Patents

Literature

1525 results about "Gas consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

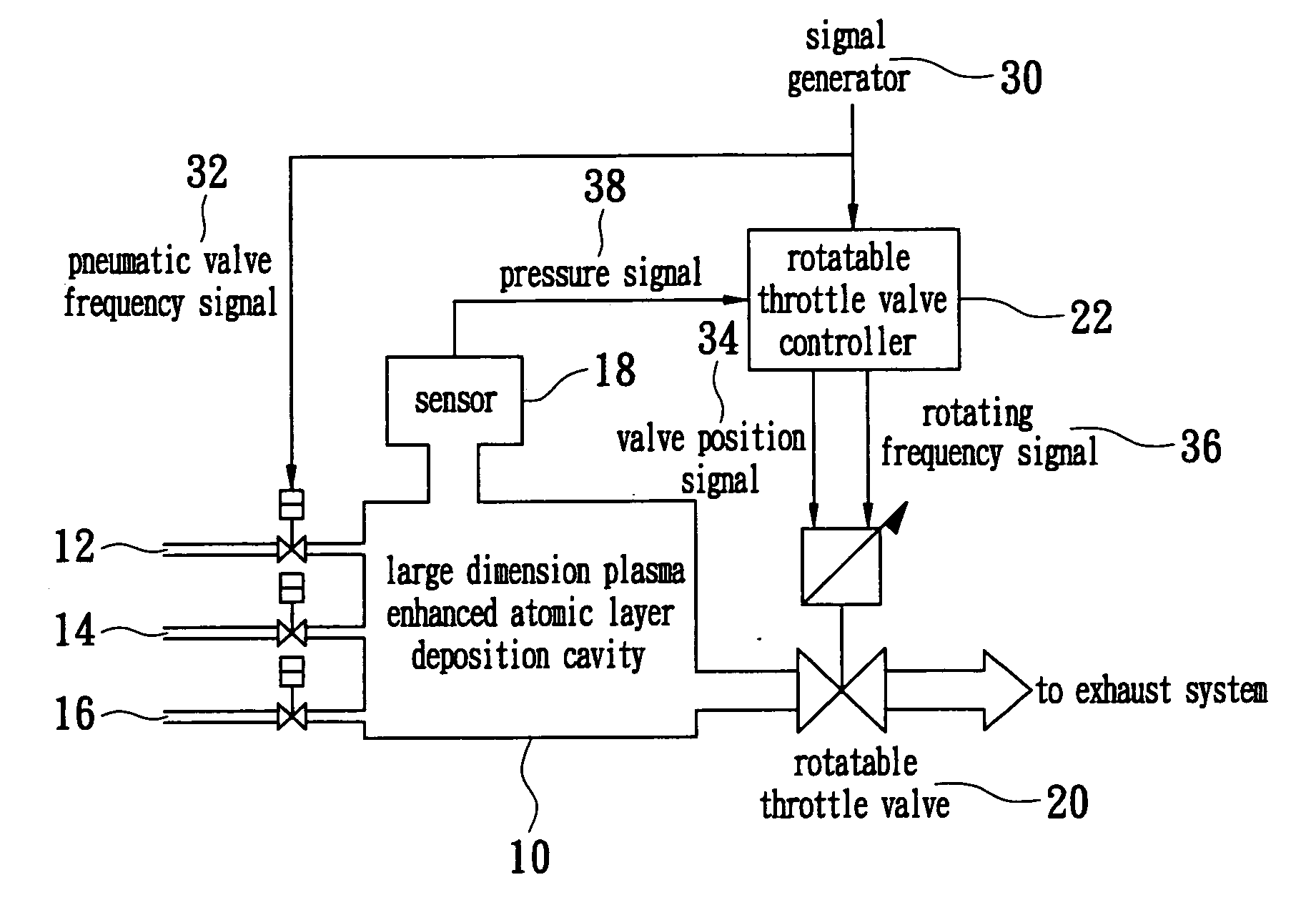

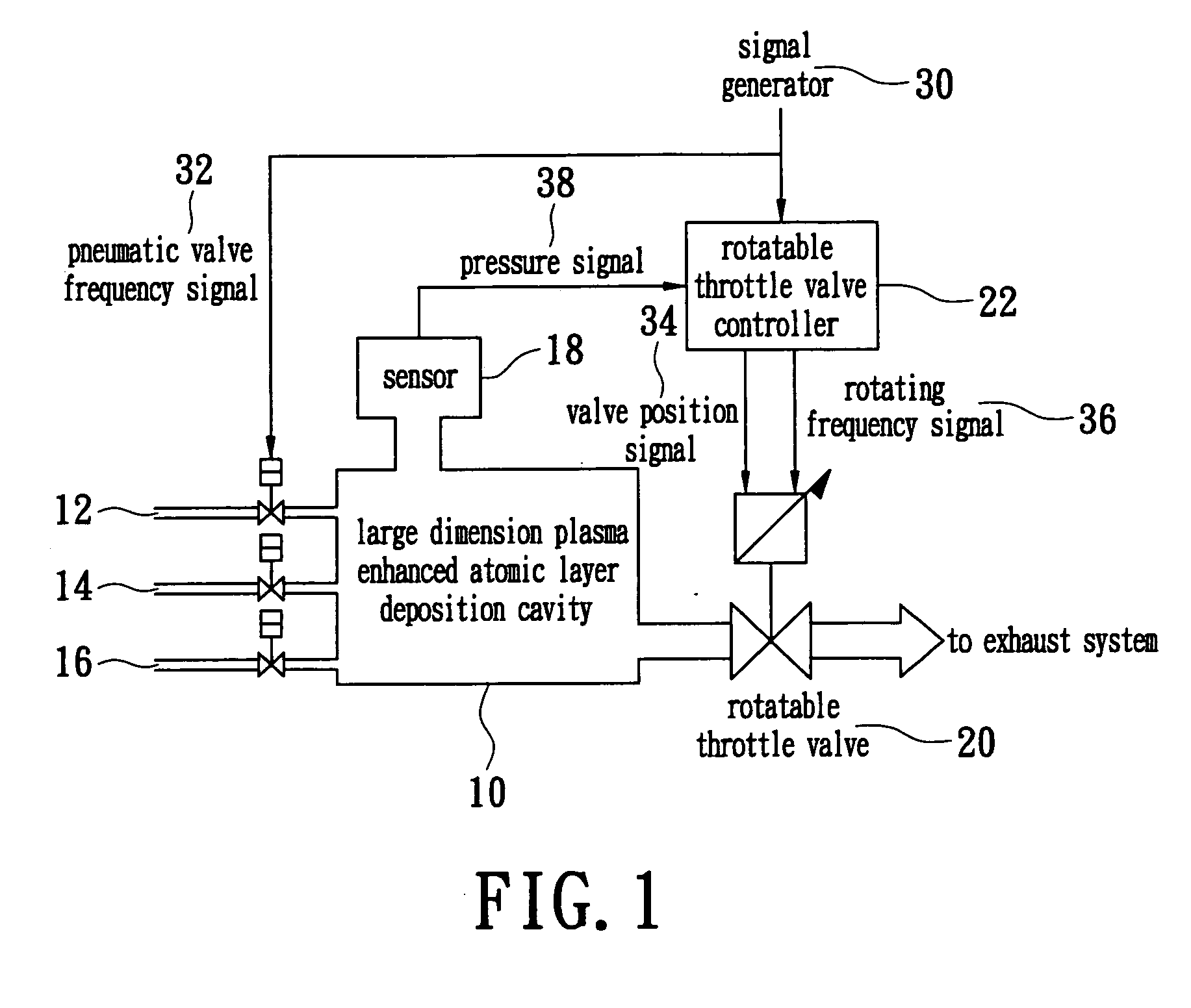

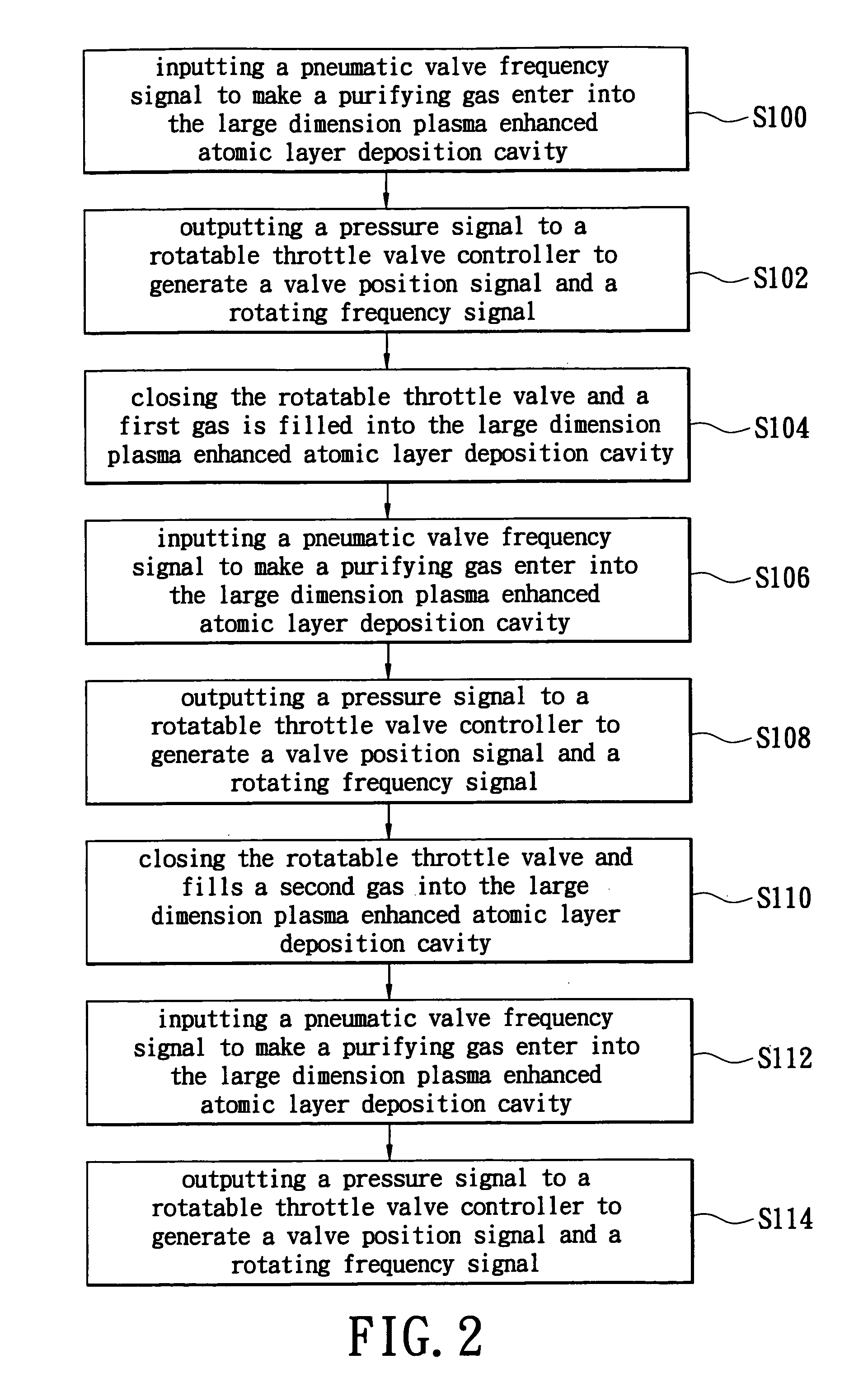

Operating method for a large dimension plasma enhanced atomic layer deposition cavity and an apparatus thereof

ActiveUS20070026162A1Effectively control pressureIncrease airflowSemiconductor/solid-state device manufacturingChemical vapor deposition coatingManufacturing cost reductionEngineering

An operating method for a large dimension plasma enhanced atomic layer deposition cavity and an apparatus thereof are provided. The present invention reduces the time needed for filling the manufacturing gas into the large volume manufacturing cavity. Therefore, the plasma enhanced atomic layer deposition apparatus can switch the precursors rapidly to increase the thin film deposition rate, reduce the manufacturing gas consumption and lower the manufacturing cost.

Owner:CHINA STAR OPTOELECTRONICS INT HK

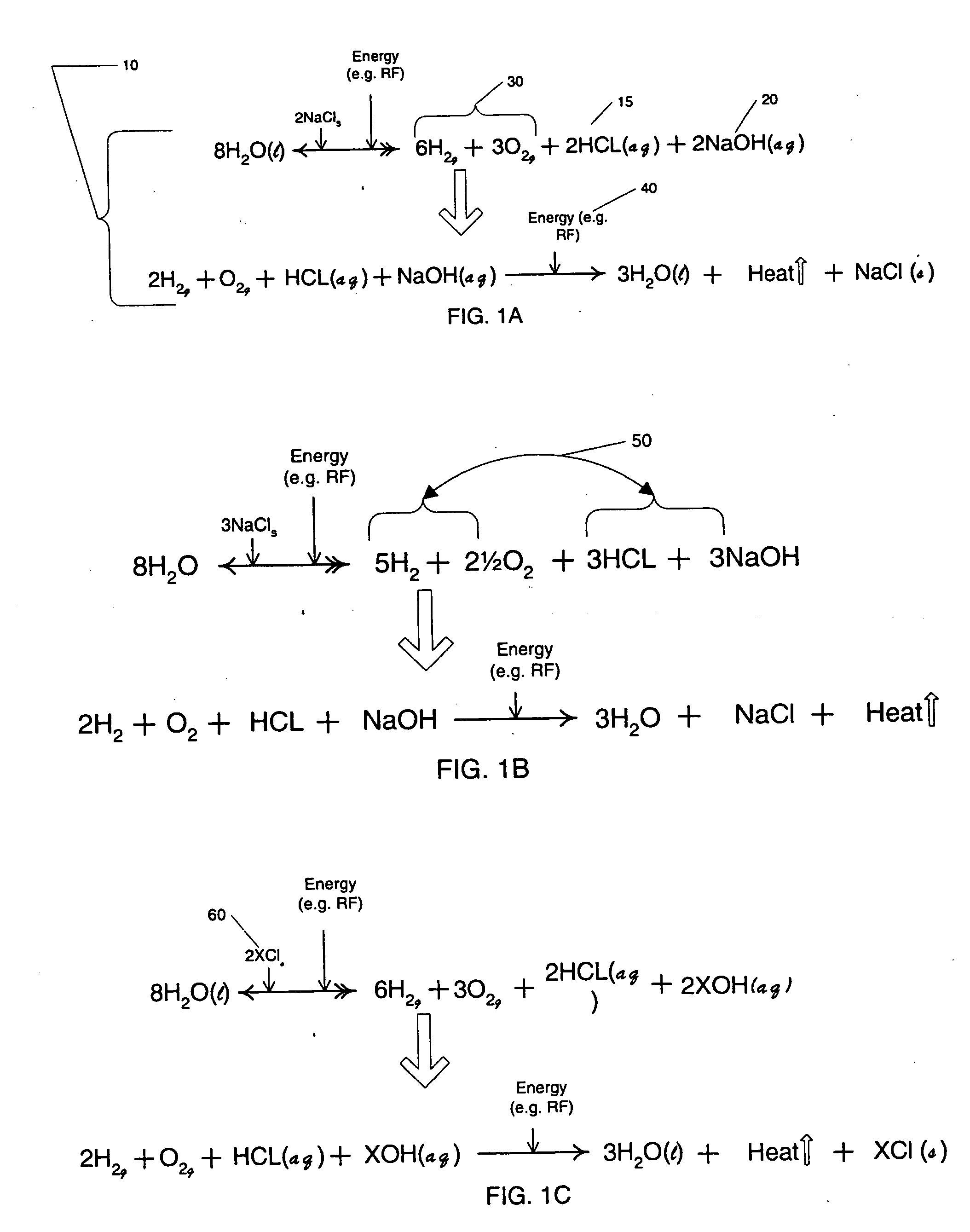

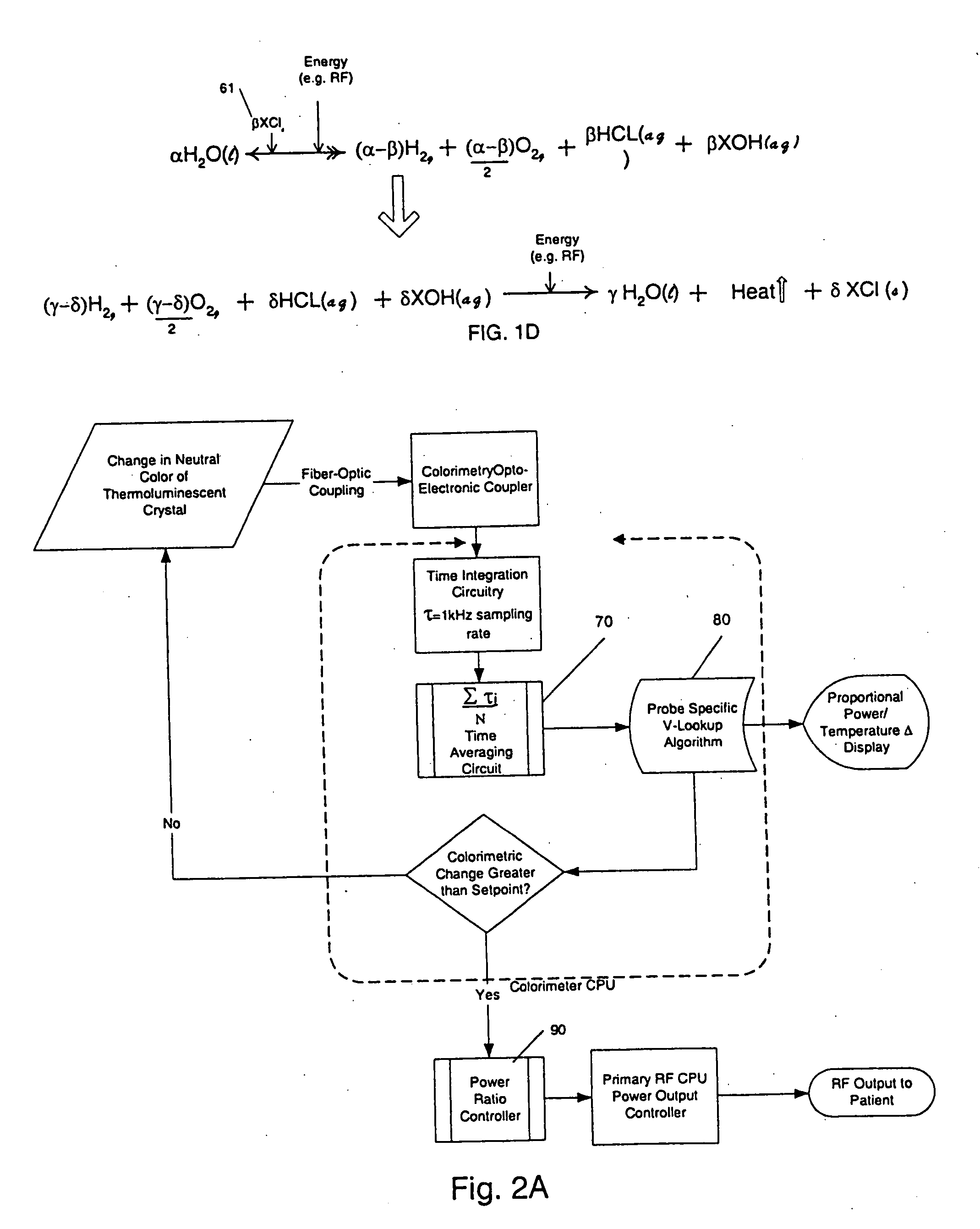

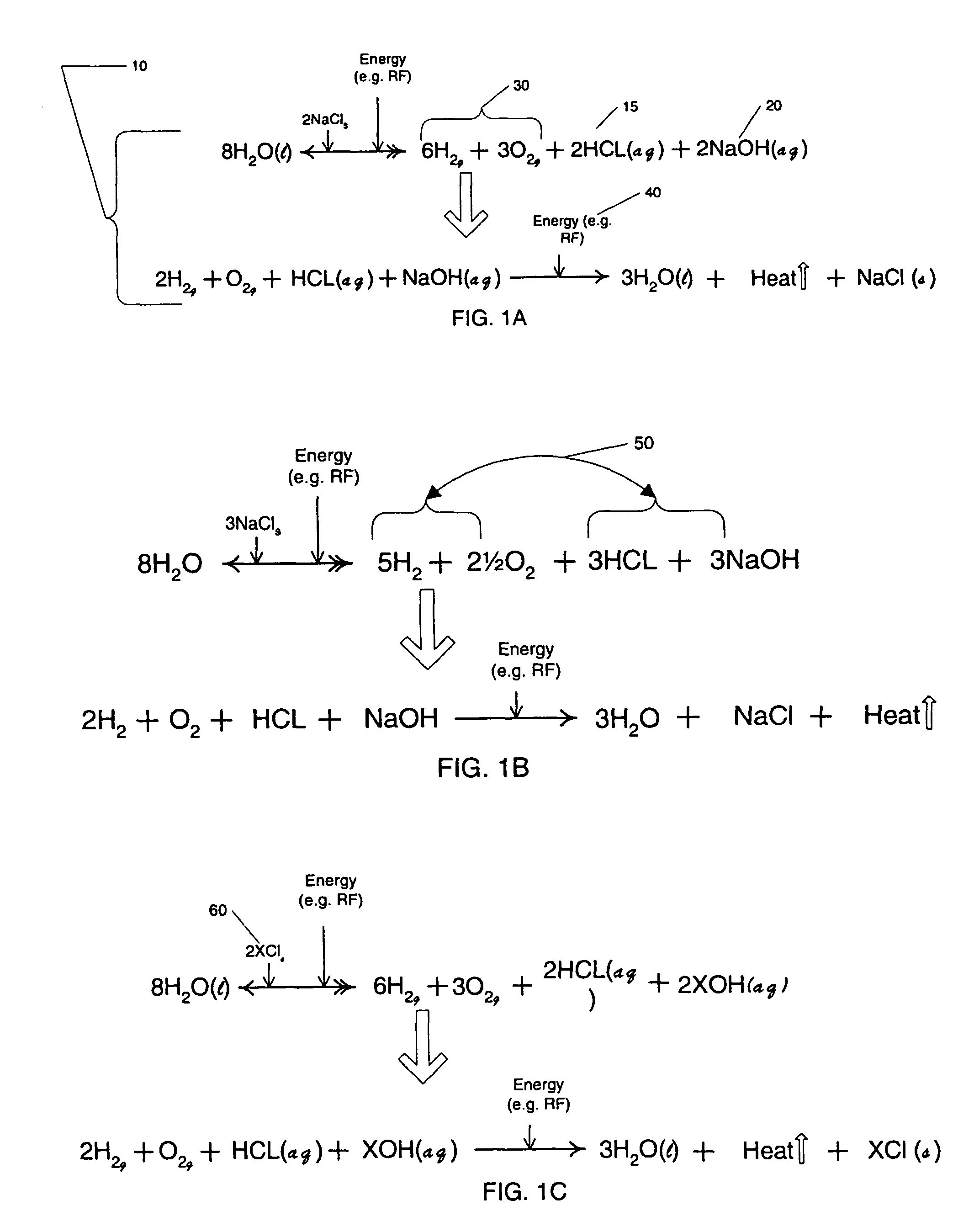

Methods and devices for electrosurgery

InactiveUS20050085806A1Efficient use ofImprove efficacySurgical instruments for heatingElectrolysisControl system

Devices and methods for electrolytic electrosurgery wherein a detector is located proximal to an active electrode on an electrosurgical probe, optionally disposed between the active electrode and a return electrode, the detector detecting at least on parameter relating to electrolysis. The detected parameter can include pH concentration, temperature, conductivity, impedance, ion, concentration, electrolytic gas consumption, electrolytic gas production, pressure or sound. The detected parameter can be employed in control systems to control systems to control activation or operation of the electrosurgical probe.

