Patents

Literature

2395 results about "Aqueous sodium hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

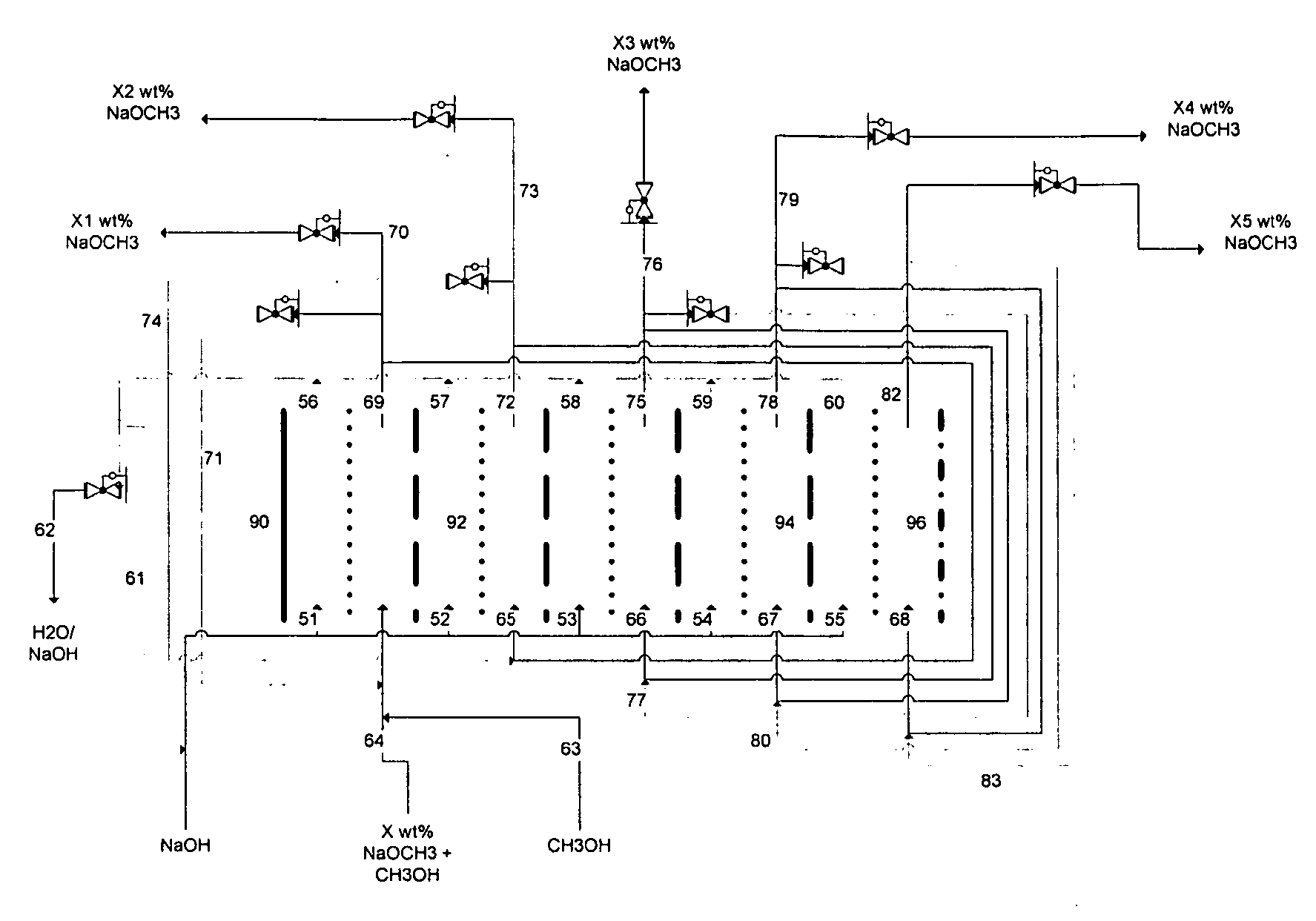

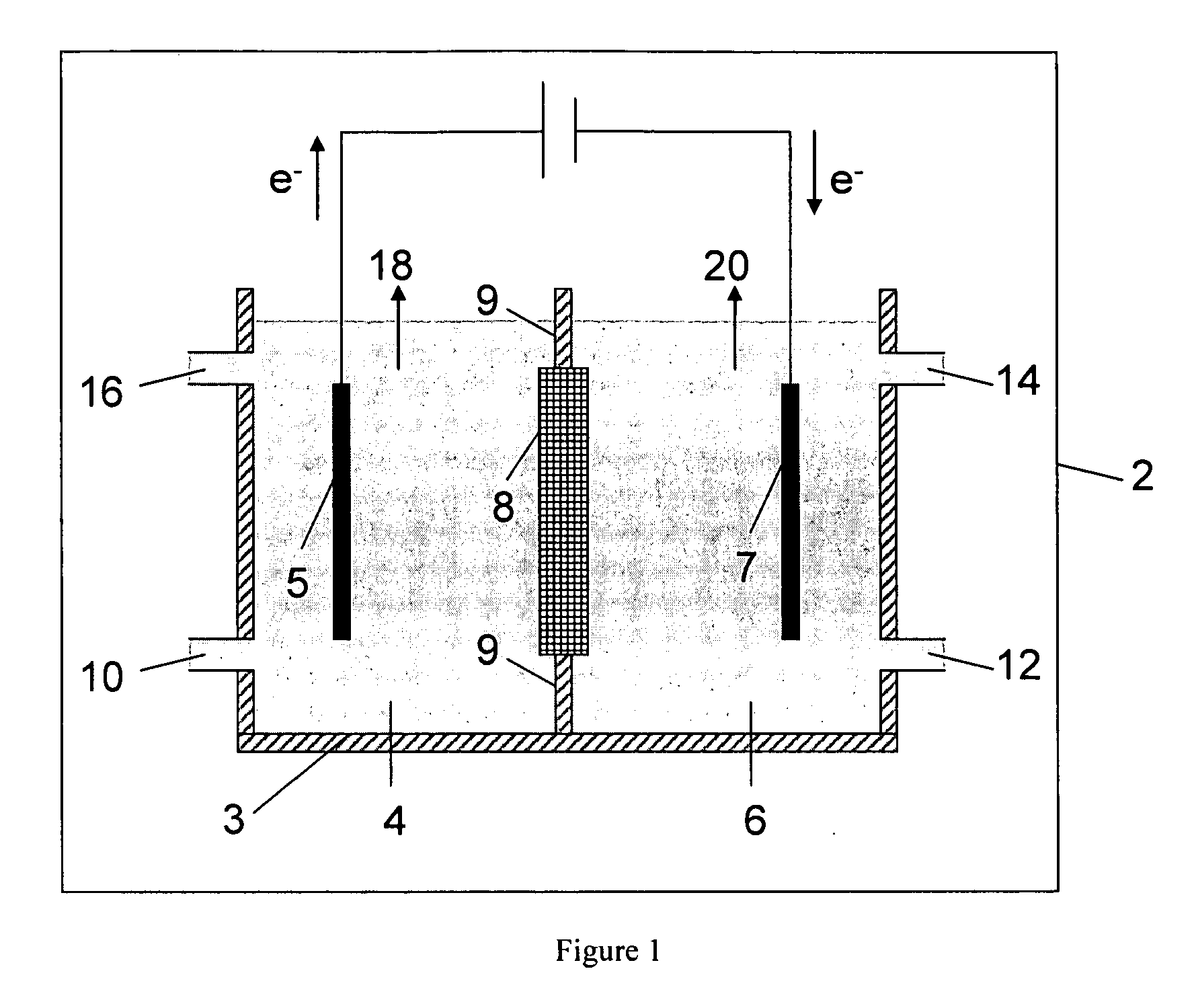

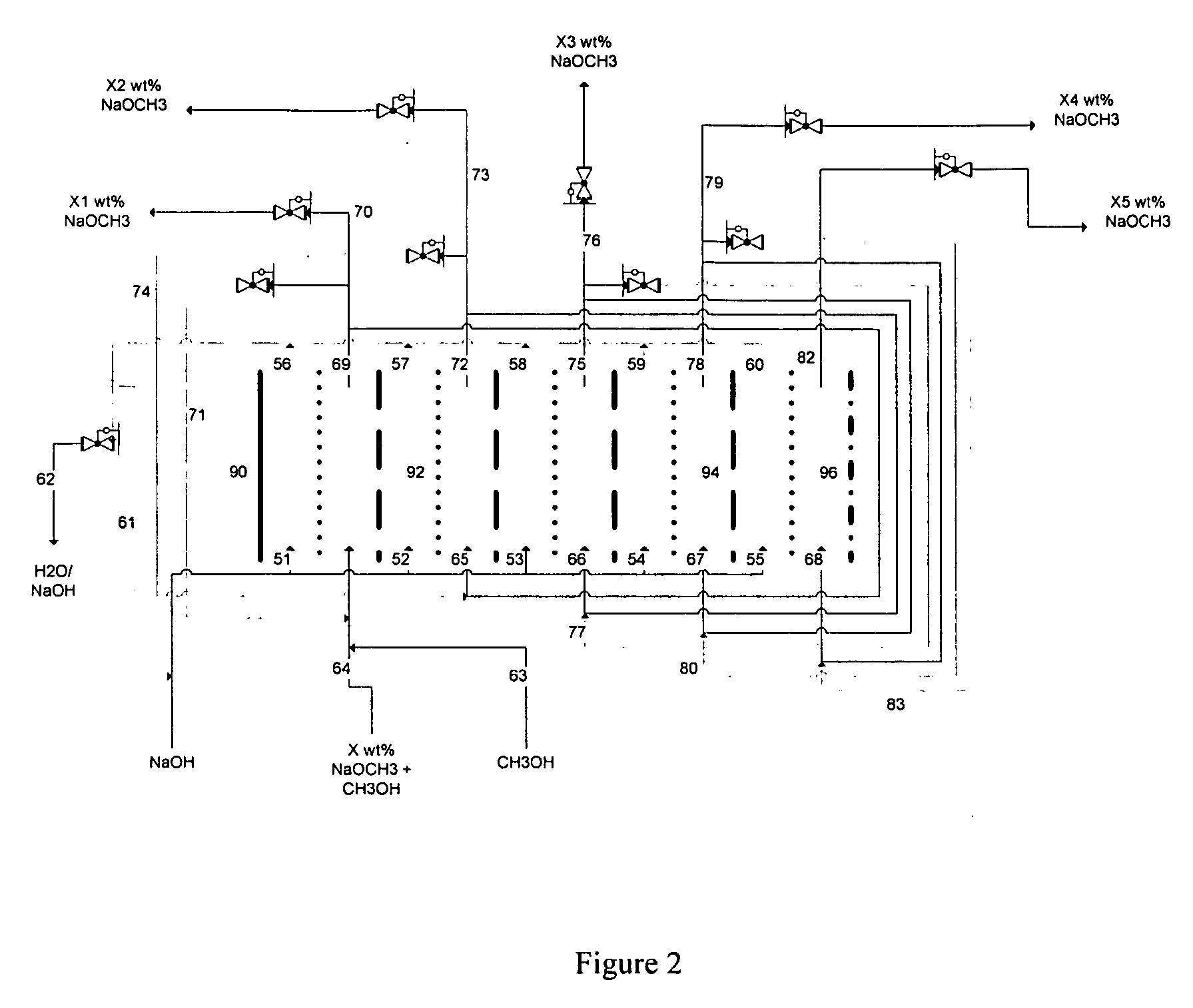

Electrolytic method to make alkali alcoholates using ceramic ion conducting solid membranes

Disclosed are processes of making solutions of alkali alkoxides in their corresponding alcohols using an electrolytic process. In one embodiment, sodium methoxide in methanol is made from methanol and aqueous sodium hydroxide solution, where the aqueous sodium hydroxide solution is present in the anolyte compartment and a solution of sodium methoxide in methanol is present in the catholyte compartment, the two compartments are separated by a ceramic membrane that selectively transports sodium ions under the influence of an electric potential, and wherein the composition of the solution of sodium methoxide in methanol in the catholyte compartment of the electrolytic cell comprises between at least about 2% by weight sodium methoxide and at most about 20% by weight sodium methoxide.

Owner:ENLIGHTEN INNOVATIONS INC

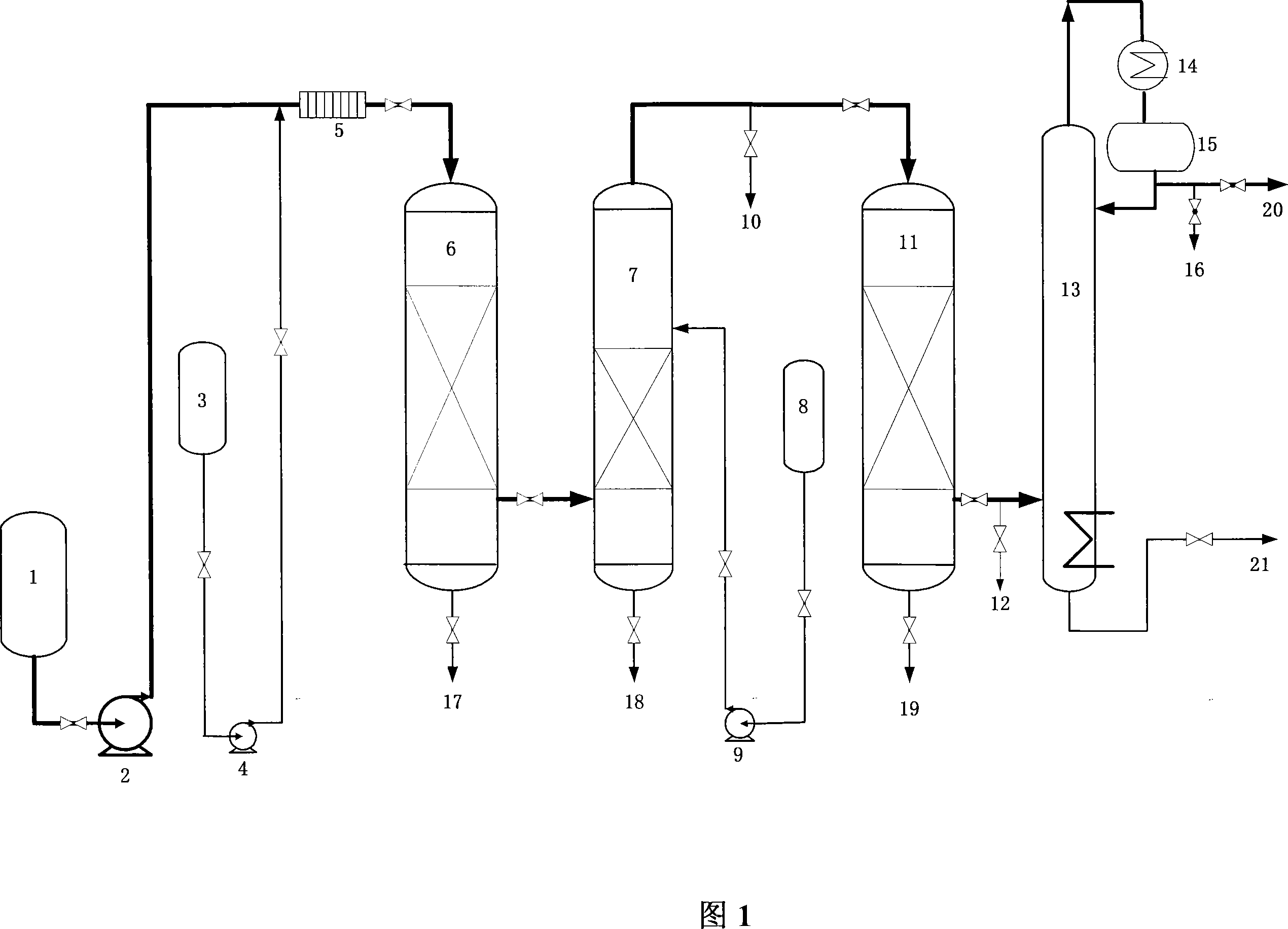

Deep desulfurization method for liquefied petroleum gas

The liquefied petroleum gas deep desulfurizing process includes the following steps: mixing alcohol amine treated liquefied petroleum gas with desulfurizer aqua, feeding the mixture into a reactor with carbonyl sulfide hydrolyzing catalyst for hydrolyzing carbonyl sulfide into hydrogen sulfide and CO2 and eliminating hydrogen sulfide, regenerating the used desulfurizer, water washing the liquefied petroleum gas to eliminate residual desulfurizer with water containing dissolved oxygen or hydrogen peroxide in a water washing tower with hydrogen peroxide decomposing catalyst in the stuffing layer, eliminating mercaptan from the liquefied petroleum gas through oxidizing mercaptan into disulfide in a mercaptan eliminating reactor with catalyst, and final rectifying in a rectifying tower to eliminate disulfide. The process is simple and practical, and can lower the total sulfide content in liquefied petroleum gas to below 5 ppm.

Owner:北京石大世通科技发展有限公司

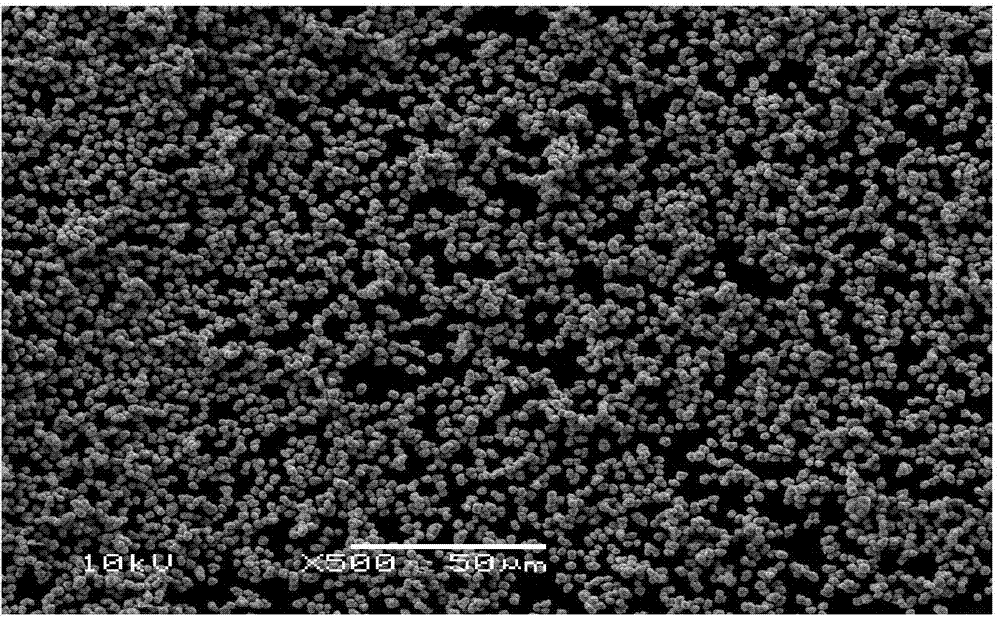

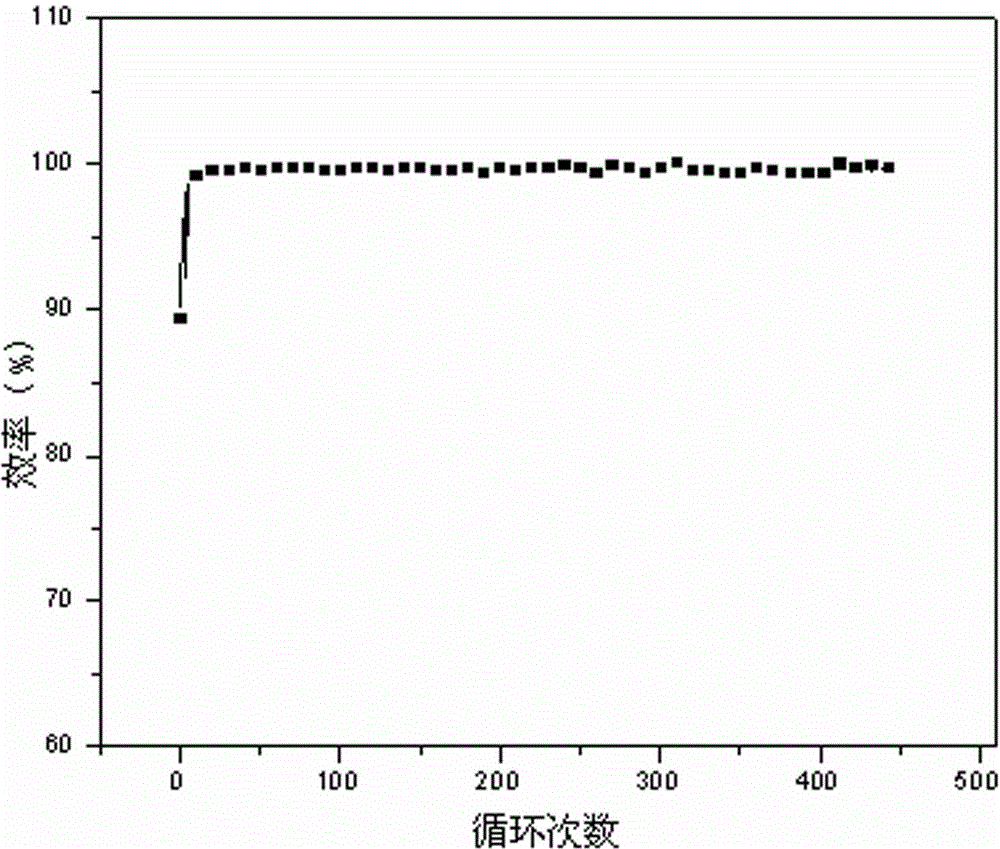

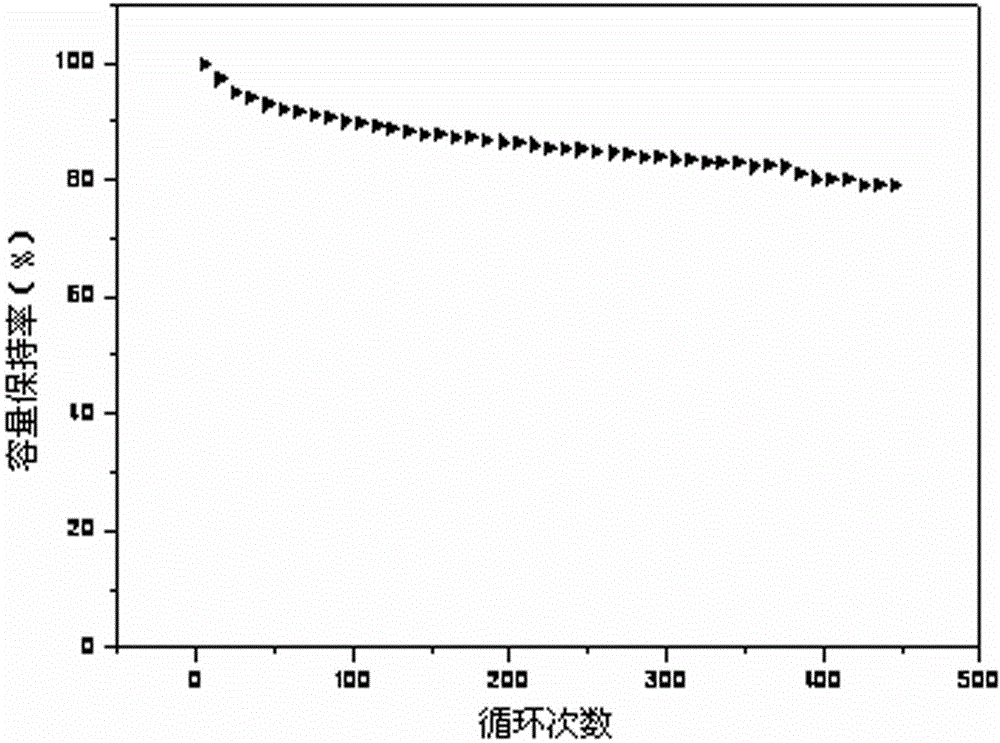

Method for continuously synthesizing precursor of lithium ion battery positive material

