Patents

Literature

261results about How to "Constant flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

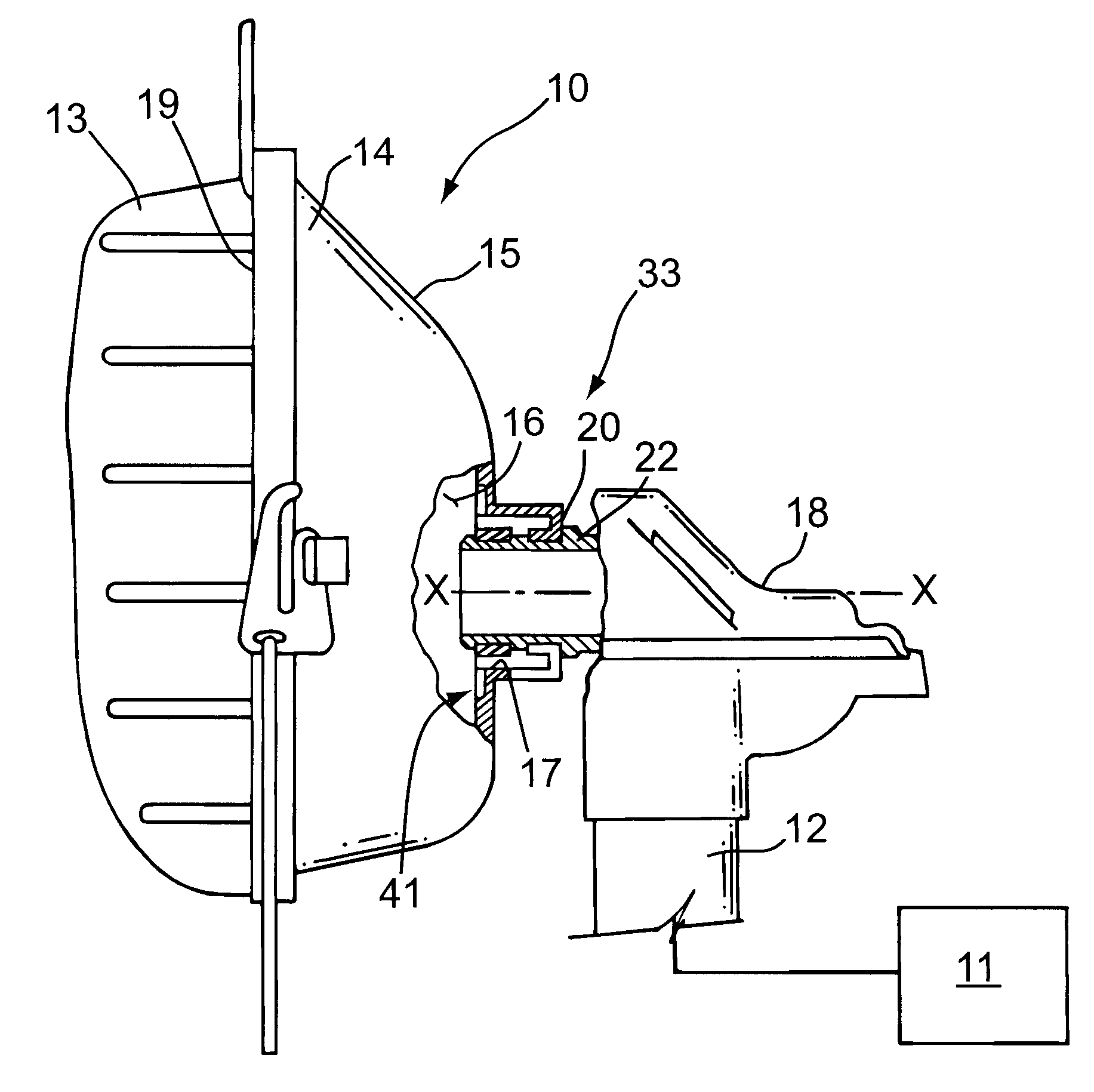

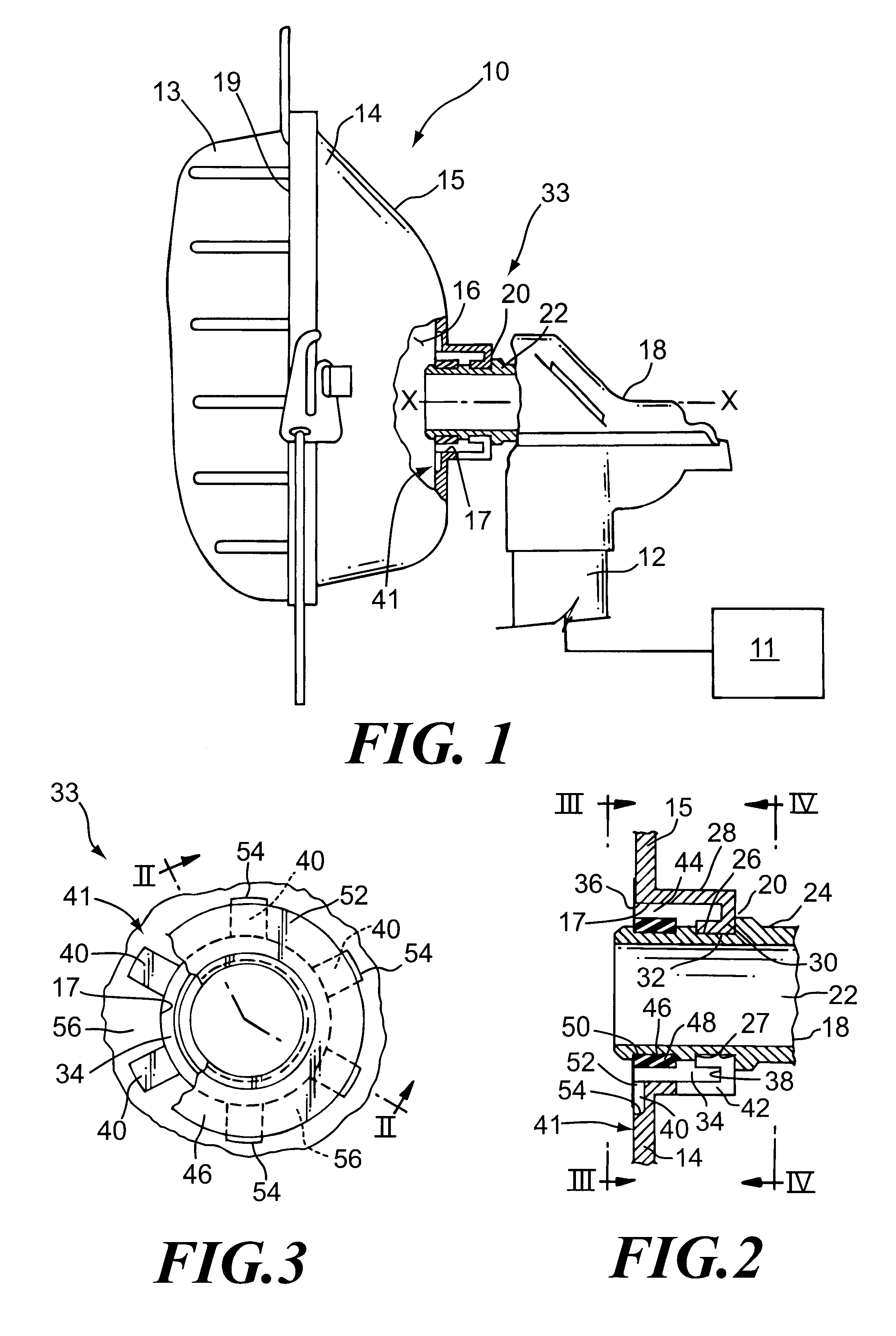

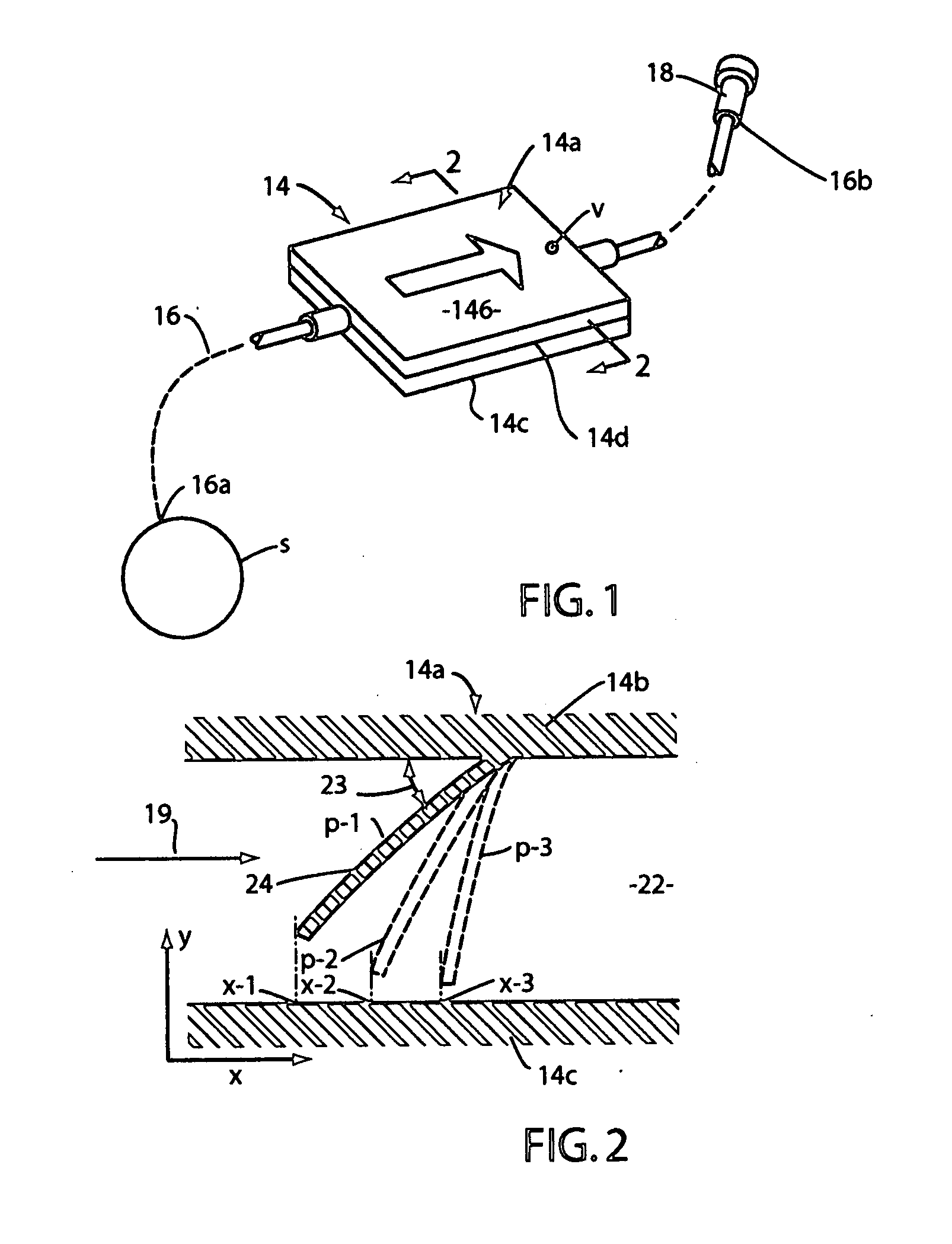

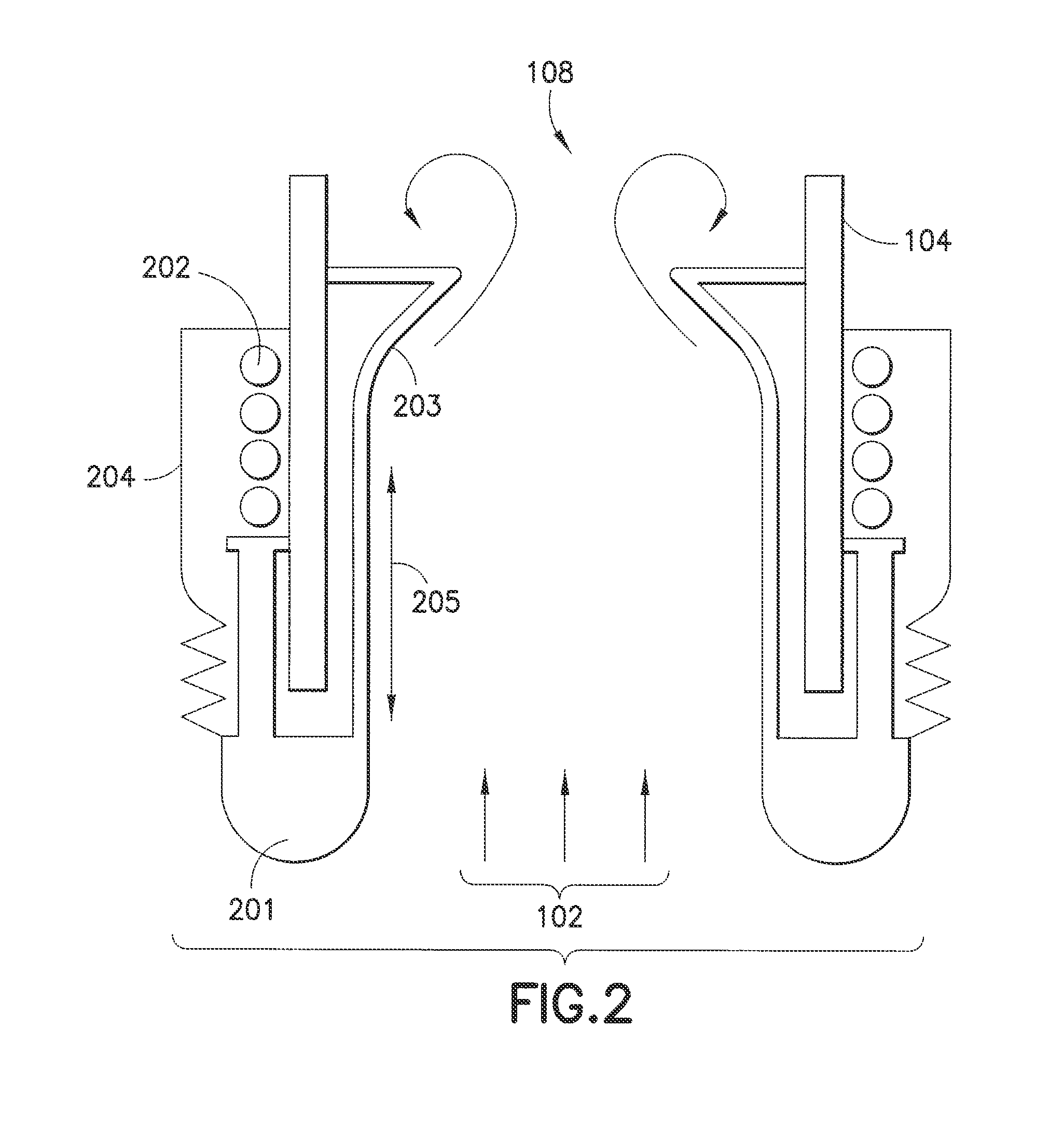

Combined patient interface and exhaust assembly

InactiveUS6584977B1Narrowing the exhaust pathReduce the effective cross-sectional areaBreathing masksRespiratory masksMedicineMechanical engineering

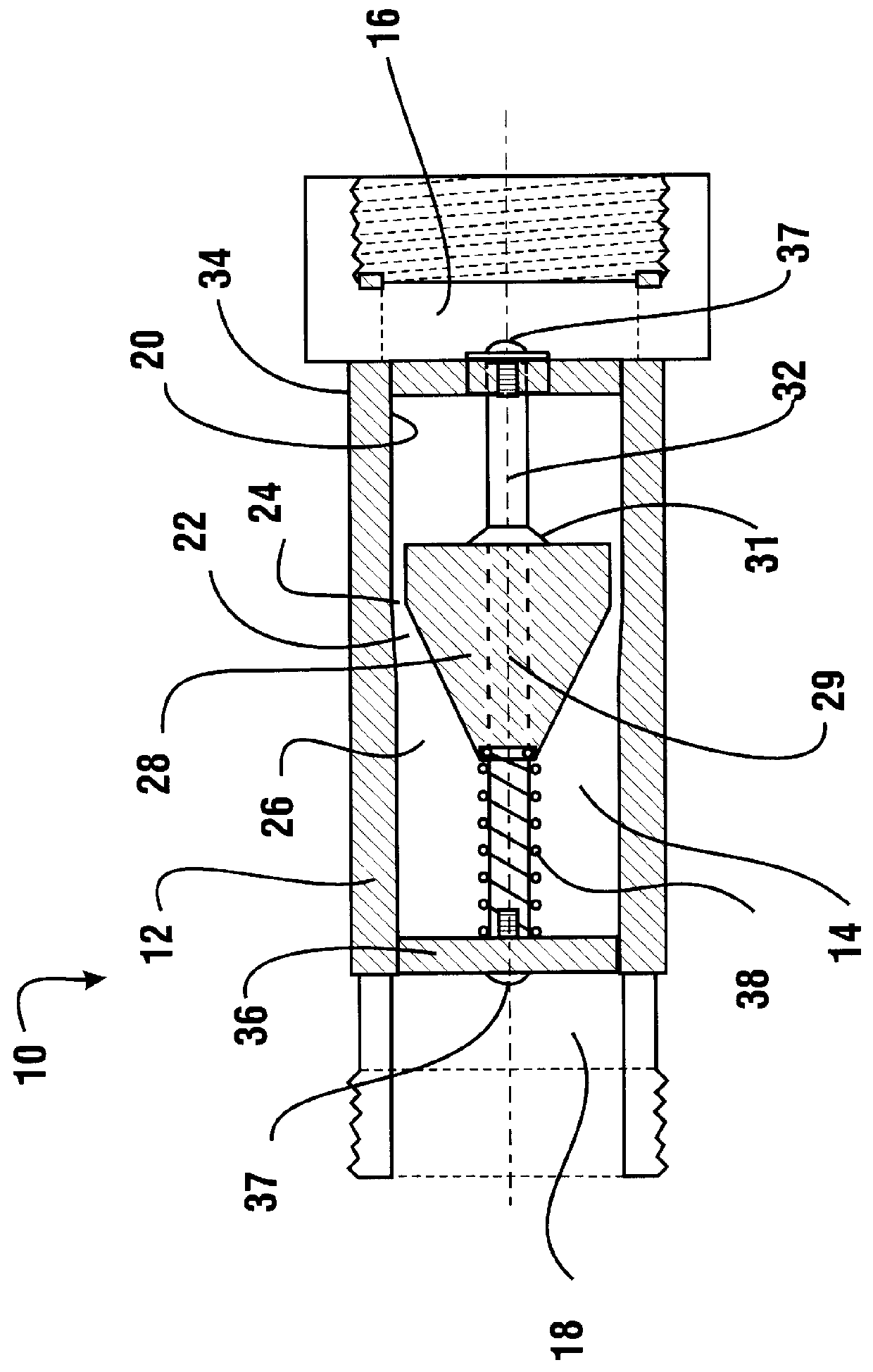

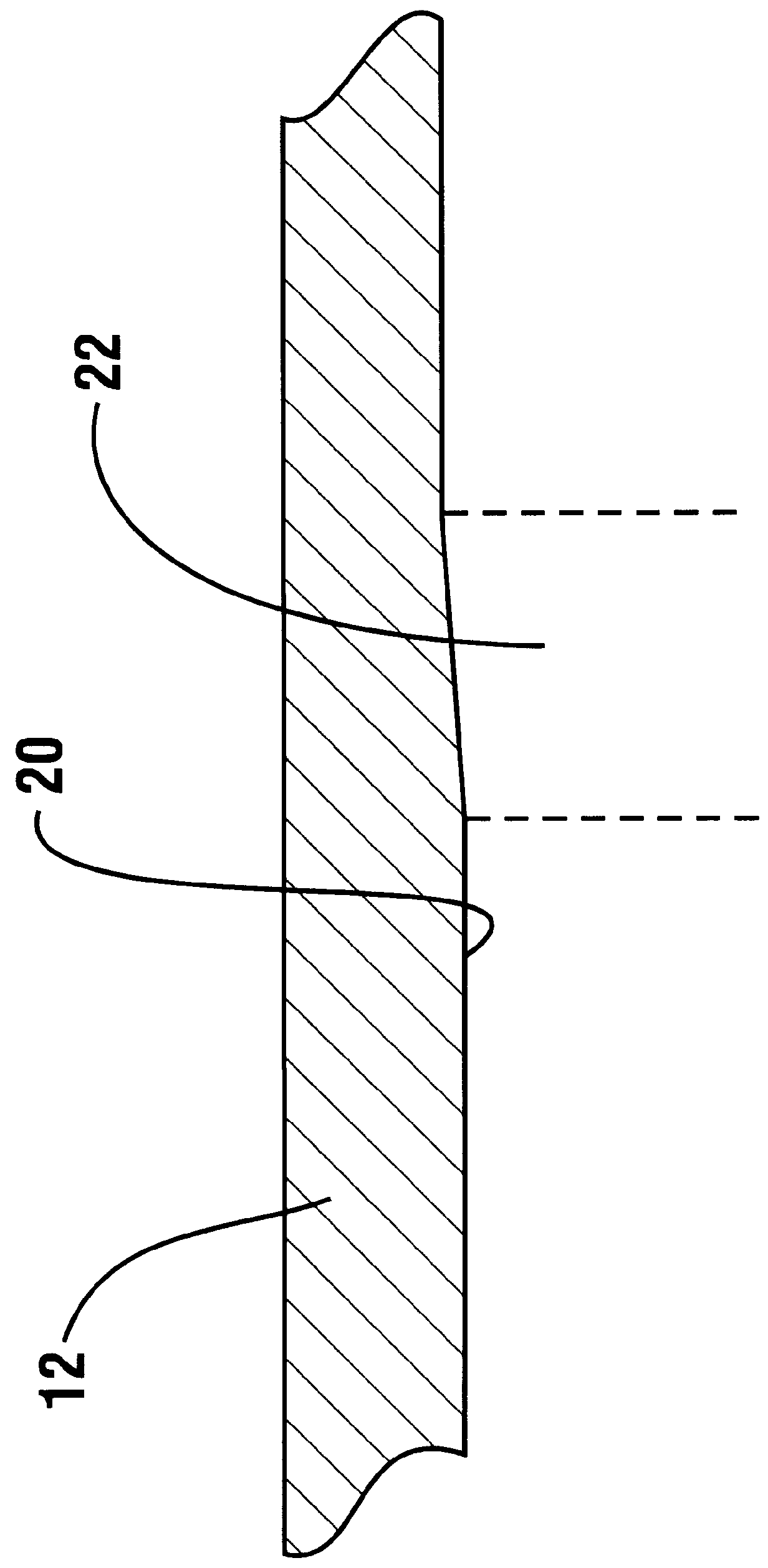

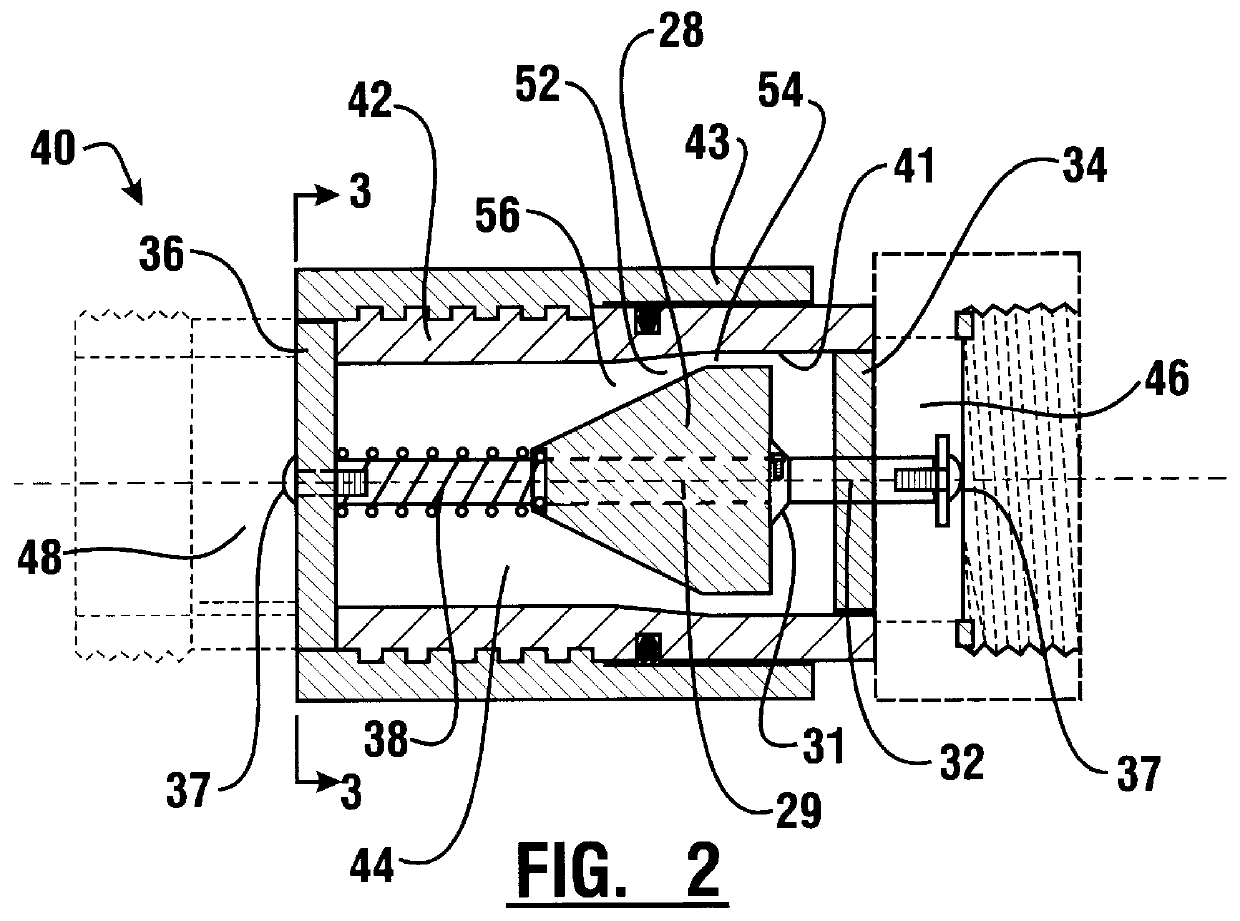

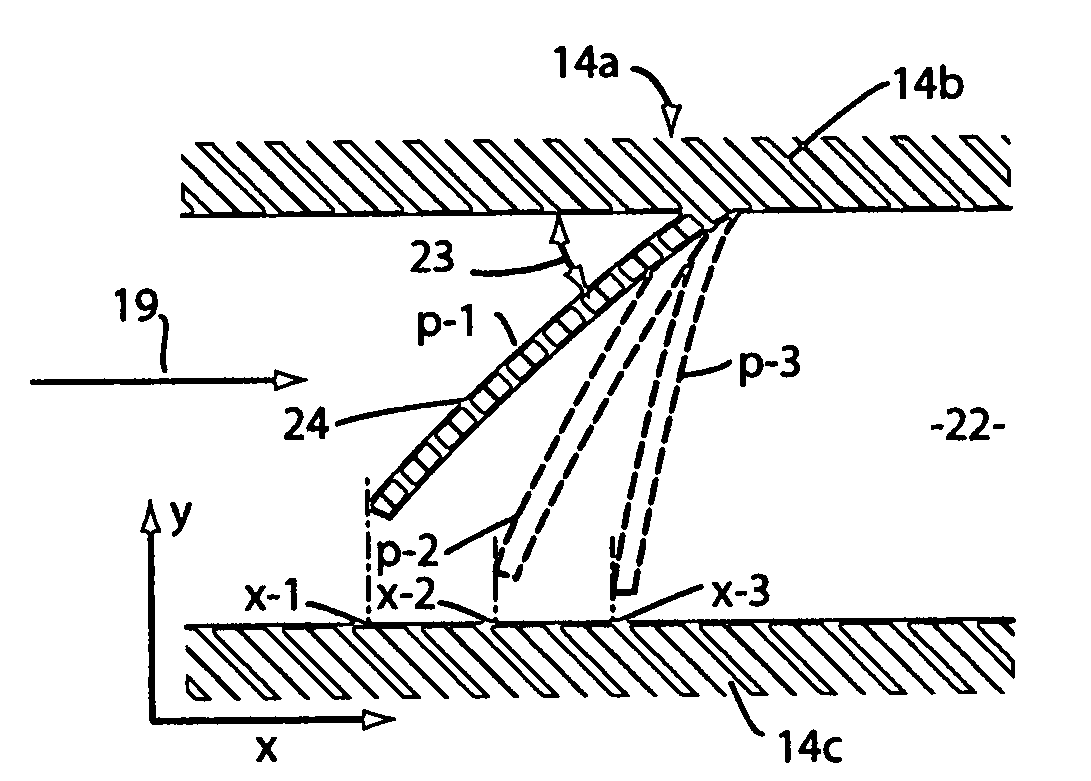

A combined patient interface and integrated exhaust assembly that passes a controlled flow of gas from an interior of a patient interface to ambient atmosphere at a predetermined flow rate irrespective of variations of pressure in the interior of the patient interface device relative to ambient atmosphere. Control of the flow of exhaust gas is achieved by varying the effective cross sectional area of the exhaust path communicating the interior of the patient interface with ambient atmosphere based on the pressure in the interior of the patient interface relative to ambient atmospheric pressure.

Owner:RIC INVESTMENTS LLC

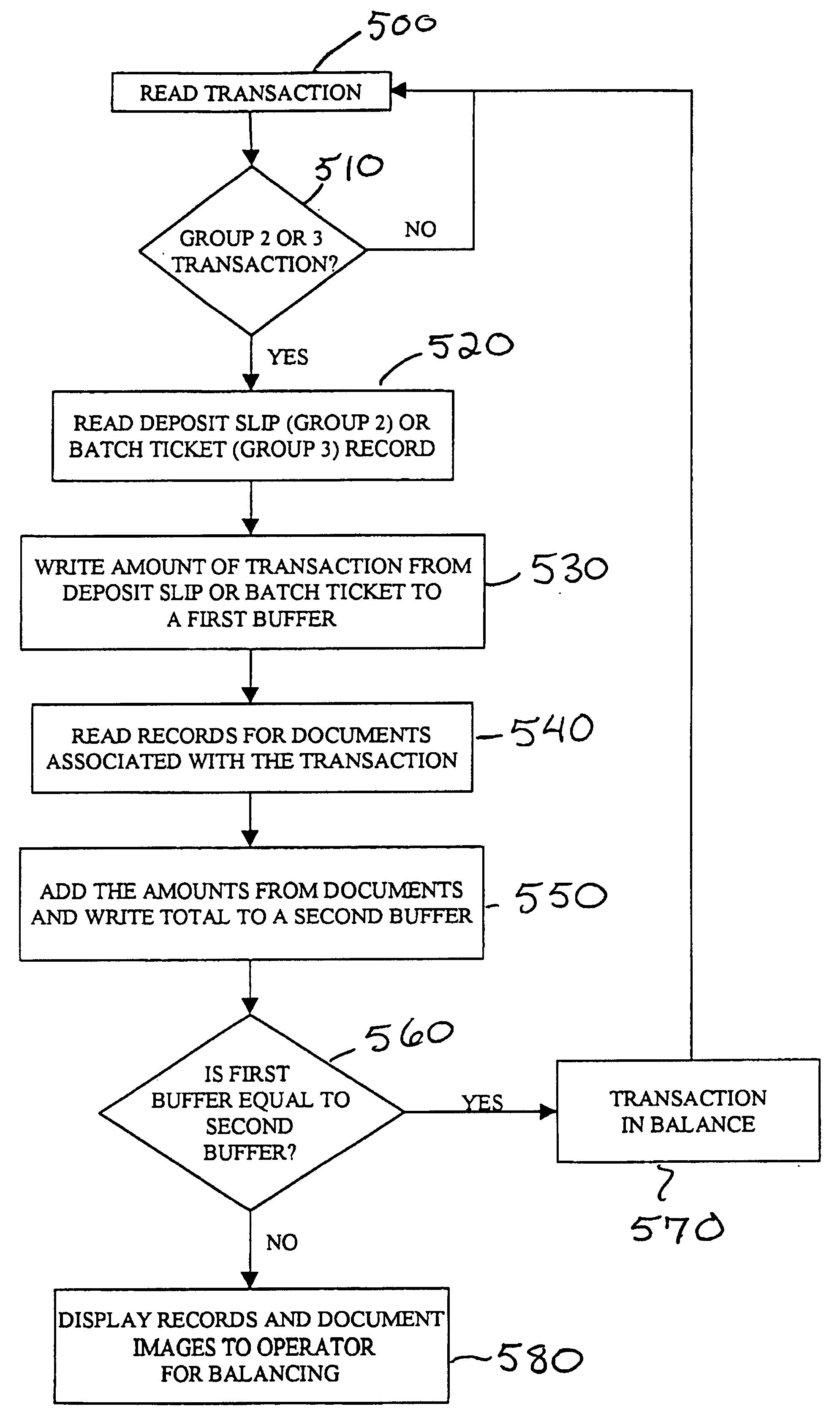

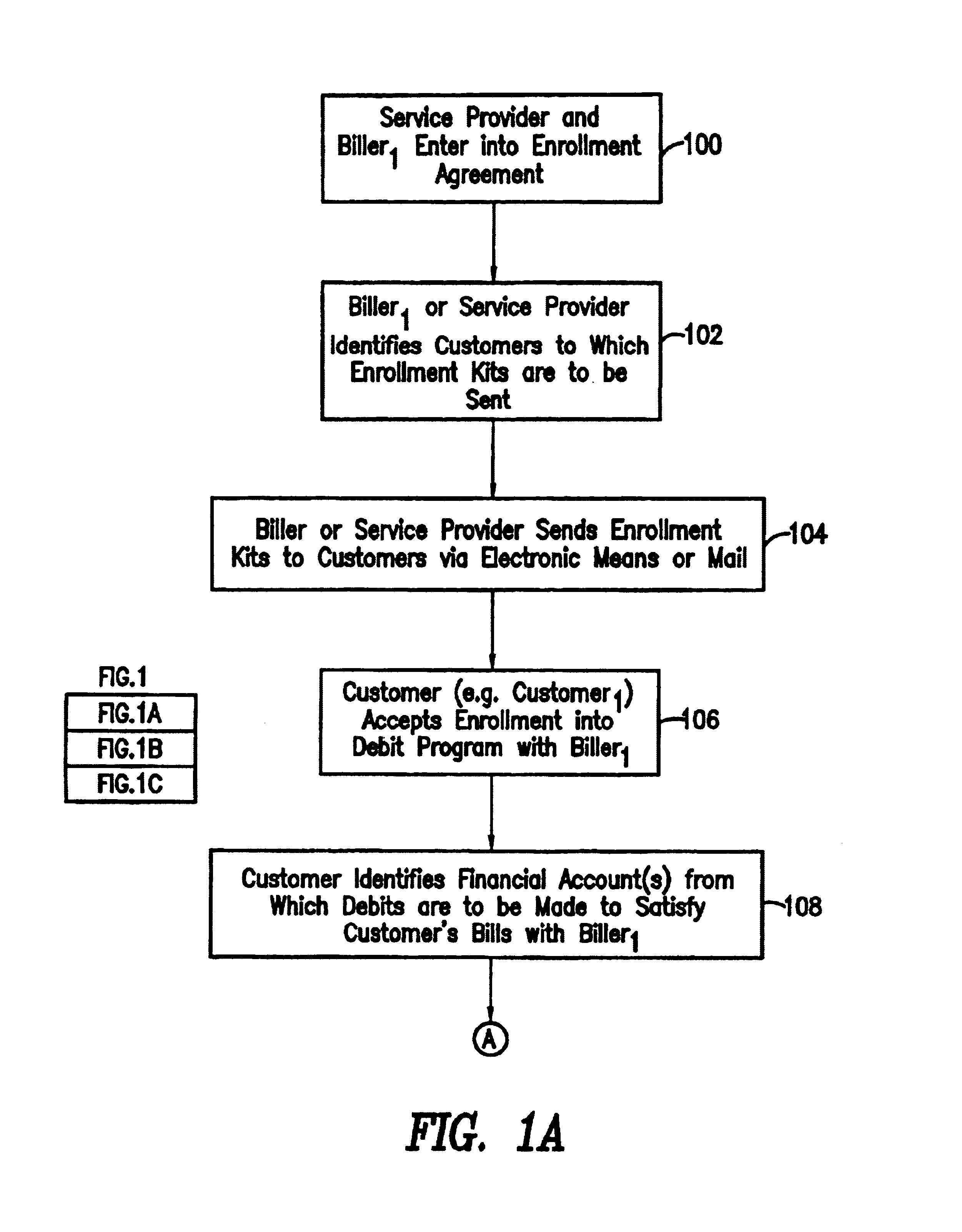

System and method for back office processing of banking transactions using electronic files

InactiveUS7062456B1Reduce equipmentReduce laborFinanceAutomatic teller machinesBank tellerRelevant information

As banking transactions are processed by a bank teller, all of the relevant information with respect to the transaction (e.g., dollar amount) is captured in an electronic file. Each of the electronic files from the various branches of the bank are forwarded to a central back office processing center where the electronic files are combined into a single Transaction Repository. At the end of the branch day, all of the paper associated with the transactions is forwarded from the branches to the back office processing center. The paper transactions are imaged in the conventional manner and the Magnetic Ink Character Recognition (MICR) data is read from the paper. The present invention then automatically correlates the images and MICR data captured from the paper with the complete transaction record contained in the Transaction Repository. Most of the conventional back office processing can now be performed without the need to perform character recognition and without the need for excess human intervention.

