Patents

Literature

1420results about "Mixing gases with gases/vapours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

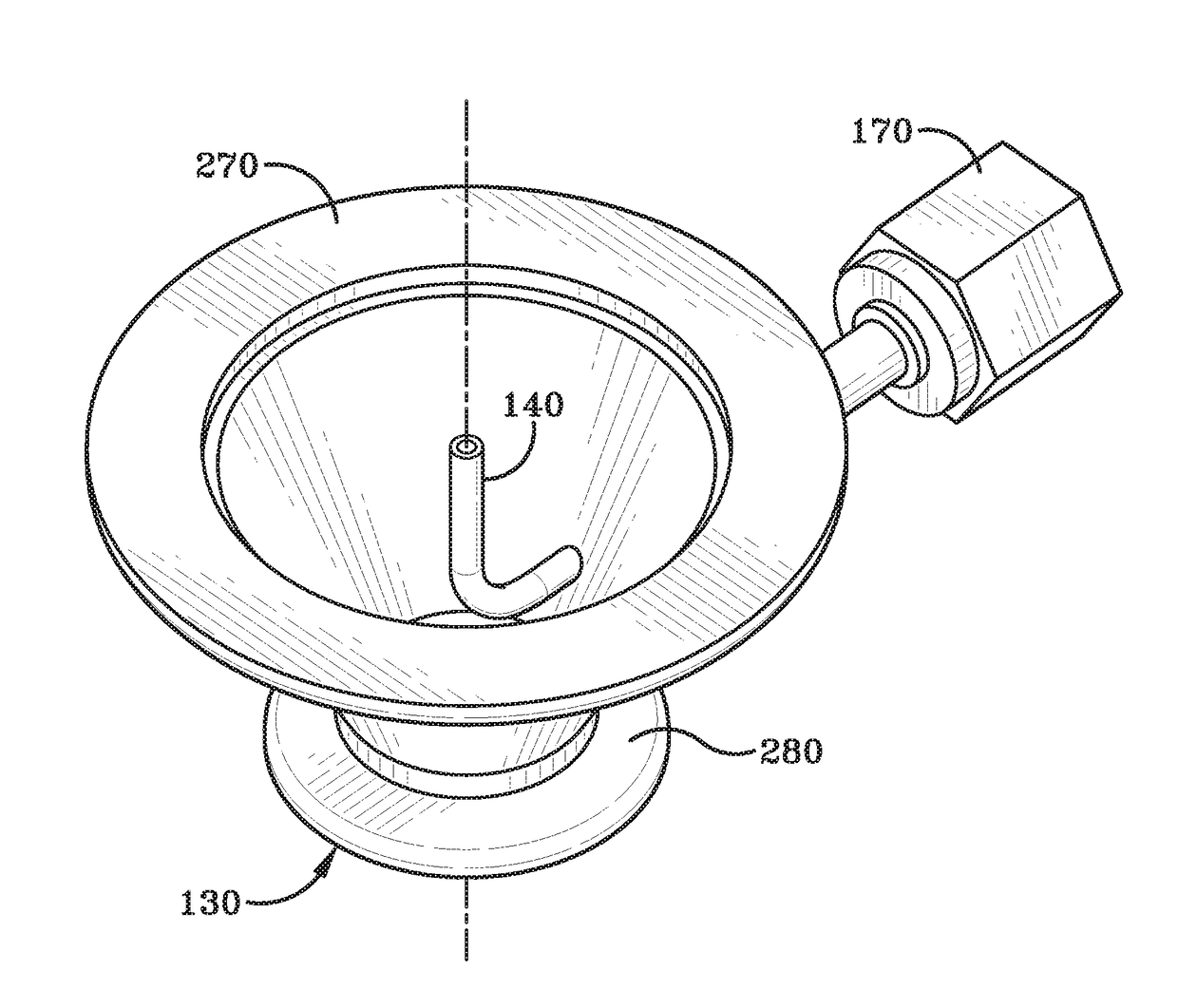

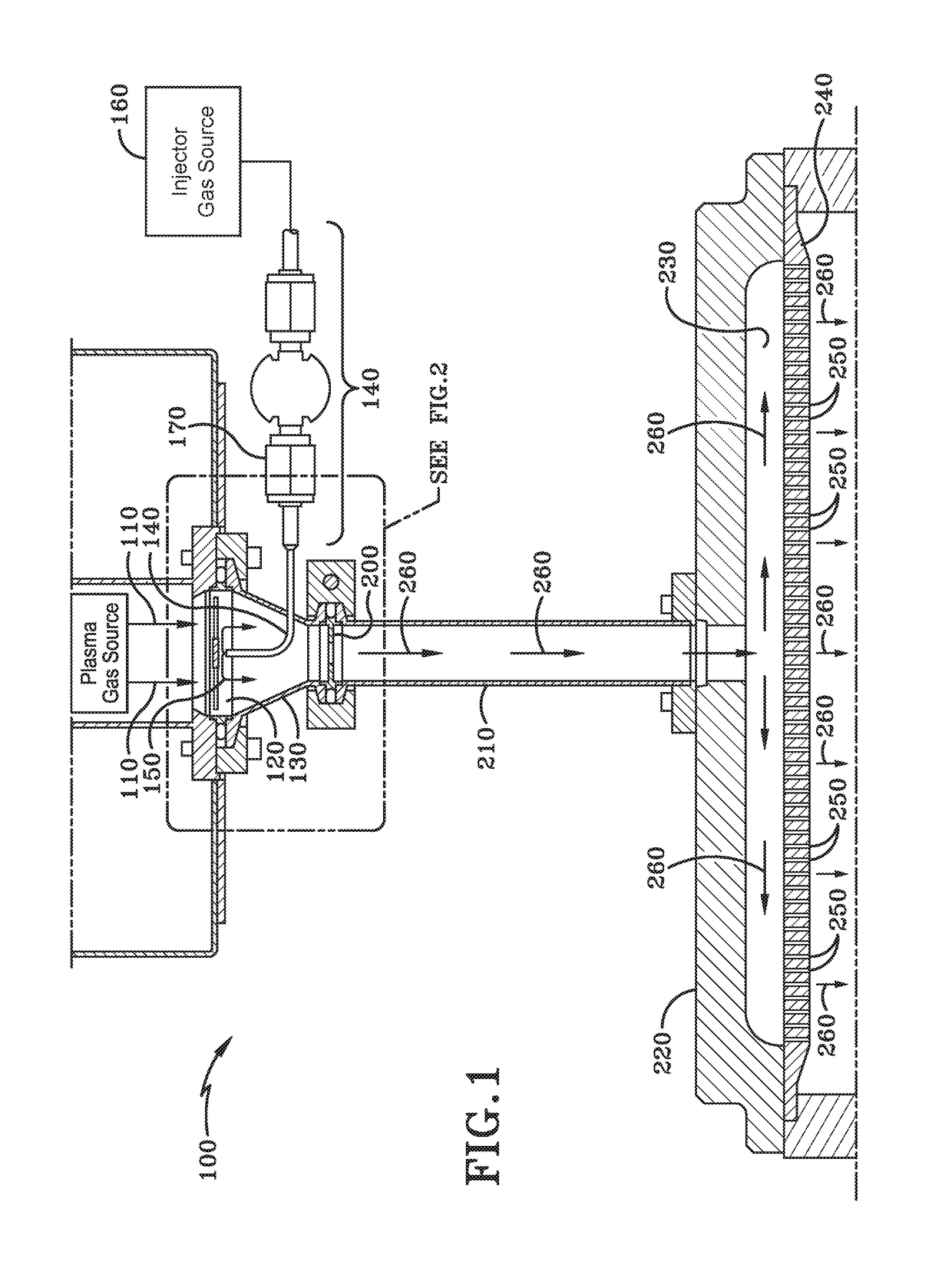

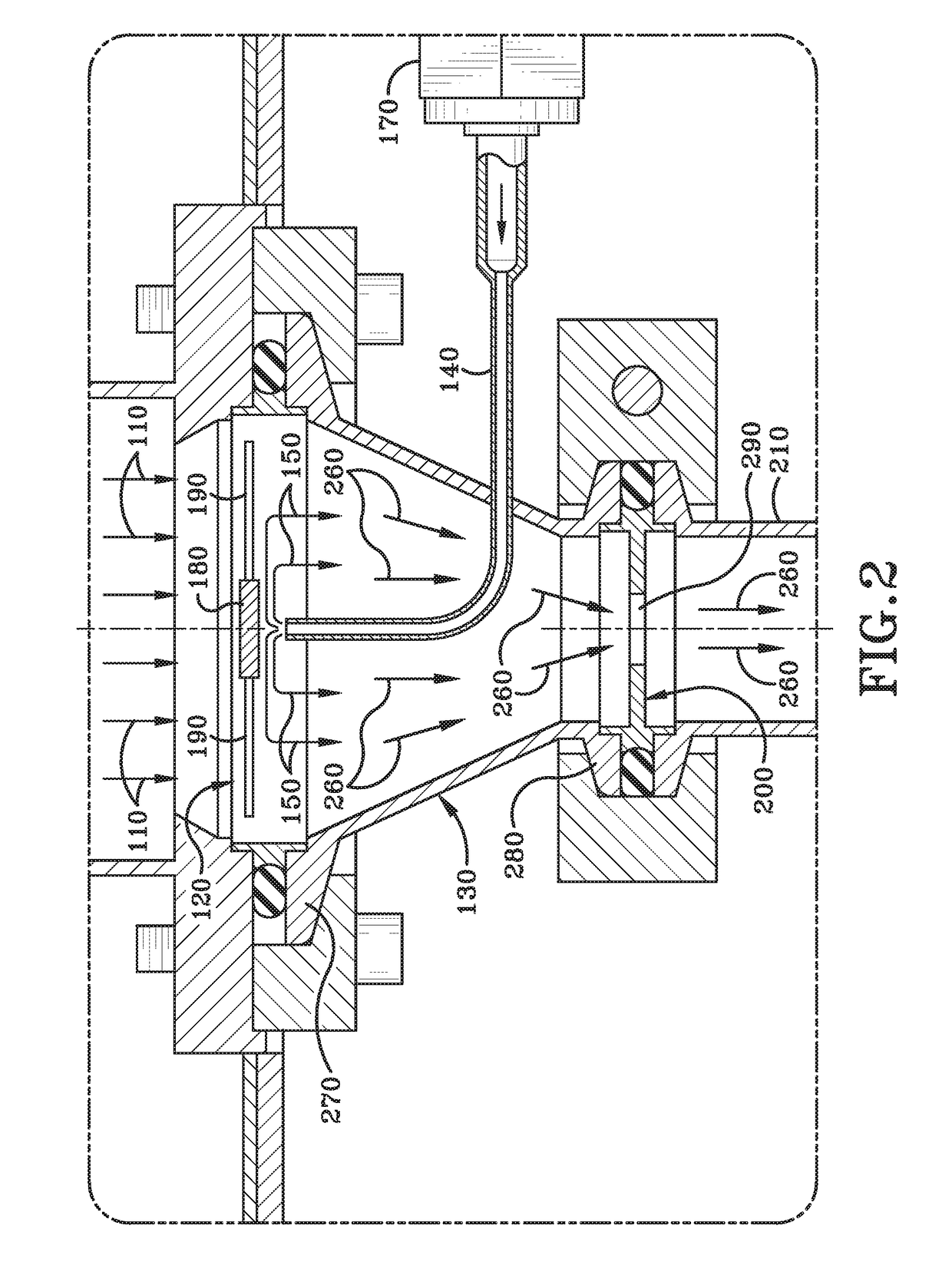

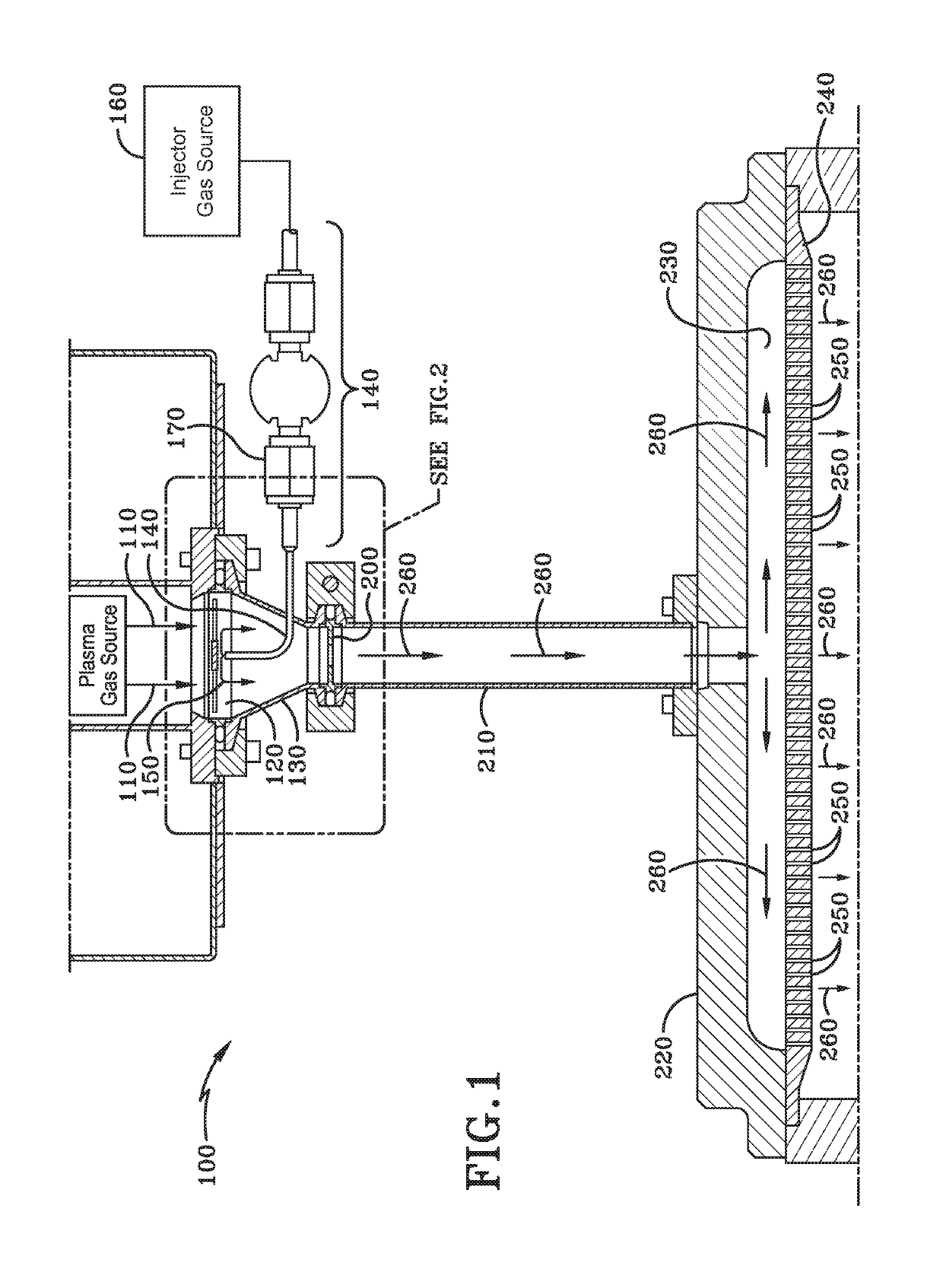

Counter flow mixer for process chamber

A counterflow mixing device for a process chamber is disclosed, comprising an injection tube that introduces a fluid in a manner counter to a flow of a post-plasma gas mixture traveling downward from a plasma source. The invention allows for proper mixing of the fluid as well as avoiding recombination of generated ions and radicals.

Owner:ASM IP HLDG BV

Counter flow mixer for process chamber

Owner:ASM IP HLDG BV

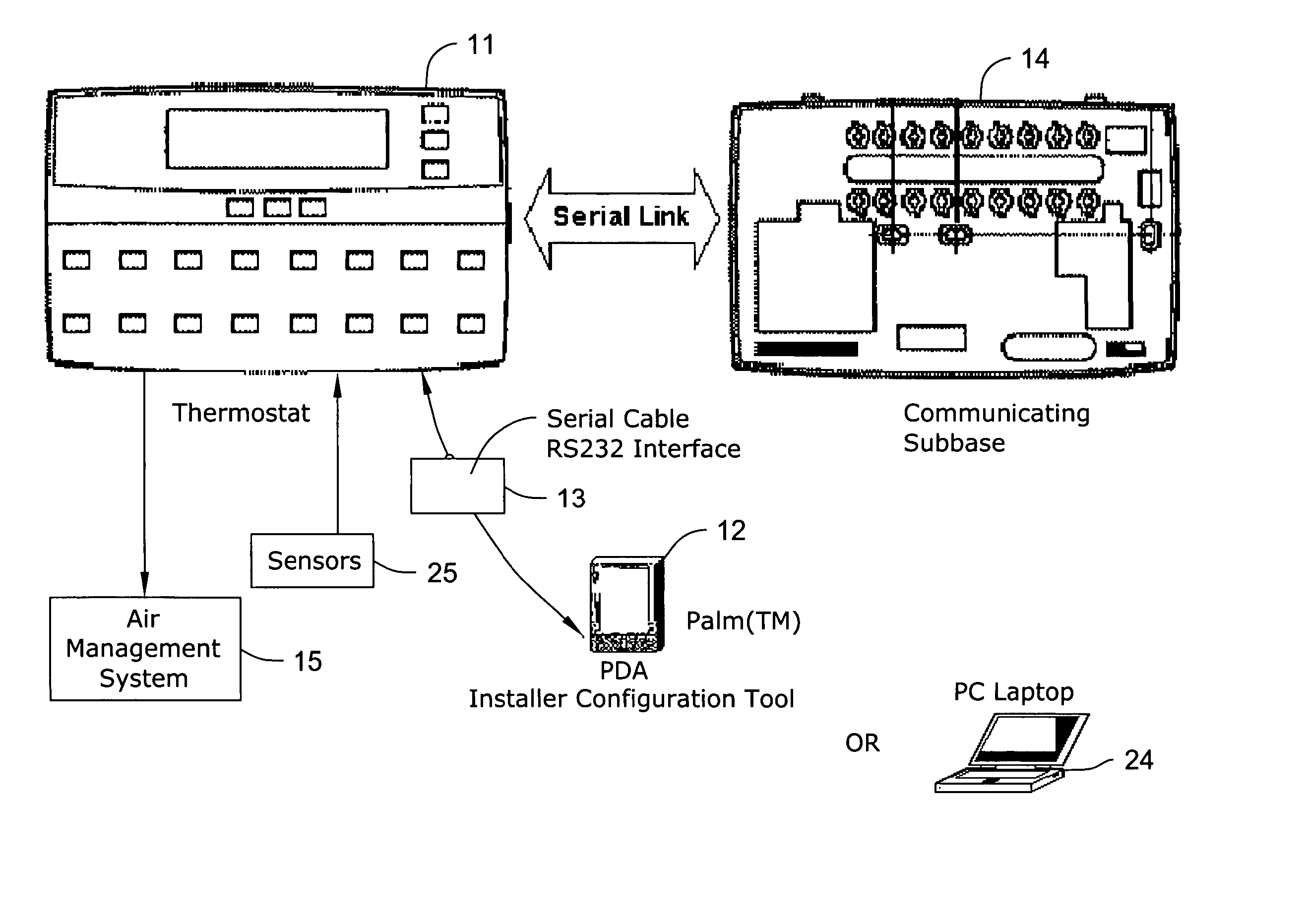

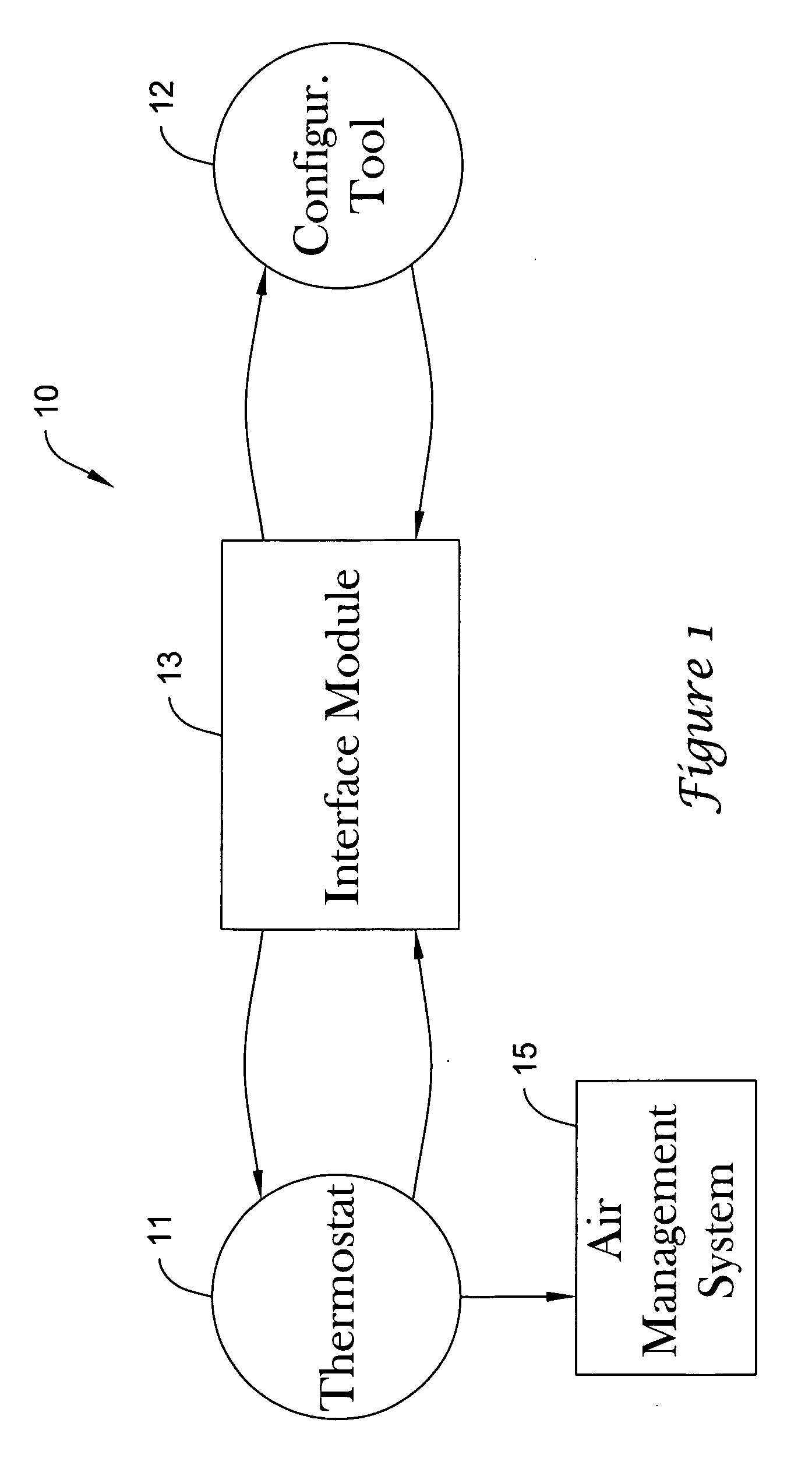

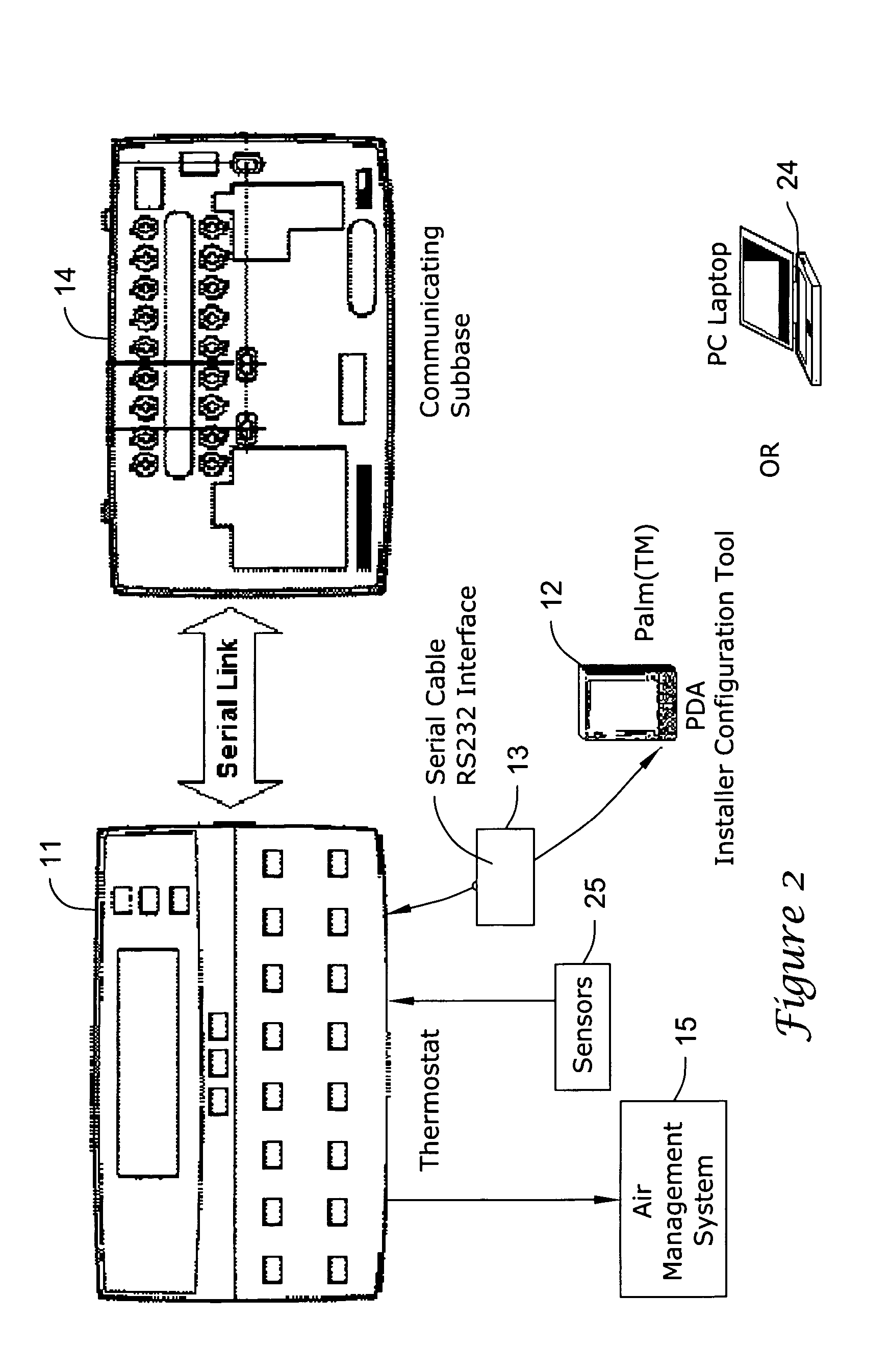

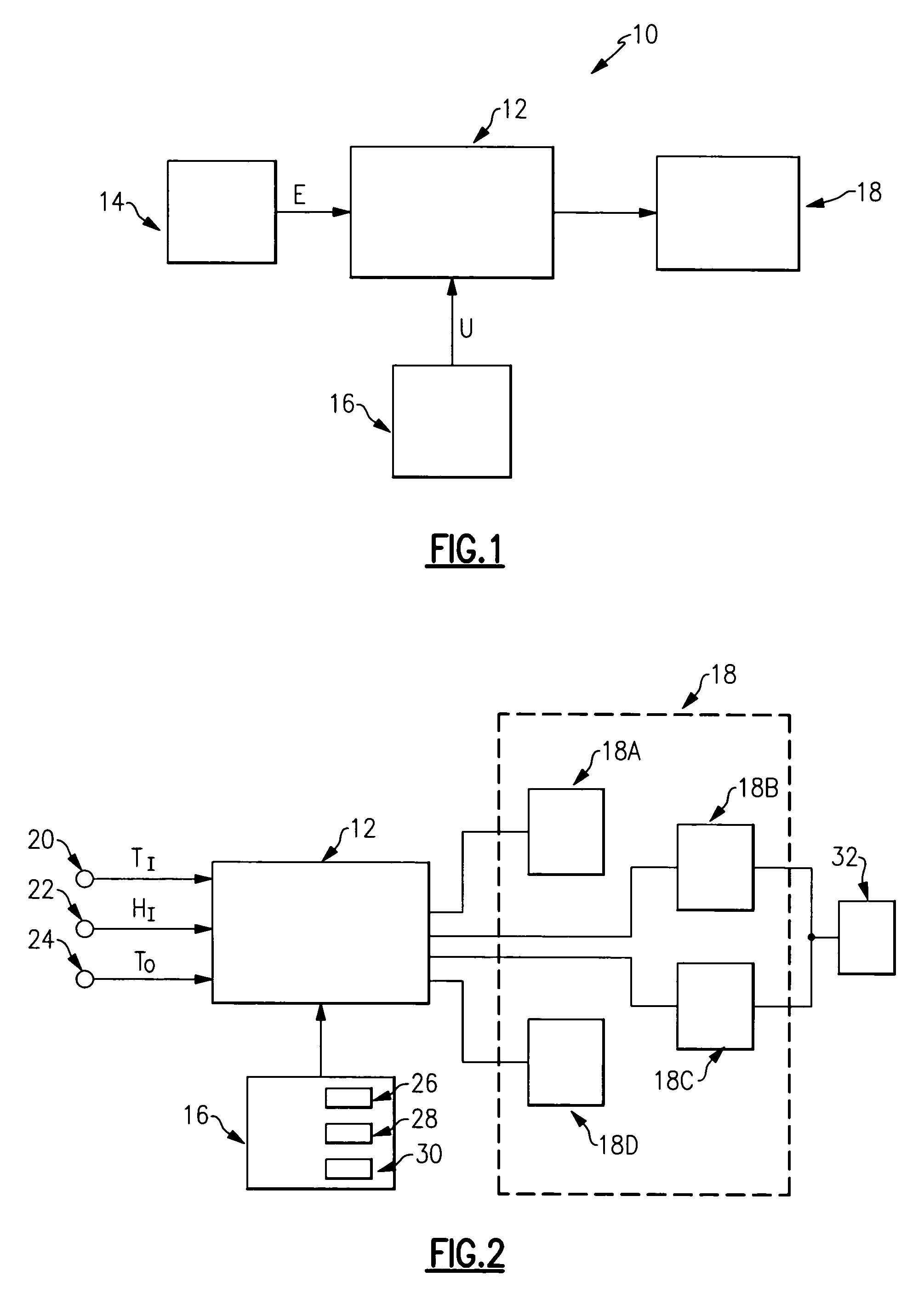

Thermostat having modulated and non-modulated provisions

ActiveUS20050040247A1Quick and efficientEasy to adaptMechanical apparatusSpace heating and ventilation safety systemsAir managementEngineering

A thermostat providing modulated or analog control of valves or dampers of an air management system. This permits operating a single cooling or heating stage with partially open valves or dampers as needed, since one full stage that is either fully on or off may not be easy to manage for effective air management of a particular type of building, zone or facility. The thermostat may also provide non-modulated control of multi-stage cooling and heating systems. The thermostat may even be used to control a modulated system having more than one stage of cooling or heating.