Owner:NUORTHO SURGICAL

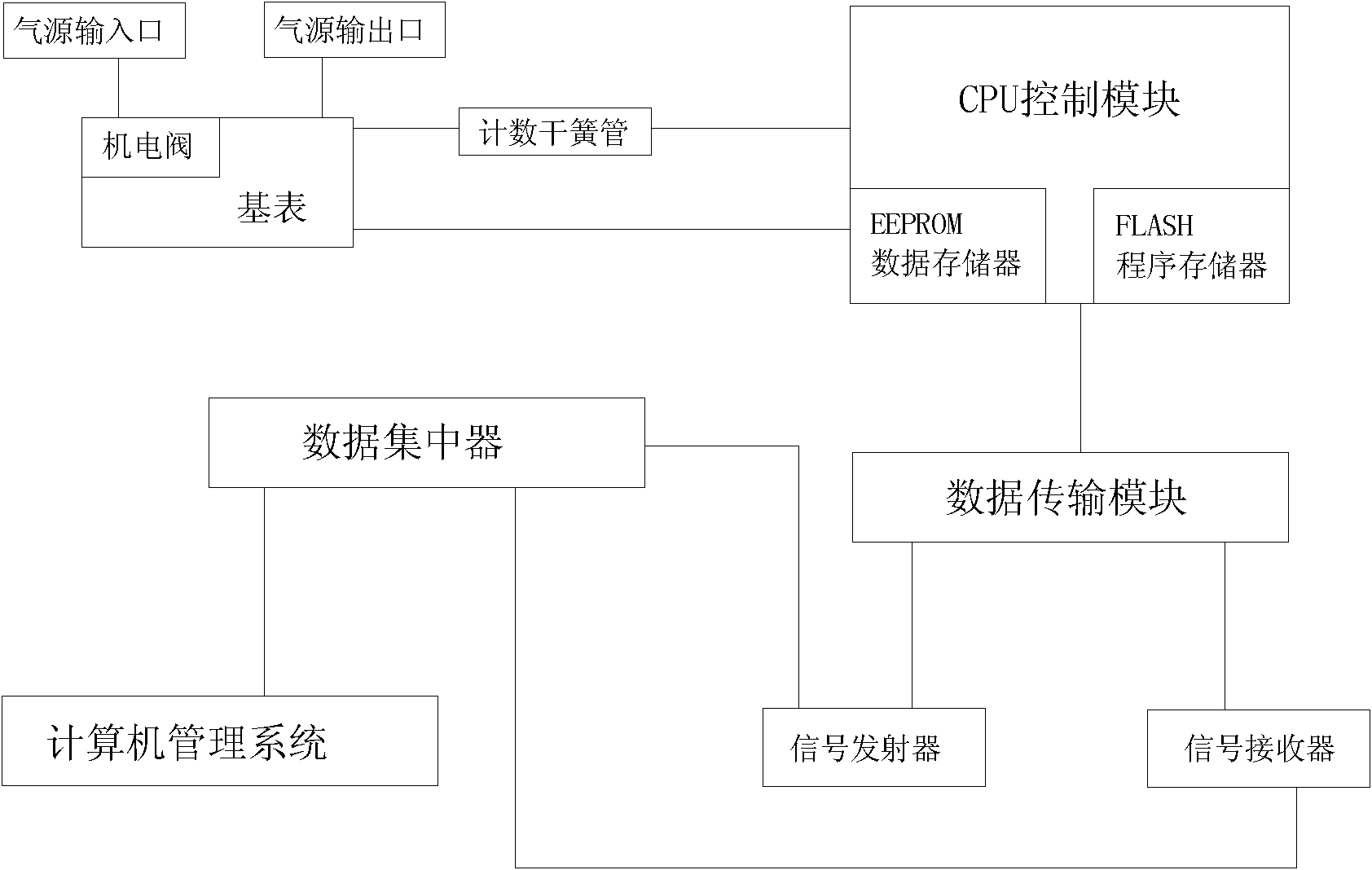

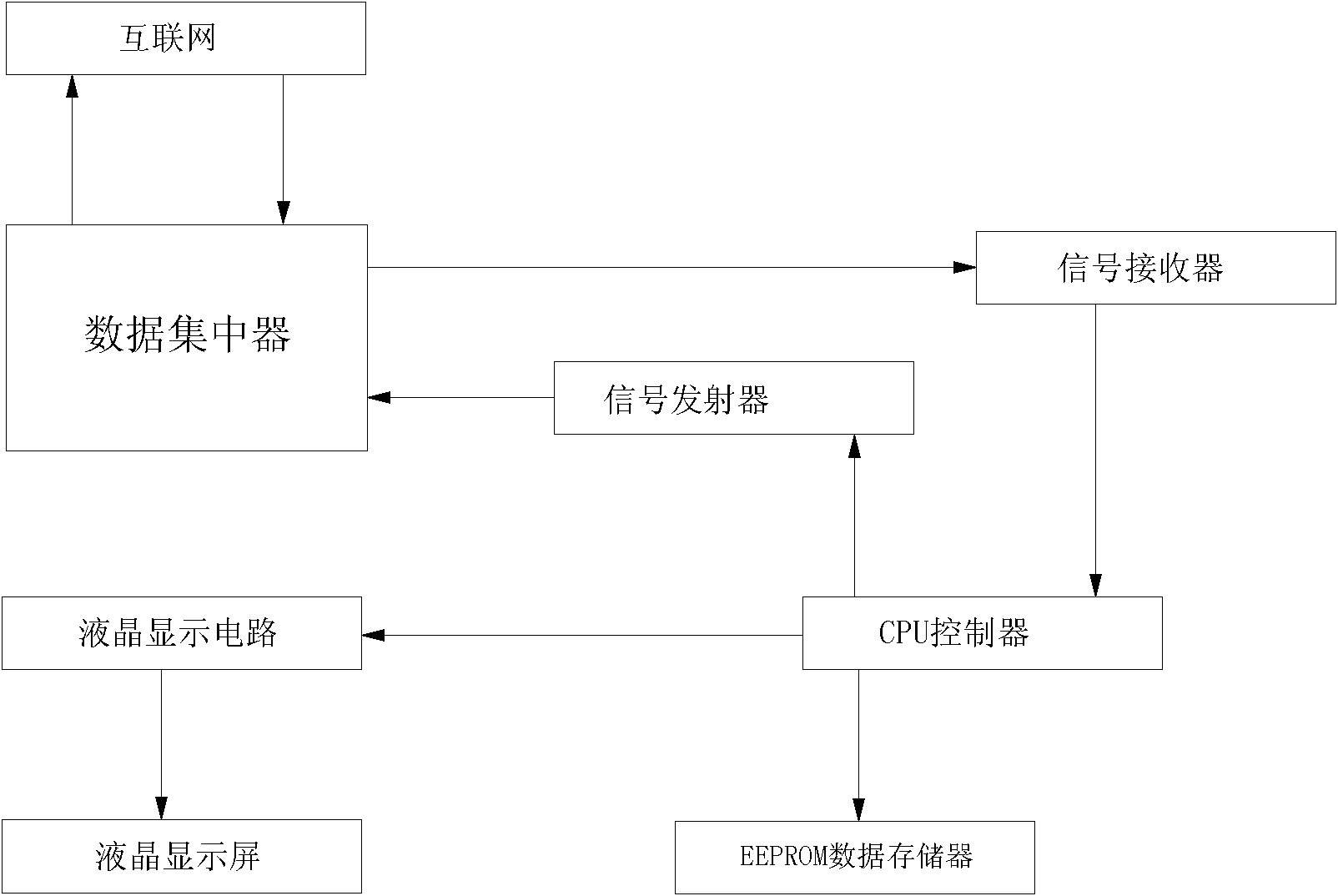

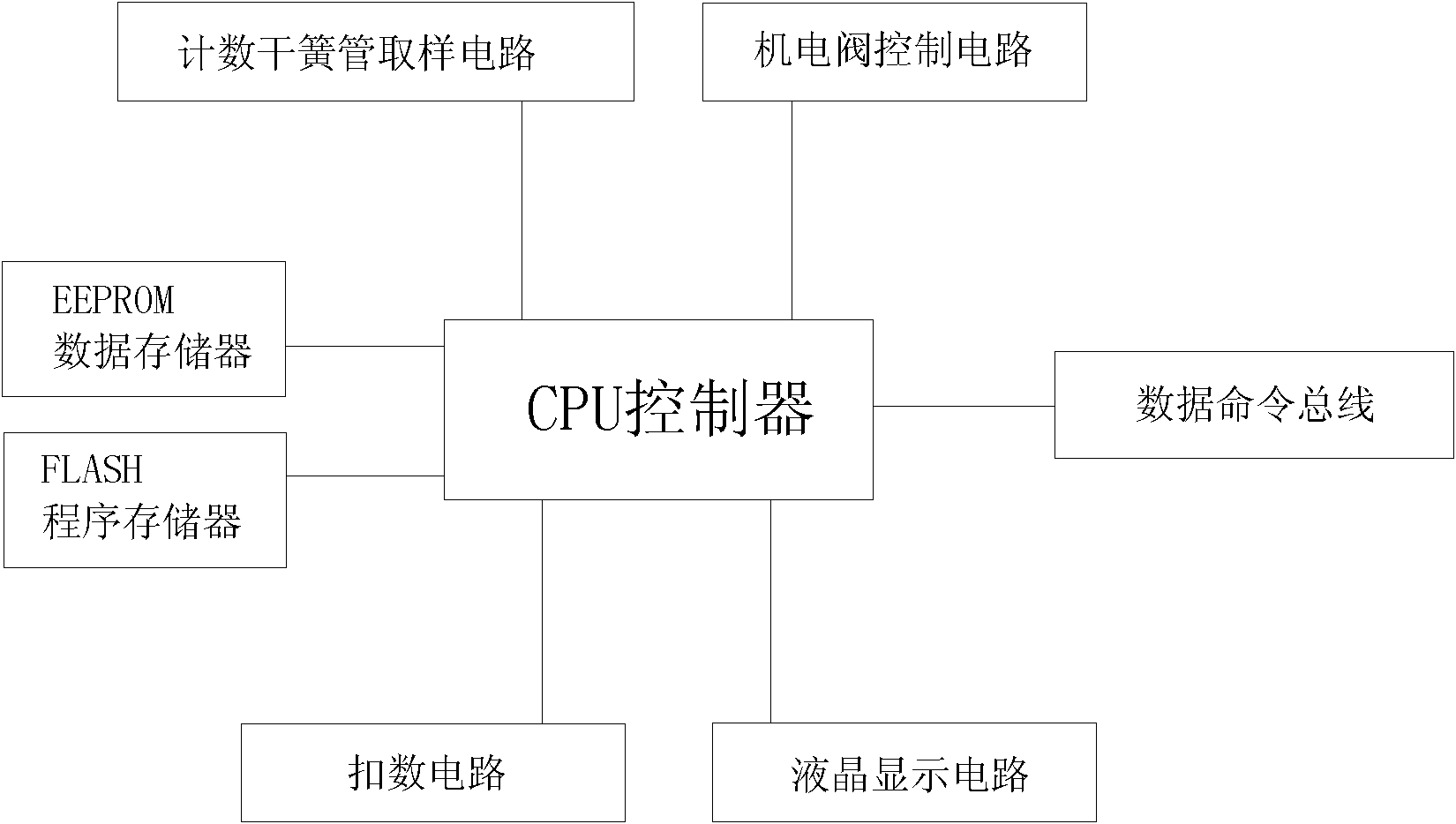

Intelligent gas meter of Internet of things and control system thereof

ActiveCN102063764AAvoid hoardingRealize remote control managementTariff metering apparatusVolume meteringProgrammable read-only memoryControl signal

The invention discloses an intelligent gas meter of the Internet of things and a control system thereof, belonging to an intelligent gas meter. The intelligent gas meter comprises a base meter, a CPU (Central Processing Unit) control module and a data transmission module. The base meter is provided with a source gas outlet and a source gas inlet. An electromechanical valve is installed close to the source gas inlet. The CPU control module is connected with the base meter and transmits a control signal to the base meter. The gas consumption standard of the base meter can be adjusted by the CPU control module. The CPU control module comprises an EEPROM (Electrically Erasable Programmable Read-Only Memory) data memory. The data transmission module is indirectly connected with the Internet of things and is also connected with a remote computer management system via the Internet of things. The data transmission module receives the control signal from the remote computer management system and feeds back the gas consumption information transmitted by the CPU control module to the computer management system. The intelligent gas meter of the Internet of things and the control system thereof are suitable for the gas use networks in areas and has the advantages of wide application range and easiness of generalization.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

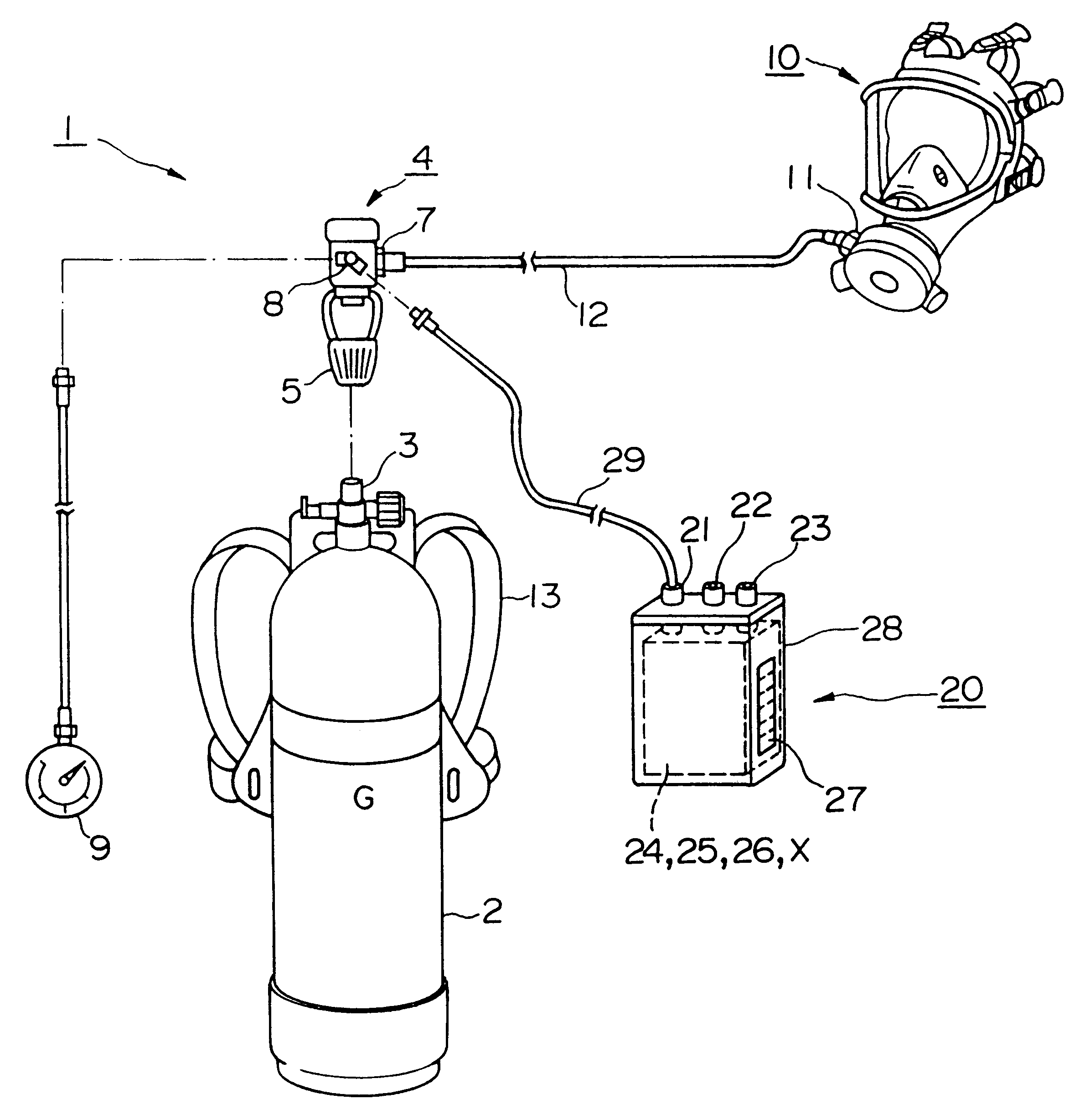

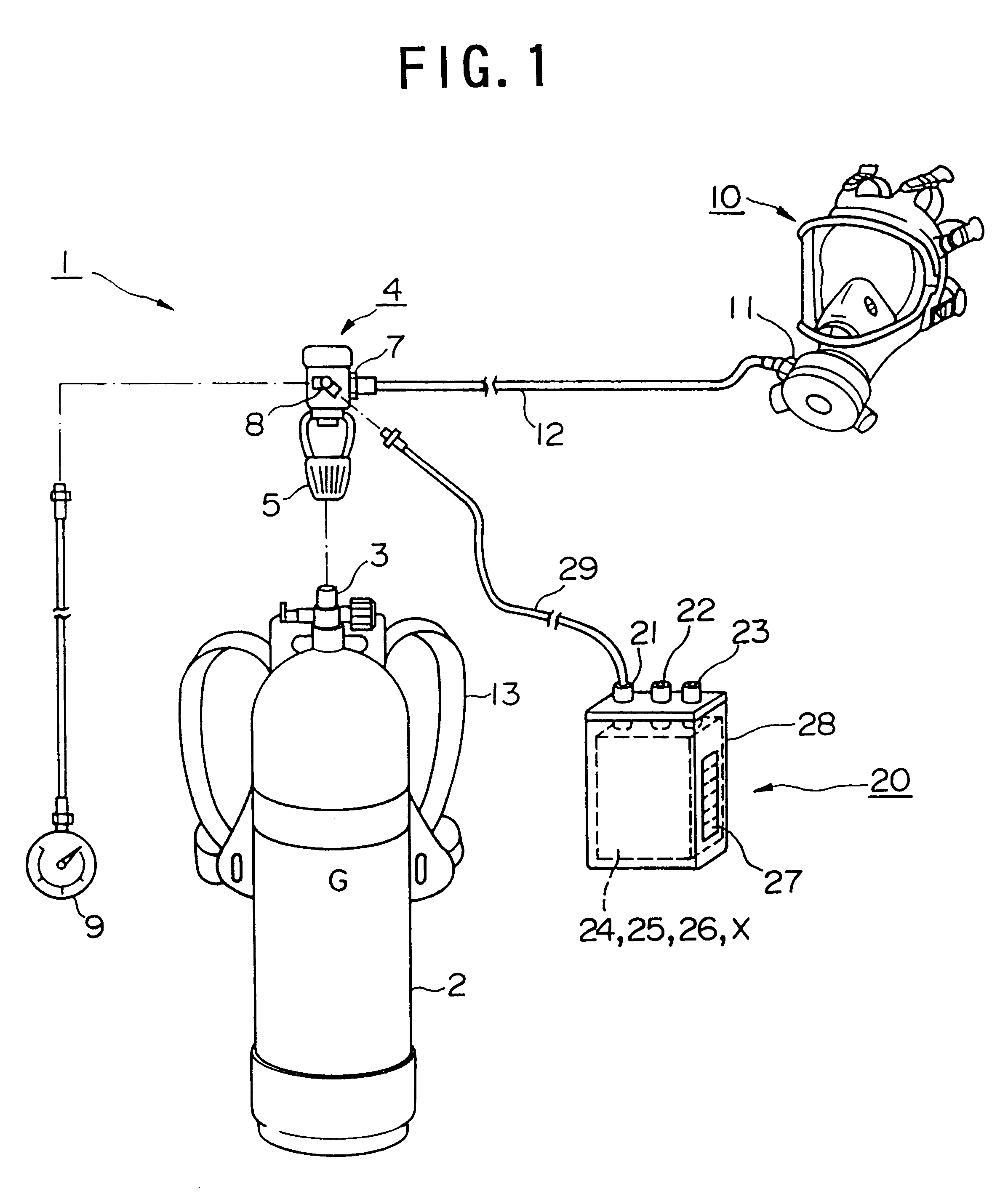

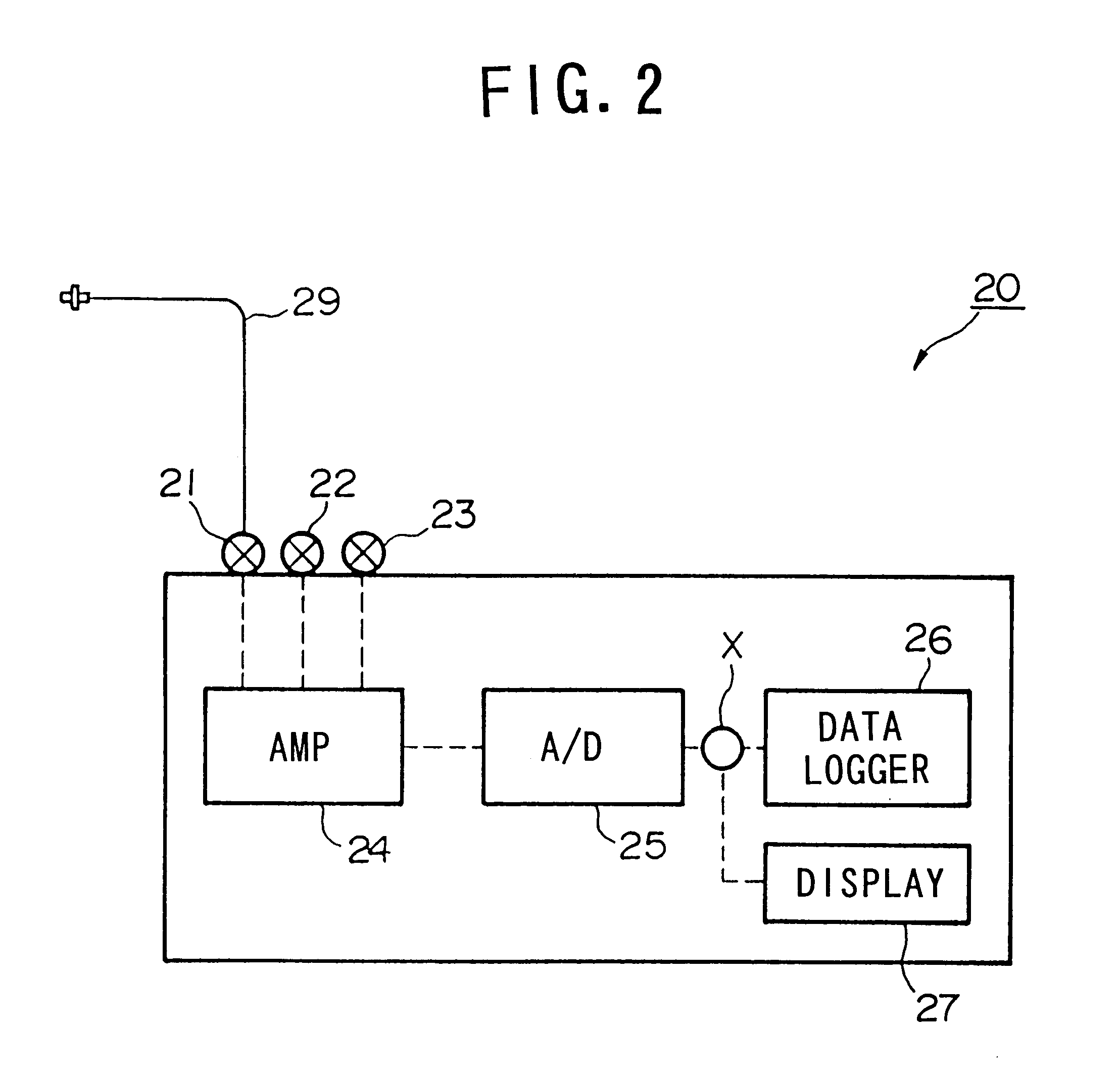

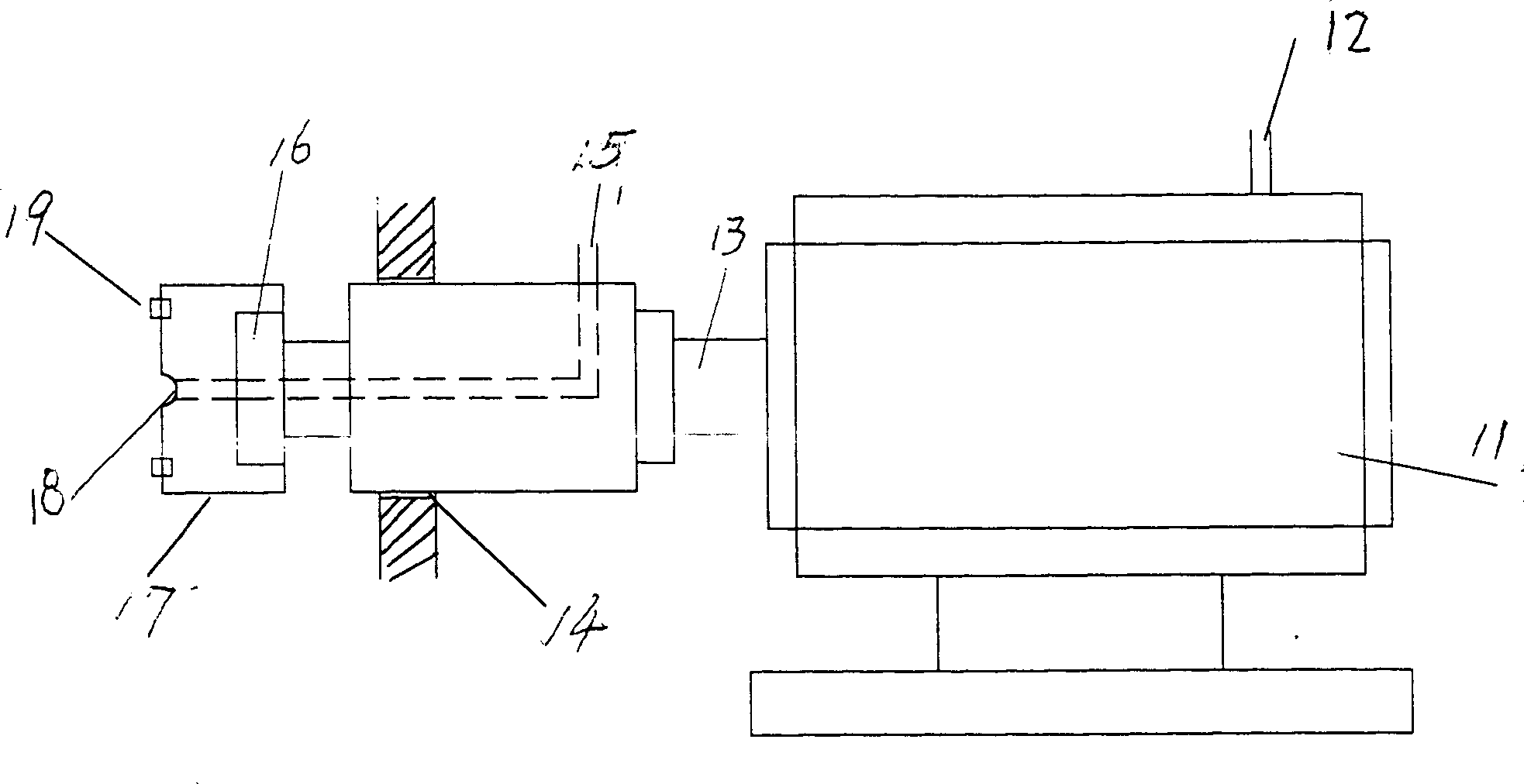

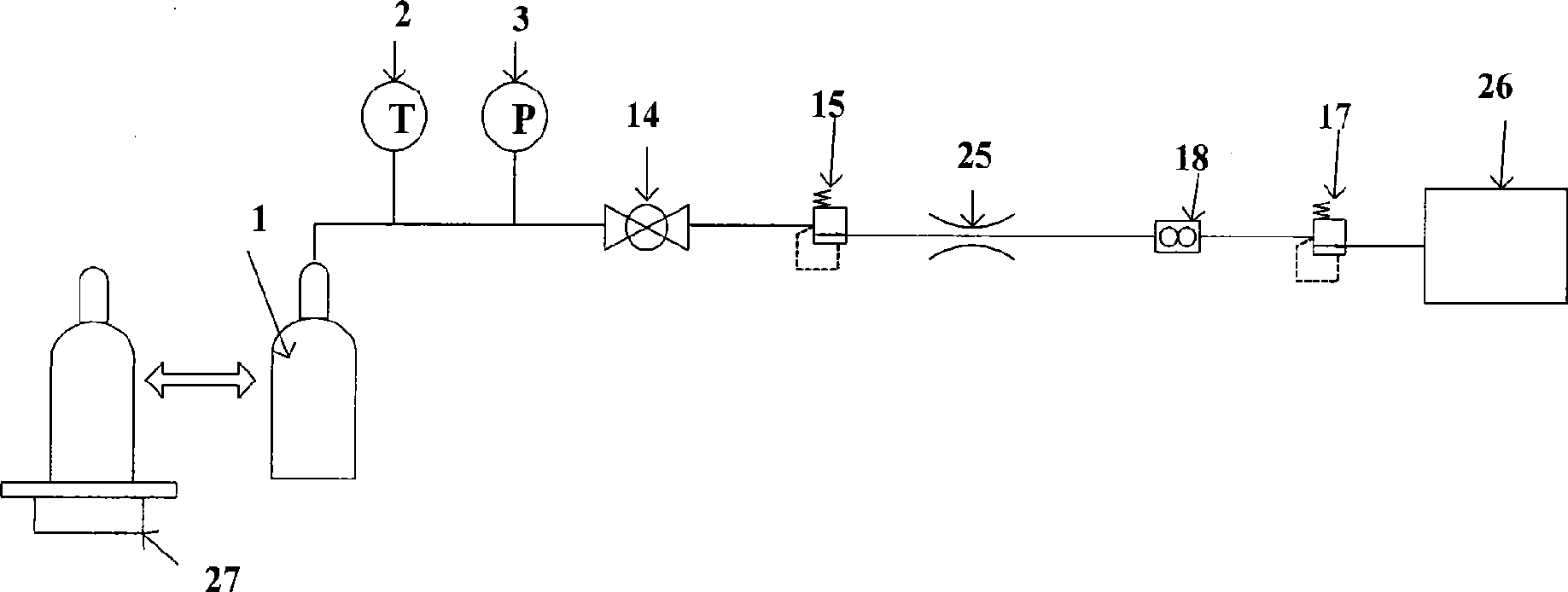

Respiratory gas consumption monitoring device and monitoring method

InactiveUS6258039B1Accurate measurementEasy to useRespiratorsRespiratory organ evaluationDisplay deviceEngineering

The present invention relates to a respiratory gas consumption monitoring method and monitoring device that is portable and has high measurement accuracy, for enabling the analysis and prediction of the respiratory behavior of subjects employing a variety of different types of breathing apparatuses in water, etc. Respiratory gas consumption monitoring device (20), for monitoring the respiratory gas consumption of the user of a breathing apparatus (1) in which a respiratory gas (G) inside a high pressure gas container (2) is reduced in pressure at pressure regulator (4) and supplied to a breathing mask (10), is provided with:a primary pressure sensor (21) for detecting the pressure prior to pressure reduction at pressure regulator (4);a temperature sensor (22) for correction;an environmental pressure sensor (23) for detecting the environmental pressure;an amplifier (24) for amplifying the signals from the aforementioned sensors;an A / D converter (25) for performing analog / digital conversion of the amplified signal;a data logger (26) for recording and storing the analog / digital converted signals; anda display (27) for display.In addition, as needed, a computer (X) for calculating, analyzing, and predicting data may be housed in housing (28), and connected to breathing apparatus (1) by connecting primary pressure sensor (21) to a high pressure opening (8) of pressure regulator (4) using a high pressure hose (29).

