Patents

Literature

9912results about "Energy based chemical/physical/physico-chemical processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

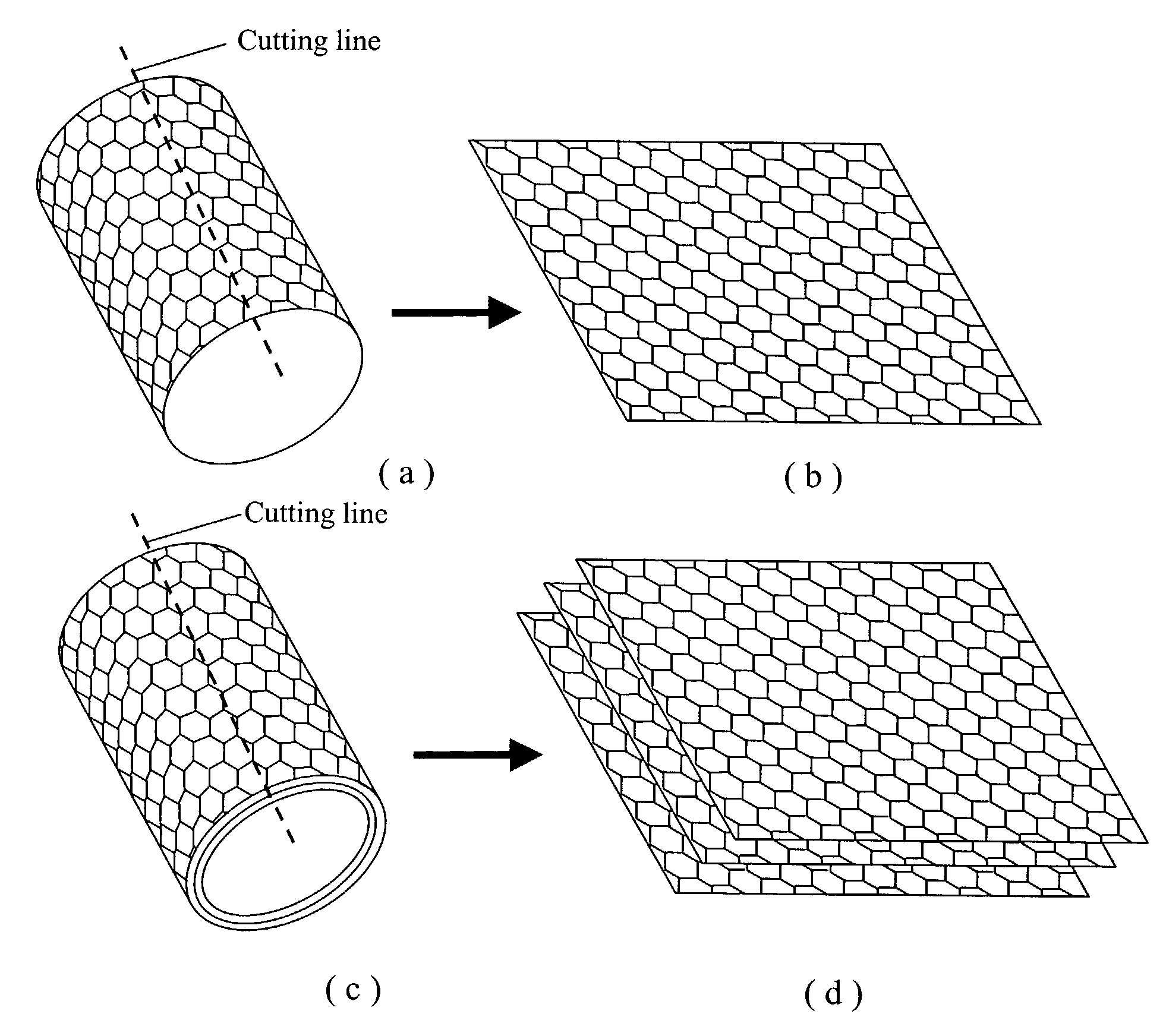

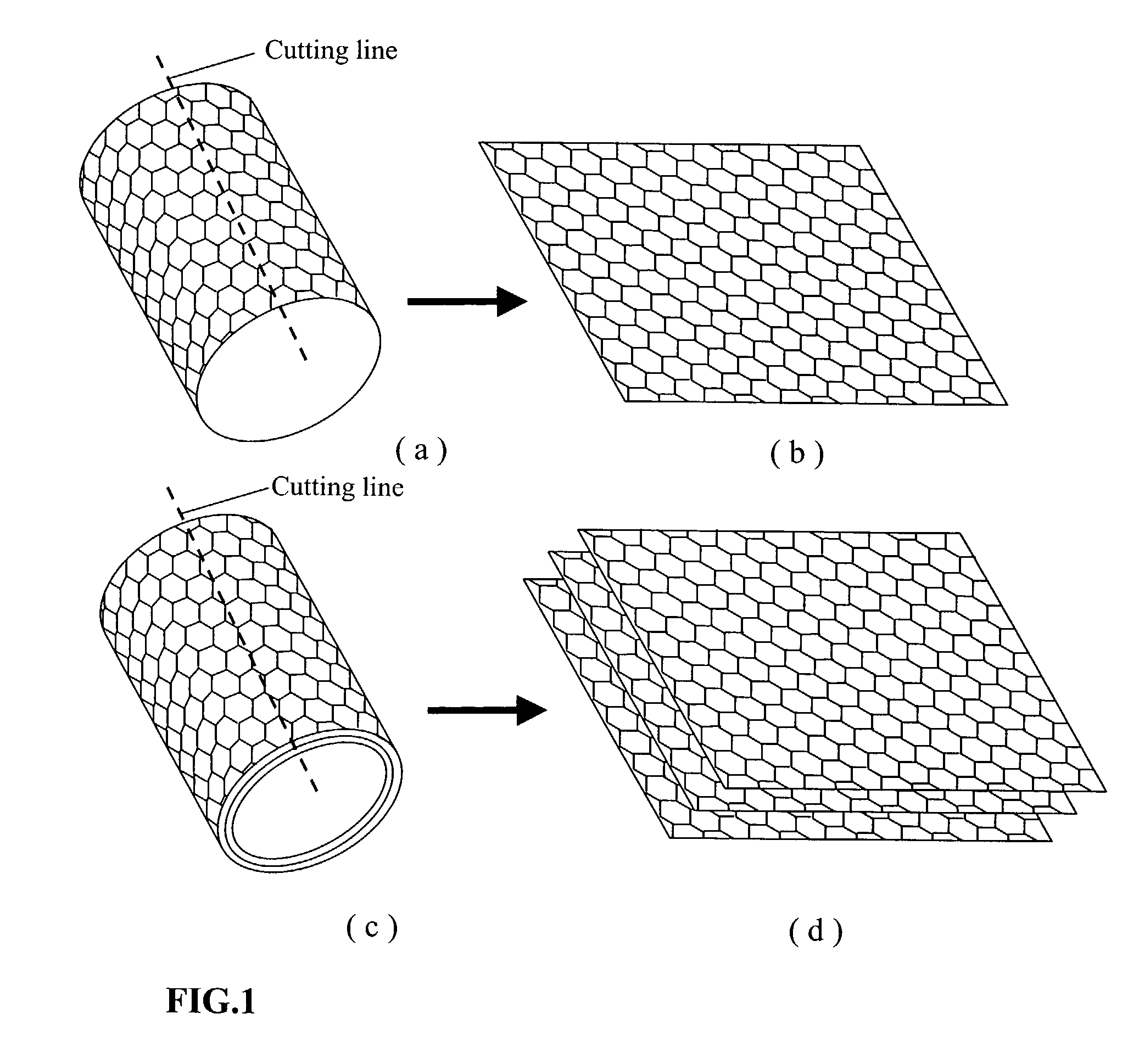

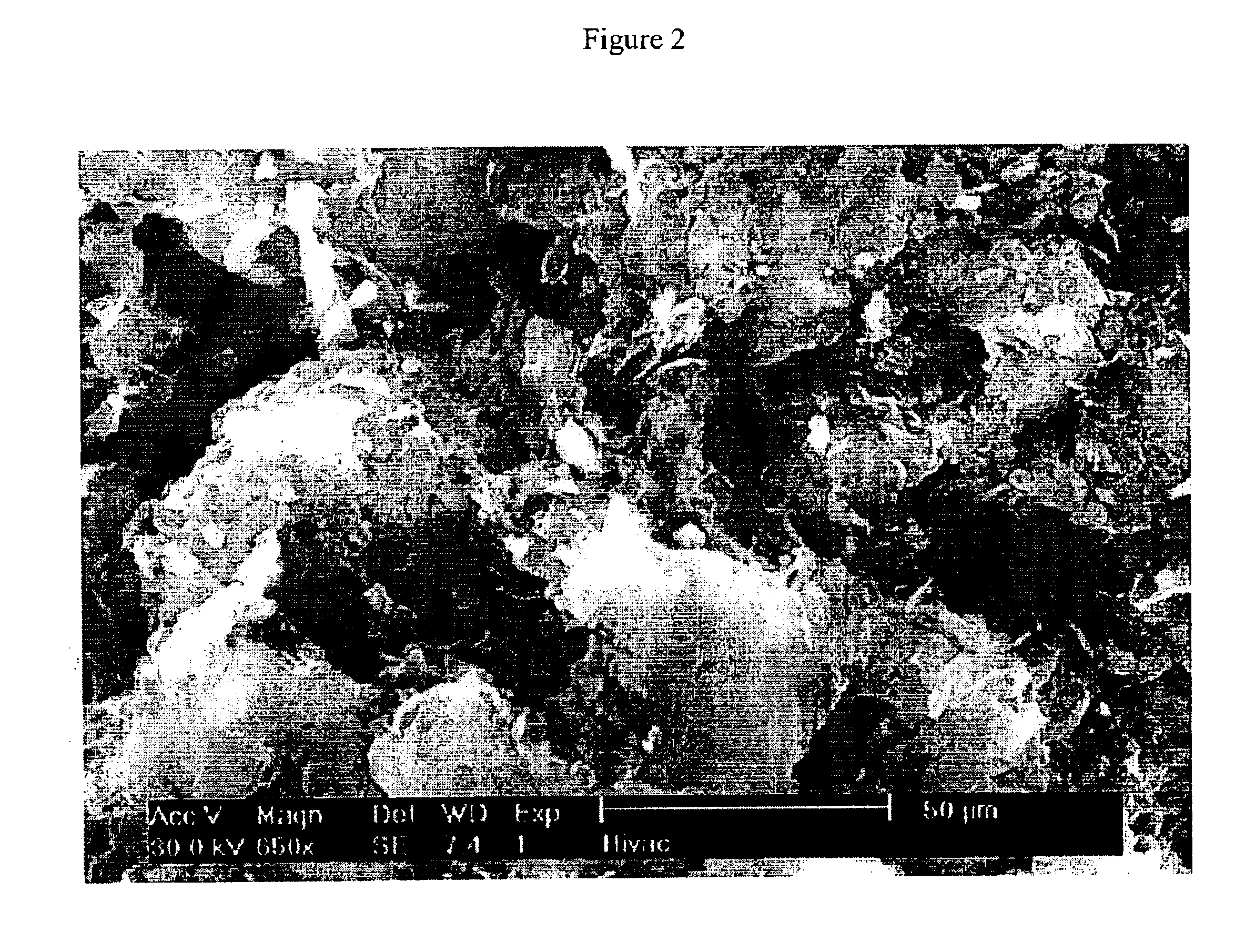

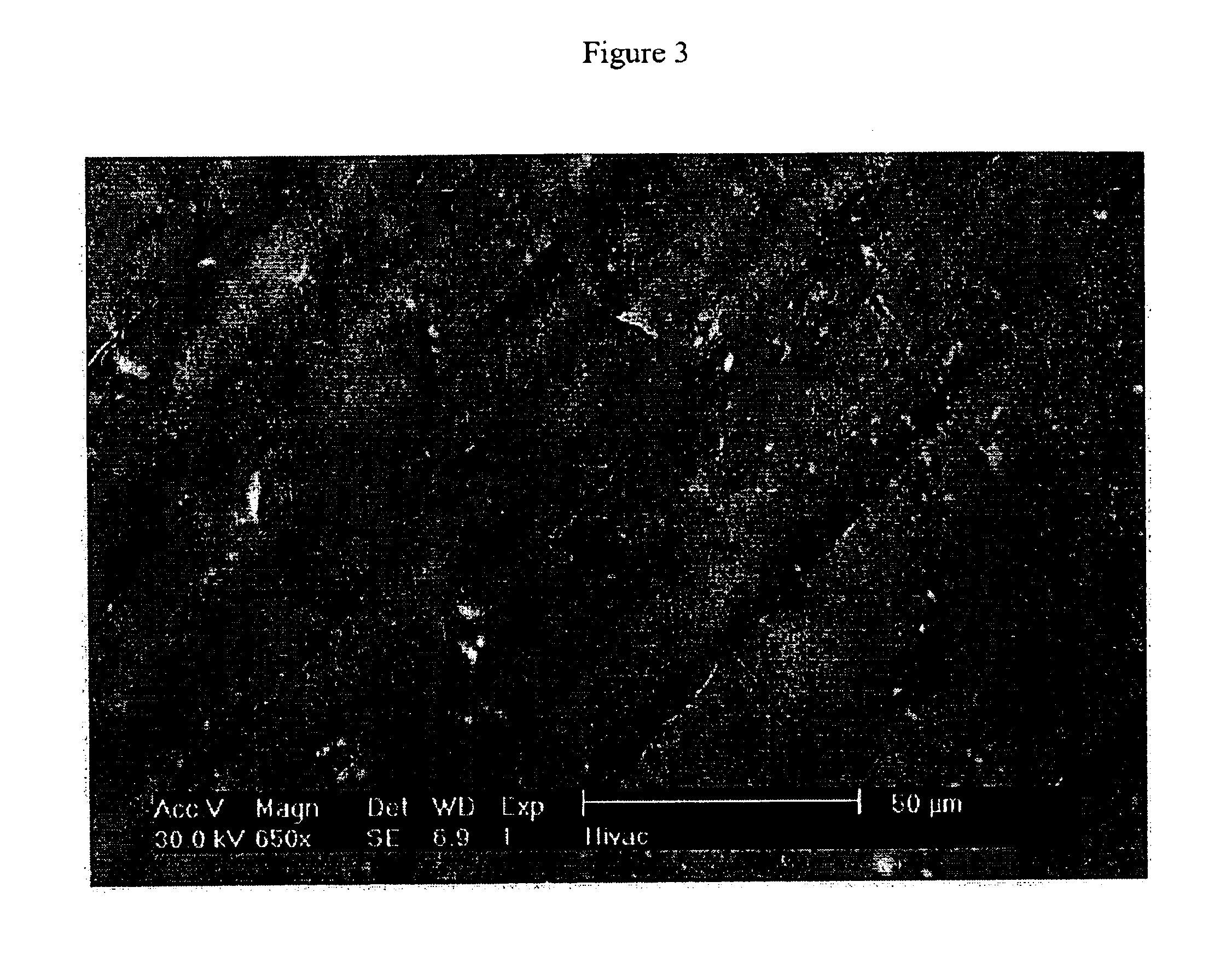

Nano-scaled graphene plates

A nano-scaled graphene plate material and a process for producing this material. The material comprises a sheet of graphite plane or a multiplicity of sheets of graphite plane. The graphite plane is composed of a two-dimensional hexagonal lattice of carbon atoms and the plate has a length and a width parallel to the graphite plane and a thickness orthogonal to the graphite plane with at least one of the length, width, and thickness values being 100 nanometers or smaller. The process for producing nano-scaled graphene plate material comprises the steps of: a). partially or fully carbonizing a precursor polymer or heat-treating petroleum or coal tar pitch to produce a polymeric carbon containing micron- and / or nanometer-scaled graphite crystallites with each crystallite comprising one sheet or a multiplicity of sheets of graphite plane; b). exfoliating the graphite crystallites in the polymeric carbon; and c). subjecting the polymeric carbon containing exfoliated graphite crystallites to a mechanical attrition treatment to produce the nano-scaled graphene plate material.

Owner:GLOBAL GRAPHENE GRP INC

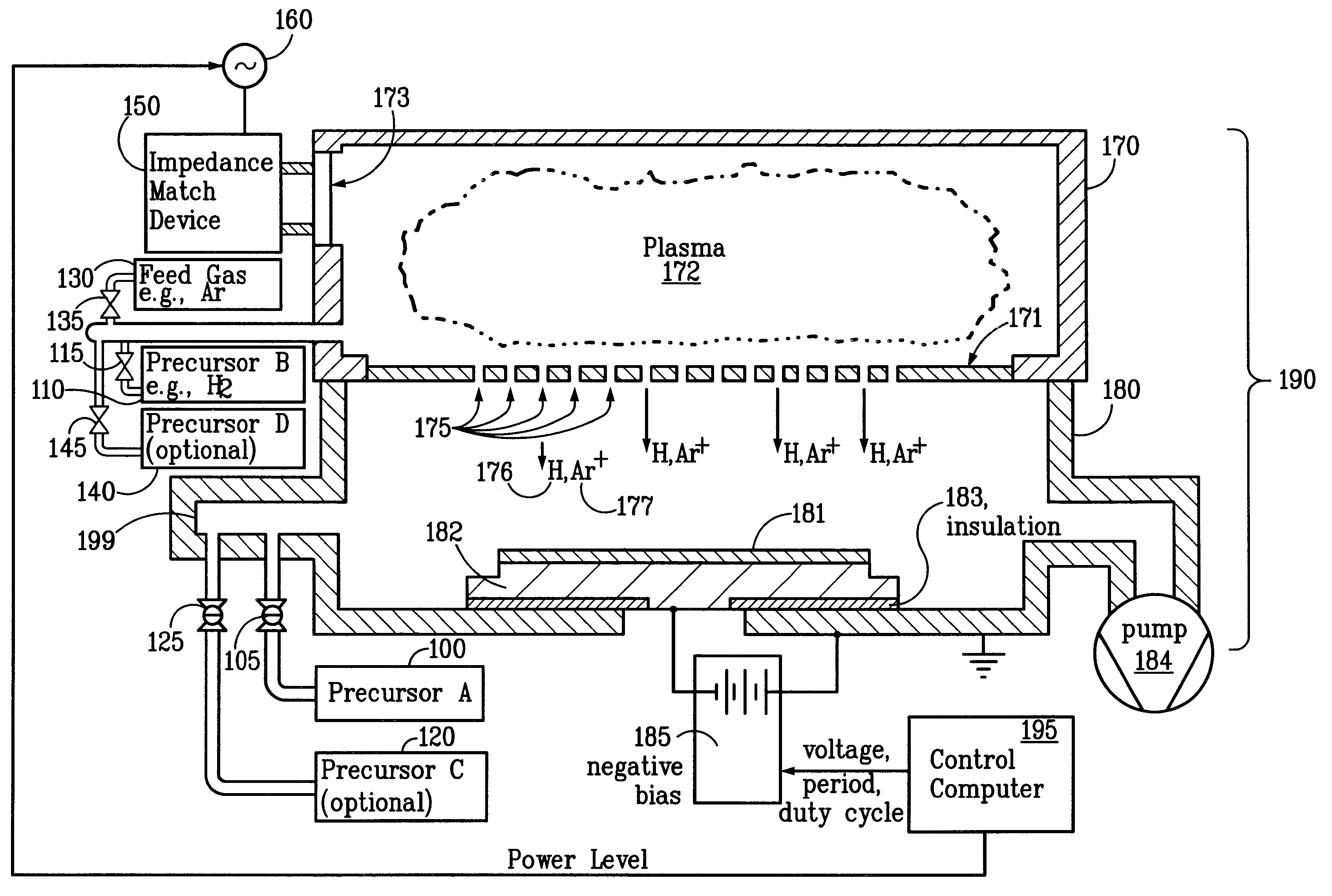

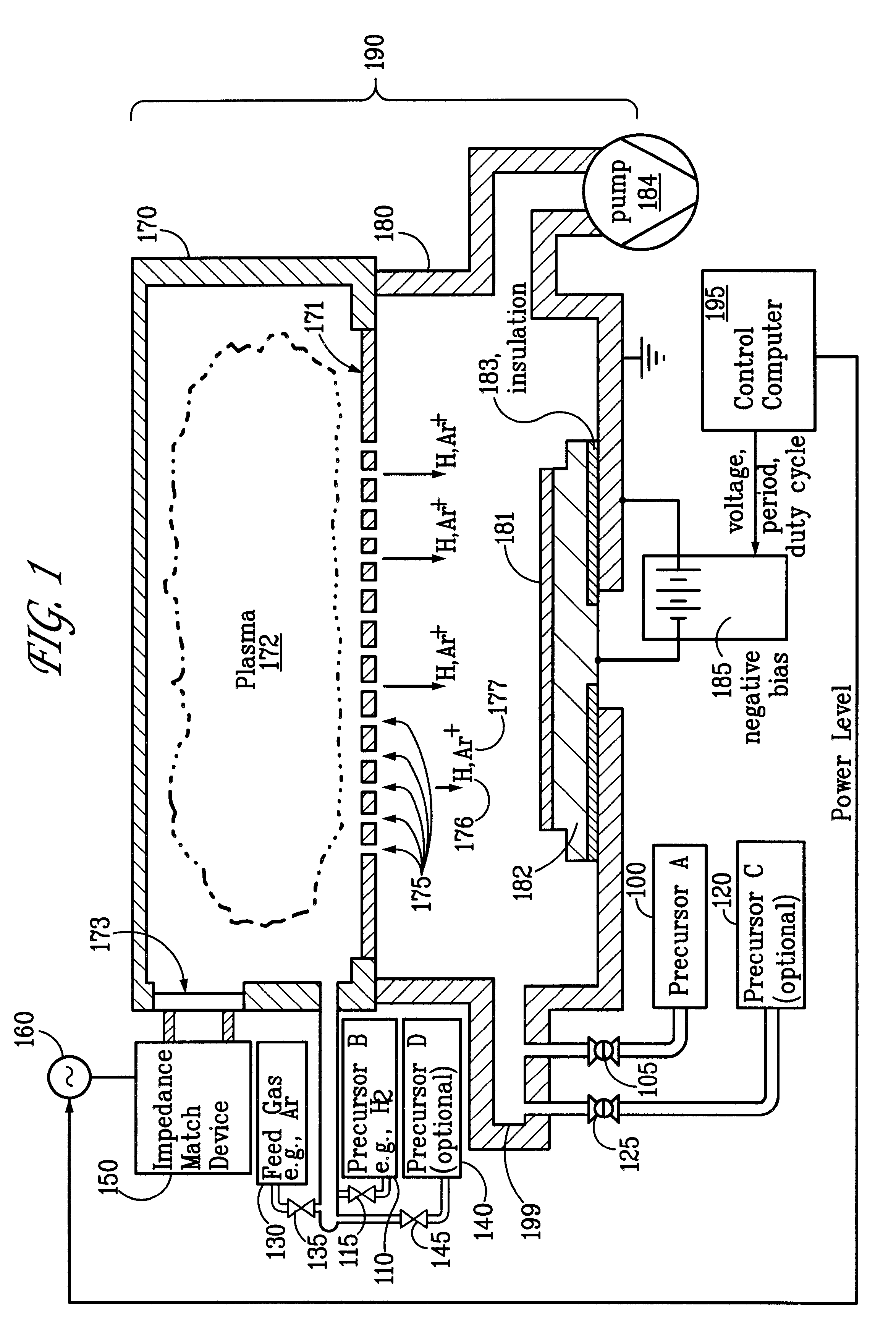

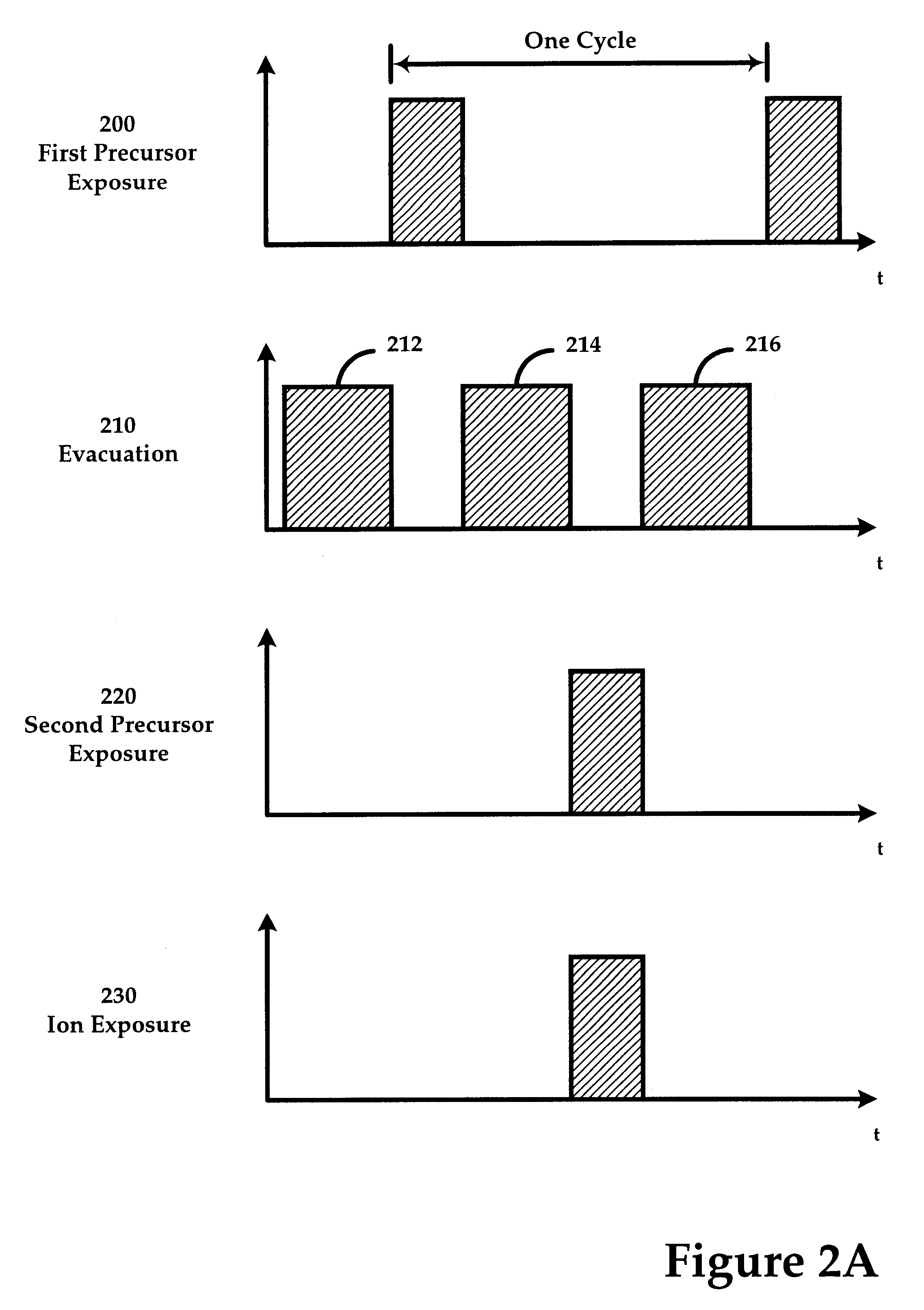

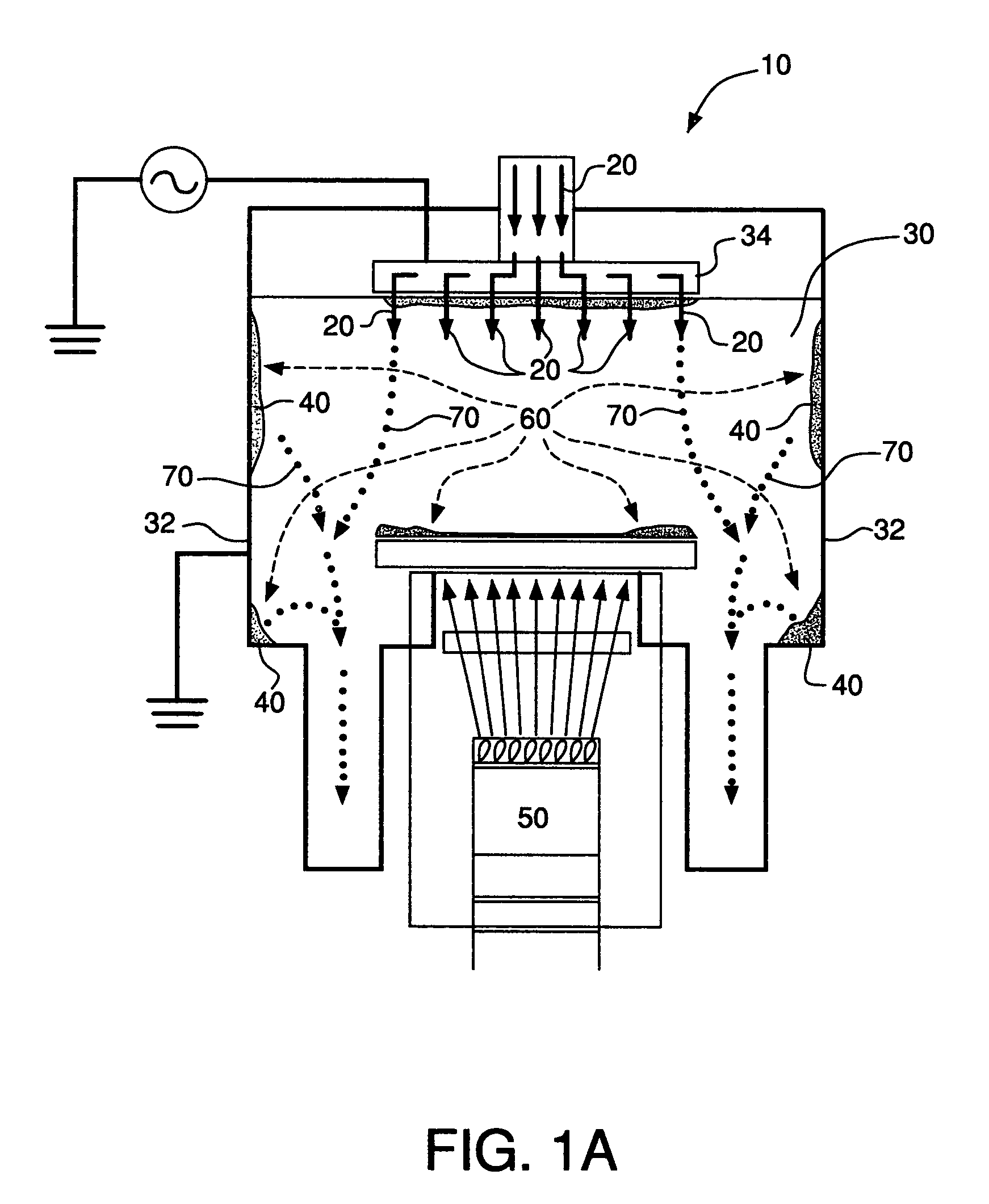

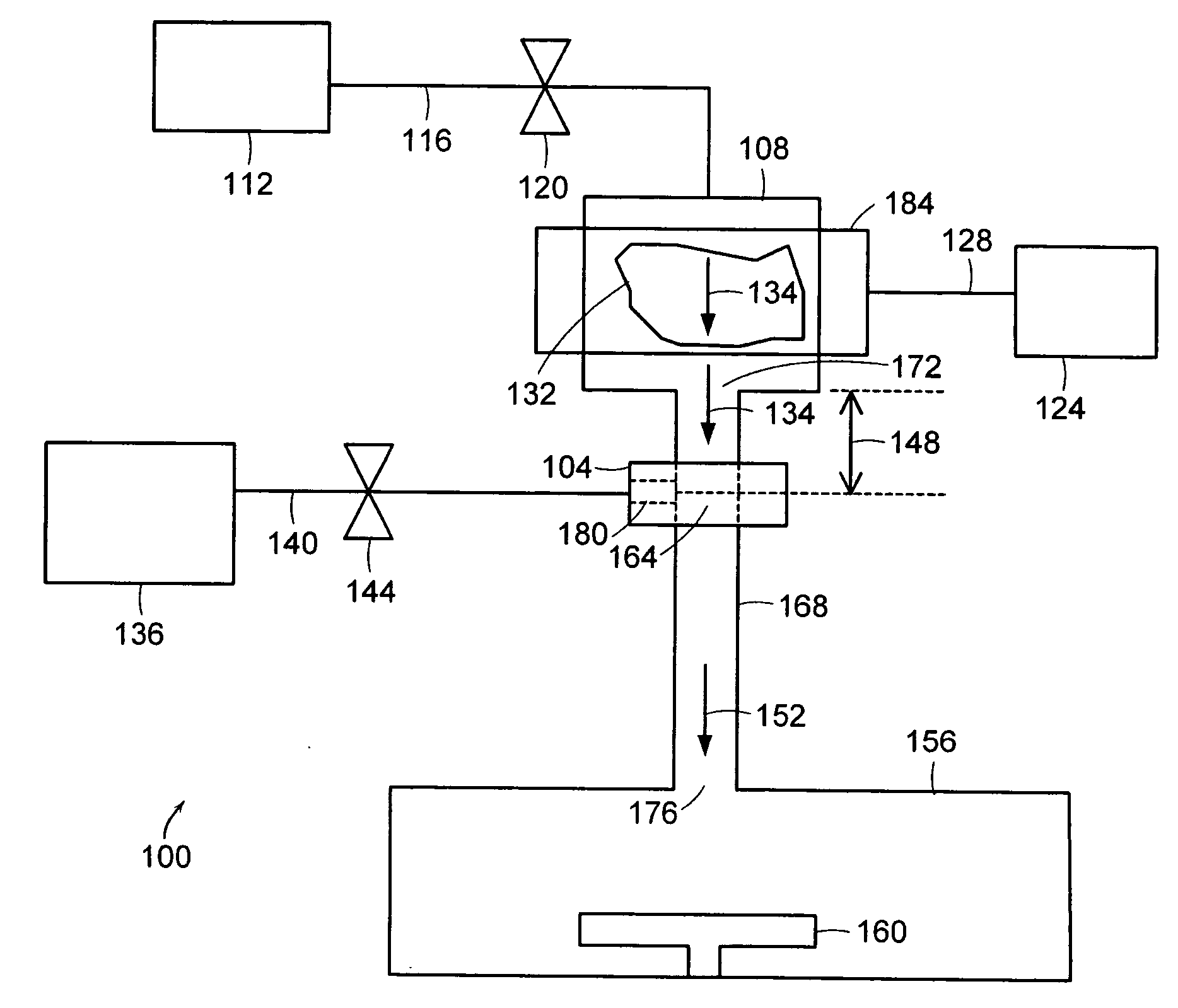

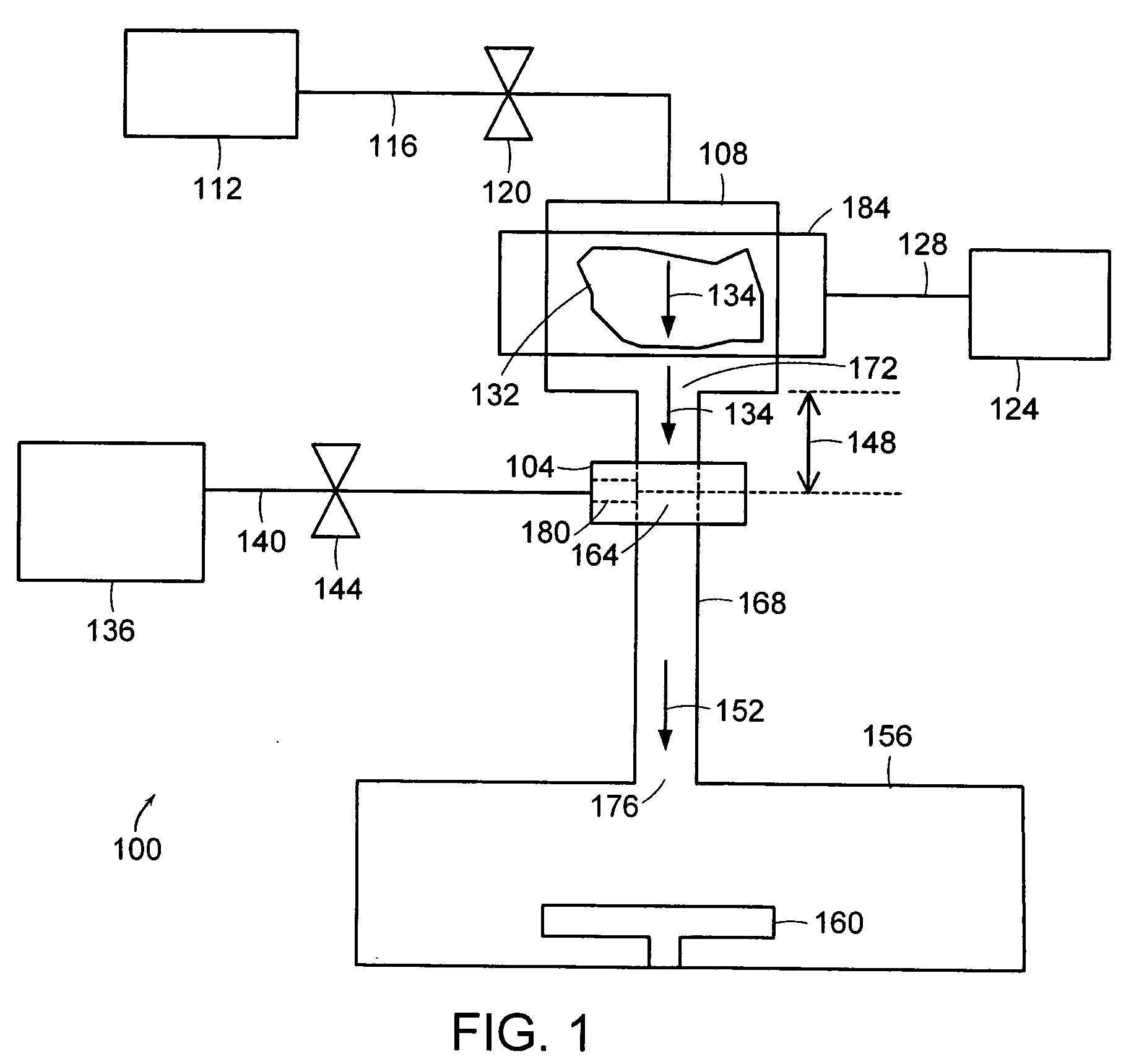

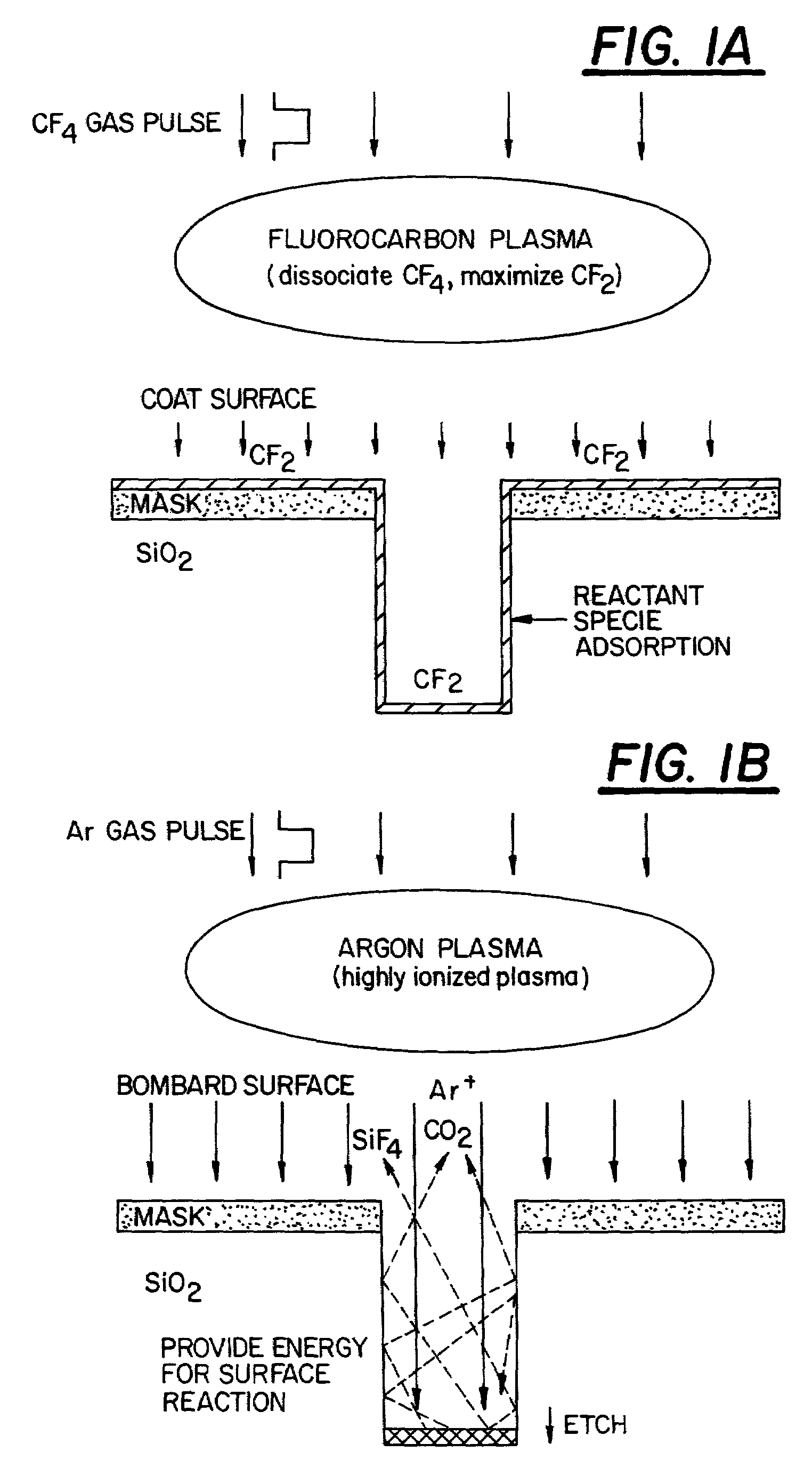

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6428859B1Faster efficient meanSimple methodVacuum evaporation coatingSputtering coatingSequential methodHigh density