Owner:HONEYWELL INT INC

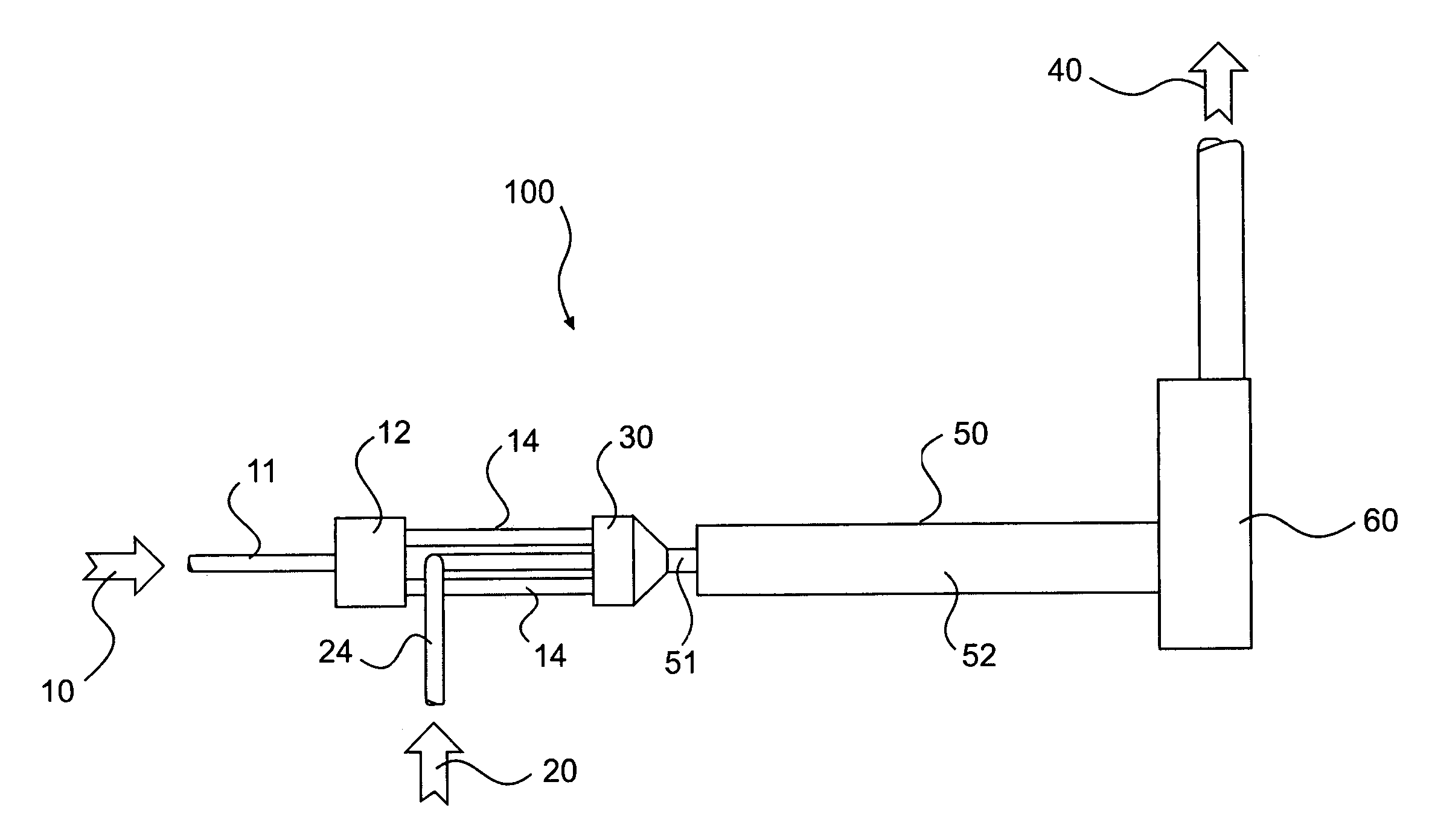

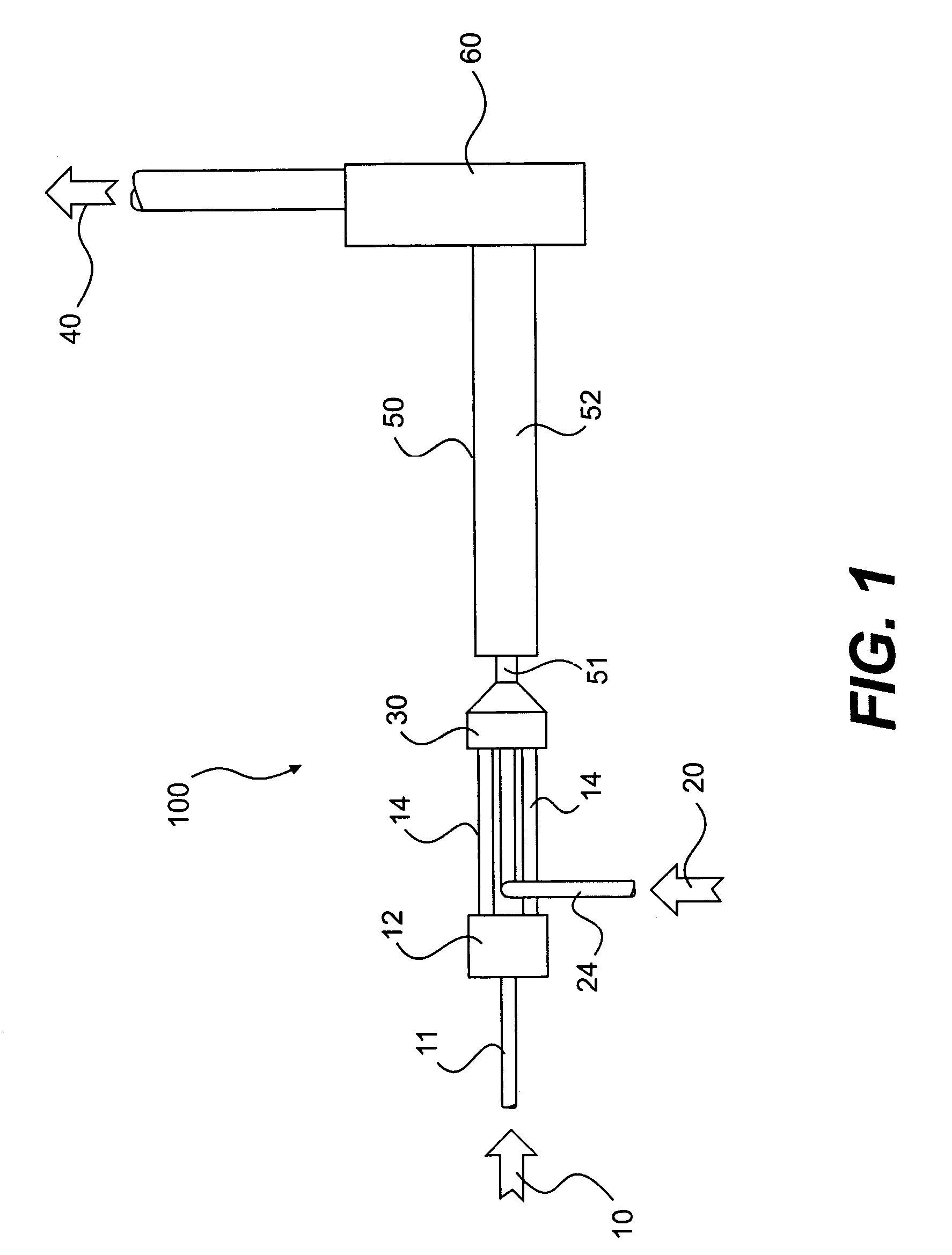

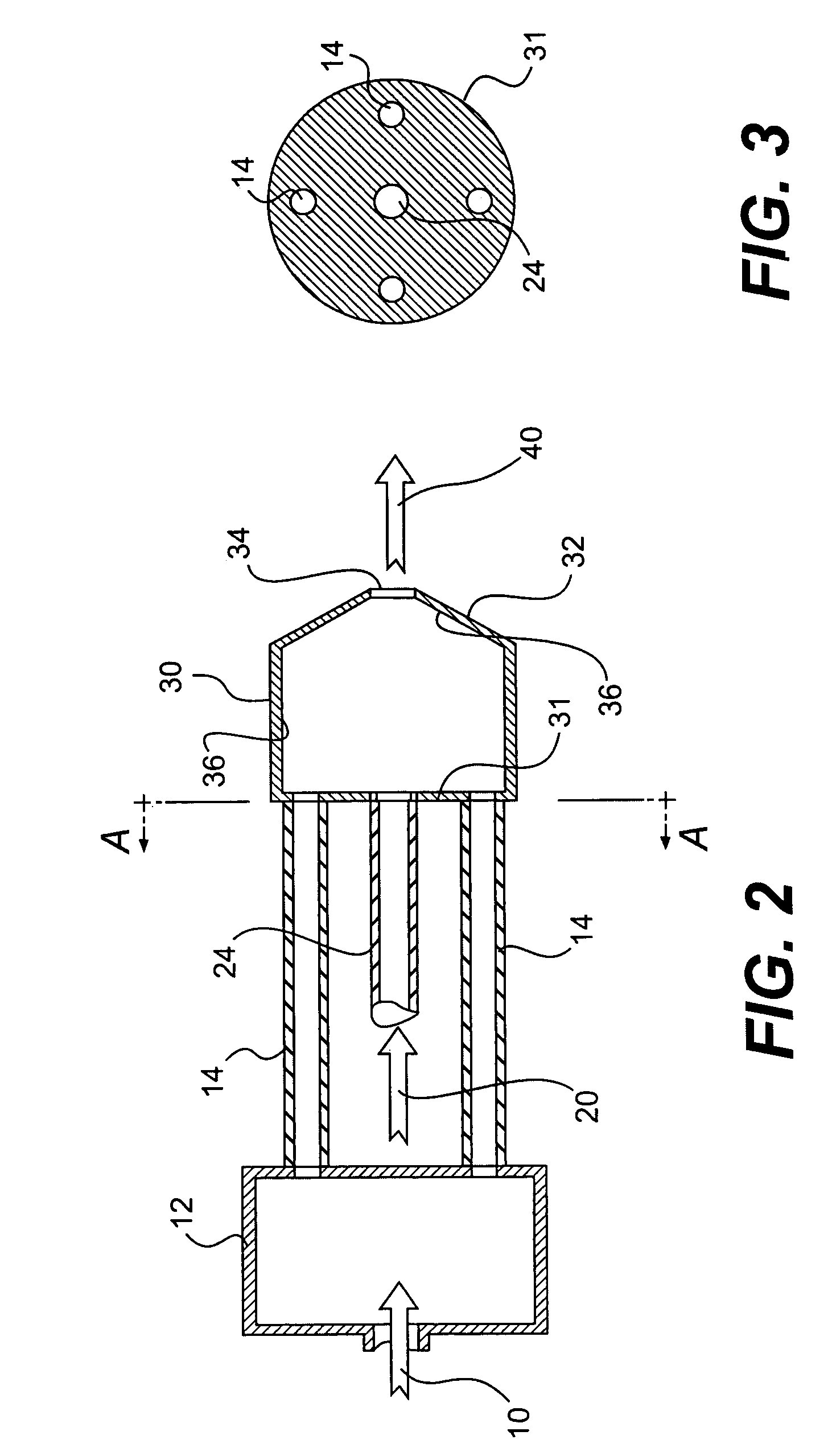

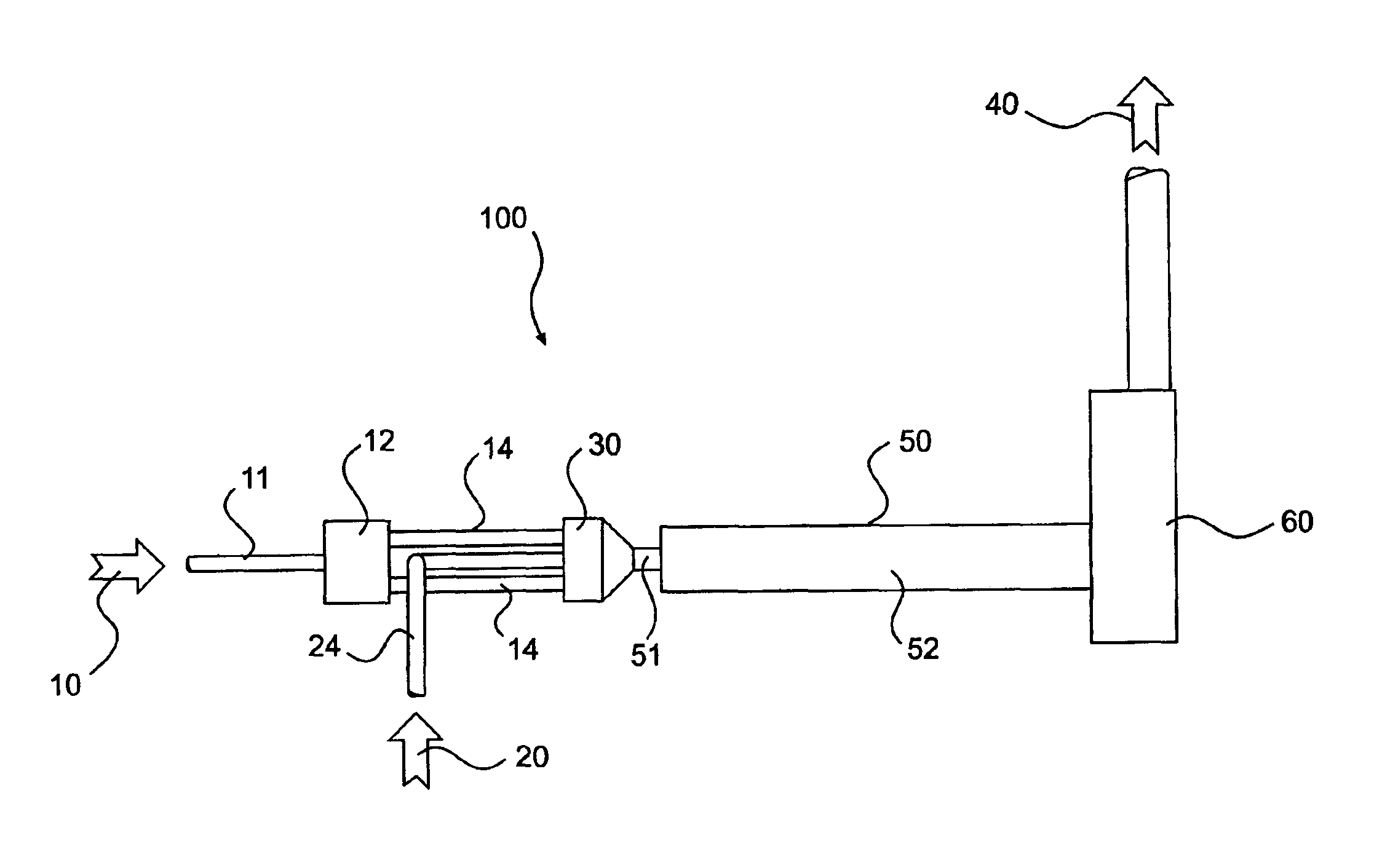

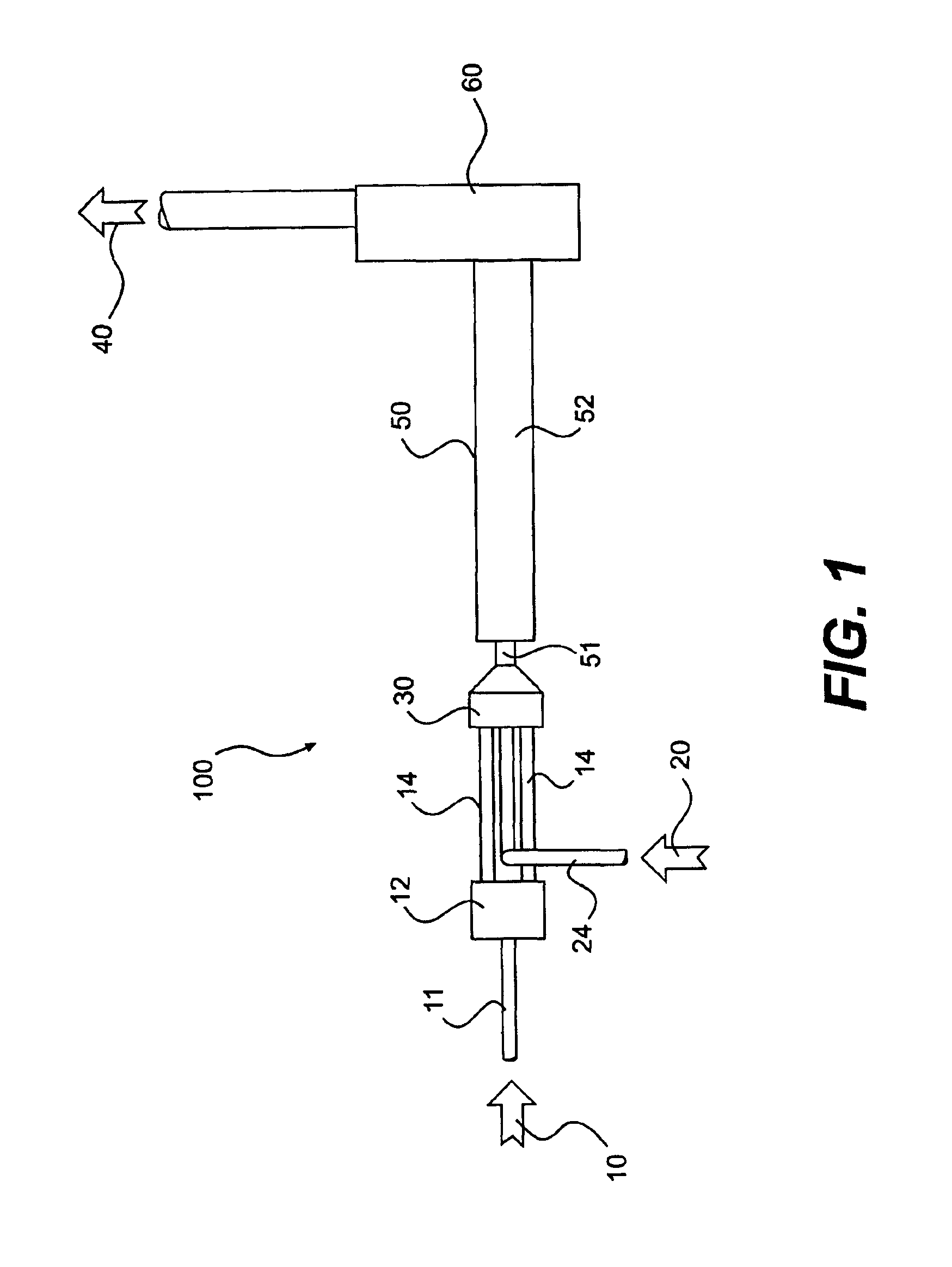

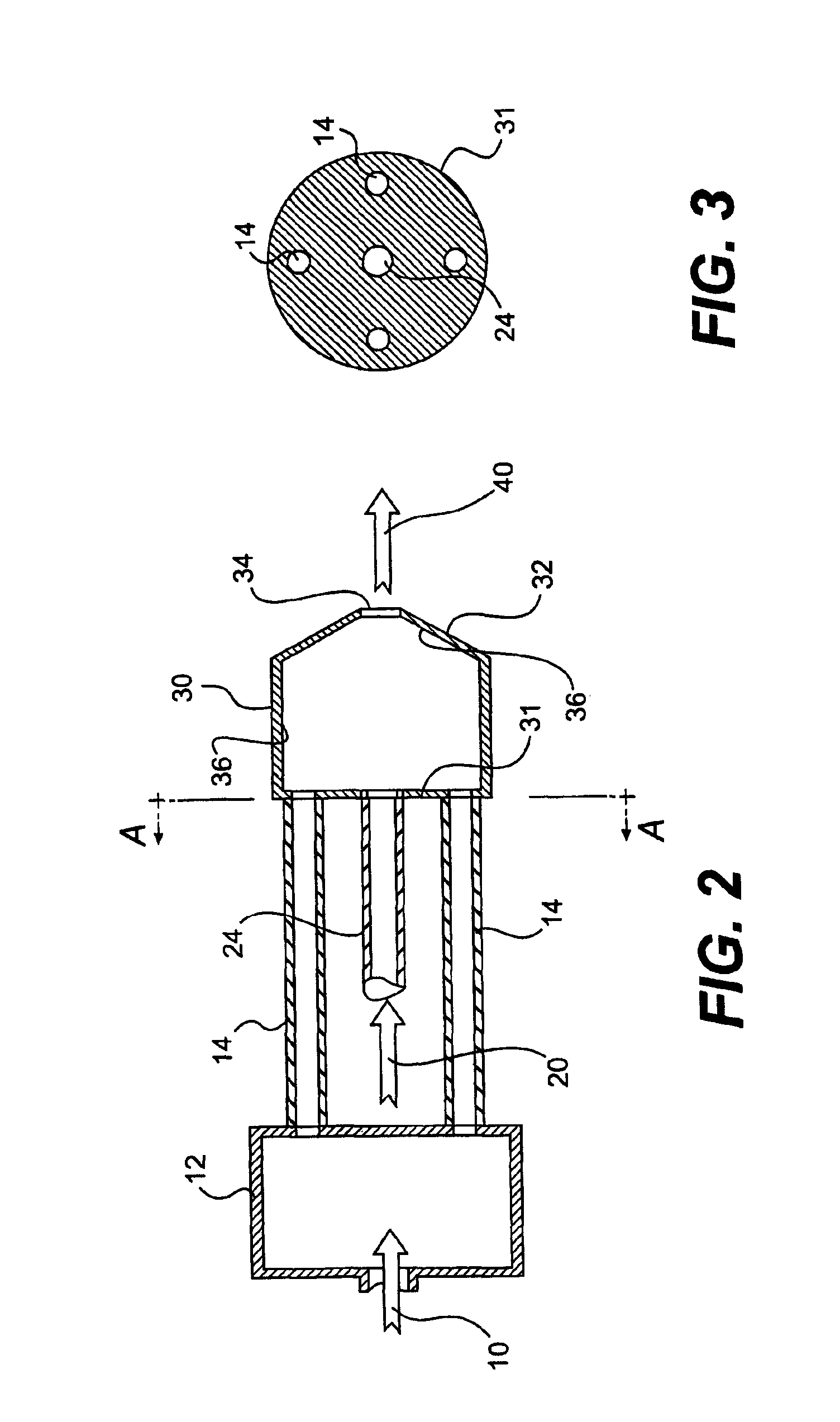

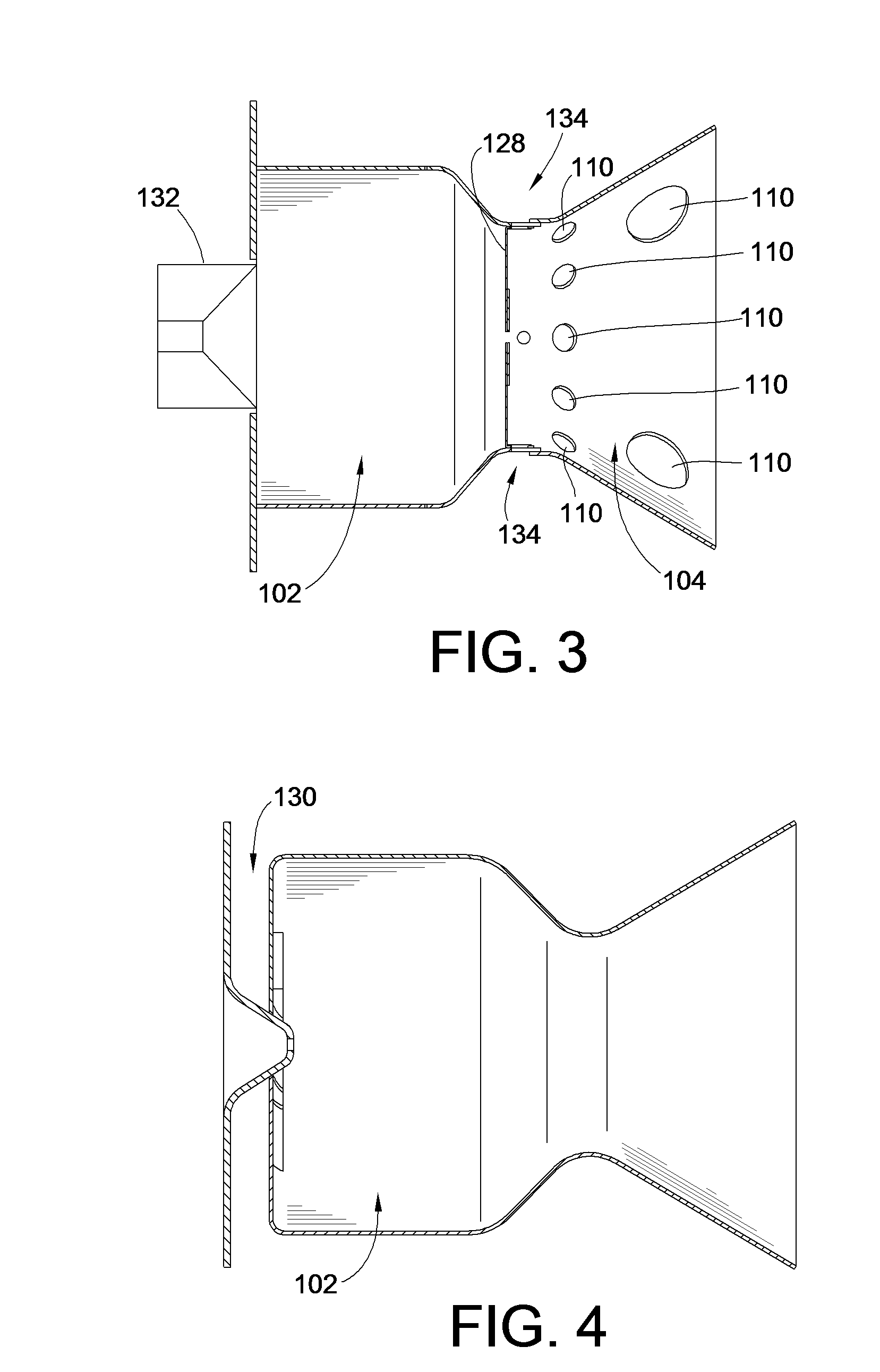

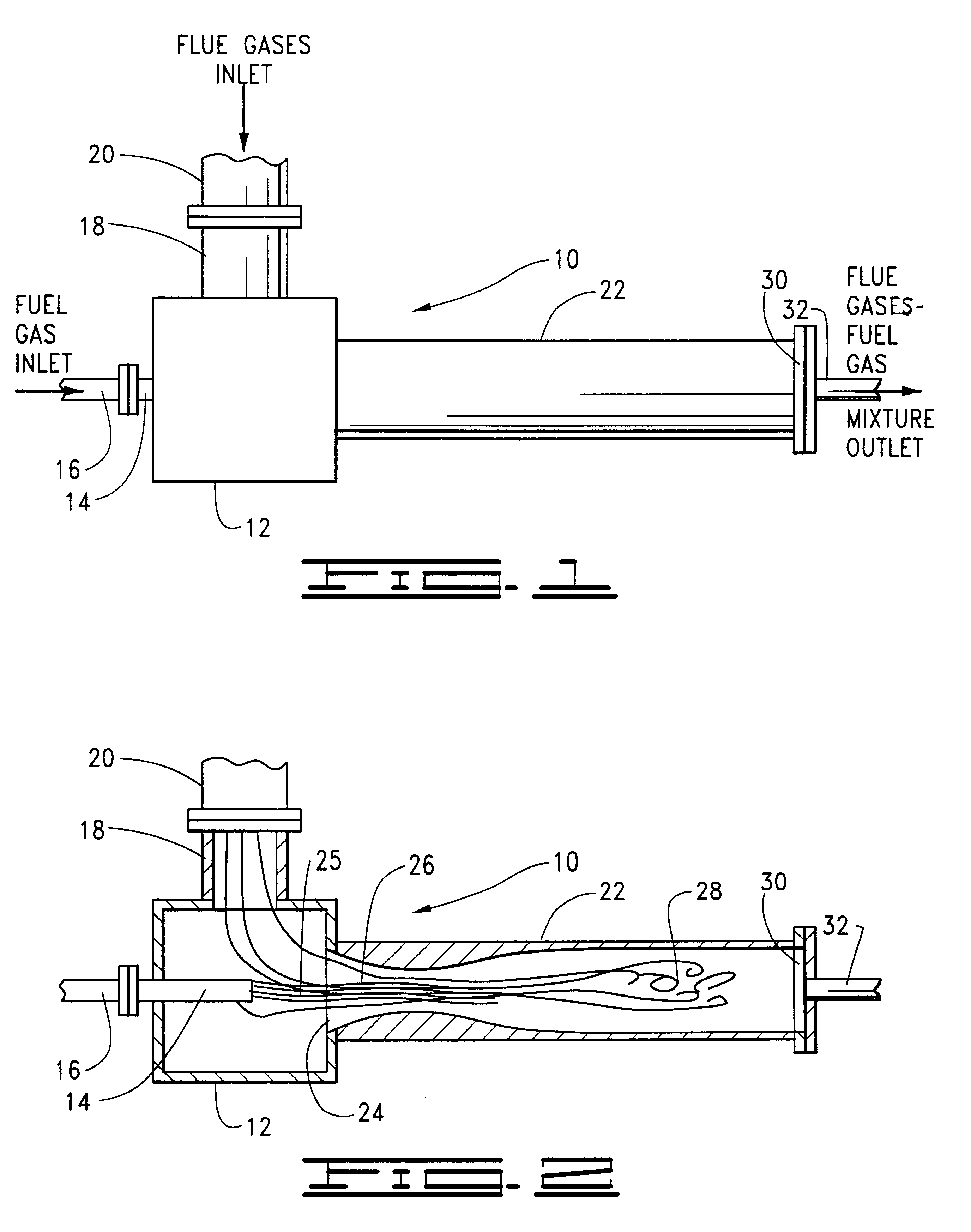

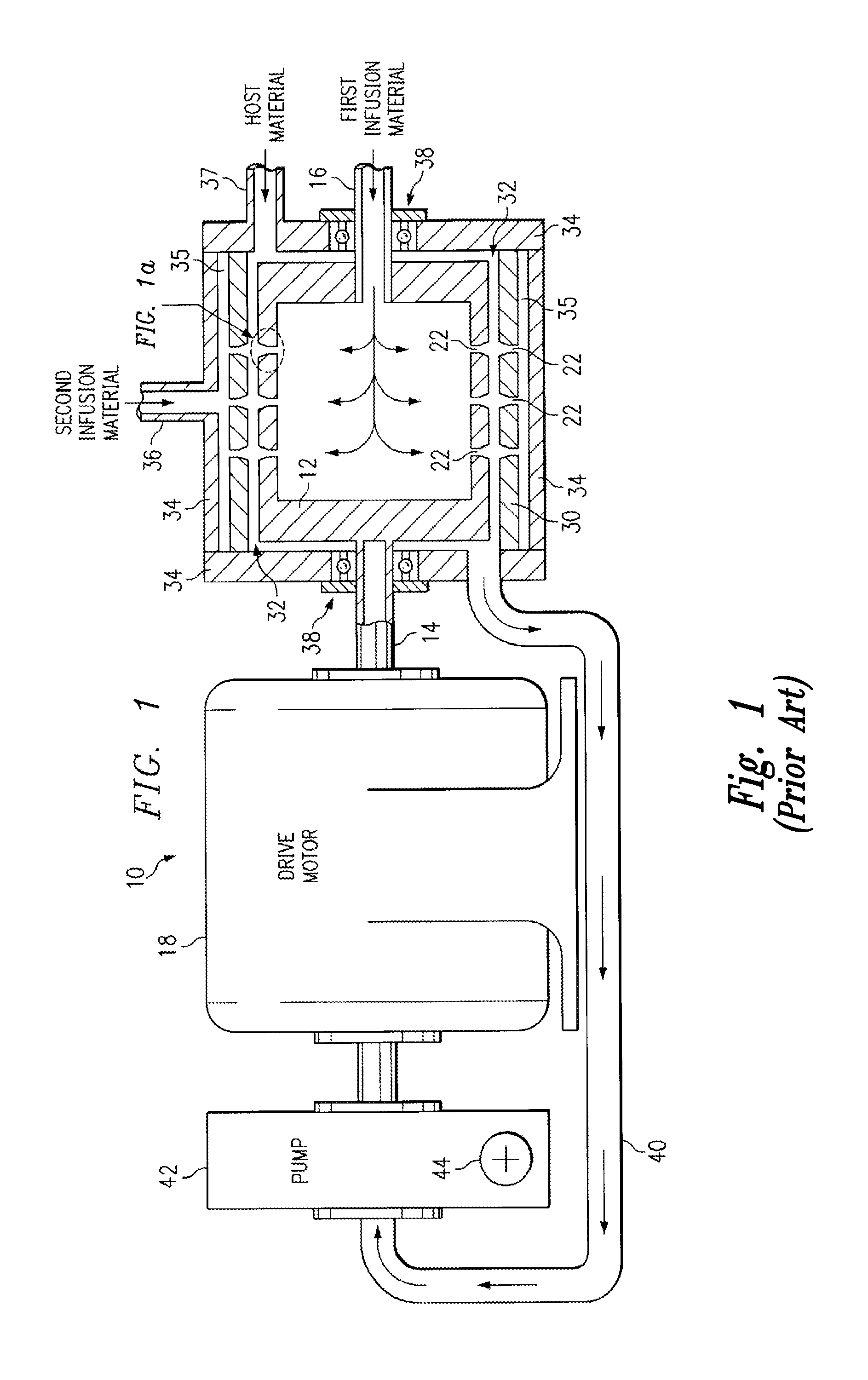

Method and apparatus for mixing gases

A method and apparatus for mixing a first stream of gas with a second stream of gas is provided. The method includes introducing a first stream of gas into a first stream manifold and directing the first stream from the first stream manifold into a mixing chamber via a plurality of first stream passages flow coupled to the mixing chamber. A second stream of gas is directed into the mixing chamber via at least one second stream passage flow coupled to a first end of the mixing chamber. A combined stream is formed from the first and second streams, gradually converged, and discharged from the mixing chamber through a mixing chamber exit port.

Owner:CATERPILLAR INC

Method and apparatus for mixing gases

A method and apparatus for mixing a first stream of gas with a second stream of gas is provided. The method includes introducing a first stream of gas into a first stream manifold and directing the first stream from the first stream manifold into a mixing chamber via a plurality of first stream passages flow coupled to the mixing chamber. A second stream of gas is directed into the mixing chamber via at least one second stream passage flow coupled to a first end of the mixing chamber. A combined stream is formed from the first and second streams, gradually converged, and discharged from the mixing chamber through a mixing chamber exit port.

Owner:CATERPILLAR INC

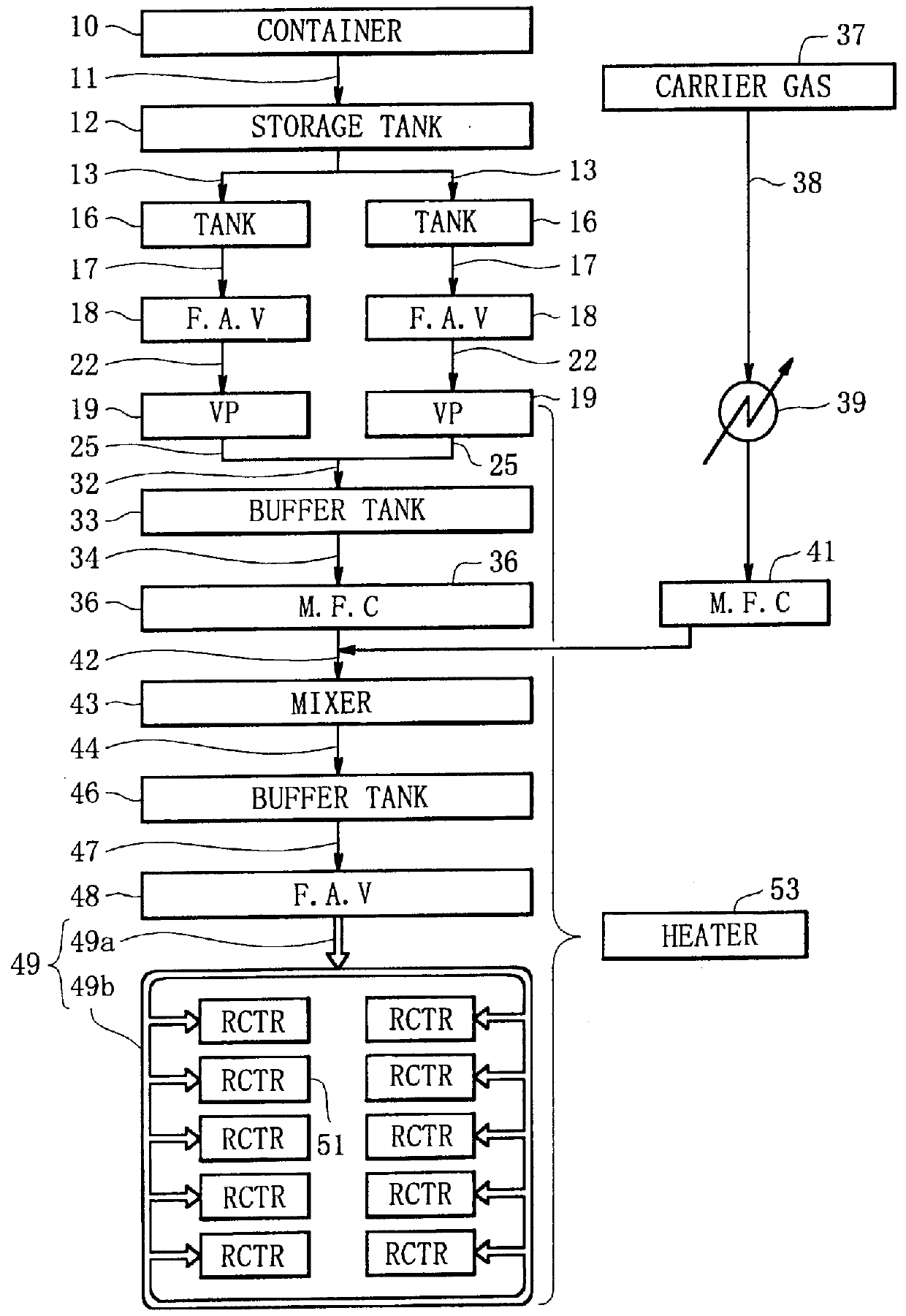

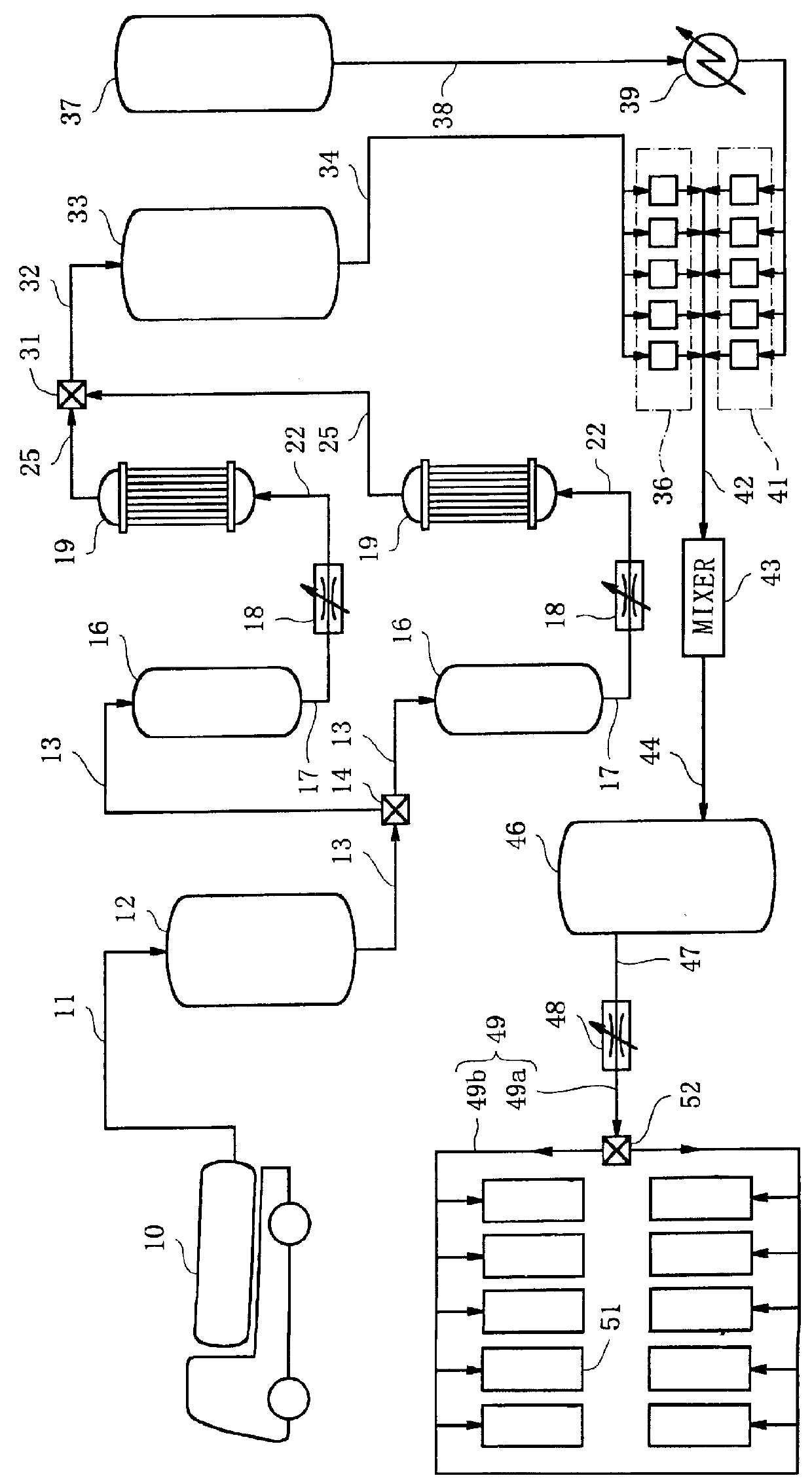

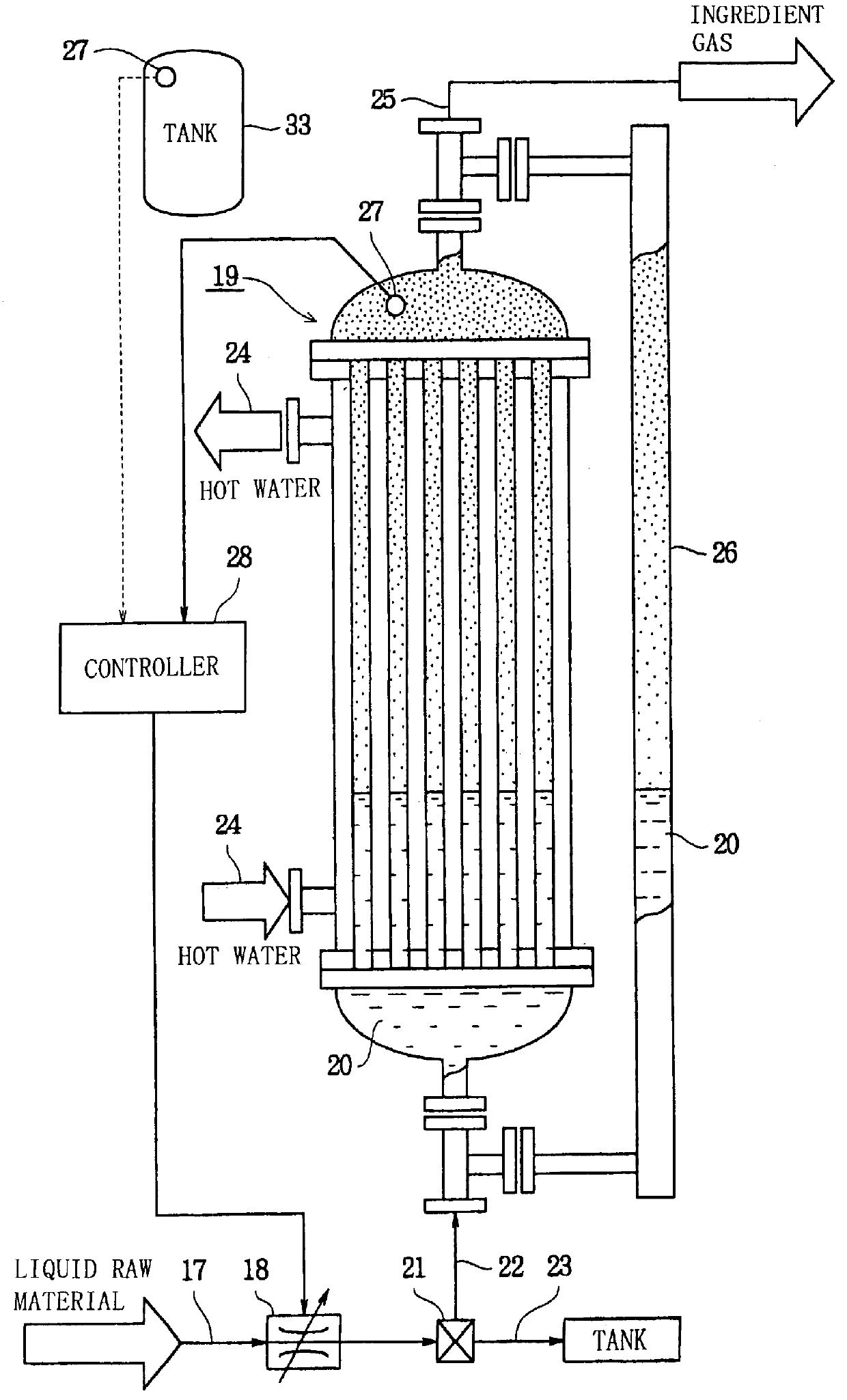

Method and apparatus for feeding a gas for epitaxial growth

InactiveUS6039809APolycrystalline material growthTransportation and packagingBoiling pointProduct gas

A liquid raw material is heated to its boiling point or higher at a vaporizer to mix the vaporized ingredient gas and a carrier gas at a mixer at predetermined concentrations. The flow of the mixed gas is adjusted while the mixed gas is heated to over its condensing point and the temperature thereof is kept. Subsequently, the mixed gas is fed to a reactor for epitaxial growth while the mixed gas is heated to over its condensing point and the temperature thereof is kept. When the temperature of a heating medium is kept constant at the vaporizer to vaporize the liquid raw material and the feeding amount of the liquid into the vaporizer is adjusted by the pressure of the gas inside the vaporizer, the liquid surface level can be controlled to be constant.

