Patents

Literature

2245 results about "Chlorosilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chlorosilanes are a group of reactive, chlorine-containing chemical compounds, related to silane and used in many chemical processes. Each such chemical has at least one silicon-chlorine bond. Trichlorosilane is produced on the largest scale. The parent chlorosilane is Silicon tetrachloride (SiCl₄).

Low Temperature Deposition of Silicon-Containing Films

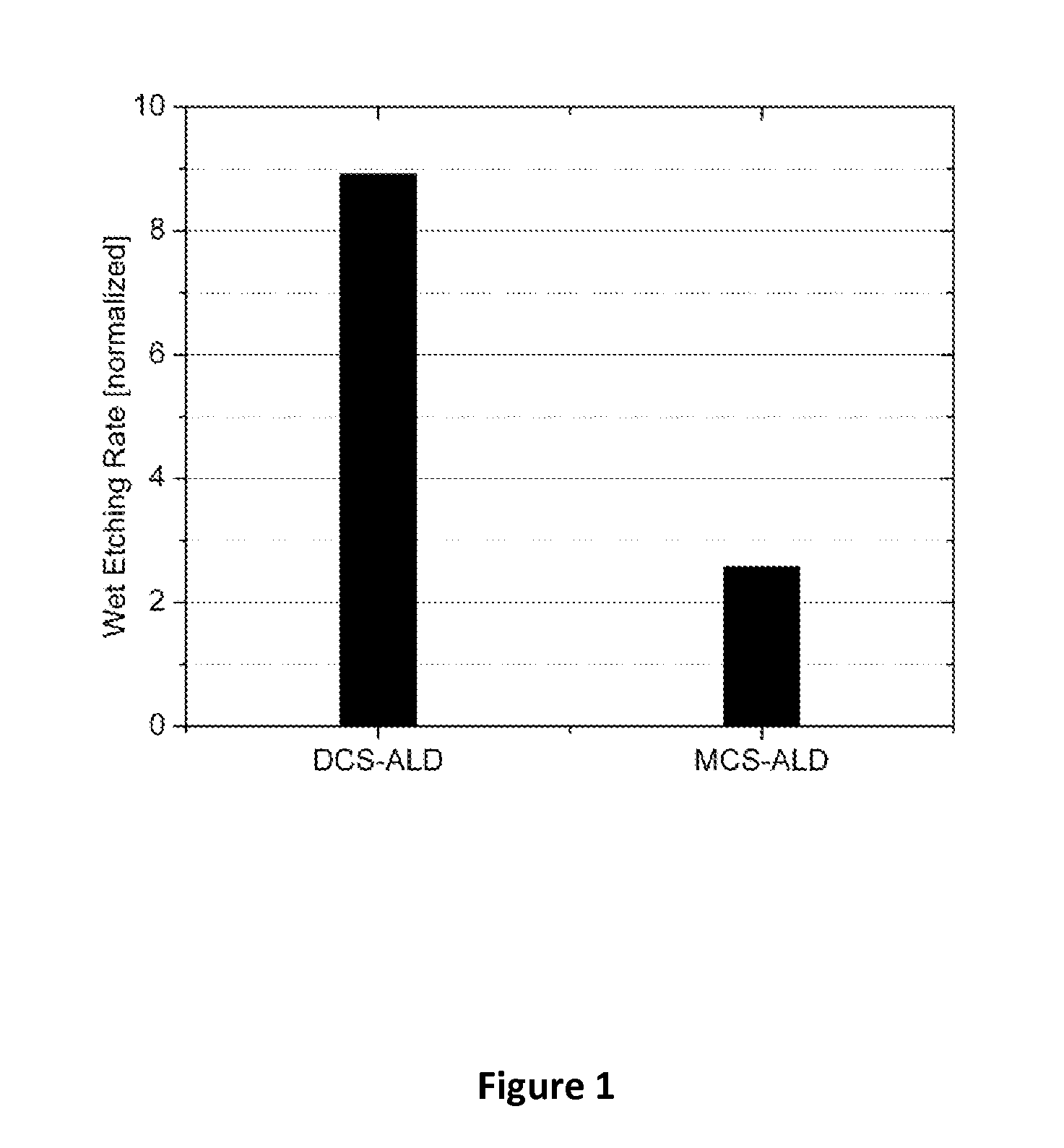

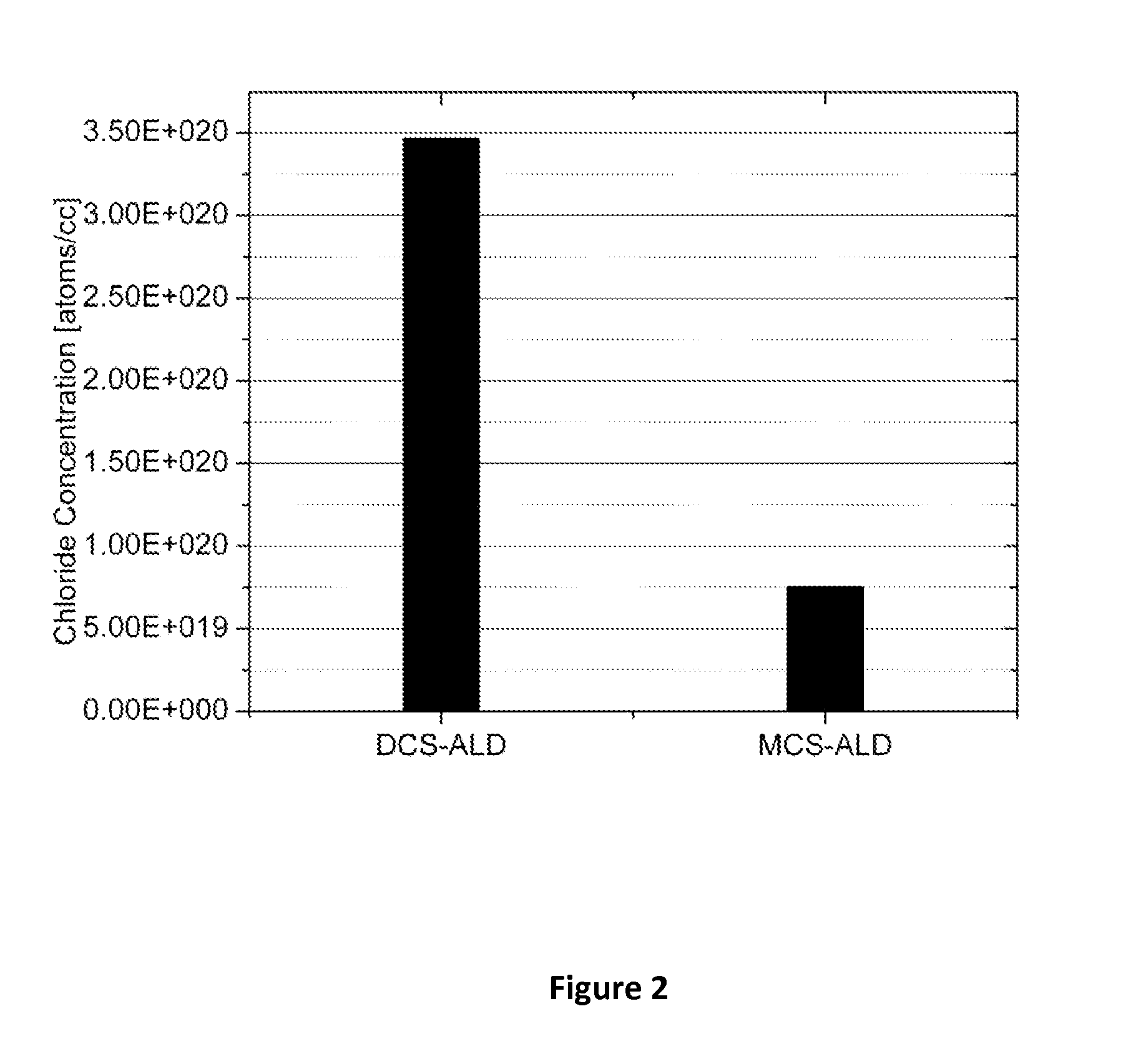

ActiveUS20100304047A1Low deposition temperatureSemiconductor/solid-state device manufacturingSpecial surfacesLow temperature depositionDeposition temperature

This invention discloses the method of forming silicon nitride, silicon oxynitride, silicon oxide, carbon-doped silicon nitride, carbon-doped silicon oxide and carbon-doped oxynitride films at low deposition temperatures. The silicon containing precursors used for the deposition are monochlorosilane (MCS) and monochloroalkylsilanes. The method is preferably carried out by using plasma enhanced atomic layer deposition, plasma enhanced chemical vapor deposition, and plasma enhanced cyclic chemical vapor deposition.

Owner:TOKYO ELECTRON LTD +1

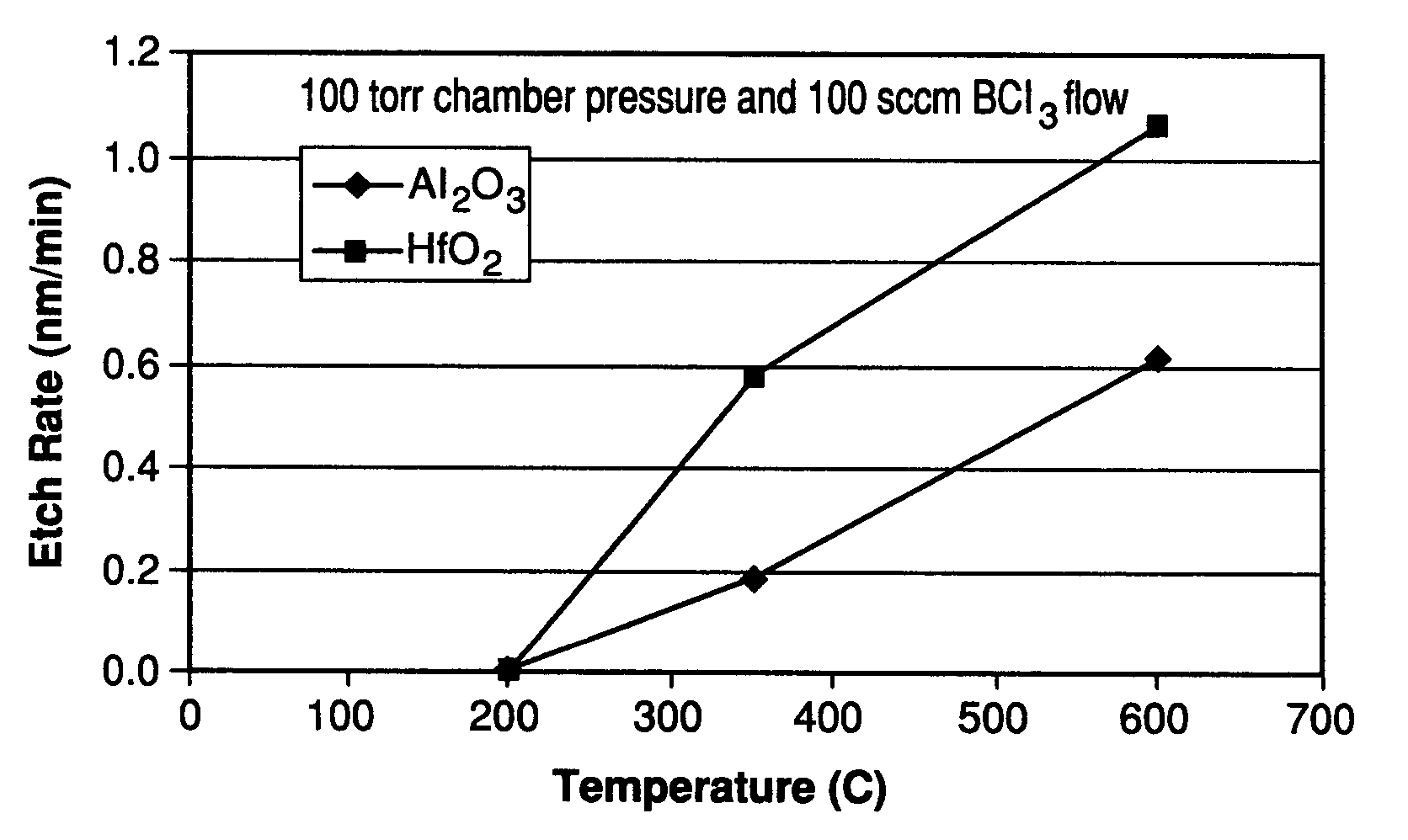

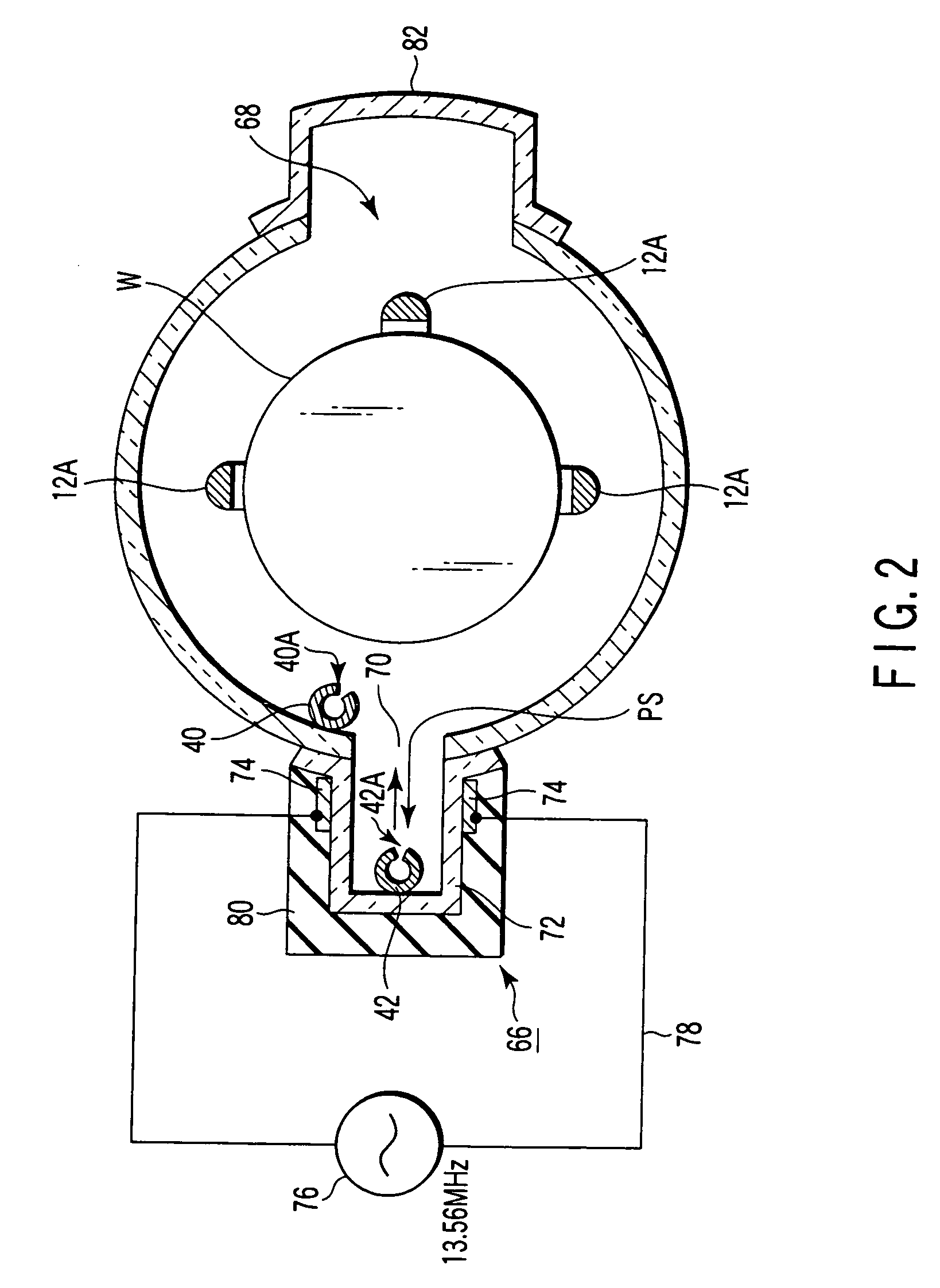

Method for etching high dielectric constant materials and for cleaning deposition chambers for high dielectric constant materials

A process for the removal of a substance from a substrate for etching and / or cleaning applications is disclosed herein. In one embodiment, there is provided a process for removing a substance having a dielectric constant greater than silicon dioxide from a substrate by reacting the substance with a reactive agent that comprises at least one member from the group consisting a halogen-containing compound, a boron-containing compound, a hydrogen-containing compound, nitrogen-containing compound, a chelating compound, a carbon-containing compound, a chlorosilane, a hydrochlorosilane, or an organochlorosilane to form a volatile product and removing the volatile product from the substrate to thereby remove the substance from the substrate.

Owner:VERSUM MATERIALS US LLC

Preparation method of silica aerogel aqueous heat-insulating coating

InactiveCN102719129ADoes not require surface hydrophobic modificationWon't collapseCoatingsSilicon compoundsMicrosphereAlkoxy group

The invention discloses a preparation method of a silica aerogel aqueous heat-insulating coating, and is characterized in that: prepared SiO2 microspheres are hydrophobic inside and hydrophilic outside; and the aerogel microspheres can be added into an aqueous coating carrier to prepare a good heat-insulating material. The main preparation method comprises the following steps of: before drying the prepared wet gel microspheres, performing surface modification by using an organic silane or an organic chlorosilane, so that the prepared wet gel microspheres are hydrophobic by grafting a large number of alkoxy groups or alkyl groups on the surfaces thereof, or directly preparing the hydrophobic wet gel microspheres; performing surface modification on the microspheres by using a hydrophilic silane coupling agent, and drying to obtain the SiO2 microspheres which are hydrophobic inside and hydrophilic outside; and adding the prepared microspheres into an aqueous coating for preparing the aqueous heat-insulating coating.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

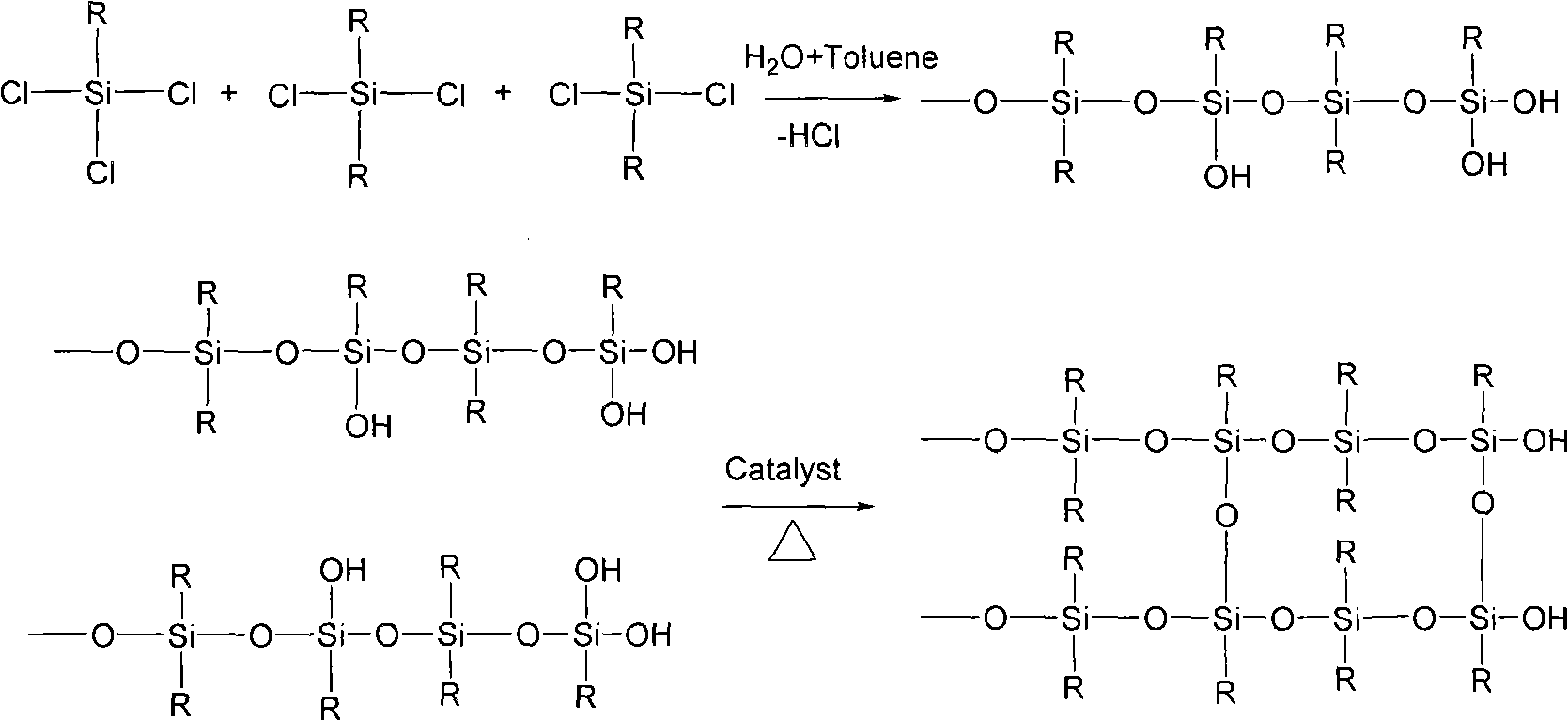

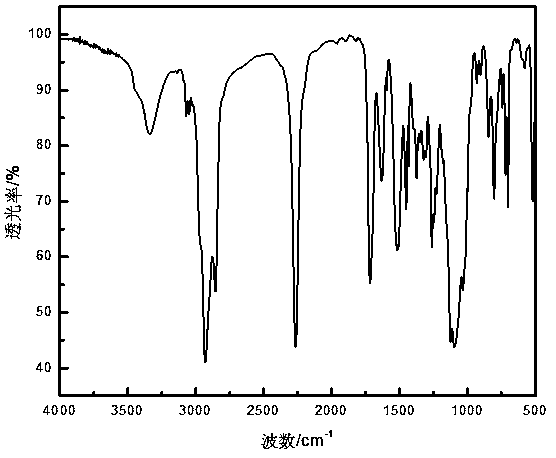

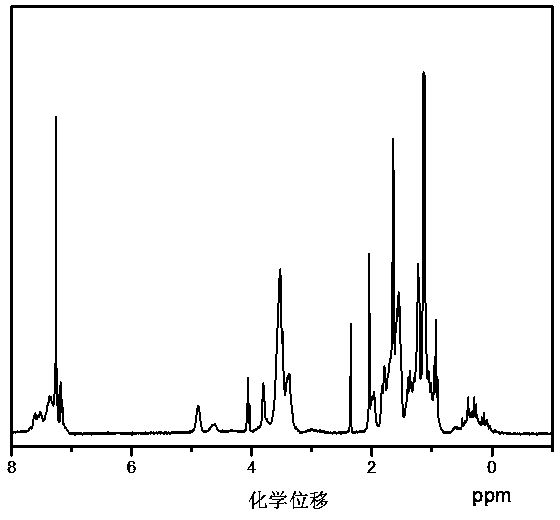

Preparation method for methyl phenyl vinyl polysiloxane for packaging LED

The invention discloses a preparation method for organosilicon, in particular relates to a preparation method of methyl-phenyl-vinyl silicone resin with high refractive index and high light transmission rate for packaging LED. The preparation method adopts the steps that the mixture of chlorosilane and toluene is added into the solvent which is composed of water and the toluene, the hydrolysis reaction is performed, then an amount of catalyzer is added into the silanol-toluene solution as hysrolysis product, the polycondensation reaction is performed, end capping reagent is finally added to perform the reaction, thus the objective product is obtained. The methyl-phenyl-vinyl silicone resin prepared by utilizing the method has the advantages of high refractive index, transparent clarification, radiation resistance, and high and low temperature resistance and weather resistance, thereby being especially suitable for the high modular basic glue in the packaging material for LED and expected to be applied in organosilicon material such as elastomeric sealant, pouring sealant, elastomoric adhesive and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