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:NOVELLUS SYSTEMS

Free-standing and aligned carbon nanotubes and synthesis thereof

One or more highly-oriented, multi-walled carbon nanotubes are grown on an outer surface of a substrate initially disposed with a catalyst film or catalyst nano-dot by plasma enhanced hot filament chemical vapor deposition of a carbon source gas and a catalyst gas at temperatures between 300° C. and 3000° C. The carbon nanotubes range from 4 to 500 nm in diameter and 0.1 to 50 μm in length depending on growth conditions. Carbon nanotube density can exceed 104 nanotubes / mm2. Acetylene is used as the carbon source gas, and ammonia is used as the catalyst gas. Plasma intensity, carbon source gas to catalyst gas ratio and their flow rates, catalyst film thickness, and temperature of chemical vapor deposition affect the lengths, diameters, density, and uniformity of the carbon nanotubes. The carbon nanotubes of the present invention are useful in electrochemical applications as well as in electron emission, structural composite, material storage, and microelectrode applications.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

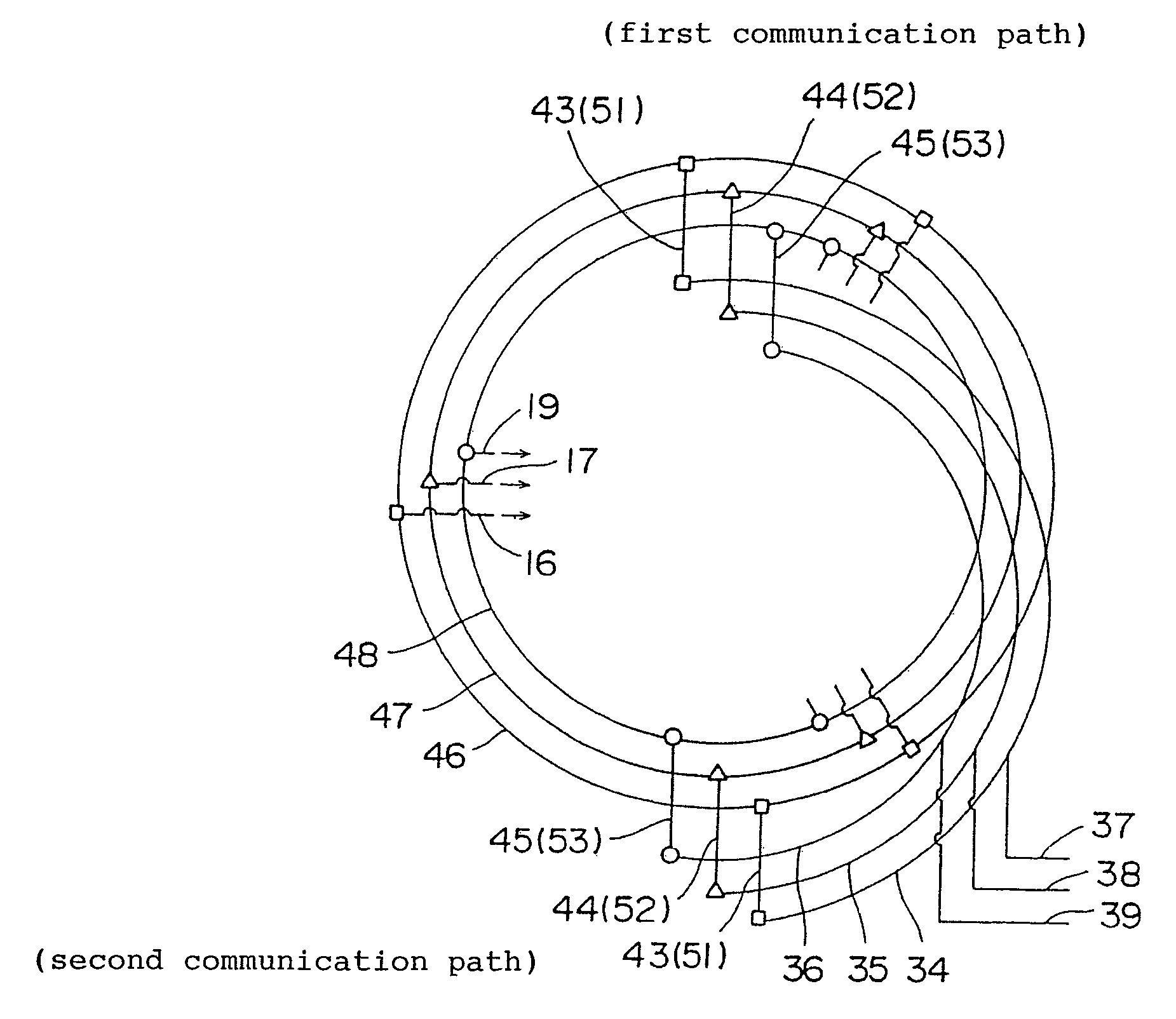

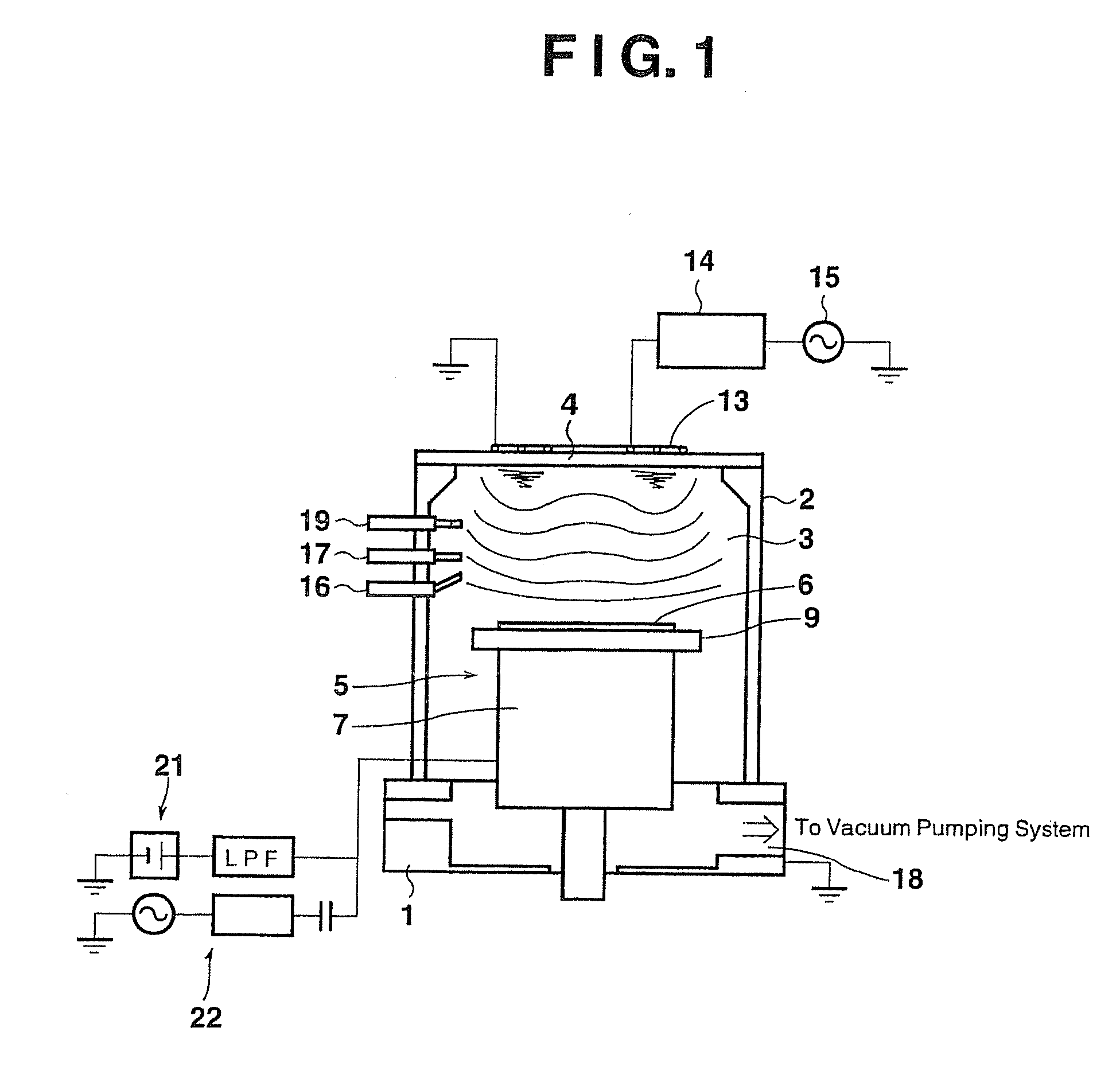

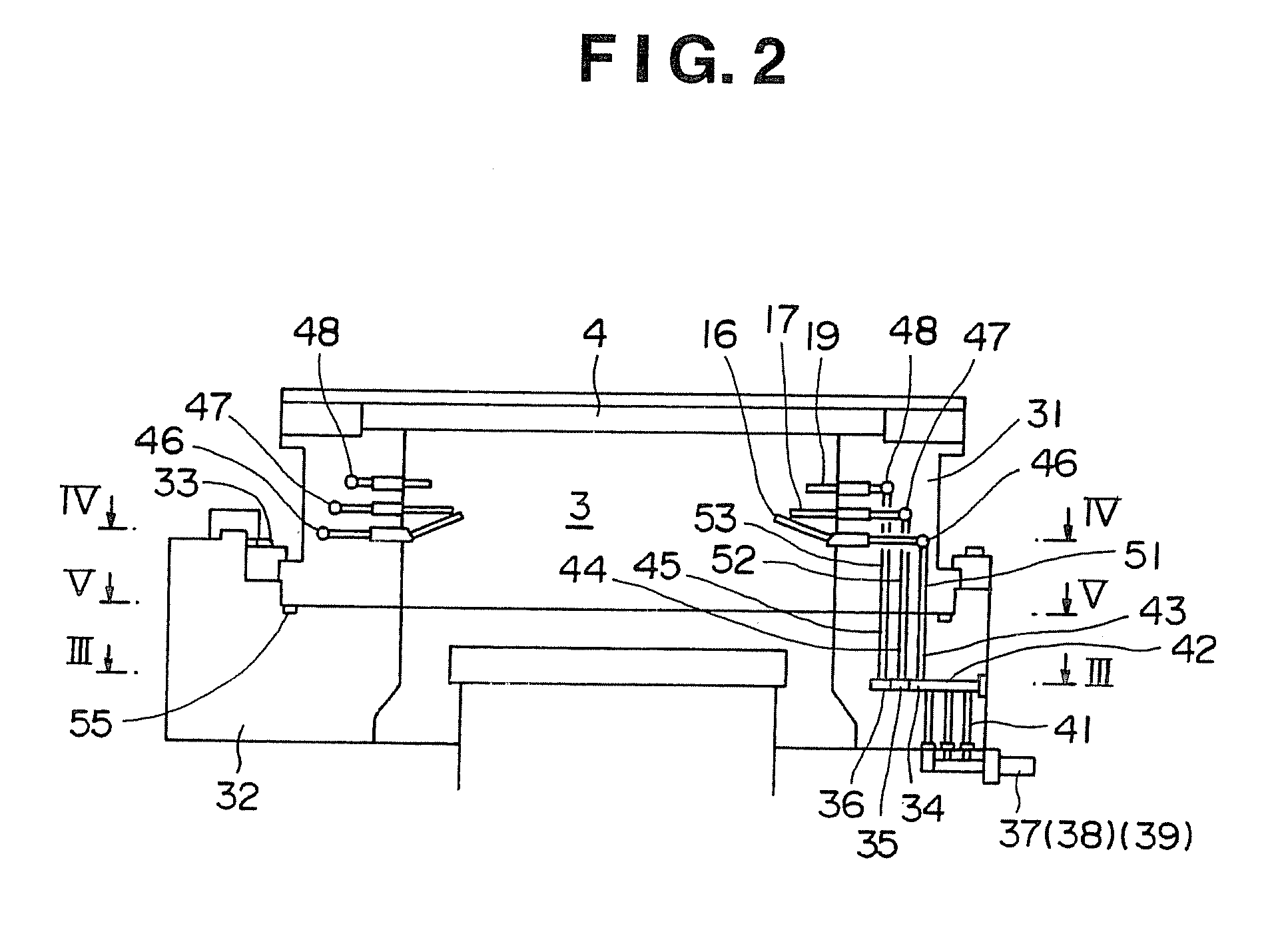

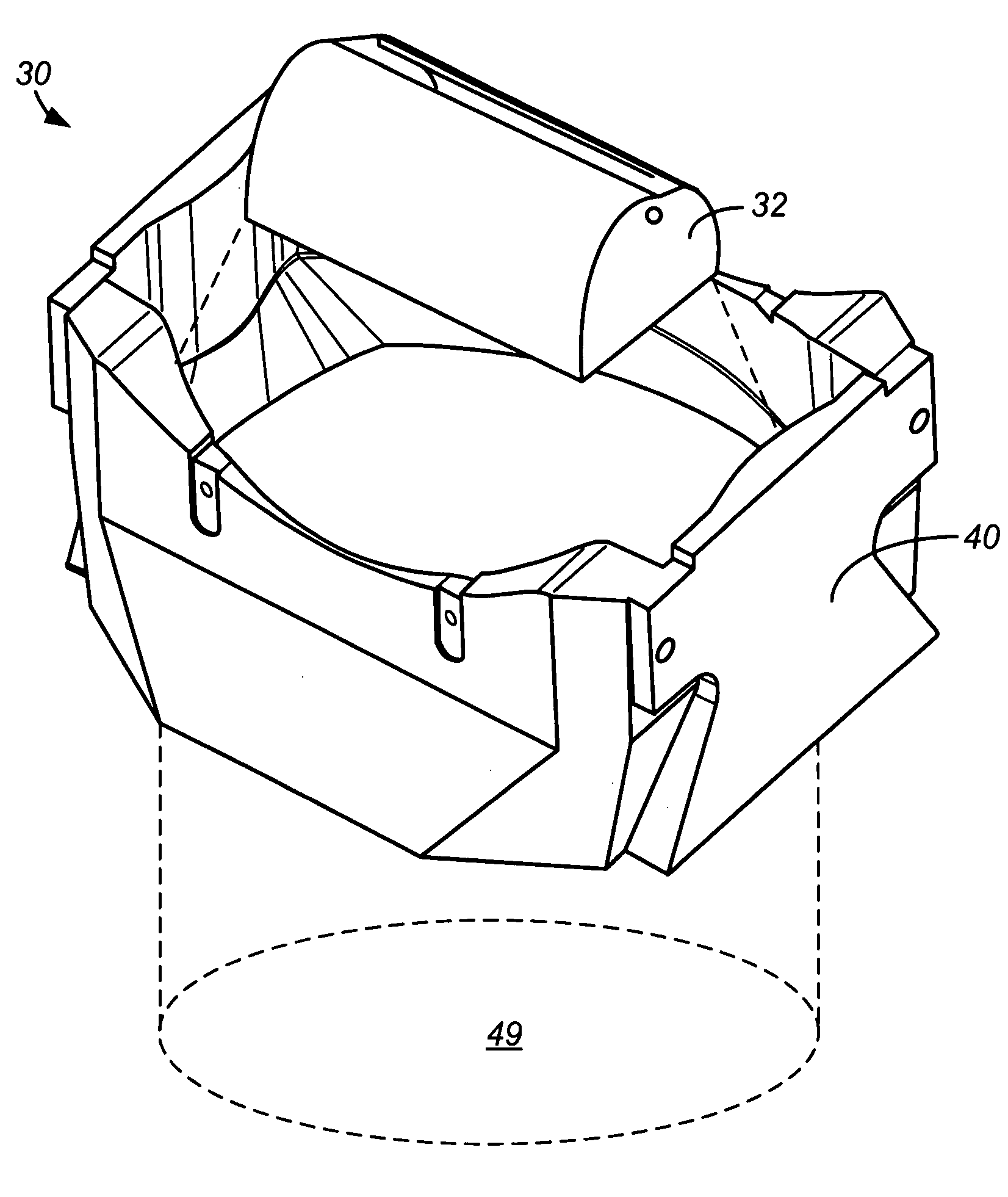

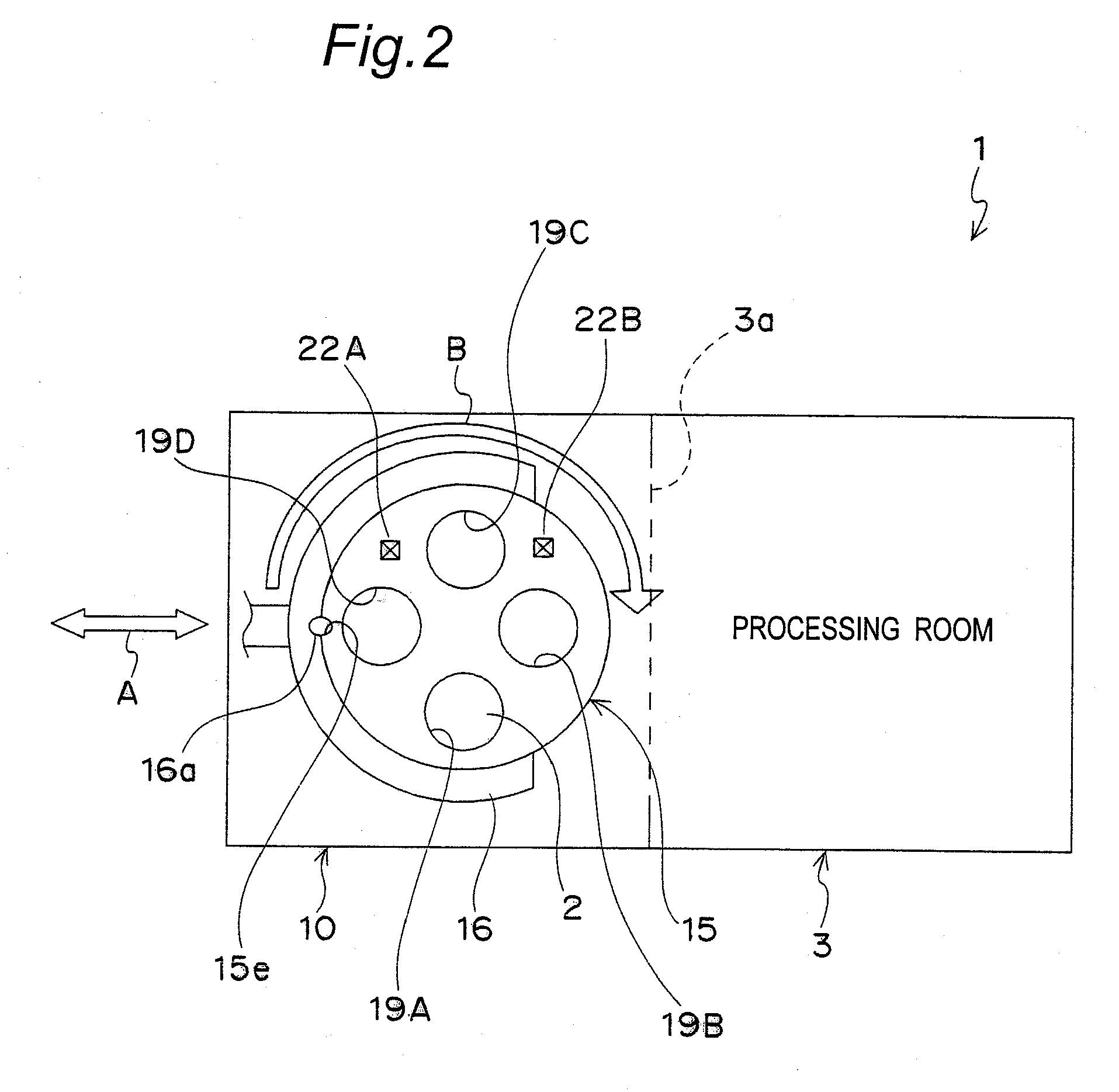

Plasma treatment apparatus

InactiveUS7806078B2Simply the configuration of the containerContainer can be simplifiedElectric discharge tubesSemiconductor/solid-state device manufacturingProduct gasEngineering

A plasma CVD apparatus has a container, and channels composed of introduction grooves and circumferential grooves for different types of gases are formed within the container. The gases introduced through source gas piping, auxiliary gas piping, and cleaning gas piping are equally supplied to a plurality of supply nozzles, a plurality of auxiliary gas supply nozzles, and a plurality of cleaning gas nozzles. The configuration of the container can be simplified without complicating pipings for the gases.

Owner:MITSUBISHI HEAVY IND LTD

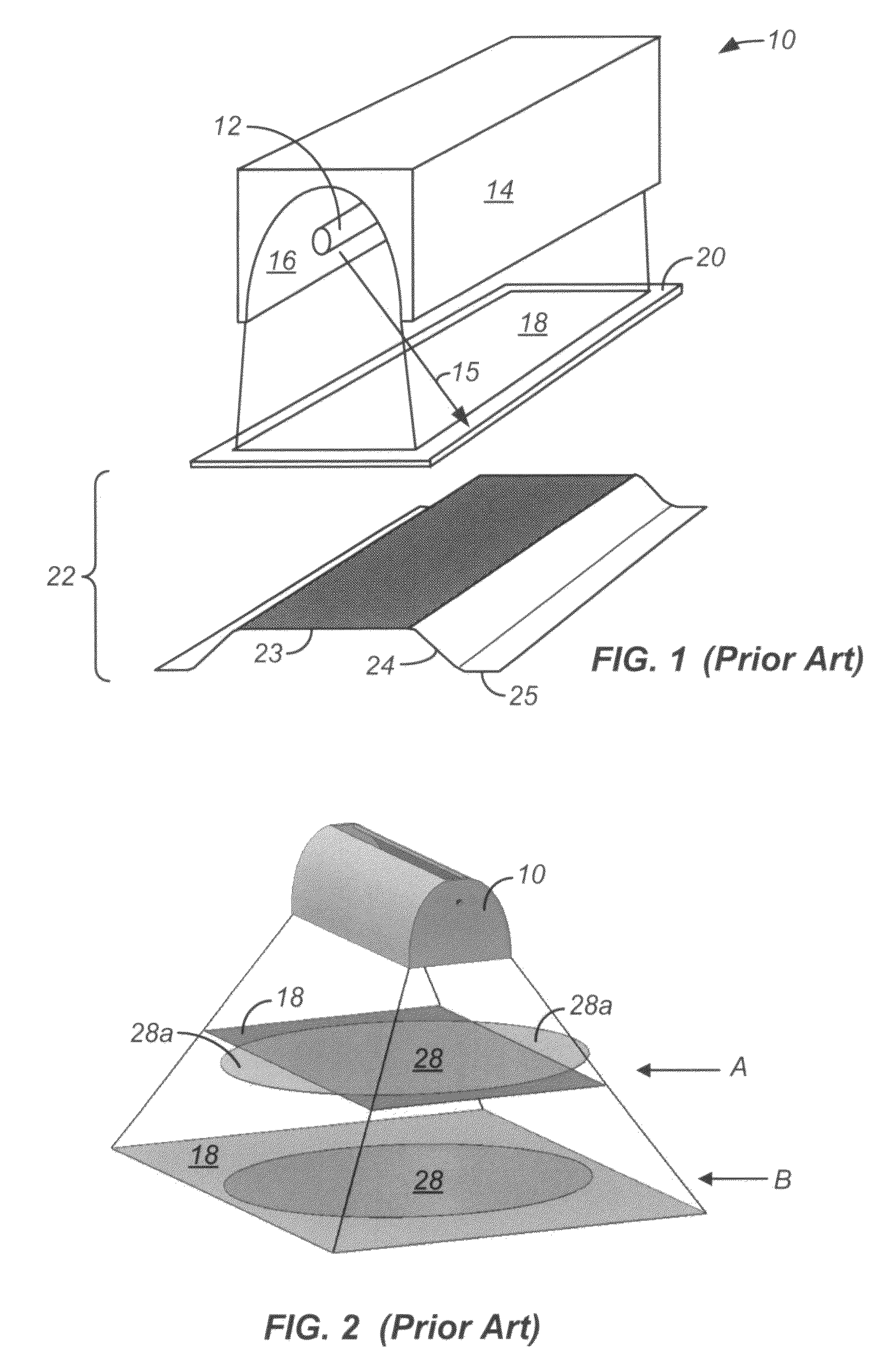

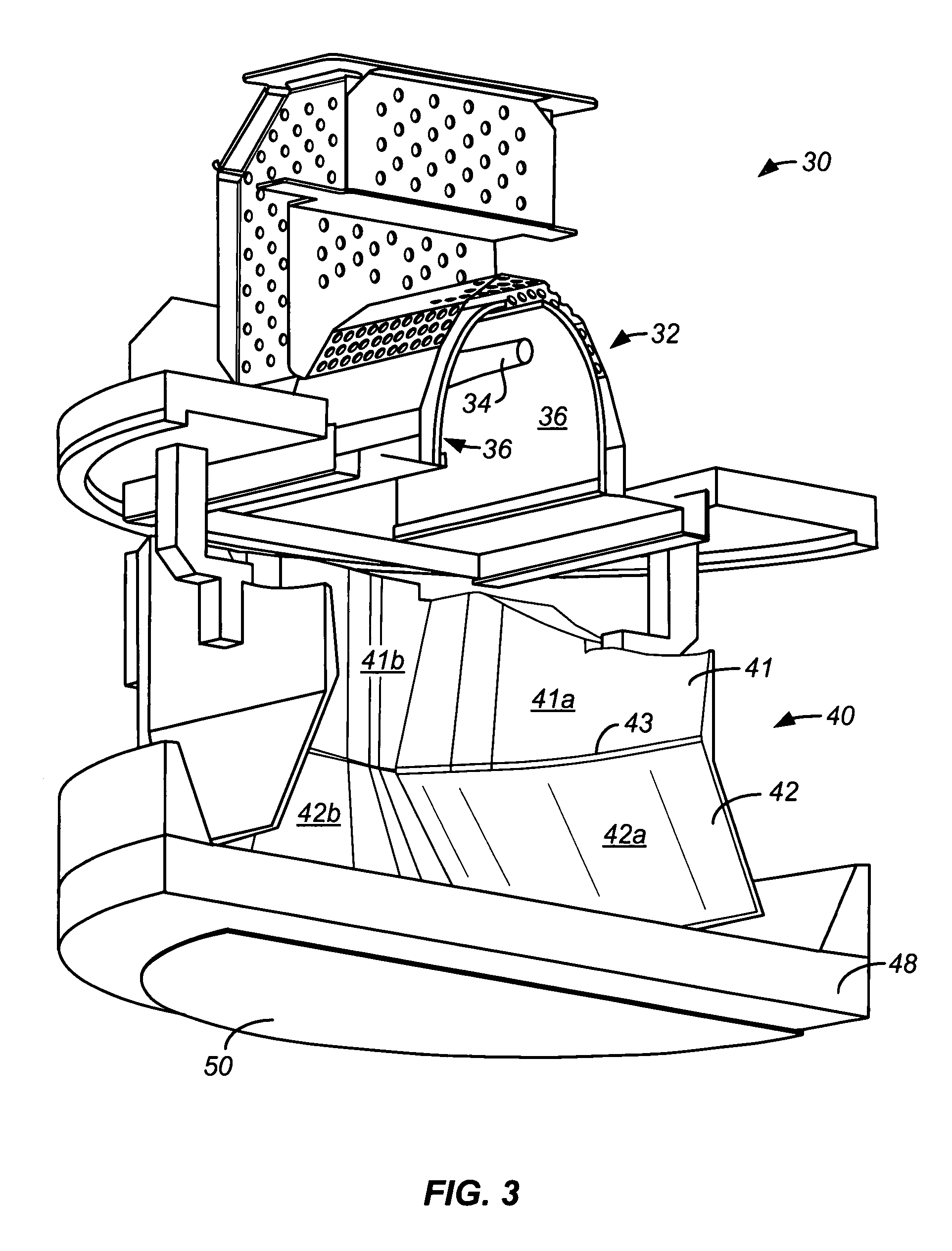

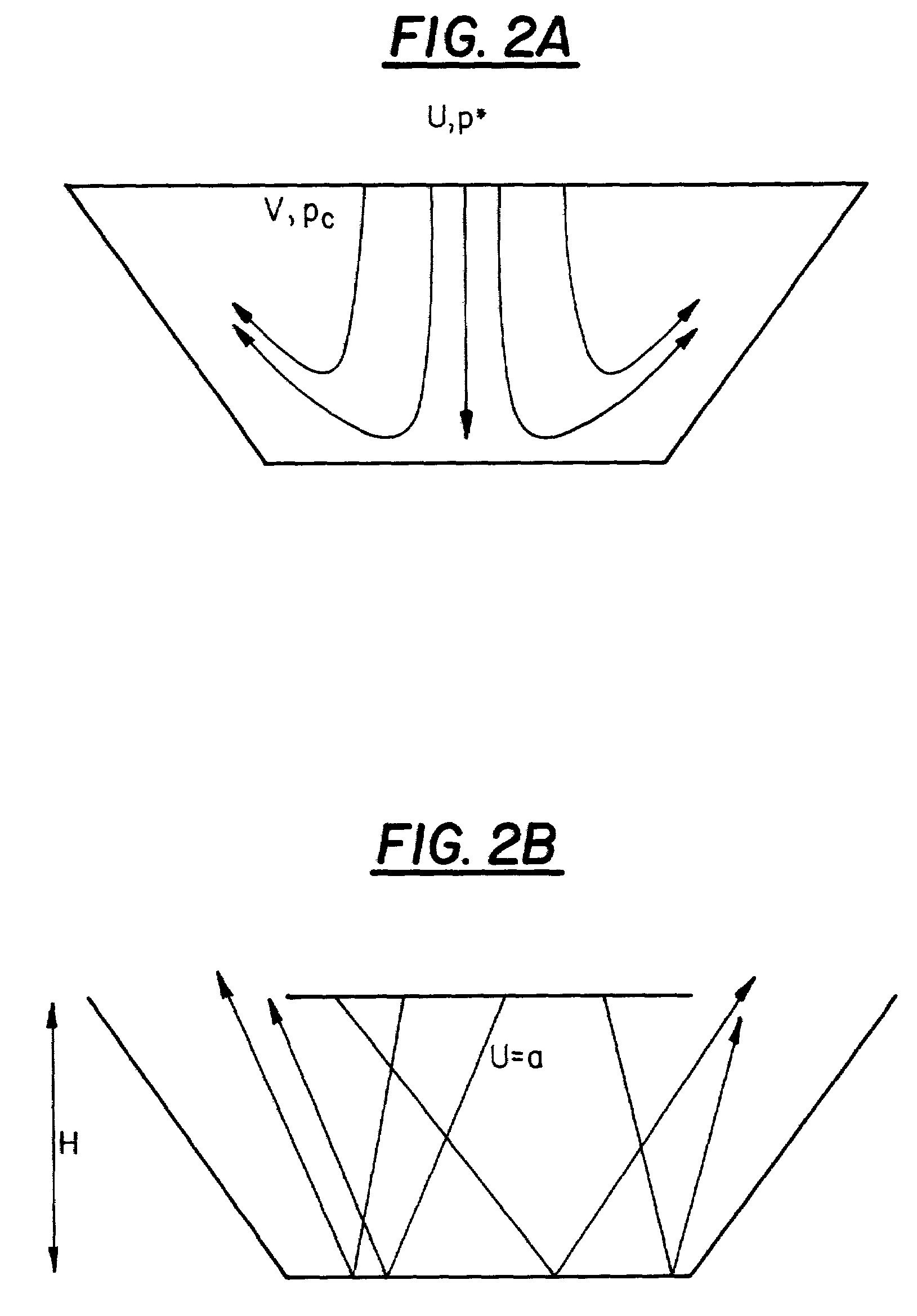

Apparatus and method for treating a substrate with UV radiation using primary and secondary reflectors

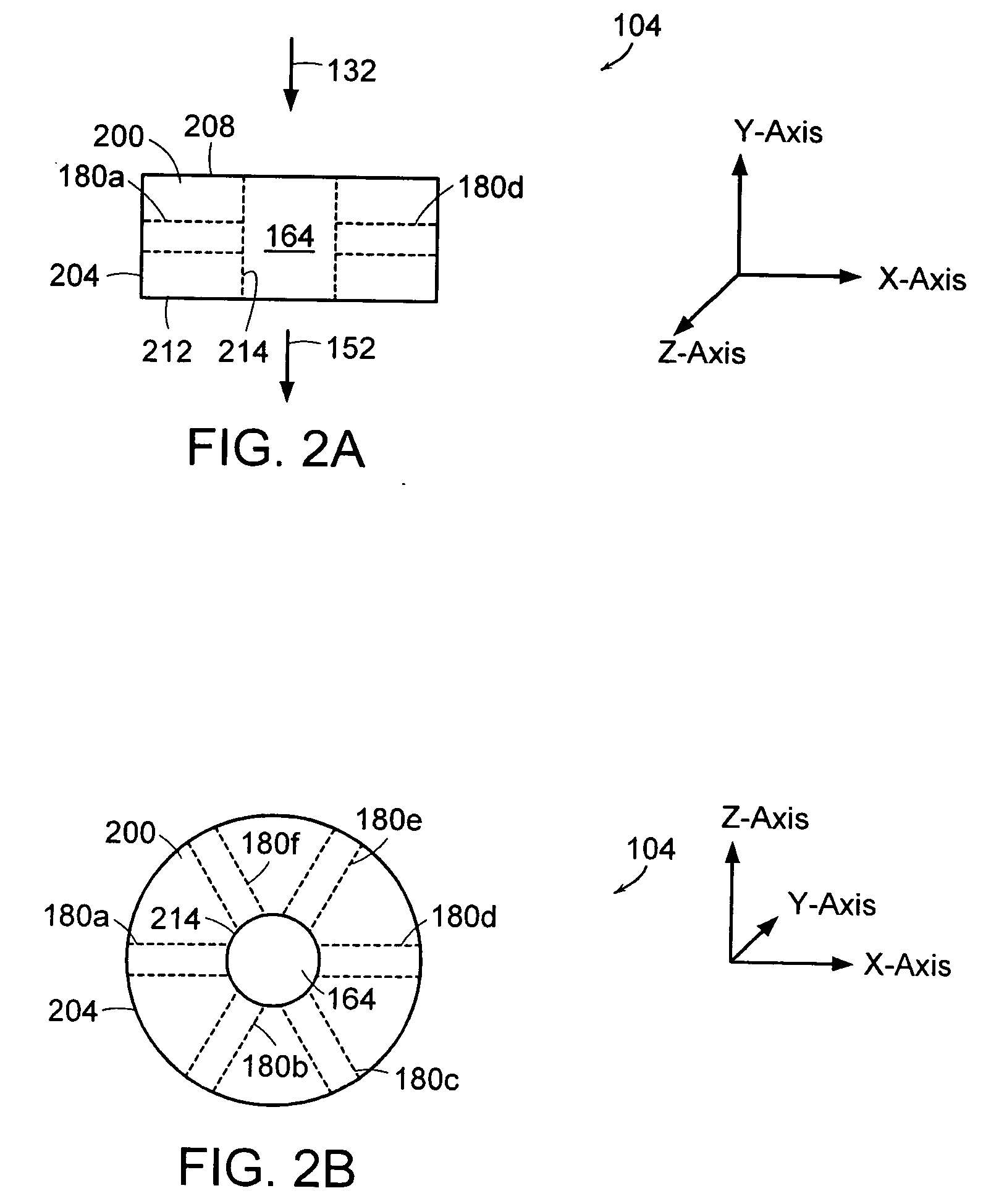

ActiveUS7566891B2Reduce light lossRadiation pyrometryPretreated surfacesProcess regionUltraviolet radiation

Embodiments of the invention relate generally to an ultraviolet (UV) cure chamber for curing a dielectric material disposed on a substrate and to methods of curing dielectric materials using UV radiation. A substrate processing tool according to one embodiment comprises a body defining a substrate processing region; a substrate support adapted to support a substrate within the substrate processing region; an ultraviolet radiation lamp spaced apart from the substrate support, the lamp configured to transmit ultraviolet radiation to a substrate positioned on the substrate support; and a motor operatively coupled to rotate at least one of the ultraviolet radiation lamp or substrate support at least 180 degrees relative to each other. The substrate processing tool may further comprise one or more reflectors adapted to generate a flood pattern of ultraviolet radiation over the substrate that has complementary high and low intensity areas which combine to generate a substantially uniform irradiance pattern if rotated. Other embodiments are also disclosed.