Owner:NIPPON SANSO CORP +1

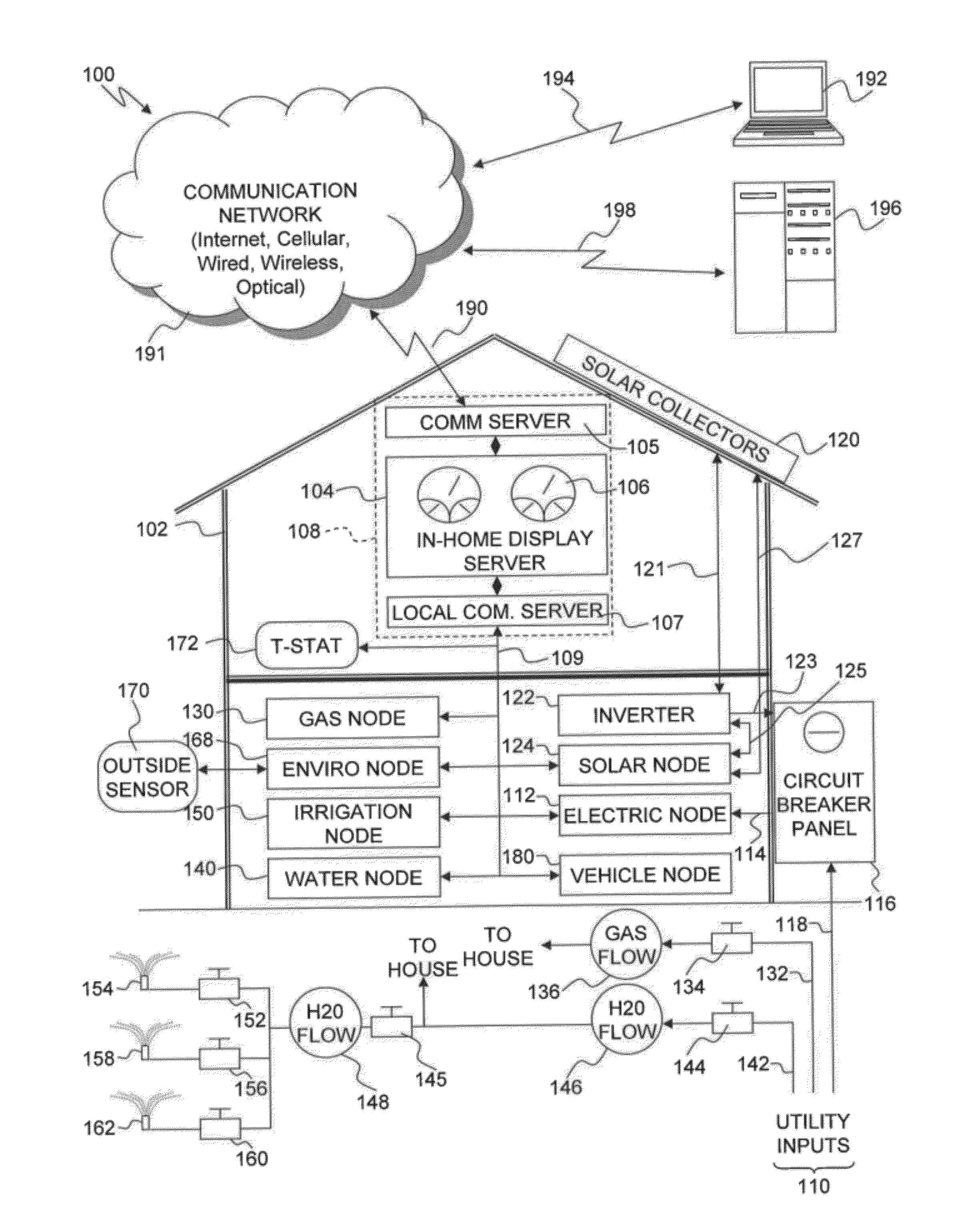

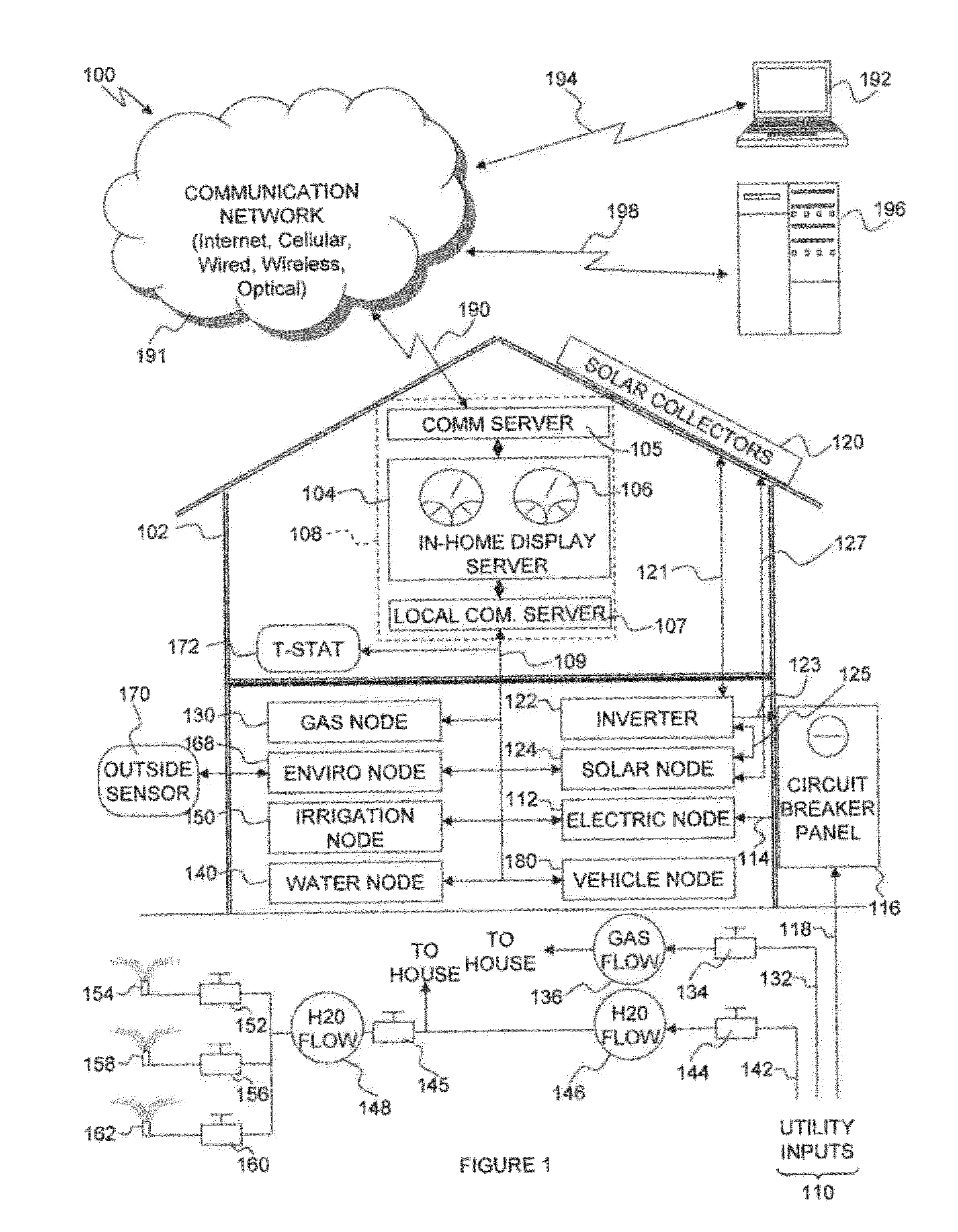

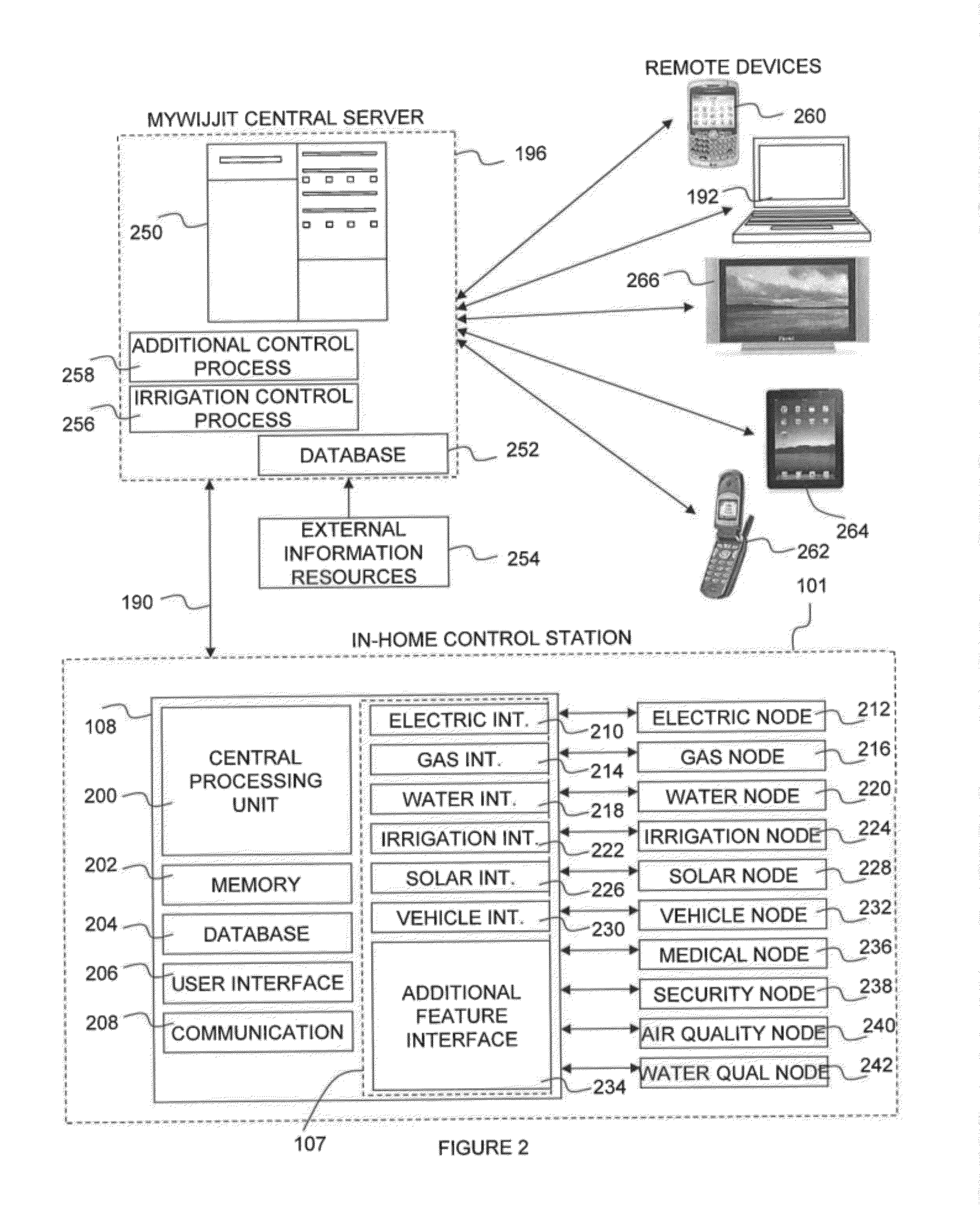

Resource management and control system

InactiveUS20120054125A1Easy to useSave effortProgramme controlData processing applicationsWater useService-level agreement

A resource management and control system includes real-time visibility to energy and water consumption. The resource management platform is flexible and allows users to create a system to suit their individual needs, and to make changes to that platform as their needs change and new needs arise. The resource management and control system monitors electricity and gas consumption, solar production, and water use in real time. The control system includes a number of wireless access nodes for interfacing with the various systems within a property, and also includes monitoring, diagnostic and alerting capabilities. Billing system integration provides historical data for the cost of resource usage and production relative to time, geography and consumer service level agreements and allows the user the ability to directly correlate consumption behaviors with cost implications. Autonomously operating control processes are incorporated to automatically configure and control devices for optimal resource consumption and application.

Owner:CELEVATORON ERIC DOUGLASS +1

Methods and devices for electrosurgery

InactiveUS7771422B2Improve efficacyImprove securitySurgical instruments for heatingElectrolysisControl system

Devices and methods for electrolytic electrosurgery wherein a detector is located proximal to an active electrode on an electrosurgical probe, optionally disposed between the active electrode and a return electrode, the detector detecting at least on parameter relating to electrolysis. The detected parameter can include pH concentration, temperature, conductivity, impedance, ion, concentration, electrolytic gas consumption, electrolytic gas production, pressure or sound. The detected parameter can be employed in control systems to control systems to control activation or operation of the electrosurgical probe.

Owner:NUORTHO SURGICAL

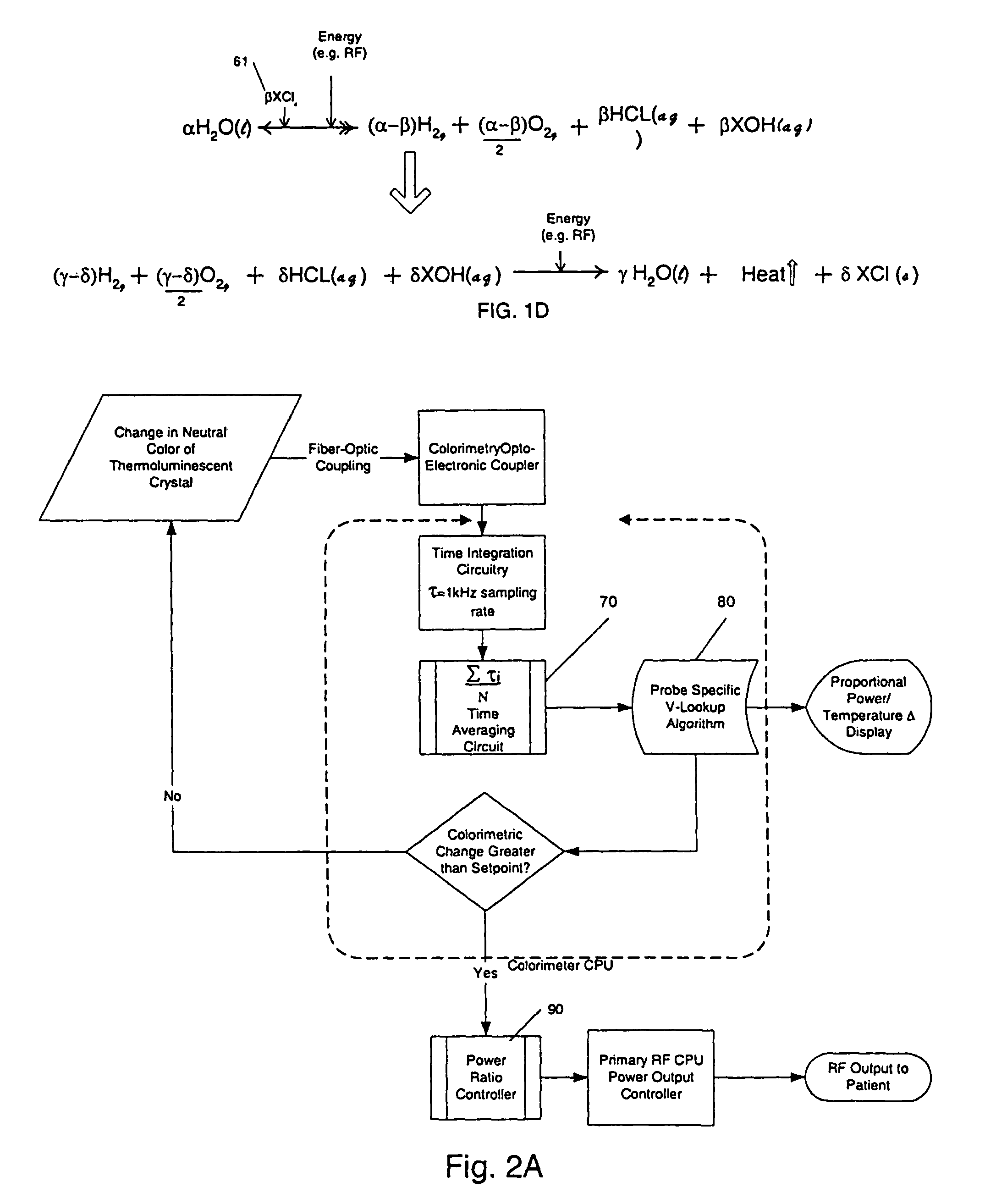

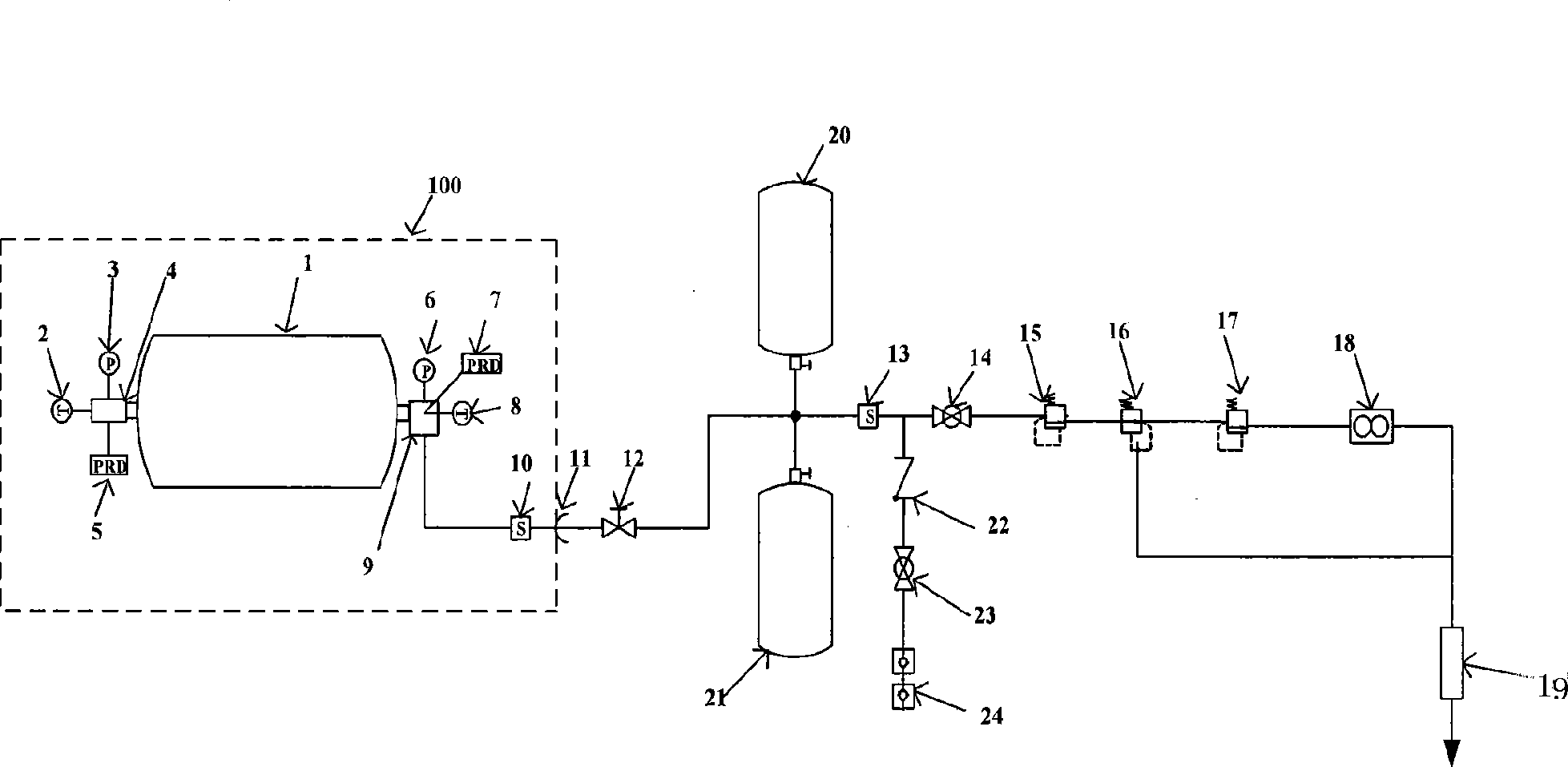

Safe and environment-friendly method for protecting storage tanks

InactiveCN104370000AShort processReduce dosageLarge containersEnvironmental resistancePositive pressure

The invention relates to a safe and environment-friendly method for protecting storage tanks to mainly solve the problems that in the prior art, the gas consumption of nitrogen protection is excessively large, cost is high, and sulfur-containing gas and other peculiar smell gas are hard to treat. According to the safe and environment-friendly method for protecting the storage tanks, the gas produced by liquid in the storage tanks enters a compressor (18) through a main gas pipe (19) and an inflation pipe (21), the gas is pressurized by the compressor (18) and stored in a buffering tank (5) to serve as one part of positive-pressure protection gas, when the gas stored in the buffering tank (5) cannot meet the positive-pressure protection of all storage tanks, the nitrogen from a nitrogen inlet pipeline (22) is used for performing supplementation, and when the pressure stored in the buffering tank (5) exceeds the designed pressure, the residual gas is sent to a torch or combustion furnace through a torch or combustion furnace leading pipeline (22), the problems are well solved through the technical scheme, and the method can be used in storage tank protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

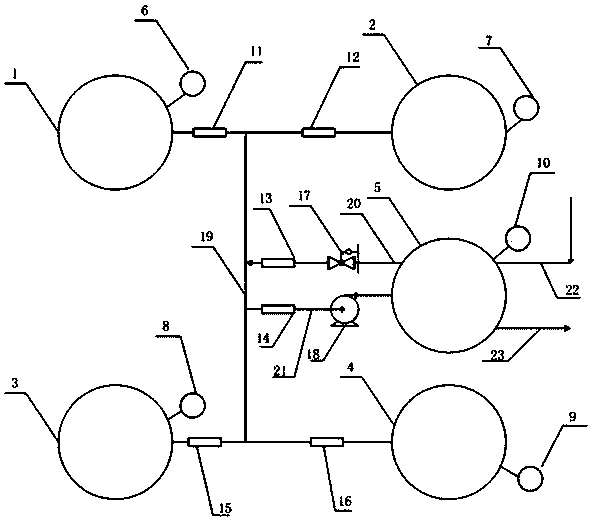

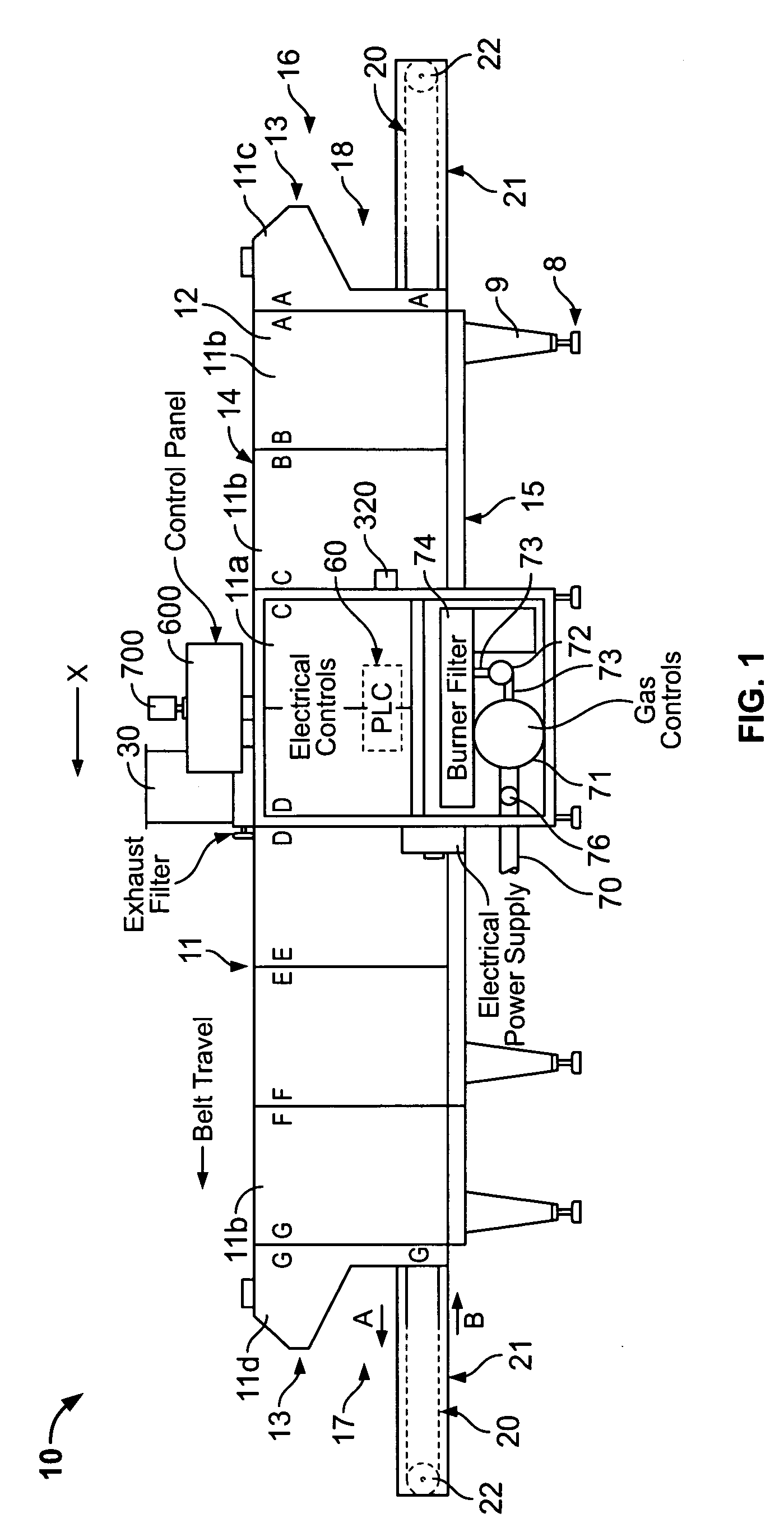

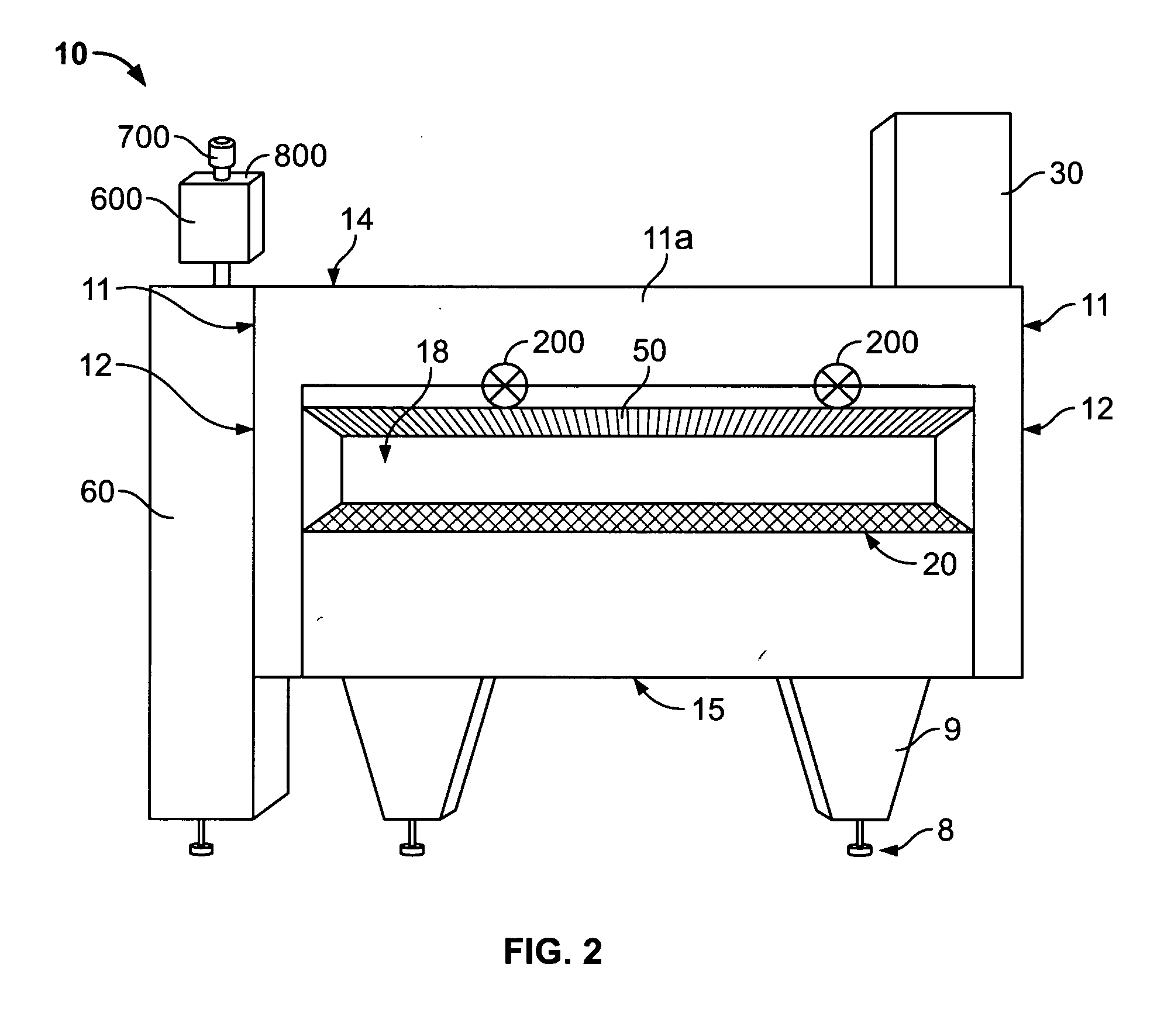

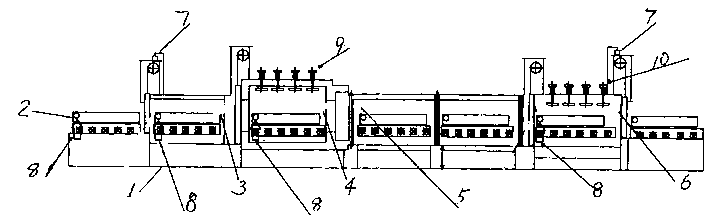

Dryer assembly

InactiveUS20070193056A1Large capacityFast curingDrying solid materials with heatDrying gas arrangementsProcess engineeringThermocouple

A textile dryer capable of monitoring heating chamber temperature (internal thermocouple), peak ink temperature (absorption infrared probe at exit), real-time ink temperature (donut thermocouple) as the textile travels through the chamber, and gas consumption is disclosed. A controller permits one to set numerous parameters and view graphs of the monitored variables over time. Recipes or job settings can be stored for recall and use later. In addition, visual and audible warnings and alarms are incorporated into the system.

