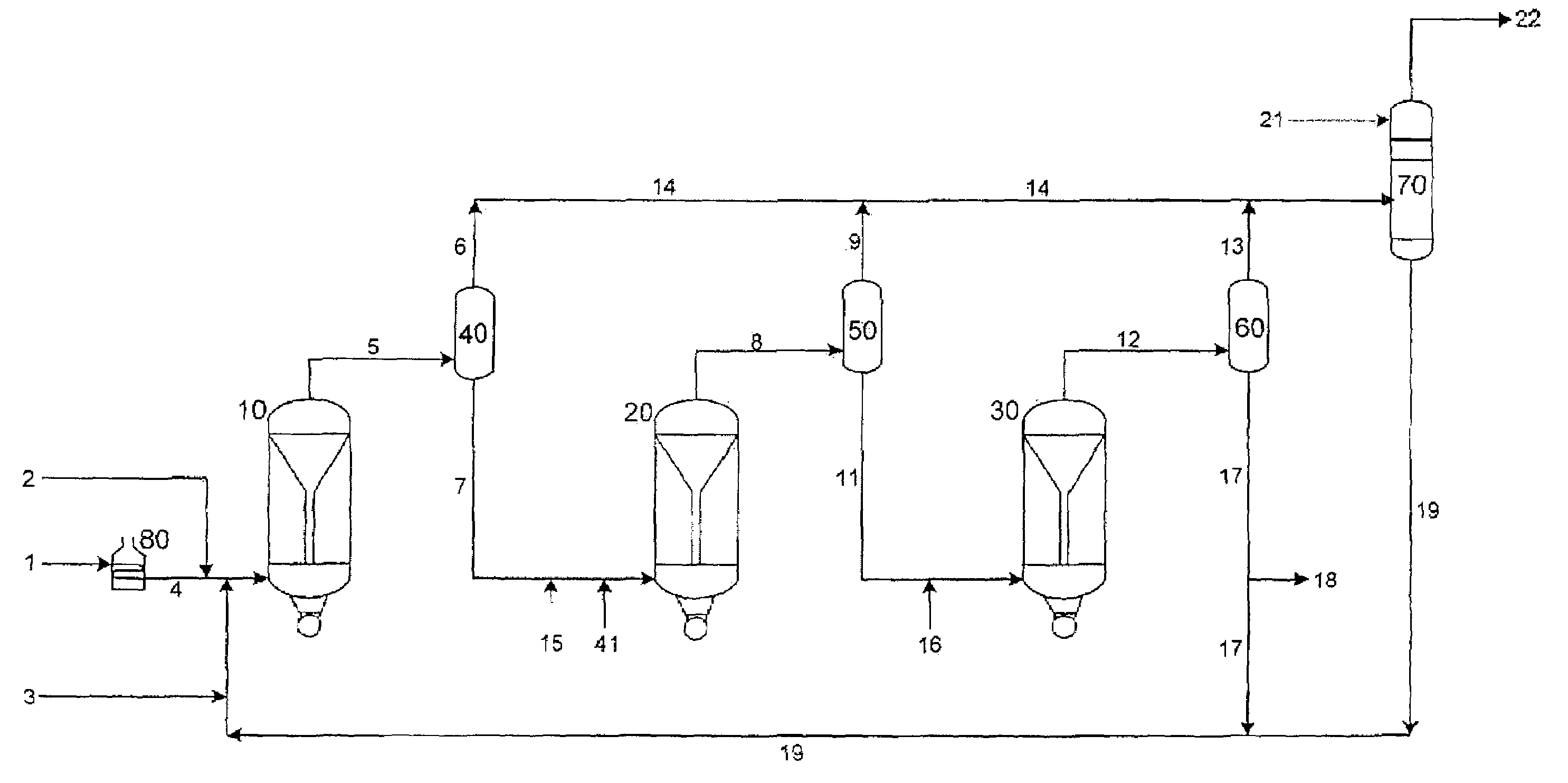

Process for upgrading heavy oil using a highly active slurry catalyst composition

ActiveUS7390398B2Treatment with plural serial cracking stages onlyCoke ovensContinuous reactorHydrogen

Applicants have developed a new residuum full hydroconversion slurry reactor system that allows the catalyst, unconverted oil and converted oil to circulate in a continuous mixture throughout an entire reactor with no confinement of the mixture. The mixture is partially separated in between the reactors to remove only the products and hydrogen gas, while permitting the unconverted oil and the slurry catalyst to continue on into the next sequential reactor. A portion of the unconverted oil is then converted to lower boiling point hydrocarbons, once again creating a mixture of unconverted oil, products, hydrogen, and slurry catalyst. Further hydroprocessing may occur in additional reactors, fully converting the oil. Additional oil may be added at the interstage feed inlet, possibly in combination with slurry. The oil may alternately be partially converted, leaving a highly concentrated catalyst in unconverted oil which can be recycled directly to the first reactor.

Owner:CHEVROU USA INC

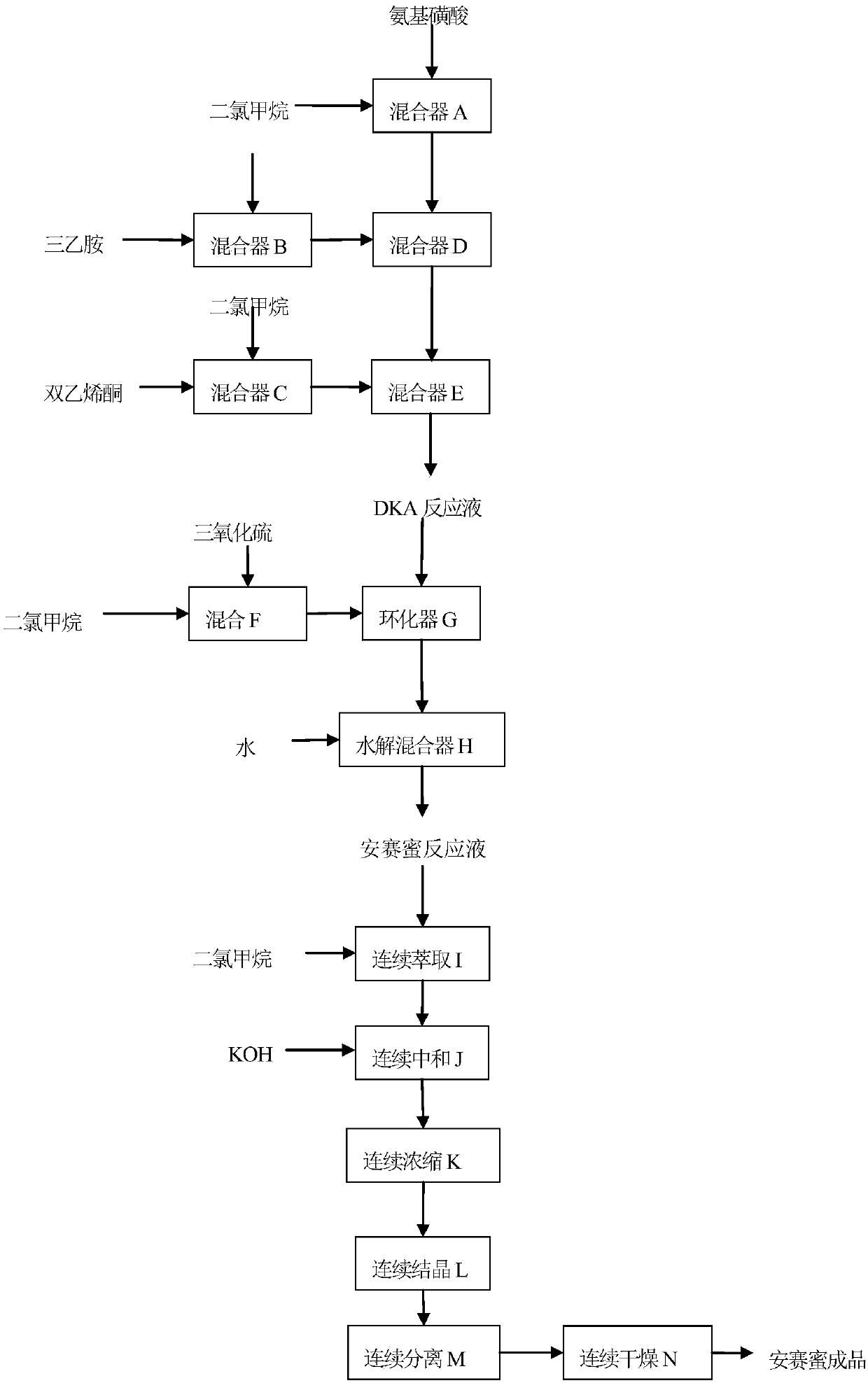

Method for continuously producing acesulfame potassium

The invention belongs to the field of chemical production, and provides a method for continuously producing acesulfame potassium, which comprises the following steps: continuously mixing and dissolving sulfamic acid and dichloromethane, continuously neutralizing with a triethylamine solution, introducing the neutralized reaction solution and ketene dimer into a continuous reactor, and carrying outaddition acylation reaction to obtain a DKA reaction solution; sulfur trioxide and solvent micro-mixing: S03, enabling dichloromethane to enter a micro-mixer, so as to prepare a cyclizing agent; cyclization and hydrolysis: continuously feeding the DKA reaction solution and a cyclizing agent into a cyclization microreactor to generate a cyclization reaction solution, and continuously feeding the cyclization reaction solution into a hydrolysis microreactor to obtain an acesulfamic acid reaction solution; enabling the acesulfame acid reaction liquid and dichloromethane to enter continuous extraction equipment, enabling an extracted organic phase and a potassium hydroxide aqueous solution to enter a continuous neutralization reactor to obtain acesulfame acid potassium reaction liquid, and subjecting the acesulfame acid potassium reaction liquid to continuous concentration, continuous crystallization, continuous separation and continuous drying to obtain the acesulfame acid potassium finished product. The process has the characteristics of simple process, low cost, good product quality, continuous whole process and the like.

Owner:NANTONG ACETIC ACID CHEM +1

Method for anionic polymerization of lactames

The invention relates to a novel process for the anionic polymerization of lactams, in which:(a) (i) a catalyst capable of creating a lactamate and (ii) a regulator chosen from the amides of formula R1-NH-CO-R2, in which R1 can be substituted with a radical R3-CO-NH- or R3-0- and in which R1, R2 and R3 denote an aryl, alkyl or cycloalkyl radical, are dissolved in the molten lactam; the temperature of this reaction mixture being between the melting point of the lactam and 15° C. higher in order to ensure its good stability,(b) the solution from step (a) is introduced into a mixing device and is then heated to a temperature which is sufficient to obtain bulk polymerization of the lactam in no more than 15 minutes.(b) is usually a continuous reactor, for example an extruder; however, it can be replaced with a mold.