Owner:MITSUBISHI MATERIALS CORP

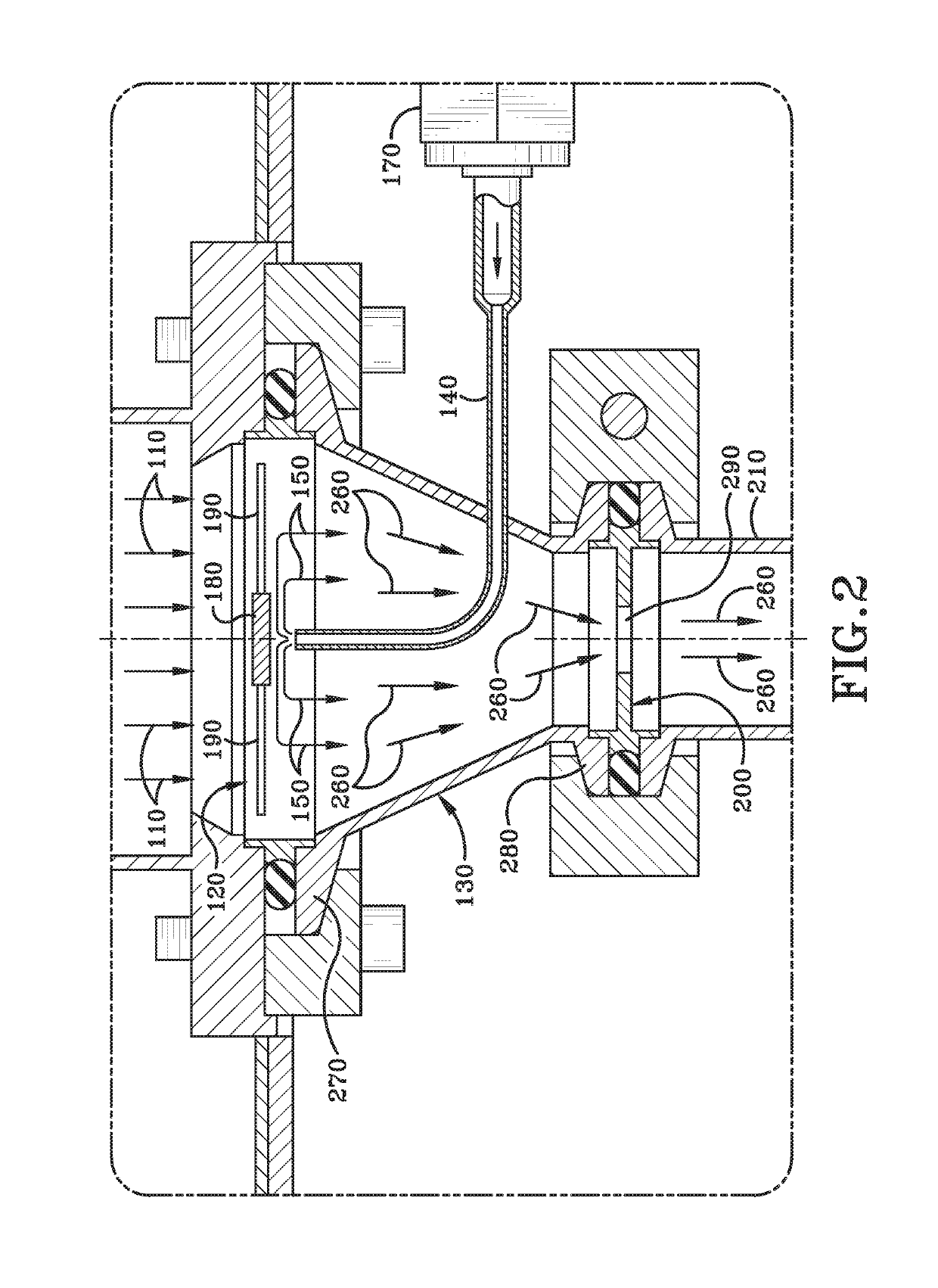

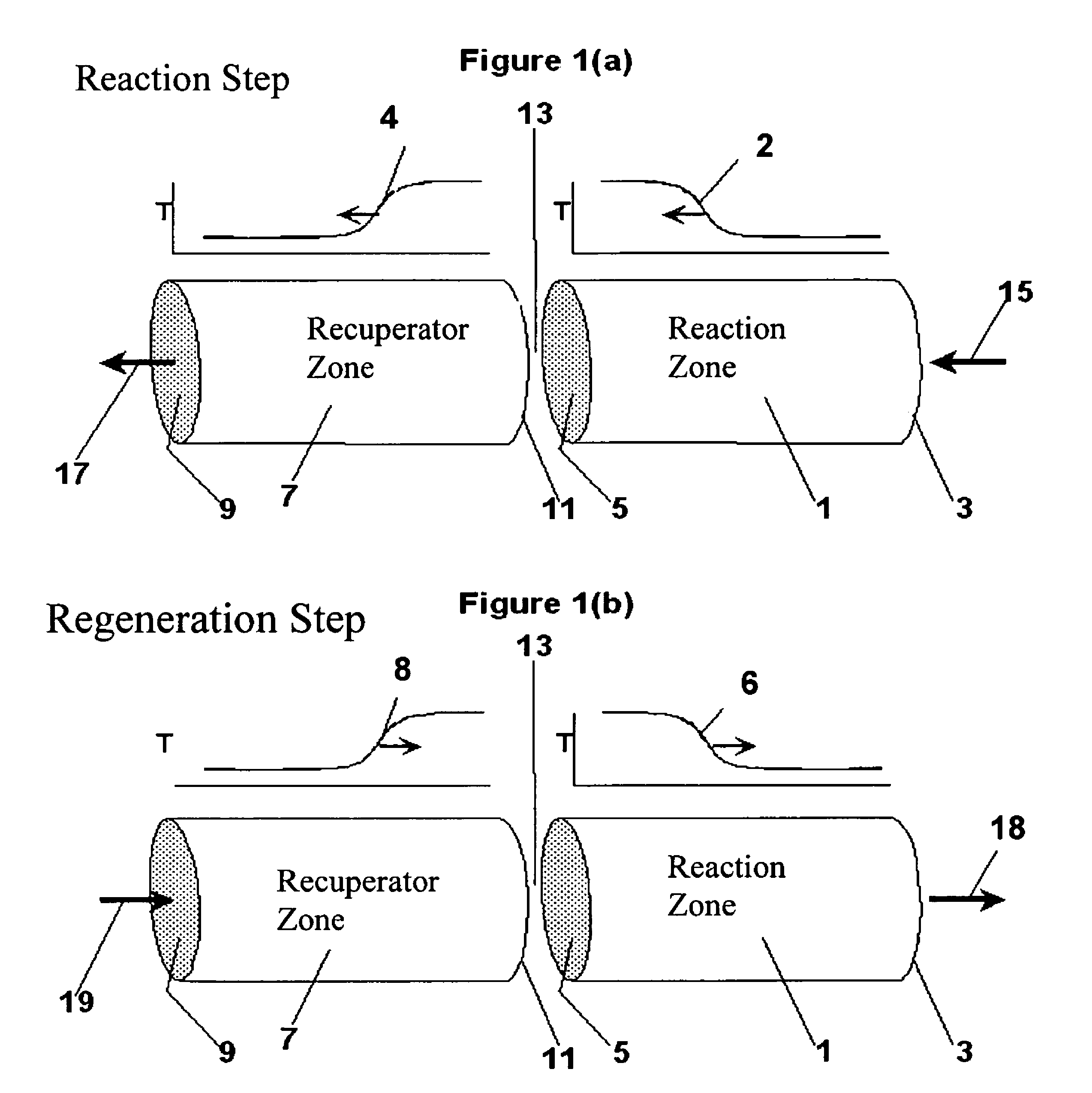

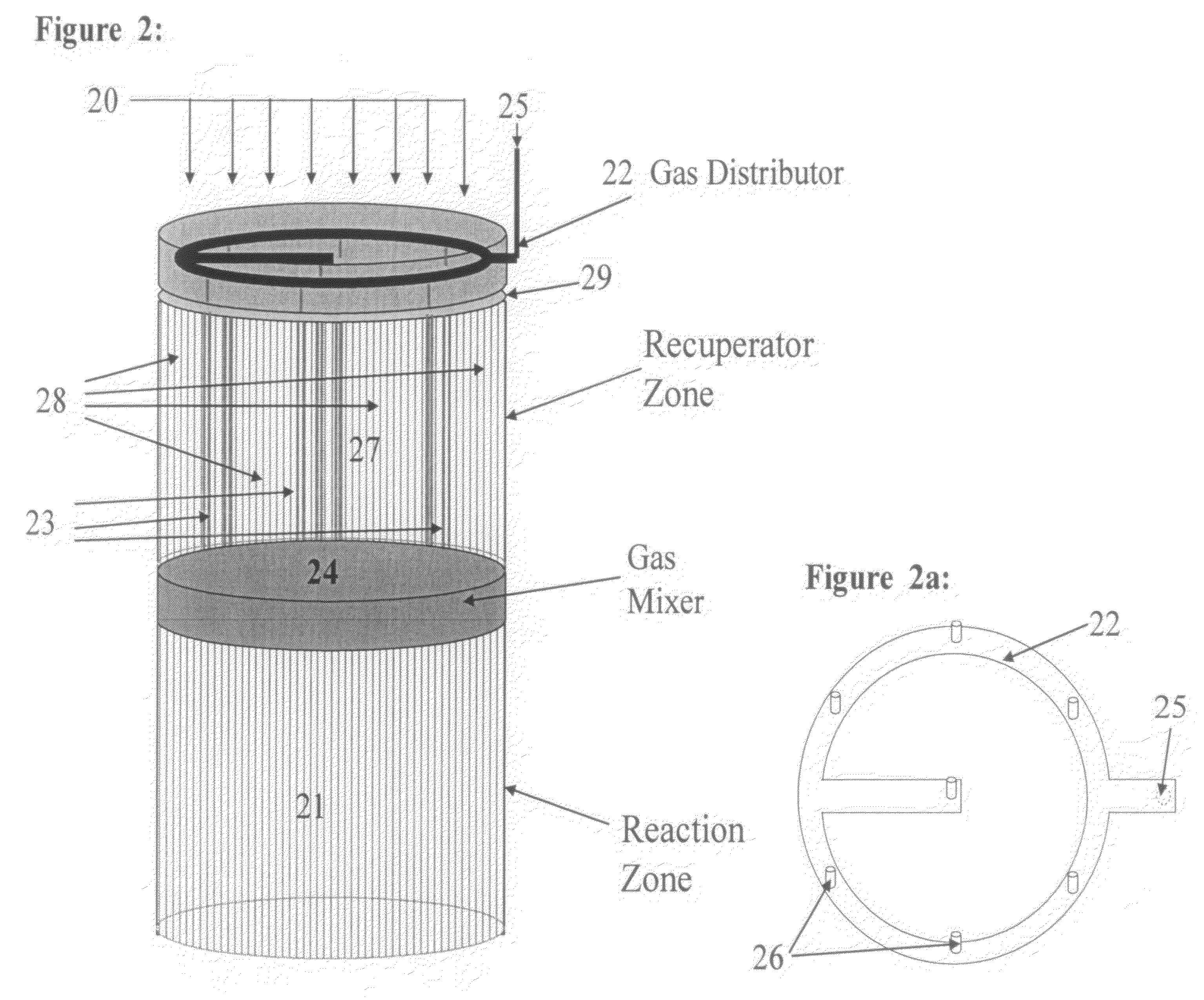

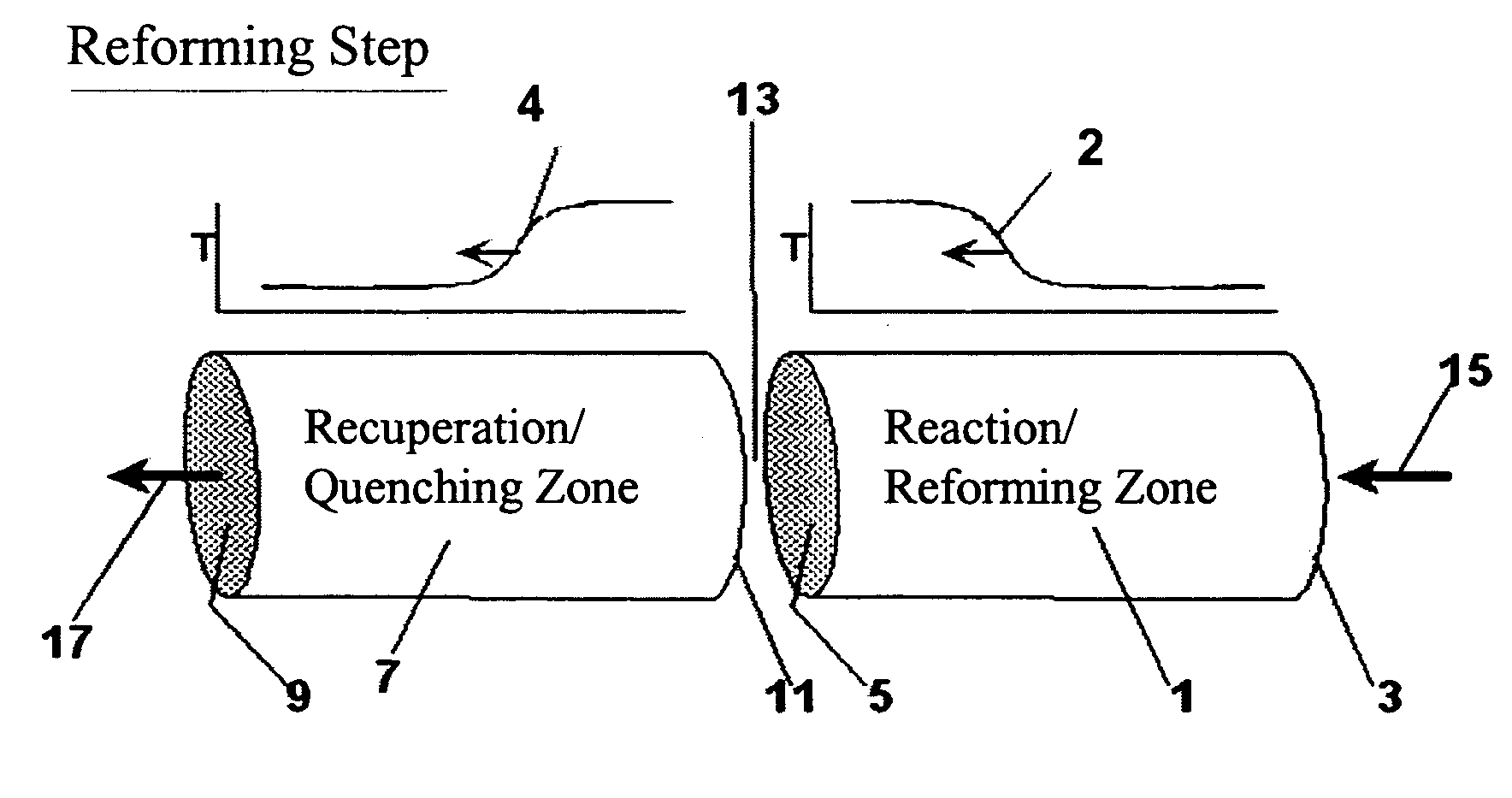

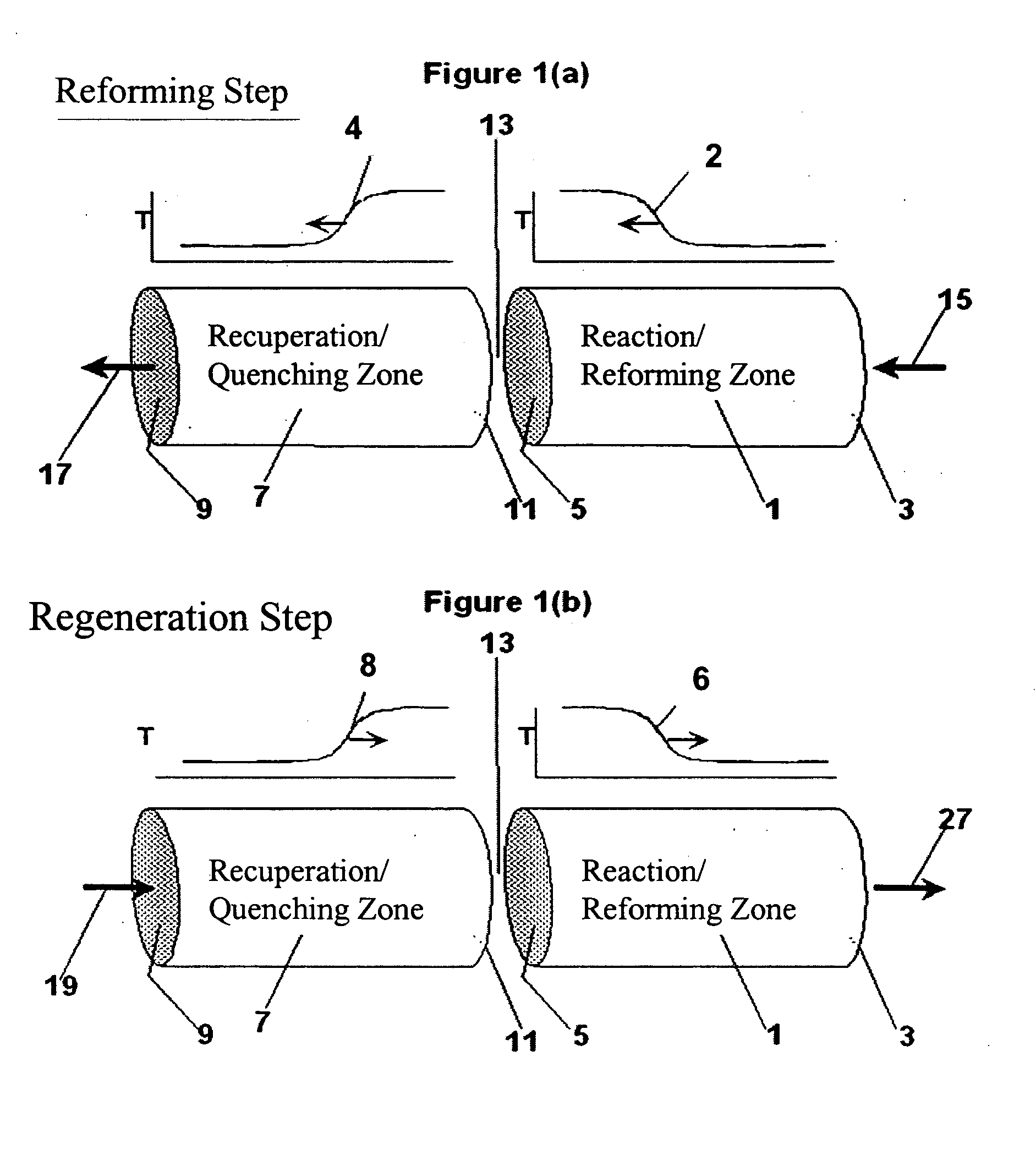

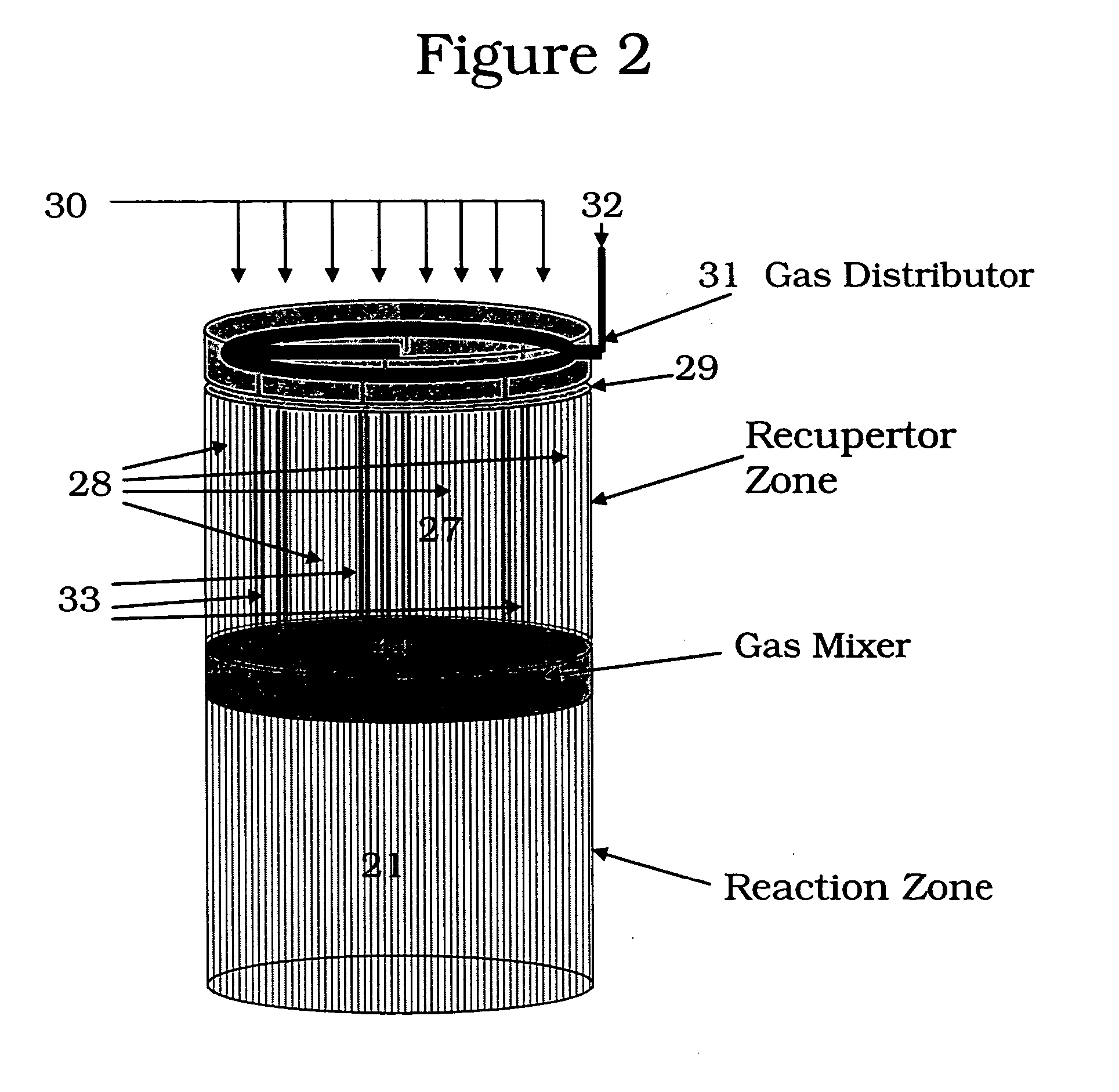

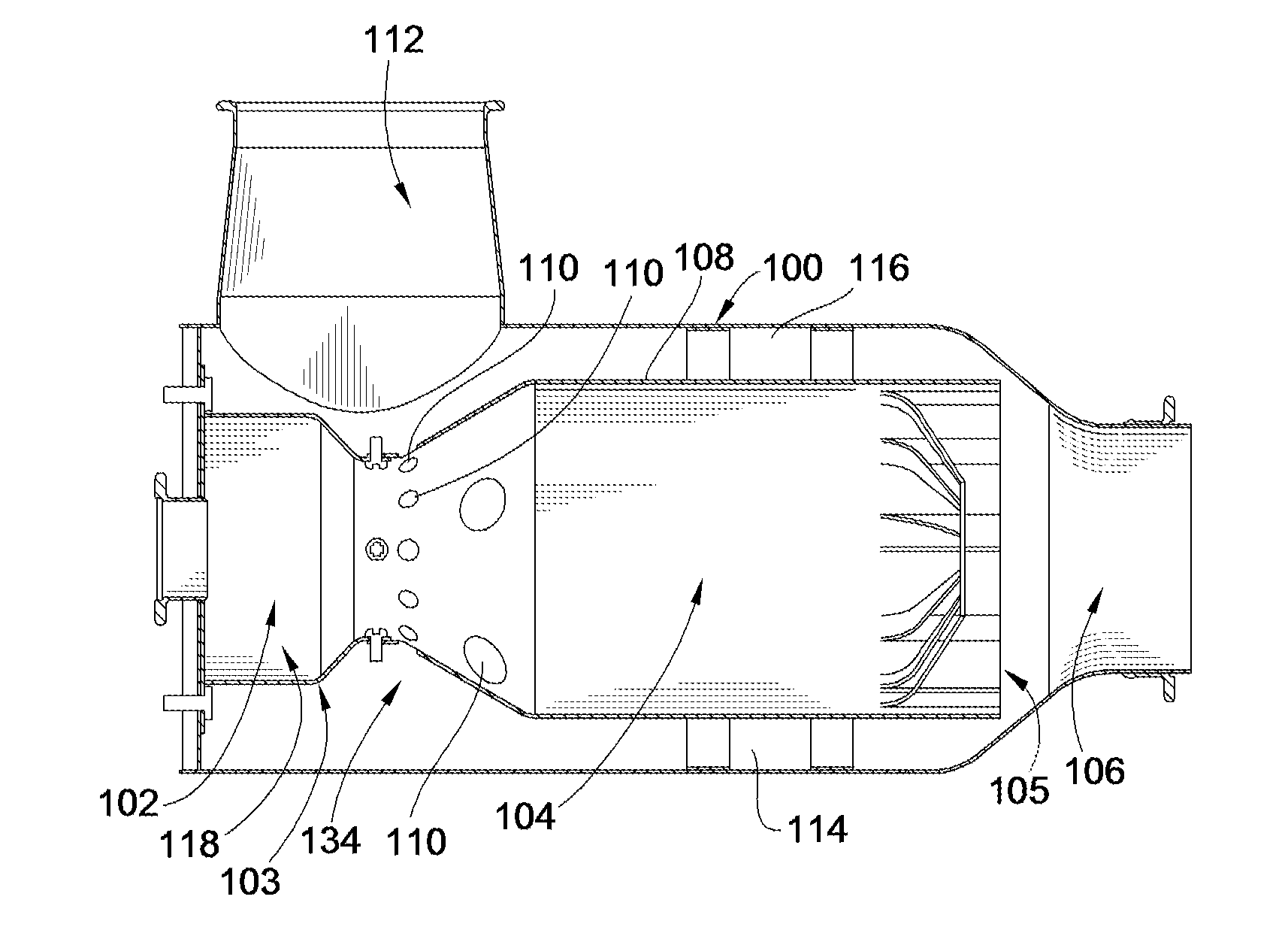

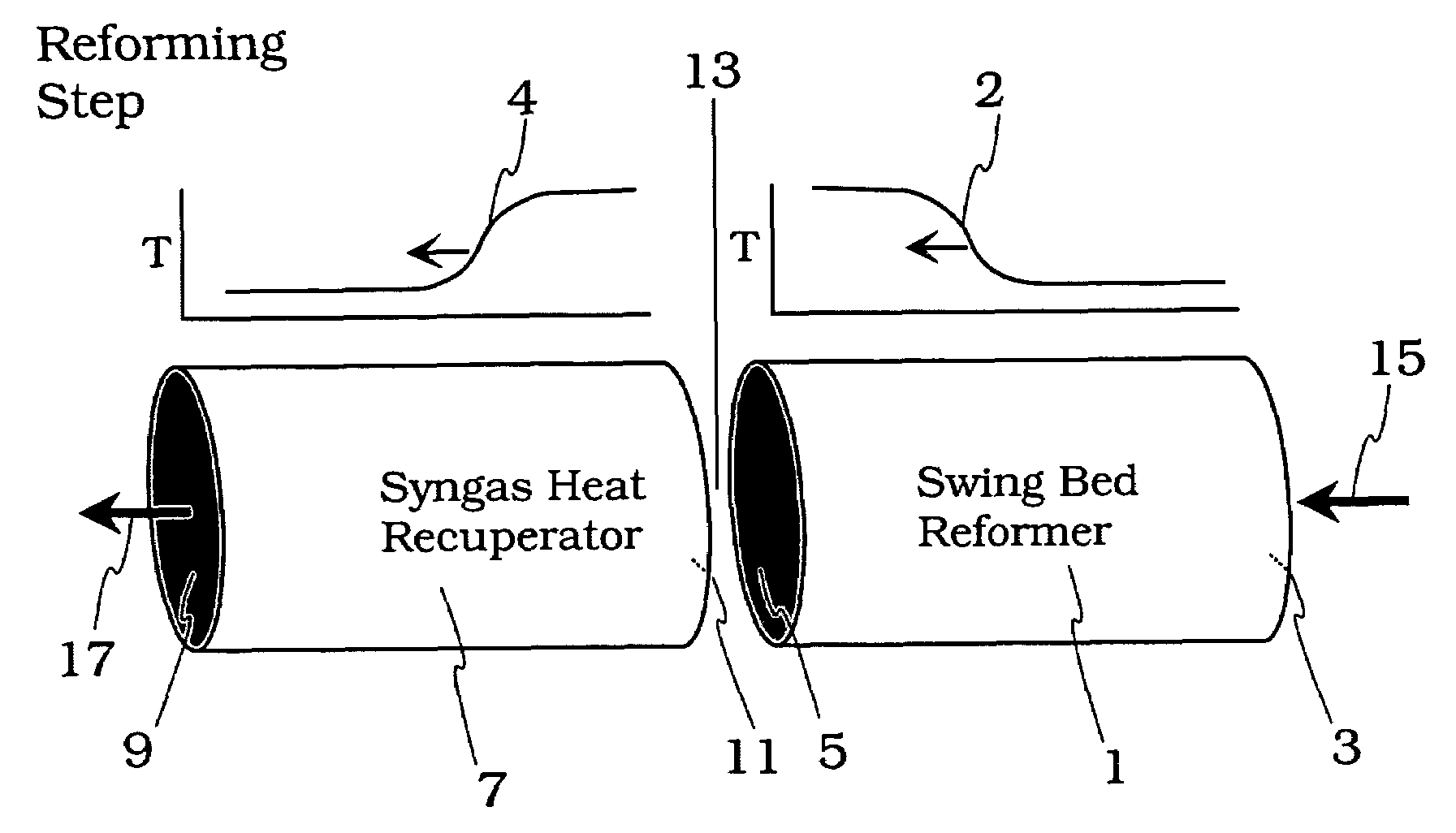

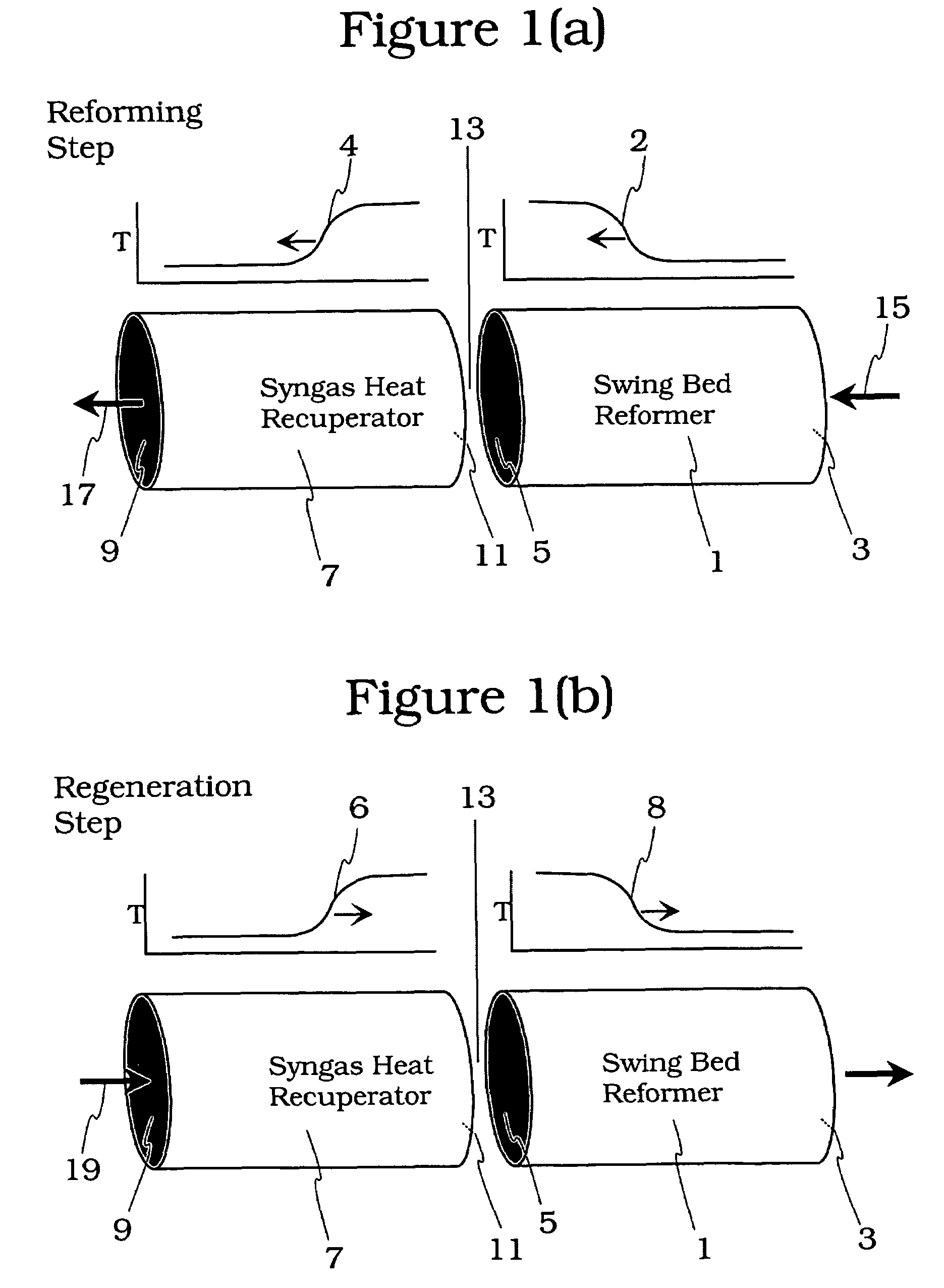

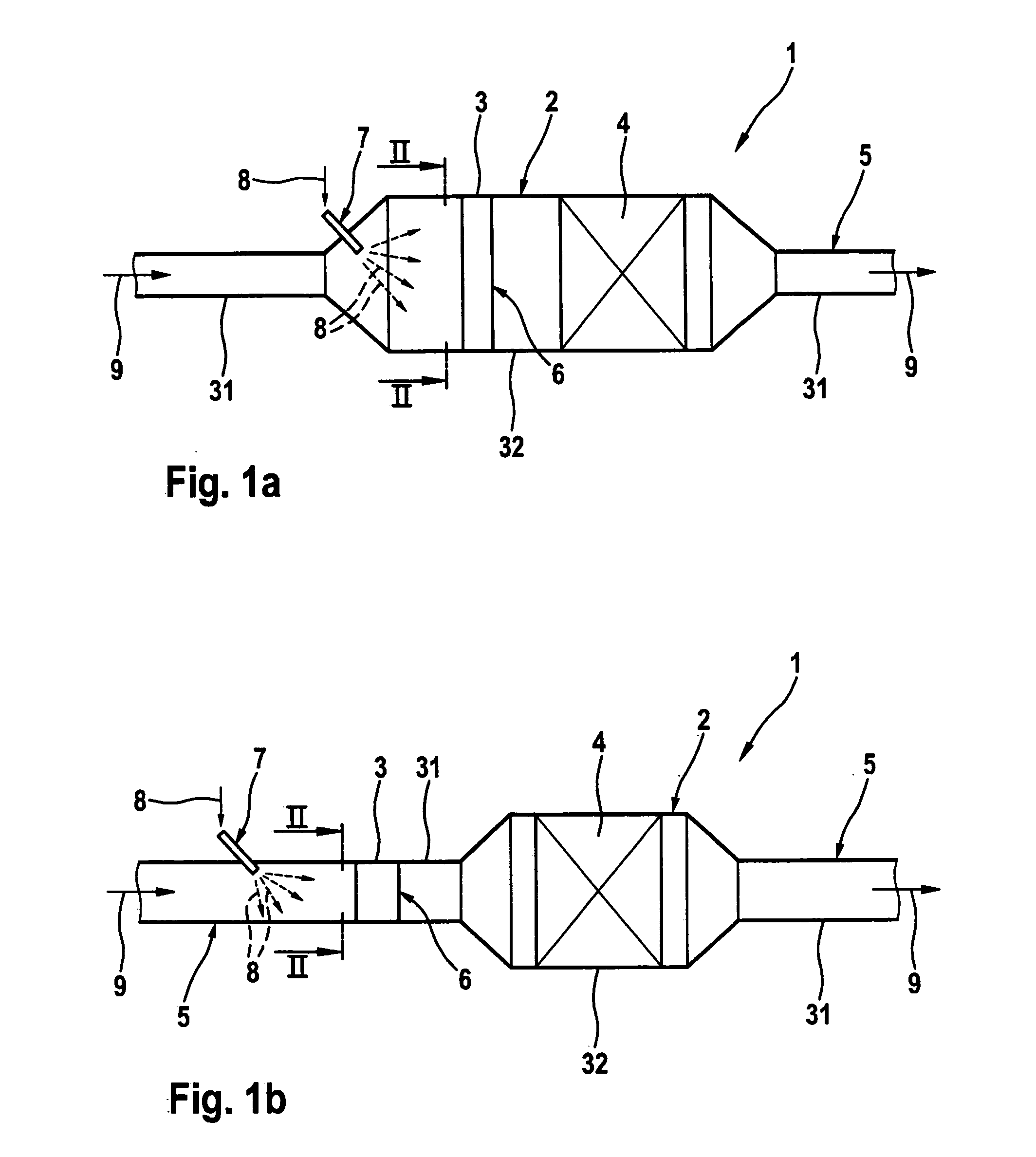

Controlled combustion for regenerative reactors with mixer/flow distributor

ActiveUS7815873B2Efficient transferEvenly distributedHydrocarbon by dehydrogenationFlow mixersReactor systemCombustion

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

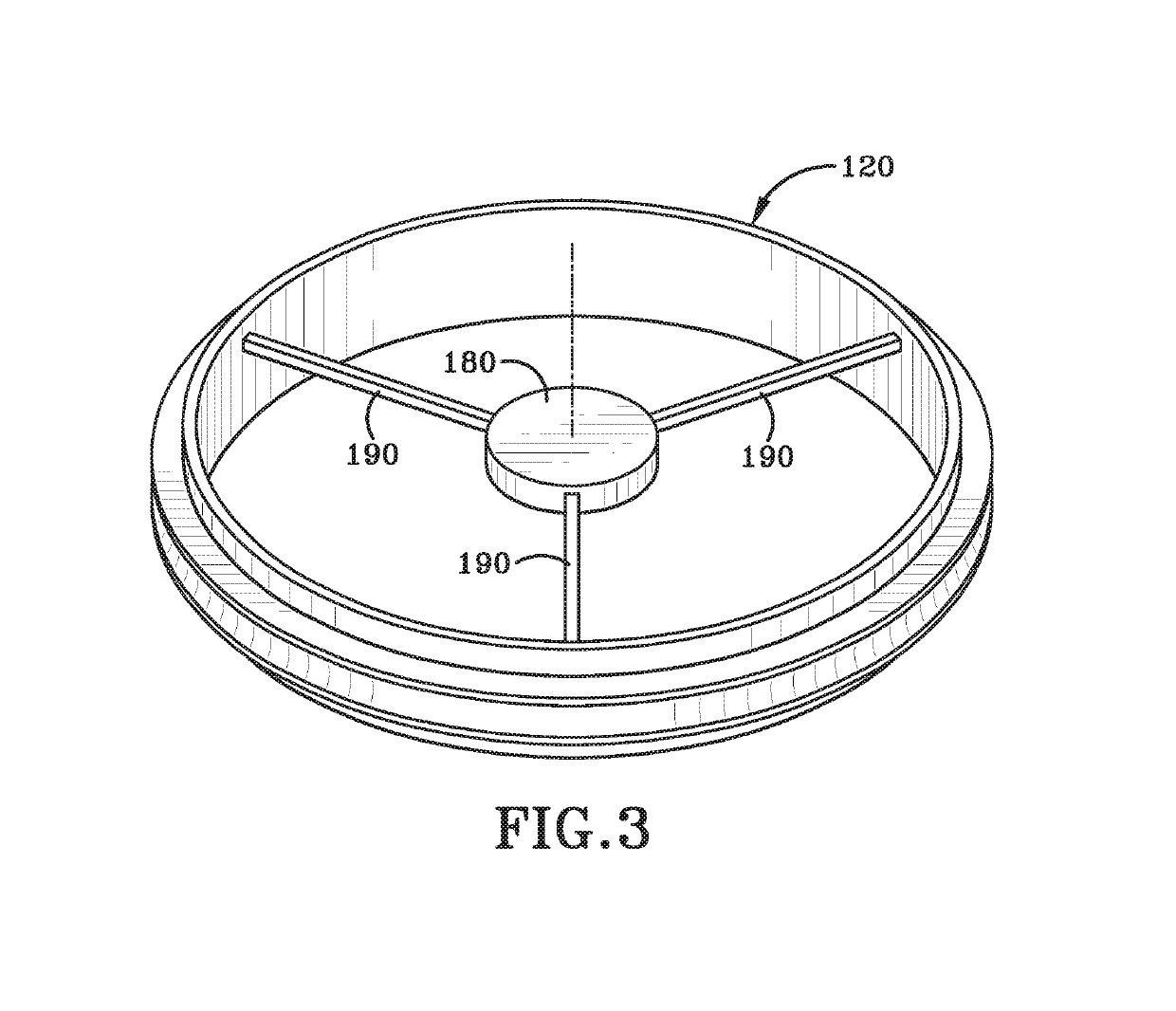

Methane conversion to higher hydrocarbons

ActiveUS20070191664A1Efficient preparationValid conversionGenerators with non-automatic water feedFlow mixersReactor systemReagent

The present invention provides a process for the manufacture of acetylene and other higher hydrocarbons from methane feed using a reverse-flow reactor system, wherein the reactor system includes (i) a first reactor and (ii) a second reactor, the first and second reactors oriented in a series relationship with respect to each other, the process comprising supplying each of first and second reactant through separate channels in the first reactor bed of a reverse-flow reactor such that both of the first and second reactants serve to quench the first reactor bed, without the first and second reactants substantially reacting with each other until reaching the core of the reactor system.

Owner:EXXONMOBIL CHEM PAT INC

Systems and methods for extended volume range ventilation

InactiveUS20090205661A1RespiratorsOperating means/releasing devices for valvesProcess engineeringBreathing

Owner:TYCO HEALTHCARE GRP LP

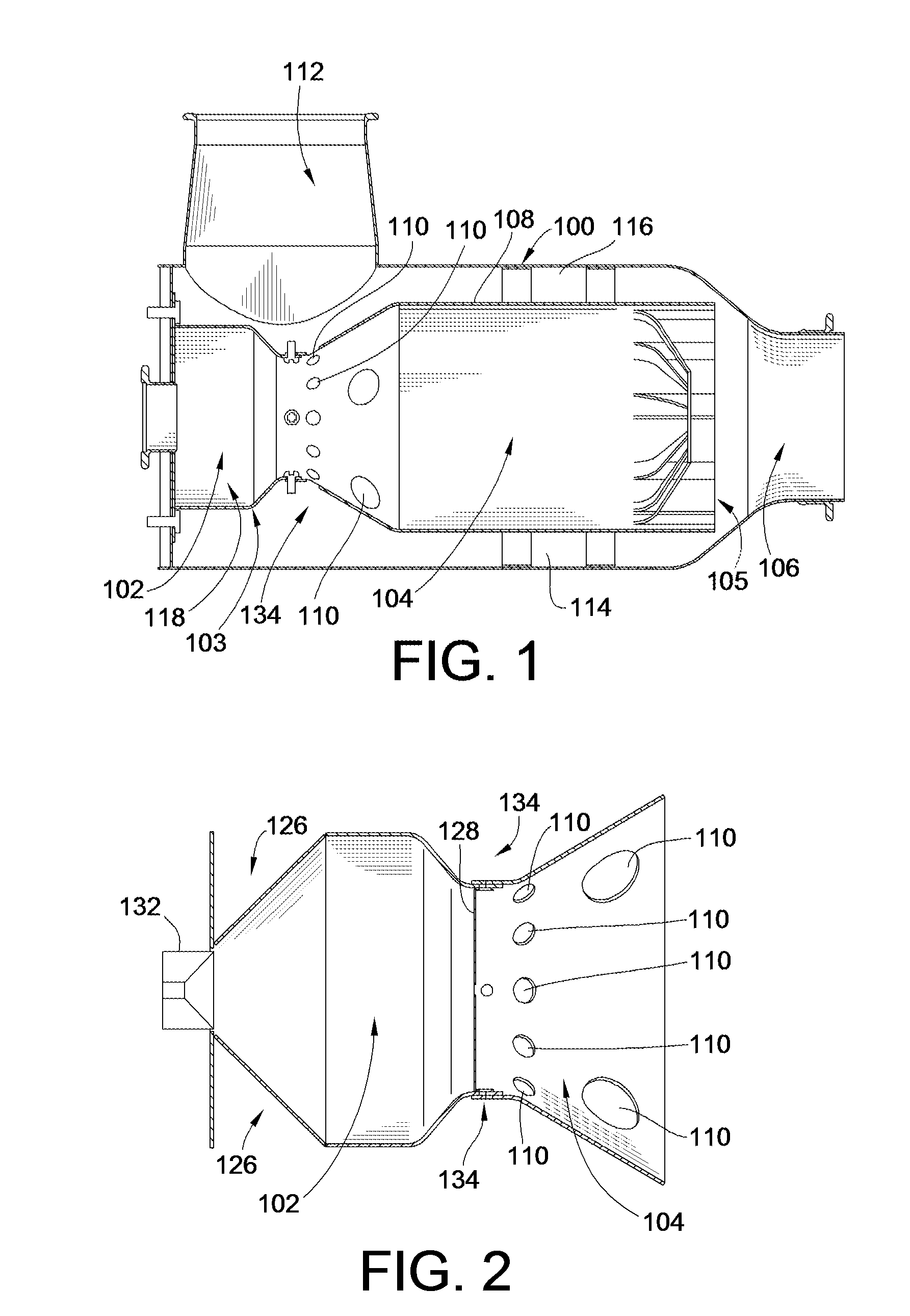

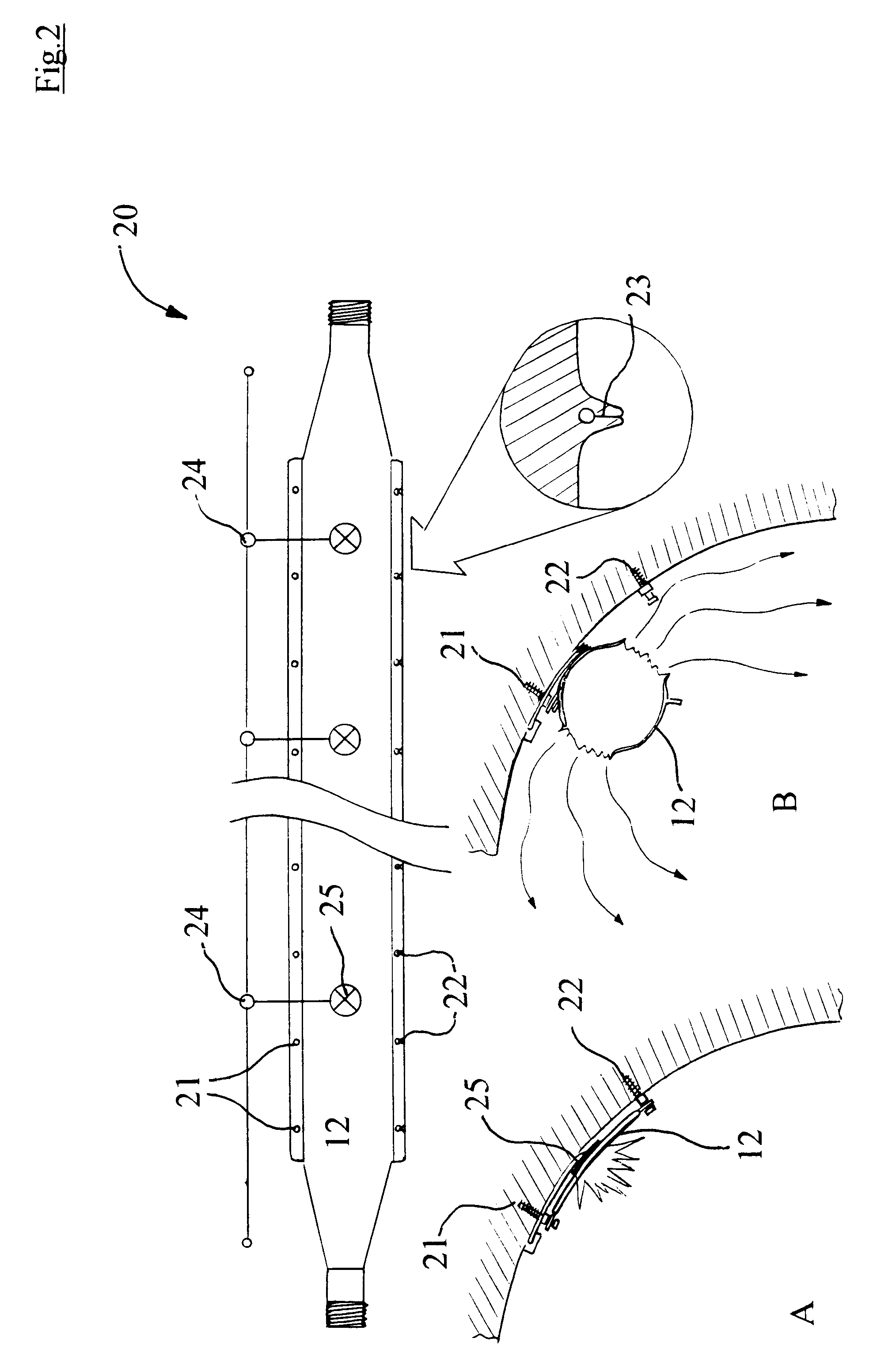

Low Pressure Drop Mixer for Radial Mixing of Internal Combustion Engine Exhaust Flows, Combustor Incorporating Same, and Methods of Mixing

ActiveUS20090255242A1Increase surface areaEnhanced interactionInternal combustion piston enginesFlow mixersCombustion chamberCombustor

An exhaust aftertreatment system is provided. The exhaust aftertreatment system includes a mixing arrangement for mixing flows of exhaust along a flow path. The mixing arrangement radially and angularly rearranges segments of two different portions of flow to mix the different portions of flow. The mixing arrangement initially converts a generally radially stratified temperature profile into an angularly stratified temperature profile to increase surface area between cool segments of exhaust gas and hot segments of exhaust gas. The aftertreatment system may also include a combustion chamber, a combustor housing and a combustor liner. The mixing arrangement is downstream from the combustion chamber to direct radially outward hot gas passing through the combustor liner and to direct radially outer cool gas passing between the liner and the combustor housing radially inward in an interleaving fashion.