Owner:M&R PRINTING EQUIP

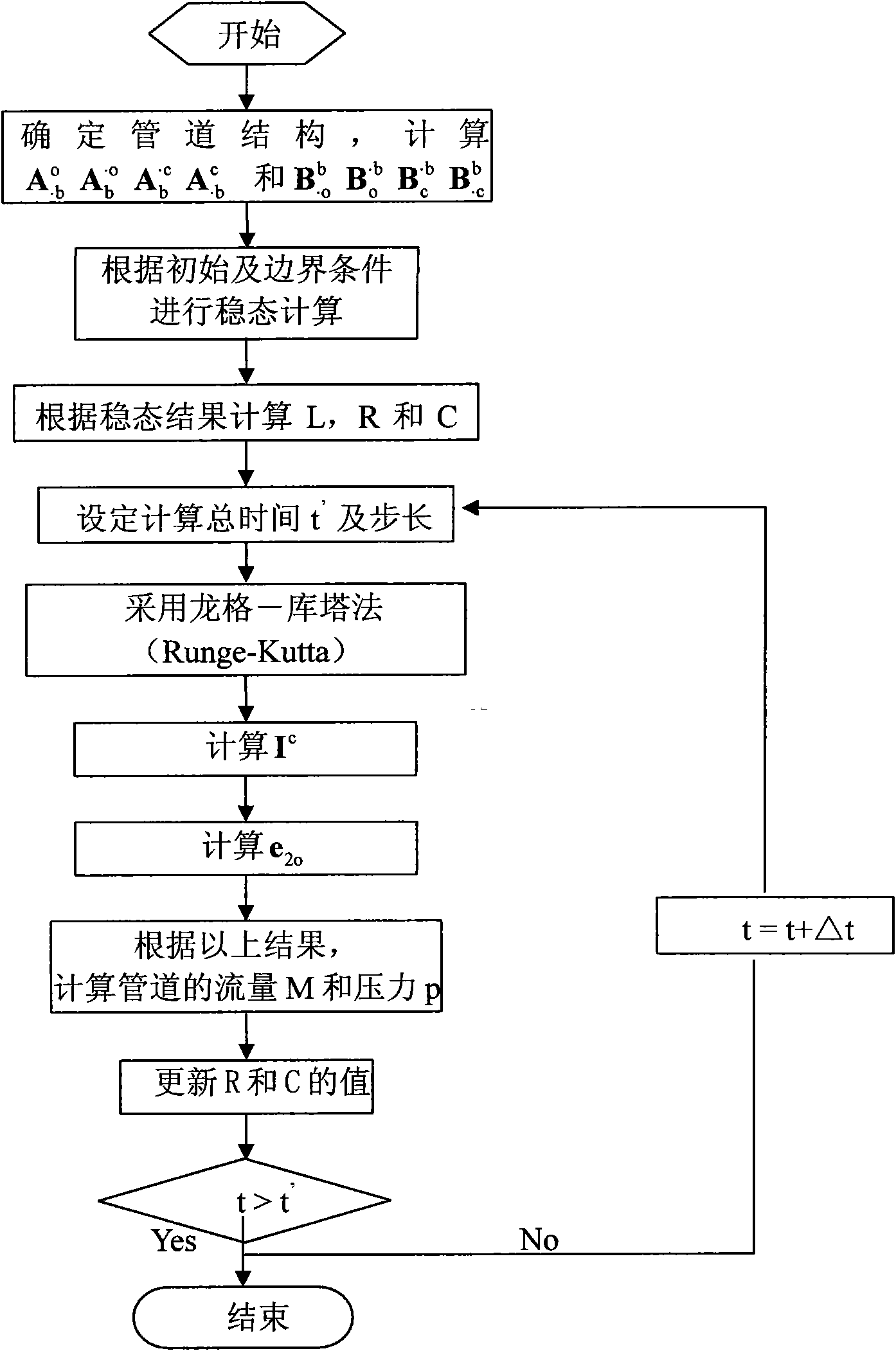

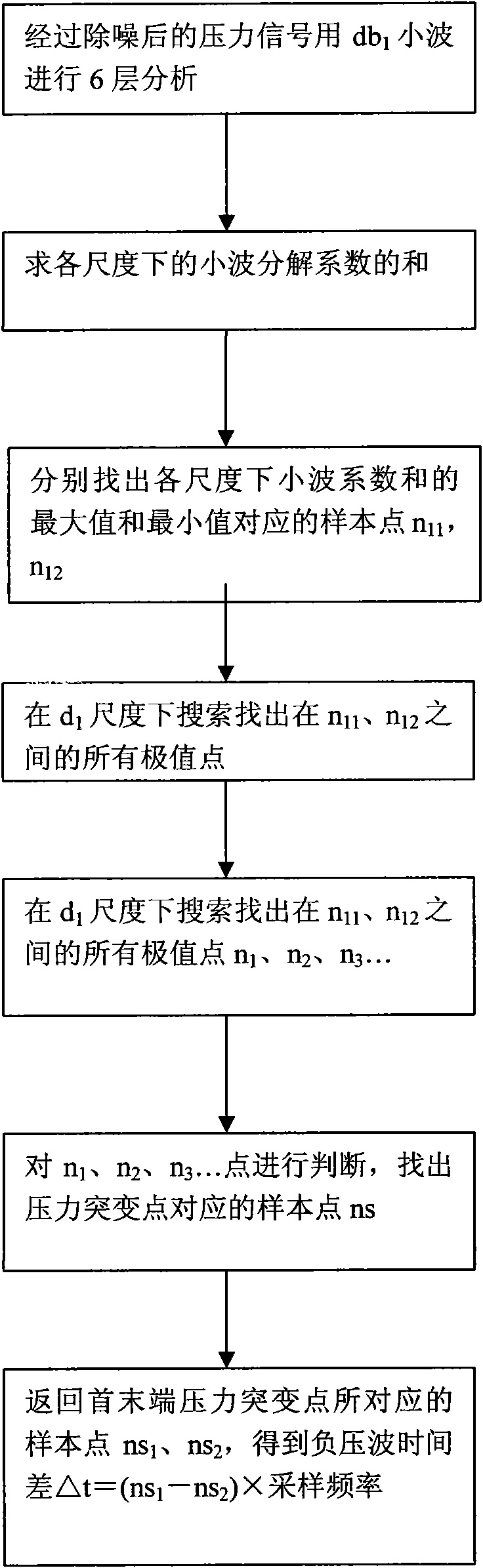

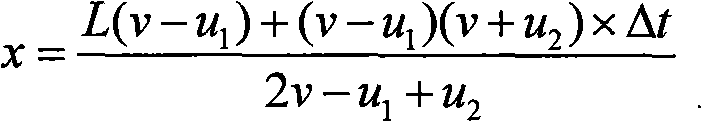

Method for measuring and locating leakage of gas pipelines

ActiveCN101625071ARealize the monitoring functionRealize the positioning functionPipeline systemsData acquisitionEngineering

The invention discloses a method for measuring and locating leakage of a gas pipeline network based on a geographic information system (GIS) and supervisory control and data acquisition technology (SCADA). The specific method comprises the following steps of establishing a gas pipeline network GIS system; reading and storing a pipe network graph, pipeline network attribute data and the like; collecting parameters of pressure, temperature and flow for each section of gas pipeline in real time by the SCADA system; comparing the collected parameters and the stored data and calculating; calculating the measuring values of the head end and the tail end of the pipeline and calculating the difference among parameter values; representing the abnormal pipeline information; searching extreme points and determining the pressure catastrophe points; calculating the position of the leakage point according to the parameters of gas consumption, temperature and pressure by using a leakage locating formula. By adopting SCADA, GIS and simulation calculations, the invention can realize self monitoring and locating of the gas pipelines with the advantages of quick measuring speed, high measuring precision, low missing report rate and false report rate and the like.

Owner:TIANJIN UNIV

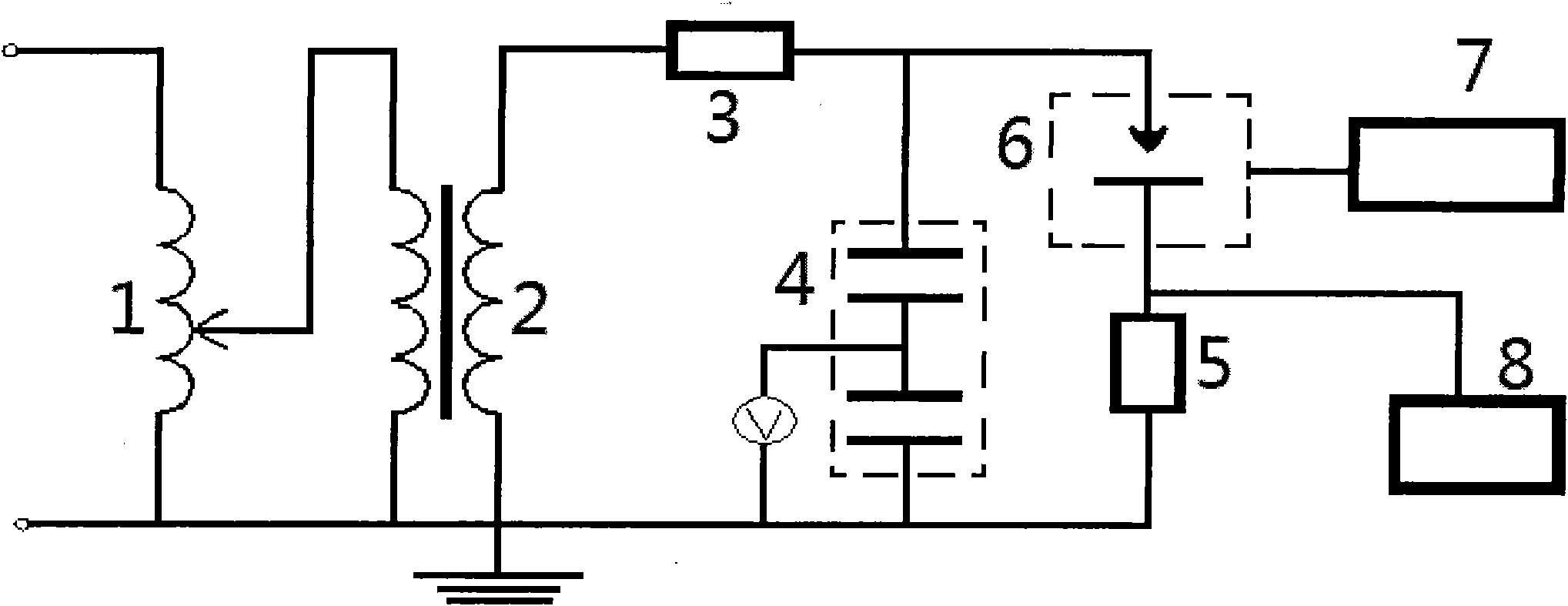

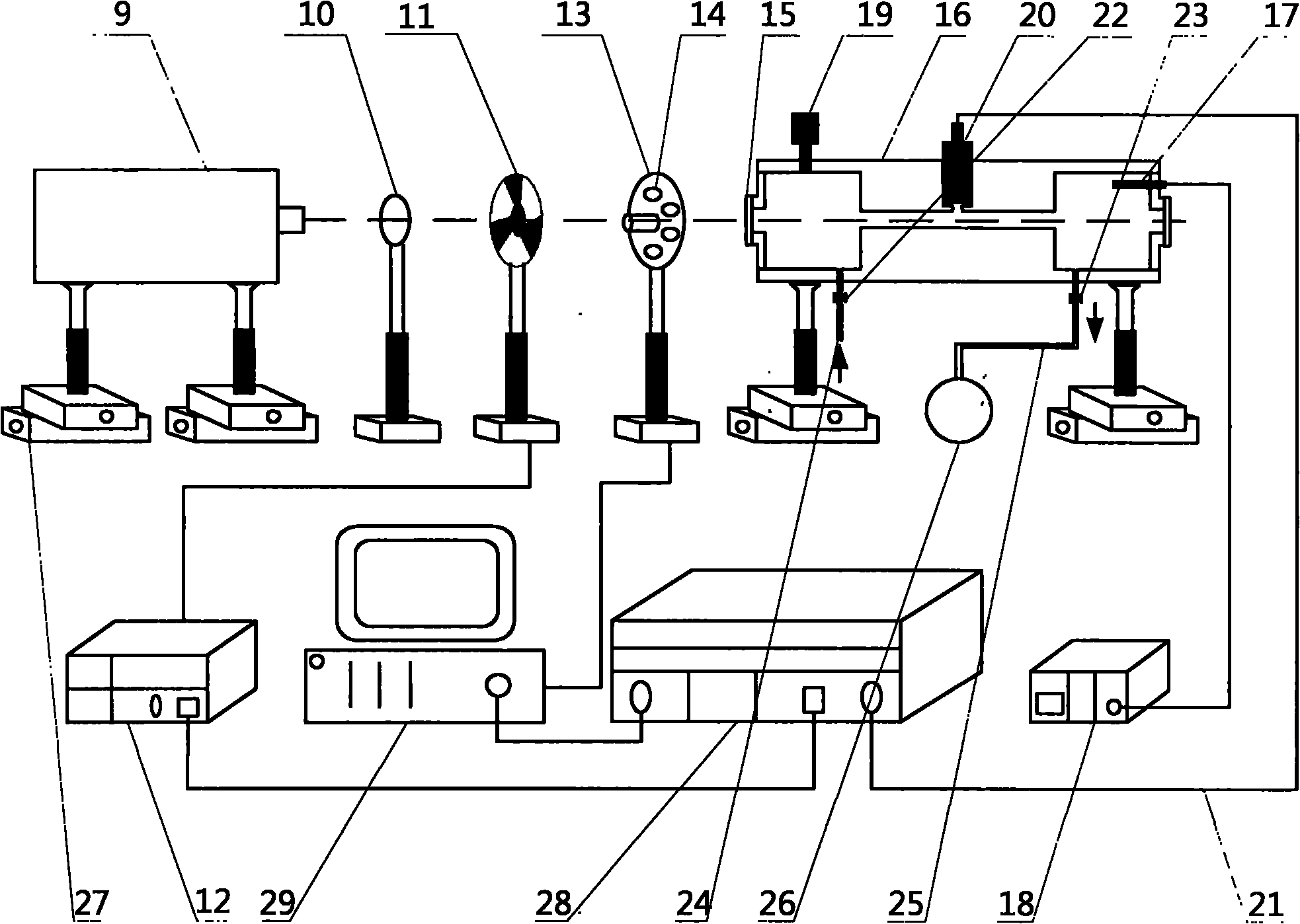

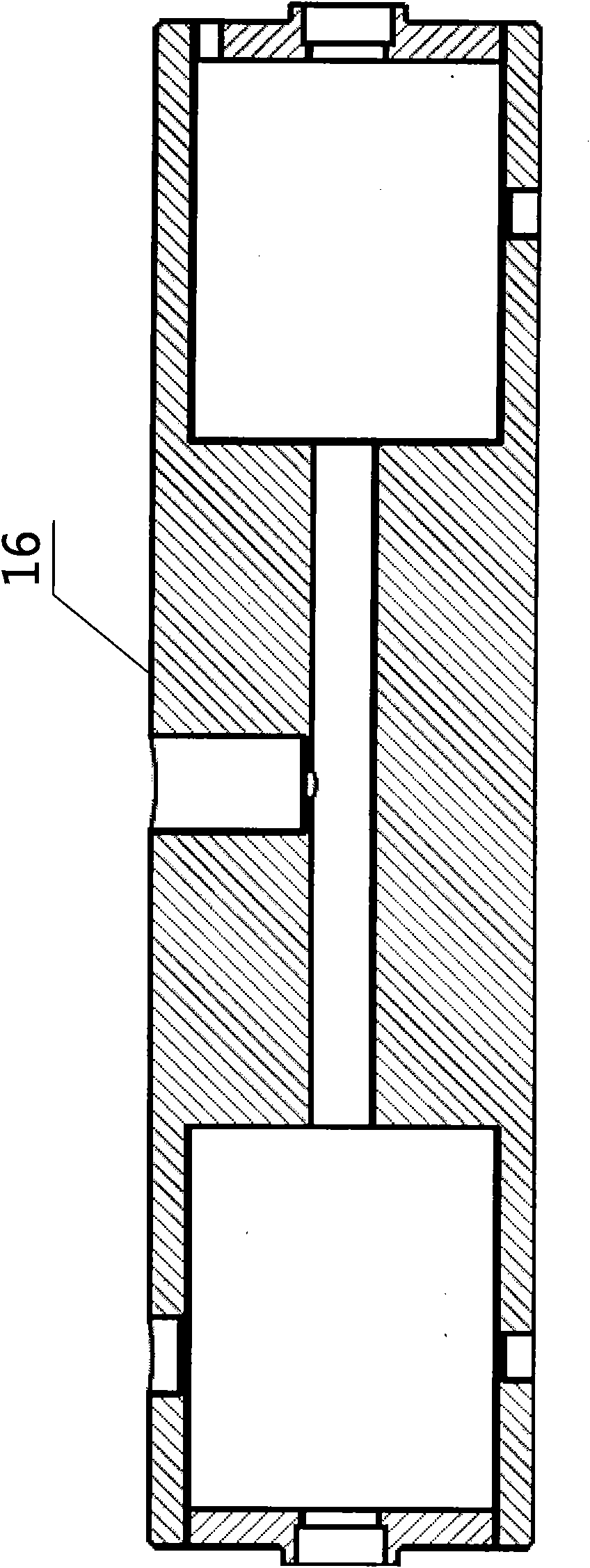

Infrared photoacoustic spectroscopy detection device and method for decomposed components of sulfur hexafluoride under partial discharge

InactiveCN101982759AQualitatively accurateAccurate quantitative analysisColor/spectral properties measurementsAnti jammingSulfur hexafluoride

The invention relates to an infrared photoacoustic spectroscopy detection device and method for decomposed components of sulfur hexafluoride under partial discharge, belonging to the technical field of partial discharge on-line monitoring of SF6 gas insulating electrical equipment. The device of the invention mainly comprises an induction voltage regulator, a corona free experimental transformer, a partial discharge free protective resistor, a standard capacitive voltage divider, a non-inductive resistor, a GIS analog element, a wide-frequency high-speed ultrahigh-capacity digital storage oscillograph and an infrared photoacoustic spectroscopy system. In the method of the invention, infrared photoacoustic spectroscopy detection is carried out on the decomposed gas of SF6 under partial discharge in the GIS analog element by the device of the invention. The invention has high sensitivity, little gas consumption, multiple detection components and strong anti-jamming capability, can effectively detect SF6, CF4, SO2F2, SOF2, SO2, HF and the like as low as 0.01 muL / L, and is suitable for on-line detection. The invention can be widely used for detection of partial discharge decomposed gas of SF6 in the SF6 gas insulating electrical equipment, especially the GIS equipment.

Owner:CHONGQING UNIV

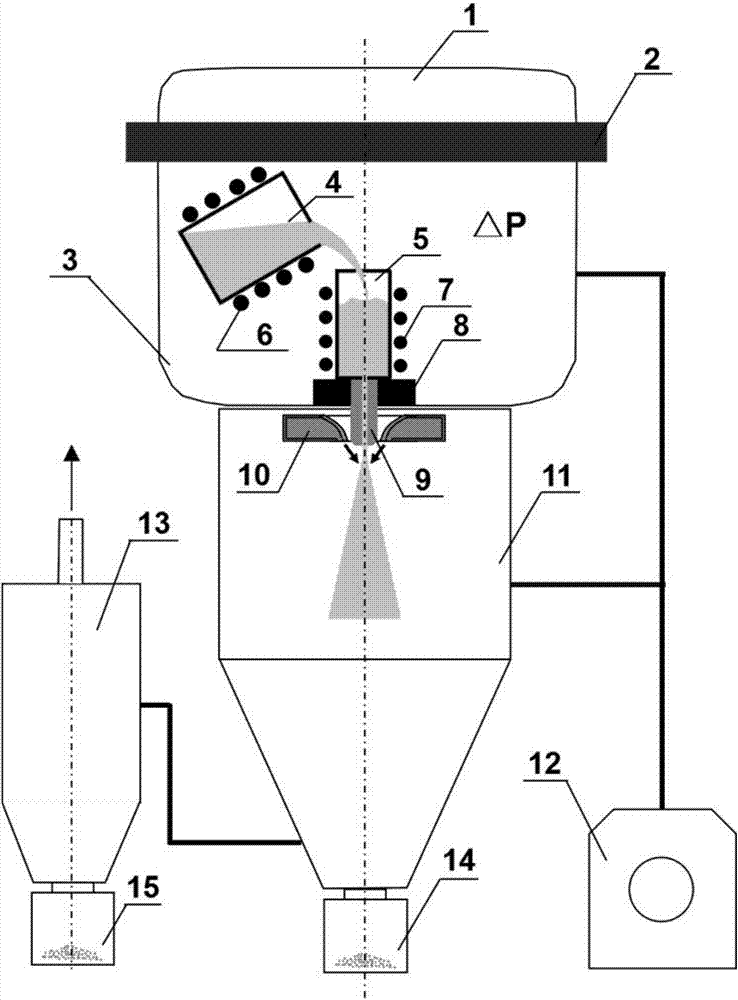

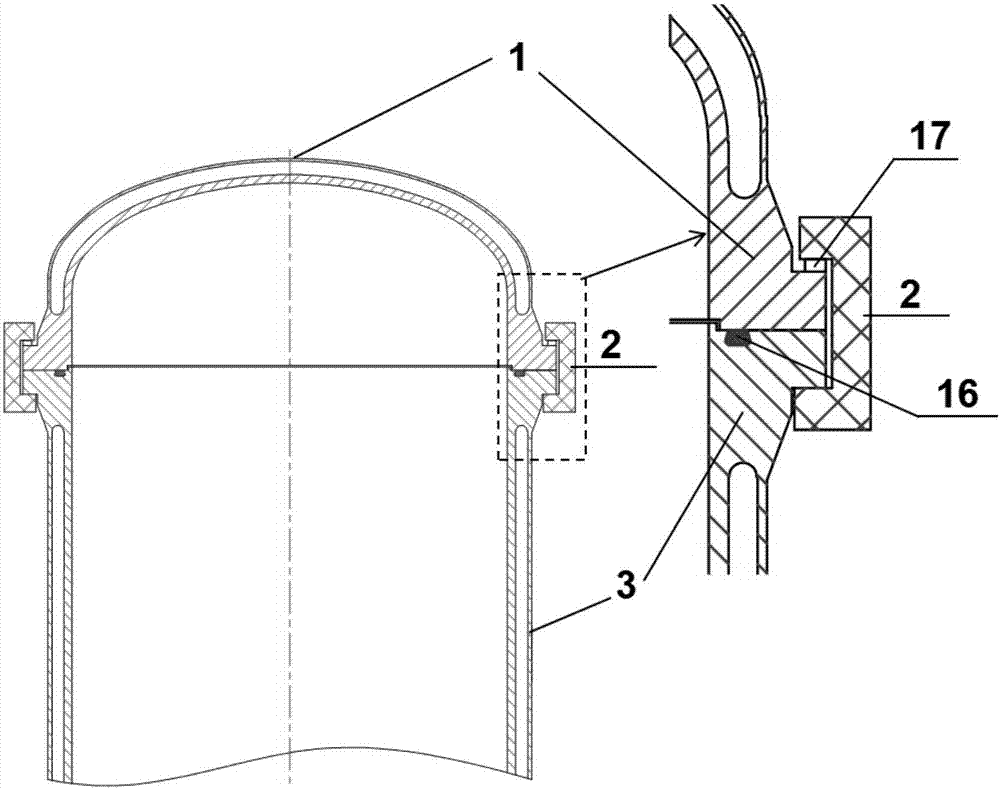

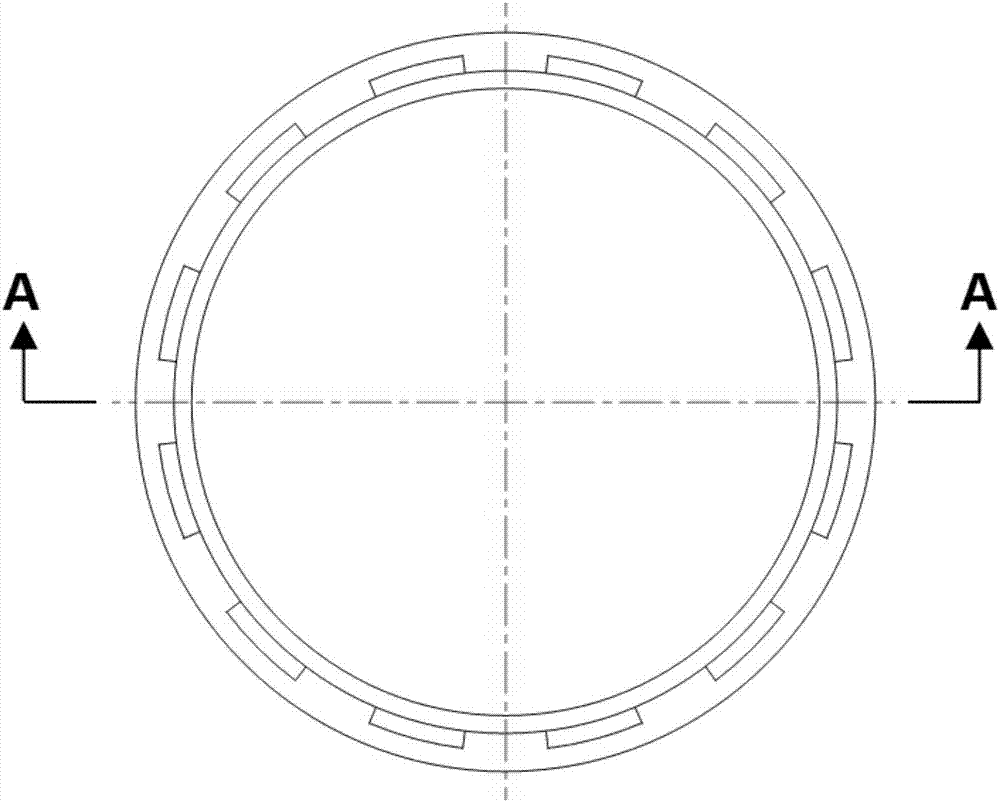

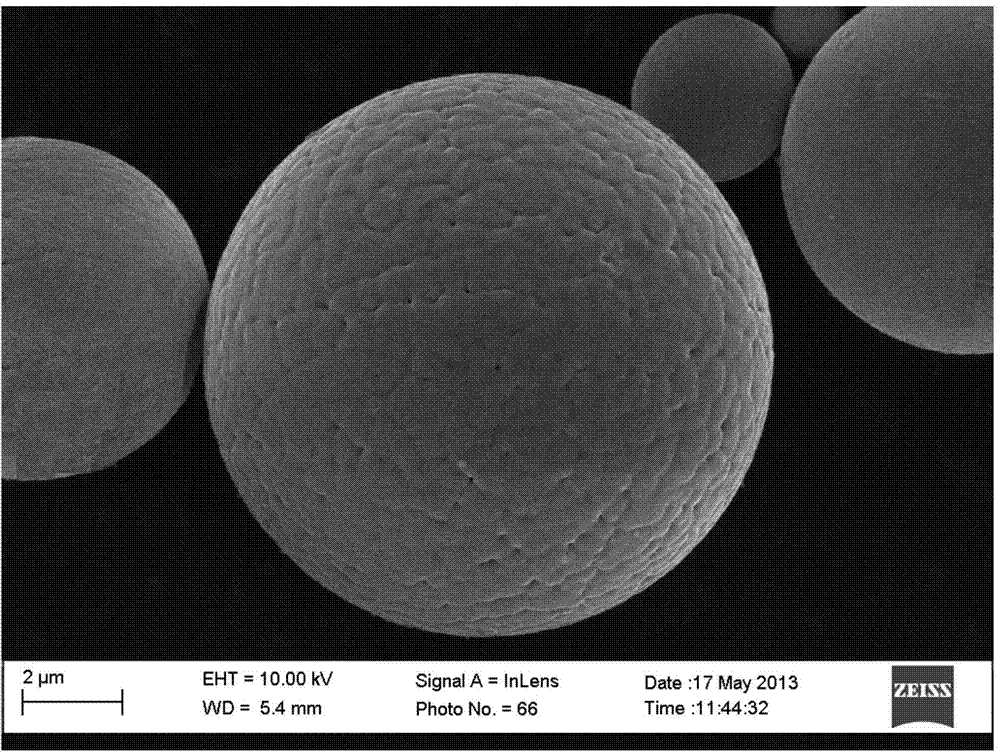

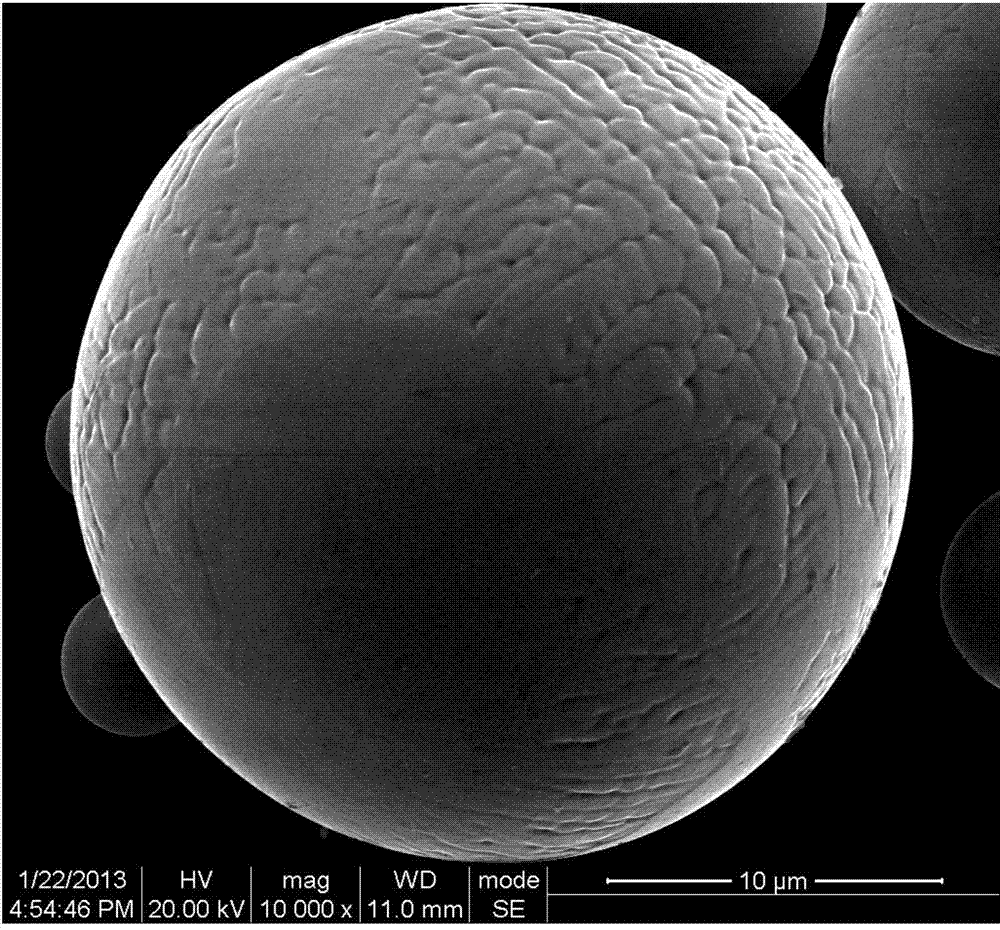

Gas atomization preparing method for micro spherical metal powder and equipment thereof

ActiveCN107262730AIncrease characteristic surface energyHigh yield of fine powderTransportation and packagingMetal-working apparatusPositive pressureProduct gas

The invention belongs to the technical field of preparing a metal powder material and provides a gas atomization preparing method for micro spherical metal powder and equipment thereof. The preparing method comprises the technological process of smelting a material, driving molten metal jet flow through positive pressure, atomizing gas, carrying out cooling, collecting powder, detecting performance, and carrying out screening, packaging and the like, by reducing the outlet hole diameter of a flow guide nozzle, inert gas is reversely filled into a smelting chamber to certain positive pressure, the smelting chamber in the gas atomizing equipment is designed into a pressure container, a locking sealing device is adopted in the connecting portion of a furnace cover and a furnace body, the smelting chamber and an atomizing tank are designed into cavities which are isolated mutually and communicate only through the flow guide nozzle, and the fine powder yield of the metal powder is effectively increased. Compared with the existing gas atomizing metal powder preparing technology, the fine powder yield of the metal powder prepared by the utilization of the method is high, size distribution is narrow, the sphericity degree is good, the oxygen content is small, atomized gas consumption is low, and the technology equipment is simple, high in continuity and suitable for industrialized production and can be widely applied.