Owner:GENERAL ELECTRIC CO +1

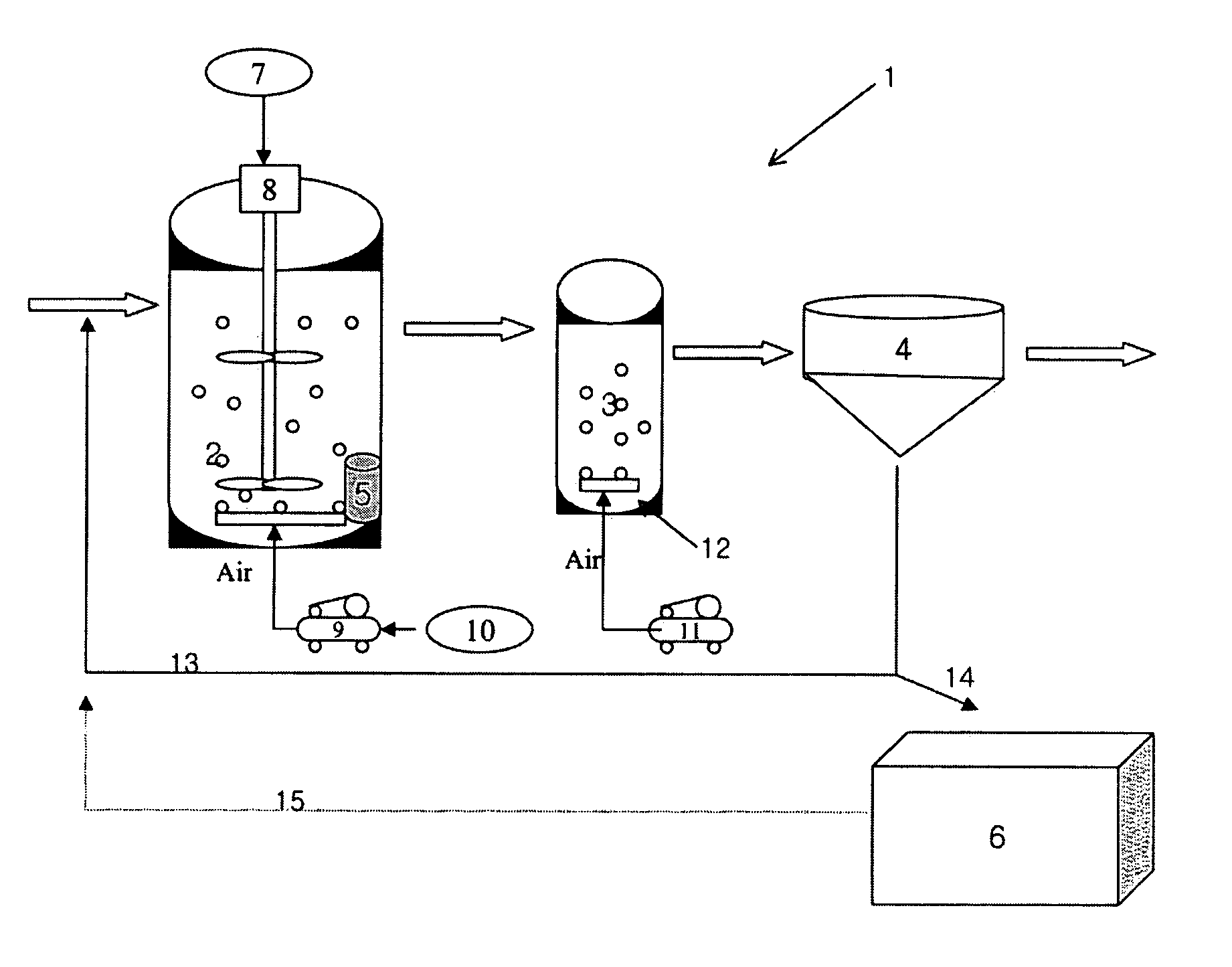

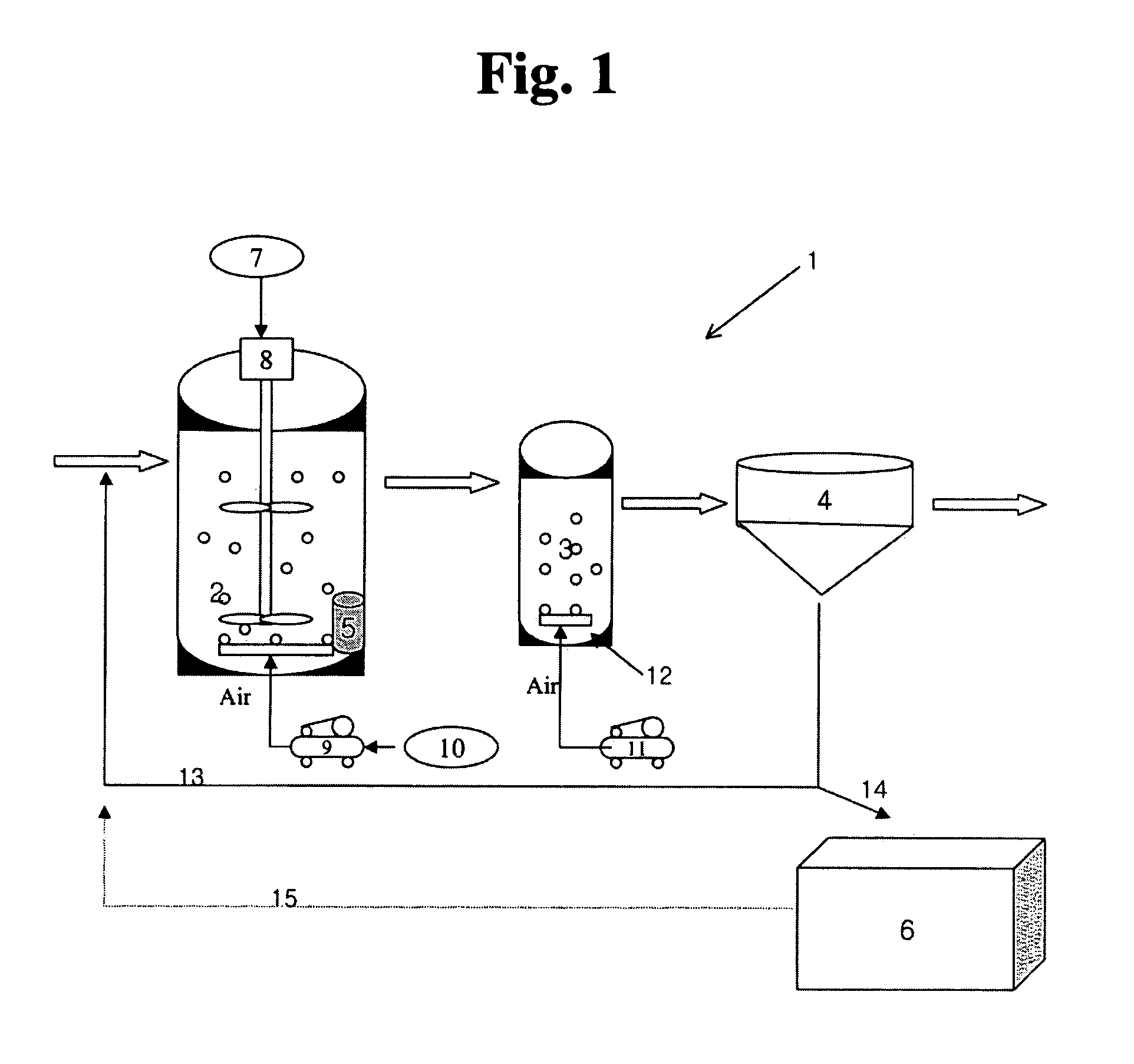

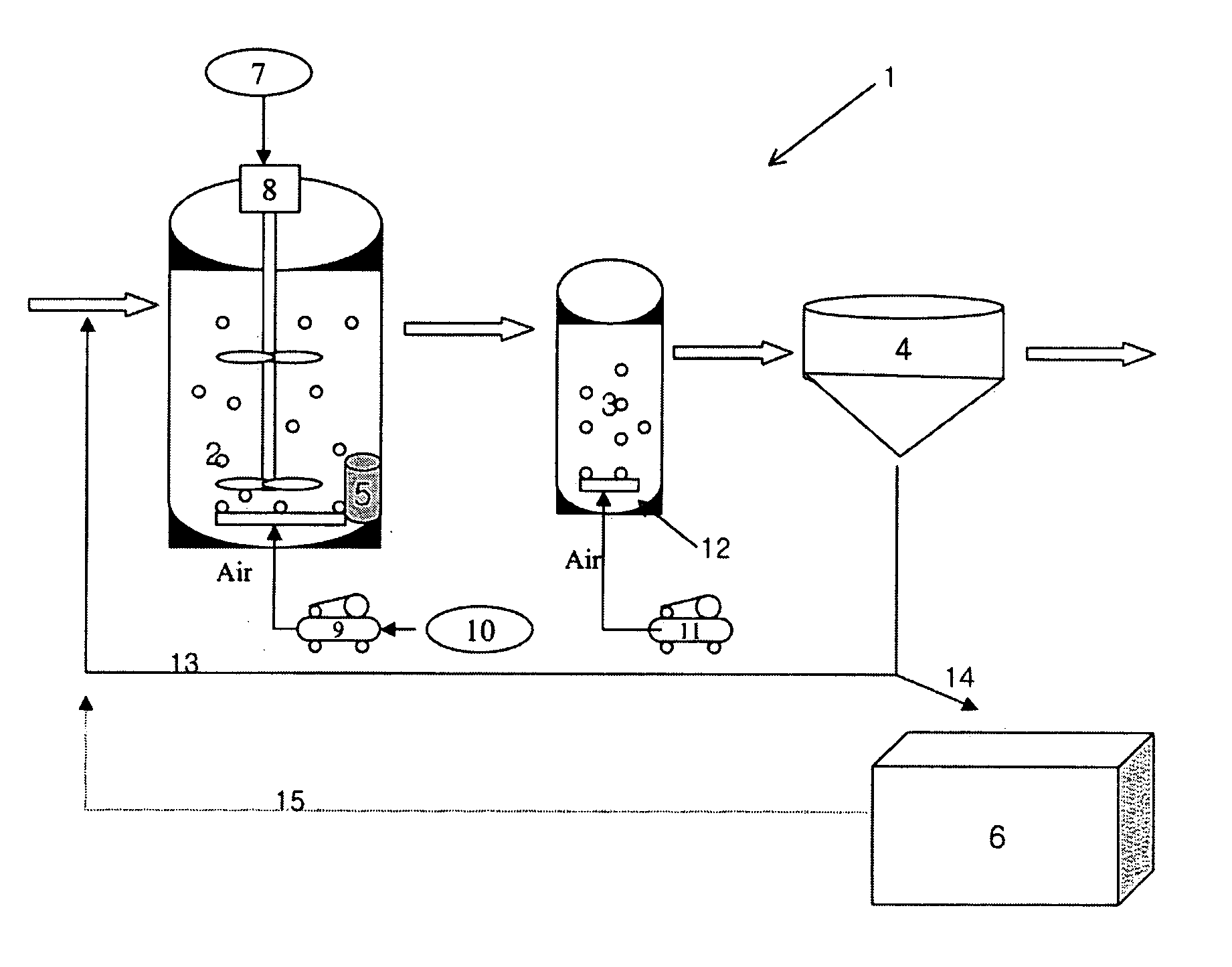

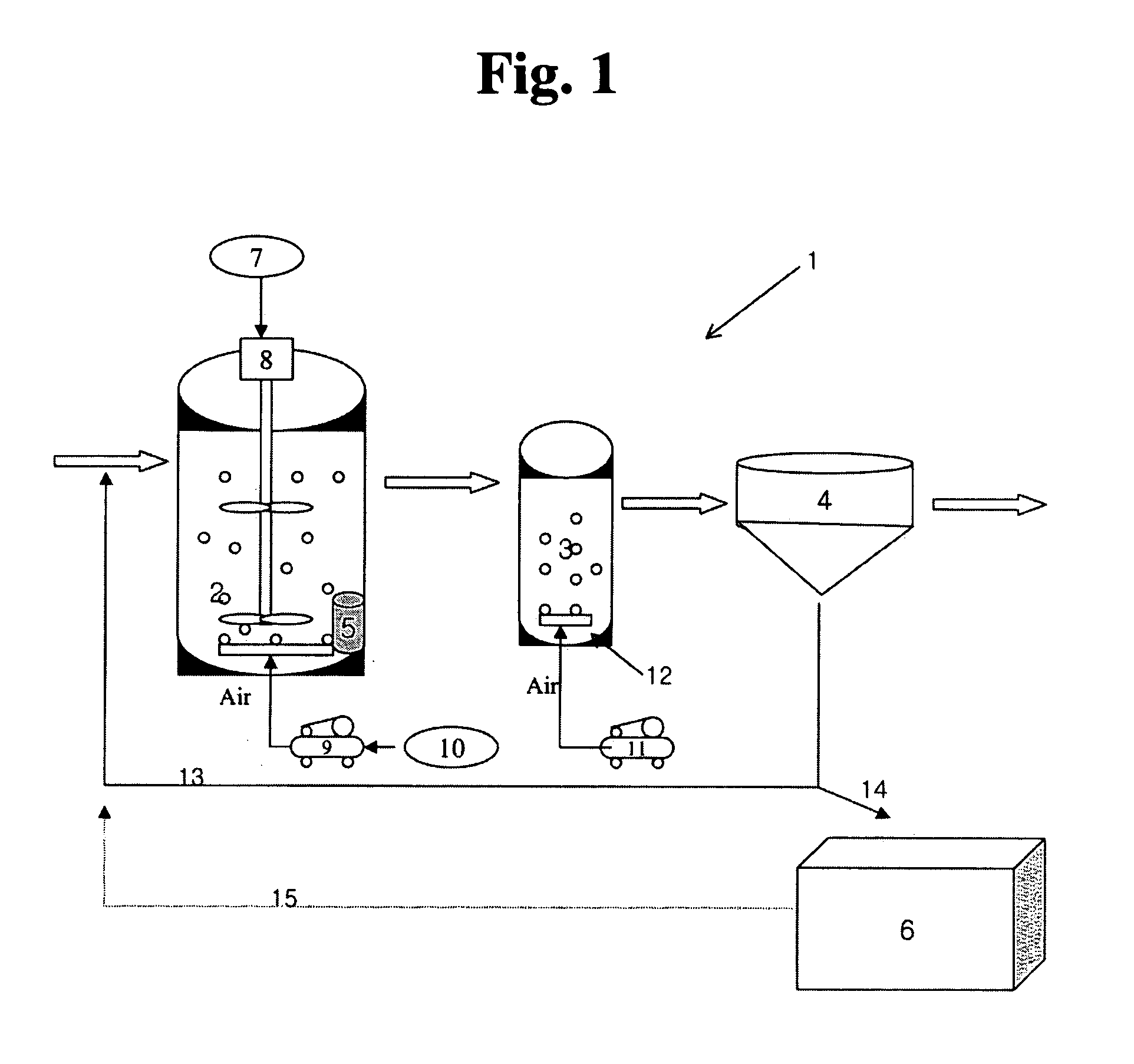

Municipal wastewater treatment apparatus and process with a continuous feed and cyclic aeration

InactiveUS7033503B2Remove the organic materials more efficientlyEfficient removalTreatment using aerobic processesSeparation devicesContinuous reactorWastewater

Disclosed are efficient municipal wastewater treatment apparatus and process characterized in that the nitrogen is removed by nitrification and denitrification reaction in the cyclic aeration reactor wherein Anaerobic state, Anoxic state and Oxic state are change into time concept in a single reactor, and the untreated organic materials are further removed by the 24-hour-continuous reactor.

Owner:KOREA INST OF SCI & TECH

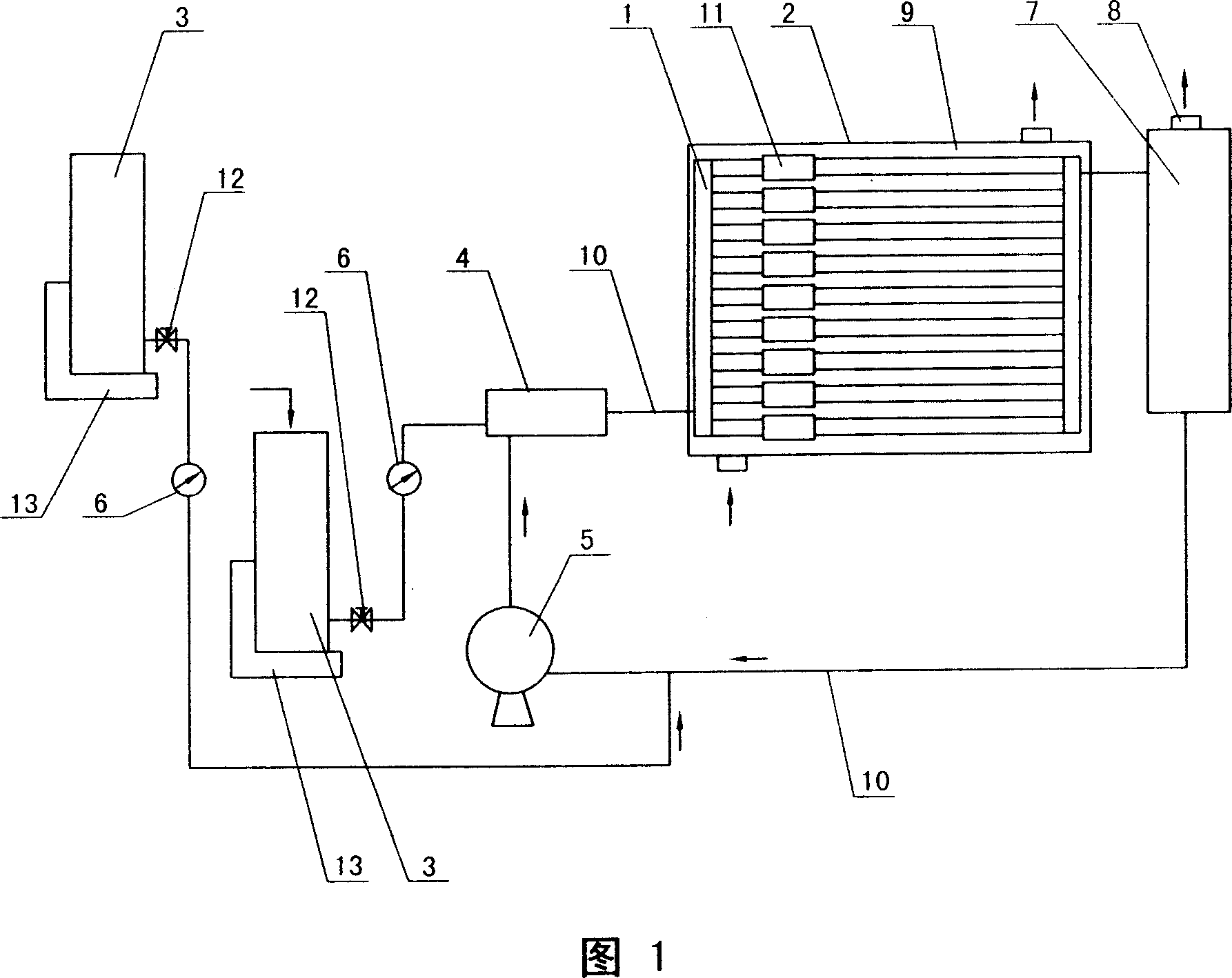

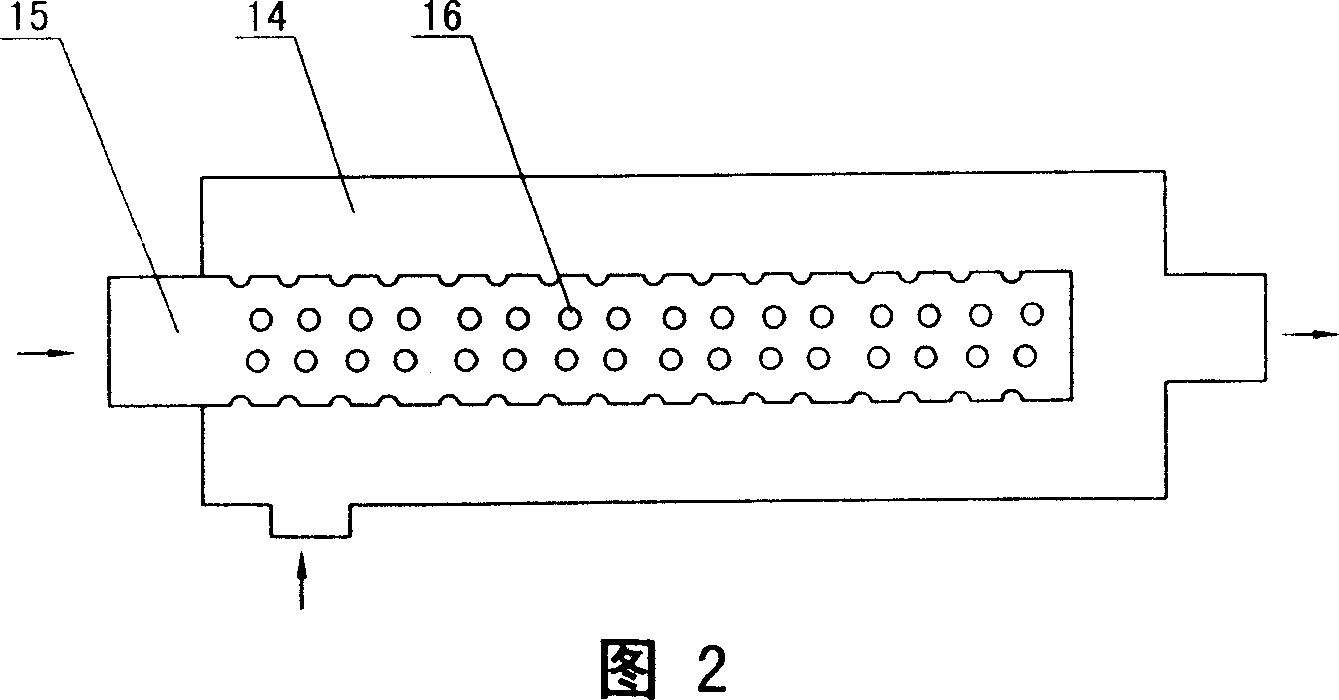

Pipe type continuously reacting apparatus

InactiveCN1927446AAvoid latent heat of liquefactionReduce production energy consumptionGroup 5/15 element organic compoundsLiquid-liquid reaction processesContinuous reactorProcess engineering

The invention relates to a tubular continuous reactor, which comprises reactor, heat exchanger and material pot used to contain materials. Wherein, it is characterized in that: it also comprises pre-mixer, circulate pump and flux controller; said mixer is tubular and mounted inside the heat exchanger, while its input via pre-mixer is connected to the output of circulate pump and the outlet of material pot with flux controller; the outlet of tubular reactor is connected to the buffer pot whose top has product outlet and bottom has input connected to another outlet of material pot with flux controller to connect the circulate pump; before reaction, the system is filled with final products, then start the circulate pump and material valve, via the power of circulate pump, the reaction materials are mixed by pre-mixer, to enter into tubular reactor to process esterification; and part of product will enter into thermal-insulated pot via the outlet of buffer pot to be stored, and another part enters into circulate pump to be stored in reactor.

