Patents

Literature

945results about How to "Alleviate volume expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

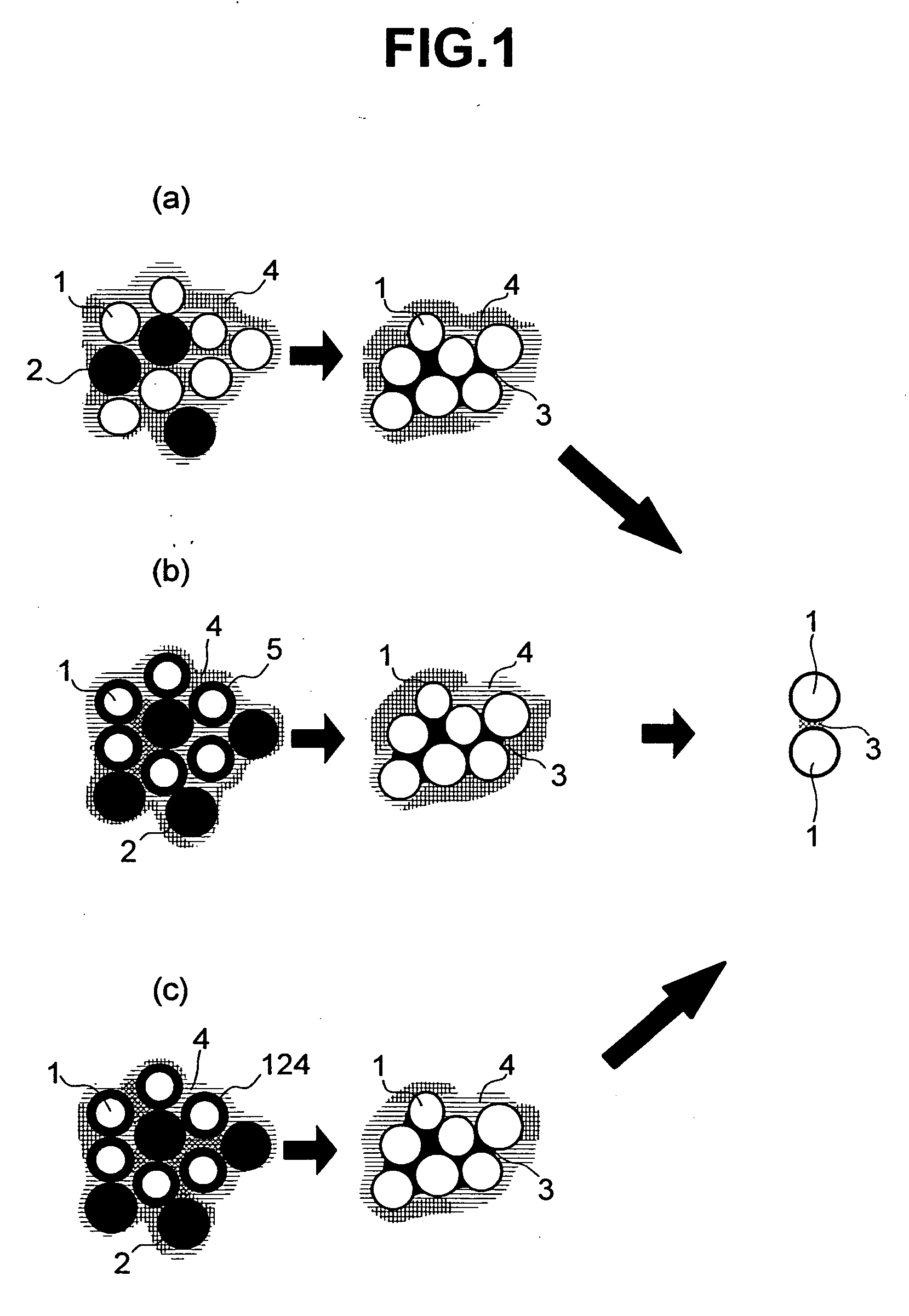

Non-aqueous electrolyte secondary battery, negative electrode material, and making method

ActiveUS20090239151A1Improve cycle performanceImprove efficiencyNon-aqueous electrolyte accumulatorsActive material electrodesSilicon oxideSilicon particle

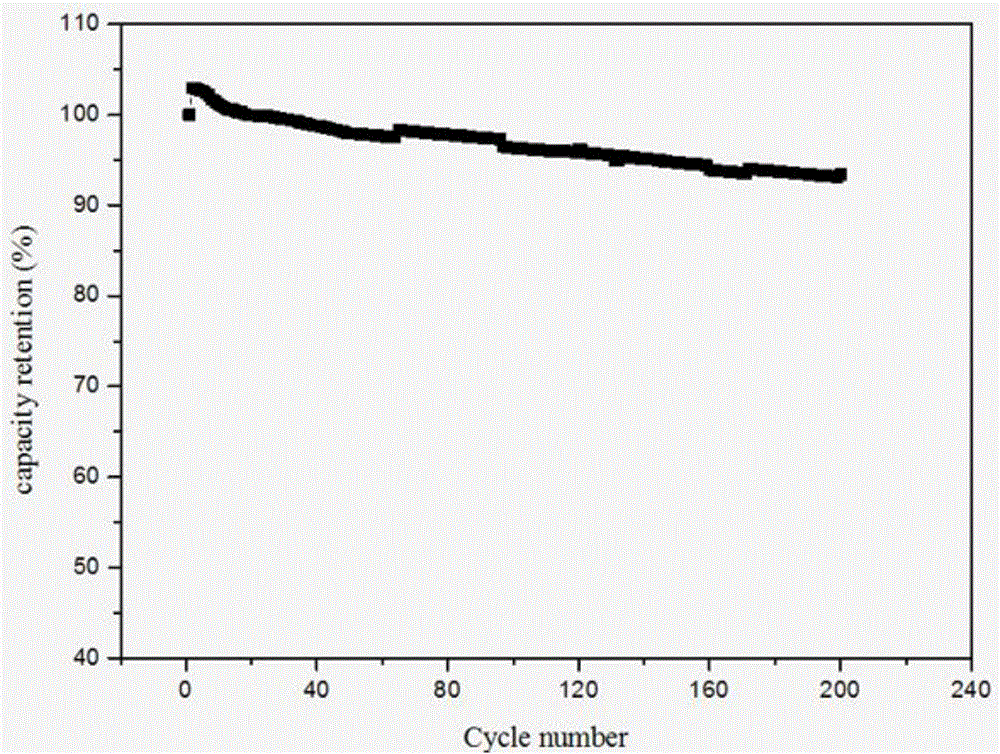

A negative electrode material comprising an active material and 1-20 wt % of a polyimide resin binder is suitable for use in non-aqueous electrolyte secondary batteries. The active material comprises silicon oxide particles and 1-50 wt % of silicon particles. The negative electrode exhibits improved cycle performance while maintaining the high battery capacity and low volume expansion of silicon oxide. The non-aqueous electrolyte secondary battery has a high initial efficiency and maintains improved performance and efficiency over repeated charge / discharge cycles by virtue of mitigated volumetric changes during charge / discharge cycles.

Owner:SHIN ETSU CHEM IND CO LTD

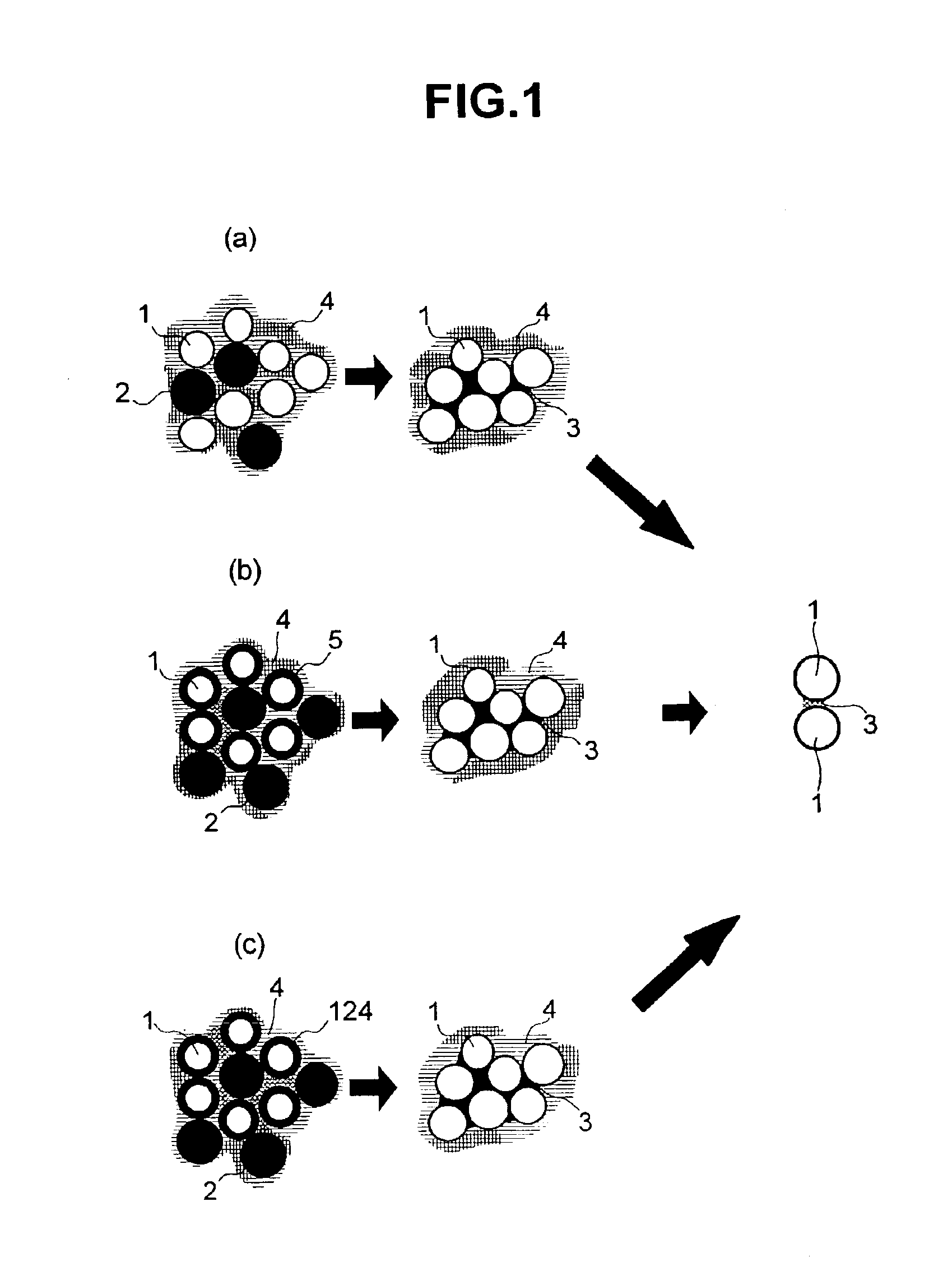

Negative electrode material for nonaqueous electrolyte secondary battery, making method and lithium ion secondary battery

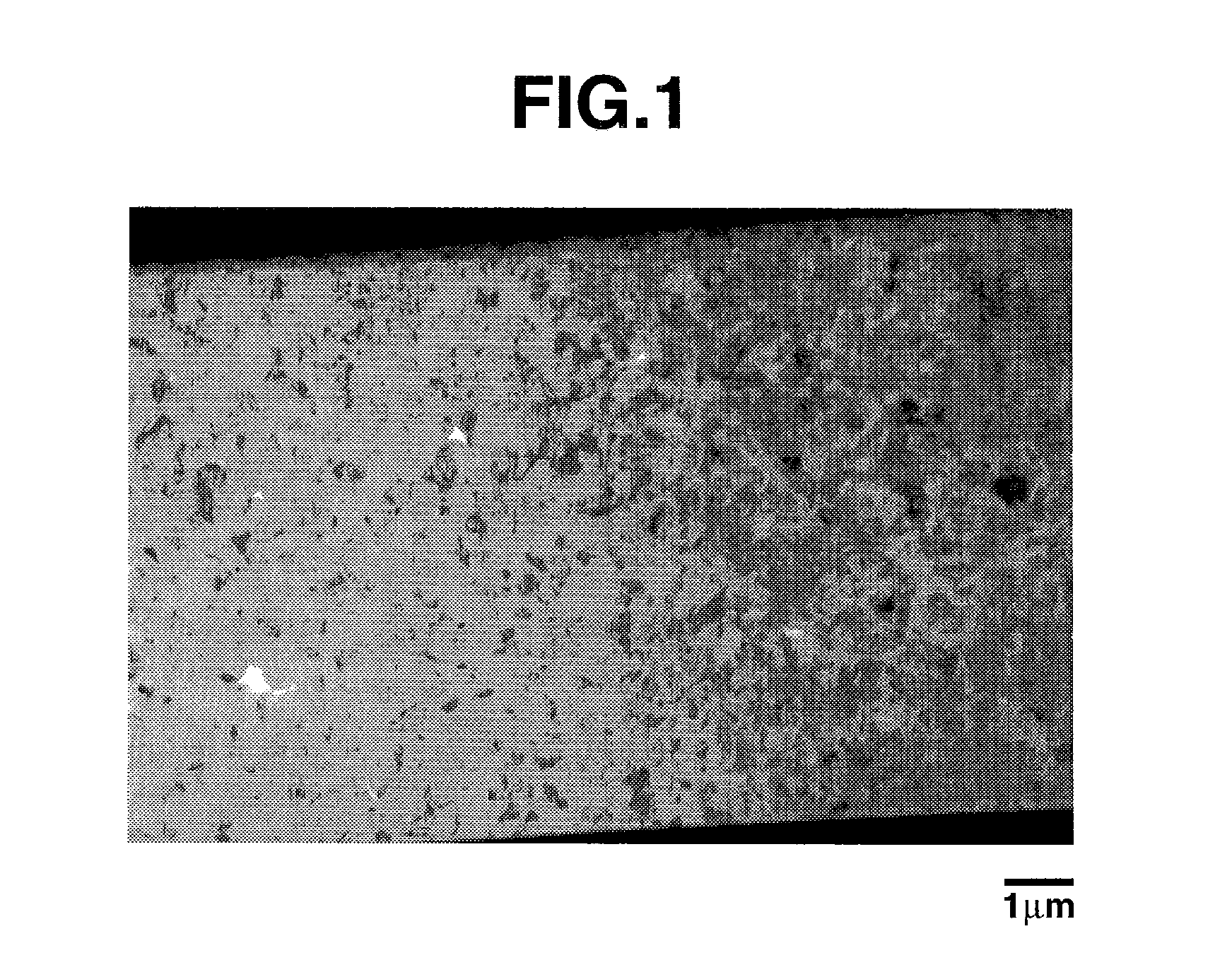

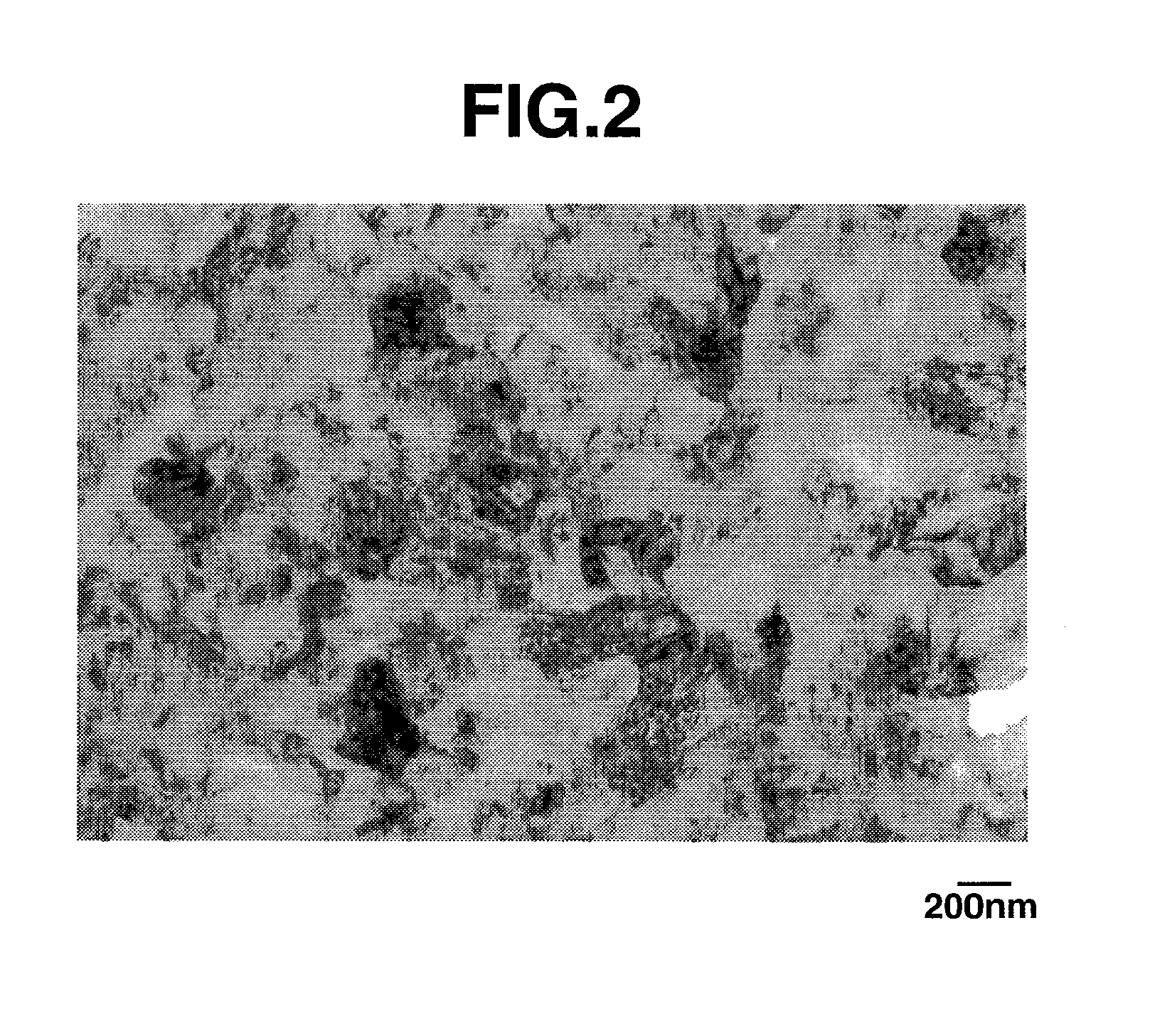

InactiveUS20100288970A1High charge-discharge efficiencyImprove cycle performanceHybrid capacitor electrodesSecondary cellsDischarge efficiencyCarbon coating

