Patents

Literature

4012results about "Burners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

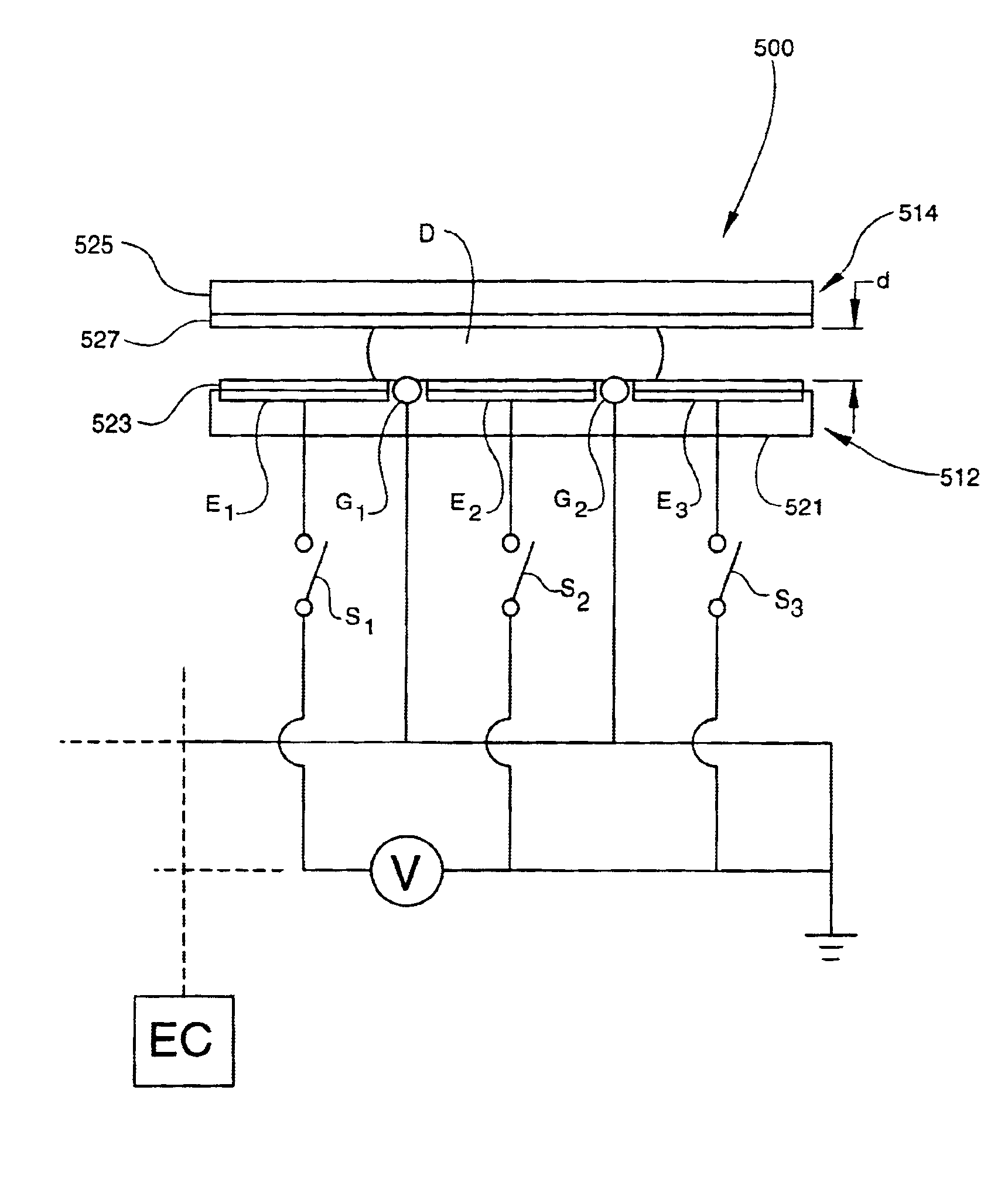

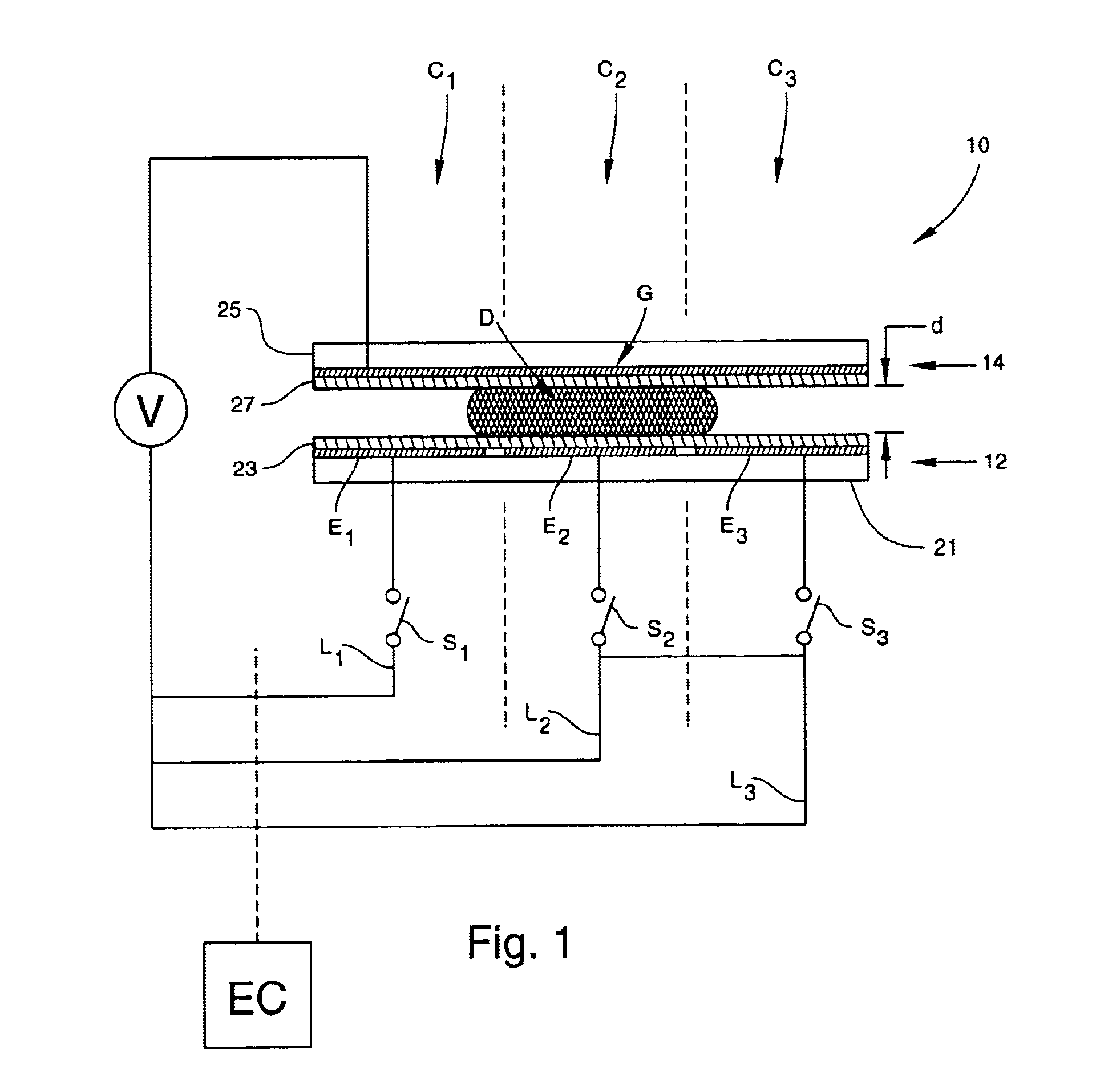

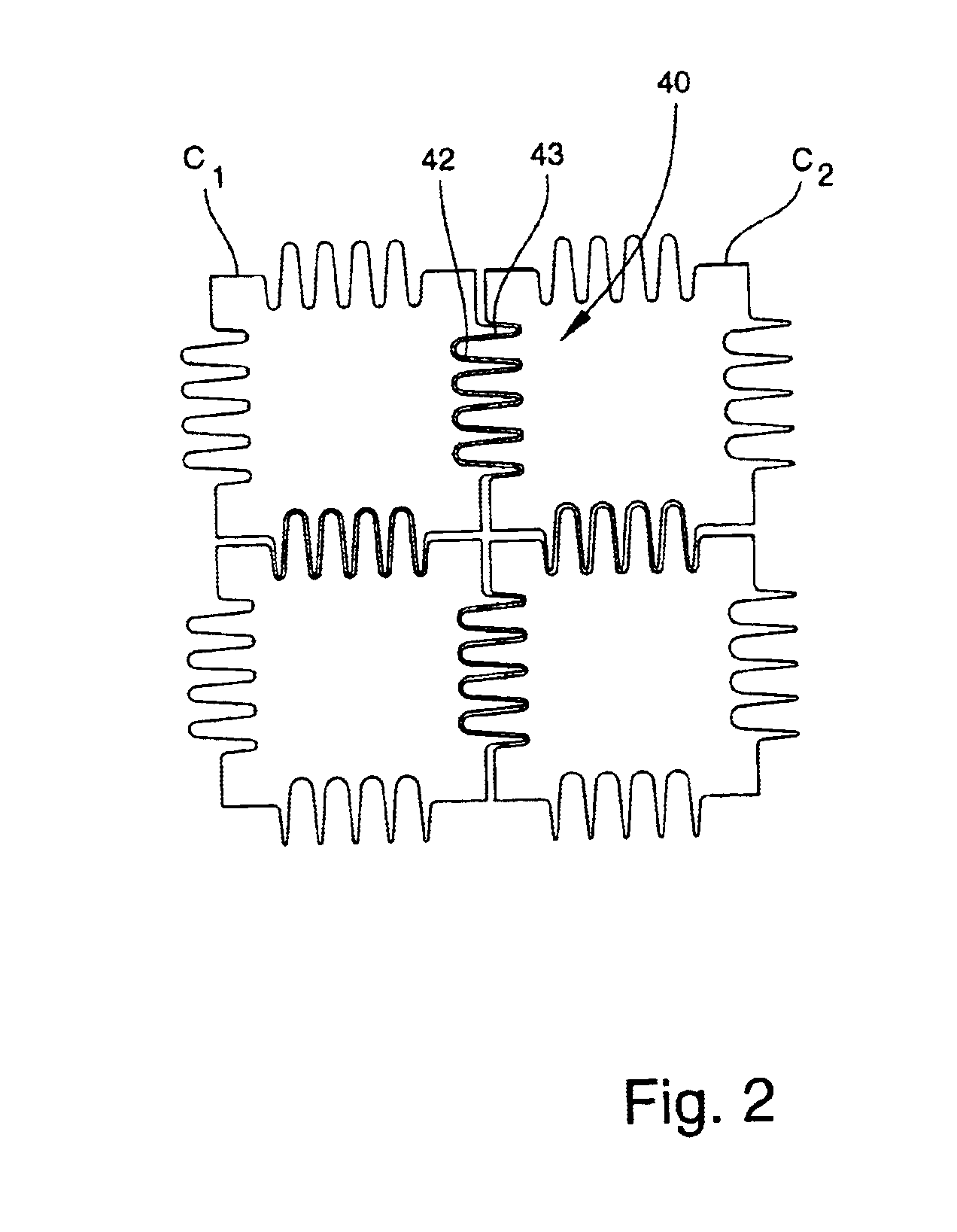

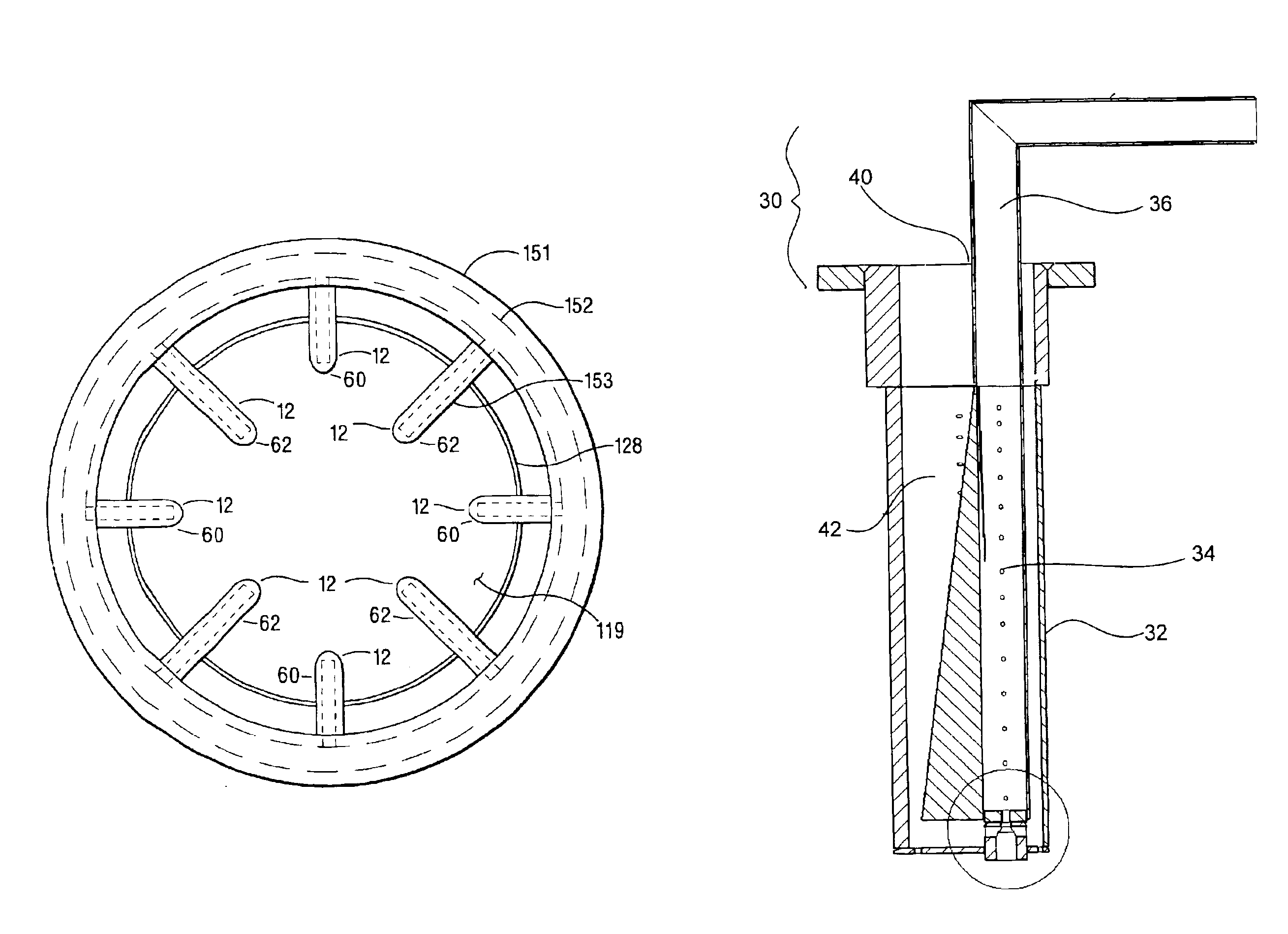

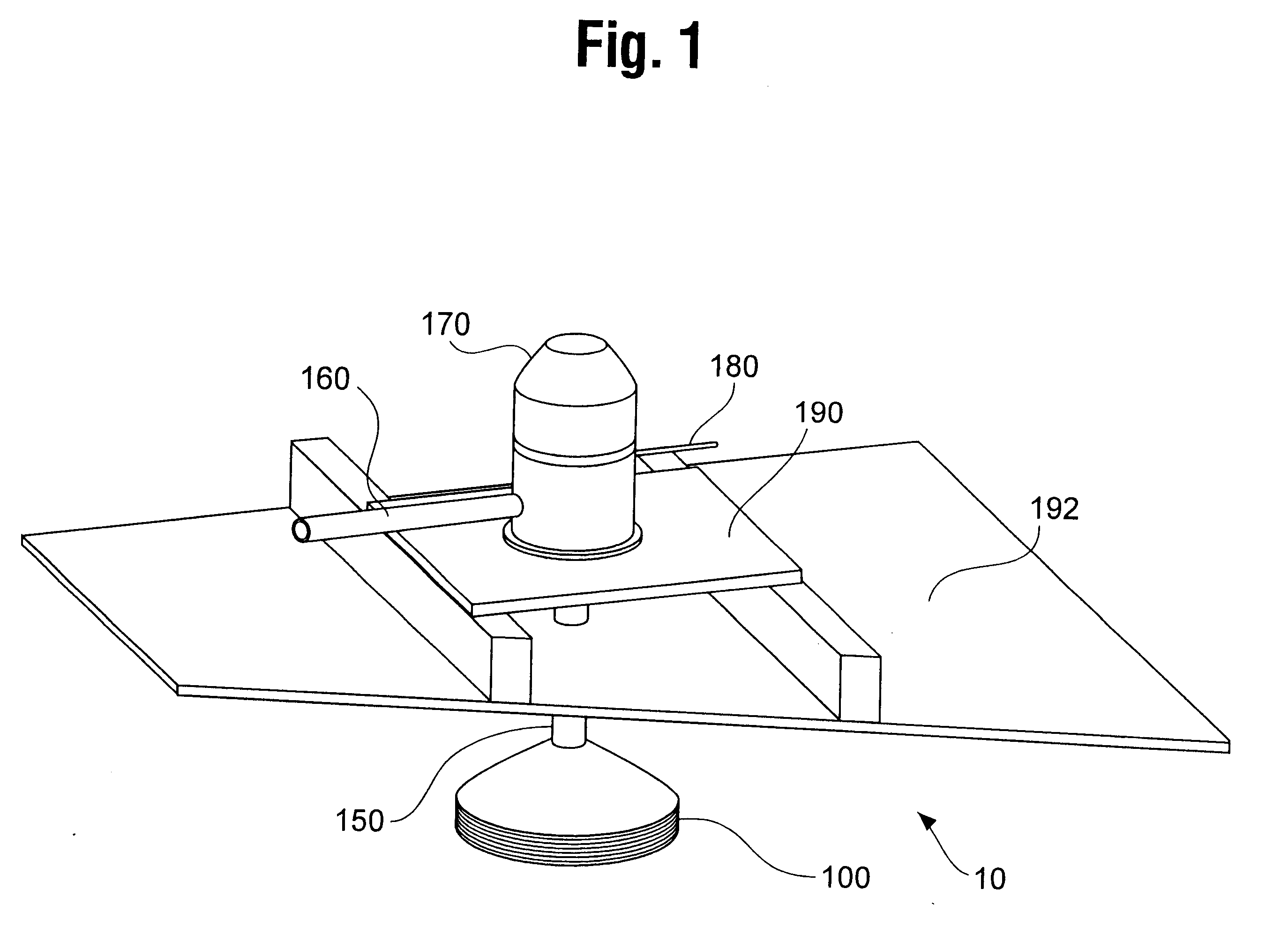

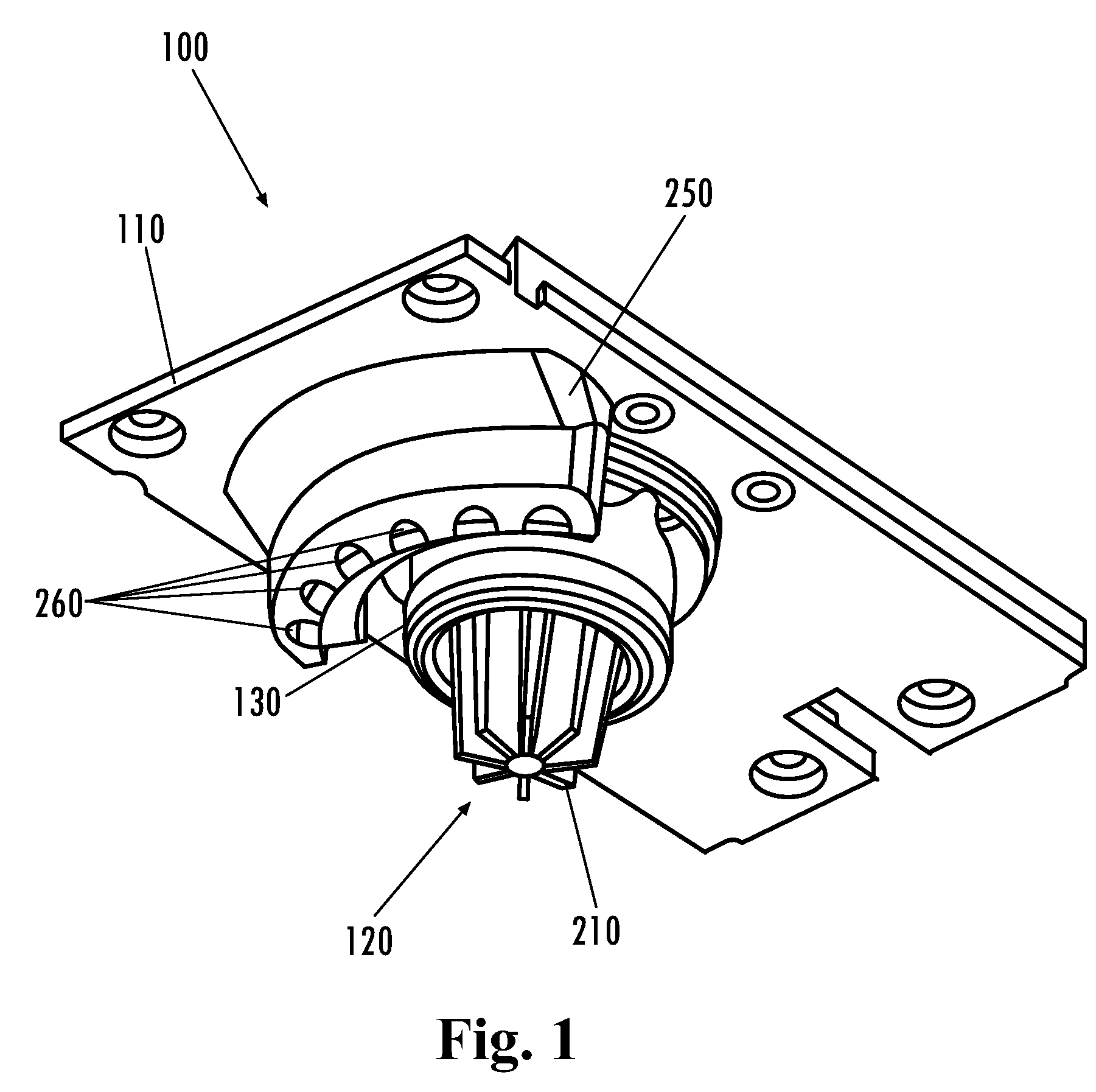

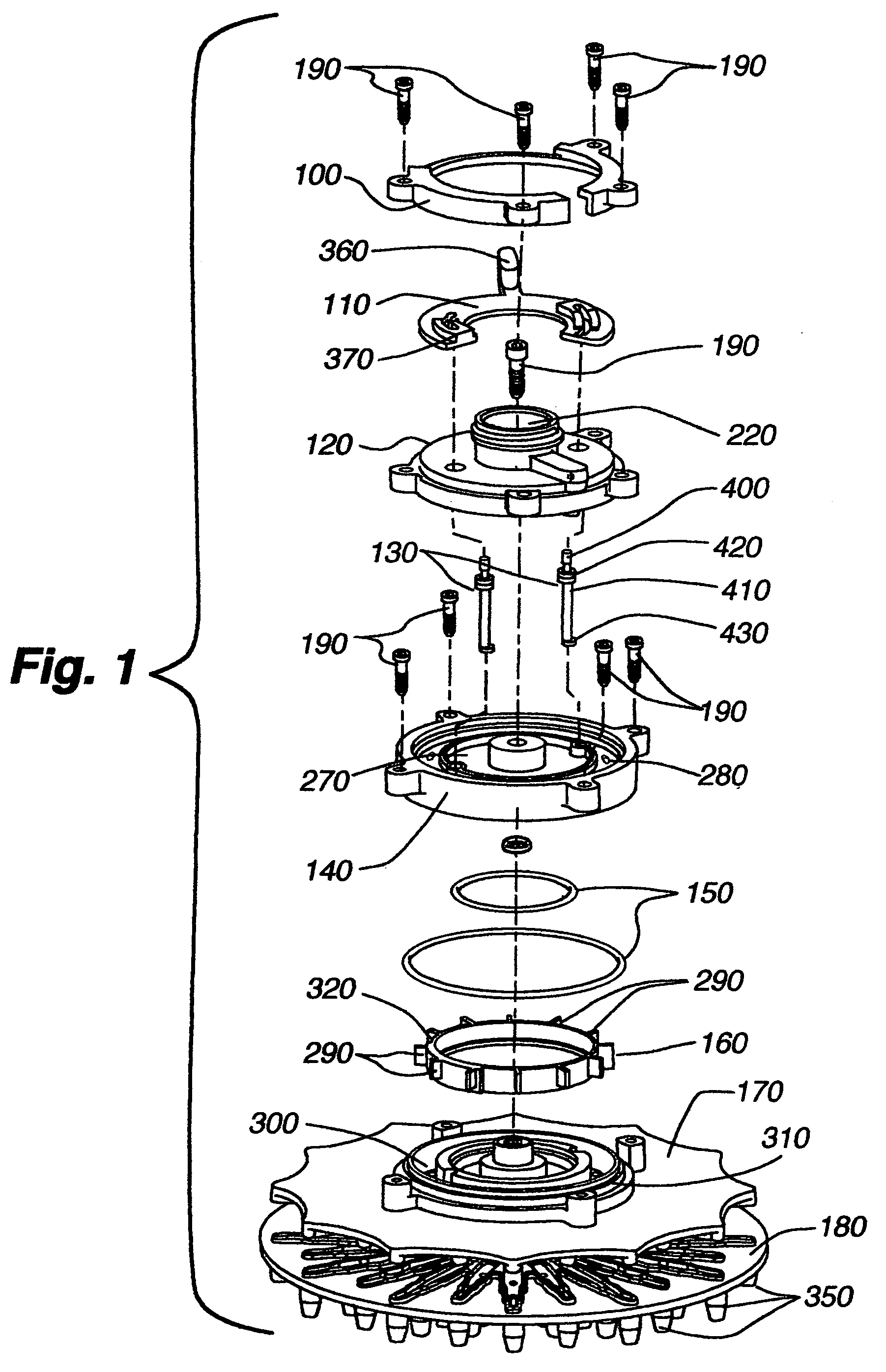

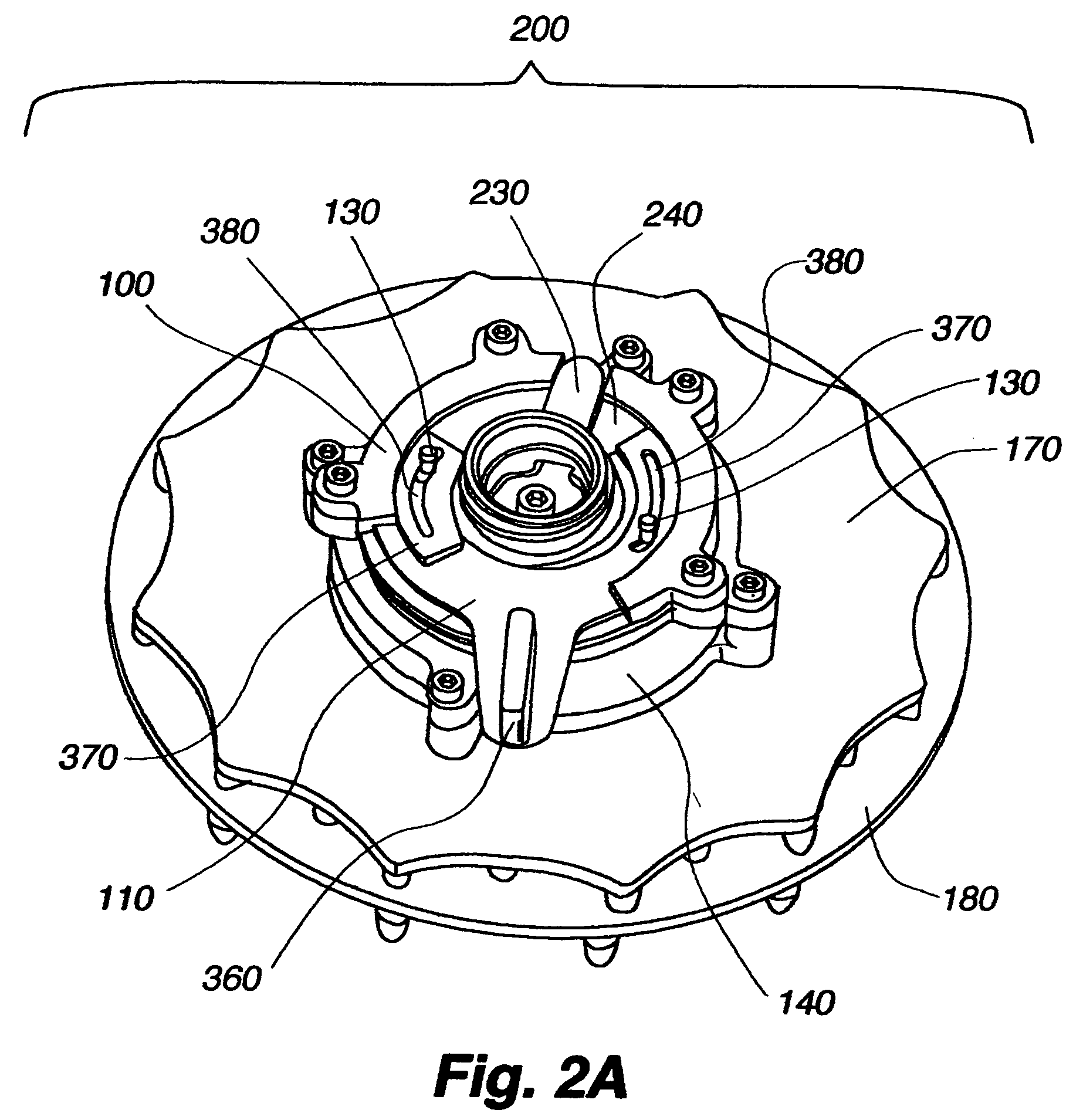

Apparatus for manipulating droplets by electrowetting-based techniques

InactiveUS6911132B2Improve controllabilityImprove accuracyBurnersElectrostatic separatorsElectricityControl manner

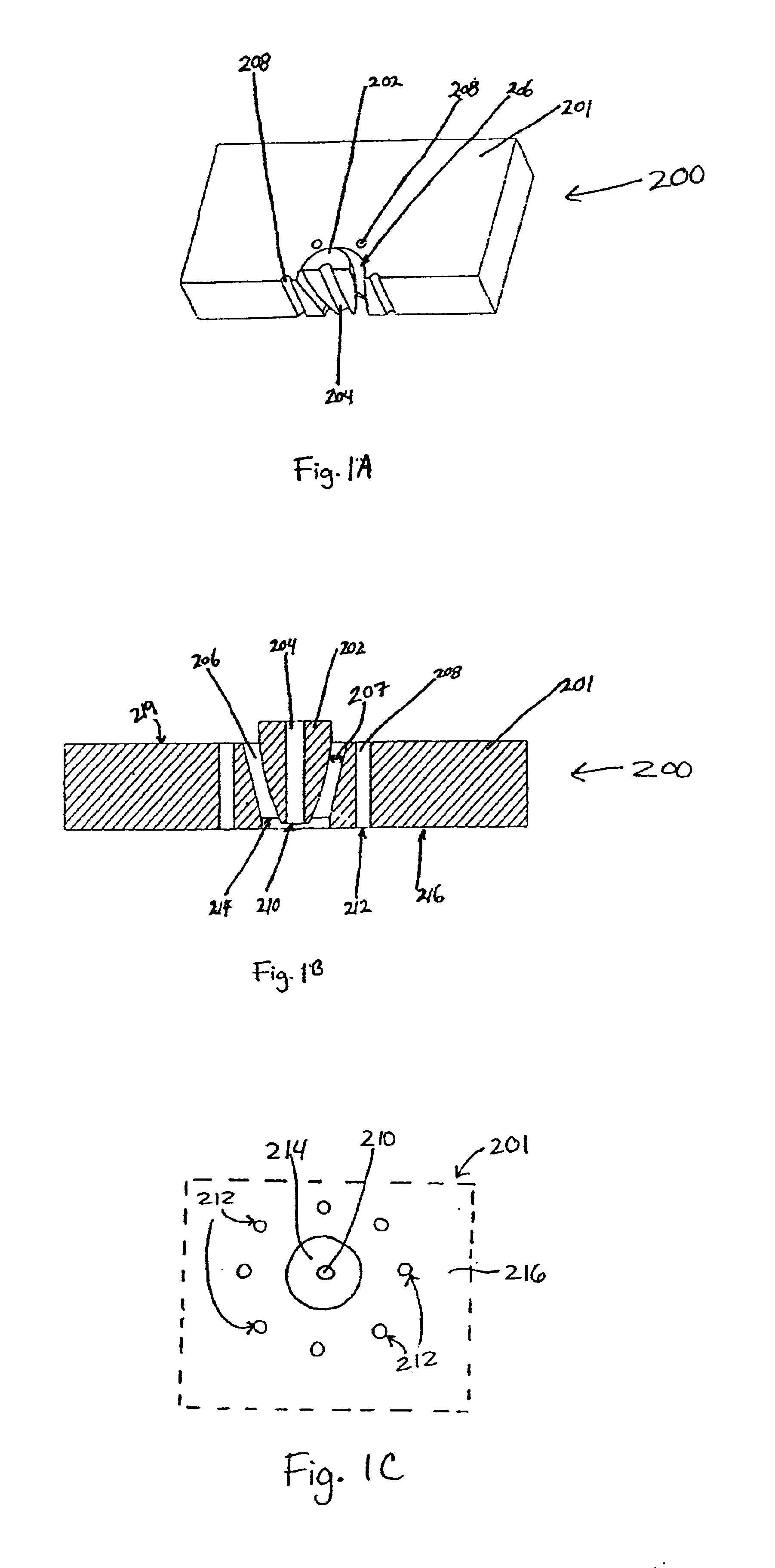

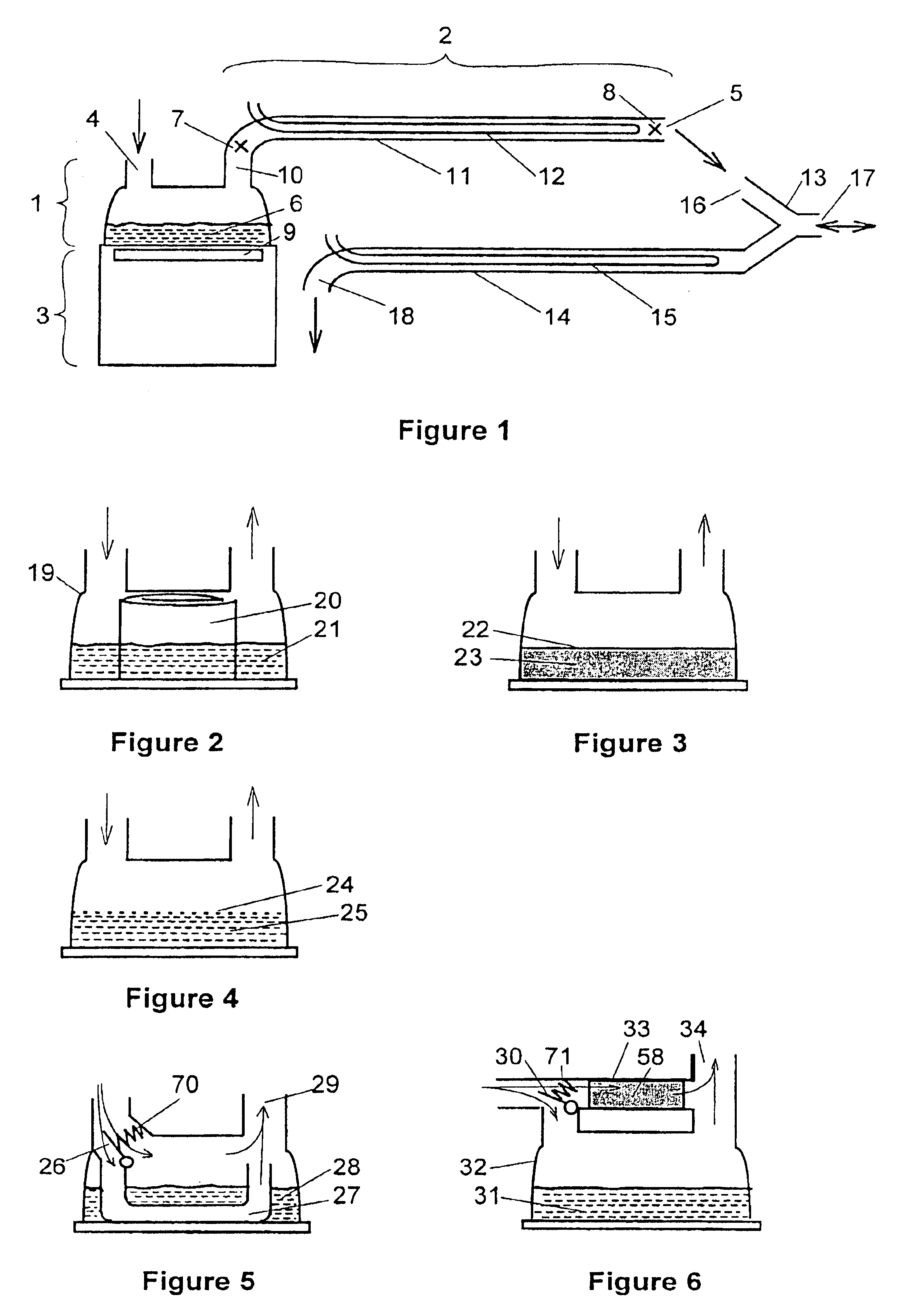

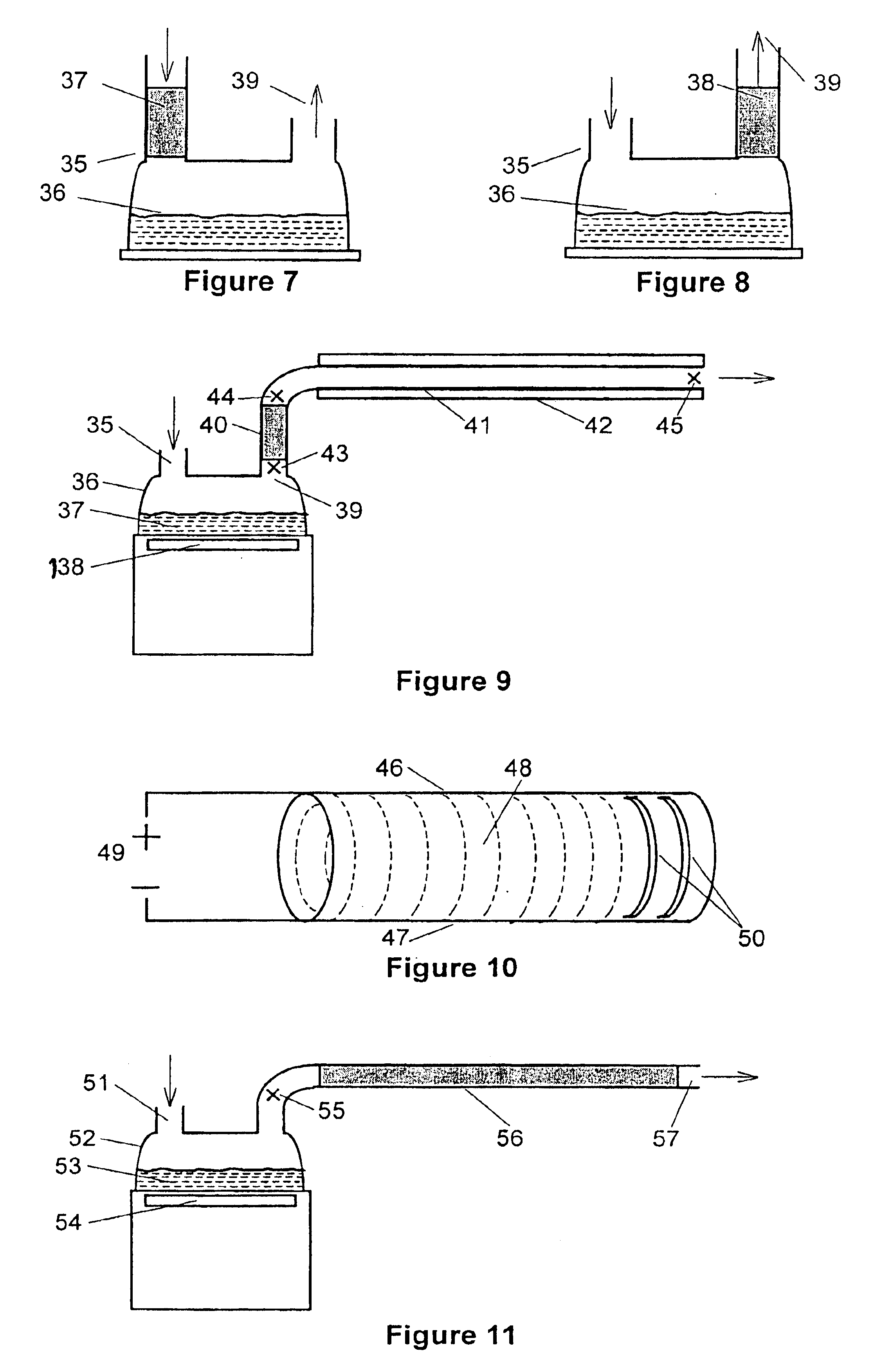

An apparatus is provided for manipulating droplets. The apparatus is a single-sided electrode design in which all conductive elements are contained on one surface on which droplets are manipulated. An additional surface can be provided parallel with the first surface for the purpose of containing the droplets to be manipulated. Droplets are manipulated by performing electrowetting-based techniques in which electrodes contained on or embedded in the first surface are sequentially energized and de-energized in a controlled manner. The apparatus enables a number of droplet manipulation processes, including merging and mixing two droplets together, splitting a droplet into two or more droplets, sampling a continuous liquid flow by forming from the flow individually controllable droplets, and iterative binary or digital mixing of droplets to obtain a desired mixing ratio.