Owner:左德兴 +1

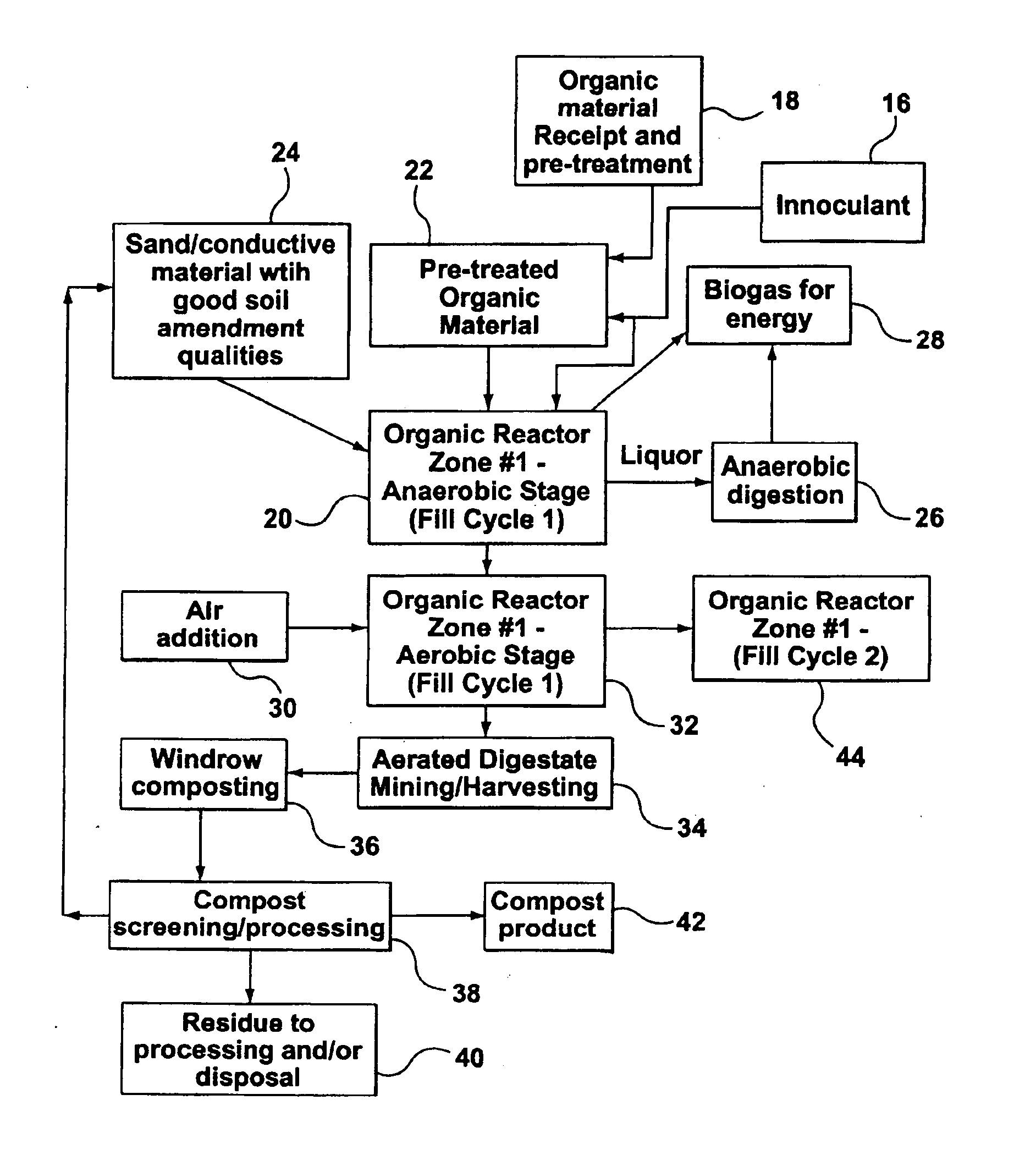

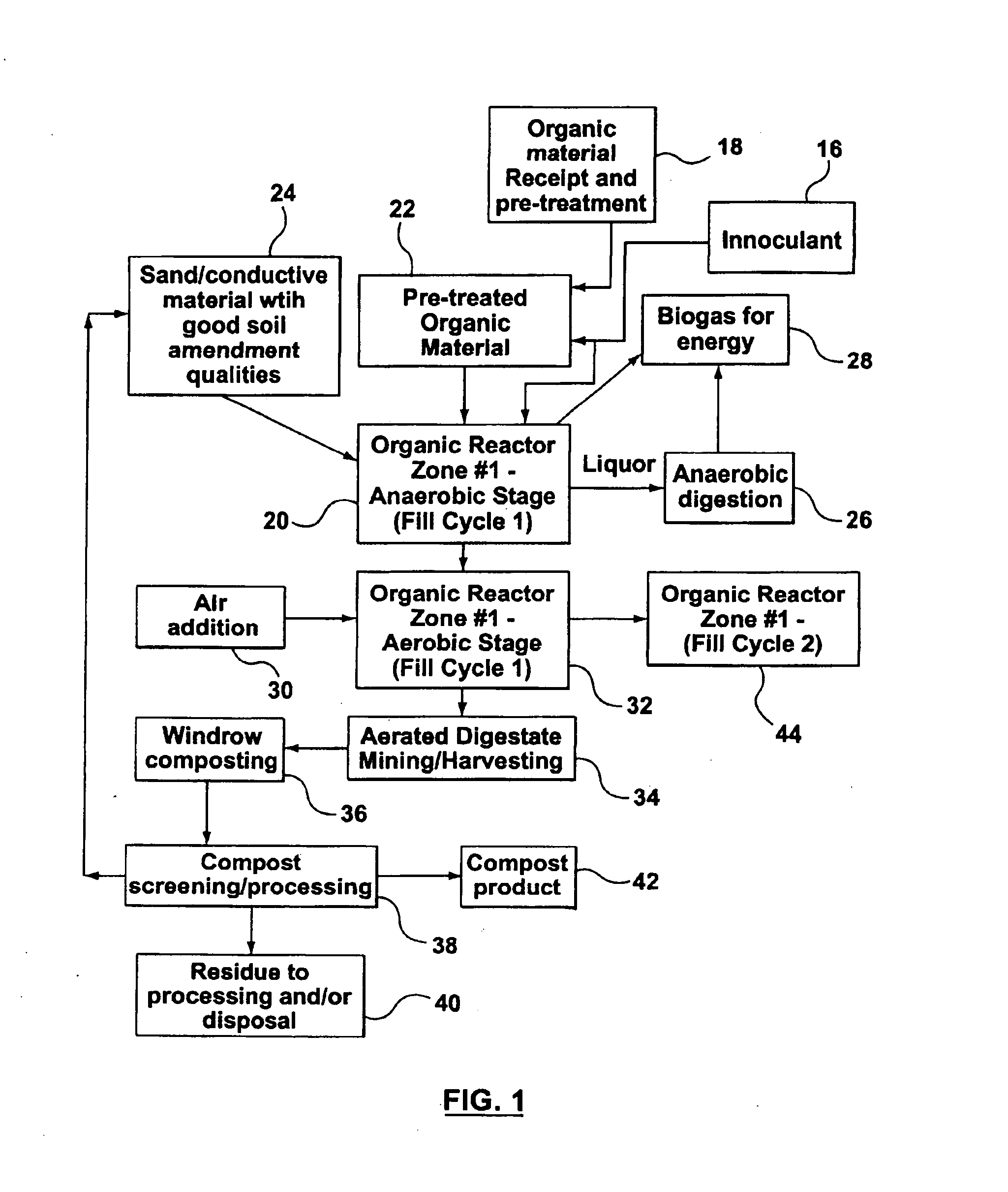

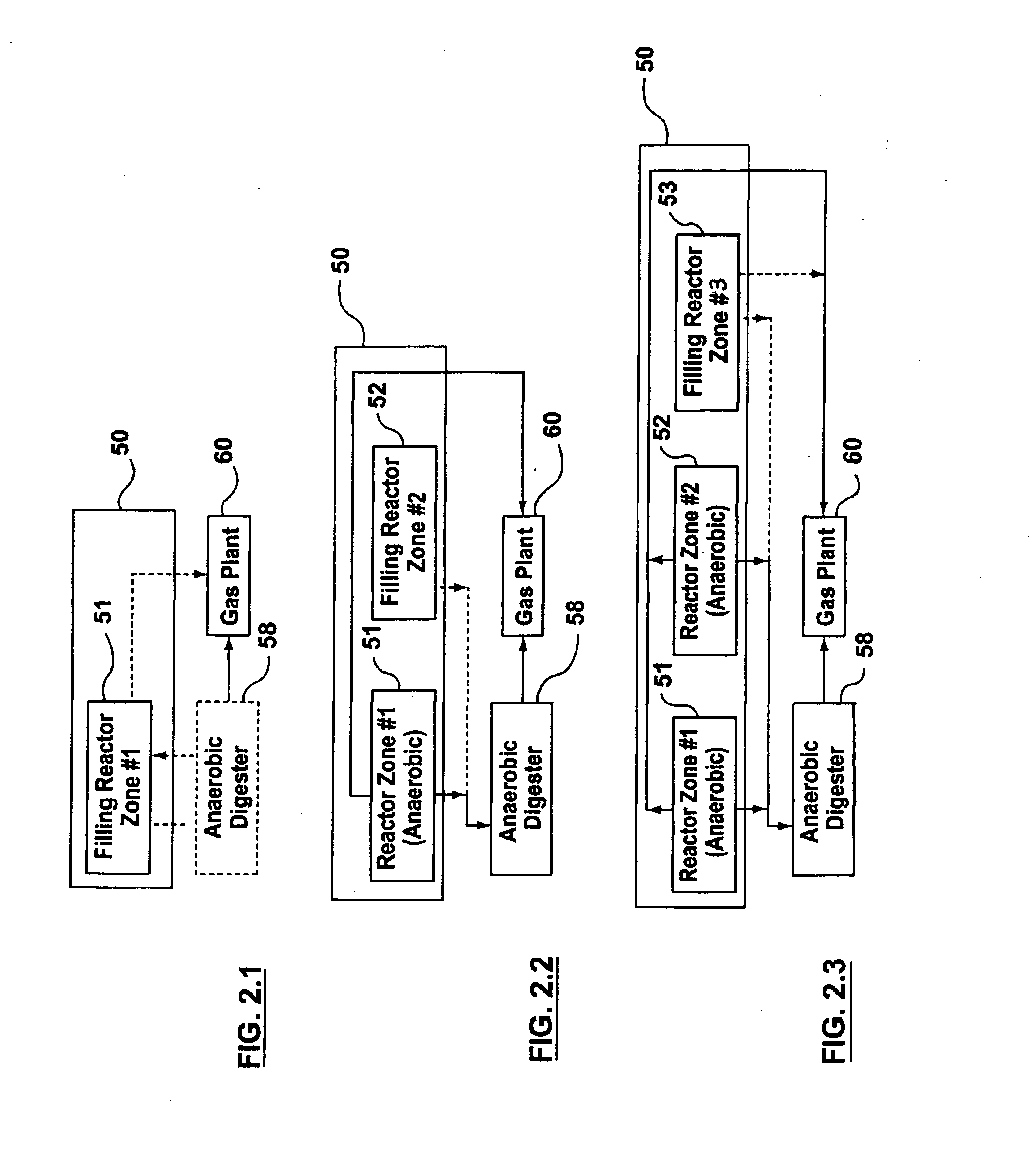

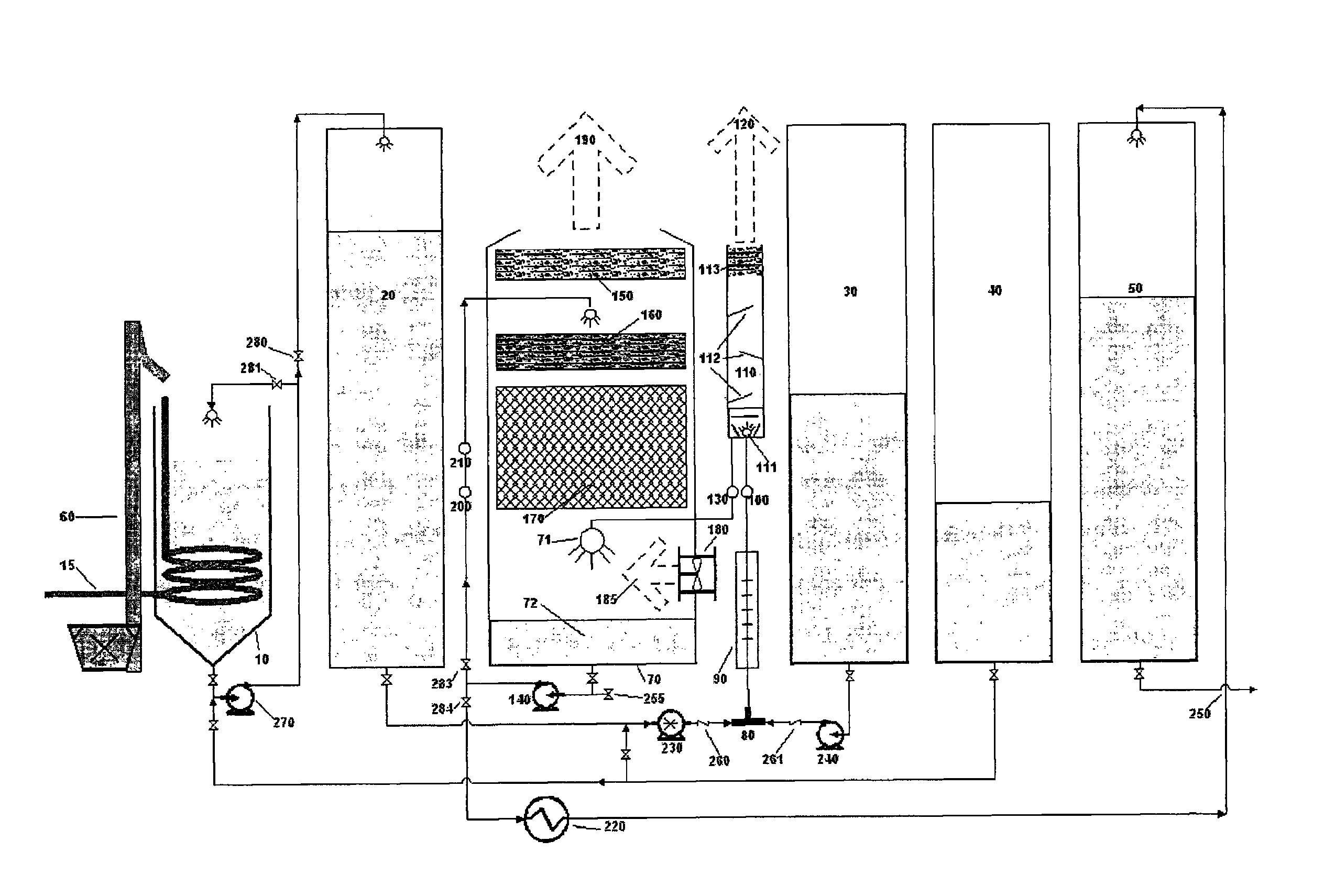

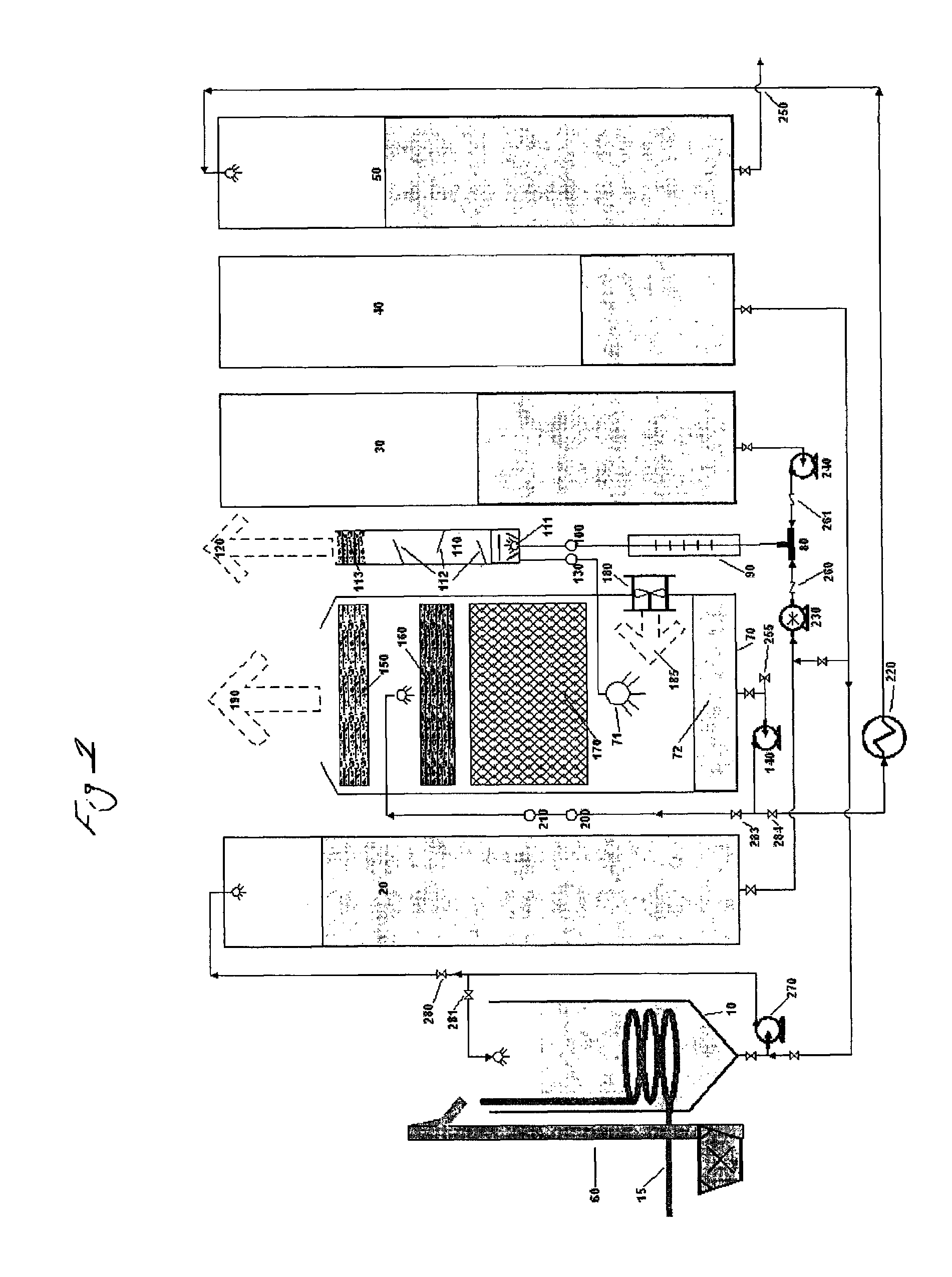

System for the production of biogas and compost from organic materials and method of operating an organic treatment facility

ActiveUS20050035058A1Enhance anaerobic decompositionEasy to useBio-organic fraction processingLiquid degasificationAnaerobic decompositionContinuous reactor

A system and method for continuous decomposition of organic material to produce biogas and compost in which successive reactor zones in a primary reactor are used in turn to receive organic material which is decomposed in situ anaerobically followed by aerobic decomposition and excavation of raw compost from the same reactor zone where it is received into the organic treatment facility. Organic rich liquor recovered during anaerobic decomposition is further decomposed in a secondary reactor from which spent liquor is returned to the primary reactor while biogas harnessed from both the primary and secondary reactors is treated, and optionally used to fuel the operation of the organic treatment facility or for sale as fuel or electricity.

Owner:BIOPOWER ENERGY

Process for the production of low molecular weight impact polyethers

