Patents

Literature

71results about How to "Reasonable flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

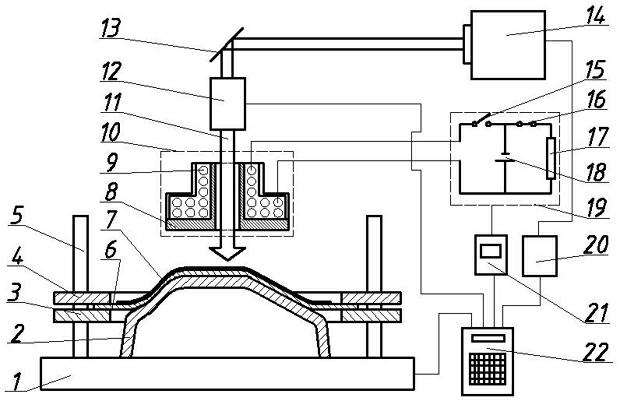

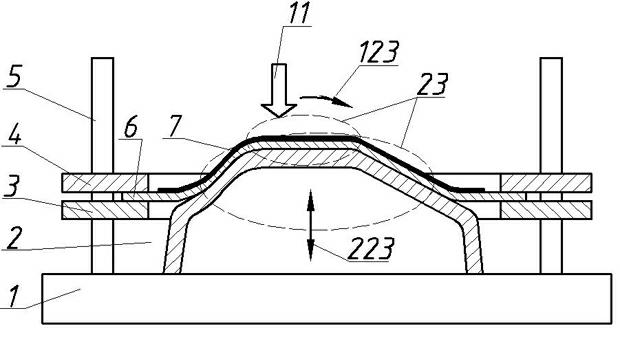

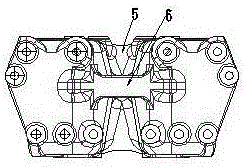

Method and device for laser pulse and electromagnetic pulse composite forming of metal sheet

InactiveCN102125951AMeet the forming requirementsLocality of changeManufacturing technologyEnergy absorption

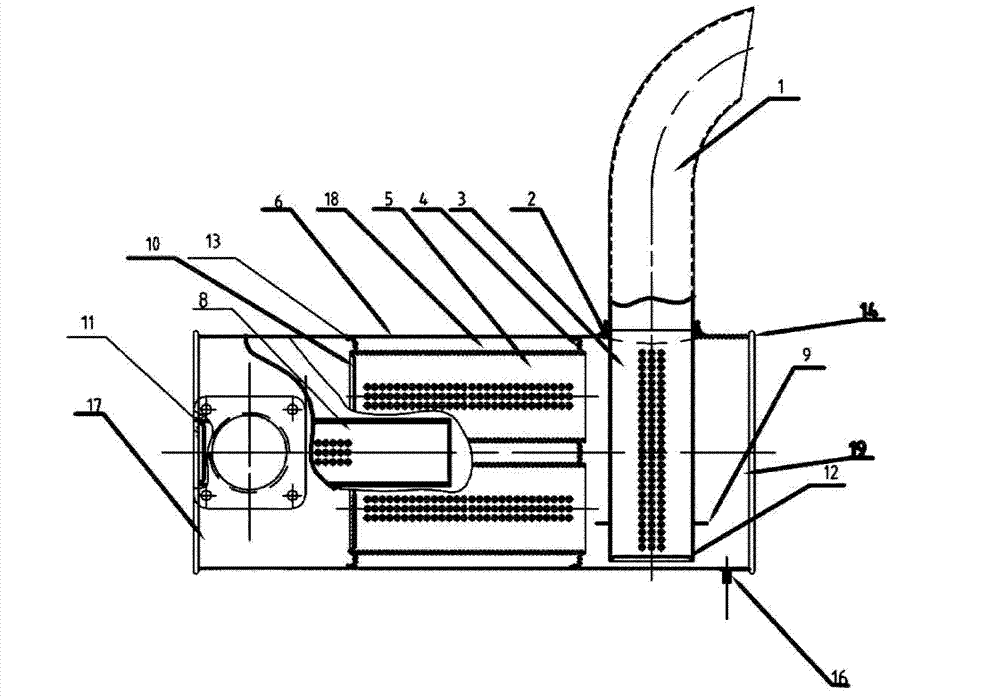

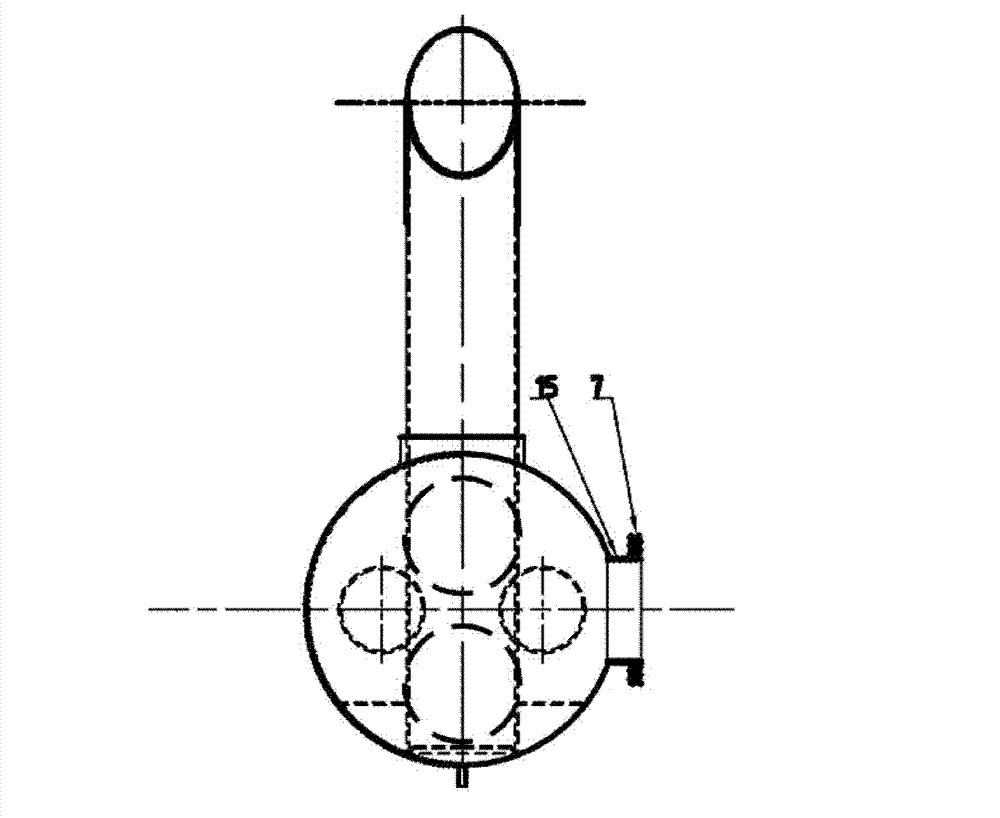

The invention discloses a method and device for laser pulse and electromagnetic pulse composite forming of a metal sheet and relates to the technical field of processing and manufacturing fastening holes. The head part of an energy absorption rod (10) is a conical surface; a high-power pulse laser outputs an annular laser pulse (8) by means of a light spot regulator (15); the annular laser pulse (8) accommodates the tip part of the conical surface on the head part of the energy absorption rod (10) in a hollow part of a laser beam, and meanwhile, the annular laser pulse (8) is acted on the conical surface on the head part of the energy absorption rod (10) to induce plasma (17) to explode and generate impact waves acted on the internal walls of the fastening holes, so that the fastening holes are strengthened. The method and the device are suitable for strengthening the fastening holes with small diameter; the hollow part of the annular laser pulse (8) keeps away from the tip part of the conical surface of the energy absorption rod (10), so that the energy absorption rod (10) is difficult to damage, which is beneficial to continuously working and achieving a good strengthening effect.

