Patents

Literature

1500results about "Electrostatic spraying apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

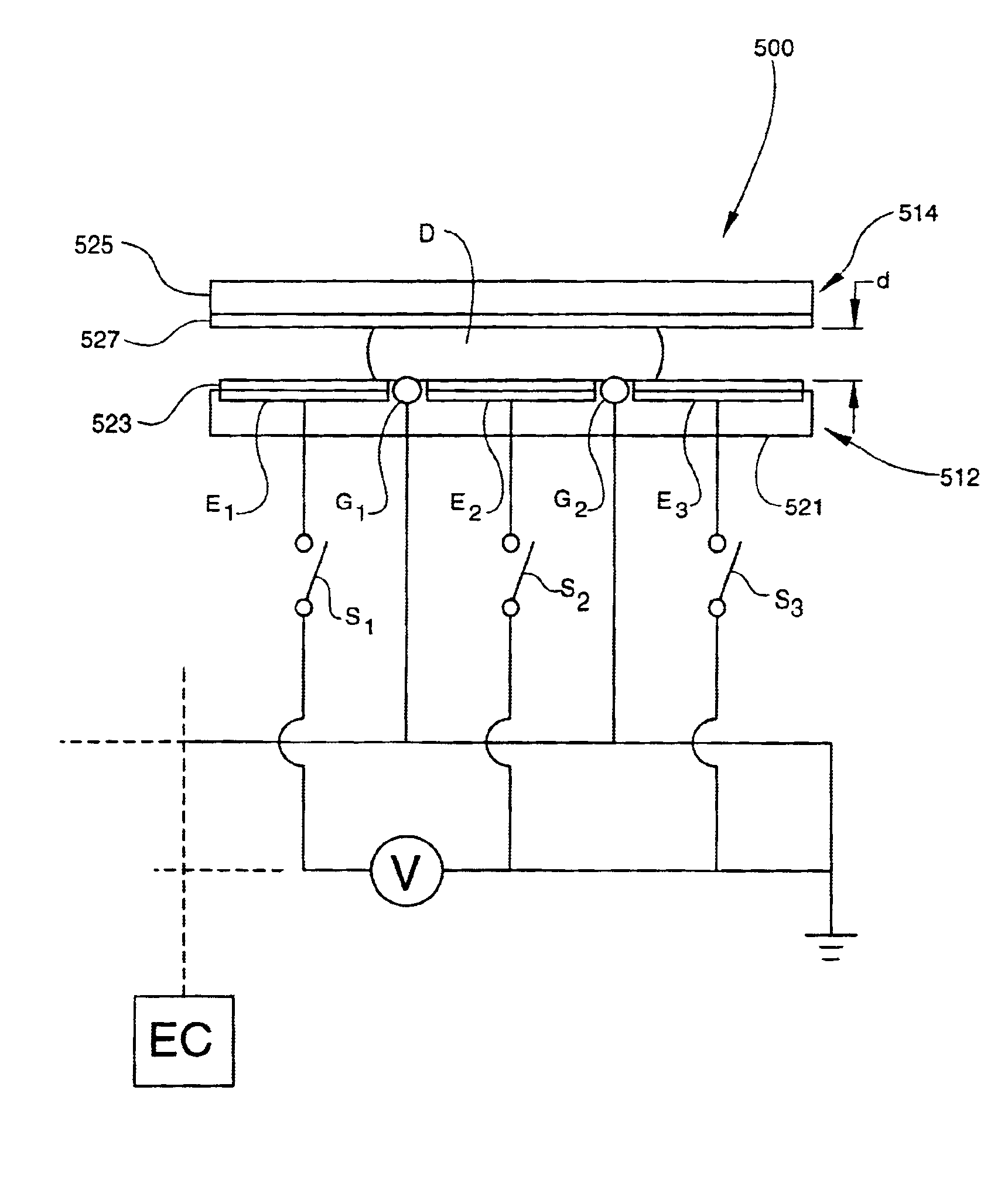

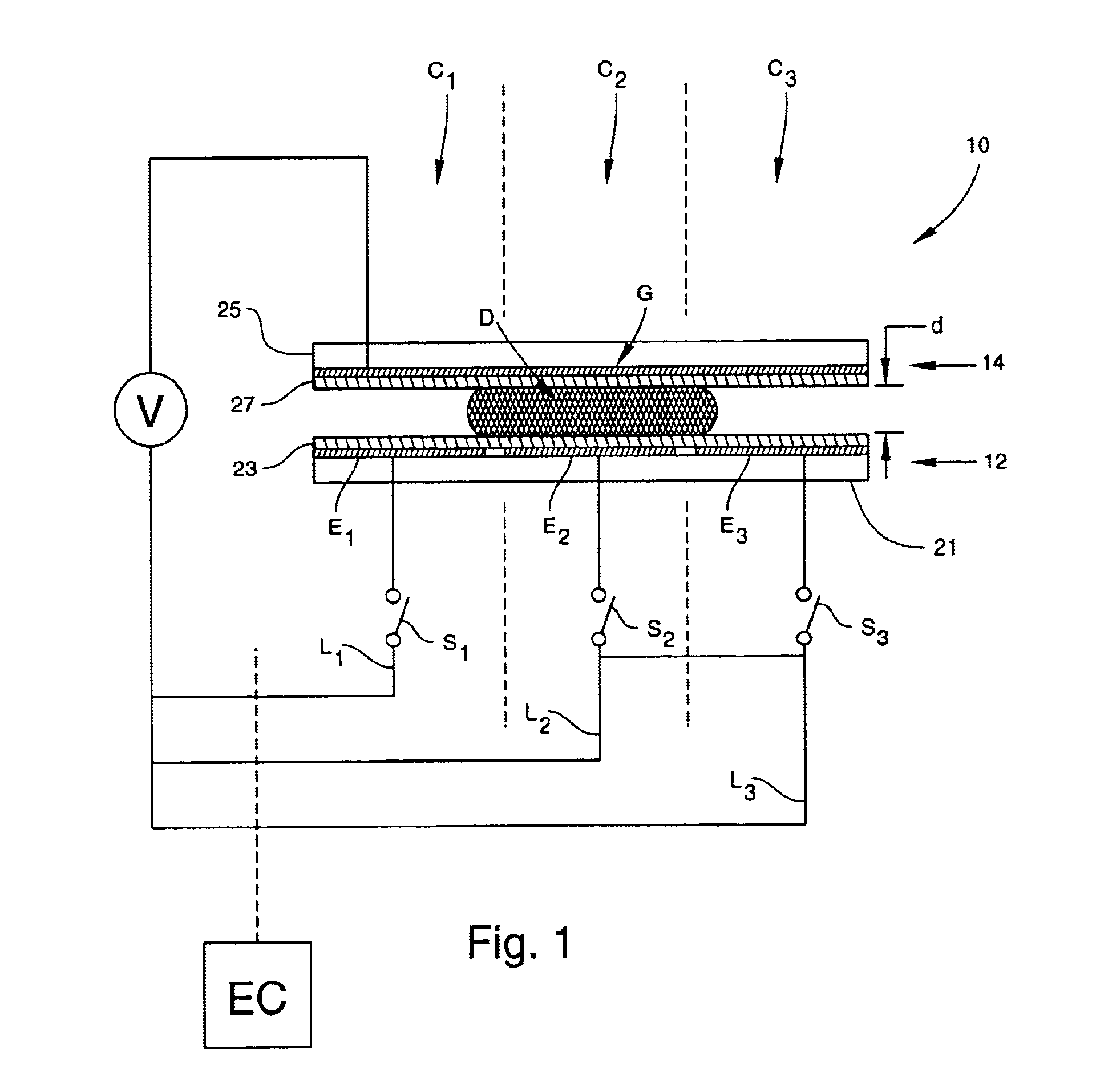

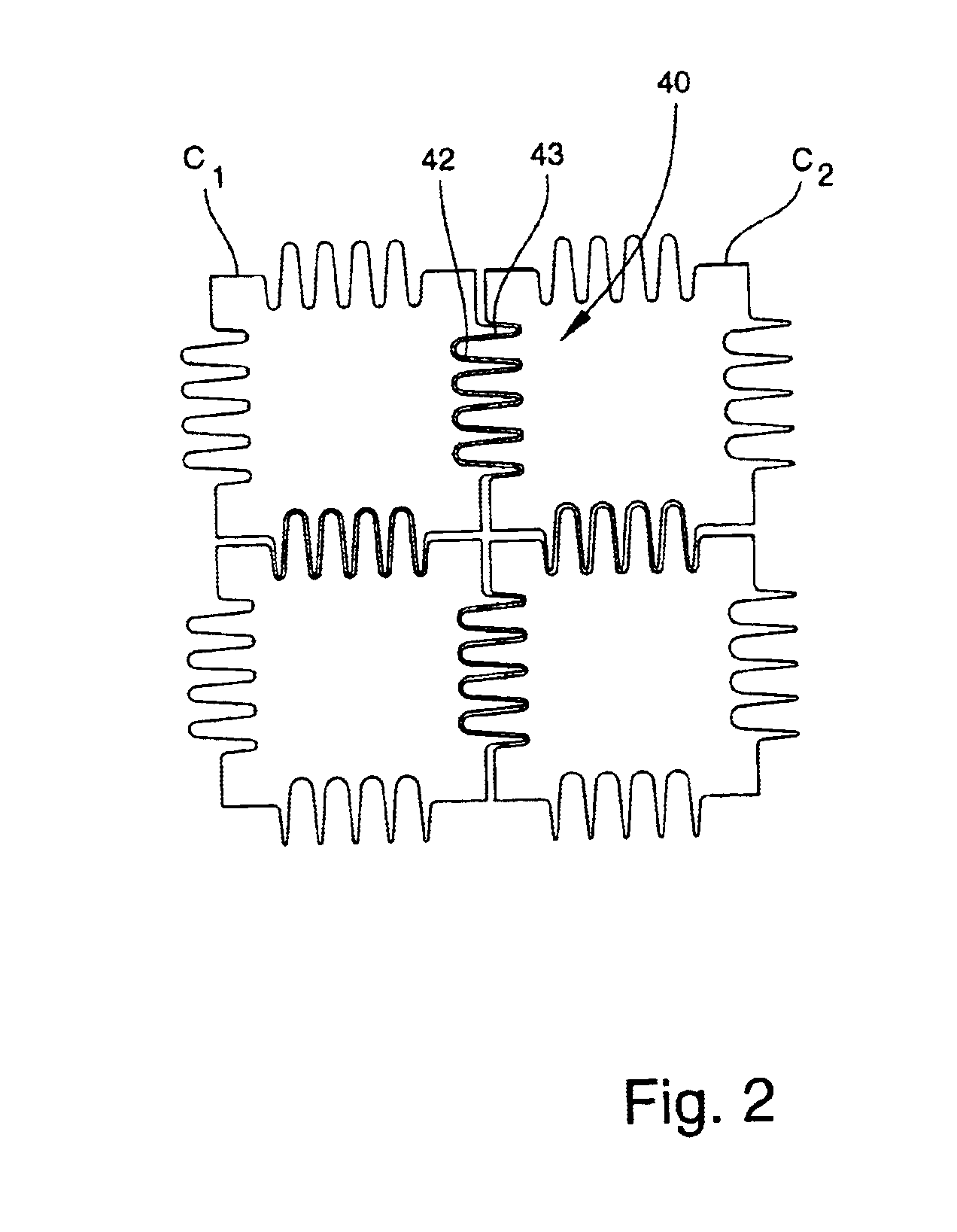

Apparatus for manipulating droplets by electrowetting-based techniques

InactiveUS6911132B2Improve controllabilityImprove accuracyBurnersElectrostatic separatorsElectricityControl manner

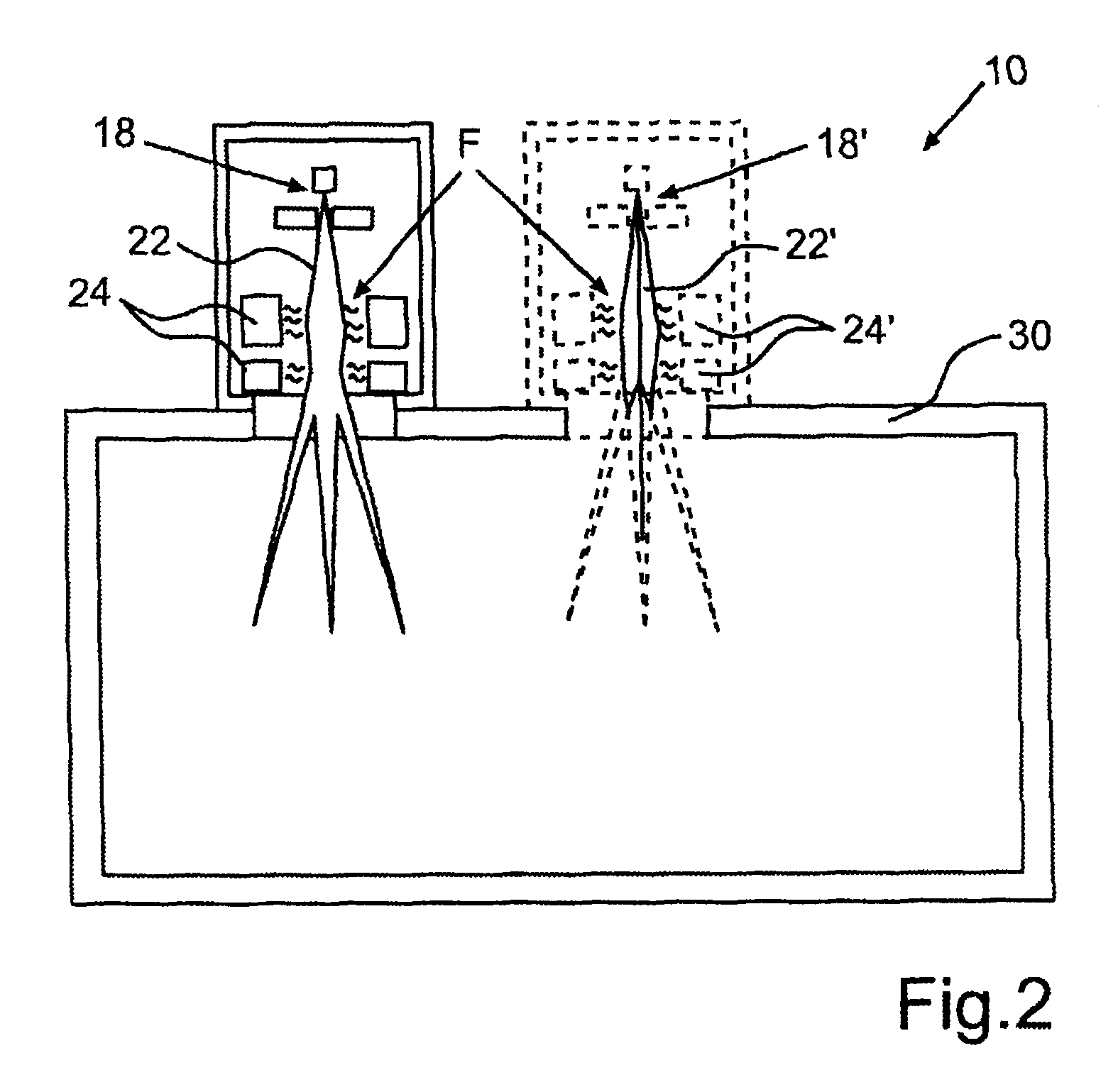

An apparatus is provided for manipulating droplets. The apparatus is a single-sided electrode design in which all conductive elements are contained on one surface on which droplets are manipulated. An additional surface can be provided parallel with the first surface for the purpose of containing the droplets to be manipulated. Droplets are manipulated by performing electrowetting-based techniques in which electrodes contained on or embedded in the first surface are sequentially energized and de-energized in a controlled manner. The apparatus enables a number of droplet manipulation processes, including merging and mixing two droplets together, splitting a droplet into two or more droplets, sampling a continuous liquid flow by forming from the flow individually controllable droplets, and iterative binary or digital mixing of droplets to obtain a desired mixing ratio.

Owner:DUKE UNIV

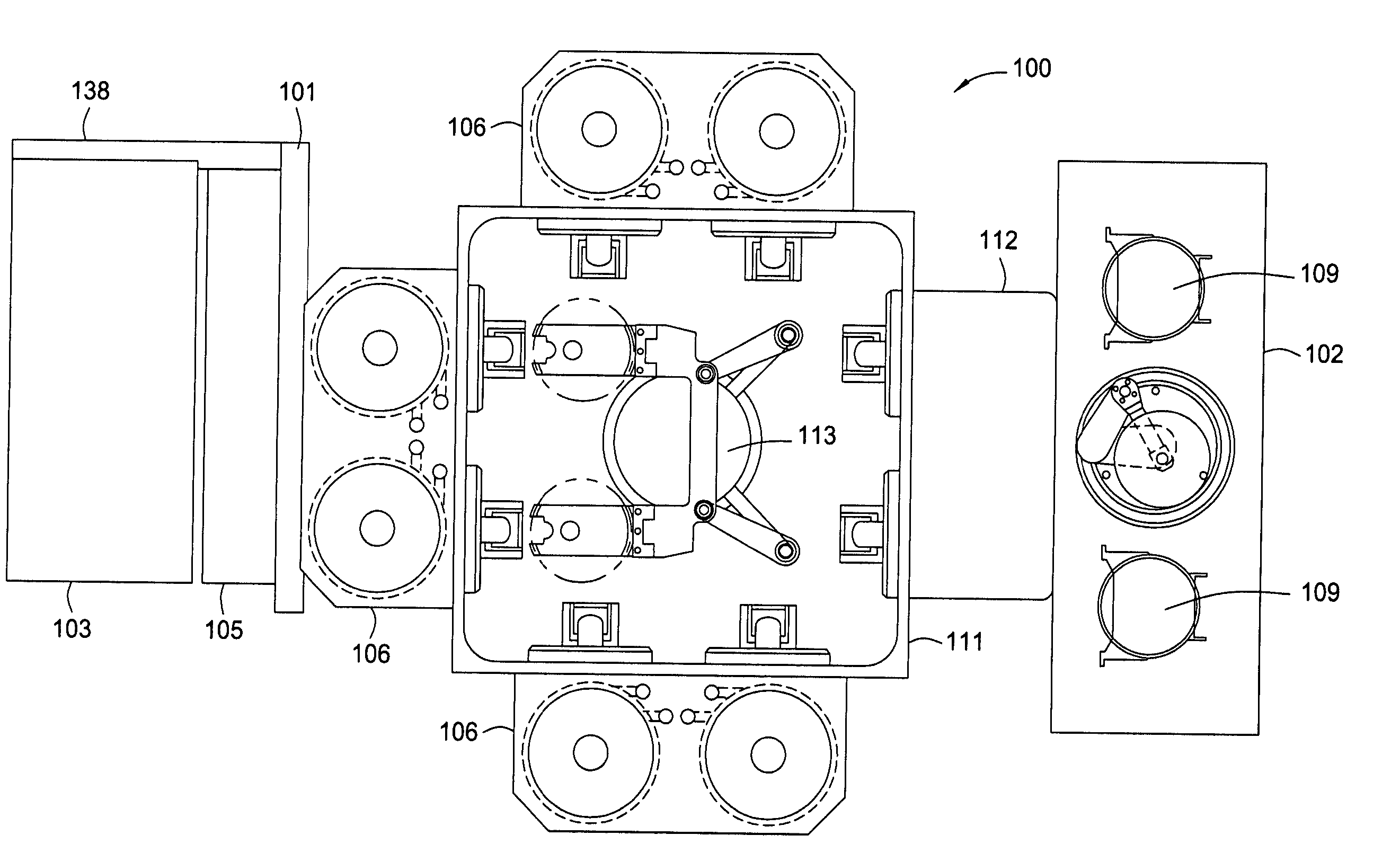

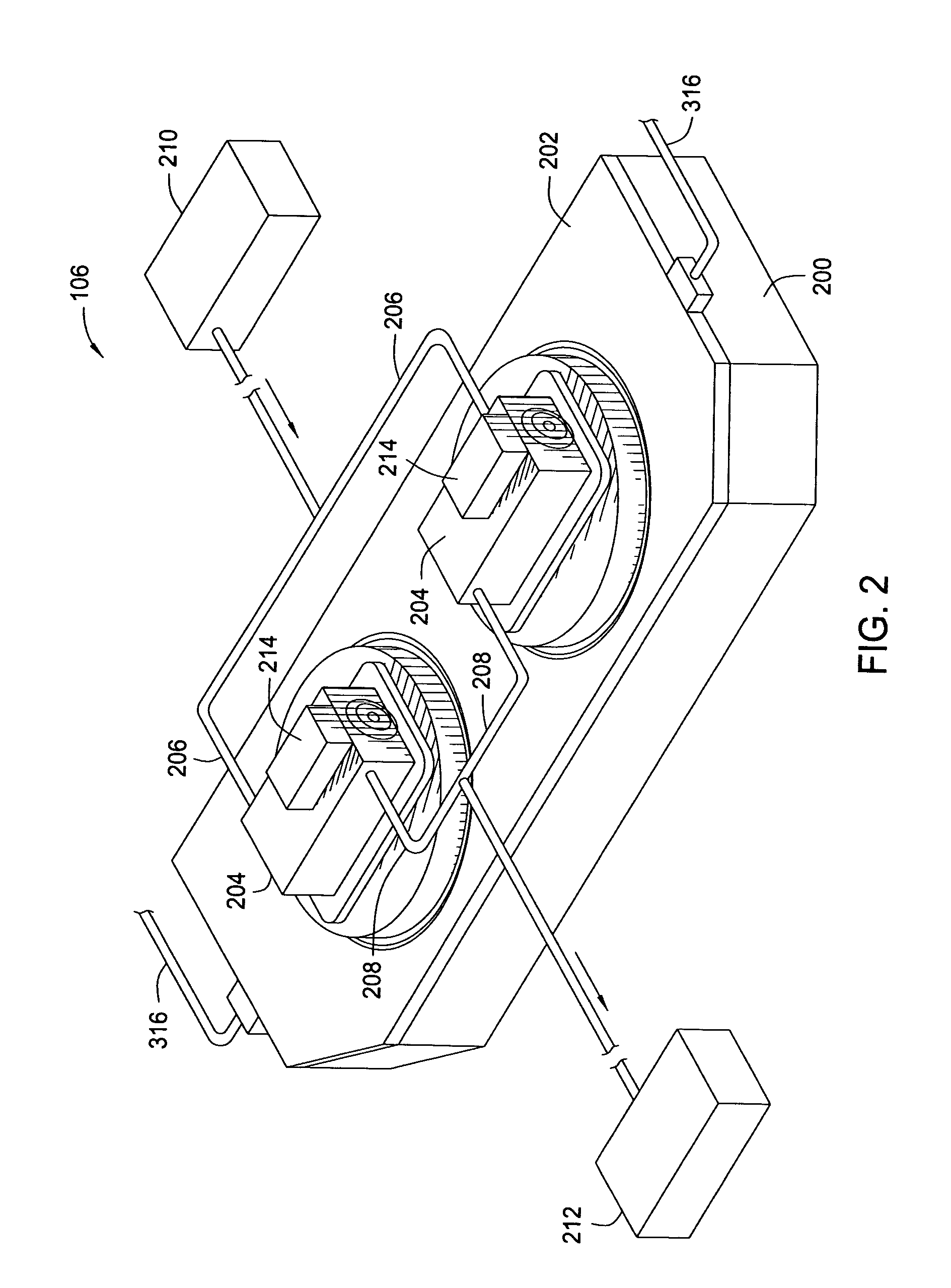

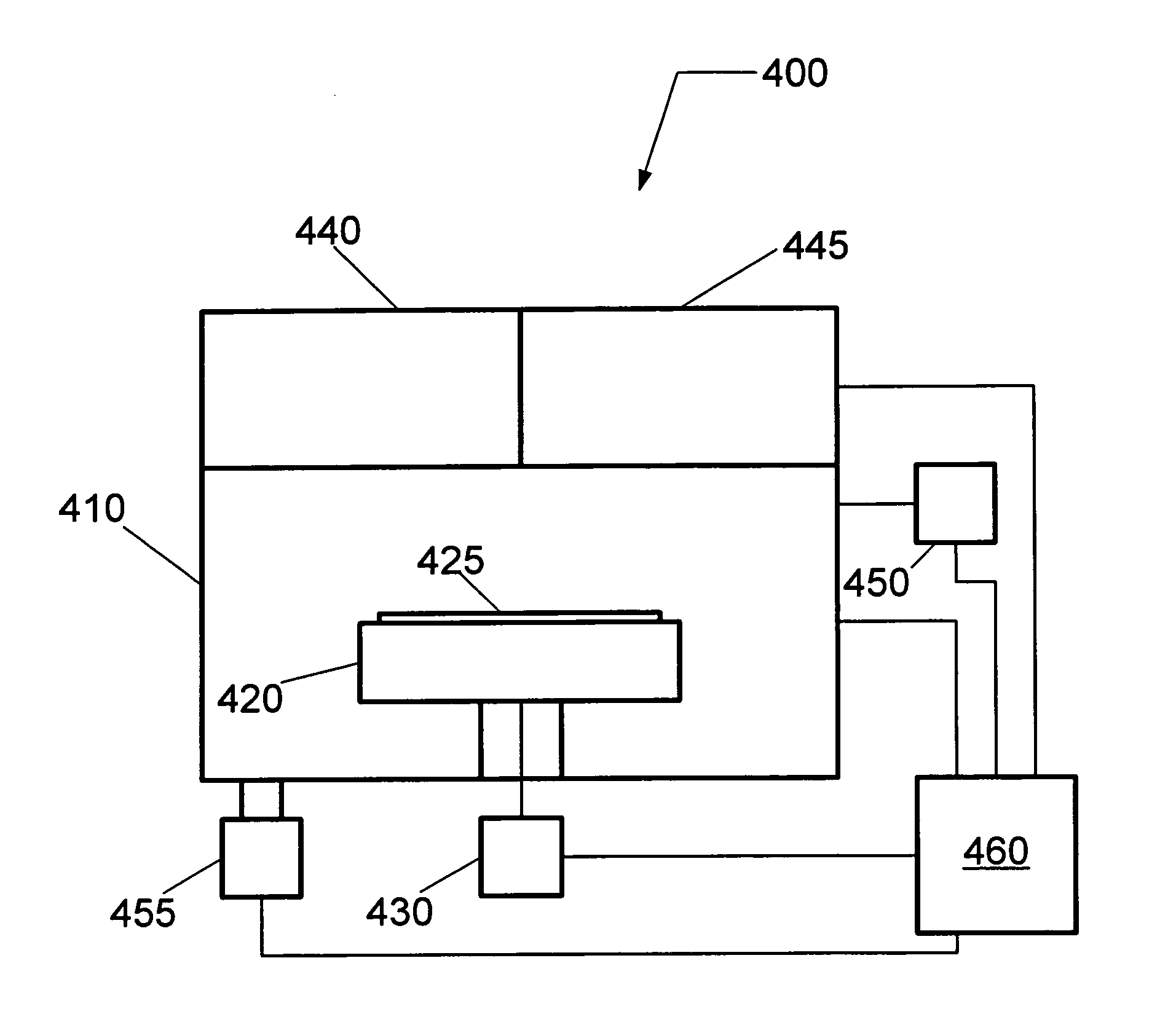

Tandem UV chamber for curing dielectric materials

InactiveUS20060251827A1Improve uniformityDrying solid materials with heatSemiconductor/solid-state device manufacturingUltravioletProcess region

An ultraviolet (UV) cure chamber enables curing a dielectric material disposed on a substrate and in situ cleaning thereof. A tandem process chamber provides two separate and adjacent process regions defined by a body covered with a lid having windows aligned respectively above each process region. One or more UV bulbs per process region that are covered by housings coupled to the lid emit UV light directed through the windows onto substrates located within the process regions. The UV bulbs can be an array of light emitting diodes or bulbs utilizing a source such as microwave or radio frequency. The UV light can be pulsed during a cure process. Using oxygen radical / ozone generated remotely and / or in-situ accomplishes cleaning of the chamber. Use of lamp arrays, relative motion of the substrate and lamp head, and real-time modification of lamp reflector shape and / or position can enhance uniformity of substrate illumination.

Owner:APPLIED MATERIALS INC

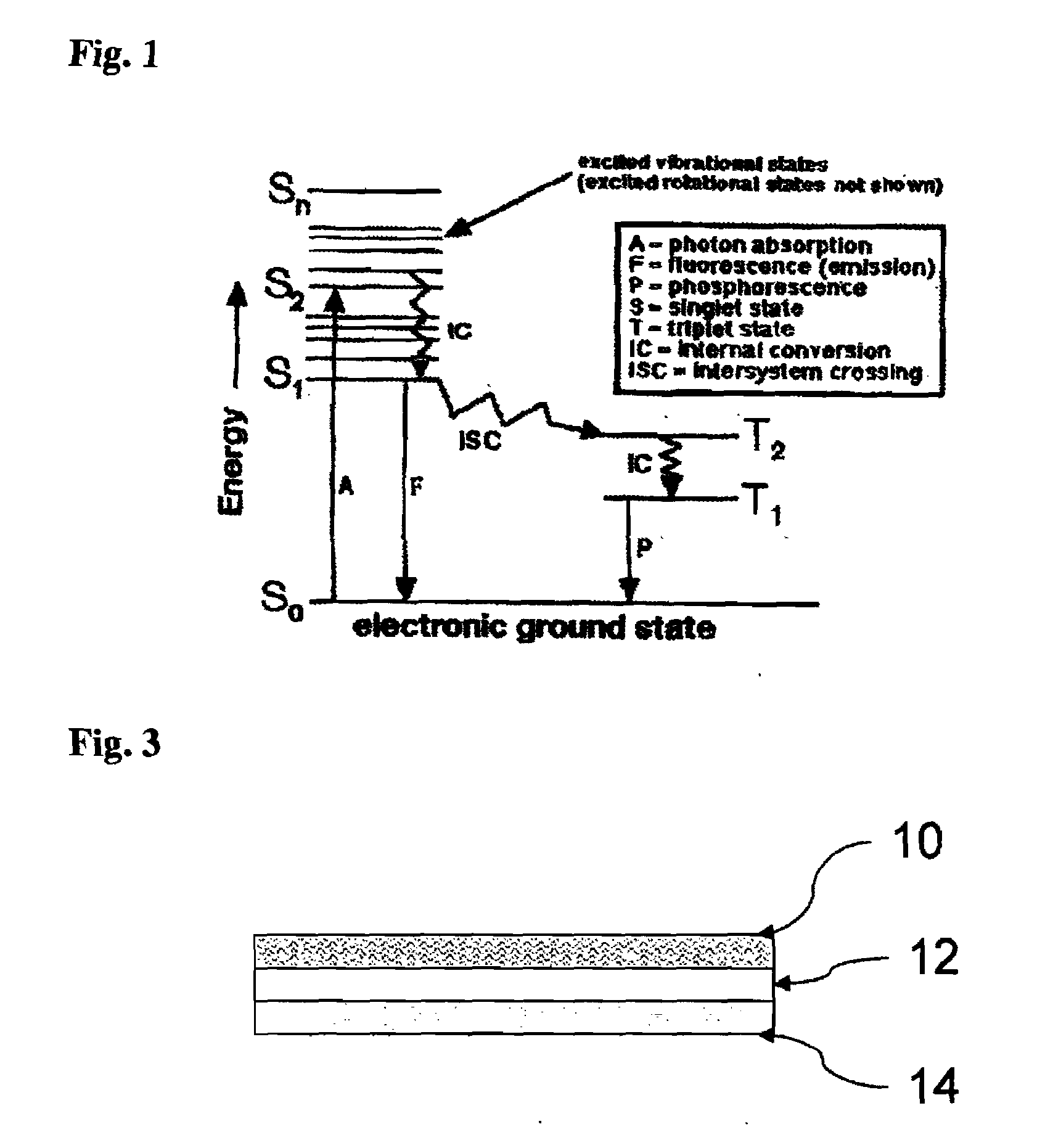

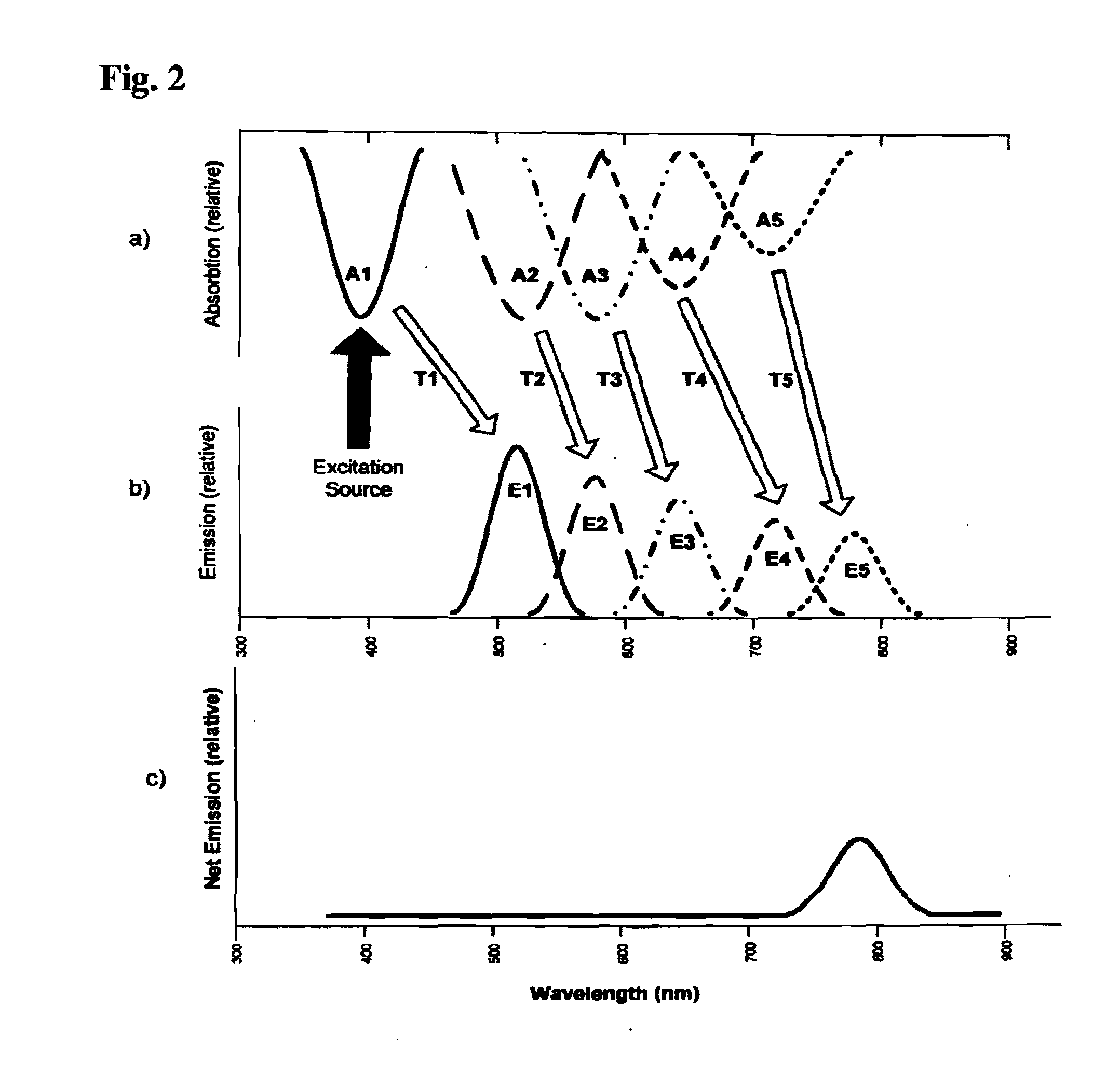

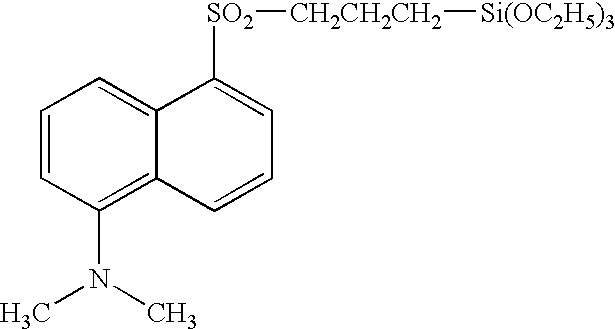

Photoluminescent Compositions, Methods of Manufacture and Novel Uses

InactiveUS20120183677A1High strengthImprove durabilityPhotometryBleaching apparatusPhotoluminescenceElectromagnetic radiation

Owner:PERFORMANCE INDICATOR LLC

Multi-step system and method for curing a dielectric film

ActiveUS7622378B2Pretreated surfacesSemiconductor/solid-state device manufacturingUltravioletMoisture

A multi-step system and method for curing a dielectric film in which the system includes a drying system configured to reduce the amount of contaminants, such as moisture, in the dielectric film. The system further includes a curing system coupled to the drying system, and configured to treat the dielectric film with ultraviolet (UV) radiation and infrared (IR) radiation in order to cure the dielectric film.

Owner:TOKYO ELECTRON LTD

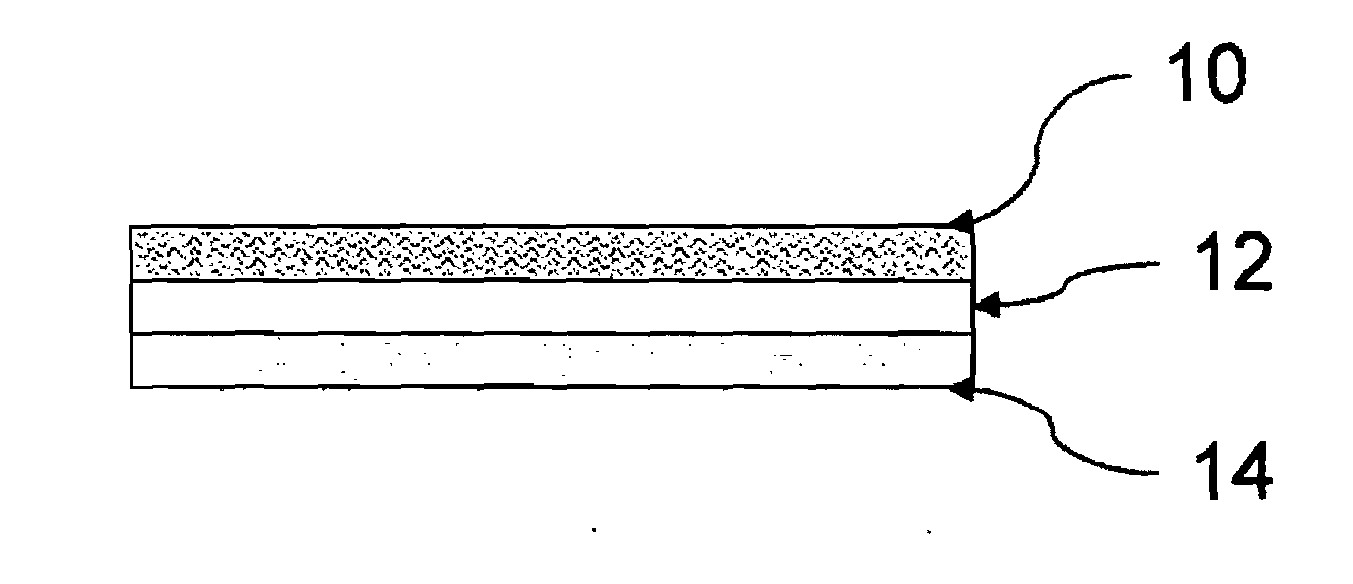

Color-shifting pigments and foils with luminescent coatings

InactiveUS6565770B1Improve thermal stabilityImprove mechanical stabilityMaterial nanotechnologyLiquid surface applicatorsLiquid mediumColor shift

Interference pigment flakes and foils are provided which have luminescent and color-shifting properties. A luminescent material coating structure is provided which partially covers or encapsulates a color-shifting pigment flake, or covers the outer surface of a foil. The pigment flakes can have a symmetrical coating structure on opposing sides of a core layer, can have an asymmetrical coating structure with all of the layers on one side of the core layer, or can be formed with encapsulating coatings around the core layer. The coating structure of the flakes and foils includes a core layer, a dielectric layer overlying the core layer, and an absorber layer overlying the dielectric layer. The luminescent pigment flakes and foils exhibit a discrete color shift so as to have a first color at a first angle of incident light or viewing and a second color different from the first color at a second angle of incident light or viewing. The luminescent pigment flakes can be interspersed into liquid media such as paints or inks to produce colorant materials for subsequent application to objects or papers. The luminescent foils can be laminated to various objects or can be formed on a carrier substrate.

