Patents

Literature

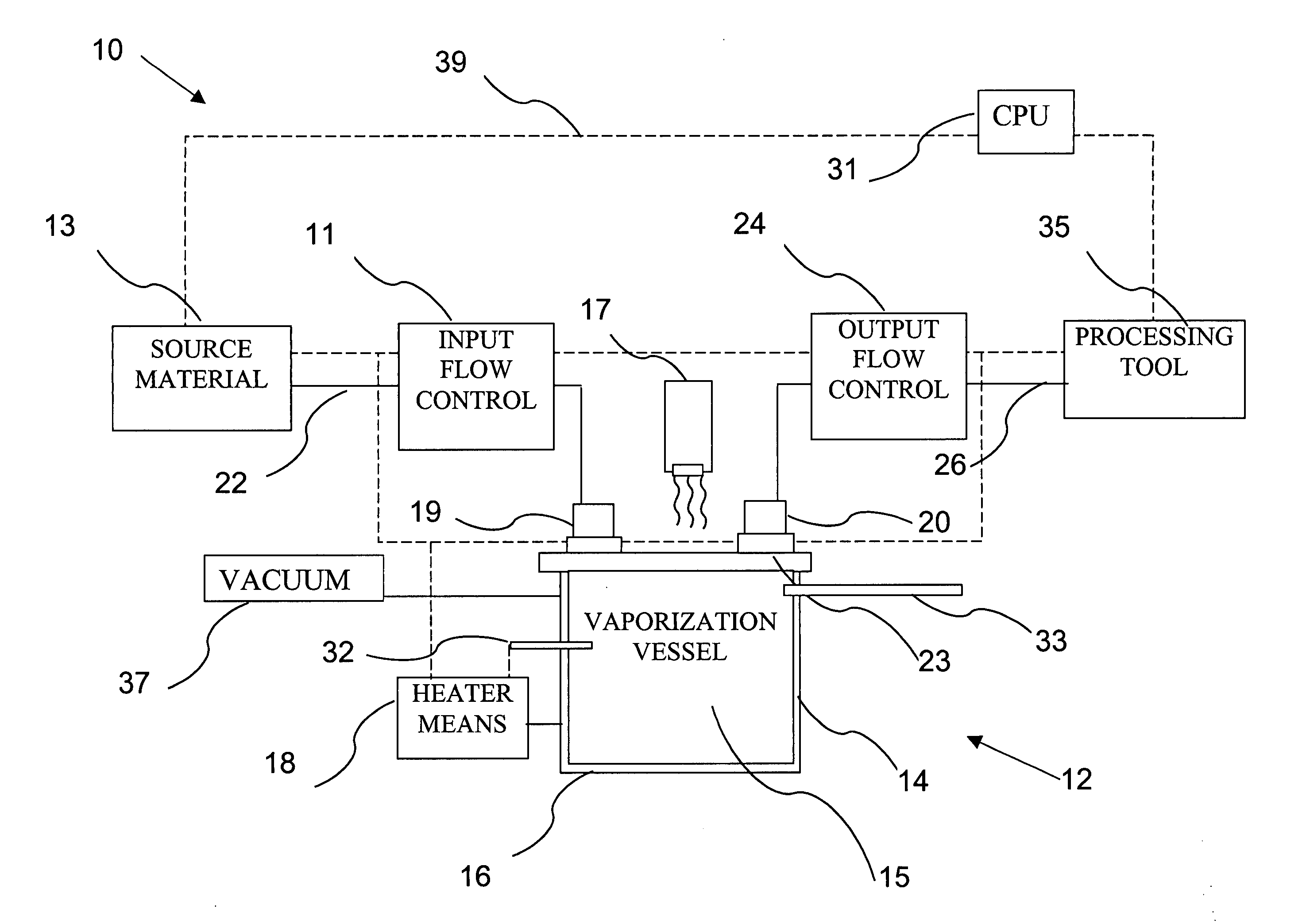

2181 results about "Source material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

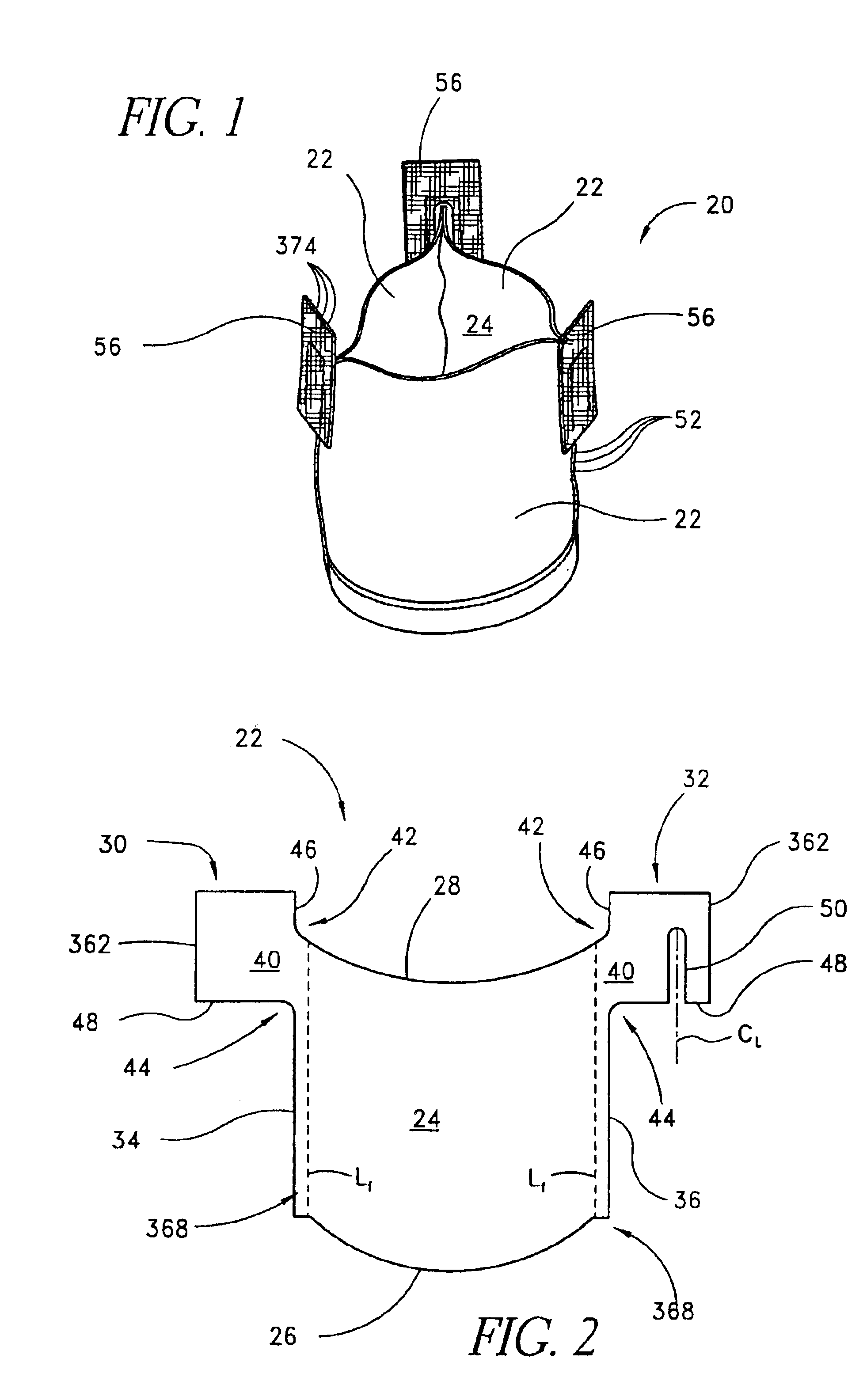

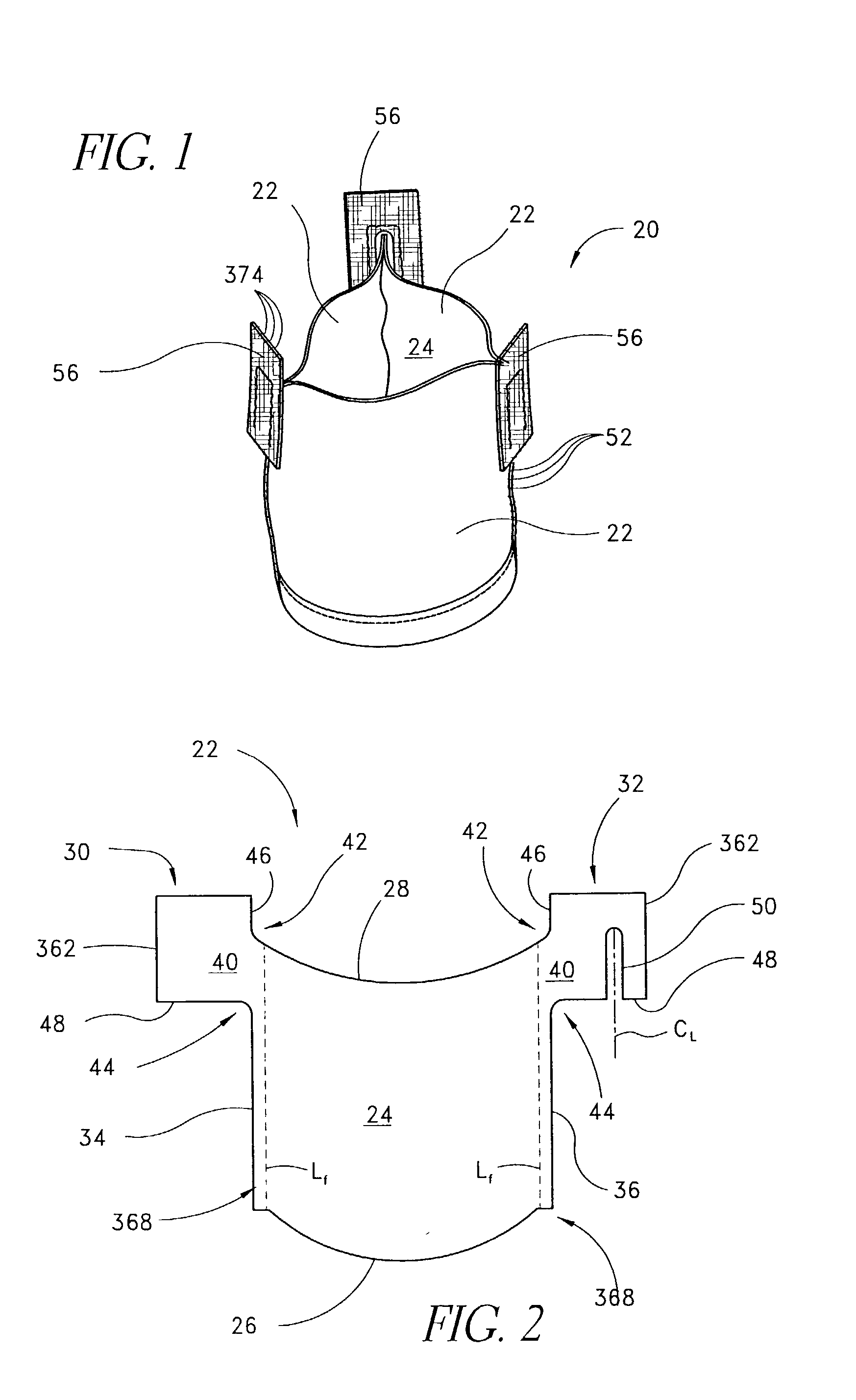

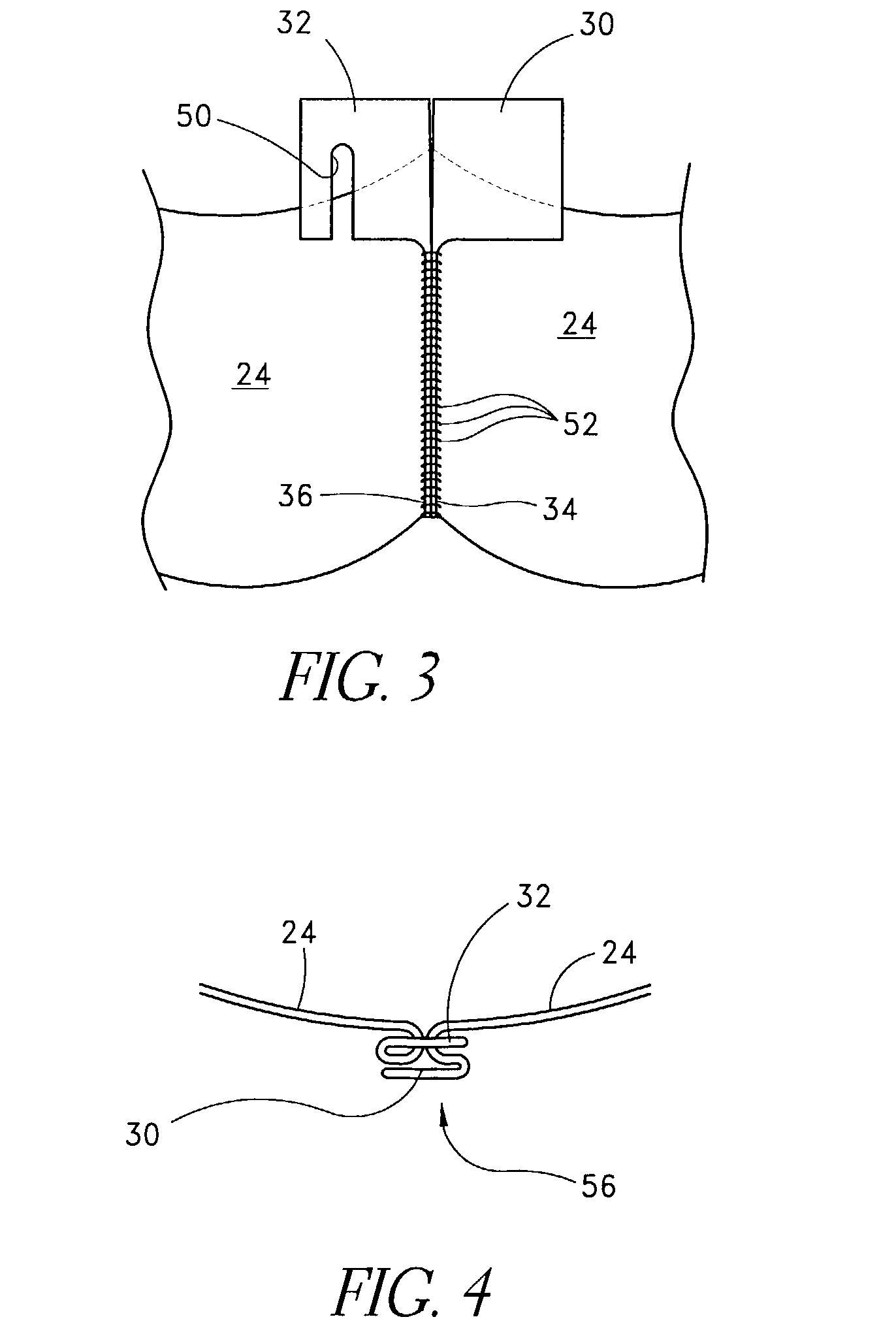

Smoking article

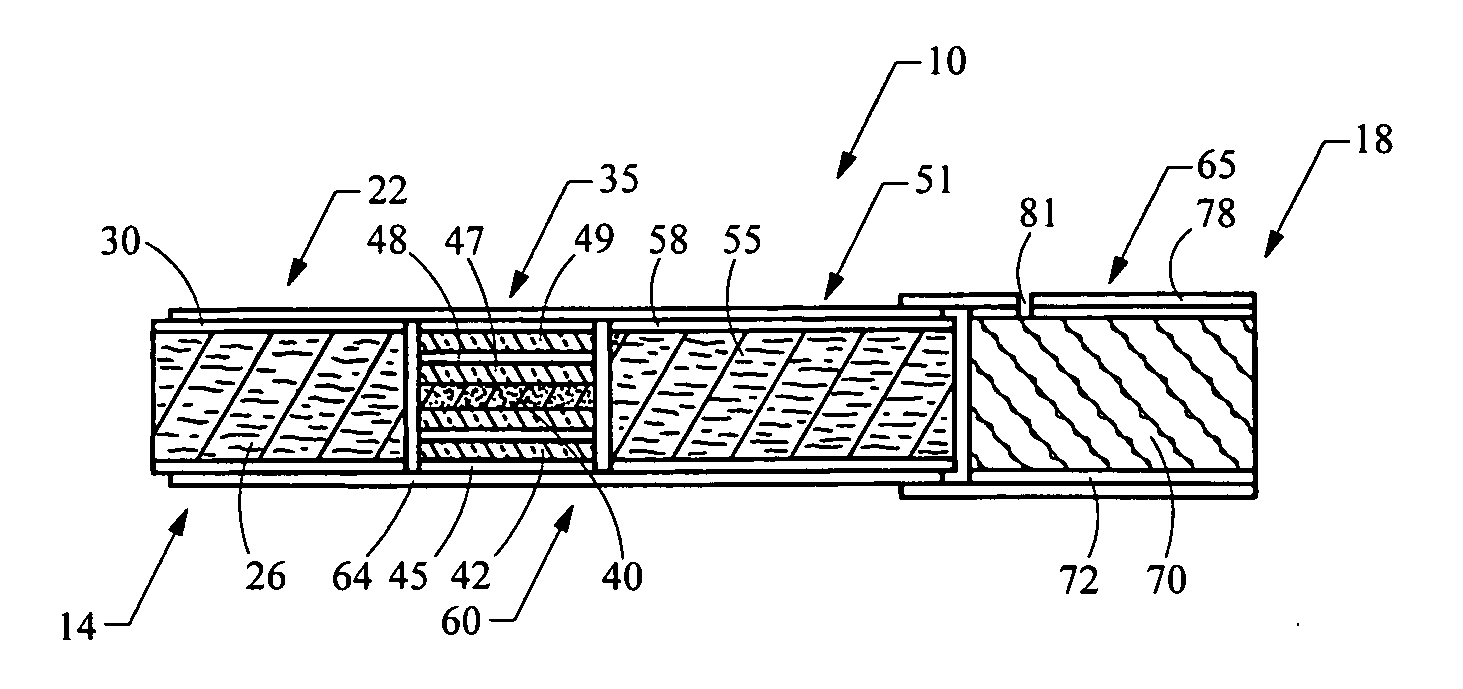

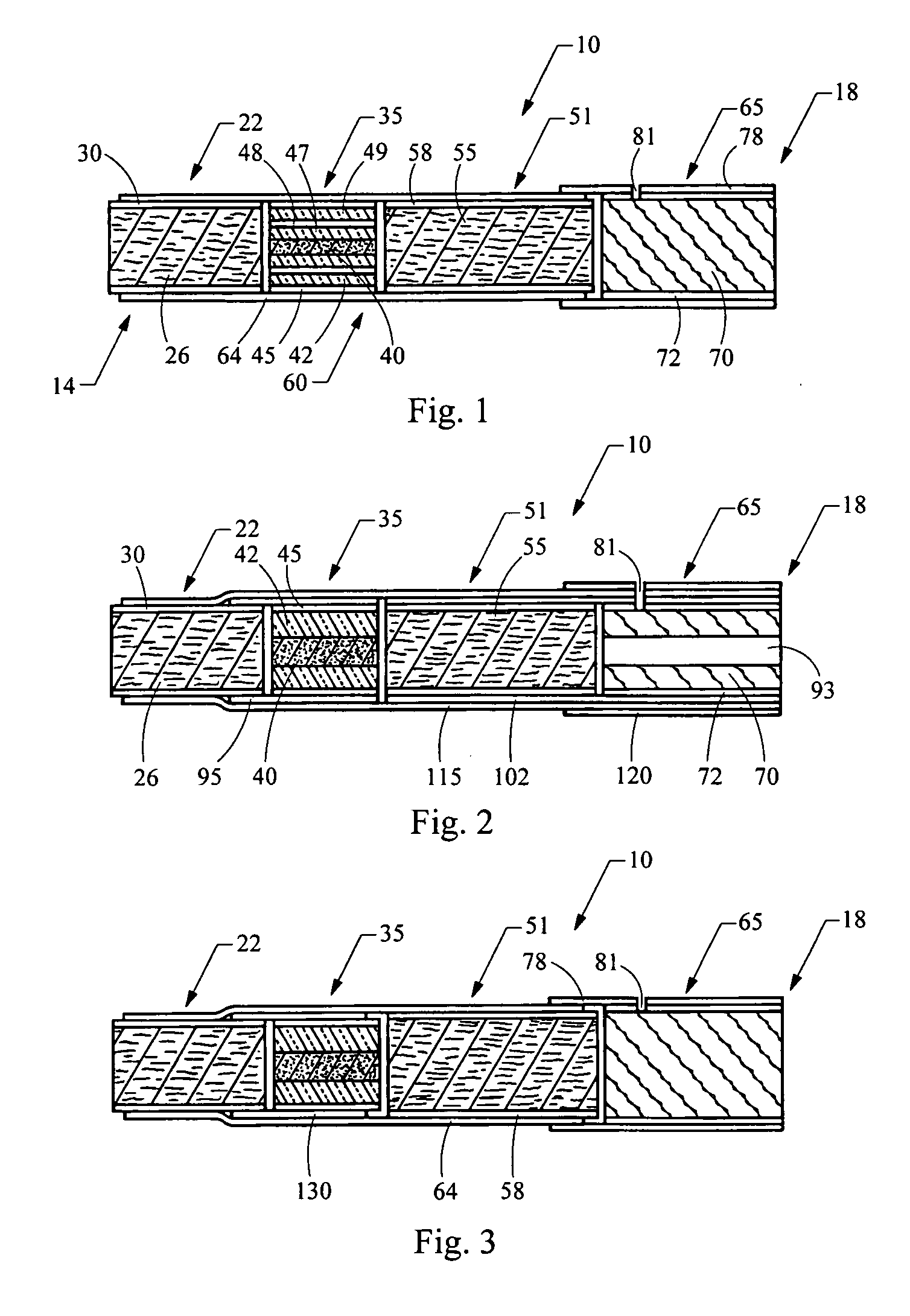

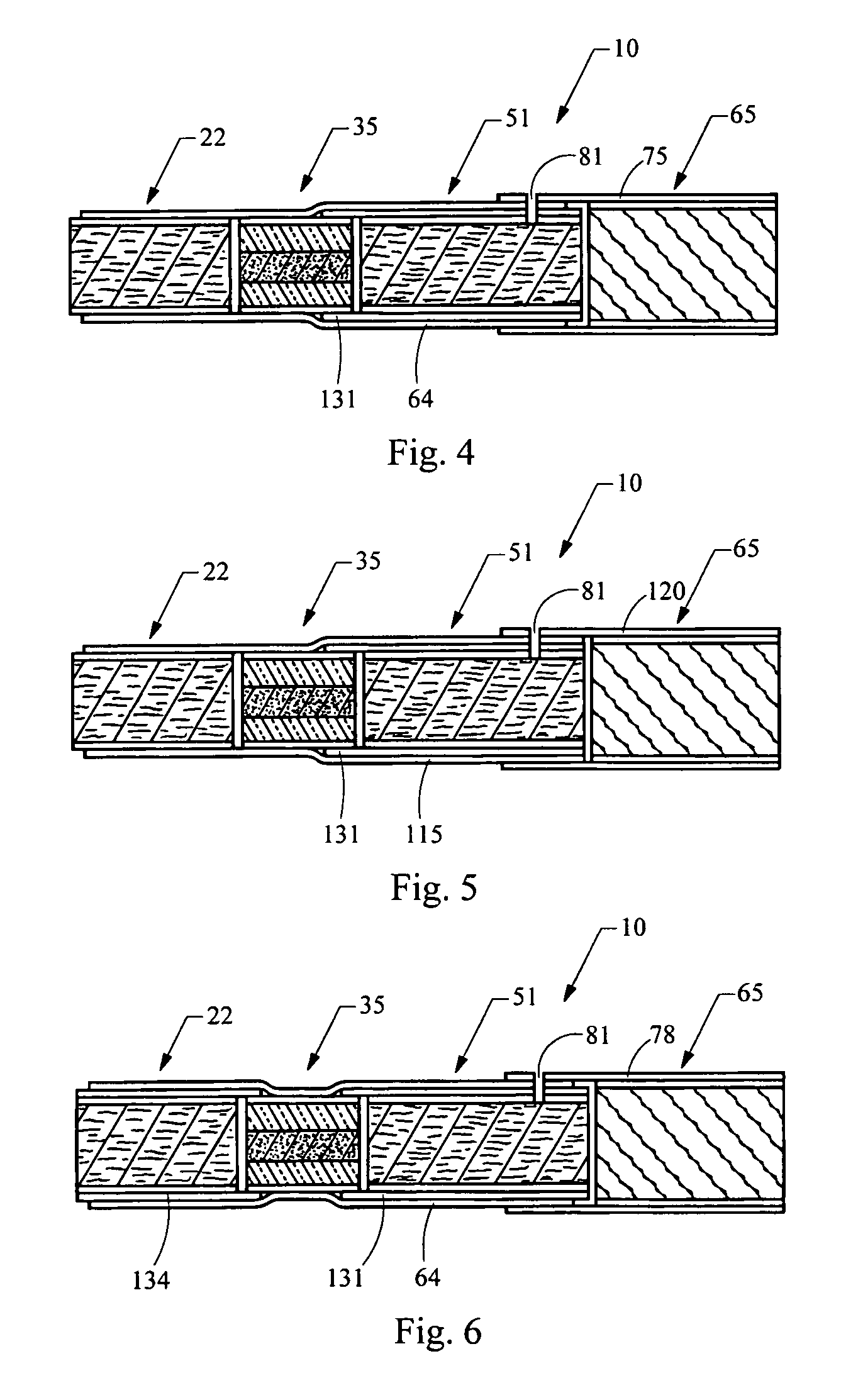

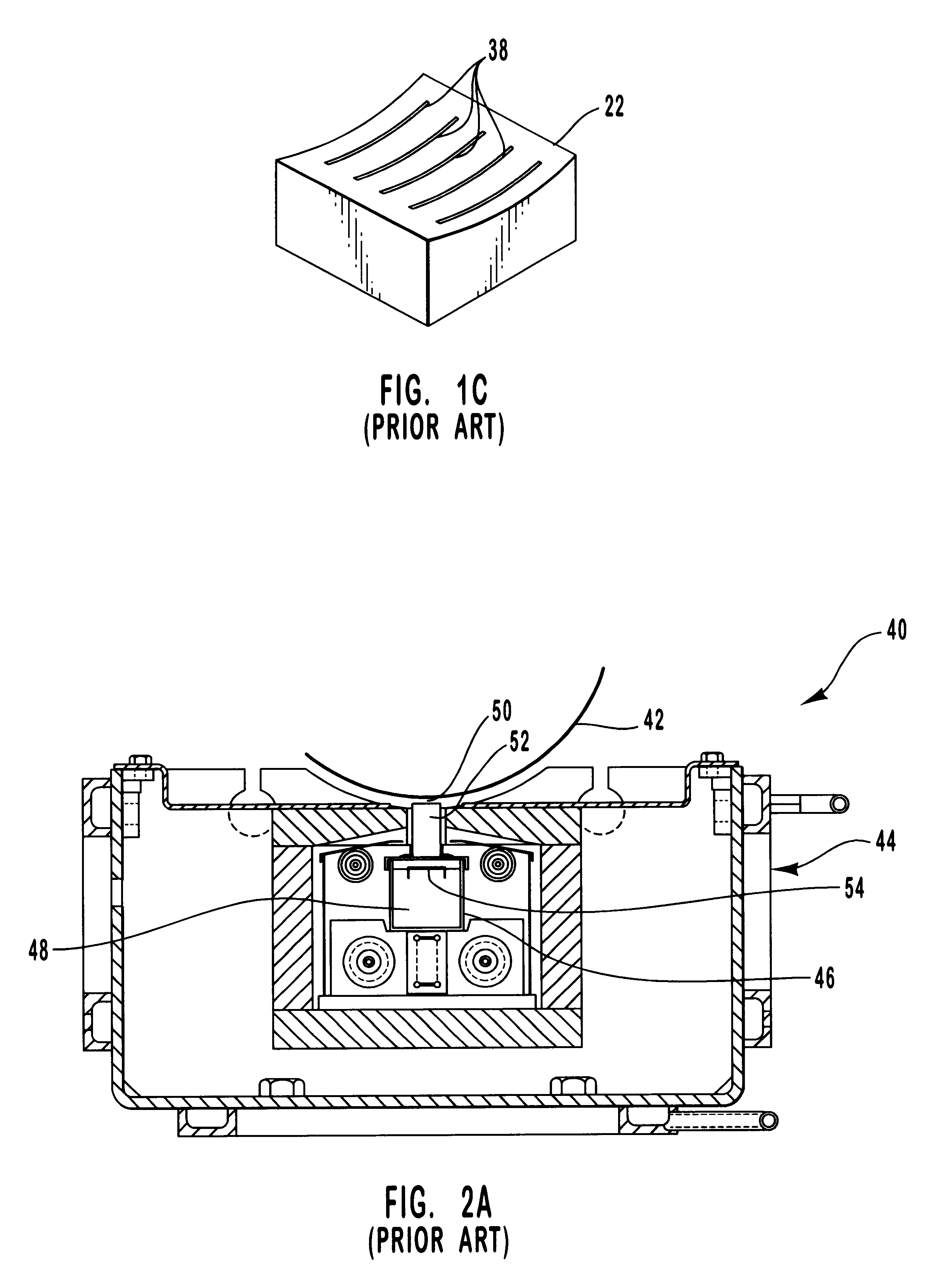

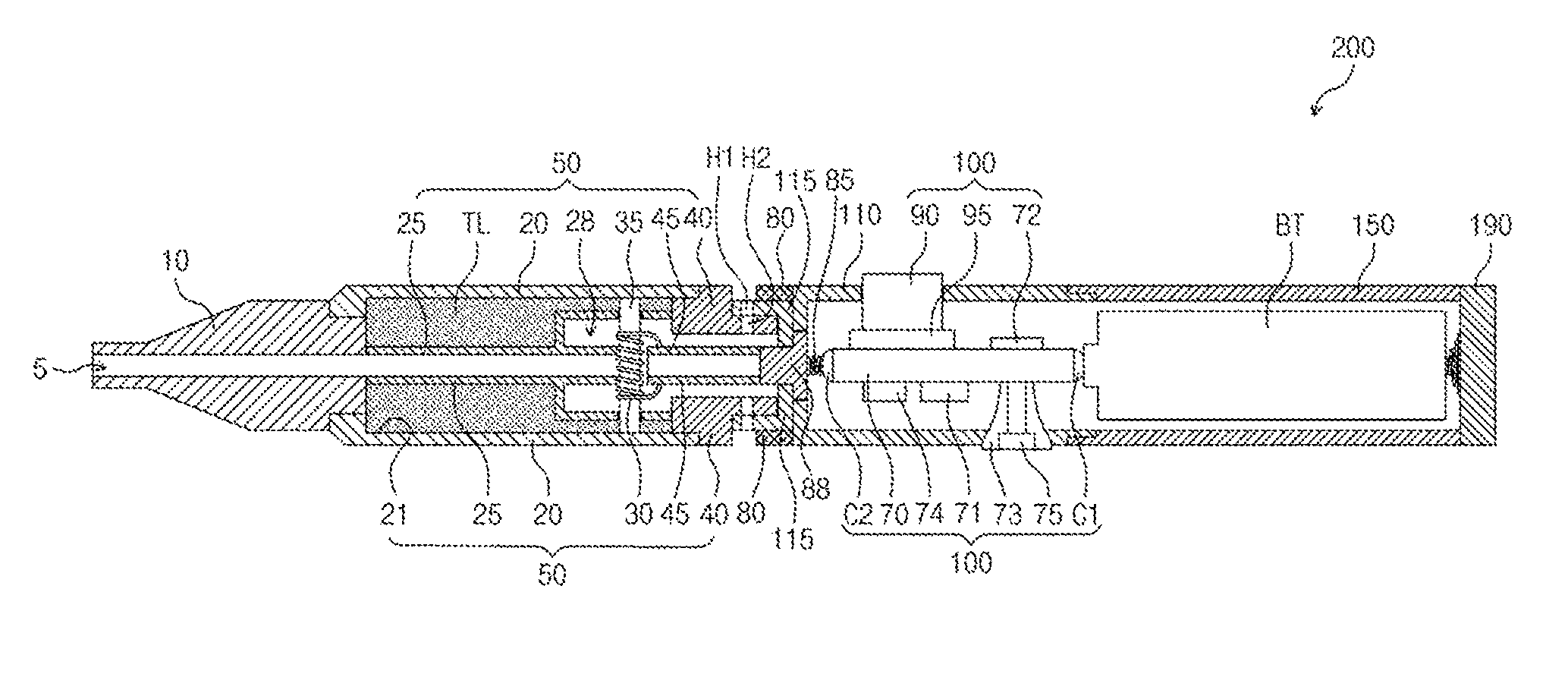

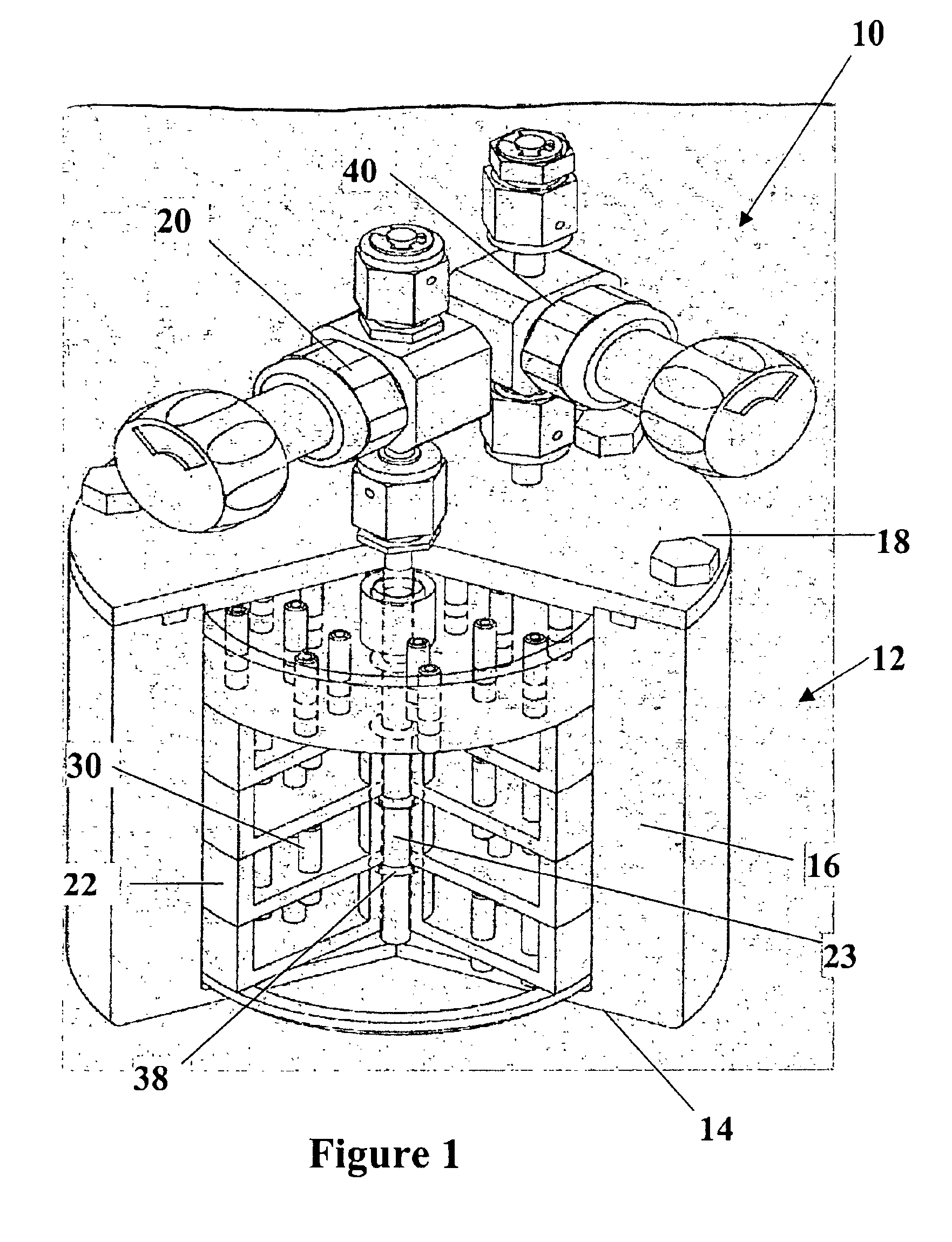

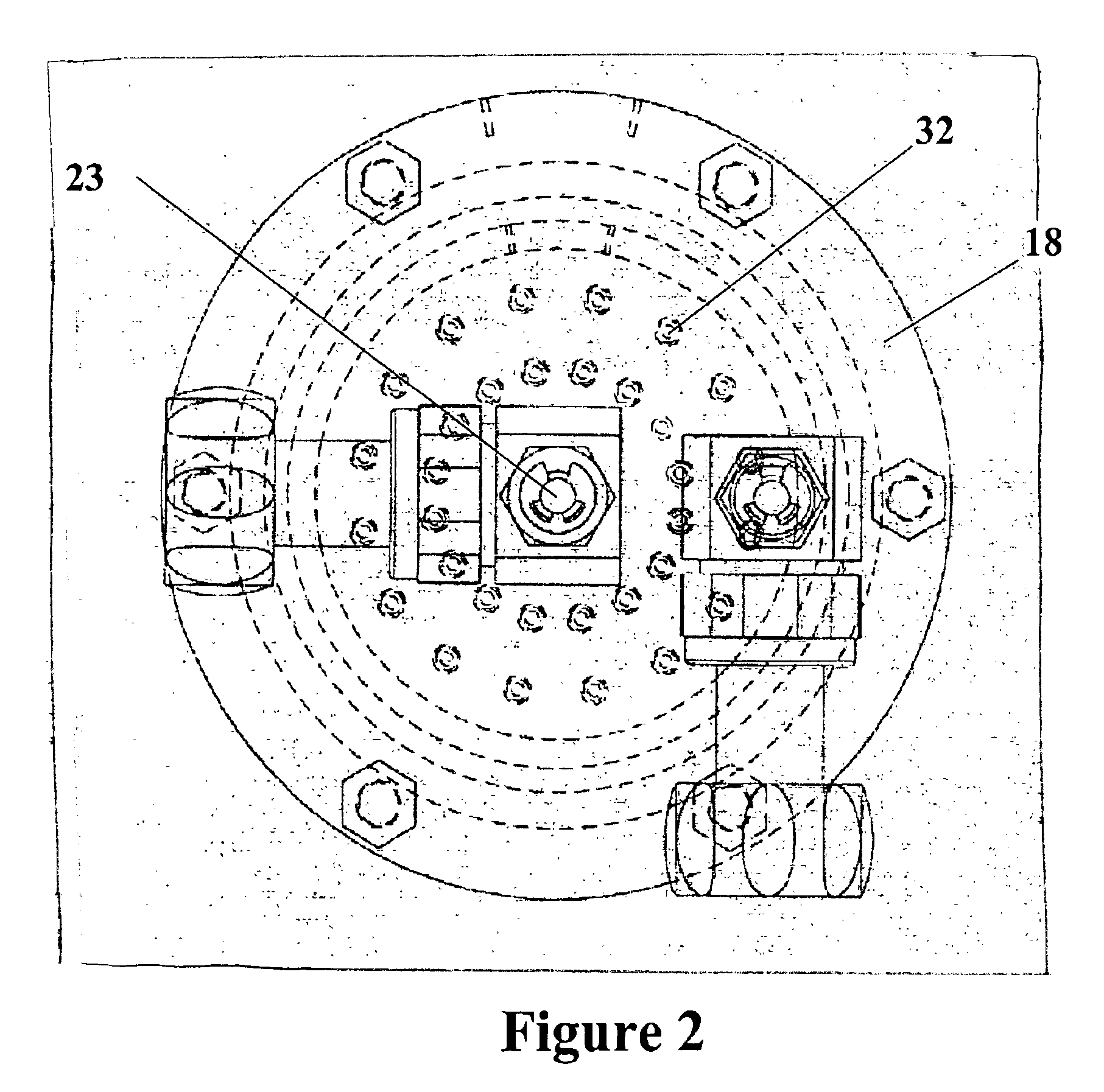

A smoking article, such as a cigarette, comprises a lighting end and a mouth end. The smoking article possesses an aerosol-generation system that includes (i) a heat generation segment, and (ii) an aerosol-generating region or segment. A mouth end piece segment can be located at the mouth end of the smoking article. A segment of tobacco cut filler, gathered tobacco paper, or other type of flavor source material, can be positioned between the mouth end piece segment and the aerosol-generation segment. Optionally, segment composed of tobacco cut filler can be positioned so as to provide a lighting end segment. The smoking article possesses an overwrap (e.g., a single paper overwrap) that extends over the longitudinally extending surface of the mouth end piece segment, the aerosol generation segment, at least a portion of the length of the heat generation segment, any segment located between the mouth end piece and aerosol generation segments, and at least a portion of the length of the optional lighting end segment. Alternatively, the smoking article possesses an overwrap (e.g., a single paper overwrap) that extends over the longitudinally extending surface of the aerosol-generating segment, at least a portion of the length of the heat generation segment, at least a portion of any segment located downstream from the aerosol-generating segment, and at least a portion of the length of the optional lighting end segment, thereby forming a cigarette rod; and the cigarette rod is connected or attached to a filter element using a tipping type of material and arrangement.