Owner:JPMORGAN CHASE BANK NA

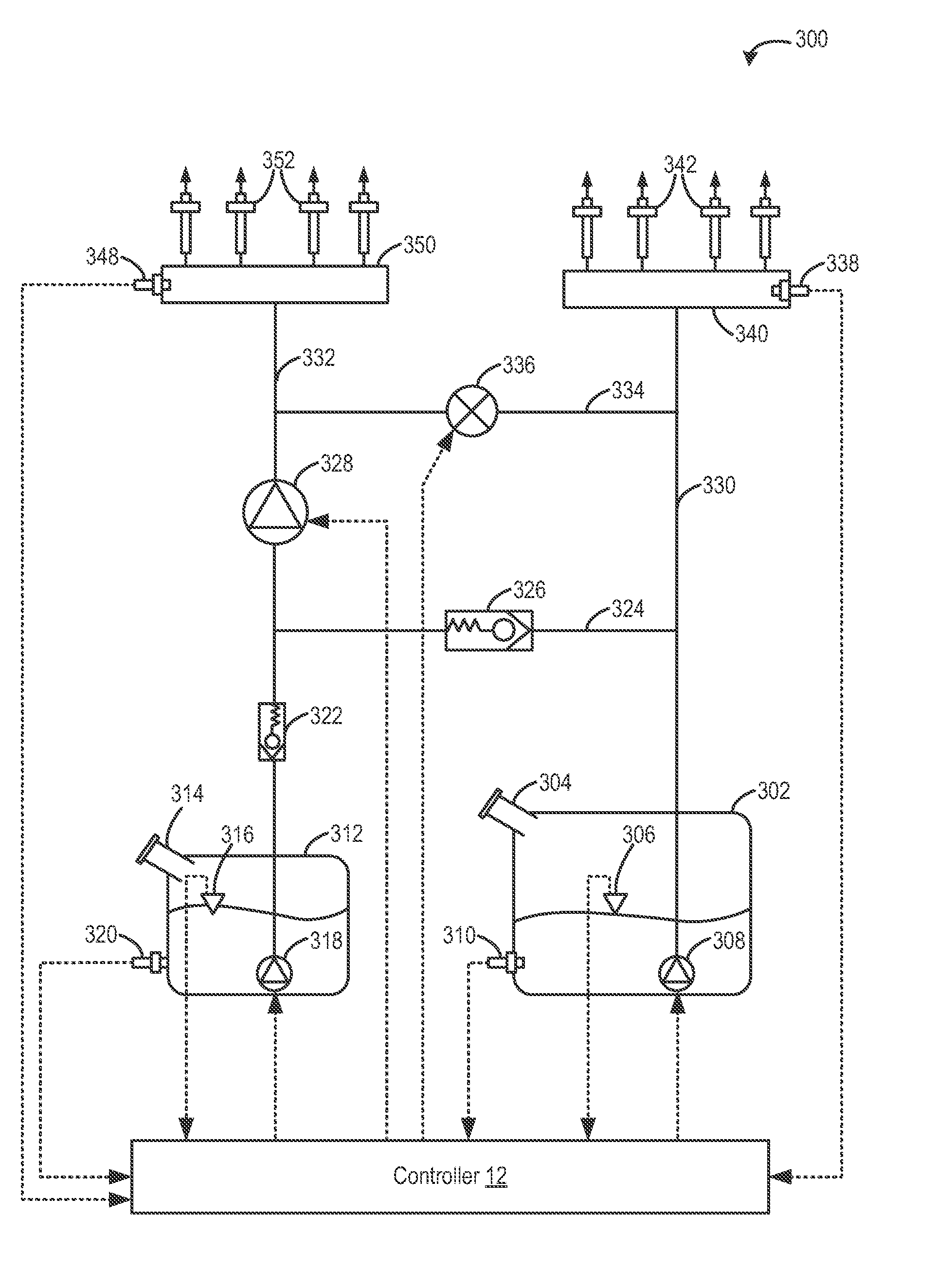

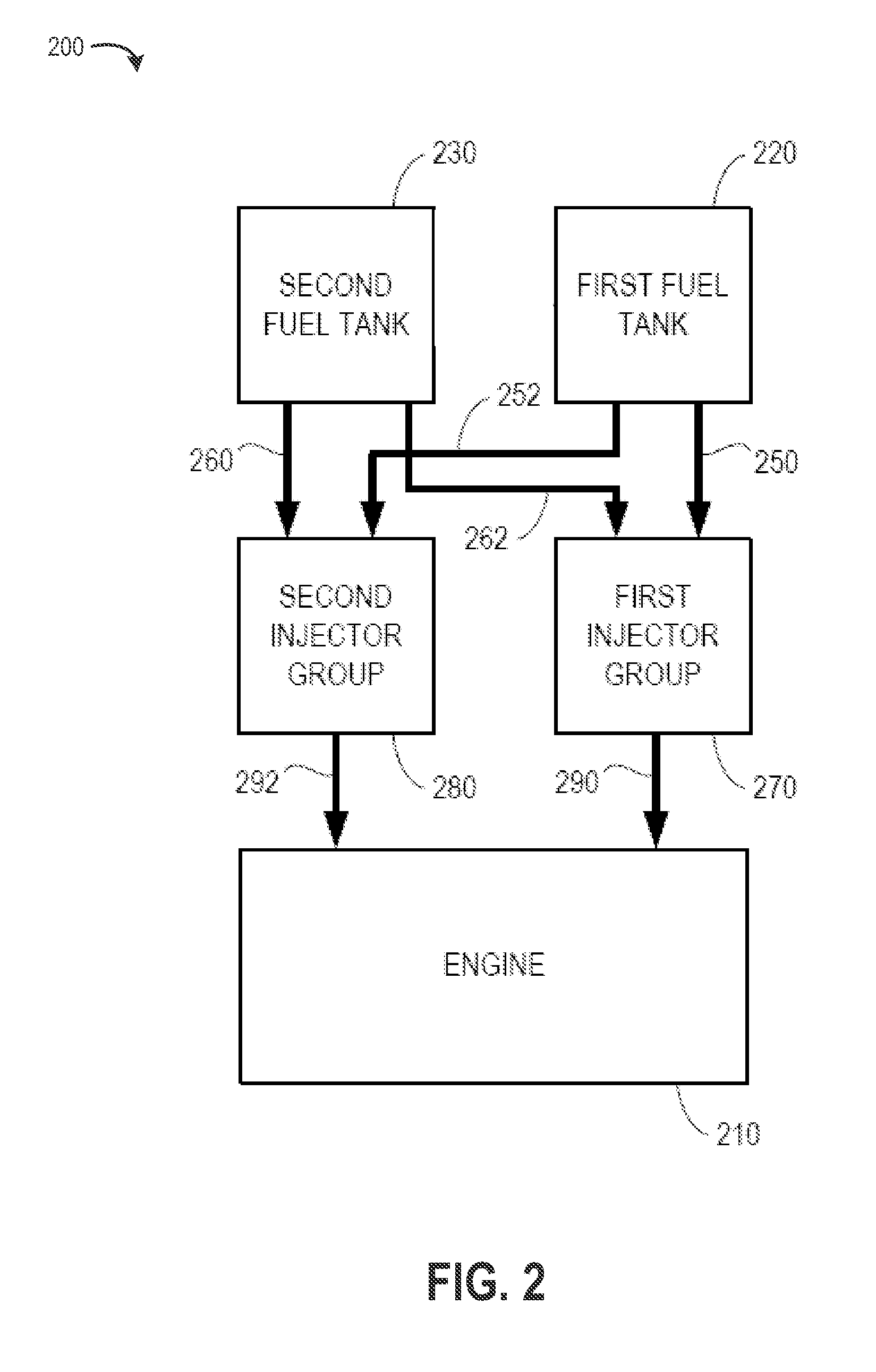

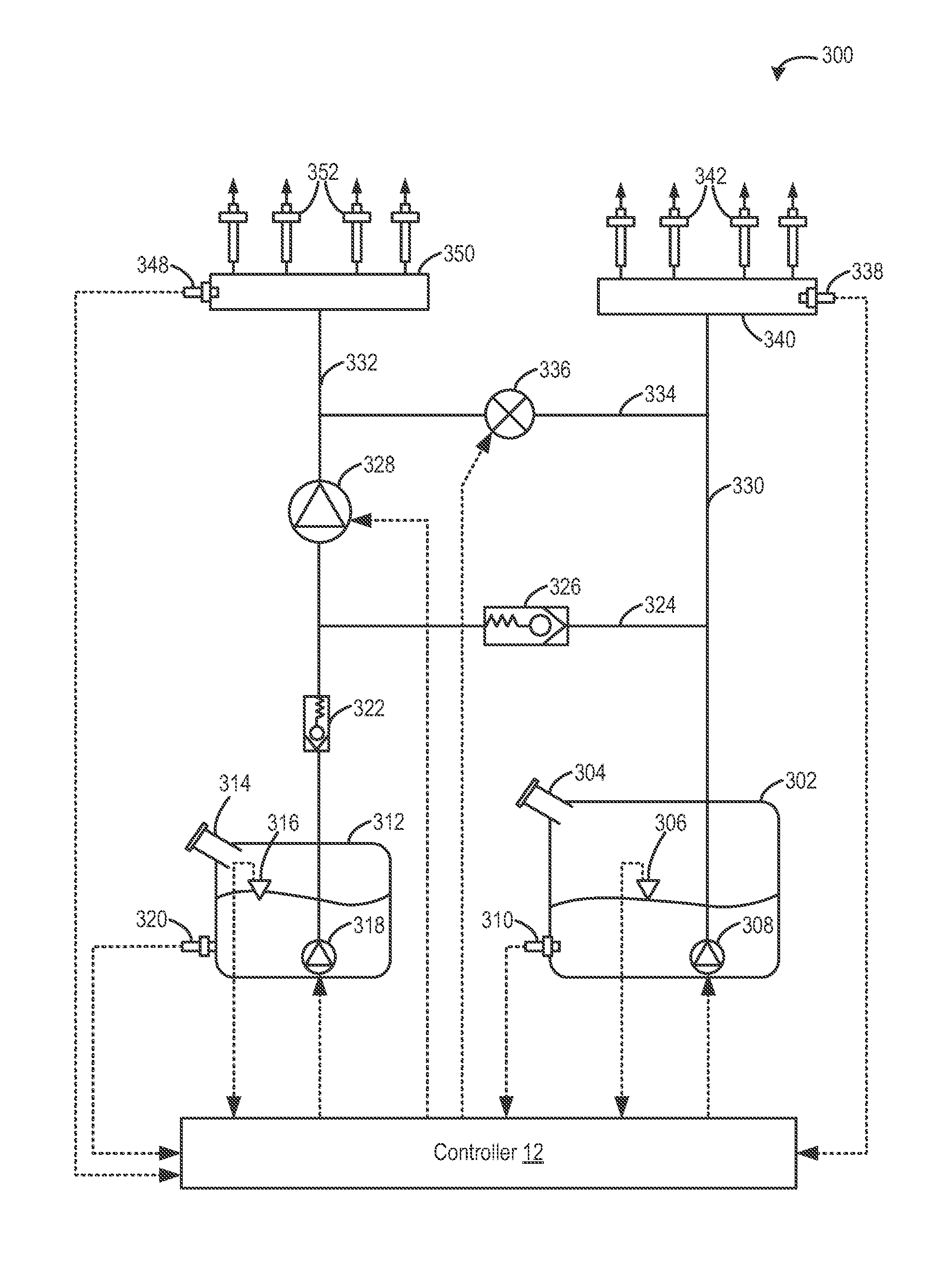

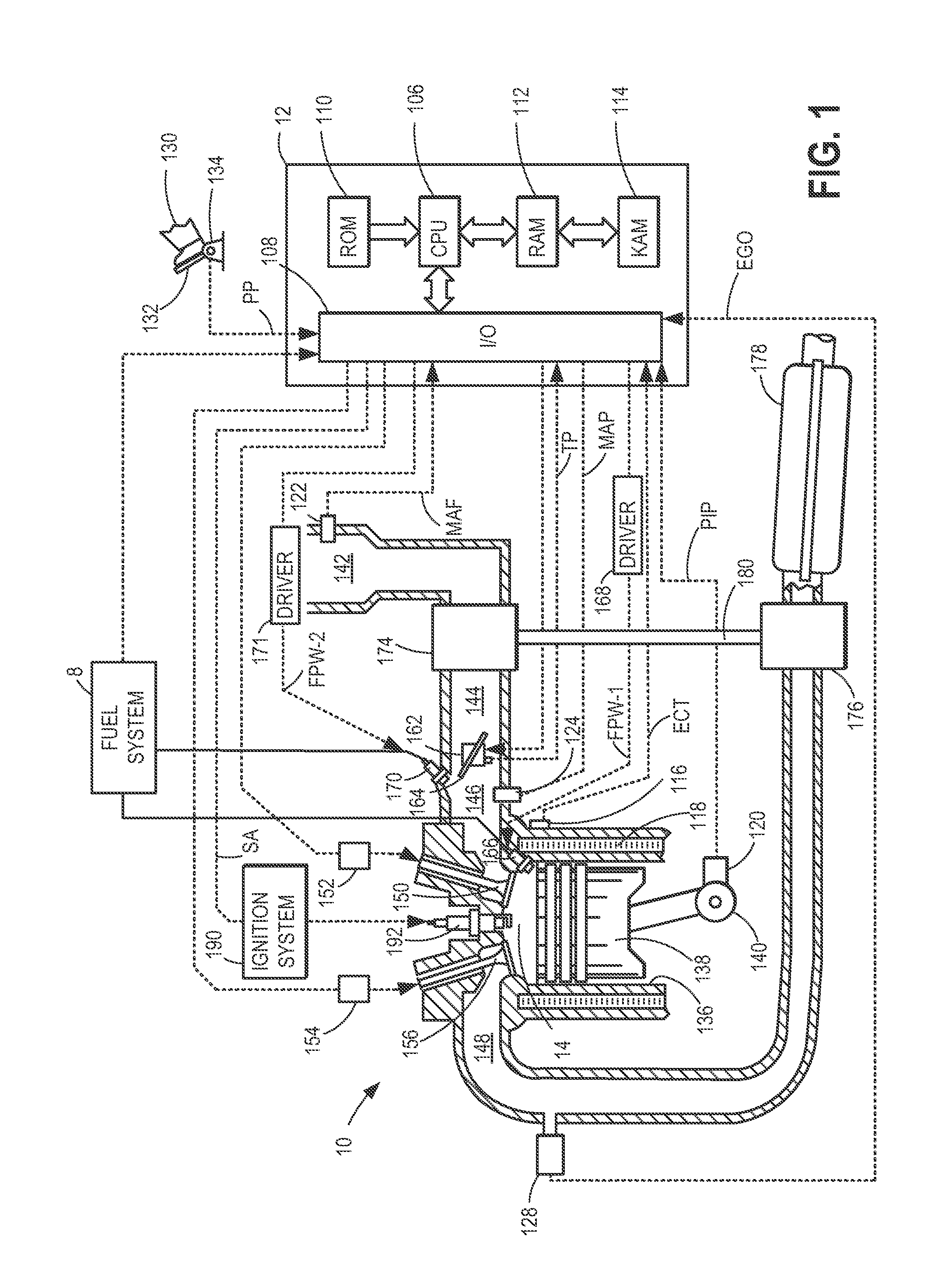

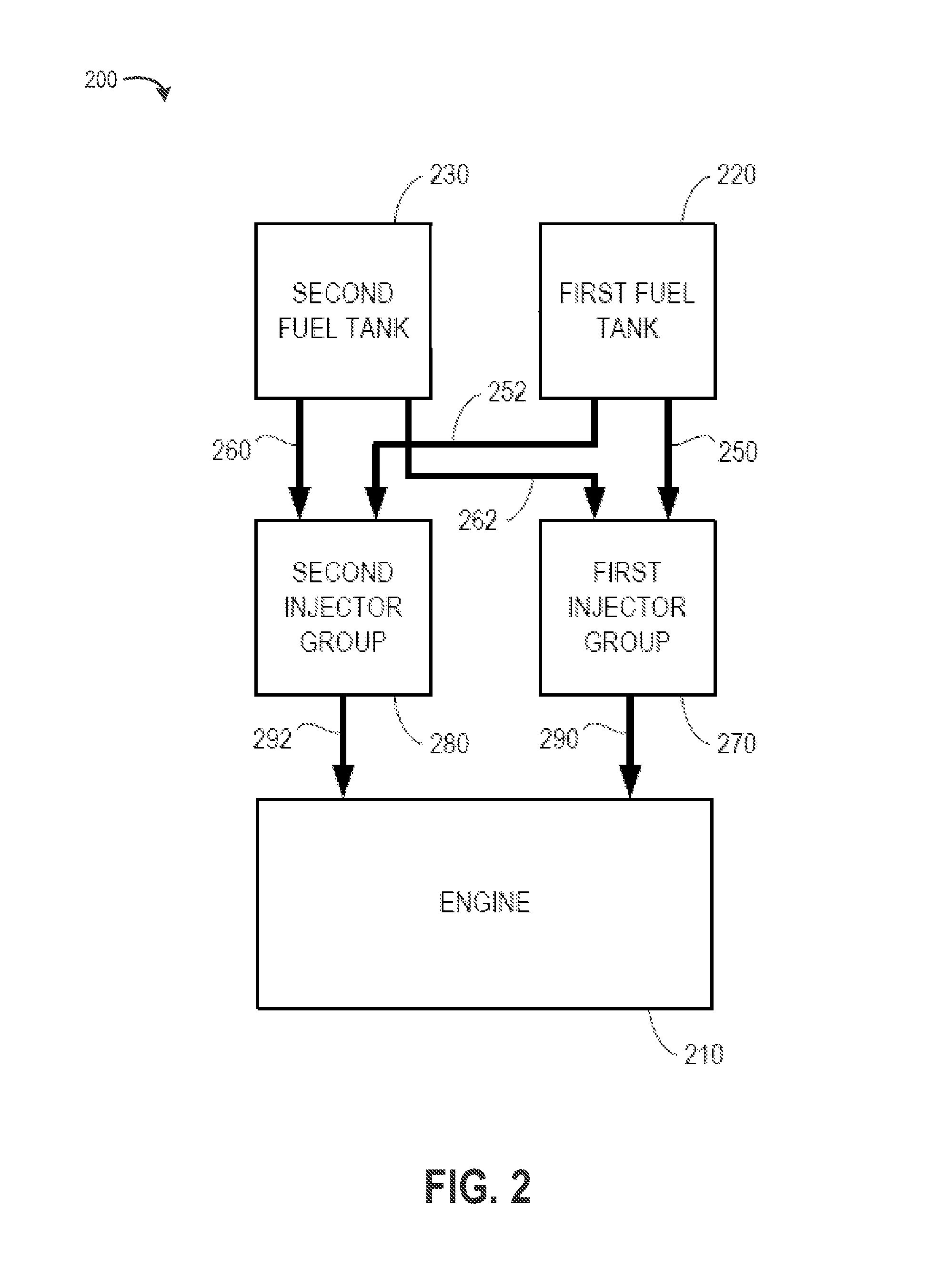

Fuel system for a multi-fuel engine

InactiveUS20120048242A1Reducing high pressure pump degradationReduce degradationElectrical controlInternal combustion piston enginesFuel typeHigh pressure

Methods and systems are provided for operating an engine fuel system including fuels of different fuel types. A first fuel type is delivered for port injection upon circulation through a high pressure pump when direct injection of a fuel is not requested to cool and / or lubricate the high pressure pump.

Owner:FORD GLOBAL TECH LLC

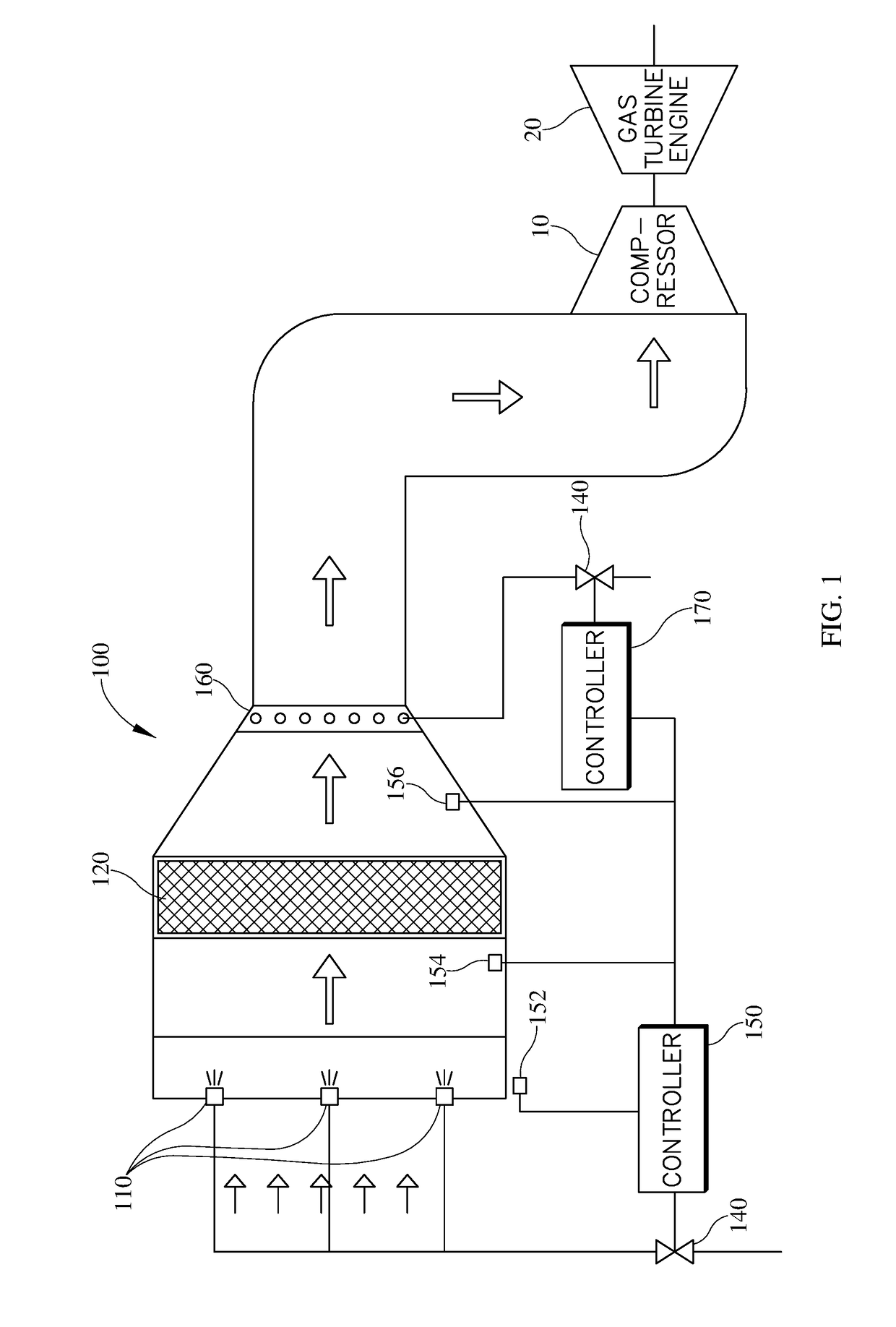

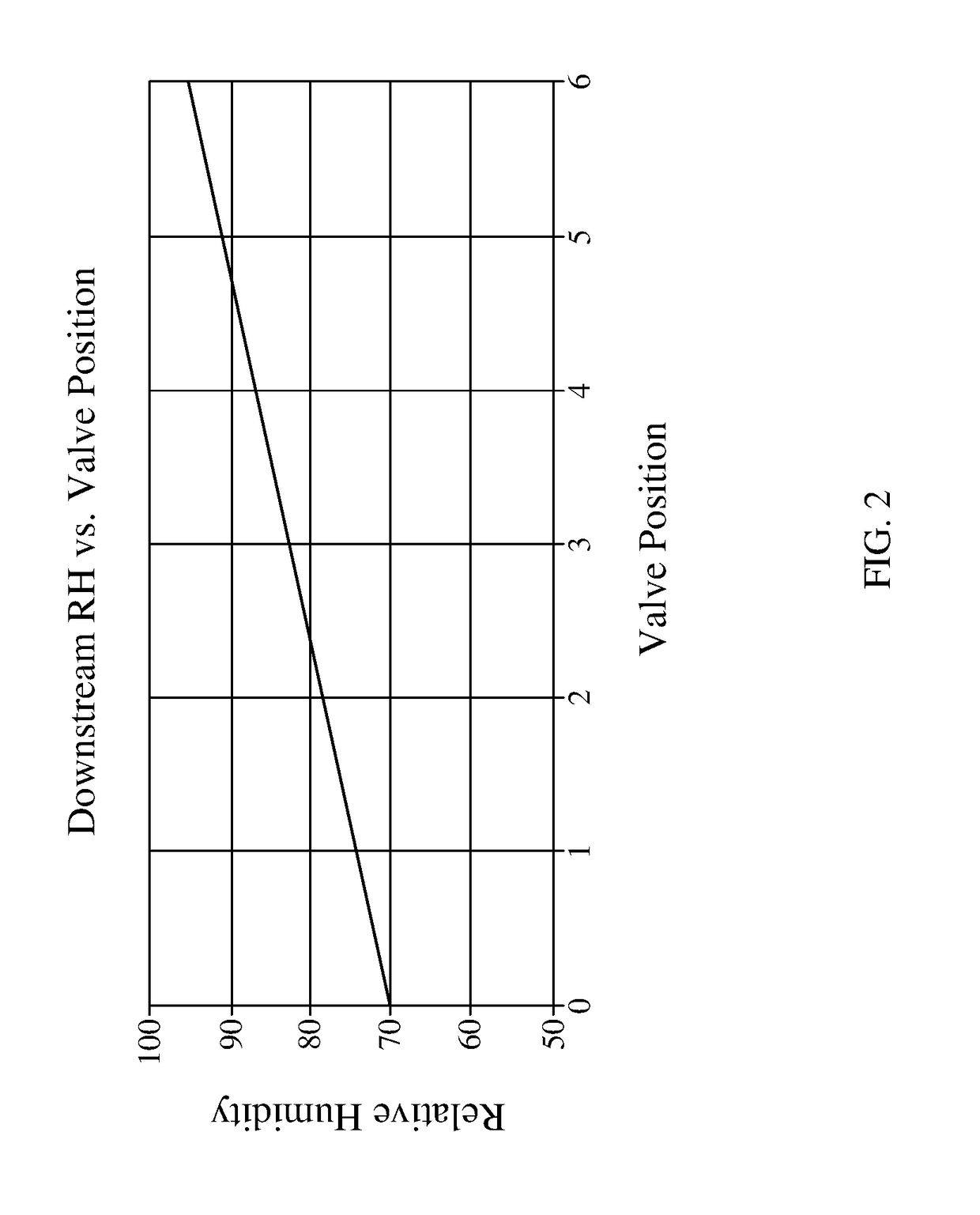

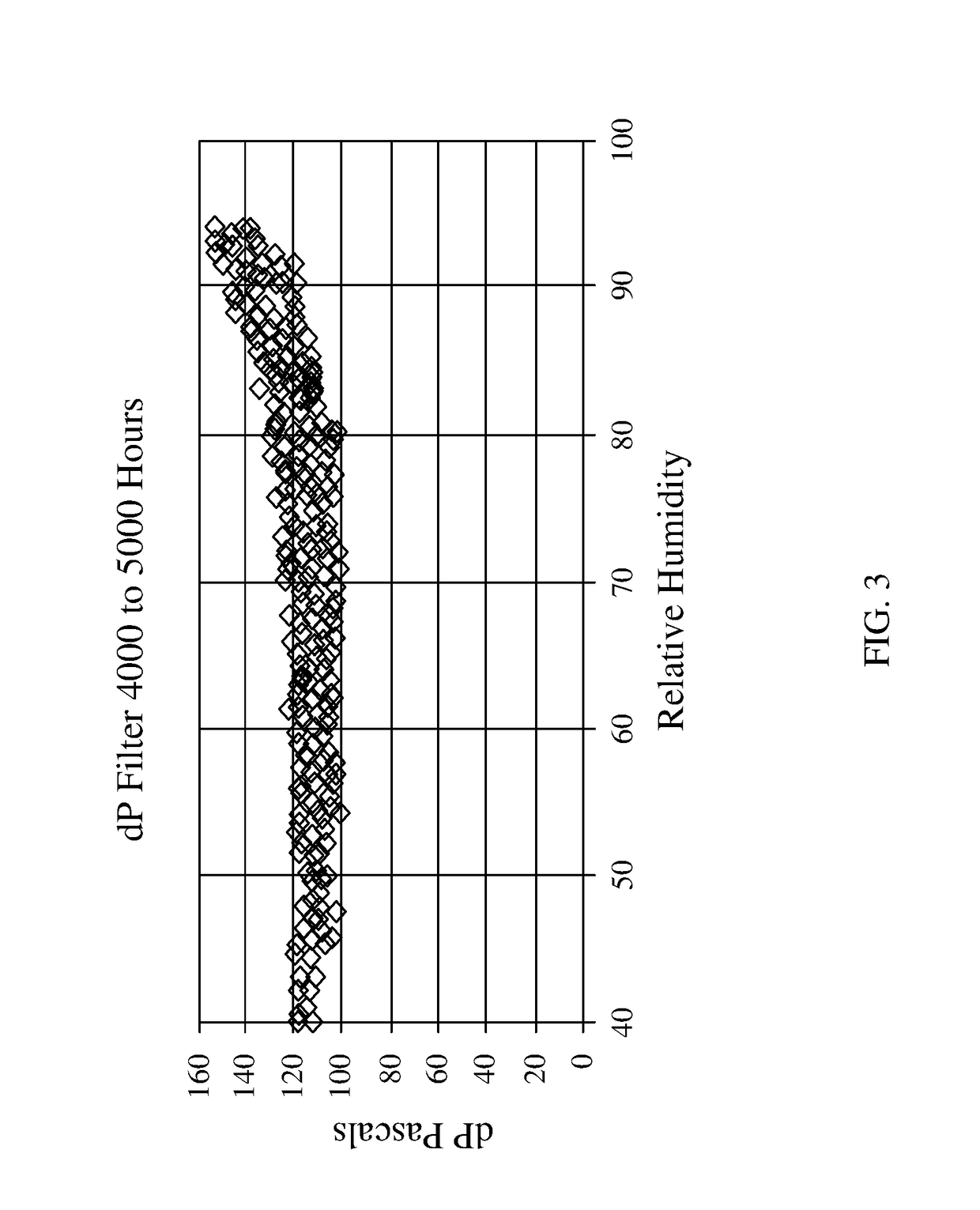

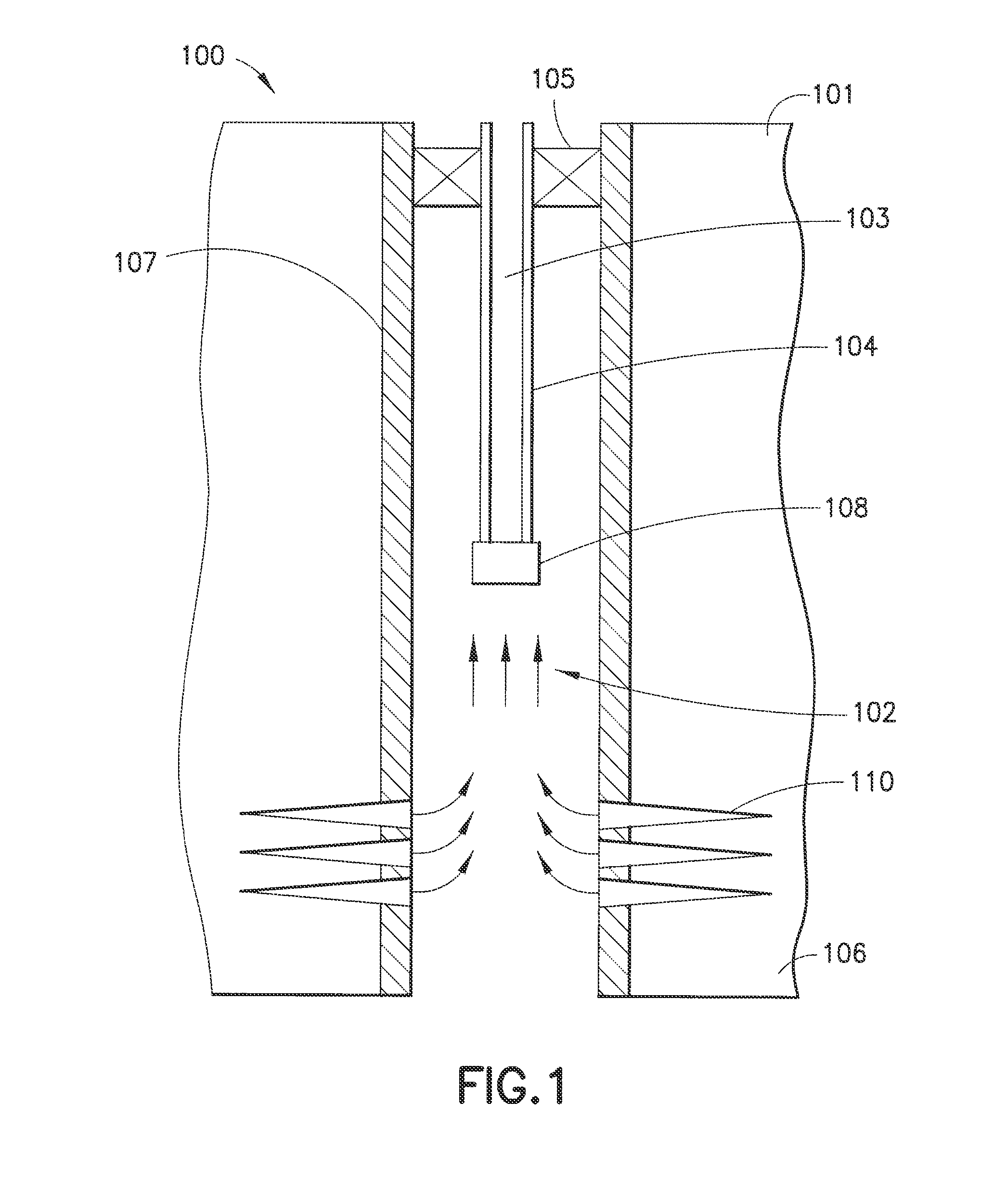

System for reducing inlet air temperature of a device

ActiveUS20180172294A1Reduce device temperatureSimple nozzle designCoolant flow controlLighting and heating apparatusBiomedical engineeringAir temperature

The present embodiments disclose a system (100) for reducing inlet air temperature of a device, comprising: a fogging system that provides air cooling, wherein the fogging system comprises at least one low pressure atomiser (110).

Owner:AAF LTD

Overflow downdraw glass forming method and apparatus

ActiveUS20060016219A1Process can be modifiedMinimizing thickness variationGlass furnace apparatusVolume/mass flow measurementThermal creepEngineering

The present invention significantly modifies “The Overflow Process”. It includes a method and apparatus for measuring glass flow rate and maintaining a constant glass flow rate. It also embodies design features and methods that support and stress the forming apparatus in a manner such that the deformation that results from thermal creep is corrected, thus minimizing the effect of the thermal creep on the thickness variation of the glass sheet. The present invention also embodies design features that change the process from a single step (combined flow distribution and cooling) to a two step process; step one being flow distribution and step two being cooling.

Owner:CORNING INC

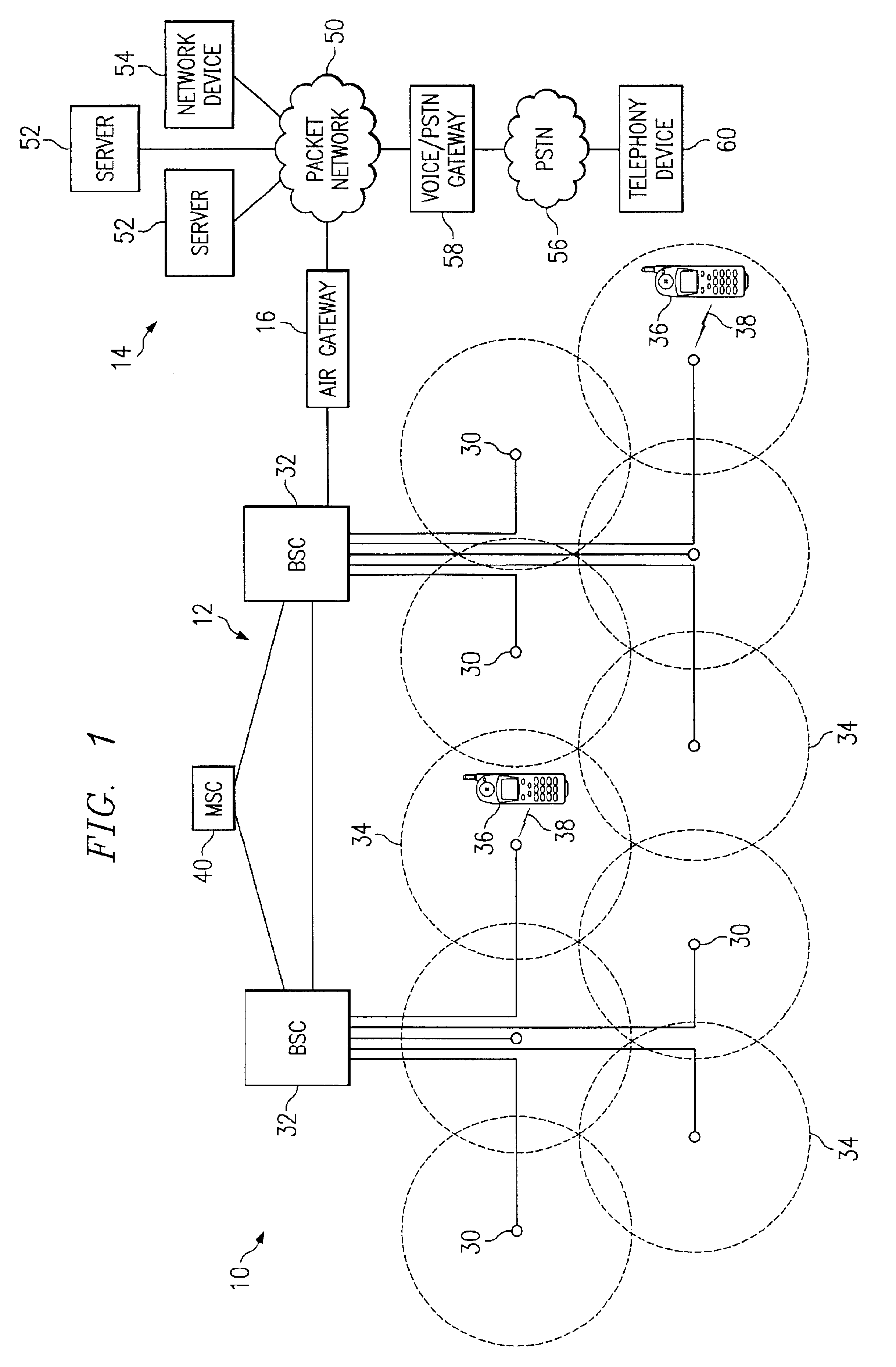

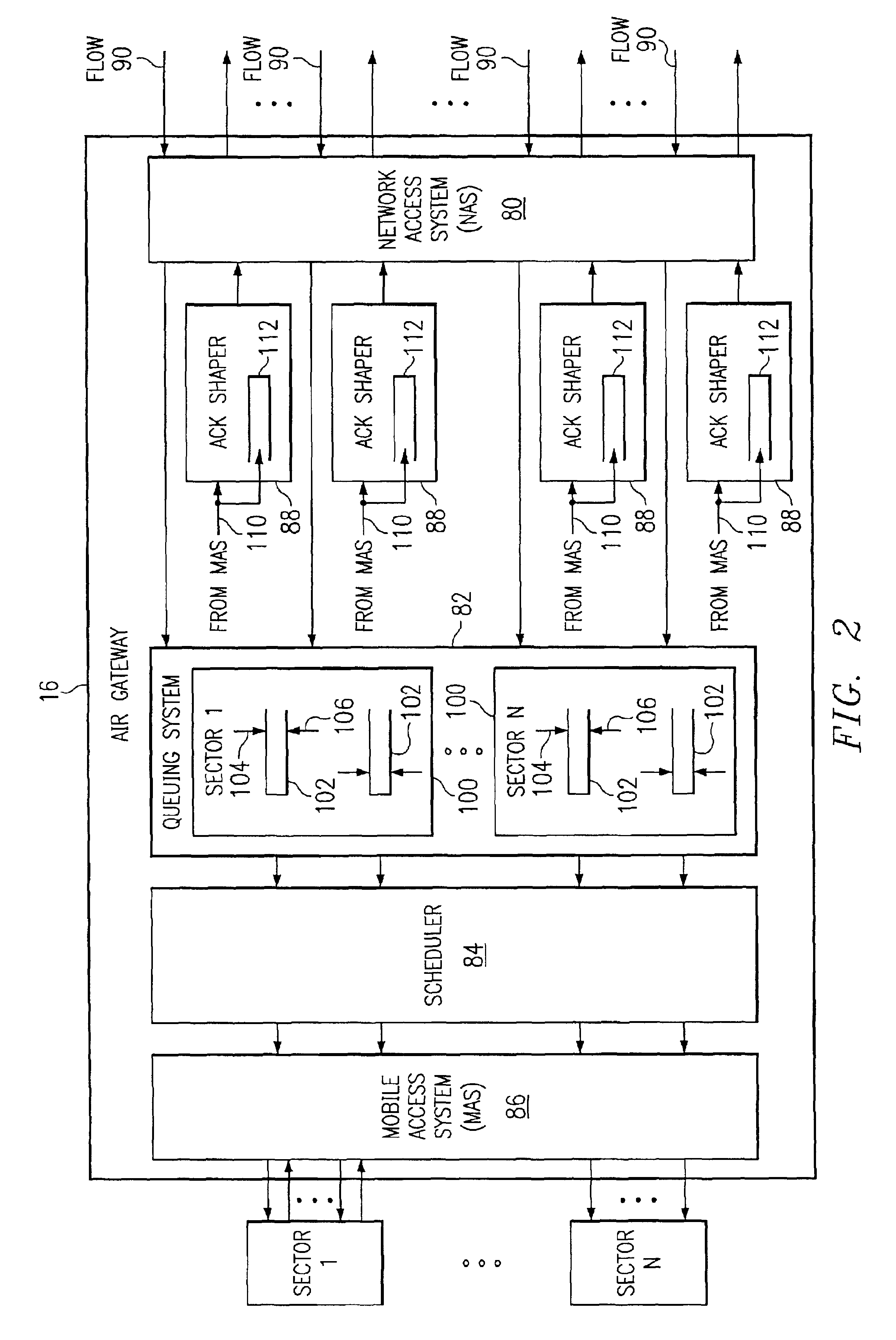

Method and system of integrated rate control for a traffic flow across wireline and wireless networks