Owner:APPLIED MATERIALS INC

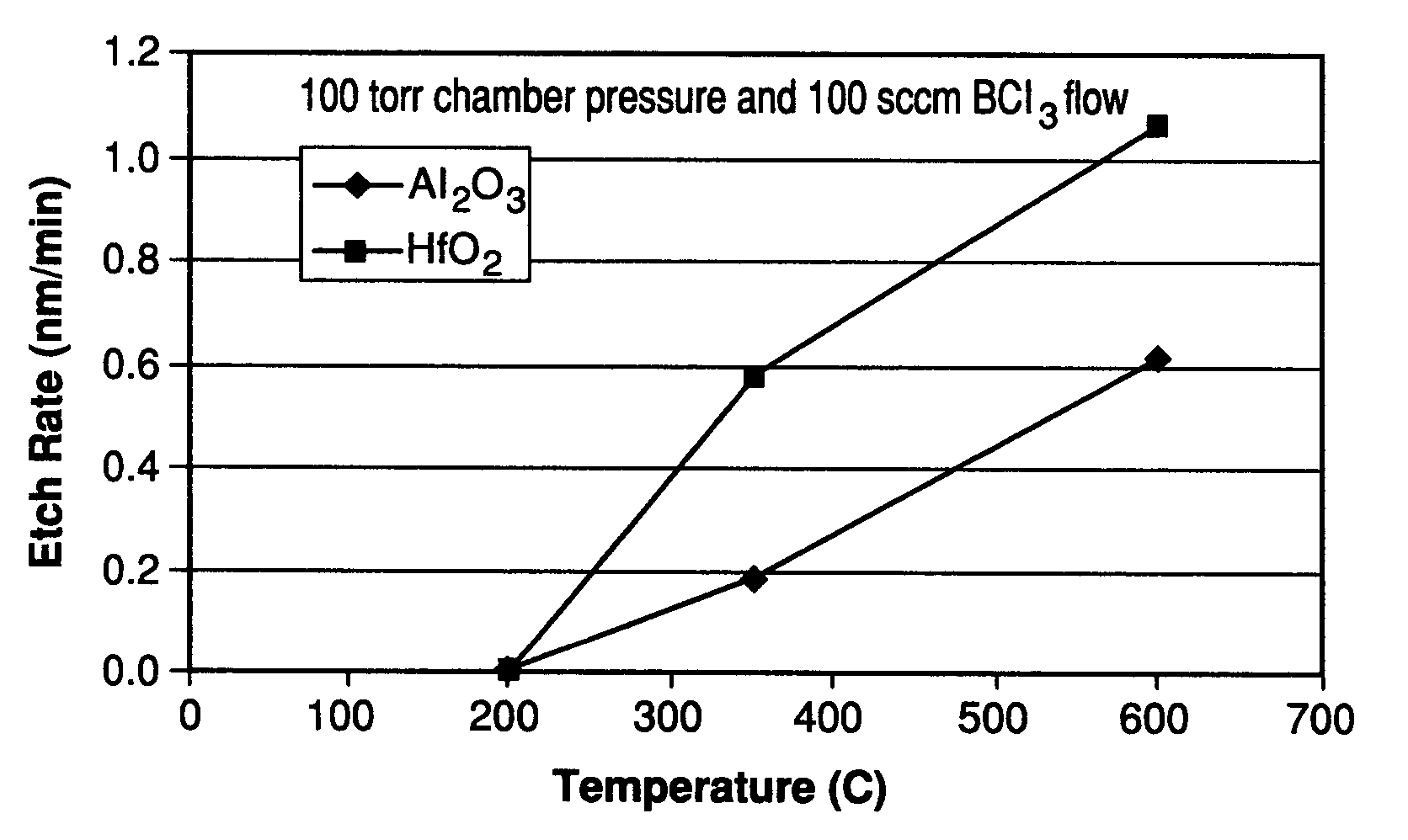

Method for etching high dielectric constant materials and for cleaning deposition chambers for high dielectric constant materials

A process for the removal of a substance from a substrate for etching and / or cleaning applications is disclosed herein. In one embodiment, there is provided a process for removing a substance having a dielectric constant greater than silicon dioxide from a substrate by reacting the substance with a reactive agent that comprises at least one member from the group consisting a halogen-containing compound, a boron-containing compound, a hydrogen-containing compound, nitrogen-containing compound, a chelating compound, a carbon-containing compound, a chlorosilane, a hydrochlorosilane, or an organochlorosilane to form a volatile product and removing the volatile product from the substrate to thereby remove the substance from the substrate.

Owner:VERSUM MATERIALS US LLC

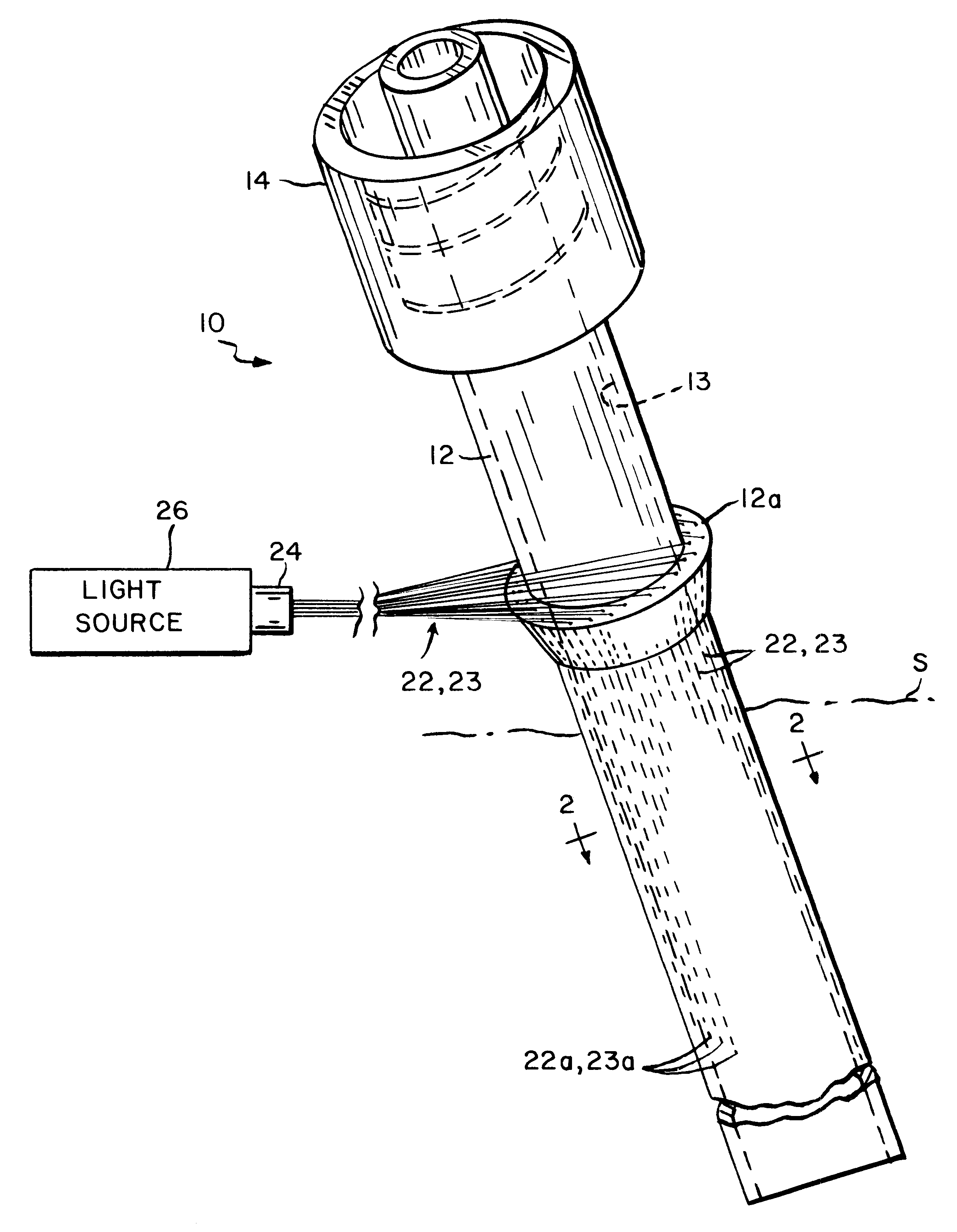

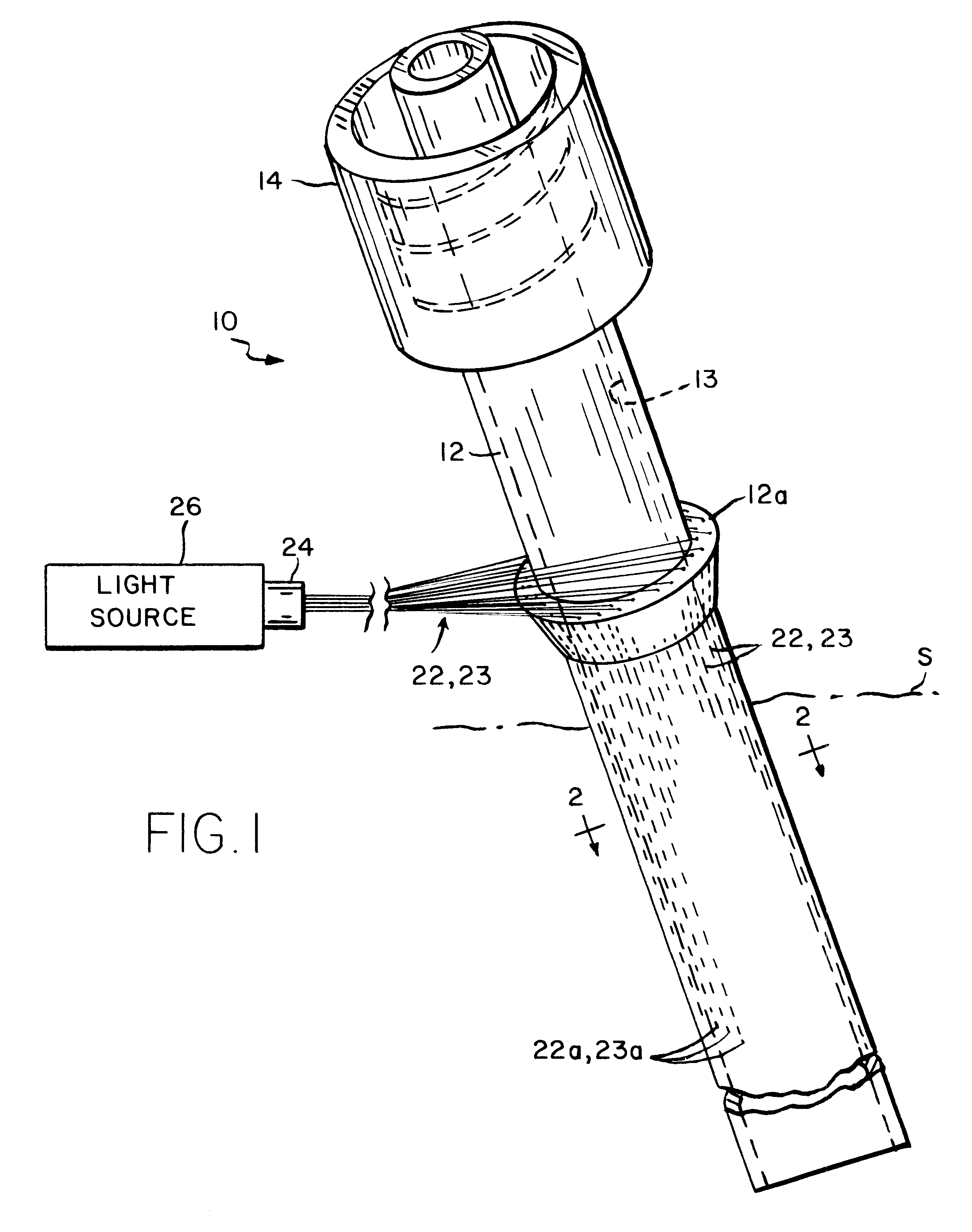

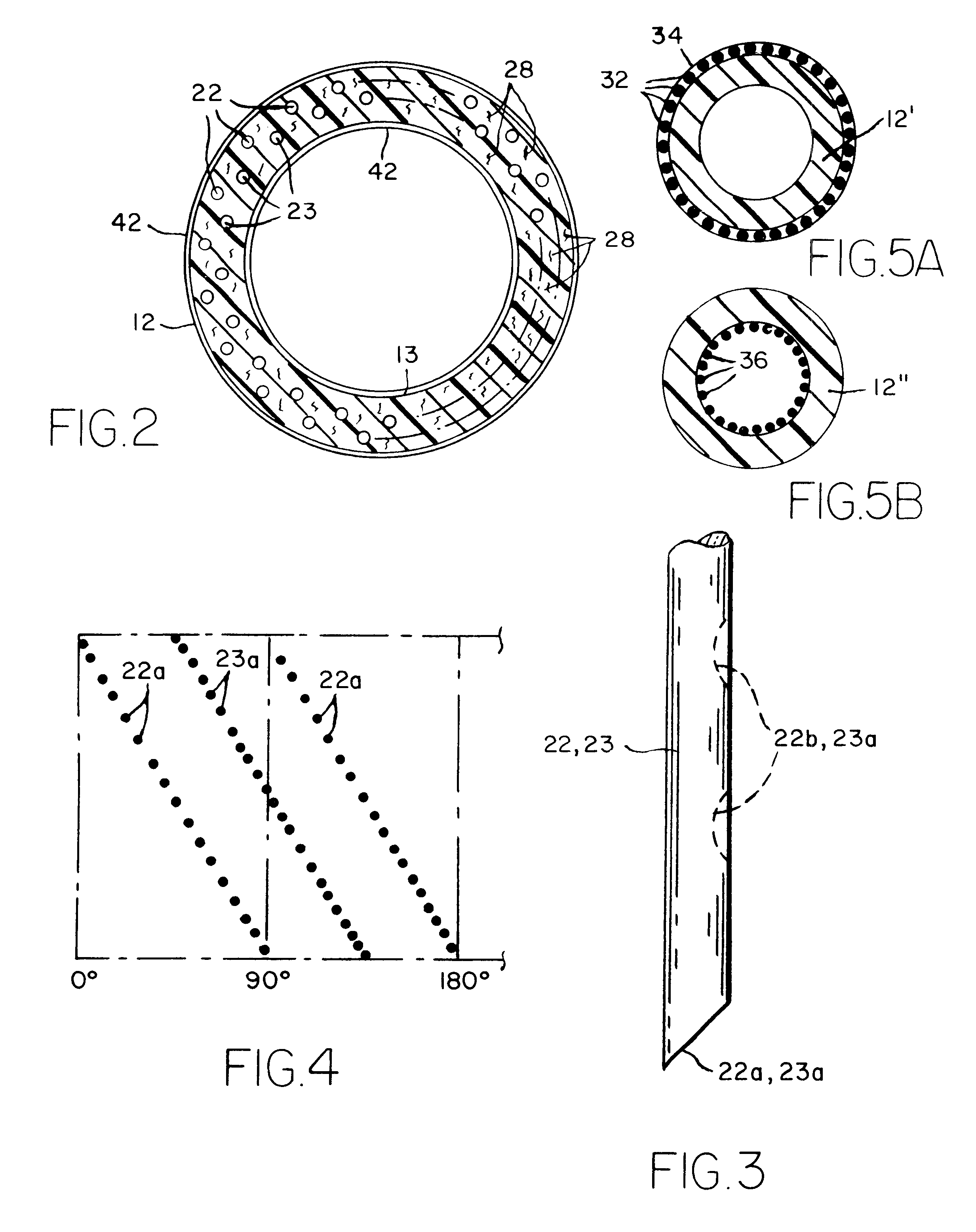

Method and apparatus to prevent infections

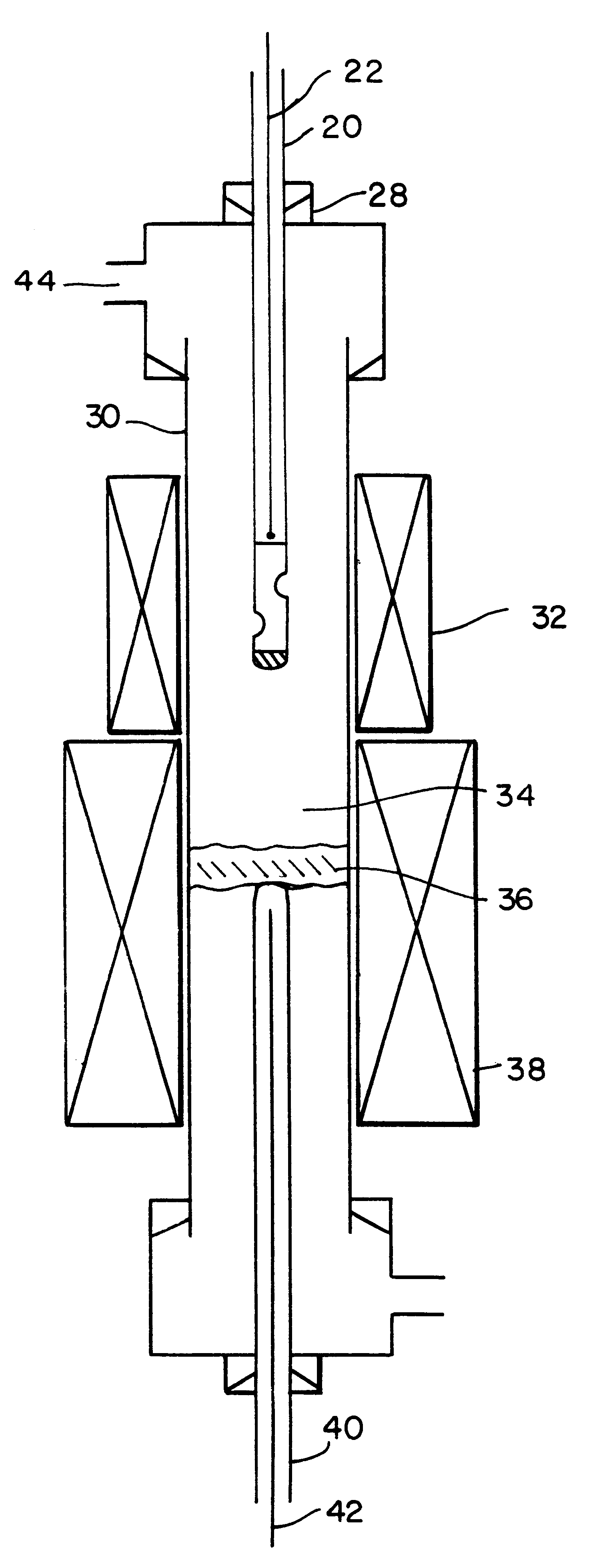

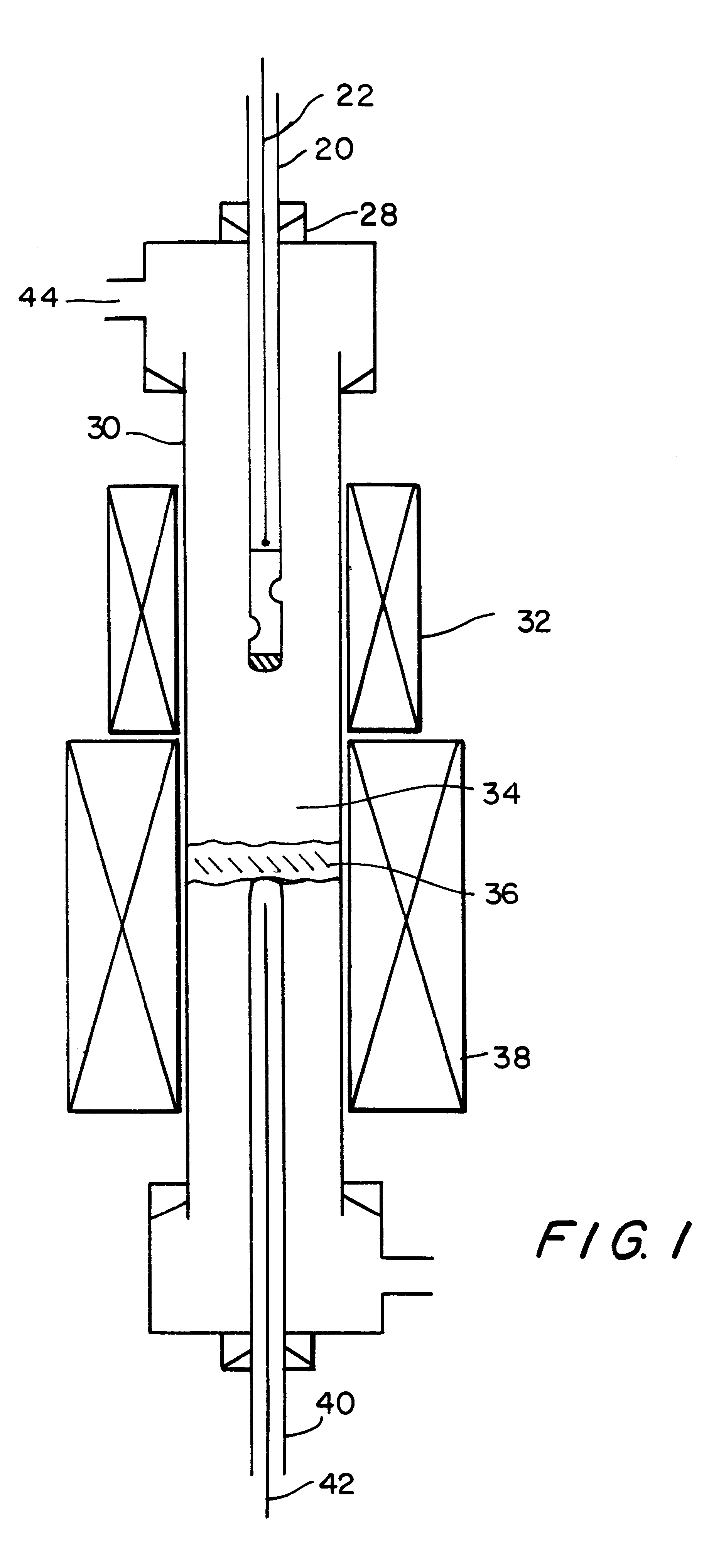

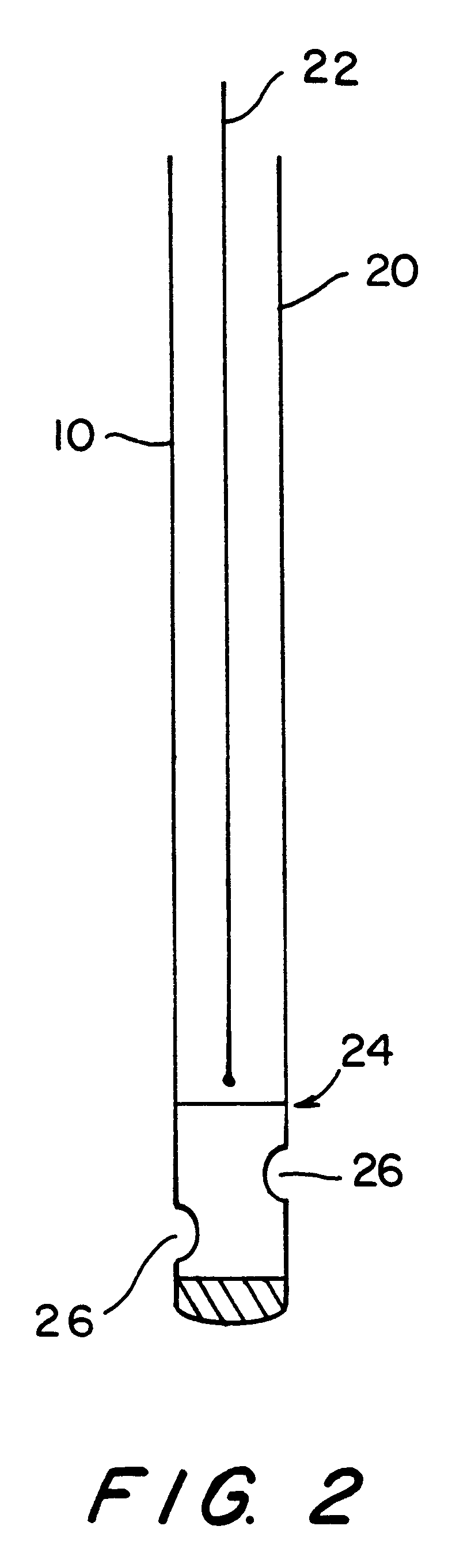

InactiveUS6551346B2Avoid infectionInhibition of colonizationElectrotherapySurgical instrument detailsPhotosensitizerLight energy

A photosensitizer together with complementary light energy are used to prevent the development of infection associated with an indwelling medical catheter or device. Light of a selected wavelength or wavelength band is coupled to the catheter or device and transmitted by a wall or walls thereof to one or both of the external and internal surfaces thereof. The catheter or device also incorporates at least one photosensitizer which releases a toxic substance when activated by the light energy which destroys bacteria on or around the catheter or device. A method of preventing infection using photosensitizers and complementary light energy is also disclosed.

Owner:CHAMPION ENT PROD INC

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS20020086501A1High purityIncrease resistanceFrom solid stateVacuum evaporation coatingMetallurgySemiconductor

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

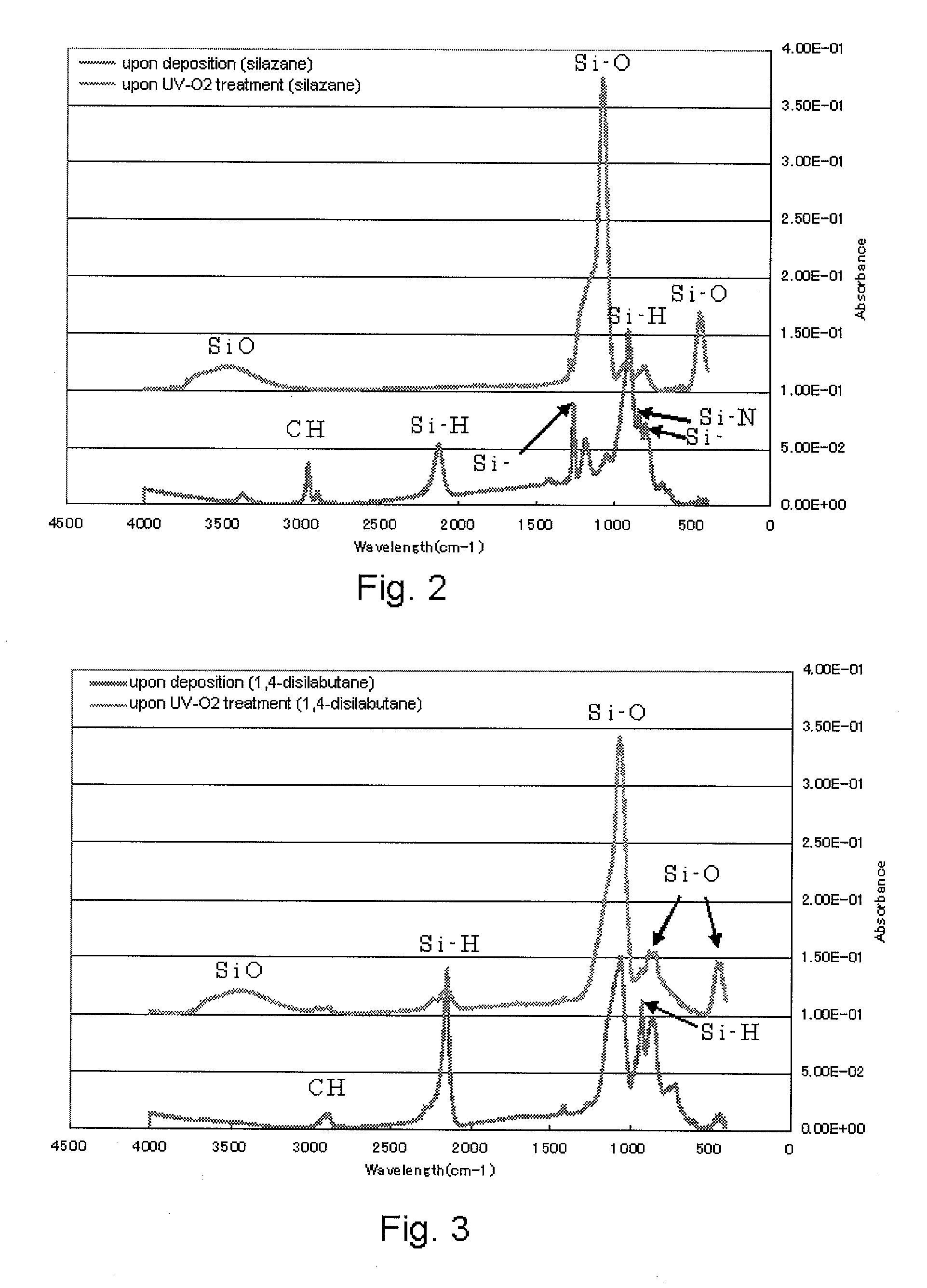

Method for forming low-carbon CVD film for filling trenches

ActiveUS20100143609A1Semiconductor/solid-state device manufacturingSolid state diffusion coatingBoiling pointSilicon membrane

A method of forming a low-carbon silicon-containing film by CVD on a substrate having trenches includes: introducing a silicon-containing compound having three or less hydrocarbon units in its molecule and having a boiling temperature of 35° C. to 220° C.; applying RF power to the gas; and depositing a film on a substrate having trenches wherein the substrate is controlled at a temperature such that components of the silicon-containing compound are at least partially liquidified on the substrate, thereby filling the trenches with the film.

