Patents

Literature

9921 results about "Gas pipeline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enhanced acoustic detection of gas leaks in underground gas pipelines

InactiveUS6725705B1Improve efficiencyIncrease the lengthDetection of fluid at leakage pointMaterial analysis using sonic/ultrasonic/infrasonic wavesGas leakEngineering

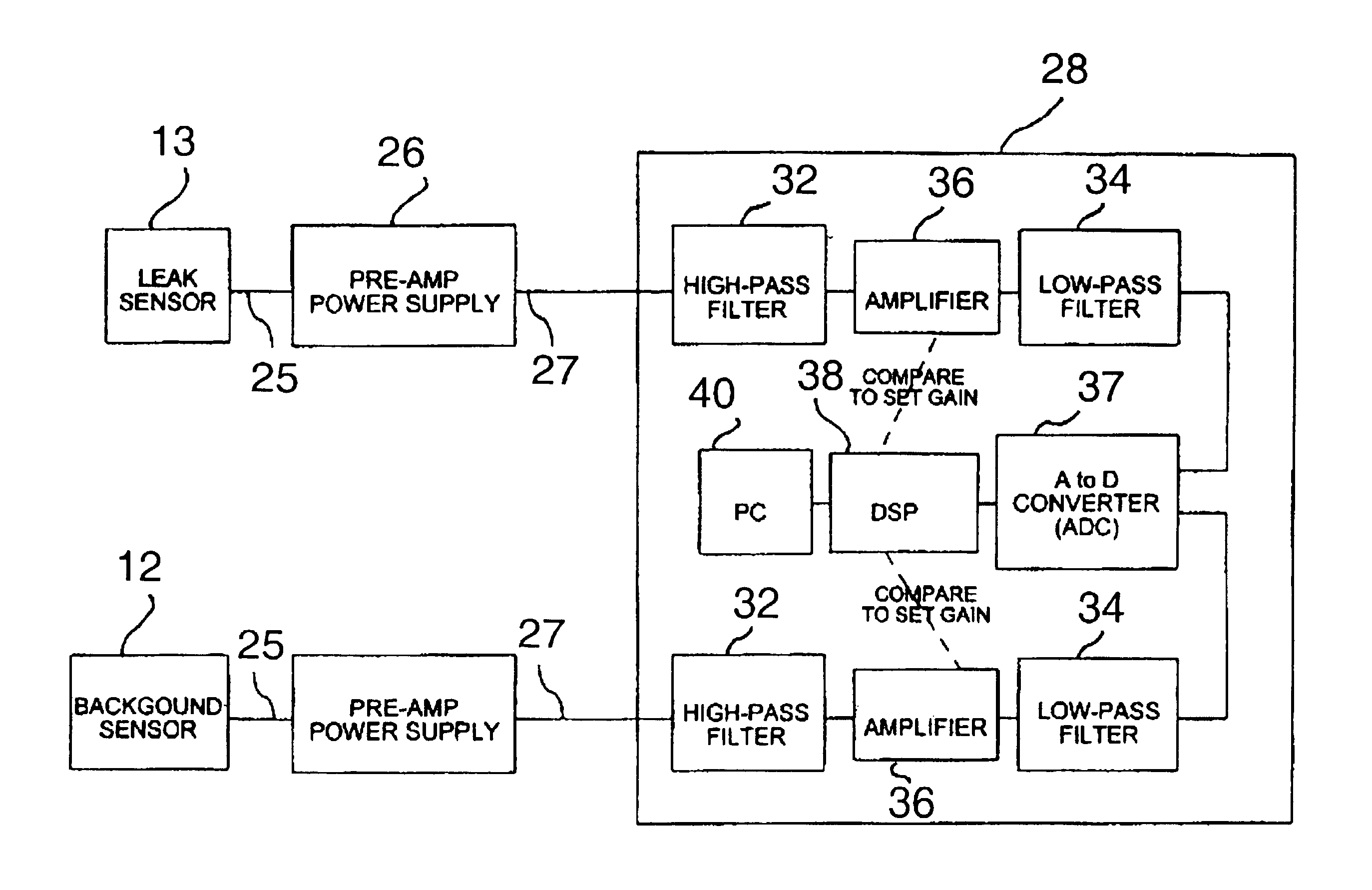

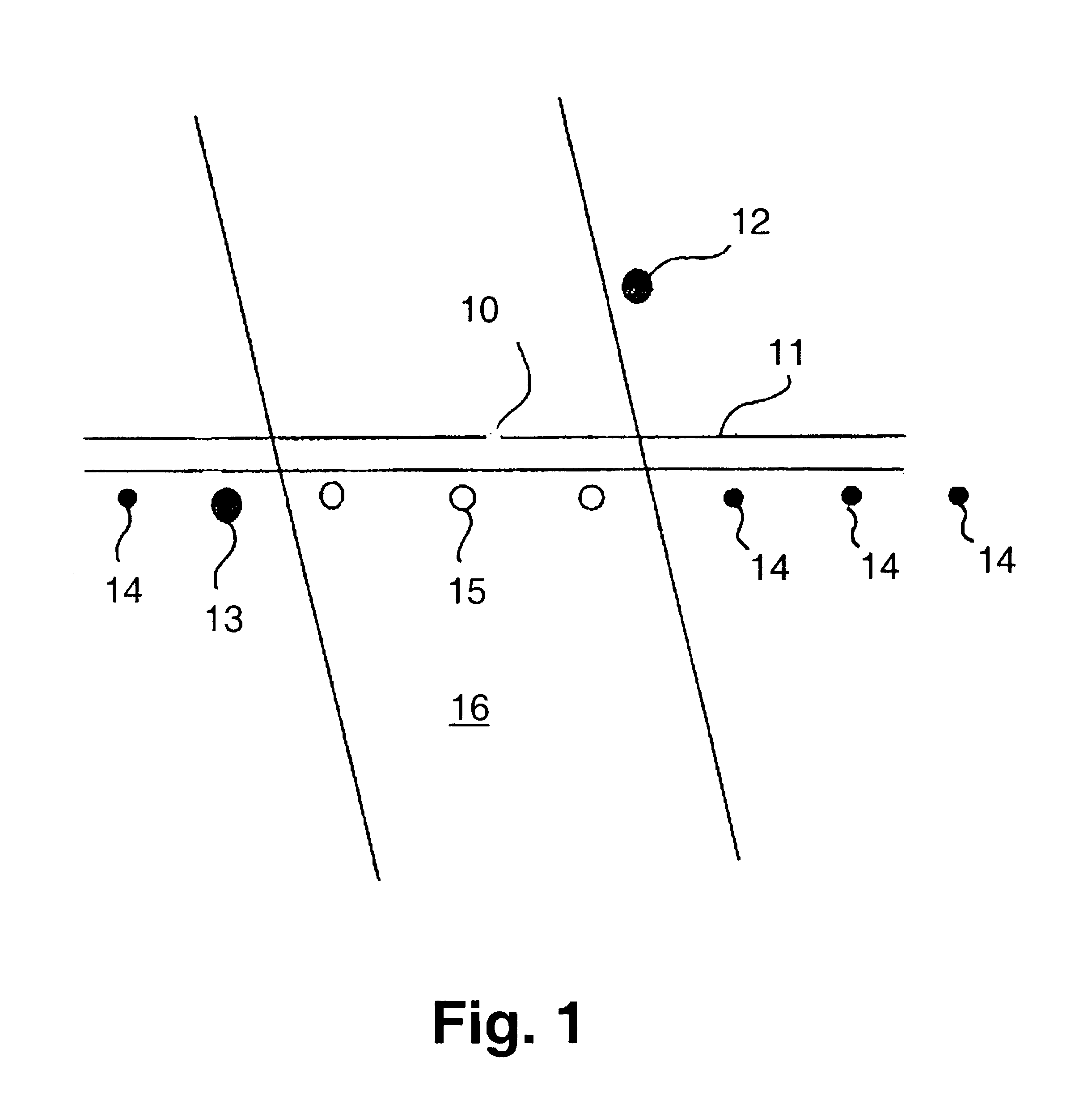

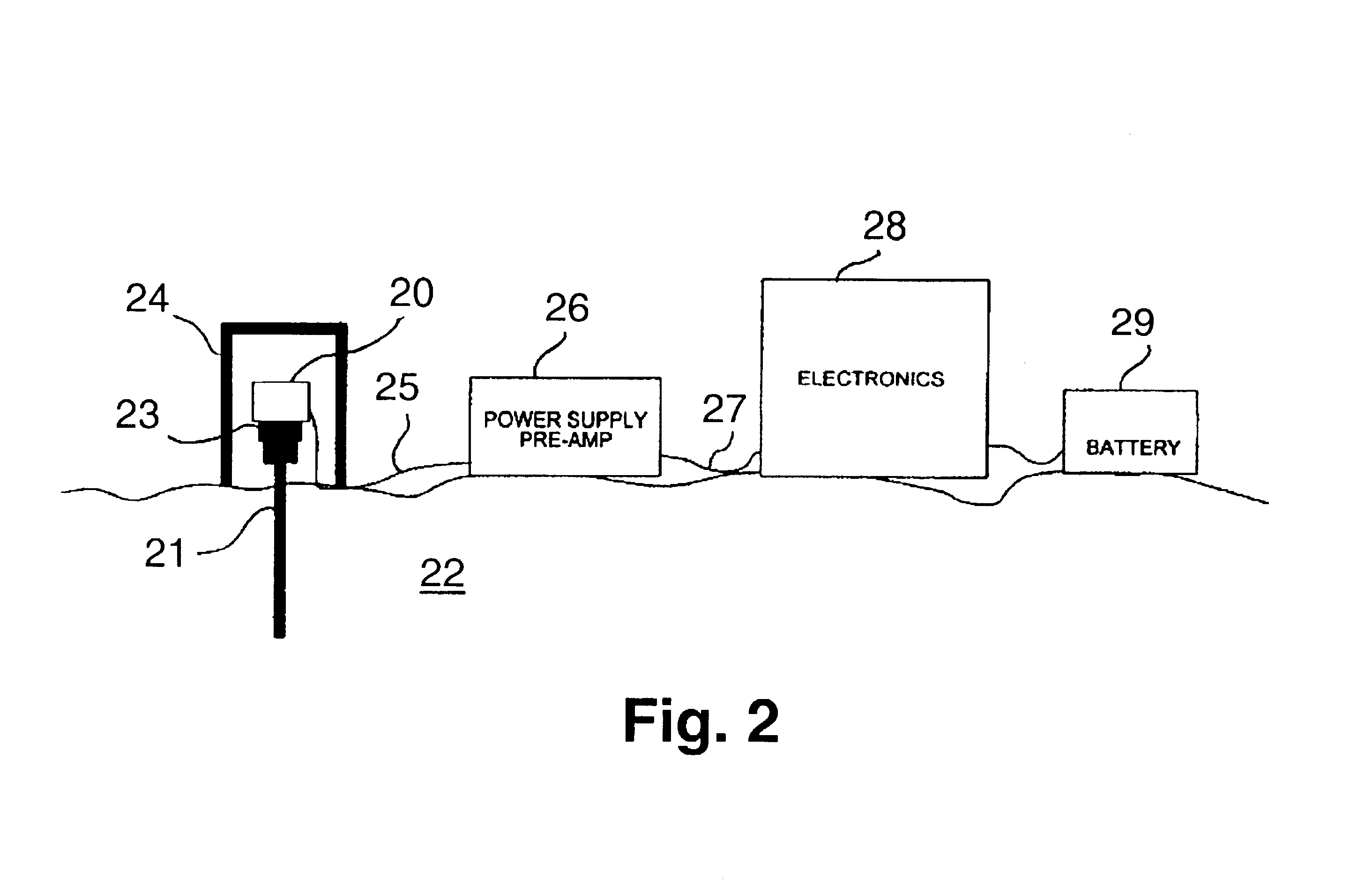

A method for locating gas leaks from underground gas pipelines in which a first acoustic sensor having a first signal output is positioned in ground disposed substantially above or at a distance from the underground gas pipeline. At least one second acoustic sensor having a second signal output is positioned in the ground at a plurality of locations substantially above the underground gas pipeline. The output signals from the acoustic sensors are measured for each location of the second acoustic sensor and the signals are adaptively filtered to remove common noise signal components. The statistical minima of these rms voltages are determined for both the first output signal and the adaptively filtered second output signals and the differences determined. The location of the second acoustic sensor corresponding to the largest positive said difference is the location closest to the leak site.

Owner:GAS TECH INST

Vertical takeoff and landing (VTOL) small unmanned aerial system for monitoring oil and gas pipelines

Owner:MOHAMADI FARROKH

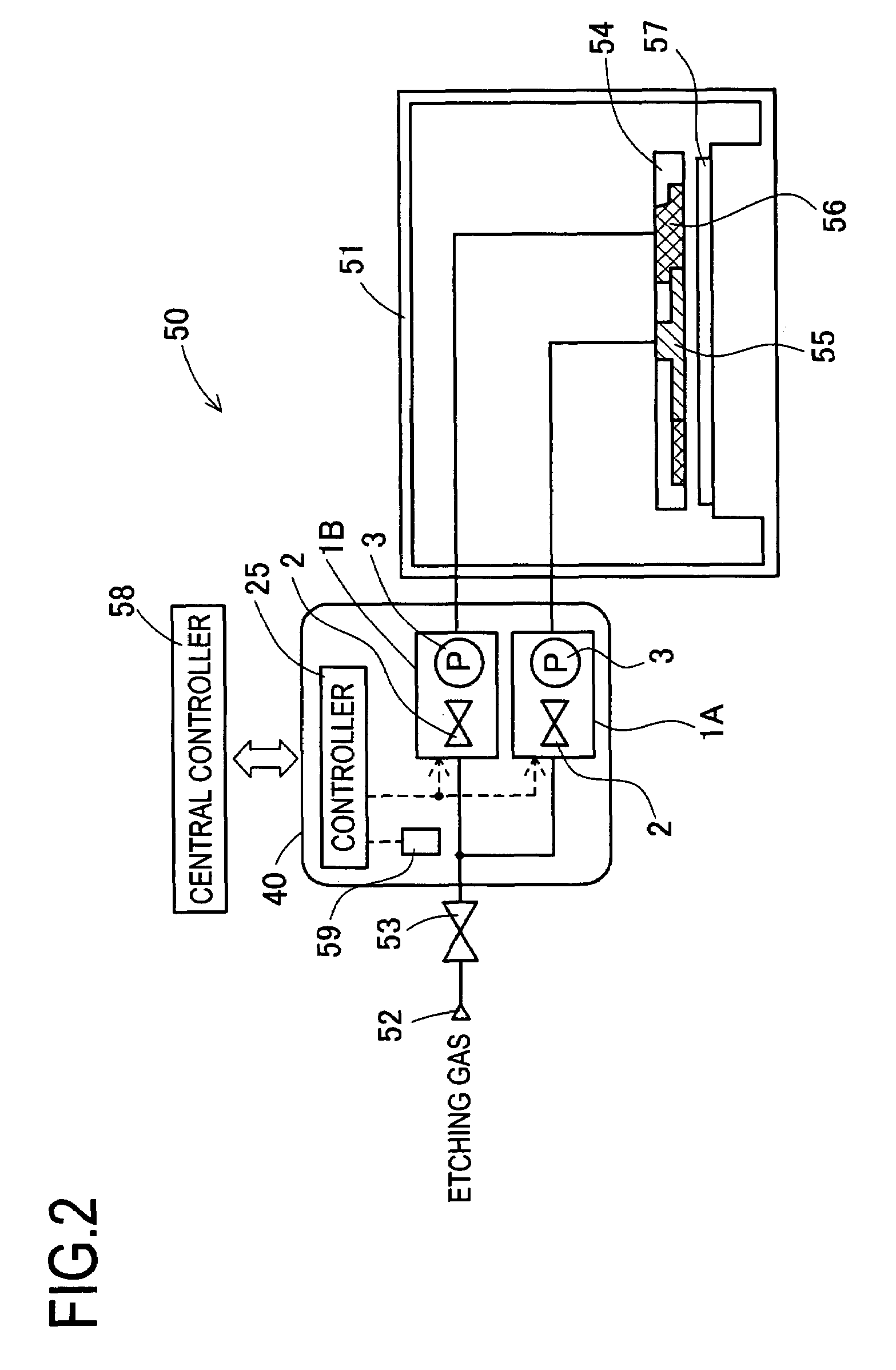

Relative pressure control system and relative flow control system

ActiveUS7353841B2Accurate supervisionReduce the amount of controlOperating means/releasing devices for valvesControlling ratio of multiple fluid flowsRelative pressureSolenoid valve

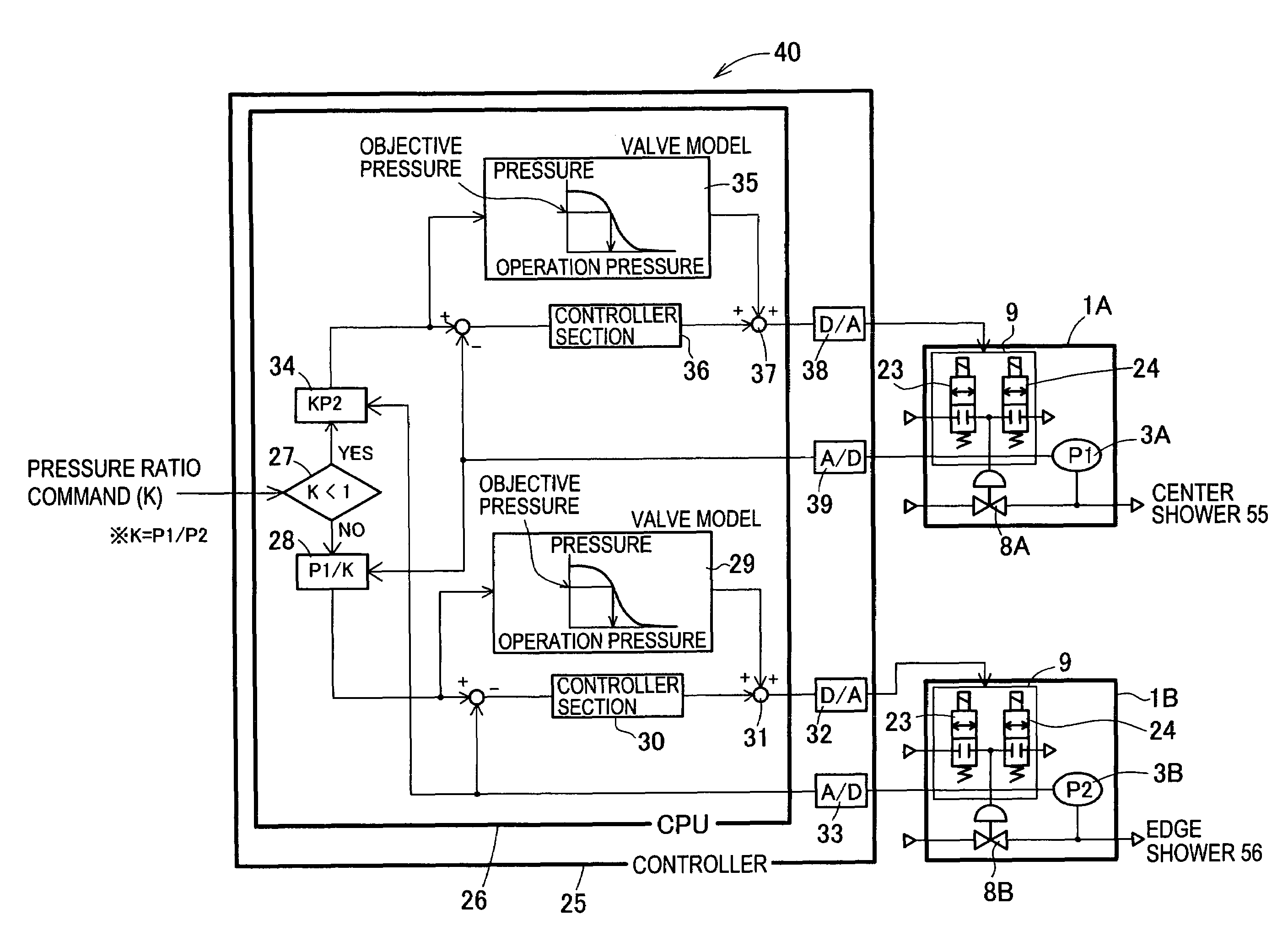

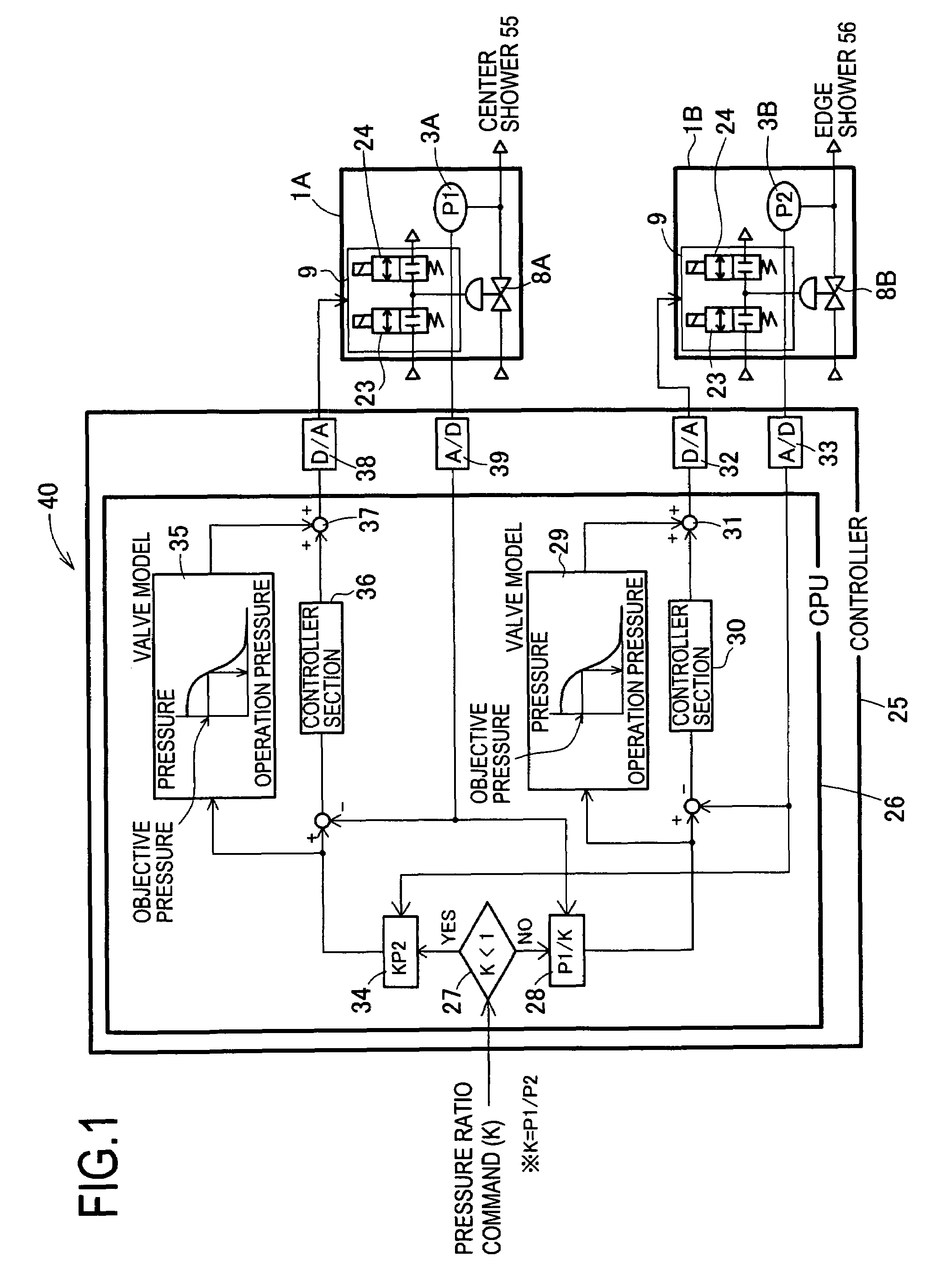

Provided is a relative pressure control system has a simple configuration, but enables accurate regulation of a division ratio of an operation gas, and concurrently makes it possible to securely drain the operation gas from an operation gas pipeline in case of emergency. The system includes a plurality of air operated valves of a normally open type that are connected to an operation gas pipeline supplied with an operation gas; pressure sensors that are series connected to the respective air operated valves and that detect output pressures of the respective air operated valves; a controller that controls operation pressures of the respective air operated valves in accordance with the pressures detected by the pressure sensors; and a hard interlock solenoid valve that correlates the plurality of air operated valves to one another so that at least one of the plurality of air operated valves is normally opened. In the configuration, an opening of a specified one of the plurality of air operated valves is regulated, the operation gas is output at a predetermined division ratio.

Owner:CKD +1

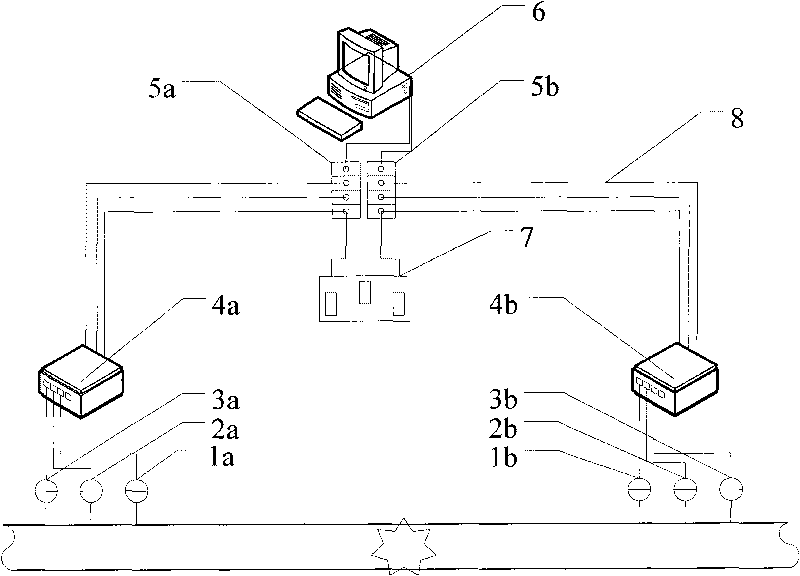

Gas pipeline leakage detecting and positioning device and method thereof

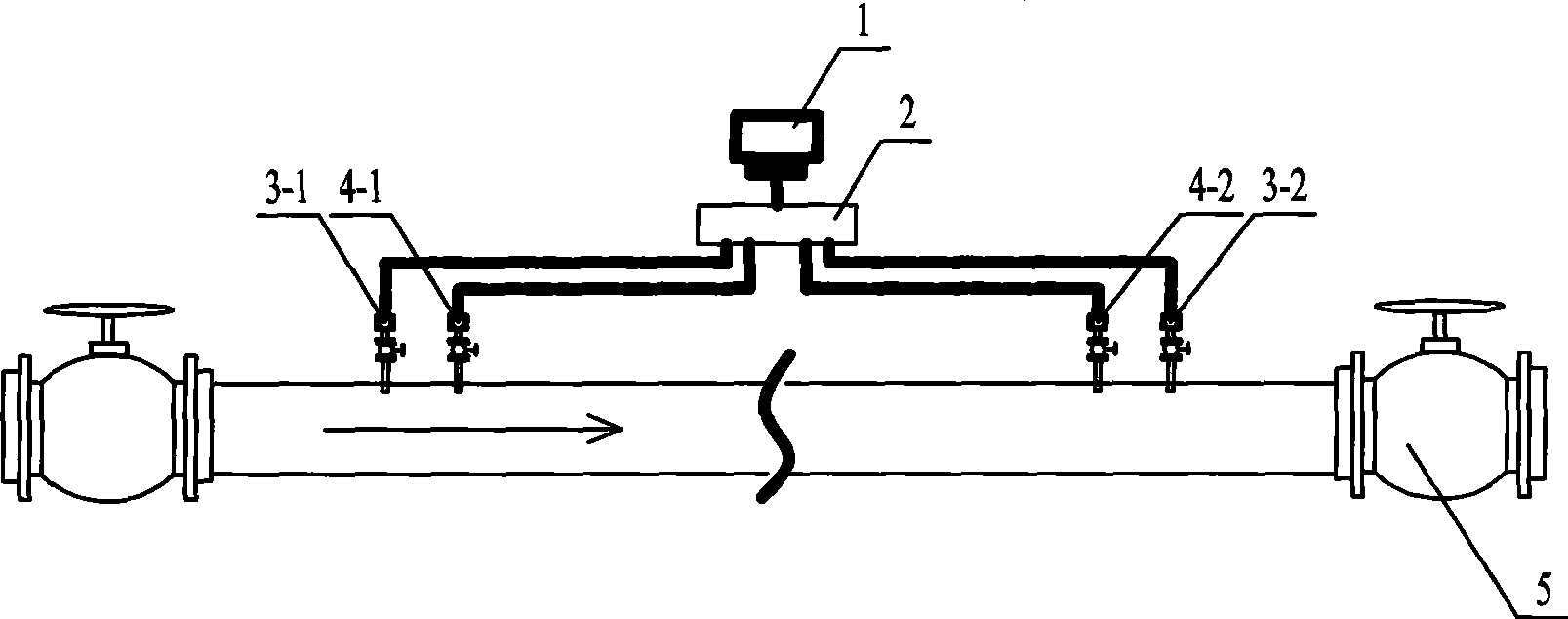

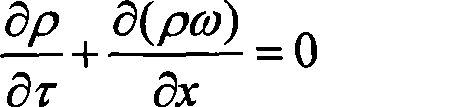

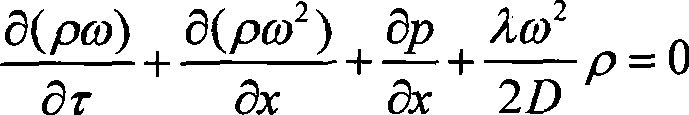

InactiveCN101761780AHigh sensitivityReduce false alarm ratePipeline systemsModel methodMathematical model