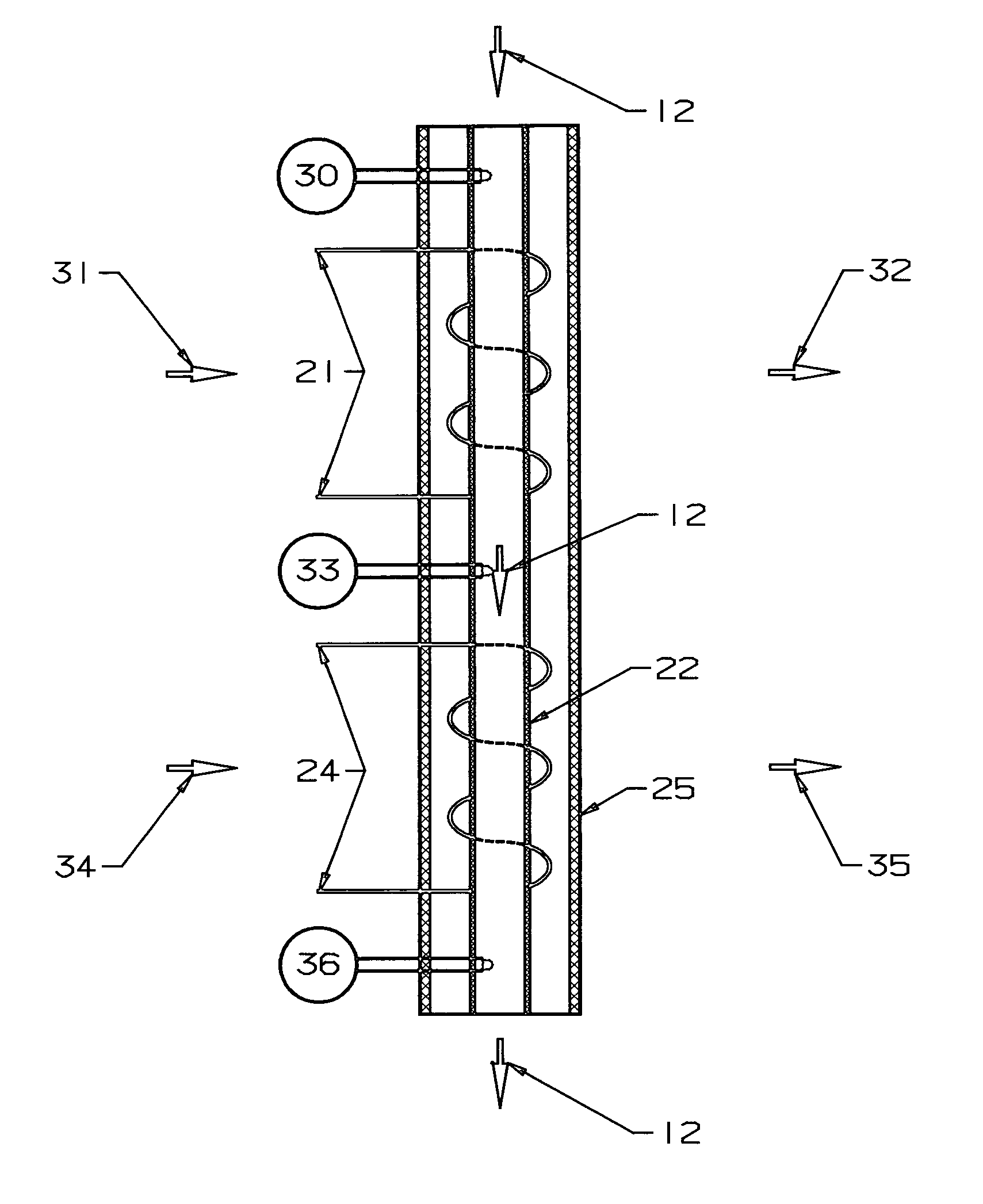

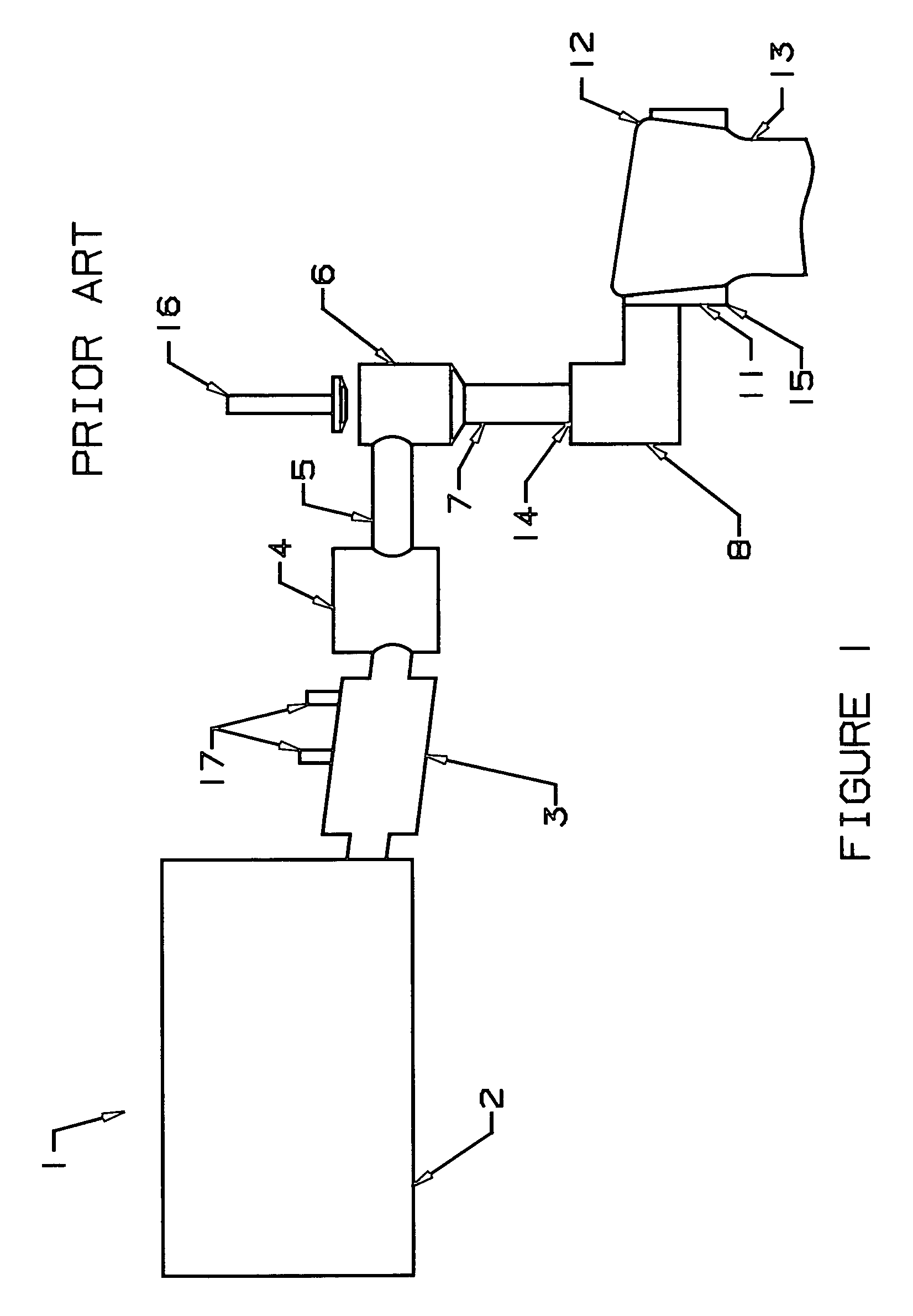

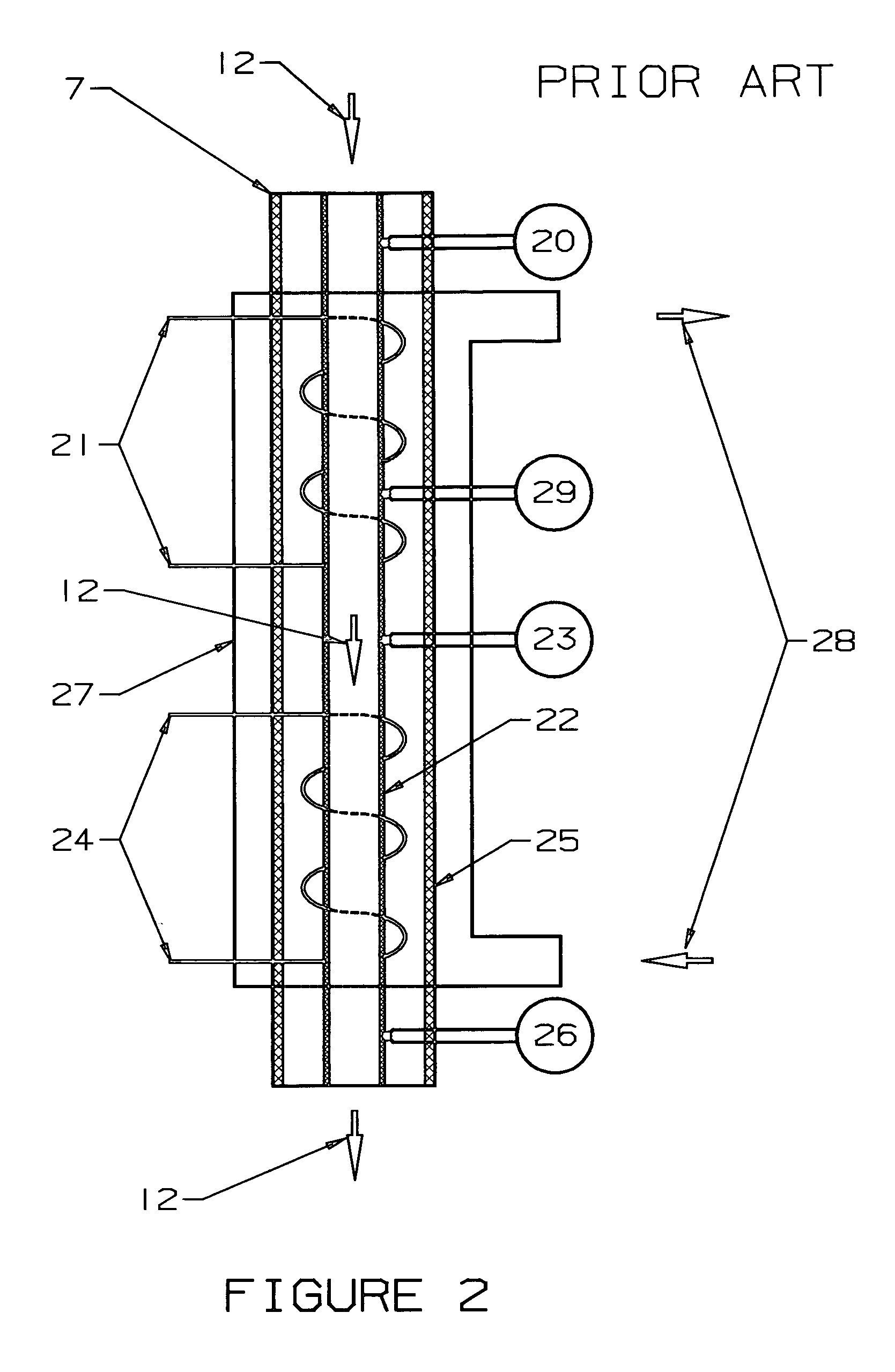

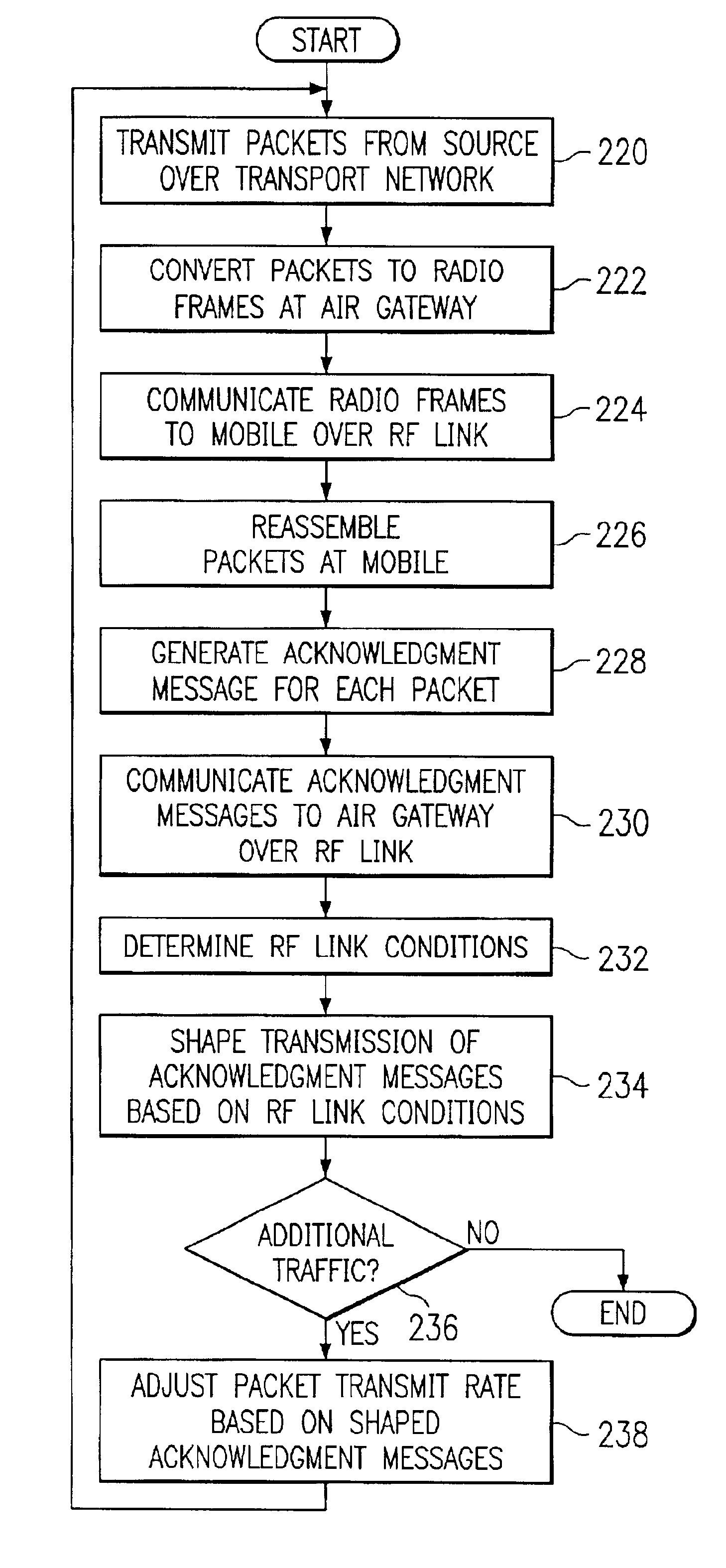

InactiveUS6904286B1Minimized sector burstynessConstant traffic flowNetwork traffic/resource managementRadio/inductive link selection arrangementsEngineeringTraffic flow

A method and system of integrated rate control for a traffic flow extending across wireline and wireless networks includes determining a power indicator for a wireless link of a traffic flow between a source and a mobile device. Delivery of a feedback message generated by the mobile device is shaped based on the power indicator for the wireless link to control the source transmit rate of the traffic flow.

Owner:CISCO TECH INC

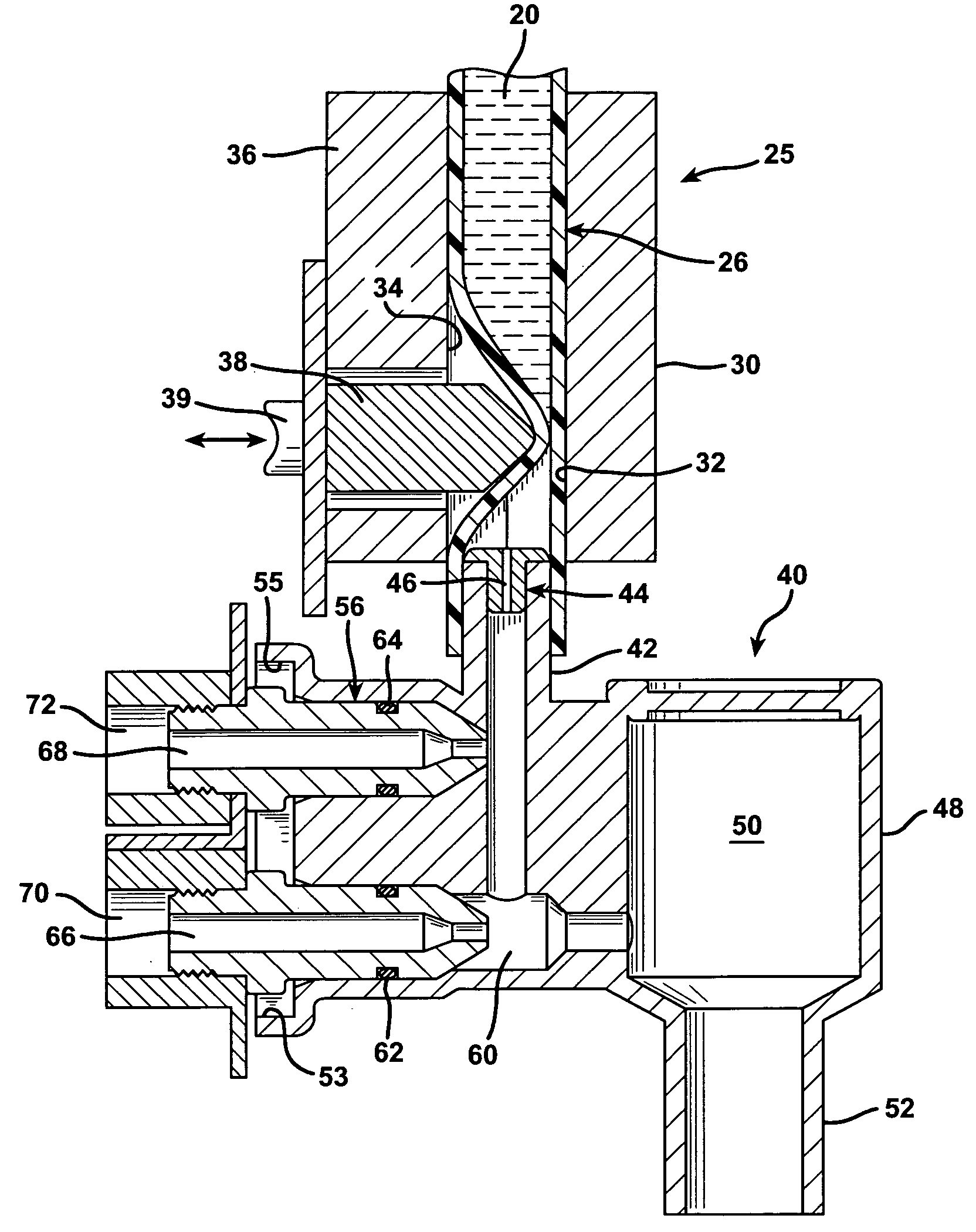

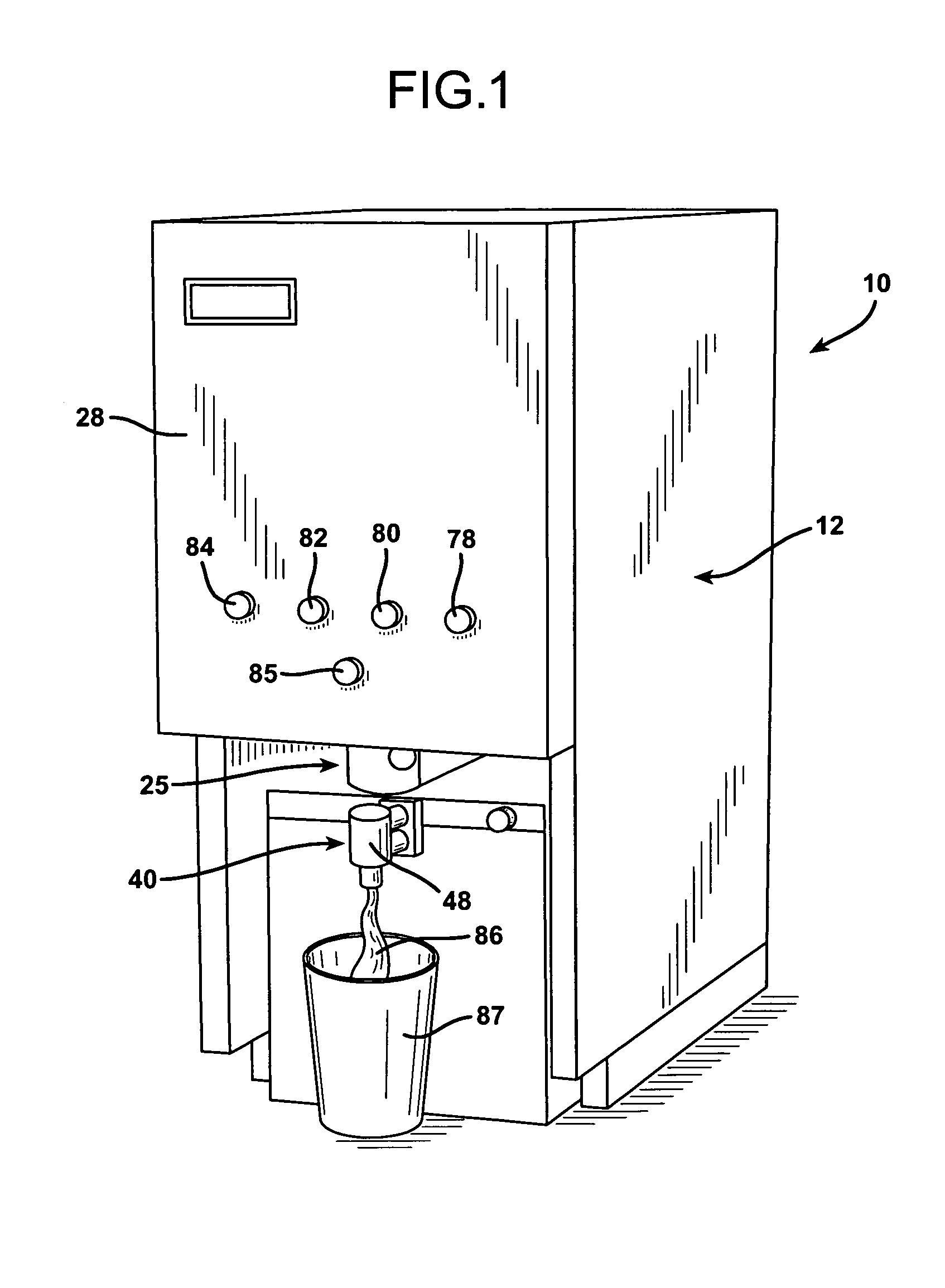

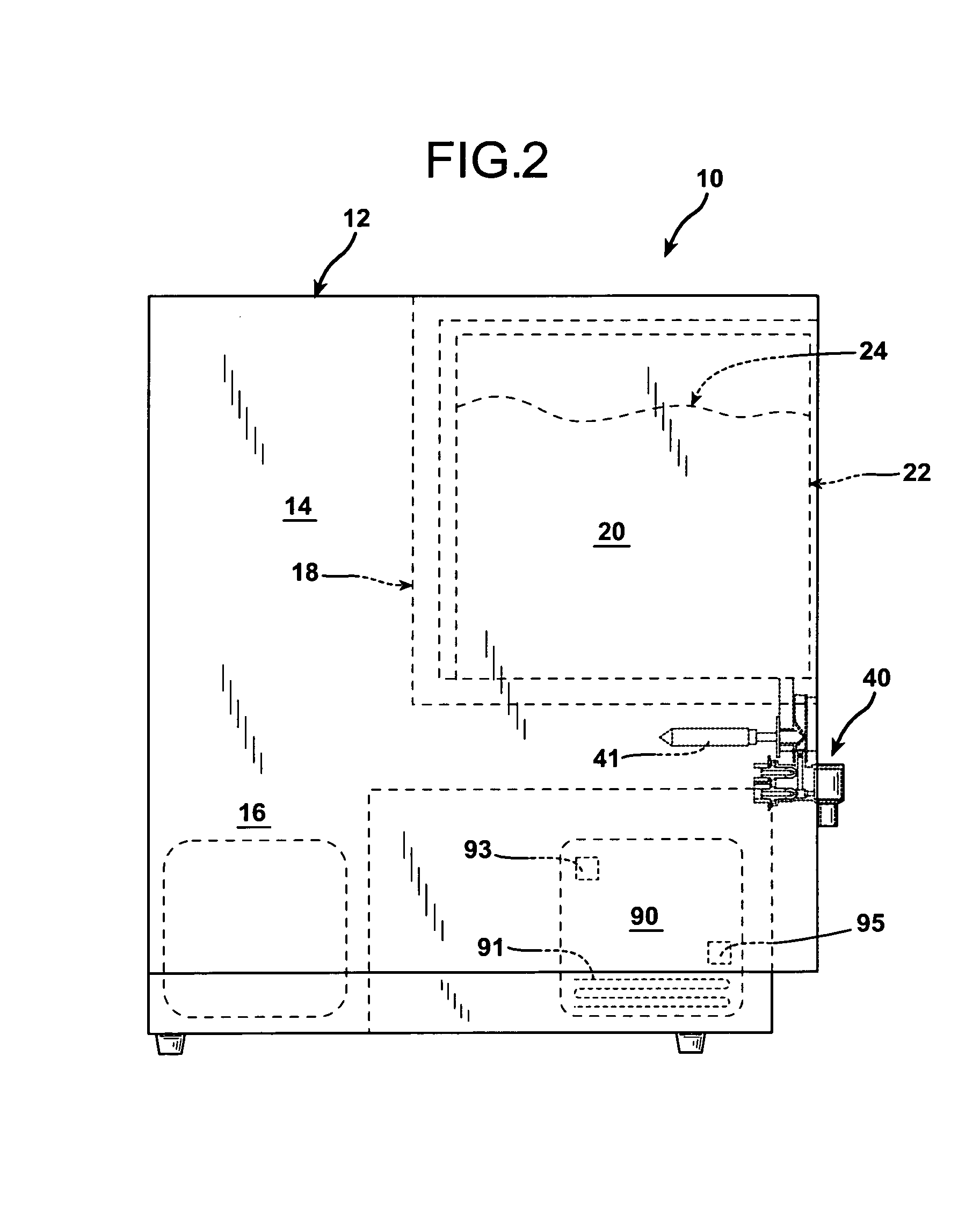

Hot dairy-based beverage dispenser

InactiveUS7021206B2Reduce eliminateConstant flowLighting and heating apparatusUsing liquid separation agentPinch valveEngineering

A dispensing unit for dispensing hot, dairy-based beverages has a self-contained refrigerated unit located above a venturi-type emulsification foaming head. The dispensing unit has particular applicability to the dispensation of foamy, hot milk for use in beverages such as cappuccino and nonfoamy, hot milk for use in beverages such as coffee latte, hot chocolate, and other hot dairy-based beverages. The refrigeration unit accommodates a “bag in box” cold milk storage container of the type widely used in food service establishments. The dispensing unit employs a pinch valve that avoids direct contact between the milk and the valve components. The refrigerated milk is stored above the level of the foamer head so that the flow of milk results partially from gravitational force on the milk, and is not totally dependent upon venturi suction created in the foamer head.

Owner:ECKENHAUSEN ROLAND B +1

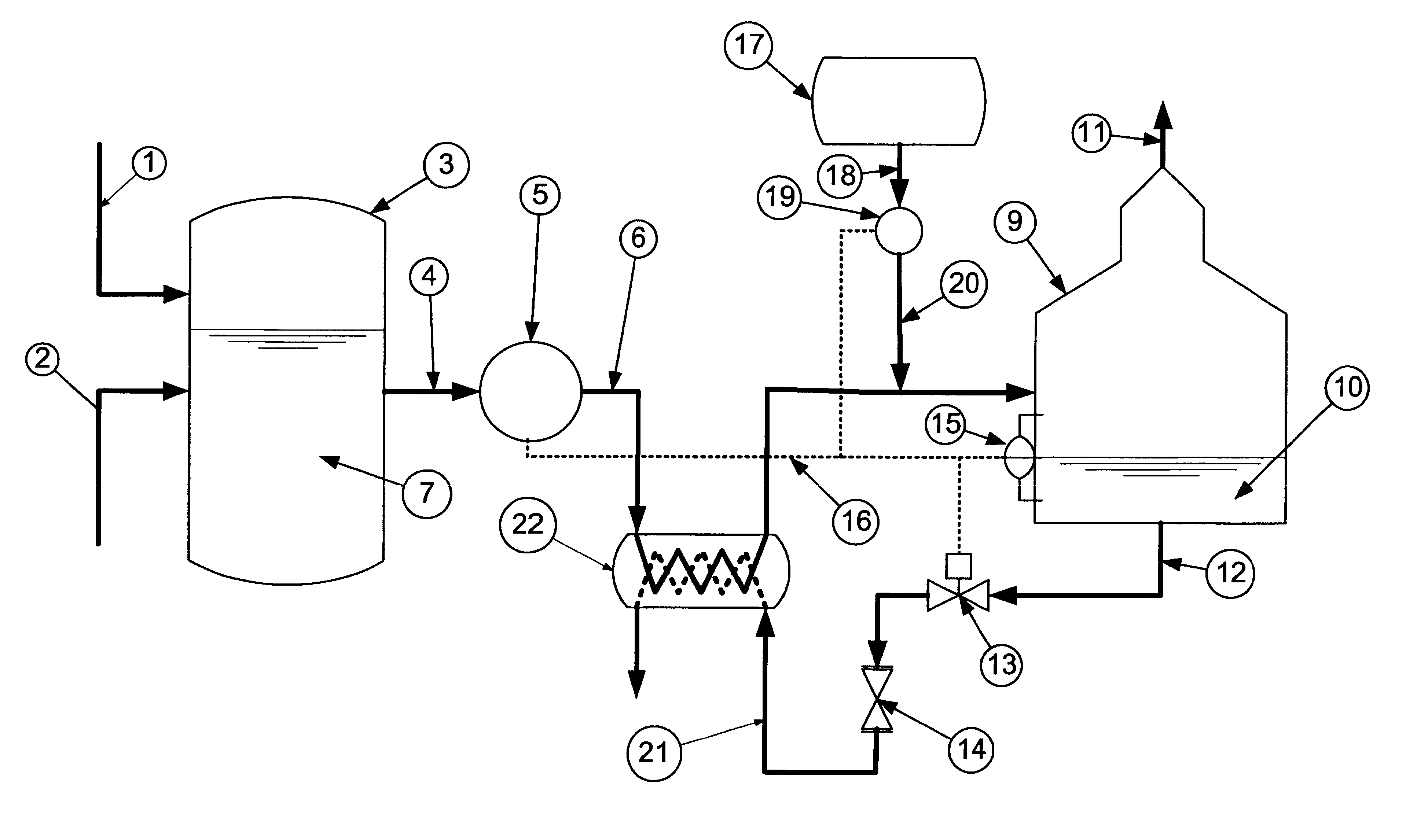

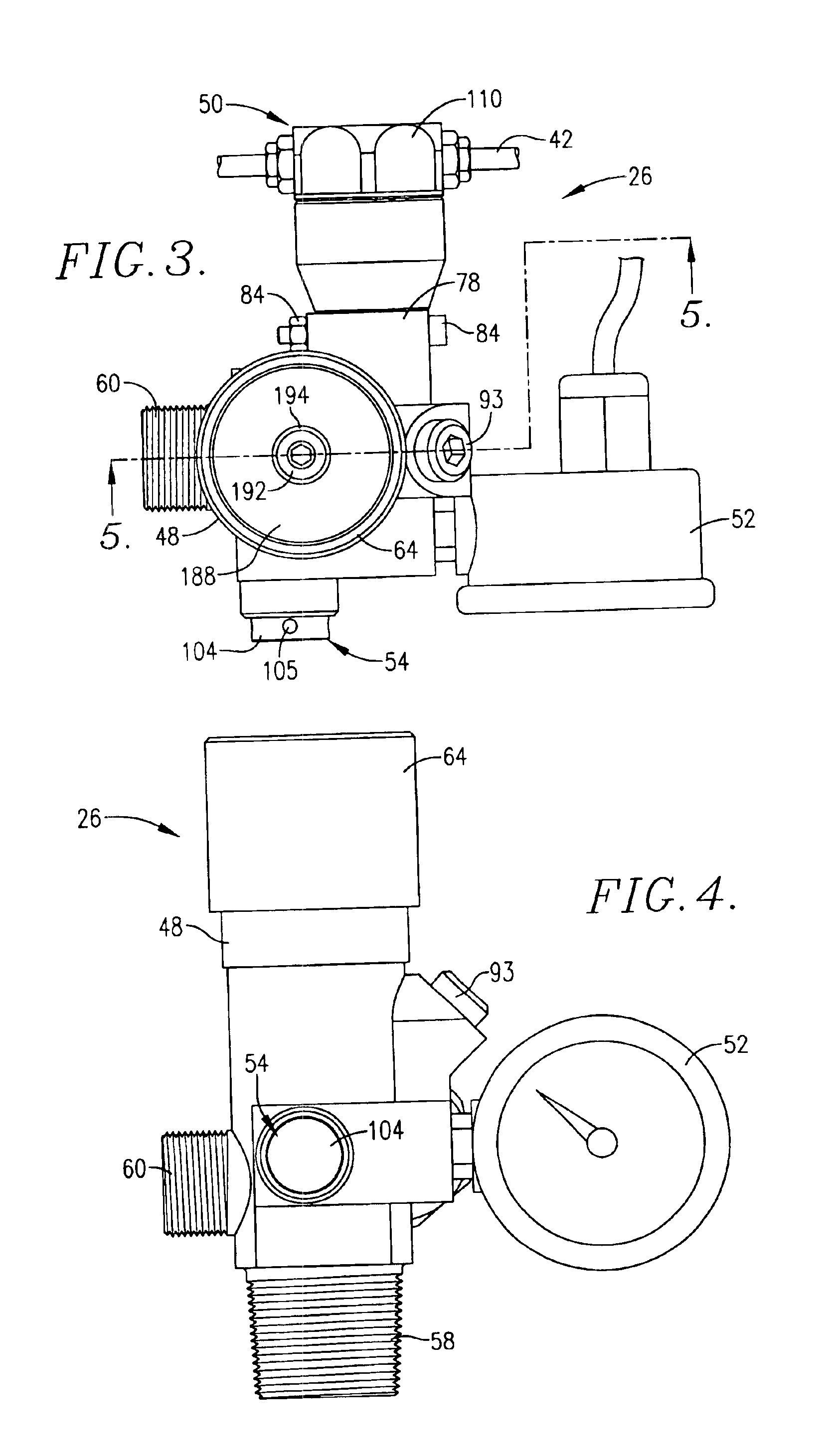

Boiler water blowdown control system

InactiveUS6655322B1Constant flowThe process is simple and accurateBoiler cleaning apparatusMachines/enginesControl systemEngineering

The present invention relates to a method for automatically maintaining the concentration of scale forming minerals in boiler water for boiler systems utilizing bimodal feedwater pumps that deliver a substantially constant feedwater flow to the boiler drum when activated. According to the present invention, the feedwater supply pump and blowdown rate control valve are synchronized to remove boiler water at a predetermined rate when the feedwater pump is activated. The present invention thereby provides a simplified and less expensive method for controlling the concentration of dissolved solids in boiler water despite variations in the steam loads and / or other boiler operation parameters.

Owner:CHEMTREAT

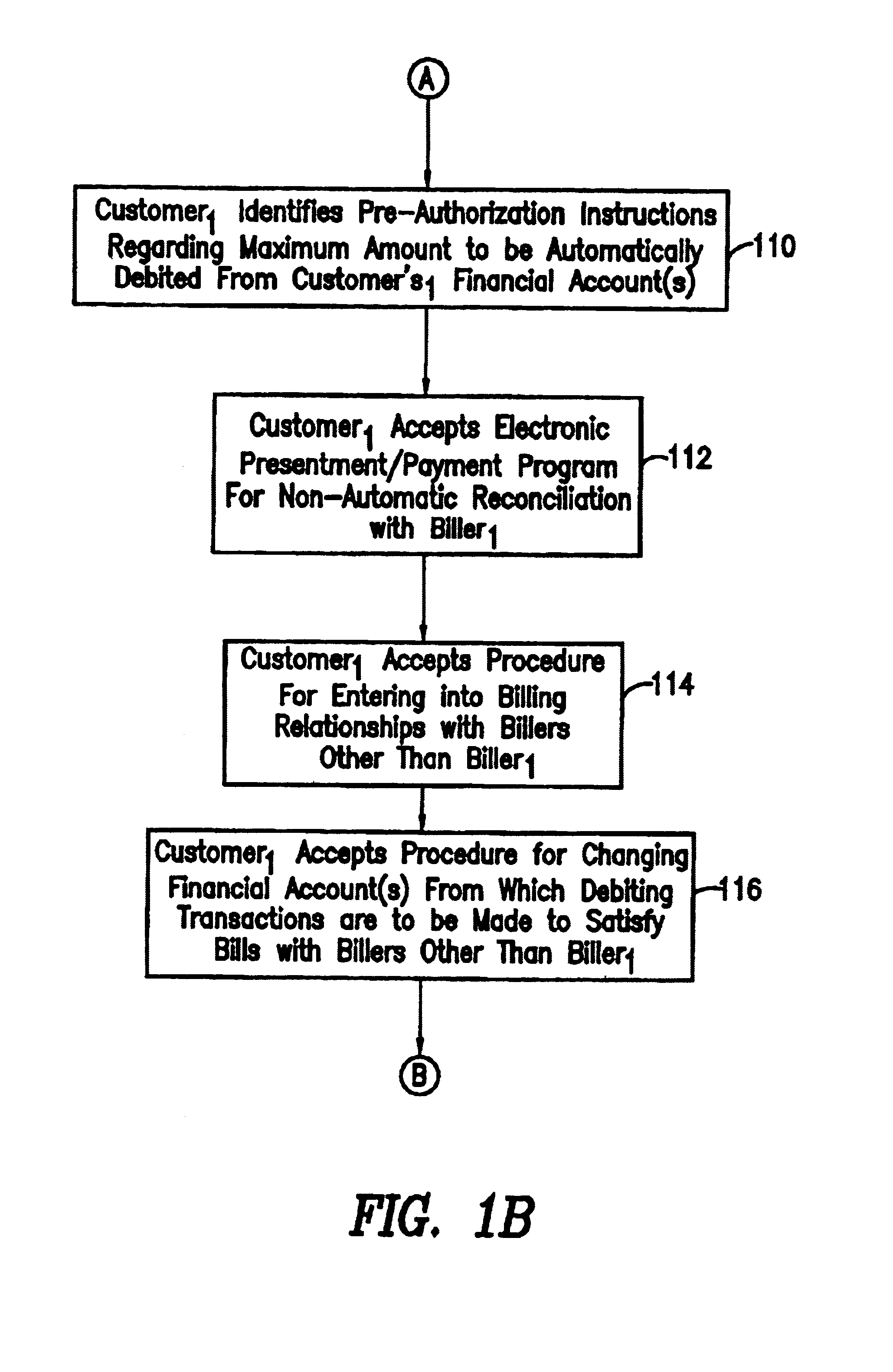

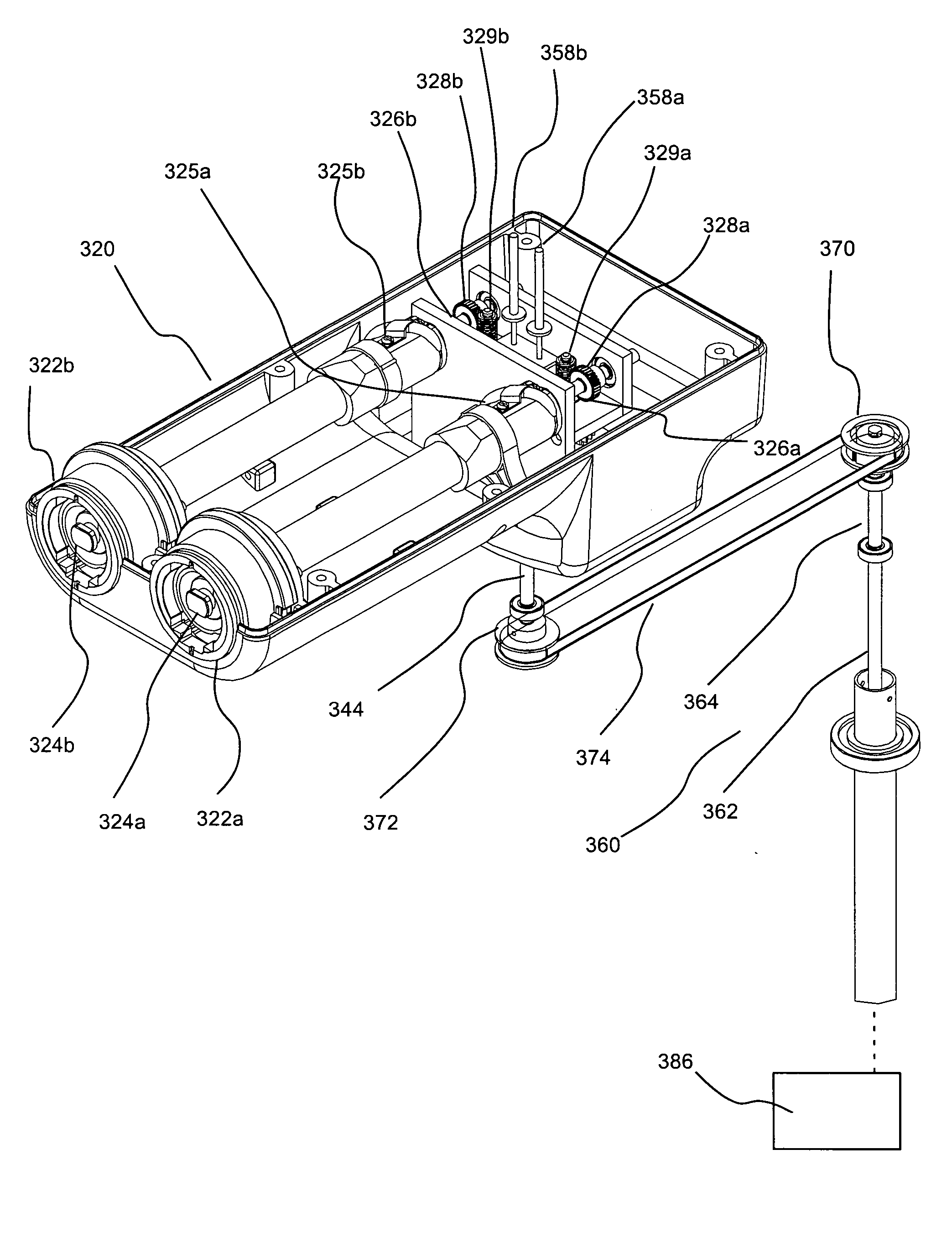

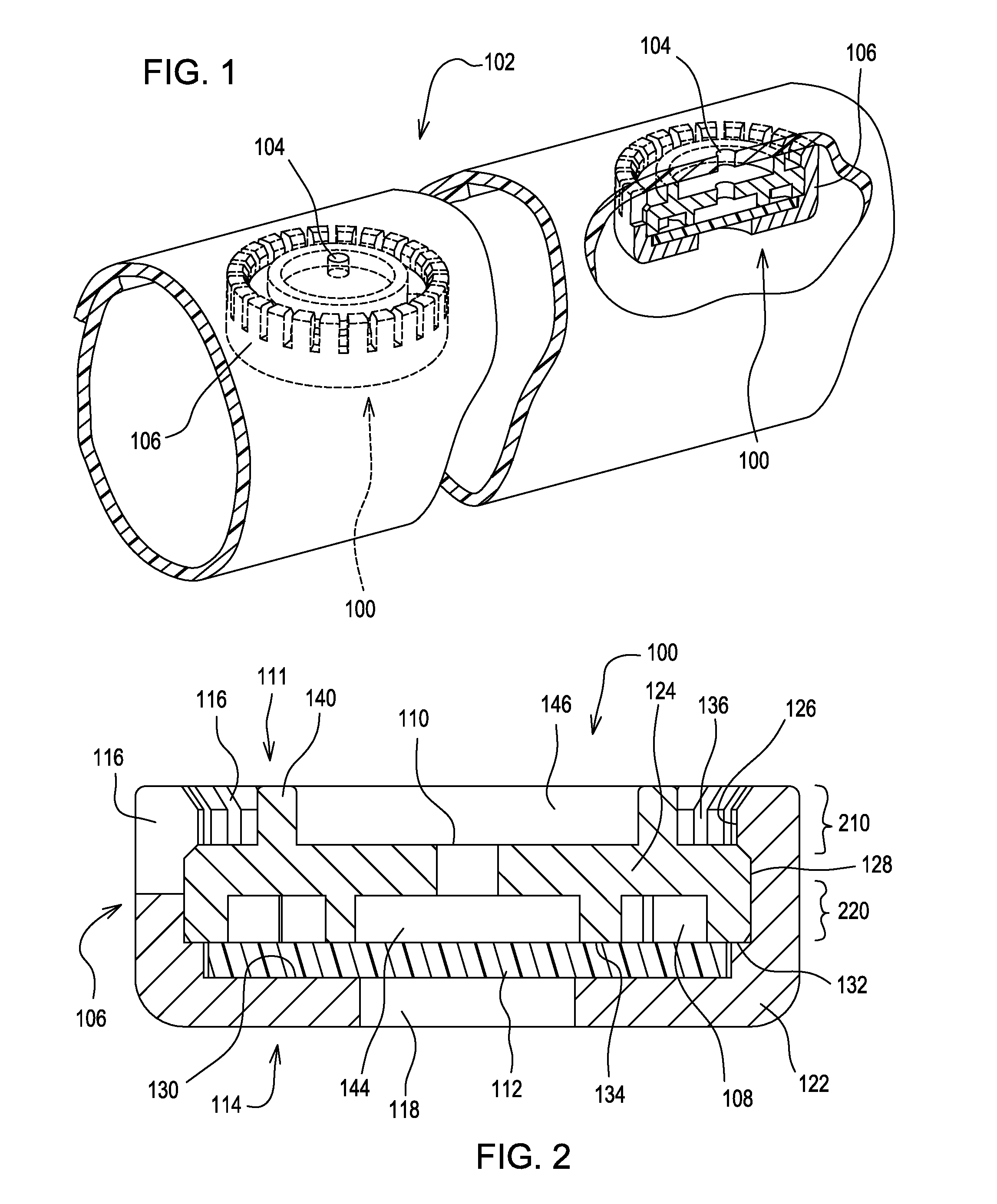

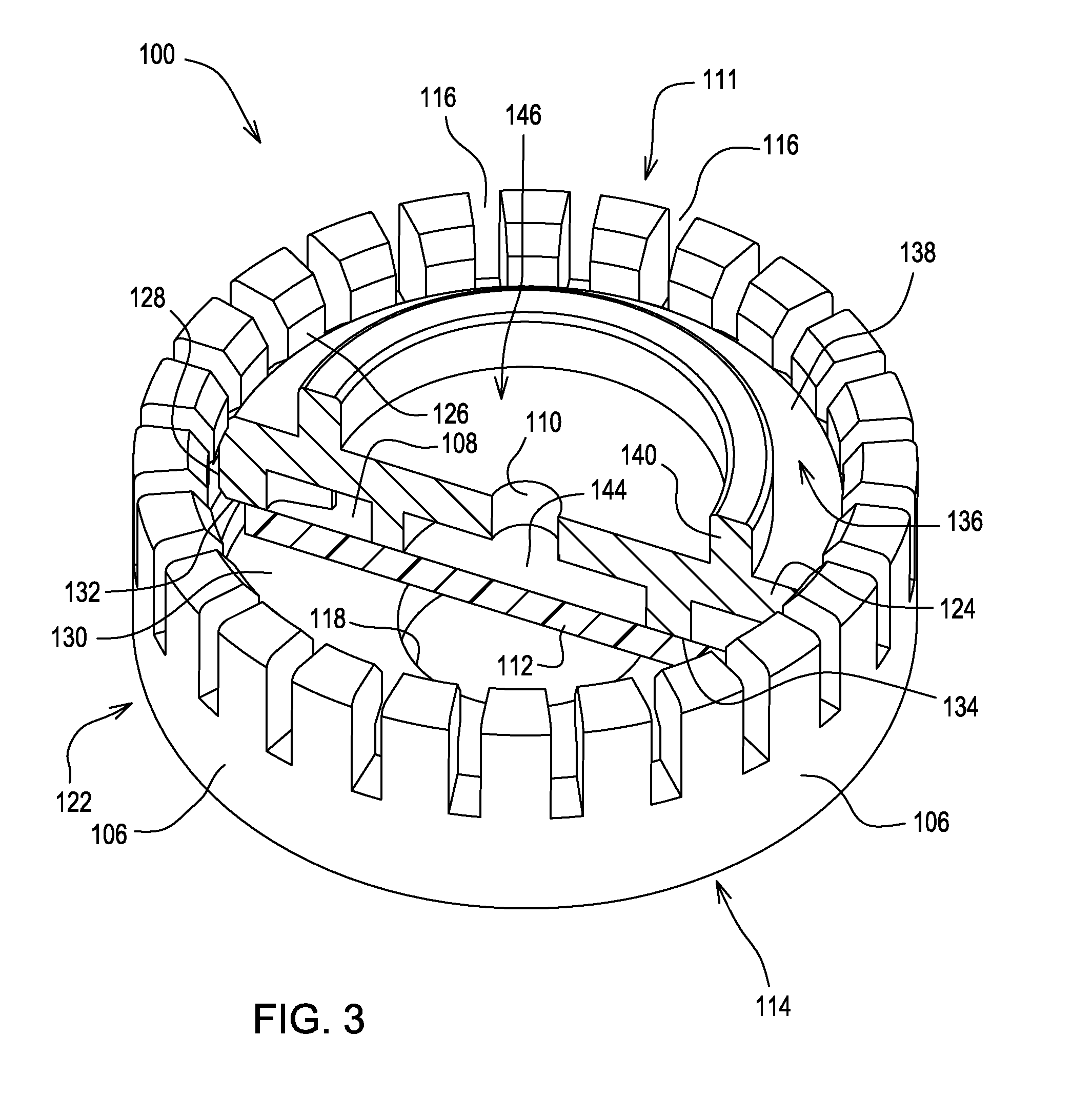

Injectors, injector systems and methods for injecting fluids

InactiveUS20060184124A1Constant flowPrevent backdriveMedical devicesPressure infusionInjectorElectric motor

An injector for injection a fluid into a patient, including: a first pressurizing mechanism adapted to operatively connect with a first fluid container to pressurize fluid therein; at least a second pressurizing mechanism to operatively connect with a second fluid container to pressurize a fluid therein; a single drive; and a transmission to control how power from the drive is distributed to the first pressurizing mechanism of the first container and to the second pressurizing mechanism of the second container to control injection of fluid from the first container and from the second container. The drive can, for example, be an electric motor or other drive.