Owner:有研金属复材技术有限公司

Method for preparing ultrathin metal powder

The invention provides a method for preparing ultrathin metal powder and belongs to the field of material preparation. The method comprises the steps of smelting, atomization, cooling, solid-liquid separation and the like. In the step of atomization, one or more of water, nitrogen, helium and argon serves / serve as an atomizing medium. According to the method, the metal powder or alloy powder with the grain size smaller than 10 micrometers is basically obtained, the ratio of the metal powder or the alloy powder with the grain size smaller than 10 micrometers is over 50%, the sphericity of the obtained metal powder or the alloy powder is over 90%, the oxygen content is smaller than 100ppm, the gas consumption is small, the cooling efficiency is high, and the requirements for devices are low. The method for preparing the ultrathin metal powder is capable of satisfying the requirements of the metal powder or the alloy powder used for injection forming, thermal spraying, thermal spray welding and 3D printing.

Owner:四川有色金源粉冶材料有限公司

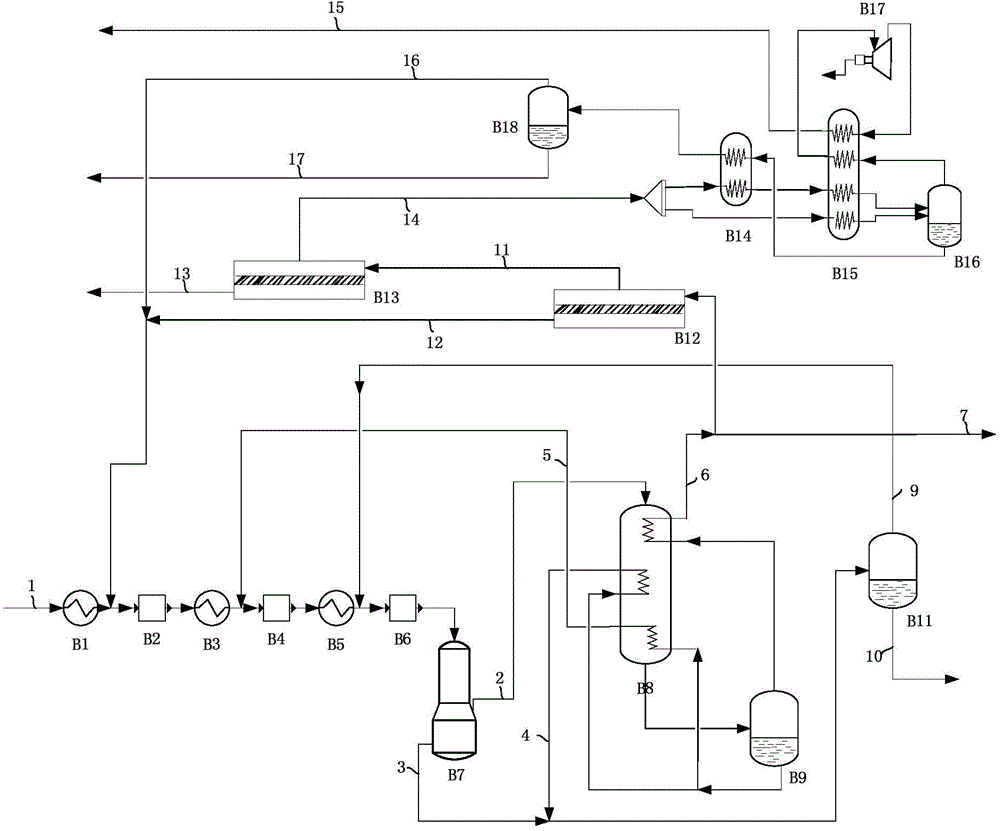

Method for recovering exhaust gas according to polyolefin gas phase method

ActiveCN104923029AHigh recovery rateHigh purityNitrogen purification/separationSolidificationRecovery methodPolyolefin

The invention relates to a method for recovering exhaust gas according to the polyolefin gas phase method. The method for recovering the exhaust gas comprises the following steps: 1) compression, condensation and separation steps are carried out; 2) after the compression, condensation and separation steps, gas enters a heat exchanger to be subjected to cryogenic separation; 3) compressed and condensed liquid and liquid subjected to cryogenic separation are subjected to gas-liquid separation through a separation tank, and after the flash evaporation, light component gas flows to a compressor to be recycled; 4) after cryogenic separation, part of uncondensed gas enters a membrane separation device to enable hydrocarbons to be further recovered; 5) after membrane separation, hydrocarbon-rich phase gas returns back to the compressor to be recycled, hydrogen-deficient phase gas flows to an unpowered expansion refrigeration device to enable hydrocarbons to be recovered, and obtained high-purity nitrogen is used as supplementation gas for sweeping gas of a product receiving bin or a degassing bin. According to the method for recovering the exhaust gas, unreacted monomers can be effectively recovered, the gas emission can be reduced, the total utilization of the monomers can be increased, the gas consumption amount of the sweeping gas can be reduced, the cost can be reduced, the power of the compressor can be reduced, and the energy consumption of the heat exchanger can be reduced.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

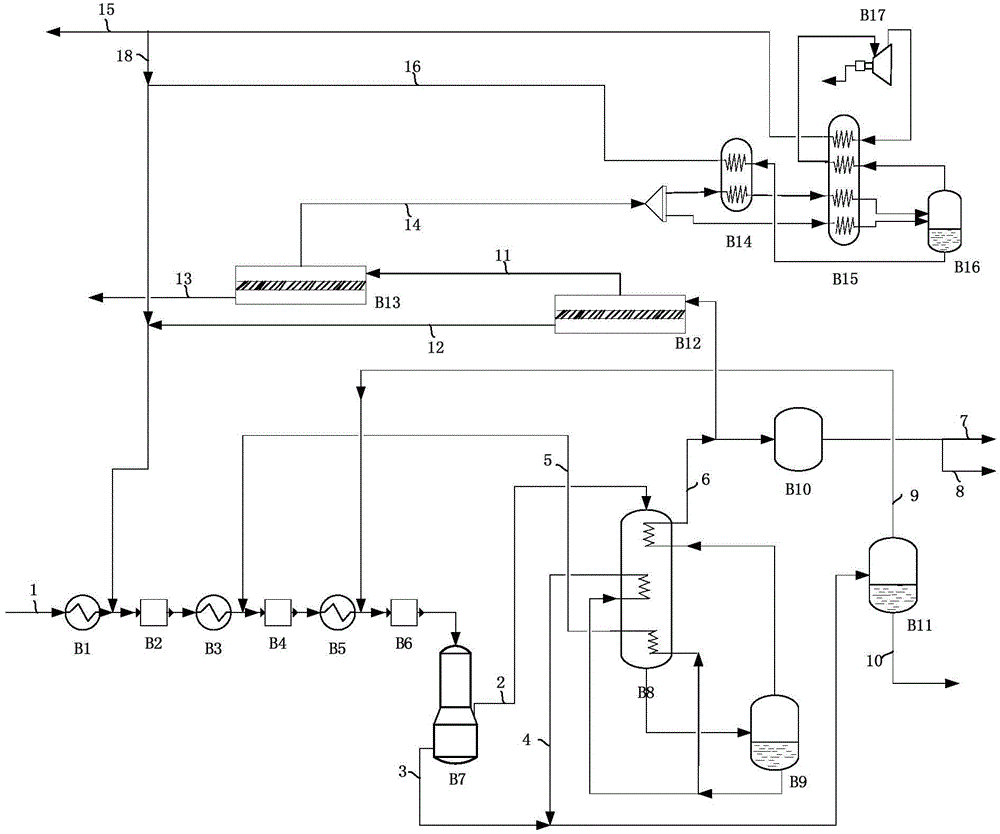

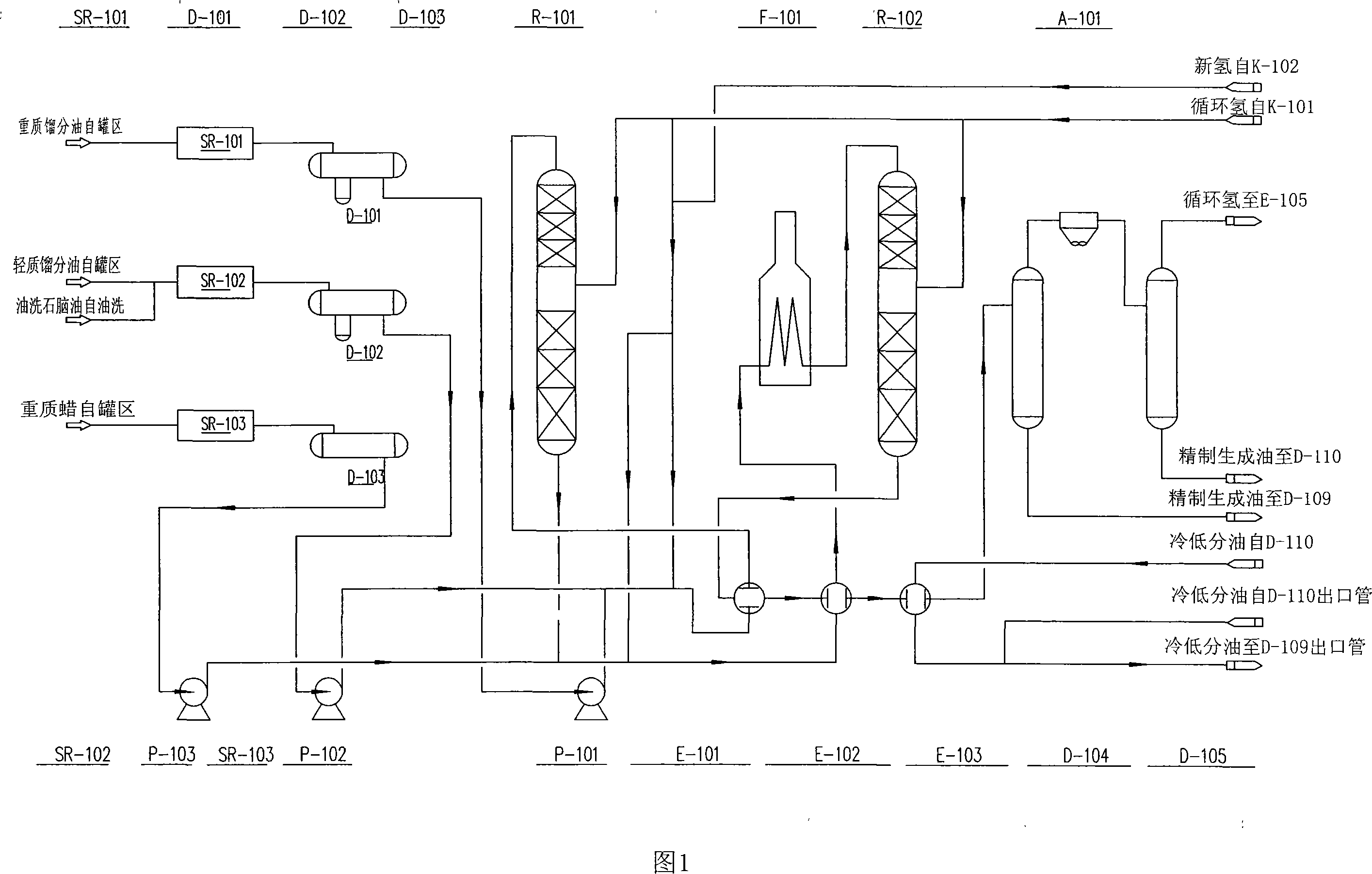

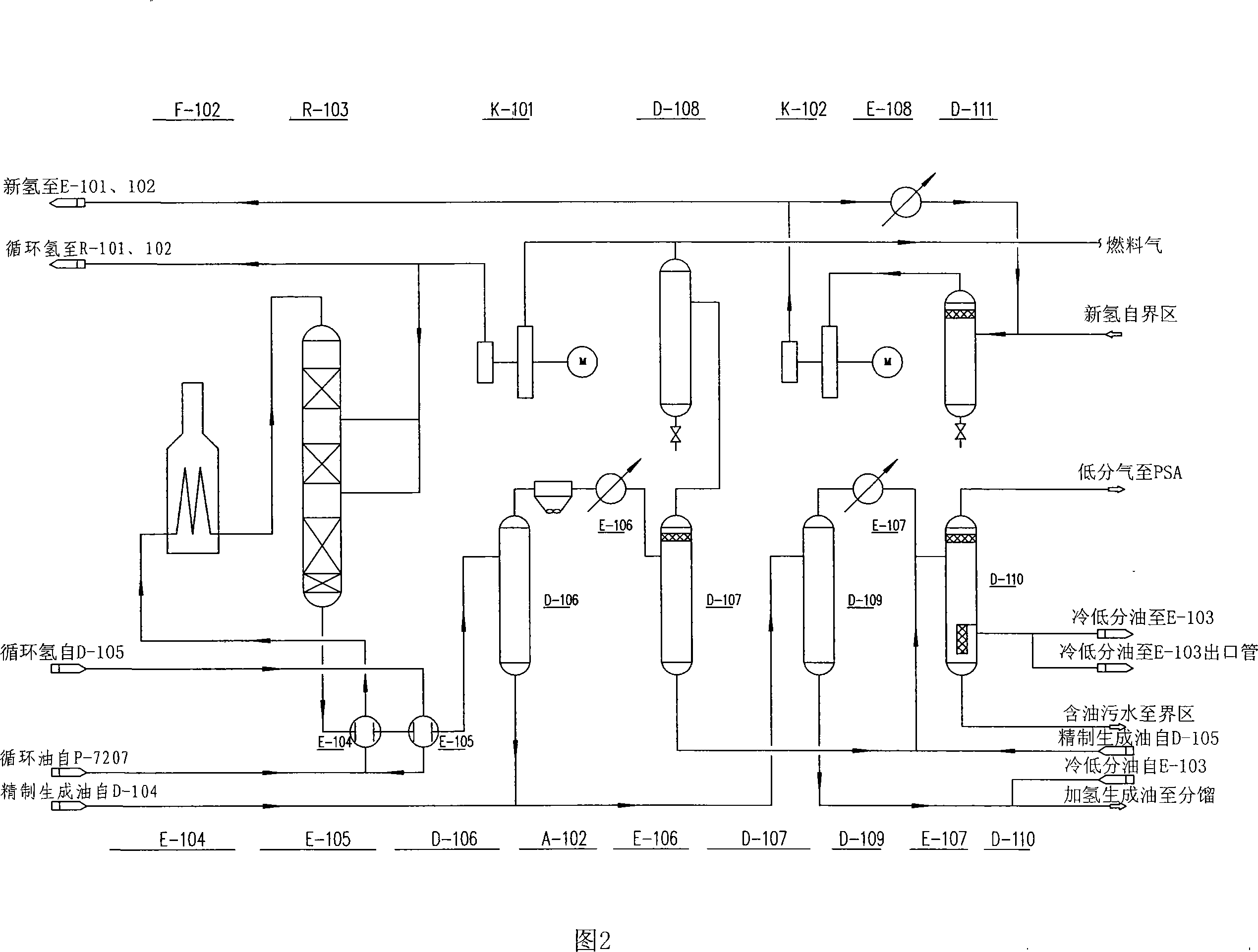

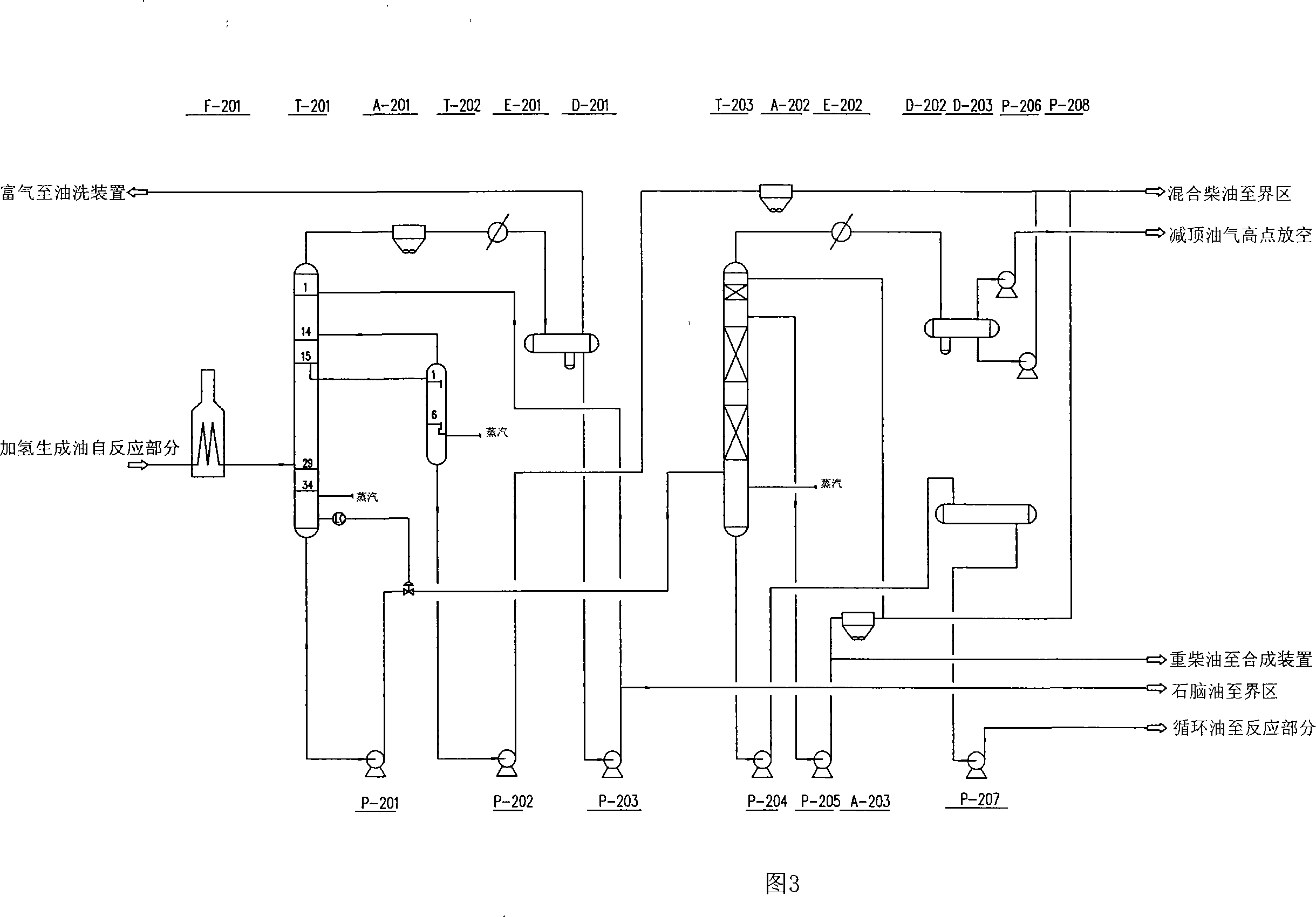

Feito synthetic oil processing line

ActiveCN101173190AReduce design flowStable temperature controlTreatment with hydrotreatment processesGas phaseMetal impurities

The invention relates to a processing flow of FT synthetic oil, which comprises hydrogenation, low-temperature oil washing, decarburization and PSA. The invention is characterized in that the synthetic oil is mixed with hydrogen via a filter, and enters a hydrogenated prerefining reactor after heat exchange, then enters a hydrogenated refining reactor after the synthetic oil is heated to 300 to 380 DEG C by a heating furnace; oxygen-containing compounds, unsaturated hydrocarbons and metal impurities in the raw material are extracted; the hydrogenated refined product enters a high thermal separator for separation of oil phase and gas phase after heat exchange, and enters a hydrocracking reactor for hydrocracking after heat exchange and heating of the heating furnace; the cracked product and the refined product are mixed to enter a fractionation system; a combined flow with two stages connected in series is adopted for the hydrogenated refining reactor and the hydrocracking reactor which share a recycle hydrogen system; a fractionation system is shared by the hydrogenated refined oil and the hydrocracked oil; and a three-column process flow is adopted for the fractionation system. The invention has the advantages of low gas consumption of the low-temperature oil washing process, high recovery of light hydrocarbons, less matching investment, and reduction of energy consumption and improvement of hydrogen recovery rate due to the decarburization process.