InactiveCN102092798AInhibition formationSolve the problem of easy oxidationCell electrodesManganese oxides/hydroxidesSynthesis methodsManganese

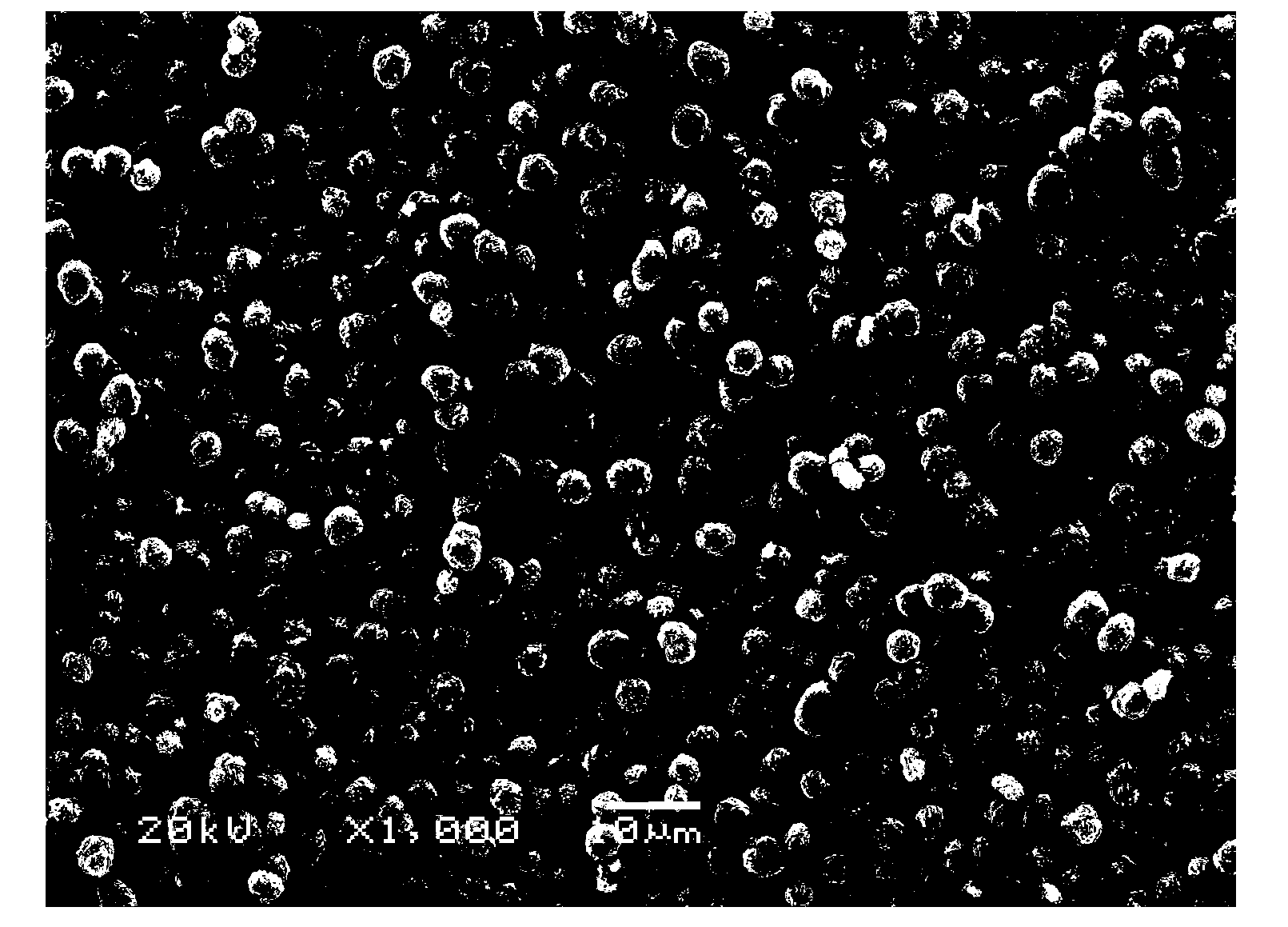

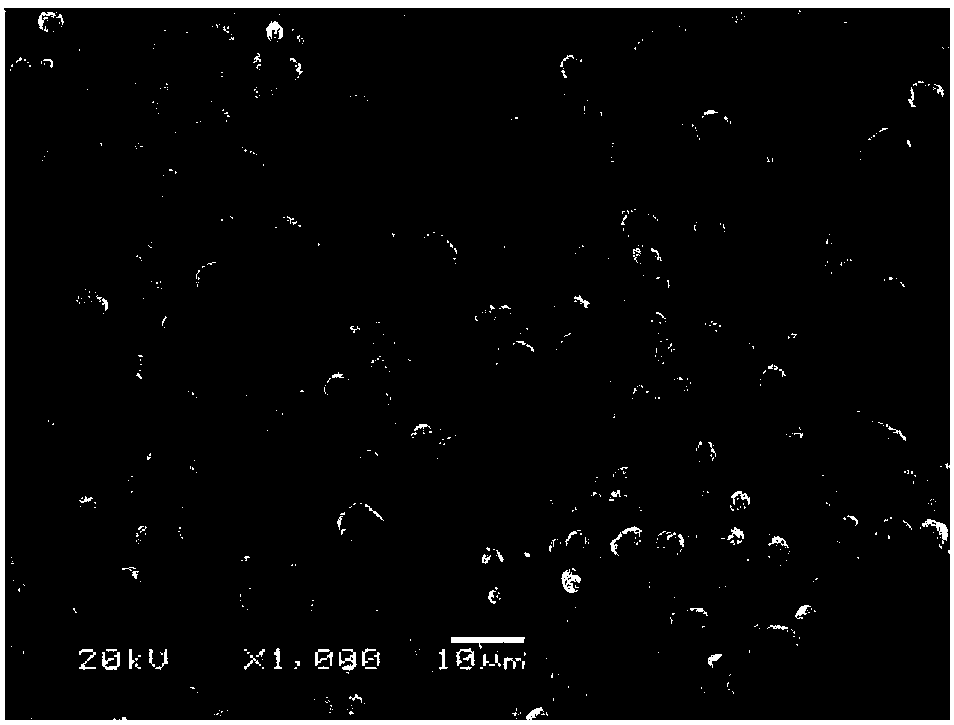

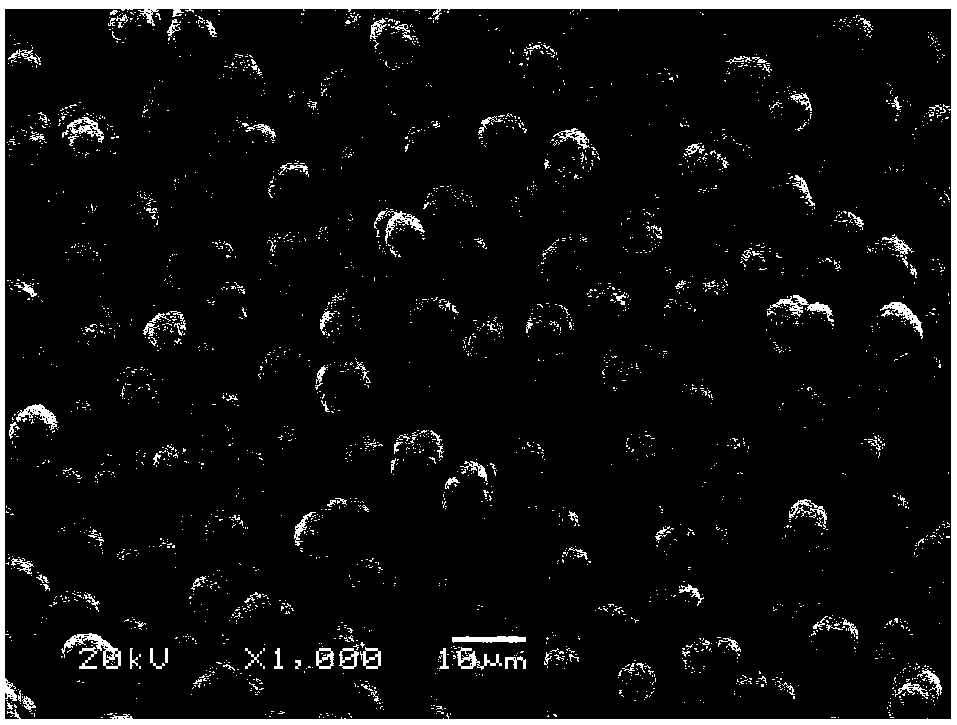

The invention provides a method for continuously synthesizing a precursor of a lithium ion battery positive material, relating to an improvement of a synthesis method of a nickle cobalt manganese termary positive material nickle cobalt lithium manganate of the lithium ion battery positive material. The method is characterized in that the synthesis process is as follows: merging a complexing agent ammonia, an aqueous solution of metal nickle cobalt manganese ions and a precipitator sodium hydroxide solution and then continuously adding the substances into a reaction kettle for a synthesis reaction under the strong stirring condition in the presence of protective gas; and aging, filtering and washing the effluent from the reaction kettle, and then drying to obtain the lithium ion battery positive material precursor spherical nickle cobalt manganese termary hydroxide. The method has the advantages that the preparation process is continuous, the particle size of the prepared nickle cobalt manganese compound hydroxide powder is controlled in a range of 5-20 microns, and the prepared nickle cobalt manganese compound hydroxide powder is even in distribution and excellent in electrochemistry property. The method has the advantages of high production efficiency, low production cost and significant economic and social benefits, and the energy is saved.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH +1

Natural cooling-making soap and low-temperature soap-making process

InactiveCN101649262AIncreased sensitivitySolve the problem of not moisturizingAlkali/ammonium soap compositionsAqueous sodium hydroxideDistilled water

The invention relates to a low-temperature soap-making process of natural cooling-making soap, which belongs to a washing article and a making process thereof. The cooling-making soap is made of the following raw materials in proportion by weight at low temperature: 20-28 distilled water, 60-71 base grease, 6-12 sodium hydroxide, essential oil accounting for 0.5-1.5 percent of the total weight ofthe distilled water, the base grease and the sodium hydroxide, and Chinese medicine accounting for 1.5-2.5 percent of the total weight of the distilled water, the base grease and the sodium hydroxide.The making process comprises the following steps: firstly, weighing the raw materials; secondly, adding the sodium hydroxide into the distilled water; thirdly, adding the base grease into a stainlesscontainer, heating by separating from water; fourthly, after reducing the temperature of the sodium hydroxide solution and the base grease solution, slowly pouring the sodium hydroxide solution intothe base grease solution, and completely stirring uniformly; fifthly, adding the essential oil and the powder of the Chinese medicine, and stirring uniformly; sixthly, pouring the liquid mixture intoa mould, demoulding, and standing thus obtaining the soap. The invention solves the problem of poor washing effect of the washing soap produced by the prior art.

Owner:王硕

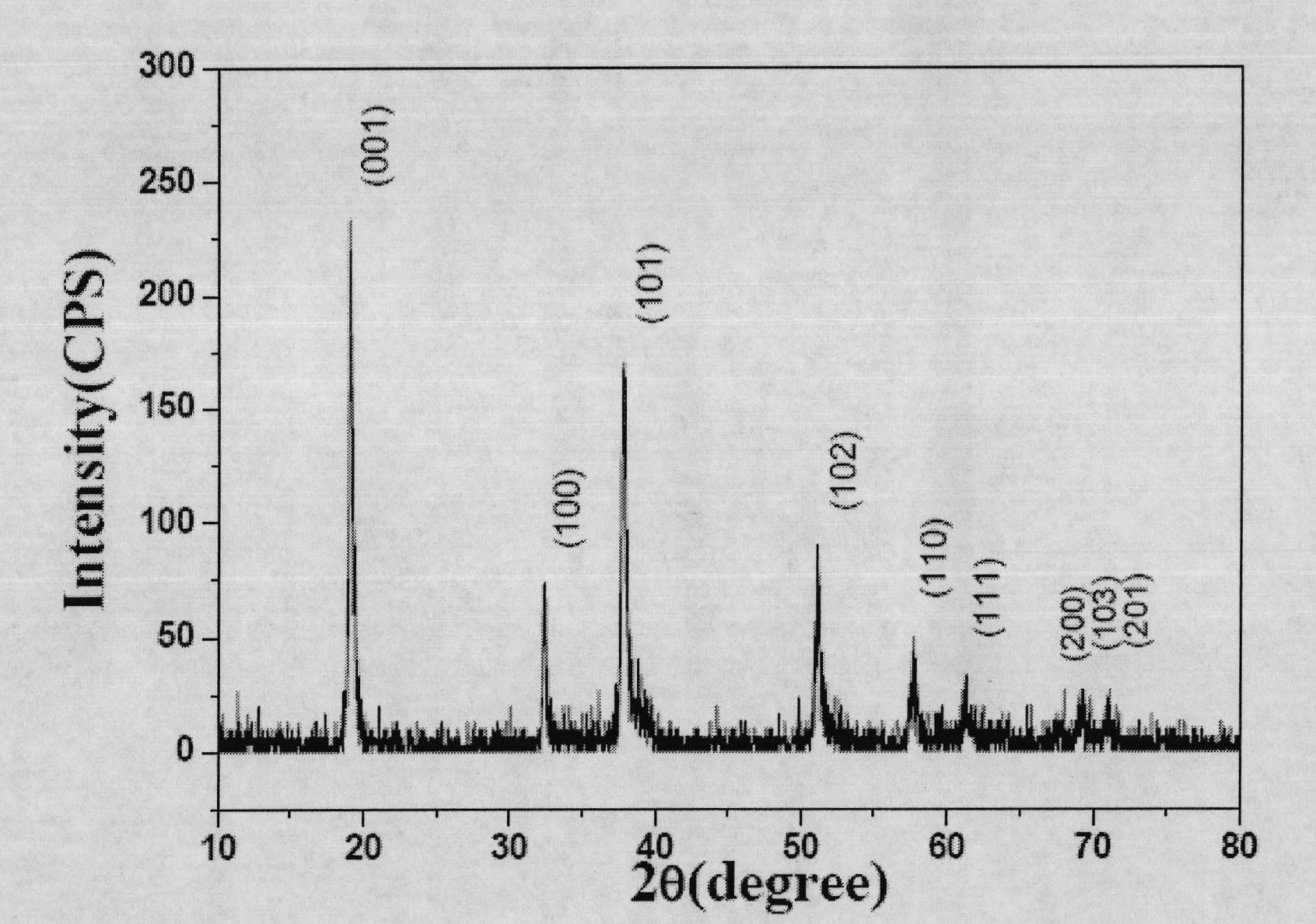

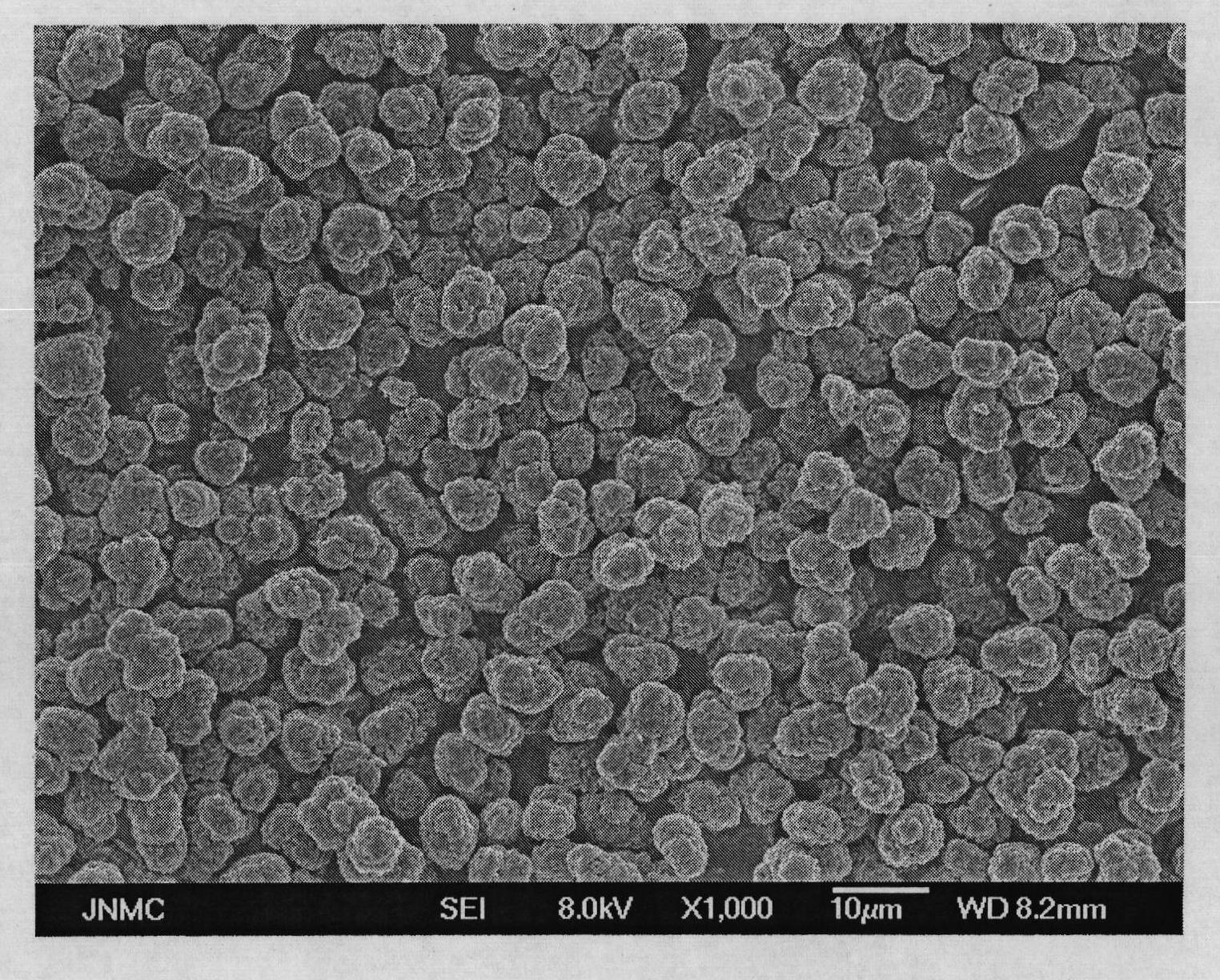

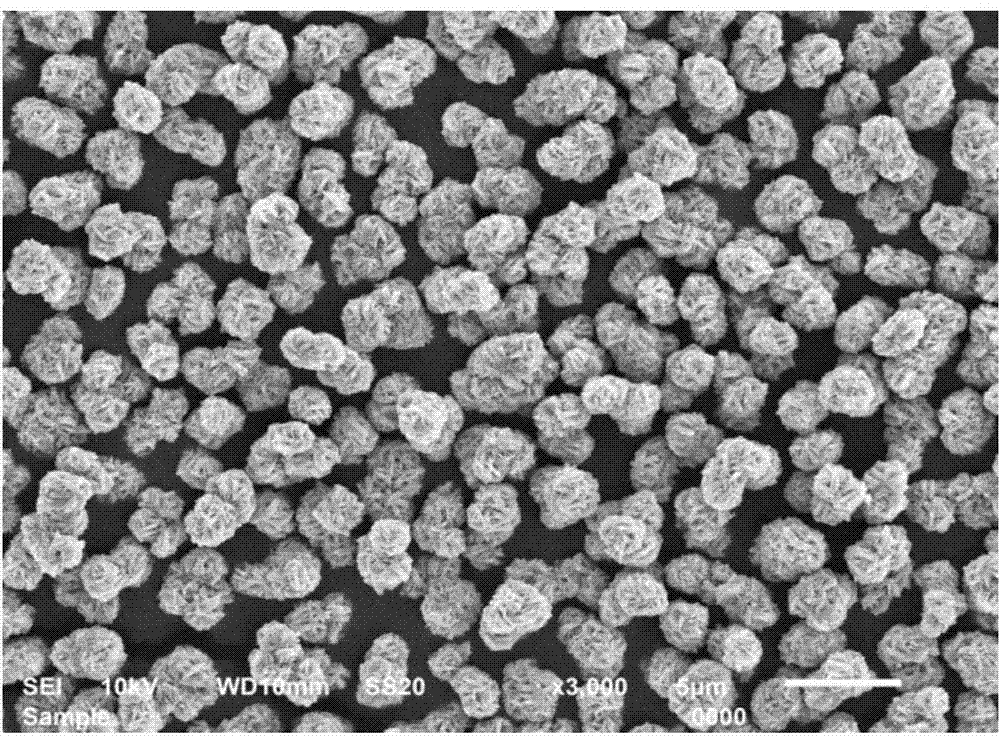

High-density small-particle-size nickel-cobalt-manganese hydroxide and preparing method thereof