Owner:BAYER HEALTHCARE LLC

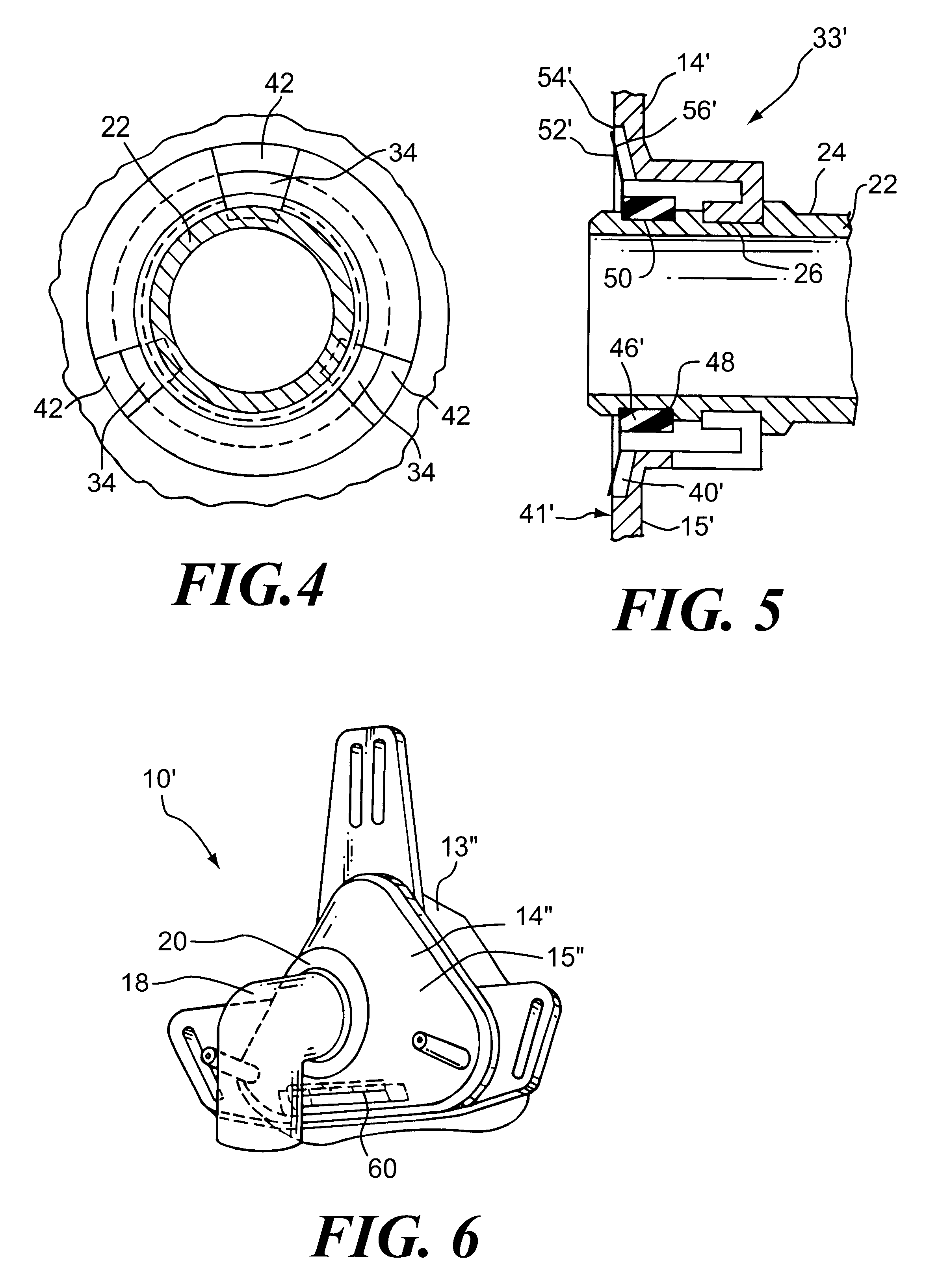

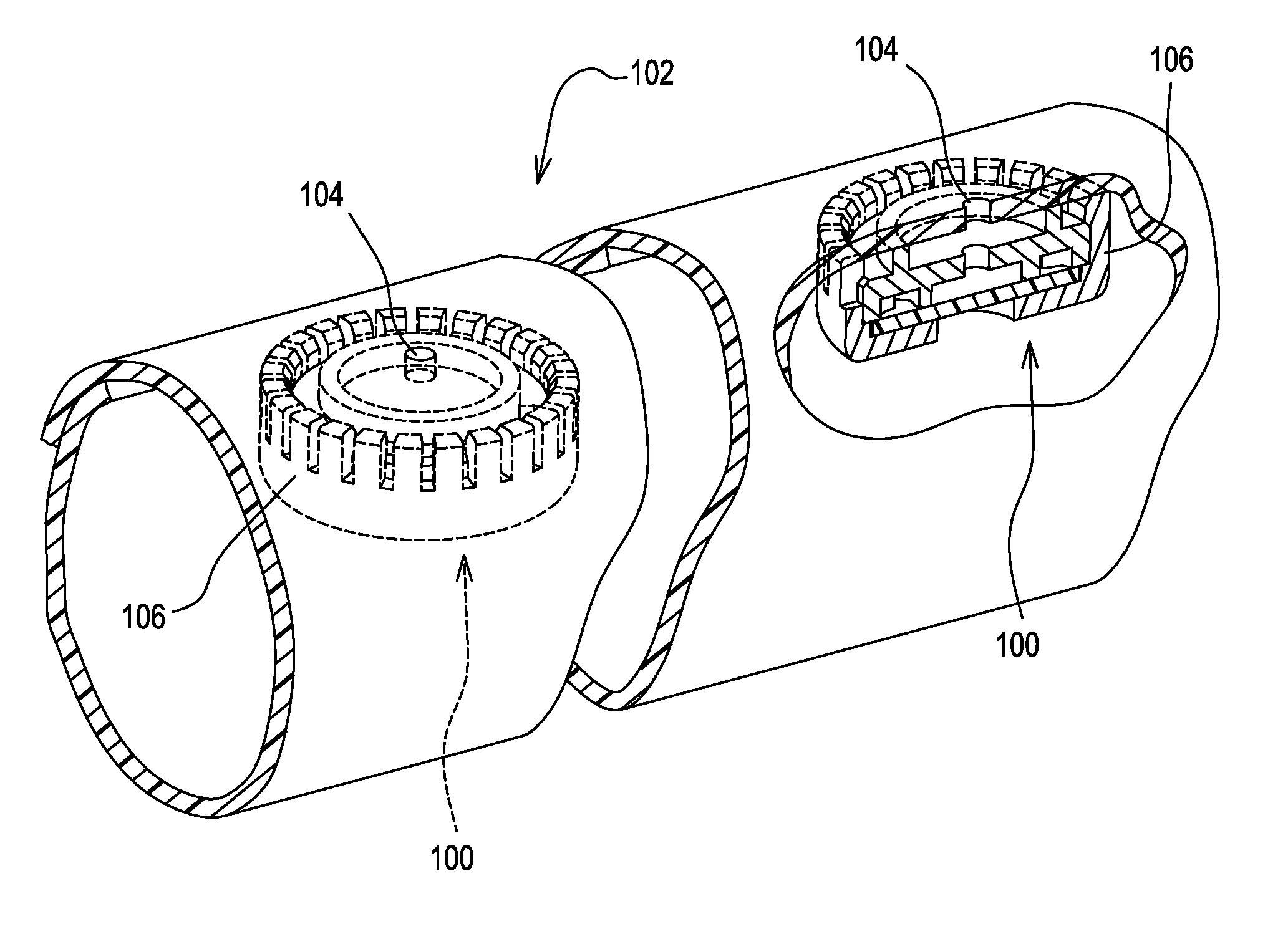

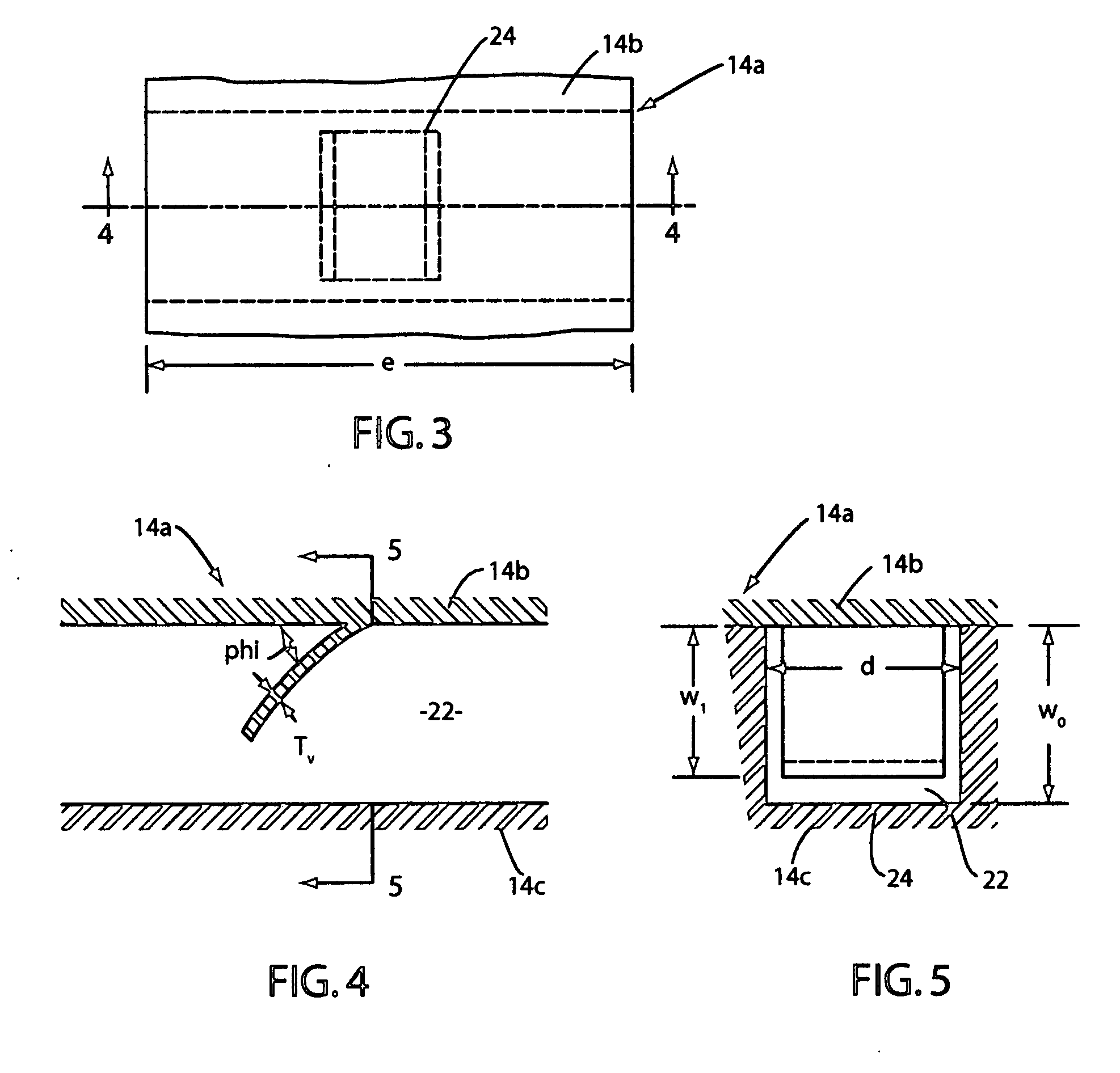

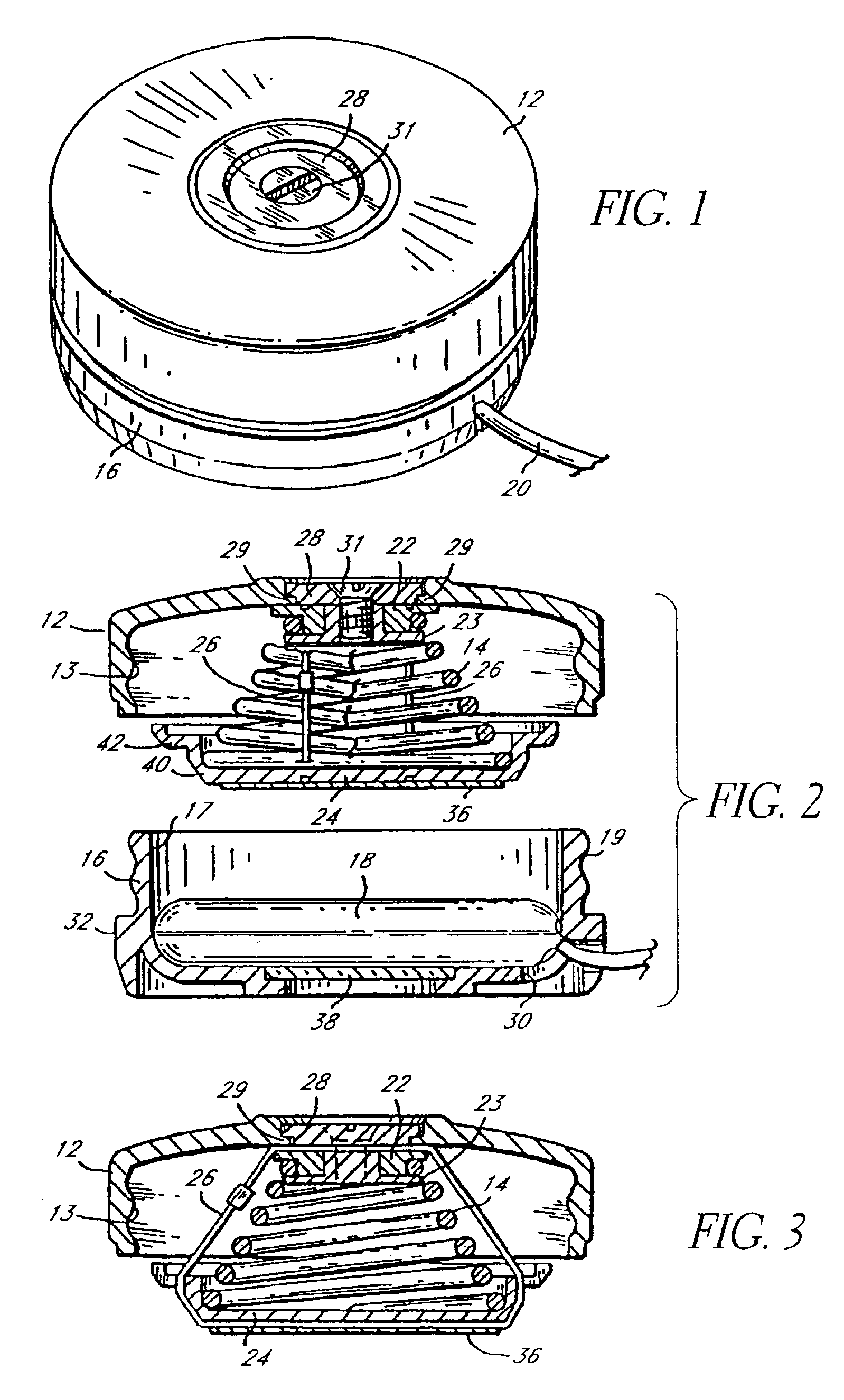

Disc shaped regulated drip irrigation emitter

ActiveUS20120267454A1Low costMinimize sizeClimate change adaptationWatering devicesWater filterDrip irrigation

A drip irrigation emitter includes a disc shaped body having a pressure reducing labyrinth between a water inlet area and an outlet hole, and a pressure regulating diaphragm changing flow through the outlet hole in response to water pressure fluctuations in the water conduit where the emitter is mounted. The water filtering inlet of the emitter is located entirely at the sides of the disc shaped body.

Owner:RIVULIS PLASTRO LTD

Self-modulating inert gas fire suppression system

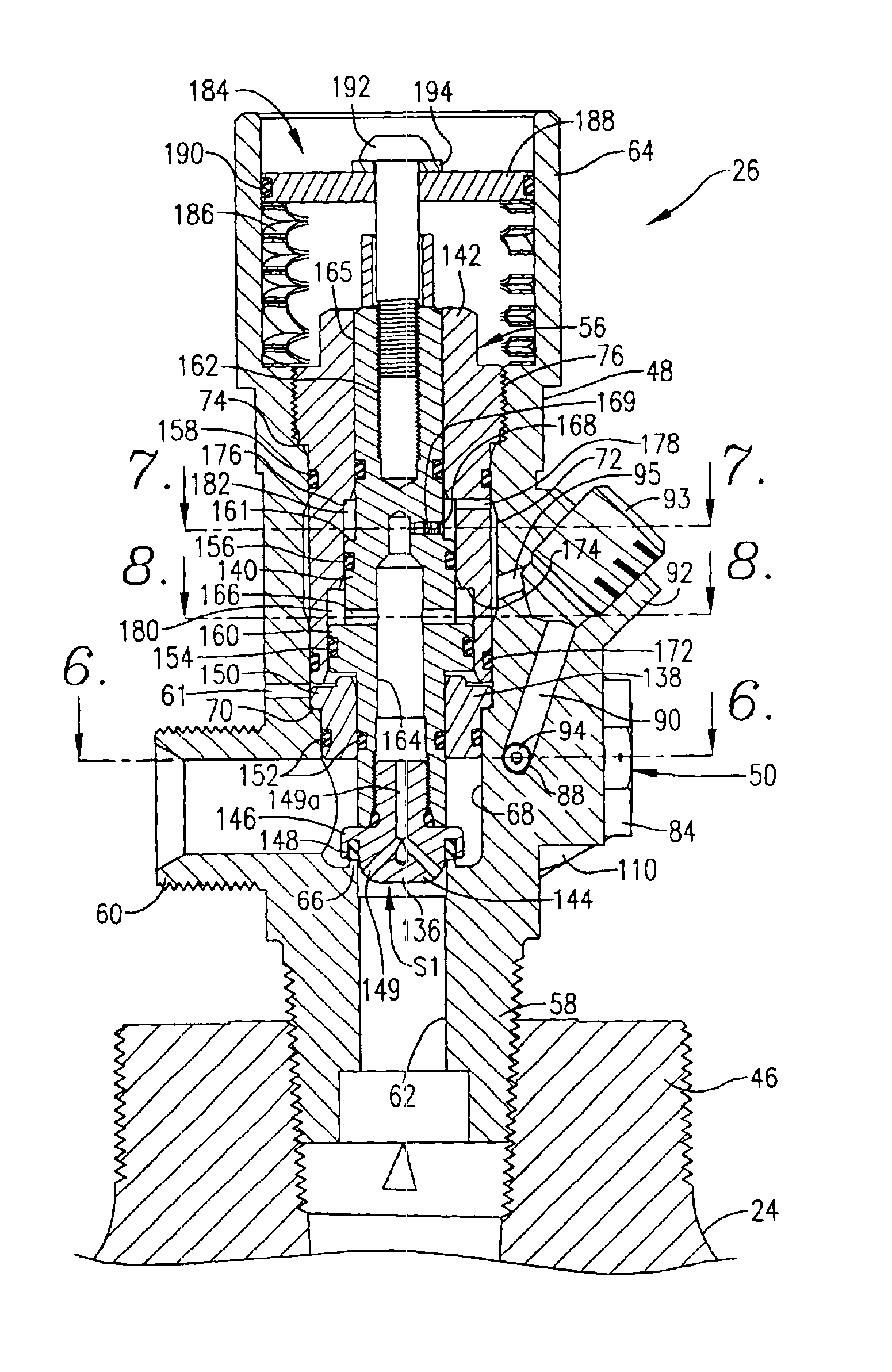

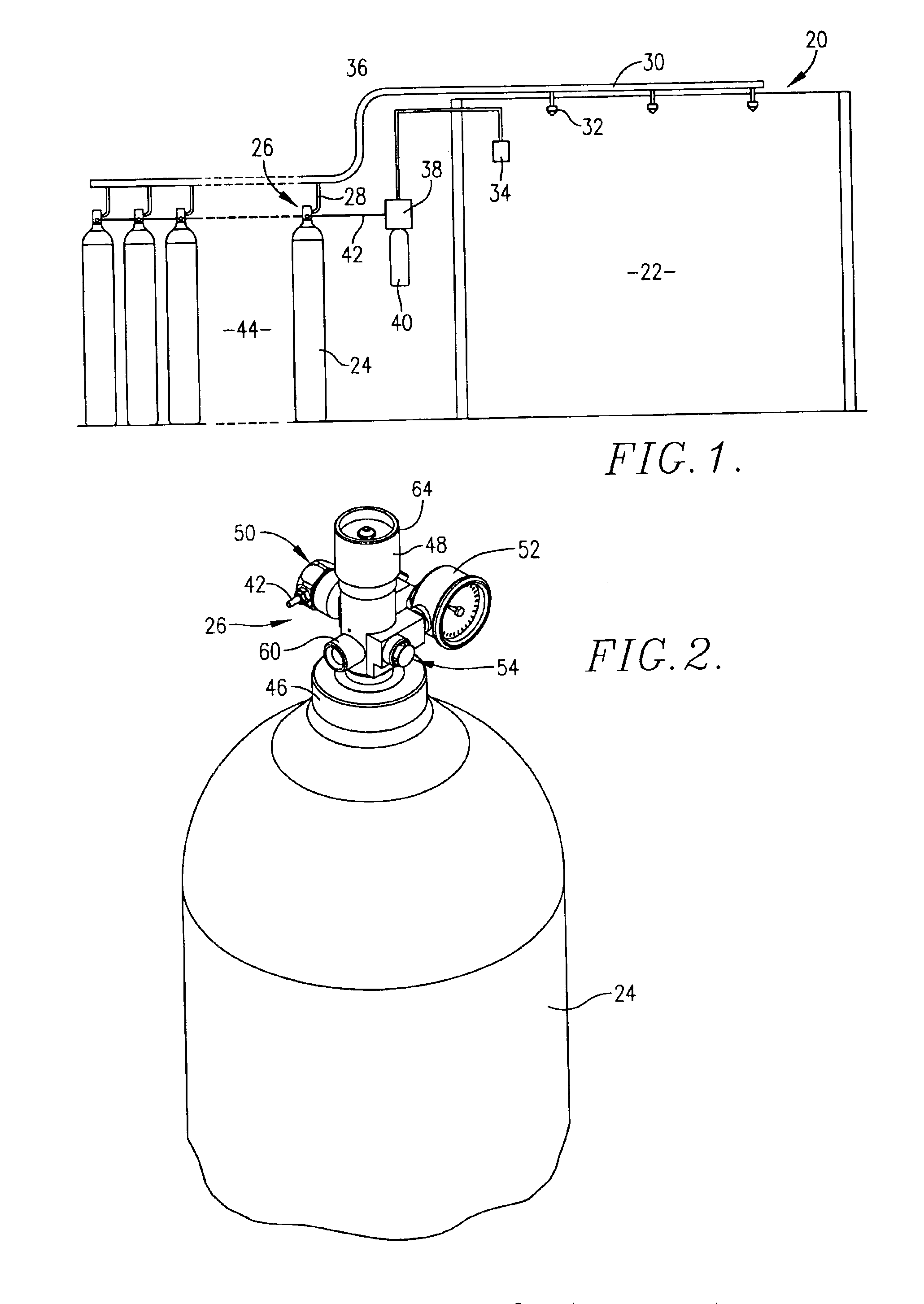

InactiveUS6871802B2Effectively suppressing hazardsConstant flowContainer filling methodsGas handling applicationsEngineeringHigh pressure

A relatively low pressure inert gas hazard suppression system (20) is provided which is designed to protect a room (22) or the like from the effects of fire or other hazard. The system (20) includes a plurality of pressurized inert gas cylinders (24) each equipped with a valve unit (26); each valve unit (26) is in turn coupled via a conduit (28) to a delivery manifold (30). The respective valve units (26) are operable to deliver gas from the cylinders (24) at a generally constant pressure (usually around 10-100 bar) throughout a substantial portion of the time of gas delivery, to thereby provide effective hazard suppression without the need for expensive high-pressure gas handling and distribution hardware and a reduction in room venting area due to lower room over-pressurization. Each valve unit (26) has a valve body (48) and a shiftable piston-type sealing member (56). Gas pressure from the cylinder (24) and a spring assembly (184) biases the member 56 to the valve open position, this being counterbalanced by gas pressure within equalization and modulation chambers (180, 182) provided in the valve unit (26). When a hazard is detected, the valve units (26) are actuated by draining of gas from the modulation chambers (182), allowing gas flow from the cylinders (24). As gas discharge proceeds, gas flows into and out of the modulation chambers (182) so as to achieve the desired generally constant pressure gas output. Near the end of gas discharge, the spring assembly (184) becomes predominant and holds the valve unit (26) open until all gas is discharged.

