Patents

Literature

1536results about How to "Large filter area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

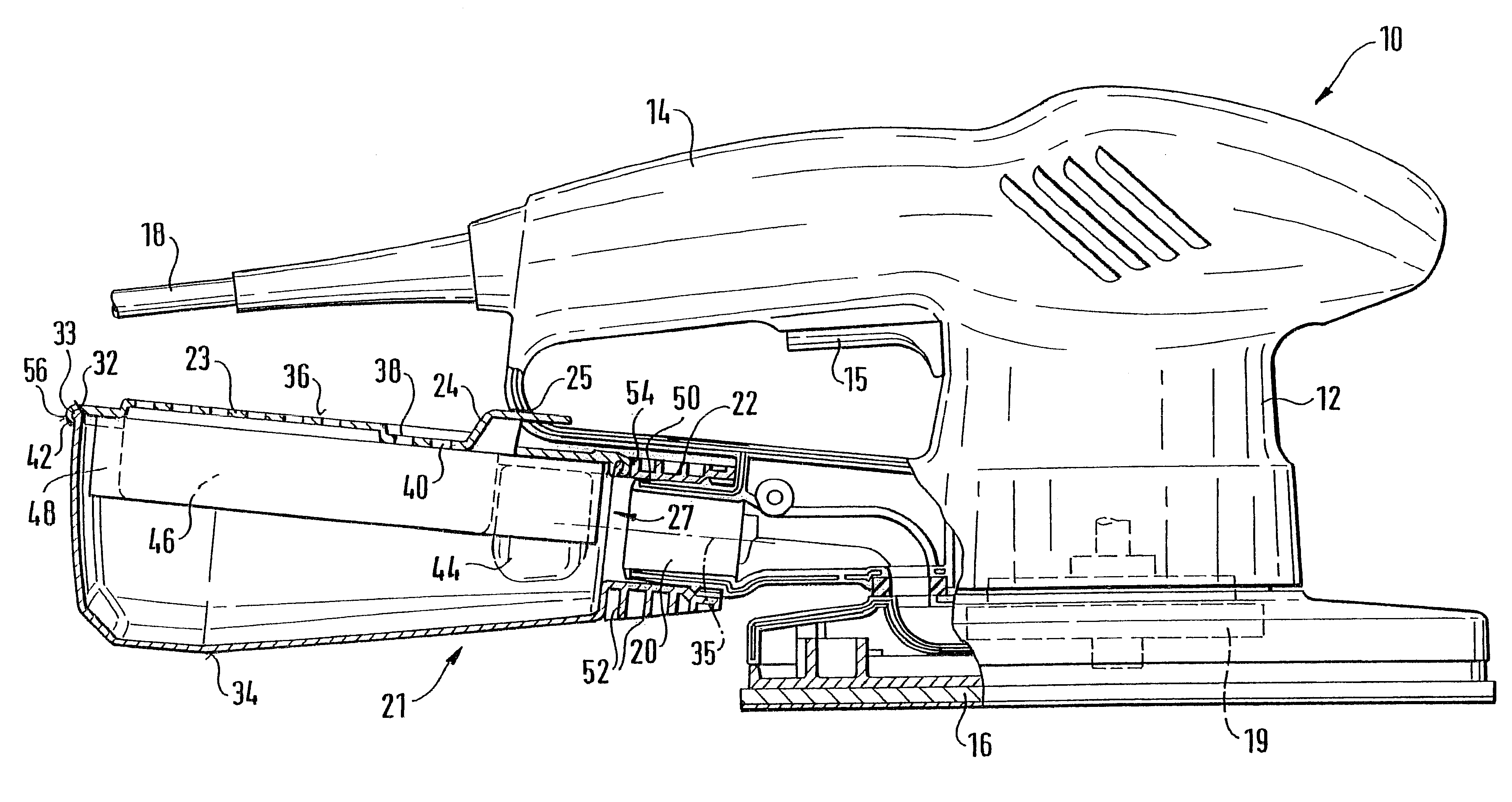

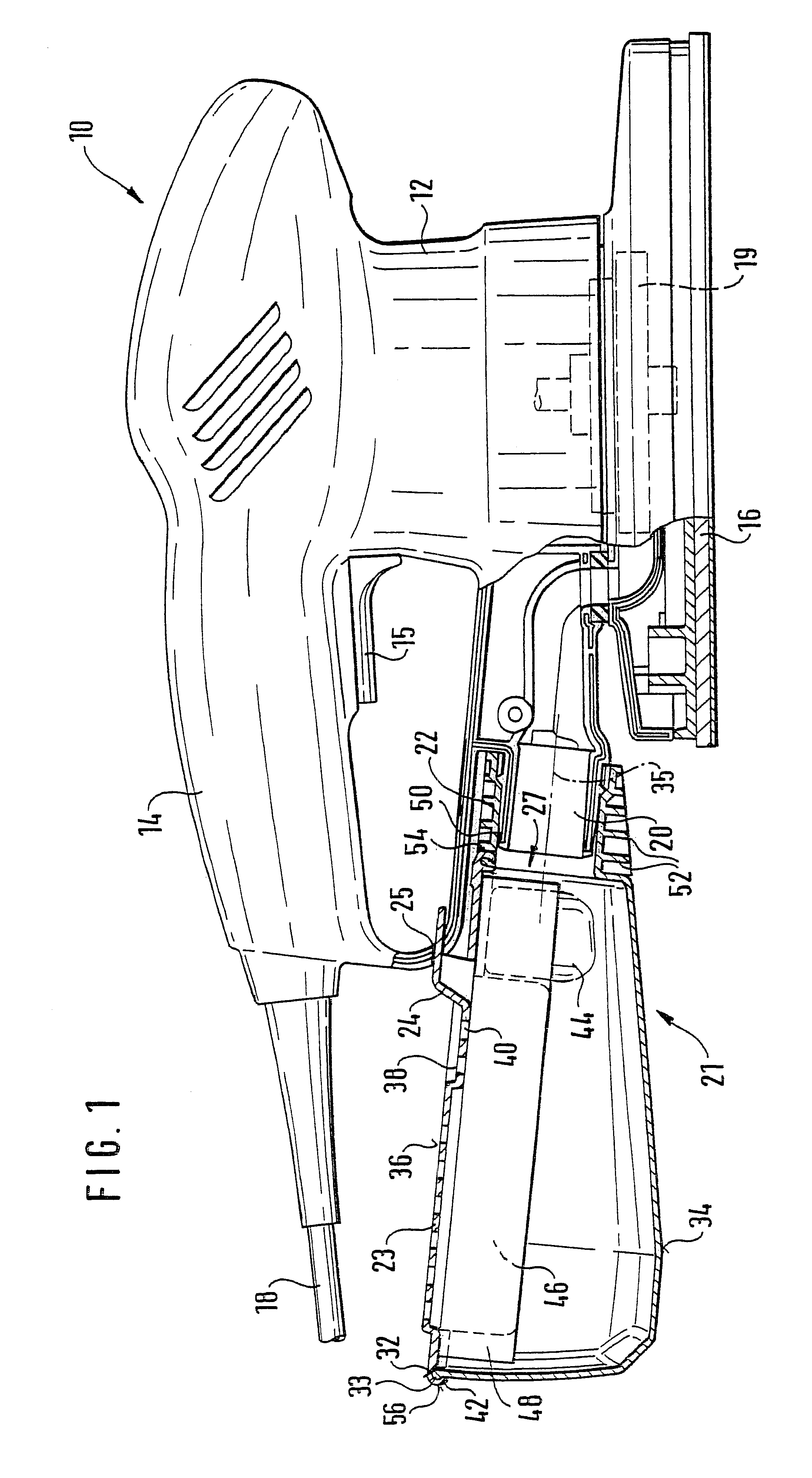

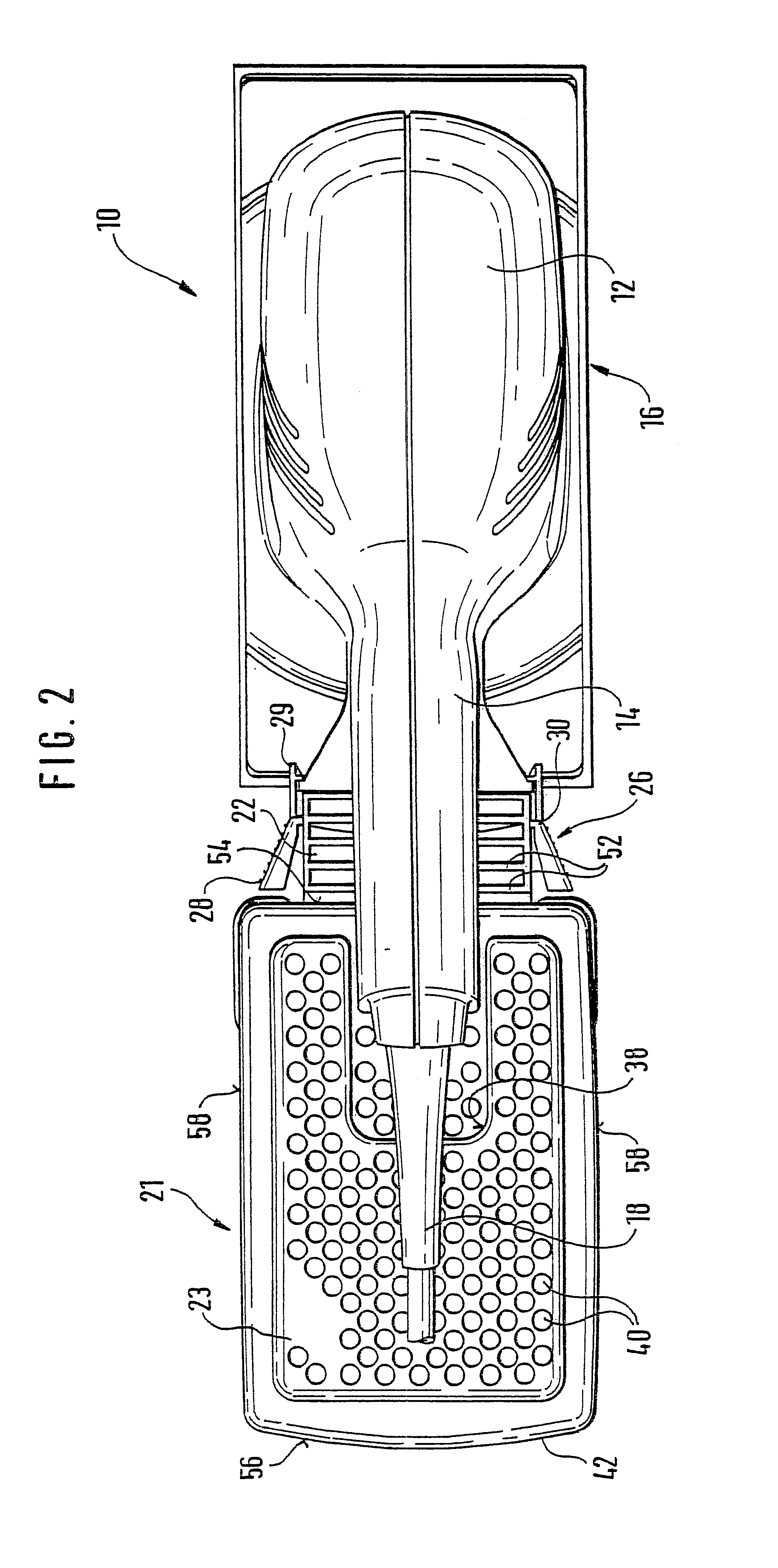

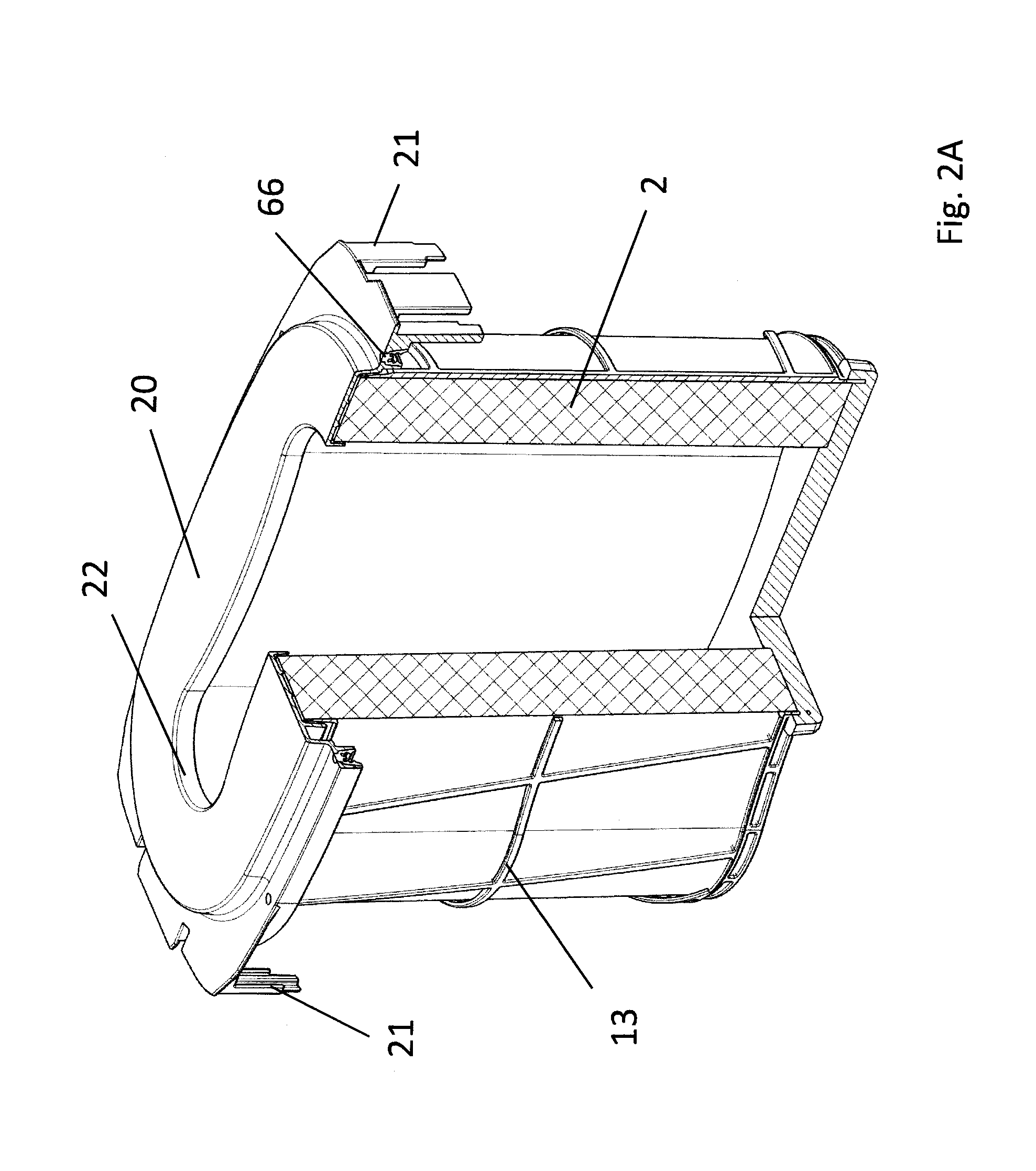

Hand-held machine tool with dust extraction

InactiveUS6514131B1Large filter areaHigh degreePortable grinding machinesMaintainance and safety accessoriesHand heldPower tool

A power tool (10) having a dust suction device (19) integrated into its housing (12) and having an ejection fitting (20) which is connected to the dust suction device (19) and can be detachably fastened with its injection fitting (22) to a dustproof dust box (21) is particularly suitable for containing sanding dust because of a number of side walls (34) of the dust box (21) have air openings (40) and on the inside, support at least one filter element (48), in particular a folded filter, which overlaps the air openings (40).

Owner:ROBERT BOSCH GMBH

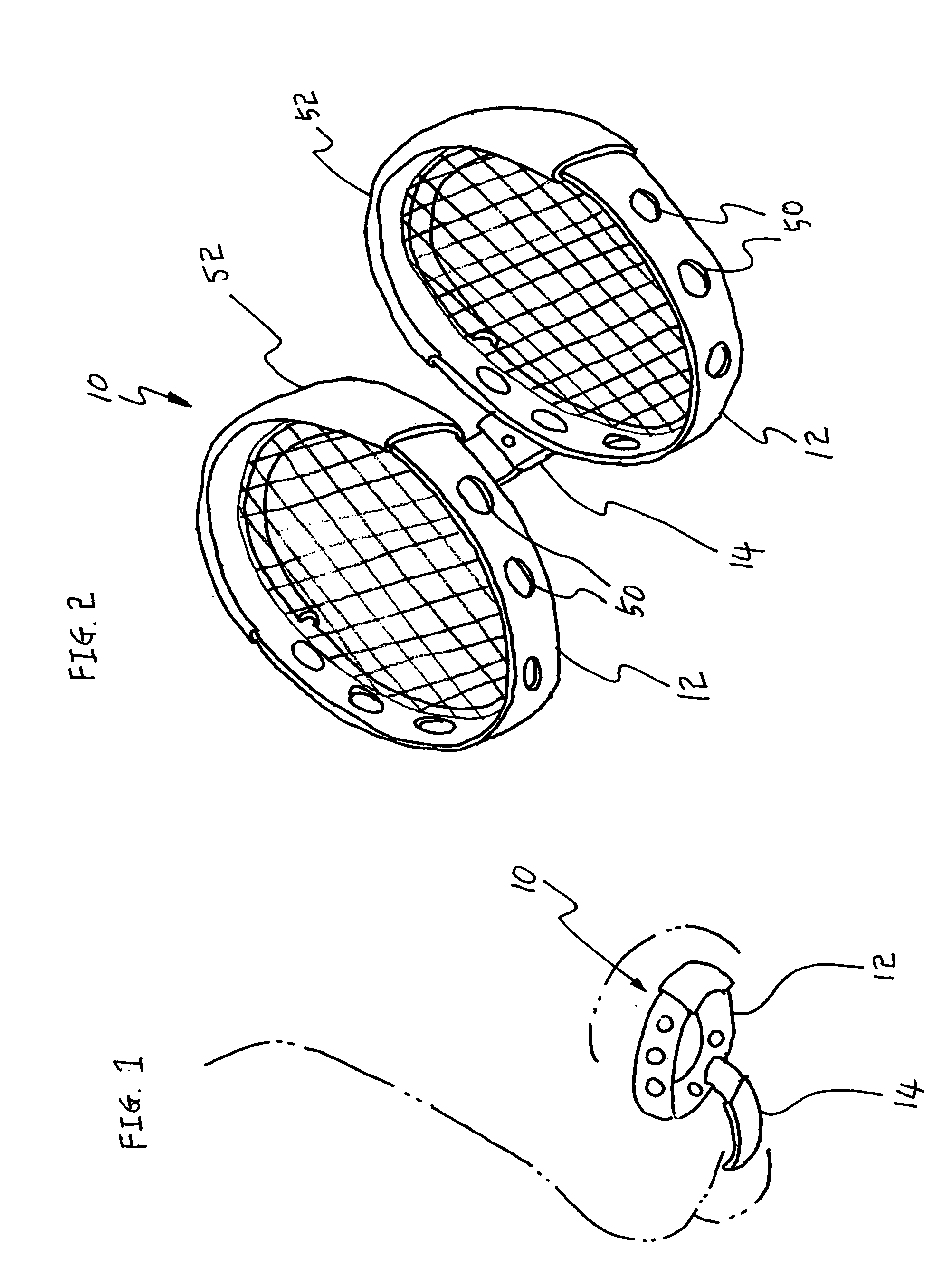

Wearable inhalation filter

InactiveUS20050051170A1Large filter areaSlow breathingRespiratorsBreathing filtersBreathing processInhalation

A wearable inhalation filter for a user to wear in her or his nostrils is provided. The filter includes two nose rings that are inserted into the nostrils, and a bridge that connects the nose rings. The nose ring includes a filter assembly for filtering air being inhaled, and the length of the bridge between the two nose rings is adjustable. The filter assembly includes a filter web having a plurality of pores, the size of which is from 4 to 25 μ. The filter web protrudes from the nose ring, and is corrugated to give wider filter area and to ease breathing. The bridge can rotate with respect to the nose ring. The distance between the bridge and the nose ring can be adjusted.