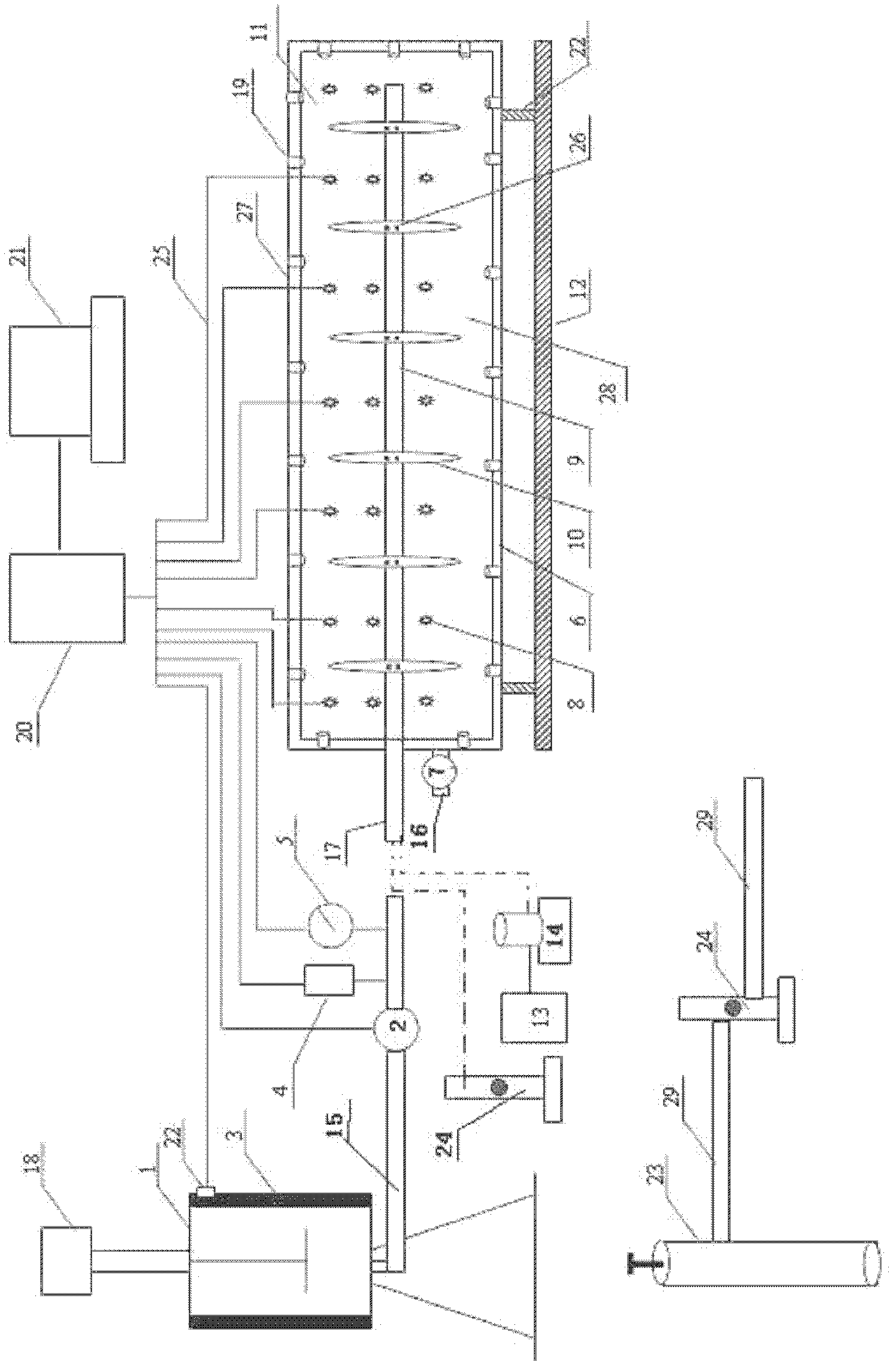

The invention discloses a gas pipeline leakage detecting and positioning device and a method based on transient model method, which belong to the technical field of failure diagnosis and flow safety security. The detecting device comprises a sensor group, a signal pre-processing device, an I / V plate, a collecting card, a voltage-stabilized power supply, and an operating condition machine; the detecting method includes of establishing a math model for the liquid flowing in the pipe, solving the flow parameters change in the pipe through a computer under a certain boundary condition, and comparing the model calculating values with the true measuring values at the pipe end; when the difference of the true measuring values and calculating values exceeds a certain range, then a leakage can be identified, and the leakage is positioned through a pressure gradient method. The invention provides a leakage detecting method based on the transient model method, and has the advantages of less investment, high sensitivity and good adaptability, and can be used for detecting and positioning gas leakage and leakage point for on-site gas pipeline.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

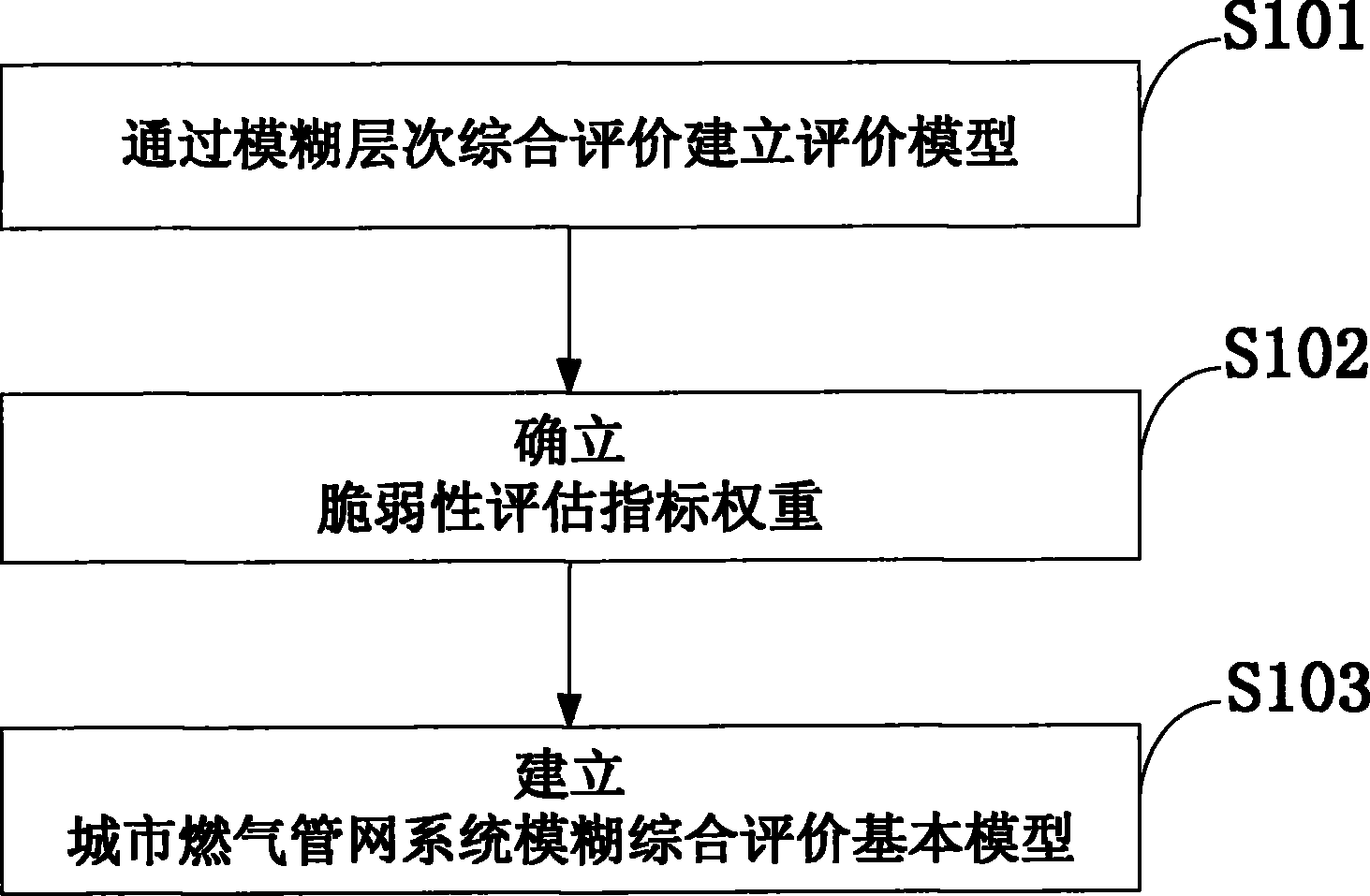

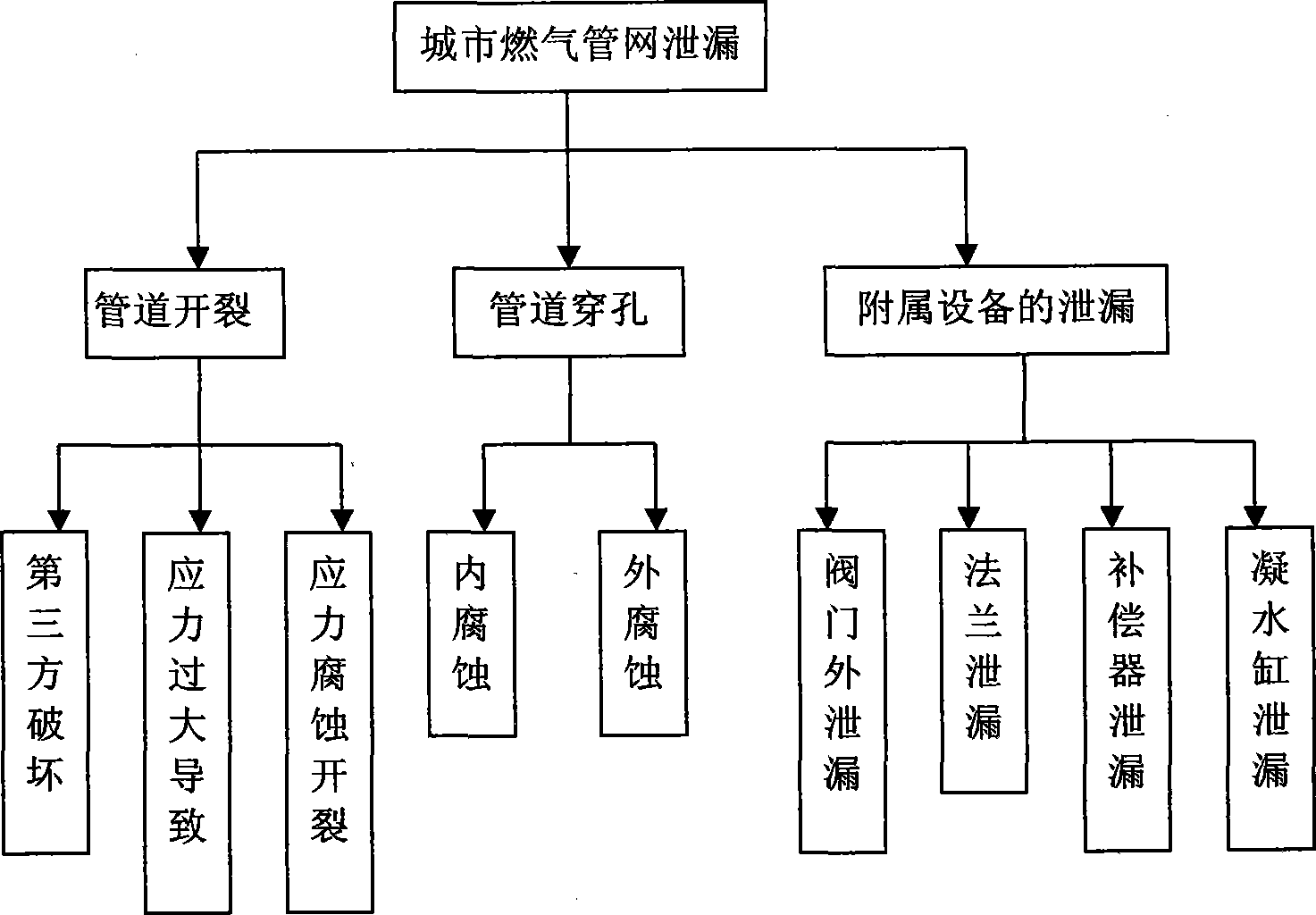

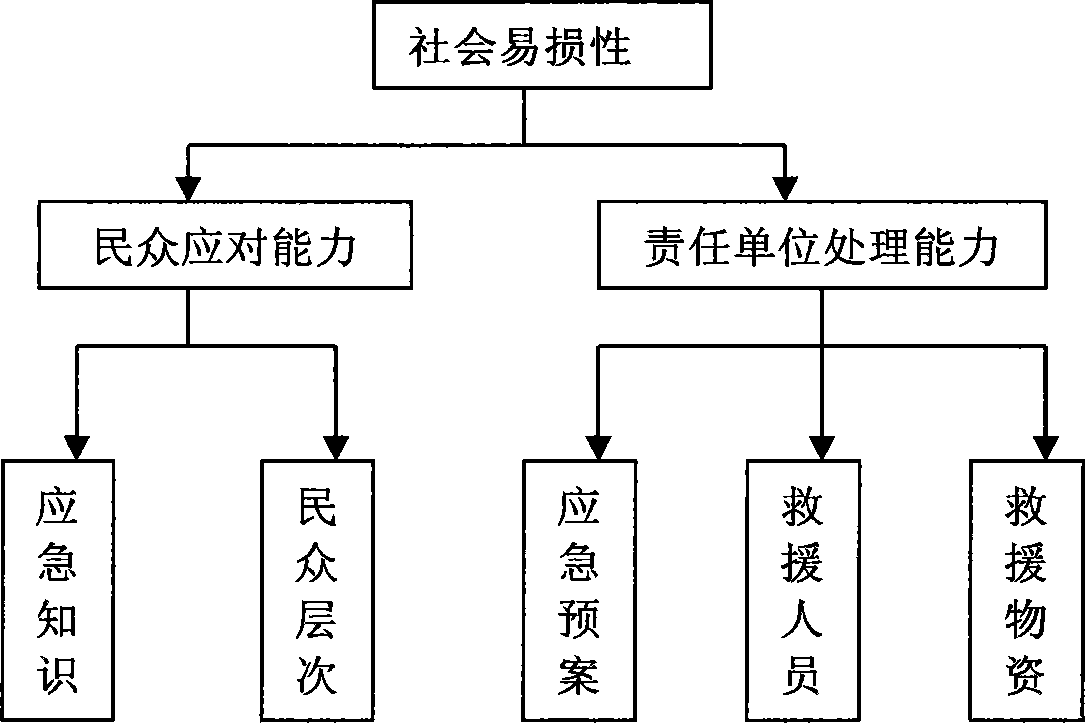

Method for building city gas pipe network vulnerability evaluation model

InactiveCN103413015AImprove the level of management technologyExtended service lifeSpecial data processing applicationsMathematical modelEngineering

The invention discloses a method for building a city gas pipe network vulnerability evaluation model. The method comprises the following steps that an evaluation model is built through fuzzy hierarchy comprehensive evaluation; a vulnerability evaluation index weight is determined; a city gas pipe network system fuzzy comprehensive evaluation basic model is built. As the system vulnerability evaluation and traditional risk evaluation are similar and both need to build evaluation index systems according to evaluation purposes, a proper evaluation method is selected to build an evaluation mathematical model, the model is utilized to conduct system vulnerability calculation and vulnerability grading, the quantitative and qualitative combined system vulnerability evaluation is achieved, and a research result of the city gas vulnerability can lay the foundation for improving the level of a Chinese gas pipeline management technology, prolonging the service life of a city gas pipeline and avoiding or reducing sudden invalidation accidents. With the deepening of the vulnerability research, the vulnerability evaluation is introduced in the filed of research of the science of disasters, the point of view of the safety evaluation is made to be wider, the content of the safety evaluation is made to be fuller, and the evaluation result has more practical value.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

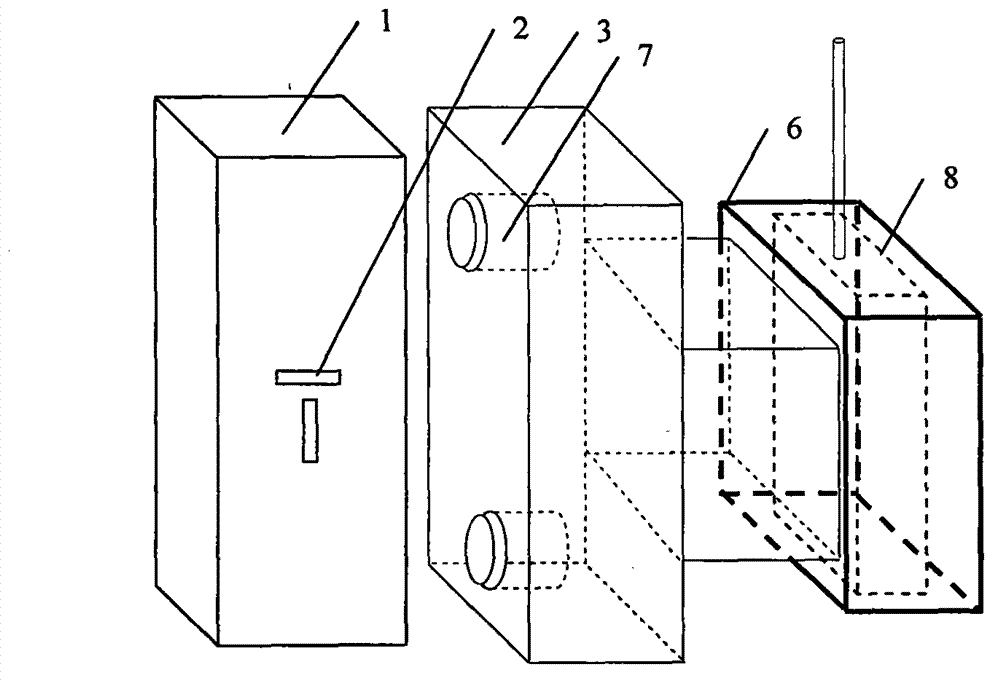

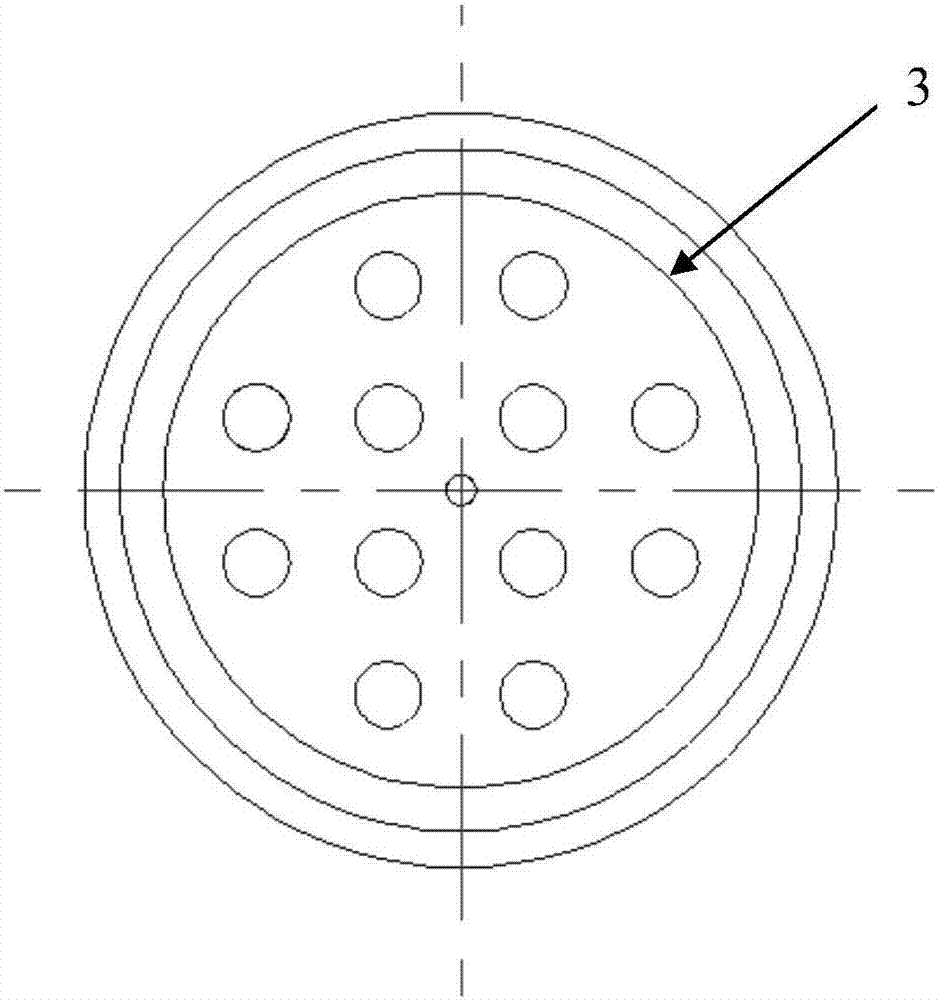

Device and method for simulating volume fracturing of horizontal well on shale reservoir stratum

ActiveCN102590456ATruly reflect the impact of fracturing productivityDetermination of densityMaterial analysisGas pipelineEnvironmental geology

The invention relates to a device and a method for simulating volume fracturing of a horizontal well on a shale reservoir stratum; when crack propagation of the shale reservoir stratum is simulated, a valve at a liquid inlet of a supply source is set to be closed, and a fluid reservoir is communicated with a liquid inlet of a horizontal shaft by a pipe line; when the production process of the shale reservoir stratum is simulated, the fluid reservoir is communicated with the liquid inlet of the supply source by the pipe line, and the liquid inlet of the horizontal shaft is communicated with the atmosphere; a man-made fracture model is arranged at a bullet hole of the horizontal shaft; when the production process of the shale reservoir stratum is simulated, a gas tank is communicated with the liquid inlet of the supply source by a gas pipeline, and the liquid inlet of the horizontal shaft is communicated with the atmosphere. According to the invention, according to the similarity principle, the crack initiation and extending processes of the volume fracturing can be simulated, the density and the volume of a fracture network are determined, the effect of crack parameters on the fracturing capacity of the horizontal well on the shale reservoir stratum is researched, fracturing construction parameters and the crack parameters are optimized and a key problem of fracturing of the shale reservoir stratum is solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

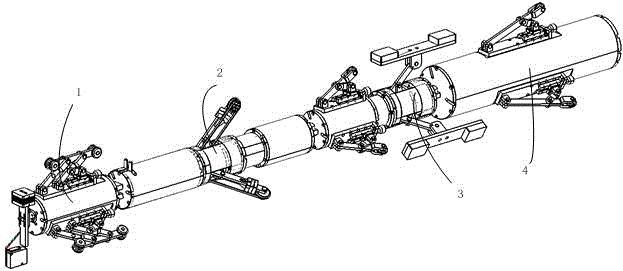

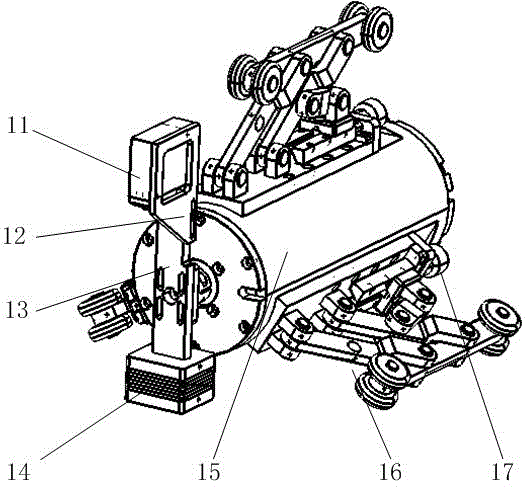

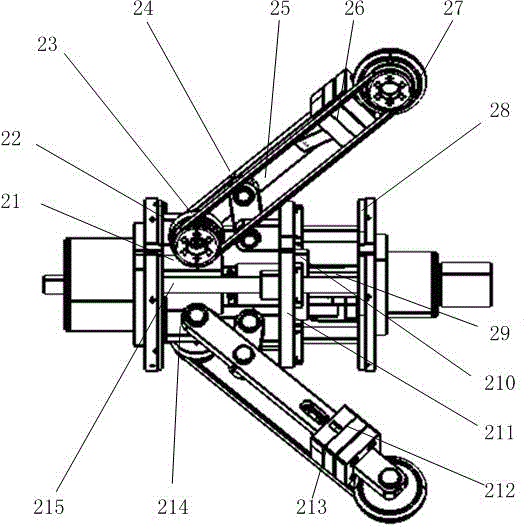

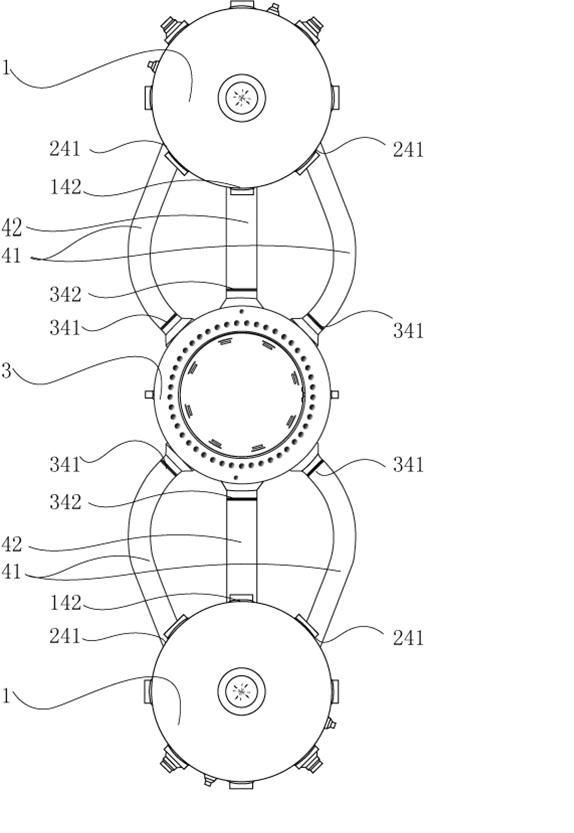

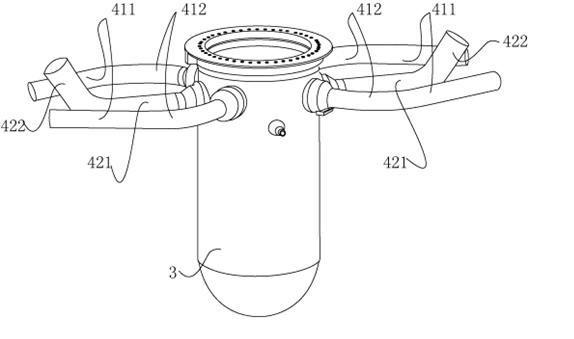

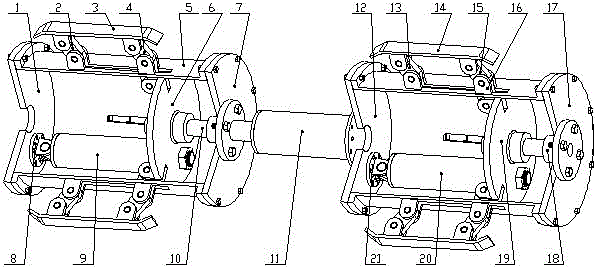

Pipeline detection robot

The invention relates to a pipeline detection robot. The pipeline detection robot mainly comprises a laser detection mechanism (1), a traction mechanism (2), an electromagnetic ultrasonic detection mechanism (3) and an electronic cabin (4), all of which are connected through connecting hinge shafts; the traction mechanism (1) adopts a single-motor all-drive mode and is driven by a turbo-worm synchronous belt to supply a walking power to the robot; the laser detection mechanism (2) comprises a laser displacement sensor, a rotating arm, a counterweight, a support body and the like and is used for measuring surface corrosion and deformation of a pipeline; the electromagnetic ultrasonic detection mechanism (3) comprises a support assembly, a probe and a fixing plate and is used for measuring the wall thickness and the crack defect of the pipeline; the electronic cabin (4) is used for carrying auxiliary components, such as a stepping motor controller, a servo motor driver, a power supply and an FPGA (Field Programmable Gate Array) control panel. The pipeline detection robot disclosed by the invention can be used for finding the defects, such as pipeline corrosion, cracks and deformation, carrying out in-service detection on an oil and gas pipeline in a working process, carrying out targeted repair, maintenance and replacement according to a detection result, reducing the maintenance cost and guaranteeing safe and stable operation of the oil and gas pipeline.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

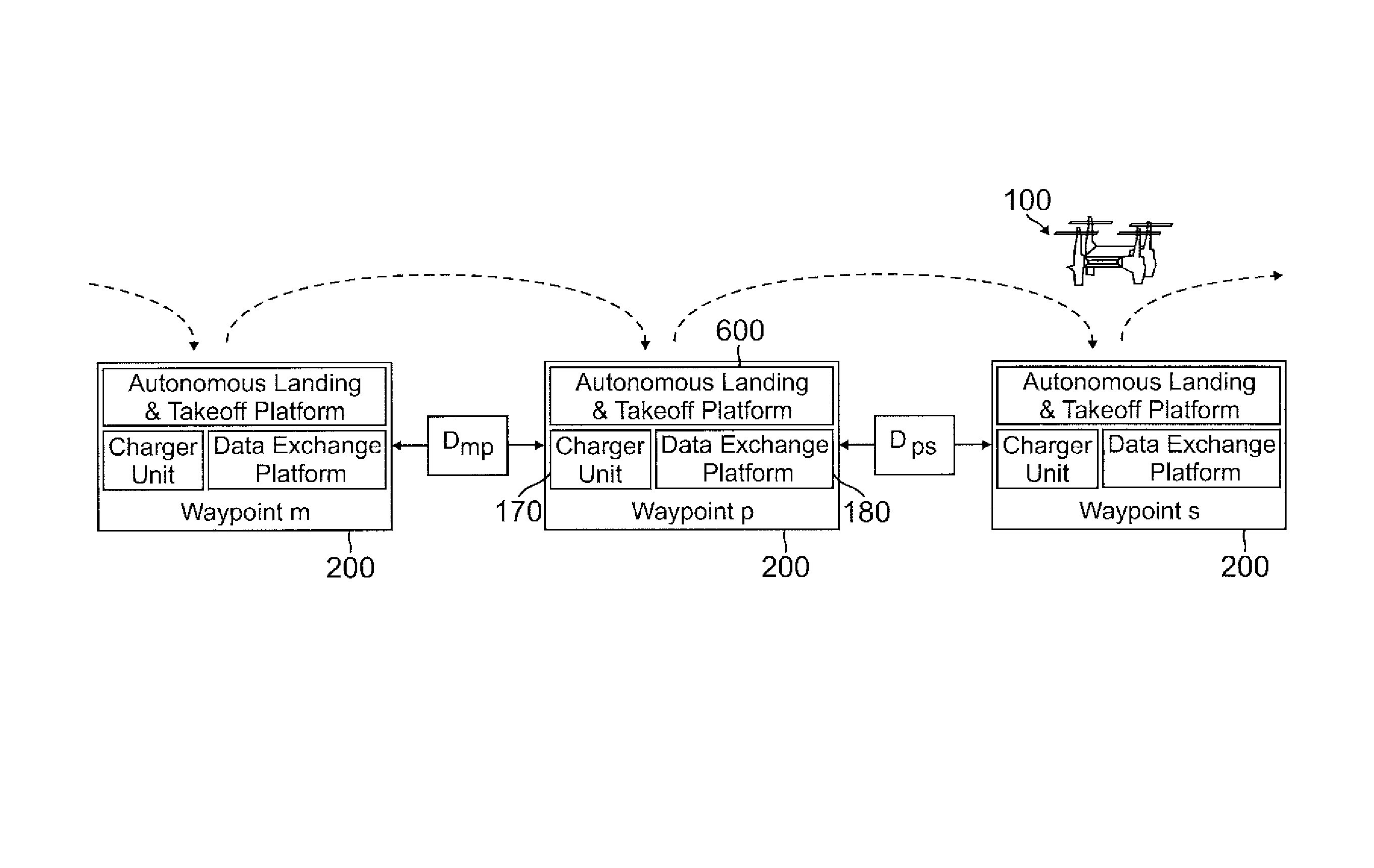

Vertical takeoff and landing (VTOL) small unmanned aerial system for monitoring oil and gas pipelines