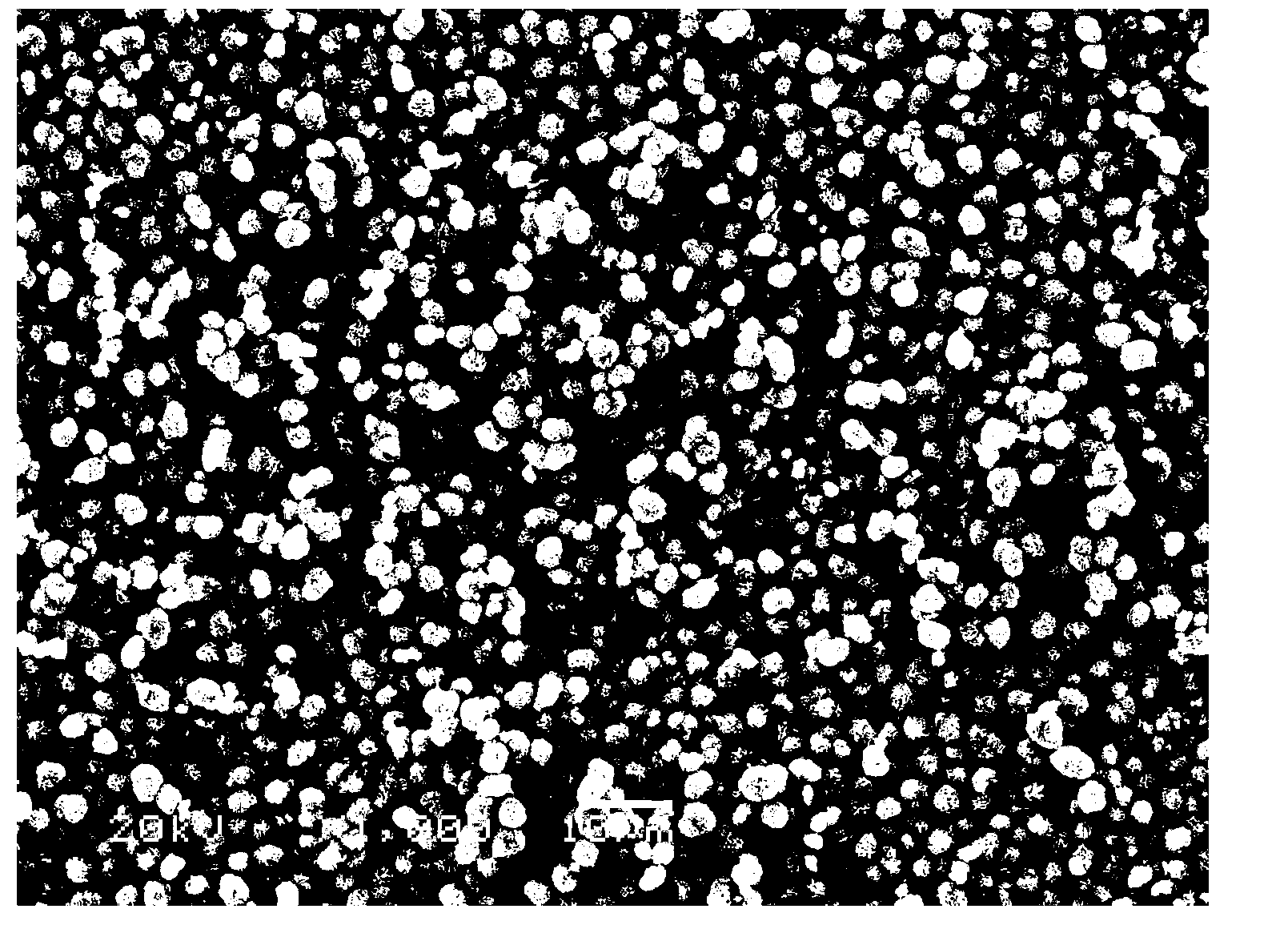

The invention relates to a high-density small-particle-size nickel-cobalt-manganese hydroxide and a preparing method thereof. The nickel-cobalt-manganese hydroxide and the preparing method thereof are characterized in that: the general chemical formula of the nickel-cobalt-manganese hydroxide is NixCoyMnz(OH)2, wherein the sum of the x, the y and the z is 1, the x is not more than 0.8 and not less than 0.3, the y is not more than 0.4 and not less than 0.1, and the z is not more than 0.4 and not less than 0.1. The nickel-cobalt-manganese hydroxide is provided, so that problems of small-particle-size nickel-cobalt-manganese hydroxides prepared by methods at present, namely nonuniform element distribution, poor particle appearance, loose surfaces, difficult particle size control, nonuniformity, low tap density, and the like are overcome. A complexing control crystallization coprecipitation method is adopted. By a special technical process of producing nucleuses, growing, and subjecting particles to continuous frictional collision under a continuously increased solid liquid ratio, an aqueous solution of a nickel-cobalt-manganese soluble salt and an aqueous sodium hydroxide solution are subjected to coprecipitation under complexing of ammonia to obtain the small-particle-size nickel-cobalt-manganese hydroxide having characteristics of uniform element distribution, good degree of sphericity, uniform particle size distribution and high tap density.

Owner:宁夏中色金辉新能源有限公司

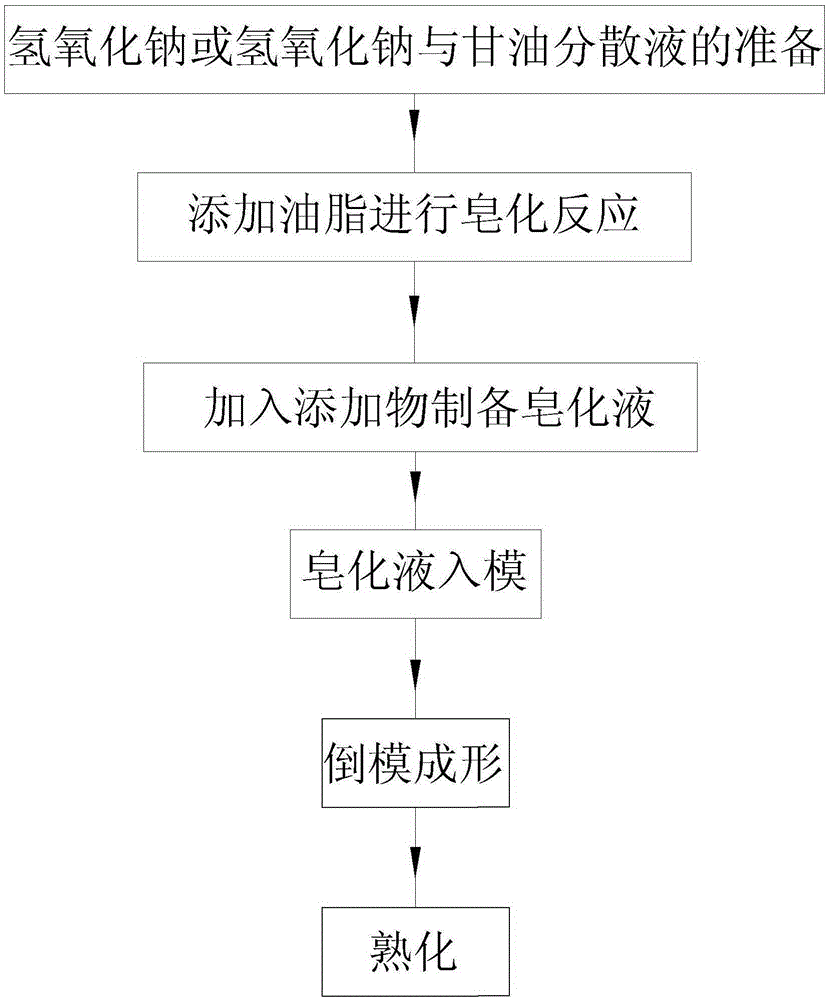

Preparation method of cold-formed soap

ActiveCN105400617AAvoid contact reactionsGive full play to effective functionsShaping soapAlkali/ammonium soap compositionsCold formedReaction rate

The invention relates to a preparation method of a cold-formed soap. The method has simple process steps, and substitutes traditional aqueous solution of sodium hydroxide with sodium hydroxide or a dispersion of sodium hydroxide and glycerol; sodium hydroxide is completely soluble in glycerol but disperses in glycerol, so as to avoid fast reaction after mixing of sodium hydroxide solution with oil too, reduce the initial reaction rate of saponification, and effectively control saponification reaction rate; along with the saponification reaction, the reaction product of glycerol continuously increases to help more fully dispersion of sodium hydroxide, accelerate the reaction rate of sodium hydroxide and the remaining oil. Since the method employs an anhydrous formula, water evaporation process is not needed after soap formation by liquid soap, and the production cycle is significantly shortened; and the nutrition substances are added in solid form powder to effectively prevent the contact reaction of non-alkali-resistant nutrients and alkali hydroxide molecules, so as to retain the active nutrient ingredients in the soap and give full play to the role of skin care of the nutrients.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

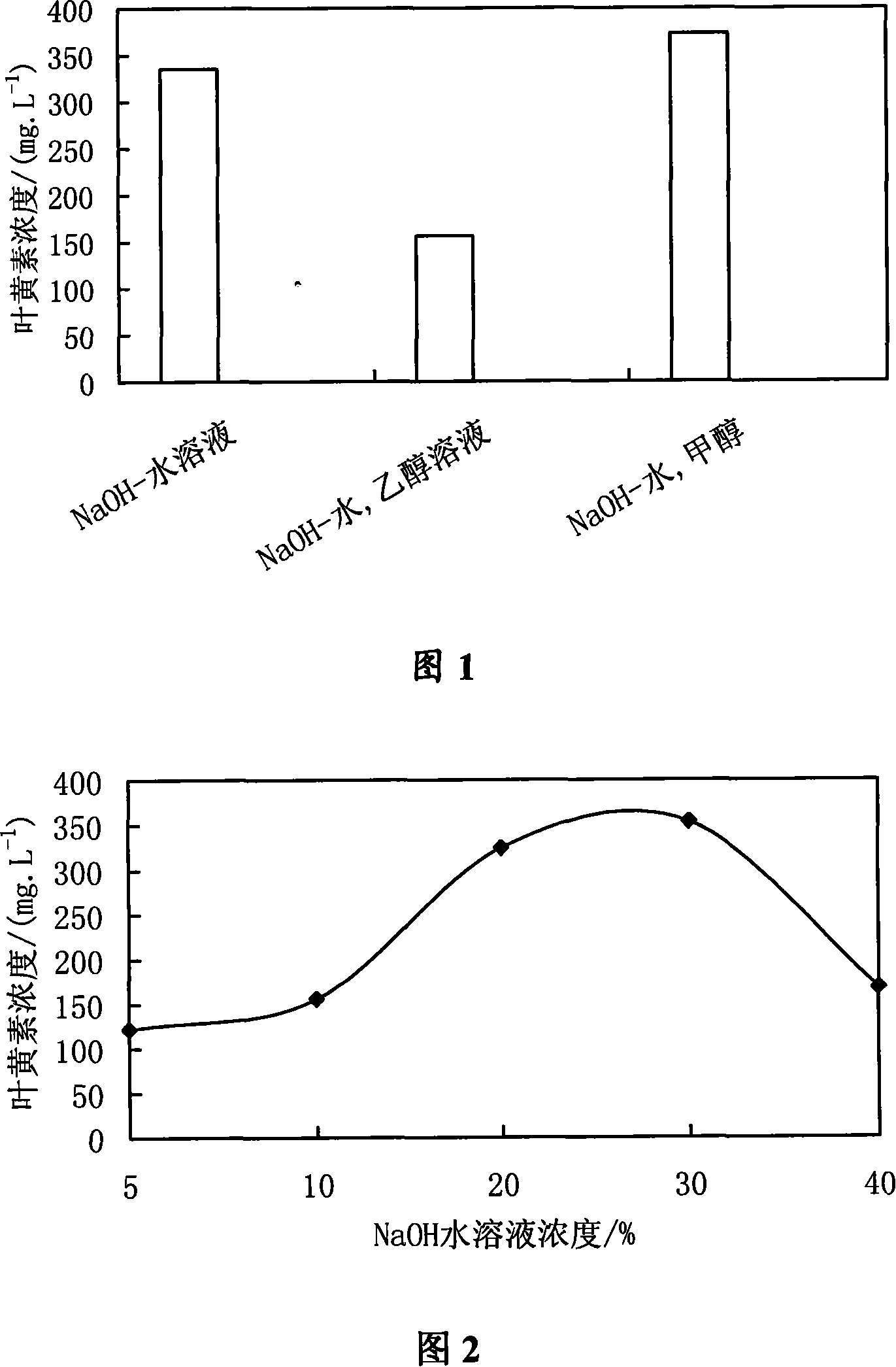

Method for extracting and purifying xanthophyl from chlorella algae powder

InactiveCN101130513AEfficient extractionOrganic chemistryAlgae medical ingredientsLuteinAqueous sodium hydroxide

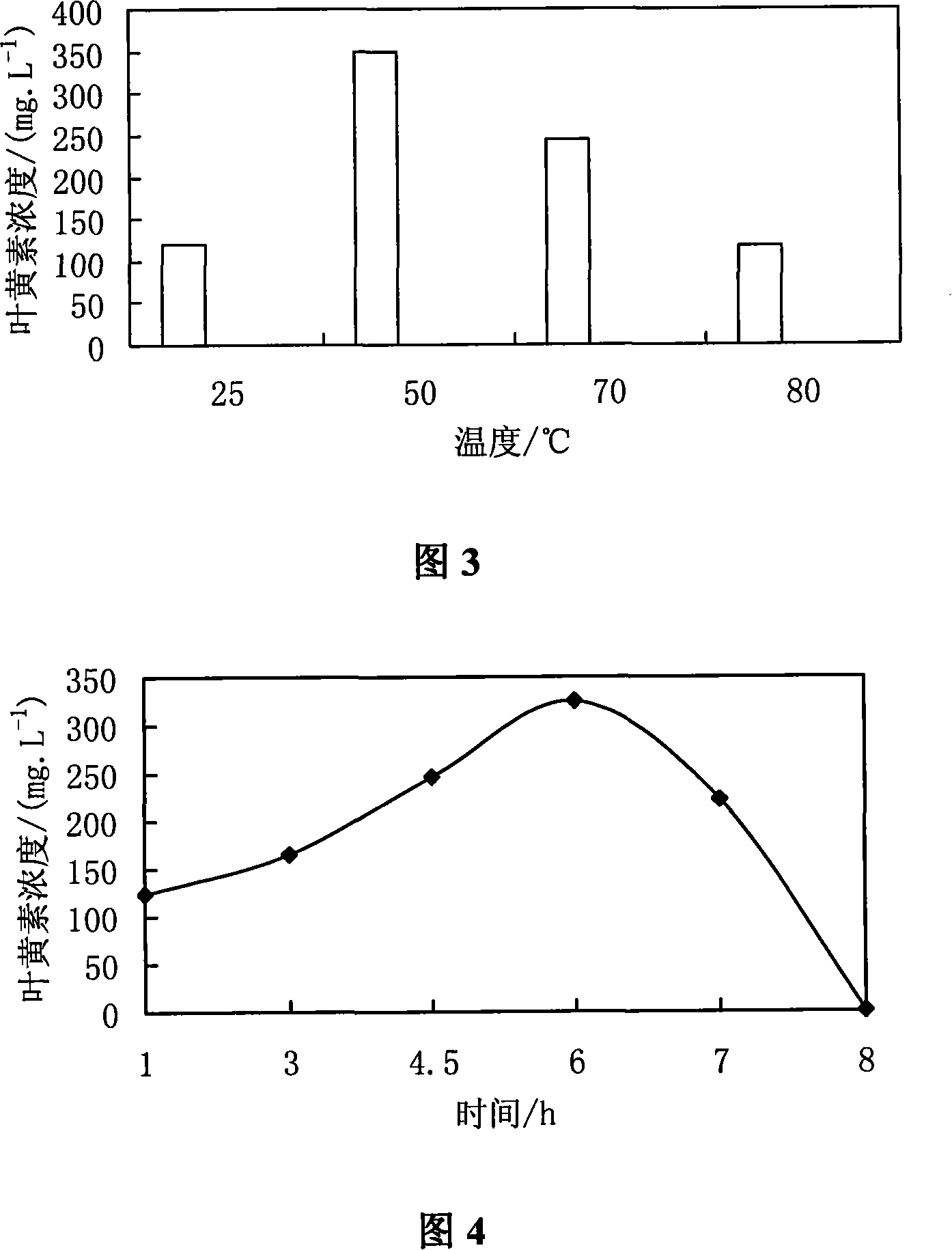

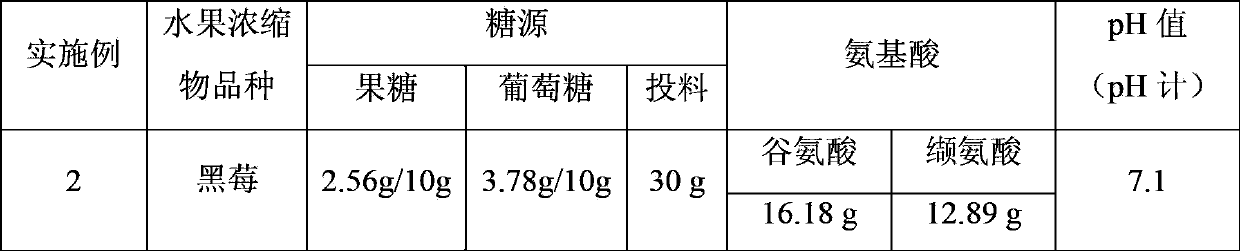

The invention discloses an extracting and purifying method of lutein from pellet algae in the biological technical domain, which comprises the following steps: extracting lutein and ester through composite agent; using 5-20% sodium hydroxide to saponify; rotating; evaporating; washing; crystallizing; obtaining high-purity lutein crystal; weighing 0. 2-2g algae powder to place in the 50-500ml centrifuge tube; adding 8. 0-80. 0ml composite liquid solvent to extract under 10-40 deg. c for 0. 5-2h; adding 10-100ml 5%-30% sodium hydroxide solution into the test tube with hybrid extractant; saponifying at 30-70 deg. c for 3-8h; centrifuging under low temperature for 5-10 min; extracting the product from organic phase. The invention ensures the optimum saponifying technique, which is extracted from pellet algae cell effectively.