Owner:ASM JAPAN

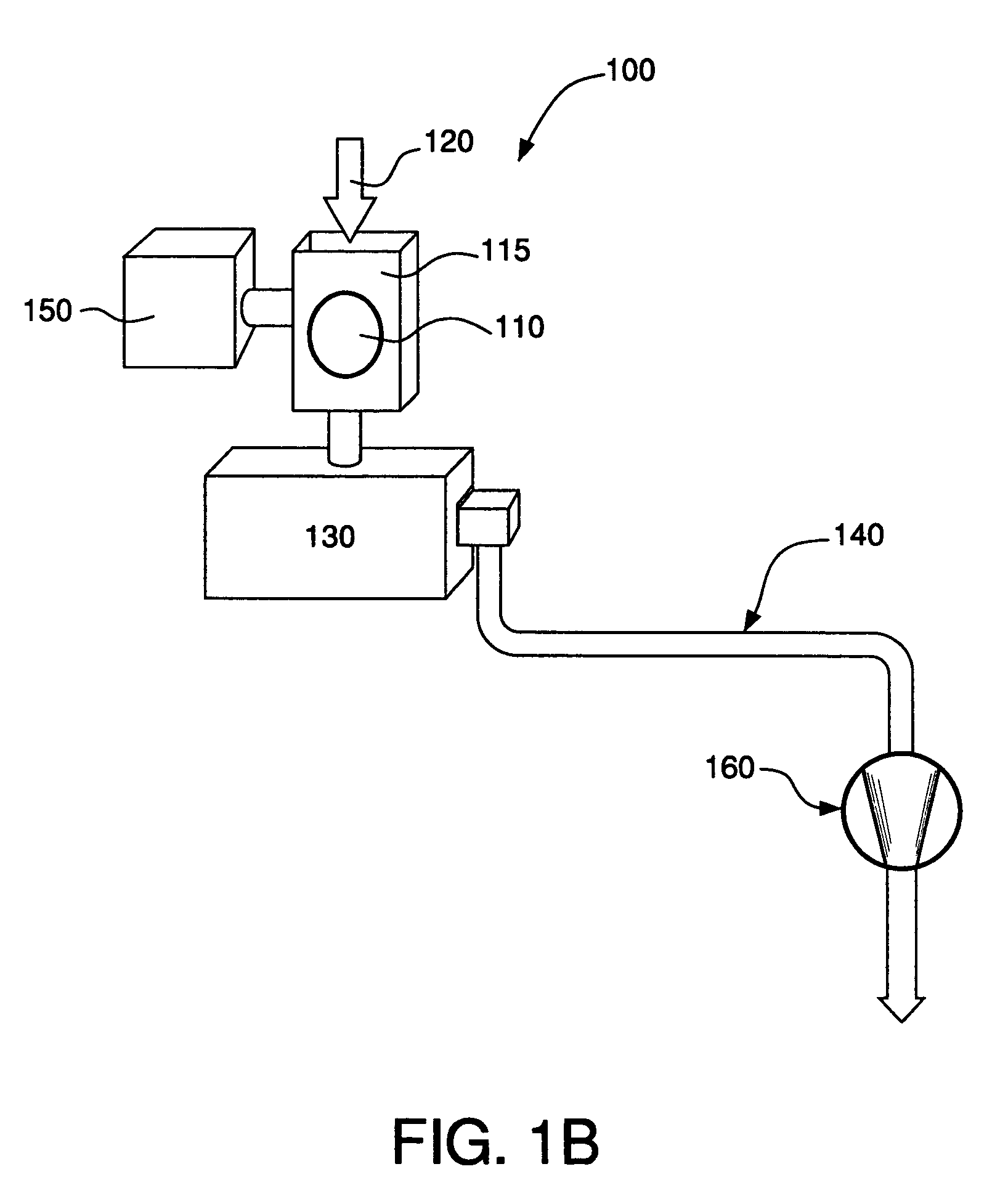

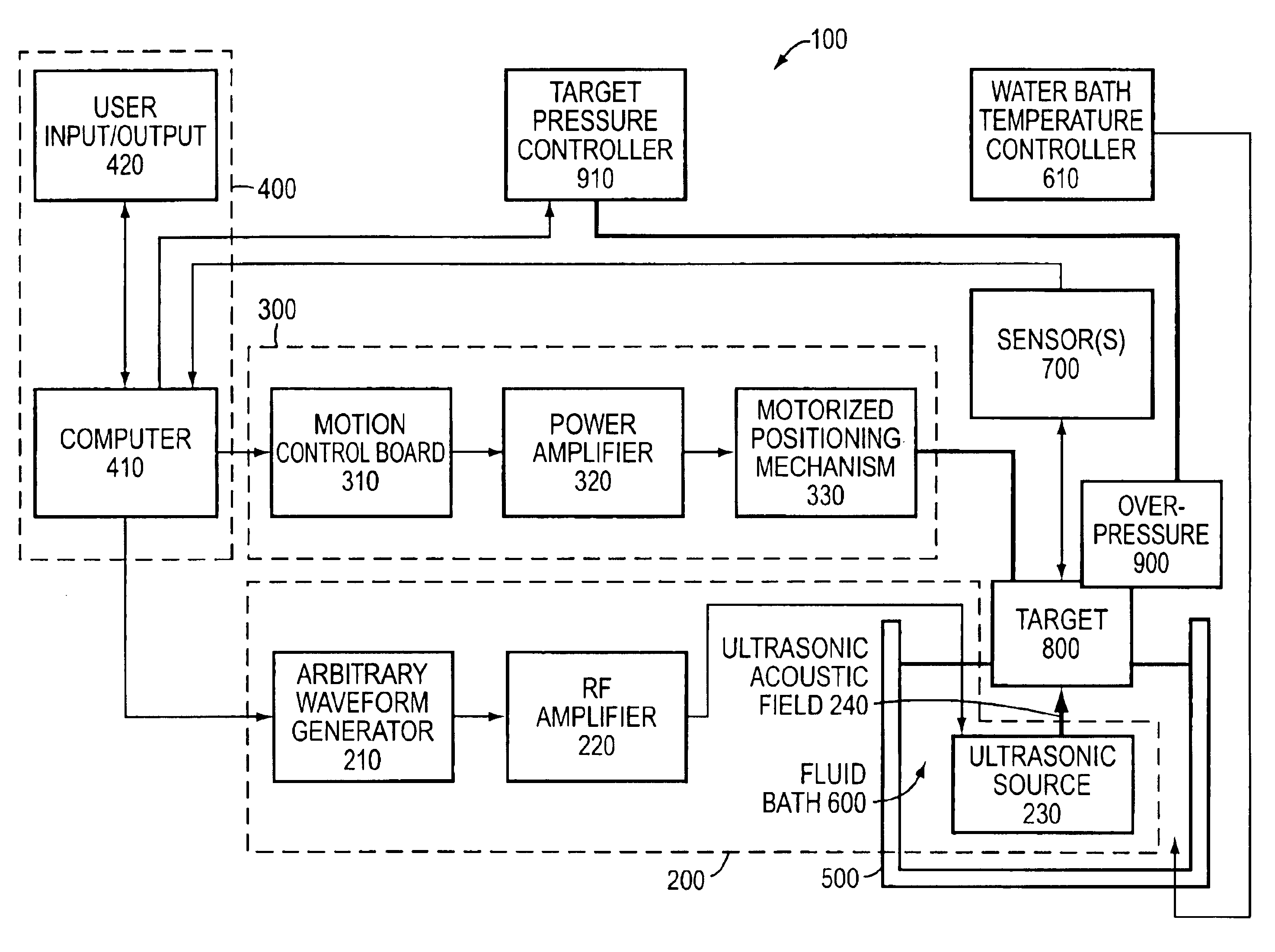

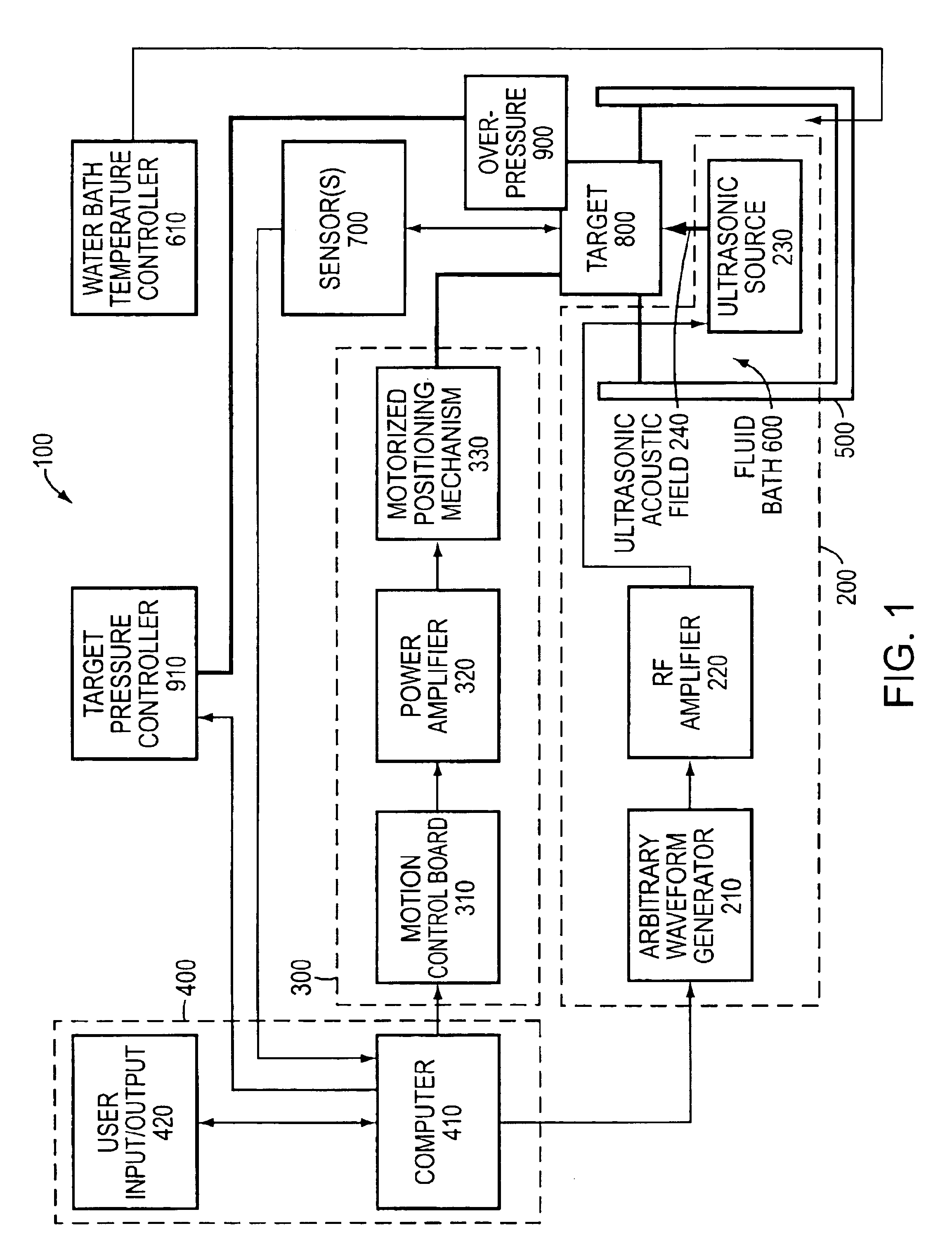

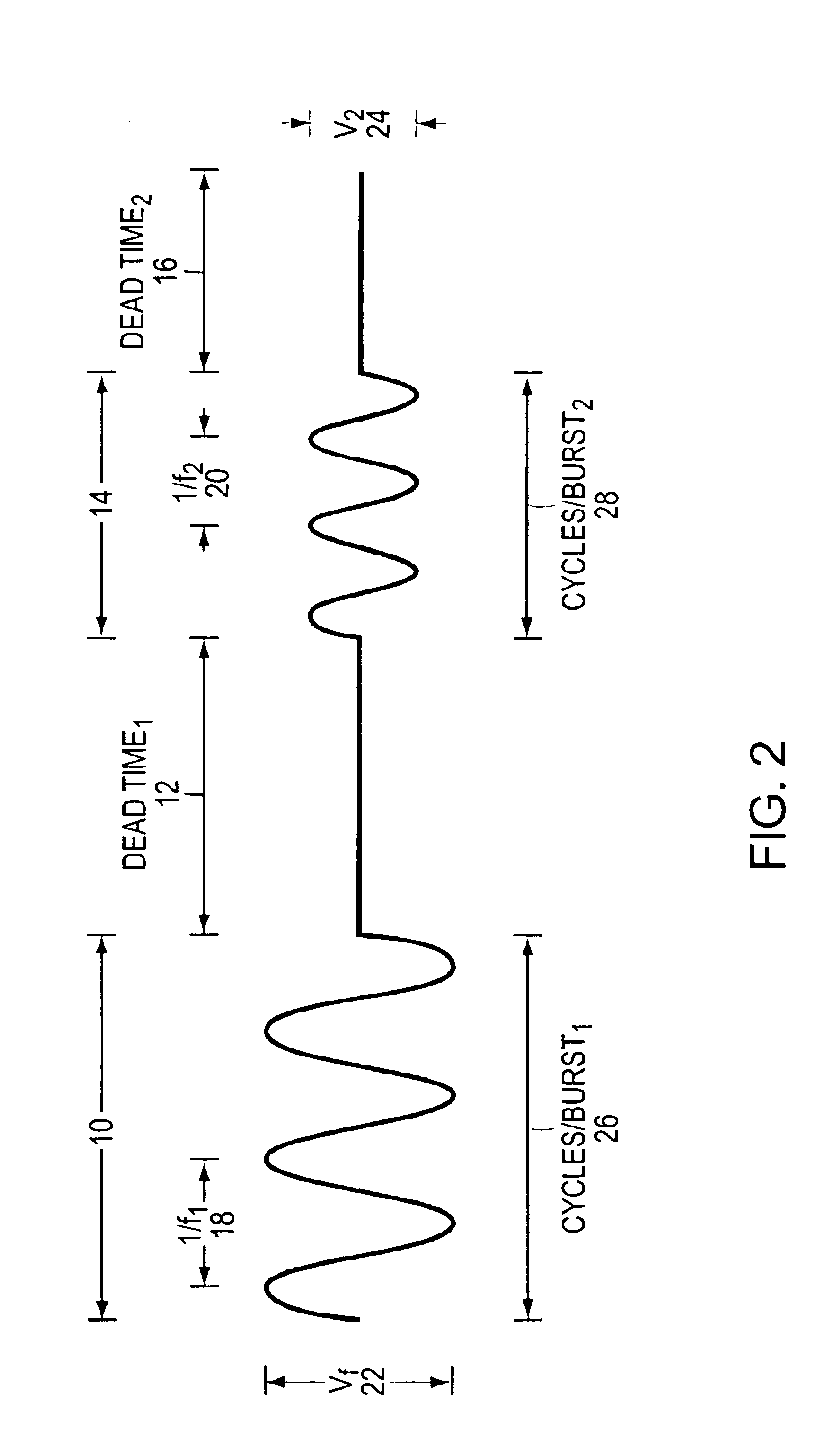

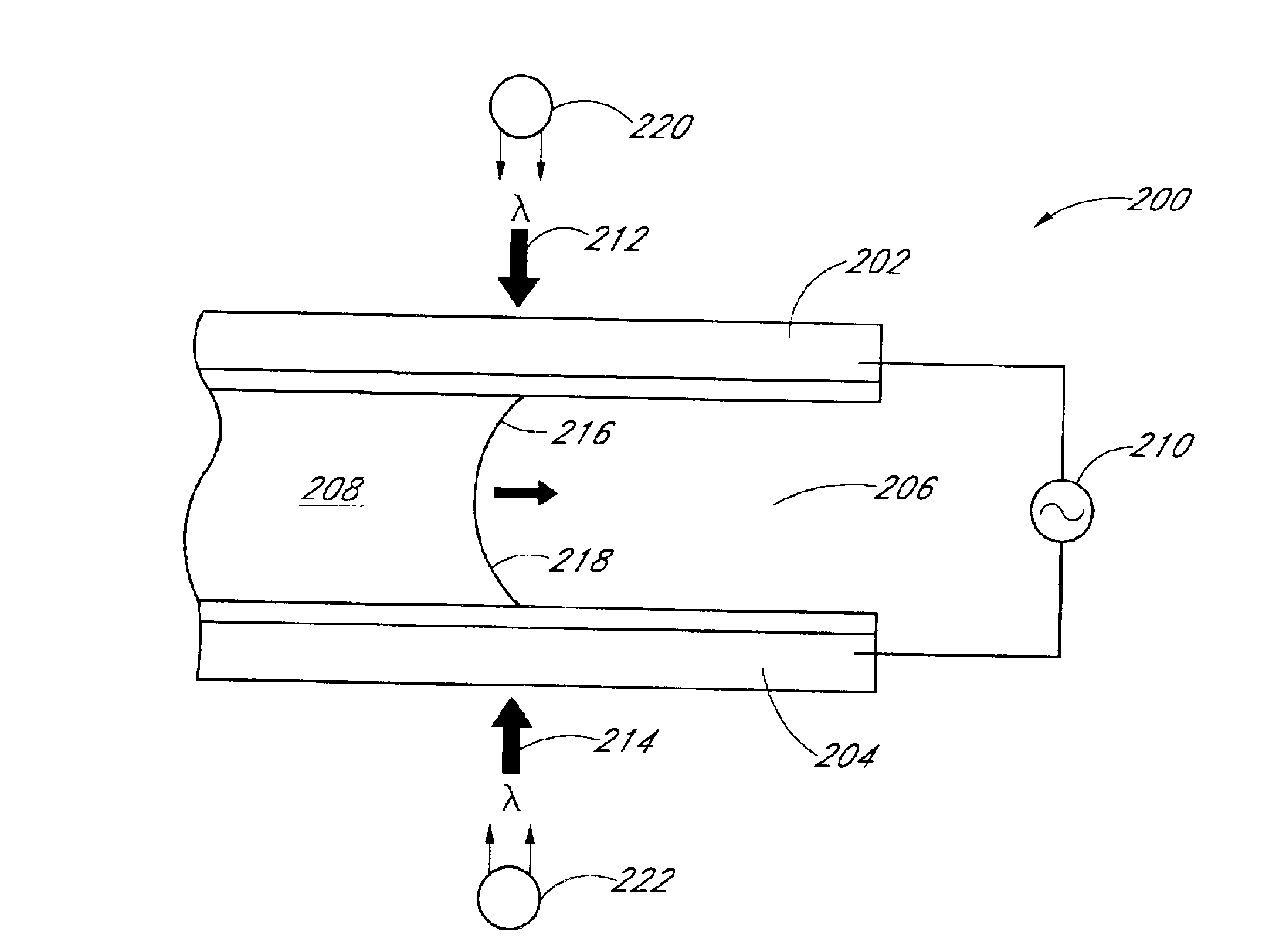

Method and apparatus for acoustically controlling liquid solutions in microfluidic devices

InactiveUS6948843B2Improve reaction speedAccelerating molecular interactionSequential/parallel process reactionsShaking/oscillating/vibrating mixersSound sourcesAcoustic energy

Acoustic energy is used to control motion in a fluid. According to one embodiment, the invention directs acoustic energy at selected naturally occurring nucleation features to control motion in the fluid. In another embodiment, the invention provides focussed or unfocussed acoustic energy to selectively placed nucleation features to control fluid motion. According to one embodiment, the invention includes an acoustic source, a controller for controlling operation of the acoustic source, and one or more nucleation features located proximate to or in the fluid to be controlled.

Owner:COVARIS INC

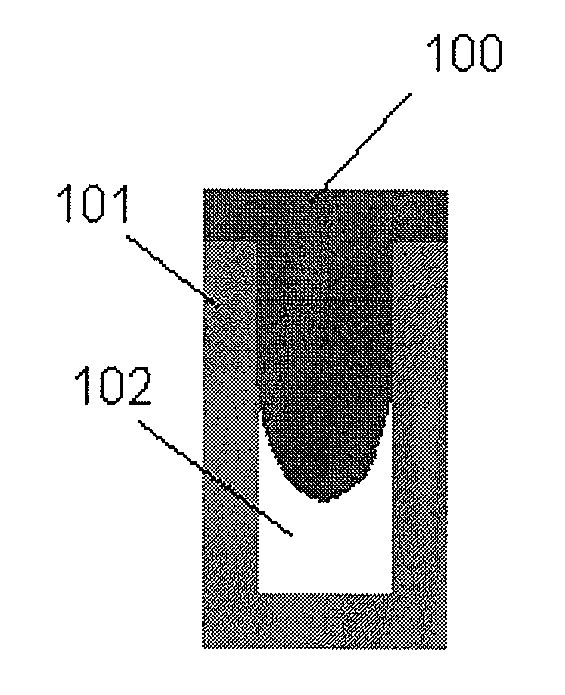

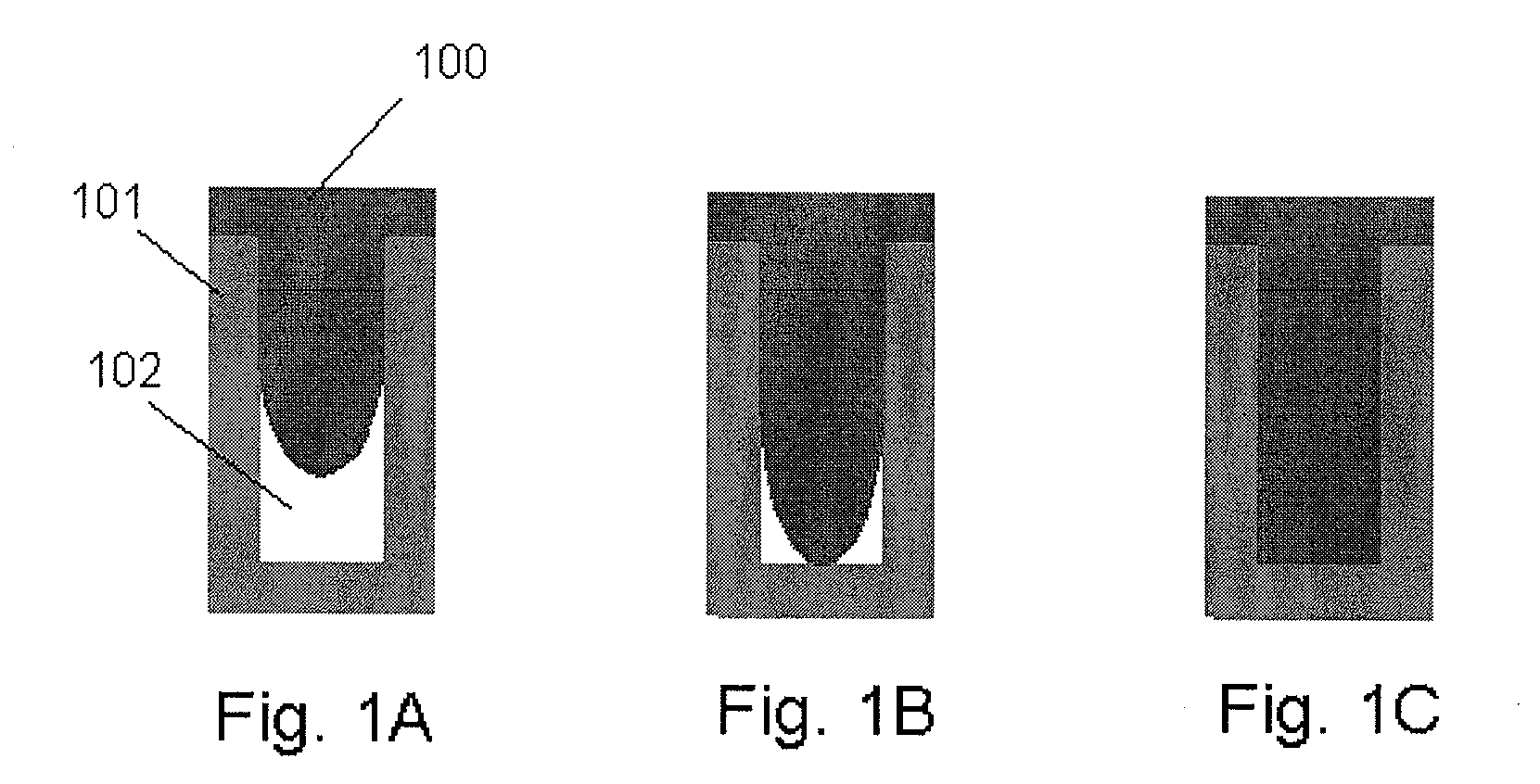

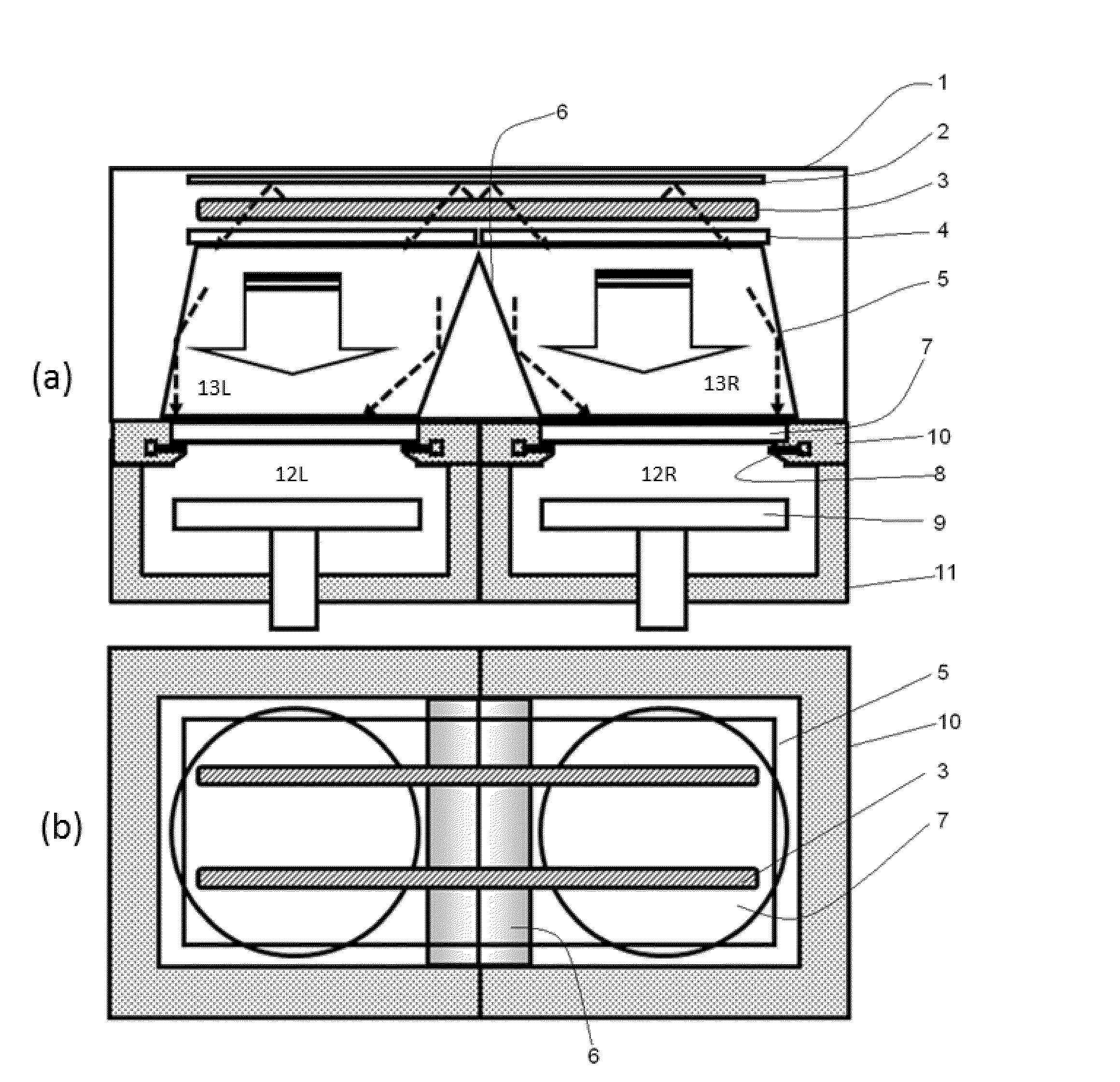

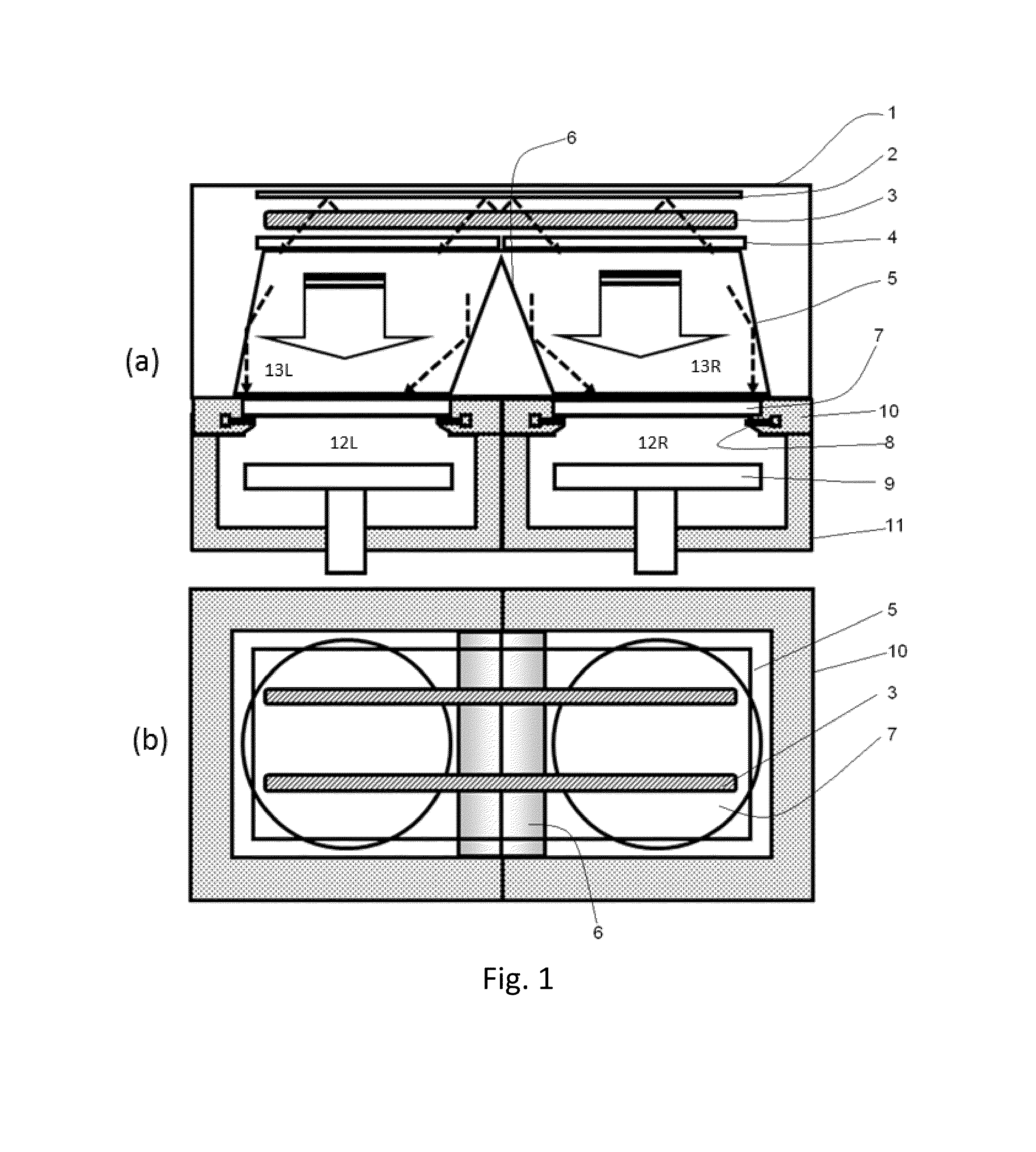

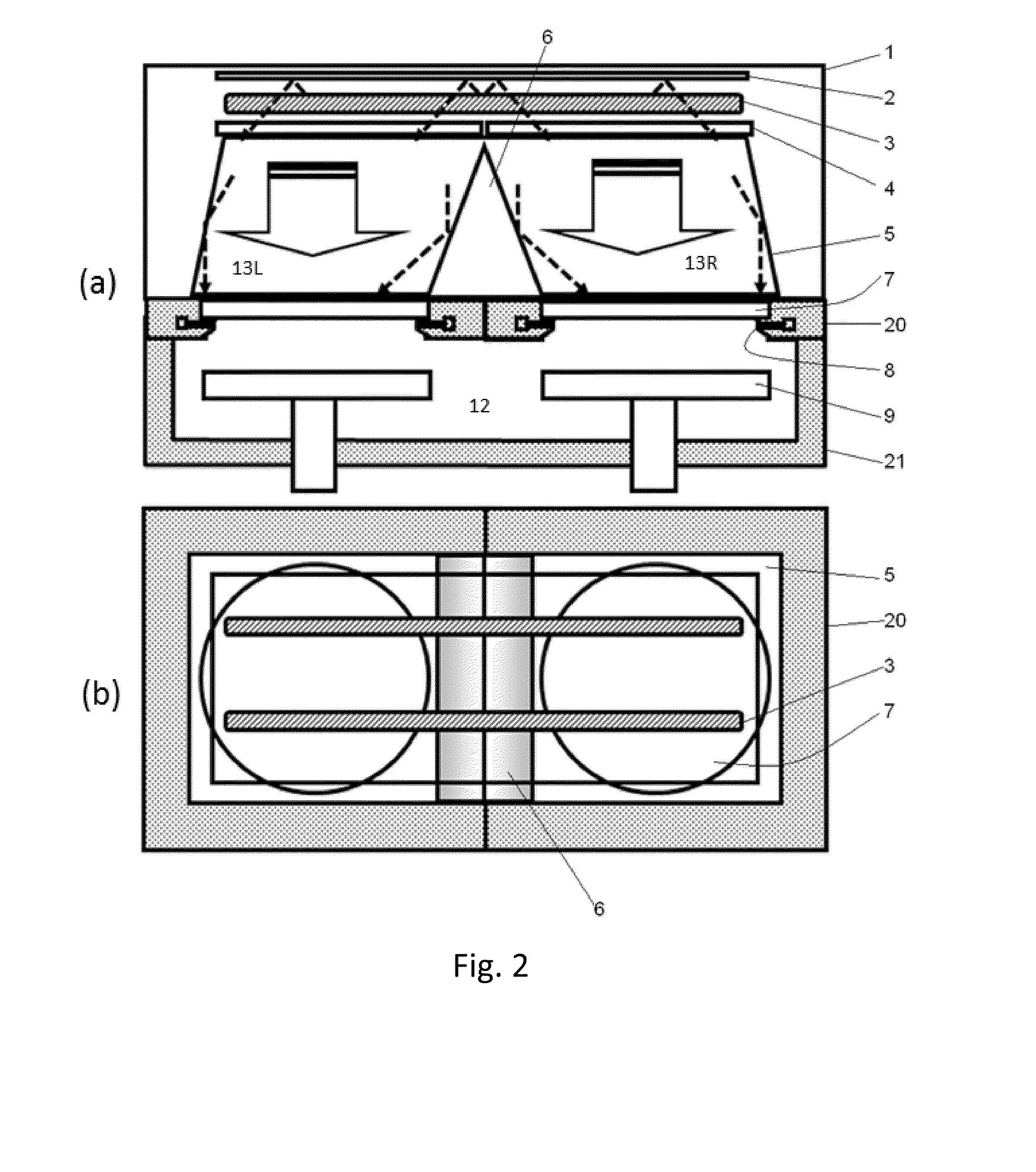

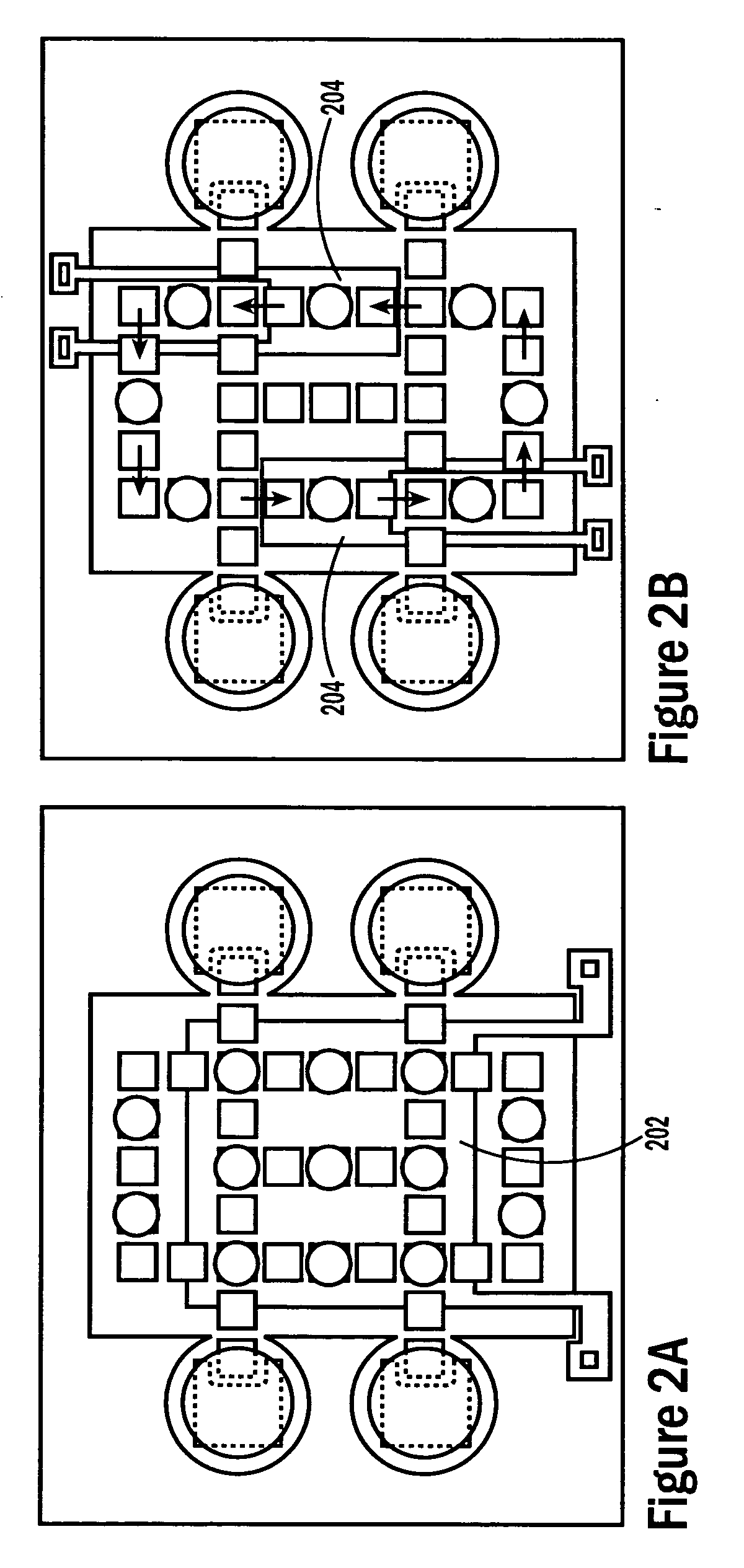

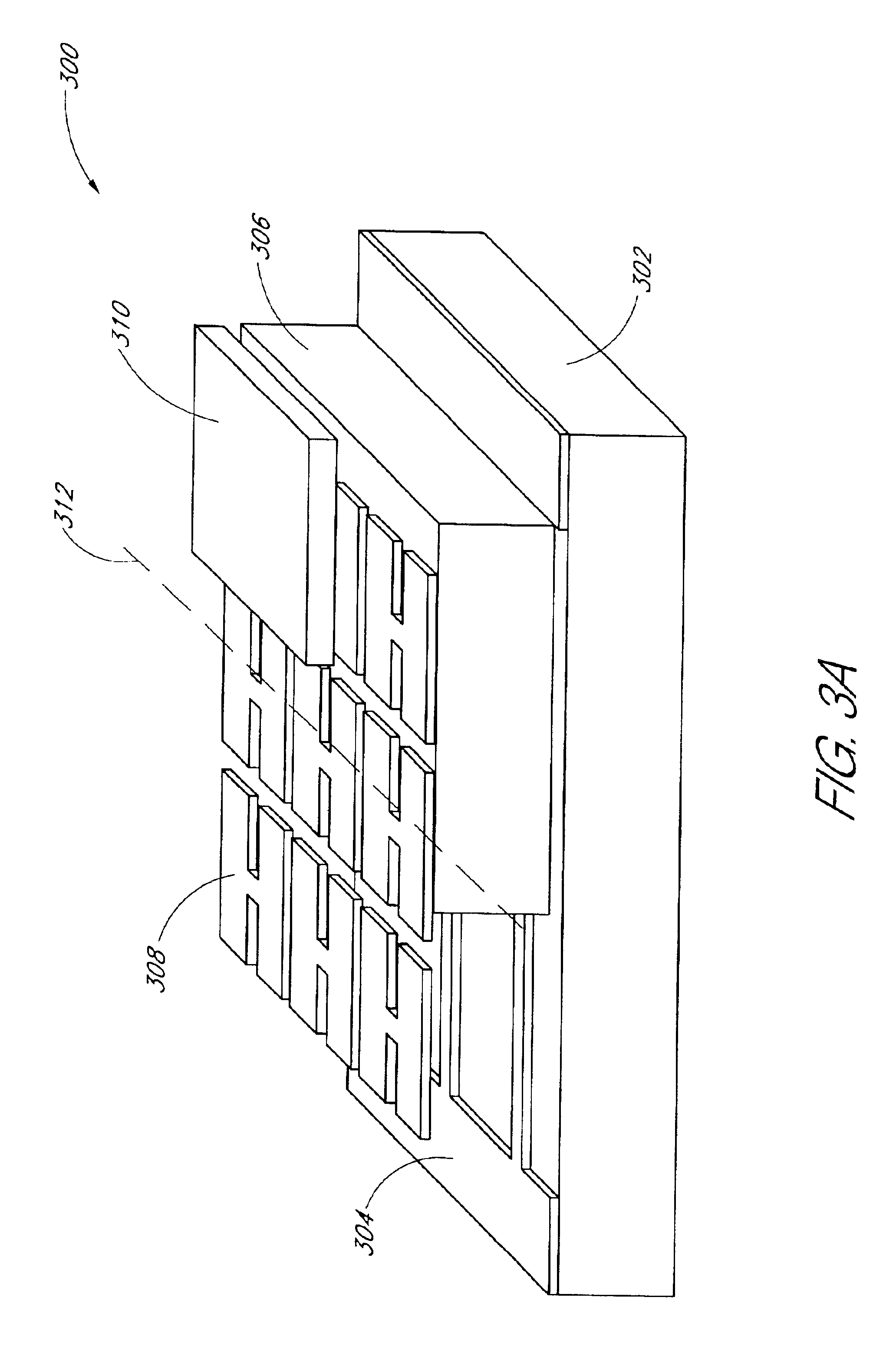

UV Irradiation Apparatus Having UV Lamp-Shared Multiple Process Stations

InactiveUS20130068970A1Simple systemEffective exposureSemiconductor/solid-state device manufacturingEnergy based chemical/physical/physico-chemical processesUltravioletEngineering

A UV irradiation apparatus for treating substrates includes: at least two process stations each provided with a UV transmissive window; at least one electric UV lamp using two electrodes in a gas tube extending over the UV transmissive windows of the process stations aligned along the gas tube and shared by the process stations; a UV transmissive zone disposed between the UV lamp and the process stations and provided with reflectors; and shutters for blocking UV light from being transmitted to the respective process stations independently.