ActiveUS8880241B2Analogue computers for vehiclesDigital data processing detailsJet aeroplaneUncrewed vehicle

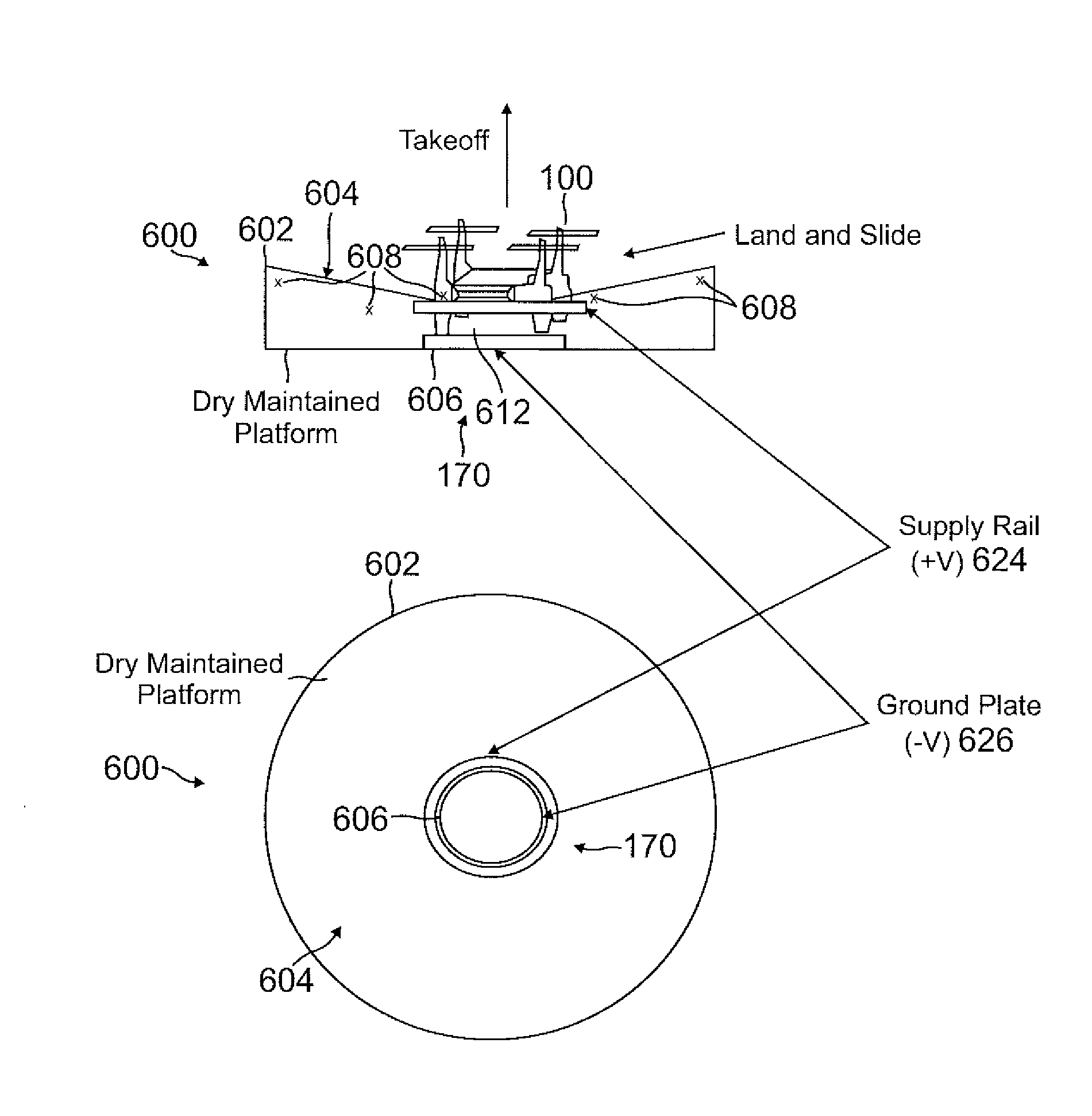

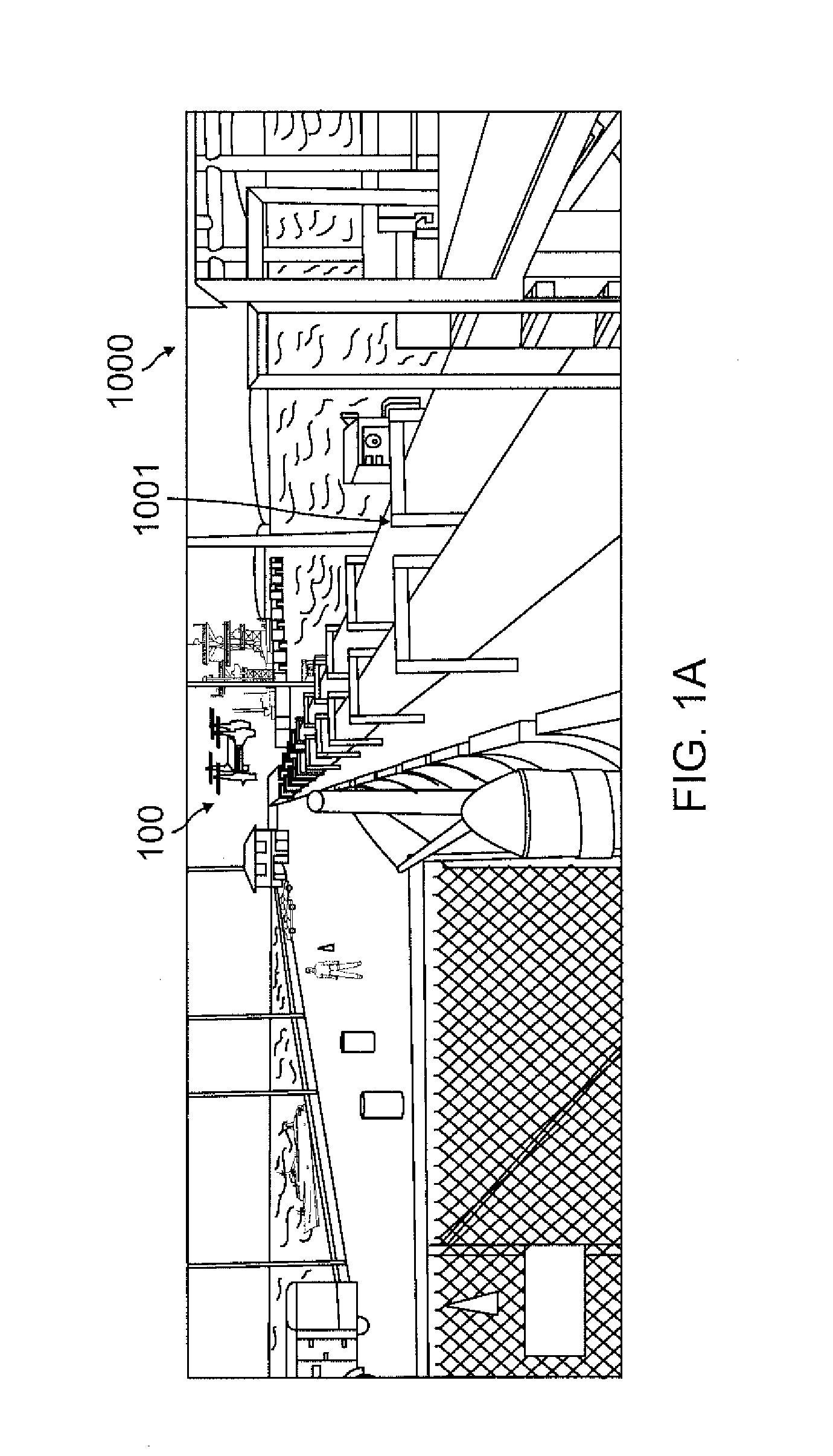

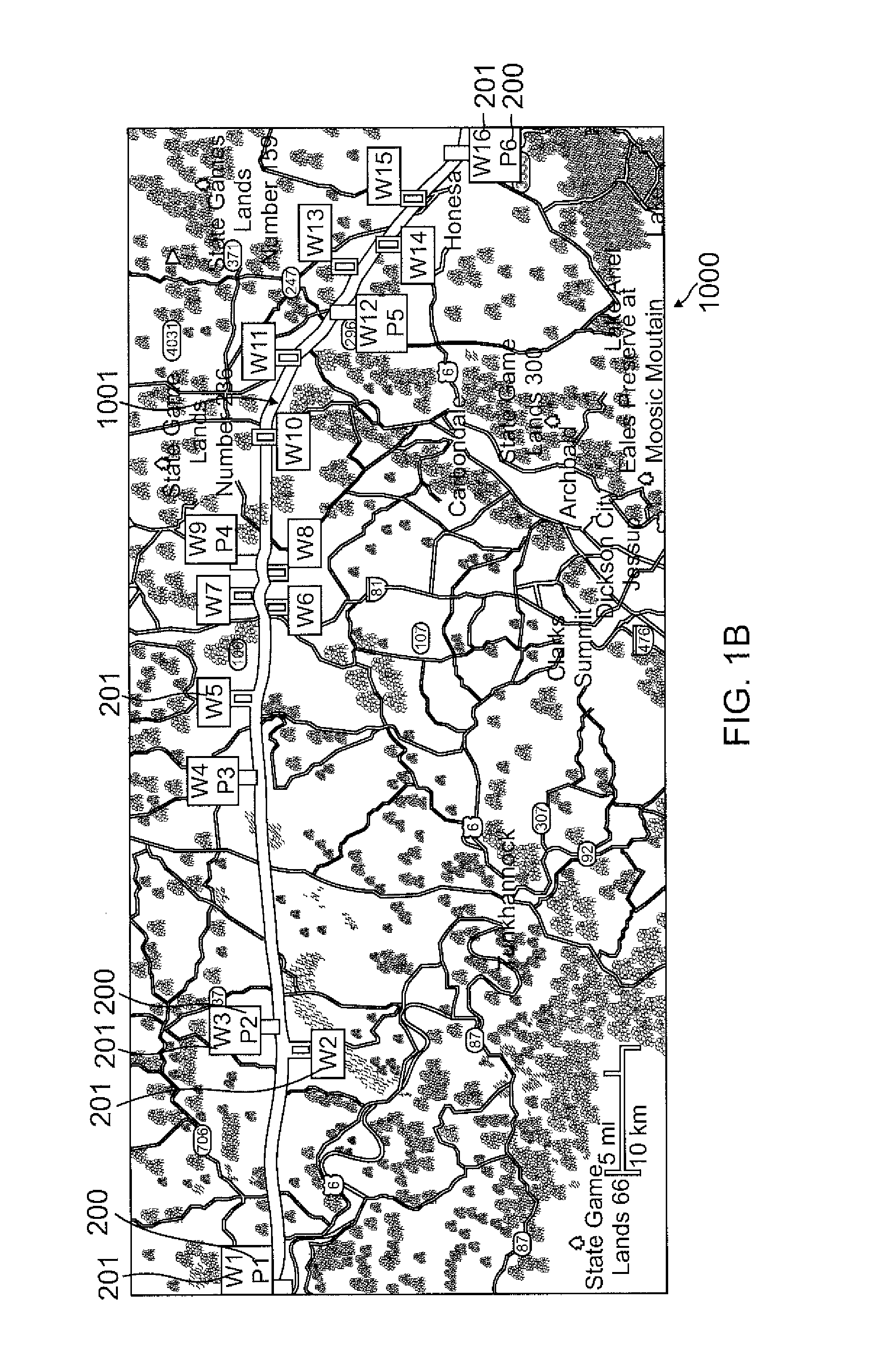

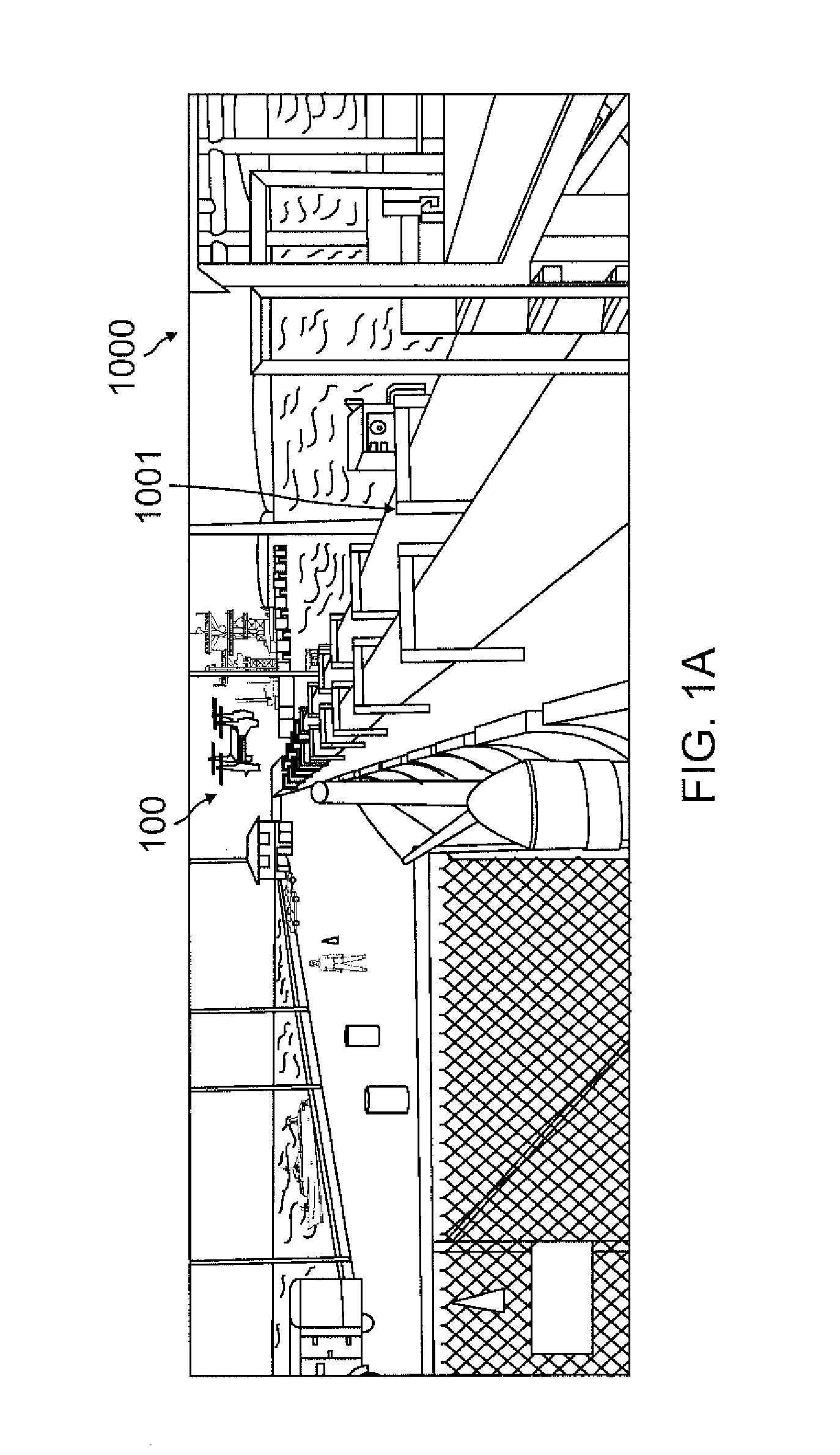

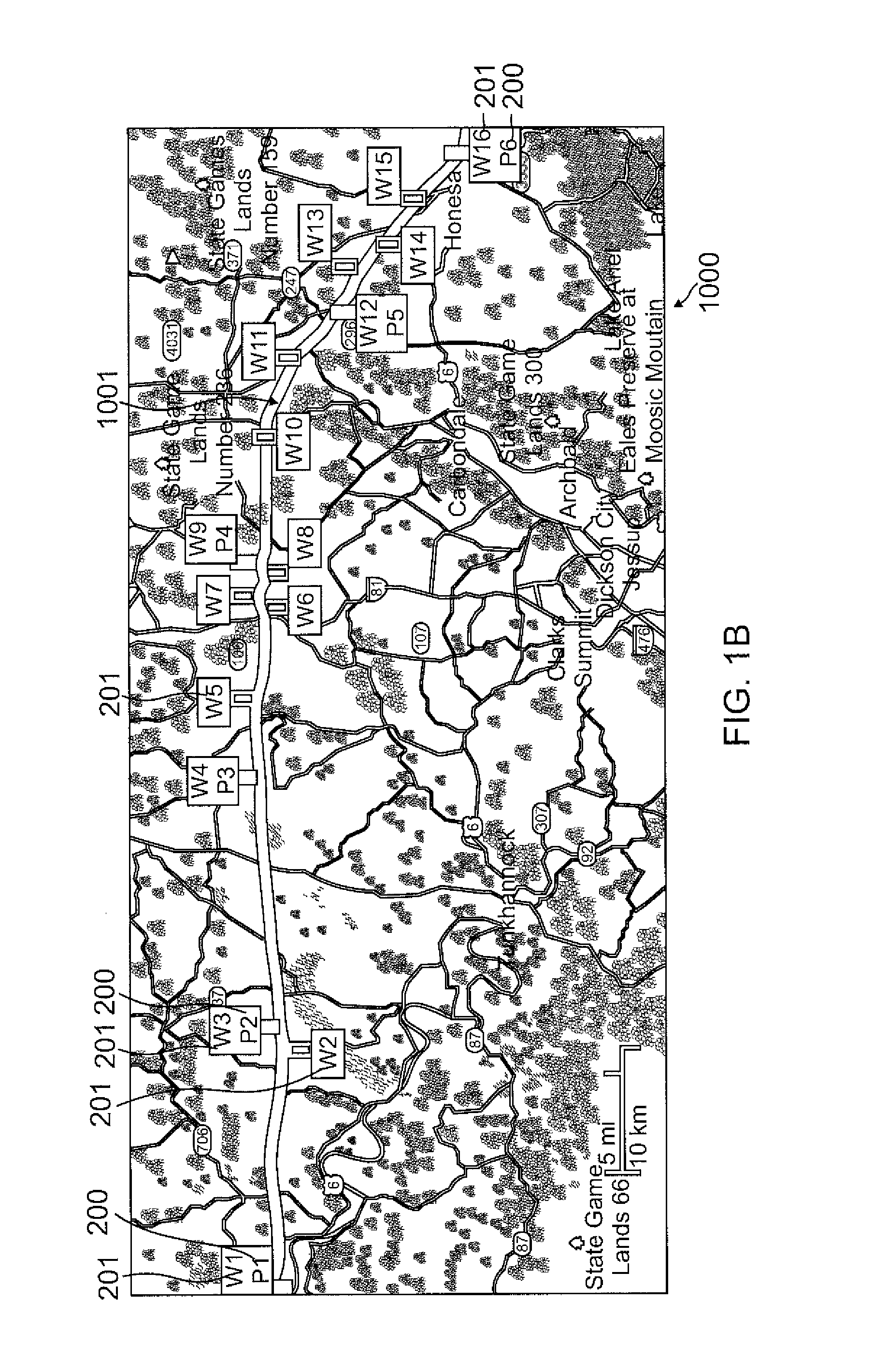

Extended-range monitoring and surveillance of facilities and infrastructure—such as oil, water, and gas pipelines and power lines—employs autonomous vertical take-off and landing (VTOL) capable, small unmanned aerial system (sUAS) aircraft and docking platforms for accommodating the sUAS aircraft. Monitoring and surveillance of facilities using one or more embodiments may be performed continually by the sUAS flying autonomously along a pre-programmed flight path. The sUAS aircraft may have an integrated gas collector and analyzer unit, and capability for downloading collected data and analyzer information from the sUAS aircraft to the docking platforms. The gas collector and analyzer unit may provide remote sensing and in-situ investigation of leaks and other environmental concerns as part of a “standoff” (e.g., remote from operators of the system or the facilities) survey that can keep field operators out of harm's way and monitor health of the environment.

Owner:MOHAMADI FARROKH

Optimized heating value in natural gas liquids recovery scheme

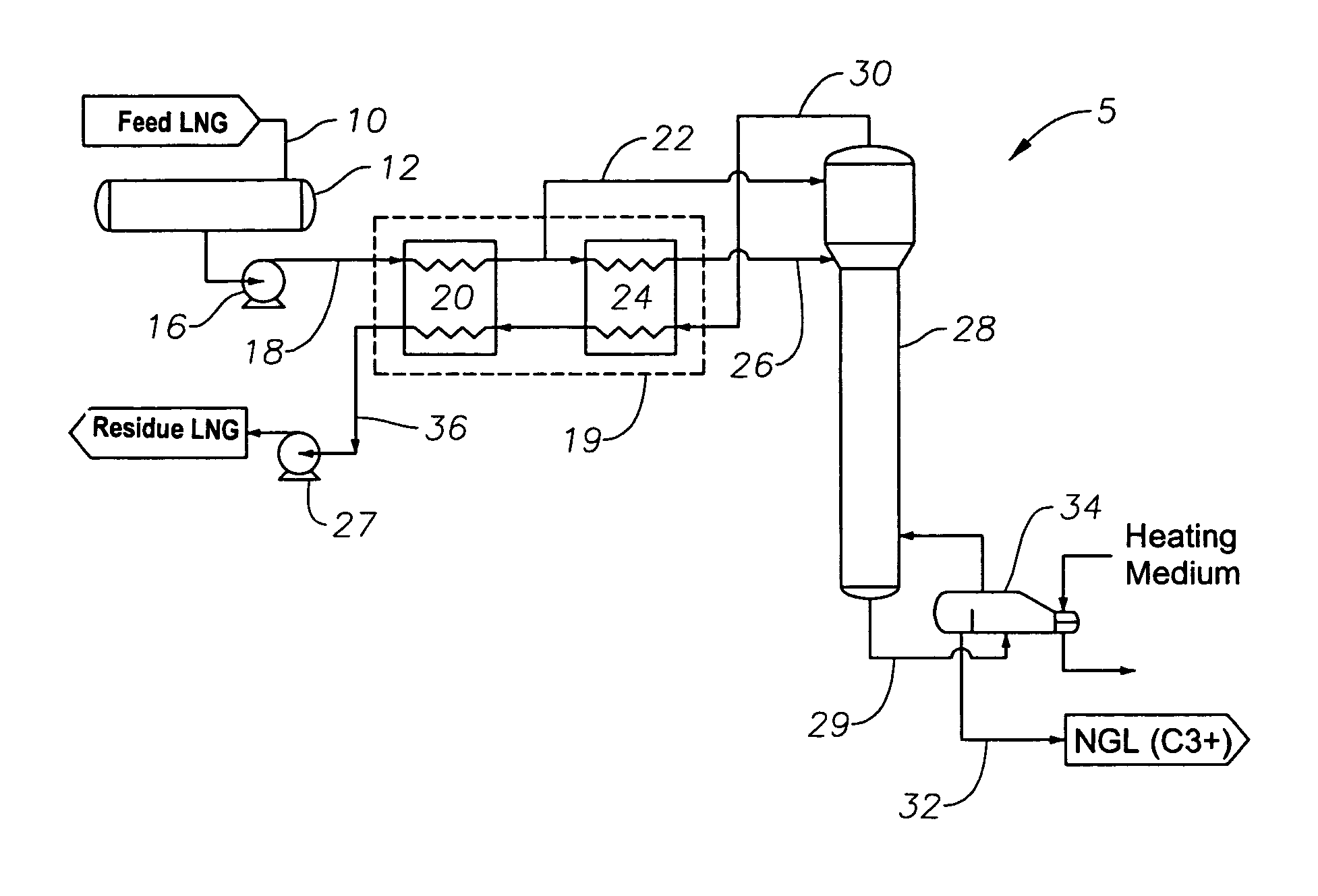

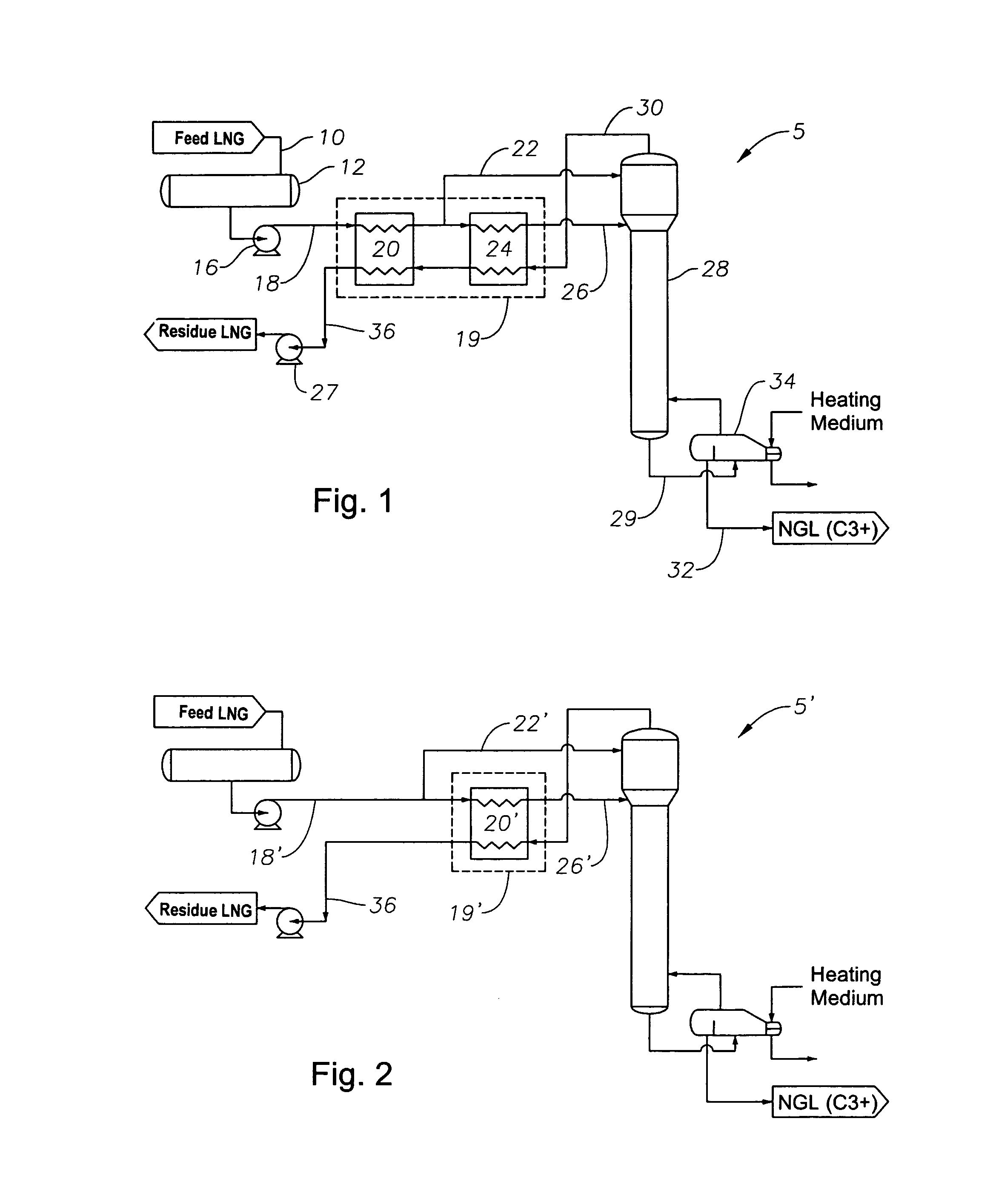

ActiveUS6964181B1Control and decrease heating valueIncrease volumeSolidificationLiquefactionFractionationProcess engineering

A process and apparatus for controlling or reducing the heating value or BTU content of NGL recovered from LNG streams. LNG pipelines have a maximum allowable heating value that LNG must be within prior to entering the pipeline. If the LNG heating value is too high, the components contributing to the high heating value must be removed prior to being introduced in the pipeline. The process controls the heating value of the residue LNG gas stream by splitting a feed stream and warming at least a portion of the feed stream. Substantial differences in enthalpy content and temperature between the two portions of the feed stream exist prior to being sent to a fractionation tower.