Owner:VIAVI SOLUTIONS INC

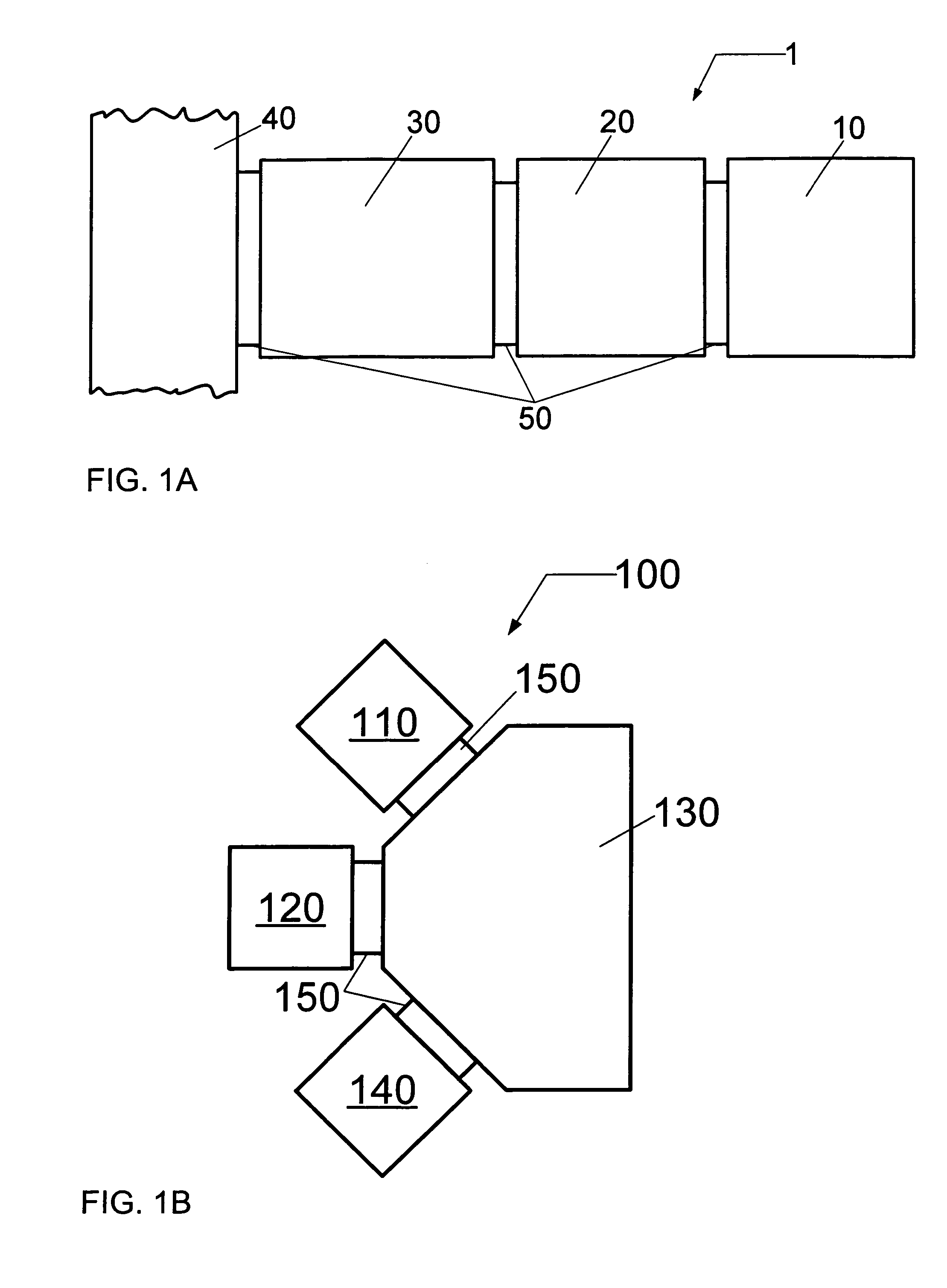

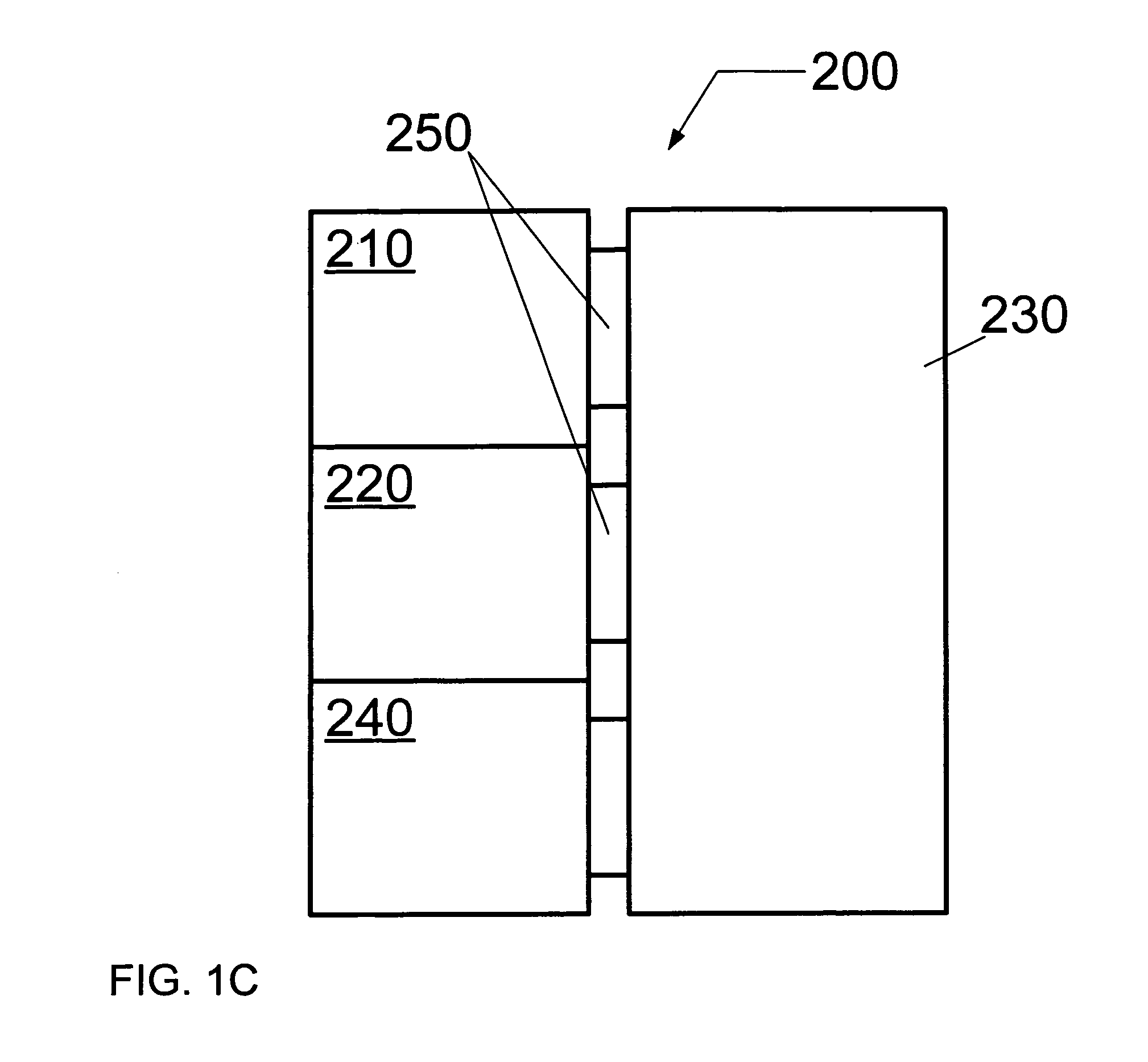

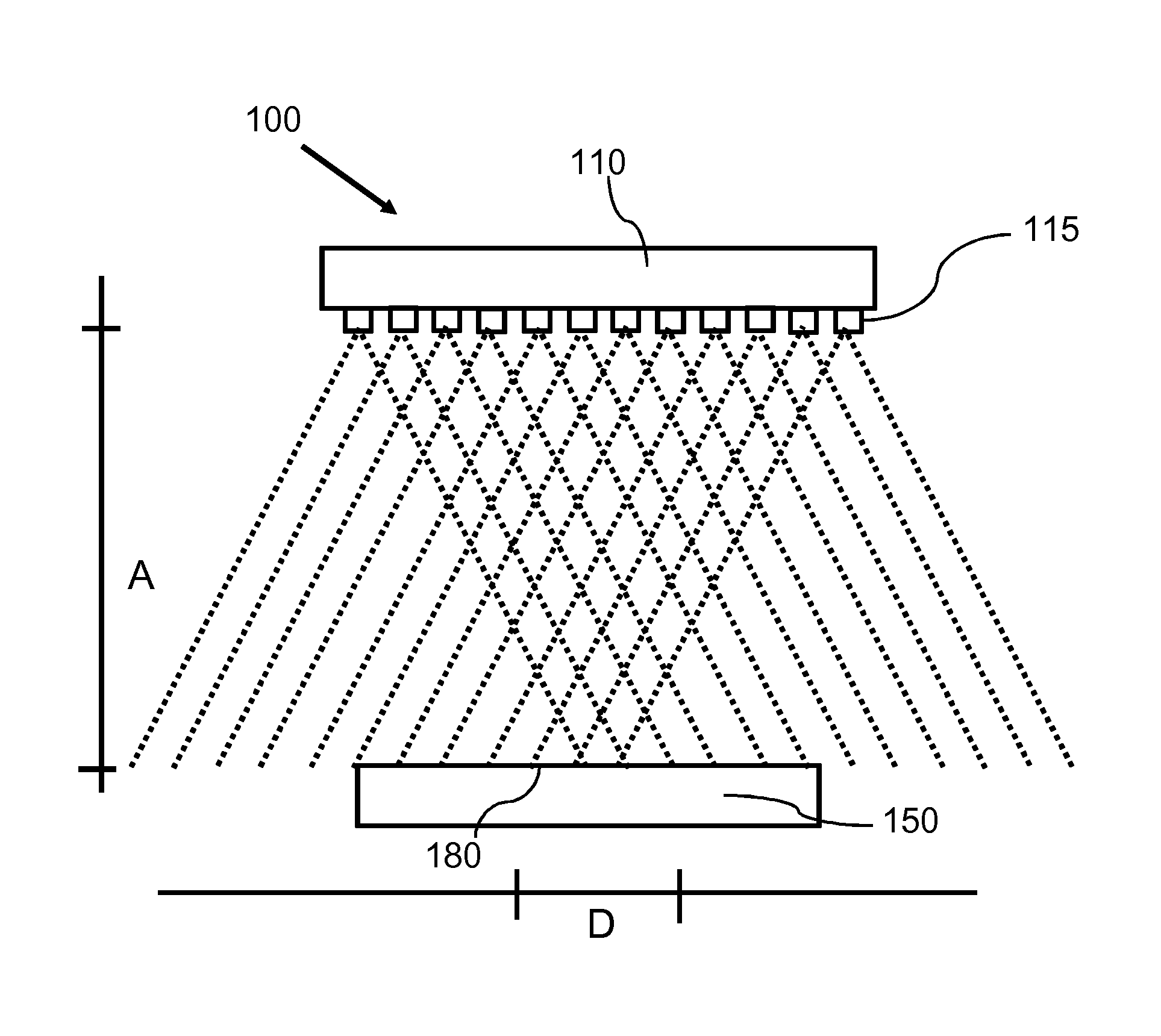

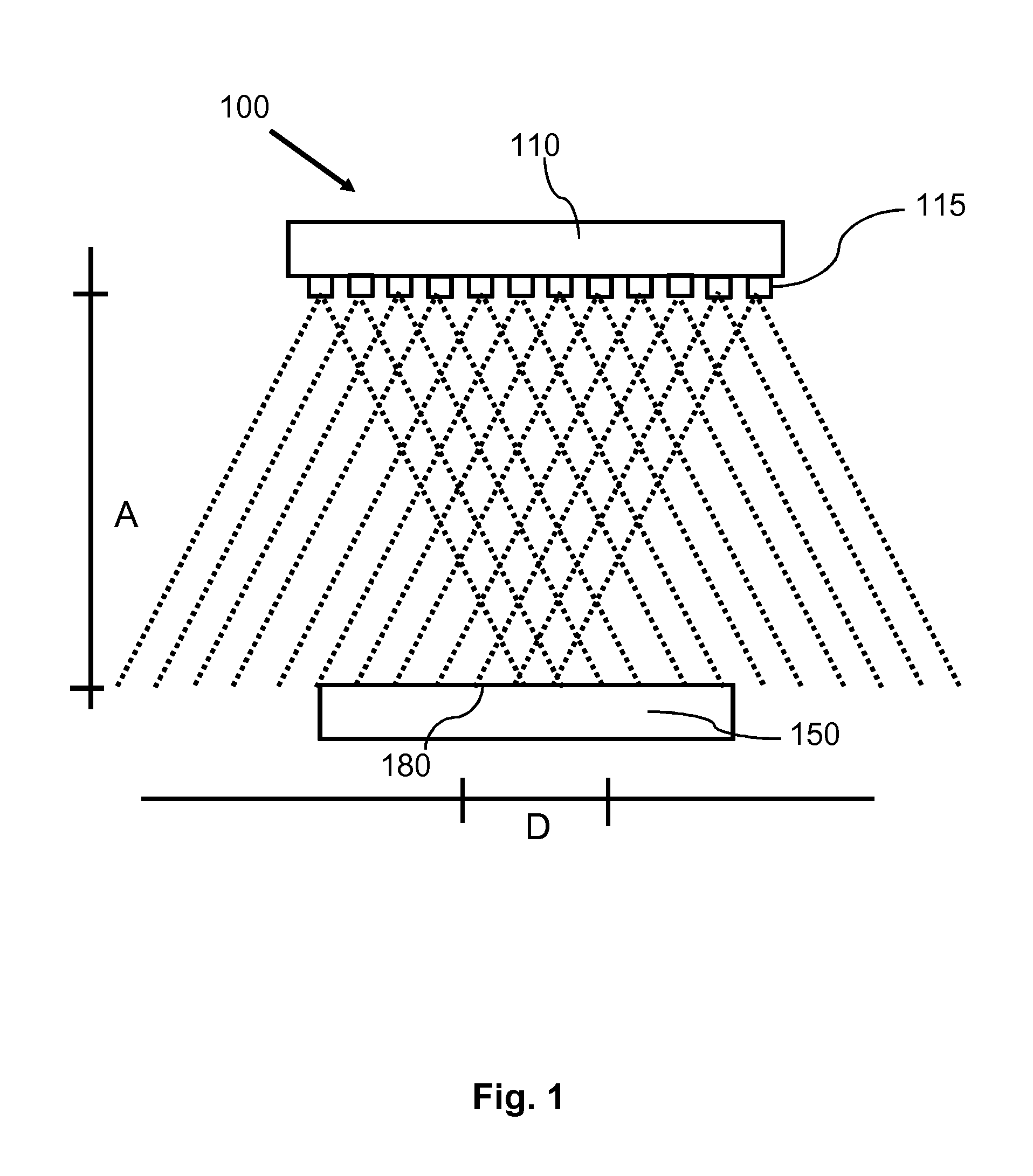

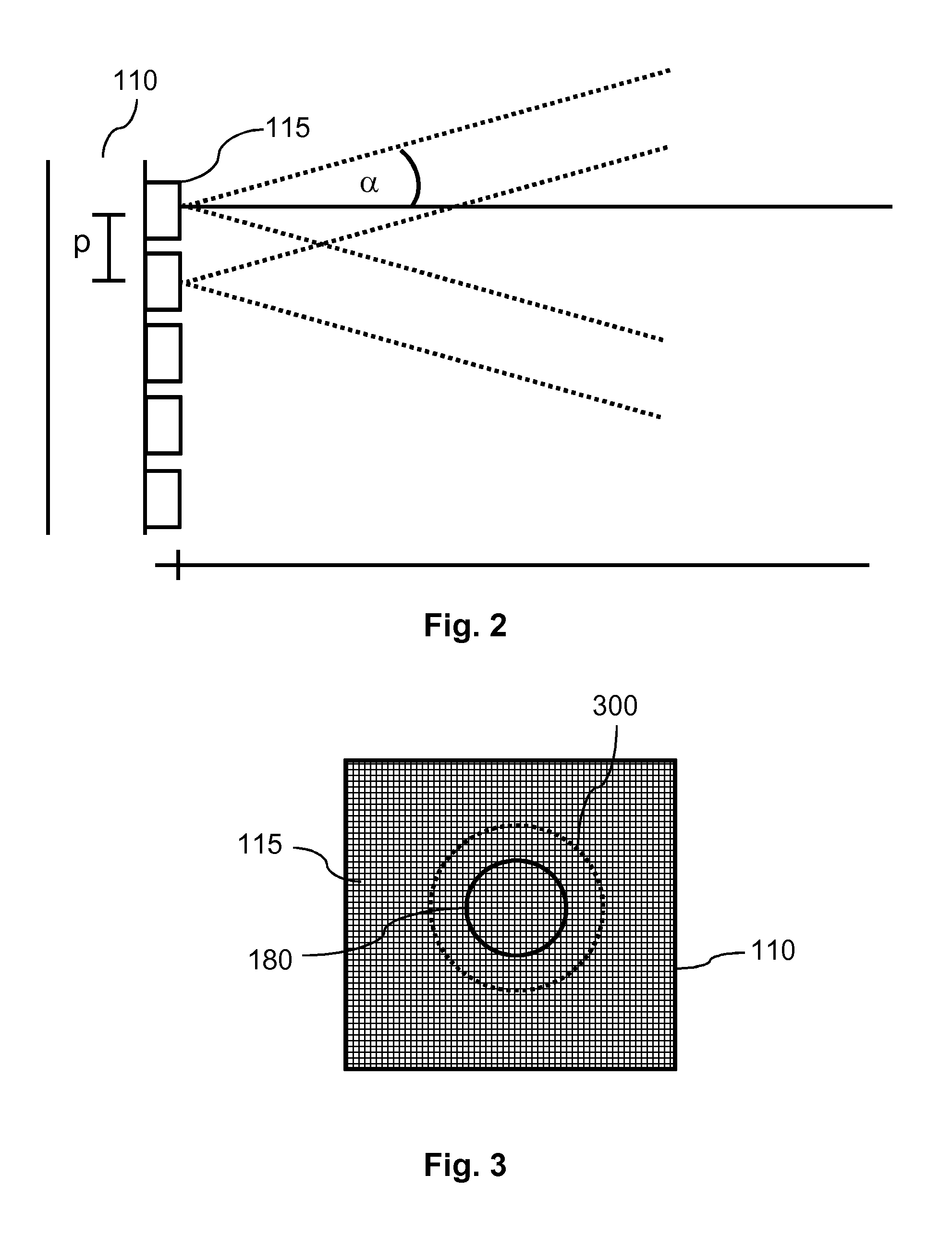

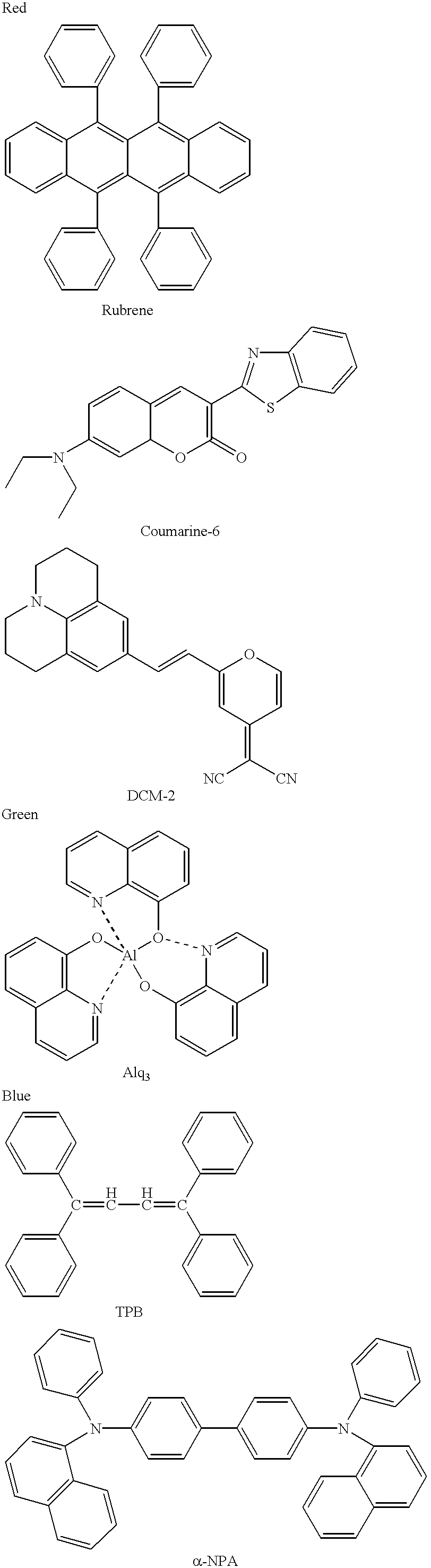

Heating system comprising semiconductor light sources

ActiveUS20160381732A1Improve homogeneityHeating system be improvedSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

The invention describes a heating system (100) and a corresponding method of heating a heating surface (180) of an object (150, 950) to a processing temperature of at least 100° C., wherein the heating system (100) comprises semiconductor light sources (115), and wherein the heating system (100) is adapted to heat an area element of the heating surface (180) with at least 50 semiconductor light sources (115) at the same time. The heating system (100) may be part of a reactor for processing semiconductor structures. The light emitted by means of the semiconductor light sources (115) overlaps at the heating surface (180). Differences of the characteristic of one single semiconductor light source (115) may be blurred at the heating surface (180) such that a homogeneous temperature distribution across a processing surface of a, for example, wafer may be enabled.

Owner:TRUMPF PHOTONIC COMPONENTS GMBH

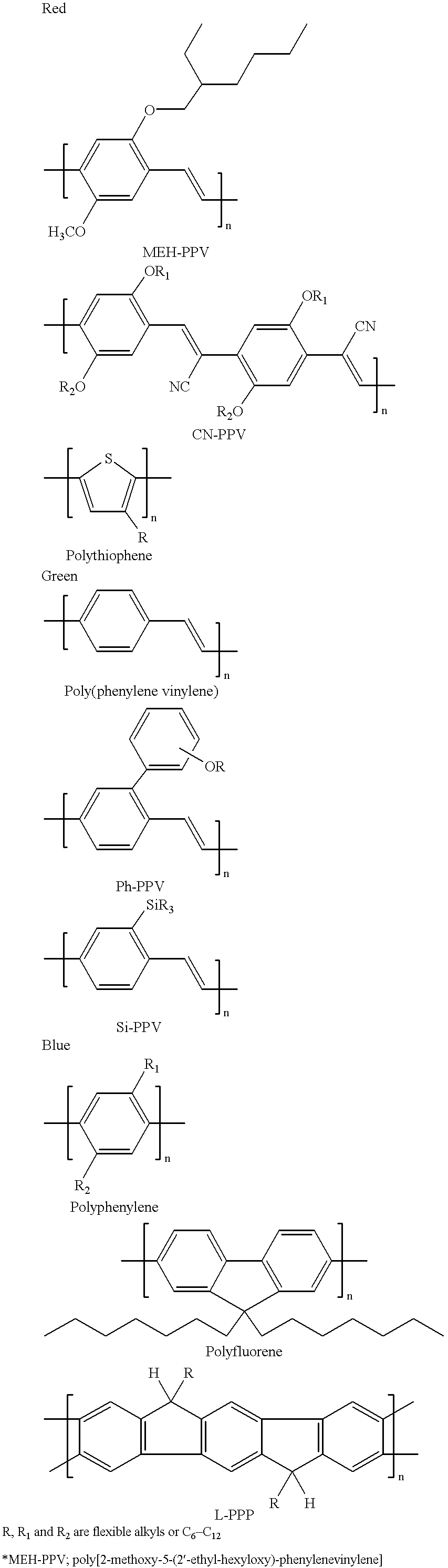

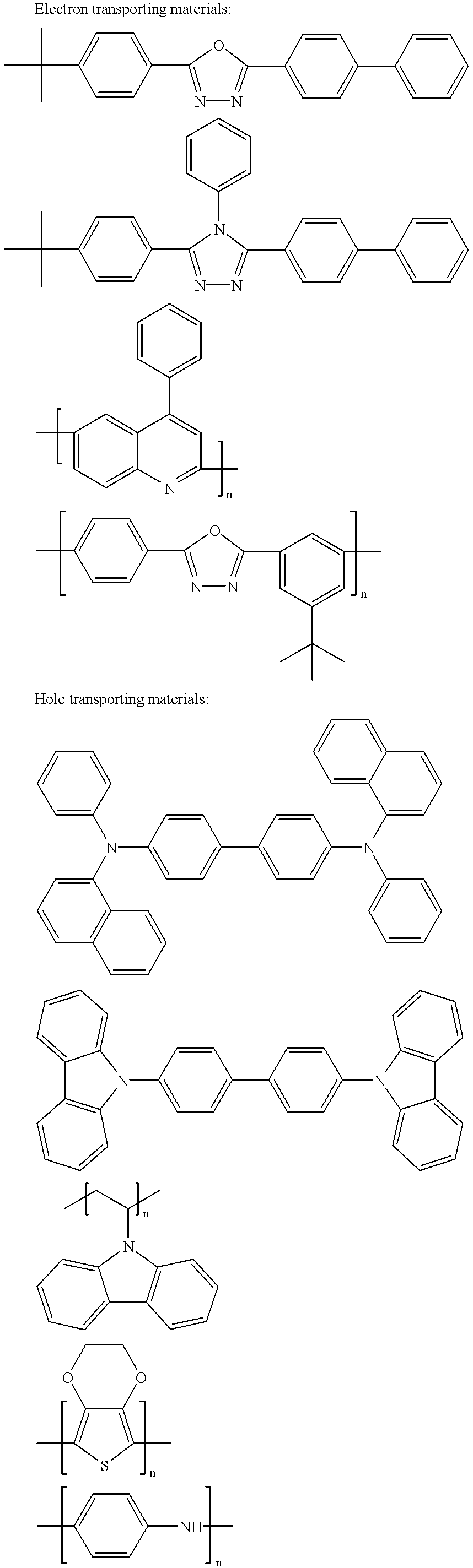

Luminescent ink for printing of organic luminescent devices

InactiveUS6372154B1Improve efficiencyEasy transitionSolid-state devicesSemiconductor/solid-state device manufacturingSolventOrganic compound

Organic luminescent ink (L-ink) is disclosed for use in printing thin films of organic luminescent material. The L-ink is particularly useful in fabricating organic optoelectronic devices, e.g. organic luminescent devices. The L-ink contains at least one organic luminescent material mixed with a solvent and other functional additives to provide the necessary optical, electronic and morphological properties for light-emitting devices (LEDs). The additives play an important role either for enhanced thin film printing or for better performance of the optoelectronic device. The functional additives may be chemically bound to the luminescent compounds or polymers. Luminescent organic compounds, oligomers, or polymers with relatively low solution viscosity, good thin film formability, and good charge transporting properties, are preferred. The L-inks can be cross-linked under certain conditions to enhance thin film properties. The L-ink can be used in various printing methods, such as screen printing, stamp printing, and preferably ink-jet printing (including bubble-jet printing).

Owner:CANON KK

Luminescent pigments and foils with color-shifting properties

InactiveUS6572784B1Improve thermal stabilityImprove mechanical stabilityMaterial nanotechnologyLiquid surface applicatorsLiquid mediumColor shift

Interference pigment flakes and foils are provided which have luminescent and color-shifting properties. The pigment flakes can have a symmetrical coating structure on opposing sides of a core layer, can have an asymmetrical coating structure with all of the layers on one side of the core layer, or can be formed with encapsulating coatings around the core layer. The coating structure of the flakes and foils includes a core layer, a dielectric layer overlying the core layer, and an absorber layer overlying the dielectric layer. A luminescent material is incorporated into the flakes or foils as a separate layer or as at least part of one or more of the other layers. The pigment flakes and foils exhibit a discrete color shift so as to have a first color at a first angle of incident light or viewing and a second color different from the first color at a second angle of incident light or viewing. The pigment flakes can be interspersed into liquid media such as paints or inks to produce colorant materials for subsequent application to objects or papers. The foils can be laminated to various objects or can be formed on a carrier substrate.

Owner:VIAVI SOLUTIONS INC

Gas distribution showerhead for semiconductor processing

ActiveUS6983892B2Easy to disassembleAvoid ignitionSelf-acting watering devicesSpray nozzlesGas passingEngineering

Owner:APPLIED MATERIALS INC

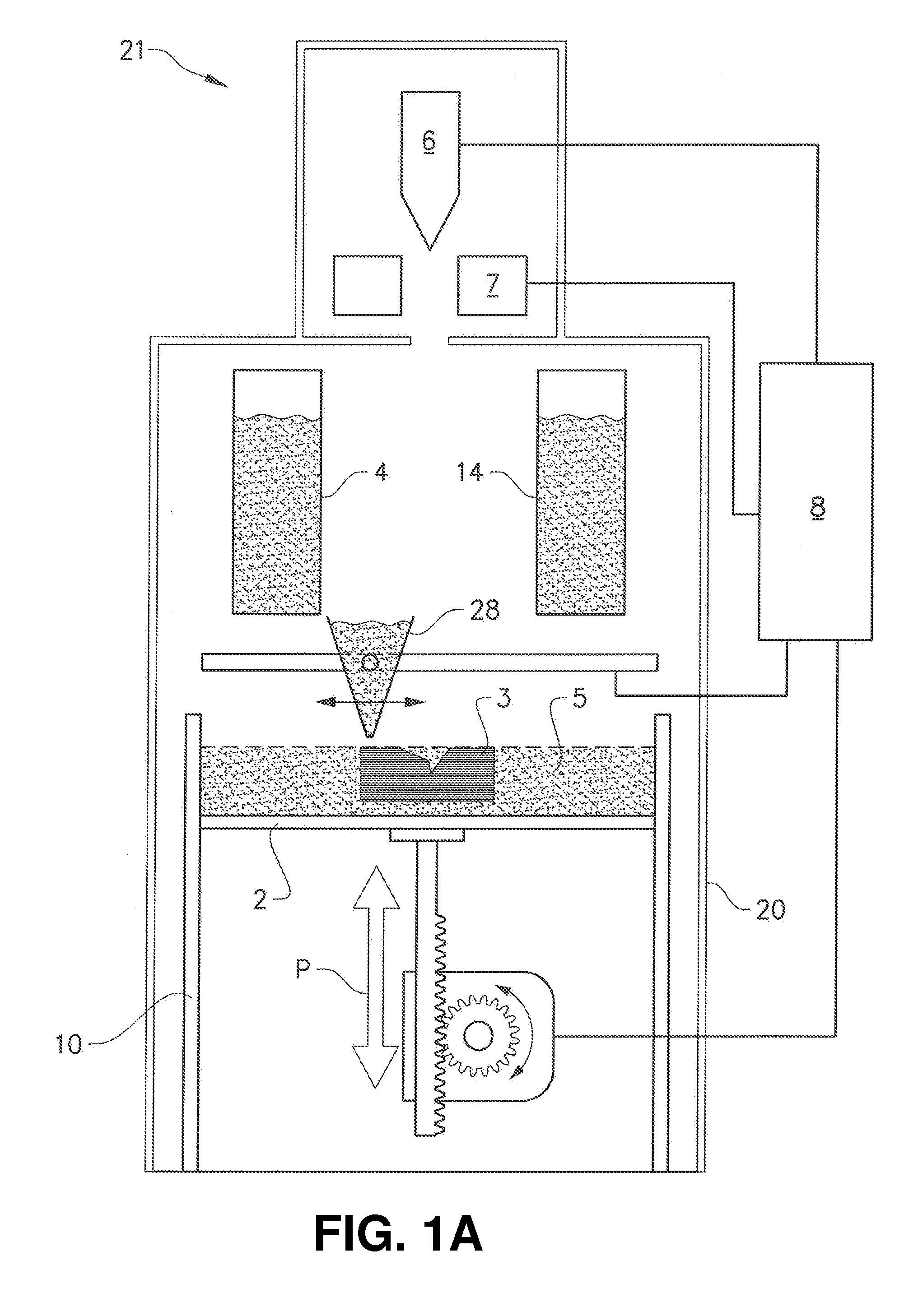

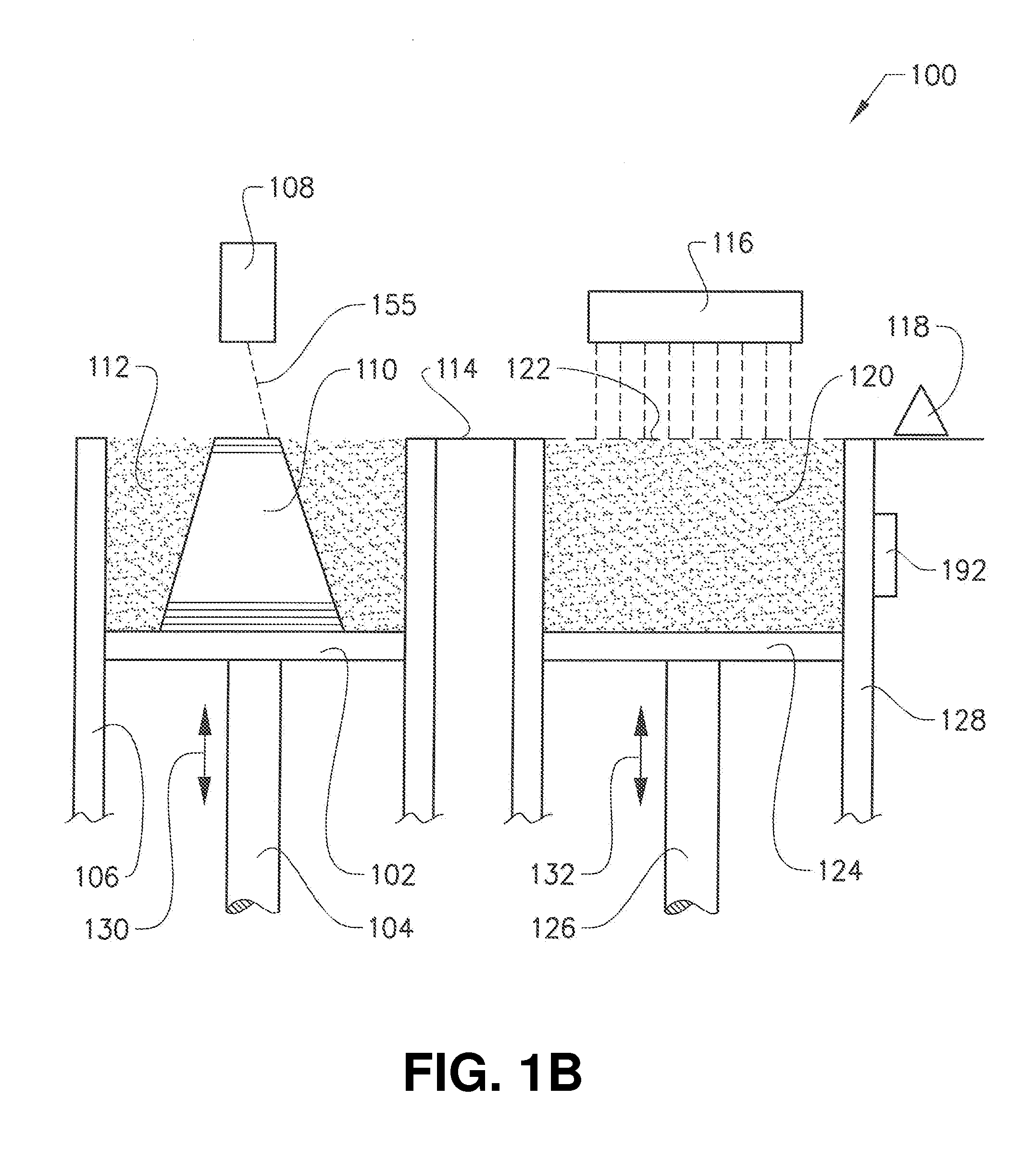

Method and apparatus for additive manufacturing

ActiveUS20140314964A1Improve conductivityReduce probabilityVacuum evaporation coatingPretreated surfacesMetallurgyElectron

Various embodiments provide a method and apparatus for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table in an additive manufacturing machine, which parts corresponds to successive cross sections of the three-dimensional article. The method comprises the steps of: applying a layer of predetermined thickness of powder particles on the work table, applying a coating on at least a portion of the powder particles, which coating is at least partially covering the powder particles, and fusing the powder particles on the work table with an electron beam.