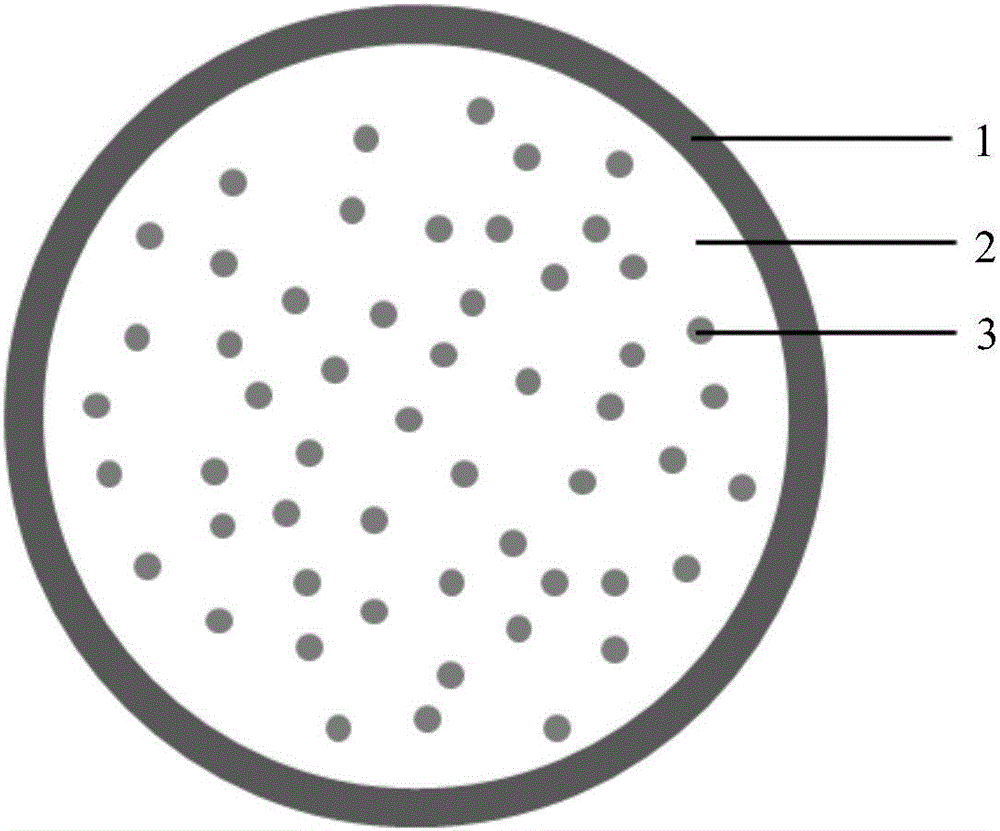

A negative electrode material for nonaqueous electrolyte secondary batteries comprises composite particles which are prepared by coating surfaces of particles having silicon nano-particles dispersed in silicon oxide with a carbon coating, and etching the coated particles in an acidic atmosphere. The silicon nano-particles have a size of 1-100 nm. The composite particles contain oxygen and silicon in a molar ratio: O<O / Si<1.0. Using the negative electrode material, a lithium ion secondary battery can be fabricated which features a high 1st cycle charge / discharge efficiency, a high capacity, and improved cycle performance.

Owner:SHIN ETSU CHEM IND CO LTD

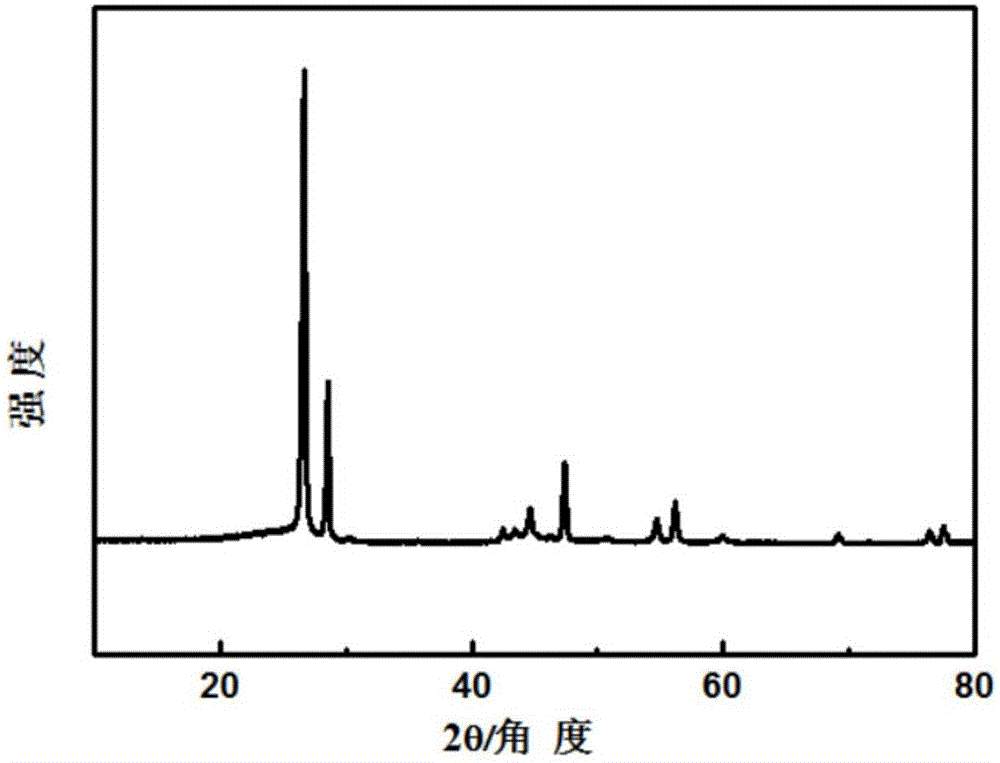

Silicon-carbon composite material, lithium ion battery, and preparation method and application of silicon-carbon composite material

ActiveCN103633295AAlleviate volume expansionAvoid direct contactCell electrodesSecondary cellsCarbon compositesSilicon monoxide

The invention discloses a silicon-carbon composite material, a lithium ion battery, and a preparation method and application of the silicon-carbon composite material. The preparation method of the silicon-carbon composite material comprises the steps: uniformly mixing silicon powder and silicon monoxide powder, then mixing with a solution containing an organic carbon source dispersant, and performing wet-process ball milling to obtain a slurry; uniformly mixing the slurry, graphite and a conductive agent, and performing spray drying to obtain spherical-like particles, wherein graphite is synthetic graphite and / or intermediate-phase graphite; mixing the spherical-like particles and asphalt, performing cladding processing under the inert atmosphere to obtain a cladded material; and then performing carbonizing processing to obtain the silicon-carbon composite material, wherein silicon powder, silicon monoxide powder, graphite and asphalt respectively accounts for 5-15%, 3-10%, 45-75% and 5-40% by weight of the sum of the above materials, and the organic carbon source dispersant and the conductive agent both accounts for 0.1-2% by weight of the sum of silicon powder, silicon monoxide powder and graphite. The silicon-carbon composite material has relatively good cycle performance, and can be directly used as a cathode material of the lithium ion battery. The preparation method is simple in technology, low in cost and applicable to industrial production.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Silicon-carbon composite negative pole material preparation method and lithium ion battery

ActiveCN106257716AEvenly dispersedAvoid direct contactNegative electrodesSecondary cellsCarbon compositesElectric capacity

The invention relates to a silicon-carbon composite negative pole material preparation method and a lithium ion battery. The preparation method comprises putting nanometer silicon and graphite micro-powder into a ball mill, carrying out ball milling uniform dispersion in an organic solvent environment, carrying out vacuum drying, putting the dried mixture and asphalt into a cone-type mixer, carrying out coarse mixing, putting the mixed powder subjected to coarse mixing into a mechanical fusion machine, carrying out mechanical fusion, carrying out heat treatment in an inert gas protective atmosphere and carrying out cooling to obtain the silicon-carbon composite negative pole material. The preparation method carries out asphalt softening coating on nanometer silicon so that silicon particle and electrolyte direct contact is avoided, a capacity reduction rate is delayed, a lithium ion diffusion path is shortened, an electrode material electron conduction loss is avoided, and first charge-discharge efficiency, a charge-discharge electric capacity and cycle performances are improved. Before coating, nanometer silicon is dispersed through graphite micro-powder so that it is avoided that in asphalt coating, nanometer silicon aggregation causes local capacity excess and nanometer silicon is uniformly dispersed.

Owner:浙江超恒动力科技有限公司

Flexible lithium metal cell negative pole and preparation method thereof

The invention discloses a flexible lithium metal cell negative pole and a preparation method thereof, and belongs to the technical field of lithium metal cells. The flexible lithium metal cell negative pole is prepared from two-phase structures of lithium metal and a framework material, wherein the content of the lithium metal is 10-99.9wt.%, and the framework material is a conductive material or an insulating material; the flexible lithium metal cell negative pole can be bent within 0-180 degrees, and the losses of electrochemical performance in the bending process is 0.001-50%. Solid metal lithium is melt into liquid or gasified into gas, and then the liquid or the gas is mixed with the framework material, so that the flexible lithium metal cell negative pole is prepared. Compared with a lithium sheet negative pole, the lithium metal cell negative pole effectively improves the mechanical property of lithium metal negative poles, restrains dendritic growth and alleviates the volume swelling of an electrode in the lithium removing and inlaying process; if a flexible positive pole is matched with the negative pole to obtain flexible cells, realization of the business application to flexible wearable electronic equipment with high energy density can be facilitated.

Owner:TSINGHUA UNIV

Composite, preparation method and application thereof in lithium ion secondary battery

ActiveCN106816594AImprove performanceRaw materials are easy to getMaterial nanotechnologySilicaCarbon coatingSilicon oxide

The invention discloses a composite. The composite comprises nanometer silicon, a lithium-containing compound and a carbon coating, or comprises nanometer silicon, a silicon oxide, a lithium-containing compound and a carbon coating. The method comprises the following steps: (1) mixing a carbon-coated silicon oxide and a lithium-source solid phase; and (2) thermally processing a prefabricated lithium precursor obtained in step (1) in a vacuum or non-oxidative atmosphere to obtain the composite. The method is simple, small in requirement on equipment, and low in cost; the obtained composite is stable in structure; the structure and property cannot be degraded after long-term storage; a battery prepared from a negative electrode material containing the composite is high in lithium taking-off capacity, high in first coulomb efficiency, and high in circulating performance; the charging capacity is equal to or above 1920mAh / g; the discharging capacity is equal to or above 1768mAh / g; and the first effect is equal to or more than 90.2%.

Owner:BTR NEW MATERIAL GRP CO LTD

Solid-state composite metal lithium negative electrode

InactiveCN108511708AIncrease profitAlleviate volume expansionCell electrodesLi-accumulatorsSolid state electrolyteSpray coating

The invention provides a solid-state composite metal lithium negative electrode. The solid-state composite metal lithium negative electrode consists of a composite layer and a solid-state electrolyteprotecting layer, wherein the composite layer consists of metal lithium and lithium-favoring framework material; the solid-state electrolyte protecting layer comprises an inorganic solid-state electrolyte and an organic solid-state electrolyte; the composite layer of metal lithium and lithium-favoring framework material is provided by melting and lithium filling, electrochemical deposition or physical and mechanical mixing; the solid-state electrolyte protecting layer is applied to the surface of the composite layer by impregnating, scrape coating, rotary coating, spray coating or spattering.Compared with the common lithium piece negative electrode, the solid-state composite metal lithium negative electrode has the advantages that the problem of volume expansion of the negative electrodeis relieved, the deposition behavior of the metal lithium can be regulated and controlled, the growth of lithium dendrites can be inhibited, the safety property of a metal lithium battery is improved,and the cycle life of the metal lithium battery is prolonged; in the testing process of a lithium and copper semi-battery, the volume is expanded by 1 to 20% in the charge and discharge process, theobvious dendrites do not occur in the 20 to 5000 cycles of the battery, and the utilization rate is increased to 80 to 99.9999%.