Owner:ABB LUMMUS GLOBAL INC

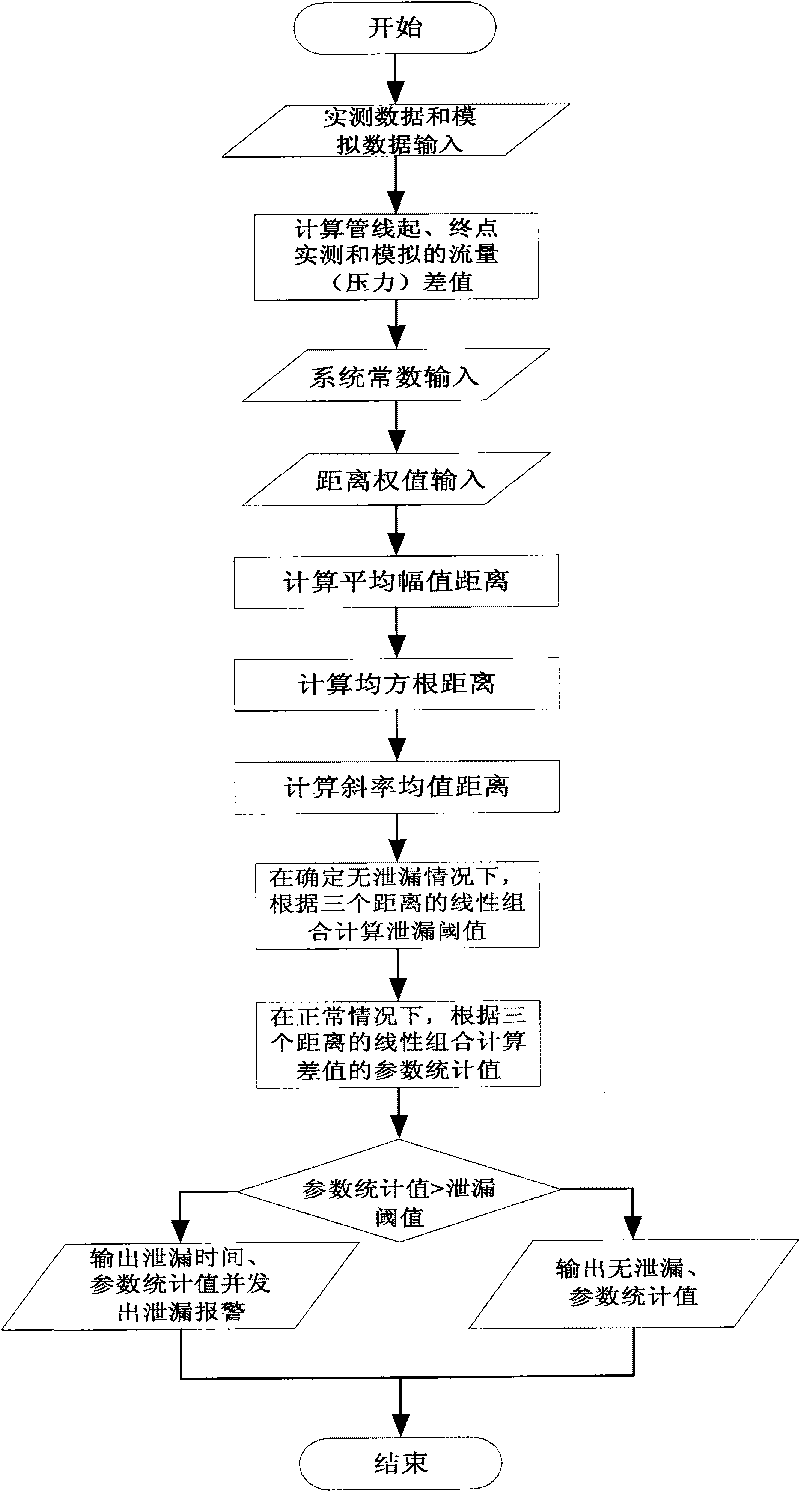

Method for performing gas pipeline leakage position by using instant change on-line diagnosis coupling excitation frequency response

InactiveCN101413628ARealize online real-time detectionReduce false alarm ratePipeline systemsEngineeringPressure response

The invention provides a method which uses transient online diagnosis coupling frequency response to position the leakage of natural gas pipeline, and relates to a natural gas pipeline failure detection and positioning method which can solve the problems that the existing method for detecting and positioning the leakage of the natural gas pipeline can not detect in real time, has long detection period, low positioning precision and high error report rate; real-time pressure value and real-time flux value are respectively collected at the upstream and downstream of the pipeline; the real-time downstream pressure value and the real-time flux value when the pipeline runs stably are reduced by the practical real-time pressure value and the practical real-time flux value at the downstream; if both of the two differences exceed the valve value, the leakage is considered to occur, otherwise the values are collected again; an excitation pressure wave is generated at the downstream end of the pipeline and the wave speed of the response wave of the excitation pressure wave is gained; according to the wave speed of the excitation pressure response wave and the time difference when the excitation pressure response wave is transmitted to the upstream and the downstream, the position of the leakage point is gained. The measurement and collection of the values are completed by normal equipments and the method can be used both in the built pipeline or pipelines under construction.

Owner:HARBIN INST OF TECH

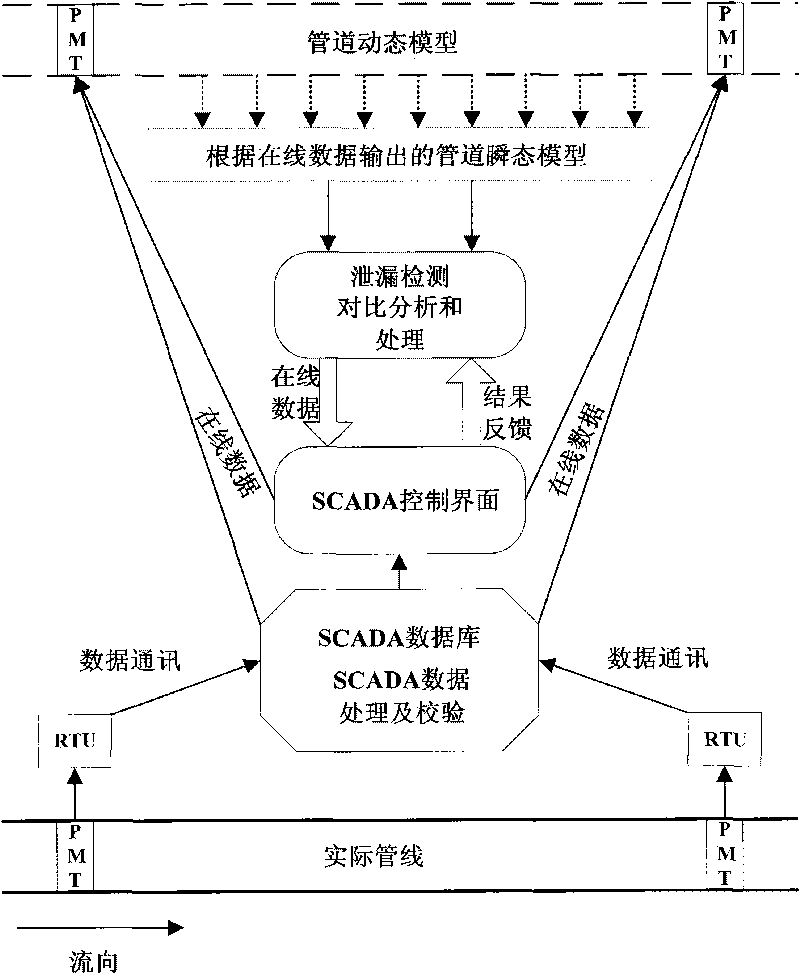

Method for measuring and locating leakage of gas pipelines

ActiveCN101625071ARealize the monitoring functionRealize the positioning functionPipeline systemsData acquisitionEngineering

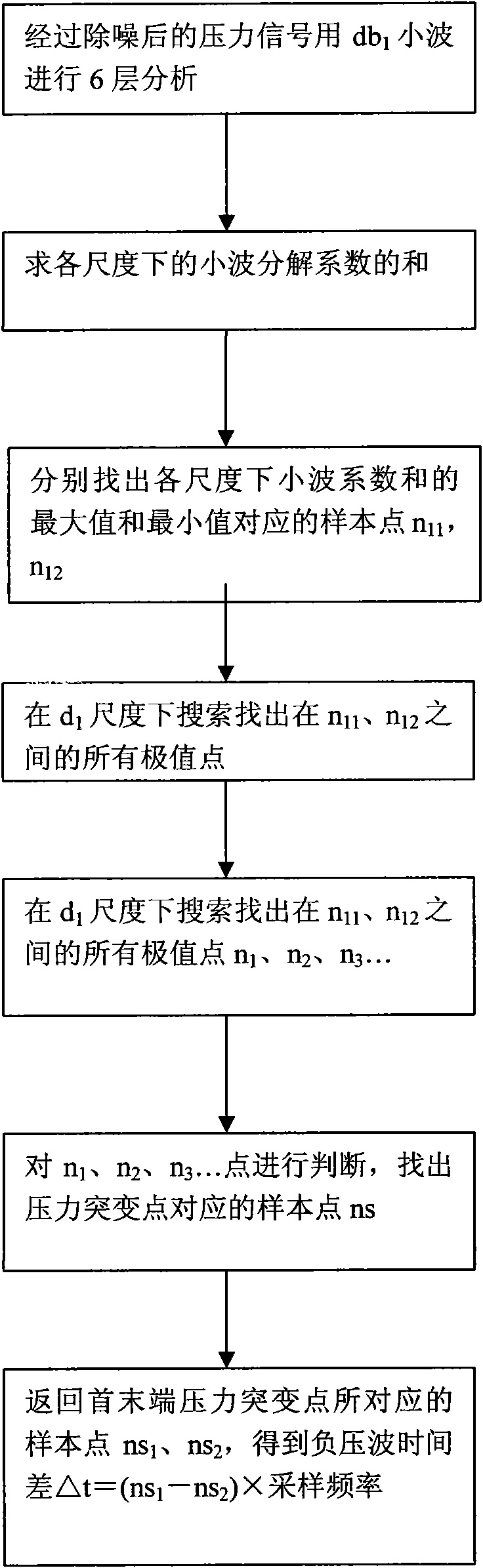

The invention discloses a method for measuring and locating leakage of a gas pipeline network based on a geographic information system (GIS) and supervisory control and data acquisition technology (SCADA). The specific method comprises the following steps of establishing a gas pipeline network GIS system; reading and storing a pipe network graph, pipeline network attribute data and the like; collecting parameters of pressure, temperature and flow for each section of gas pipeline in real time by the SCADA system; comparing the collected parameters and the stored data and calculating; calculating the measuring values of the head end and the tail end of the pipeline and calculating the difference among parameter values; representing the abnormal pipeline information; searching extreme points and determining the pressure catastrophe points; calculating the position of the leakage point according to the parameters of gas consumption, temperature and pressure by using a leakage locating formula. By adopting SCADA, GIS and simulation calculations, the invention can realize self monitoring and locating of the gas pipelines with the advantages of quick measuring speed, high measuring precision, low missing report rate and false report rate and the like.

Owner:TIANJIN UNIV

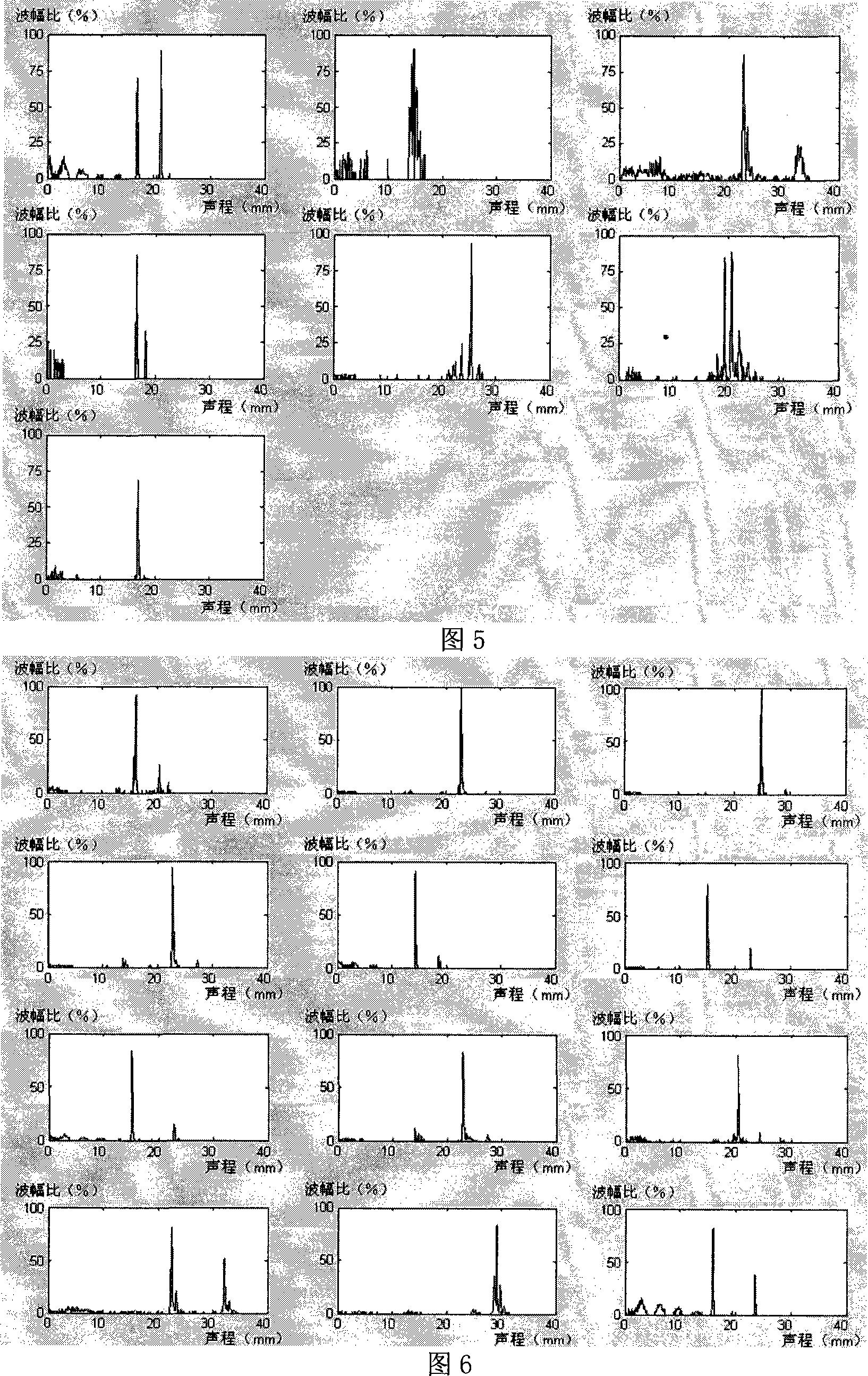

Automatic identification method for supersonic phased array for detecting oil gas pipeline girth weld defect type

InactiveCN101122585ARealize filteringReduce needProcessing detected response signalSpecial data processing applicationsSupport vector machineFeature extraction

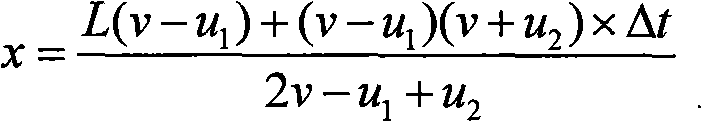

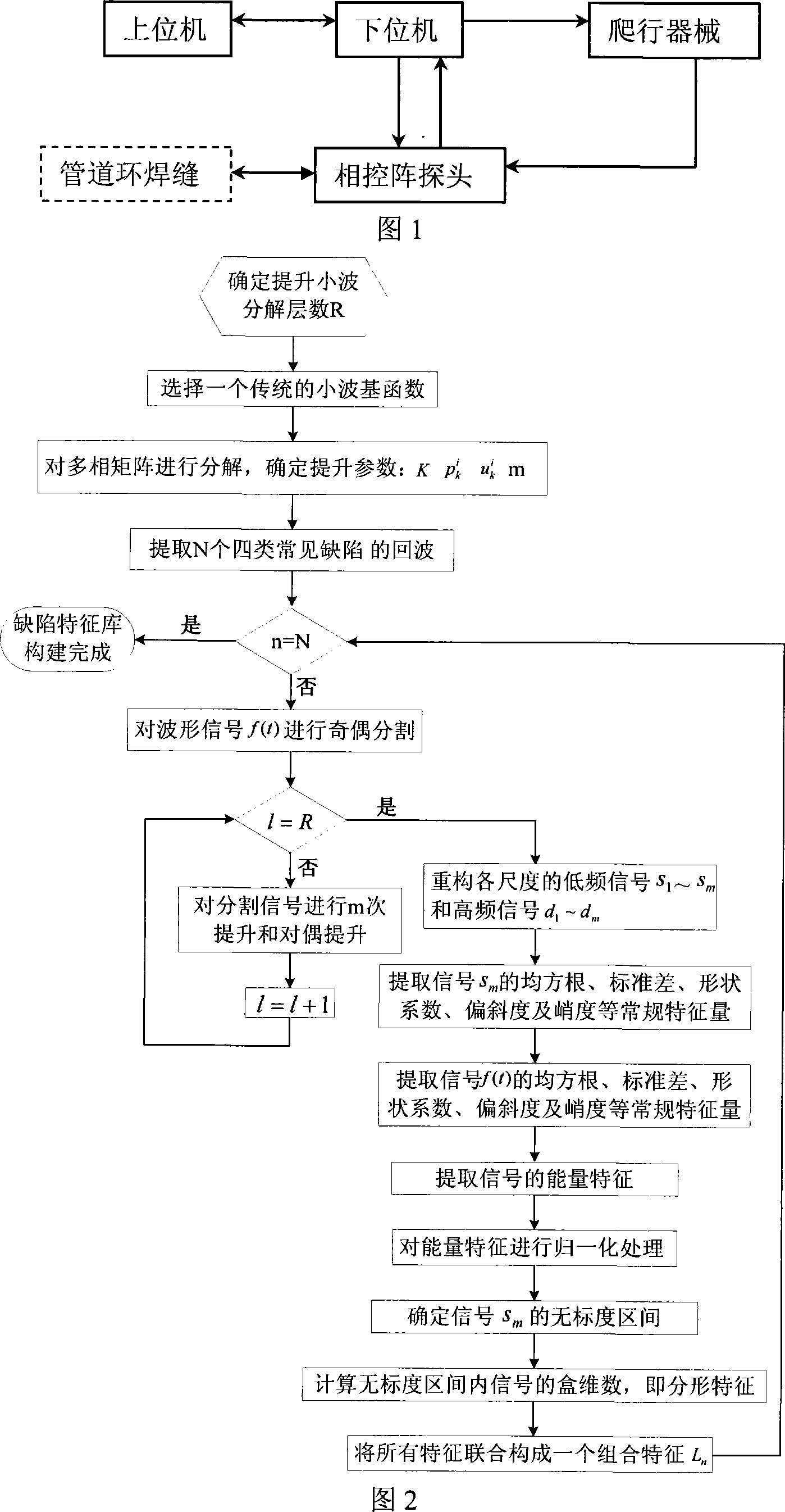

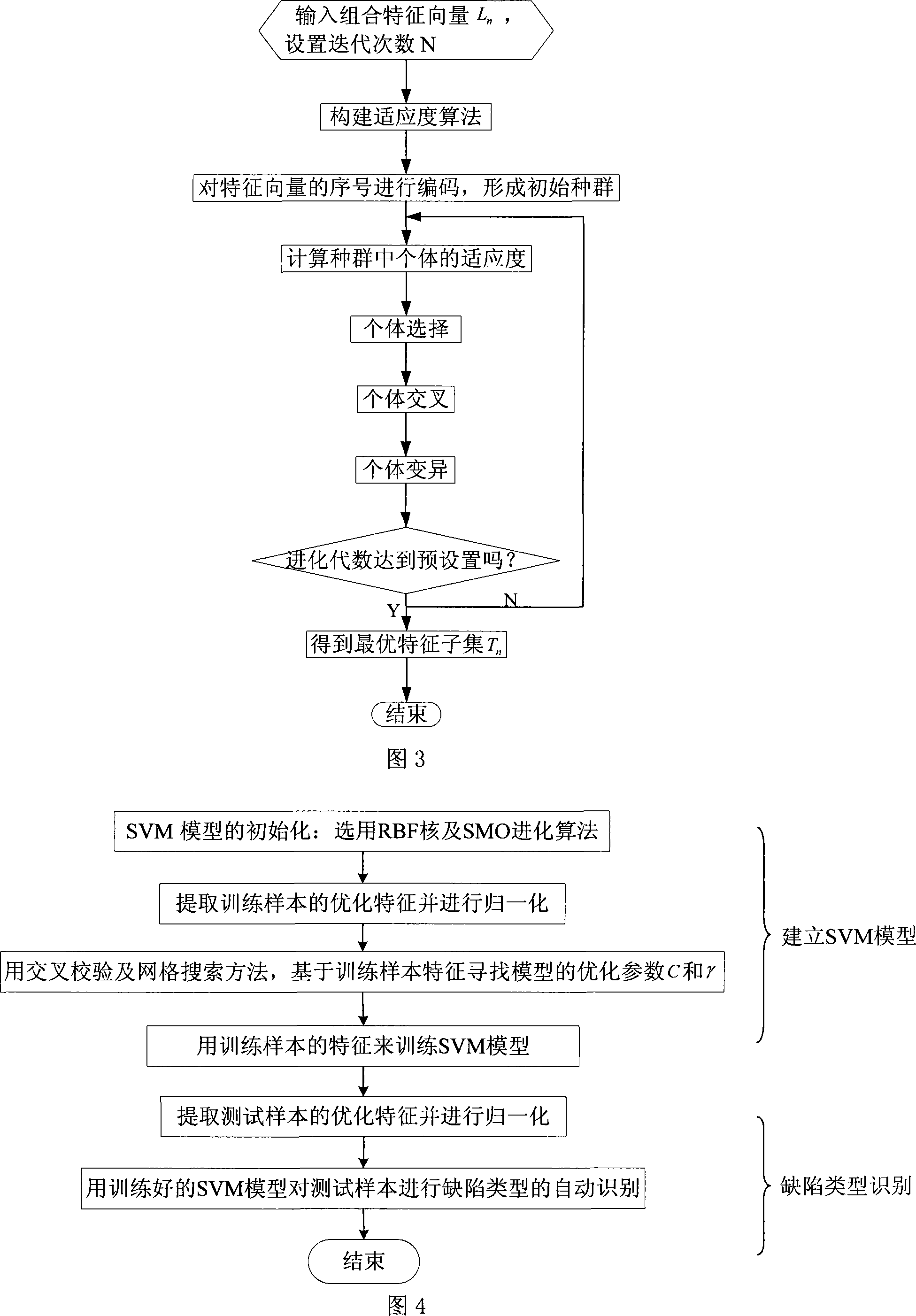

The invention discloses an ultrasonic phased array inspection oil-gas pipe circular weld defect automatic recognition method, in particular to an ultrasonic phased array inspection oil-gas pipe circular weld defect automatic recognition method for a support vector machine, which belongs to a pipe circular weld defect type recognition technology. The recognition method includes two parts of the construction of a support vector machine model and the automatic recognition of unknown defect types in circular weld. The construction steps of the support vector machine model include artificial defect signals extraction, wavelet decomposition promotion, feature extraction, feature optimization and the training of the support vector machine model. The automatic recognition steps of unknown defect types in circular weld include defect signals extraction, optimized feature calculation and automatic recognition based on the support vector machine. The invention combines a lifting wavelet transform with a fractal technology and has the advantages of high recognition accuracy and fast recognition speed. The automatic recognition of the defect types can be realized.

Owner:TIANJIN UNIV

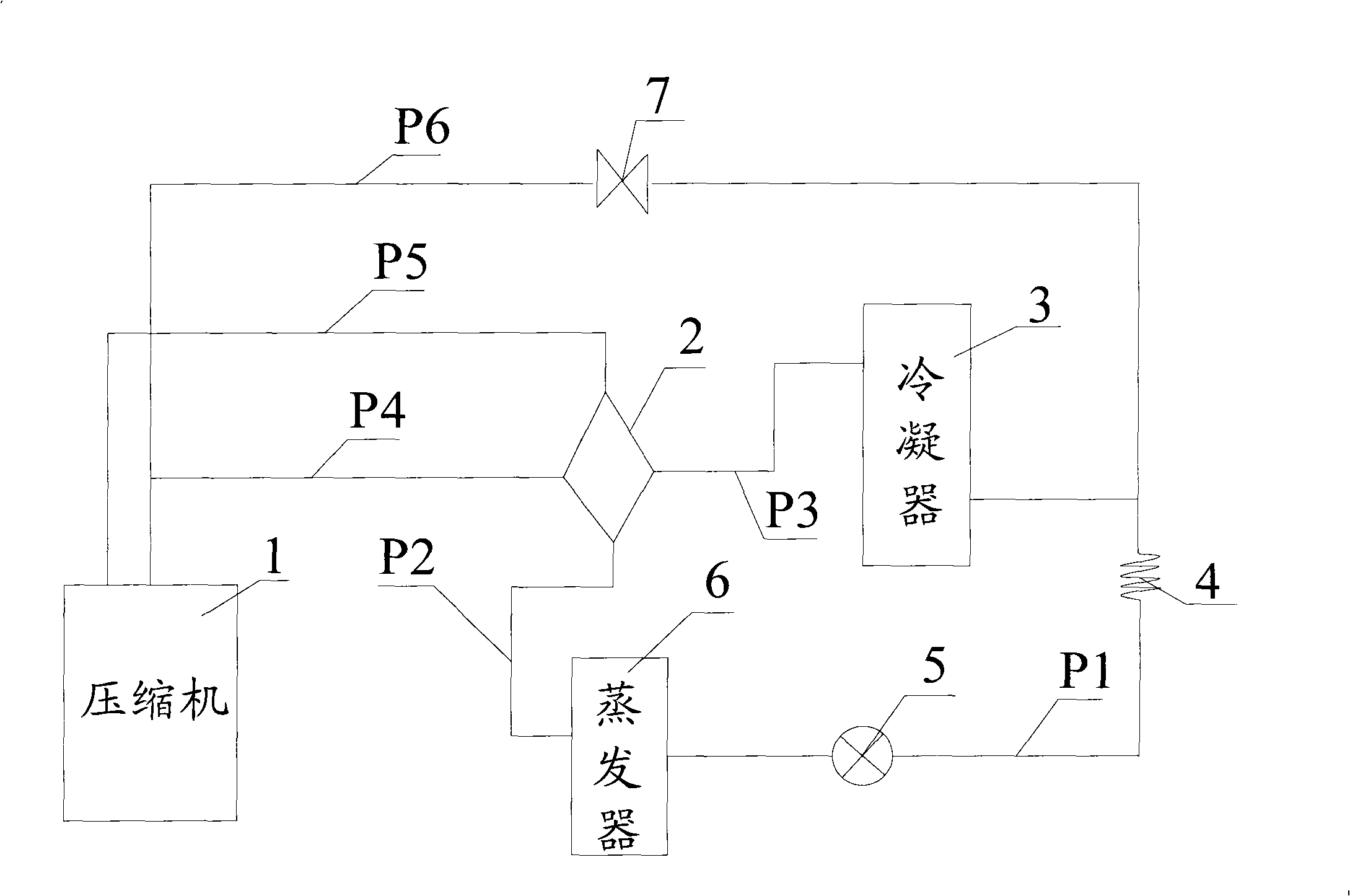

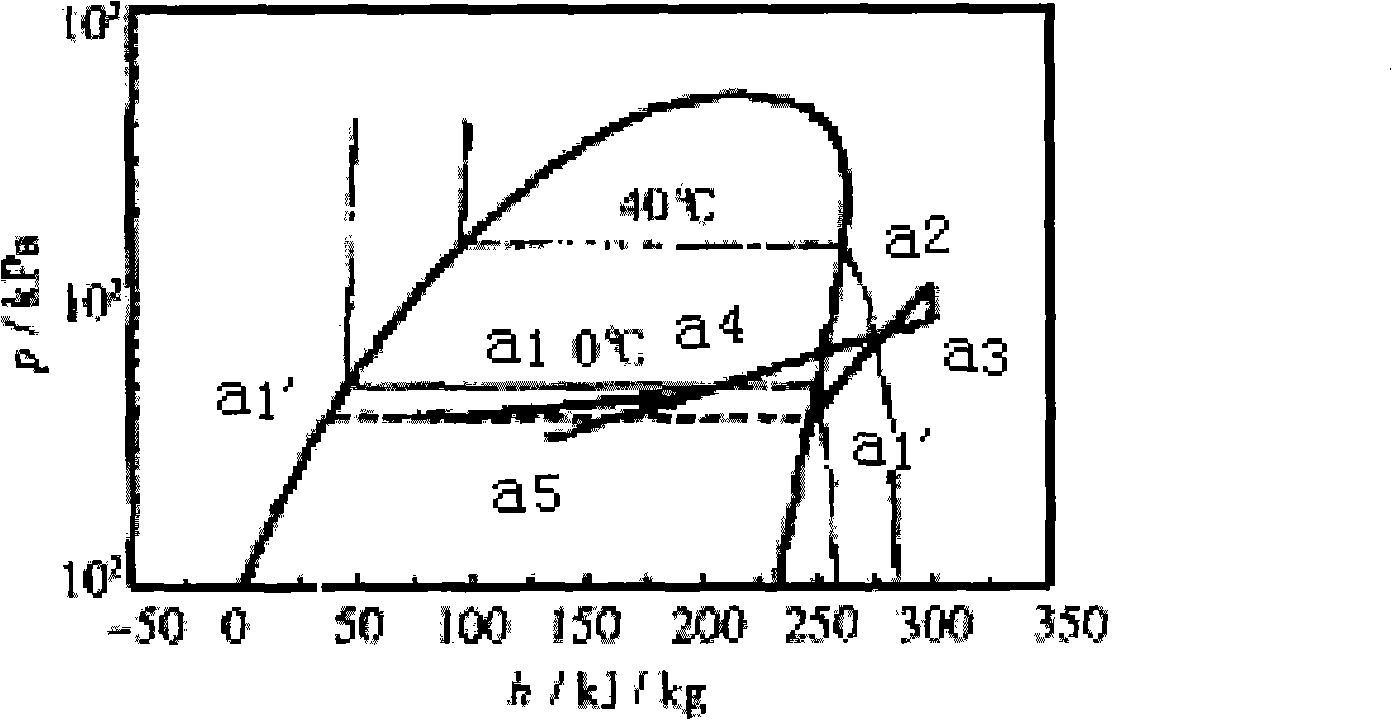

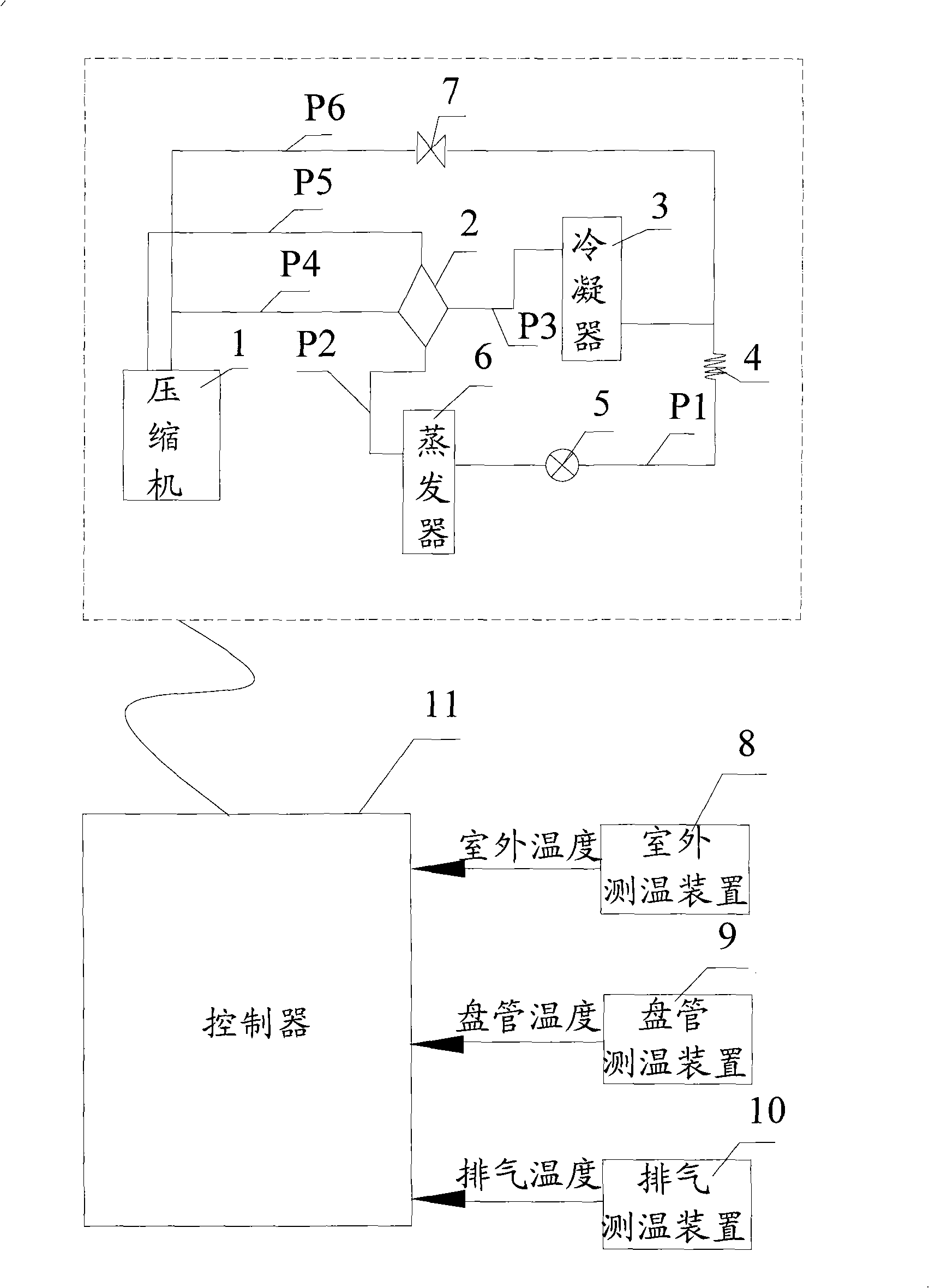

Air-conditioner defroster

ActiveCN101526288AImprove defrosting effectReduce energy lossProgramme controlComputer controlFour-way valveEngineering

The invention discloses an air-conditioner defroster. The defroster comprises a compressor, a four-way valve, an evaporator and a condenser. The defroster also comprises a first pipeline for connecting a liquid inlet of the evaporator with a liquid outlet of the condenser; a second pipeline for connecting an air return inlet of the evaporator with a first port of the four-way valve; a third pipeline for connecting an air inlet of the condenser with a second port of the four-way valve; a fourth pipeline for connecting an air outlet of the compressor with a third port of the four-way valve; a fifth pipeline for connecting a suction inlet of the compressor with a fourth port of the four-way valve; a bypass pipeline with one end communicated with the first pipeline and the other end communicated with the fourth pipeline; a bypass control valve arranged on the bypass pipeline for starting / closing the bypass pipeline; a throttle valve arranged on the first pipeline for regulating the flow of refrigerant in the first pipeline through adjusting the openness of the throttle valve. The invention combines the advantages of heat pump defrosting and hot gas bypass defrosting and can achieve the most effective defrosting.