Owner:ARCAM AB

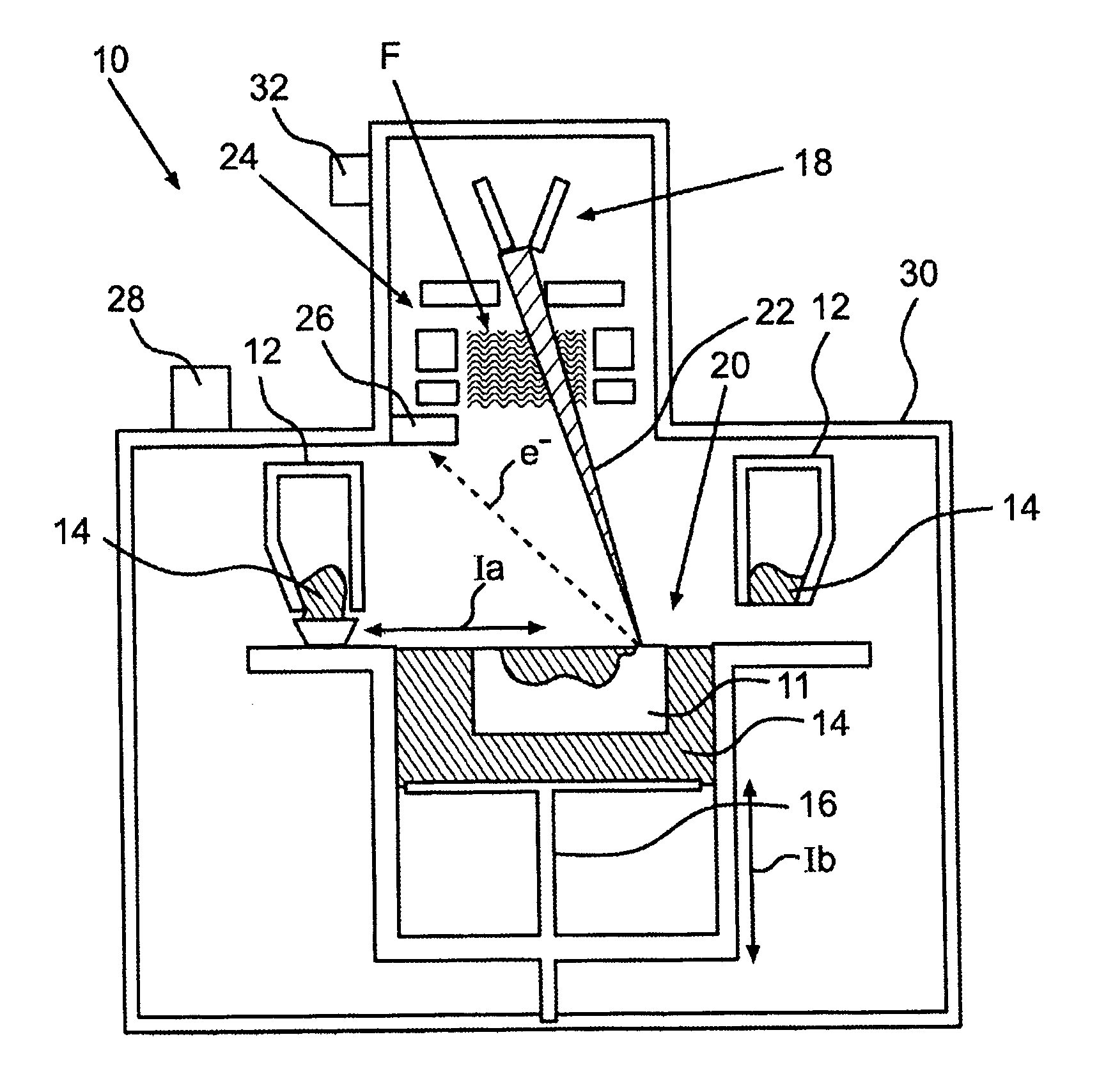

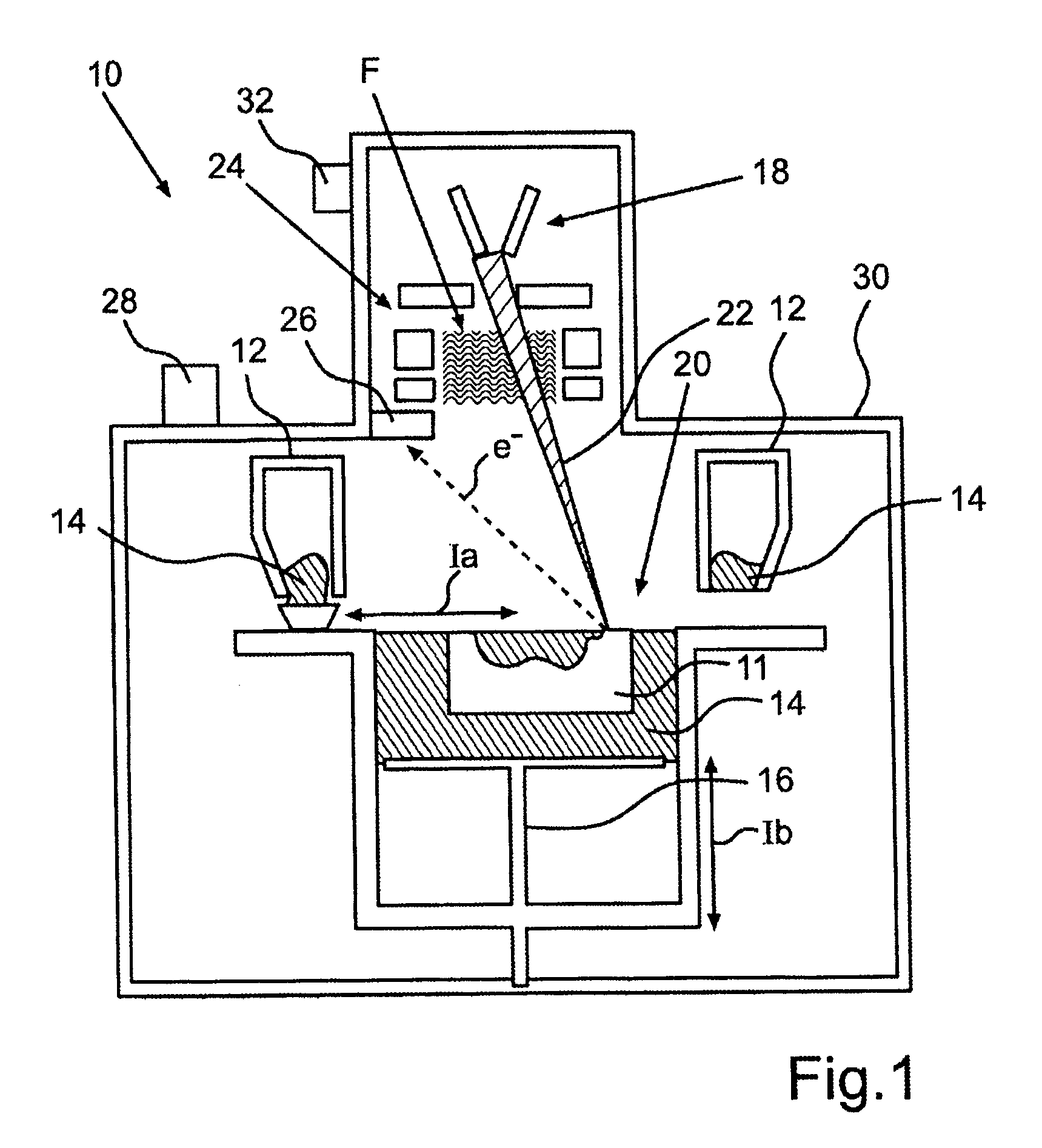

Method and device for producing a component

InactiveUS20130055568A1High build rateSpeed up preparationTurbinesAdditive manufacturing apparatusMetallurgyLayer thickness

A method for manufacturing a component, in particular a component of a turbine or a compressor, in which at least these steps are carried out: application in layers of at least one powdered component material to a component platform in the area of a buildup and joining zone; melting and / or sintering locally in layers of the component material by supplying energy with the aid of at least one electron beam in the area of the buildup and joining zone; lowering of the component platform in layers by a predefined layer thickness; and repeating steps a) through c) until completion of the component. During the manufacturing, electrons emitted due to the interaction of the electron beam with the component material are detected, after which material information, characterizing the topography of the melted and / or sintered component material, is ascertained on the basis of the emitted electrons. Alternatively or additionally, the component material is melted and / or sintered by at least two, preferably at least four electron beams.

Owner:GLOBAL BEAM TECH +1

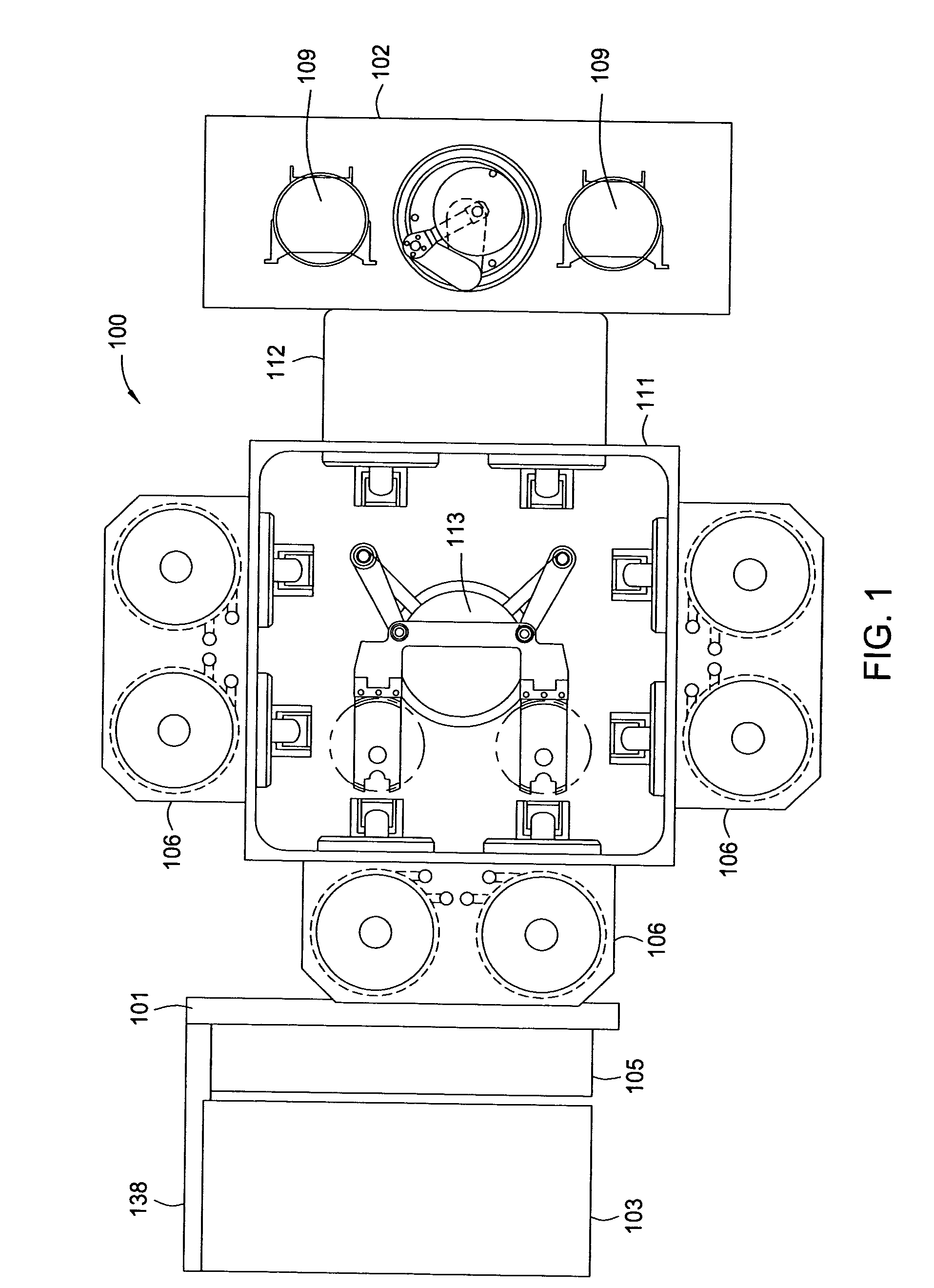

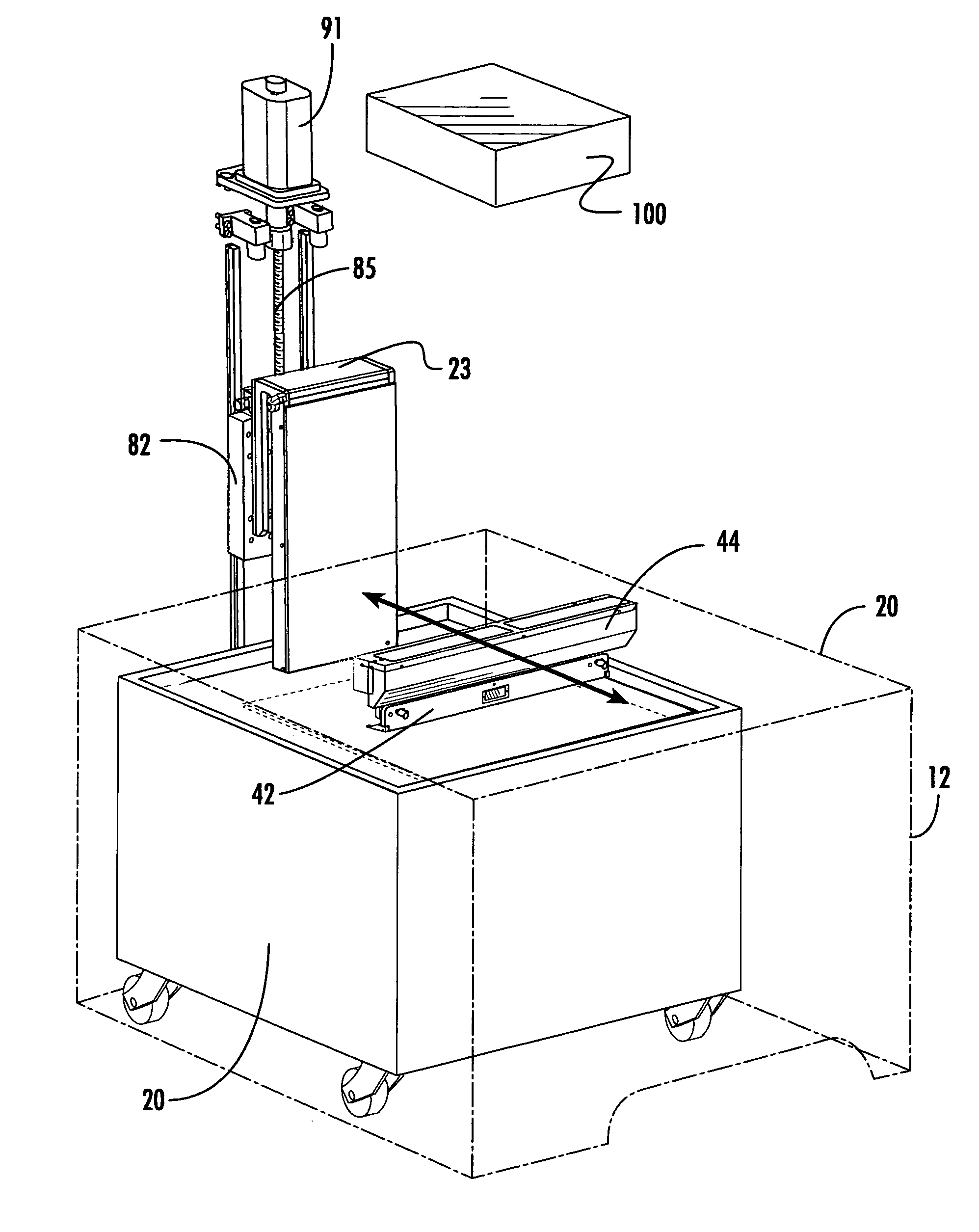

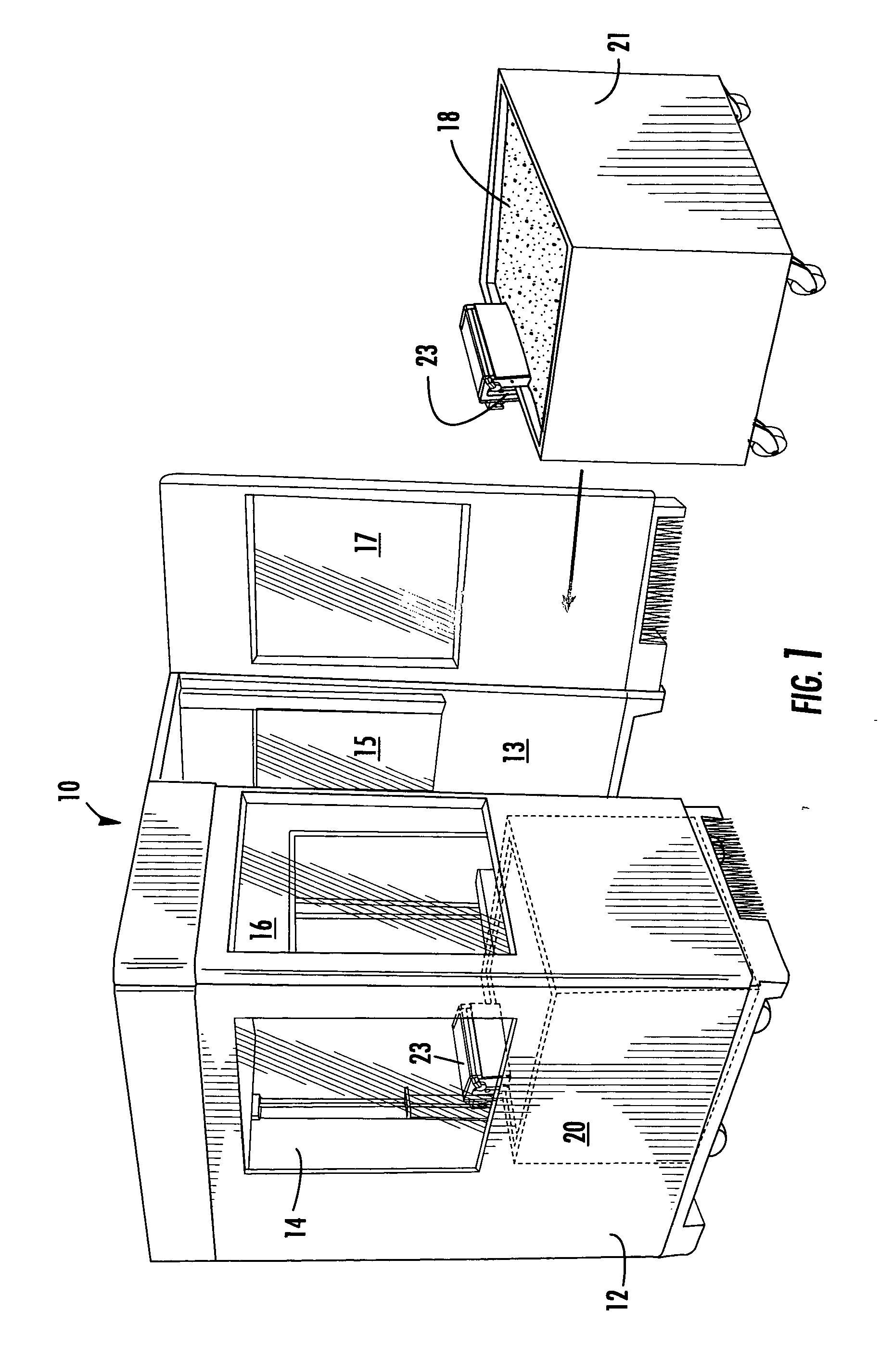

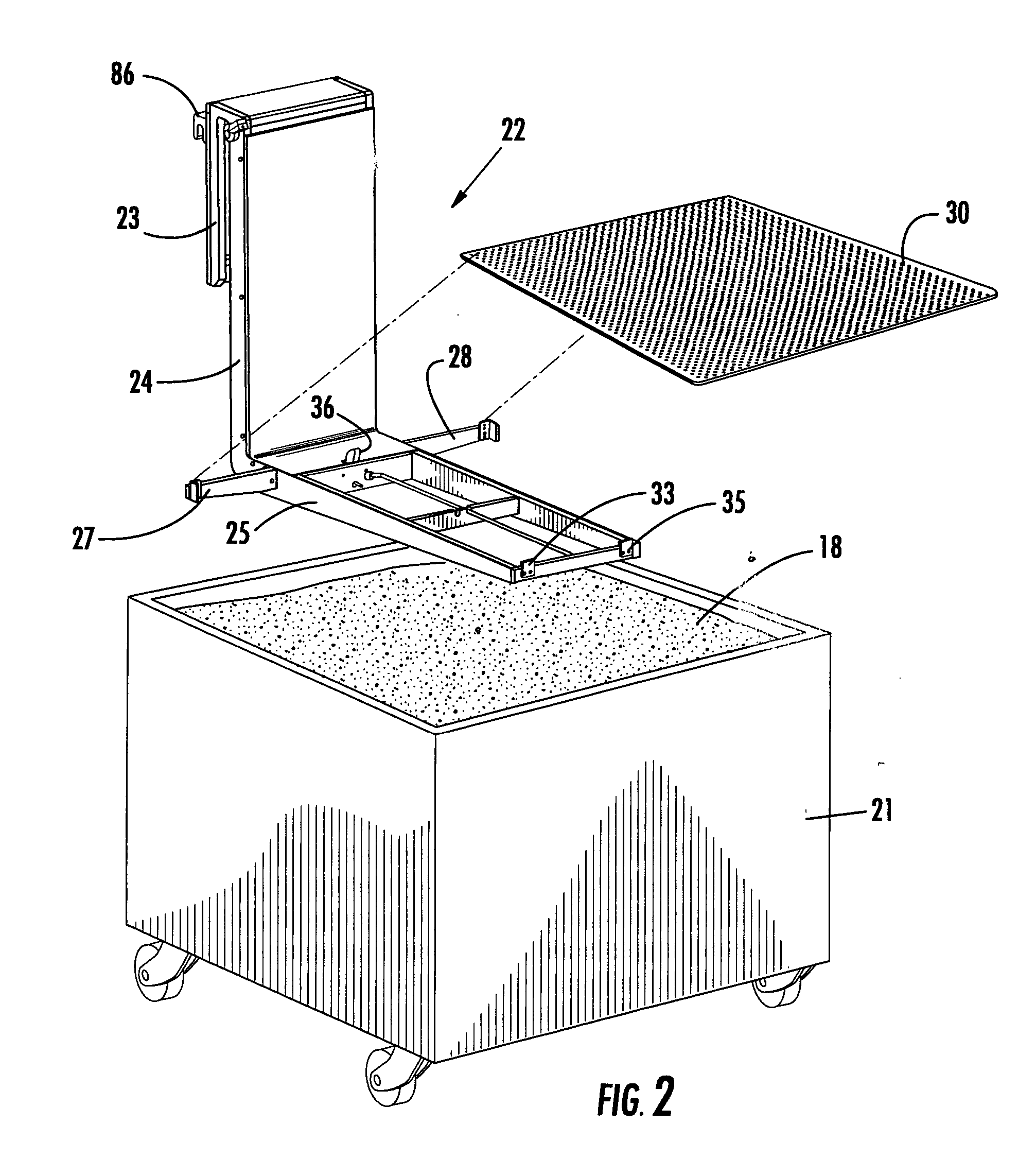

Rapid prototyping and manufacturing system and method

ActiveUS20070074659A1Simplify obtaining precisionFast preparationConfectioneryPretreated surfacesEngineeringRapid prototyping

A stereolithography apparatus having a resin vat with resupply containers in one-way flow communication and a leveling container in two-way flow communication, an automatic offload cart to remove and replace build support platforms, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater assembly and recoater blade for mapping the resin surface in the vat and applying a fresh coating of resin to a cross-section being built in the vat.

Owner:3D SYST INC

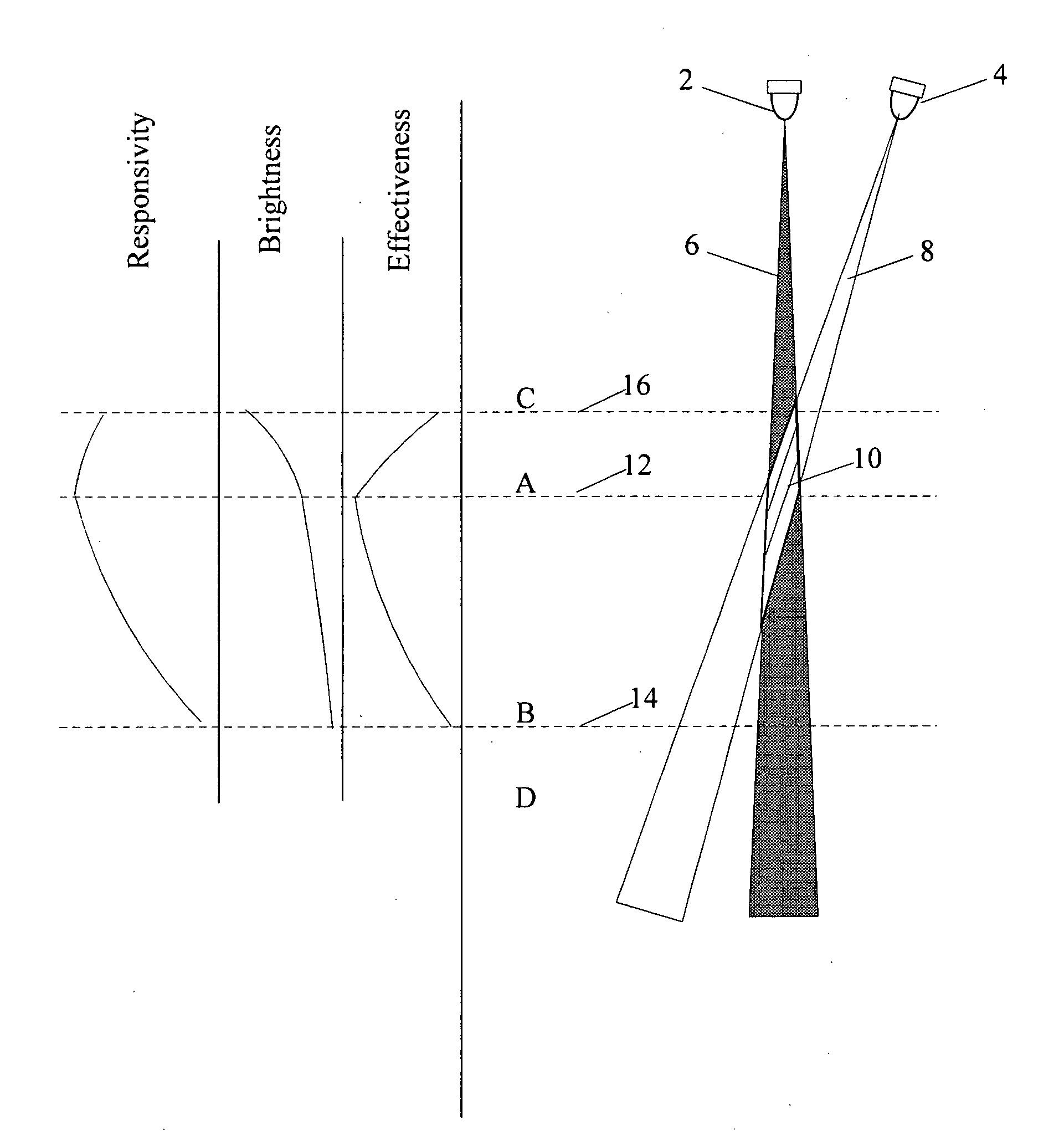

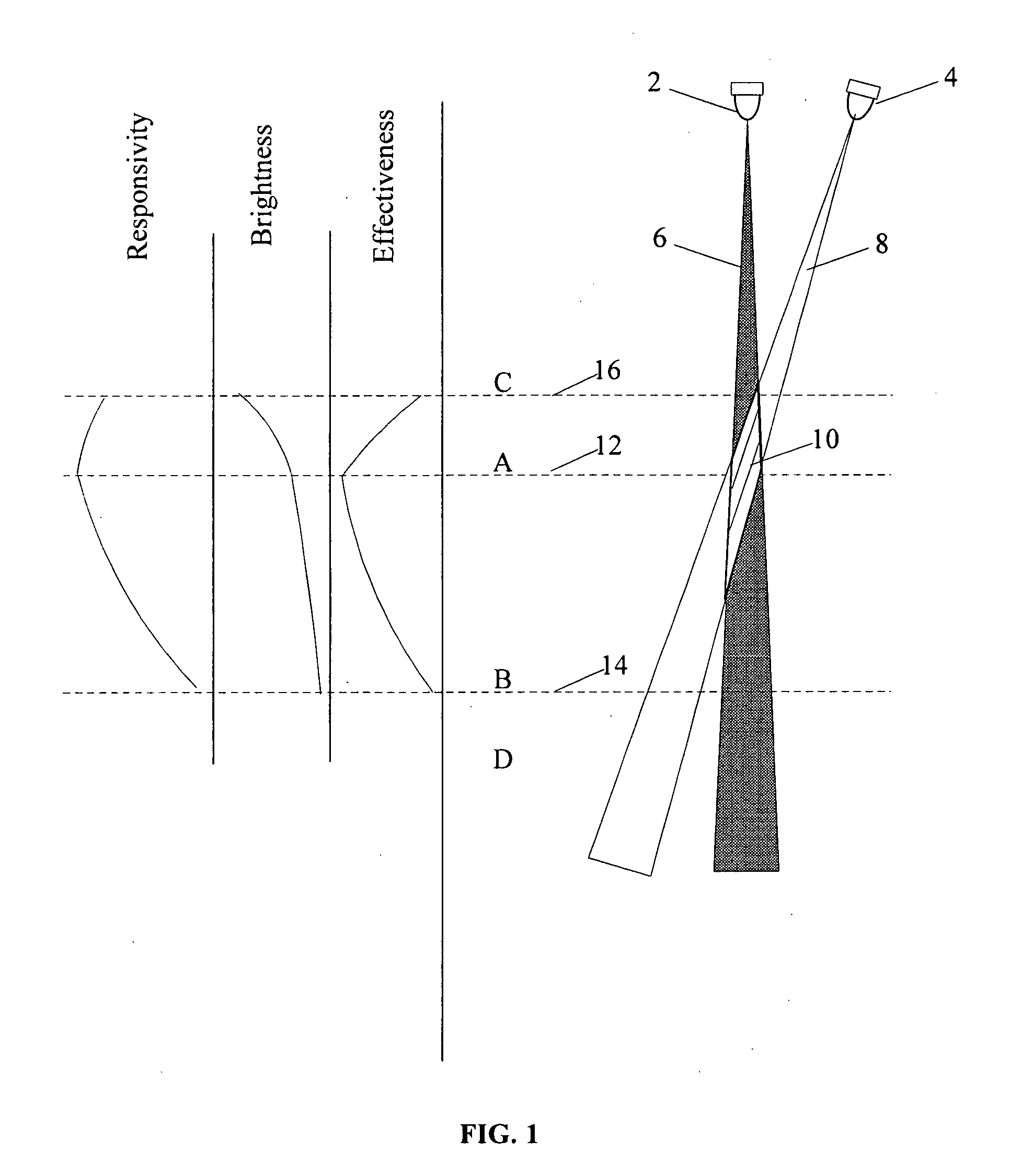

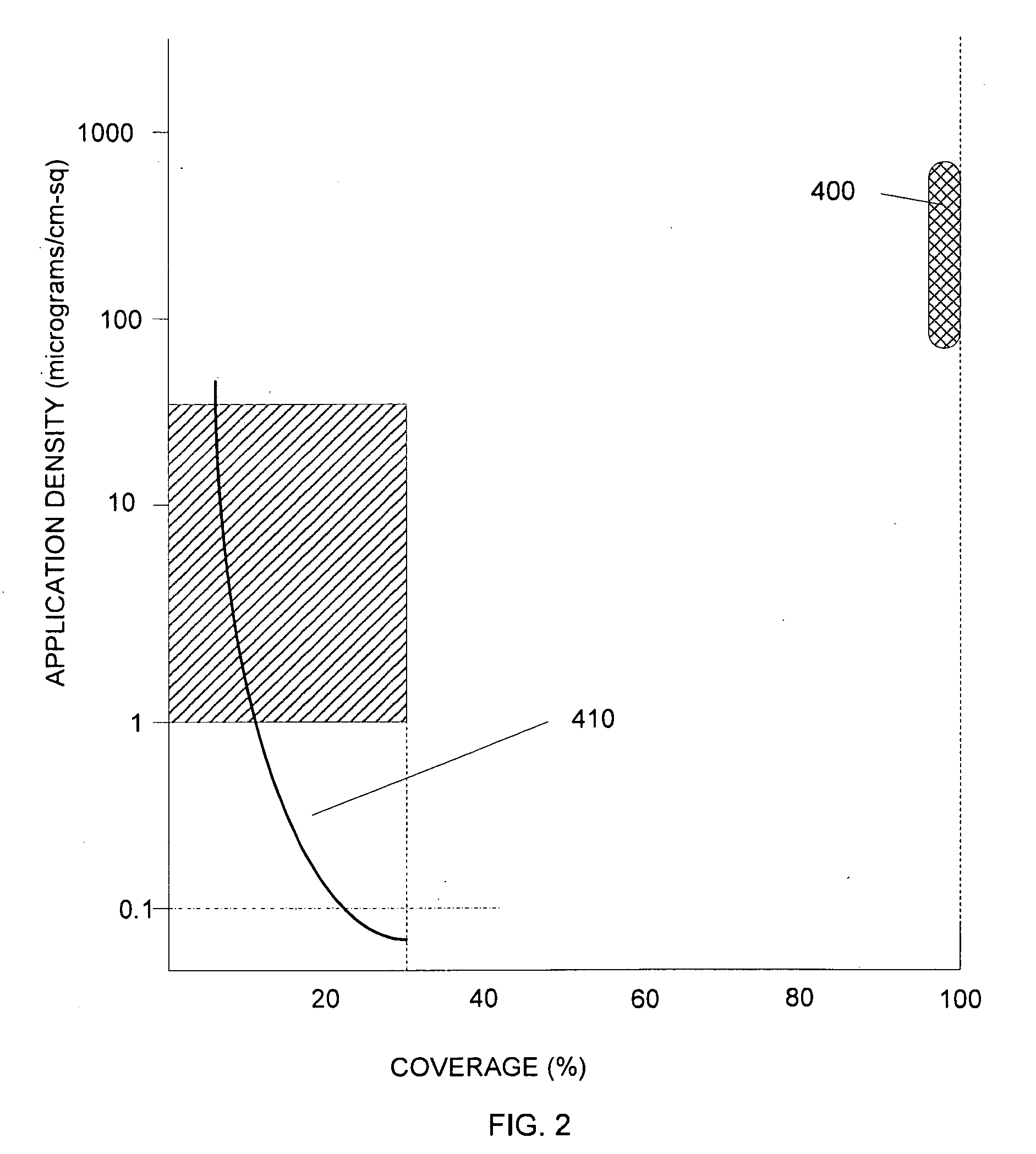

Apparatus and method for the precision application of cosmetics

ActiveUS20090025747A1Easy to moveArea coveredTypewritersPackaging toiletriesCamera imageVolumetric Mass Density

One or more reflectance modifying agent (RMA) such as a pigmented cosmetic agent is applied selectively and precisely with a controlled spray to human skin according to local skin reflectance or texture attributes. One embodiment uses digital control based on the analysis of a camera images. Another embodiment, utilizes a calibrated scanning device comprising a plurality of LEDs and photodiode sensors to correct reflectance readings to compensate for device distance and orientation relative to the skin. Ranges of desired RMA application parameters of high luminance RMA, selectively applied to middle spatial frequency features, at low opacity or application density are each be significantly different from conventional cosmetic practice. The ranges are complementary and the use of all three techniques in combination provides a surprisingly effective result which preserves natural beauty while applying a minimum amount of cosmetic agent.

Owner:TCMS TRANSPARENT BEAUTY LLC

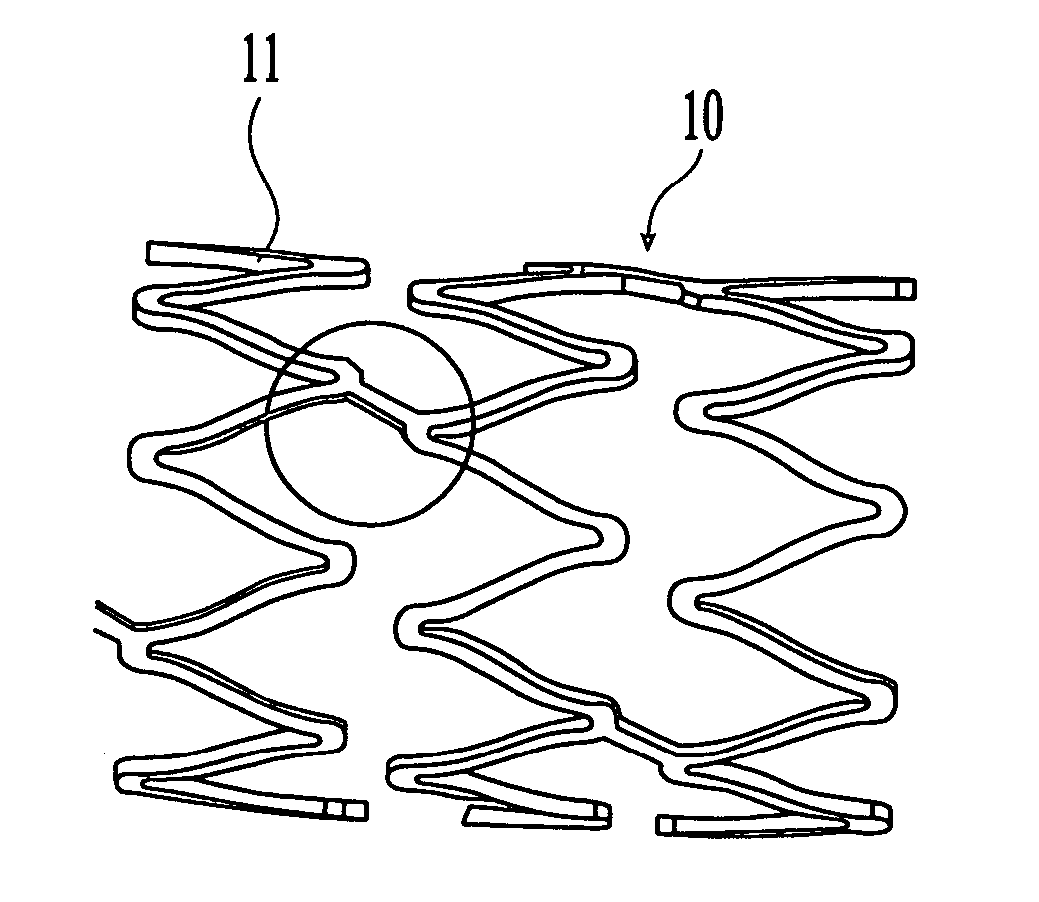

Coated medical device and method for manufacturing the same

The medical device of the invention comprises a surface comprising at least one outermost portion and a plurality of depressions. The depressions occupy at least about 80% of the surface area of the surface. The depressions contain a coating material that preferably comprises a biologically active material and / or polymer, and the outermost portion is substantially free of any coating material. The invention is also directed to a method for manufacturing a medical device. The method comprises applying a coating material to the surface of the medical device by using at least one roller.