Owner:R J REYNOLDS TOBACCO COMPANY

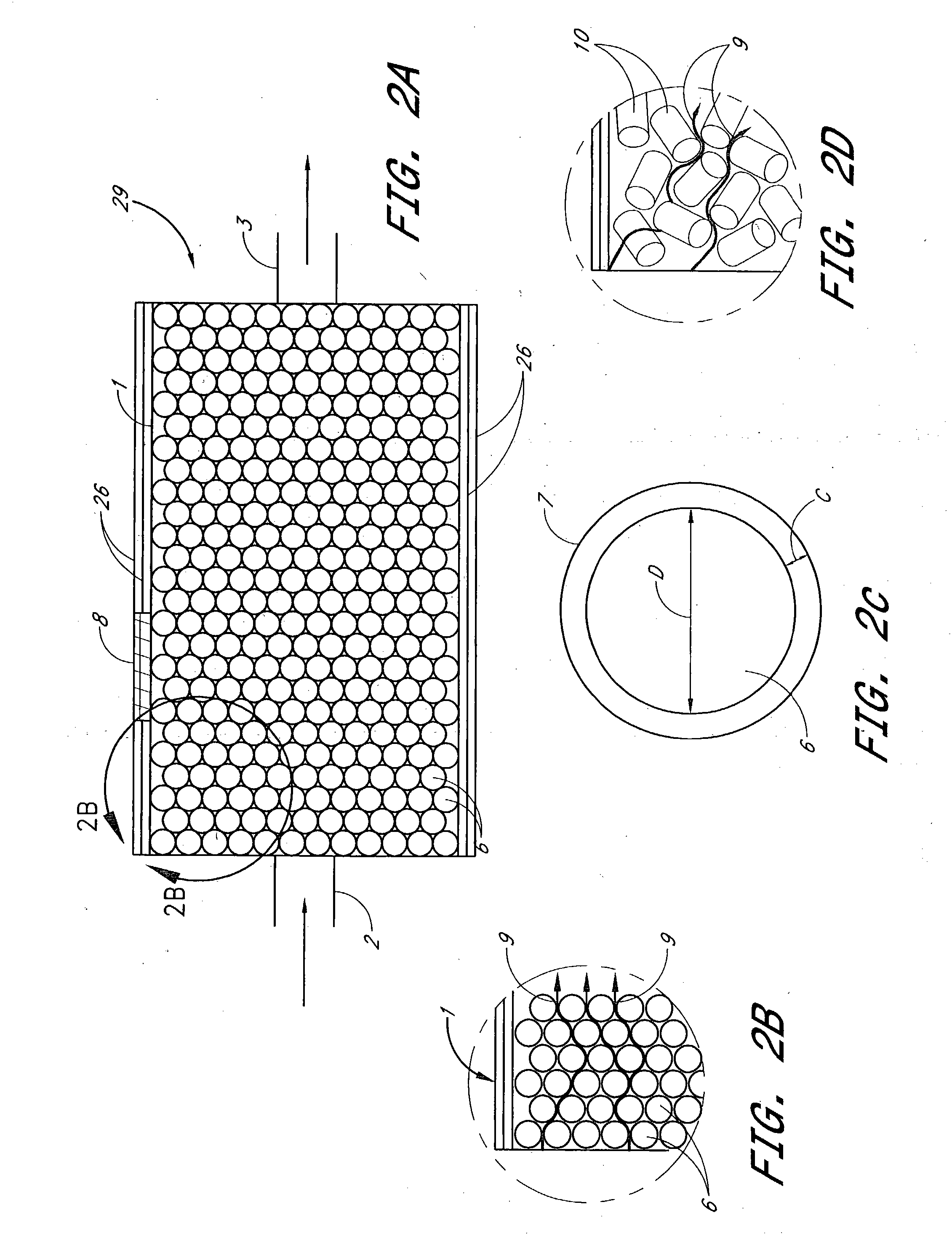

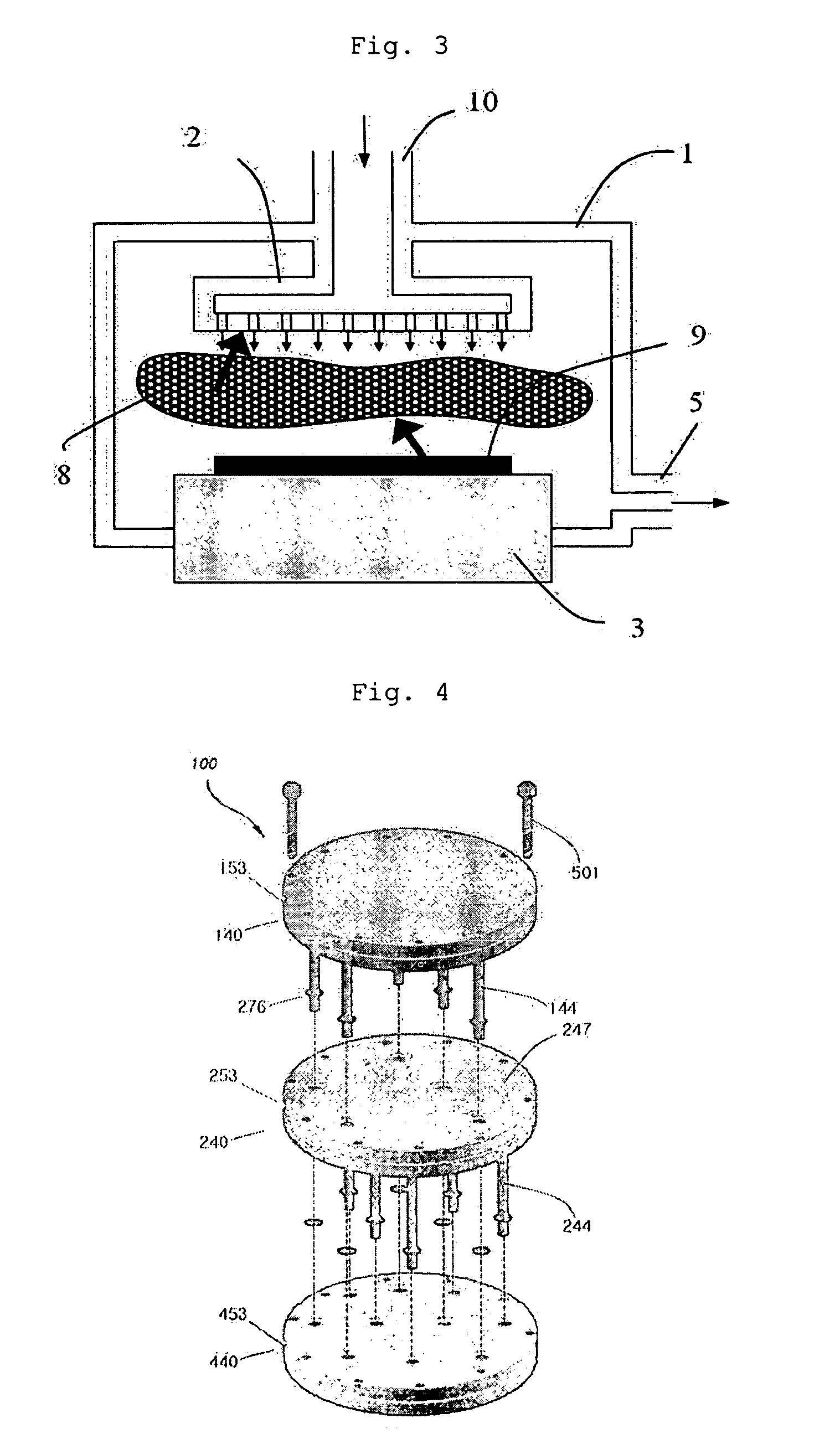

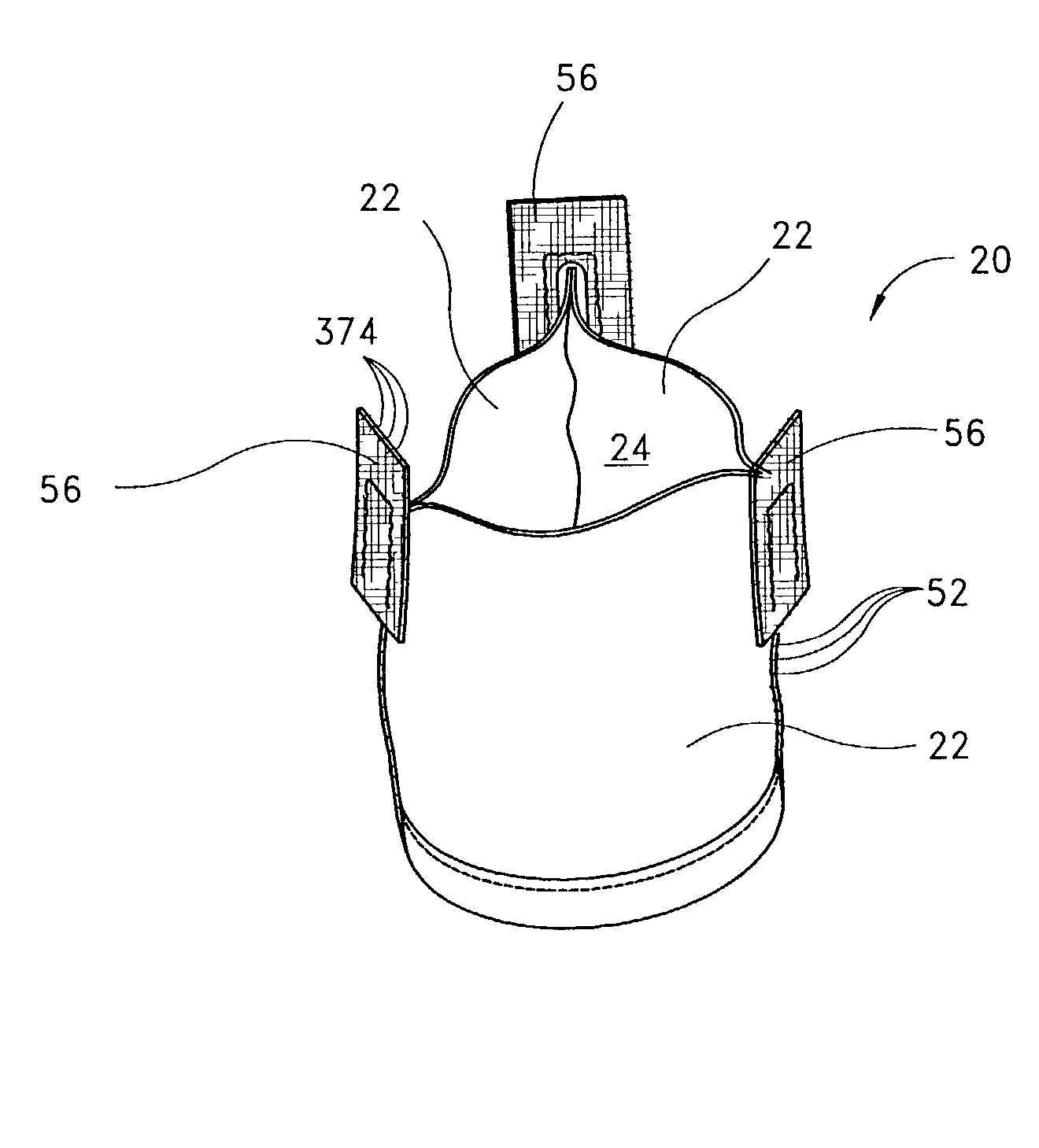

Sublimation bed employing carrier gas guidance structures

ActiveUS20050072357A1Raise the ratioIncrease contact timeLiquid spraying plantsLiquid surface applicatorsSource materialEngineering

Preferred embodiments of the present invention provides a sublimation system employing guidance structures including certain preferred embodiments having a high surface area support medium onto which a solid source material for vapor reactant is coated. Preferably, a guidance structure is configured to facilitate the repeated saturation of the carrier gas with the solid source for a vapor reactant. Methods of saturating a carrier gas using guidance structures are also provided.

Owner:ASM IP HLDG BV

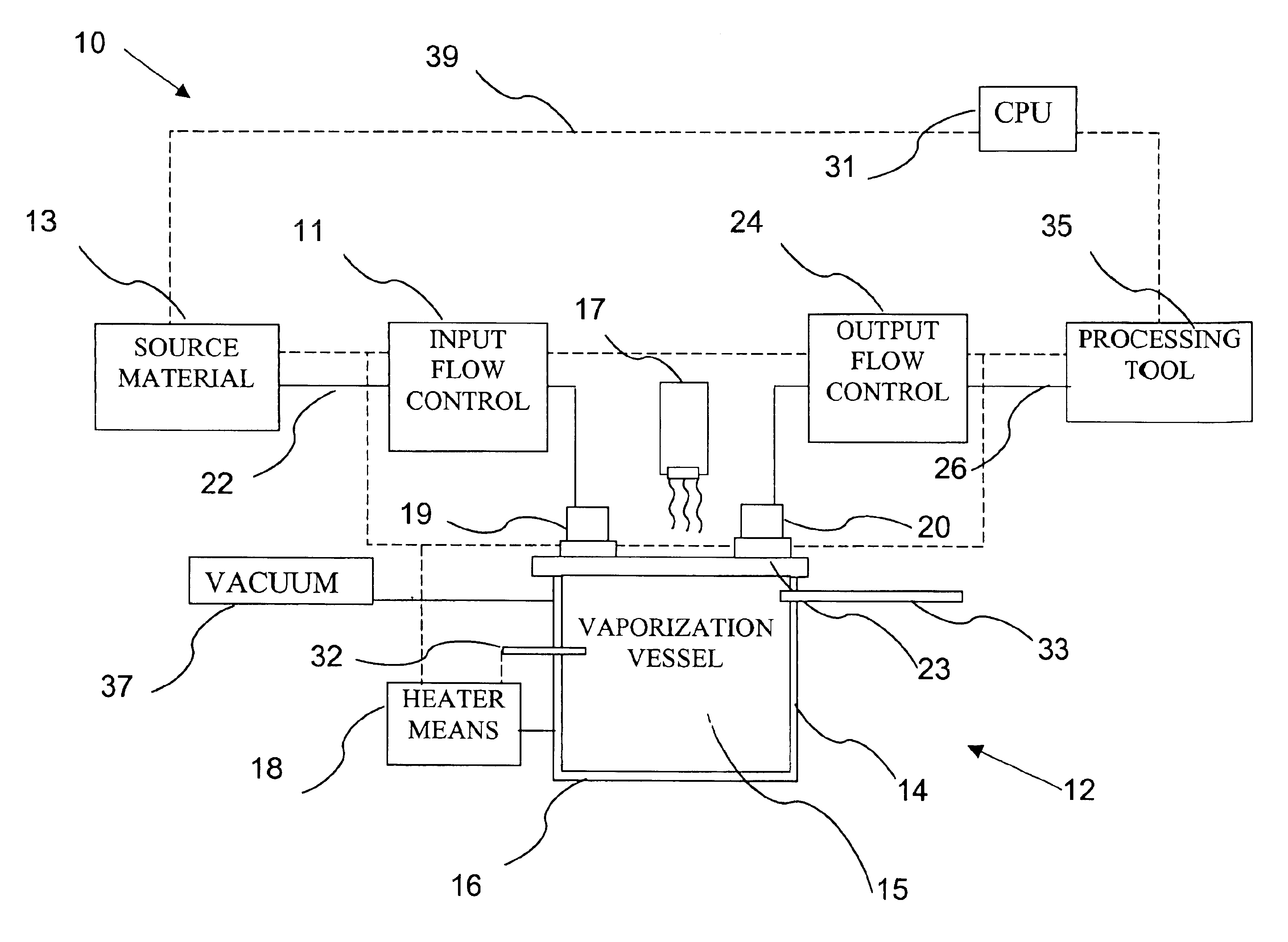

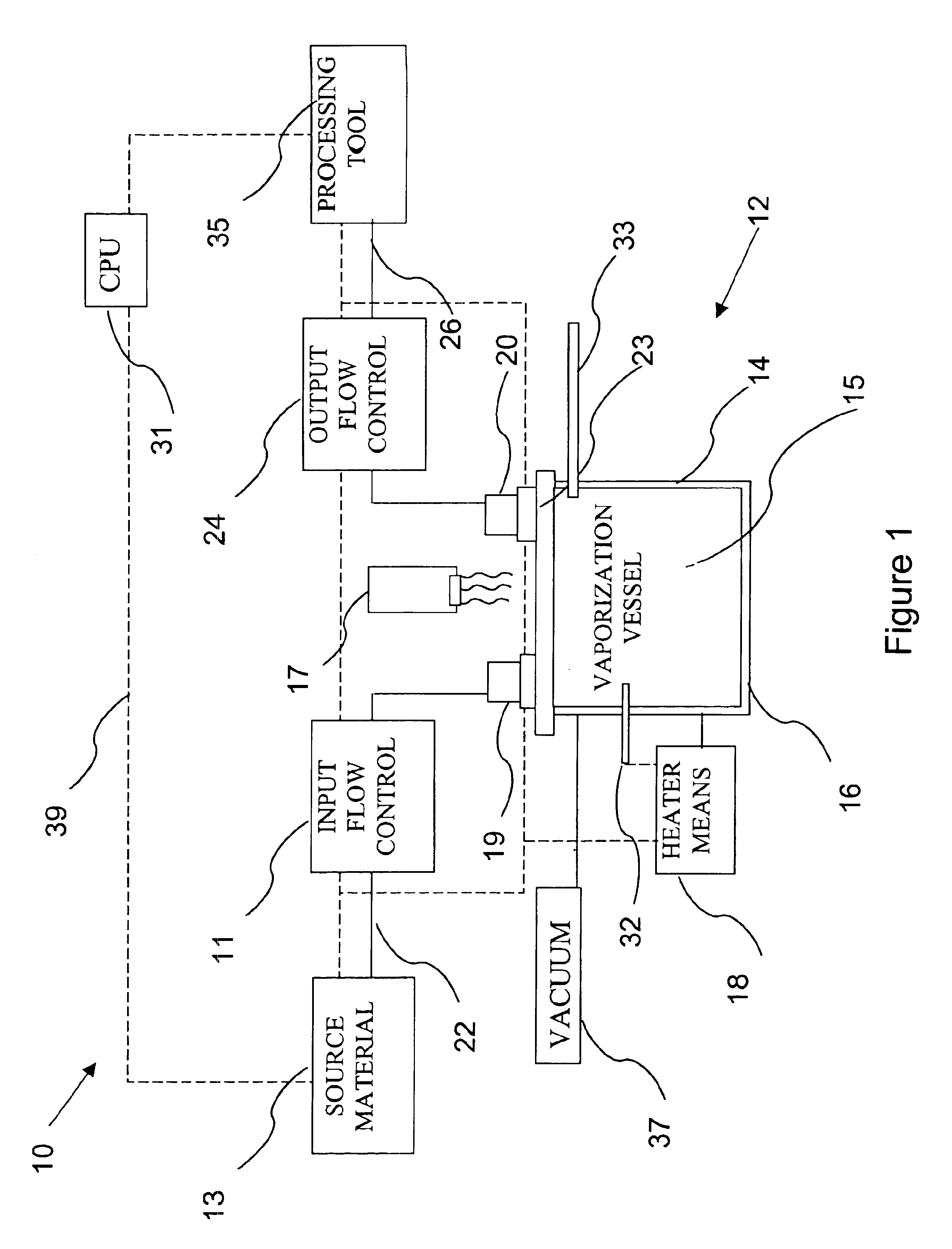

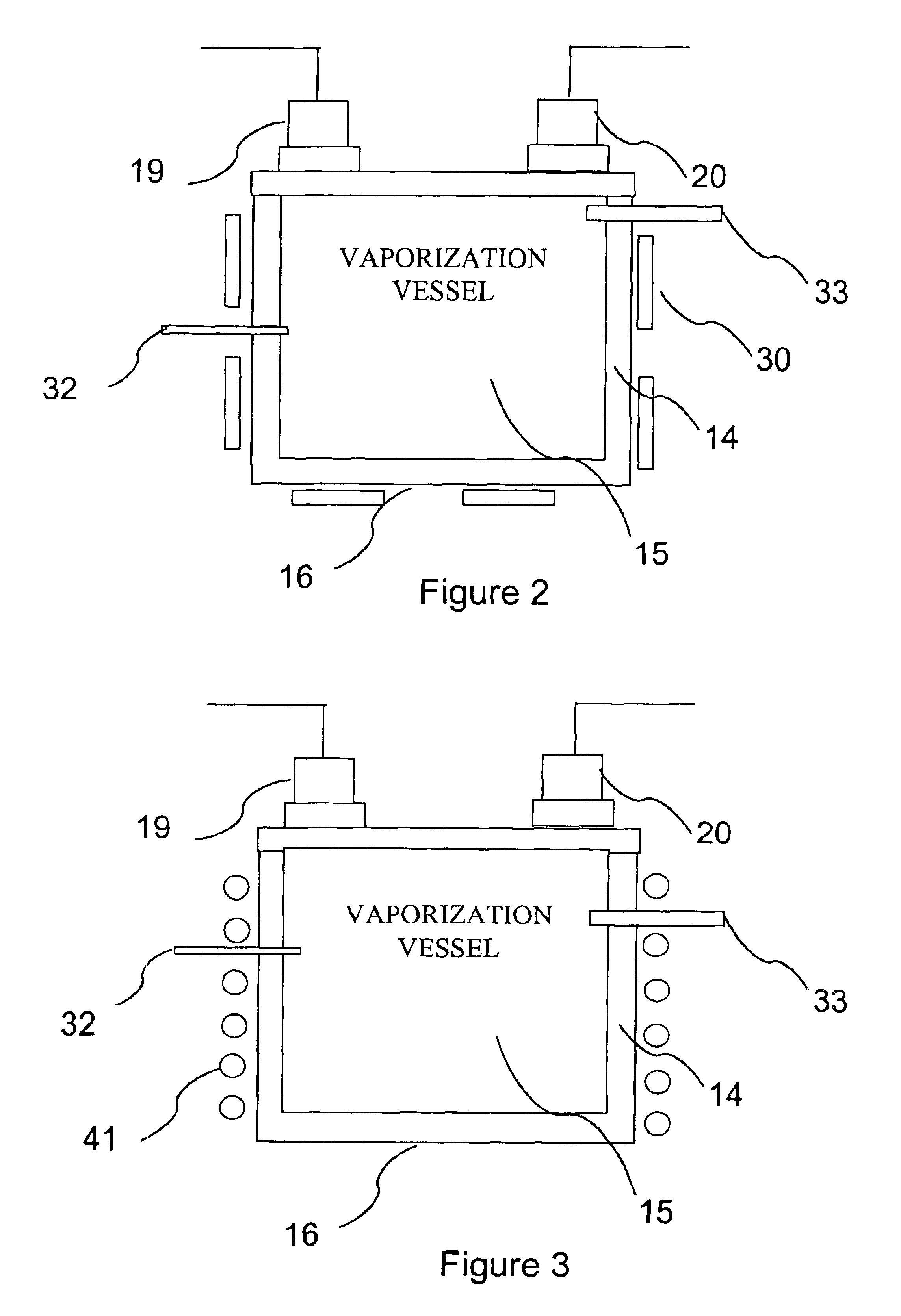

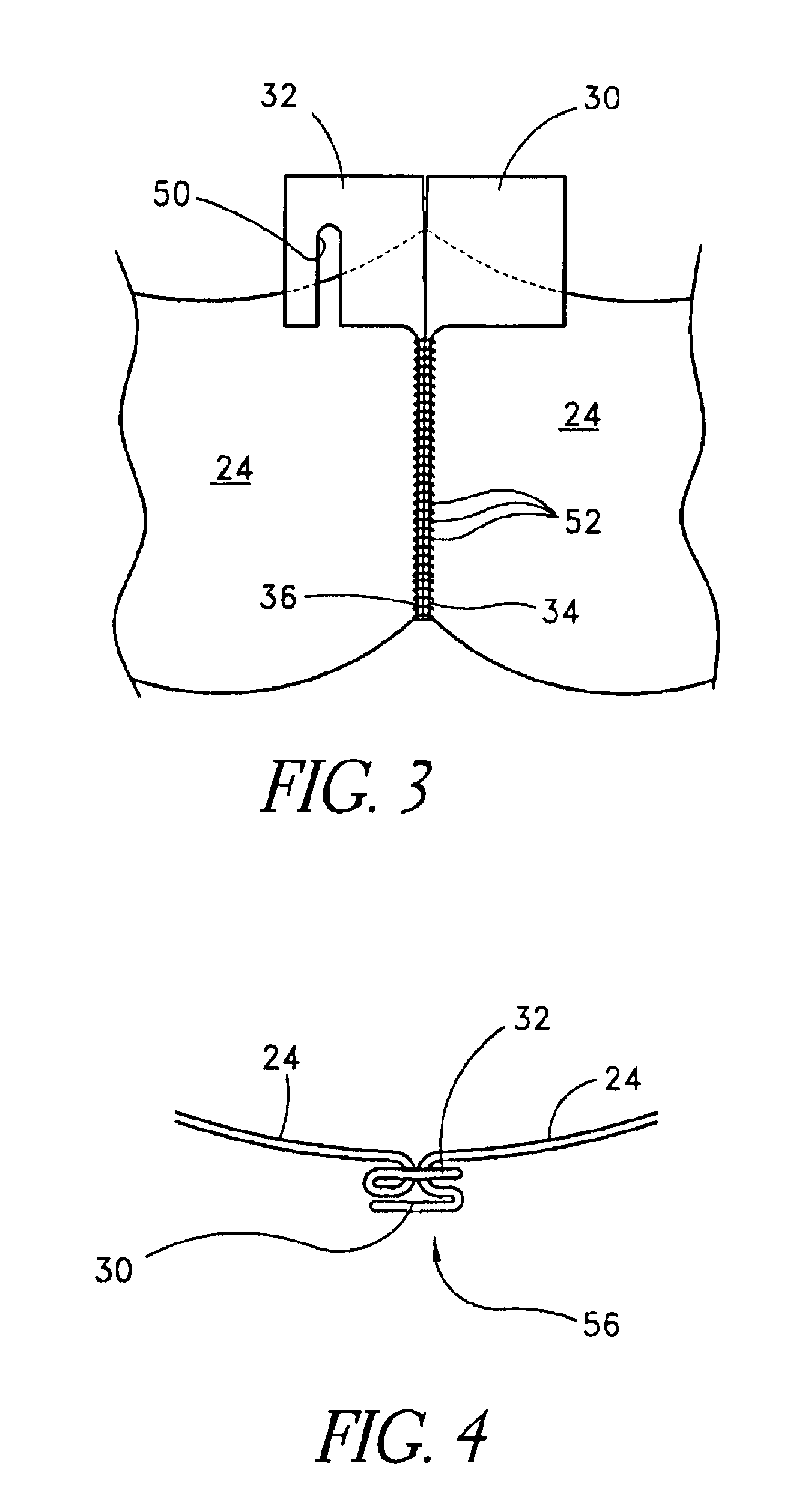

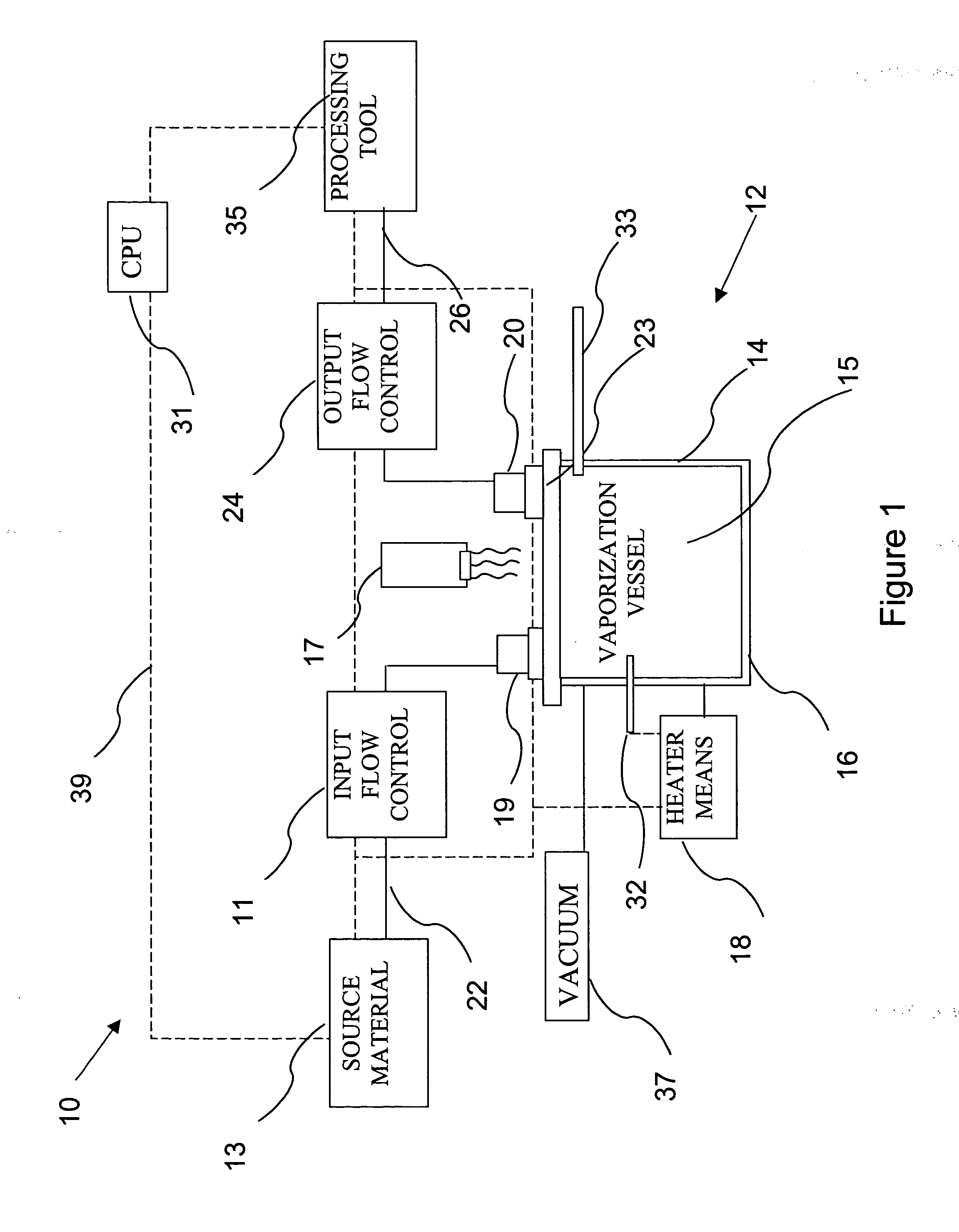

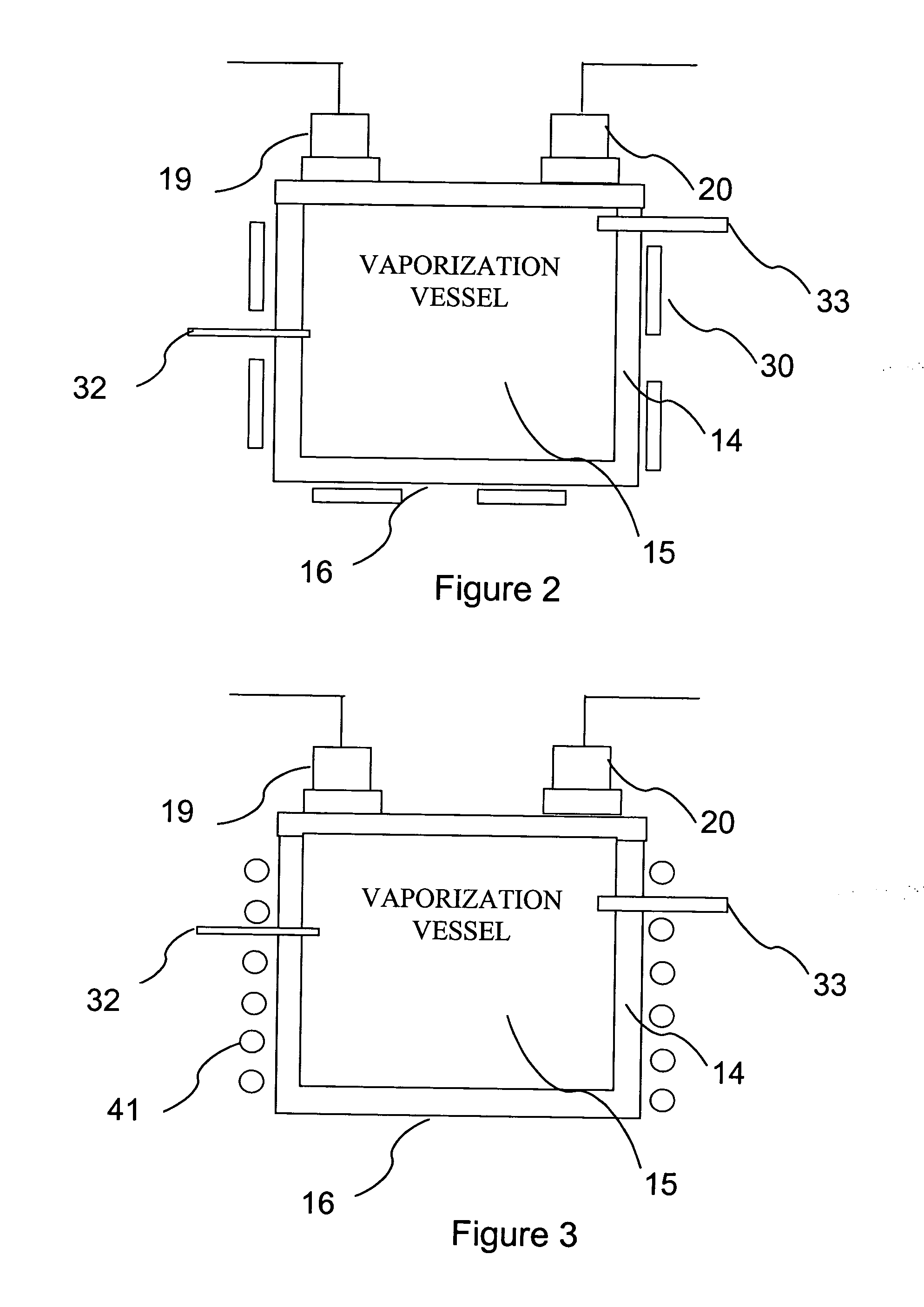

Delivery systems for efficient vaporization of precursor source material

InactiveUS6909839B2Precise deliveryVacuum evaporation coatingSputtering coatingControl flowSource material

The present invention relates to a delivery system for vaporizing and delivering vaporized solid and liquid precursor materials at a controlled rate having particular utility for semiconductor manufacturing applications. The system includes a vaporization vessel, a processing tool and a connecting vapor line therebetween, where the system further includes an input flow controller and / or an output flow controller to provide a controlled delivery of a vaporizable source material to the vaporization vessel and a controlled flow rate of vaporized source material to the processing tool.

Owner:ENTEGRIS INC

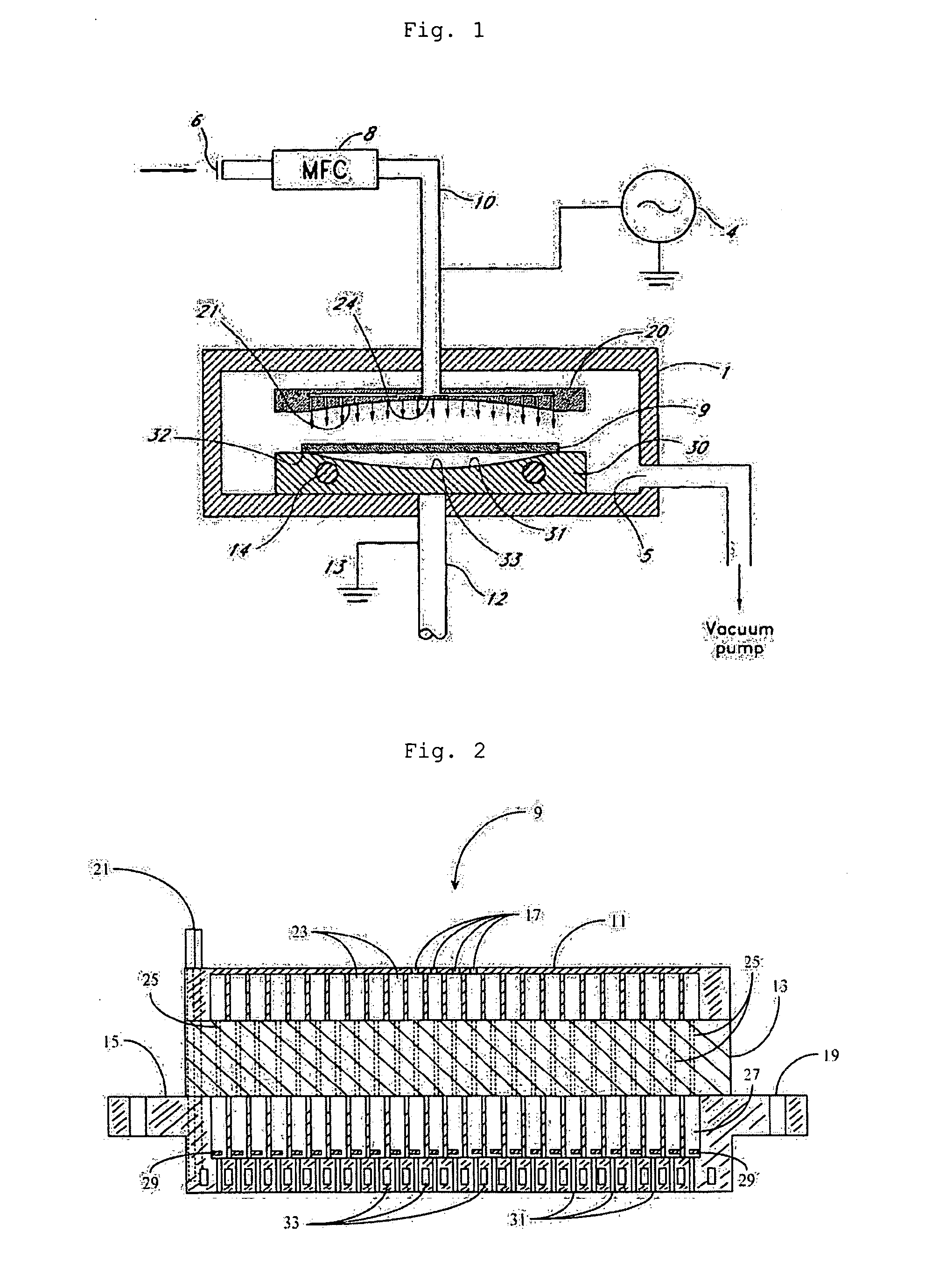

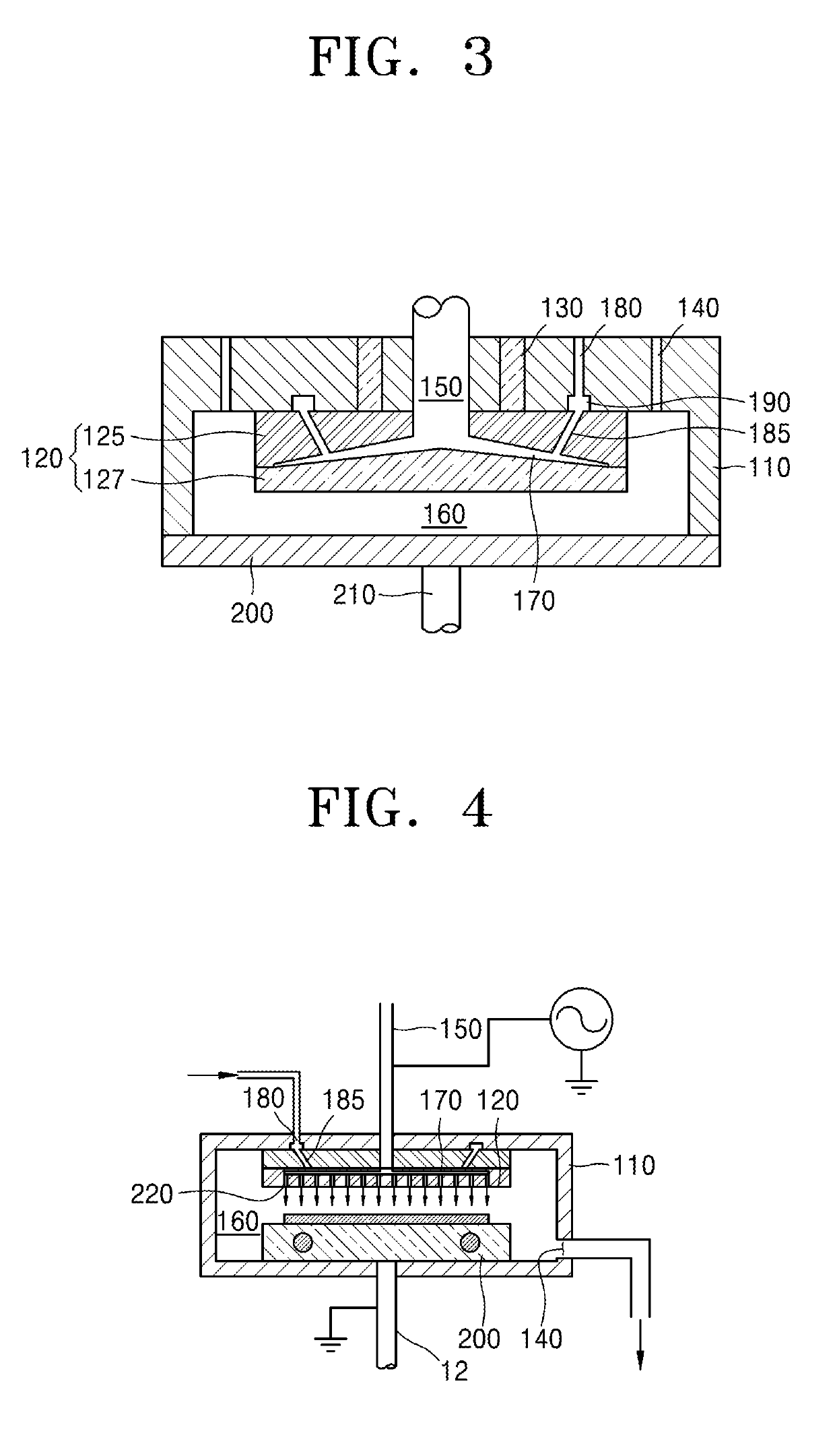

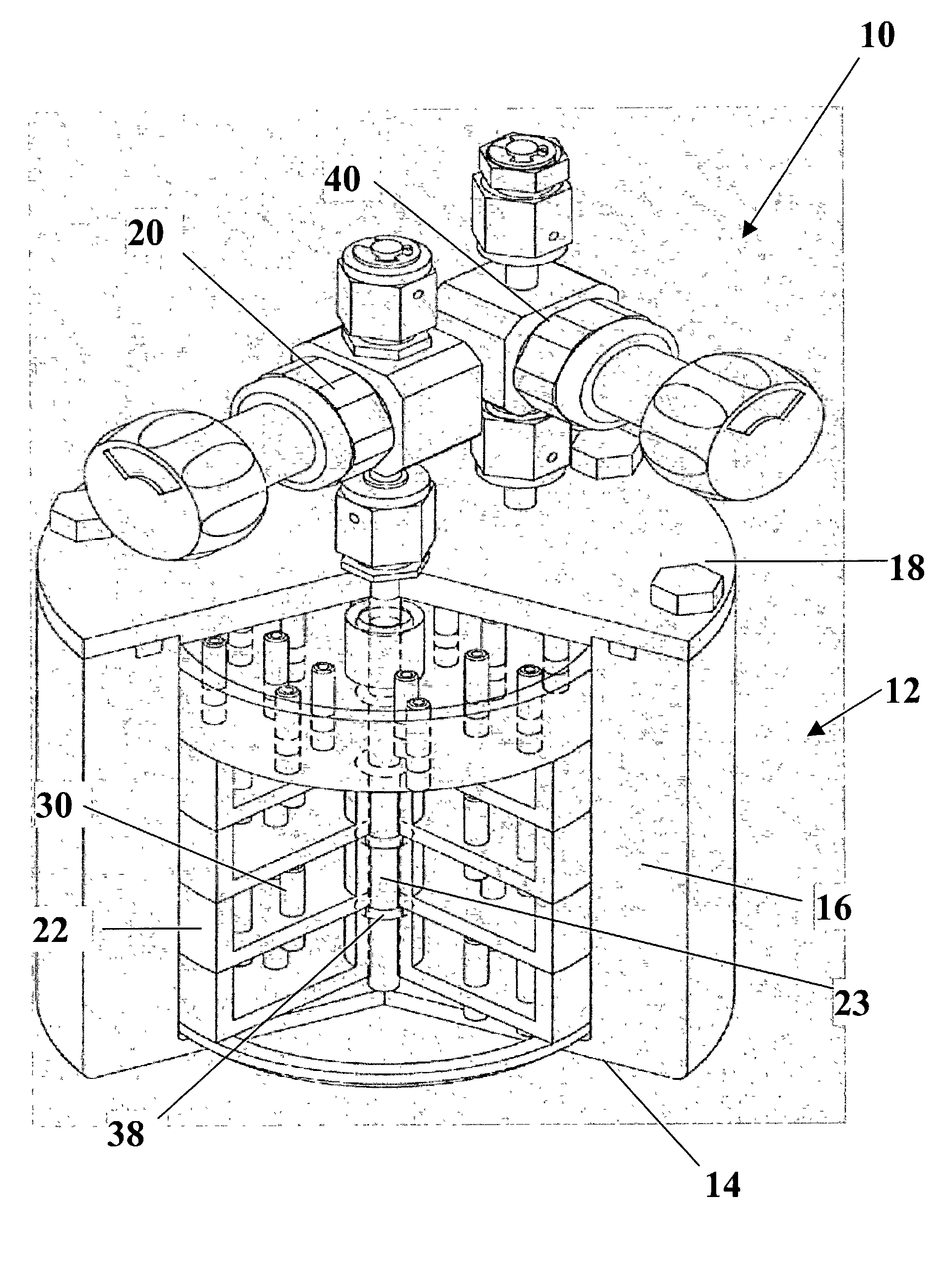

Apparatus for chemical vapor deposition (CVD) with showerhead and method thereof

ActiveUS20060263522A1Unwanted chemical reactionFrom chemically reactive gasesChemical vapor deposition coatingSource materialGas phase