Owner:TSINGHUA UNIV

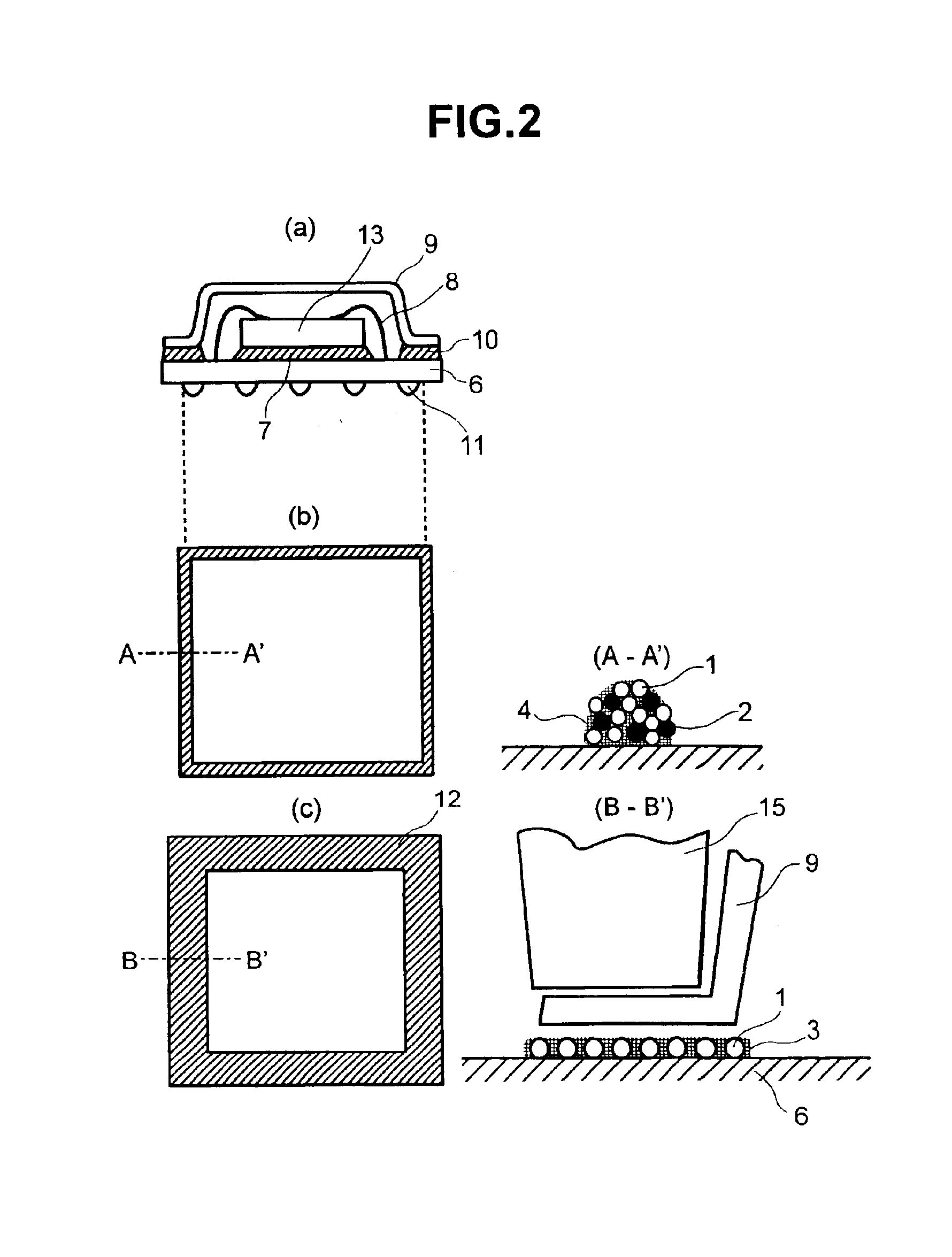

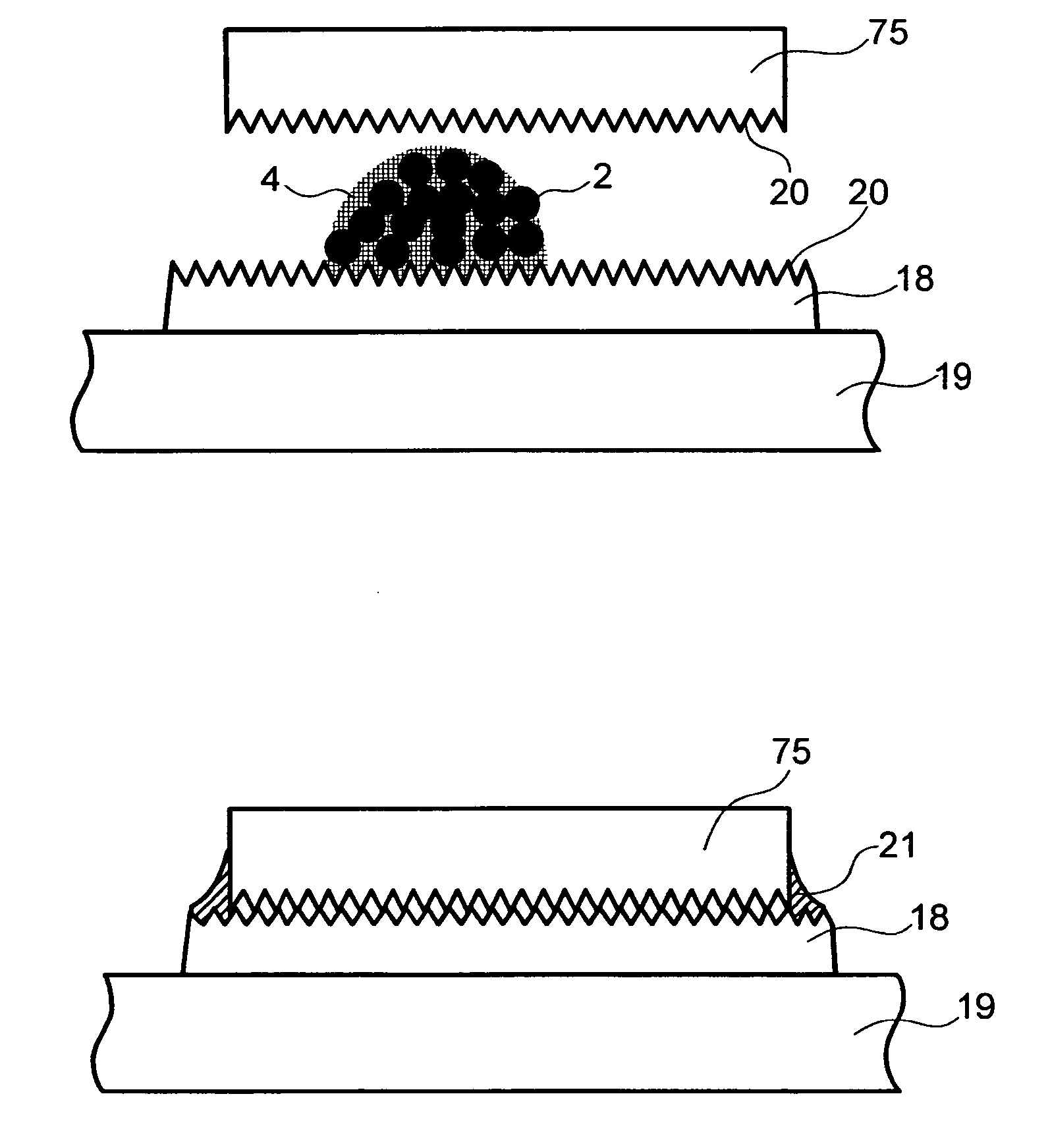

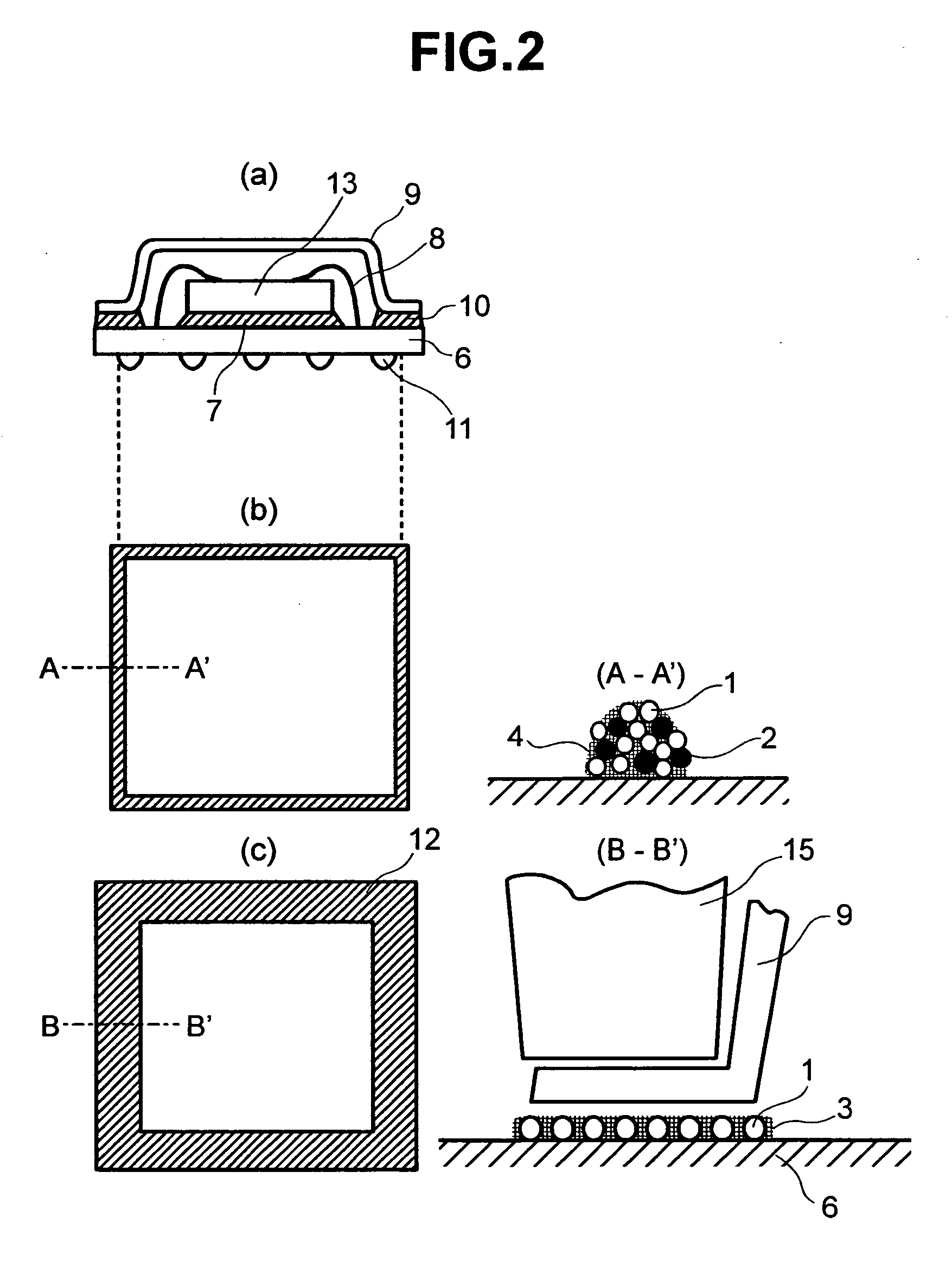

Solder

InactiveUS6872465B2Prevent solder outflowLow costPrinted circuit assemblingSemiconductor/solid-state device detailsSemiconductorMetal

In a solder that realizes high-temperature-side solder bonding in temperature-hierarchical bonding, a connection portion between a semiconductor device and a substrate is formed of metal balls made of Cu or the like and compounds formed of metal balls and Sn, and the metal balls are bonded together by the compounds.

Owner:RENESAS ELECTRONICS CORP

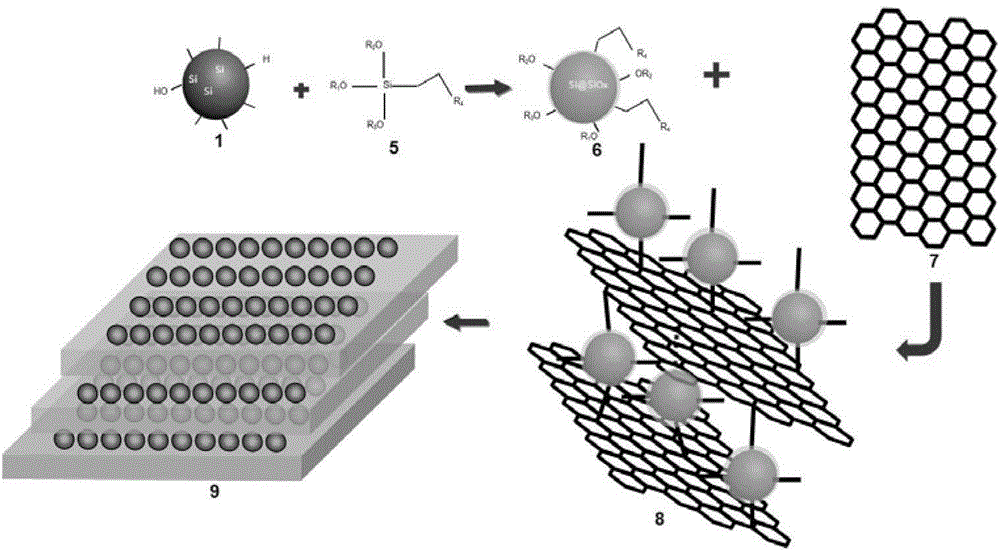

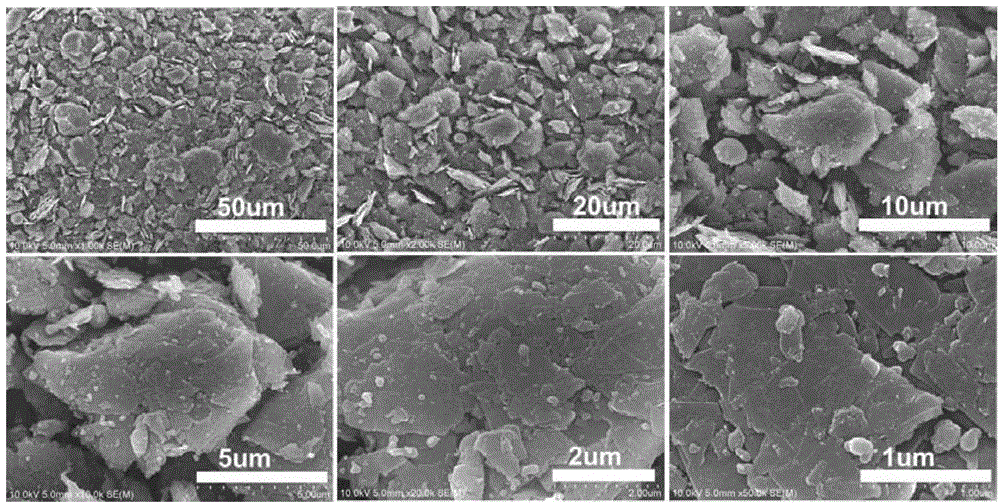

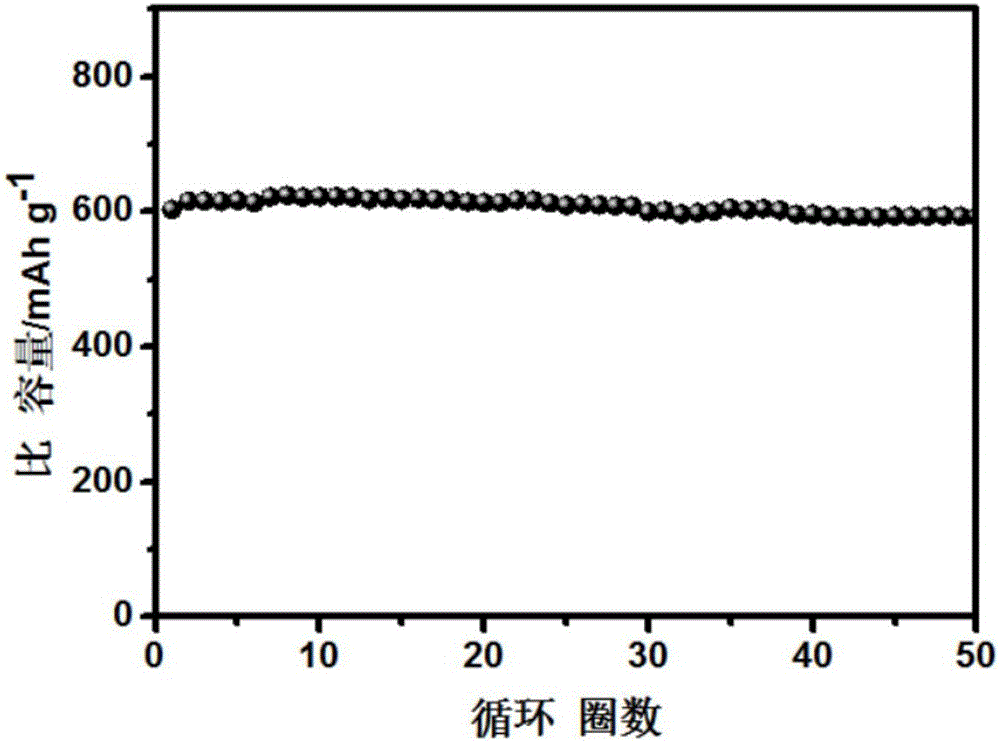

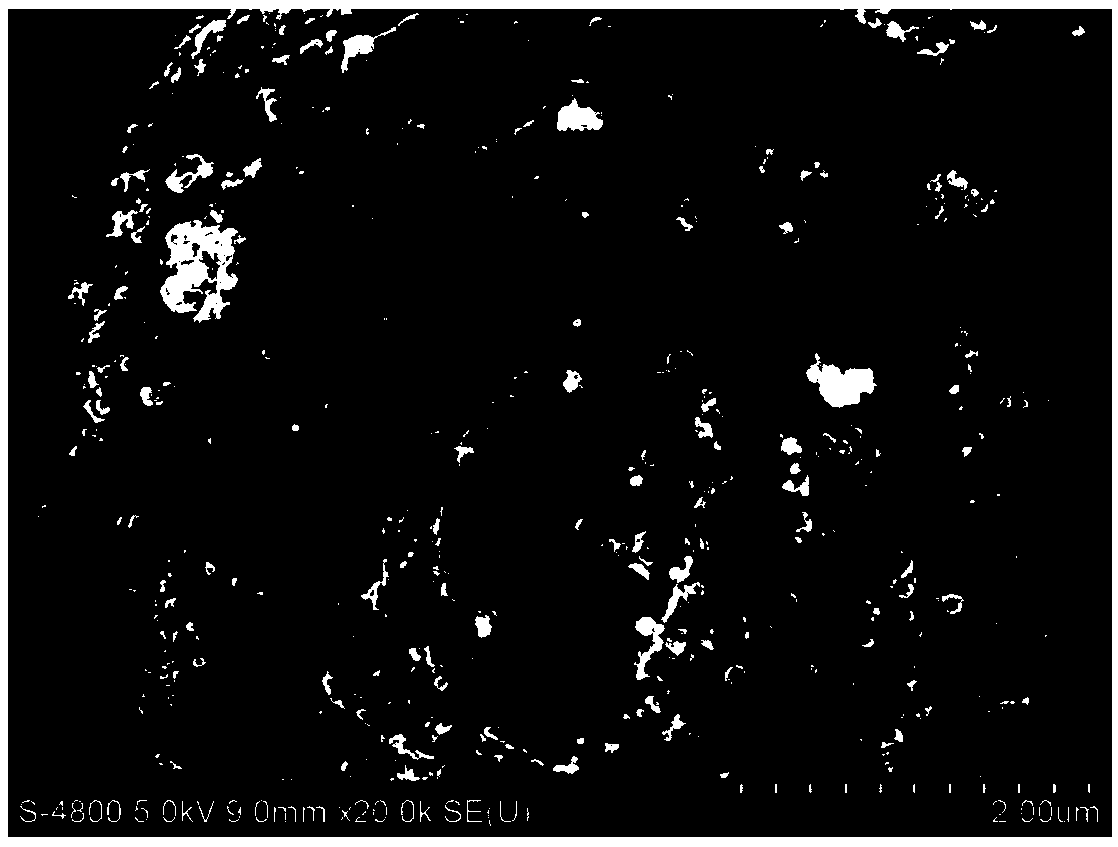

Graphene modified silicon monoxide and carbon composite microsphere, and preparation method and application thereof

ActiveCN106410158AAlleviate volume expansionActive connectionCell electrodesBatteriesCarbon compositesSilicon monoxide

The invention provides a graphene modified silicon monoxide and carbon composite microsphere prepared from graphene, asphalt and silicon monoxide, and a preparation method and an application thereof. Asphalt and silicon monoxide bulk are adopted as raw materials, so the cost is low; a high temperature and high pressure reaction is adopted to obtain a silicon monoxide and carbon composite material in a liquid phase, so the technology is simple; and a dispersant can be recycled, so no waste liquid is generated, and no toxic substances are discharged. The above obtained material has a small specific surface area, and is in favor of forming a stable SEI film; a graphene two-dimensional material has an obvious modification effect, effectively connects active substances, and alleviates volume expansion of an electrode, and good dispersion and reasonable cavity of silicon monoxide make the material have excellent cycle performances.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

Si@C lithium-ion battery negative electrode material of core-shell structure and preparation method thereof

ActiveCN107359326AFacilitated DiffusionImproved magnification performanceMaterial nanotechnologyCell electrodesCarbon layerChemical reaction

The invention discloses an Si@C lithium-ion battery negative electrode material of a core-shell structure and a preparation method thereof. The material uses a metal organic frame compound MOFs as a carbon source, and comprises a core and a cladding layer, the core is spherical nanometer silicon, and the cladding layer is an amorphous carbon layer of a porous structure. The material is prepared through the following steps: A, surface activation of nanometer silicon; B, preparation of an Si@MOFs precursor; and C, preparation of Si@C. The carbon layer in the obtained composite material is of good electrical conductivity and an abundant porous structure, quick transfer of electrons and diffusion of electrolyte ions are facilitated, the volume expansion of the core in the electrochemical reaction process can be effectively buffered, and the composite material has excellent electrochemical performance; and the preparation method is simple in production technology, easily controlled for reaction conditions and environmentally-friendly, and is beneficial for performance optimization and industrial production of silicon negative electrode materials.