Owner:ASM JAPAN

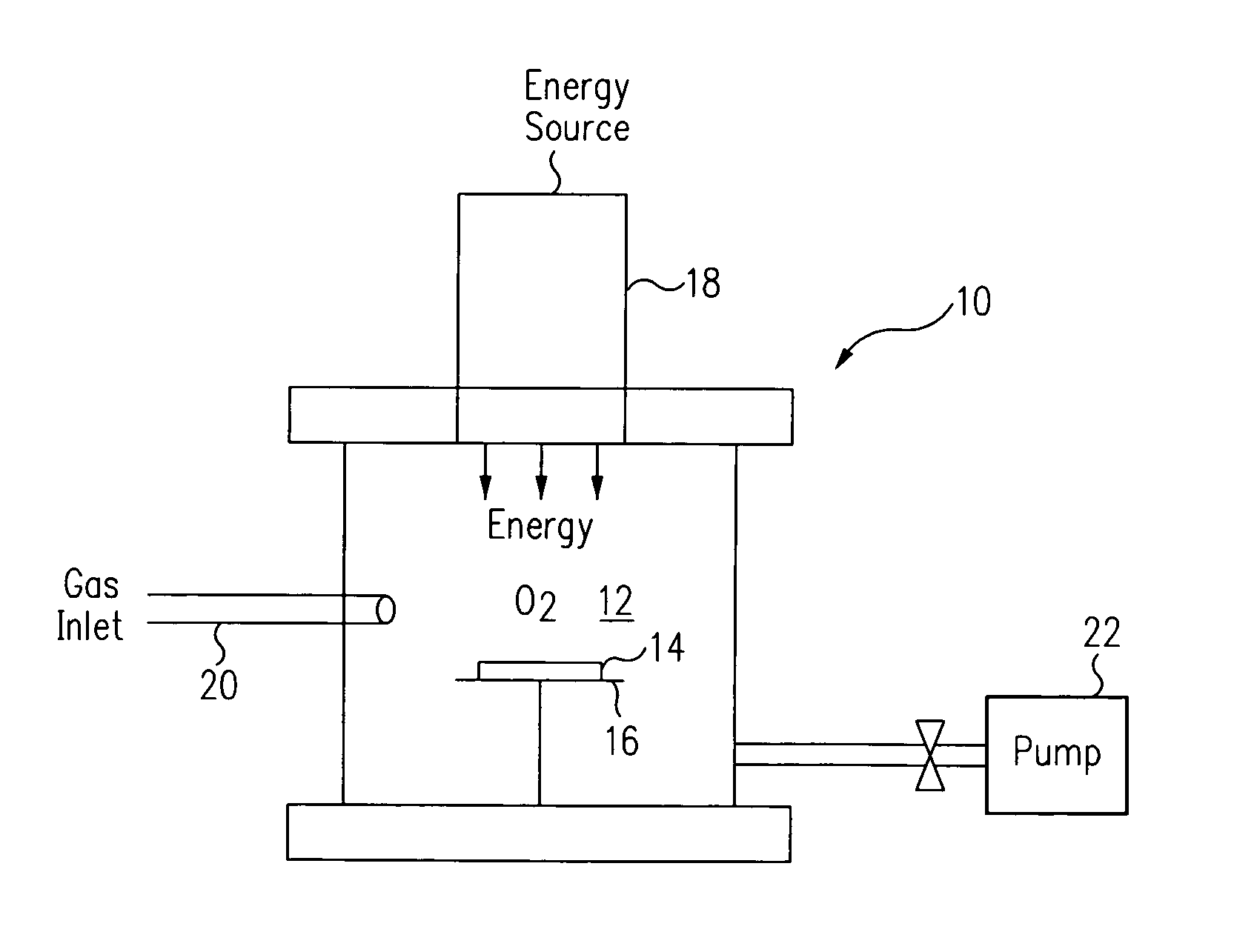

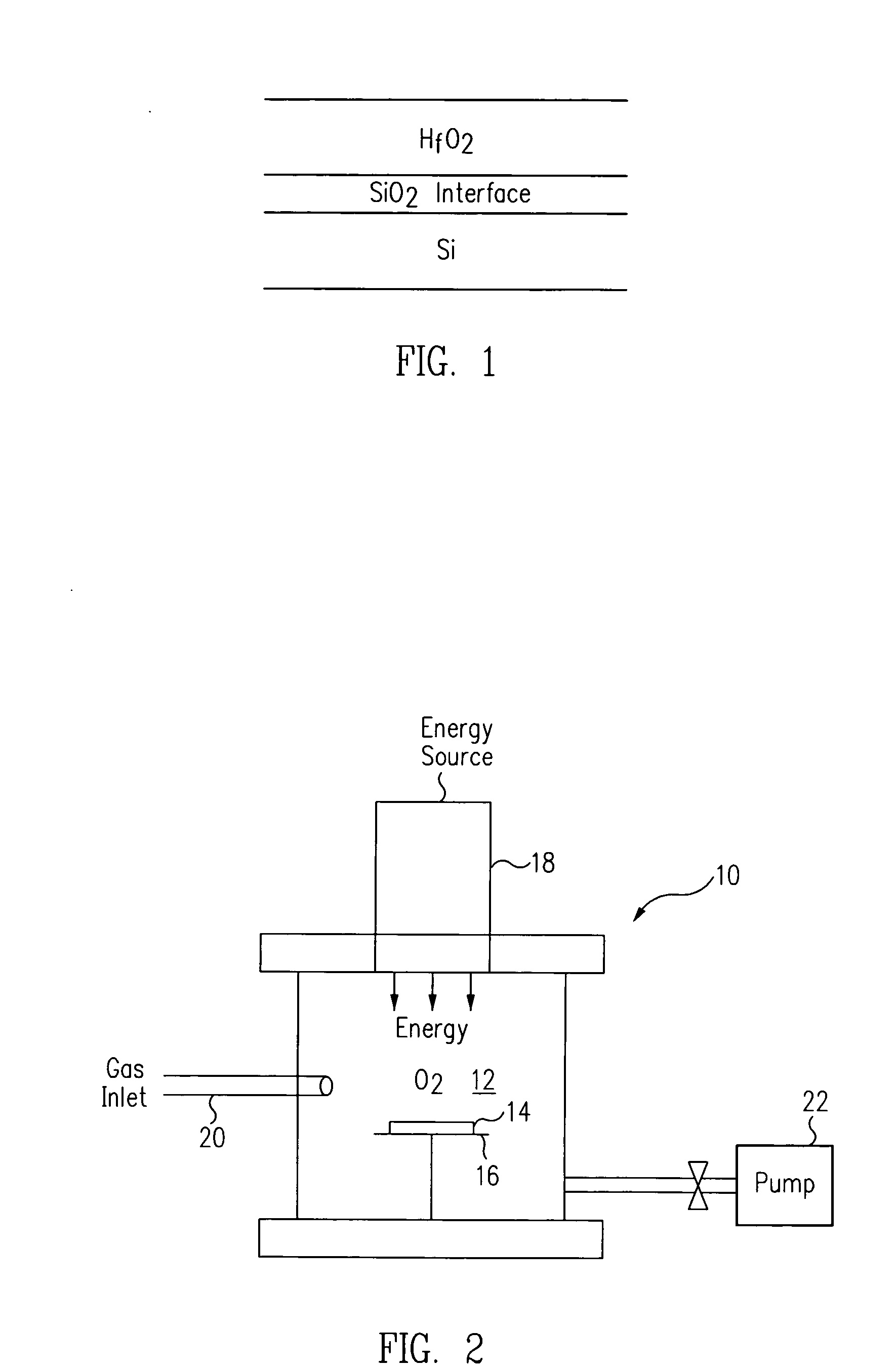

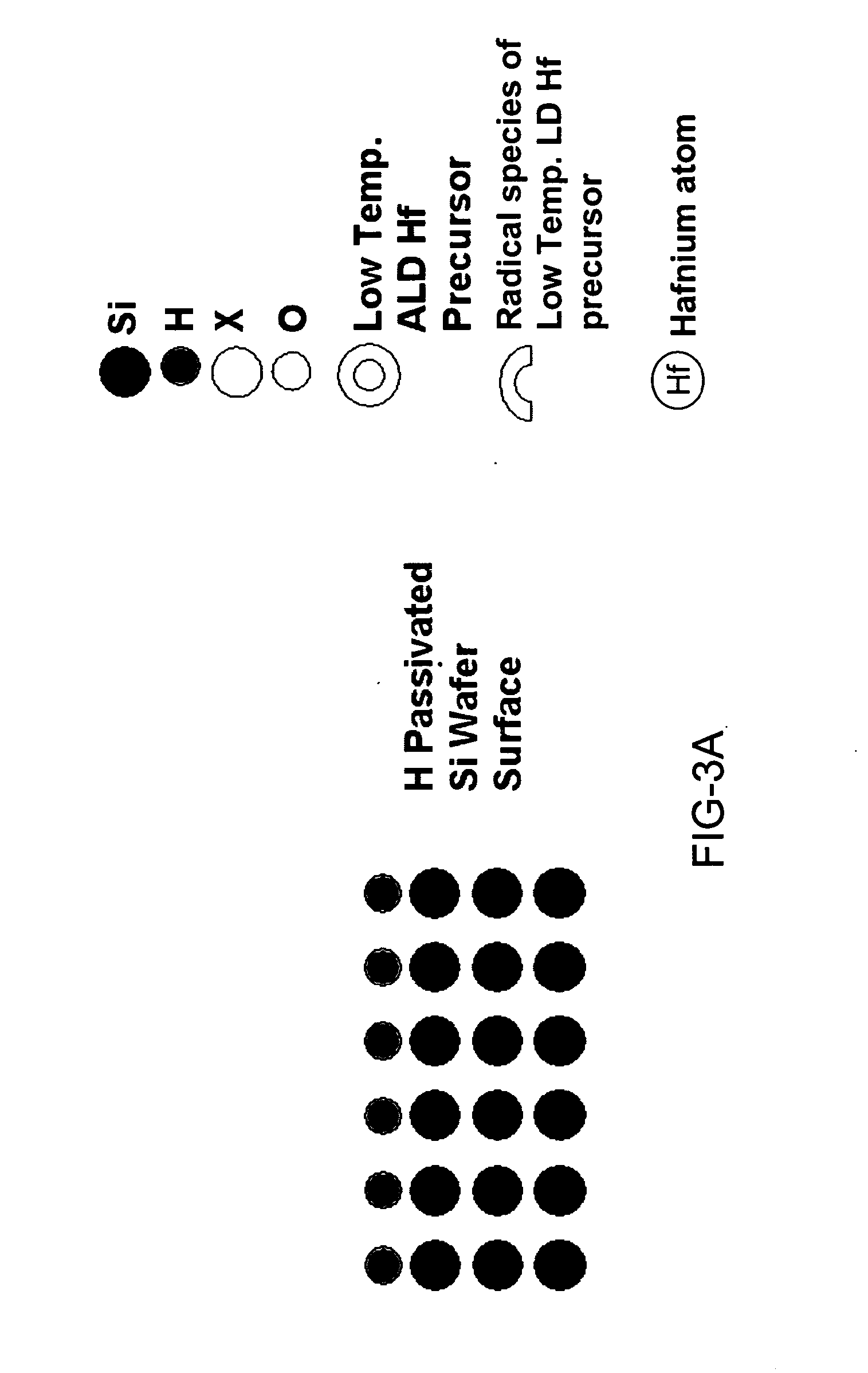

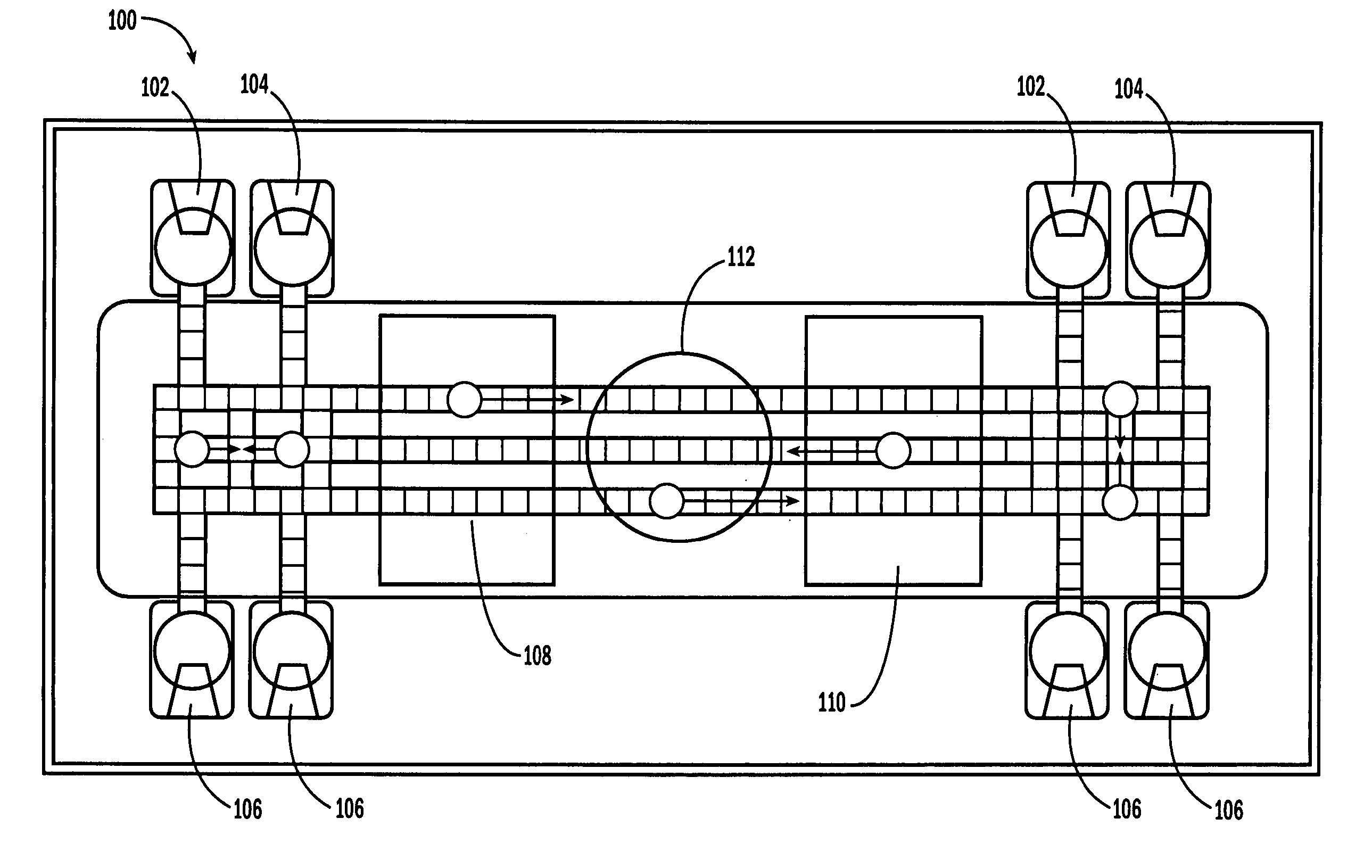

Method for energy-assisted atomic layer deposition and removal

InactiveUS20050175789A1High energyGood initiativeSemiconductor/solid-state device manufacturingPretreated surfacesProduct gasElectromagnetic radiation

A method for energy-assisted atomic layer deposition and removal of a dielectric film are provided. In one embodiment a substrate is placed into a reaction chamber and a gaseous precursor is introduced into the reaction chamber. Energy is provide by a pulse of electromagnetic radiation which forms radical species of the gaseous precursor. The radical species react with the surface of the substrate to form a radical terminated surface on the substrate. The reaction chamber is purged and a second gaseous precursor is introduced. A second electromagnetic radiation pulse is initiated and forms second radical species. The second radical species of the second gas react with the surface to form a film on the substrate. Alternately, the gaseous species can be chosen to produce radicals that result in the removal of material from the surface of the substrate.

Owner:HELMS JR AUBREY L +3

Droplet-based particle sorting

InactiveUS20080053205A1Large facilityEasy to testSludge treatmentVolume/mass flow measurementChemical physicsParticle sorting

Owner:ADVANCED LIQUID LOGIC

Electromagnetic susceptors with coatings for artificial dielectric systems and devices

InactiveUS20030226840A1Enhanced radiationLow dielectric constantGas treatmentMethane captureChemical treatmentSusceptor

A coated susceptor of electromagnetic energy for chemical processing made of a matrix material that surrounds a non-matrix material that is made from a material that is different from the matrix material, in which the matrix material is constructed of material having lower dielectric losses compared to the non-matrix material, the non-matrix material initially absorbs electromagnetic energy applied to the electromagnetic susceptor to a greater extent than the matrix material, the non-matrix material produces subsequent heat in the matrix material, and the surface of the susceptor is coated with a material that interacts with applied electromagnetic energy of at least one frequency and initially absorbs electromagnetic energy and produces heat.

Owner:DALTON ROBERT C

Process for producing single wall nanotubes using unsupported metal catalysts

InactiveUS6221330B1Continuous and efficient productionMaterial nanotechnologyFibre chemical featuresHydrogenGas phase

A process for producing hollow, single-walled carbon nanotubes by catalytic decomposition of one or more gaseous carbon compounds by first forming a gas phase mixture carbon feed stock gas comprising one or more gaseous carbon compounds, each having one to six carbon atoms and only H, O, N, S or Cl as hetero atoms, optionally admixed with hydrogen, and a gas phase metal containing compound which is unstable under reaction conditions for said decomposition, and which forms a metal containing catalyst which acts as a decomposition catalyst under reaction conditions; and then conducting said decomposition reaction under decomposition reaction conditions, thereby producing said nanotubes.

Owner:HYPERION CATALYSIS INT

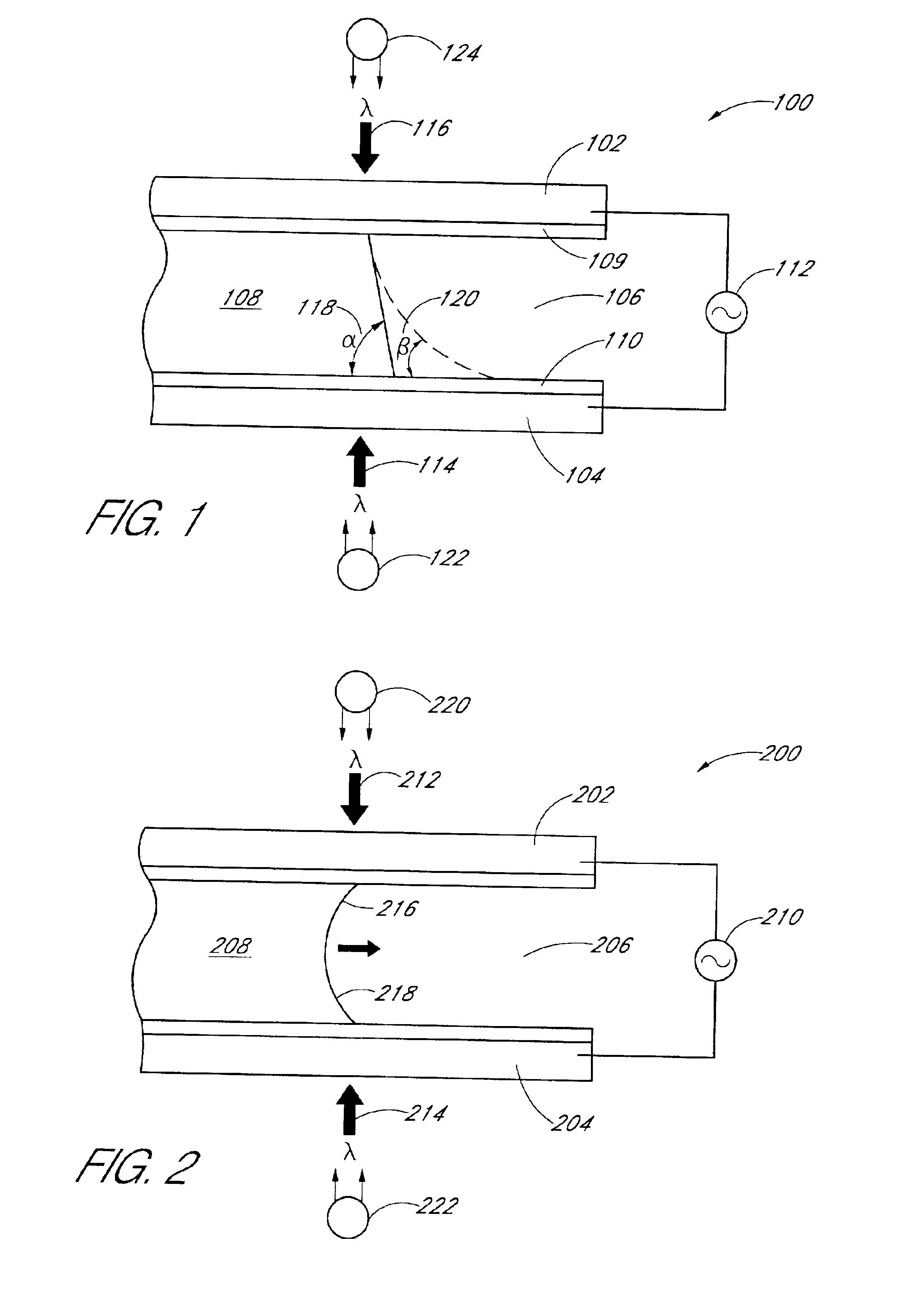

Systems and methods for optical actuation of microfluidics based on opto-electrowetting

InactiveUS6958132B2Improve performanceSludge treatmentMaterial analysis by electric/magnetic meansElectricityMicrofluidics

Owner:RGT UNIV OF CALIFORNIA

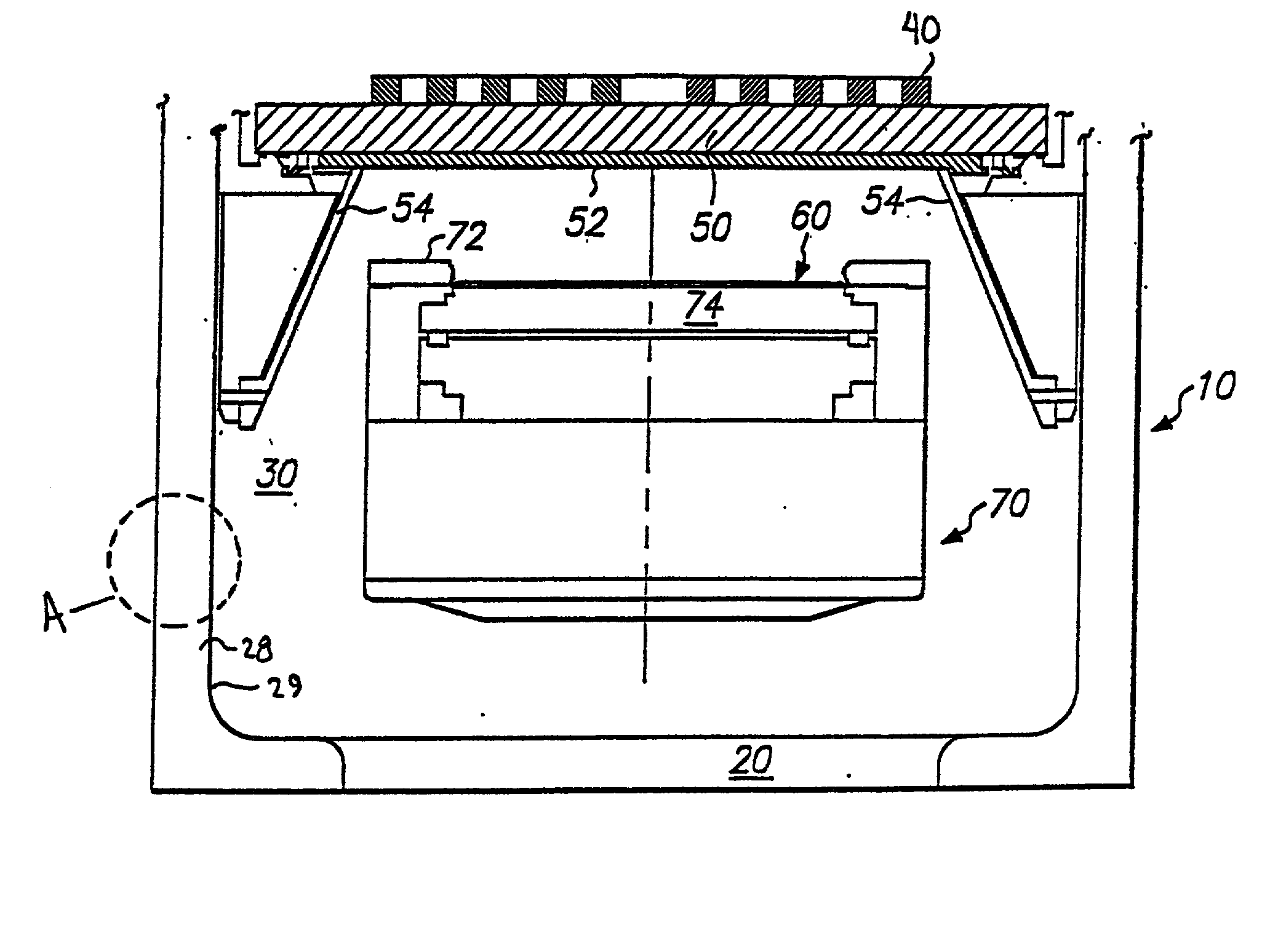

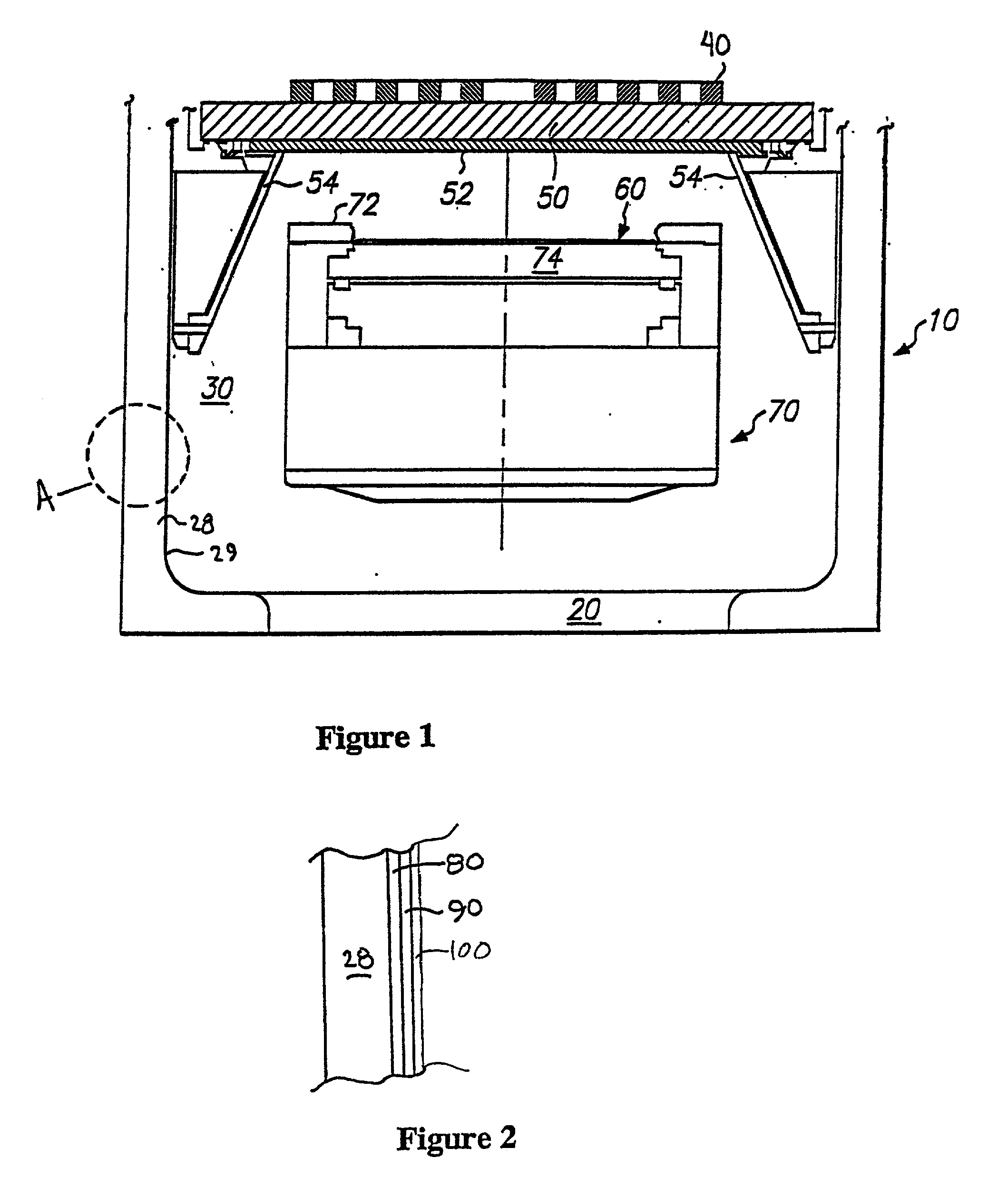

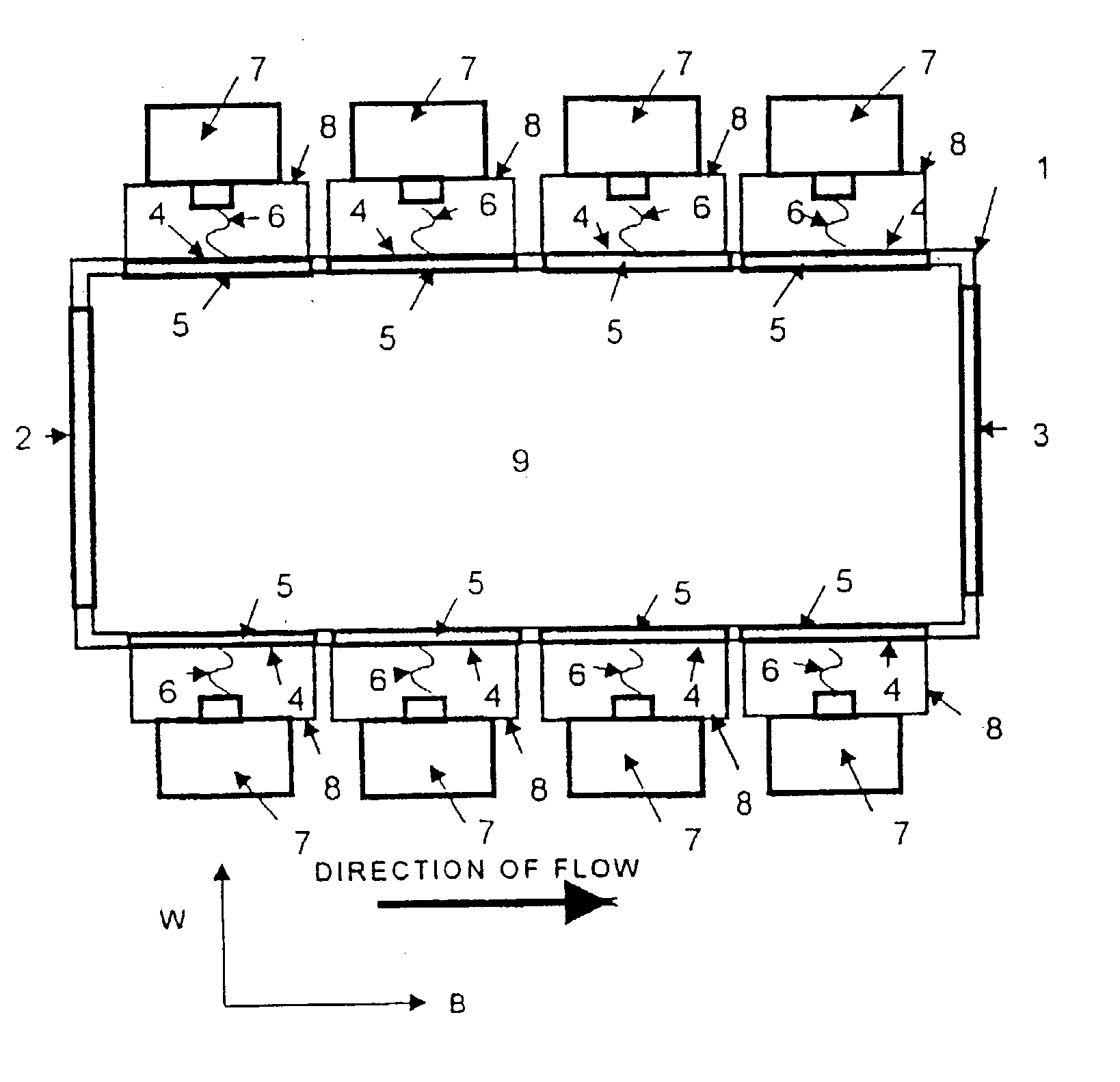

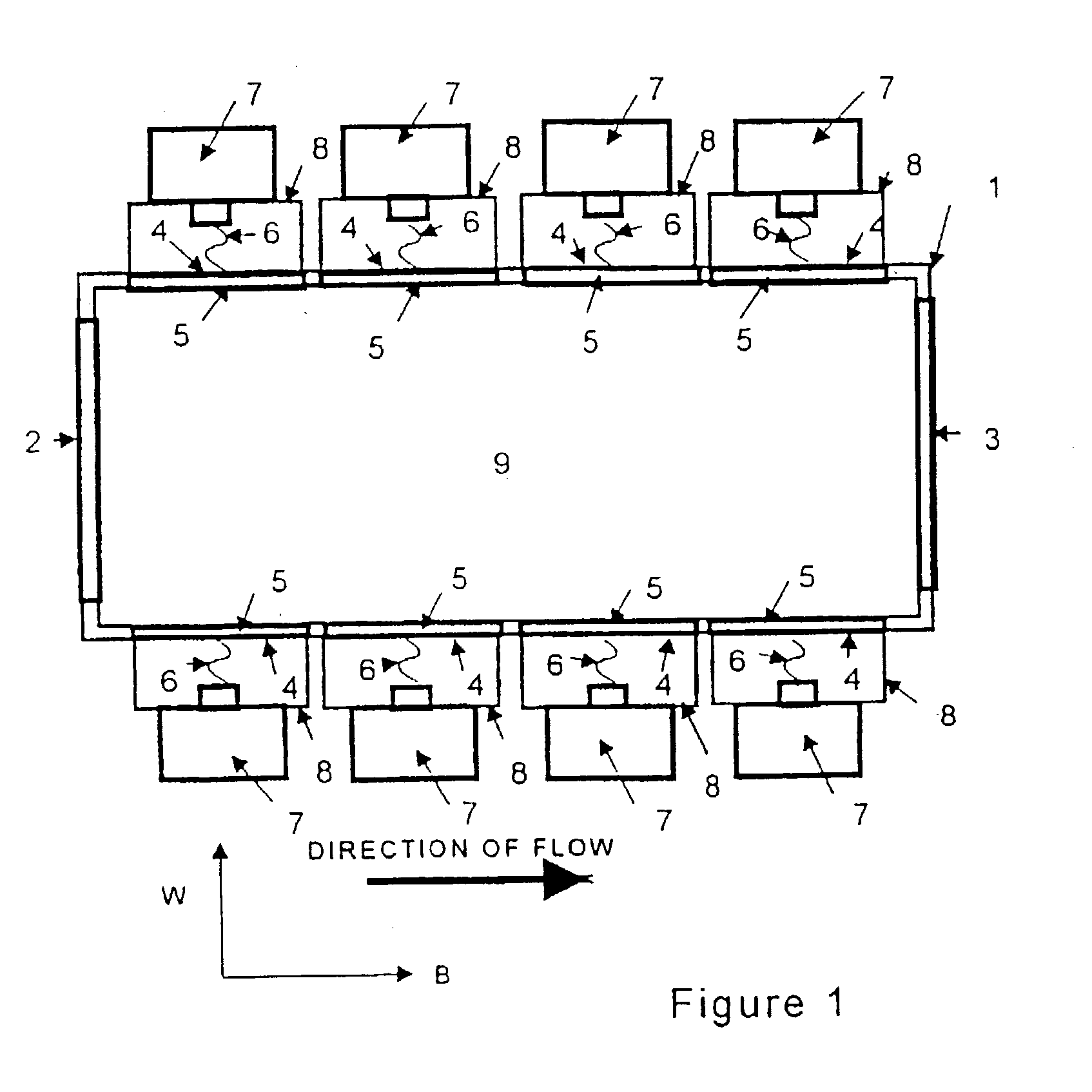

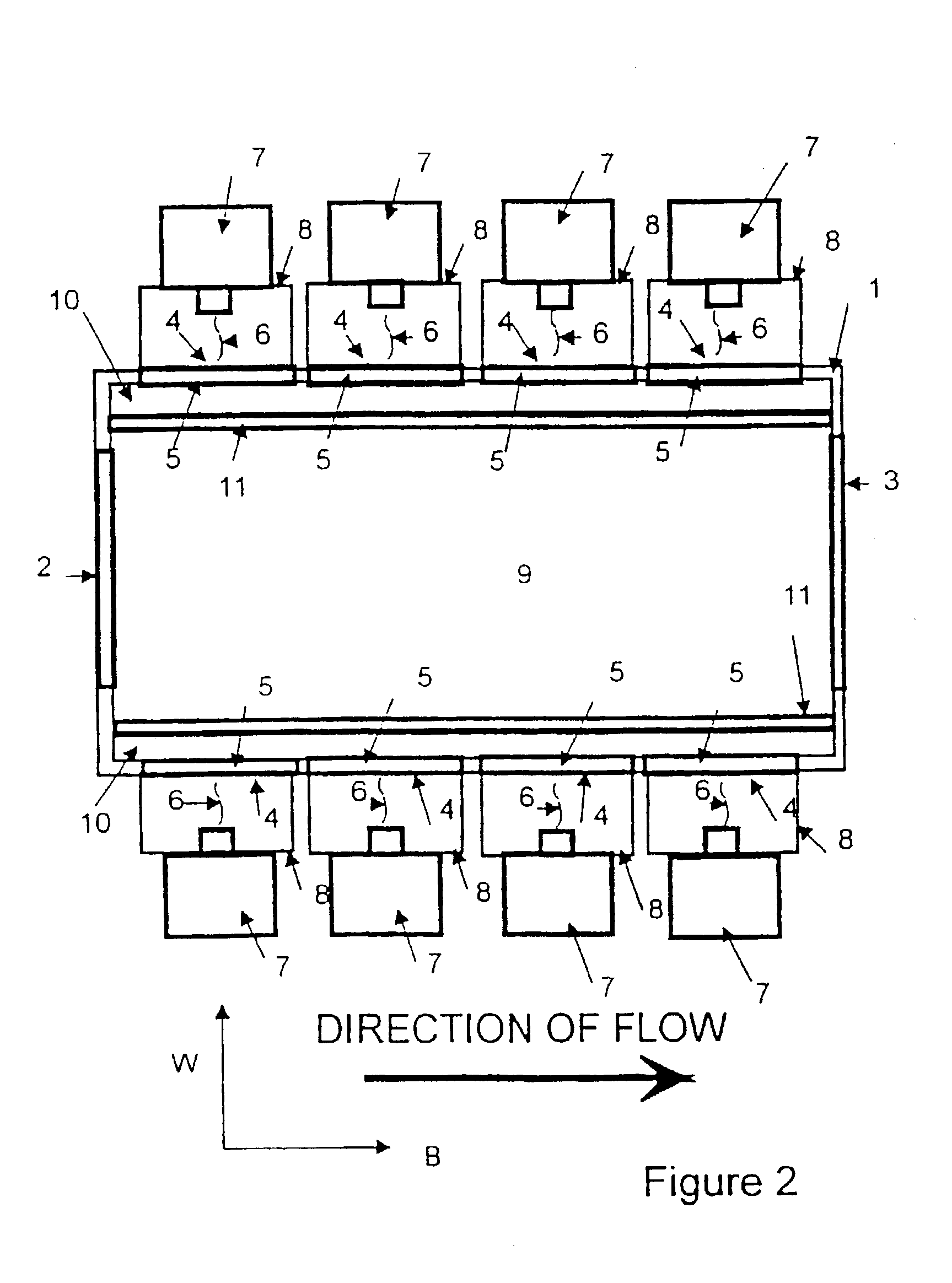

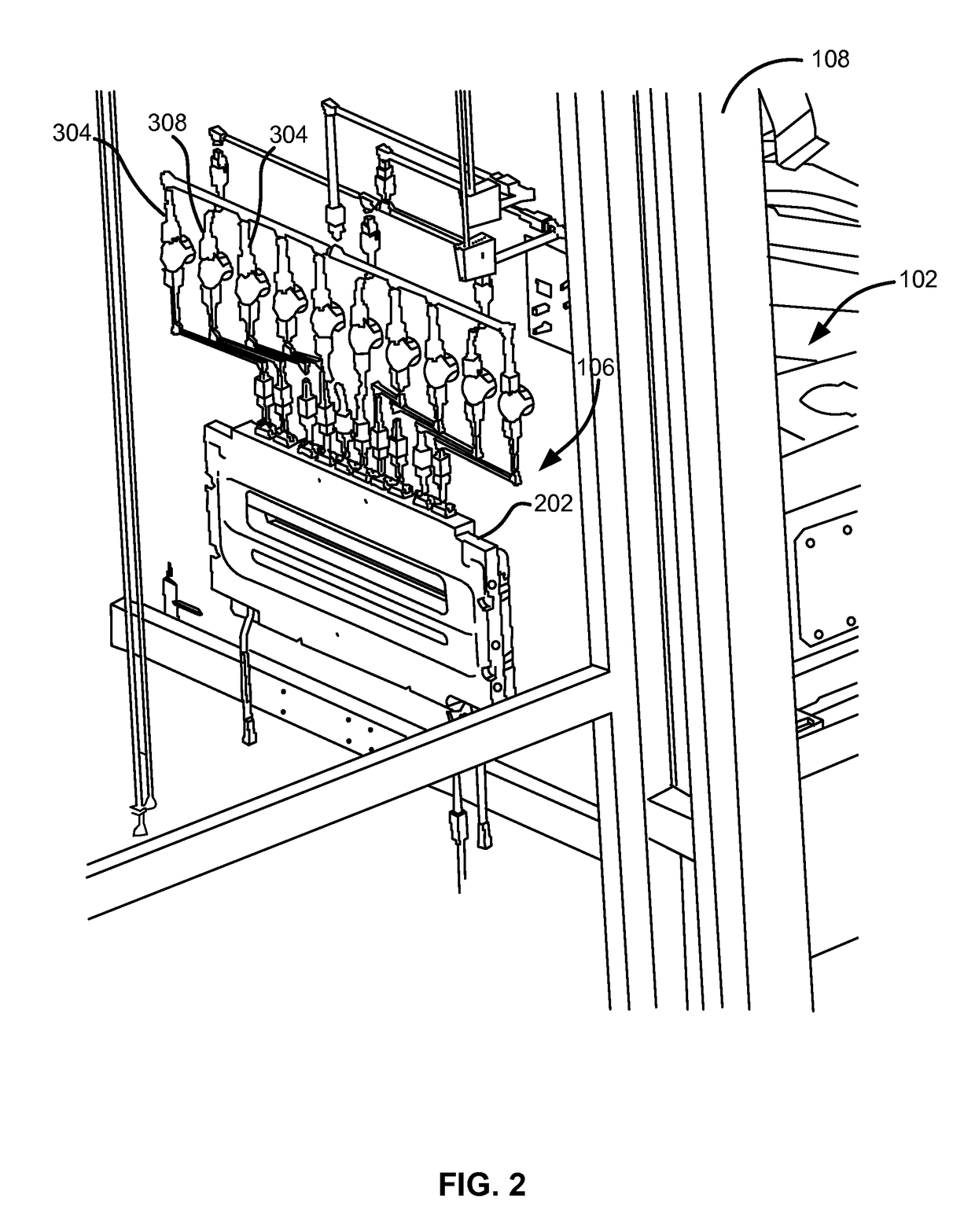

Gas distribution system, reactor including the system, and methods of using the same

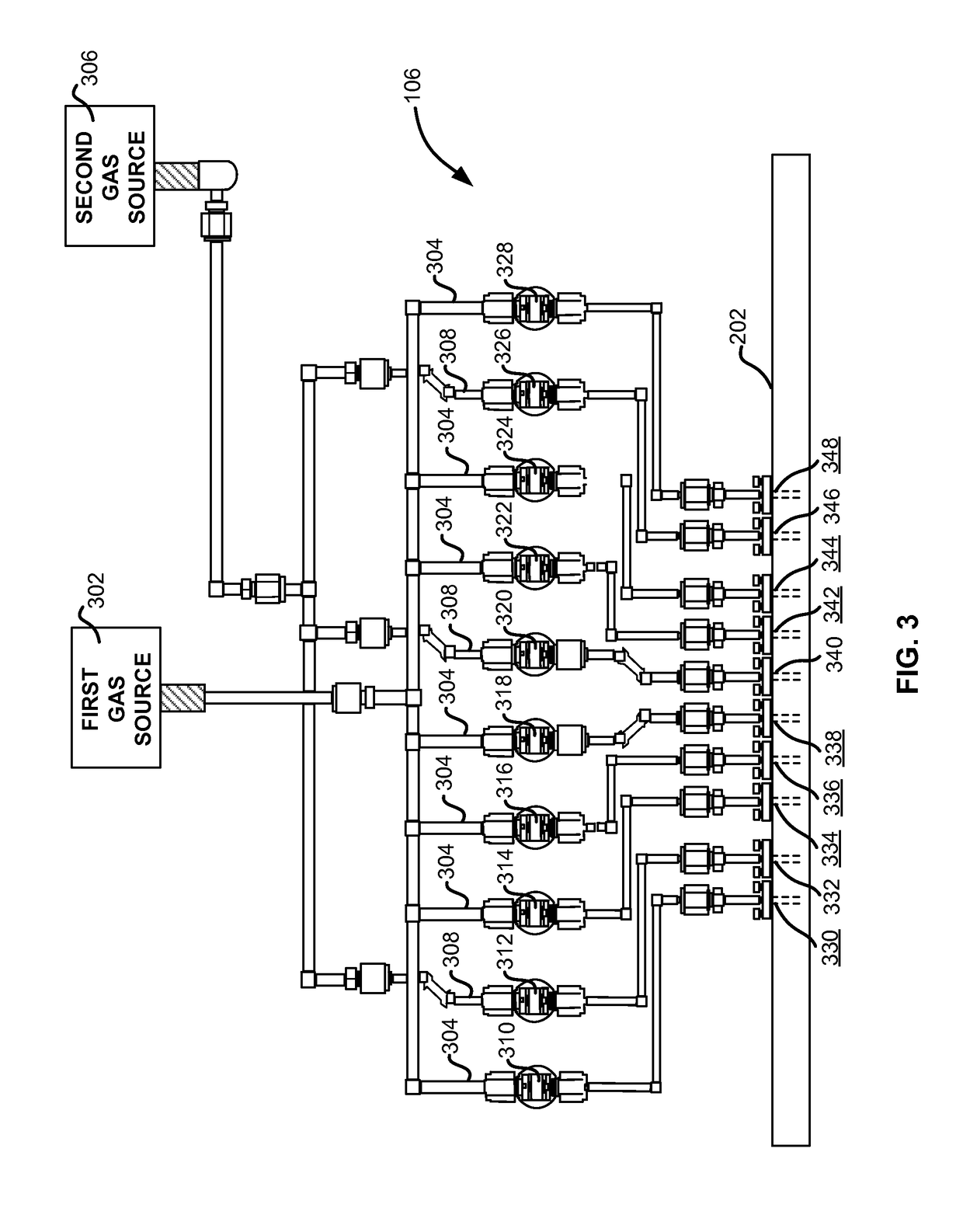

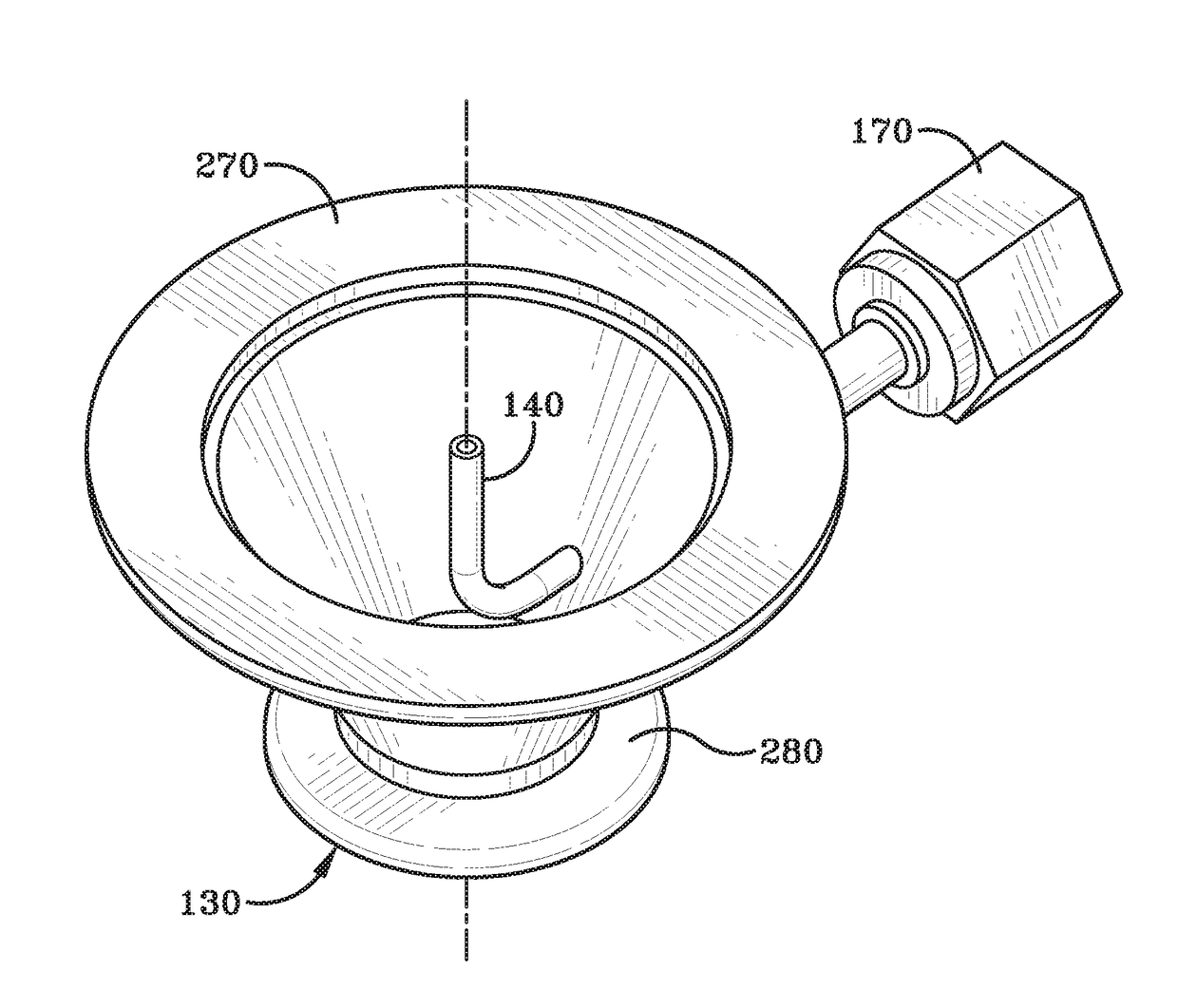

ActiveUS10167557B2Facilitate localized mixingChemical/physical/physico-chemical nozzle-type rreactorsEnergy based chemical/physical/physico-chemical processesReactor systemGas phase

A gas distribution system, a reactor system including the gas distribution system, and method of using the gas distribution system and reactor system are disclosed. The gas distribution system can be used in gas-phase reactor systems to independently fine tune gas source locations and gas flow rates of reactants to a reaction chamber of the reactor systems.