Owner:KOREA INST OF IND TECH +1

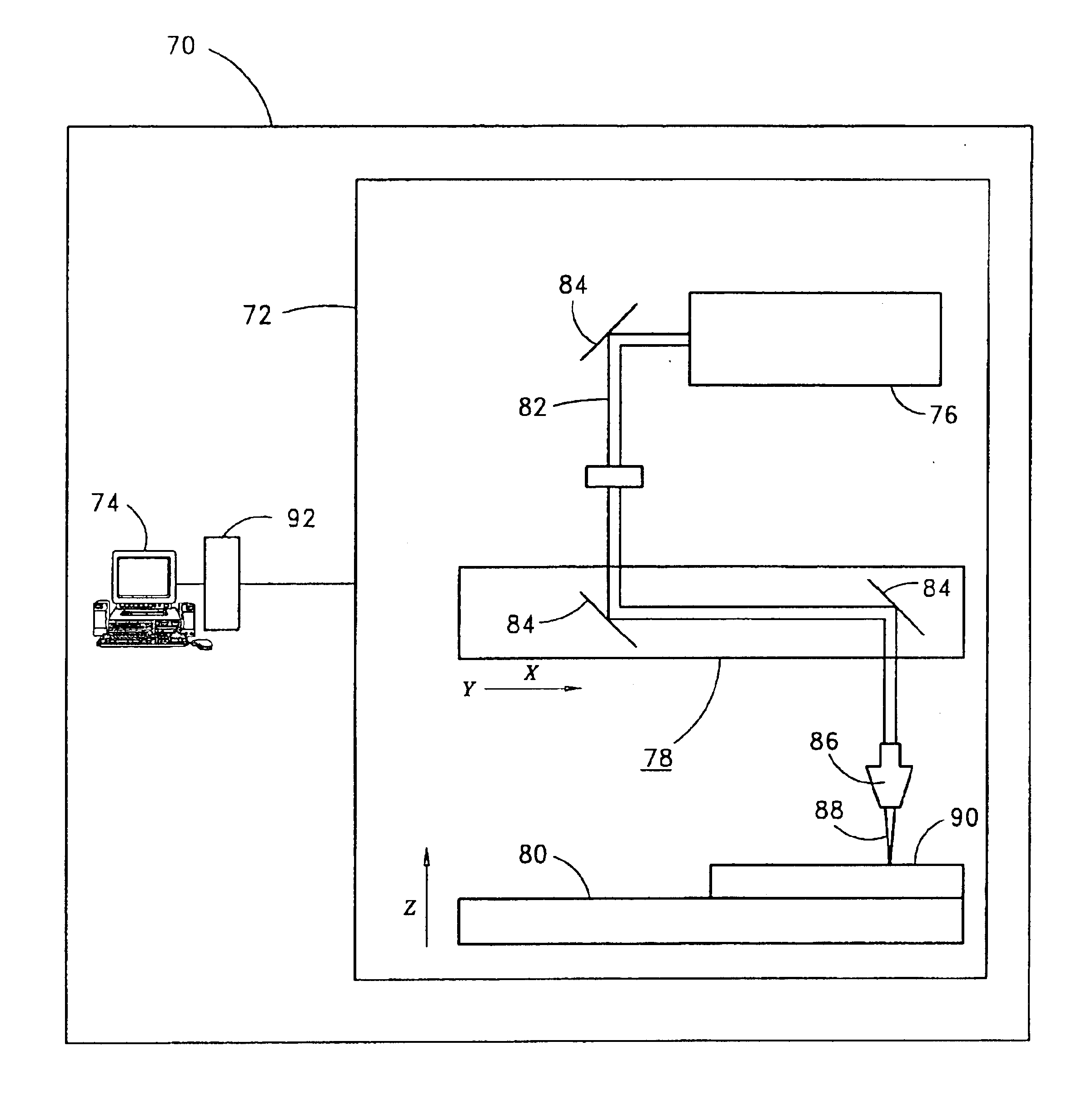

Method of cutting material for use in implantable medical device

A method of cutting material for use in an implantable medical device employs a plotted laser cutting system. The laser cutting system is computer controlled and includes a laser combined with a motion system. The laser precisely cuts segments out of source material according to a predetermined pattern as designated by the computer. The segments are used in constructing implantable medical devices. The cutting energy of the laser is selected so that the cut edges of the segments are melted to discourage delamination or fraying, but communication of thermal energy into the segment beyond the edge is minimized to avoid damaging the segment adjacent the edge.

Owner:3F THERAPEUTICS

Delivery systems for efficient vaporization of precursor source material

InactiveUS20050019026A1Precise deliveryVacuum evaporation coatingSemiconductor/solid-state device manufacturingControl flowSource material

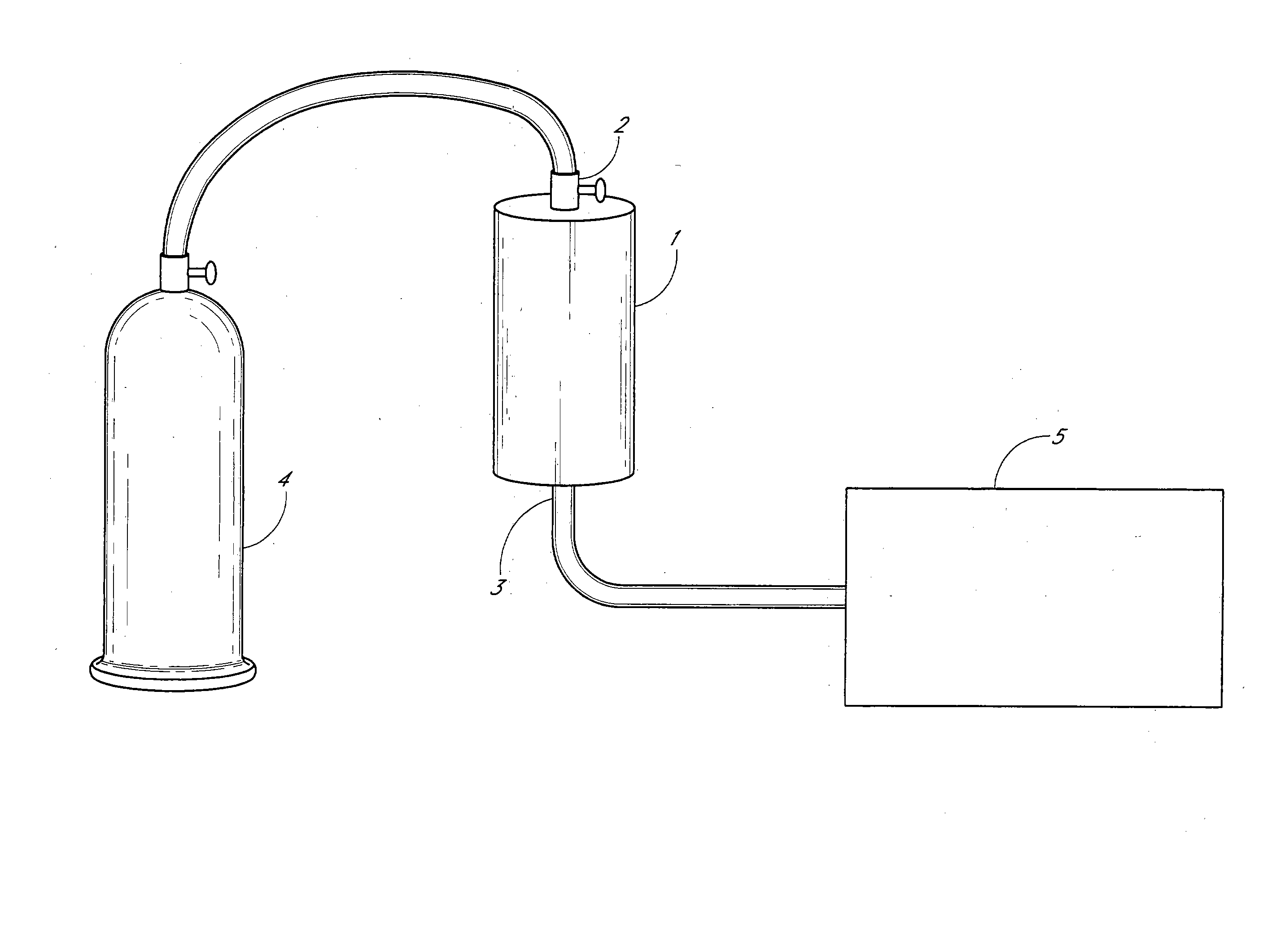

The present invention relates to a delivery system for vaporizing and delivering vaporized solid and liquid precursor materials at a controlled rate having particular utility for semiconductor manufacturing applications. The system includes a vaporization vessel, a processing tool and a connecting vapor line therebetween, where the system further includes an input flow controller and / or an output flow controller to provide a controlled delivery of a vaporizable source material to the vaporization vessel and a controlled flow rate of vaporized source material to the processing tool.

Owner:ENTEGRIS INC

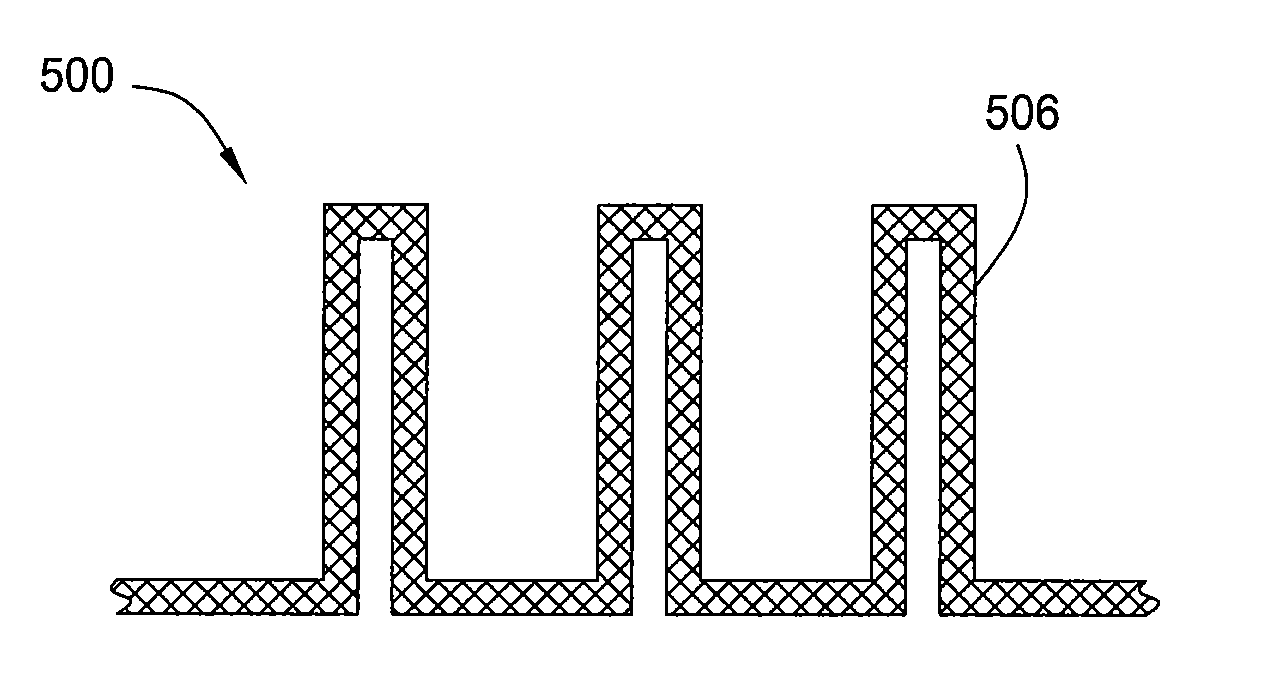

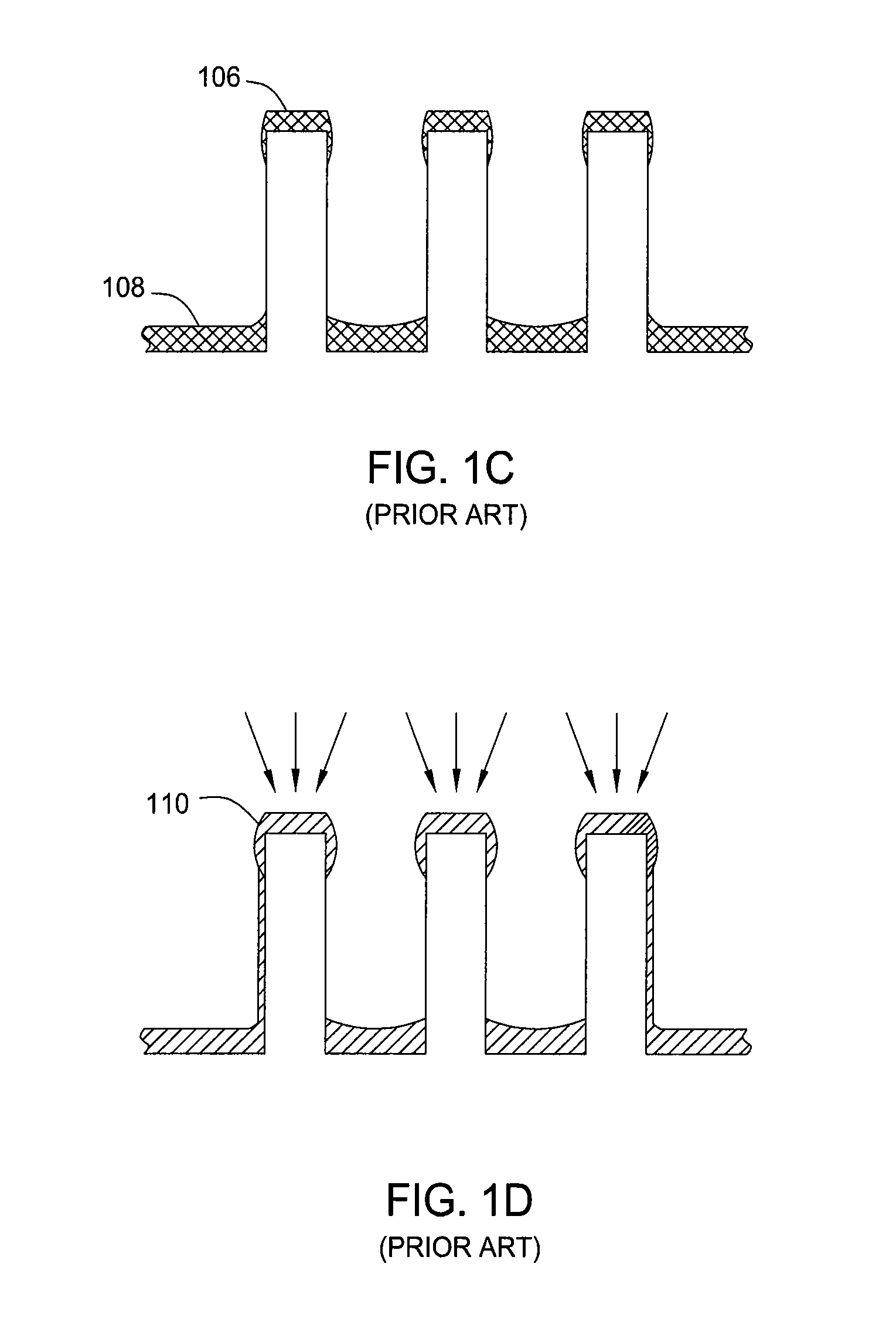

Novel method for conformal plasma immersed ion implantation assisted by atomic layer deposition

ActiveUS20110159673A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantSource material

Embodiments of the invention provide a novel apparatus and methods for forming a conformal doped layer on the surface of a substrate. A substrate is provided to a process chamber, and a layer of dopant source material is deposited by plasma deposition, atomic layer deposition, or plasma-assisted atomic layer deposition. The substrate is then subjected to thermal processing to activate and diffuse dopants into the substrate surface.

Owner:APPLIED MATERIALS INC

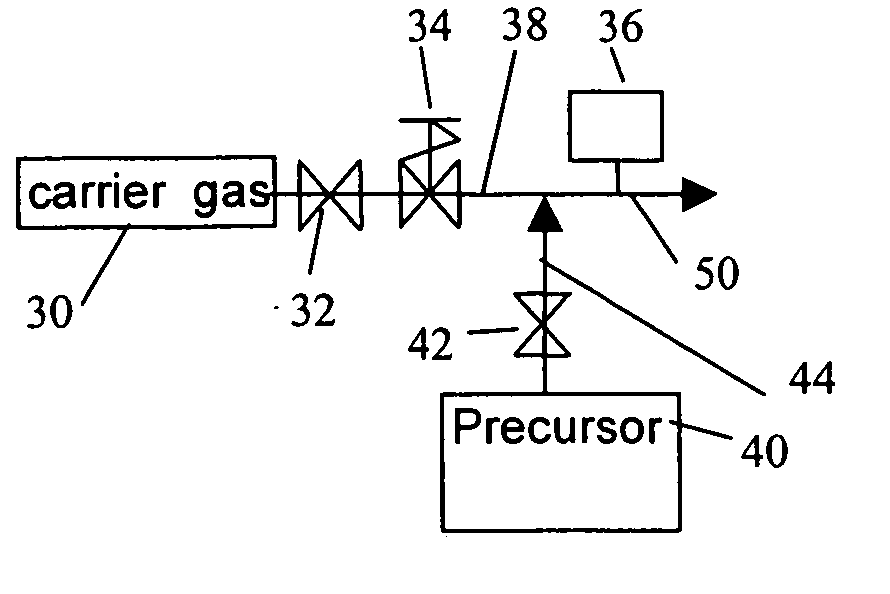

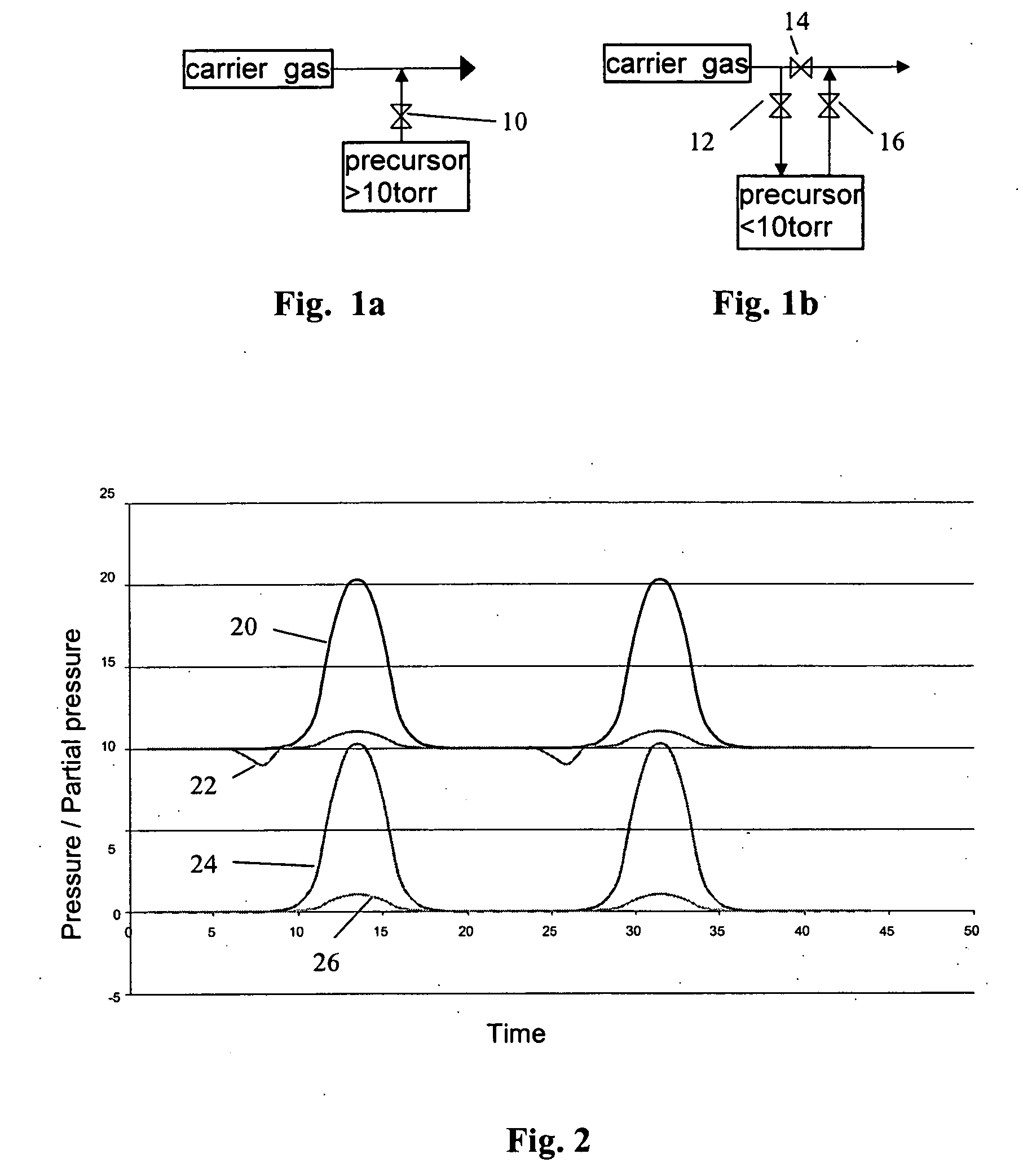

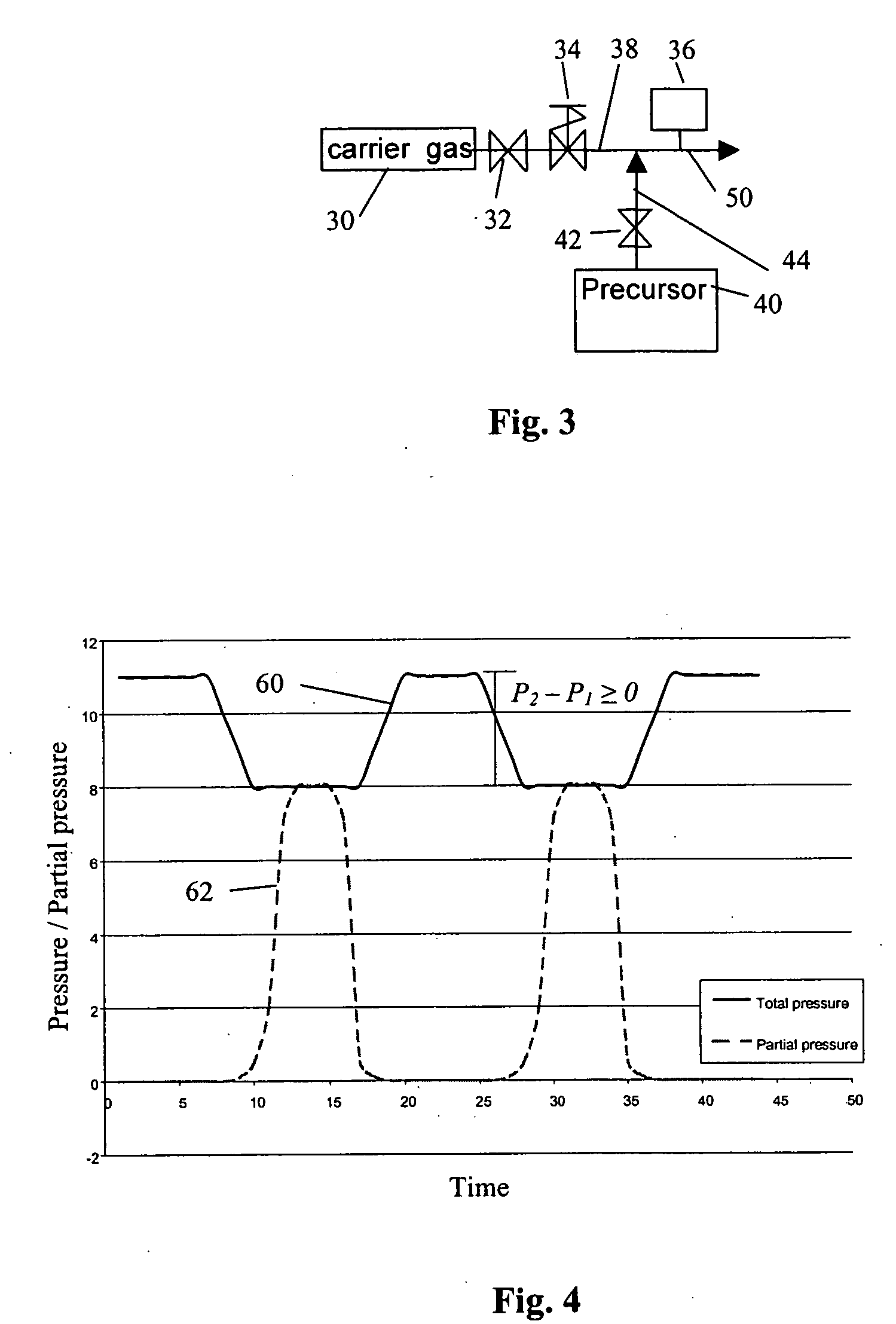

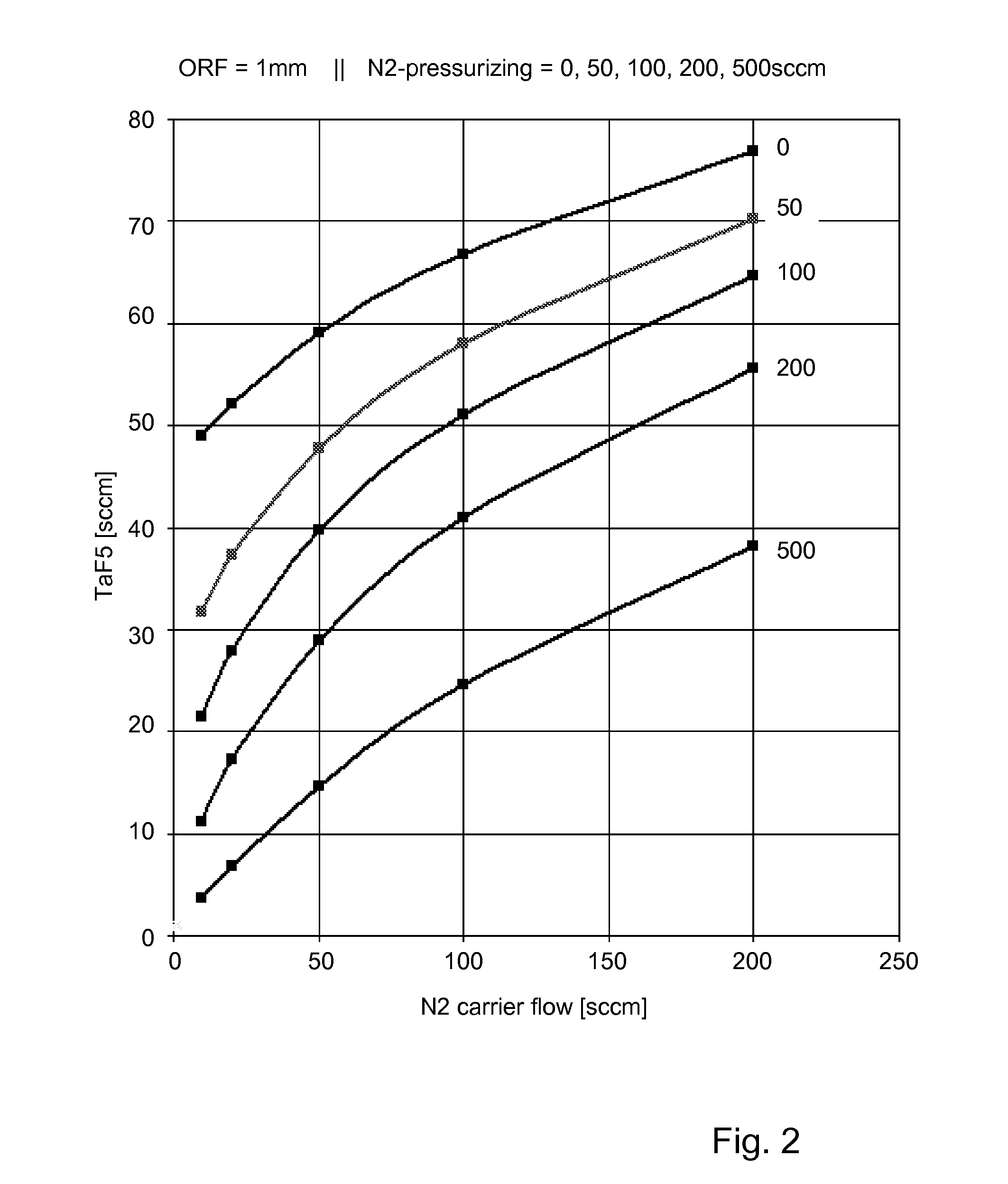

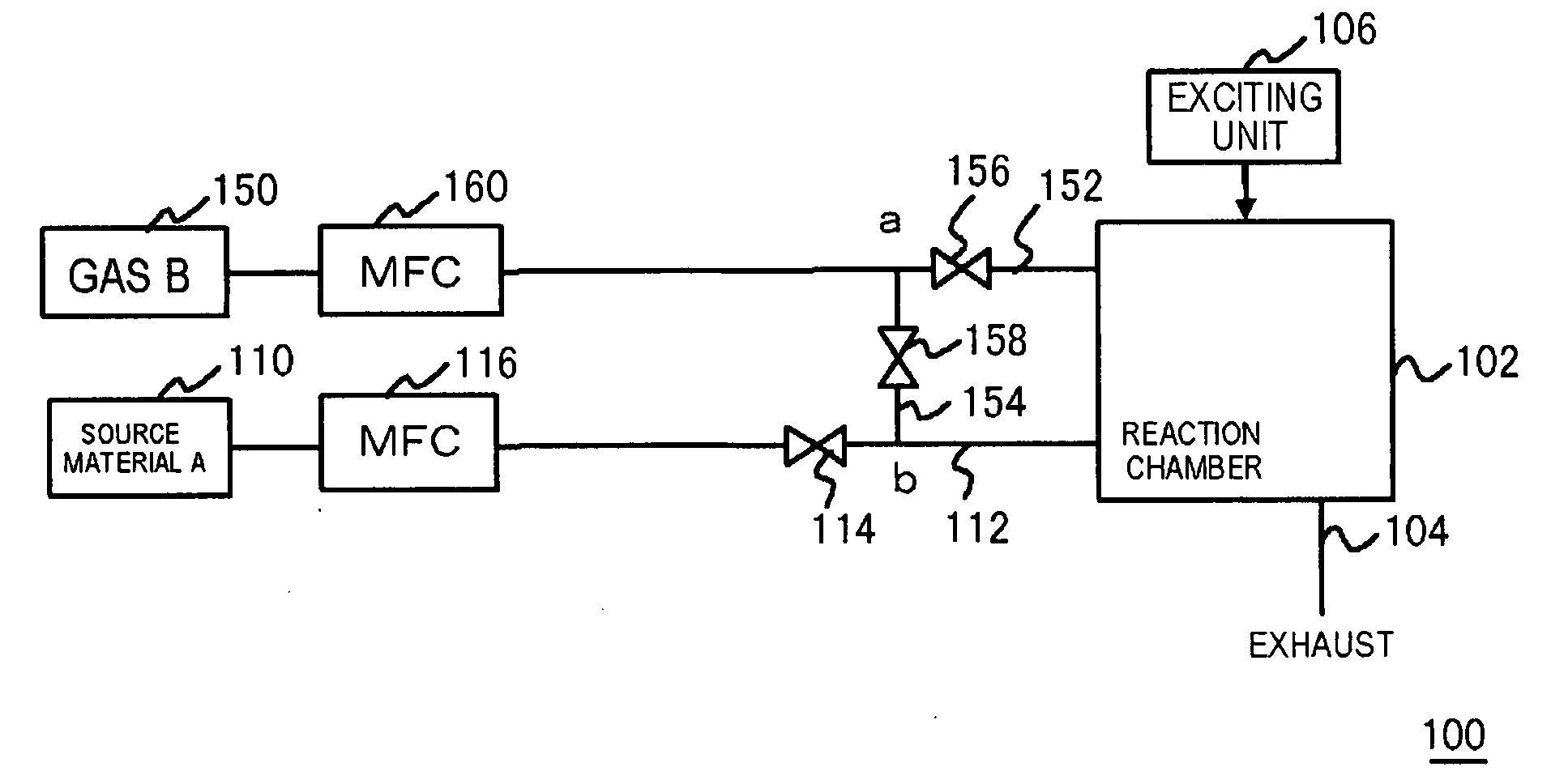

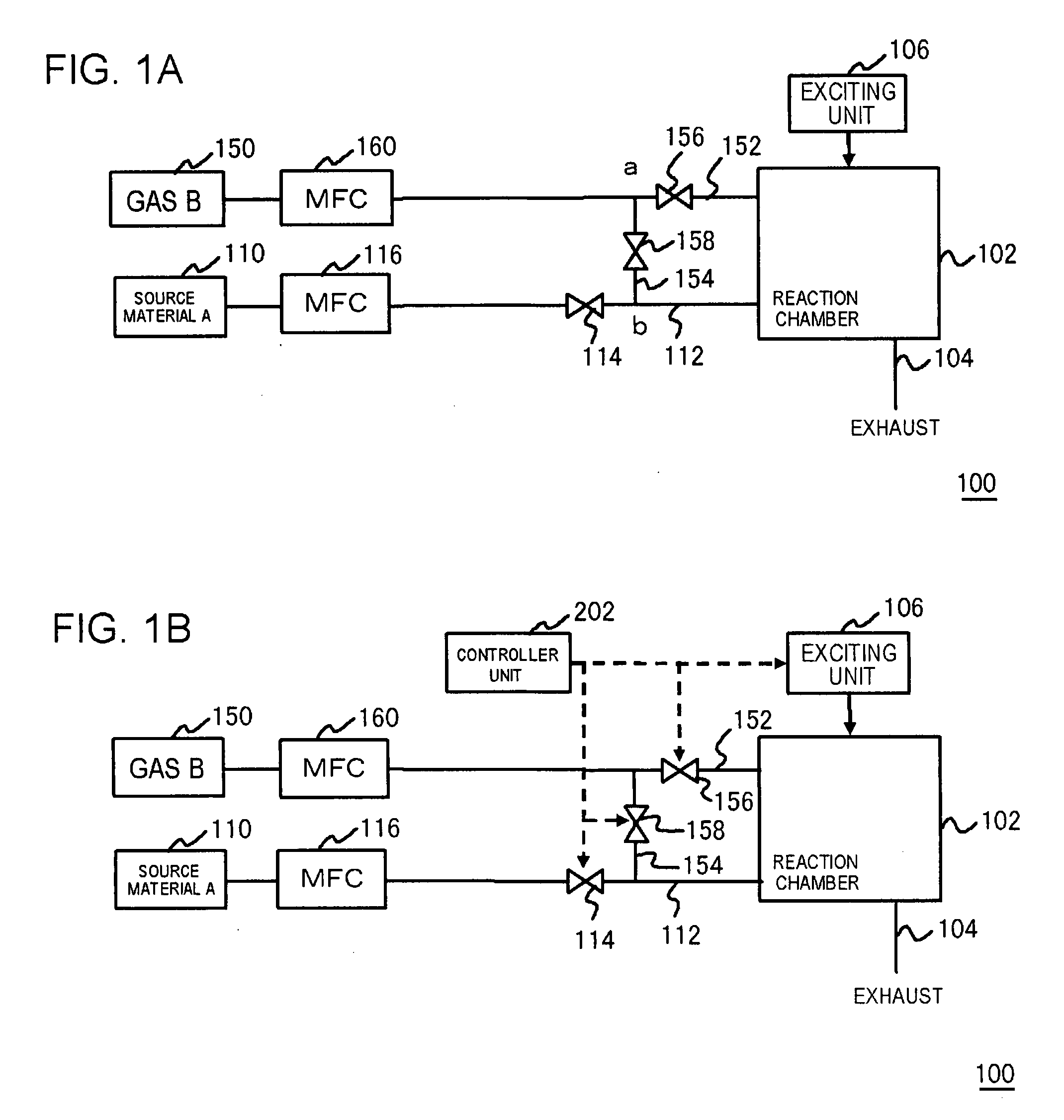

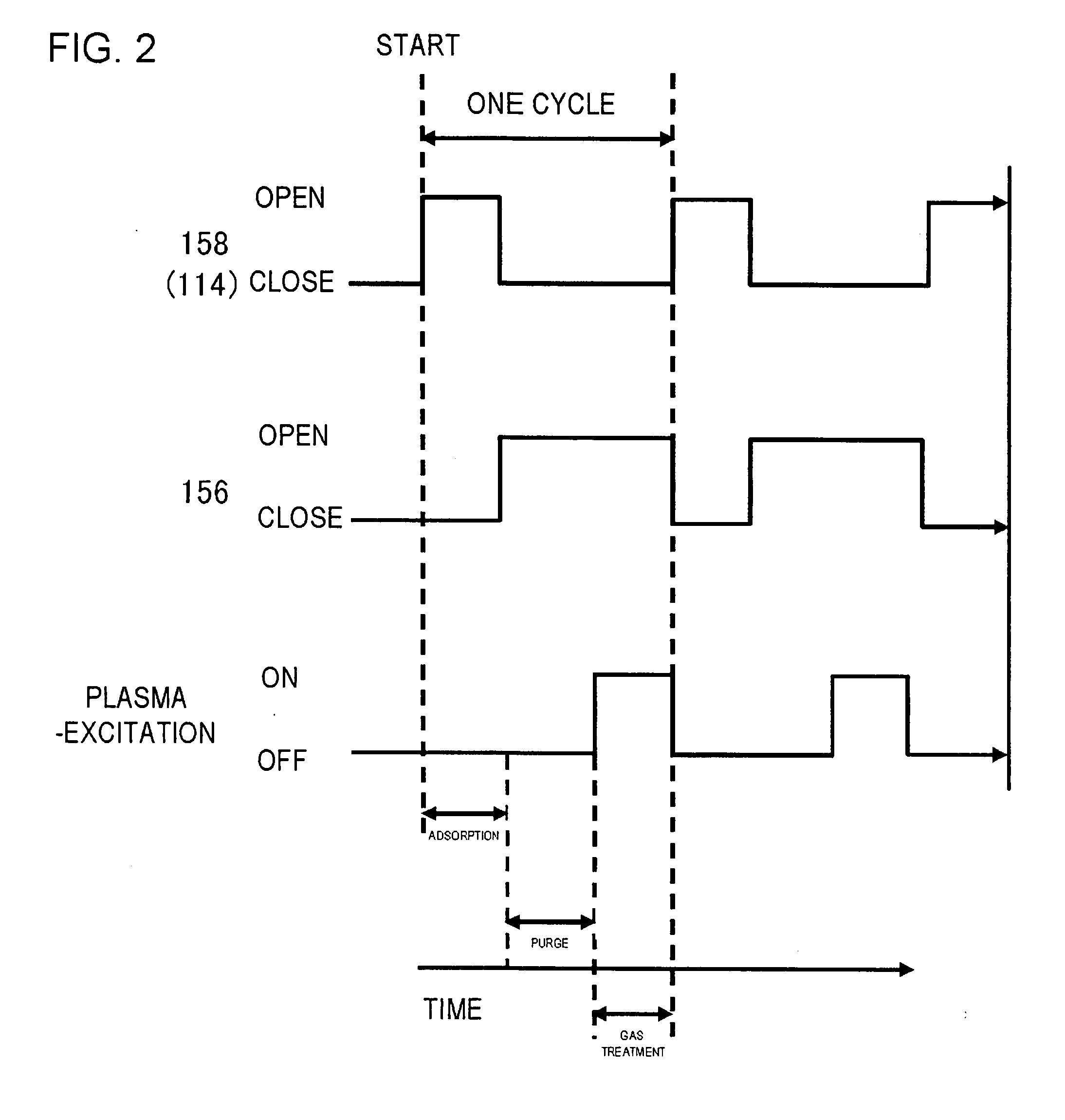

Method of pulsing vapor precursors in an ALD reactor

ActiveUS20060147626A1Faster film growthImproved pulse separationPolycrystalline material growthFrom chemically reactive gasesSource materialGas phase

A method of growing a thin film on a substrate by pulsing vapor-phase precursors material into a reaction chamber according to the ALD method. The method comprises vaporizing at least one precursor from a source material container maintained at a vaporising temperature, repeatedly feeding pulses of the vaporized precursor via a feed line into the reaction chamber at a first pressure, and subsequently purging the reaction chamber with pulses of inactive gas fed via the feed line at a second pressure. The second pressure is maintained at the same as or a higher level than the first pressure for separating successive pulses of said vaporized precursor from each other.