Owner:JIANGSU UNIV

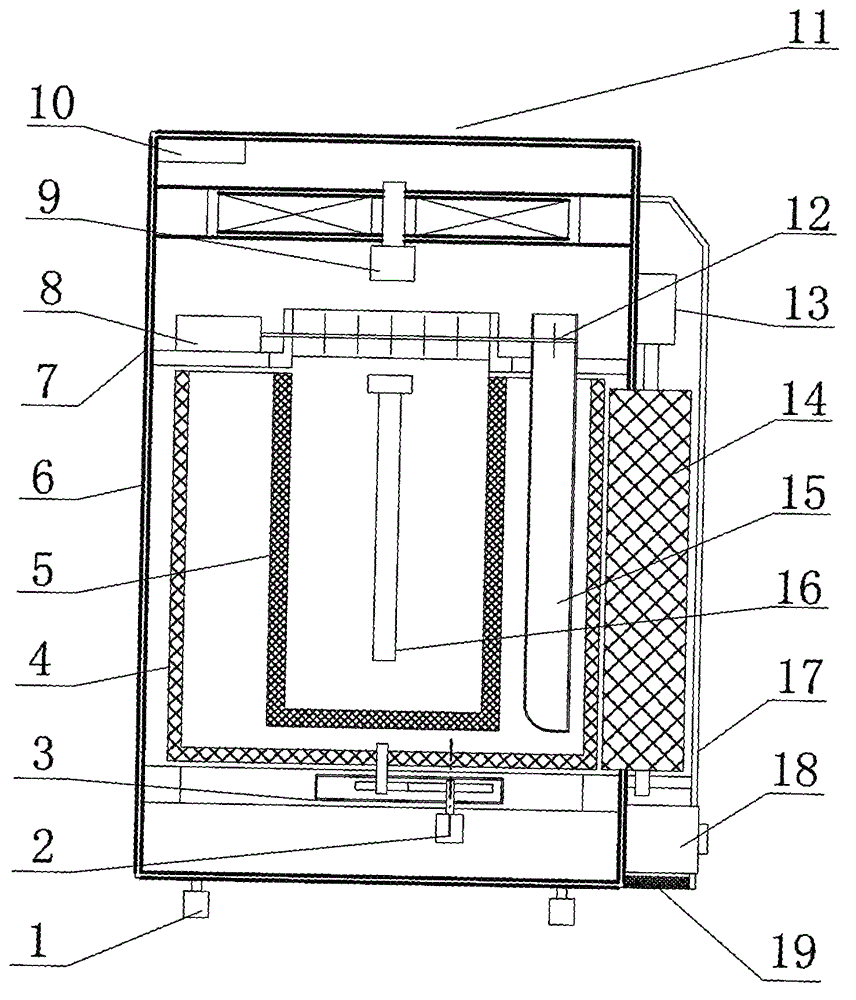

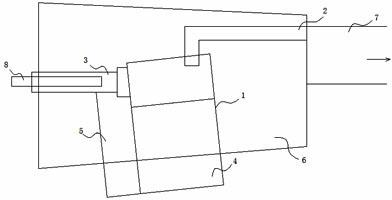

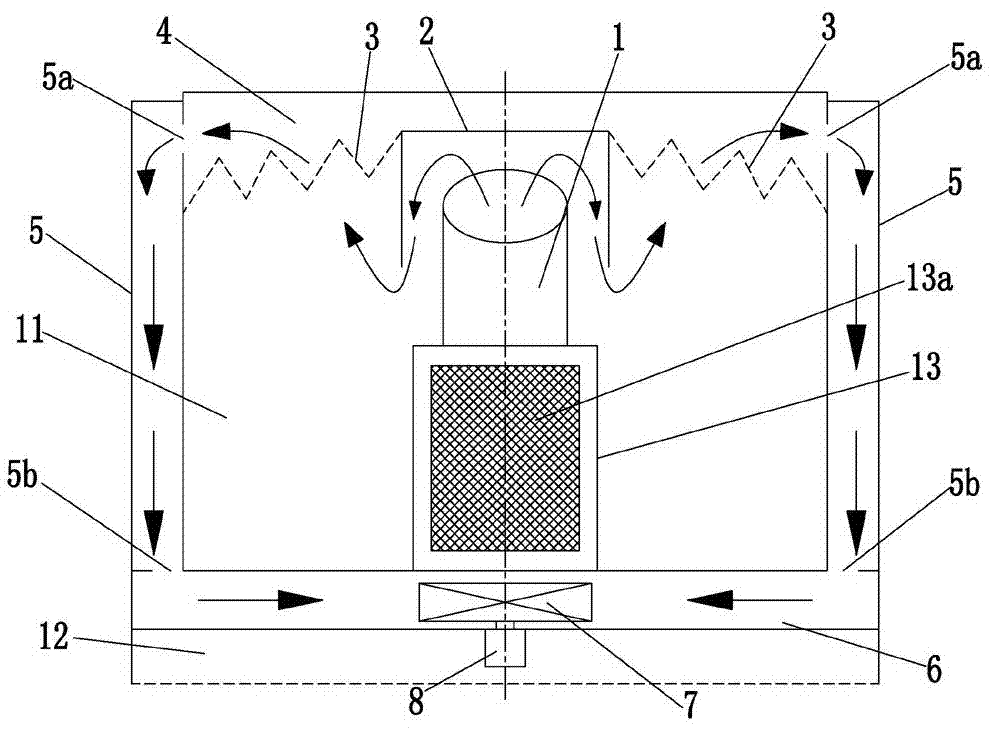

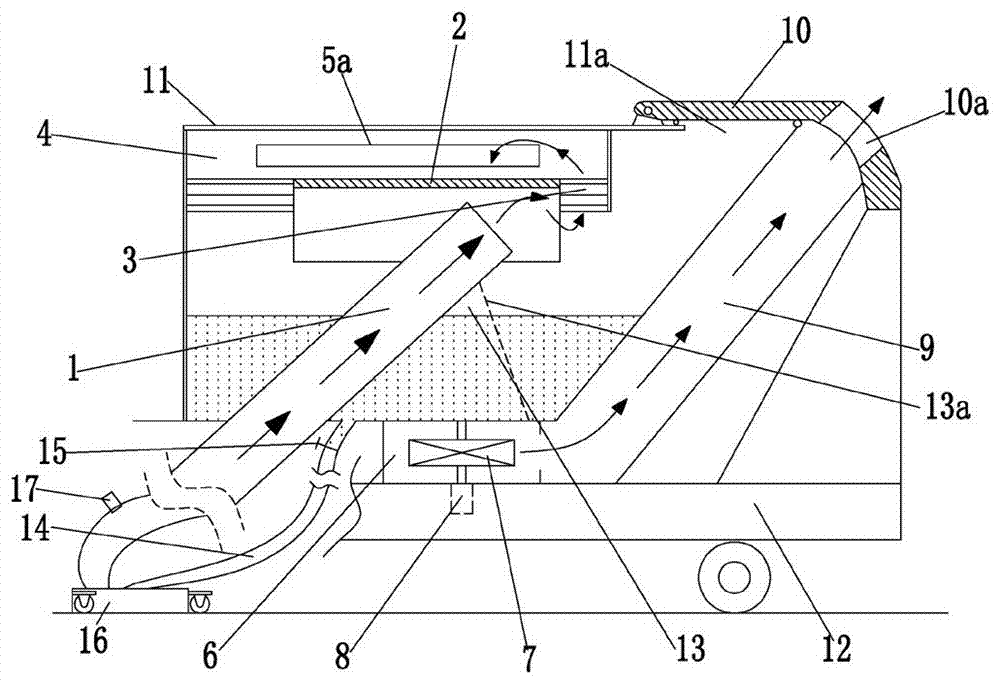

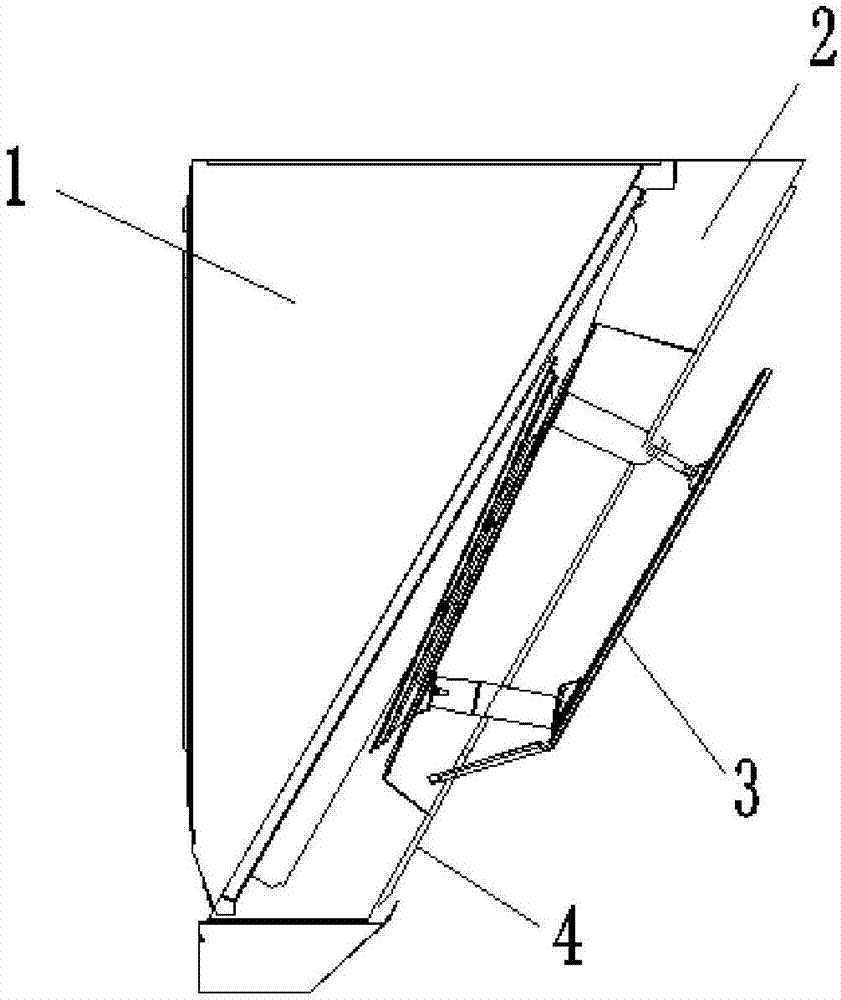

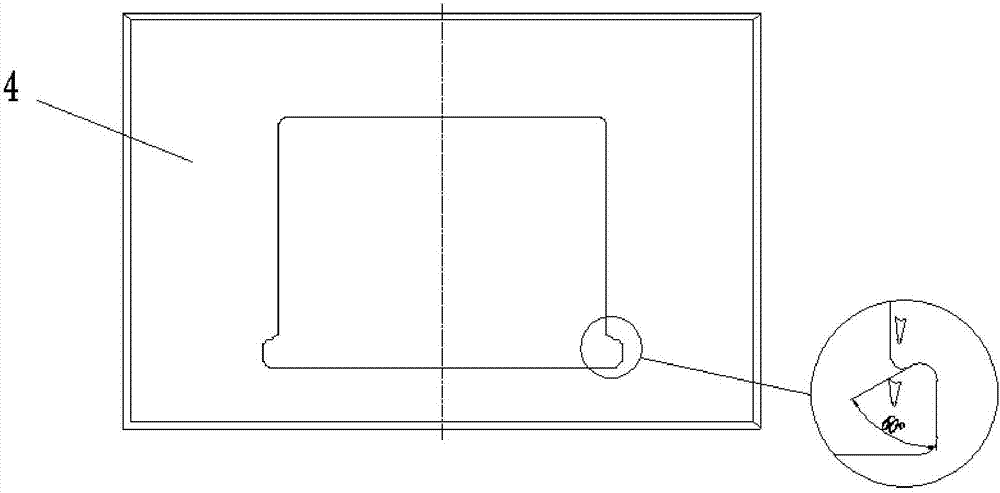

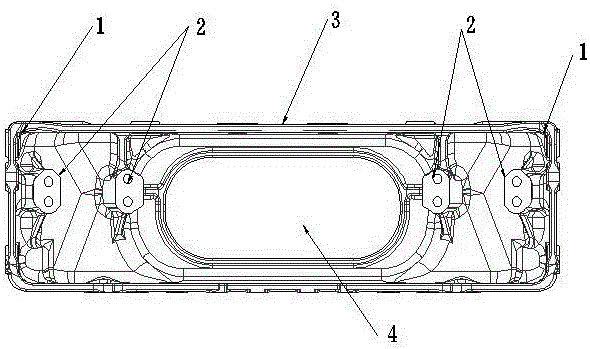

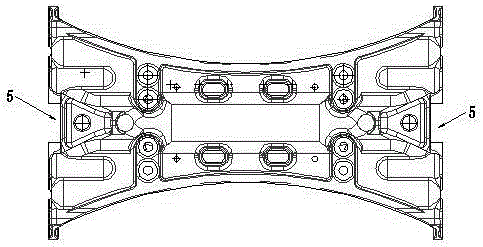

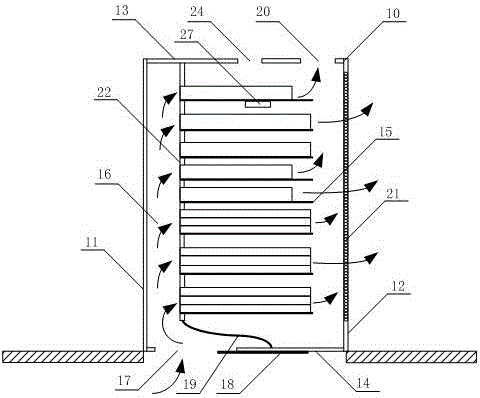

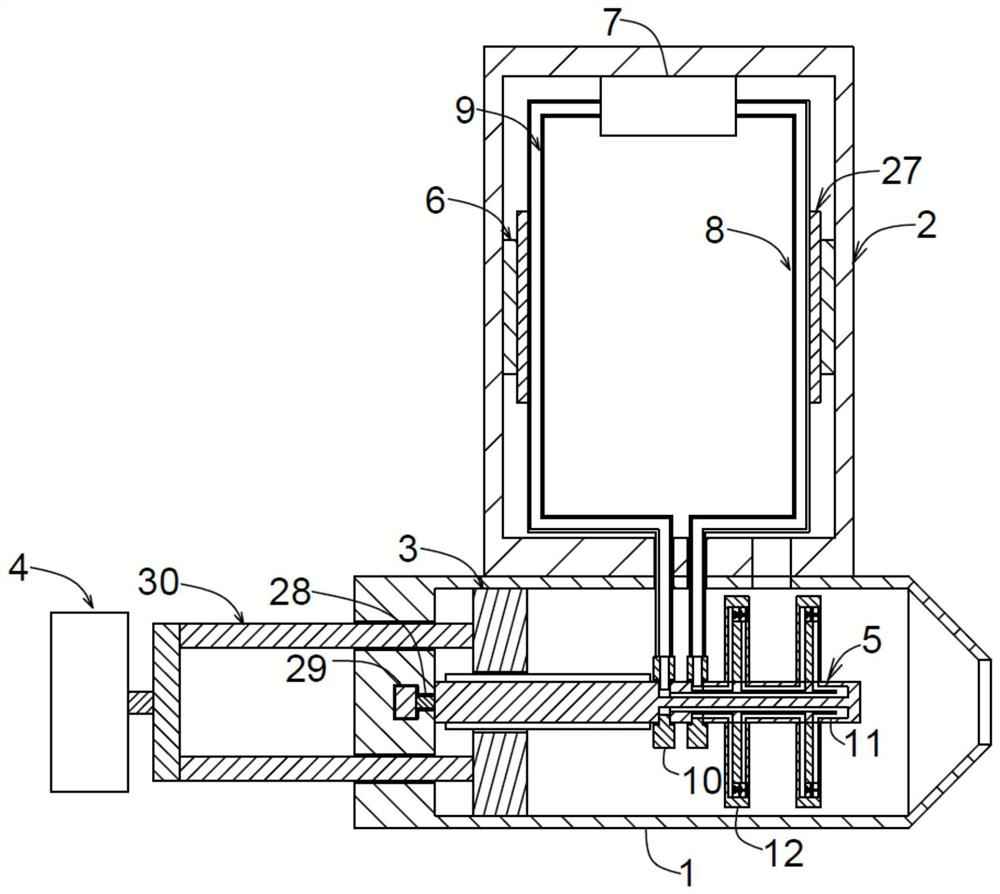

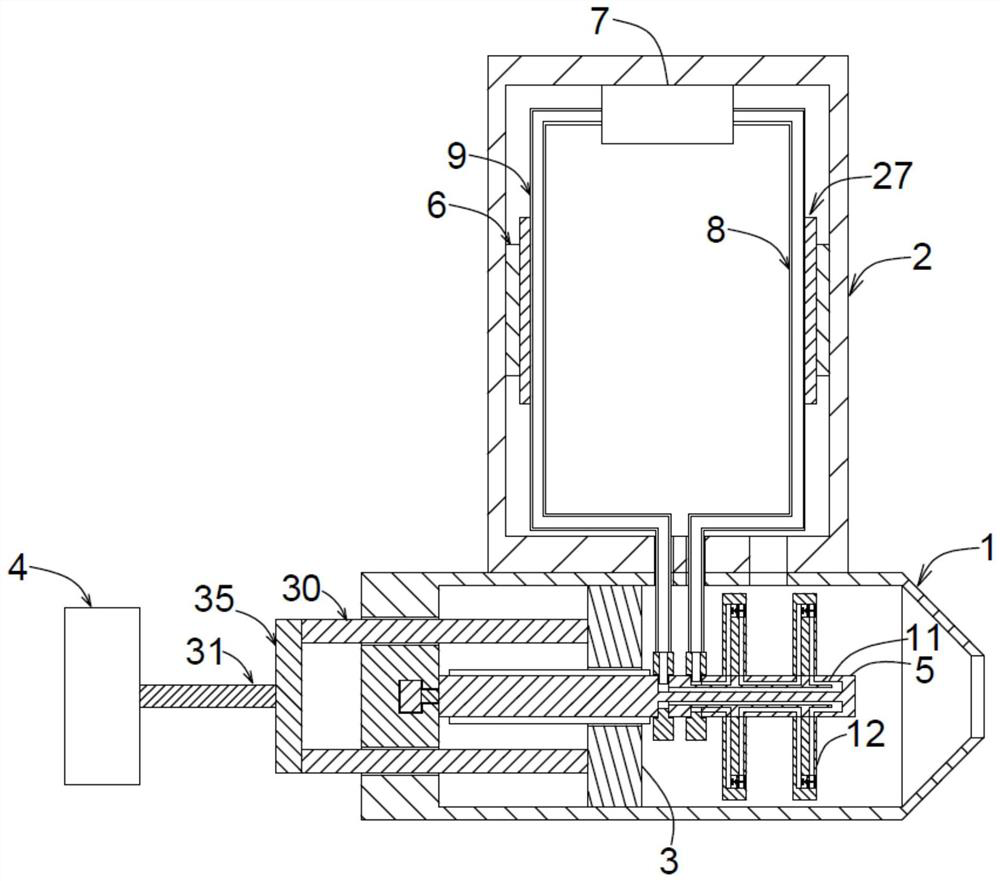

Air purifier capable of automatically cleaning ash

InactiveCN105879516AReasonable flowImprove efficiencyDispersed particle filtrationRadiationAir purifiersFilter system

The invention provides an air purifier capable of automatically cleaning ash. The air purifier is provided with a dust filtering system, a gas back-flowing system and an ash cleaning system. A cylinder-bucket-shaped filter screen structure is adopted, and deposited dust on a filter screen can be automatically cleaned; air enters the purifier from four side faces and is discharged out from the upper part; an air inlet area is several folds of that of an existing product, so that the working efficiency of the air purifier is improved and utilization time and electric energy consumption are reduced; and the air purifier has relatively good practicability.

Owner:陈光

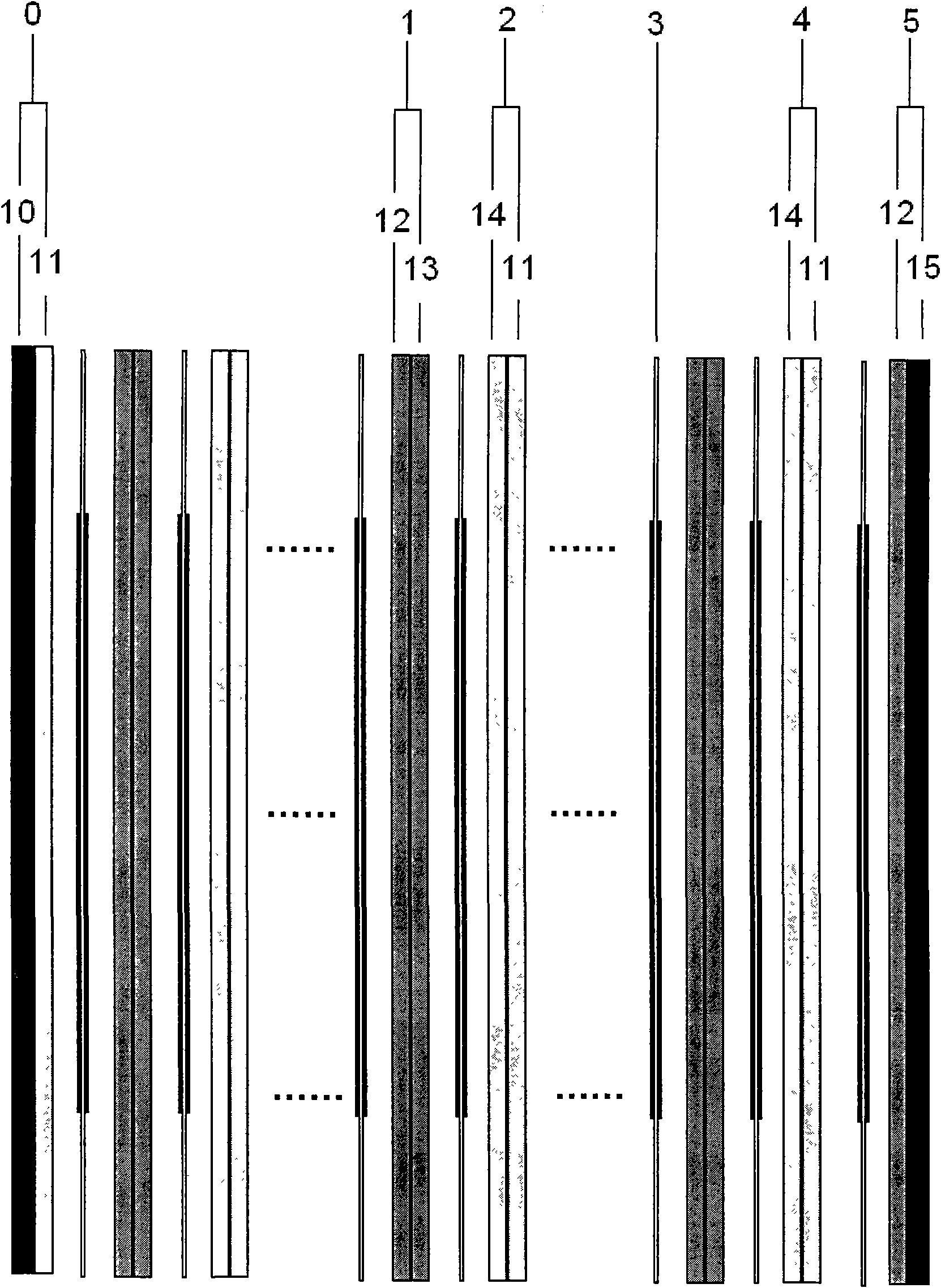

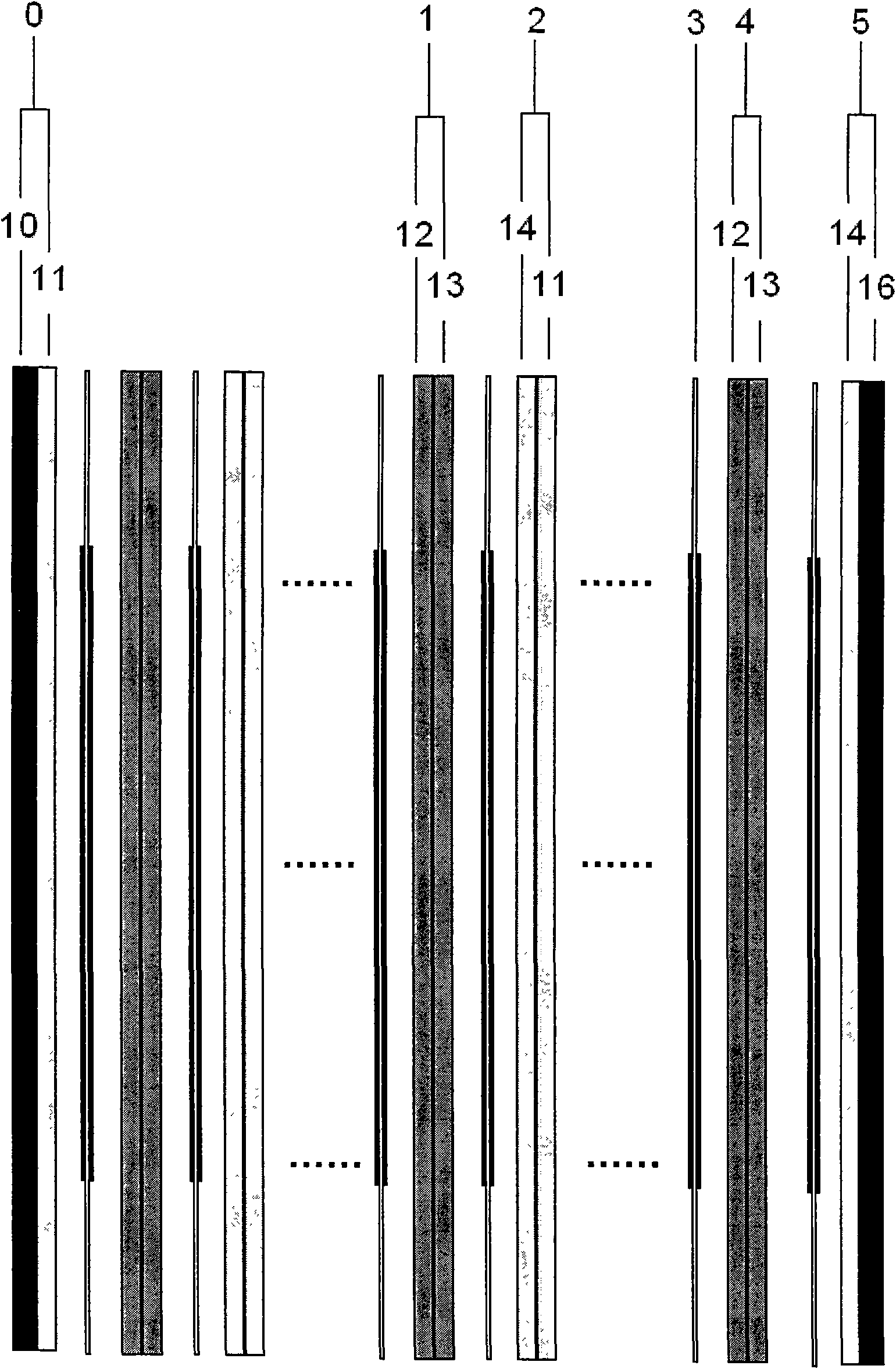

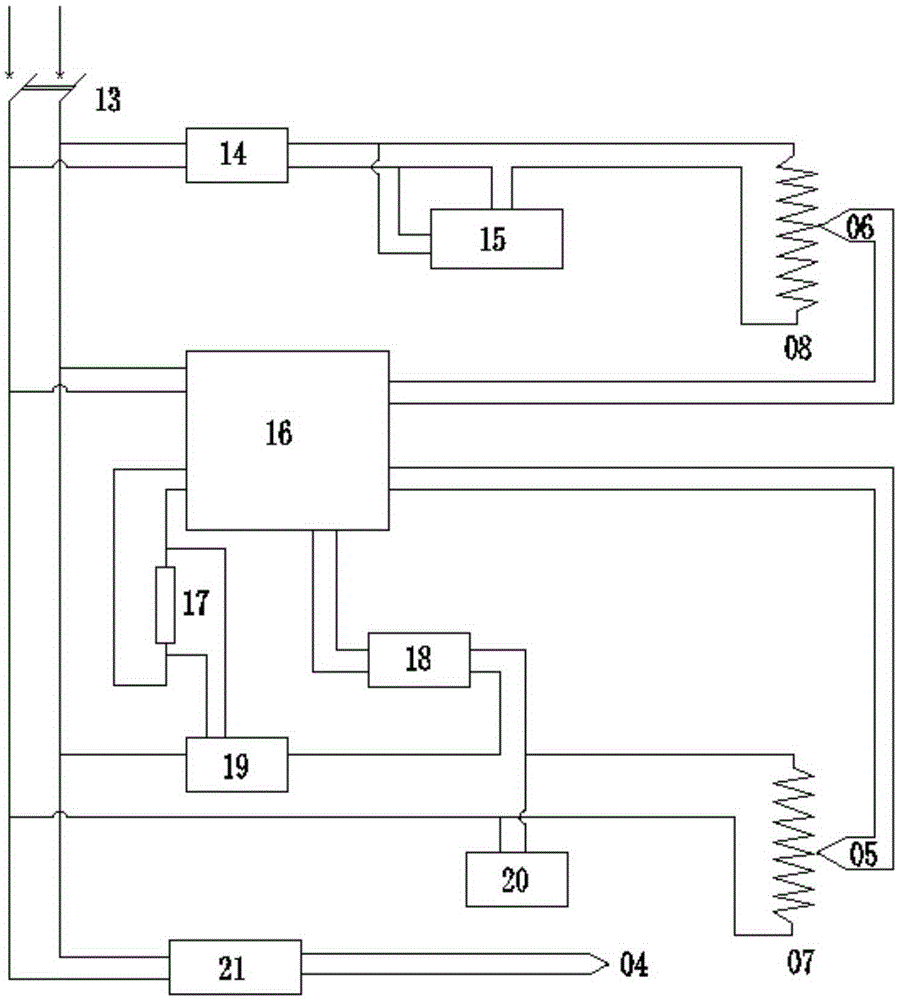

Fuel cell stack for jointly applying intraplate counter-flow flow field and interpolate counter-flow flow field

ActiveCN101867053AEvenly distributedReasonable distributionElectrolyte holding meansFuel cell heat exchangeCounter flowFuel cells

The invention relates to a fuel cell stack for jointly applying an intraplate counter-flow flow field and an interpolate counter-flow flow field, belonging to the technical field of fuel cells. In the cell stack, the two sides of any membrane electrode are respectively provided with an intraplate counter-flow air flow field and an interpolate counter-flow fuel flow field, and the two sides of any membrane electrode are provided with cooling agents which flow to two types of cooling agent flow fields which are just opposite. The air flow field and the fuel flow field cross two relevant surfaces of single-pole plates, and the two types of cooling agent flow fields are respectively embedded at the middle of the back surfaces of the two types of reaction agent flow fields. Two groups of runners of the intraplate counter-flow air flow field, two groups of runners of the counter-flow fuel flow field and two types of cooling agent flow fields of the intraplate counter flow are respectively communicated with two pairs of air inlets and outlets, two pairs of fuel inlets and outlets and two pairs of cooling agent inlets and outlets. The six pairs of inlets are respectively distributed in an opposite angle manner; and in two pairs of inlets and outlets of each type of fluid, the inlet of one pair of inlet and outlet is always adjacent to the outlet of the pair of inlet and outlet. The fuel cell stack has the advantages of simultaneously realizing uniform distribution of four variants such as temperature, concentration, current density and stress and the like.