Owner:BOSTON SCI SCIMED INC

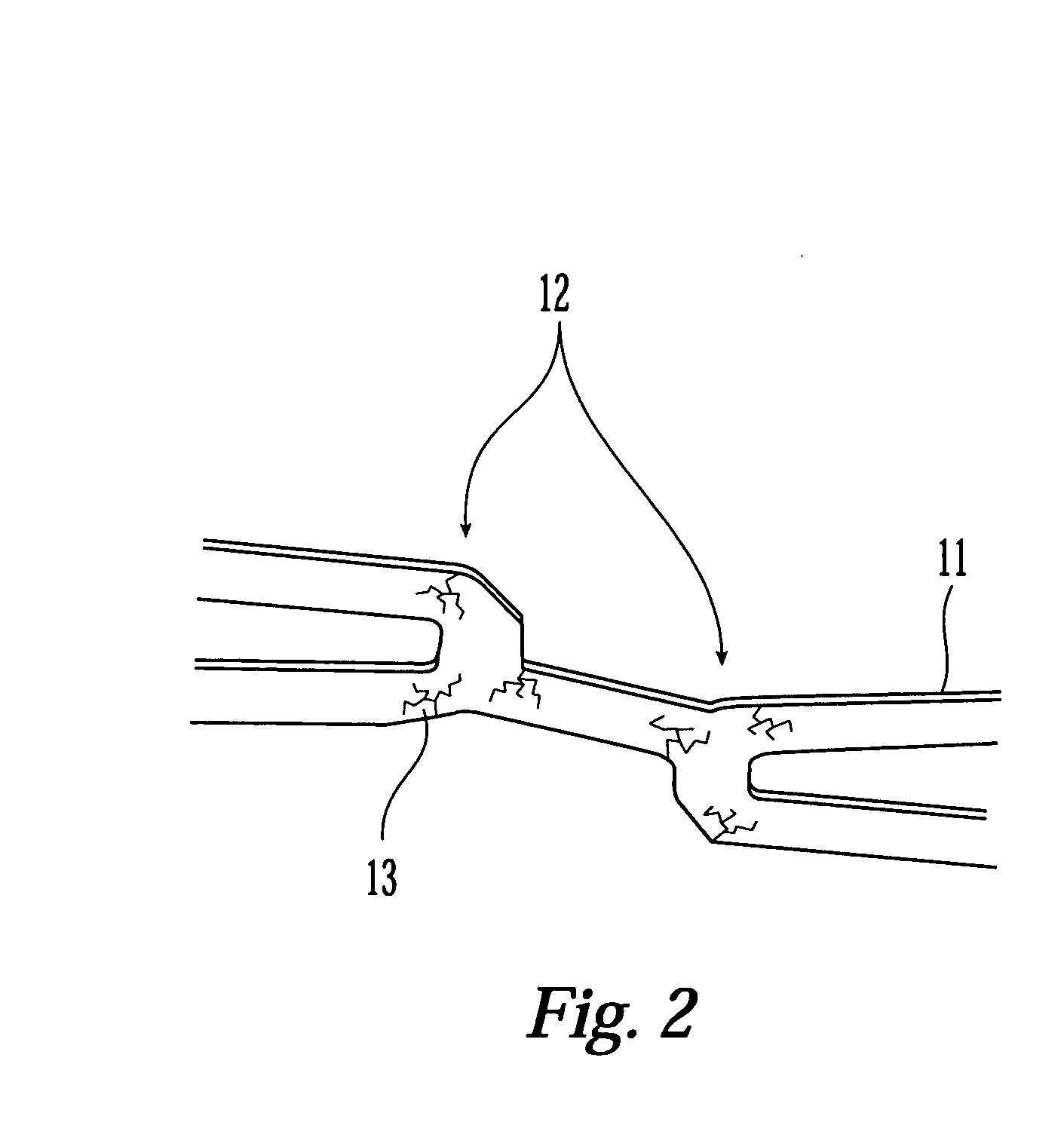

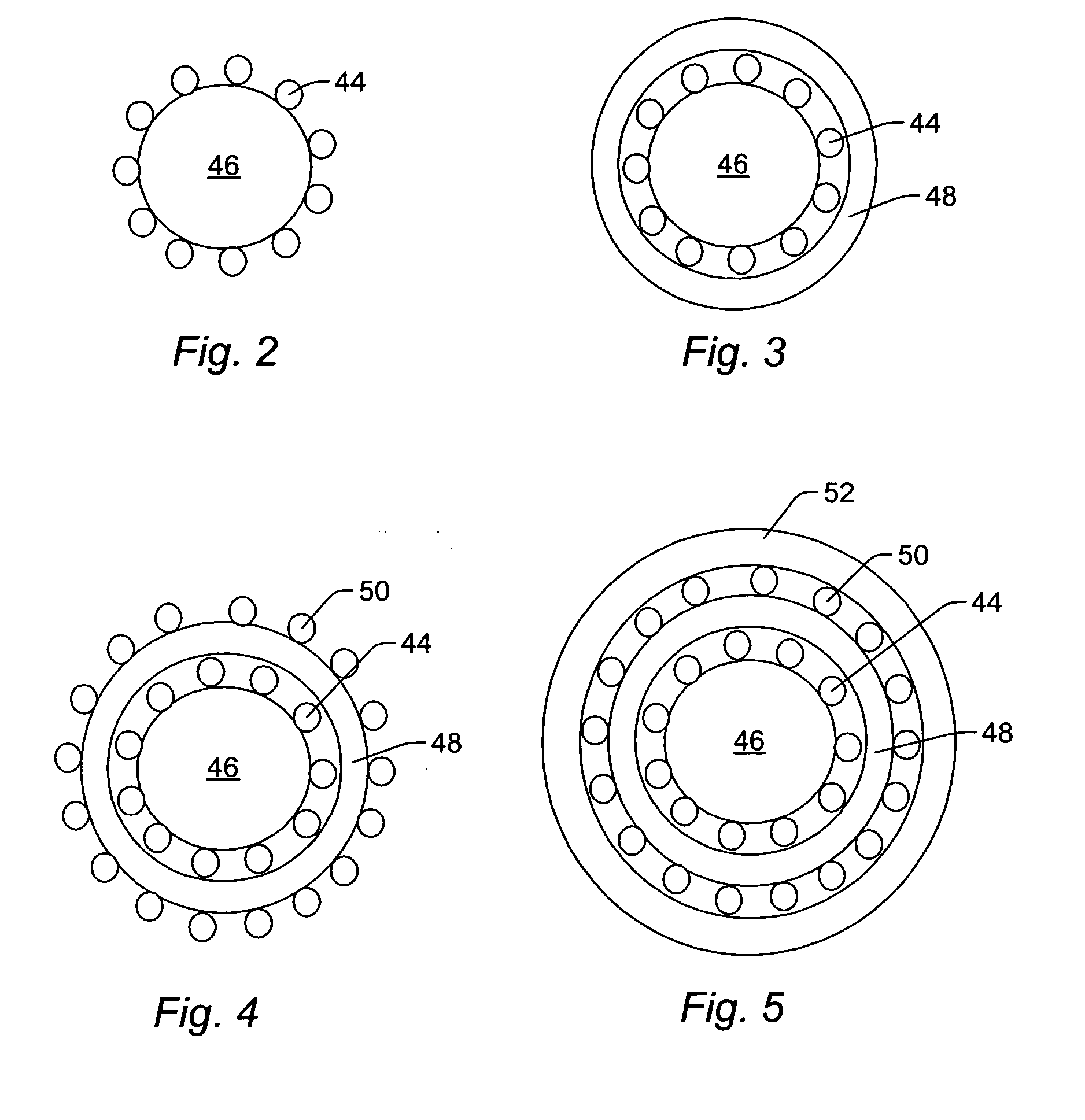

Magnetic microspheres for use in fluorescence-based applications

ActiveUS20060159962A1Avoid light transmissionEmission reductionNanomagnetismMagnetic materialsMicrosphereFluorescence

Microspheres, populations of microspheres, and methods for forming microspheres are provided. One microsphere configured to exhibit fluorescent and magnetic properties includes a core microsphere and a magnetic material coupled to a surface of the core microsphere. About 50% or less of the surface of the core microsphere is covered by the magnetic material. The microsphere also includes a polymer layer surrounding the magnetic material and the core microsphere. One population of microspheres configured to exhibit fluorescent and magnetic properties includes two or more subsets of microspheres. The two or more subsets of microspheres are configured to exhibit different fluorescent and / or magnetic properties. Individual microspheres in the two or more subsets are configured as described above.

Owner:LUMINEX

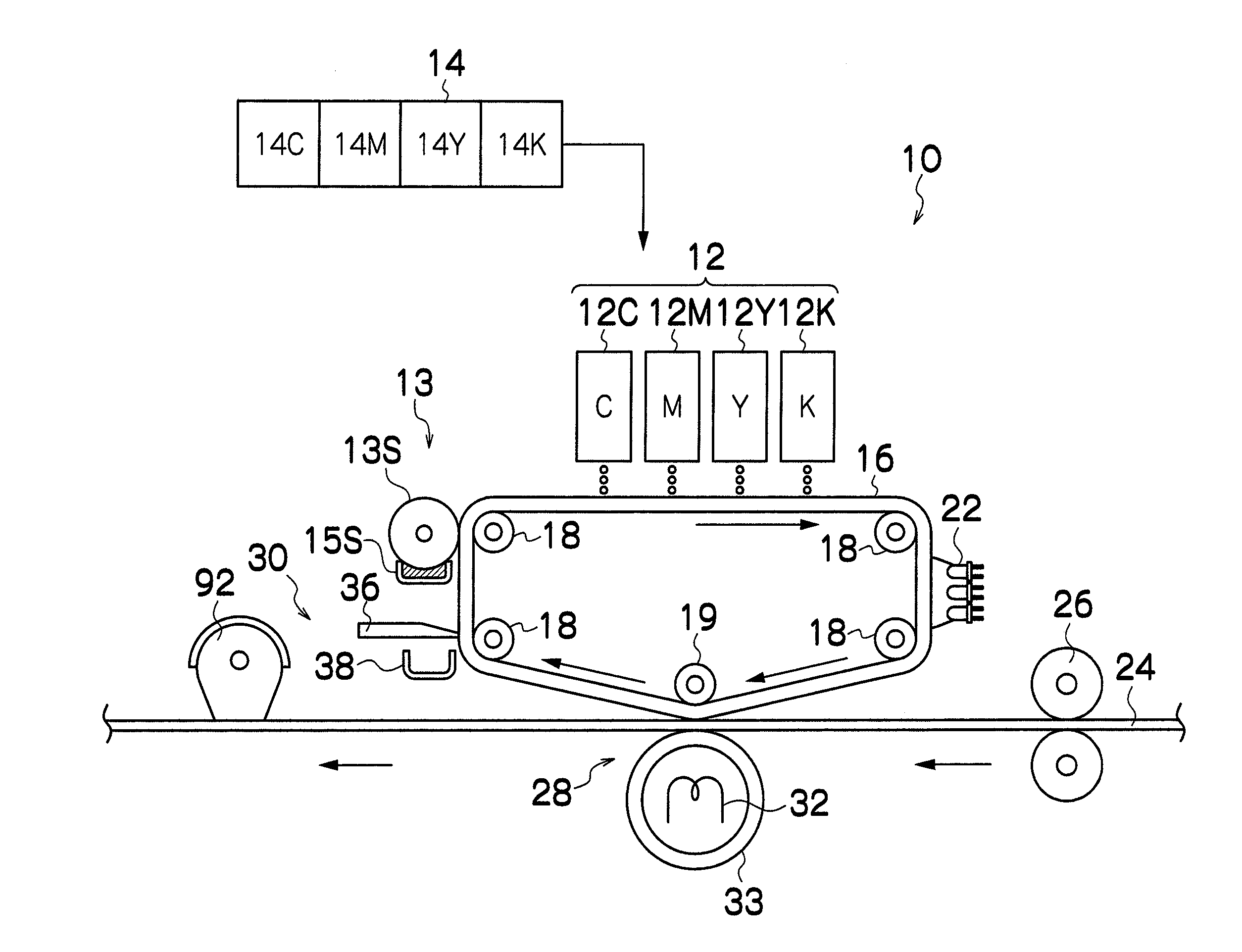

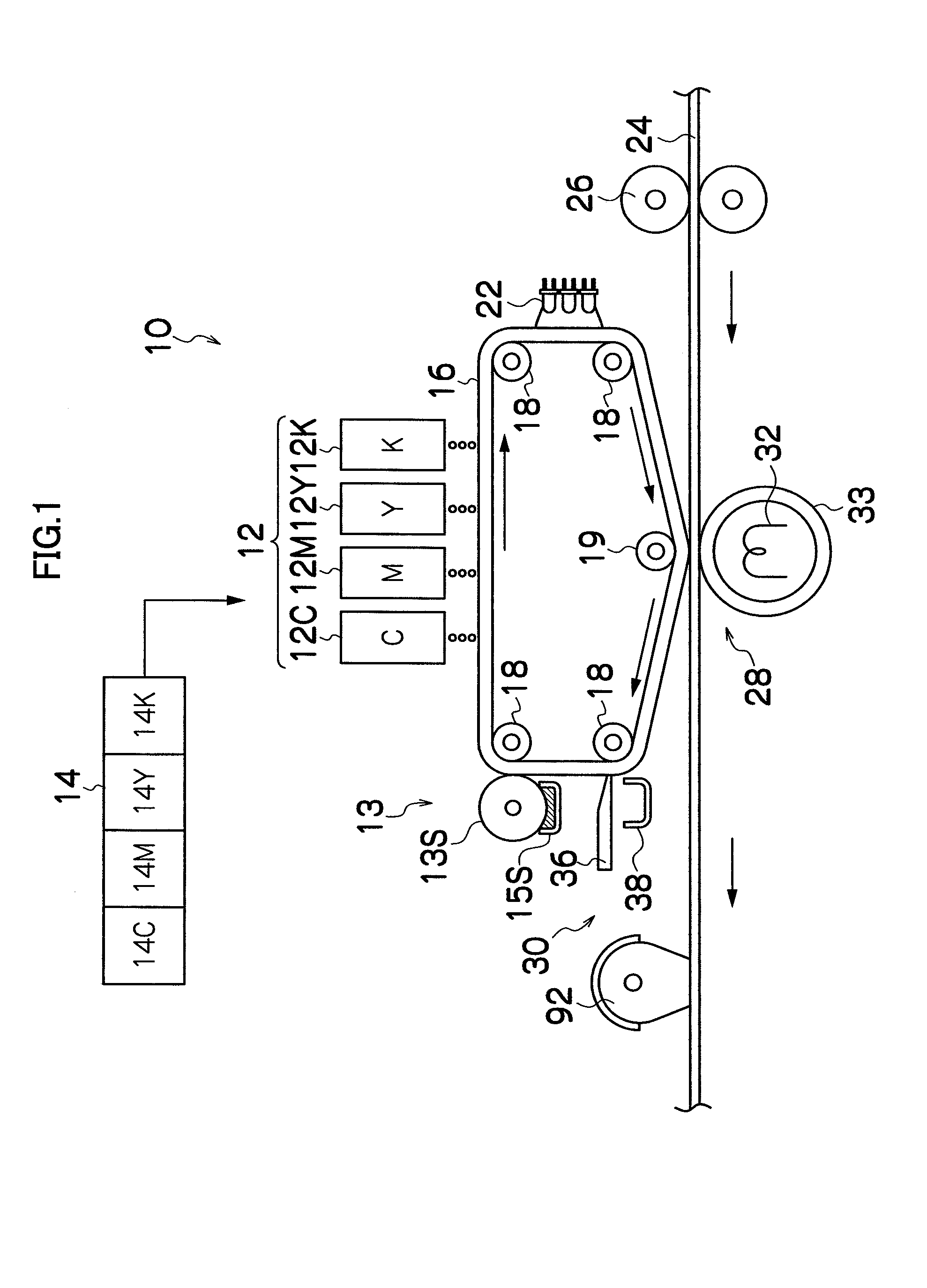

Image forming method and apparatus

InactiveUS20080166495A1Improve ink adhesionHigh strengthInking apparatusDuplicating/marking methodsImage formationPhotochemistry

The image forming method includes the steps of: ejecting and depositing an ink containing a coloring material and a radiation polymerizable compound on an intermediate transfer body, the radiation polymerizable compound having a molecular structure including a radical polymerizable group and a cationically polymerizable group; then irradiating the ink on the intermediate transfer body with a first radiation so that one of the radical polymerizable group and the cationically polymerizable group is selectively polymerized and cured; then heating the selectively polymerized and cured ink to a temperature not lower than a softening point of the selectively polymerized and cured ink and not higher than a temperature above the softening point by 10° C., while transferring the selectively polymerized and cured ink from the intermediate transfer body to a recording medium; and then irradiating the ink on the recording medium with a second radiation so that the other of the radical polymerizable group and the cationically polymerizable group is polymerized and cured.

Owner:FUJIFILM CORP

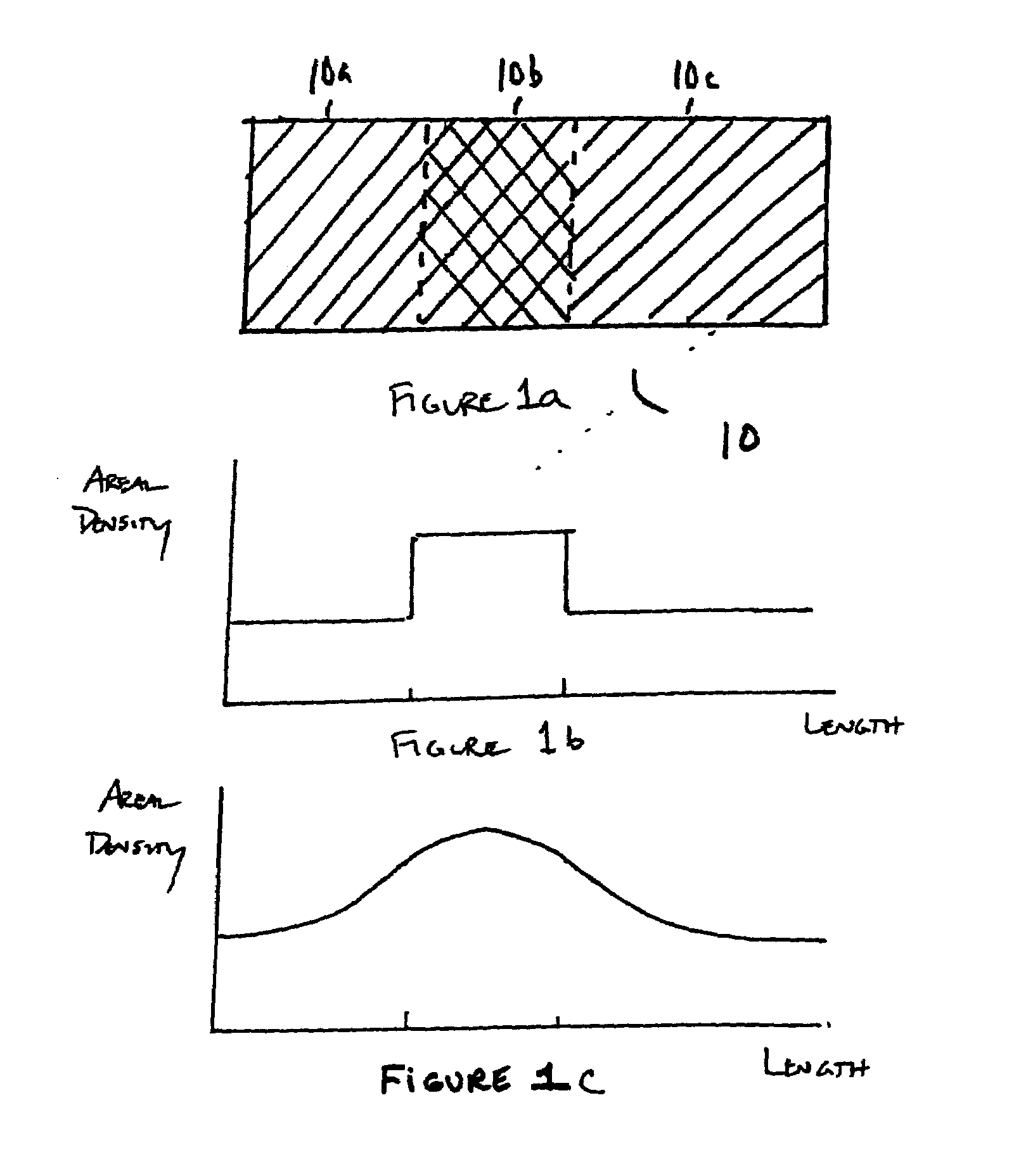

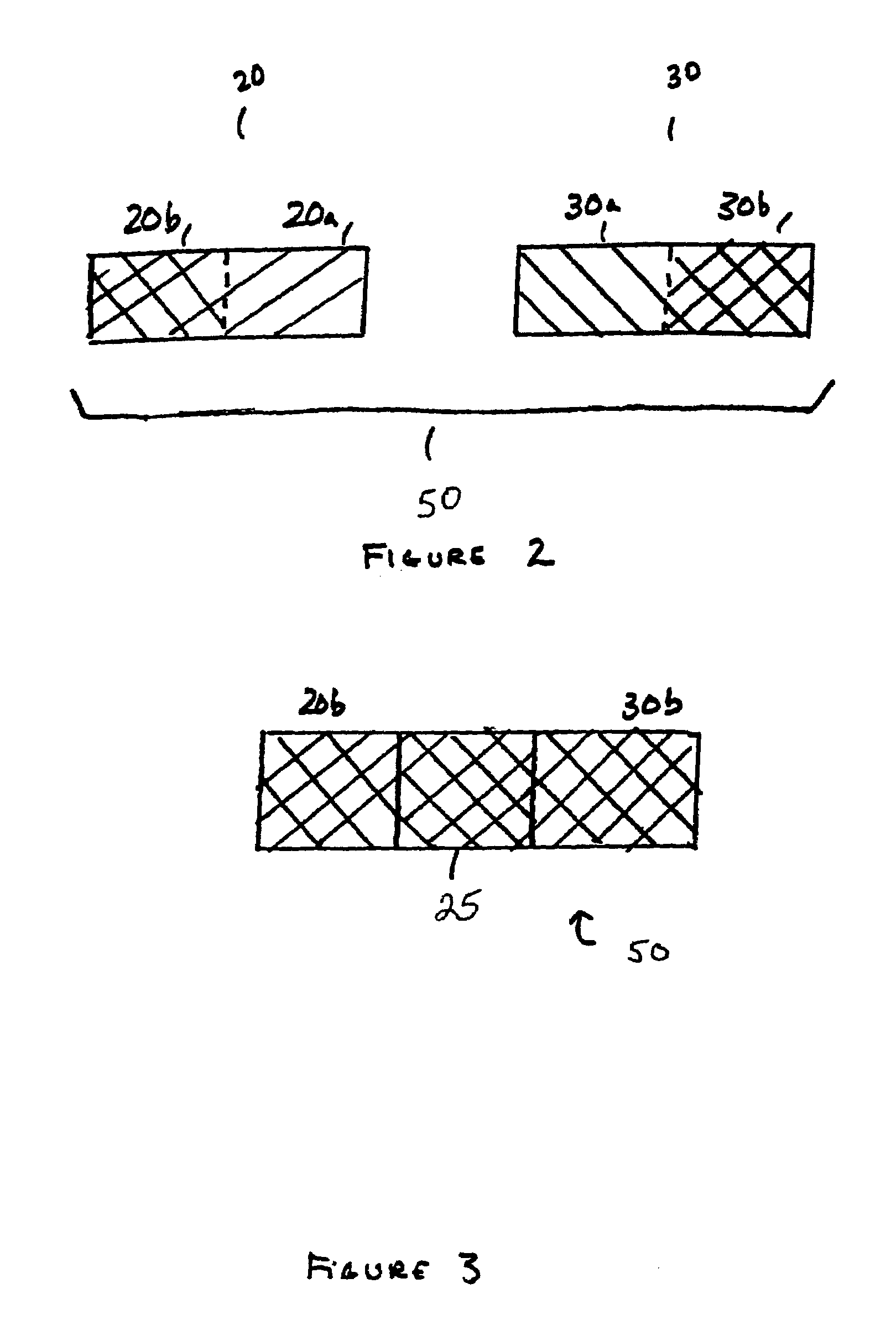

Evaporating method for forming thin film

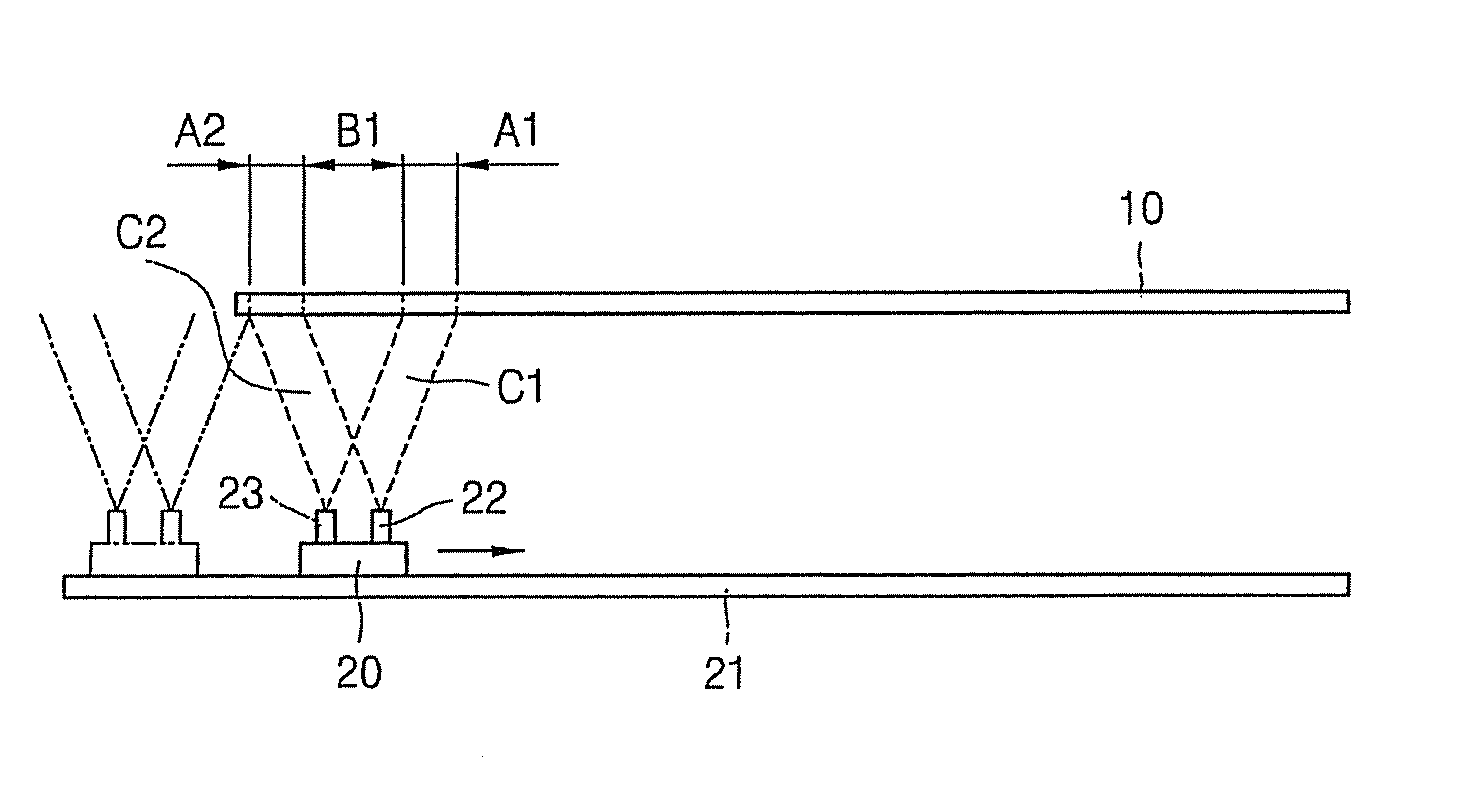

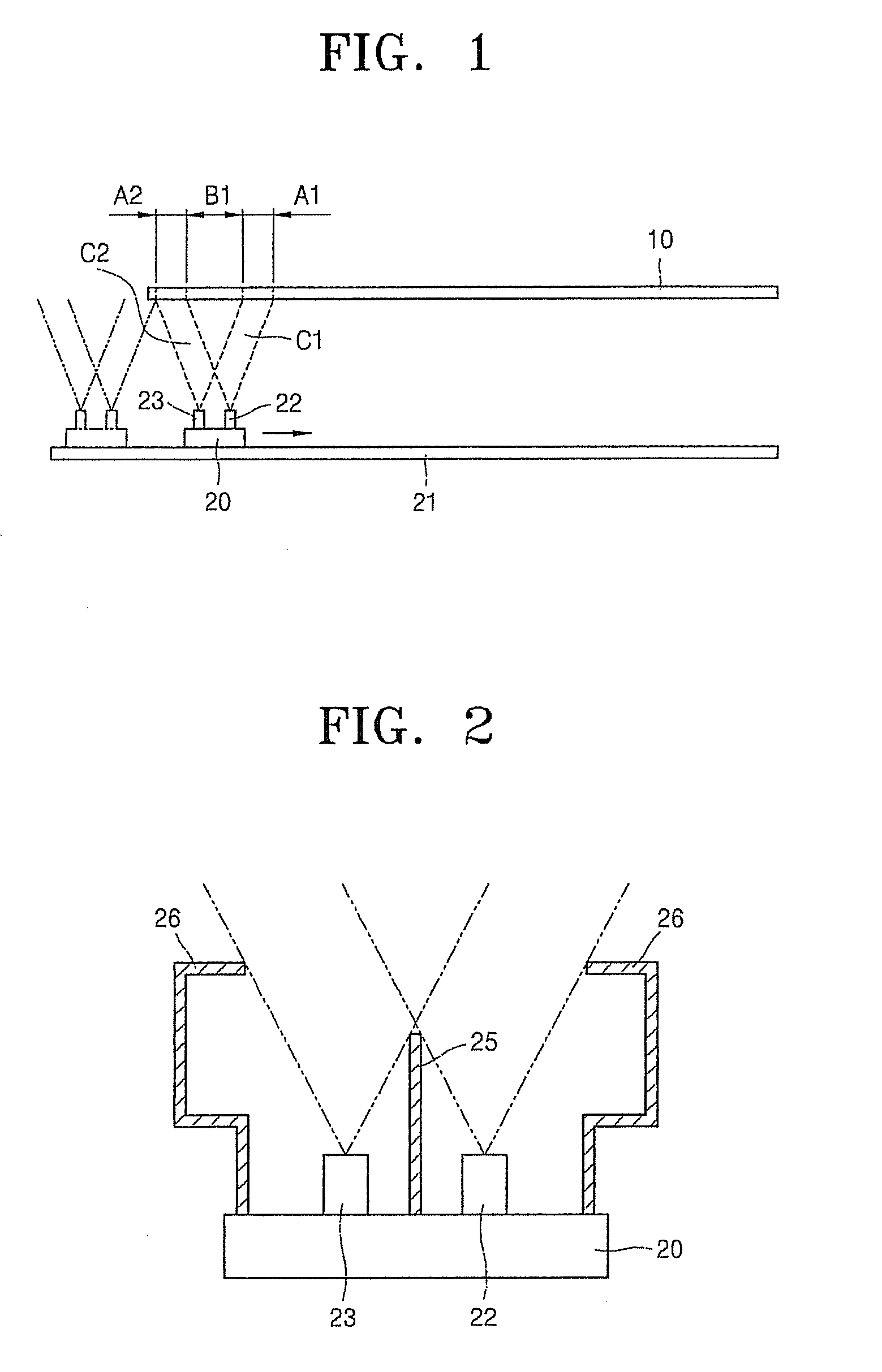

ActiveUS20090232976A1Efficient stackingQuality improvementElectrical apparatusElectroluminescent light sourcesOrganic filmSingle process

A method of forming a plurality of multi-layer organic films in a single process includes preparing a first evaporating source that evaporates a first evaporating source material onto a first deposition region and a second evaporating source that evaporates a second evaporating source material onto a second deposition region, wherein the first evaporating source material and the second evaporating source material are different from each other, adjusting the first evaporating source and the second evaporating source in order to obtain a first overlapping region in which the first deposition region and the second deposition region overlap each other, driving the first evaporating source and the second evaporating source to deposit the first evaporating source material and the second evaporating source material onto a portion of an object to be processed, and moving the first evaporating source and the second evaporating source from a first end of the object to a second end of the object to form a multilayer film comprising a first layer that is a deposition of only the first evaporating source material, a second layer that is a deposition of a mixture of the first evaporating source material and the second evaporating source material and a third layer that is a deposition of only the second source material.

Owner:SAMSUNG DISPLAY CO LTD

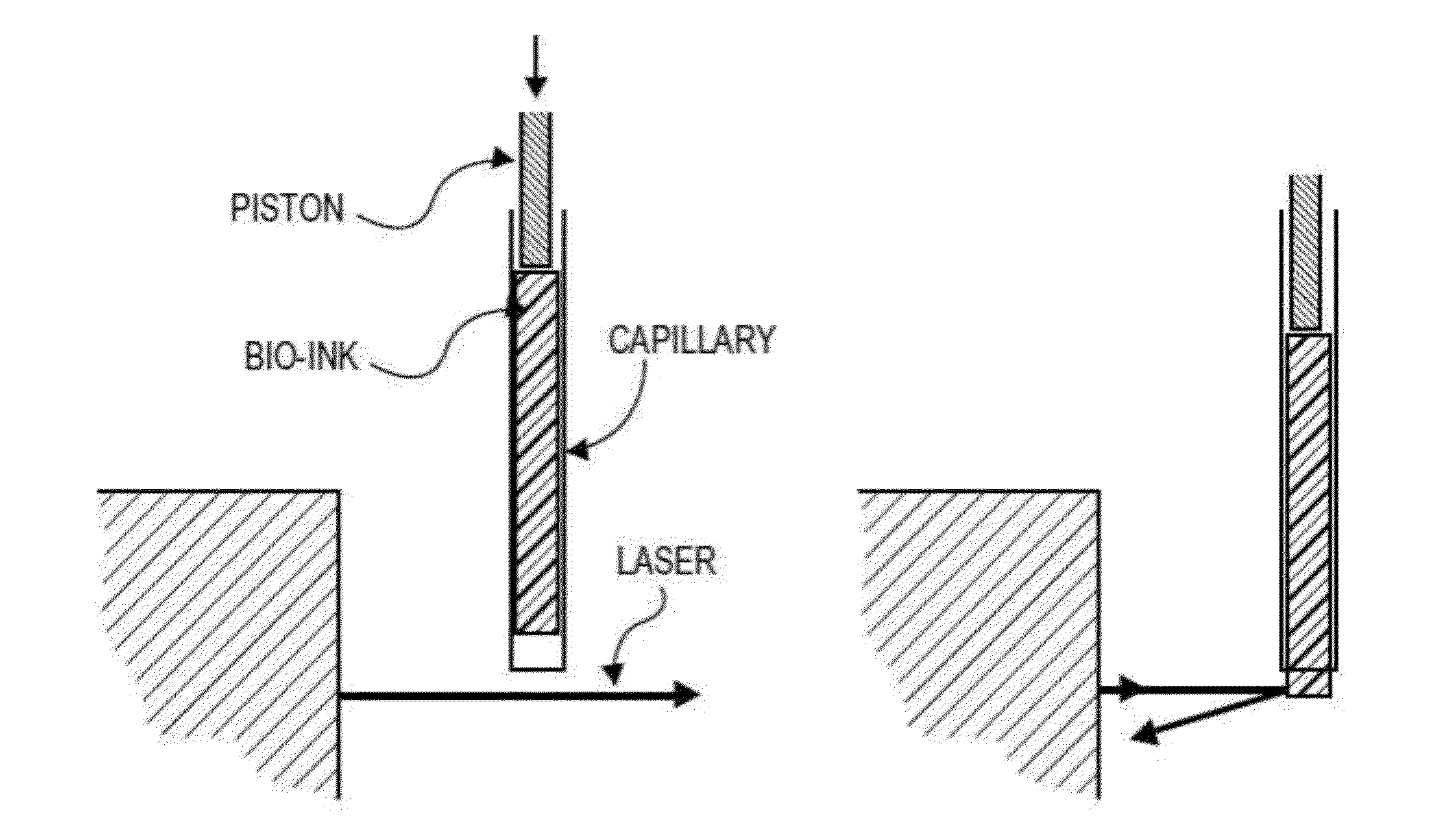

Devices, systems, and methods for the fabrication of tissue

ActiveUS20120116568A1Increase the number ofQuality improvementManufacturing platforms/substratesLiquid surface applicatorsComputer moduleEngineering

Described herein are bioprinters comprising: one or more printer heads, wherein a printer head comprises a means for receiving and holding at least one cartridge, and wherein said cartridge comprises contents selected from one or more of: bio-ink and support material; a means for calibrating the position of at least one cartridge; and a means for dispensing the contents of at least one cartridge. Further described herein are methods for fabricating a tissue construct, comprising: a computer module receiving input of a visual representation of a desired tissue construct; a computer module generating a series of commands, wherein the commands are based on the visual representation and are readable by a bioprinter; a computer module providing the series of commands to a bioprinter; and the bioprinter depositing bio-ink and support material according to the commands to form a construct with a defined geometry.