Owner:WOODWARD GOVERNOR CO

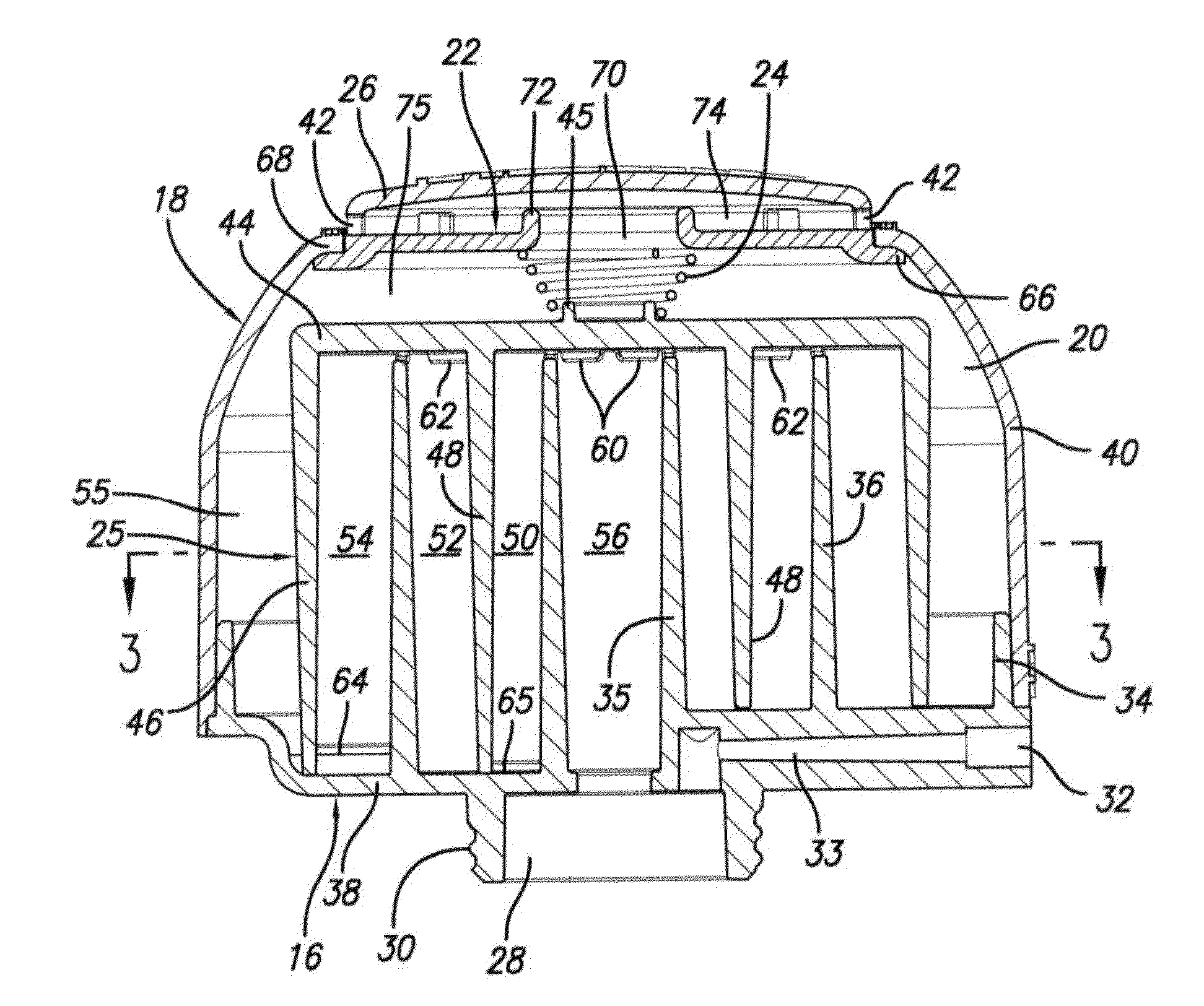

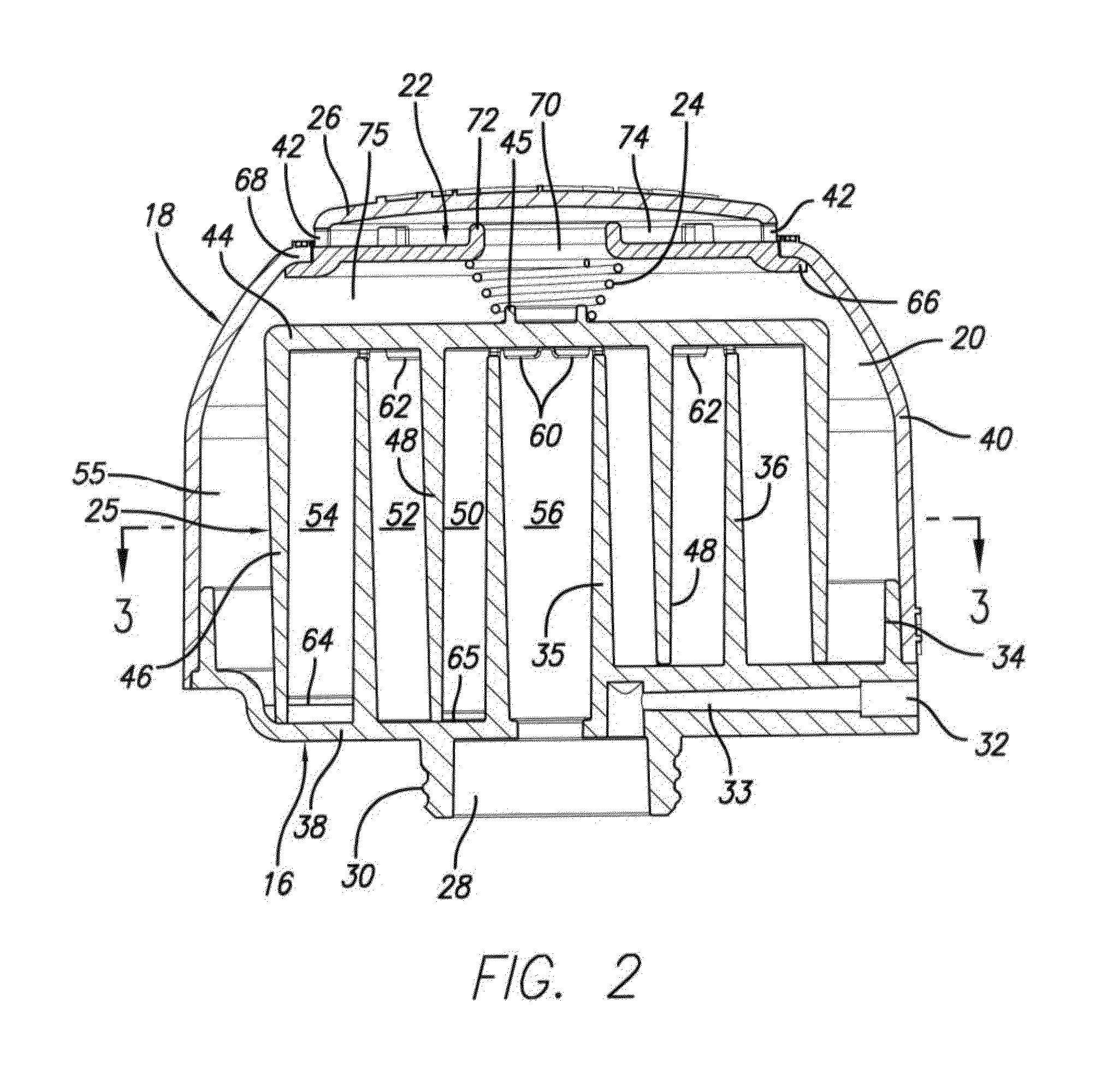

Oxygen enrichment device for ventilator

An enrichment device for mixing ambient air with a gas such as oxygen has a rigid outer housing defining a reservoir. The housing has an outlet port for attachment to a cyclic low pressure source, an ambient air inlet, and a second inlet for connection to a supply of pressurized gas. The reservoir has a plurality of internal walls defining a passageway having a plurality of turns defining a tortuous path for gas flow between the ambient air inlet and the outlet port, and the second inlet communicates with the passageway at a location at or close to the outlet port.

Owner:TYCO HEALTHCARE GRP LP

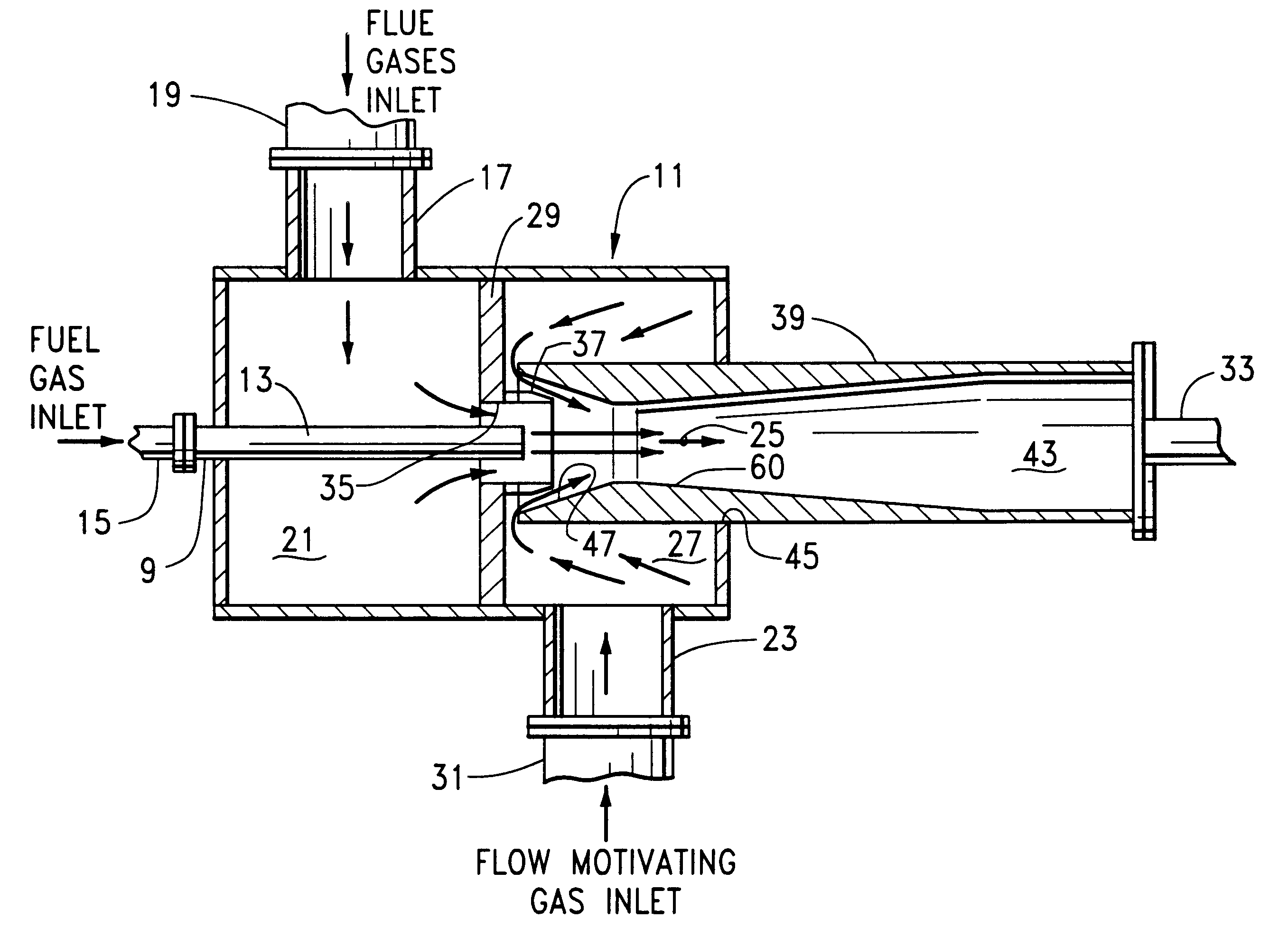

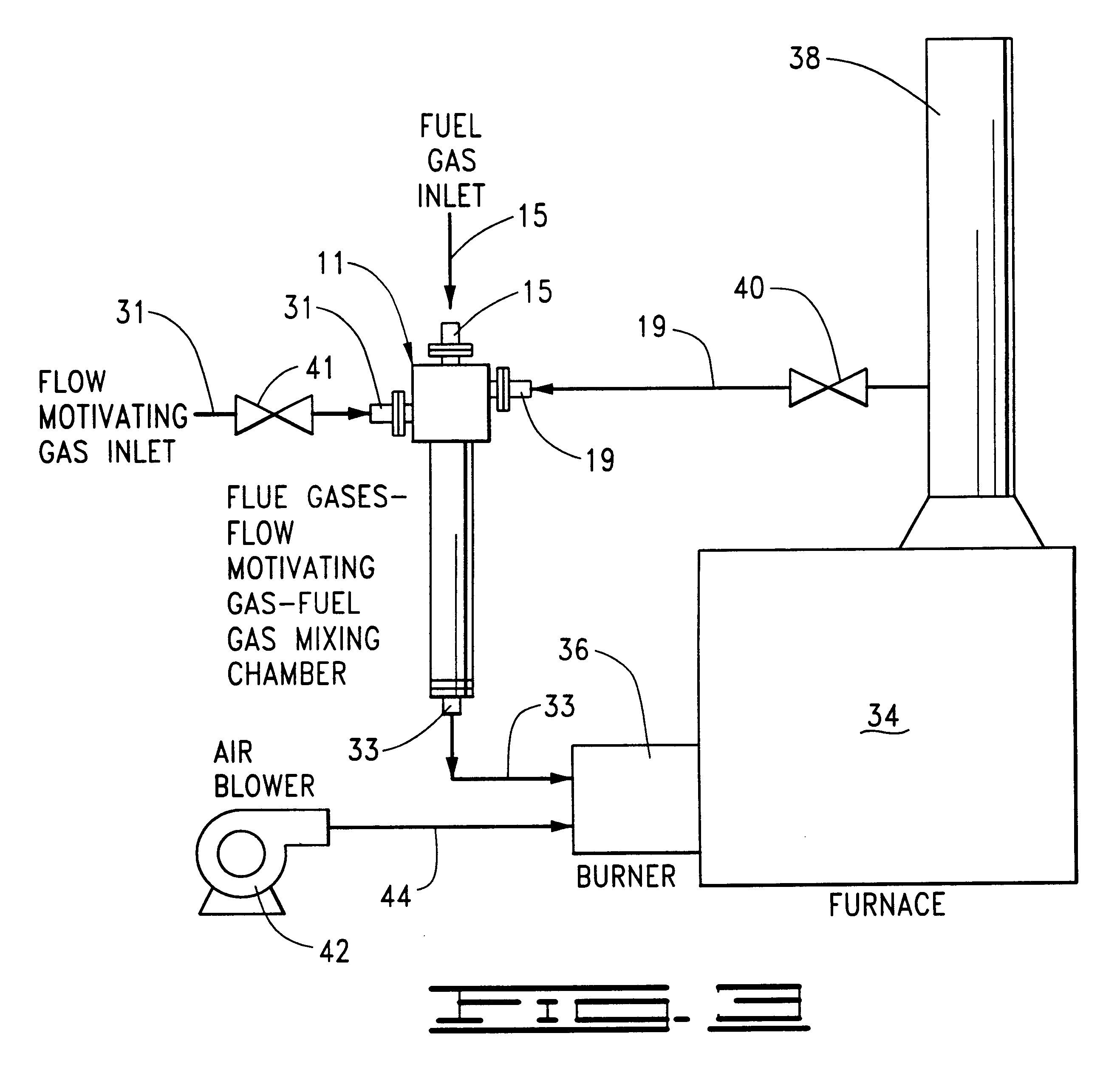

Fuel dilution methods and apparatus for NOx reduction

Methods and apparatus for reducing the content of nitrogen oxides in the flue gases produced by the combustion of fuel gas and combustion air introduced into a burner connected to a furnace are provided. The methods basically comprise the steps of conducting the combustion air to the burner, providing a chamber outside of the burner and furnace for mixing flue gases from the furnace with the fuel gas, discharging the fuel gas in the form of a fuel jet into the mixing chamber so that flue gases from the furnace are drawn into the chamber and mixed with and dilute the fuel gas therein and conducting the resulting mixture of flue gases and fuel gas to the burner wherein the mixture is combined with the combustion air and burned in the furnace.

Owner:JOHN ZINK CO LLC

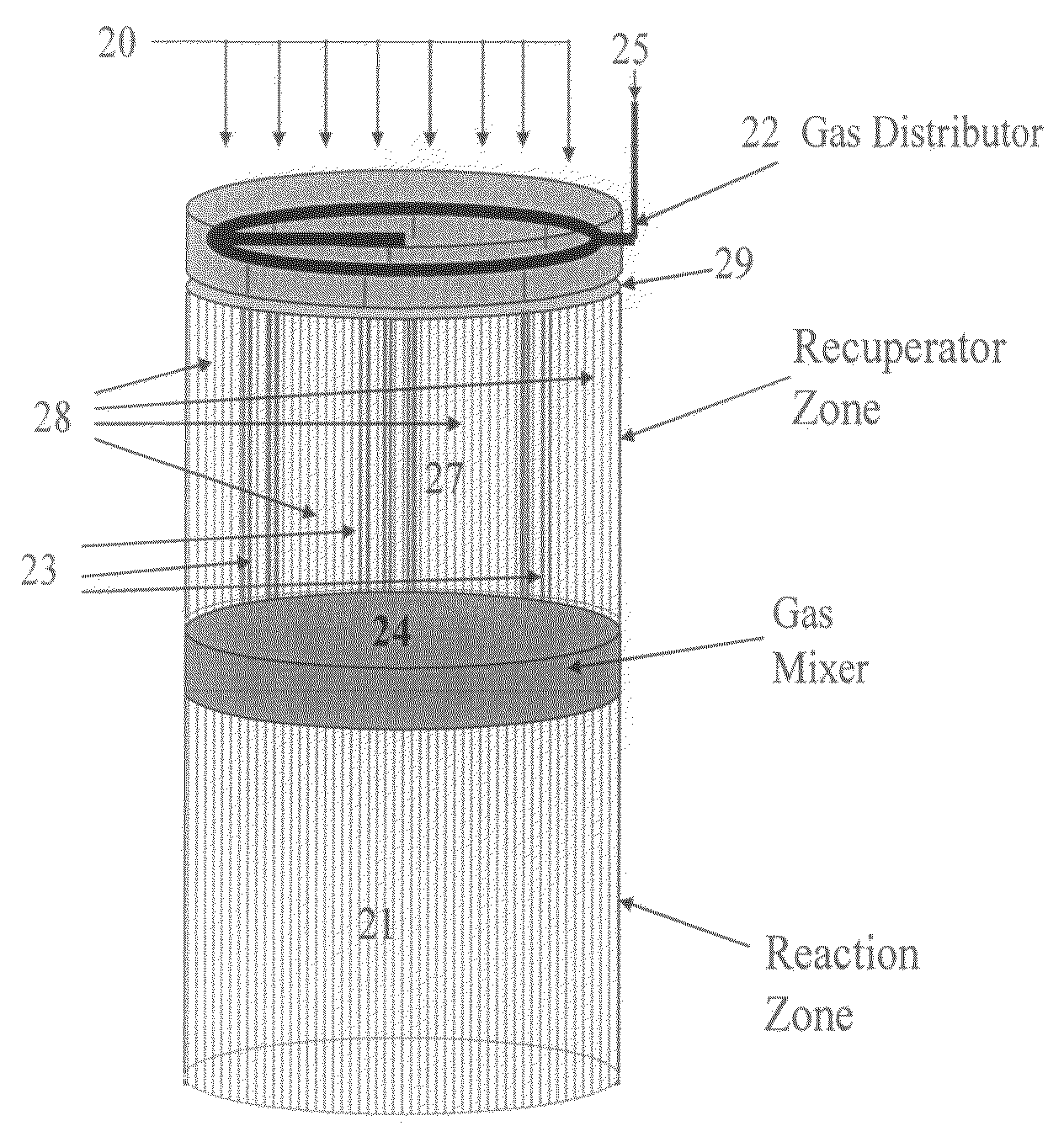

Controlled combustion for regenerative reactors

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

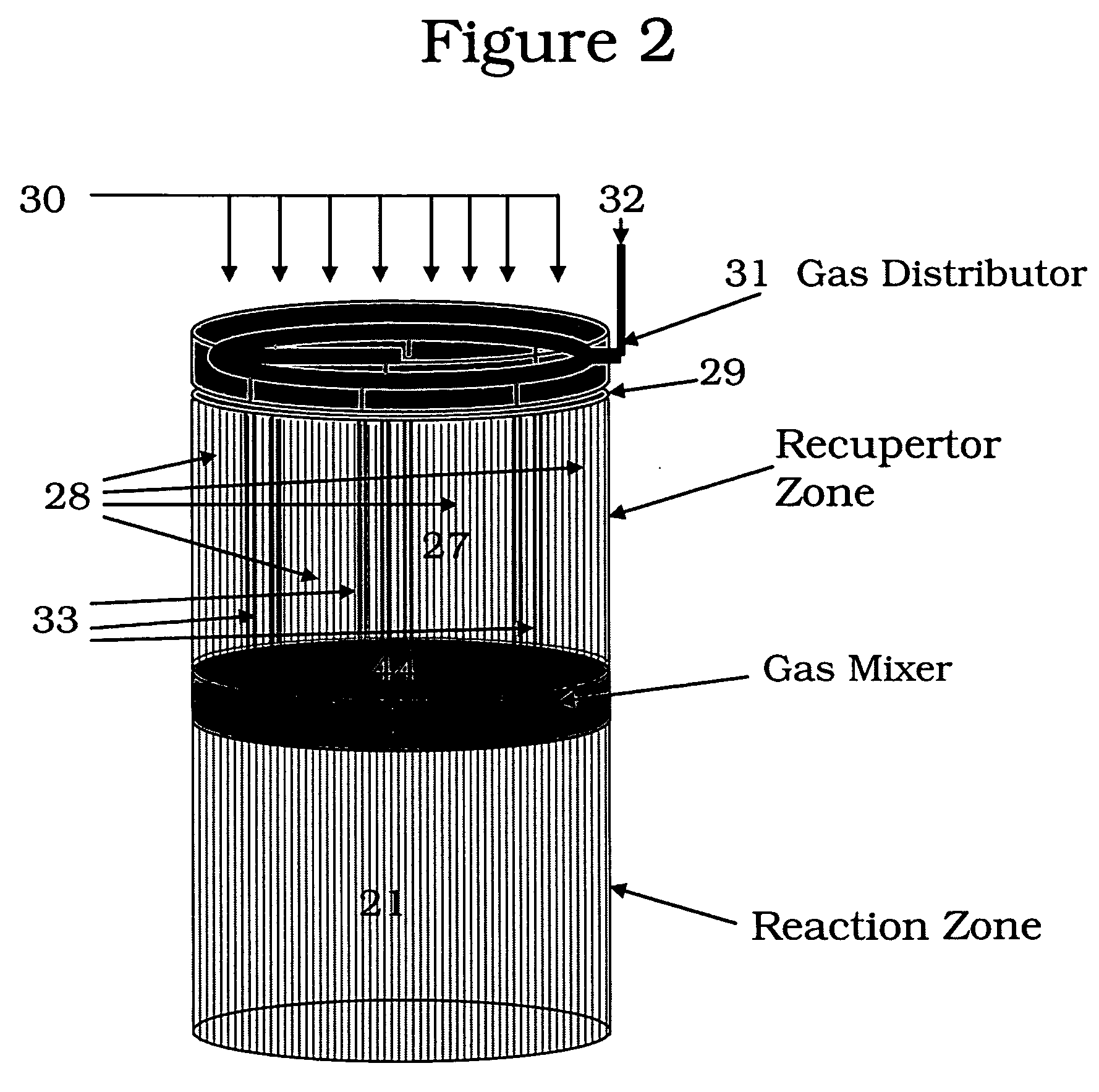

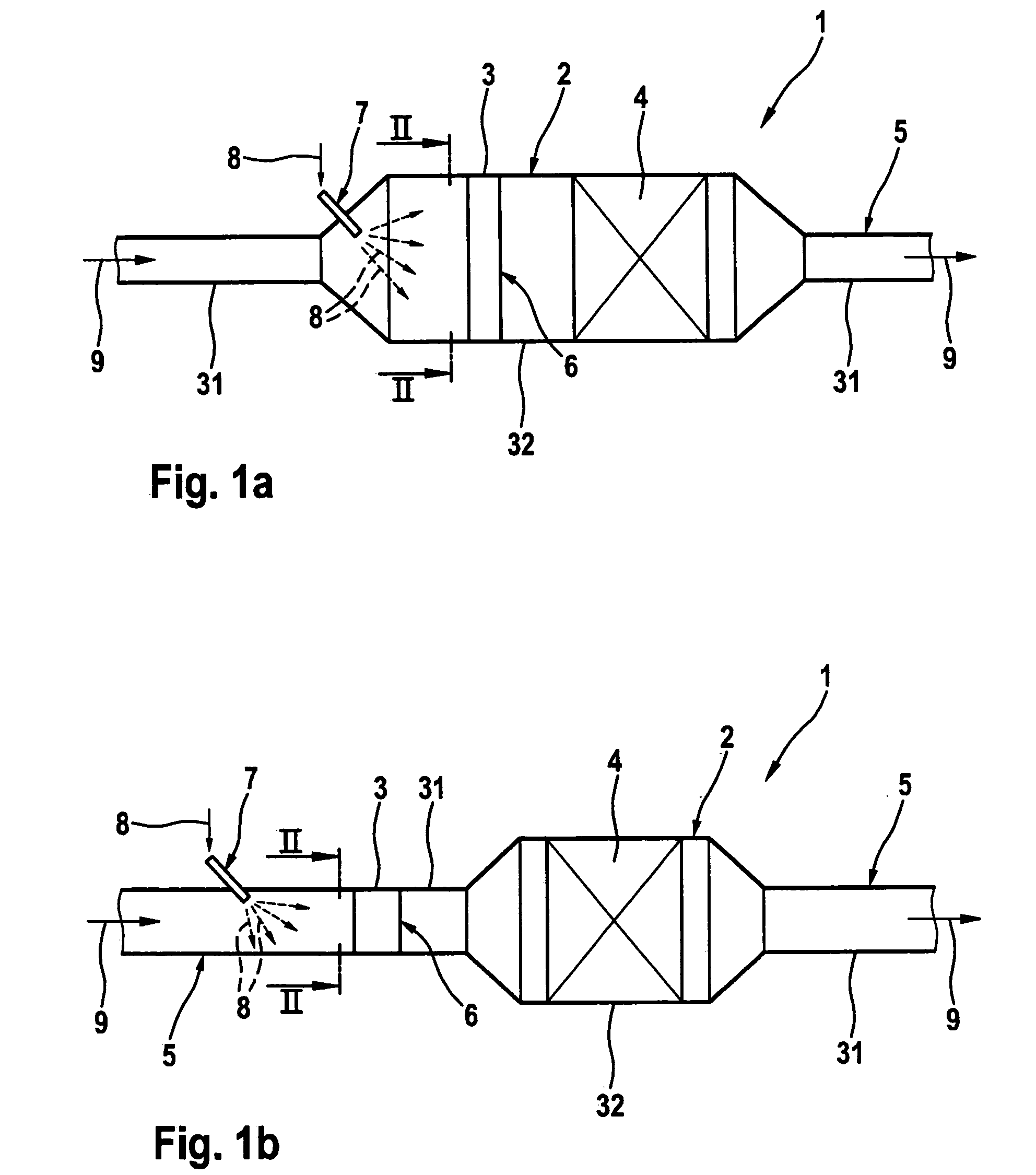

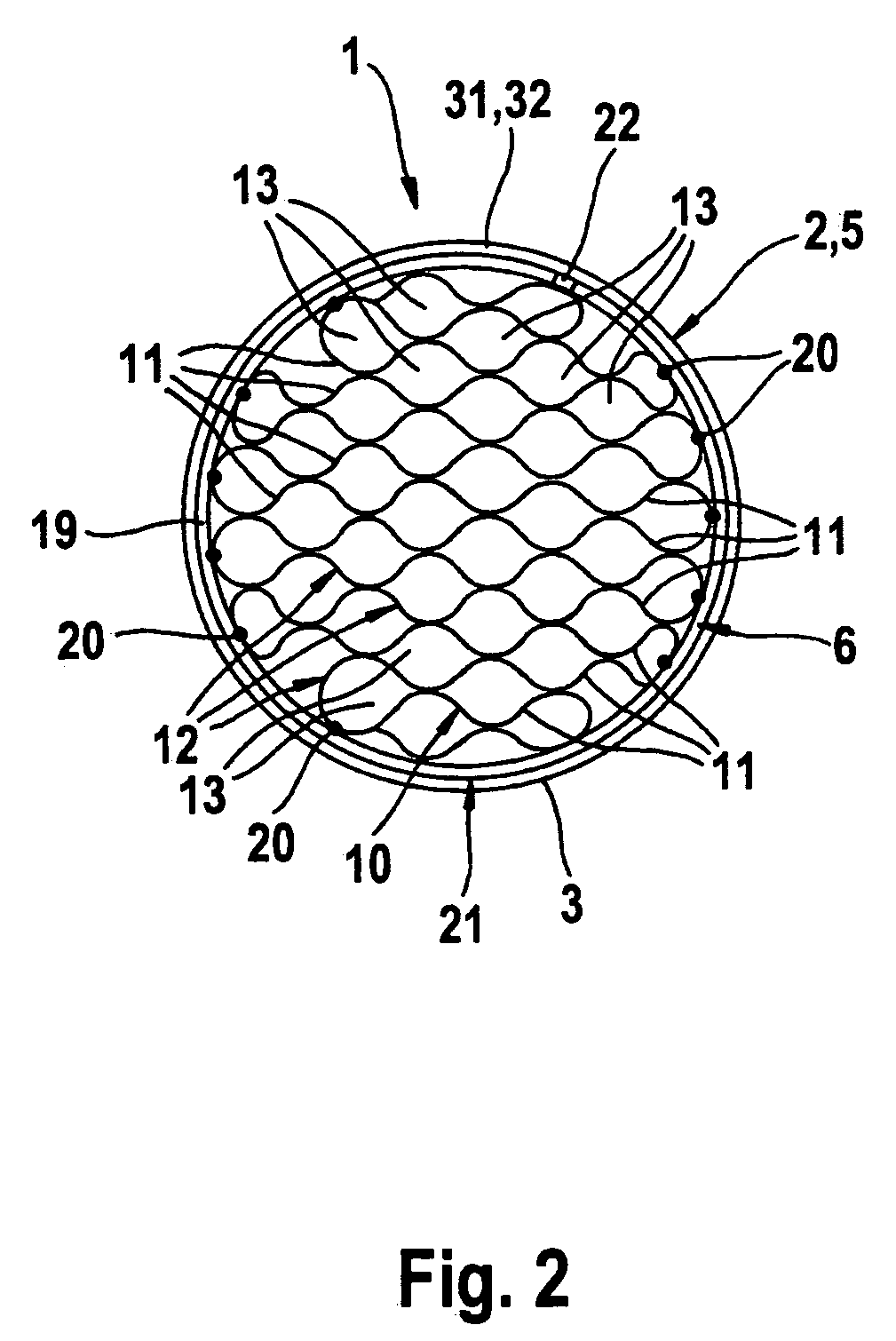

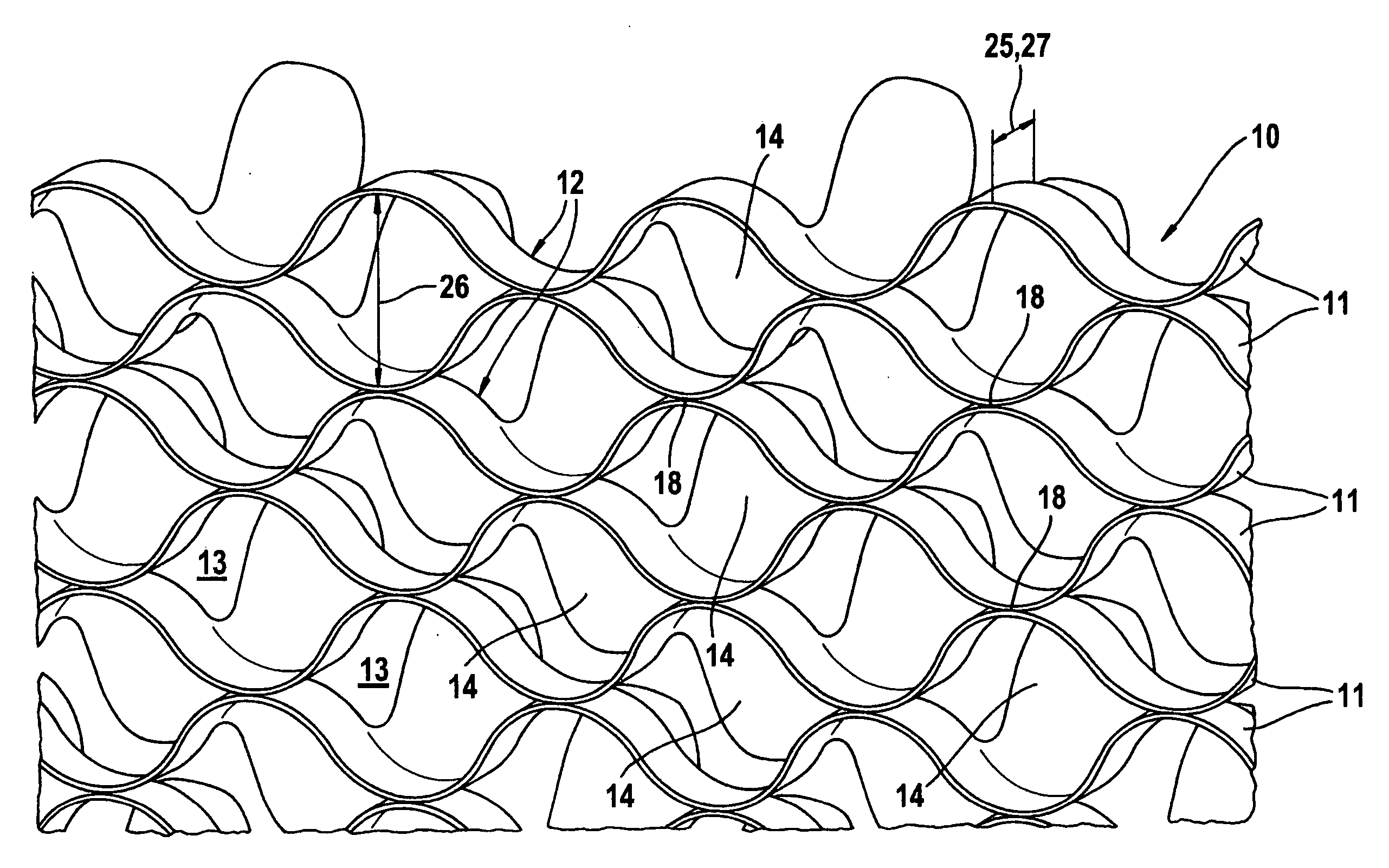

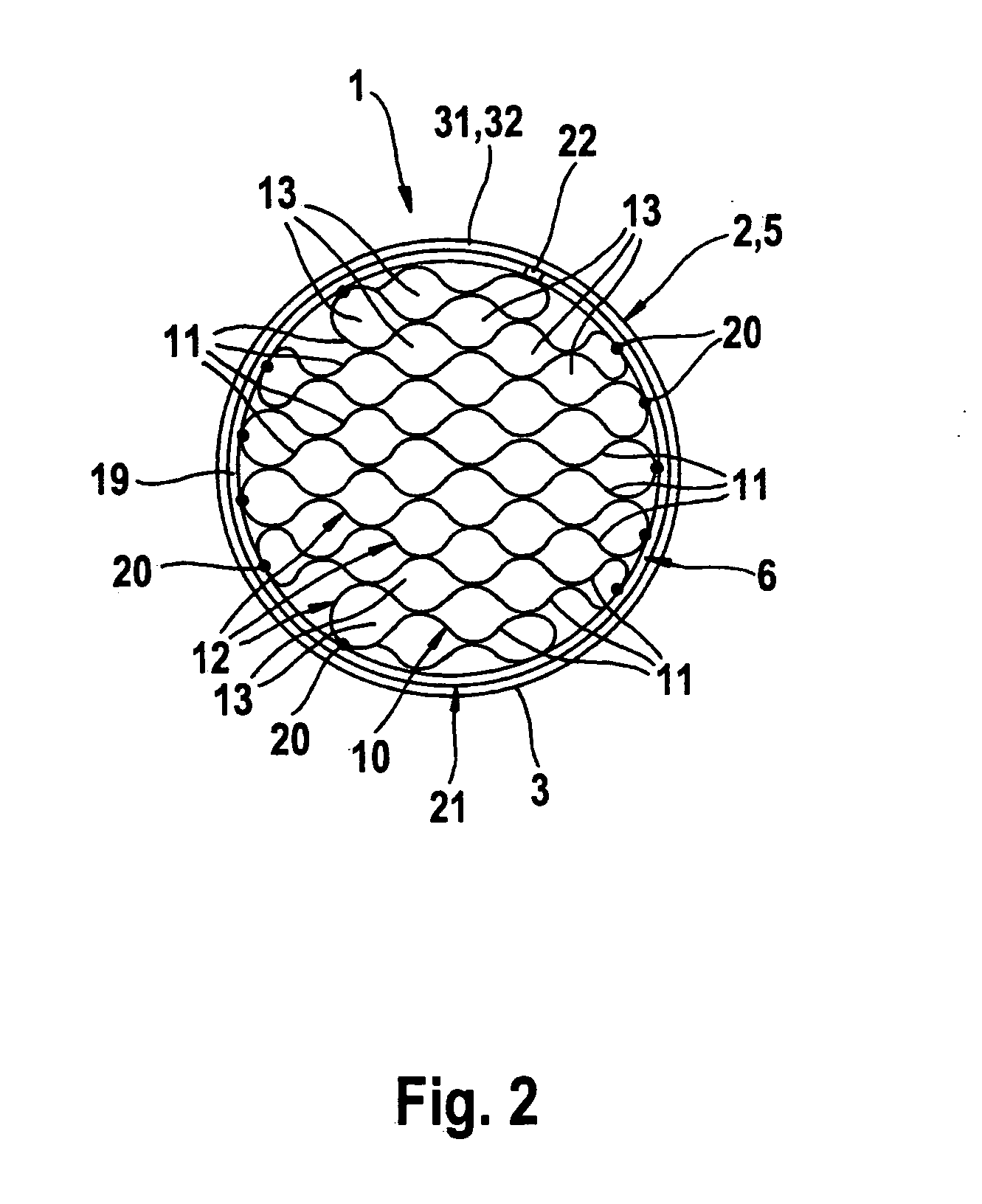

Static mixer and exhaust gas treatment device

InactiveUS7793494B2Design economyIntense mixing effect and vaporization effectInternal combustion piston enginesFlow mixersExhaust fumesEngineering

The invention relates to a static mixer for an exhaust system of an internal combustion engine. The mixer has a wall structure that is arranged across the directional of flow in a pipe and has several layers of a corrugated sheeting material laying across one another in the direction of flow. The cells through which the flow can pass in the direction of flow are provided between the sheeting material of neighboring layers. The sheeting material has baffles for all or several of the cells. The baffles are arranged on the sheeting material so that they are arranged on their outgoing flow side in the case of said cells and extend in the direction of flow and across it.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

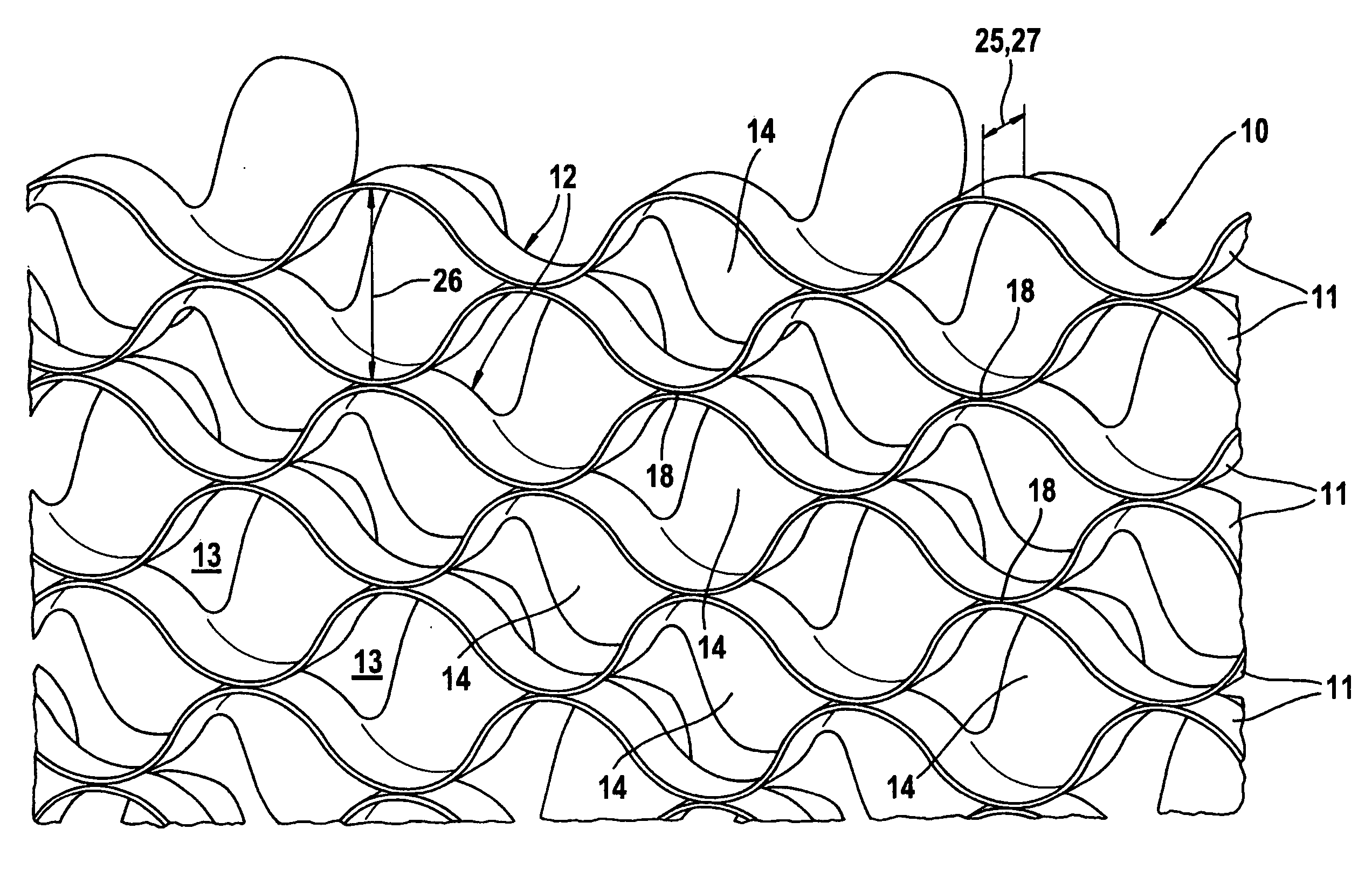

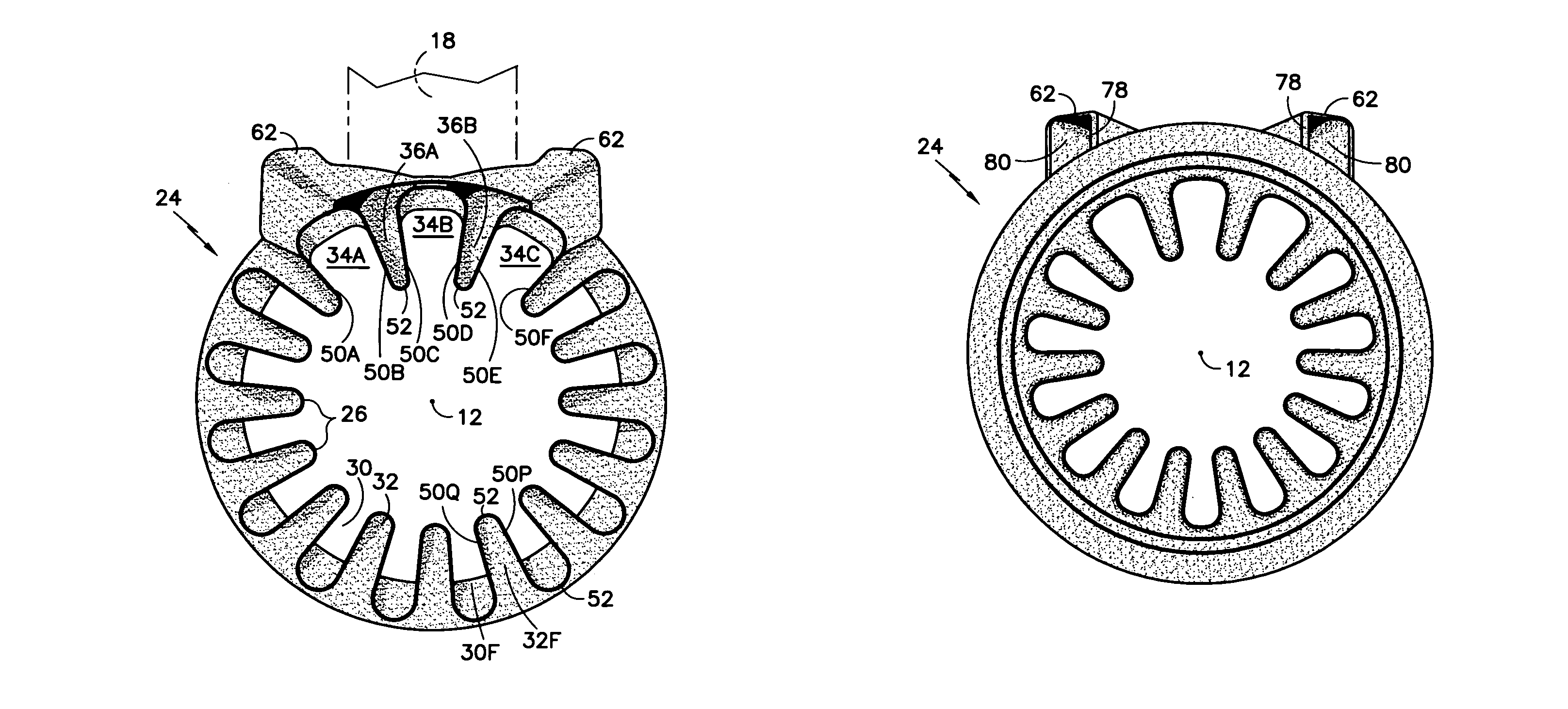

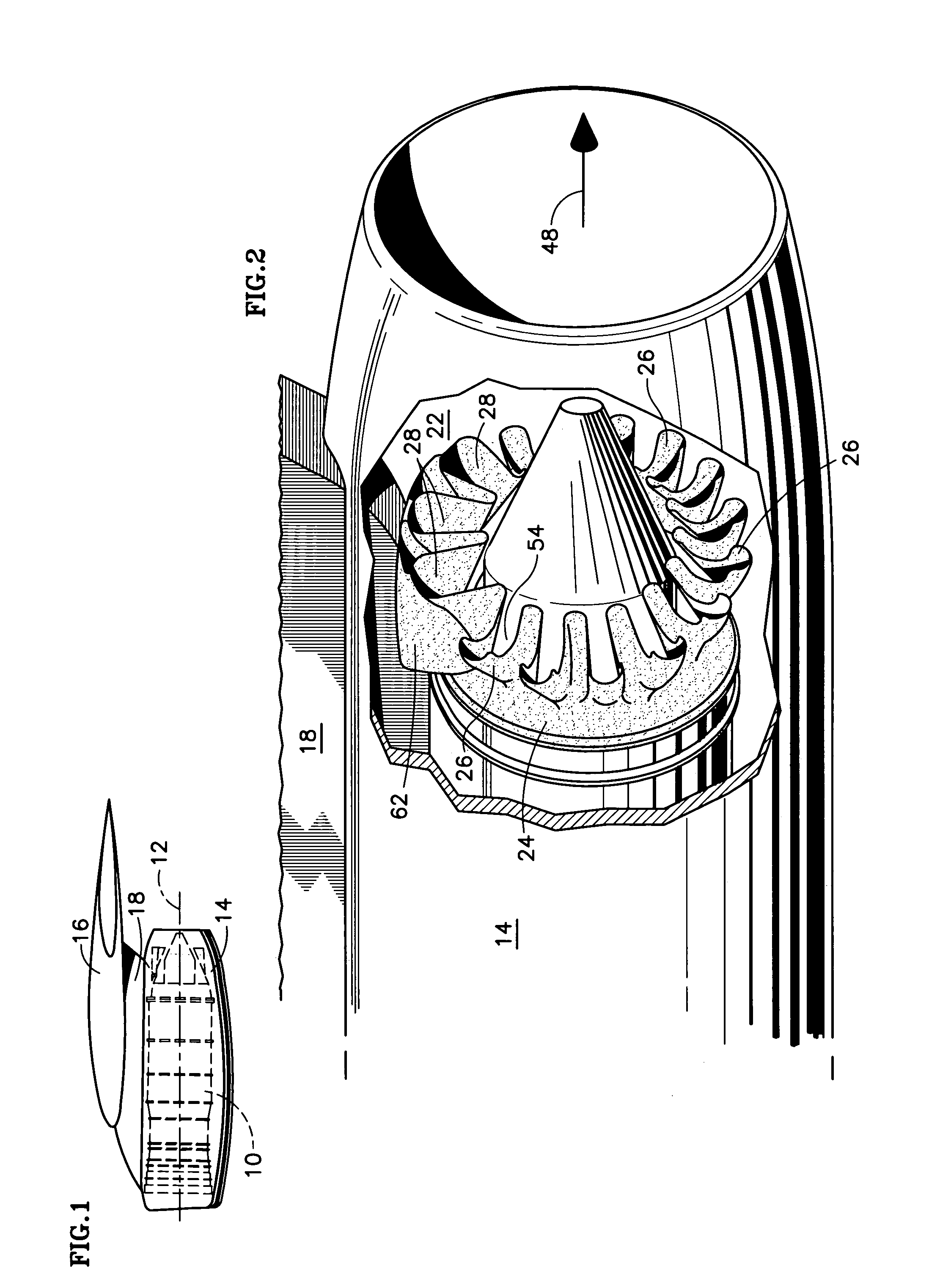

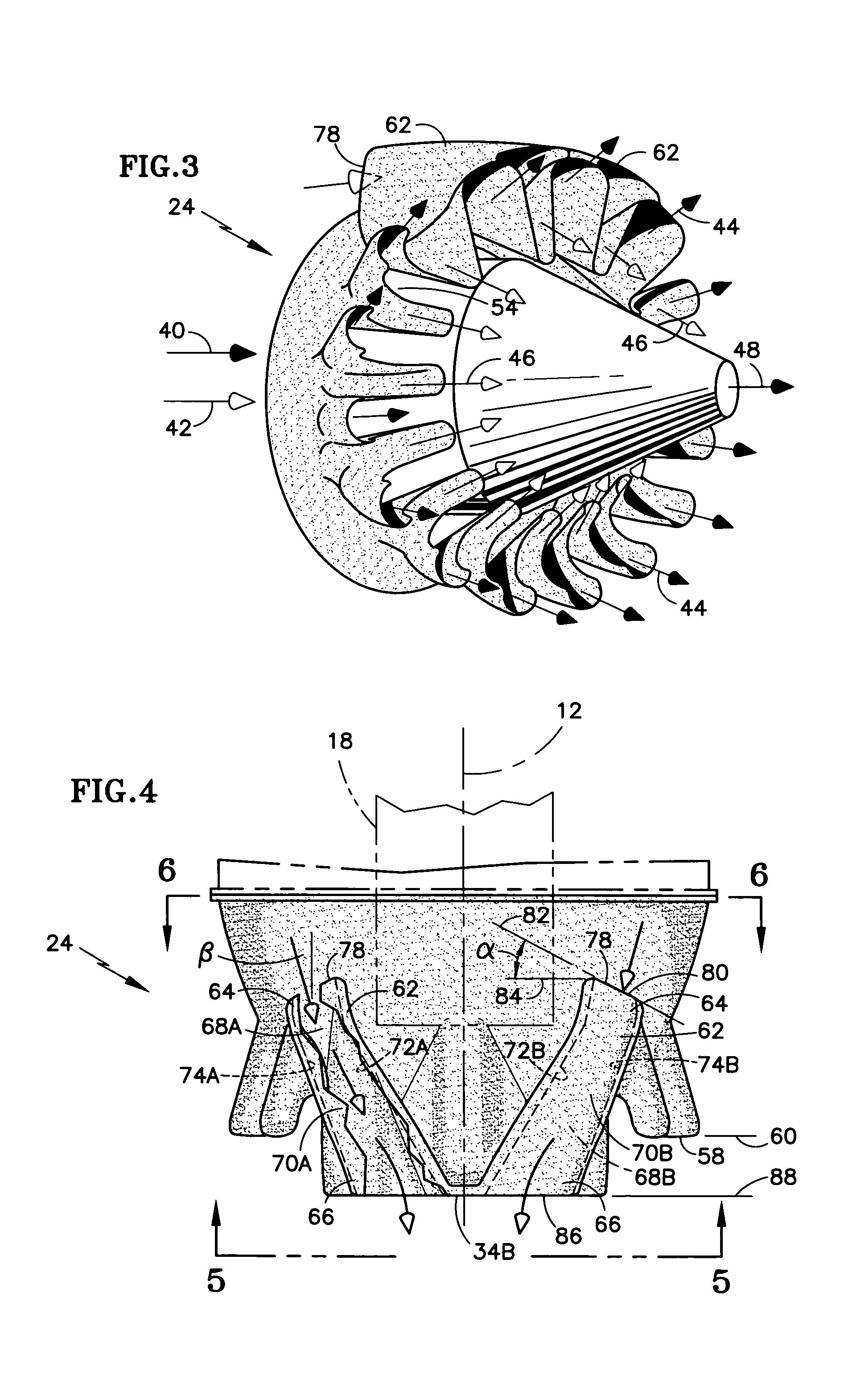

Fluid mixer with an integral fluid capture ducts forming auxiliary secondary chutes at the discharge end of said ducts