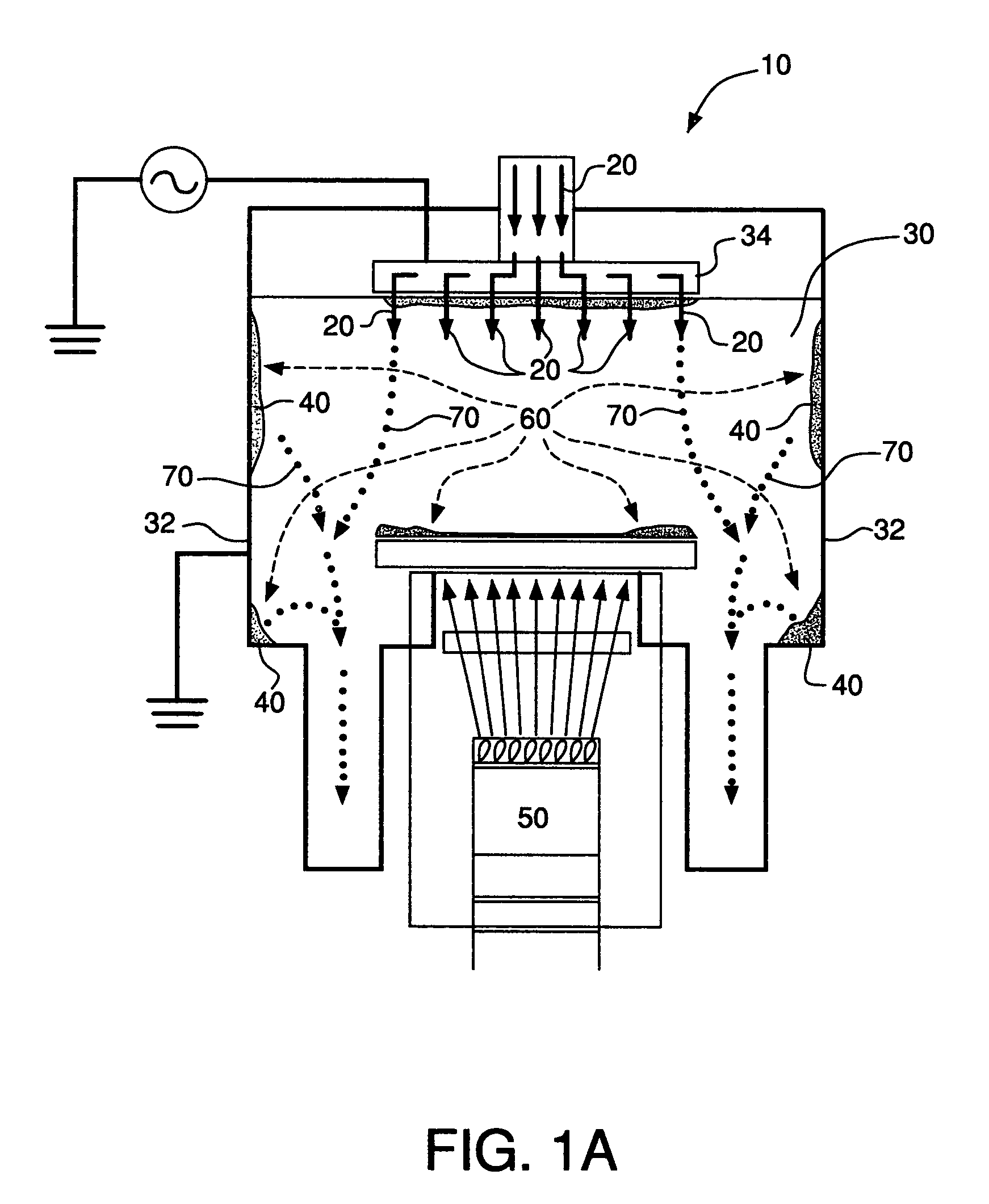

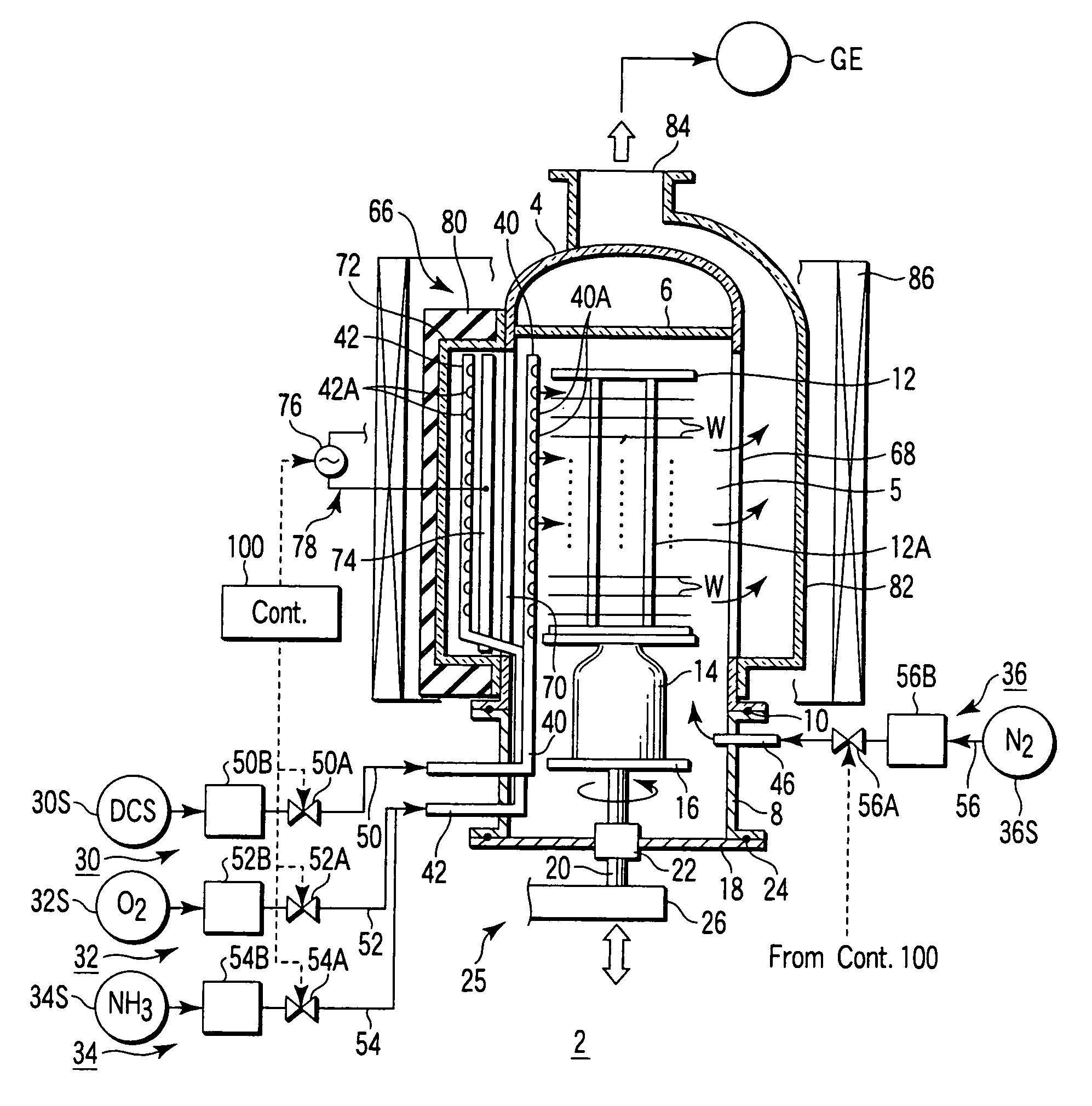

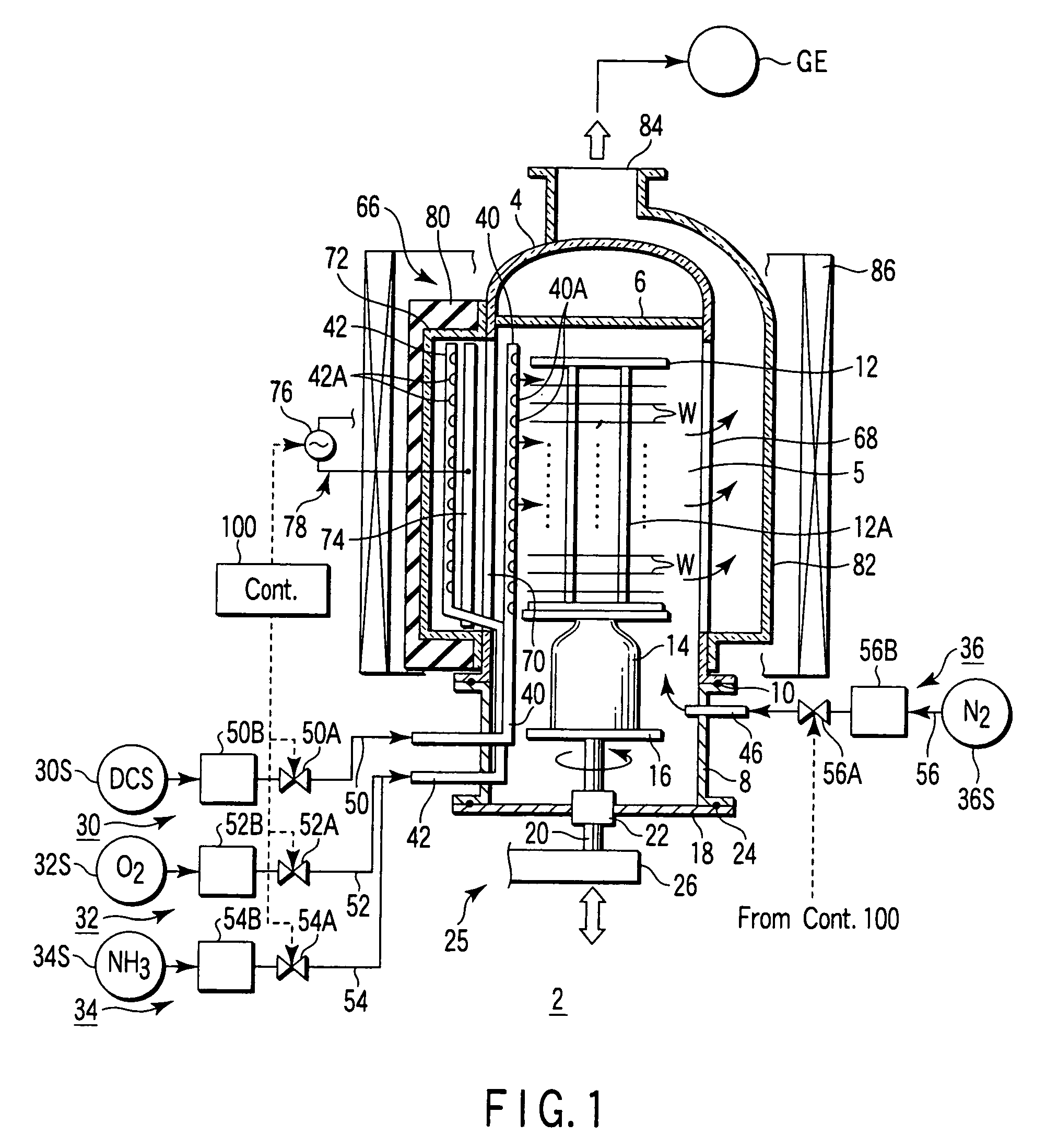

Method for forming silicon oxynitride film

InactiveUS7632757B2Good step coverageReduce the temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess regionProcess engineering

A silicon oxynitride film is formed on a target substrate by CVD, in a process field configured to be selectively supplied with a first process gas containing a chlorosilane family gas, a second process gas containing an oxidizing gas, and a third process gas containing a nitriding gas. This method alternately includes first to sixth steps. The first, third, and fifth steps perform supply of the first, second, and third process gases, respectively, while stopping supply of the other two process gases. Each of the second, fourth, and sixth steps stops supply of the first to third process gases. The third and fifth steps include an excitation period of supplying the second and third process gases, respectively, to the process field while exciting the respective process gases by an exciting mechanism.