Owner:ORGANOVO

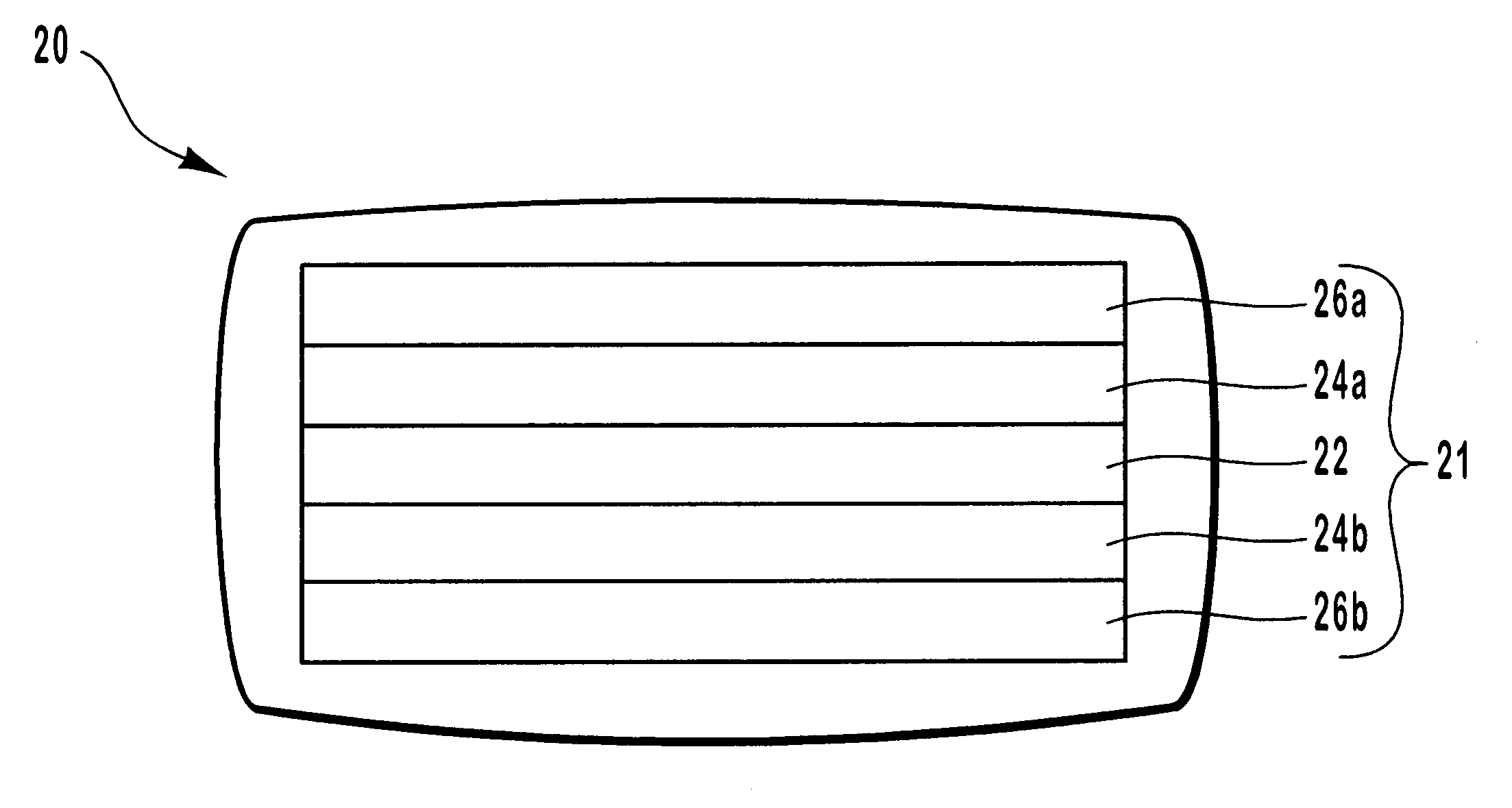

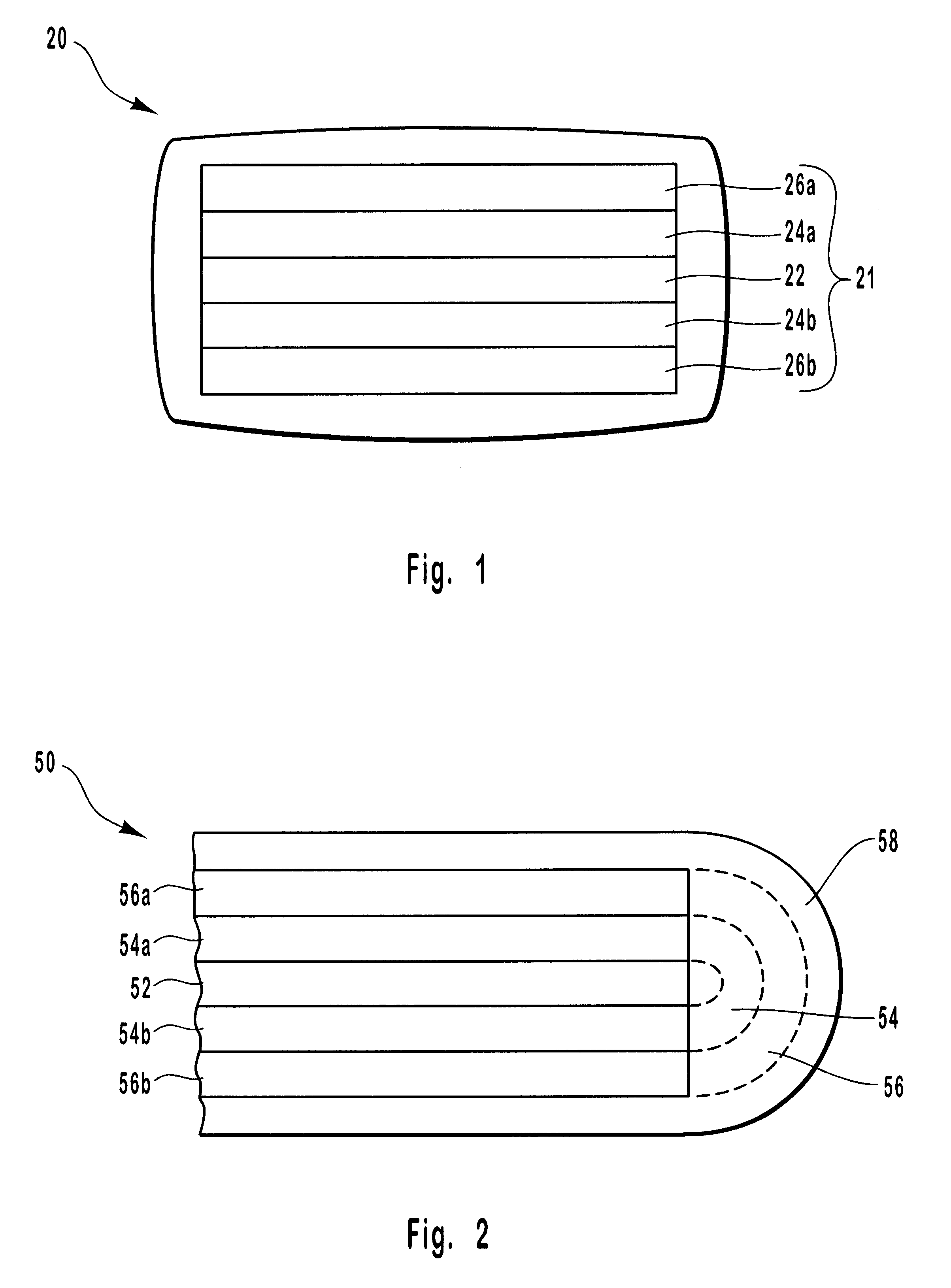

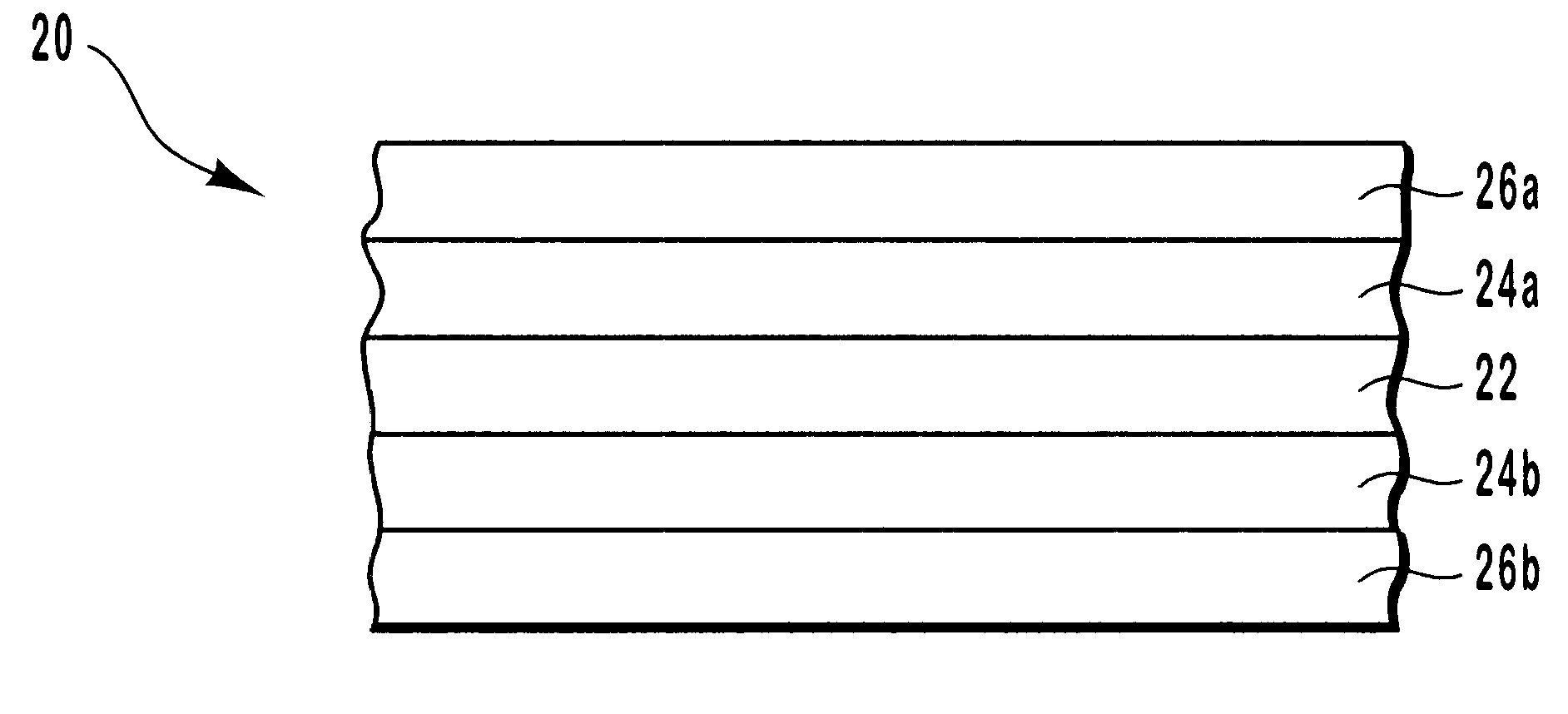

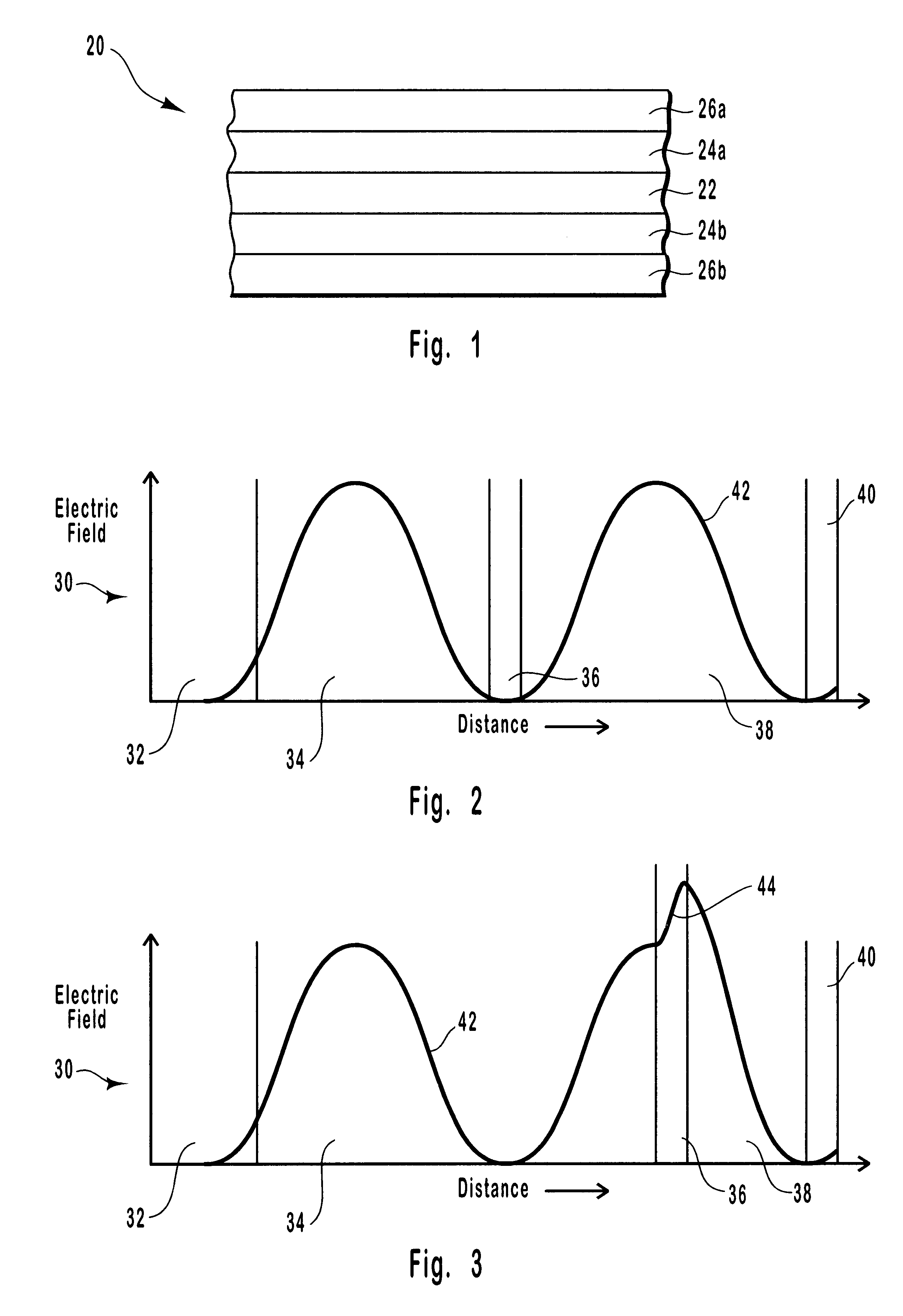

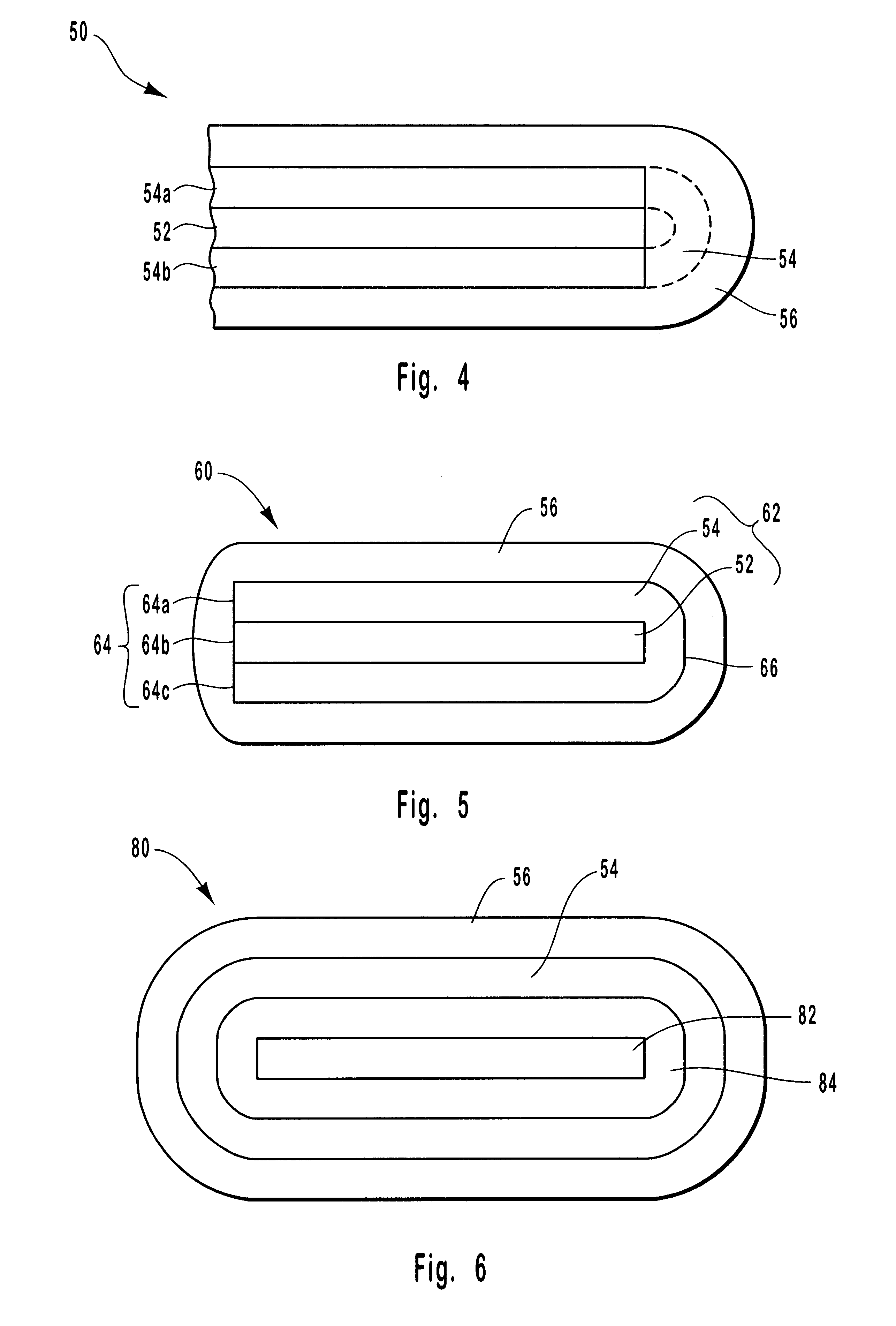

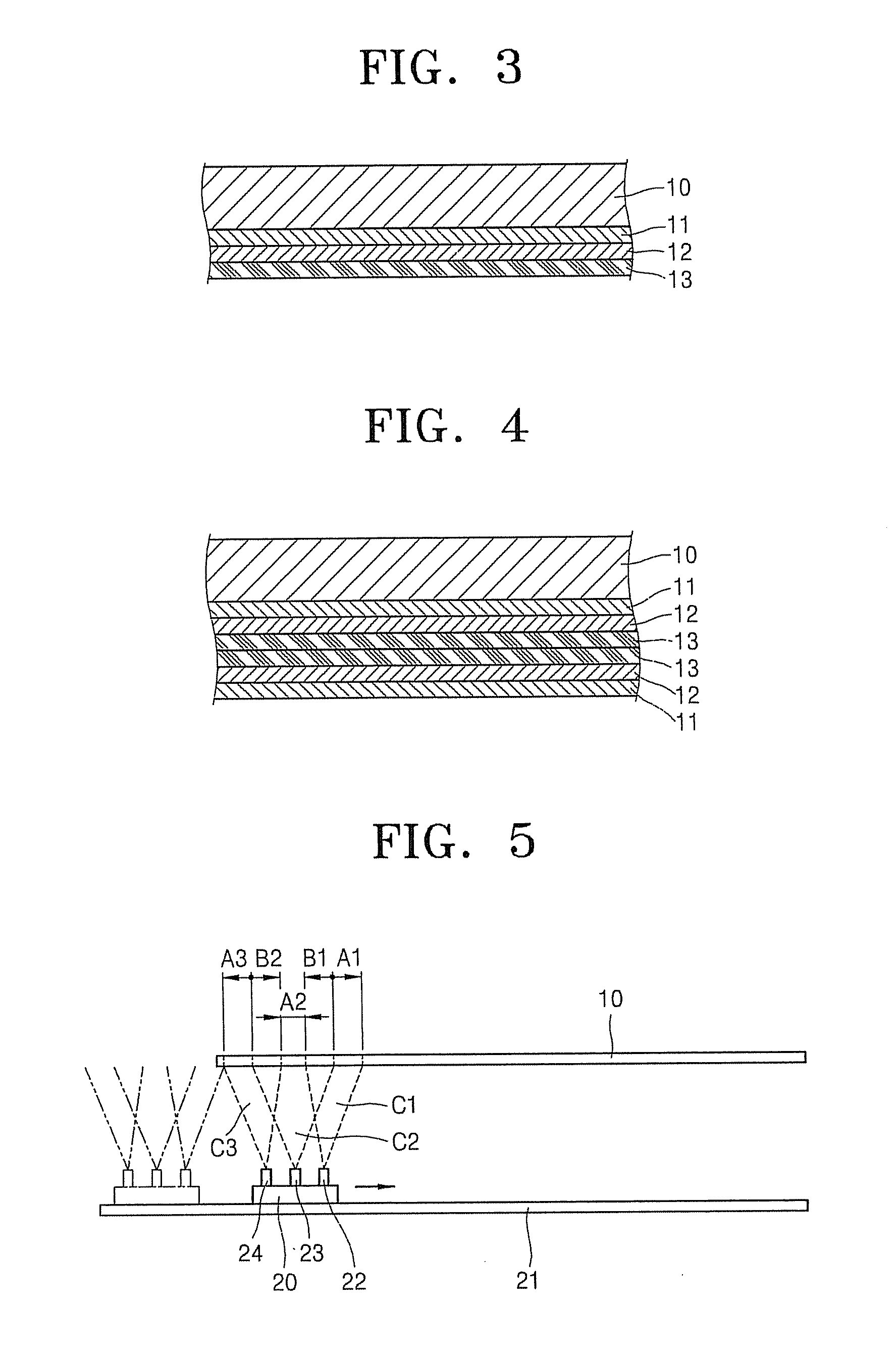

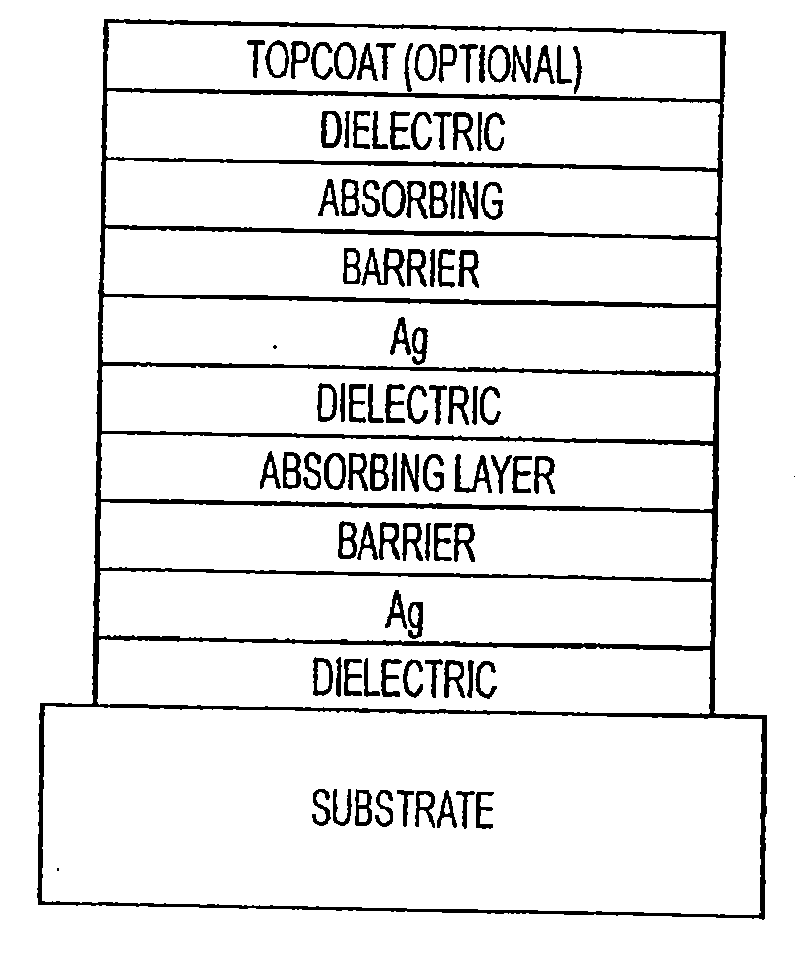

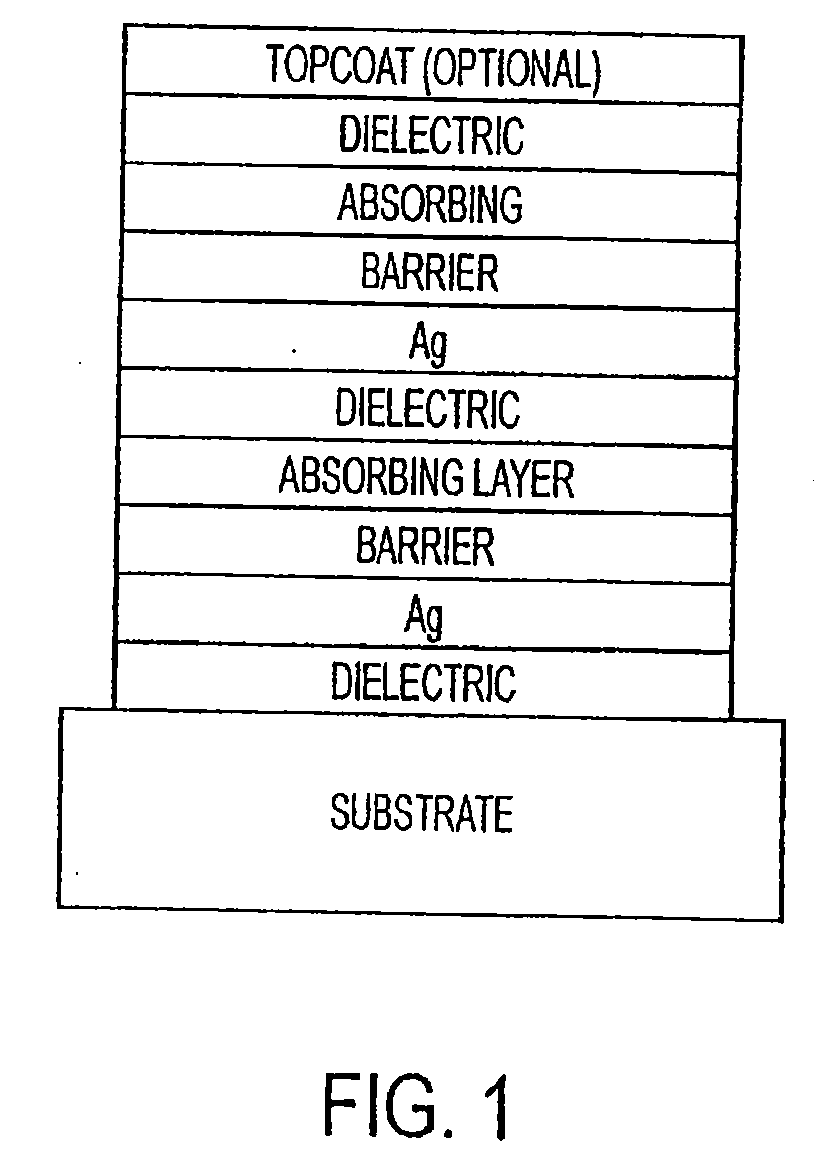

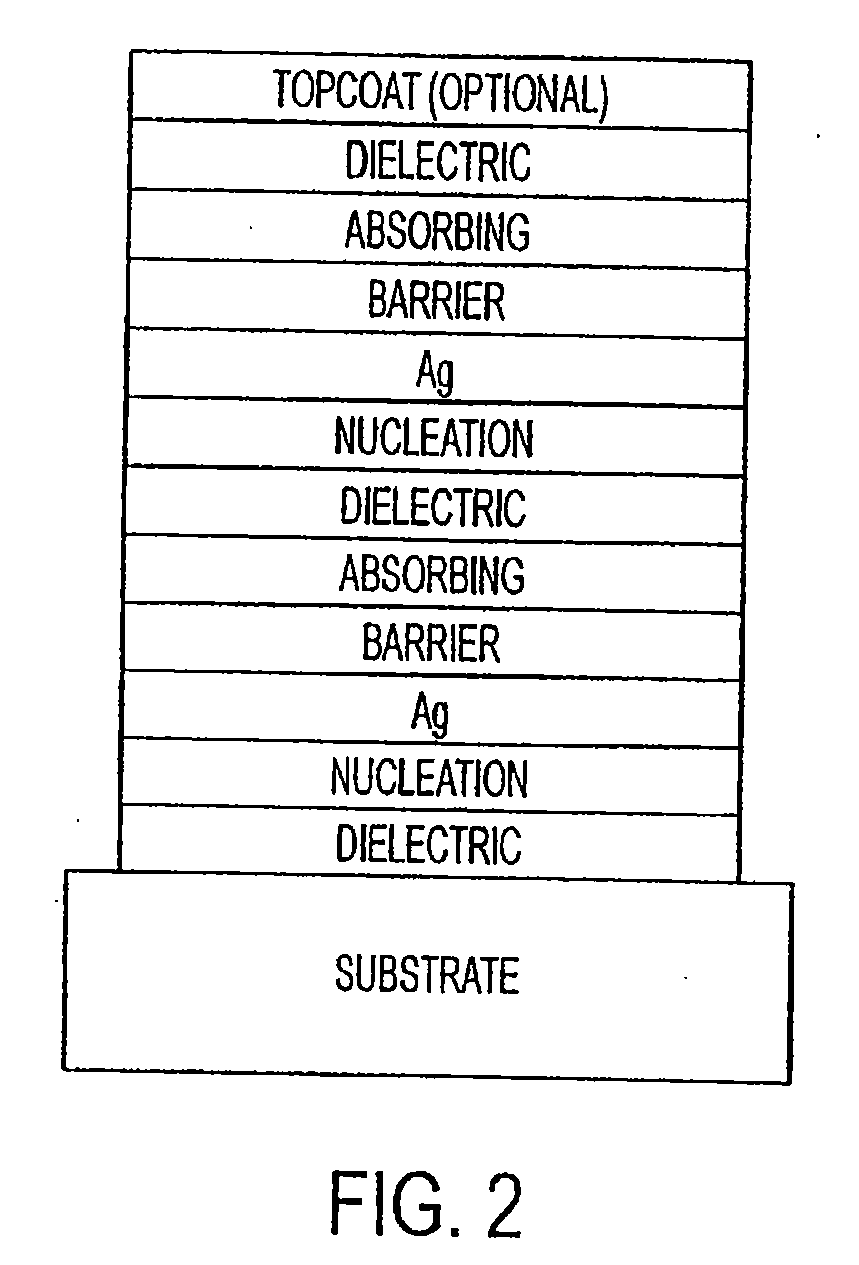

Low emissivity coating with low solar heat gain coefficient, enhanced chemical and mechanical properties and method of making the same

ActiveUS20090136765A1Equal and good chemical and durabilityEqual and good and mechanical durabilityGlass/slag layered productsElectrostatic spraying apparatusRadianceLow emissivity

The invention provides low-emissivity stacks being characterized by a low solar heat gain coefficient (SHGC), enhanced aesthetics, mechanical and chemical durability, and a tolerance for tempering or heat strengthening. The invention moreover provides low-emissivity coatings comprising, in order outward from the substrate a first dielectric layer; a first nucleation layer; a first Ag layer; a first barrier layer; a second dielectric layer; a second nucleation layer; a second Ag layer; a second barrier layer; a third dielectric layer; and optionally, a topcoat layer, and methods for depositing such coatings on substrates.

Owner:CARDINAL CG

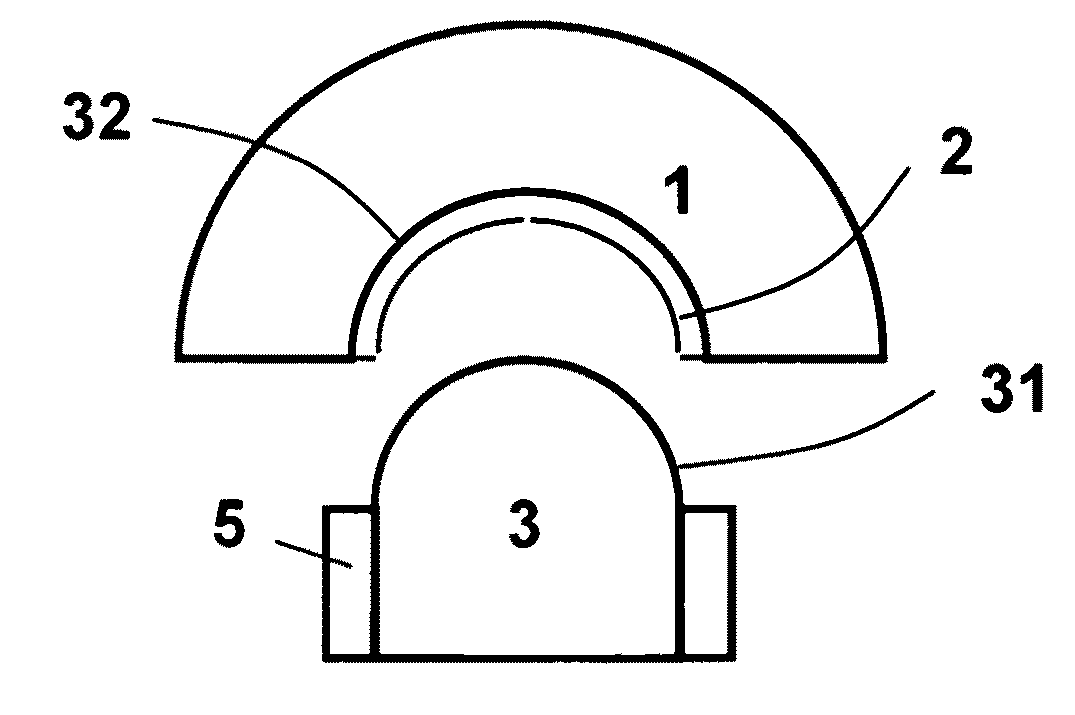

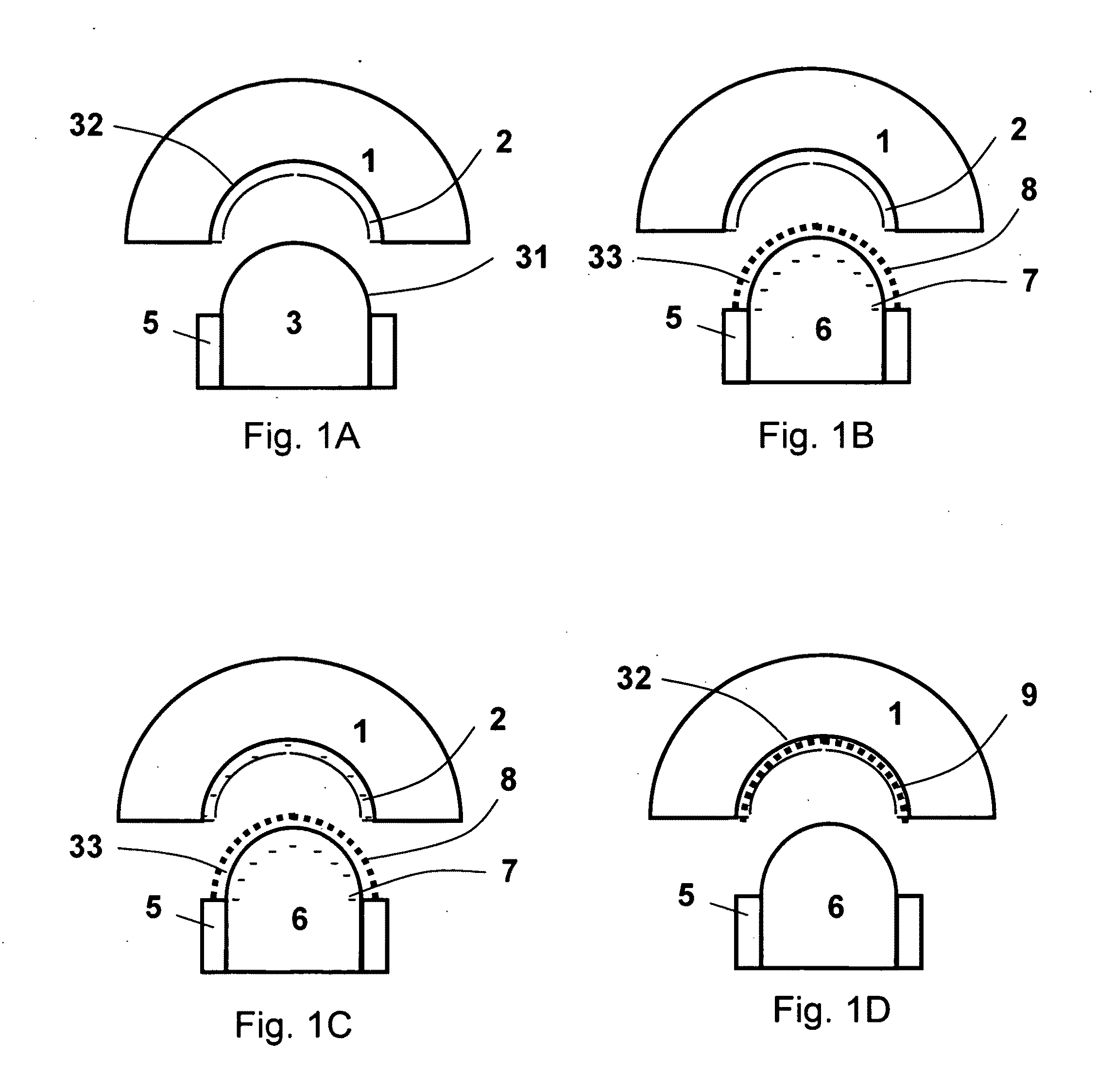

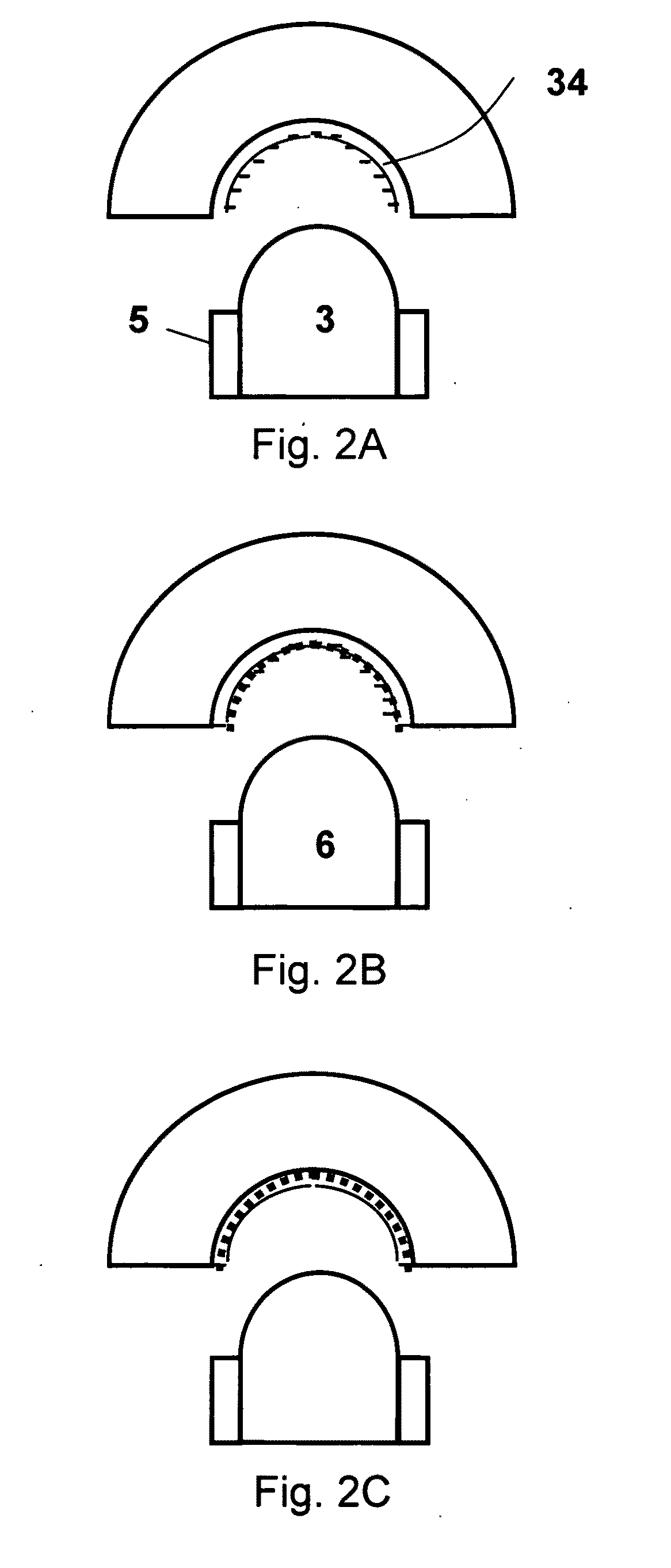

Methods and apparatus for forming uniform particle layers of phosphor material on a surface

InactiveUS20100291313A1Easy to controlHigh bulk densityLiquid surface applicatorsElectric shock equipmentsPhosphorStatic electricity

A method for forming a layer of an LED phosphor material includes disposing a first surface in a proximity of a powder that includes an LED phosphor material, forming electrostatic charges on the first surface, and forming a layer of the LED phosphor material on the first surface at least partially by using the electrostatic charges. In an embodiment, the method includes disposing the first surface in an interior of a chamber and forming an airborne distribution of the powder in the interior of the chamber in a vicinity of the first surface. In another embodiment, the method includes providing a reservoir of the powder and applying to said phosphor powder an electrostatic charge opposite to that of said electrostatic charge on the first surface.