Owner:GUANGDONG CHIGO AIR CONDITIONING

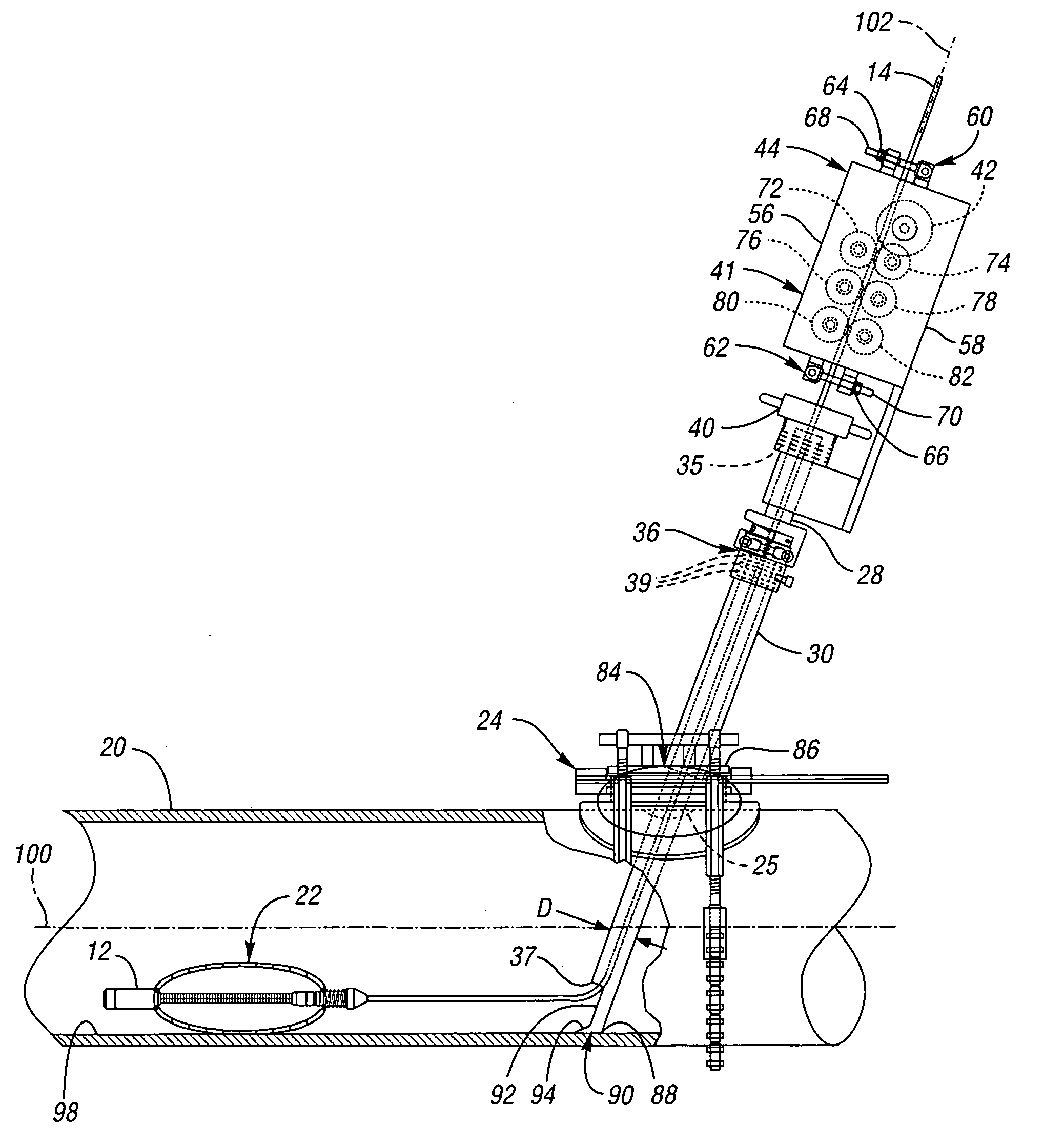

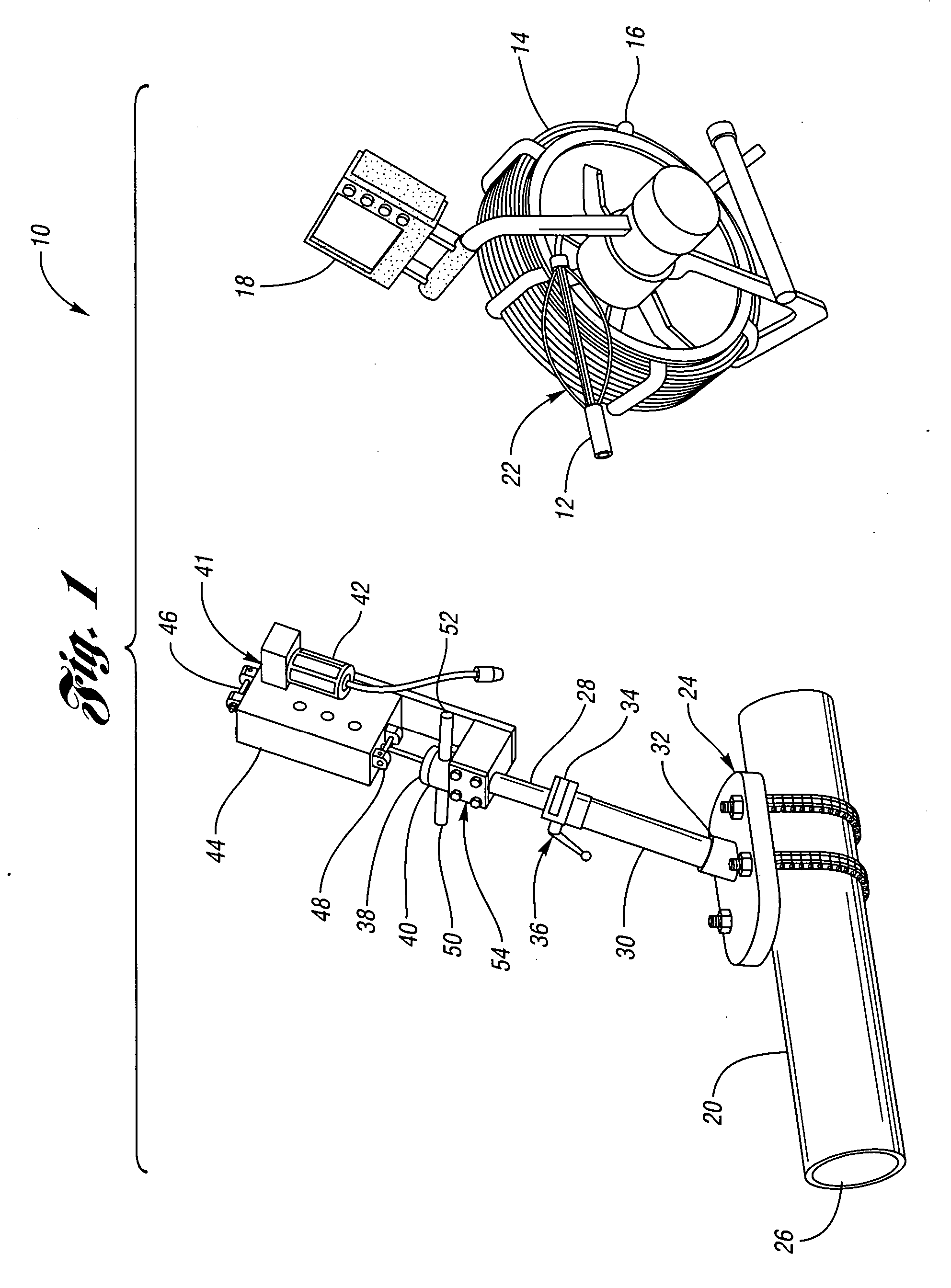

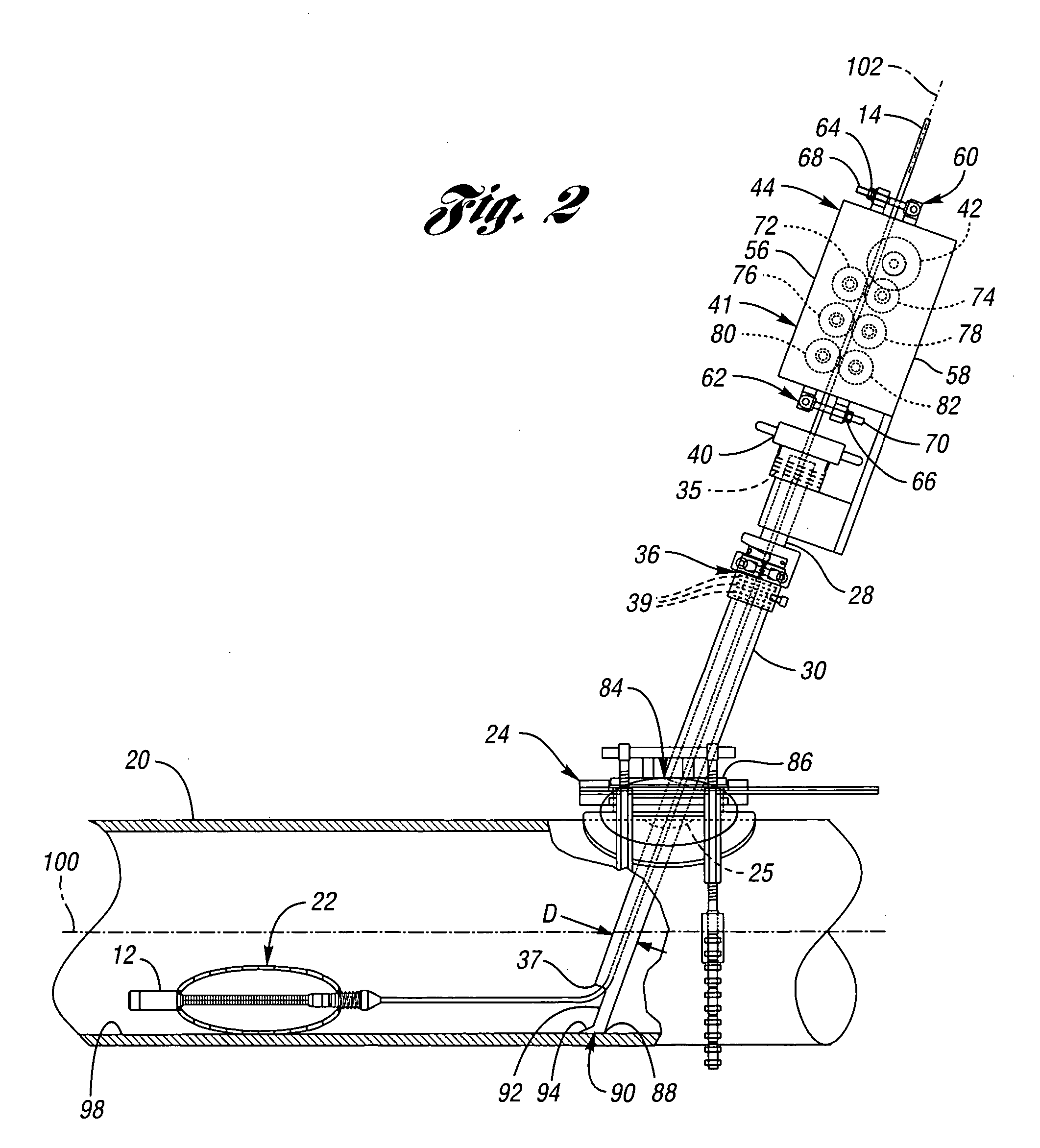

Pipeline inspection system

ActiveUS20070051192A1Facilitate entryPrevent escapeDiaphragm valvesEngine diaphragmsEngineeringPositioning system

An inspection system configured for “no-blow” use in a pressurized gas pipeline includes a push rod wound around a spool for convenient deployment and portability. A camera disposed on one end of the push rod is configured to relay images back to a monitor. A motor is configured for remote actuation by an operator, and provides for self-propelled movement of the camera in the pipeline. An entry tube is configured for sealed entry into the pipeline to facilitate entry of the camera and push rod. A guide shoe at the end of the entry tube provides a smooth transition-for the camera and push rod as it leaves the entry tube and enters the pipeline. An automatically deployable and retractable positioning system is used to keep the camera away from an interior surface of the pipeline, and in the case of smaller pipelines, centers the camera within the pipeline.

Owner:ULC TECH LLC

Installing method for main pipeline of coolant system of nuclear power station

ActiveCN102169736ASimple structureReduce elbowNuclear energy generationReactors manufactureNumerical controlPressurized water reactor

The invention relates to an installing method for a main pipeline of a coolant system of a nuclear power station, which is characterized in that the main pipeline of the coolant system of a reactor of the pressurized water reactor nuclear power station comprises a cool section (41) and a hot section (42), and a steam generator is directly connected with a main pump. According to the invention, the problem that the main pipeline is installed and welded by only a pressure container or steam generator in place by adopting the installing method of the main pipeline without a transition section issolved, and technical limit that the main pipeline is installed after the pressure container is in place and the steam generator or main pump is in place in the traditional main pipeline constructiontechnology is eliminated. A main pipeline groove is processed by adopting a site numerical control machining technology, the main pipeline and equipment connected with the main pipeline are subjectedto measurement, modeling and process monitoring by adopting a laser tracking measuring and 3D modeling technology, the main pipeline is regulated to meet the assembly welding requirement and is installed by using a narrow TIG (argon tungsten-arc welding) automatic welding technology, thus a feasible method is provided for shortening the construction period of the nuclear power station.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

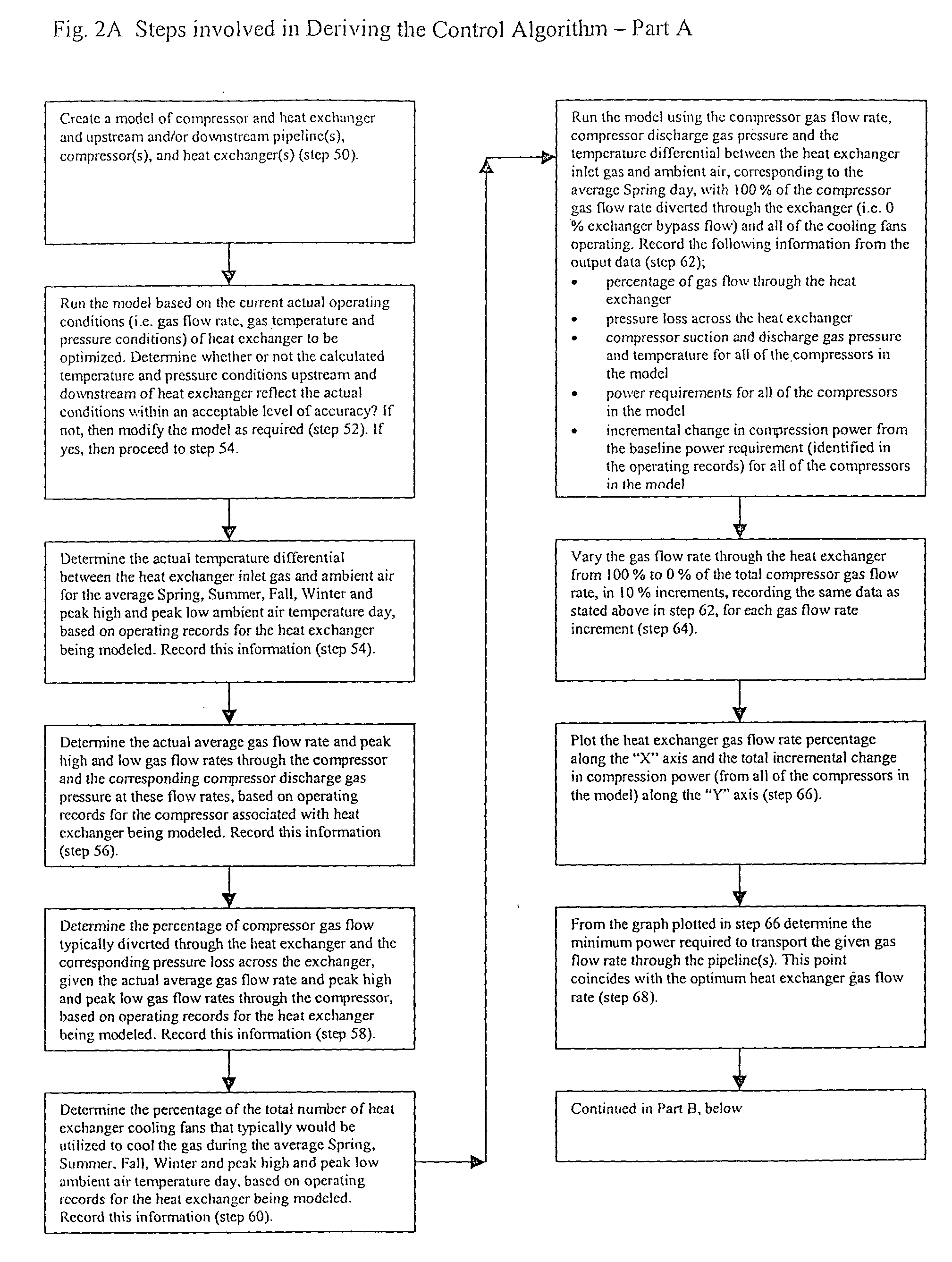

Heat exchanger optimization process and apparatus

InactiveUS20050034467A1Speed up the gas flowImprove heat transfer performanceSolidificationLiquefactionStream flowEngineering

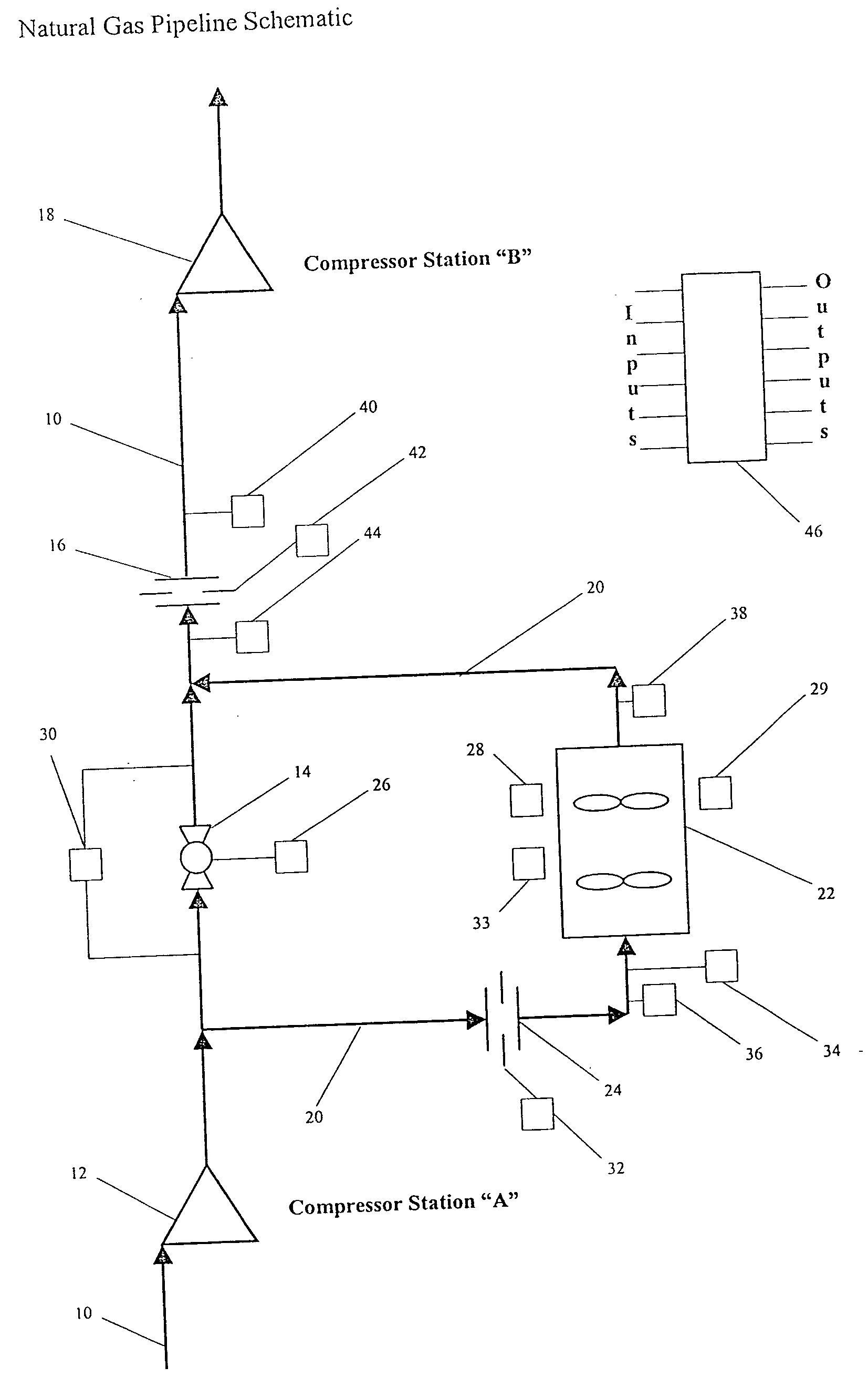

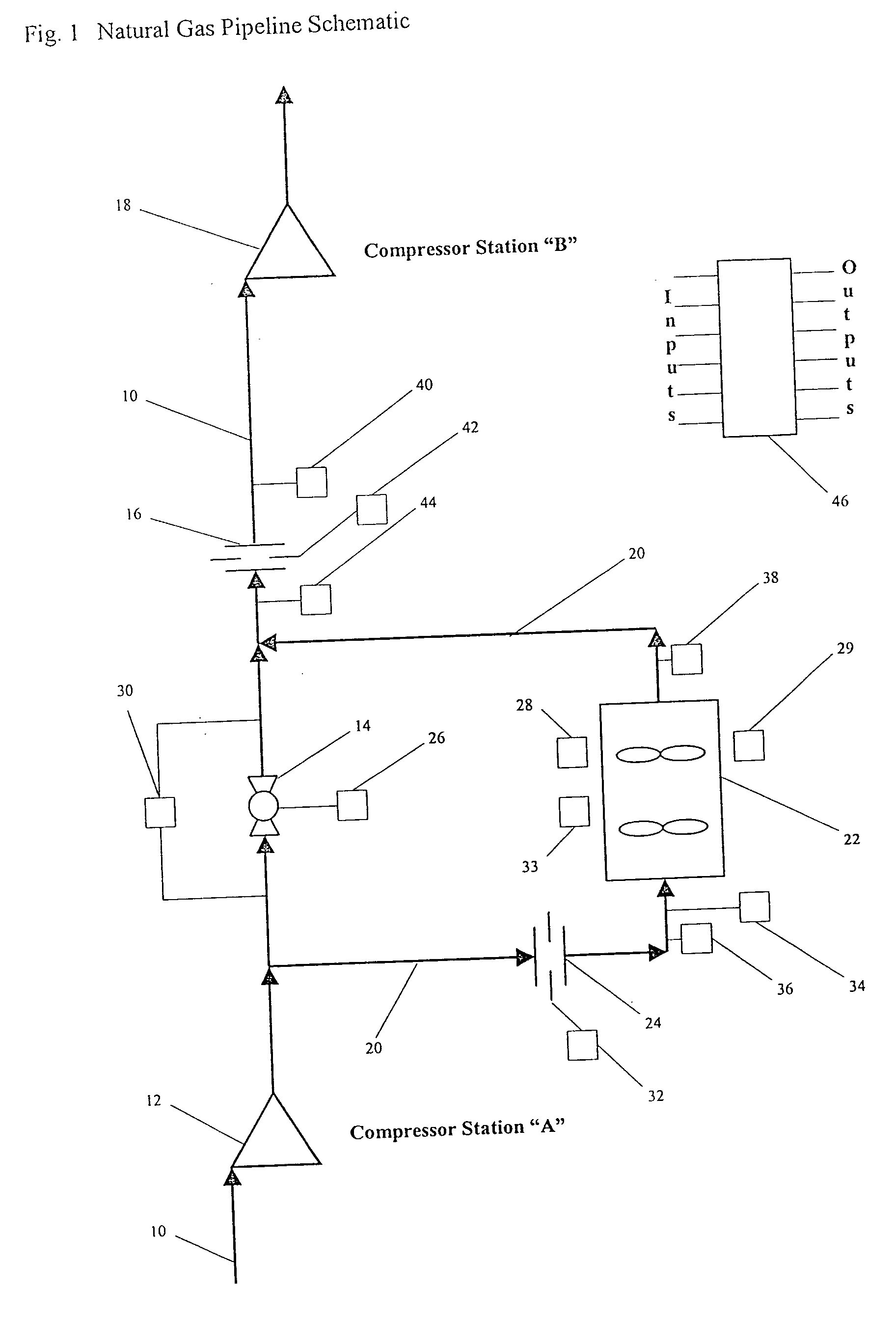

An electronic HEMD determines the optimum balance between gas cooling and heat exchanger pressure loss, for any given operating condition, and adjusts the gas flow rate through the exchanger accordingly, to yield the maximum net power savings (and thereby energy savings) afforded by the exchanger. Maintaining the optimum balance between cooling and exchanger pressure loss reduces the amount of energy required to transport a given volume of gas through a pipeline and thereby increases the transmission efficiency of the gas pipeline system. A method of operating a heat exchanger on a natural gas transmission pipeline using a control algorithm that in turn controls the position of a heat exchanger bypass valve. The current operating conditions of the upstream compressor and gas cooling system are continually monitored for any changes and the control algorithm determines, the optimum flow through the heat exchanger and initiates a command signal to the exchanger bypass valve operator to move the bypass valve and thereby increase or decrease the gas flow rate through the exchanger, as required, until the optimum balance between gas cooling and heat exchanger pressure loss has been achieved.