Owner:中国石油集团工程设计有限责任公司抚顺分公司

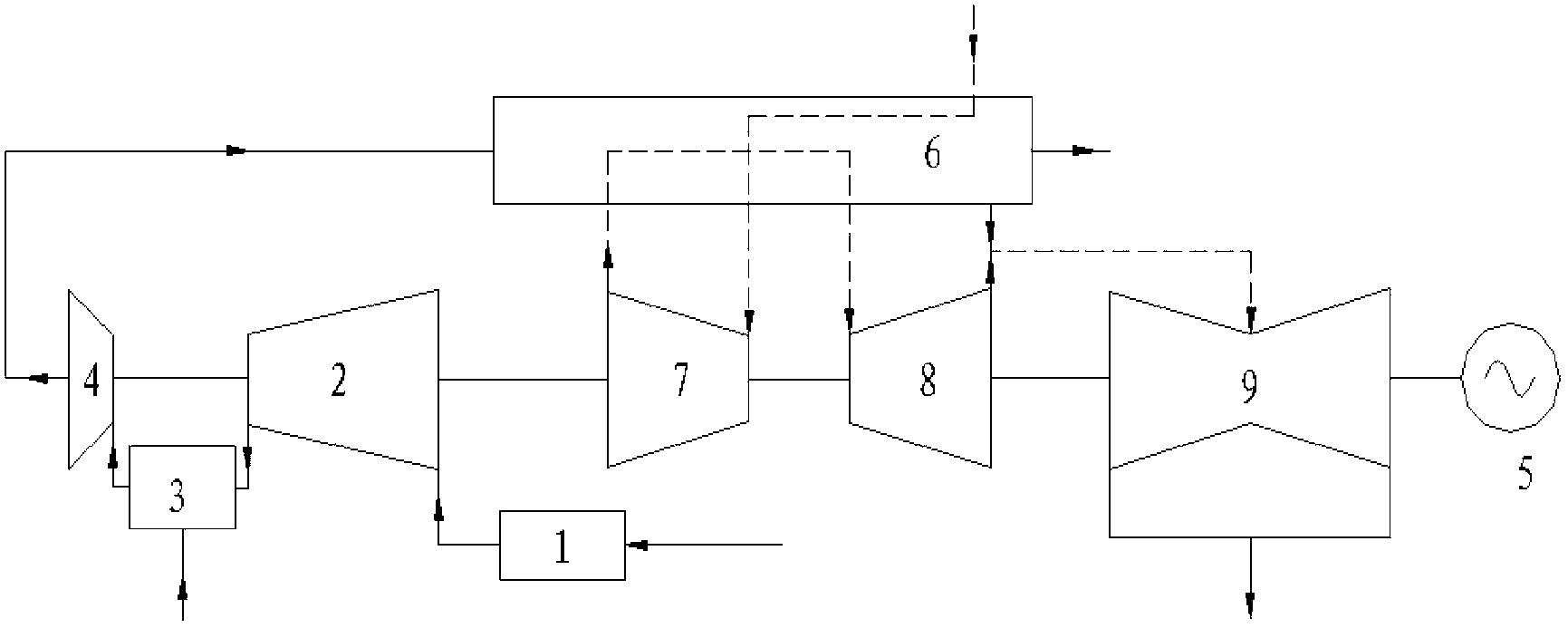

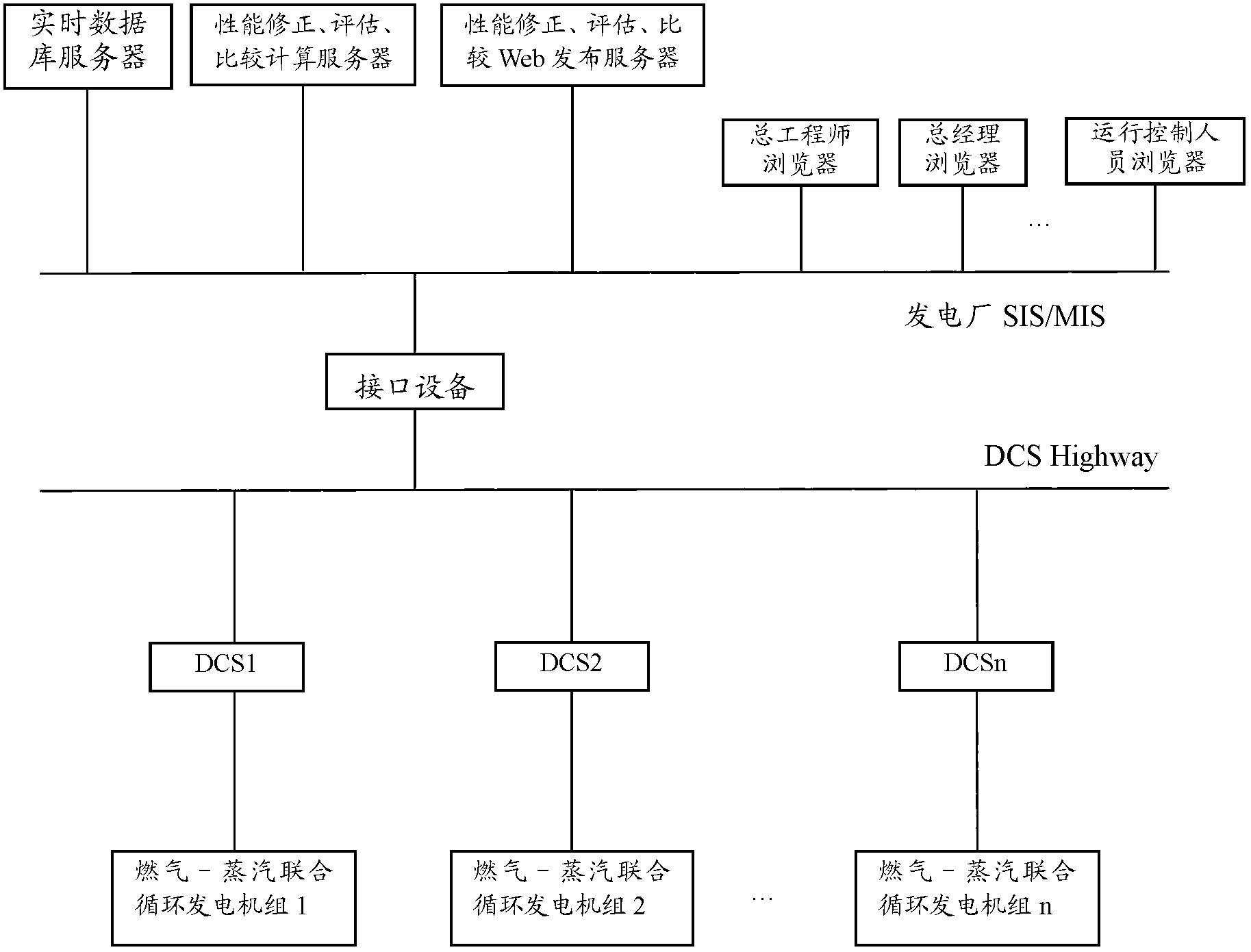

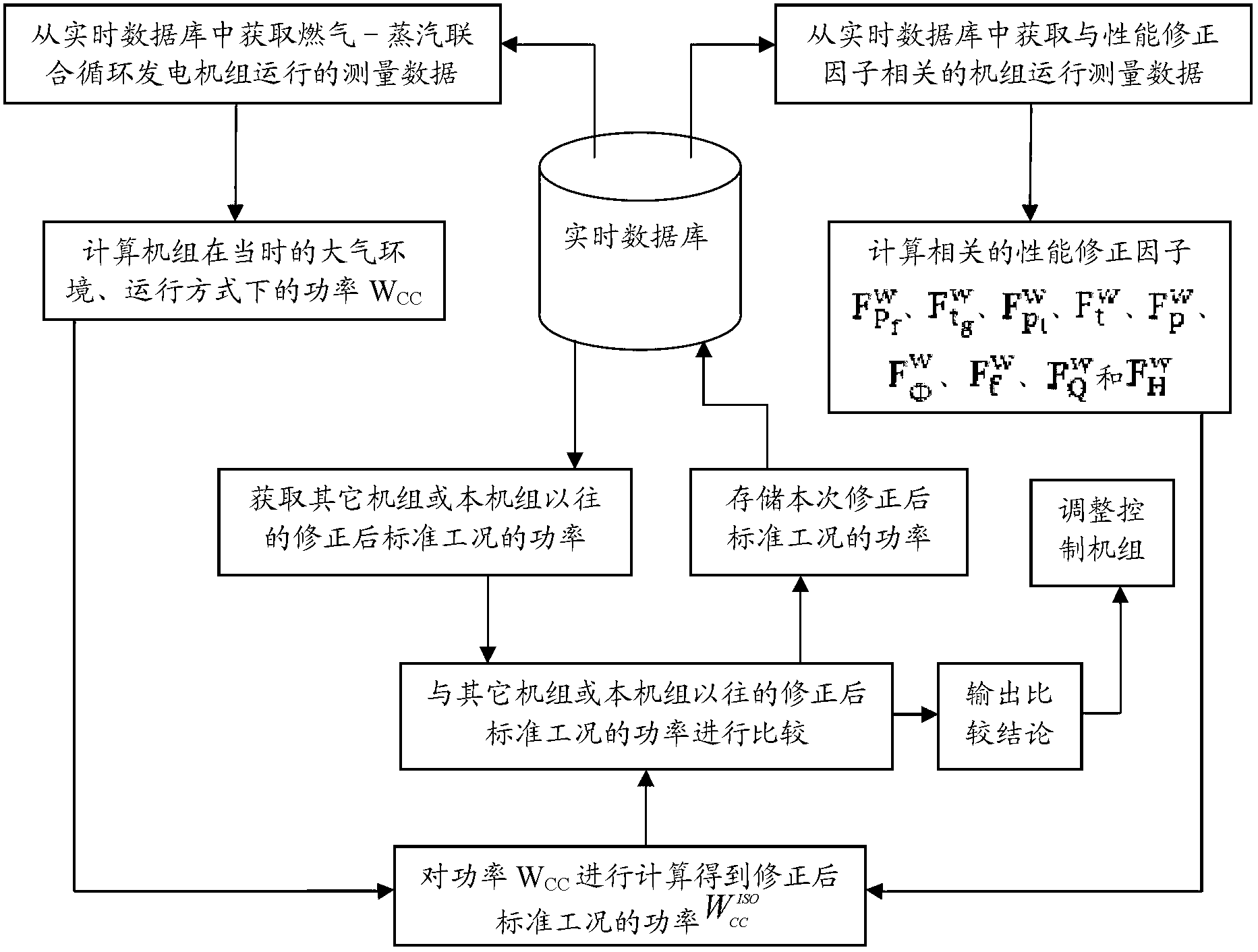

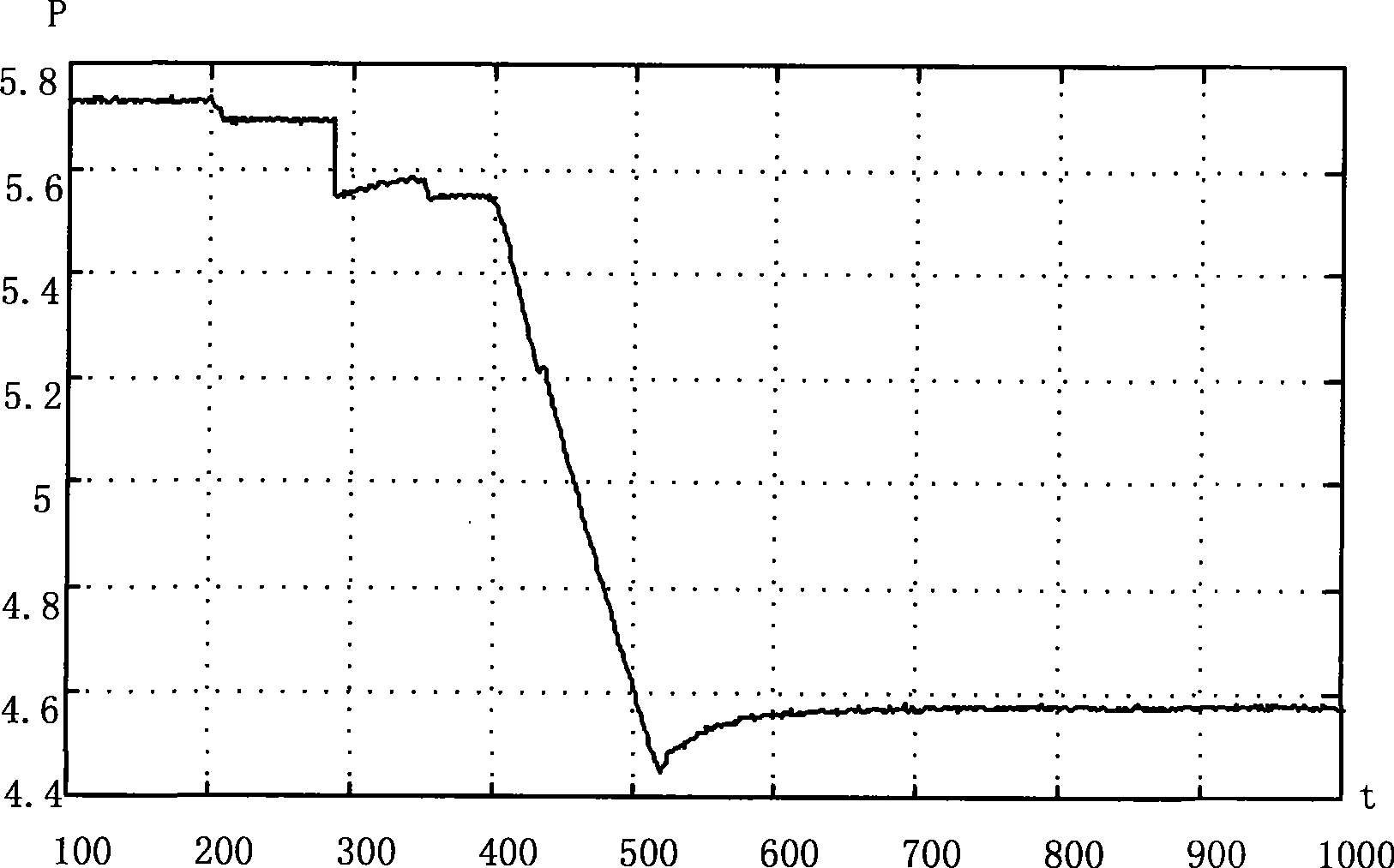

Performance index correcting and comparing method and regulation control system of combined cycle generating unit

InactiveCN102799161AImprove reliabilityImprove economyGas turbine plantsSteam engine plantsInternational standardControl system

The invention discloses a performance index correcting and comparing method for a combined cycle generating unit. The performance index correcting and comparing method comprises the following steps: 1), calculating the integral power, heat consumption rate and gas consumption rate of the combined cycle generating unit under the current atmospheric environment and an operation mode according to measurement data in a real-time database; 2), acquiring measurement data relevant with a performance correction calculation factor and calculating the relevant performance index correction calculation factor; 3), correcting various performance indexes in the step 1 and obtaining a corrected and calculated performance index of a standard ISO (International Standard Organization) working condition; and 4), comparing performance index data of the standard ISO working condition with traditional corrected and calculated performance index data of the standard ISO working condition of the unit or other units and outputting a corresponding operation regulating control instruction by an operator according to the evaluation result. The invention further discloses a regulation control system based on the performance index correcting and comparing method of the combined cycle generating unit. According to the performance index correcting and comparing method provided by the invention, the unit operation can be optimized and the economy and the safety are improved.

Owner:ZHEJIANG UNIV

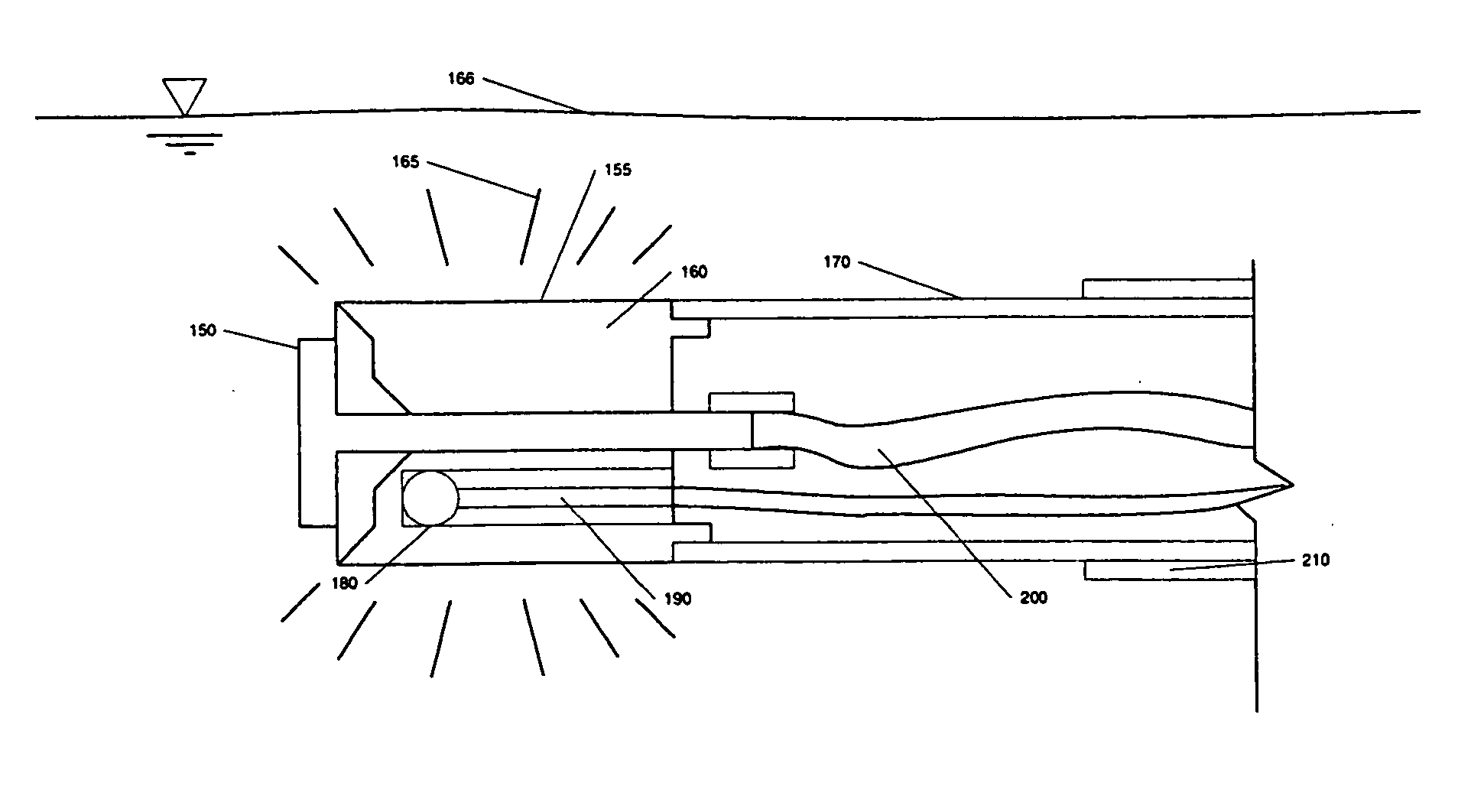

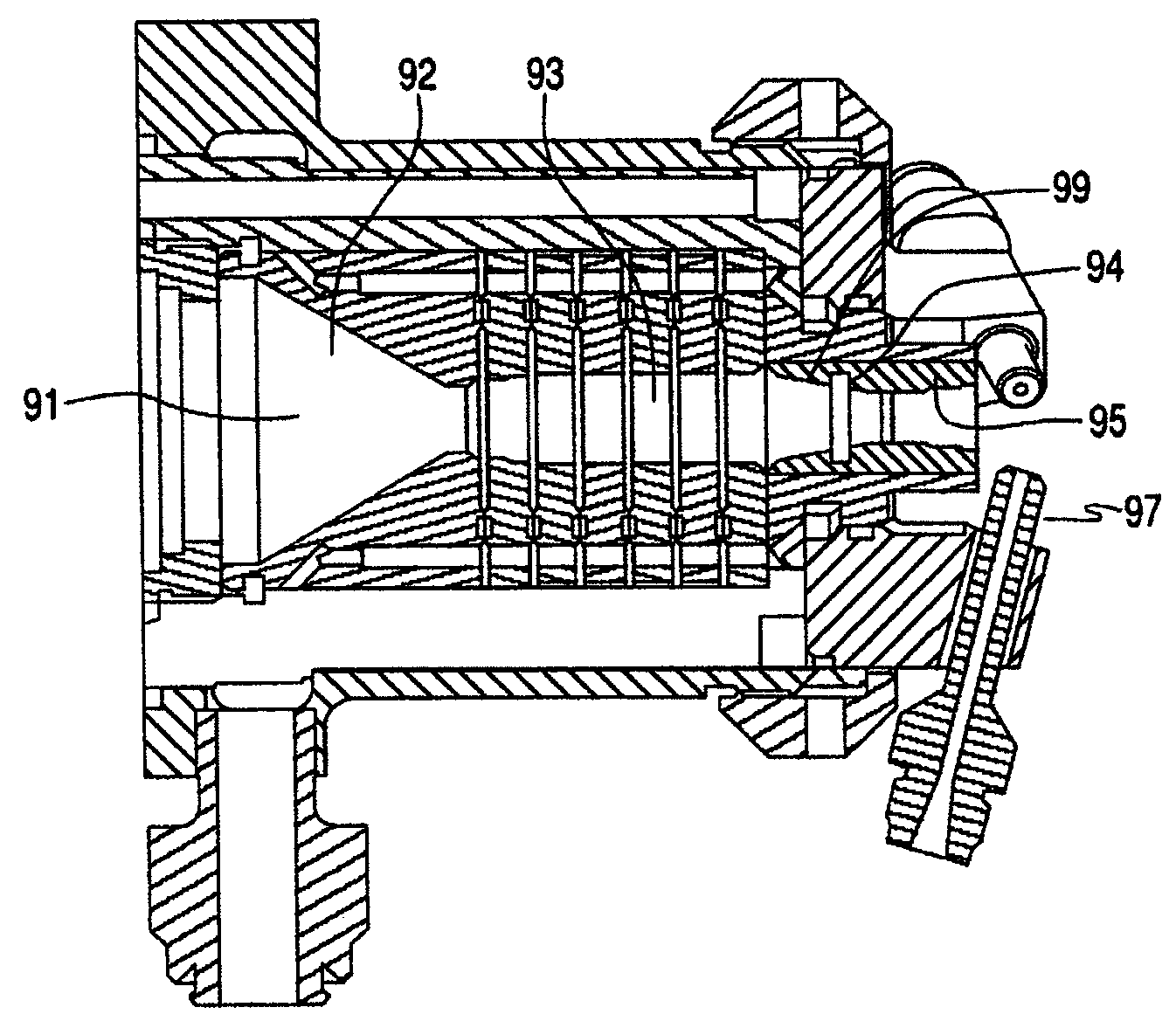

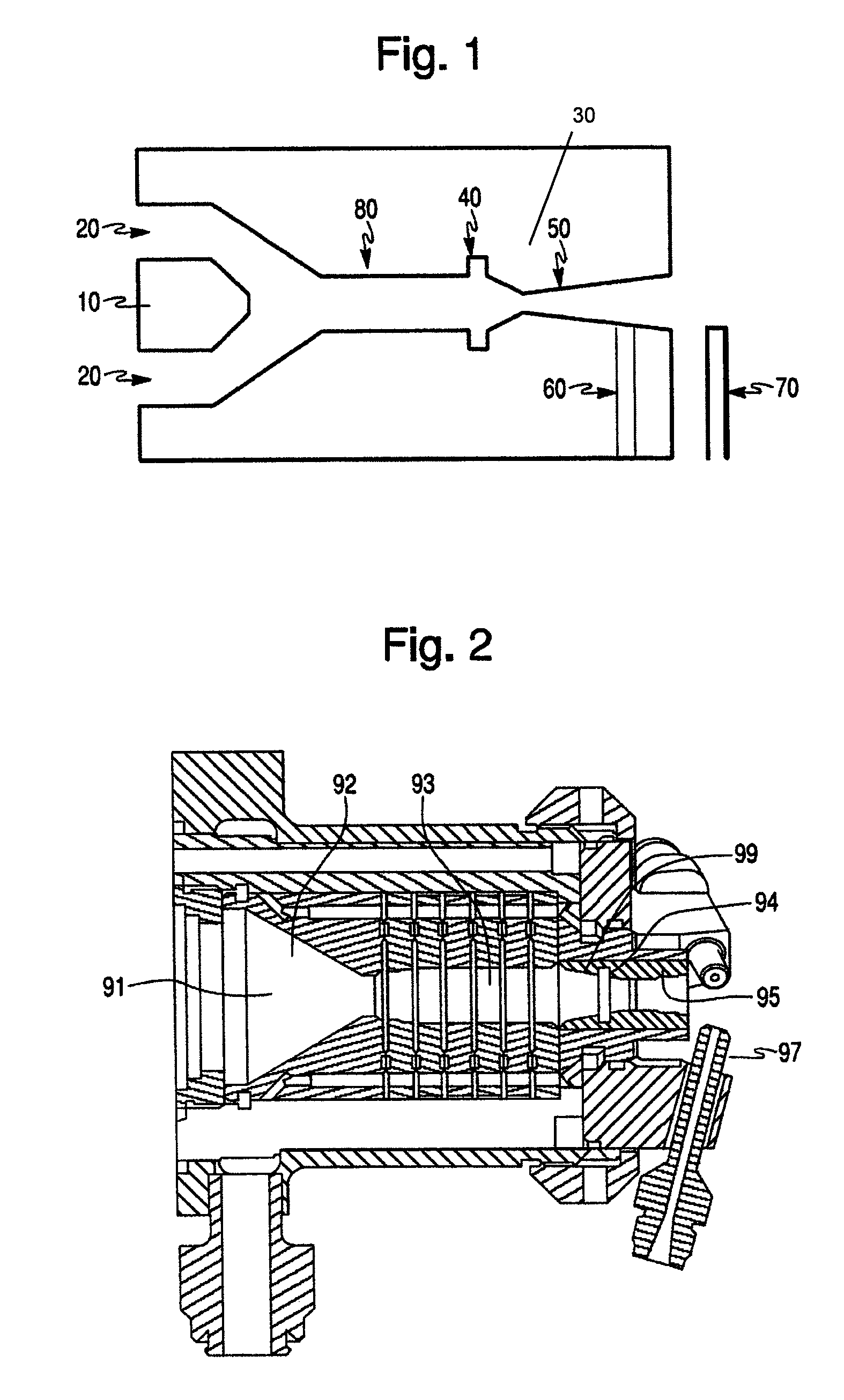

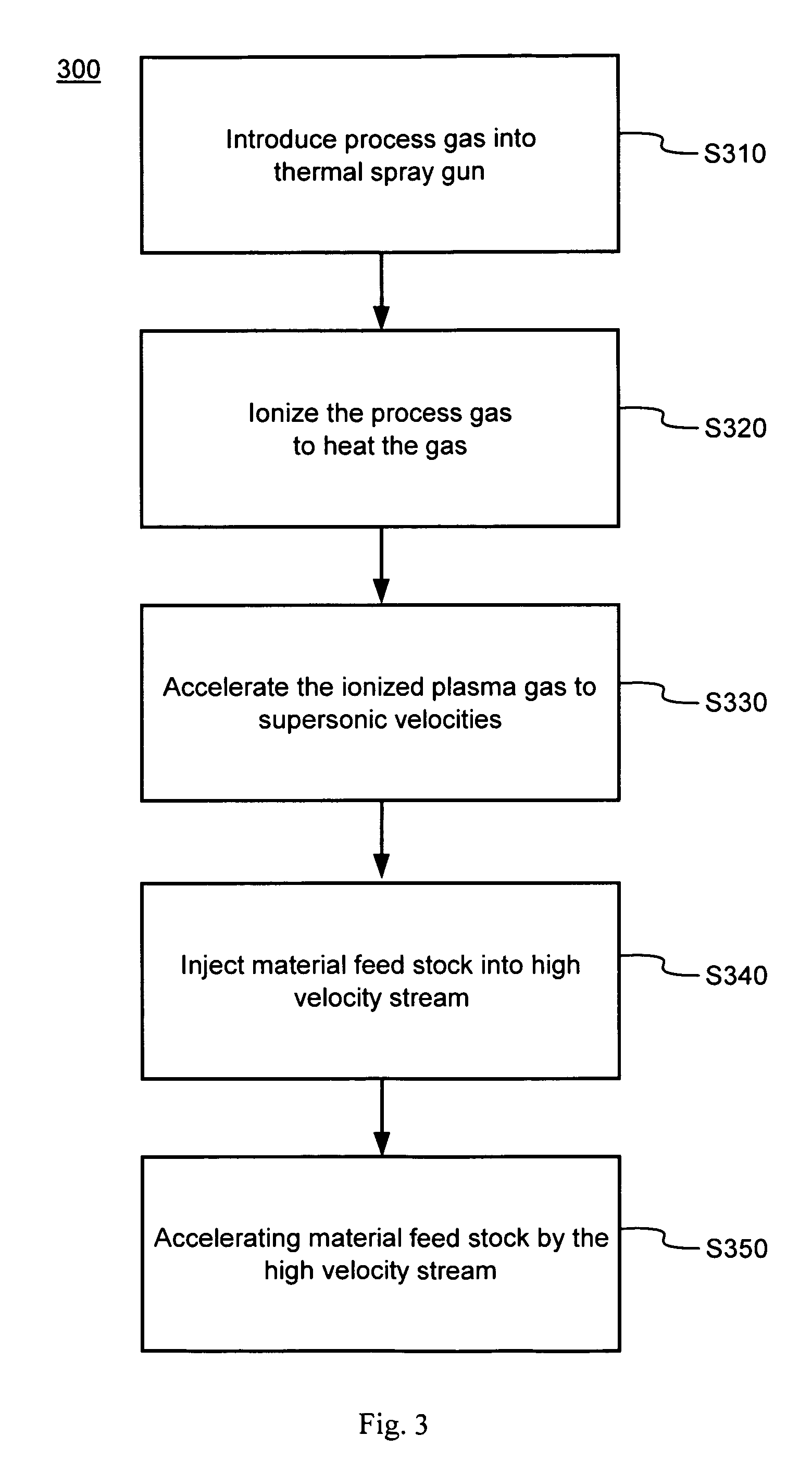

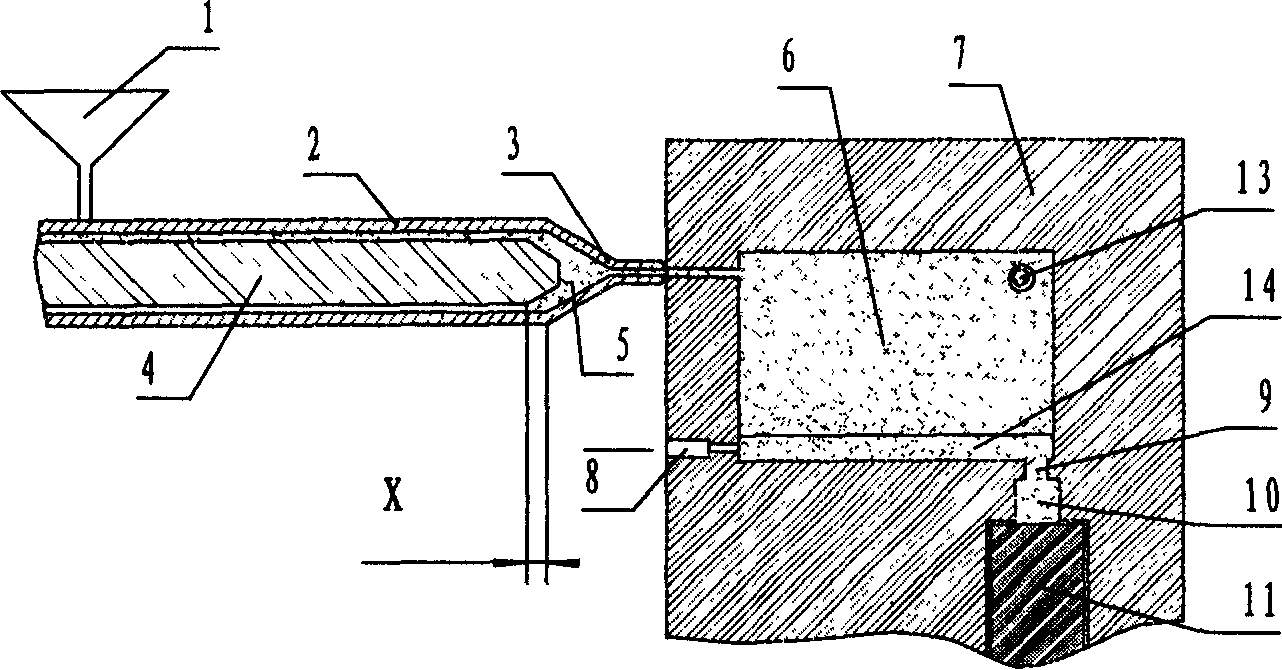

Hybrid plasma-cold spray method and apparatus

ActiveUS7582846B2Wide range of operationsImprove processing effectivenessMolten spray coatingArc welding apparatusStress conditionsProcess engineering

The present invention provides a method and apparatus of producing a dense coating with desirable stress conditions similar to coatings produced by a cold spray processes, but with higher process efficiencies and lower gas consumption. The inventive process combines features of a plasma process method of gas heating and a cold spray process to accelerate the gas, incorporating these elements into a single hybrid process.

Owner:SULZER METCO (US) INC

Clean natural gas exploiting method

The invention discloses a clean natural gas exploiting method which comprises the following steps of: 1) adding an ice inhibitor, 2) separating liquid from natural gas, 3) sending the gas obtained in step 2) into an open container, 4) adding alkali into the open container for regeneration, 5) separating waste slag, 6) sending the gas obtained in step 5) into another open container, 7) ventilatingand removing moisture, 8) conducting separation and purification, and 9) recycling the ice inhibitor solution. The invention has the advantages that the clean natural gas exploiting method overcomes the defects of the existing natural gas exploiting method, effectively exploits natural gas, effectively solves the problems that natural gas hydrate or ice affects the exploitation of the natural gasand that the natural gas exploitation causes environmental pollution and has high energy consumption, effectively eliminates potential safety hazards in the natural gas exploitation, significantly reduces the fixed investment, exploitation cost, energy consumption, self gas consumption, management workload and the like of the exploitation of the natural gas, and is characterized by easy implementation, safety, reliability, wide application range, easy promotion, high economic and environmental benefits and obvious safety benefits.

Owner:BEIJING UNITY BENEFICIAL TECH CO LTD

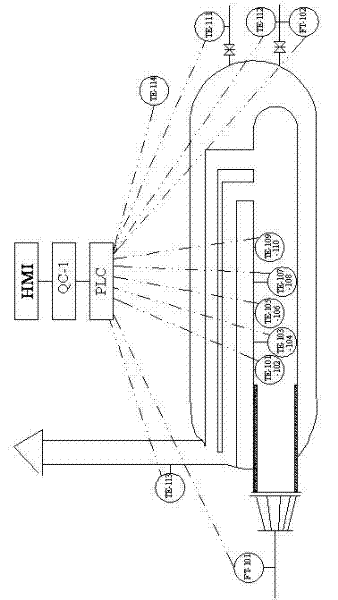

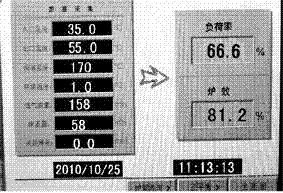

Optimization operation monitoring method of heating furnace

InactiveCN102338471AElevate evenlyPromote combustionFluid heatersAutomatic controlTemperature difference

The invention relates to an optimization operation monitoring method of a heating furnace, mainly solving the problems of overlarge excess air system and difficulty in diagnosis of fault and operation efficiency of the heating furnace, caused by imperfection of the traditional operation monitoring method of the heating furnace. The optimization operation monitoring method is characterized by comprising the following steps of: (1) detecting the flow rate of a heated medium and the temperatures of the heated medium entering and exiting the furnace and calculating a temperature difference, and calculating effective heat; meanwhile, detecting the gas consumption amount of the heating furnace, calculating heat generated by natural gas combustion, calculating the positive balance furnace efficiency through a computer, and displaying the positive balance furnace efficiency on a screen; (2) controlling flame combustion through a gas adjusting valve according to the temperatures of the heated medium entering and exiting the furnace; (3) detecting the gas flow rate and the flue temperature, and automatically adjusting an air flue for air distribution; and (4) detecting the temperature of a furnace tube and setting a temperature alarm point. The method disclosed by the invention can be used for monitoring the whole operation process of the heating furnace, realizing automatic control and alarming while a fault happens, thereby realizing the purposes of combustion optimization, energy saving and consumption reduction of the heating furnace.