Owner:ASM IP HLDG BV

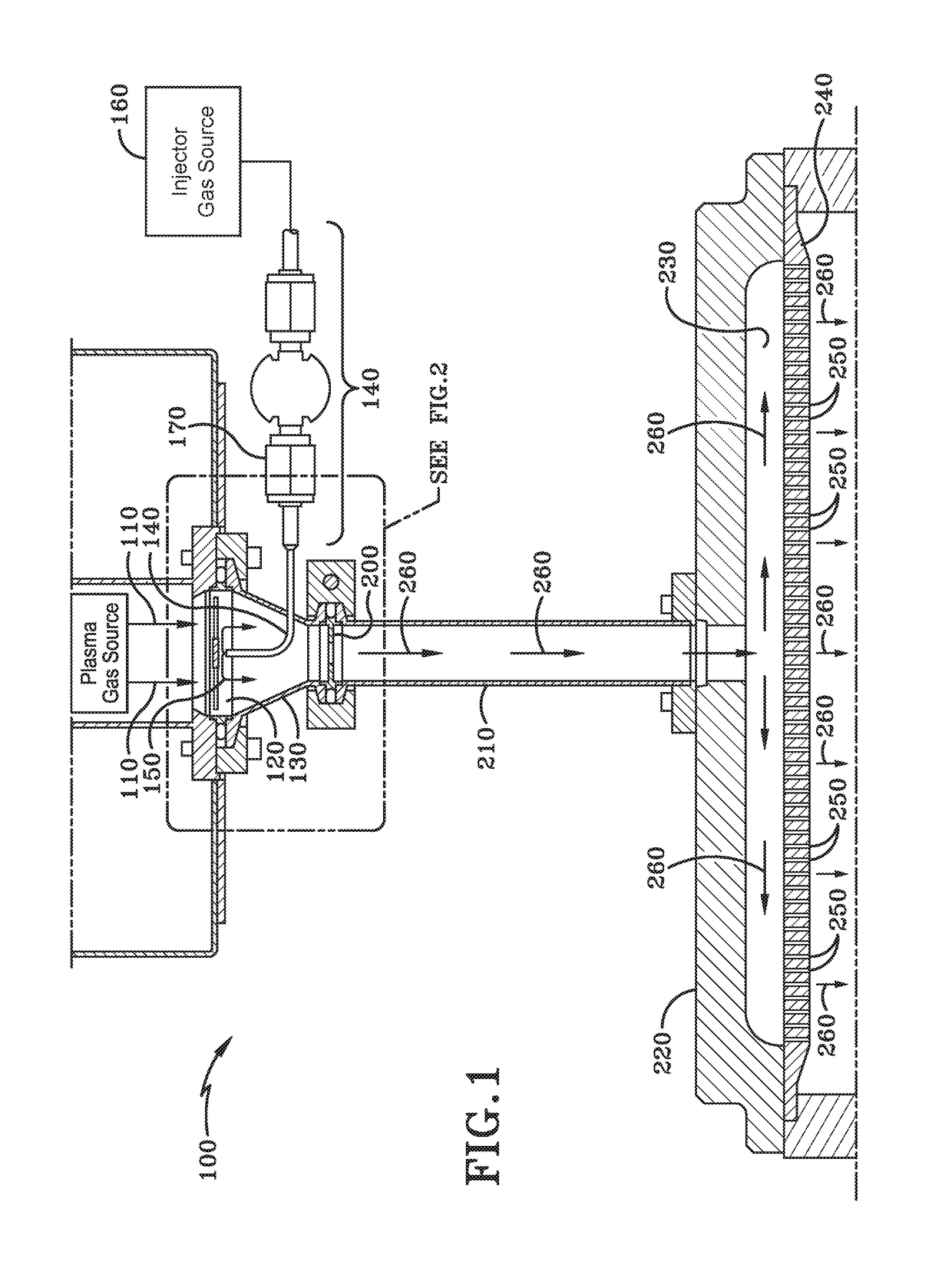

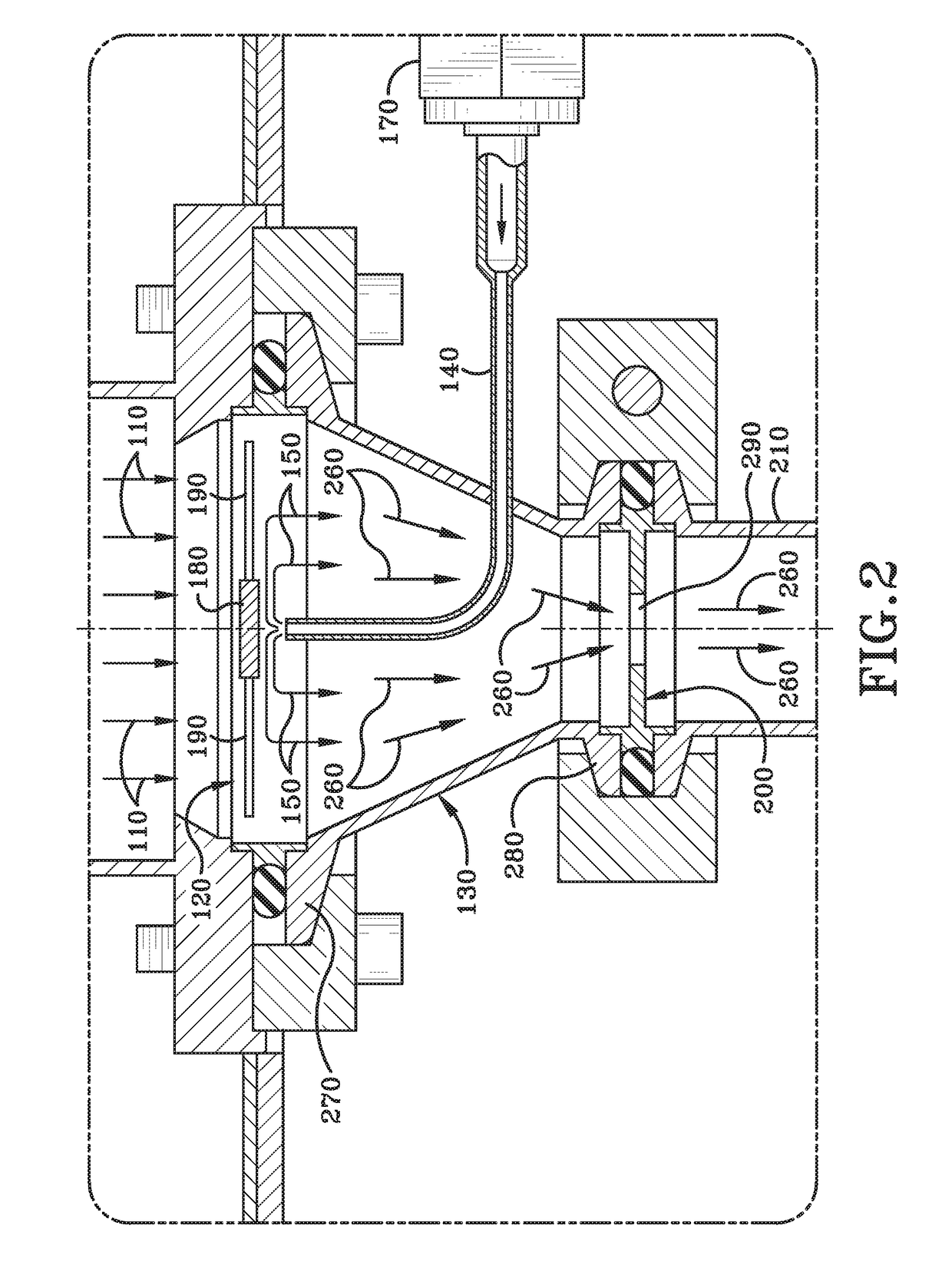

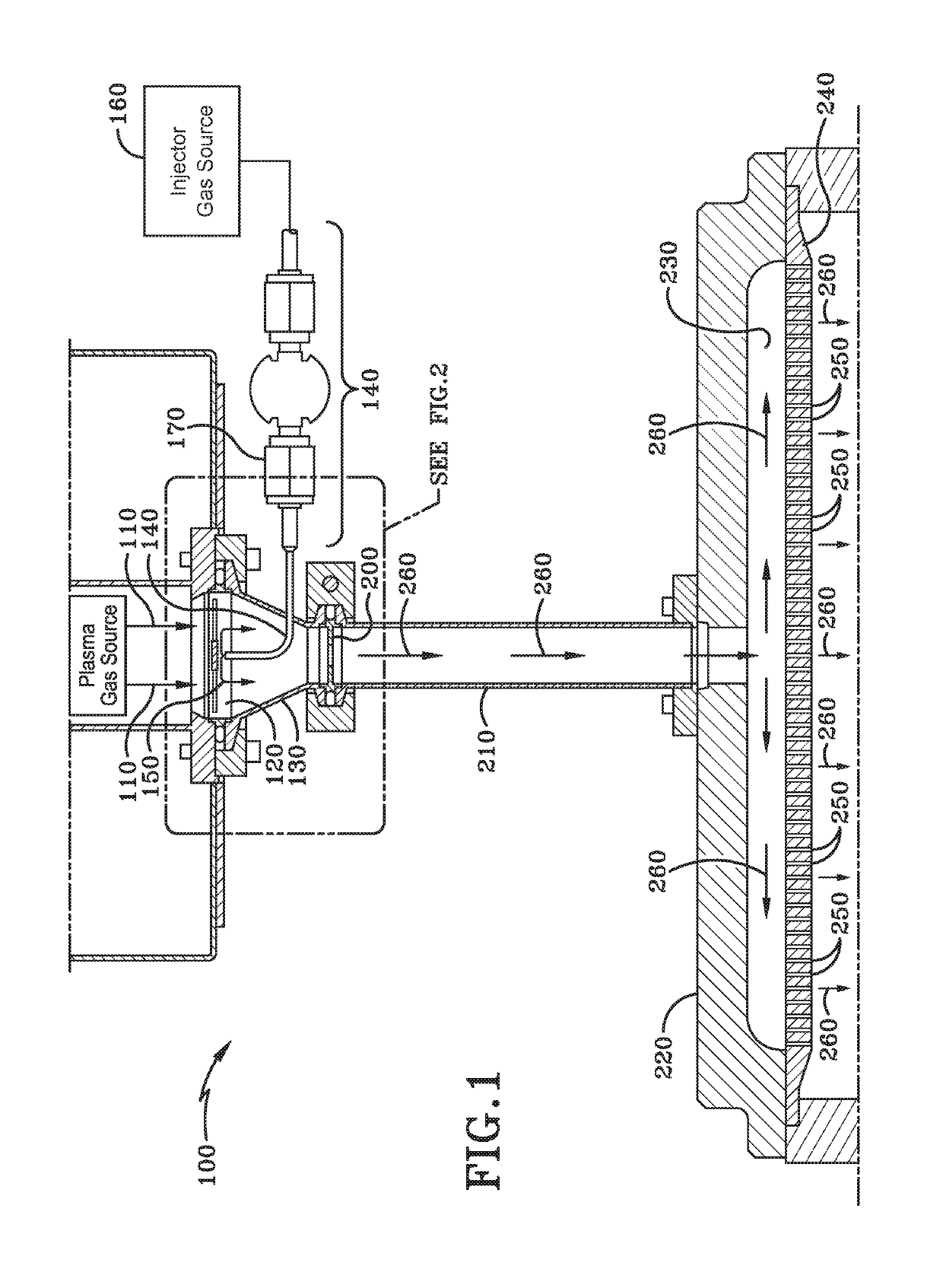

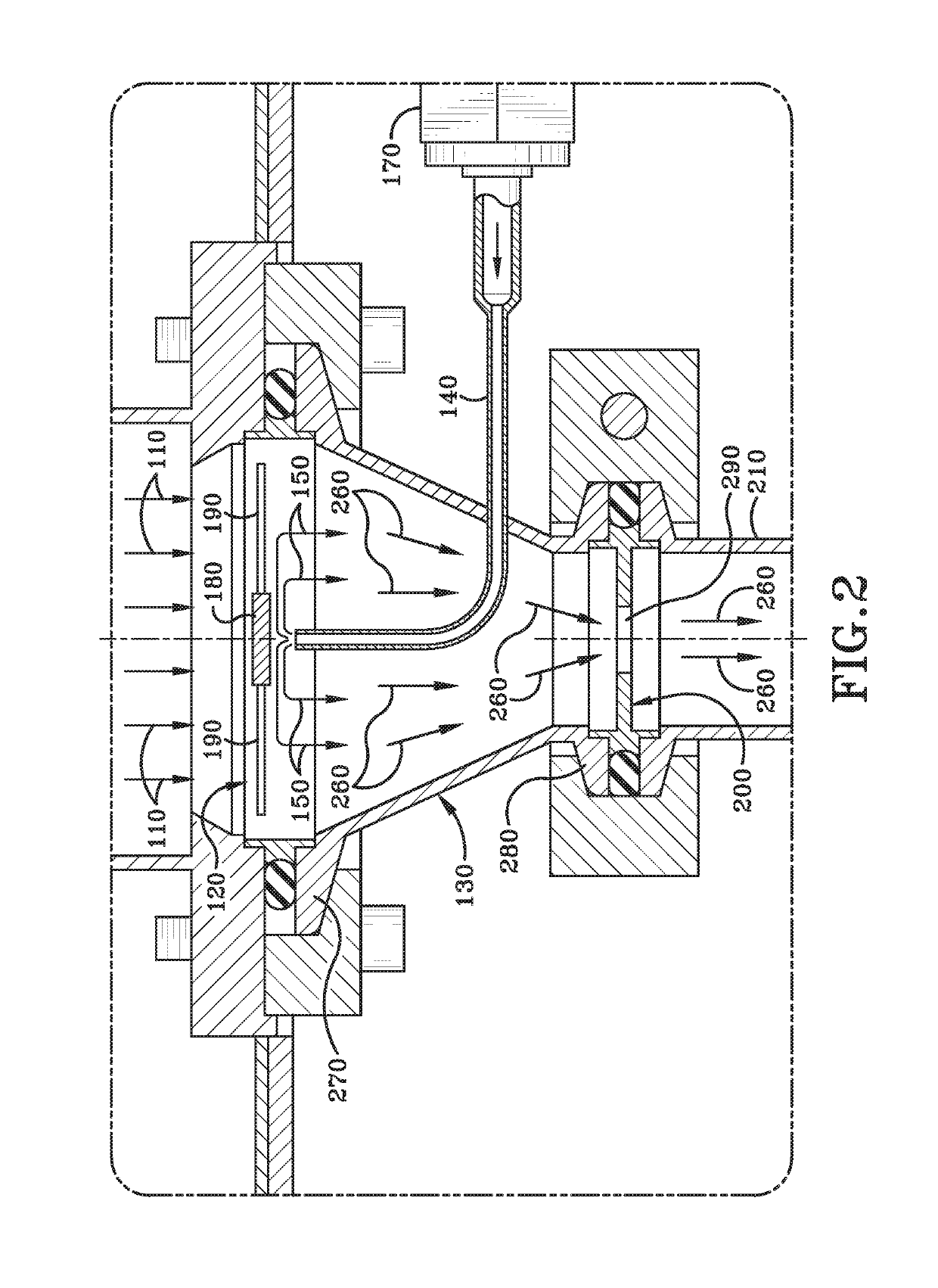

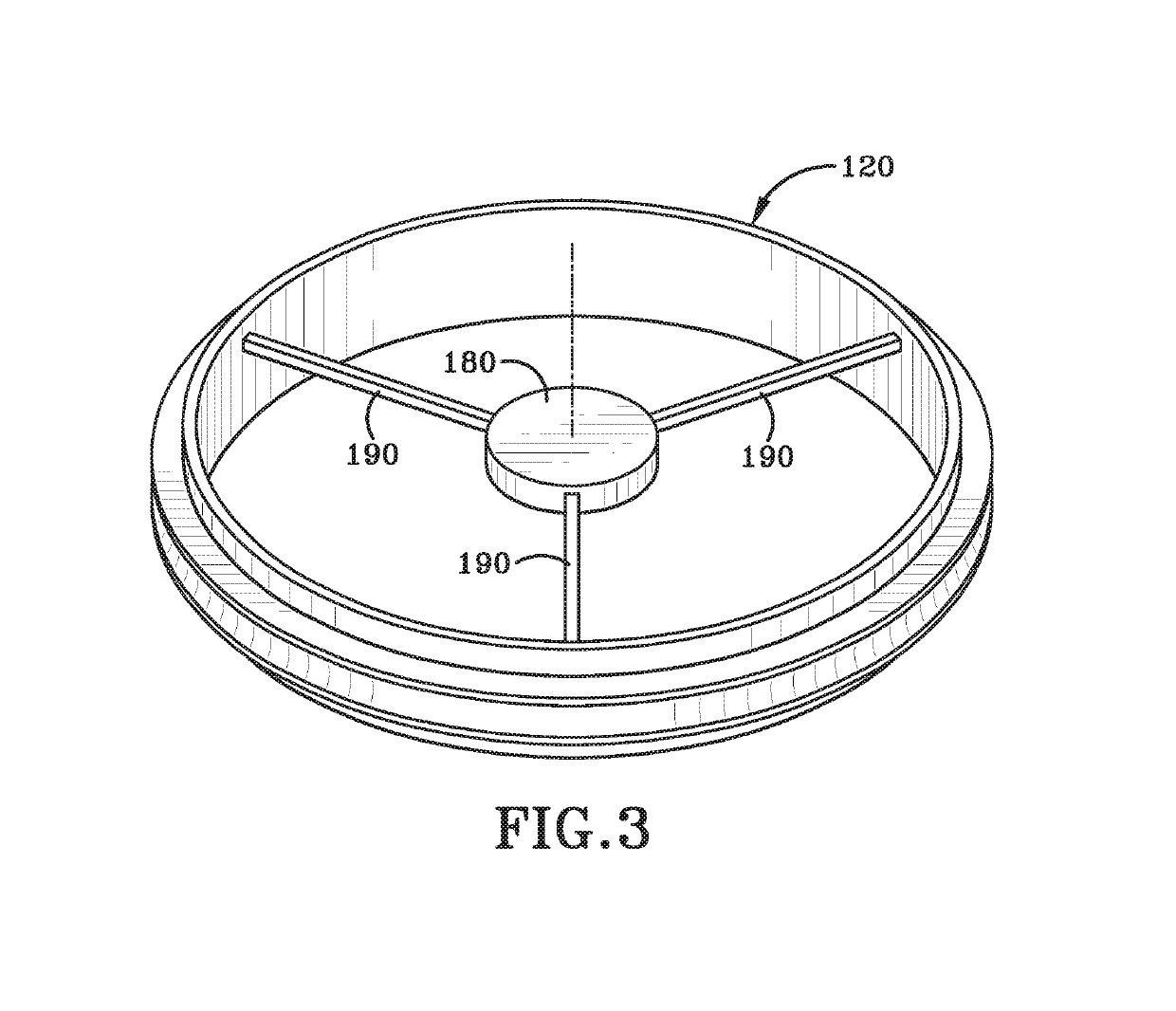

Counter flow mixer for process chamber

A counterflow mixing device for a process chamber is disclosed, comprising an injection tube that introduces a fluid in a manner counter to a flow of a post-plasma gas mixture traveling downward from a plasma source. The invention allows for proper mixing of the fluid as well as avoiding recombination of generated ions and radicals.

Owner:ASM IP HLDG BV

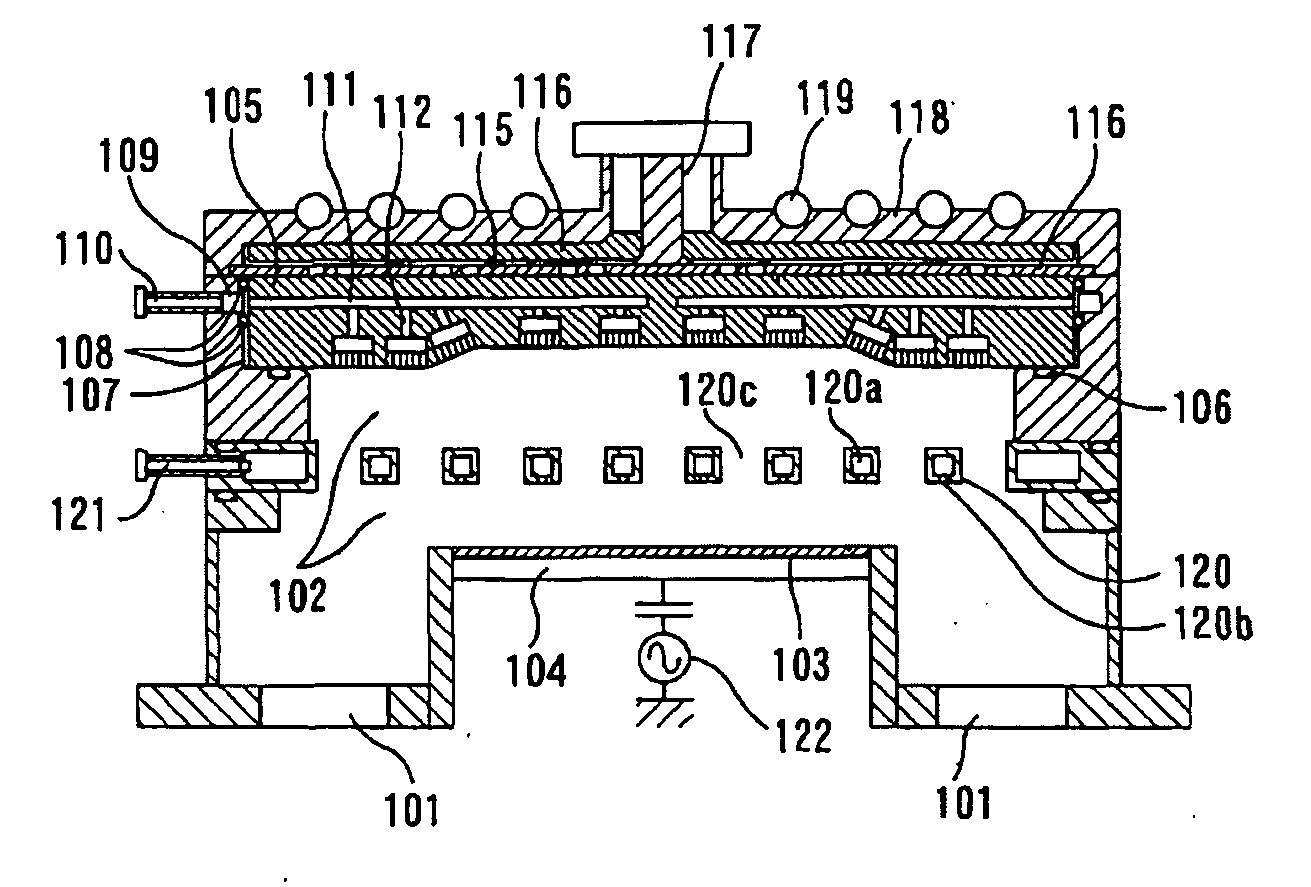

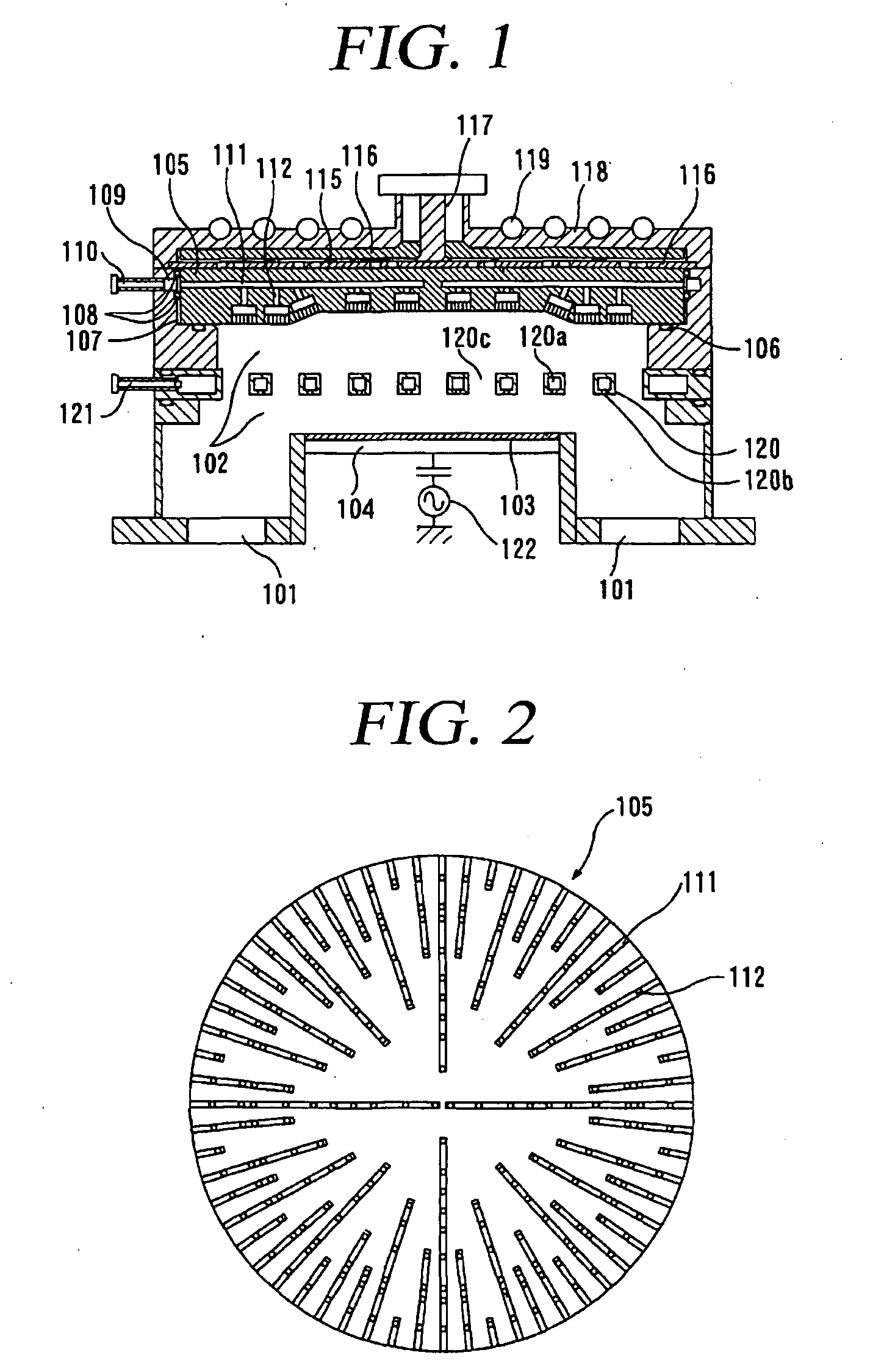

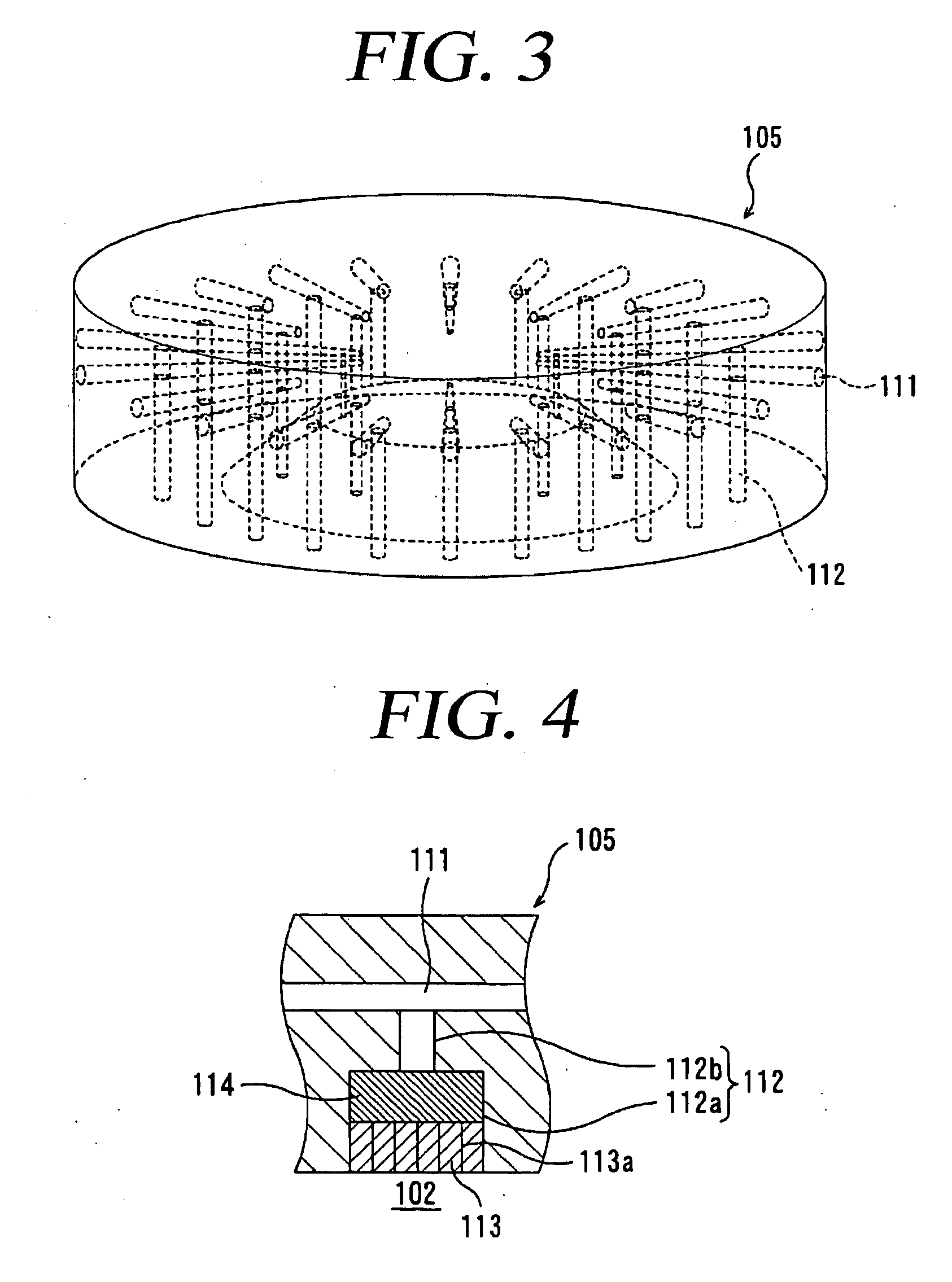

Shower plate, and plasma processing apparatus, plasma processing method and electronic device manufacturing method using the shower plate

InactiveUS20090286405A1Improve stabilityConvenience to workElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringElectron

Provided is a shower plate in which there's no need for a cover plate. The shower plate 105 is disposed in a processing chamber 102 of a plasma processing apparatus, for discharging a plasma excitation gas to generate plasma in the processing chamber 102, and the shower plate 105 includes a horizontal hole 111 for introducing the plasma excitation gas into the shower plate 105 from a gas inlet port 110 of the plasma processing apparatus; and a vertical hole 112 communicating with the horizontal hole 111, wherein the shower plate 105 is formed as a single body.

Owner:TOKYO ELECTRON LTD +1

Entangled single-wall carbon nanotube solid material and methods for making same

InactiveUS6899945B2Material nanotechnologySynthetic resin layered productsCross-linkSolvent evaporation

Buckyrock is a three-dimensional, solid block material comprising an entangled network of single-wall carbon nanotubes (SWNT), wherein the block comprises greater than 75 wt % SWNT. SWNT buckyrock is mechanically strong, tough and impact resistant. The single-wall carbon nanotubes in buckyrock form are present in a random network of individual single-wall carbon nanotubes, SWNT “ropes” and combinations thereof. The random network of the SWNT or SWNT ropes can be held in place by non-covalent “cross-links” between the nanotubes at nanotube contact points. In one embodiment, SWNT buckyrock is made by forming a SWNT-water slurry, slowly removing water from the slurry which results in a SWNT-water paste, and allowing the paste to dry very slowly, such that the SWNT network of the SWNT-water paste is preserved during solvent evaporation. Buckyrock can be used in applications, such as ballistic protection systems, involving light-weight material with mechanical strength, toughness and impact resistance.

Owner:RICE UNIV

Methods and apparatus for downstream dissociation of gases

InactiveUS20060118240A1Reduce erosionMinimize interactionElectric discharge tubesDecorative surface effectsProduct gasMolecular physics

A method and apparatus for activating and dissociating gases involves generating an activated gas with a plasma located in a chamber. A downstream gas input is positioned relative to an output of the chamber to enable the activated gas to facilitate dissociation of a downstream gas introduced by the gas input, wherein the dissociated downstream gas does not substantially interact with an interior surface of the chamber.