Owner:STATE GRID CORP OF CHINA +3

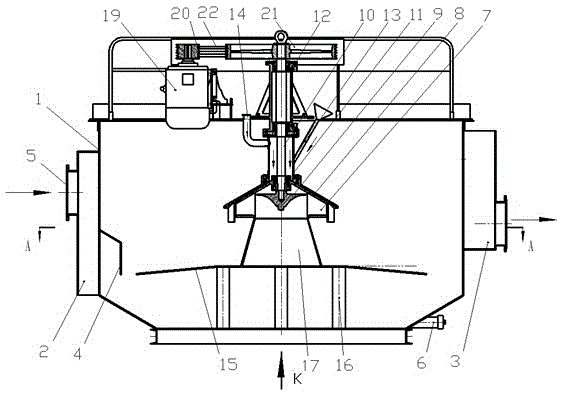

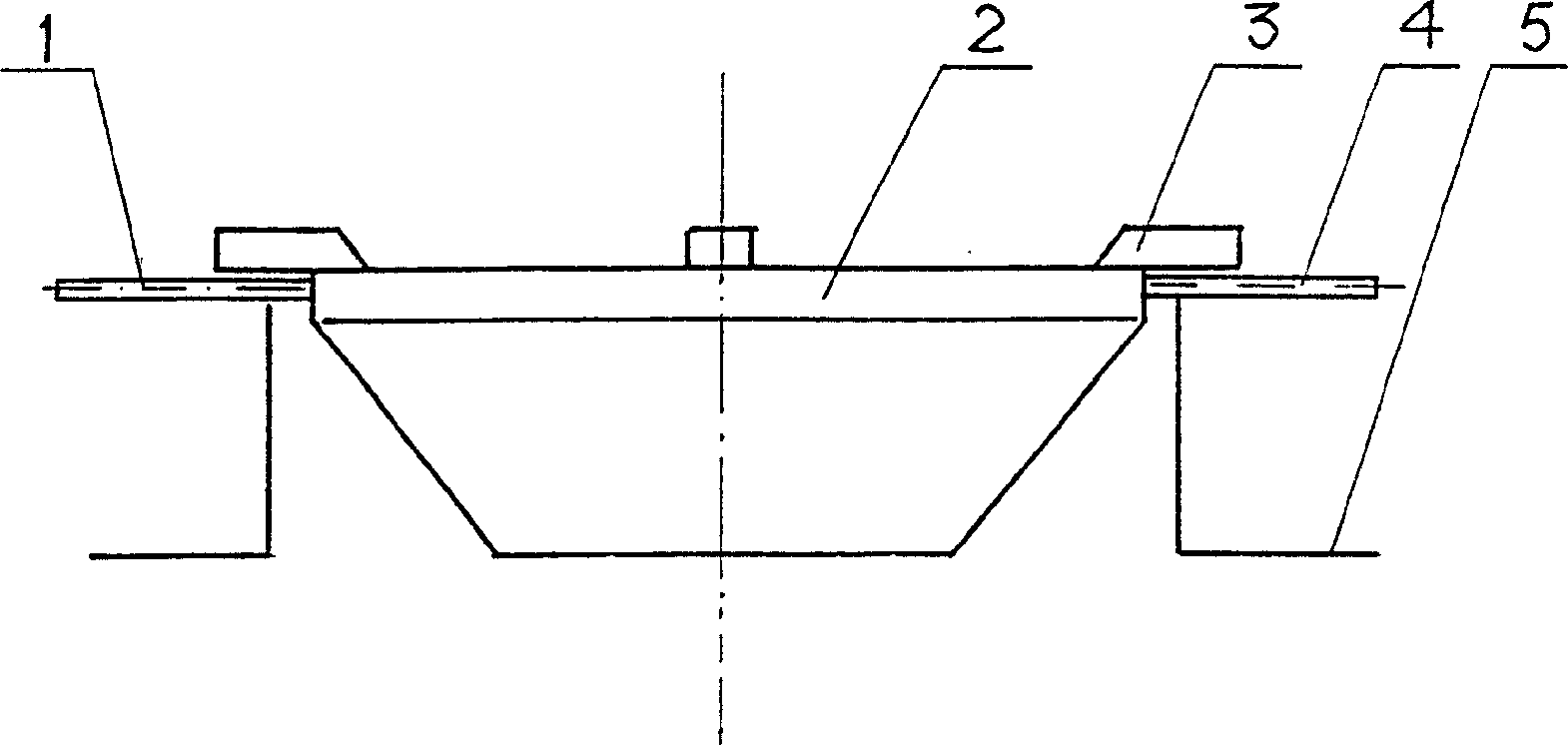

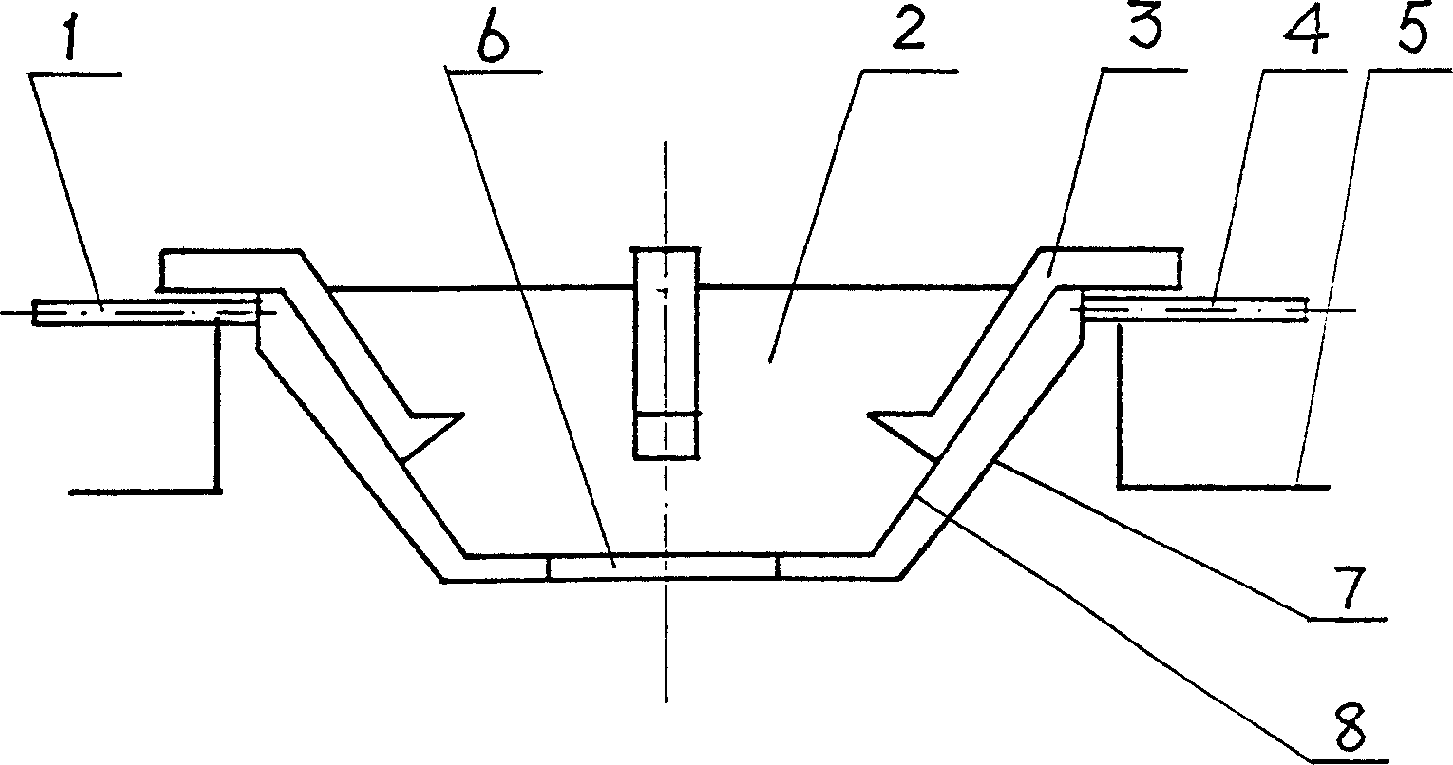

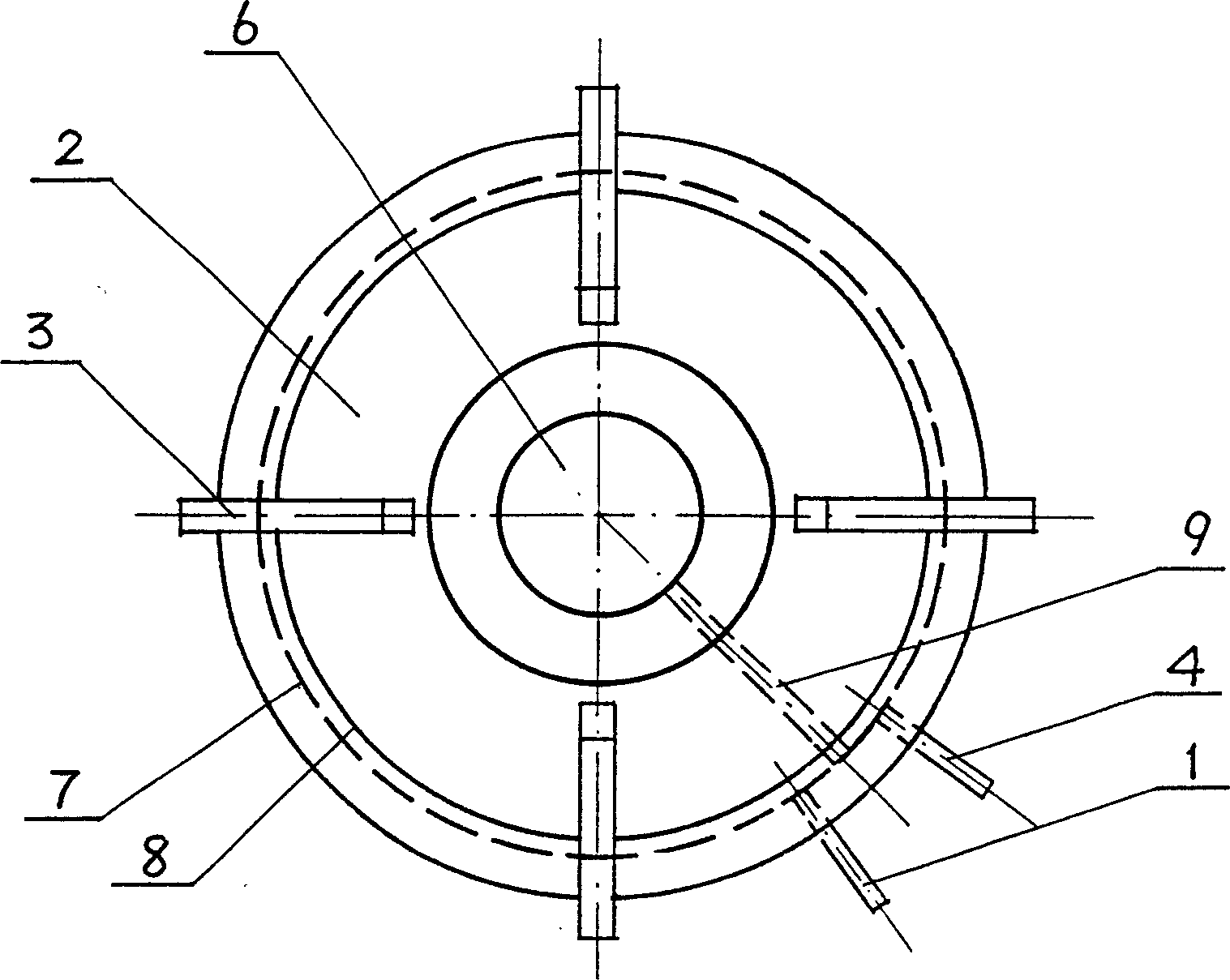

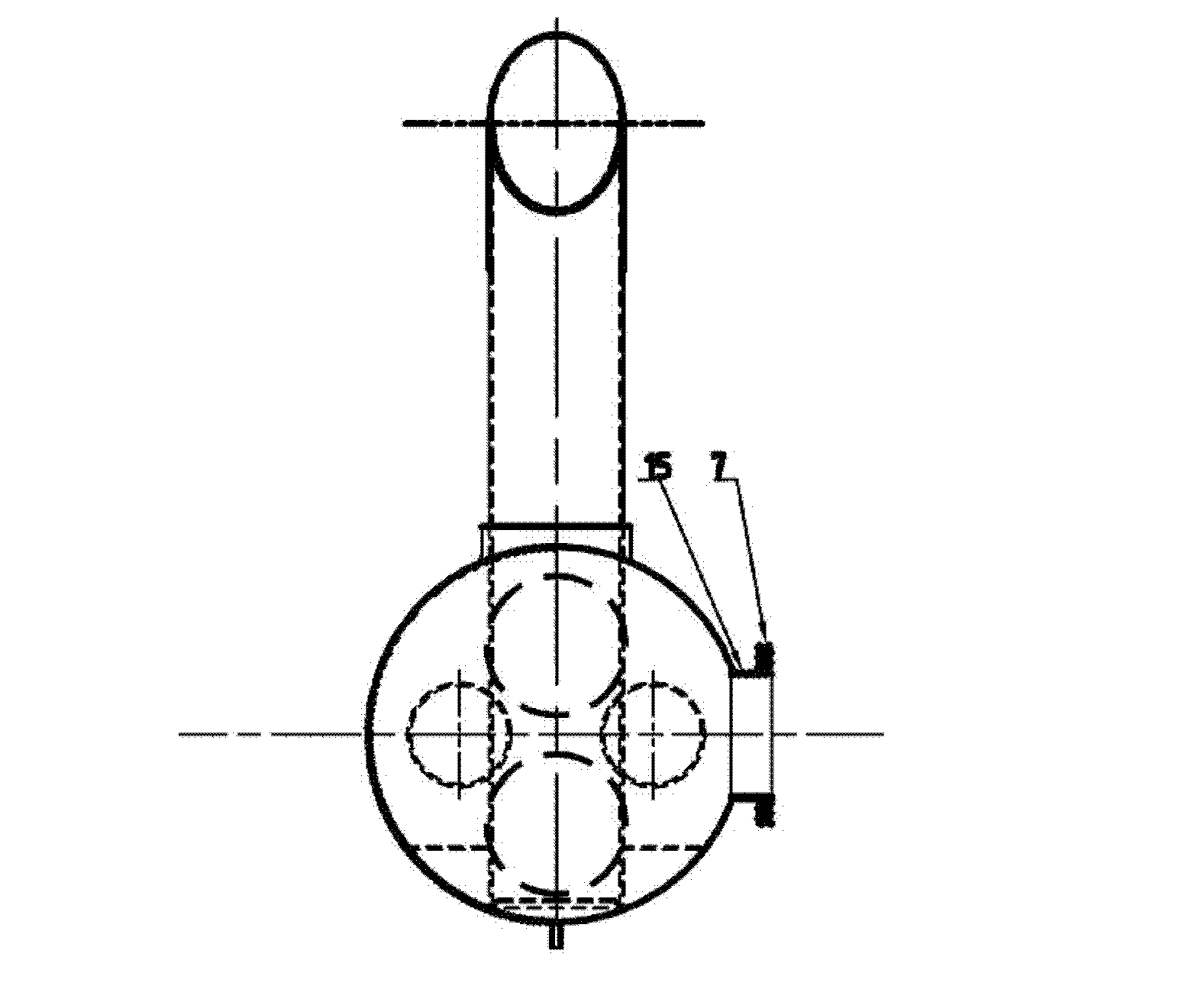

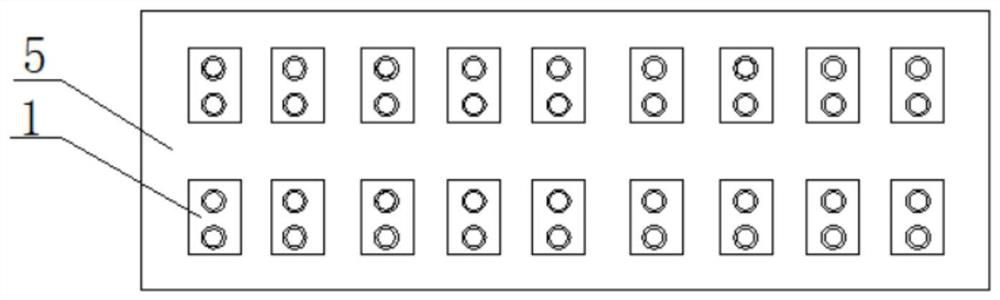

Pretreatment equipment for coal slime before floatation feed

The invention relates to pretreatment equipment for coal slime before floatation feed, belongs to the technical field of flotation equipment for the coal slime, and is used for pretreatment of the coal slime before entering flotation equipment for sorting. The pretreatment equipment adopts the technical scheme that a feeding box and a discharging box are respectively arranged on two sides of a cylinder body of a casing; a motor is fixed at the upper part of the casing, and is connected with the upper end of a stirring shaft through a leather belt; a vane wheel is mounted at the lower end of the stirring shaft, a sleeve sleeves the stirring shaft, the upper end of the sleeve is fixedly connected with the casing, and the lower end of the sleeve is connected with a stator; the lower end of a chemical dosing pipe is connected to the wall of the sleeve; the lower end surface of the stator and the upper end surface of the vane wheel are in clearance fit; a false bottom plate is a flat plate, a gap is reserved between the false bottom plate and the bottom plate of the casing, and a plurality of circular holes are uniformly distributed in the plate surface of the false bottom plate. The equipment disclosed by the invention is low in electricity consumption, the service life of the vane wheel is long, the flow state of ore pulp is reasonable, and medicament and the ore pulp are sufficiently mixed during operation; the equipment has the characteristics of high volume utilization rate, large ore pulp treatment quantity, wide particle size treatment ranges and high adaptability to coal properties.

Owner:TIANDI TANGSHAN MINING TECH

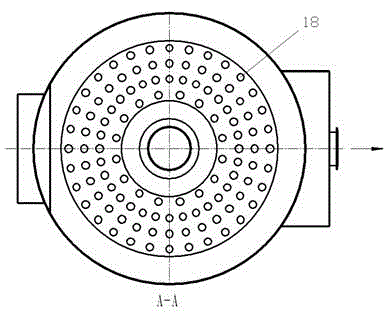

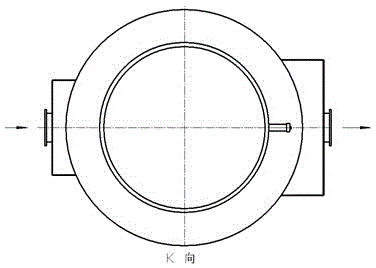

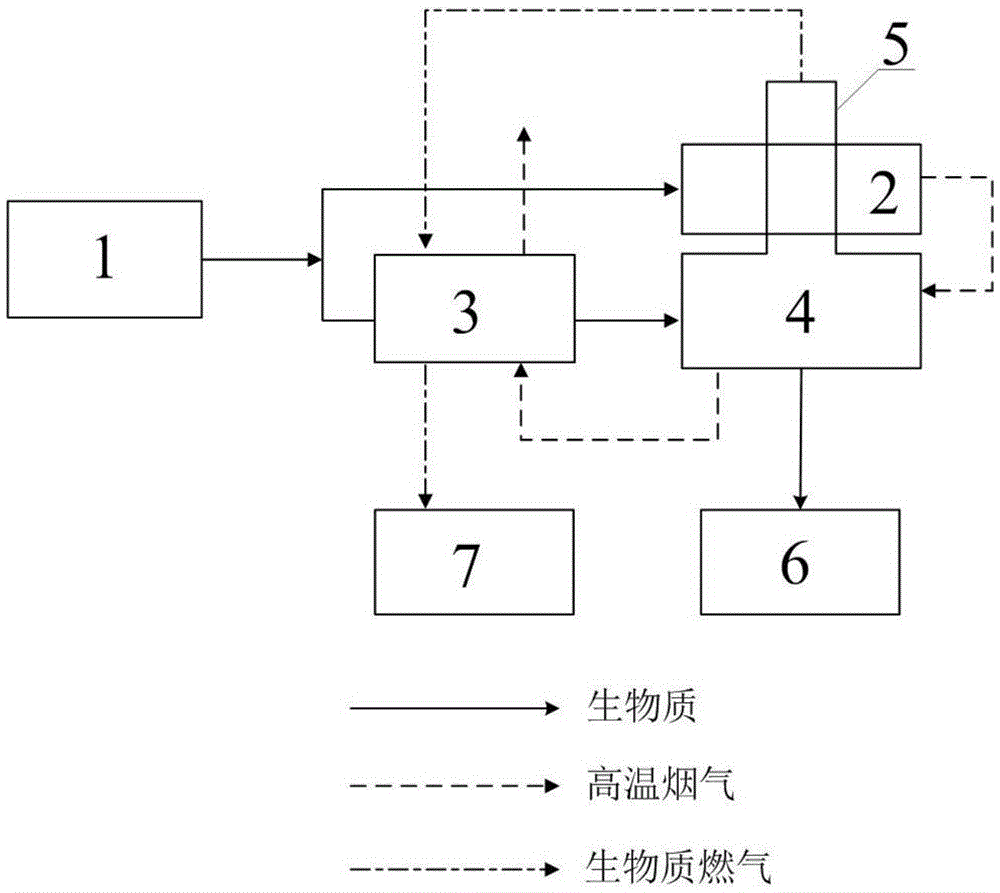

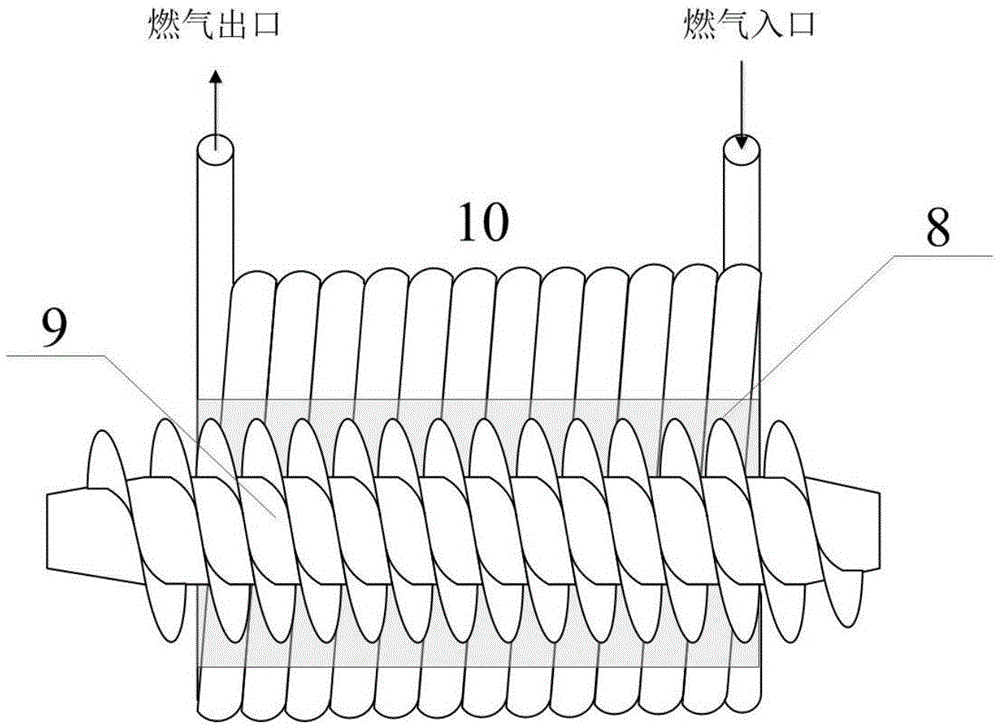

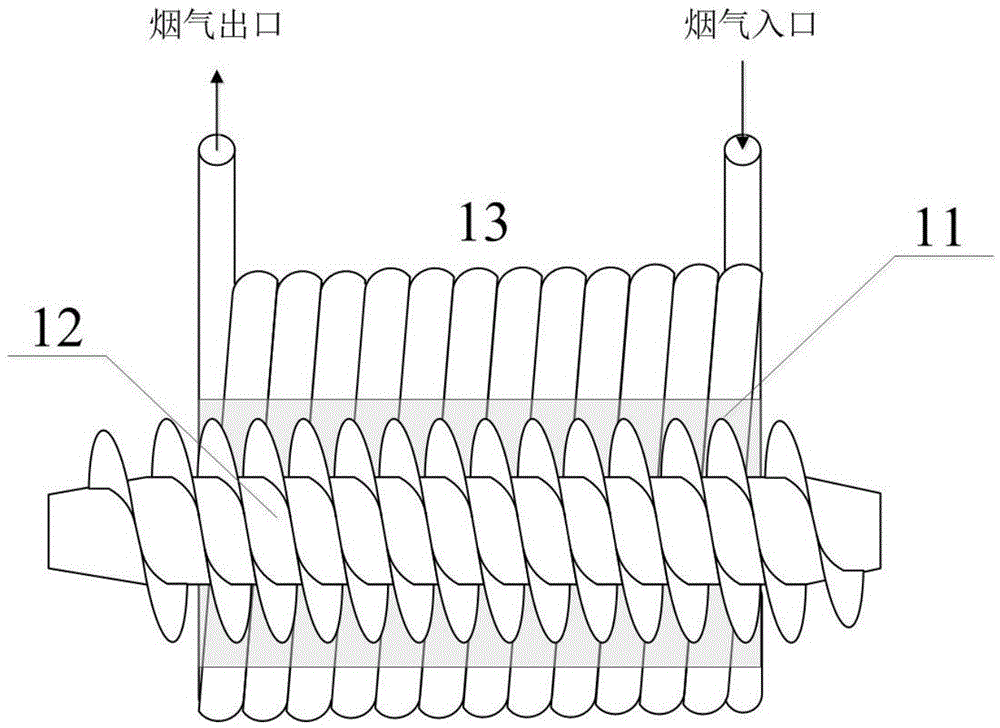

Device and method for producing clean fuel gas and biomass charcoal through continuous biomass carbonization

InactiveCN105542806AReduce tar contentWide range of usesBiofuelsGas purification by catalytic conversionHeat flowFlue gas

The invention discloses a device and method for producing clean fuel gas and biomass charcoal through continuous biomass carbonization. The device mainly comprises a raw material conveying unit, a biomass boiler, a biomass drying unit, a biomass carbonization unit, a catalytic cracking unit, a biomass charcoal storage unit and a biomass gas storage unit. High temperature flue gas generated by the biomass boiler provides heat for the biomass carbonization unit, after sufficient heat exchange is conducted with the biomass carbonization unit, the flue gas provides heat for the biomass drying unit, dried biomass enters the biomass carbonization unit for carbonization, and biomass generated after carbonization enters the biomass charcoal storage unit; biomass fuel gas generated by the biomass carbonization unit enters the catalytic cracking unit to remove tar, and after entering the biomass drying unit to provide heat and conducting sufficient heat exchange with the biomass drying unit, clean fuel gas enters the biomass gas storage unit. The device is compact in process structure, reasonable in material and heat flow direction, environmentally friendly in product, great in controllability and suitable for energy using requirements of villages and towns in China.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for producing H-steel by chopping and rolling slabs with universal mills

ActiveCN105057345AImproved surface quality of rolled piecesThere is no problem of chopping instabilityMetal rolling arrangementsStrip millInstability

The invention provides a method for producing H-steel by chopping and rolling slabs with universal mills. The method comprises the following steps: firstly, a suitable slab is selected; then the slab is heated, is conveyed in front of a universal mill group through a roller bed, and is fed into the universal mills; each universal mill is of a hole-type structure formed by up-down horizontal rolls and left-right vertical rolls, wherein the up-down horizontal rolls are driving rolls, and the left-right vertical rolls are driven rolls; the up-down horizontal rolls first grab the slab and then drive the slab to pass through the powerless left-right vertical rolls; the left-right vertical rolls are provided with convex roll rings for cutting the slab; the slab is subjected to multiple steps of rolling of the multiple universal mills; and the angles of the roll rings of the vertical rolls of each universal mill are changed sequentially, so that the slab is milled into an intermediate blank of H-steel. The slab is clamped by the up-down horizontal rolls, so that the problem of cutting instability does not exist; blanks with small thickness can be cut; in a chopping and cutting process of the vertical rolls, along with the pressing of the horizontal rolls, the thickness at the waist part of the rolled slab is reduced at the same time; the extension coefficients of the whole rolled slab tend to be uniform; the internal stress is small; and the quality of products is high.