Owner:VARNEY BRIAN WILSON

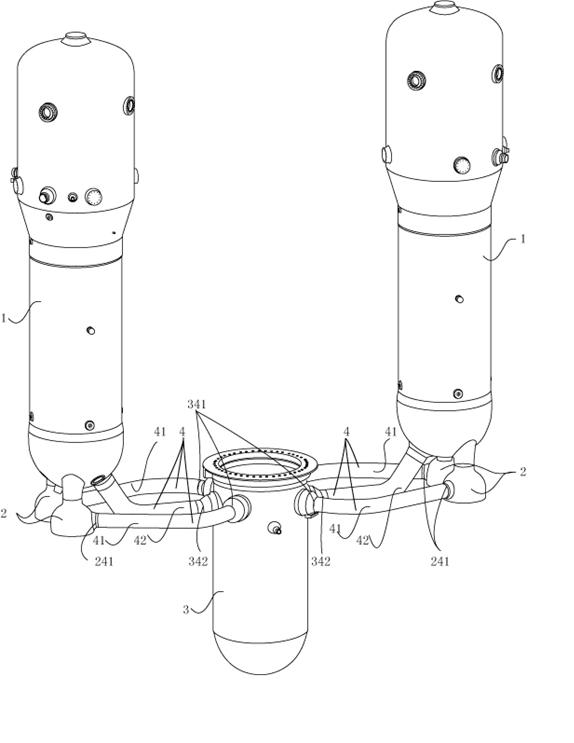

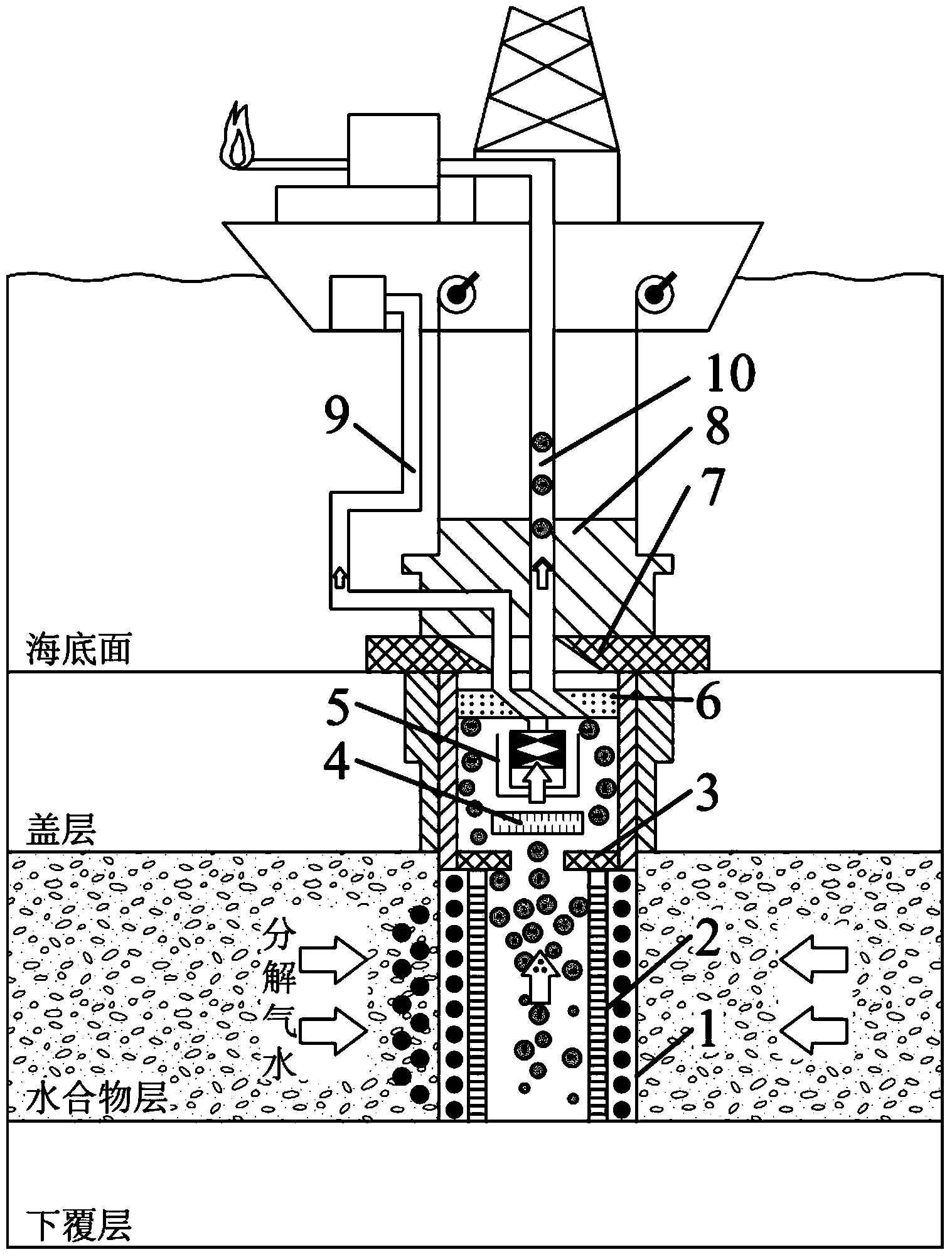

Device and method for safely and efficiently exploiting ocean natural gas hydrate through depressurizing decomposition

ActiveCN103867165AAvoid enteringAvoid secondary generationFluid removalSealing/packingDecompositionWater flow

The invention discloses a device and a method for safely and efficiently exploiting an ocean natural gas hydrate through depressurizing decomposition. The device comprises a sand production preventing device, a gas-water separation device and a safety protection device, and can be provided with a secondary hydrate generation preventing device. The method for safely and efficiently exploiting the ocean natural gas hydrate through the depressurizing decomposition by using the device comprises the following steps that gas, water and sands, which are formed by decomposition, flow to a shaft, the mud and the sands of a deposition layer are blocked, and the gas and the water enter the shaft; under the extraction action of a water pump, the gas and the water flow upwards along the shaft, are separated to enter respective pipelines, and are lifted to an exploitation platform or an exploitation ship finally; well pressure is detected in real time; once a hydrate layer is abnormally self-isolated, the gas pipeline and the water pipeline are turned off, and gas production is temporarily stopped. According to the device and the method, the flowing sands formed by the decomposition of the hydrate can be well prevented from entering the shaft, gas-water separation is realized in the shaft, secondary generation of the hydrate in the shaft is prevented, and the ocean natural gas hydrate can be safely and efficiently exploited.

Owner:DALIAN UNIV OF TECH

Pipeline cleaning method

ActiveCN101637768AWashed away wellCleaning time is shortHollow article cleaningIsolation valveEngineering

The invention relates to a pipeline cleaning method, which uses cleaning oil as medium and uses a pump to clean forcibly and circularly. The pipeline cleaning method comprises the following steps: 1)steps of processing and installing the pipeline: respectively installing a separating valve at a main pipeline, a branch pipeline and connecting part of bypass pipelines; 2) steps of installing a temporary cleaning device and disassembling the branch pipeline; 3) step of primary cleaning; 4) step of restoring the normal pipelines; and 5) step of secondary cleaning. Compared with the traditional construction process, the construction technique increases a control valve on the original basis, increases the step of reverse cleaning, uses the control of the bypass valve, has circular and thoroughcleaning, high cleanness, short time and low cost, avoids the defects that the dead angles are formed in cleaning and the like and has better technical effect and promotion value.

Owner:CHINA HUAYE GROUP

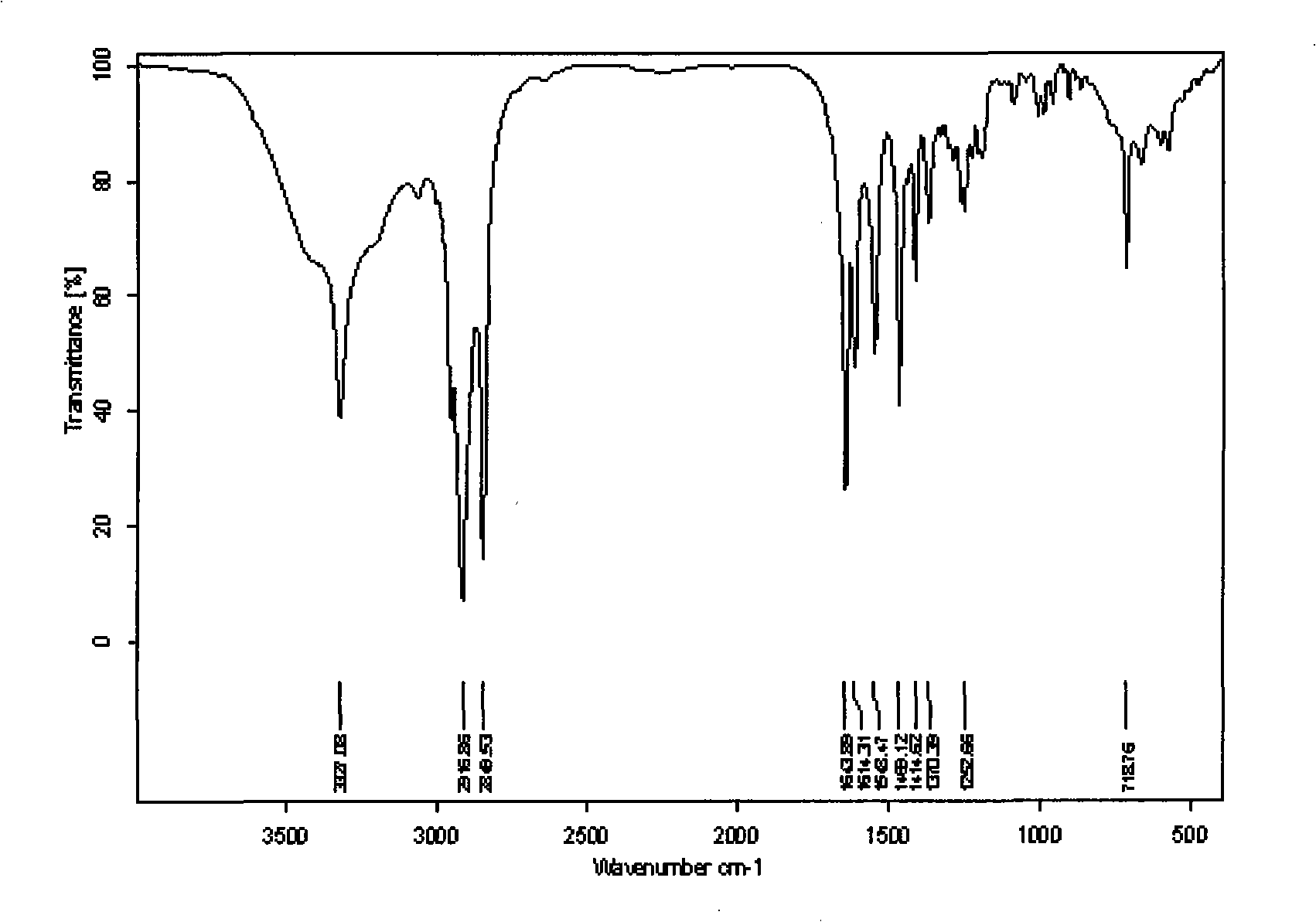

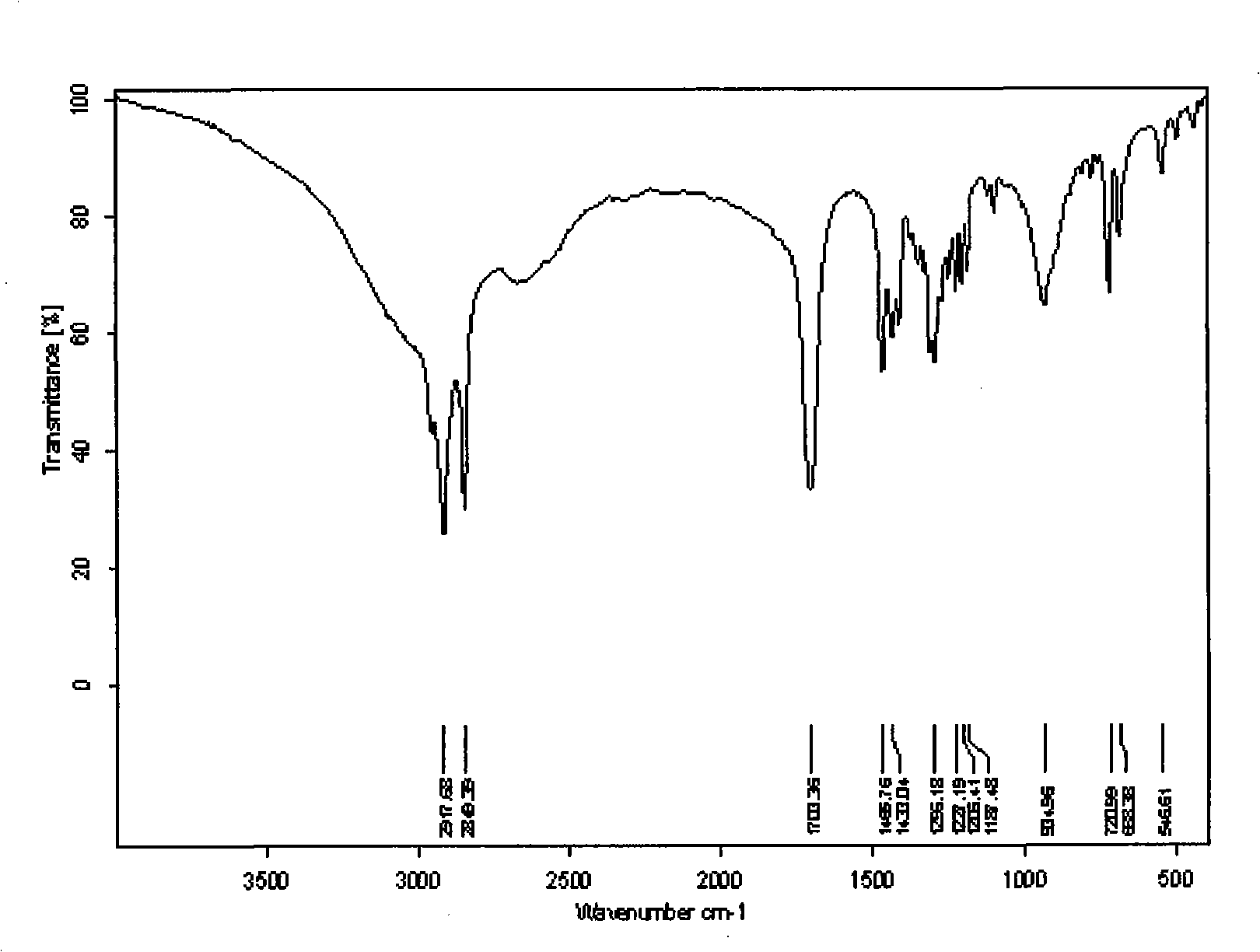

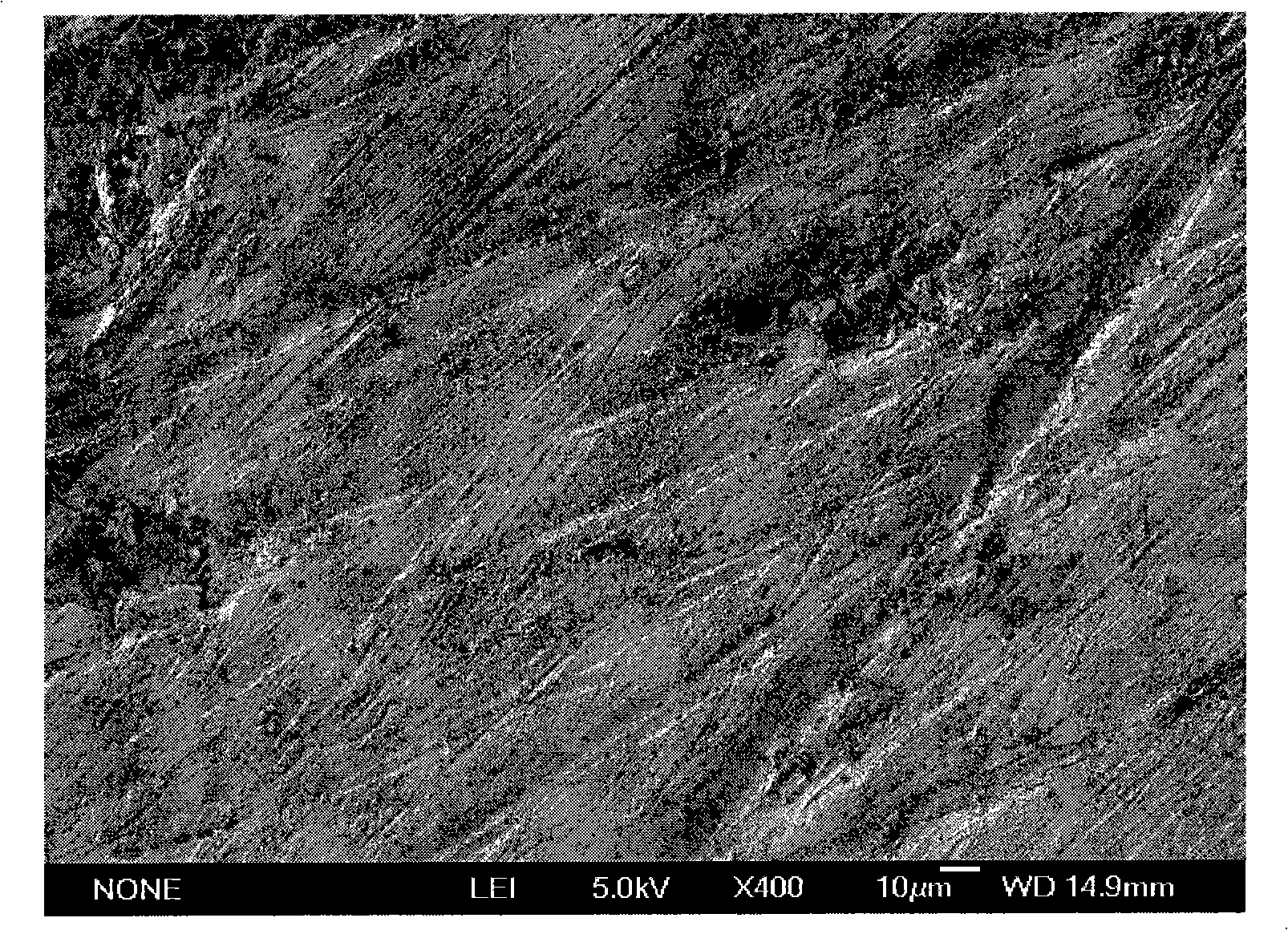

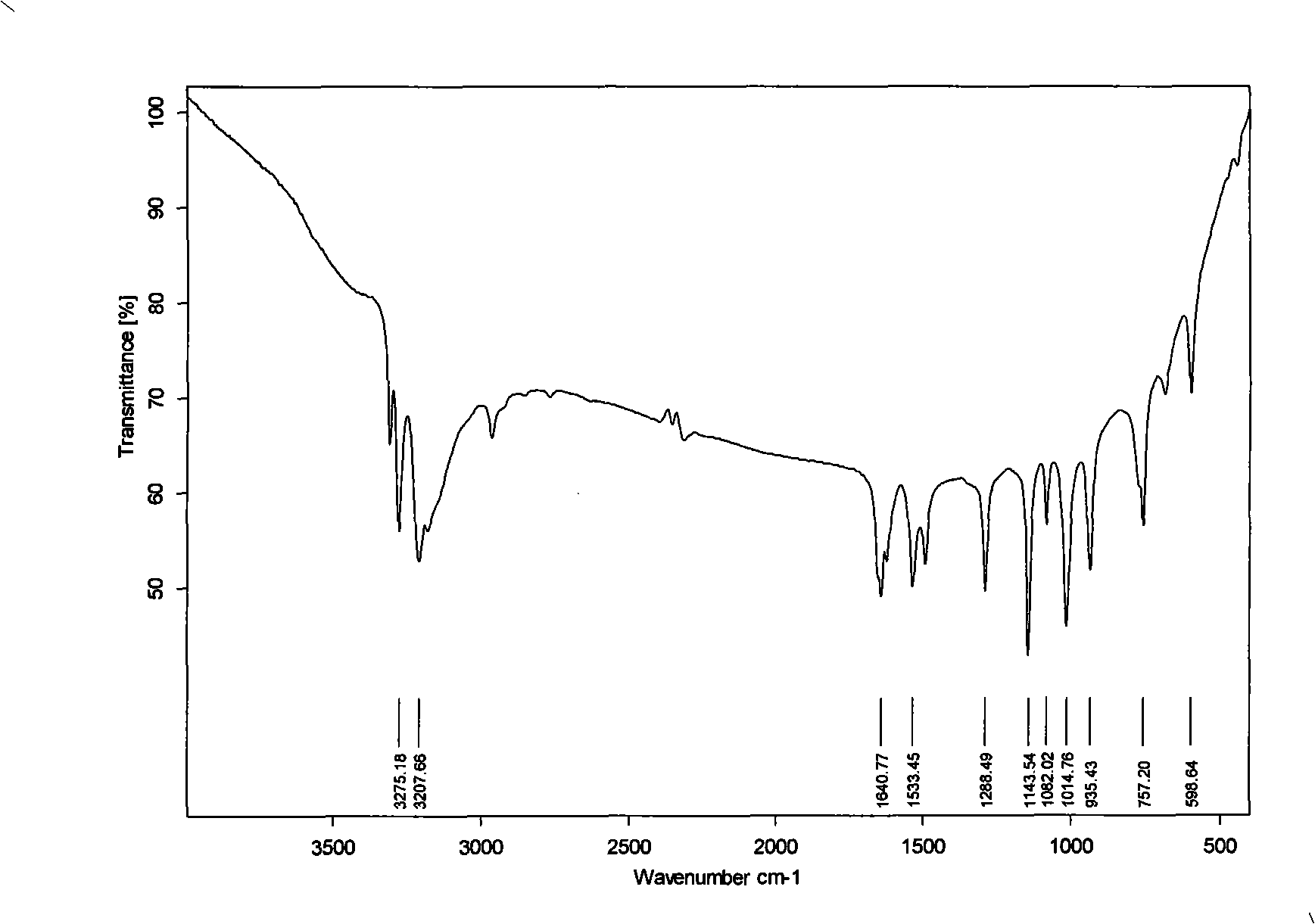

Gas pipeline drag reducer and preparation thereof

The invention relates to a gas pipeline drag reducer used in gas and particularly natural gas conveying pipeline drag reduction and a preparation method thereof, relating to a macromolecular compound composition and the pipeline system technical field. The gas pipeline drag reducer is characterized in that: the drag reducer is synthesized by long-chain acid and enamine according to a molar ratio of between 1:1 and 2.2:1. The preparation method comprises the following steps that: the long chain acid in proportional quantity is added in a reaction container; a heater is started so as to carry out heating while stirring; when temperature reaches to 100 DEG C, the long chain acid is melted, and the enamine in proportional quantity is added at the same time; nitrogen is fed in to carry out protection, and the mixture is preheated to between 120 and 140 DEG C; after preheating is finished, programmed heating is carried out till temperature is increased to between 210 and 220 DEG C; a stirrer is removed and a vacuum pump is connected to carry out evacuation for 2 to 4 hours; when reaction is finished, brown solid crude product can be obtained after cooling down. The gas pipeline drag reducer has obvious drag reduction effect on gas pipelines, direct source of raw materials, simple operation, moderate reaction conditions, relatively simple process and low requirements on equipment, and is easy to realize large-scale industrialized production.

Owner:PETROCHINA CO LTD

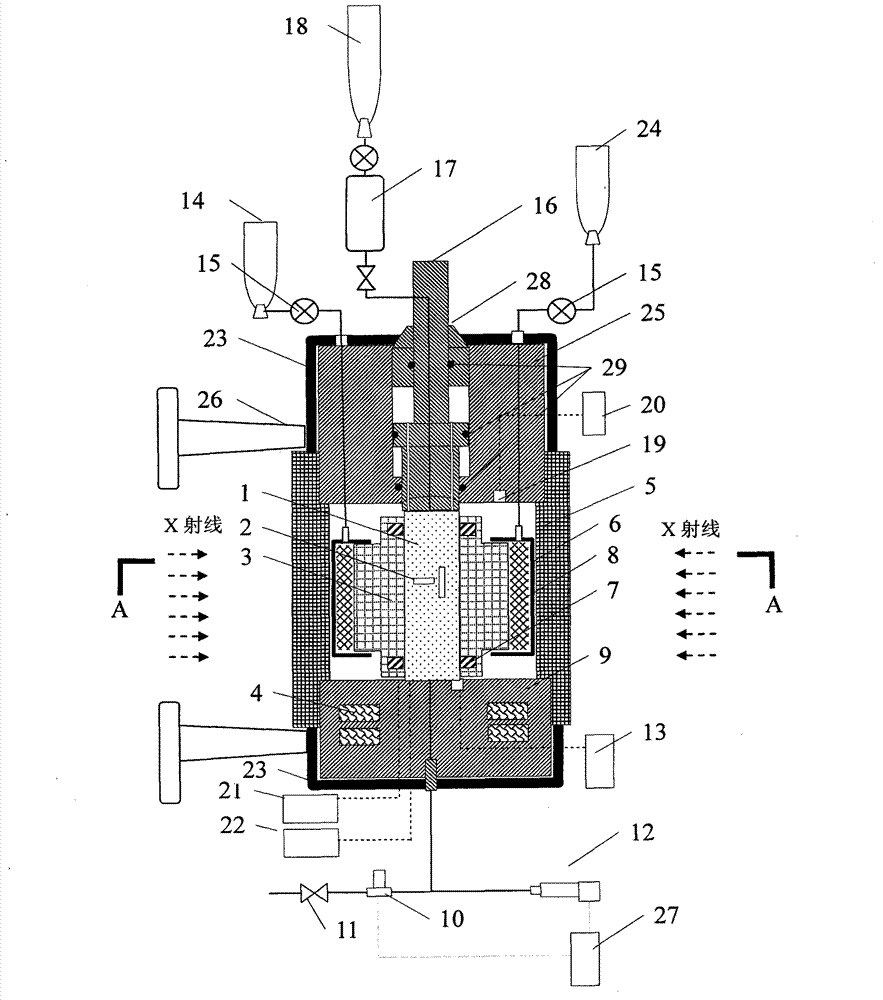

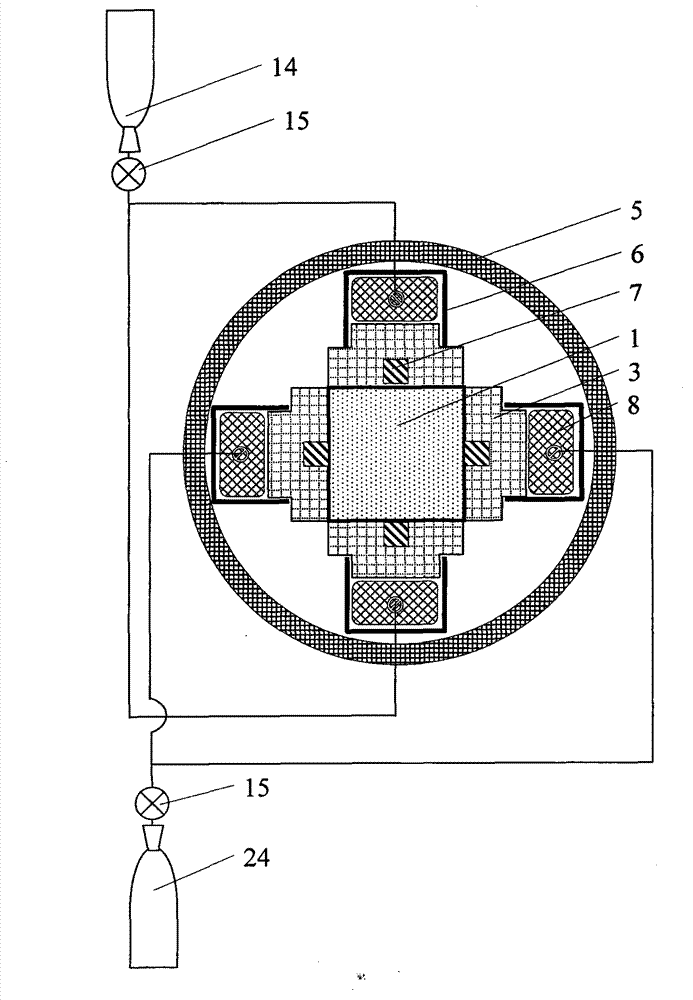

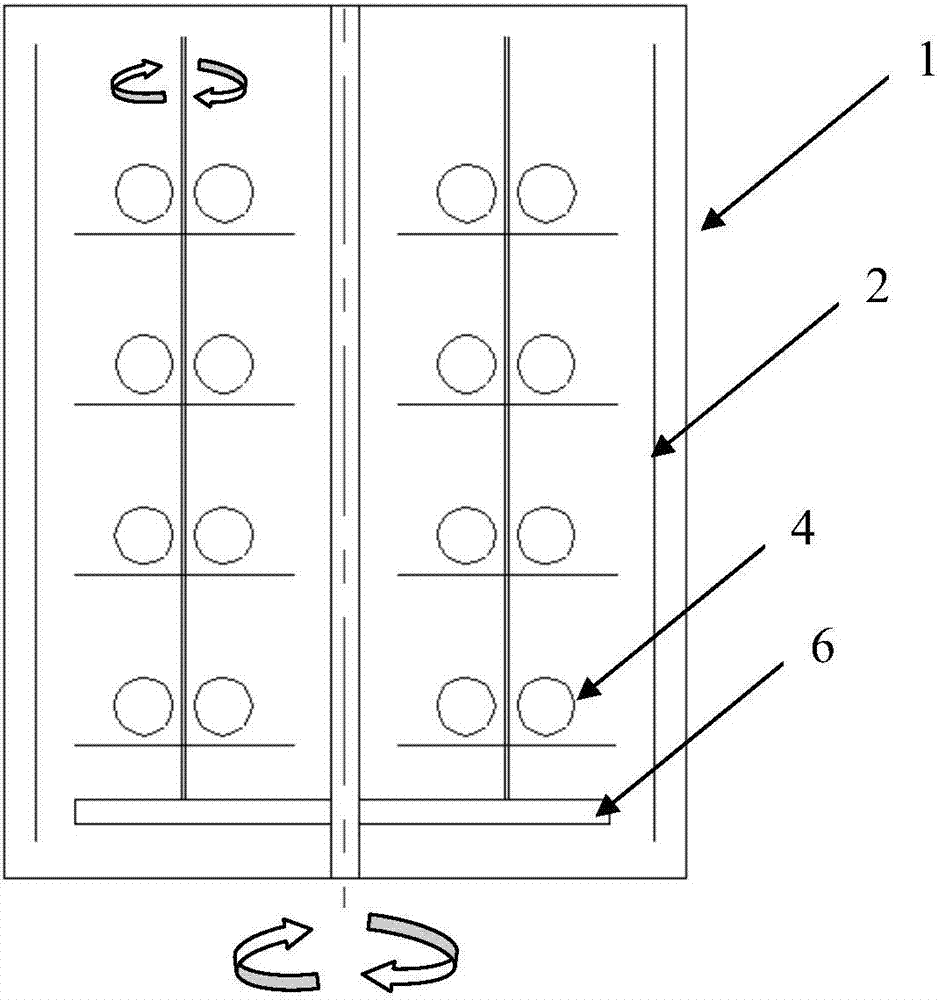

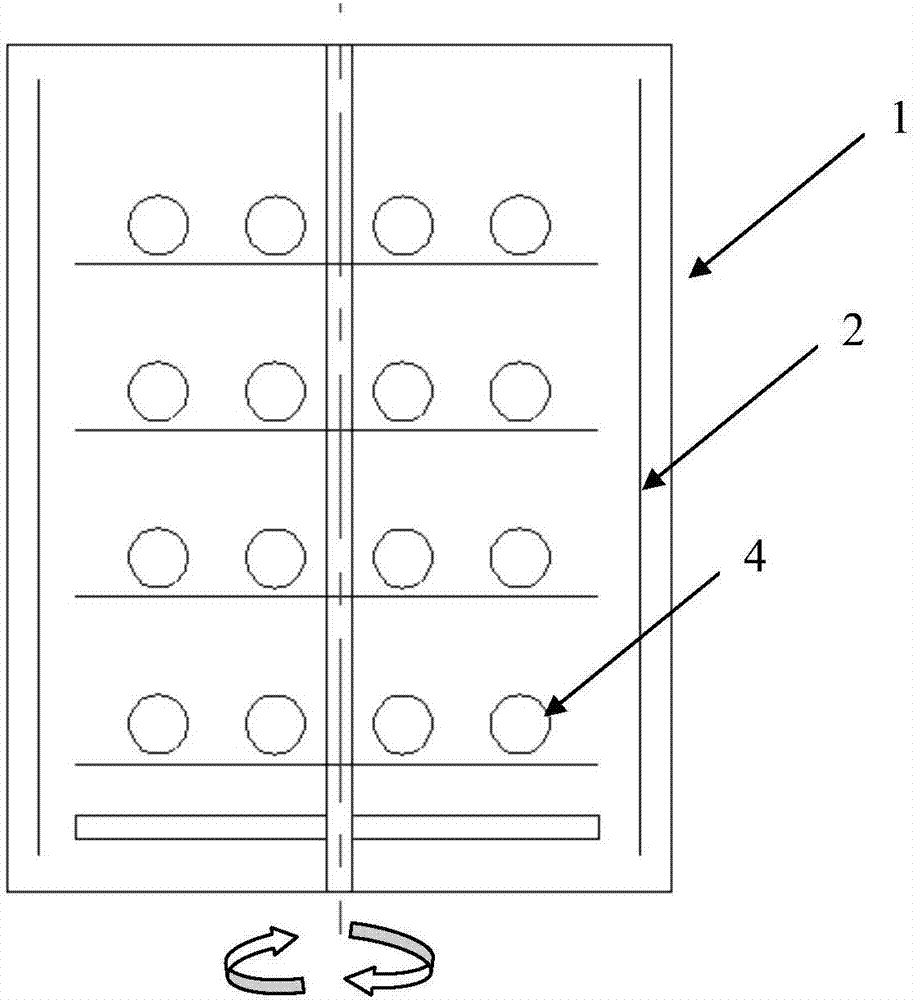

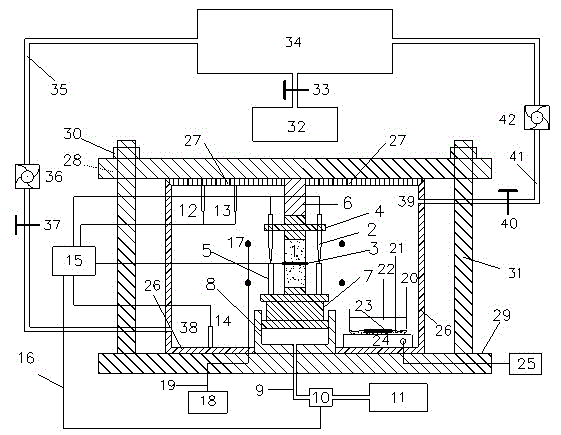

Device for testing coupling function of multi-physics field of core rock and use method of device

The invention discloses a device for testing a coupling function of a multi-physics field of core rock and a use method of the device. The device is a sealed barrel body which is composed of a top cover, a barrel body and a base disc; a column chamber and a temperature sensor are arranged in the device; a plunger is installed inside the column chamber; a pressure groove is arranged inside the barrel body; an airbag and a convex rubber piston are arranged inside the pressure groove; the airbag is connected with an external high pressure gas source; a gas pipeline for filling gas to the barrel body is arranged in the plunger; an acoustic emission sensor is installed inside the rubber piston; the acoustic emission sensor is connected with an external acoustic emission acquiring system; a gas discharge port is arranged on the base disc and is connected with a gas pressure difference transmitter, a gas mass flowmeter and a gas data acquirer; and electric heating wires are arranged inside the base disc. With the adoption of the device, not only the transformation and the acoustic emission activity of a coal test piece at different temperatures and stress states are recorded in real time, but also the absorption and desorption processes of coal-gas are carried out; and the visual microstructure characteristics of the coal test piece are quantified by using the CT (computed tomography) technology.