Owner:FIKE CORP

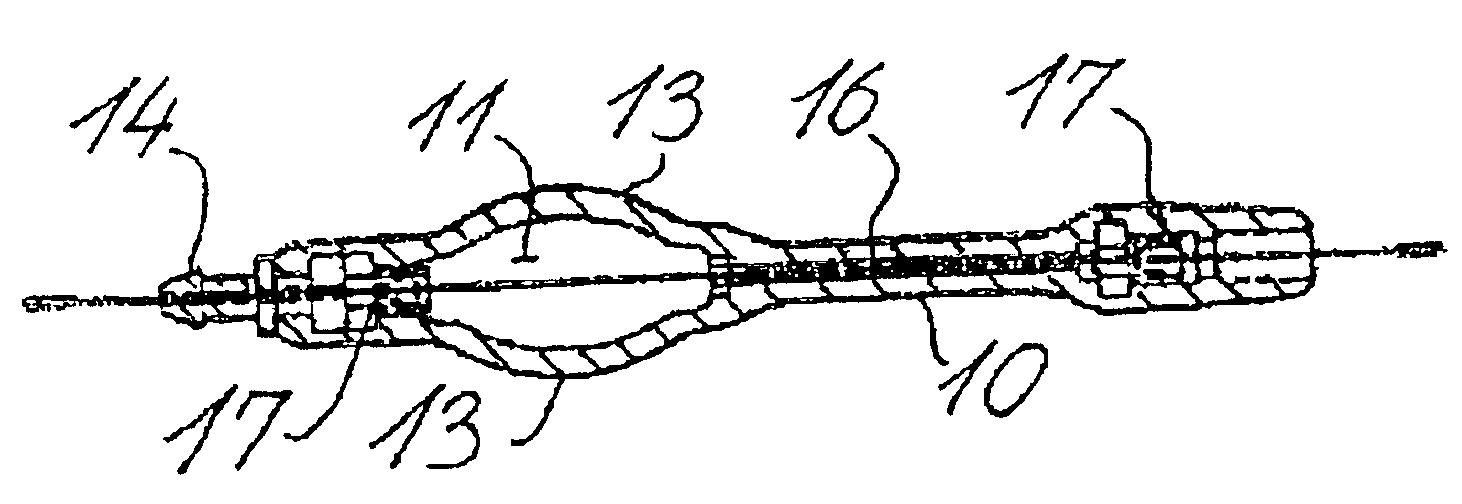

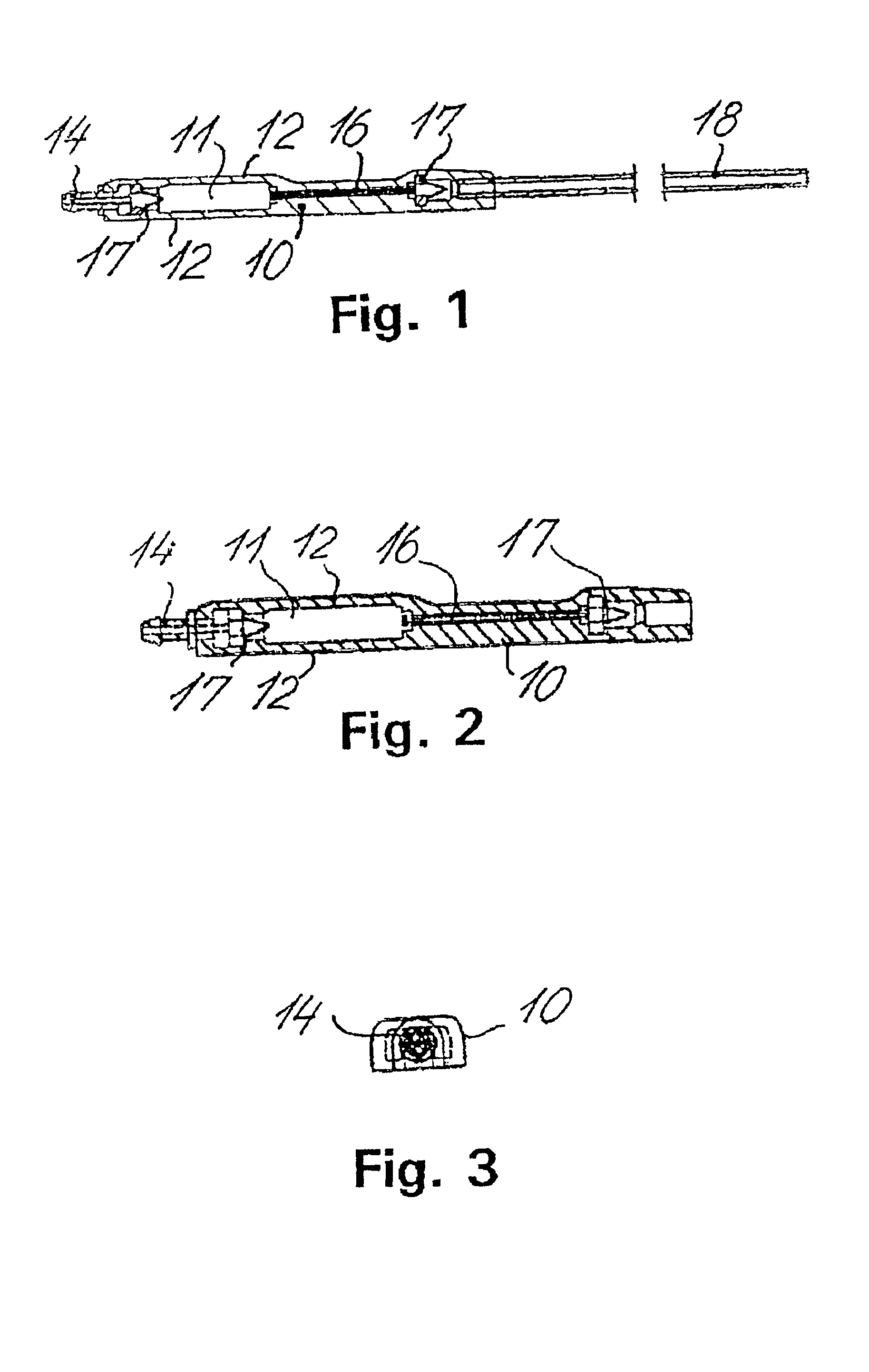

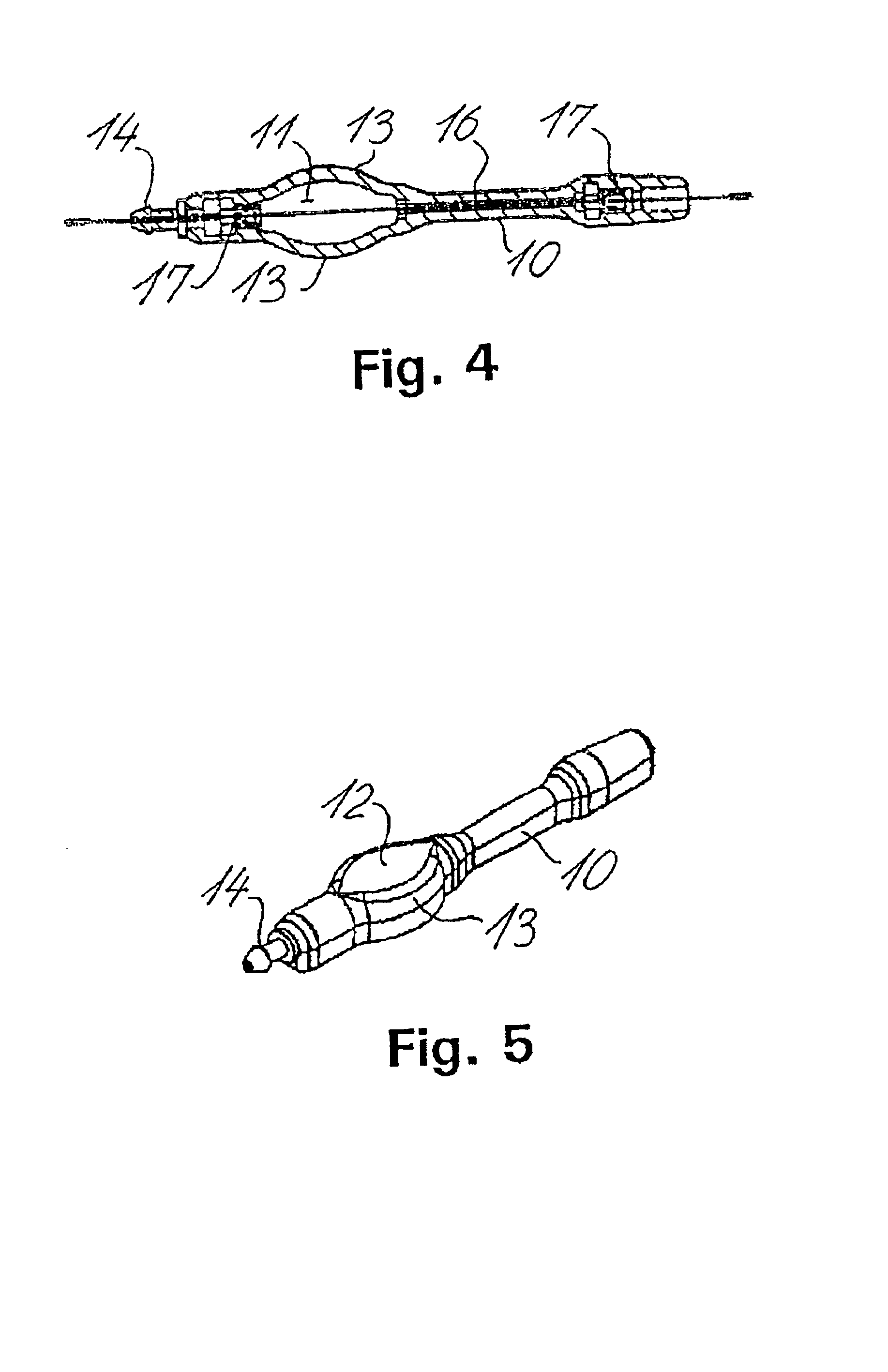

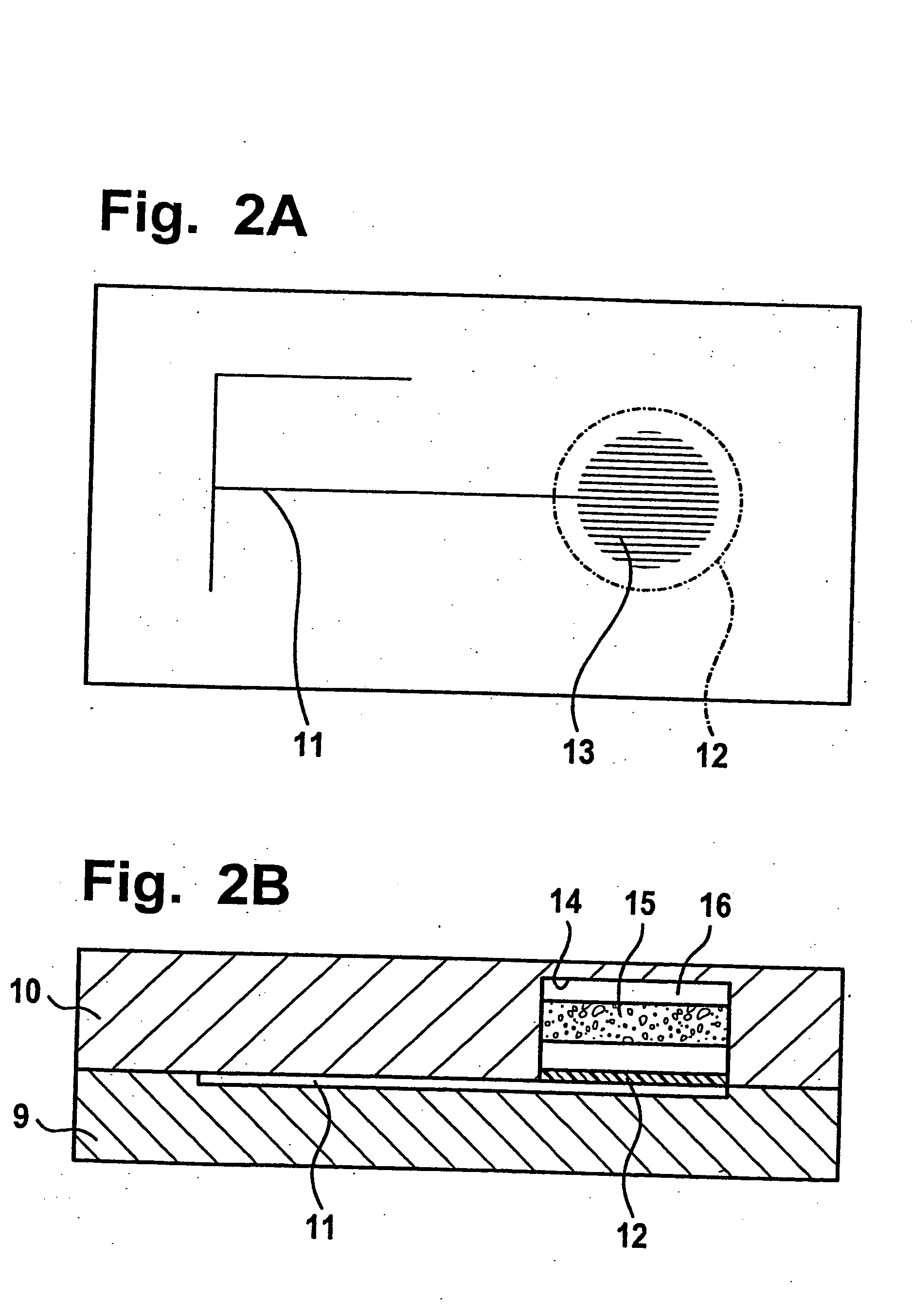

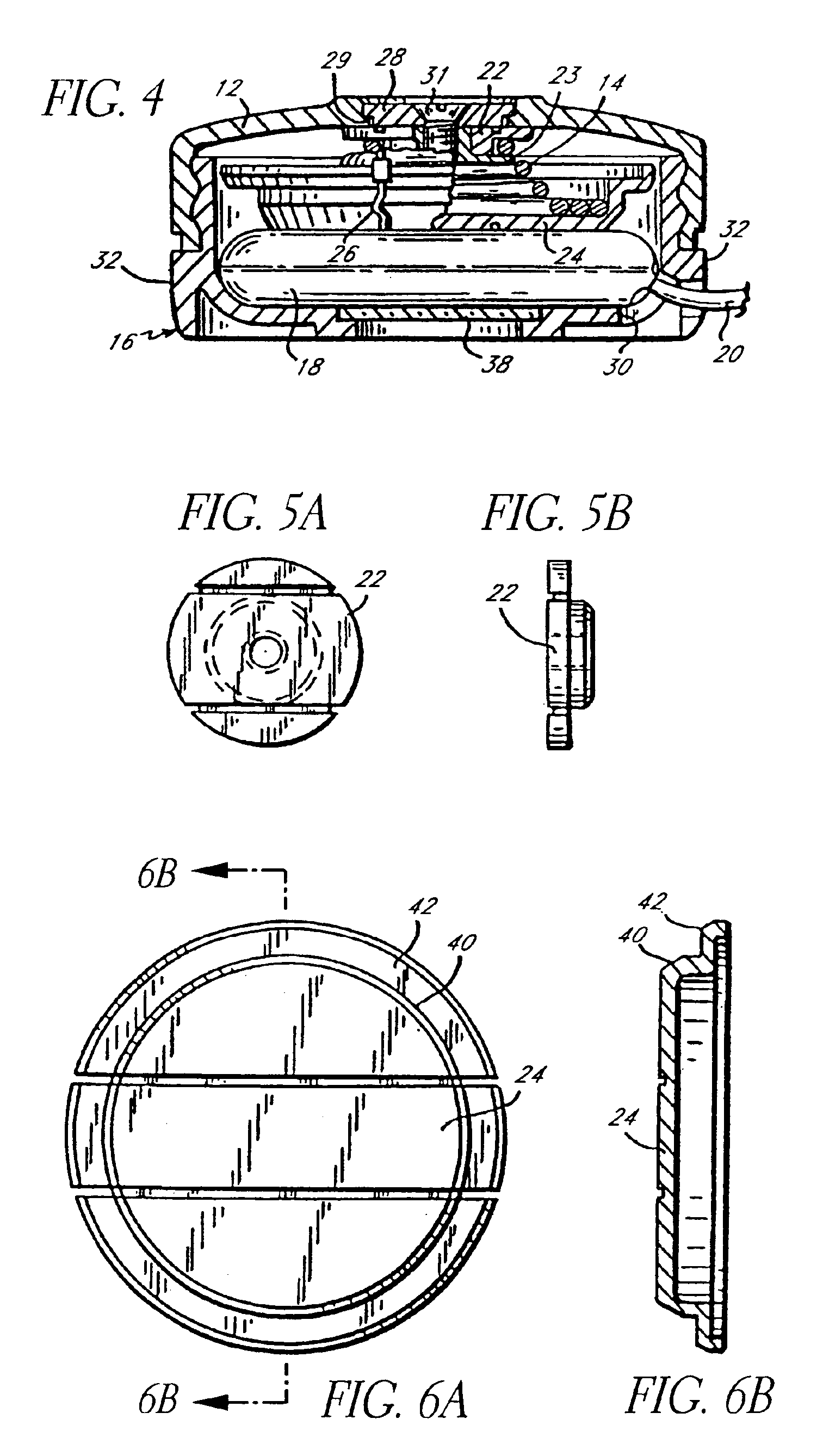

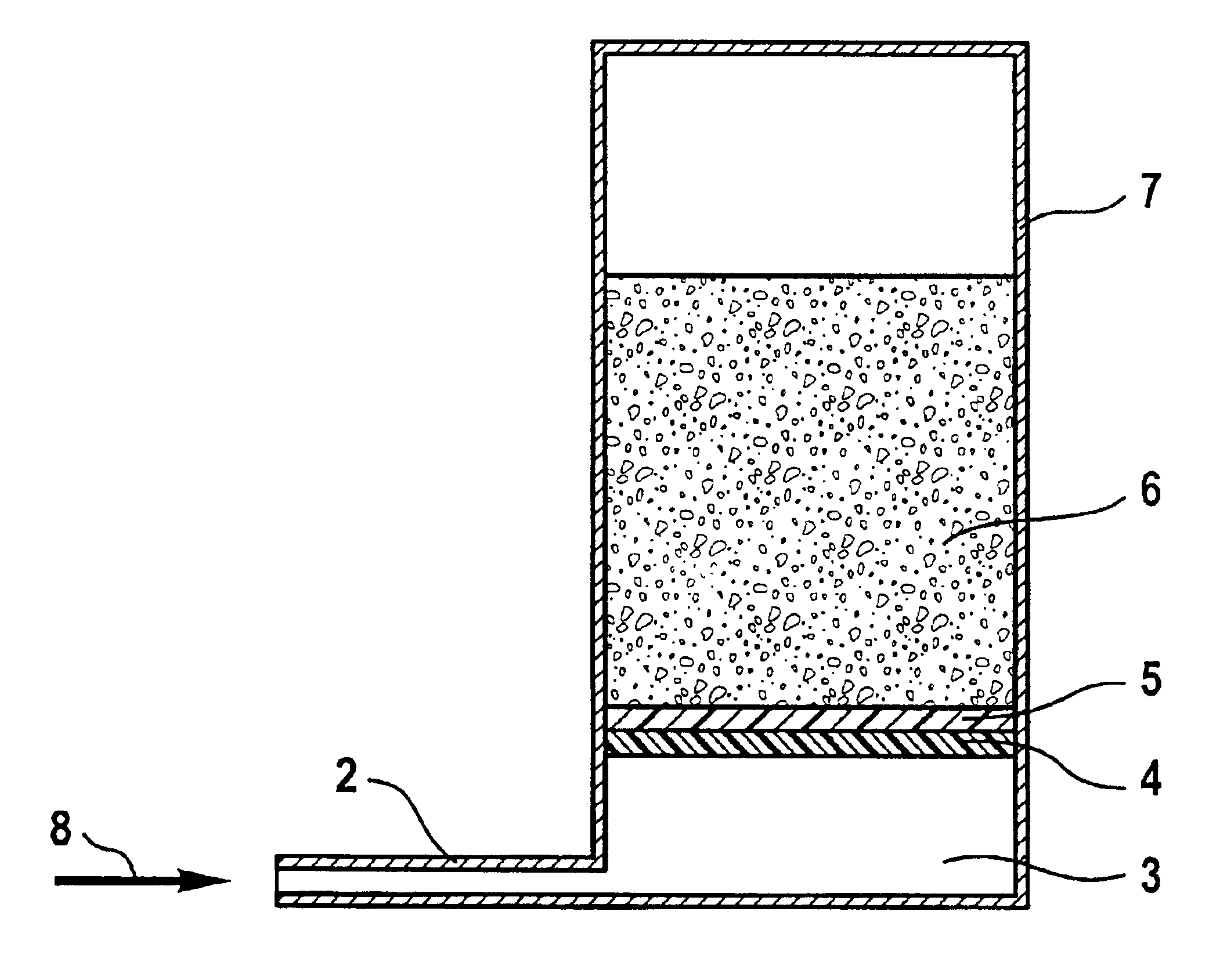

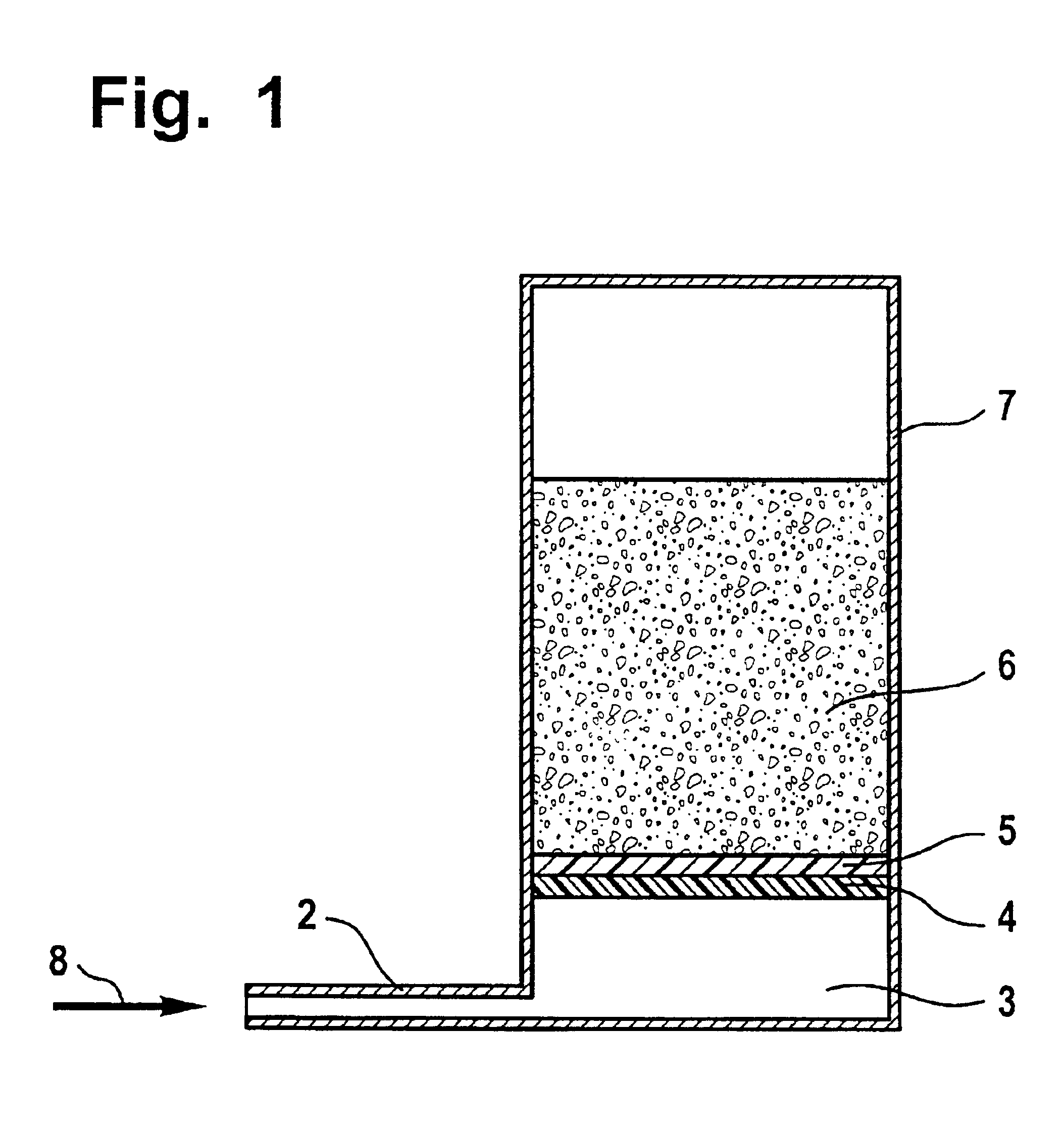

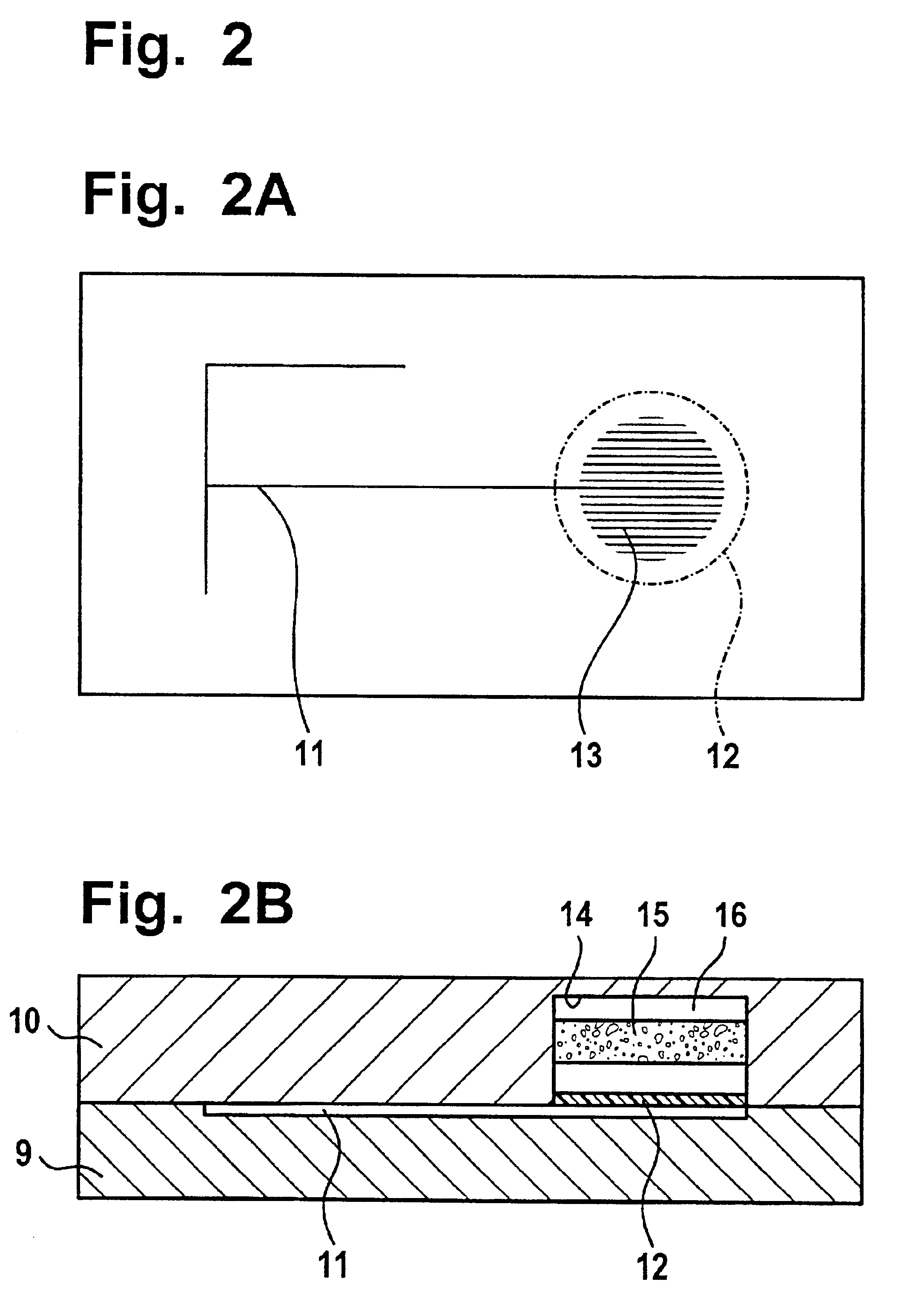

Fluid shunt system and a method for the treatment of hydrocephalus

InactiveUS6905474B2Lower resistanceInhibit posture changesWound drainsMedical devicesFlow diverterBrain Ventricle

A cerebrospinal fluid shunt system comprises a brain ventricle catheter (15) to insert into the brain ventricle (21) so as to drain cerebrospinal fluid from the brain ventricle, a sinus catheter (18) to insert into the sinus sagittalis system (22) for feeding the cerebrospinal fluid into the sinus sagittalis system, a shunt body member (10) connected at one end thereof to said brain ventricle catheter and at another end thereof to said sinus catheter system to provide fluidic communication between said brain ventricle catheter (15) and said sinus catheter (18), and a flow restriction (16) defined within the shunt body member (10) to maintain a resistance to fluid flow of the shunt system of less than 8 mm Hg / ml / min, such as 2-7 or 4-6 and preferably about 5 mm Hg / ml / min. When the shunt system is implanted the shunt body member (10) is placed subcutaneously on top of the calvarium of a patient, behind the coronal suture on one of side of the sagittal suture. One end of each of the catheters (15, 18) is then connected to a respective end of the shunt body member (10), and a second end of each catheter is inserted in the right ventricle (21) and in the sinus sagittalis system (22), respectively, via holes bored in the scull (19).

Owner:CSF DYNAMICS

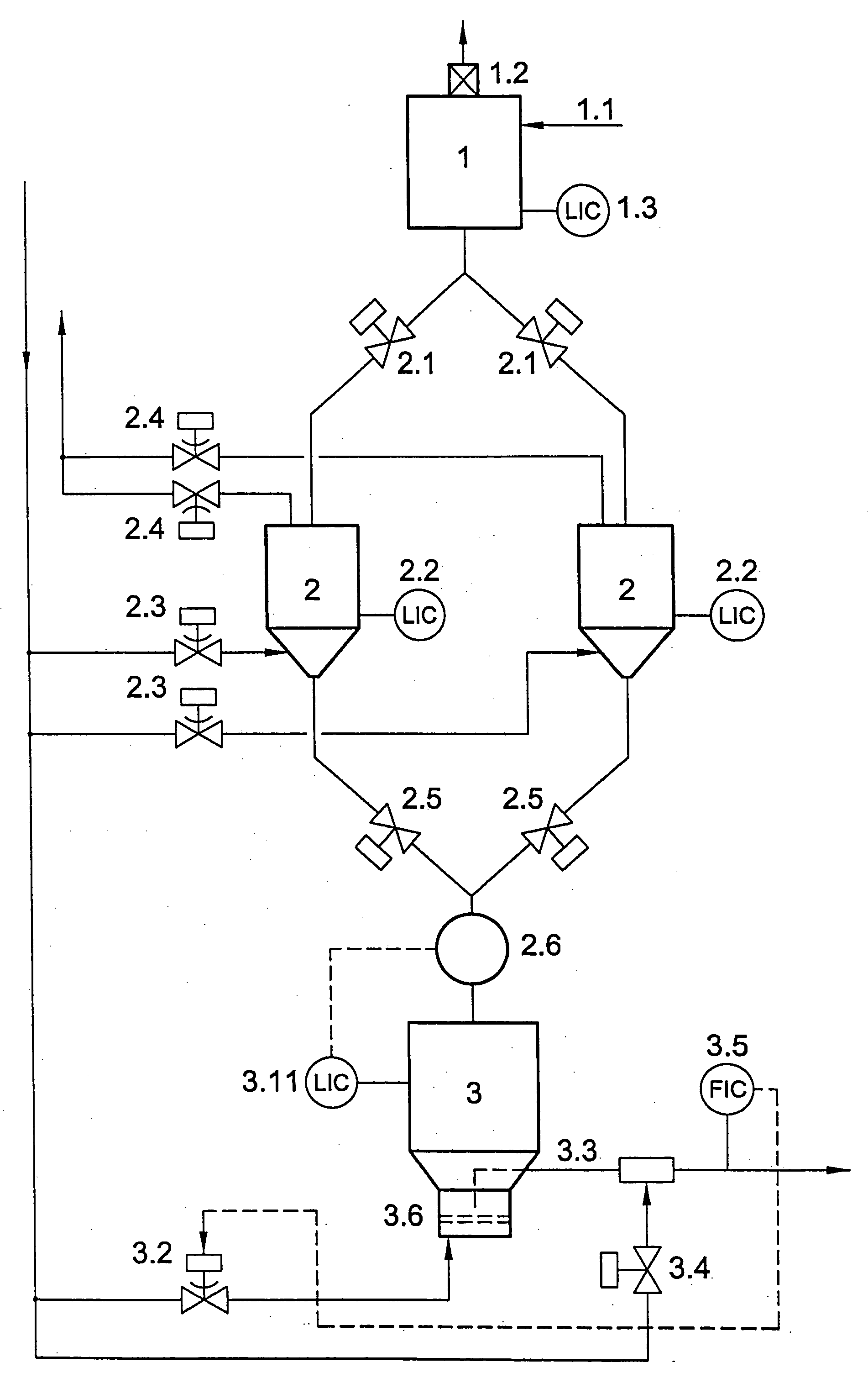

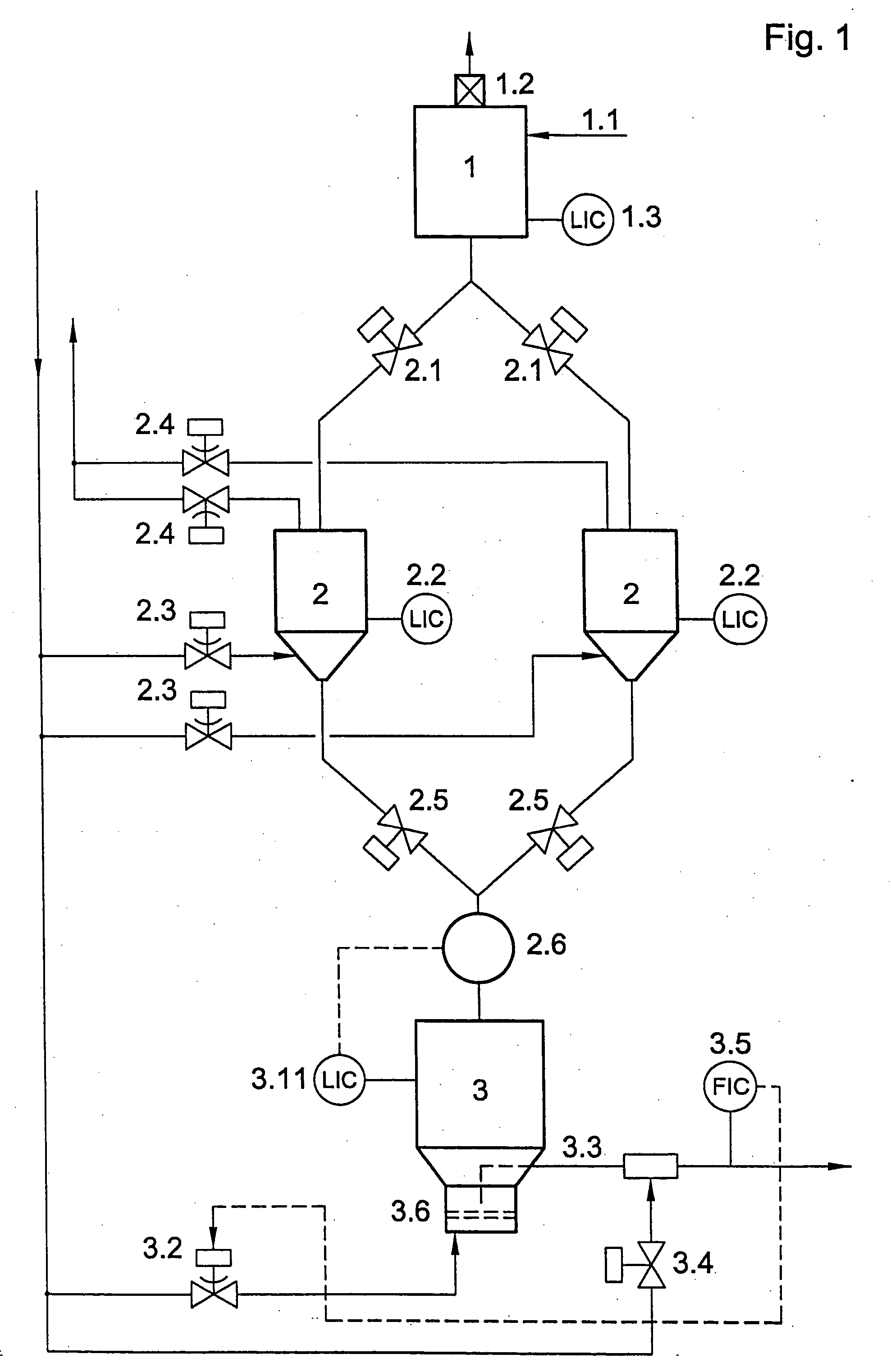

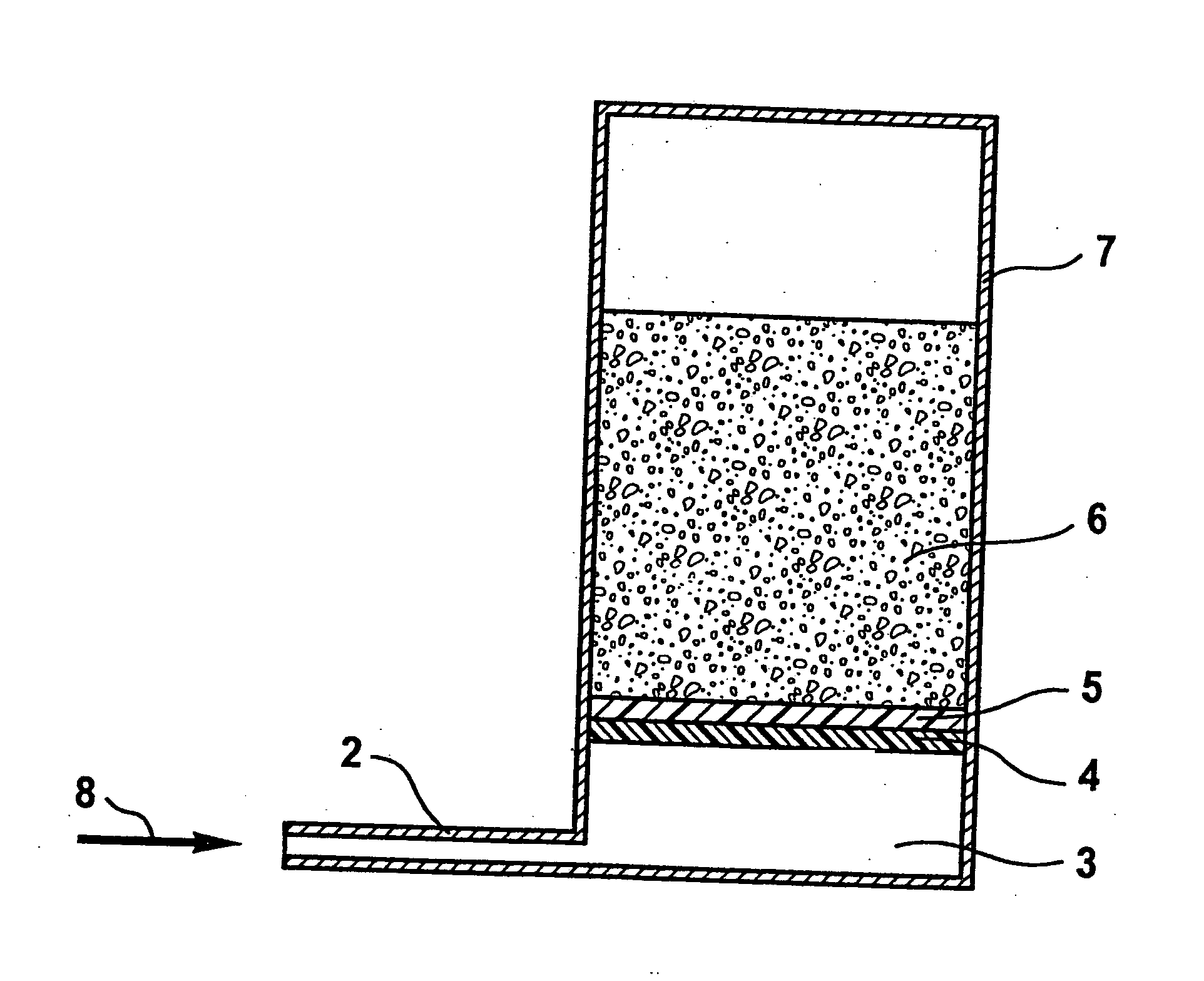

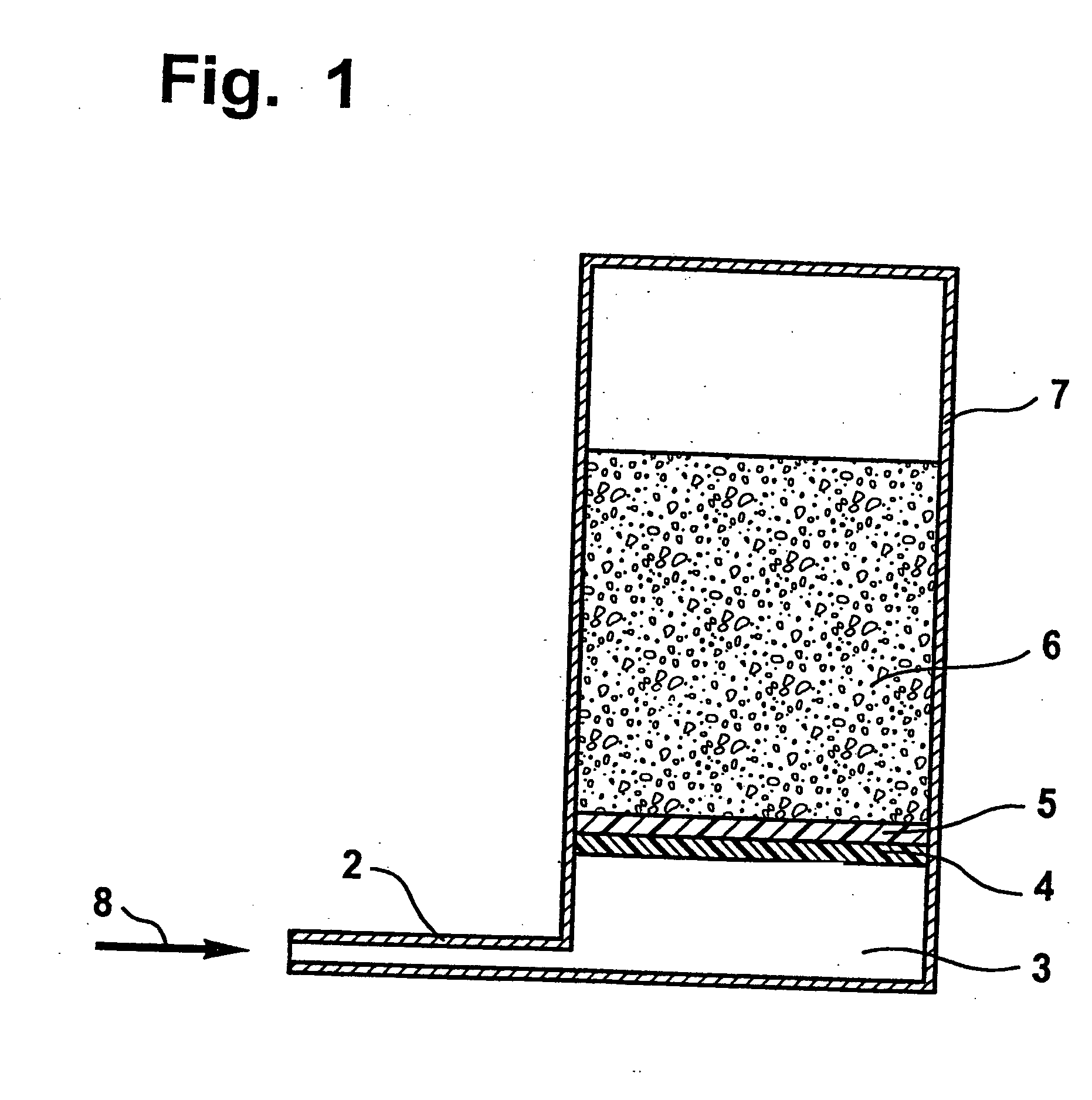

Method and device for the regulated feed of pulverized fuel to an entrained flow gasifier

ActiveUS20070074643A1Constant flowDouble gratePulverulent fuel combustion burnersCombustorFluidized bed

A method and device for metering and feeding pulverized fuels under pressure into gasification reactors, with the pulverized fuel being supplied alternately from an operational bunker through pressurized sluices to a metering tank, in the bottom of which a dense fluidized bed is formed by introducing fluidizing gas through a turbulence plate, with transport pipes immersed in the fluidized bed horizontally or vertically, by which the fluidized fuel is fed continuously through burners to a pressurized gasification reactor. By feeding in auxiliary gas in the immediate vicinity of the transport line inlet into the metering tank or the transport lines, the pressure differential between the metering tank and the gasification reactor is controlled and is utilized as a control parameter for pulverized fuel transport.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Disc shaped regulated drip irrigation emitter

ActiveUS8511586B2Constant flowLarge filter areaClimate change adaptationWatering devicesWater filterDrip irrigation

A drip irrigation emitter includes a disc shaped body having a pressure reducing labyrinth between a water inlet area and an outlet hole, and a pressure regulating diaphragm changing flow through the outlet hole in response to water pressure fluctuations in the water conduit where the emitter is mounted. The water filtering inlet of the emitter is located entirely at the sides of the disc shaped body.

Owner:RIVULIS PLASTRO LTD

Pump for low flow rates

InactiveUS20050006309A1Reduce flow ratePrevent penetrationUltrafiltrationFlexible member pumpsEngineeringMembrane configuration

Owner:ROCHE DIABETES CARE INC

Fuel system for a multi-fuel engine

InactiveUS8590510B2Improve fuel vaporizationEmission reductionElectrical controlInternal combustion piston enginesFuel typeEngineering

Owner:FORD GLOBAL TECH LLC

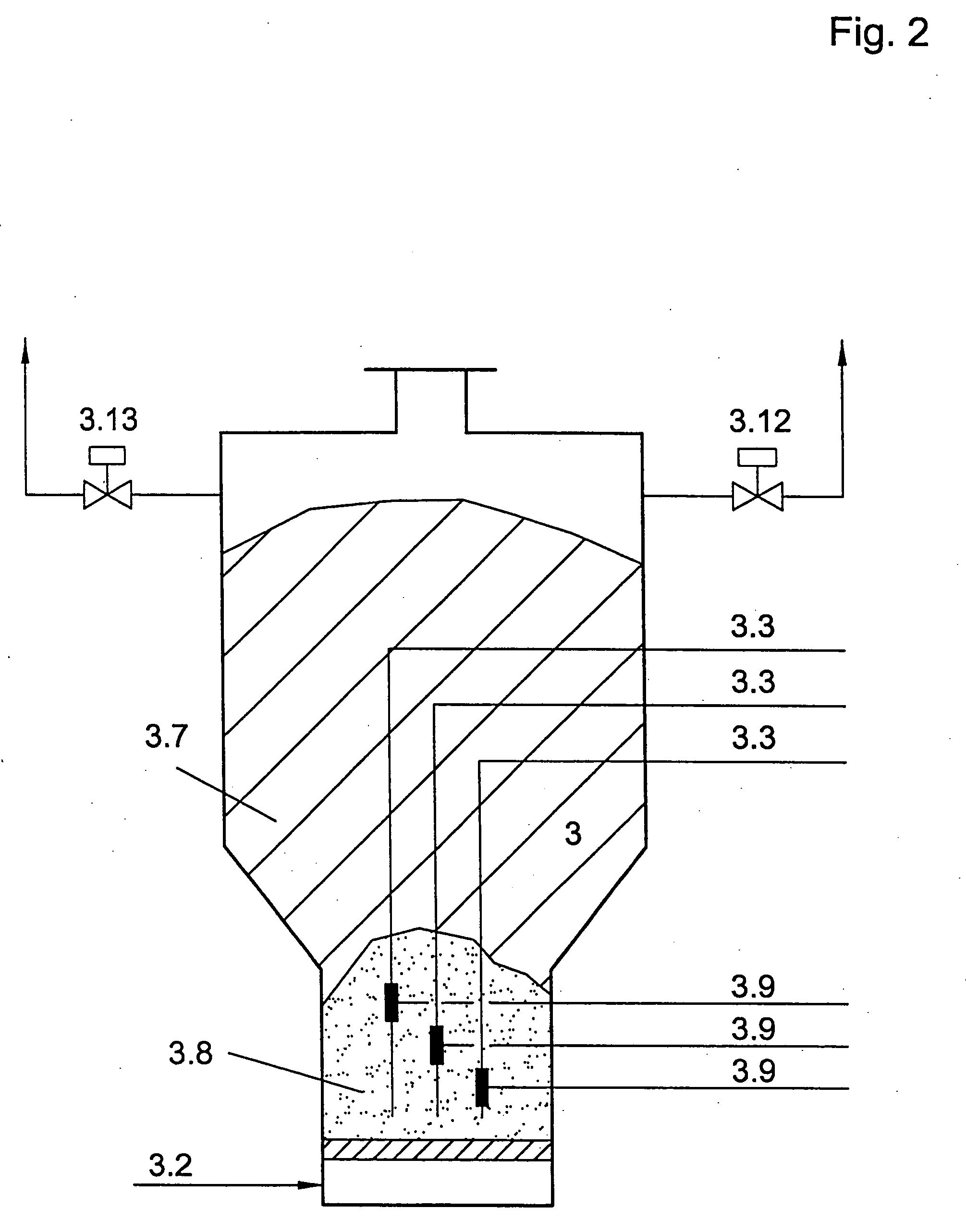

Hose nozzle apparatus and method

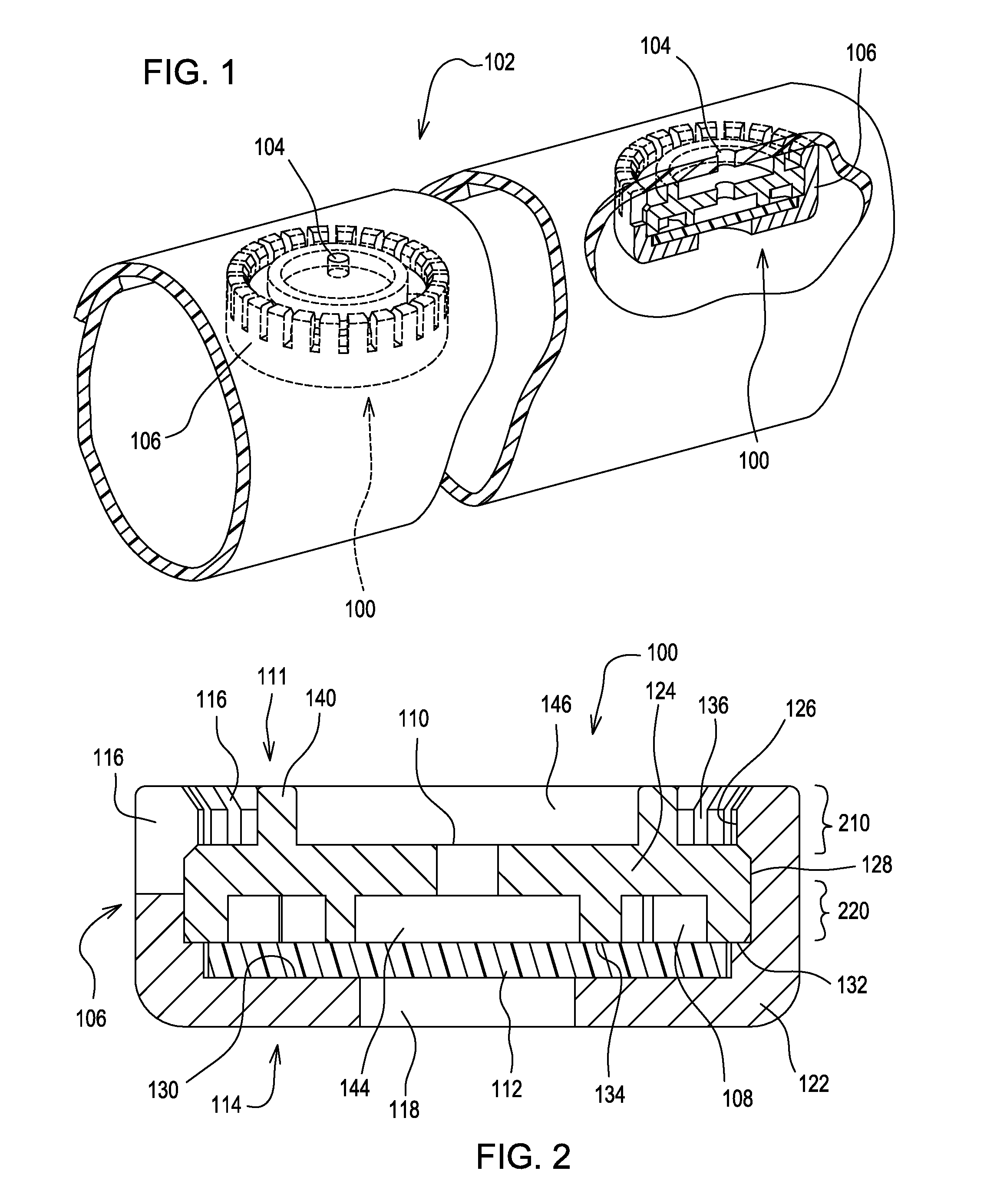

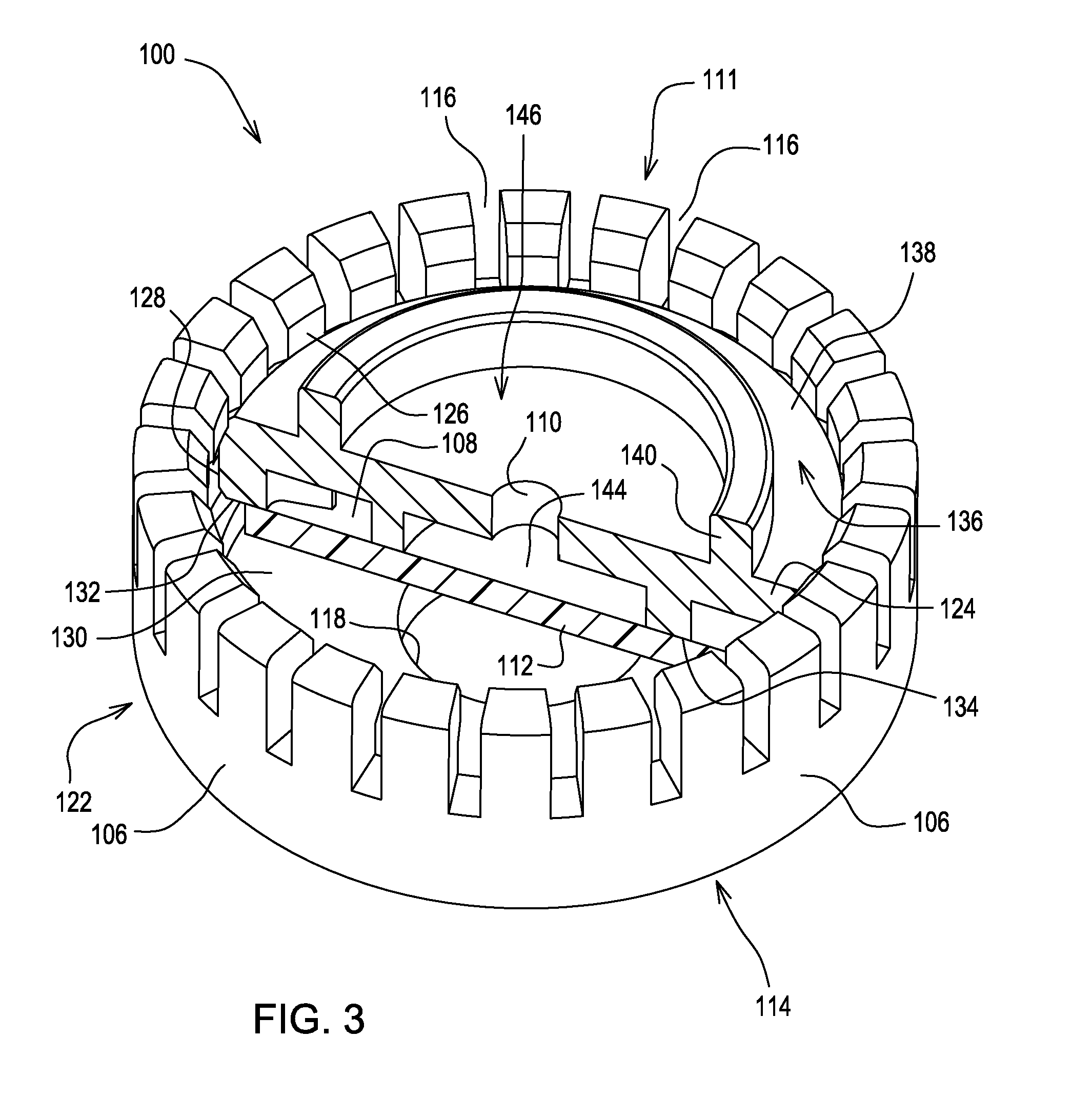

InactiveUS6089474AShorten the axial distanceMore aerodynamicOperating means/releasing devices for valvesCheck valvesSpray nozzleEngineering

An apparatus (100) for selectively discharging a stream of liquid has a body (102) adapted for connection to a source of liquid under pressure, a throttle valve assembly (120) for maintaining a constant output flow throughout changes in supply pressure, a smooth bore barrel (140) for providing a deluge stream, a fog tip (160) for providing an aspirated fog spray and a shut off valve (180). The fog spray pattern is variable from a straight stream parallel to the axis of the apparatus to a wide spray at an angle to the axis of the apparatus. The deluge stream and the fog spray are selectable separately or in combination.

Owner:WS ACQUISITION LLC

Fluid flow control device

InactiveUS20080000539A1Reduce manufacturing costConstant flowFluid heatersFlow mixersEngineeringTemperature and pressure

A flow control device of the character having a fluid pathway for permitting fluid flow therealong under conditions of varying temperature and pressure for achieving substantially constant output flow rate from the fluid pathway. One or more flexibly deformable vanes, which extend into the fluid pathway, are constructed and arranged to flexibly deform in a manner to further occlude the fluid pathway when the pressure within said fluid path way increases.

Owner:BIOQ PHARMA

Energy harvesting from flow-induced vibrations

Electrical energy is produced at a remote site by converting kinetic energy from fluid flow to electrical energy using a downhole harvesting apparatus. The downhole harvesting apparatus includes a vibrating sleeve member that vibrates in response to fluid flow through a tubular housing structure. The vibration of the sleeve is used to generate electrical power. The harvesting apparatus may include features to help maintain constant fluid flow in the tubular structure. The harvesting apparatus can be tuned to different vibration and flow regimes in order to enhance energy conversion efficiency.