Owner:PETROCHINA CO LTD +1

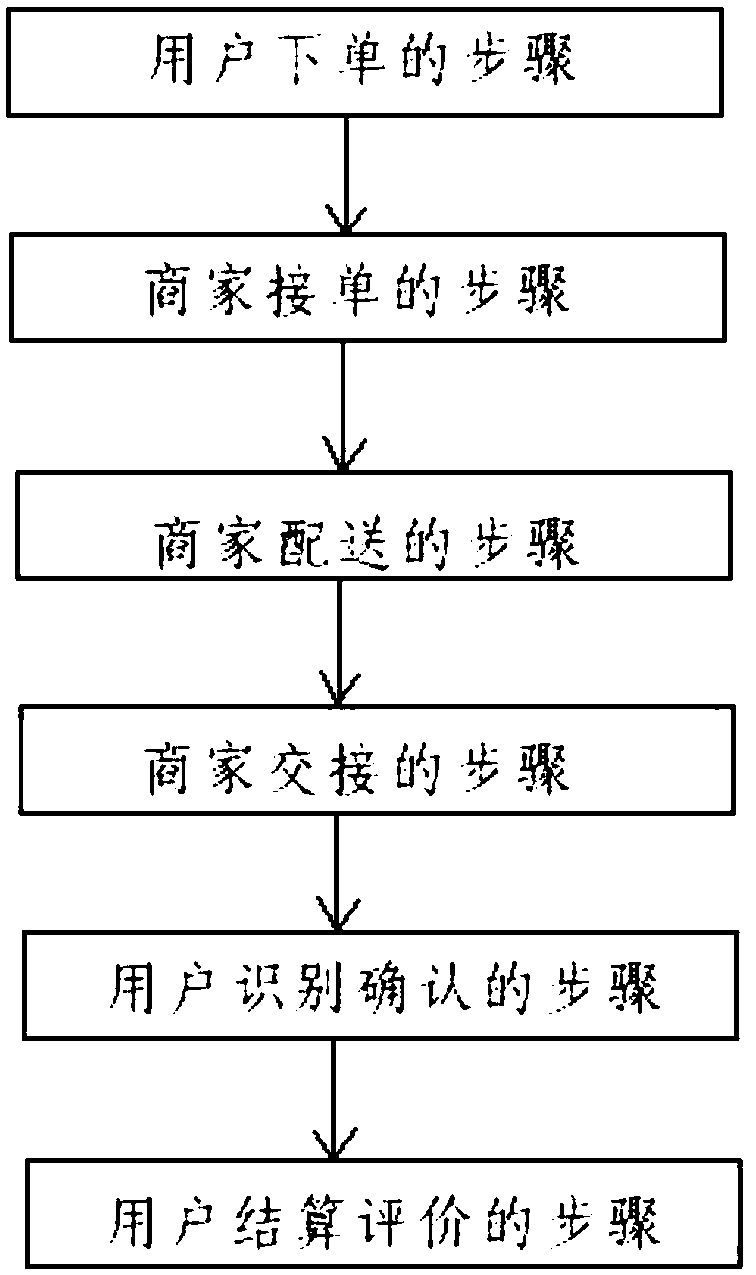

Liquefied petroleum gas pot distribution method based on O2O mode

InactiveCN105184625AEasy to understandLow costBuying/selling/leasing transactionsLogisticsGas cylinderDistribution method

The invention discloses a liquified petroleum gas pot distribution method based on an O2O mode. The liquified petroleum gas pot distribution method comprises a user ordering step, a merchant order-receiving step, a merchant distribution step, a merchant handover step, a user identification and confirmation step, and a user settlement evaluation step. The liquified petroleum gas pot distribution method based on the O2O mode combines an off-line user liquified petroleum gas consumption business opportunity with the Internet of things, reduces marketing and distribution costs of the merchants, creates a new market channel, and has incomparable advantages than the traditional system in aspects of gas pot safety, field distribution, filling quality, process tracking and the like.

Owner:无锡乾元智能安全技术研究有限公司

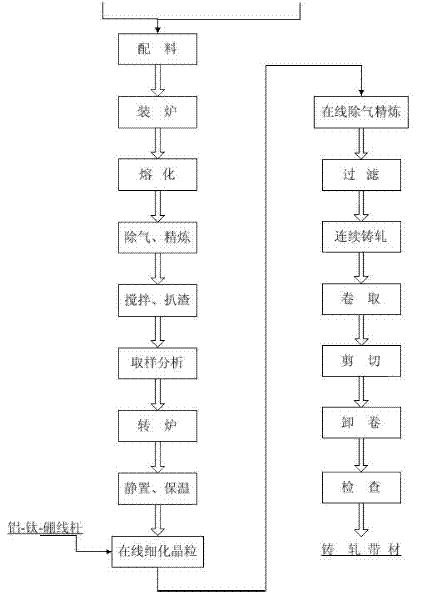

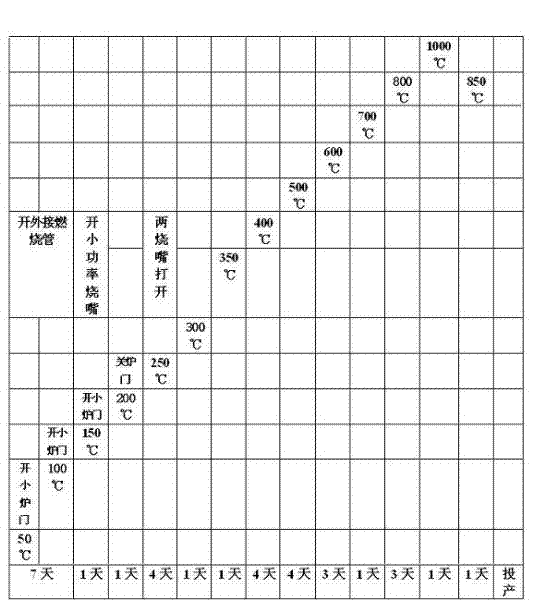

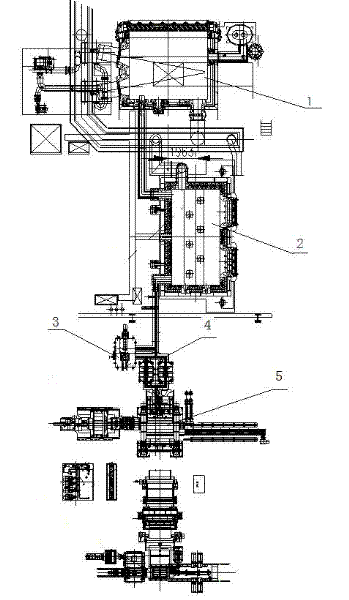

A continuous casting and rolling process for producing 5005 aluminum-plastic strip blanks

InactiveCN102266924AReduce burning lossReduce energy consumptionMetal rolling stand detailsMetal rolling arrangementsFoundryDual stage

The invention relates to the aluminum processing industry, in particular to a continuous casting and rolling process for producing 5005 aluminum-plastic strip blanks. The invention includes a holding furnace, an aluminum melting furnace, an on-line refining device, a two-stage filter item, and a continuous casting and rolling unit used in the production method. The process method includes the following steps: 1) batching step; 2) furnace loading step; 3 ) melting and stirring steps; 4) slag removal, sampling and analysis steps; 5) degassing refining, standing, heat preservation steps; 6) online melt processing steps; 7) continuous casting and rolling steps; 8) coiling and shearing steps ;9) Check the steps. The advantages of the method of the present invention: due to the use of 80% electrolytic aluminum liquid in the production process, the burning loss of aluminum is reduced to below 15‰, and the unit consumption of natural gas is reduced to below 80Nm3 / tAl, which is similar to the production of 3005 aluminum-plastic strips by using aluminum ingots for remelting Compared with the casting and rolling method of the billet, the burning loss and energy consumption of aluminum are reduced by 50%; the finished product rate reaches more than 99%. The invention discloses a continuous casting and rolling process for producing 5005 aluminum-plastic strip blanks, which is suitable for domestic and foreign aluminum and aluminum alloy casting industries.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

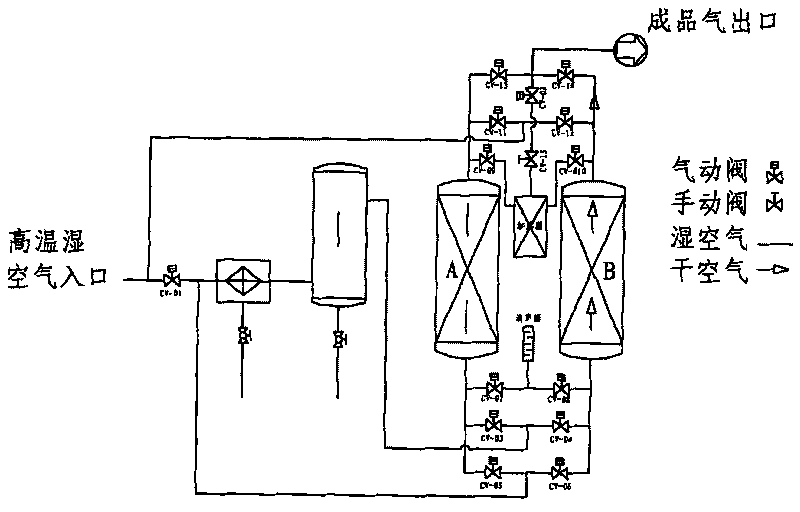

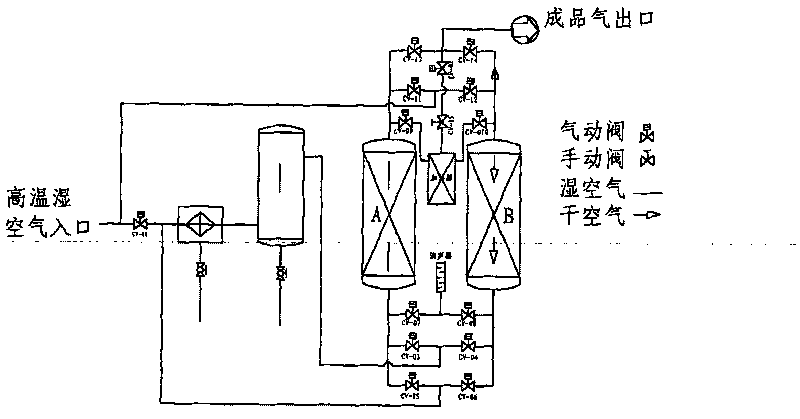

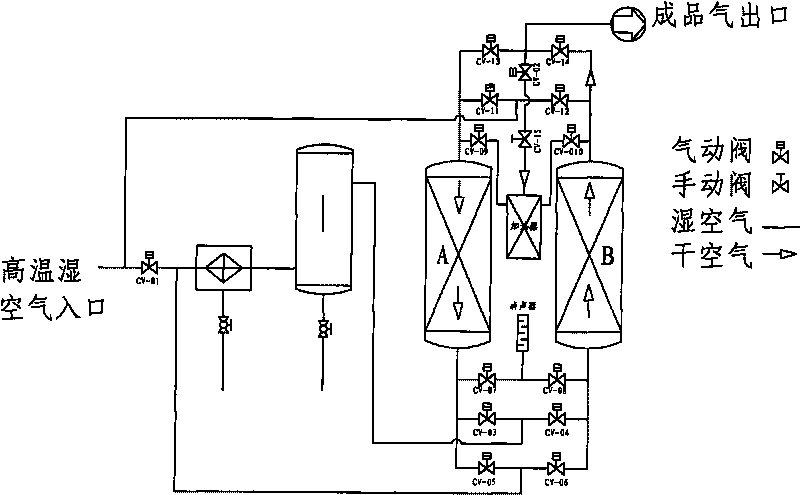

Energy-saving compressed air drying method and device special for compression heat regenerative pipelines

InactiveCN101732953AHigh frequencyHigh quality gasDispersed particle separationSwitching timeEnergy conservation

The invention discloses an energy-saving compressed air drying method and an energy-saving compressed air drying device special for compression heat regenerative pipelines. The method comprises the following two stages: a drying-heating regeneration stage, wherein high temperature gas is delivered to a regenerator, enters an air cooler for temperature reduction, flows into a gas-water separator and then enters a drying tower; and a drying-cold blowing regeneration stage, wherein the high temperature gas is controlled by a valve to change the direction, flows into the air cooler and the gas-water separator and then directly enters the drying tower for drying, wherein partial dried air taken from an outlet of the drying tower enters the regenerator for cold blowing regeneration. The device comprises a pair of adsorption towers which are formed by connecting a plurality of control valves and pipelines and is a drying tower and a regenerator mutually; the control valves are connected with a PLC program controller; a pipeline for delivering high temperature air is connected in parallel with a dry air supply pipeline formed by connecting the air cooler and the gas-water separator in series; and the front end of the dry air supply pipeline is connected with an outlet of a regenerative gas pipeline of the regenerator through a control valve. The energy-saving compressed air drying method and the energy-saving compressed air drying device avoid the defects of short switching time, high frequency and high gas consumption for generation of a heatless regenerative adsorption type drier, also overcome the defect that a heat regenerative adsorption type drier needs a heater to consume much electric energy, and ensure continuous production of high-quality gas and energy conservation.

Owner:杭州博大净化设备有限公司

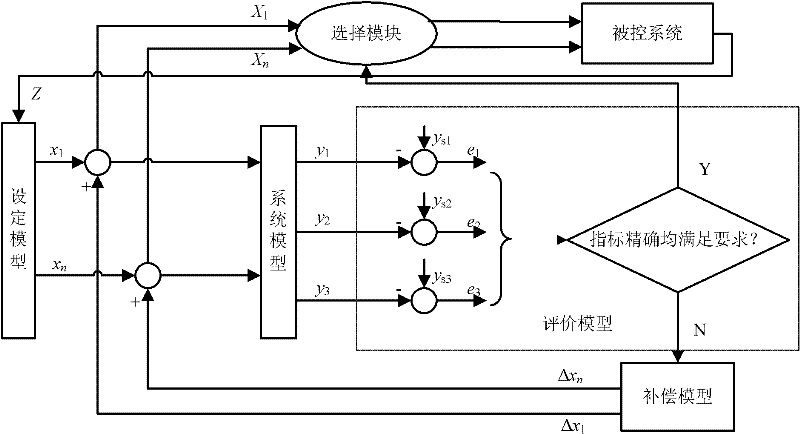

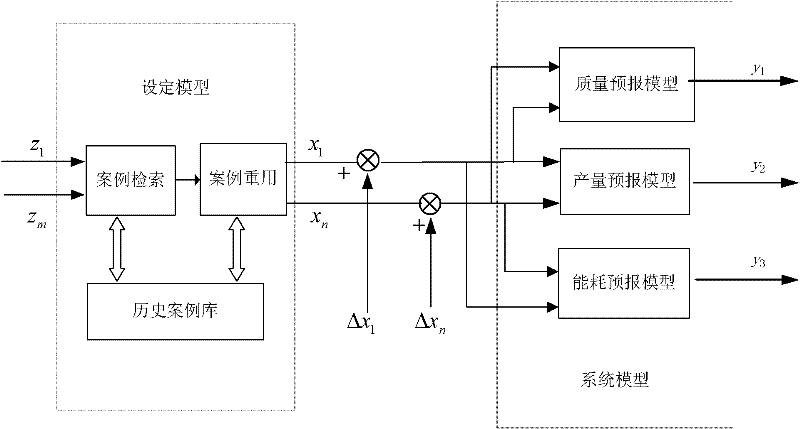

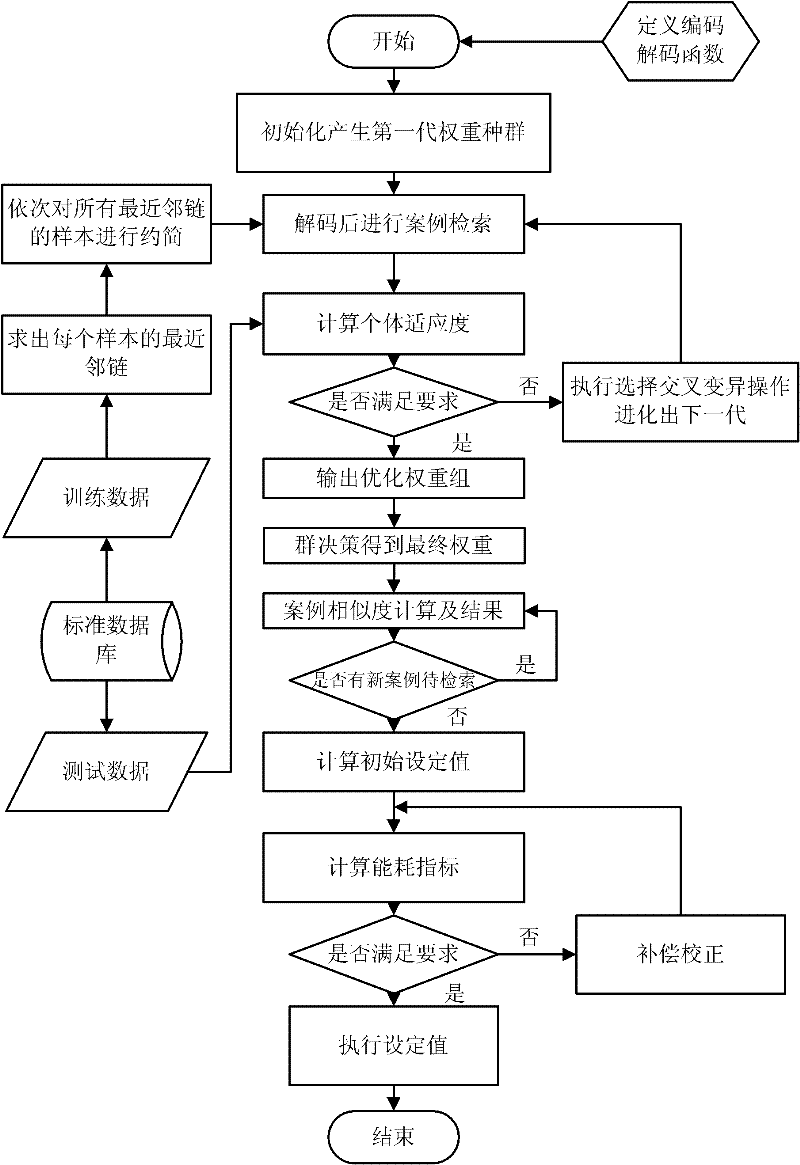

Multi-target evaluation optimization method based on group decision making retrieval strategy

InactiveCN102540879ARealize rationality evaluationQuality improvementAdaptive controlImage retrievalPhase retrieval

The invention discloses a multi-target evaluation optimization method based on a group decision making retrieval strategy and a multi-target evaluation structure for the optimization calculation of set values. The method comprises the following steps of: defining an encoding function; randomly assigning weights for initialization; performing case retrieval after decoding; calculating individual adaptability; judging whether the accuracy meets requirements or not (outputting optimized weights if the accuracy meets the requirements, otherwise, performing the case retrieval again); obtaining final weights by adopting group decision making; calculating case similarity to obtain new retrieval results; judging whether new cases to be retrieved exist or not; calculating product quality, product yield and an energy consumption index within a unit time; evaluating the set values; judging whether to perform compensation and correction on the set values or not; and outputting final set values. The method and the structure are applied to control over the roasting process of a shaft furnace in the metallurgical industry; the rationality of the set values can be evaluated; the quality of roasted ore is improved by 2 percent, the yield of the roasted ore is improved by 4 percent, and energy consumption is reduced by 5 percent; and optimal target values of production indexes are realized, the quality of the roasted ore is improved, gas consumption in a production process is reduced, and the aims of energy saving and consumption reduction are fulfilled.

Owner:BEIJING UNIV OF TECH

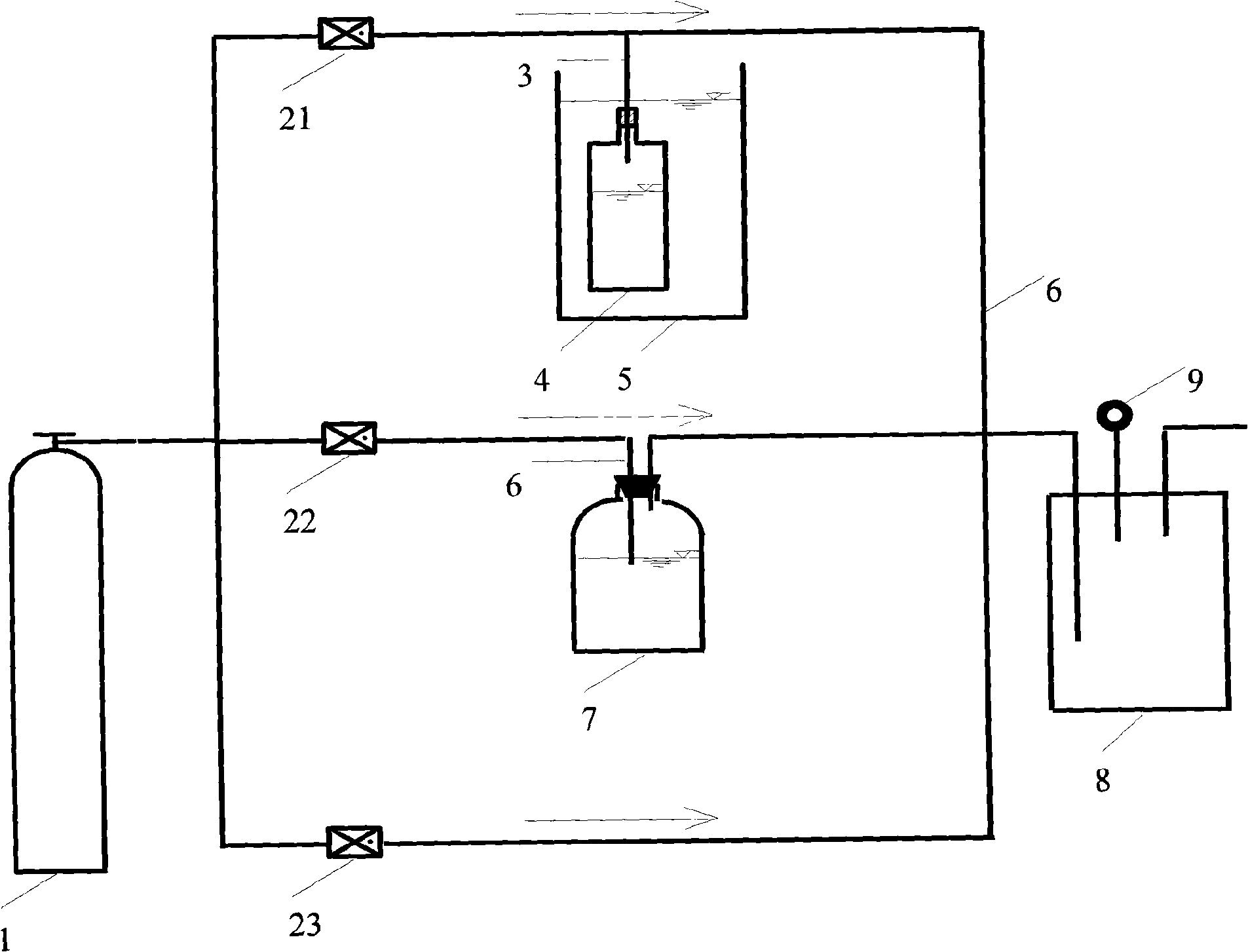

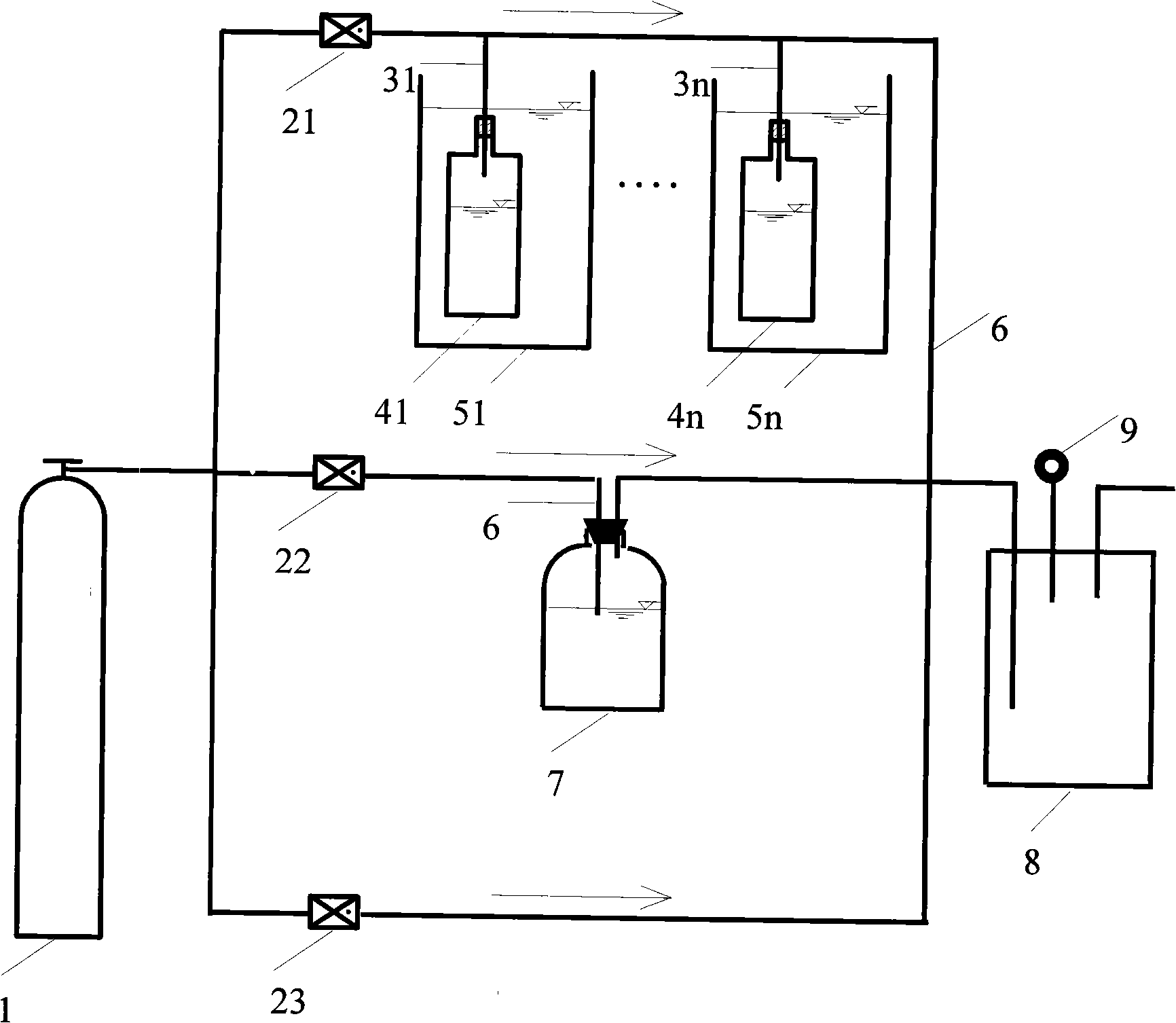

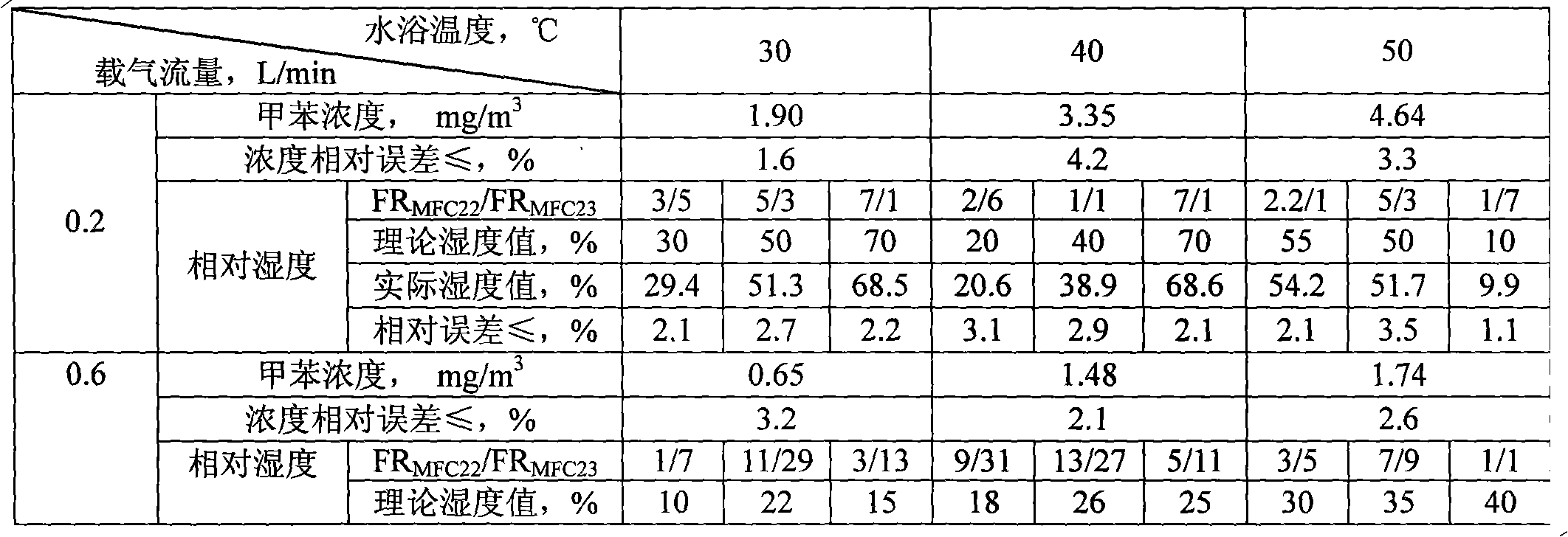

Preparation device and method of low-concentration gas of certain humidity

InactiveCN101357305ARealize low-concentration mixed gas distributionGuaranteed uptimeMixer accessoriesMixing gases with gases/vapoursDiffusionGas cylinder

A preparation device of low-concentration gas with certain humidity consists of a capillary tube and a tee or two-way air-tight joint which are communicated with a carrier gas cylinder, a mass flow controller, a heating diffusion bottle, a humidity generating bottle and a gas mixing tank. The diffusion bottle is arranged in a heater, is communicated with the capillary tube by a capillary needle tube, and a diffusion gas control section is arranged with corresponding numbers and parameters according to the varieties and numbers of the prepared gas components. The gas mixing tank is provided with a hygrometer for real-time determination of the humidity of the prepared gas. The device of the invention adopts a diffusion-dilution type dynamic gas distribution method, can prepare the low-concentration gas with certain humidity, and is characterized by low cost, simple operation, low gas consumption, stable gas distribution, wide humidity regulation range, wide application, etc.