Owner:KOO MYUNG HOE

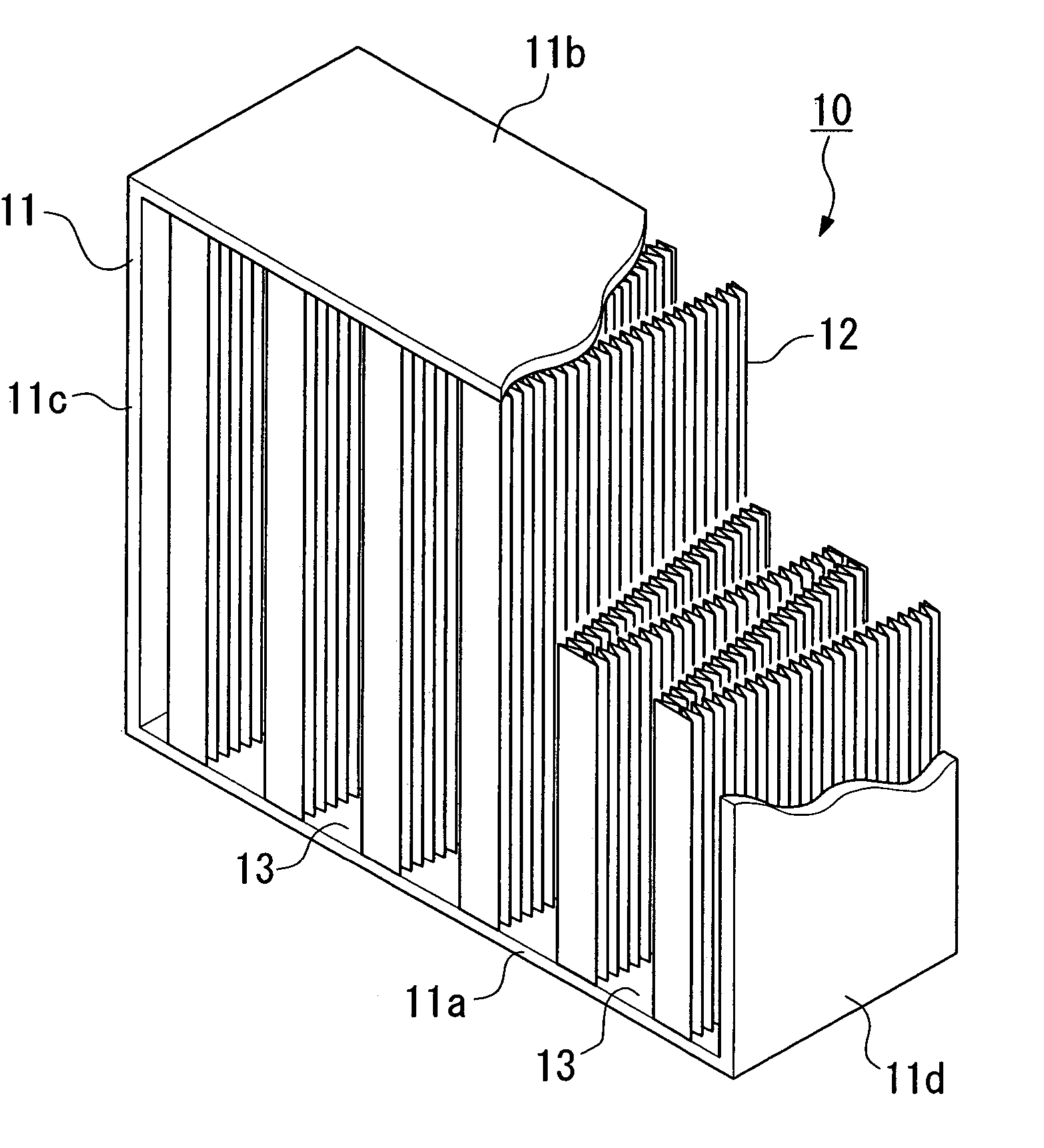

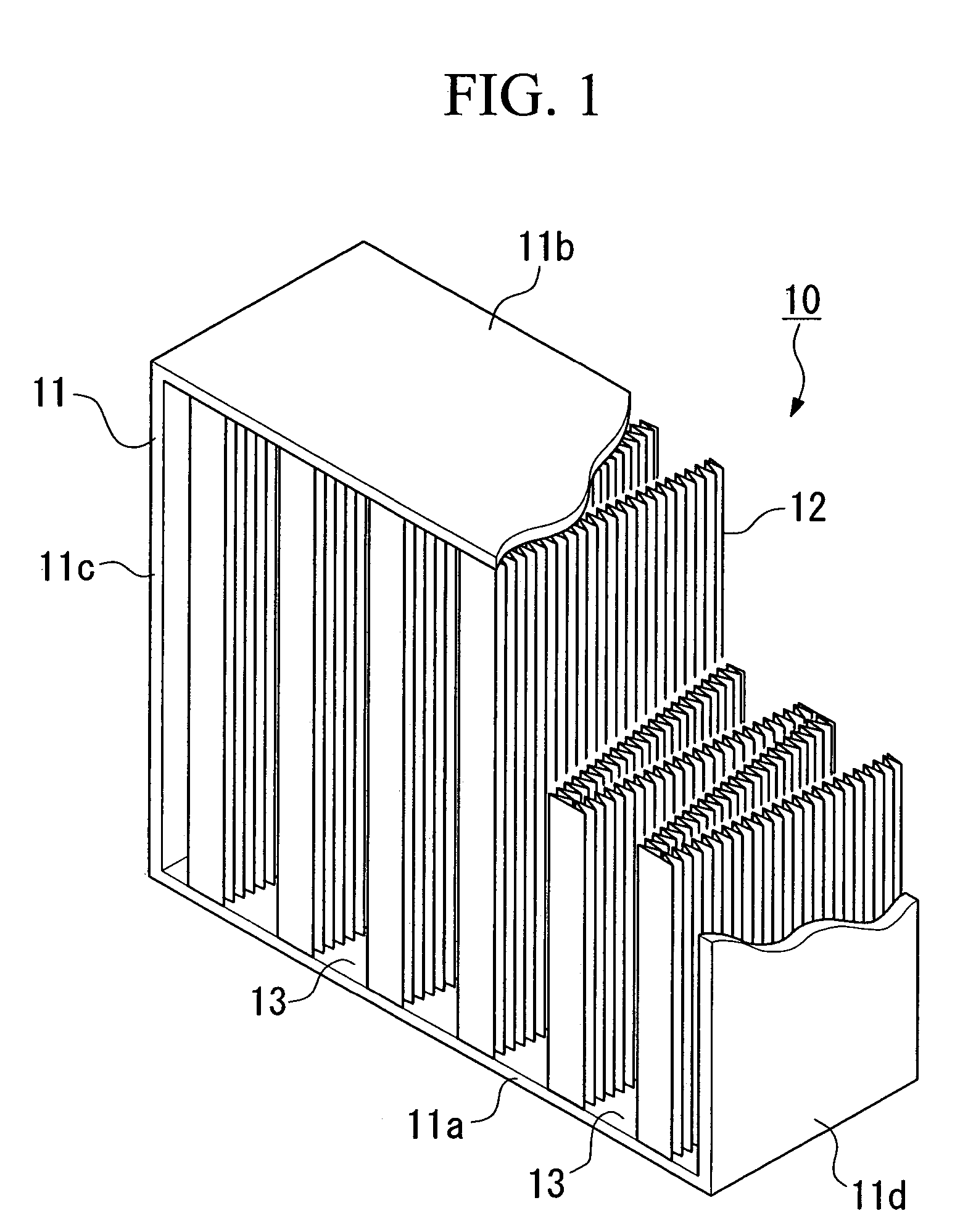

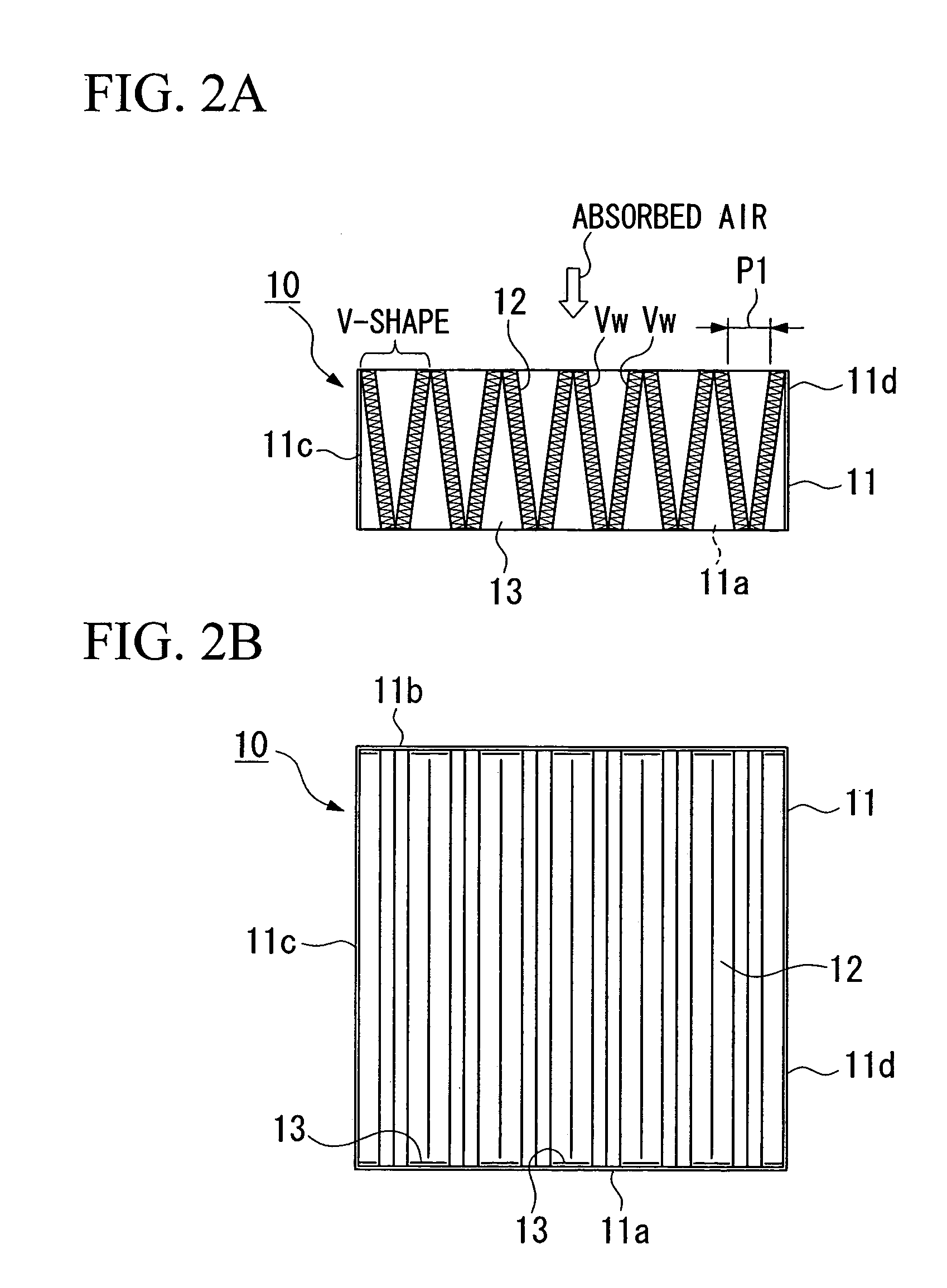

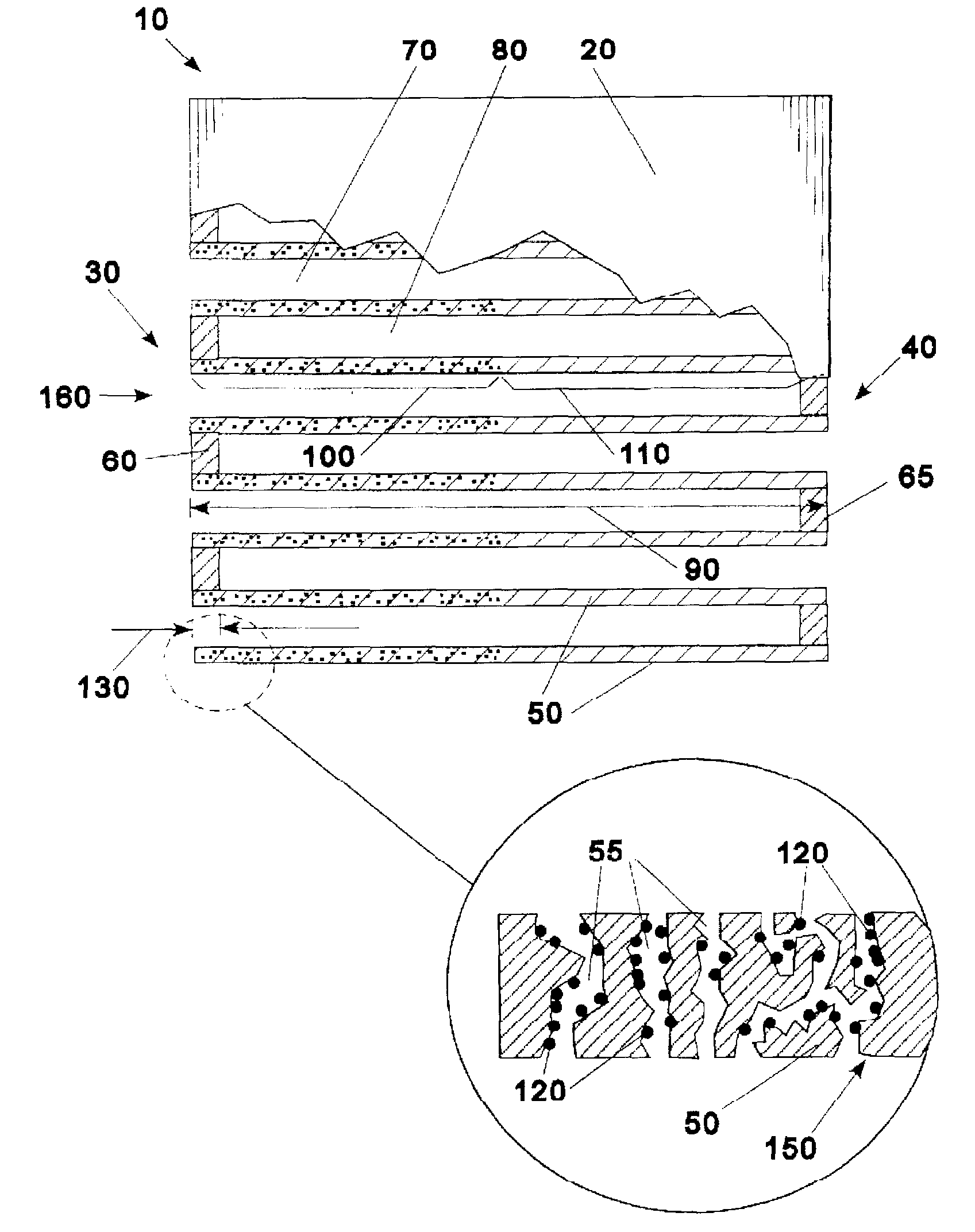

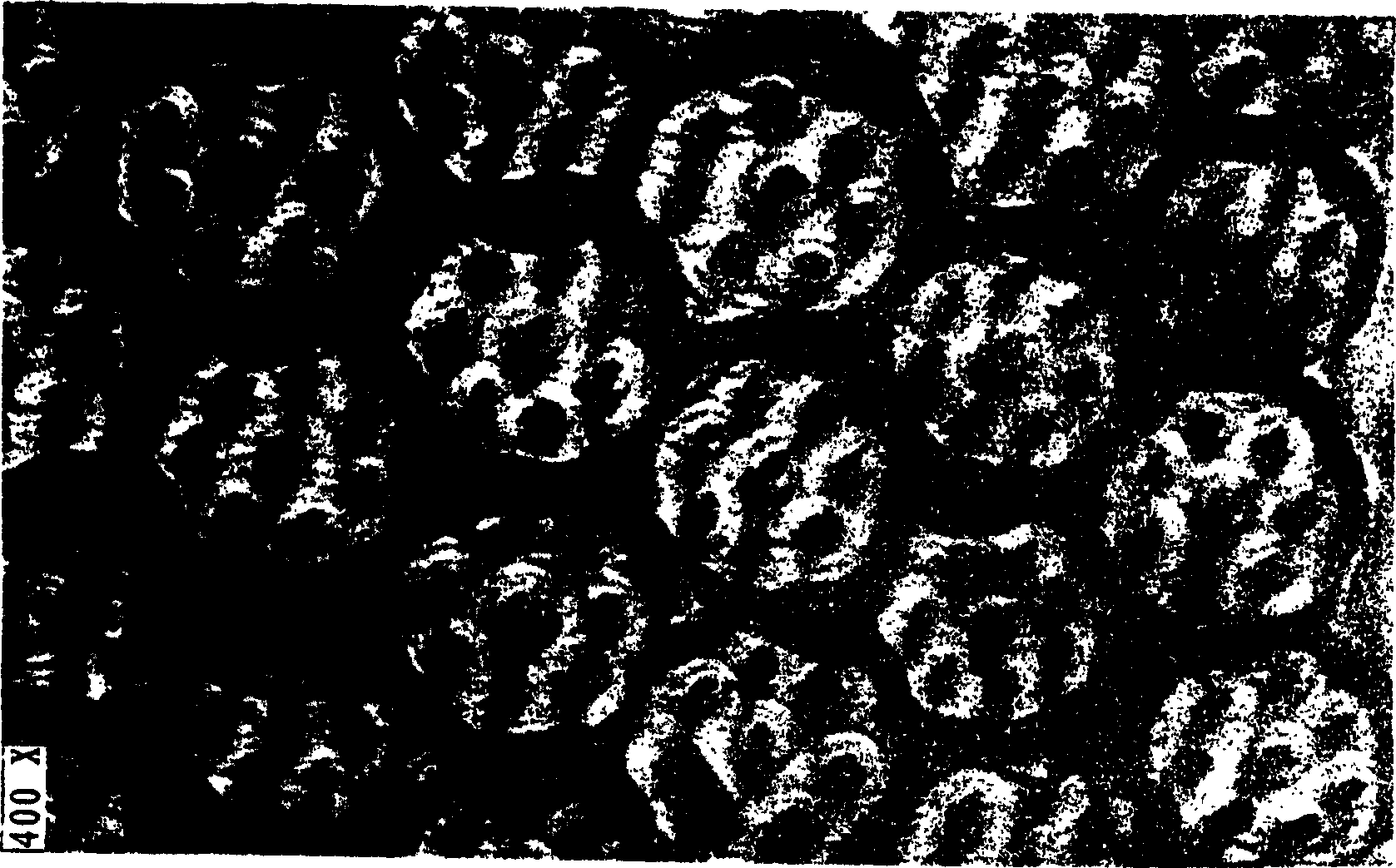

Dust collecting filter, dust collecting device, and air intake device for gas turbine

InactiveUS7048501B2Improve dust collection efficiencyImprove efficiencyCombination devicesPump componentsHEPAFilter media

A large capacity HEPA filter is produced having a layered filter medium unitarily formed by an upstream non-woven fabric, which can remove 70 to 90% of 0.3 μm particles, and a downstream non-woven fabric, which can remove 99.9% of 0.3 μm particles or more. The layered filter medium is shaped as a mini pleat shape in a thickness direction and an entire shape in the thickness direction is a plurality of continuous Vs. Also, a dust collecting device having such a large capacity HEPA filter is produced and an air intake device for a gas turbine is provided with such a dust collecting device.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

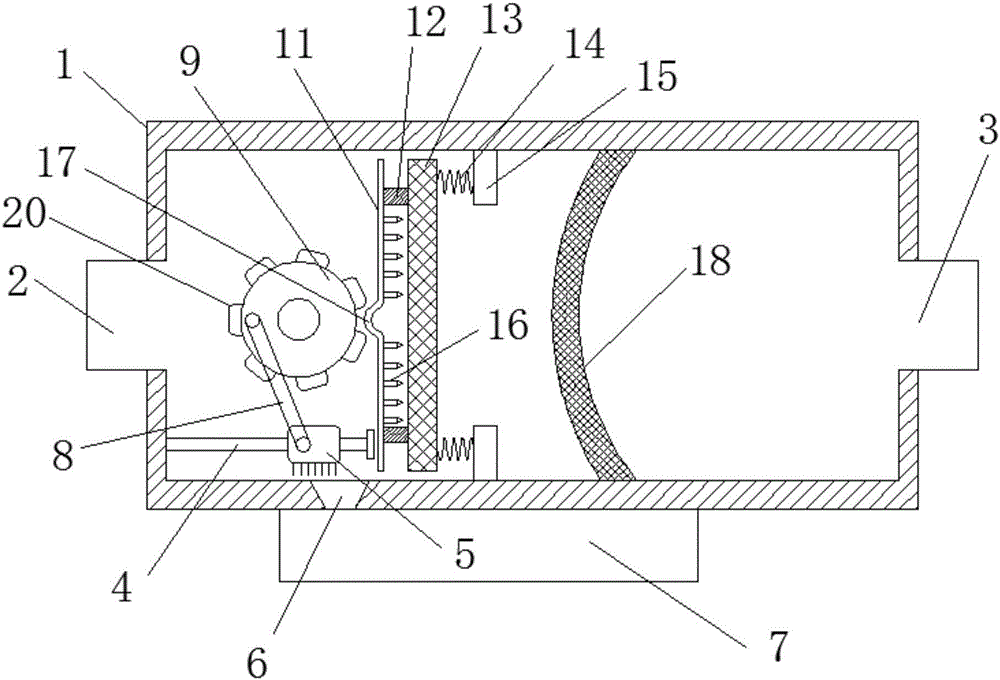

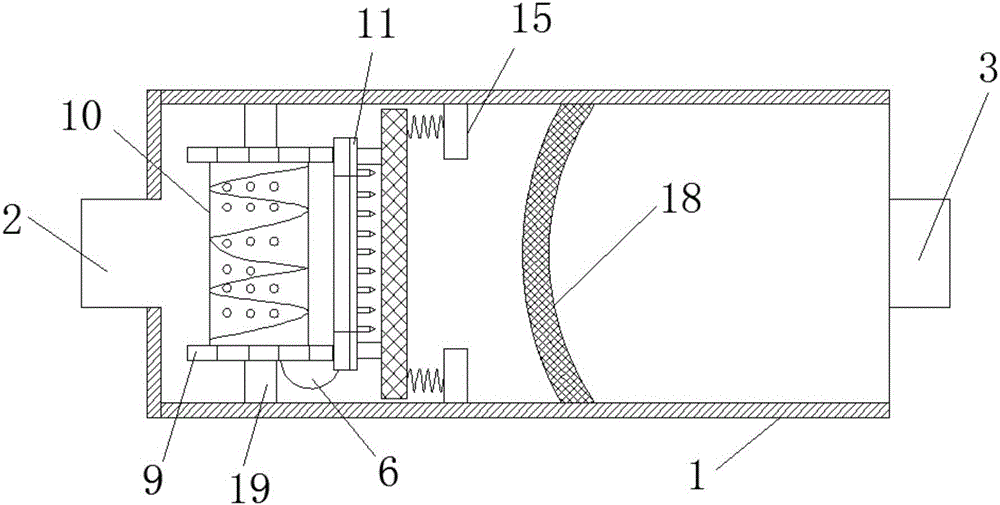

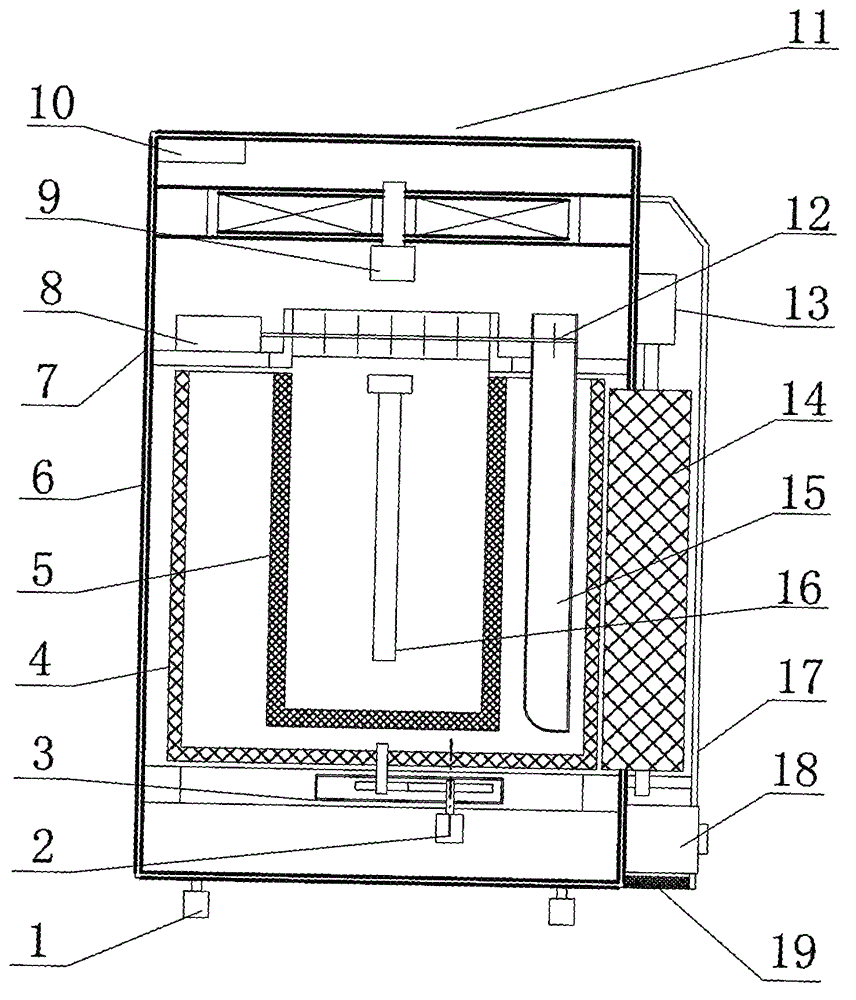

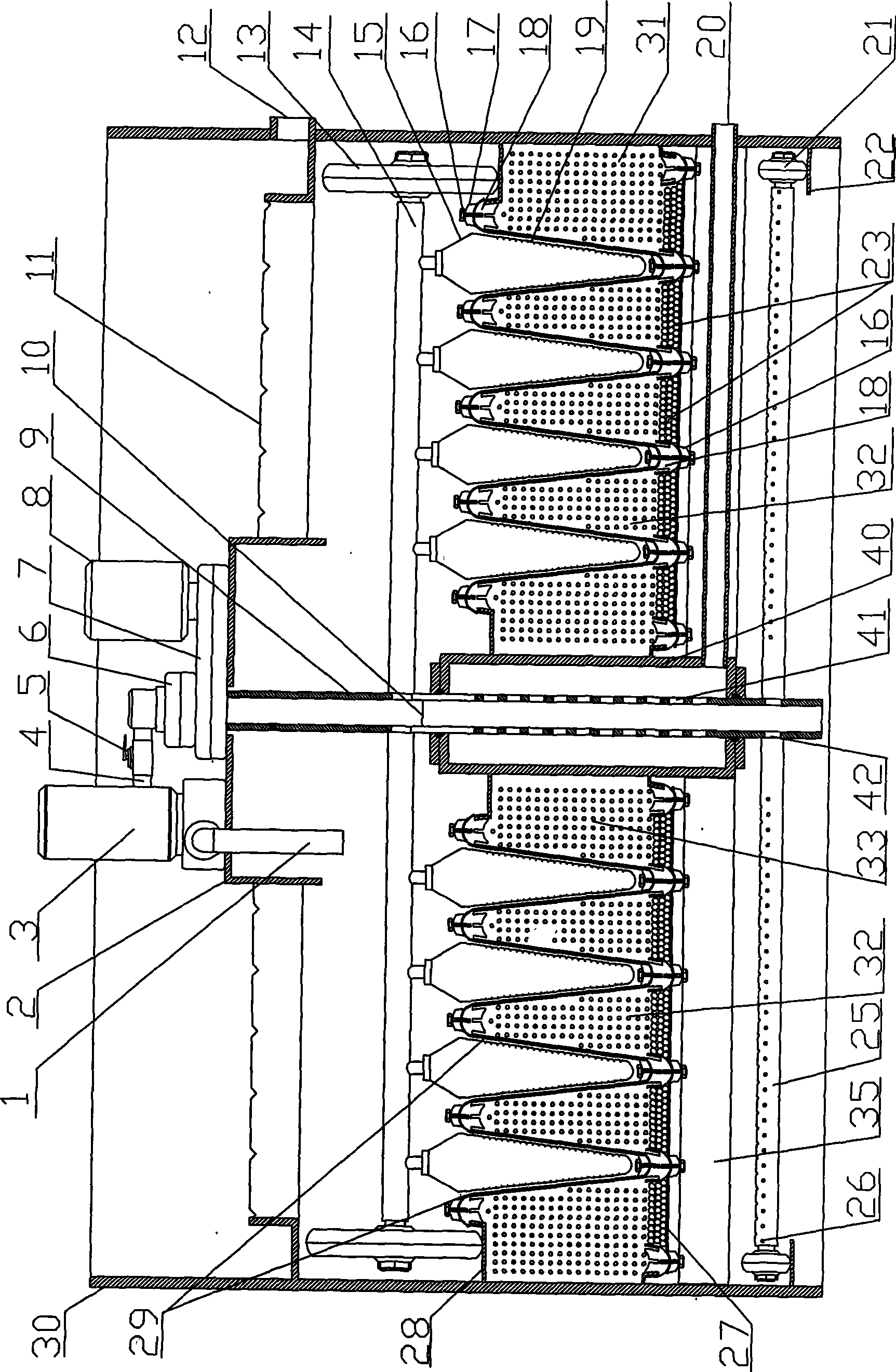

Environment-friendly wastewater filtering device

The invention discloses an environment-friendly wastewater filtering device. The environment-friendly wastewater filtering device comprises a box body, a water inlet, a water outlet, a drain outlet and a collecting bin, wherein the box body is of a cuboid hollow structure, the water inlet and the water outlet are formed in two ends of the box body respectively, the drain outlet is formed in the lower end of the box body and is in communicated connection with the collecting bin, and a slide rod is perpendicularly fixedly connected to the sidewall of an inner cavity of the box body. The environment-friendly wastewater filtering device has the advantages that the environment-friendly wastewater filtering device is simple in structure; a sleeve brush arranged inside the filtering box body is used for sweeping filtered residues; flow dynamic of the filtering device pushes a filtering roller to rotate by passing through a spiral groove in the surface of the filtering roller so as to drive a rotary disk to rotate; through addition of a combined structure of a movable rod, the sleeve brush and the slide rod, the sleeve brush can reciprocate linearly on the slide rod according to a mechanism connection relation of theoretical mechanics, so that dirt of the box body is drained into the drain outlet so as to complete dirt clearing.

Owner:JIANGXI ACADEMY OF SCI

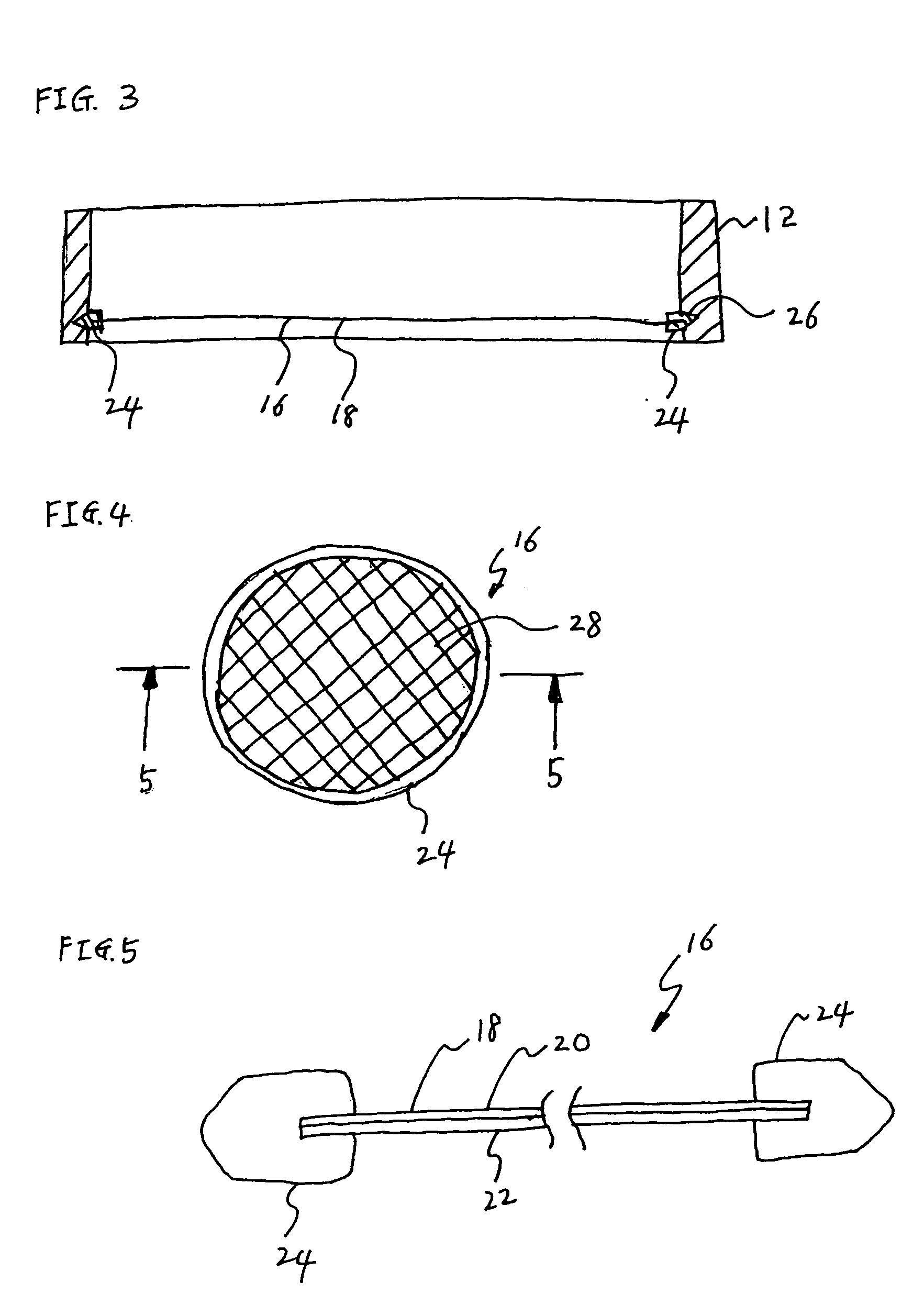

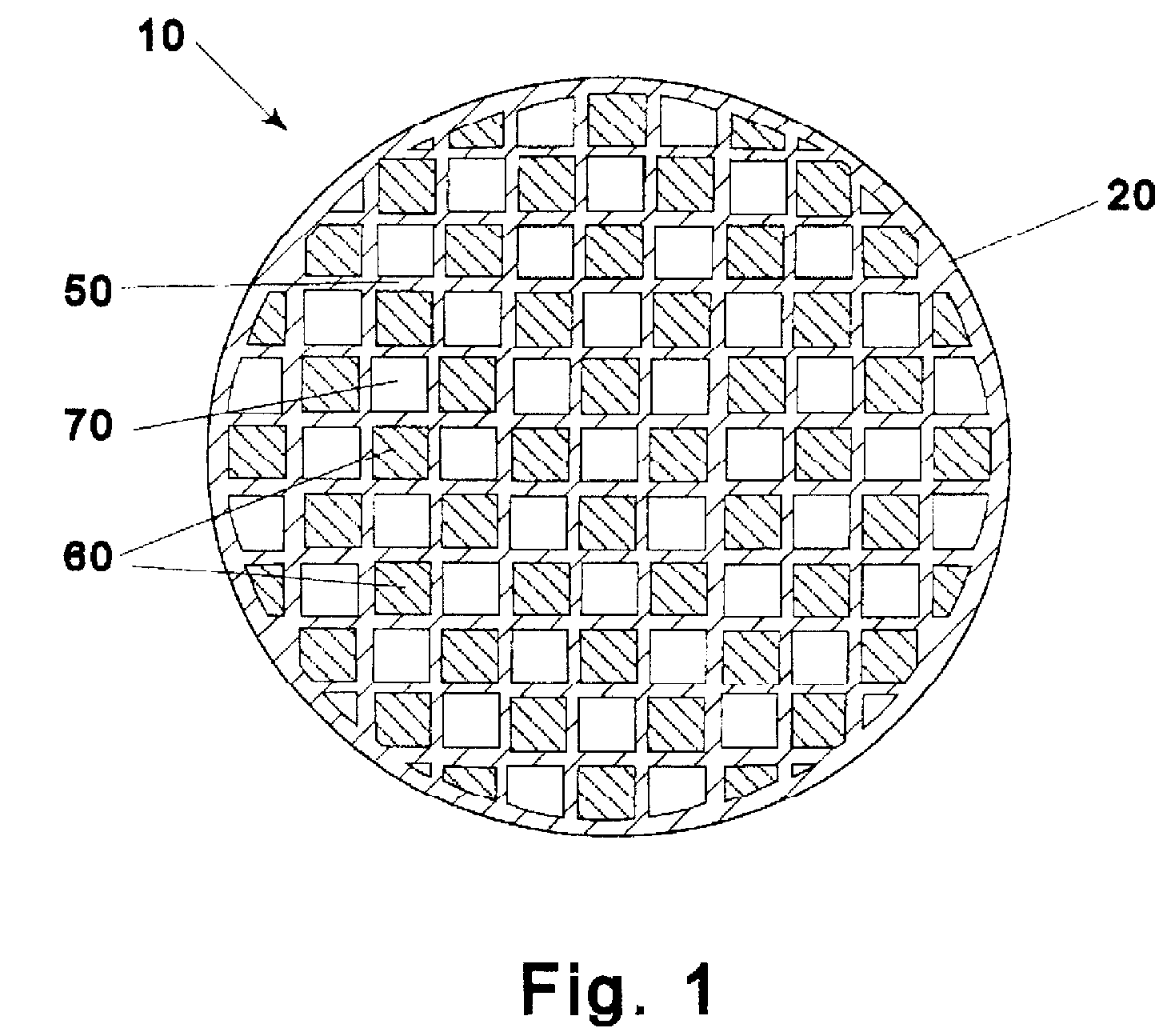

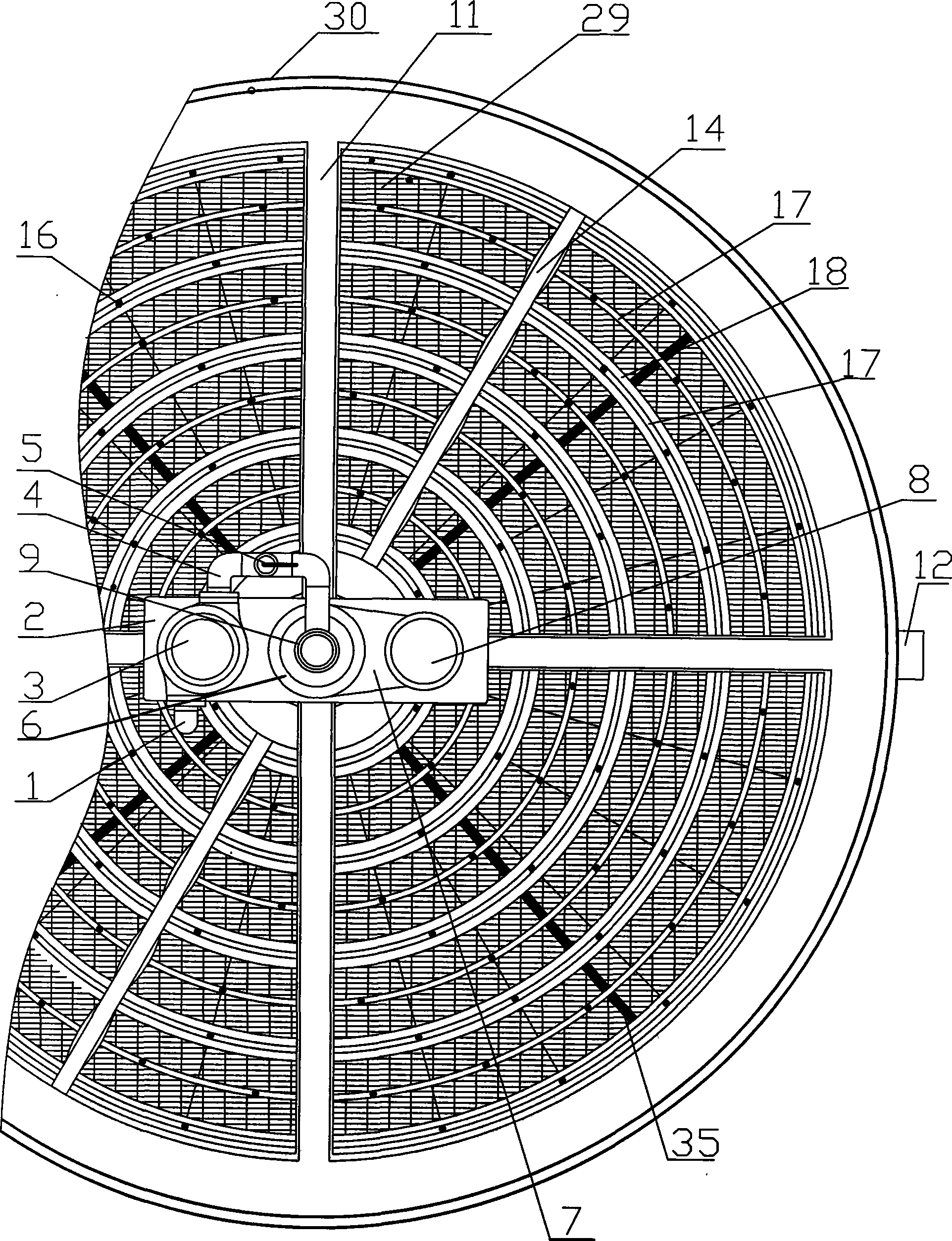

Disc shaped regulated drip irrigation emitter

ActiveUS8511586B2Constant flowLarge filter areaClimate change adaptationWatering devicesWater filterDrip irrigation

A drip irrigation emitter includes a disc shaped body having a pressure reducing labyrinth between a water inlet area and an outlet hole, and a pressure regulating diaphragm changing flow through the outlet hole in response to water pressure fluctuations in the water conduit where the emitter is mounted. The water filtering inlet of the emitter is located entirely at the sides of the disc shaped body.

Owner:RIVULIS PLASTRO LTD

Preparation method of layer-by-layer self-assembled hollow fiber forward osmosis membrane

ActiveCN108325400ALess materialSimple production processSemi-permeable membranesGeneral water supply conservationHollow fibreFiber

The invention discloses a preparation method of a layer-by-layer self-assembled hollow fiber forward osmosis membrane. The preparation method comprises the steps of: preparing hollow fiber forward osmosis base film, modifying hollow fiber ultrafiltration base film, repeating layer-by-layer assembly of polycation and polyanion layers, performing interface cross-linking polymerization for preparinga selective functional layer, conducting moisturizing, and carrying out treatment and storage so as to prepare the layer-by-layer self-assembled hollow fiber forward osmosis membrane. The surface of the hollow fiber self-support base film which is prepared by using a phase conversion method is activated firstly, layer-by-layer assembly of polycation and polyanion is repeated on the surface of thefilm so as to form an functional polarization layer for an electrolyte solution, and the polyamide selective layer is prepared through interfacial chemical cross-linking polymerization. The prepared hollow fiber forward osmosis membrane has a controllable thickness and an internal polarization layer with a high charge capacity, and the internal concentration polarization phenomenon can be alleviated effectively during the forward osmosis process; therefore, the hollow fiber forward osmosis membrane can simultaneously obtain high flux and low reverse salt flux, has high filtration separation efficiency, easy cleaning and a long service life, and can be widely applied to seawater desalination and concentration and desalination of brine.

Owner:西安金藏膜环保科技有限公司

Zone catalyzed soot filter

InactiveUS7772151B2Improve combustionIncrease resistanceCombination devicesDispersed particle filtrationPorositySoot

A catalyzed soot filter is comprised of a monolithic ceramic honeycomb body that has a catalyzed inlet zone that has a catalyst within the walls of the ceramic honeycomb inlet end to at most about 45% of the length of the catalyzed soot filter. The catalyzed inlet zone has a porosity that is at least ⅓ the porosity of a wall of the ceramic honeycomb that does not have a catalyst in the wall.