Owner:XUZHOU NORMAL UNIVERSITY

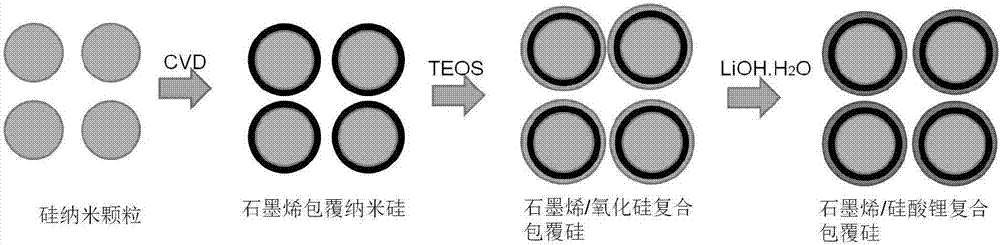

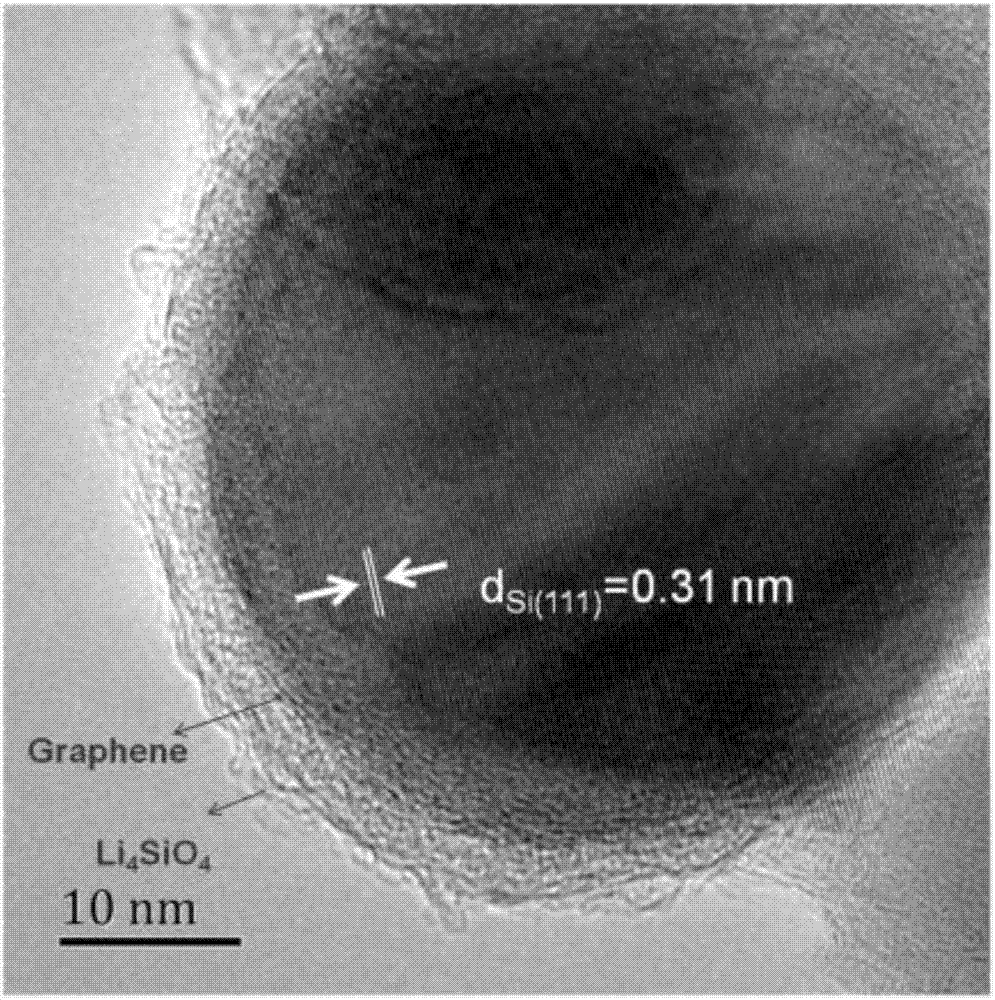

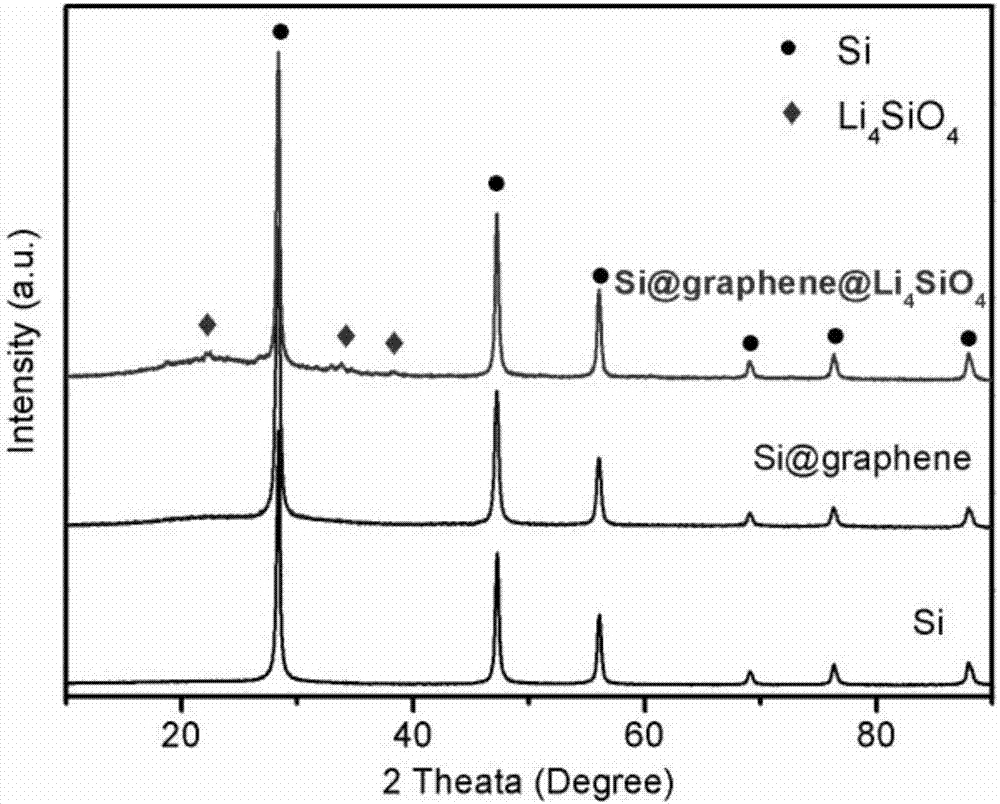

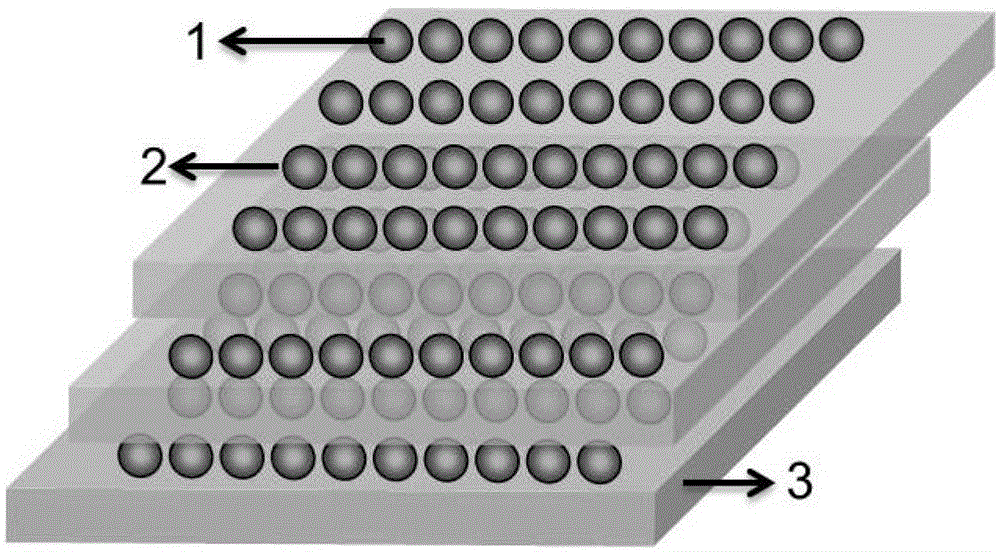

Graphene/solid-state electrolyte composite coated silicon composite negative electrode and preparation method thereof

ActiveCN107579239ASimple processCoated evenlyCell electrodesSecondary cellsElectrochemical responseSolid state electrolyte

The invention discloses a graphene / solid-state electrolyte coated silicon composite material and a preparation method thereof. The preparation method comprises the following steps: coating a silicon-based material with a layer of graphene through a chemical vapor deposition method, and accumulating concentrated ammonia water into an oxide through a precursor ester of an oxide for coating to obtainan oxide and graphene co-coated silicon negative electrode material; performing lithiation on the composite material with lithium hydroxide monohydrate to finally obtain the graphene / solid-state electrolyte coated silicon composite material. In the composite material, graphene directly grows on the surfaces of silicon particles, and the surface of graphene is coated with solid-state electrolyte,thereby forming double-layer coating. The graphene inside can increase the electronic conductivity of the silicon-based material, and relieve volume expansion of silicon. The coating solid-state electrolyte outside can improve the Coulomb efficiency and the magnification performance of the silicon-based negative electrode material, reduce the electrochemical reaction between the negative electrodematerial and electrolyte, increase the Coulomb efficiency of the silicon-based negative electrode and improve the high current charging and discharging performance of the material.

Owner:深圳索理德新材料科技有限公司

Silicon/silicon oxycarbide/graphite composite negative electrode material

ActiveCN104466142AAdjustable capacityStable structureElectrode carriers/collectorsSecondary cellsSilicon oxygenLithium-ion battery

The invention relates to a silicon / silicon oxycarbide / graphite composite negative electrode material which is a silicon-containing material which has the size being lower than 3 microns uniformly and is firmly distributed on the surface of a negative electrode of graphite. The invention further provides a preparation method of the composite negative electrode material. The preparation method comprises the steps of dispersing a silicon-containing material in a liquid organo-siloxane monomer, sequentially adding an acid liquid of alcohol and water, a curing agent and a graphite negative electrode material, then carrying out ball milling or mechanical stirring, pinching and mixing to obtain a paste-type mixture; calcining the paste-type mixture at high temperature under a protective atmosphere, crushing and sieving to obtain different-particle-size silicon / silicon oxycarbide / graphite lithium-ion battery negative electrode material. The silicon-containing materials of the silicon / silicon-oxygen carbon / graphite composite negative electrode material are firmly and uniformly distributed on the surface of a graphite material; due to the structure, the silicon-containing materials can be effectively adsorbed on the surface of the graphite, the self agglomeration of the silicon-containing material can be avoided and the silicon-containing material is prevented from peeling off from the graphite; the silicon / silicon oxycarbide / graphite composite negative electrode material has the characteristics that the charge and discharge specific capacities are adjustable, and the electrochemical cycle stability is high.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Electronic device

InactiveUS20060145352A1Reduce the possibilityEasy to cutPrinted circuit assemblingFinal product manufactureDevice materialSemiconductor

In an electronic device which realizes high-temperature-side solder bonding in temperature-hierarchical bonding, a bonding portion between a semiconductor device and a substrate is formed of metal balls made of Cu, or the like, and compounds formed of metal balls and Sn, and the metal balls are bonded together by the compounds.

Owner:HITACHI LTD

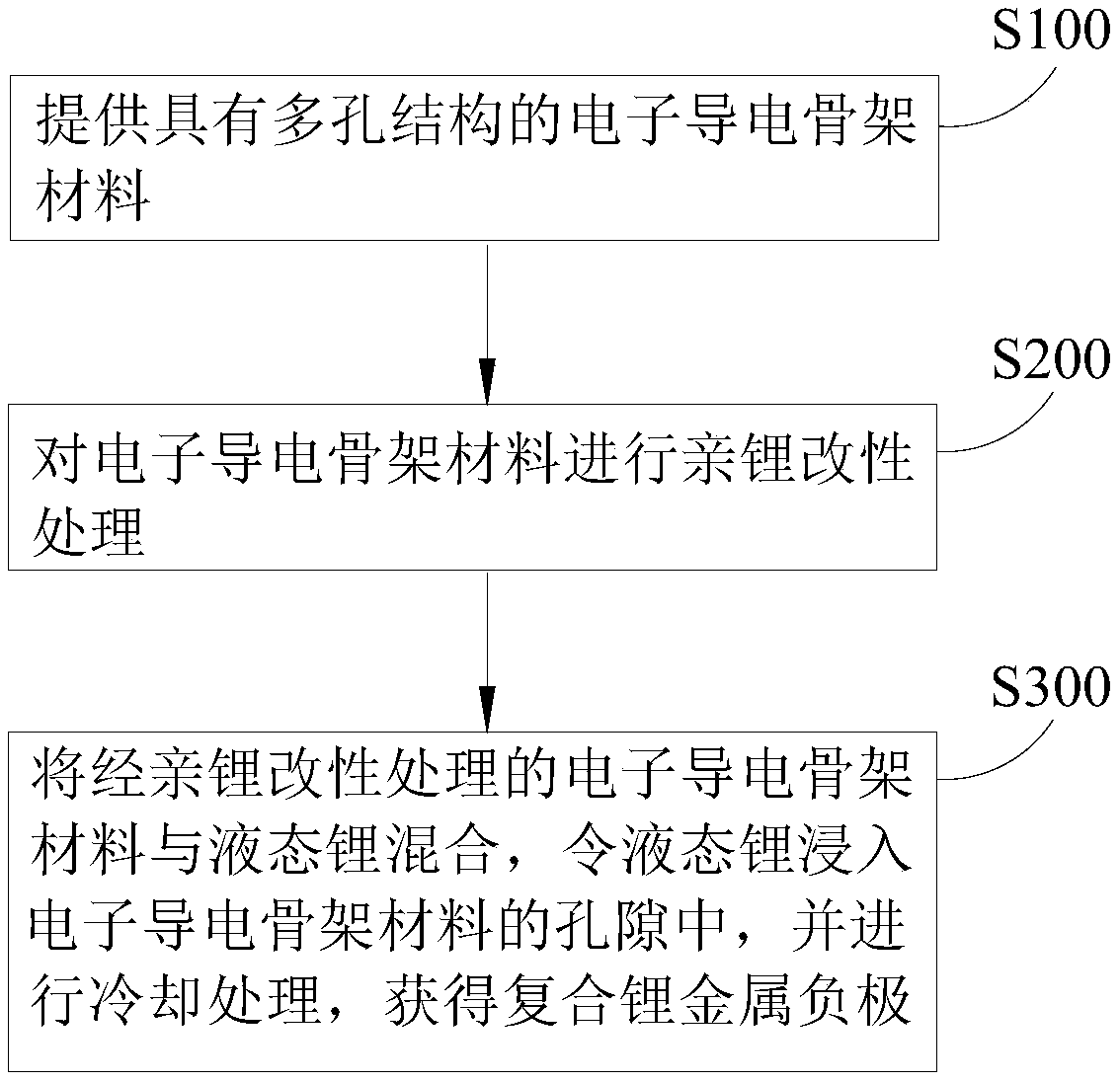

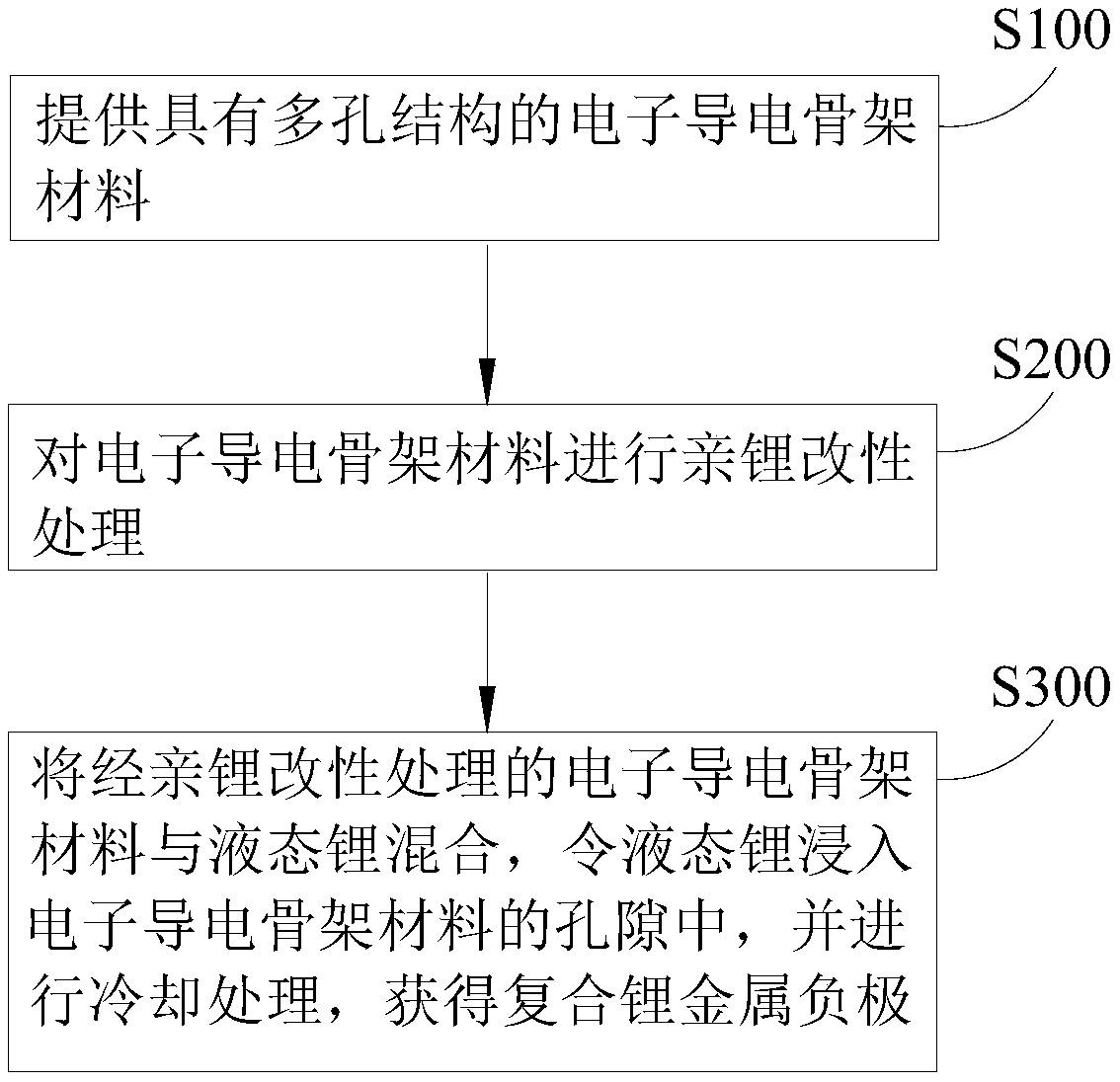

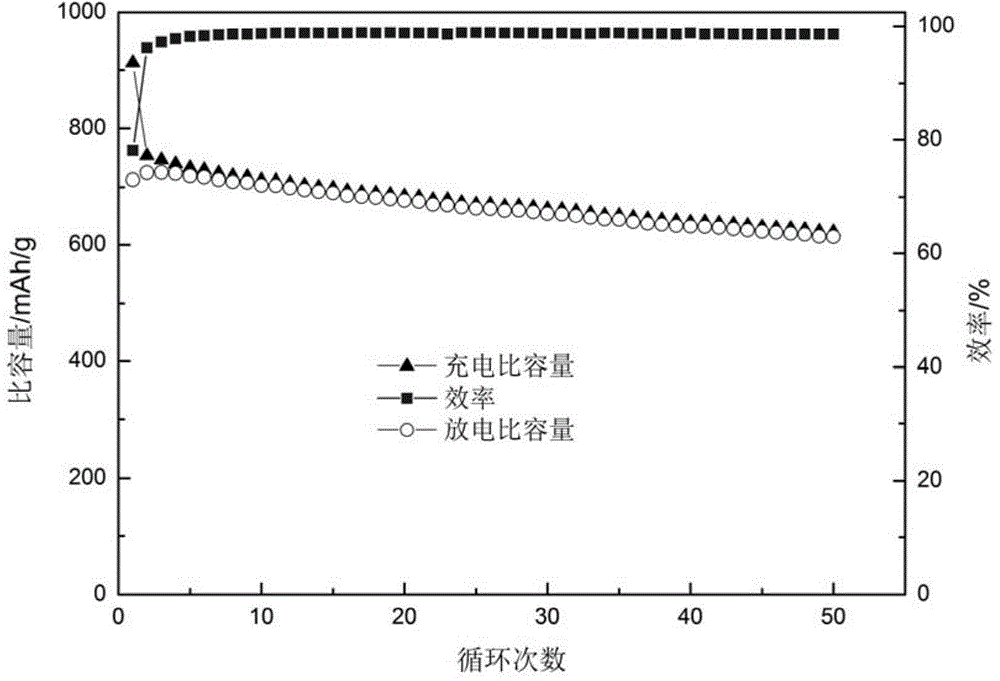

Composite lithium metal negative electrode, preparation method and lithium ion battery

ActiveCN109713224APrecise control of porositySufficient porosityActive material electrodesSecondary cellsPorosityAluminium-ion battery

The invention provides a composite lithium metal negative electrode, a preparation method and a lithium ion battery. The method for preparing the composite lithium metal negative electrode comprises the following steps: providing an electronic conductive framework material with a porous structure; carrying out lithium-philic modification treatment of the electronic conductive framework material; mixing the electronic conductive framework material subjected to the lithium affinity modification treatment with liquid lithium; immersing the liquid lithium into pores of the electronic conductive framework material, and performing cooling to obtain the composite lithium metal negative electrode; controlling the ratio of the volume of the liquid lithium to the total volume of the pores in the electronic conductive framework material to ensure that the porosity of the composite lithium metal negative electrode is 20-98% and lithium content of 0.01-0.01% 10mg / cm2. According to the invention, the porosity and the lithium content of the composite lithium metal negative electrode can be accurately controlled through the method, dendritic crystals are effectively prevented from being formed, and the problems of volume expansion, poor cycle performance, high safety risk and the like of the lithium metal negative electrode are solved, so that a battery applying the composite lithium metal negative electrode has high energy density and long-cycle stability.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Preparation method of silicon-carbon negative electrode material for lithium ion battery

ActiveCN104538607AInhibition of volume expansionAlleviate volume expansionCell electrodesCarbon coatingHigh energy

The invention discloses a preparation method of a silicon carbon negative electrode material for a lithium ion battery. The preparation method comprises the following steps: high-energy ball milling, organic carbon coating, high-temperature carbonization and micro-oxidation, wherein the micro-oxidation step is carried out after the high-energy ball milling step and before the organic carbon coating step, and is carried out at least once after the high-temperature carbonization step. The previous and / or subsequent micro-oxidation treatment can ensure that a SiO2 layer is oxidized on the Si surface, and play a role of oxidation and pore-forming on graphite and pyrolytic carbon; a SiO2 electrochemical inert layer inhibits the volume expansion of Si to a certain extent, while the porous structure can relieve the volume expansion of Si to a certain extent, thereby improving the cyclic performance of the silicon carbon negative electrode material.