Owner:UNIV OF SCI & TECH BEIJING +1

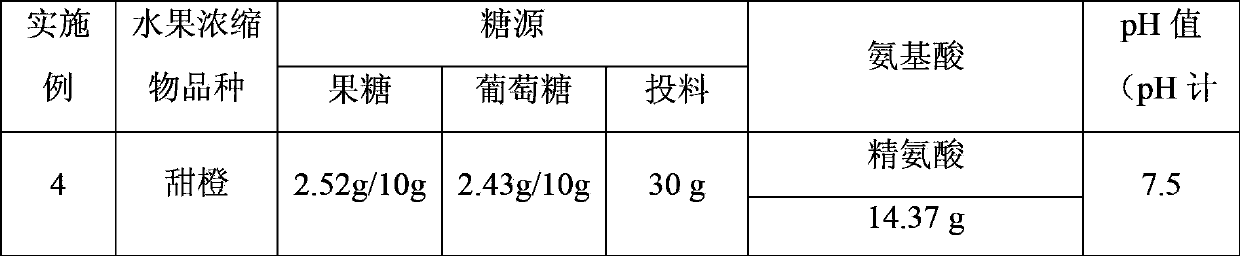

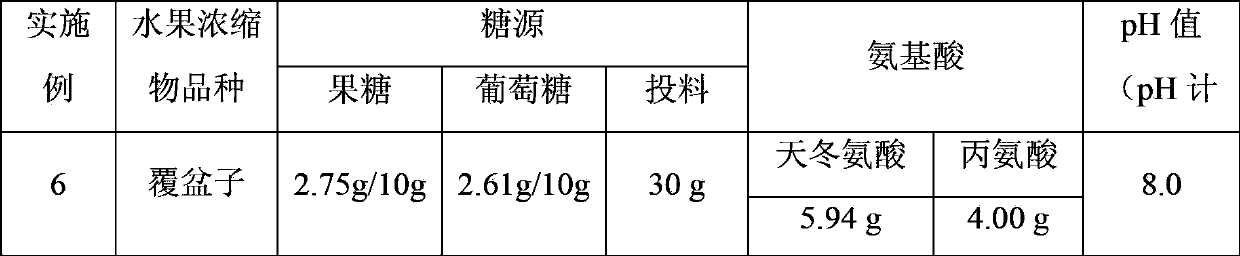

Preparation method of fruit concentrate Maillard reaction product, and application of product in tobacco perfuming

ActiveCN103865645AHigh fullnessMild reaction conditionsTobacco preparationEssential-oils/perfumesMaillard reactionFlavor

The invention relates to a preparation method of a fruit concentrate Maillard reaction product, and an application of the product in tobacco perfuming. The preparation method comprises the following steps: mixing a fruit concentrate or the fruit concentrate containing reducing monosaccharide with amino acids and a reaction solvent, using an aqueous solution of sodium hydroxide to adjust the pH value of a reaction system to 6-9, heating to 80-100DEG C within 20-90min, continuously reacting for 0.5-1.5h, and cooling to obtain the corresponding reaction product. The Maillard reaction product generated after reacting the fruit concentrate with the amino acids is rich in the natural perfume of fruits, can be naturally coordinates with the original perfume of tobacco, and is safe and reliable. The above reactive perfume prepared in the invention is used to process cut tobacco under certain conditions, and is added to tobacco according to different proportions, so the smoking quality of the the prepared cut tobacco is substantially improved. The fruit concentrate Maillard reaction product can improve the fullness and the softness of the smoke of cigarette, improves the smoking smell comfortableness, and highlights the delicate perfume style of the cigarette.

Owner:APPLE FLAVOR & FRAGRANCE GRP +1

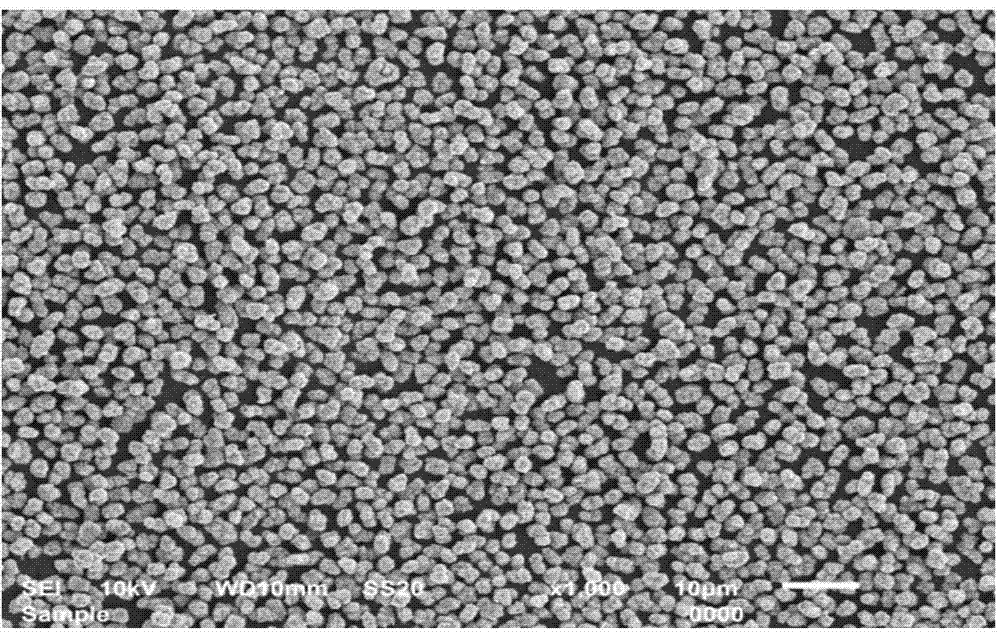

Method for preparing small-size nickel-cobalt lithium manganate precursor

ActiveCN103253717ARealize industrial productionConcentrated particle size distributionManganese oxides/hydroxidesNickel oxides/hydroxidesManganateManganese

The invention relates to a method for preparing a small-size nickel-cobalt lithium manganate precursor. The method is characterized by comprising the following steps of: (1) preparing a solution from soluble salts of nickel, cobalt and manganese as materials, adopting a sodium hydroxide water solution as a precipitator, and adopting ammonia water or ammonium salt as a complexing agent; (2) merging and adding the obtained three solutions into a reaction kettle which contains bottom water and includes stirring and temperature control devices; leading in nitrogen to protect in a reaction process, and continuously carrying out reaction; and (3) stirring and aging for 4-6 hours after a temporary kettle is full, putting the aged material into washing and press filtering equipment to wash; removing moisture in a filter pressing manner; and then mixing and sieving by a 200mesh screen after baking and crushing. By adopting the method disclosed by the invention, industrialized production of the small-size nickel-cobalt lithium manganate precursor can be conveniently achieved; and the method is stable to control the particle size, and convenient to achieve requirements of the materials and equipment.

Owner:宁夏中色金辉新能源有限公司

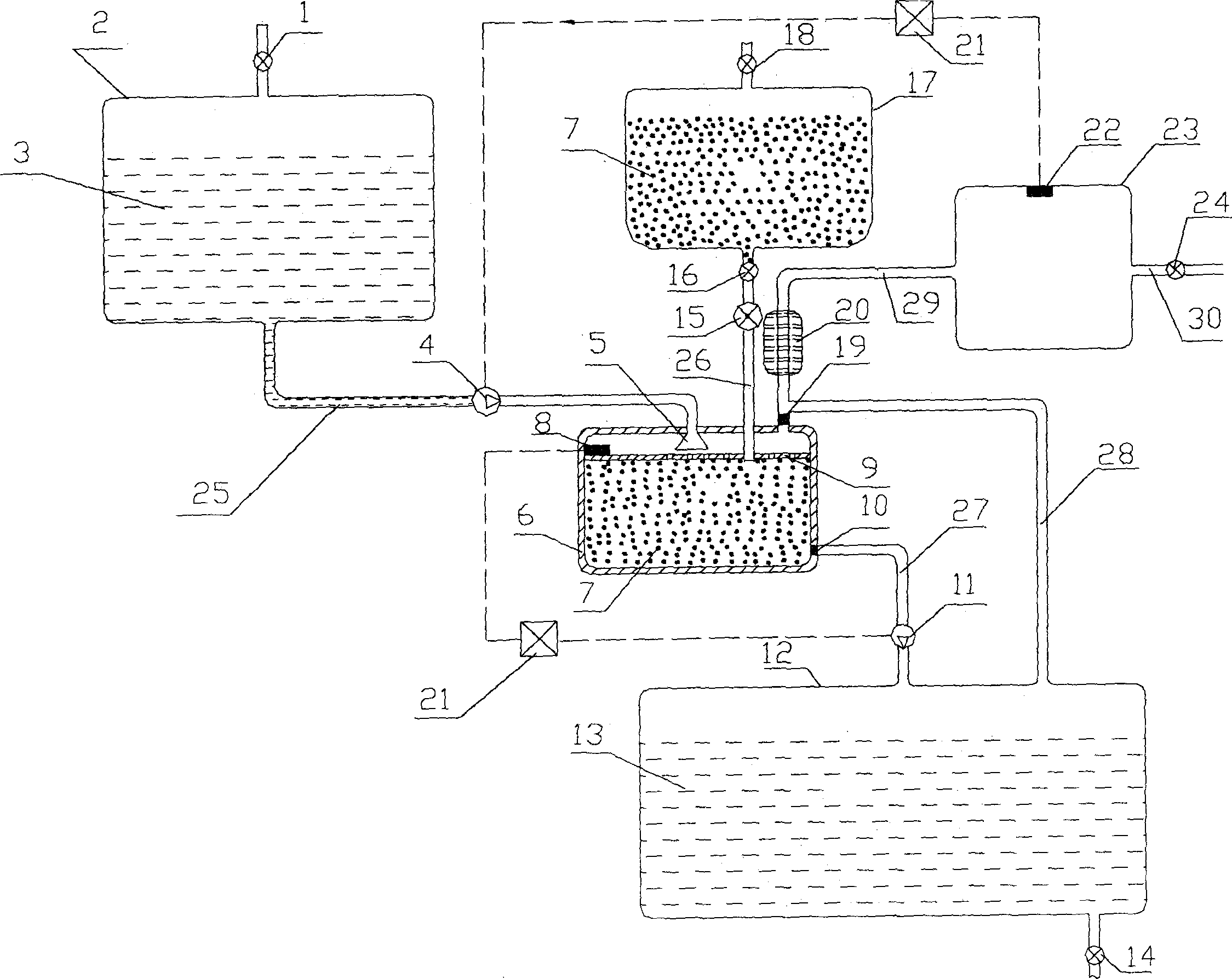

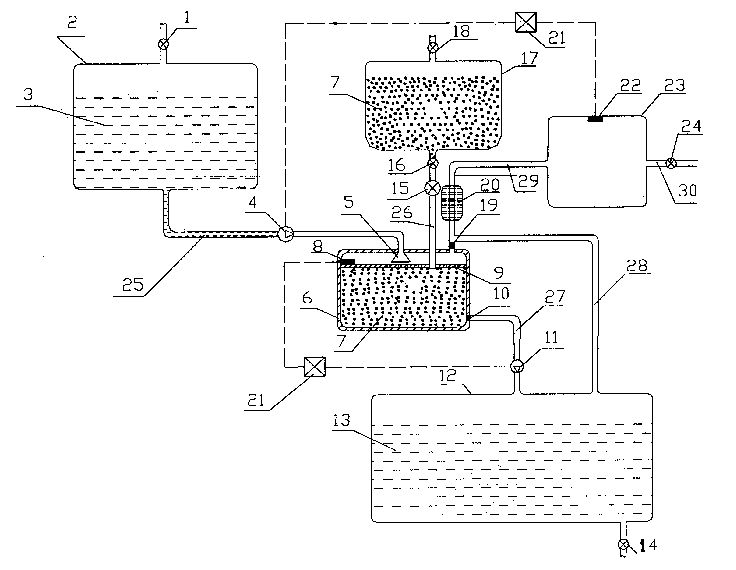

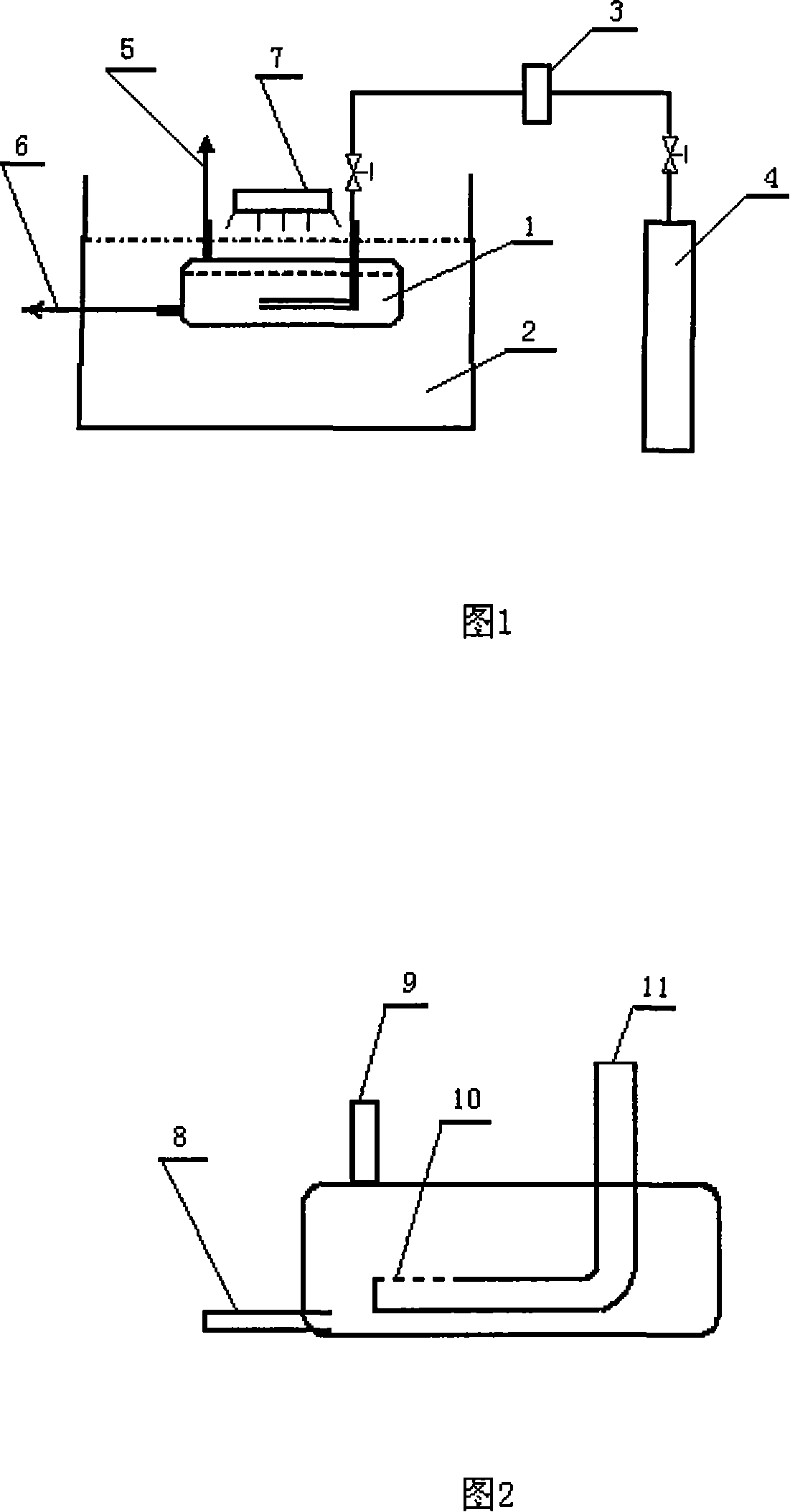

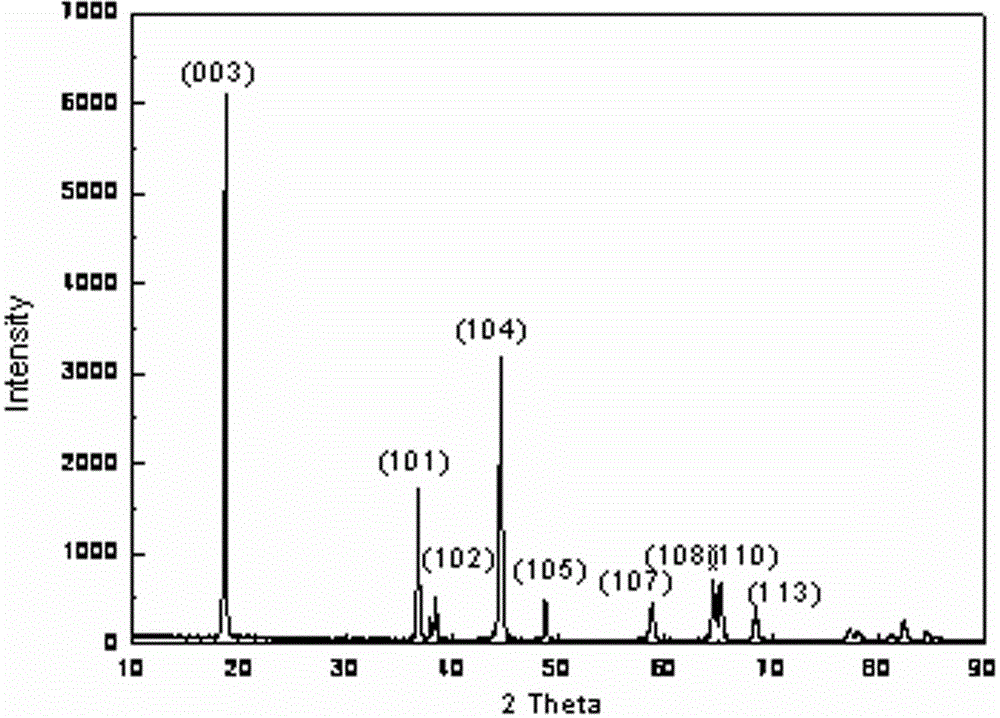

Hydrogen preparing method and device

InactiveCN1384044AHigh hydrogen storage capacityWill not cause poisoningHydrogen productionManufacturing technologyAqueous sodium hydroxide

The present ivnention relates to hydrogen preparation. Hydrogen is prepared through the reaction of metal aluminum powder with average size of 10 nm to 10 nm with water solution of sodium hydroxide of concentration 0.1-30 % in a reactor. The hydrogen preparing apparatus includes liquid container, reactor, aluminum powder container, hydrogen storing tank and liquid exhaust unit connected via pipeline and valve. The present invention has low material cost, easily controlled reaction speed, stable hydrogen output, no environmental pollution and other advantages and is especially suitable for hydrogen fuel battery.