Owner:SCHLUMBERGER TECH CORP

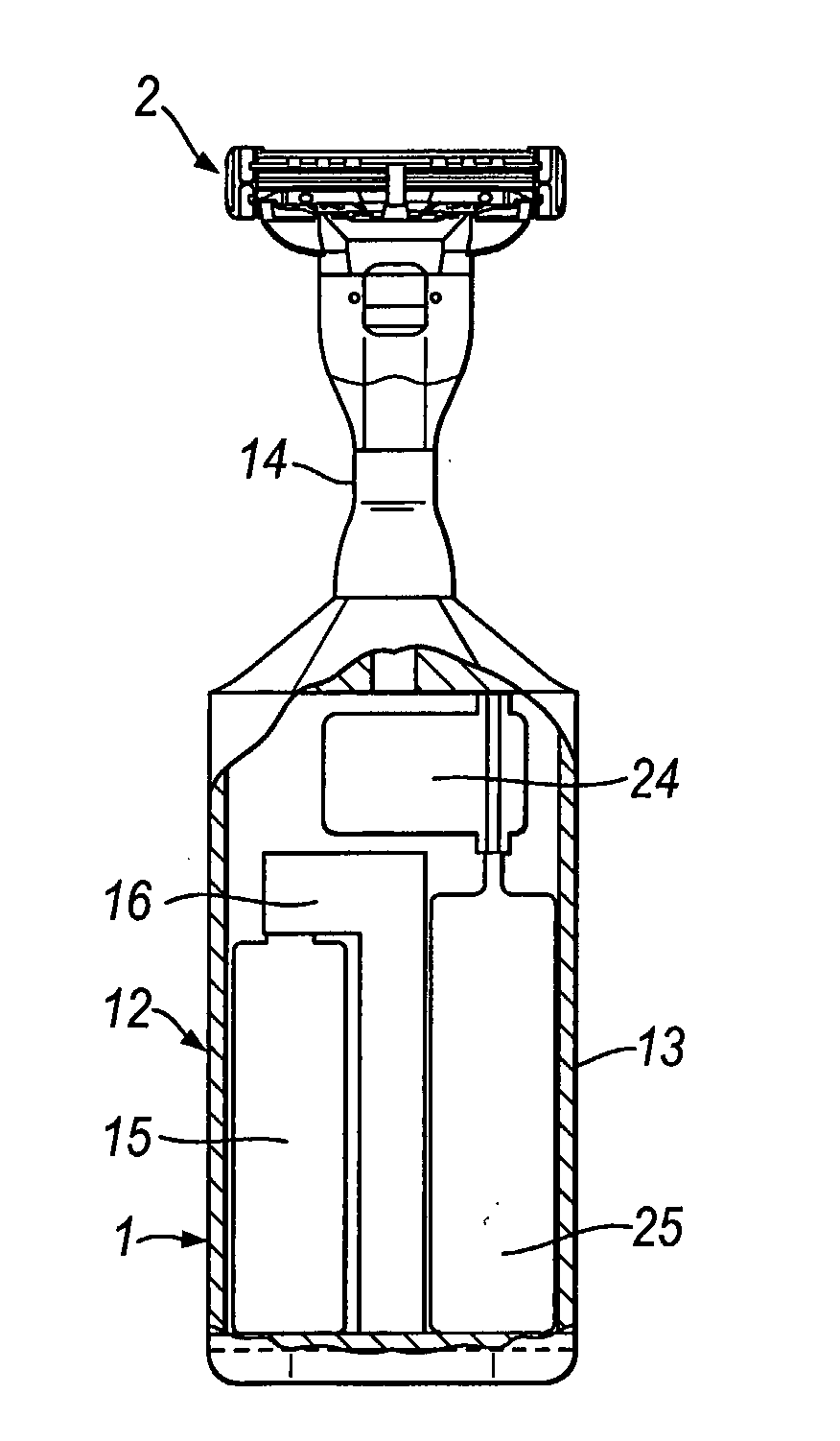

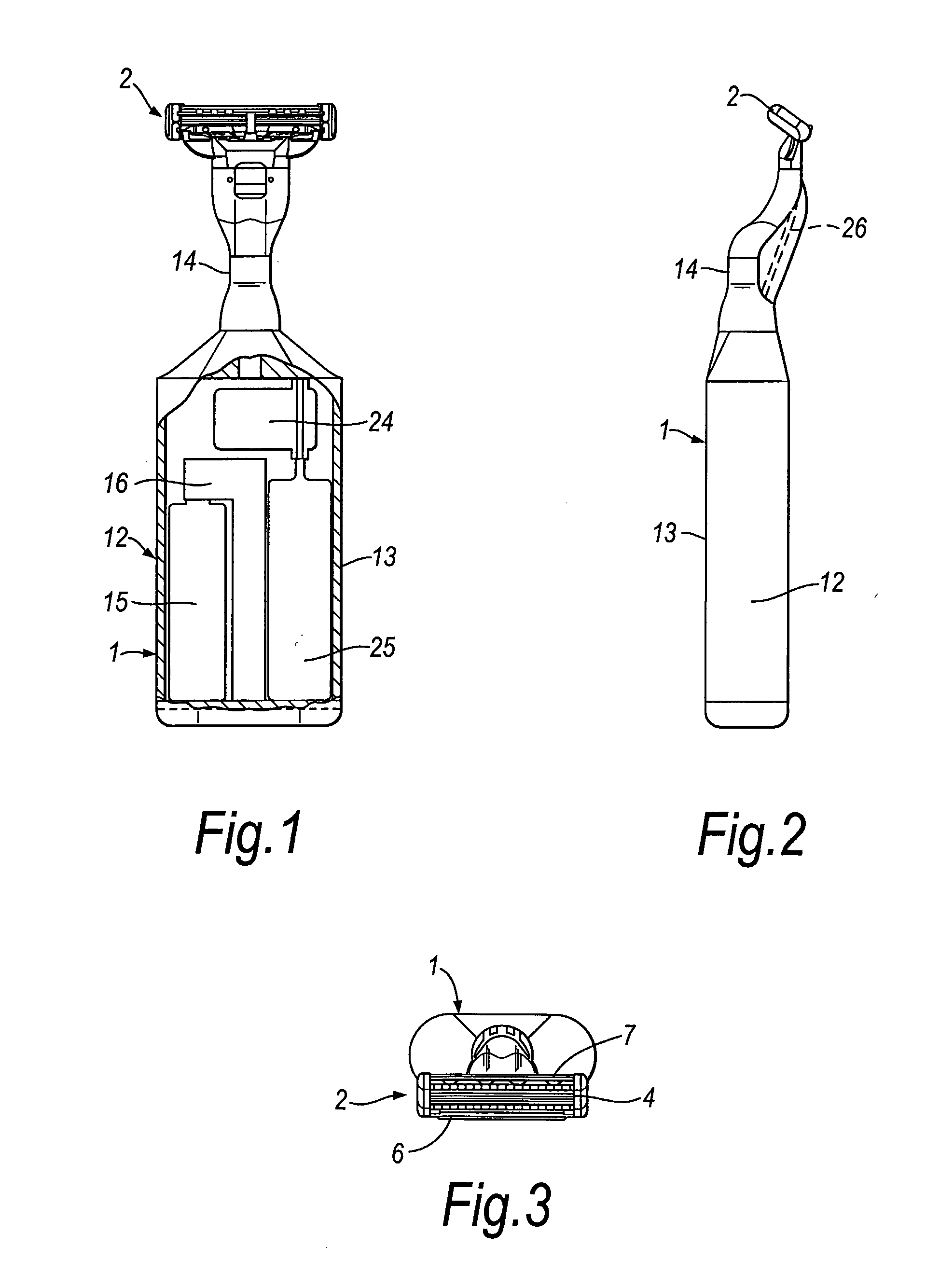

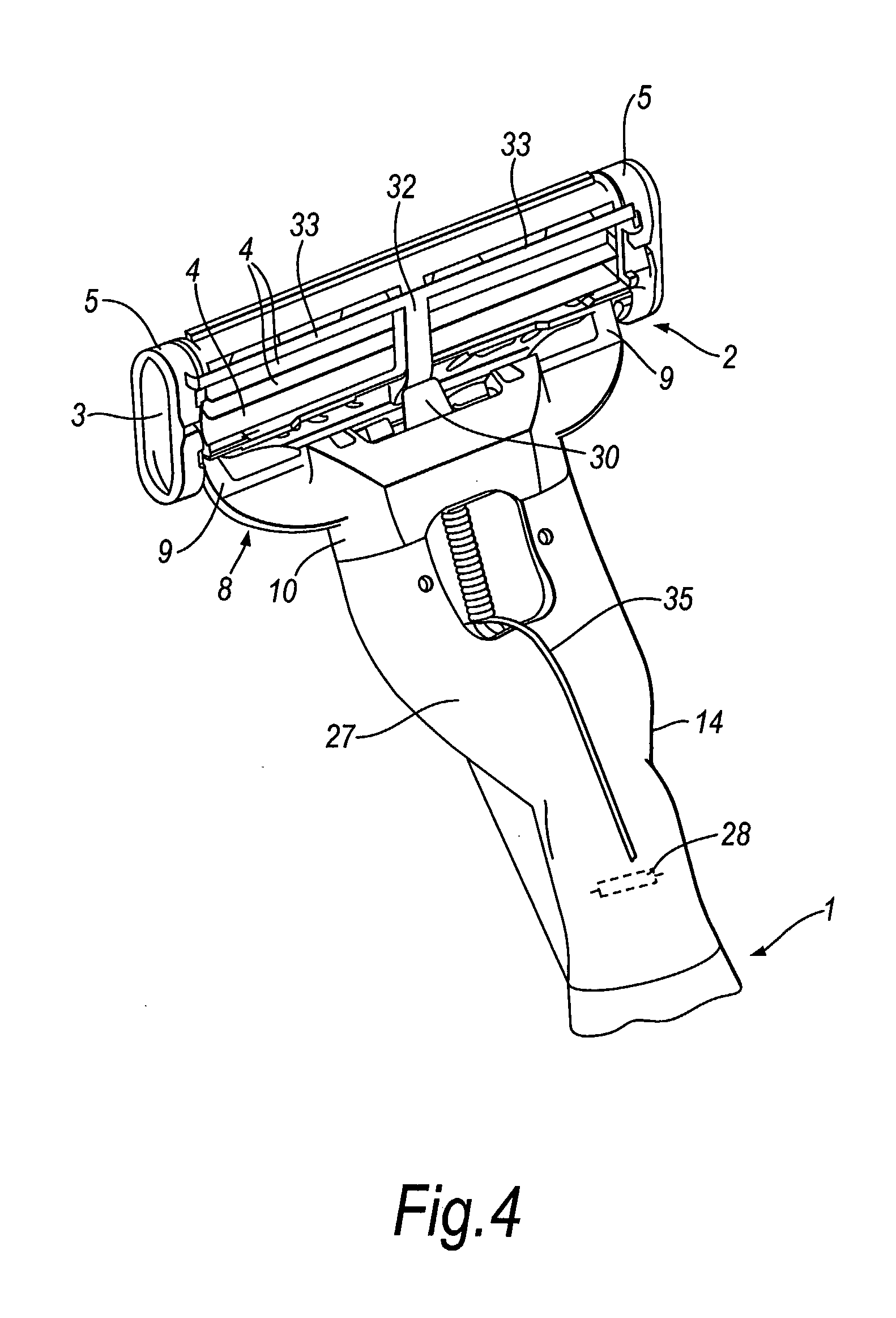

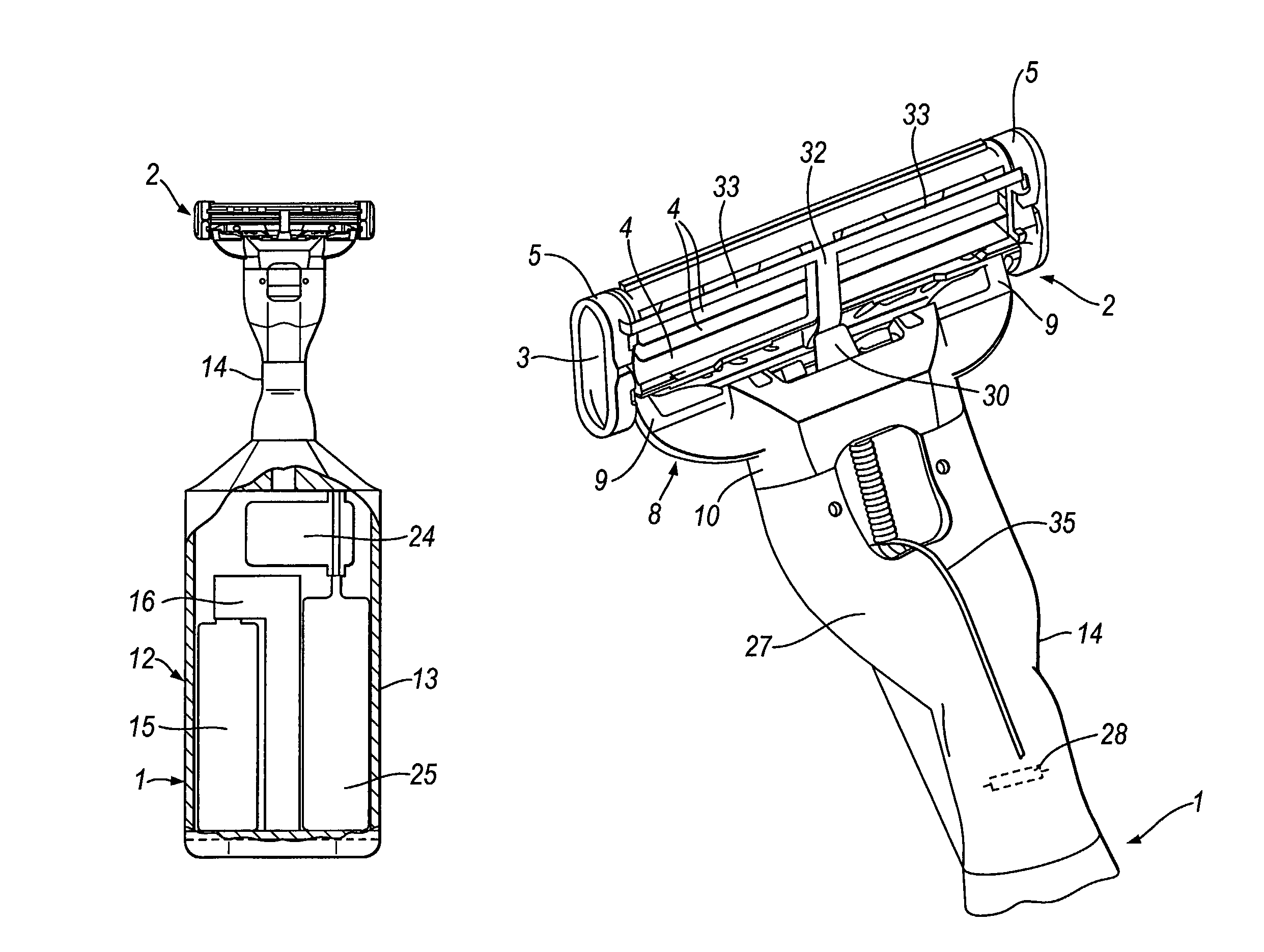

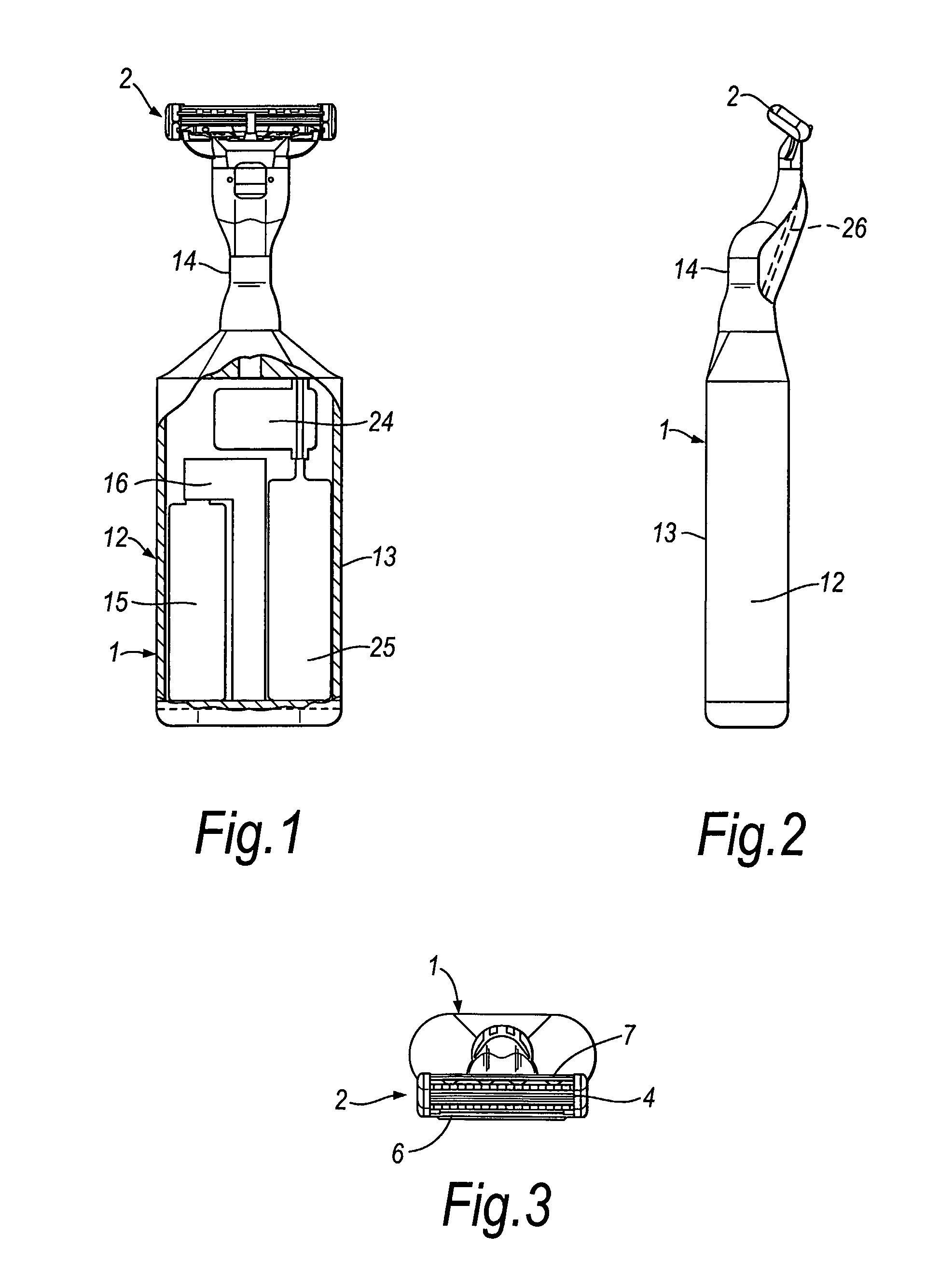

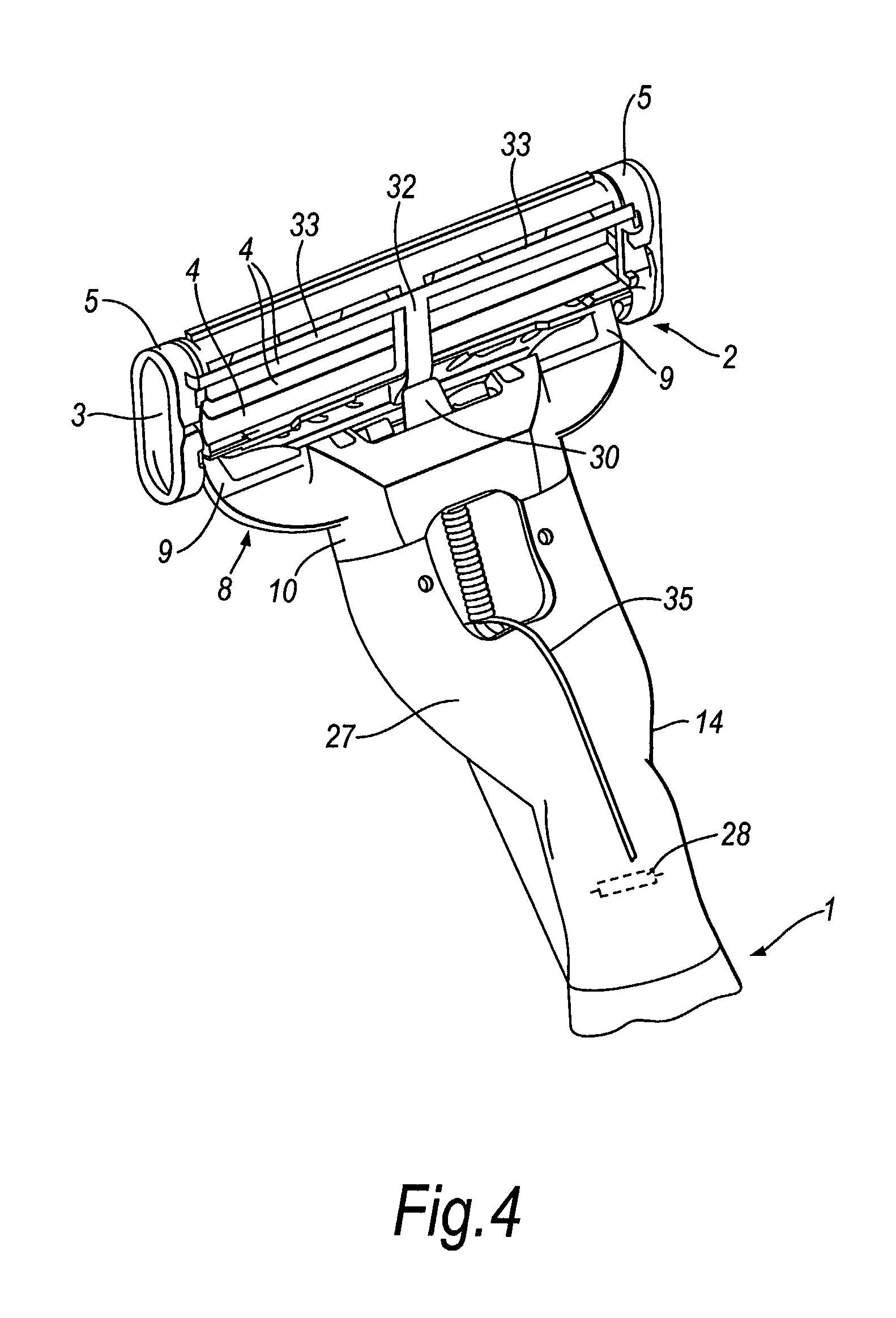

Razors

ActiveUS20080289185A1Slow charging rateAcceptable dispensing rateThrusting weaponsWeapon componentsRazor stropEngineering

A razor, especially a safety razor, comprises a fluid delivery system including a pump (24) for conducting a fluid, such as a lubricant, from a reservoir (25) for application to the skin, and a control device (16) for actuating the pump (24) when the razor is brought into contact with the skin by a person holding the razor, and deactuating the pump (24) after a certain time of actuation, e.g. 0.1 to 2 seconds. The control device is arranged to ensured a delay of 1 to 10 seconds between successive actuations, and so that the pump is actuated only every second third or fourth shaving stroke.

Owner:THE GILLETTE CO

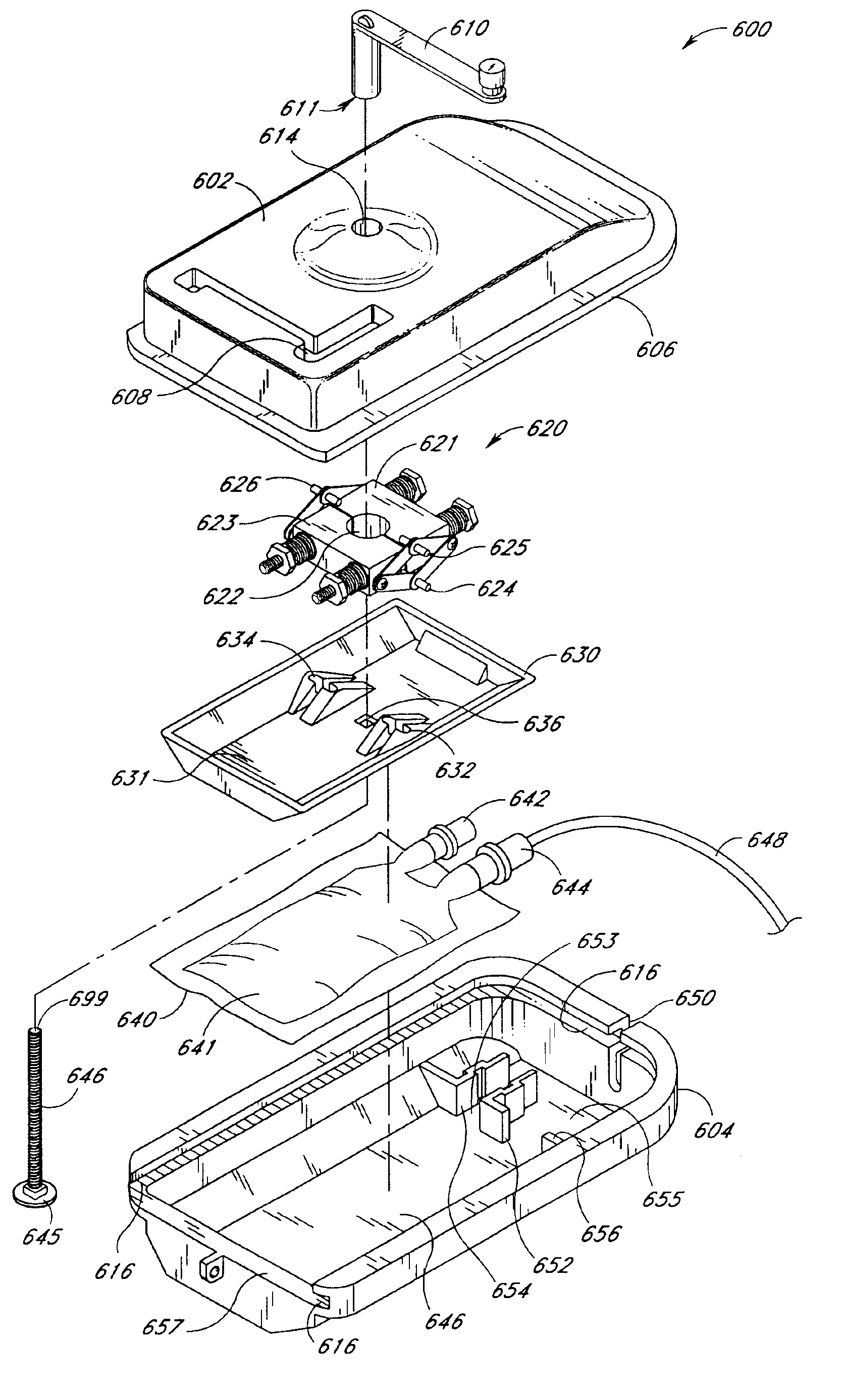

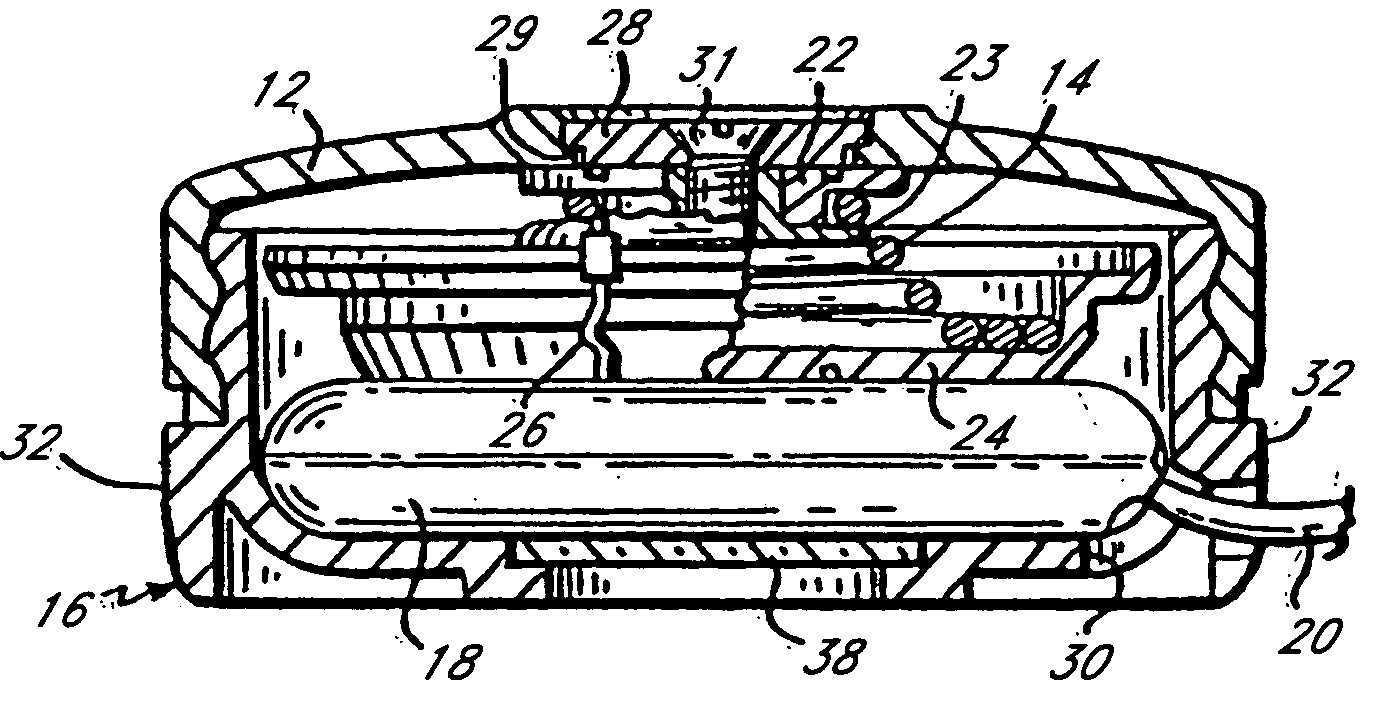

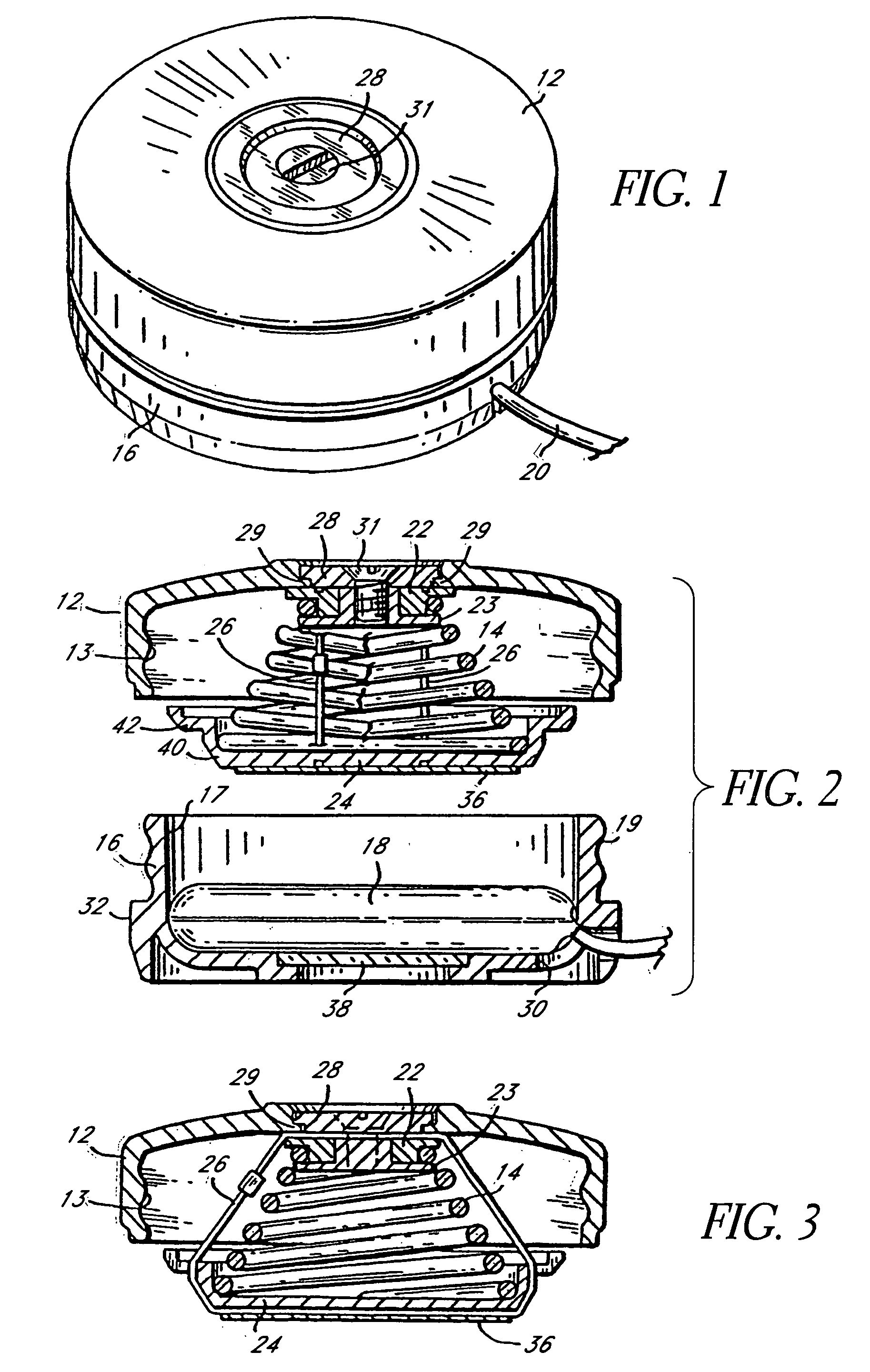

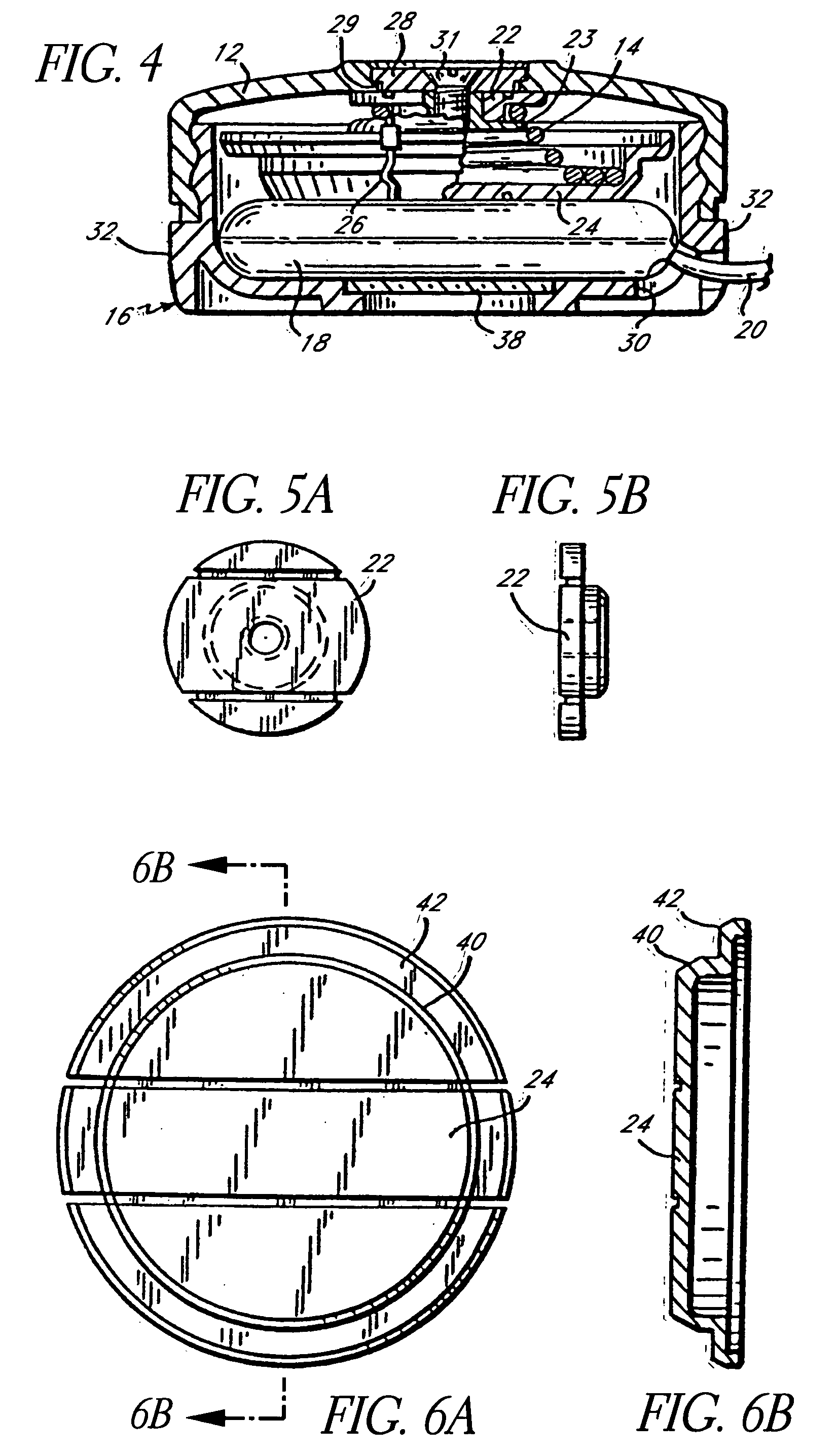

Platen pump

Disclosed is an infusion pump for expelling a fluid from a collapsible fluid reservoir to a patient. The pump includes a housing having a chamber therein for receiving the fluid reservoir. A first wall is provided on the housing for contacting the fluid reservoir, and a second wall is movable from a first position distanced from the first wall to form the chamber therebetween, and a second position relatively closer to the first wall. Advancing the movable wall from the first position to the second position expels fluid from the collapsible reservoir at a substantially constant rate by applying increasing force on the fluid reservoir through the dispensation cycle. Preferably, the first and second walls are provided with non-planar complementary surface configurations for contacting the collapsible reservoir. Retraction mechanisms for retracting the movable wall from the second position to the first position, and user readable indicium of the status of the dispensation cycle are also disclosed.