Owner:DOW GLOBAL TECH LLC

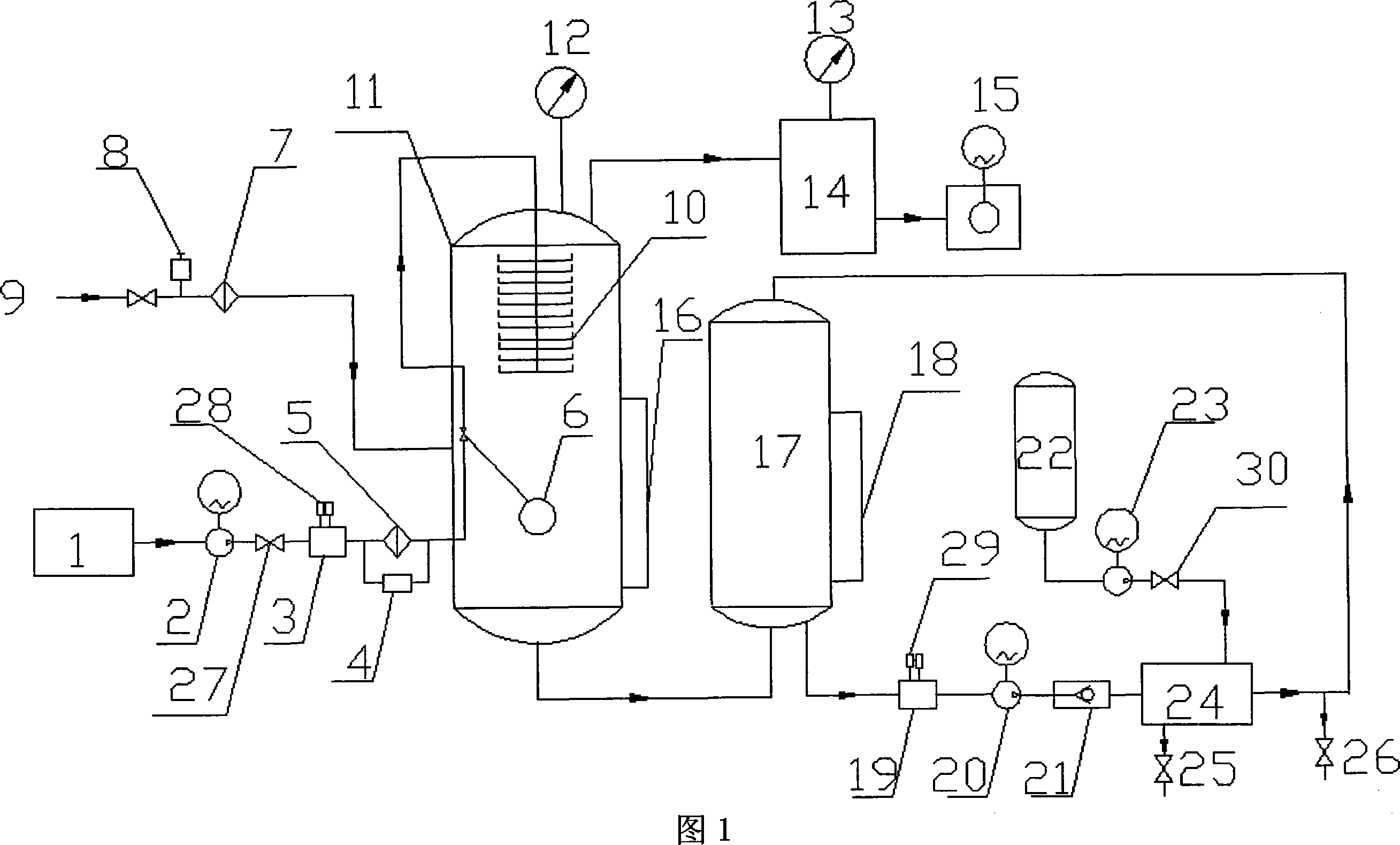

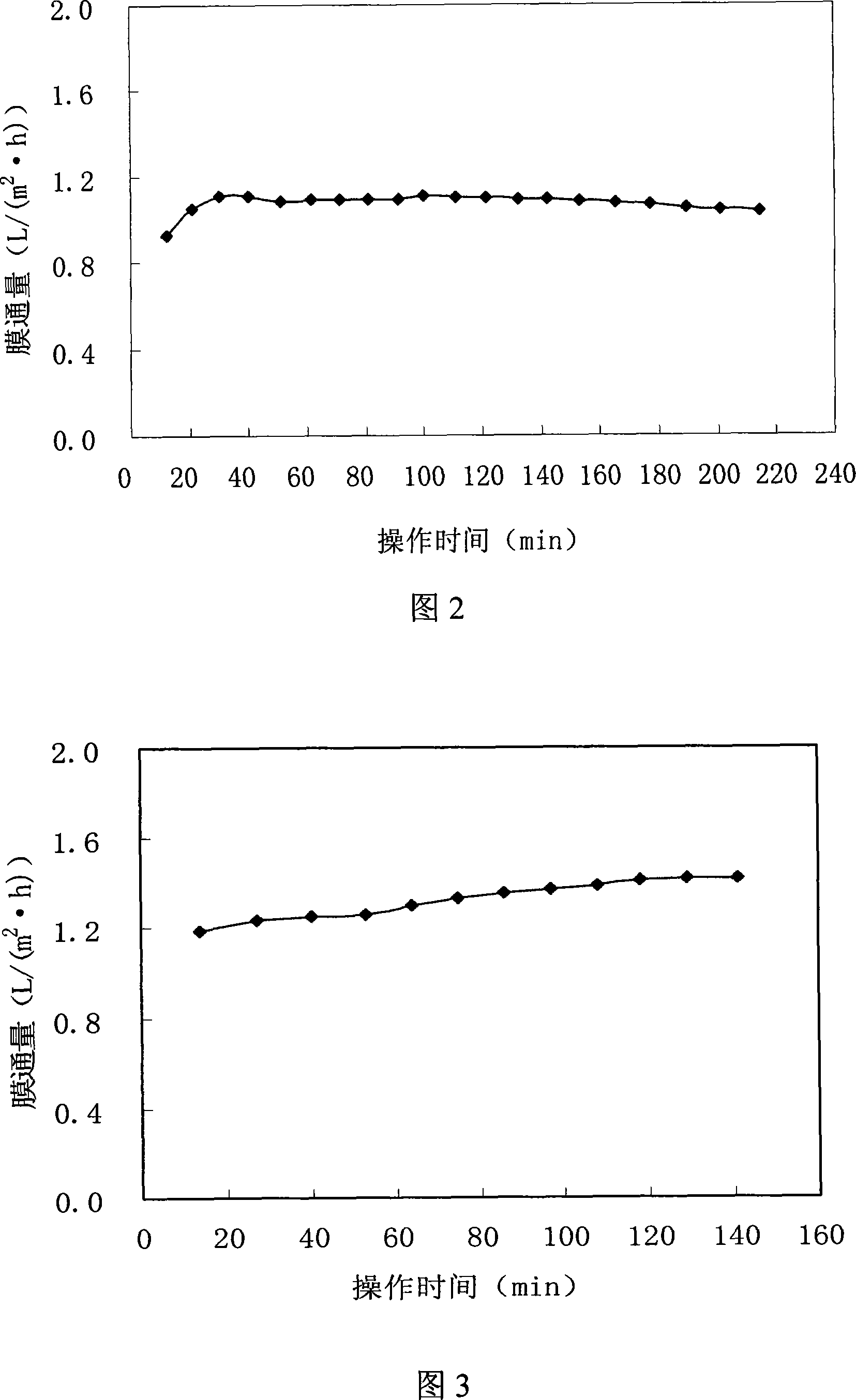

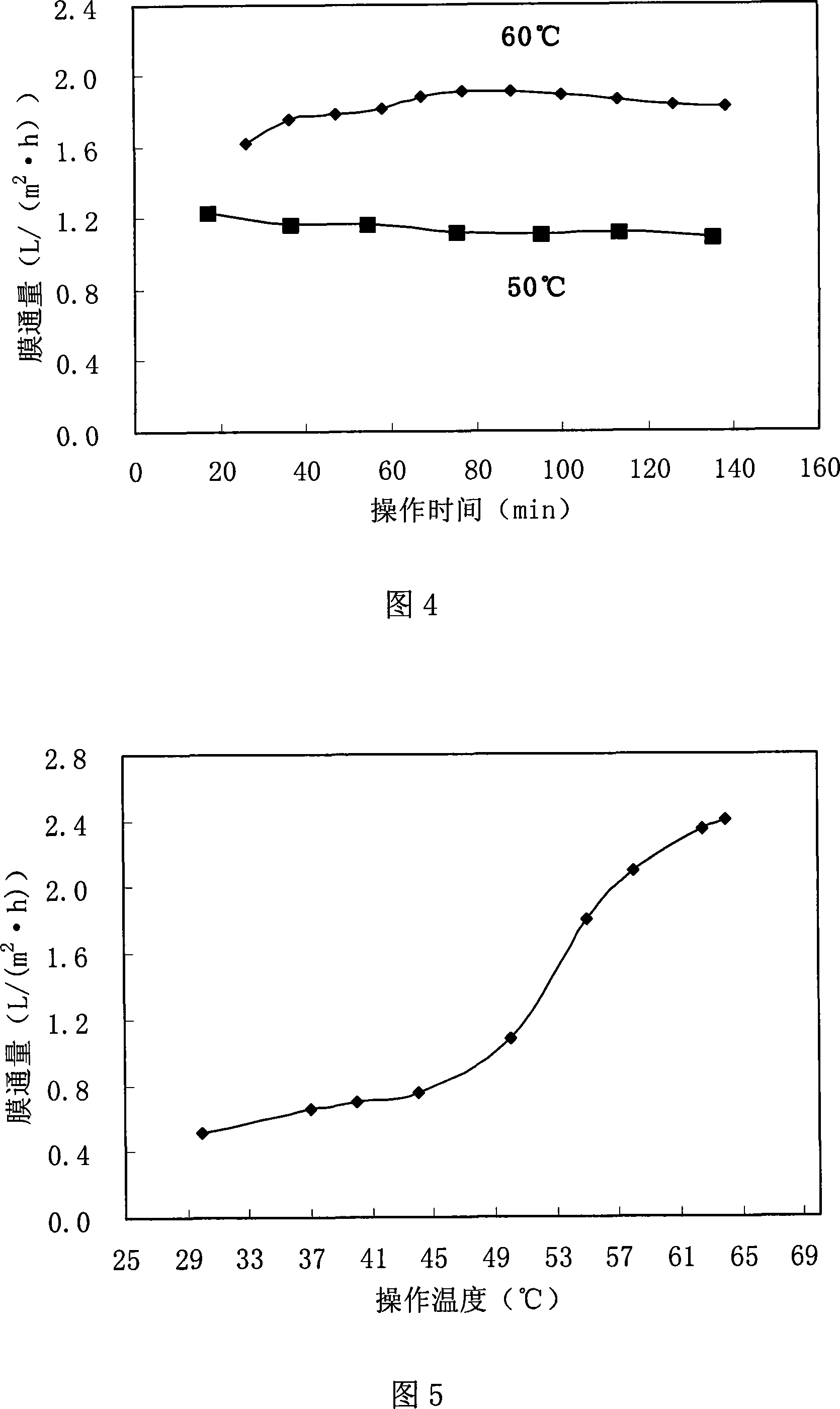

Regeneration method for waste lubricant and apparatus

InactiveCN101070507AReduce consumptionSimple processSemi-permeable membranesLubricant compositionTextile fiberHigh energy

This invention relates to the regeneration method and equipment of one kind of waste lubricating oil, the regeneration method includes below crafts: impurity subsidence, pelletthickly filter, vacuum dehydration, its characteristic is that there has heat up craft after the impurity subsidence craft, there also has second time heats up craft and membrane separation craft after vacuum dehydration craft; The temperature of heat up craft is 65-75degree C; the temperature of second time heats up craft is 50-90degree C; The membrane separation craft uses the spatial textile fibermembrane, its average aperture is 0.01-0.5mum, it can bear 80-90degree C high temperature, and can resistant oil corrosion. This regenerative equipment characteristic is that it is suitable for this invention regeneration method, it at least includes a front heater, a set of vacuum dehydration installment, a intermediate storage tank, at least an heater and at least a center spatial textile fiber membrane module. The craft of using this invention method and the equipment is simple, its operation is easy, it is easy to control, high energy conversion rate and good separation effect, it also does not pollute the environment, low energy consumption, it is effective to recycle waste lubricating oil.

Owner:李建新

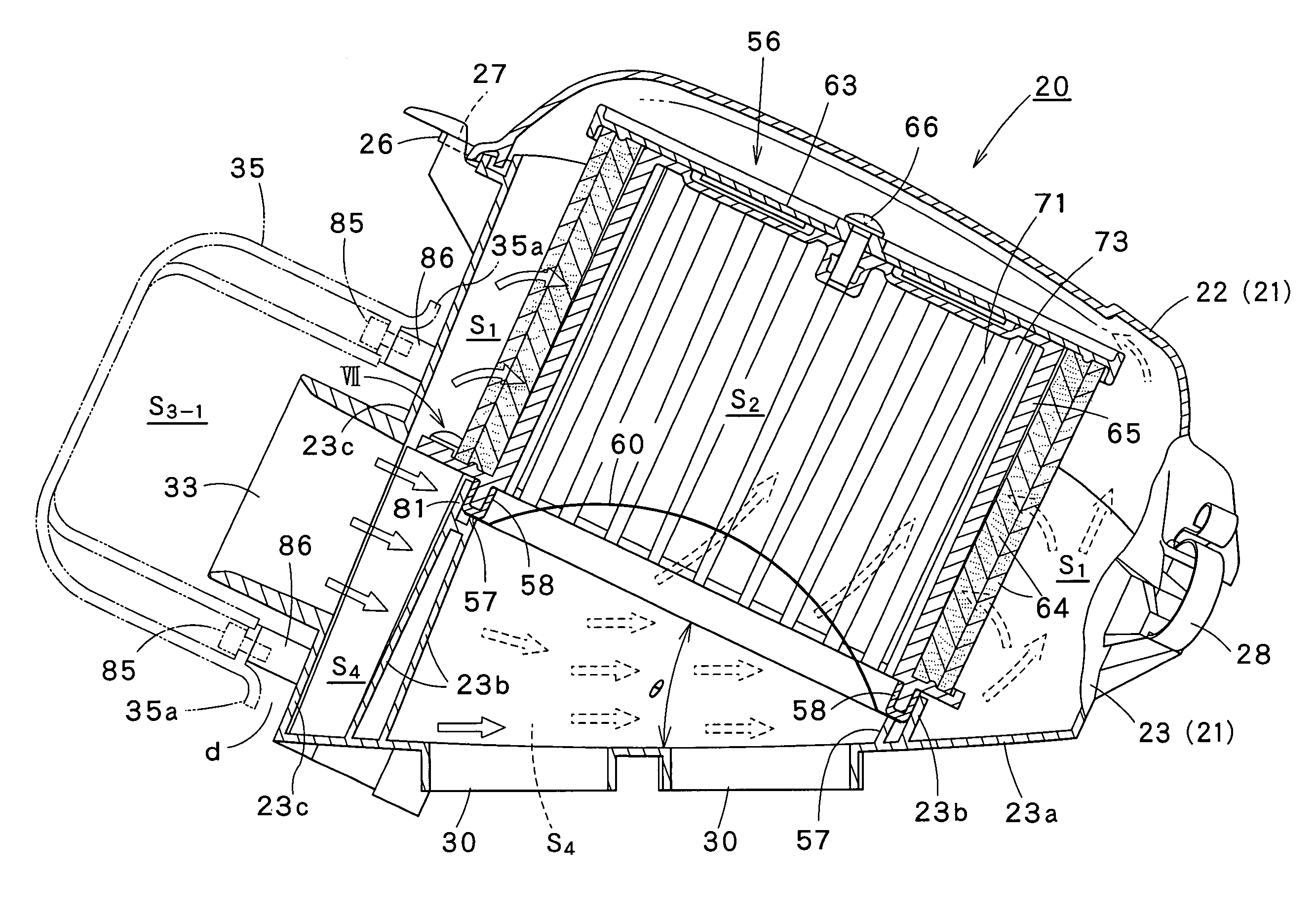

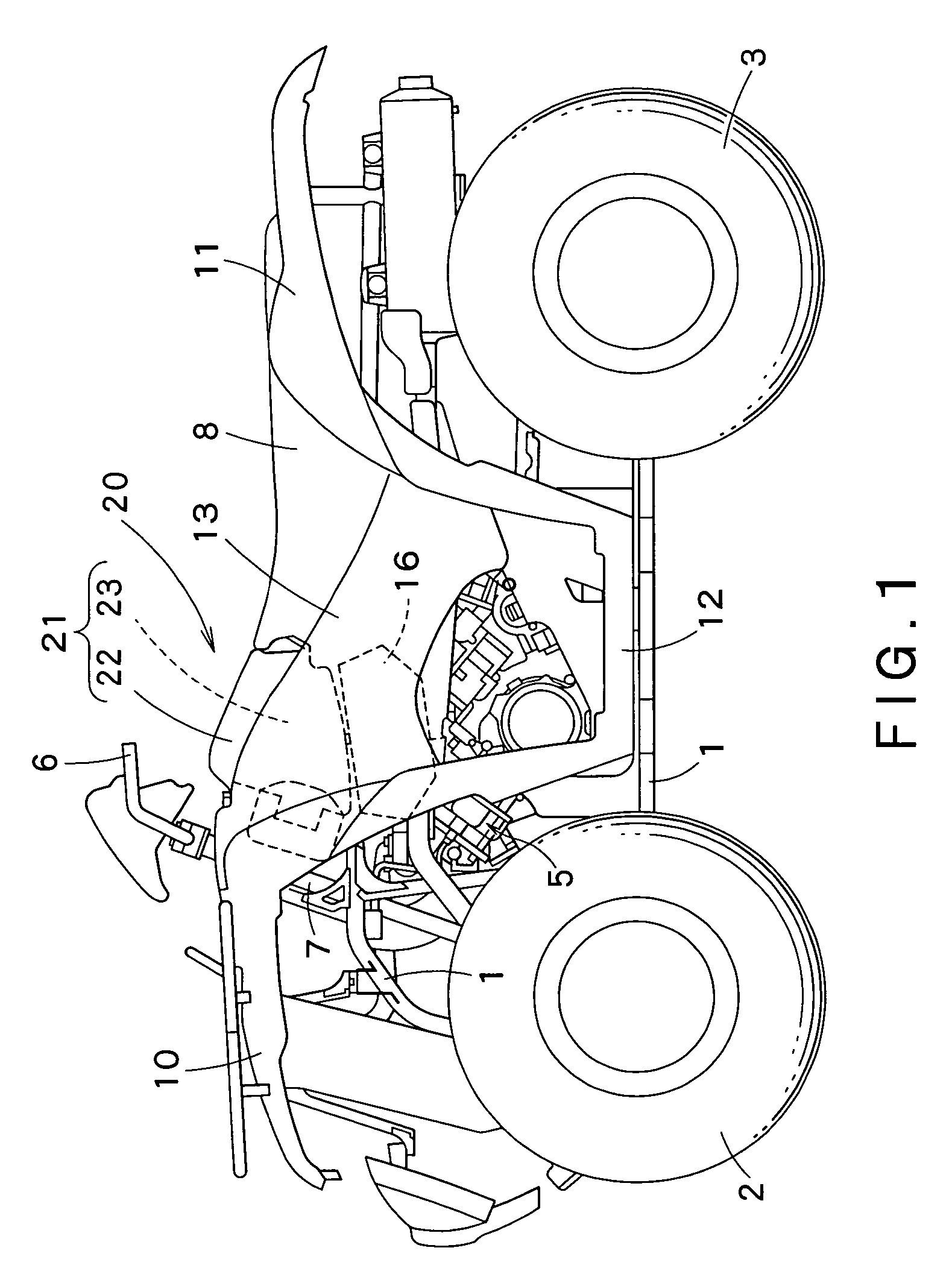

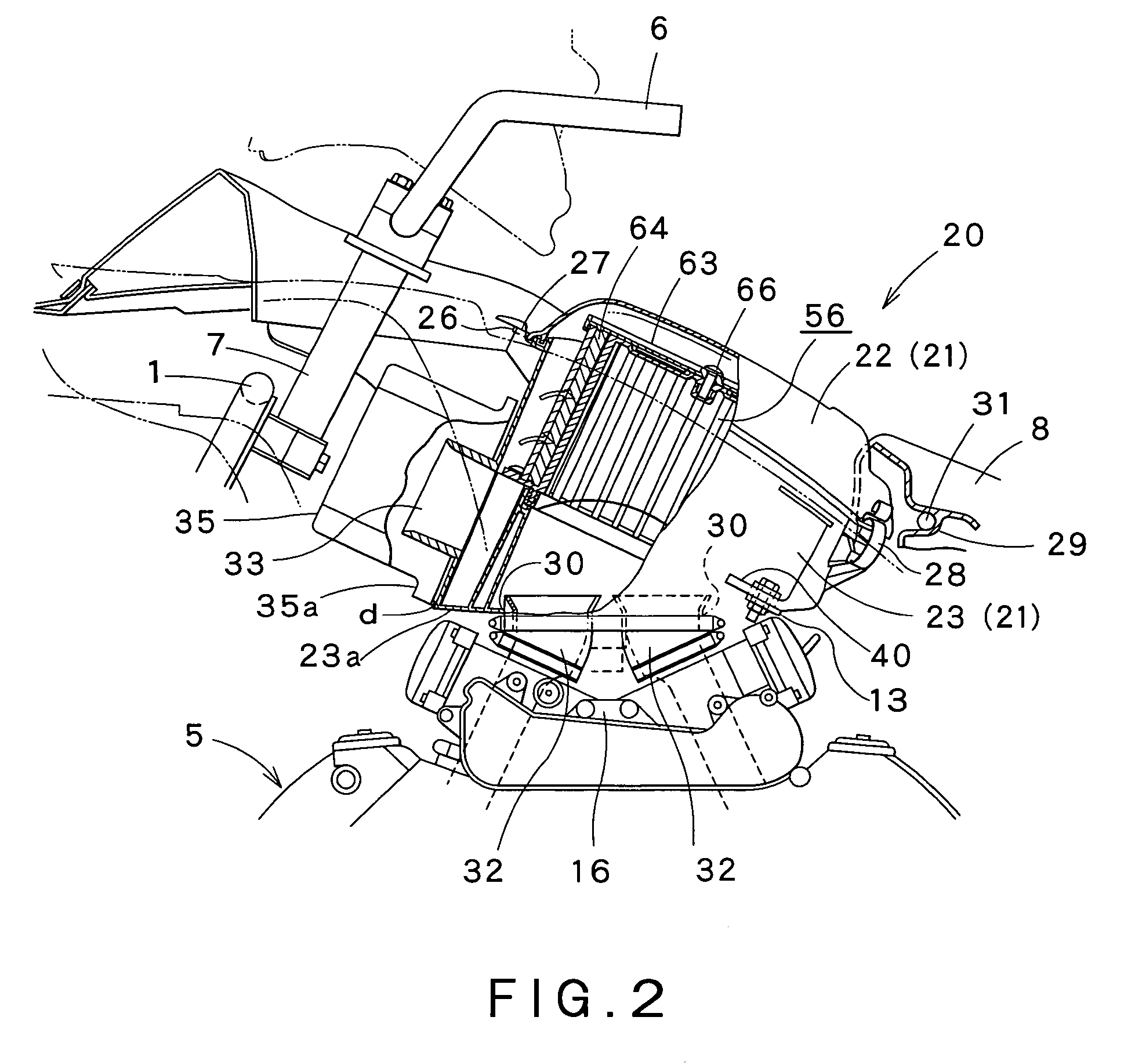

Air cleaner

ActiveUS7753980B2Reduce airflow resistanceSpeed up the flowCombination devicesDispersed particle filtrationEngineeringAir cleaners