Owner:DUKE UNIV

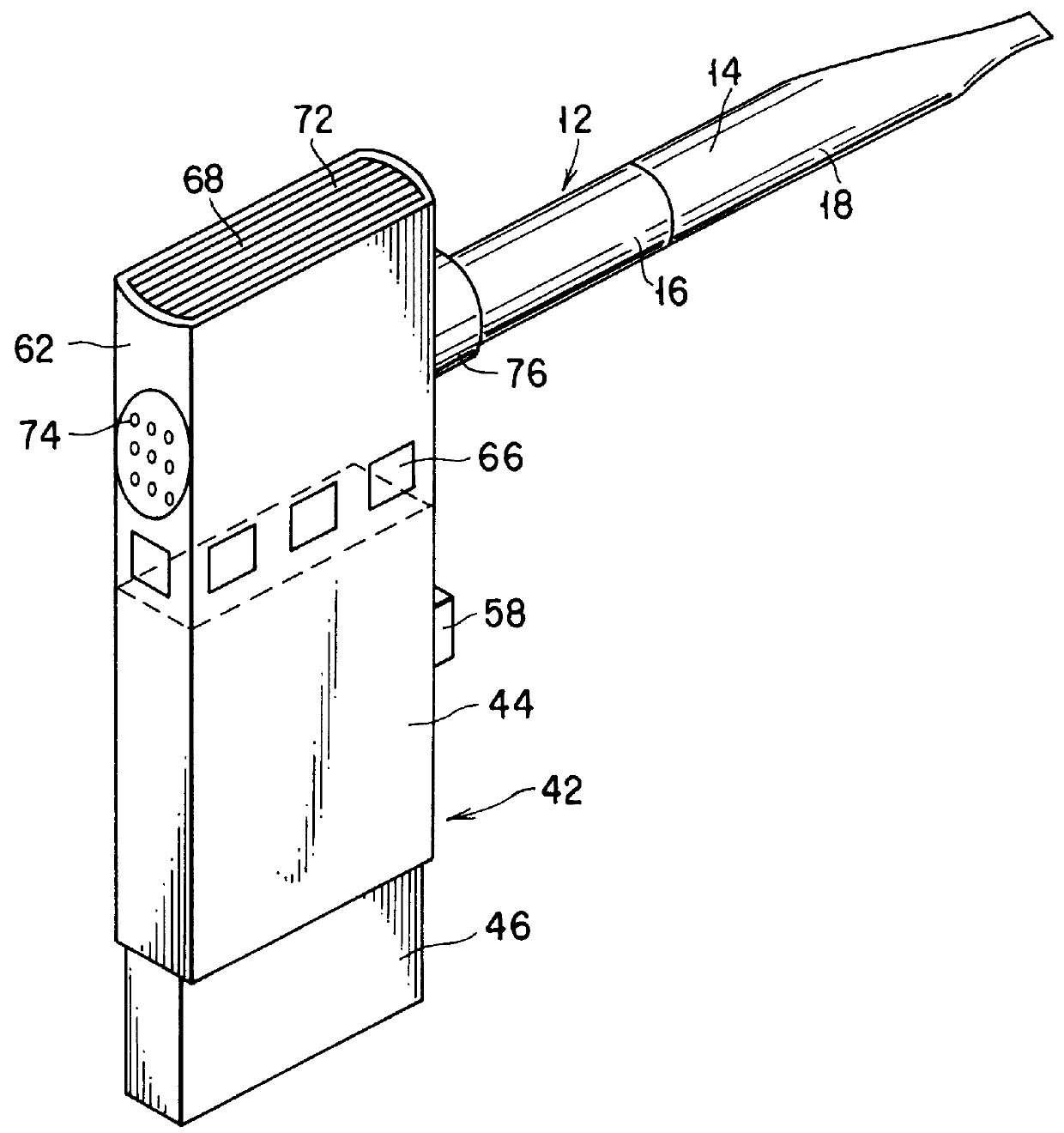

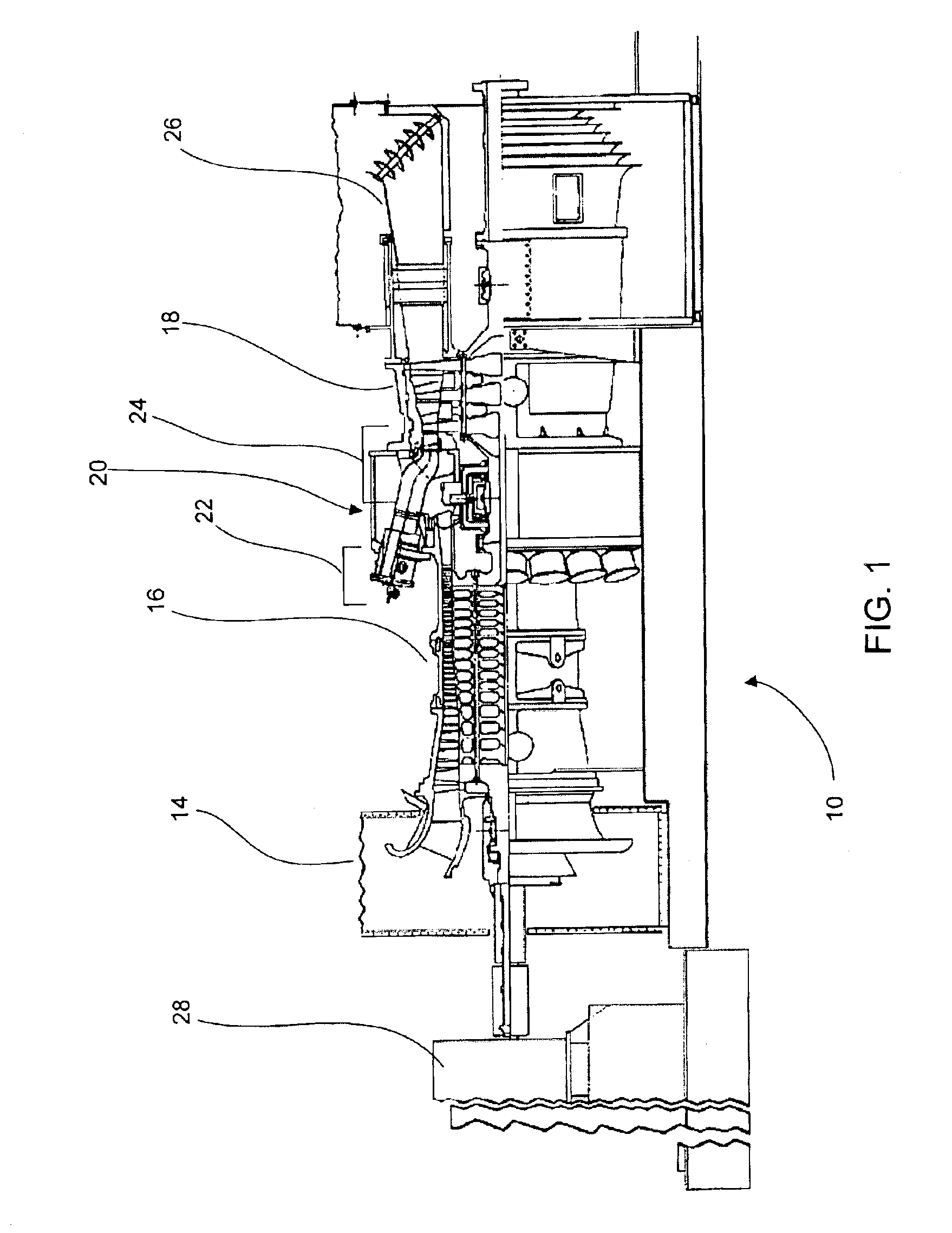

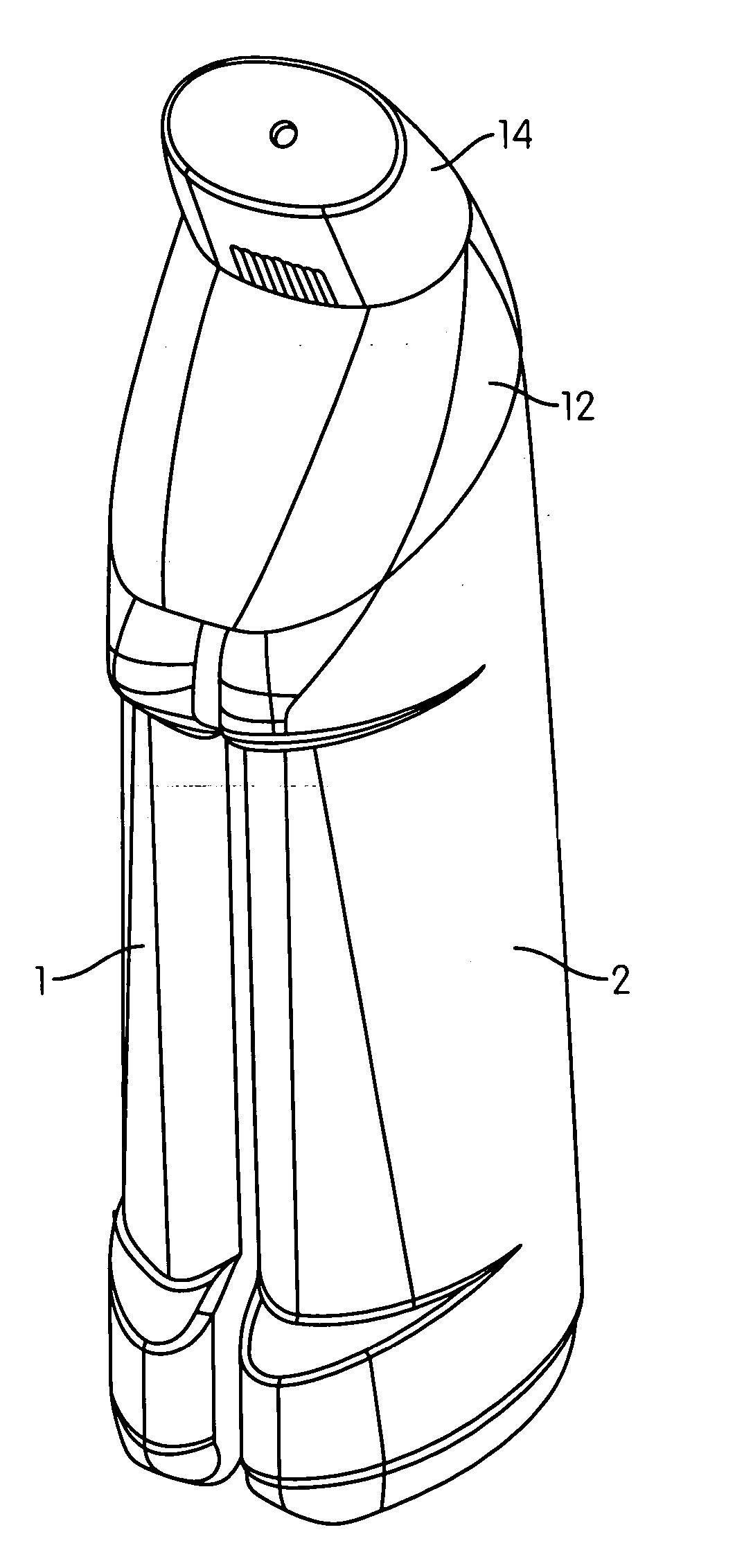

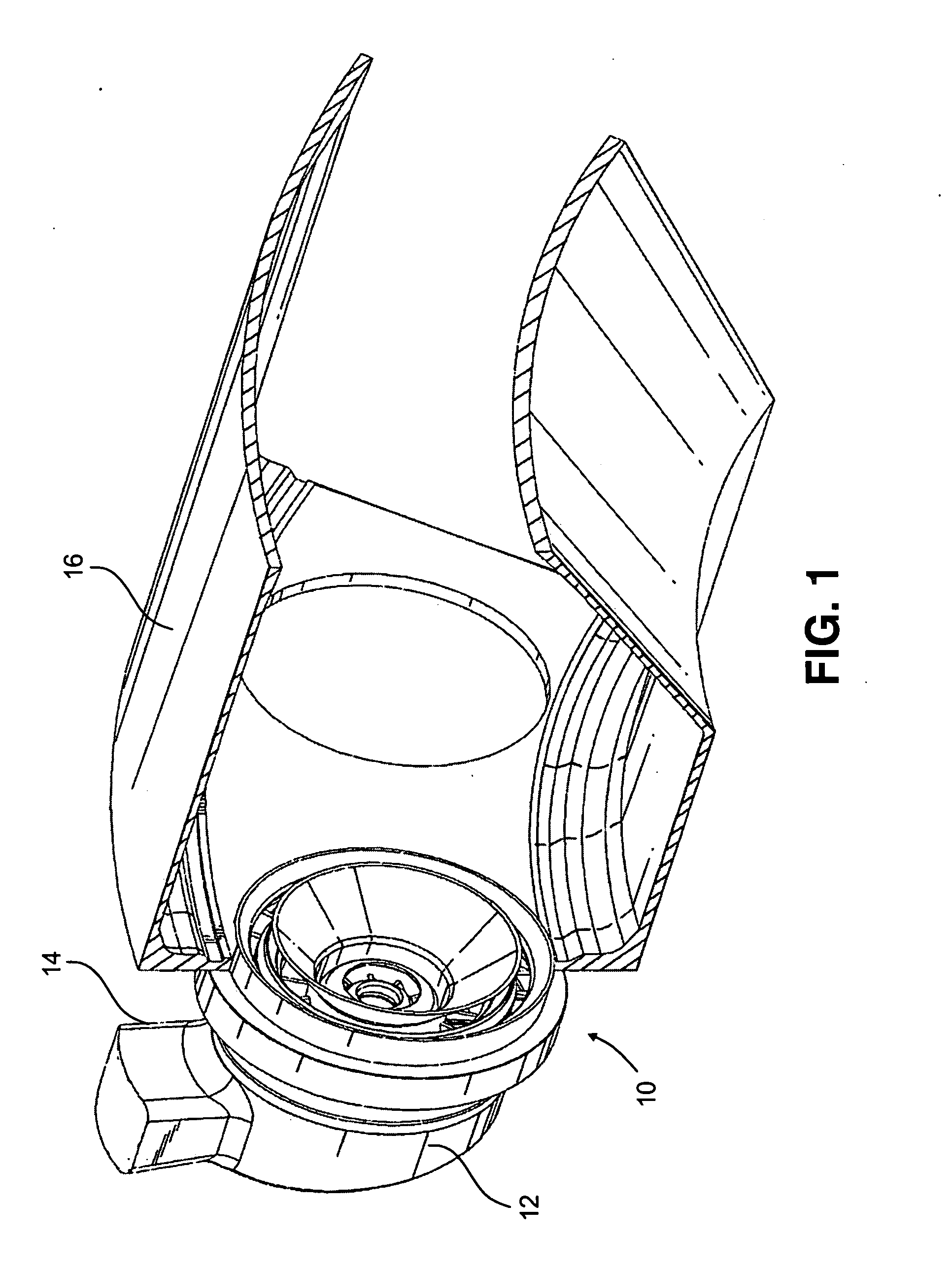

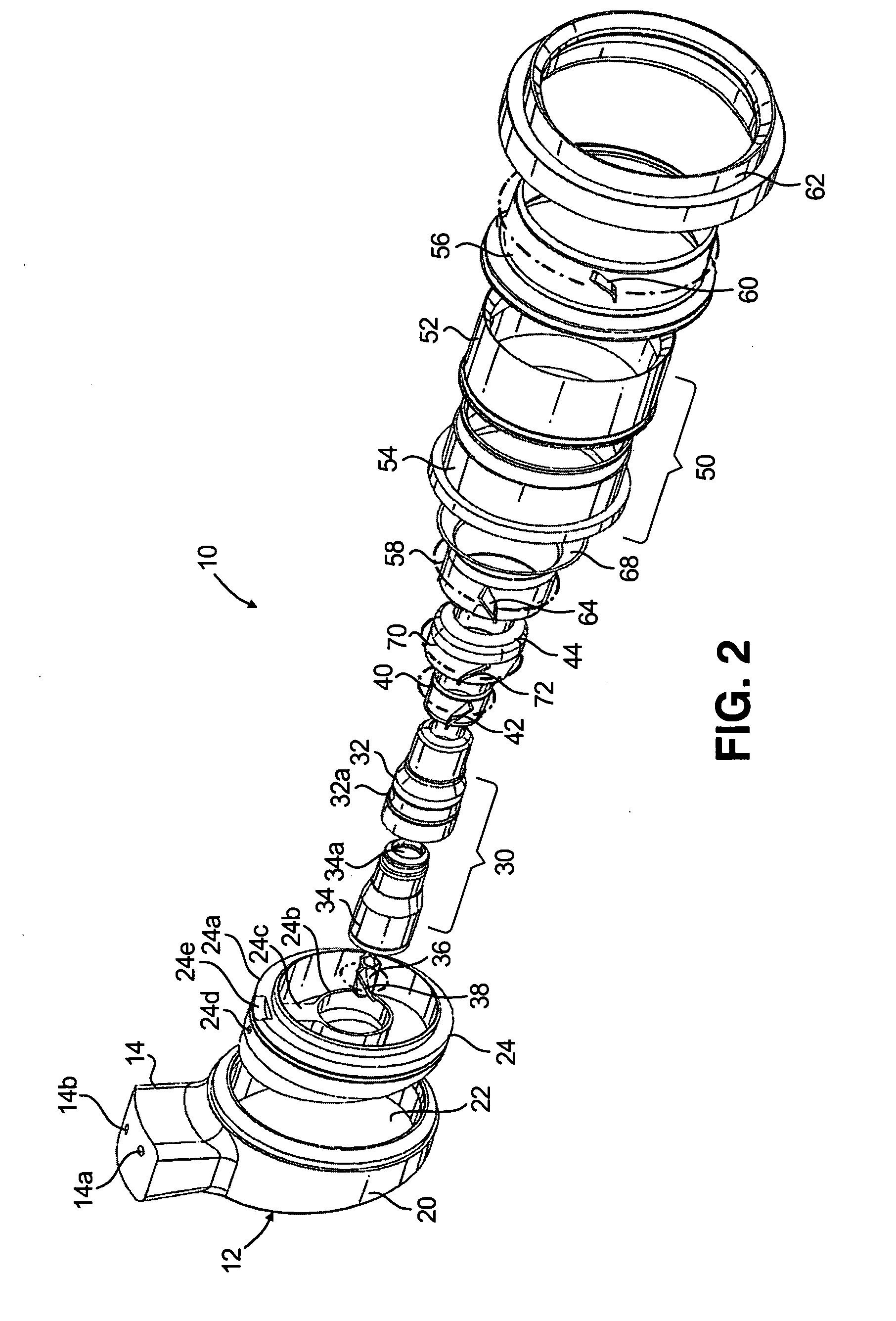

Heater for generating flavor and flavor generation appliance

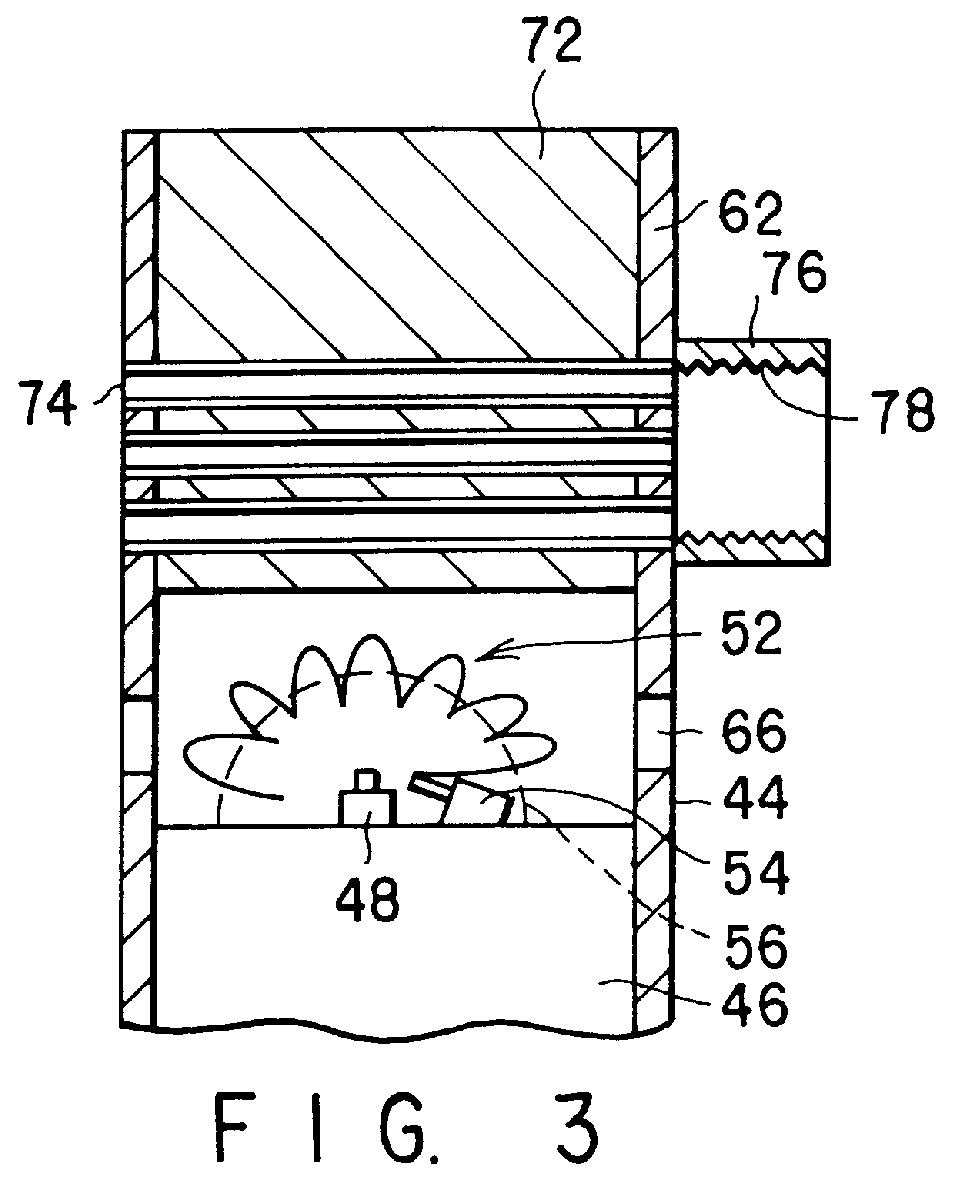

PCT No. PCT / JP97 / 01954 Sec. 371 Date Feb. 20, 1998 Sec. 102(e) Date Feb. 20, 1998 PCT Filed Jun. 9, 1996 PCT Pub. No. WO97 / 48294 PCT Pub. Date Dec. 24, 1997A flavor generation piece (12) incorporates a formed body (32) of a material containing a flavor substance. A heater (42) heats the flavor generation piece (12) without burning it, thereby generating a flavor. The heater (42) has a tank (46) mounted in a heat-insulating holder (44) to store a combustible gas. A combustion portion (52) for burning the combustible gas is disposed on the tank (46). Ignition or extinction of the combustion portion (52) is selected by a switch (58). The upper portion of the heat-insulating holder (44) forms a heat exchange duct (62) surrounding the combustion portion (52) and providing an exhaust path (64). An air pipe (74) is disposed to cross the heat exchange duct (62) transversely in the exhaust path (64). Heat exchange is performed between a fluid flowing in the exhaust path (64) and a fluid flowing in the air pipe (74). A socket (76) communicating with the air pipe (74) to detachably mount the flavor generation piece (12) is disposed on the outer side surface of the heat-insulating holder (44).

Owner:JAPAN TOBACCO INC

Tapered post, showerhead design to improve mixing on dual plenum showerheads

Owner:NOVELLUS SYSTEMS

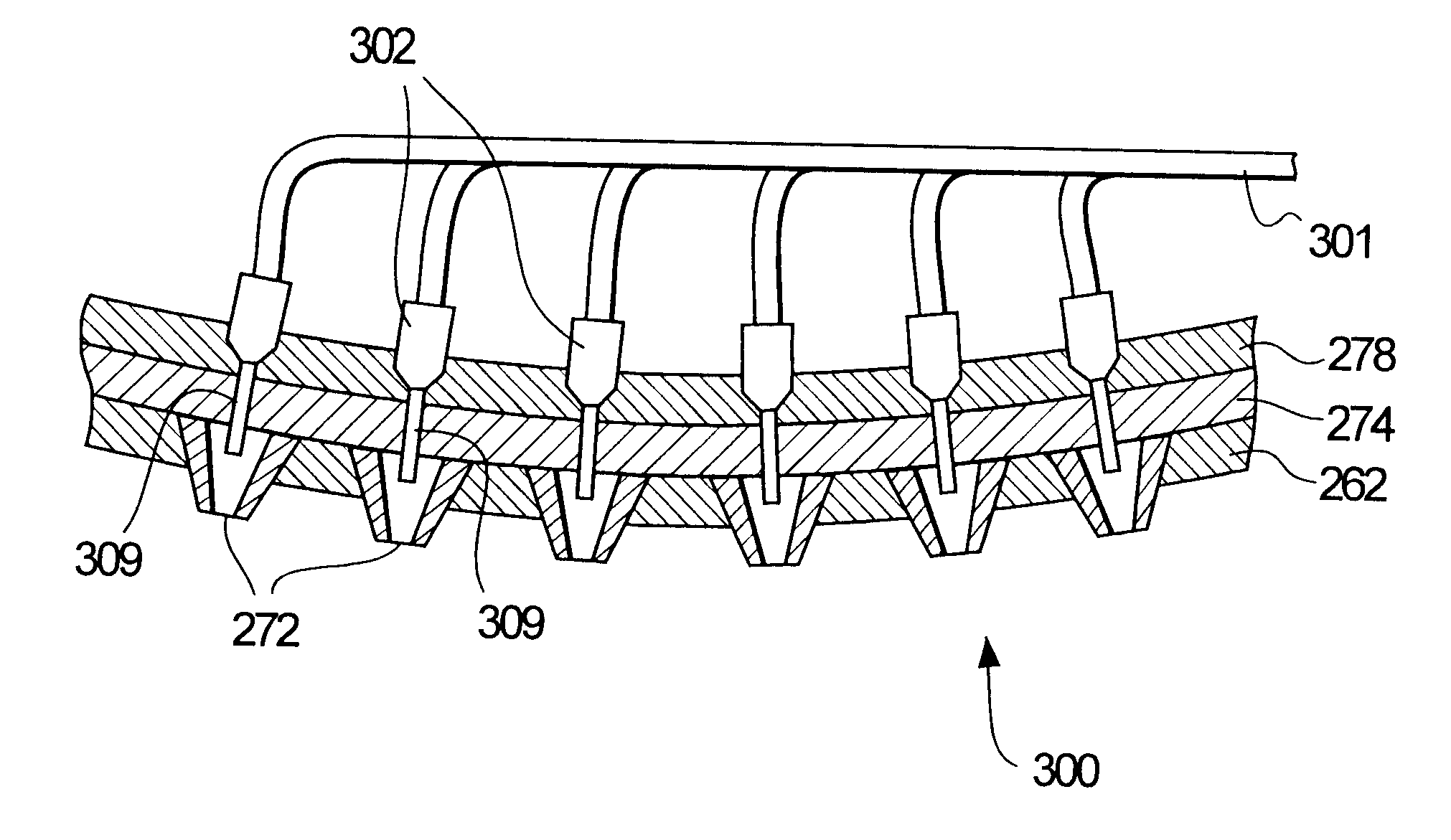

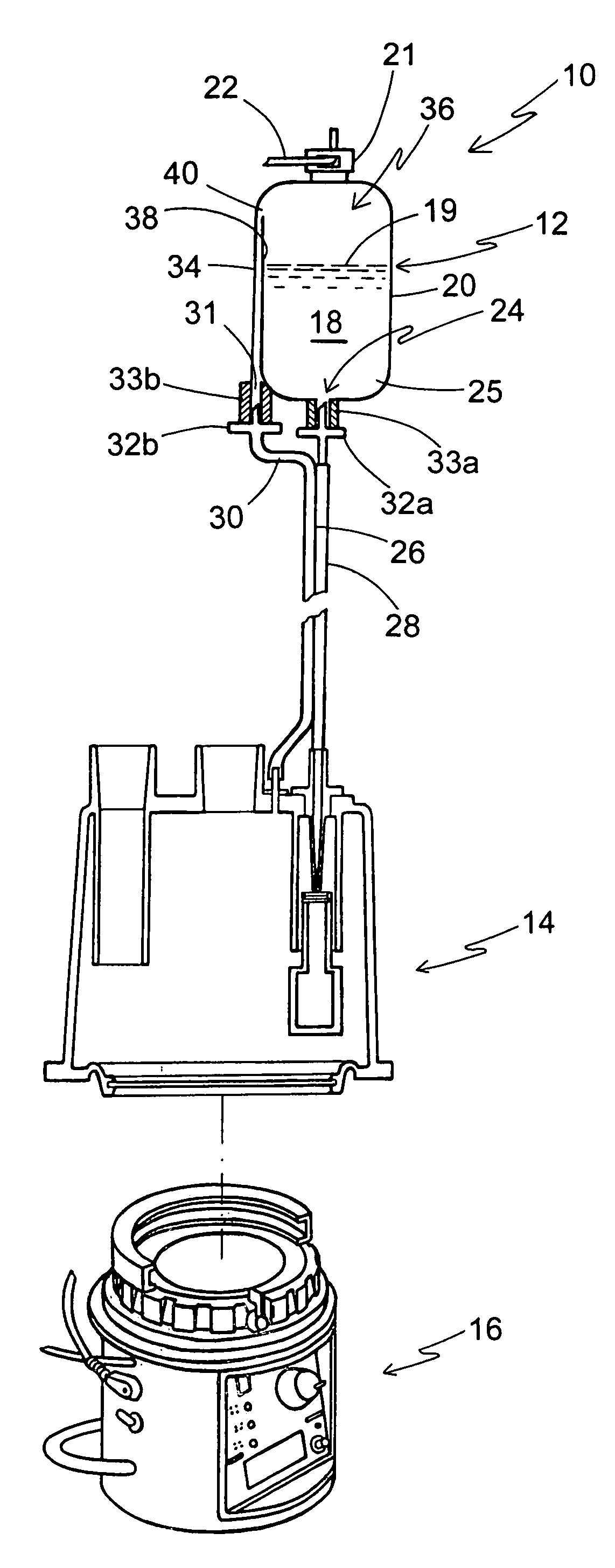

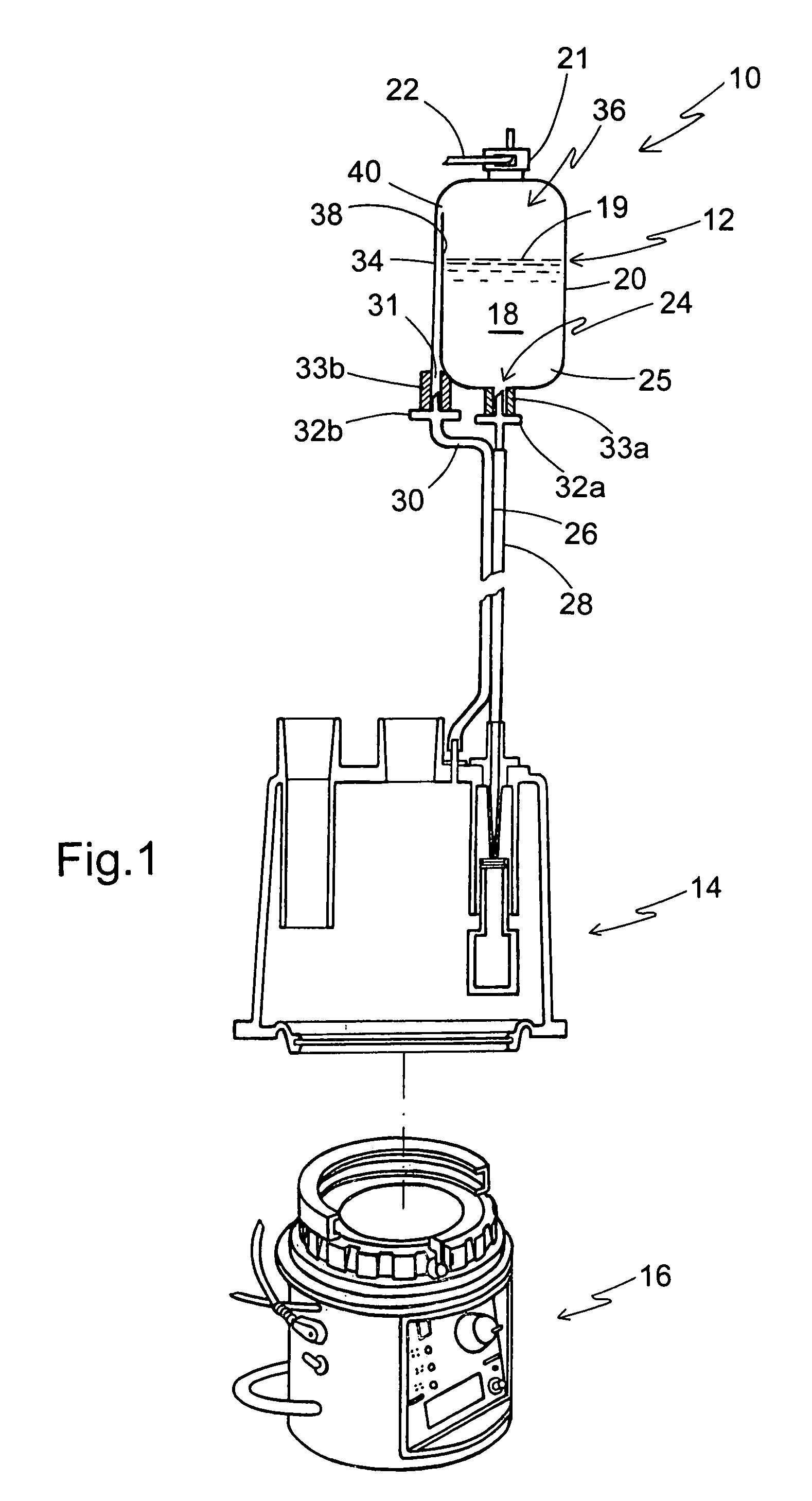

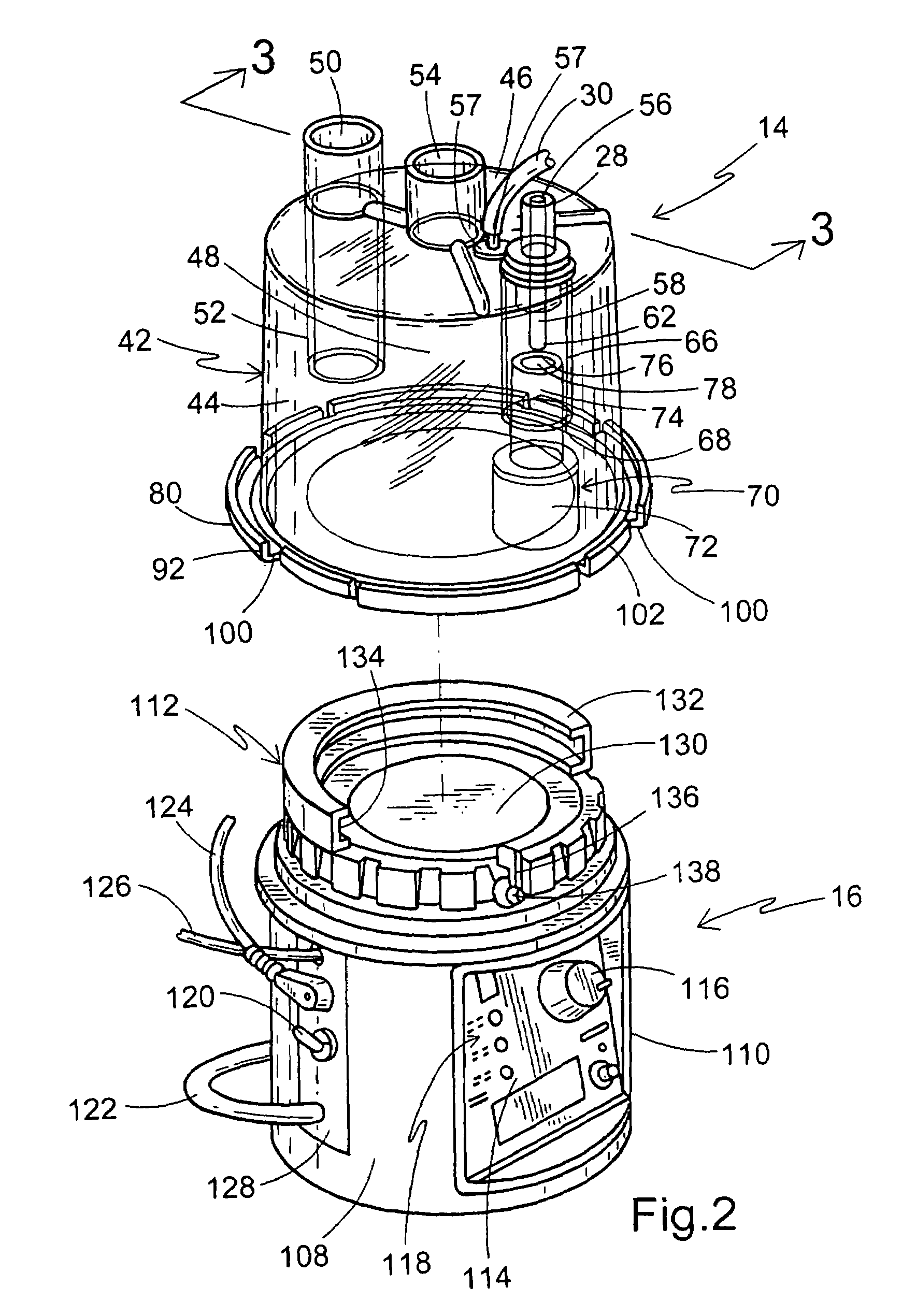

Breathing assistance apparatus

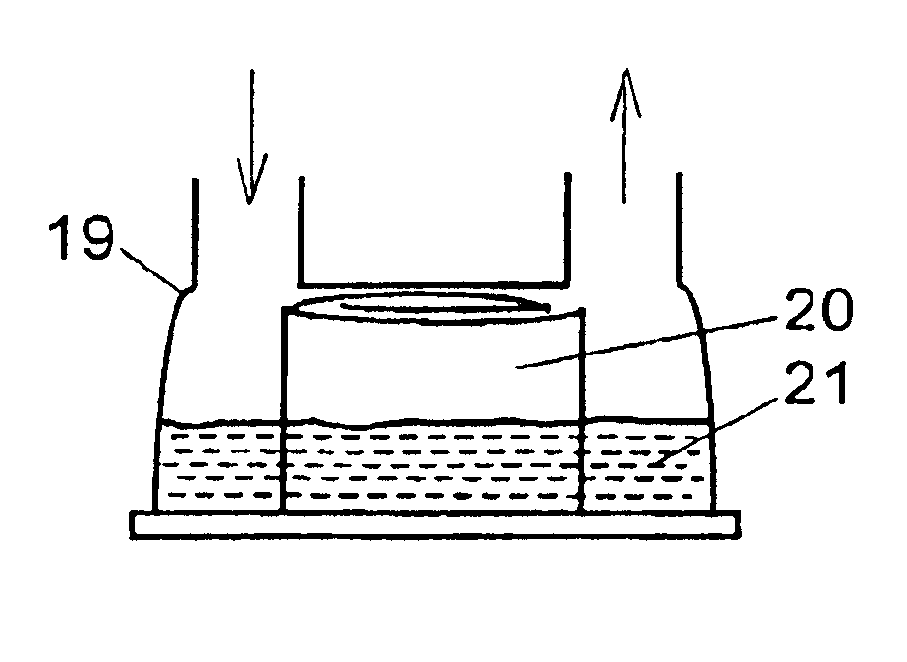

A humidifier and humidity sensor for use with a breathing assistance apparatus. The humidity sensor senses absolute humidity, relative humidity and / or temperature at both the patient end and humidifier end. The humidifier may also include provision to both control independently the humidity and temperature of the gases. Further, a chamber manifold facilitates easy connection of the humidifier to various outlets, inlets and sensors. A heated conduit provides a more effective temperature profile along its length.