Owner:TOKYO ELECTRON LTD

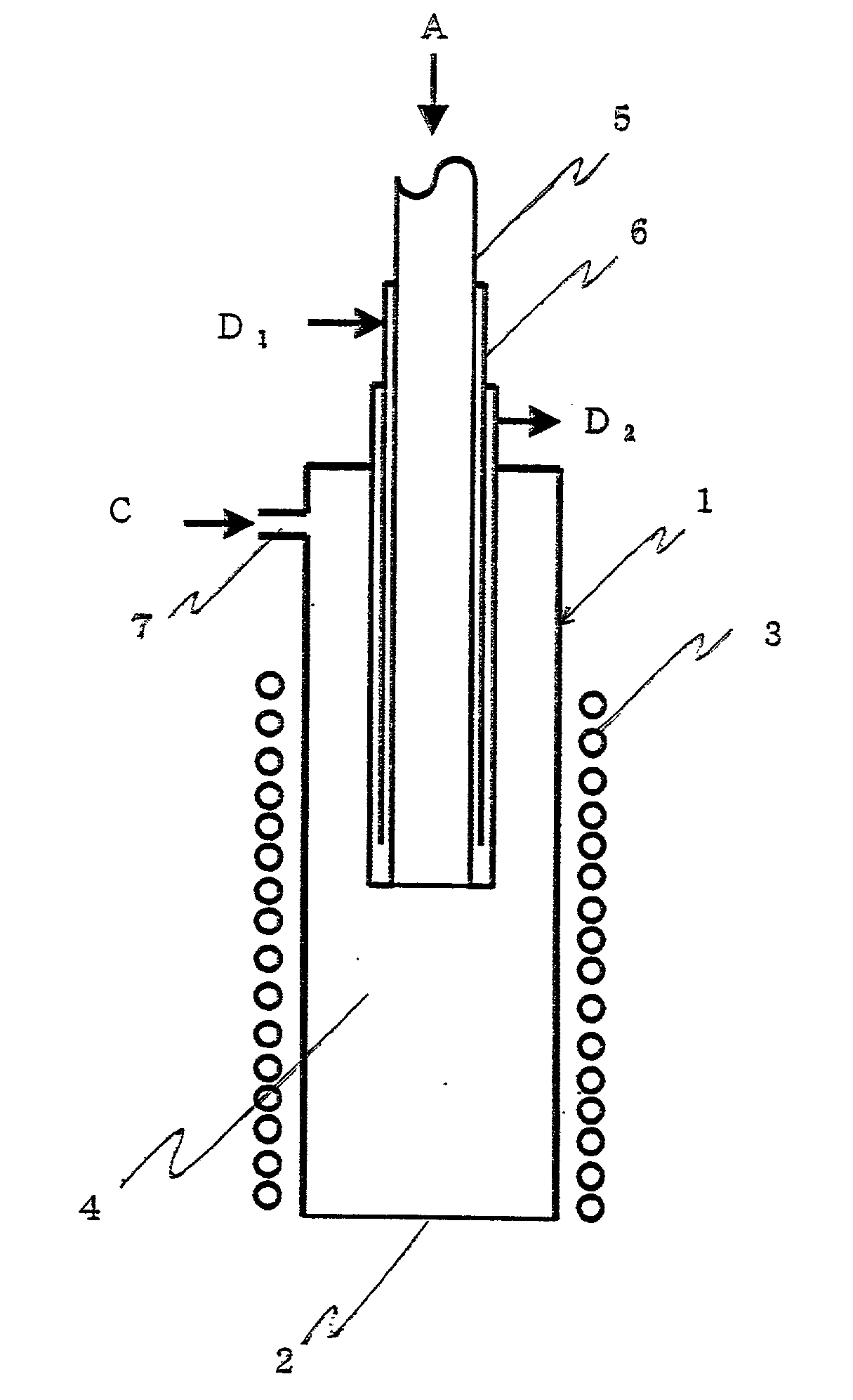

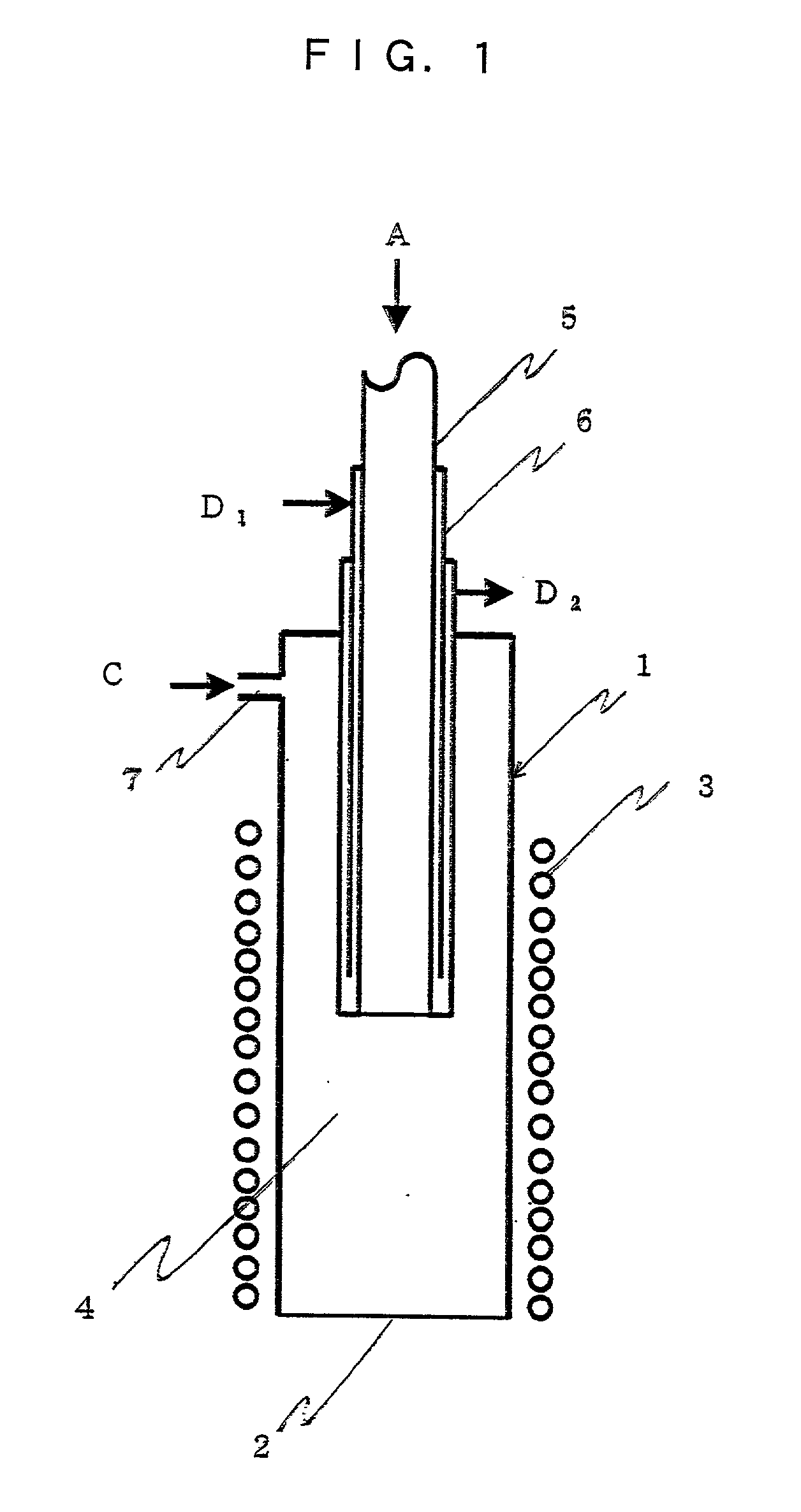

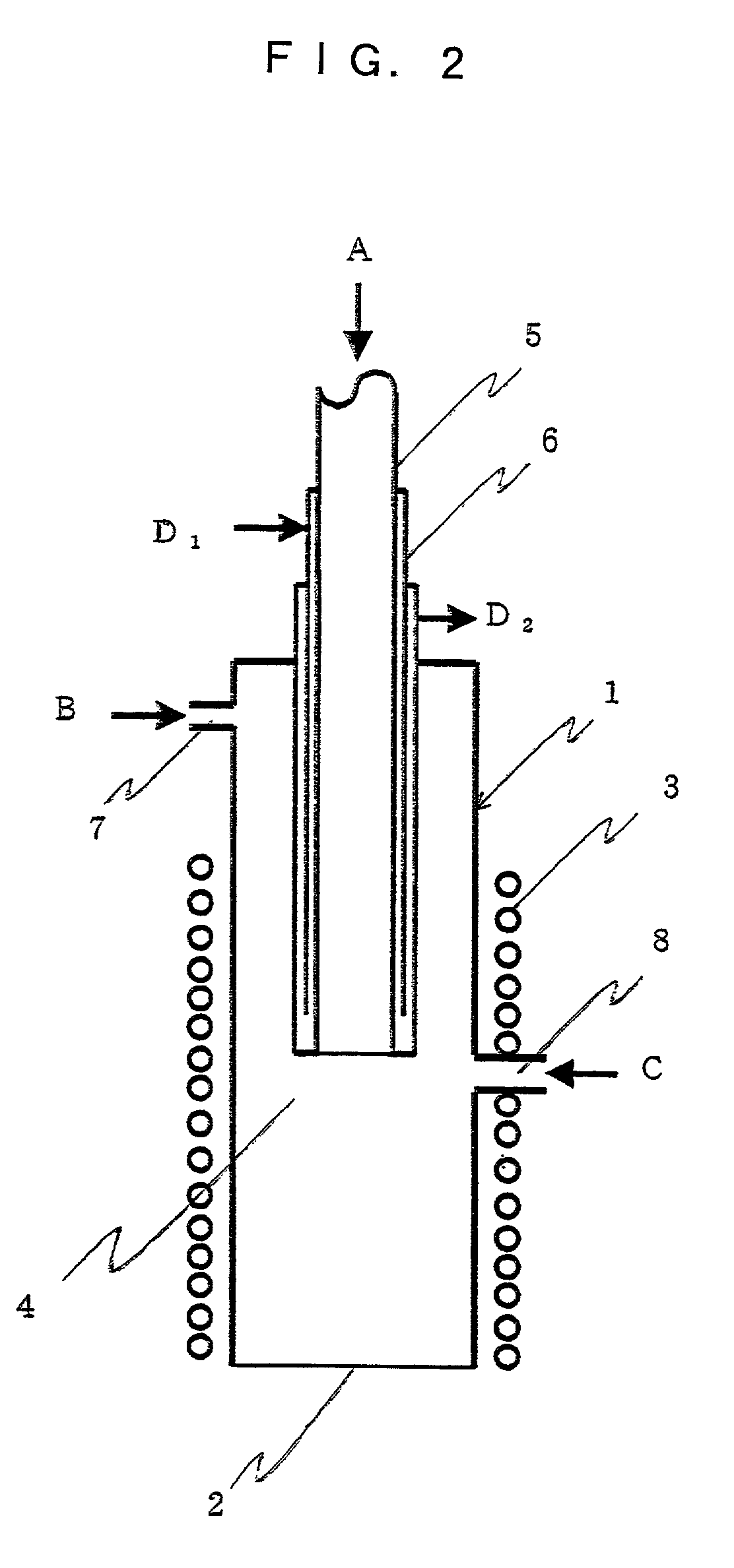

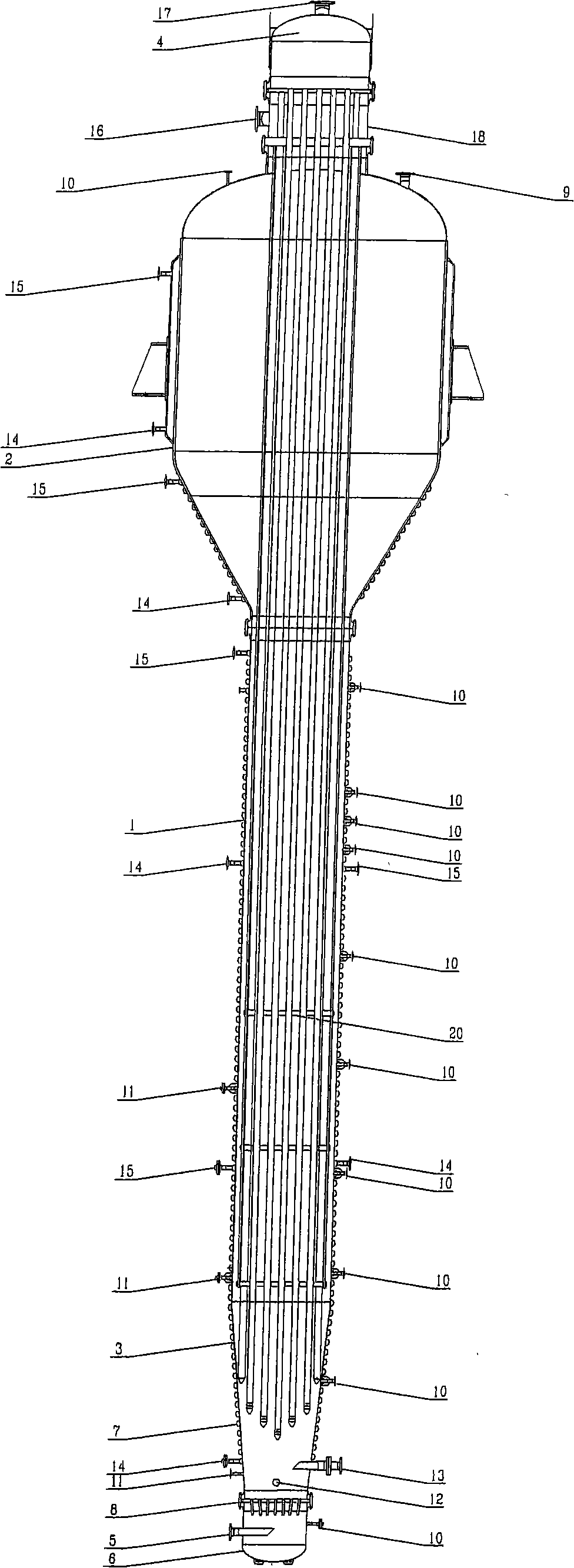

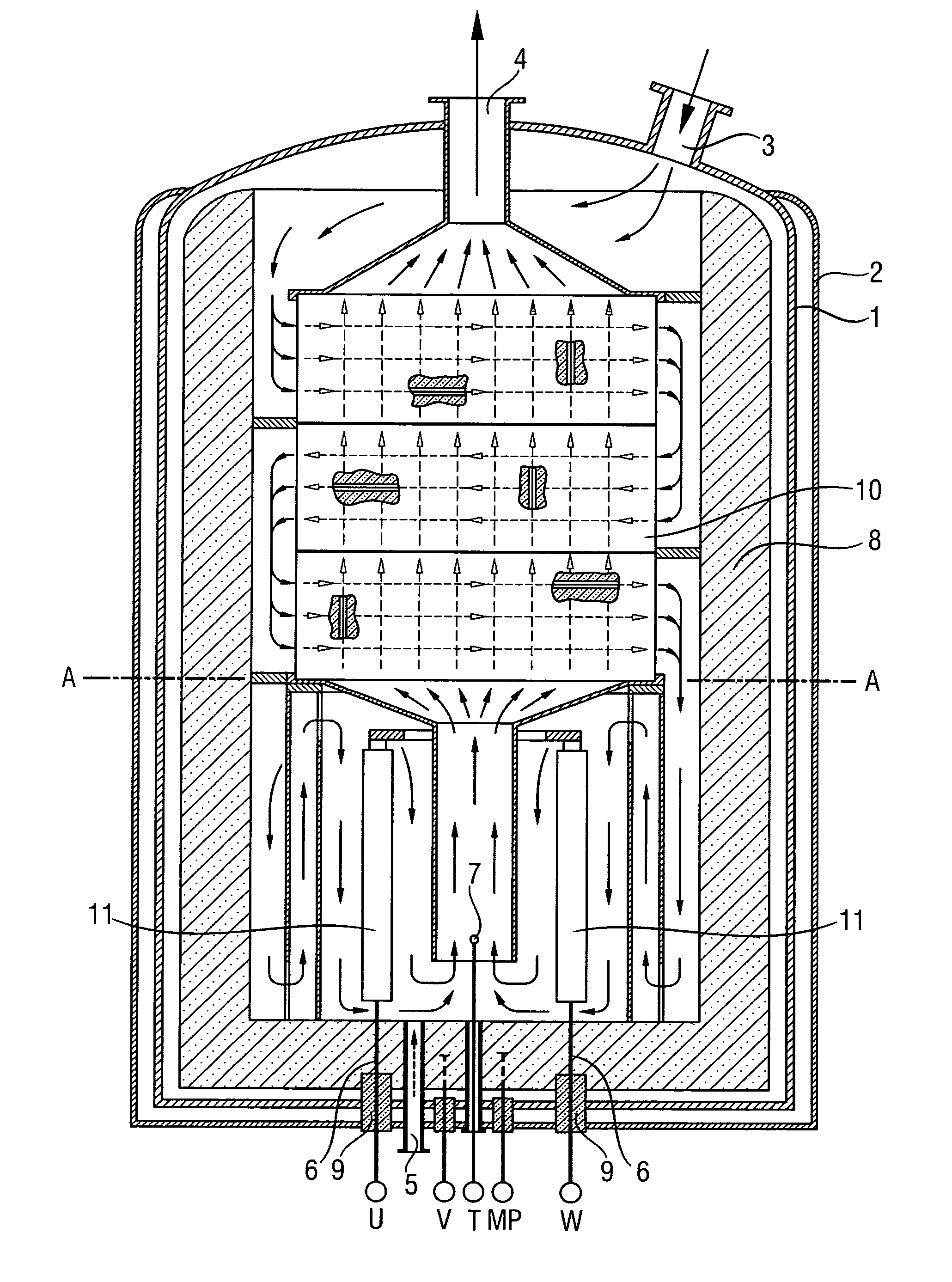

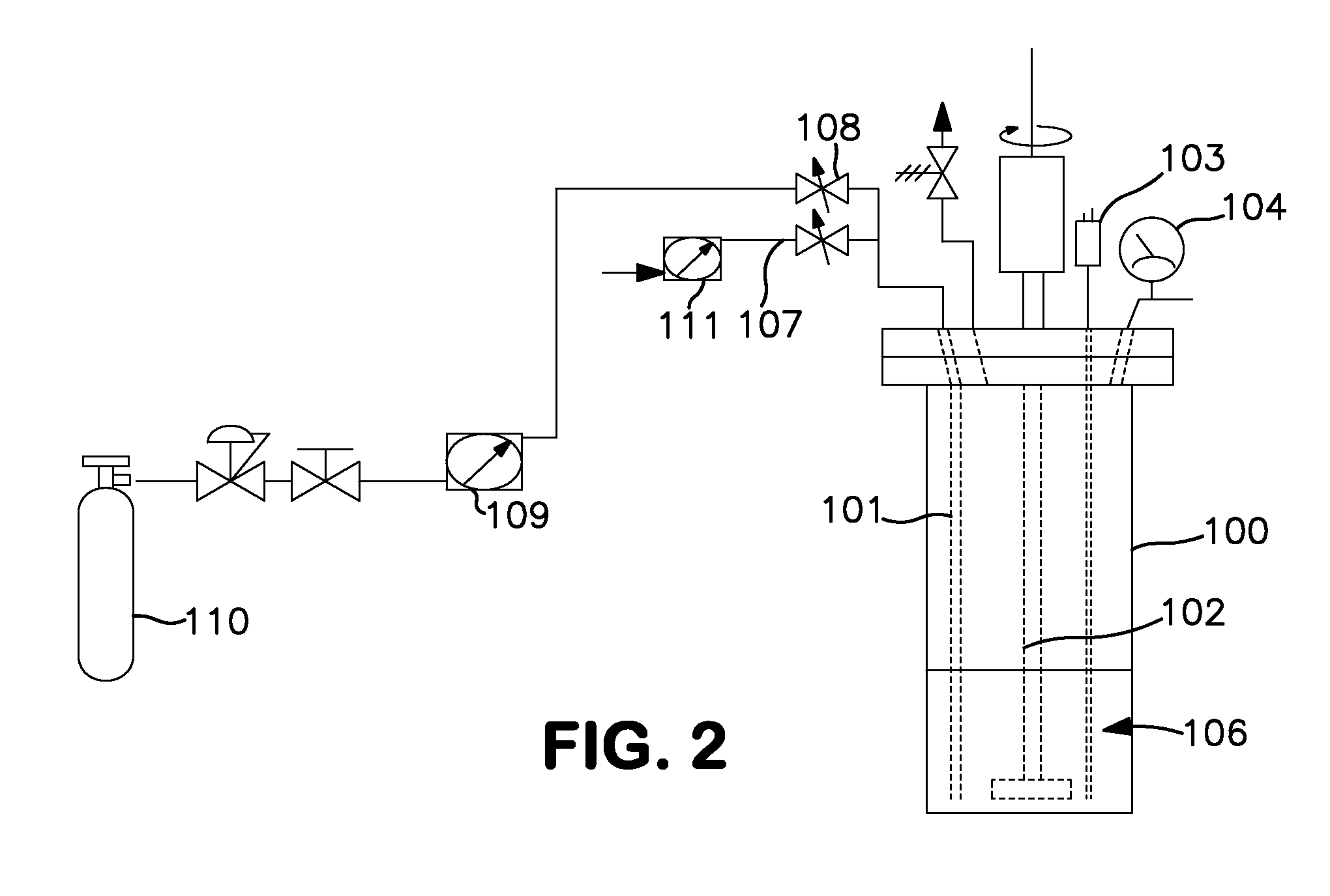

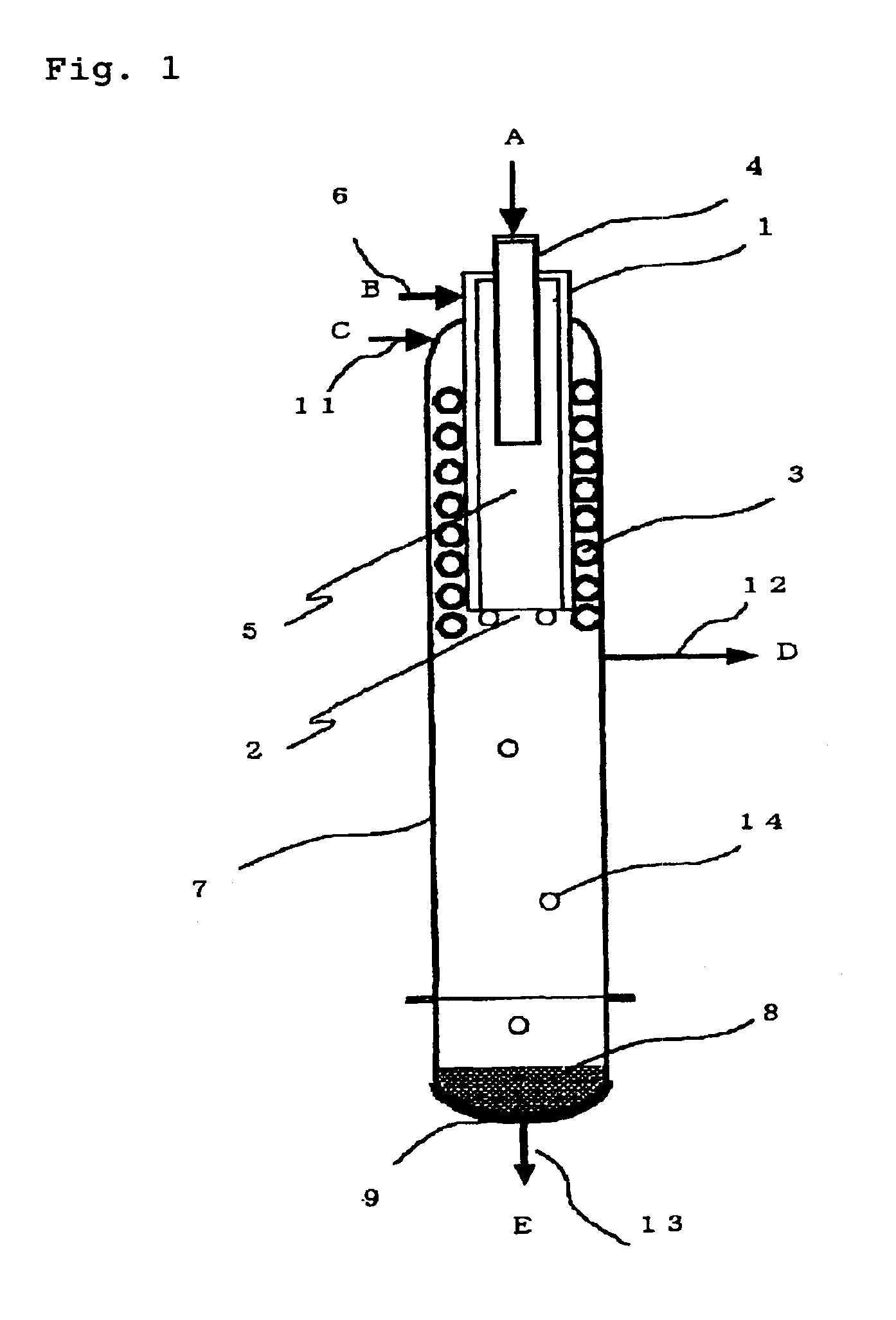

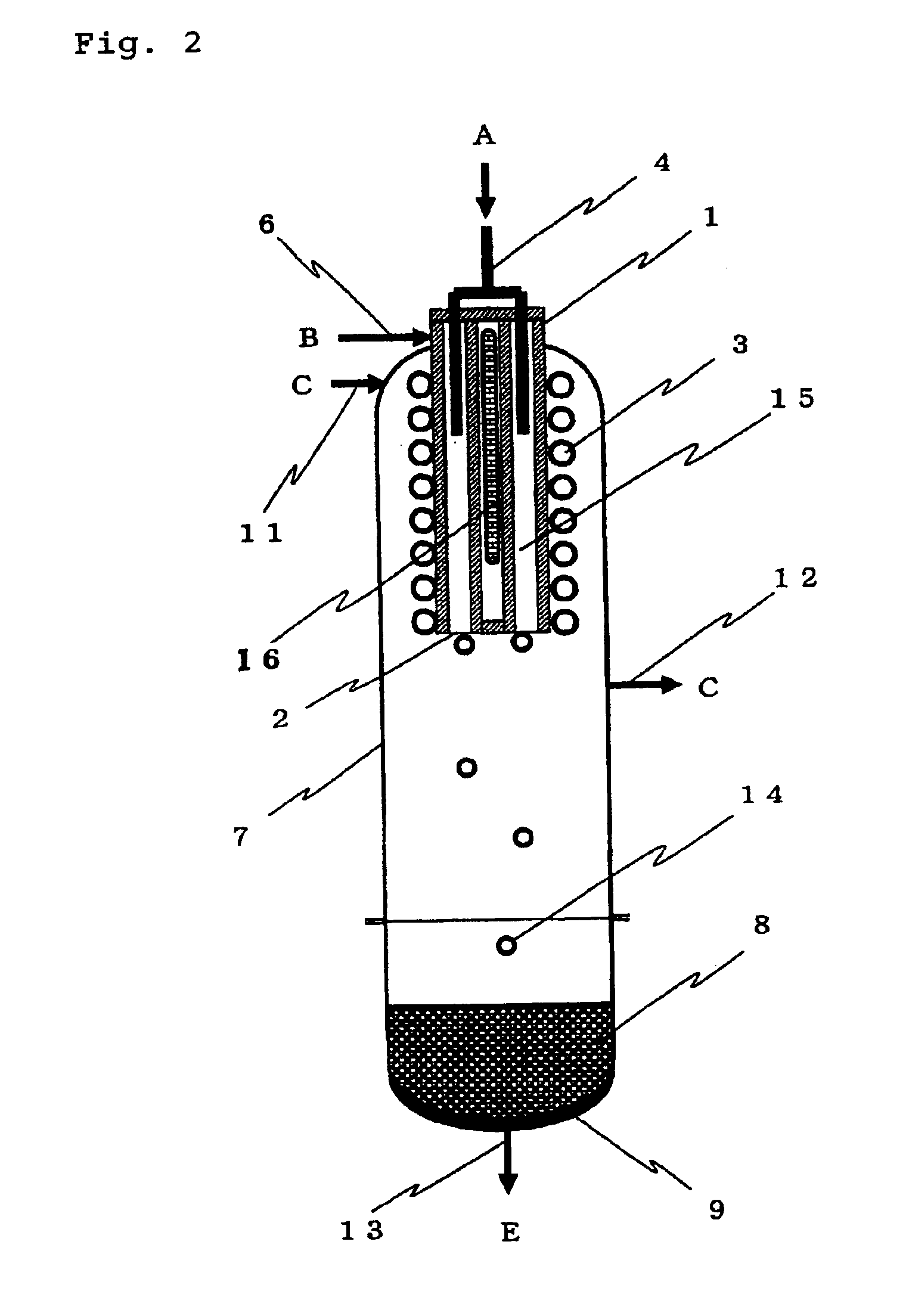

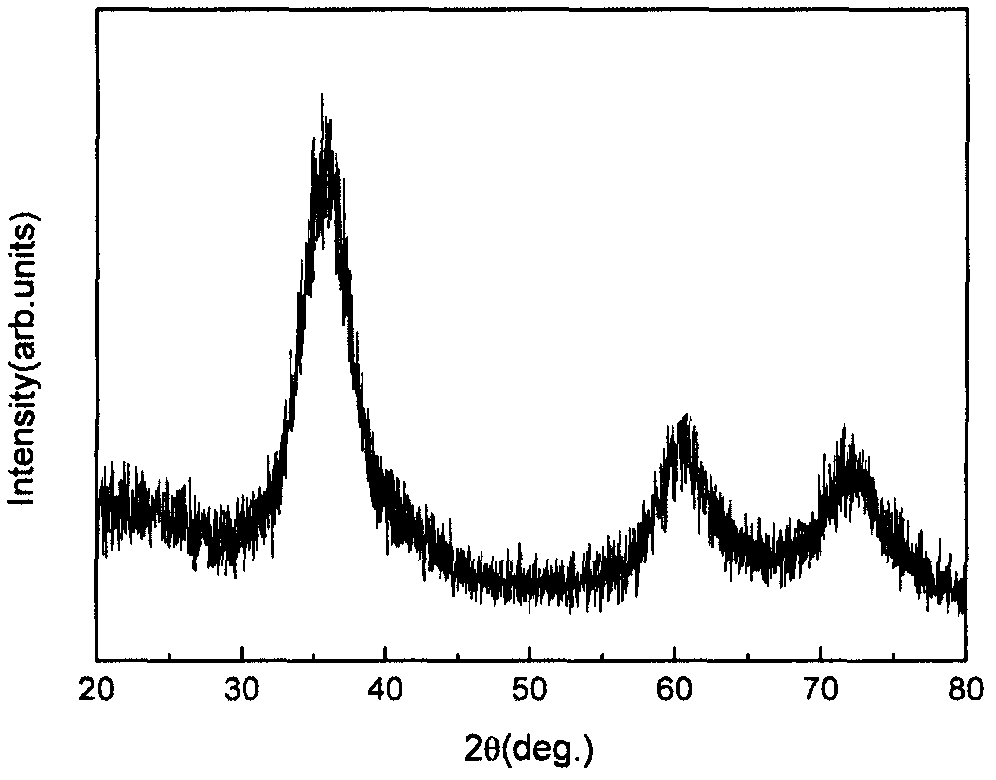

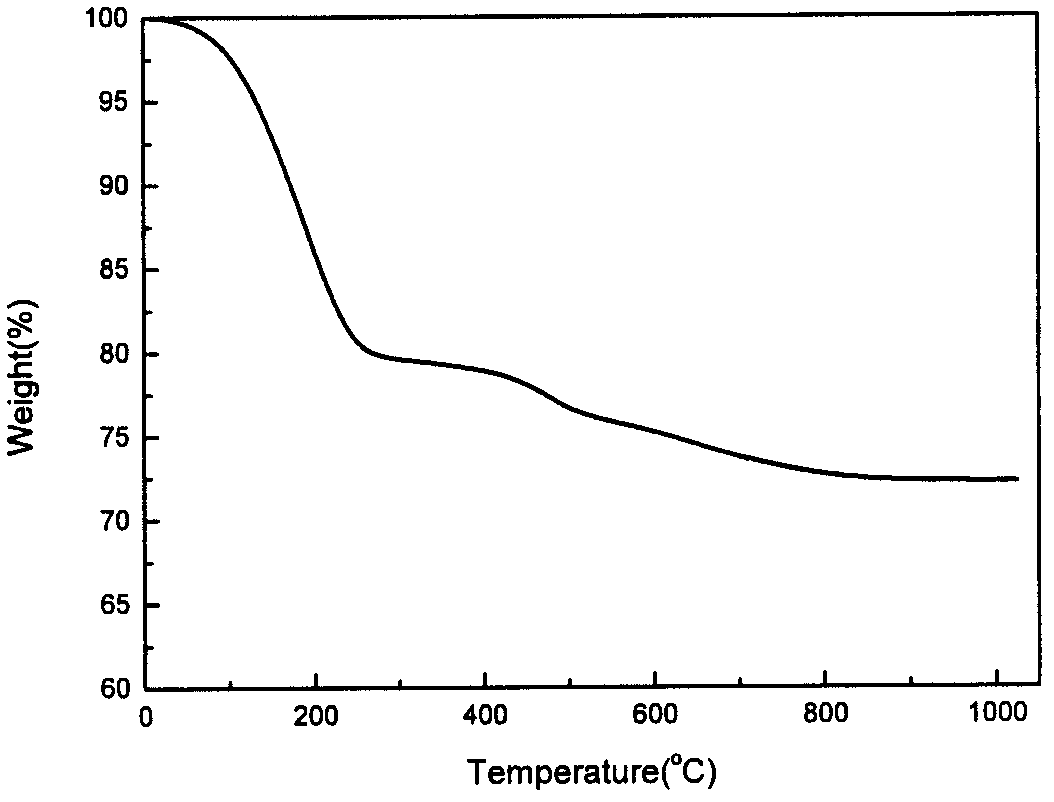

Polycrystalline silicon and process and apparatus for producing the same

InactiveUS20020104474A1Improve the heating effectSuitable structureFrom solid stateSemiconductor/solid-state device manufacturingChlorosilanePolycrystalline silicon

Foamed polycrystalline silicon having bubbles therein and an apparent density of 2.20 g / cm3 or less. This silicon generates an extremely small amount of fine grains by crushing and can be easily crushed. There is also provided a method of producing foamed polycrystalline silicon. There is further provided a polycrystalline silicon production apparatus in which the deposition and melting of silicon are carried out on the inner surface of a cylindrical vessel, a chlorosilane feed pipe is inserted into the cylindrical vessel to a silicon molten liquid, and seal gas is supplied into a space between the cylindrical vessel and the chlorosilane feed pipe.

Owner:TOKUYAMA CORP

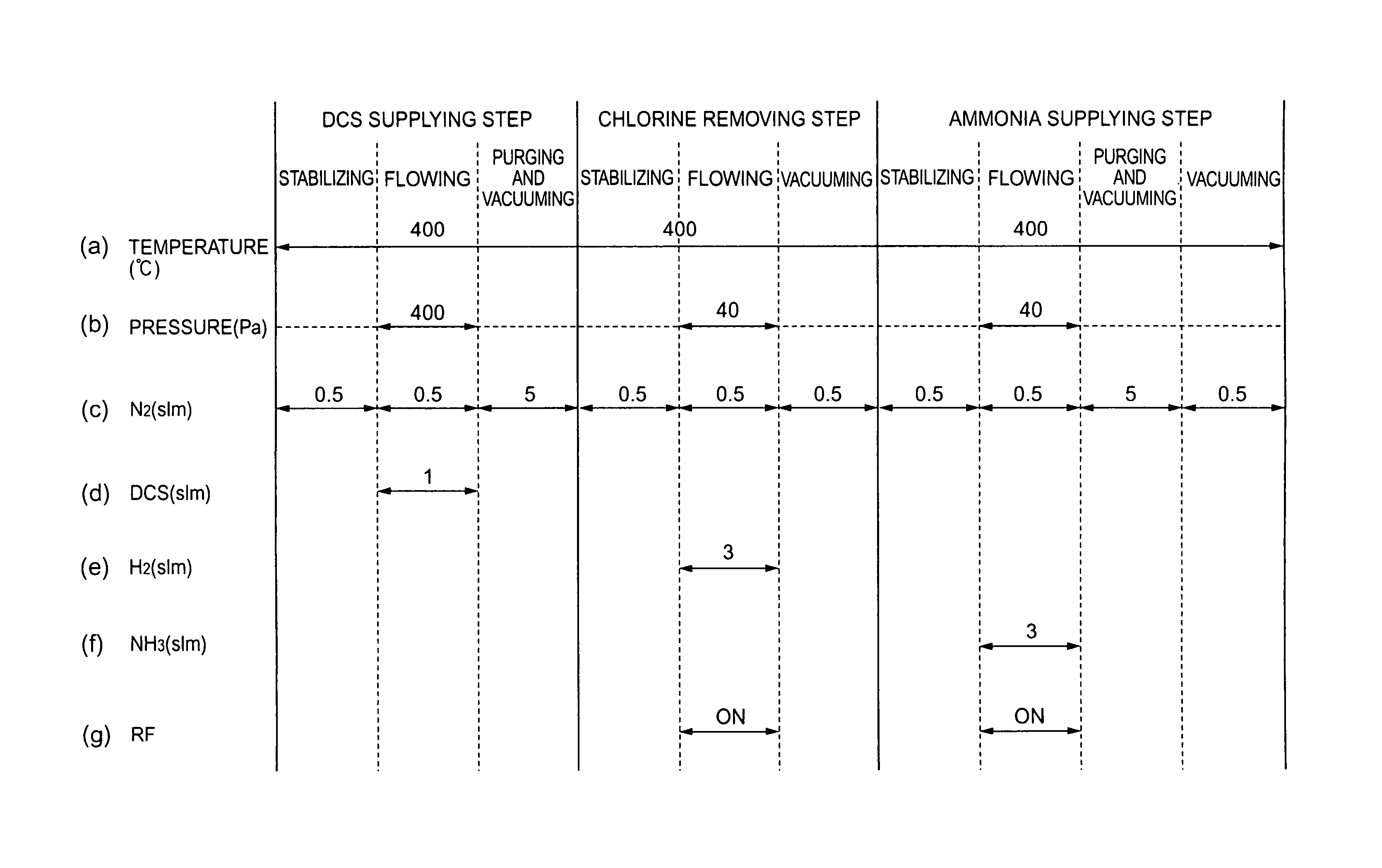

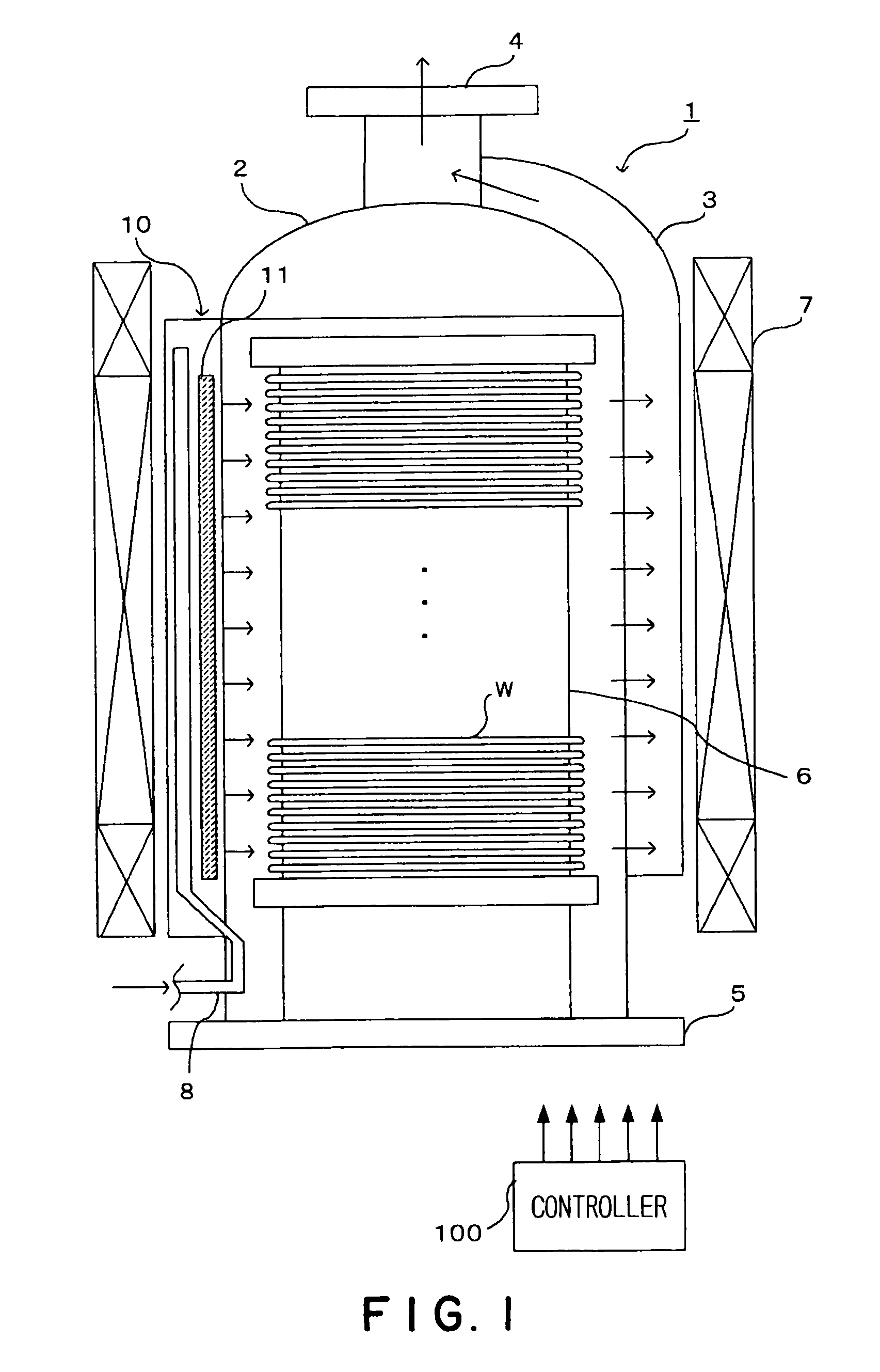

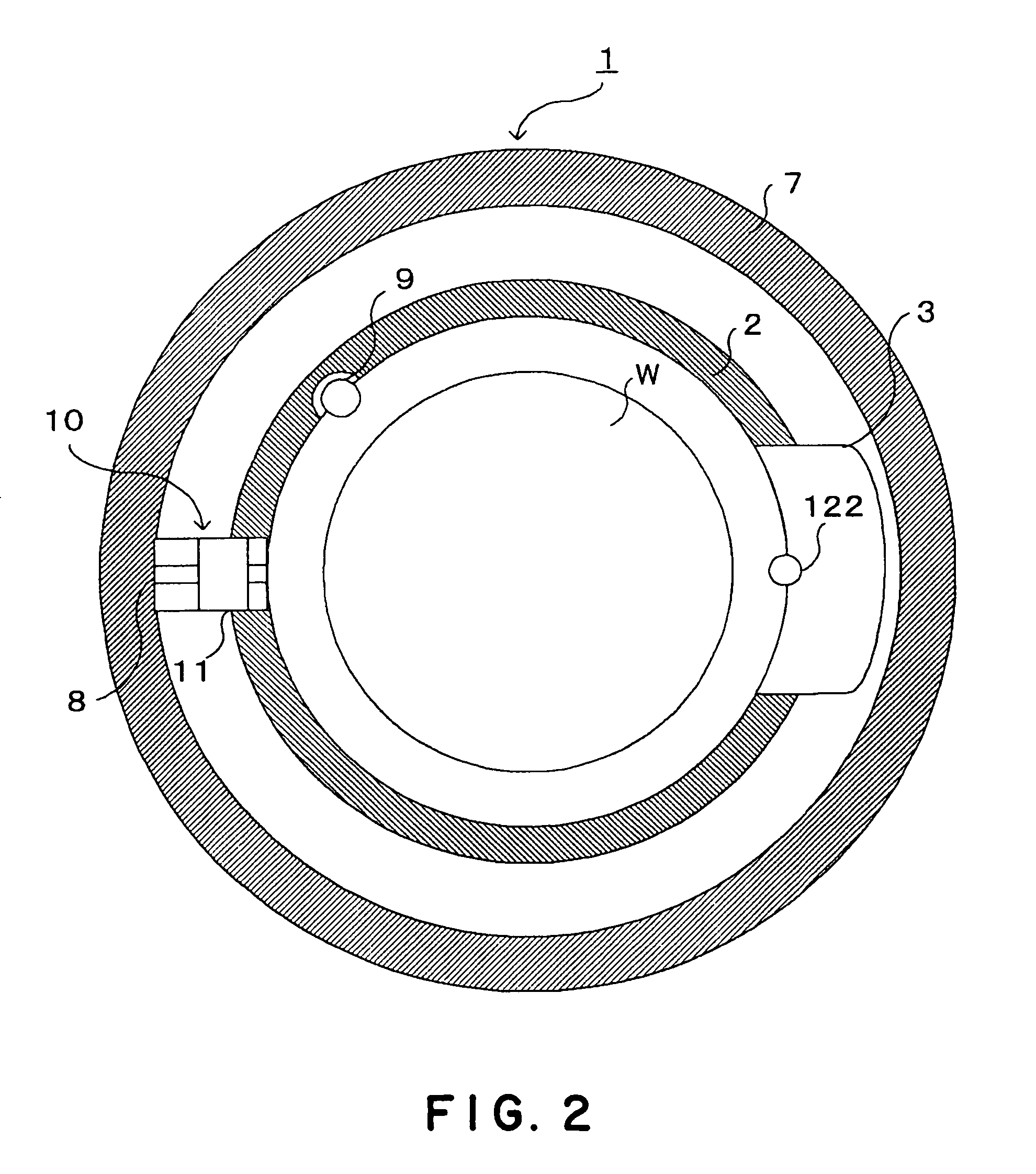

Formation of silicon nitride film

ActiveUS7625609B2Increase pressureLow process temperaturePolycrystalline material growthSemiconductor/solid-state device manufacturingWaferingChemical species