ActiveUS7434384B2Improve performanceEfficient capturePower plant exhaust arrangementsPower plant constructionEngineeringMain lobe

A fluid mixer for mixing two fluid streams 40, 42 includes a set of main lobes 26 defining alternating primary and secondary main chutes 30, 32, one or more auxiliary lobes 28 intermediate two of the main lobes, and an auxiliary fluid capture duct 62. The auxiliary lobes are defined, at least in part, by the discharge end of the duct. In operation, the duct conveys secondary fluid to secondary chutes 36 defined by the lobes thereby improving the performance of the mixer despite the presence of an obstruction 18 that would otherwise impede thorough mixing of two fluid streams.

Owner:RTX CORP

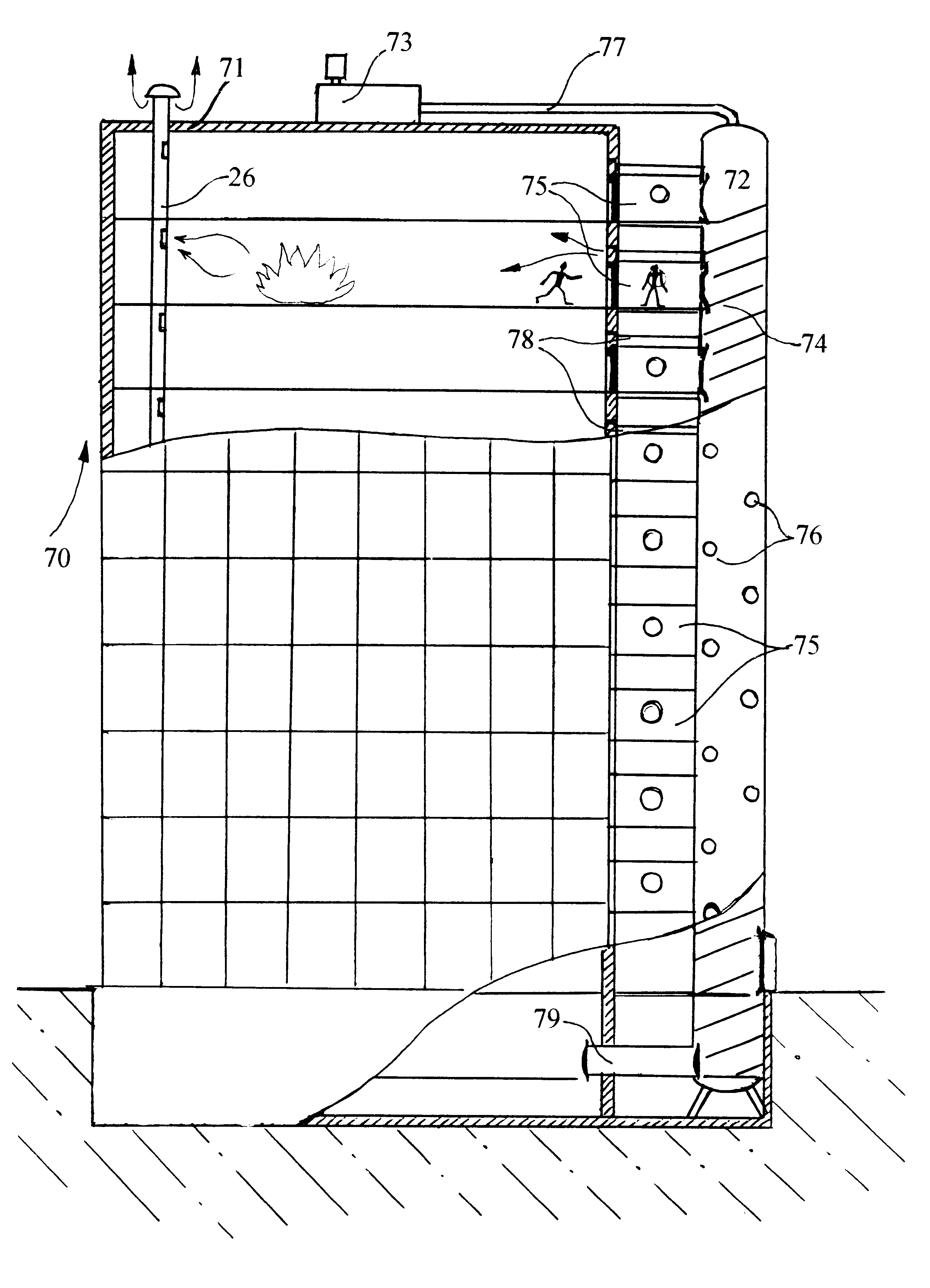

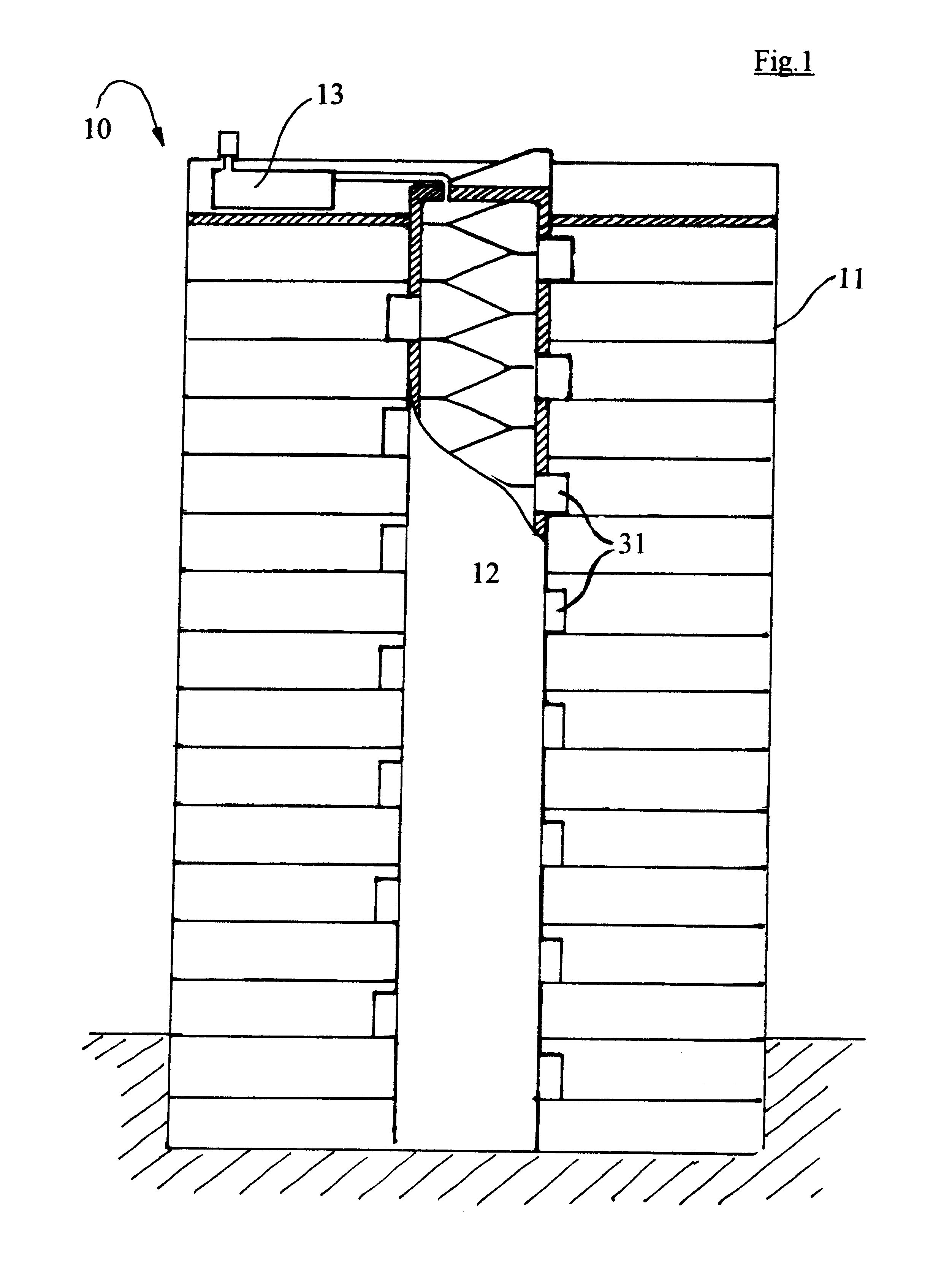

Hyperbaric hypoxic fire escape and suppression systems for multilevel buildings, transportation tunnels and other human-occupied environments

Hyperbaric Hypoxic Fire Escape and Suppression System is provided for multilevel buildings, transportation tunnels and other human-occupied environments. The system produces and maintains a hypoxic hyperbaric environment in a separate part of a building (staircase shaft) or a tunnel (service tunnel) in order to provide an entirely secure escape area in case of a fire emergency and instantly extinguish an ongoing fire in a building or a tunnel by releasing a breathable hyperbaric hypoxic fire-extinguishing composition into location affected by fire. Additionally, the system provides continuing adequate protection against biological and chemical warfare and contaminants by filtering ambient air before processing it by the system and by establishing breathable fire-suppressive atmosphere at a positive atmospheric pressure inside a building or tunnel.

Owner:FIREPASS CORP

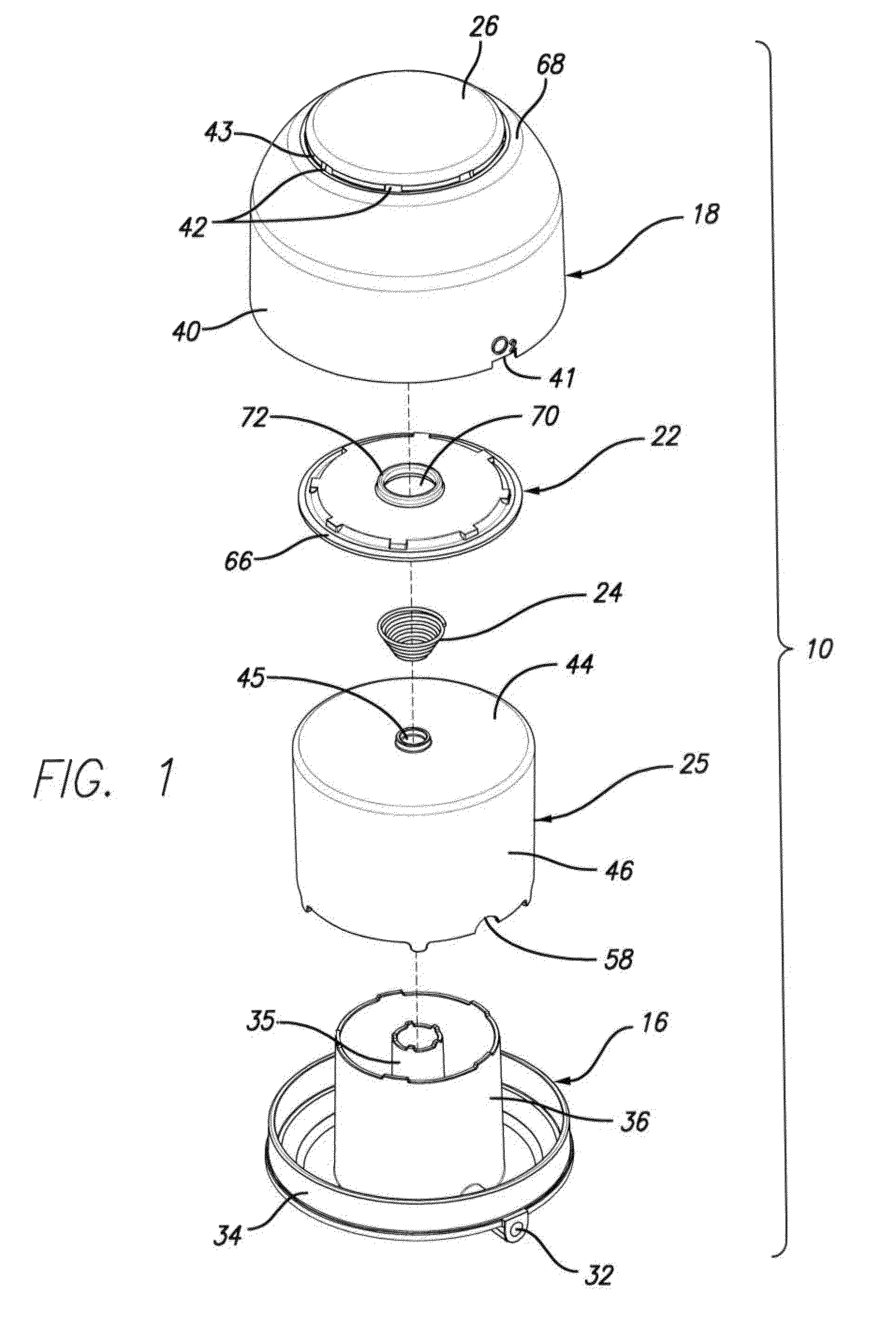

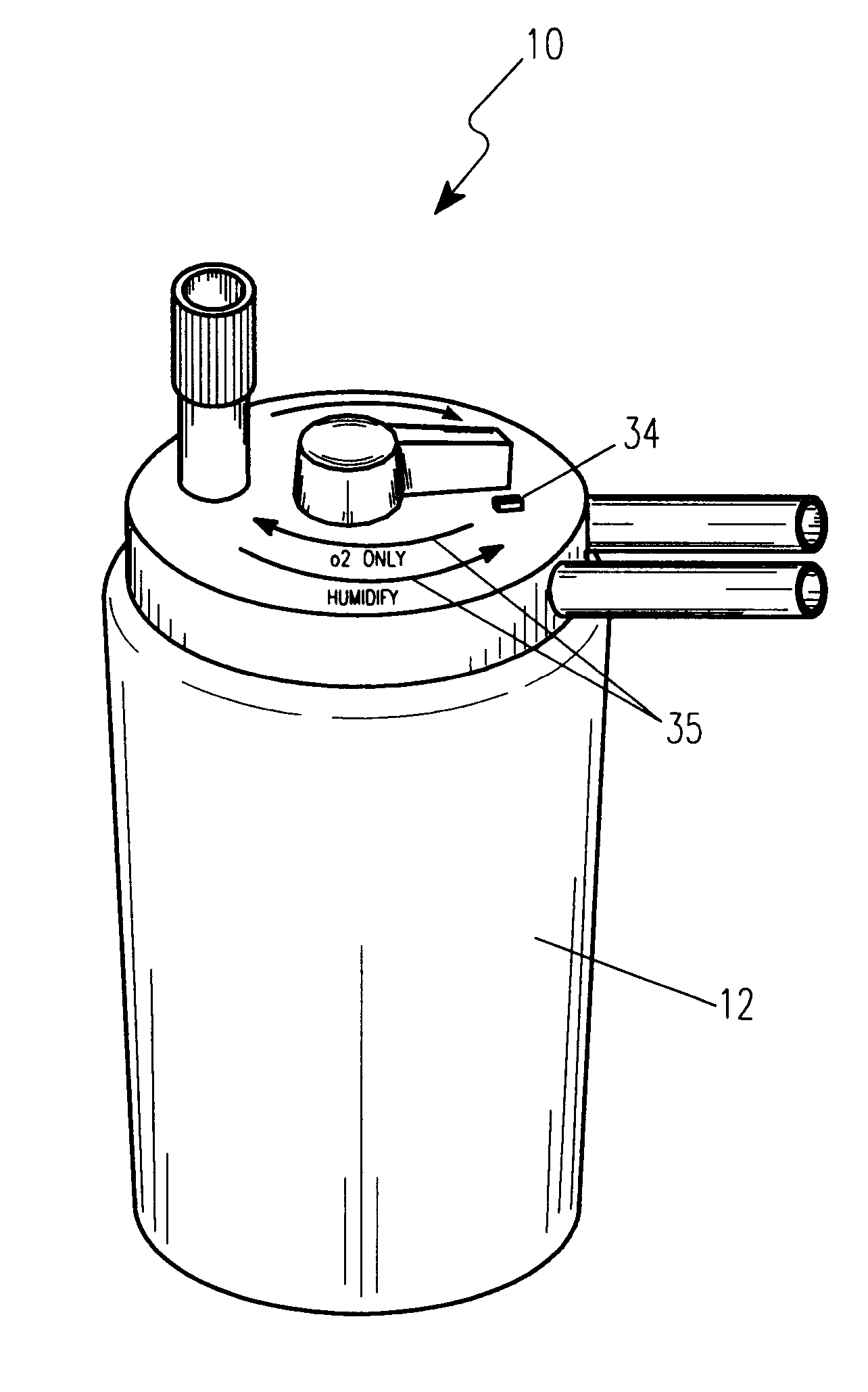

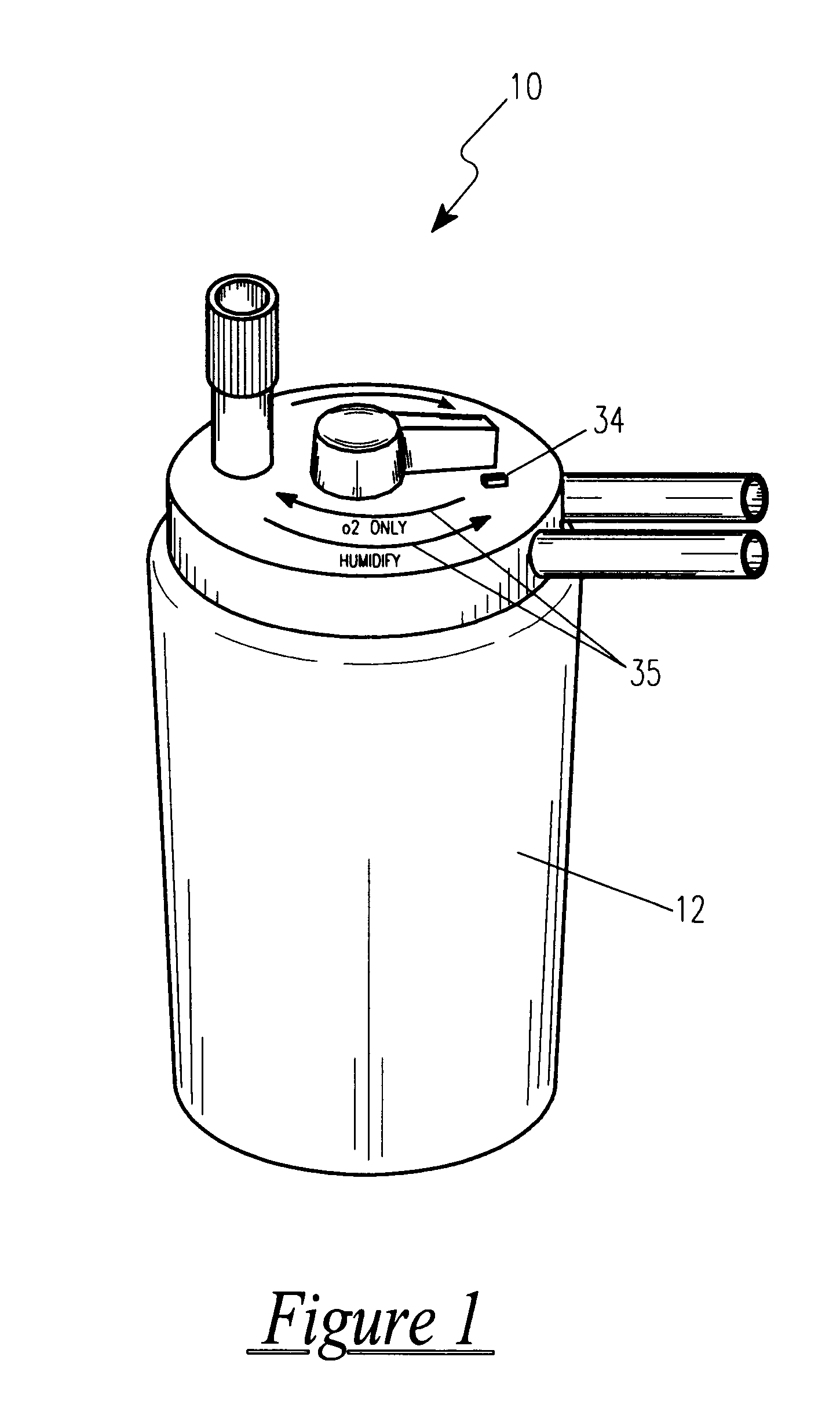

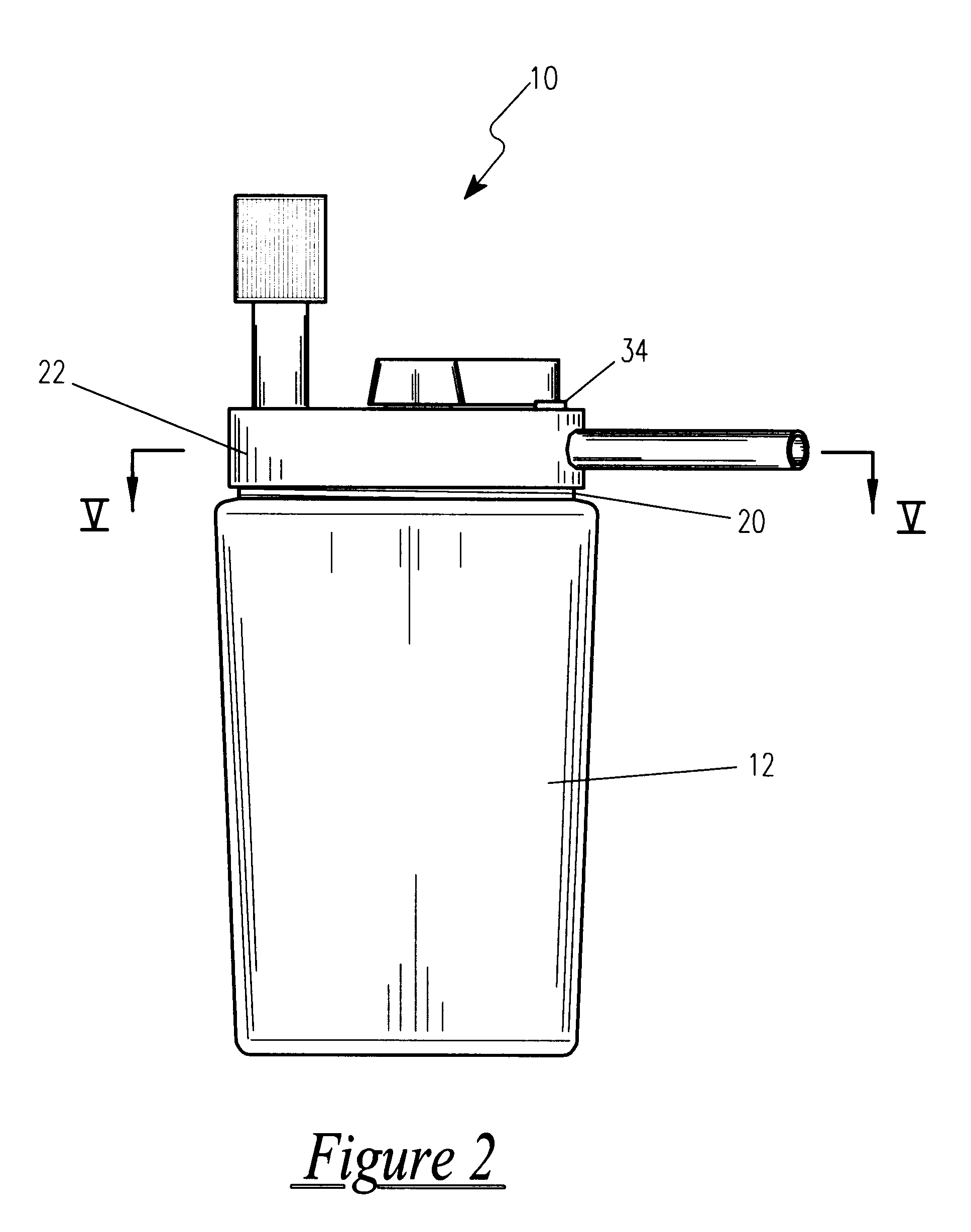

Dual port medical oxygen humidifier

InactiveUS6189870B1Easy to switchReduces and eliminates possibilityLighting and heating apparatusTransportation and packagingEngineeringMoisture

An improved disposable bubble oxygen humidifier is provided having a humidifying chamber included for the blending of oxygen and moisture. A slide switch on the top of the humidifier directs pure oxygen to the patient, or alternately, routes the oxygen through the humidifier and on to the patient. Hoses are attached at an inlet supply port and an outlet discharge port.

Owner:WITHALL GORDON

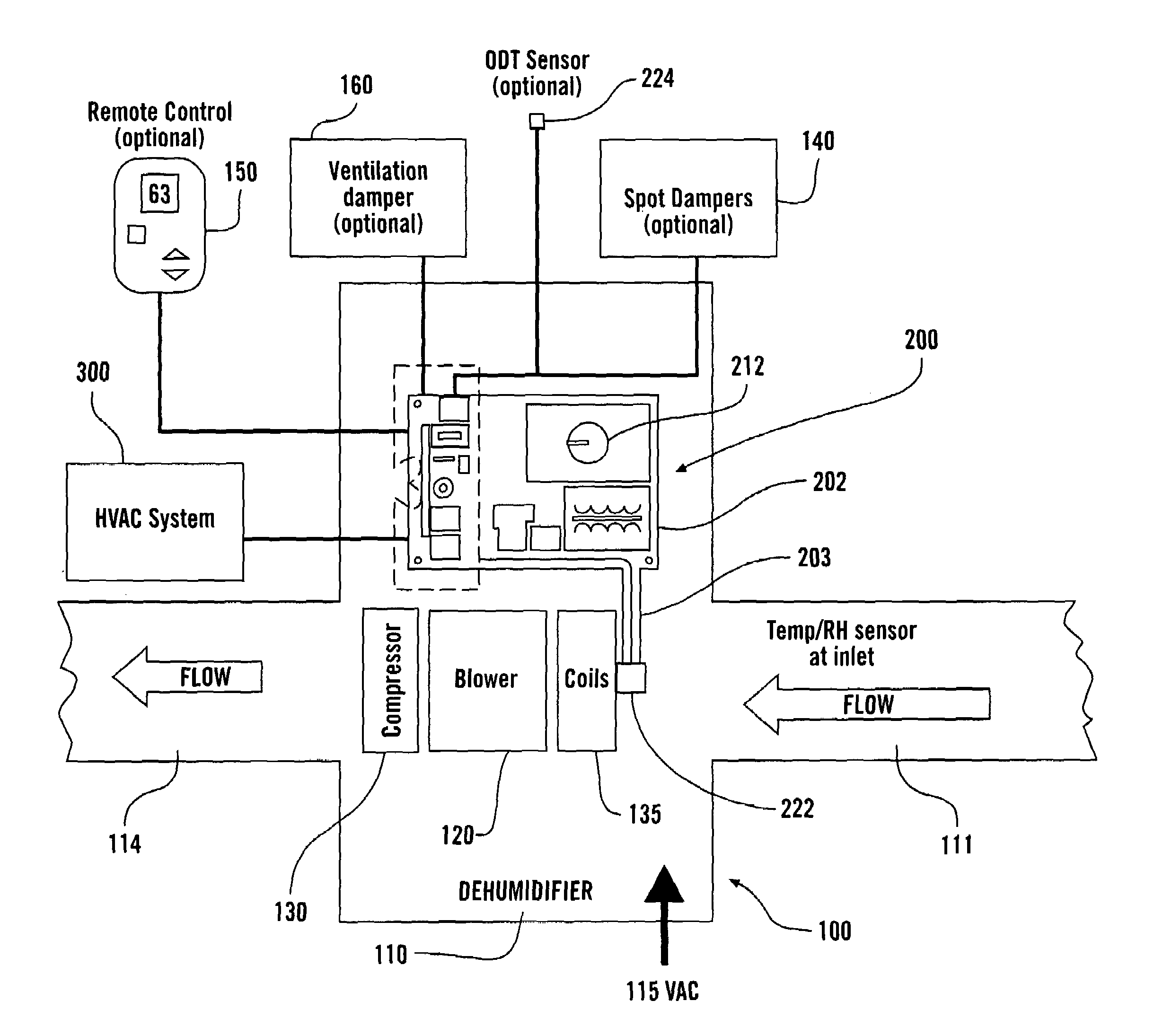

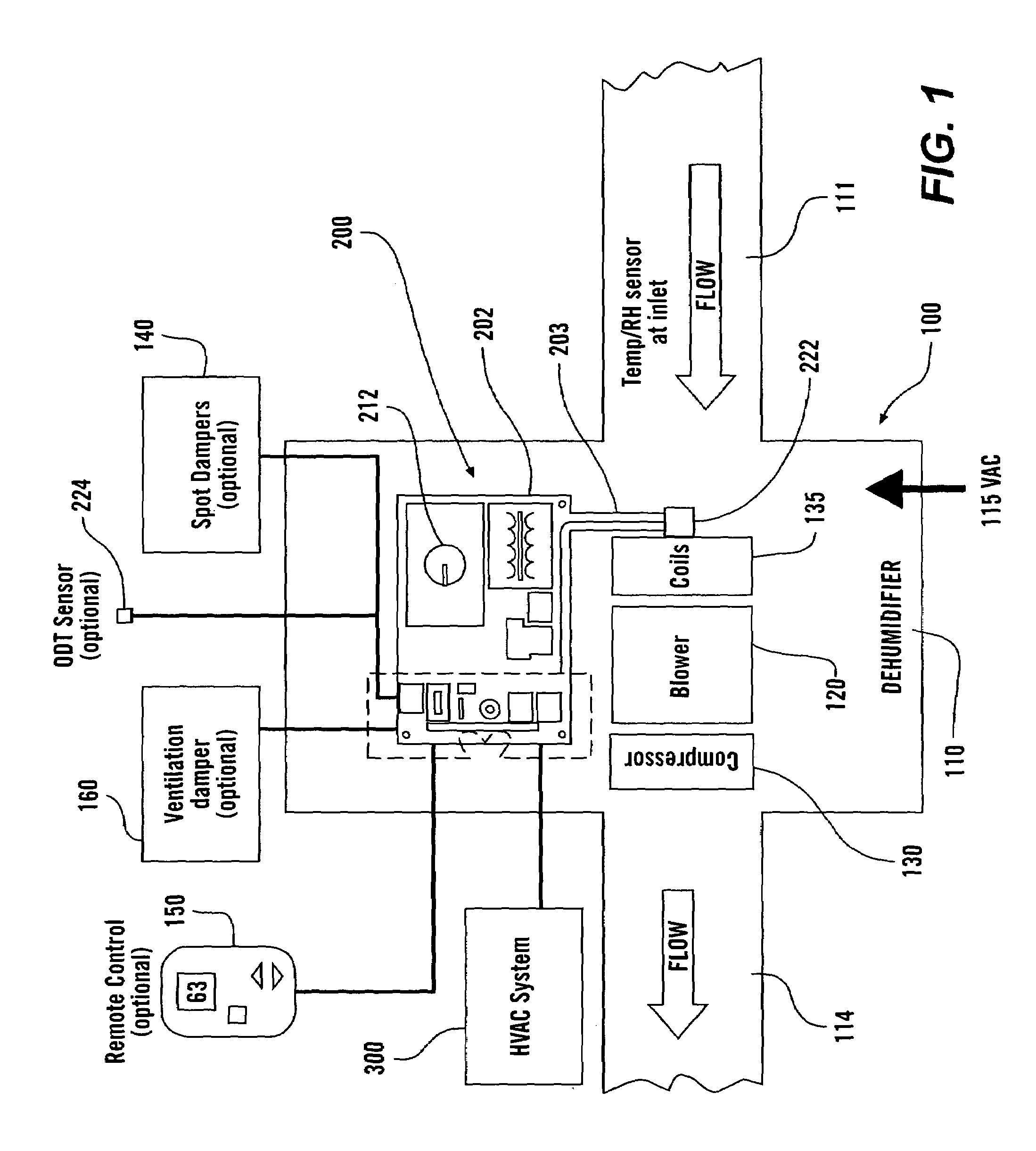

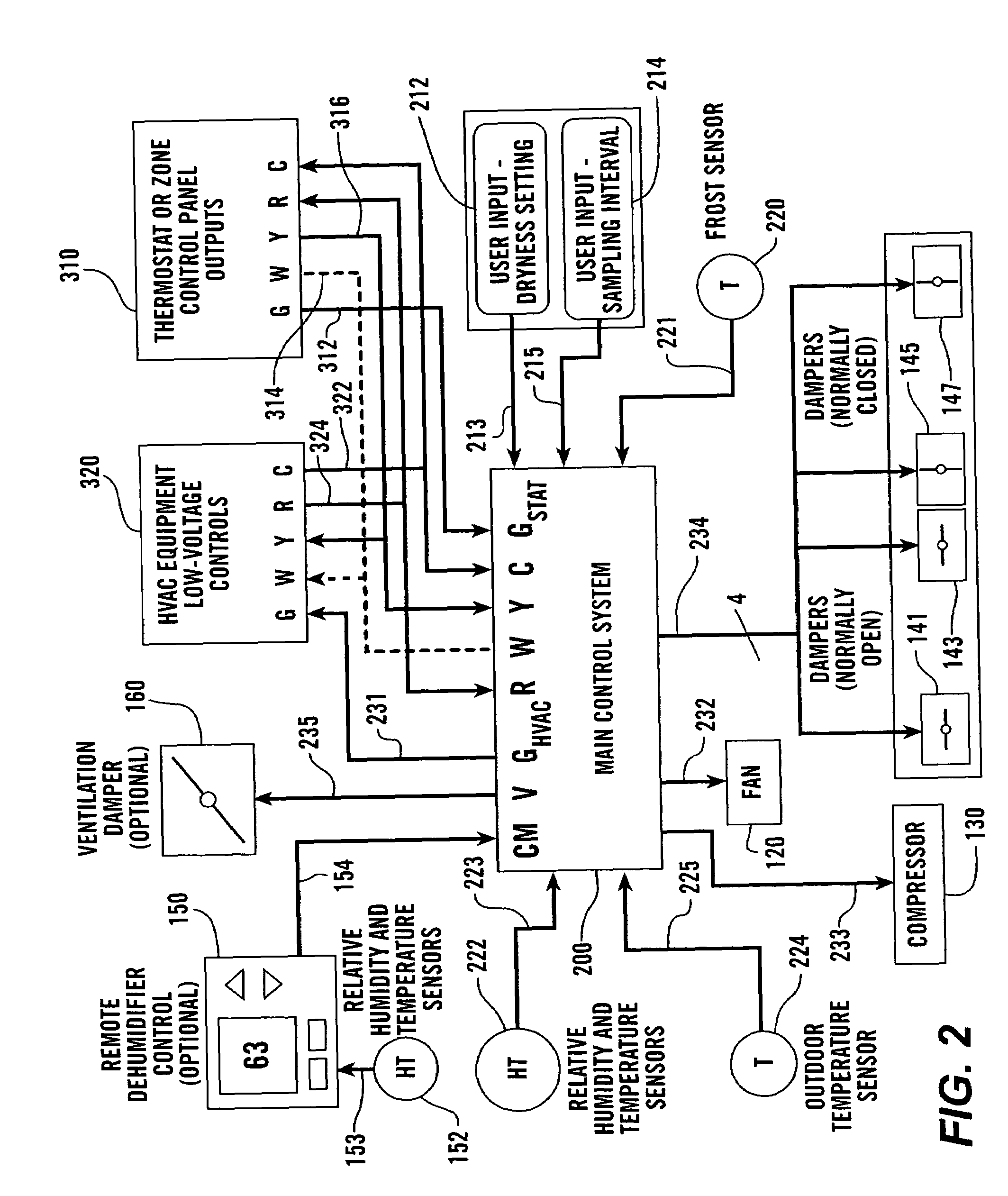

Systems and methods for whole-house dehumidification based on dew point measurements

ActiveUS7574871B2Speed up evaporationEfficient dehumidificationMechanical apparatusControlling ratio of multiple fluid flowsInterior spaceEngineering

A dehumidifier system is connected to an interior space of a building through supply and return ducts, either directly and / or through an HVAC system. Controllable dampers can be used to select how the dehumidifier system is connected to the interior space and the HVAC system. The dehumidifier determines the dew point of the ambient air from temperature and relative humidity measurements taken at location(s) of relative humidity and temperature sensors. Based on the determined dew point, the dehumidifier system determines whether to operate. The temperature and relative humidity sensors can be located in the interior space or within the dehumidifier, where they project into the air stream flowing through the dehumidifier. The dehumidifier system operates in response in part to blower calls to the HVAC system and controls the HVAC system and a ventilation system to distribute the dehumidified air and outside air throughout the building.