Owner:FISHER & PAYKEL HEALTHCARE LTD

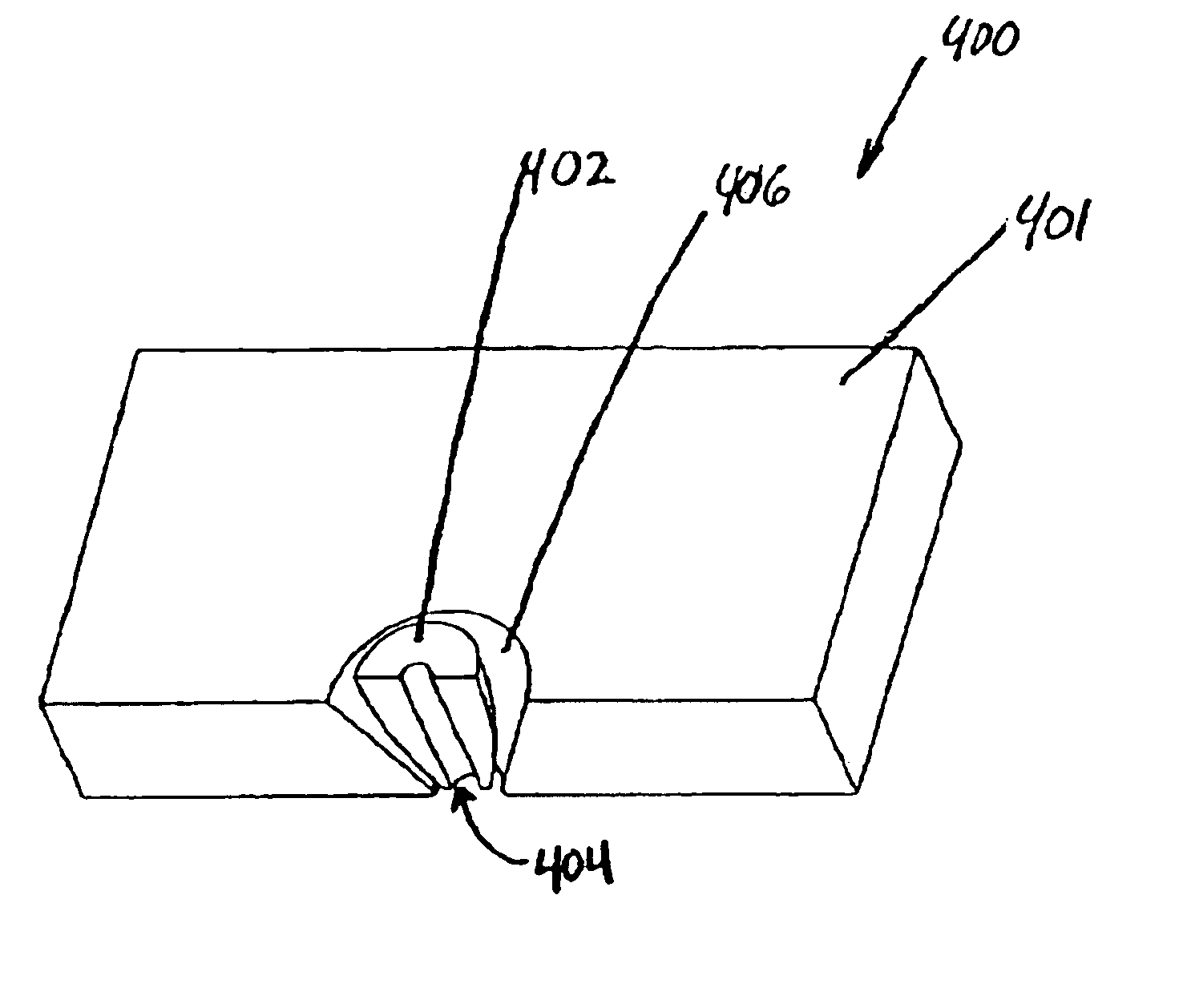

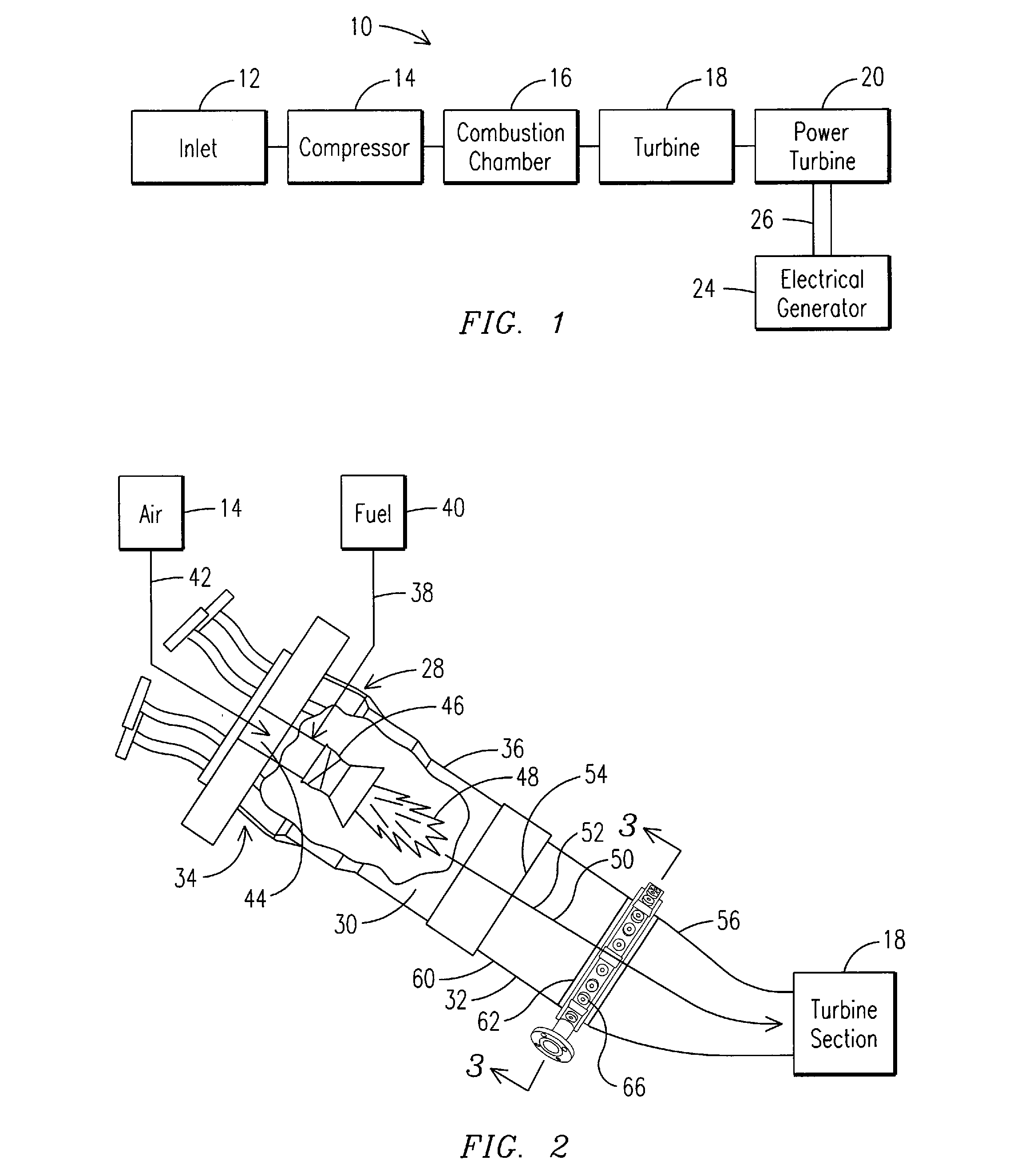

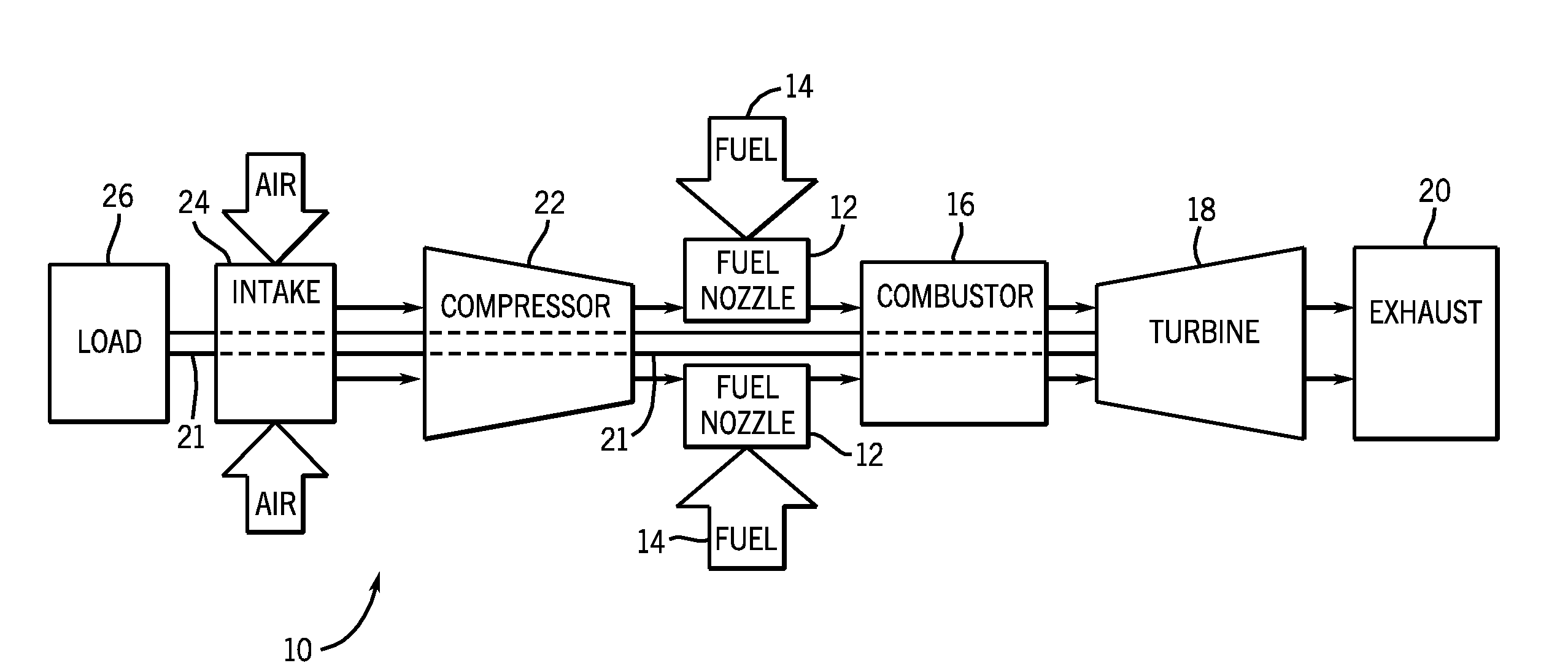

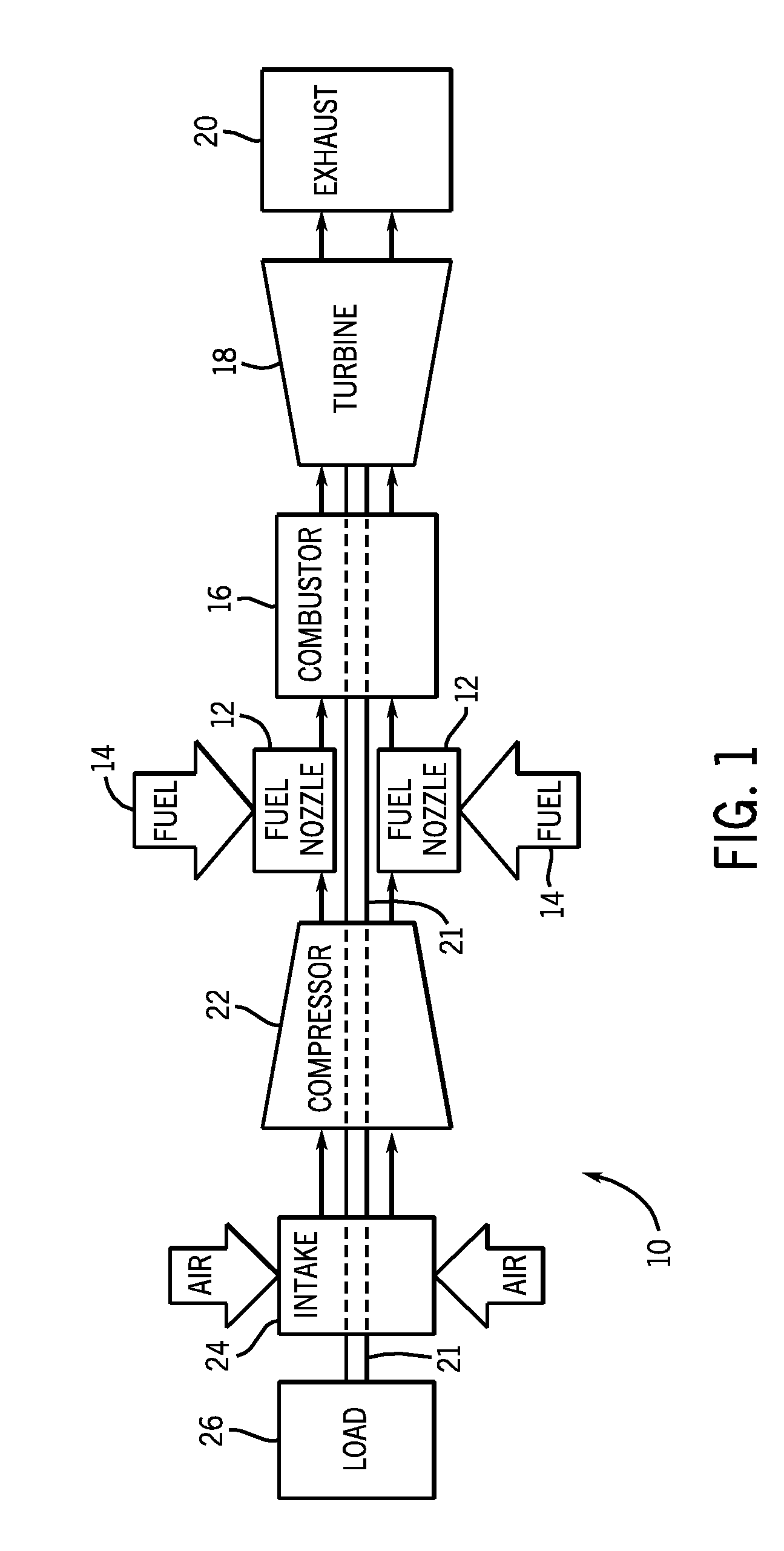

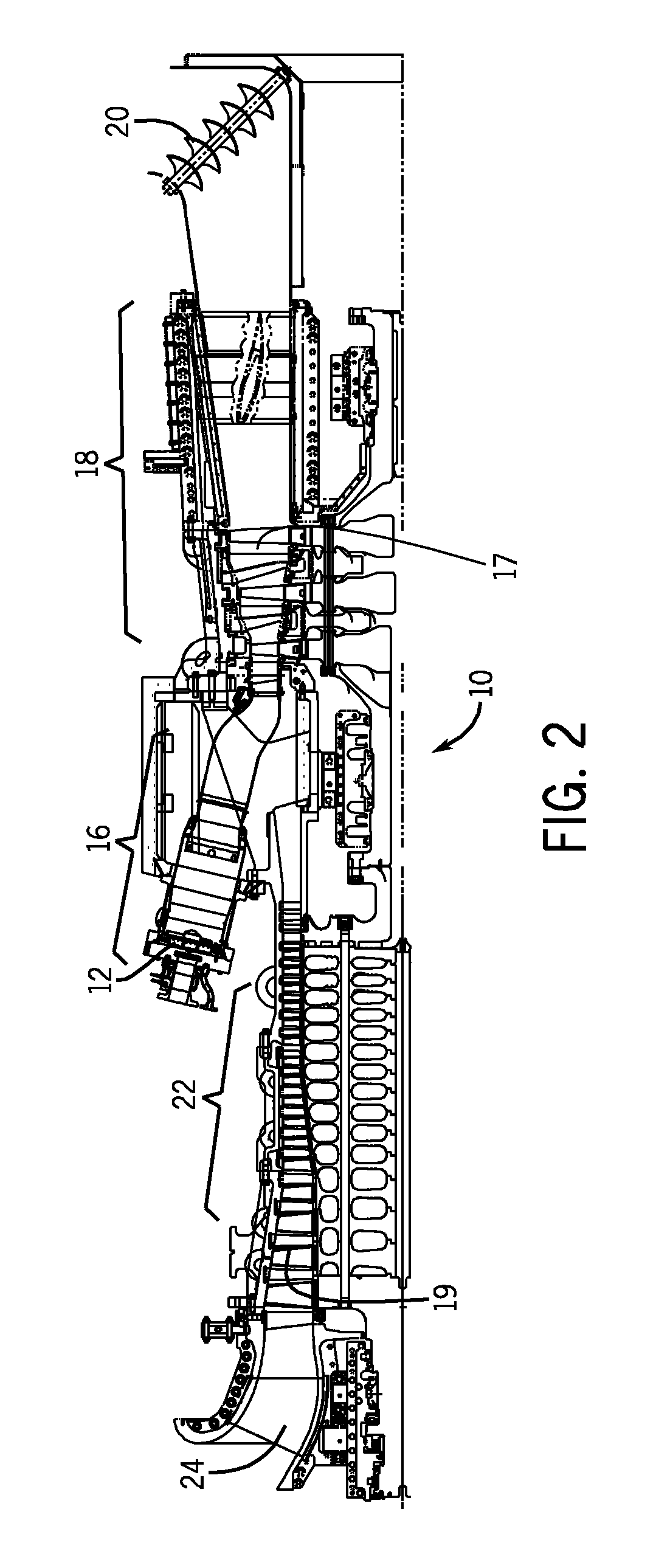

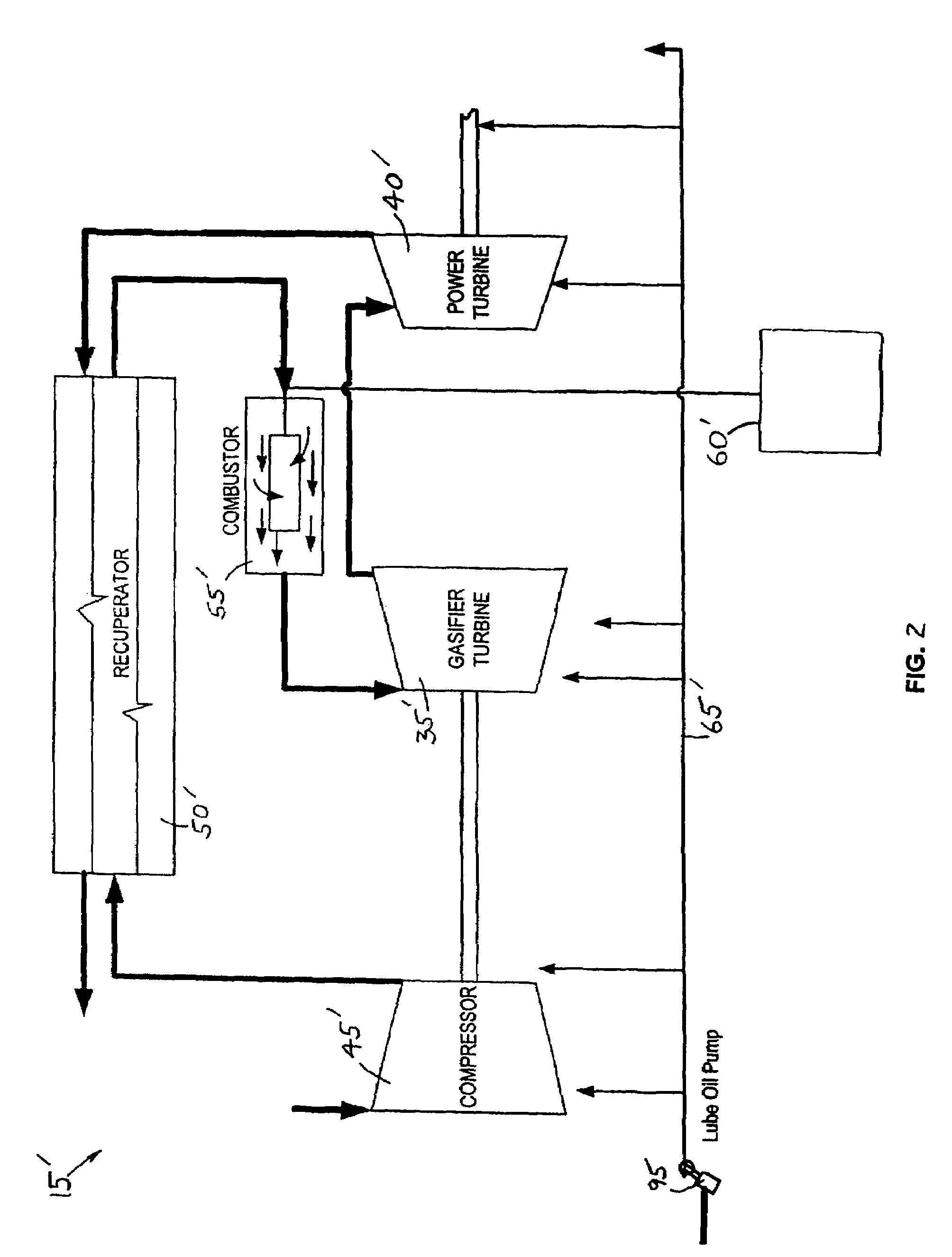

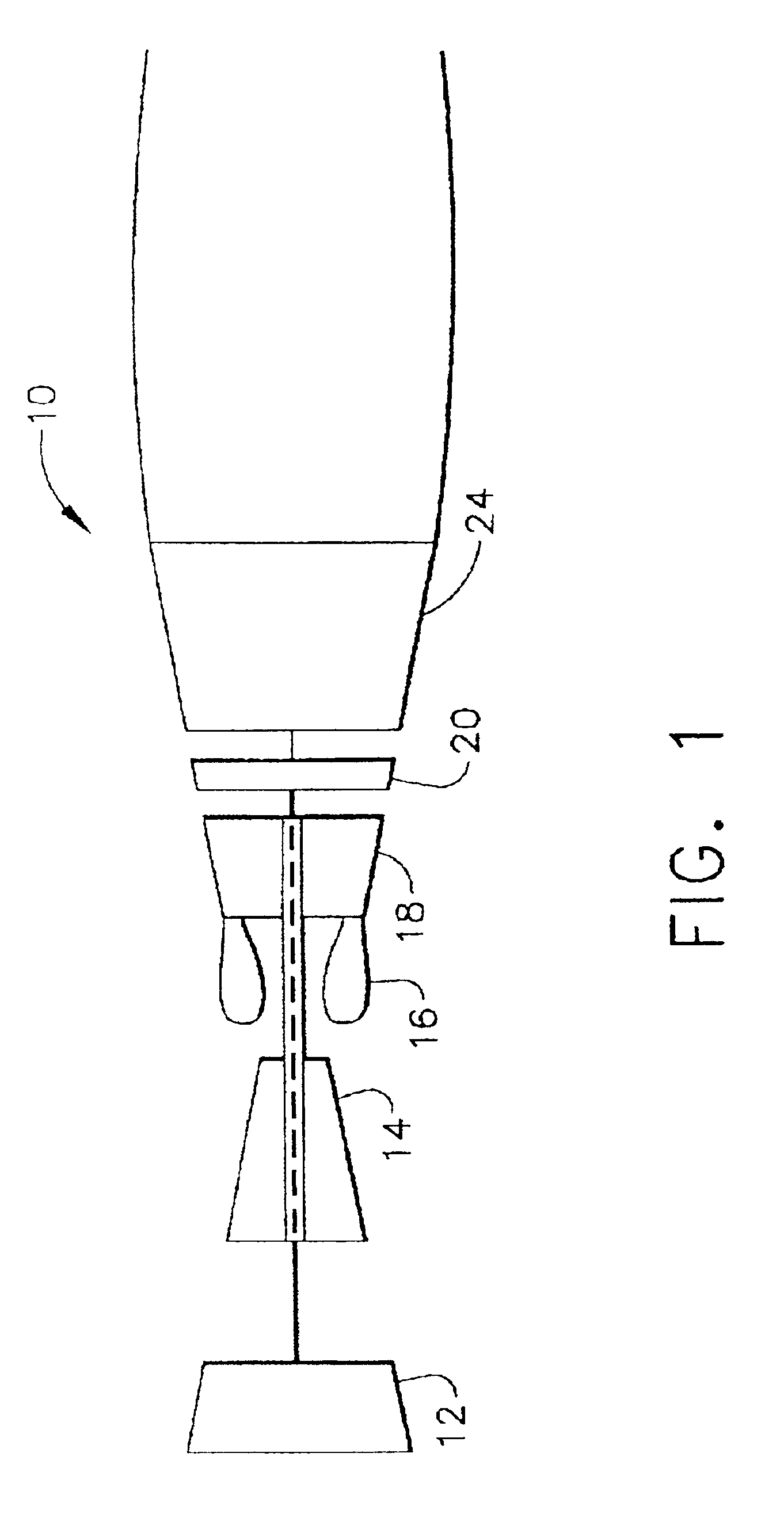

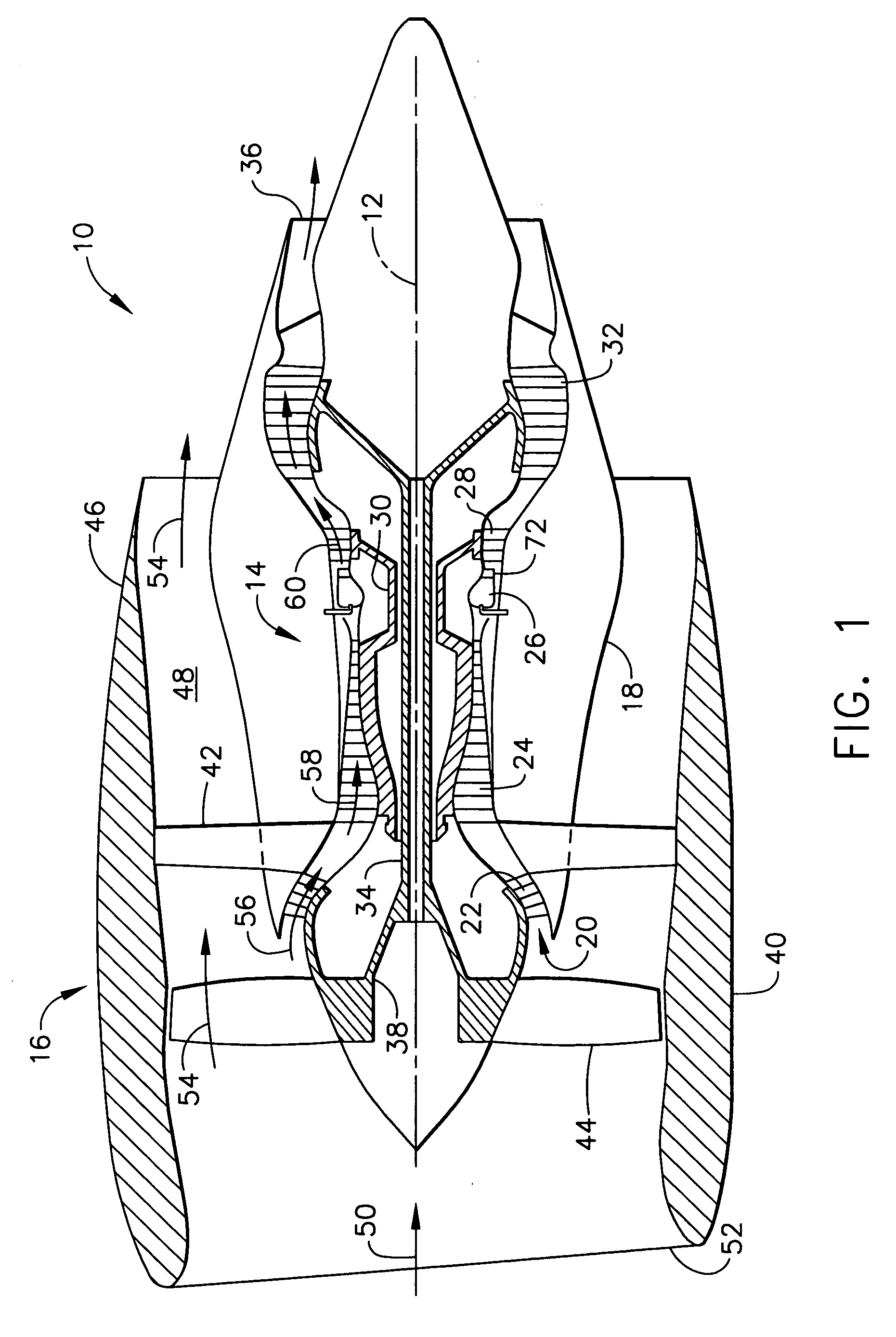

Turbine containing system and an injector therefor

A turbine containing system is disclosed. The system includes an intake section, a compressor section downstream from the intake section, a combustor section having a primary combustion system downstream from the intake section, a secondary combustion system downstream from the primary combustion system, a turbine section, an exhaust section and a load. The secondary combustion system includes an injector for transversely injecting a secondary fuel into a stream of combustion products of the primary combustion system. The injector including a coupling, a wall defining an airfoil shape circumscribing a fuel mixture passage, and at least one exit for communication between said fuel mixture passage and said stream of primary combustion products.

Owner:GENERAL ELECTRIC CO

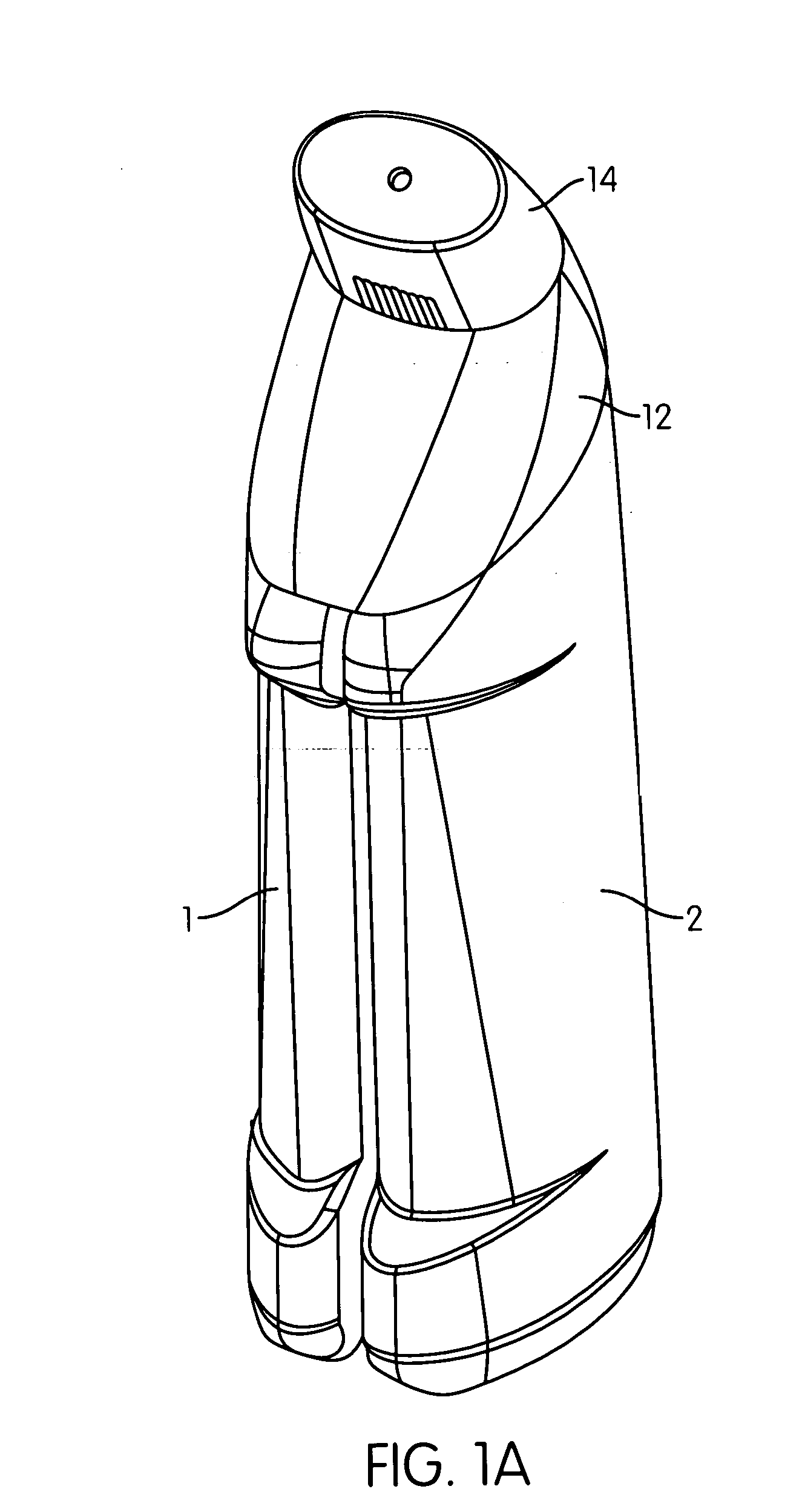

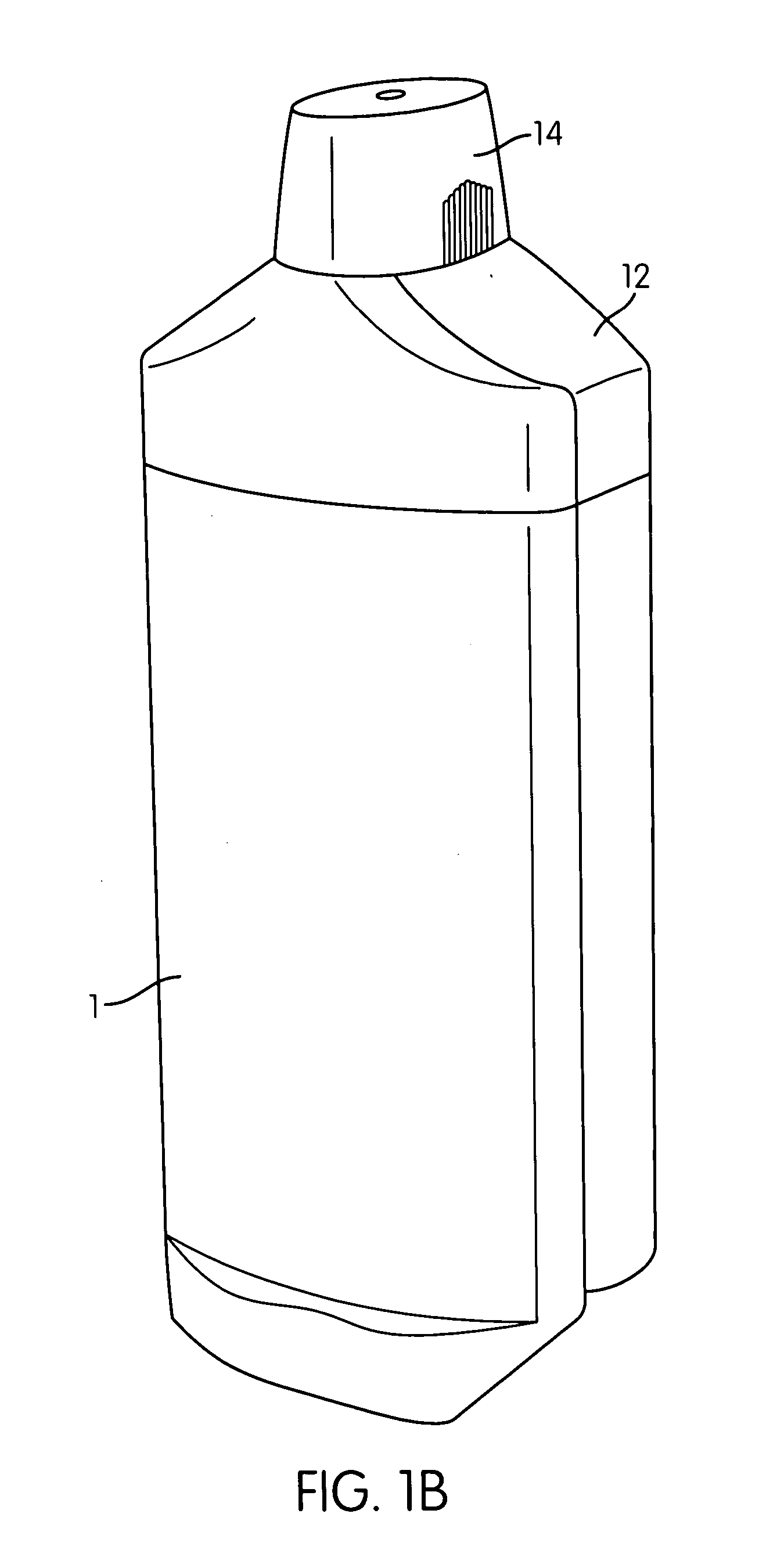

Dispenser bottle for at least two active fluids

A dispenser bottle having a first receiving container for a first active fluid and at least a second receiving container for a second active fluid, wherein the receiving containers each have a respective outlet for the active fluid and the outlets are arranged adjacently such that the two active fluids can be applied in a common application field of an application region, and wherein the outlets each comprise a respective discharge nozzle, which nozzles are spaced from one another such that the active fluids intermix only after departing the discharge nozzles.