Owner:TOKYO ELECTRON LTD

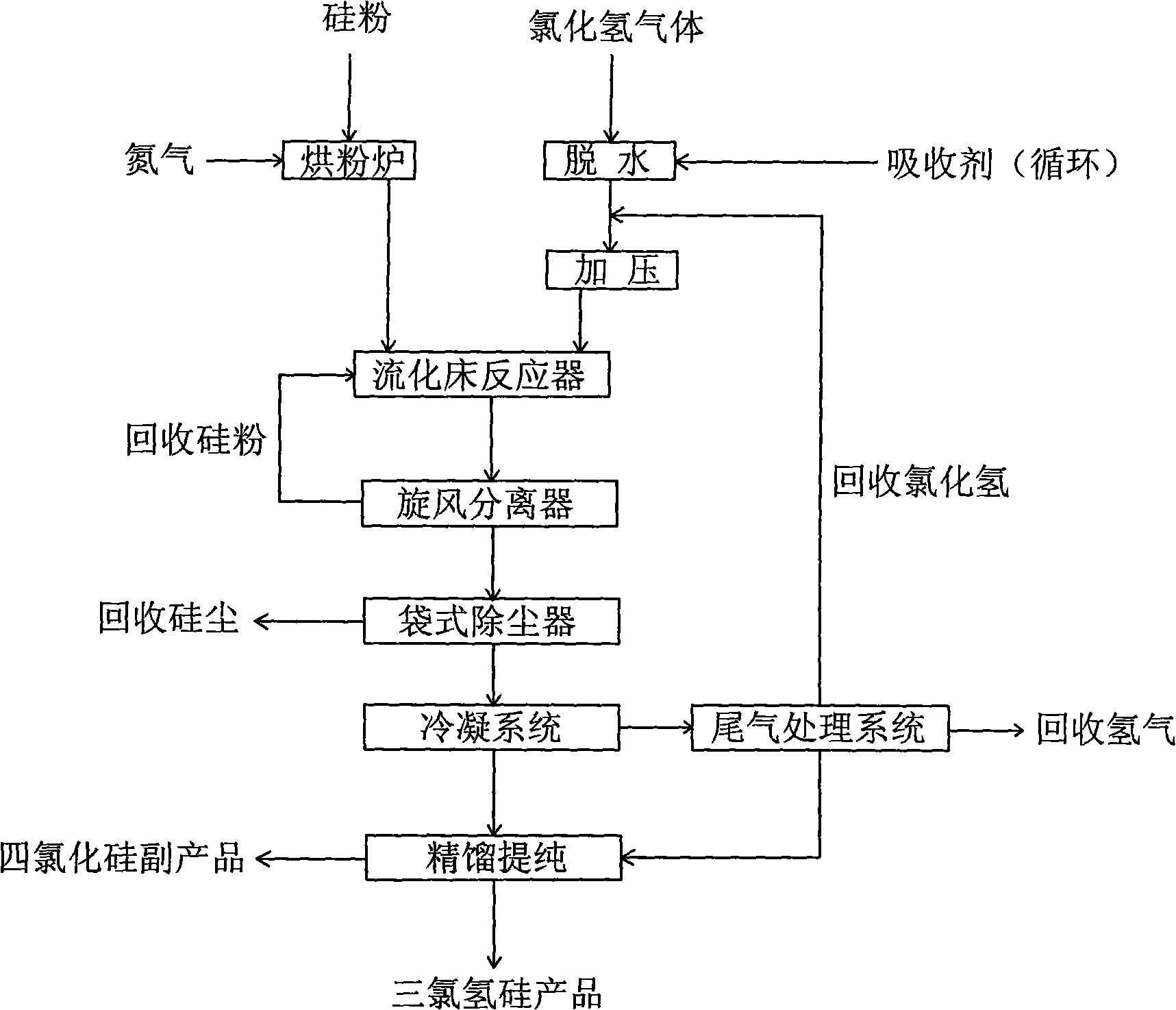

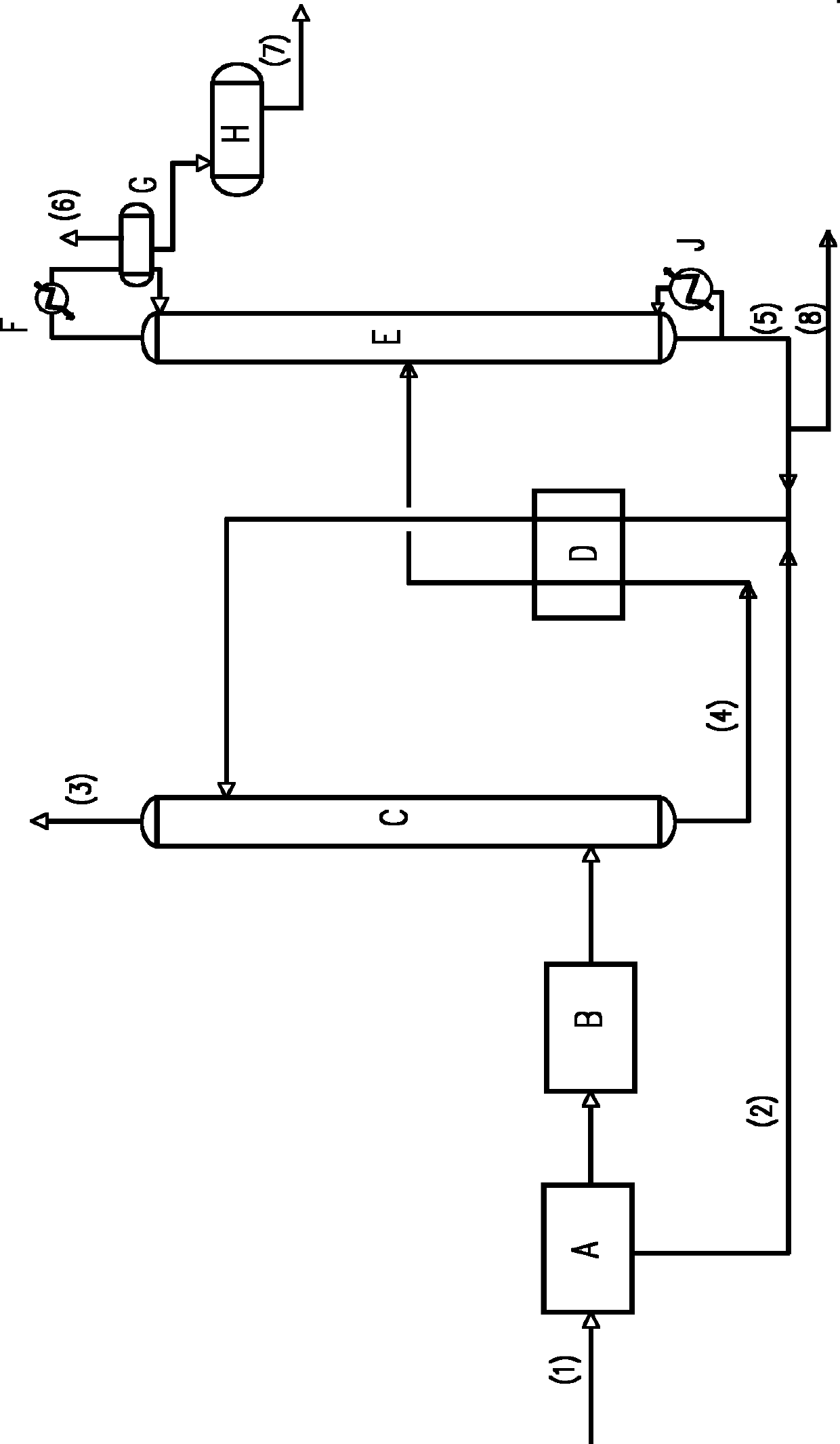

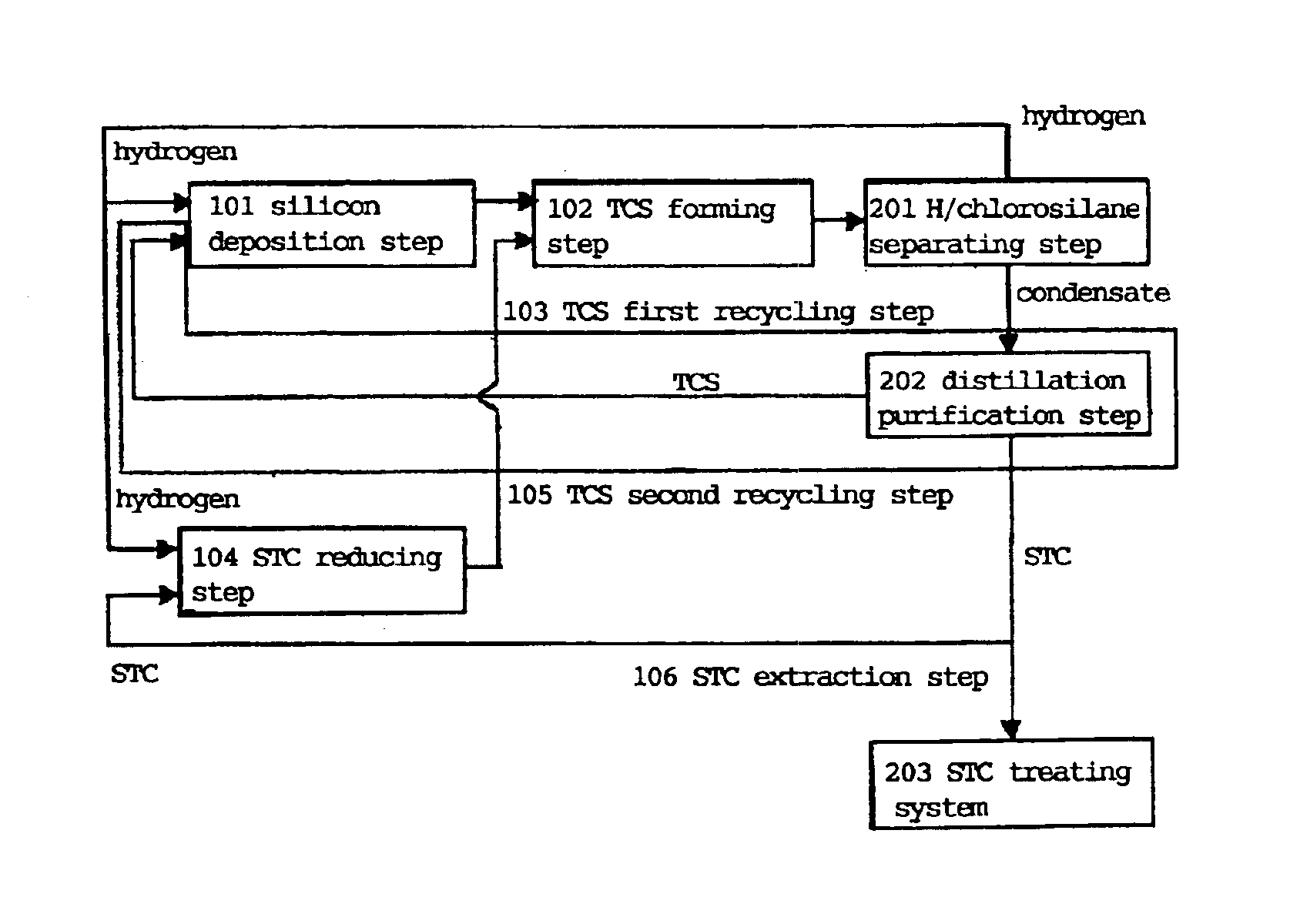

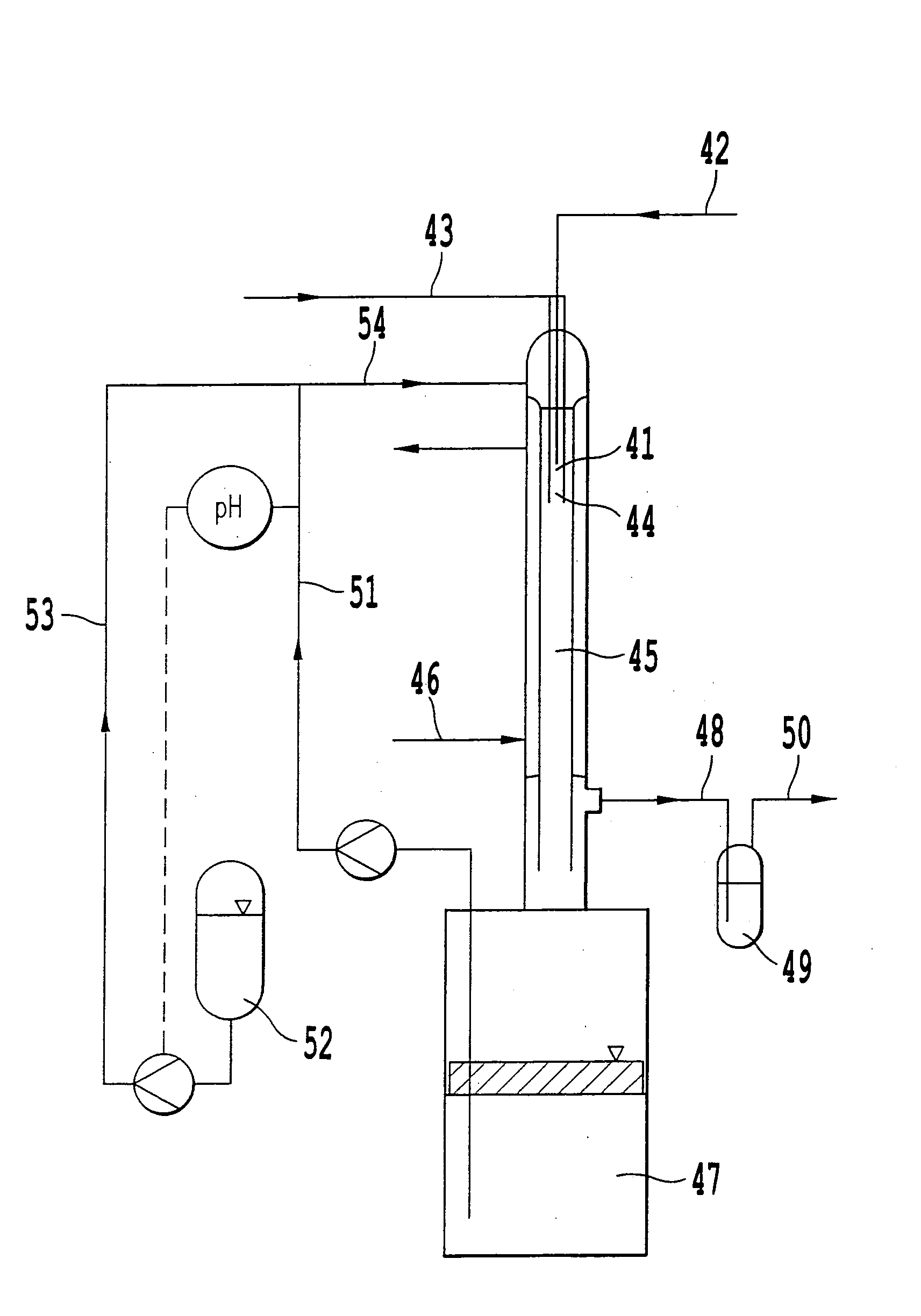

Production method and apparatus for trichlorosilane

InactiveCN101279735AReduce consumptionReduce automatic controlEnergy inputHalogenated silanesReaction temperatureEnergy recovery

The invention relates to a method for producing chlorosilane, in particular to a method for producing trichlorosilane and a device thereof and pertains to the chemical field. The method comprises six steps, namely, hydrogenchloride treatment, silica powder drying and pushing material, synthesis reaction, dust removal and condensation, rectification separation and tail gas recovery, and the device relates to a special equipment large fluidized bed reactor. The invention reduces corrosion on the system equipment by hydrogenchloride gas and the fluidization quality of the reactor is high. The tail gas contains chlorosilane and is easy to be condensed, and the consumption of low temperature refrigerant is greatly reduced. The synthesis tail gas is recovered fully, no temperature runaway phenomenon happens at the expansion section of the reactor, reaction heat is removed by heat transfer oil and sent in a waste heat boiler to produce by product steam which is merged into a steam pipe network or directly applied in part heating equipment; the whole technique system is a closed system with self materials cycling and energy recycling. The technique of the invention is advanced and reliable, the reaction temperature can be adjusted accurately and the fluidized bed reactor has long service life and low production cost and is applicable to popularization and application.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Increased polysilicon deposition in a CVD reactor

ActiveUS20070251455A1Reduce voltageShorten the timeSilicon compoundsChemical vapor deposition coatingProduction rateGas phase

A method and process for the production of bulk polysilicon by chemical vapor deposition (CVD) where conventional silicon “slim rods” commonly used in Siemens-type reactors are replaced with shaped silicon filaments of similar electrical properties but larger surface areas, such as silicon tubes, ribbons, and other shaped cross sections. Silicon containing gases, such as chlorosilane or silane, are decomposed and form a silicon deposit on the hot surfaces of the filaments The larger starting surface areas of these filaments ensures a higher production rate without changing the reactor size, and without increasing the number and length of the filaments. Existing reactors need only the adaptation or replacement of filament supports to use the new filaments. The filaments are grown from silicon melt by Edge-defined, Film-fed Growth (EFG) method. This also enables the doping of the filaments and simplification of power supplies for new reactors.

Owner:ADVANCED MATERIAL SOLUTIONS LLC

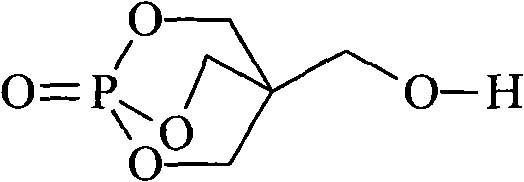

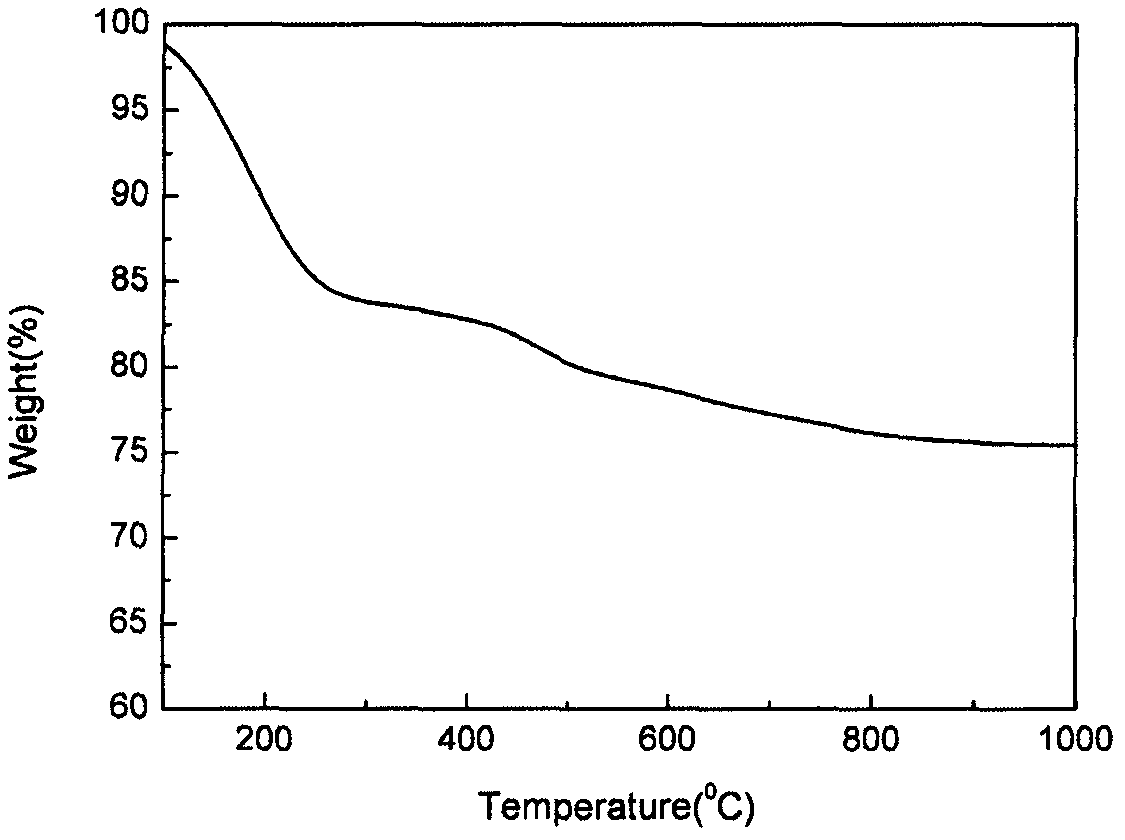

Caged bicyclic phosphate siloxane flame retardant and preparation method thereof

ActiveCN102153590AImprove thermal stabilityHigh molecular weightGroup 5/15 element organic compoundsCombustionSilanes

The invention discloses a caged bicyclic phosphate siloxane flame retardant and a preparation method thereof. A structural formula of the caged bicyclic phosphate siloxane flame retardant is shown in a general formula (I). During the preparation, the needed product can be obtained by reacting 1-oxophospha-4-hydroxymethyl-2,6,7-trioxabicyclo[2.2.2]octane and chlorosilane or alkoxy silane. A plurality of rigid caged bicyclic phosphate groups and silicon element which are contained in the compound play a role in synergistic flame retardancy; and the flame retardant has higher thermal stability and carbon-forming performance, and can effectively reduce the smoke produced in the combustion.

Owner:SOUTH CHINA UNIV OF TECH

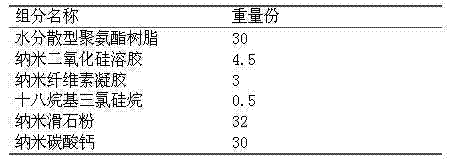

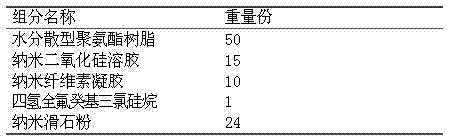

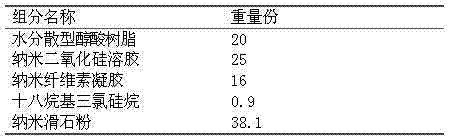

Transparent super-hydrophobicity wood coating and preparation method thereof

InactiveCN103756541AParticle size controllableHydrophobic hasPolyurea/polyurethane coatingsPolyester coatingsOctadecyltrichlorosilanePolymer science

The invention discloses a transparent super-hydrophobicity wood coating which comprises the following components in parts by weight: 20-50 parts of water dispersive polyurethane resin or water dispersive alkyd resin, 4.5-25 parts of nano silica sol, 3-16 parts of nano cellulose gel, 0.1-1 part of octadecyl trichlorosilane or tetrahydroperfluorodecyltrichlorosilane or stearic acid and 0-45 parts of nano talc powder or nano calcium carbonate. A preparation method of the transparent super-hydrophobicity wood coating comprises the following steps: adding matrix resin and filler into a stirring kettle, and stirring uniformly to obtain slurry; grinding the slurry with a sand mill; adding a low-surface energy substance and supported nano silica sol; performing ultrasonic sufficient mixing for 30 minutes to obtain the transparent super-hydrophobicity coating. The transparent super-hydrophobicity wood coating disclosed by the invention has the advantages of low cost, controllable process, adjustable size and good applicability and is suitable for a preparation method of large-area preparation of transparent super-hydrophobicity surface; the prepared super-hydrophobicity film has good self-cleaning property, antifouling property, hydrophobic property, oleophobic property and the like.

Owner:GUANGDONG YIHUA TIMBER IND +1

Hexaboride particles, hexaboride particle dispersion, and article making use of hexaboride particles or hexaboride particle dispersion

ActiveUS20050161642A1Improve water resistanceImprove waterproof performancePigmenting treatmentBoron/boridesAlkoxy groupSide chain

In hexaboride particles having particles of a hexaboride of at least one element (X) selected from Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Sr and Ca, or a dispersion of such particles, the surfaces of the hexaboride particles have physically been coated with a surface treatment agent containing silicon, selected from a silazane type treatment agent, a chlorosilane type treatment agent, an inorganic treatment agent having at least one alkoxyl group in the molecular structure, and an organic treatment agent having at least one alkoxyl group at a molecular terminal or in the side chain, or have been coated with the surface treatment agent, having chemically combined with hexaboride particles on the surfaces of the hexaboride particles.