Owner:中重科技(天津)股份有限公司

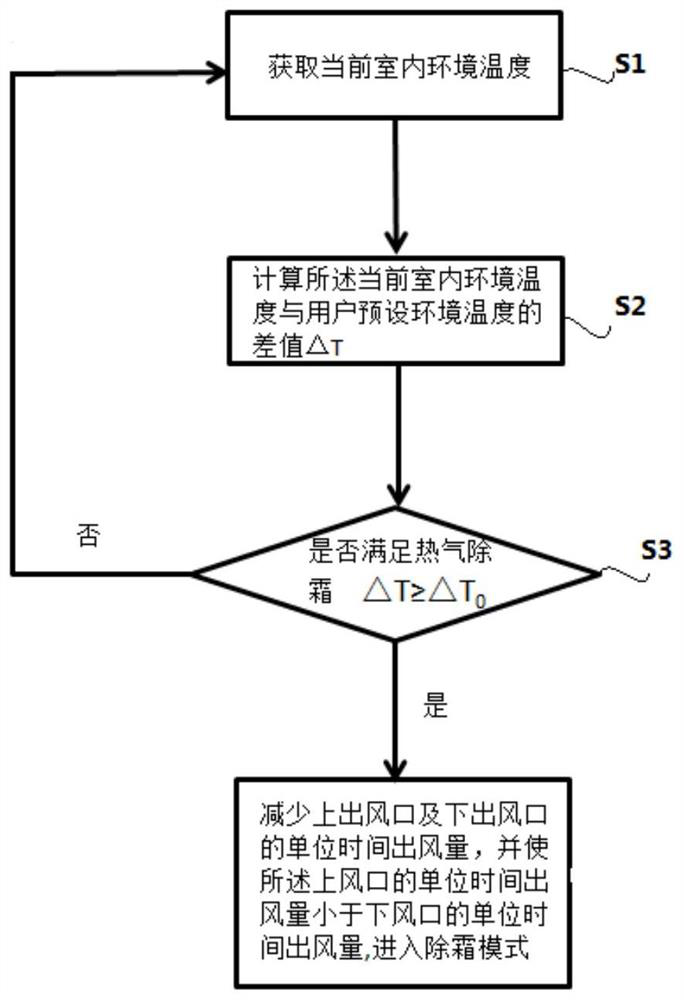

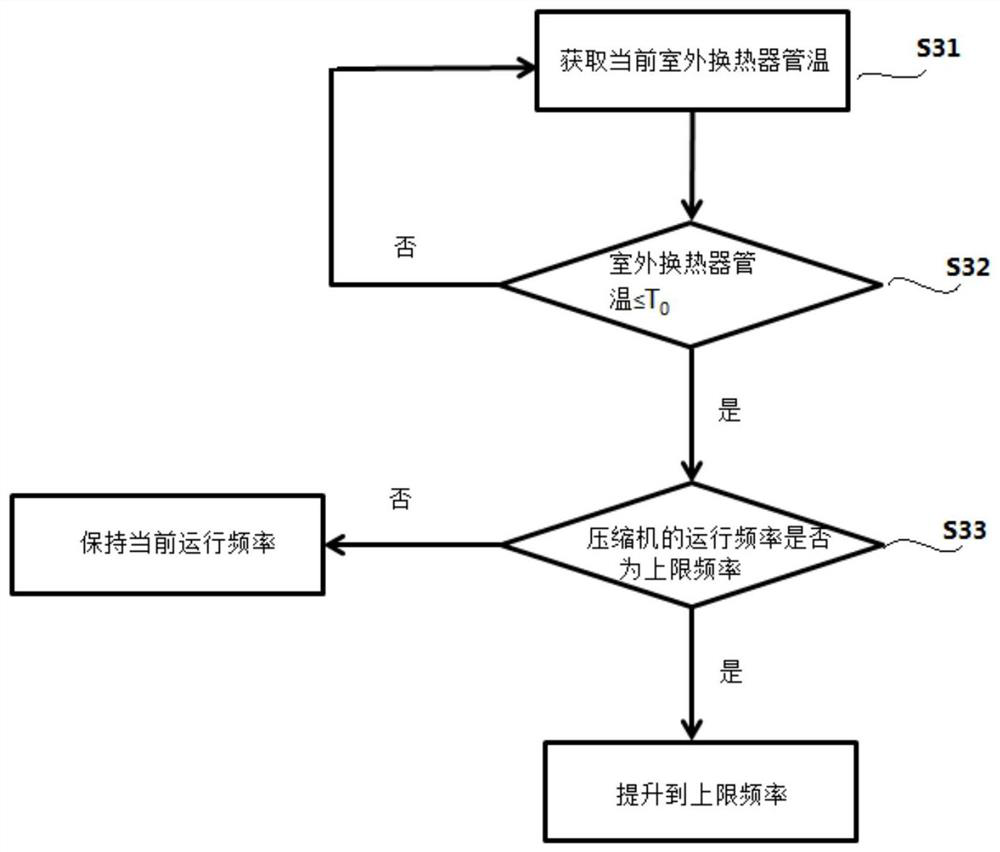

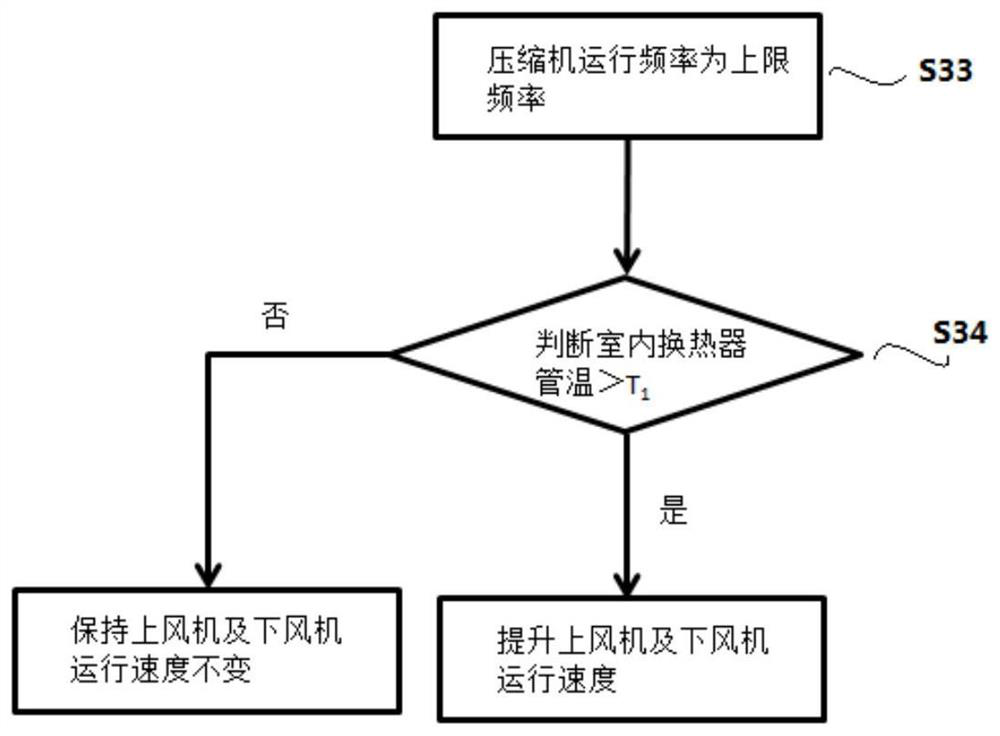

Multi-fan air conditioner defrosting method and air conditioner

InactiveCN111720952AReduce releaseReduce heat releaseMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsAir volume

The invention provides a multi-fan air conditioner defrosting method and an air conditioner. The air conditioner defrosting method is used for a multi-fan air conditioner, and comprises the steps of acquiring a current indoor ambient temperature; calculating the difference value Delta T between the current indoor ambient temperature and a user preset ambient temperature; comparing the Delta T witha preset temperature difference value Delta T0 under a hot air defrosting condition to determine whether a hot air defrosting condition is satisfied or not; and if the hot air defrosting condition issatisfied, at the time, reducing the air outlet amount per unit time of an upper air outlet and a lower air outlet, and making the air outlet amount per unit time of the upper air outlet less than the air outlet amount per unit time of the lower air outlet to enter a defrosting mode. According to the multi-fan air conditioner defrosting method and the air conditioner, the problems of great indoorambient temperature fluctuation and poor body sense of user caused during defrosting process of the air conditioner are solved.

Owner:GREE ELECTRIC APPLIANCES INC +1

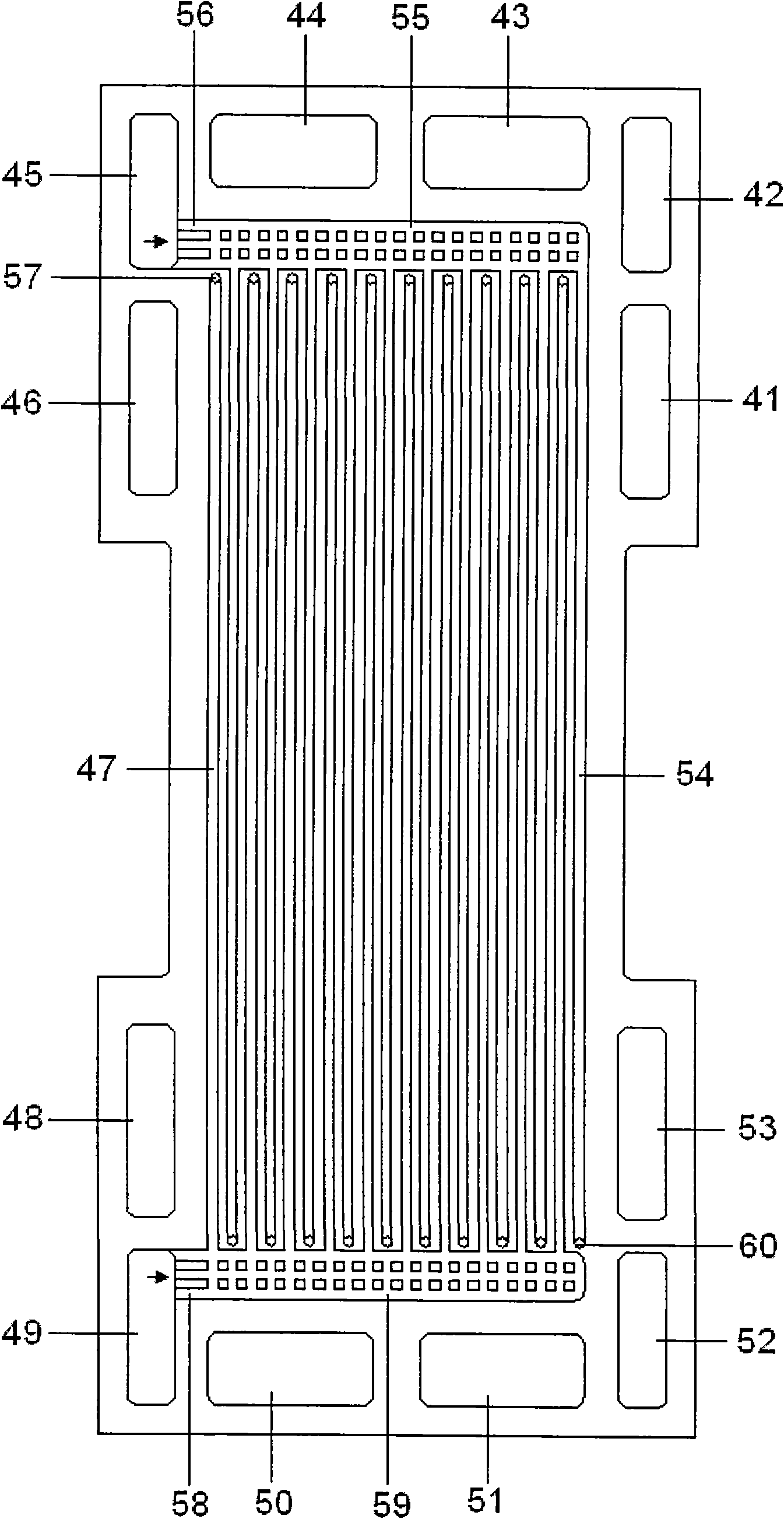

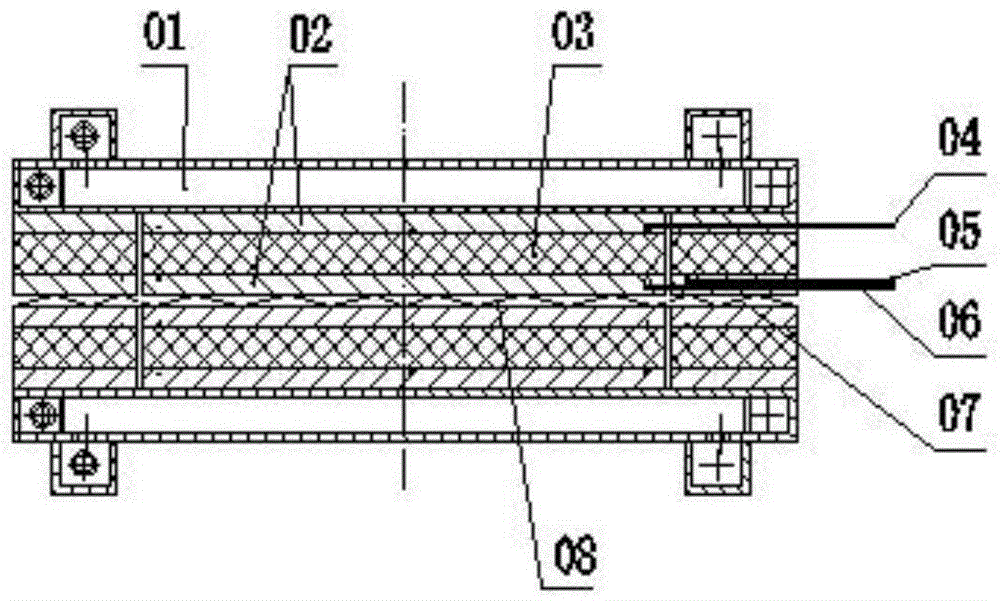

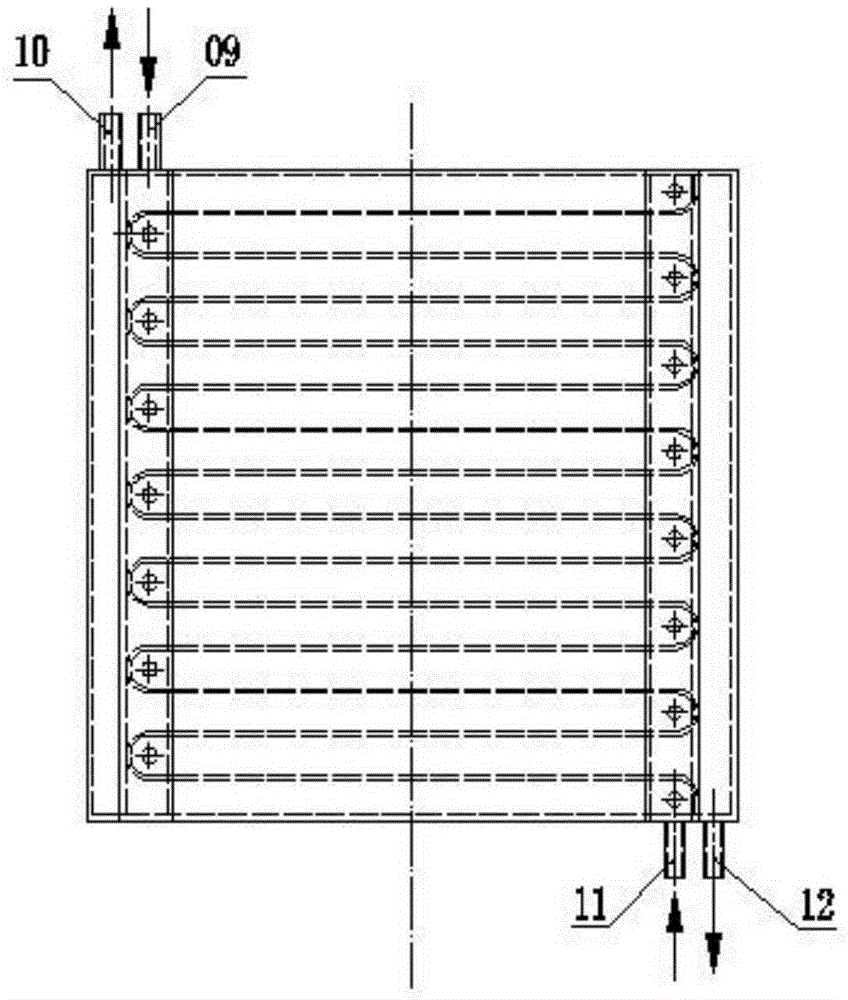

Plane table thermo-conductivity meter based on guarded hot plate method

InactiveCN105372292AEasy to operateReasonable flowMaterial heat developmentMeasuring instrumentEngineering

The invention relates to the field of measuring instruments, in particular to a plane table thermo-conductivity meter based on a guarded hot plate method. On the basis of an existing thermo-conductivity meter, a voltage input method of heating power of protective heating units is improved, and automatic follow-up is conducted according to the hot surface temperature of a metering unit; a flow and heat exchange mode of cooling water in cooling units is improved, and the accuracy of equalization of the cooling surface temperature is increased; the temperature measurement accuracy of hot surfaces, cold surfaces and the protective heating units of test pieces are increased, and the electric power measurement accuracy of heating of the metering unit is increased through a digital electric power meter. According to the plane table thermo-conductivity meter based on the guarded hot plate method, operation is easy, and experimental data are not needed; flow of the cooling water is reasonable, the cooling temperature is uniform, and the temperature difference is small; for temperature measurement, electric power measurement of heating of the metering unit is accurate, and the electric power measurement is accurate to mW level; therefore, the coefficient of thermal conductivity is greatly increased.

Owner:JILIN UNIV

Energy-saving cooker frame with combustion gas range residual heat utilizing function

The invention discloses a pan support for reusing of waste heat from gas kitchen range, aiming to solve the existing pan support problems of function singleness and a great deal of heat energy dissipation through pan support when using gas kitchen range. It comprises couple supporting claws and basined inner wall; there is outerwall corresponded to the form of basined inner wall and made up of basined interlayer water jacket at outside of basined inner wall, opening through port underside of basined interlayer water jacket, admitting pipe and rising pipe have their location on the outerwall top of basined interlayer water jacket. On one side of basined interlayer water jacket, setting radial water jacket cavum isolating plate, admitting pipe and rising pipe are placed separated on outerwall of basined interlayer water jacket of two sides of jacket cavum isolating plate. In basined interlayer water jacket, radial setting symmetrically two water jacket cavum isolating plate; under the water jacket cavum, setting separated connecting pipes connected to water jacket cavum of connected body underside. The invention fastens heat generated from burning to suffice of cooker, absorbs wasted heat by interlayer water jacket, and meantime is also a quick water heater.

Owner:林庆森

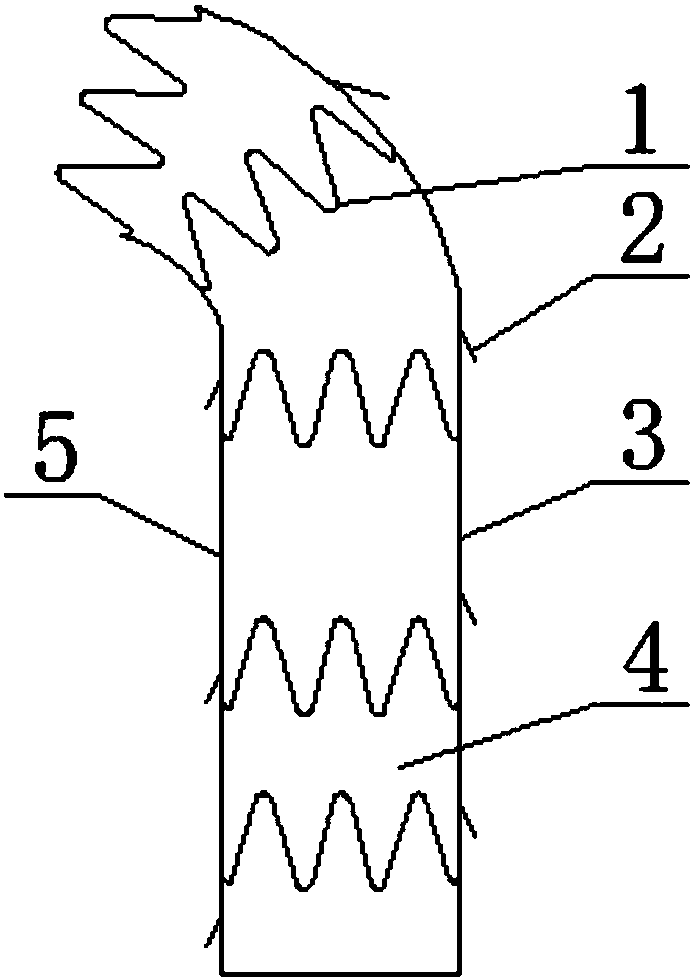

Arch aorta covered stent

The invention discloses an arch aorta covered stent which comprises supporting bodies, barbs, an outer connecting wire, a covered film and an inner connecting wire. The multiple connecting bodies arearranged, the supporting bodies and the inner and outer connecting wires are connected at certain intervals, the outer connecting wire and the inner connecting wire are arranged in an S shape, the stent has the good flexibility in the implantation process, a developing piece is stuck to the outer connecting wire of the stent, surgical observation and positioning are facilitated, and the arch portion can be bent to form a certain angle so as to adapt to different positions and meet individual requirements.

