Gas filter

A gas filter and filter material technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems affecting the filter effect filter service life, unreasonable gas flow direction, higher filter core requirements, etc., to achieve flexibility The effect of increasing the gas flow, reasonable gas flow, and good filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

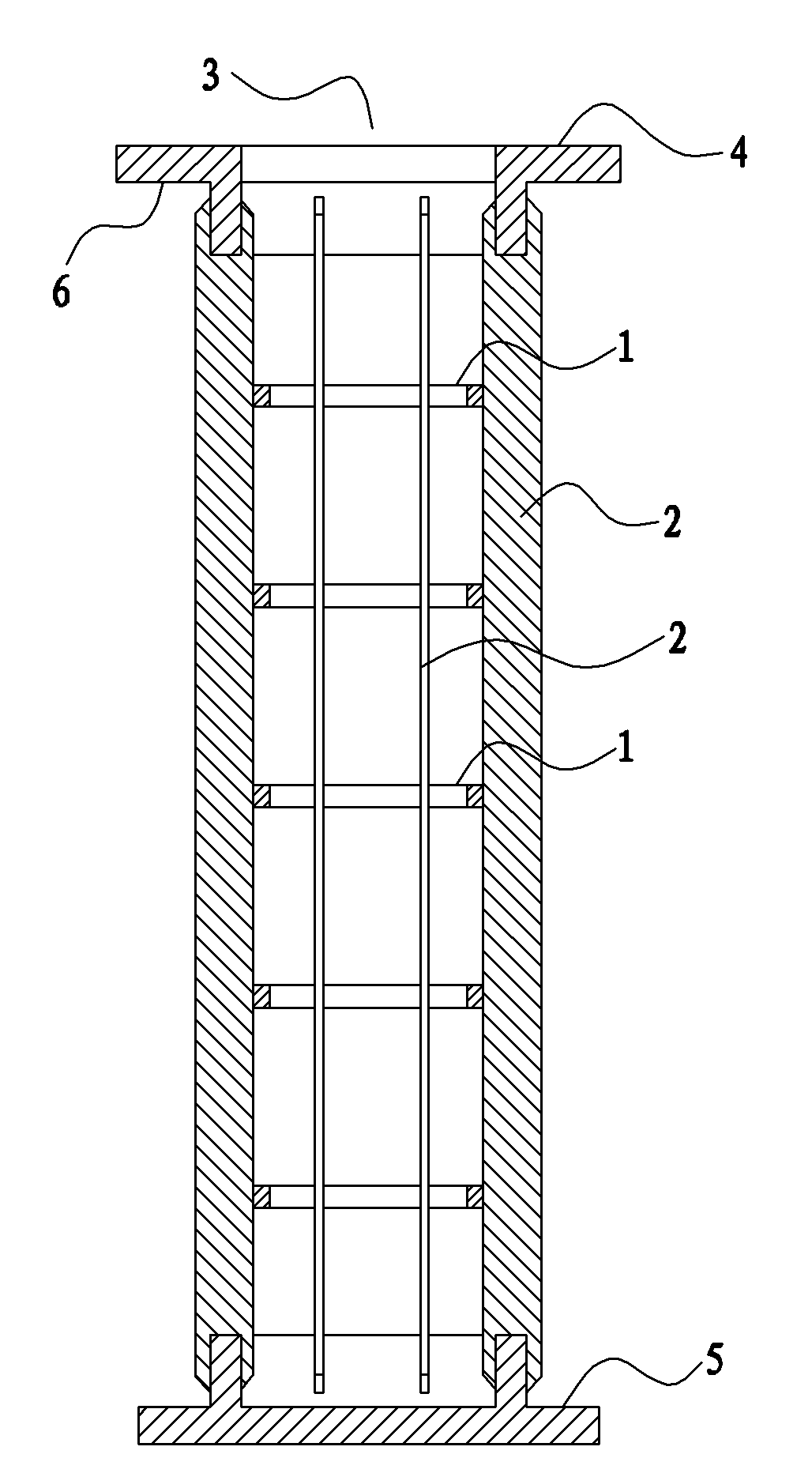

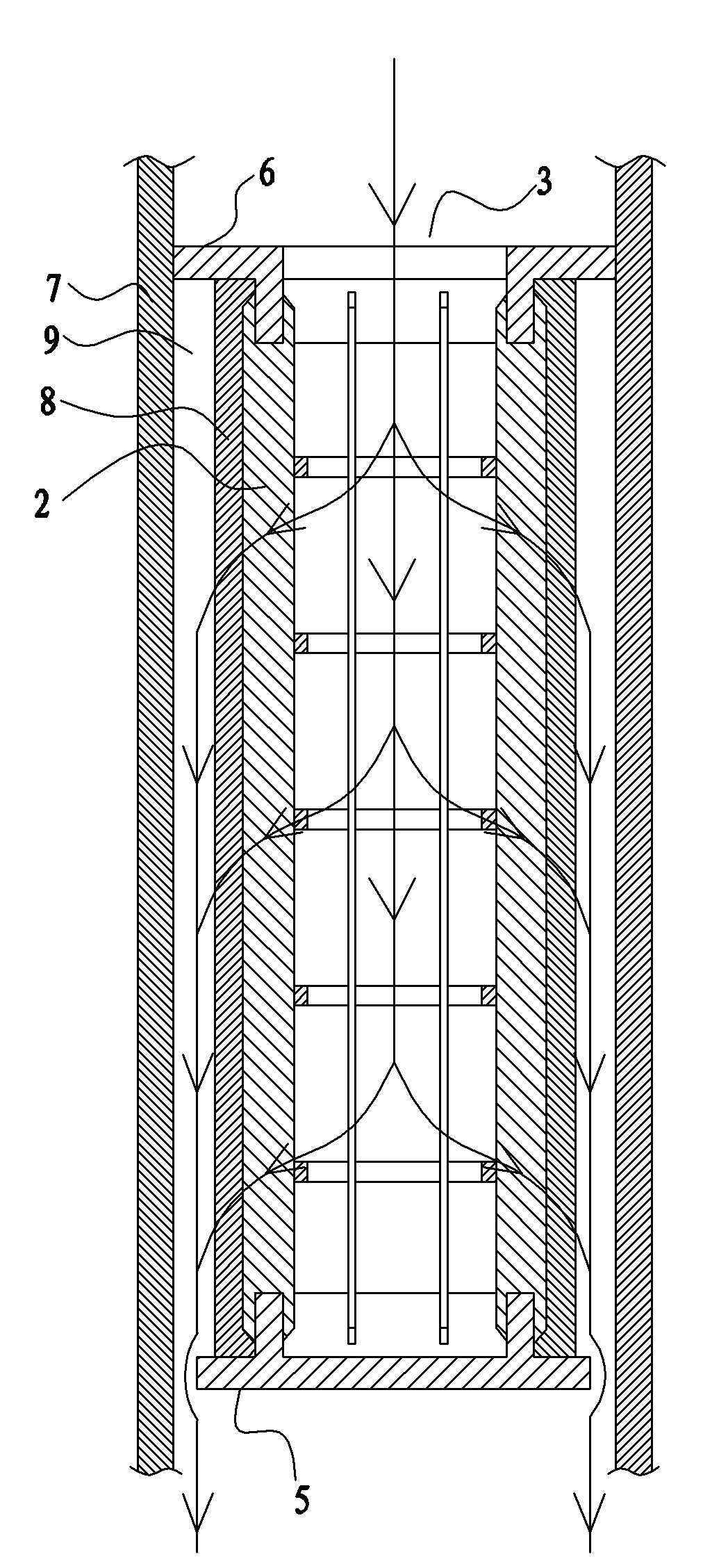

[0034] The invention relates to a gas filter, comprising a support frame and a filter component.

[0035] Referring to the accompanying drawings, the support frame is a cylindrical frame structure, including:

[0036] Several supporting rings 1 distributed in parallel, five supporting rings in the figure;

[0037] Several support bars 2 arranged axially and connected to the inner wall of the support ring 1, six support bars in this embodiment;

[0038] A connecting cylinder 4 with an outer flange 6 located at the inlet end 3, and the end of the support bar 2 at the inlet end 3 is fixedly connected with the connecting cylinder 4;

[0039] A blind plate 5 located at the end opposite to the inlet end 3 .

[0040] The axial length and radial dimension of the support frame are not strictly limited, and can be determined according to the gas pipeline conditions. The support frame is made of polyvinyl chloride.