Owner:SUMITOMO METAL MINING CO LTD

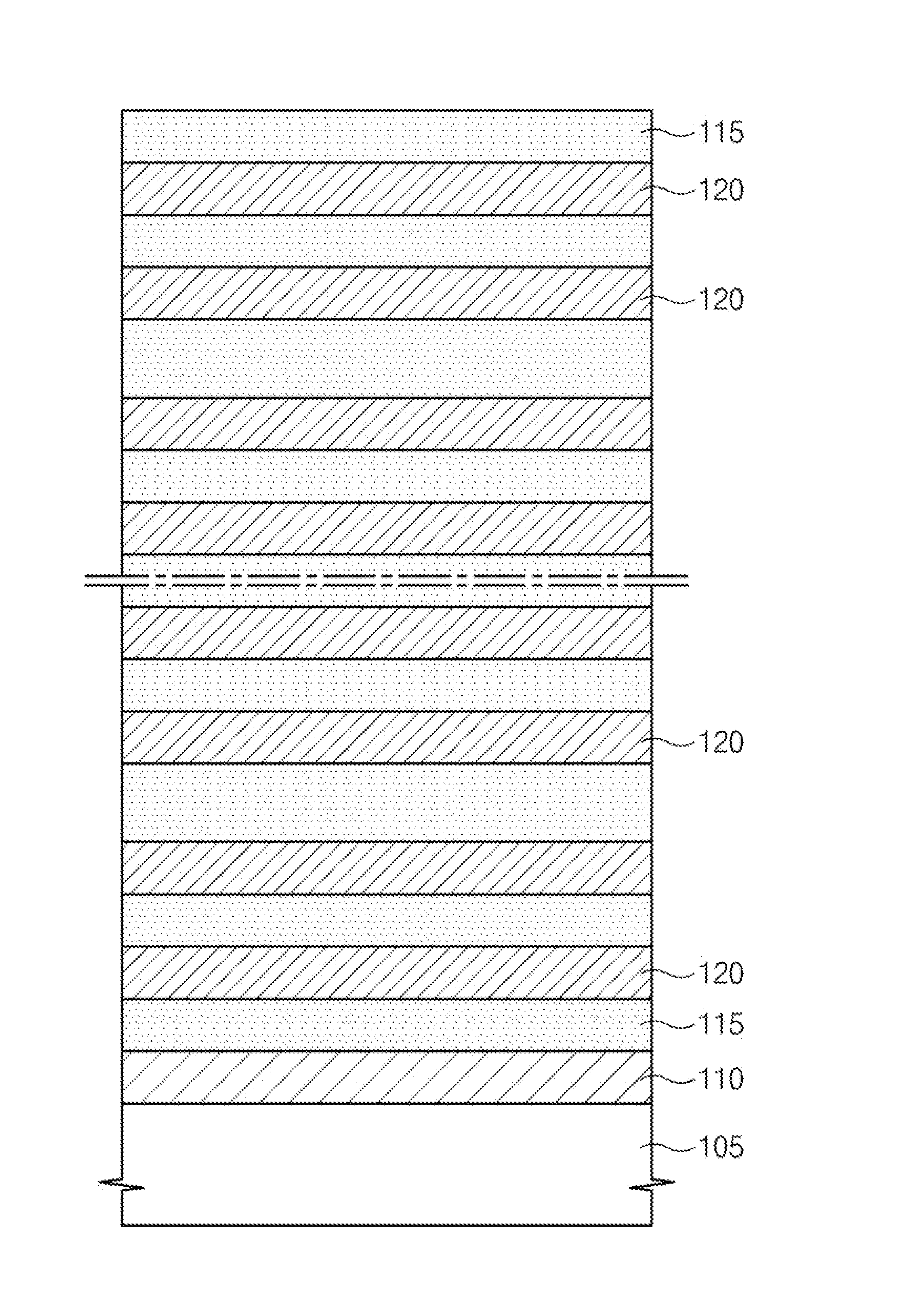

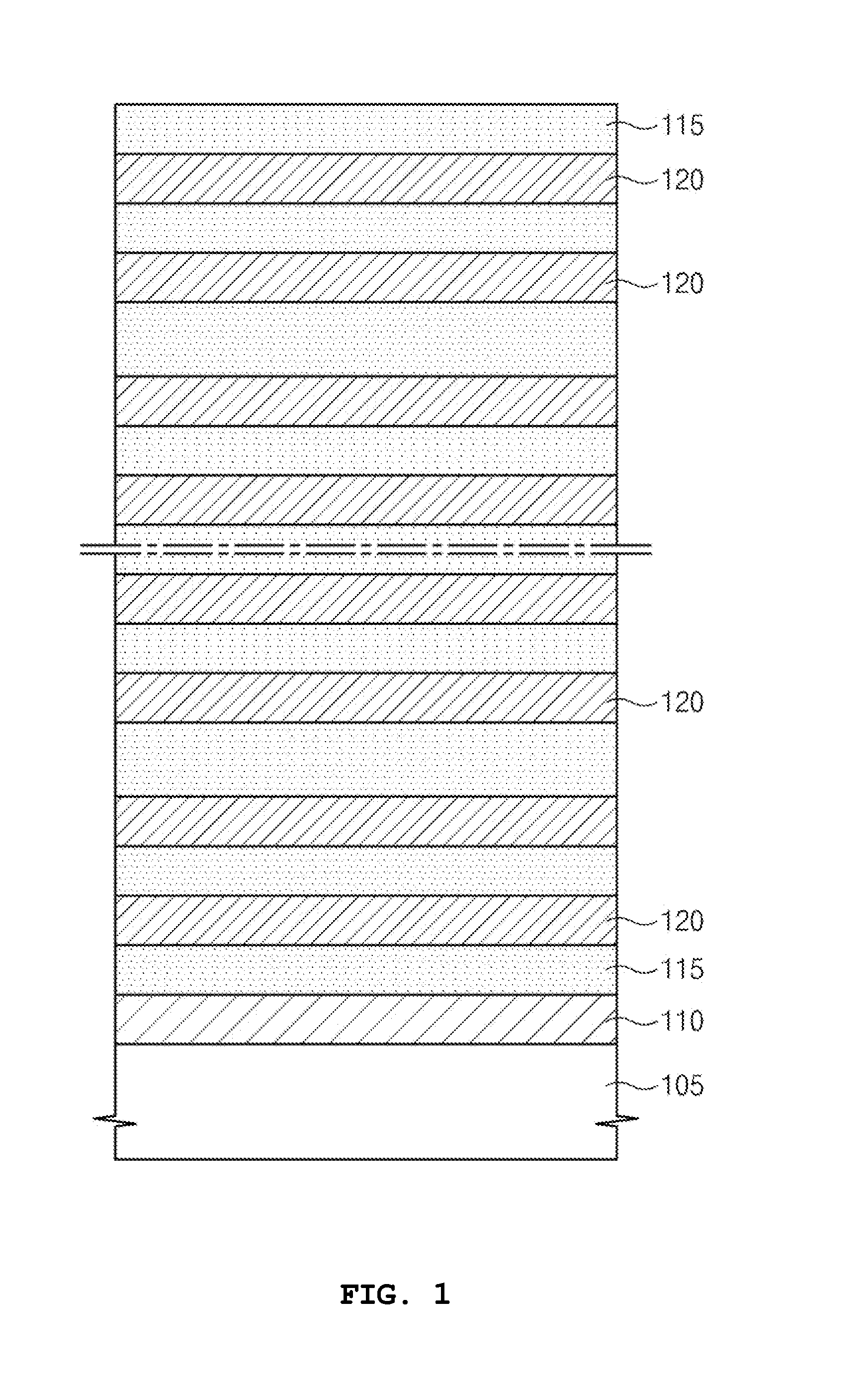

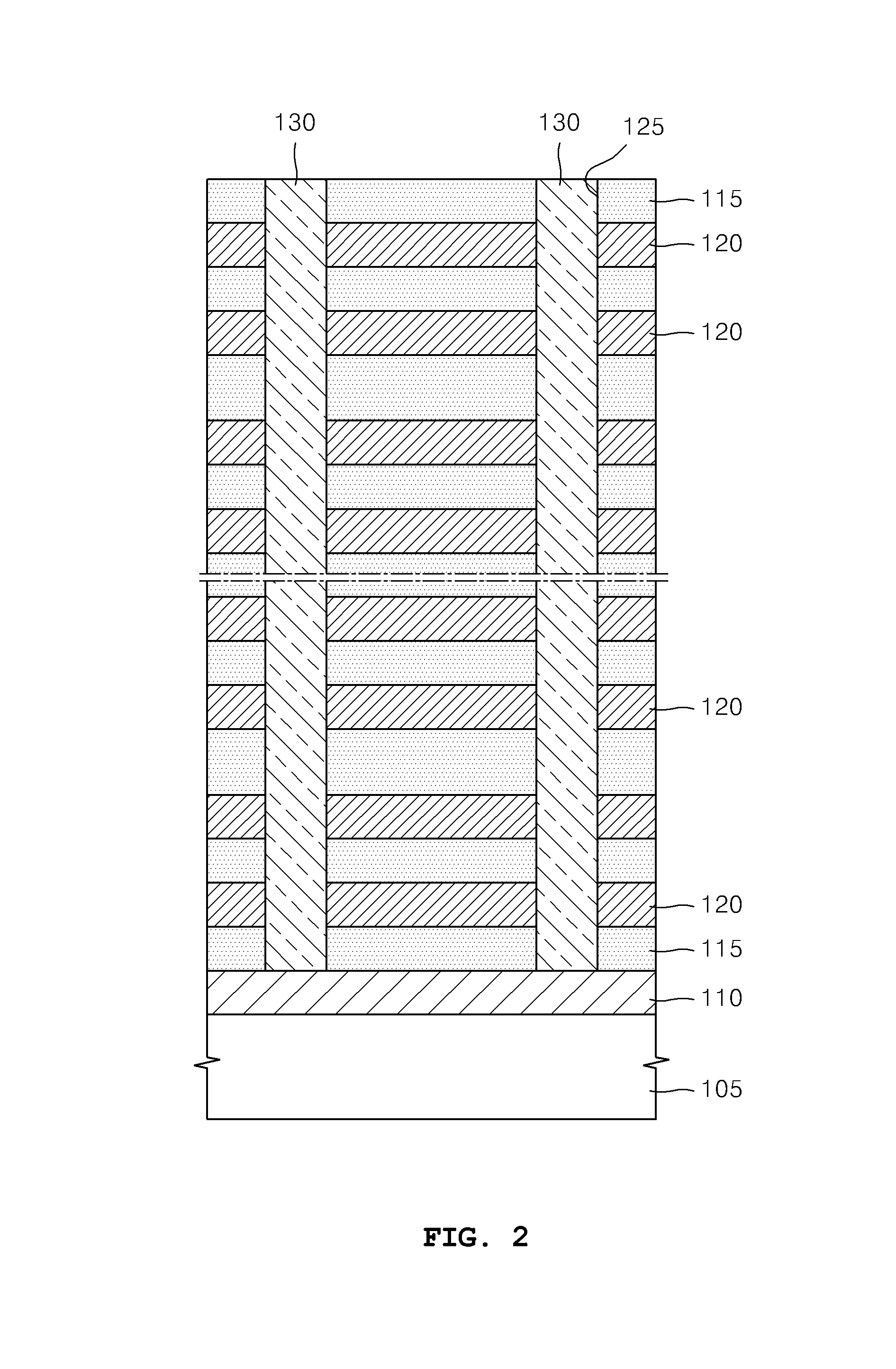

Method and apparatus for manufacturing three-dimensional-structure memory device

ActiveUS20130171827A1Lower the volumeAvoid deformationSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerSilicon monoxide

A method for manufacturing a memory device having a vertical structure according to one embodiment of the present invention comprises: a step for alternatingly laminating one or more insulation layers and one or more sacrificial layers on a substrate; a step for forming a penetration hole for penetrating the insulation layer and the sacrificial layer; a step for forming a pattern for filling up the penetration hole; a step for forming an opening for penetrating the insulation layer and the sacrificial layer; and a step for removing the sacrificial layer by supplying an etchant through the opening, wherein the step for laminating the insulation layer includes a step for depositing a first silicon oxide film by supplying to the substrate at least one gas selected from the group consisting of SiH4, Si2H6, Si3H8, Si4H10, and the step for laminating the sacrificial layer includes a step for depositing a second silicon oxide film by supplying dichlorosilane (SiCl2H2) to the substrate.

Owner:EUGENE TECH CO LTD

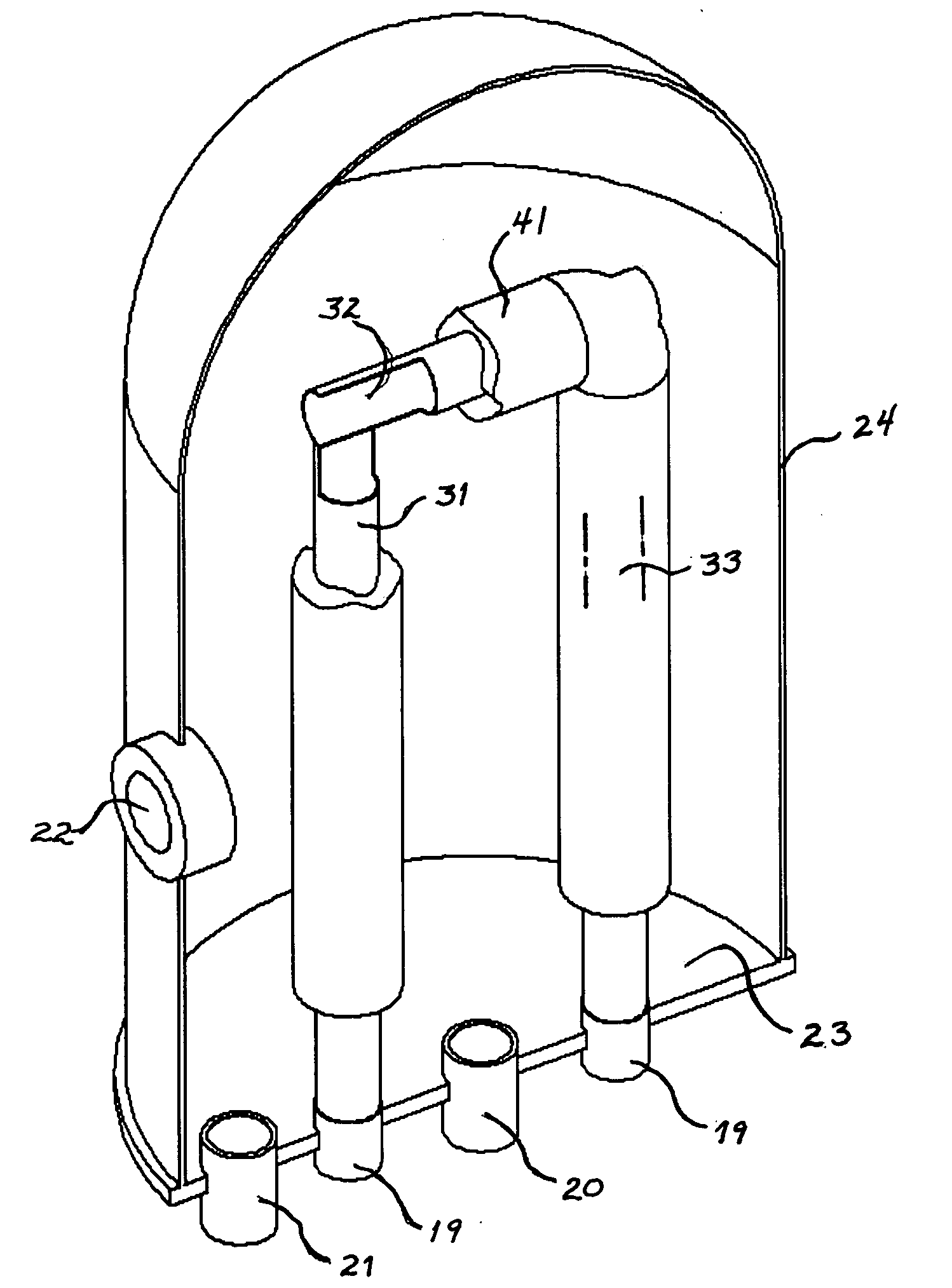

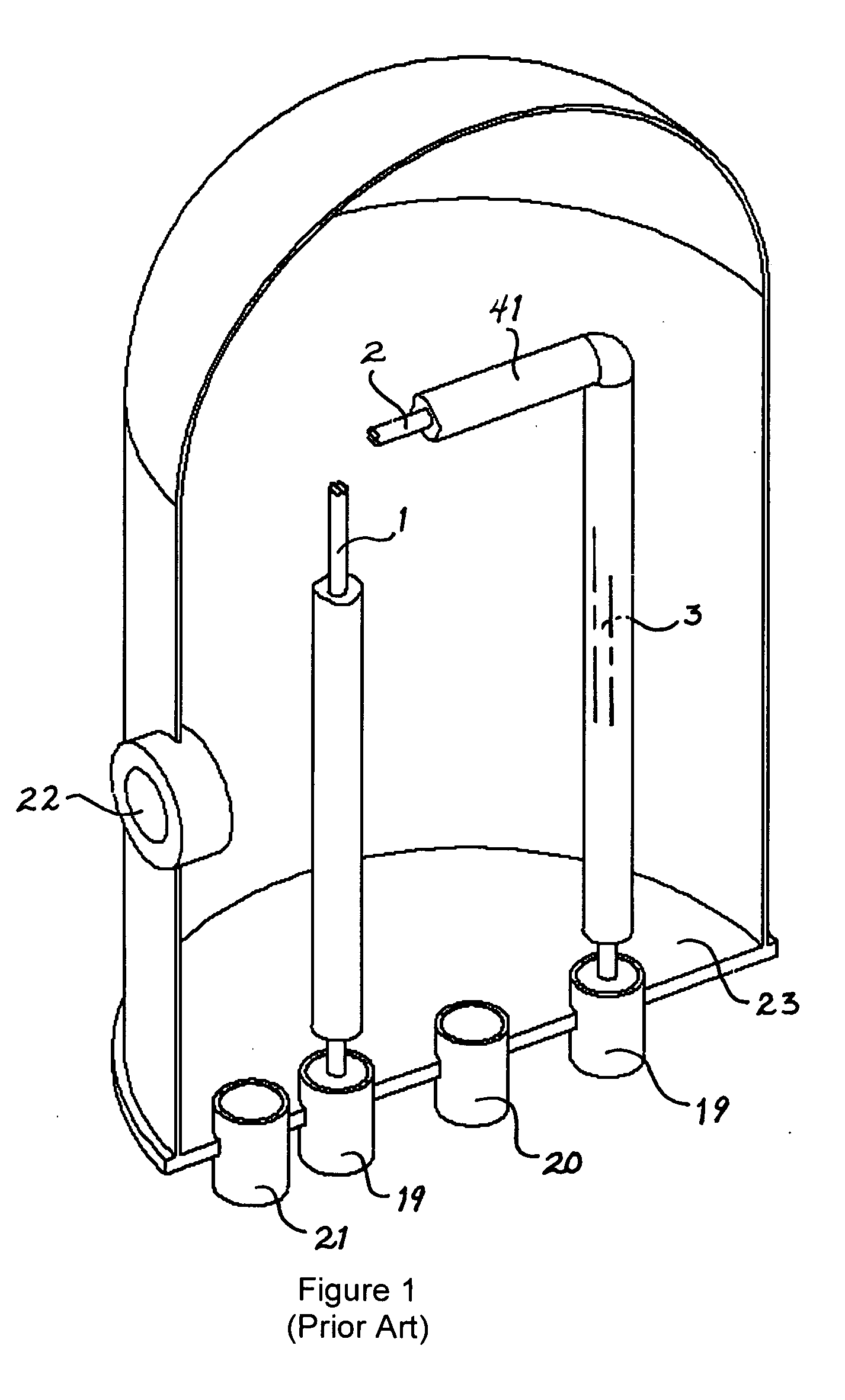

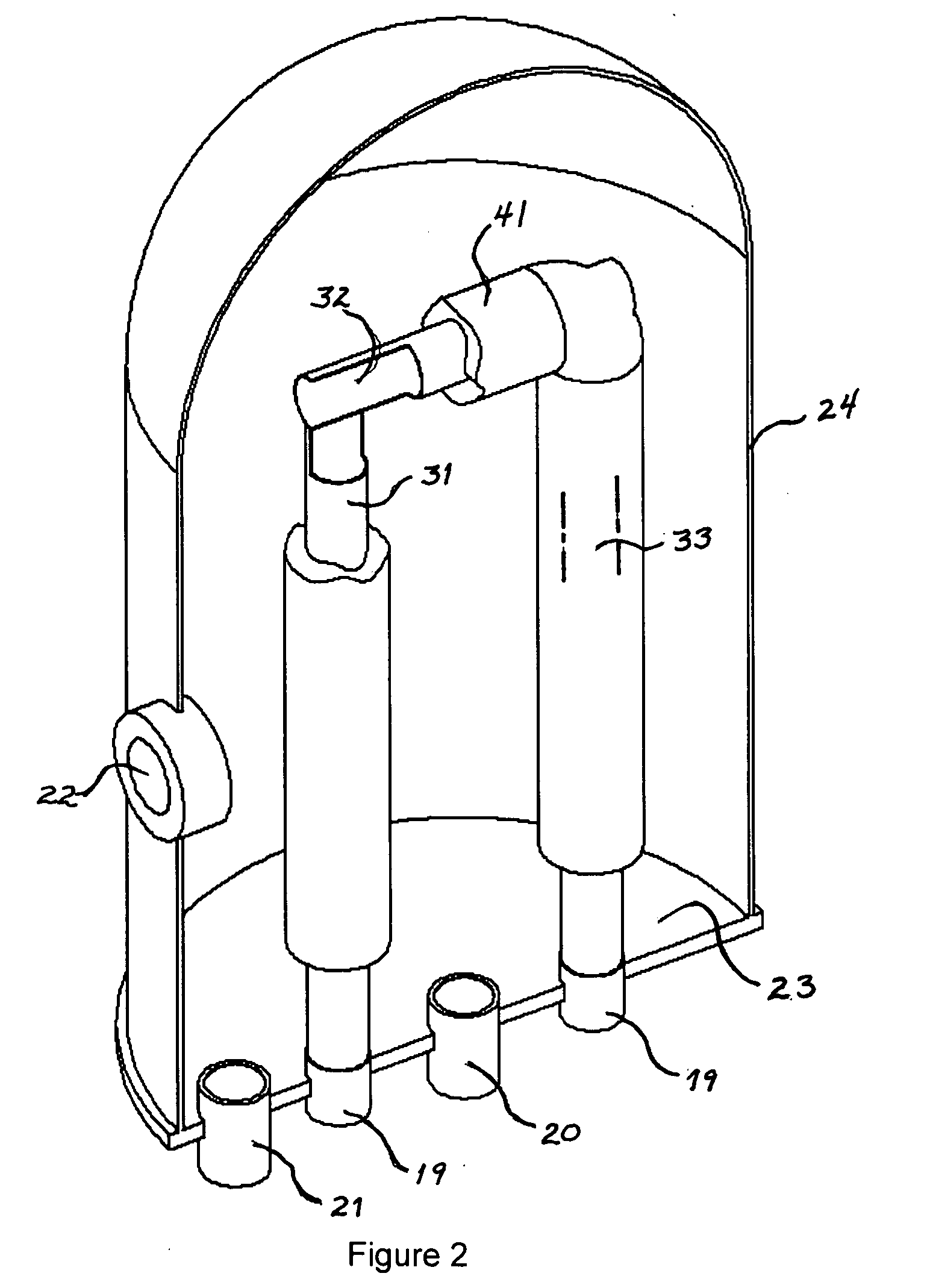

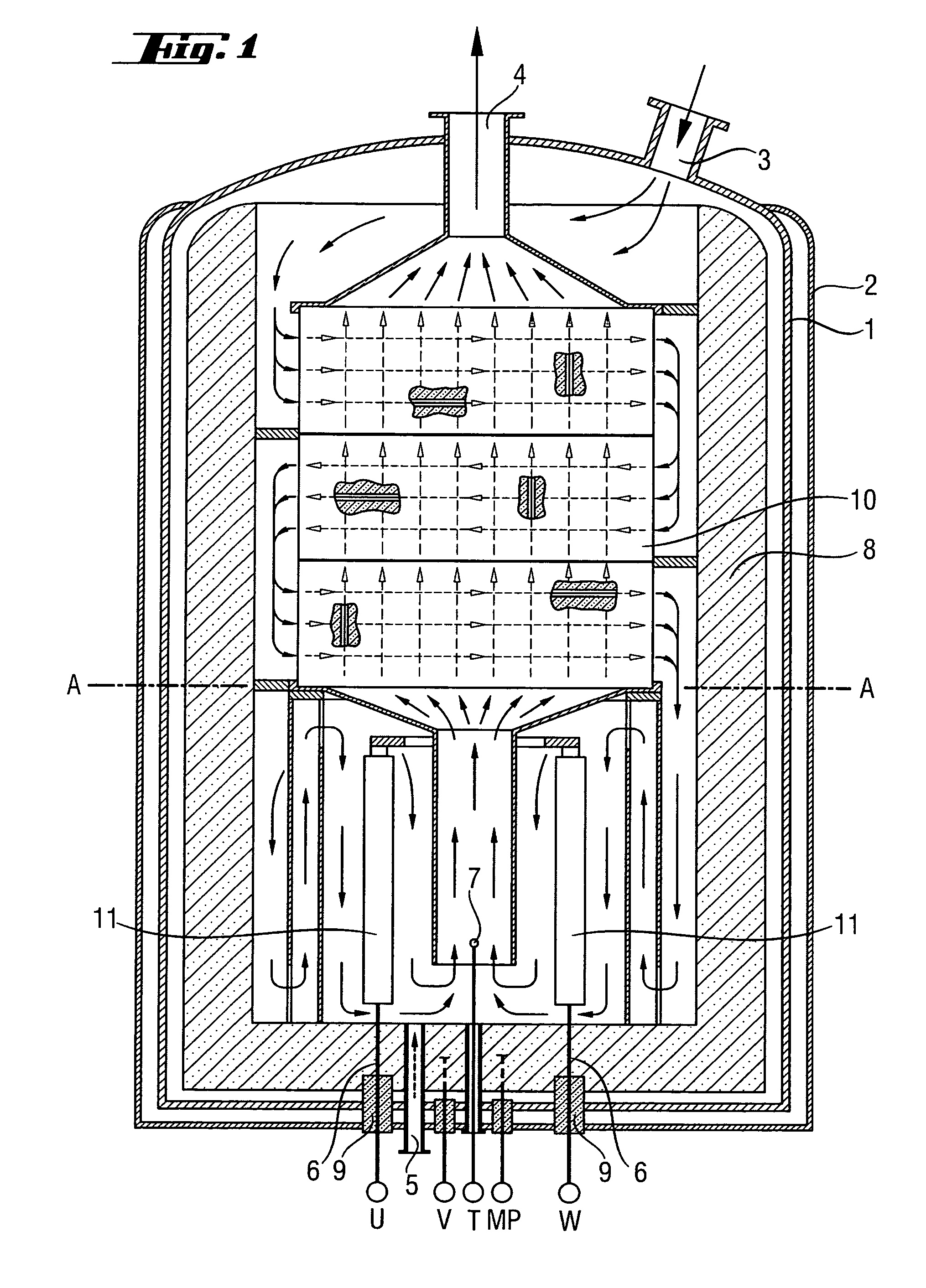

Process and apparatus for the hydrogenation of chlorosilanes

ActiveUS20070073075A1Operation moreAvoid introducingGroup 4/14 element organic compoundsExhaust apparatusHydrogenSilanes

Hydrogenation of a chlorosilane takes place in a reactor having a graphite reaction chamber with a surface which contacts the chlorosilane and a graphite electric heating element which also contacts the chlorosilane, wherein an Si-containing compound and hydrogen are contacted with the reaction chamber and the heating element such that an SiC coating is formed in situ on their surfaces in a first process step, and hydrogenation of the chlorosilane is effected by heating of a chlorosilane / hydrogen mixture in the reaction chamber by means of the heating element in a second process step, the first process step carried out at a reaction temperature which is higher than the reaction temperature of the second process step.