Owner:KAWASAKI MOTORS LTD

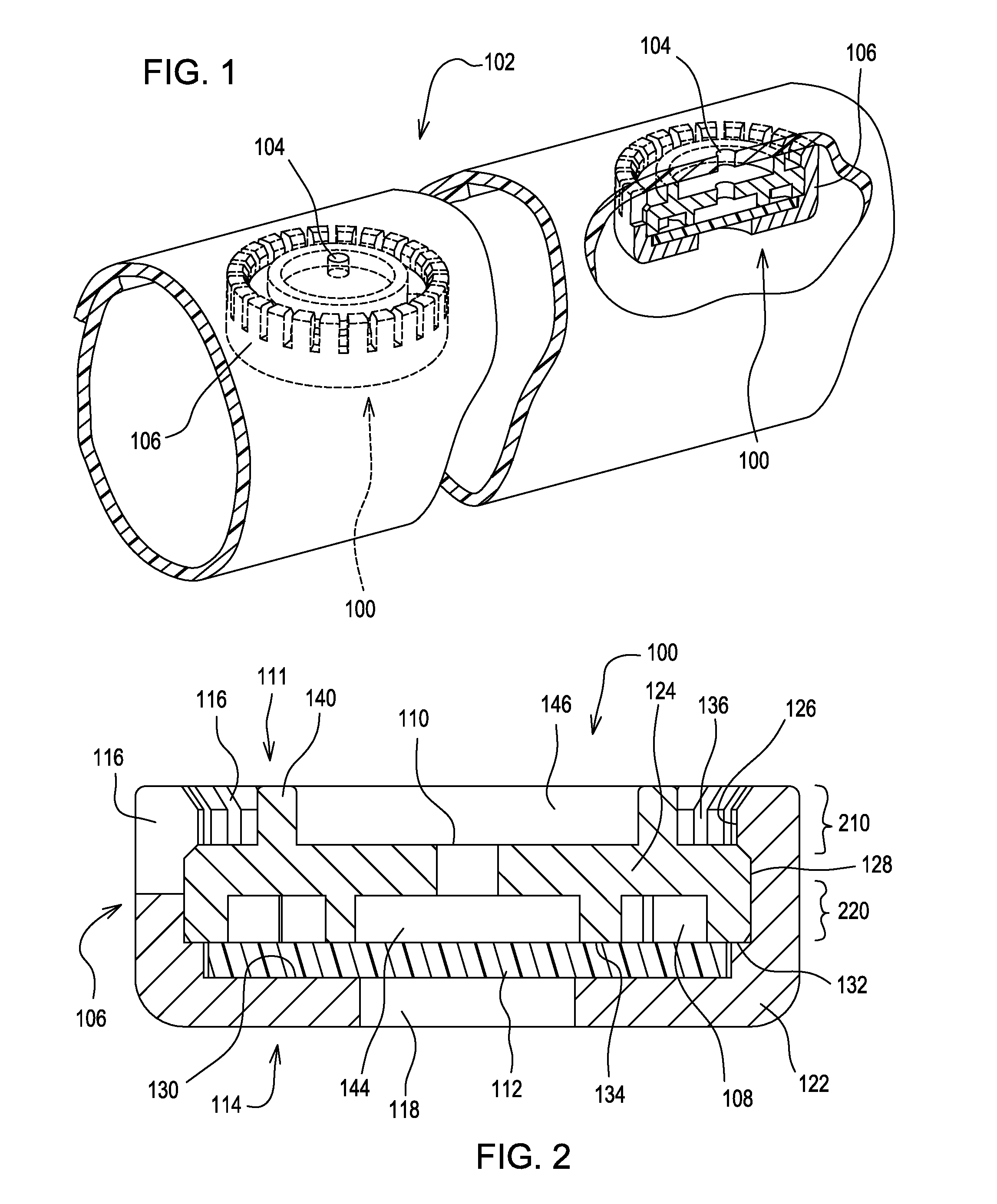

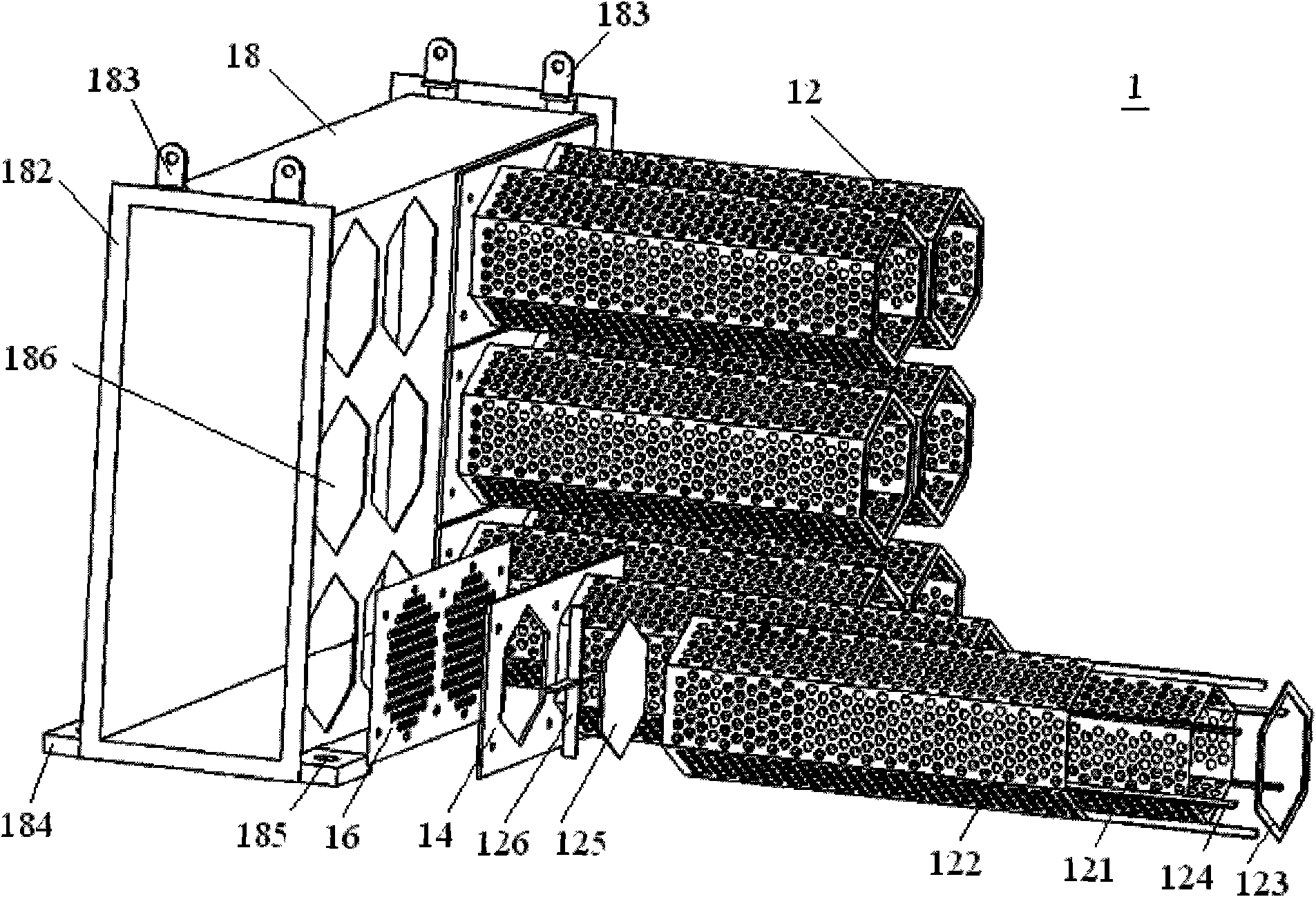

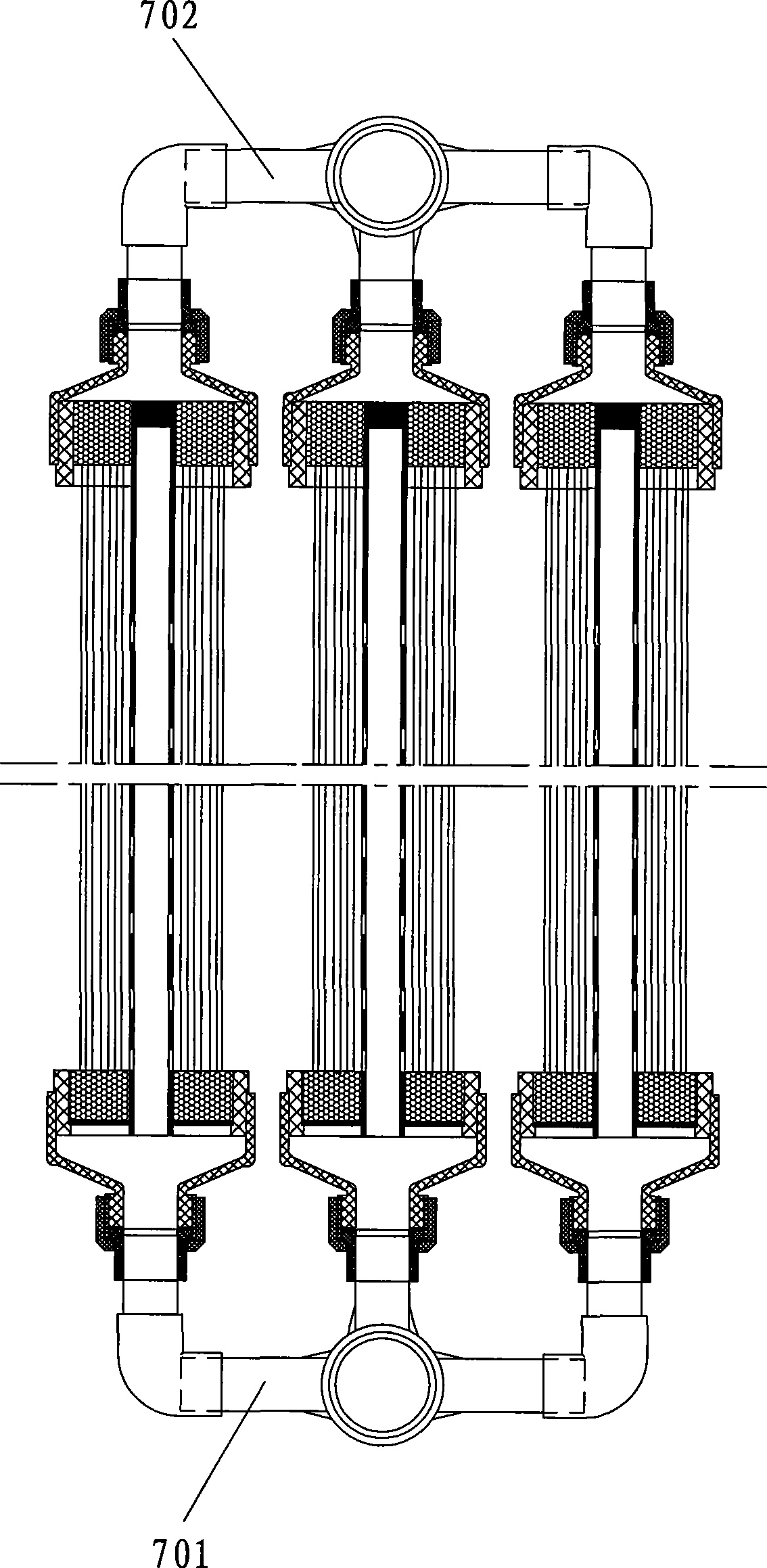

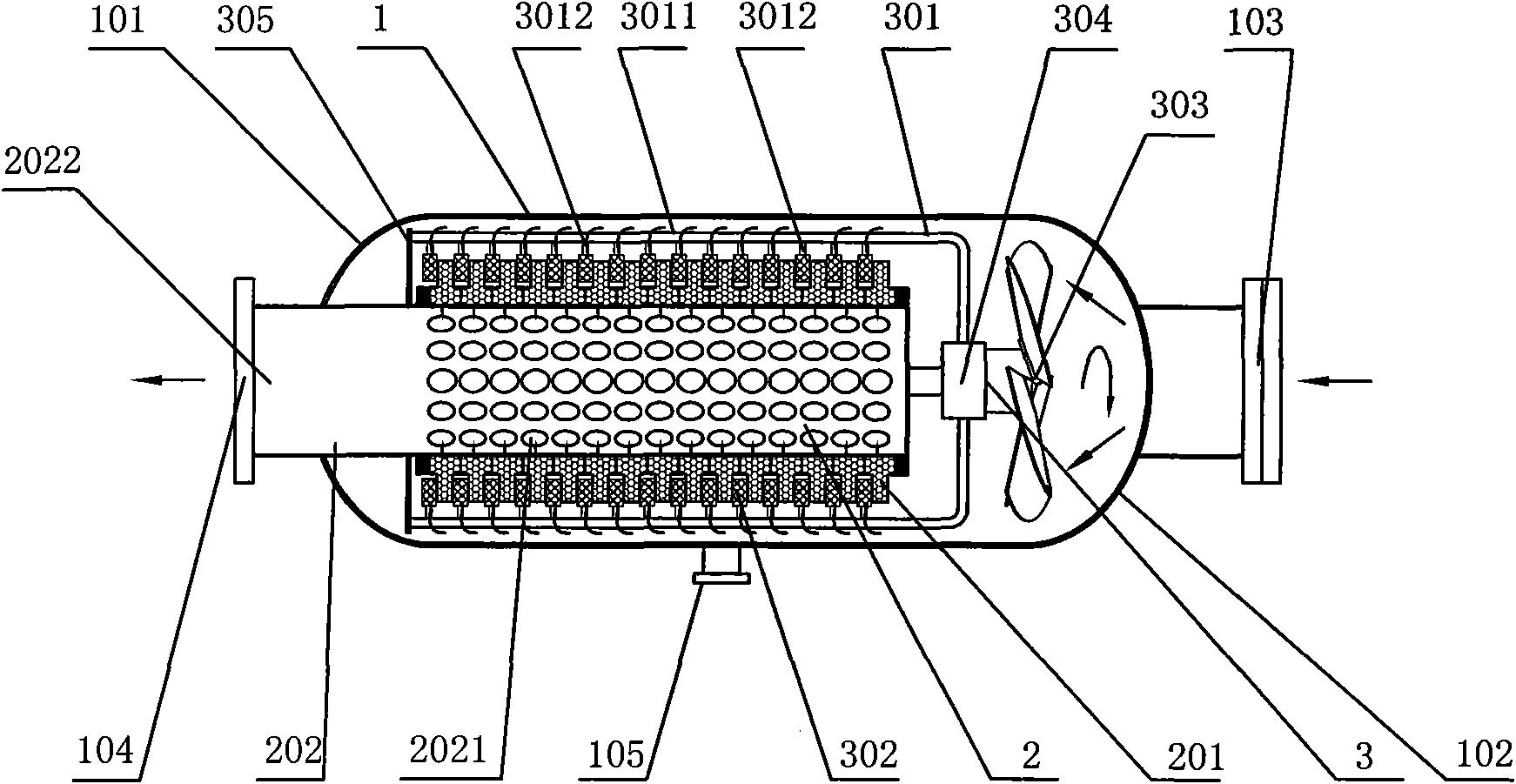

Containment sump filter

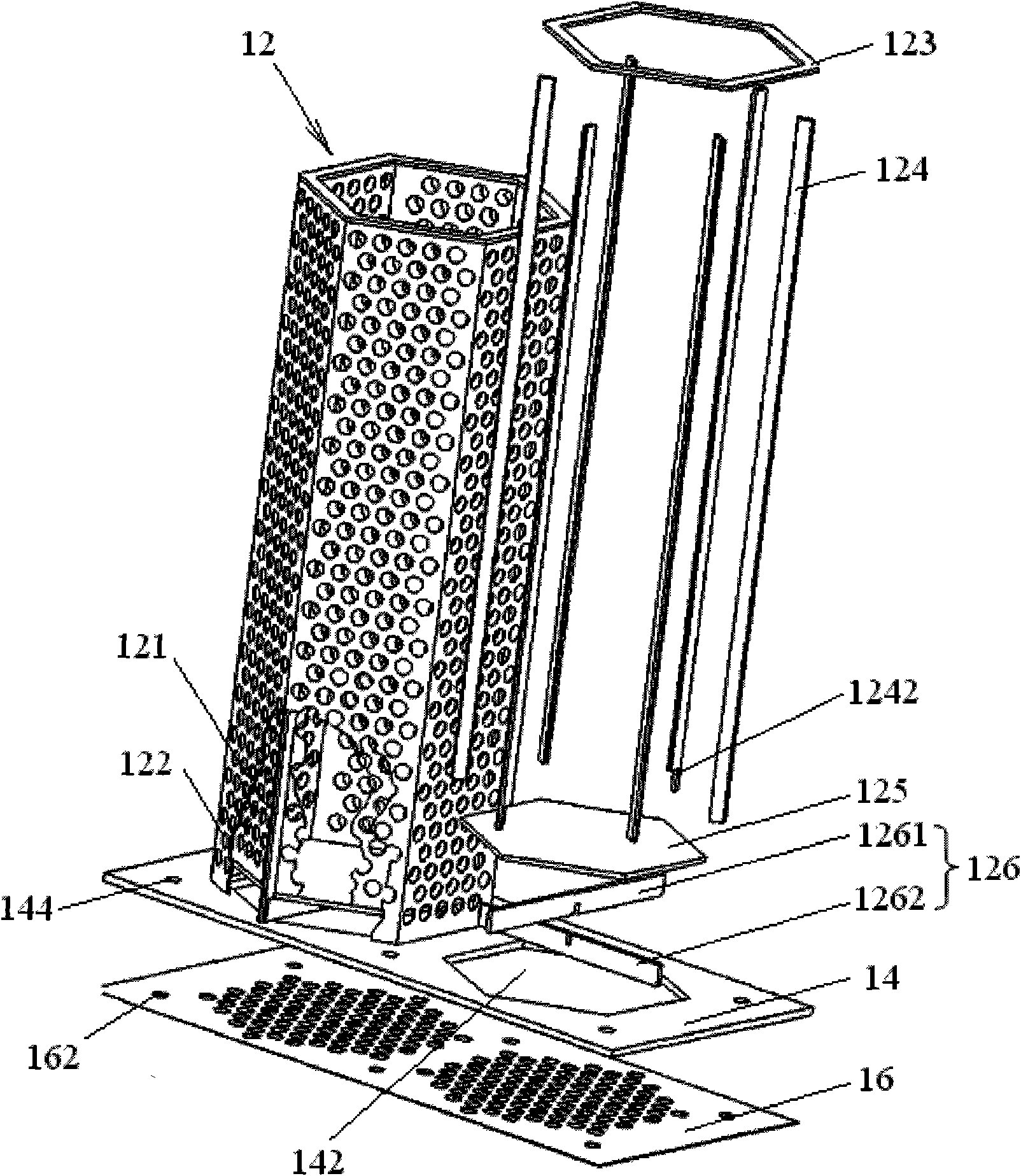

ActiveCN101569806AReduced risk of cloggingLarge filter areaNuclear energy generationEmergency protection arrangementsFiltrationEngineering

The embodiment of the invention discloses a containment sump filter, comprising a plurality of filter modules which comprise a filter cartridge and a base; the invention is characterized in that: the containment sump filter also comprises a plurality of pipeline modules, the two ends of each pipeline are open, the pipeline modules forms a pipeline part by being connected with each other in an end-to-end way, the pipeline part is communicated with a plurality of pump inlets in the containment vessel pit and the two ends thereof are respectively connected with a plurality of filter modules which are connected with each other by the bases in an end-to-end way, so that the fluid passage formed by the bases of the filter modules at the two ends of the pipeline part can be communicated with the fluid of the pipeline part formed by the pipeline module. With the containment sump filter of the embodiment adopted, the filtration area in the flow passage of the refrigerant is increased remarkably without being restricted by the inlet location of the pump in the containment sump filter and at the same time, the risk of jam of the containment sump filter Is reduced.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

Air-filtration paper for automobile engine filter and preparation method of air-filtration paper

ActiveCN102912677AImprove adsorption capacityImprove filtering effectNon-macromolecular organic additionPaper/cardboardBursting strengthFiber

The invention discloses air-filtration paper for an automobile engine filter and a preparation method of the air-filtration paper. The air-filtration paper for the automobile engine filter is prepared from the following materials in parts by weight: 60-70 parts of hardwood pulp, 30-40 parts of cotton pulp, 10-15 parts of modified polyester fiber, 2-5 parts of nanocarbon, 1-3 parts of kaolin, 1-2 parts of lime milk, 2-4 parts of modified zealite sieve, 0.5-0.8 parts of water talcum powder, 3-4 parts of polyacrylic emulsion, 2-5 parts of polyvinyl acetate emulsion, 0.5-1 part of sodium laurylsulfate, 0.5-1 part of silane coupling agent DL171, 0.4-0.8 parts of sodium laurylsulfate and 4-6 parts of dialdehyde starch. The filtration paper prepared by the method has the advantages of good water permeability, large filter area, small maximum aperture, high filter precision, high water tolerance, strong bursting strength, thermostability and the like, has a stable performance index at a normal temperature under a high-temperature work condition, and has better effects of temperature resistance and filtering, and filtering efficiency can be up to 99.98%.

Owner:ANHUI PHOENIX INT CO LTD

High temperature resistant flame retardant filter paper used for diesel filter and preparation method thereof

ActiveCN102877368AHigh temperature resistant and flame retardantBursting strengthPaper/cardboardFiltration separationBursting strengthCellulose

The invention discloses a high temperature resistant flame retardant filter paper used for a diesel filter and a preparation method thereof. The high temperature resistant flame retardant filter paper comprises the following raw materials in parts by weight: 60-70 parts of wood pulp celluloses, 30-40 parts of vinylon fibers, 10-15 parts of glass fibers, 2-5 parts of dolomite dust, 1-3 parts of nanometer titanium dioxide, 2-4 parts of light calcium carbonate, 1-2 parts of modified nano-carbon, 1-2 parts of nanometer titanium oxide, 0.5-0.8 part of ammonium dihydrogen phosphate, 3-4 parts of modified water-soluble phenolic resin emulsion, 2-5 parts of styrene-acrylic emulsion, 0.5-1 part of diethanolamide, 0.5-1 part of silane coupling agent KH550, 0.4-0.8 part of sodium laurylsulfate and 4-6 parts of a wet strength agent. The filter paper, prepared by the invention, has the advantages of good water permeability, large filtering area, small maximum aperture, high filtering precision, strong bursting strength, high temperature resistance and flame resistance, the filtering efficiency is 99.999%, the filter paper has stable performance index at normal temperature and high temperature, and better temperature resistance and filtering effect.

Owner:ANHUI PHOENIX INT CO LTD

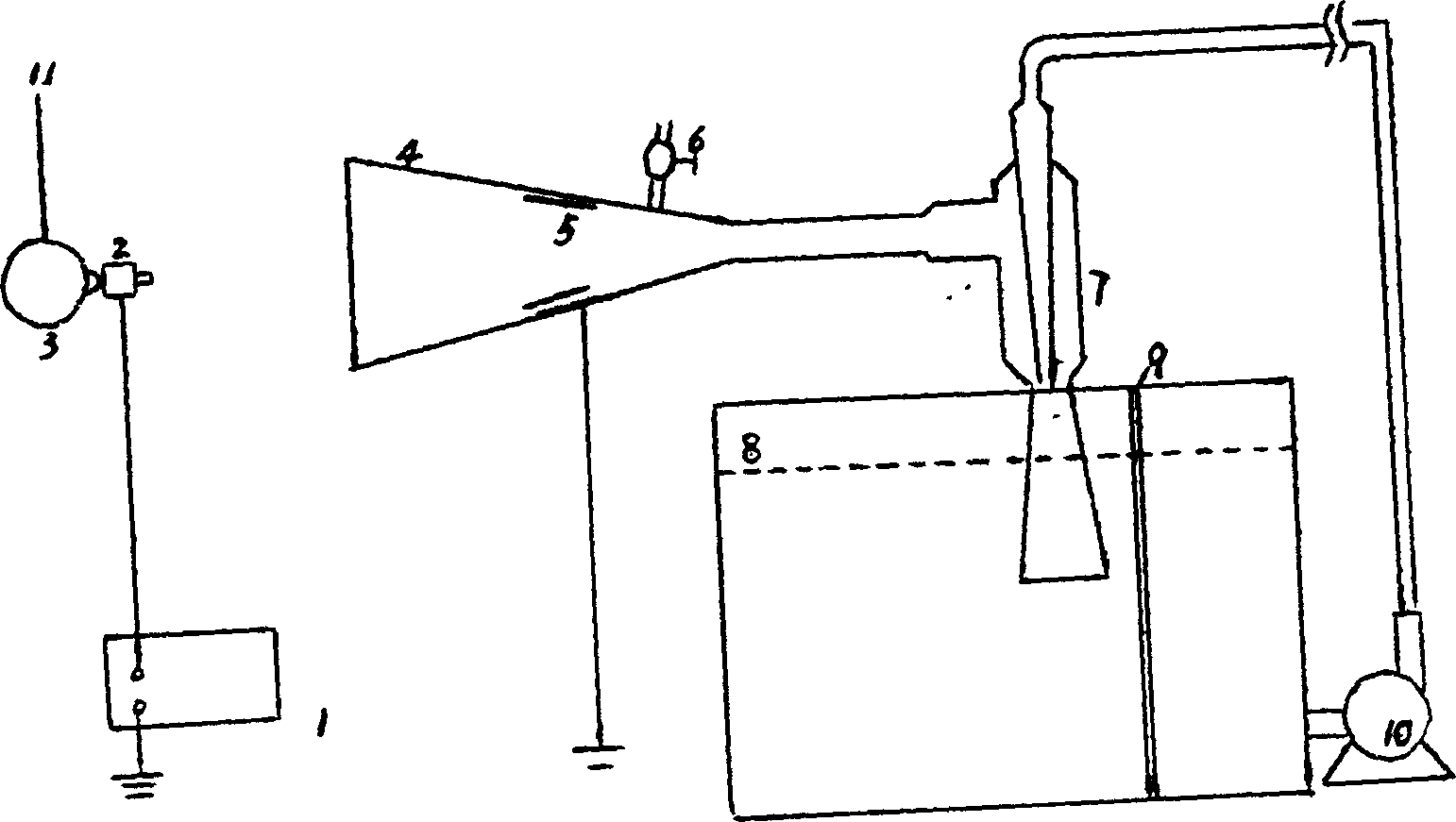

Preparation of functional nanometer short fiber and its application in cigarette filter tip

InactiveCN1603036AImprove filtration efficiencyReduce contentArtifical filament manufactureFiberCellulose acetate

The invention relates to a preparation of the function nanometer short fiber. It is mainly utilized the electrostatic spinning technique to quickly draw and transform the polymer solution to solid superfine fiber in high voltage electric field, produce nanometer fiber whose diameter is form fifty nanometers to one thousand nanometers. The fiber is directly collected in the water, and accelerated to collect by using the circulating water vacuum pump. It is utilized the shearing effect caused by the high velocity flow while the forming of the vacuum to quickly shear the collected nanometer long fiber into short one whose length is several millimeters. The catalyst is added in to the spinning liquid while the nanometer is preparing. The cellulose acetate nanometer short fiber and the filter tip fiber filament tow that is prepared by the above method are compounded to manufacture cigar filter. Not only can the compounded filter body effectively increase the filter efficiency of the inhalator grain with the submicron grade and nanometer grade, but also greatly increase the filter area at the same time to effectively reduce the content of the tar and other chemical composition in the smog.

Owner:林童 +2

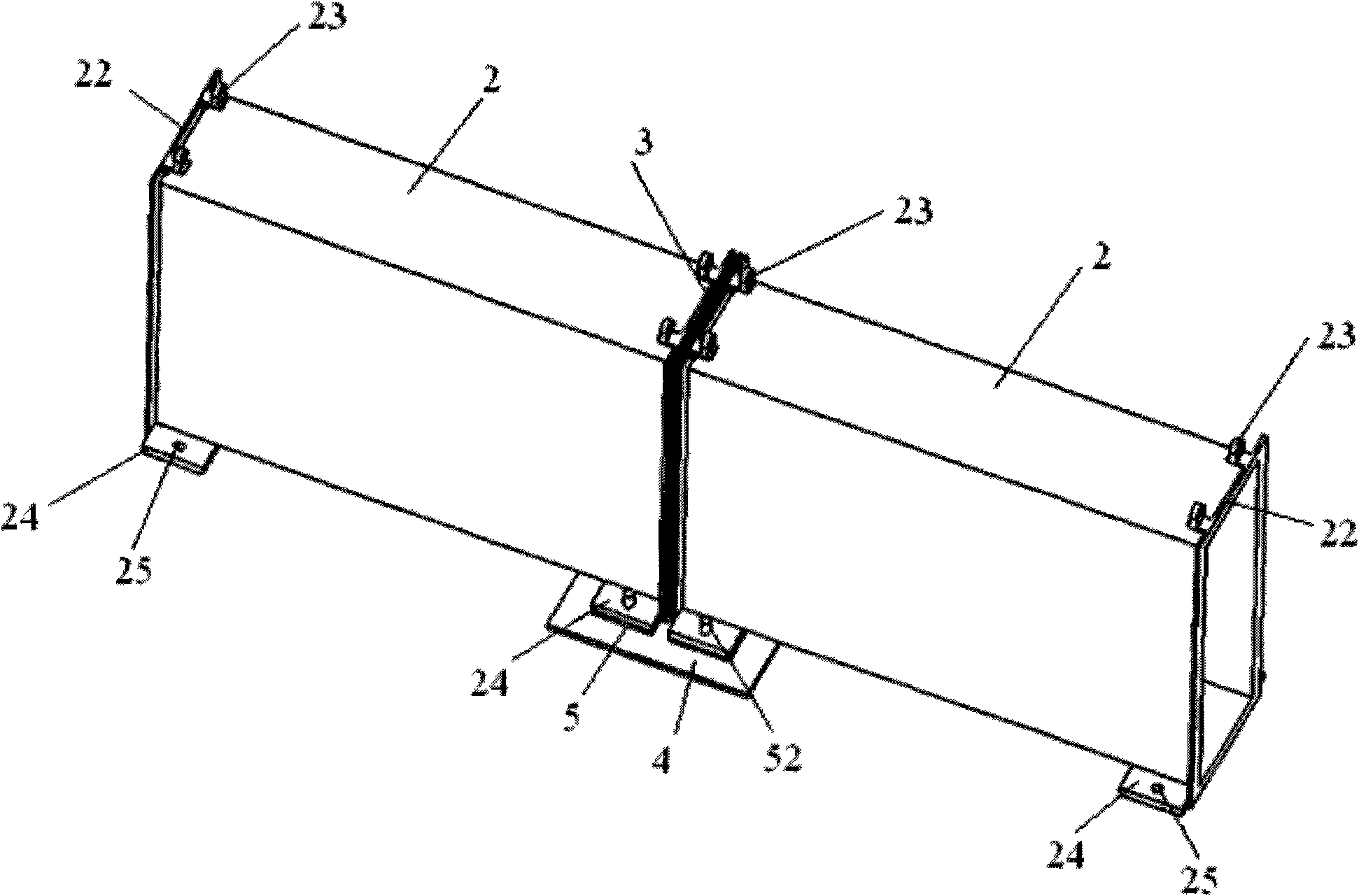

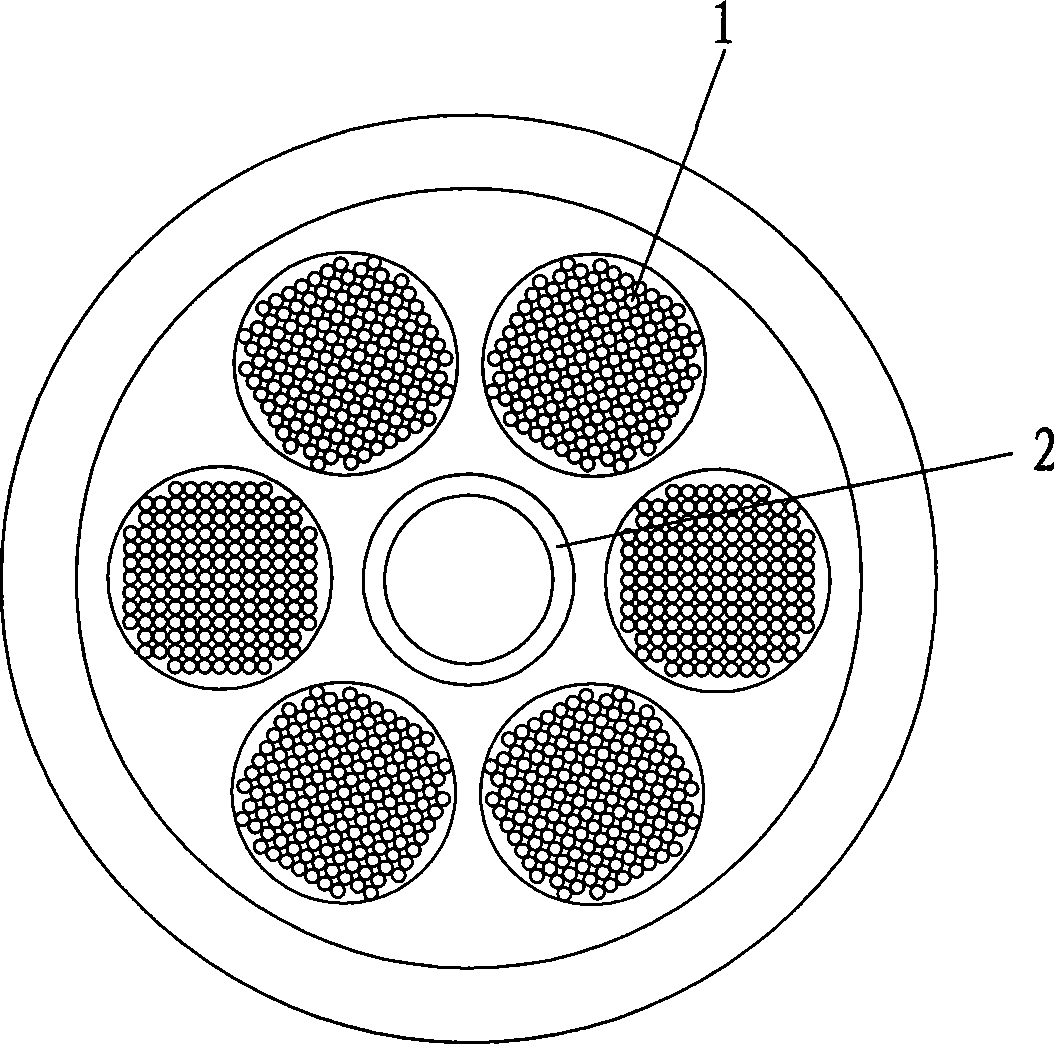

Immersion type hollow fiber membrane component and complete equipment thereof

ActiveCN101497000AReduce the probability of wire breakageReduce rigid fatigue damageSemi-permeable membranesFiberHollow fibre membrane

The invention discloses an immersion-type hollow fibrous membrane component and complete equipment thereof and belongs to the technical field of manufacturing a membrane component through water treatment. The immersion-type hollow fibrous membrane component consists of membrane silk bundles, membrane end sockets and a central supporting tube; the membrane silk bundles have at least four bundles and are distributed on the periphery of the central supporting tube; two ends of the membrane silk bundles are provided with one membrane end socket respectively, wherein one membrane end socket is a gas inlet end socket; and the other one is a water producing end socket. A plurality of membrane components can be combined into a small unit and a large unit till membrane stacks on the equipment so as to improve service life of the membrane silk and the membrane component; and the structural design of the membrane component concentrates the advantages that the prior strip curtain-type membrane component is uneasy to pollute and the prior columnar membrane component has large membrane filtering area into a whole and has the advantages of large membrane filtering area, convenient mounting of the membrane component, convenient maintenance and the like.

Owner:XIAMEN LEEBAM MEMBRANE TECH

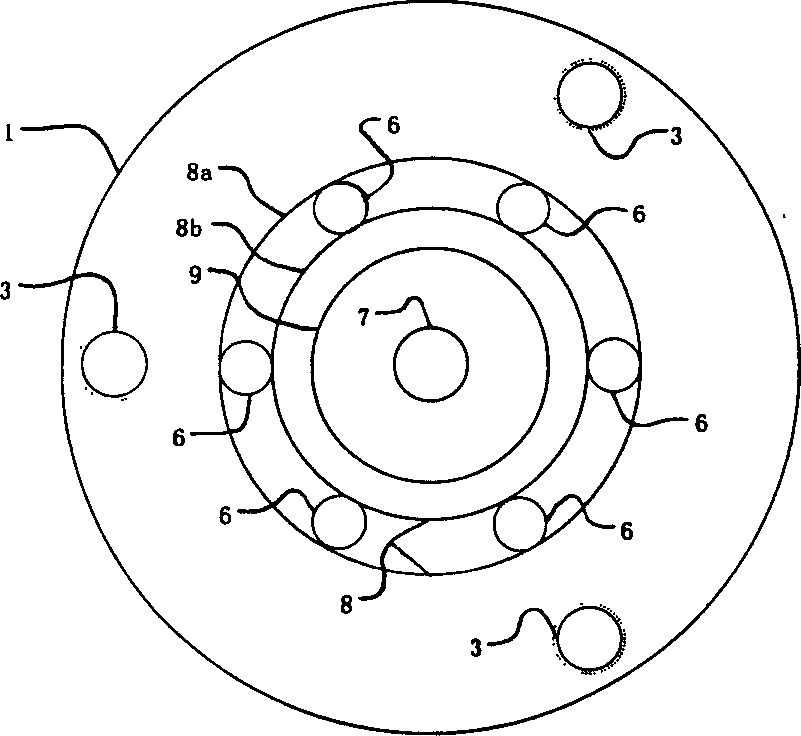

Composite spinning component entities including double constituents

ActiveCN1563523AExtend continuous operation timeReduce labor intensityFilament/thread formingFiltrationEngineering

This invention discloses a bi-component compound fiber spinning component including an up and down shell, a sand pool, a ring sand cavity, a bearing plate, a series distribution plate, a composite plate and a fiber spraying plate characterizing that the sand pool and the ring sand cavity are coaxial filtering melts of the bi-component separately and serial pin holes are designed on the third distributing plate in the lower shell, pin tubes are mounted in the holes, bottoms of the tubes are set in composite holes matched to duplate which are greatly increase filtration areas of the two melts.

Owner:SINOPEC YIZHENG CHEM FIBER

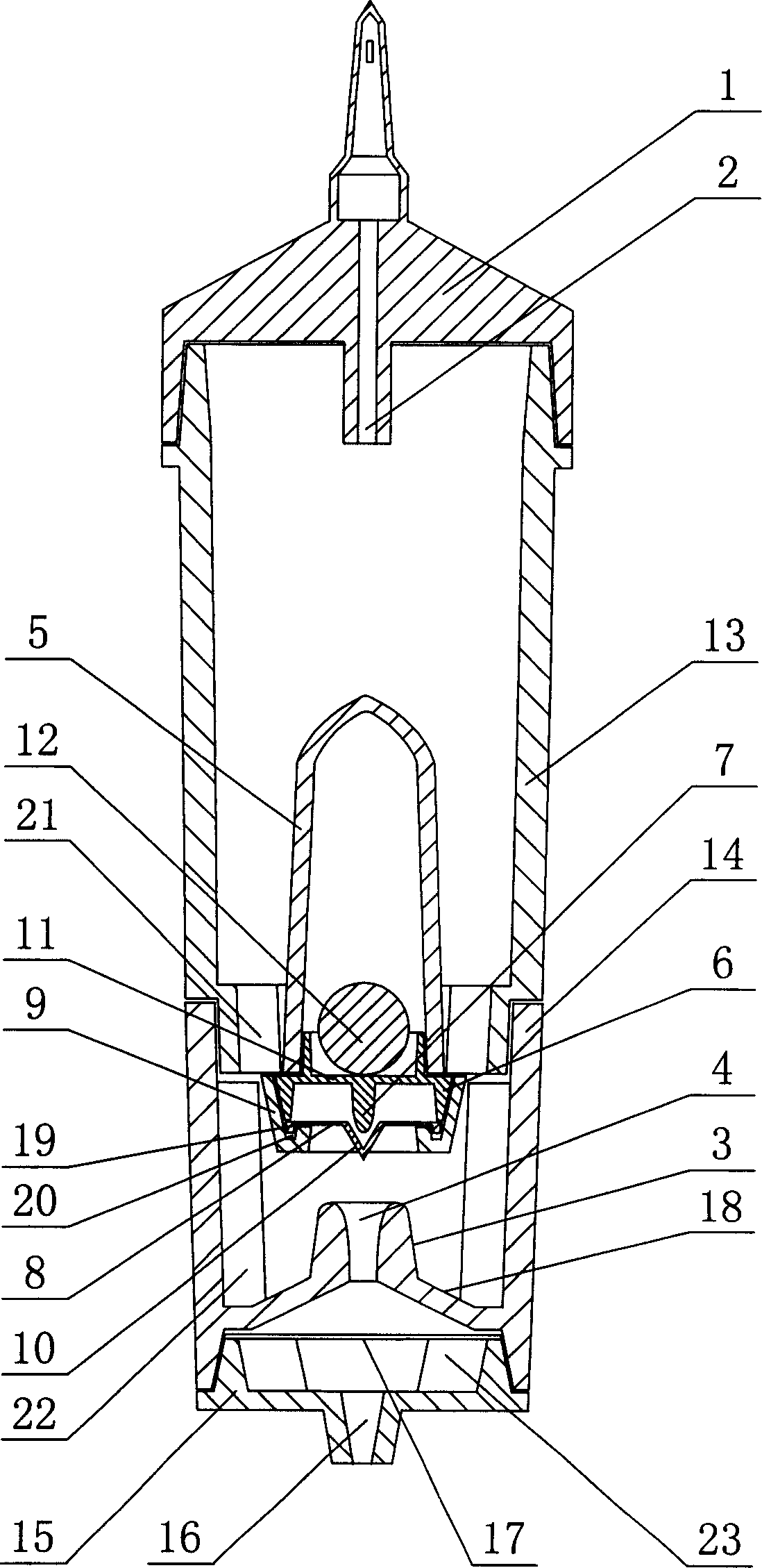

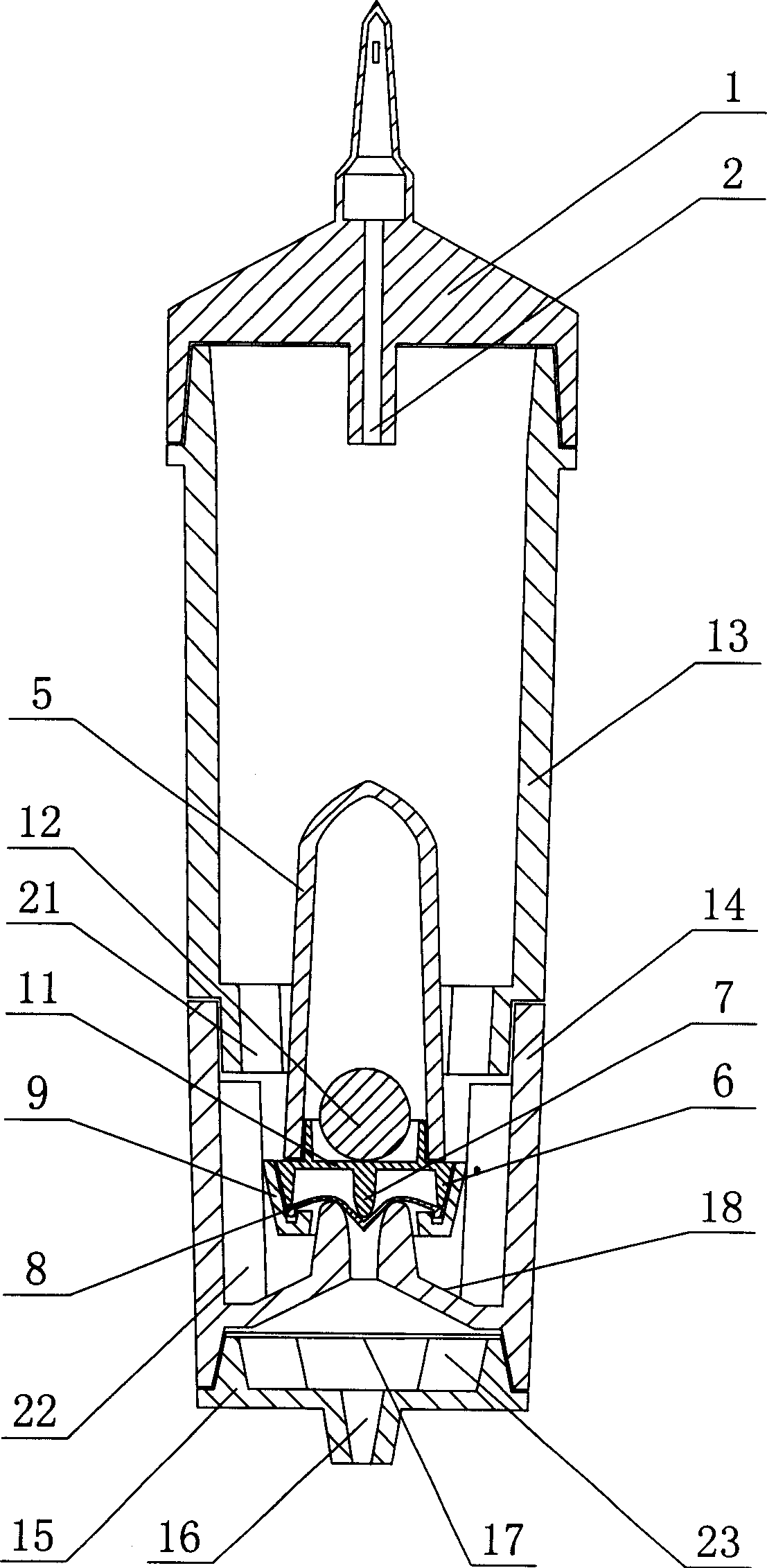

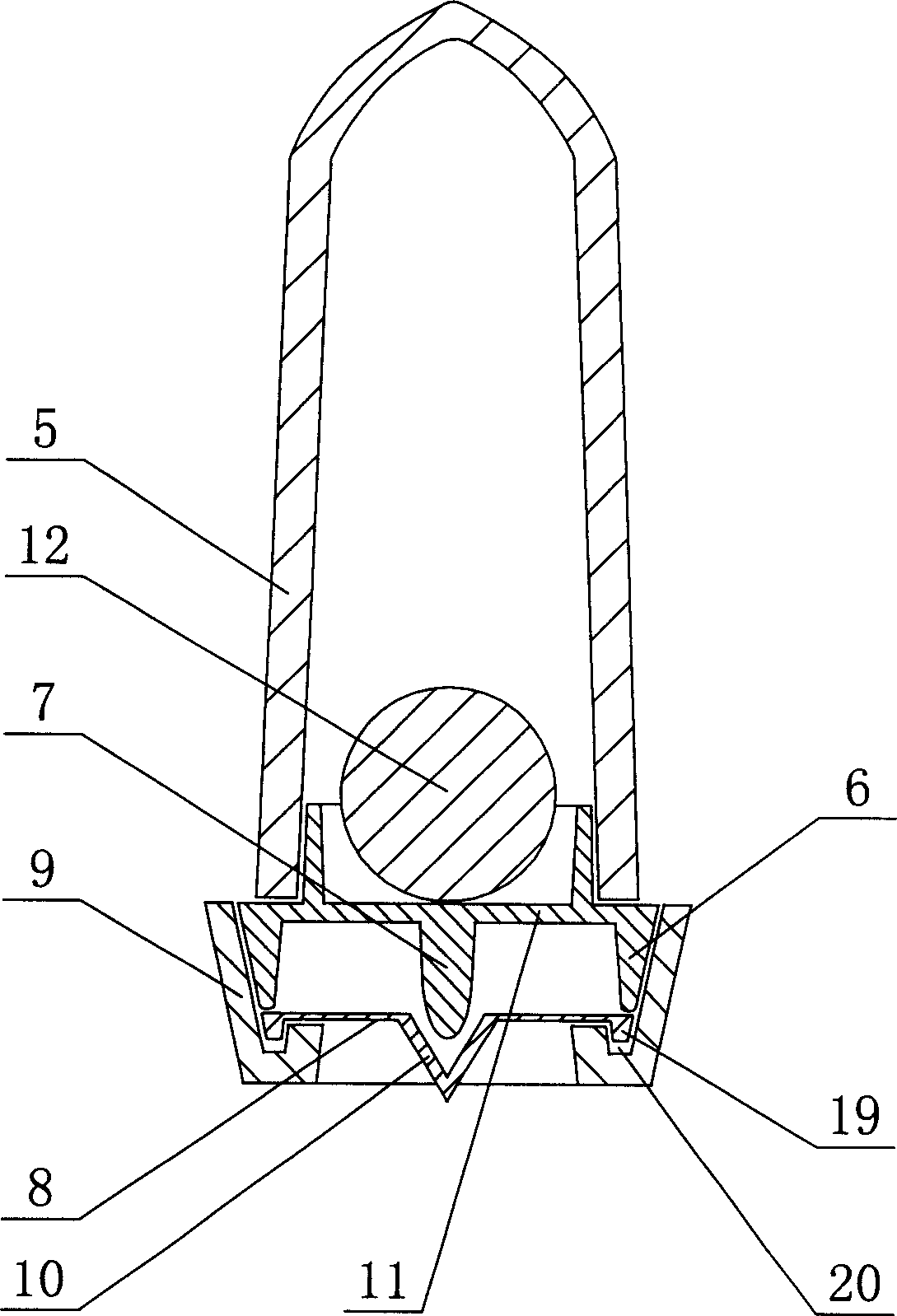

Automatic controlling arrangement of transfusion system

The invention discloses an automatic control device of drop transfusion system, which consists of lye storage and float in the lye storage, wherein the liquid-in needle (1) with liquid-in opening (2) and vertical convex area (3) toward intracavity with liquid-out opening (4); the float contains cylindrical floater (5) and soft elastomer sealer (8). There is longitudinal gap between sealer (8) and vertical convex area (3) that matches each other. The invention provides a precise and reliable sealed transfusion system with automatic closing system effectively, which can be applied in the medical treatment domain widely.