Owner:ZHEJIANG UNIV

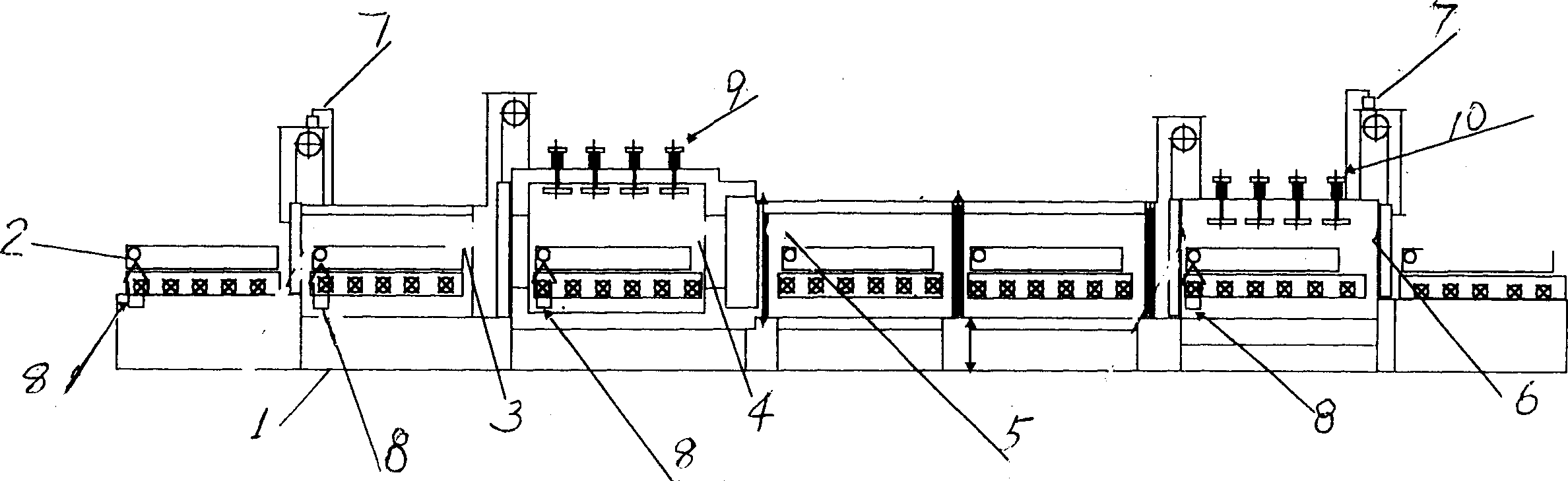

Protective gas on-line purging copper tube bright continuous annealing furnace

The continuous copper tube bright annealing furnace features that there are air intake pipe and air exhaust pipe in the material rack; copper tube inner purging unit and inner air exhaust unit in the front chamber, heating chamber, water cooling chamber and forcing cooling chamber; that all the air intake pipes are communicated and so do the air exhaust pipes. The present invention may be used to produce bright copper tube with inner surface of superhigh cleanness. The annealing furnace also has the features of low manufacture cost, low air consumption, low power consumption, high production efficiency and continuous production.

Owner:张民苏 +2

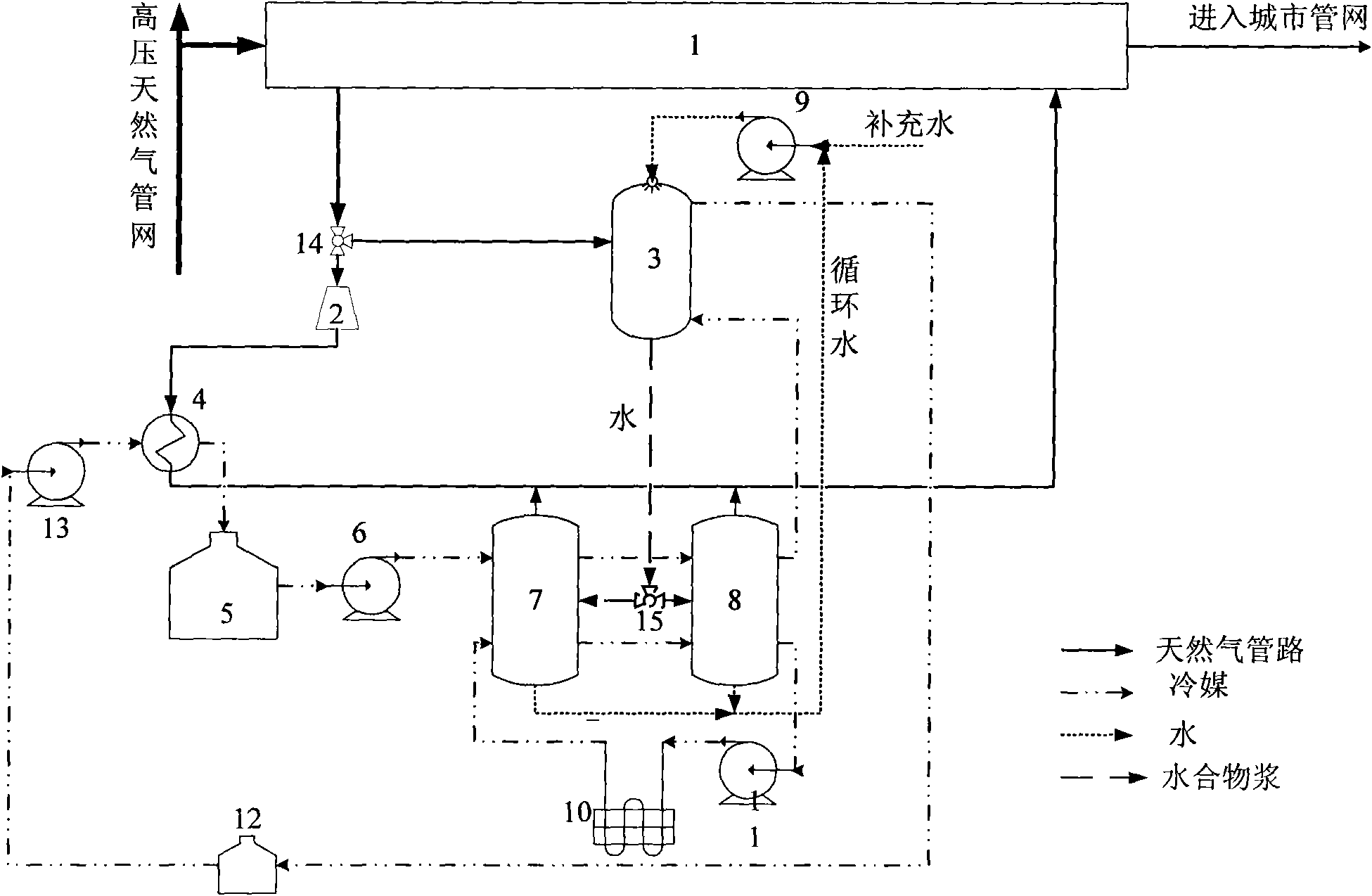

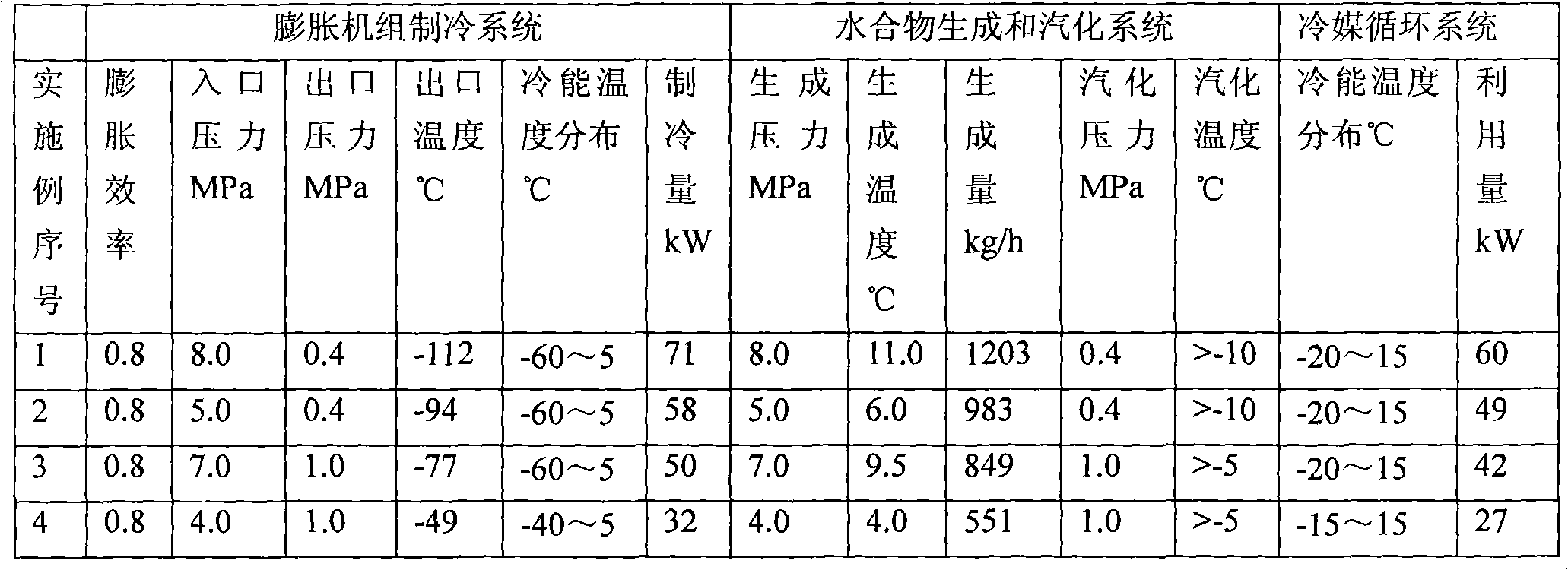

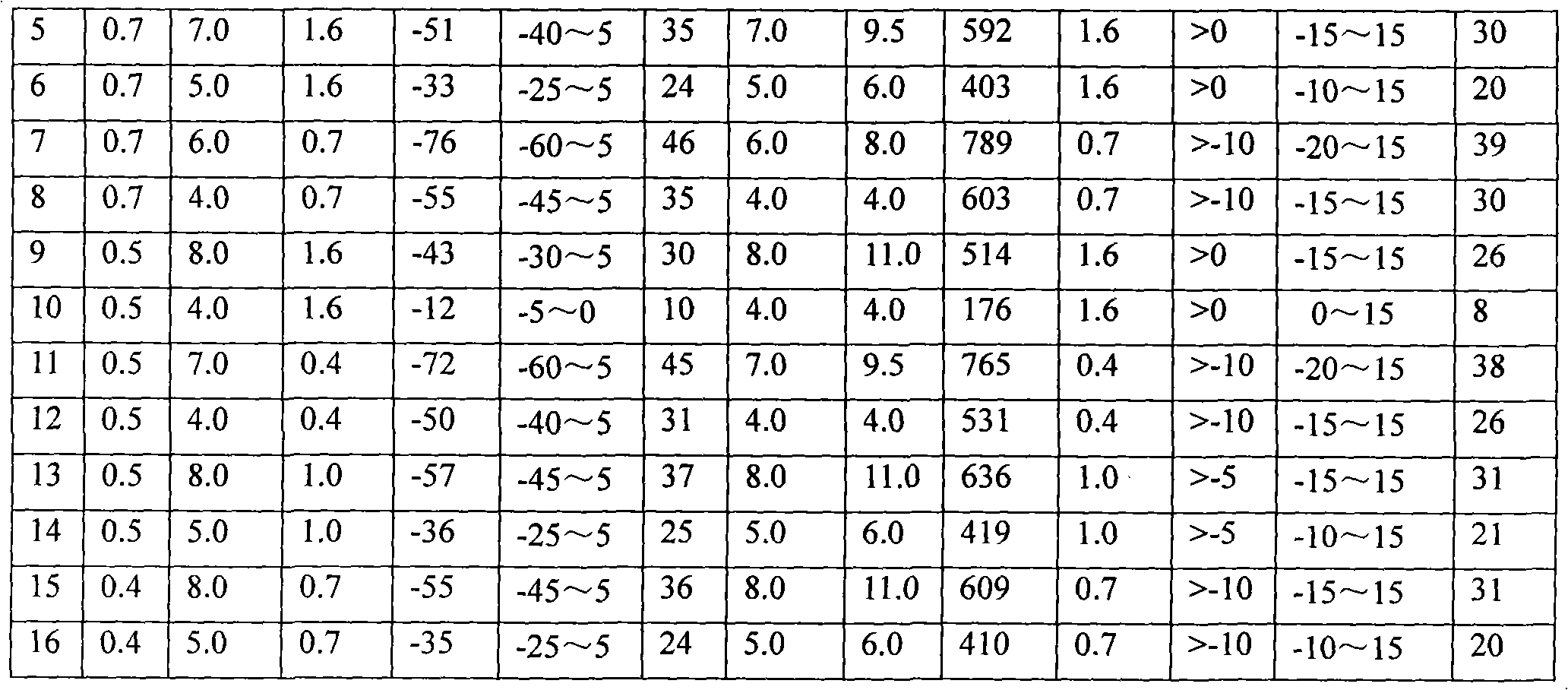

Method and device for integrated utilization of natural gas pipe network pressure energy refrigeration and hydrate

InactiveCN101551060ASolve the peak shaving problemLow running costPipeline systemsFixed capacity gas holdersDecompositionElectric network

The invention discloses a method and a device for integrated utilization of natural gas pipe network pressure energy refrigeration and hydrate, wherein the method comprises the steps of carrying out shunting on the high pressure pipe network natural gas of a natural gas gate station; carrying out depressurization refrigeration on the natural gas which meets the instantaneous demand of urban pipe networks and storing the cold energy through cooling mediums; leading the depressurized natural gas to enter downstream urban pipe networks; leading another part of high pressure natural gas to enter ahydrate generation tower to generate natural gas hydrate slurry which flows into a hydrate storage tank for storage; using the cooling mediums in a low-temperature storage tank to provide cold energyfor the hydrate storage tank and the generation tower to generate the hydrate when in gas consumption trough; and heating to vaporize the hydrate in the storage tank for supplementing the downstreampipe networks when in gas consumption peak; and simultaneously applying the cold energy generated by the decomposition of the hydrate to cold water air conditioners and cold storages. The invention uses the natural gas pressure energy refrigeration to generate the natural gas hydrate, simultaneously applies the cold energy of the vaporization of the hydrate to air conditioners and cold storages, thus realizing the peak regulation function of the urban natural gas pipe networks and the electric network, and greatly improving the energy utilization efficiency.

Owner:广东众通利华能源科技有限公司

Method for forming hollow plastic products and device therefor

InactiveCN1836880AIncrease productivityPhenomenon that will not rush inHollow articlesEngineeringInjection molding machine

Owner:BEIJING CHN TOP MACHINERY

Detection system and method for mesomeric state hydrogen gas consumption

InactiveCN101470020AEasy to pour directlyEasy to pour directly intoFuel cell auxillariesWeighing apparatus for materials with special property/formFlame arresterGas cylinder

The invention relates to a steady hydrogen gas consumption detection system and a detection method thereof, belonging to the gas detection technical field. In the system, the main pipeline connected with the bottle valve of a high pressure bottle is mounted with a bottle mouth electromagnetic valve, a ferrule type joint, a detachable pipeline swirling valve, a primary road electromagnetic valve, a primary road manual valve, a first stage decompression valve, a safety valve, a second decompression valve, a flux controller and a flame arrester in turn. The method measures the weights before and after discharging the gas of the gas bottle, the temperatures and the pressures at the tail block of the gas bottle and the bottle valve, to obtain three hydrogen gas consumption value groups. The invention arranges a hydrogen bottle, a hydrogen gas bottle purging pipeline and a temperature pressure sensor in the bottle to improve measurement accuracy, comprises a filling pipeline to simply and directly fill gas into the high pressure gas bottle, and utilizes weighting method and counter weight calibration as reference, thus being convenient for the research on steady hydrogen gas consumption detection.

Owner:TSINGHUA UNIV

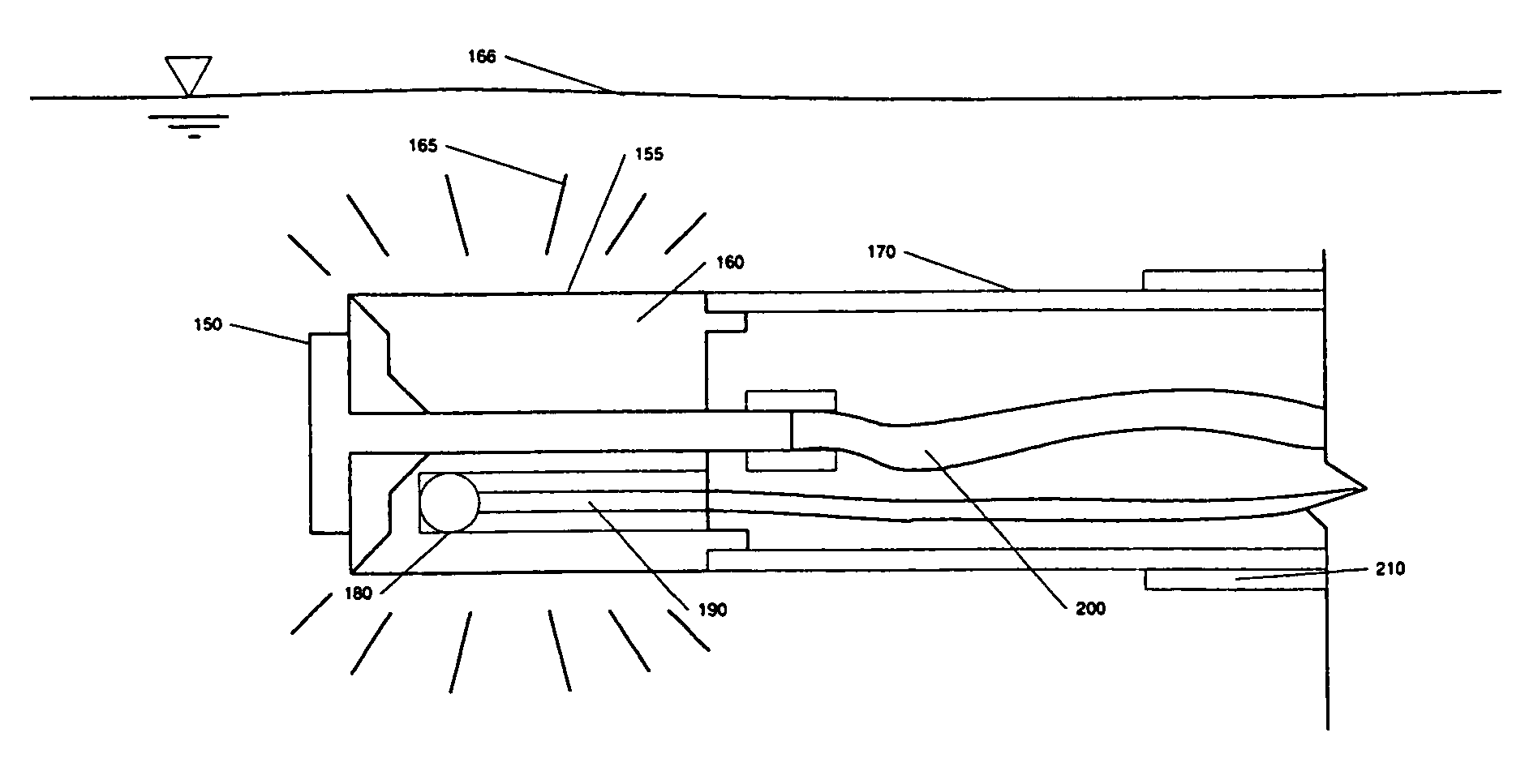

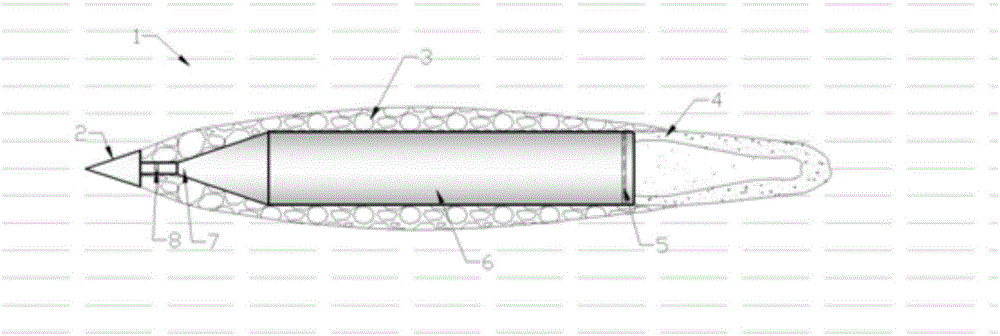

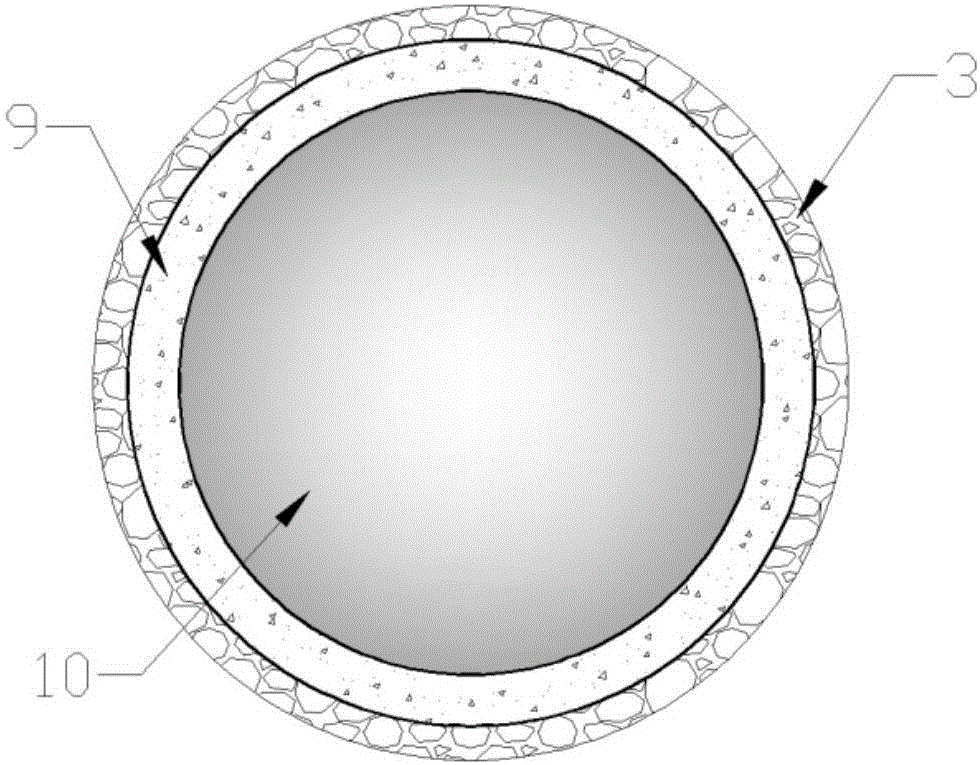

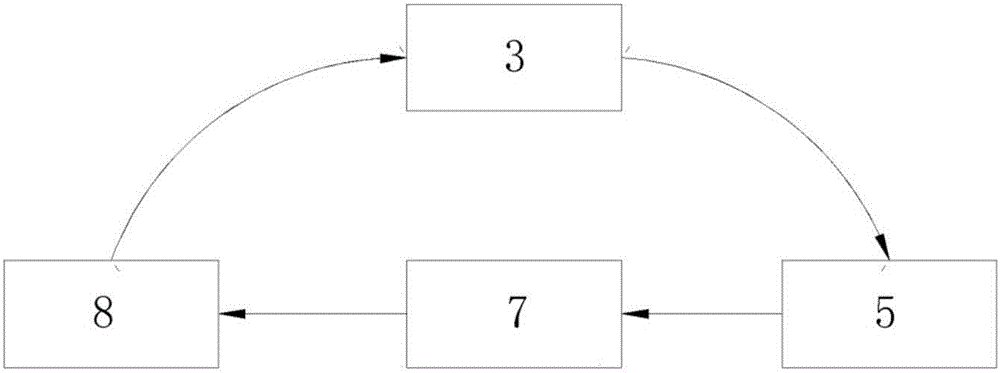

Control device and method applied to autonomous and stable navigation of navigation body

ActiveCN106364624AAvoid oscillationReduce leakageWatercraft hull designPropulsive elementsTraffic capacityStreamflow

The invention discloses a control device and method applied to autonomous and stable navigation of a navigation body. A ring-shaped tail axial nozzle is arranged on the outer edge of the bottom end of the tail of the navigation body. A small-flow-quantity circumferentially-closed axial jet stream is formed through jetting, the ejecting effect of the formed axial jet stream can play a role in stabilizing periodic falling and breaking generated due to shrinkage of the tail of a supercavity, oscillation of the tail of the supercavity is prevented, gas leakage of the tail of the supercavity is reduced, and reduction of gas consumption during high-speed navigation of an aircraft is facilitated. In addition, the tail axial jet stream rather than a hard protrusion is used for stabilizing the supercavity, extra resistance is avoided, and high-speed navigation achieving supercavity drag reduction is facilitated.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

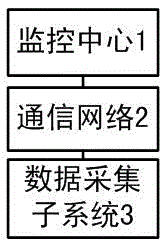

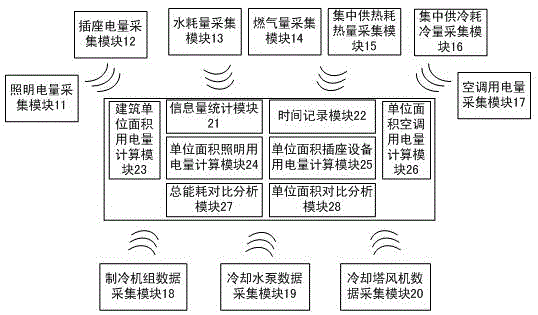

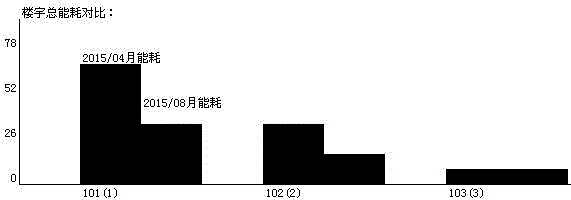

Public building energy consumption monitoring system

ActiveCN105549516ARealize dynamic analysisSave energyProgramme controlComputer controlData informationData acquisition

The invention discloses a public building energy consumption monitoring system. According to the system, a data collection sub-system collects electric quantity information, water consumption amount information, gas consumption, central heating heat consumption and central cooling coolness consumption and operation information of central air conditioning units of all monitoring points in a building; a communication network transmits all the data information collected by the data collection sub-system to a monitoring center; the monitoring center receives the data information, conducts storage, statistics, analysis and processing on all the collected data information and release a control command through the communication network; implementation bases are provided for proprietors to effectively use energy and conduct continuous energy conservation. By means of the public building energy consumption monitoring system, the integrated solution to conduct building energy consumption monitoring and equipment energy conservation operation management is provided for energy-saving application of the large-scale public building. The building electromechanical equipment energy conservation control technology is adopted as a means, dynamic analysis can be conducted on operation efficiency of such system equipment as central air-conditioning units, draught fans, water pumps, heating devices and illuminating devices, and operation energy conservation control can be conducted on the equipment.

Owner:YAZON EAST SHANDONG SCI & TECH CO LTD

Method for producing ammonia synthesis gas from coke-oven gas

The invention relates to a method for producing ammonia synthesis gas from coke-oven gas. The method comprises the steps of: by taking coke-oven gas subjected to dedusting, decoking and rough desulfurization as a raw material, firstly separating out hydrogen in the coke-oven gas for later use; respectively converting remaining high methane gas with vapor and air, further converting into conversion gas containing hydrogen and carbon dioxide after converting hydrocarbon gas into hydrogen and carbon monoxide; after removing carbon dioxide from the conversion gas, mixing the remaining gas from the separated hydrogen, and finally purifying through a terminal to obtain ammonia synthesis gas, wherein all operation units can be operated by a conventional mode. Compared with the conventional method in which pure oxygen or high oxygen is needed, with the method, the higher water vapor partial pressure and higher conversion rate can be obtained under the conditions of water vapor using the same water-air ratio and water-carbon ratio, the investment can be reduced, the utilization ratio of raw materials can be improved, the energy consumption and gas consumption can be remarkably reduced, and the economic benefits can be obvious.

Owner:黄家鹄

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com