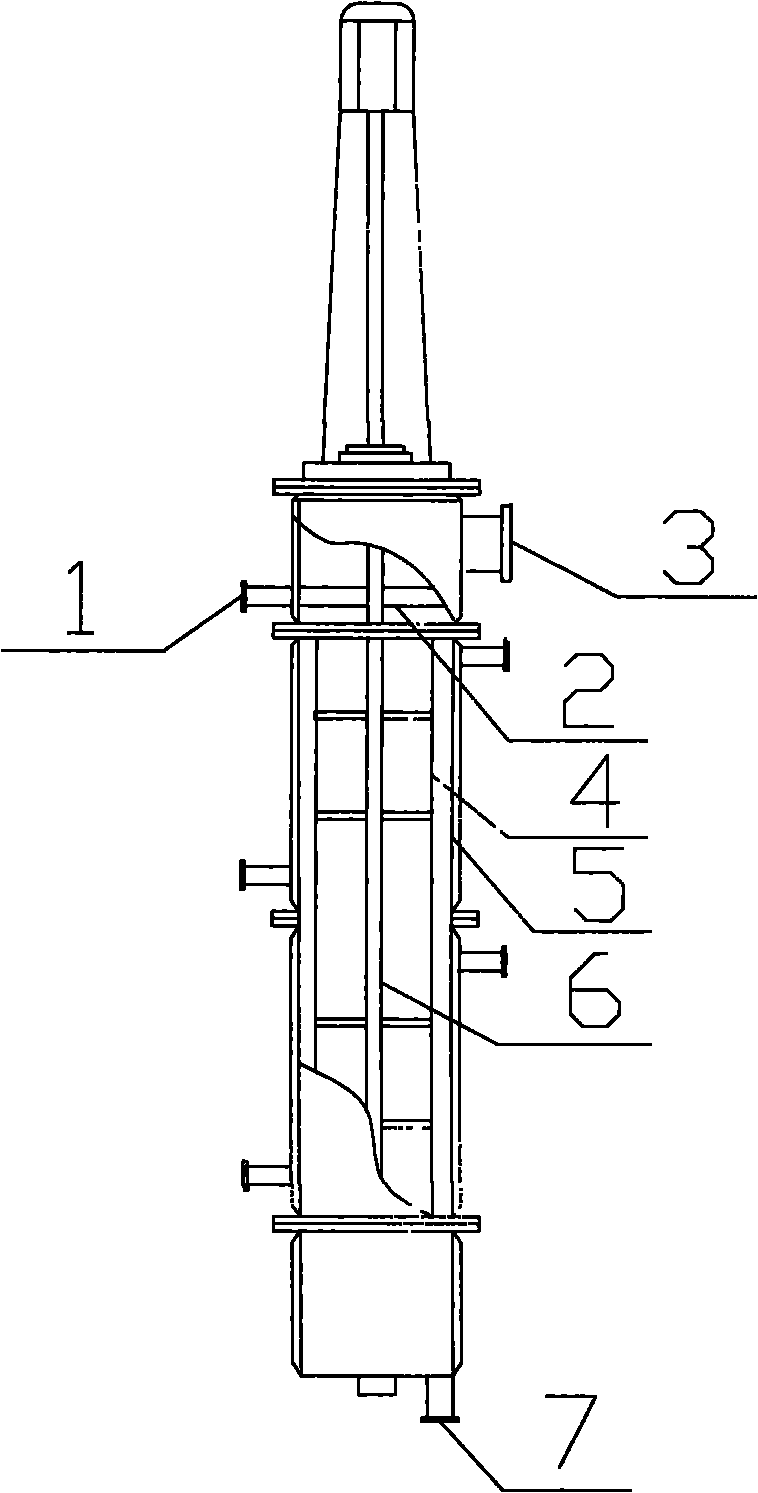

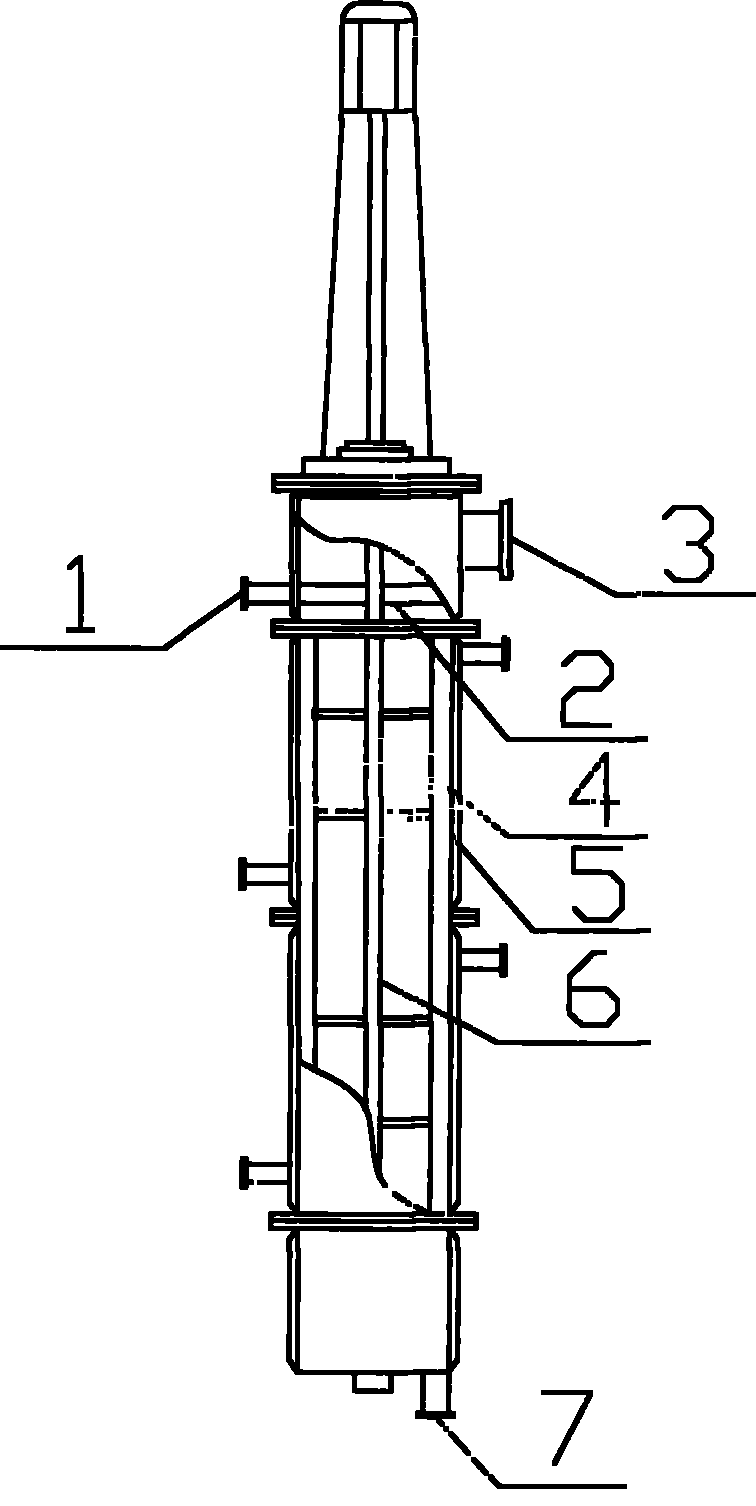

Process for synthesizing sucrose polyester by using rotating film transesterification flow reactor

A technology of rotating film and sucrose polyester, which is applied in the direction of esterification of saccharides, sugar derivatives, sugar derivatives, etc., can solve the problems of high peroxide value of products, unfavorable large-scale production, and affecting production efficiency and quality. Improve equipment capacity and production efficiency, facilitate continuous production, and improve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

