Wet-dusting and high-boiling-point separation technology for organic silane chloride synthesized gas

An organochlorosilane, wet dust removal technology, applied in the fields of silicon organic compounds, separation methods, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

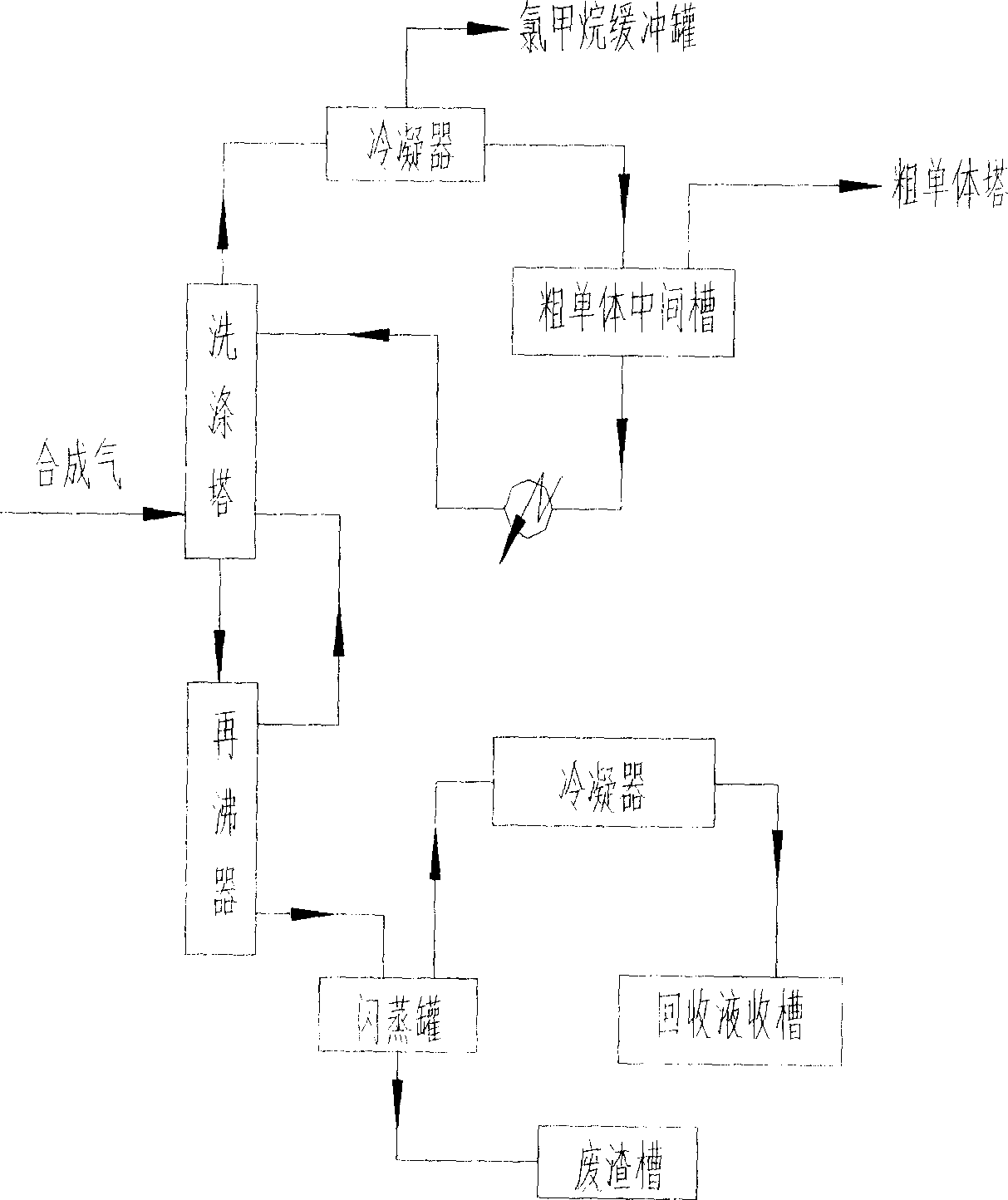

[0008] The high-temperature synthesis gas from the secondary cyclone separator enters the scrubber from the bottom of the scrubber, and the pressure at the top of the scrubber is controlled at 0.3 MPa. The reflux ratio of the scrubber and the temperature at the top of the scrubber are 60°C. After being washed by the scrubber, the temperature drops to 70°C. Liquid and solid impurities such as washing liquid and silicon powder overflow from the tower kettle to the tower kettle re-evaporator, and the re-evaporator is heated with heat transfer oil, and the gas phase temperature of the re-evaporator is controlled at 220°C. The liquid level of the re-evaporator is controlled by a two-position switch at the bottom, and the high-boiled methylchlorosilane with a solid content of 30% and dust is discharged into the flash tank, and the flashed gas enters the flash condenser for condensation without condensation. The gas is washed by the water washing tower and then emptied, and the conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com