Owner:HENKEL KGAA

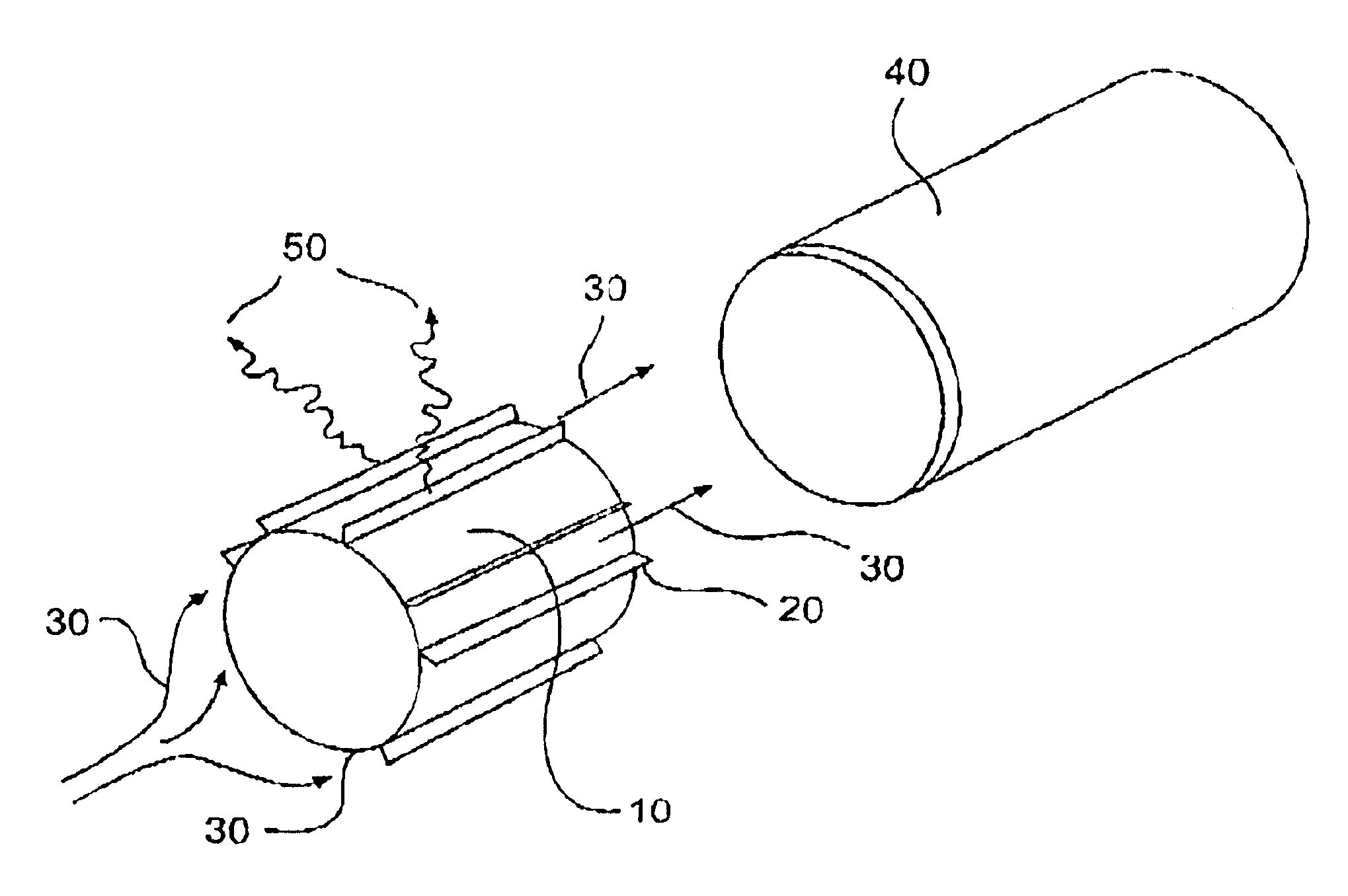

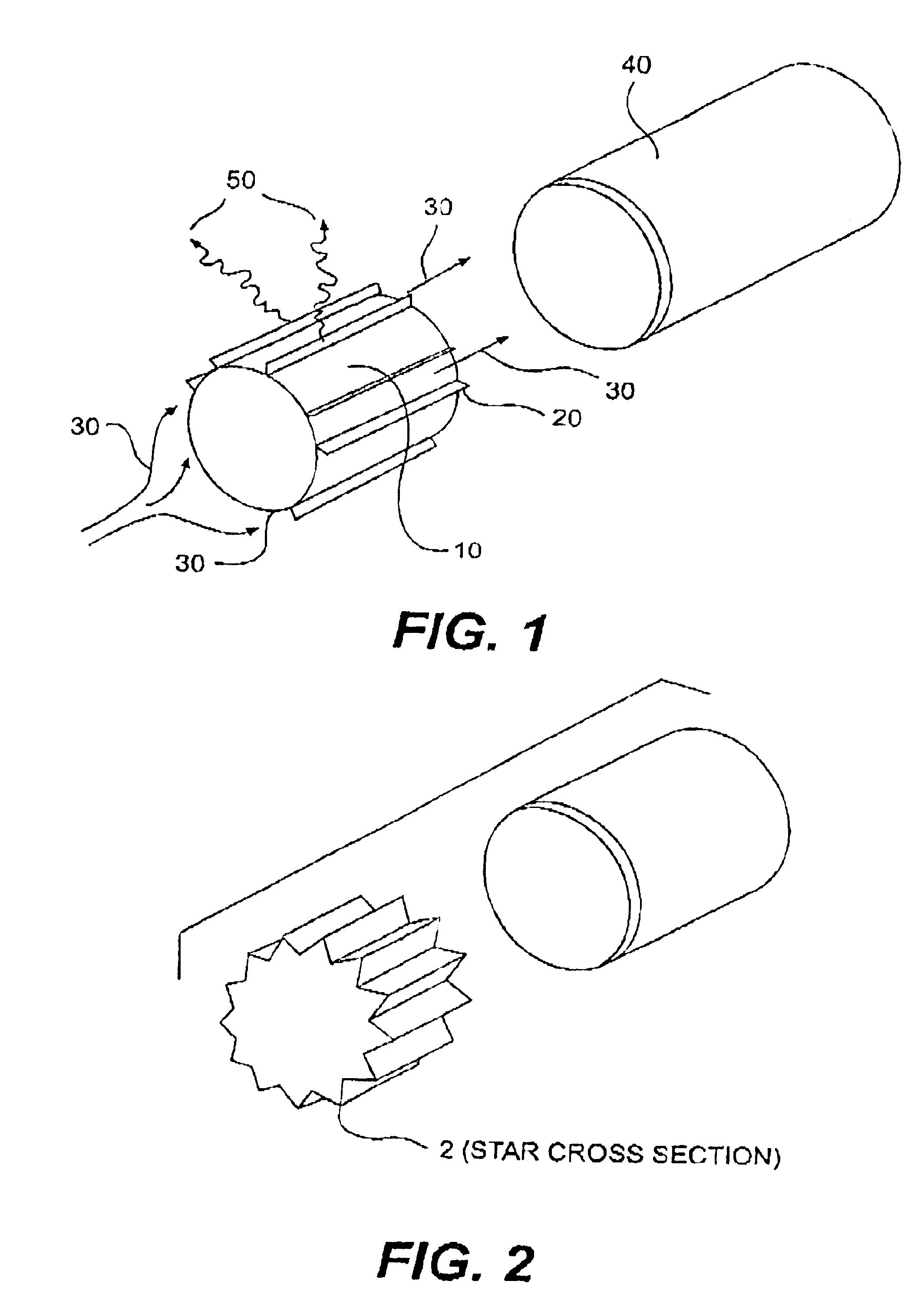

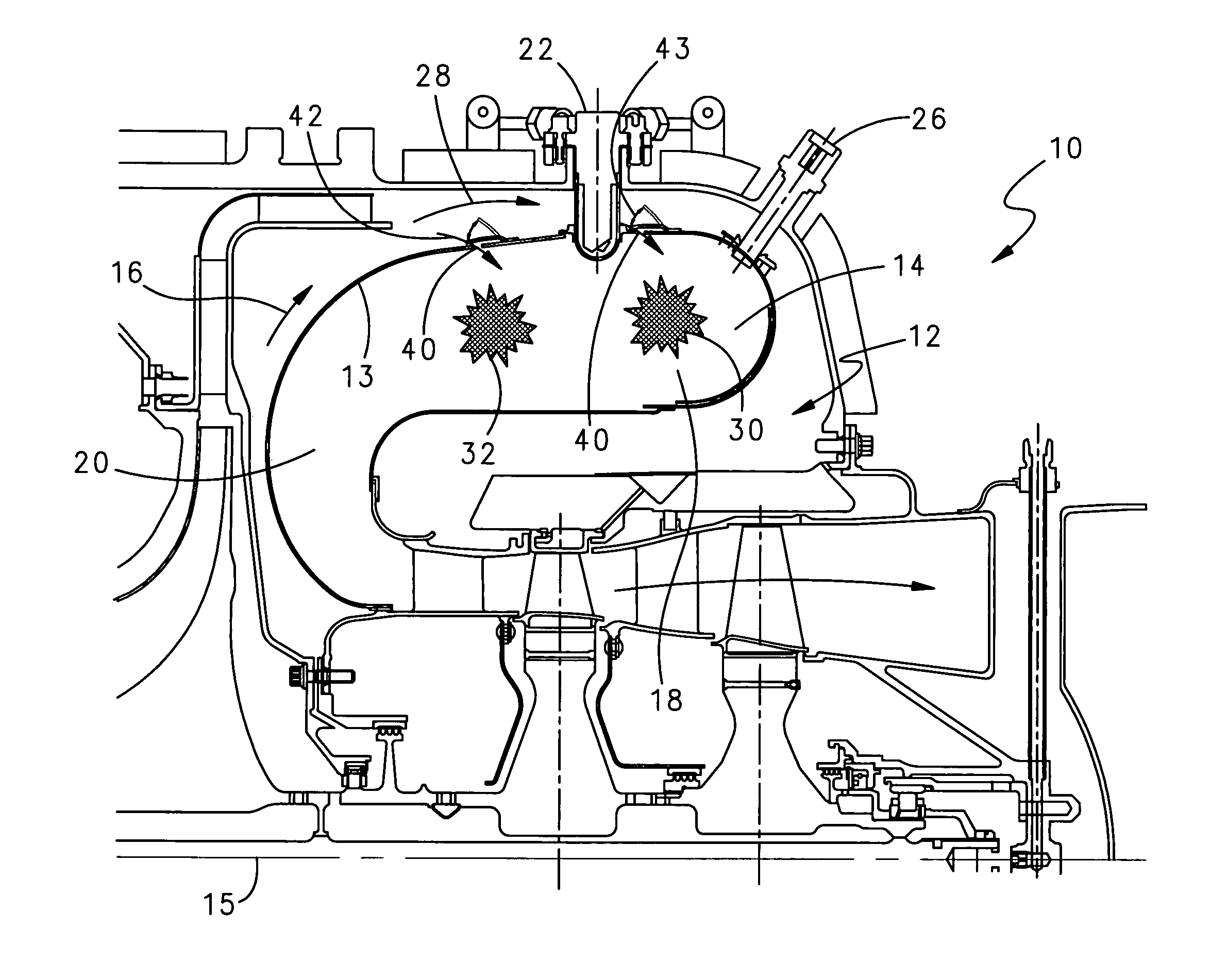

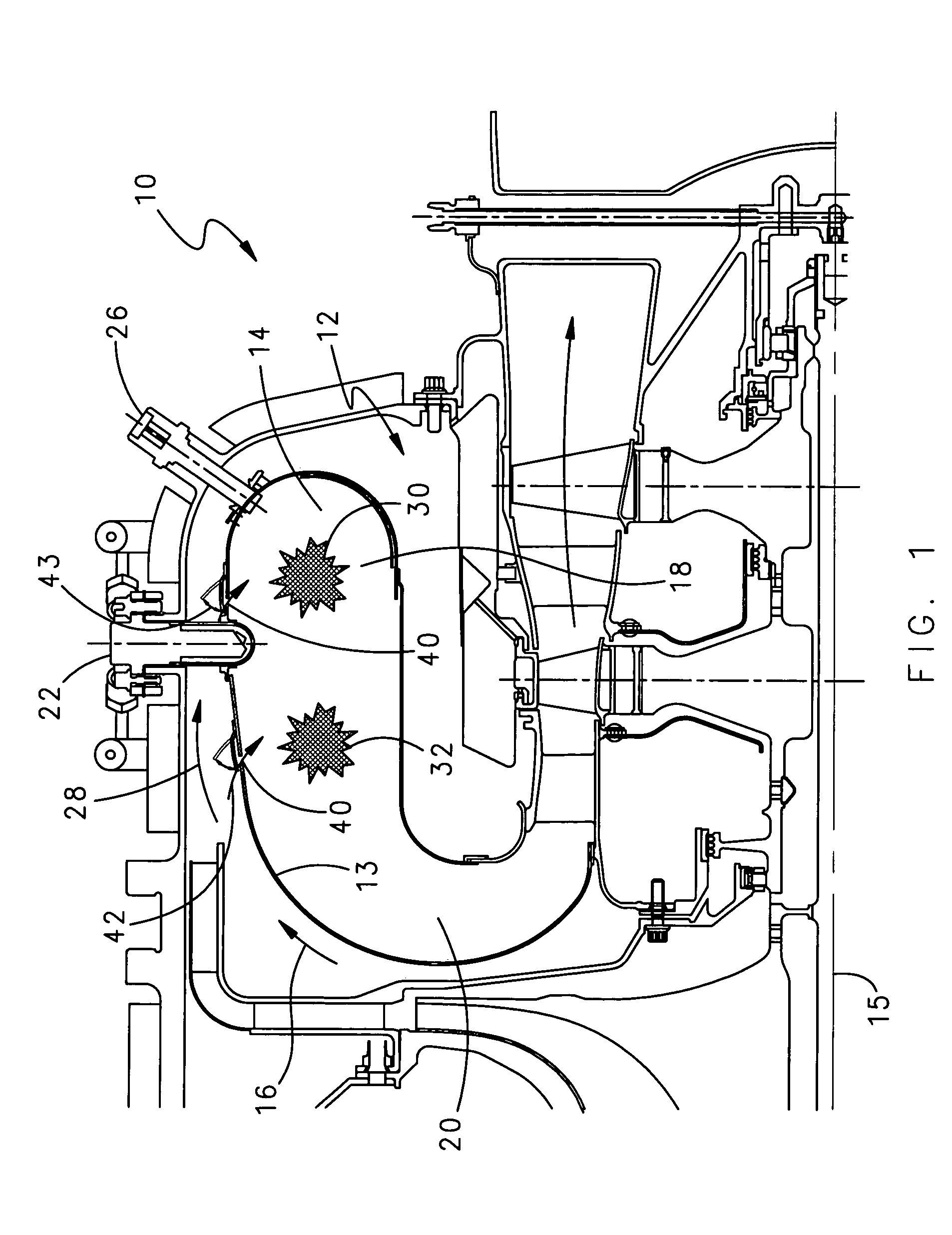

Method and apparatus to increase combustion efficiency and to reduce exhaust gas pollutants from combustion of a fuel

InactiveUS6851413B1Improve combustion efficiencyFacilitate fuel combustionBurnersLiquid fuel feeder/distributionCombustorExhaust fumes

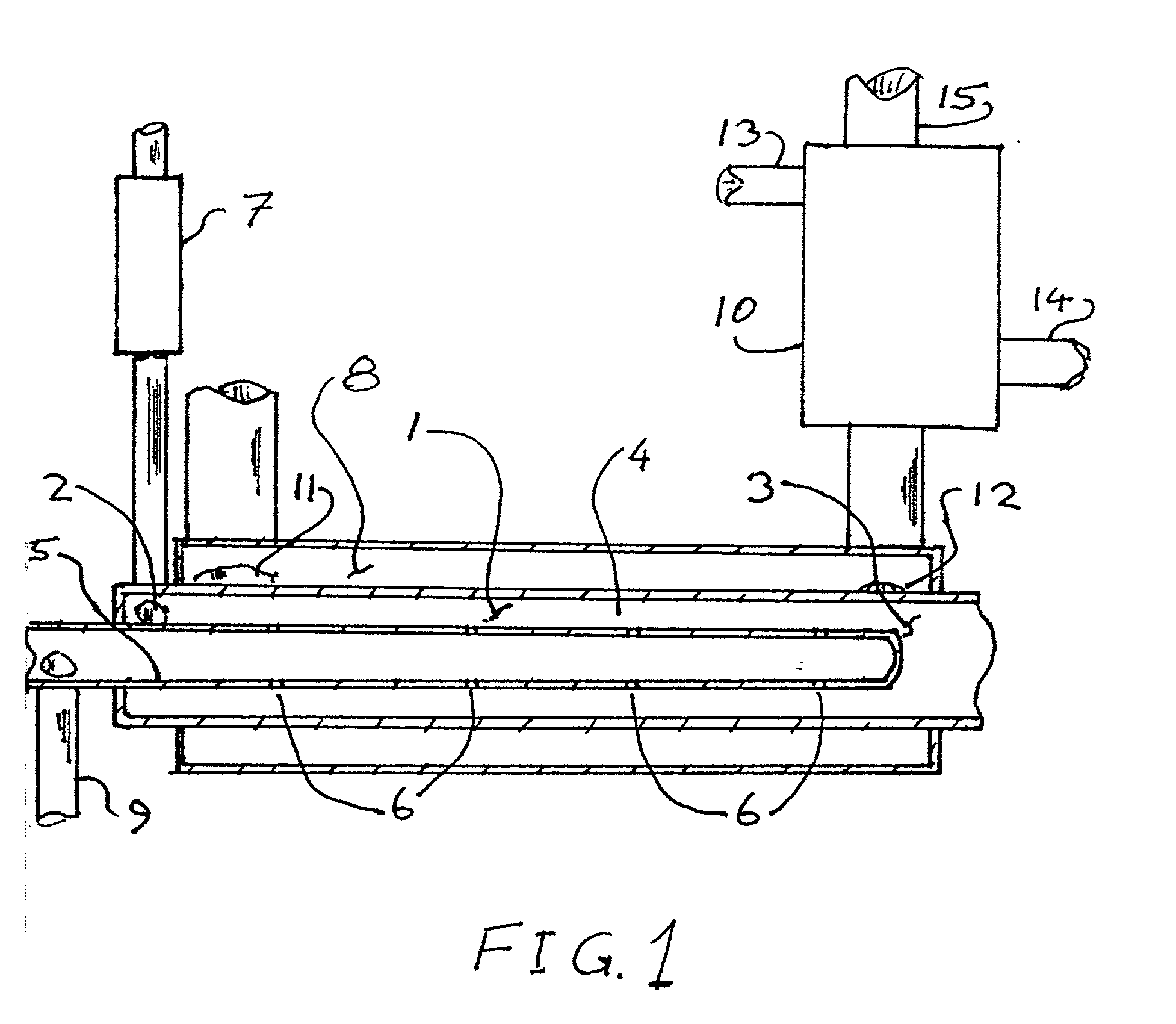

A method and apparatus is disclosed for increasing combustion efficiency in internal combustion engines and external combustors resulting in increased fuel economy and reduced exhaust pollutants. The same principles and apparatus of the invention are used in the exhaust stream to further reduce pollutants.

Owner:RONNELL

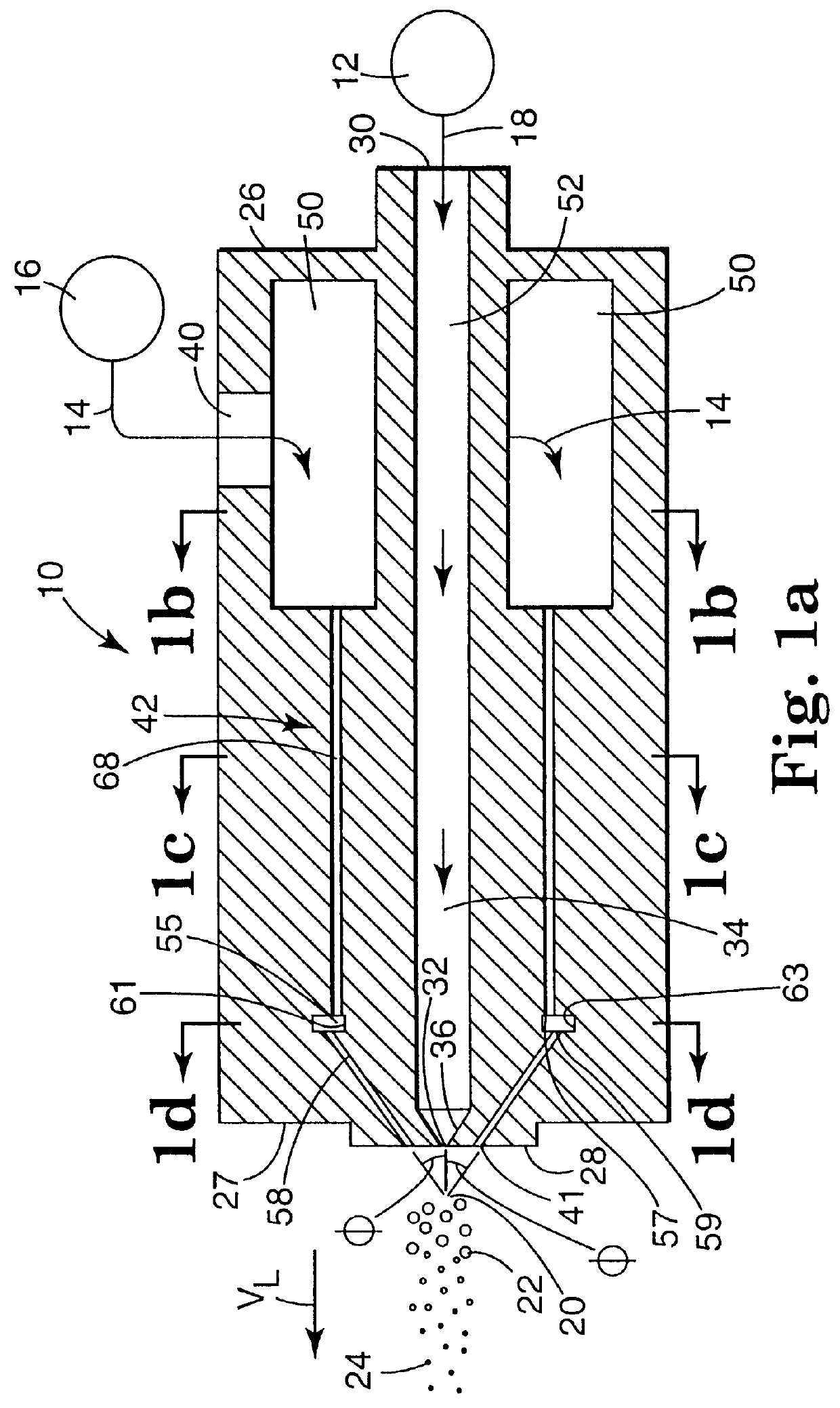

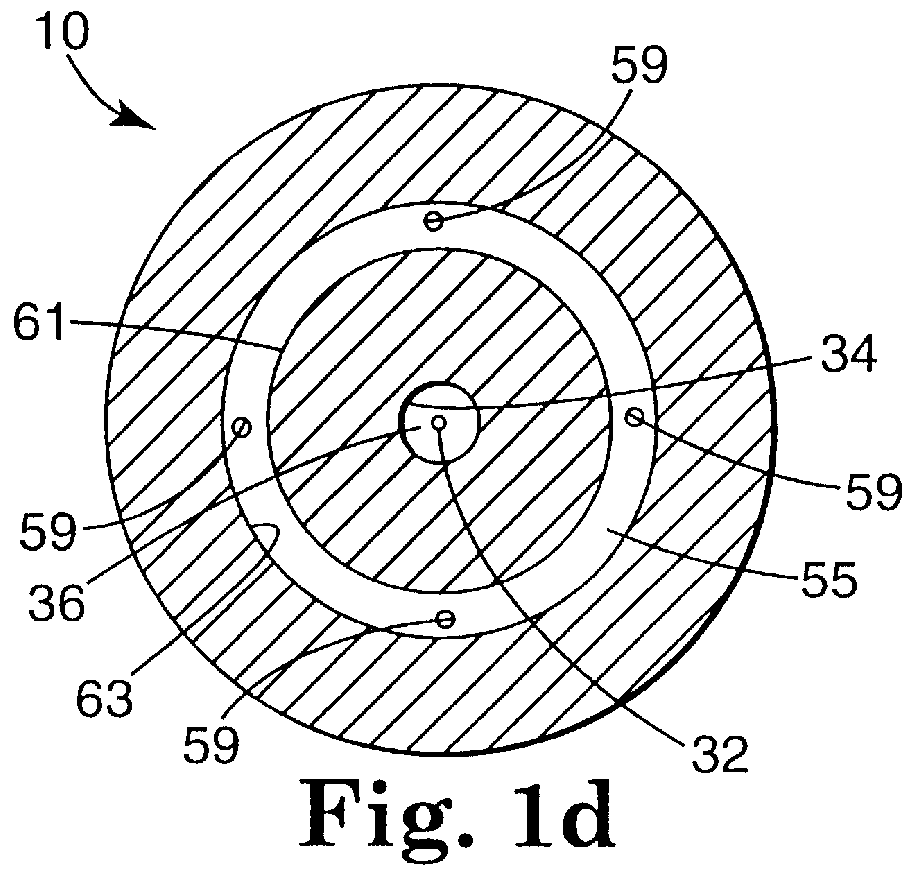

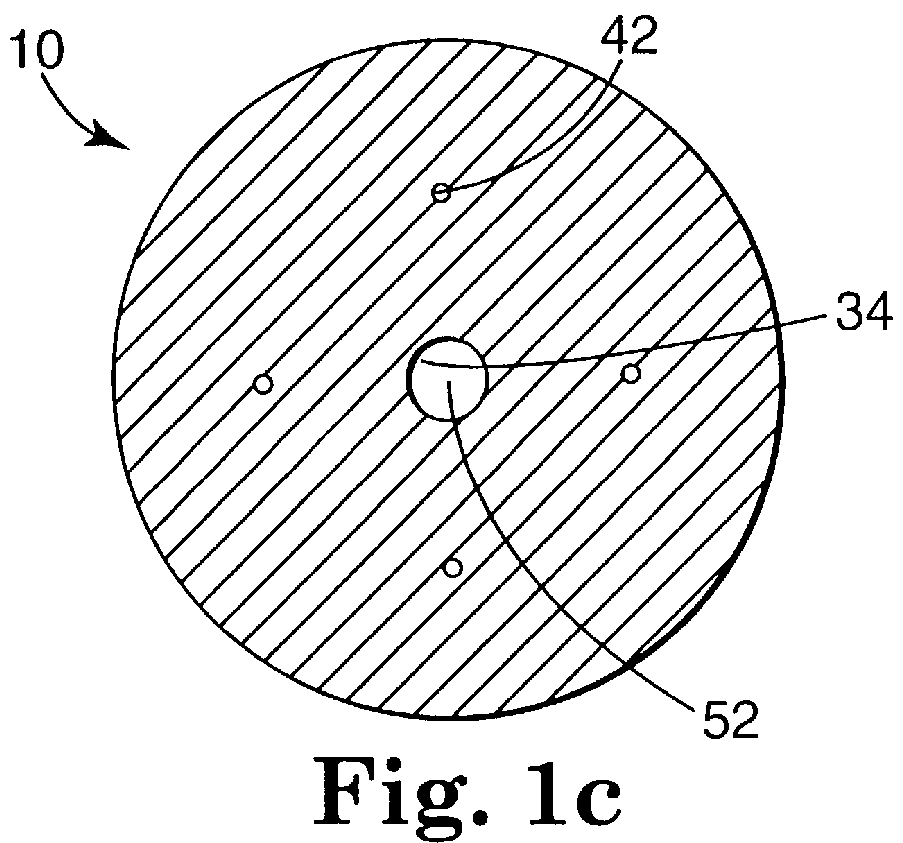

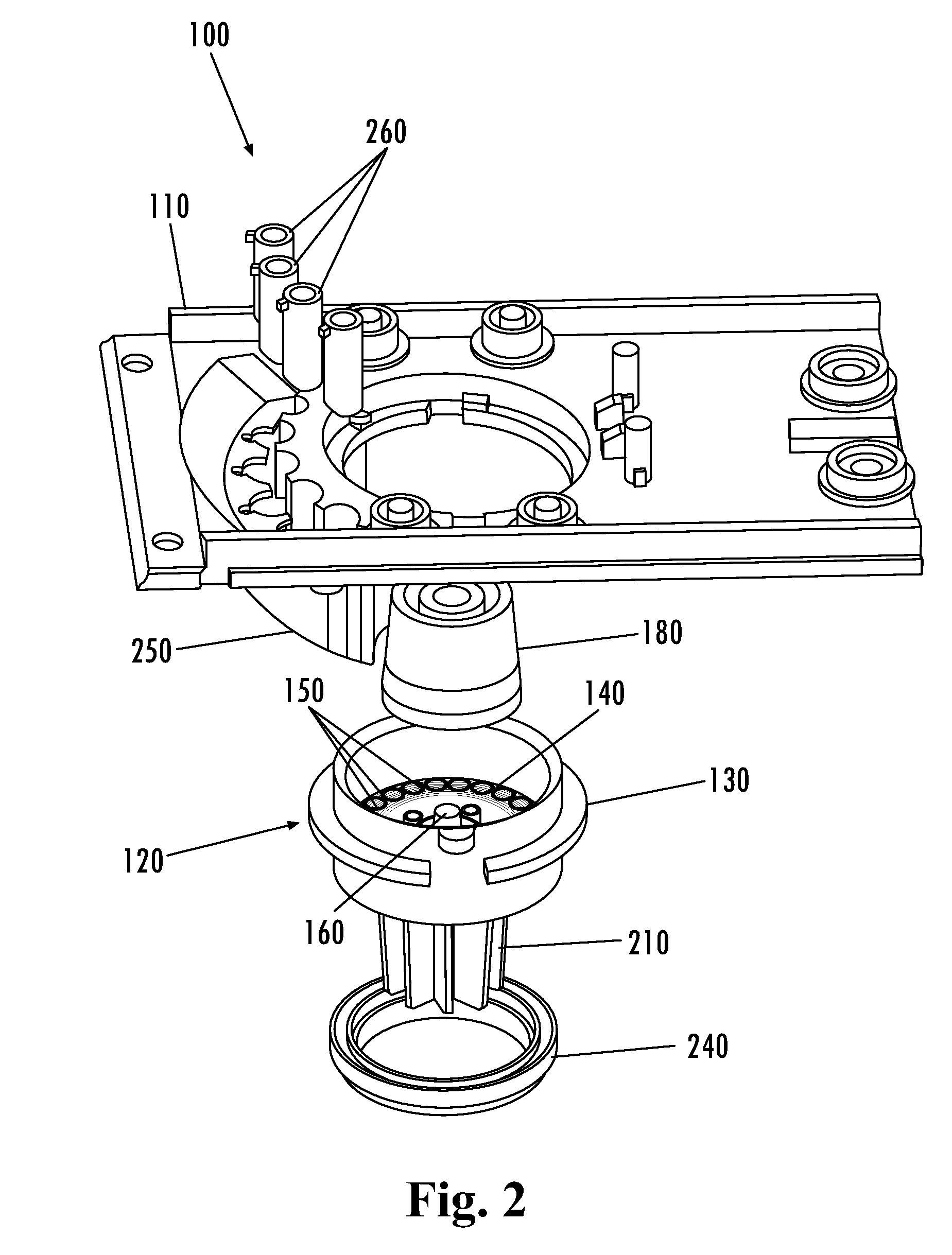

Apparatus and method of atomizing and vaporizing

InactiveUS6012647AMinimal slippageVaporization fastBurnersSpray nozzlesGas passingProcess engineering

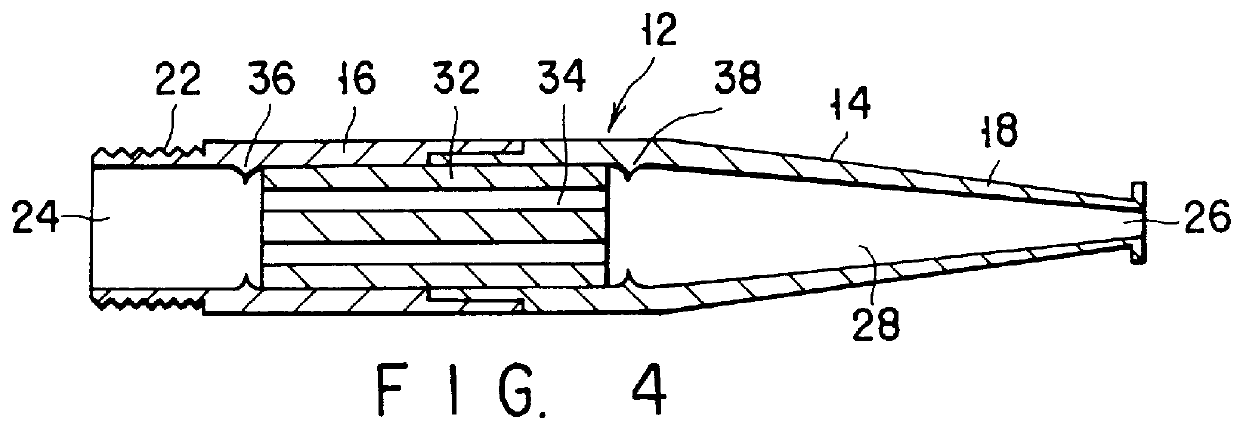

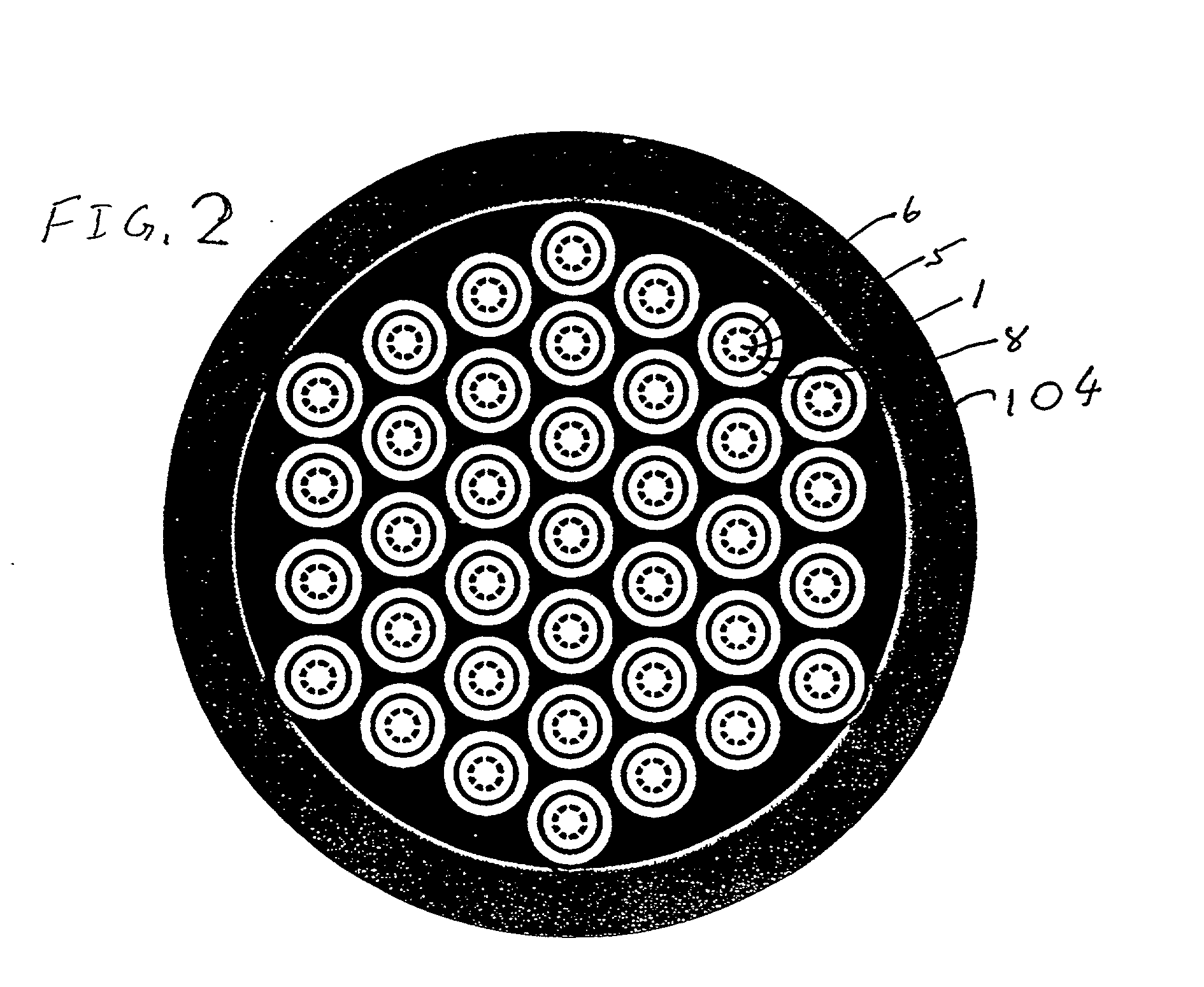

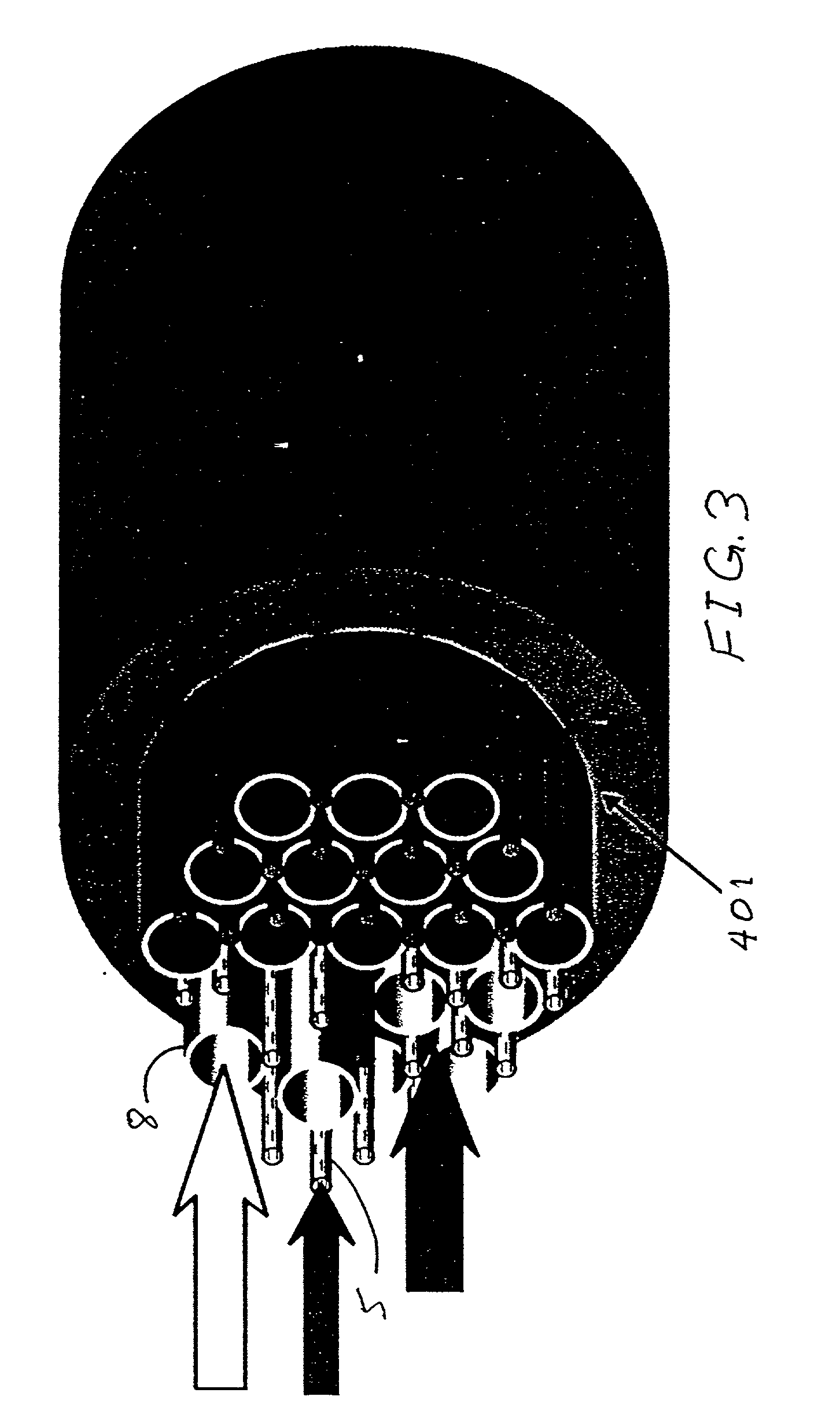

Apparatus suitable for atomizing and vaporizing at least a first liquid by colliding at least one gas with the first liquid. The apparatus includes a gas inlet through which the gas enters the apparatus and a first liquid inlet through which the first liquid enters the apparatus. A discharge end of the apparatus includes at least one first liquid discharge outlet through which at least one stream of the first liquid is discharged from the apparatus. The discharge end also includes at least one gas discharge outlet through which at least one stream of gas is discharged from the apparatus to collide with and thereby atomize the discharged stream of the first liquid. A first liquid passageway interconnects the first liquid inlet with the first liquid discharge outlet. A gas passageway interconnects the gas inlet with the at least one gas discharge outlet. In one embodiment, the gas passageway comprises at least one gas chamber in thermal contact with an initial portion of the first liquid passageway such that a heated quantity of the gas in the chamber preheats the first liquid in the initial portion of the first liquid passageway. In alternative embodiments, the gas passageway includes a pressure dampening chamber allowing gas to be continuously discharged without pulsating.

Owner:3M INNOVATIVE PROPERTIES CO

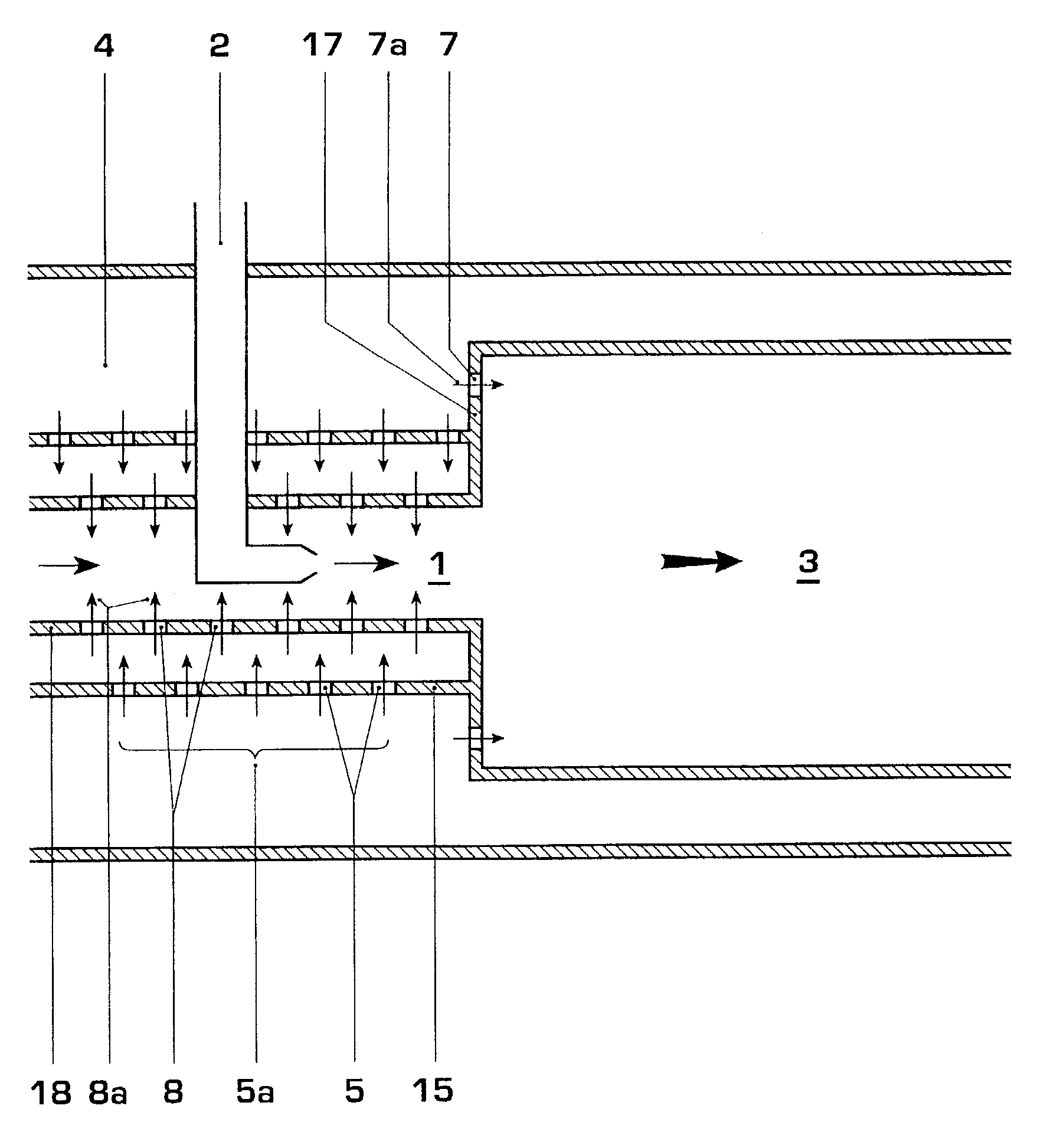

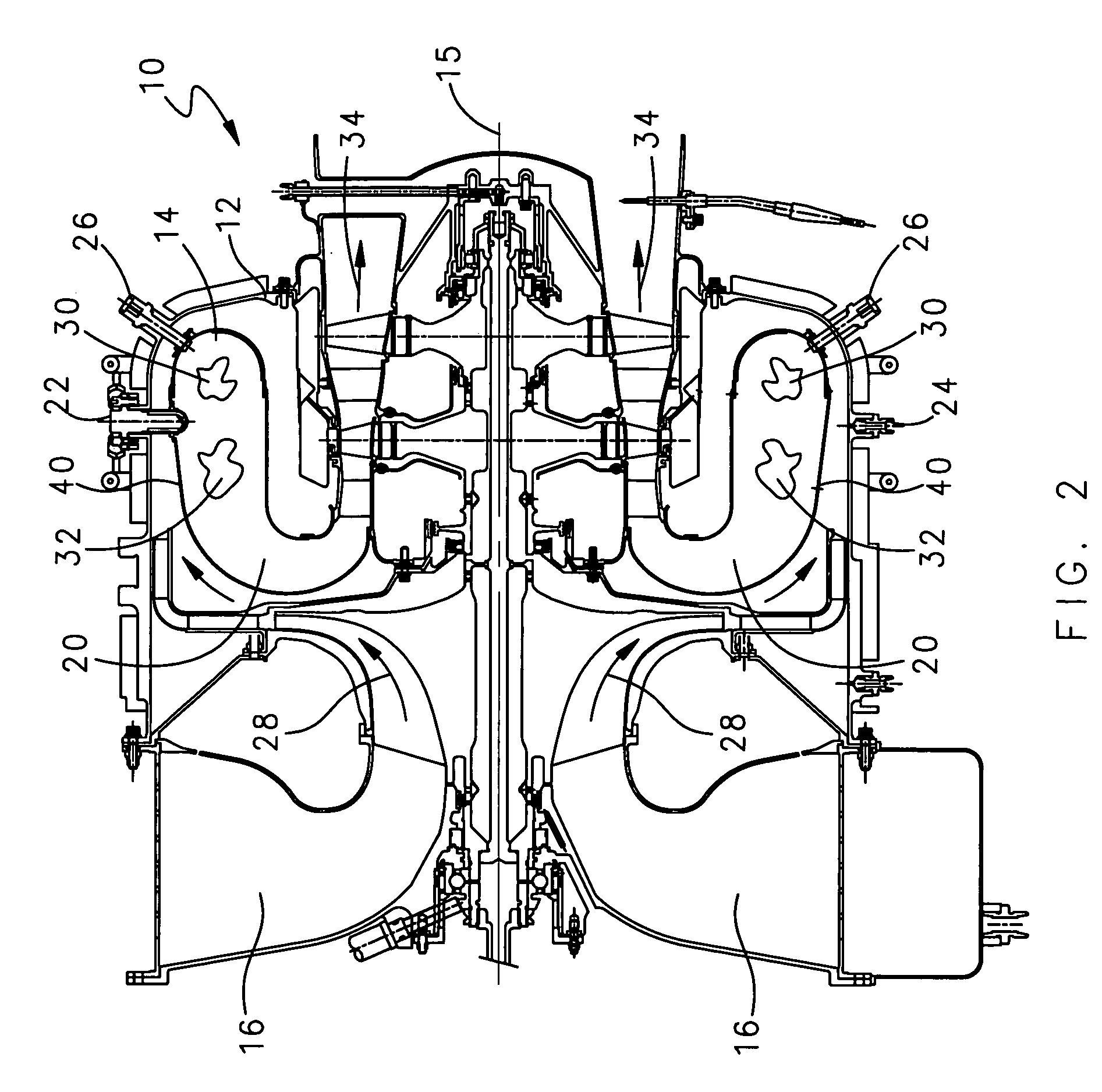

Reheat combustion system for a gas turbine

ActiveUS6981358B2Good cooling propertiesDamp pulsationBurnersContinuous combustion chamberCombustion systemCombustion chamber

A reheat combustion system for a gas turbine comprises a mixing tube adapted to be fed by products of a primary combustion zone of the gas turbine and by fuel injected by a lance; a combustion chamber fed by the said mixing tube; and at least one perforated acoustic screen. The or each said acoustic screen is provided inside the mixing tube or the combustion chamber, at a position where it faces, but is spaced from, a perforated wall thereof. In use, the perforated wall experiences impingement cooling as it admits air into the combustion system for onward passage through the perforations of the said acoustic screen, and the acoustic screen damps acoustic pulsations in the mixing tube and combustion chamber.