Owner:ACHROLUX

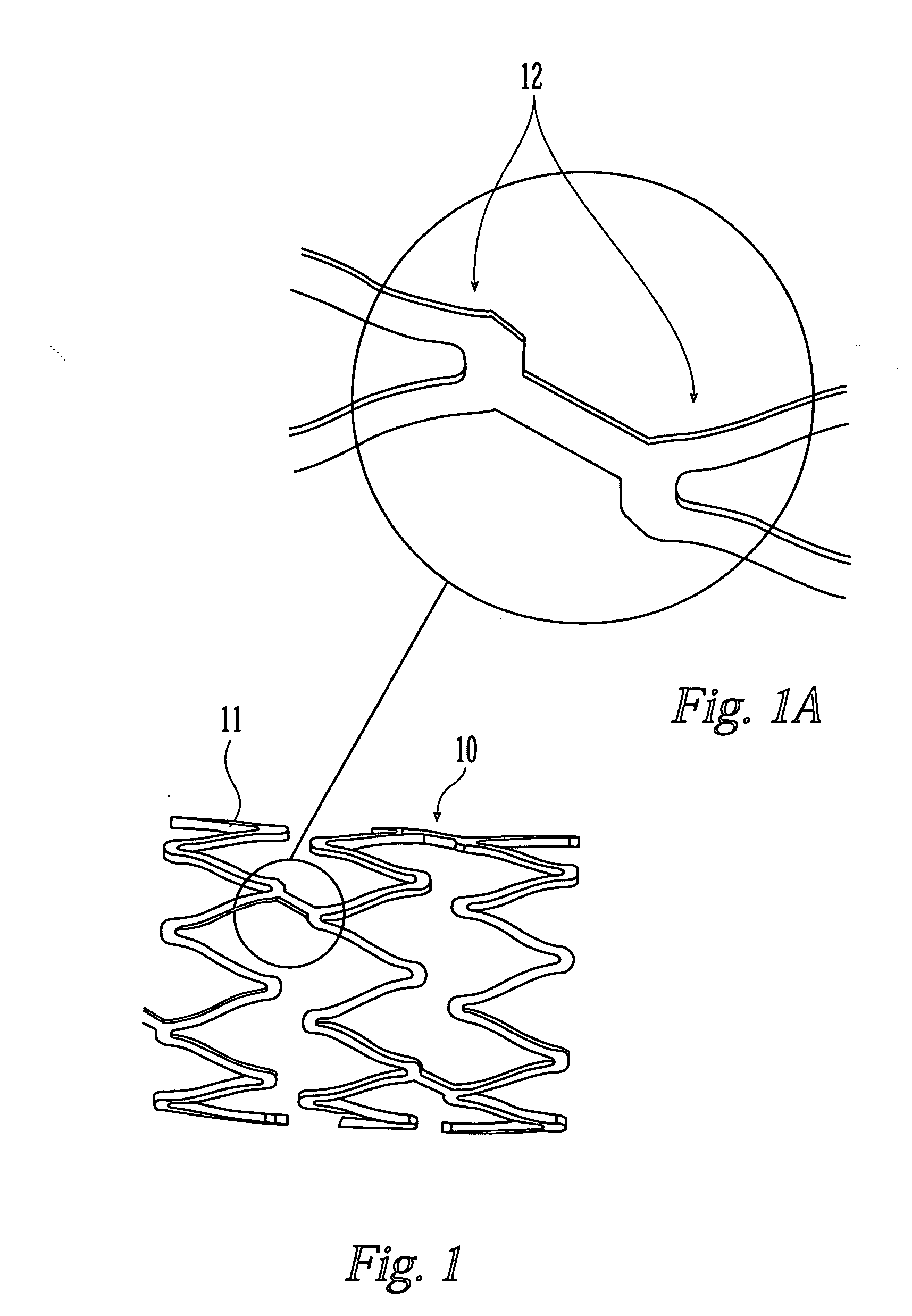

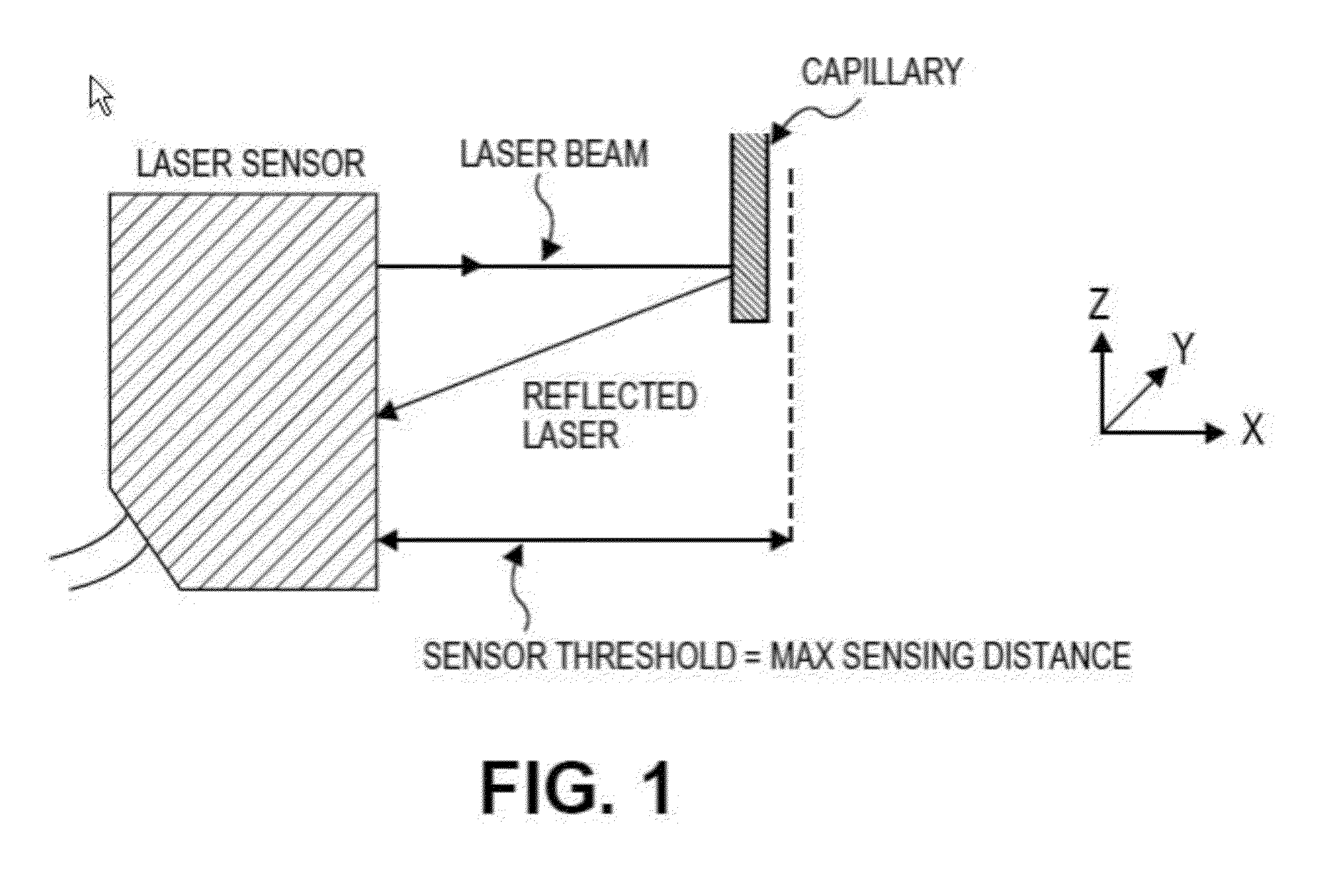

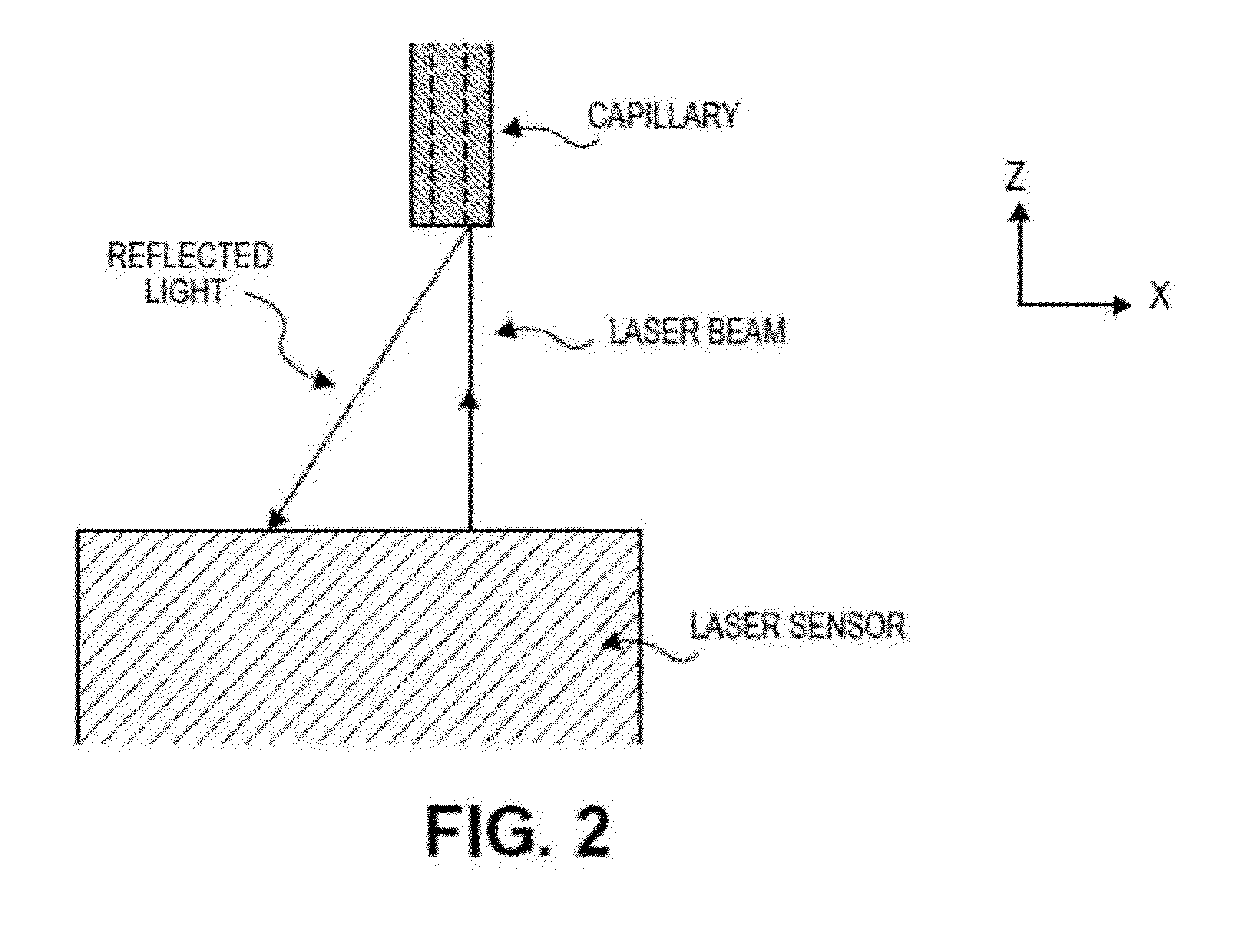

Method and system for making a coated medical device

InactiveUS20050196518A1Increase flow rateShorten production timeConfectionerySurgeryInsertion stentMedical device

Methods of making medical devices, such as stents, having a surface and a coating layer disposed on a portion of the surface are described herein. The coating is formed by applying a coating composition to a portion of the surface of the medical device and then at least partially drying the coating composition substantially simultaneously with the application of the coating composition. The process may be repeated until a desired amount of the coating composition is applied to the surface of the medical device. This method allows for a more efficient and effective method of applying a coating composition to a medical device such as a stent. Also disclosed is a system for making a coated medical device.

Owner:BOSTON SCI SCIMED INC

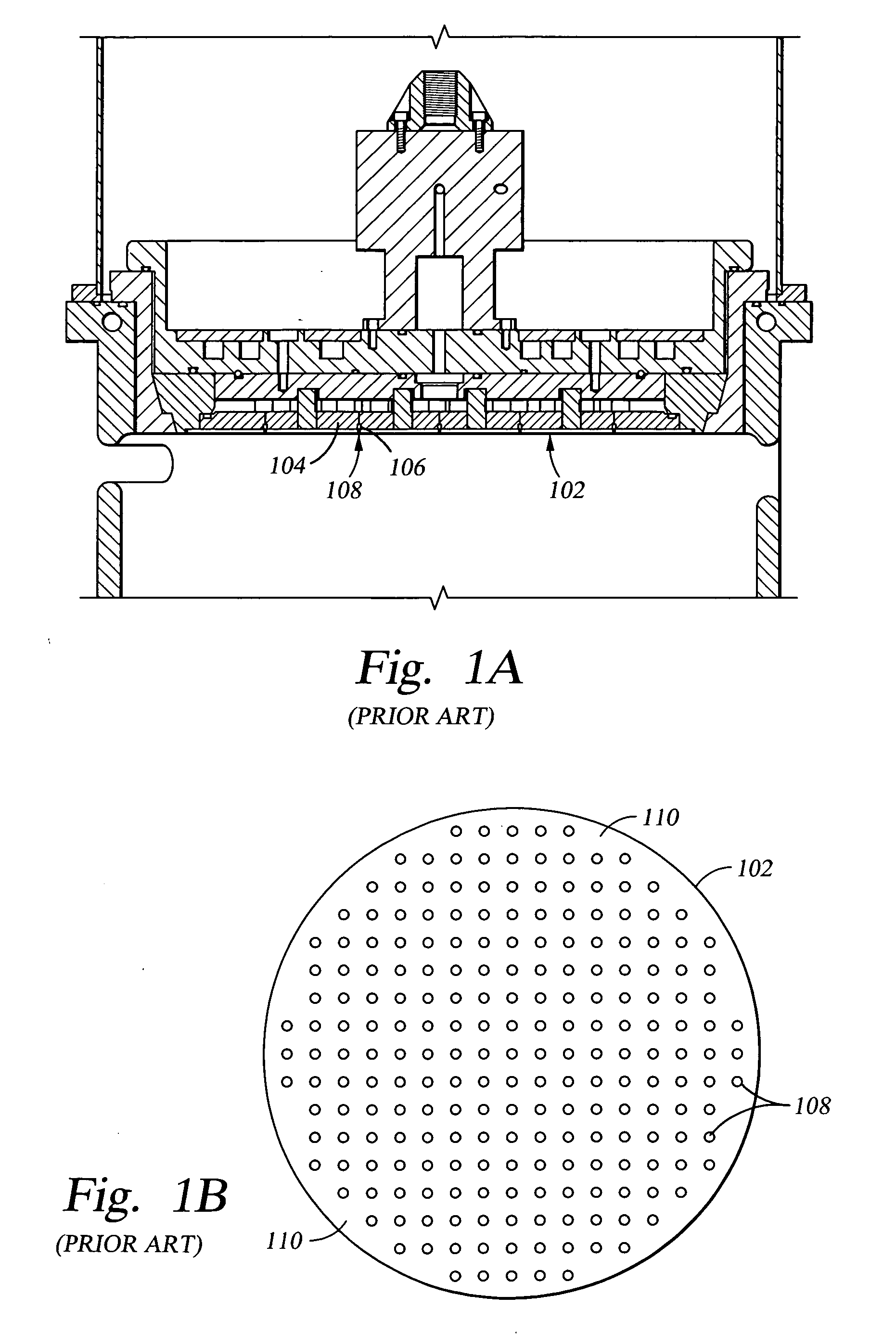

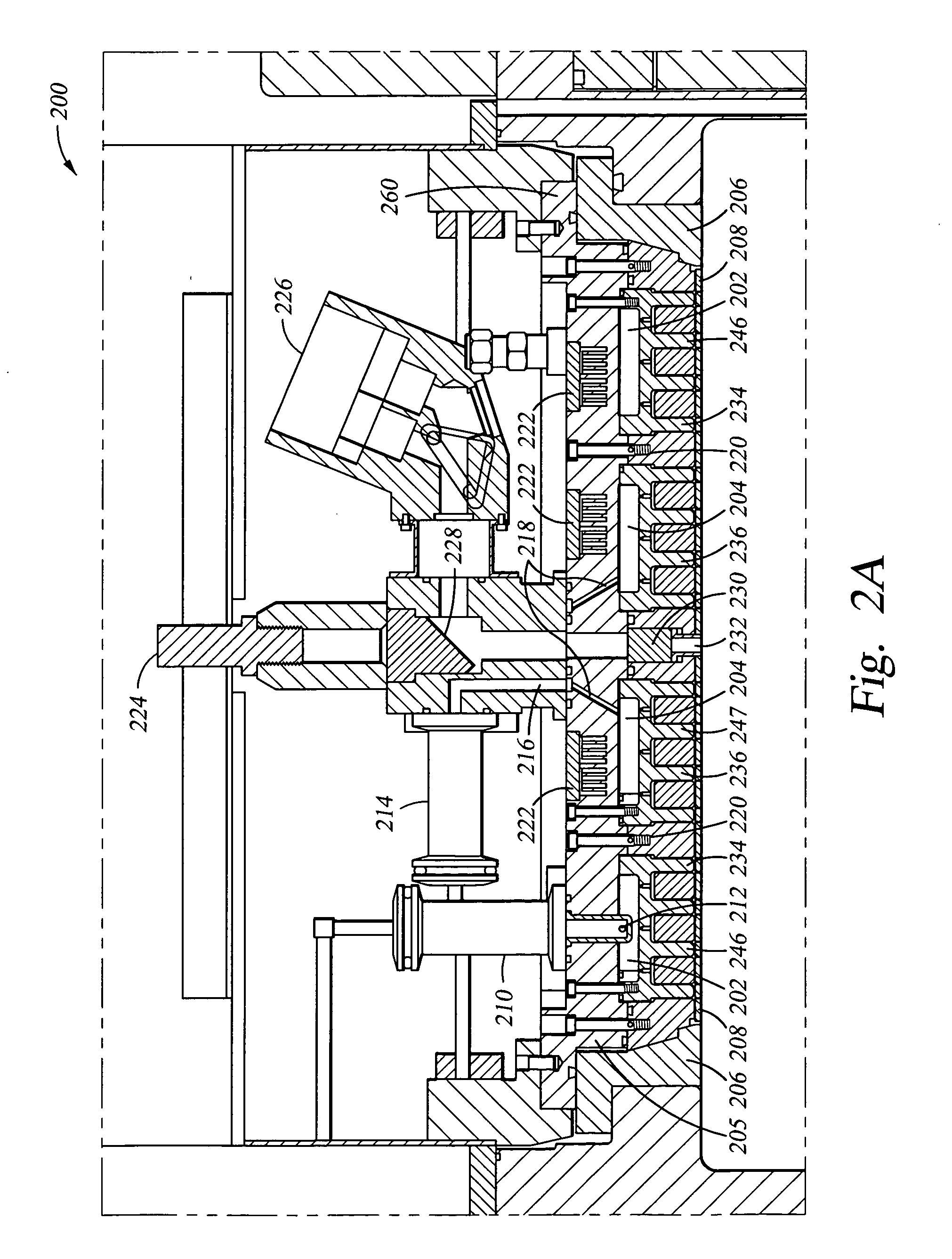

Gas distribution showerhead for semiconductor processing

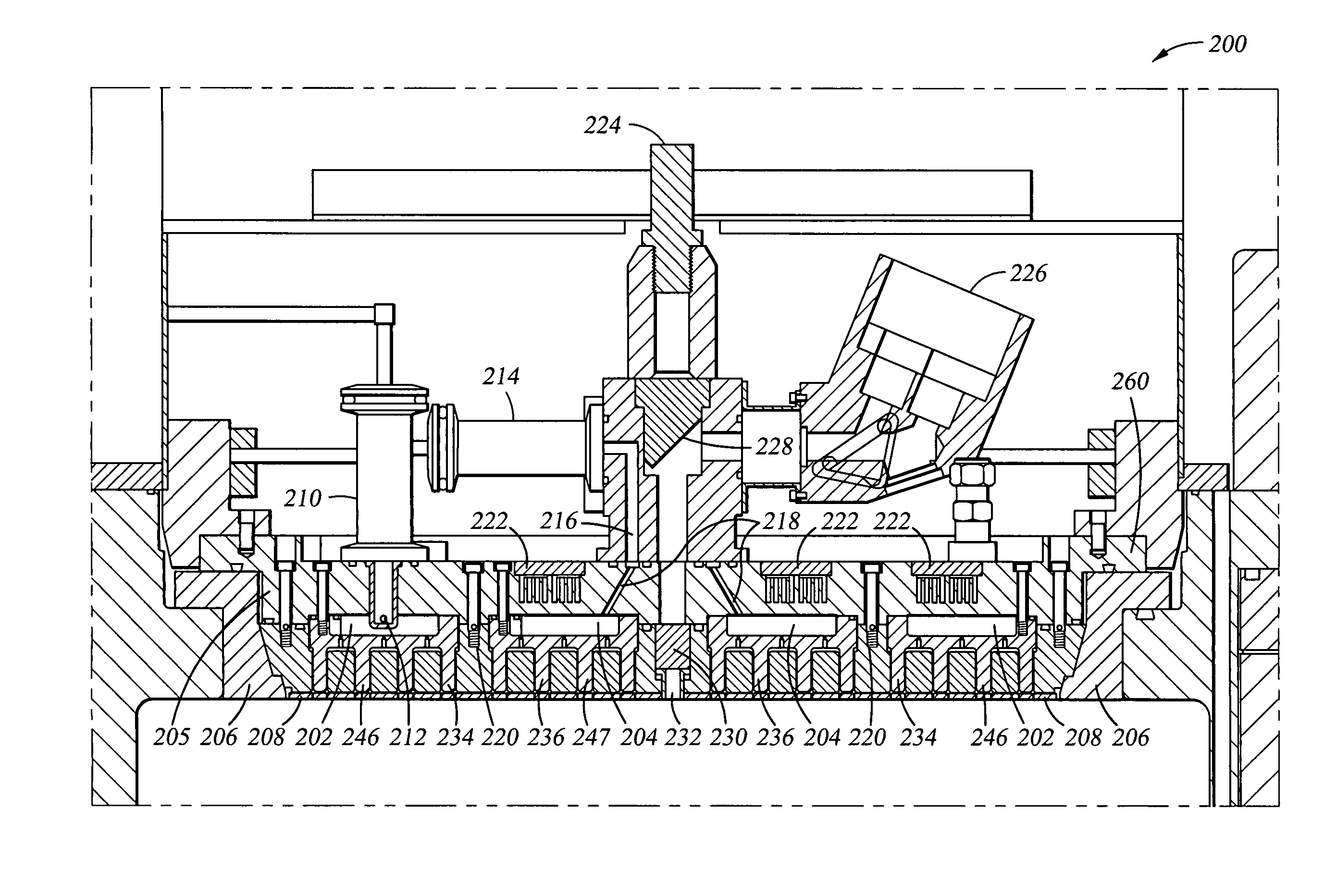

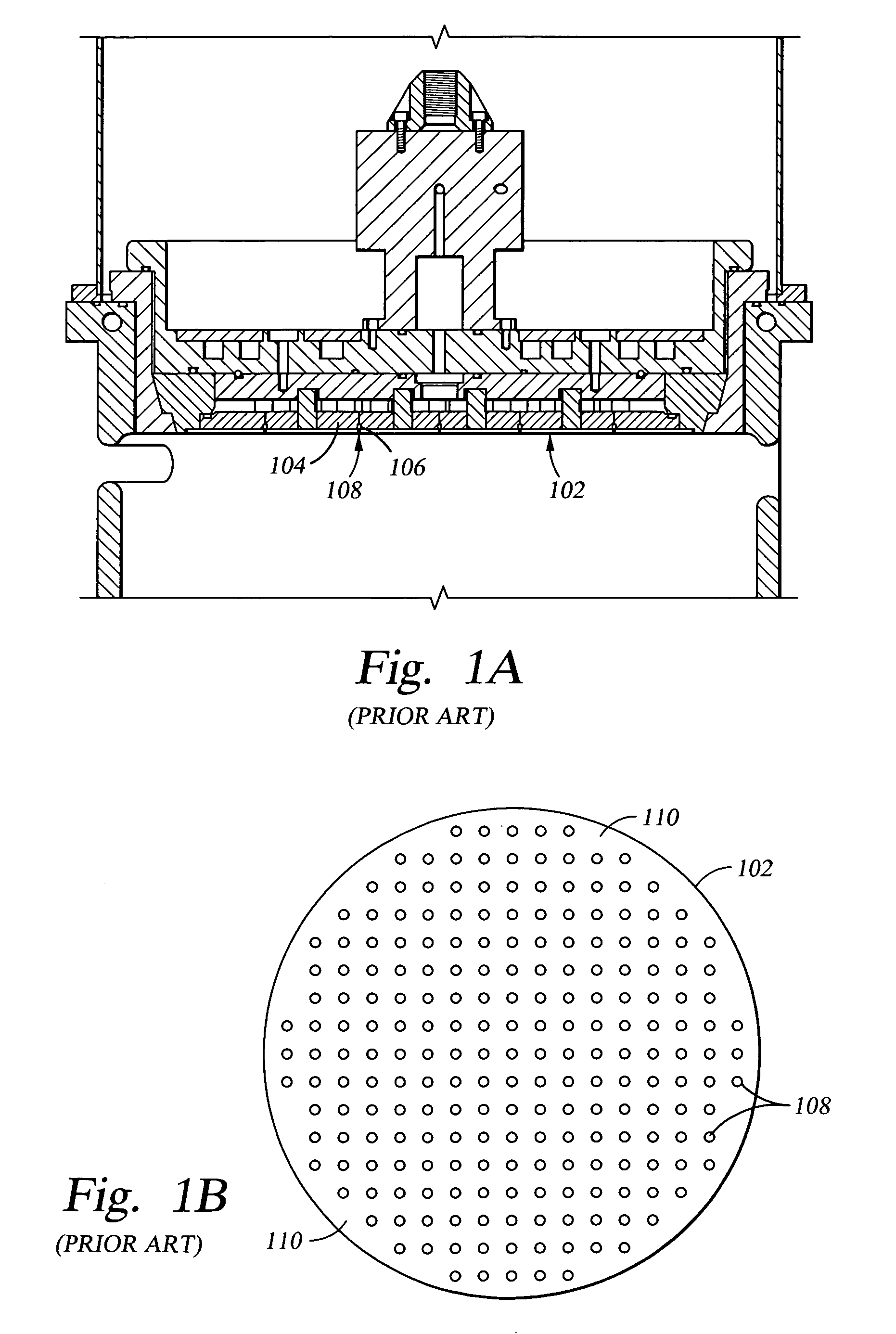

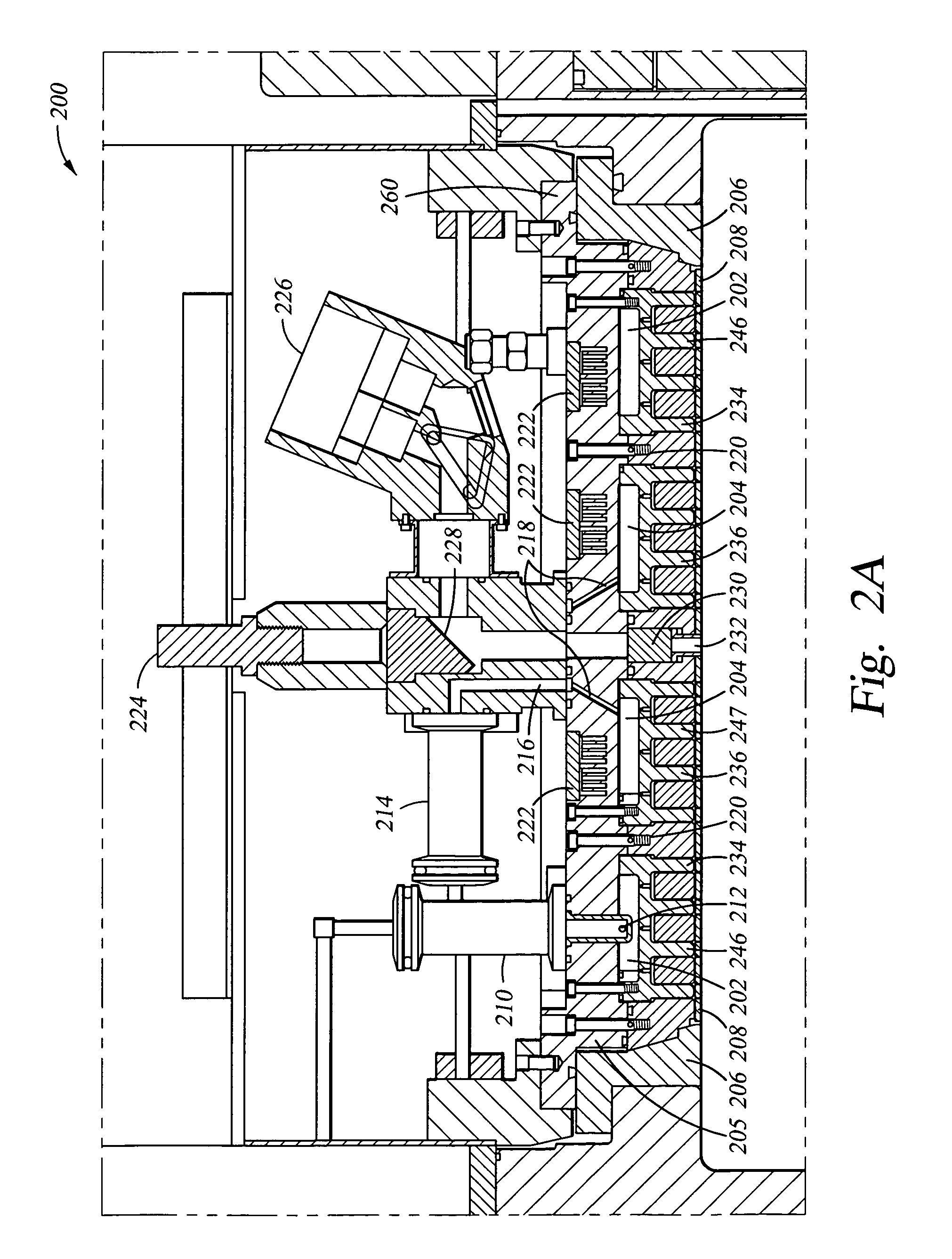

ActiveUS20050173569A1Easy to disassembleAvoid ignitionSelf-acting watering devicesSpray nozzlesEngineeringPlasma ignition

We have developed a gas distribution showerhead assembly, for use in a semiconductor processing chamber, which can be easily cleaned, with minimal chamber downtime. The gas distribution showerhead assembly includes an electrode having openings therethrough, and a gas distribution plate which includes a plurality of through-holes for delivering processing gases into the semiconductor processing chamber. The gas distribution plate is bonded to a first, lower major surface of the electrode. A removable insert which fits into an opening in the electrode through which gas flows. Spacing between surfaces of the removable insert and surfaces of the electrode is adequate to permit gas flow, but inadequate for plasma ignition within the opening. The removable insert can be easily removed during cleaning of the gas distribution showerhead, permitting the holes in the gas distribution plate to be easily accessed from both sides of the gas distribution plate.

Owner:APPLIED MATERIALS INC

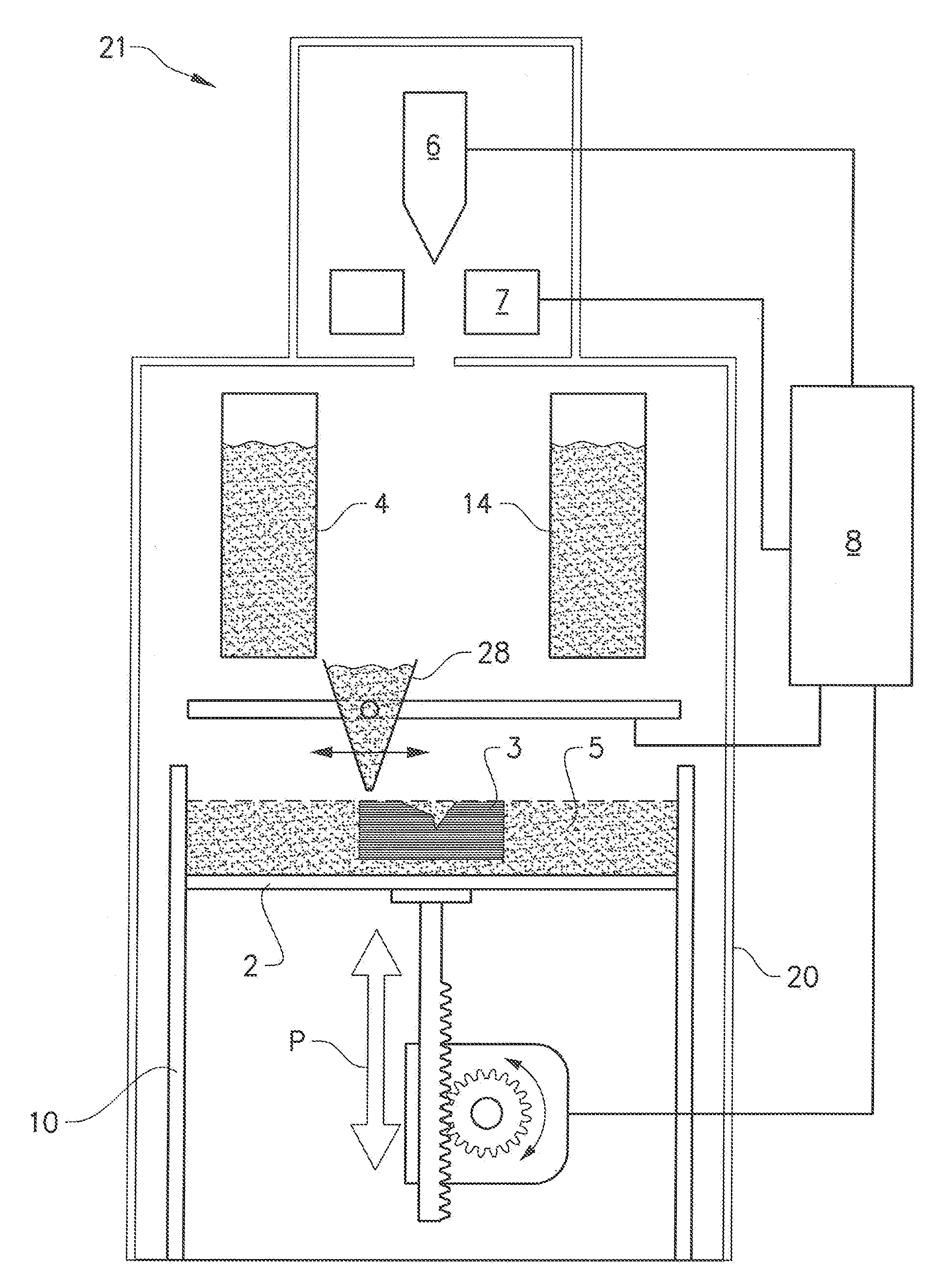

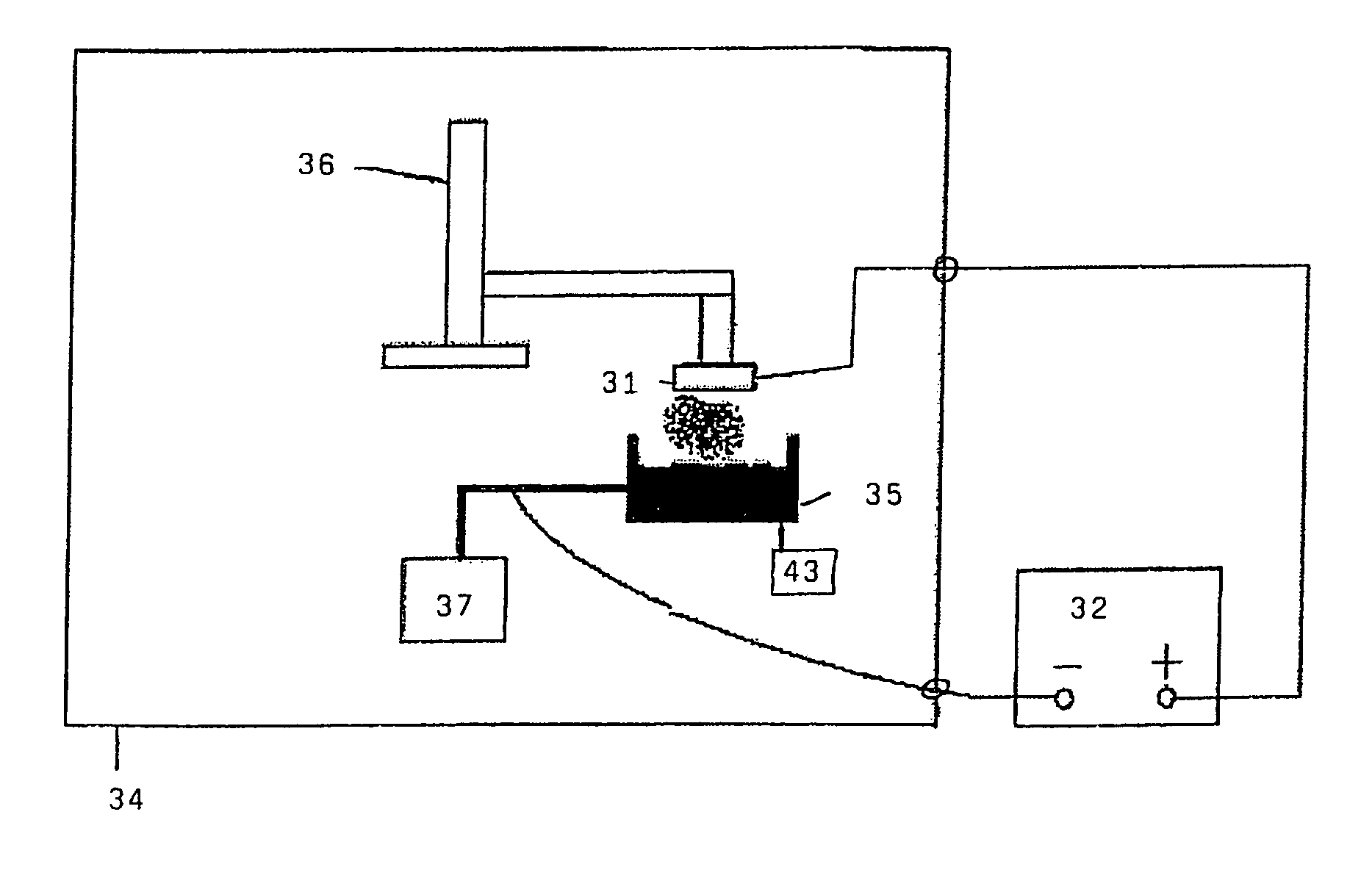

Layer application device for an electrostatic layer application of a building material in powder form and device and method for manufacturing a three-dimensional object

ActiveUS8124192B2Disadvantageous accuracyDisadvantageous ratioLiquid surface applicatorsAdditive manufacturing apparatusConductive materialsVoltage source

A device and a method for applying powder onto an application surface has a powder container (35) and a voltage source (32) for applying a voltage between the powder container and the application surface, wherein the powder container (35) at least partially consists of a conductive material and the powder container (35) has an opening (35a) or is completely open at its side facing the application surface when the voltage is applied.