Owner:天津海蓝德能源技术发展有限公司

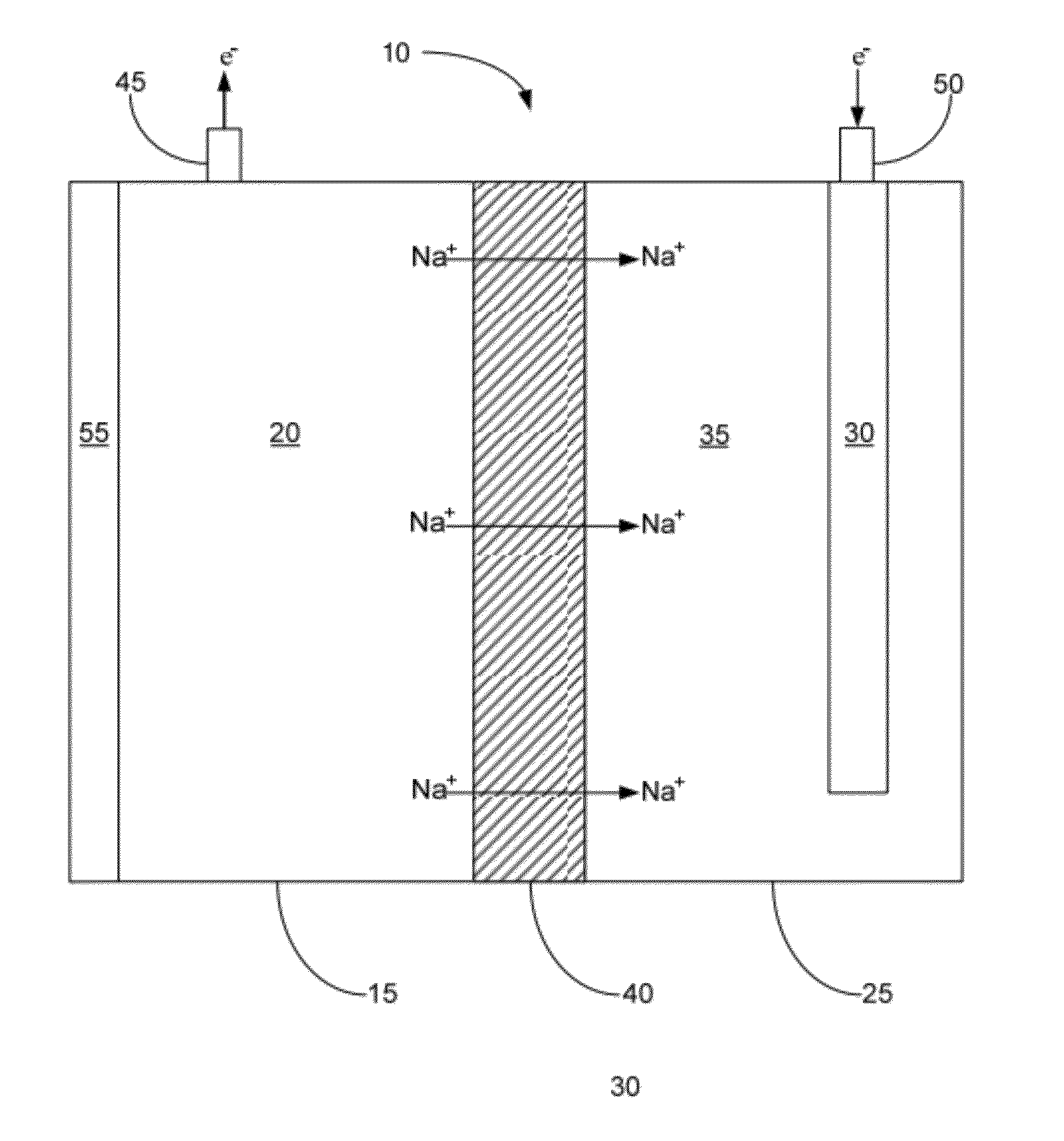

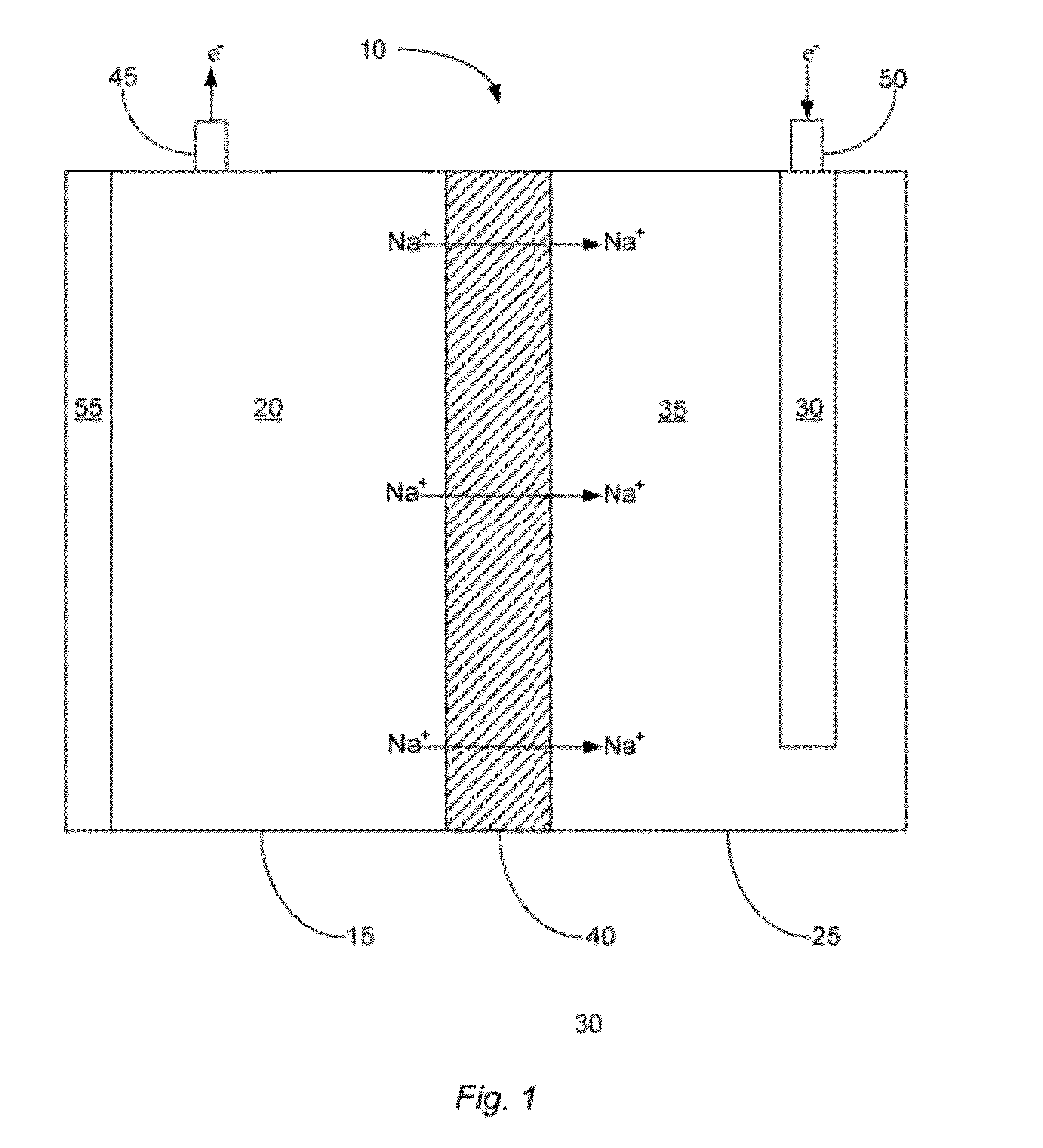

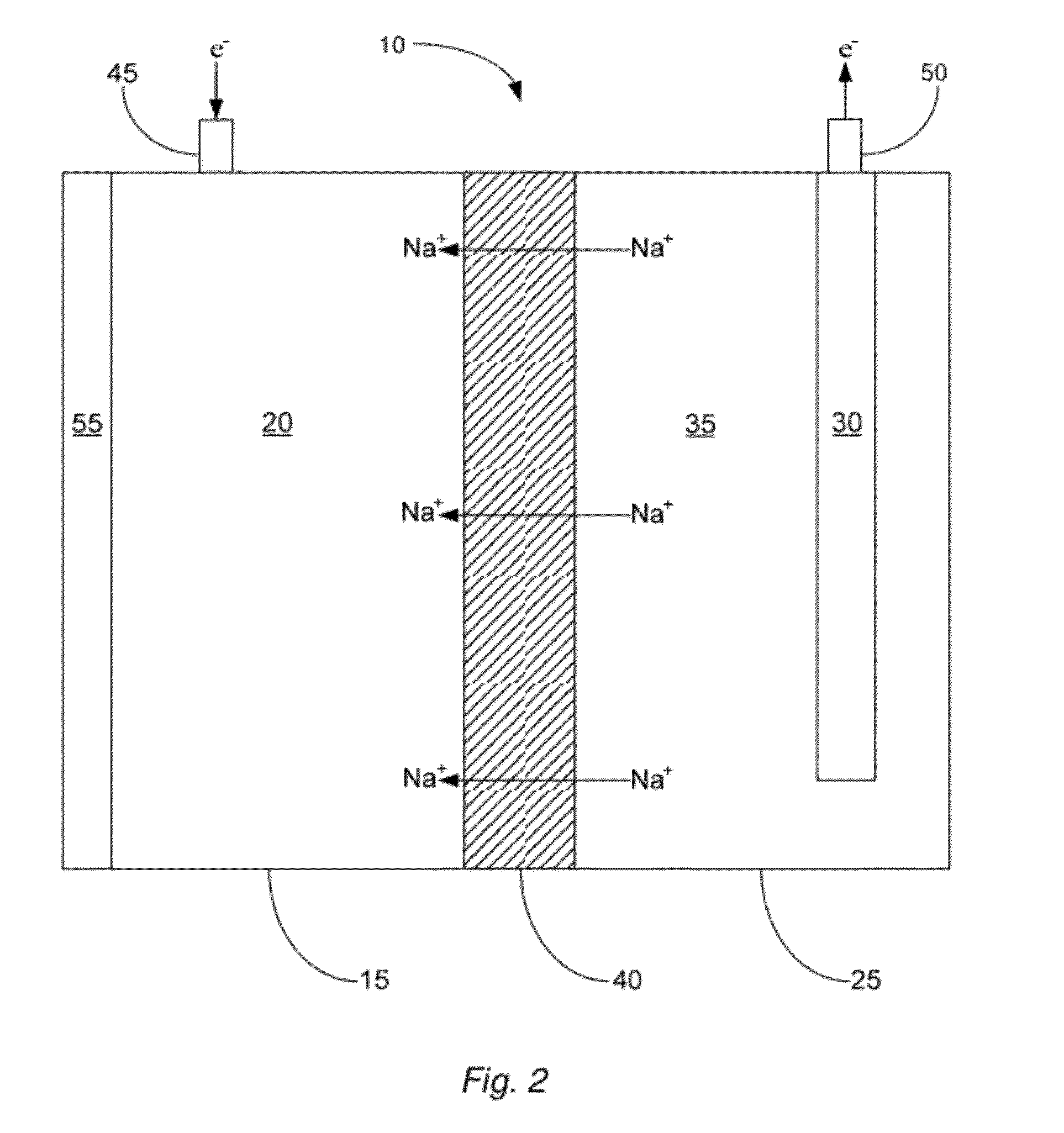

Low temperature molten sodium secondary cell with sodium ion conductive electrolyte membrane

ActiveUS20120219833A1Final product manufactureConductive materialAqueous sodium hydroxideOperating temperature

The present invention provides a molten sodium secondary cell. In some cases, the secondary cell includes a sodium metal negative electrode, a positive electrode compartment that includes a positive electrode disposed in a liquid positive electrode solution, and a sodium ion conductive electrolyte membrane that separates the negative electrode from the positive electrode solution. In such cases, the electrolyte membrane can comprise any suitable material, including, without limitation, a NaSICON-type membrane. Furthermore, in such cases, the liquid positive electrode solution can comprise any suitable positive electrode solution, including, but not limited to, an aqueous sodium hydroxide solution. Generally, when the cell functions, the sodium negative electrode is molten and in contact with the electrolyte membrane. Additionally, the cell is functional at an operating temperature between about 100° C. and about 170° C. Indeed, in some instances, the molten sodium secondary cell is functional between about 110° C. and about 130° C.

Owner:FIELD UPGRADING USA INC

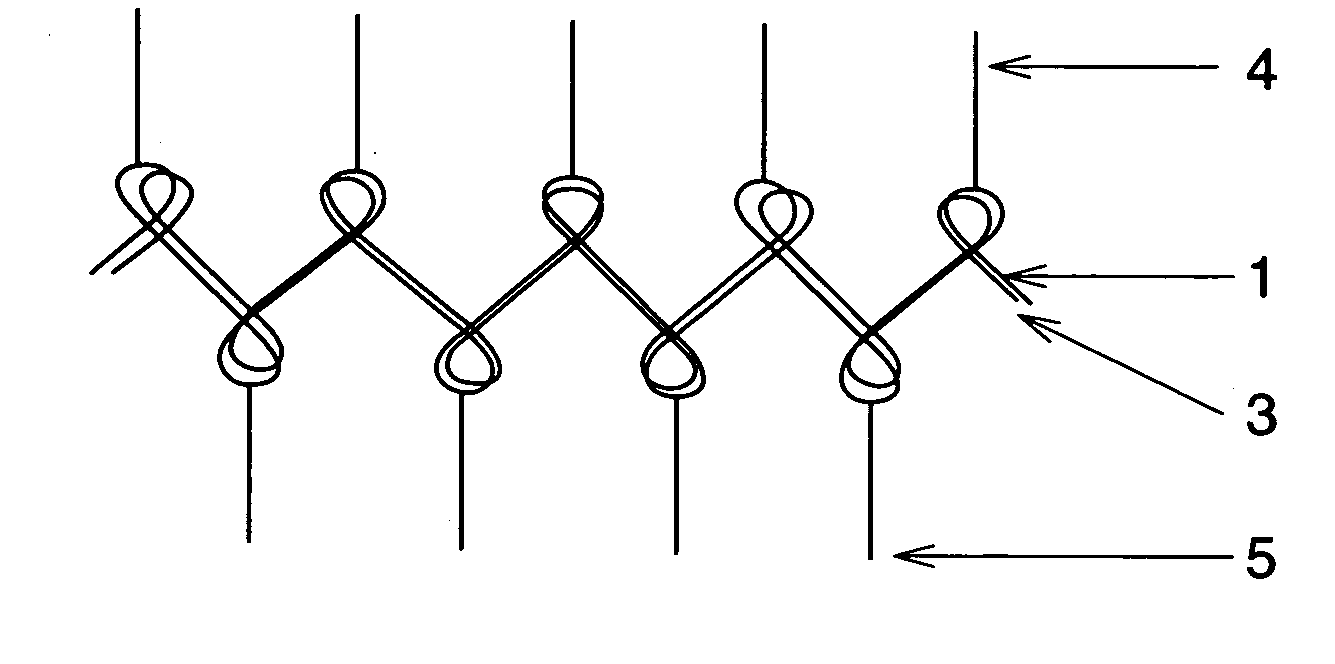

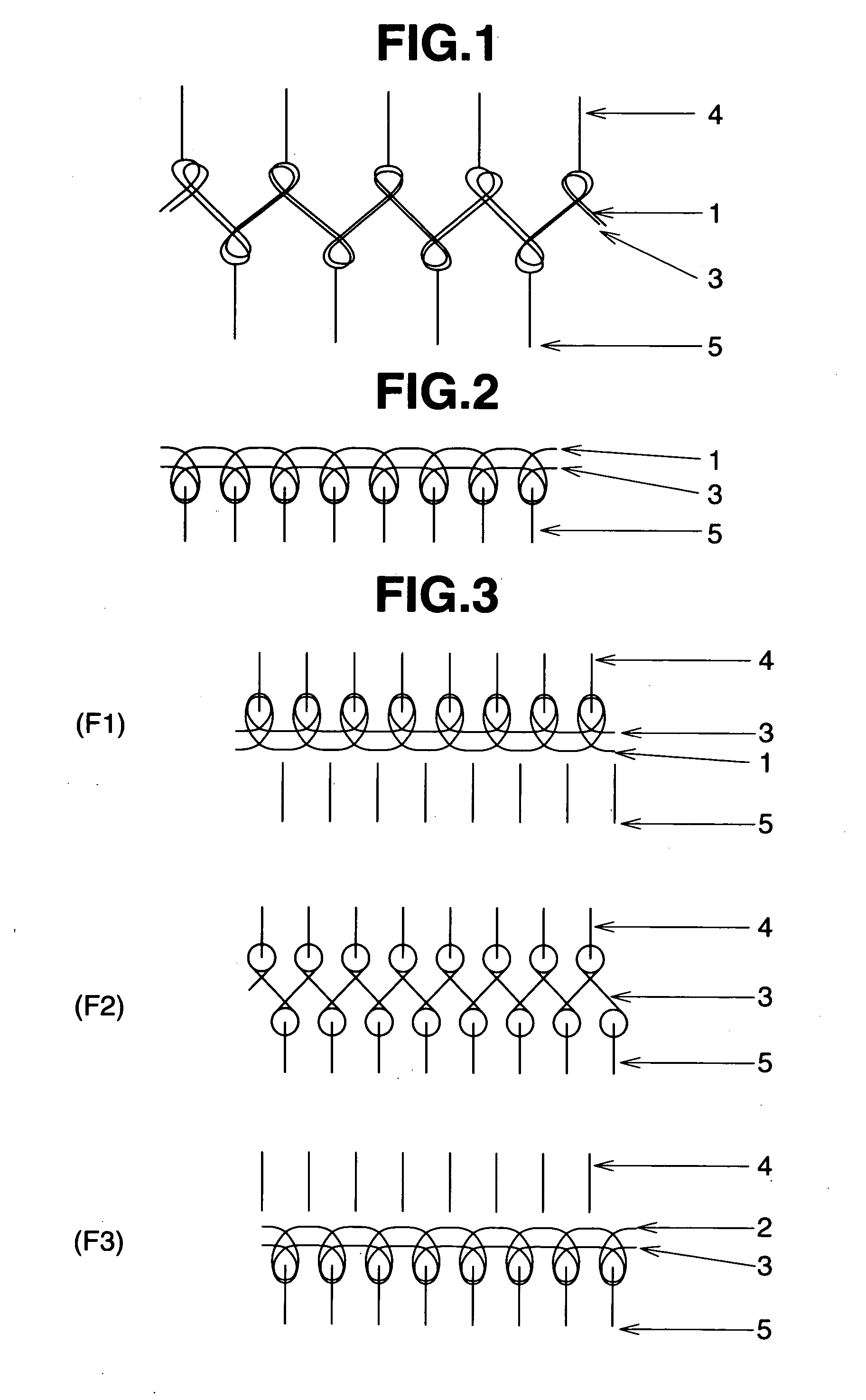

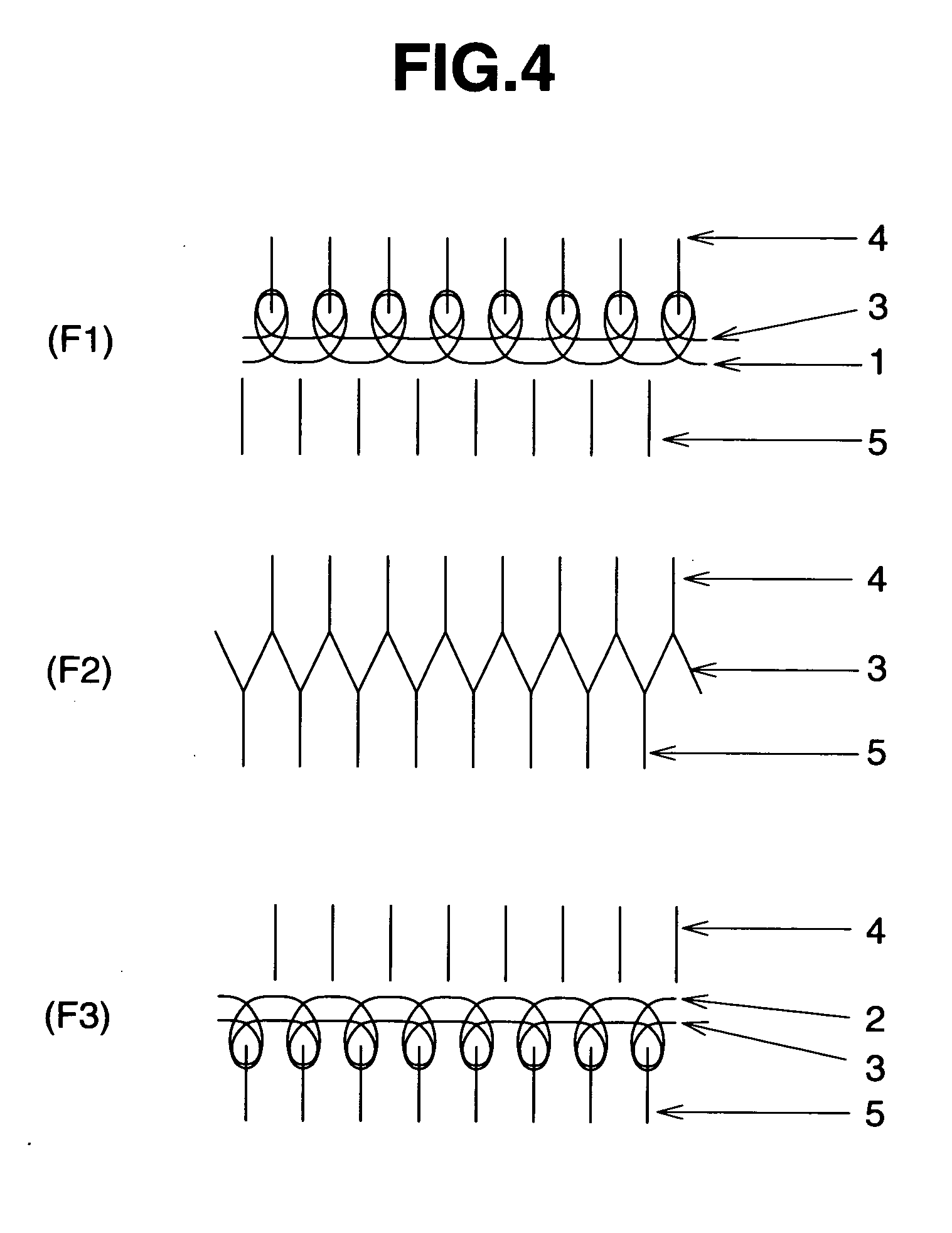

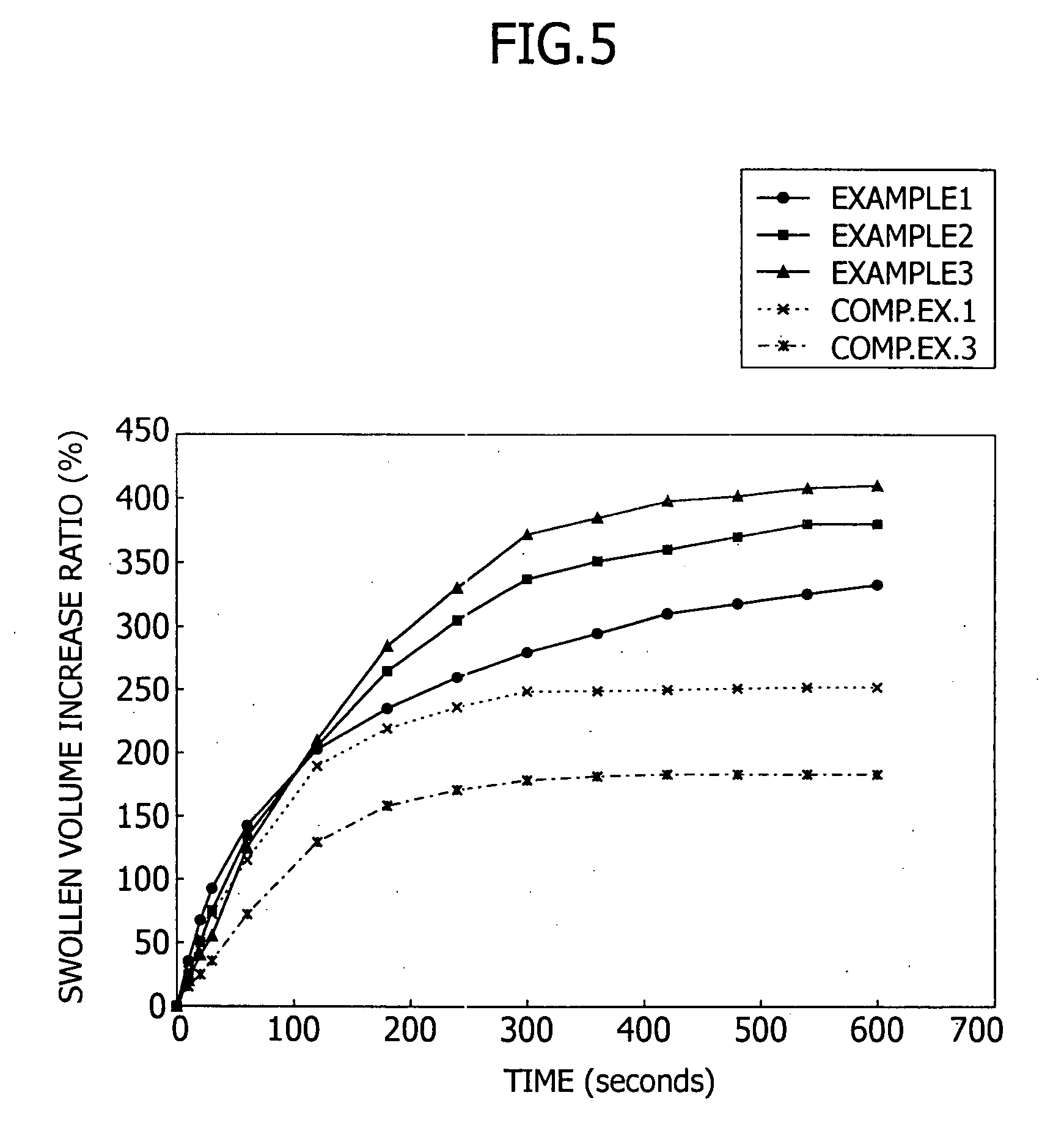

Weft Knitted Fabric Including Polyurethane Elastomer Fiber and Process for Producing the Same

ActiveUS20080032580A1Good extensibilityPromote recoveryOrnamental textile articlesWarp knittingYarnPolyurethane elastomer

A polyurethane elastomeric filament-containing weft knit fabric is obtained by plating a bare yarn of highly fusible, alkali-resistant polyurethane elastomeric filament having at least 50% retention of tenacity following dry heat treatment under 100% extension at 150° C. for 45 seconds, a melting point of 180° C. or below, and at least 60% retention of tenacity following treatment in a 2 g / L aqueous sodium hydroxide solution under 100% extension at 100° C. for 60 minutes at every loop of a weft knit fabric having a 1×1 rib. knit structure or a center yarn-containing reversible knit structure composed of at least one type of non-elastomeric yarn, then heat setting the plated structure so as to thermally fuse the highly fusible, alkali-resistant polyurethane elastomeric filaments to each other or to the non-elastomeric yarns at crossover points therebetween.