Owner:虞家珍

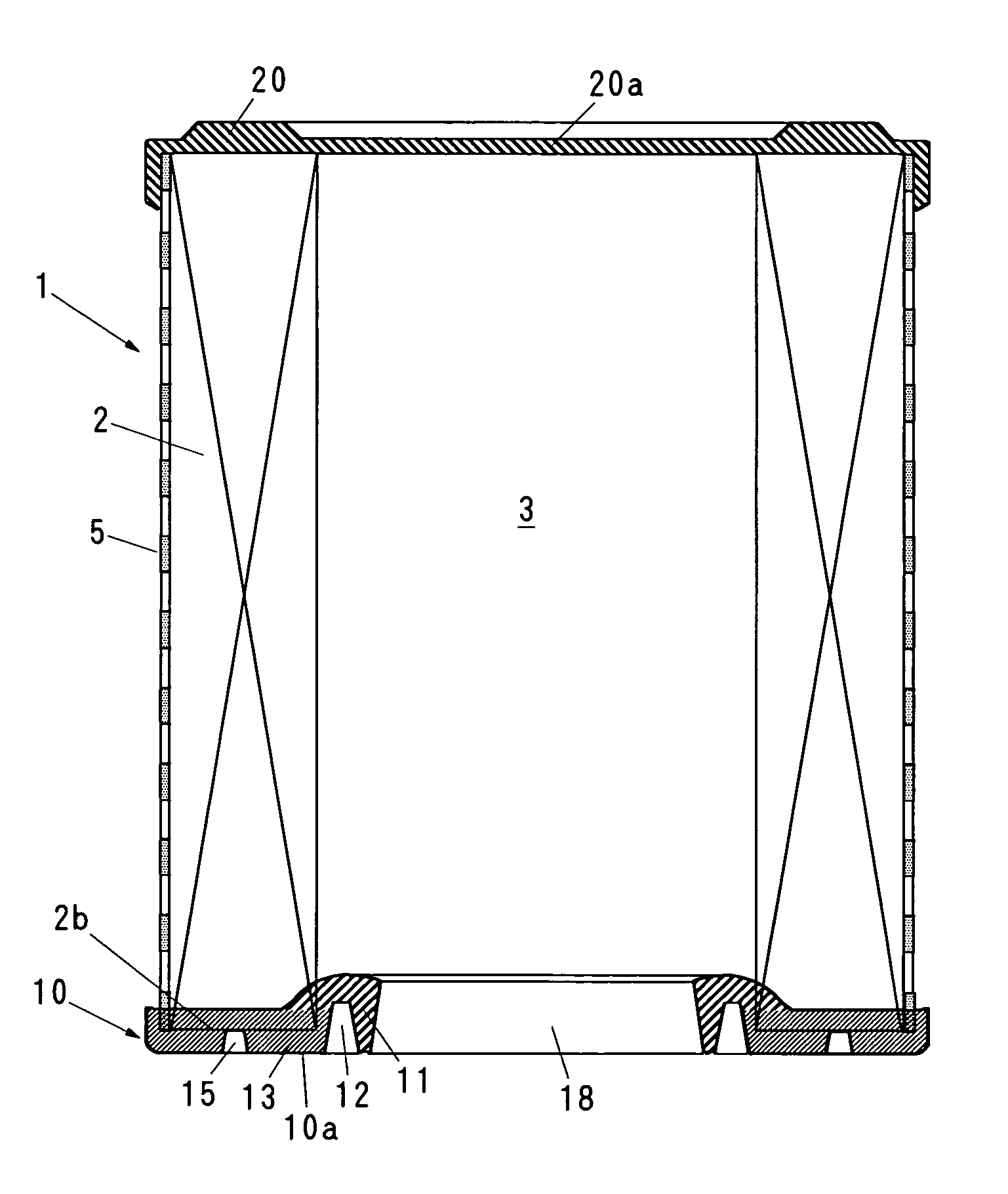

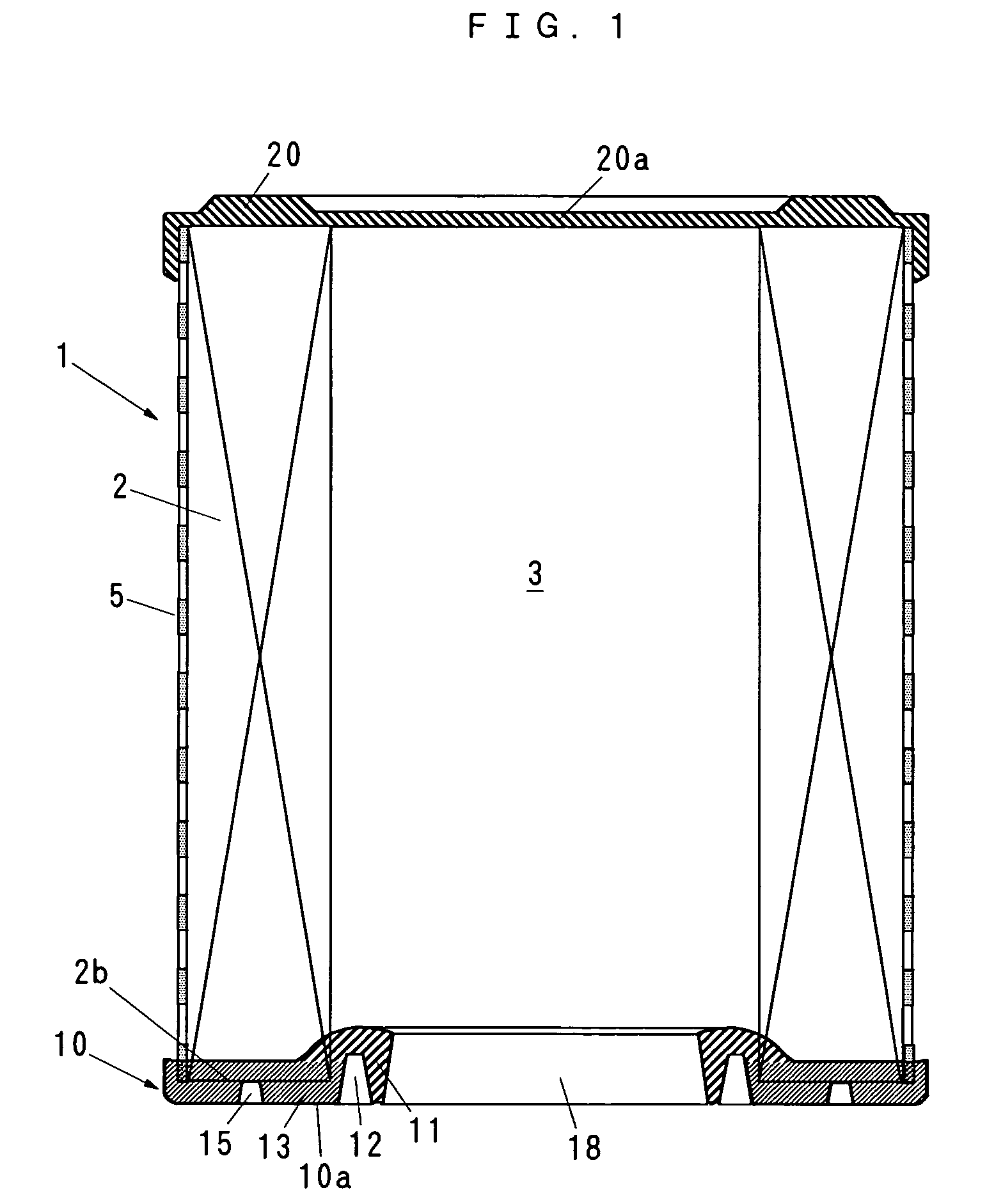

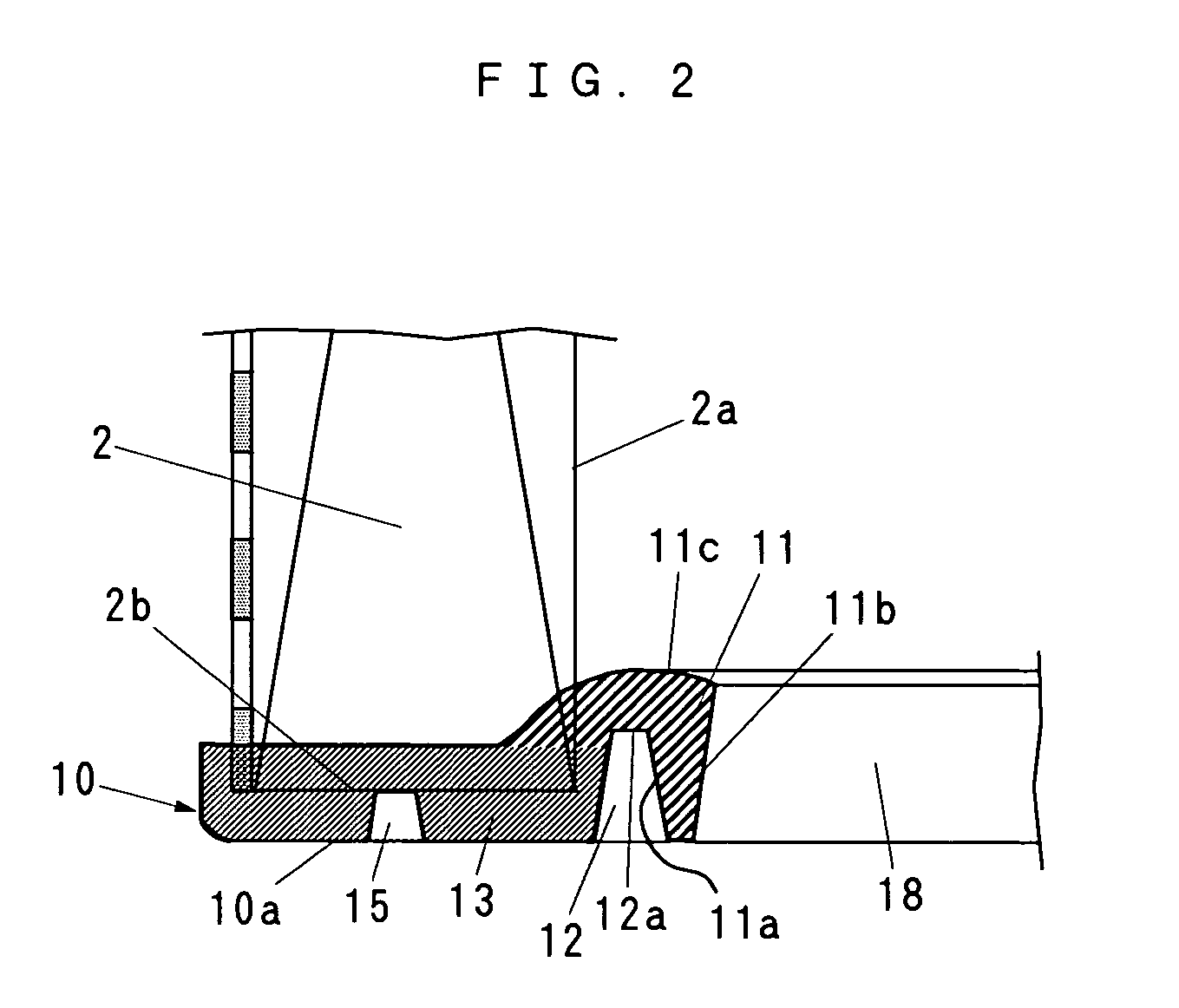

Air filter element and method of producing the same

InactiveUS7083661B2Reliable and easy to produceImprove rigidityDispersed particle filtrationCombustion-air/fuel-air treatmentComposite constructionAir filter

There is provided an air filter element which is used by fitting a central opening in its end plate on a cylindrical portion projecting into a casing, wherein the air filter element has a novel seal construction (end plate). An end plate (10) closing the end surface of a hollow cylindrical filter portion (2) includes a soft inner peripheral seal portion (11) capable of sticking to the outer surface of a cylindrical member (33) and a rigid closure portion (13) which is disposed on the outer periphery side of the inner peripheral seal portion and in which the end surface of the filter portion is embedded, the end plate being of composite construction in which the inner peripheral seal portion (11) and the closure portion (13) are integrally molded. On the outer periphery side of the inner peripheral seal portion (11), a groove (12) axially extending from an end surface (10a) of the end plate is formed along the opening. The inner peripheral seal portion (11) effects reliable center seal with respect to the cylindrical member (33), while the closure portion (13) on the outside thereof improves the rigidity of the air filter element.

Owner:TOYO ELEMENT IND

Unpowered automatic cleaning laminated filter

InactiveCN101961572AAchieve cleaningDriving realization of cleaning deviceMembrane filtersStationary filtering element filtersBallastFilter element

The invention provides an unpowered automatic cleaning laminated filter, which comprises a shell and a filter element, wherein the shell is a cylinder with end covers at two ends; a water inlet and a water outlet are arranged on the two end covers or at positions close to the end parts of the cylinder; the filter element consists of a group of hollow filter discs and a water outlet core pipe; the hollow filter discs are sleeved on the water outlet core pipe; a distance is kept between each two adjacent hollow filter discs; the effluent of the hollow filter discs flows into the water outlet core pipe; and one end of the water outlet pipe is closed, while the other end is provided with a water outlet, which is connected with the water outlet of the filter or directly serves as the water outlet of the filter. The filter also has a washing device which comprises a cleaning brush holder, a cleaning brush, a driving device and a mounting frame, wherein the mounting frame is connected with the driving device; the cleaning brush is fixed on the mounting frame; the head of the cleaning brush is positioned on the surface of the annular filter discs; and the cleaning device is driven by the driving device to rotate to realize the cleaning of the filter discs. The filter can be used for filtering ship ballast water, cooling water and the like.

Owner:FUJIAN NEWLAND ENTECH CO LTD

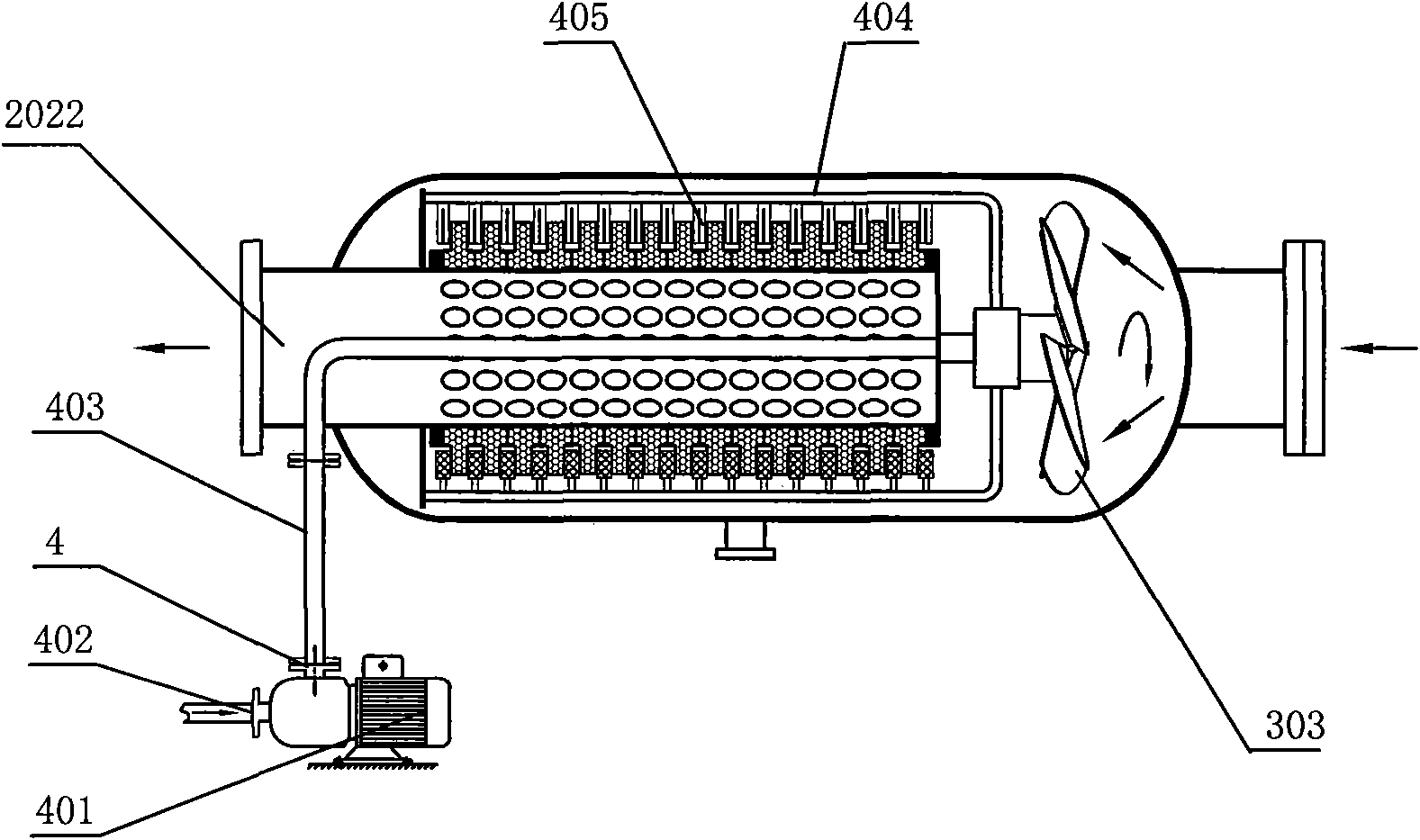

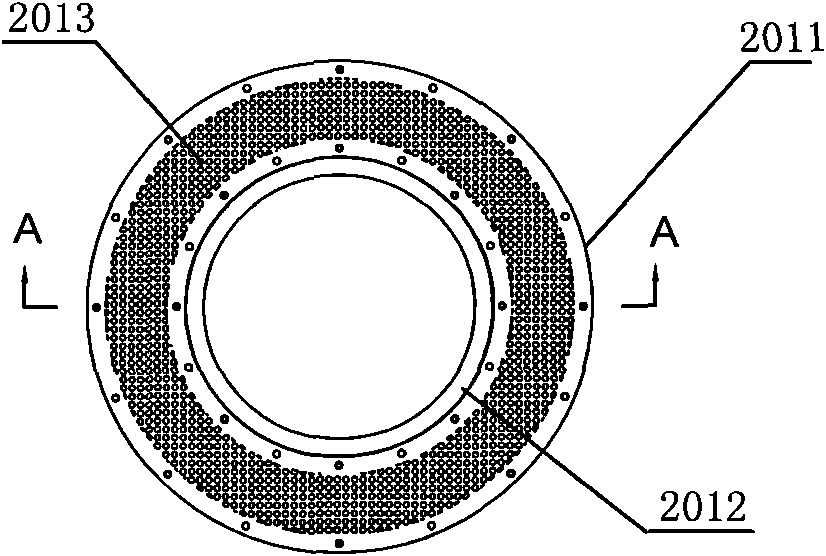

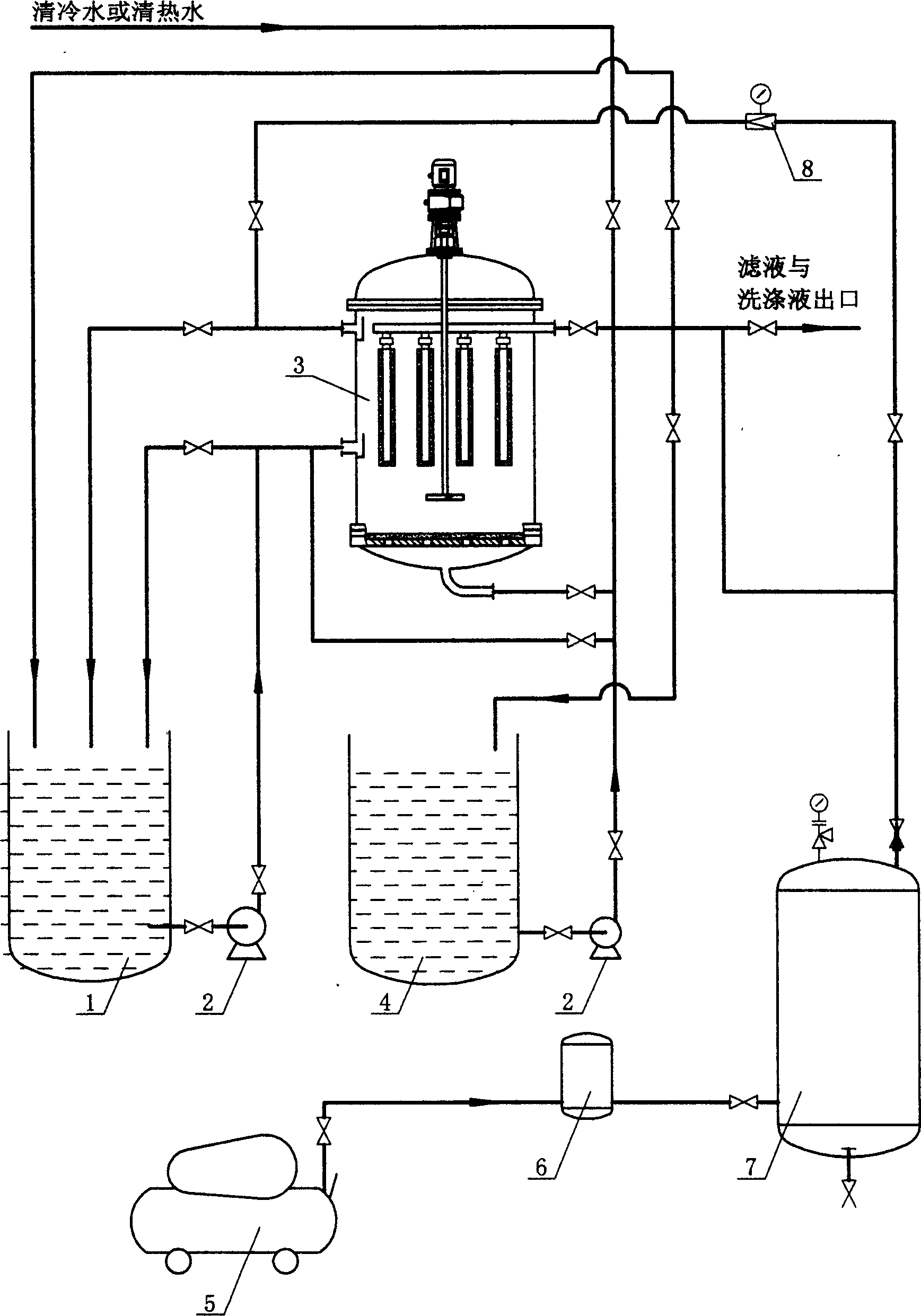

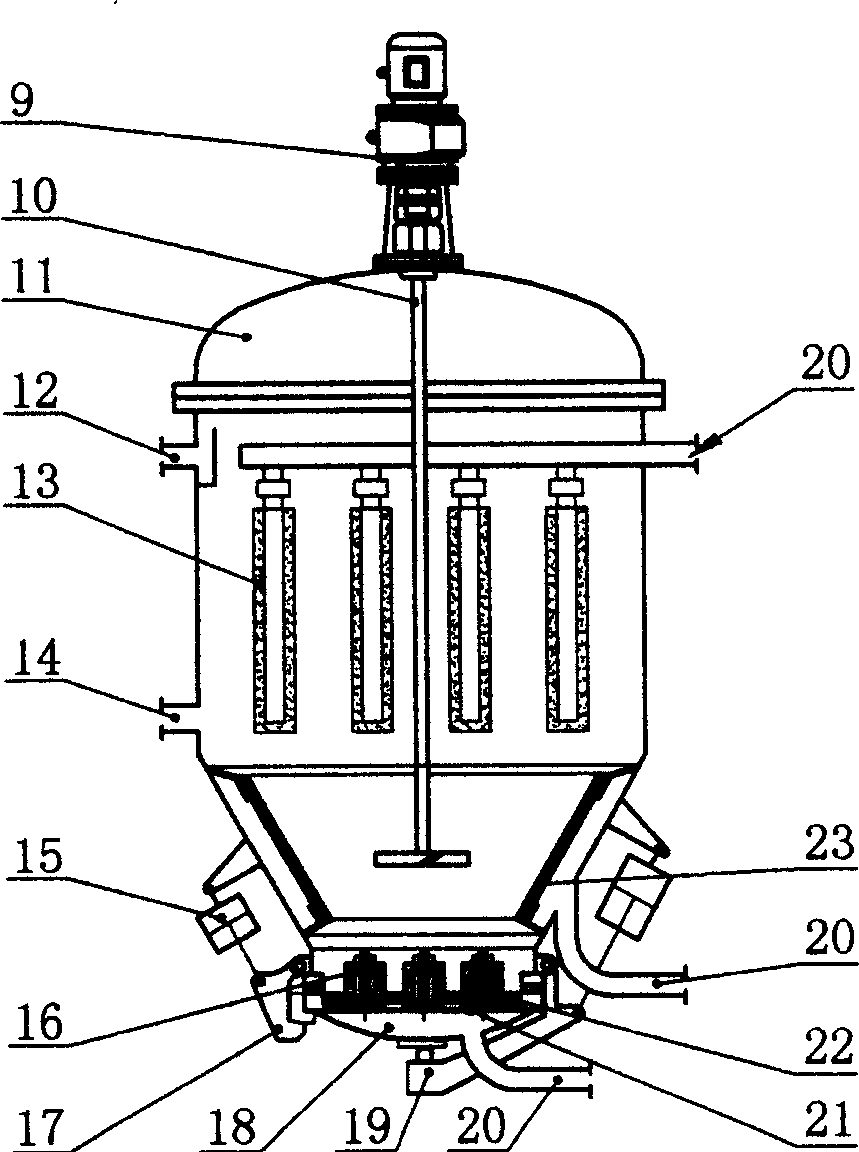

Filtration and washing technology in preparing metal or non metal fine granular powder

ActiveCN1686593AOvercome the disadvantages of filtrationHigh yieldFiltration circuitsEngineeringSpherical form

A filtering and washing process for preparing the metallic or non-metal fine particles includes filtering, washing, blow-drying of filtered cake, discharging and cleaning filter. Said filtering step features use of the precise millipore filter with at least two filter regions for respective filtering. Said washing step includes reversely blowing the washing liquid to drop the filtered cake onto filter plate, instantaneously reversely blowing compressed air several times, and stirring the mixture of filtered cake and washing liquid.