This invention relates to an improved continuous process for the production of low molecular weight polyoxyalkylene polyether polyols. These polyoxyalkylene polyether polyols have a hydroxyl content of from about 3.4 to about 12.1% by weight, and may also be characterized as having an OH number of from about 112 to about 400. The process comprises establishing oxyalkylation conditions in a continuous reactor in the presence of a DMC catalyst; continuously introducing alkylene oxide and a low molecular weight starter into the continuous reactor; recovering a partially oxyalkylated polyether polyol from the reactor; and allowing the recovered partially oxyalkylated polyether polyol to further reactor until the unreacted alkylene oxide content of the mixture is reduced to 0.001% or less by weight.

Owner:COVESTRO LLC

Acrylic pressure-sensitive adhesive and process for producing the same

InactiveUS20010053814A1Low viscosityAvoid reactionFilm/foil adhesivesOrganic dyesContinuous reactorMeth-

An acrylic pressure-sensitive adhesive which is produced by advantageous continuous polymerization and has a reduced low molecular component content and therefore hardly contaminates an adherend, and a process of producing such an adhesive. The process comprises continuously feeding a monomer mainly comprising at least one alkyl (meth)acrylate, a radical polymerization initiator and carbon dioxide to a continuous reactor through a mixer and performing continuous bulk polymerization at a polymerization temperature of 50 to 180° C. for a residence time of 0.5 to 60 minutes in a continuous reaction zone of said reactor.