Owner:MKS INSTR INC

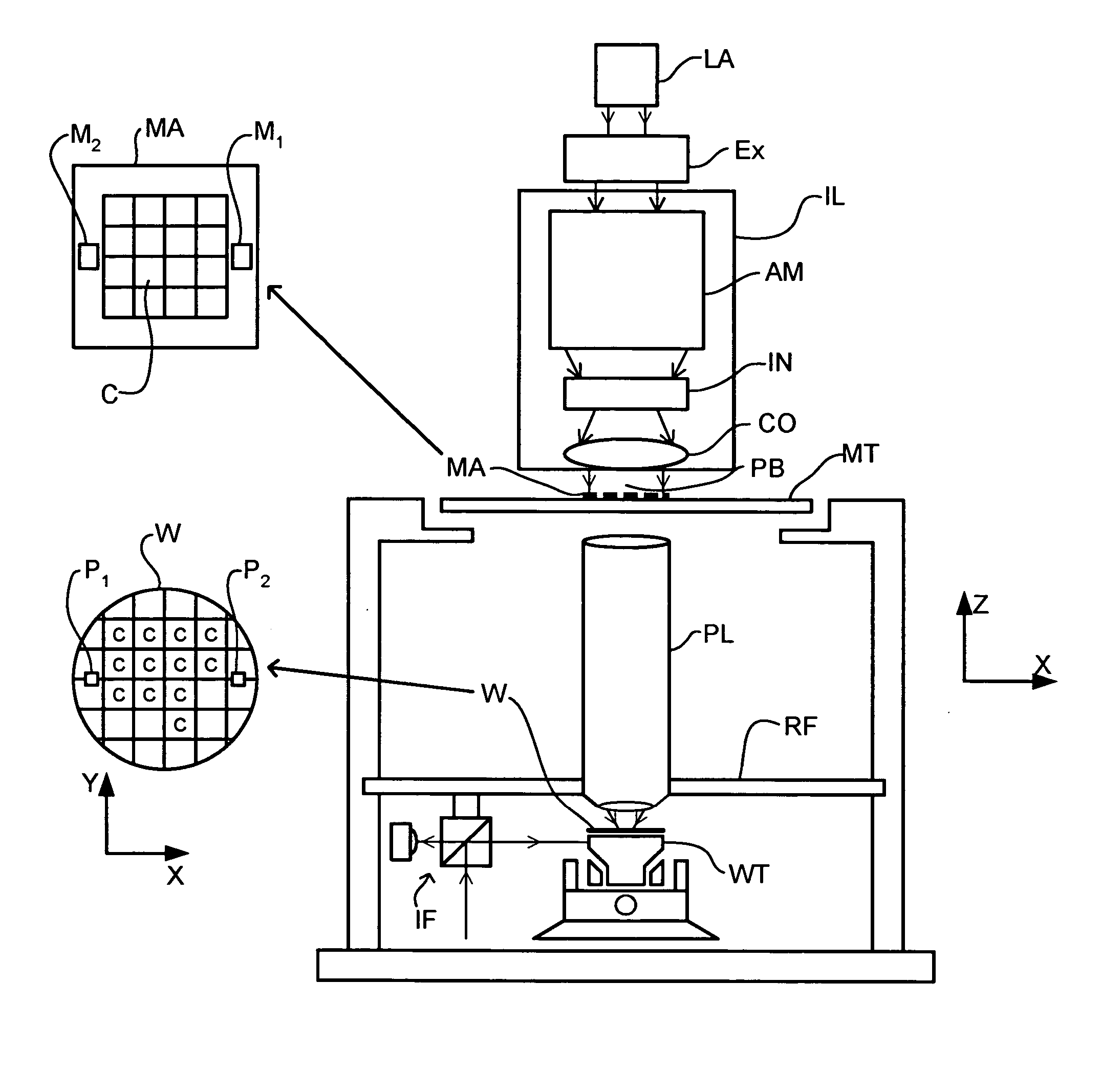

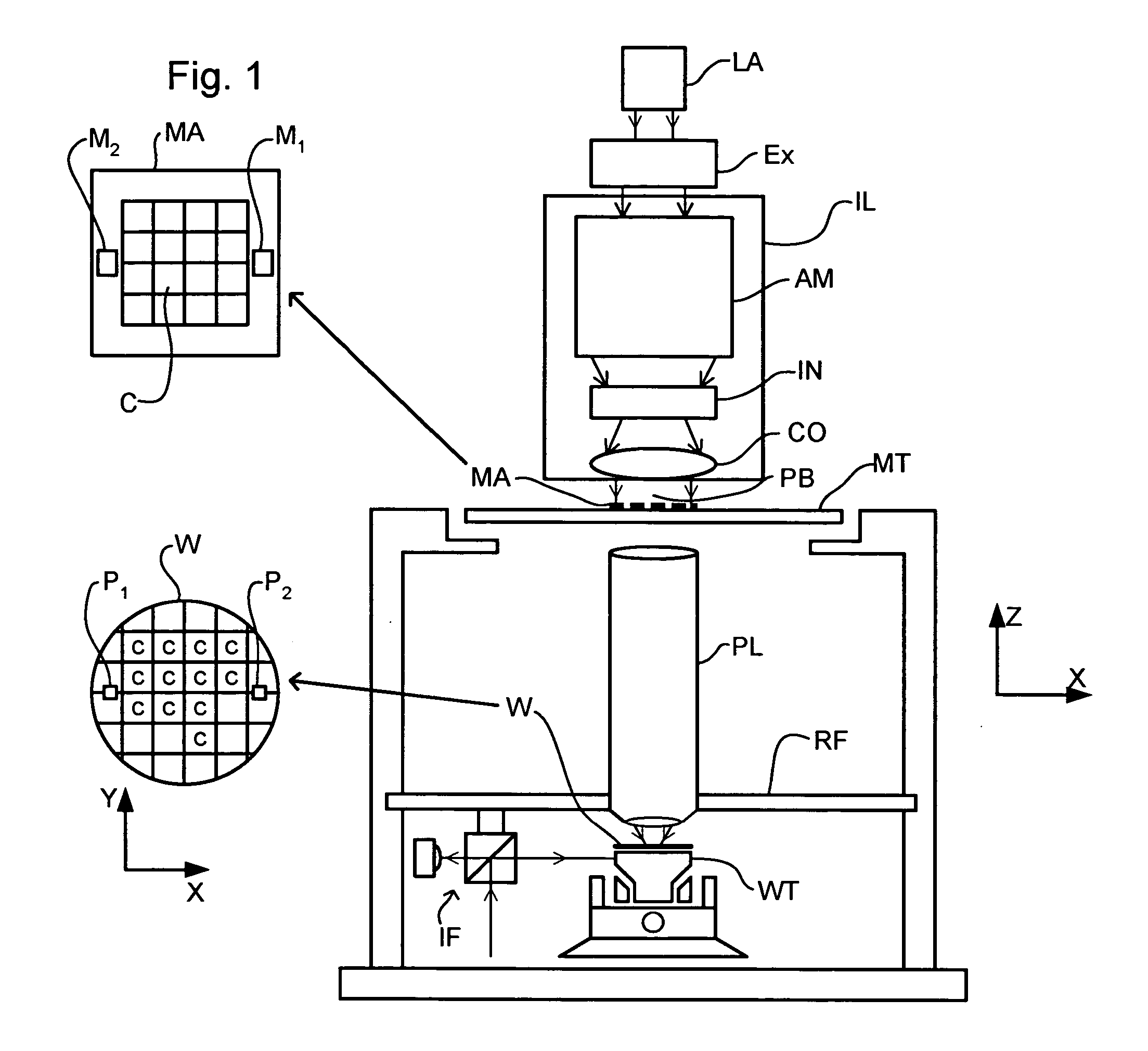

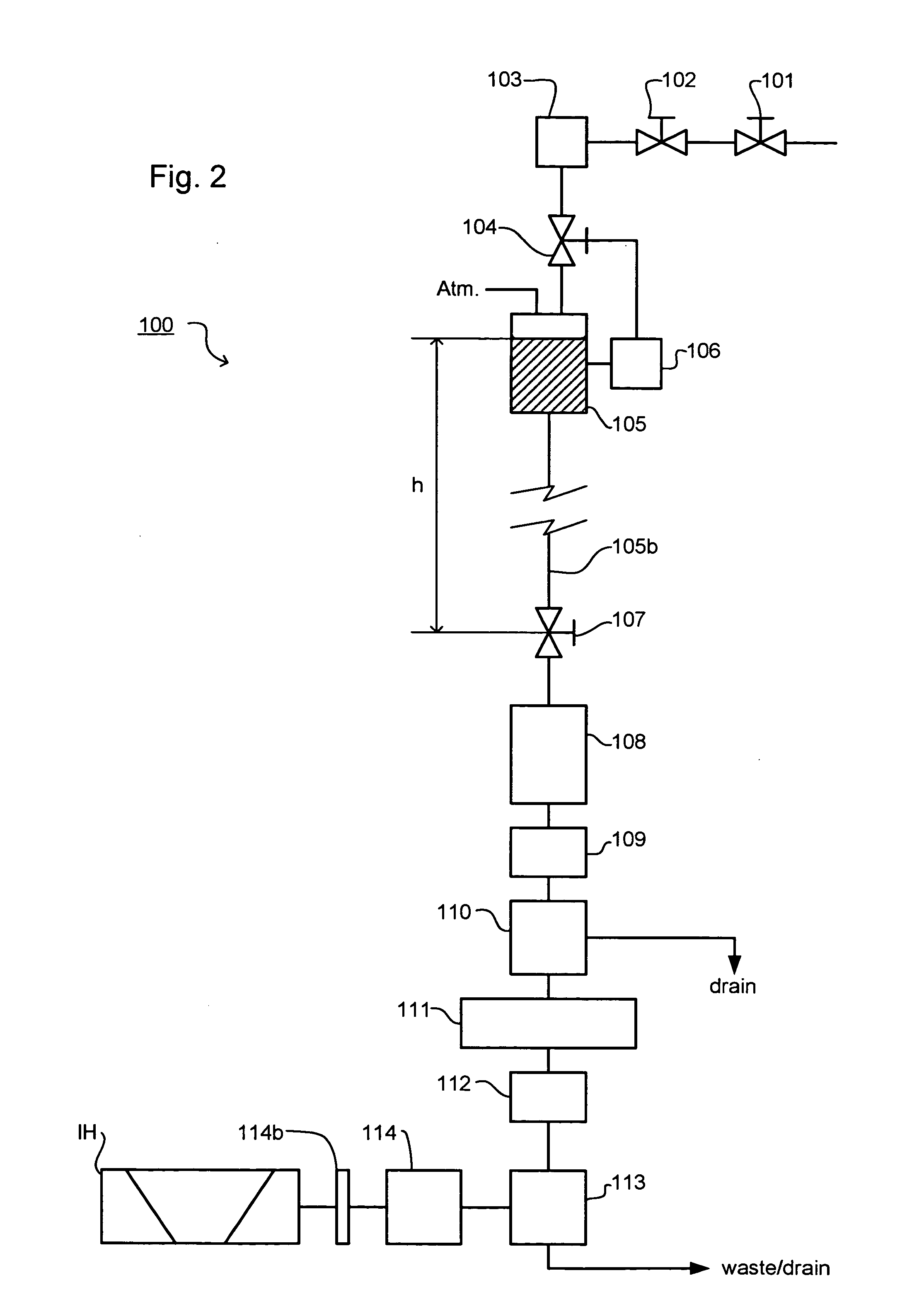

Lithographic apparatus and device manufacturing method

InactiveUS20050048220A1ConstantAvoid pollutionSemiconductor/solid-state device manufacturingPretreated surfacesEngineeringImmersion lithography

In an immersion lithography apparatus, the immersion liquid is supplied from a tank via a flow restrictor. The liquid held in the tank is maintained at a substantially constant height above the flow restrictor to ensure a constant flow of liquid.

Owner:ASML NETHERLANDS BV

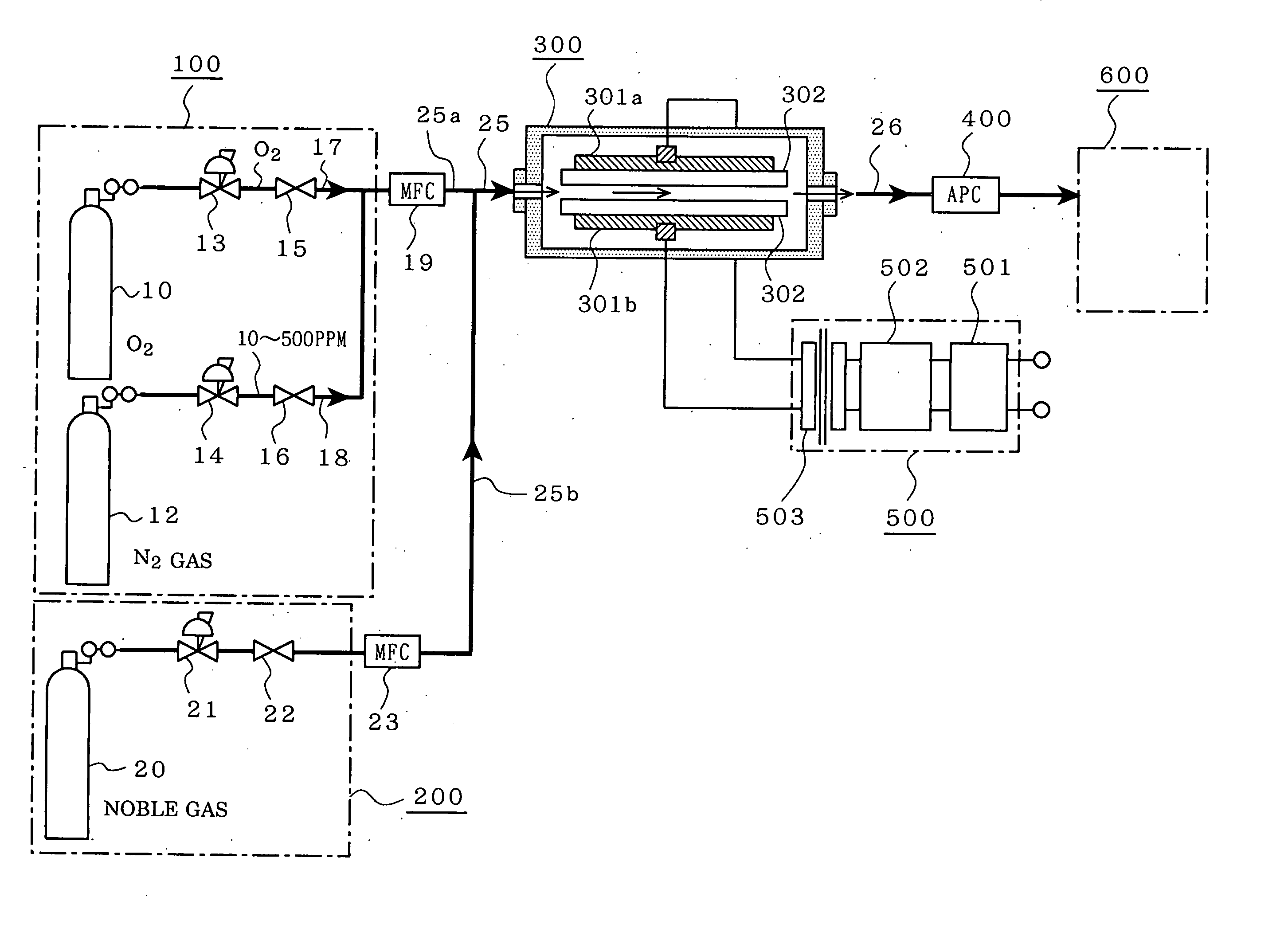

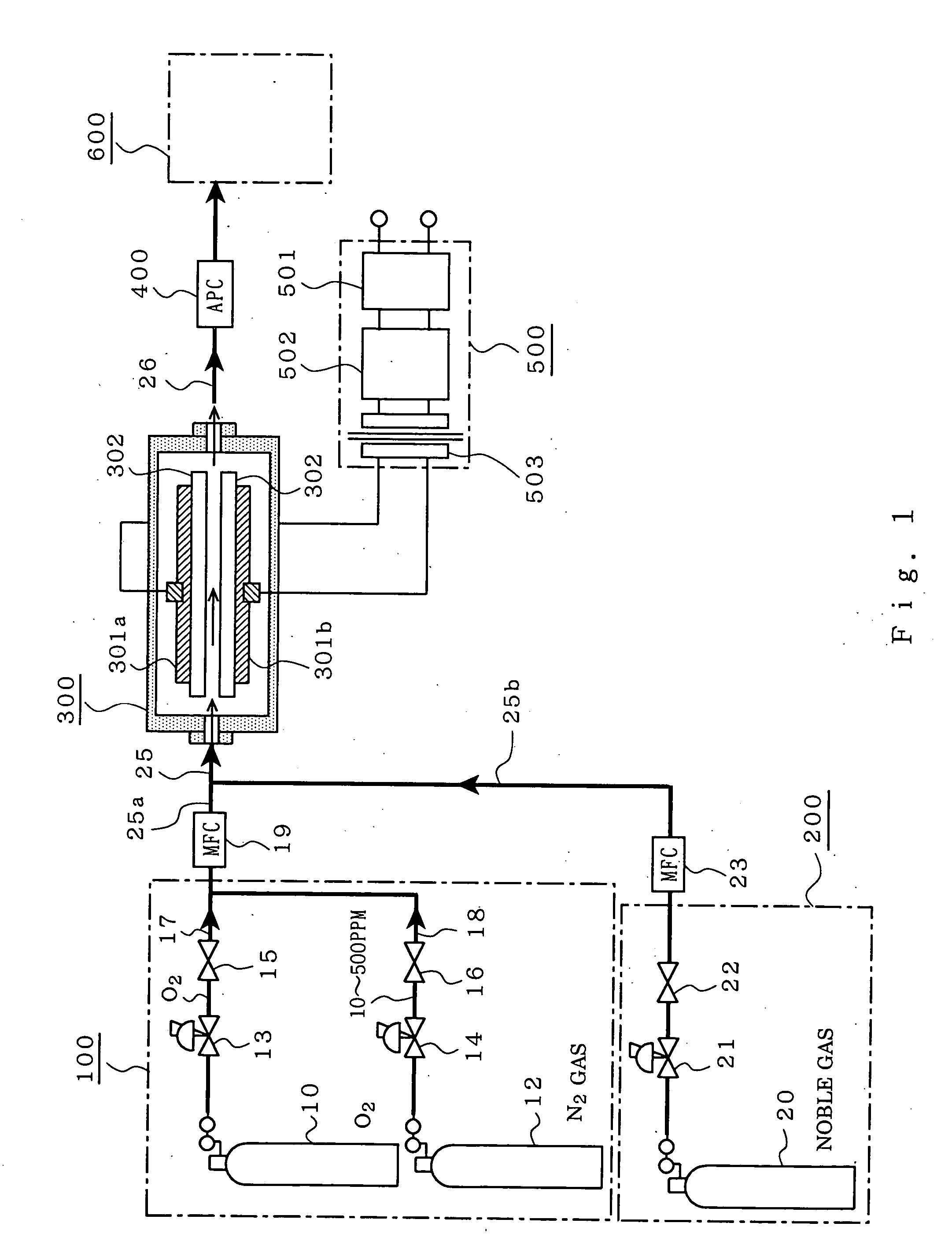

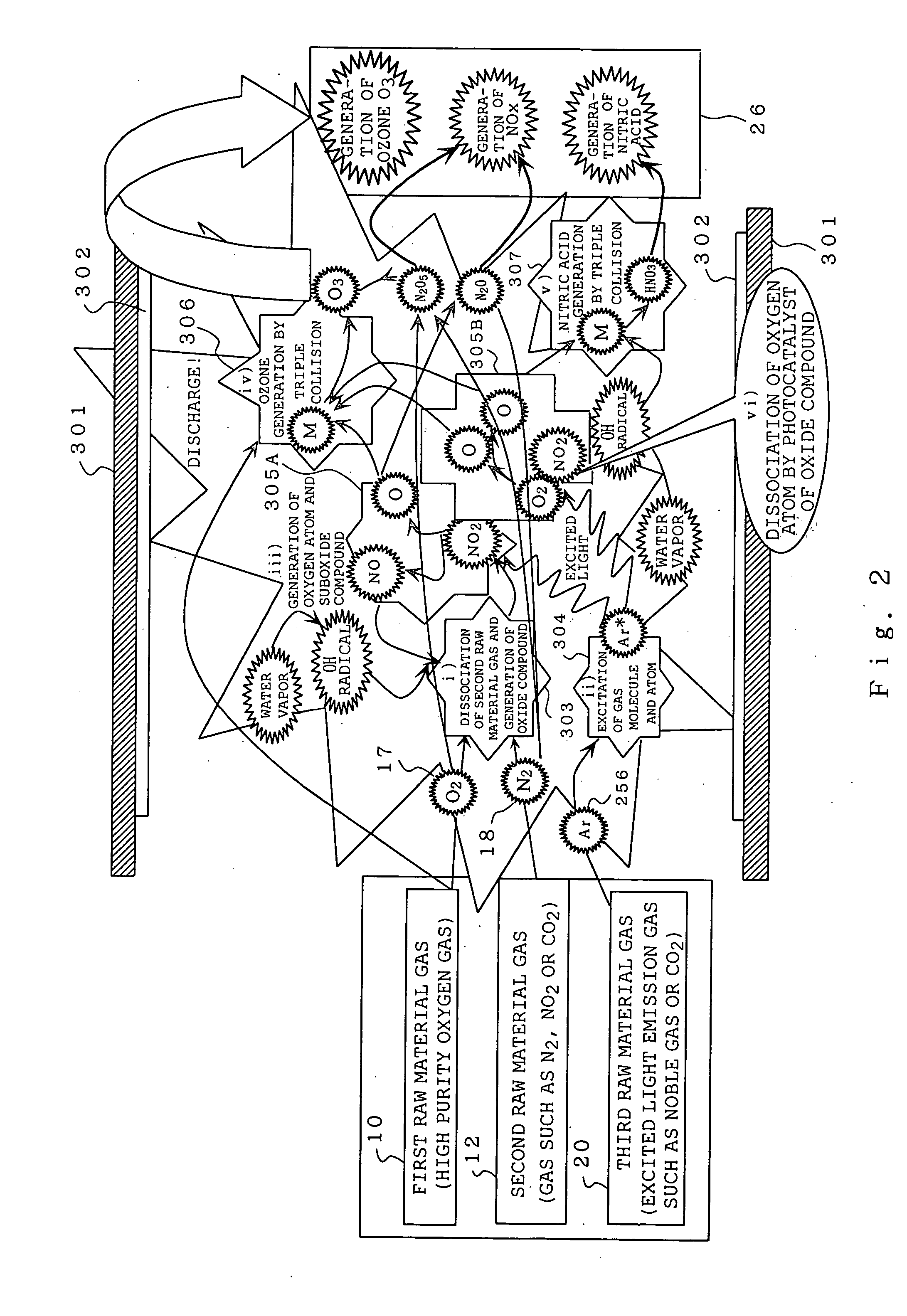

Ozone generator

ActiveUS20040223893A1Physical/chemical process catalystsElectrical discharge ozone preparationAtmospheric sciencesGas supply

An ozone generator for generating ozone by applying a specified process to oxygen by discharge includes a first raw material gas supply unit for supplying the oxygen as a first raw material gas, and a second raw material gas supply unit for supplying an oxide compound gas as a second raw material gas, in which, by excited light, excited and generated by a discharge in the oxygen and the oxide compound gas, the oxide compound gas is dissociated, or the oxide compound gas is excited accelerating dissociation of the oxygen, and ozone is generated. In this way, ozone generation efficiency is raised.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Counter flow mixer for process chamber

Owner:ASM IP HLDG BV

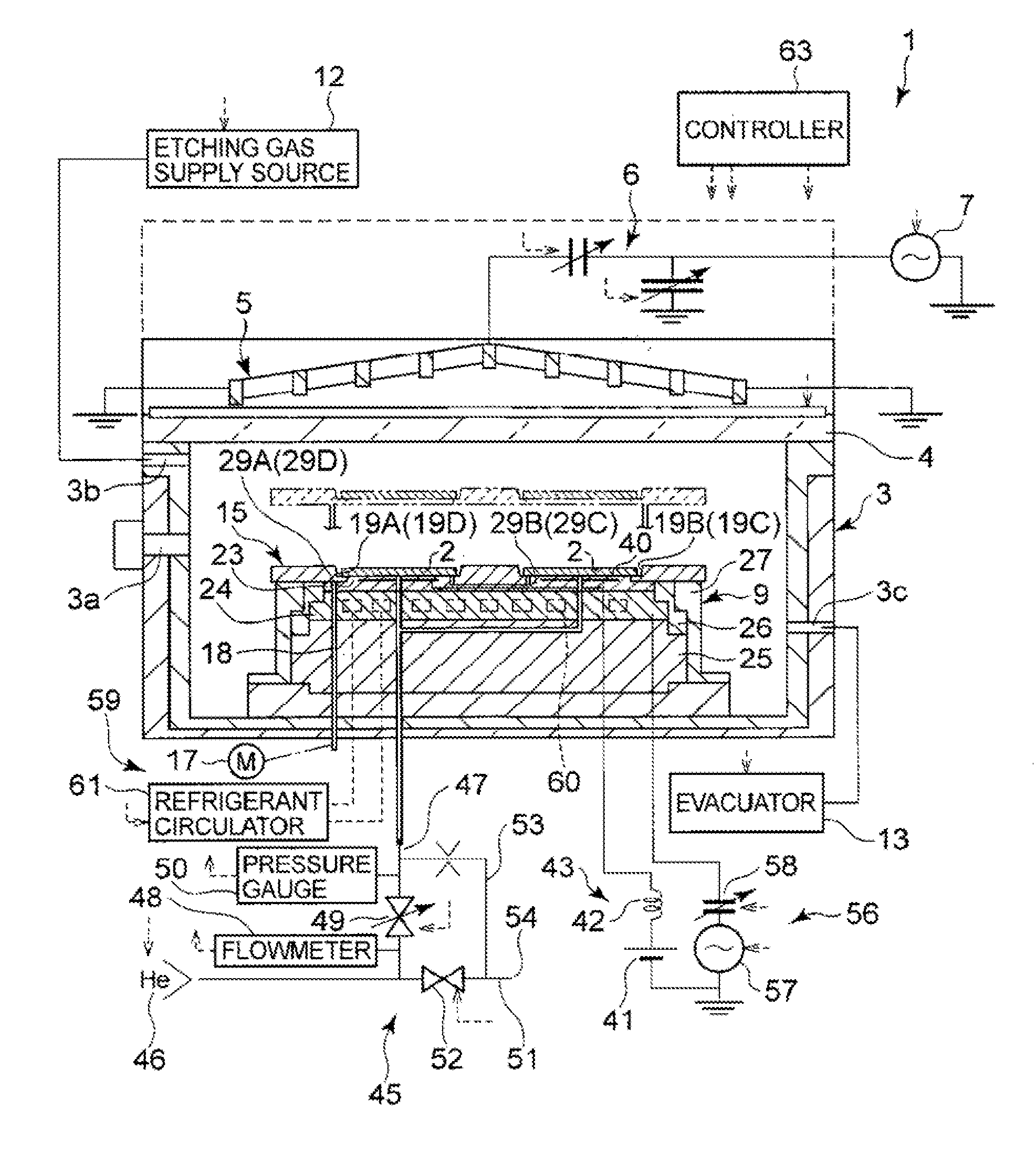

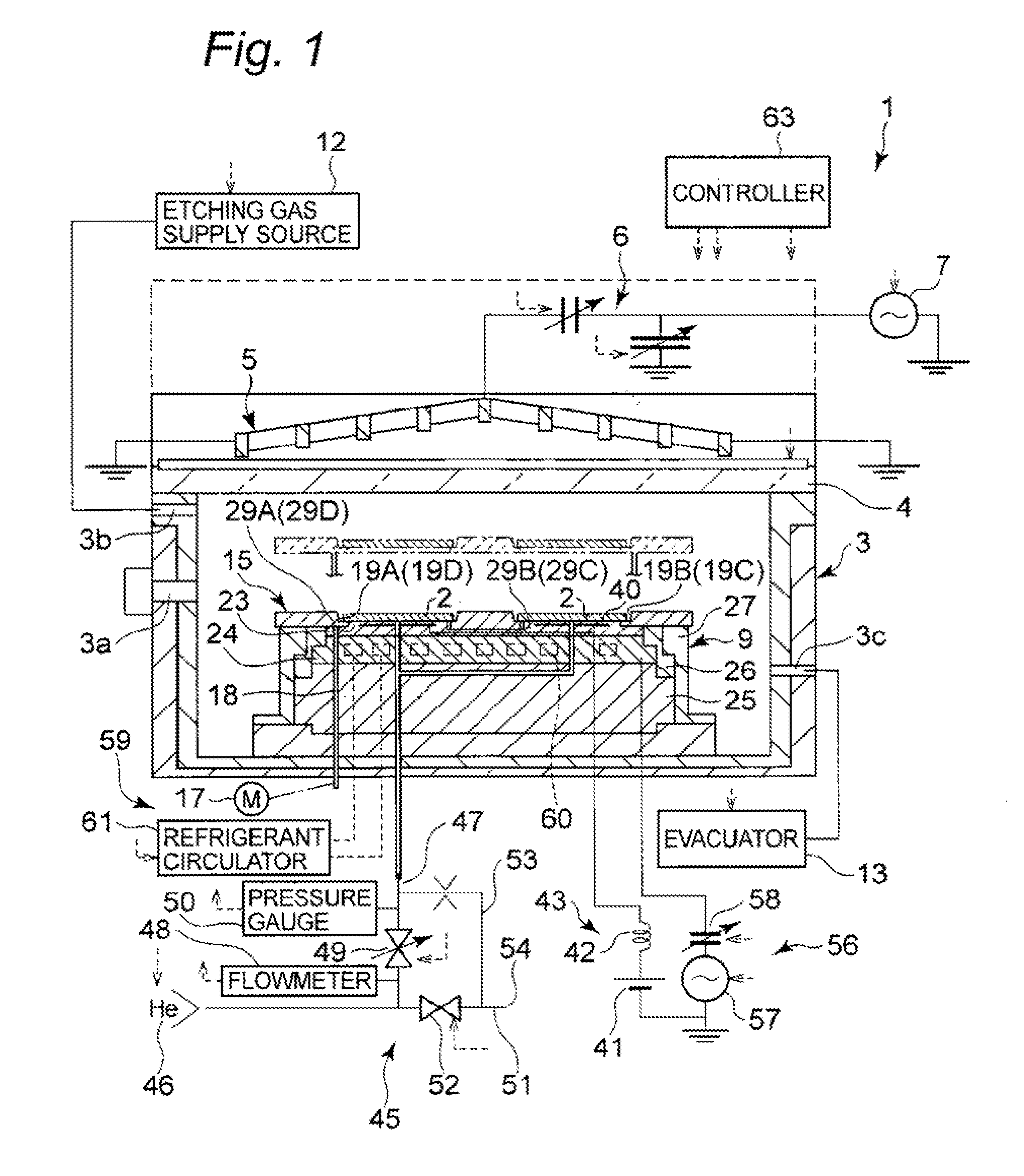

Plasma processing apparatus and plasma processing method

ActiveUS20100051584A1Improve adhesionImprove cooling efficiencyElectric discharge tubesDecorative surface effectsDielectric plateEngineering

A tray 15 for a dry etching apparatus 1 has substrate accommodation holes 19A to 19D penetrating thickness direction and a substrate support portion 21 supporting an outer peripheral edge portion of a lower surface 2a of a substrate 2. A dielectric plate 23 has a tray support surface 28 supporting a lower surface of the tray 15, substrate placement portions 29A through 29D inserted from a lower surface side of the tray 15 into the substrate accommodation holes 19A through 19D and having a substrate placement surface 31 at its upper end surface for placing the substrate 2. A dc voltage applying mechanism 43 applies a dc voltage to an electrostatic attraction electrode 40. A heat conduction gas supply mechanism 45 supplies a heat conduction gas between the substrate 2 and substrate placement surface 31. The substrate 2 can be retained on the substrate placement surface 31 with high degree of adhesion. This results in that the cooling efficiency of the substrate 2 is improved and processing is uniformed at the entire region of the substrate surface including the vicinity of the outer peripheral edge.

Owner:PANASONIC CORP

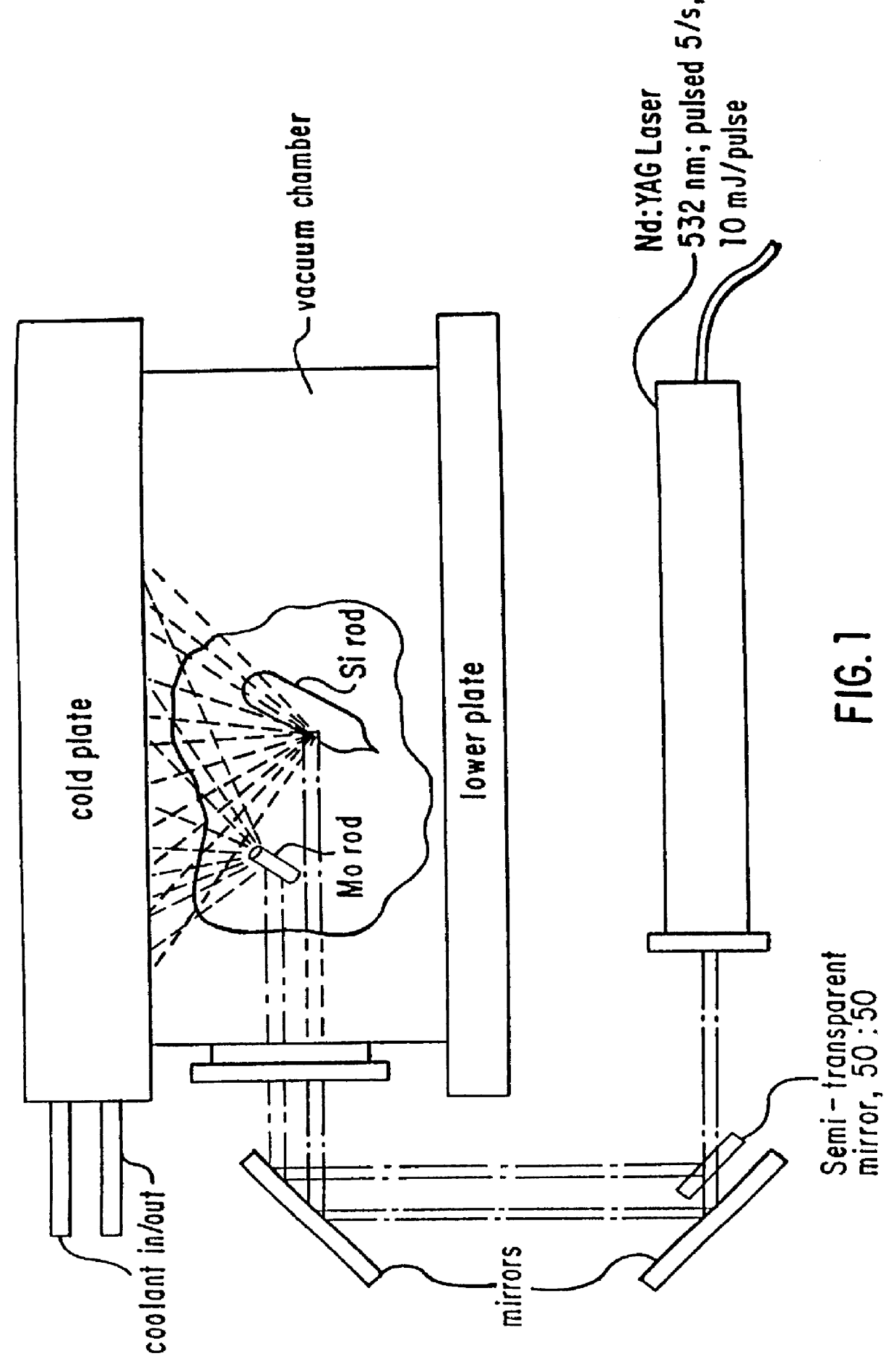

Nanoparticles of silicon oxide alloys

Nanoparticles of silicon oxide alloys (i.e., oxides of SiMo, SiPt, and SiAl) are produced by laser vaporization of a silicon target and a target of a metal (i.e., Mo, Pt, or Al), in an oxygen containing atmosphere in a diffusion cloud chamber, where the target metal vapors aggregate into novel three-dimensional porous web structures. The structures have a homogeneous composition with a uniform ratio of silicon to the metal.