Owner:ASM IP HLDG BV

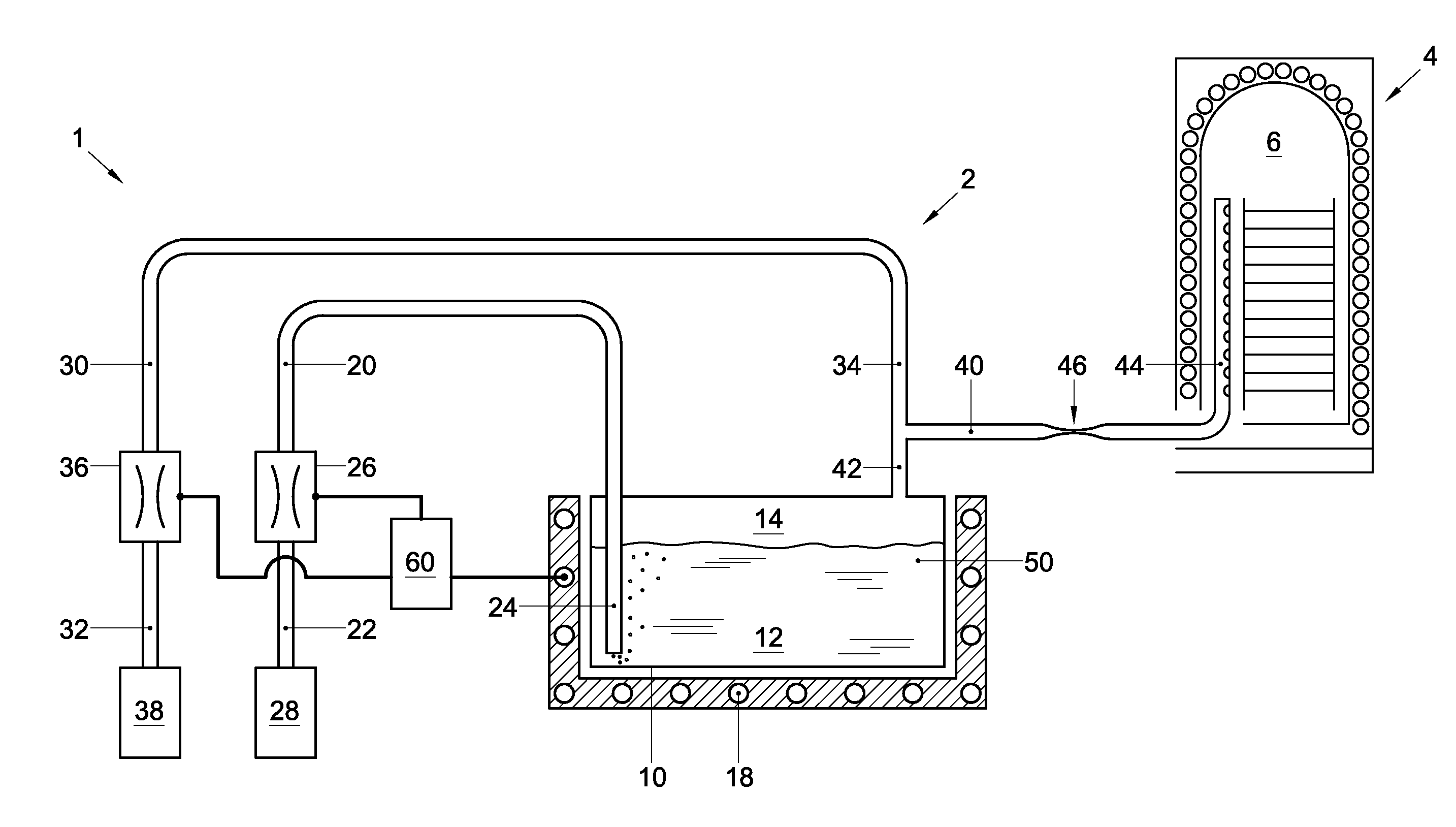

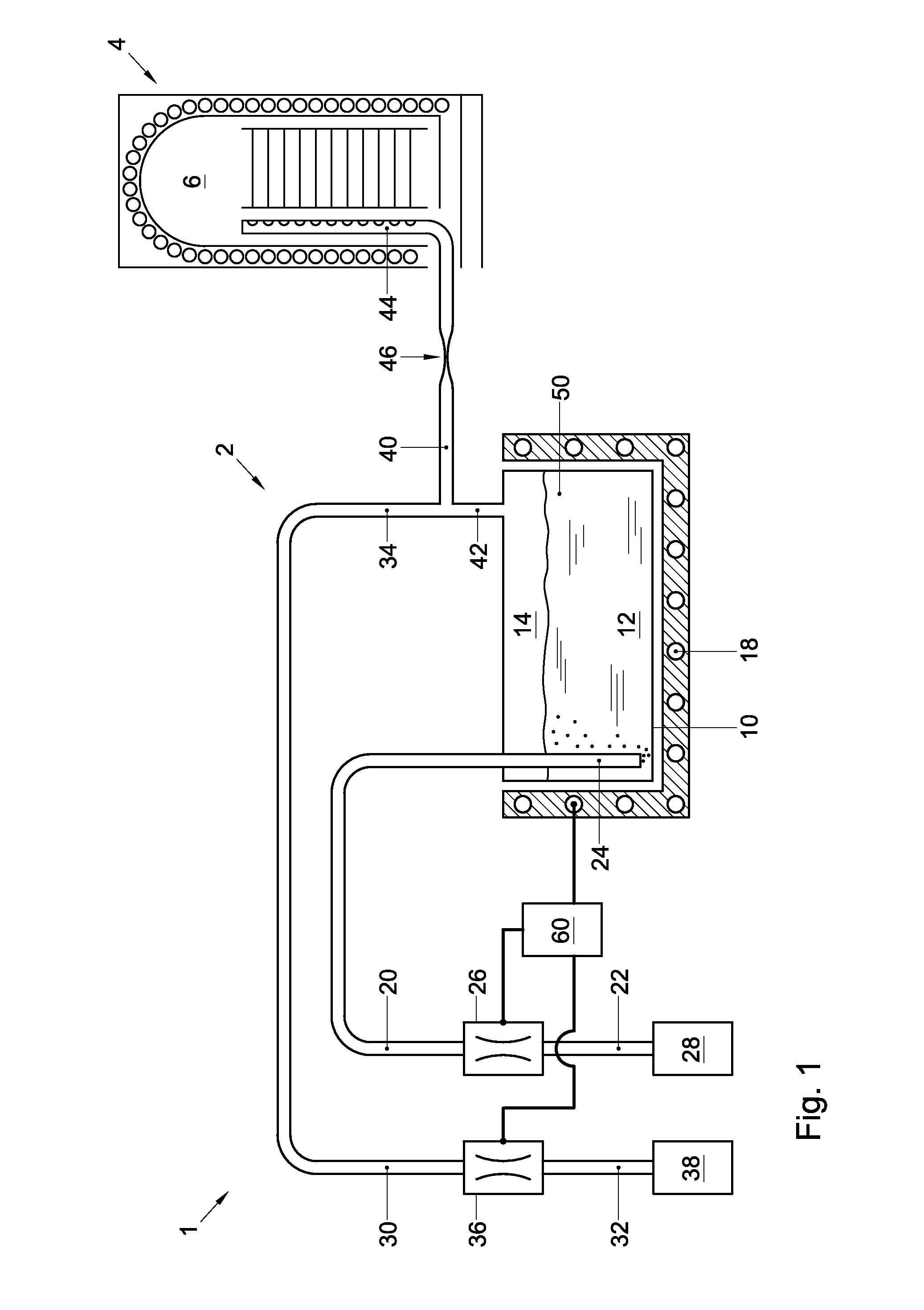

Bubbler assembly and method for vapor flow control

InactiveUS20120304935A1Mitigate and overcomeLess expensiveUsing liquid separation agentMixing methodsSource materialEngineering

Disclosed is a bubbler assembly. The bubbler assembly includes a vessel configured to contain a liquid source material and its vapor. It also includes a carrier gas supply line, a downstream end of which discharges in a lower portion of the vessel, and a gas outlet line, an upstream end of which is in fluid communication with an upper portion of the vessel. The gas outlet line includes a constriction. The bubbler assembly further includes a pressurizing gas supply line, a downstream end of which discharges in either the upper portion of the vessel or in the gas outlet line at a point upstream of the constriction.

Owner:ASM INTERNATIONAL

Method of cutting material for use in implantable medical device

A method of cutting material for use in an implantable medical device employs a plotted laser cutting system. The laser cutting system is computer controlled and includes a laser combined with a motion system. The laser precisely cuts segments out of source material according to a predetermined pattern as designated by the computer. The segments are used in constructing implantable medical devices. The cutting energy of the laser is selected so that the cut edges of the segments are melted to discourage delamination or fraying, but communication of thermal energy into the segment beyond the edge is minimized to avoid damaging the segment adjacent the edge.

Owner:3F THERAPEUTICS

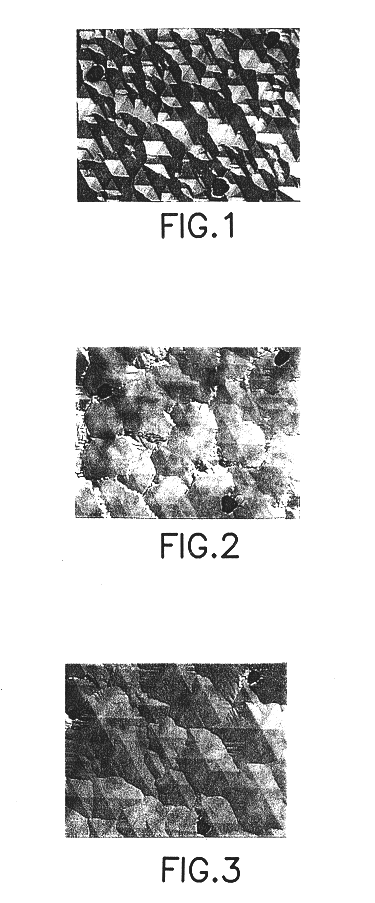

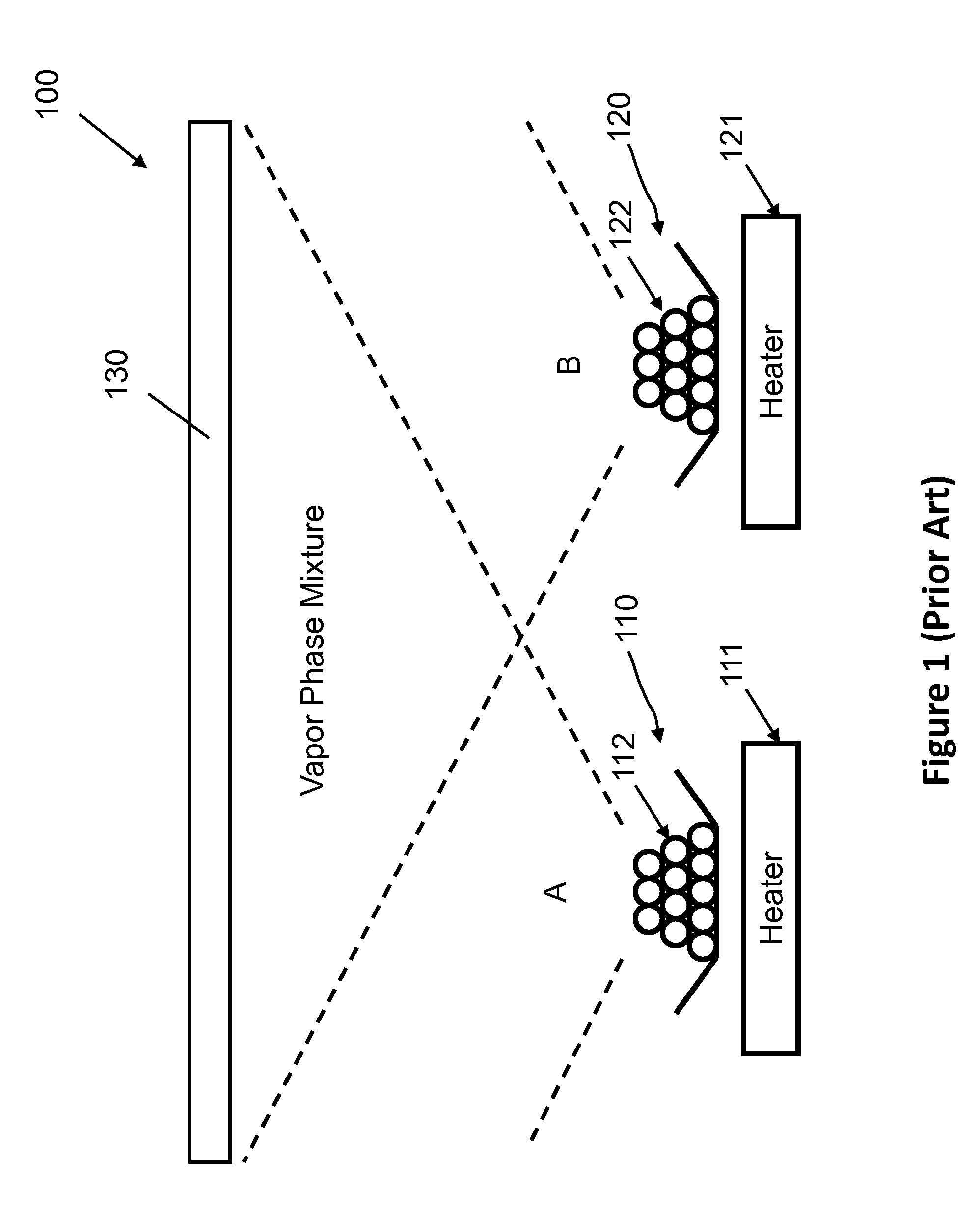

Method for achieving improved epitaxy quality (surface texture and defect density) on free-standing (aluminum, indium, gallium) nitride ((al,in,ga)n) substrates for opto-electronic and electronic devices

A III-V nitride homoepitaxial microelectronic device structure comprising a III-V nitride homoepitaxial epi layer on a III-V nitride material substrate, e.g., of freestanding character. Various processing techniques are described, including a method of forming a III-V nitride homoepitaxial layer on a corresponding III-V nitride material substrate, by depositing the III-V nitride homoepitaxial layer by a VPE process using Group III source material and nitrogen source material under process conditions including V / III ratio in a range of from about 1 to about 105, nitrogen source material partial pressure in a range of from about 1 to about 103 torr, growth temperature in a range of from about 500 to about 1250 degrees Celsius, and growth rate in a range of from about 0.1 to about 500 microns per hour. The III-V nitride homoepitaxial microelectronic device structures are usefully employed in device applications such as UV LEDs, high electron mobility transistors, and the like.

Owner:WOLFSPEED INC

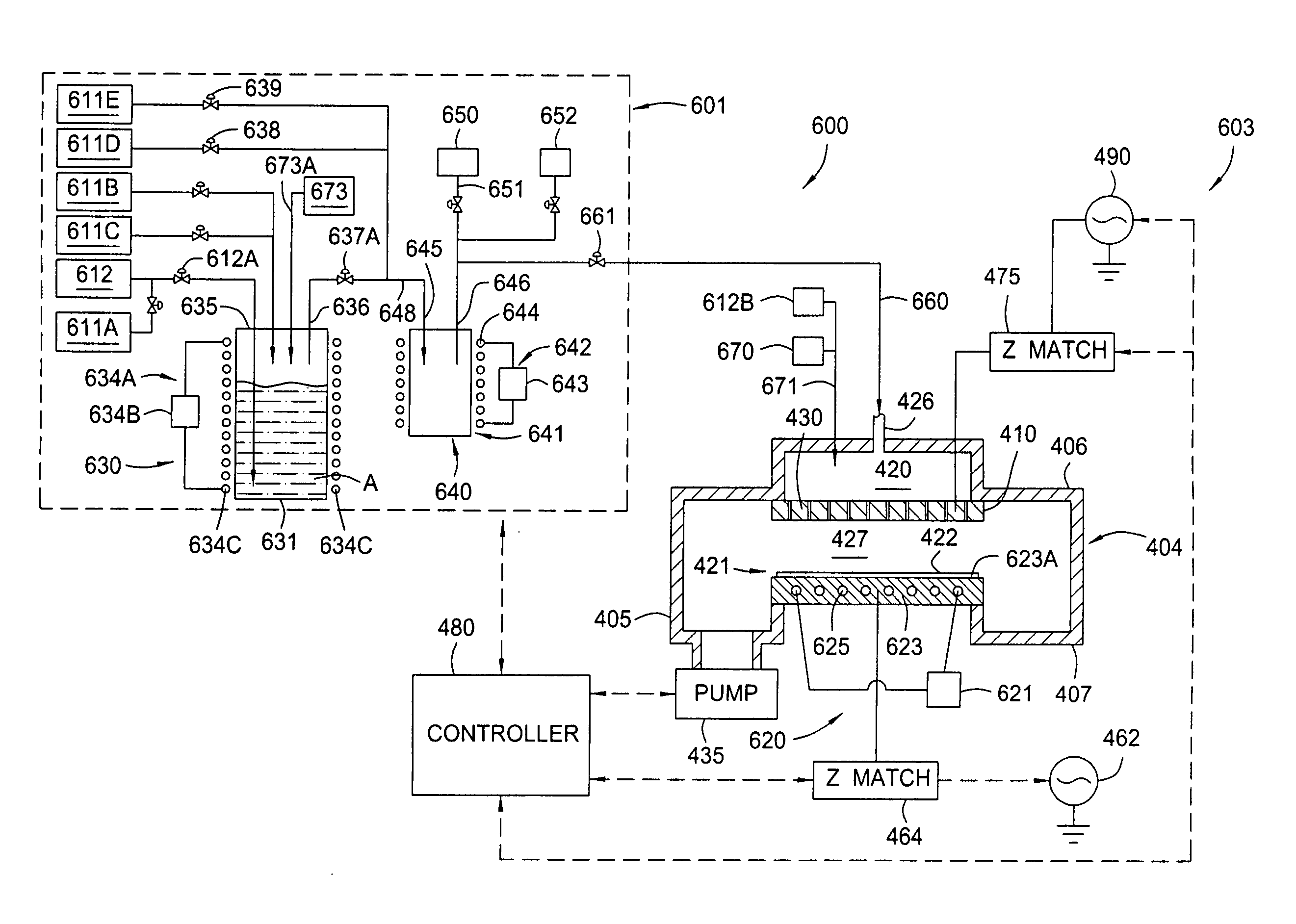

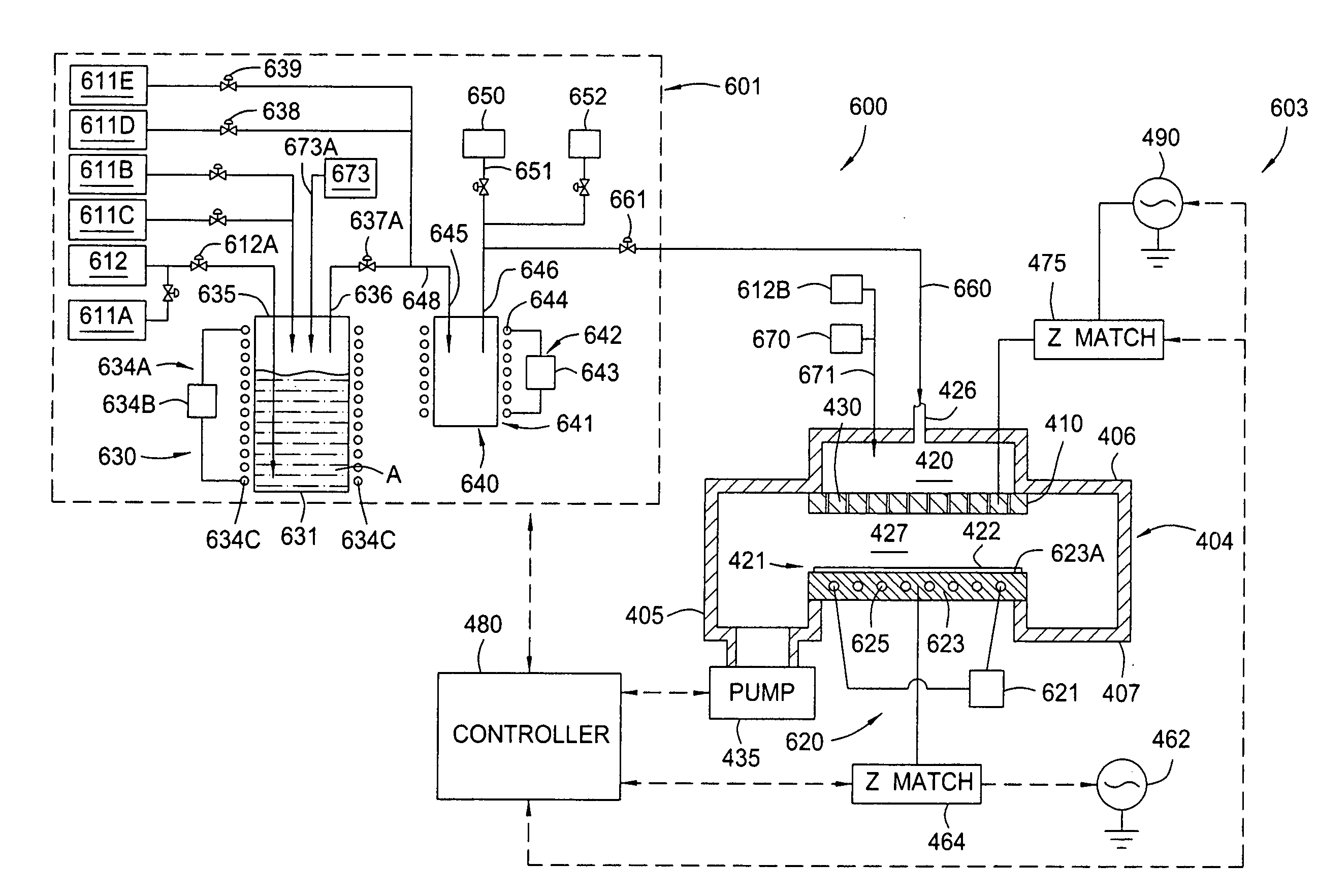

Ruthenium containing layer deposition method

ActiveUS20060165892A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTemperature controlSource material

An exemplary apparatus and method of forming a ruthenium tetroxide containing gas to form a ruthenium containing layer on a surface of a substrate is described herein. The method and apparatus described herein may be especially useful for fabricating electronic devices that are formed on a surface of the substrate or wafer. Generally, the method includes exposing a surface of a substrate to a ruthenium tetroxide vapor to form a catalytic layer on the surface of a substrate and then filling the device structures by an electroless, electroplating, physical vapor deposition (PVD), chemical vapor deposition (CVD), plasma enhanced CVD (PECVD), atomic layer deposition (ALD) or plasma enhanced ALD (PE-ALD) processes. In one embodiment, the ruthenium containing layer is formed on a surface of a substrate by creating ruthenium tetroxide in an external vessel and then delivering the generated ruthenium tetroxide gas to a surface of a temperature controlled substrate positioned in a processing chamber. In one embodiment, a ruthenium tetroxide containing solvent formation process is used to form ruthenium tetroxide using a ruthenium tetroxide containing source material. In one embodiment, of a ruthenium containing layer is formed on a surface of a substrate, using the ruthenium tetroxide containing solvent. In another embodiment, the solvent is separated from the ruthenium tetroxide containing solvent mixture and the remaining ruthenium tetroxide is used to form a ruthenium containing layer on the surface of a substrate.

Owner:APPLIED MATERIALS INC

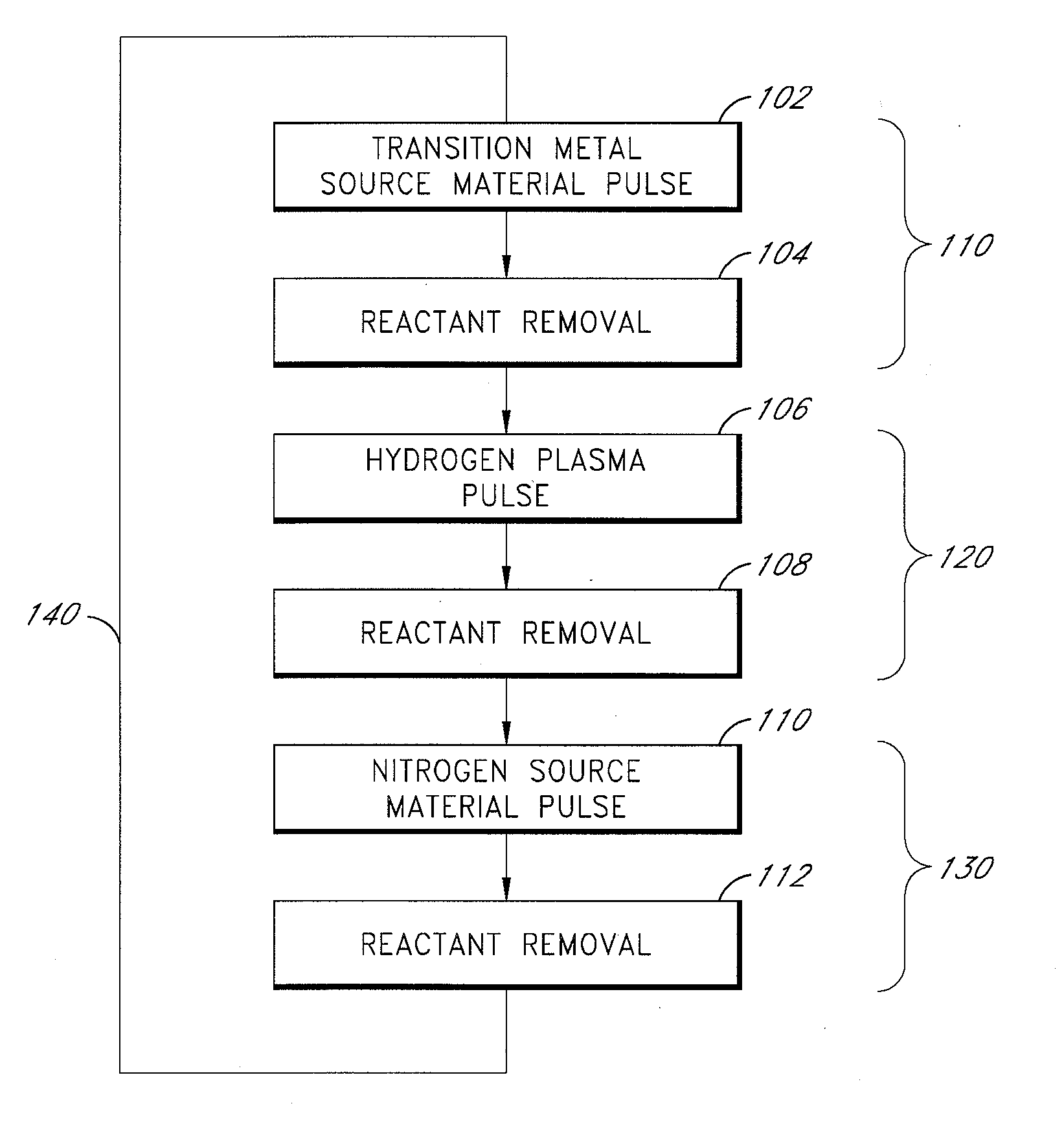

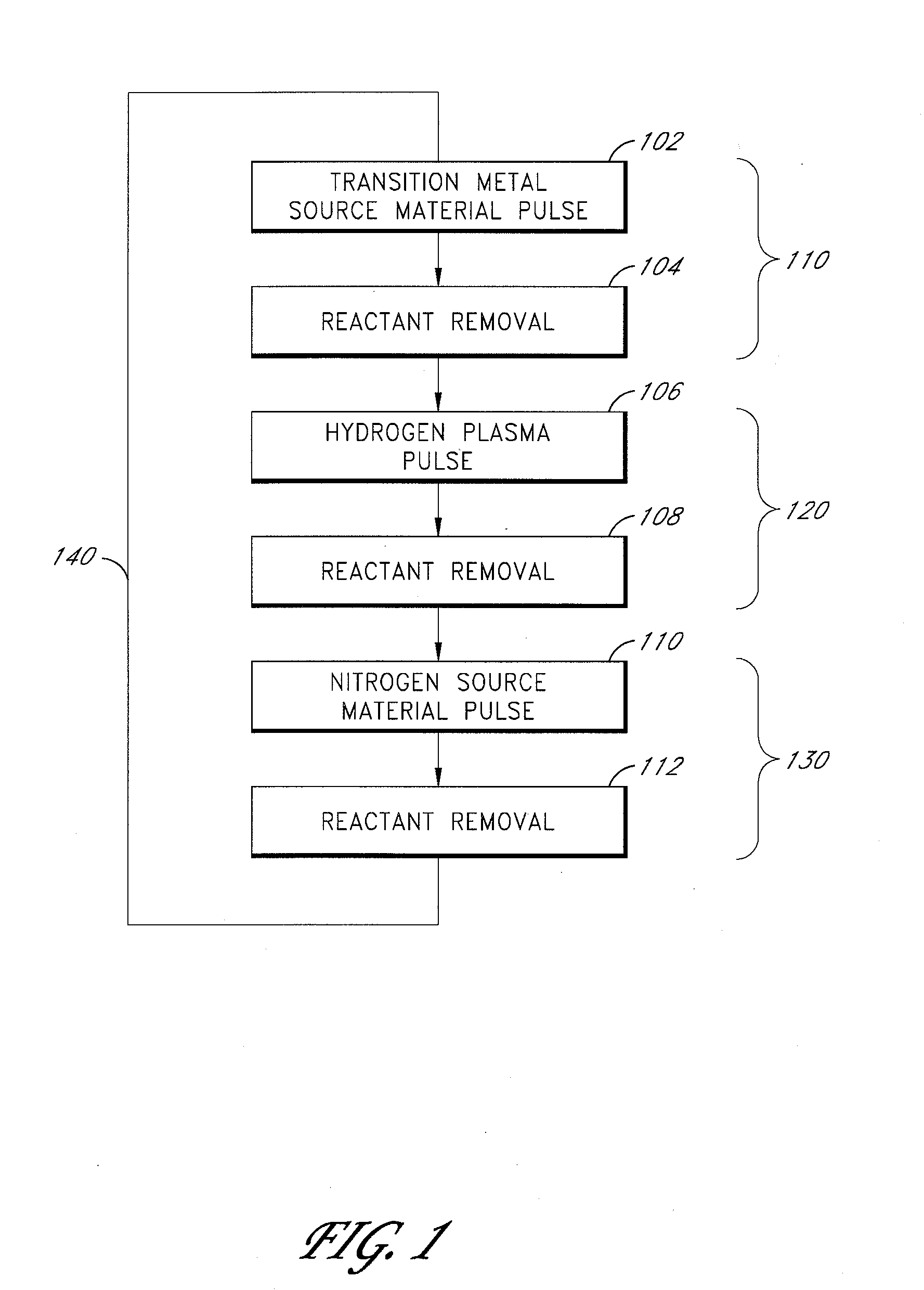

Plasma-enhanced ald of tantalum nitride films

ActiveUS20080182411A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenSource material

Methods of controllably producing conductive tantalum nitride films are provided. The methods comprise contacting a substrate in a reaction space with alternating and sequential pulses of a tantalum source material, plasma-excited species of hydrogen and nitrogen source material. The plasma-excited species of hydrogen reduce the oxidation state of tantalum, thereby forming a substantially conductive tantalum nitride film over the substrate. In some embodiments, the plasma-excited species of hydrogen react with and removes halide residues in a deposited metallic film.

Owner:ASM IP HLDG BV

Single crystal and quasi-single crystal, composition, apparatus, and associated method

InactiveUS20060037529A1Material nanotechnologyPolycrystalline material growthMischmetalSource material

Owner:SORAA

Resonant cavity light emitting devices and associated method

InactiveUS20060118799A1Increase probabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingResonant cavitySource material

A method may produce a resonant cavity light emitting device. A seed gallium nitride crystal and a source material in a nitrogen-containing superheated fluid may provide a medium for mass transport of gallium nitride precursors therebetween. A seed crystal surface may be prepared by applying a first thermal profile between the seed gallium nitride crystal and the source material. Gallium nitride material may be grown on the prepared surface of the seed gallium nitride crystal by applying a second thermal profile between the seed gallium nitride crystal and the source material while the seed gallium nitride crystal and the source material are in the nitrogen-containing superheated fluid. A stack of group III-nitride layers may be deposited on the single-crystal gallium nitride substrate. The stack may include a first mirror sub-stack and an active region adaptable for fabrication into one or more resonant cavity light emitting devices.