Owner:SHANDONG UNIV OF SCI & TECH

Base material motion type device and method for preparing nano coating through plasma discharge

PendingCN106958012APlay an active roleSolve uneven thicknessElectric discharge tubesNanotechnologySolventDeposition process

The invention discloses a base material motion type device and method for preparing a nano coating through plasma discharge, and belongs to the technical field of plasmas. The device comprises electrodes, a vacuum exhaust device, a gas pipeline and a base material fixing device; and the method comprises the following steps that the base material fixing device can do motions in the space formed by the electrodes under the driving of a moving mechanism, and monomer steam is introduced into a reaction chamber to carry out plasma chemical vapor deposition, wherein the deposition process comprises a pretreatment stage and a coating stage, the plasma discharge mode in the pretreatment stage is high-power continuous discharge and the plasma discharge mode in the coating stage is small-power continuous discharge. In the preparation process of the coating, the movement characteristic of the base material and the plasma discharge energy are combined and linked; the base material does motions while the plasma discharge occurs, so that the coating deposition efficiency is improved, and the uniformity and compactness of the thickness of the coating are improved; and the coating prepared by the method has the characteristics of being waterproof, moisture-proof, and anti-fungus, and has acid solvent resistance, alkaline solvent resistance, acid salt mist resistance, alkaline salt mist resistance and the like.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

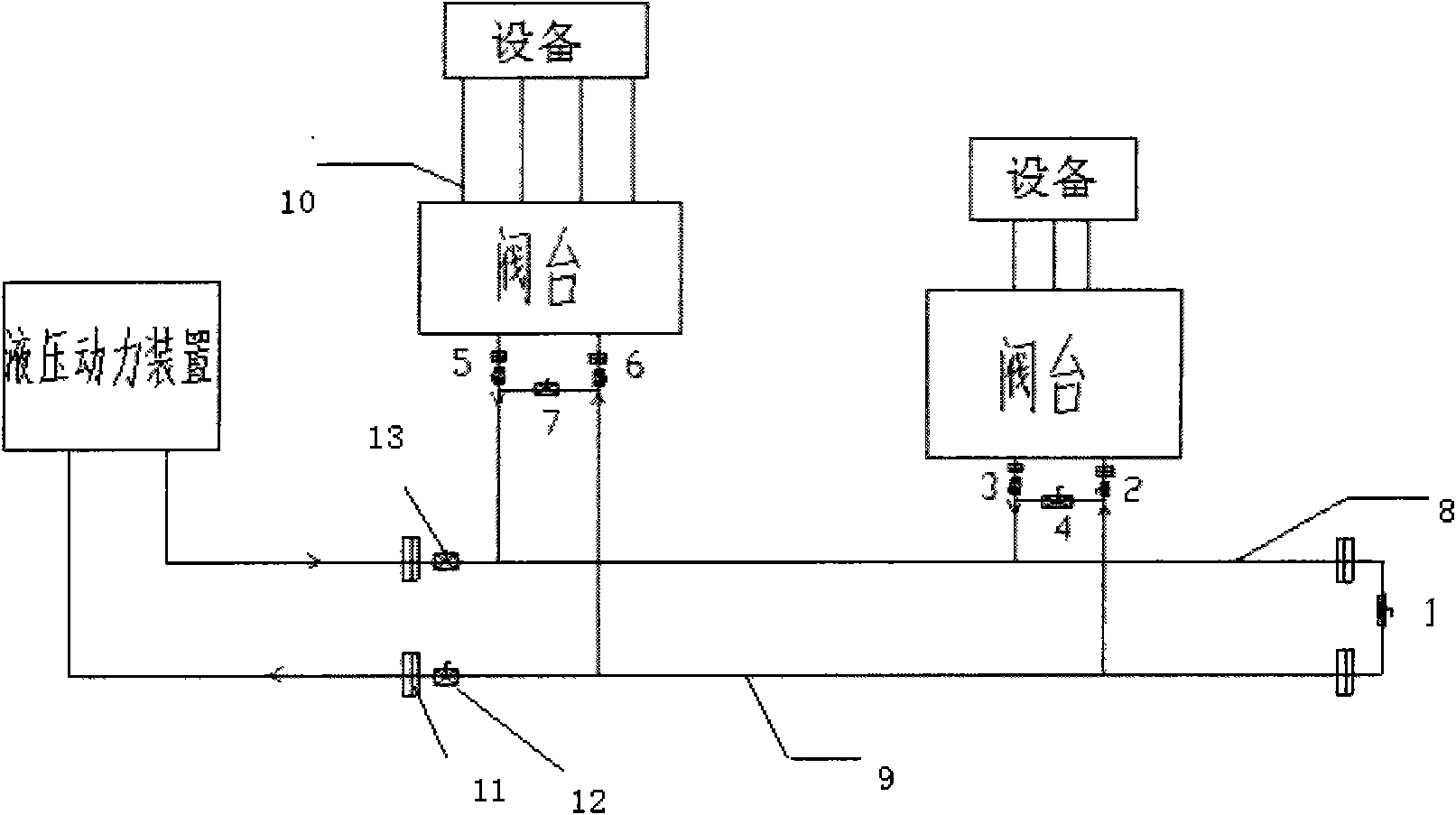

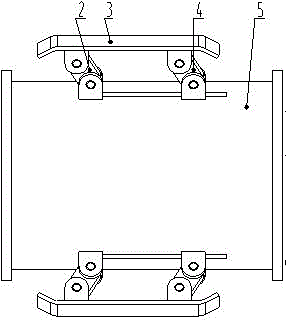

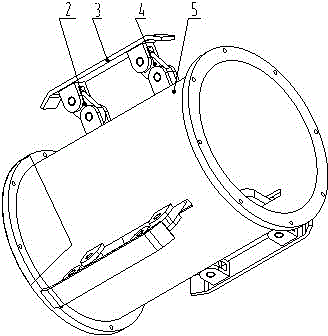

Hydraulic peristaltic pipeline robot traction device

InactiveCN104565674AGuaranteed loading capacityIncrease loading capacityPigs/molesCarrying capacitySimulation

The invention relates to a hydraulic peristaltic pipeline robot traction device, which can provide powerful traction force for robots in pipeline operation such as an oil-gas pipeline, a sewage pipeline and the like. The hydraulic peristaltic pipeline robot traction device mainly consists of an extension cabin, a propelling cabin and a propelling oil cylinder, wherein the extension cabin mainly consists of an extension cabin body, an extension cabin front cover, extension cabin supporting legs, extension cabin brackets, extension cabin supporting rods, an extension cabin supporting leg oil cylinder, a synchronous plate, a synchronous plate slide shaft and an extension cabin rear cover; the propelling cabin mainly consists of a propelling cabin body, a propelling cabin front cover, propelling cabin supporting legs, propelling cabin brackets, propelling cabin supporting rods, a propelling cabin supporting leg oil cylinder, a synchronous plate, a synchronous plate slide shaft and a propelling cabin rear cover. The hydraulic power is adopted as a power source, sufficient traction power can be provided for a pipeline operation robot, and the successful traveling of the pipeline robot in the pipeline can be guaranteed. The hydraulic peristaltic pipeline robot traction device has advantages of simplicity in structure, high carrying capacity, high reliability, high environmental adaptability and the like.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

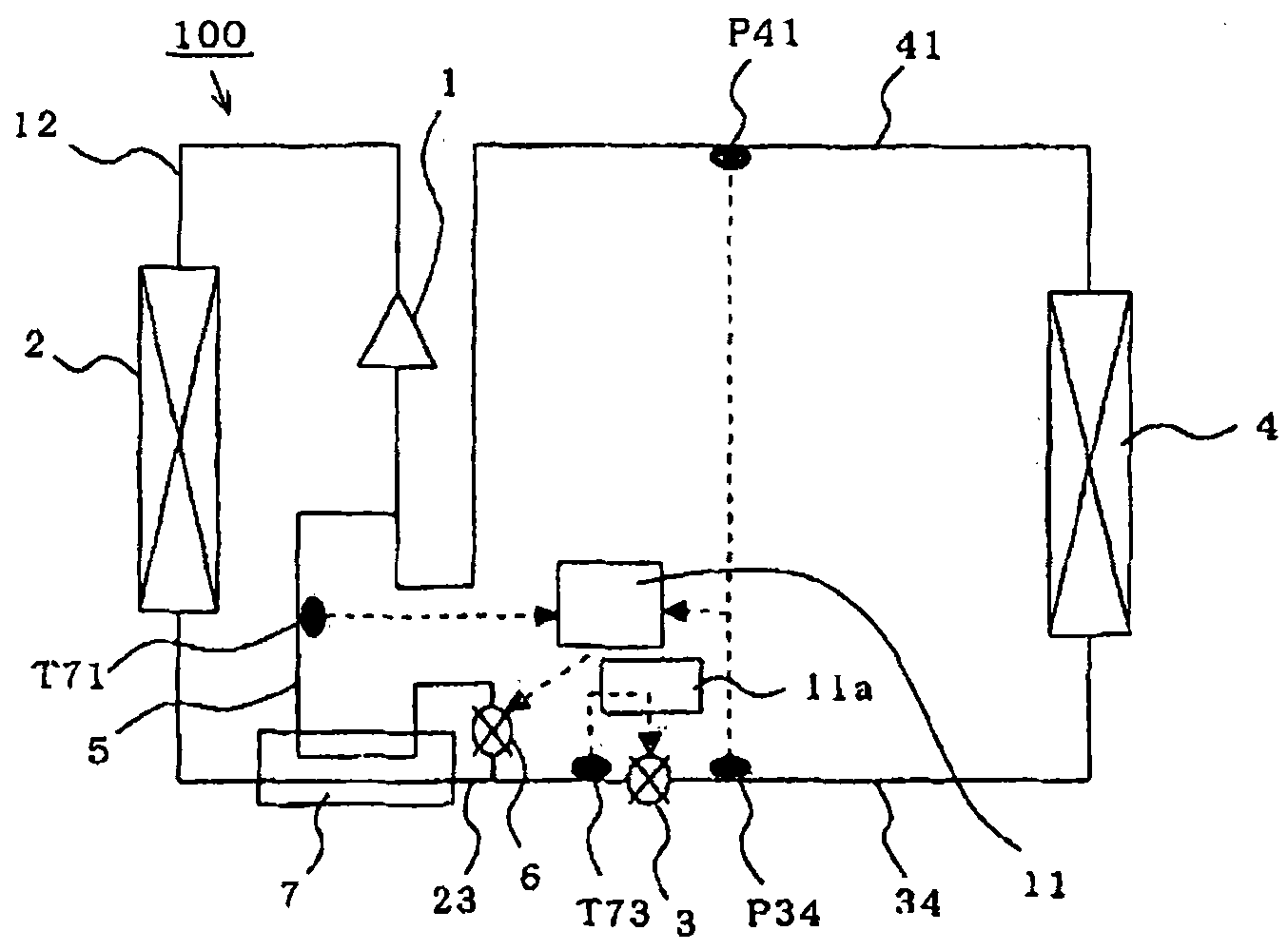

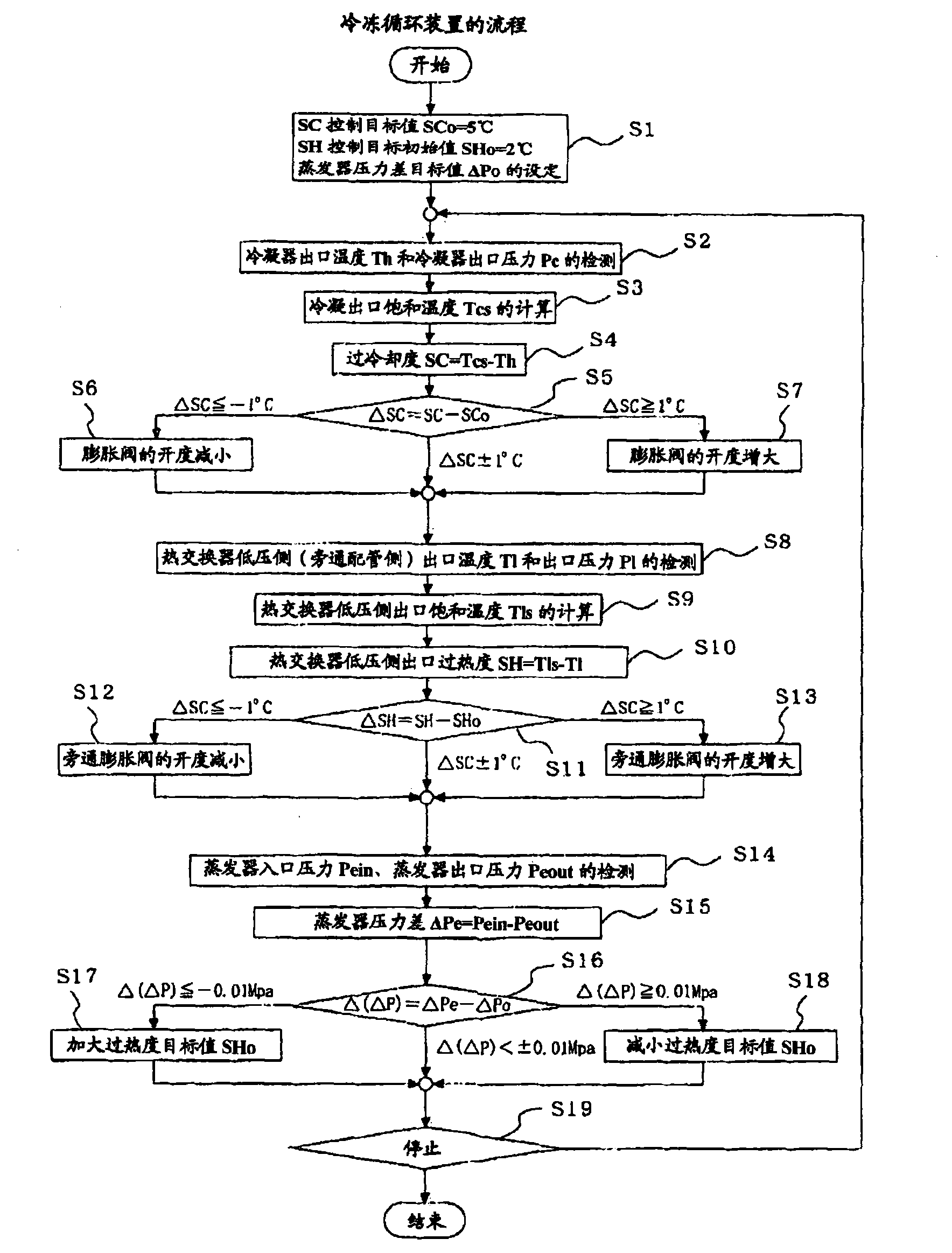

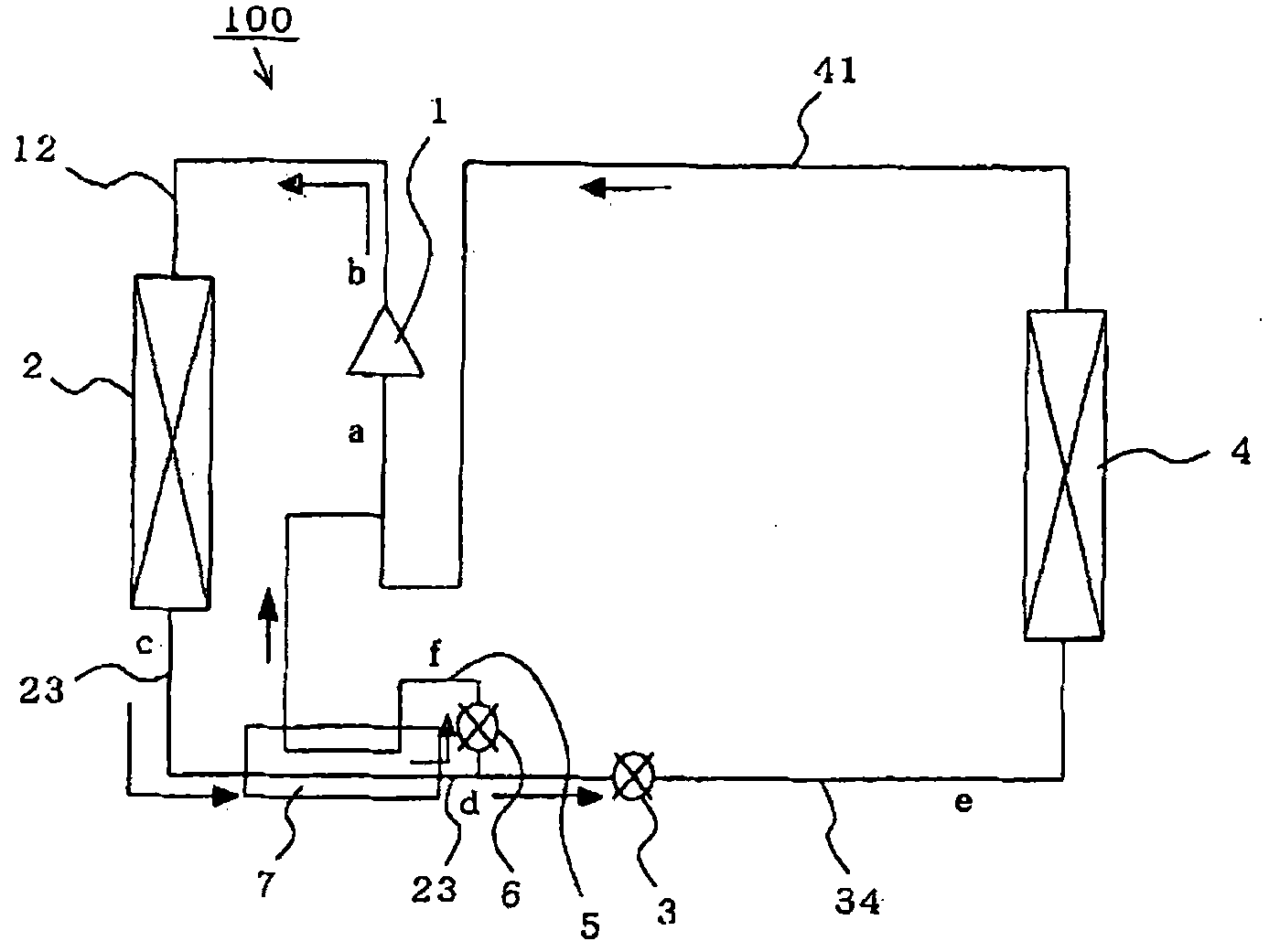

Refrigeration cycle device and control method therefor

ActiveCN102066851AEasy to operateIncreased pressure lossMechanical apparatusSpace heating and ventilation safety systemsEngineeringControl valves

A refrigeration cycle device (100) in which a flammable refrigerant circulates comprises a bypass pipeline (5) connected such that part of the refrigerant flowing through a circulation pipeline from a condenser (2) to a flow control valve (3) bypasses the flow control valve (3) and an evaporator (4), a bypass flow control valve (6) for controlling the flow rate of the refrigerant flowing through the bypass pipeline (5), a heat exchanger (7) for allowing the refrigerant flowing through the bypass pipe line (5) after flowing out from the bypass flow control valve (6) and the refrigerant flowingthrough the circulation pipeline after flowing out from the condenser (2) to exchange heat with each other, and a supercooling degree sensor (T73) for detecting the supercooling degree of the refrigerant at an inlet of the flow control valve (3). At least either the flow control valve (3) or the bypass flow control valve (6) is so controlled that the supercooling degree of the refrigerant at the inlet of the flow control valve (3) is equal to or more than a predetermined value.

Owner:MITSUBISHI ELECTRIC CORP

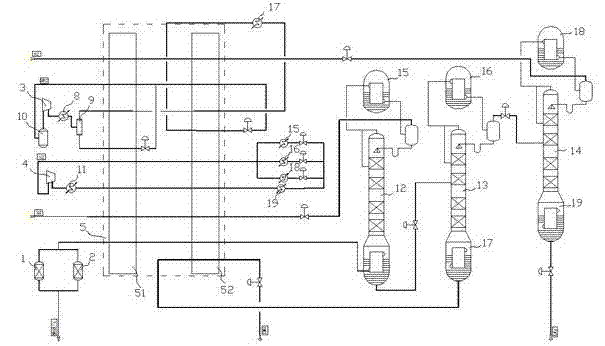

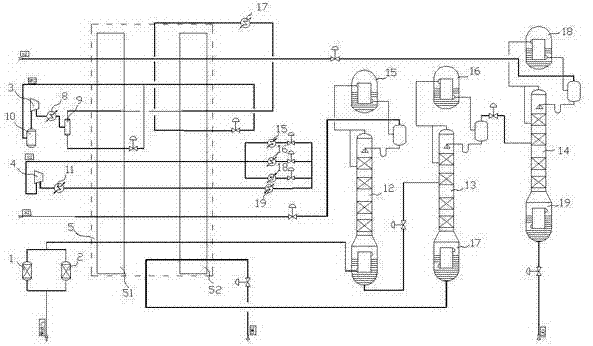

Separation and recycling device and recycling method for methane and argon in synthetic ammonia relief gas

ActiveCN102419071ARealize separation and recoveryImprove heat transfer efficiencySolidificationLiquefactionDehydrogenationProcess engineering

The invention relates to the technical field of recycling of a synthetic ammonia relief gas, and discloses a separation and recycling device and a recycling method for methane and argon in the synthetic ammonia relief gas. The device comprises a cooling box, a virgin gas pipeline, a water cooler, a gas-liquid separator, a gas-liquid balancing tank, a throttling reducing valve, a purification system, a refrigeration system and a rectifying system, wherein the refrigeration system comprises a mixed refrigerant circulating compressor, a medium-pressure circulating nitrogen compressor and a main heat exchanger; the medium-pressure circulating nitrogen compressor is connected with the water cooler and the main heat exchanger through a pipeline respectively; the rectifying system comprises a dehydrogenation tower, a methane rectifying tower and an argon rectifying tower; and the main heat exchanger, the dehydrogenation tower, the methane rectifying tower and the argon rectifying tower are connected through pipelines. By the device and the method for separating and recycling the methane and the argon from the synthetic ammonia relief gas by utilizing the mixed refrigerant and argon double-refrigeration system, high-purity methane and high-purity argon can be obtained, and nitrogen with relatively higher purity and hydrogen with relatively higher purity can be obtained at the same time.