Owner:RES PRODS

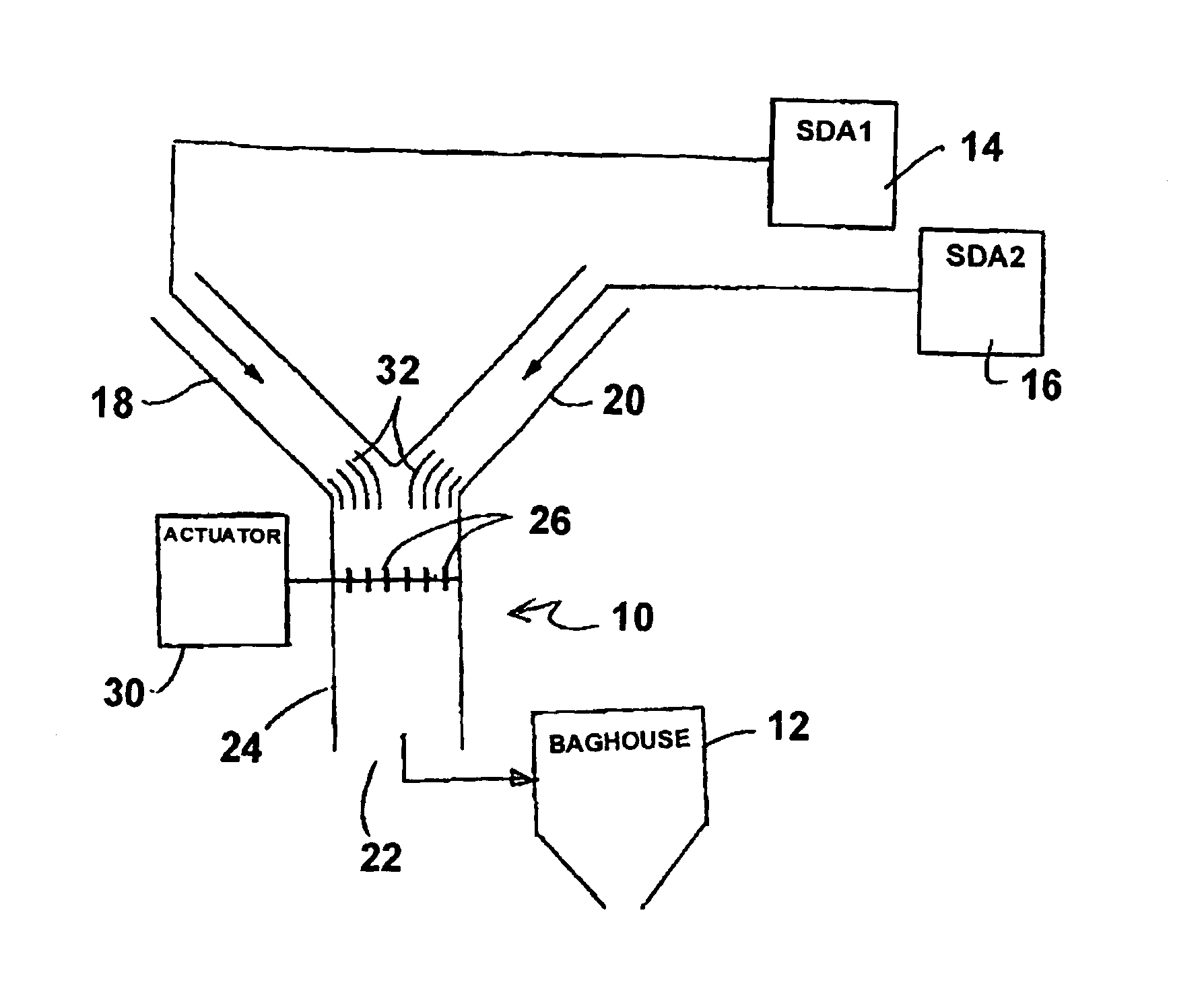

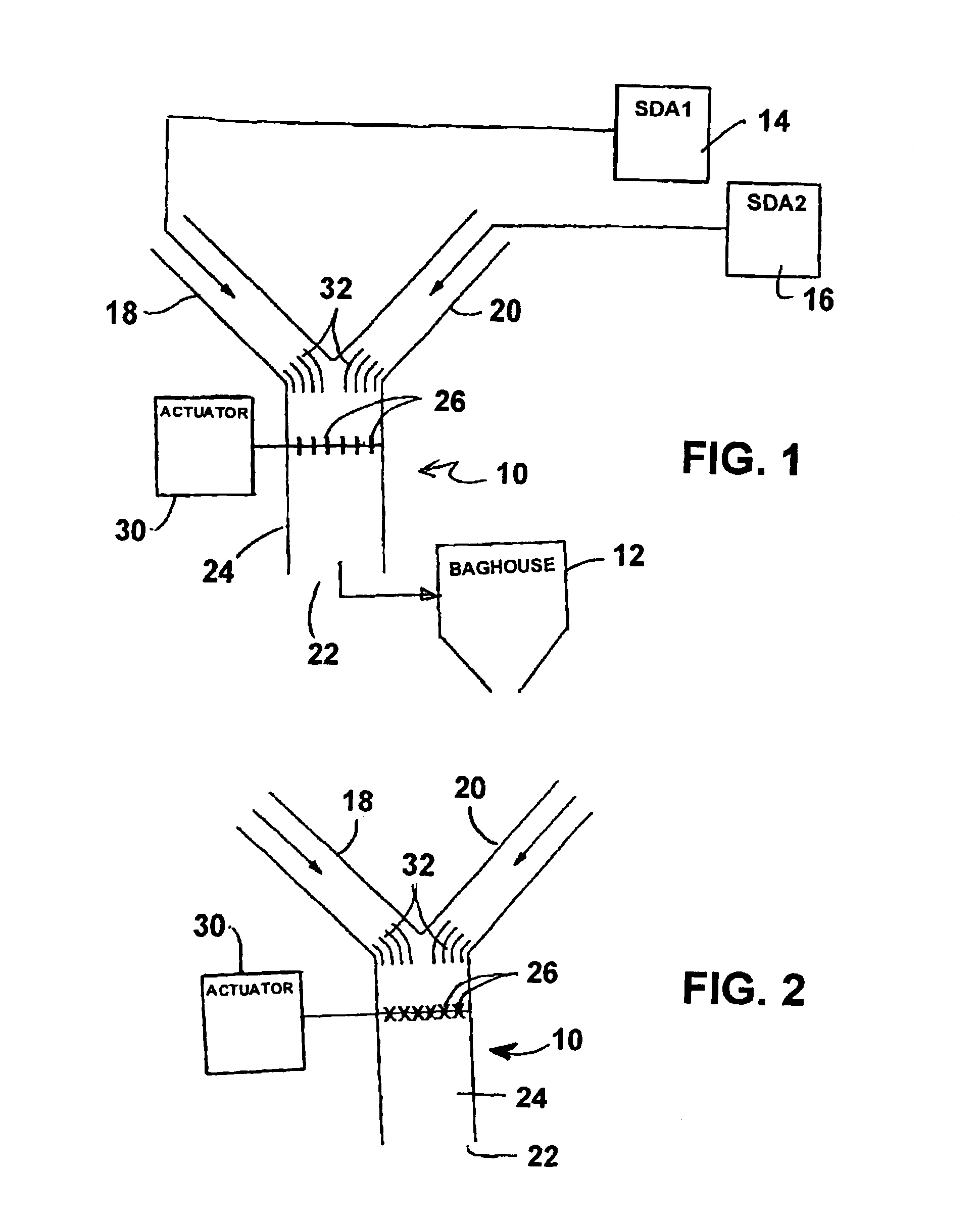

Intermittent mixer with low pressure drop

InactiveUS6946011B2Reduce the temperatureAuxillary pretreatmentOther chemical processesChemical compositionFlue gas

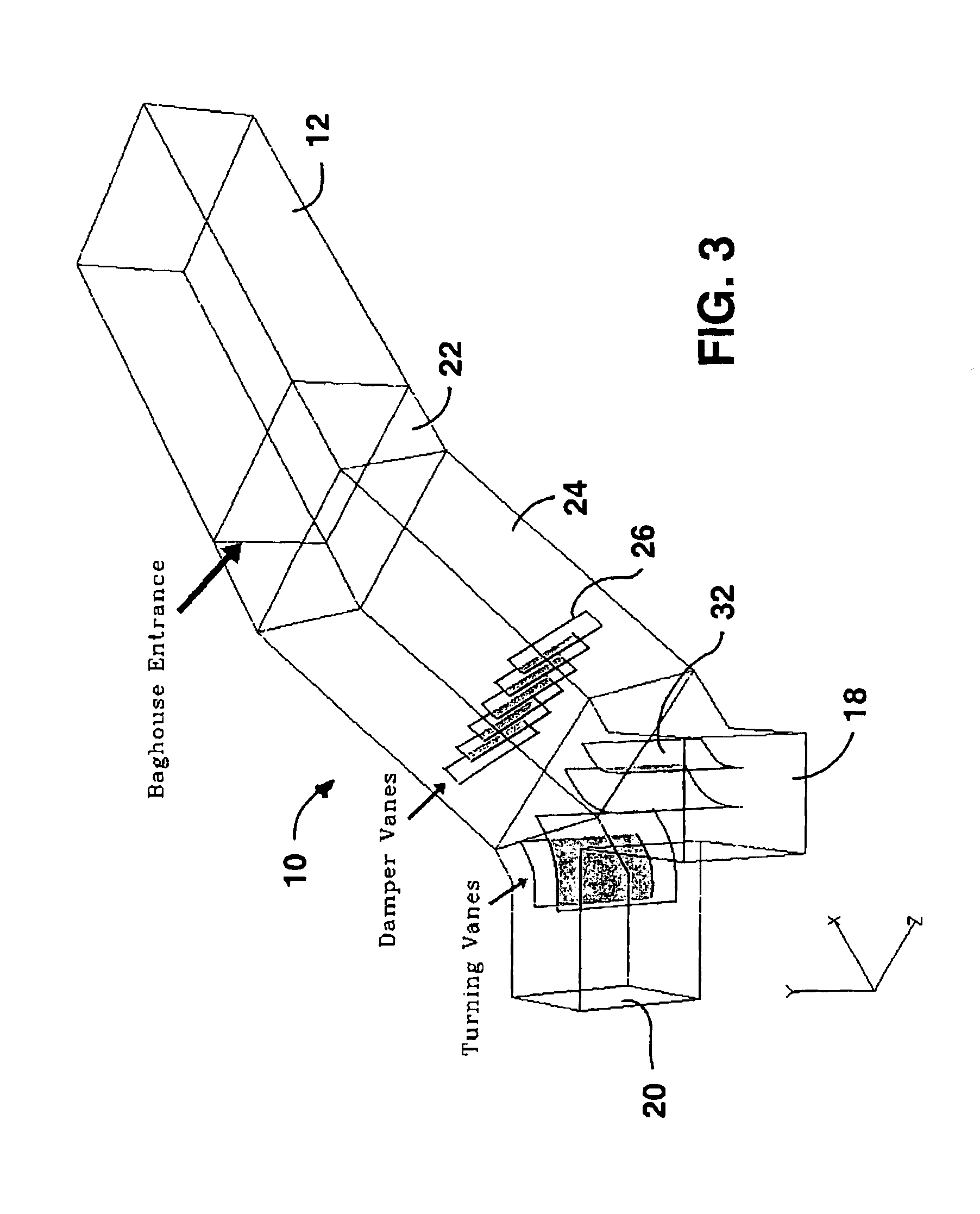

A thermal mixer reduces the temperature of flue gas supplied to a fabric filter. Two spray dry absorbers are operable to cool flue gas. A housing of the mixer has first and second inlet passages for gas from the absorbers, an outlet passage for gas to the fabric filter, and a mixing passage. A set of damper vanes extends in the mixing passage and has a mixing position for mixing the flue gases from the inlet passages to supply mixed gas to the outlet passage at relatively high pressure drop but lower temperature if one of the absorbers in not operating. They have a non-mixing position for passage of gases without mixing and at low pressure drop when both absorbers are operating. The invention can also be used to improve mixing of combined gas streams initially having different chemical compositions or amounts of particle loading.

Owner:THE BABCOCK & WILCOX CO

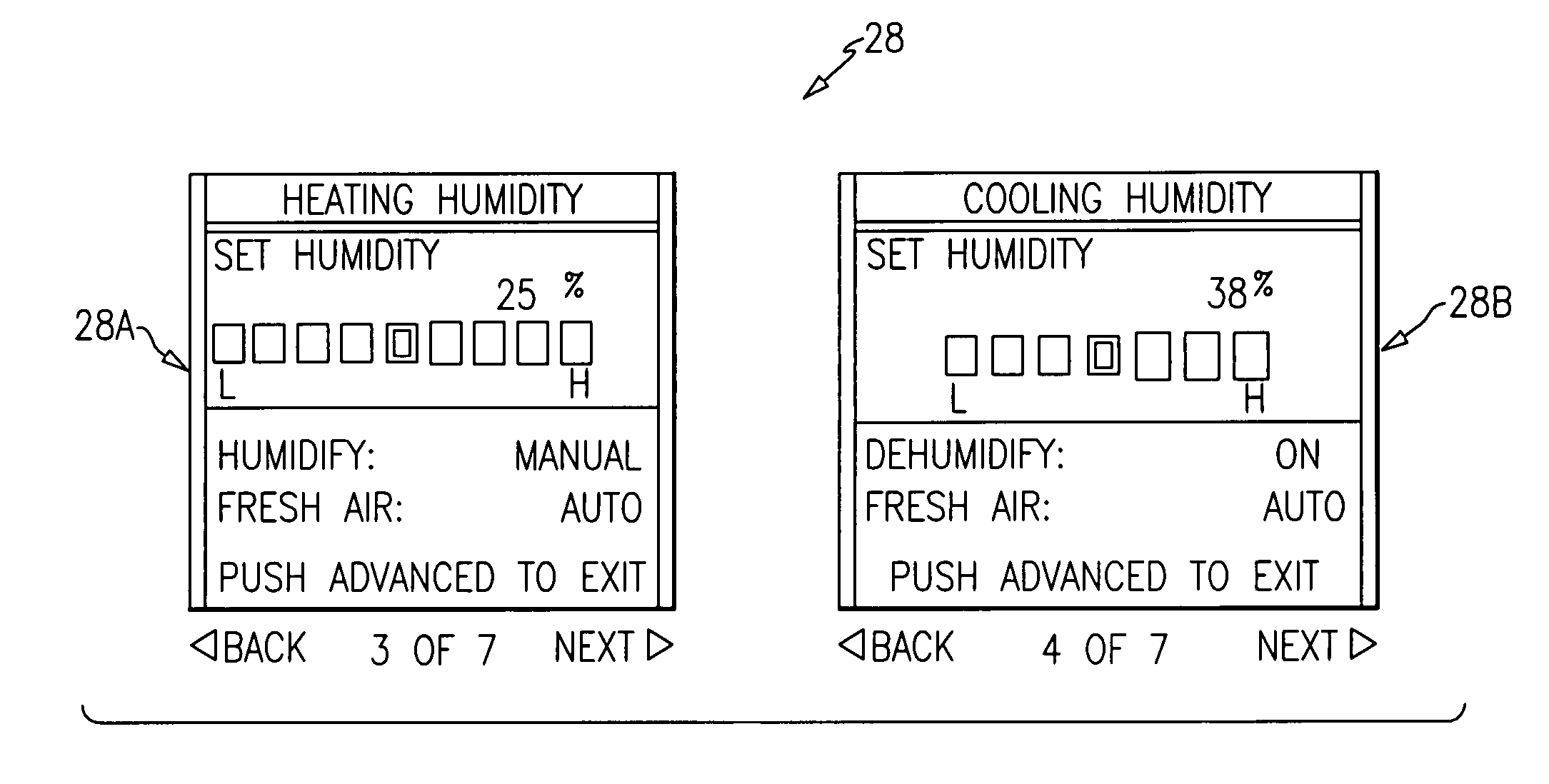

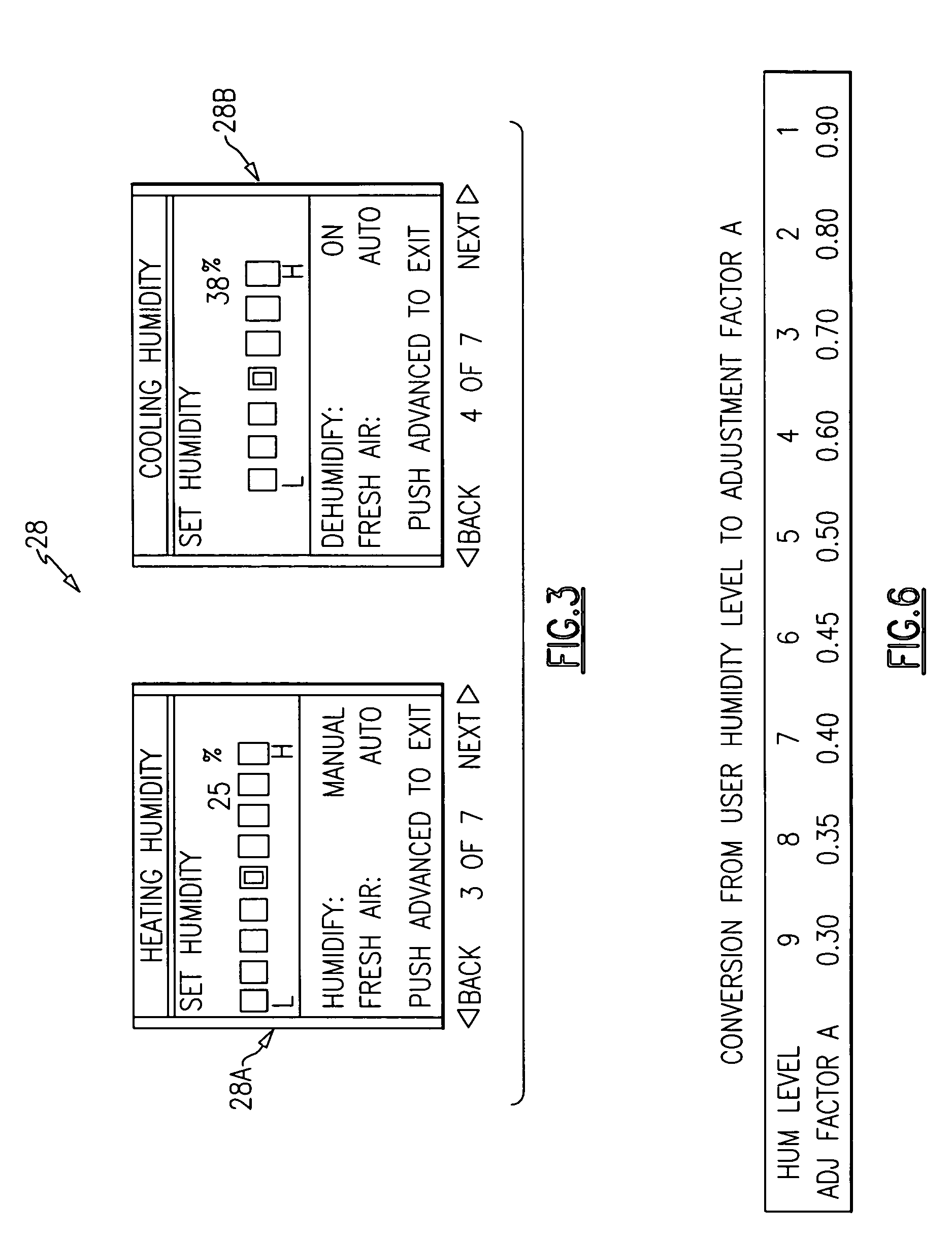

Single integrated humidity and ventilation control in an HVAC system

ActiveUS7266960B2Avoid condensationMechanical apparatusSpace heating and ventilation safety systemsFresh airHeating season

HVAC systems are employed to control the indoor environmental characteristics of a building structure to make it comfortable for its inhabitants. An HVAC system includes one single integrated central control to regulate an indoor temperature level, an indoor relative humidity level and an indoor fresh air level of a building structure during both a heating season and a cooling season. Further, the single integrated central control is operable to selectively activate / deactivate an indoor blower to control a sensible ratio within a building structure. In addition, a protection feature for avoiding condensation on the interior surfaces of the building structure is included as an user selectable option.

Owner:CARRIER CORP

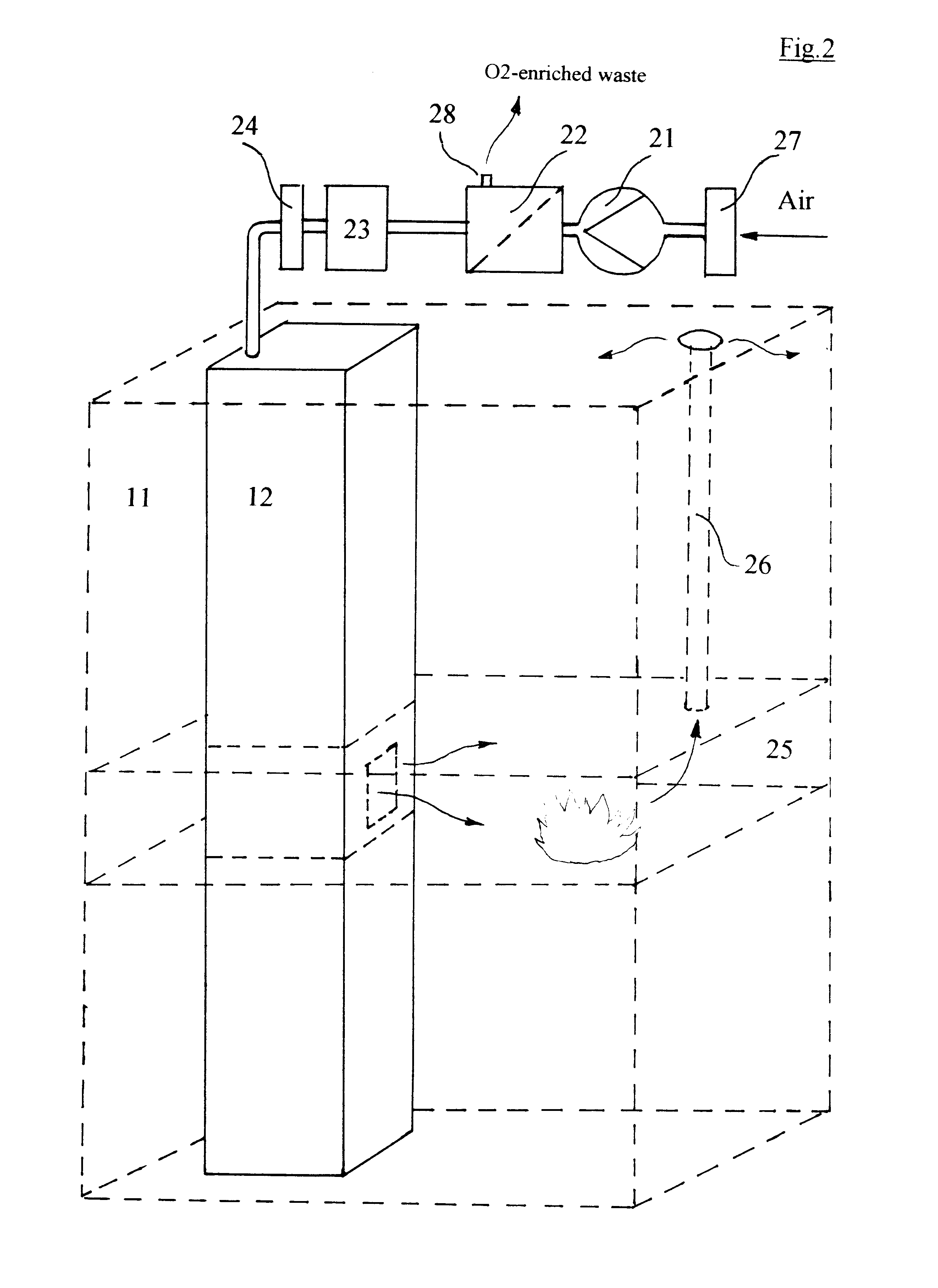

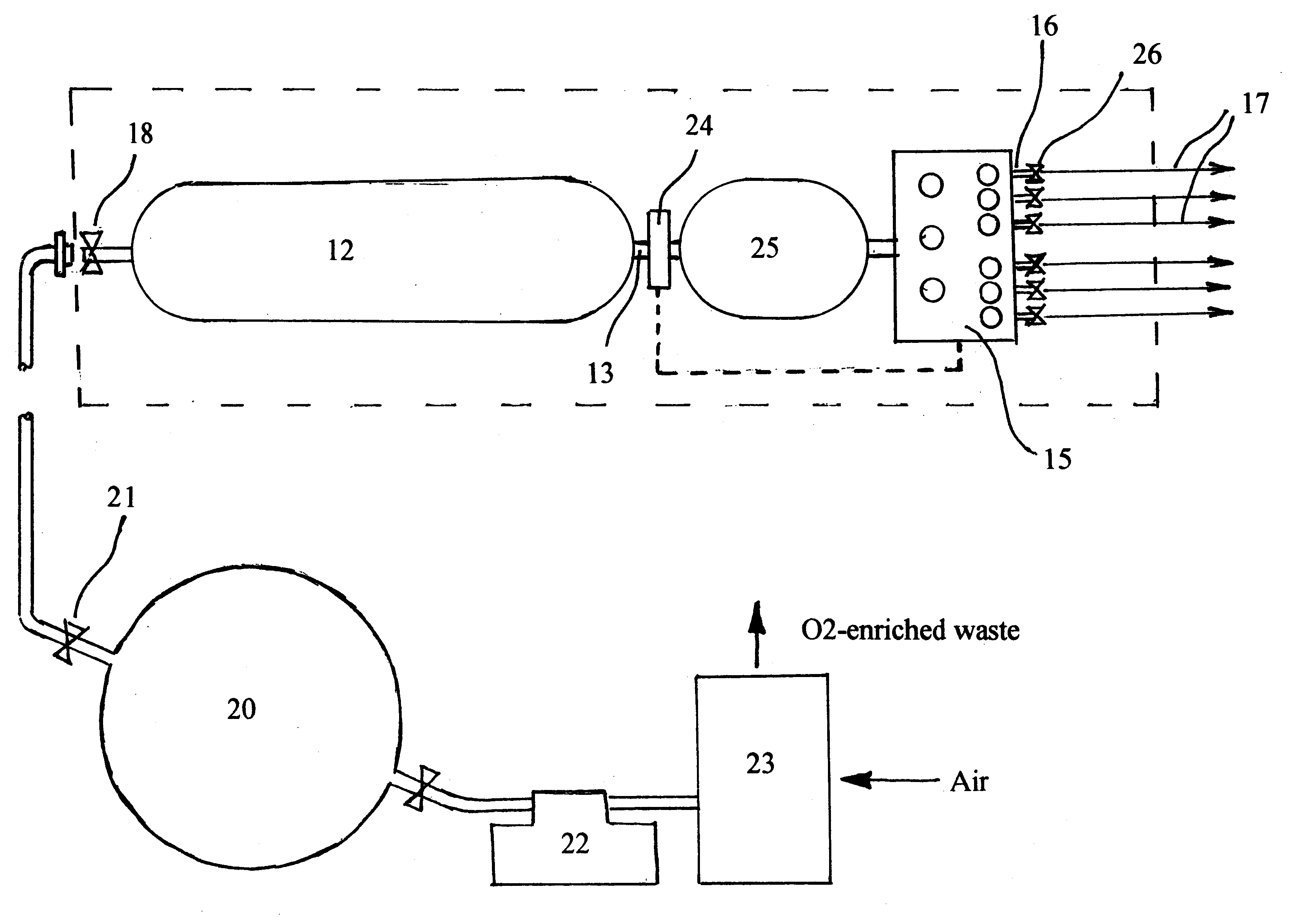

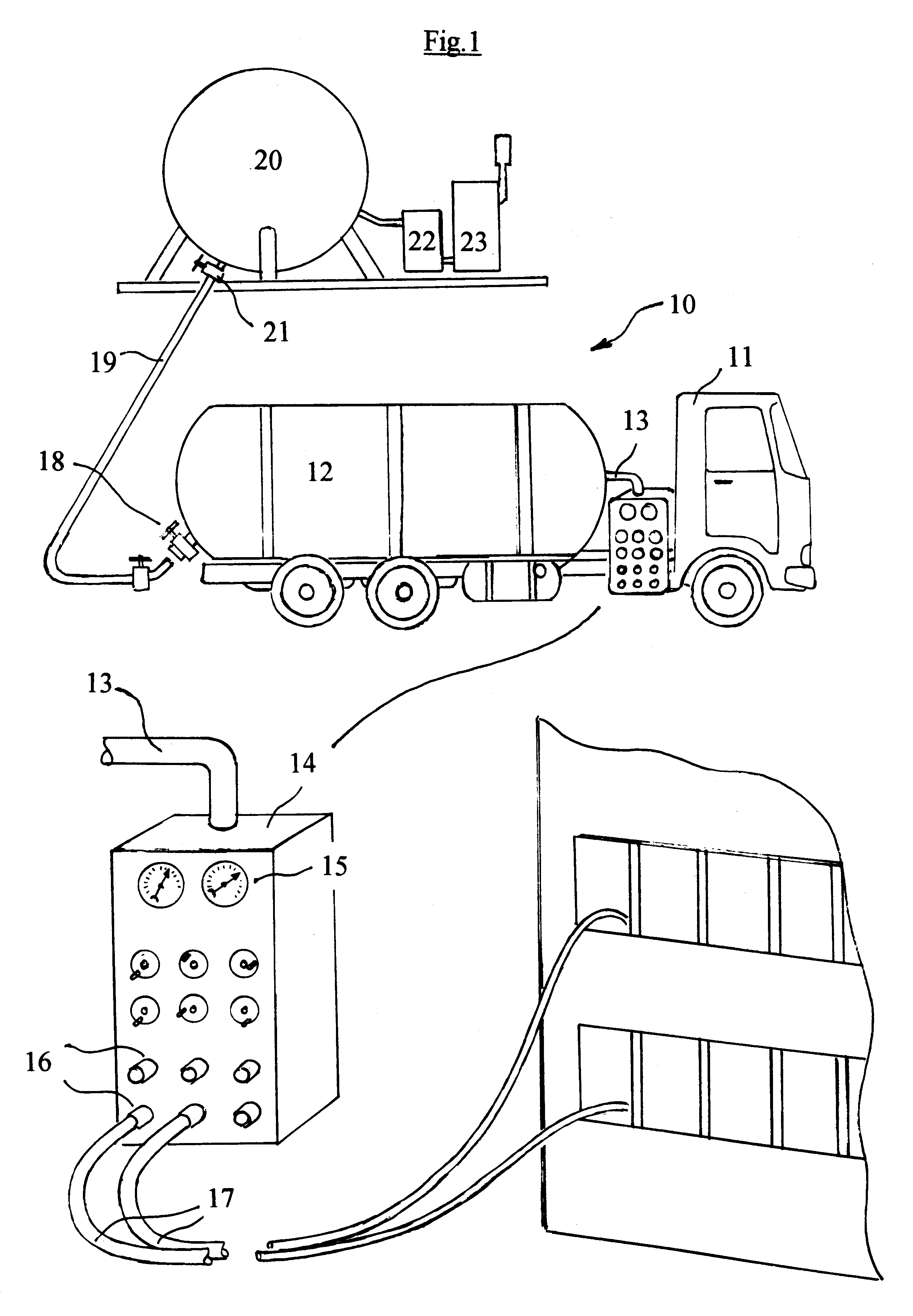

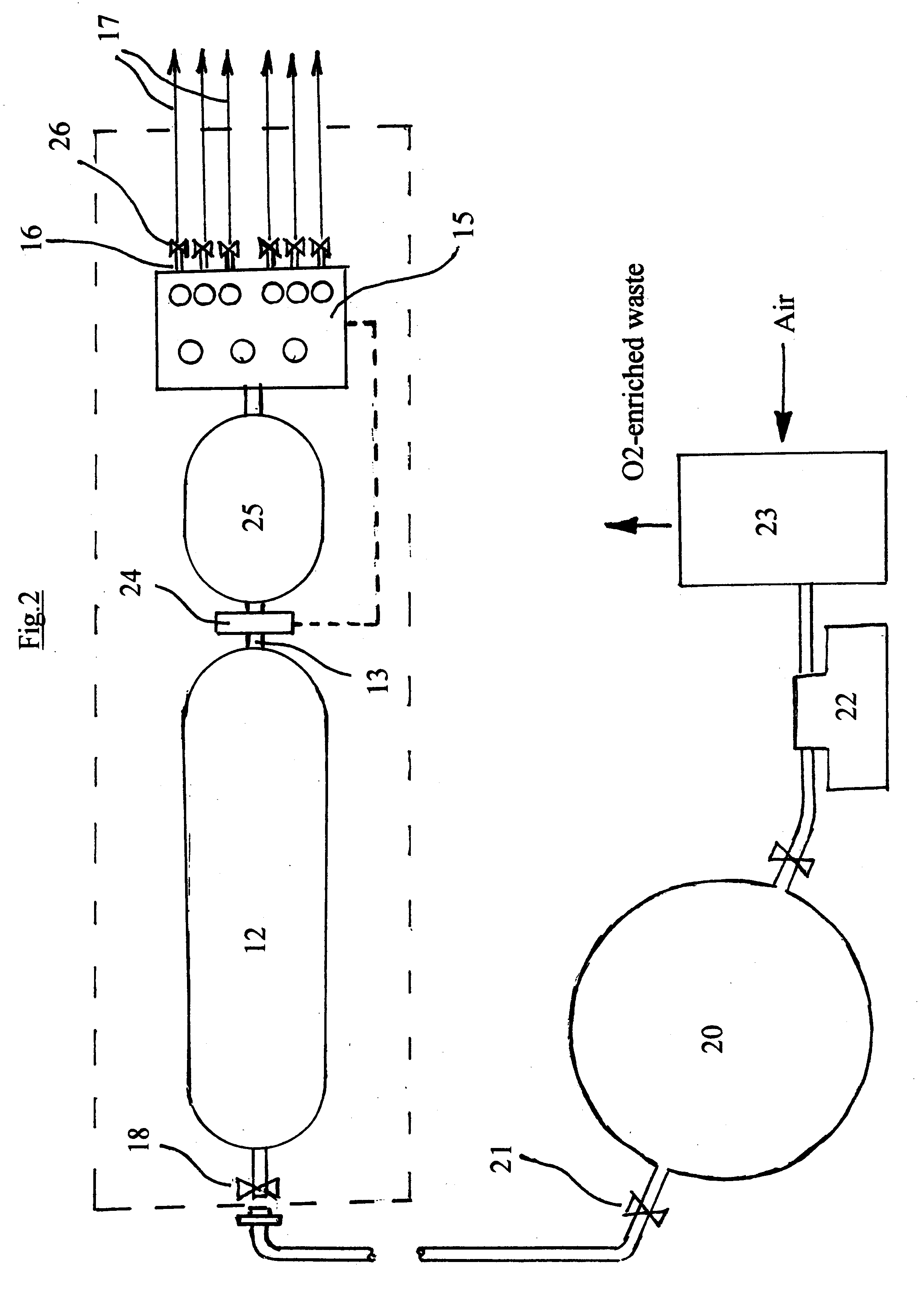

Mobile firefighting systems with breathable hypoxic fire extinguishing compositions for human occupied environments

Mobile fire-fighting systems and a method of producing breathable fire-suppression compositions are provided for extinguishing fires in buildings, and other human occupied structures, being also effective in suppressing fires under ruins of collapsed buildings. The systems employ a transportable high-pressure container having the breathable composition or nitrogen gas, or a liquid nitrogen container, vaporizer and a mixing chamber, wherein a vaporized nitrogen gas is mixed with an ambient air in order to produce said breathable fire-suppression composition. Refilling stations are provided for refilling the mobile systems with said composition, nitrogen gas or liquid nitrogen, all being generated at site from the ambient air. The method of producing said composition at a fire site employs mixing of nitrogen gas with ambient air or, alternatively, vaporizing of liquid nitrogen in necessary quantities and mixing it with ambient air in provided proportions. A method of delivery of the breathable fire-suppressive composition inside a building on fire is provided as well. The systems are also suitable for installation as a stationary fire-suppression system for a building or other structure. A breathable fire-suppression composition is provided for use in said mobile systems, said composition having an oxygen content below 16% or from 10% to 12% for the majority of civil applications.

Owner:FIREPASS CORP

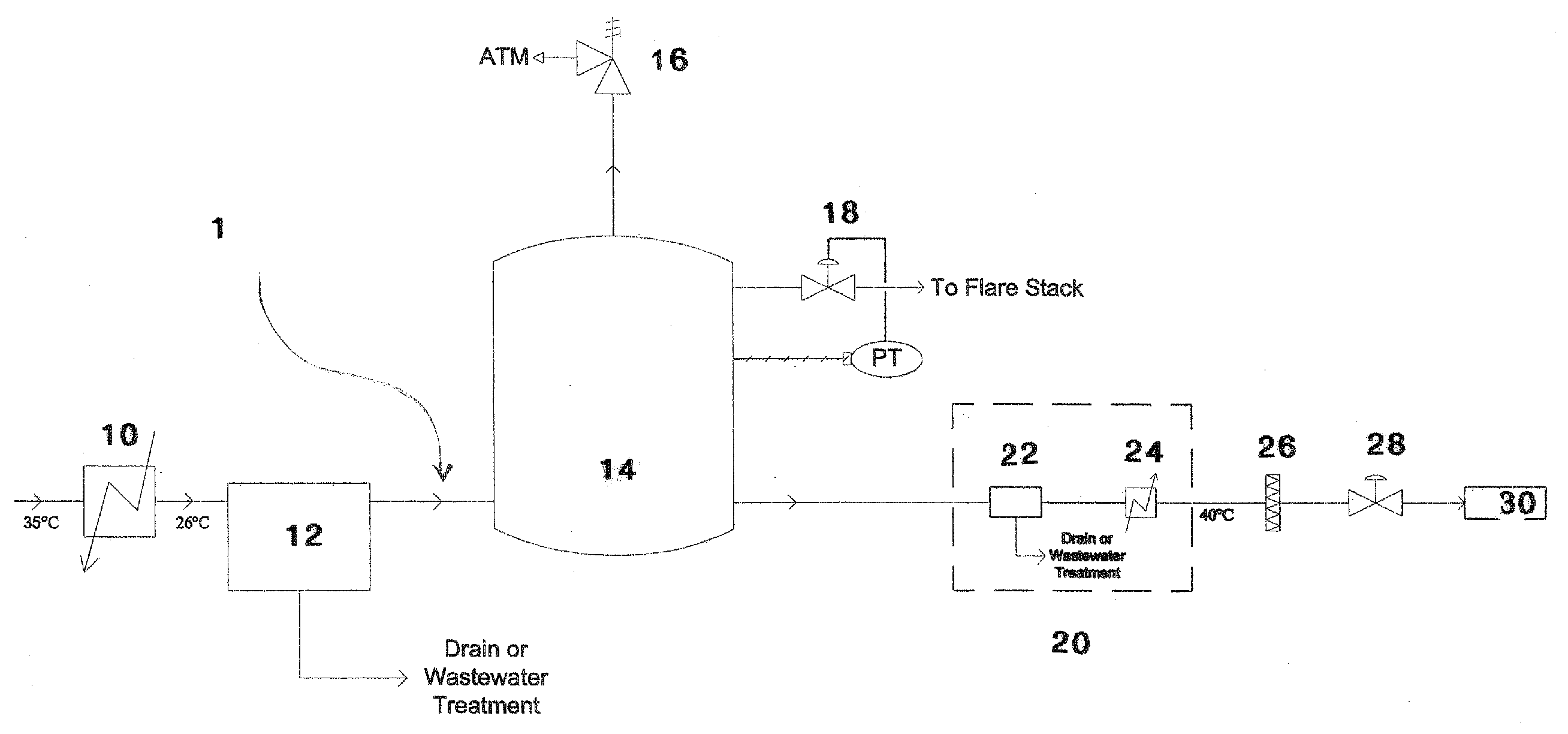

Gas Homogenization System

InactiveUS20070266632A1Satisfies requirementCombination devicesAuxillary pretreatmentChemical synthesisStream flow

A system and process for gas homogenization is disclosed. This has application in the areas of generation of gas and its conversion to electricity in downstream applications. The homogenization system minimizes variance in the gas characteristics (composition, flow, pressure, temperature), thereby rendering a steady stream of gas of consistent quality to the downstream machinery. This homogenization system can be adjusted to optimize the output gas stream for specific end-applications, or to optimize the output gas stream for different input feedstocks. This ensures that overall conversion efficiencies are maximised while keeping the process cost-effective. Such a uniform, steady output gas stream has a wide range of applications in the broad areas of generation of electricity (e.g. using internal combustion engines and combustion turbine engines), chemical synthesis (e.g. of compounds such as ethanol, methanol, hydrogen, methane, carbon monoxide, hydrocarbons), fuel-cell technologies and in polygeneration processes (processes that result in co-production of electricity and synthetic fuels).