Owner:ANSALDO ENERGIA IP UK LTD

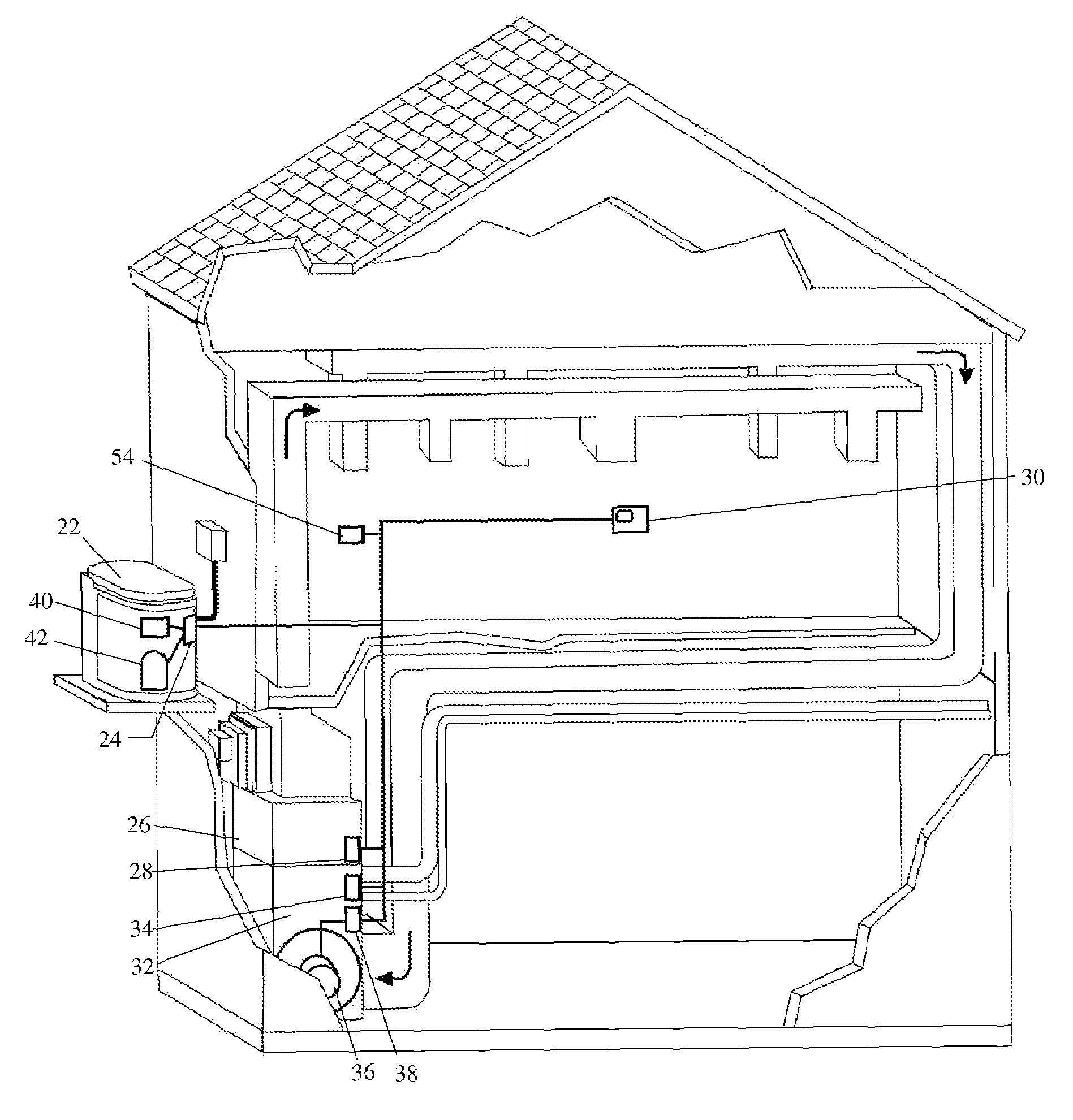

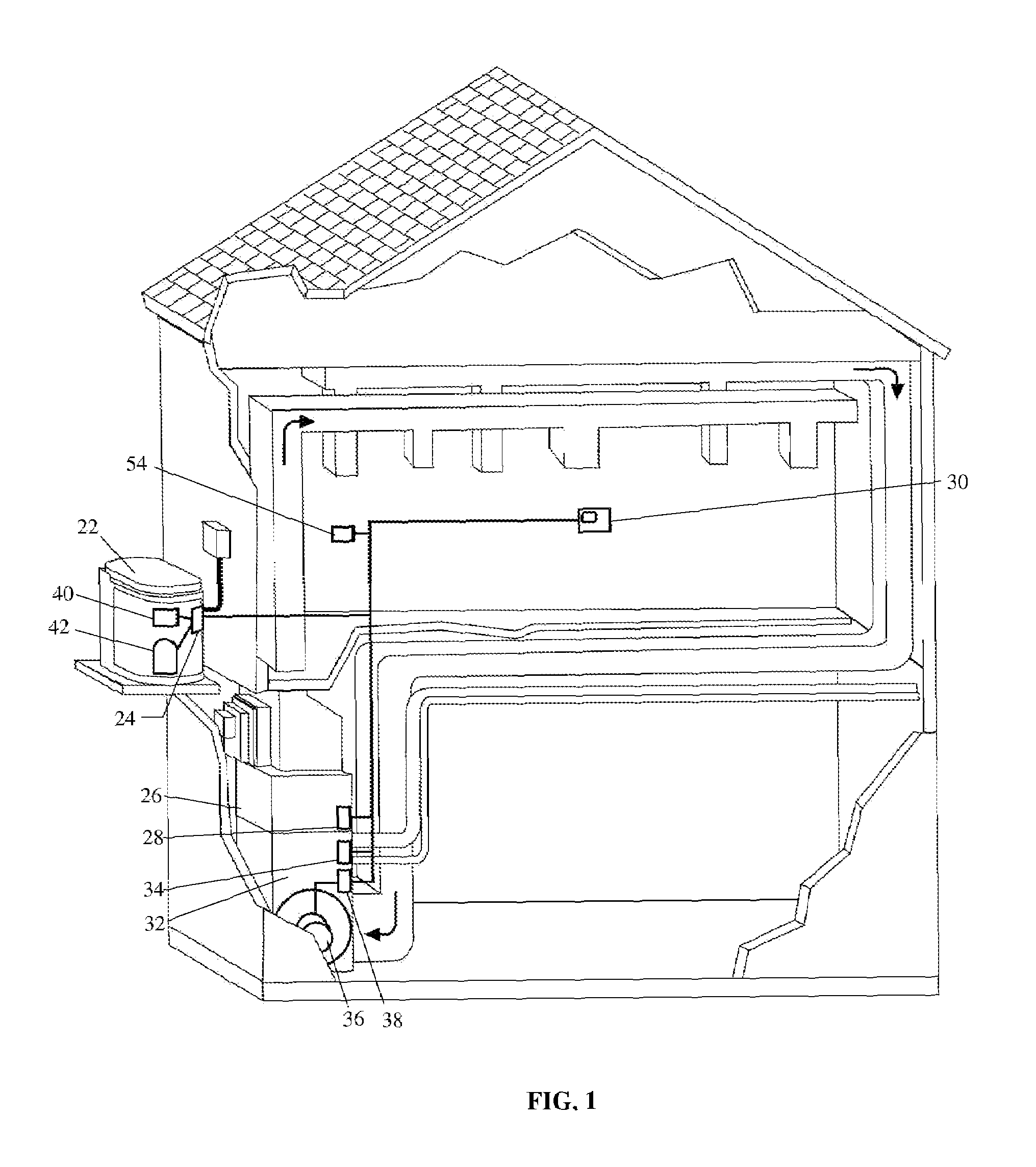

Interactive control system for an HVAC system

An interactive system for controlling the operation of an HVAC system is provide that comprises a thermostat for initiating the operation of the HVAC system in either a full capacity mode of operation or at least one reduced capacity mode of operation, and a controller for an outside condenser unit having a condenser fan motor and a compressor motor, the controller being capable of operating the compressor in a full capacity mode and at least one reduced capacity mode. The system also comprises a controller for an indoor blower unit having a blower fan motor, the controller being capable of operating the blower fan motor in a full capacity mode an at least one reduced capacity mode. The system further includes a communication means for transmitting information between the outside condenser unit controller and at least the indoor blower controller, where the information relates to the operation of the indoor blower and the outdoor condenser unit. The indoor blower controller responsively controls the operation of the blower fan motor in a full capacity mode or a reduced capacity mode based on the information received from the outdoor unit controller, and the outdoor unit controller responsively controls the operation of the compressor in a full capacity mode or a reduced capacity mode based on the information received from the indoor blower controller.

Owner:COPELAND COMFORT CONTROL LP

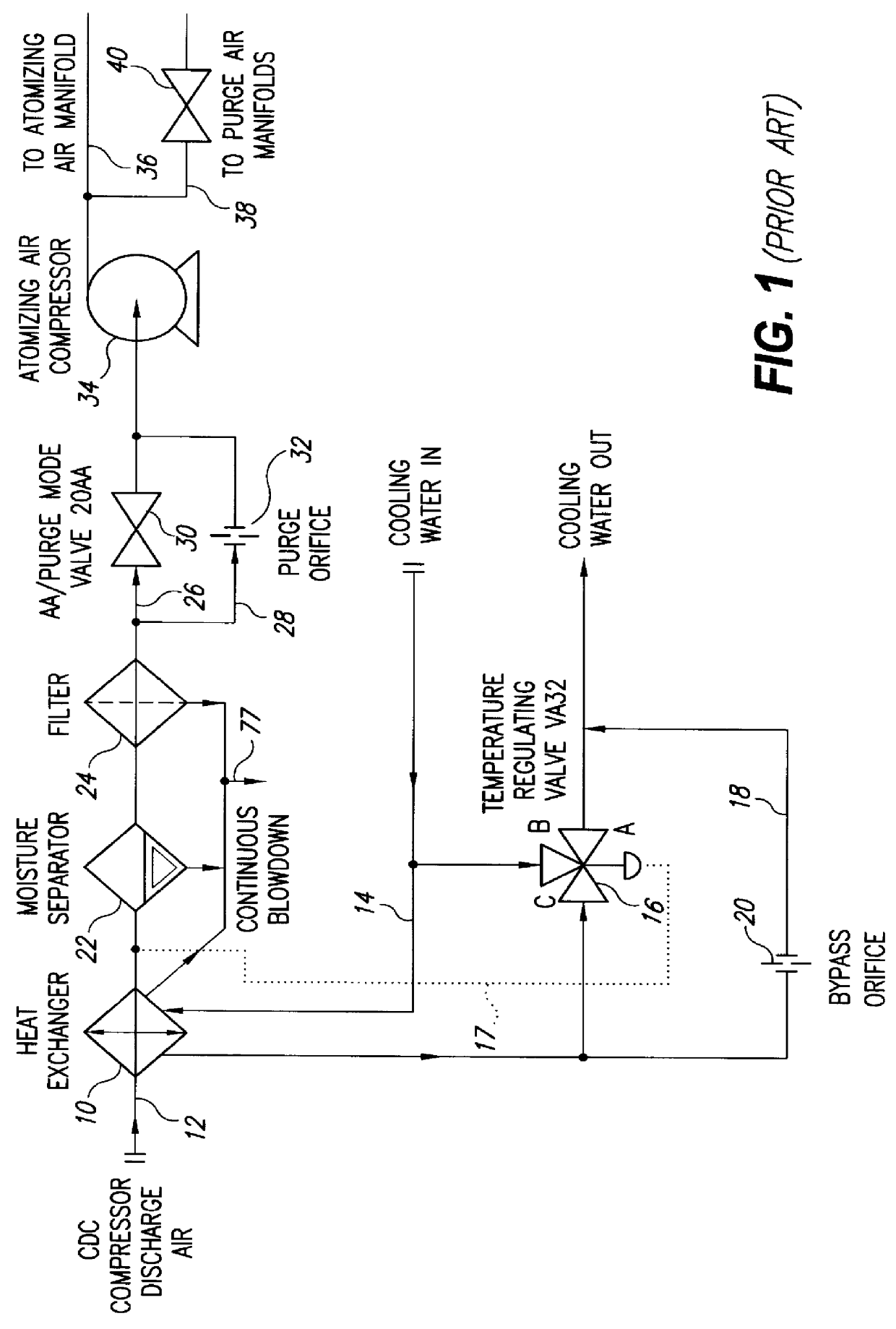

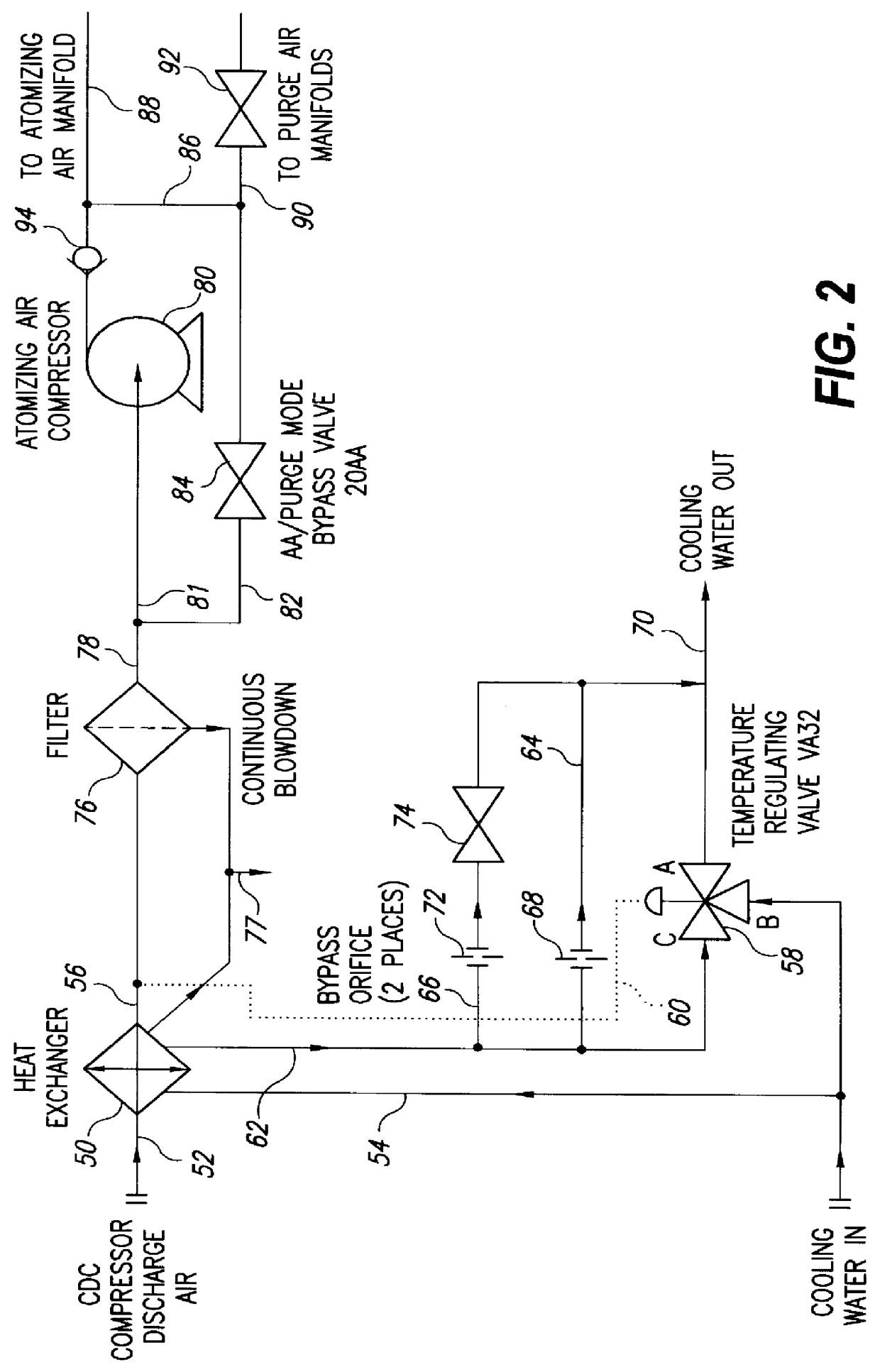

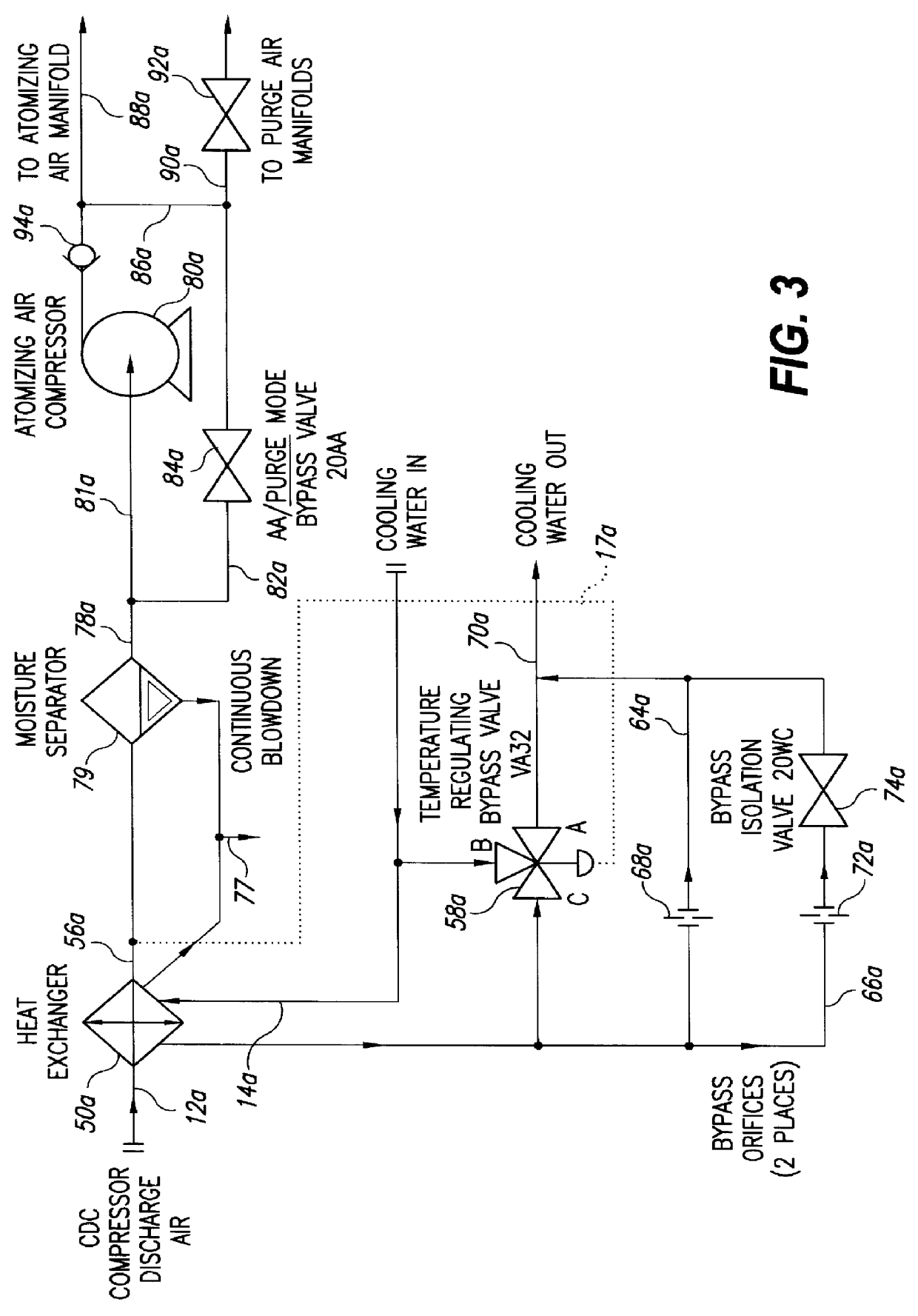

Dual orifice bypass system for dual-fuel gas turbine

InactiveUS6145318AReduce trafficAvoid heat buildupBurner safety arrangementsBurnersCombustorHeat rejection

Compressor discharge air flows through a heat exchanger in heat exchange relation with cooling water and is supplied at reduced temperature in atomizing air and purge modes to combustors in a dual-fuel gas turbine. The heat exchanger has a pair of bypass passages in parallel with a temperature regulating valve controlling flow of water through the heat exchanger in response to the temperature of the compressor discharge air exiting the heat exchanger. Should the flow control valve close in response to low temperature of the compressor discharge air, in the air atomizing mode, the bypass passages with orifices therein provide a minimum protective flow of cooling water to the heat exchanger. In the purge mode where only half the air flow and heat rejection is required in the heat exchanger and the flow control valve closes, a bypass valve in one of the bypass passages closes to enable reduced flow of cooling water through the heat exchanger.

Owner:GENERAL ELECTRIC CO

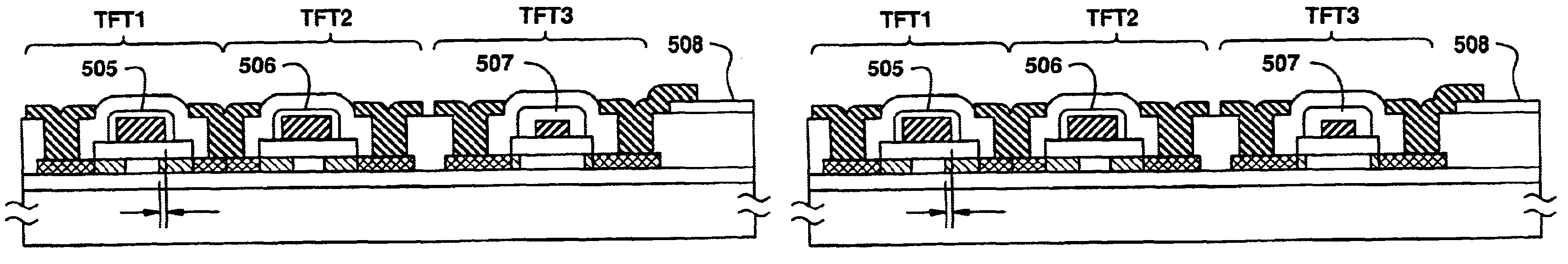

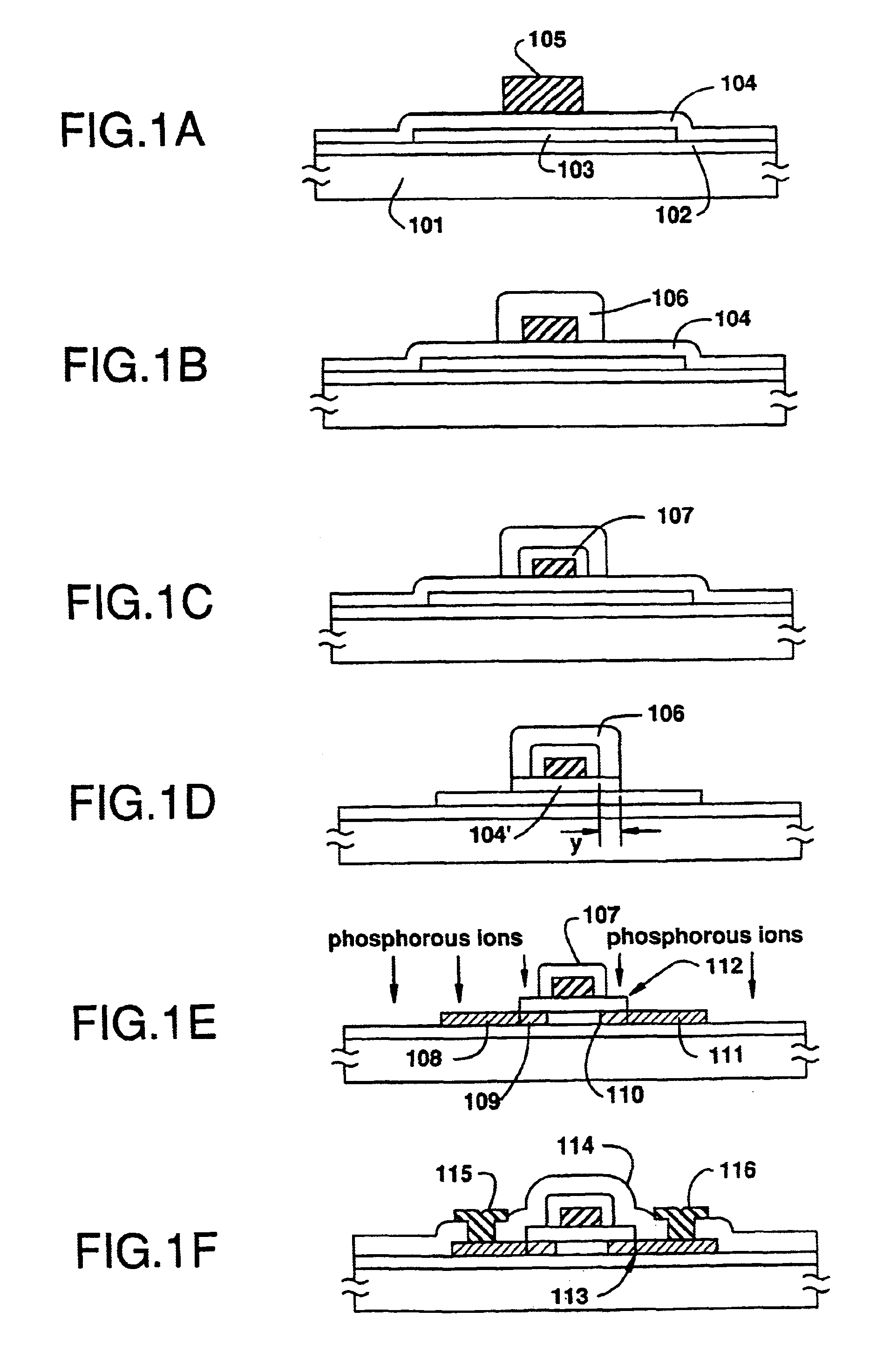

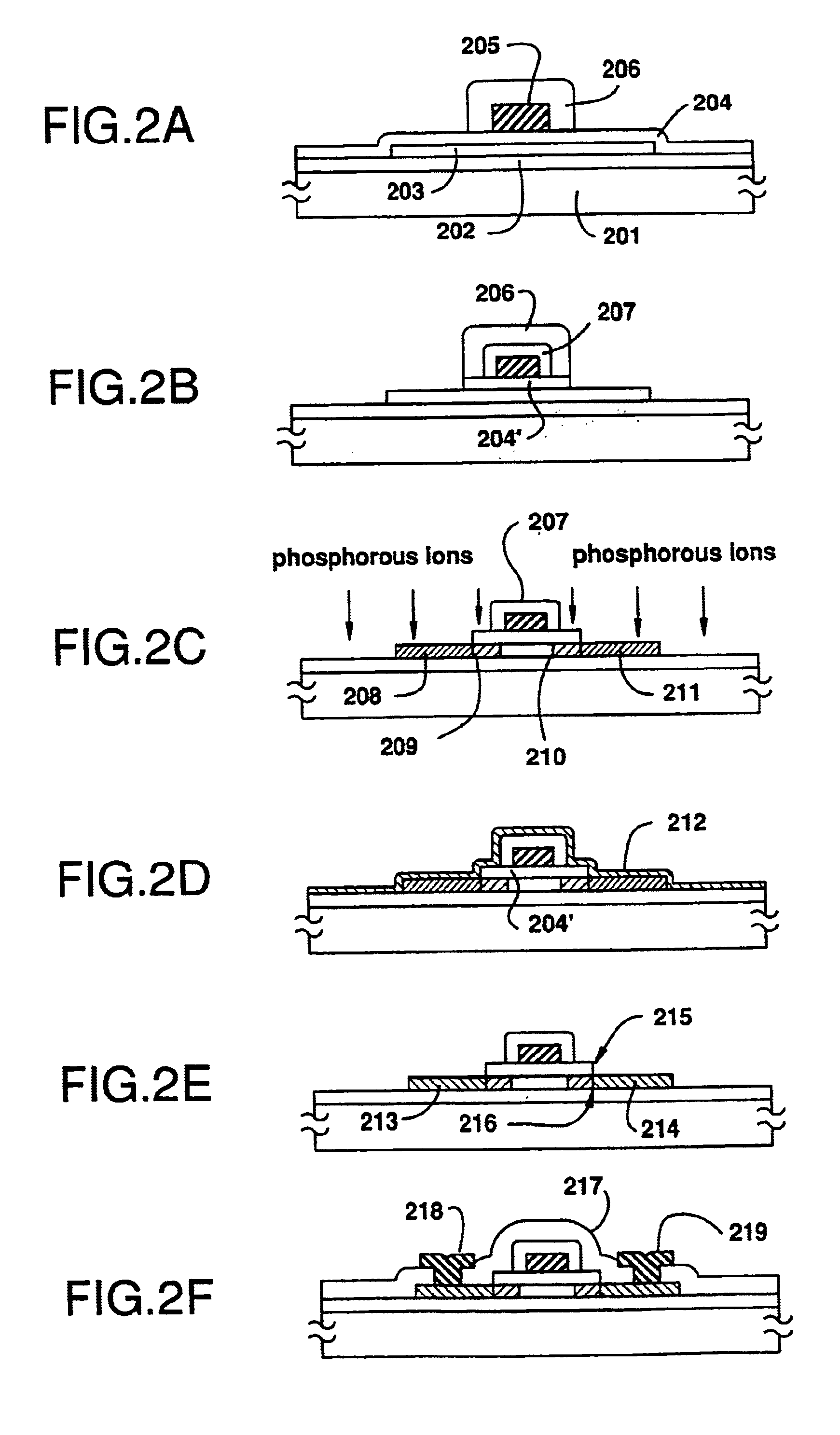

Semiconductor device and method for manufacturing the same

A TFT formed on an insulating substrate source, drain and channel regions, a gate insulating film formed on at least the channel region and a gate electrode formed on the gate insulating film. Between the channel region and the drain region, a region having a higher resistivity is provided in order to reduce an Ioff current. A method for forming this structure comprises the steps of anodizing the gate electrode to form a porous anodic oxide film on the side of the gate electrode; removing a portion of the gate insulating using the porous anodic oxide film as a mask so that the gate insulating film extends beyond the gate electrode but does not completely cover the source and drain regions. Thereafter, an ion doping of one conductivity element is performed. The high resistivity region is defined under the gate insulating film.

Owner:SEMICON ENERGY LAB CO LTD

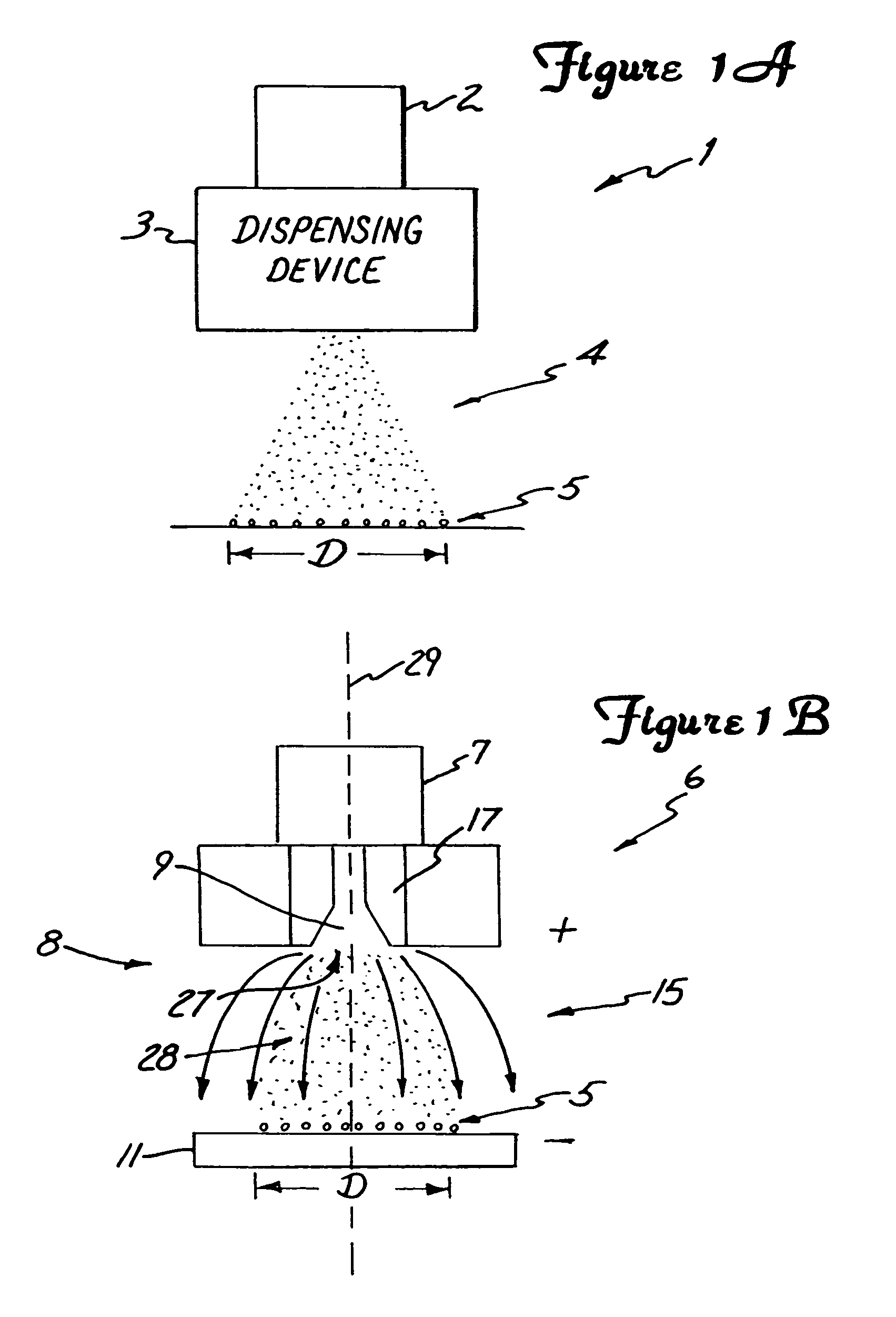

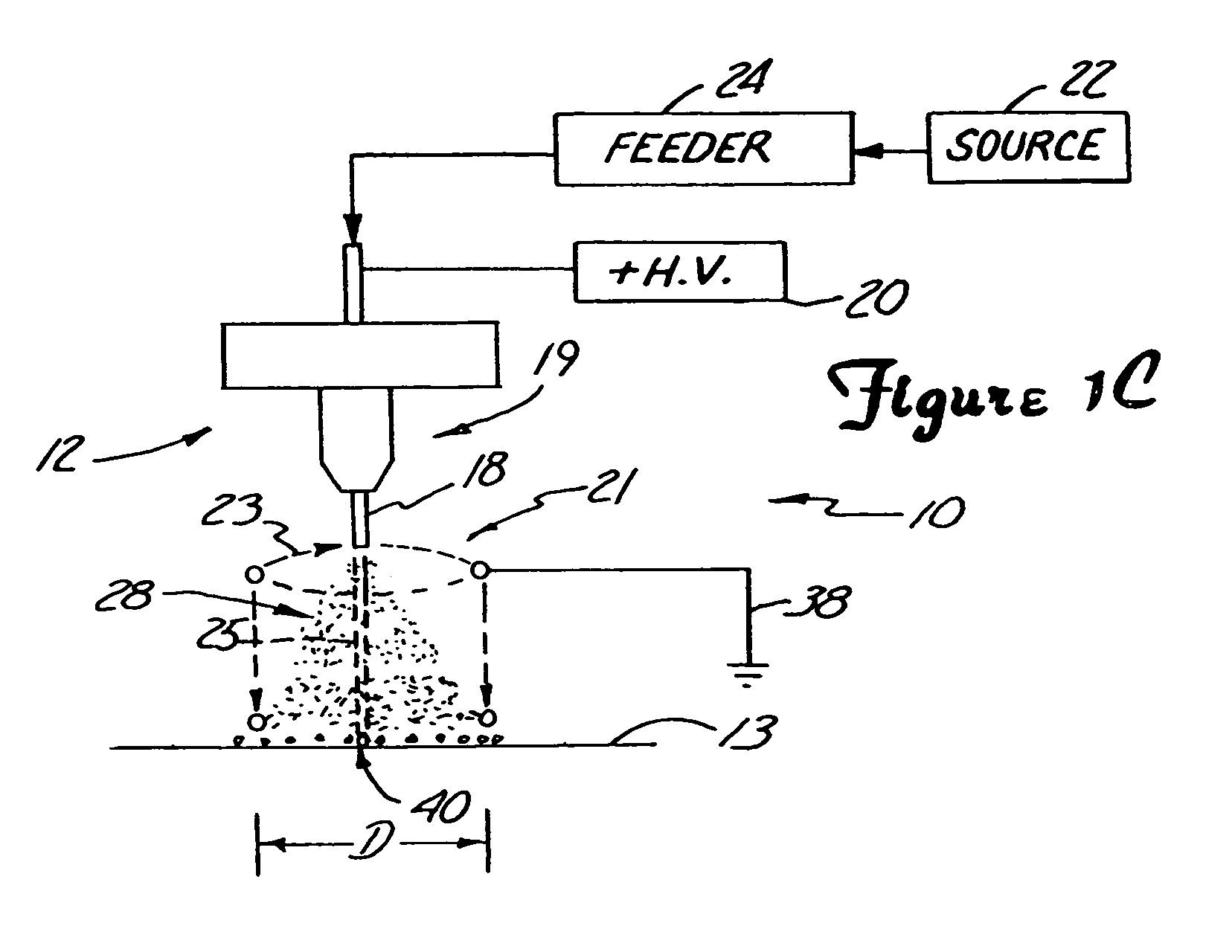

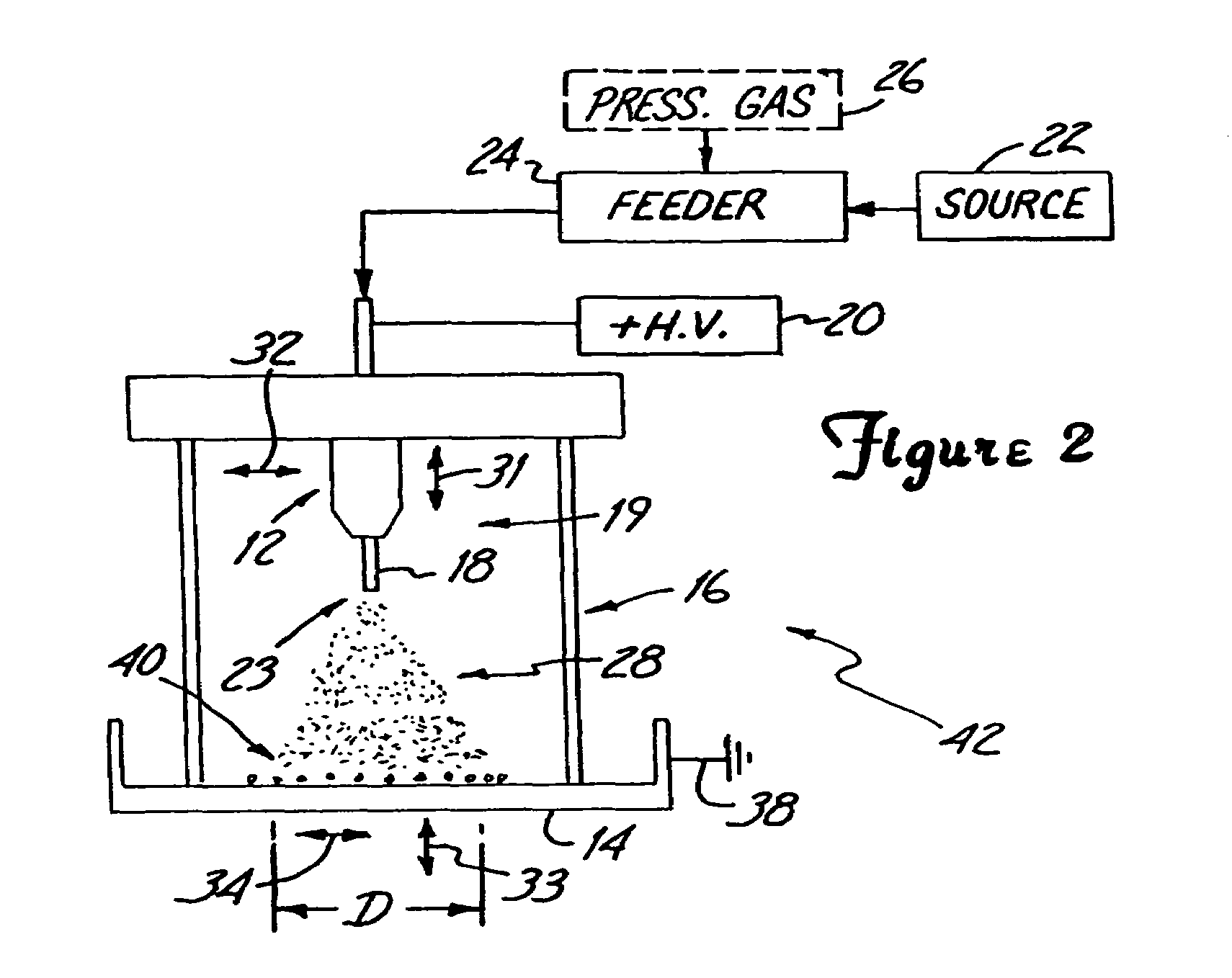

Electrospraying apparatus and method for coating particles

An electrospraying apparatus and / or method is used to coat particles. For example, a flow including at least one liquid suspension may be provided through at least one opening at a spray dispenser end. The flow includes at least particles and a coating material. A spray of microdroplets suspending at least the particles is established forward of the spray dispenser end by creating a nonuniform electrical field between the spray dispenser end and an electrode electrically isolated therefrom. The particles are coated with at least a portion of the coating material as the microdroplet evaporates. For example, the suspension may include biological material particles.

