Deep desulfurization method for liquefied petroleum gas

A technology of liquefied petroleum gas and deep desulfurization, which is applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of excessive liquefied gas total sulfur, complicated process flow, corrosion, etc., to reduce the pressure of environmental protection, high catalyst activity, process Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

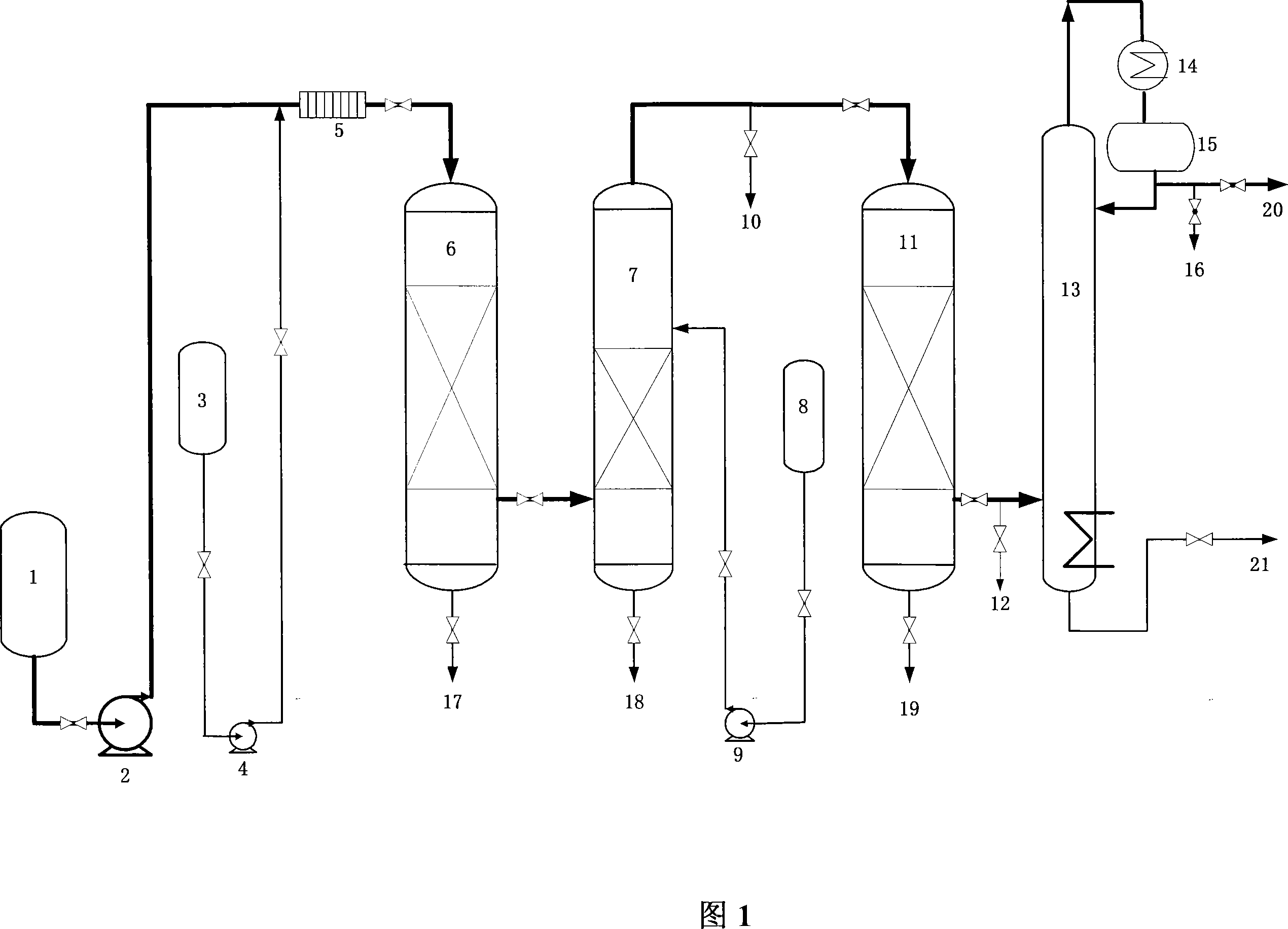

Method used

Image

Examples

Embodiment 1

[0055] The raw material contains 29μg·g -1 Hydrogen sulfide sulfur, 50μg·g -1 Carbonyl thiosulfur and 355μg·g -1 The liquefied petroleum gas of mercaptan sulfur, the treatment steps include: ①Using 15wt% monoethanolamine as a desulfurizer, and the addition amount is 3000 μg g of the total weight of the liquefied petroleum gas -1 , the reaction temperature of the carbonyl sulfide hydrolysis reactor is 30°C, the pressure is 0.8MPa, and the volume of the carbonyl sulfide hydrolysis catalyst bed is 5h -1 , the carbonyl sulfide hydrolysis catalyst is K 2 O / γ-Al 2 o 3 ; ② When washing with water in the washing tower, the amount of oxygen-containing deionized water added is 3000 μg·g of the total amount of washing water -1 , the preparation method of oxygen-containing deionized water is as follows: in a tank containing deionized water, air with a pressure of 0.4MPa is introduced, and the volume space velocity of the liquefied petroleum gas passing through the inert ceramic ball ...

Embodiment 2

[0057] The raw material contains 35μg·g -1 Hydrogen sulfide sulfur, 50μg·g -1 Carbonyl thiosulfur and 355μg·g -1 The liquefied petroleum gas of mercaptan sulfur, the treatment steps include: ① use 20wt% methyldiethanolamine as a desulfurizer, and the addition amount is 6000 μg·g of the total weight of the liquefied petroleum gas -1 , the reaction temperature of the carbonyl sulfide hydrolysis reactor is 30°C, the pressure is 0.8MPa, and the volume of the carbonyl sulfide hydrolysis catalyst bed is 5h -1 , the carbonyl sulfide hydrolysis catalyst is K 2 O+MgO / γ-Al 2 o 3 ; ② When washing with water in the washing tower, the amount of oxygen-containing deionized water added is 3000 μg·g of the total amount of washing water -1 , the preparation method of oxygen-containing deionized water is as follows: in a tank containing deionized water, air with a pressure of 0.4MPa is introduced, and the volume space velocity of the liquefied petroleum gas passing through the inert cerami...

Embodiment 3

[0059] The raw material contains 35μg·g -1 Hydrogen sulfide sulfur, 50μg·g -1 Carbonyl thiosulfur and 355μg·g -1 The liquefied petroleum gas of mercaptan sulfur, the treatment steps include: ① use 30wt% diglycolamine as a desulfurizer, and the addition amount is 4000 μg·g of the total weight of the liquefied petroleum gas -1 , the reaction temperature of the carbonyl sulfide hydrolysis reactor is 30°C, the pressure is 0.8MPa, and the volume of the carbonyl sulfide hydrolysis catalyst bed is 5h -1 , the carbonyl sulfide hydrolysis catalyst is K 2 O+MgO / γ-Al 2 o 3 +TiO 2 ; 2. When washing with water in the washing tower, the amount of hydrogen peroxide in the deionized water containing hydrogen peroxide is 3000 μg·g of the total amount of washing water -1 , the concentration of hydrogen peroxide in the deionized water is 2wt%, and the liquefied petroleum gas is decomposed by hydrogen peroxide catalyst MnO 2 / γ-Al 2 o 3 The volumetric space velocity of the bed is 5h -1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com