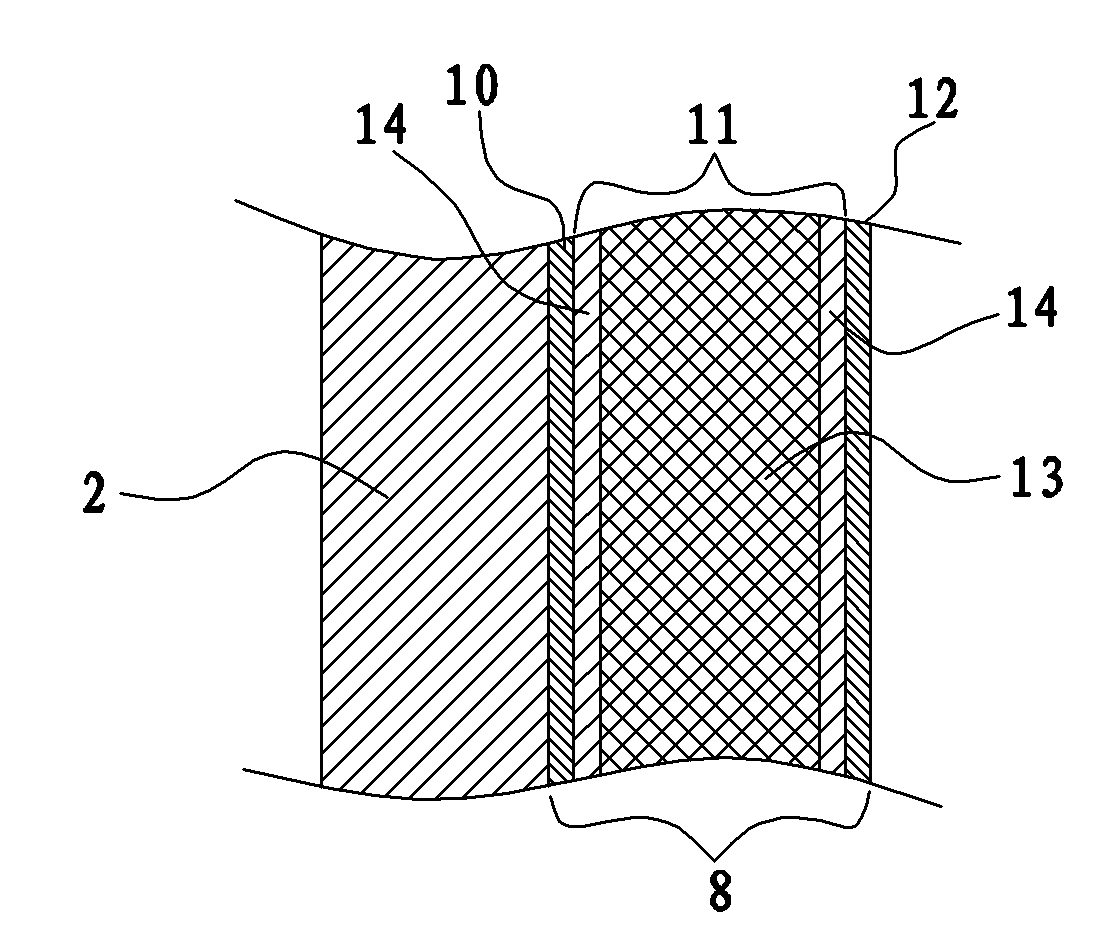

[0041] The filter component is a filter material layer 8 distributed...

Embodiment 2

[0052] The filter support frame in this embodiment is made of polyvinyl chloride, and the glass fiber is directly used as a glass fiber mat wrapped in a glass fiber bag. Before use, the glass fiber mat is immersed in a mixed solution of xylene and silicone oil, and soaked at room temperature for 100 minutes. Then take it out and dry it. In the mixed solution of xylene and silicone oil, the mass percent content of xylene is 80%, and the remaining part adopts the same structure as the filter in Example 1.

[0053] Used in the chlorine pipeline, the flow rate is 1300NM 3 / h, under the condition of 24 hours non-stop, the service life reaches 8 months, and the weight ratio of water in chlorine gas after filtration is less than 0.05%.

Embodiment 3

[0055] The filter support frame in this embodiment is made of stainless steel (316L), and the glass fiber is directly used as a glass fiber mat. Before use, the glass fiber mat is immersed in a mixed solution of xylene and silicone oil, and after soaking at room temperature for 120 minutes, it will be taken out and air-dried. Dry, in the mixed solution of xylene and silicone oil, the mass percent content of xylene is 90%, and the rest adopts the same structure as the filter in Example 1.

[0056]Used in the hydrogen pipeline, the flow rate is 1400NM 3 / h, under the condition of 24 hours without interruption, the service life reaches 8 months, and the weight ratio of water in the filtered hydrogen is less than 0.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com