Owner:ZHEJIANG DONGOU FILTERING MASCH MFG CO LTD

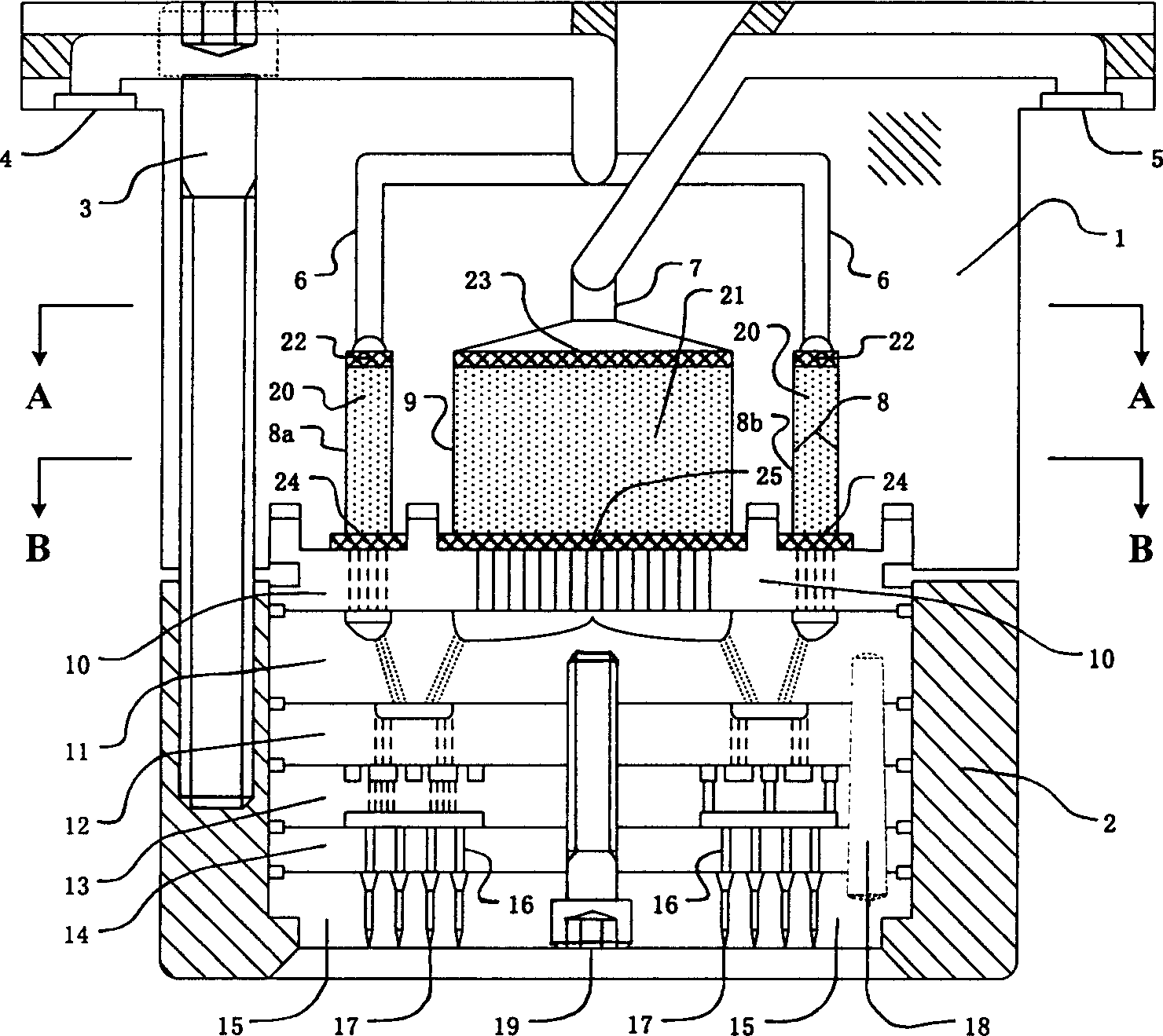

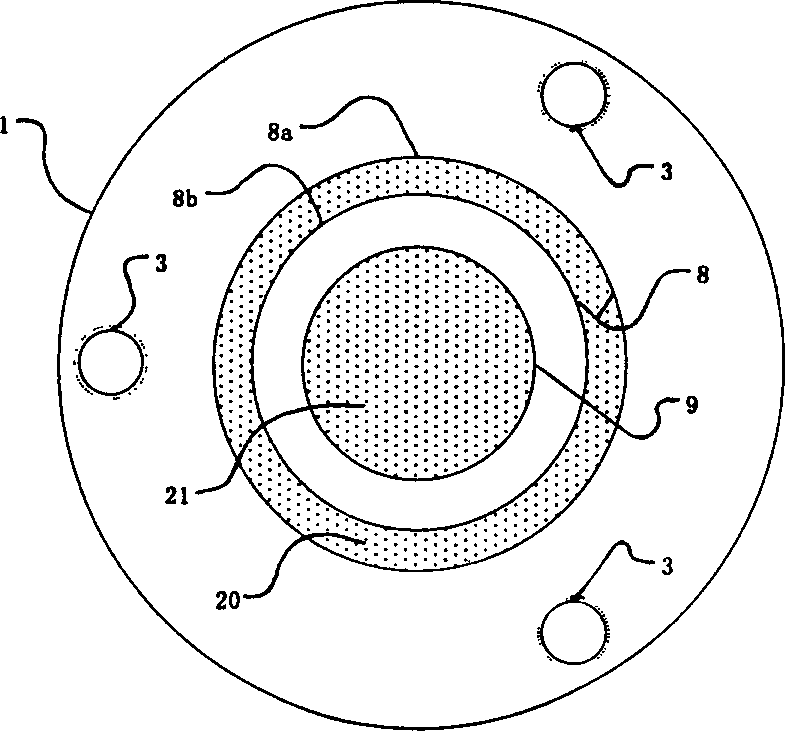

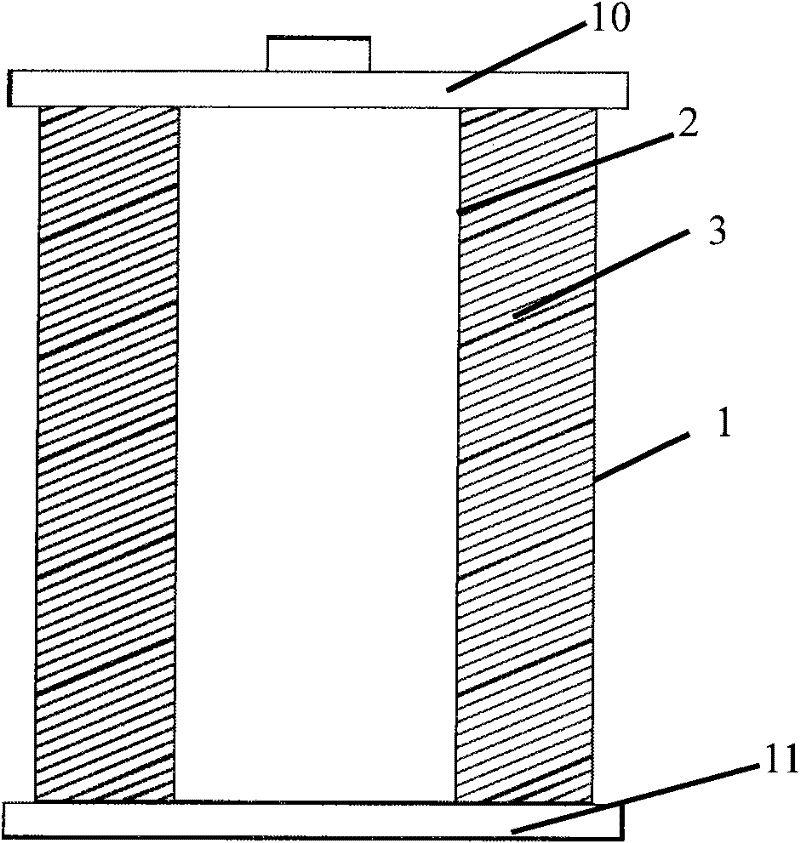

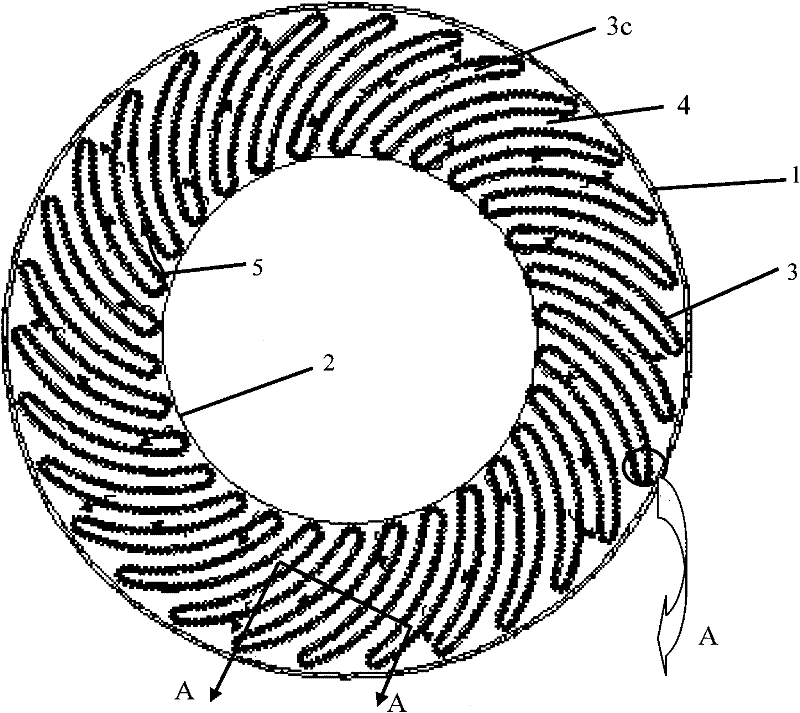

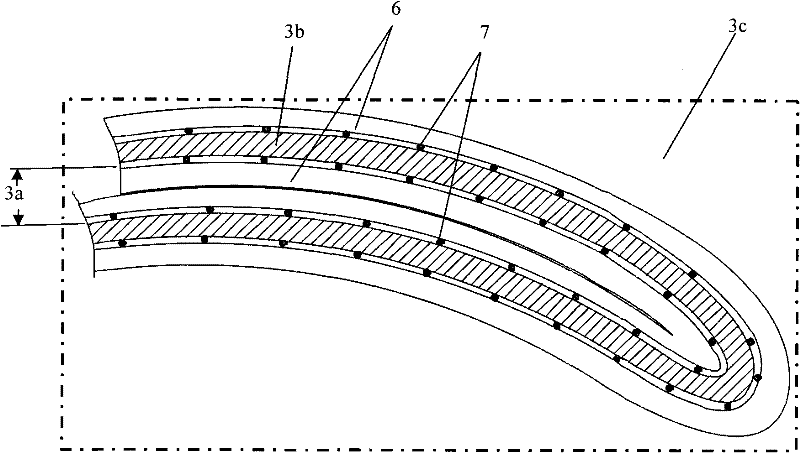

High-flux high-dirt-holding-capacity filtering element and preparation method thereof

InactiveCN102188848AExtended service lifeEven distribution of water flowStationary filtering element filtersCENBOLFiltration membrane

The invention discloses a high-flux high-dirt-holding-capacity filtering element, which comprises a filtering medium layer (3), a central tube (2), a shell (1) and upper and lower end covers (10, 11), wherein the filtering medium layer (3) is folded into an arc-shaped fold and then encloses the central tube (2), and the whole is cylindrical; the shell (1) is sleeved outside a cylindrical filtering medium; the filtering medium layer comprises a filtering layer (3b) and plastic net layers (8) which are positioned on two sides of the filtering layer; the filtering layer consists of at least two layers of filtering materials (3d); and the upper and lower ends of the central tube (2) and the shell (1) are fixedly connected with the upper and lower end covers. A high-flux folding filtering element is wide in runner, relatively low in fluid resistance, and more uniform in flow distribution of water inlet and outlet ends of the filtering element. Compared with the conventional W-shaped linear fold designing filtration membrane, the high-flux folding filtering element is improved by over 30 percent in terms of filling density, large in filtering area, high in total dirt-holding capacity and long in service life of the filtering element.

Owner:浙江瑞普环境技术有限公司

Air purifier capable of automatically cleaning ash

InactiveCN105879516AReasonable flowImprove efficiencyDispersed particle filtrationRadiationAir purifiersFilter system

The invention provides an air purifier capable of automatically cleaning ash. The air purifier is provided with a dust filtering system, a gas back-flowing system and an ash cleaning system. A cylinder-bucket-shaped filter screen structure is adopted, and deposited dust on a filter screen can be automatically cleaned; air enters the purifier from four side faces and is discharged out from the upper part; an air inlet area is several folds of that of an existing product, so that the working efficiency of the air purifier is improved and utilization time and electric energy consumption are reduced; and the air purifier has relatively good practicability.

Owner:陈光

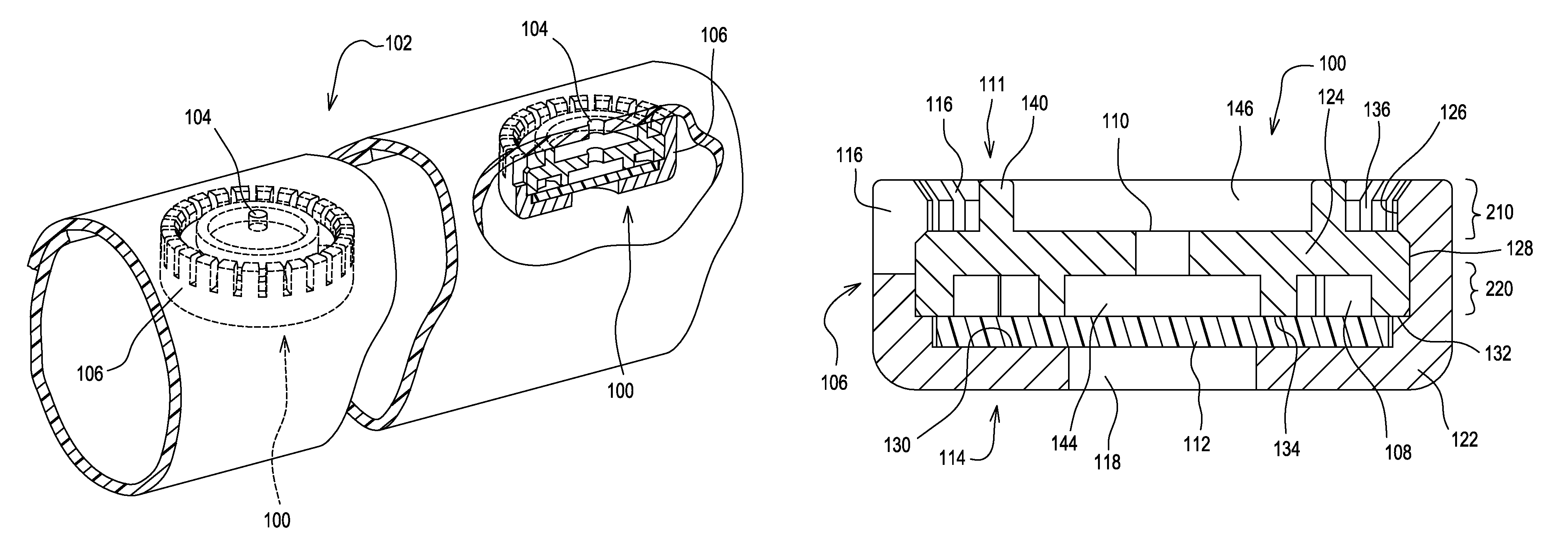

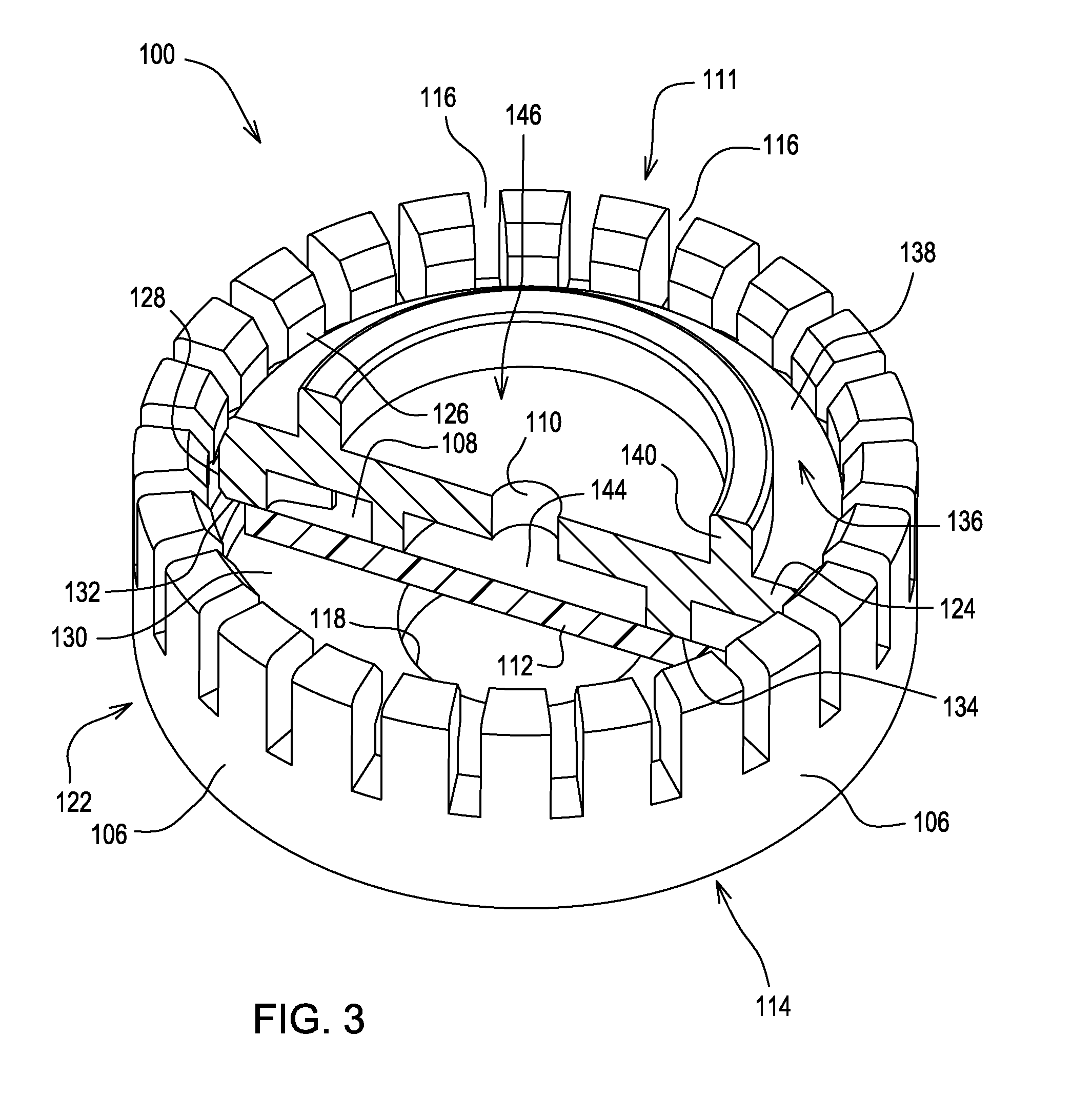

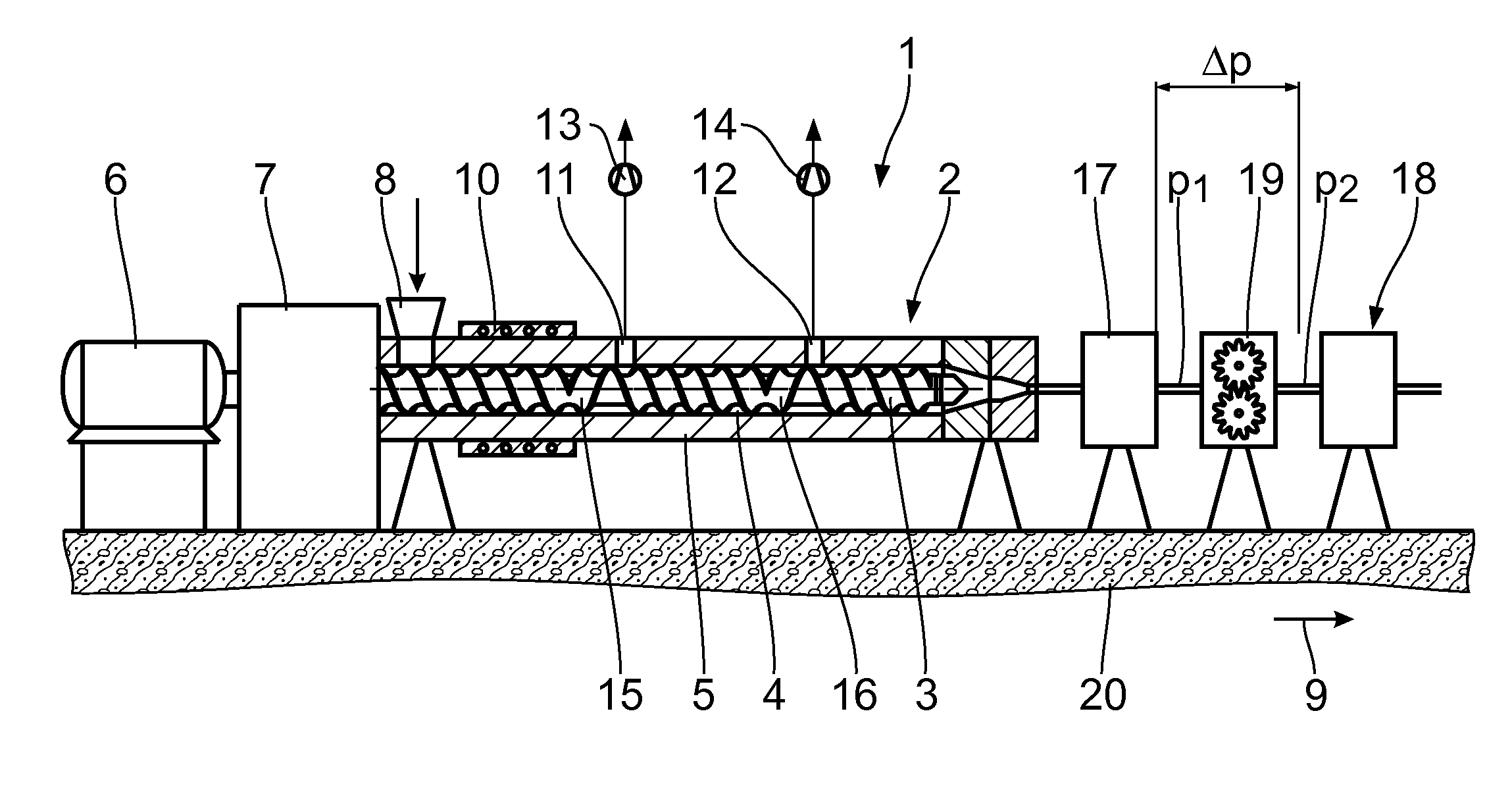

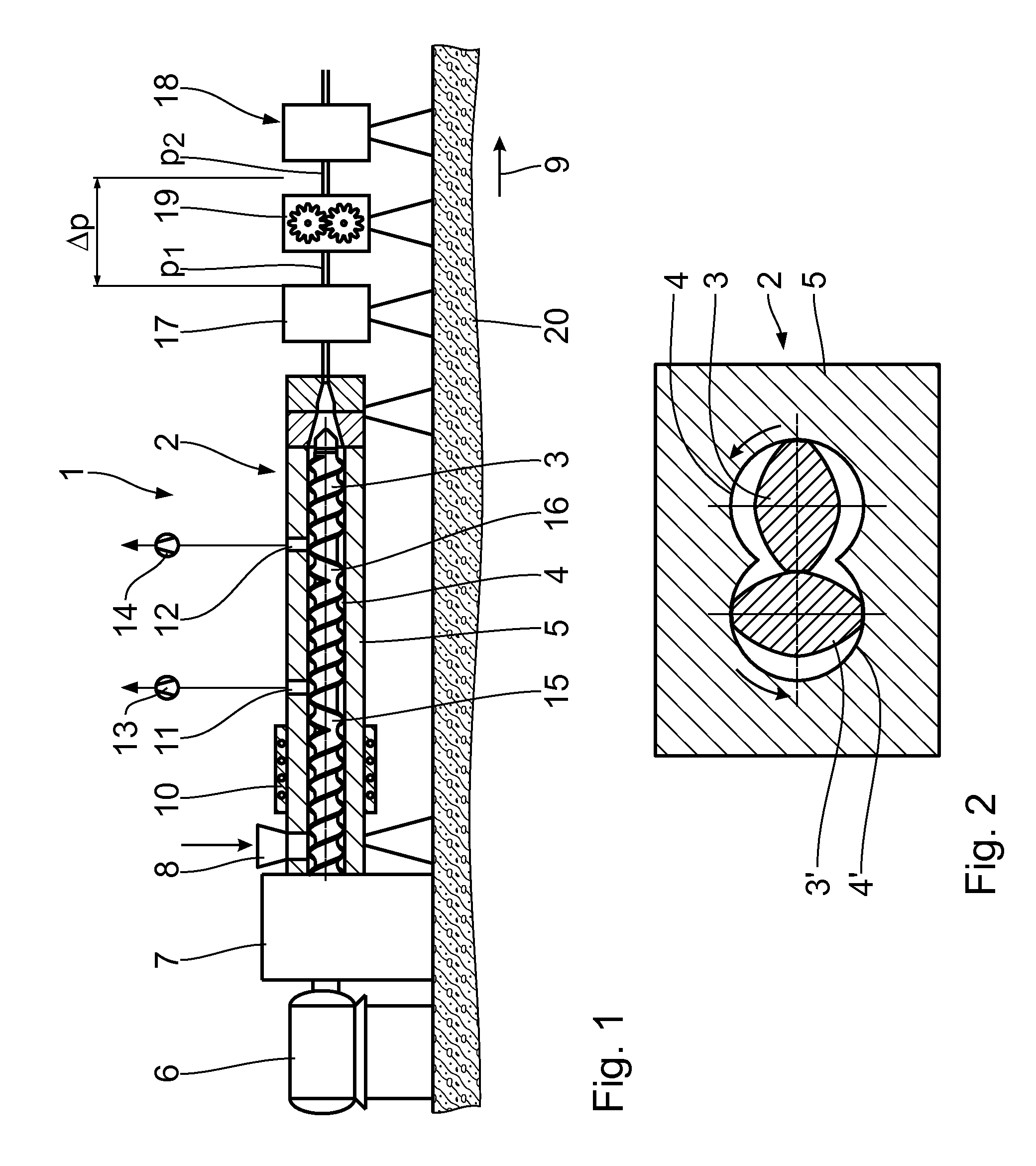

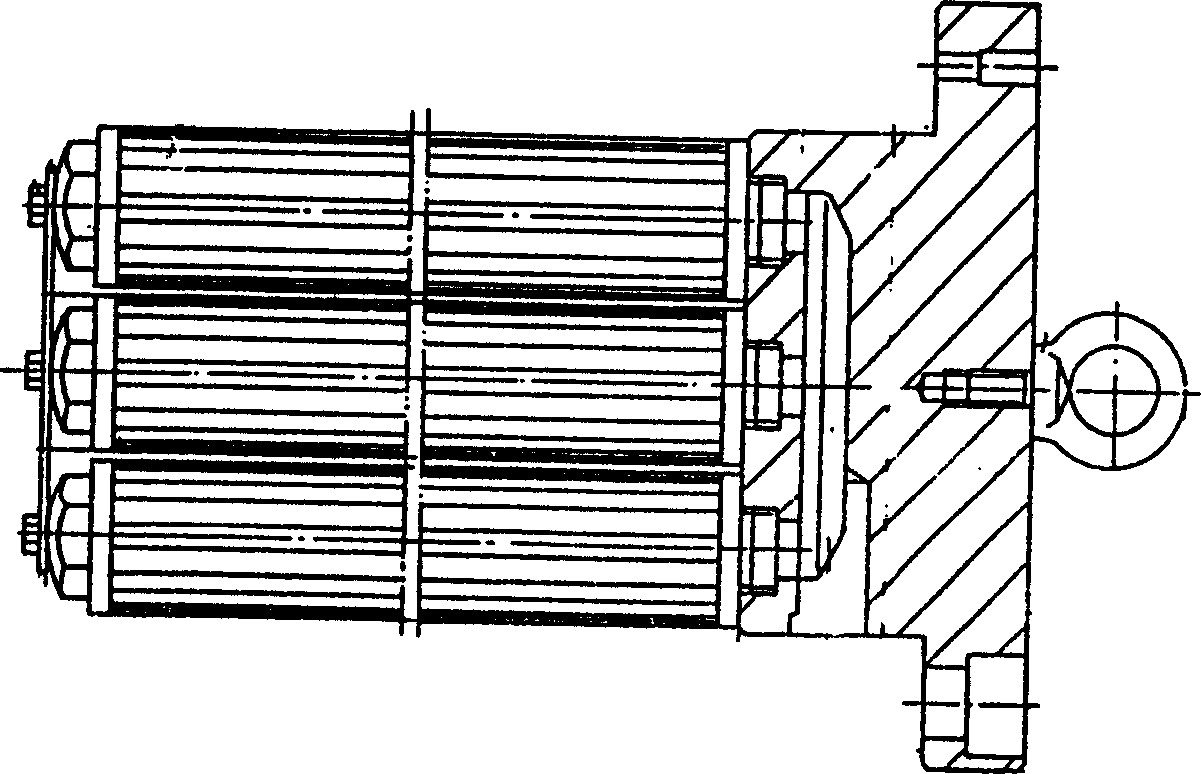

Filter unit for an extruder system and filter arrangement and associated sieve changing device for an extruder system with a filter unit of this type

InactiveUS20130020247A1Reduce differential pressureIncrease throughputLoose filtering material filtersCartridge filtersPlastic materialsSieve

A filter unit for an extruder system has an outer support body, which is hollow cylindrical and limits an interior. A plurality of outer through-openings open into the interior. An outer filter element is arranged on the support body in the region of the outer through-openings. An inner support body with a plurality of inner through-openings is arranged in the interior. An inner filter element is arranged on the inner support body in the region of the inner through-openings. Using the filter unit according to the invention, a low differential pressure of a plastics material melt to be filtered can be achieved as both the outer filter element and the inner filter element provide a corresponding filter area.