Owner:TIANJIN B&M SCI & TECH

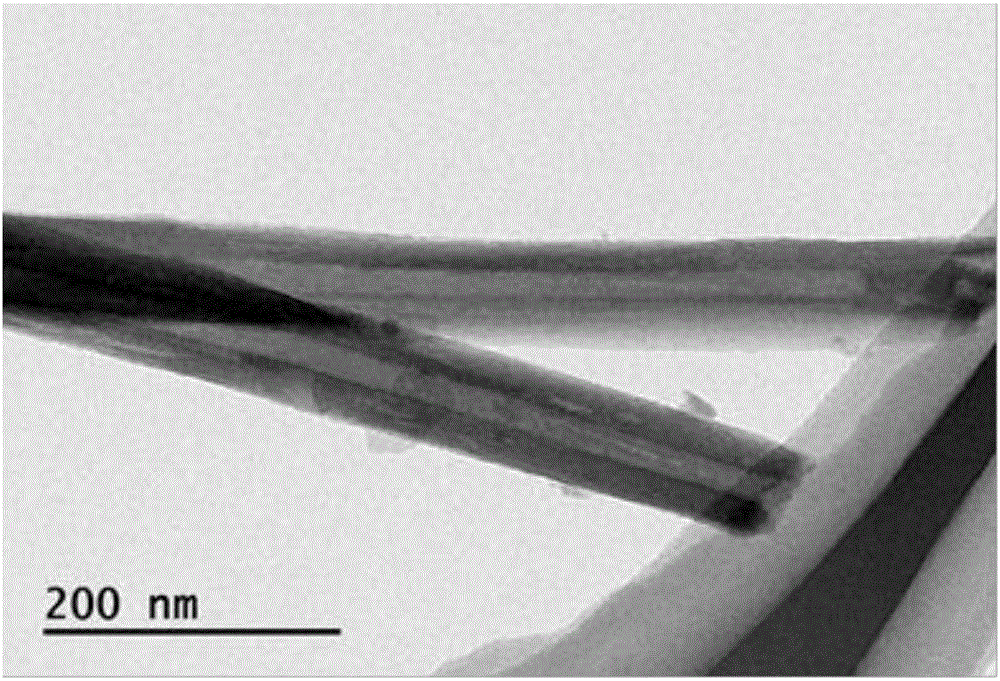

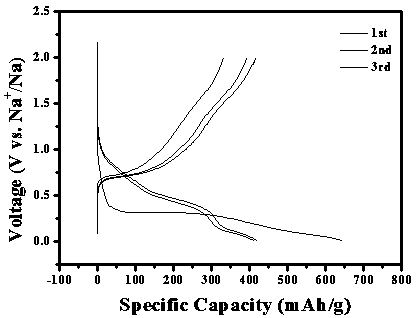

Stannic selenide/graphene oxide negative pole composite material for sodium ion battery and preparation method thereof

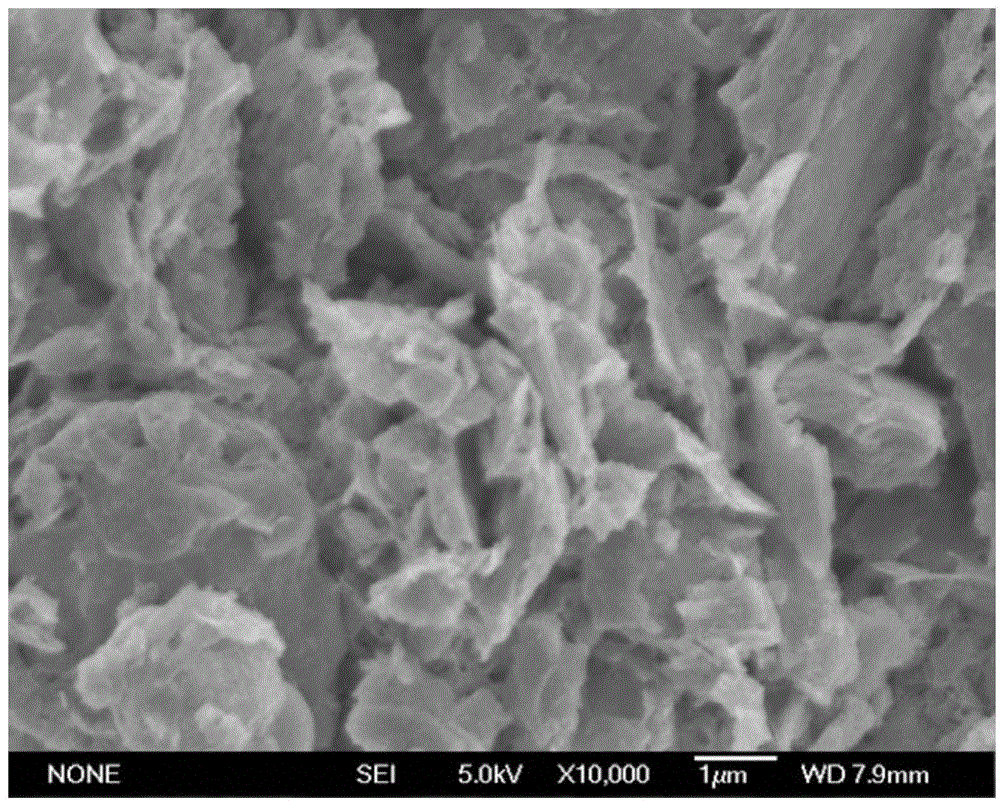

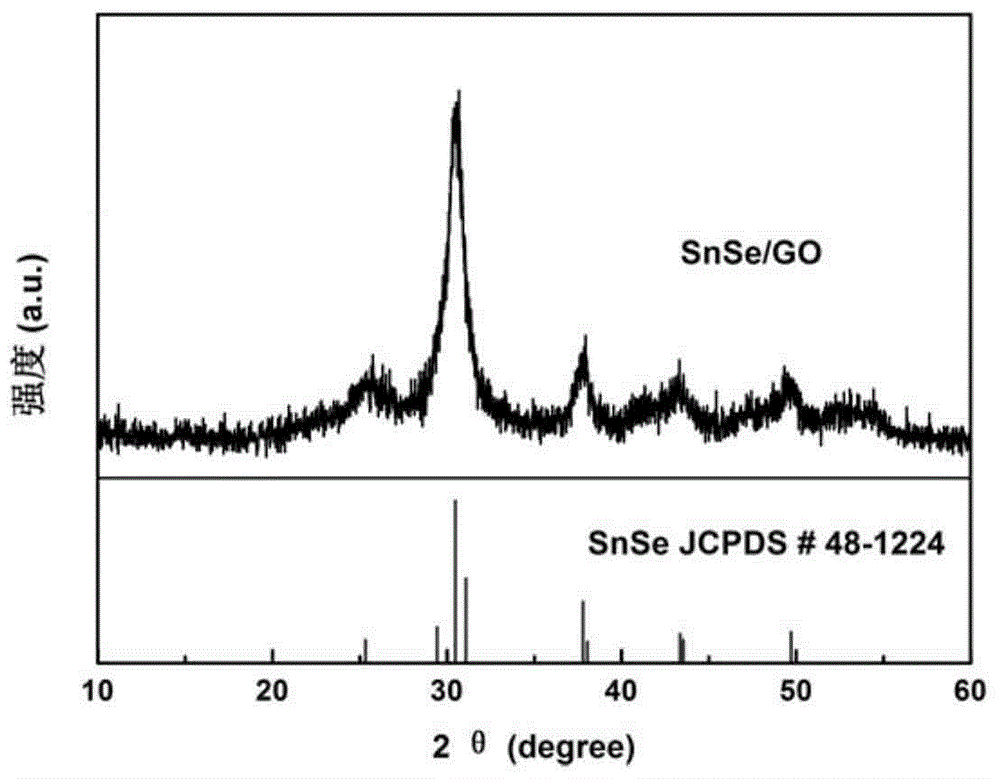

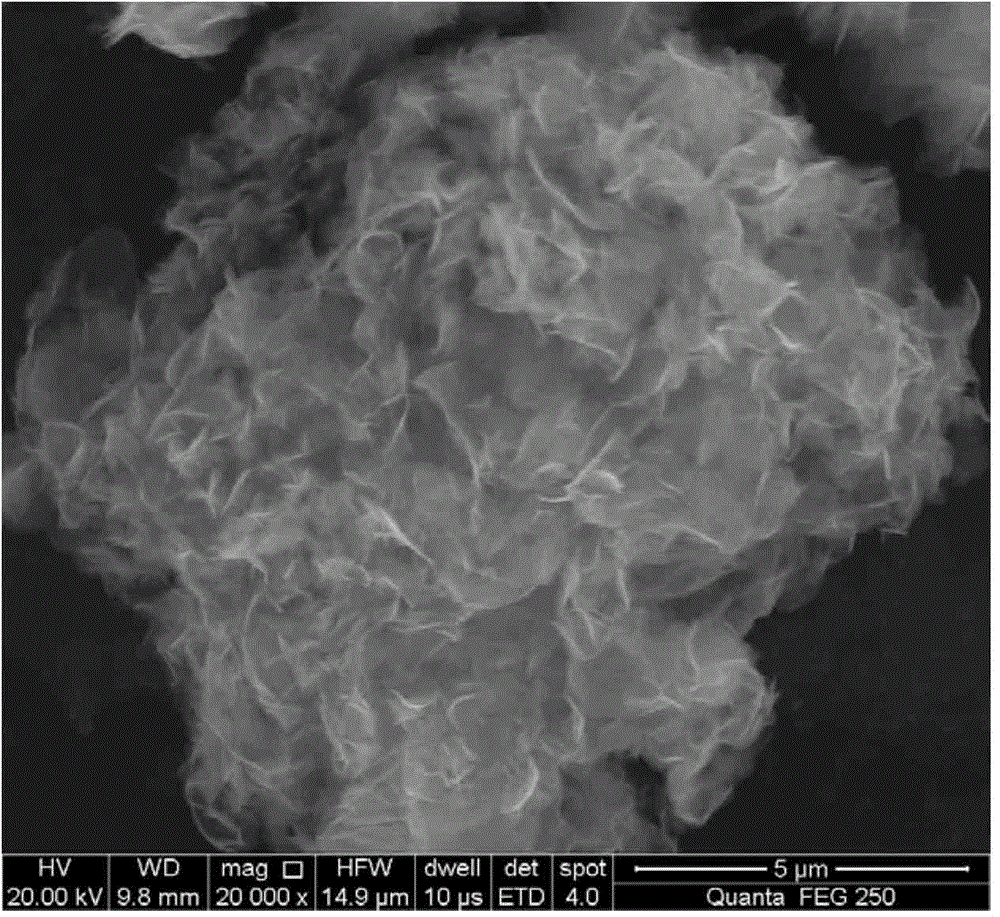

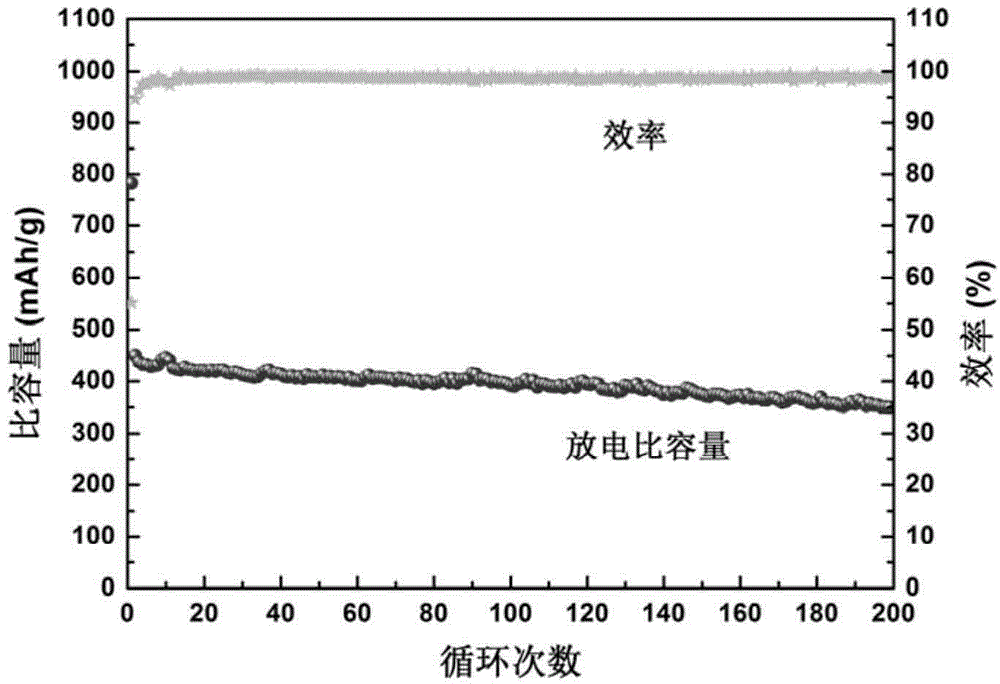

ActiveCN104617271AEasy to prepareGood repeatabilityMaterial nanotechnologyElectrode manufacturing processesOperabilitySodium-ion battery

The invention discloses a stannic selenide / graphene oxide negative pole composite material for a sodium ion battery and a preparation method thereof. The negative pole composite material is formed by uniformly growing nanometer stannic selenide on the surface of graphene oxide. The preparation method comprises the following steps of: ultrasonically dispersing graphene oxide powder into a mixed solution of water and ethylene glycol to obtain a dispersion solution; adding tin salt and selenite to the dispersion solution, then carrying out hydrothermal reaction, and placing a hydrothermal reaction product into an inert gas protective tube furnace for heat treatment so as to obtain a negative pole composite material which has nanometer sheet-like morphology and is formed by uniformly growing nanometer stannic selenide on the surface of graphene oxide. The composite material disclosed by the invention can be used for preparing the sodium ion battery which has the characteristics of high discharging specific capacity, excellent magnification property, long cycle life and the like. The preparation method disclosed by the invention has the advantages of simplicity, reliability, good process repeatability, high operability, low cost and suitability for industrialized production.

Owner:CENT SOUTH UNIV

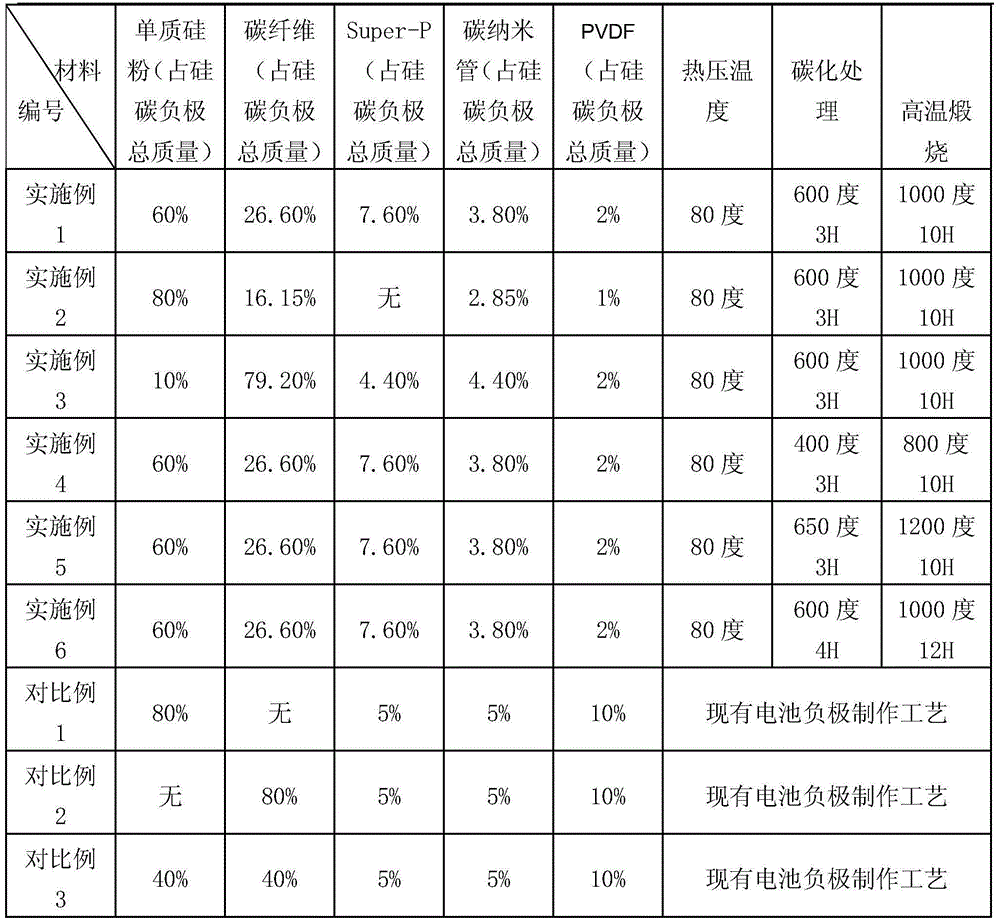

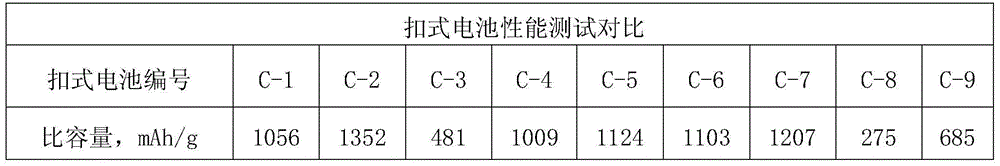

Method for preparing silicon-carbon composite anode and lithium ion battery

ActiveCN104681797APromote circulationSimple preparation processCell electrodesSecondary cellsCarbon compositesCyclic process

The invention discloses a silicon-carbon composite anode comprising a silicon source and a carbon source, wherein silicon source is monatomic silicon, the particle size distribution is 100 nm to 80 microns, and the mass of the silicon source accounts for 10-80% of the total mass of the silicon-carbon composite anode; the carbon source comprises a carbon anode material and a conductive agent, the carbon anode material is one or more of carbon fiber, graphite and mesocarbon microbead, and the mass of the carbon anode material accounts for 10-90% of the total mass of the carbon source. According to the silicon-carbon composite anode disclosed by the invention, one-step coating forming, hot pressing flaking, carbonization treatment and high-temperature calcination are carried out on anode slurry prepared by mixing the silicon source with the carbon source, so as to guarantee that the silicon material is effectively dispersed in a carbon skeleton, the prepared silicon-carbon anode can effectively relieve the volume expansion of the silicon material in charging and discharging processes in a circulation process and guarantee excellent cycle performance of the battery; the silicon-carbon composite anode is prepared by one-step coating forming, and no current collector is needed, so that the production process is simplified and the battery is guaranteed to have high energy density; meanwhile, the invention further provides a lithium ion battery containing the silicon-carbon composite anode.