Owner:PLASCO ENERGY GROUP INC

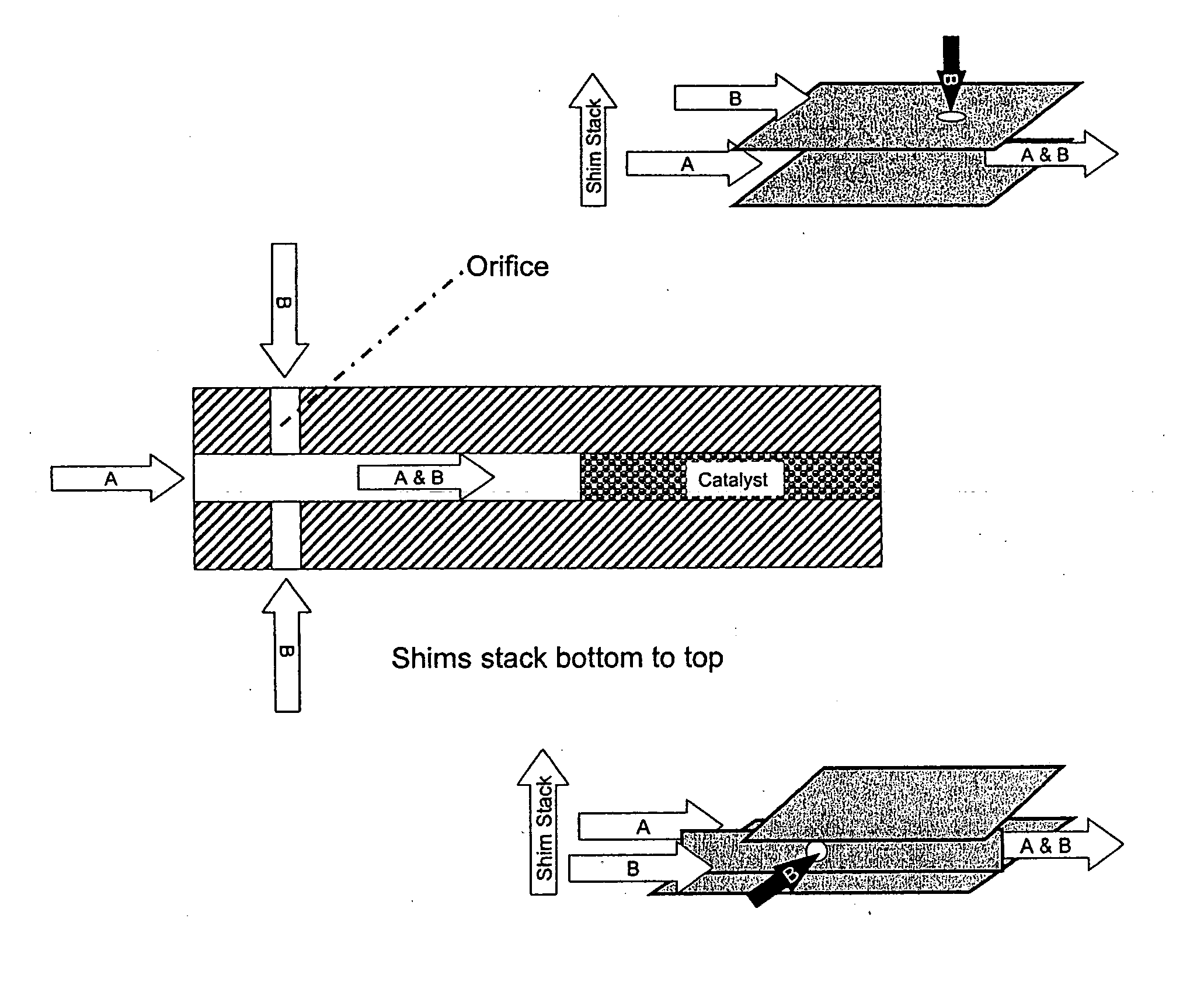

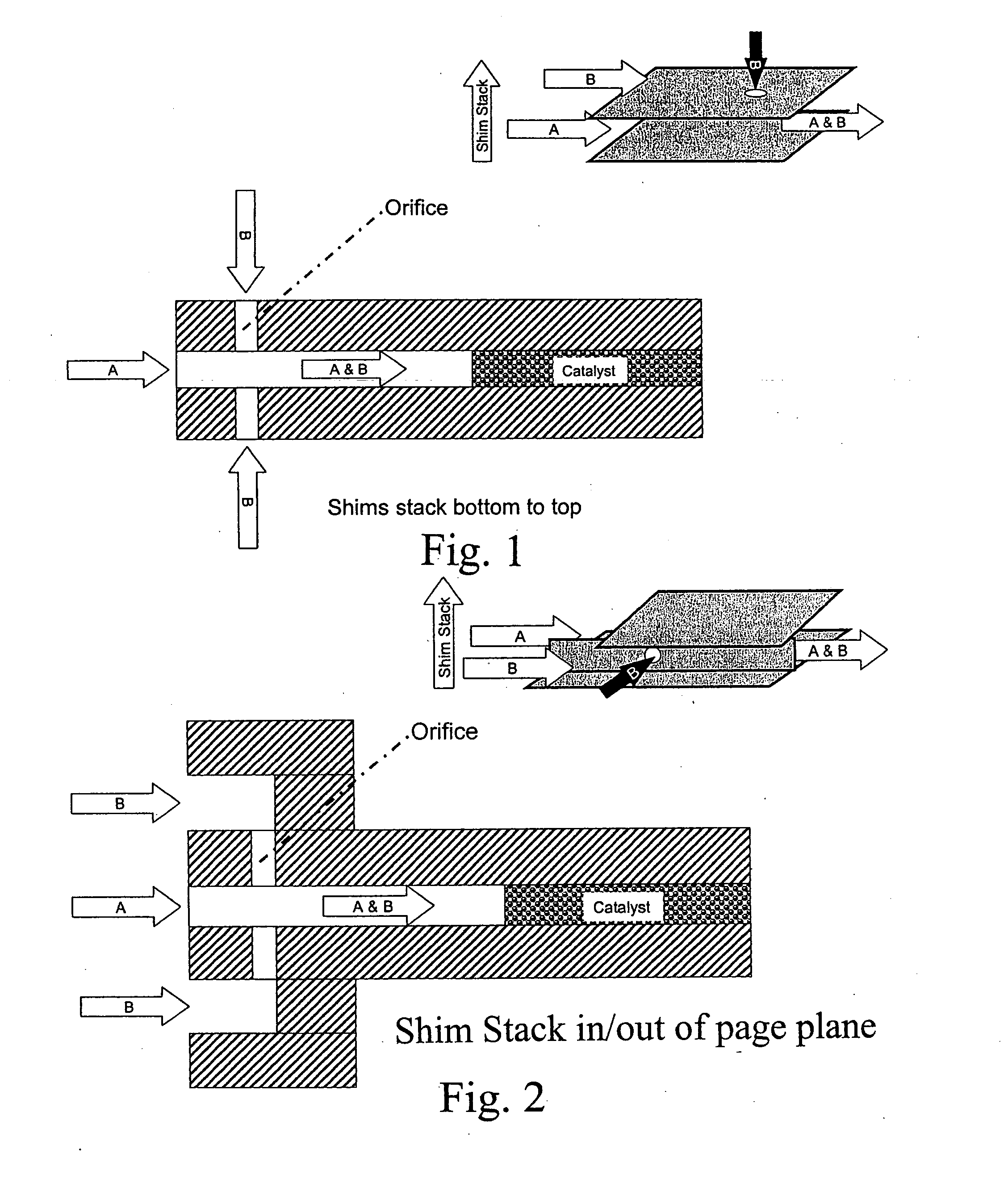

In situ mixing in microchannels

InactiveUS20050133457A1Reduce flammabilityImprove thermal conductivityPhysical/chemical process catalystsFlow mixersEngineering

Owner:VELOCYS CORPORATION

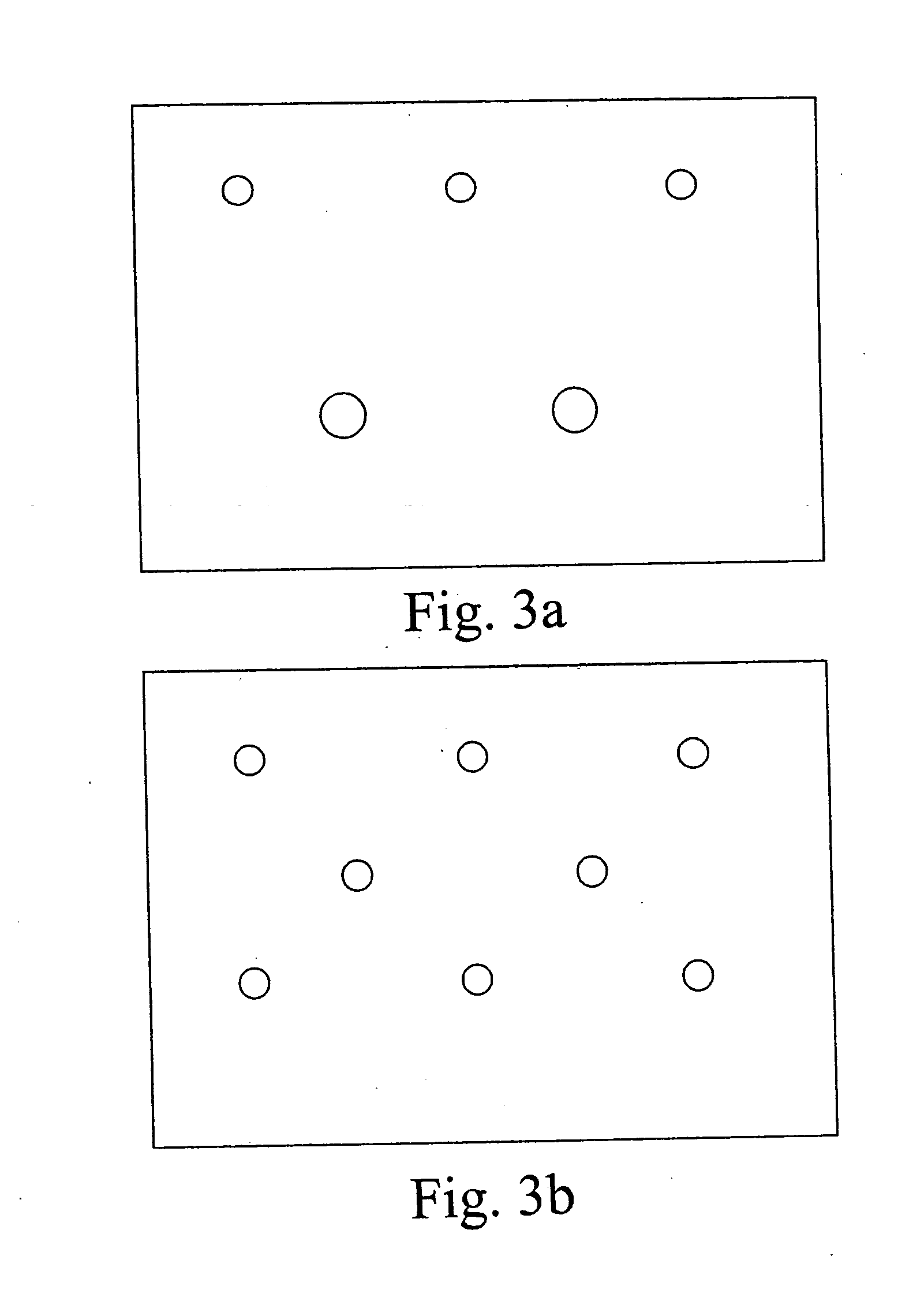

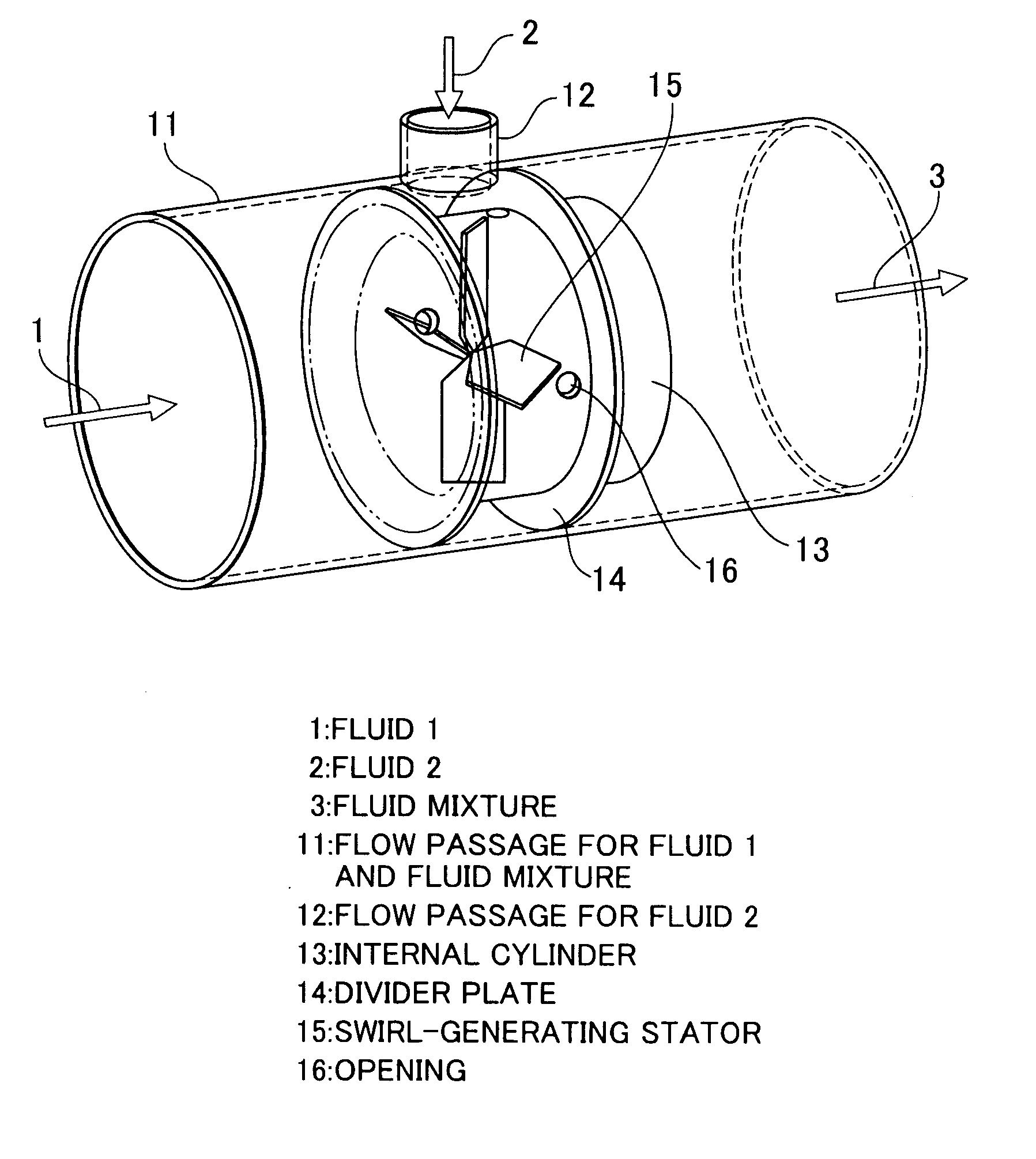

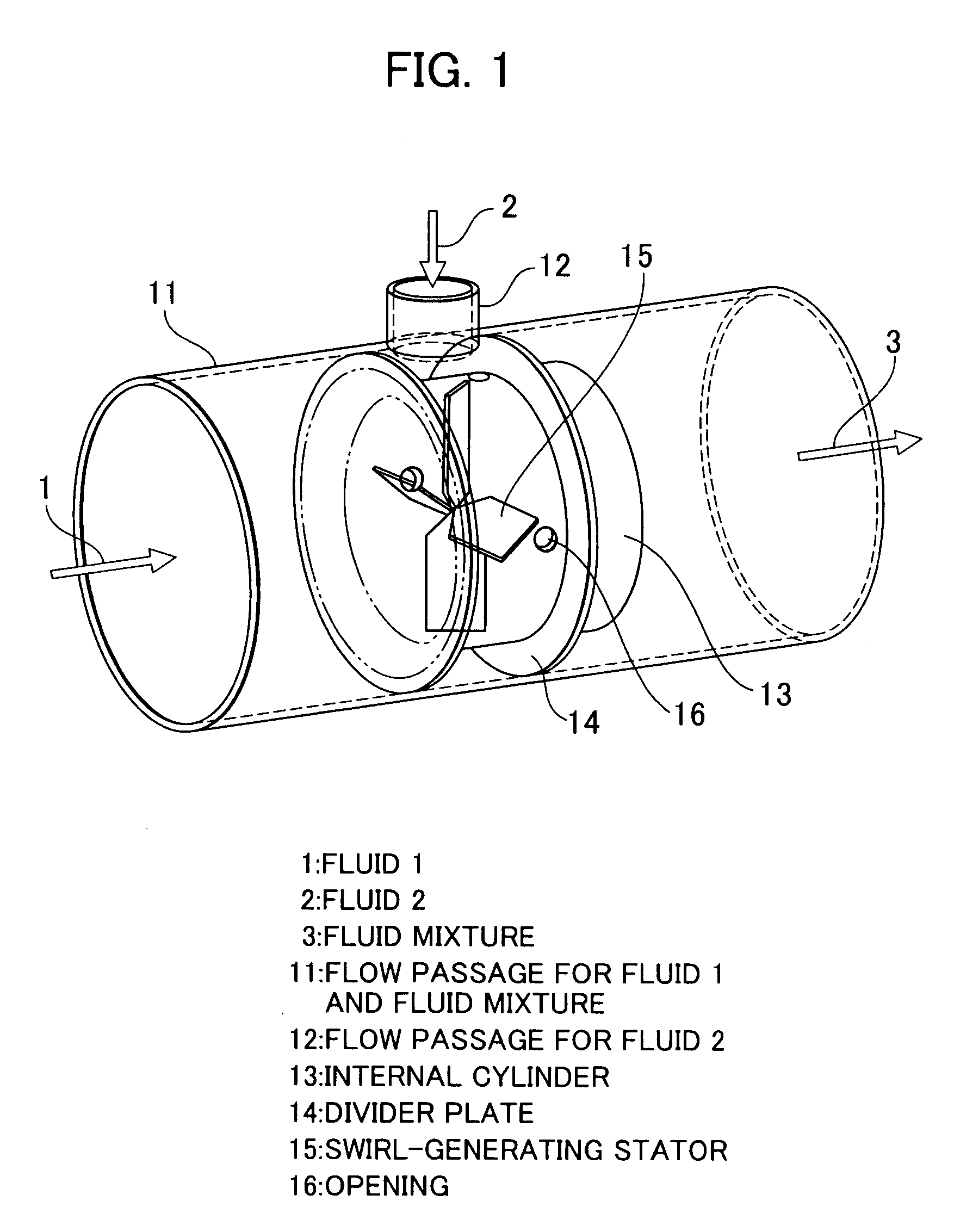

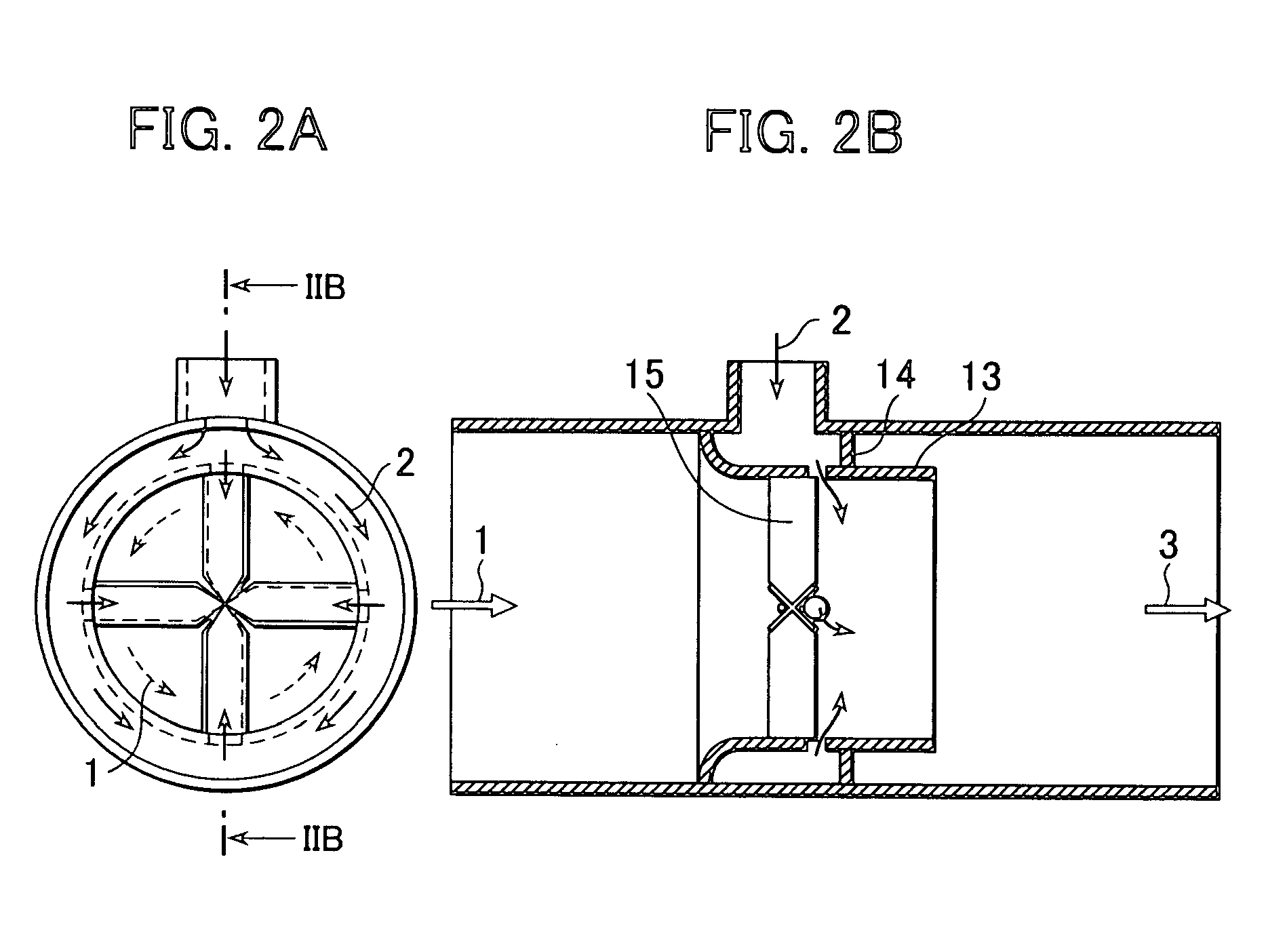

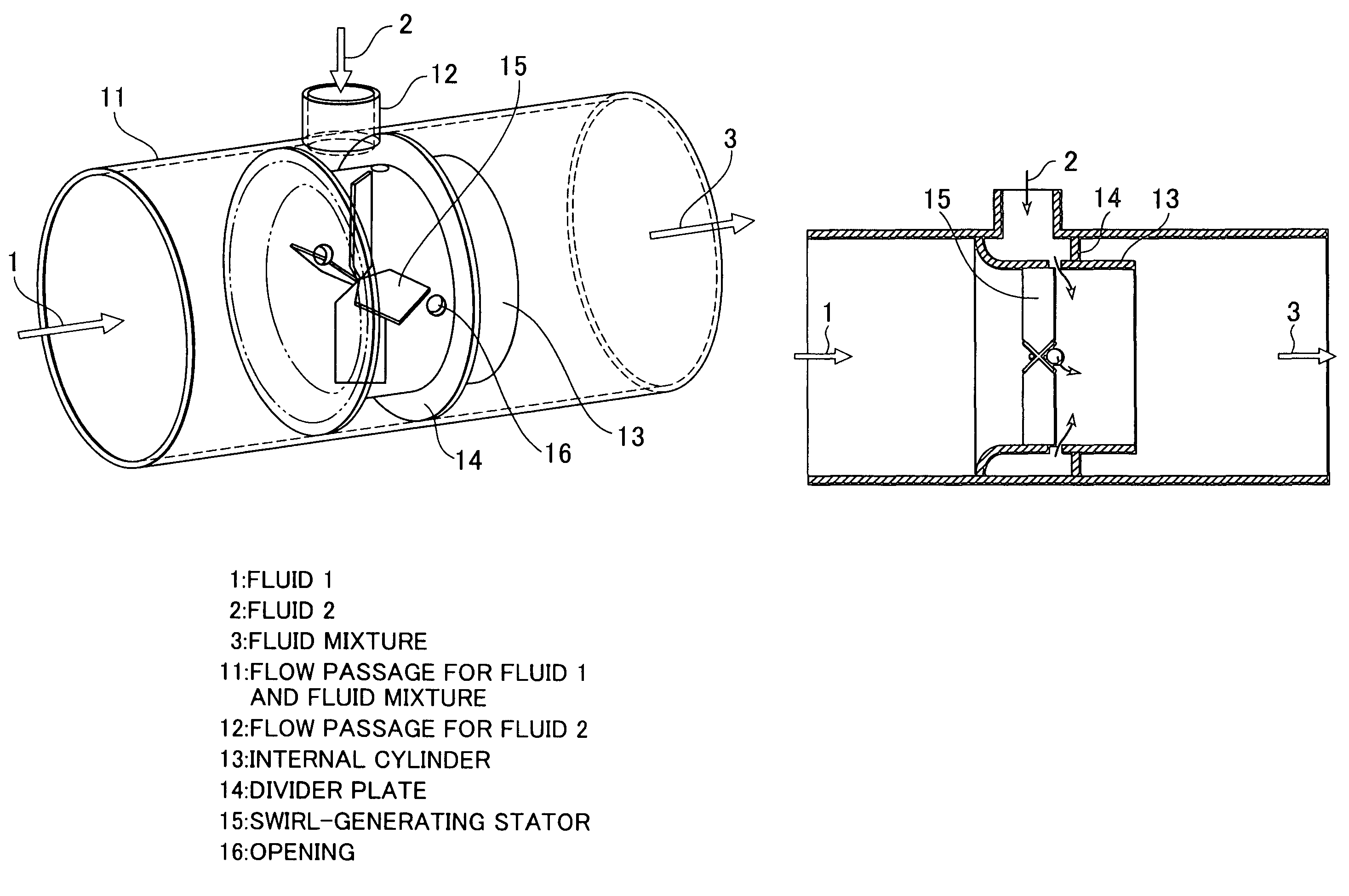

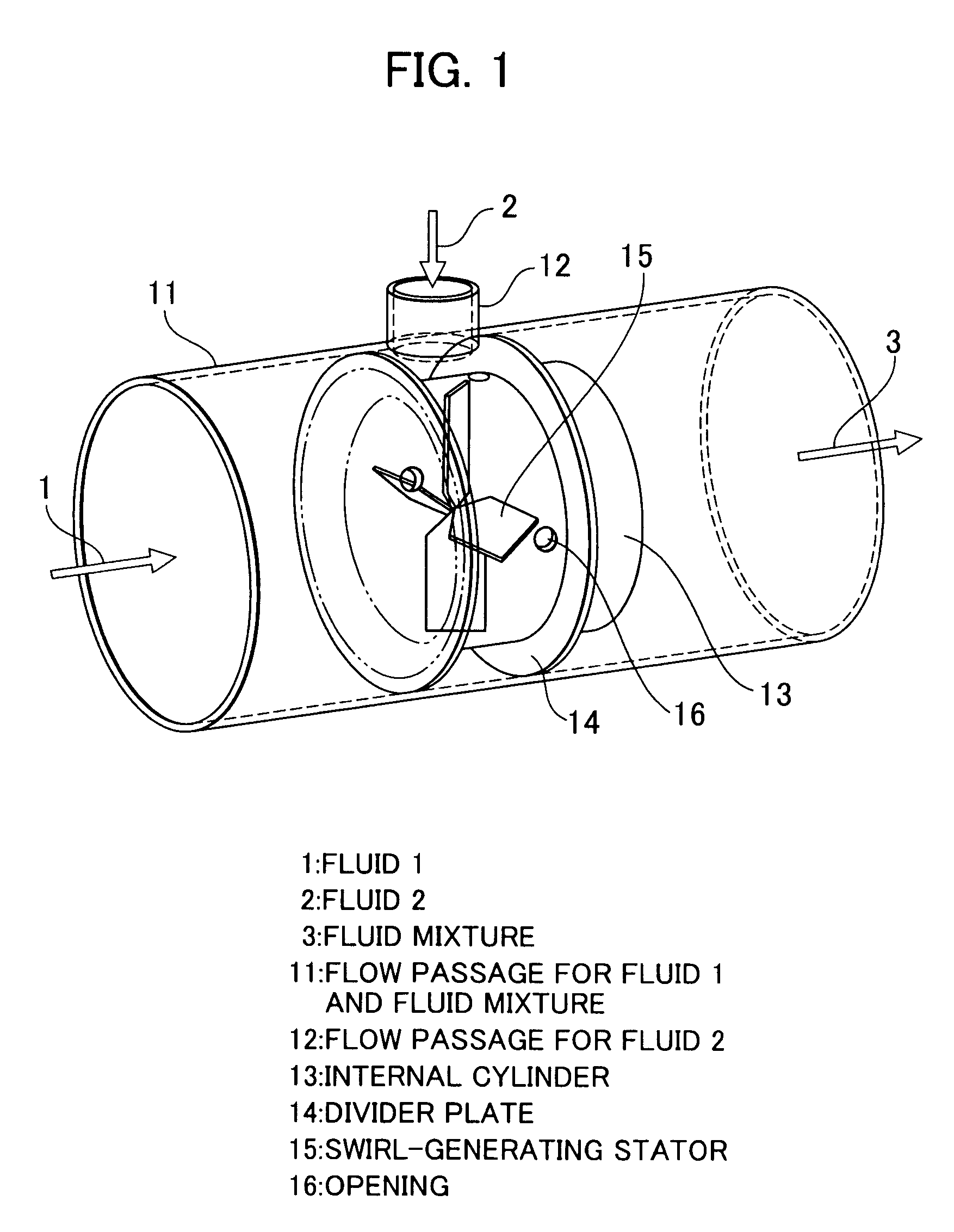

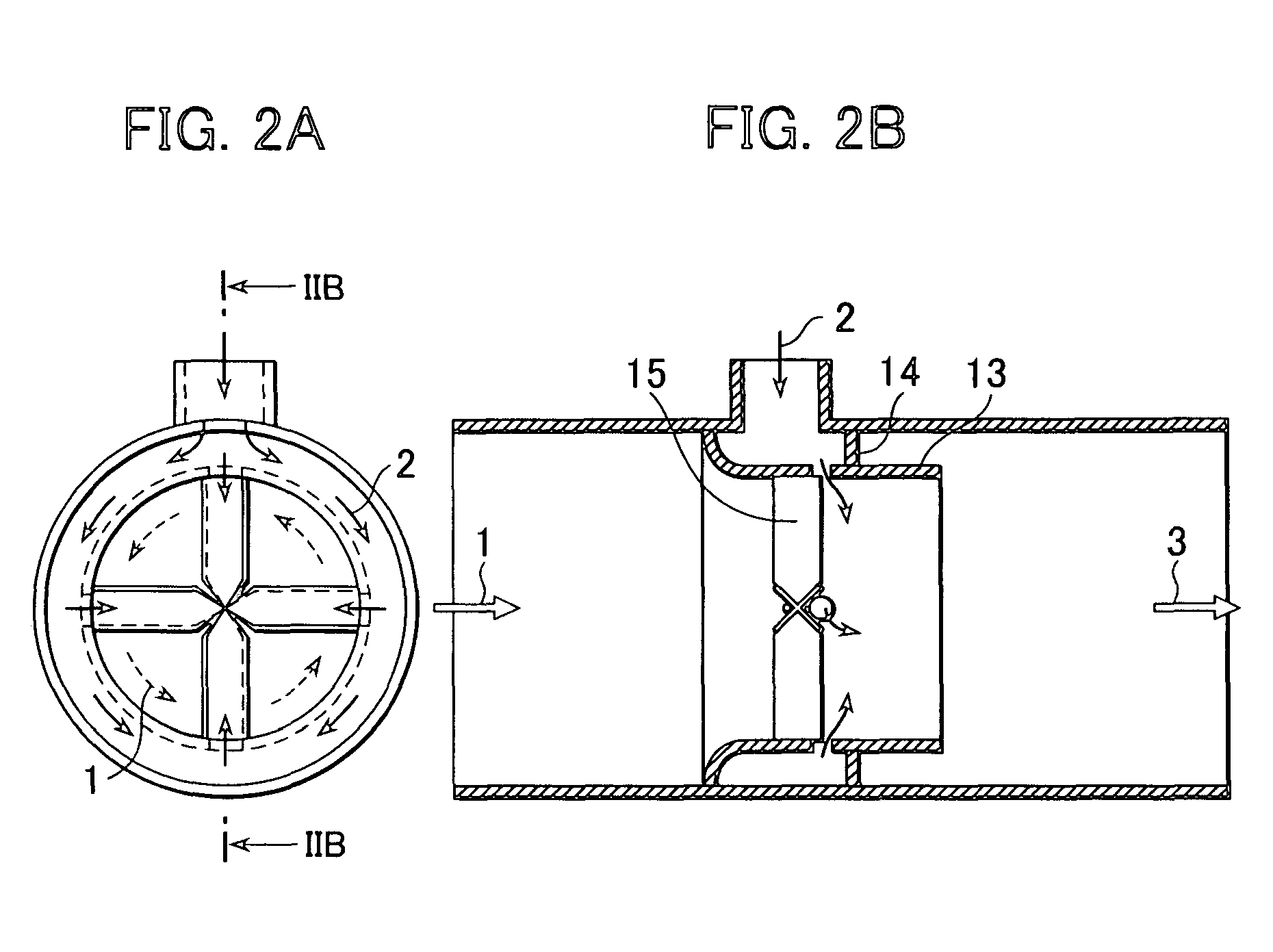

Fluid mixing apparatus

InactiveUS20060245296A1Suppress pressure lossWell mixedContinuous combustion chamberFlow mixersEngineeringFluid supply

A cylinder-shaped flow passage in which a first fluid flows includes an internal cylinder which is smaller in diameter than the flow passage. A swirl-generating stator having four vanes is radially fixed in the internal cylinder. A header space for supplying a second fluid is provided to the outer circumference of a wall surface of the internal cylinder in contact with flow separation areas which are formed along downstream surfaces of the swirl-generating stator as the first fluid runs into the swirl-generating stator. The wall surface of the internal cylinder is formed with openings through which the flow separation areas communicate with the header space. The second fluid supplied into the header space flows through the openings into the flow separation areas, and is diffused along the vanes of the swirl-generating stator to be swirled and mixed into the first fluid applied with swirling force by the swirl-generating stator.

Owner:HITACHI HIGH-TECH CORP +1

Fluid mixing apparatus

InactiveUS8033714B2Suppress pressure lossWell mixedContinuous combustion chamberFlow mixersEngineeringFluid supply

A cylinder-shaped flow passage in which a first fluid flows includes an internal cylinder which is smaller in diameter than the flow passage. A swirl-generating stator having four vanes is radially fixed in the internal cylinder. A header space for supplying a second fluid is provided to the outer circumference of a wall surface of the internal cylinder in contact with flow separation areas which are formed along downstream surfaces of the swirl-generating stator as the first fluid runs into the swirl-generating stator. The wall surface of the internal cylinder is formed with openings through which the flow separation areas communicate with the header space. The second fluid supplied into the header space flows through the openings into the flow separation areas, and is diffused along the vanes of the swirl-generating stator to be swirled and mixed into the first fluid applied with swirling force by the swirl-generating stator.

Owner:HITACHI HIGH-TECH CORP +1

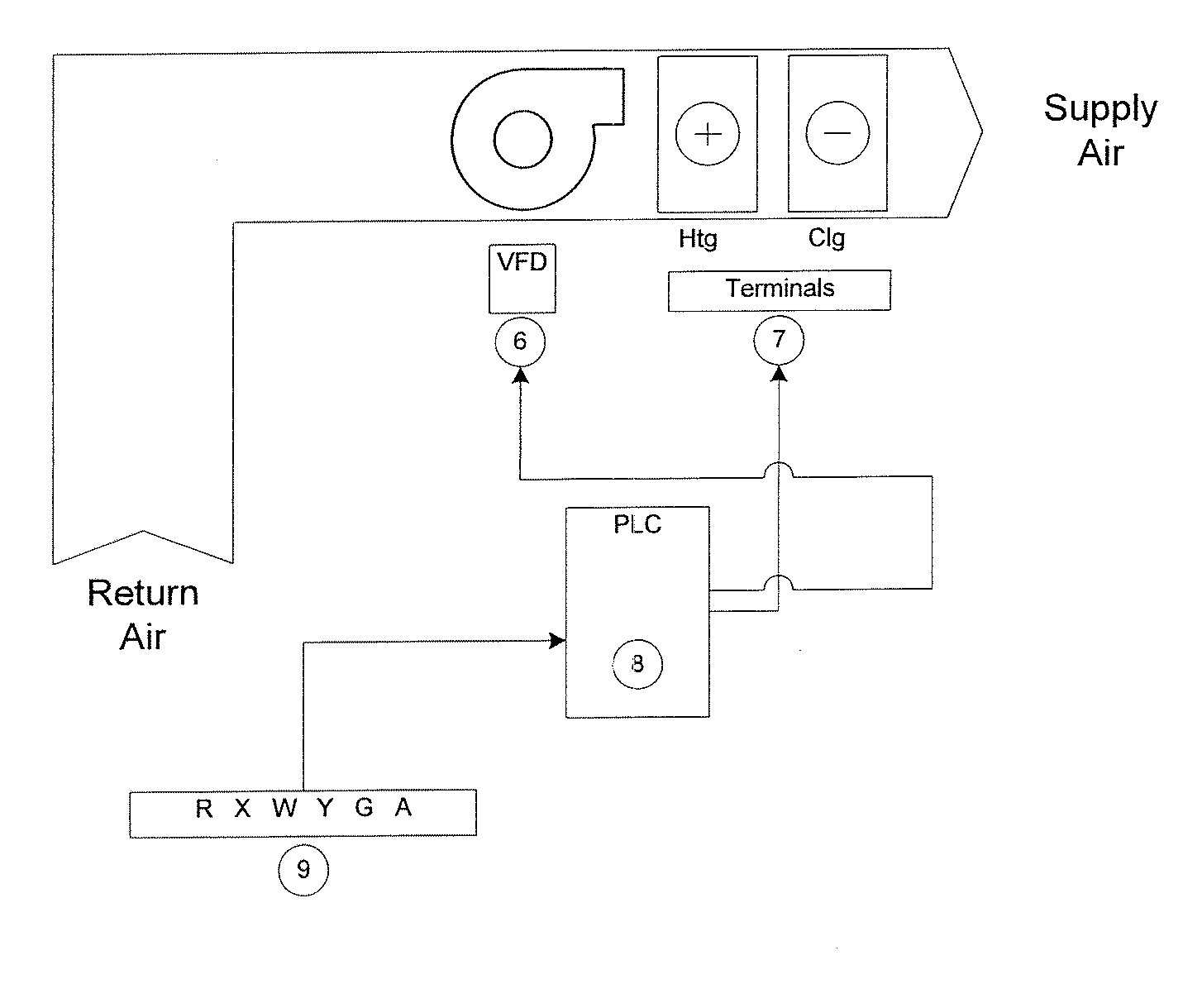

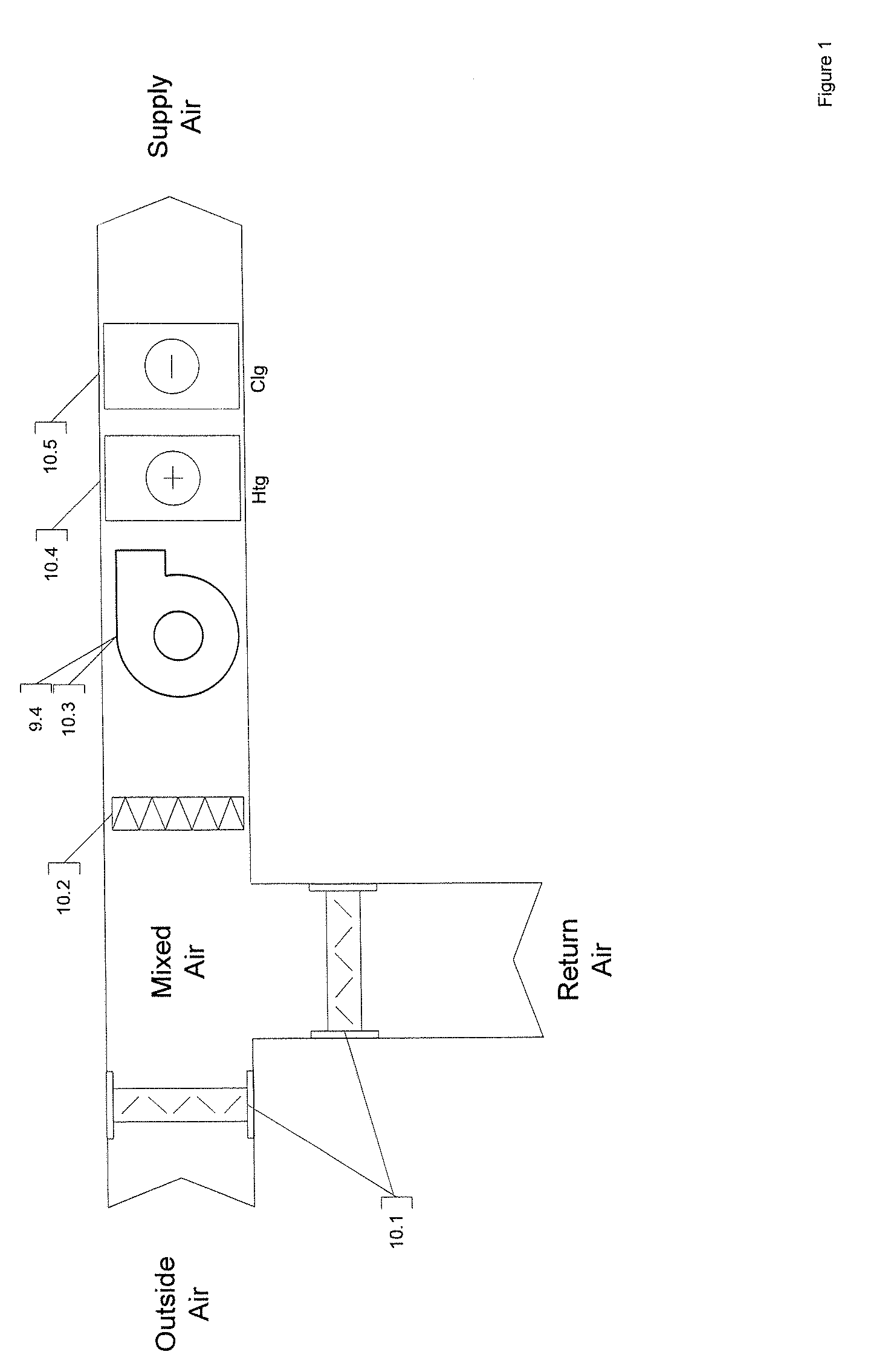

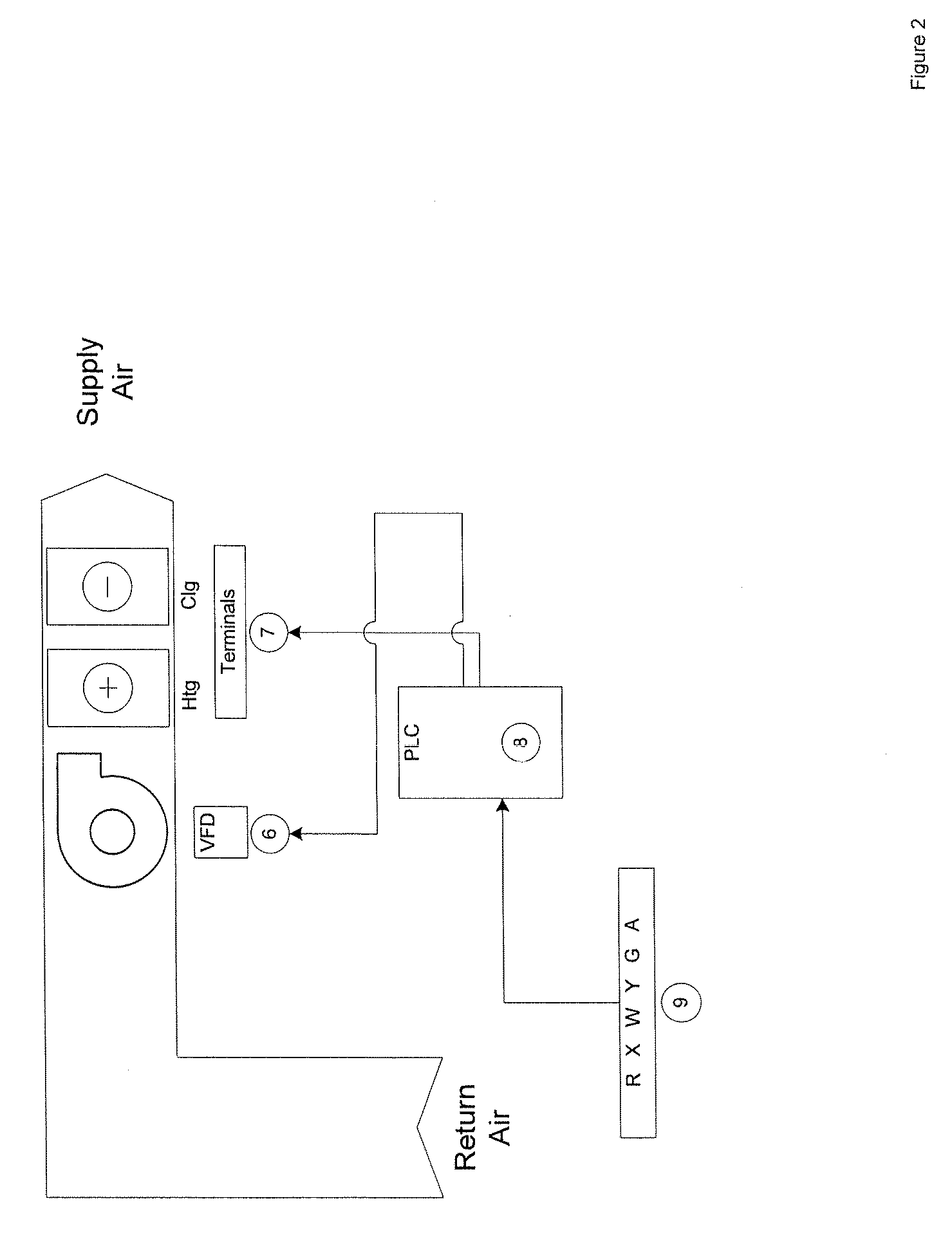

Energy reducing retrofit method and apparatus for a constant volume HVAC system

ActiveUS20110046790A1Match occupancy needReduce motor speedLevel controlSpace heating and ventilationProgrammable logic controllerFree cooling

An energy-reducing method and apparatus for retrofitting a constant volume HVAC system, with or without an economizer, that provides heating, cooling, and ventilation to occupants within a building space. The present invention includes the introduction of a programmable logic controller and variable frequency drive (VFD) that takes control of the existing fan, heating, cooling, and optional economizer operation. The controller is programmed for the reduction of fan speed in the heating and cooling modes. The reduction of the fan speed in the ventilation mode when the 100% operation is not needed saves significant energy of the existing constant volume HVAC system where the fan motor is designed to run 100% of the time. The fan speed may be further reduced upon a reduction in sensed occupancy levels of the space, such as with a CO2 sensor. Additionally, the fan speed may be reduced in the heating and / or cooling mode to further reduce energy consumption. The controller may also be programmed and equipped with sensors to allow simultaneous mechanical compressor cooling and economizer free cooling operation, for the operation of the economizer in response to the monitoring of outside air and return air to determine the preferred source for cooling operations, to keep the outside air damper closed during the unoccupied heating modes such as morning warm-up, and / or to provide fault detection. The retrofit method and apparatus may be employed in a stand-alone or networked version.