Owner:NISSHINBO TEXTILE INC +1

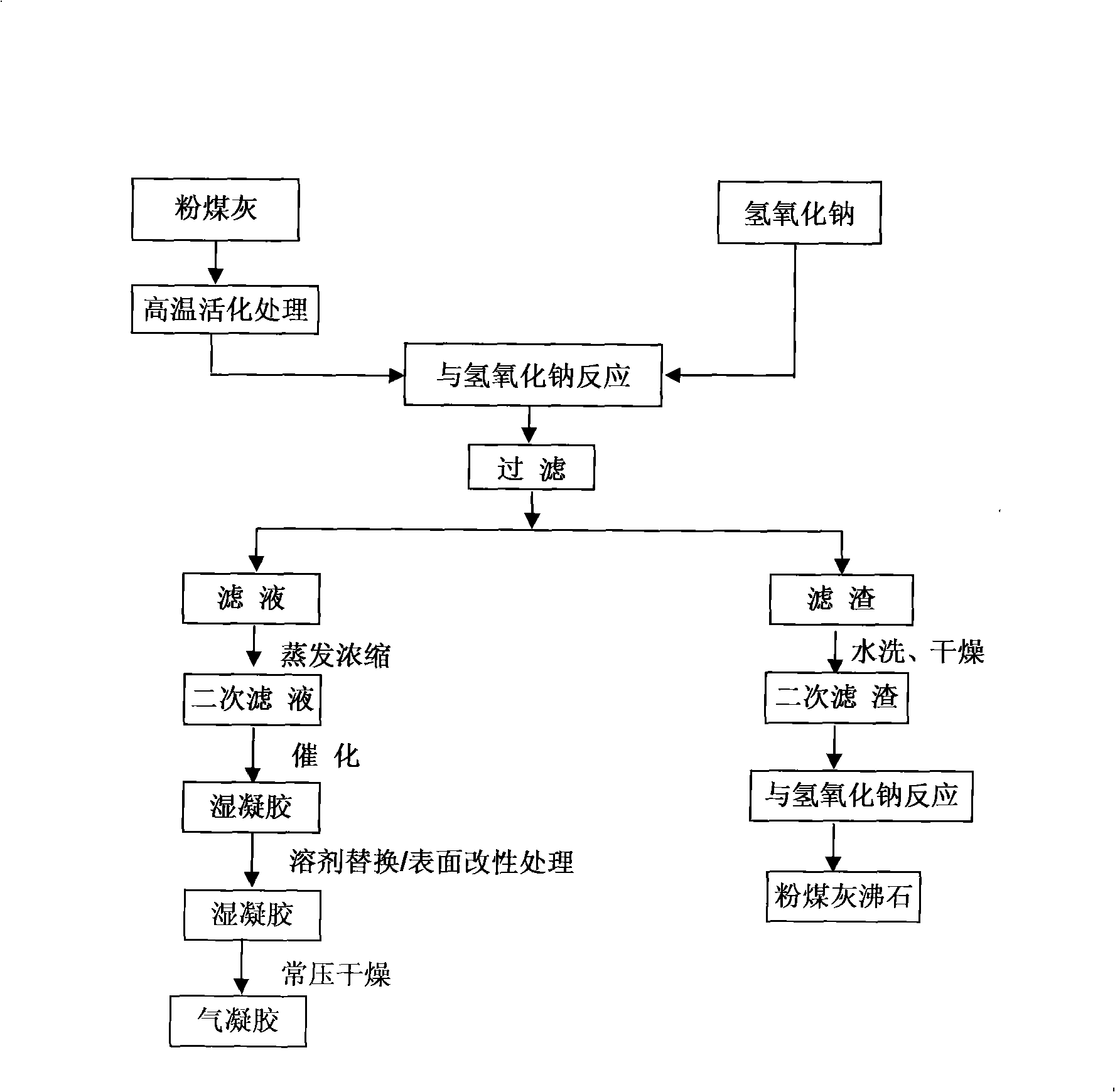

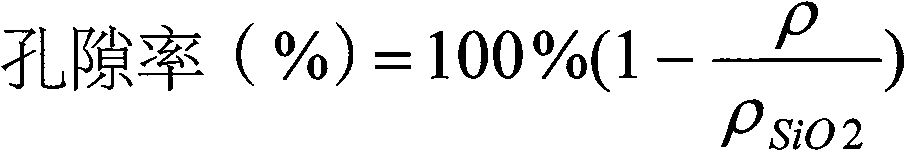

Method for simultaneously preparing SiO2 aerogel and zeolite by utilizing fly ash

InactiveCN101538046AGood workmanshipHigh porositySilicaCrystalline aluminosilicate zeolitesResource utilizationSoluble glass

The invention relates to a method for simultaneously preparing SiO2 aerogel and zeolite by utilizing fly ash, belonging to the technical field of the high-efficiency resource utilization of solid wastes and chemical material preparation. The method is as follows: the fly ash is firstly processed by high-temperature activation and then carries out hydro-thermal synthesis reaction with a sodium hydroxide water solution, soluble glass is catalyzed by a sulphuric acid with certain concentration, or the solution carries out cation exchange resin and is then processed by base catalysis to obtain SiO2 gel; aquagel is processed by solvent exchange / surface modification by utilizing a mixed solution of alcohols / alkanes solvent and trimethylchlorosilane, and the SiO2 aerogel is obtained under the condition of normal pressure and dryness; the fly ash is reacted with NaOH and then filtered to obtain filter residue, and the filter residue is further reacted with the NaOH so as to synthesize fly ash zeolite. The invention is not only a new way of the high-efficiency recycling of the solid wastes, but also a new technical method of the low-cost preparation of the SiO2 aerogel and the zeolite.

Owner:DALIAN POLYTECHNIC UNIVERSITY

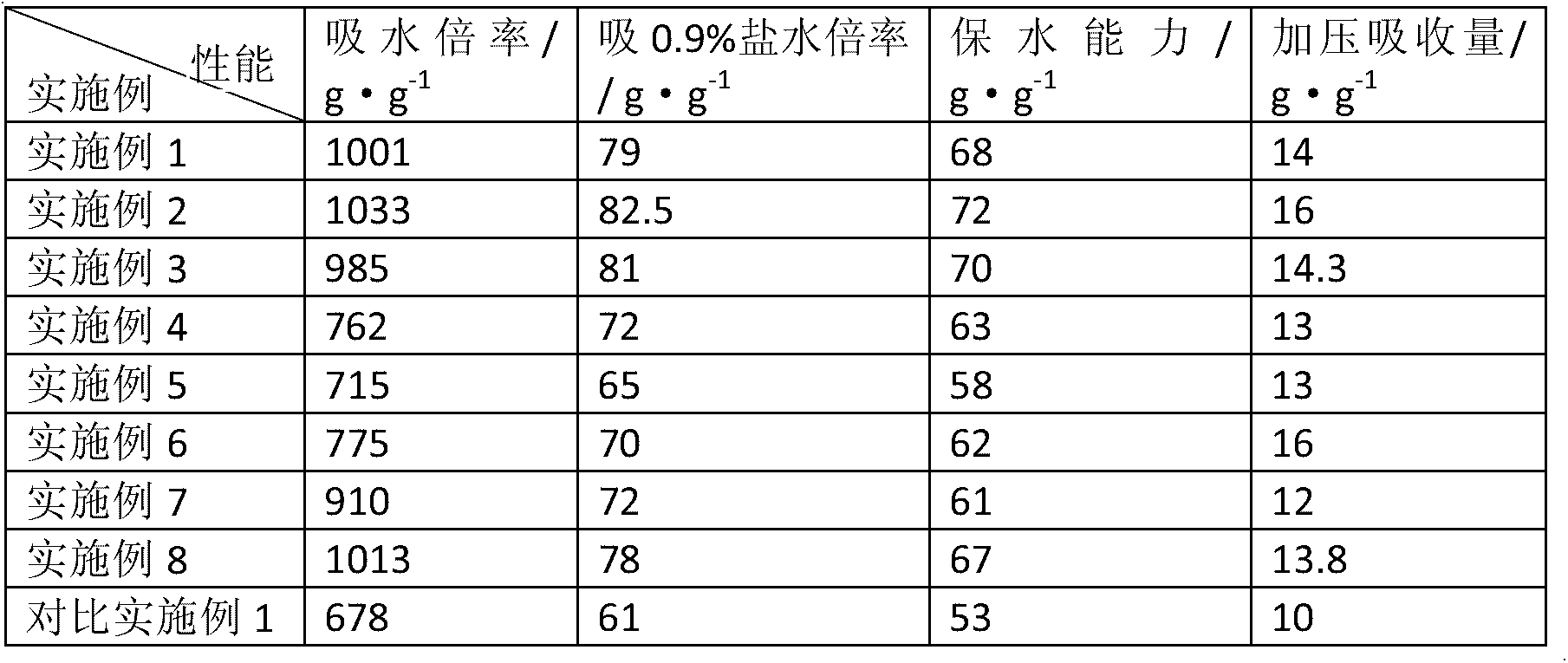

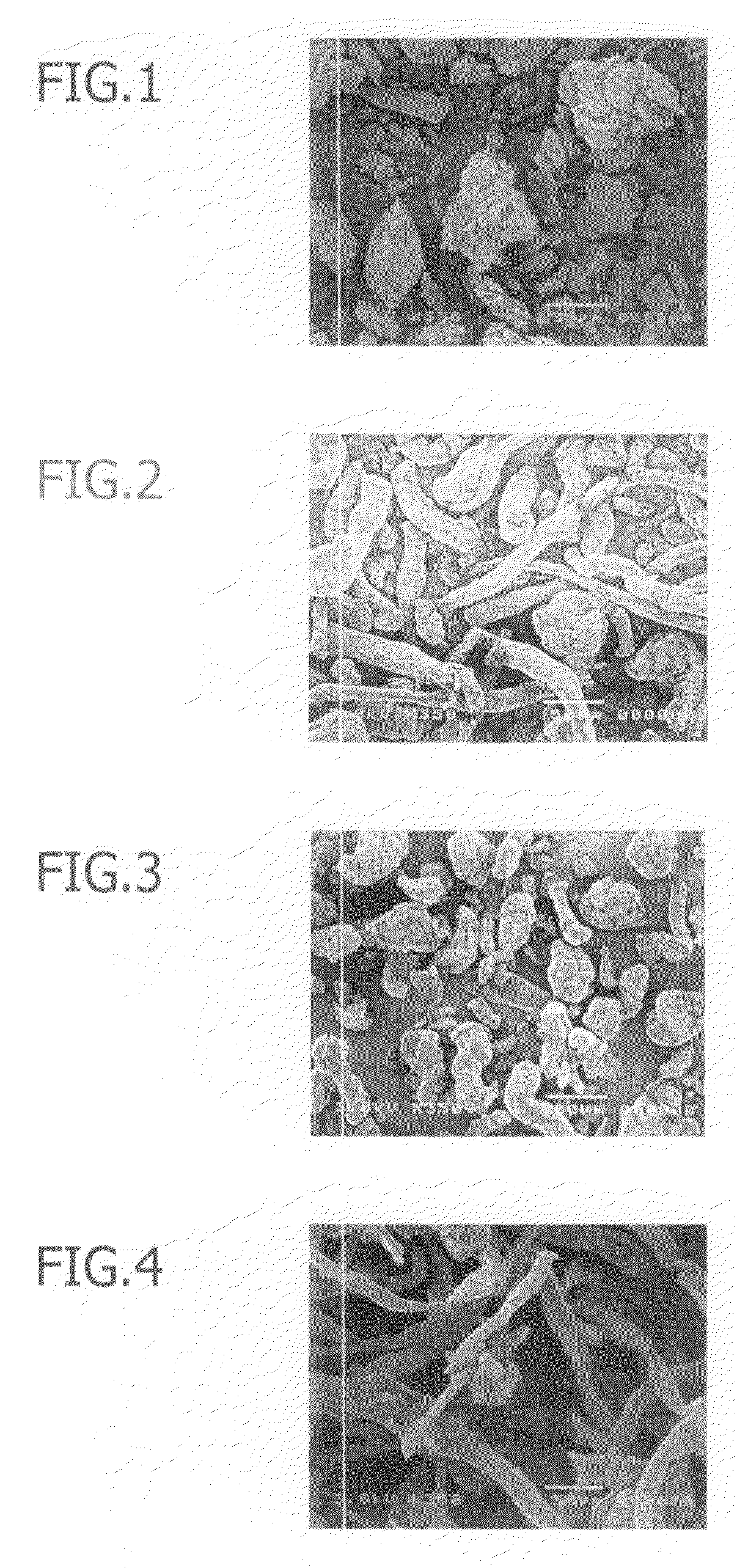

Method for preparing water absorption polymer with high liquid absorption speed, dispersity and dried degree

The invention discloses a preparation method of absorbent polymer which is characterized in high speed rate of liquid absorption, good dispersibility and high dry-touch degree. Acrylic acid is added into sodium hydroxide aqueous solution, which is uniformly mixed with acrylamide and then crosslinking agent, and foam stabilizer aqueous solution is added; while being aerated with nitrogen gas, the solution is ordinally added with polymerization initiator azodi (2-amidinopropane hydrochloride) aqueous solution, ammonium persulphate aqueous solution, sodium bisulfite aqueous solution and uniformly mixed; the aeration of nitrogen gas is stopped, and when the temperature of the solution is raised to 35 to 45 DEG C, the solution is added with foamer aqueous solution and uniformly mixed, so that porous gel is obtained; when the temperature is raised to 100 DEG C to 110 DEG C, the porous gel is put in the temperature environment of 80 to 90 DEG C for two the three hours; after being cooled down, the porous gel is taken out of a container, scissored into pieces, dried, crumbled and filtered, and grains are collected; crosslinking treatment agent is sprayed on the surface of grains, and after stirring and heating, the absorbent polymer is obtained. In three minutes, the volume of saline absorbed by the product prepared by the invention can reach 70 ml / gSAP.

Owner:段梦麟

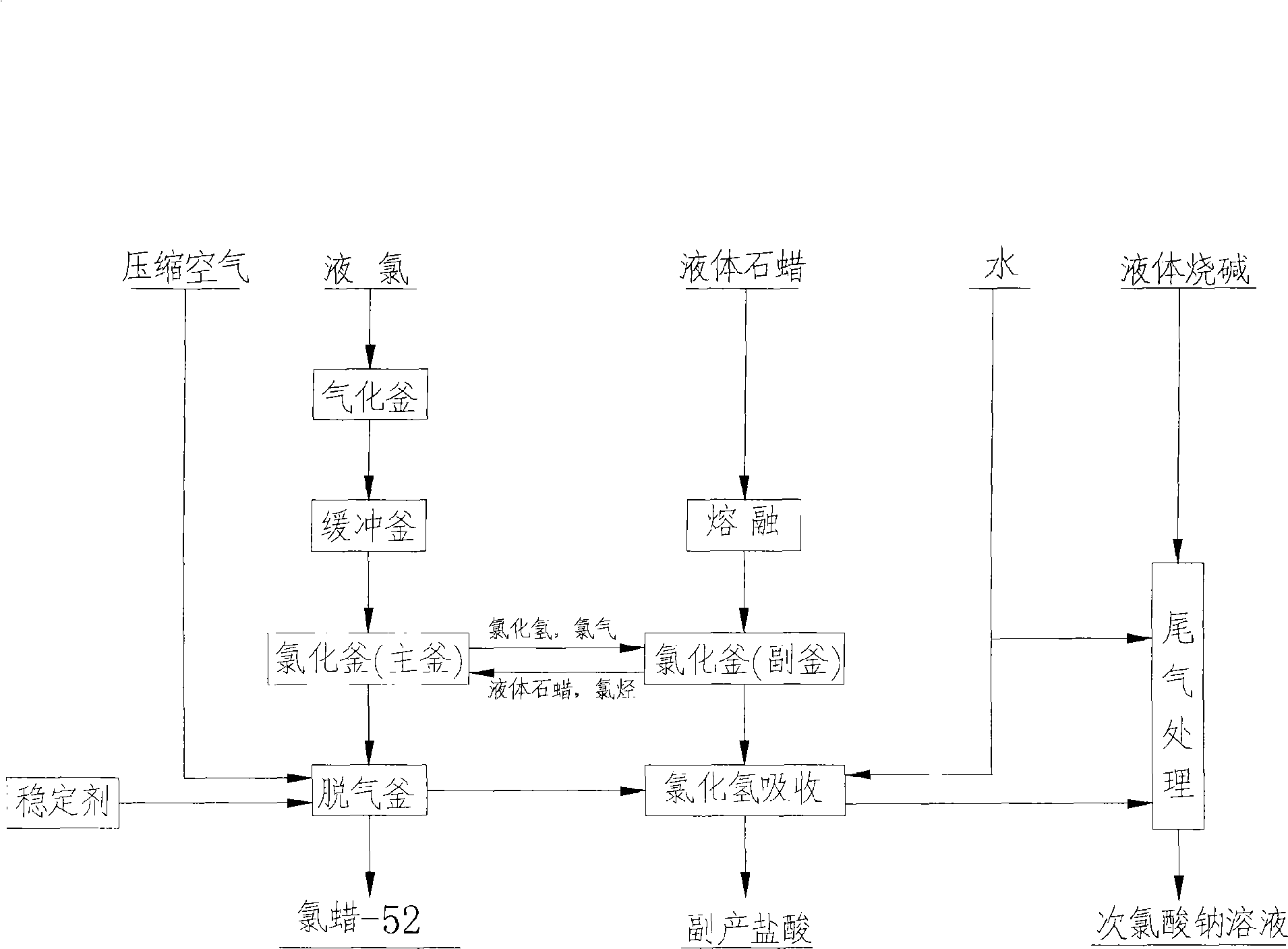

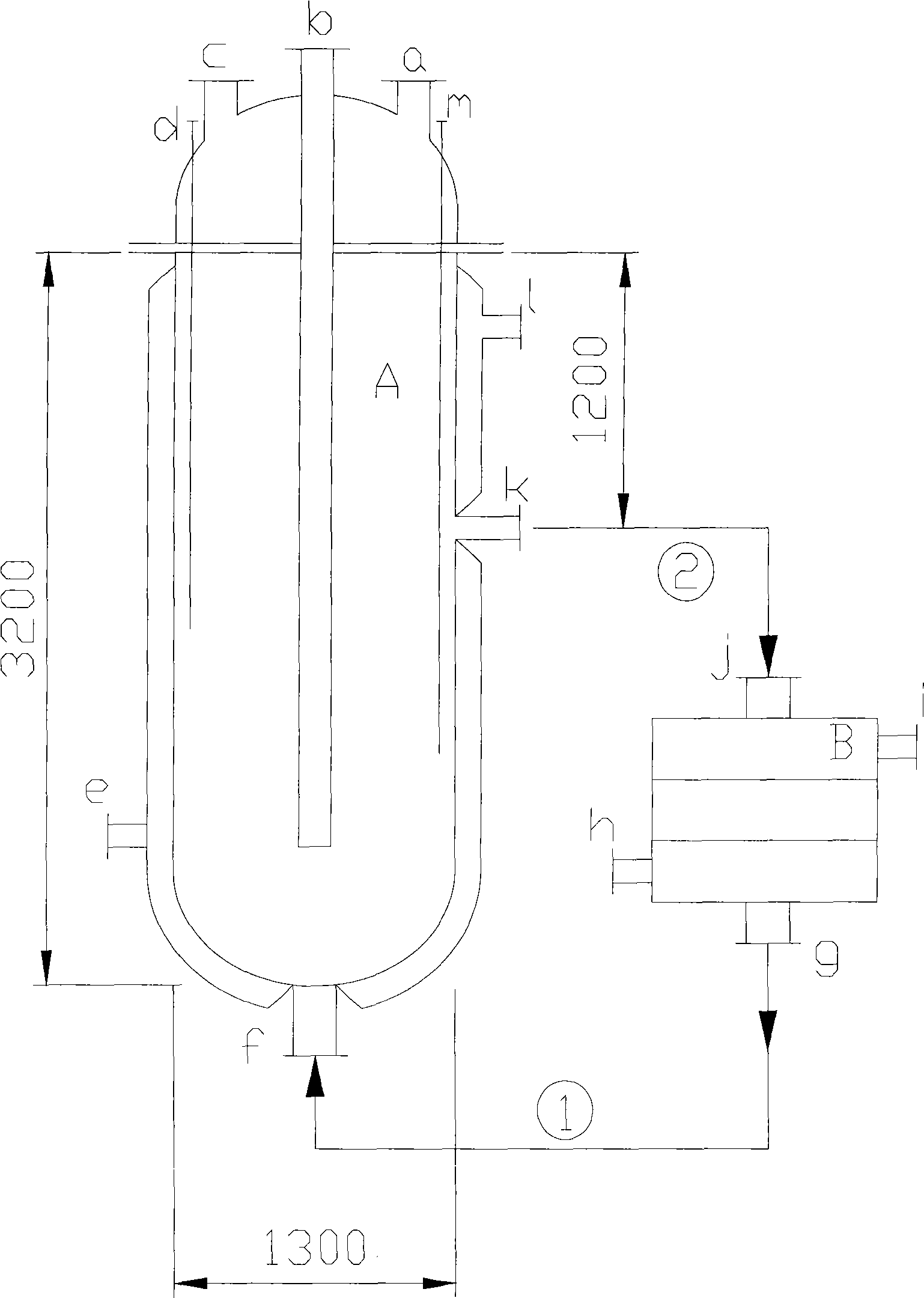

Self circulation heat exchange method for materials in production of chlorinating paraffin-52 and chlorination reaction device therefor