Owner:3D MICROPRINT +1

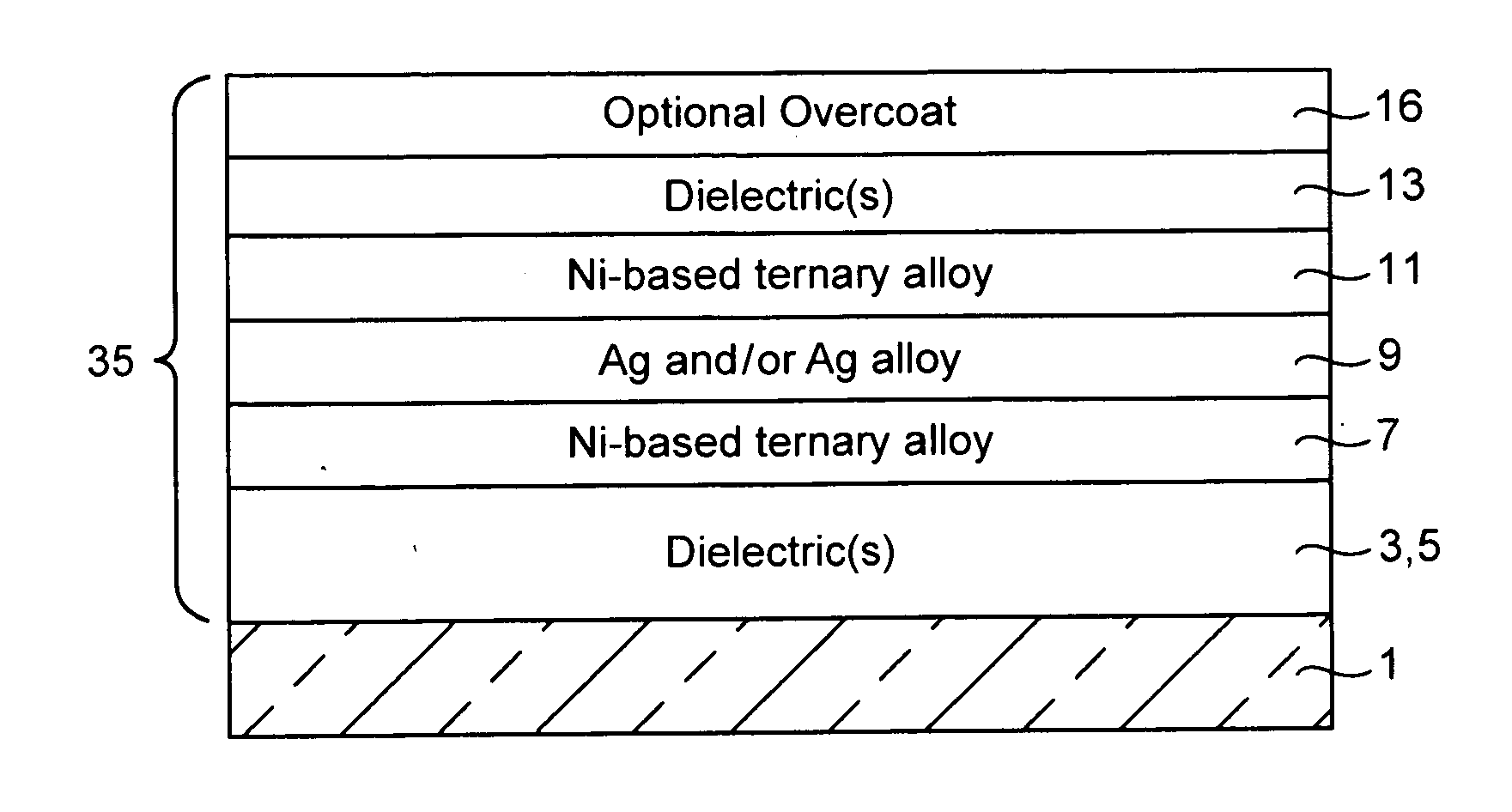

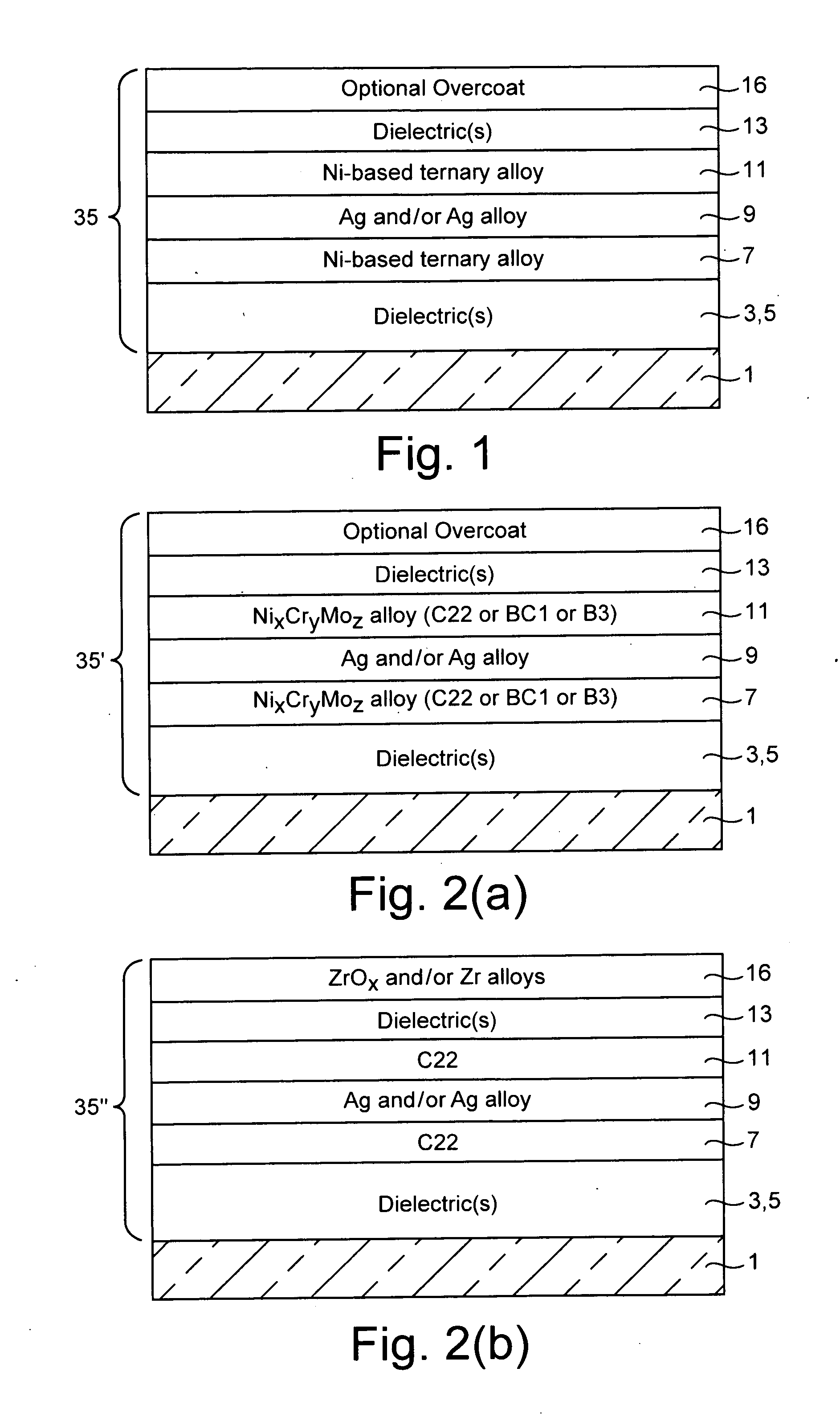

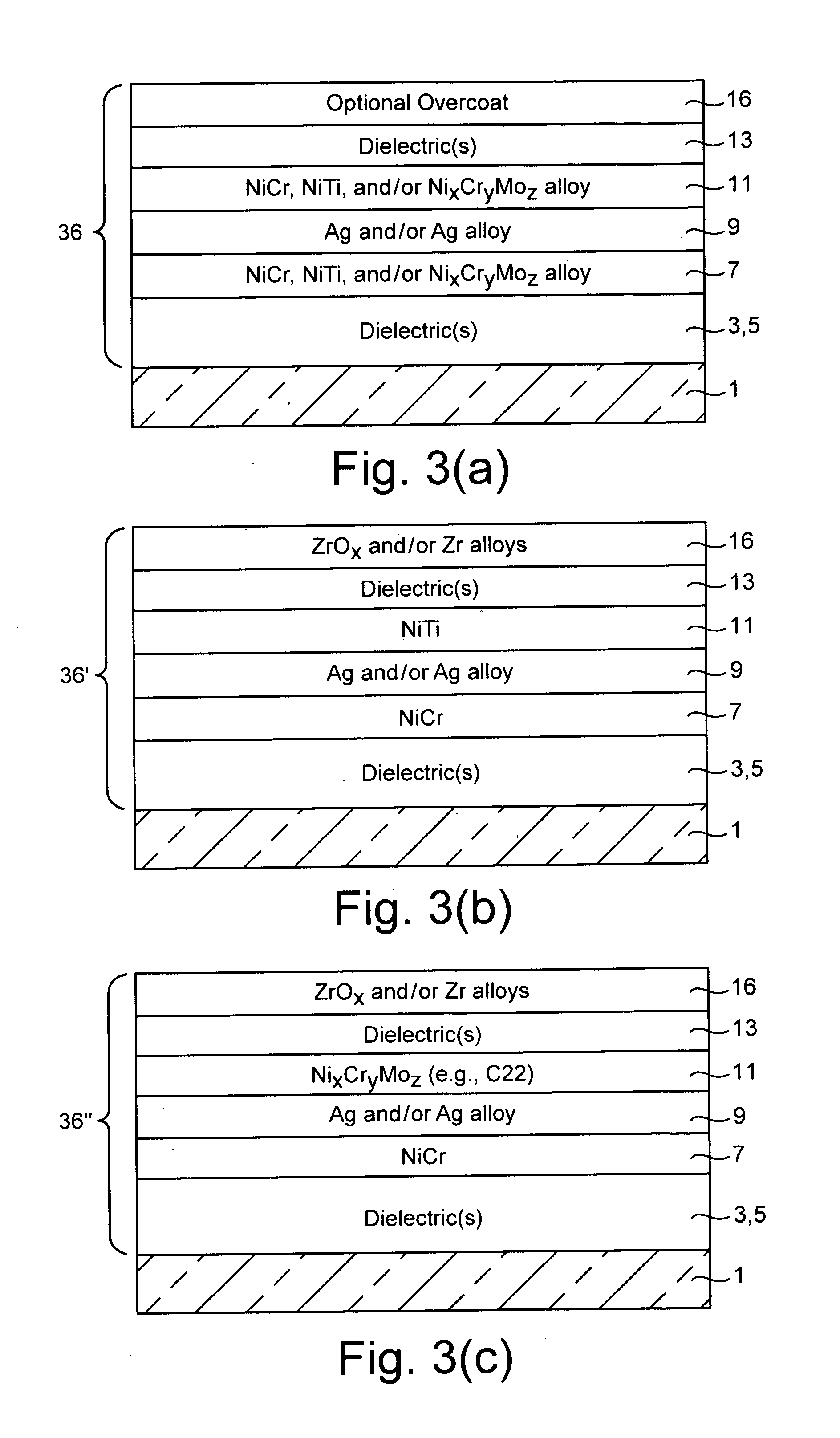

Barrier layers comprising Ni-inclusive ternary alloys, coated articles including barrier layers, and methods of making the same

ActiveUS20120225317A1Reduce sheet resistanceImprove transmittanceVacuum evaporation coatingSputtering coatingMaterials scienceChromium

Certain example embodiments relate to Ni-inclusive ternary alloy being provided as a barrier layer for protecting an IR reflecting layer comprising silver or the like. The provision of a barrier layer comprising nickel, chromium, and / or molybdenum and / or oxides thereof may improve corrosion resistance, as well as chemical and mechanical durability. In certain examples, more than one barrier layer may be used on at least one side of the layer comprising silver. In still further examples, a NixCryMoz-based layer may be used as the functional layer, rather than or in addition to as a barrier layer, in a coating.

Owner:GUARDIAN GLASS LLC

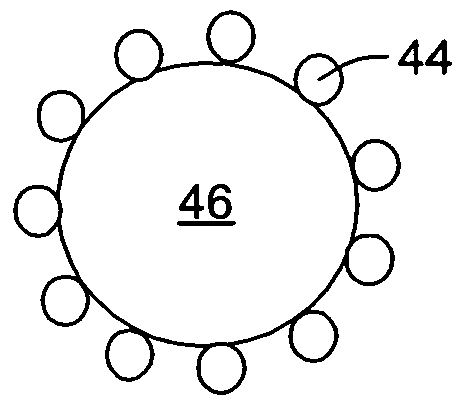

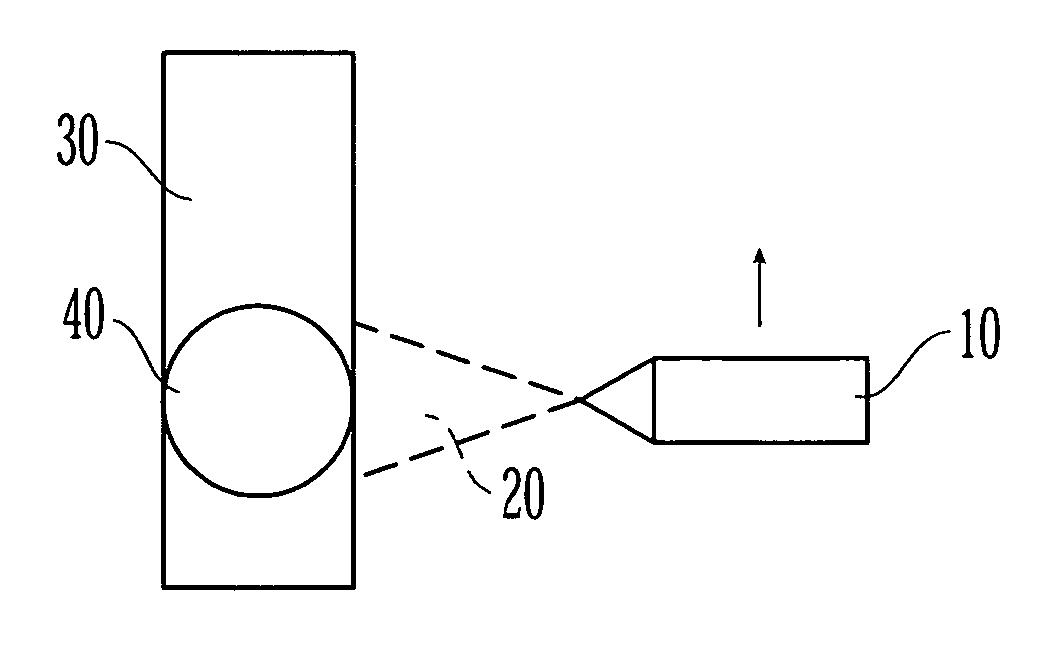

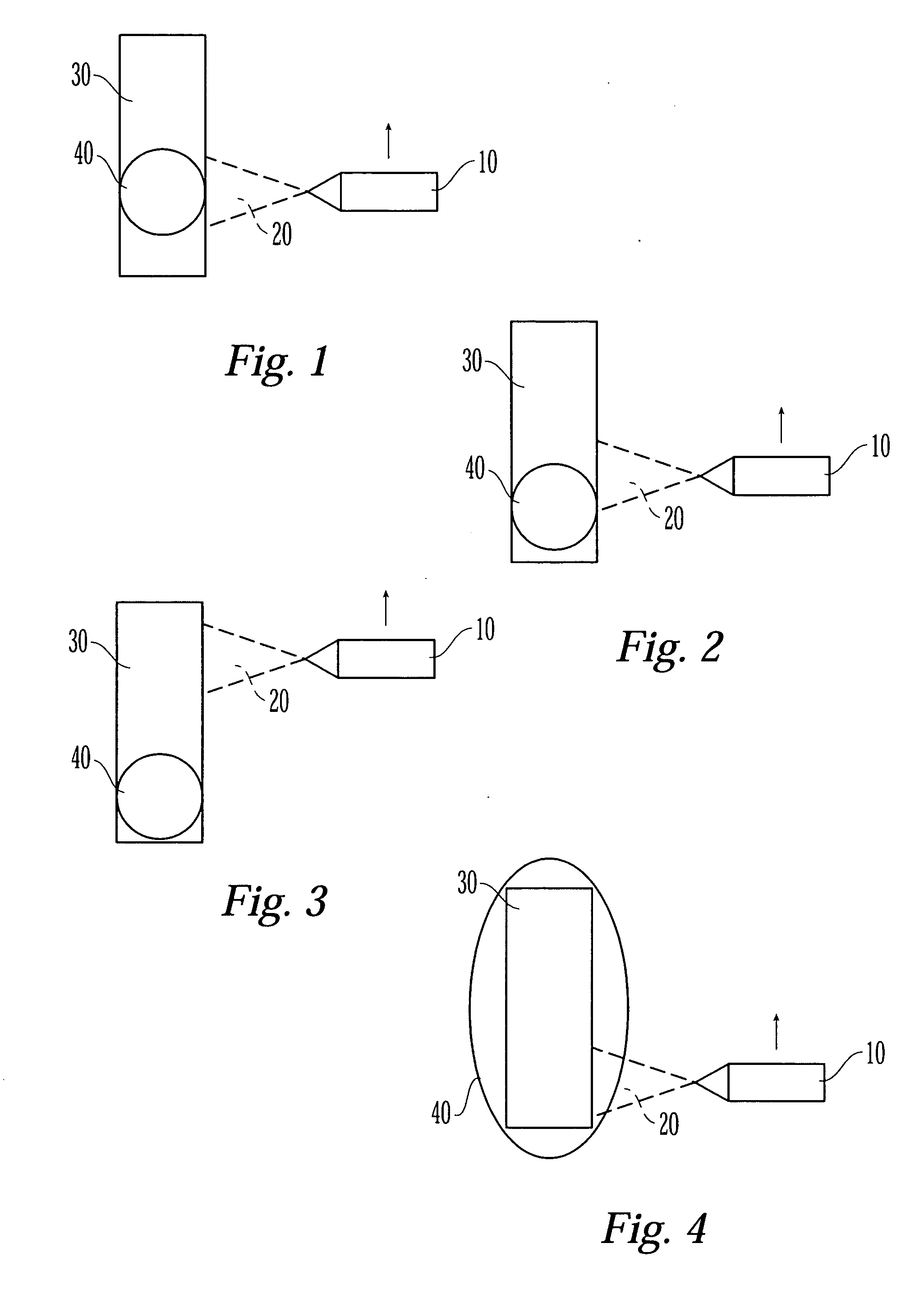

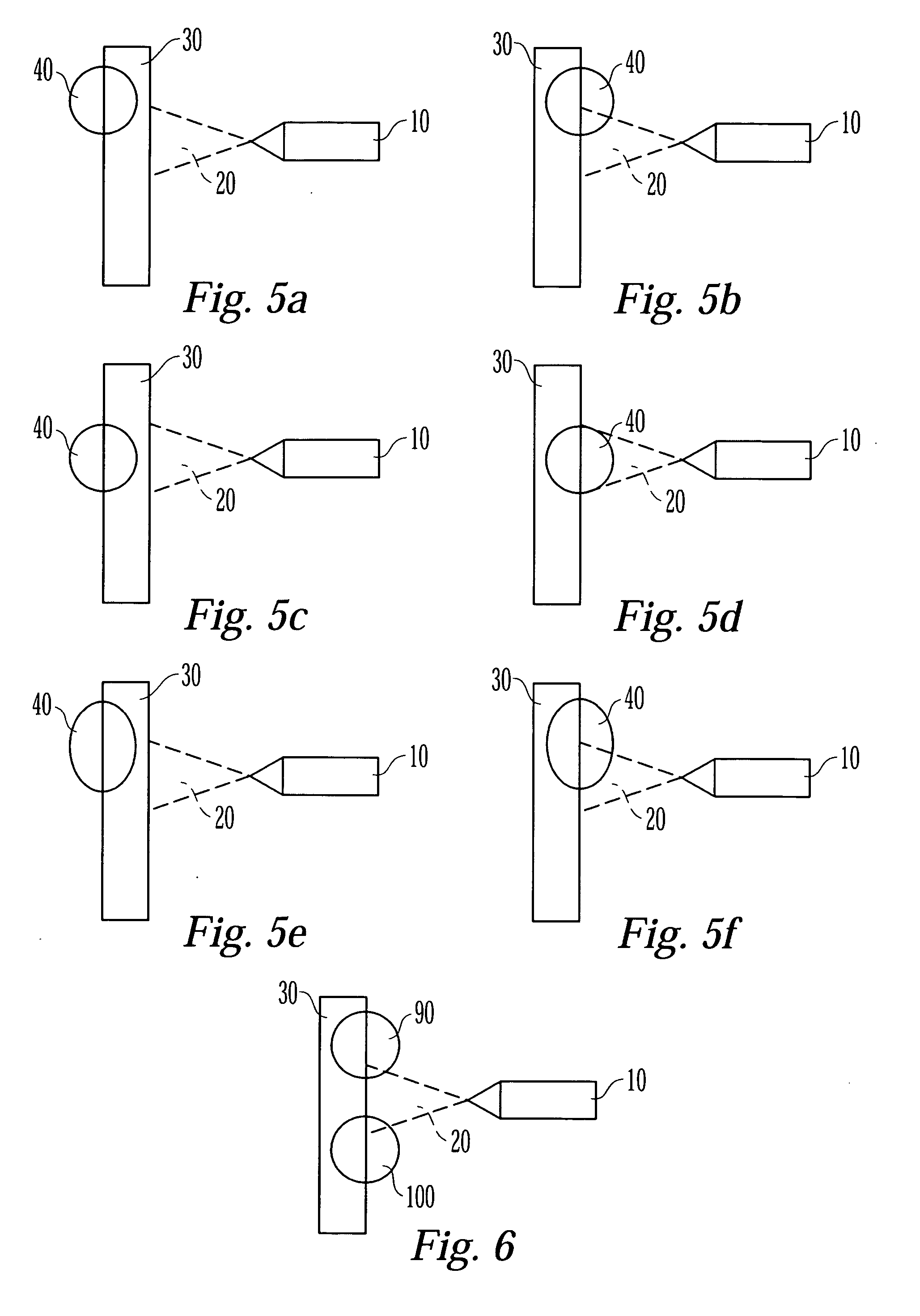

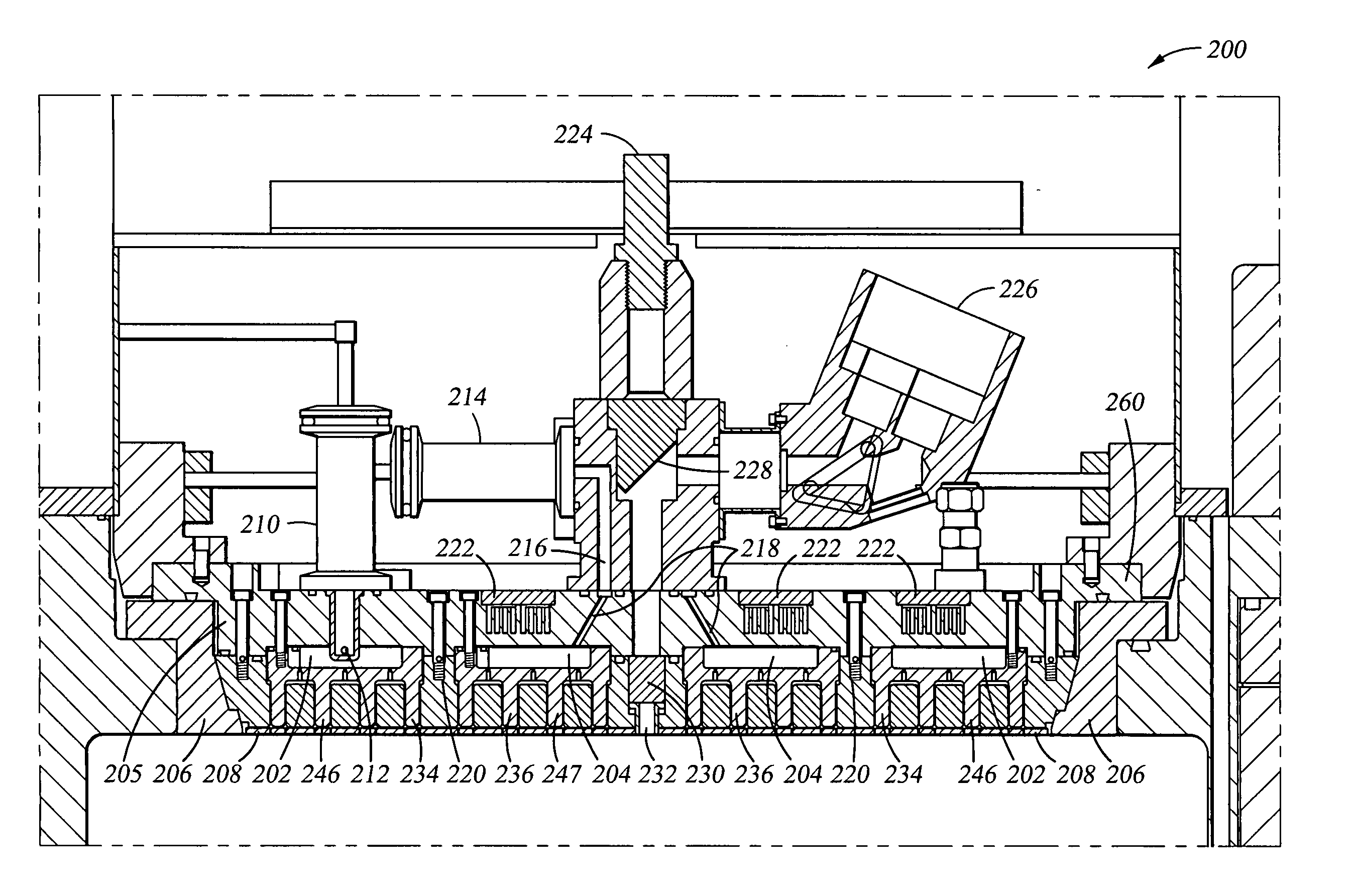

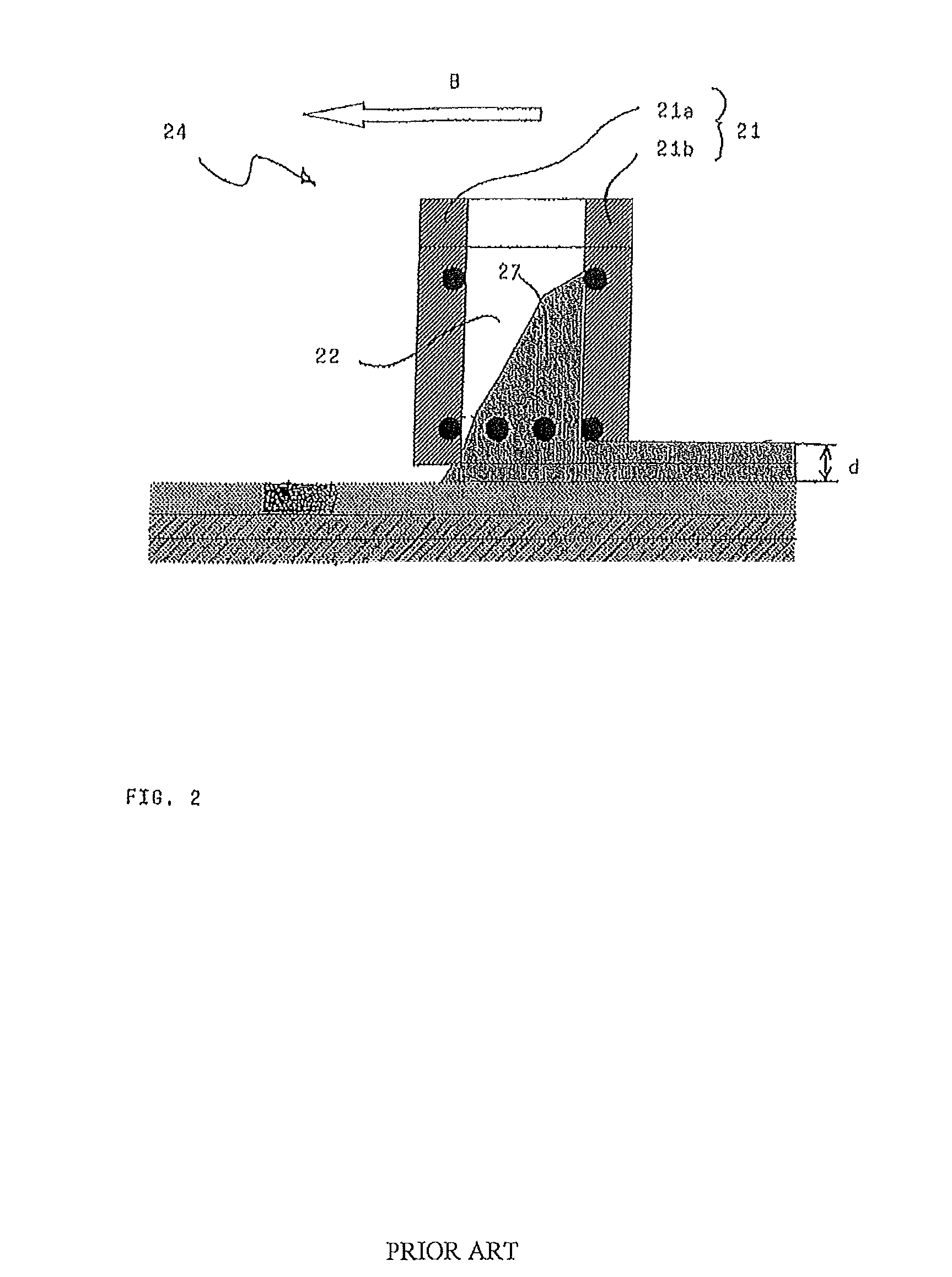

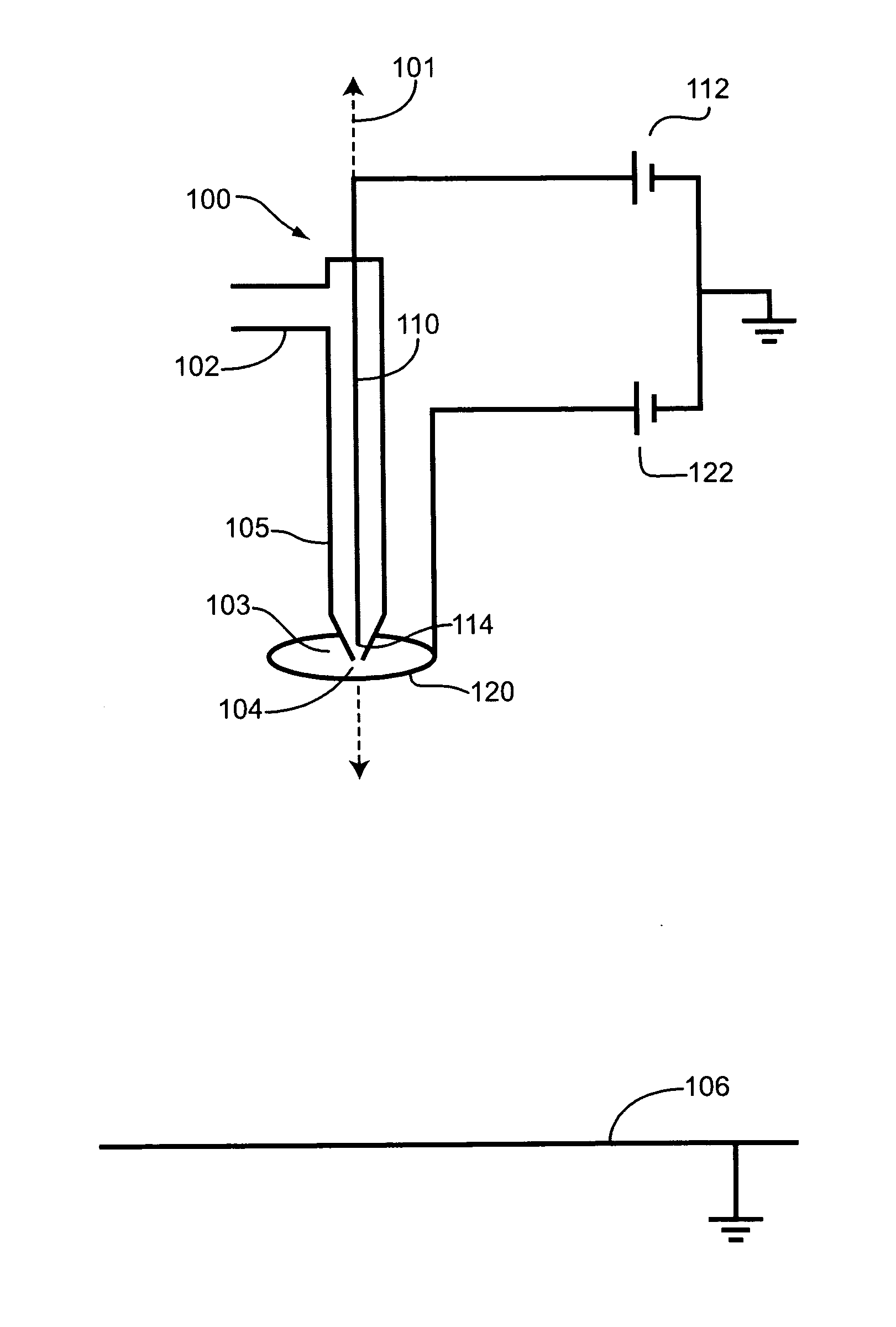

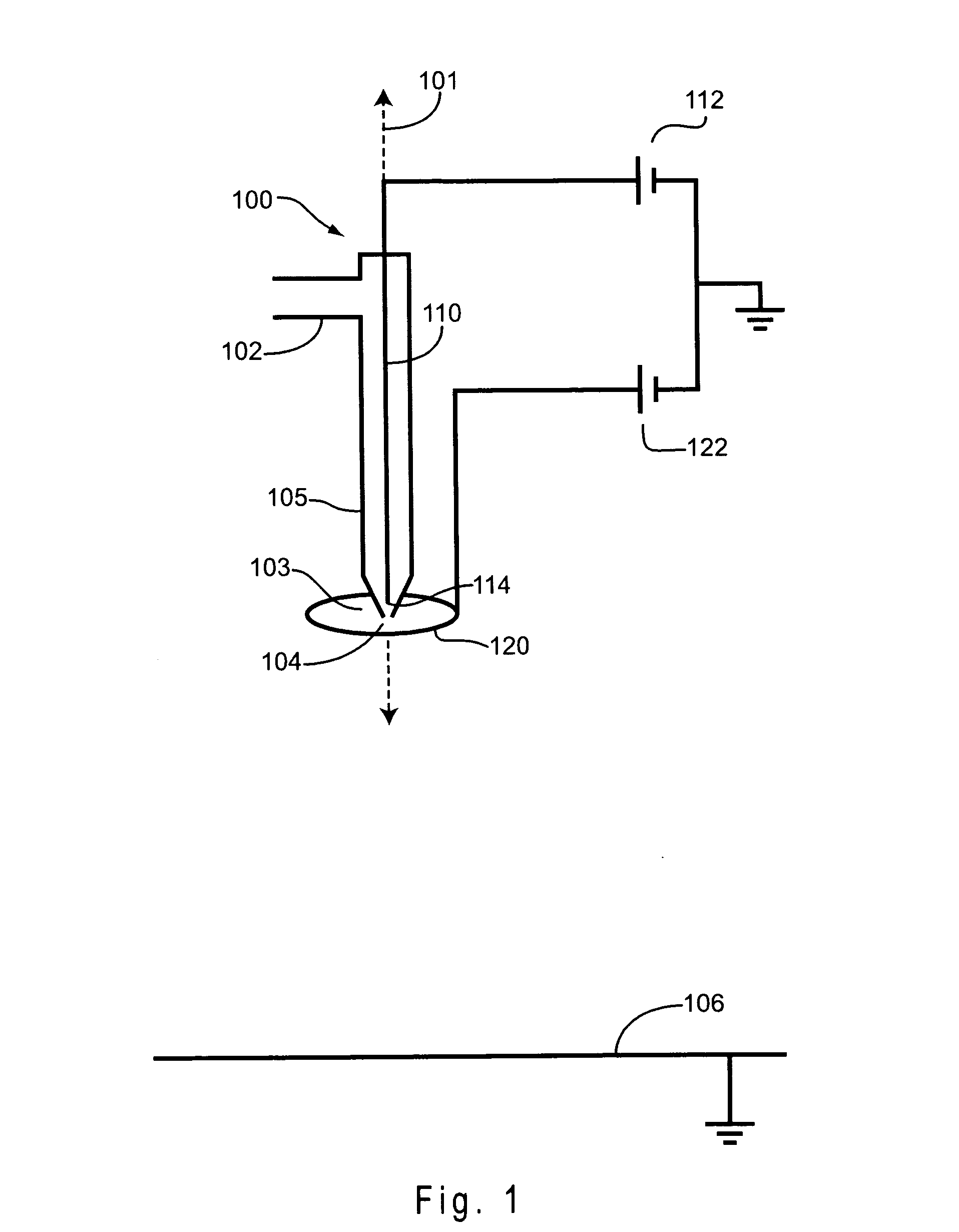

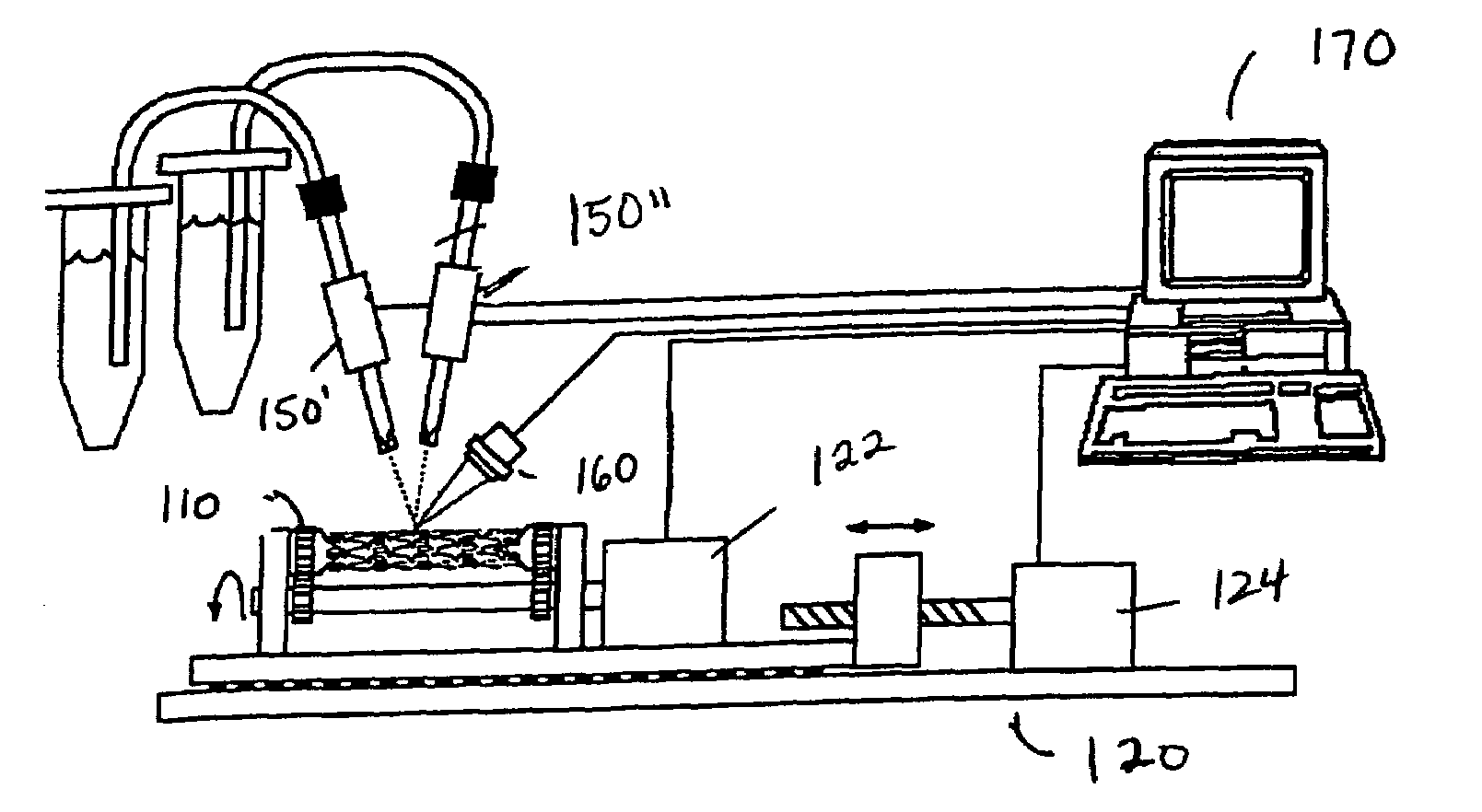

Electrohydrodynamic spraying system

An electrohydrodynamic spray apparatus includes a liquid inlet and a spray nozzle in fluid communication with the liquid inlet, where the spray nozzle has an opening downstream of the liquid inlet. An inner electrode is situated at least partially inside the spray nozzle. An outer electrode is situated external to the spray nozzle and within about 100 mm of the opening of the nozzle. The electrohydrodynamic spray apparatus can be combined with a substrate to form an electrohydrodynamic spray system. The electrohydrodynamic spray apparatus or system can be used to form nanostructures such as nanodrops, nanoparticles and thin films.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