Owner:SORAA

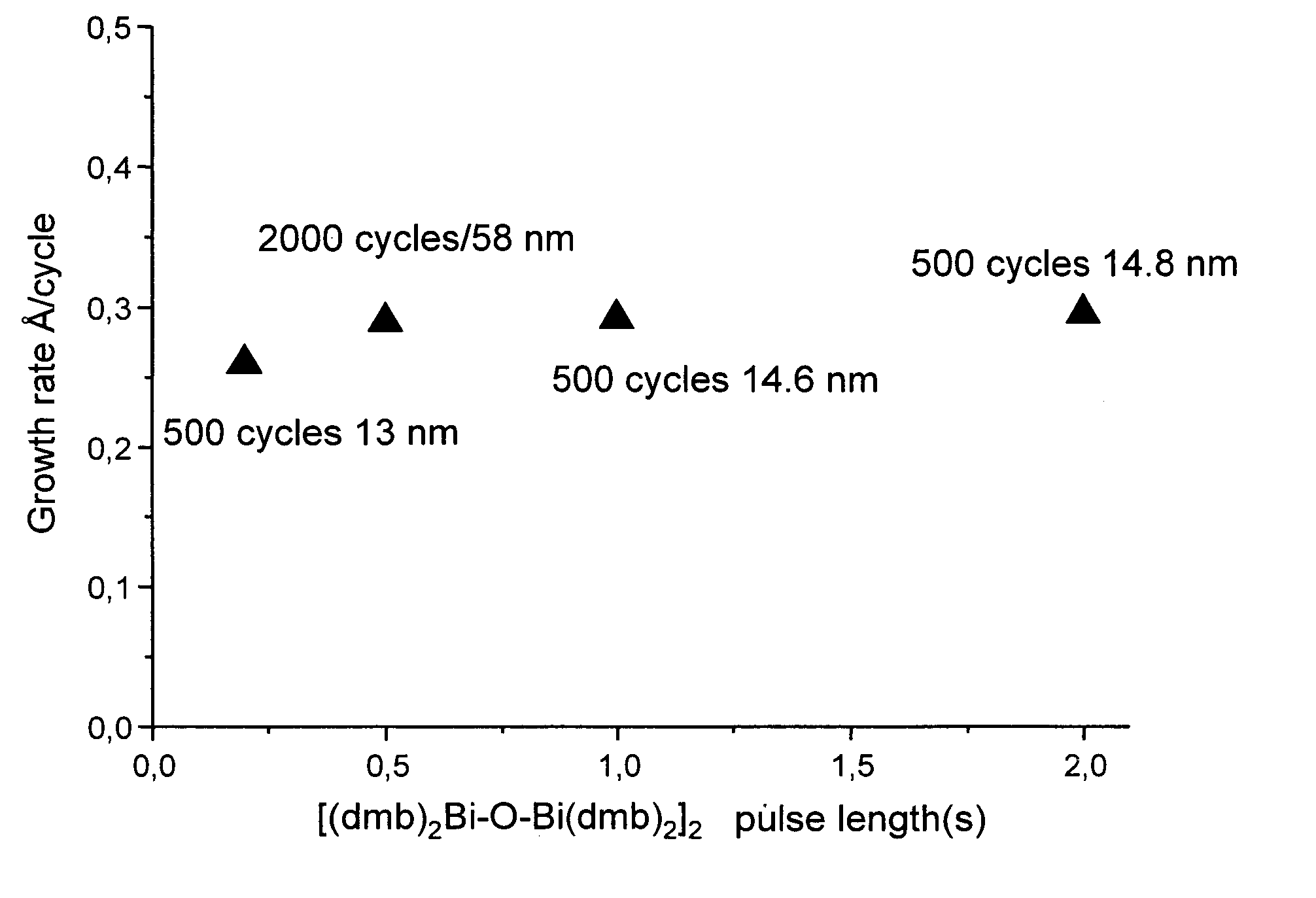

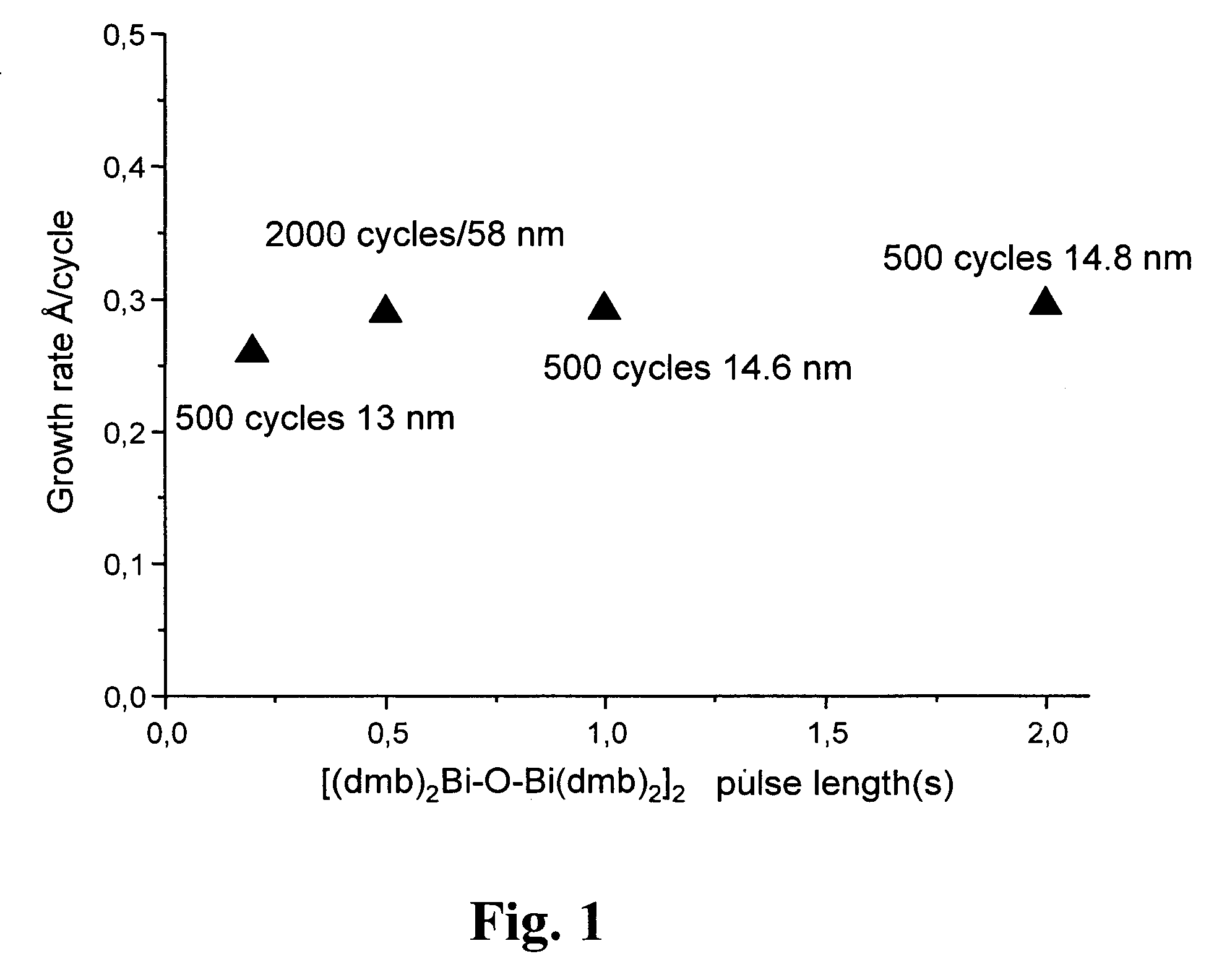

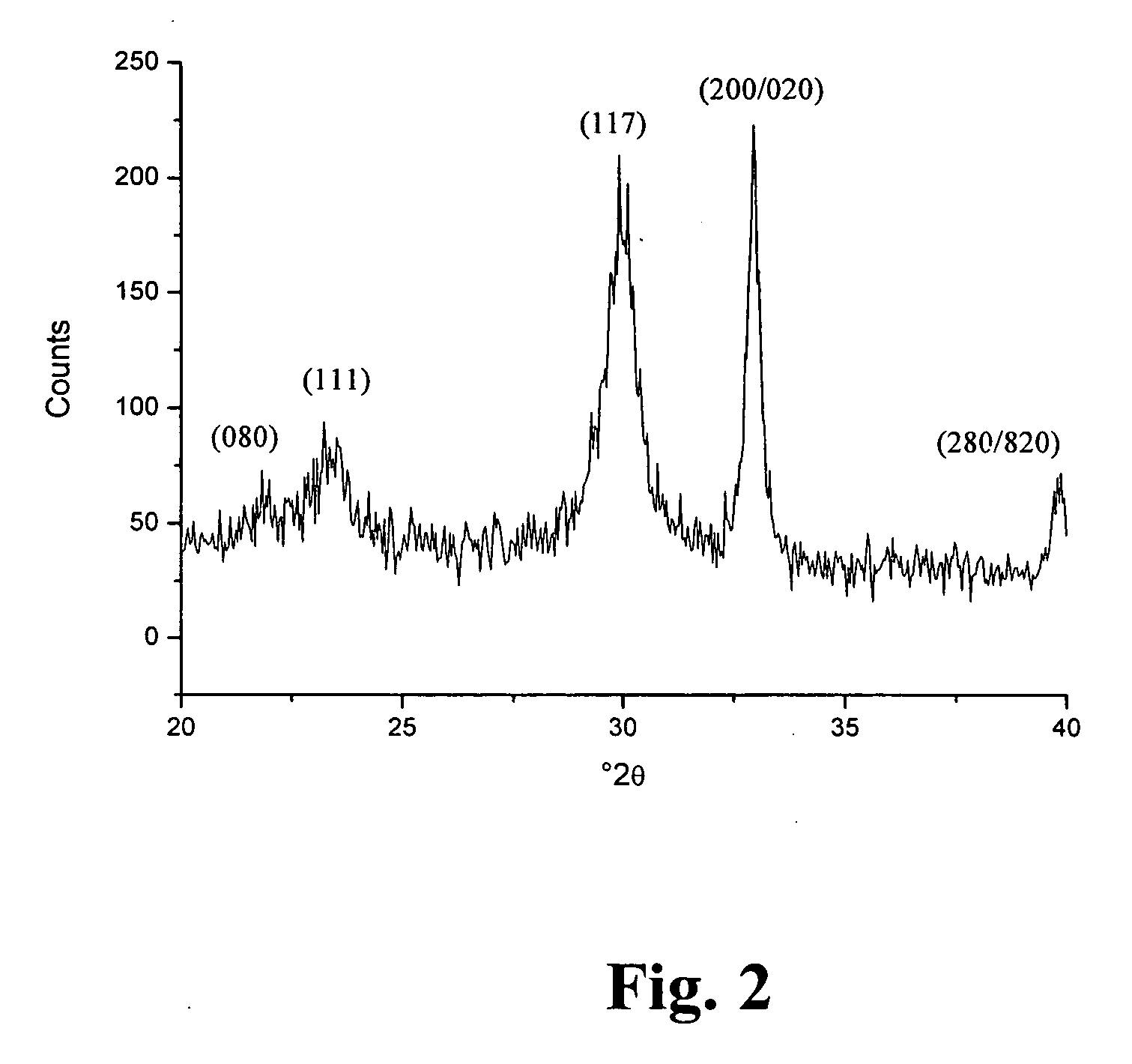

Process for producing oxide films

ActiveUS20070148347A1Group 5/15 element organic compoundsFixed capacitor dielectricSource materialBismuth compound

Processes are provided for producing bismuth-containing oxide thin films by atomic layer deposition. In preferred embodiments an organic bismuth compound having at least one monodentate alkoxide ligand is used as a bismuth source material. Bismuth-containing oxide thin films can be used, for example, as ferroelectric or dielectric materials in integrated circuits and as superconductor materials.

Owner:ASM INTERNATIONAL

Deposition apparatus and method for depositing film

ActiveUS20070186849A1Improved deposition characteristicsConstant flowChemical vapor deposition coatingSource materialProcess engineering

Owner:RENESAS ELECTRONICS CORP

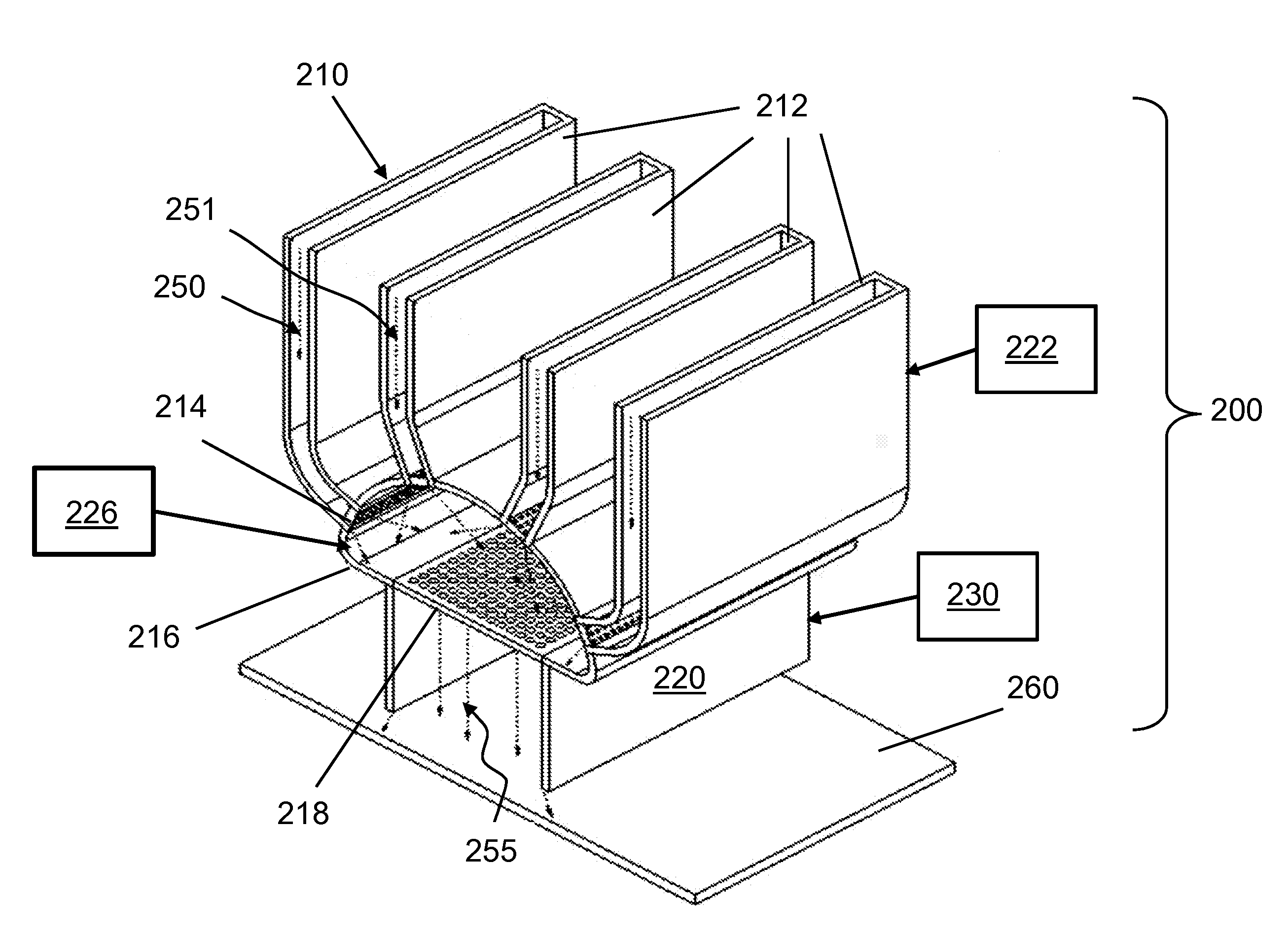

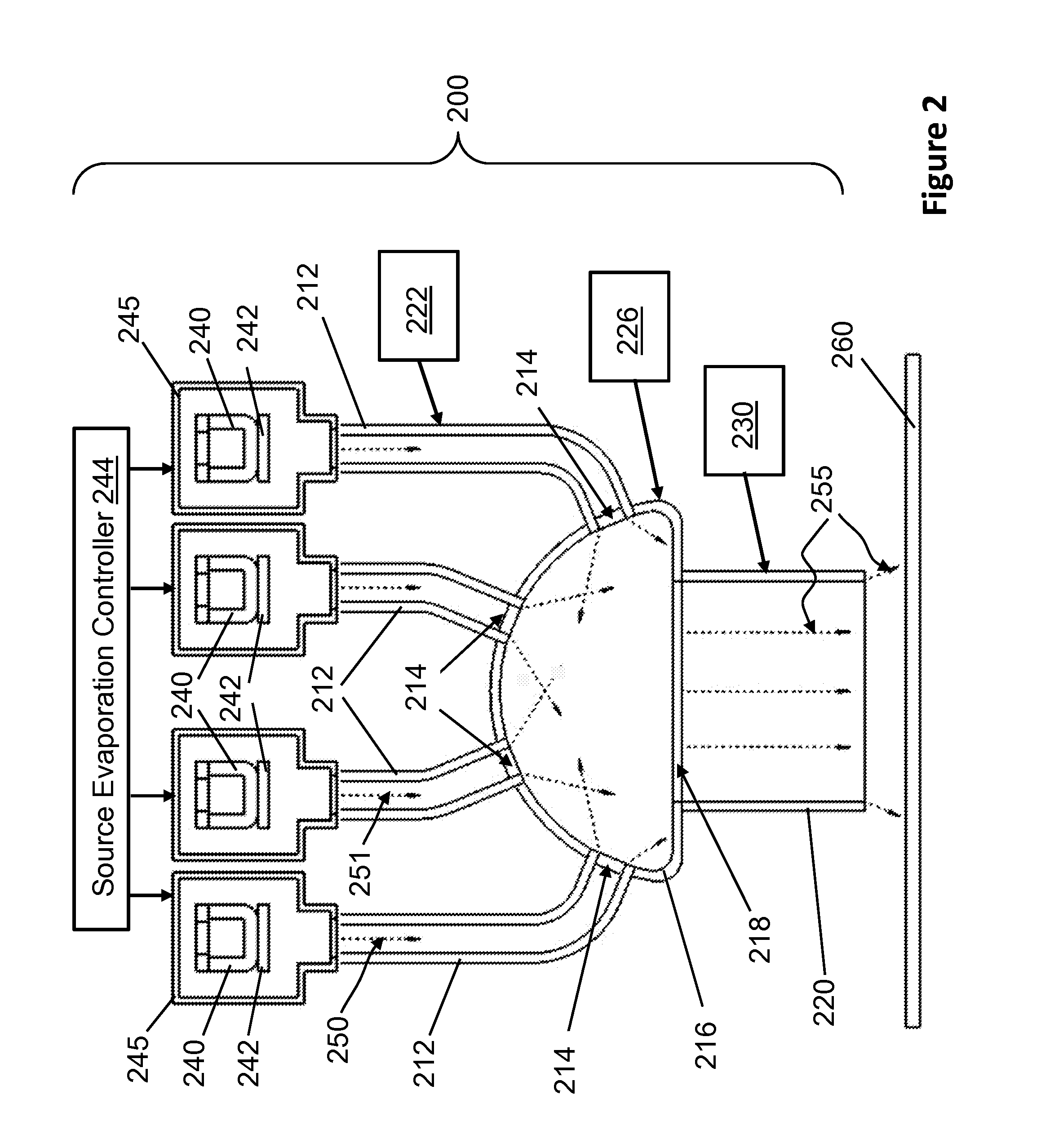

Co-evaporation system comprising vapor pre-mixer

InactiveUS20130302520A1Uniform depositionUniform composition ratioVacuum evaporation coatingSputtering coatingSource materialEvaporation

A processing system for depositing a plurality of source materials on a substrate, includes a first thermal evaporation source that can evaporate a first source material to produce a first vapor, a second thermal evaporation source that can evaporate a second source material to produce a second vapor, a vapor mixing chamber that allows the first vapor and the second vapor to be mixed to produce a mixed vapor, and conduits that can separately transport the first vapor and the second vapor to the vapor mixing chamber. The mixed vapor can be directed toward a substrate to deposit a mixture of the first source material and the second source material on the substrate. The processing system can also include vapor filters configured to regulate flows of the first vapor and the second vapor, and a mixed vapor filter to regulate flow of the mixed vapor.

Owner:WANG KAI AN +4

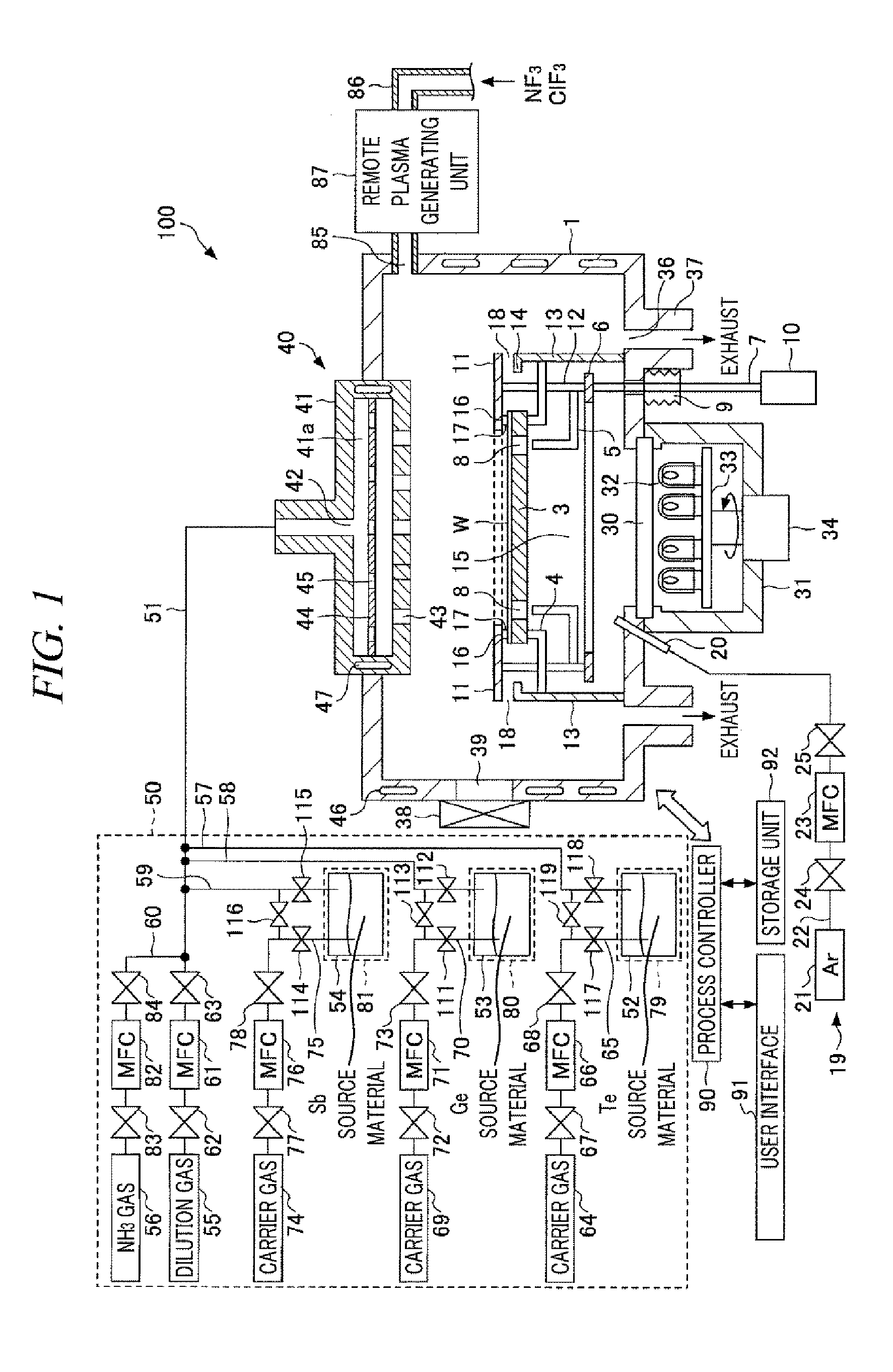

Ge-Sb-Te FILM FORMING METHOD, Ge-Te FILM FORMING METHOD, AND Sb-Te FILM FORMING METHOD

ActiveUS20140162401A1Improve surface smoothnessImprove featuresSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDimethylhydrazineMetallurgy

A Ge—Sb—Te film forming method includes a Sb source material introducing process, a first purging process, a Te source material introducing process, a second purging process, a Ge source material introducing process, a third purging process. An additive gas containing at least one of ammonia, methylamine, dimethylamine, hydrazine, monomethylhydrazine, dimethylhydrazine and pyridine is introduced in at least one of the Sb, Te and Ge source material introducing processes and the first to third purging processes.

Owner:TOKYO ELECTRON LTD

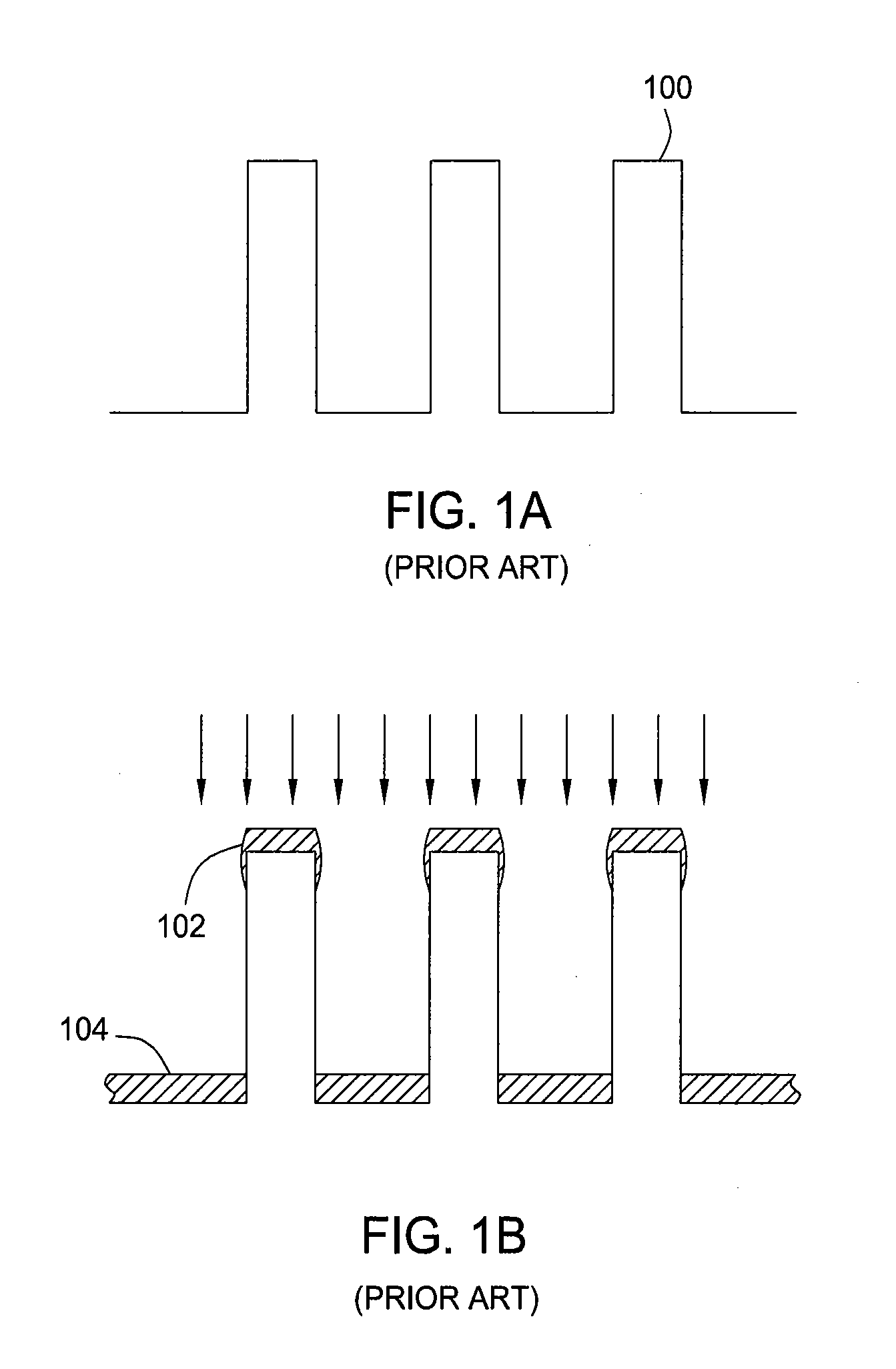

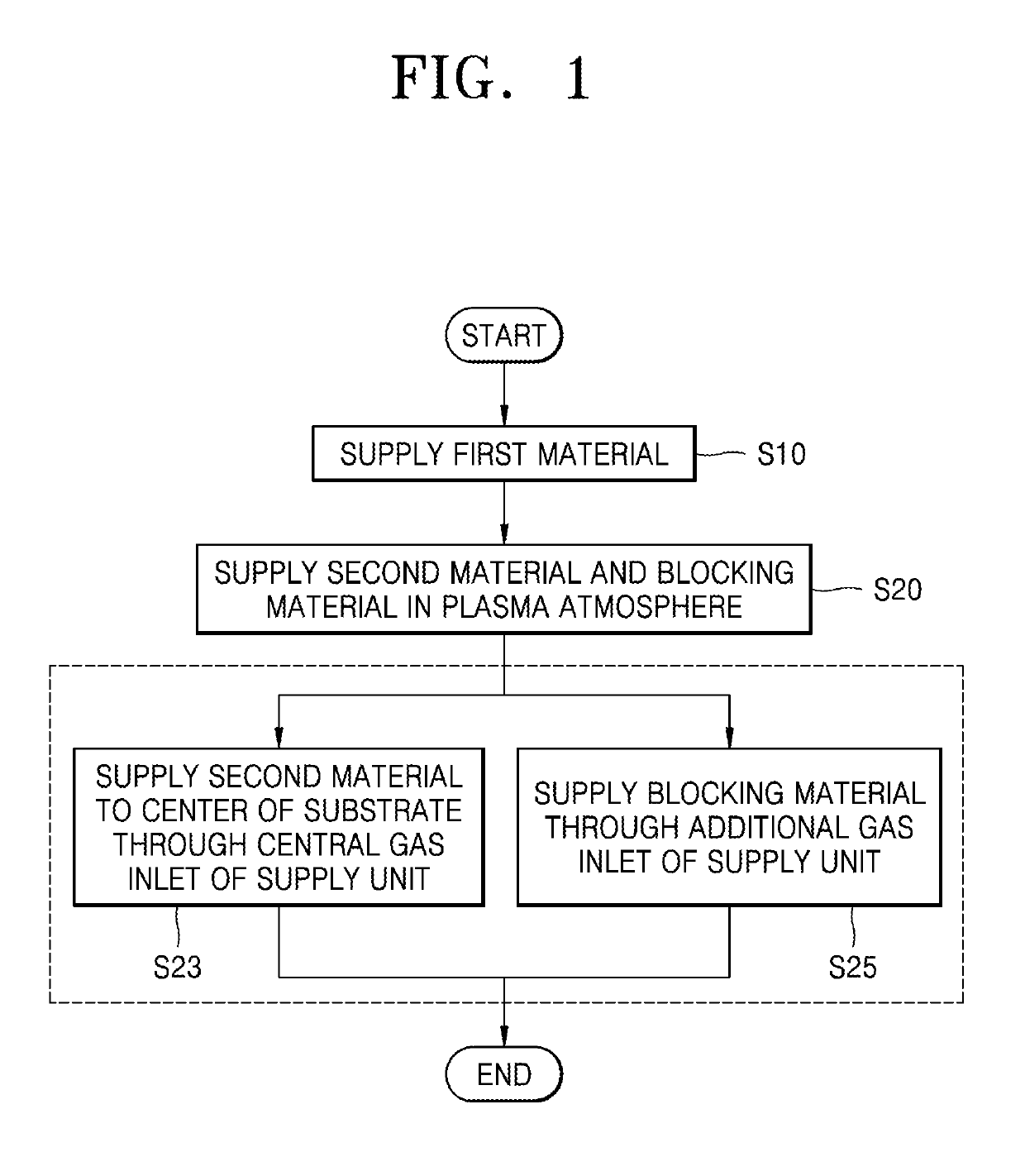

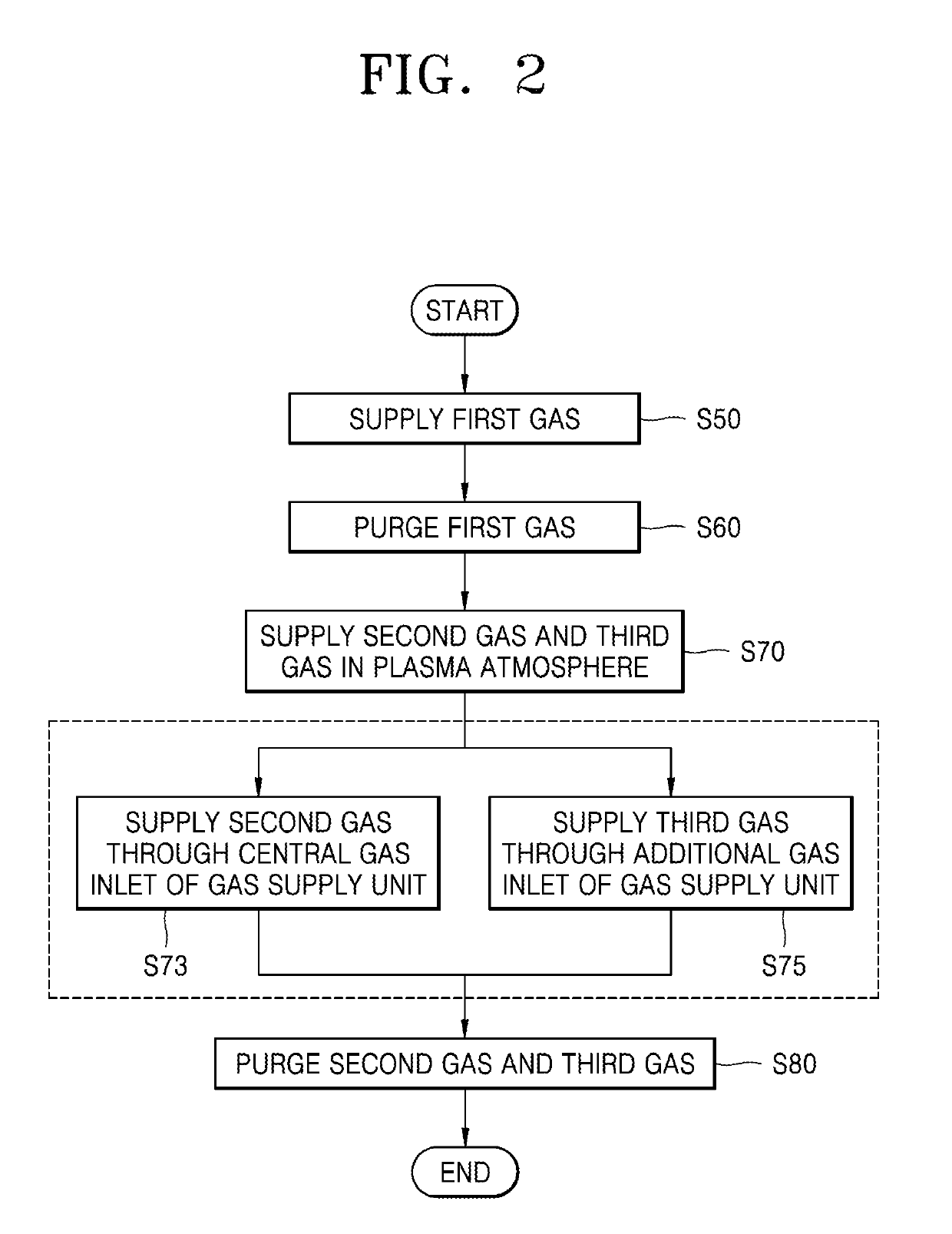

Substrate processing method

ActiveUS20190304776A1High densityUniform damageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSource materialEngineering

A substrate processing method capable of uniformly maintaining damage to a pattern structure under a thin film formed on a substrate includes supplying a source material to a substrate on which a pattern structure that is reactive with a reactant is formed; and supplying the reactant through at least a central gas inlet of a supply unit in a plasma atmosphere, wherein, during the supplying of the reactant, a blocking material different from the reactant is supplied through an additional gas inlet that is spaced apart from the central gas inlet of the supply unit, and a flow of the blocking material at the edge of the substrate is increased, thereby increasing a radical density of the reactant near a center of the substrate.