InactiveCN101544911AOrderly escapeNo reduction in mass transfer efficiencyPetroleum chemical modificationComing outParaffin wax

The invention provides a self circulation heat exchange method for materials in production of chlorinating paraffin-52 and a chlorination reaction device therefor. The method comprises the steps that: a, liquid paraffin is added into an automatic circulation main and auxiliary chlorination reaction kettle provided with a catalytic light source and a heat exchanger outside the kettle, and a catalytic light source lamp is turned on; b, liquid chlorine is introduced into a gasification kettle, stabilized by an accumulator still, and is introduced into a main kettle of the chlorination reaction kettle at a chlorine flowrate of between 200 and 230Kg / h, the chlorination temperature is controlled to be between 100 and 110 DEG C, the reaction is stopped when the chlorine content analyzed in a taken sample is between 50 and 54 percent to obtain a crude product of the chlorinating paraffin-52, dissolved chlorine and chlorine hydride in the crude product of the chlorinating paraffin-52 are removed by a degasification kettle, and then a stabilizing agent is added to obtain a finished product of the chlorinating paraffin-52; and c, gas coming out of the main kettle of the chlorination reaction kettle enters an auxiliary kettle of the chlorination reaction kettle, gas coming out of the auxiliary kettle of the chlorination reaction kettle passes through a graphitic absorber, a water falling film is used for absorbing the chlorine hydride in the gas to prepare hydrochloric acid, micro chlorine and chlorine hydride contained in tail gas which is discharged by the graphic absorber pass through a waste gas processor and are absorbed by water solution of sodium hydroxide to generate sodium hypochlorite and sodium chloride.

Owner:HENAN CHEM IND RES INST

Three-phase ultrasound light-catalyzed reaction device and method for CO2 reduction thereof

InactiveCN101138700AImprove photocatalytic efficiencyShort reaction timeDispersed particle separationEnergy based chemical/physical/physico-chemical processesWater bathsUltrasound - action

The present invention discloses a three-phase ultrasonic photo-catalyzed reaction device and a CO2 reducing method with the device. With the device, a photo-catalyst is placed in a photo-reactor, and the reactor is placed in a water bath of an ultrasonic generator. A light source is arranged above the photo-reactor. The method is that the CO2 gas to be reduced is mixed evenly with the photo-catalyst and a sodium hydroxide solution in the photo-reactor under the ultrasonic action, and reacts for 3-20 hours with radiation of the light source. Then the CO2 gas is reduced. The photo-catalyst is made from titanium dioxide or silicon dioxide and metal phthalocyanine. Metal phthalocyanine is supported on the surface of titanium dioxide in the way of in-situ synthesis, sol-gel, and immersion. The present invention promotes the photo-catalysis efficiency, reduces the reaction time, and saves the energy. Visible light can be used for reducing. Moreover, the phot-catalyst can be recycled, which reduces the pollution and the cost, sot the present invention is quite applicable for the three-phase ultrasonic photo-catalyzed reaction device and photo-catalyzed CO2 reducing.

Owner:TAIYUAN UNIV OF TECH

Multi-element co-polymerization oil well cement fluid loss additive and preparation method thereof

ActiveCN101397491ASimple preparation processDrilling compositionPotassium persulfateSodium hydroxide

The invention relates to a multicomponent copolymerization oil well cement fluid loss additive and a preparation method thereof. The method comprises: 10-120 portions of 2-acrylamide-2-methyl-1-AMPSA, 1-5 portions of acrylic acid and 15-50 portions of deionized water are added, stirred and then added with sodium hydroxide aqueous solution with the mass fraction of 5-10 percent for neutralizing to pH equal to 3-11; then 10 portions of acrylamide, 0.1-1 portion of complexing agent EDTA and 0.01-1 portion of chain transfer agent are added, the chain transfer agent is isopropyl alcohol or sodium benzoate, the temperature is controlled between 30 DEG C and 60 DEG C and N2 is introduced for 30 minutes; 2-10 portions of N-vinyl pyrrolidone and 0.01-0.5 portion of initiator are added, the initiator is potassium persulfate or ammonium persulfate, and the reaction is carried out for 4-12 hours. The solution keeps still for 5 hours at the temperature of 180 DEG C, and is cooled through flowing water after being taken out, without sedimentation or water separating; and the water loss is zero at the temperature of 180 DEG C according to the standards of drilling fluid, and the water loss is 48ml according to the standards of cement.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Wet-method preparation process of ternary positive material for lithium ion battery

The invention provides a wet-method preparation process of a ternary positive material for a lithium ion battery. The synthesis process of a ternary precursor comprises the steps of: adding complexing agent ammonia water, an aqueous solution of metal nickel-cobalt-manganese ions, and a precipitating agent aqueous solution of sodium hydroxide into a reaction kettle to prepare the liquid-phase ternary precursor under the condition of protection gas; and the synthesis process of the ternary material comprises the steps of: carrying out preliminary-stage sintering in a muffle furnace after ball grinding, mixing, smashing and fast drying the ternary precursor and lithium salt, secondarily introducing of the lithium salt into the materials according to a proportion after the preliminary-stage sintering, and carrying out secondary sintering in the muffle furnace after mixing the materials, so as to obtain the nickel-cobalt-manganese acid lithium ternary positive material. The method provided by the invention is simple in preparation process, the particle size of the prepared nickel-cobalt-manganese acid lithium ternary positive material ranges from 0.5 to 10 microns, the prepared nickel-cobalt-manganese acid lithium ternary positive material is controllable and can be uniformly distributed, and the nickel-cobalt-manganese acid lithium ternary positive material has an excellent electrochemical performance.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Preparation method of porous-super-absorbent resin

InactiveCN103214616AShorten the polymerization reaction timeIncrease productivityCross-linkSodium hydroxide

The invention discloses a preparation method of porous-super-absorbent resin. The preparation method comprises the following steps of: adding acyclic acid to deionized water, neutralizing with a sodium hydroxide aqueous solution, and controlling neutralization temperature at 50 DEG C to 80 DEG C and neutralization degree at 60-80%; mixing the solution; adding a cross-linking agent and stirring till completely dissolving, then adding an oxidant and a foaming agent, afterwards, adding a reducing agent, carrying out polymerization reaction by heat of neutralization, and generating porous-super-absorbent resin gel; and pelleting, drying, crushing and screening to obtain the porous-super-absorbent resin. Additional heating equipment is not needed in the porous-super-absorbent resin preparation method; heat released in neutralization process is directly used for enabling a polymerization reaction system to reach the temperature needed by the reaction; and an oxidation reduction initiating agent is added at high temperature, so that the whole polymerization reaction time is shortened, and the production efficiency is improved; and the added foaming agent can be used for preparing porous gel, so that the water retaining capacity and the water-absorption capability of the water-absorbent resin are improved.

Owner:SOUTH CHINA UNIV OF TECH

Method for dissolving cellulos

The invention discloses a method for dissolving the cellulose, including having the sodium hydroxide and urea as material, firstly pre-cooling the 12-20 wt.% of sodium hydroxide water solution to -4-10 DEG C, adding cellulose to produce an alkaline cellulase, or mixing the cellulase and 12-20 wt.% of sodium hydroxide water solution, mixing and pre-cooling to -4-10 DEG C to produce an alkaline cellulase, than adding -4-10 DEG C 0-40 wt.% urea water solution, blending uniformly, immediately getting the transparent cellulose solution. The method can swiftly dissolve the natural cellulose with a molecular weight under 13*104 and the II-type cellulose with a molecular weight under 15*104 and may obtain a dense cellulose solution with a high solubility (100%).

Owner:WUHAN UNIV

Method for preparing Nano SiO2 fire retardant viscose fiber, and film

ActiveCN101050559ASimple processEasy to operateFlame-proof filament manufactureArtificial filaments from viscoseFire retardantSodium sulfate

The present invention relates to a preparation method of nano SiO2 fire-retardant viscose fiber and film, specially, it relates to a preparation method of fire-retardant viscose fiber formed from cellulose and SiO2 and organic-inorganic polymer nano composite membrane made of cellulose and SiO2. Said method includes the following steps: adding silicone sol with a certain mass into a viscose solution whose composition contains alpha-cellulose whose mass percentage content is 6-9% and sodium hydroxide whose mass percentage content is 5-6%; fully stirring and mixing them at 10-50 deg.C, deforming so as to obtain viscose-silicone sol solution, then adding said viscose-silicone sol into a coagulation acid bath prepared by using sulfuric acid, sodium sulfate, zinc sulfate and water, coagulating at 10-100 deg.C, spinning so as to obtain nano SiO2 fiber-retardant viscose fiber, utilizing coating process so as to obtain organic-inorganic polymer nano composite membrane of cellulose / SiO2.

Owner:QINGDAO UNIV

Green alkaline paint remover for eliminating coating from electronic circuit board and its prepn and usage

InactiveCN1887979AReduce poisonNo corrosionChemical paints/ink removersAqueous sodium hydroxideEngineering

The present invention is green alkaline paint remover for eliminating coating from electronic circuit board and its preparation and usage, and belongs to the field of paint remover technology. The paint remover consists of NaOH in 40-150 g / L, surfactant in 0.5-50 g / L, additive in 0-50 g / L, corrosion retardant 0.1-2.5 g / L, and water for the rest. It is prepared through mixing and heating at 50-80 for dissolving completely. When the paint remover is used, the electronic circuit board is soaked in the paint remover and heated at 50-100 deg.c for 10-60 min to eliminate its paint layer. The present invention has the advantages of low cost, fast paint eliminating speed, low toxicity, use safety and capacity of being used repeatedly.

Owner:UNIV OF SCI & TECH BEIJING

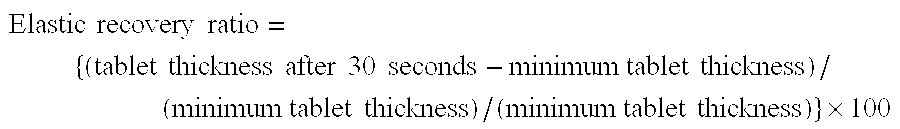

Low-substituted hydroxypropylcellulose powder and method for producing the same

ActiveUS20080039621A1Improve compression performanceGood lowabilityPill deliveryGranular deliveryAqueous sodium hydroxideLow-substituted hydroxypropylcellulose

Provided are a low-substituted hydroxypropylcellulose powder having high compressibility, good flowability and excellent disintegration, and a method for producing the same. More specifically, provided is a method for producing a low-substituted hydroxypropylcellulose powder having a molar substitution number per anhydrous glucose unit of 0.05 to 1.0, which is insoluble in water and swollenable by absorbing water, comprising the steps of: adding an aqueous sodium hydroxide solution to powdered pulp in such a manner that weight ratio of sodium hydroxide with respect to anhydrous cellulose is 0.1 to 0.3 so as to produce alkali cellulose; etherifying the obtained alkali cellulose to obtain a crude product; neutralizing the sodium hydroxide contained in the obtained crude reaction product; washing the resultant; drying; and pulverizing using by compaction-grinding.

Owner:SHIN ETSU CHEM IND CO LTD

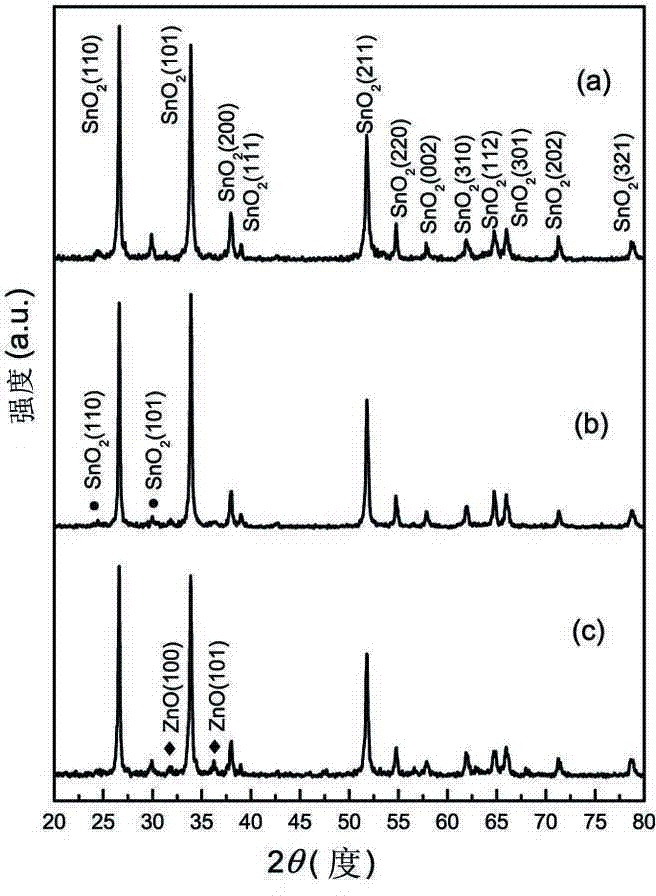

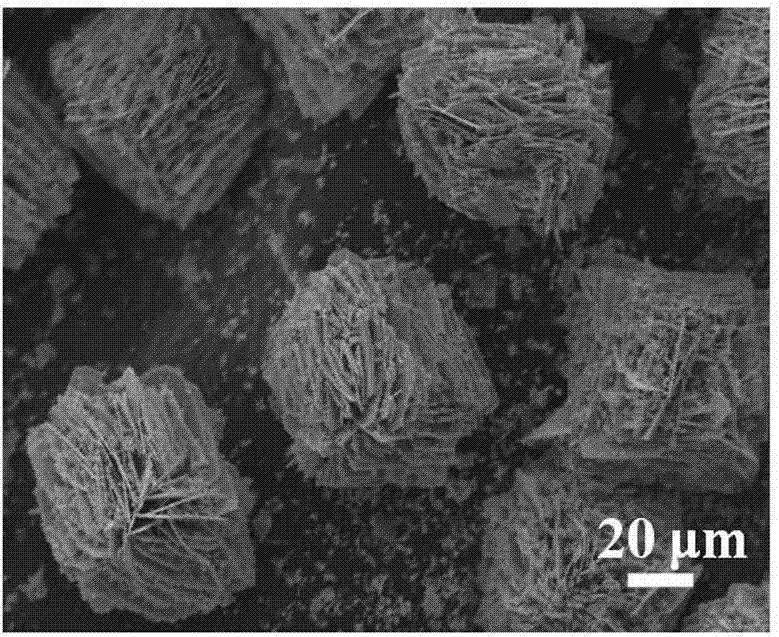

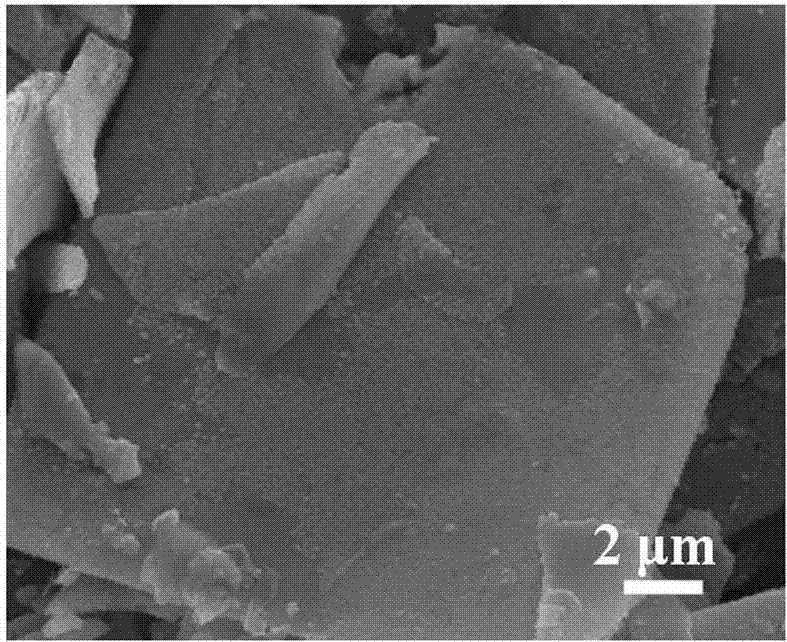

ZnO/SnO2 nano composite gas-sensitive material with flower-shaped grading structure and preparation method of material

InactiveCN103776870AReduced ethanol gas sensitivity performanceGood dispersionMaterial nanotechnologyMaterial analysis by electric/magnetic meansAir atmosphereSTANNOUS OXIDE

The invention provides a ZnO / SnO2 nano composite gas-sensitive material with a flower-shaped grading structure. The ZnO / SnO2 nano composite gas-sensitive material is prepared by the following steps: dripping a sodium hydroxide water solution into an ethanol solution of cetyl trimethyl ammonium bromide and stannous chloride dihydrate under electromagnetic stirring; after dripping, preparing a precursor solution by the continuous electromagnetic stirring; adding the precursor solution into a reaction kettle, reacting at 130 DEG C; carrying out centrifuging on a reactant, washing and drying to obtain a flower-shaped stannous oxide sacrifice template; adding the flower-shaped stannous oxide sacrifice template into a zinc acetate solution; agitating and carrying out ultrasonic treatment; removing a solvent to obtain a ZnO / SnO2 precursor; and carrying out heat preservation on the ZnO / SnO2 precursor for 2-4 hours in an air atmosphere of 700 DEG to obtain the composite gas-sensitive material. According to the ZnO / SnO2 nano composite gas-sensitive material with the flower-shaped grading structure, the controllable preparation of the composite gas-sensitive material on the appearance and components can be realized; the mass percent content of zinc oxide in the composite gas-sensitive material is 5%-15%; a flower shape is assembled by sheet-shaped tin dioxide and zinc oxide nano particles; the ZnO / SnO2 nano composite gas-sensitive material has a good gas sensitive performance and has a wide application prospect in the aspect of manufacturing a novel high-efficient gas sensor.