Owner:PRO STAR ENERGY SOLUTIONS LP

Static mixer and exhaust gas treatment device

InactiveUS20070204751A1Design economyIntense mixing effect and vaporization effectInternal combustion piston enginesFlow mixersExhaust fumesEngineering

The invention relates to a static mixer for an exhaust system of an internal combustion engine. The mixer has a wall structure that is arranged across the directional of flow in a pipe and has several layers of a corrugated sheeting material laying across one another in the direction of flow. The cells through which the flow can pass in the direction of flow are provided between the sheeting material of neighboring layers. The sheeting material has baffles for all or several of the cells. The baffles are arranged on the sheeting material so that they are arranged on their outgoing flow side in the case of said cells and extend in the direction of flow and across it.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

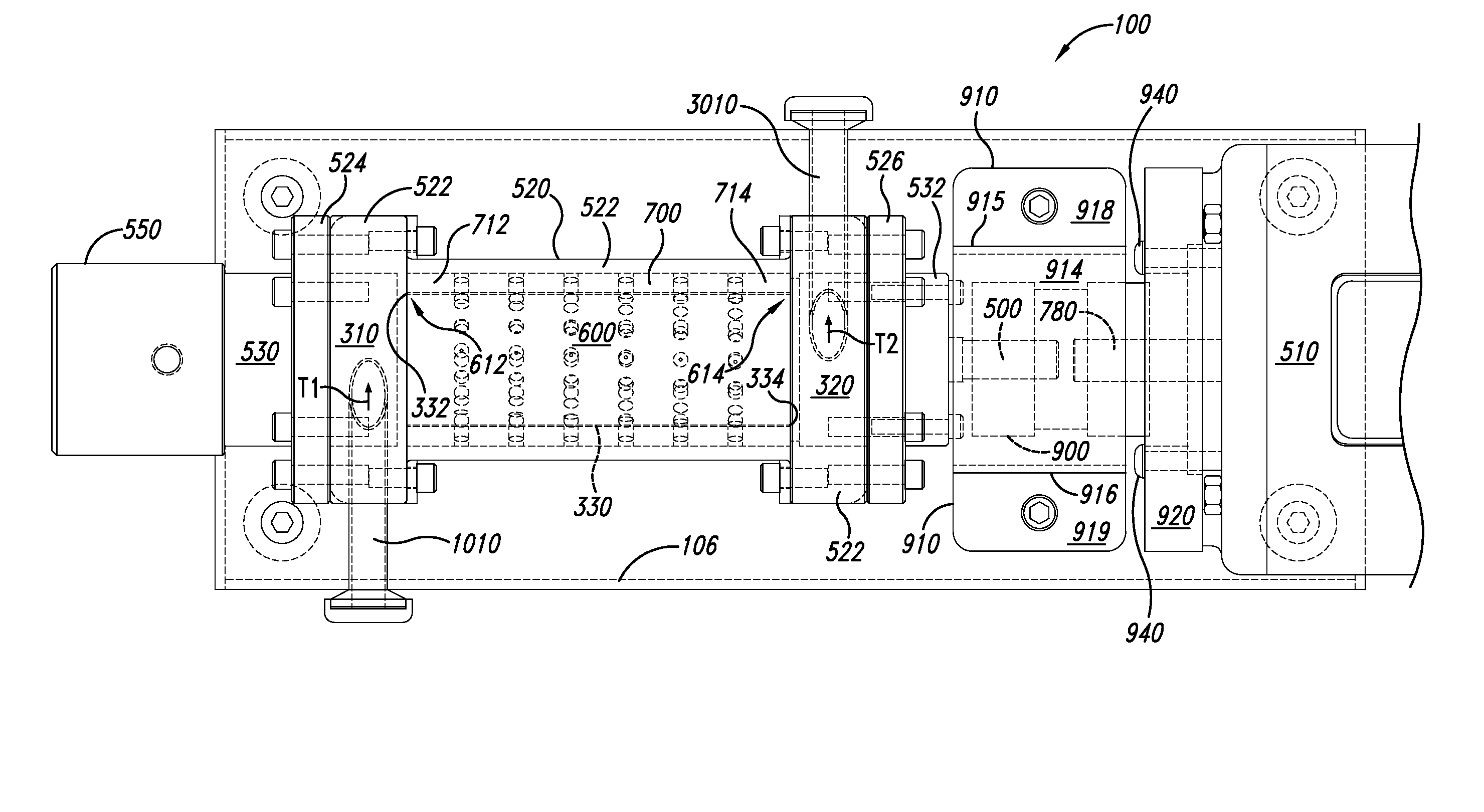

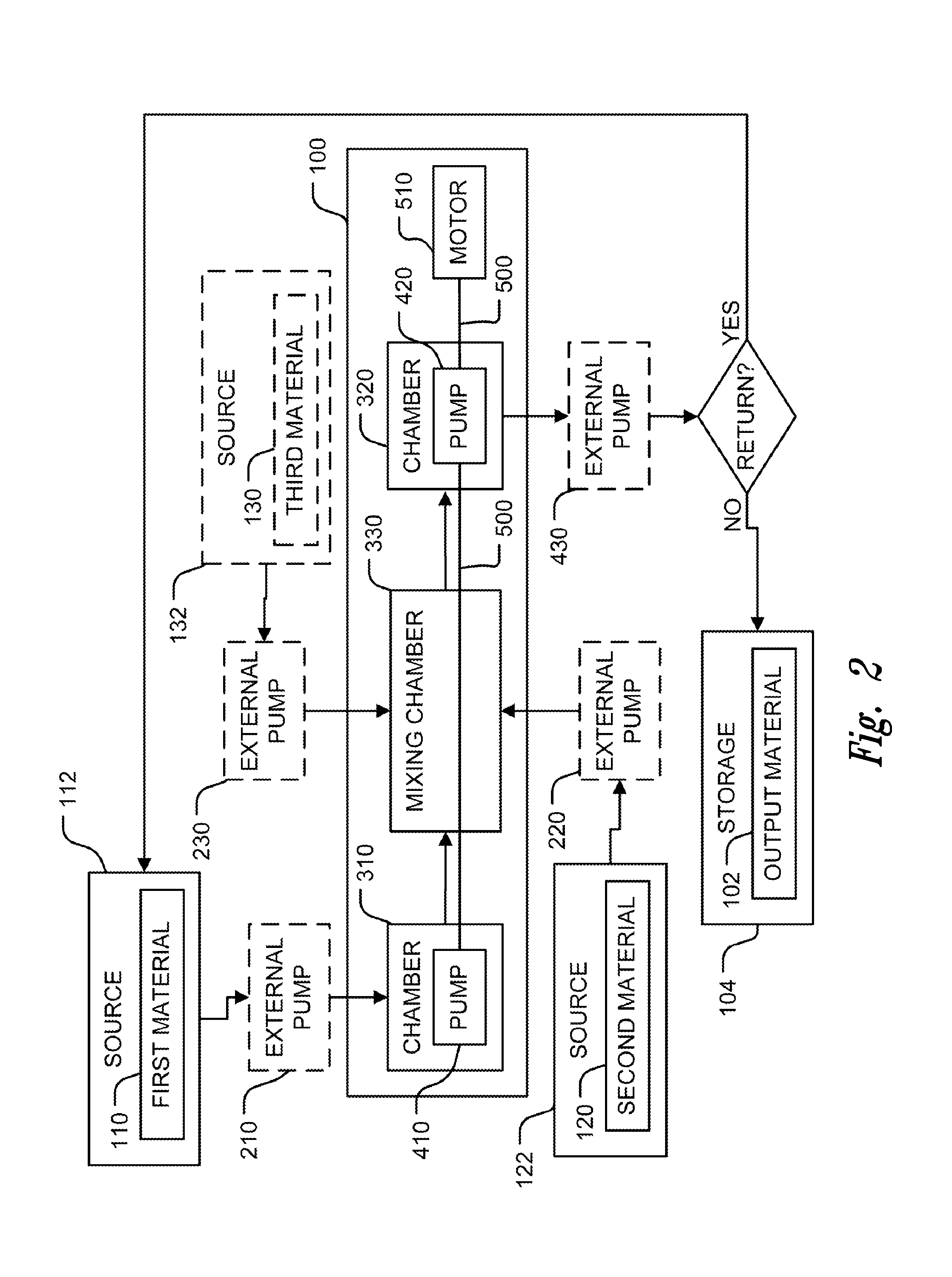

Mixing device

ActiveUS20080219088A1Bioreactor/fermenter combinationsSenses disorderEngineeringMechanical engineering

A mixing device for mixing a first and second material together to create an output mixture. The device includes a first chamber containing the first material coupled to a mixing chamber defined between a rotor and a stator. The rotor is disposed inside the stator and rotates therein about an axis of rotation. The first chamber houses an internal pump configured to pump the first material from the first chamber into the mixing chamber. The pump may be configured to impart a circumferential velocity into the first material before it enters the mixing chamber. At least one of the rotor and stator have a plurality of through-holes through which the second material is provided to the mixing chamber. Optionally, a second chamber is coupled to the mixing chamber. The second chamber may house an internal pump configured to pump the output material from the mixing chamber into the second chamber.

Owner:REVALESIO CORP

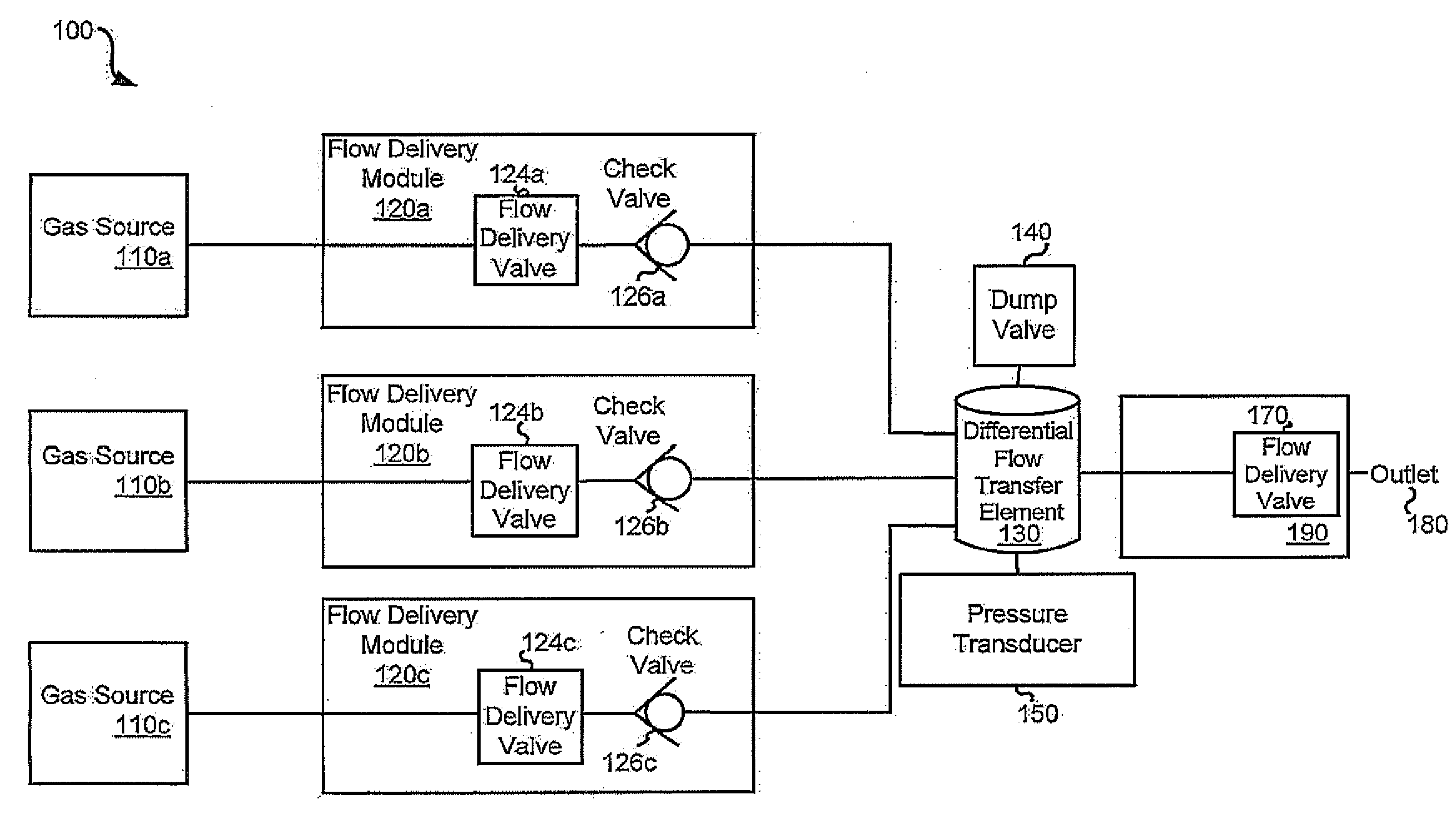

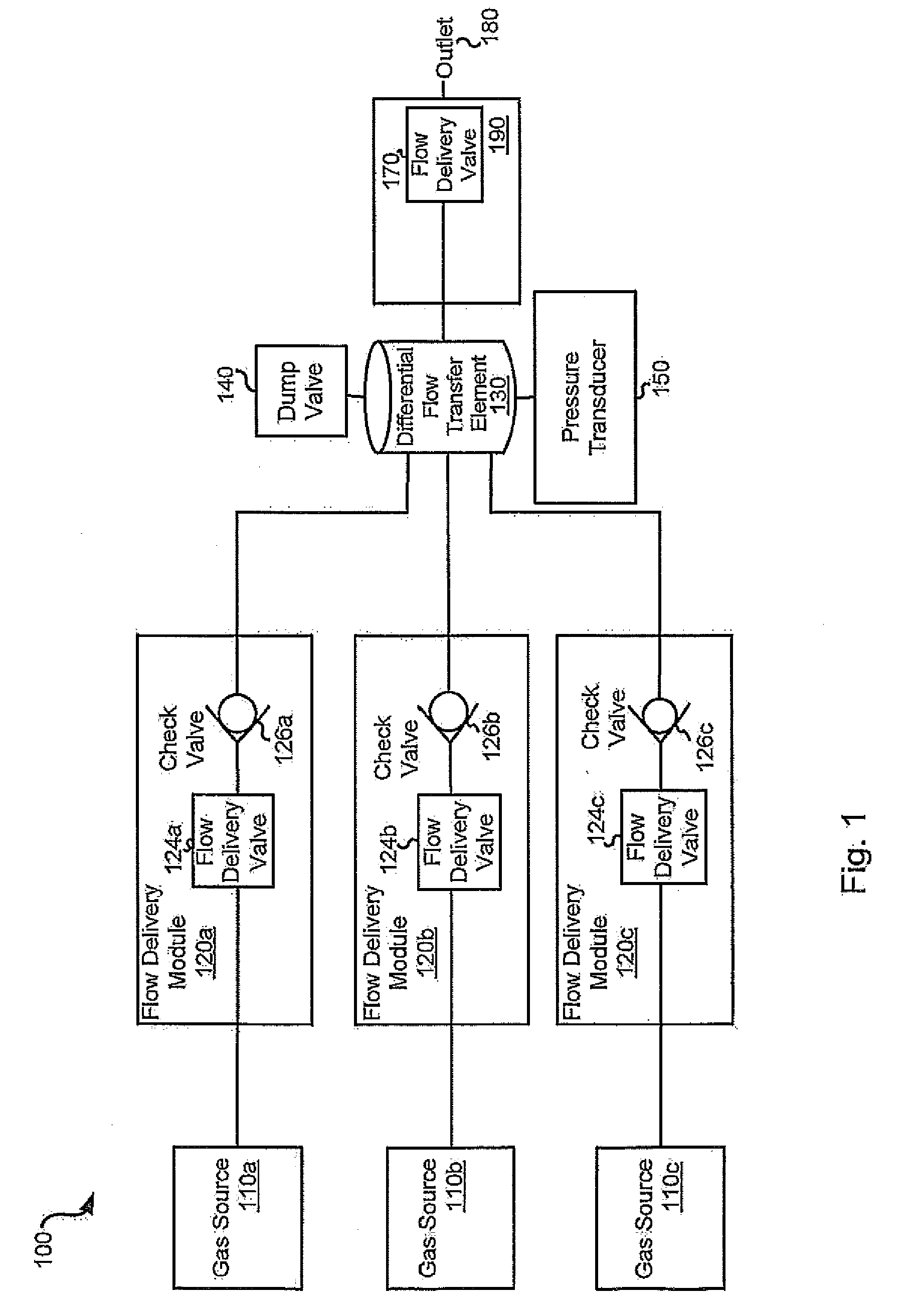

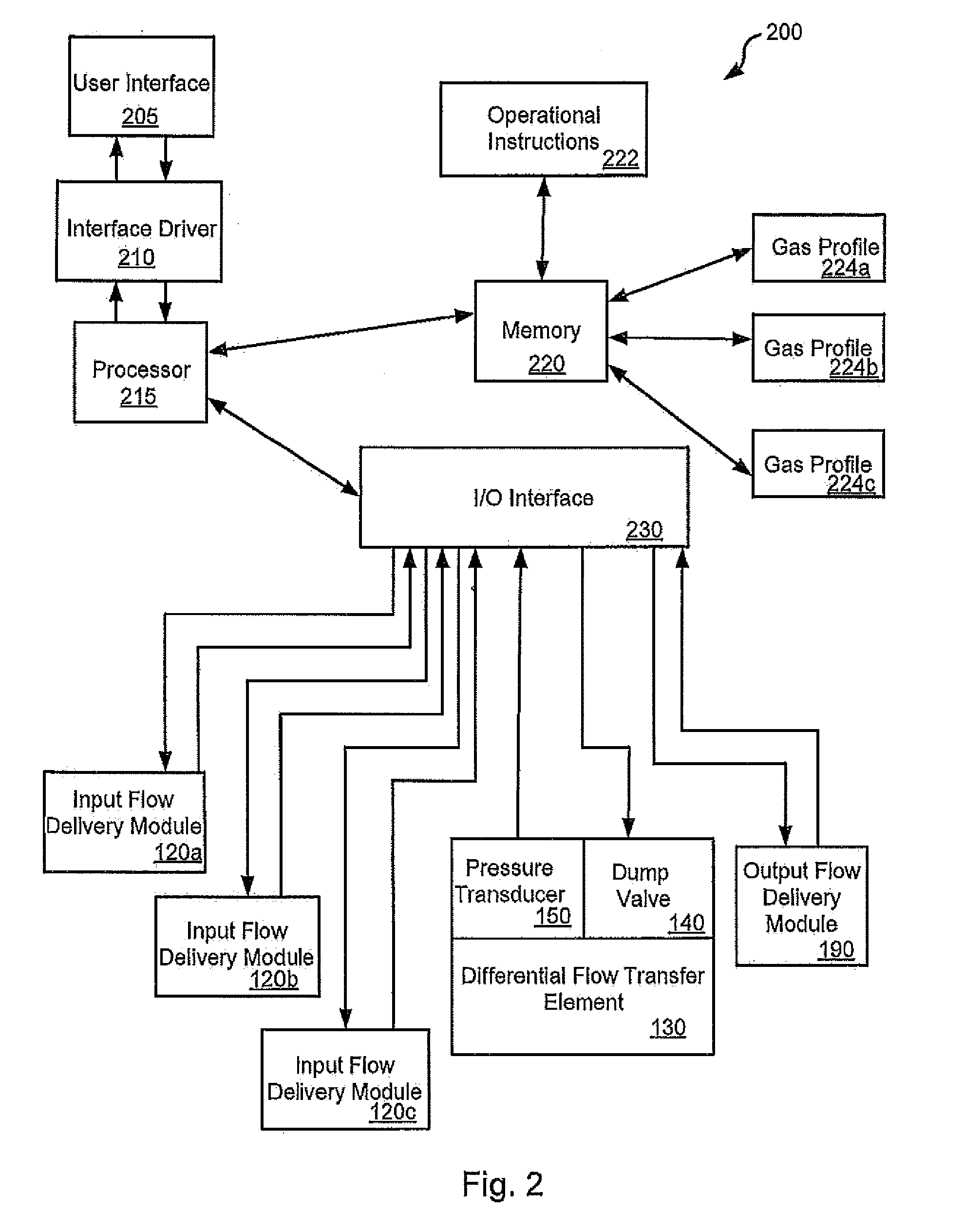

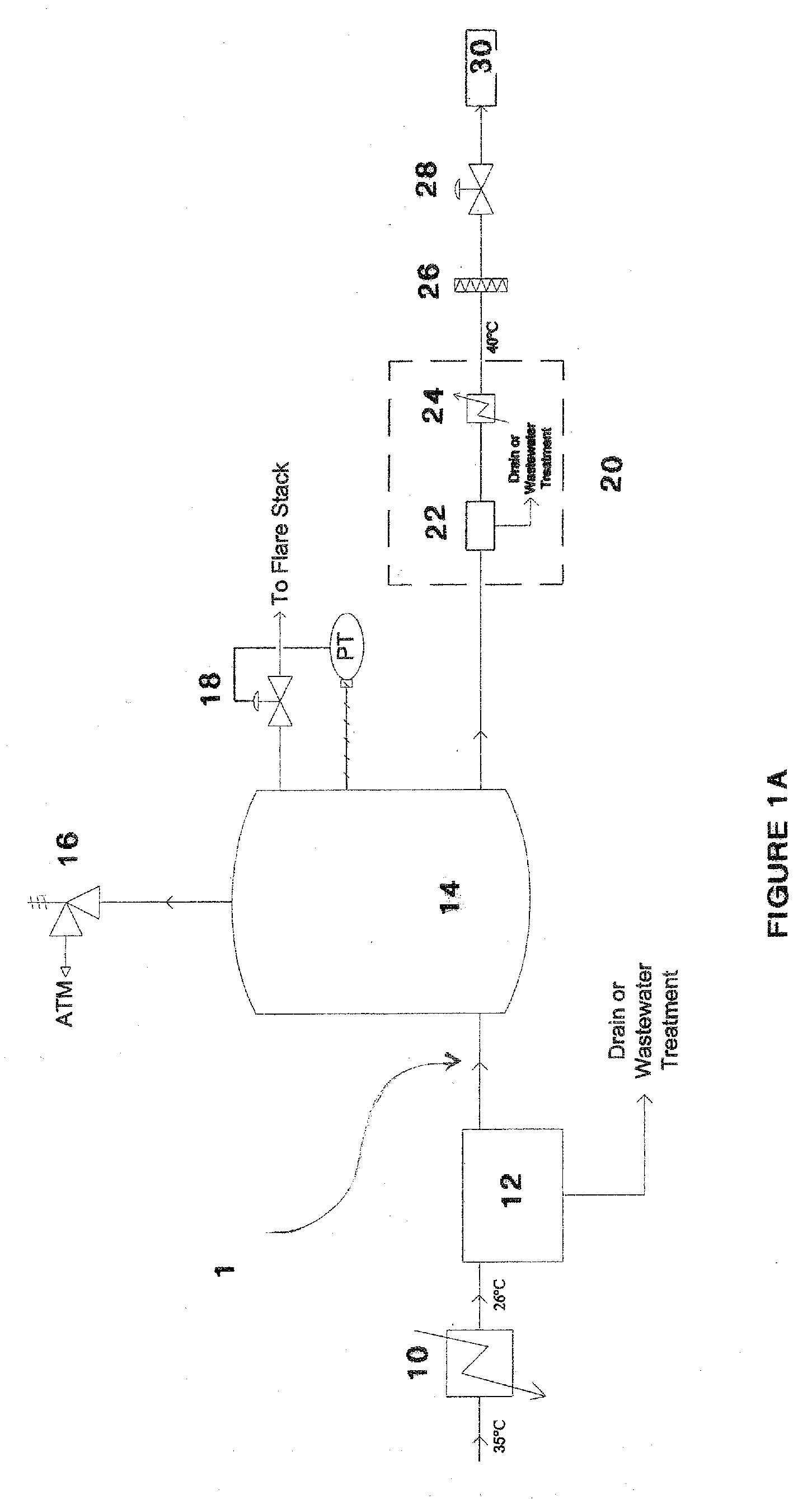

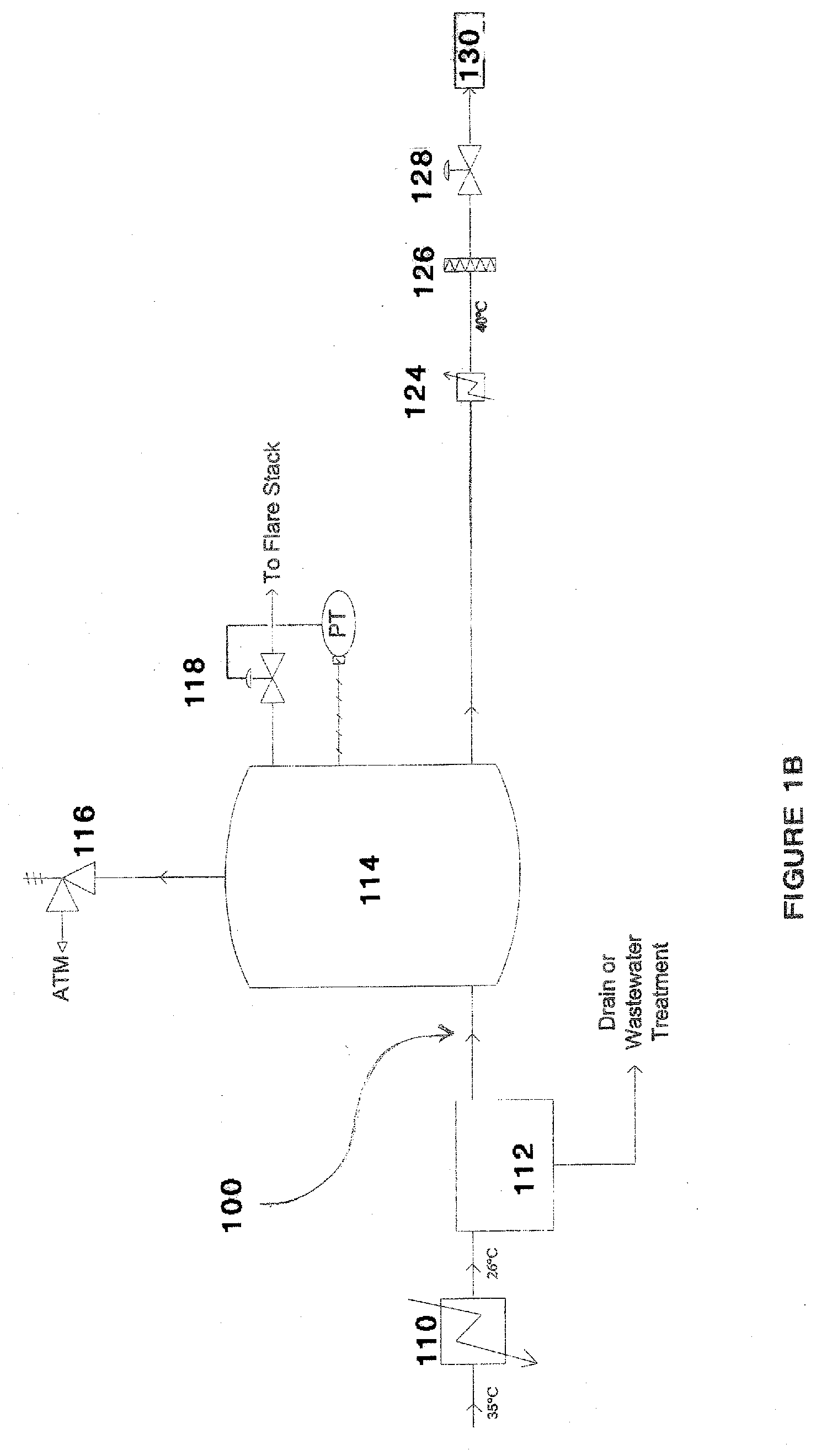

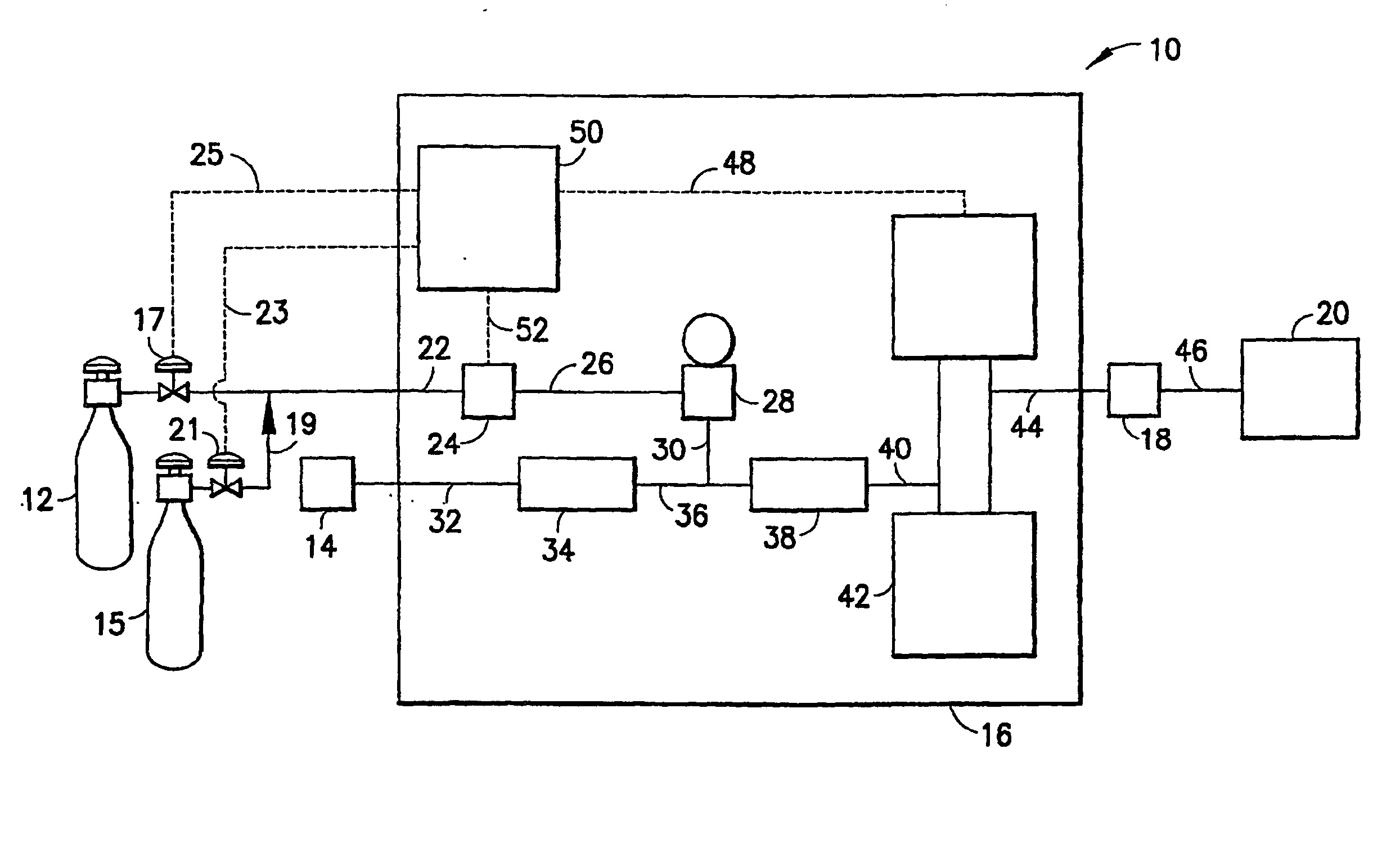

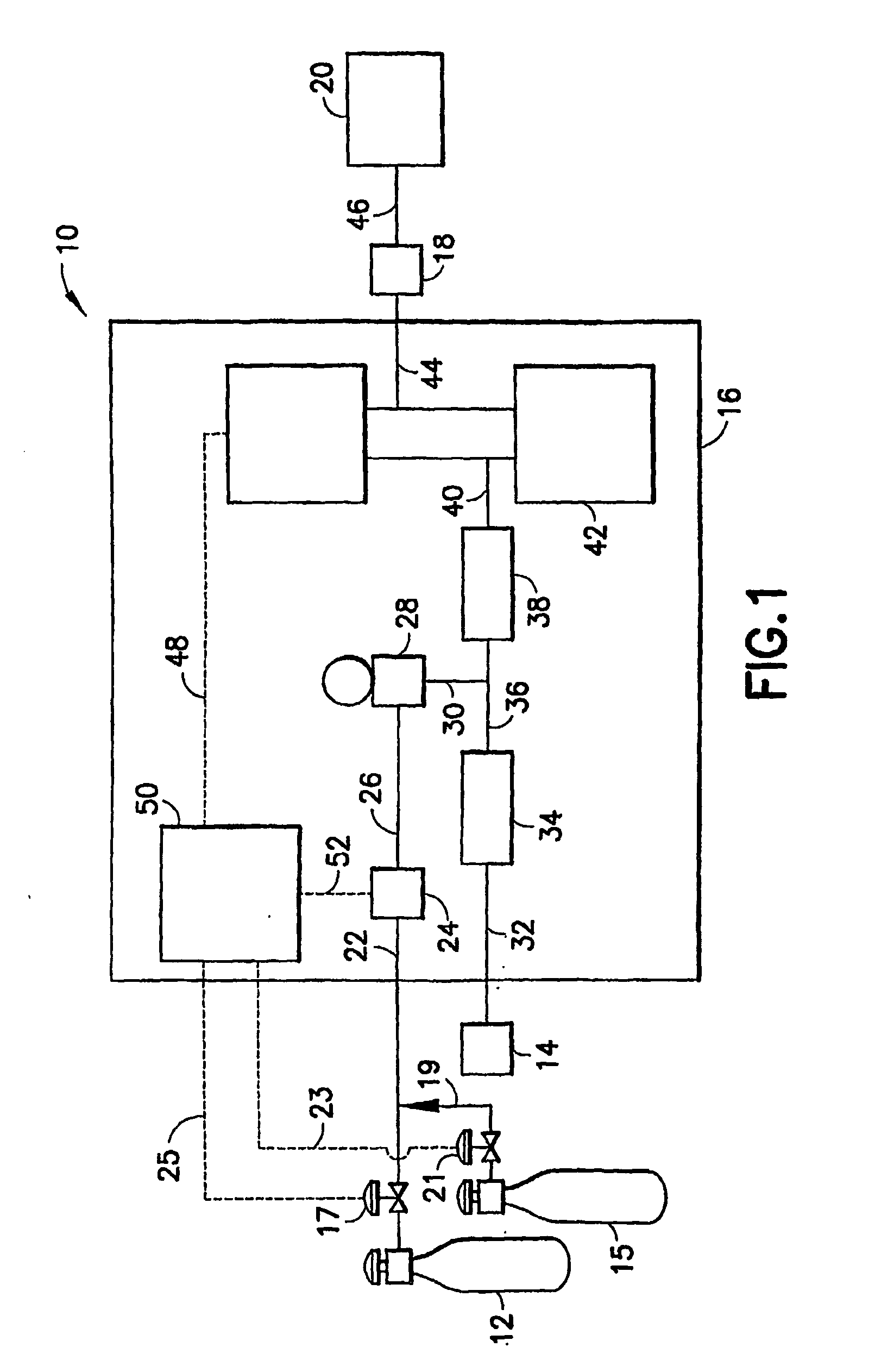

Apparatus and process for integrated gas blending

InactiveUS20100224264A1Keep the pressureFrozen sweetsSemiconductor/solid-state device manufacturingDiluentEngineering

A system (10) for delivery of dilute fluid, utilizing an active fluid source (12), a diluent fluid source (14), a fluid flow metering device (24) for dispensing of one of the active and diluent fluids, a mixer (28) arranged to mix the active and diluent fluids to form a diluted active fluid mixture, and a monitor (42) arranged to sense concentration of active fluid and / or diluent fluid in the diluted active fluid mixture, and responsively adjust the fluid flow metering device (24) to achieve a predetermined concentration of active fluid in the diluted active fluid mixture. A pressure controller (38) is arranged to control flow of the other of the active and diluent fluids so as to maintain a predetermined pressure of the diluted active fluid mixture dispensed from the system. The fluid dispensed from the system then can be adjustably controlled by a flow rate controller, e.g., a mass flow controller, to provide a desired flow to a fluid-utilizing unit, such as a semiconductor process tool. An end point monitoring assembly is also described, for switching fluid sources (12, 15) to maintain continuity of delivery of the diluted active fluid mixture.

Owner:ENTEGRIS INC

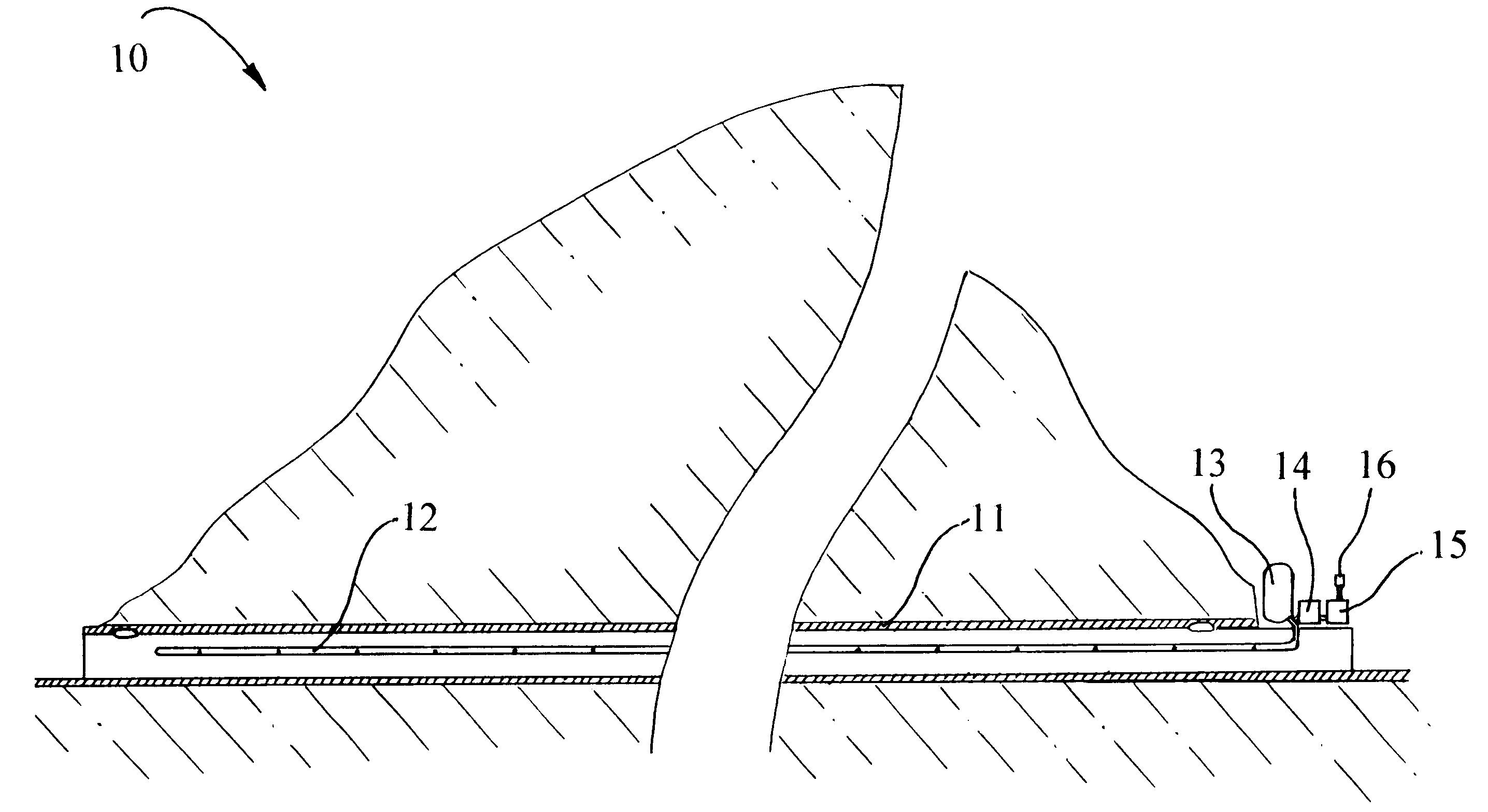

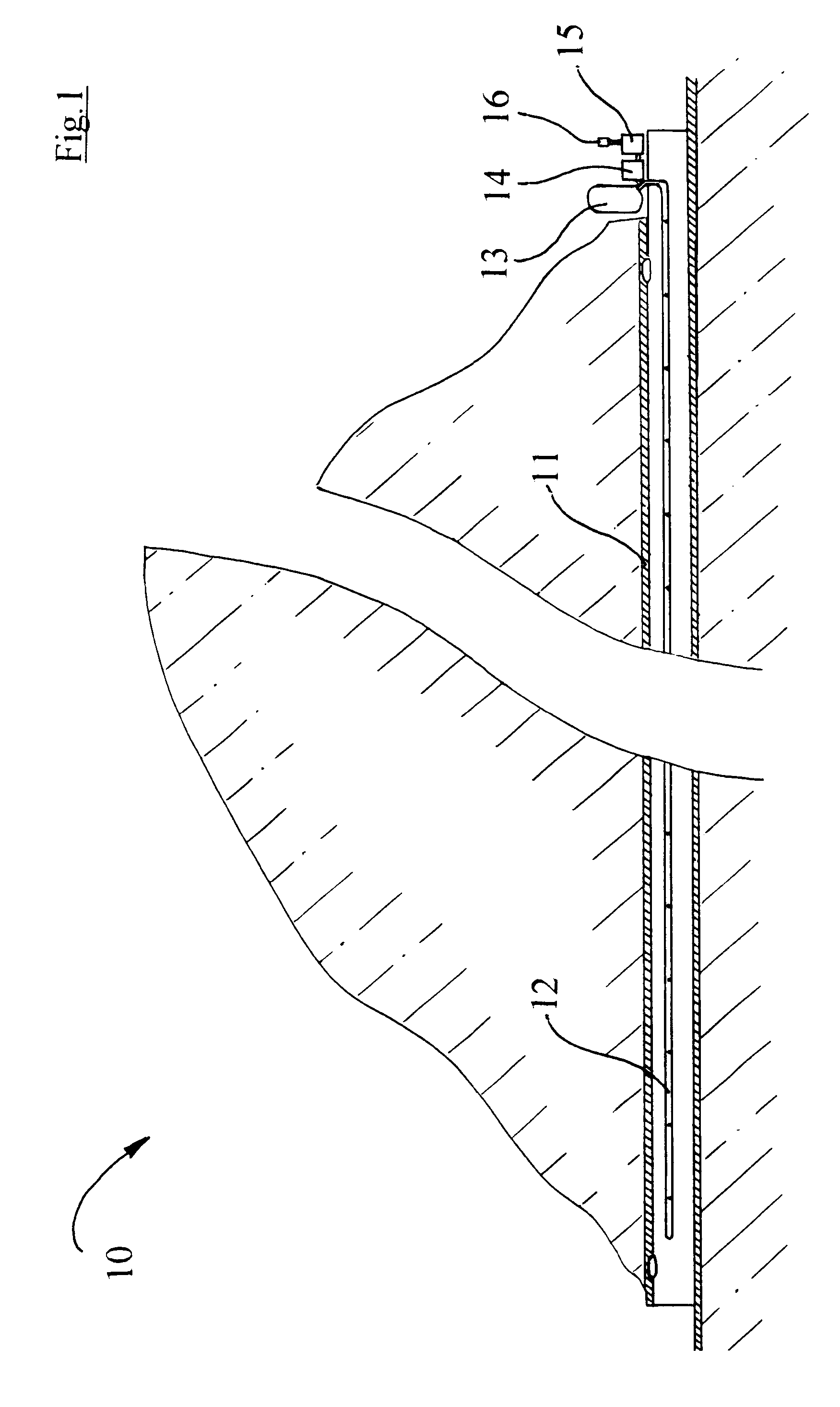

Tunnel fire suppression system and methods for selective delivery of breathable fire suppressant directly to fire site

A total flood fire suppression system is provided for transportation tunnels and other human-occupied environments, which employs a selective gas delivery method for supplying a breathable fire-extinguishing agent to a location closest to a fire site. The agent is produced from ambient air at site and stored in high-pressure containers communicating with an addressed gas delivery hose installed throughout a tunnel. When fire is detected, the agent is released from storage containers into the gas delivery hose that simultaneously becomes penetrated or broken in a location next to the fire site, allowing releasing the agent there and extinguishing the fire by totally flooding the affected portion of a tunnel. Additionally, the direction of the agent flow can be controlled by air blocks or inflatable tunnel plugs that, via a signal from a central control station, can inflate and block a tunnel tube in order to redirect the agent flow into the opposite to a block direction.

Owner:FIREPASS CORP

Popular searches

Solid-state devices Mixing gases with gases/vapours Energy based chemical/physical/physico-chemical processes Chemical vapor deposition coating Semiconductor devices Space heating and ventilation control systems Humidity control Compression machines with cascade operation Temperature control using electric means Refrigeration safety arrangement

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com