Owner:BMR MEDICAL LTDA

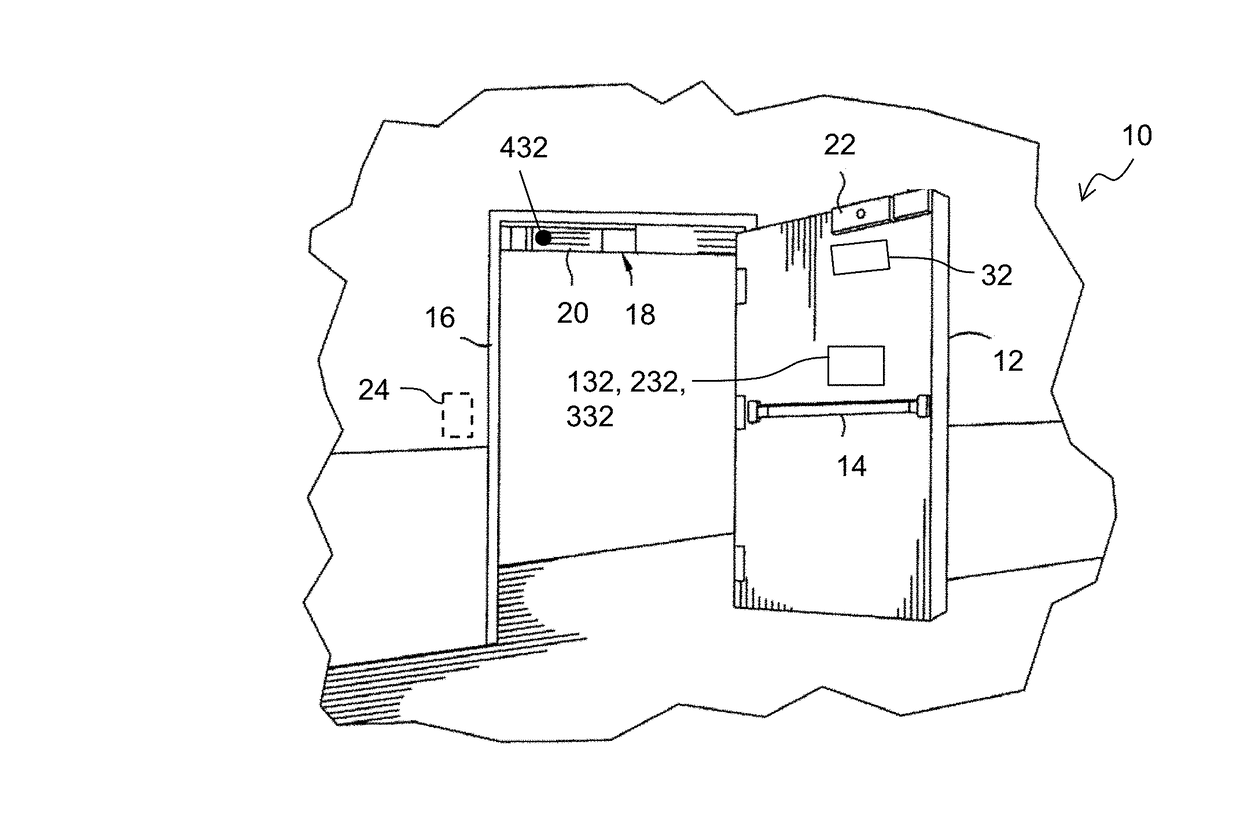

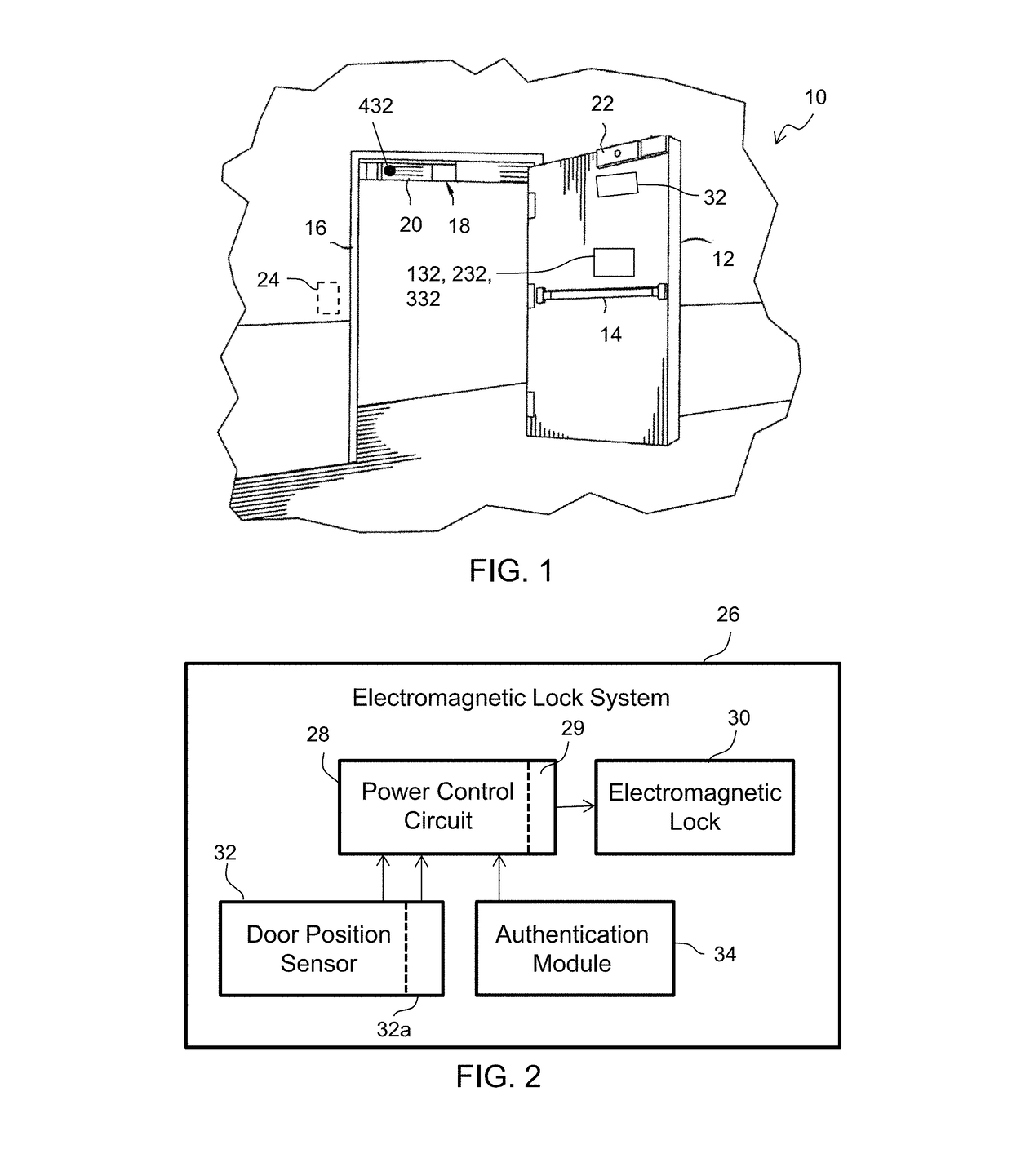

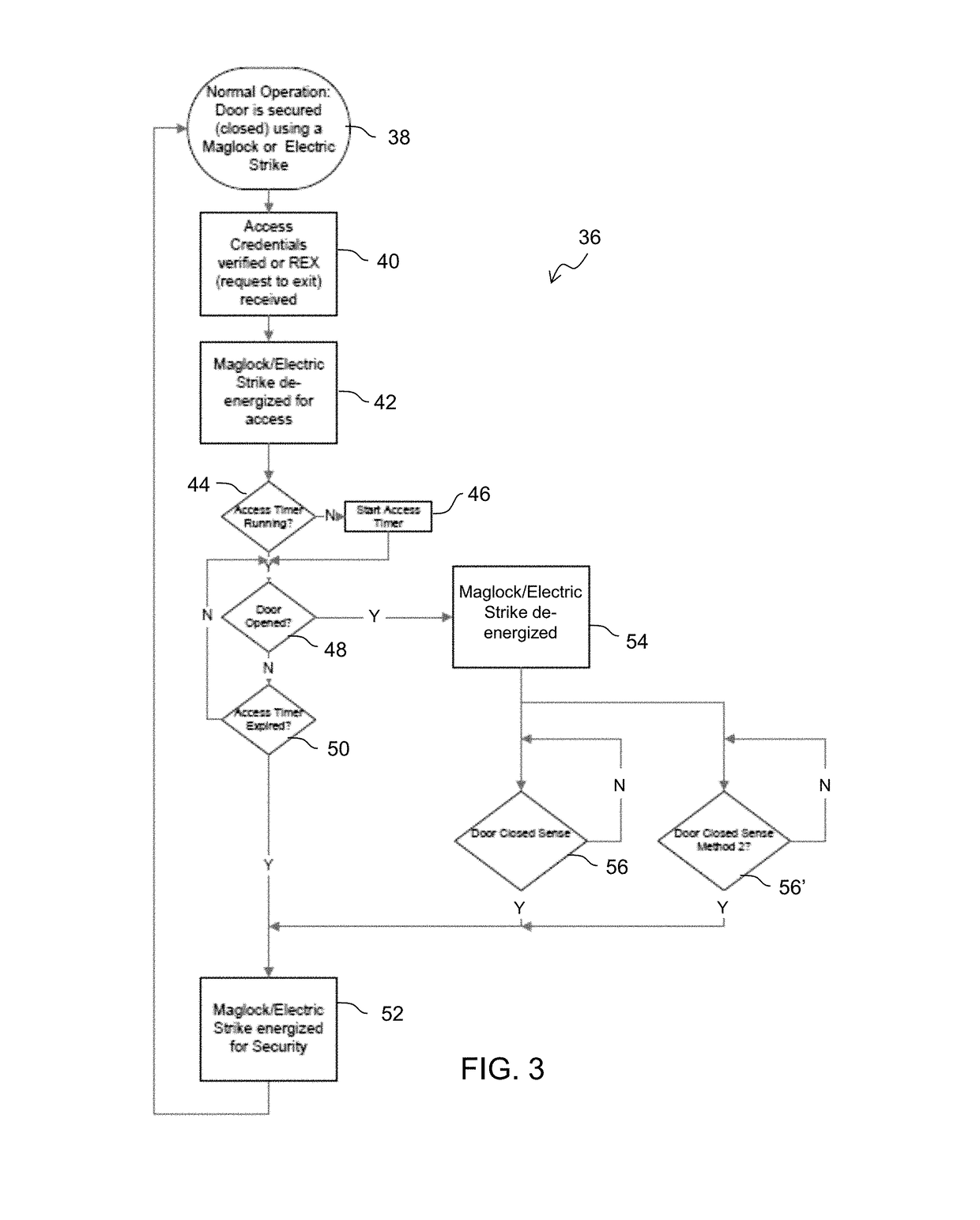

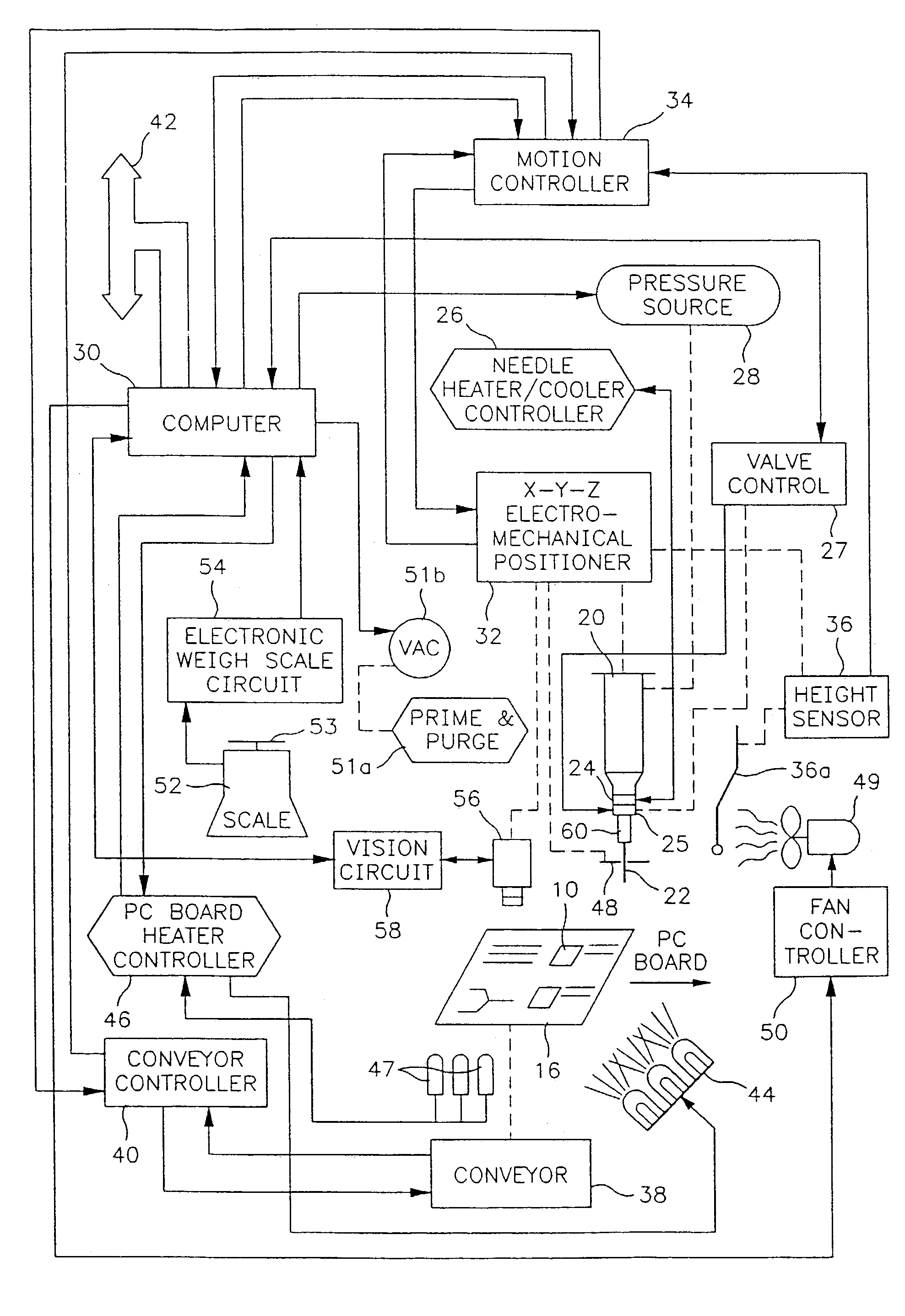

Reduced power consumption electromagnetic lock

ActiveUS20170226784A1Constant flowNon-mechanical controlsWing fastenersMagnetic tension forceEngineering

An energizable electromagnet of a door locking system is affixed to the door or the door frame for electromagnetically attracting an armature affixed to the other. A power control circuit is configured to selectively energize the electromagnet using a pulse-width modulated current cycle wherein two levels of magnetic force may be selectively applied to the system. A door position sensor is configured to provide a first communication signal to the power control circuit when the door is in a closed position. A second communication signal is provided when the door is not in the closed position. The electromagnet is energized at the lower level of magnetic force when the power control circuit receives the first communication signal and at the higher level of magnetic force only when an unauthorized attempt to open the door is initiated.

Owner:HANCHETT ENTRY SYST

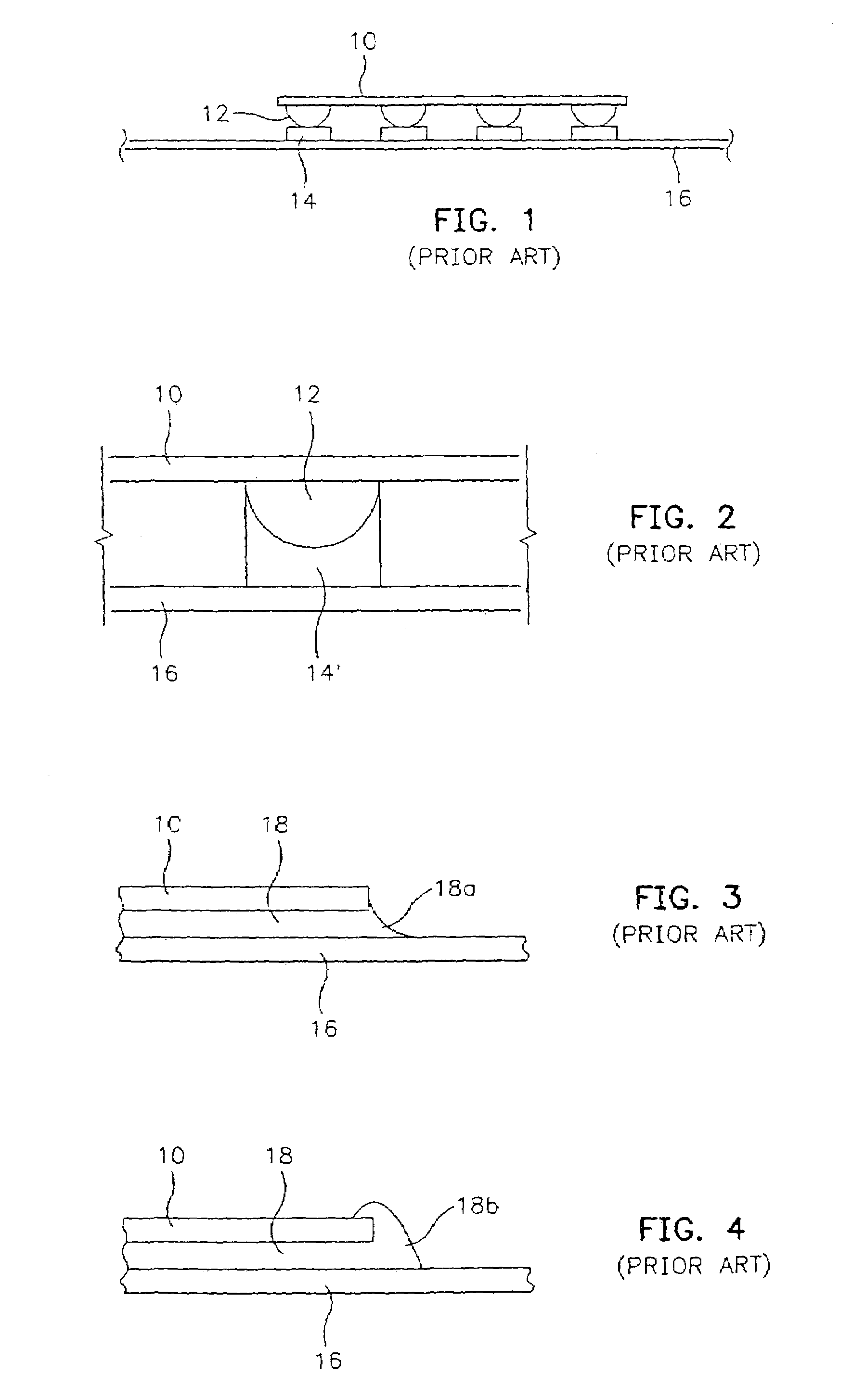

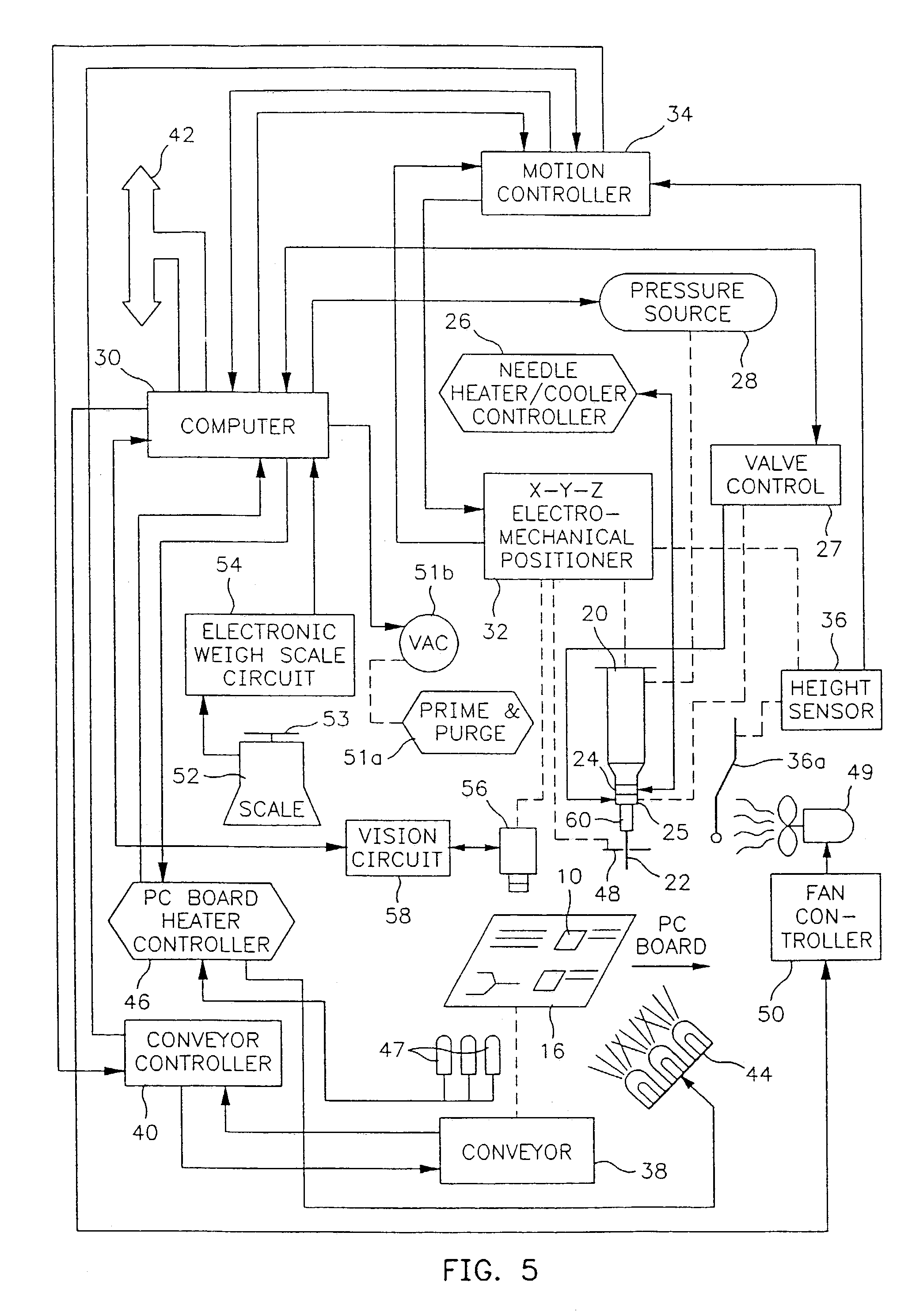

Flip chip underfill system and method

InactiveUS6955946B2Constant viscosityConstant flowLiquid surface applicatorsSolid-state devicesTemperature controlClosed loop

A system for dispensing a viscous material onto a substrate which includes a dispensing element, a viscous material reservoir and a metering device coupled between the reservoir and the dispensing element for metering a variable amount of a viscous material through the dispensing element. The dispensing element and metering device can be moved by a positioner along a predetermined pattern adjacent a surface of a substrate. A weigh scale located adjacent the substrate receives a metered amount of the viscous material and produces signals representative of a variable weight of the material dispensed during a predetermined time interval. A controller adjusts a speed of movement of the positioner along the predetermined pattern to cause the dispensing element to dispense a desired amount of material based on a calculated flow rate. Alternatively, the controller adjusts a rate of delivery of the metering device based on the calculated flow rate to cause the dispensing element to dispense the desired amount of material along the predetermined pattern. Closed loop temperature control may be provided for the dispensing element and / or the substrate to ensure a substantially constant viscosity and a substantially constant flow rate. A prime and purge station may be provided adjacent the substrate for sucking air bubbles from the dispensing element and metering device.

Owner:NORDSON CORP

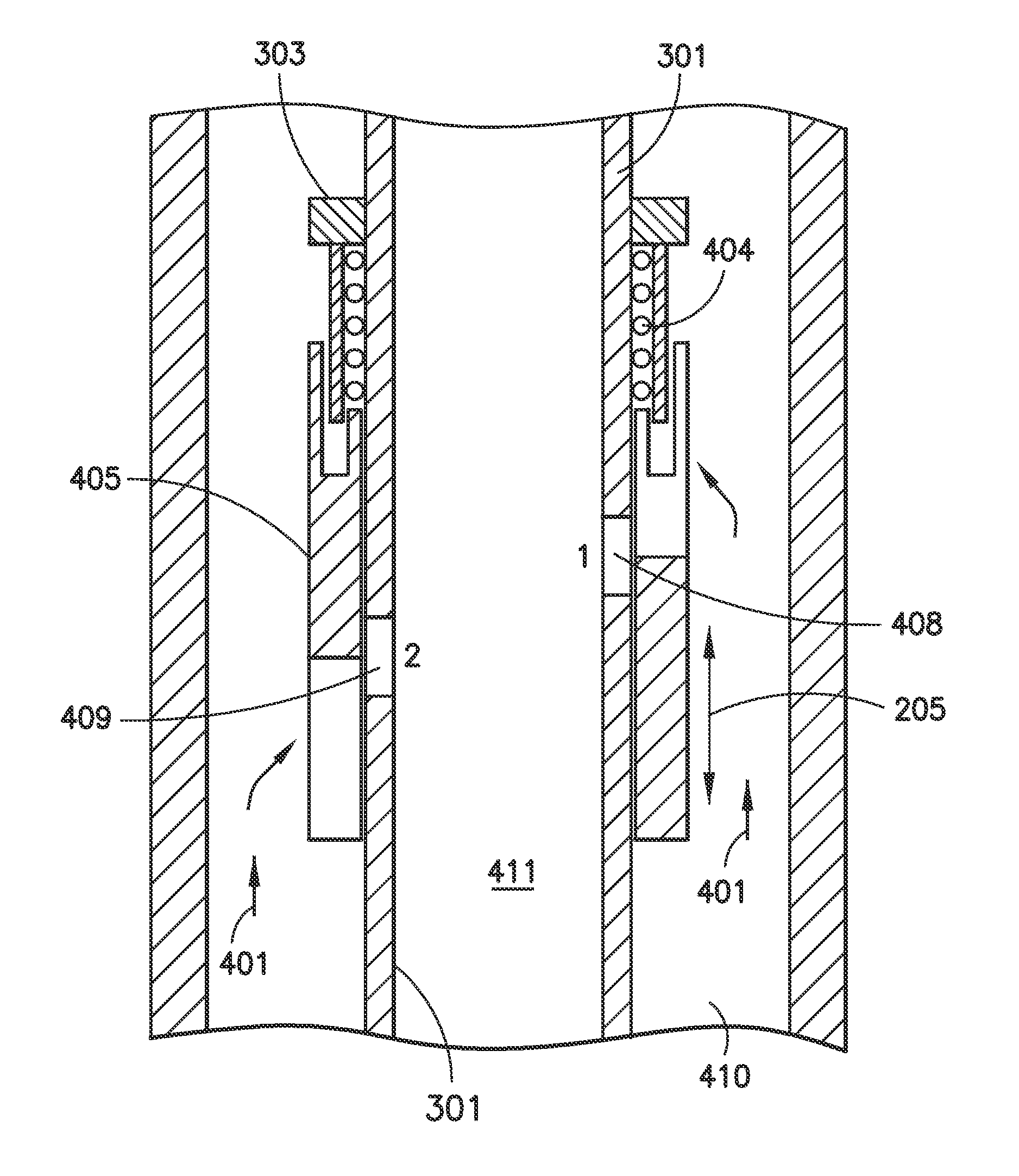

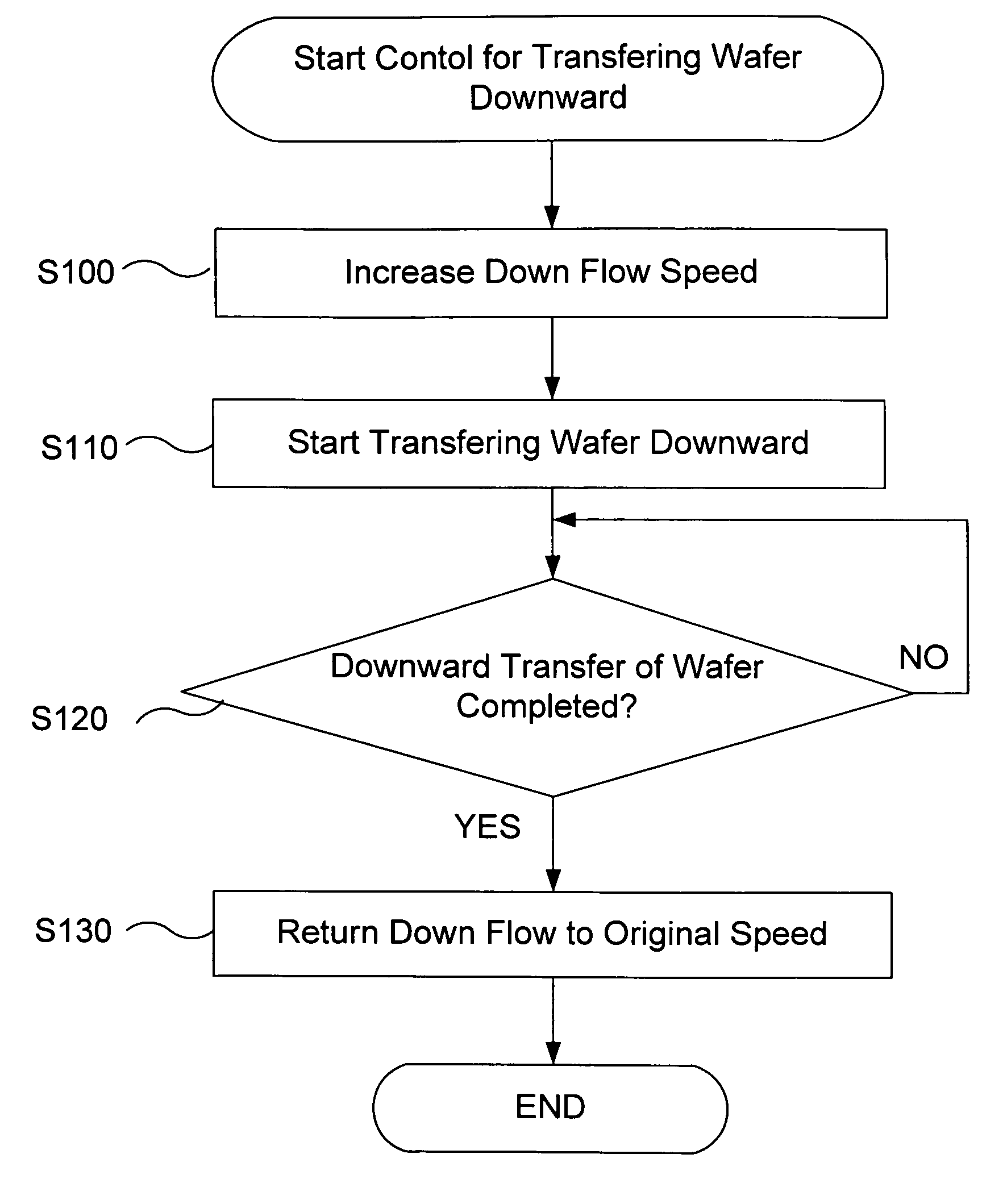

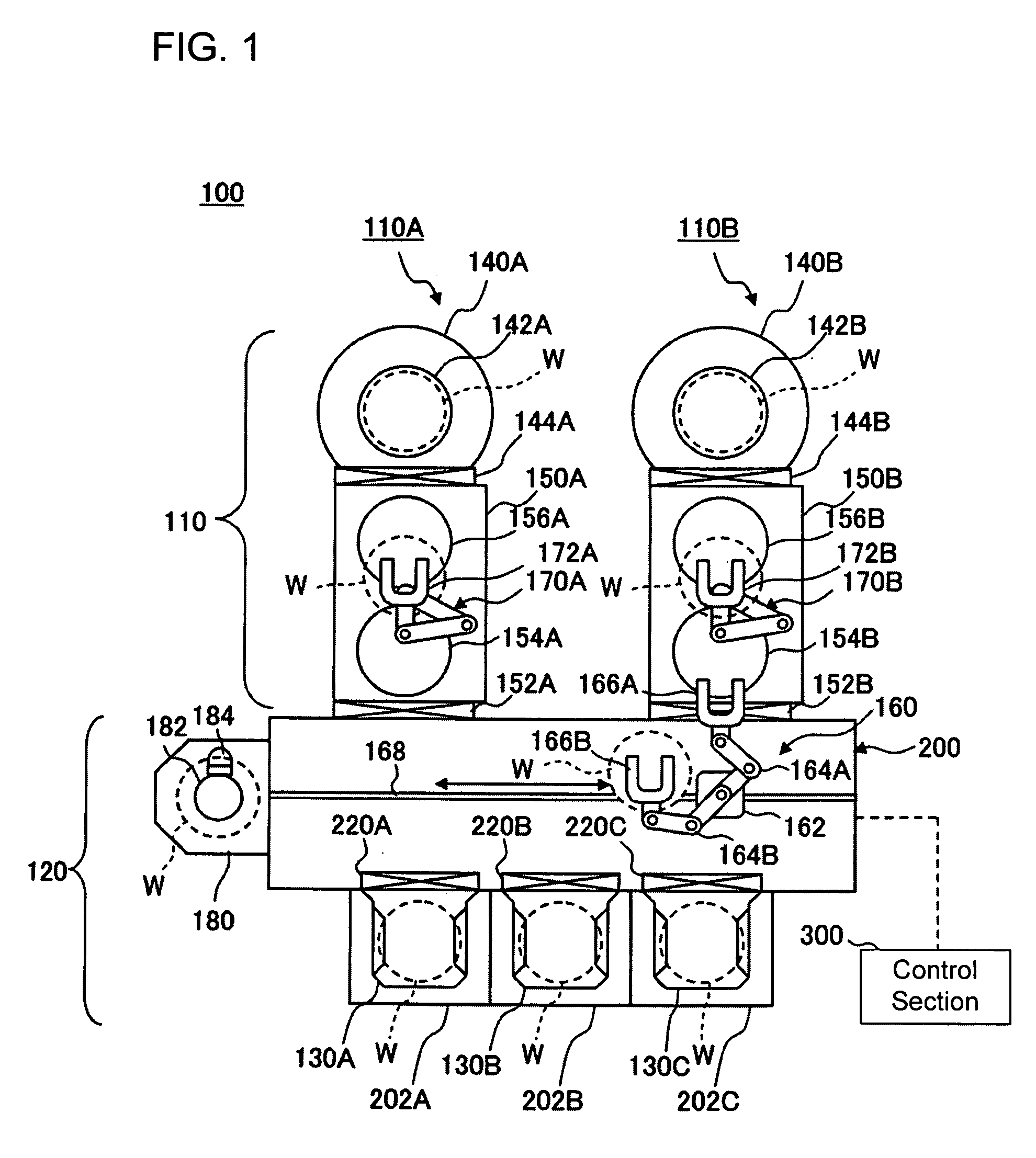

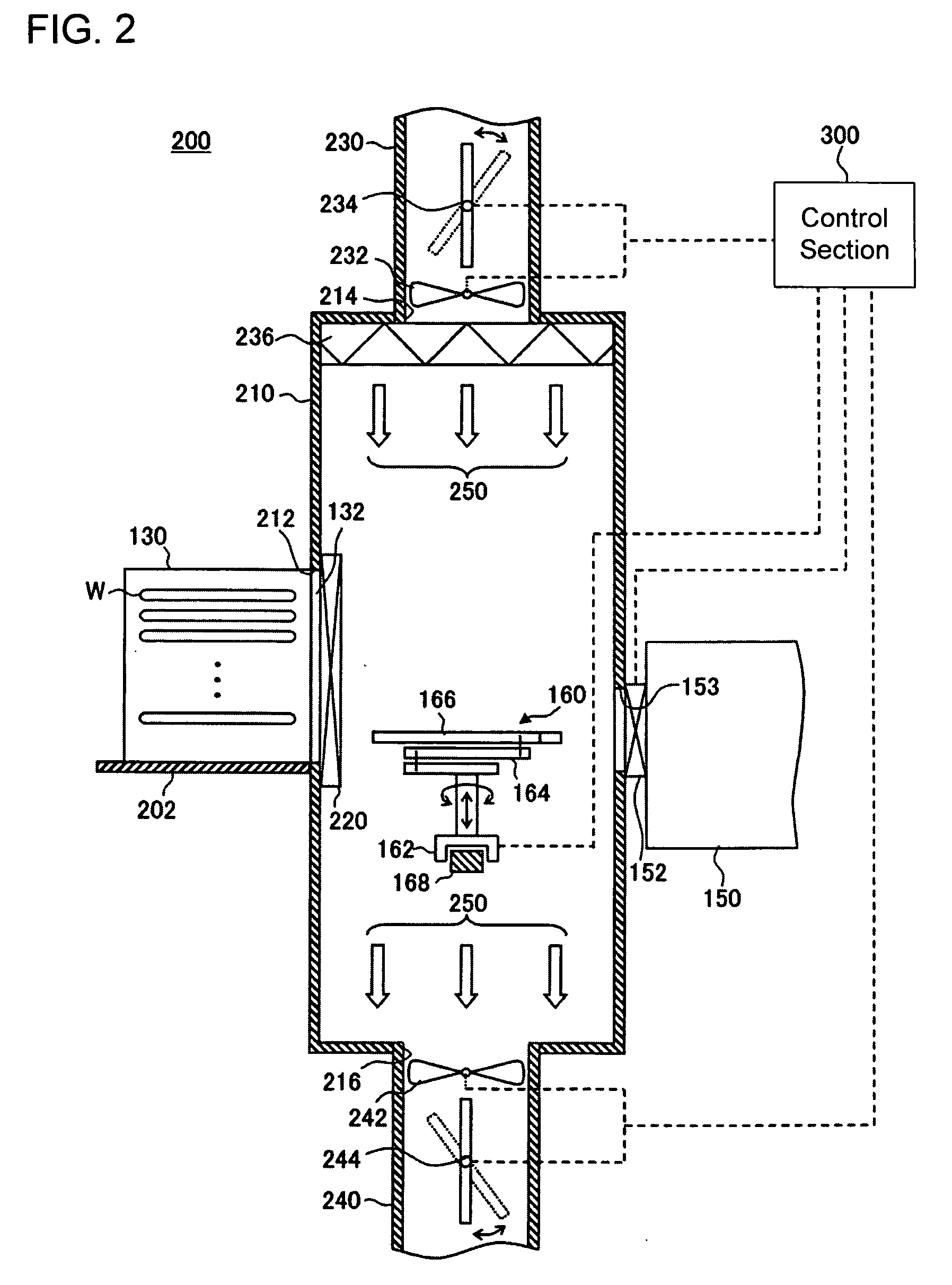

Substrate transfer apparatus and method for controlling down flow

InactiveUS20090081005A1Low costIncrease power consumptionSemiconductor/solid-state device manufacturingBulk conveyorsTransfer systemMoving speed

The present invention relates to an apparatus for transferring a substrate through a gate for loading and unloading is provided, and includes a transfer chamber having the gate for loading and unloading the substrate, a transfer system, which is able to move up and down in the transfer chamber and transfers the substrate by accessing each gate, an adjustment section for a gas down flow, which produces the gas down flow in the transfer chamber and is able to adjust a speed of the gas down flow, and a control section for controlling the speed of the gas down flow using the movement speed of the substrate.

Owner:TOKYO ELECTRON LTD

Pump for low flow rates

InactiveUS6860993B2Simple and cost-effective to manufactureEasy to manufactureFlexible member pumpsUltrafiltrationUltrafiltrationEvaporation

The present invention concerns a pump for flow rates from about 1 to 1000 nl / min in which liquid transport takes place by evaporation of a transport liquid through a wettable membrane. The pumps according to the invention are particularly suitable for applications in the field of medical diagnostics such as microdialysis or ultrafiltration.

Owner:ROCHE DIABETES CARE INC

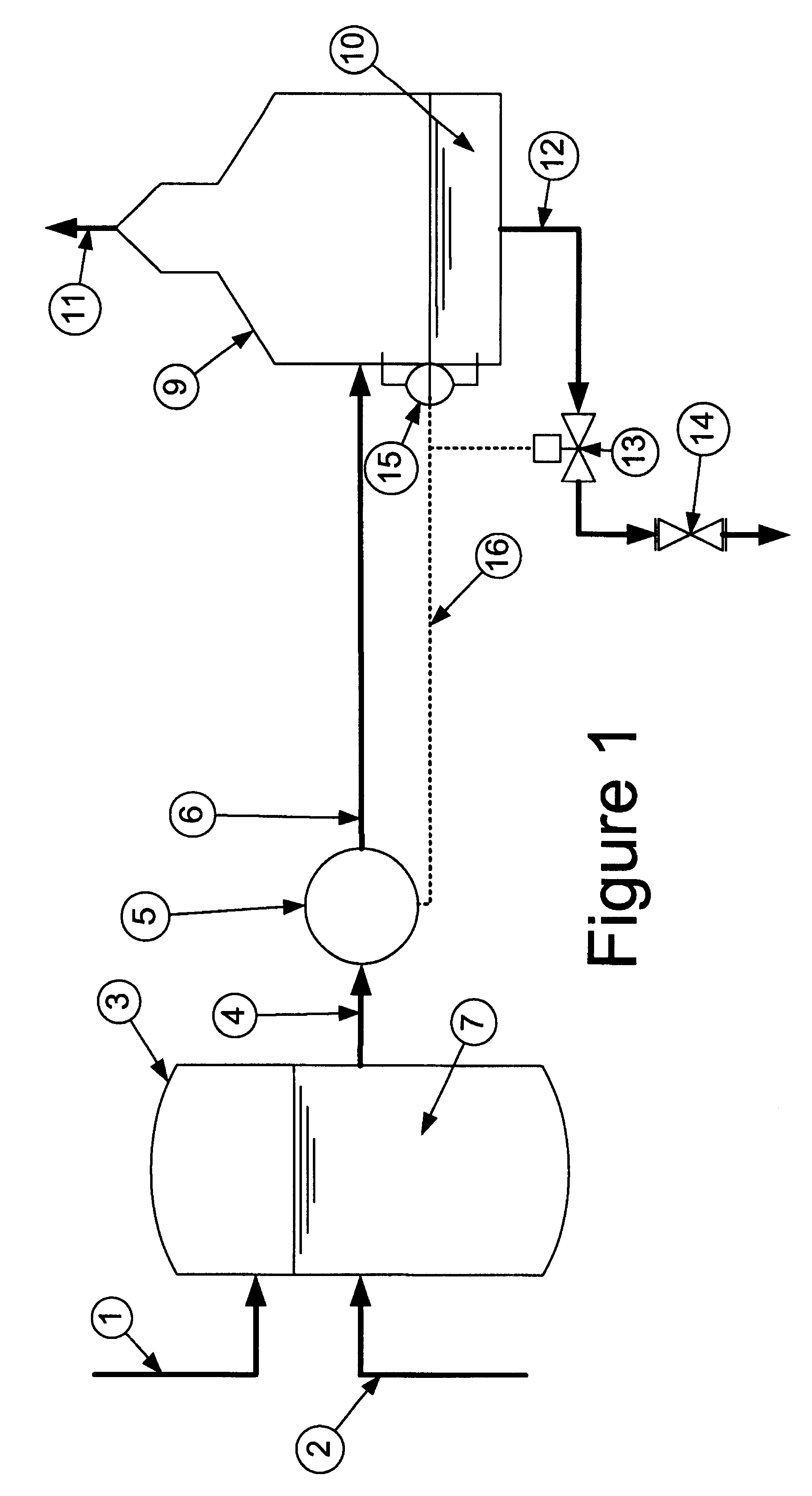

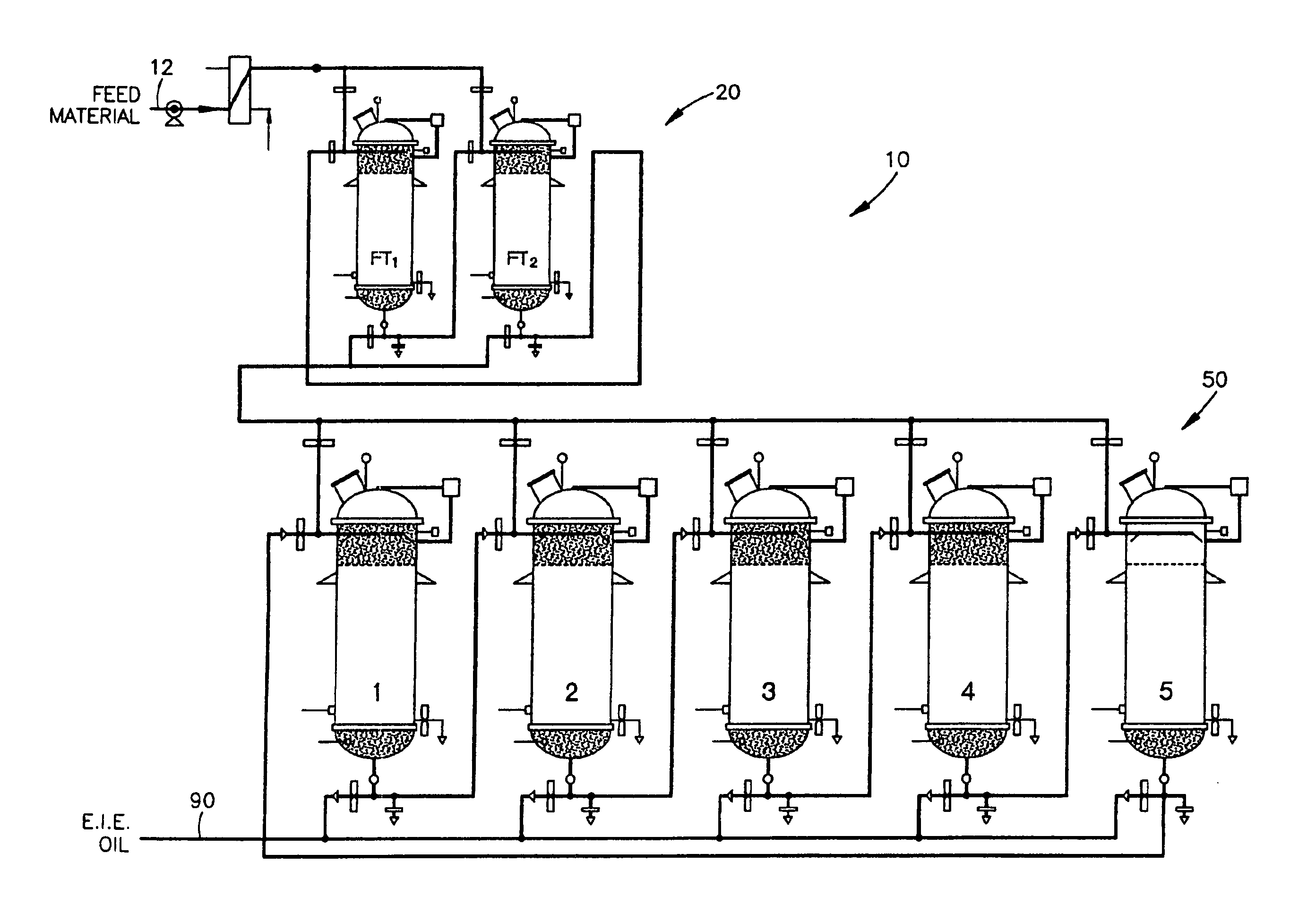

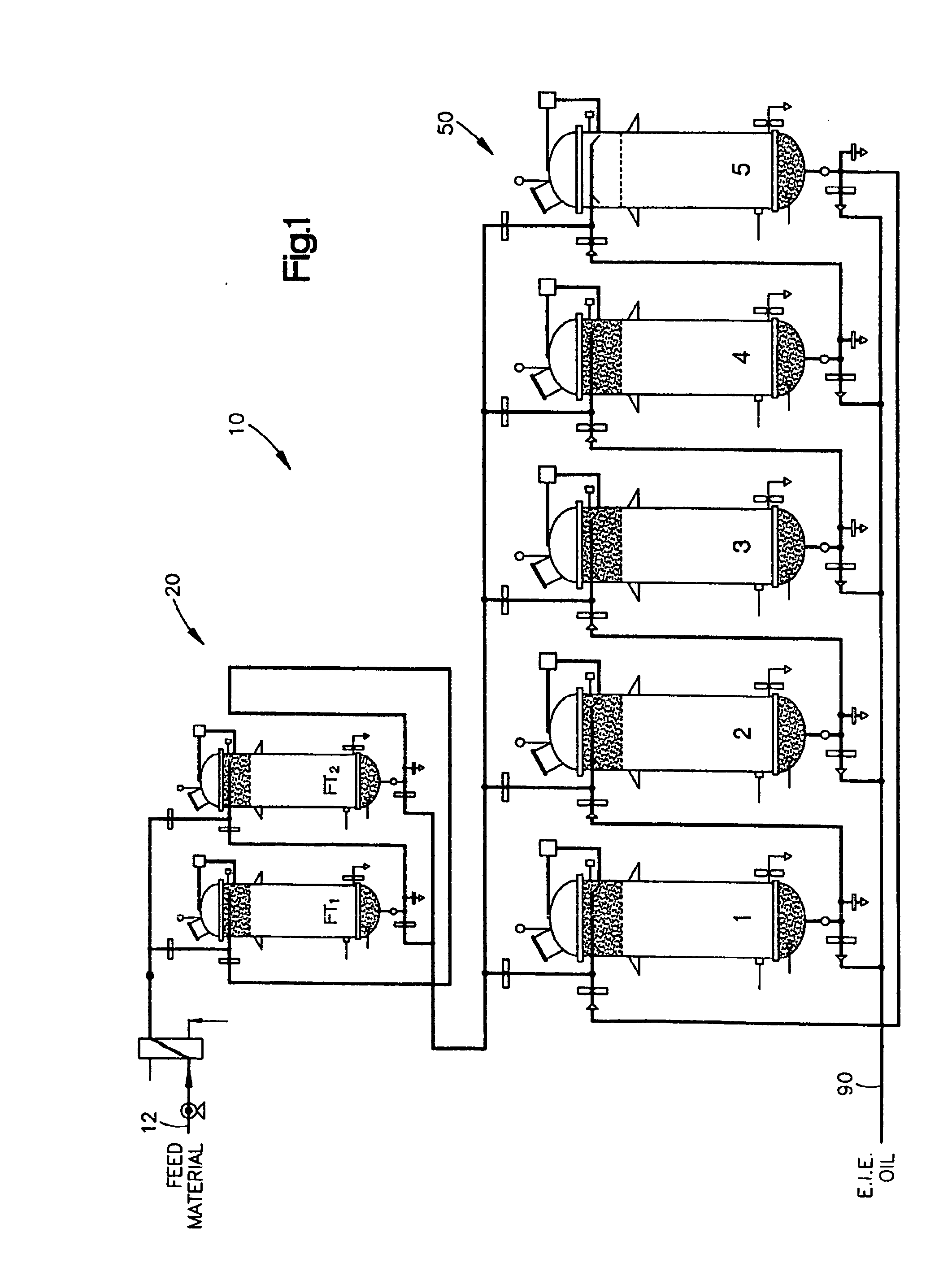

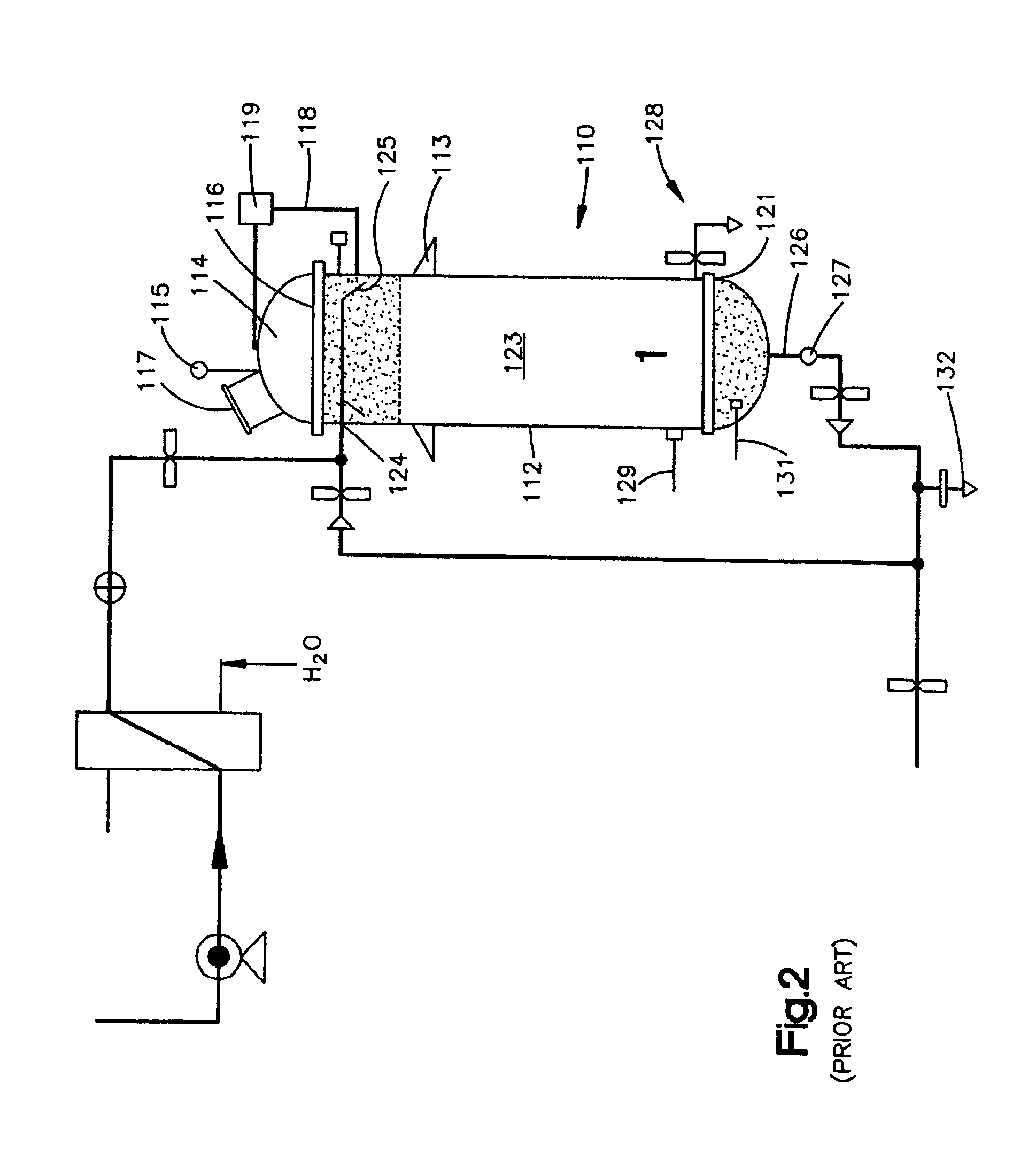

Continuous Process and Apparatus for Enzymatic Treatment of Lipids

ActiveUS20080138867A1Constant flowLess operator monitoringBioreactor/fermenter combinationsBiological substance pretreatmentsLipid formationFixed bed