Owner:WACKER CHEM GMBH

Process and apparatus for the hydrogenation of chlorosilanes

ActiveUS7442824B2Operation moreAvoid introducingGroup 4/14 element organic compoundsExhaust apparatusHydrogenReaction temperature

Hydrogenation of a chlorosilane takes place in a reactor having a graphite reaction chamber with a surface which contacts the chlorosilane and a graphite electric heating element which also contacts the chlorosilane, wherein an Si-containing compound and hydrogen are contacted with the reaction chamber and the heating element such that an SiC coating is formed in situ on their surfaces in a first process step, and hydrogenation of the chlorosilane is effected by heating of a chlorosilane / hydrogen mixture in the reaction chamber by means of the heating element in a second process step, the first process step carried out at a reaction temperature which is higher than the reaction temperature of the second process step.

Owner:WACKER CHEM GMBH

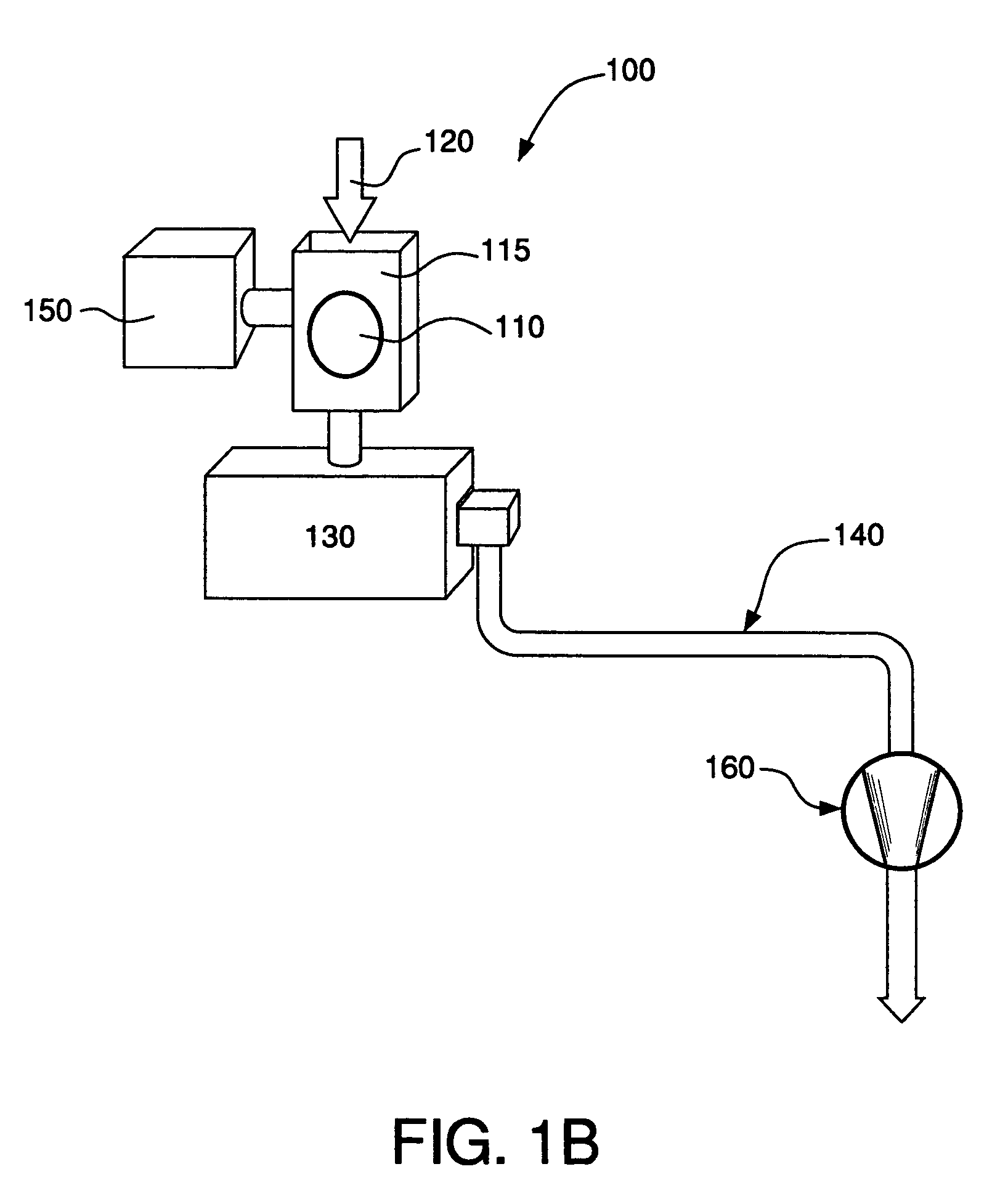

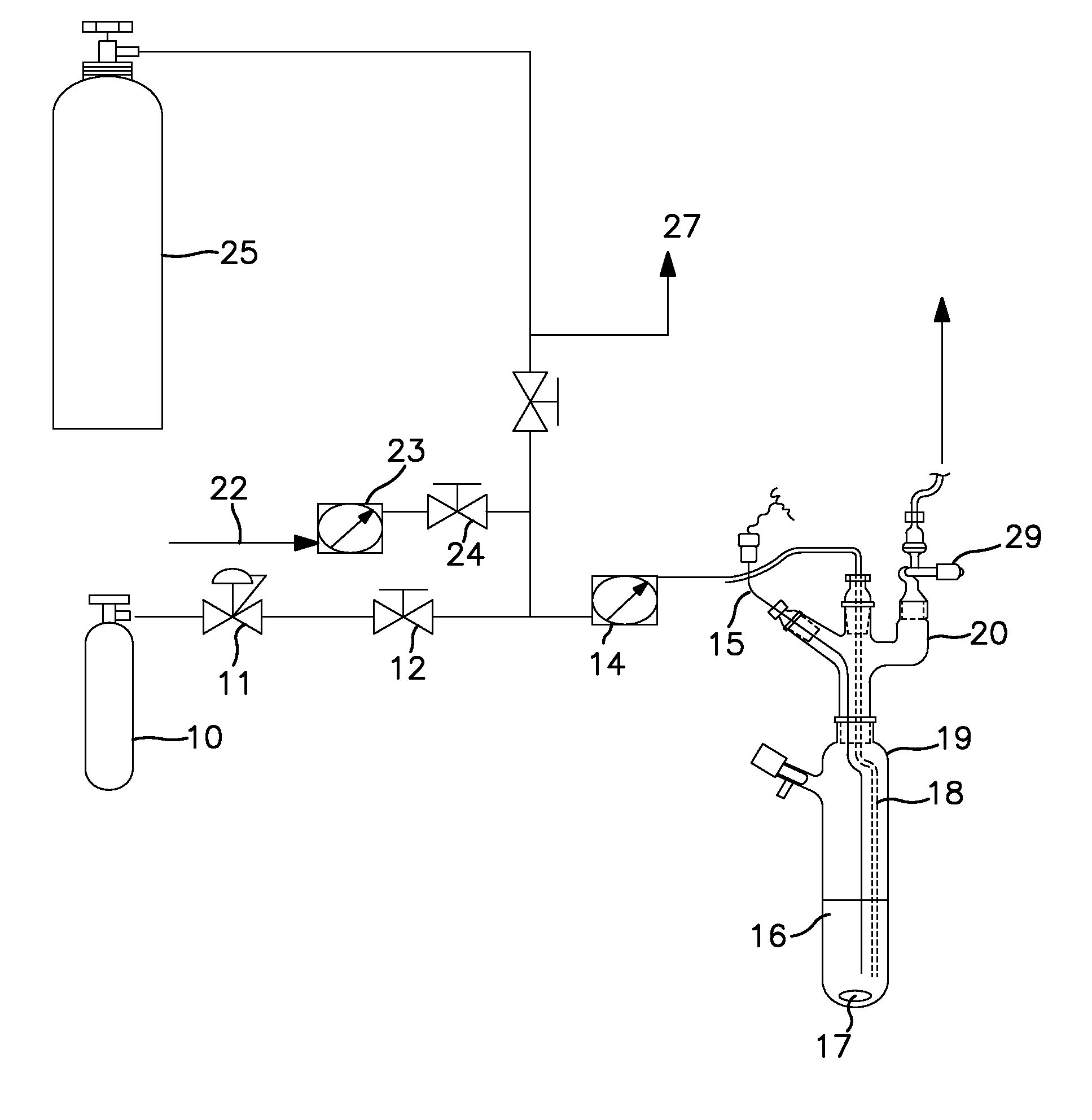

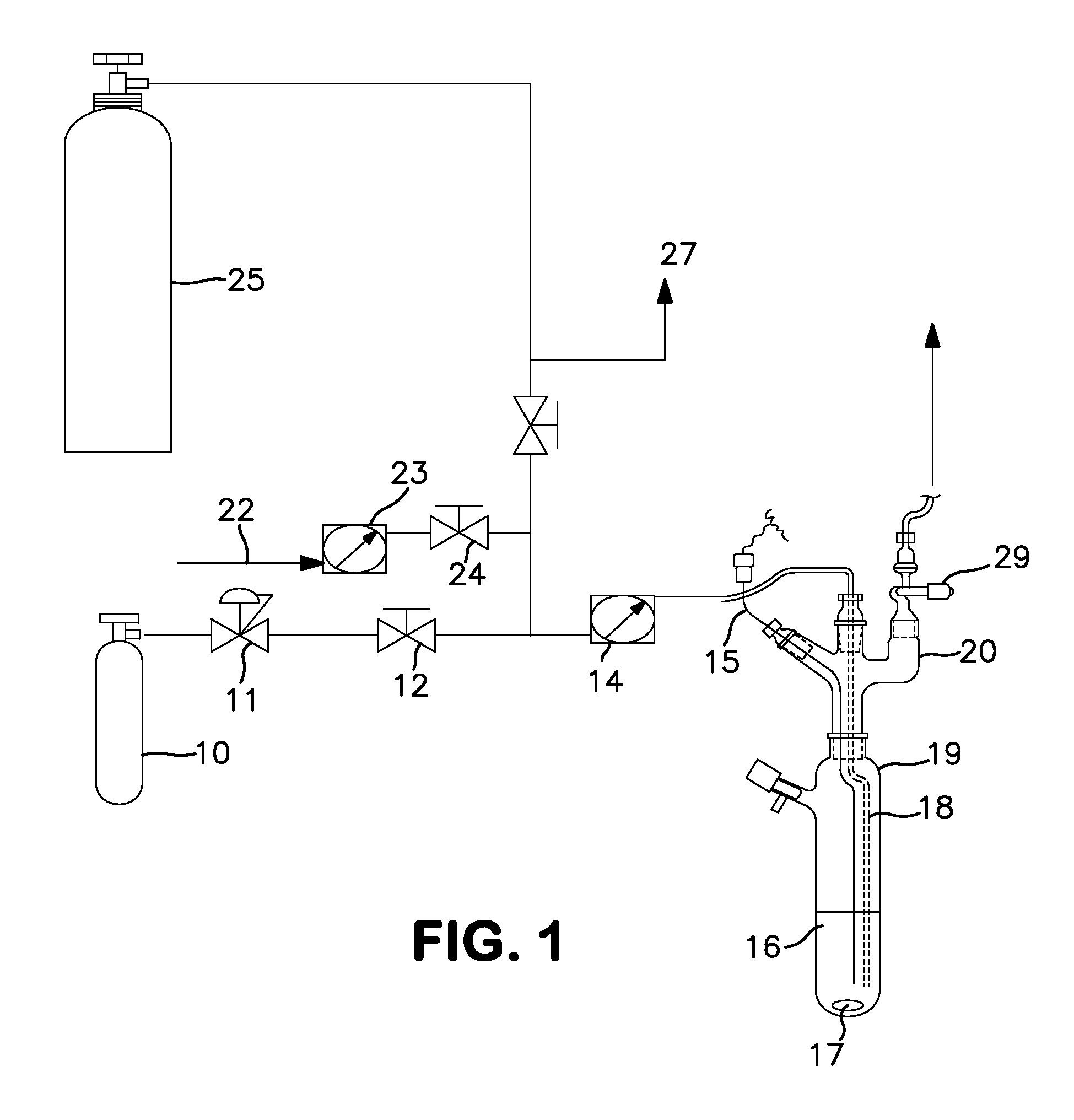

Apparatus and method for the condensed phase production of trisilylamine

ActiveUS20130089487A1Increased formationPromote formationSilicon compoundsNitrogen and non-metal compoundsDistillationSynthesis methods

The present invention is directed to a condensed phase batch process for synthesis of trisilylamine (TSA). An improved synthesis method that incorporates a solvent to help promote a condensed-phase reaction between ammonia gas (or liquid) and liquified monochlorosilane (MCS) in good yields is described. This method facilitates the removal of the byproduct waste with little to no reactor down time, substantial reduction of down-stream solids contamination and high-purity product from first-pass distillation.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

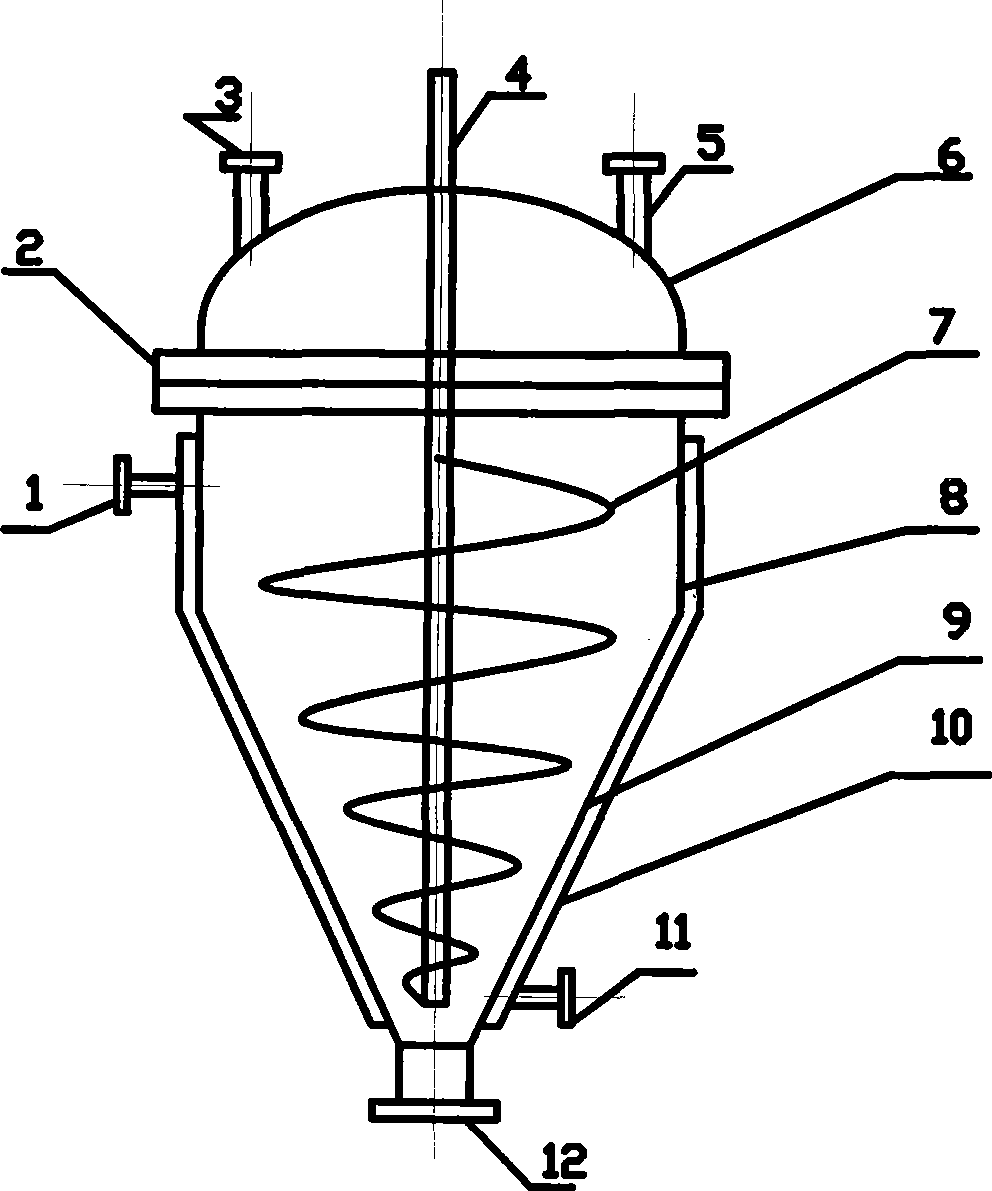

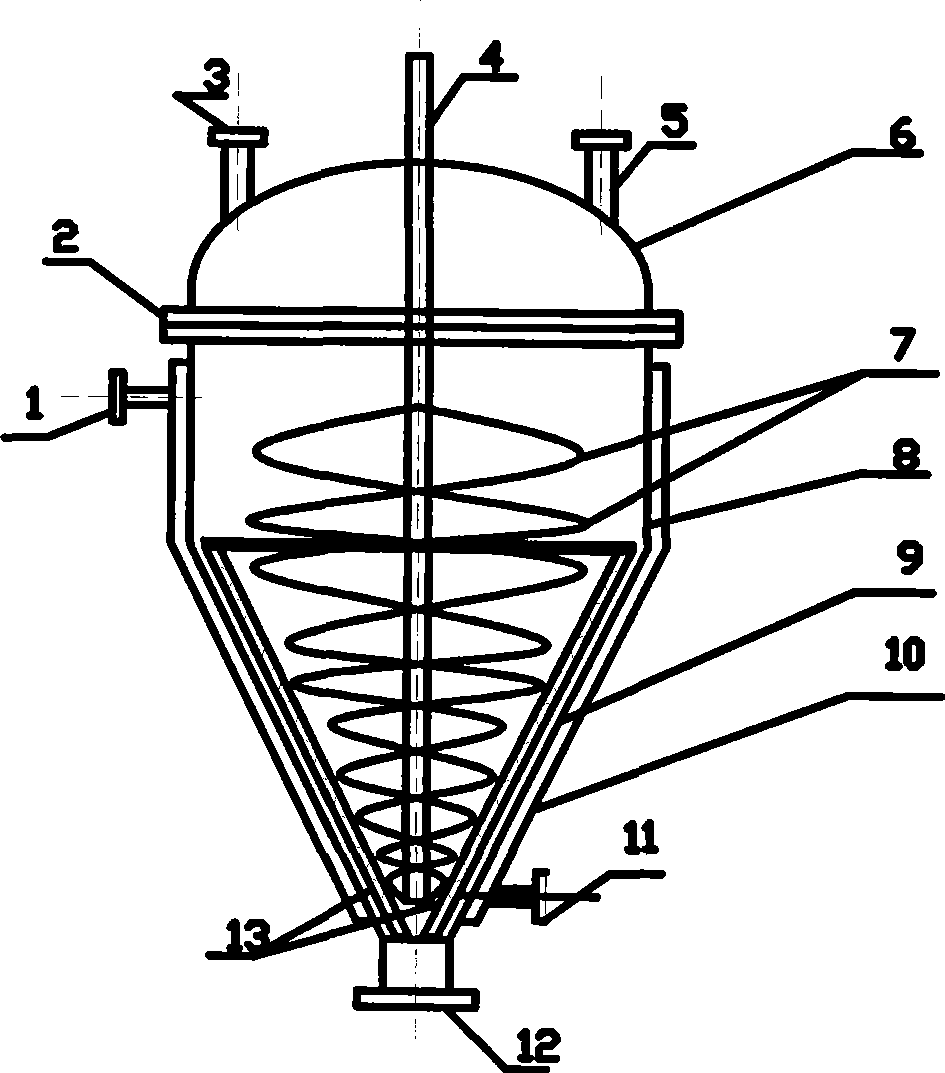

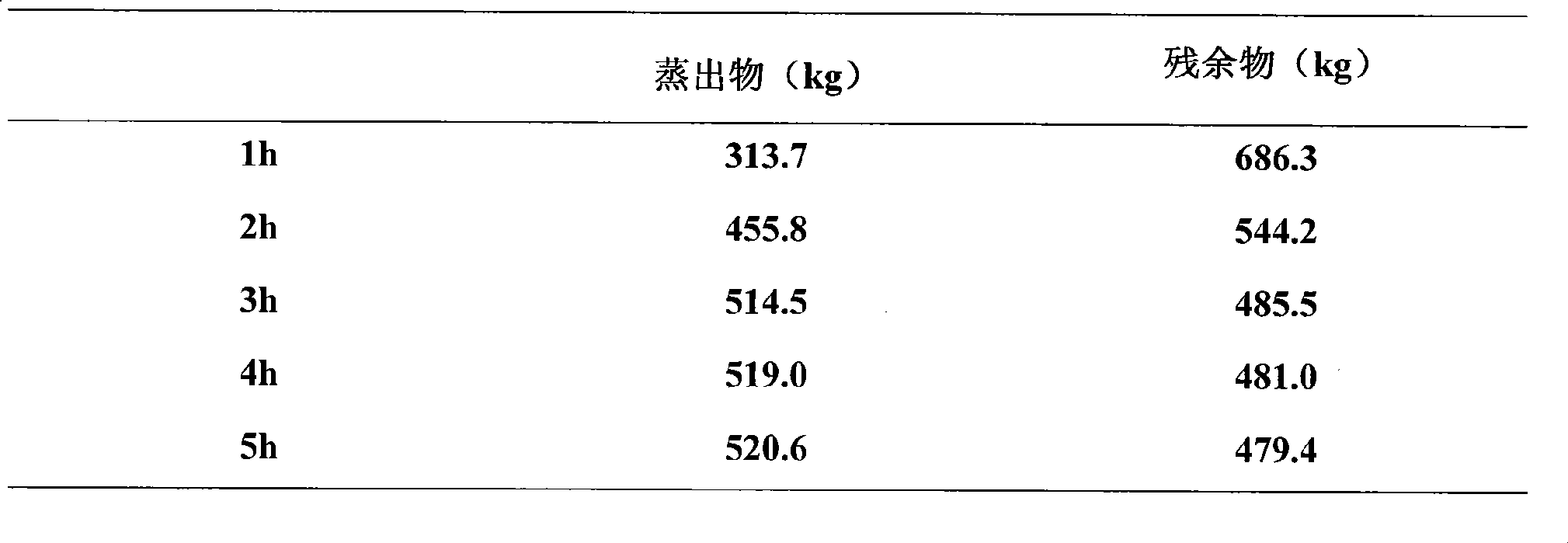

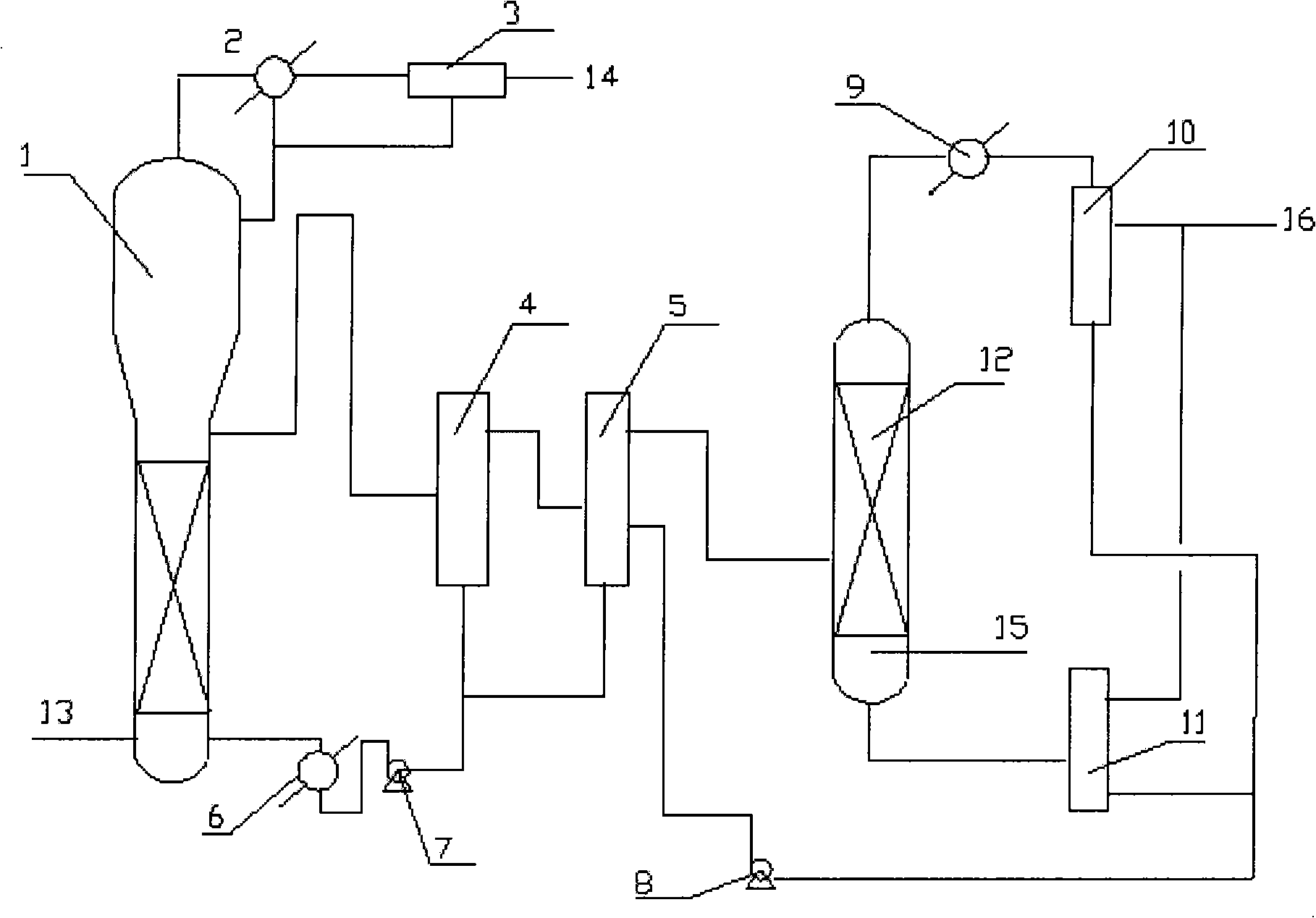

Organosilicon slag slurry treatment method and apparatus thereof

The invention relates to the field of organosilicon production, in particular to a method and a device for processing organosilicon slurry. The method is characterized by pre-heating the organosilicon slurry, guiding the organosilicon slurry in a cone-shaped evaporator, evaporating high boiling materials through stirring, condensing and then collecting the high boiling materials to a storage tank, and discharging the residue. The invention also discloses a cone-shaped evaporator. The method for processing the organosilicon slurry overcomes the defect of the prior art of failing to recycle large amount of high boiling materials, the high boiling materials can be evaporated out to the maximum while ensuring no serious slurry conglomerates, and the recovery rate is more than or equal to 80 percent. The recycled high boiling materials are cracked to obtain a methyl chlorosilane monomer and the residue after evaporation can be recycled better. The method not only solves the problems of environmental protection and safety, but also saves the cost for processing the slurry.