Owner:ASM IP HLDG BV

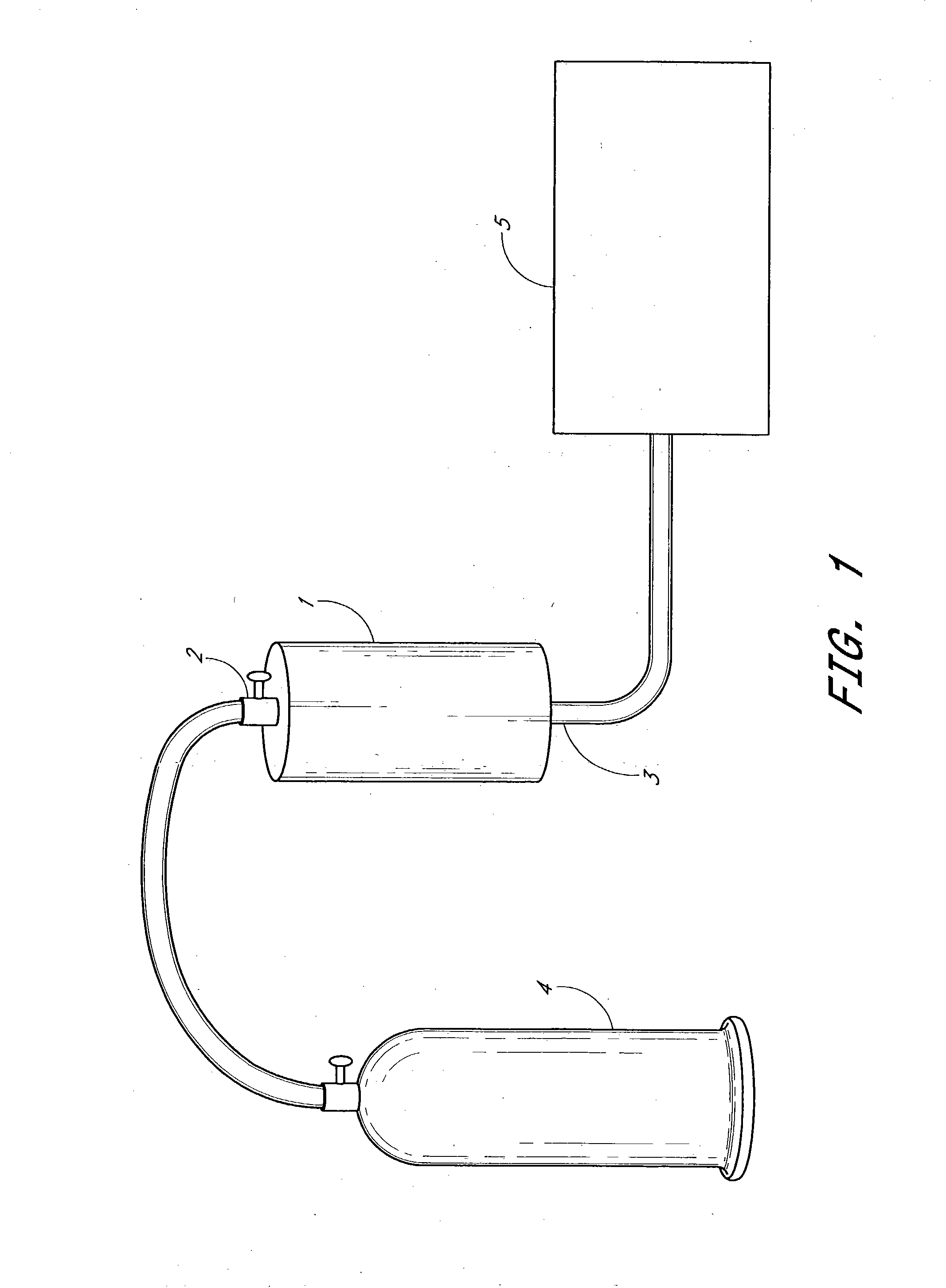

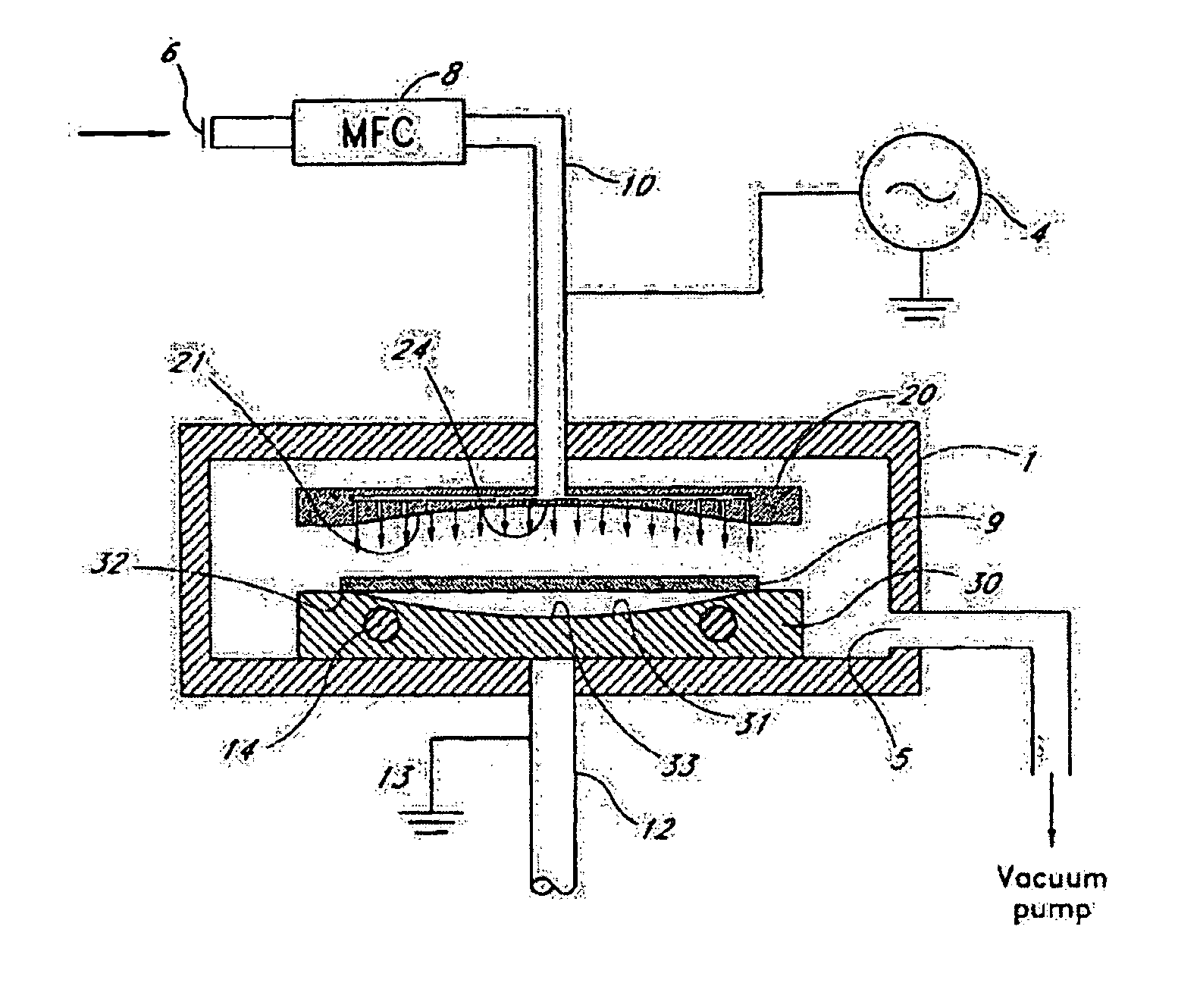

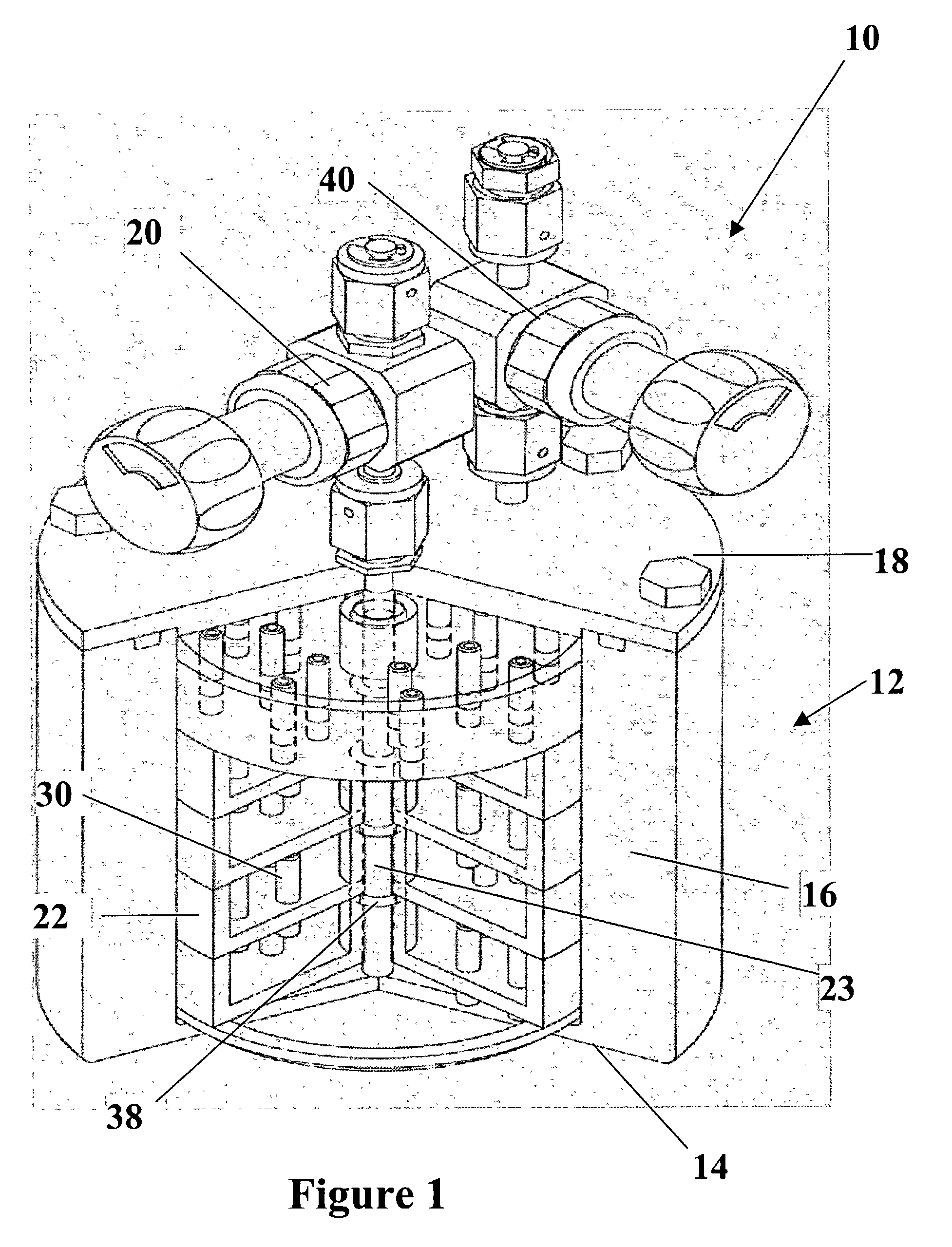

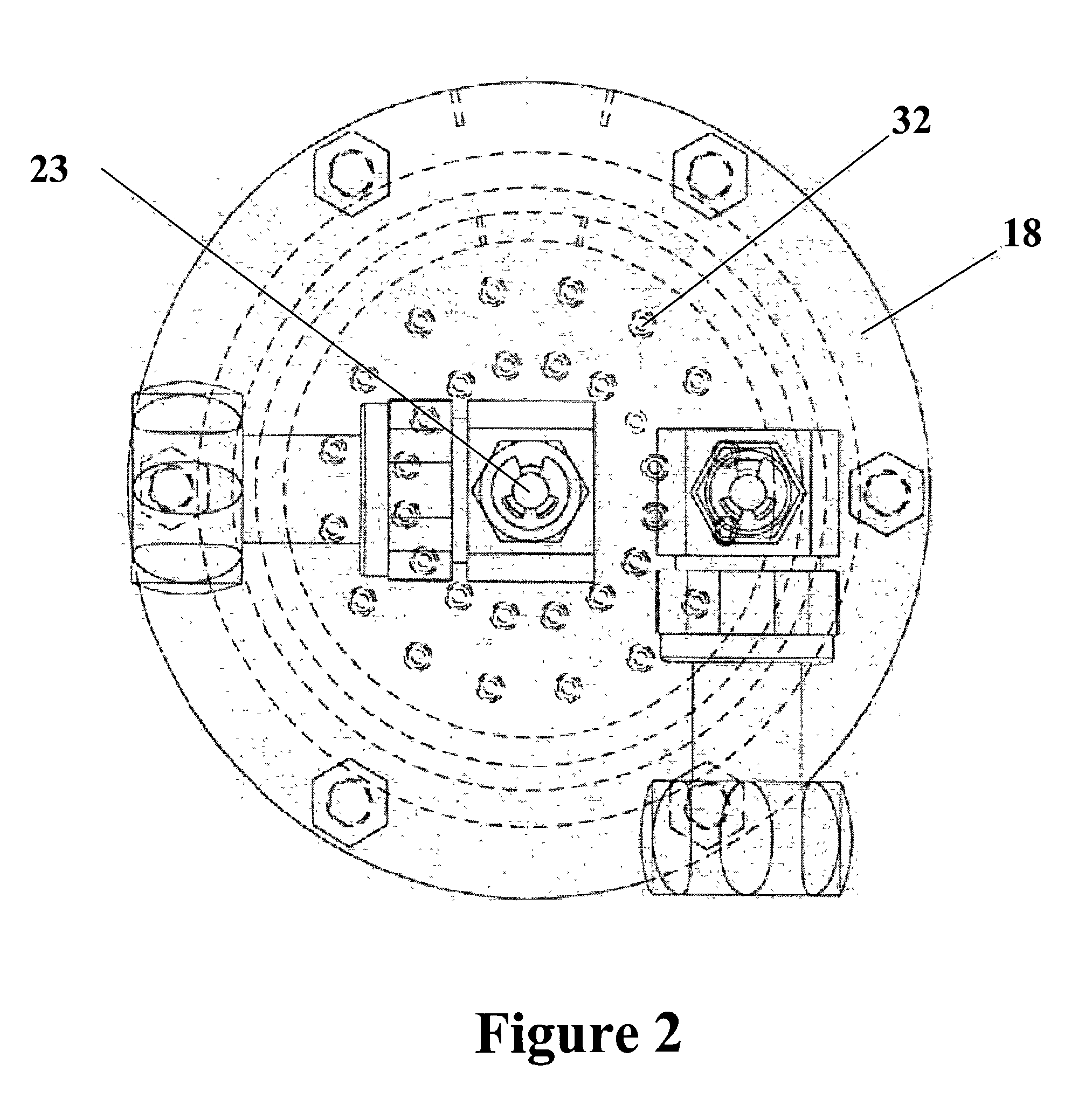

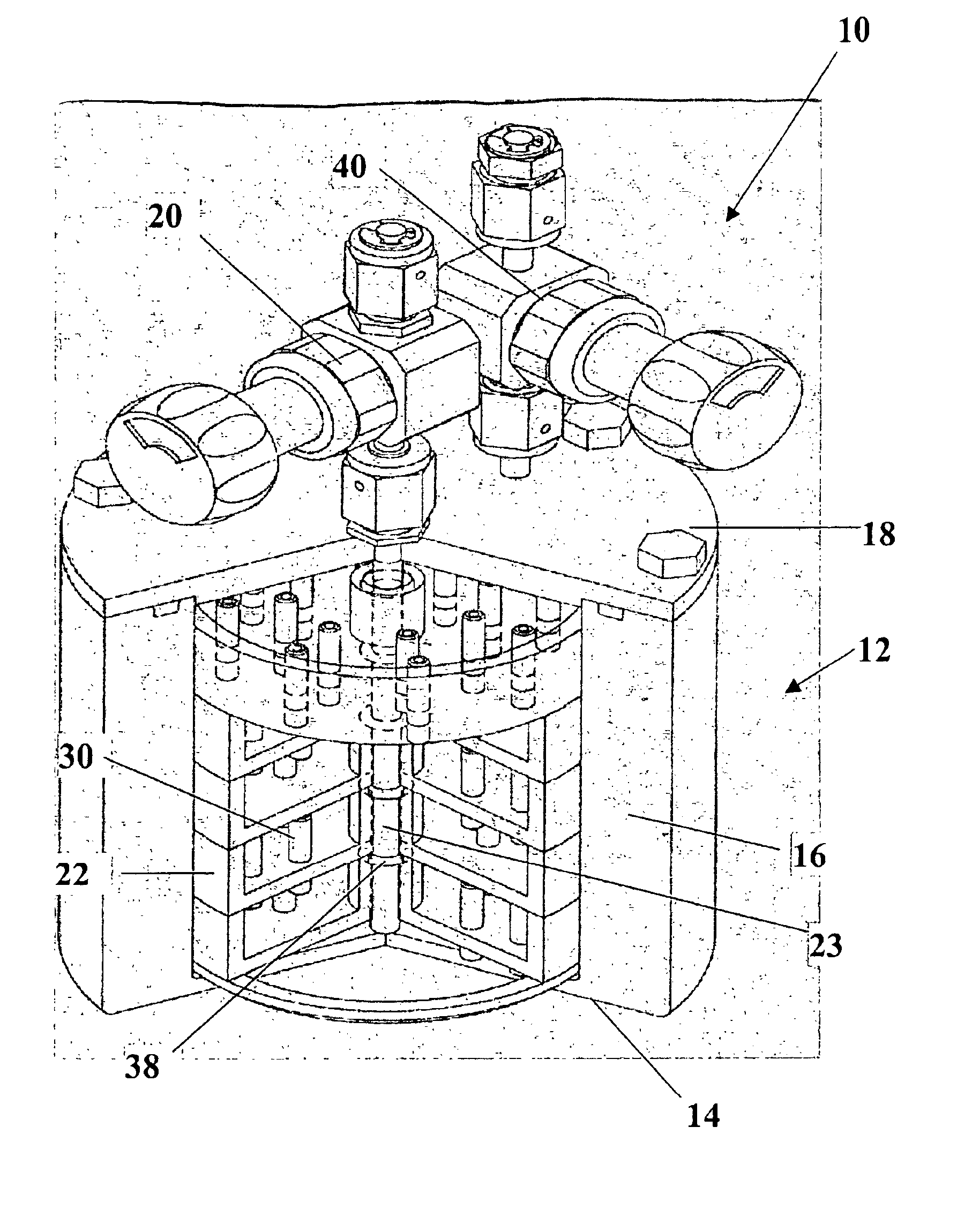

Vaporizer delivery ampoule

InactiveUS20040016404A1Increase the areaShorten closing timeVessel wallsNon-pressured vesselsSource materialEngineering

A vaporizer delivery system for use in semiconductor manufacturing processes including a plurality of vertically stacked containers for holding a vaporizable source material. Each of the vertically stacked containers includes a plurality of vented protuberances extending into the interior of the each stacked container thereby providing channels for passage of a carrier gas between adjacent vertically stacked containers.

Owner:ENTEGRIS INC

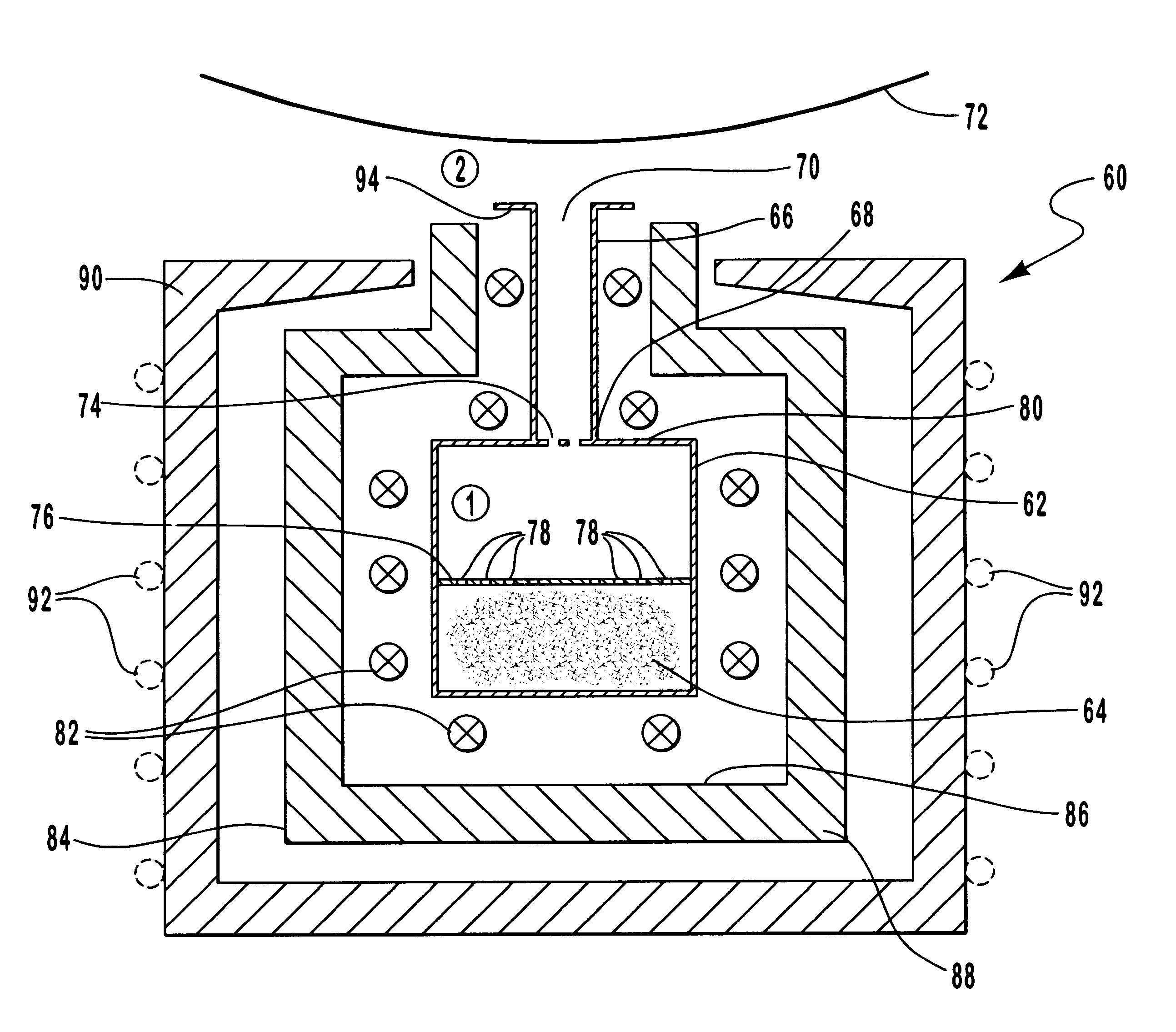

Linear aperture deposition apparatus and coating process

InactiveUS6202591B1High and stable rateEasy to useVacuum evaporation coatingSputtering coatingParticulatesSource material

A linear aperture deposition apparatus and process are provided for coating substrates with sublimed or evaporated coating materials. The apparatus and process are particularly suited for producing flexible films having an optical interference coating with a very high surface thickness uniformity and which is substantially free of defects from particulate ejection of a source material. The apparatus includes a source box containing a source material, a heating element to sublime or evaporate the source material, and a chimney to direct the source material vapor from the source box to a substrate. A flow restricting baffle having a plurality of holes is positioned between the source material and the substrate to confine and direct the vapor flow, and an optional floating baffle is positioned on the surface of the source material to further restrict the vapor flow, thereby substantially eliminating source material spatter.

Owner:JDS UNIPHASE CORP

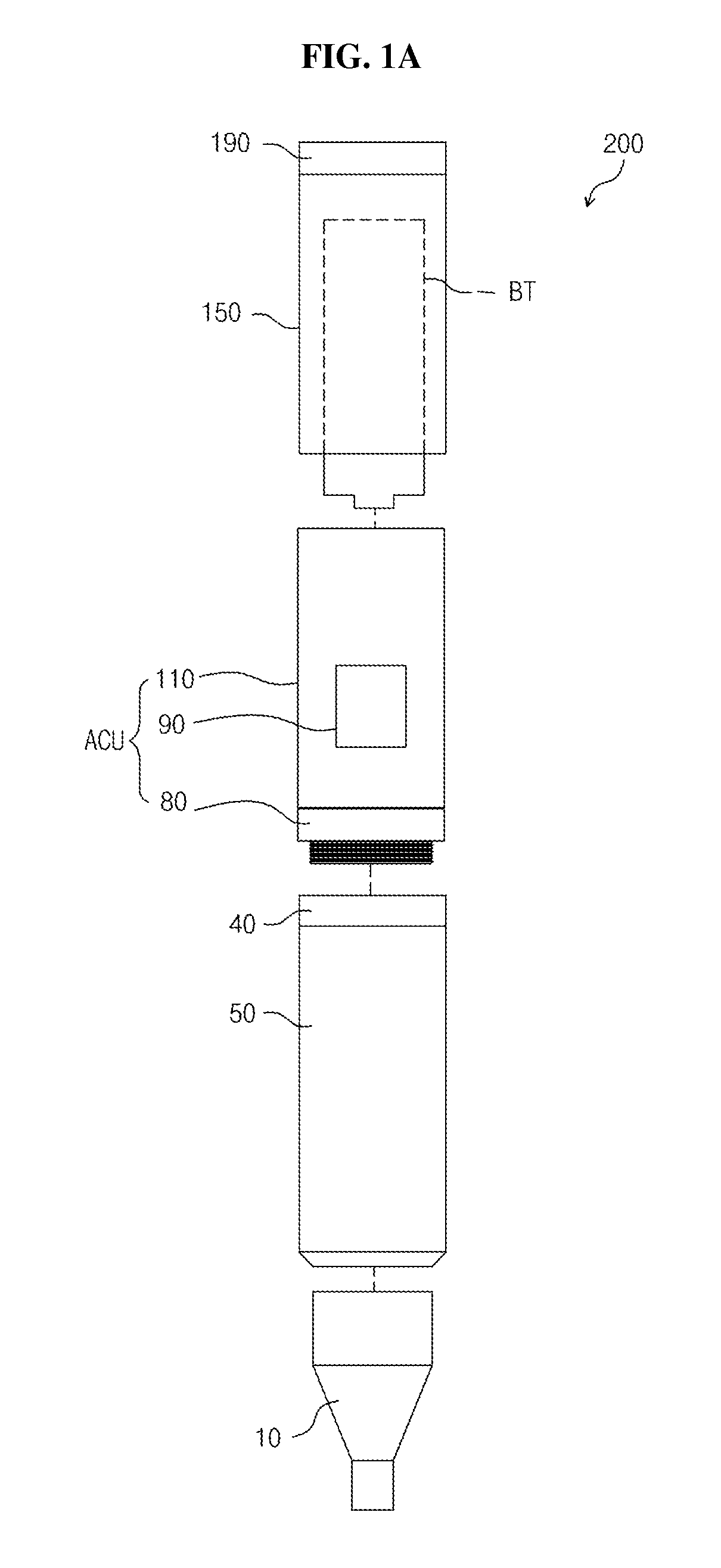

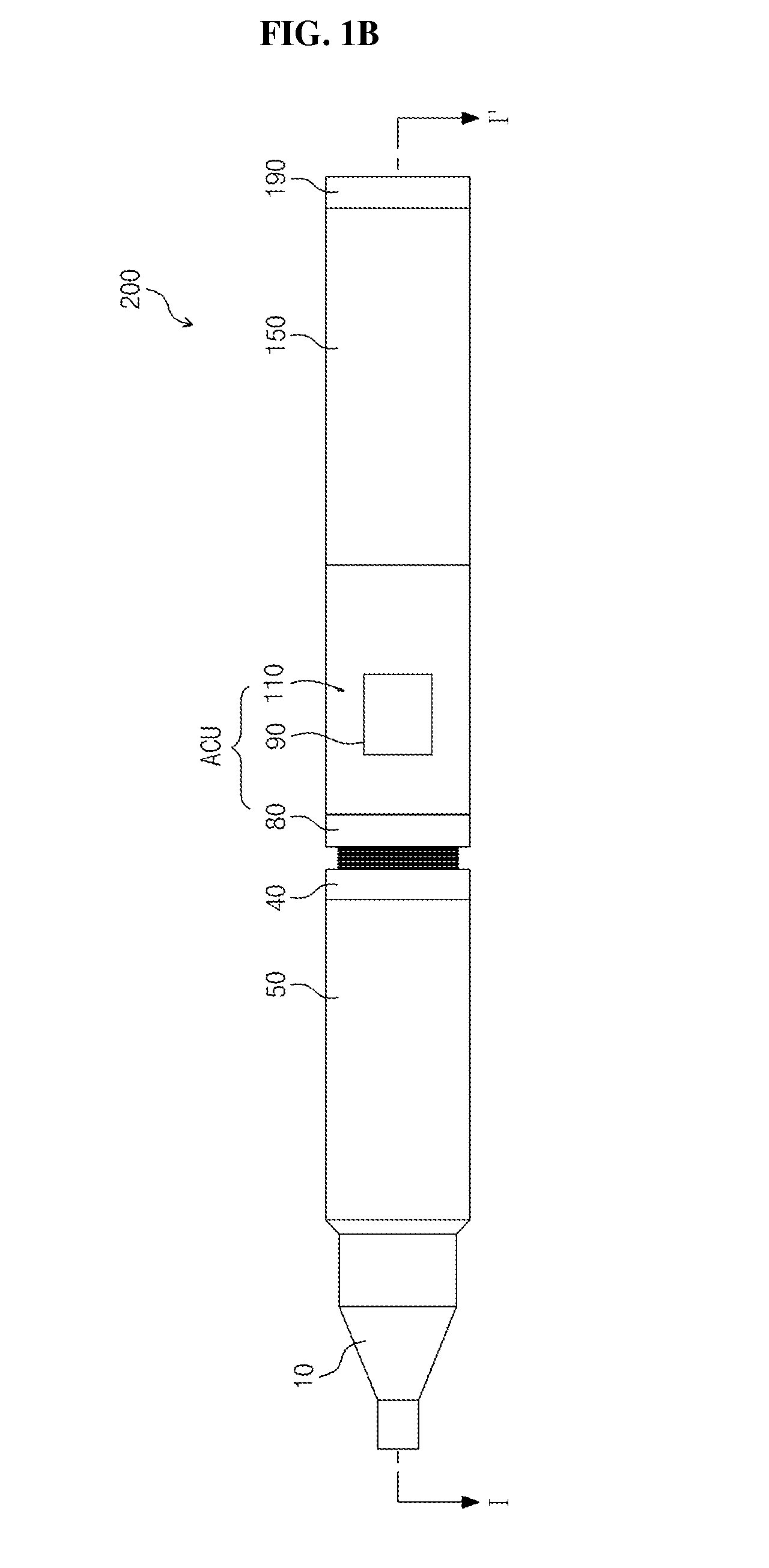

Atomization control unit and a portable atomizing apparatus having the same

InactiveUS20140334804A1Constant power supplyReduce smokeSteam generation heating methodsMedical devicesElectricitySource material

A portable atomizing apparatus according to the present invention includes a battery case, an atomizing device, a body case, a control unit, and a suction adjustment. The battery case receives a battery, and the atomizing device includes a heating member electrically connected to the battery for generating heat to atomize a source material. The body case is connected between the battery case and the atomizing device. Besides, the control unit is mounted inside the body case, electrically connected to the battery and to the heating member, so that the control unit receives an electrical power from the battery to control the output signal delivered to the heating member. Also, the suction adjustment opens or closes an air inlet of the atomizing apparatus so as to adjust the amount of air entering the atomizing apparatus.

Owner:ENBRIGHT

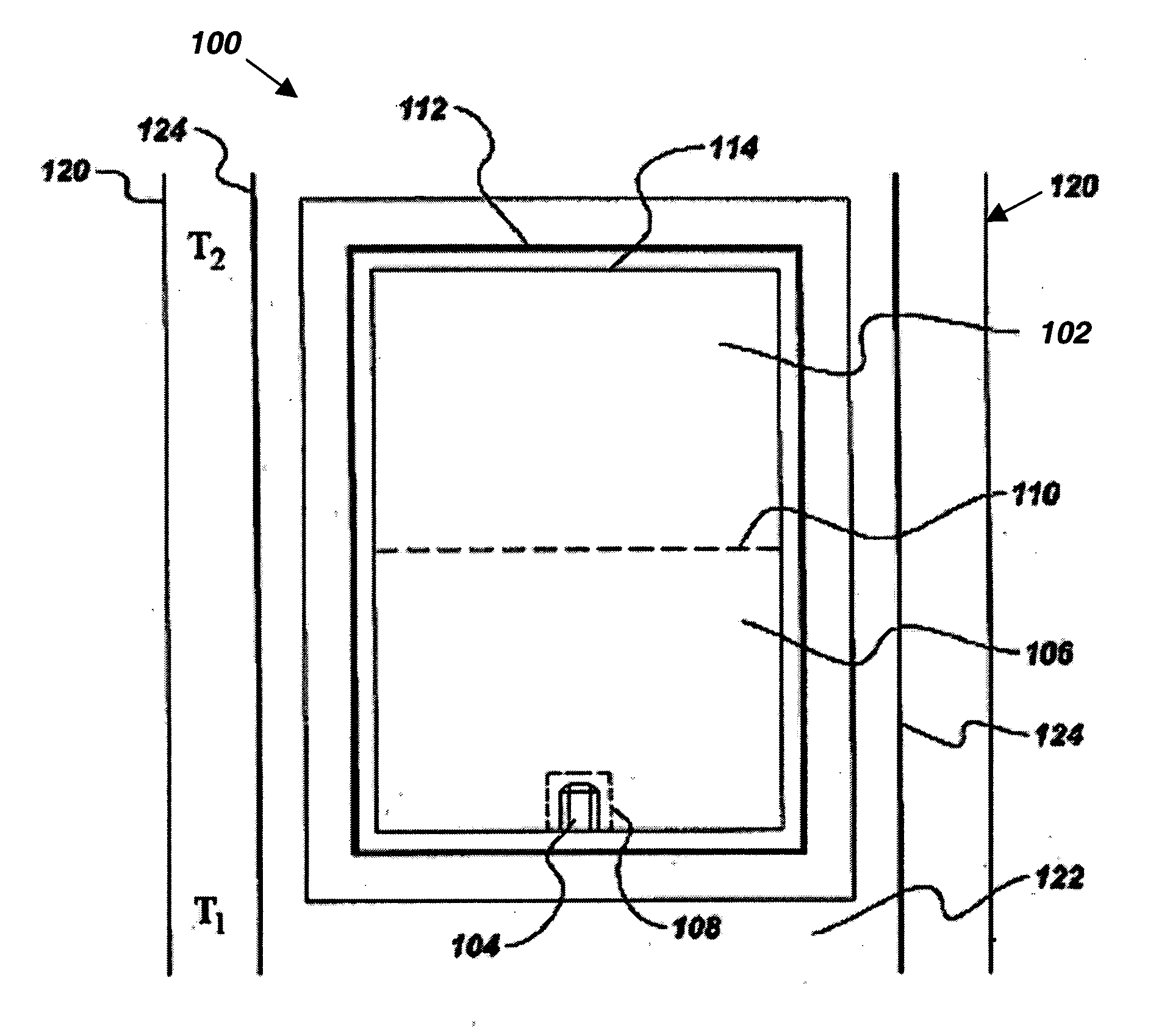

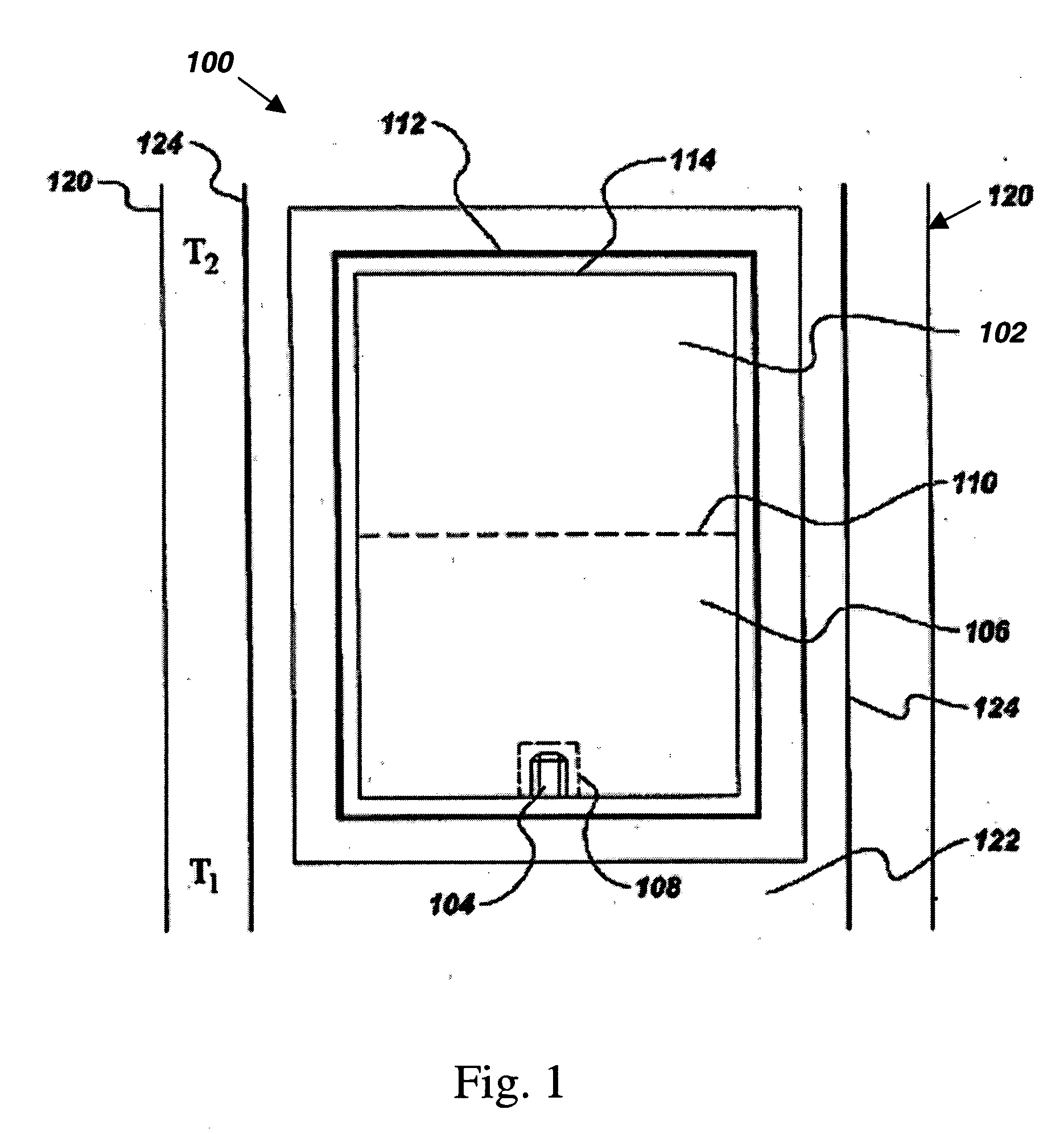

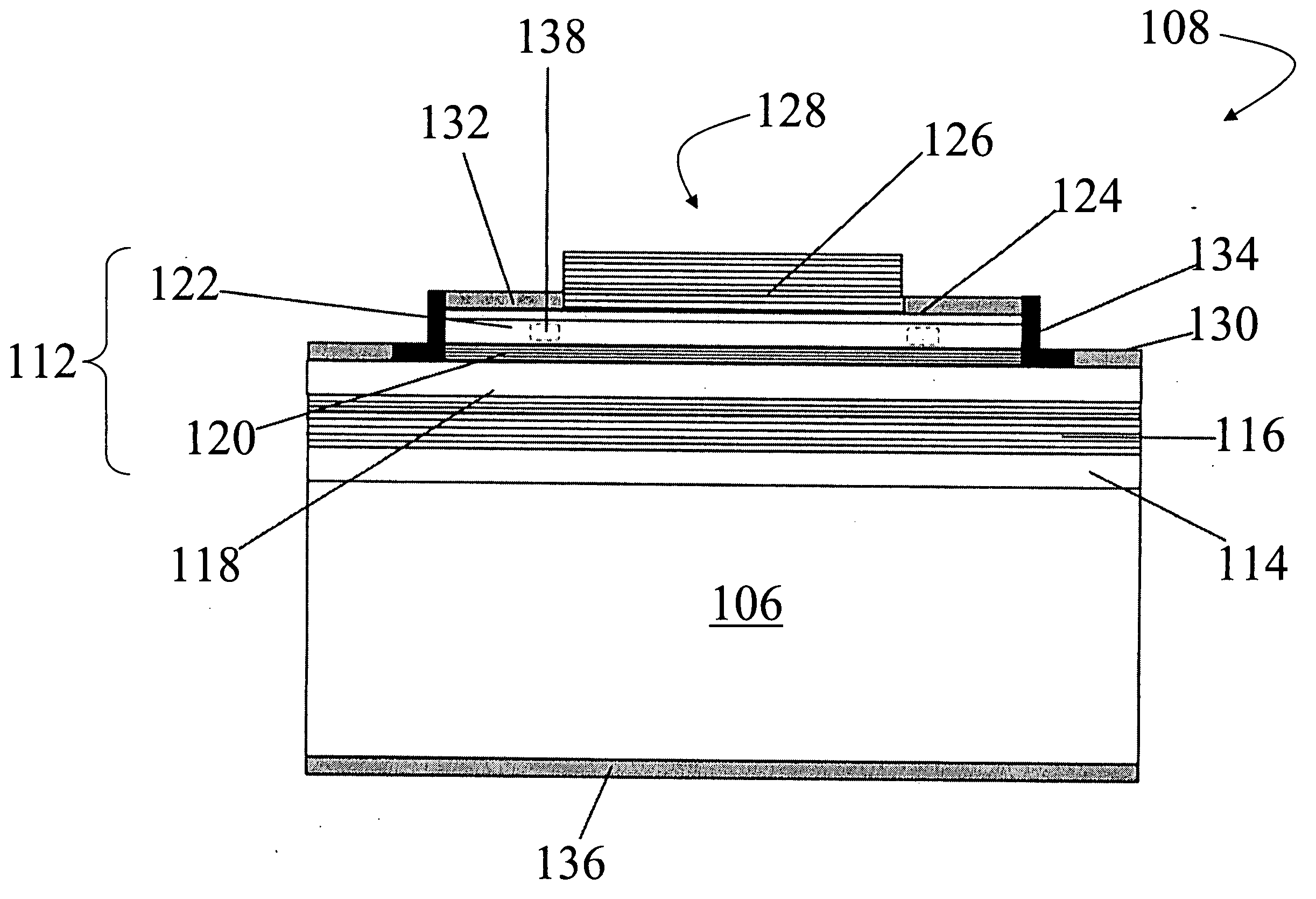

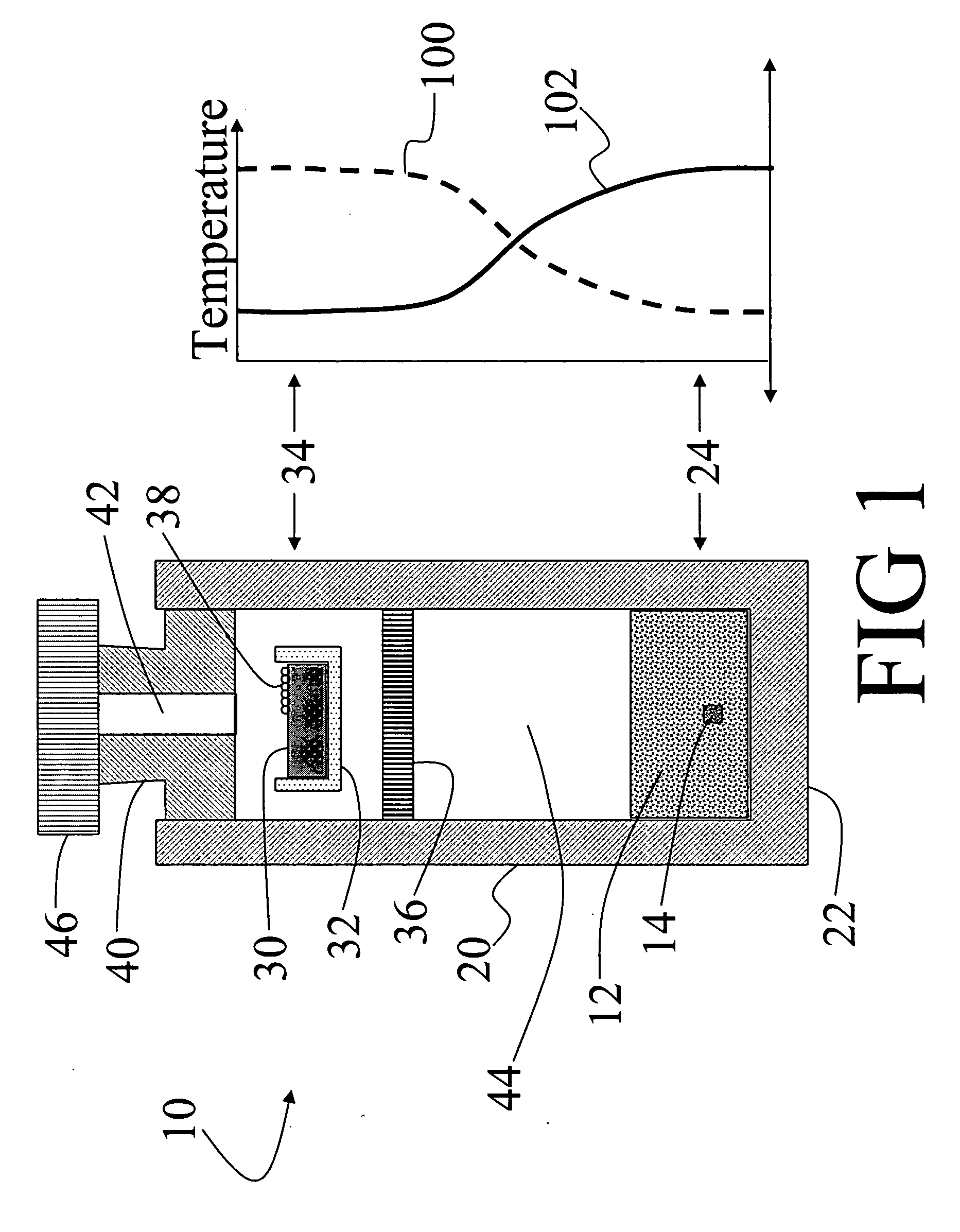

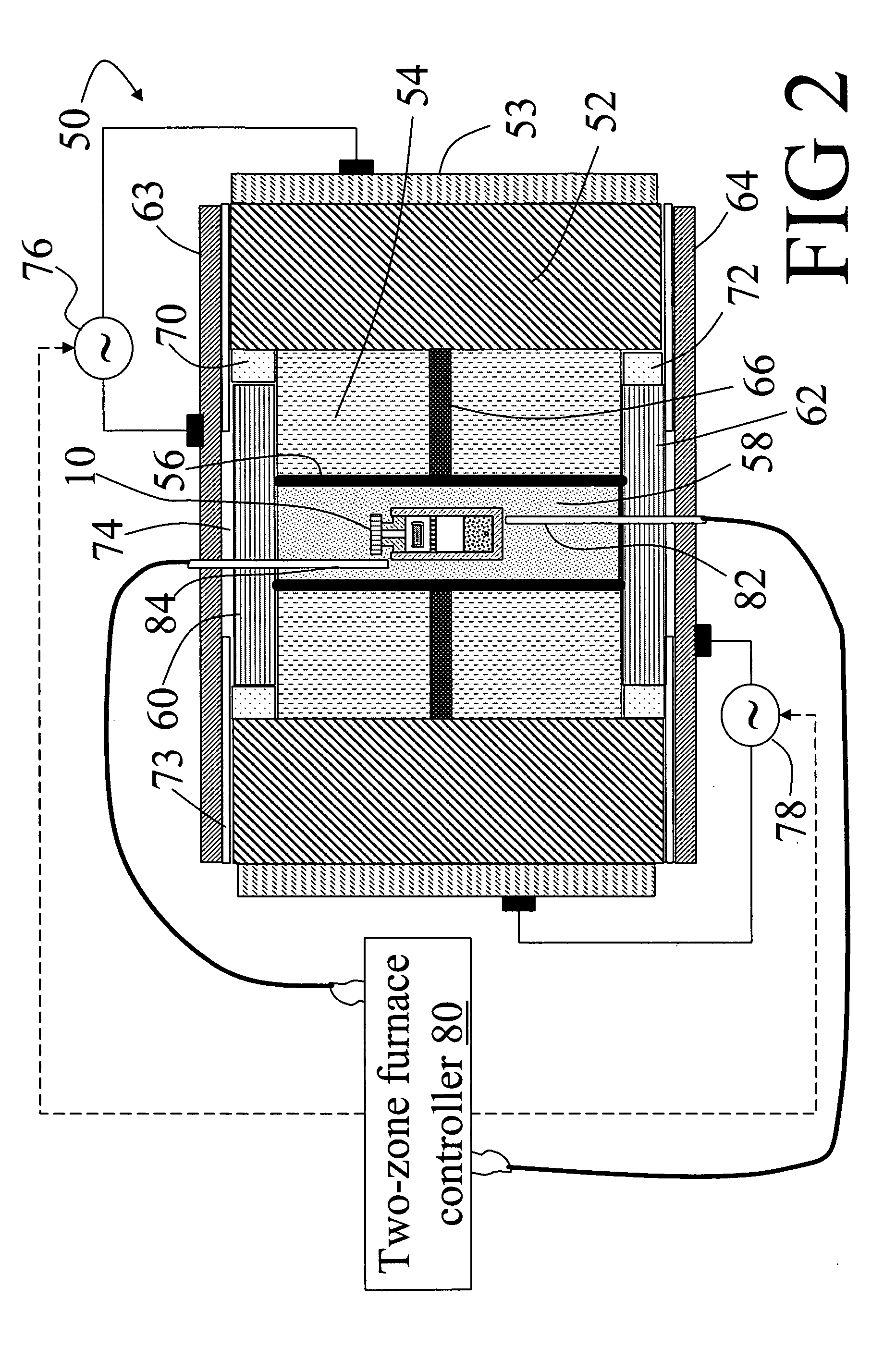

Group III-nitride based resonant cavity light emitting devices fabricated on single crystal gallium nitride substrates