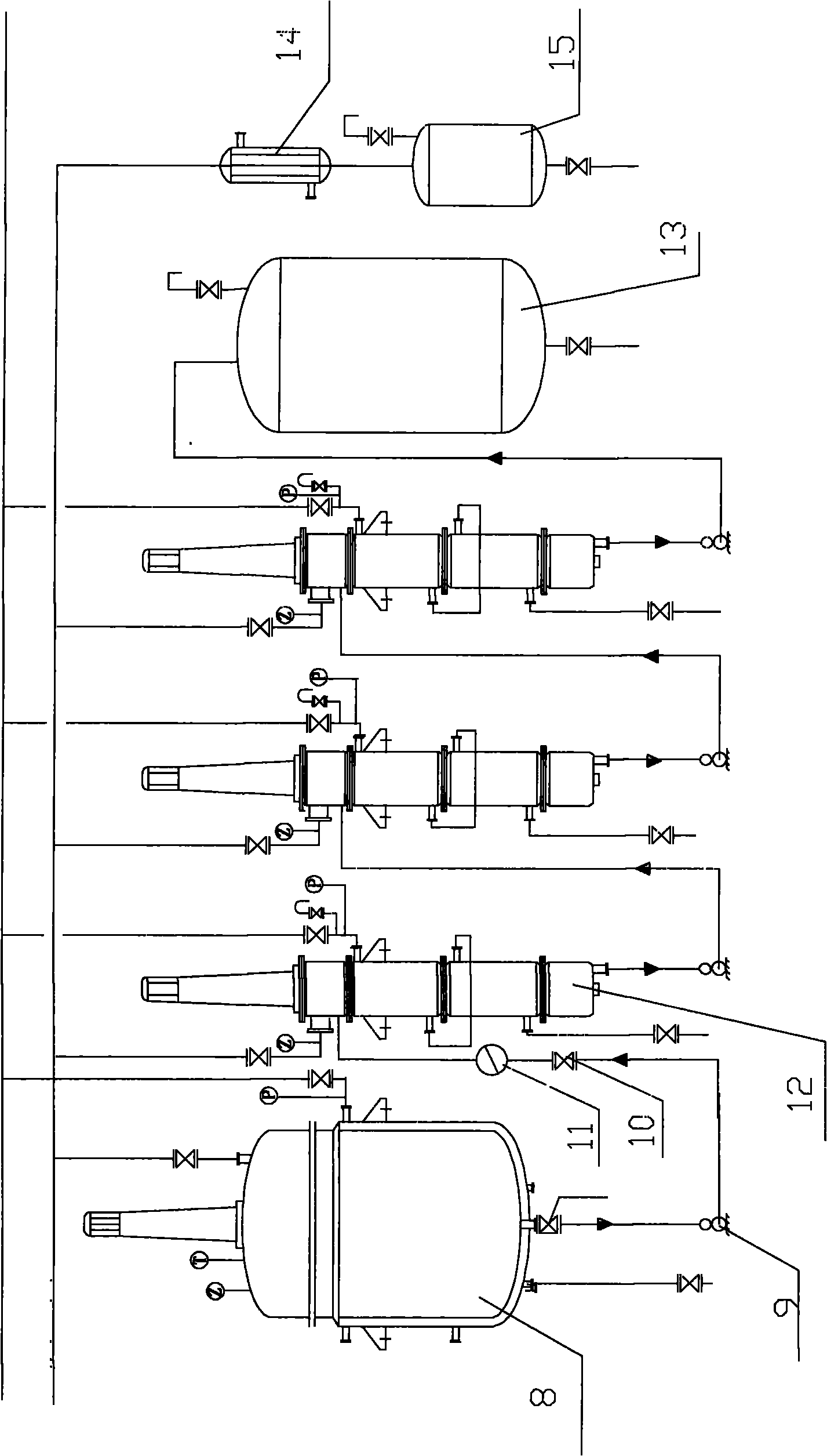

Method used

Image

Examples

Embodiment 1

[0021] Add 1000kg of fatty acid methyl ester, 90kg of 200-mesh sucrose powder, 30kg of fatty acid potassium, and 30kg of potassium carbonate into the mixing kettle, heat to 115°C under stirring, and maintain a constant temperature of the material during the whole production process, open the discharge valve of the mixing kettle, and the material passes through The gear pump and the material pipe equipped with a steam jacket enter the rotary film transesterification continuous reactor at a flow rate of 300L / h under the adjustment of the flow regulating valve for reaction. The reaction temperature is controlled at 125-135°C, and the reactor pressure is maintained at - 0.1-0.092MPa, it takes about 10 minutes for the material to flow through the reactor. The crude fatty acid sucrose polyester obtained after the reaction enters the product storage tank, and the product methanol obtained after the reaction is cooled by the condenser and then enters the methanol receiver. When the mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com