Owner:ZHENJIANG JIANGNAN CHEM

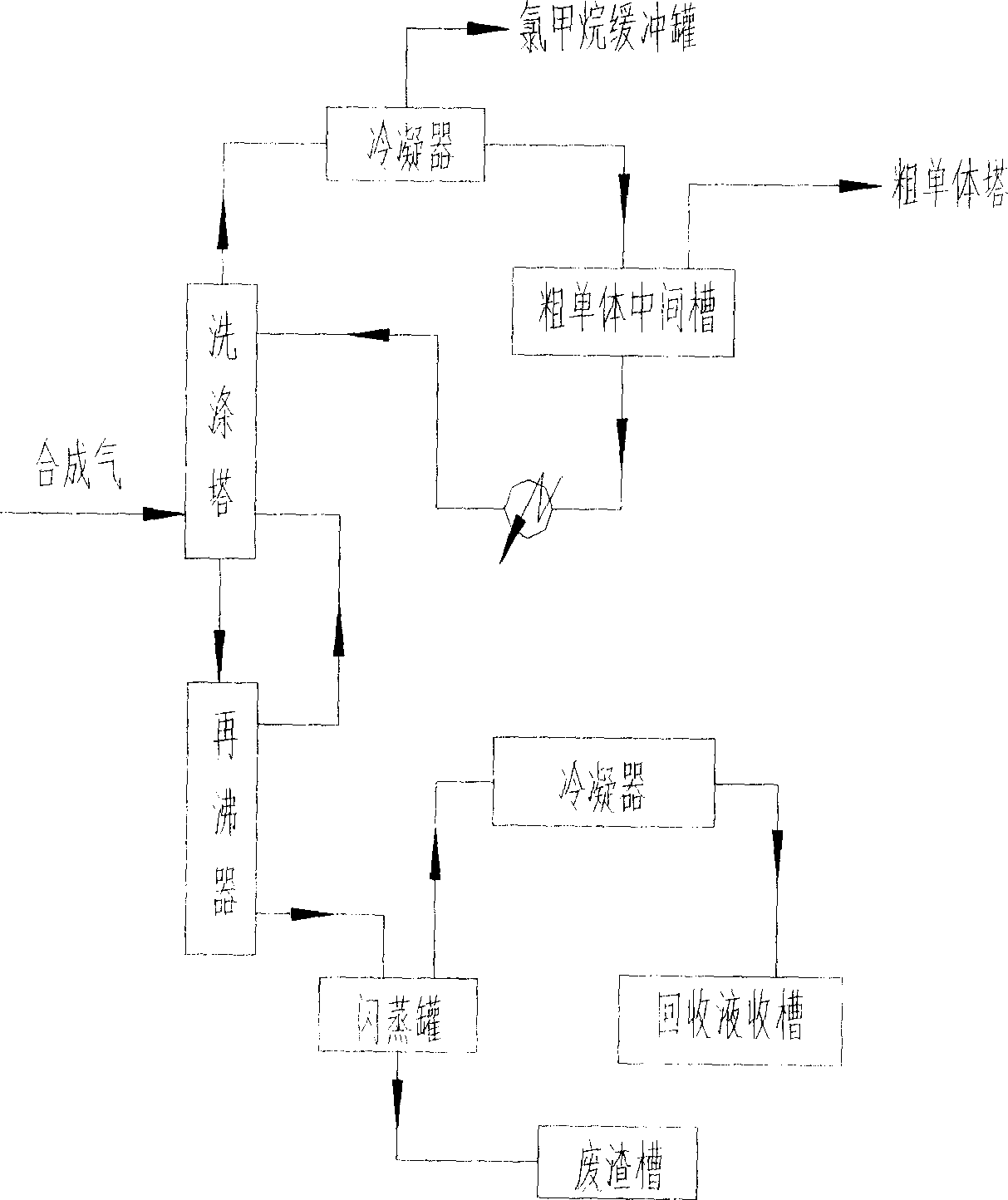

Wet-dusting and high-boiling-point separation technology for organic silane chloride synthesized gas

The invention describes a dust-cleaning technique using wetting method of organic chlorosiline gas. The synthetical gas from double cyclone enters inside from the bottom of washing tower, the discharged liquid from the kettle enters in flash pot, evaporated gas enters in flash condenser, non-condensing gas is entirely discharged after washed by washing tower, condensed liquid enters in liquid-recovery tank and residue is discharged into residual tank. The gas on the top enters in precooling device on top of the tower, after gas-phase is deeply cooled, non-condensing gas goes to chlorine methane buffering pot, condensed liquid enters in rough monomer medium pot, part of which returns to the tower and part of discharging is sent to rough monomer tower for processing.

Owner:蓝星安迪苏股份有限公司

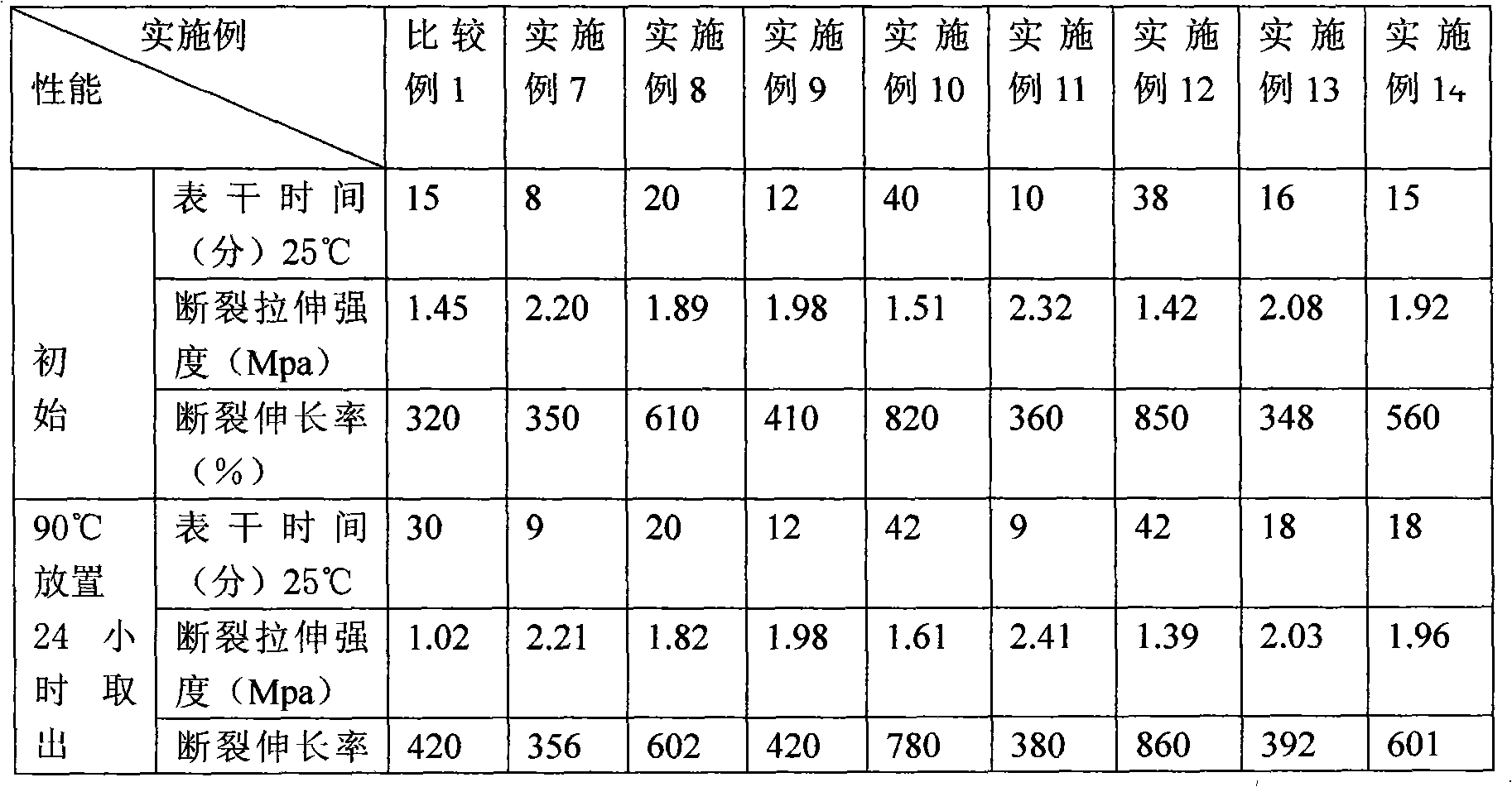

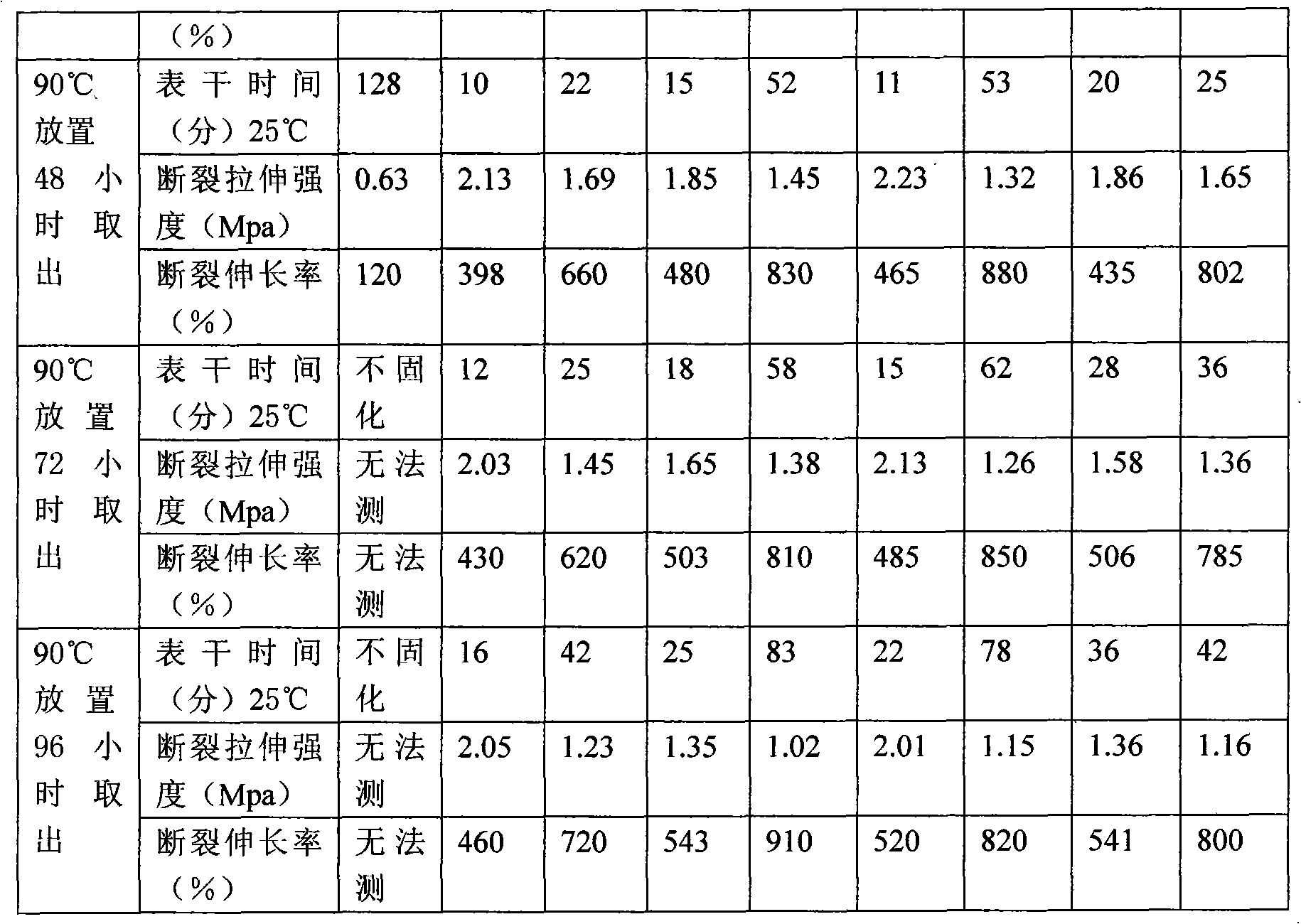

Novel crosslinker of single-component de-alcoholized room temperature vulcanized silicone rubber and preparation method thereof

InactiveCN101624446AGood storage stabilityGood physical and mechanical propertiesPolymer scienceVulcanization

The invention relates to a method for synthesizing poly alkyl methoxy silane by taking alkylchlorosilane or alkyl methoxy silane as main raw materials, or the poly alkyl methoxy silane replaces methyl trimethoxy silane and other crosslinkers partially or wholly for being used as a novel crosslinker of single-component de-alcoholized room temperature vulcanized silicone rubber, so as to lead the storage stability and the physical mechanical properties (fracture tensile strength and fracture elongation) after being solidified to be improved.

Owner:朱旭 +2

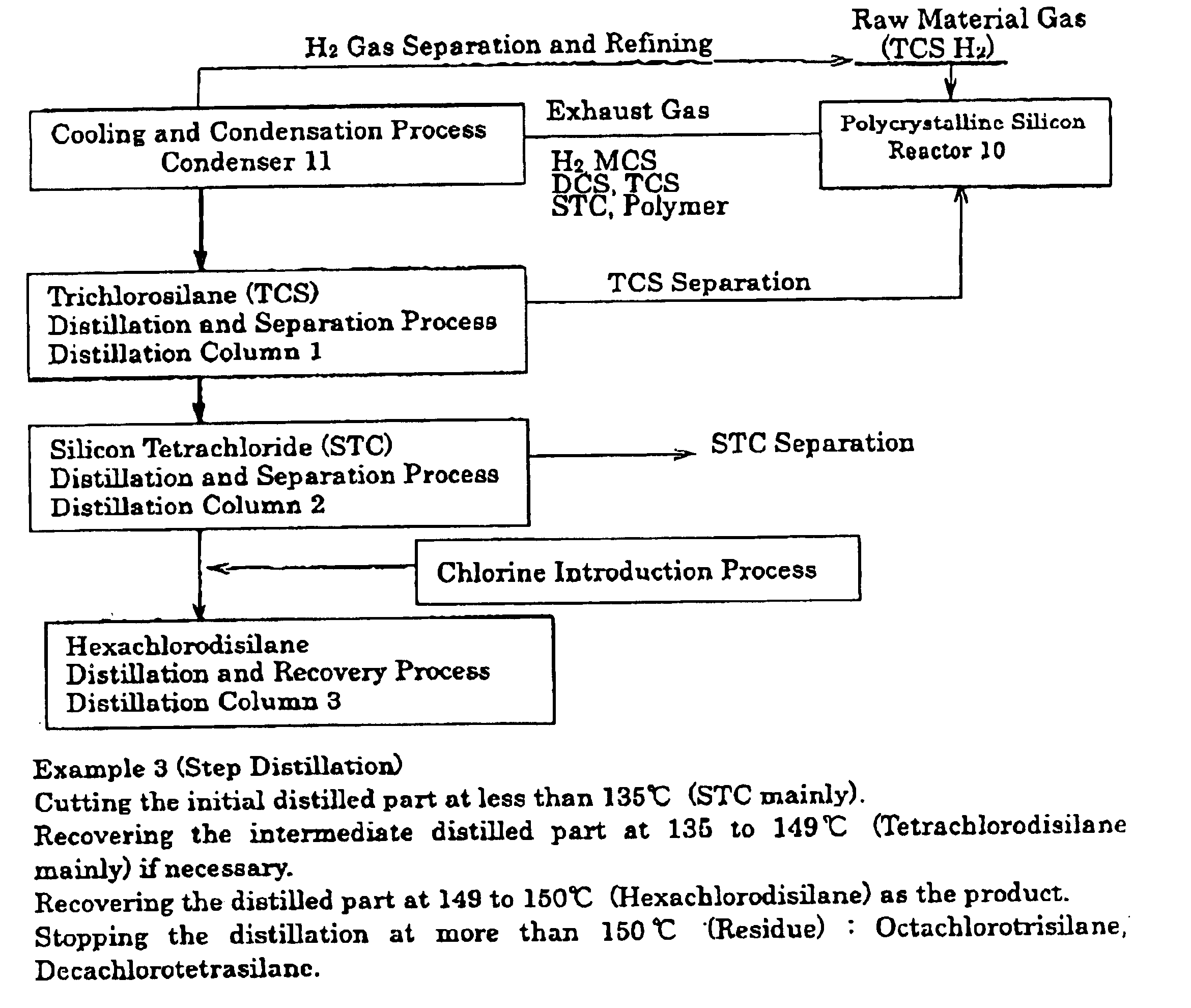

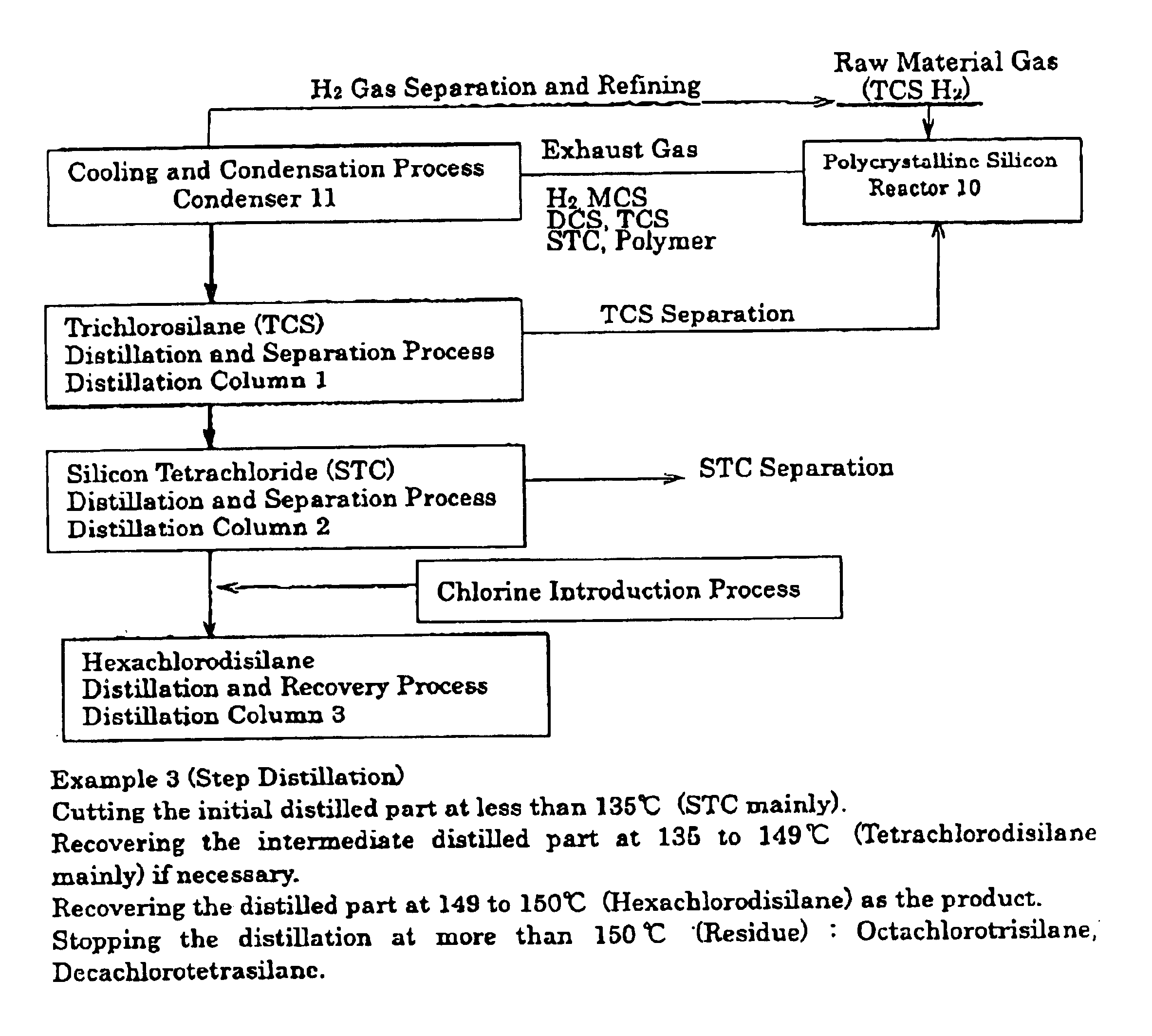

Process for producing hexachlorodisilane

InactiveUS6846473B2High purityEffective recoverySiliconDistillation separationHydrogenSilicon tetrachloride

A process for producing hexachlorodisilane comprising, condensing an exhaust gas discharged from a reactor for producing polycrystalline silicon from a chlorosilane and hydrogen to separate the hydrogen, distilling the resultant condensate to separate the unreacted chlorosilane and by-product silicon tetrachloride, and then further distilling to recover hexachlorodisilane, wherein tetrachlorodisilane can be recovered together with the hexachlorodisilane, and the hexachlorodisilane and tetrachlorodisilane recovered have a far higher purity than the conventional ones produced from metallic silicon.

Owner:MITSUBISHI MATERIALS CORP

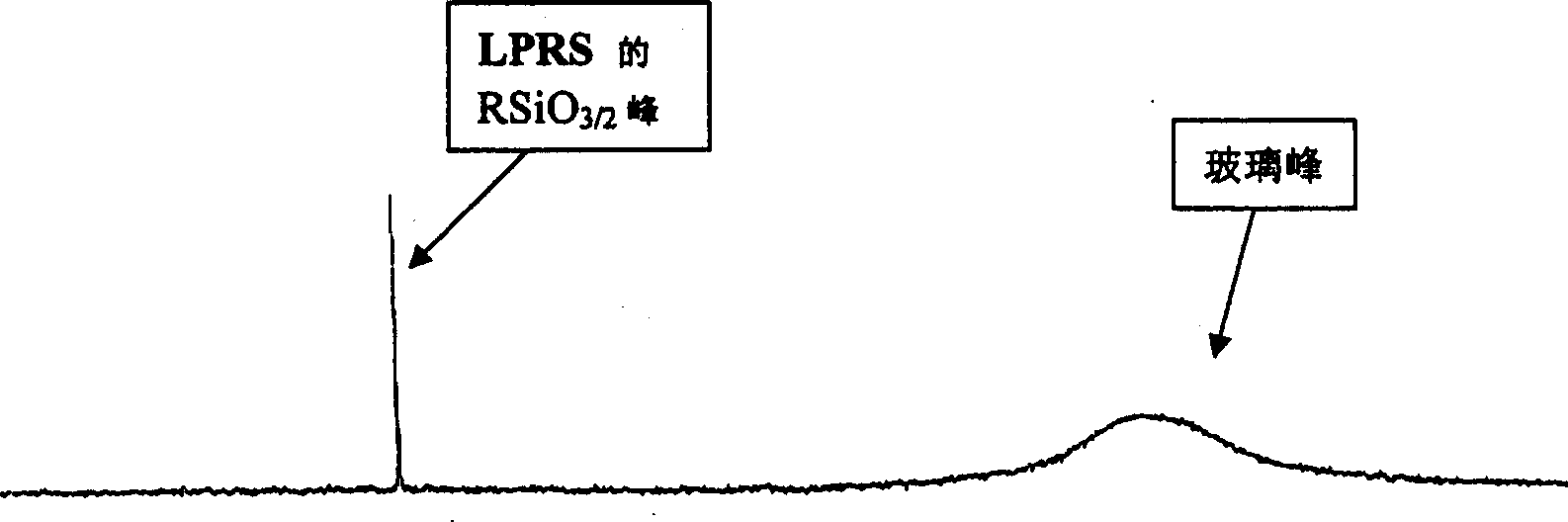

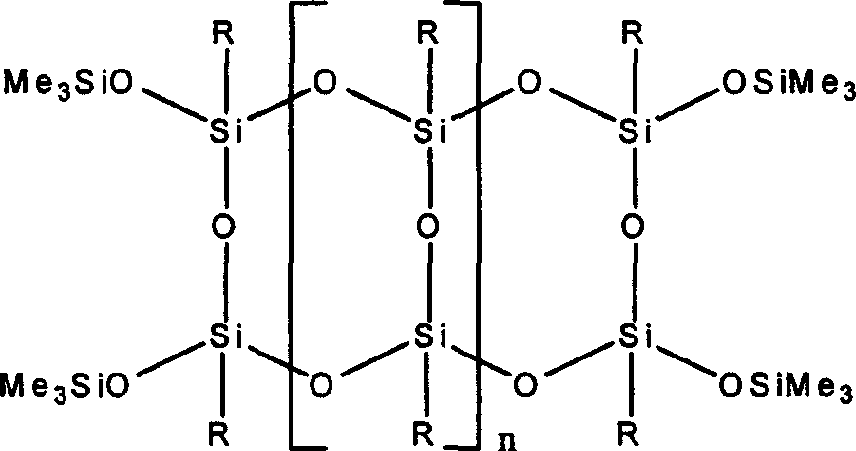

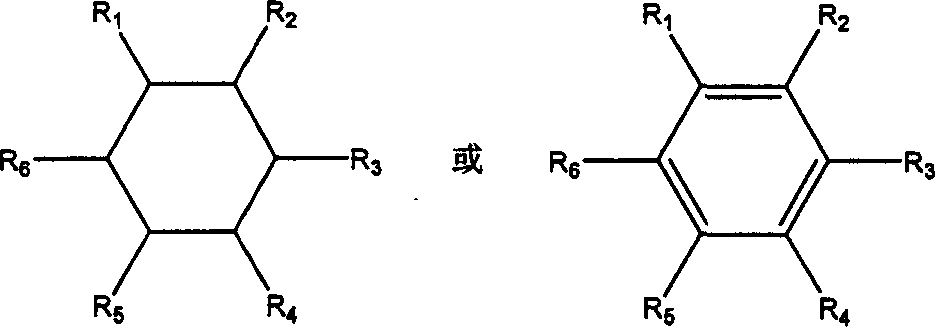

Trapezoidal organic poly sesquisiloxane and preparation method

A preparation method for highly tactic ladder-like polysilsequioxane with solubility, high molecular weight and different organic side groups is introduced in this invention. Trichlorosilicane with different substituents reacts with template-1, 4-dianiline or its derivatives with ladder-brace template method to produce conjugate precursor containing four silicon-chlorine bonds, which self-assembles into ladder polymers by hydrogen bond template function of p-dianiline and transforms into silanol end-capping organic bridging siloxane polymers after hemihydration-hydrolysis-condensation. Such a compound is then end-capped with trimethylsiloxyl and hydrolyzed to remove p-dianiline, and ladder-like polysilsequioxane can be obtained after further condensation. Or tetrafunctional disiloxane monomers with template-function side groups self-assemble into ladder-like polymers, which are then condensation-polymerized and end-capped with trimethylsiloxyl to obtain ladder-like polysilsequioxane.