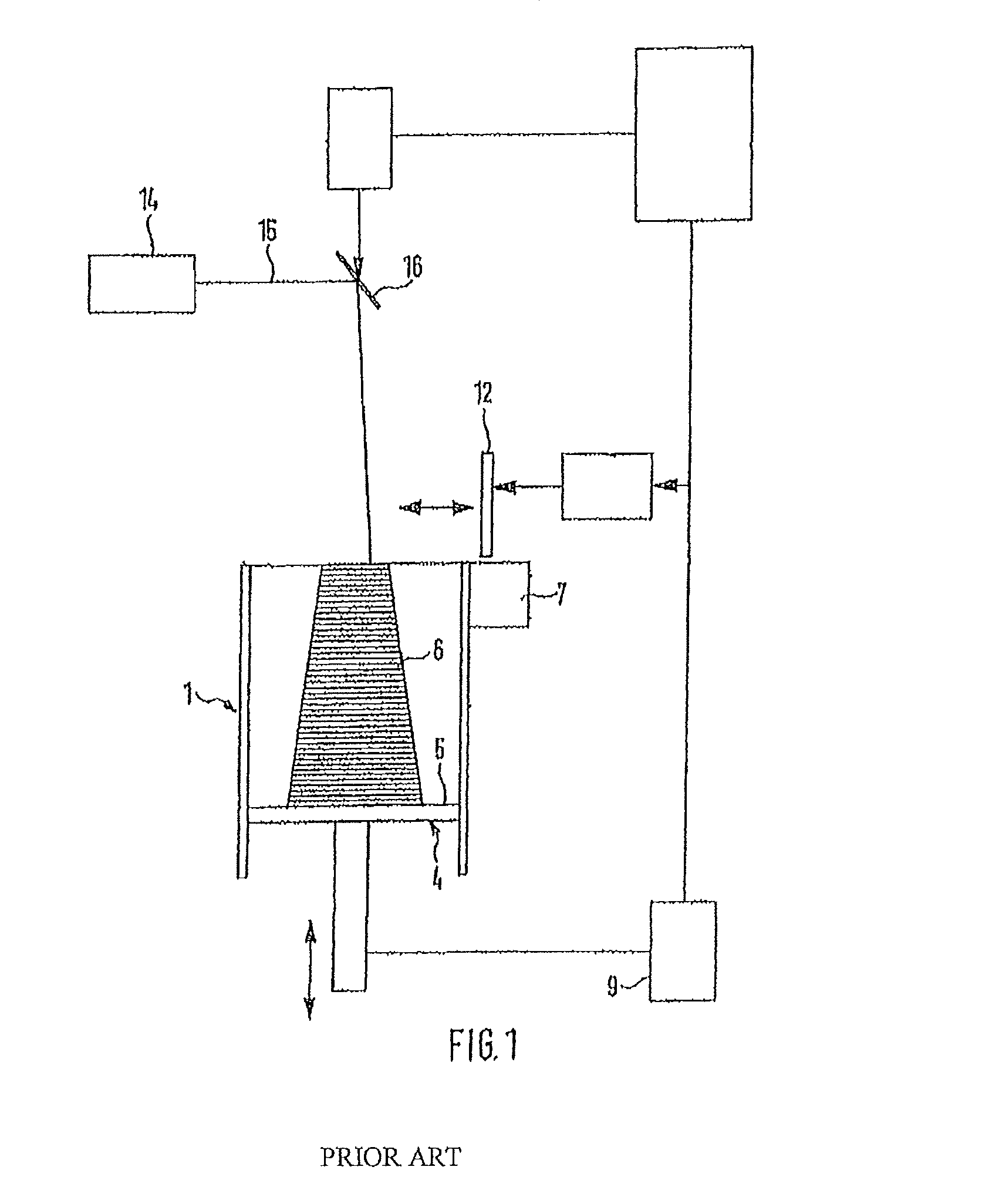

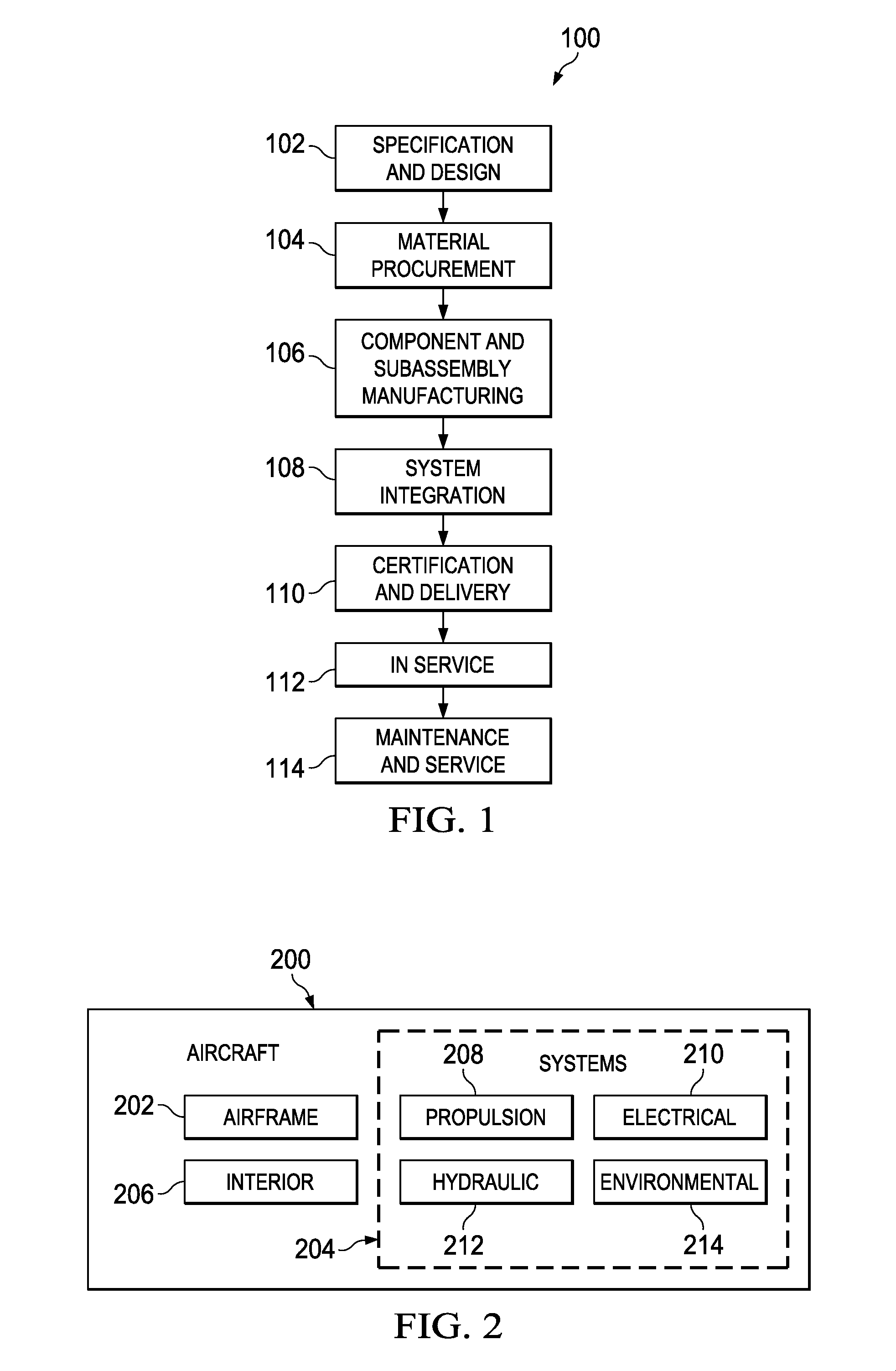

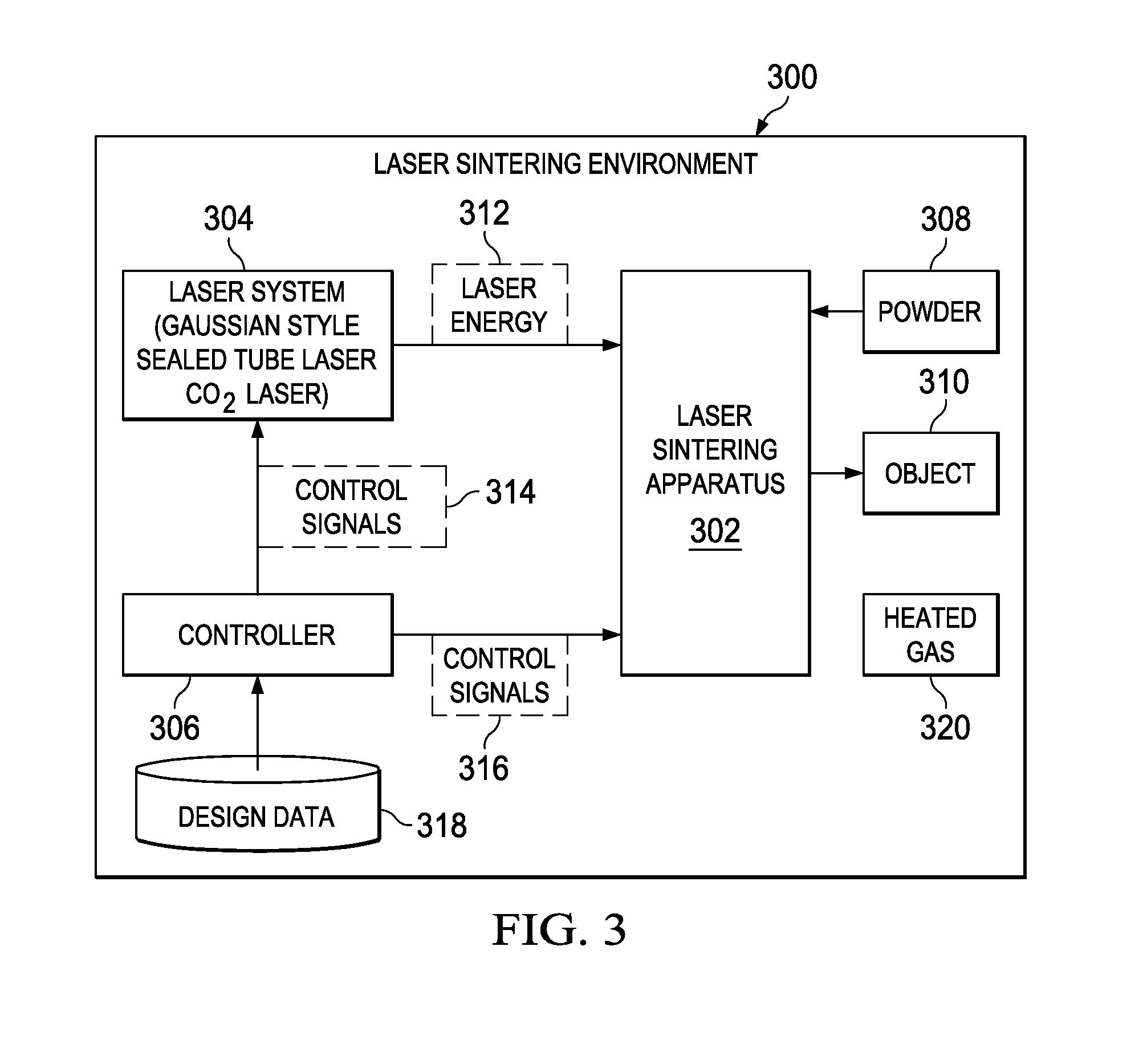

Geometry adaptive laser sintering system

An apparatus comprises a deformable platform and a laser delivery system. The deformable platform has a surface capable of changing to conform to a shape of an object as the object is being manufactured during a sintering process. The laser delivery system is capable of sintering powder on the deformable platform to manufacture the object.

Owner:THE BOEING CO

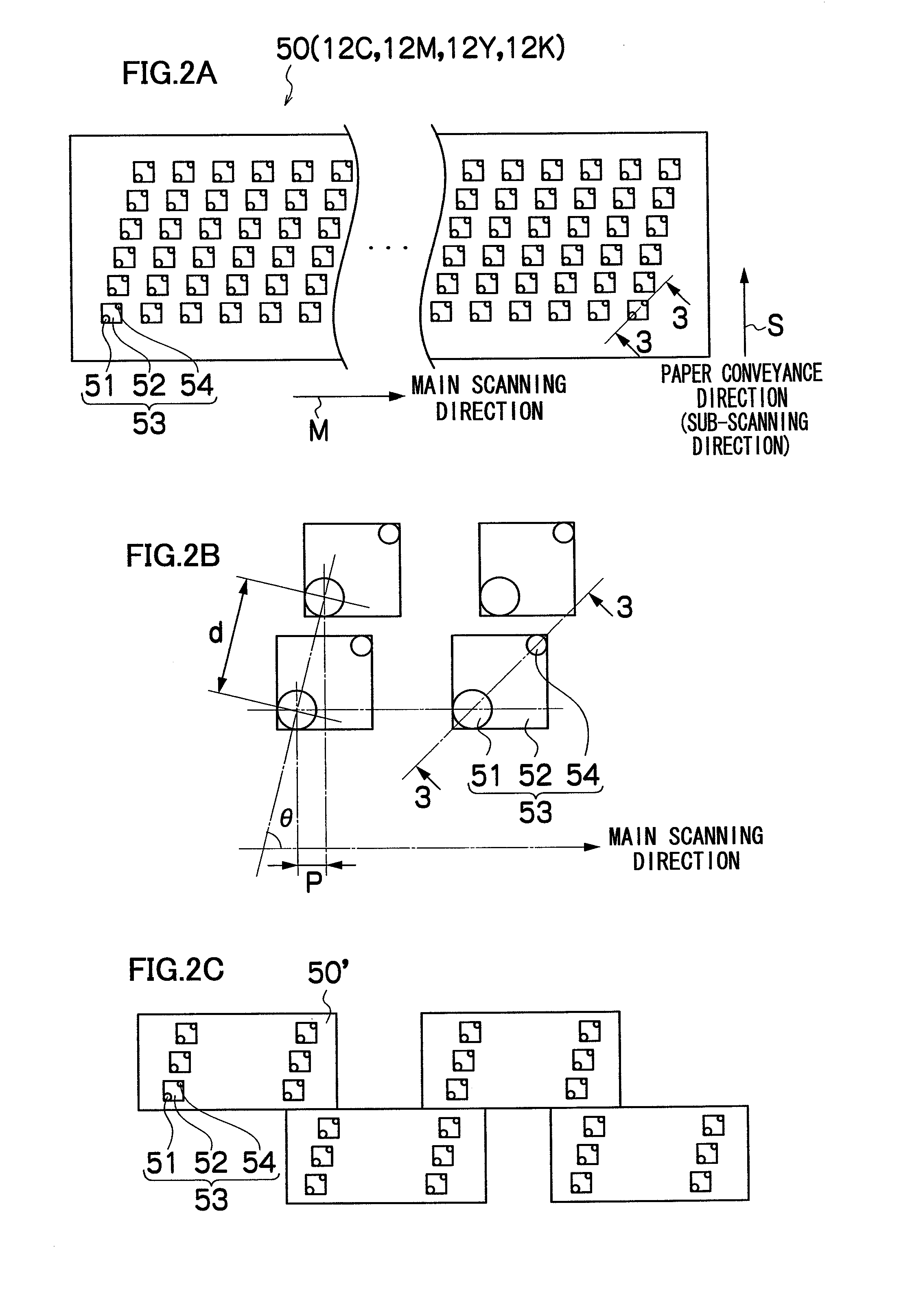

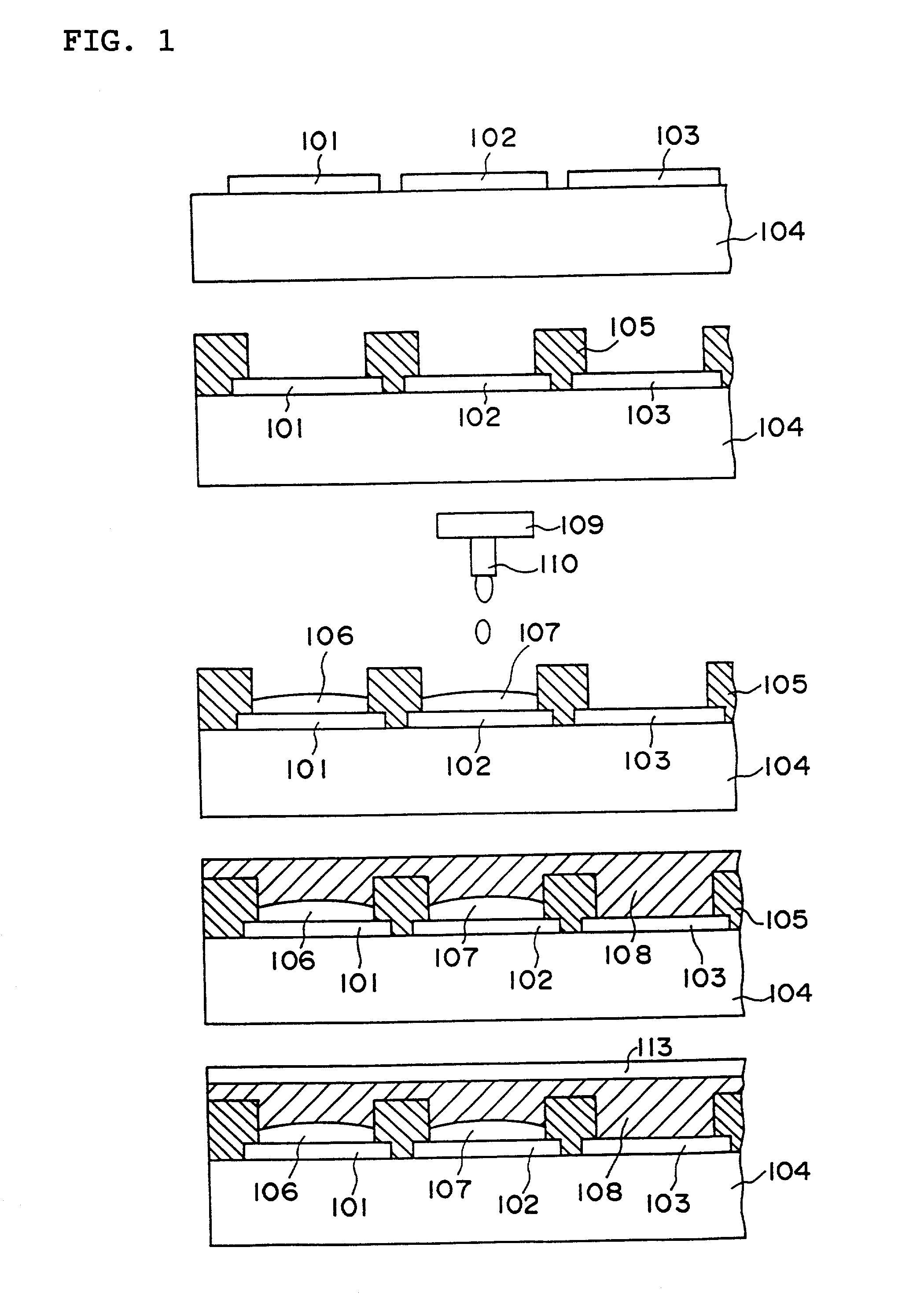

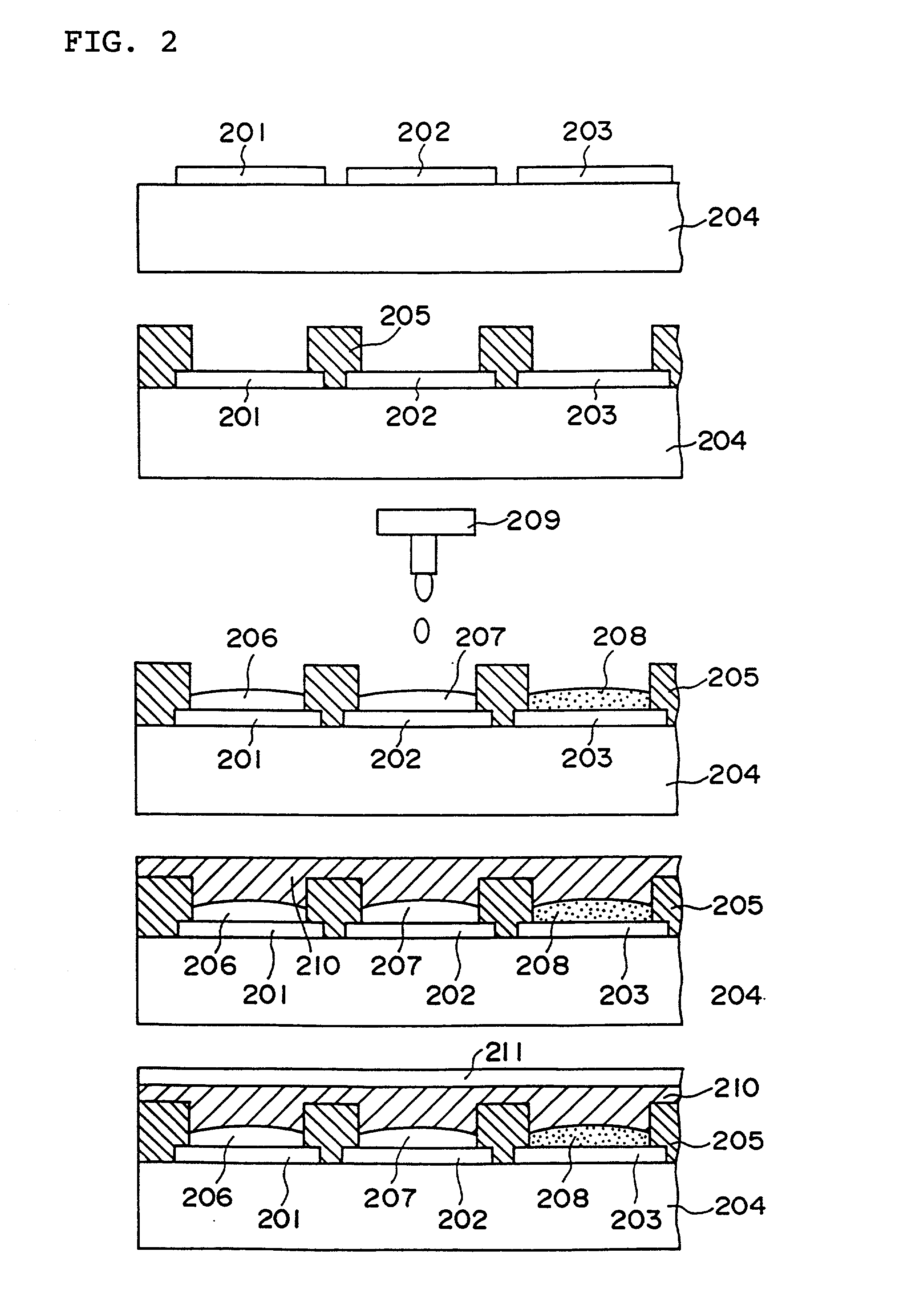

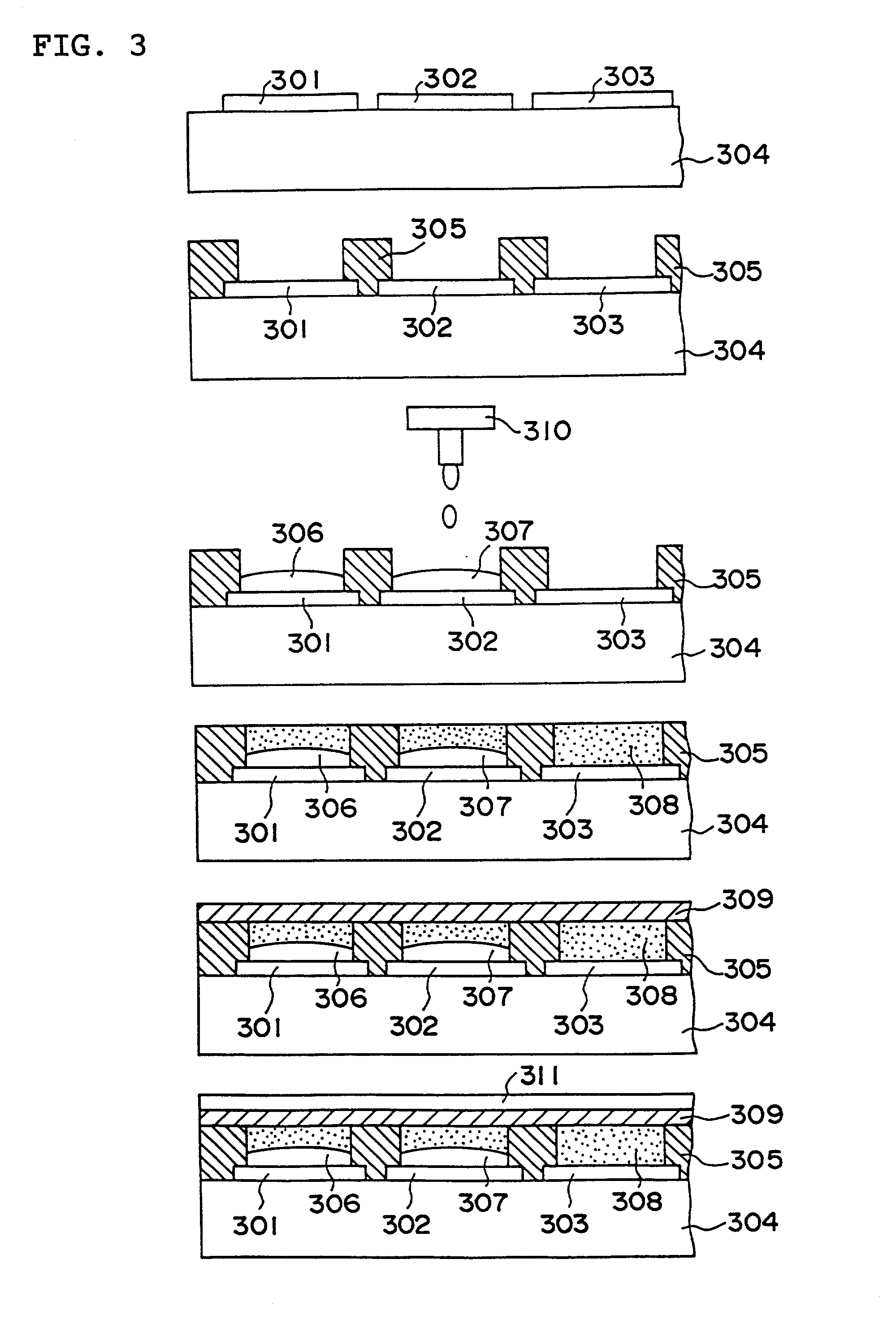

Method of manufacturing organic EL element, organic EL element, and organic EL display device

InactiveUS20020136823A1Excellent luminous propertiesEasy to carryMeasurement apparatus componentsSolid-state devicesDisplay deviceEngineering

A method of manufacturing an organic EL element according to the present invention comprises the steps of forming pixel electrodes (801), (802), (803) on a transparent substrate (804) and forming on the pixel electrodes by patterning luminescent layers (806), (807), (808) made of an organic compound by means of an ink-jet method. According to this method, it is possible to carry out a high precise patterning easily and in a short time, thereby enabling to carry out optimization for a film design and luminescent characteristic easily as well as making it easy to adjust a luminous efficiency.

Owner:SEIKO EPSON CORP

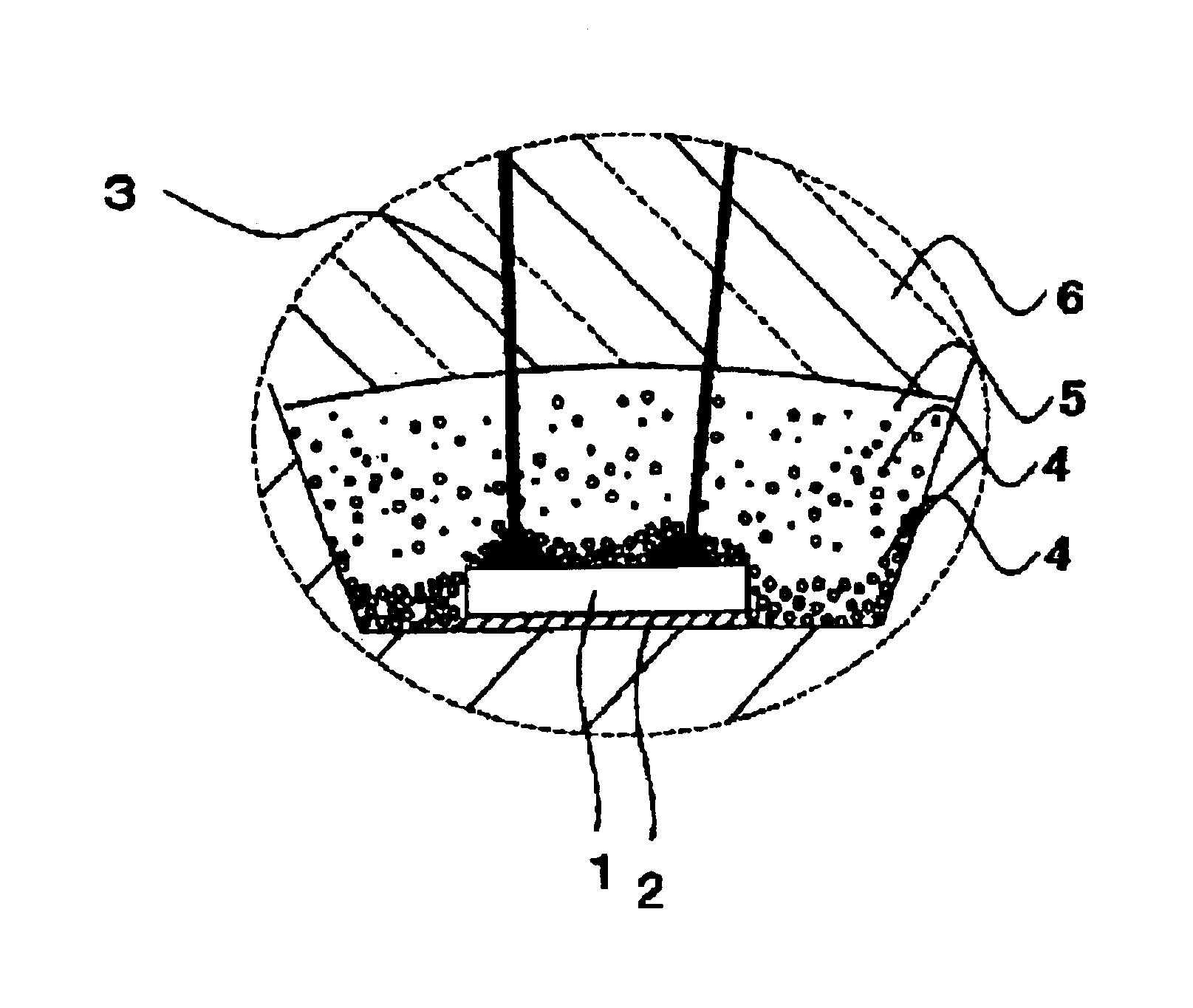

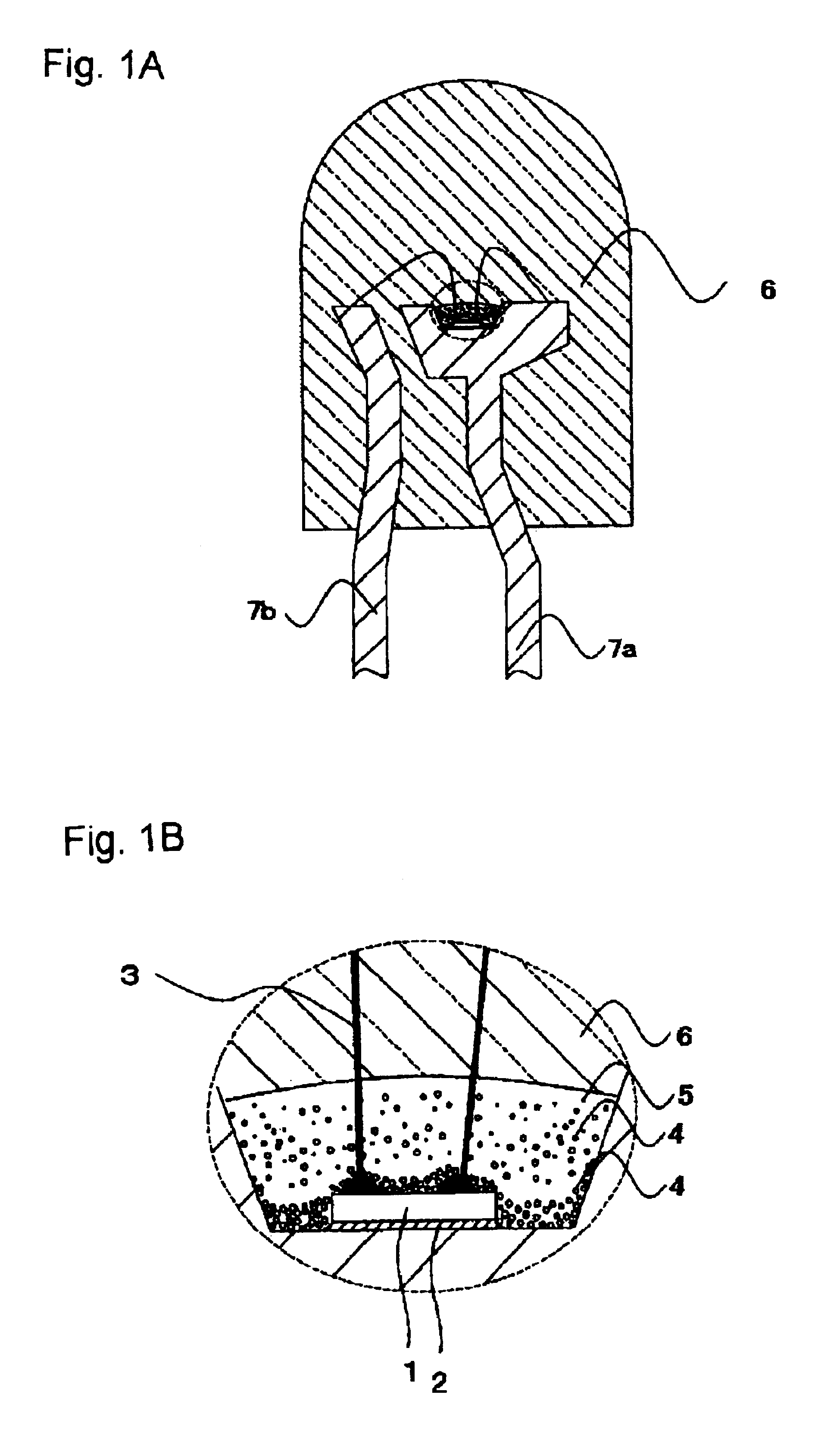

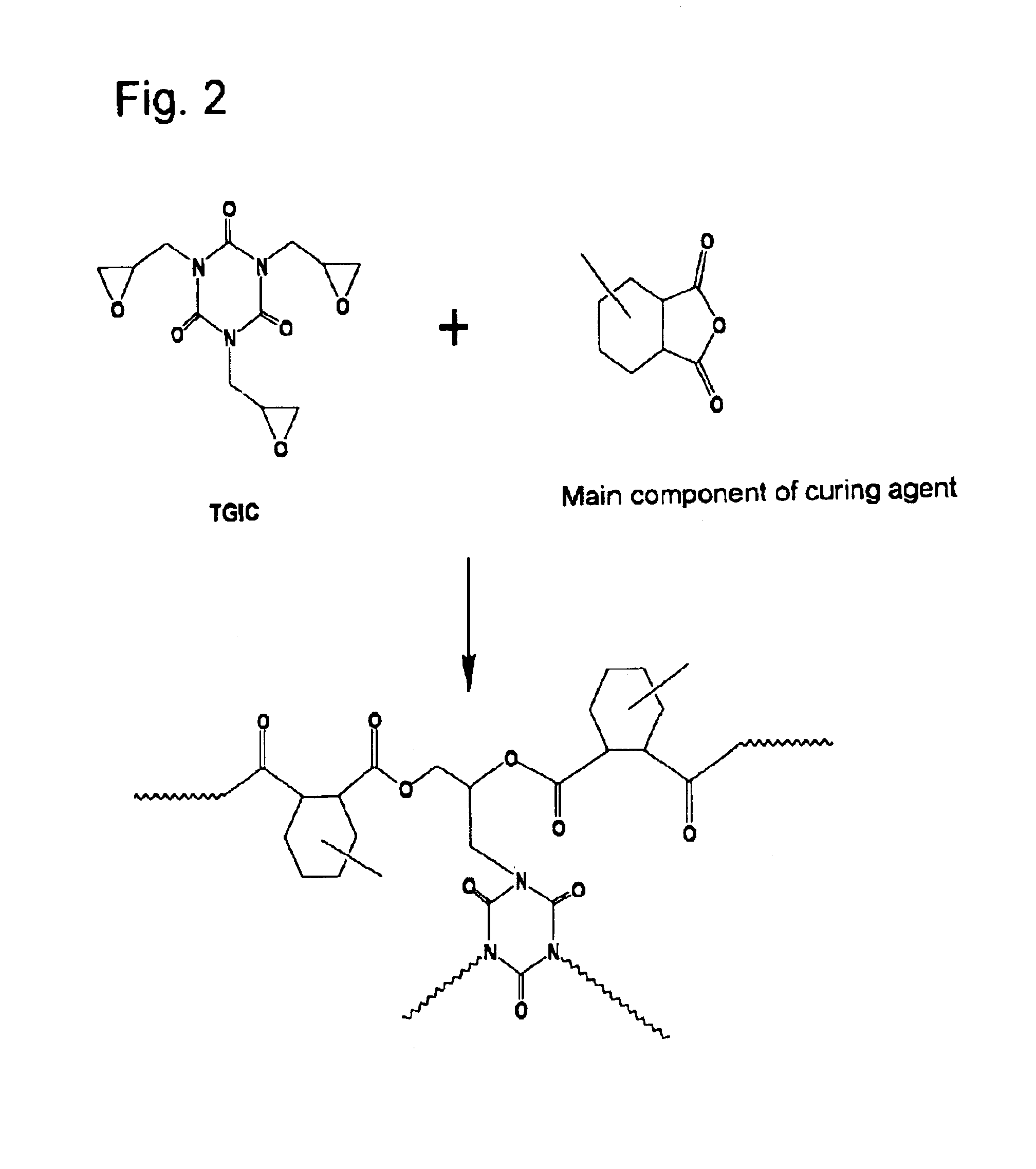

Light emitting apparatus provided with fluorescent substance and semiconductor light emitting device, and method of manufacturing the same

InactiveUS6924596B2Easy to manufactureGood dispersionDischarge tube luminescnet screensElectroluminescent light sourcesFluorescenceTriazine

In a light emitting apparatus comprising a light emitting device, a fluorescent substance capable of absorbing at least a portion of light emitted by the light emitting device and emitting light having a different wavelength, and a color converting member which contains the fluorescent substance and directly coat the light emitting device, the color converting member contains at least an epoxy resin derived from triazine and a mixing ratio of the epoxy resin derived from triazine to the acid anhydride curing agent in the color converting member is from 100:80 to 100:240.

Owner:NICHIA CORP

Method of loading beneficial agent to a prosthesis by fluid-jet application

An interventional device for delivery of beneficial agent to a lumen and methods of loading and manufacture of the same, which include a prosthesis loaded with beneficial agent to provide a controlled dosage concentration of beneficial agent to the lumen. The beneficial agent is loaded onto the prosthesis by a fluid-dispenser having a dispensing element capable of dispensing the beneficial agent in discrete droplets, each droplet having a controlled trajectory. The method of loading beneficial agent includes dispensing beneficial agent in a raster format and / or an off-axis format along a dispensing path.

Owner:ABBOTT LAB INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com