Owner:RGT UNIV OF MINNESOTA

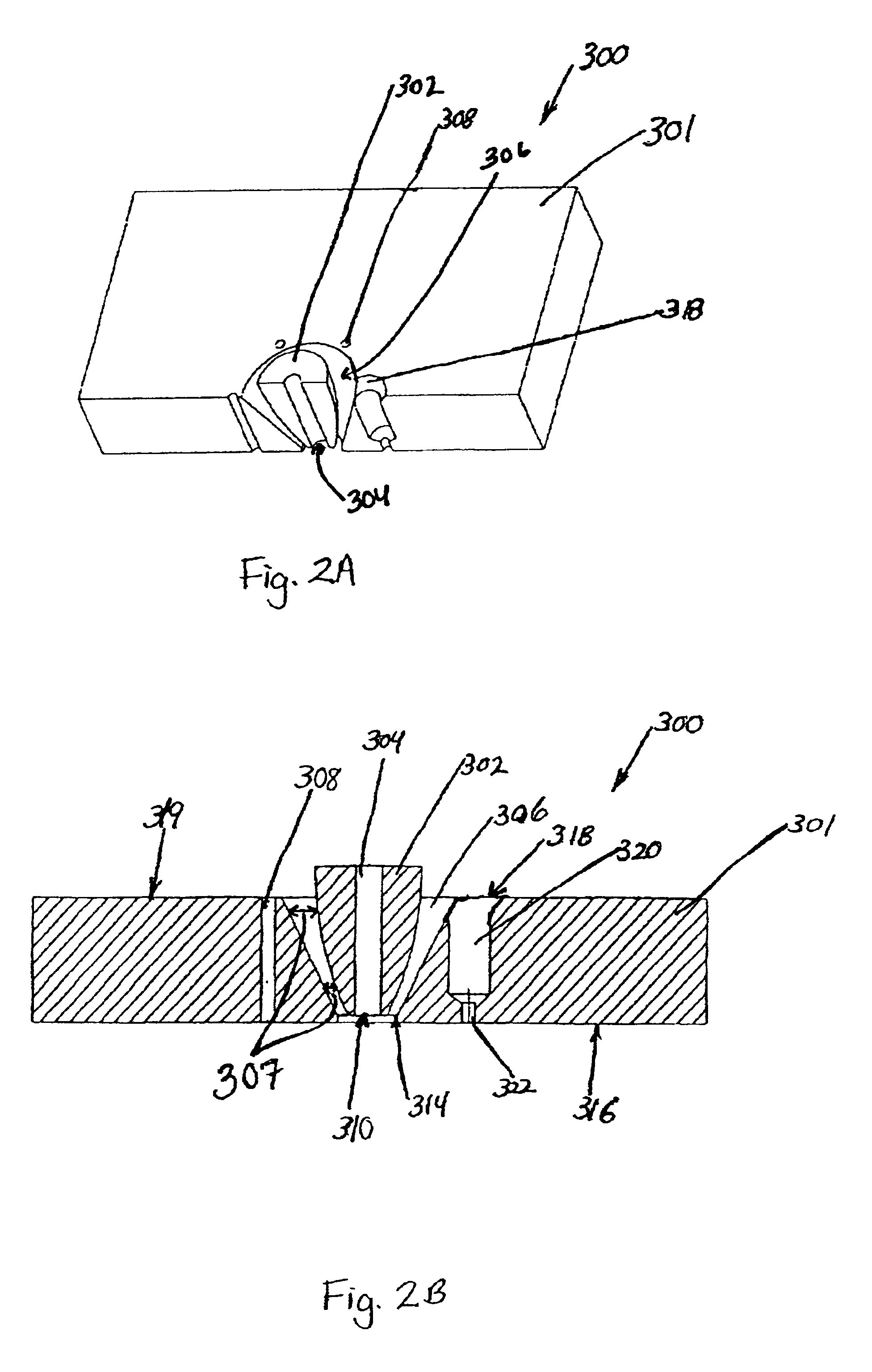

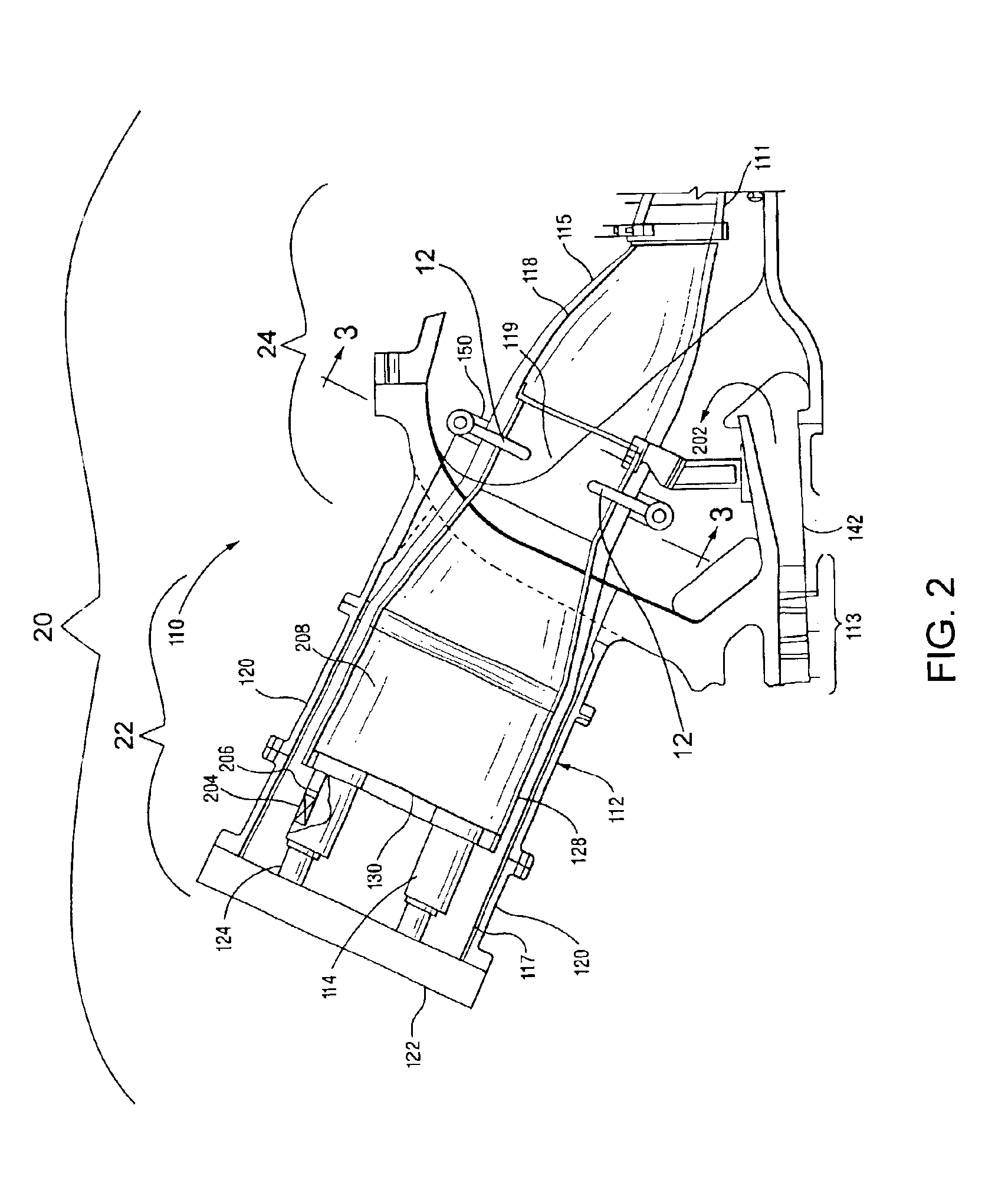

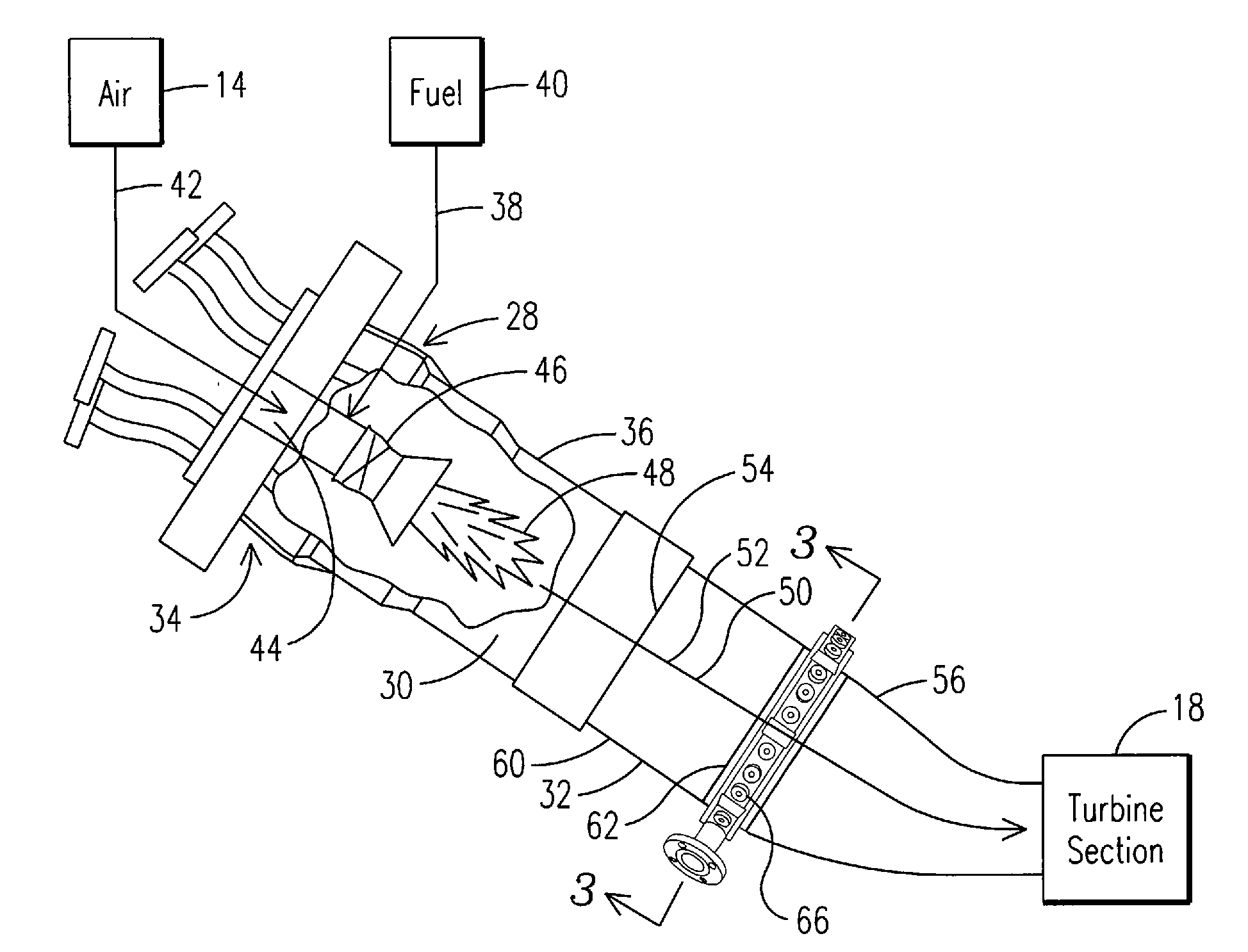

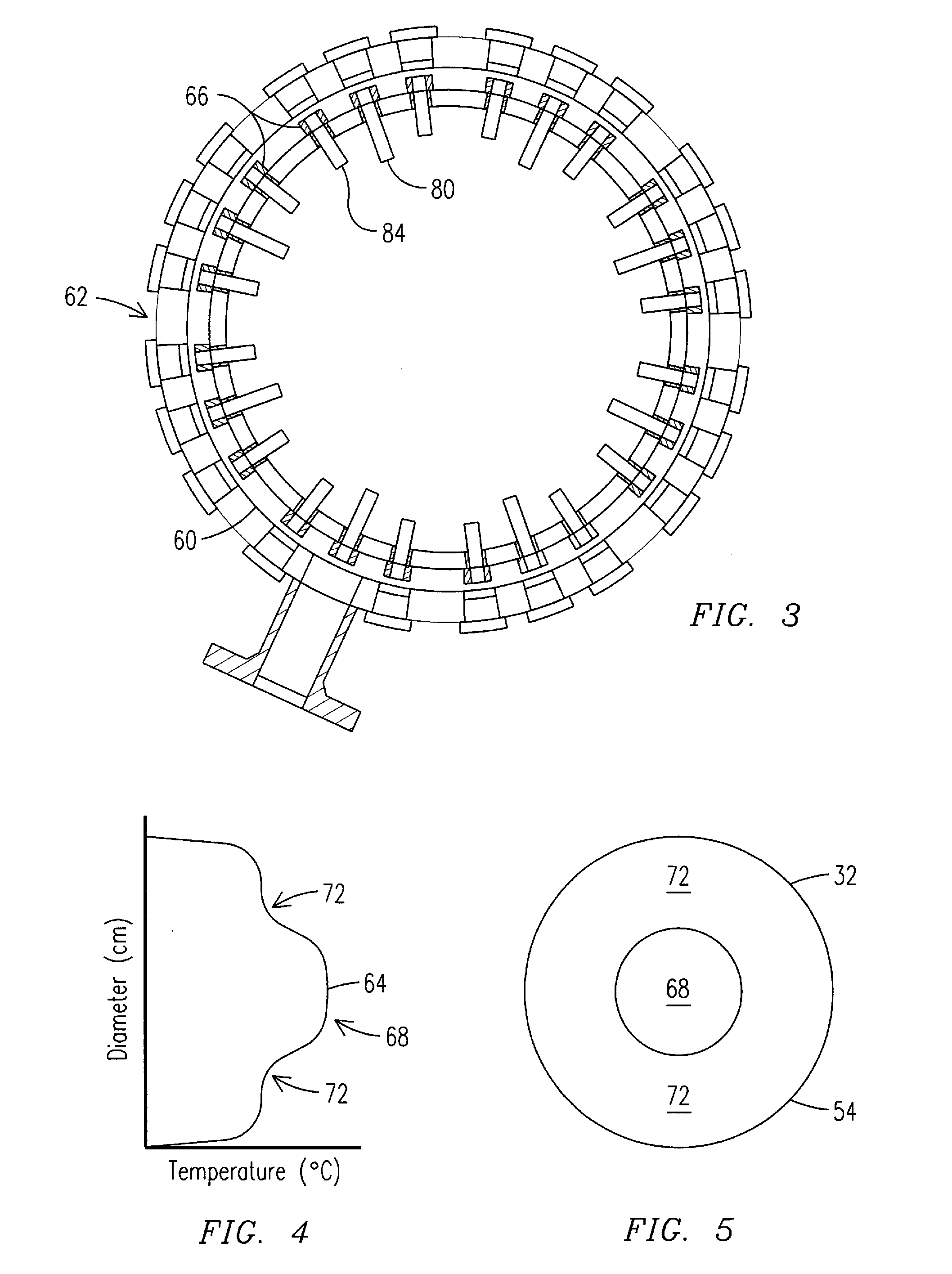

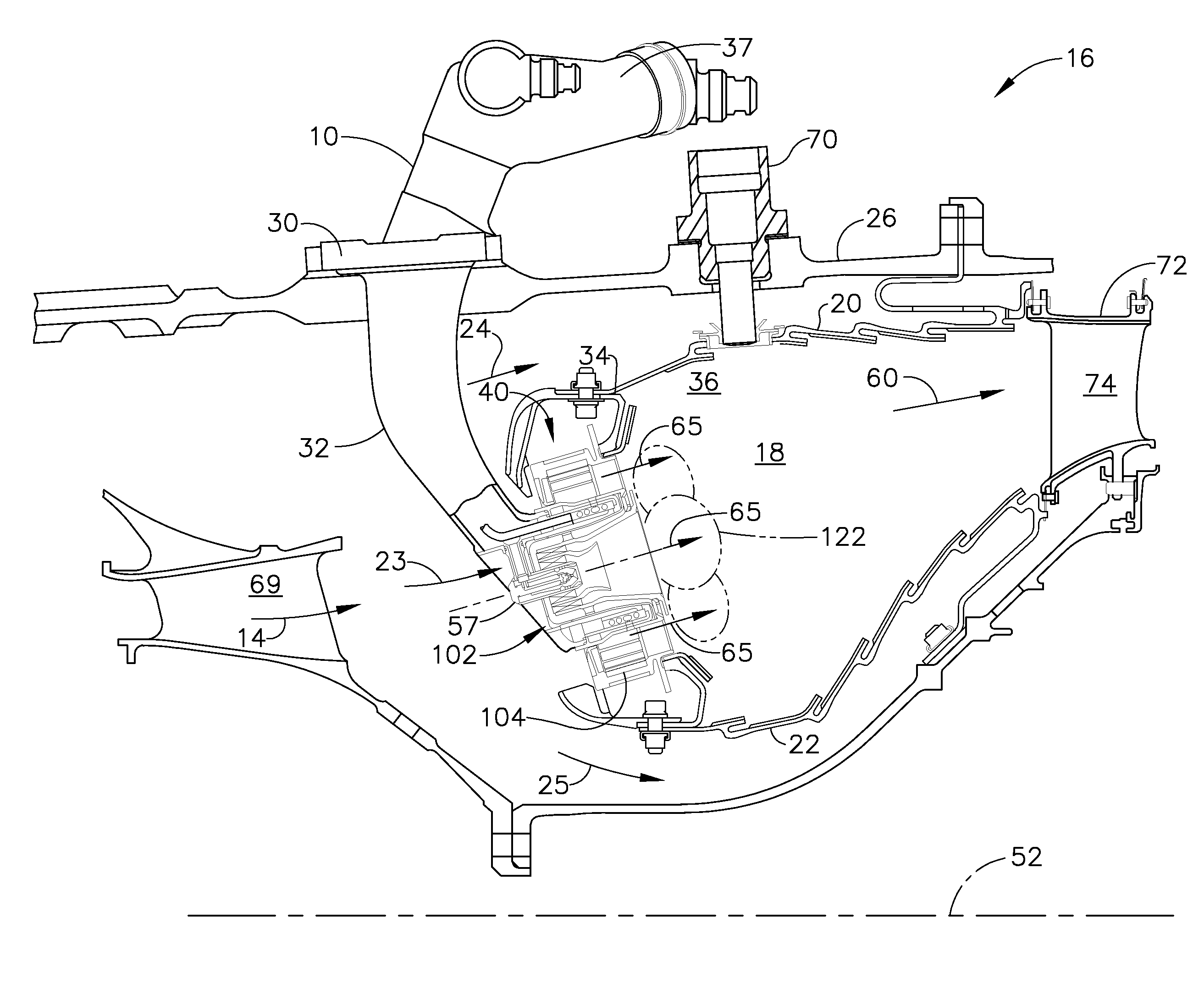

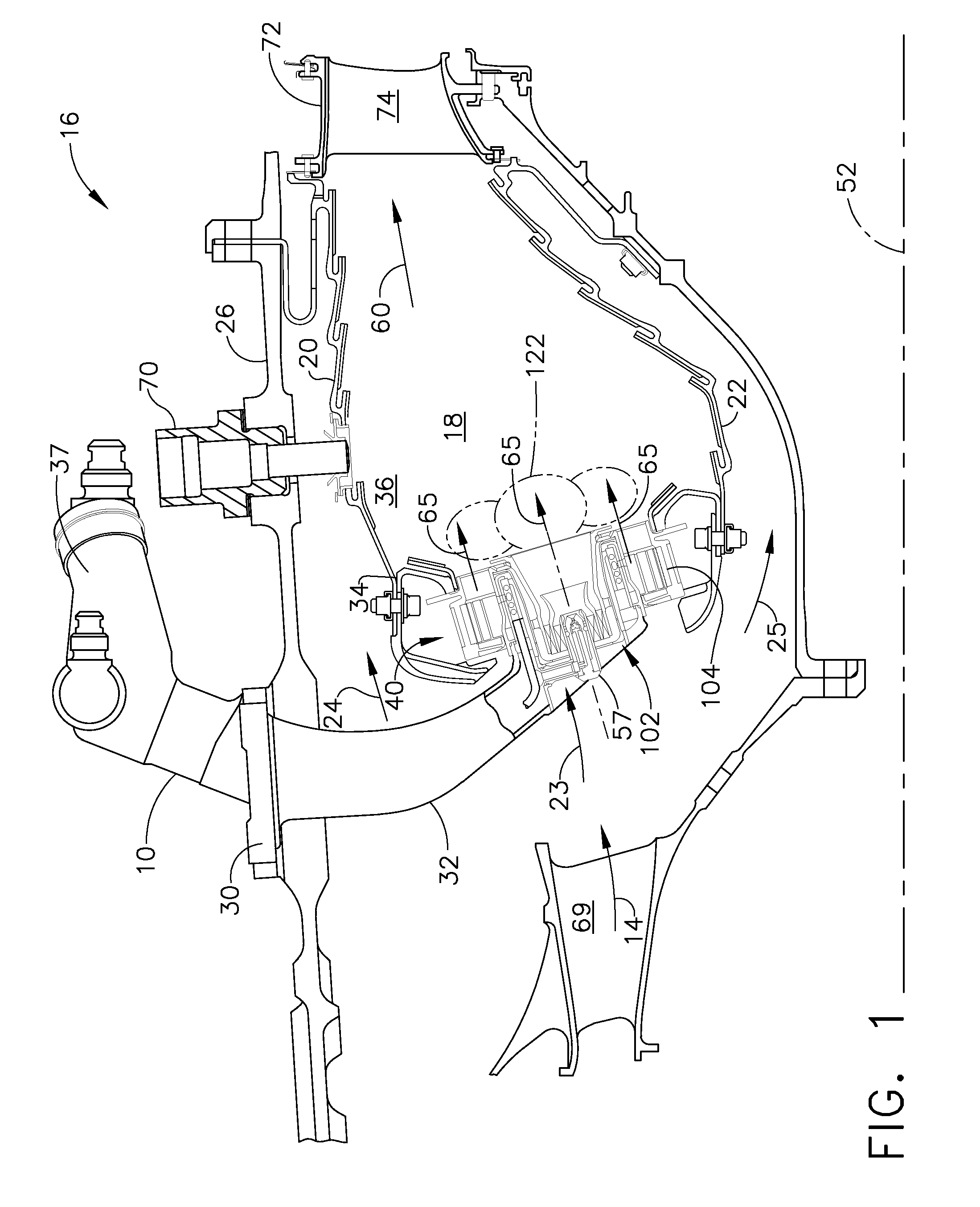

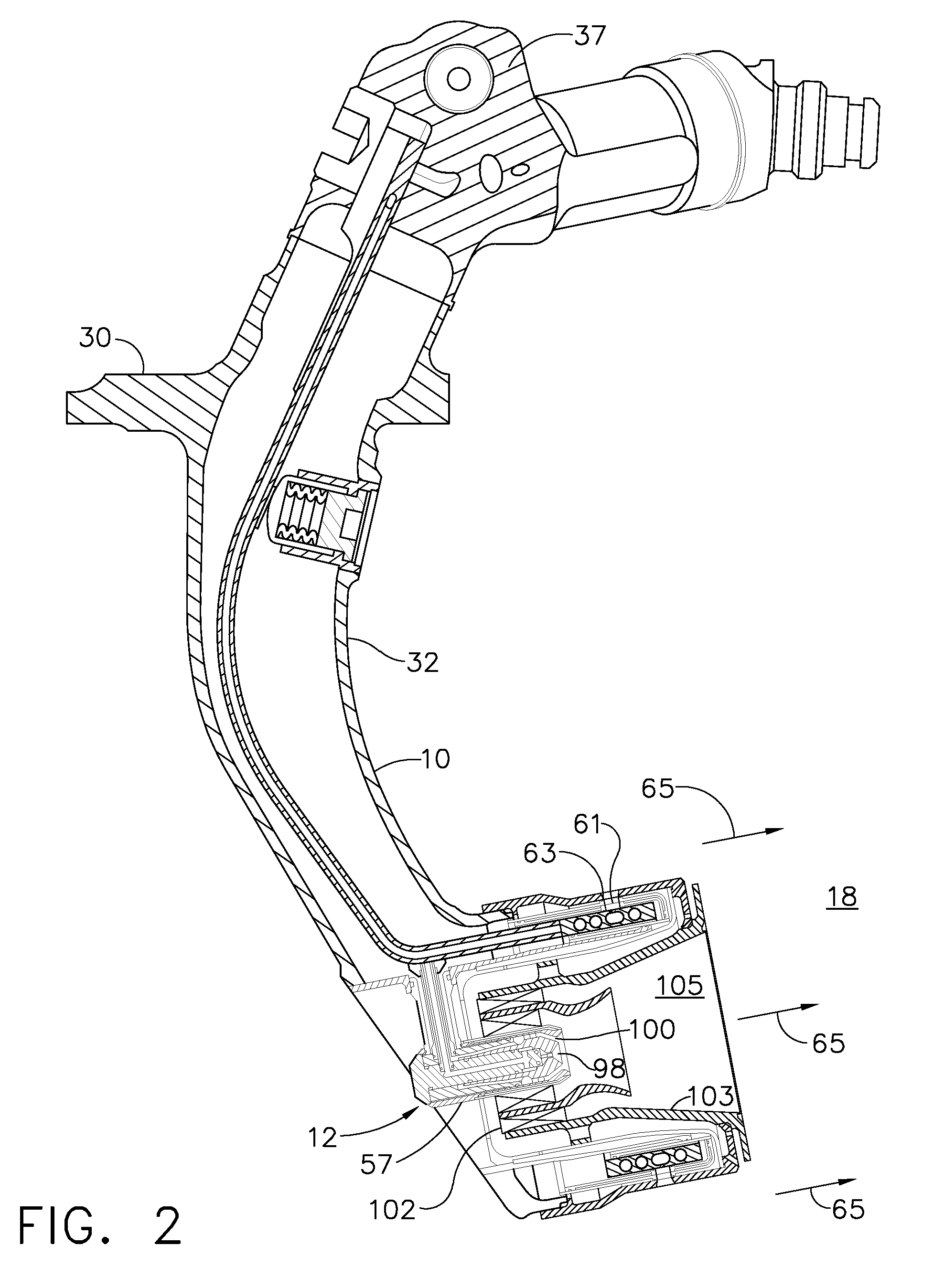

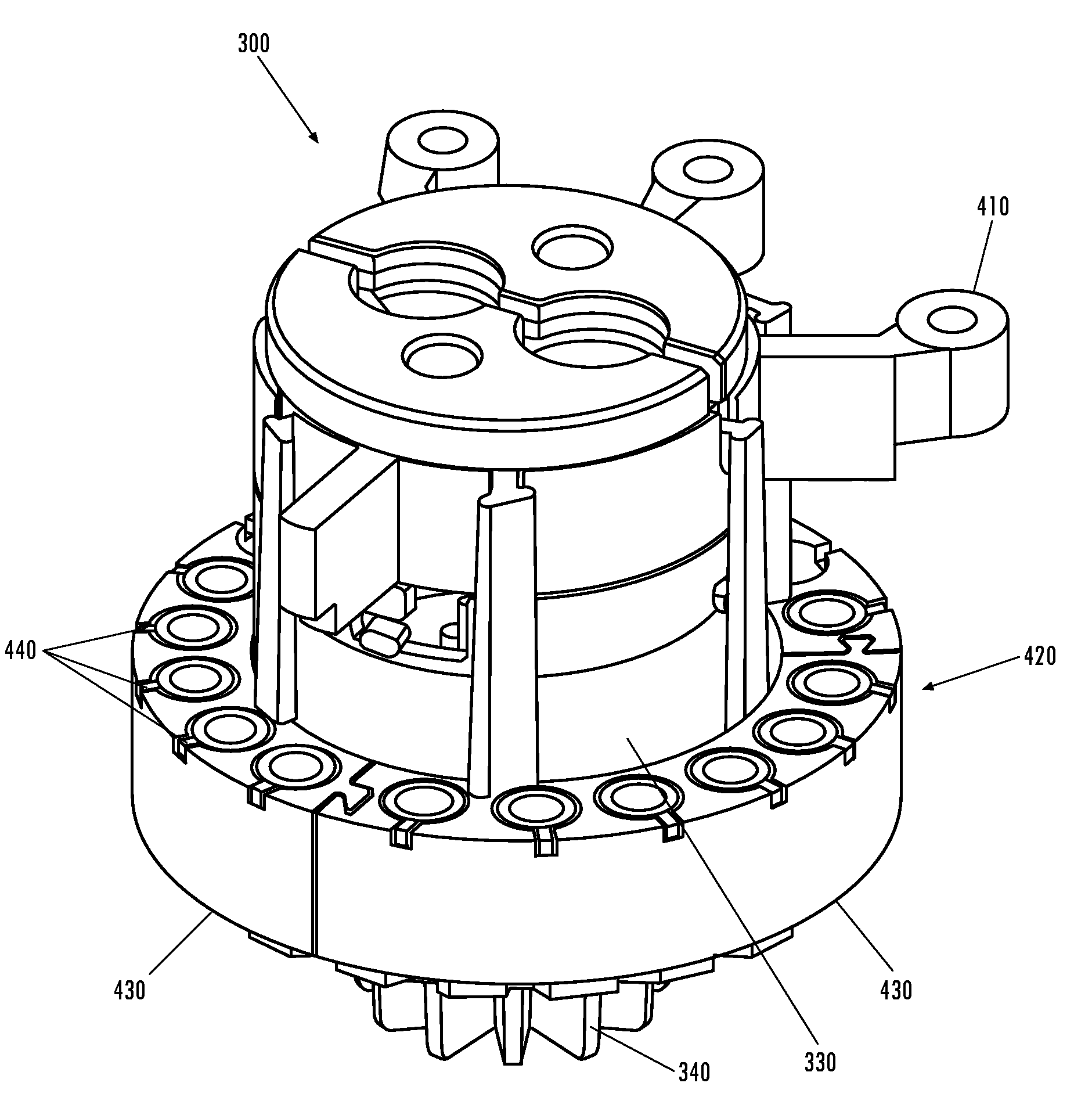

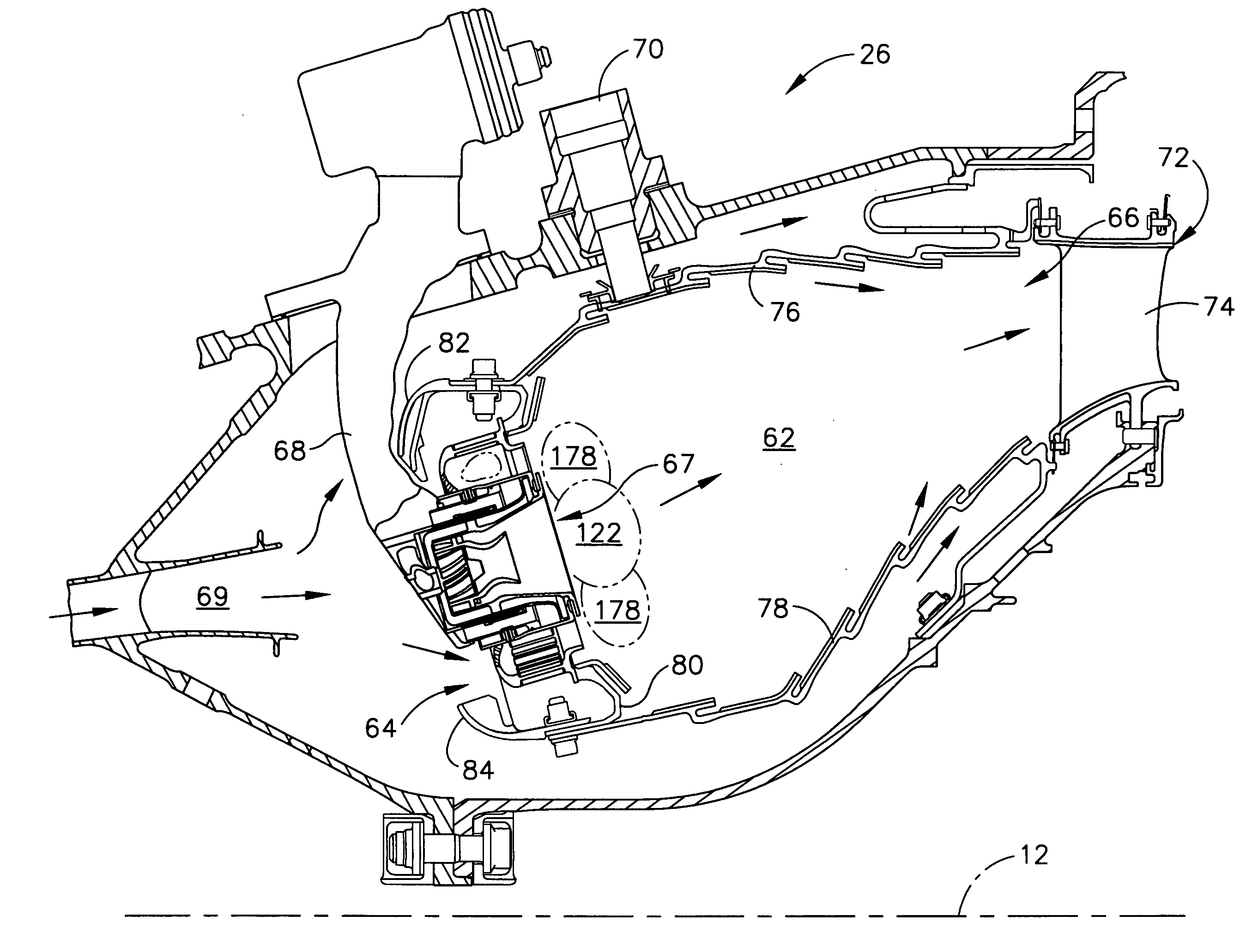

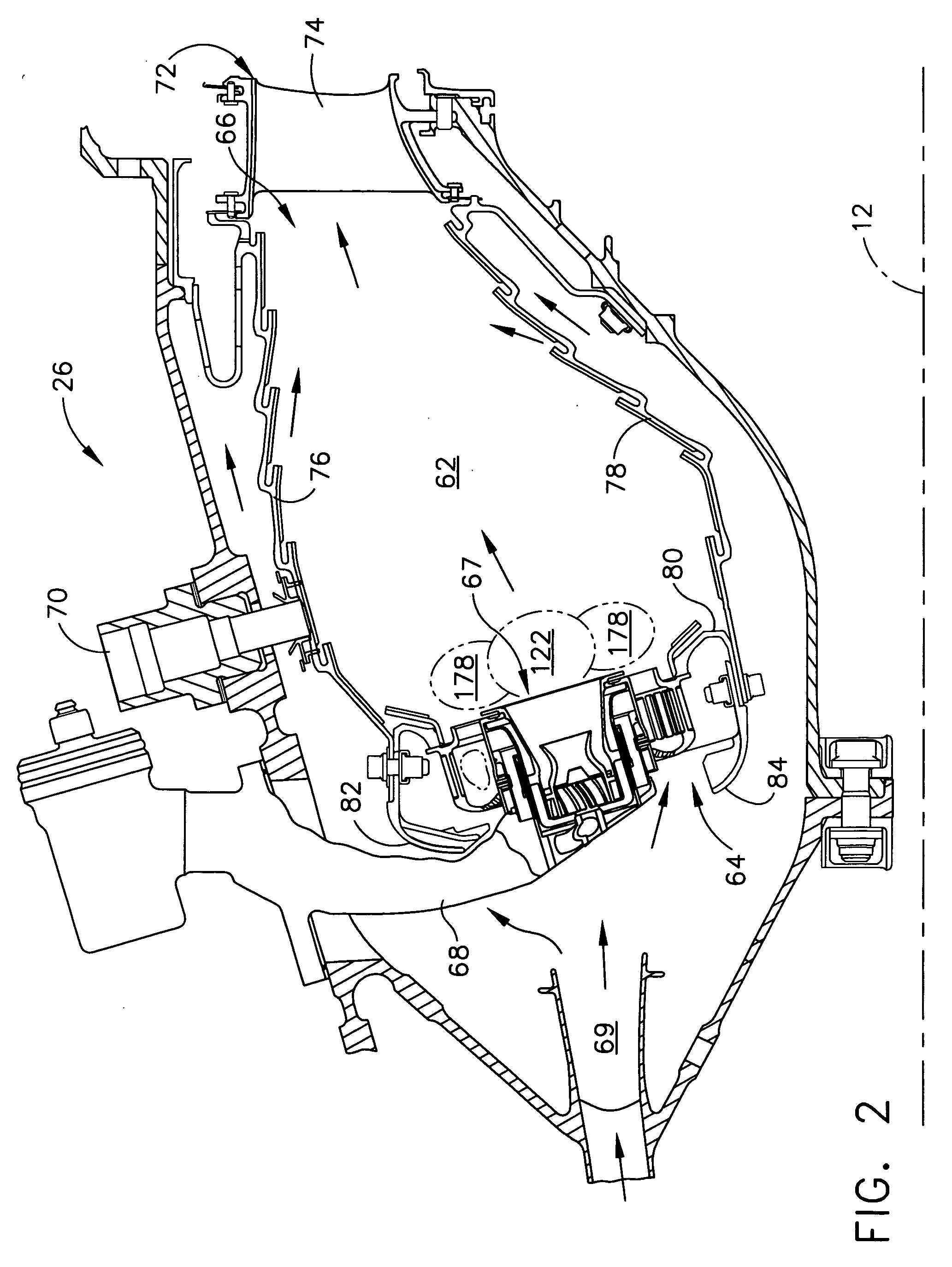

Apparatus and Method for Controlling the Secondary Injection of Fuel

In one embodiment, a combustor (28) for a gas turbine engine is provided comprising a primary combustion chamber (30) for combusting a first fuel to form a combustion flow stream (50) and a transition piece (32) located downstream from the primary combustion chamber (30). The transition piece (32) comprises a plurality of injectors (66) located around a circumference of the transition piece (32) for injecting a second fuel into the combustion flow stream (50). The injectors (66) are effective to create a radial temperature profile (74) at an exit (58) of the transition piece (32) having a reduced coefficient of variation relative to a radial temperature profile (64) at an inlet (54) of the transition piece (32). Methods for controlling the temperature profile of a secondary injection are also provided.

Owner:SIEMENS ENERGY INC

Illuminated showerhead

A showerhead which may be utilized as a source of illumination includes a source of illumination which is efficiently coupled to individual ones of a plurality of water sprays. In an exemplary embodiment, a plurality of fiber-optic members transmit light from one or more individual light sources to corresponding ones of a plurality of individual shower sprays or nozzles. Light from the source of illumination is thus transferred to and is transmitted through a plurality of individual water sprays.