Owner:江苏中兴派能电池有限公司

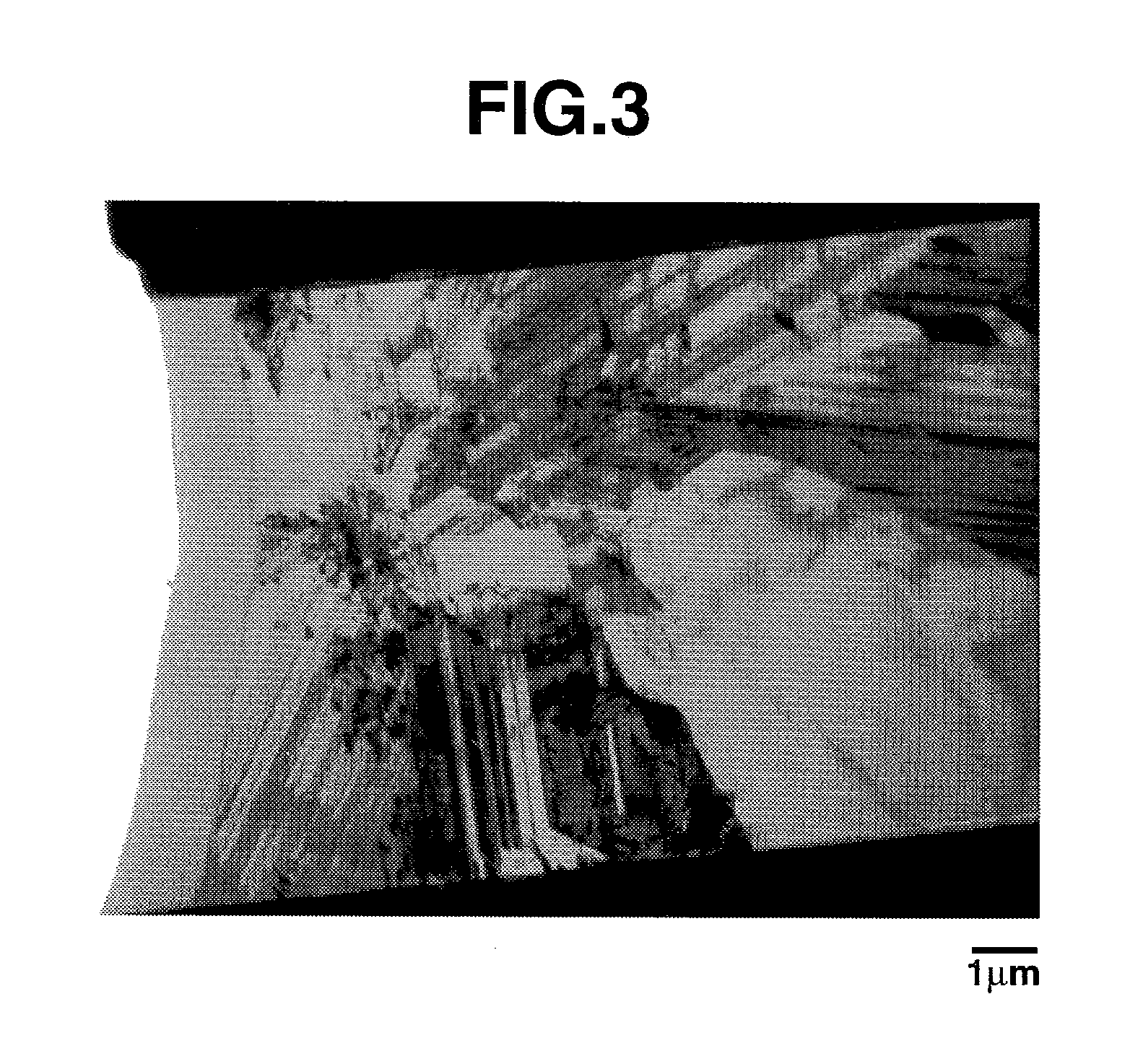

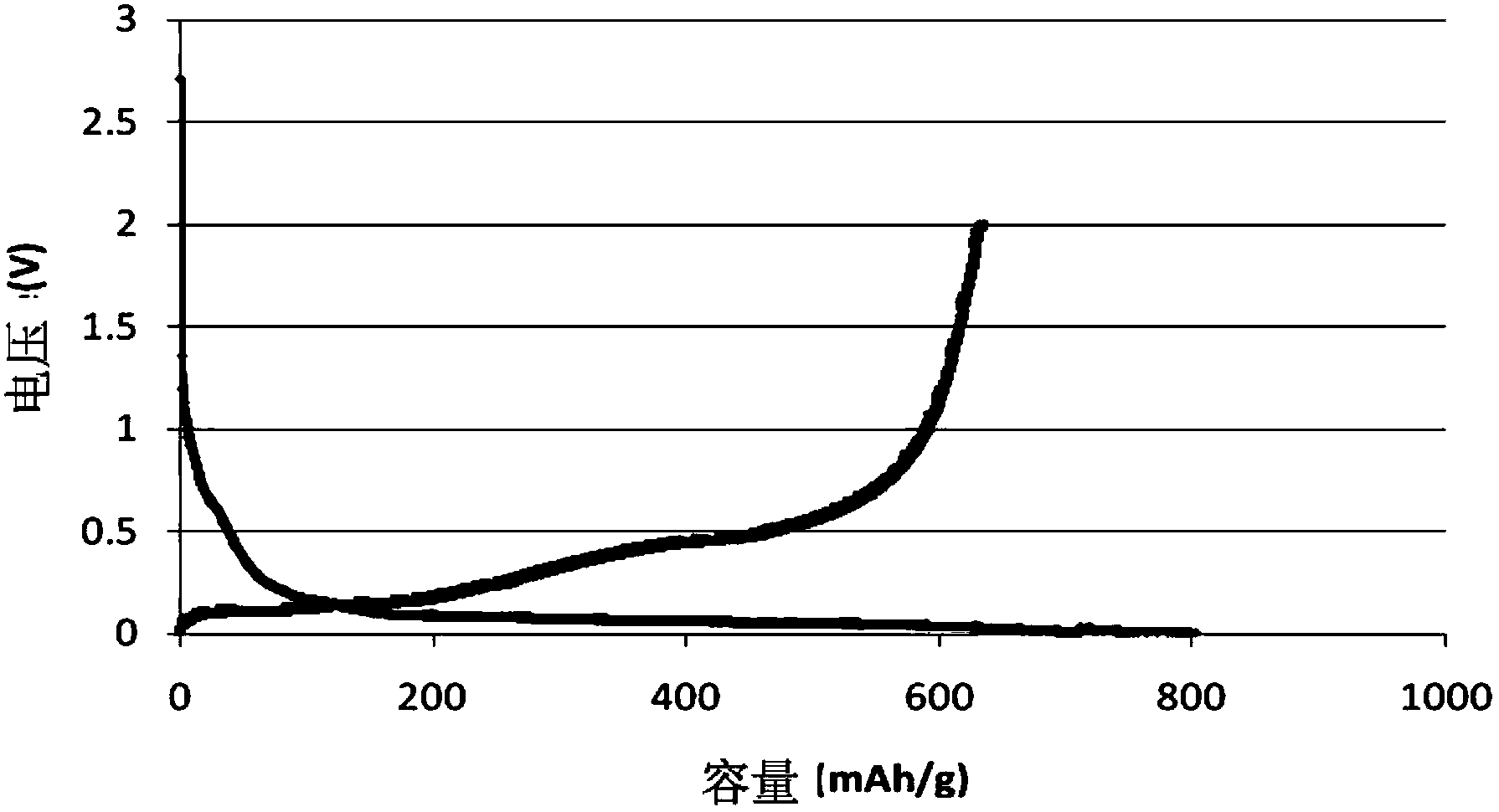

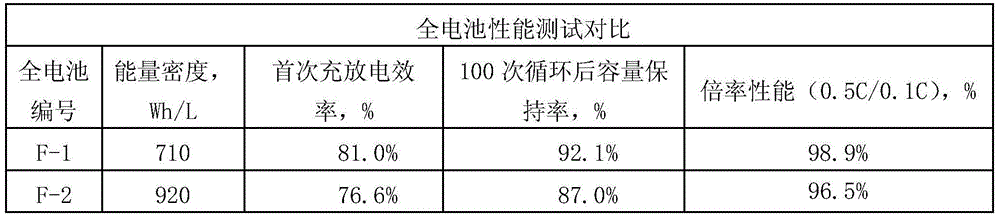

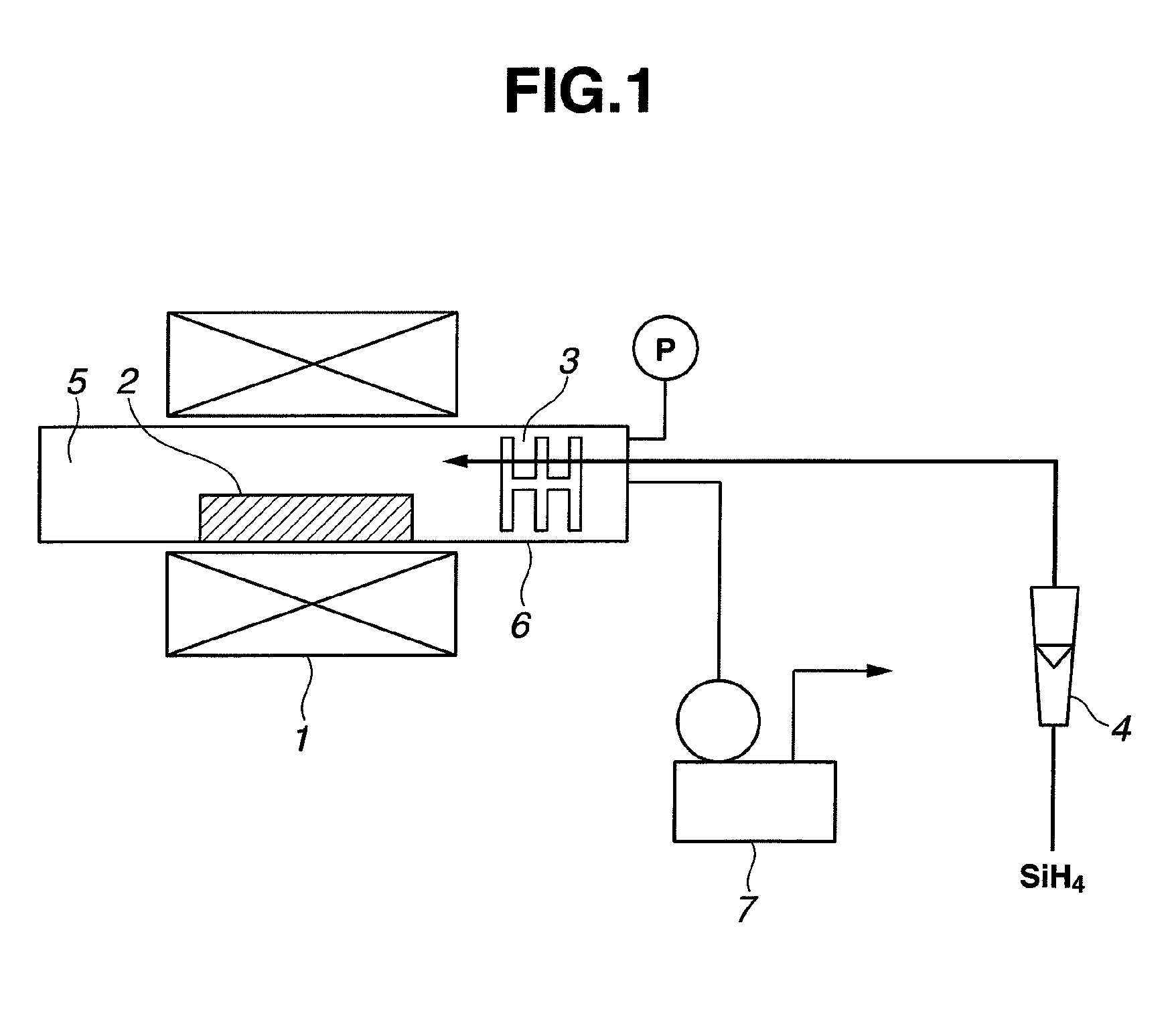

Silicon oxide material for nonaqueous electrolyte secondary battery negative electrode material, making method, negative electrode, lithium ion secondary battery, and electrochemical capacitor

InactiveUS20110287313A1High charge-discharge efficiencyImprove cycle performanceSolid electrolytic capacitorsHybrid capacitor electrodesDischarge efficiencyLithium

A silicon oxide material is obtained by cooling and precipitating a gaseous mixture of SiO gas and silicon-containing gas and has an oxygen content of 20-35 wt %. Using the silicon oxide material as a negative electrode active material, a nonaqueous electrolyte secondary battery is constructed that exhibits a high 1st cycle charge / discharge efficiency and improved cycle performance while maintaining the high battery capacity and low volume expansion of silicon oxide.