Owner:INNER MONGOLIA UNIV OF TECH

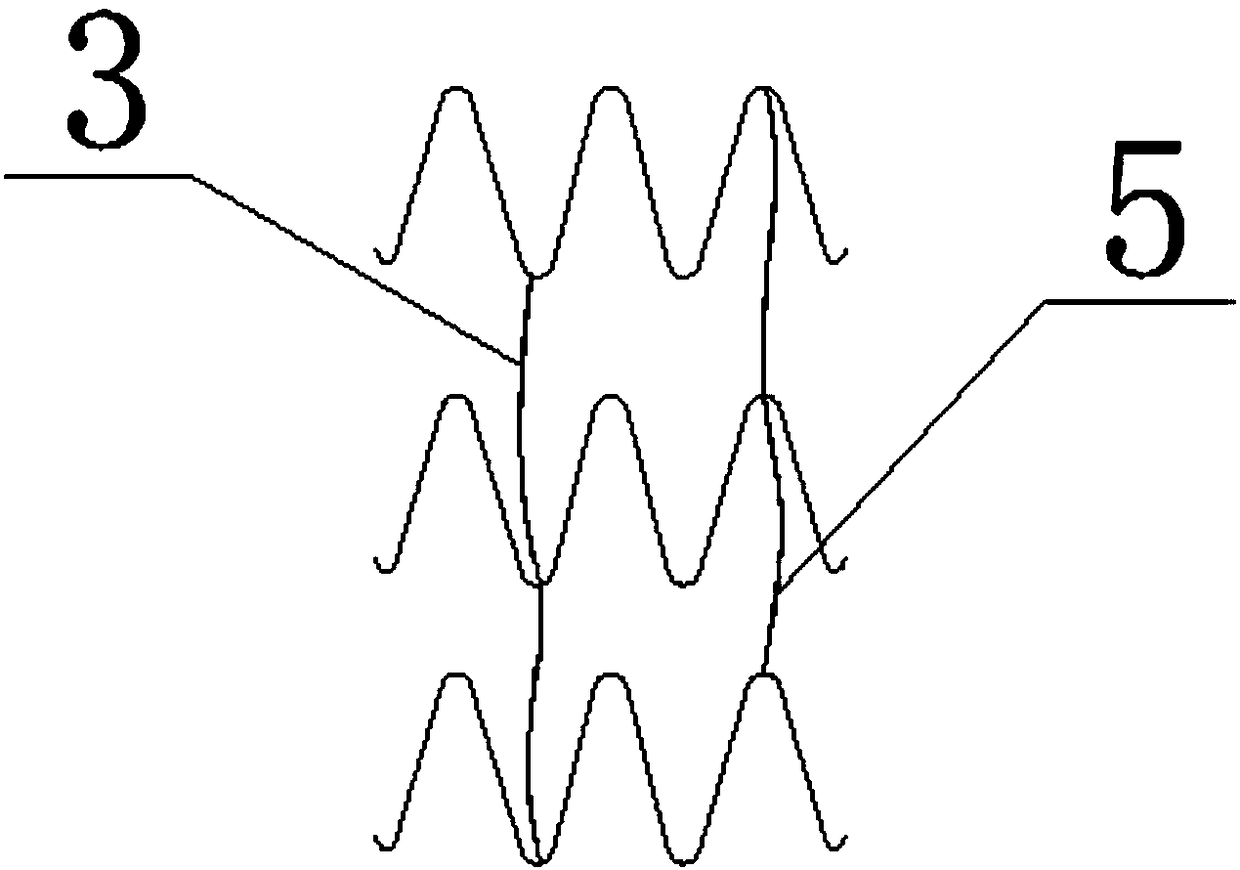

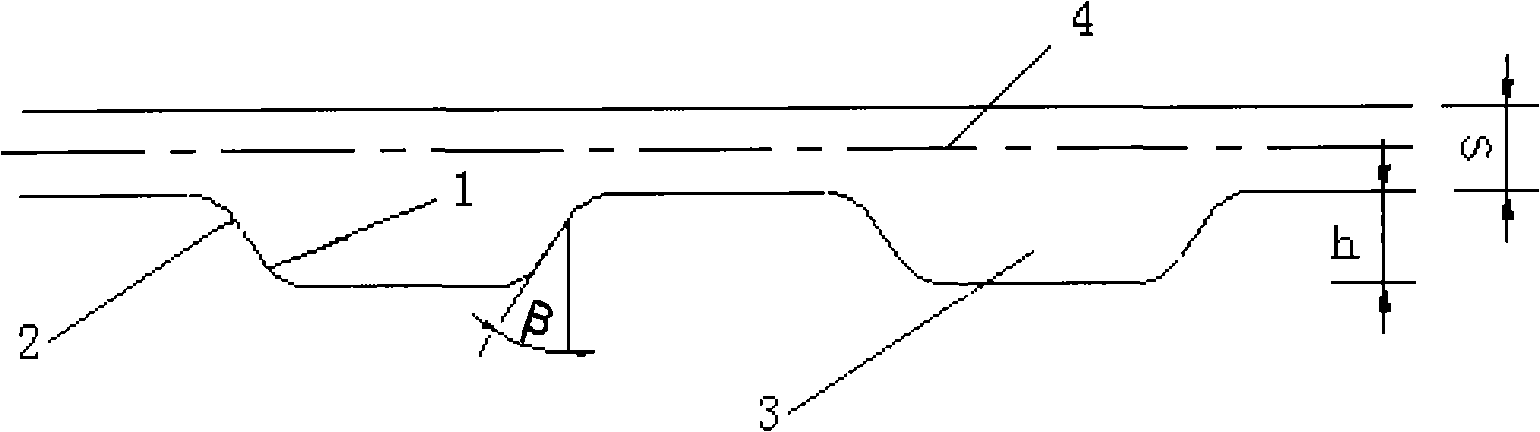

Roll caliber for rolling special-shaped wide steel strip

InactiveCN101314165AReasonable metal flowReasonable flowRollsMetal rolling arrangementsStrip millStrip steel

The invention relates to a roll pass used to roll a special wide steel band, which belongs to the steel rolling technical field. A roll comprises an upper roll and a lower roll of a final stand of a strip mill, the roll pass of the upper roll or the lower roll is of a long narrow rectangle, and lug bosses of the upper edge or the lower edge of the rectangle are arranged equidistantly. The special wide steel band which meets the requirement can be rolled through the roll pass, and the size and the service performance meet the requirement; and the steel band rolled by the roll pass has reasonable metal flow, good strip shape, and no surface defects.

Owner:KUNMING IRON & STEEL

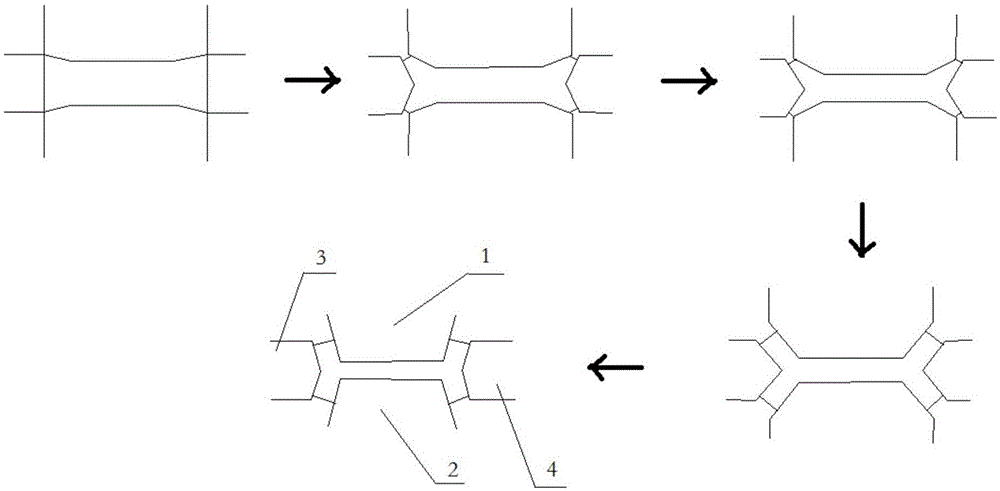

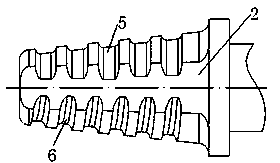

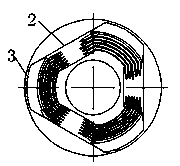

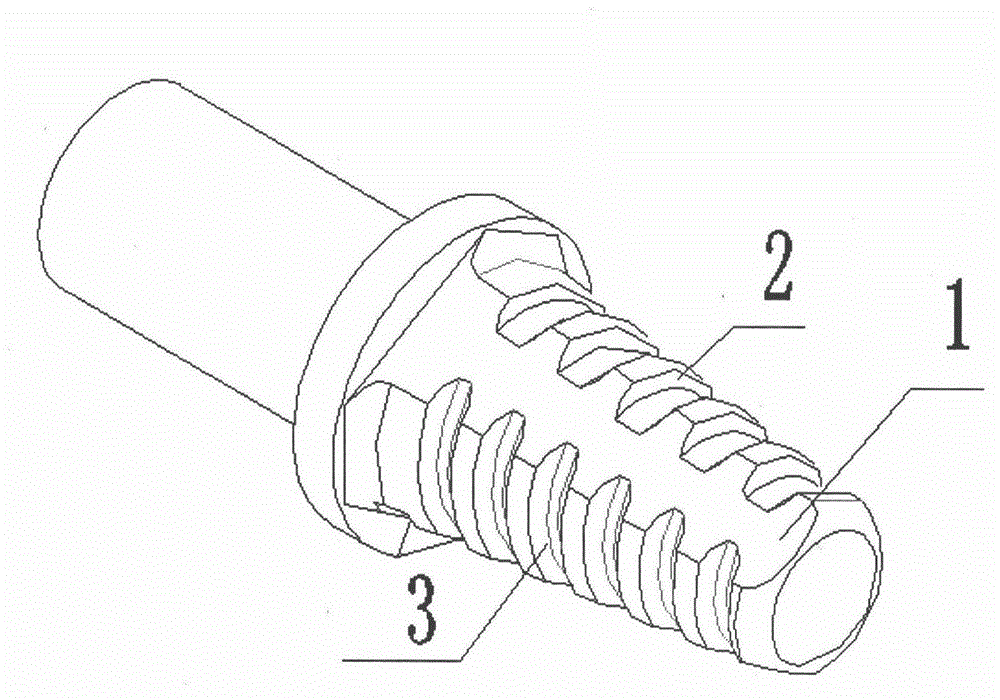

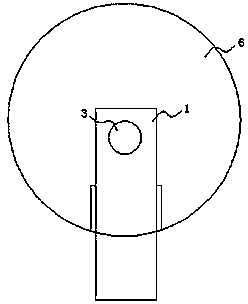

Novel aluminum alloy plugging rod for plug welding

InactiveCN104368907AReasonable flowLow costWelding/soldering/cutting articlesNon-electric welding apparatusCircular coneHelix

The invention relates to a novel aluminum alloy plugging rod for plug welding. The novel aluminum alloy plugging rod for plug welding comprises a conical plugging rod body. Three straight edge surfaces are uniformly distributed on the conical plugging rod body in the length direction of the conical plugging rod body. A conical surface is formed between every two adjacent straight edge surfaces, and three conical surfaces are formed and provided with different spiral grooves respectively, namely, the annular spiral grooves, the left-handed spiral grooves and the right-handed spiral grooves. By means of the novel aluminum alloy plugging rod for plug welding, the welding thickness can be greatly increased to 100 mm from original 40 mm, heat generated by friction is more uniform, material flowing is more reasonable, and the quality of weld joint products is better.

Owner:NANJING HAOWEI MACHINERY

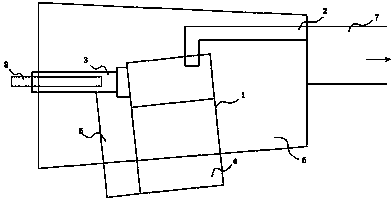

Cigarette smoke absorbing device

ActiveCN102601095AReasonable flowBurn helpsFouling preventionTobacco devicesEngineeringSmoke Emission

The invention discloses a device capable of absorbing harmful smoke which is released in cigarette combustion and exhaled by smokers. The device comprises a box provided with a guide tube connected to a negative pressure air source. The device is characterized in that a cigarette sleeve is arranged on the box, a cigarette ash and butt storage container is arranged inside the box, the box extends into a smoke-absorbing cup from the lower side, the direction of the cigarette sleeve is the same as that of the cup, and the smoke-absorbing cup is connected onto the negative pressure air source. The device is simple in structure and can completely absorb the exhaled smoke and the combusted smoke by the aid of the fewest structural elements and components. Further, the cigarette ash and butt storage container and an ignition device are arranged at reasonable positions, and convenience in operation and cleaning is ensured. Fresh air flows axially along cigarettes in a more reasonable manner, and combustion of the cigarettes is facilitated.

Owner:李乃华

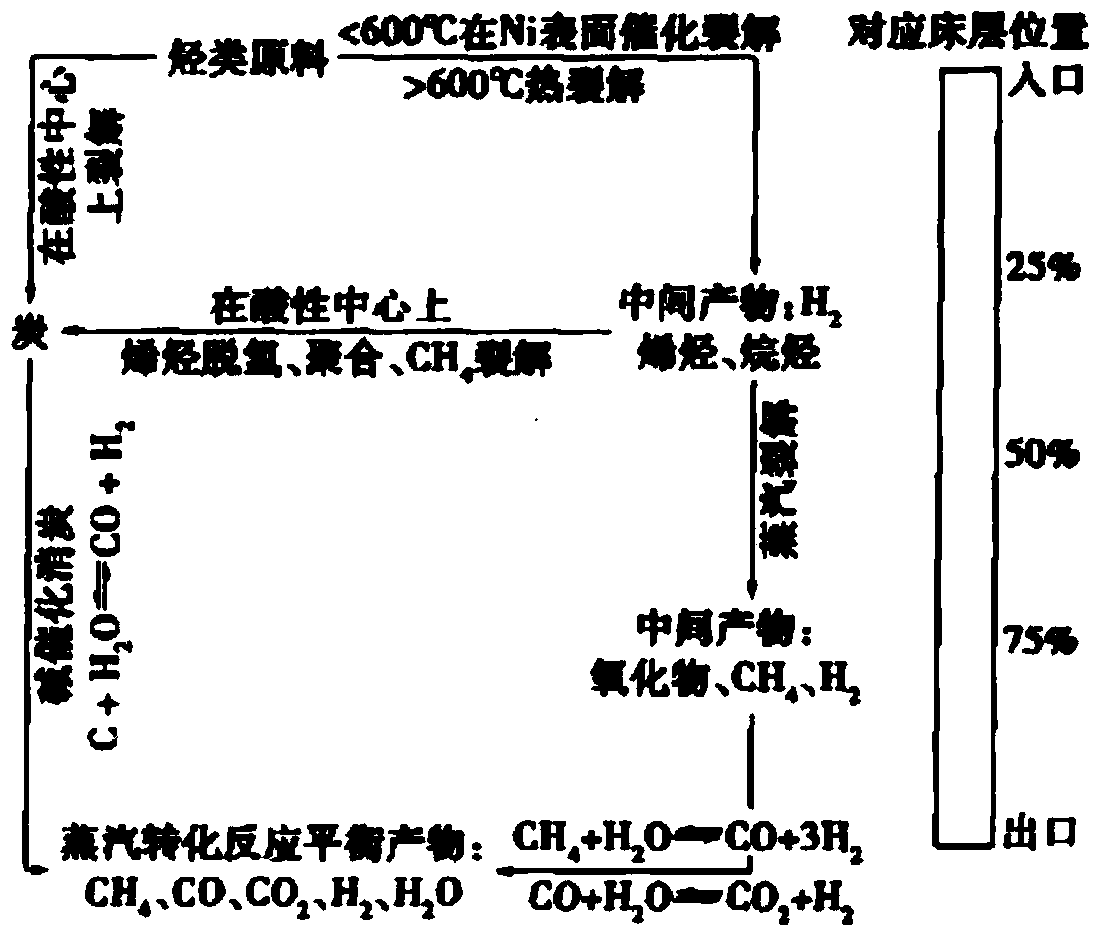

Preparation method of hydrocarbon conversion catalyst carrier

ActiveCN103736524ADoes not affect strengthIncrease the outer surface areaCatalyst carriersHydrocarbon from carbon oxidesCarboxymethyl cellulosePtru catalyst

The invention discloses a preparation method of a hydrocarbon conversion catalyst carrier. The preparation method of the hydrocarbon conversion catalyst carrier comprises the steps: taking pseudo-boehmite AlOOH.nH2O as an initial material, adding a first auxiliary agent and a proper amount of a nitric acid solution, and carrying out ball-milling material mixing, water mixing and molding, steam treatment and calcining procedures to obtain the carrier, wherein during the ball-milling material mixing process, a second auxiliary agent and a bonding agent are also added, the second auxiliary agent is MgCO3, CaCO3, SrCO3 or BaCO3, and the binding agent is sodium carboxymethyl cellulose (CMC), carboxyl methyl cellulose, methyl cellulose (MC) or poly sodium ethoxide (PVA). With a technology of opening pores in pores in the preparation method of the catalyst carrier, the obtained catalyst carrier has high pore volume of 0.25-0.45 mL / g and large specific surface area of 5-20 m<2> / g. At the same time, the bulk density of the carrier is lower than that of a carrier obtained by an ordinary process.

Owner:四川蜀泰化工科技有限公司

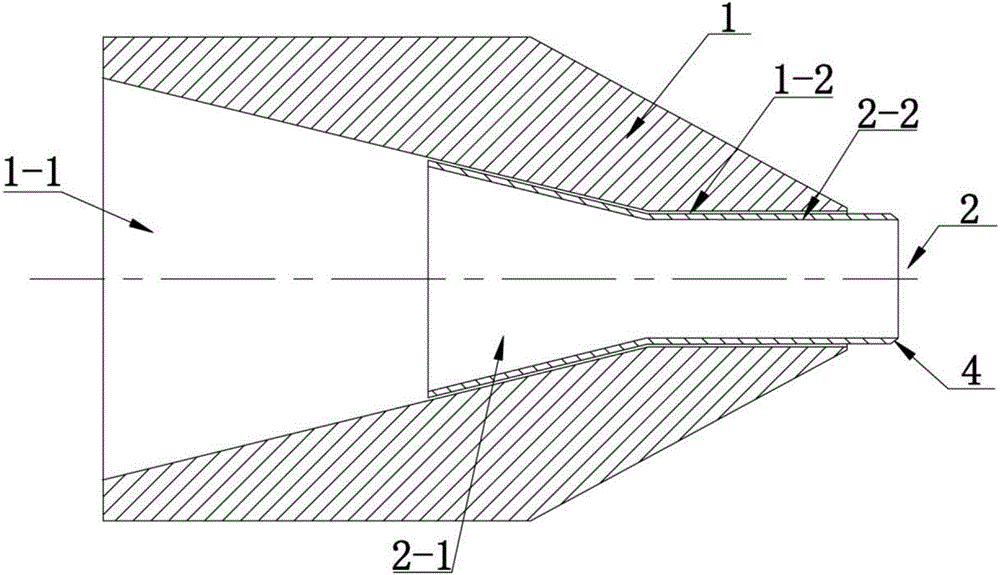

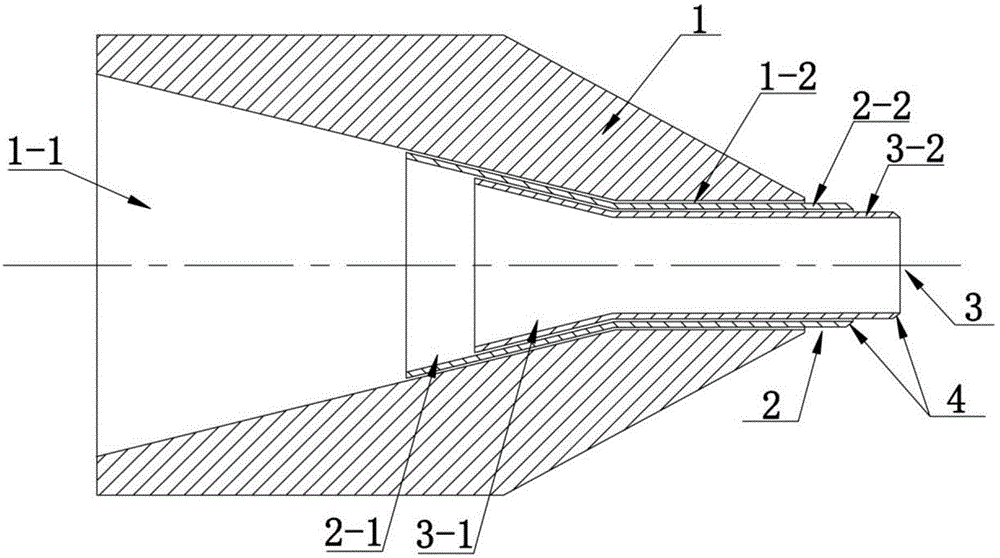

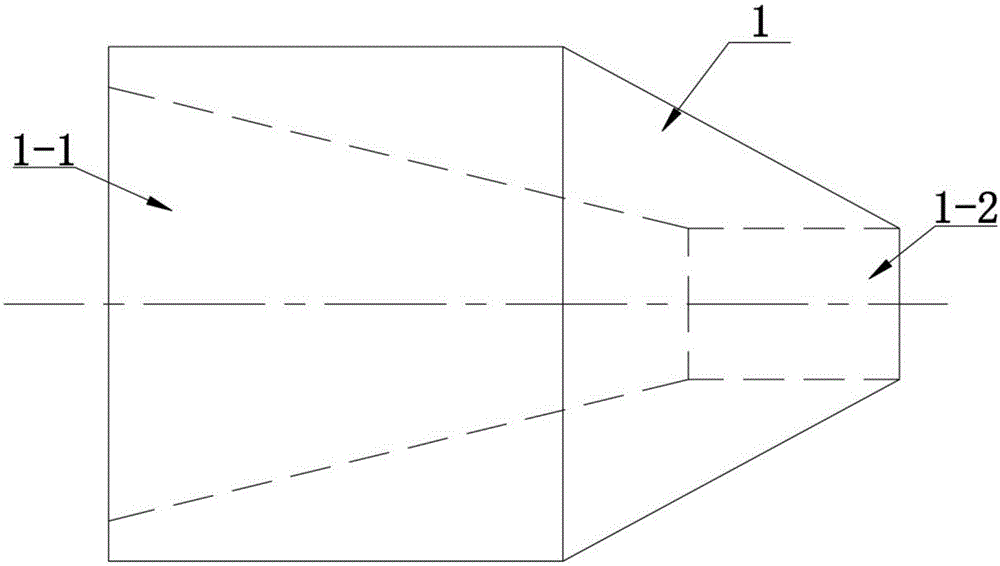

Catenary-chain type cross-linked cable production die and production method

ActiveCN104900346AReduce product quality riskArrive successfullyCable/conductor manufactureCross-linkElectrical conductor

The invention discloses a catenary-chain type cross-linked cable production die and a production method, and belongs to the technical field of wire and cable manufacturing. The die comprises a basic die body, and the interior of the basic die body is provided with a wire-bearing circular hole and an incoming wire tapered hole. The die also comprises a first inner die body and a second inner die body, wherein the inner die bodies are in an integrated structure. The first inner die body is disposed in the basic die body in a sleeved manner, and the second inner die body is disposed in the first inner die body in a sleeve manner. One end of the first inner die body and one end of the second inner die body are respectively provided with a first incoming wire hole and a second incoming wire hole, and the other ends of the first and second inner die bodies are respectively provided with a first bushing and a second bushing. The conical degree of the first incoming wire hole is consistent with the conical degree of the incoming wire tapered hole. The conical degree of the second incoming wire hole is consistent with the conical degree of the first incoming wire hole. The production method needs to produce different types of cable conductors, and enables the corresponding first inner die body to be inserted into the basic die body or enables the second inner die body to be inserted into the first inner die body. The die and method are quick and convenient in die replacement, improve the production efficiency, and achieve the continuous production of adjacent types of conductors.