ActiveUS20050087753A1Increase probabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingResonant cavitySource material

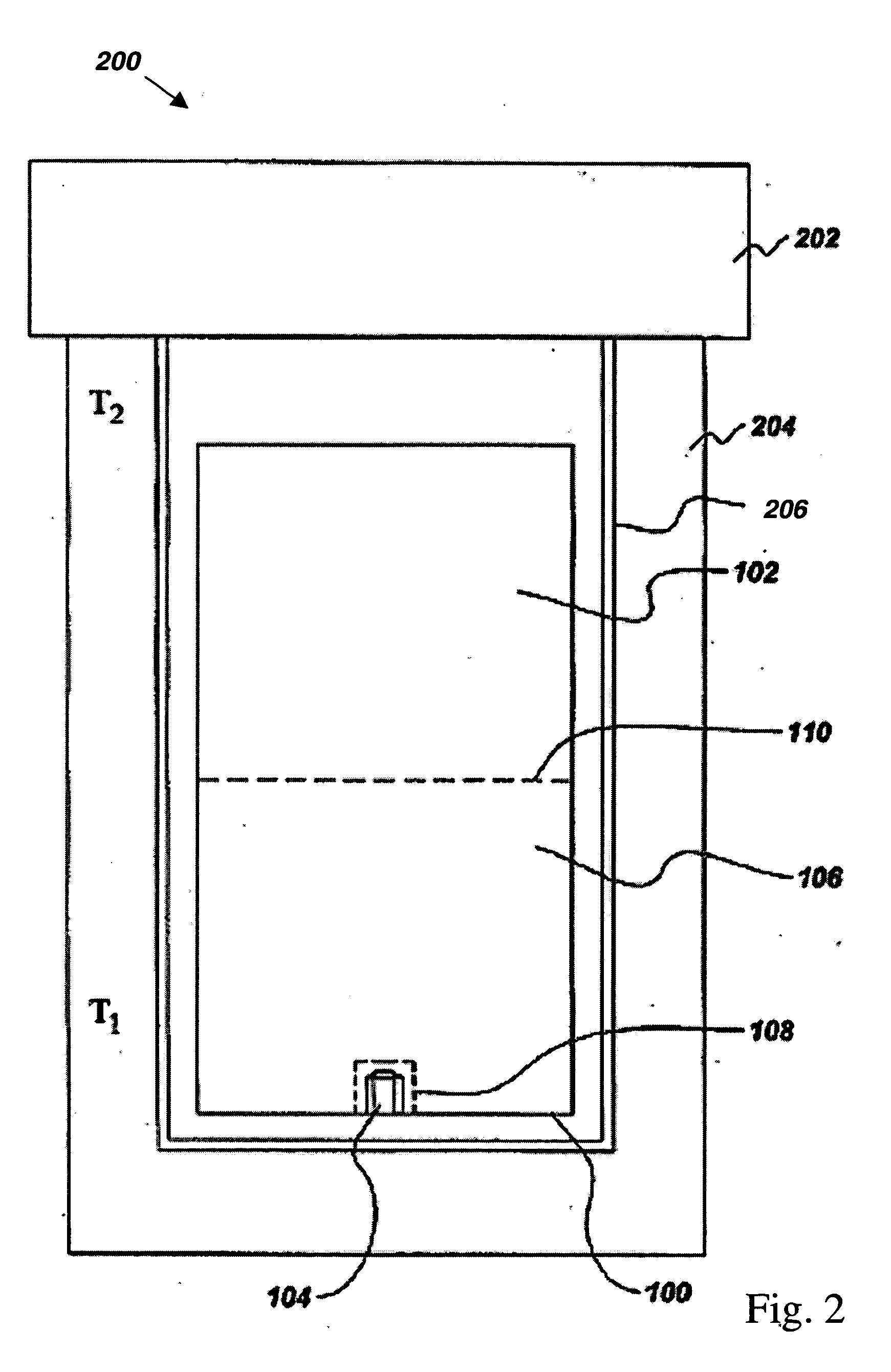

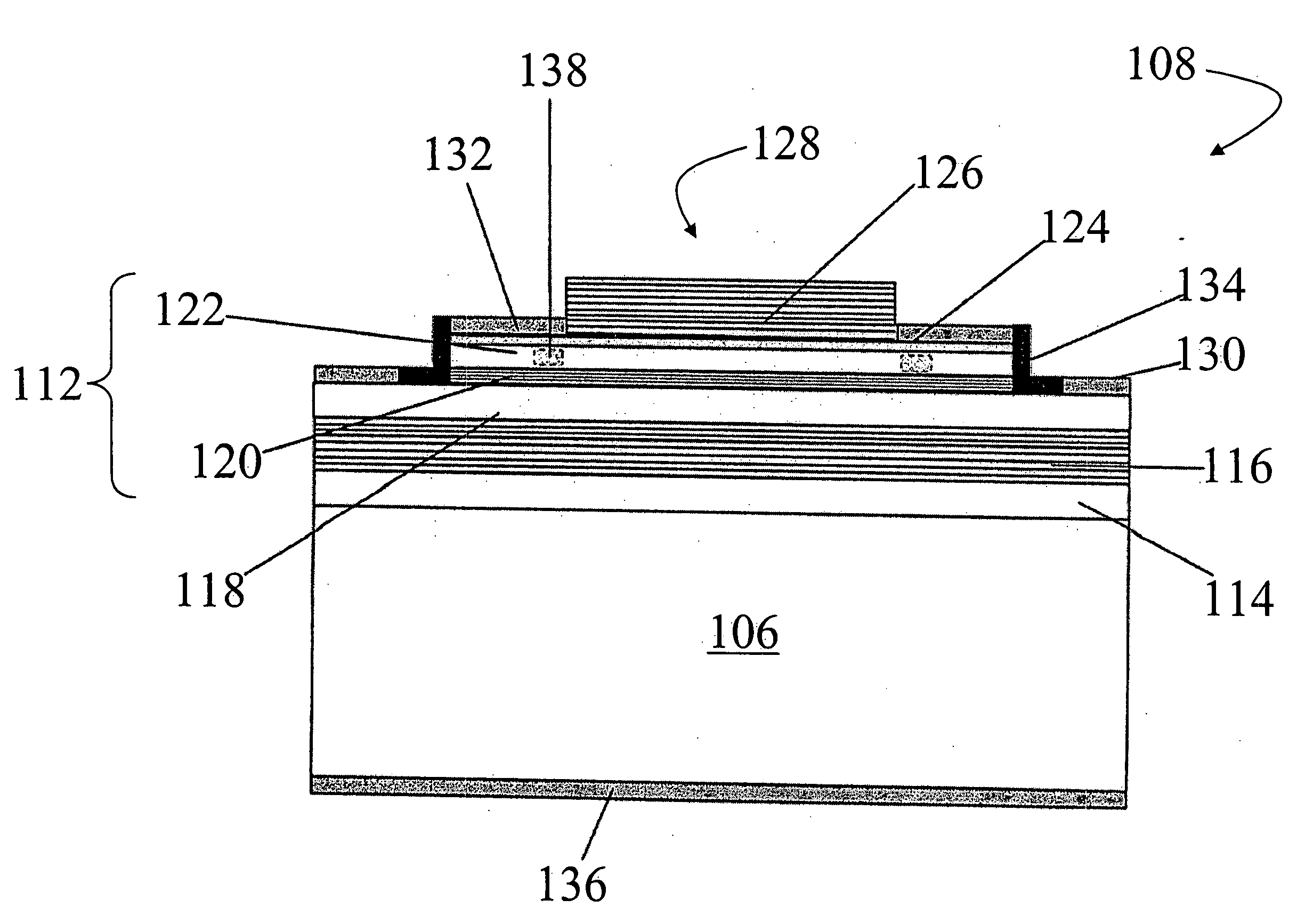

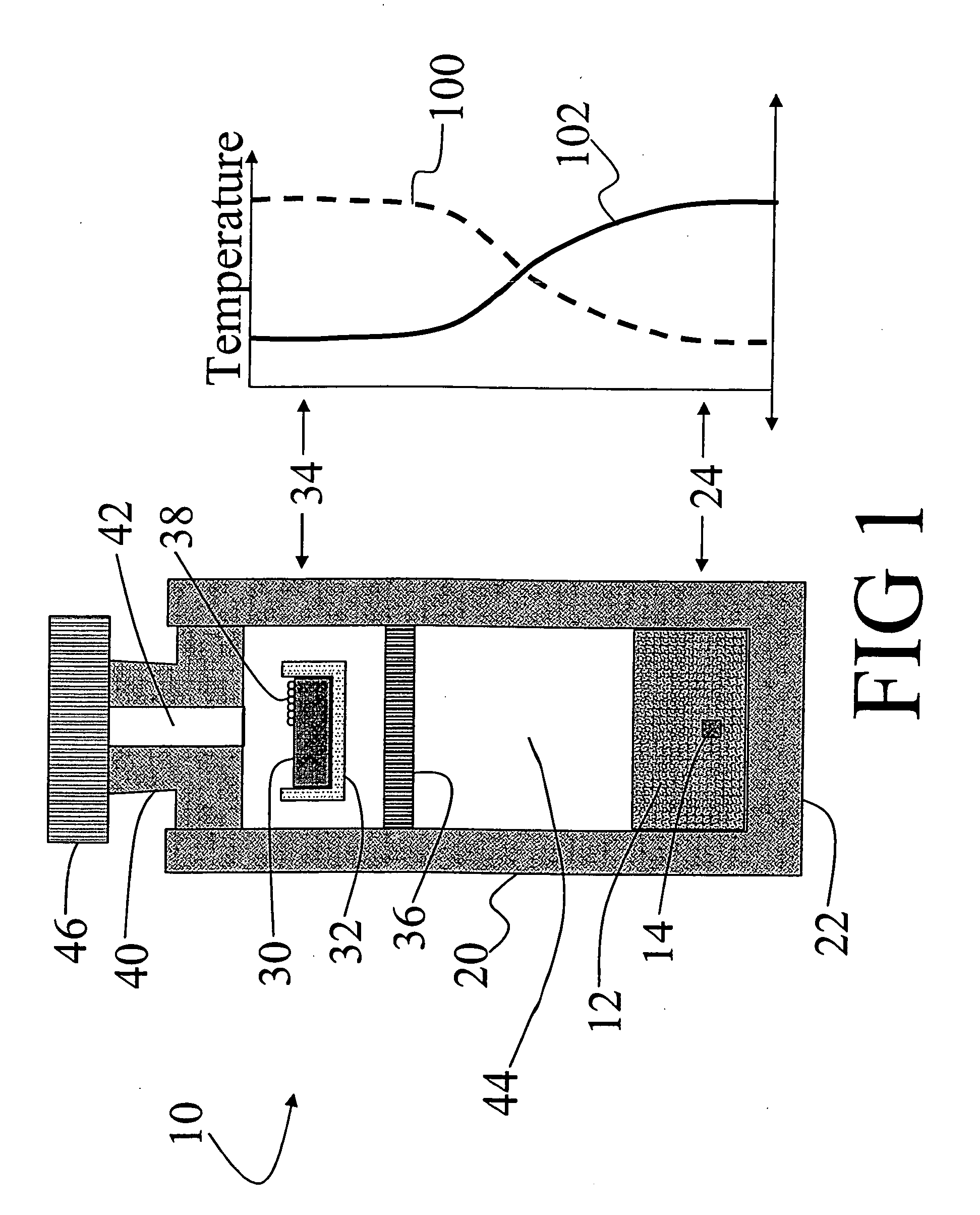

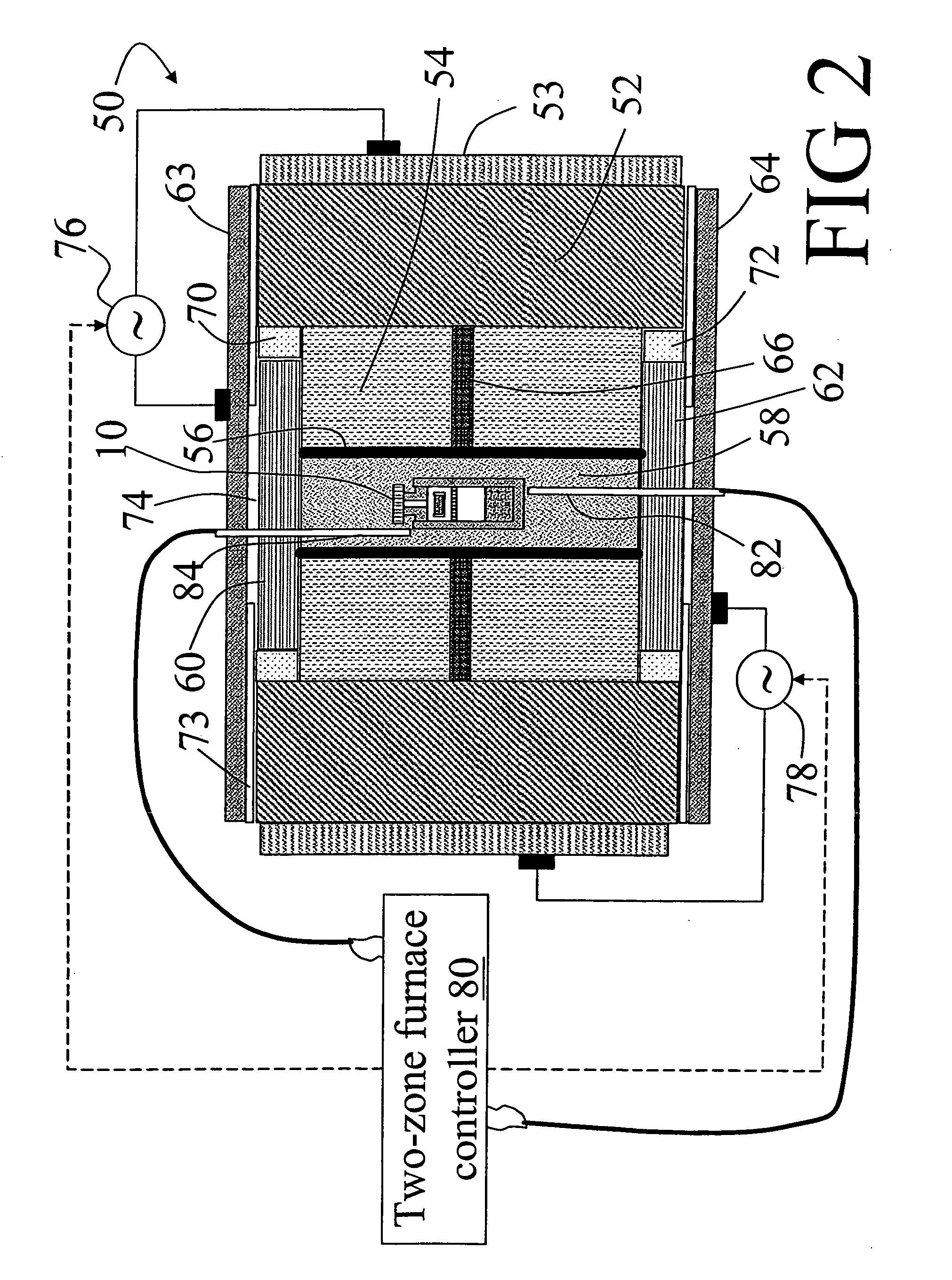

In a method for producing a resonant cavity light emitting device, a seed gallium nitride crystal (14) and a source material (30) are arranged in a nitrogen-containing superheated fluid (44) disposed in a sealed container (10) disposed in a multiple-zone furnace (50). Gallium nitride material is grown on the seed gallium nitride crystal (14) to produce a single-crystal gallium nitride substrate (106, 106′). Said growing includes applying a temporally varying thermal gradient (100, 100′, 102, 102′) between the seed gallium nitride crystal (14) and the source material (30) to produce an increasing growth rate during at least a portion of the growing. A stack of group III-nitride layers (112) is deposited on the single-crystal gallium nitride substrate (106, 106′), including a first mirror sub-stack (116) and an active region (120) adapted for fabrication into one or more resonant cavity light emitting devices (108, 150, 160, 170, 180).

Owner:SLT TECH

Vaporizer delivery ampoule

InactiveUS6921062B2Increase the areaShorten closing timeDrying using combination processesDrying solid materials with heatSource materialEngineering

A vaporizer delivery system for use in semiconductor manufacturing processes including a plurality of vertically stacked containers for holding a vaporizable source material. Each of the vertically stacked containers includes a plurality of vented protuberances extending into the interior of the each stacked container thereby providing channels for passage of a carrier gas between adjacent vertically stacked containers.

Owner:ENTEGRIS INC

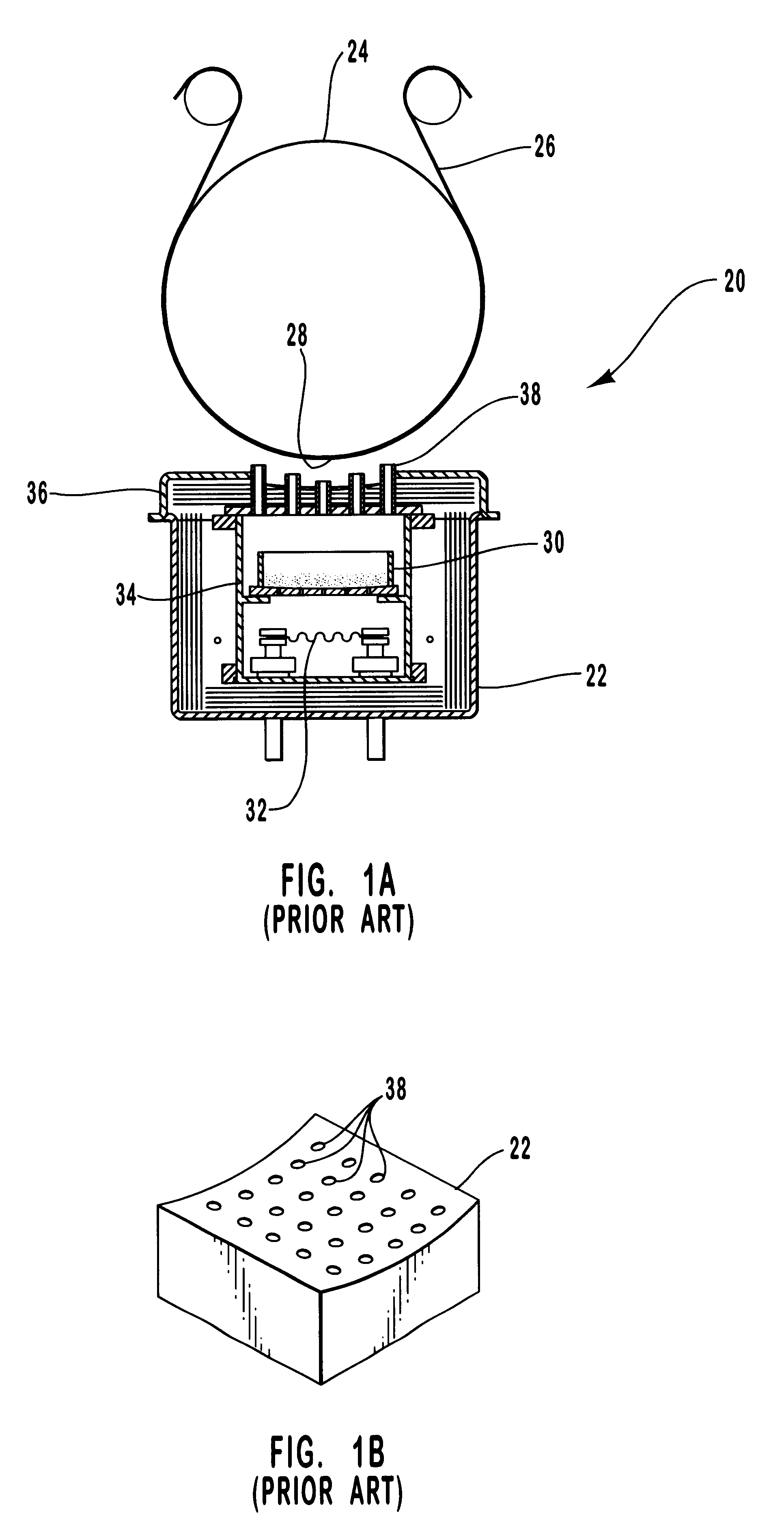

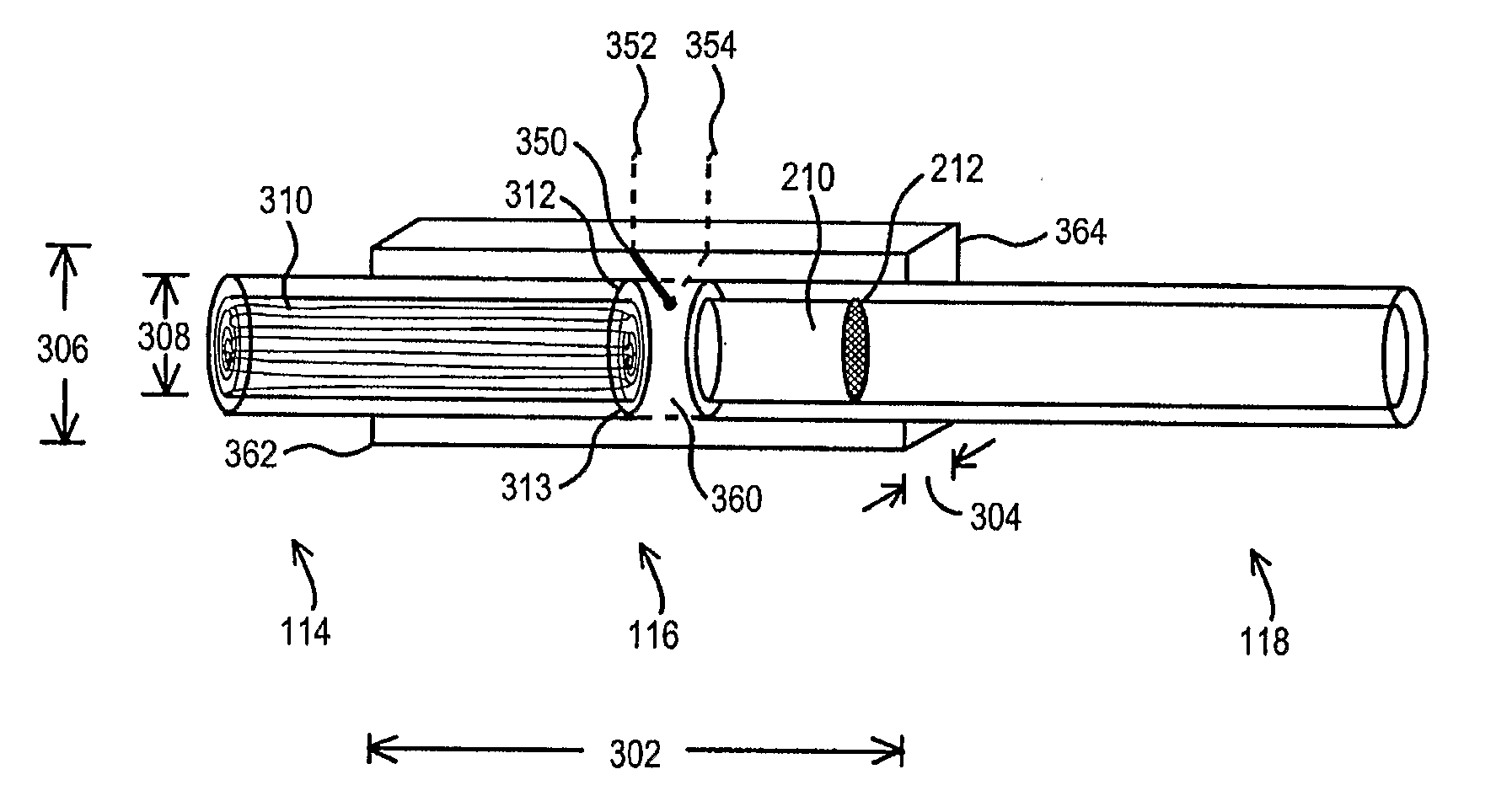

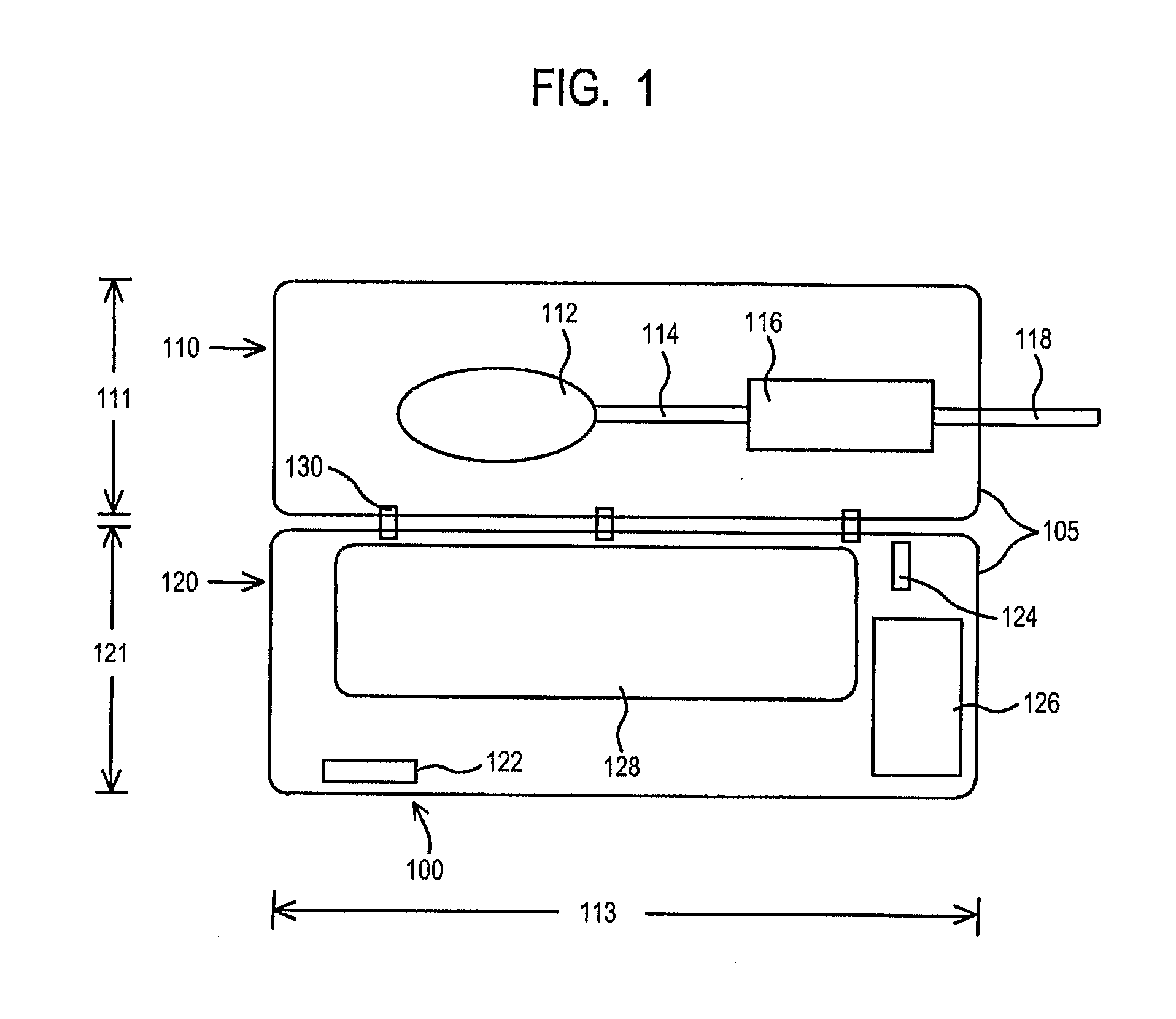

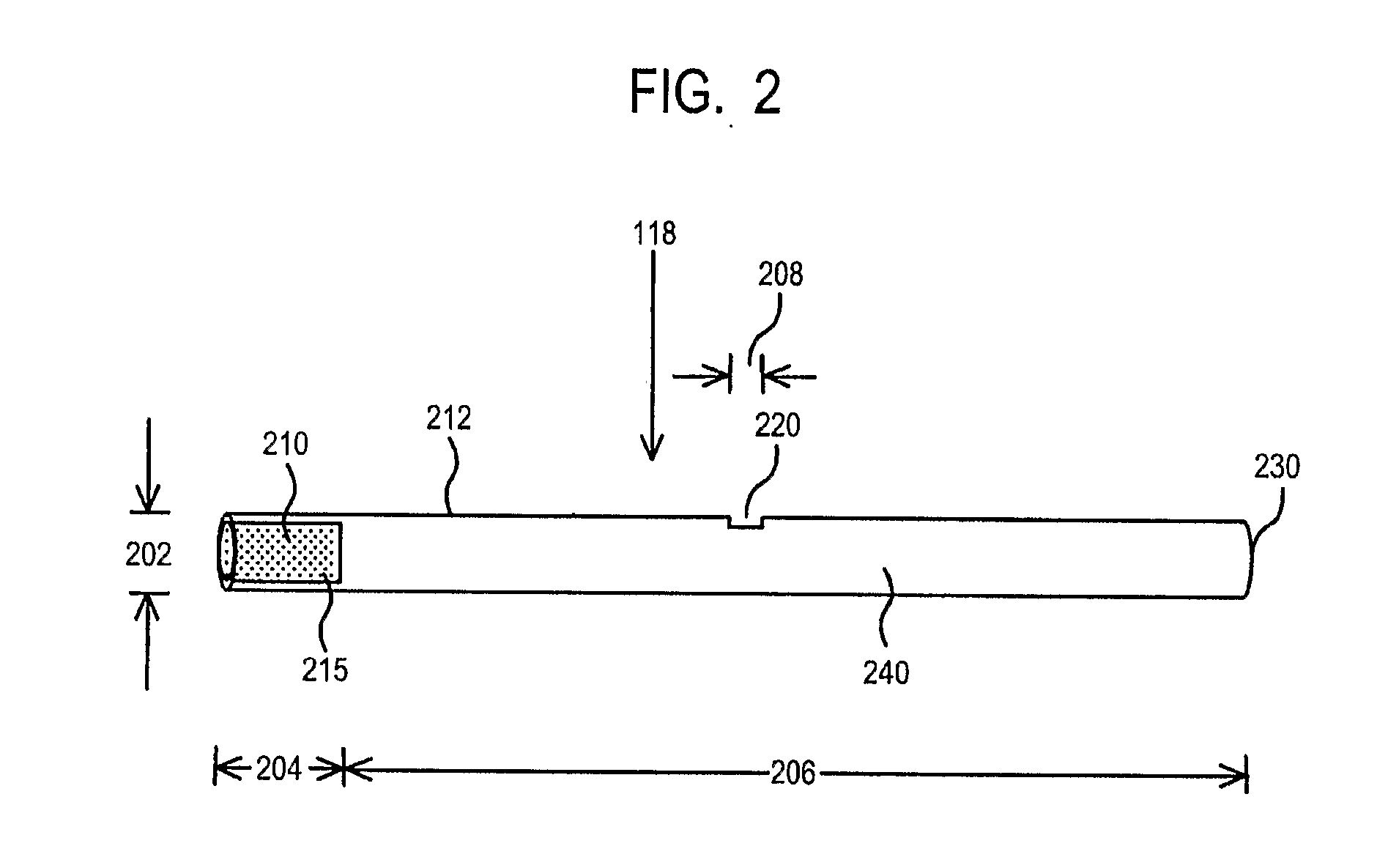

Portable vaporizing device and method for inhalation and/or aromatherapy without combustion

ActiveUS20110120482A1Even heat distributionAvoid problemsRespiratorsMedical devicesAromatherapyCombustion

A hand-held apparatus (100) to vaporize volatile compounds disposed in a solid source material is disclosed. The hand-held apparatus comprises a housing (105), a mouthpiece tube (118) removeably disposed within, and extending outwardly from, said housing, a heating element assembly (114) in communication with said mouthpiece tube, wherein said heating element assembly heats to an operating temperature of about 450° F. in about 60 seconds.

Owner:BRENNEISE JAKE

Ruthenium layer deposition apparatus and method

InactiveUS20060162658A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTemperature controlSource material

An exemplary apparatus and method of forming a ruthenium tetroxide containing gas to form a ruthenium containing layer on a surface of a substrate is described herein. The method and apparatus described herein may be especially useful for fabricating electronic devices that are formed on a surface of the substrate or wafer. Generally, the method includes exposing a surface of a substrate to a ruthenium tetroxide vapor to form a catalytic layer on the surface of a substrate and then filling the device structures by an electroless, electroplating, physical vapor deposition (PVD), chemical vapor deposition (CVD), plasma enhanced CVD (PECVD), atomic layer deposition (ALD) or plasma enhanced ALD (PE-ALD) processes. In one embodiment, the ruthenium containing layer is formed on a surface of a substrate by creating ruthenium tetroxide in an external vessel and then delivering the generated ruthenium tetroxide gas to a surface of a temperature controlled substrate positioned in a processing chamber. In one embodiment, a ruthenium tetroxide containing solvent formation process is used to form ruthenium tetroxide using a ruthenium tetroxide containing source material. In one embodiment, of a ruthenium containing layer is formed on a surface of a substrate, using the ruthenium tetroxide containing solvent. In another embodiment, the solvent is separated from the ruthenium tetroxide containing solvent mixture and the remaining ruthenium tetroxide is used to form a ruthenium containing layer on the surface of a substrate.