Owner:NITTO DENKO CORP

Municipal wastewater treatment apparatus and process with a continuous feed and cyclic aeration

InactiveUS20050205490A1Efficient removalRemove the organic materials more efficientlyTreatment using aerobic processesSeparation devicesContinuous reactorWastewater

Disclosed are efficient municipal wastewater treatment apparatus and process characterized in that the nitrogen is removed by nitrification and denitrification reaction in the cyclic aeration reactor wherein Anaerobic state, Anoxic state and Oxic state are change into time concept in a single reactor, and the untreated organic materials are further removed by the 24-hour-continuous reactor.

Owner:KOREA INST OF SCI & TECH

Production of methacrylic acid

InactiveCN1712393AAvoid it happening againFull heat absorptionOrganic chemistryContinuous reactorTemperature control

Production of methacrylic acid consists of amidation, hydrolytic reaction and distillation purification. It is characterized by using a set of continuous reactor comprising reaction vessel, tubing reactor, thermal insulating device and amide acceptor. Its advantages include easy reacting temperature control, short reacting period and higher productivity.

Owner:PEN MAKING FACTORY SHANGHAI

Late addition to effect compositional modifications in condensation polymers

A process for preparing modified polymer by withdrawing a slip stream of polymer melt from the discharge line of a continuous polymerization reactor, admixing in a highly modified polymeric additive into the polymer melt within the slip stream, then introducing the modifier containing slip stream late in the manufacturing process prior to the slip stream withdrawal point. The improved processes of the invention have particular utility for large-scale, continuous reactor where transitions and short production runs are economically prohibitive thereby limiting the product breath. The process is particularly suited for producing a family of copolyesters using a continuous melt phase production process.

Owner:ALPEK POLYESTER SA DE CV

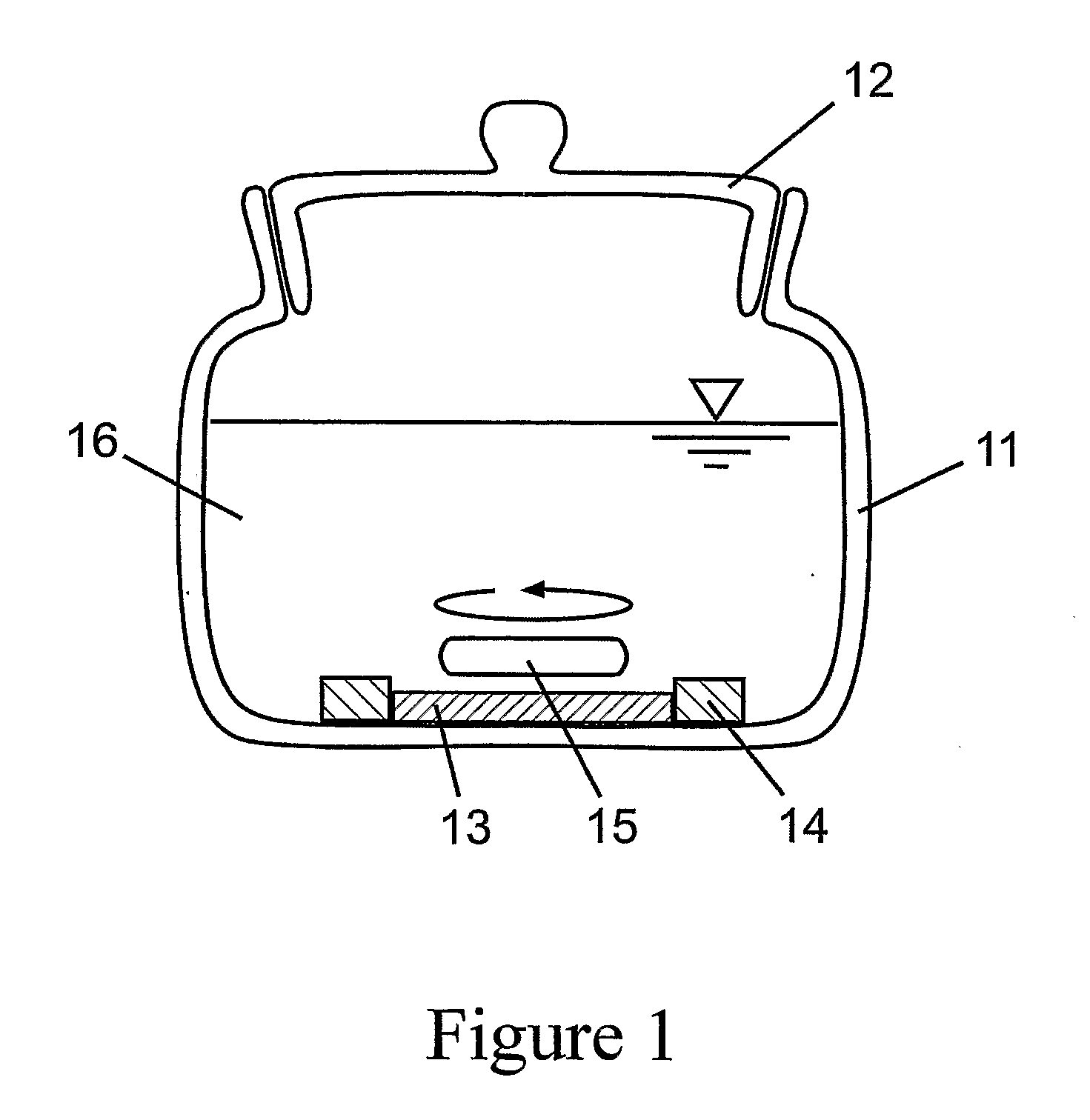

Process for synthesizing sucrose polyester by using rotating film transesterification flow reactor

InactiveCN102093438AIncrease contact areaSimple interfaceEsterified saccharide compoundsSugar derivativesResource utilizationPOTASSIUM STEARATE

The invention discloses a process for synthesizing sucrose polyester, particularly a process for synthesizing sucrose polyester by using a rotating film transesterification flow reactor. The process comprises the following steps: methyl oleate, sucrose powder, potassium stearate and potassium carbonate are added into a mixing kettle, and heated while stirring; the materials enter the rotating film transesterification flow reactor to react; the crude fatty acid sucrose polyester product obtained after the reaction enters a product storage tank, and the reaction product methanol enters a methanol receiver after being cooled by a condenser; and the crude product in the product storage tank is neutralized with acetic acid, washed and dried to obtain the sucrose polyester product. The low-boiling-point substances generated in the process provided by the invention are quickly removed out of the reaction system, thereby being beneficial to the generation of the product, greatly increasing the reaction speed and enhancing the product quality. The process can be used for continuous-feeding production, is beneficial to large-scale production, enhances the production efficiency, has the advantages of high yield and simple process, lowers the production cost and raises the resource utilization ratio.

Owner:ADANA FOOD TECH LIUZHOU

Method for preparing poly-alpha-olefin in continuous manner

ActiveCN104370675ALiquid hydrocarbon mixtures productionHydrocarbonsContinuous reactorLewis acid catalysis

A method for preparing poly-alpha-olefin in a continuous manner is disclosed and comprises the following steps: introducing alpha-olefin into a continuous reactor in a continuous manner, under the existence conditions of a lewis acid catalyst and an optional cocatalyst, performing polymerization reaction on alpha-olefin, so as to form poly-alpha-olefin, and leading out the material flow containing poly-alpha-olefin out of the reactor. The alpha-olefin is one or more selected from C6-C14 alpha-olefins.