Owner:YANTAI CABLE FACTORY

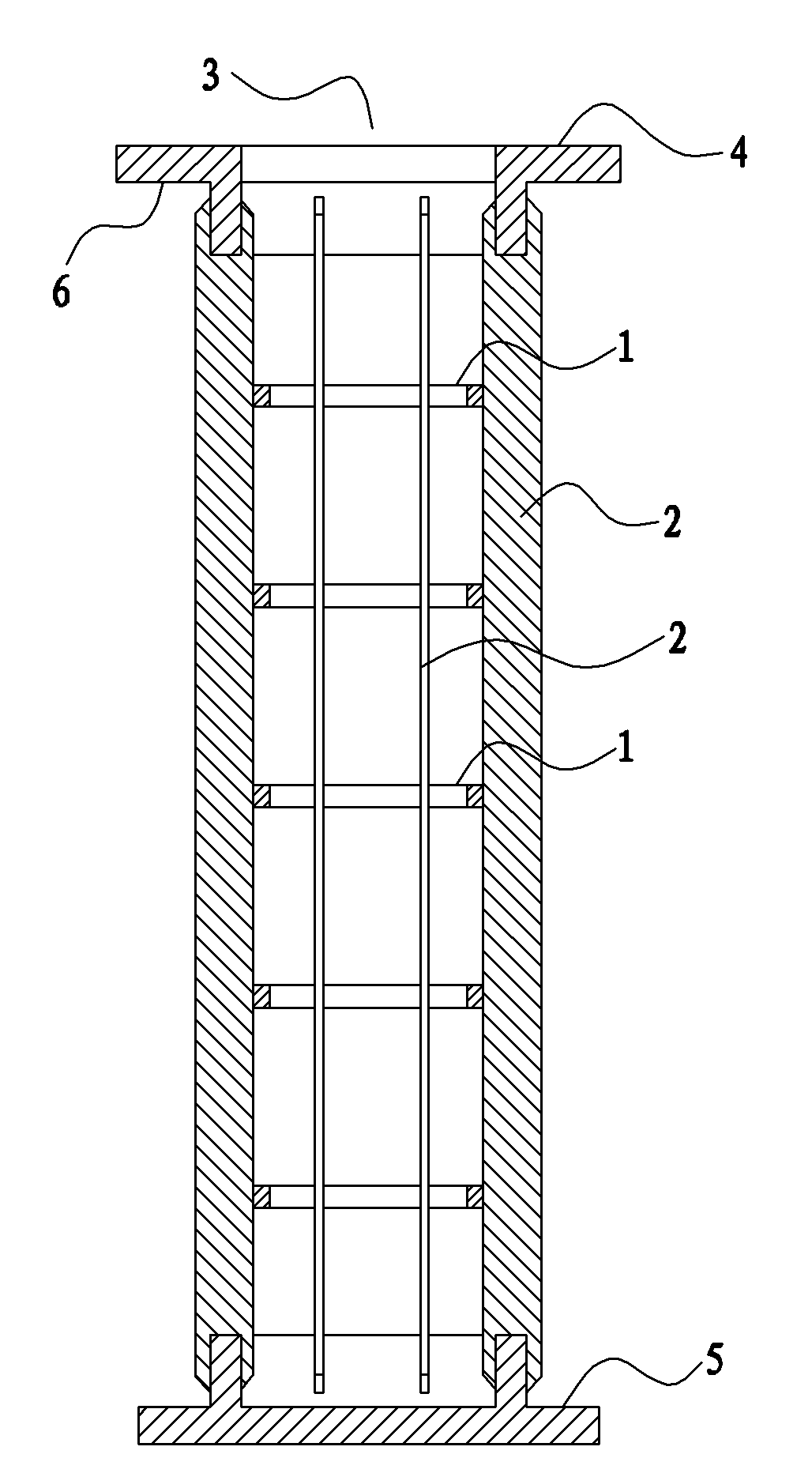

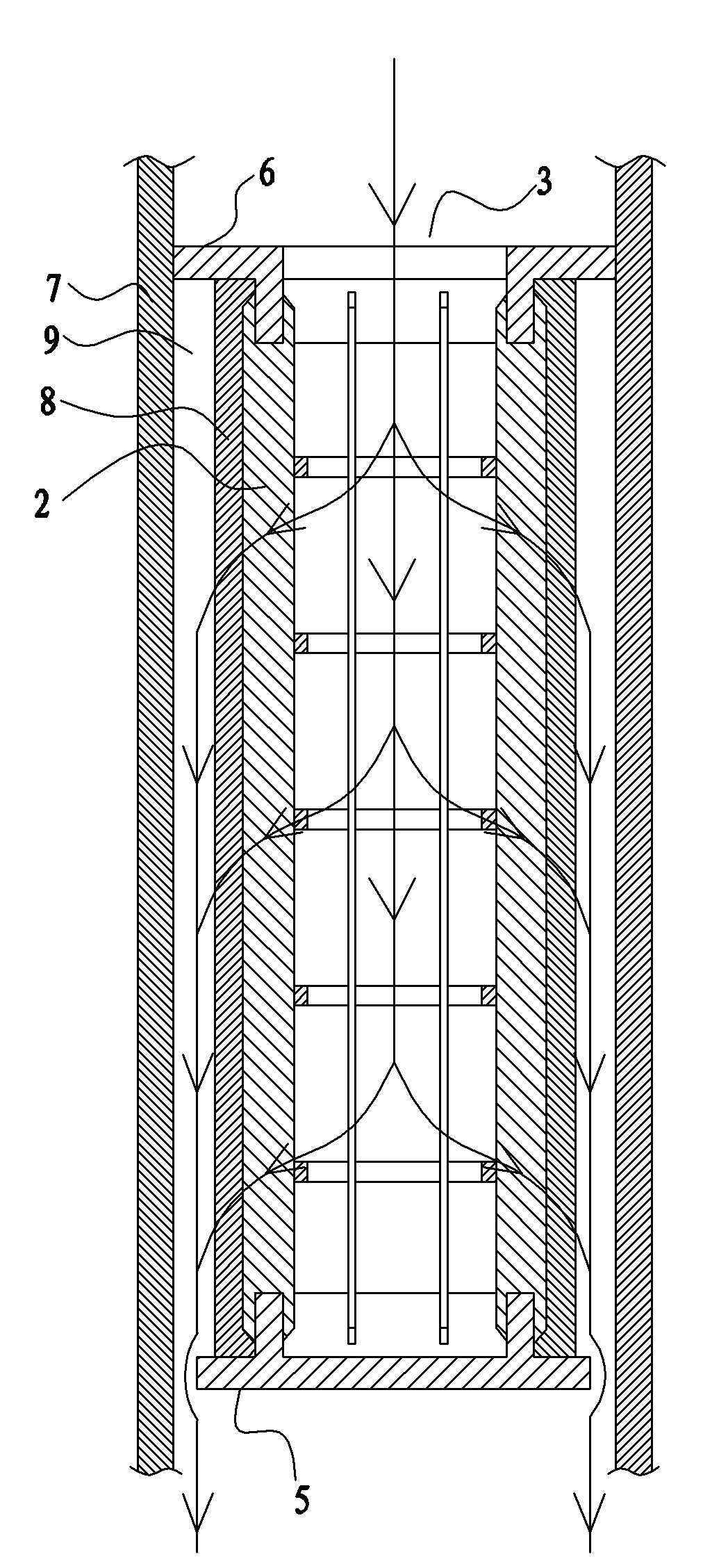

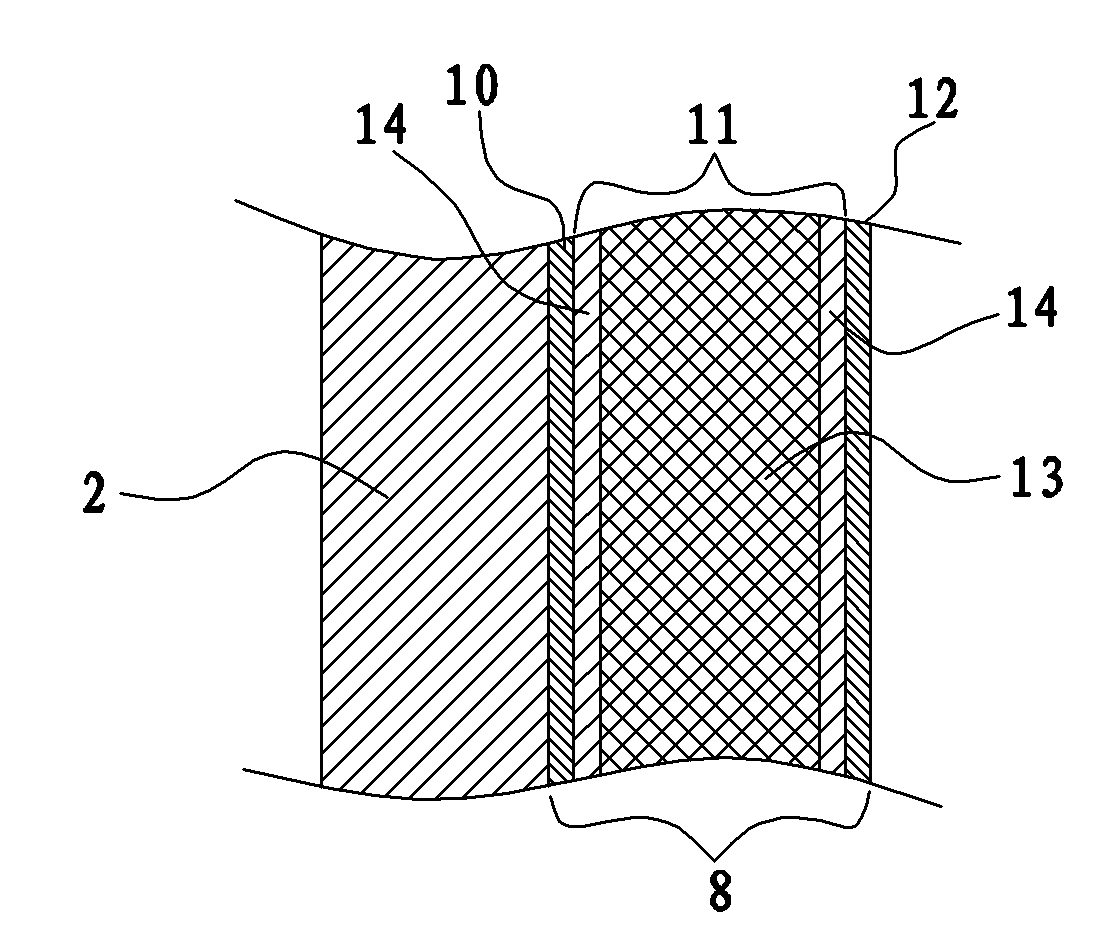

Gas filter

InactiveCN102019117AImprove filtering effectExtended service lifeDispersed particle filtrationGlass fiberEngineering

The invention discloses a gas filter. The gas filter comprises a supporting frame and a filtering part, wherein the supporting frame has a cylindrical frame structure; the filtering part is a filtering material layer distributed around the outer wall of the cylindrical frame structure; in the two ends which are positioned on the axis of the supporting frame, one end is an inlet end and the other end is provided with a blind plate; a gap is reserved between the outer wall of the filtering material layer and the inner wall of a gas pipeline; gas which needs to be filtered enters the supporting frame from the inlet end, flows through the filtering material layer, enters the gap between the outer wall of the filtering material layer and the inner wall of the gas pipeline, and then is output through the gas pipeline; the filtering material layer comprises glass fibers subjected to pretreatment; and the pretreatment comprises the steps of: soaking the glass fibers into mixed solution of dimethylbenzene and silicone oil for 20 to 240 minutes and taking the glass fibers out and drying in the air. The gas filter has the advantages that: the flow direction of the gas in the filter is reasonable; and after the glass fibers with the main filtering effect are modified through the pretreatment, the flexibility of the modified glass fibers is improved, and the filtering effect is good.

Owner:TIANJIN BAISHUNFENG METAL PRODS FACTORY

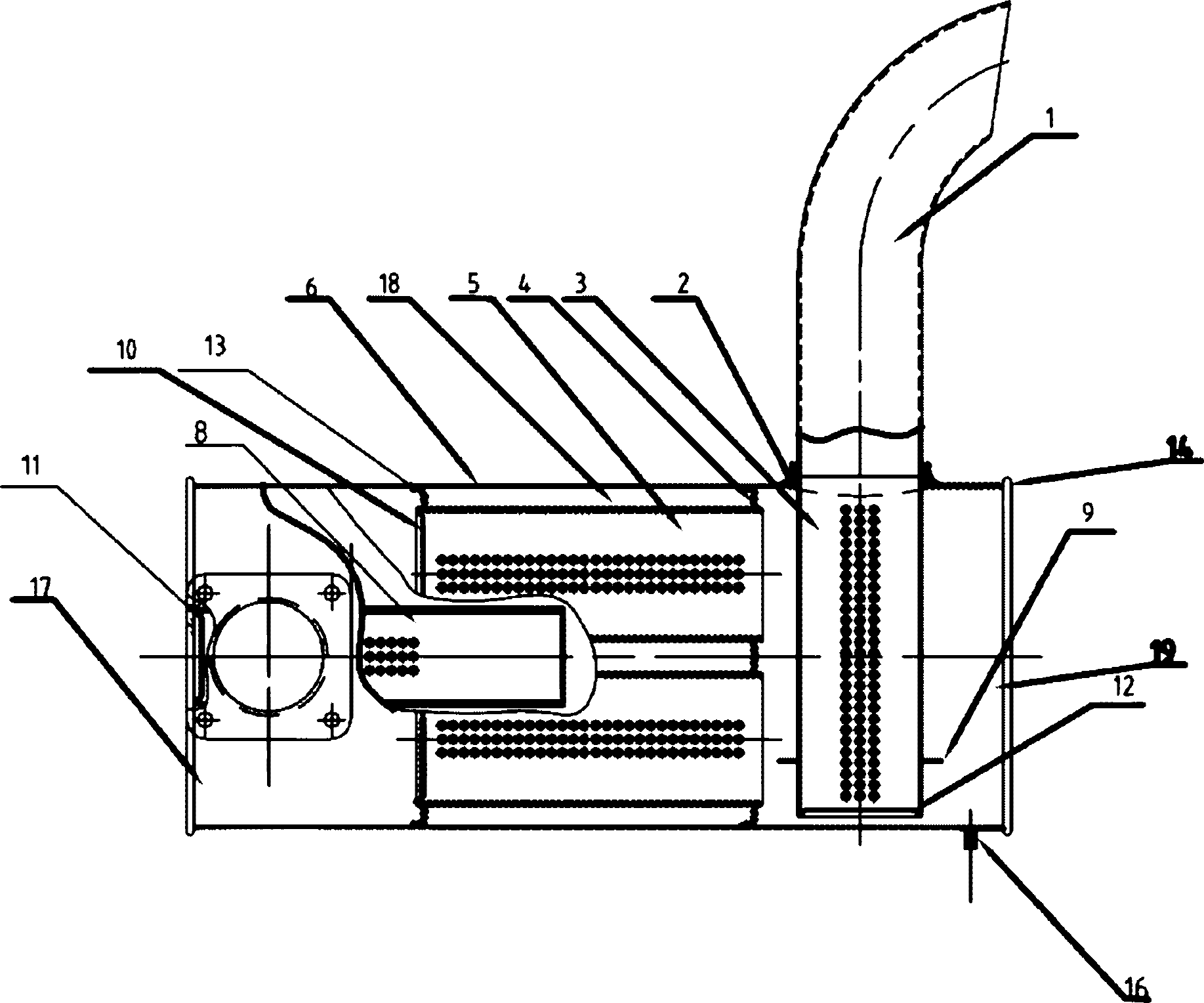

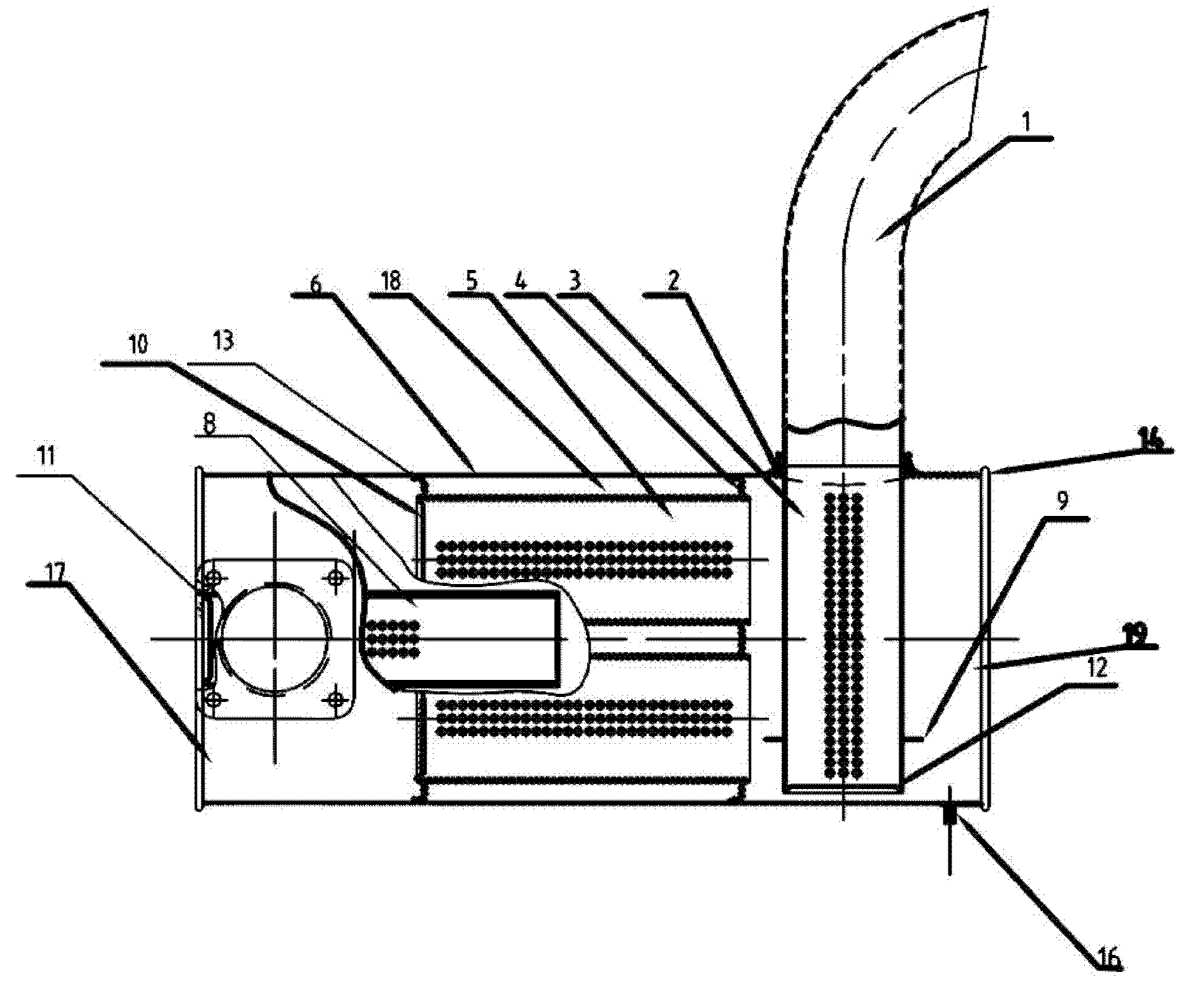

Reactive muffler for engineering machine

InactiveCN102606268AReasonable flowReduce regenerative noiseExhaust apparatusSilencing apparatusUltrasound attenuationEngineering

The invention discloses a reactive muffler for an engineering machine, which comprises a flange plate, a connecting pipe, a barrel and a smoke exhaust pipe. The inside of the barrel is sequentially divided into a cavity I, a cavity II and a cavity III by a front partition board and a rear partition board from front to back, two first sound attenuation barrels which are positioned in the cavity I and the cavity II are disposed on the front partition board, two second sound attenuation barrels are arranged in the cavity II, a third sound attenuation barrel is disposed in the cavity III, the first sound attenuation barrels and the second sound attenuation barrels are arranged along the axial direction of the barrel, the third sound attenuation barrel is perpendicular to the first sound attenuation barrels and the second sound attenuation barrels, the connecting pipe and the smoke exhaust pipe are perpendicularly connected onto the barrel and are spatially perpendicularly arranged in a crossed manner, the connecting pipe is communicated with the cavity I, the smoke exhaust pipe is communicated with the cavity III, and the flange plate is connected with the cavity I via the connecting pipe. The reactive muffler is reasonable in structure, fine in acoustic performance and long in service life, regenerated noise of airflow is low, and a muffler effect for low, medium and high-frequency noise of exhaust of an engine is remarkable.