Owner:WATER PIK INC

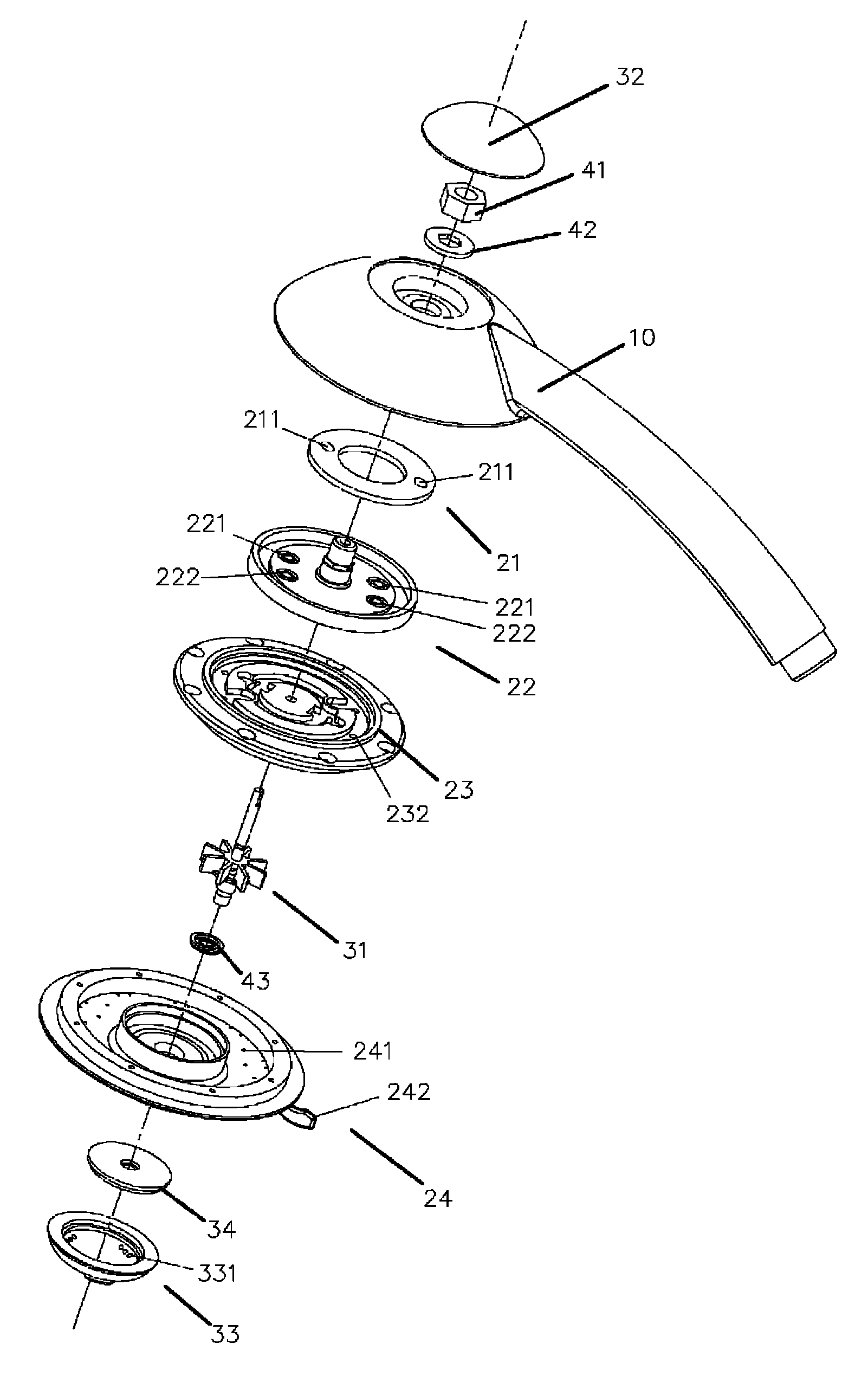

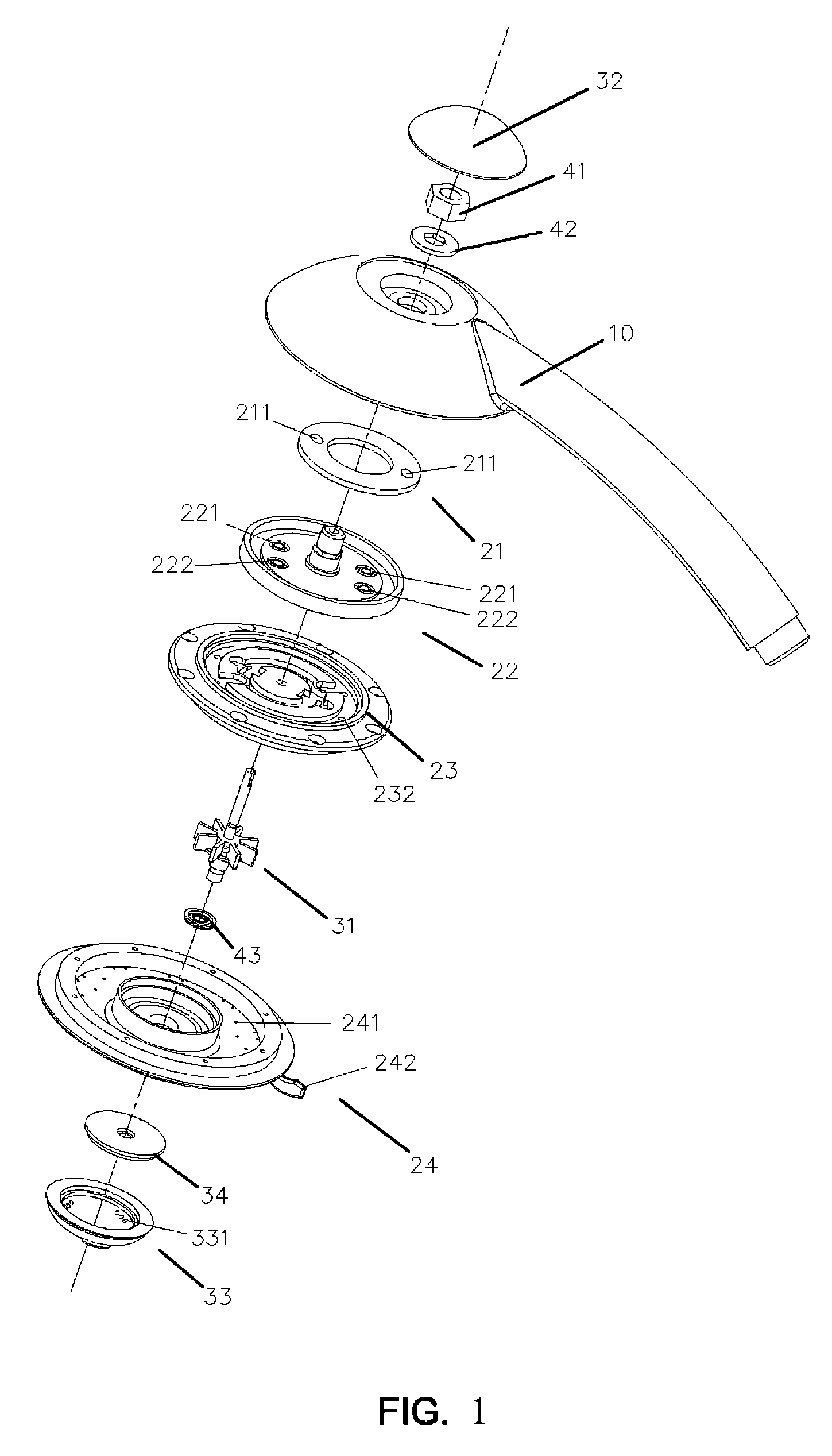

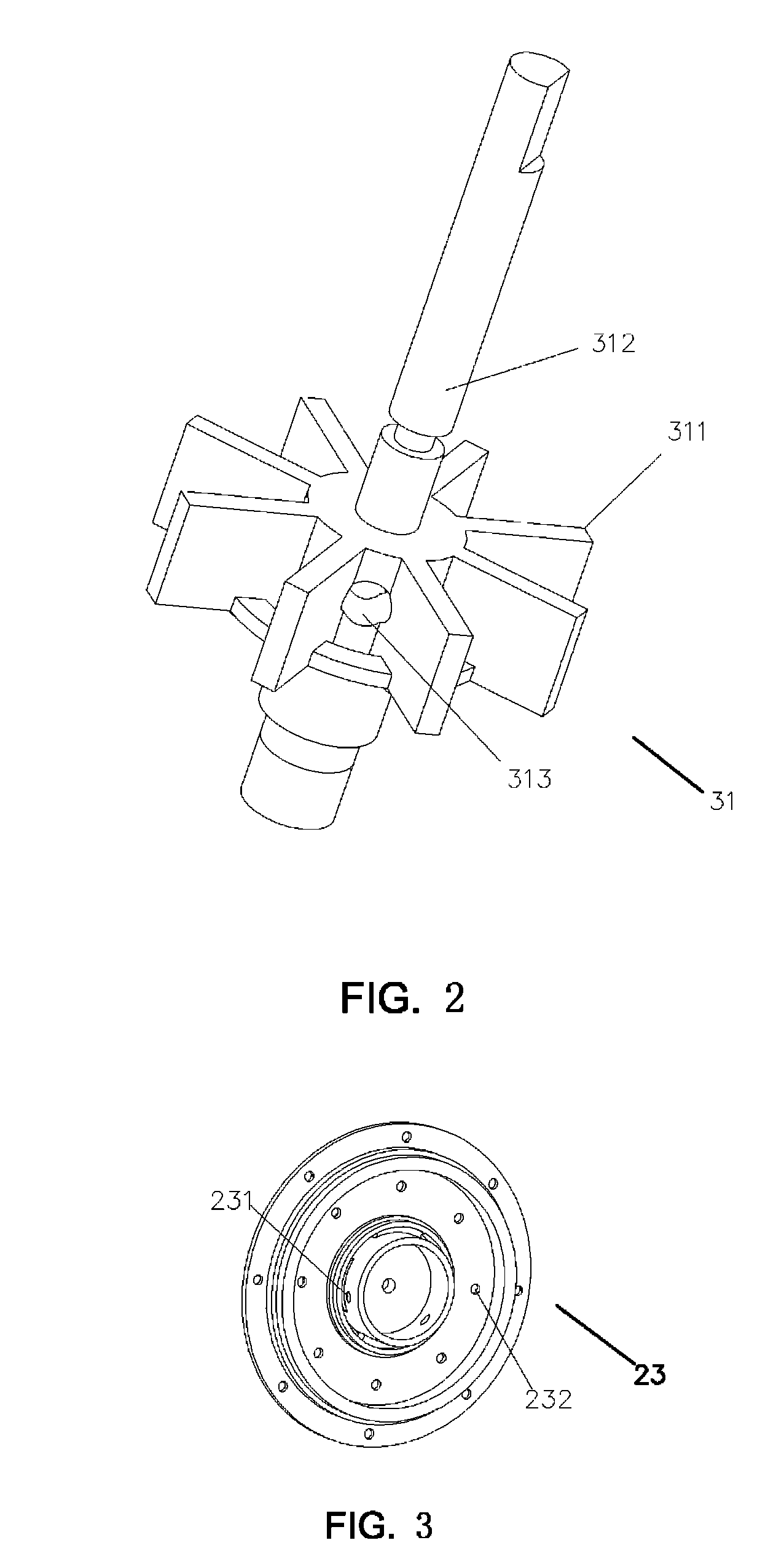

Shower with rotatable top and bottom rotating covers

InactiveUS8297534B2Dramatic watering functionImprove visual effectsBurnersMovable spraying apparatusImpellerWater flow

A shower with rotatable top and bottom rotating covers and a rotatable watering function, comprising: a shower housing, a watering unit having a tilted hole, an impeller set beneath the tilted hole and axially located between the shower housing and the watering unit, a top rotating cover protruding on the shower housing and fixed on the top of the impeller, and a bottom rotating cover protruding under the watering unit and fixed beneath the impeller. The top and bottom rotating covers rotate with the impeller around the same axis. The bottom cover contains an off-center outlet. The water stream from the tilted hole of watering unit will strike the impeller, rotating the top and bottom rotating cover around the same axis. The off-center outlet of the bottom rotating cover then generates a rotating spray.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Lean direct injection atomizer for gas turbine engines

ActiveUS20060248898A1Increase pressureBurnersContinuous combustion chamberGas turbinesDelivery system

A lean direct injection fuel nozzle for a gas turbine is disclosed which includes a radially outer main fuel delivery system including a main inner air swirler defined in part by a main inner air passage having a radially inner wall with a diverging downstream surface, an intermediate air swirler radially inward of the main inner air swirler for providing a cooling air flow along the downstream surface of the radially inner wall of the main inner air passage, and a radially inner pilot fuel delivery system radially inward of the intermediate air swirler.

Owner:ROLLS ROYCE PLC

Dual orifice pilot fuel injector

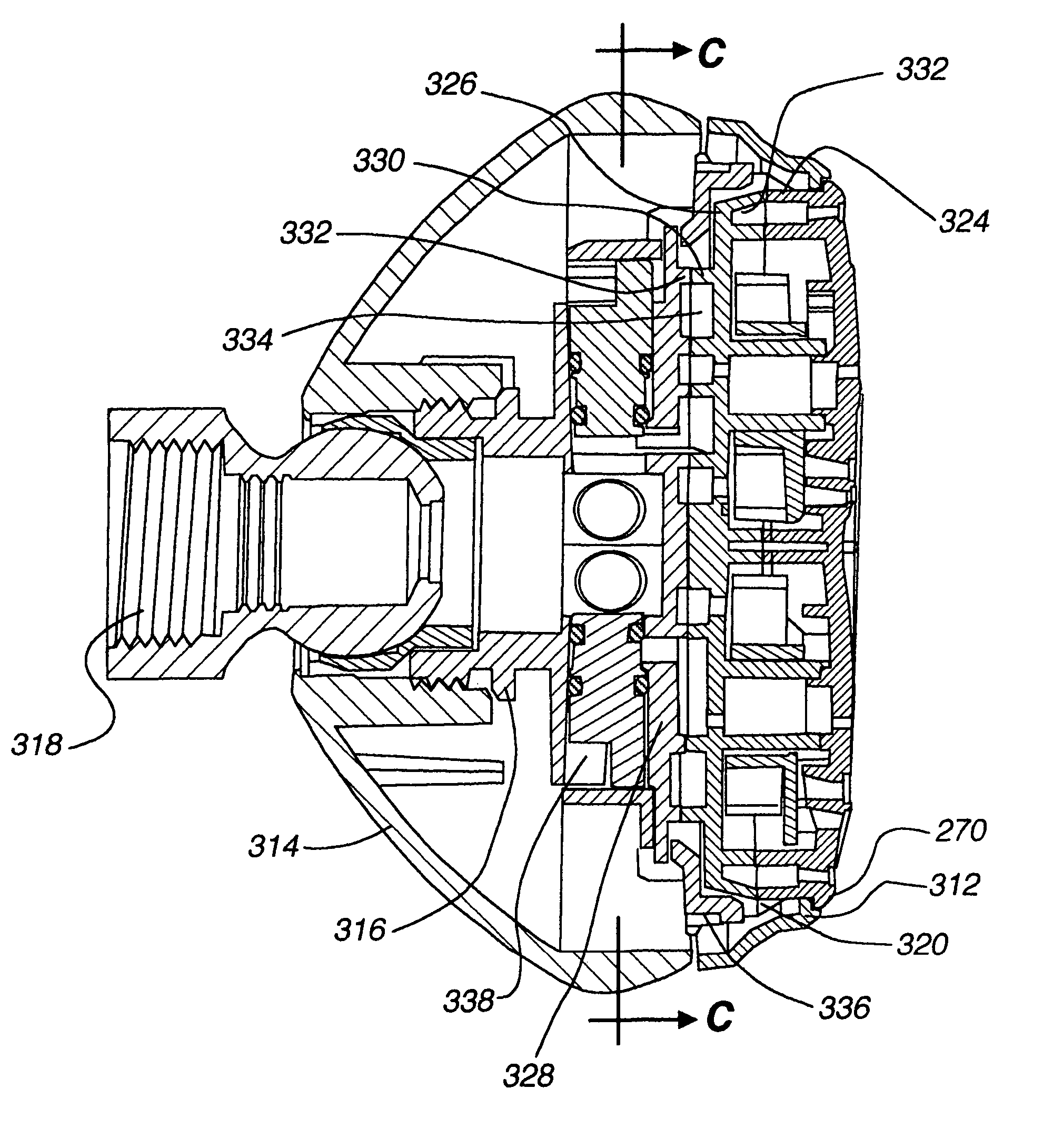

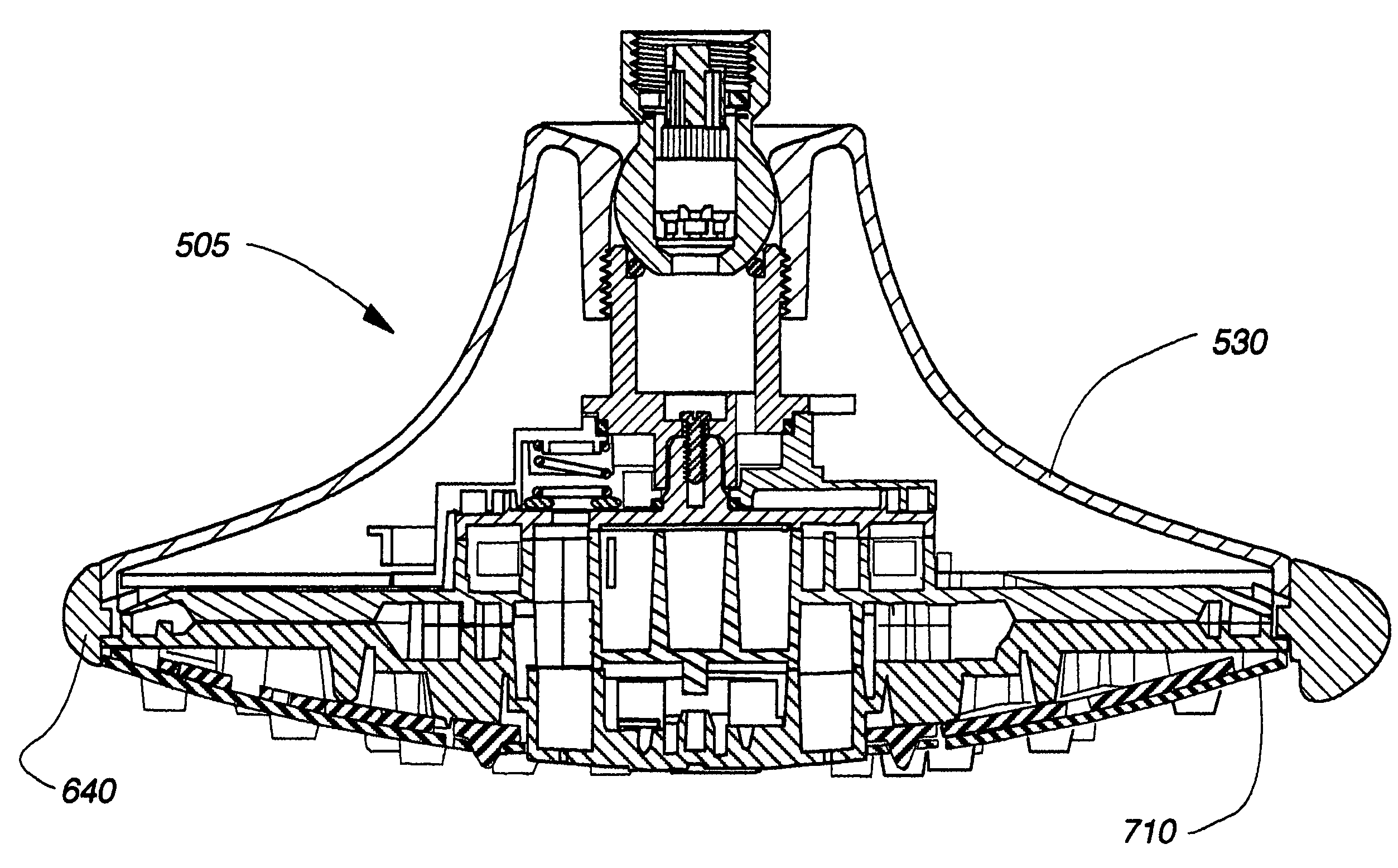

A gas turbine engine fuel nozzle assembly has concentric primary and secondary pilot fuel nozzles with circular primary and annular secondary exits respectively and a main fuel nozzle spaced radially outwardly of the pilot fuel nozzles. The primary and secondary pilot fuel nozzles include conical primary and secondary exit holes respectively. The secondary pilot fuel nozzle is located directly adjacent to and surrounding the primary pilot fuel nozzle. Alternatively the secondary pilot fuel nozzle may be radially spaced apart from the primary pilot fuel nozzle. A fuel injector having a hollow stem may be used to support the fuel nozzle assembly. A first pilot swirler may be located radially outwardly of and adjacent to the dual orifice pilot fuel injector tip, a second pilot swirler located radially outwardly of the first swirler, and a splitter radially positioned between the first and second pilot swirlers.

Owner:GENERAL ELECTRIC CO

Apparatus for equalizing air pressure in air respiratory system

InactiveUS6988497B2Accelerate liquid flowBurnersOther heat production devicesHigh concentrationBreathing gas

A humidifier apparatus for operating at an air pressure is disclosed for use with a respiratory therapy breathing apparatus that provides a breathable gas supply to patients requiring higher concentrations of liquid vapor and gas pressure. The humidifier apparatus includes a feed liquid supply bag in fluid communication with a humidifier cartridge via a conduit. The conduit enables air to flow therethrough to equalize air pressure between the humidifier cartridge and the feed liquid supply bag in response to liquid being supplied to the humidifier cartridge.

Owner:MEZZANINE OPPORTUNITIES LLC AS AGENT

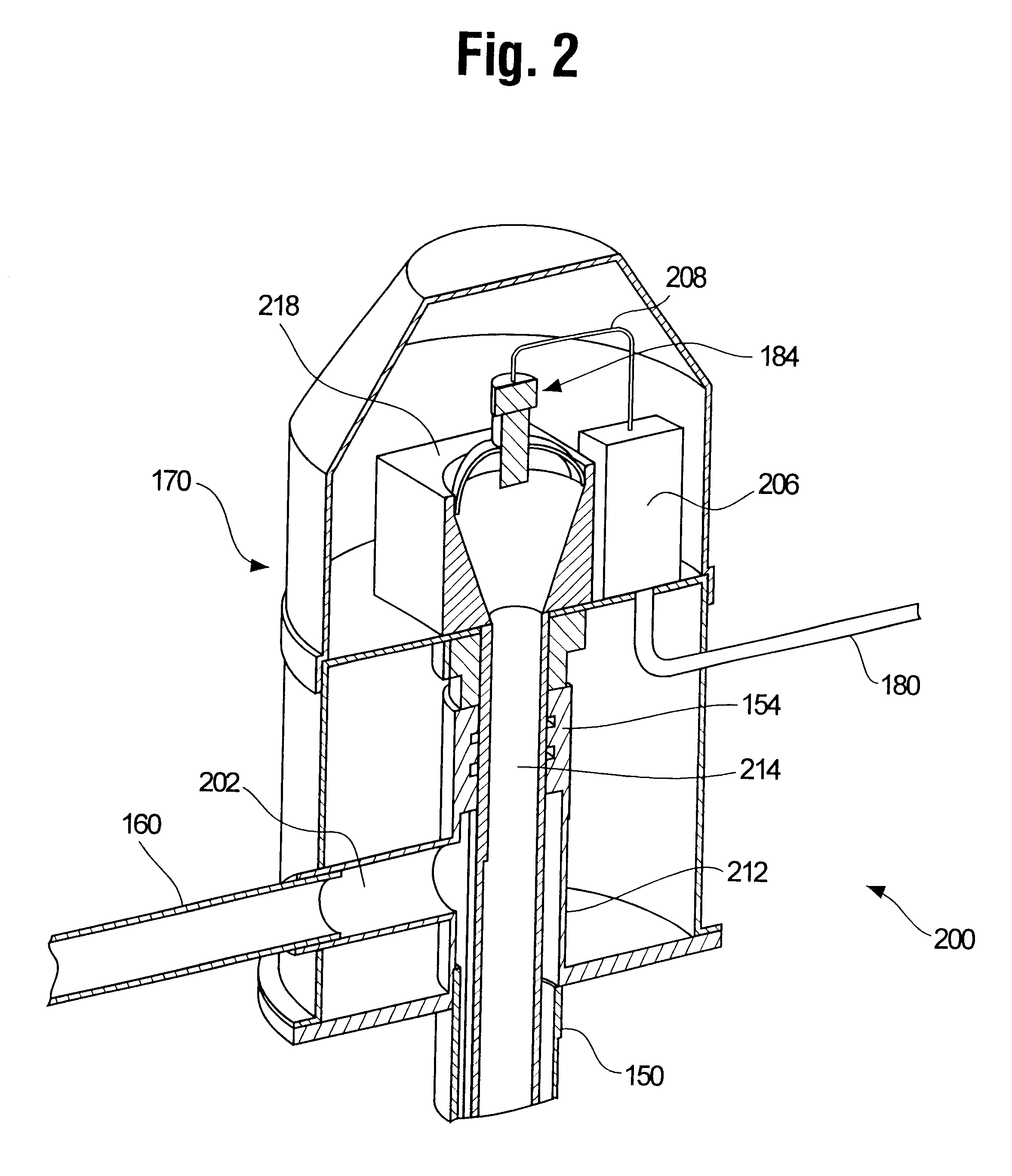

Method and apparatus for fuel injection in a turbine engine

InactiveUS20100170253A1Increase flexibilityReduce morbidityBurnersTurbine/propulsion fuel supply systemsEngineeringTurbine

In one embodiment, a turbine system, may include a fuel nozzle, that includes a plurality of fuel passages and a plurality of air passages offset in a downstream direction from the fuel passages. In the embodiment, an air flow from the air passages is configured to intersect with a fuel flow from the fuel passages at an angle to induce swirl and mixing of the air flow and the fuel flow downstream of the fuel nozzle.

Owner:GENERAL ELECTRIC CO

Dispensing nozzle assembly

The present application describes a nozzle assembly. The nozzle assembly may include a flow director with a first flow path and a second flow path, a tertiary flow assembly with a number of third flow paths, and an elongated target positioned about the flow director such that the first flow path, the second flow path, and the number of third flow paths merge along the elongated target.

Owner:THE COCA COLA CO

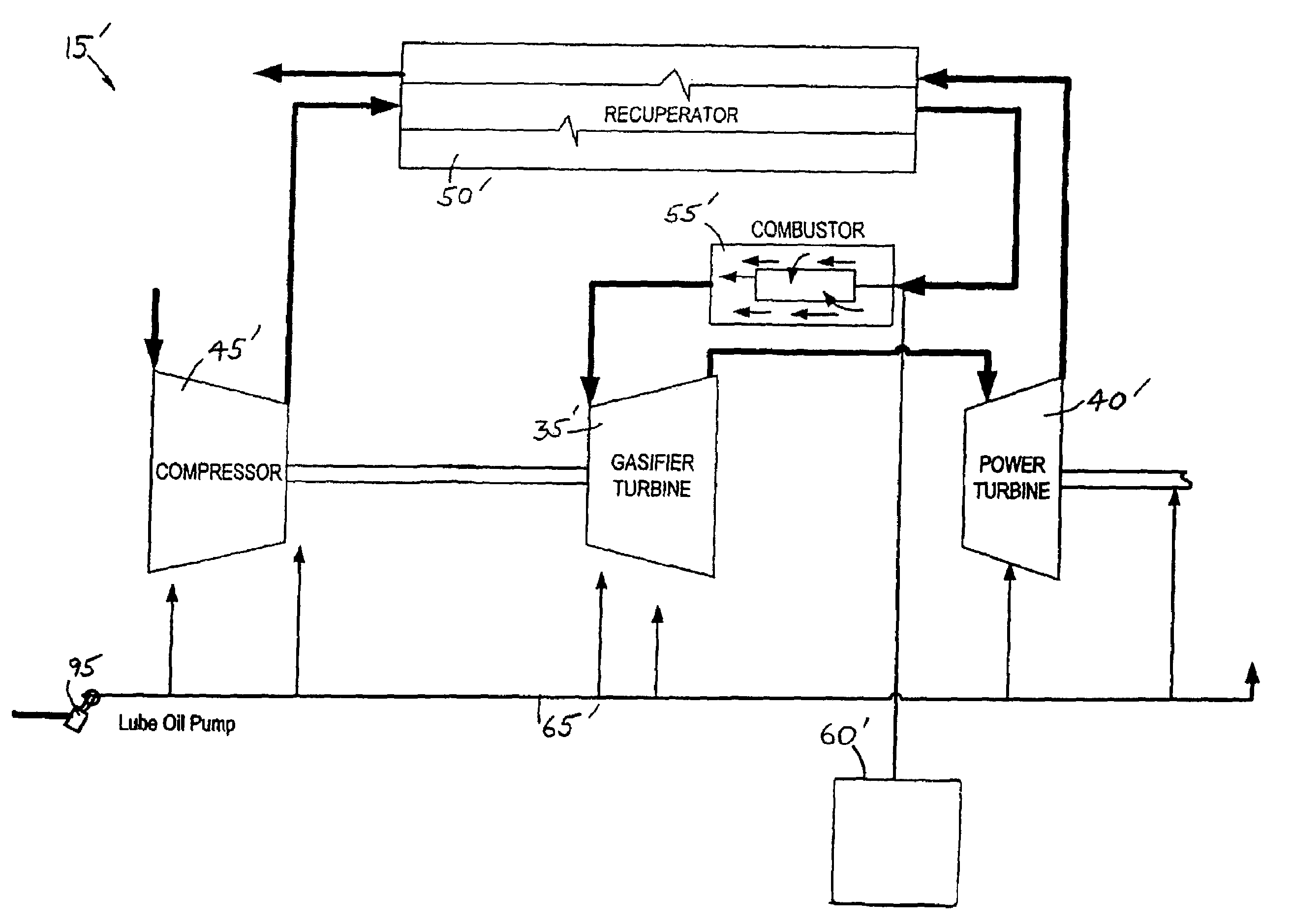

Fuel-conditioning skid

A fuel-conditioning skid for an engine. The fuel-conditioning skid includes an inlet that is connectable to a source to receive a flow of fuel containing undesirable compounds. An outlet is connectable to the engine to deliver a flow of fuel that is substantially free of undesirable compounds. An inlet cleaner is in fluid communication with the inlet and is operable to remove a portion of the undesirable compounds. A compressor is in fluid communication with the inlet cleaner to receive the flow of fuel at a first pressure and discharge the flow of fuel at a second pressure. The second pressure is greater than the first pressure. A purifier is in fluid communication with the inlet cleaner to receive the flow of fuel. The purifier is operable to remove substantially all of the remaining undesirable compounds from the flow of fuel.

Owner:FLEXENERGY ENERGY SYST

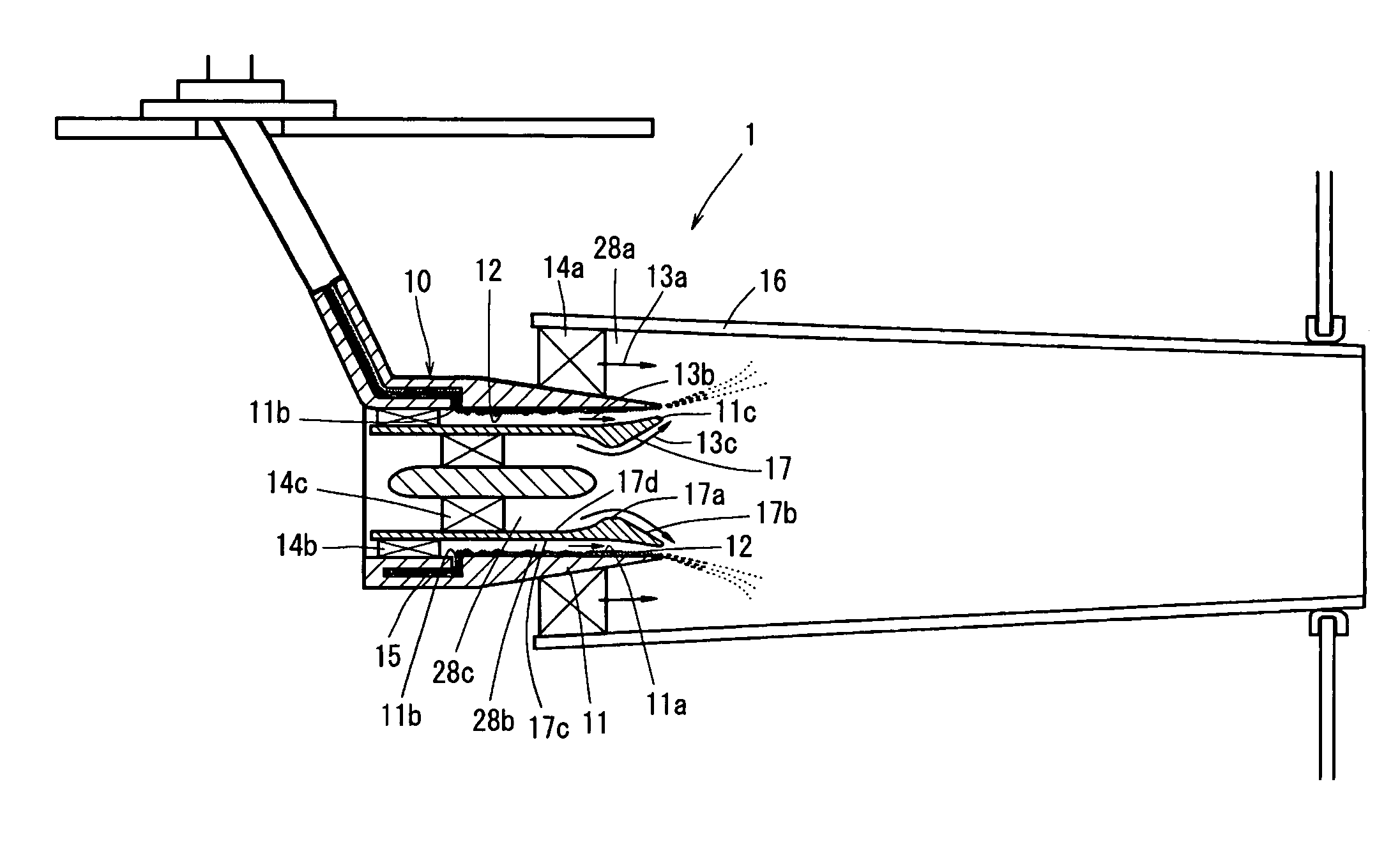

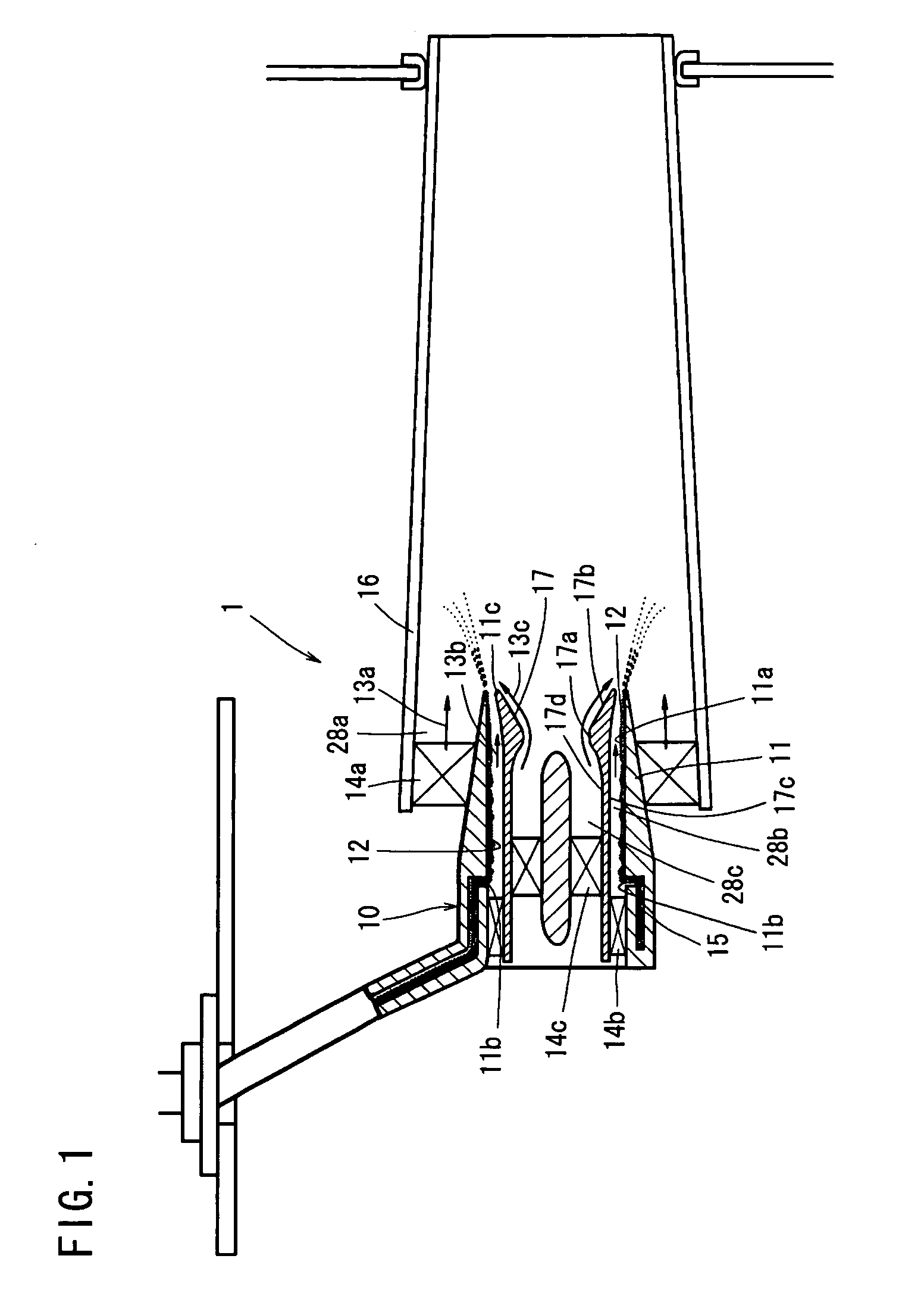

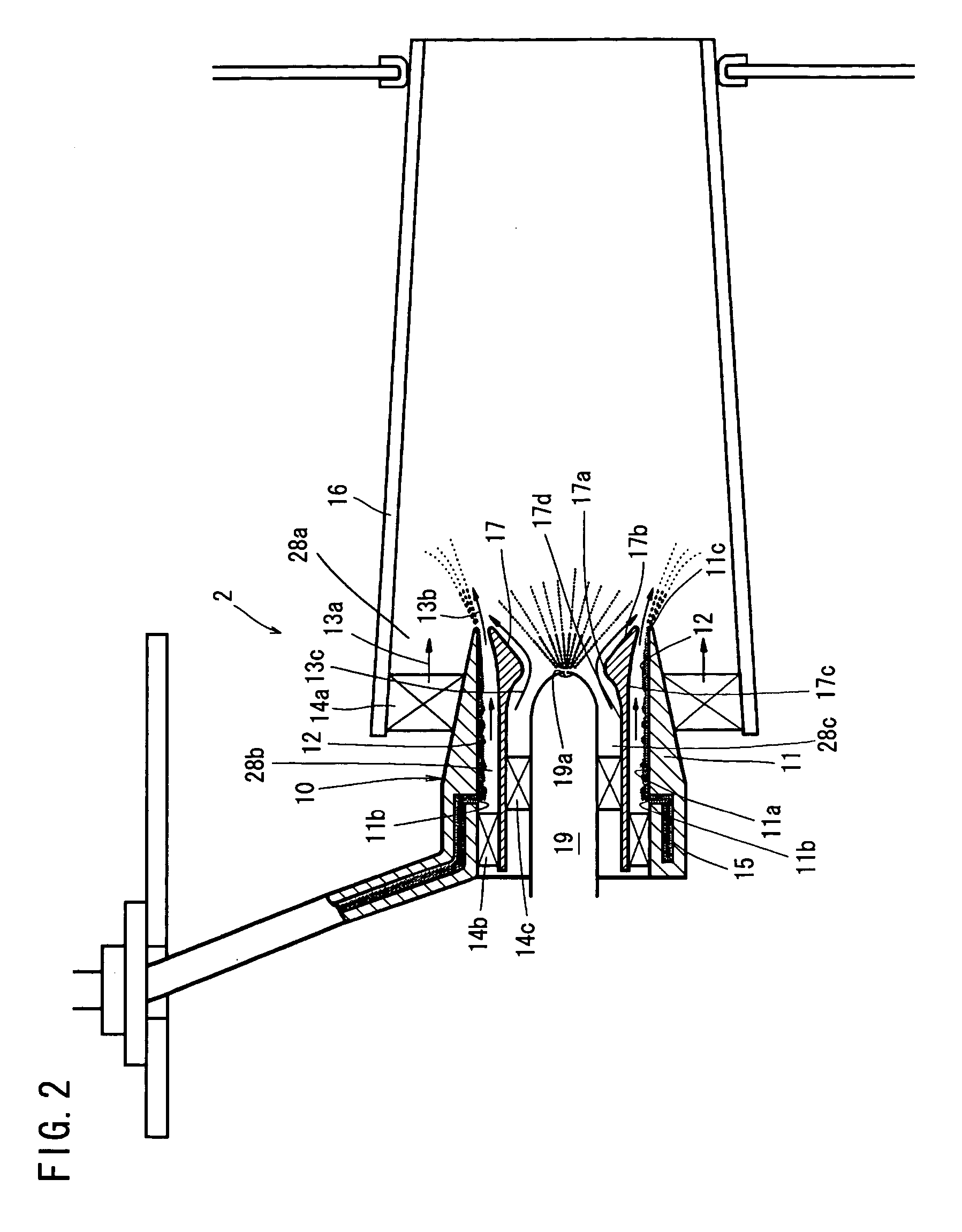

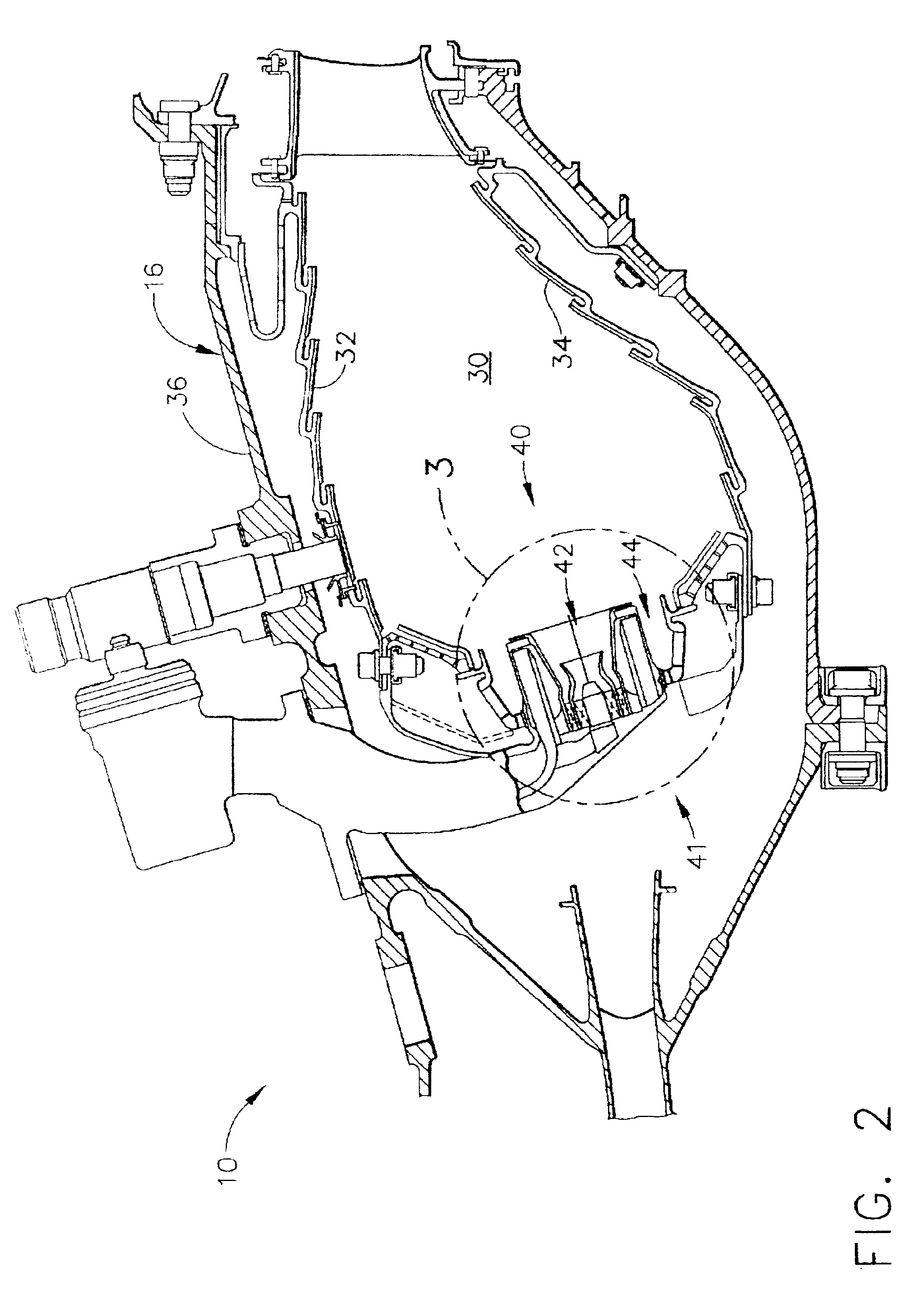

Fuel/air premixer for gas turbine combustor

InactiveUS20050039456A1Reduce weightReduce overall outer diameterBurnersContinuous combustion chamberCombustorCombustion chamber

A fuel / air premixer for use in a gas turbine improves the atomization performance and mixing performance of the fuel by guiding an air so as to flow in an outward radial direction. A flow-deflecting tubular body having an annular cross section is disposed on the inside of and coaxially with a liquid film-forming body of an airblast atomizer nozzle disposed at the inlet portion of a premixing tube. The outer peripheral surface of the flow-deflecting tubular body has a wall surface which increases in outer diameter toward the tip end of a first annular passage. The inner peripheral surface of the flow-deflecting tubular body has a form in which the inner diameter has a minimum to form a contracted portion, and then increases dramatically toward the tip end.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

Method and apparatus to decrease combustor emissions

A method for operating a gas turbine engine facilitates reducing an amount of emissions from a combustor. The combustor includes a mixer assembly including a pilot mixer, a main mixer, and a centerbody that extends therebetween. The pilot mixer includes a pilot fuel nozzle and a plurality of axial swirlers. The main mixer includes a main swirler and a plurality of fuel injection ports. The method comprises injecting fuel into the combustor through the pilot mixer, such that the fuel is discharged downstream from the pilot mixer axial swirlers, and directing flow exiting the pilot mixer with a lip extending from the centerbody into a pilot flame zone downstream from said pilot mixer.