Owner:SHIN ETSU CHEM IND CO LTD

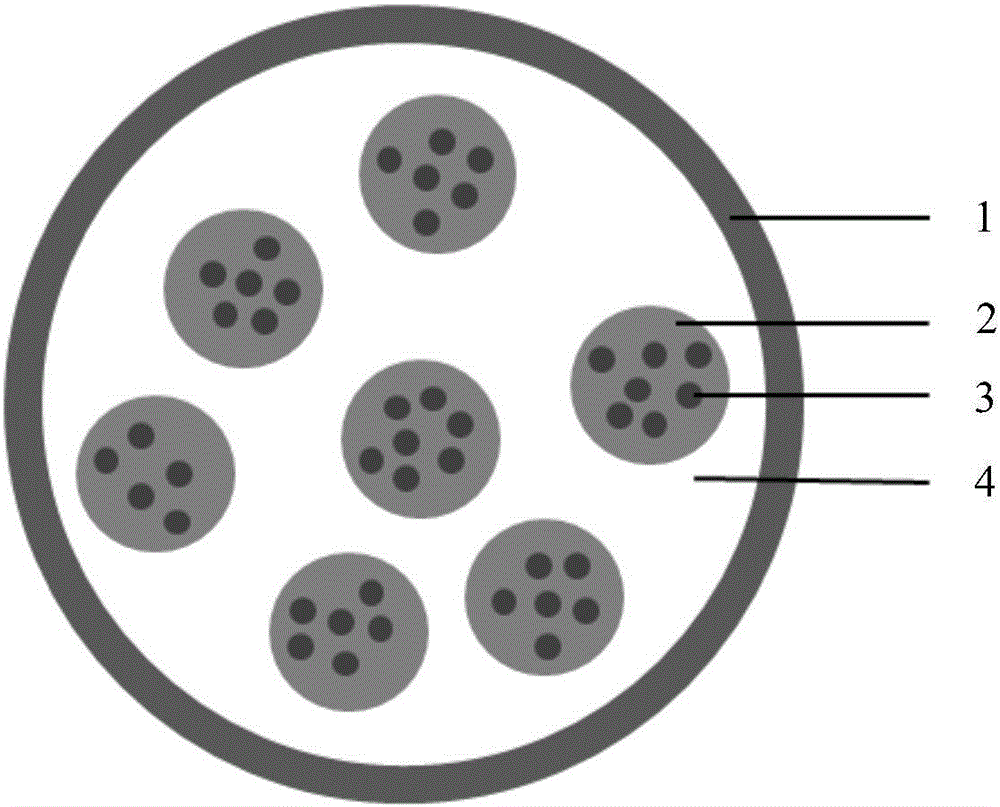

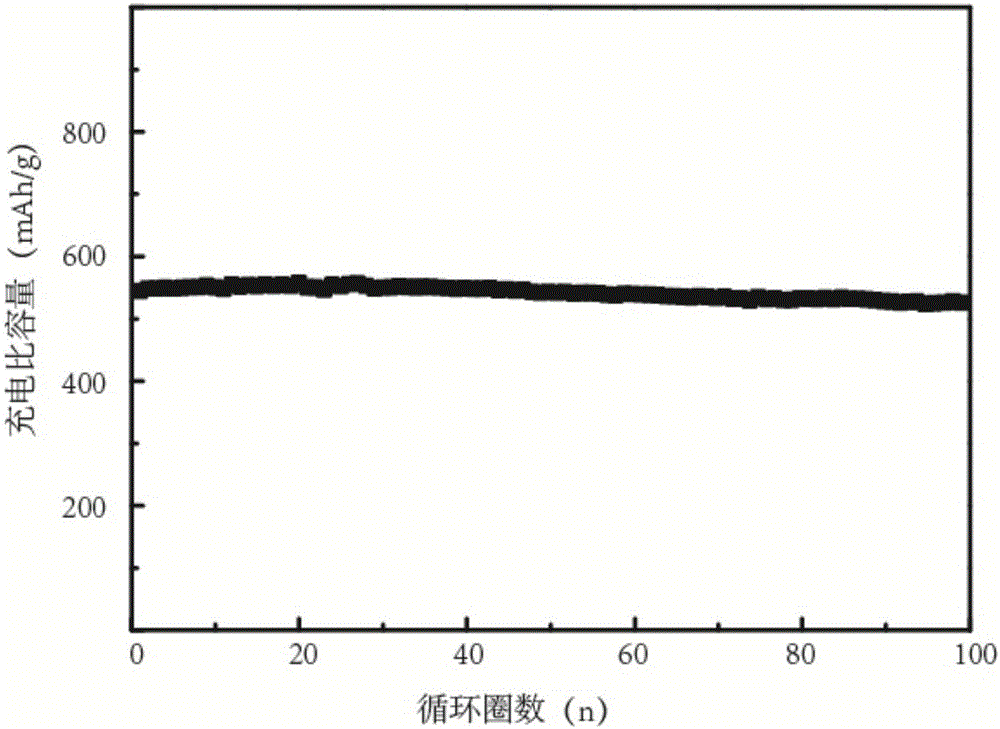

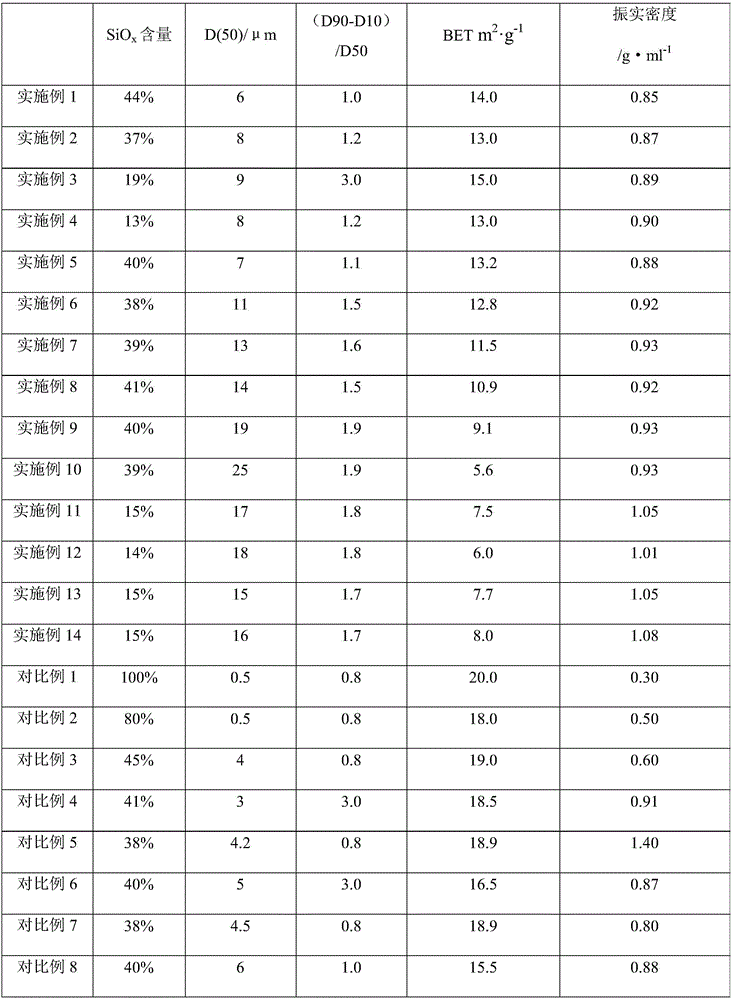

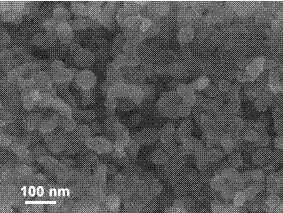

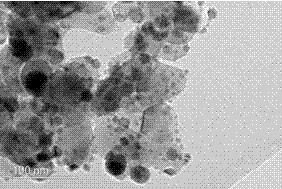

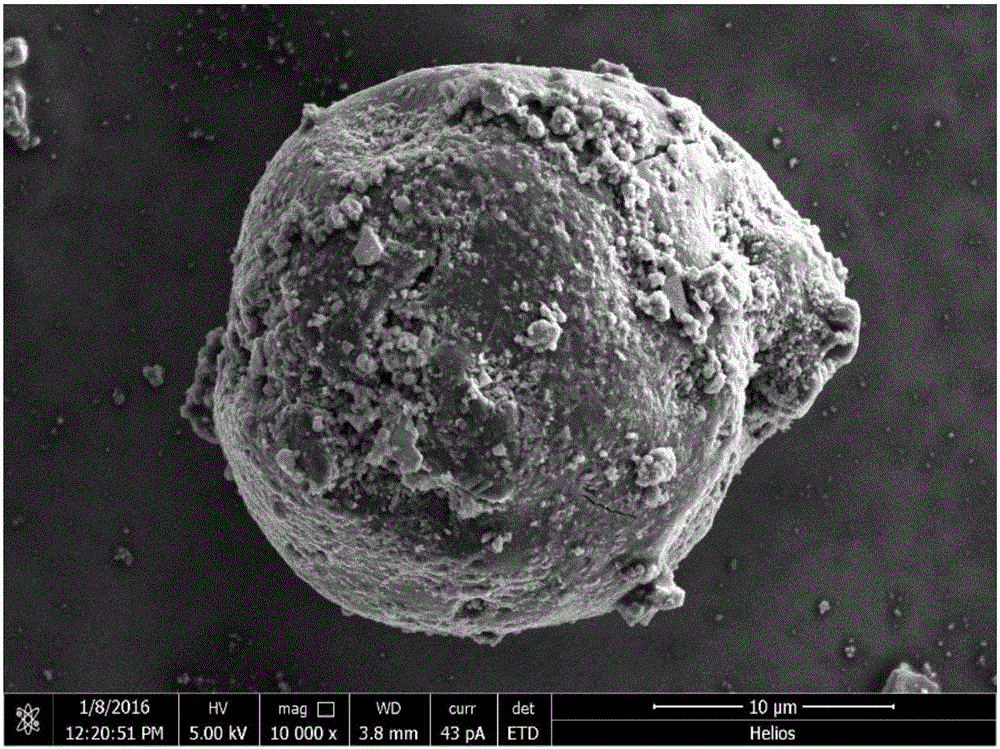

Silicon carbon composite microsphere, and preparation method and application thereof

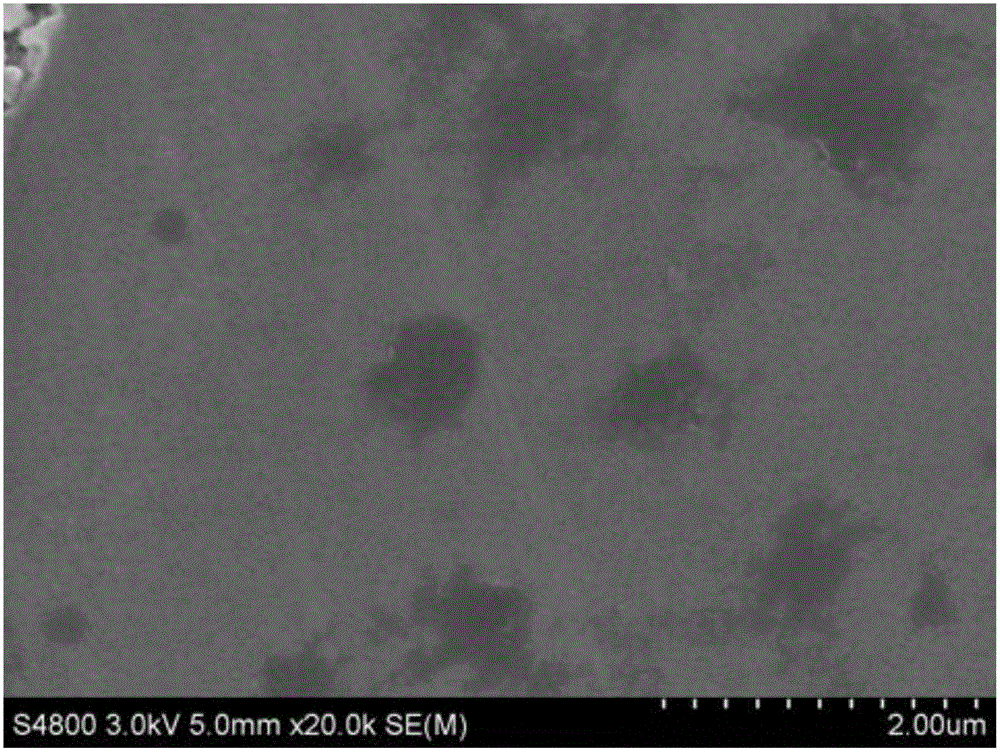

ActiveCN106384825ASmall specific surface areaImprove cycle stabilityCell electrodesSecondary cellsCarbon compositesMicrosphere

The invention provides a silicon carbon composite microsphere, and a preparation method and application thereof. The method comprises the following steps that (1) silicon dispersion liquid is prepared: 30 to 95 percent of asphalt and 5 to 70 percent of silicon are used as raw materials, and are dispersed in an organic solvent; ball milling is performed; (2) other carbon sources are added into grinding liquid; the ball milling is further performed; (3) the dispersion liquid obtained through the ball milling is added into a high-temperature high-pressure reactor; high-temperature high-pressure reaction is performed under the inert gas protection; (4) products obtained in the third step are subjected to suction filtration to obtain solid particles; (5) the solid particles obtained in the fourth step are subjected to high-temperature carbonizing treatment in inertia non-oxidizing atmosphere to obtain the silicon carbon composite microsphere. The method has the advantages that the asphalt and the micron silicon are used as raw materials; the raw materials are cheap and are easy to obtain; a dispersing agent is nontoxic and can be recovered; the process is simple; the sphericity degree of the obtained material is good; the tap density is high; the specific surface is small; a stable SEI membrane is favorably formed; the circulation stability is excellent.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

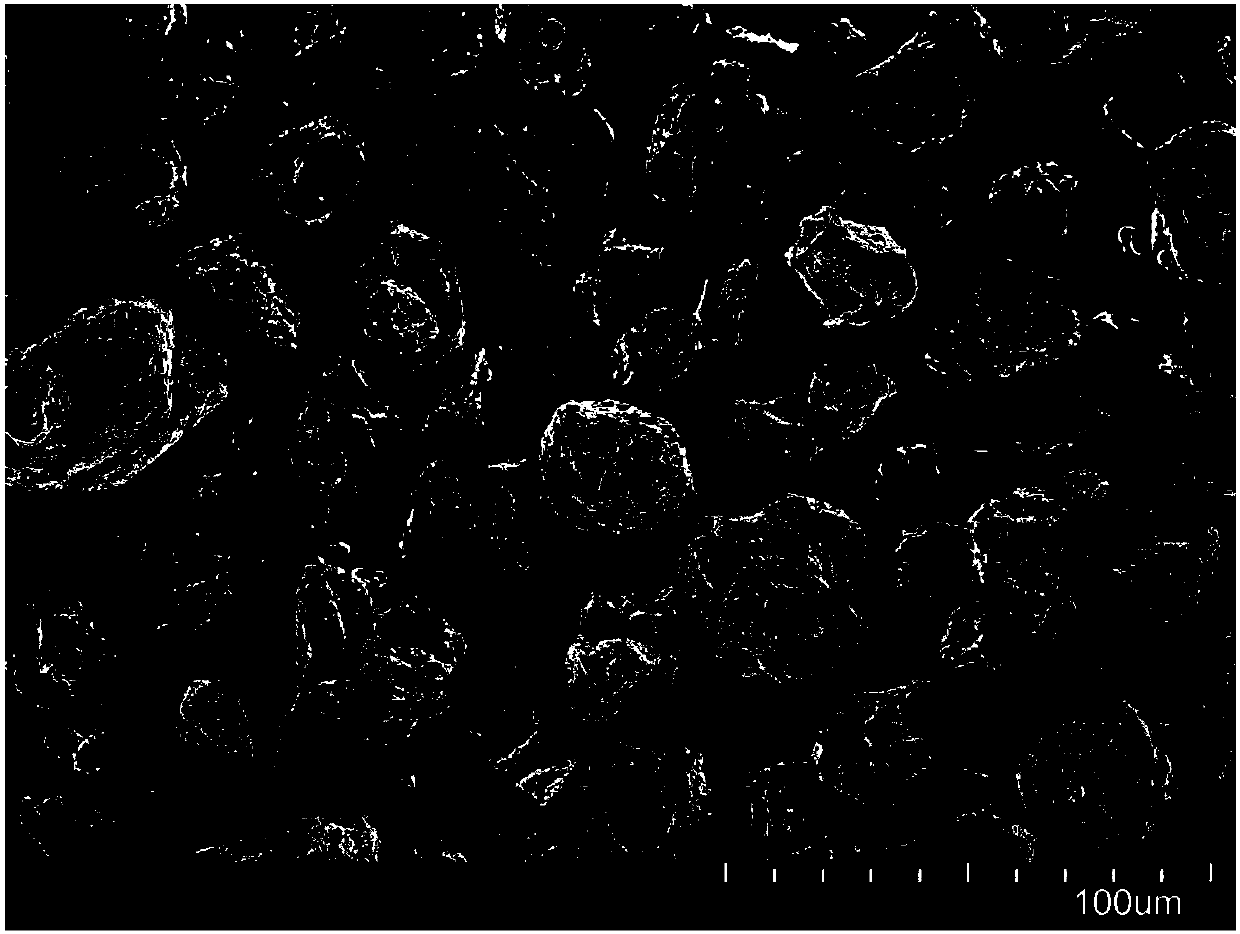

Preparation method of porous silicon/graphite/carbon composite negative electrode material for lithium-ion secondary battery

ActiveCN108199030AAlleviate volume expansionEasy to makeNegative electrodesSecondary cellsCarbon compositesHigh energy

The invention relates to a preparation method of a porous silicon / graphite / carbon composite negative electrode material for a lithium-ion secondary battery. A silicon source of the composite materialis natural mineral soil: namely kaolinite, montmorillonite, mica powder, wollastonite, vermiculite powder, pumice powder and coal gangue. The silicon source is reduced into elemental silicon by usinga metal element or alloy powder and anhydrous metal chloride under a mild condition, and the reduced porous silicon, graphite and an organic carbon source are subjected to high-energy ball mill mixing. The reduction temperature is low, the inherent pore structure of the natural mineral soil is effectively reserved and the prepared silicon material has relatively high specific surface area and abundant pores and has excellent electrochemical properties. Volume expansion can be effectively relieved through the inherent pore characteristic of the natural mineral soil; and the prepared composite material has higher charge-discharge capacity and stability. Especially the kaolinite is wide in source and low in price, so that the preparation cost of the battery material is greatly reduced. The porous silicon / graphite / carbon composite negative electrode material is friendly to environment, simple in preparation method, instrument and equipment and suitable for industrial production.

Owner:NANKAI UNIV

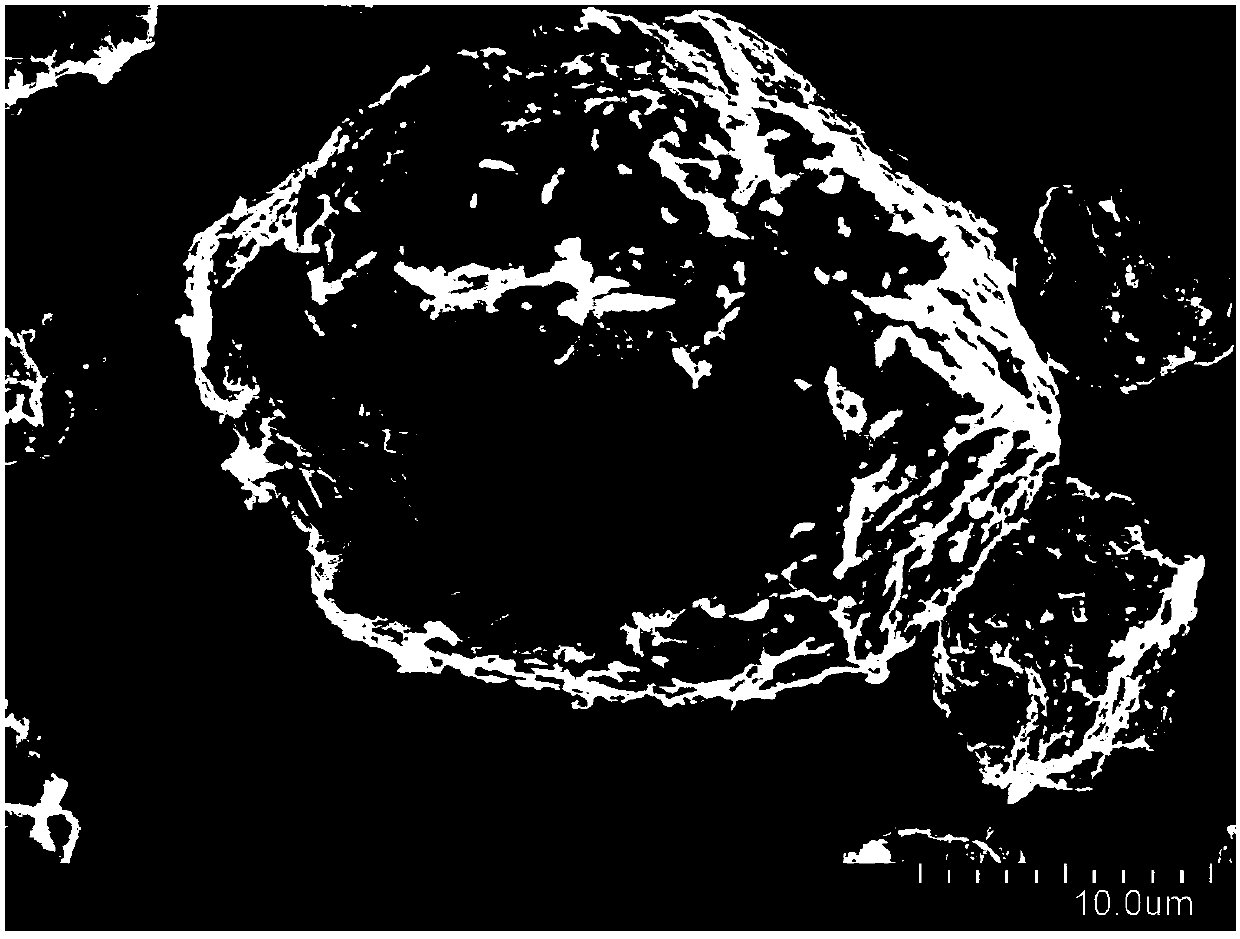

Hollow silicon-carbon composite material for lithium-ion batteries, and preparation method thereof

InactiveCN107799728AIncrease capacityImprove Coulombic efficiencyNegative electrodesSecondary cellsCarbon compositesElectrochemistry

The invention relates to a hollow silicon-carbon composite material and a preparation method thereof. According to the hollow silicon-carbon composite material, the silicon-carbon composite material is spherical or ellipsoid secondary particles; the secondary particles have hollow structures, the shell is formed by compounding graphite sheets, a silicon material and amorphous carbon, the silicon material is uniformly adhered on the surface of the graphite sheet and between the graphite sheets, and the surfaces of all the graphite sheets and the silicon material are covered with an amorphous carbon protection layer; and the graphite sheets for forming the secondary particles are randomly oriented to each other. According to the present invention, the silicon-carbon composite material used as the lithium-ion battery negative electrode has electrochemical characteristics of high capacity, high Coulomb efficiency, low expansion and good cycle performance; the lithium-ion battery prepared from the silicon-carbon composite material has characteristics of high volume energy density, low expansion and good cycle performance; and the preparation process has advantages of simpleness, wide raw material source and low cost, and can achieve the industrial application of the silicon-carbon composite material in the lithium battery field.