Owner:SHANDONG UNIV

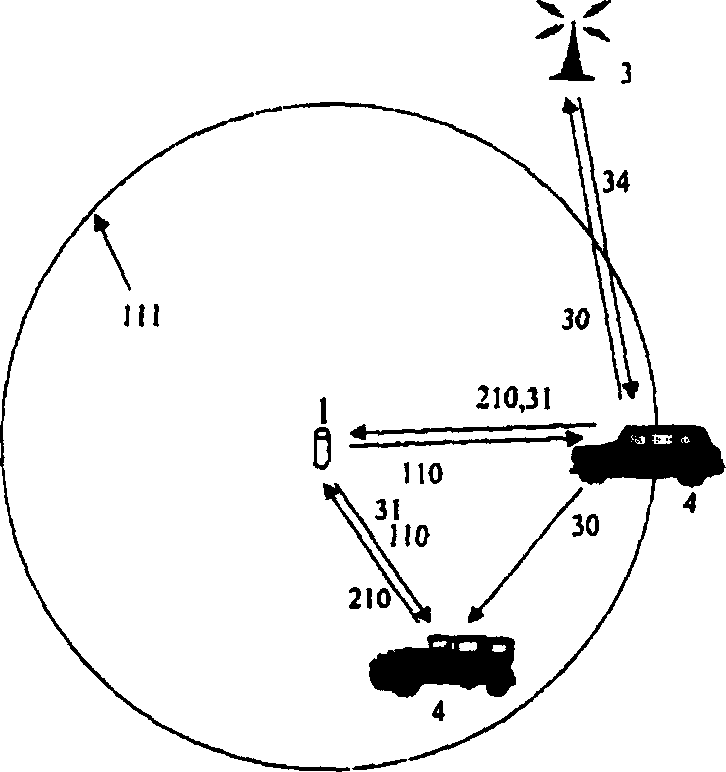

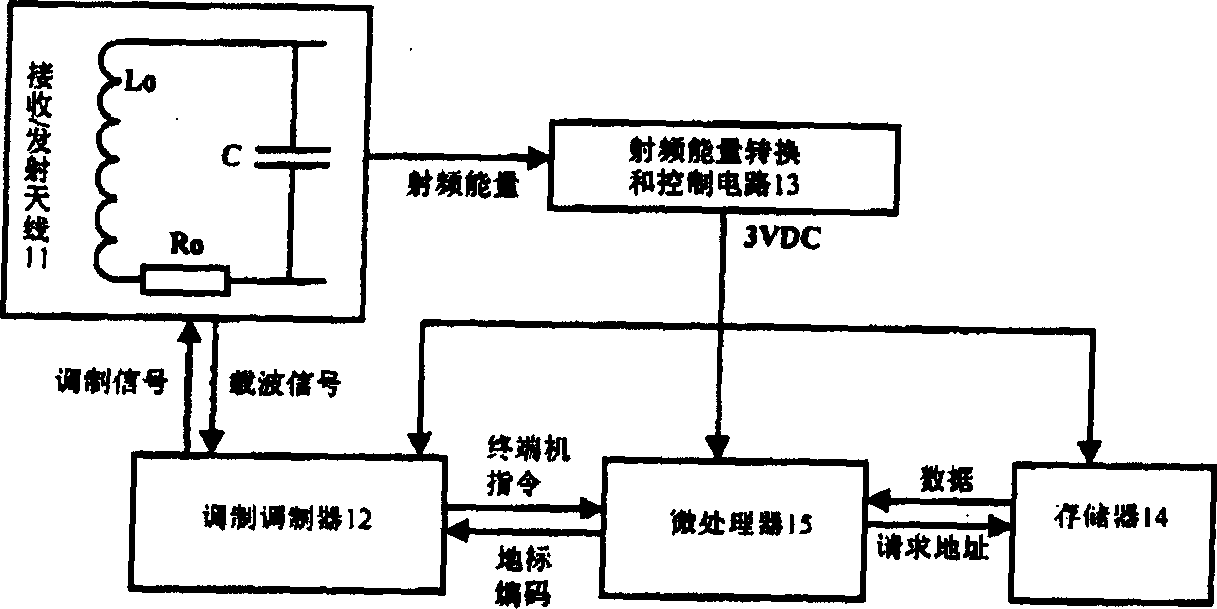

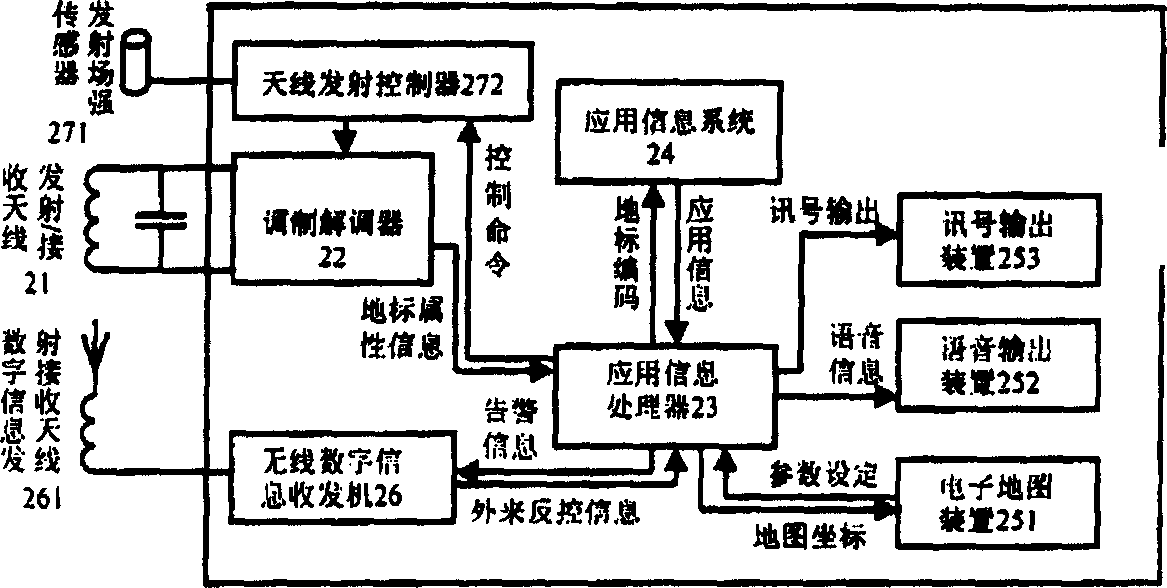

Multifunctional ground locating system

InactiveCN1147737CReduce manufacturing costExpandable and flexibleInstruments for road network navigationBeacon systems using radio wavesEngineeringMarine navigation

A multifunctional ground positioning system is composed of ground beacons, terminals and monitor center. Said beacon contains its attribute information, powered by external radiation and arranged at the desired point on ground. Said terminal installed on moving carrier can excite said ground beacon to receive its attribute information and obtain the coordinate and navigation information after its internal processing. Its advantages are high positioning precision, and low cost.

Owner:冯鲁民

Multifunctional trash recycling device based on wet dust extraction

The invention discloses a multifunctional trash recycling device based on wet dust extraction in the technical field of cleaning vehicles. The device comprises a frame, a bin body, a dust suction pipe and an upper suction chamber located on the upper portion of a bin body inner cavity; a pair of screen-shaped filter net plates are arranged on the upper suction chamber, and are arranged in a bilateral symmetry manner with the dust outlet segment of the dust suction pipe as the standard, the device further comprises a pair of side suction bins arranged on the left side and the right side of the bin body, and the device further comprises a mounting chamber arranged on the lower side of the bin body and used for mounting of a negative pressure draught fan and an exhaust chamber for guiding airflow to the outer air; the airflow passes through the bin body and is divided into two flow directions and is subject to flow dividing in the side suction bins, in the flow dividing process, most part of dust and sewage are thoroughly removed, the airflow direction is reasonable, and the sewage is prevented from entering the mounting chamber to pollute the negative pressure draught fan.

Owner:YANGZHOU JINWEI ENVIRONMENTAL PROTECTION TECH CO LTD

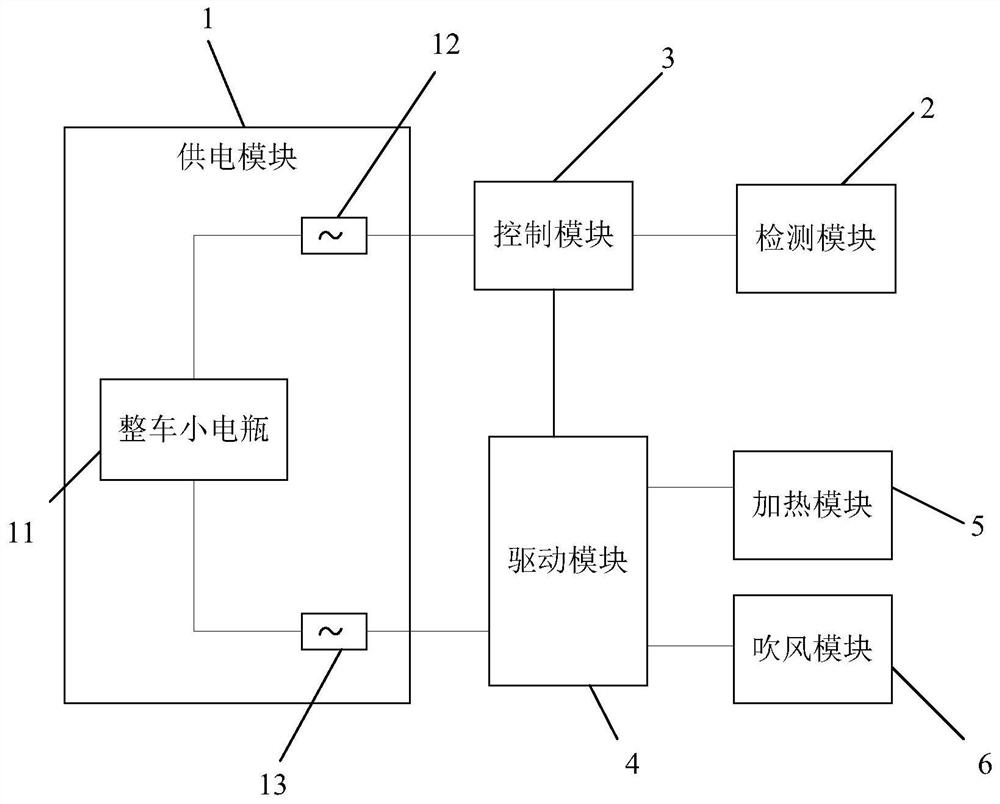

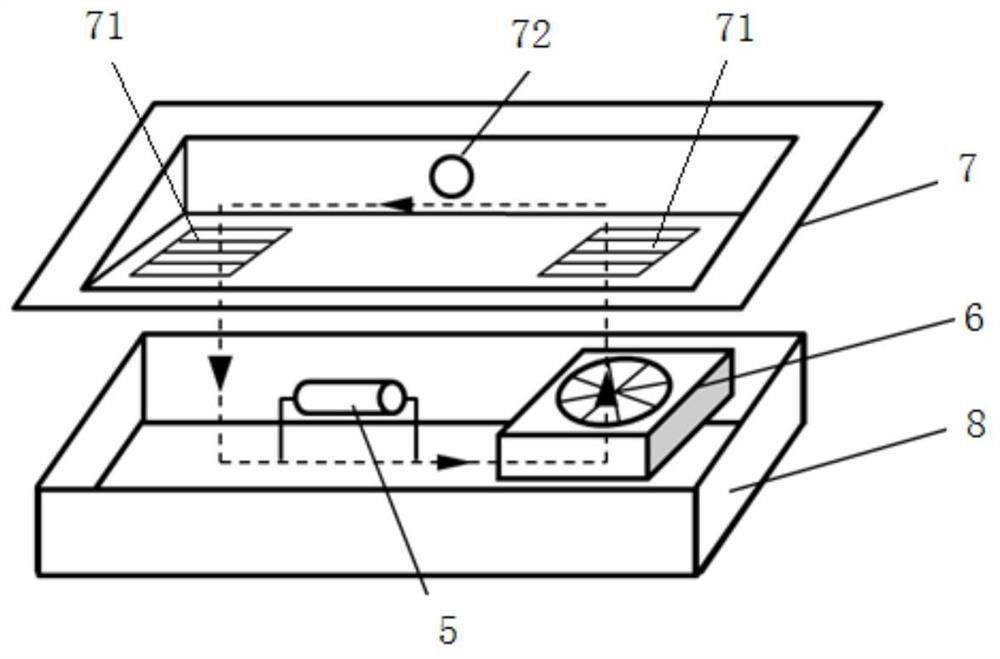

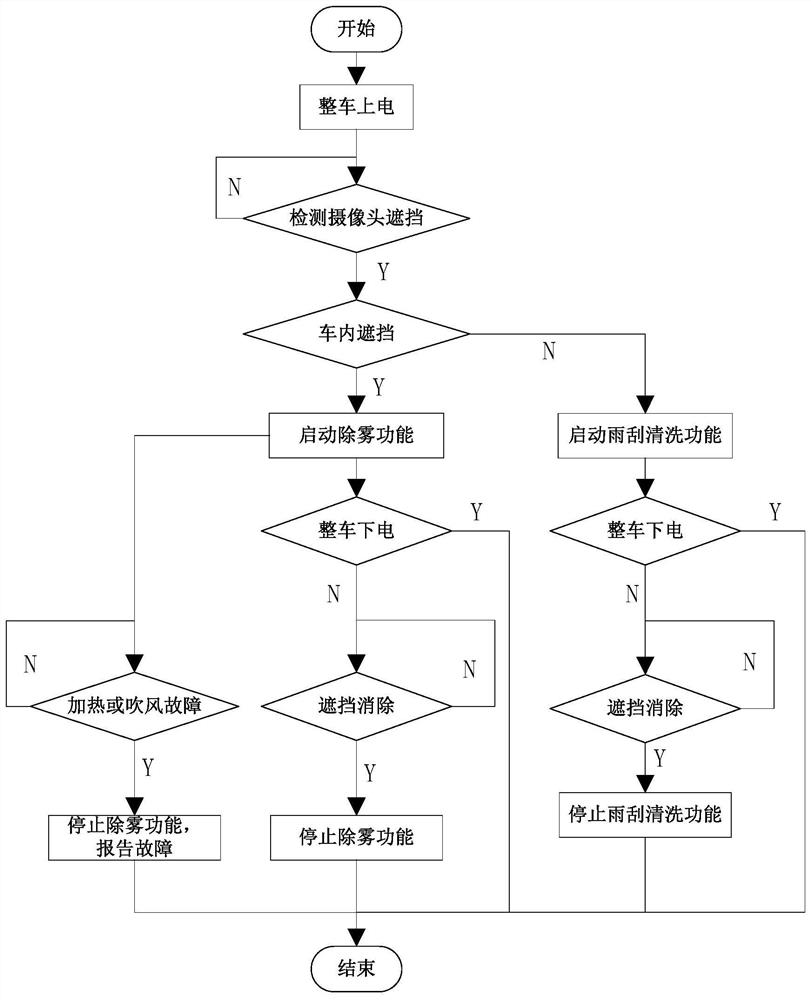

Intelligent driving camera view area windshield demisting system and vehicle

PendingCN113815565AAccelerate the dissipation of mistReduced air volume requirements and heating power requirementsVehicle cleaningWindscreen wiperElectrical and Electronics engineering

The invention discloses an intelligent driving camera view area windshield demisting system and a vehicle. The system comprises a power supply module, a detection module, a control module, a driving module, a heating module and an air blowing module, wherein the power supply module is connected with the control module and the driving module; the detection module is connected with the control module; the driving module is respectively connected with the control module, the heating module and the air blowing module; the control module is configured to receive the image information collected by the detection module in real time in response to the situation that the whole vehicle is powered on or the vehicle is started, judge whether the visual field of the camera is shielded or not based on the image information, and judge whether the visual field of the camera is shielded by fogging of in-vehicle glass or dirt of out-vehicle glass if it is detected that the visual field of the camera is shielded; if the visual field of the camera is shielded by the dirt of the out-vehicle glass, cleaning the dirt through a windscreen wiper; and if the visual field of the camera is shielded by fogging of the in-vehicle glass, starting the heating module and the air blowing module for defogging. The problem that the visual field area of the camera is shielded is solved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Reactive muffler for engineering machine

InactiveCN102606268BReasonable flowReduce regenerative noiseExhaust apparatusSilencing apparatusUltrasound attenuationEngineering

The invention discloses a reactive muffler for an engineering machine, which comprises a flange plate, a connecting pipe, a barrel and a smoke exhaust pipe. The inside of the barrel is sequentially divided into a cavity I, a cavity II and a cavity III by a front partition board and a rear partition board from front to back, two first sound attenuation barrels which are positioned in the cavity I and the cavity II are disposed on the front partition board, two second sound attenuation barrels are arranged in the cavity II, a third sound attenuation barrel is disposed in the cavity III, the first sound attenuation barrels and the second sound attenuation barrels are arranged along the axial direction of the barrel, the third sound attenuation barrel is perpendicular to the first sound attenuation barrels and the second sound attenuation barrels, the connecting pipe and the smoke exhaust pipe are perpendicularly connected onto the barrel and are spatially perpendicularly arranged in a crossed manner, the connecting pipe is communicated with the cavity I, the smoke exhaust pipe is communicated with the cavity III, and the flange plate is connected with the cavity I via the connecting pipe. The reactive muffler is reasonable in structure, fine in acoustic performance and long in service life, regenerated noise of airflow is low, and a muffler effect for low, medium and high-frequency noise of exhaust of an engine is remarkable.

Owner:SHANDONG UNIV

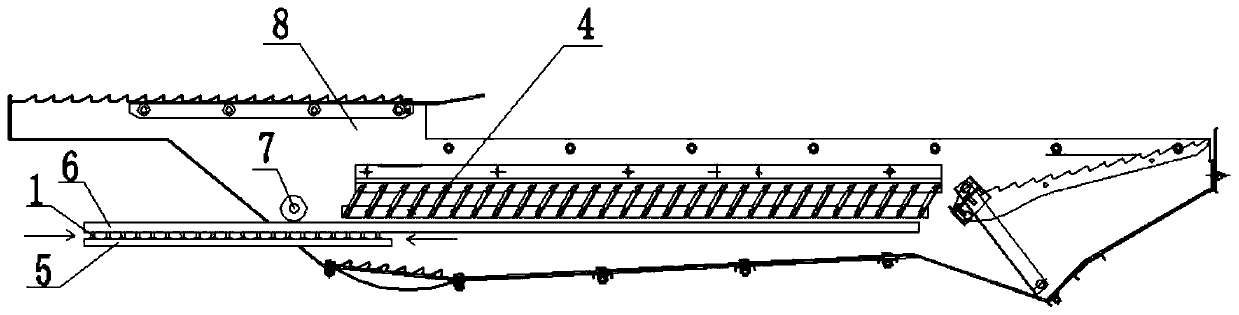

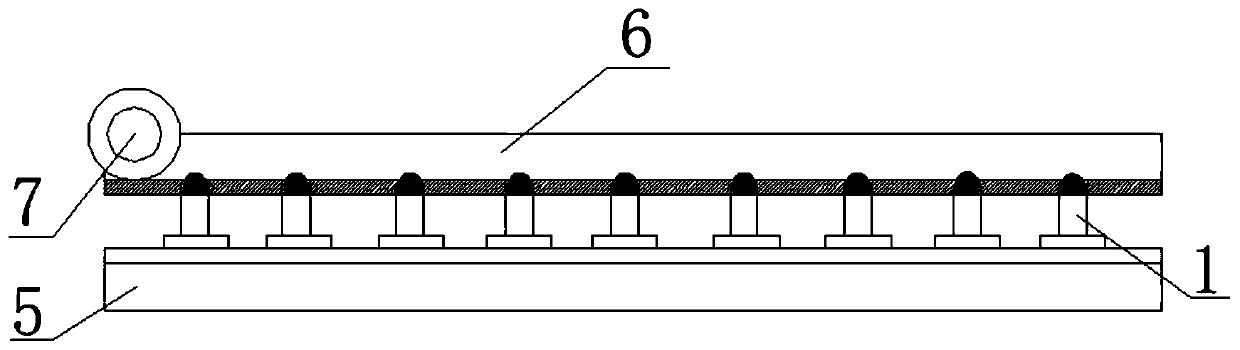

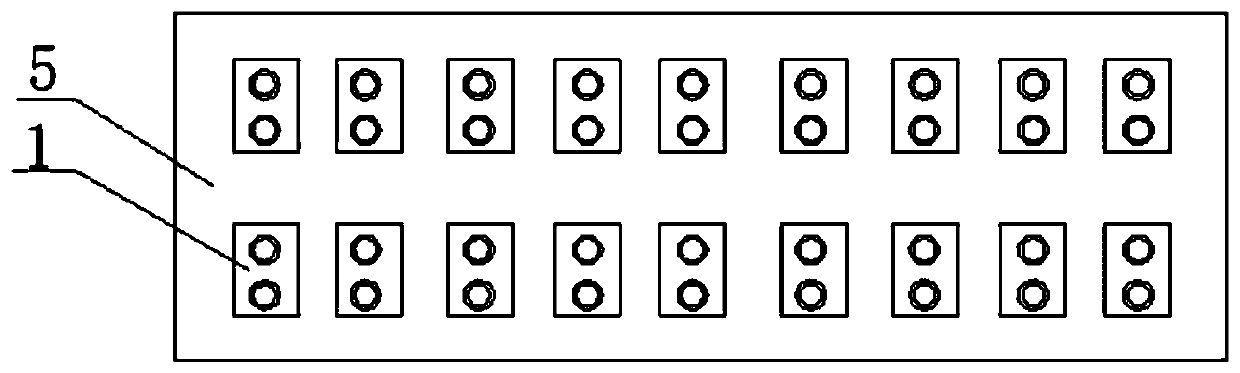

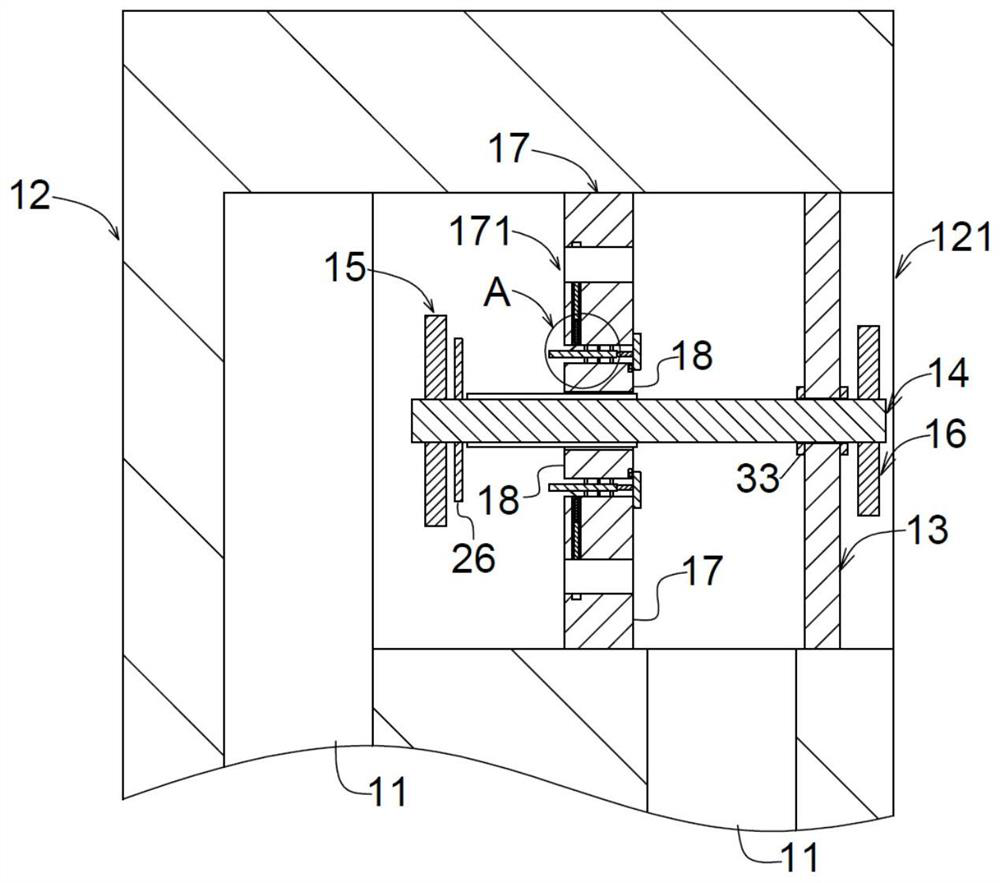

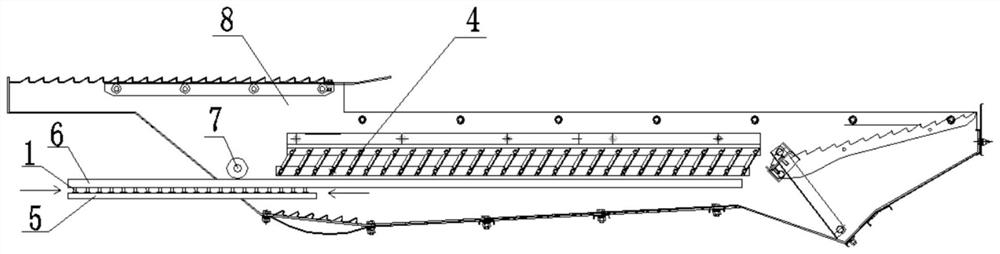

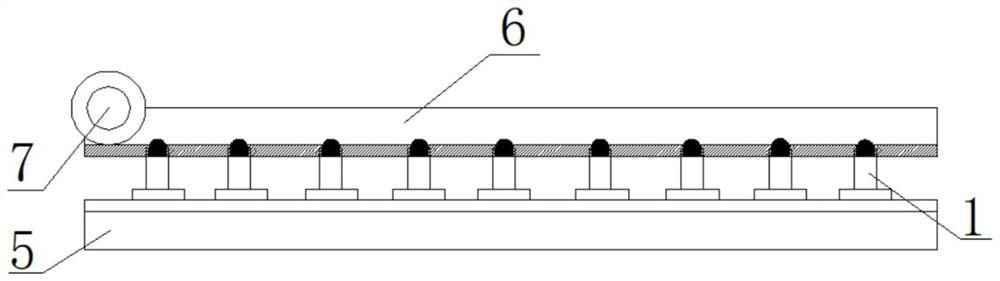

Cleaning and drying device and method and harvester

ActiveCN111448896AImprove utilization and conversion efficiencyImprove separation efficiencyBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesProcess engineeringElectric energy