Owner:APPLIED MATERIALS INC

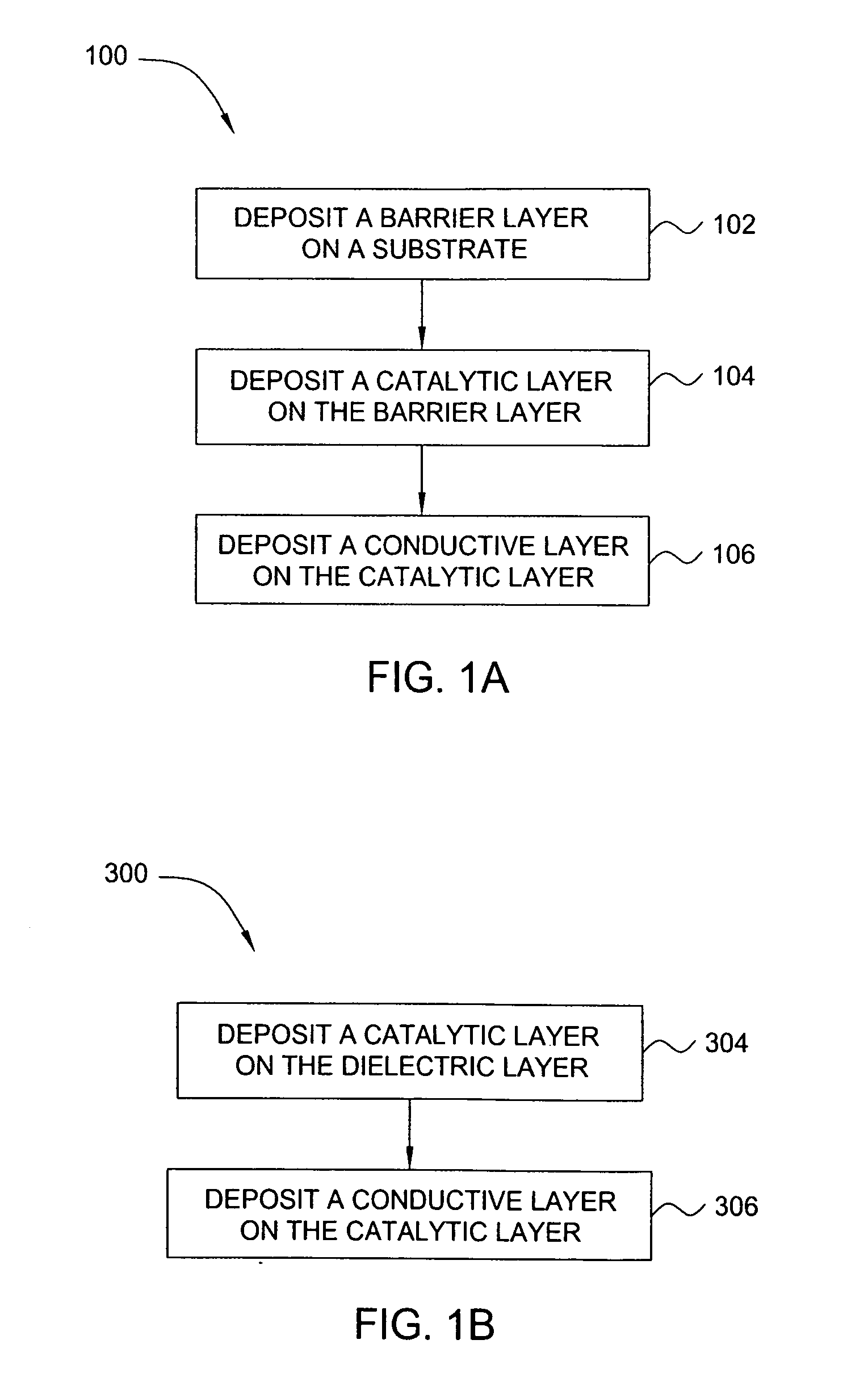

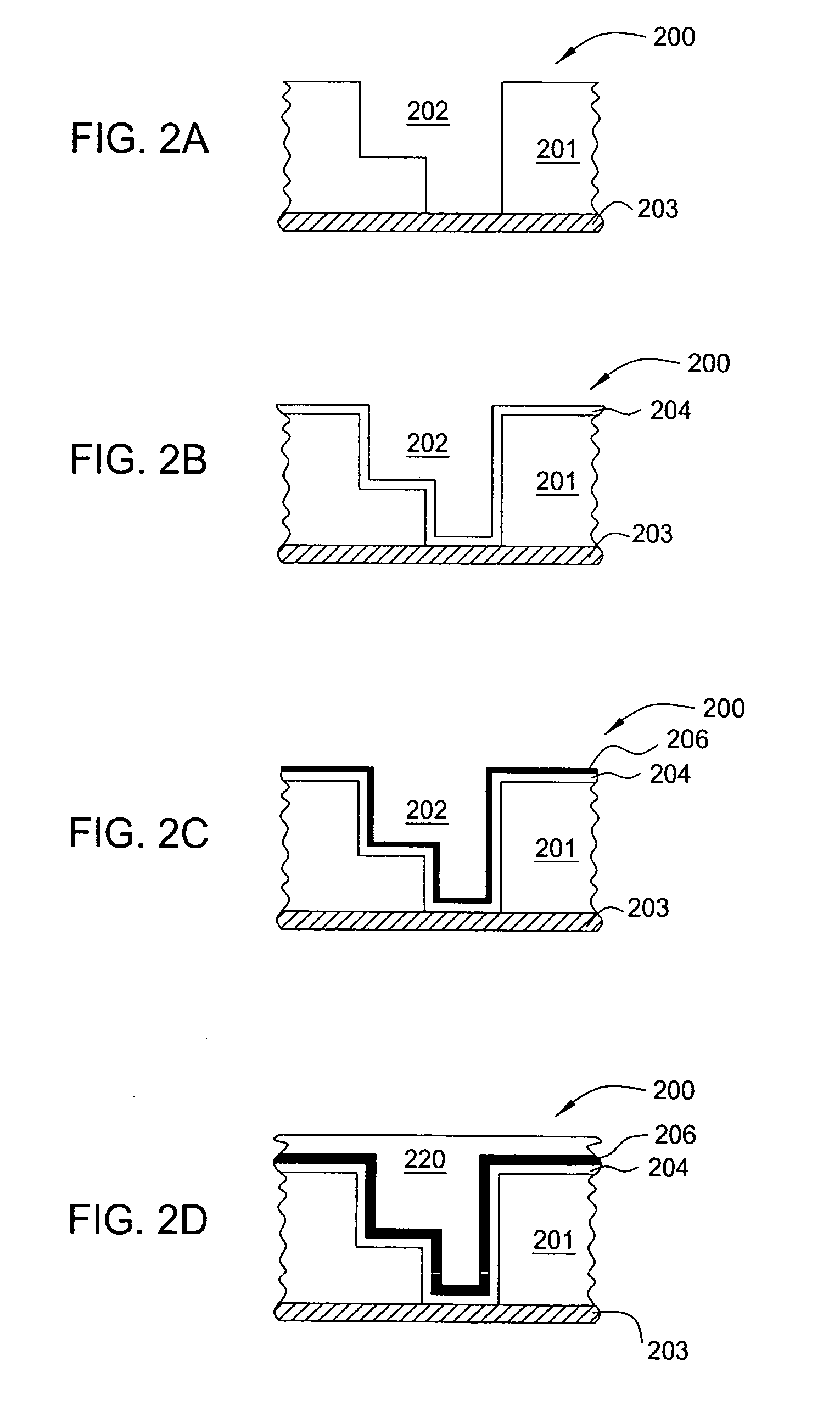

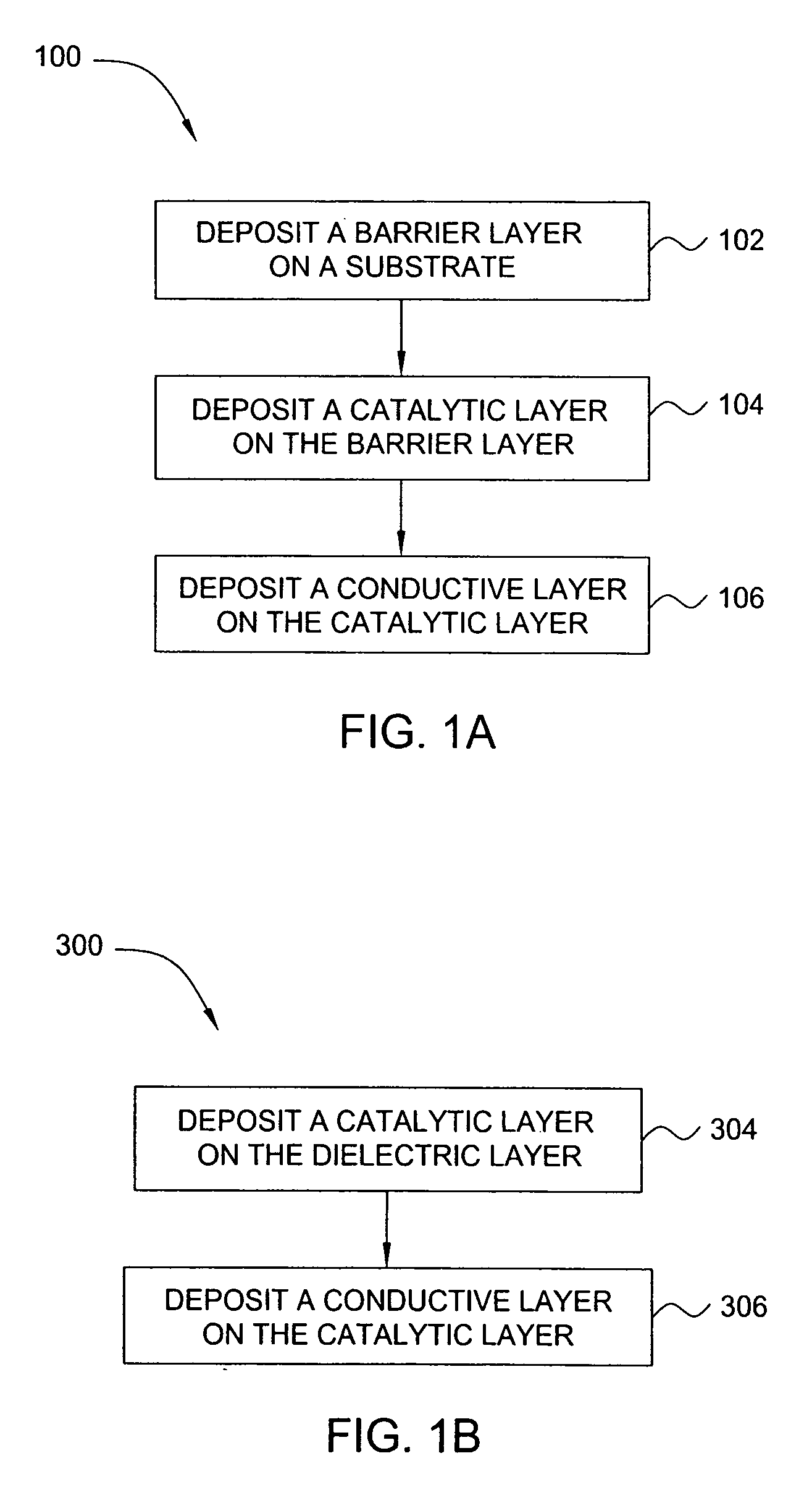

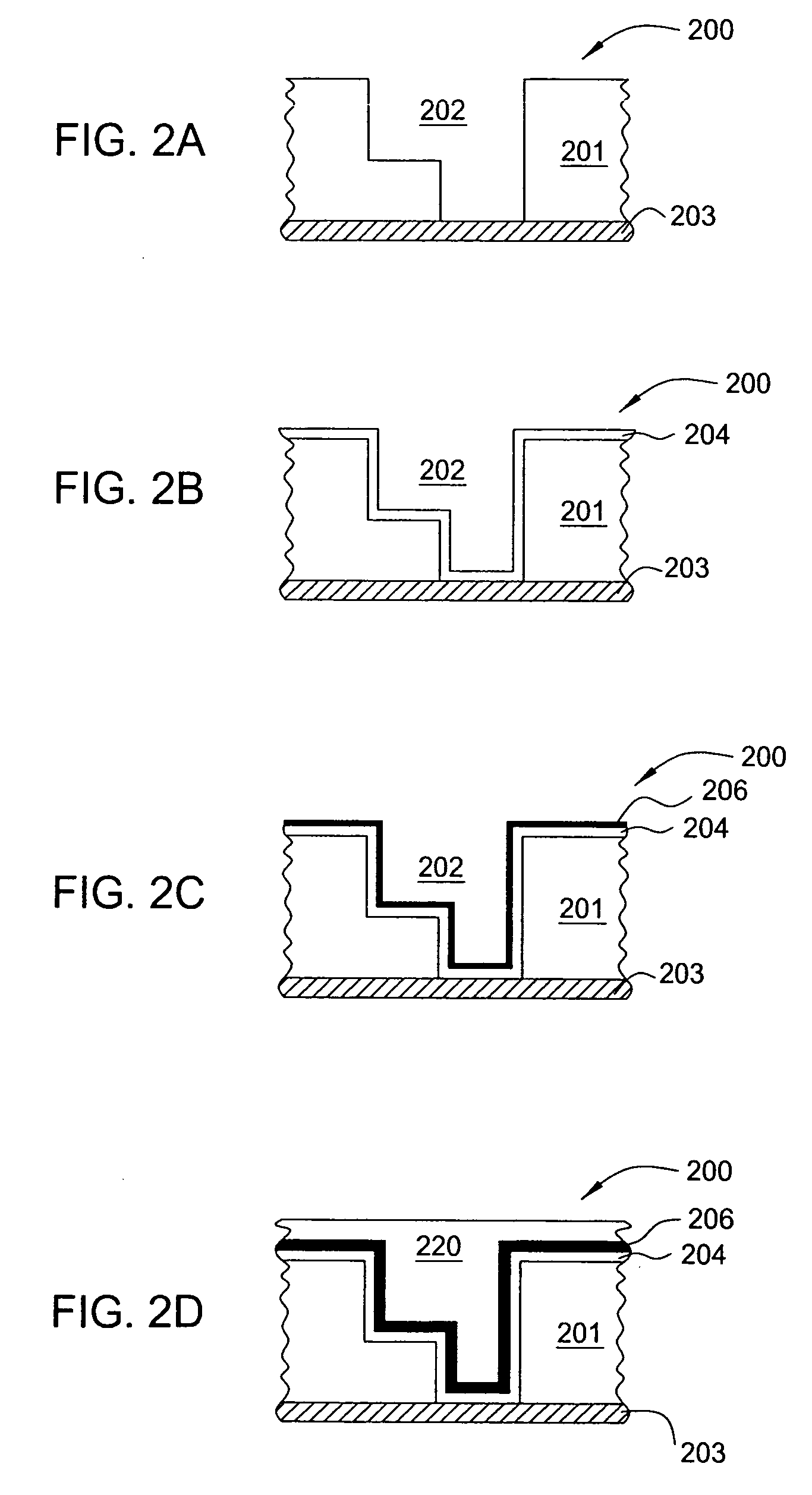

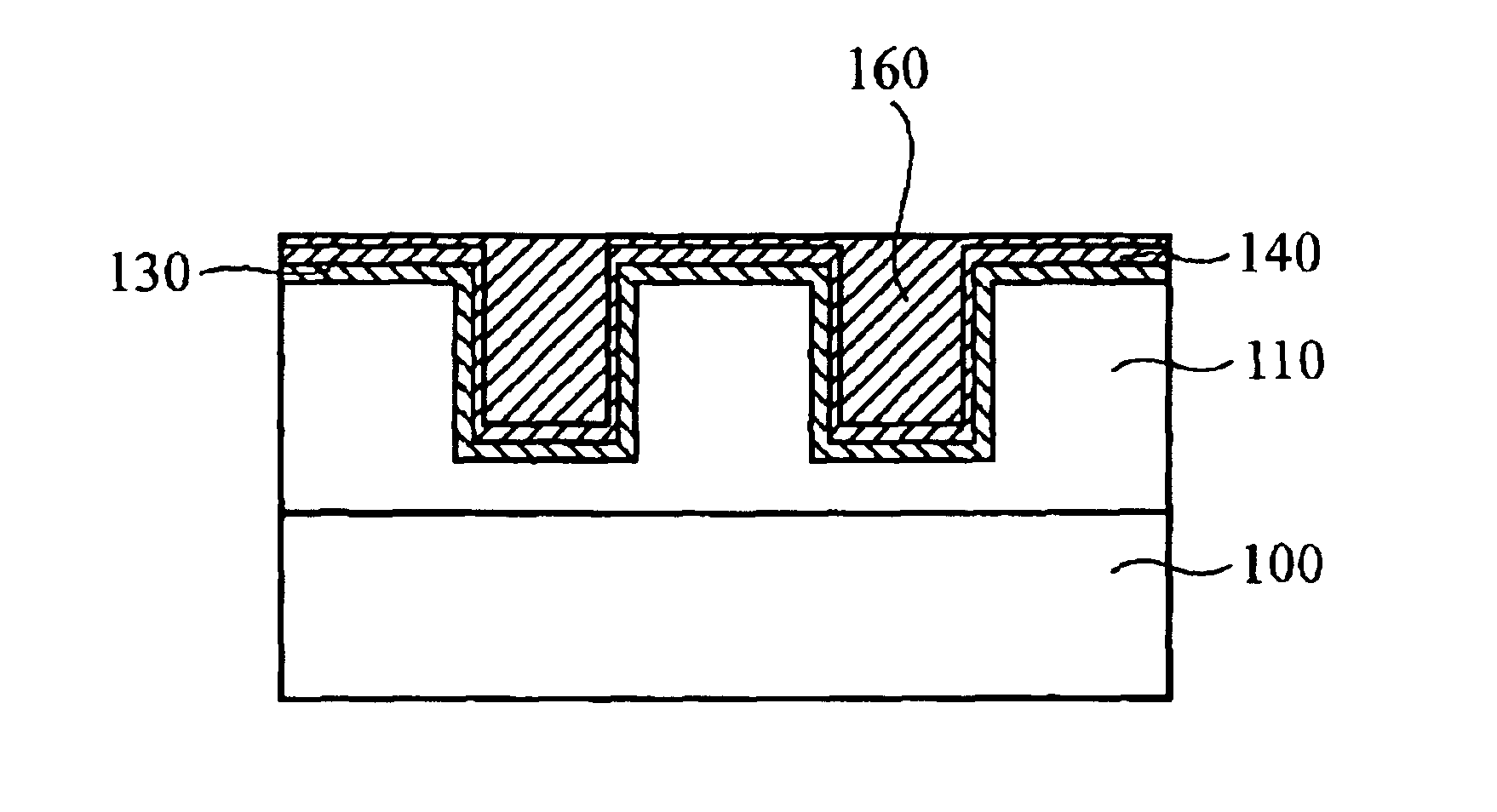

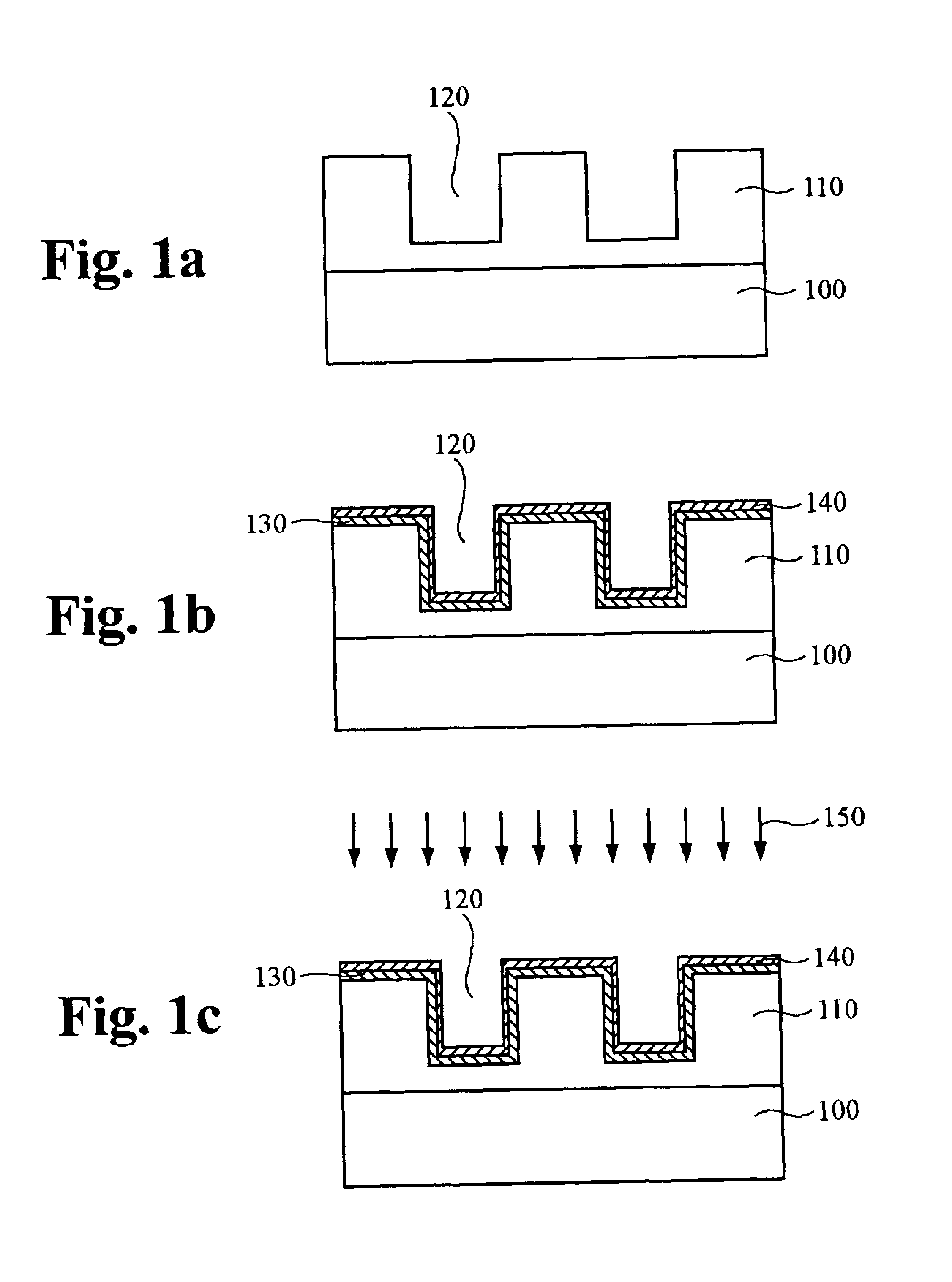

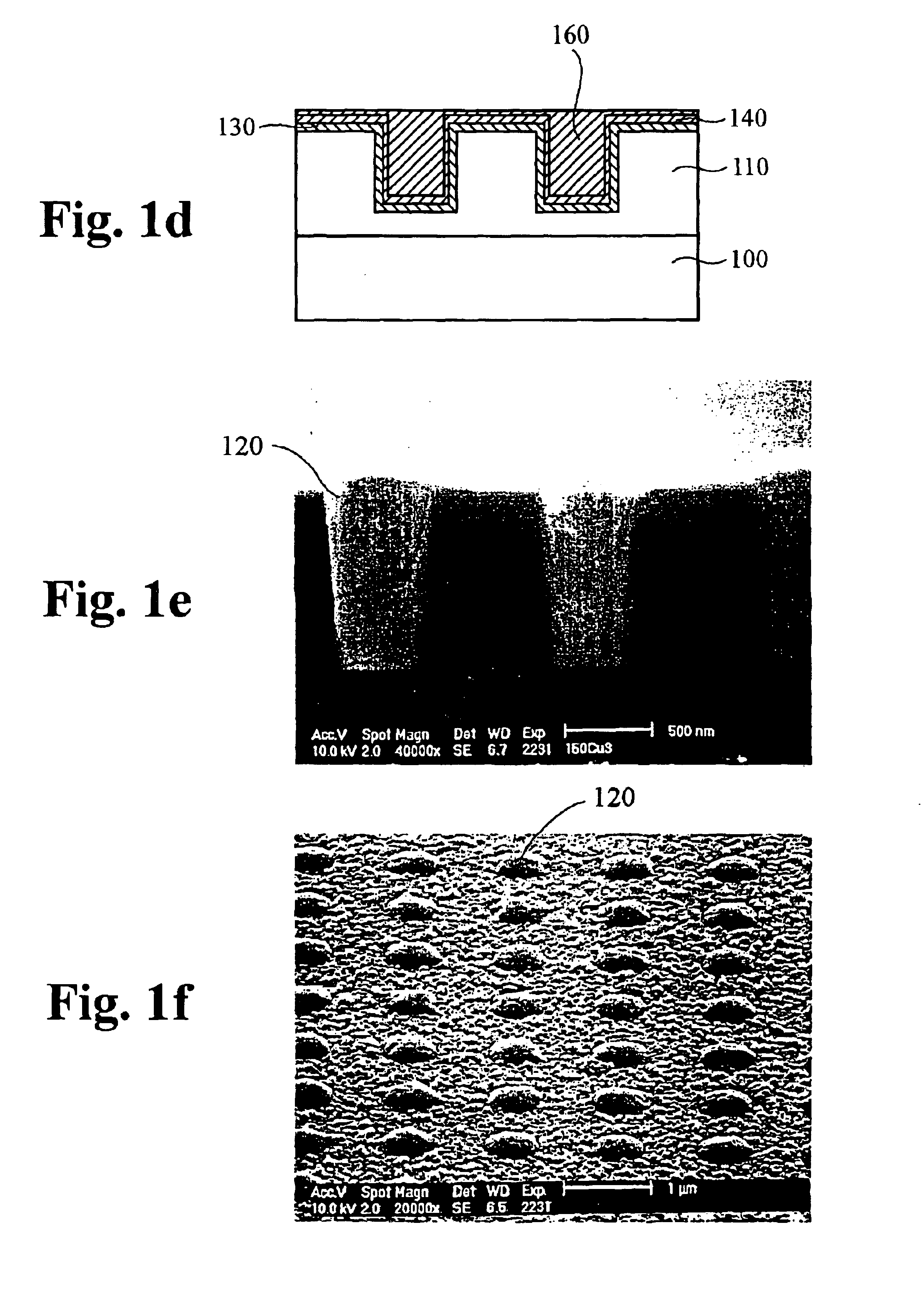

Method of forming copper interconnections and thin films using chemical vapor deposition with catalyst

InactiveUS6720262B2Semiconductor/solid-state device detailsSolid-state devicesCopper conductorSource material

A method of forming copper conductors for interconnecting active and passive elements as well as signal and power lines for circuits and devices on silicon wafers is disclosed. The method disclosed herein involves with using catalysts in conjunction with a chemical vapor deposition(CVD) process with typically using copper as a source material for forming interconnecting conductors. Interconnecting method for filling trenches, via holes, contacts, large trenches and holes for power devices and lines as well as for forming large passive elements is also disclosed. Disclosed herein are also a method of filling narrow and deep trenches and small in diameter and deep holes, and a method of forming very thin film on the flat top surface so that an etchback process, such as wet or dry etchback as well as plasma etchback processes, can be used for removing a thin film in preparation for subsequent processing steps, thereby rather expensive chemical mechanical polishing(CMP) process need not be used.

Owner:ASM KOREA LTD

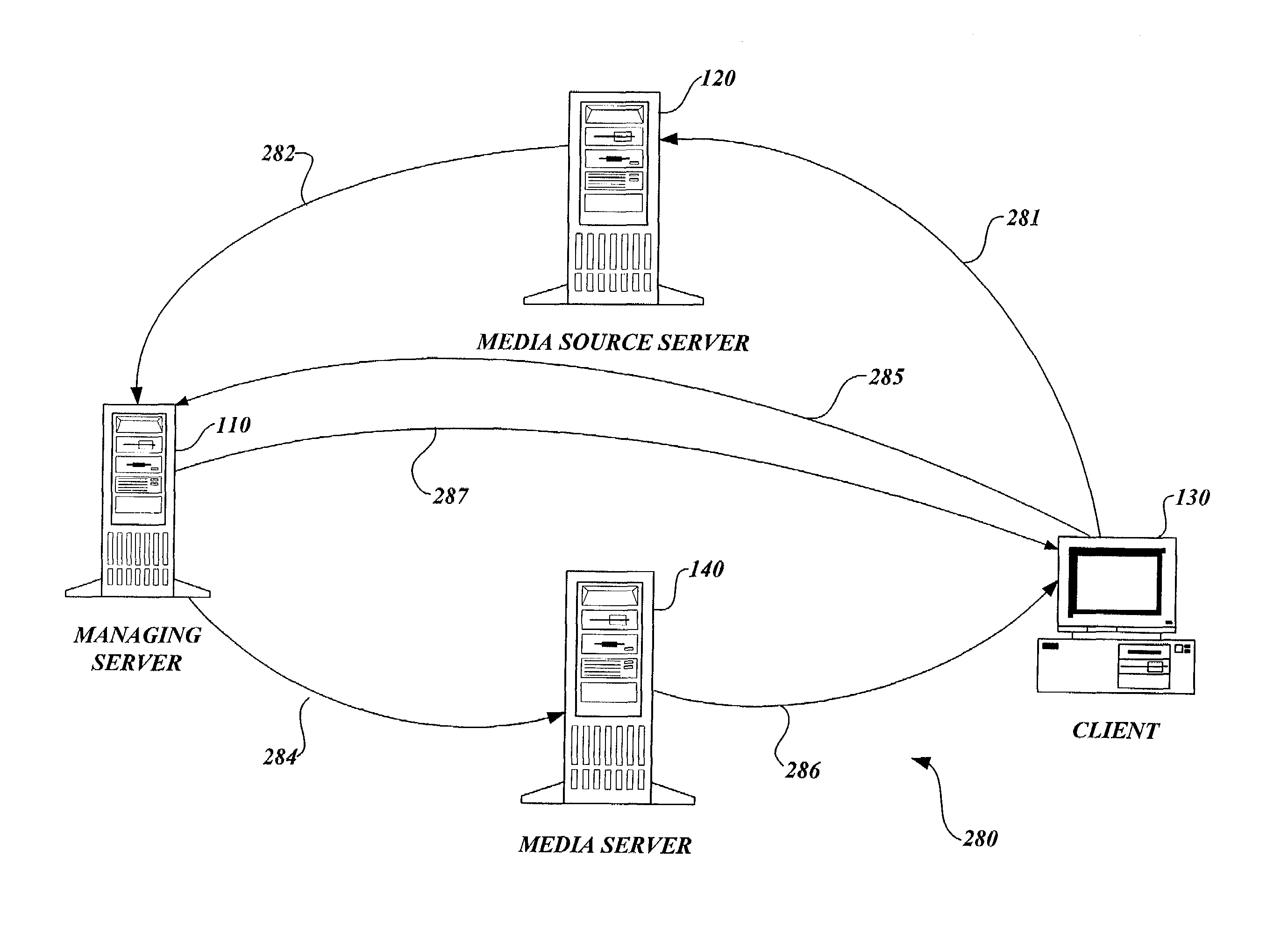

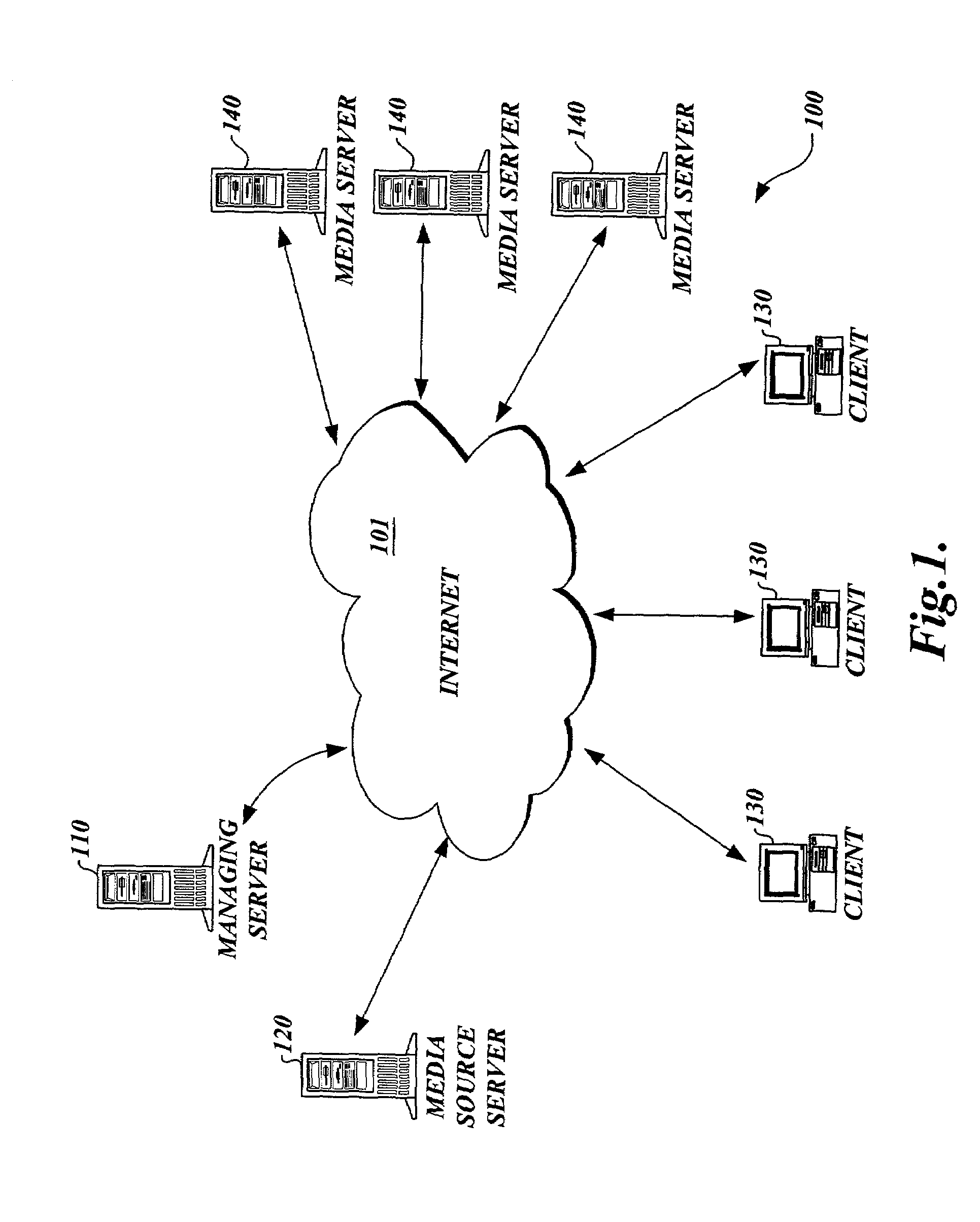

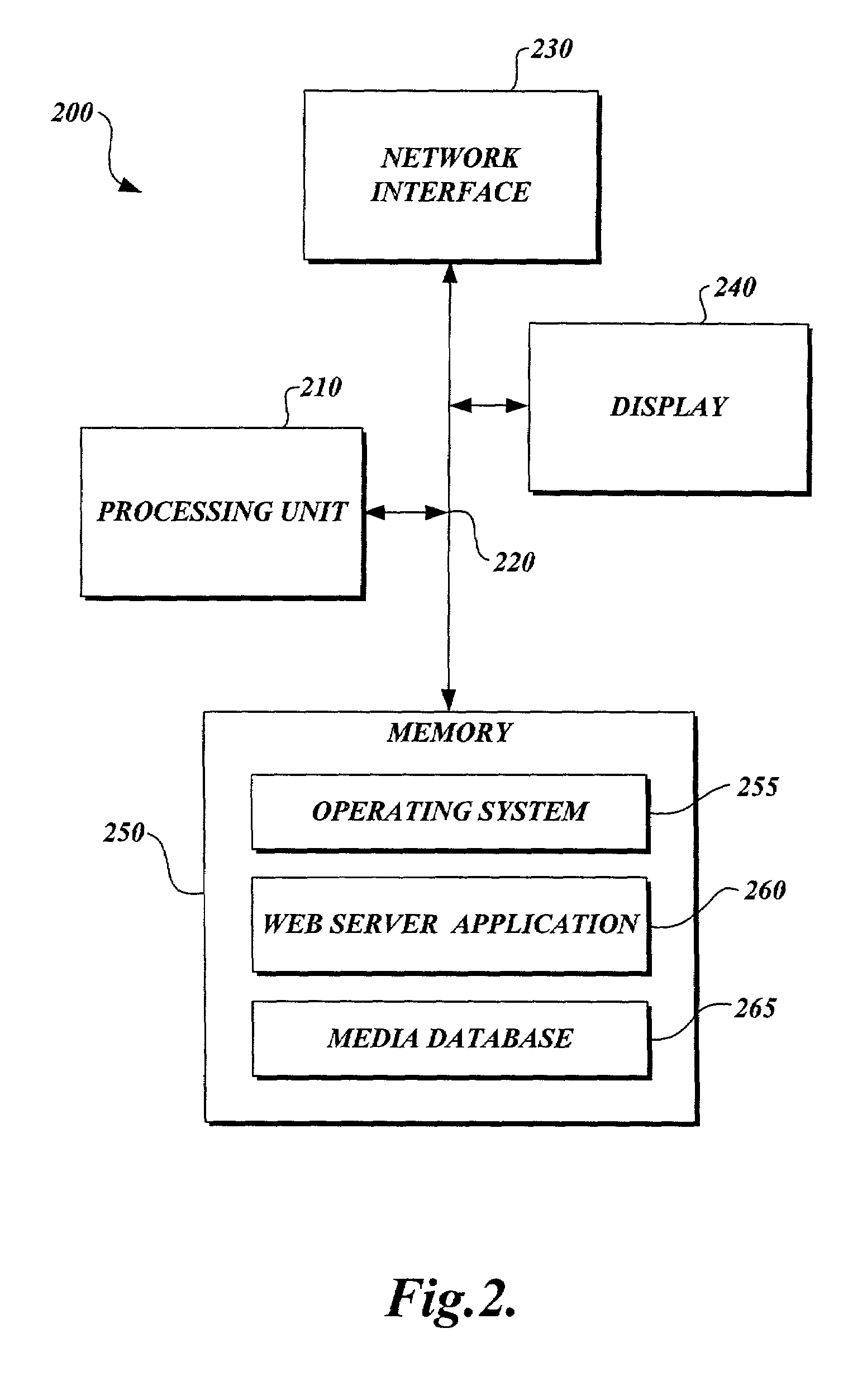

Method and system for managing and distributing digital media

InactiveUS7089309B2Easy to integrateMultiple digital computer combinationsTwo-way working systemsSource materialTranscoding

A system and method that integrates a plurality of media service systems offering different multimedia services such as media storage, syndication, delivery, and billing services. The system and method also provides automated file transcoding. In embodiment, a method of the present invention includes receiving a plurality of physical media files, organizing the plurality of physical media files so that different bit-rates and formats of a single source material are organized into a media database entity, receiving user specified delivery settings for the distribution of the physical media file, generating a release database entity storing the delivery settings of the physical media file, generating an address indicating the storage location of the release, and transmitting the address to a remote computing device.

Owner:COMCAST CABLE COMM MANAGEMENT LLC

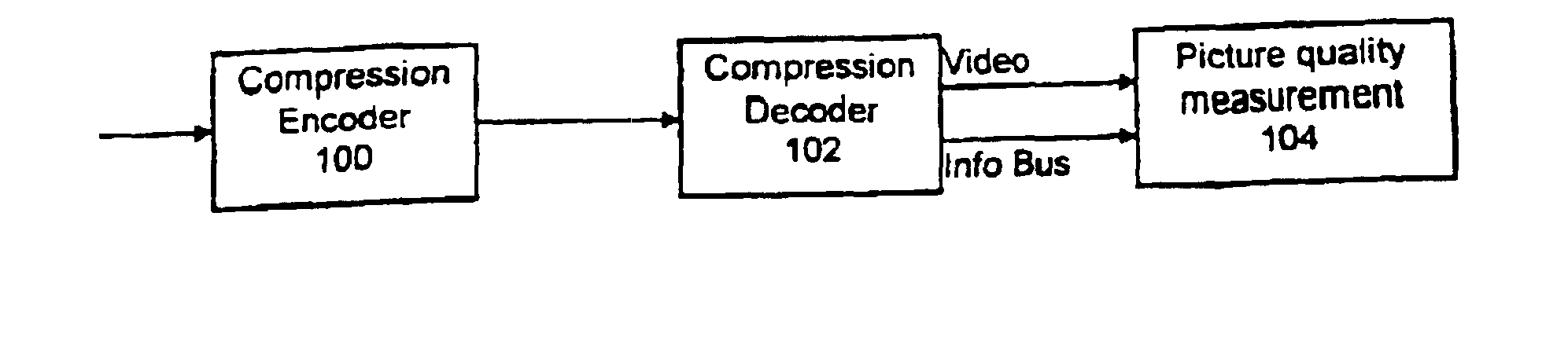

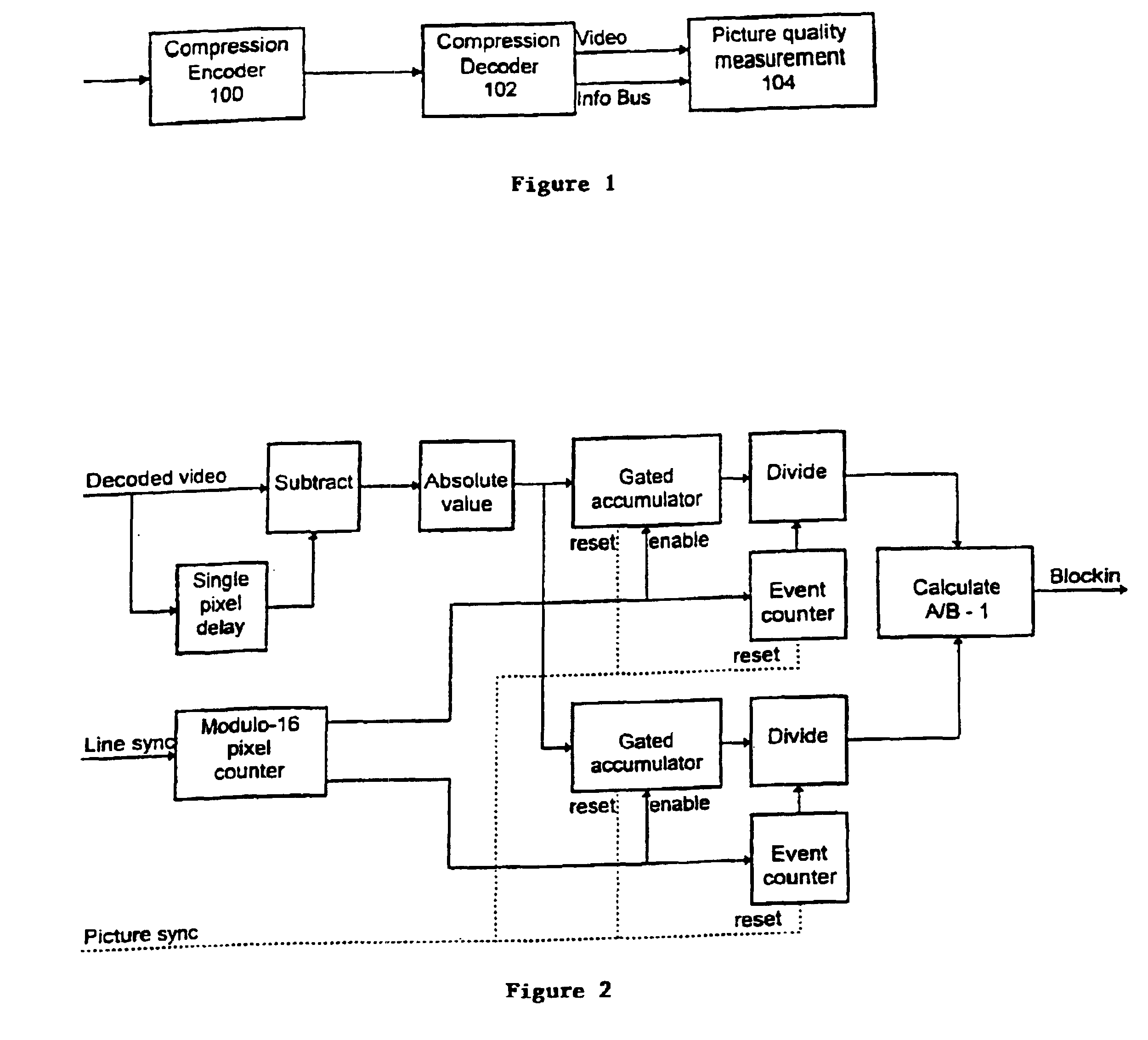

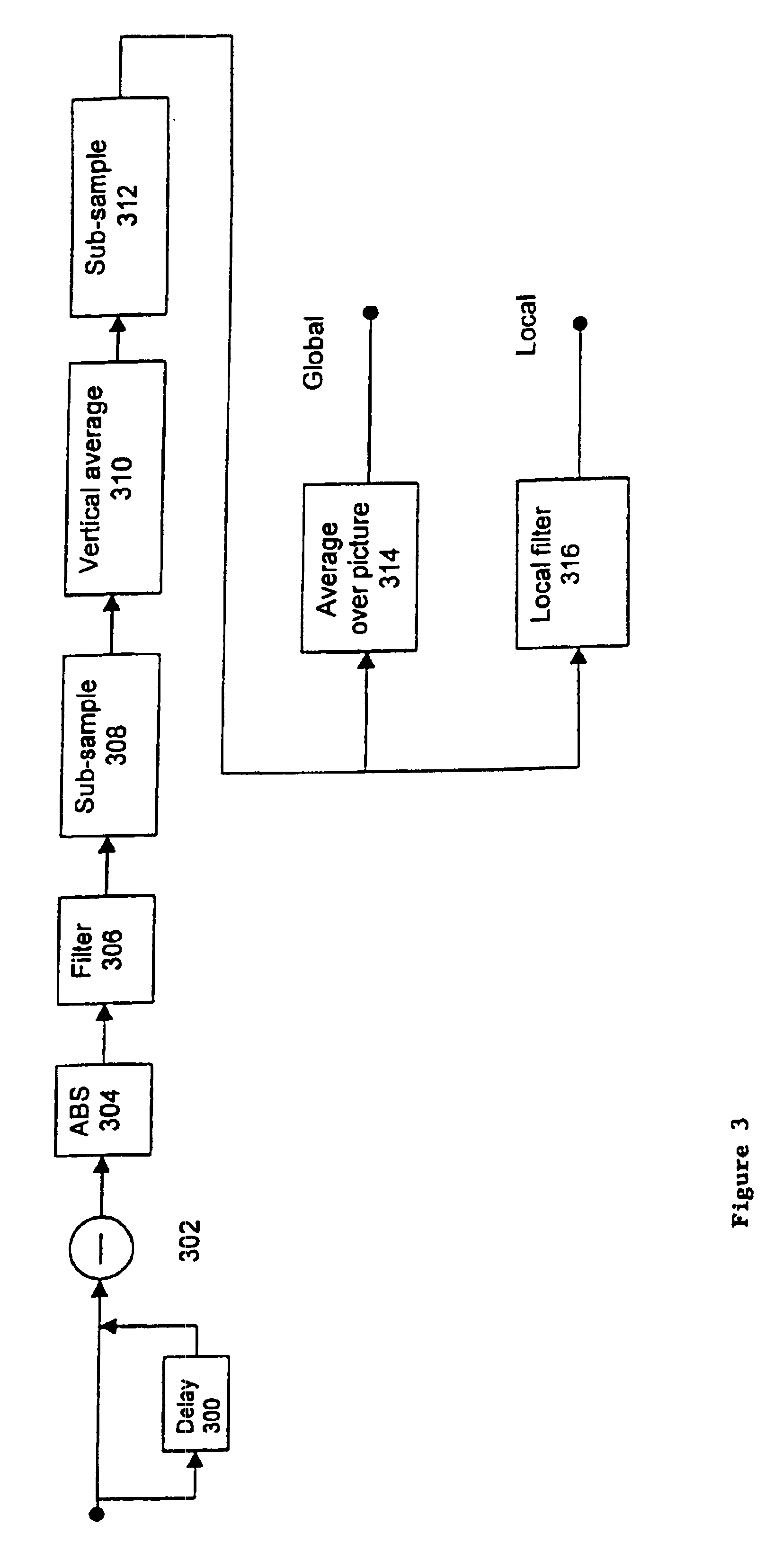

Method and apparatus for blocking effect reduction

InactiveUS6898321B1Improve subjective qualityImage enhancementPicture reproducers using cathode ray tubesSignal-to-noise ratio (imaging)Source material

By utilizing parameters derivable from a compressed bit-stream, measures are obtained of the subjective quality of a decoded picture, without the necessity for reference to source material. A blockiness measure is derived both locally and globally and used to control a de-blocking filter. An estimate of signal-to-noise ratio is derived from quantization values.

Owner:AMBERFIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com