A method and system for the enzymatic treatment of a lipid containing feedstock comprises contacting the feedstock with a processing aid, then causing the feedstock to pass at a substantially constant flow rate through a treatment system comprising a plurality of enzyme-containing fixed bed reactors connected to one another in series. The fixed bed reactors can be individually serviceable, the flow rate of the feedstock remaining substantially constant through the system when one of the fixed bed reactors is taken off line for servicing. In the most preferred embodiment, the processing aid is a substantially moisture-free silica. The processing aid can be placed in one or more of the fixed bed reactors, disposed above the enzyme in the reactor, or it can be in a pre-treatment system which can comprise one or more reactors.

Owner:BUNGE OILS INC

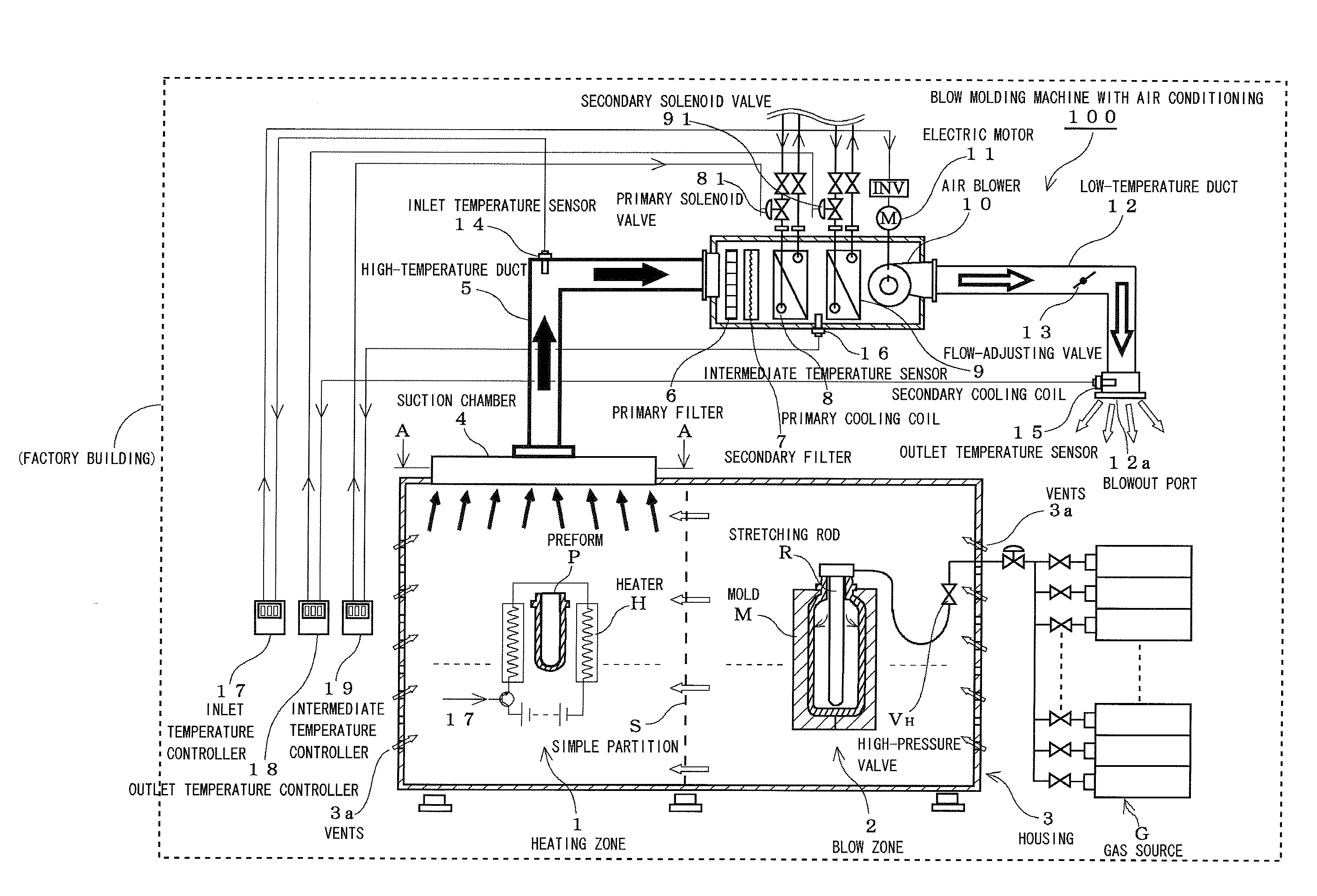

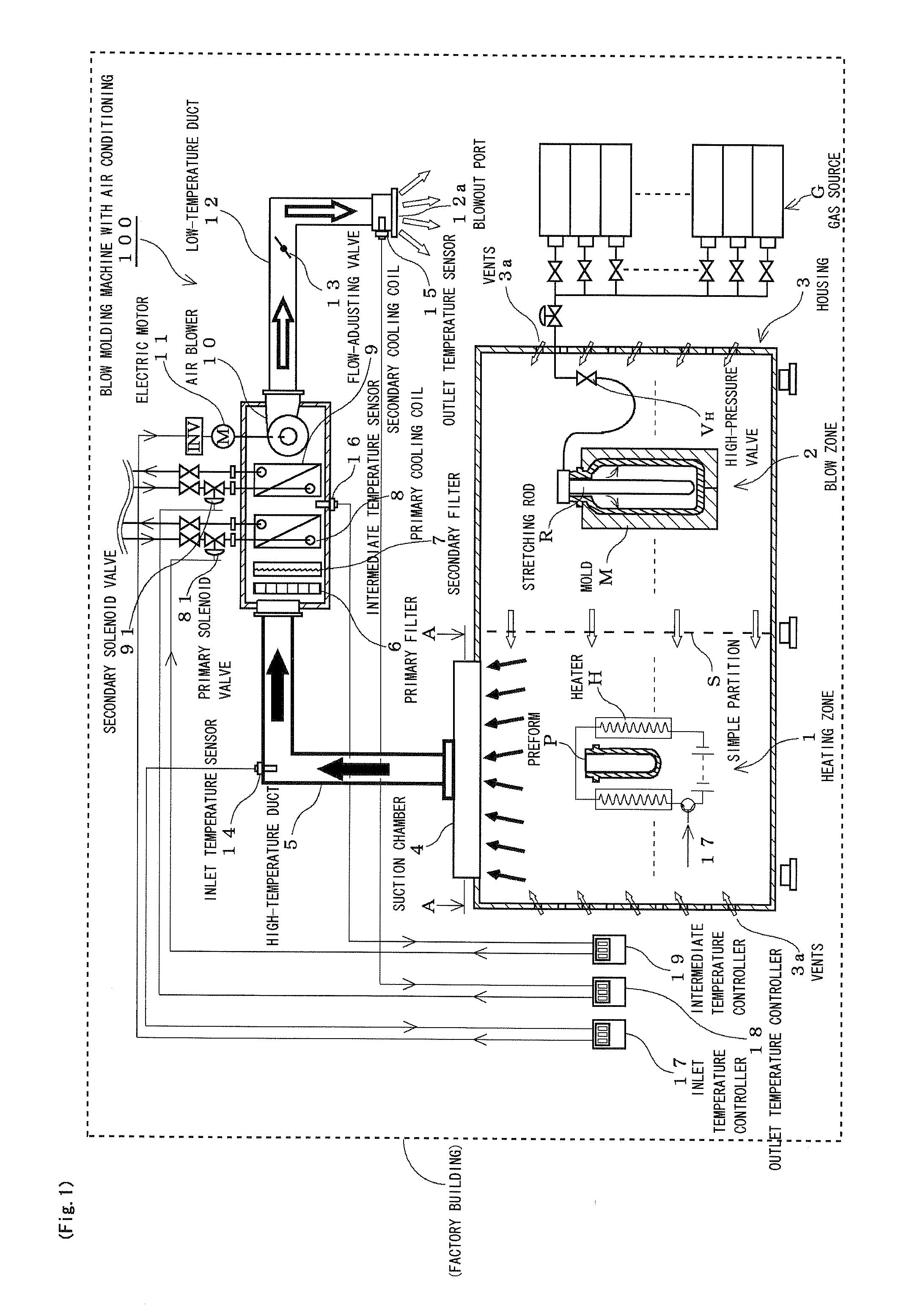

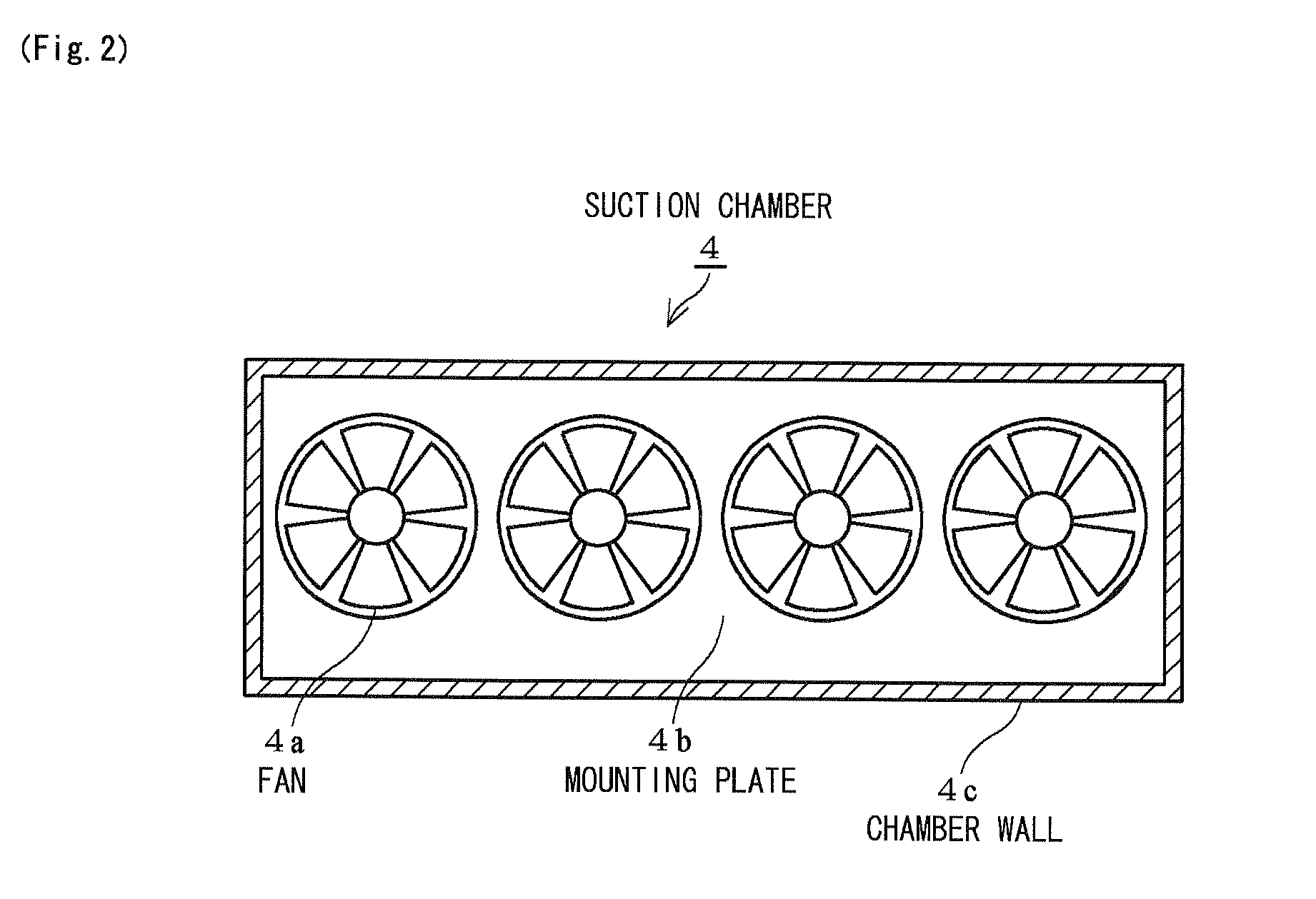

Blow molding machine with air conditioning

InactiveUS20100015269A1Avoid normal workStable temperatureAuxillary shaping apparatusBlow moldingCooling coil

A blow molding machine with air conditioning that while minimizing the introduction rate of outside air, realizes maintaining of constant temperature in not only a plant building but also the interior of a blow molding machine and production of a bottle as a final configuration with stability in its measurement value. The blow molding machine with air conditioning is constructed so that air for use in biaxially stretching blow molding together with hot air of heating zone (1) and internal air of a plant building is suctioned by means of suction chamber (4), filtered by means of primary filter (6) and secondary filter (7) into clean air, brought into heat exchange with primary cooling coil (8), fed under pressure by air blower (10) and released through low-temperature duct (12) into the interior of the plant building. Further, the construction is made so that housing (3) on its side face is provided with vent (3a) so as to allow reflux of the clean air released into the interior of the plant building and flow into the heating zone (1) and blow zone (2).

Owner:TOYO SEIKAN KAISHA LTD

Platen pump

Owner:BMR MEDICAL LTDA

Razors

ActiveUS8186063B2Efficient meteringAvoid overdoseThrusting weaponsWeapon componentsRazor stropEngineering

A razor, especially a safety razor, comprises a fluid delivery system including a pump (24) for conducting a fluid, such as a lubricant, from a reservoir (25) for application to the skin, and a control device (16) for actuating the pump (24) when the razor is brought into contact with the skin by a person holding the razor, and deactuating the pump (24) after a certain time of actuation, e.g. 0.1 to 2 seconds. The control device is arranged to ensured a delay of 1 to 10 seconds between successive actuations, and so that the pump is actuated only every second third or fourth shaving stroke.

Owner:THE GILLETTE CO

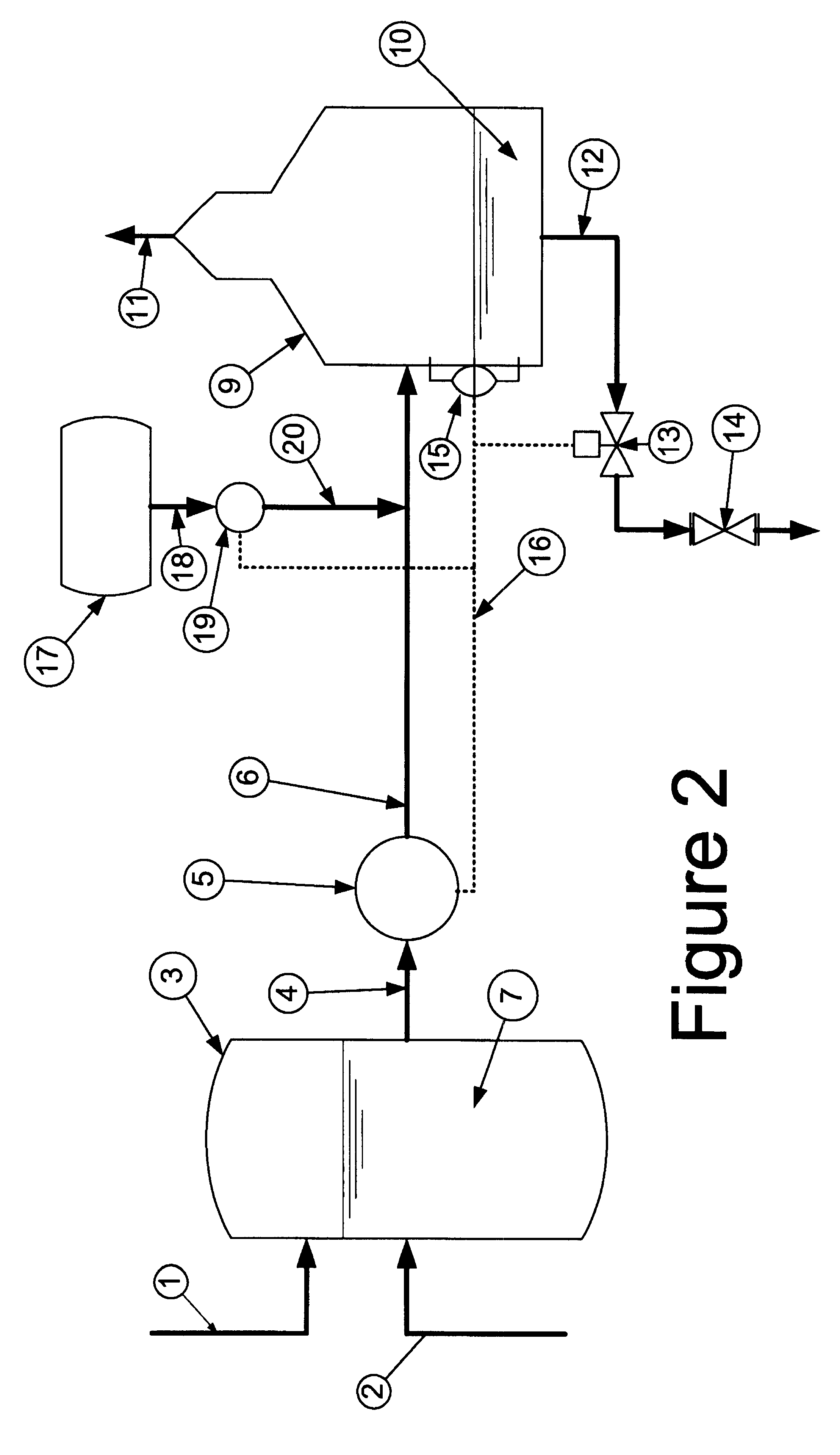

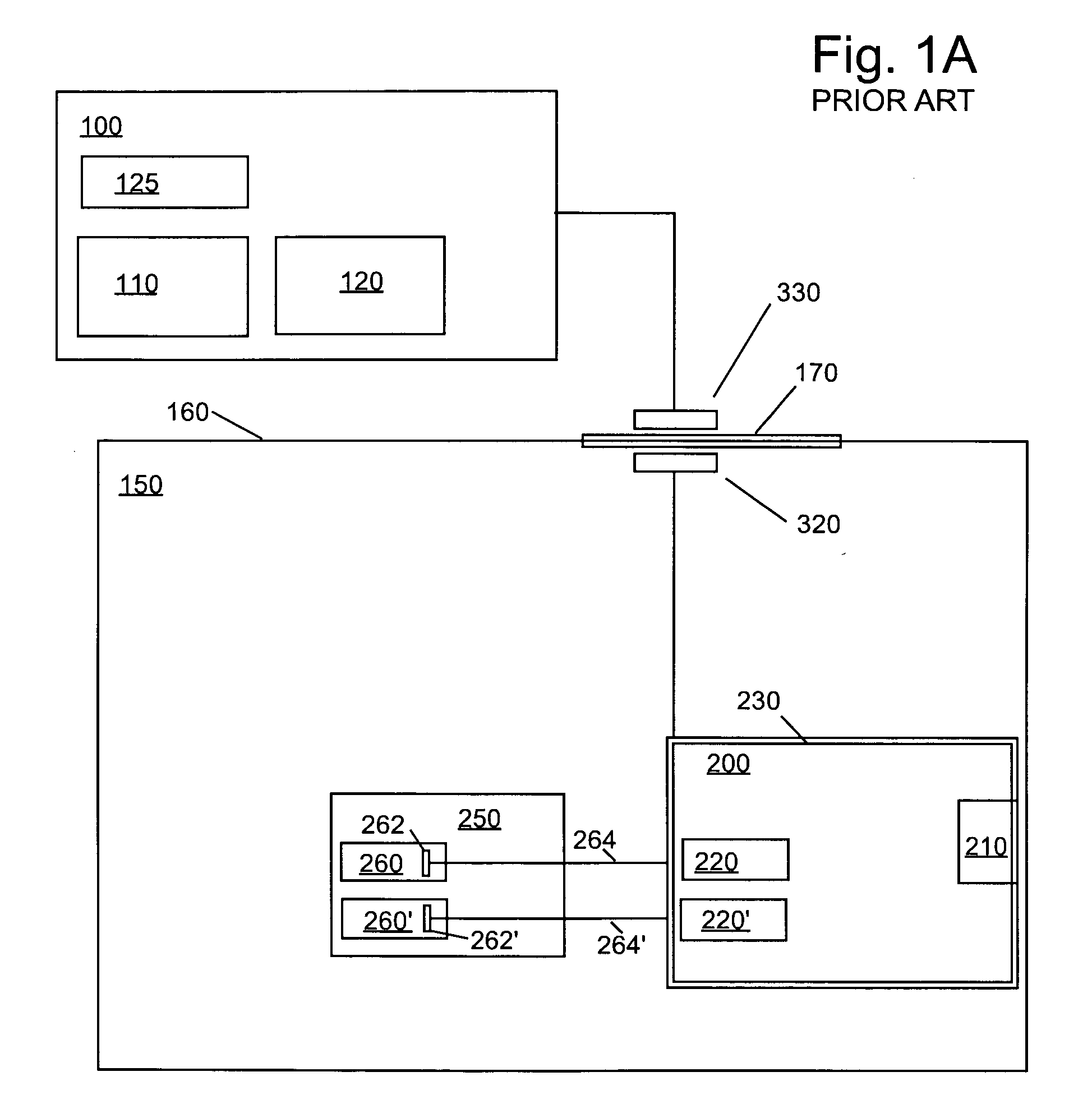

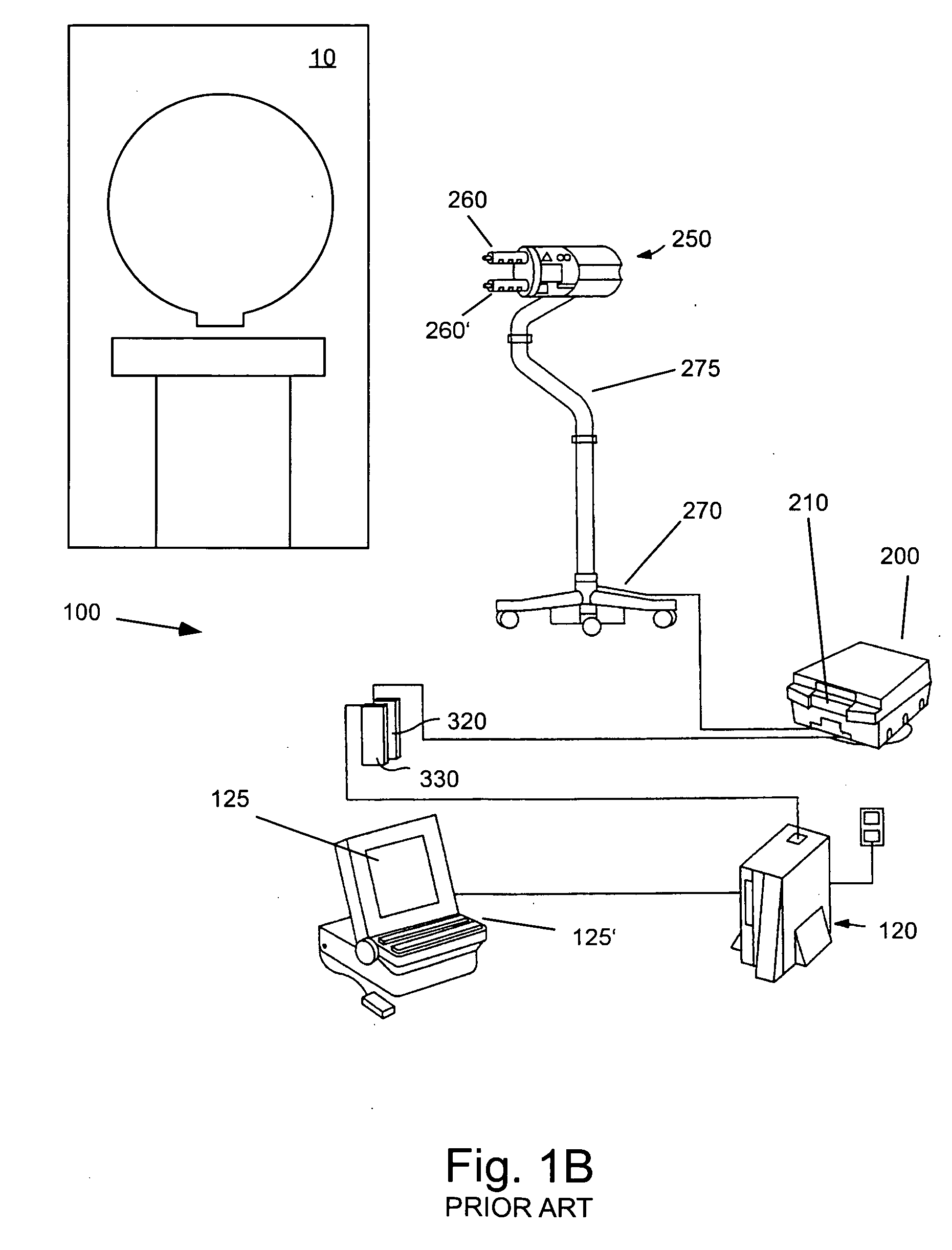

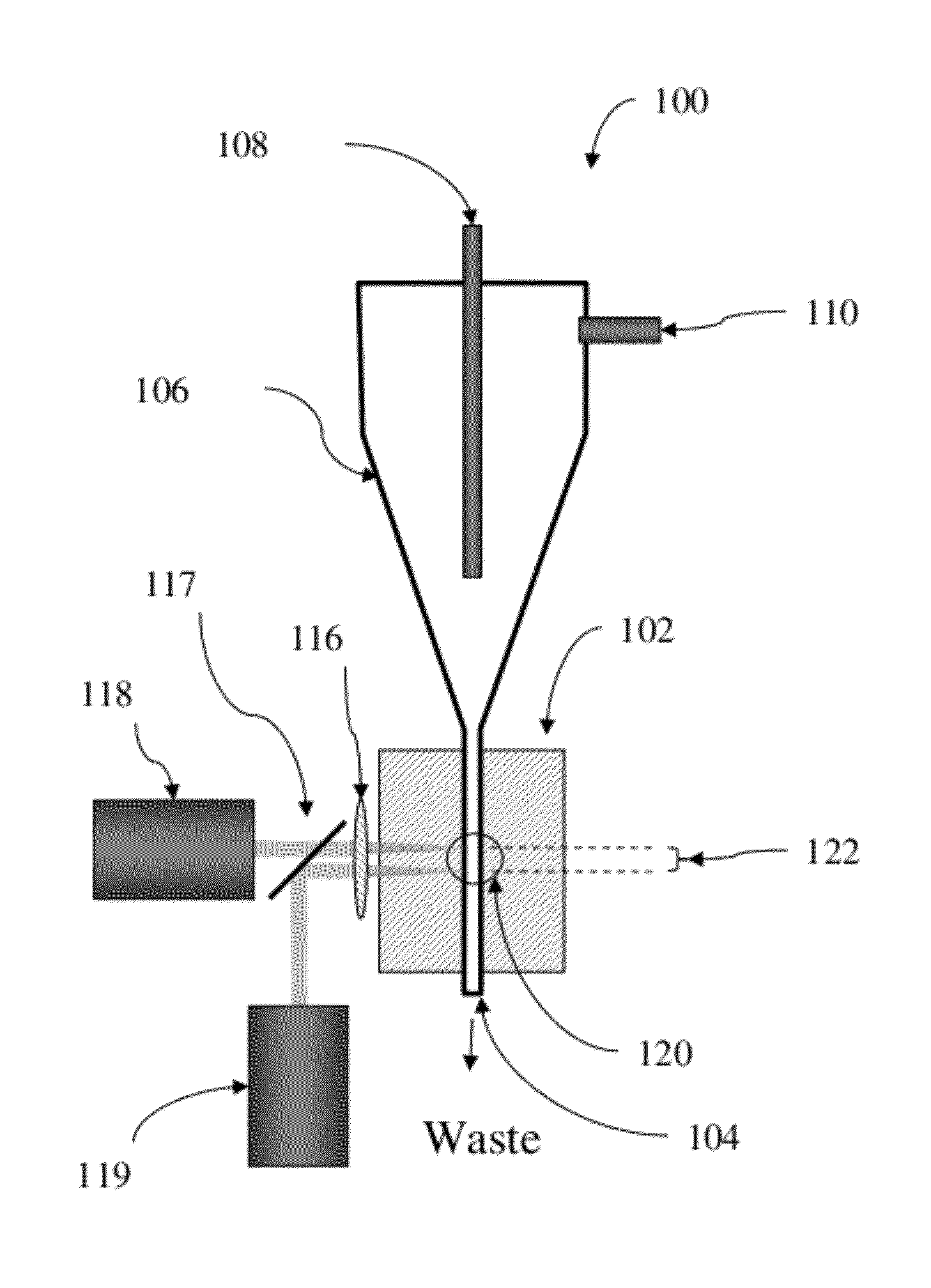

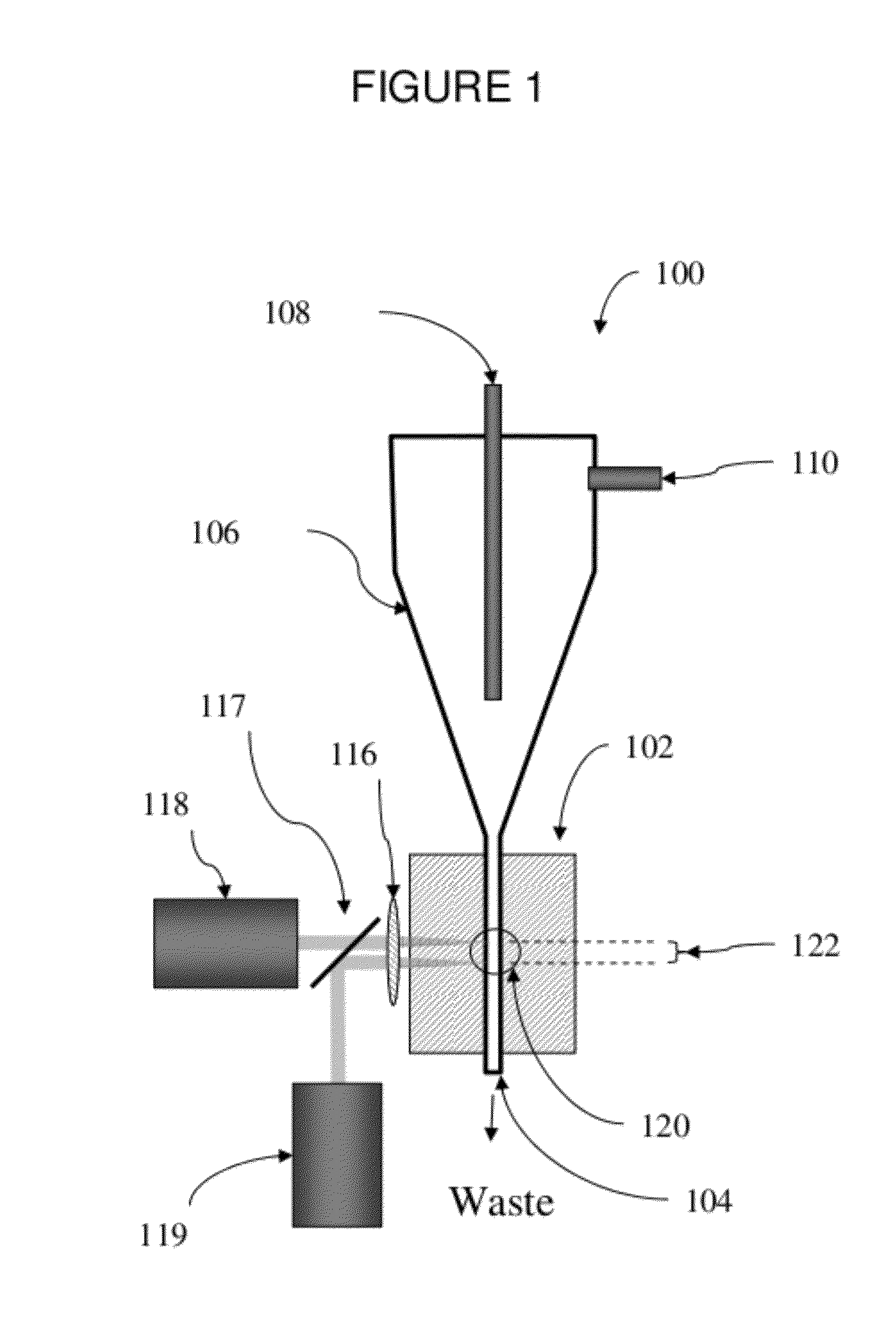

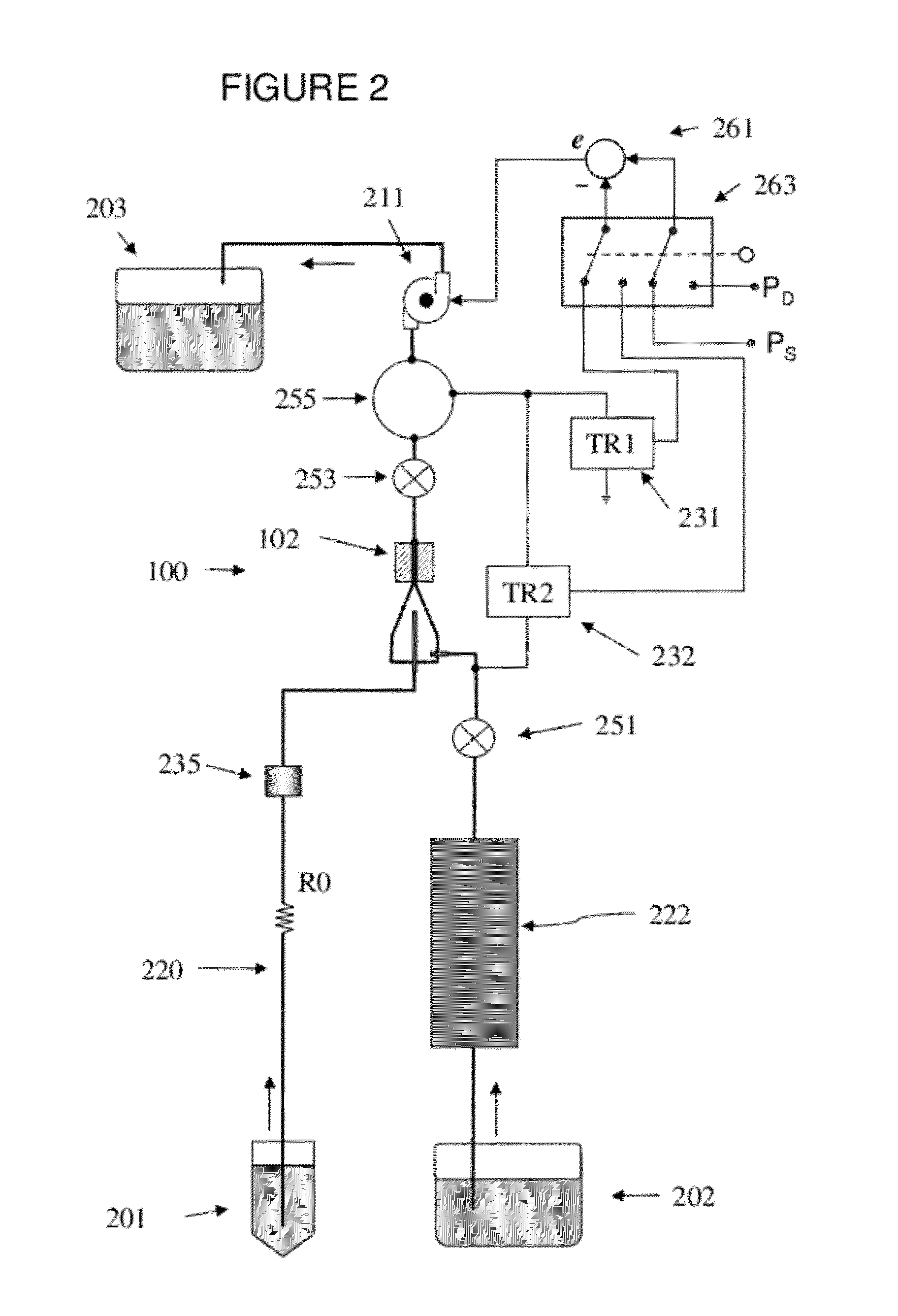

Dual feedback vacuum fluidics for a flow-type particle analyzer

ActiveUS20120103112A1Eliminate large fluctuationsConstant flowChemiluminescene/bioluminescenceWithdrawing sample devicesFluidicsFeedback circuits

The present invention relates to a vacuum-driven fluidic system for a flow-type particle analyzer. The system includes a vacuum pump which creates a pressure drop downstream of the flow cell, which pulls sheath fluid and sample fluid through the flow cell. A variable-resistance fluidic resistor is configured to control the ratio of sample fluid flow to sheath fluid flow. Dual feedback circuits, one configured to modulate the vacuum pump power in response to the pressure drop across the flow cell, referred to as the dynamic pressure drop, and a second configured to modulate the vacuum pump power in response to the pressure drop created by the vacuum pump relative to ambient pressure, referred to as the static pressure drop, are used to automatically control the system. The present invention enables adjustment of the sample fluid flow rate while maintaining a constant total fluid flow through the flow cell, and further, enables pausing the system without significant fluctuations in the vacuum.

Owner:BECTON DICKINSON & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com