Owner:HANGZHOU ZHONGTAI CRYOGENIC TECHNOLOGY CORPORATION

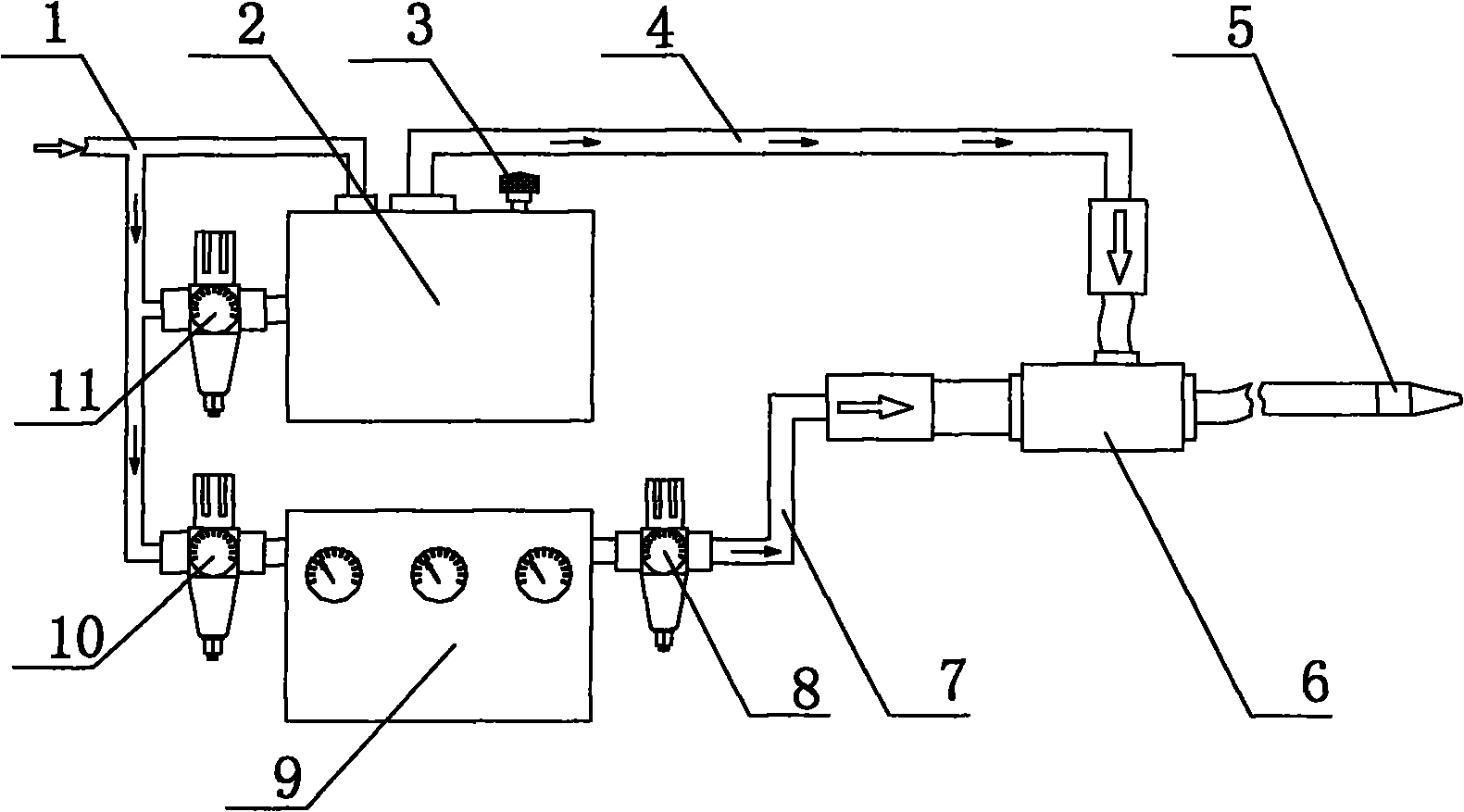

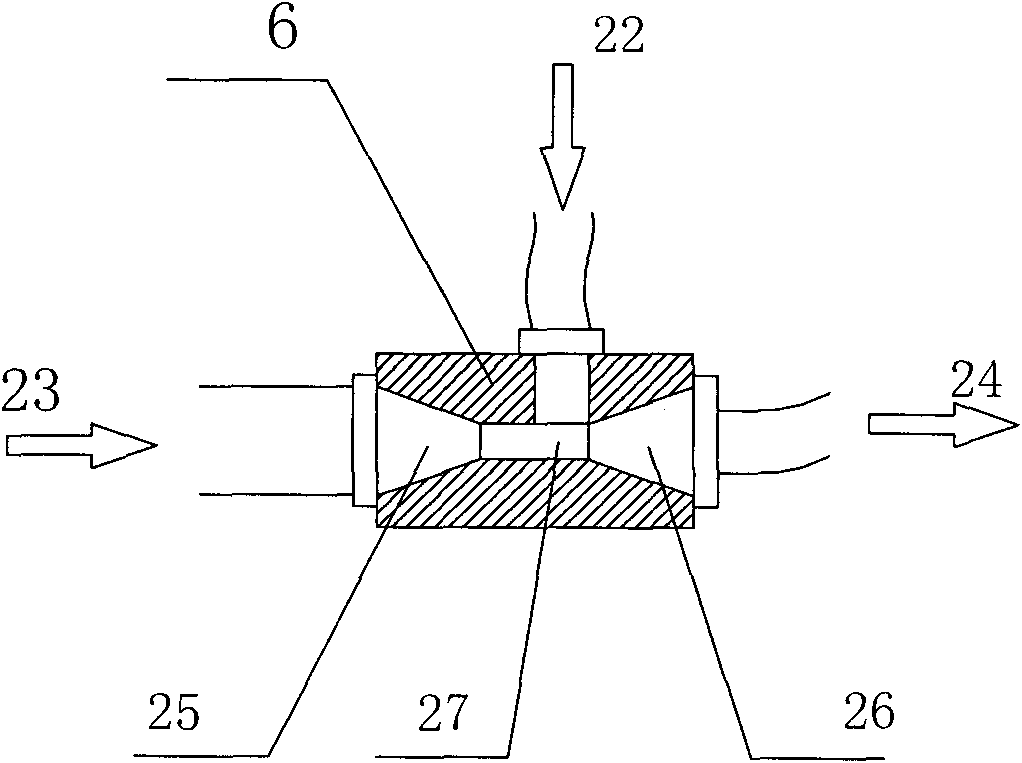

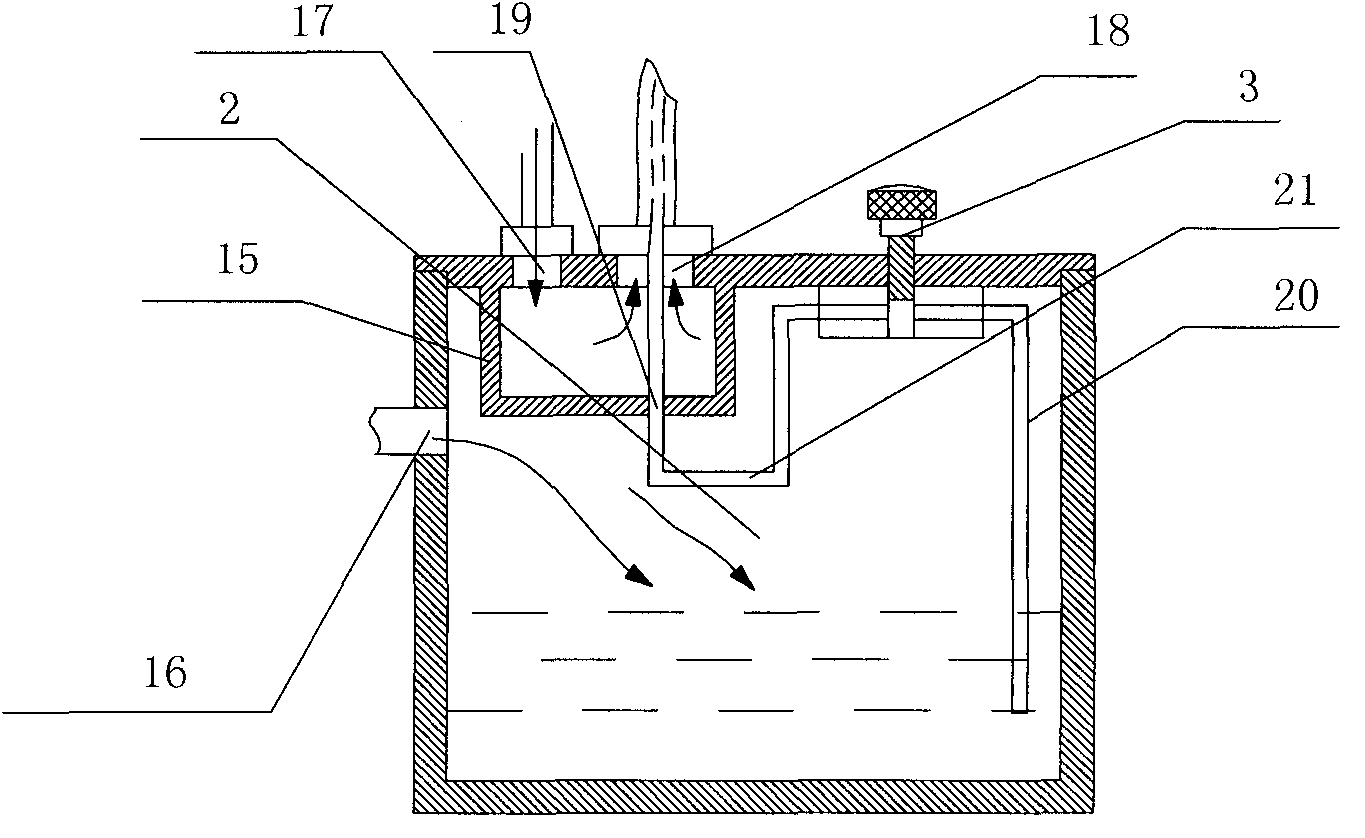

Low-temperature trace lubrication system

InactiveCN101811269ALow costConsume less resourcesMaintainance and safety accessoriesSpray nozzleGas pipeline

The invention relates to a low-temperature trace lubrication system which is characterized in that the system comprises a gas source pipeline, a trace lubrication device, an oil mass regulating valve, an oil mist pipeline, spray nozzles, a mixer, a cold gas pipeline, a low-temperature gas flow regulating valve, a low-temperature gas generation device, a pressure regulating valve of the low-temperature gas generation device and a pressure regulating valve of the trace lubrication device. Part of compressed gas enters the trace lubrication device by the gas source pipeline, and the other part of the compressed gas enters the pressure regulating valve of the low-temperature gas generation device and the pressure regulating valve of the trace lubrication device. After the pressure of the compressed gas is regulated by the pressure regulating valve of the trace lubrication device, the compressed gas enters the trace lubrication device, and a generated oil-gas mixture enters the oil mist pipeline. After the pressure of the compressed gas is regulated by the pressure regulating valve of the low-temperature gas generation device, the compressed gas enters the low-temperature gas generation device, and generated cold gas enters the cold gas pipeline after the flow of the cold gas is regulated. The mixing mode of oil mist and cold air can be mixer mixing and can also be mixing after being ejected by the respective spray nozzles.

Owner:BEIHANG UNIV

Temperature-humidity-stress-chemical coupling test platform for porous dielectric material

InactiveCN102944478AAchieve long-term mechanical loadingReal-time recording of multi-field coupling evolution processMaterial strength using tensile/compressive forcesGas compositionData acquisition

The invention discloses a temperature-humidity-stress-chemical coupling test platform for porous dielectric material. The test platform comprises a closed container, a load-bearing frame, a mechanical test system, an environment simulating system and a data acquiring system; the load-bearing structure is fixedly arranged at upper and lower two ends of the closed container; the mechanical test system comprises a loading device and a power device; the loading device is arranged in the enclosed container; the environment simulating system comprises a temperature simulating device and a humidity simulating device; the environment simulating system further comprises a chemical simulating device; the chemical simulating device comprises a chemical gas generator and a gas pipeline; the outlet of the gas pipeline is connected in the closed container; and a gas analyzer used for monitoring gas component and concentration is further arranged in the closed container. By adopting the test platform provided by the invention, the temperature and humidity changes in atmosphere environment and the influence of gas containing chemical substance to the long-term mechanical property of material can be simulated; and the test platform is feasible for mechanical multi-field coupling research on materials.

Owner:HOHAI UNIV

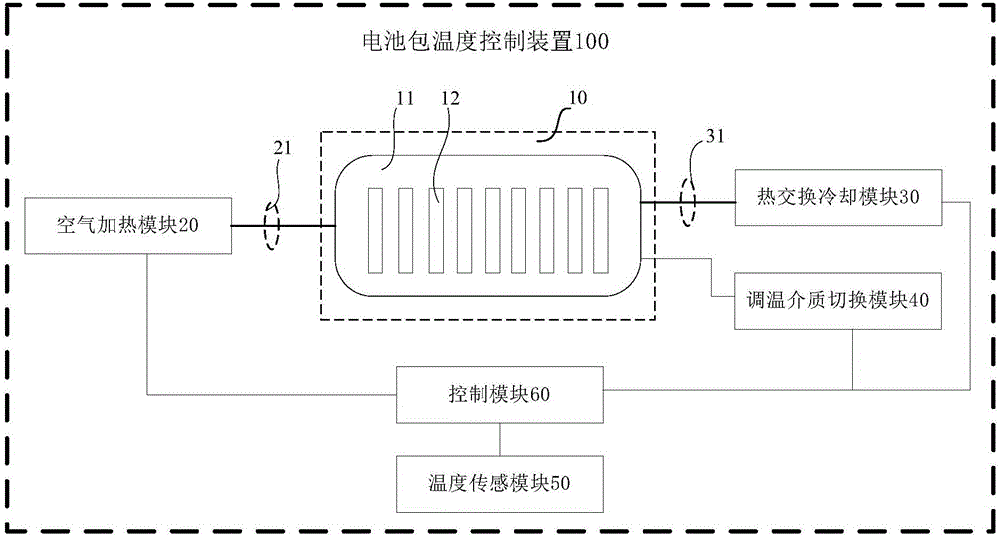

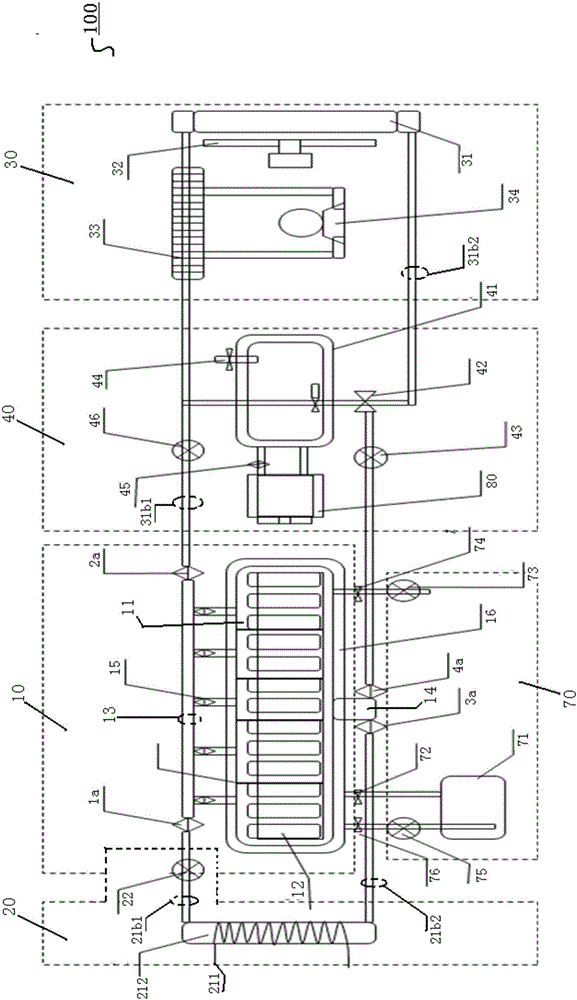

Battery pack temperature control device, temperature control method and vehicle

ActiveCN106532178AImprove work performanceAvoid damageSecondary cellsVehicular energy storageGas pipelineElectrical battery

The invention discloses a battery pack temperature control device, which comprises a battery pack module, an air heating module, a heat exchange cooling module, a temperature adjusting medium switching module, a temperature sensing module and a control module, wherein the battery pack module comprises a battery pack body; the air heating module is used for heating air and circulating hot air between the air heating module and the battery pack body through a gas pipeline; the heat exchange cooling module is used for controlling a cooling liquid to circulate through a liquid pipeline between the heat exchange cooling module and the battery pack body, and cooling the cooling liquid; the temperature adjusting medium switching module is used for switching the type of a temperature adjusting medium in the battery pack body; the temperature sensing module is used for detecting an environment temperature at which the battery pack module is; and the control module controls the air heating module, the heat exchange cooling module and the temperature adjusting medium switching module according to the environment temperature. According to the battery pack temperature control device, a battery pack can be adjusted to work at an optimum temperature and the service life of the batteries is prolonged. The invention further discloses a battery pack temperature control method and a vehicle.

Owner:BAIC MOTOR CORP LTD

Numerical analog method for impact of gas pipeline leakage on internal flow field

The invention discloses a numerical analog method for impact of gas pipeline leakage on an internal flow field, relating to the technical field of gas. The analog method comprises the following stepsof building analog software; modeling gas pipeline leakage and performing simulation analysis; and analyzing gas pipeline leakage numerical results. Before and after gas pipeline leakage, changes of the internal flow field of the pipeline are analyzed; according to computational fluid dynamics (CFD) knowledge, gas pipeline leakage is simulated by using Fluent, and according to fluid dynamics theory, characteristics of the internal flow field of the gas pipeline before and after leakage are obtained through analysis; according to CFD knowledge, gas pipeline leakage under different leakage conditions is simulated, so as to learn that the greater the inlet pressure, the more likely that a leakage accident occures, and the greater the leakage hole diameter, the higher the proportion of a highconcentration area surrounding the leakage hole.

Owner:HARBIN UNIV OF SCI & TECH

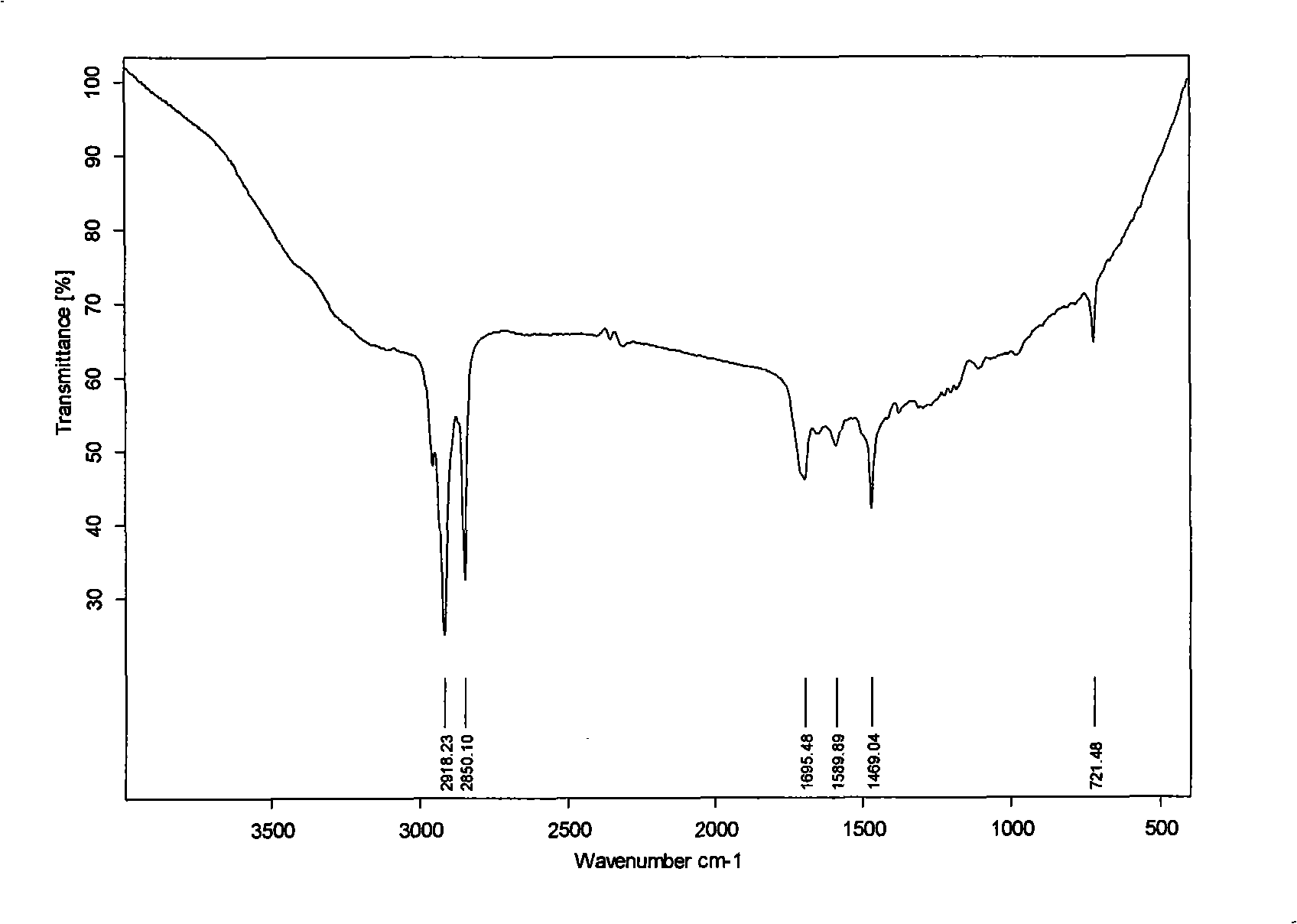

Gas pipeline drag reduction agent and preparing method thereof

The invention relates to a gas line drag reduction agent and a preparation method thereof, relating to the technical field of the composite of high-molecular compound and piping systems. The drag reduction agent consists of carbon bisulfide, hydrazine hydrate and long chain acid, the mol ratio of which is 1.8:1:1 to 2.2:1:1. The preparation method comprises the following steps: step one, CS2 is taken according to proportional quantity, dripped into the mixed liquor of the hydrazine hydrate and water with proportional quantity under agitation, reflowed for certain time in the temperature range of 90 to 95 DEG C, then cooled for 30 to 60 minutes in ice water bath and pumped and filtered, the mother liquor continues to react for two times, products of the third time are merged, washed by using ethanol and ether sequentially, and recrystallized by using boiling water so as to obtain symmetrical diaminothiourea clear crystal; and step two, symmetrical diaminothiourea with proportional quantity and the long chain acid with proportional quantity are dissolved in a pyridine solvent with nitrogen protection, reflowed at the temperature of 140 to 220 DEG C by adopting a temperature programming method, and react for 3 to 4 hours, then the mixture is cooled to the room temperature and recrystallizated by using the ethanol of 95 percent to obtain the brown product.

Owner:PIPECHINA SOUTH CHINA CO

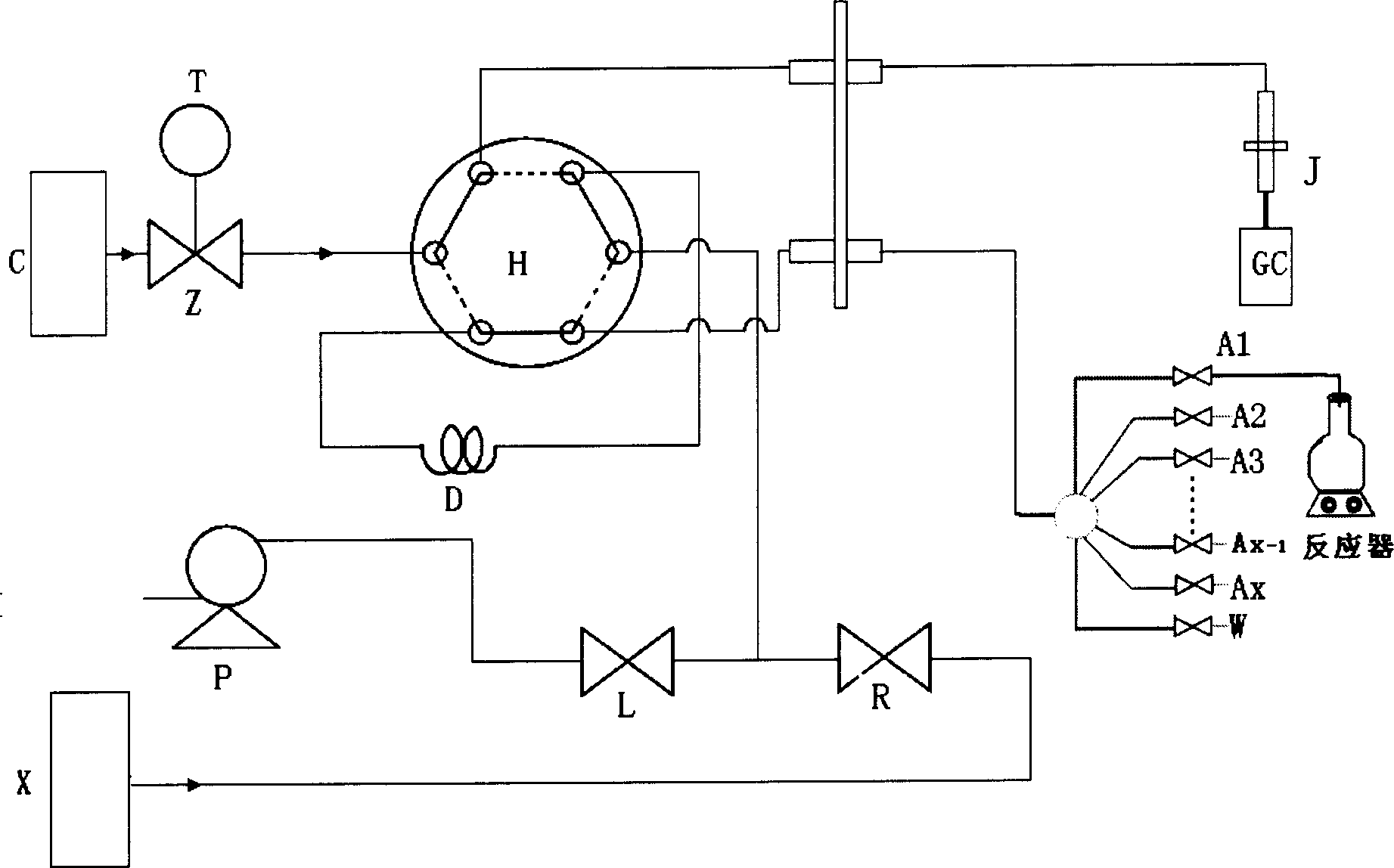

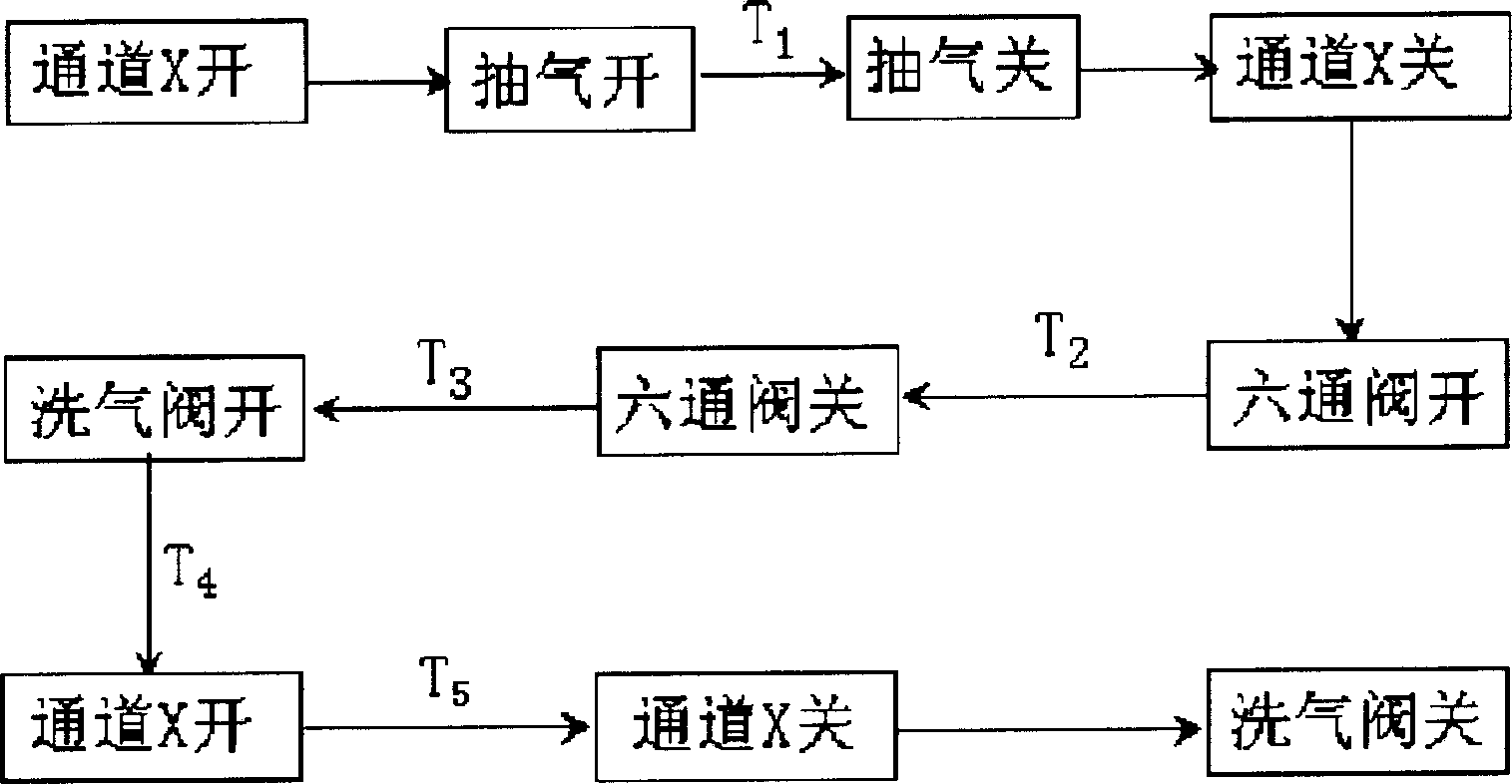

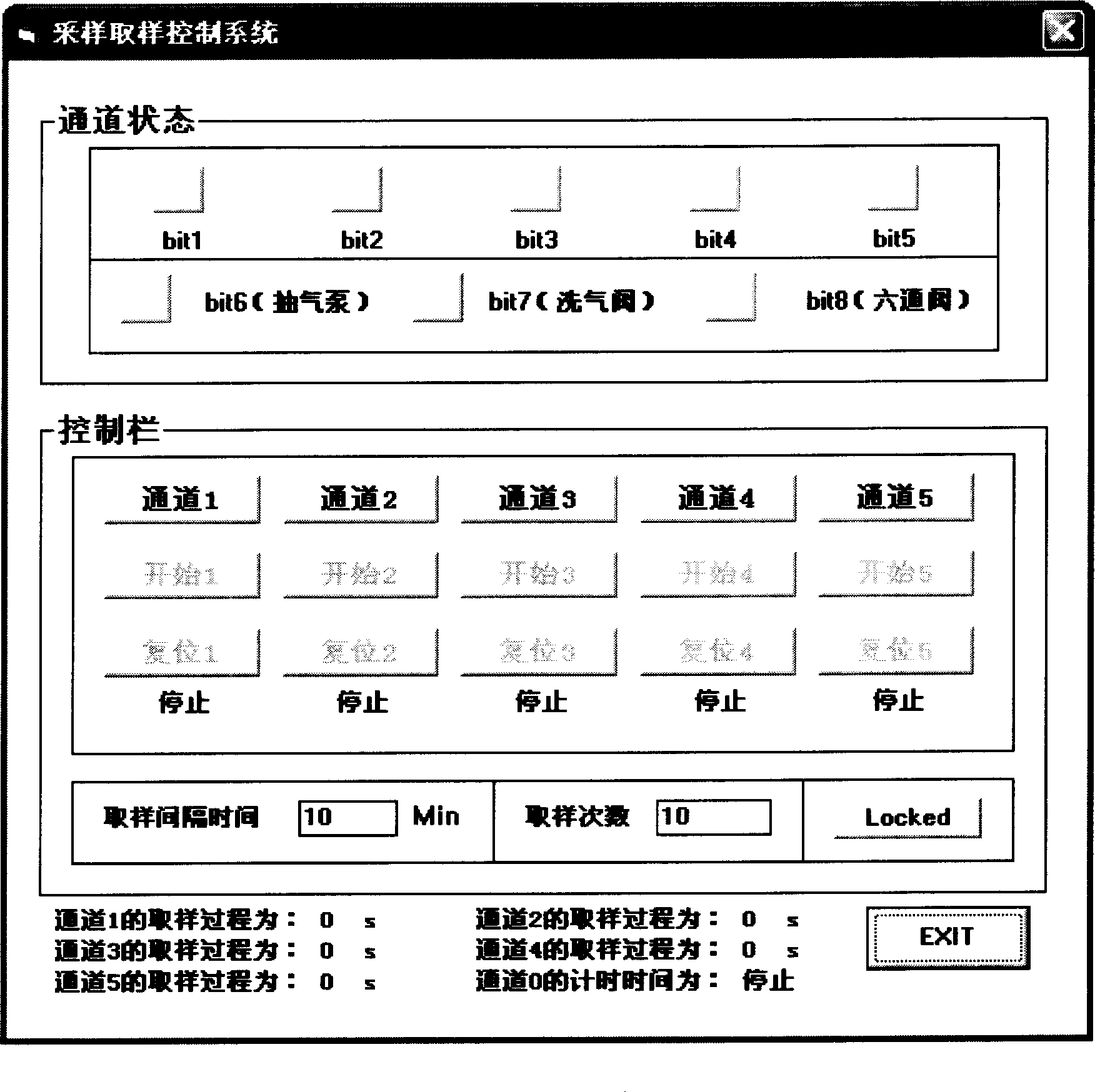

Fast On-line sampler with sample feeding for multi-channel gas and catalyst performance determining system

InactiveCN1818661AKeep the pressure constantTest accurateWithdrawing sample devicesGas handling apparatusAutomatic controlGas cylinder

An on-line quickly sampling and sample feeding device of multichannel gas consists of gas sampling unit formed by gas pipeline, multiple solenoid valves and a microdiaphragm vacuum pump; an fully-automatic six-way valve for feeding gas sample automatically; pipeline washing unit formed by a gas washing bottle and multiple solenoid valves; control unit formed by multiple switches being controlled manfully or being controlled automatically by computer .The property evaluating system of catalyst by utilizing said device is also disclosed .

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com