The invention provides a cleaning and drying device and method and a harvester. The cleaning and drying device comprises an energy conversion device, an electric energy collecting and processing system, an electric energy flow direction control system, a storage battery, a vibrating screen heating device, a supporting device and a vibrating screen bearing rolling guide rail. The energy conversiondevice is used for converting pressure energy generated by reciprocating motion of a vibrating screen body into electric energy. The electric energy collecting and processing system is used for collecting the electric energy generated by the energy conversion device. The electric energy flow direction control system is used for judging whether the electric energy is used for charging the storage battery or for working of the vibrating screen heating device or not according to the SOC value of the storage battery and the actual working current of the vibrating screen heating device and whetherthe storage battery is used for providing electric energy for the vibrating screen heating device or not. Recycling and utilization of reciprocating motion energy of the vibrating screen are achieved,the collected energy is used for rice drying during cleaning of the cleaning device and charging of a vehicle-mounted storage battery, unnecessary energy waste in the cleaning process is reduced, andthe energy utilization and conversion efficiency is effectively improved.

Owner:JIANGSU UNIV

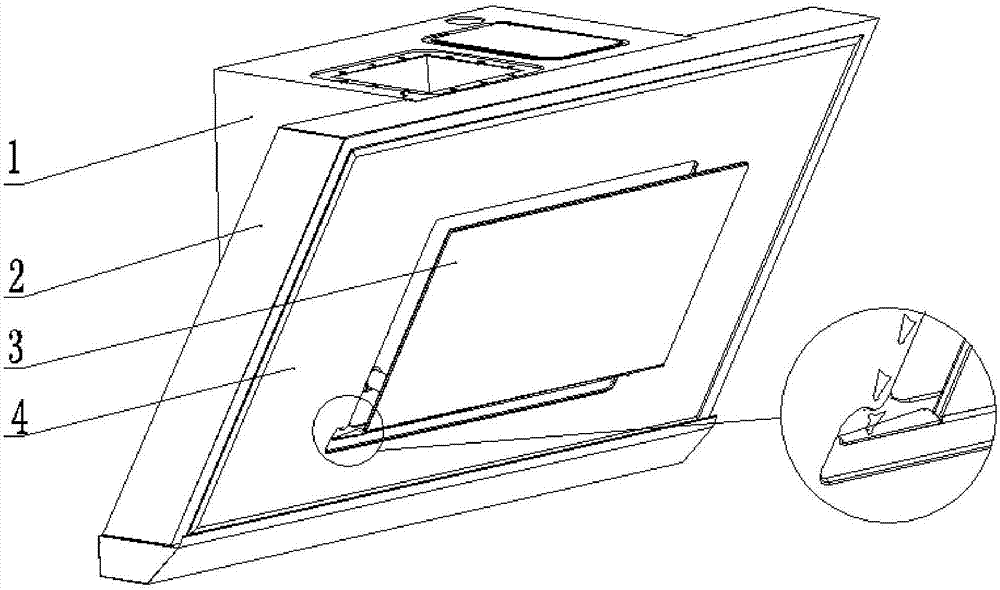

Side sucking type range hood and oil path structure thereof

PendingCN107990380AWell formedPrevent saggingDomestic stoves or rangesLighting and heating apparatusEngineering

The invention discloses an oil path structure of a side sucking type range hood. The oil path structure mainly comprises a range hood body and a panel. The range hood body is provided with the panel.The lower end of the inner side edge of the panel is of a special-shaped structure which is a notch structure. An air deflector assembly is arranged at the middle portion of the panel. The lower portion of the air deflector assembly is provided with an extending part from the exterior of the panel to the interior of the panel. The left side and the right side of the extending part are located at the lower portion of the notch structure, and an oil path channel is formed through the notch structure, the extending part towards the interior of the range hood body on the lower side of the air deflector assembly and the interior of the range hood body. According to the structure, an oil path is more reasonable, and glass front face sagging is avoided.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Evanescent mode casting technology method for lightweight balance shaft beam

The invention provides an evanescent mode casting technology method for a lightweight balance shaft beam. Specifically, firstly, according to the structural design of the lightweight balance shaft beam, connecting supports, thrust rod supports and the beam are of an integral structure cast and formed at a time, and a weight reduction structure is arranged; secondly, according to the design of a pouring system, a cross pouring gate and a straight pouring gate are connected, a pouring cup is arranged on the top of the straight pouring gate, three inner sprues are connected to the bottom of the cross pouring gate and connected with a product model, four slag collecting bags are divided into two groups arranged at the two ends of the product model, and chilling blocks are arranged at the positions, corresponding to the thrust rod supports, on the product model; thirdly, box embedding modeling is conducted; and fourthly, pouring is conducted. By means of the evanescent mode casting technology method, the pouring system is simple and compact in structure, modeling is convenient, a cavity is easily filled with molten metal, the defect that the impact resisting capability of existing balance shaft beams is commonly poor is overcome, and the purpose of casting of the integral structure is achieved.

Owner:HUBEI XINGYUAN SCI & TECH

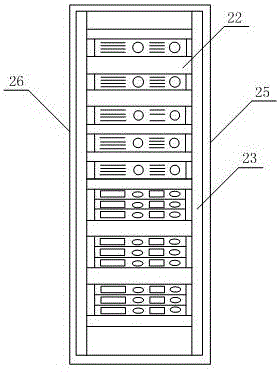

Interactive training curriculum management system

InactiveCN106061216AEffective coolingMonitor temperature in real timeCooling/ventilation/heating modificationsCold airEngineering

The invention discloses an interactive training curriculum management system which comprises an intelligent terminal, a data server, a network server and a cabinet. The cabinet comprises a cabinet body, at least two separating plates, an air inlet, a flow deflector, an air outlet, air outgoing holes and at least one wireless temperature sensor, wherein the cabinet body comprises a front door plate, a rear door plate, a top plate, a bottom plate, a left side plate and a right side plate; the separating plates are arranged in the cabinet body horizontally, and are separated from the front door plate for certain distance to form a cold air cavity; the air inlet is arranged in the base plate and communicates with the cold air cavity correspondingly, and is provided with a sliding cover plate; the flow deflector is arranged over the air inlet, one end of the flow deflector is connected to the side, close to the front door plate, of the bottommost separating plate, and the other end of the flow deflector is connected to the side, close to the rear door plate, of the air inlet; the air outlet is arranged in the top plate; the air outgoing holes are arranged in the rear door plate; and the wireless temperature sensor is mounted in the bottom side of the separating plate. According to the interactive training curriculum management system of the invention, the cabinet realizes cooling in a downward blowing manner, and the energy utilization efficiency can be improved effectively.

Owner:成都攒道管理咨询有限公司

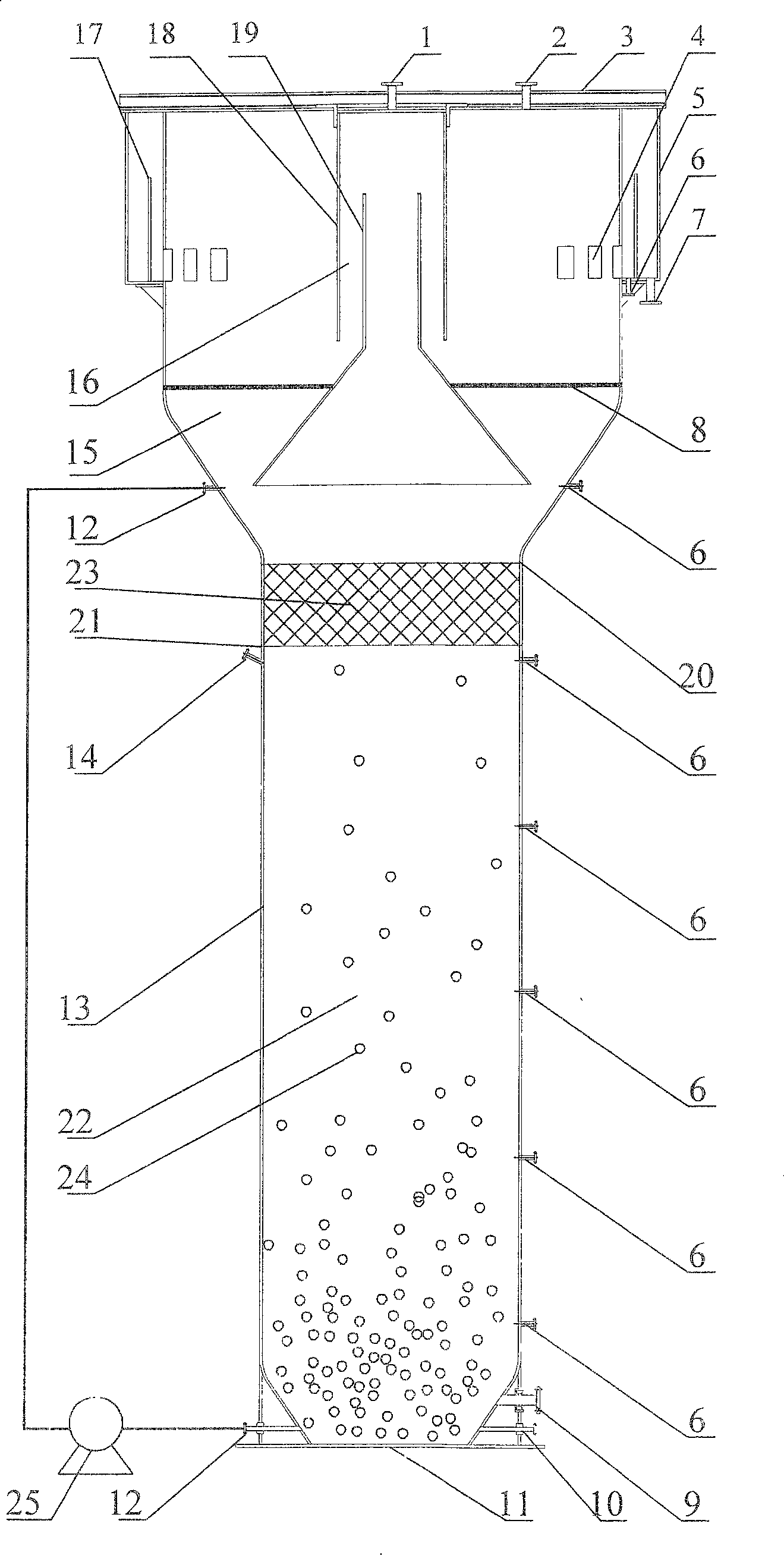

Hydrogen making apparatus using high concentrated organic wastewater and its hydrogen making method

InactiveCN100491270CImprove mass transfer efficiencyIncrease biological holdTreatment with anaerobic digestion processesFermentationHigh densityHydrogen

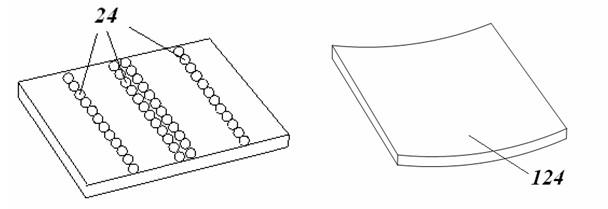

The invention discloses a making equipment and method of hydrogen through high-density organic wastewater, which comprises the following steps: 1. culturing and taming anaerobic active sludge; 2. placing the anaerobic active sludge and lightweight fill (24) into hydrogen making equipment; 3. Controlling temperature at 35+-3 deg.c for 1.5-6h in the equipment; 4. adopting high-density organic wastewater as ferment base to react with active sludge in the reacting area (22) to produce hydrogen.

Owner:HARBIN INST OF TECH

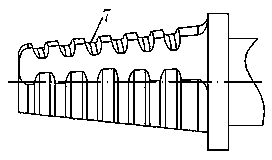

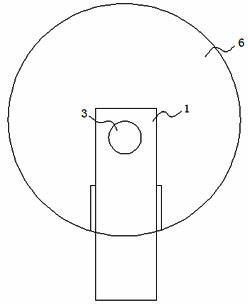

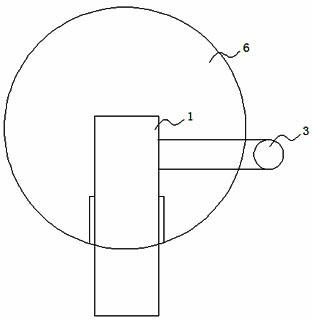

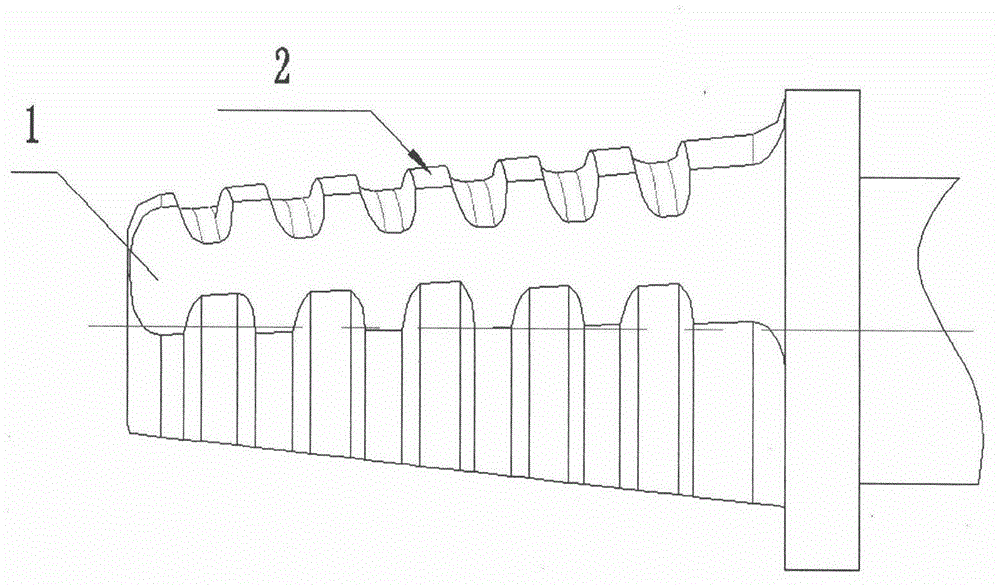

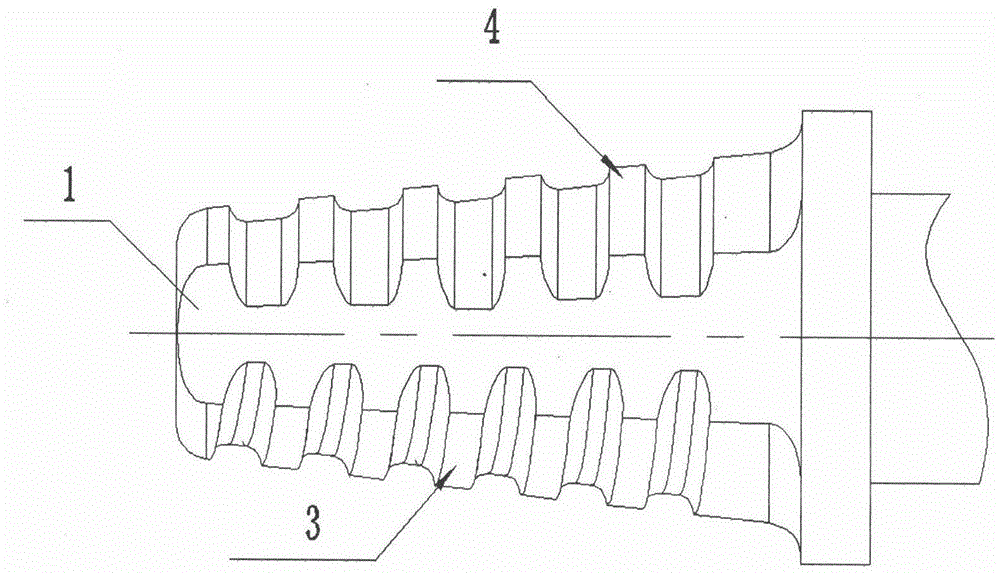

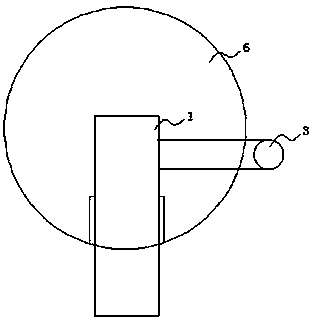

Novel aluminum alloy mixing pin

InactiveCN104308358AReasonable flowDense weld structureNon-electric welding apparatusEngineeringSpiral line

The invention discloses a novel aluminum alloy mixing pin comprising a tapered pin body. The tapered face of the tapered pin body is provided with a plurality of spiral lines. The tapered face of the tapered pin body is evenly provided with three straight-face edges and three taper-face edges; the taper-face edges are provided with spiral lines in different spiral directions, respectively, including a rightward spiral line, a leftward spiral line and a circular spiral line. The novel aluminum alloy mixing pin has the advantages that welding thickness is increased from original 40mm to existing 80mm, the welding thickness is increased by 100%, frictional heat is more evenly distributed through changes in the structure of the pin, material flow is more reasonable, and weld quality is better.

Owner:杨桂珍

Pushing device for injection molding machine and injection molding system thereof

The invention discloses a pushing device for an injection molding machine and an injection molding system thereof. The pushing device comprises a pushing barrel and a storage barrel, a pushing plate is slidably connected into the pushing barrel, a rotating rod movably penetrates through the interior of the pushing plate, a plurality of heating plates are fixedly connected to the rotating rod, a heat transfer assembly comprises a gas conveying pipe, a heat exchange agent circulating pump and a liquid return pipe which are sequentially communicated, a heating groove channel is communicated between the rotating rod and the heating plates, the two ends of the heating groove channel communicate with the gas conveying pipe and the liquid return pipe through communicating rings correspondingly, elastic sealing layers are fixedly connected into the heating plates, and a rotating blade and a stirring blade are fixedly connected to the two ends of a rotating shaft. When the pushing device is used, the heating plates are driven through the pushing plate and the rotating rod to rotate, a heat exchange agent is heated through a heating piece arranged in the storage barrel, and the heat transfer efficiency and the uniform heating effect are further improved through cooperation of the elastic sealing layers, the rotating shaft, a half-barrel assembly and other structures.

Owner:柏松

A cleaning and drying device and method and harvester

ActiveCN111448896BImprove utilization efficiencyImprove conversion efficiencyBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesBattery chargeControl system

The invention provides a cleaning and drying device and method and a harvester, including an energy conversion device, an electric energy collection and processing system, an electric energy flow control system, a storage battery, a vibrating screen heating device, a supporting device and a vibrating screen bearing rolling guide; To convert the pressure energy generated by the reciprocating motion of the vibrating screen body into electrical energy, the electrical energy collection and processing system is used to collect the electrical energy generated by the energy conversion device, and the electrical energy flow control system is used to control the energy according to the SOC value of the battery and the heating device of the vibrating screen. The actual working current determines whether the electric energy is used for charging the battery or for the operation of the vibrating screen heating device, and whether to use the battery to provide electric energy for the vibrating screen heating device. The reciprocating motion energy of the vibrating screen is recovered and utilized, and the collected energy is used for rice drying during cleaning by the cleaning device and charging of the on-board battery, reducing unnecessary energy waste during the cleaning process and effectively improving energy utilization and conversion efficiency.

Owner:JIANGSU UNIV

Cigarette smoke absorbing device

The invention discloses a device capable of absorbing harmful smoke which is released in cigarette combustion and exhaled by smokers. The device comprises a box provided with a guide tube connected to a negative pressure air source. The device is characterized in that a cigarette sleeve is arranged on the box, a cigarette ash and butt storage container is arranged inside the box, the box extends into a smoke-absorbing cup from the lower side, the direction of the cigarette sleeve is the same as that of the cup, and the smoke-absorbing cup is connected onto the negative pressure air source. The device is simple in structure and can completely absorb the exhaled smoke and the combusted smoke by the aid of the fewest structural elements and components. Further, the cigarette ash and butt storage container and an ignition device are arranged at reasonable positions, and convenience in operation and cleaning is ensured. Fresh air flows axially along cigarettes in a more reasonable manner, and combustion of the cigarettes is facilitated.

Owner:李乃华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com