Owner:VIRGINIA COMMONWEALTH UNIV

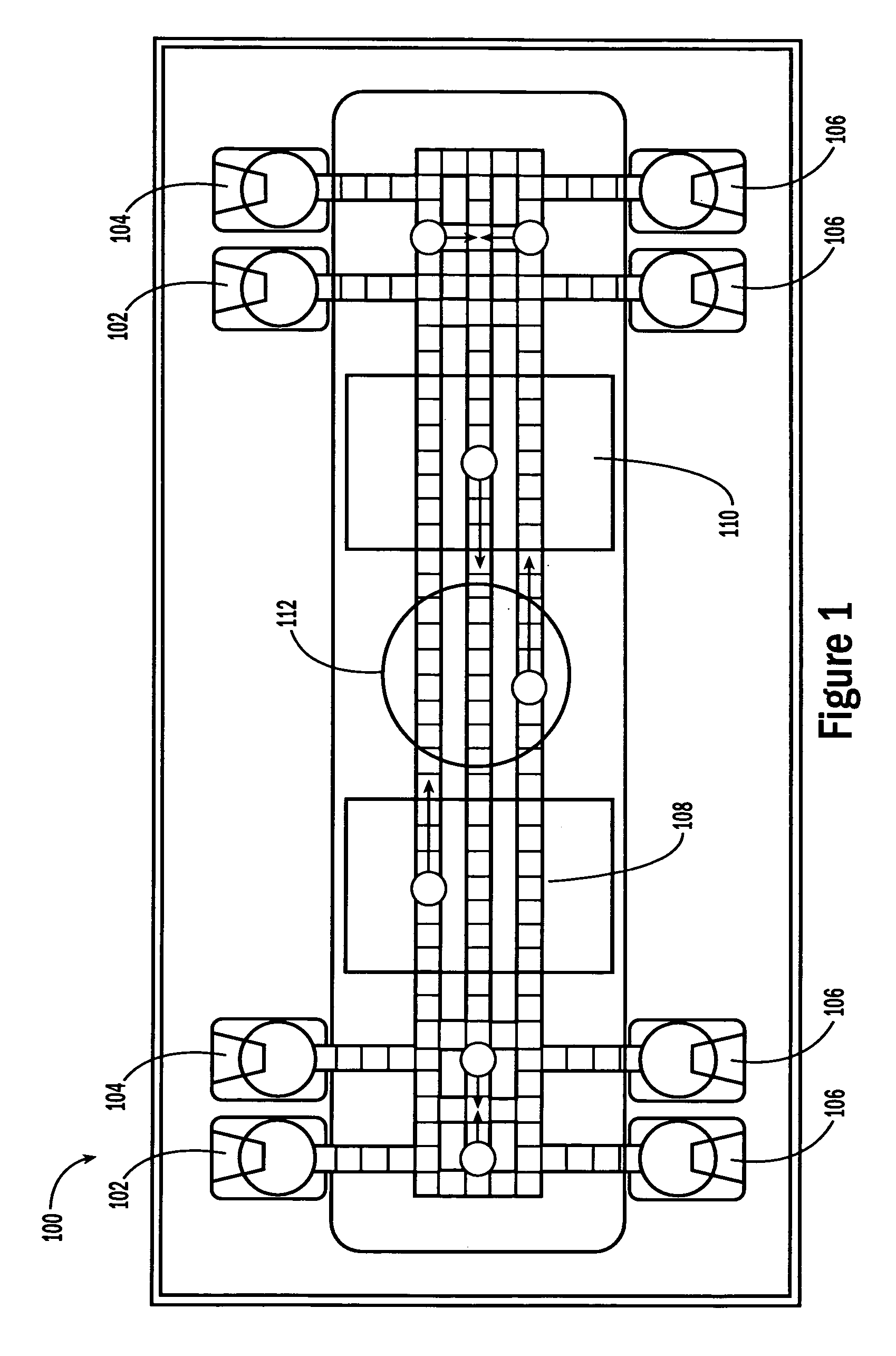

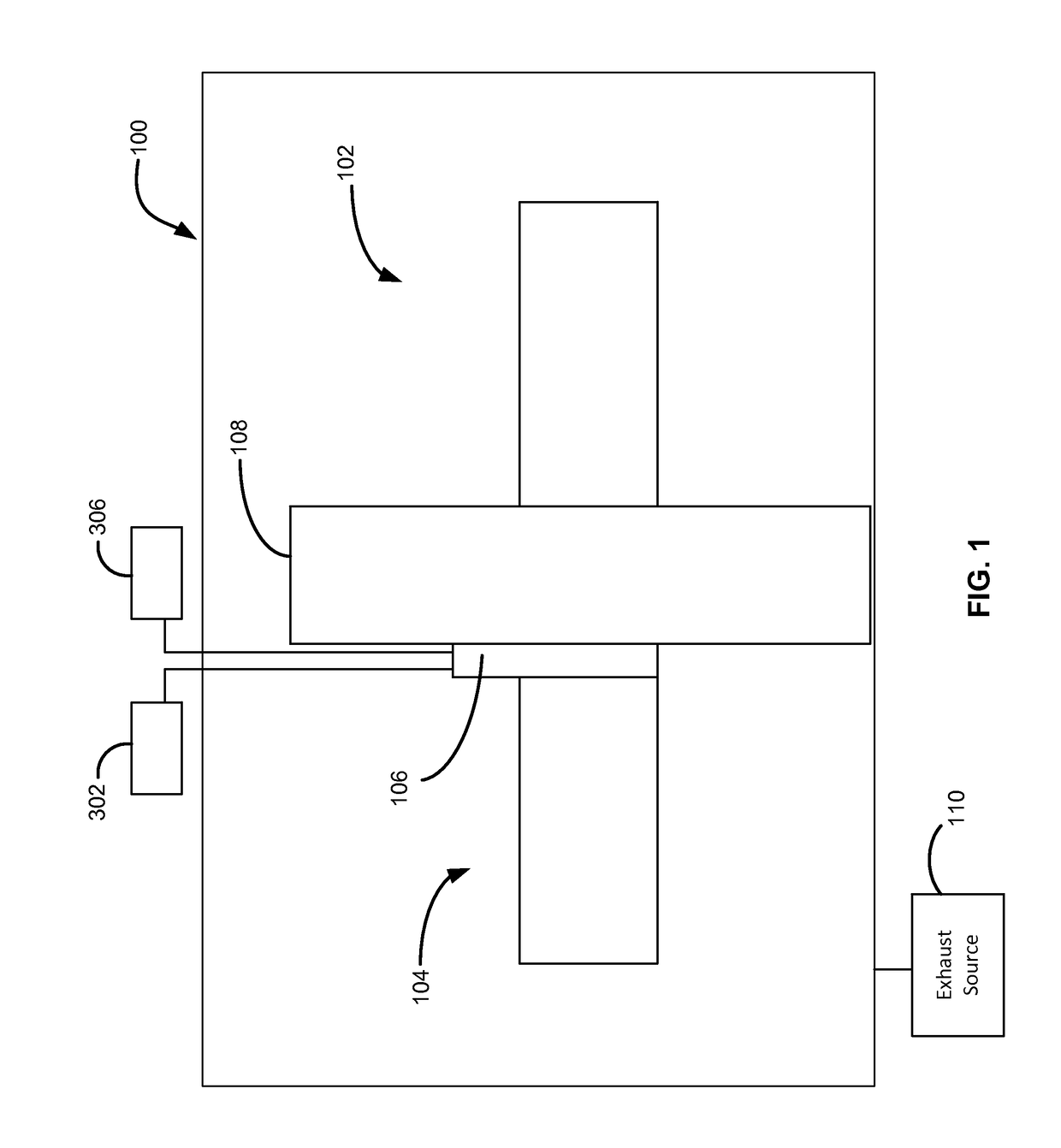

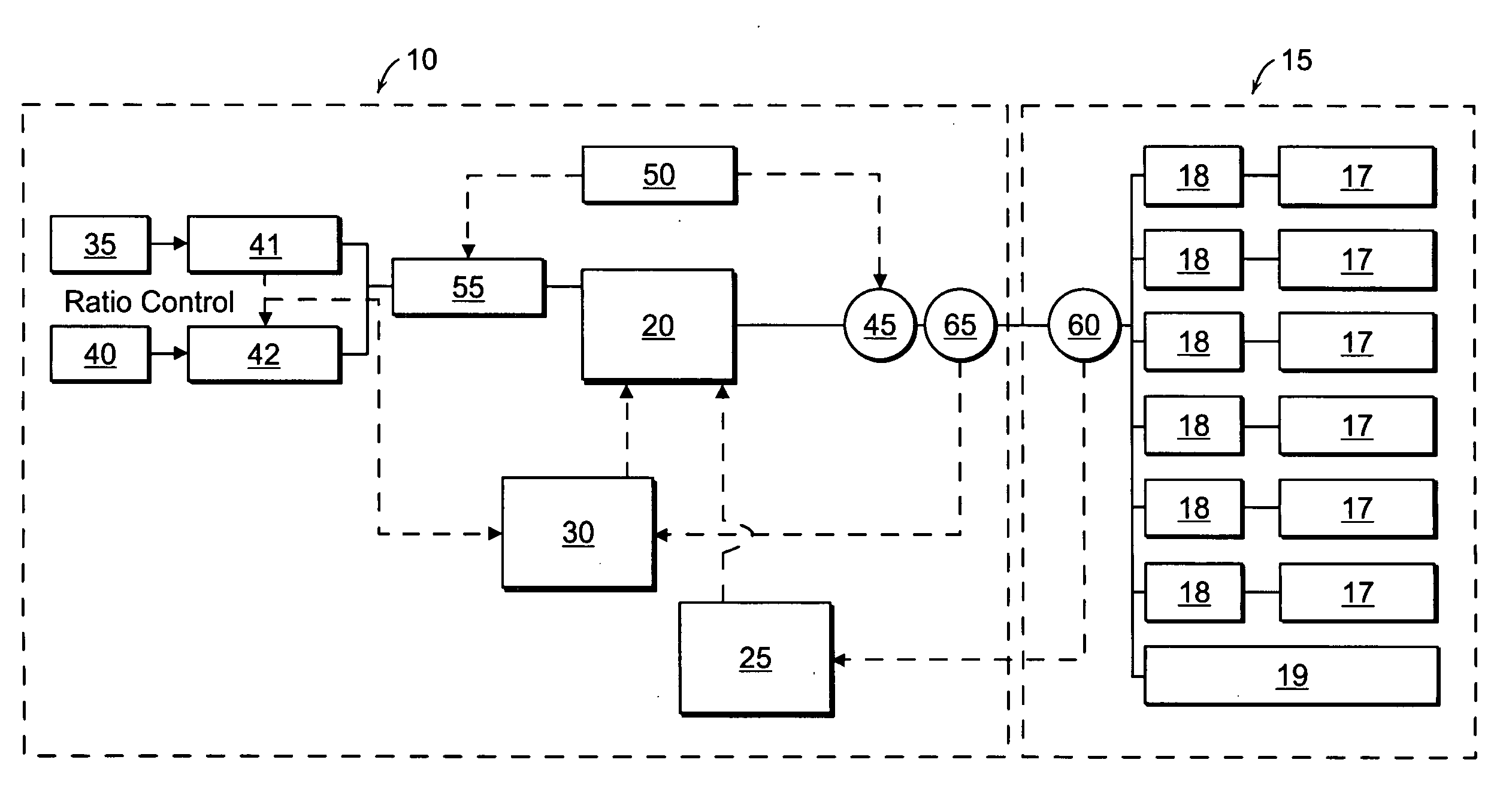

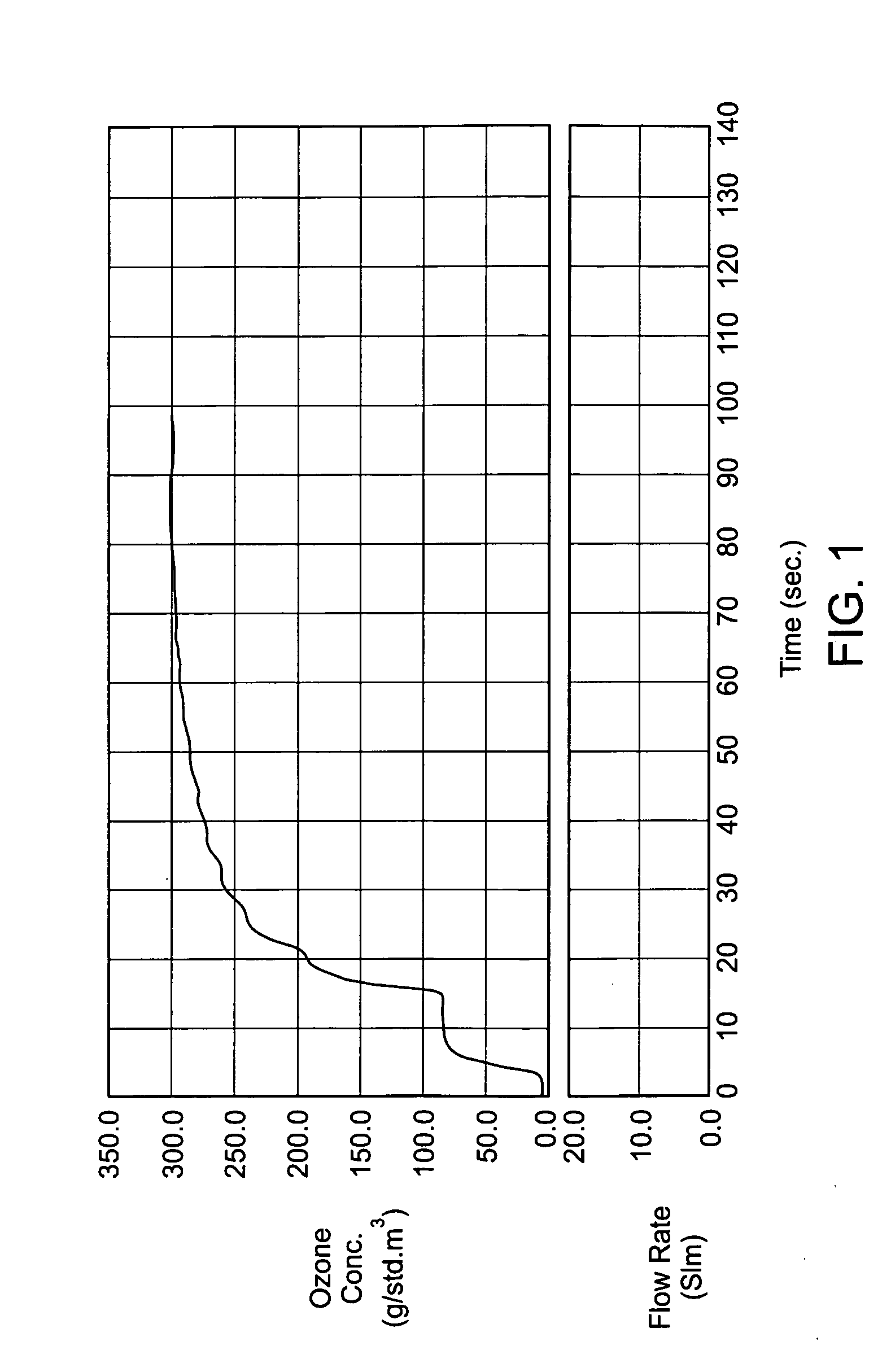

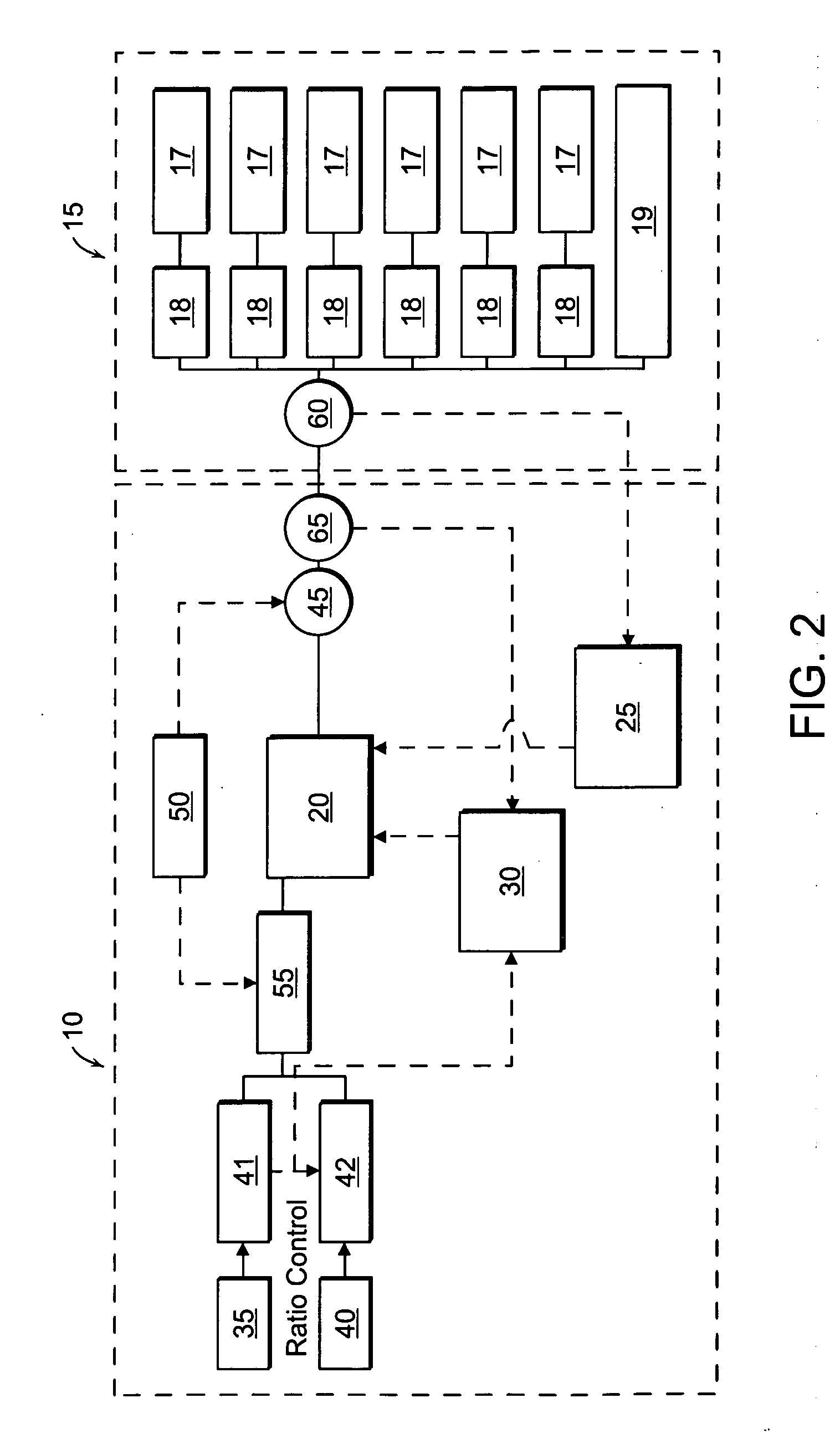

Ozone system for multi-chamber tools

ActiveUS20070020160A1Simplify System DesignReduce equipment costsSemiconductor/solid-state device manufacturingElectrical discharge ozone preparationOzone generatorControl theory

An improved system and method for controlling ozone concentration in connection with a multi-chamber tool. The system and method involve a first and a second concentration controller in combination with an ozone generator. The first concentration controller detects an EVENT (i.e., one of the chambers in the multi-chamber tool coming on-line or off-line) and in response provides a power instruction to the ozone generator in accordance with a predictive control algorithm. The first concentration controller has a fast (i.e, about 1 second) response time. The second concentration controller is masked from the ozone generator during the EVENT, but otherwise controls the generator after an interval of time has lapsed after the EVENT. The second concentration controller has a slower response time than the first concentration controller, however the second concentration controller provides the system with long-term stability and can be used to provide updated data to the predictive control algorithm.

Owner:MKS INSTR INC

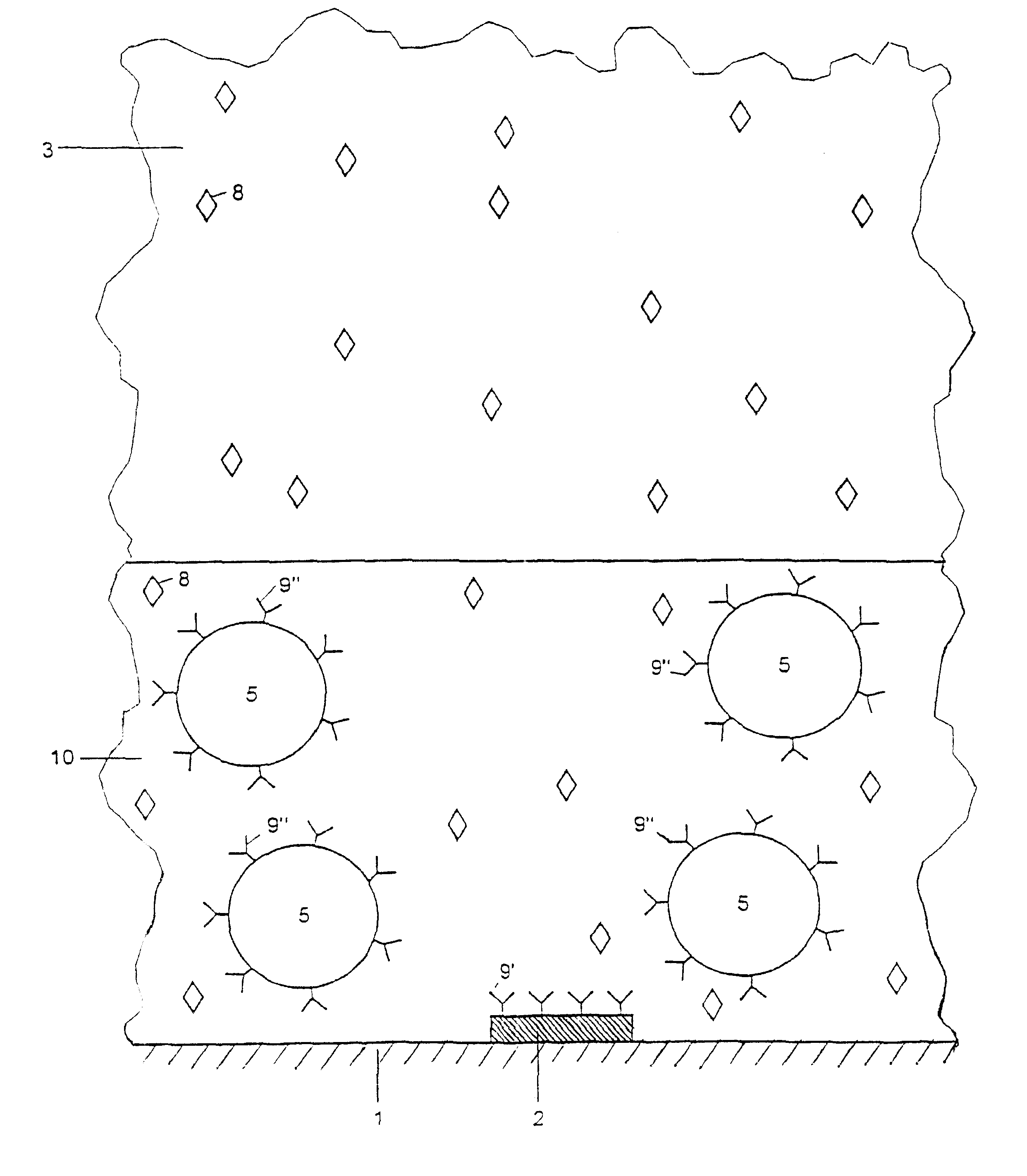

Device and method for detecting analytes

InactiveUS6548311B1Influence is negligibleRelative density is smallBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityAnalyte

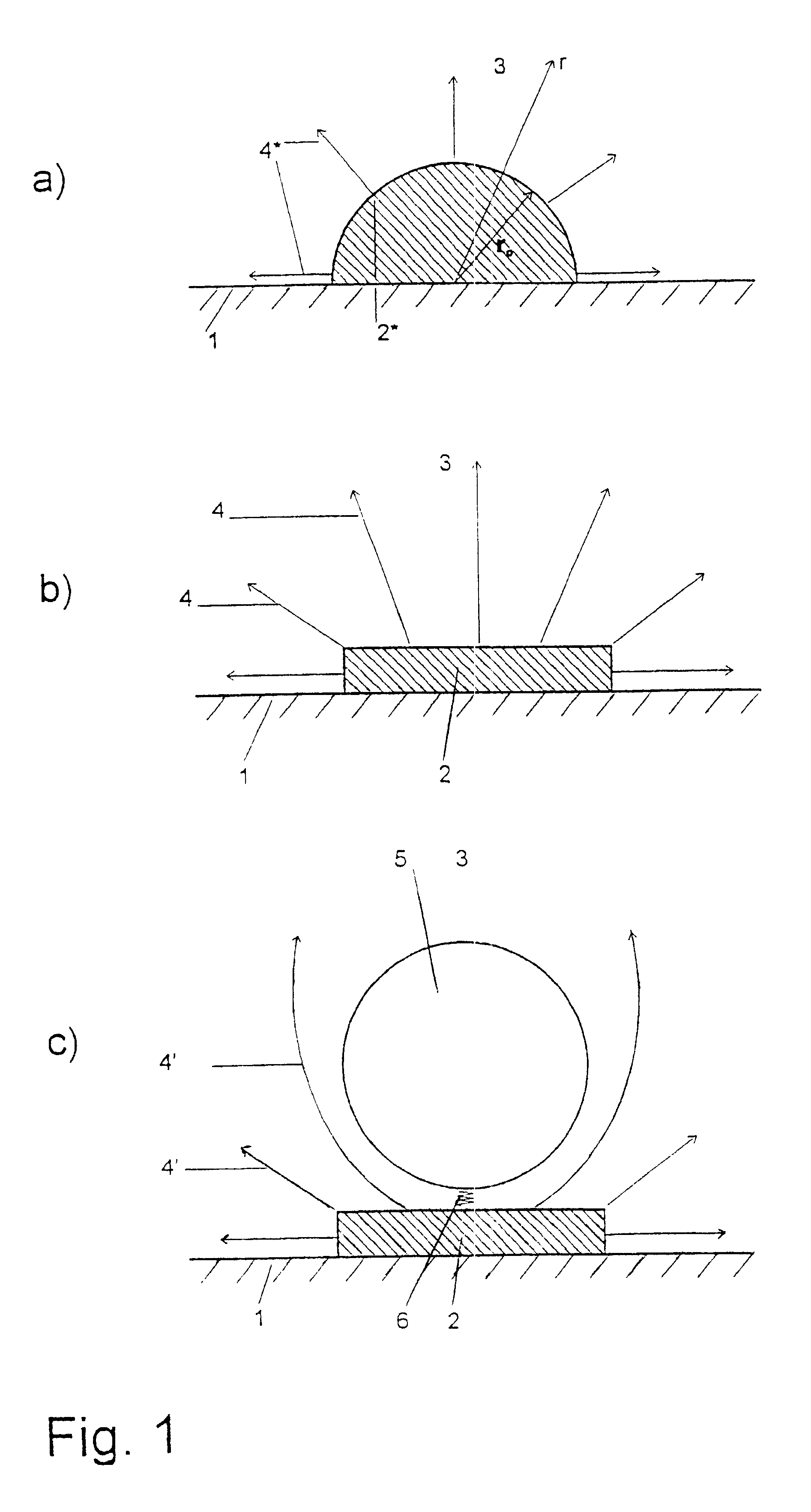

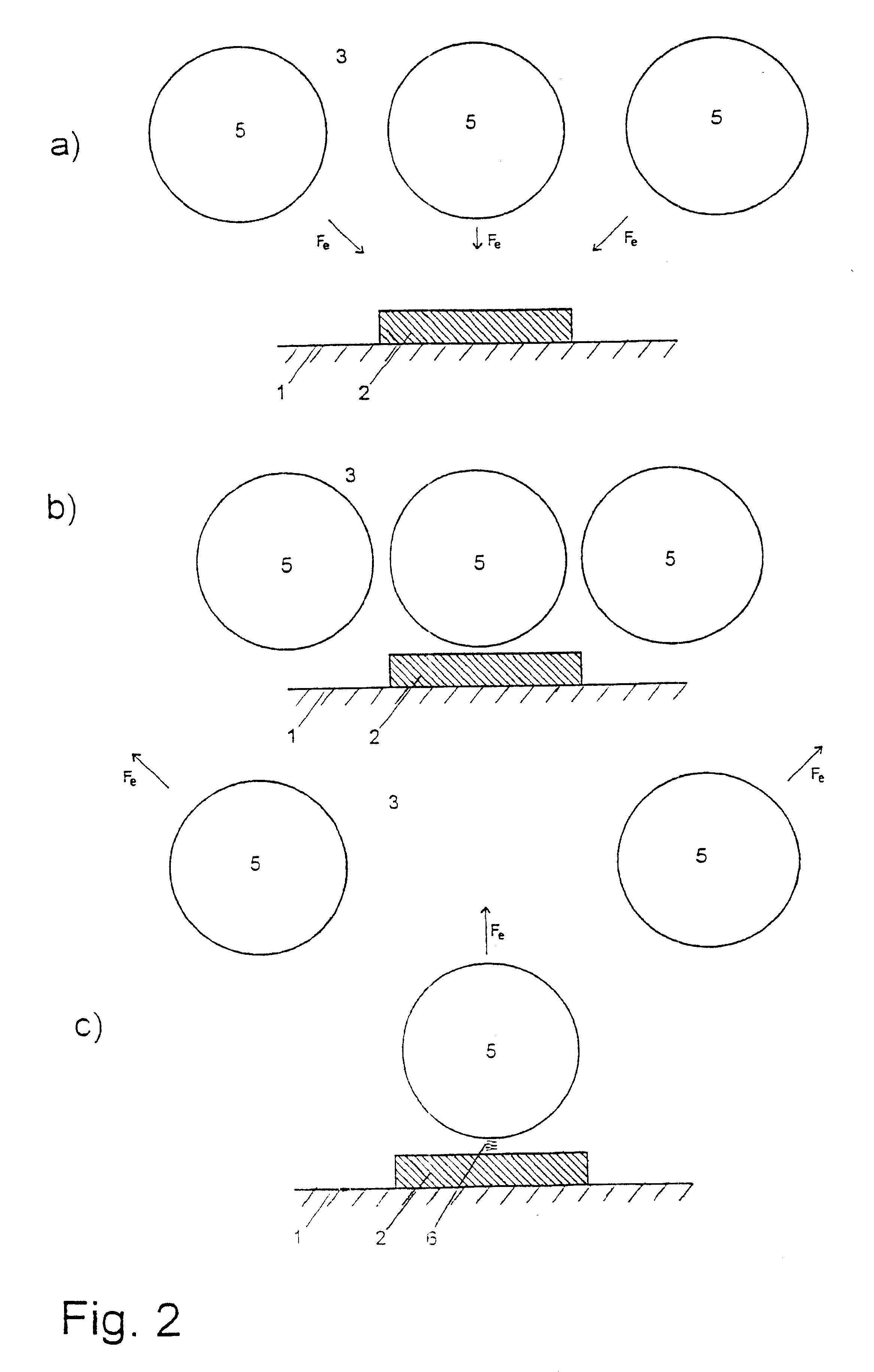

The invention relates to a method for detecting analytes and to a device for carrying out the method, for use for analysis or diagnosis in the fields of chemistry, biochemistry, molecular genetics, food chemistry, biotechnology, the environment and medicine. Marker particles (5) with different electrical properties or a different relative permeability to those of the measuring solution (3) surrounding them are used to detect the analytes (8). The marker particles (5) either bond specifically to the analytes (8) or to a base (2) in competition with the analyte. The analytes (8) are detected by the changes in an electrical field or an electrical current generated by electrodes (2) or in an electrical voltage applied to an electrode or in a magnetic field, said changes being caused by marker particles which have bonded with the analytes or by marker particles which have instead bonded to the base in an electrical field.

Owner:KNOLL MEINHARD

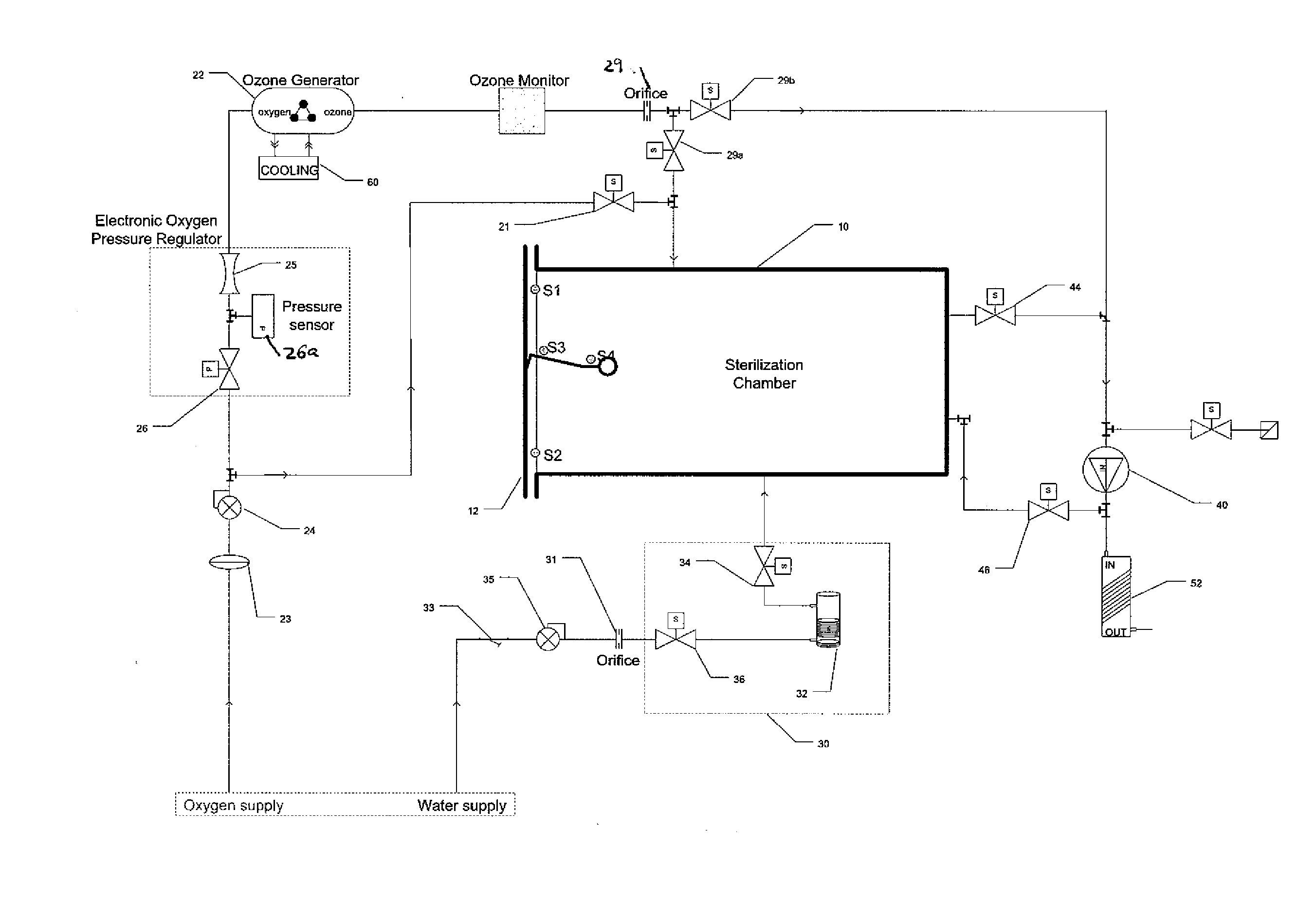

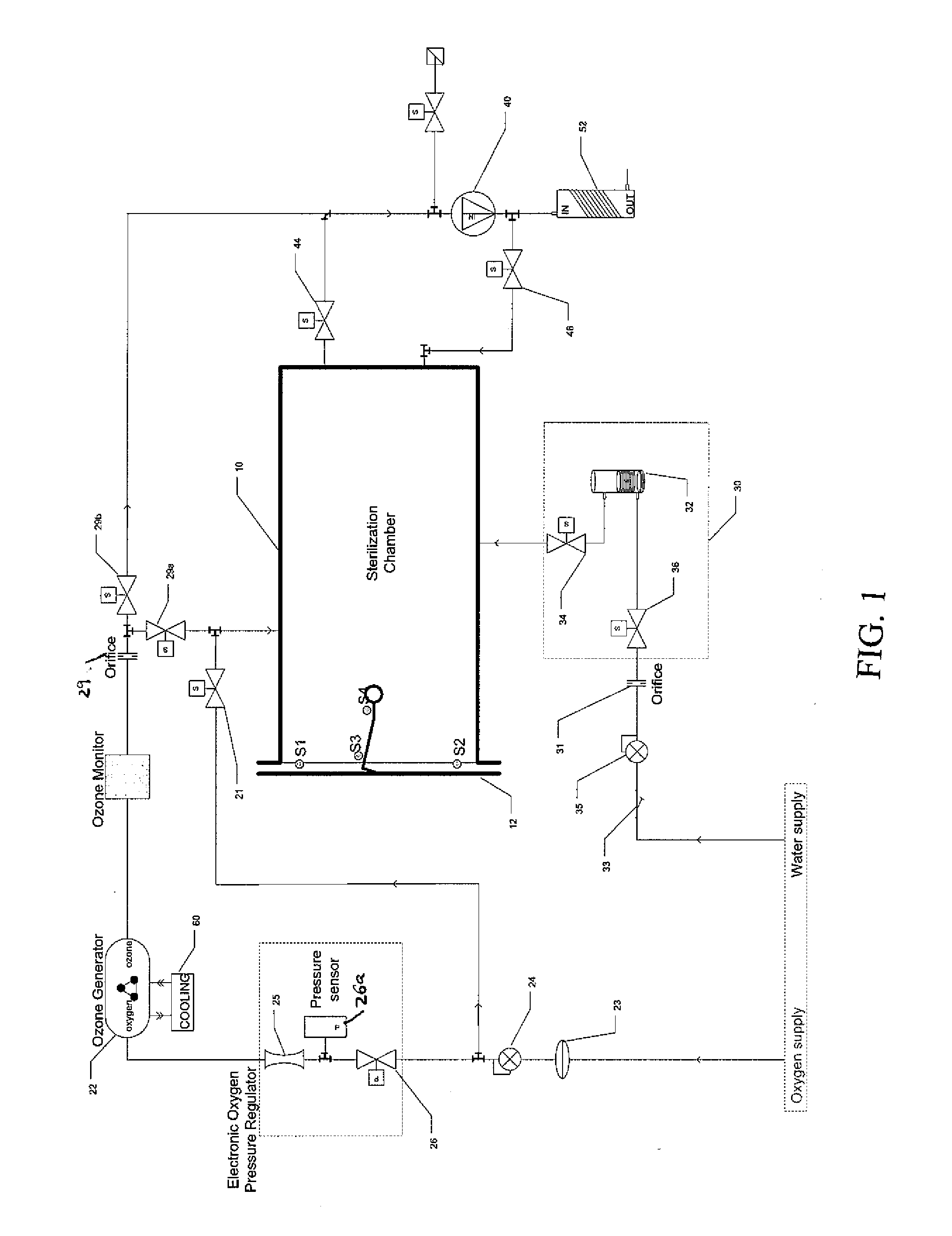

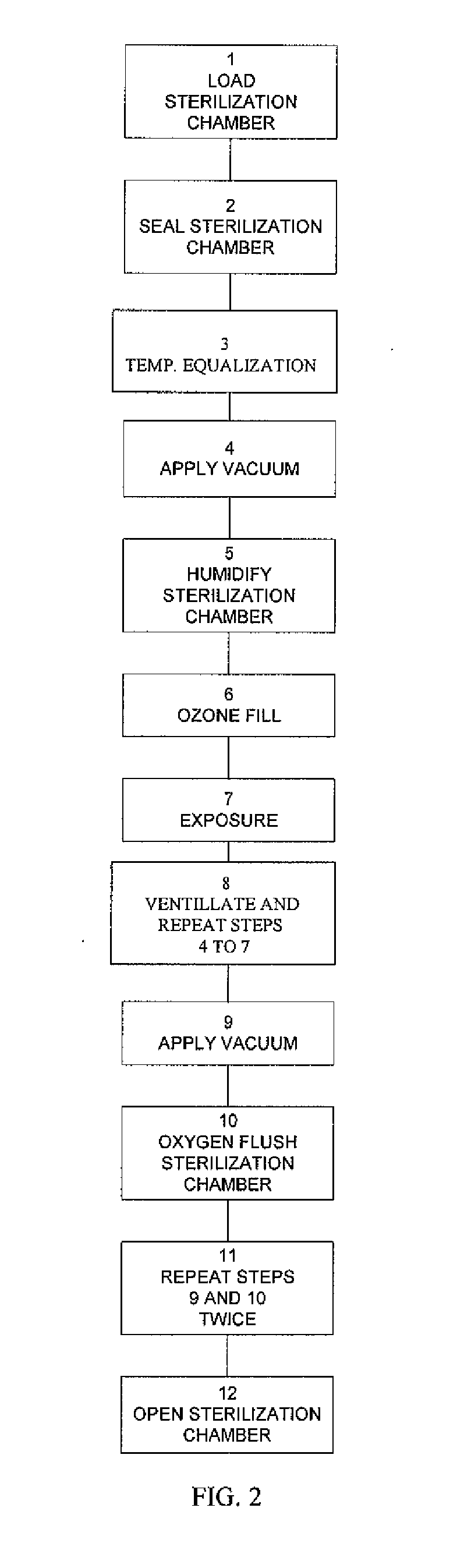

Method and apparatus for ozone sterilization

InactiveUS20070258855A1Avoid condensationPrevent water condensationElectrolysis componentsExhaust apparatusVacuum pressureWater vapor

The present invention provides a method and apparatus for sterilizing articles using an ozone-containing gas, where condensation of water from the sterilization atmosphere during the sterilization process is substantially prevented. The inventive sterilization method includes providing a sterilization chamber and placing an article into the sterilization chamber. The sterilization chamber is sealed prior to equalizing the temperature of the article and the atmosphere in the sterilization chamber. A vacuum is applied to achieve a preselected vacuum pressure in the sterilization chamber. Once the vacuum pressure is set, water vapour is supplied to the sterilization chamber. Ozone-containing gas is then supplied to the sterilization chamber and the sterilization chamber remains sealed for a preselected treatment period, where the sterilization chamber remains sealed throughout the whole process. Finally, vacuum in the sterilization chamber is released.

Owner:STRYKER CORP

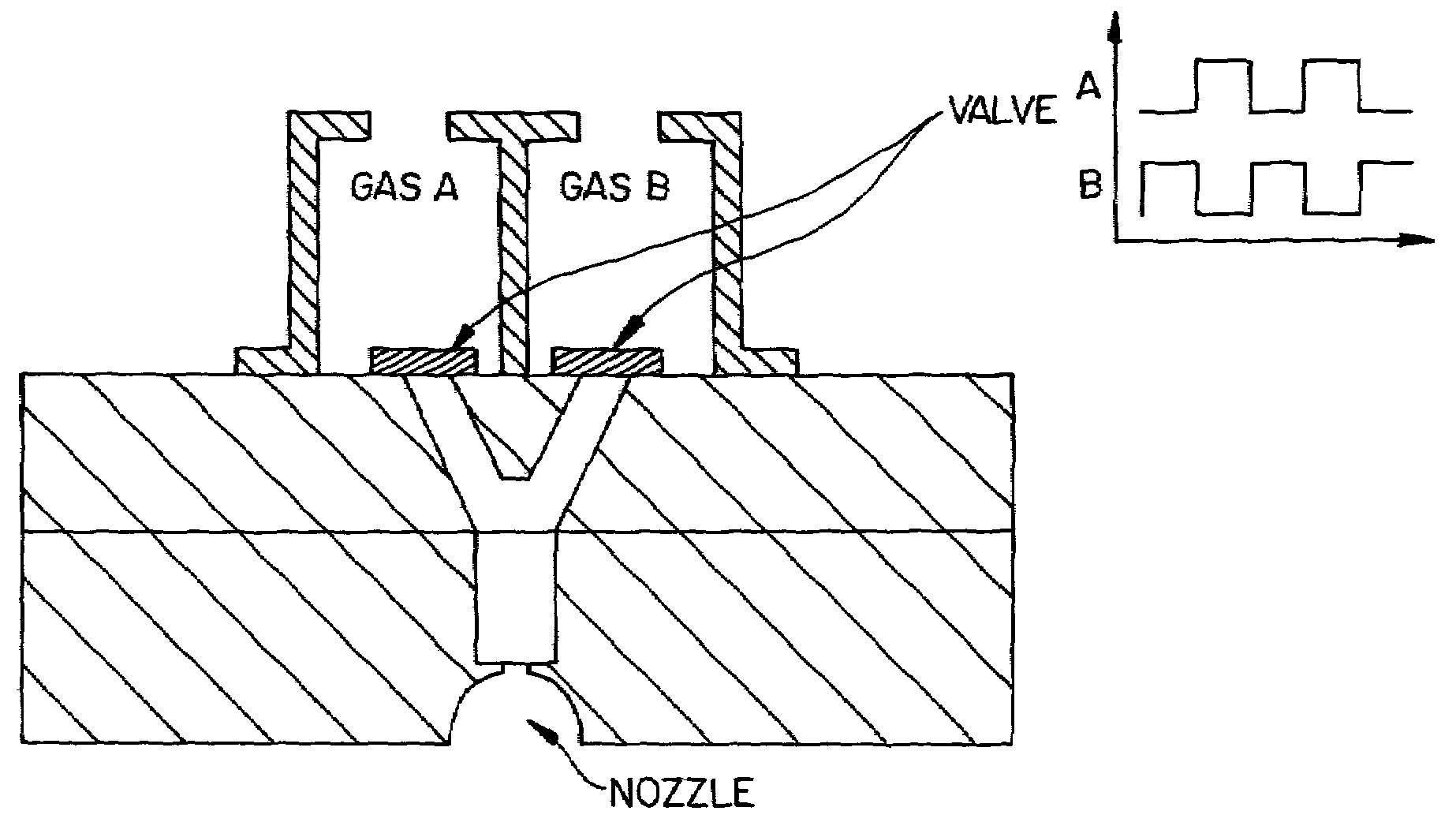

Pulsed plasma processing method and apparatus

InactiveUS7166233B2Remove restrictionsImproved profileDecorative surface effectsVacuum evaporation coatingEngineeringPlasma processing

In a method for performing a plasma-assisted treatment on a substrate in a reactor chamber by: introducing at least one process gas into the reactor chamber; and creating a plasma within the reactor chamber by establishing an RF electromagnetic field within the chamber and allowing the field to interact with the process gas, the electromagnetic field is controlled to have an energy level which varies cyclically between at least two values each sufficient to maintain the plasma, such that each energy level value is associated with performance of a respectively different treatment process on the substrate.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com