Owner:INST OF CHEM CHINESE ACAD OF SCI

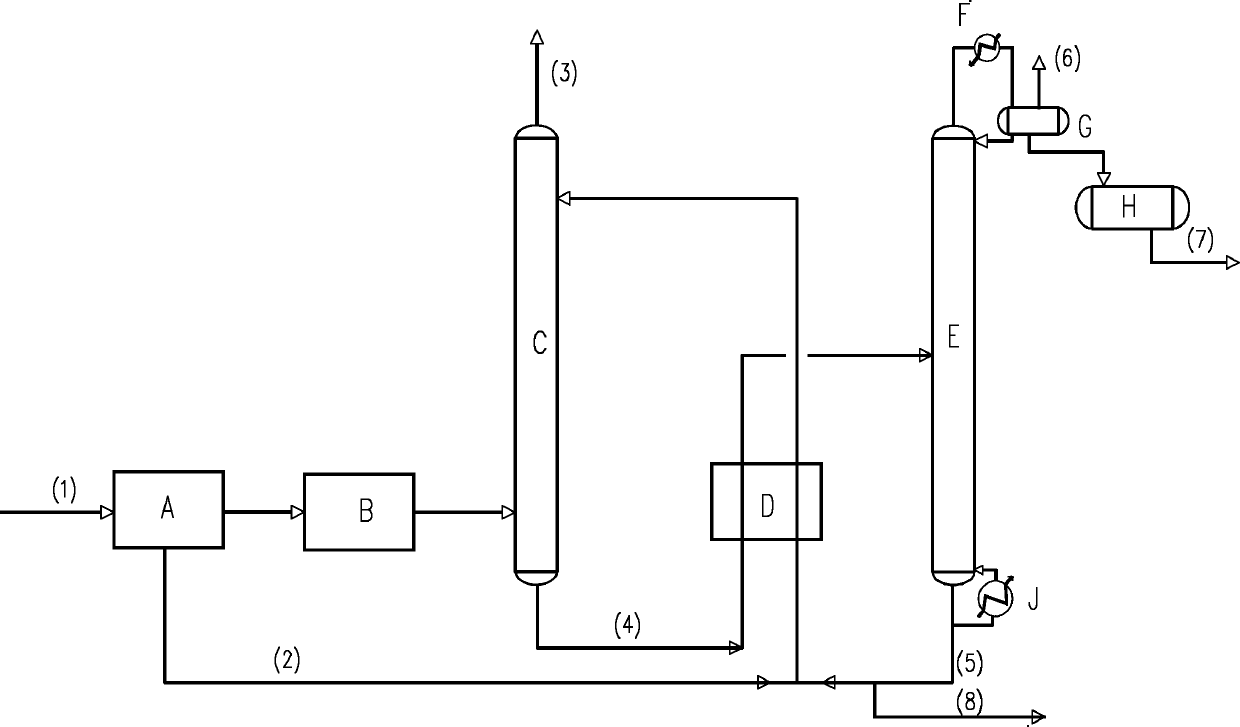

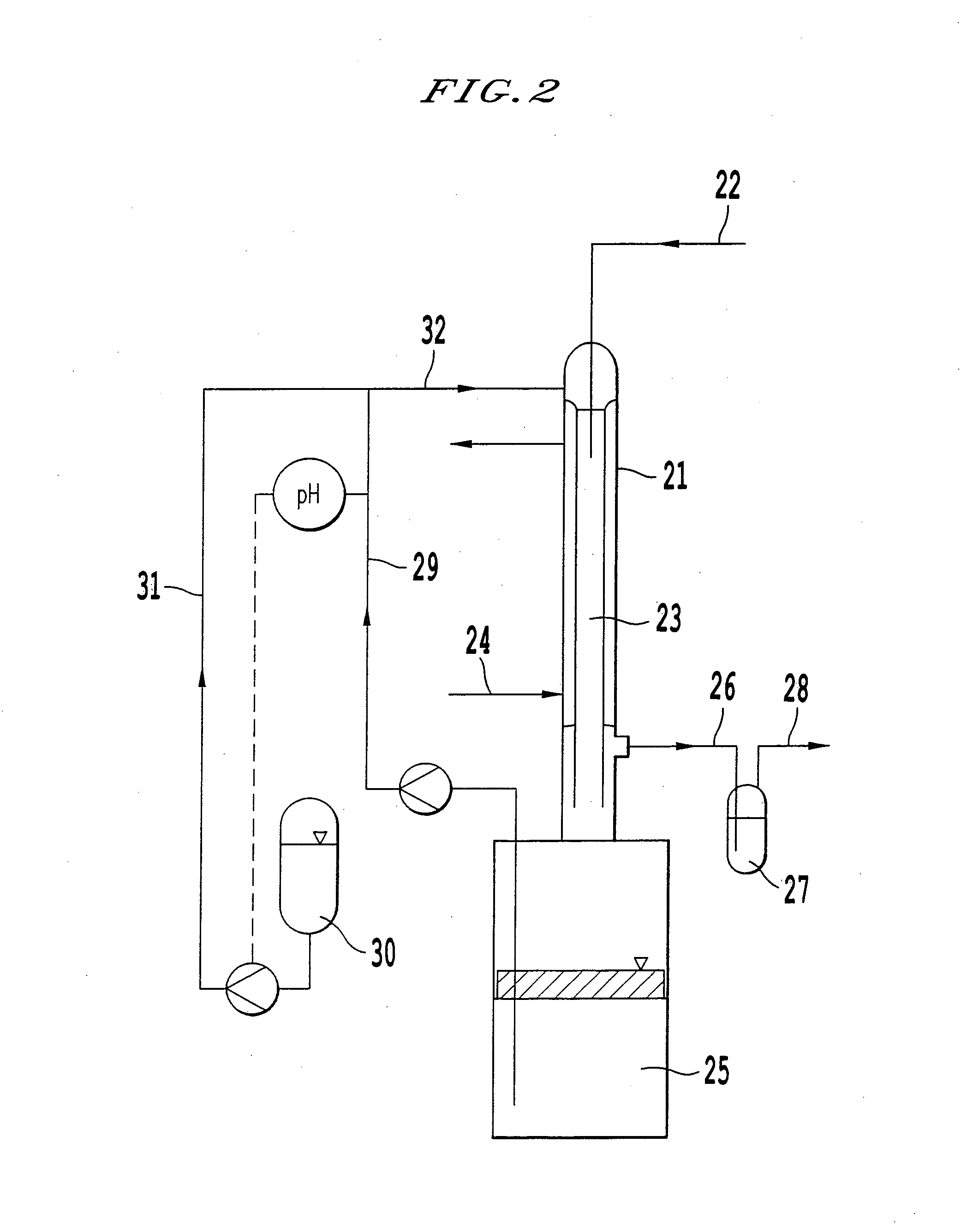

Method for recycling hydrogen chloride in tail gas of polysilicon production

ActiveCN101791487AHigh purityLarge storage capacityChlorine/hydrogen-chloride purificationSiliconDistillationChloride

The invention discloses a method for recycling hydrogen chloride in tail gas of polysilicon production. In the method, tail gas is cooled and condensed, so that most of chlorosilane is liquefied; compressed gas enters a hydrogen chloride absorption tower and absorbed by chlorosilane solution, and hydrogen gas is exhausted from the hydrogen chloride absorption tower and collected; liquid hydrogen-chloride-rich chlorosilane discharged from the bottom of the hydrogen chloride absorption tower is introduced into a hydrogen chloride distillation tower, and chlorosilane solution is discharged form the bottom of the hydrogen chloride distillation tower; and hydrogen chloride containing trace hydrogen gas is exhausted from the top of the hydrogen chloride distillation tower and enters a full condenser on the top of the distillation tower, condensate of the full condenser on the top of the distillation tower enters a return tank of the distillation tower, the trace hydrogen is exhausted from the top of the return tank of the distillation tower and collected, a part of the condensate of the return tank of the distillation tower is introduced into the hydrogen chloride distillation tower and used as return liquid, and the other part of the condensate enters a liquid hydrogen chloride reservoir for storage. The method improves the purity of recycled hydrogen chloride and the storage amount of hydrogen chloride and saves the investment of equipment.

Owner:CHINA TIANCHEN ENG

Method for producing silicon

Owner:TOKUYAMA CORP

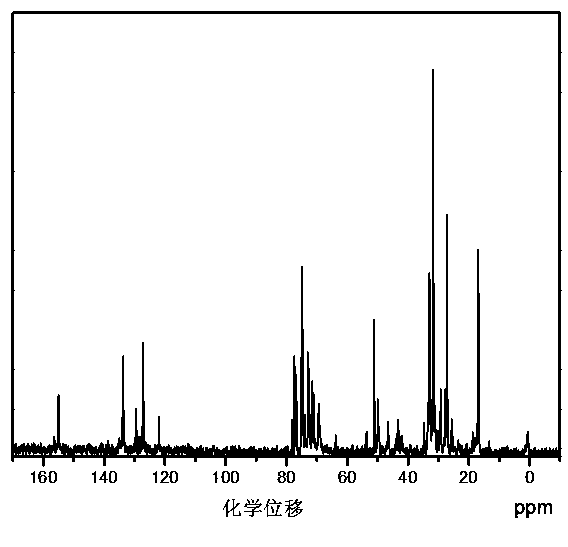

Novel polycarbosilane and preparation method thereof

The invention relates to novel polycarbosilane and a preparation method thereof. A polycarbosilane ceramic precursor is prepared by adopting a Grignard reagent coupling method; a molecular structure contains unsaturated groups such as a Si-H bond, C=C and the like; the precursor can be crosslinked and cured at a certain temperature, and has low curing weight loss and high manufacturability; the Si / C ratio in the precursor and the process performance of a precursor product can be adjusted effectively by adjusting the functionality and feed ratio of a chlorosilane monomer serving as a reactant and optimizing reaction conditions; and the obtained product has excellent heat resistance, high ceramic yield, low free carbon content in ceramic and high SiC ceramic phase purity, is suitable for serving as a high-performance SiC ceramic precursor, and can be used for preparing an ultrahigh-temperature ceramic-based composite material submerged substrate as well as high-performance materials such as SiC ceramic coatings, fibers and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

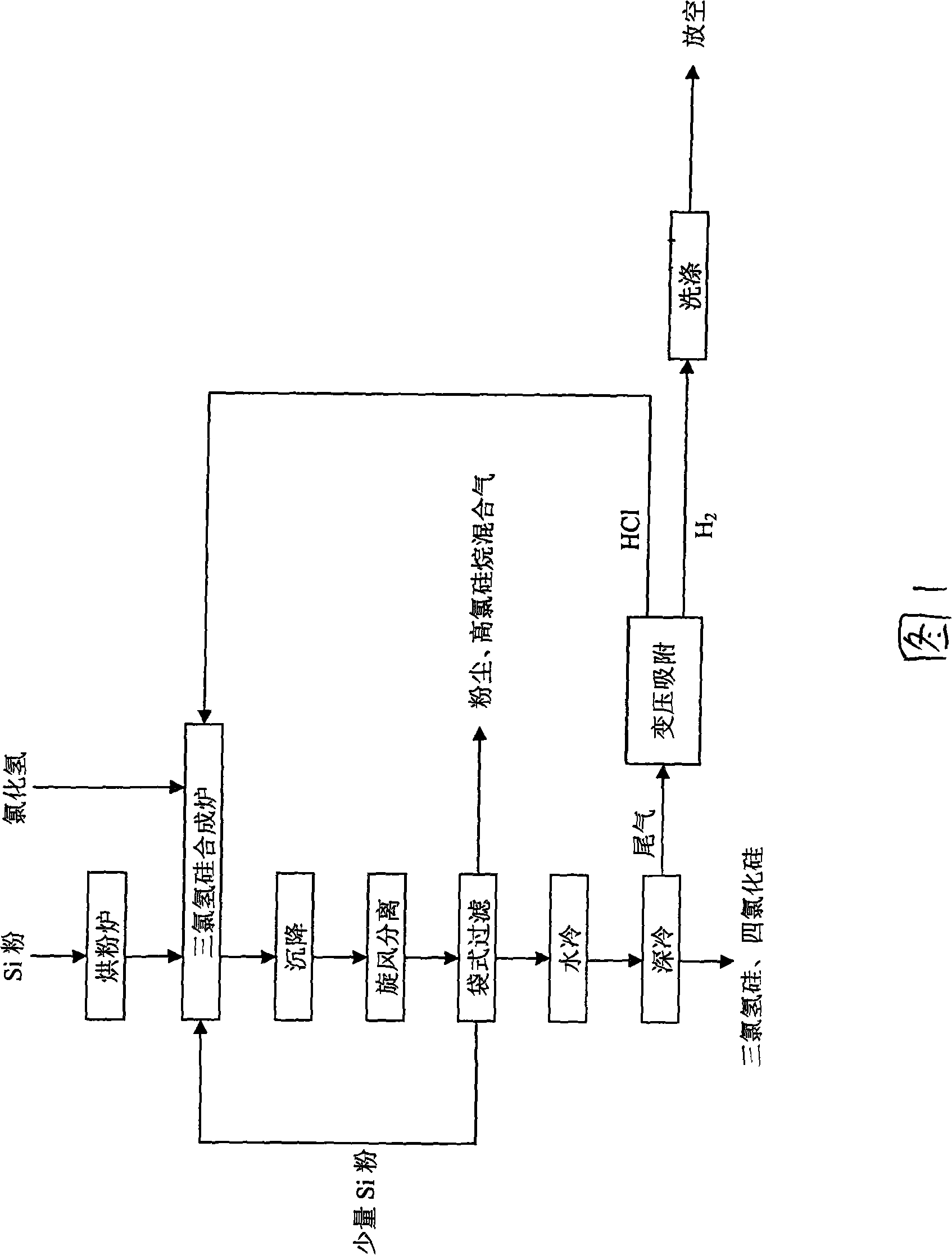

Method for synthesizing polysilicon raw material trichlorosilane

The invention discloses a method for the synthesis of a polysilicon raw material trichlorosilane. The method comprises the following steps: A) silica powder is conveyed to a trichlorosilane synthesis furnace by dried hydrogen chloride gas; B) hydrogen chloride for reaction is input into the synthesis furnace from the bottom of the trichlorosilane synthesis furnace proportionally and proper amount of hydrogen and silicon tetrachloride are added in the synthesis furnace at the same time; C) silica powder and hydrogen chloride react at the temperature of 280-310 DEG C to generate mixing gas containing trichlorosilane and silicon tetrachloride; D) the mixing gas of dust and high chlorosilane is removed, after water cooling and pressuring by a diaphragm compressor, trichlorosilane and silicon tetrachloride are condensed into liquid by a refrigerant with -40 DEG C, wherein, noncondensable gas containing H2 and HCI is separated. The method of the invention can improve the yield of trichlorosilane from 82 percent to more than 88 percent.

Owner:HUBEI HUIFU NANOMATERIAL CO LTD

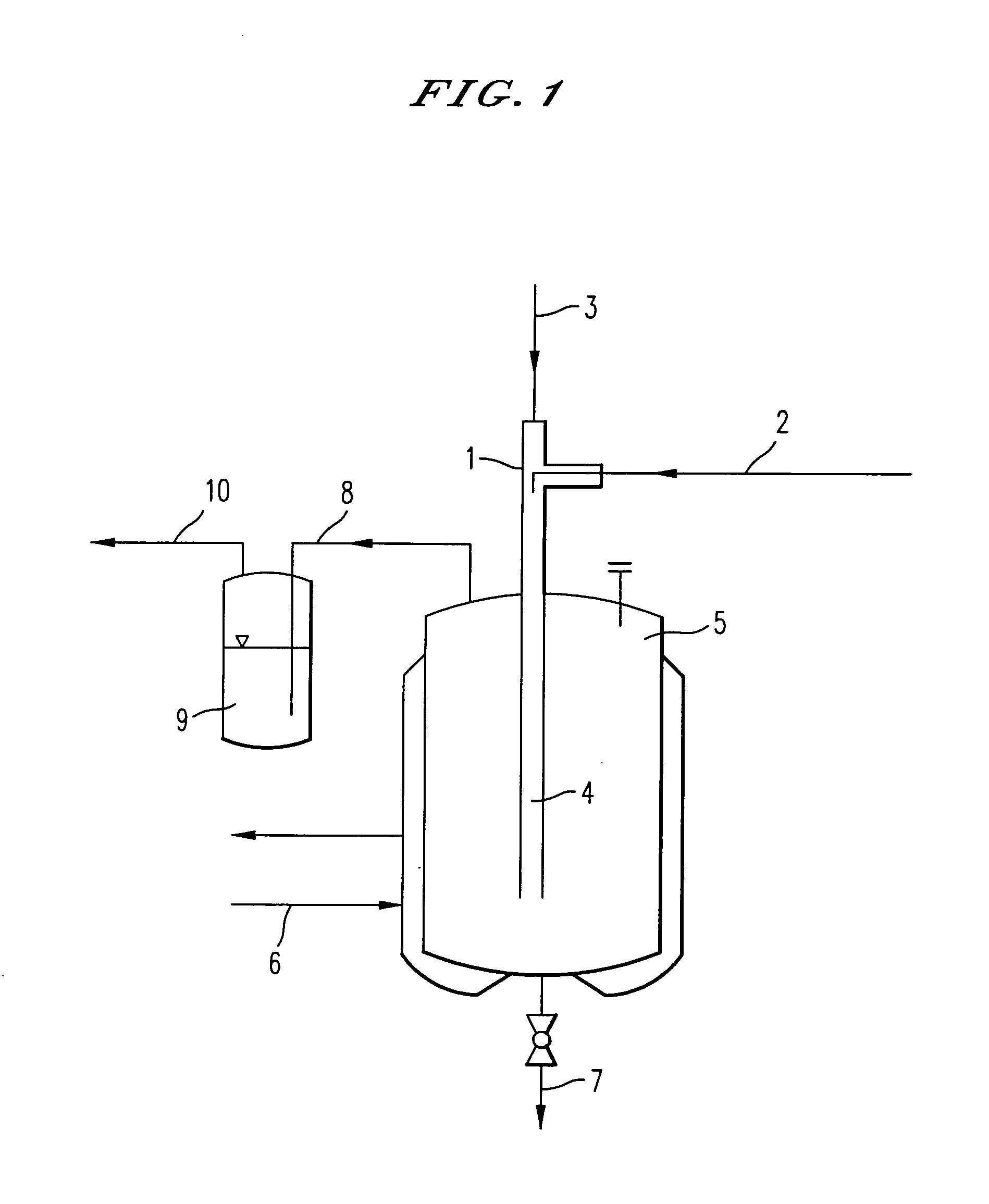

Method for continuous production hydrolysate by methylchlorosilane concentrated acid hydrolyzing

ActiveCN101323666AThe new hydrolysis process is excellentReduce or completely avoid entrainmentChlorine/hydrogen-chlorideDecompositionHydrolysate

The invention relates to a method for hydrolyzing methyl chlorosilane with concentrated acids to obtain hydrolysate, wherein, the methyl chlorosilane and the acidic oil-contained aqueous solution separated from the primary phase separator and the secondary phase separator from the hydrolysate are mixed, pass through a preheater, enter a concentrated-acid hydrolysis reaction system and undergo a circular reaction operation; the hydrogen chloride generated in the hydrolysis reaction is released from the top of a tower, goes through a defroster and a condensator and then becomes qualified HCI gas to be used in the production of methyl chloride. Qualified hydrolysate used for decomposition process is obtained after the hydrolysate of methyl chlorosilane goes through four phase separators and a steam tower.

Owner:BEIJING PETROCHEM ENG +1

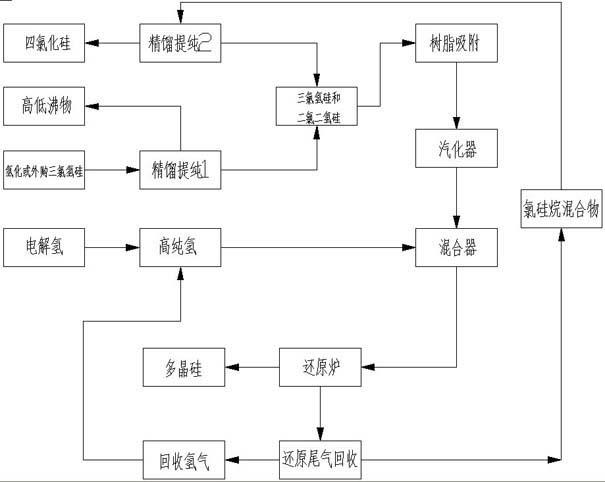

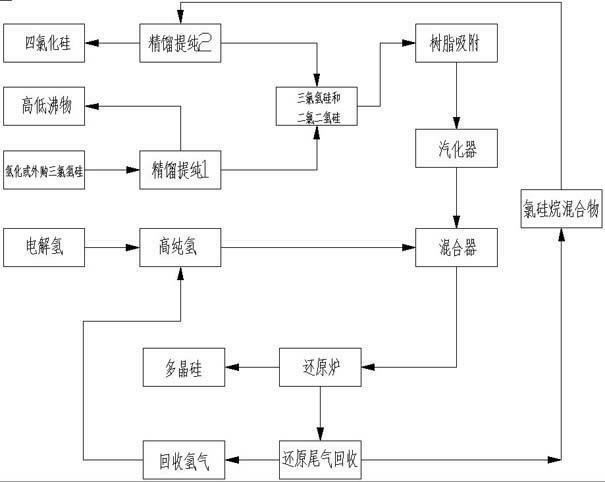

Method adopting trichlorosilane and dichlorosilane mixed raw materials to produce polycrystalline silicon

InactiveCN102642834ASolve processing problemsReduce investmentSiliconPhysical chemistryMixed materials

The invention discloses a method adopting trichlorosilane and dichlorosilane mixed raw materials to produce polycrystalline silicon. After trichlorosilane produced by hydrogenation of silicon tetrachloride or purchased outside is rectified and purified, the rectified and purified trichlorosilane is mixed with recycled trichlorosilane and dichlorosilane mixed materials, the volume percent of dichlorosilane in the mixed raw materials is controlled to be between 3% and 15%, preferably between 5% and 10%, then impurity removal by adsorption and vaporization operation are performed, vaporized chlorosilane mixed gas and high-purity hydrogen are mixed according to mole ratio of 1:2 to 1:10, preferably 1:4 to 1:6, and finally the vaporized chlorosilane mixed gas and the high-purity hydrogen enter into a reduction furnace to produce the polycrystalline silicon. After reactions, tail gas undergoes low-temperature condensation recycle, chlorosilane obtained by recycle is sent to a rectification process to perform separation of silicon tetrachloride and impurities, and the trichlorosilane and dichlorosilane mixed raw materials are obtained. The method makes full use of byproduct dichlorosilane in the polycrystalline silicon production process to improve sedimentation velocity of silicon and reduce power consumption and material consumption, simultaneously can reduce treatment cost and loss of silicon, and improves trichlorosilane utilization rate.

Owner:雅安永旺硅业有限公司

Phenyl organic silicon modified polyurethane resin, preparation method and application thereof

ActiveCN104387546AImprove surface propertiesSmall water absorptionPolyethylene glycolMethyl phenyl polysiloxane

The invention discloses a phenyl organic silicon modified polyurethane resin, a preparation method and application thereof, and belongs to the field of polyurethane resin. The structural formula of the phenyl organic silicon modified polyurethane resin is as shown in the description; the preparation method of the phenyl organic silicon modified polyurethane resin comprises the following steps: dissolving phenylsilanediol into an organic solvent, taking a reaction with chlorosilane (R<2>SiCH3Cl2) to prepare hydroxyl-terminated methyphenyl polysiloxane, under the action of a catalyst, mixing the hydroxyl-terminated methyphenyl polysiloxane with a silane compound to obtain amino or imino terminated methyphenyl polysiloxane, then in the atmosphere of argon, mixing diisocyanate, amino or imino terminated methyphenyl polysiloxane, polyethylene glycol or polyol with a mixed solvent, and taking a reaction to obtain the phenyl organic silicon modified polyurethane resin. The phenyl organic silicon modified polyurethane resin has the advantages of being capable of reducing the water absorption, improving the hydrophobicity, and improving the compatibility of organic silicon and polyurethane, and can be prepared to thin film with good properties; the preparation method is simple and feasible.

Owner:WUHAN UNIV

Process for the separation of chlorosilanes from gas streams

Chlorosilanes are continuously removed from a gas stream in an apparatus in which the gas stream is treated in a first stage with water vapor in the gas phase, and in a second stage with a liquid, aqueous phase.

Owner:EVONIK DEGUSSA GMBH

Self-cleaning film and preparation thereof

InactiveCN101280155AGood self-cleaning propertiesHigh mechanical strengthPretreated surfacesSpecial surfacesSilanesPolymer chemistry

The invention discloses self-cleaning film and the preparation method; the method provided by the invention and used for preparing the self-cleaning film is that the raw material mixtures are mixed, stirred and put into chlorosilane, alkoxy silane or fluoro-alkyl silanes solutions for self-assembly after film forming and drying; and then the self-cleaning film is obtained. The self-cleaning film and the preparation method are the break through in preparing the self-cleaning coating; the water contact angle of the film is above 150 degrees and the lag angle is less than 20 degrees; meanwhile, the mechanical intensity difference problem of the ultra-hydrophobic coating is effectively solved. The self-cleaning film in the invention has wide application range and can be coated on the surfaces of the materials including vehicle glasses, rearview mirrors, buildings and clothes, ensuring the surfaces of the materials to have the self-cleaning functions of waterproof, antifouling, frost prevention and snow cover prevention.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com