Owner:上海翔威环境科技集团有限公司

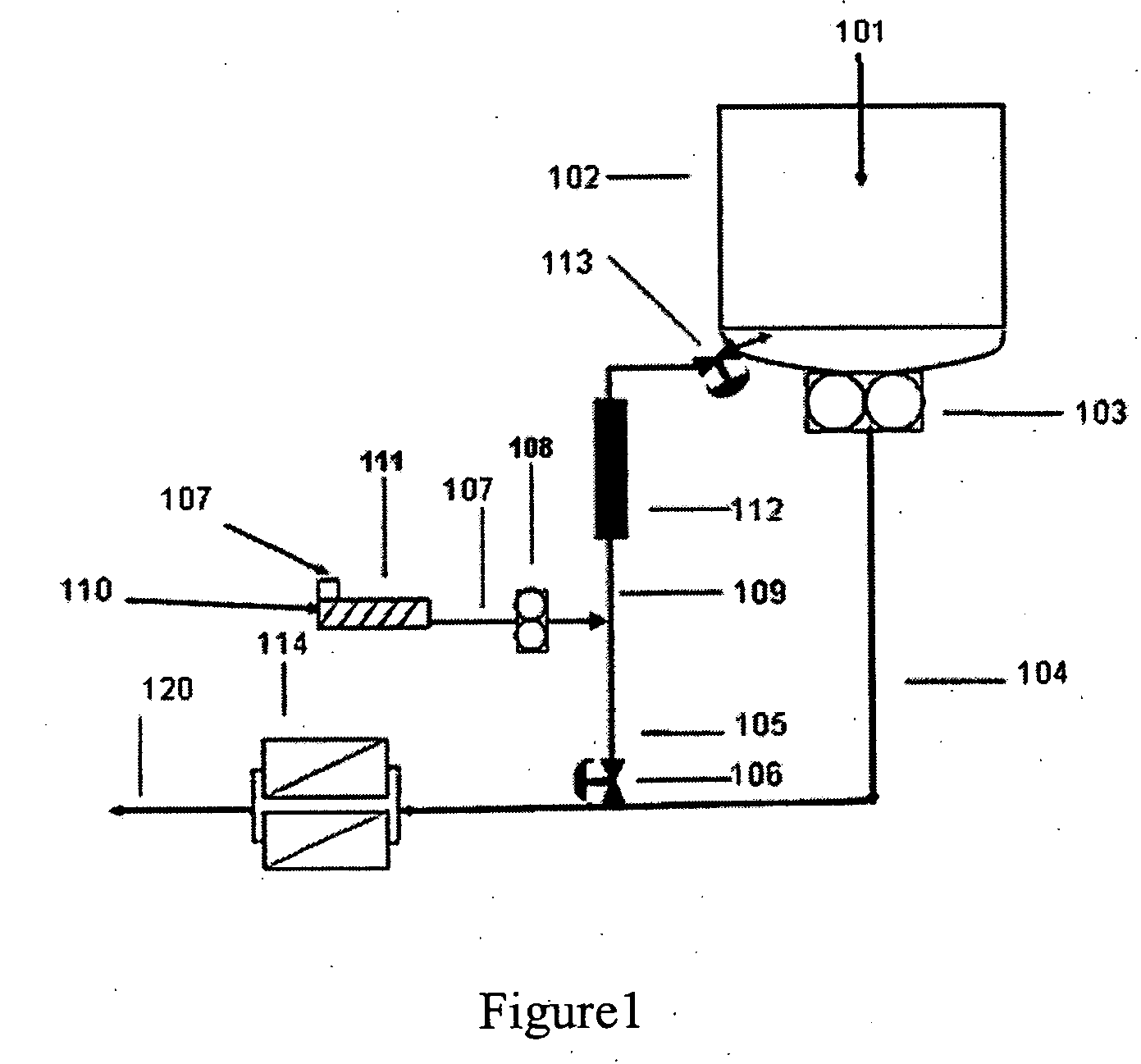

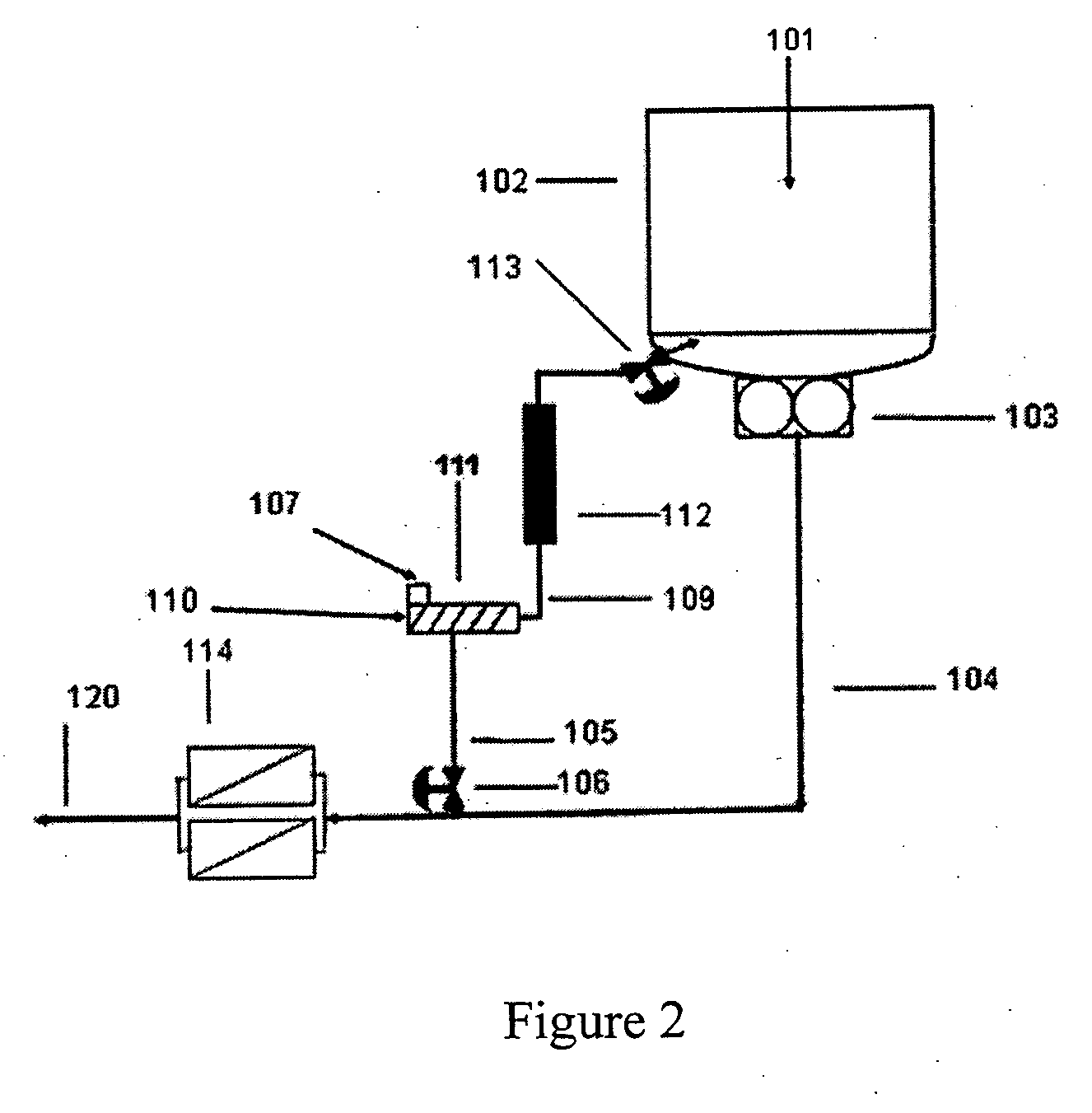

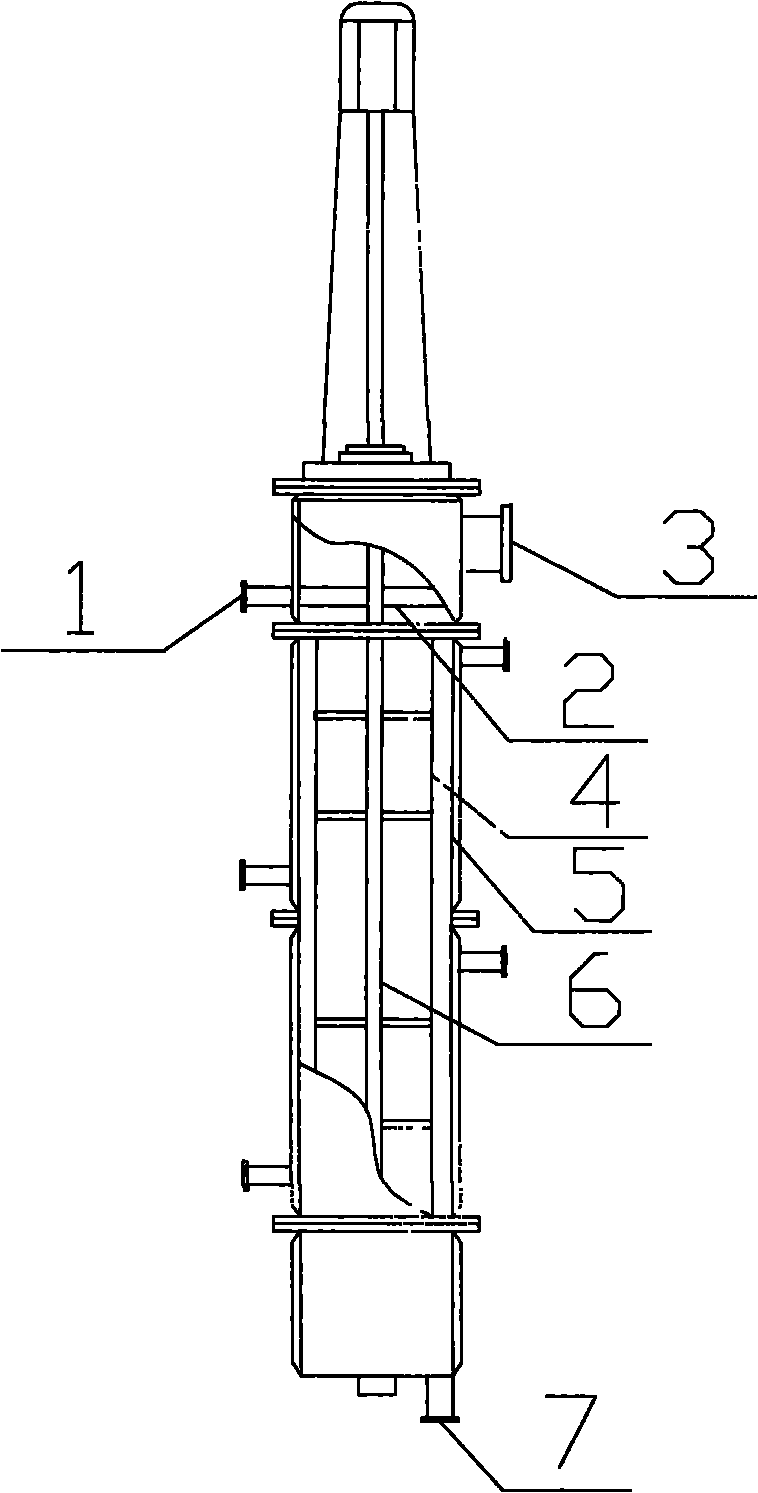

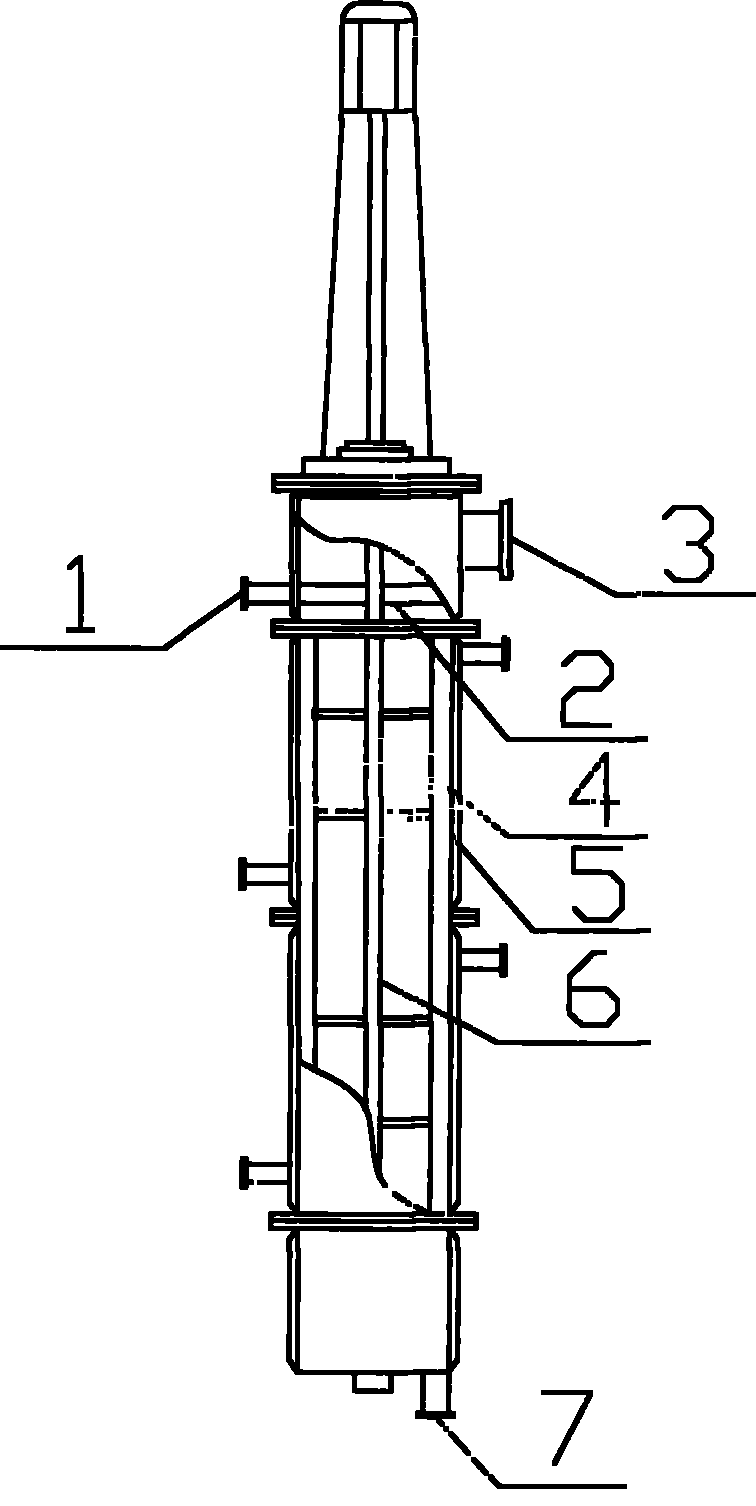

Precursor of lithium ion battery cathode material, preparation method thereof, cathode active material, lithium ion battery, and continuous reactor