Owner:HENAN POLYTECHNIC UNIV

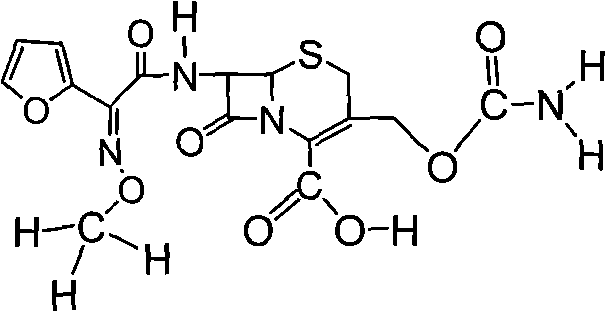

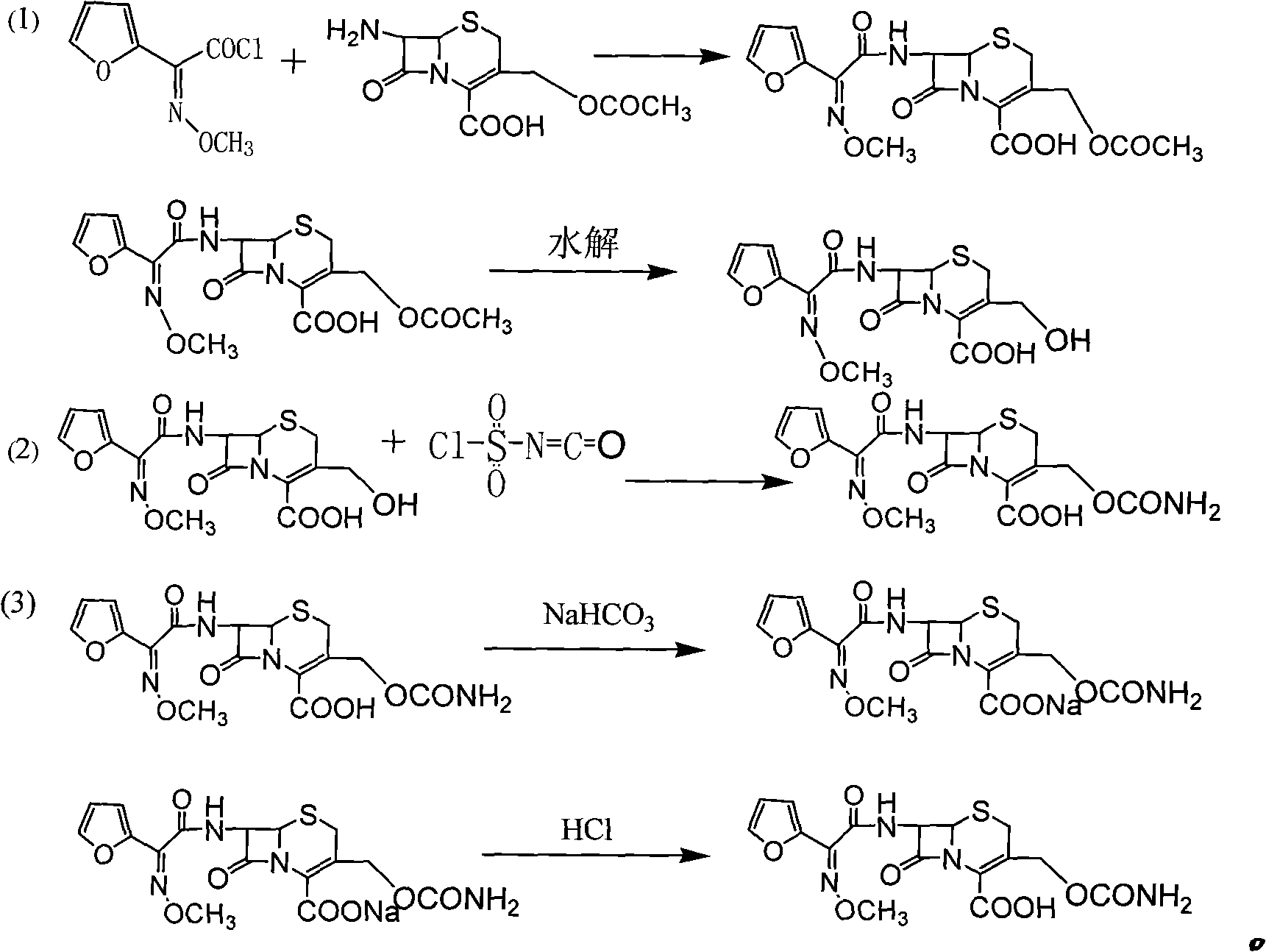

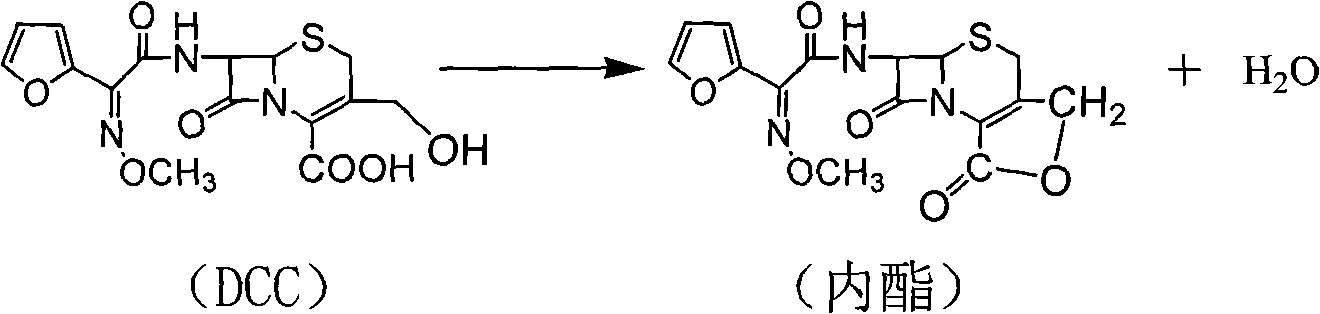

Preparation method of high-purity cefuroxime acid

The invention discloses a preparation method of high-purity cefuroxime acid which is an intermediate for synthesizing second-generation cephalosporins cefuroxime sodium and cefuroxime axetil. The preparation method comprises the following steps: based on 7-aminocephalosporanic acid (7-ACA) as a raw material, carrying out an N-acylation reaction on the 7-ACA and furoyl acetylcholine at the 7-position; at a low temperature, hydrolyzing 3-acetyl with a sodium hydroxide solution, crystallizing, filtering and drying so as to obtain the intermediate 3-deformamido cefuroxime acid (DCC); quantitatively adding the DCC in a tetrahydrofuran solvent, dropwise adding chlorosulfonyl isocyanate for a nucleophilic addition reaction so as to generate chlorosulfonyl cefuroxime acid, and adding purified water for hydrolysis so as to prepare a cefuroxime acid reaction liquid; adding sodium bicarbonate for salifying; removing by-reactant lactone and other unsaponifiable impurities in the reaction liquid with a ternary compound extracting agent of dichloromethane, ethyl acetate and tetrahydrofuran, layering, and adding hydrochloric acid in a water phase for acidification; adding the ternary compound extracting agent to extract and separate out the cefuroxime acid; and removing water-soluble impurities, crystallizing and filtering a distilled organic phase, and then drying so as to obtain the high-purity cefuroxime acid with the purity of more than or equal to 99%.

Owner:四平市精细化学品有限公司

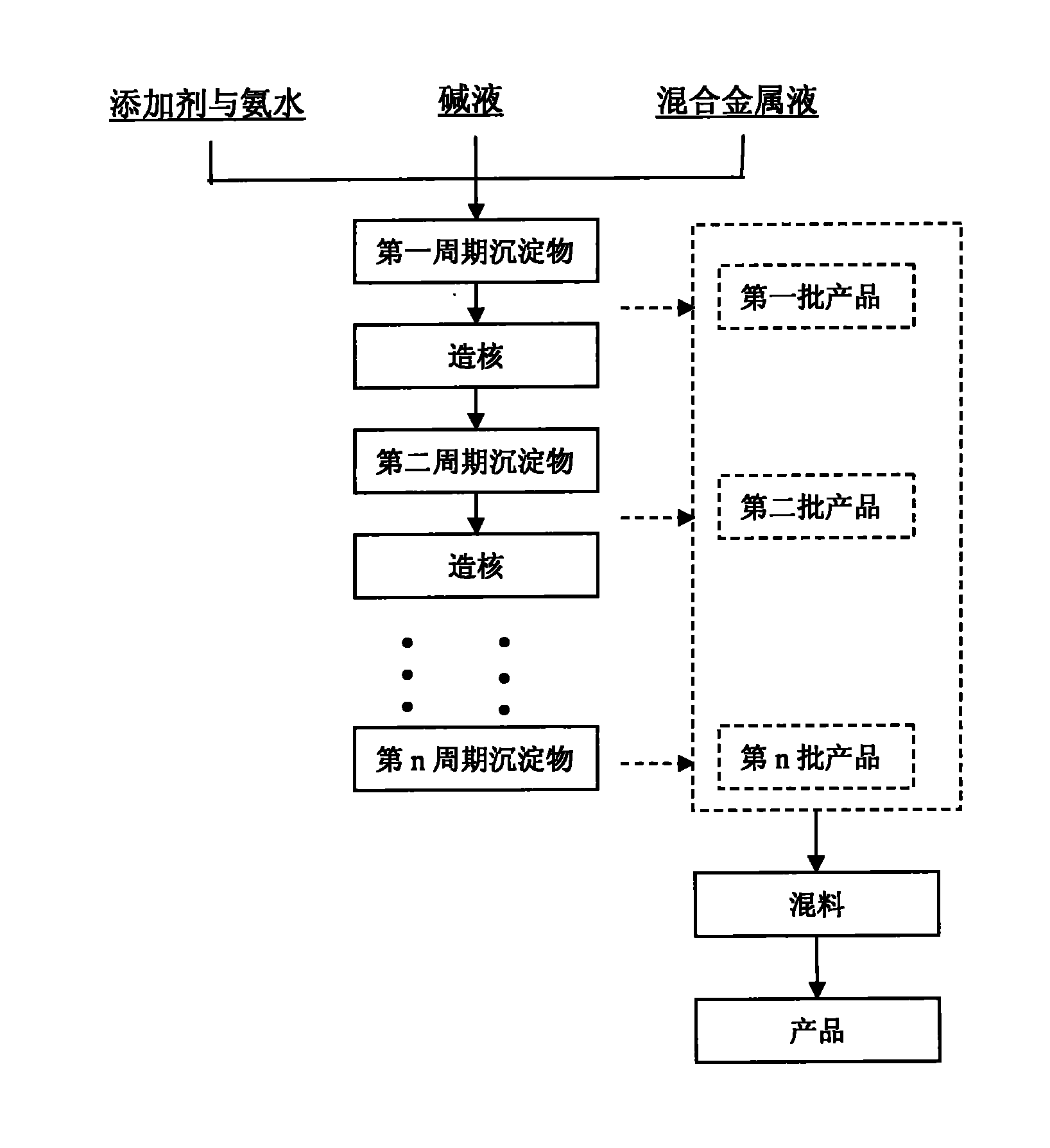

Narrow-distributed ternary precursors with different particle sizes and preparation method thereof

The invention discloses narrow-distributed ternary precursors with different particle sizes and a preparation method thereof. A complexation controlled crystal coprecipitation method is adopted for preparing and growing a nucleus in a first reaction kettle and nucleating in an environment of increasing solid-liquid ratio, a nickel-cobalt-manganese soluble salt solution and an aqueous solution of sodium hydroxide coprecipitate under complexation of ammonia, so as to prepare narrow-distributed crystal nucleuses, a part of small-size nickel-cobalt-manganese hydroxide in the first reaction kettleis transferred to a second reaction kettle and grows to medium size by increasing the solid-liquid ratio, a part of material in the second reaction kettle is transferred to a third reaction kettle andcontinues to grow to desired large size by increasing the solid-liquid ratio. Three nickel-cobalt-manganese hydroxide precursors with different particle sizes, uniformly distributed elements, good sphericity, narrow particle size distribution, and high tap density are obtained once, further, materials in the second reaction kettle and the third reaction kettle have large particle size, so that when the materials continue growing, the feeding speed is increased and the production efficiency is improved.

Owner:DONGGUAN UNIV OF TECH

Treatment of wastewater from production of p-phthalic acid and recoval of resources therewith

ActiveCN1680195AEnable recyclingRealize comprehensive utilizationWater/sewage treatment by sorptionBenzeneHigh concentration

Waste water management of terephthalic acid production and its resources recovering method are disclosed. It is carried out by passing waste water through adsorbing column with macroporous adsorbing resin, adsorbing terephthalic acid and intermediate etc. benzene series organics onto resin, eluting recovering resin after adsorbing operation by sodium hydrate aqueous solution, acidizing the adsorbed high-concentration benzene series organics solution, cooling , filtering, returning the filtered white solid to original production section or selling as by-product , and returning filtrating-liquid into cyclic use. The low-concentration desorptive liquid is used for next operation of sodium hydrated aqueous solution. It achieves effective separation and repeating use.

Owner:NANJING UNIV +1

Seedling culturing method for polygonatum cyrtonema seeds

PendingCN105248140AImprove germination rateShorten germination timePlant cultivationCultivating equipmentsAqueous sodium hydroxideDisease damage

The invention discloses a seedling culturing method for polygonatum cyrtonema seeds. The method comprises the steps of using a sodium hydroxide aqueous solution for immersing the polygonatum cyrtonema seeds, then placing the polygonatum cyrtonema seeds in fine sand for being subjected to sand storage, wherein the fine sand is mixed and moistened with mixed liquor of ABT rooting powder, indolebutyric acid and a carbendazim aqueous solution, sowing and scattering the seeds and the fine sand obtained after sand storage together onto matrix soil in a vinyl house, wherein the matrix soil is formed by mixing wood chips, decoction dregs and pine bark, watering the seeds in the morning and in the evening everyday, and after a leaf grows out of each polygonatum cyrtonema seed, conducting periodic topdressing, weeding and pest and disease damage elimination. The method is simple, easy to do and low in cost, through the specific sand storage mode and the matrix soil seedling culturing mode, it only takes five to seven months for each polygonatum cyrtonema seed from sand storage to the state of growing out a leaf, the germination rate can reach over 80%, the germination rate of the polygonatum cyrtonema seeds is raised, germination time of the polygonatum cyrtonema seed is shortened, a large number of polygonatum cyrtonema seedlings can be obtained within a short time, requirements of planting polygonatum cyrtonema in a large area and on a large scale are satisfied, and double significance on production and economy is achieved.

Owner:SHAANXI NORMAL UNIV

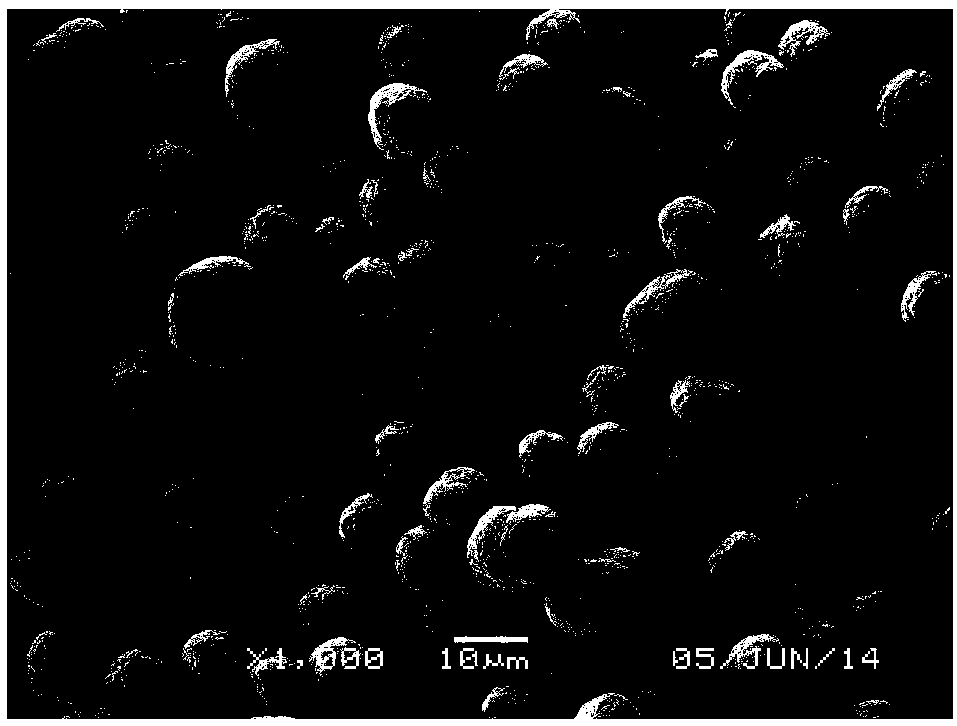

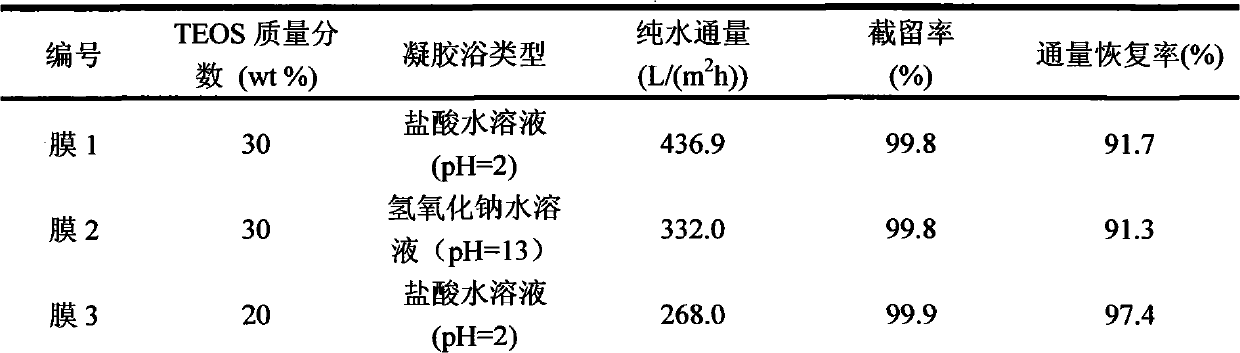

Method for preparing anti-polluting oil-water separation ultra-filtration membrane

ActiveCN102085459AEasy to makeMild conditionsSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiltration membraneCellulose acetate

The invention discloses a method for preparing an anti-polluting efficient oil-water separation ultra-filtration membrane, which comprises the following steps of: dissolving 16.0 mass percent of cellulose acetate into an N,N-dimethyl formamide solvent based on 100 percent of the mass of membrane casting solution, adding 15.0 to 30.0 mass percent of ethyl orthosilicate, and scraping a nascent state membrane with thickness of 240 microns on a glass plate; placing the nascent state membrane in the air for 10 to 30 seconds, and then soaking the nascent state membrane into gel baths of 25 DEG C, wherein the gel baths are aqueous solution of hydrochloric acid and aqueous solution of sodium hydroxide respectively; and taking out the membrane from the gel bath, placing the membrane into deionizedwater, and changing the water once every 5 hours to obtain the CA(TEOS)-HCl and CA(TEOS)-NaOH modified ultra-filtration membrane. The method is simple in process and mild in conditions; and the flux of the modified membrane is greatly improved, good anti-polluting performance is kept, and the modified membrane has high interception rate and can be used for treating oil-containing wastewater.

Owner:PETROCHINA CO LTD

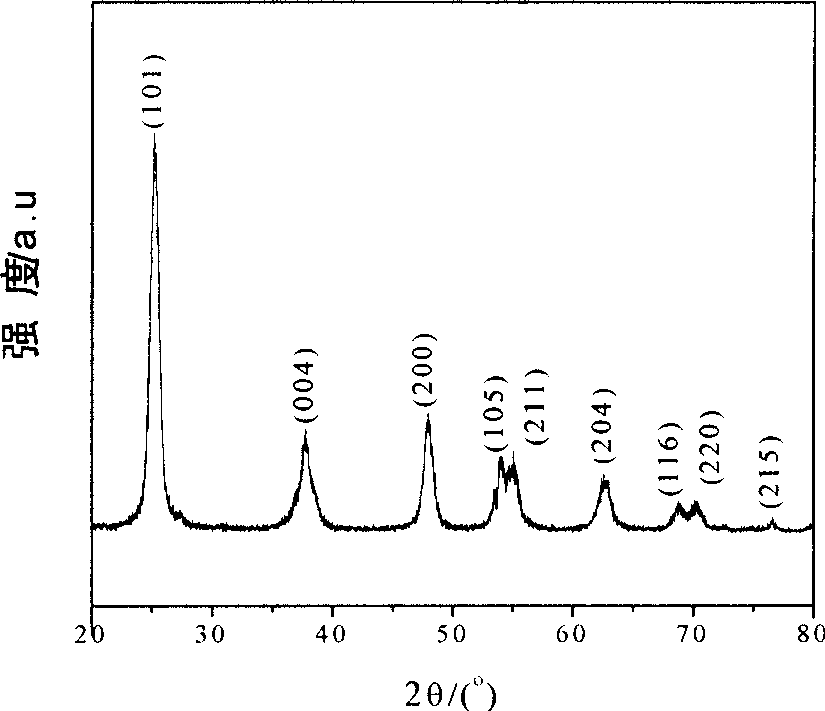

Method for preparation of unidimensional monocrystal titanium dioxide nano material

InactiveCN1699636ALow priceEasy to getPolycrystalline material growthFrom normal temperature solutionsPotassium hydroxideSingle crystal

The present invention belongs to the field of nanometer material technology. The procedure is: 1) adding 1-30 parts of TiCl4 or TiO2 powder to 70-99 parts of organic solvent, obtaining evenly distributed mixture, 2) dissolving 10-60 parts of potassium hydroxide in 40-90 parts of deionization water, obtaining NaOH solution, 3) adding 20-80 parts NaOH solution of step 2)to 10-50 parts solution of step 1), stirring and moving to an autoclave, thermostatically heating at 50-300 degree C, 4) cooling down and pouring out the supernatant liquid, washing the bottom precipitation with deionization water and diluted acid solution, followed by centrifugal separating and drying at 10-200 degree C. The product obtained is one dimension single crystal nanometer material (nano-wire, nano-rod, and nano-tube) of TiO2 with diameter of 10-100 nm and length of micrometer order of magnitude. The product of the present invention is of high purity and high yield rate, and the form and pattern can be adjusted through selecting different solvents.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com