Owner:GENERAL ELECTRIC CO

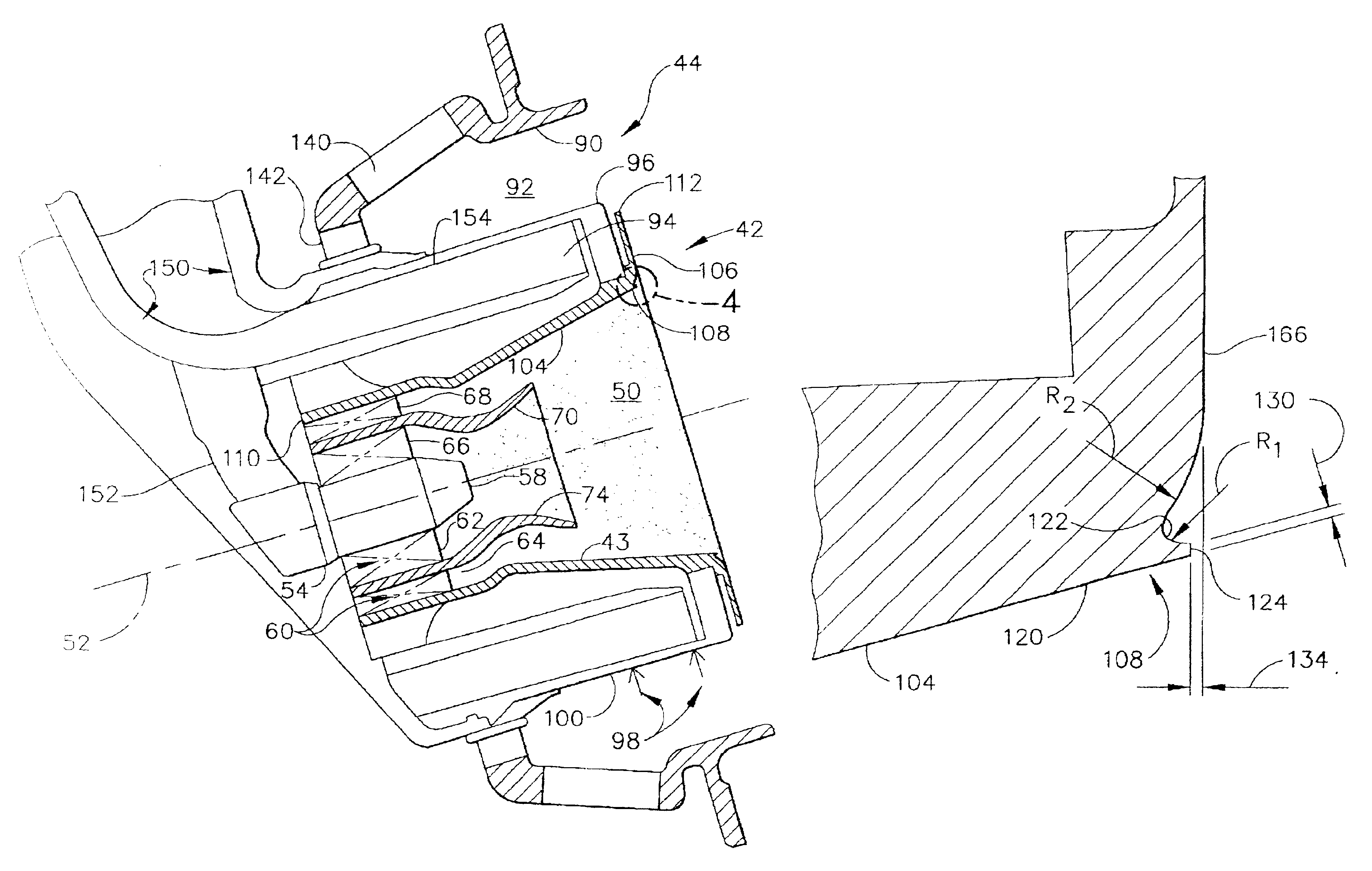

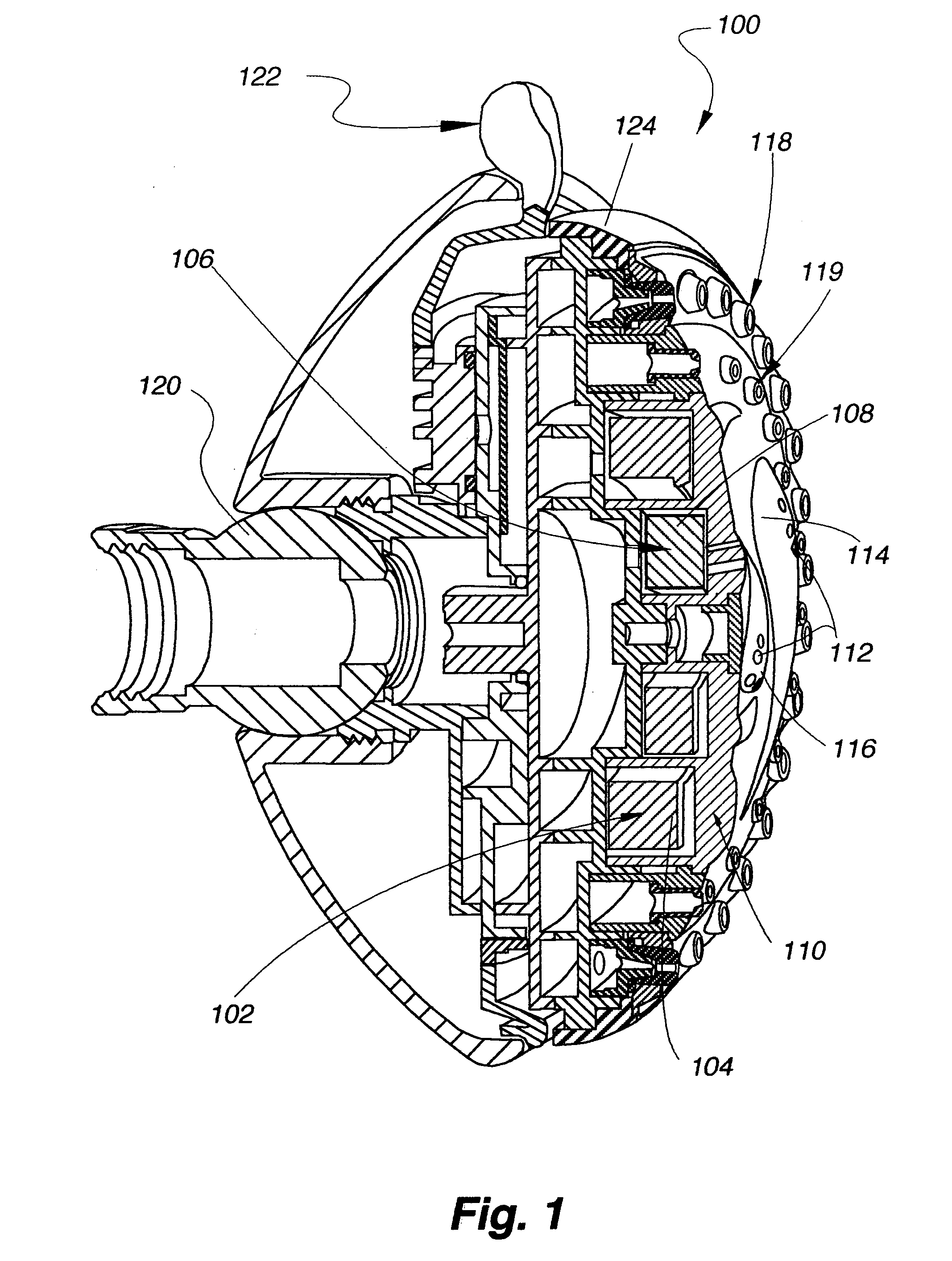

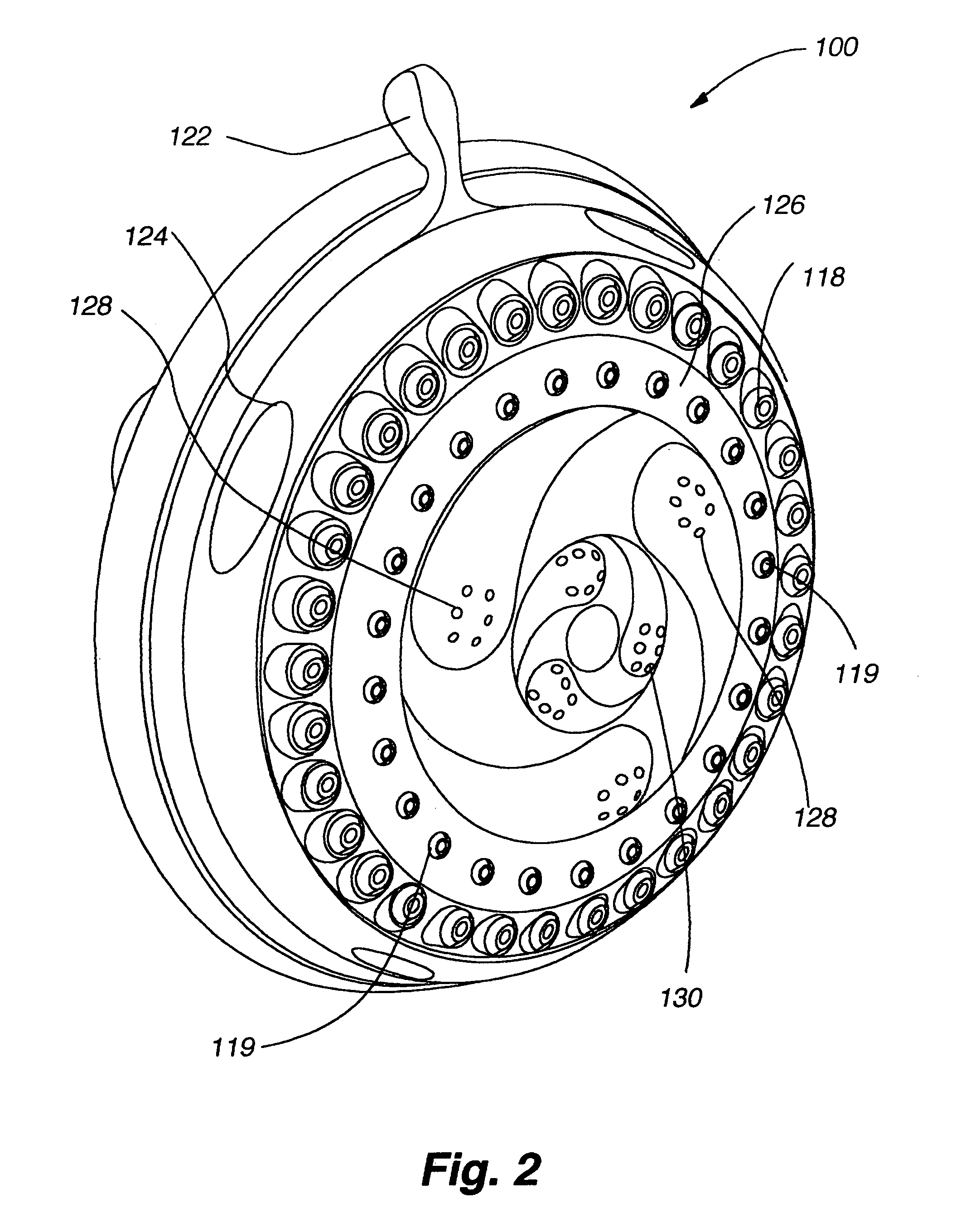

Mixer assembly for combustor of a gas turbine engine having a main mixer with improved fuel penetration

A mixer assembly for use in a combustion chamber of a gas turbine engine includes a pilot mixer, a main mixer, and a fuel manifold positioned between the pilot mixer and main mixer. The pilot mixer includes an annular pilot housing having a hollow interior and a pilot fuel nozzle mounted in the housing and adapted for dispensing droplets of fuel to the hollow interior of the pilot housing. The main mixer includes: a main housing surrounding the pilot housing and defining an annular cavity having an upstream end and a downstream end including an upstream wall, an outer wall and an inner wall; a plurality of fuel injection ports for introducing fuel into the cavity, with the fuel injection ports being circumferentially spaced at a designated axial location of the inner wall of the annular cavity; and a swirler arrangement including at least one swirler in flow communication with the annular cavity, the swirler being incorporated into the outer wall of the annular cavity and extending from an upstream end to a downstream end, wherein each swirler of the arrangement has a plurality of vanes for swirling air traveling through such swirler to mix air and the droplets of fuel dispensed by the fuel injection ports. The main housing further includes a first plurality of passages oriented to provide air jets in a substantially axial direction into the annular cavity and a second plurality of passages oriented to provide air jets in a substantially radial direction into the annular cavity

Owner:GENERAL ELECTRIC CO

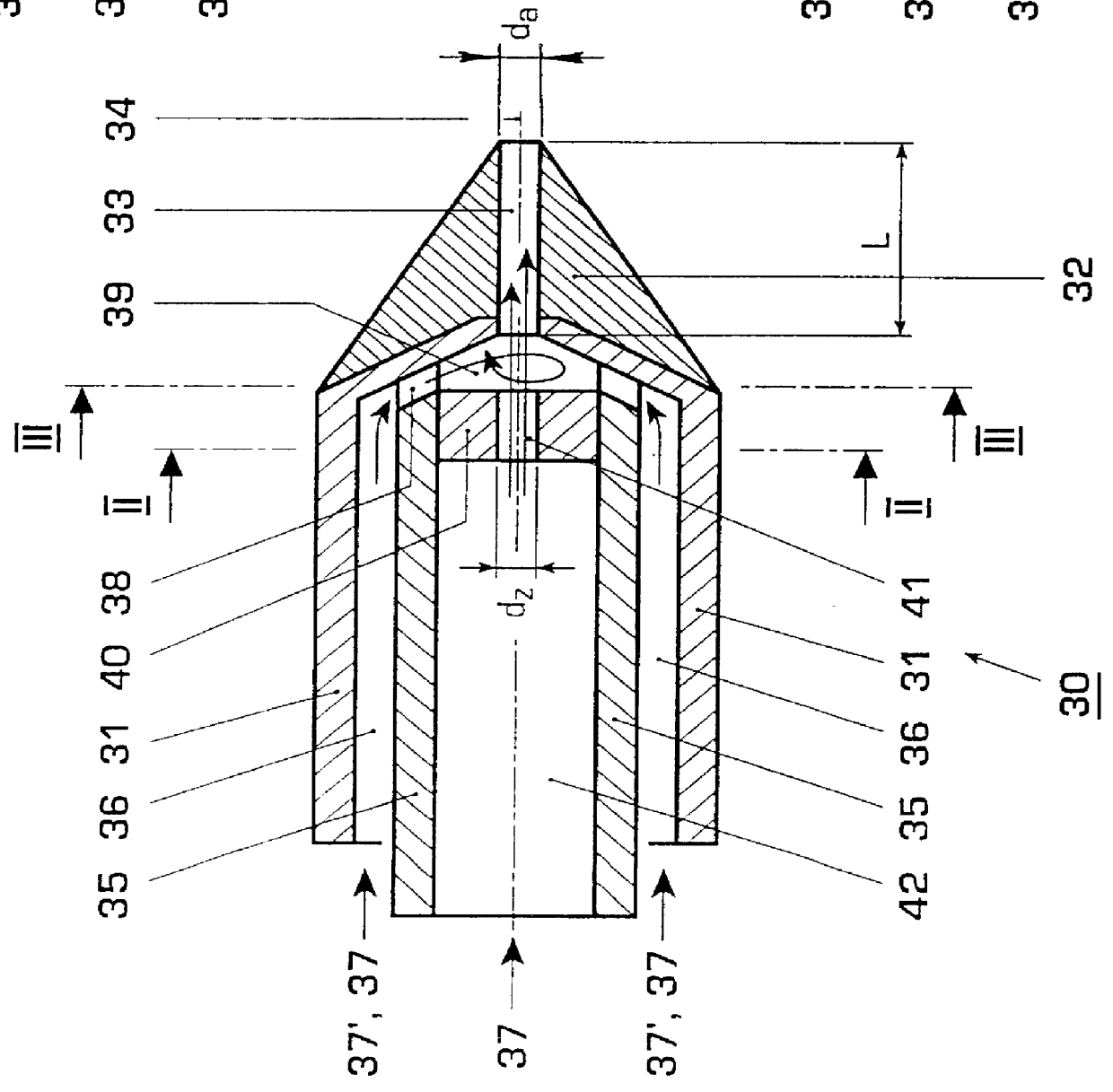

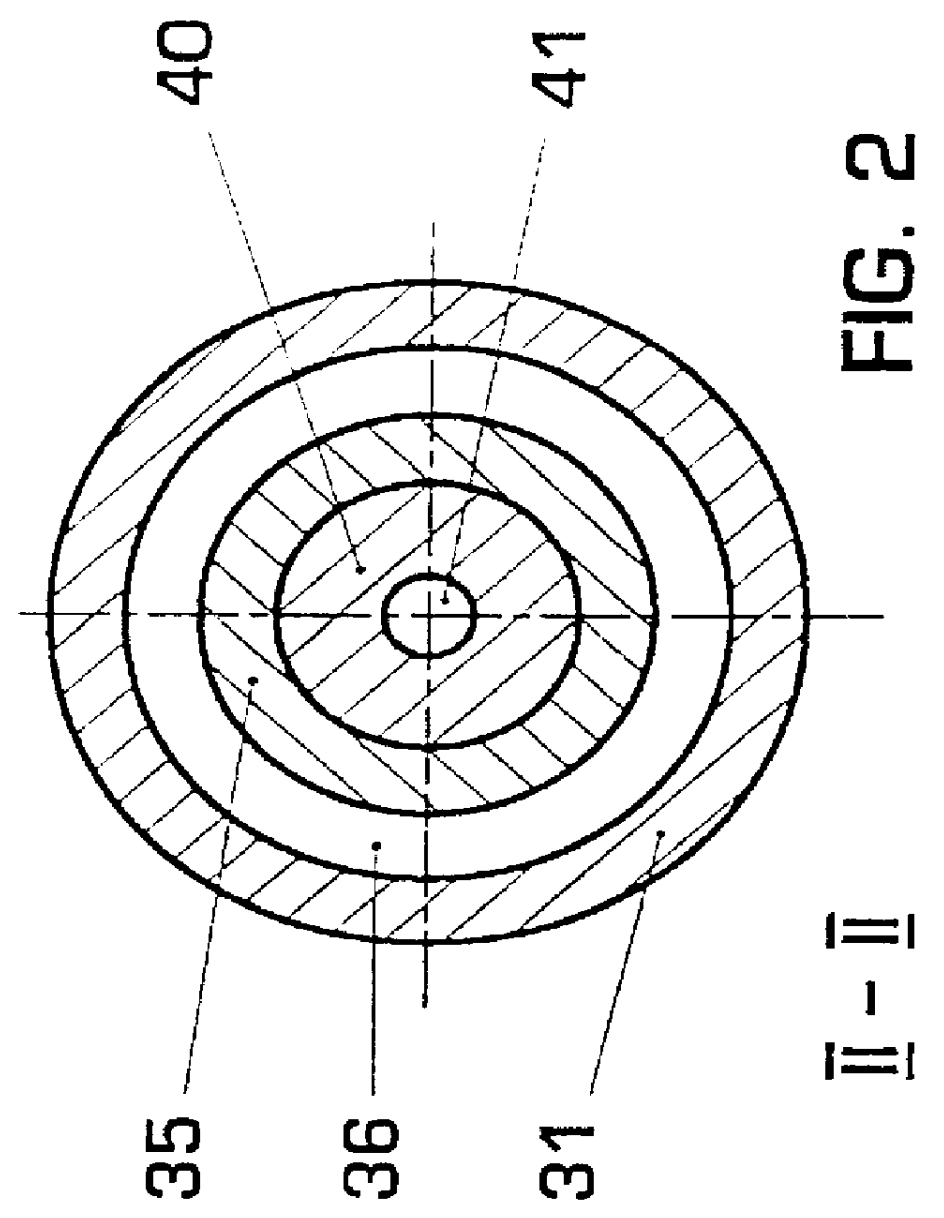

Pressure atomizer nozzle

InactiveUS6045058ASlow disintegrationReduce friction lossBurnersSpray nozzlesNebulizerAtomizer nozzle

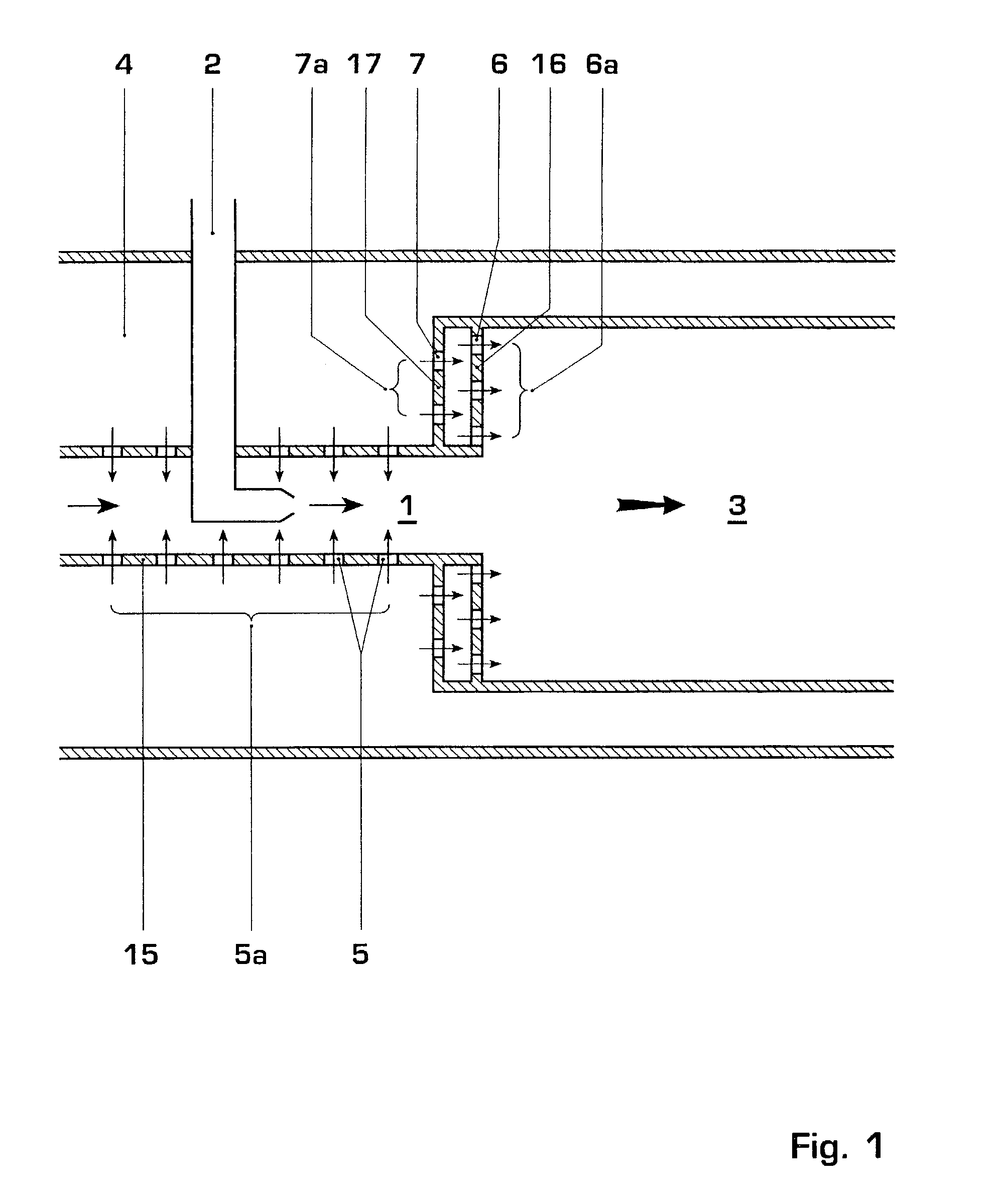

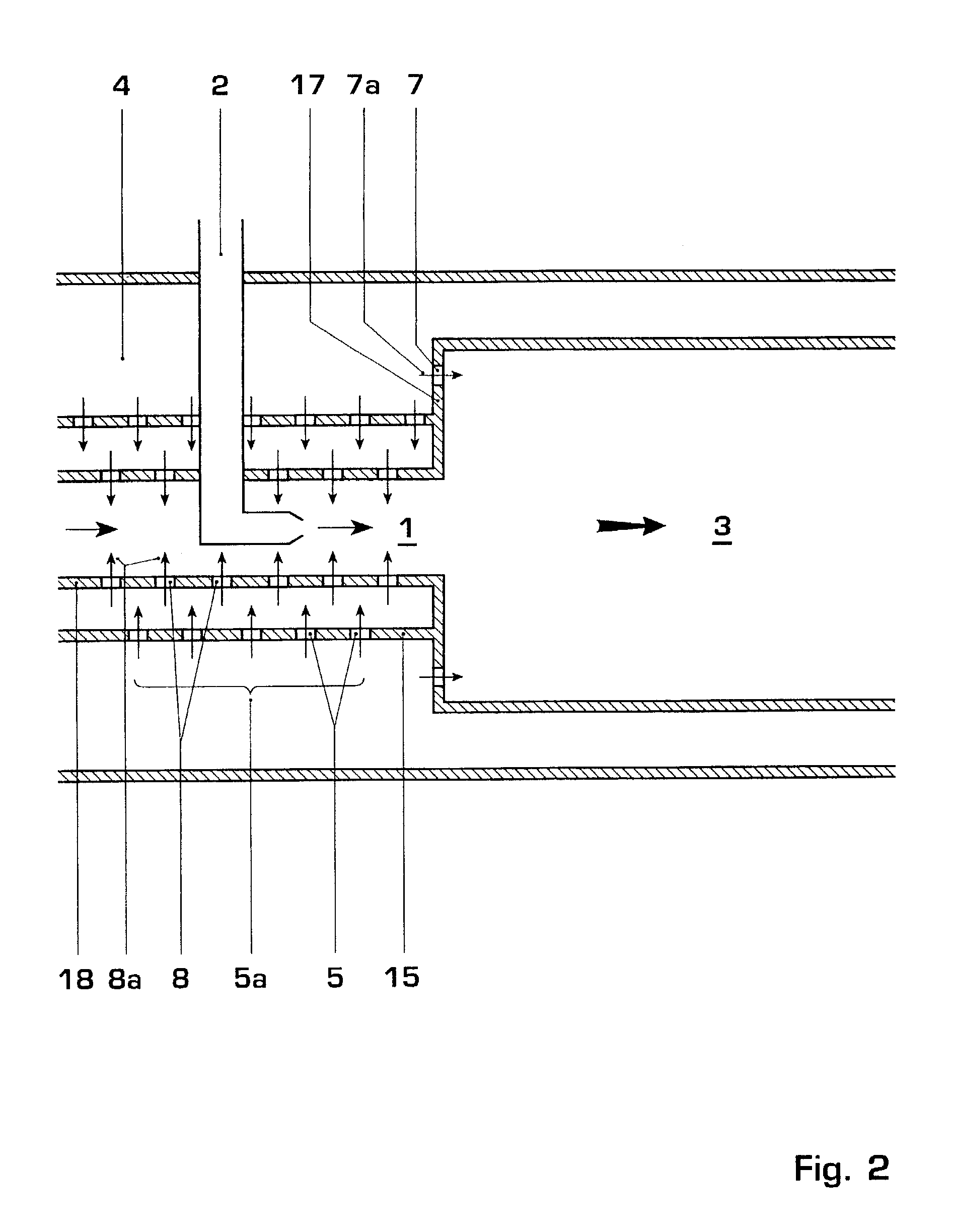

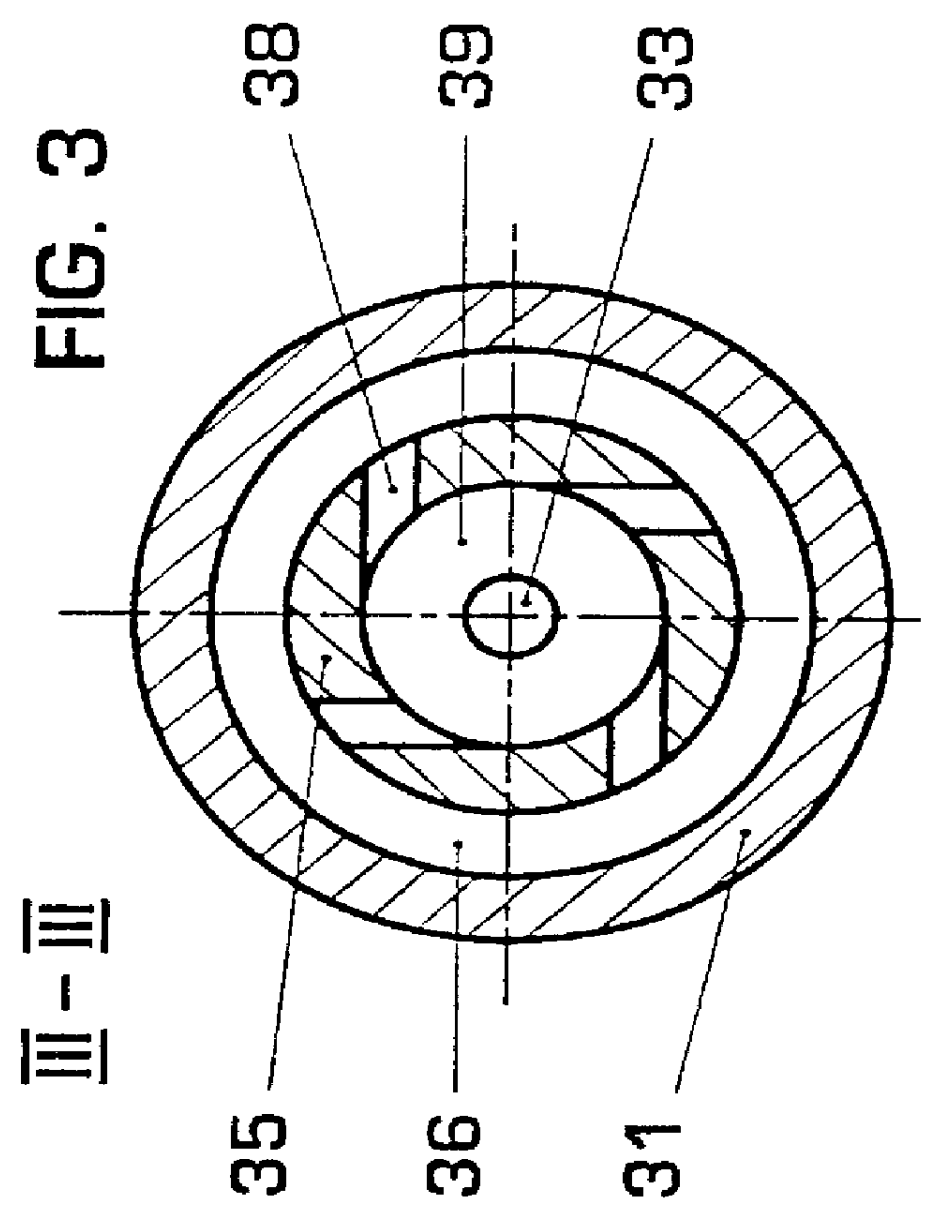

The invention relates to a two-stage pressure atomizer nozzle with a nozzle body (30) having a mixing chamber (39) which is connected to an outside space via a nozzle outlet bore (33), and with a first feed duct (42) with a feed bore (41) for a liquid (37) to be atomized, through which feed bore said liquid (37) can be fed, free of swirling and under pressure, at least one further feed duct (36) for a portion of the liquid (37) to be atomized or for a second liquid (37') to be atomized opening into the chamber (39), through which feed duct said liquid (37, 37') can be fed under pressure and with swirling. The feed bore (41) of the first feed duct (42) lies on one axis (34) with the nozzle outlet bore (33). It is defined in that the outlet-side diameter (da) of the nozzle outlet bore (33) is at most as large as the diameter (dz) of the feed bore (41) and the length (L) of the nozzle outlet bore (33) is at least twice to at most ten times the outlet-side diameter (da) of the nozzle outlet bore (33).

Owner:ANSALDO ENERGIA SWITZERLAND AG

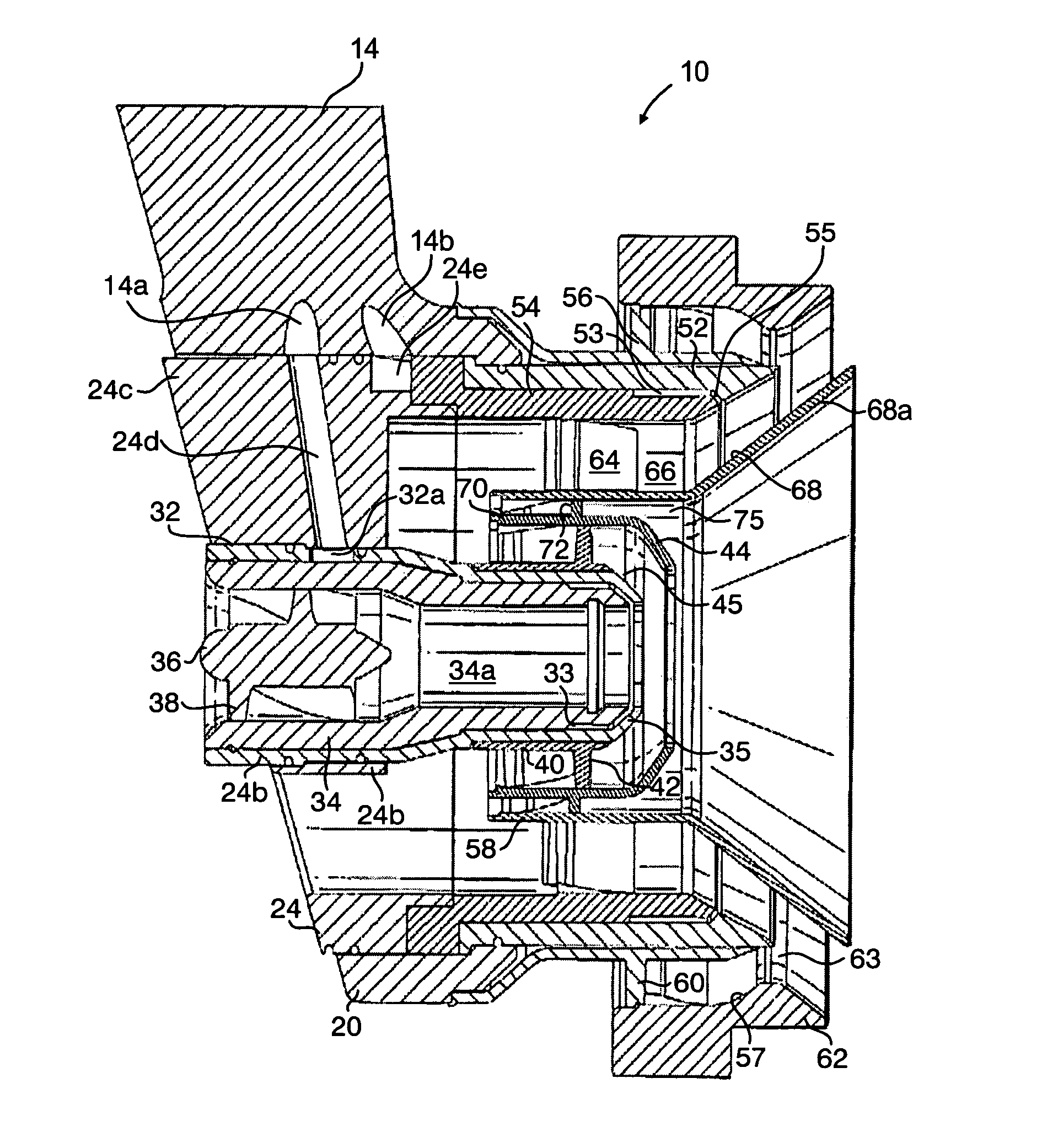

Dual massage shower head

A shower head having dual turbines. The shower head includes a body having an inlet for connection to a water conduit, a first outlet nozzle formed on the body, a second outlet nozzle formed on the body, a first turbine operably connected to the first outlet nozzle, and a second turbine operably connected to the second outlet nozzle. The shower head may include a flow actuation system taking the form of an actuator ring, a valve connected to the actuator ring and forming a flow channel, a first actuation point defined on the actuator ring, a second actuation point defined on the actuator ring, and a plunger situated within the flow channel. The plunger extends radially outwardly from a center of the valve when aligned with one of the first and second actuation points.

Owner:WATER PIK INC

Flameless combustor process heater

InactiveUS20020015670A1Reduce the temperatureLow costThermal non-catalytic crackingBurnersAutoignition temperatureEngineering

A process heater is provided utilizing flameless combustion, the process heater having: an oxidation reaction chamber, the oxidation reaction chamber having an inlet for oxidant, an outlet for combustion products, and a flow path between the inlet and the outlet; a fuel conduit capable of transporting a fuel mixture to a plurality of fuel nozzles within the oxidation reaction chamber, each nozzle providing communication from within the fuel conduit to the oxidation chamber, with each nozzle along the flowpath between the inlet and the outlet; a preheater in communication with the oxidation chamber inlet, the preheater capable of increasing the temperature of the oxidant to a temperature resulting in the combined oxidant and fuel from the fuel nozzle closest to the oxidation chamber inlet being greater than the autoignition temperature of the combined oxidant and fuel from the fuel nozzle closest to the oxidation chamber inlet; and a process chamber in a heat exchange relationship to the oxidation reaction chamber wherein the heat transferred from the oxidation section does not causes the temperature of the mixture within the oxidation reaction chamber in the vicinity of each fuel nozzle to decrease below the auto ignition temperature of the combined mixture in the oxidation chamber in the vicinity of that fuel nozzle.

Owner:SHELL OIL CO

Drenching shower head

An improved shower head having multiple modes of operation. The shower head may include a first turbine and turbine, each disposed within a unique flow channel. The first and second turbines may interrupt water flow through their respective flow channels, thereby providing at least one pulsating water spray emanating from the shower head. The shower head may include a third flow channel having no turbine disposed therein, such that water flowing through the third flow channel is not interrupted and thus emitted from the shower head as a drenching spray.

Owner:WATER PIK INC

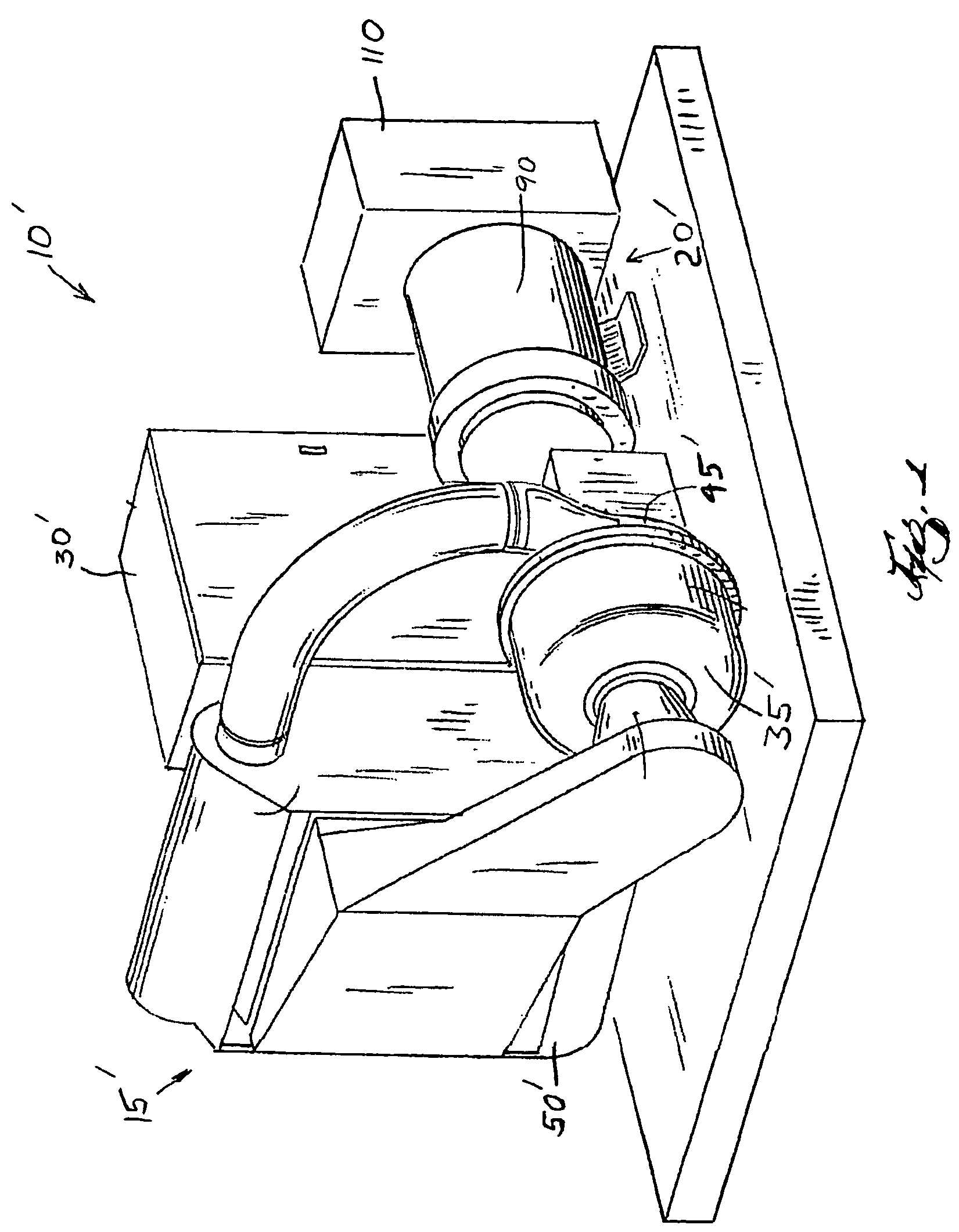

Lean-staged pyrospin combustor

ActiveUS7302801B2High power outputIncrease powerBurnersTurbine/propulsion fuel supply systemsCombustorCombustion chamber

Owner:HAMILTON SUNDSTRAND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com