Owner:COPERION WERNER & PFLEIDERER GMBH & CO KG

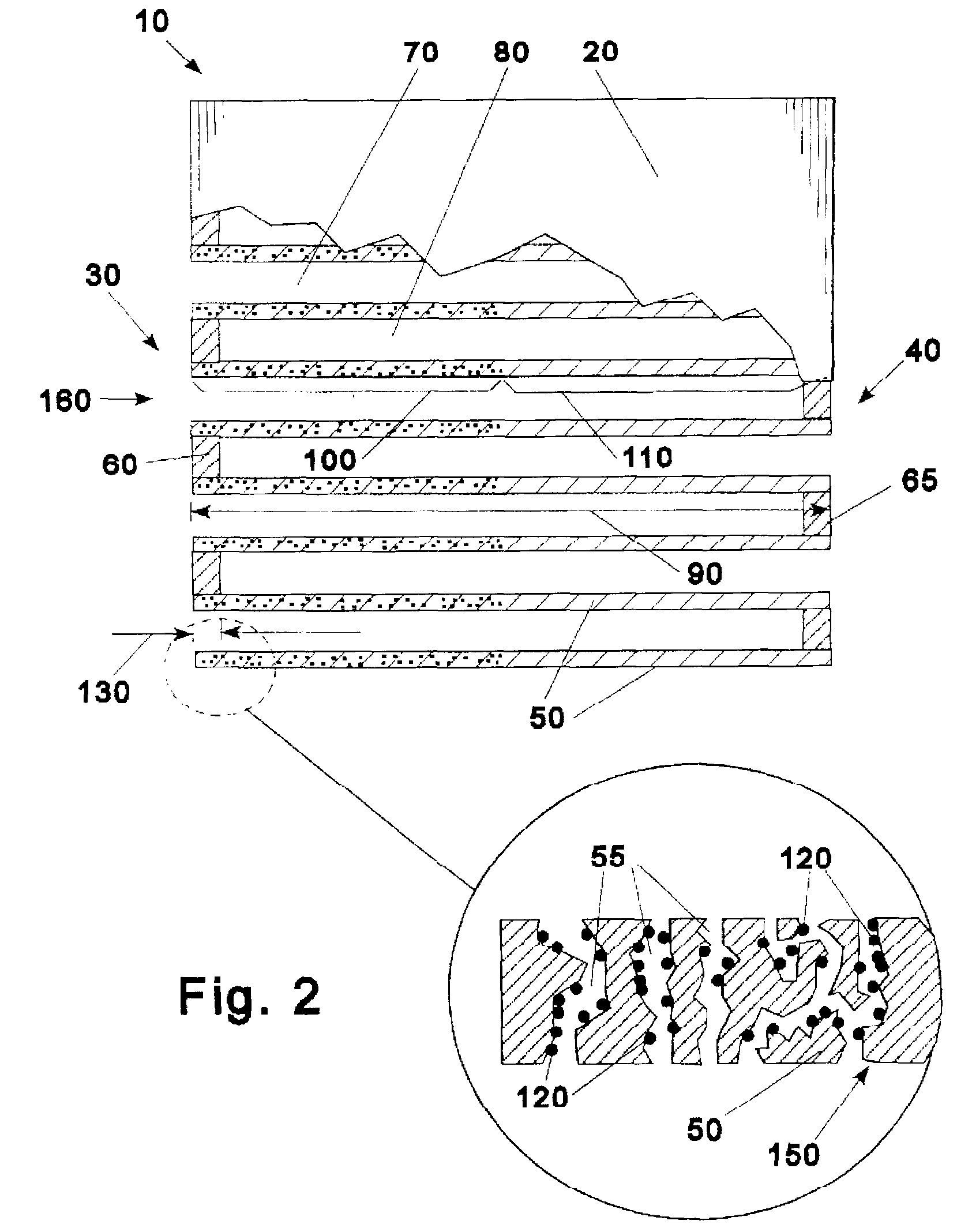

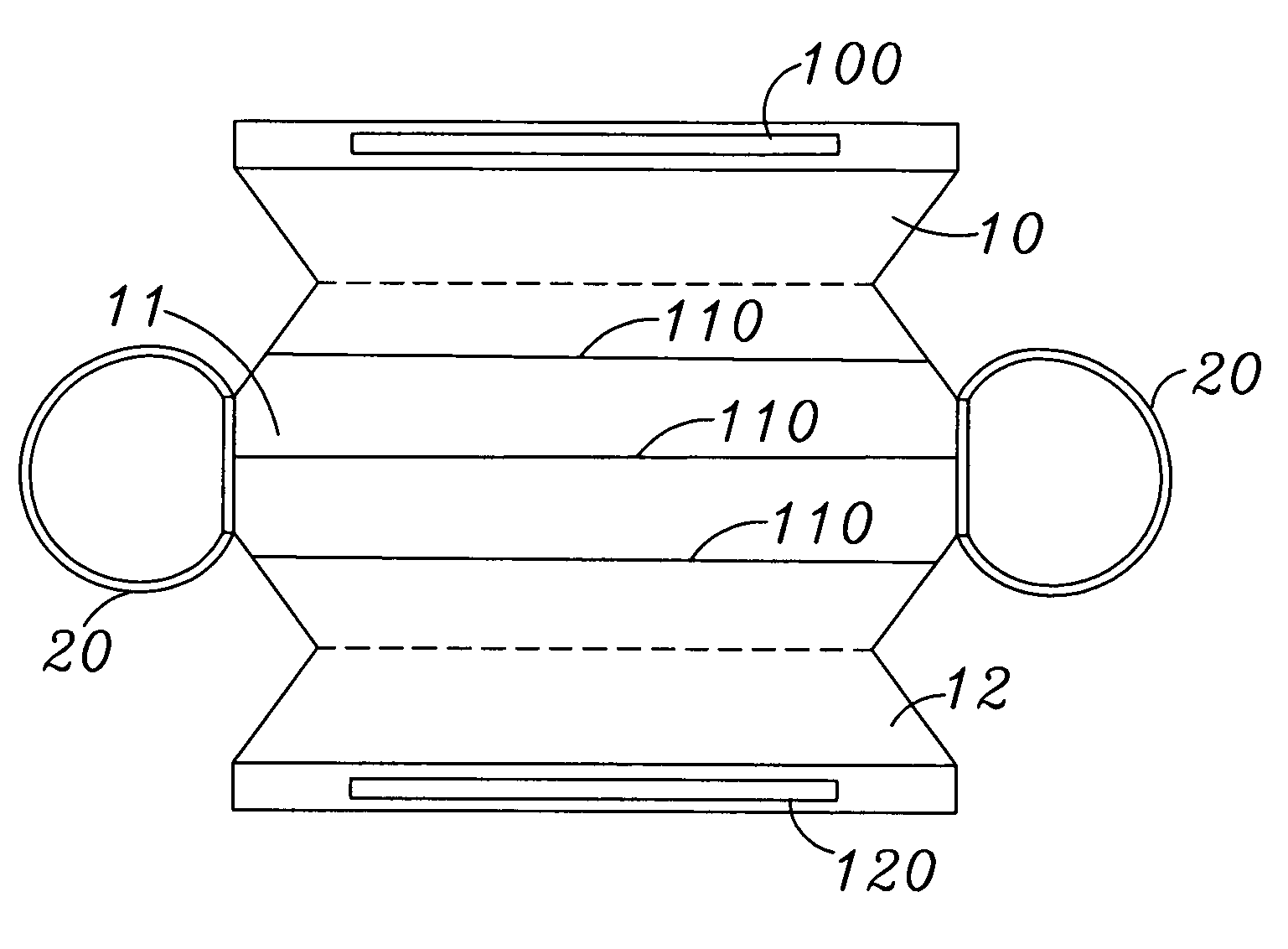

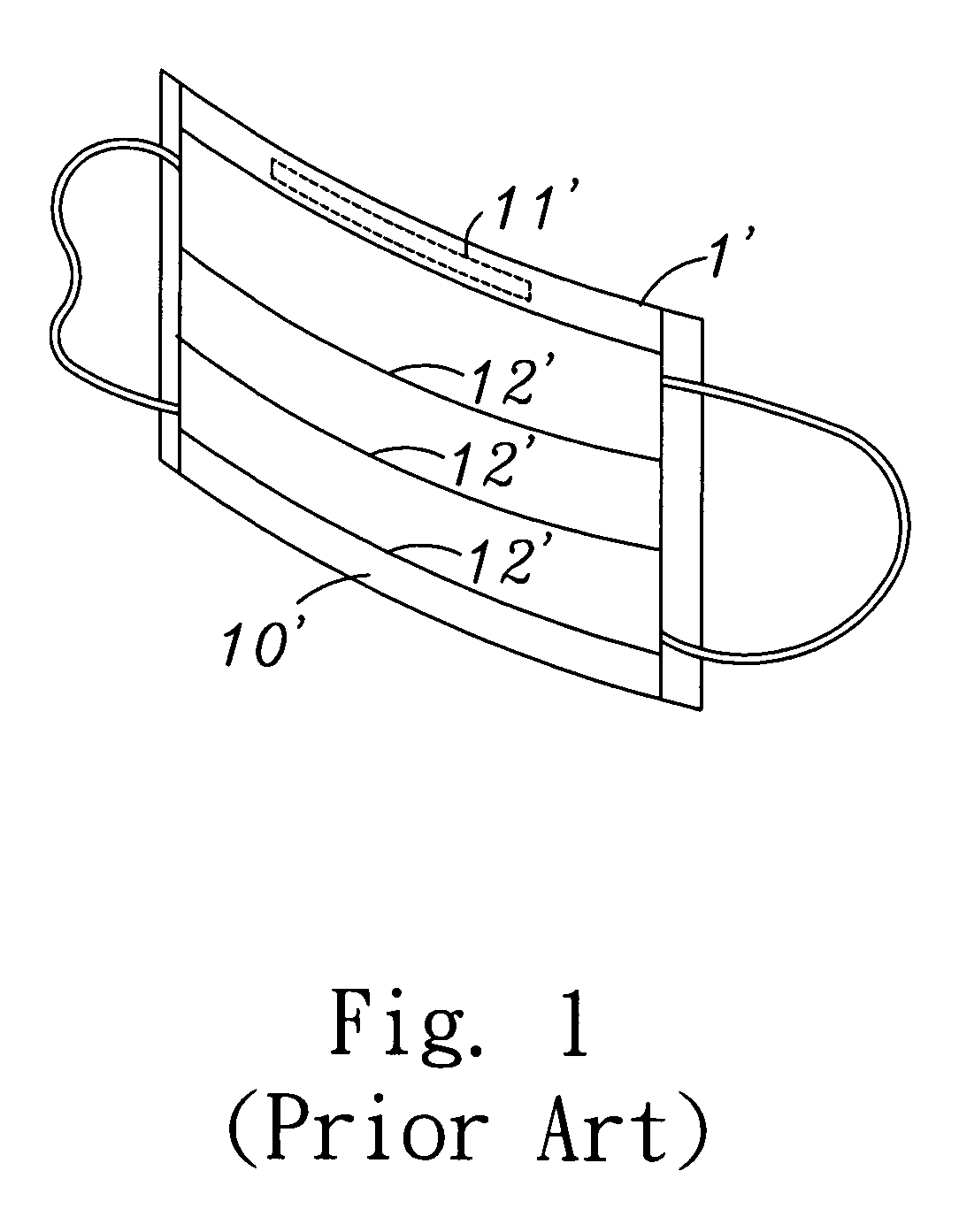

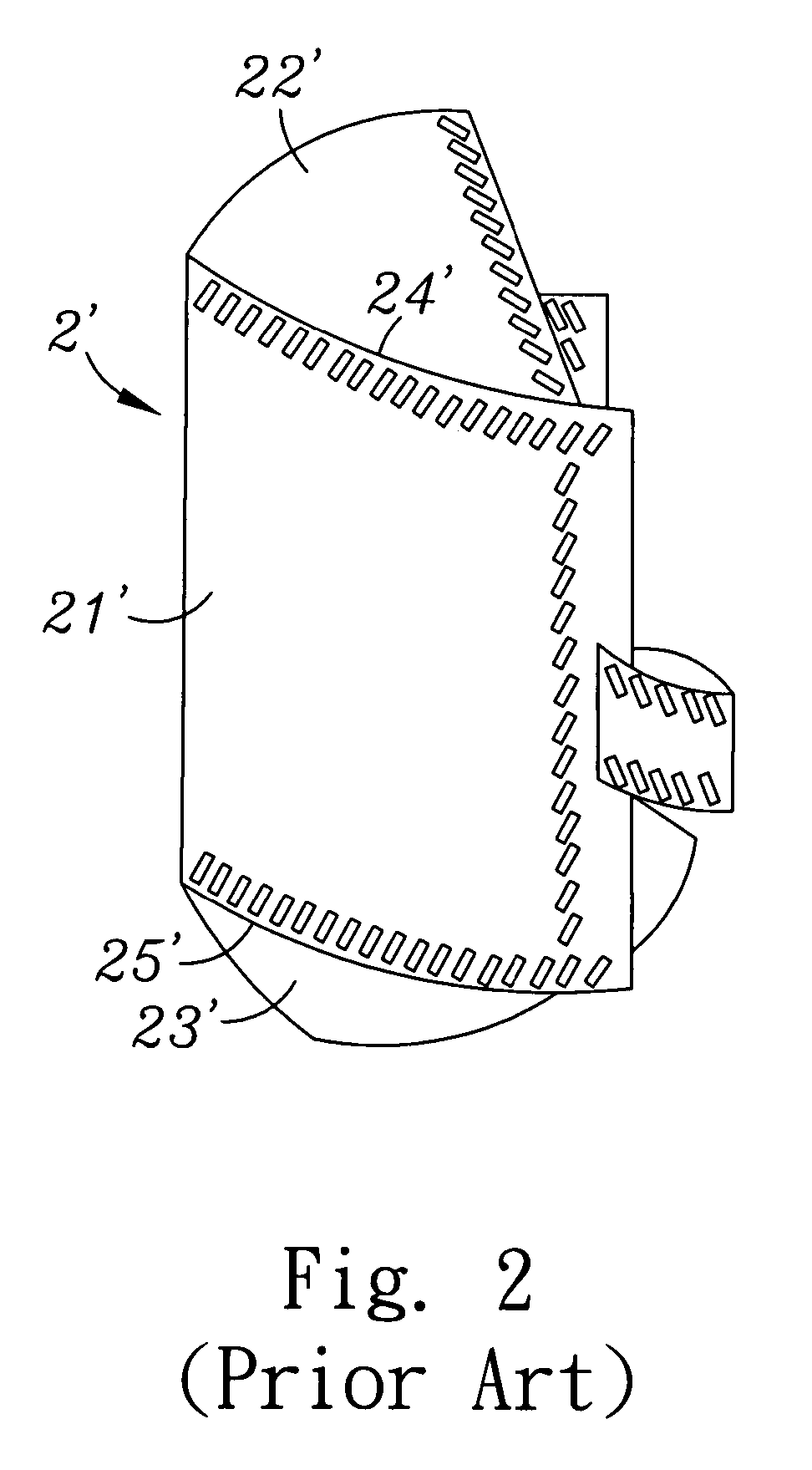

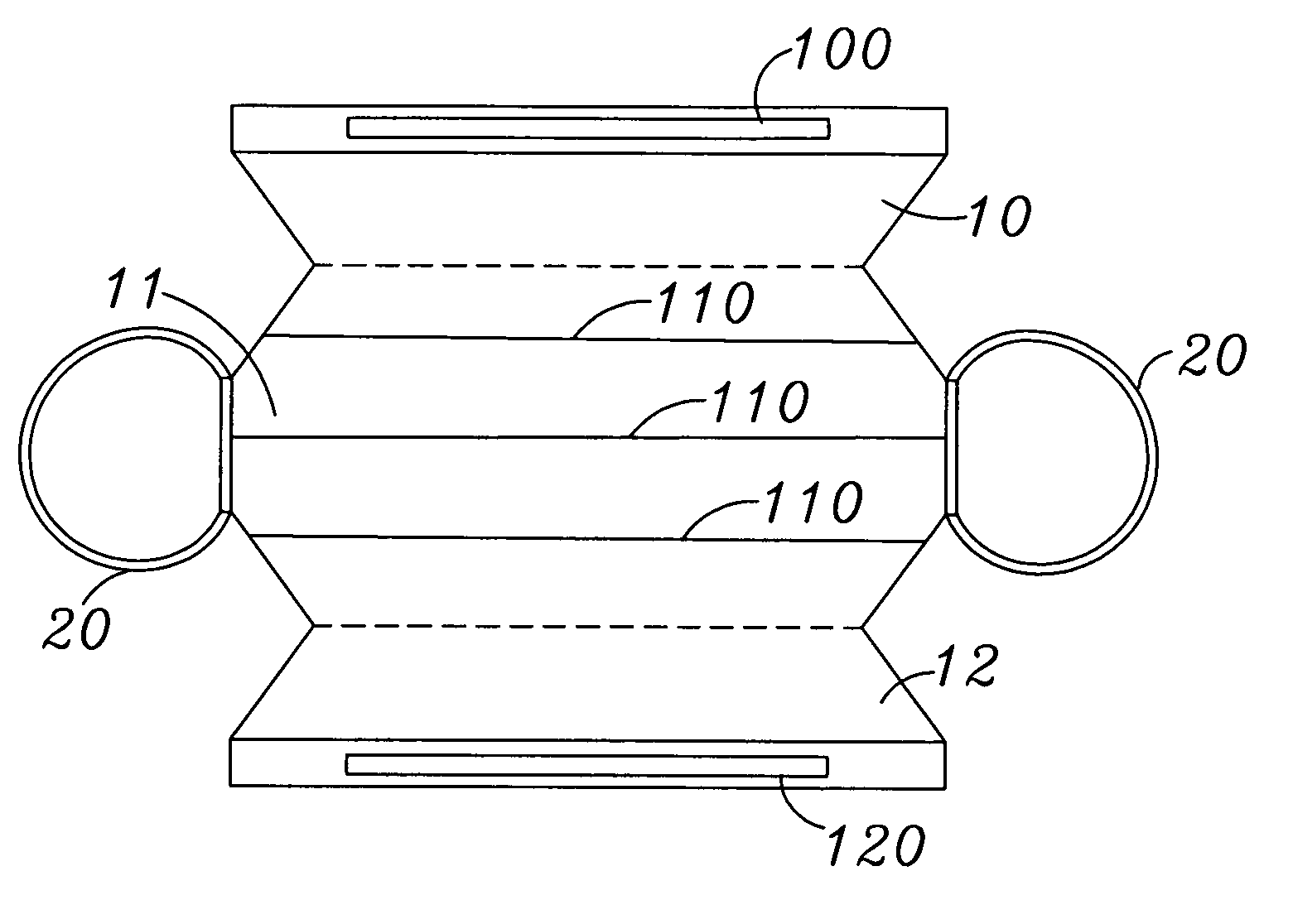

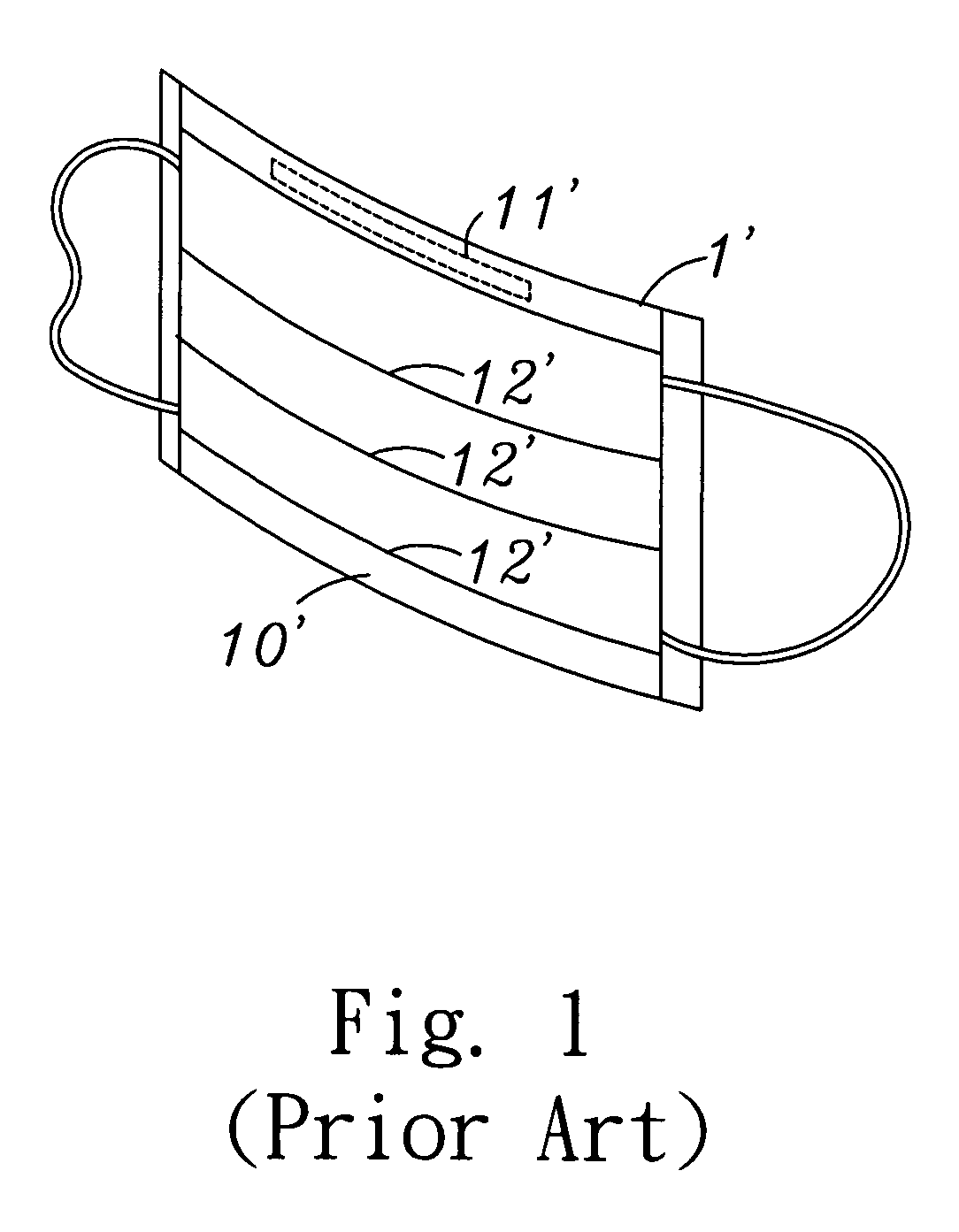

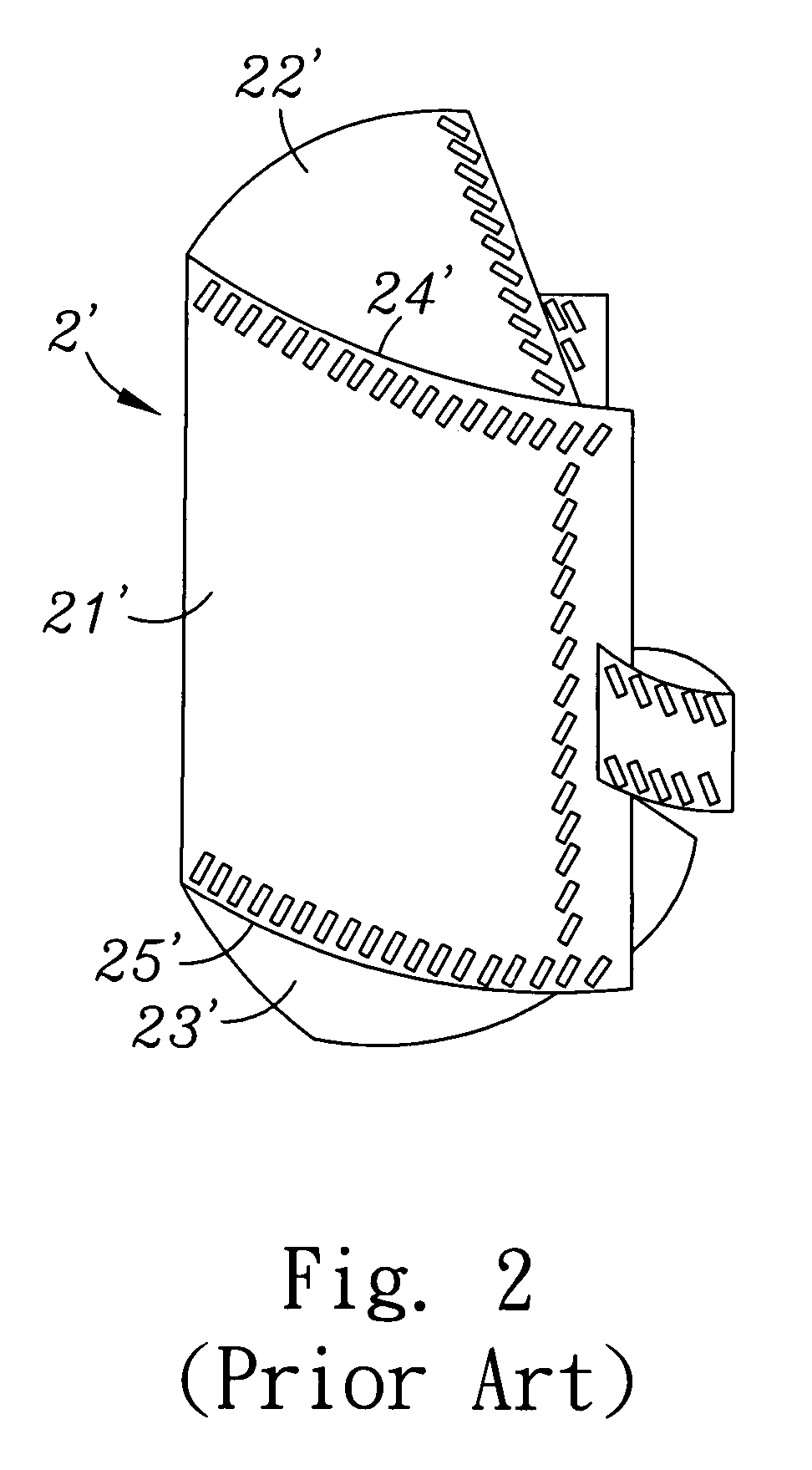

Face mask structure

ActiveUS7210482B2Reduce material consumptionIncrease the fermentation areaBreathing filtersBreathing masksInterior spaceEngineering

A face mask structure has an upper mask portion, a middle mask portion, and a lower mask portion, which are formed integrally. The upper mask portion has an upper metal stripe disposed at a proper position thereof. The lower mask portion has a lower metal stripe disposed at a proper position thereof. The upper and lower mask portions are folded in opposite directions. When in use, the upper and lower mask portions are spread out to support the middle mask portion. In this way, the face mask structure becomes fitting in with the shapes of human faces. Furthermore, the middle mask portion has multiple folding portions. When in use, the folding portions are stretched out to increase filtering area. Thereby, the inner space of the face mask structure is increased, the air-invasion rate is reduced, and the filtering efficiency is thus improved.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE +1

Face mask structure

ActiveUS20070023046A1Reduce material consumptionReduce labor costsBreathing filtersBreathing masksInterior spaceEngineering

A face mask structure has an upper mask portion, a middle mask portion, and a lower mask portion, which are formed integrally. The upper mask portion has an upper metal stripe disposed at a proper position thereof. The lower mask portion has a lower metal stripe disposed at a proper position thereof. The upper and lower mask portions are folded in opposite directions. When in use, the upper and lower mask portions are spread out to support the middle mask portion. In this way, the face mask structure becomes fitting in with the shapes of human faces. Furthermore, the middle mask portion has multiple folding portions. When in use, the folding portions are stretched out to increase filtering area. Thereby, the inner space of the face mask structure is increased, the air-invasion rate is reduced, and the filtering efficiency is thus improved.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE +1

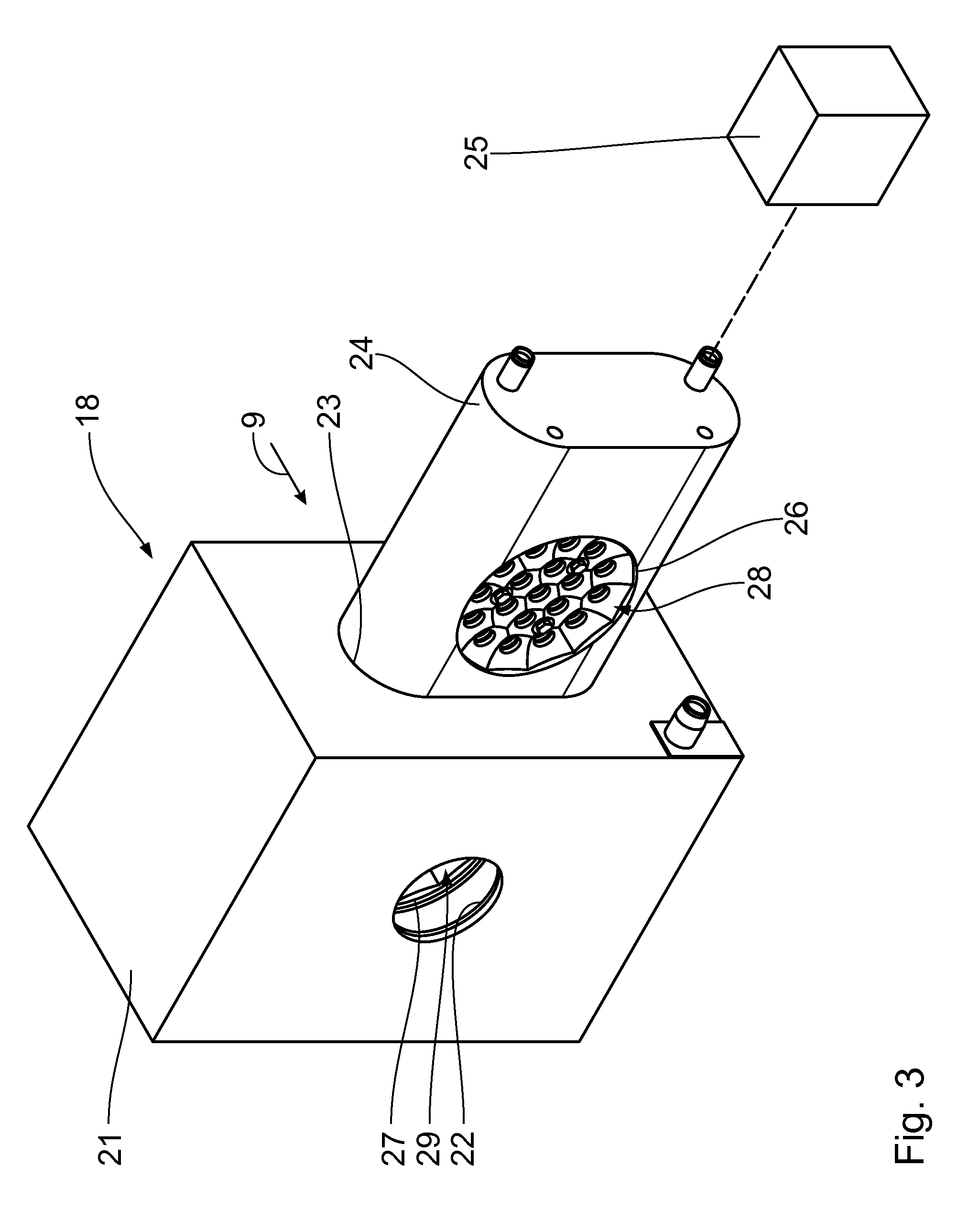

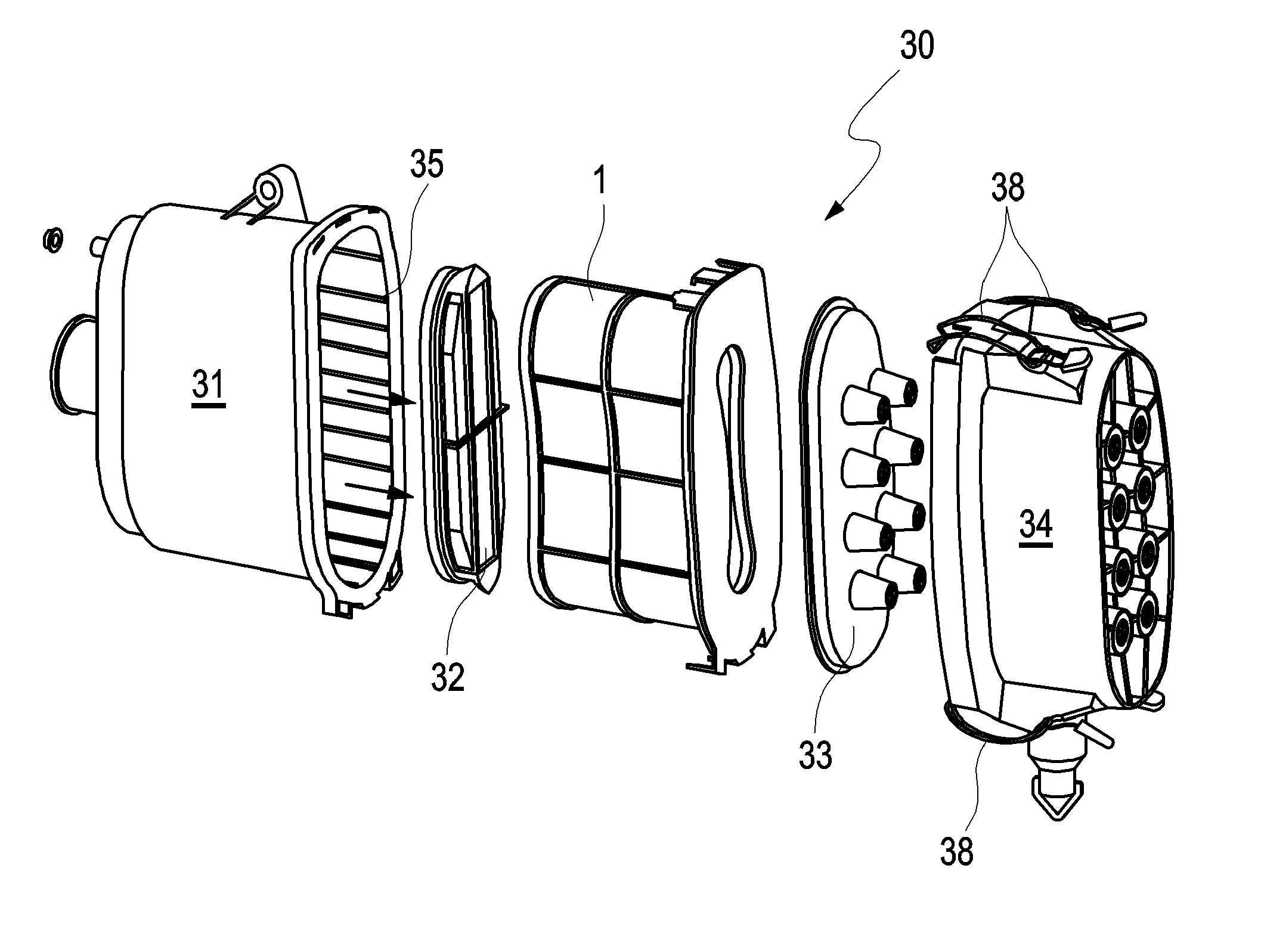

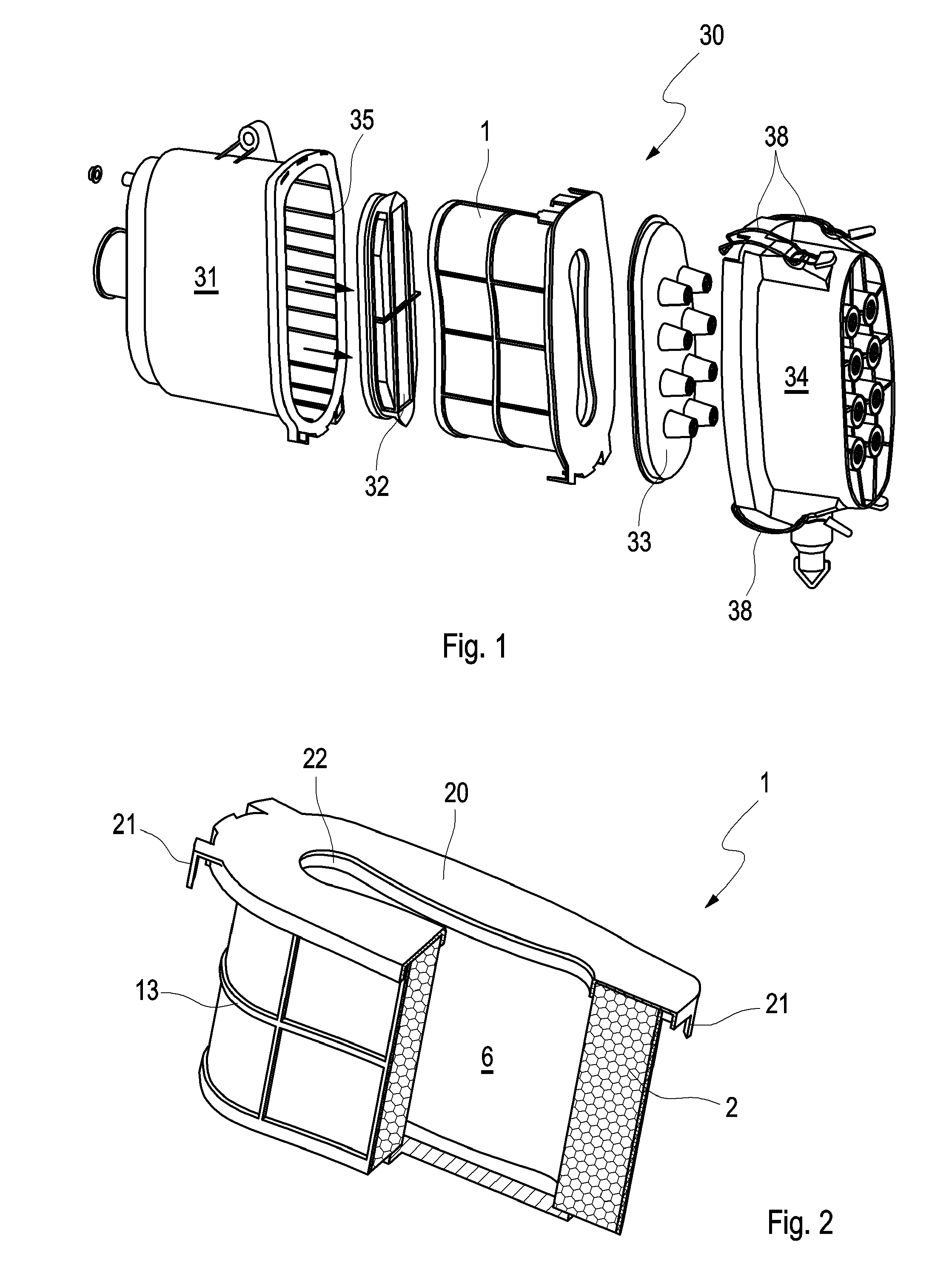

Air filter element, air filter housing and air filter system

ActiveUS20140047808A1Calm down air flowSmall spacingCombination devicesDispersed particle filtrationAir filterFilter media

A filter element (1) for an air filter (30) has a tubular filter medium (2), the annular cross-section of which encloses an interior (6) of the filter element and which has an inner wall (7) that adjoins the interior of the filter element and that extends in the form of at least one convex arch (8) and at least two concave arches (9), the concave arch (9) being located between two convex arches (8) such that the interior (6) of the filter element has a constriction (11) in the area of the concave arch (9), the constriction (11) being adjoined by two wide zones (12) of the interior of the filter element.