ActiveCN108682807AImprove electrochemical performanceUniform particle sizeCell electrodesSecondary cellsAluminium-ion batteryNickel salt

The invention relates to a precursor of a lithium ion battery cathode material, a preparation method thereof, a cathode active material of a lithium ion battery, a lithium ion battery, and a continuous reactor, and belongs to the technical field of new energy materials. The preparation method of the precursor comprises following steps: mixing nickel salt, cobalt salt, manganese salt, doped metal salt (D salt), a precipitating agent, and a complexing agent to obtain a reaction system; carrying out reactions under stirring at a temperature of 30-80 DEG C in an inert gas atmosphere, wherein the pH is 10.0-13.0 during the reaction process, raw materials are fed into the system continuously, and reaction products are discharged continuously through overflowing; and aging the overflowed materials for 1 to 5 hours to obtain the precursor. When the granularity of overflowed materials reaches a set value, the reaction system is subjected to an ultrasonic treatment until the granularity of overflowed materials is lower than the set value. The obtained precursor has the advantages of uniform granularity and morphology, and large tap density, and is benefit for the preparation of a lithium ionbattery cathode material with excellent electrochemical properties.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

Tubular continuous method for preparing cyclopropanecarboxylic acid

InactiveCN101693660AIncrease production capacityHigh yieldOxygen-containing compound preparationOrganic compound preparationContinuous reactorAutomatic control

The invention discloses a tubular continuous method for preparing cyclopropanecarboxylic acid. In the method, gamma-butyrolactone used as a raw material reacts with thionyl chloride and alcohol to produce 4-chlorobutyrate; after the reaction liquid is processed in an acid gas removing way and an alcohol recycling way, the reaction liquid and liquid sodium alkoxide are synthesized to obtain cyclopropanecarboxylate in a tubular reactor; the rectified cyclopropanecarboxylate is firstly hydrolyzed in alkali liquor and then neutralized with acid to obtain crude cyclopropanecarboxylic acid; and the crude cyclopropanecarboxylic acid is rectified to obtain the pure cyclopropanecarboxylic acid. The synthetic technique of the cyclopropanecarboxylic acid adopts the tubular continuous reactor, thereby effectively reducing the equipment investment and enhancing the investment efficiency; the continuous reaction can conveniently realize automatic control, thereby ensuring the continuity and the stability of the production, saving the manual cost, realizing the safe production operation and enhancing the purity and the yield of the product; and the invention adopts a technique of adding solid caustic soda again in the second aqueous phase for recycling, thereby fully and comprehensively utilizing the resources, enhancing the yield for hydrolysis and greatly reducing the cost.

Owner:ZHEJIANG UNIV +1

Acid combination one step reaction process for agricultural use products and associated methods

ActiveUS8193119B2Minimizes or eliminates wasteful “free water”Avoid reactionBiocidePhosphatesPhosphorous acidContinuous reactor

A process for the manufacture of an aqueous composition that is a combination of a fungicide and fertilizer comprising the following steps:(1) dissolving phosphorous acid in phosphoric acid to form a solution of an acid mixture;(2) reacting the acid mixture of step (1) with an aqueous potassium hydroxide solution at a temperature of about 65° C. to about 260° C. in a continuous reactor while maintaining the ratio of potassium to phosphorous in various mole ratios thereby forming a reaction mixture comprising potassium phosphates, potassium polyphosphates, potassium phosphites, and potassium polyphosphites and potassium phosphate phosphite copolymers; and,(3) cooling the reaction mixture rapidly at least 1° C. to 60° C., to below about 35° C. to about 65° C.Using a similar process a composition having fungicidal properties is prepared by reaction phosphoric acid with potassium hydroxide.The reaction mixtures prepared according to each of the above processes are also part of this invention.

Owner:PLANT FOOD SYST

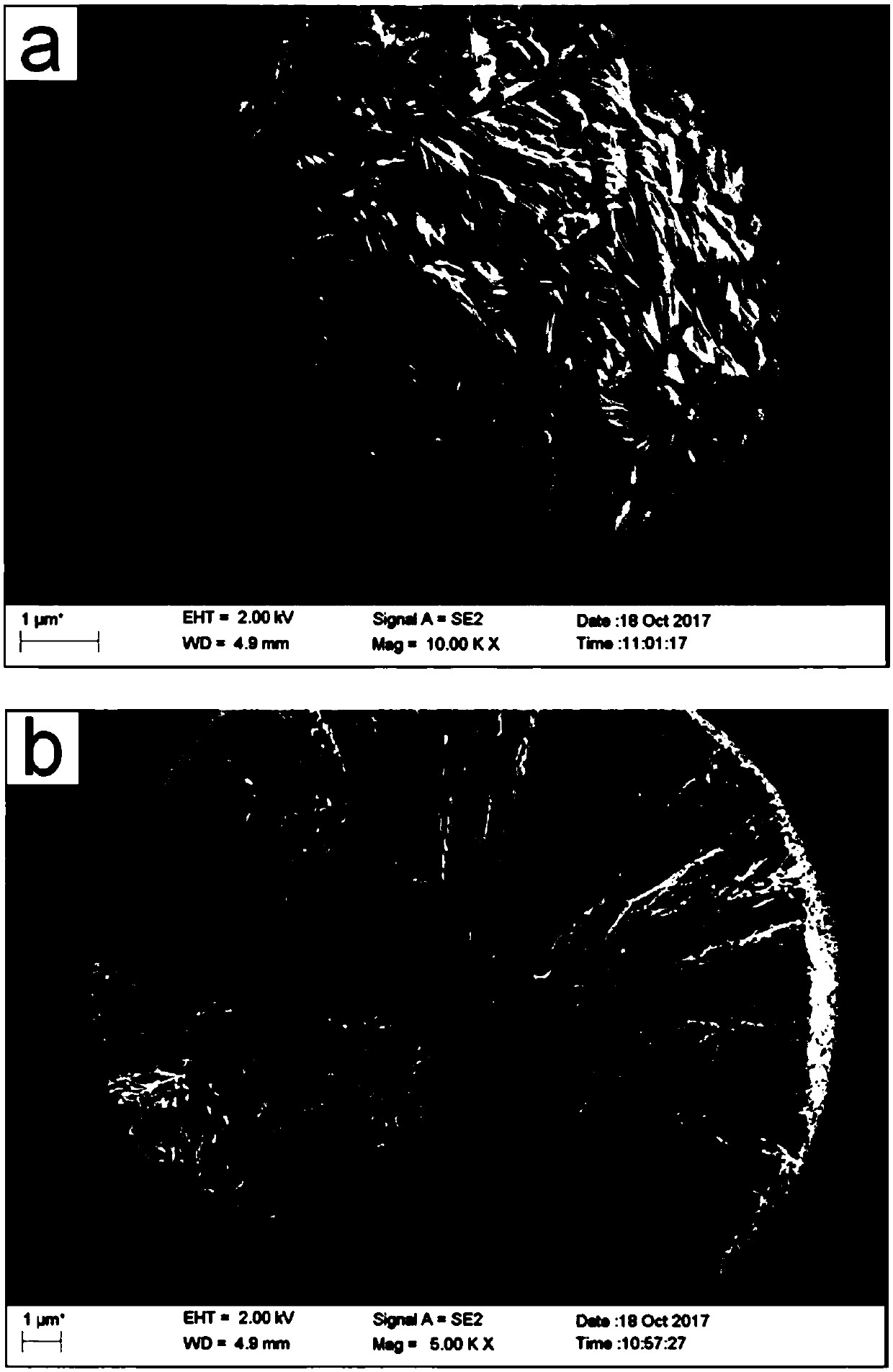

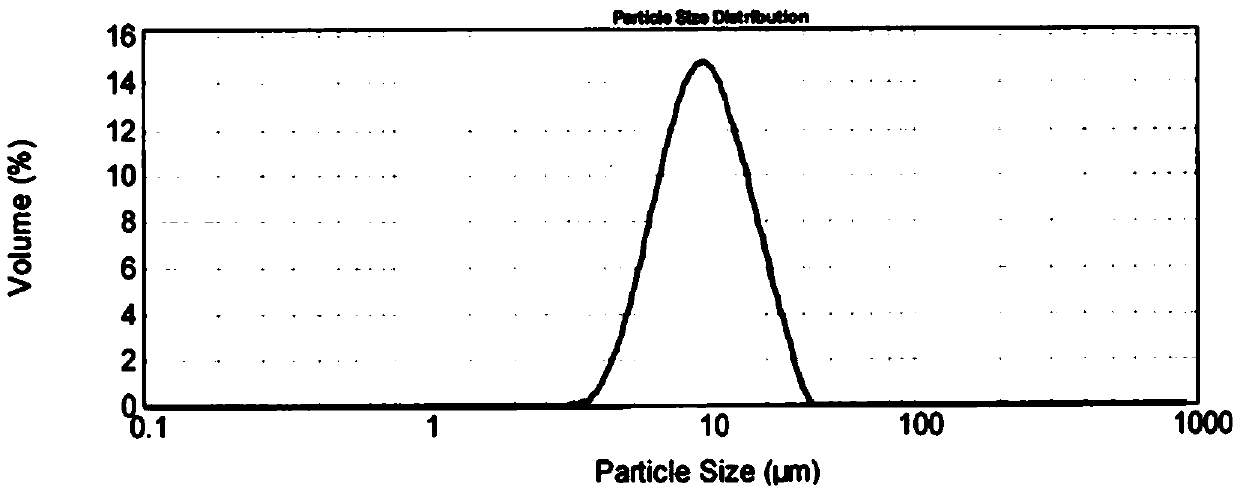

Concentrate of fine ceria particles for chemical mechanical polishing and preparing method thereof

InactiveUS20070212289A1Easy to produceImprove economyMaterial nanotechnologyPigmenting treatmentContinuous reactorCerium

Disclosed are a concentrate of fine ceria particles for chemical mechanical polishing, and a method of preparing the same. The method includes reacting a reactant mixture comprising i) water, ii) an aqueous solution of water-soluble cerium salt compound, and iii) ammonia or ammonium salt at a reaction temperature of 250-700 ? under a reaction pressure of 180-550 bar for 0.01 sec to 10 min in a continuous reactor to obtain a solution containing the fine ceria particles, the cerium salt compound being contained at an amount of 0.01 to 20 wt % in the reactant mixture; and concentrating the solution containing the fine ceria particles in a concentrator having a filter with a pore size of 0.01 to 10 ?. The concentrate is advantageous in that a CMP slurry and a dispersing solution are easily produced by diluting the concentrate and adding an additive to the concentrate.

Owner:HANWHA CHEMICAL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com