Owner:MANN HUMMEL GMBH

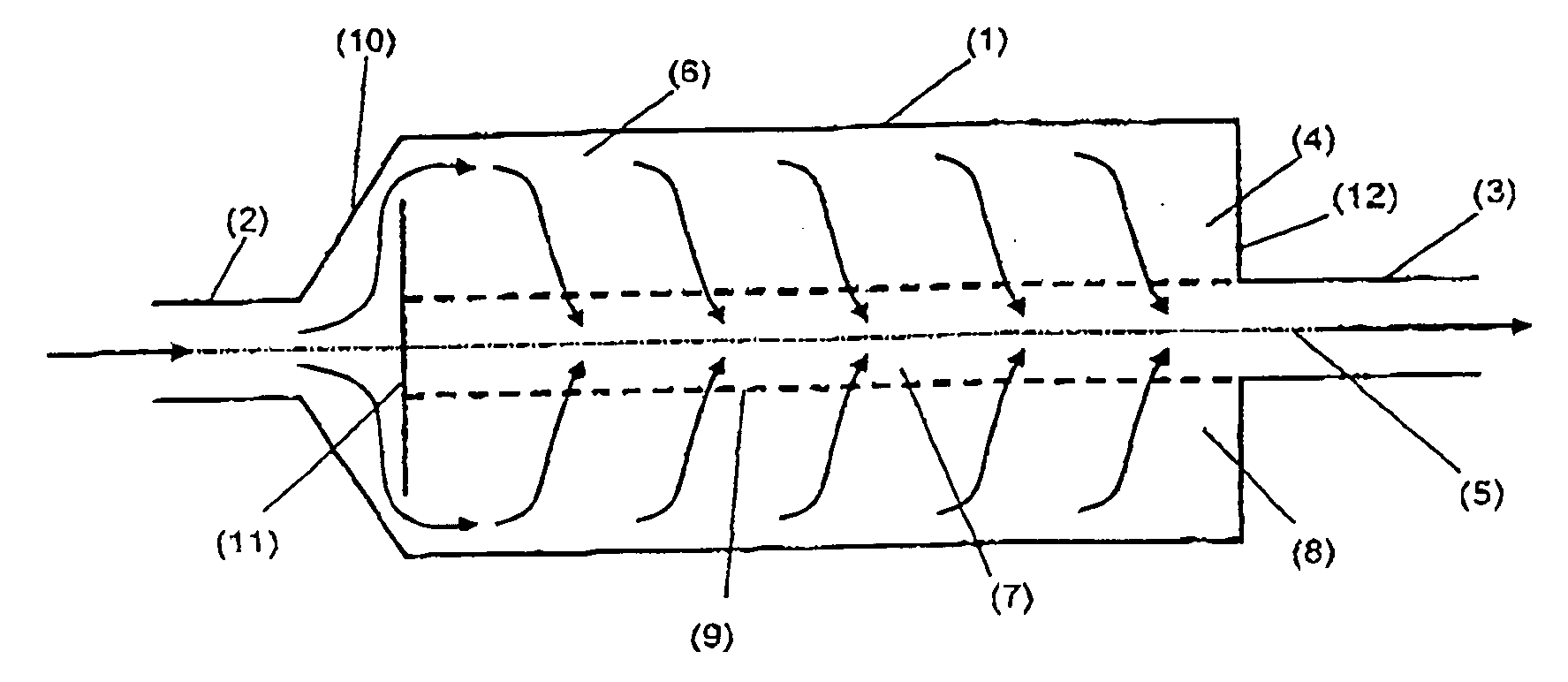

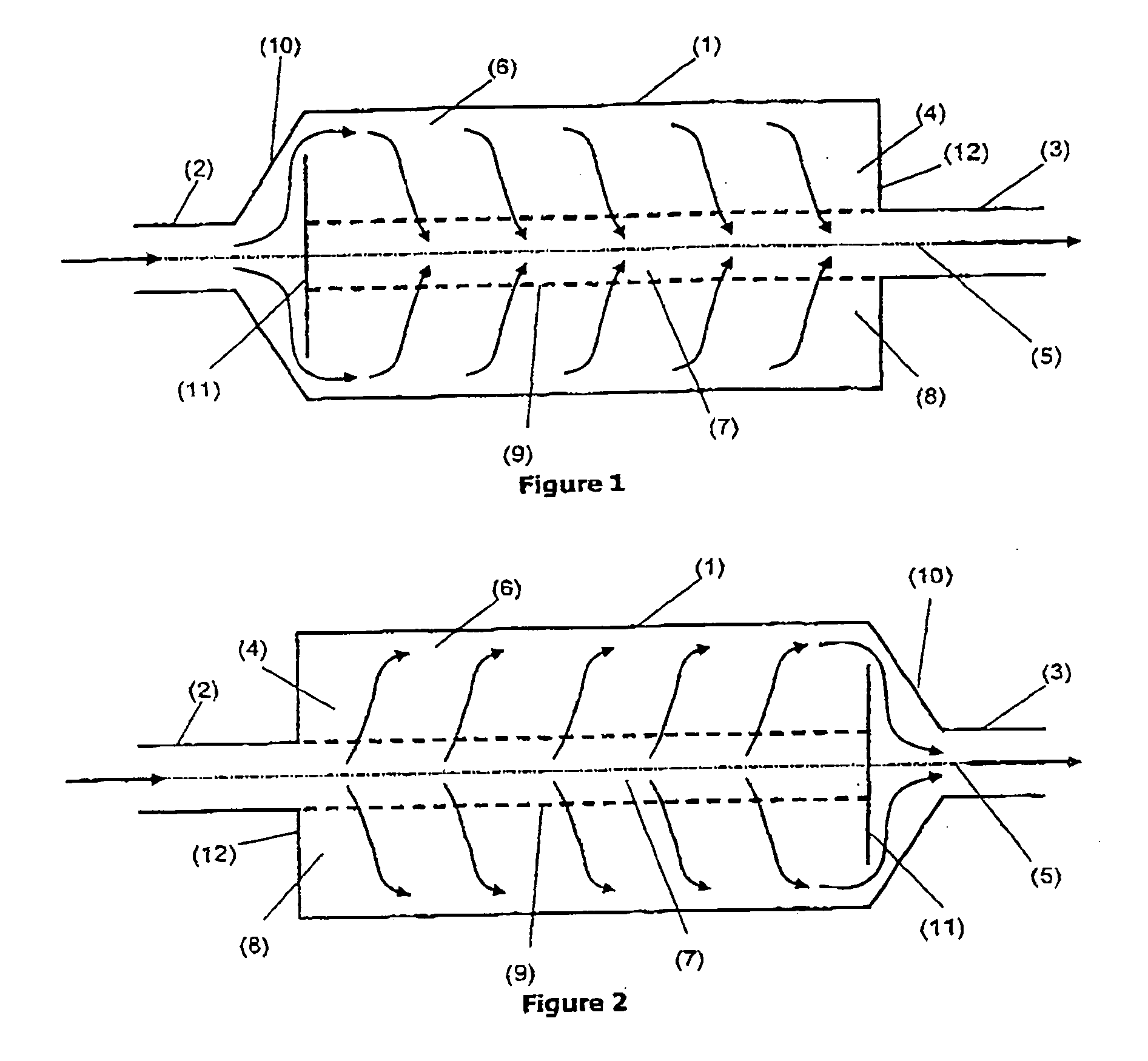

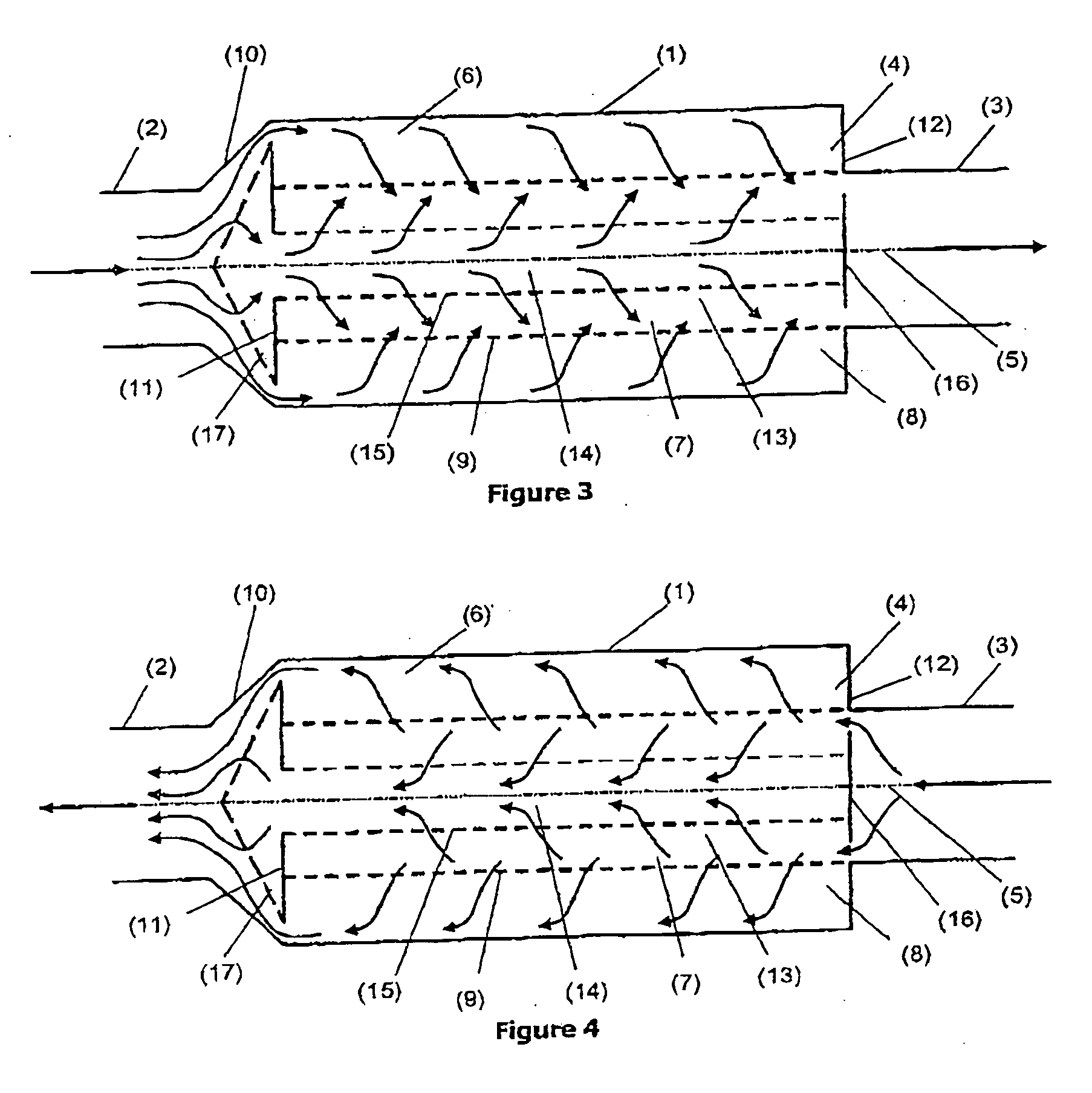

Filtering device for diesel engine exhaust gas

ActiveUS20080209872A1Easy to shapeLarge filter areaCombination devicesDispersed particle filtrationExhaust gasPollutant

A filtering device for diesel engines is based on metal foams. In order to achieve high filtration efficiency with low pressure drop using deep bed filtration metal foams, a radial flow concept is used based on a “porosity gradient”. The foams can also be coated with catalytically active material to enhance soot oxidation (regeneration), as well as reduction of other exhaust gas pollutants (CO, hydrocarbons, nitrogen oxides). This may be accomplished by using non-uniform amounts of catalytic materials within the filter depending on the targeted application. An additional secondary filter segment may be placed within the metal support of the main filter segment. The metallic diaphragms at the entrance and exit of the external shell are designed in such a way as to allow the flow to be divided between the main and the secondary filter segments according to the respective flow resistances.

Owner:ARISTOTLE UNIV THESSALONIKI RES COMMITTEE +1

V shaped groove type microgrid component capable of continuously on-line updating dynamic membrane and use method thereof

ActiveCN101481174ALow priceStable hydraulic environmentWater/sewage treatment bu osmosis/dialysisSustainable biological treatmentControl systemHigh flux

The invention relates to a V-shaped slot type micronet assembly and an application method for continuously renewing a dynamic film on line, which comprises a porous filter supporting a dynamic film. The V-shaped slot type micronet assembly is characterized in that the porous filter is a flat-cylindrical micronet net body formed by a plurality of layers of micronets of various calibers which are superposed, fixed into shape and connected sequentially by a plurality of concentric annular V-shaped slots, a sleeve shell is arranged outside the porous filter, and the bottom of the porous filter is hermetically connected with a bottom net; a plurality of closed net chambers internally provided with ceramic granule balls are formed between the micronet net body and the bottom net; the center of the micronet net body is provided with a hollow shaft pipe, a baffle is arranged in the hollow shaft pipe, and the hollow shaft pipe above the baffle is connected with a rotary driving mechanism, a water source and a reverse flushing water pipe with a liquid spray head; the hollow shaft pipe under the baffle is connected with an air source and an air injection pipe arranged under the net body, and 0.5 percent or 1 percent of environment mineral material is added into mixed liquid in application. The invention has the advantages of low manufacturing cost, small size, high flux, good out-water quality, high water-outlet rate, power and control system optimization and simplification, low energy consumption and low cost.

Owner:北京创未环境工程技术有限公司

Method for producing hollow short fibre by regenerating polyester

InactiveCN1456715AHigh cost performanceLarge filter areaHollow filament manufactureMelt spinning methodsFiberPolyester

A process for preparing hollow staples from regenerated polyester includes such steps as washing waste polyester, pulverizing, drying, fusing extruding, prefiltering, pump metering, module filtering, spinning by hollow spinnerette, cooling in circulating wind, drawing, winding, bundling, stretching in oil bath and then in over-heat steam, crimping, thermal shape fixing, cutting short, and packing. Its advantage is high P / C ratio.

Owner:NINGBO DAFA CHEM FIBER

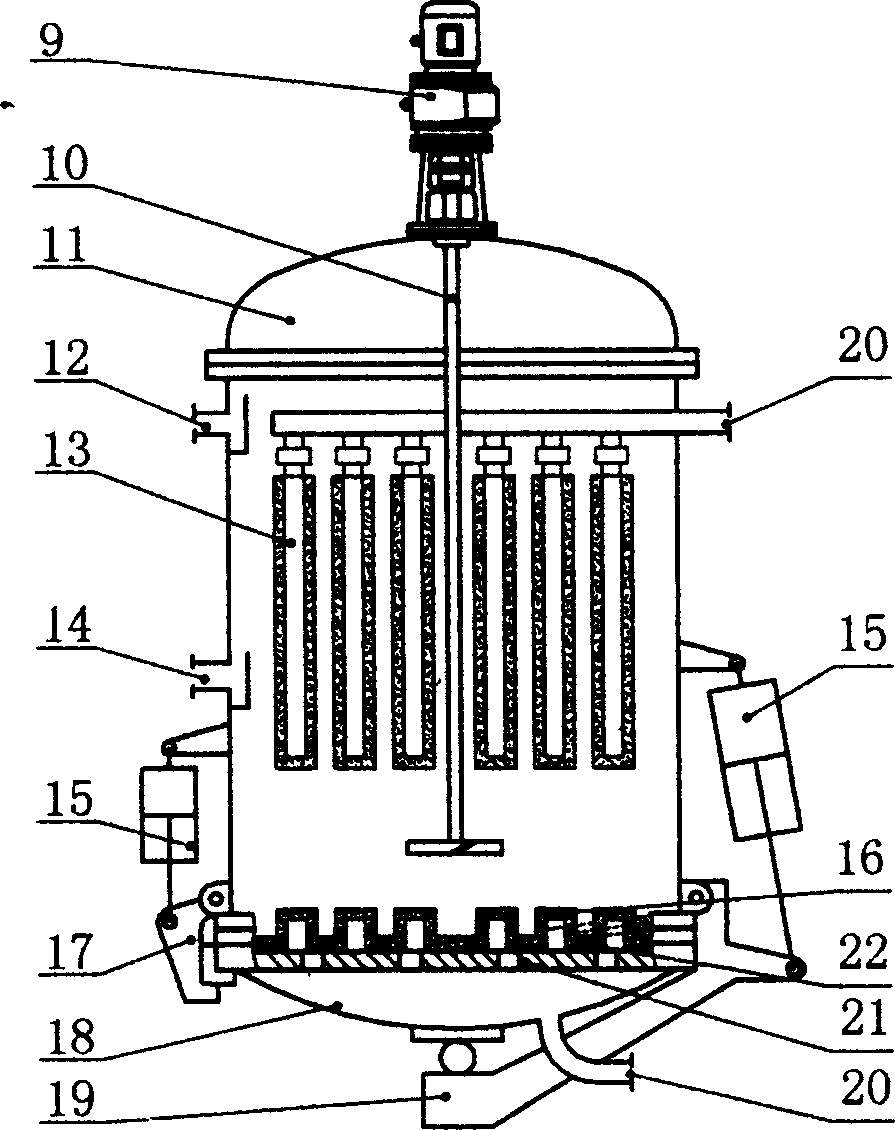

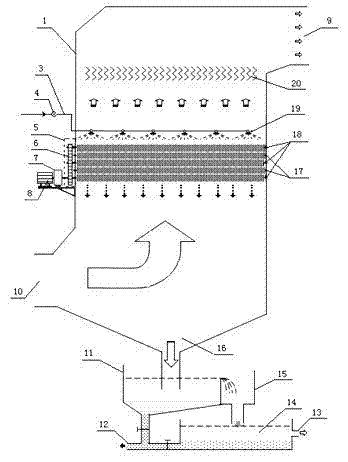

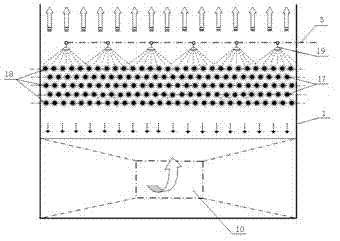

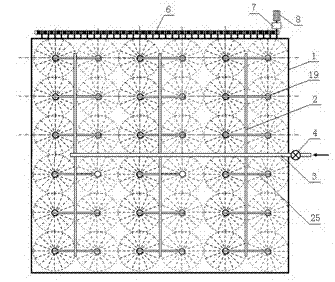

Spraying rotating brush dust collecting device

The invention discloses a spraying rotating brush dust collecting device. The entire dust collecting device is a tower body of which the lower part is provided with a flue gas inlet and the top is provided with a flue gas outlet; a demister is arranged in front of the top flue gas outlet of the tower; the middle part of the tower is provided with a spraying layer and a hair brush filtering layer; the bottom of the tower is provided with a mortar pond; the spraying layer is positioned above the hair brush filtering layer; the hair brush filtering layer consists of a plurality of rotating brush layers, a plurality of fixed brush layers, a transmission mechanism, a speed reducer and a driving motor; each rotating brush layer and each fixed brush layer consist of one group of hair brushes; the hair brushes are fixed on corresponding hair brush shafts; and each hair brush shaft of the rotating brush layer is in transmission connection with the driving motor through the transmission mechanism and the speed reducer. The spraying rotating brush dust collecting device has the characteristics of high suitability and high dust collecting efficiency, and is particularly suitable for purifying high-temperature and corrosive gases.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

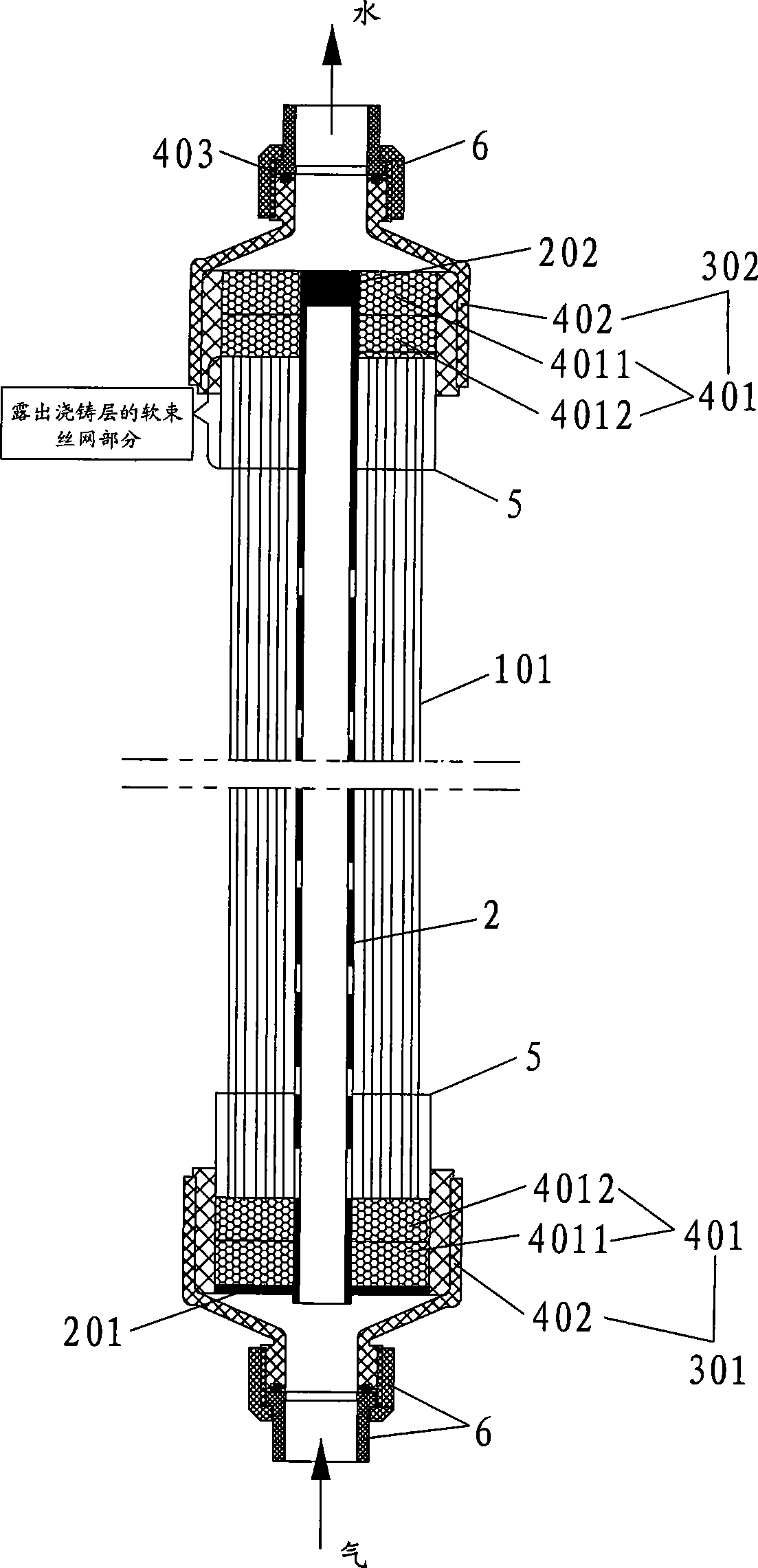

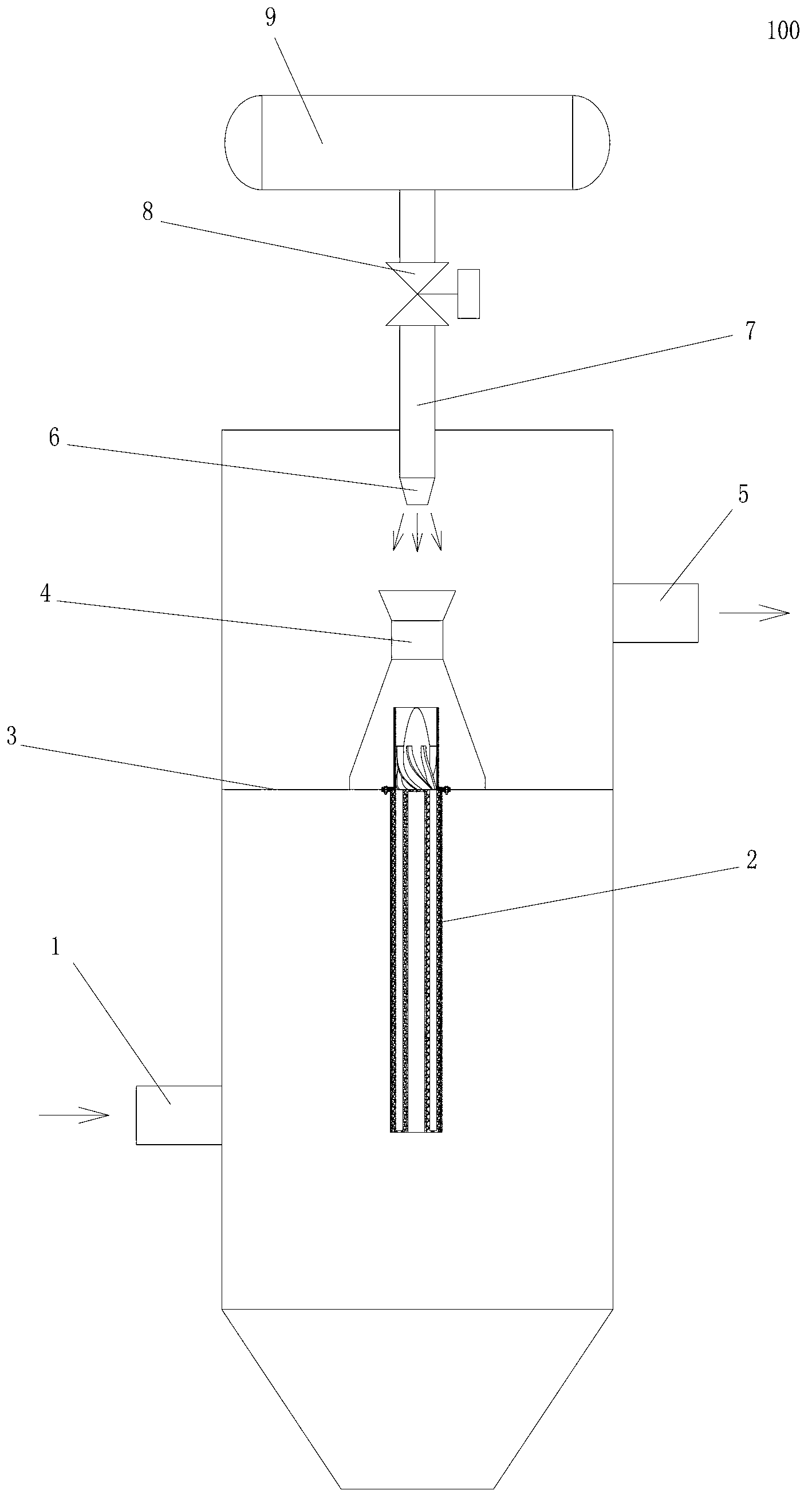

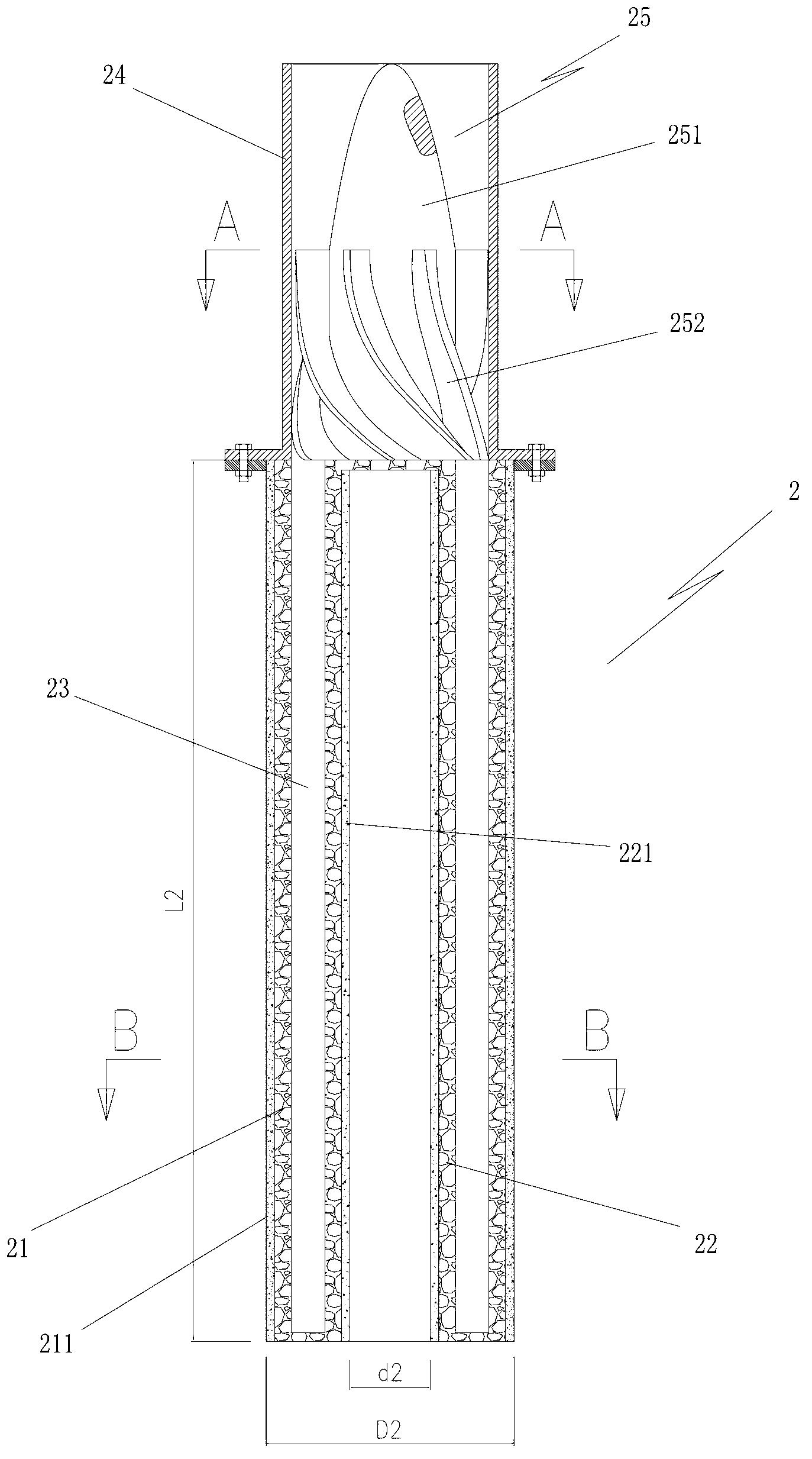

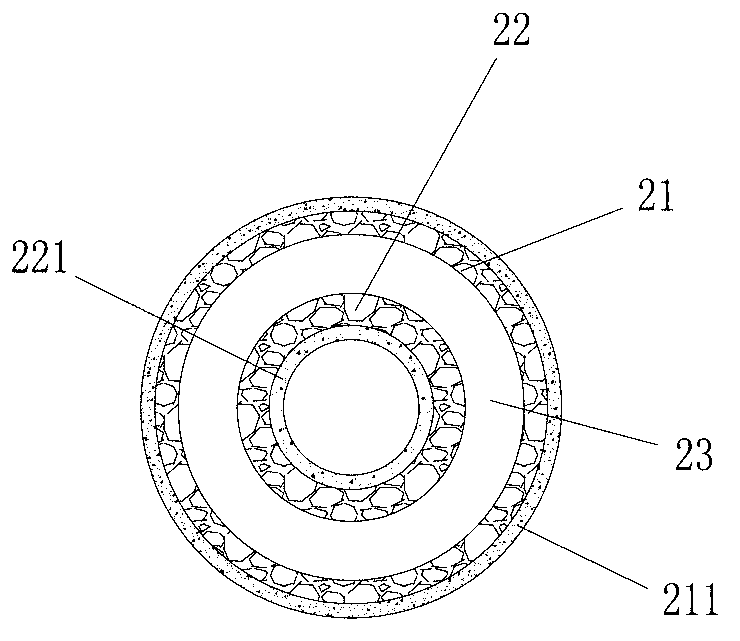

Filter tube for high-temperature gas-solid separation and filter with same

ActiveCN103007647AExtended service lifeLarge filter areaDispersed particle filtrationTransportation and packagingFiltrationEngineering

The invention relates to a filter tube for gas-solid separation. The filter tube is composed of a first cylinder and a second cylinder coaxially sleeved in the first cylinder, wherein the first cylinder is arranged to be open upward, and is provided with a first connecting flange at the cylinder opening outer rim; a round through hole is formed at the center of the bottom of the first cylinder; the second cylinder is open downward and reversely sleeved in the first cylinder; the opening end of the second cylinder is correspondingly in sealed connection with the round through hole of the first cylinder; the bottom of the second cylinder is at the same level height as the cylinder opening of the first cylinder; and an annular gas passage is formed between the first cylinder and the second cylinder. by adopting the filter tube and the filter thereof, the filtration area of the single filter tube and that of the whole filter can be increased, the dedusting effect is improved, and the production cost and the maintenance cost of the whole filter device are reduced; and at the same time, the ash removing efficiency can be effectively increased, and the problems of backflow and negative pressure zone are also solved; and the technical scheme is beneficial to prolonging the service life of the filter tube.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com