Owner:BERZELIUS (NANJING) CO LTD

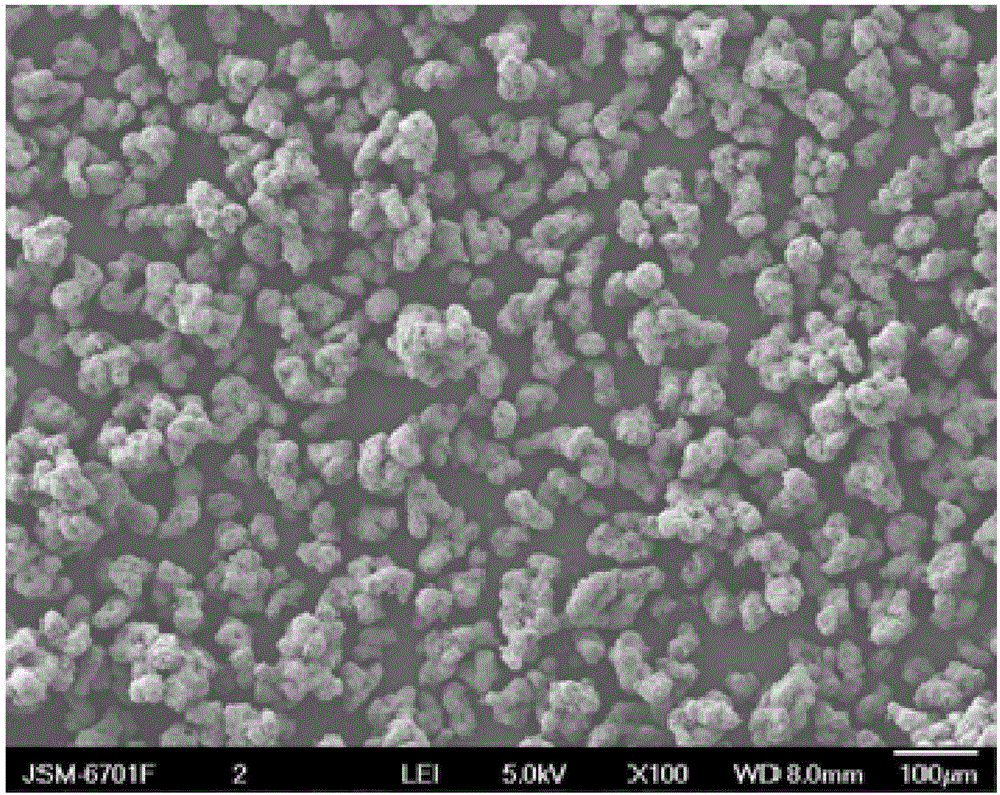

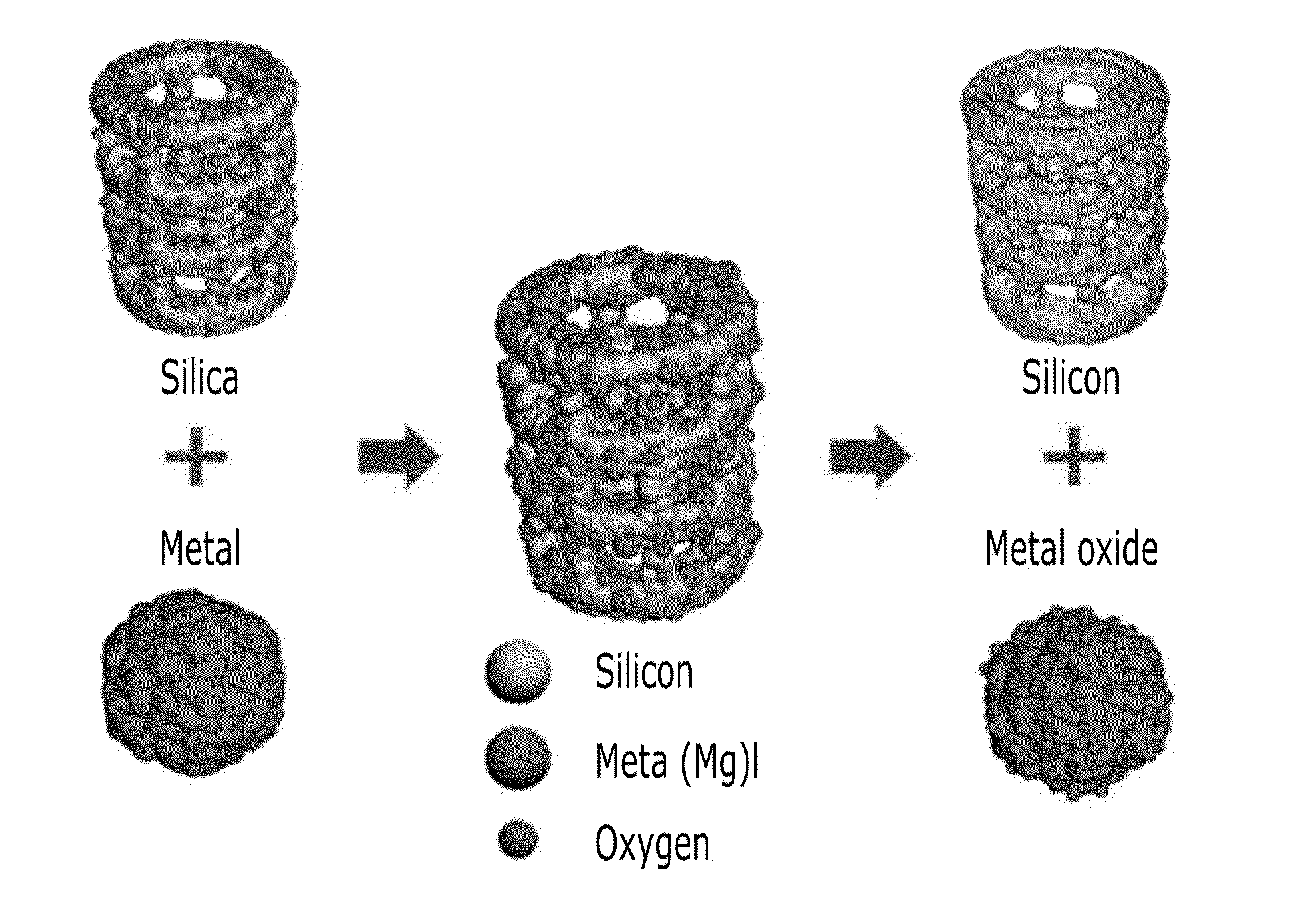

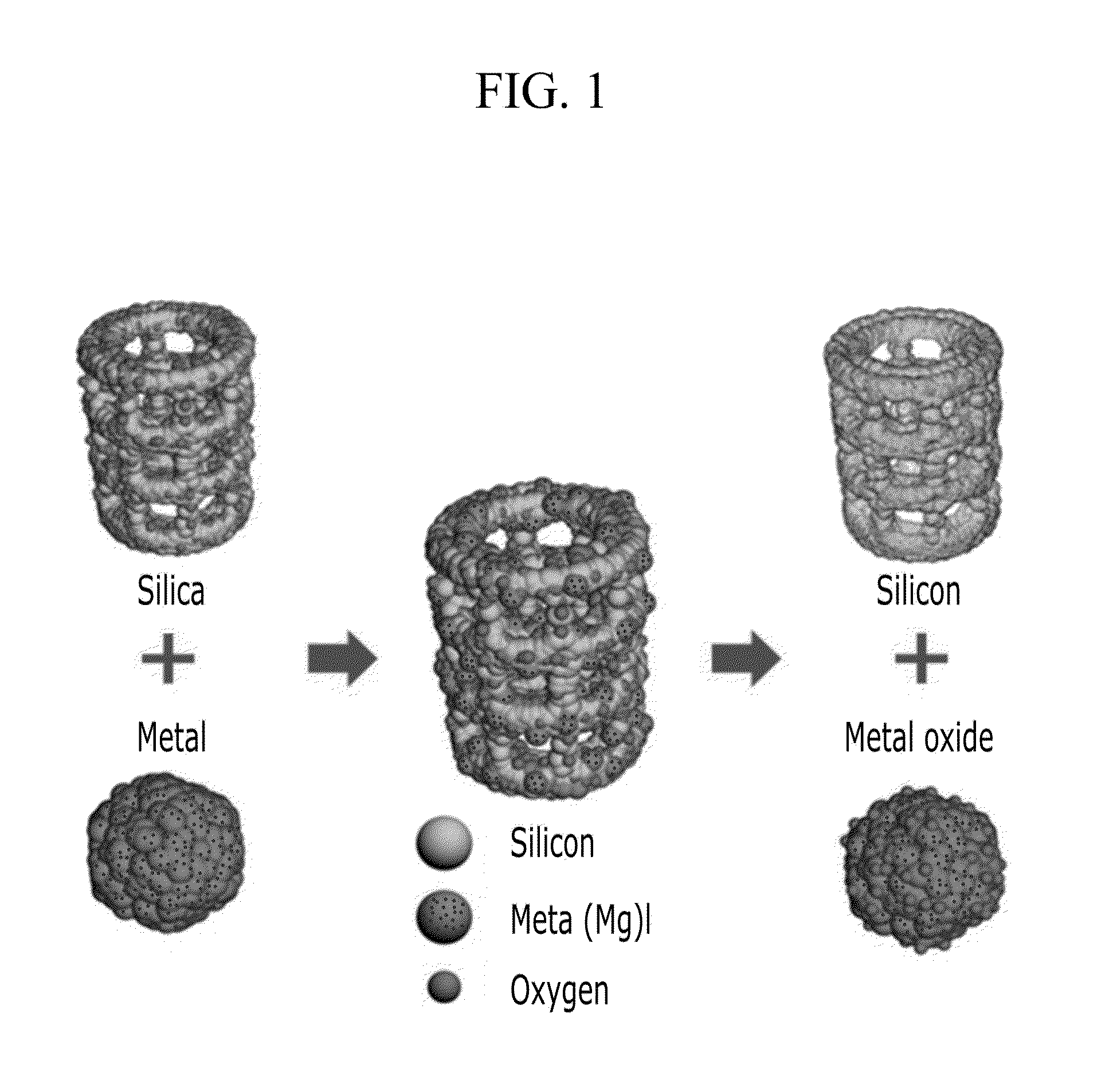

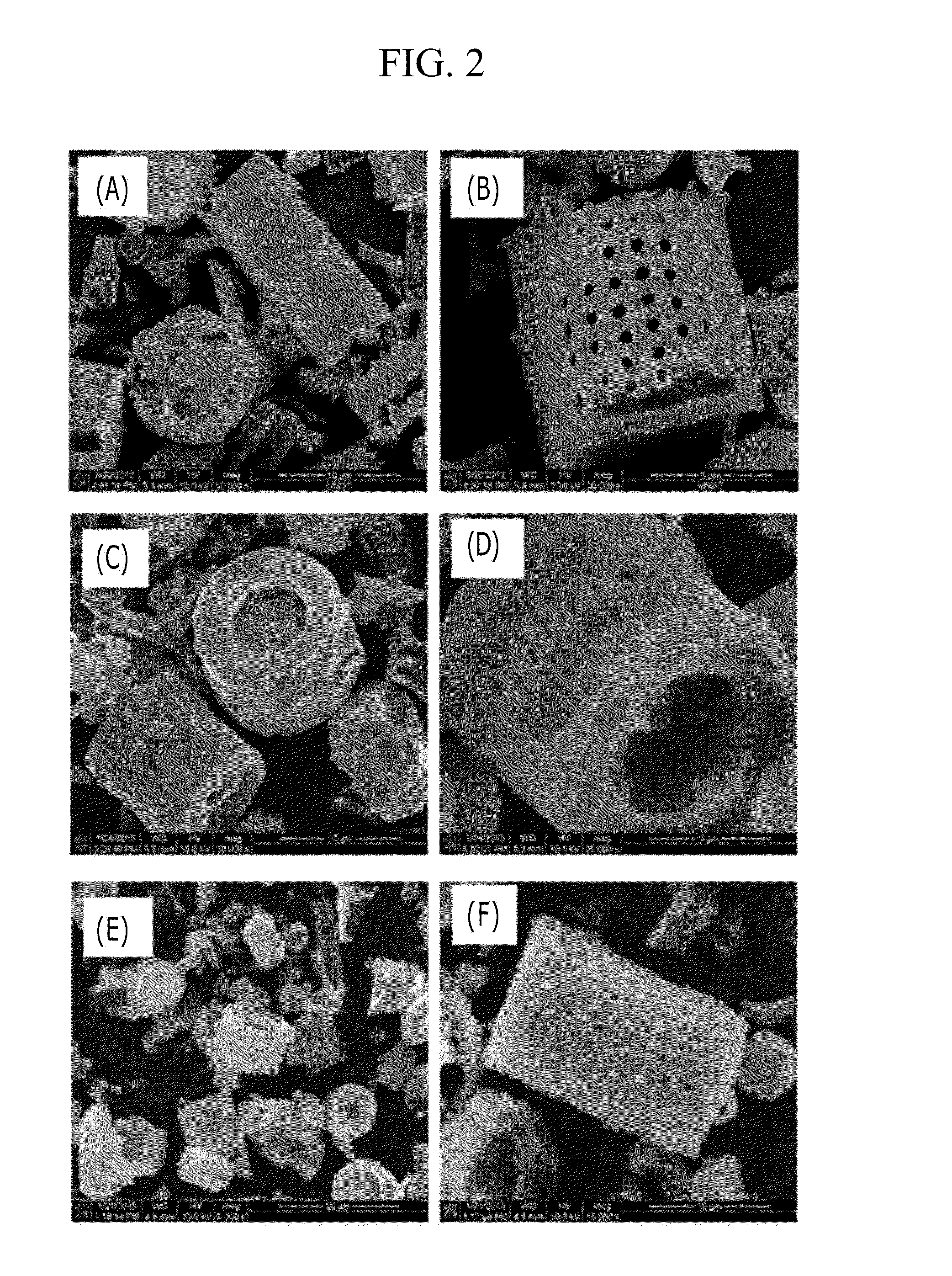

Porous silicon based negative electrode active material, method for manufacturing the same, and rechargeable lithium battery including the same

InactiveUS20140377653A1Extend the life cycleAlleviate volume expansionSiliconElectrode thermal treatmentSilicon dioxidePorous silicon

The present invention relates to a method of preparing a porous silicon-based negative electrode active material comprising: mixing a porous silica (SiO2) and an aluminum powder; oxidizing all or part of the aluminum powder as an aluminum oxide while at the same time reducing all or part of the porous silica as a porous silicon (Si) by heat-treating a mixture of the porous silica with the aluminum powder, a negative electrode active material, and a rechargeable lithium battery including the same.

Owner:UNIST ULSAN NAT INST OF SCI & TECH +1

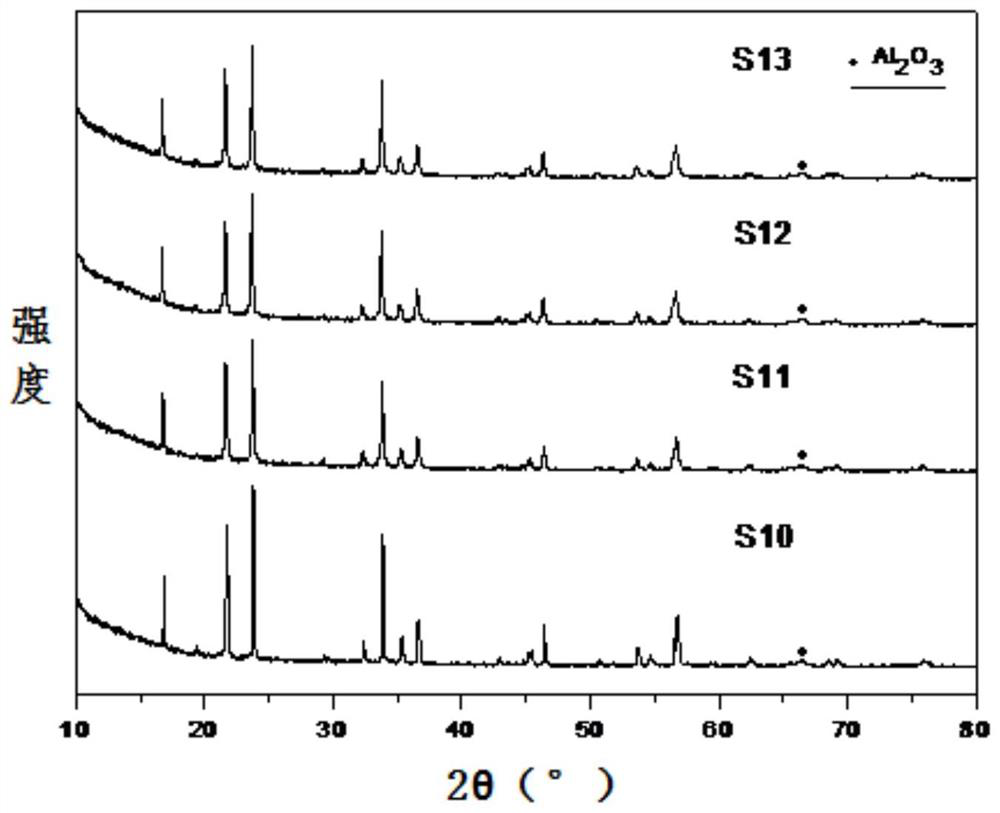

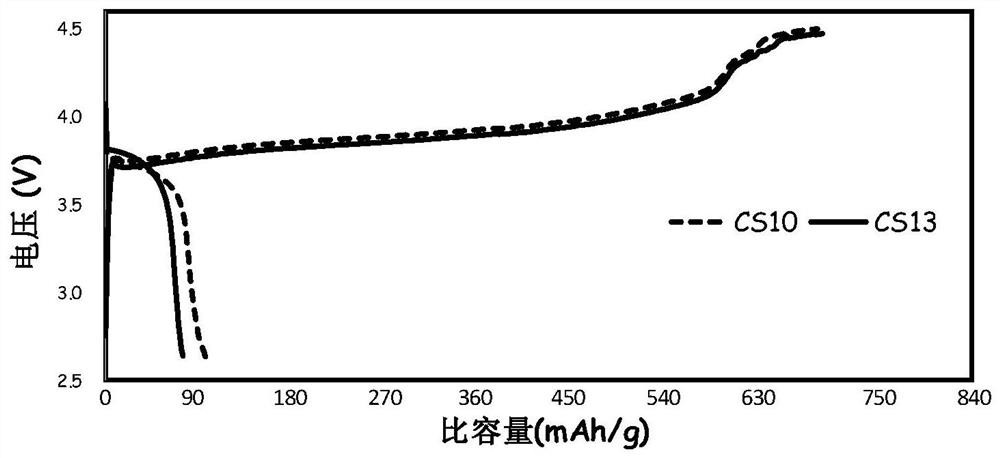

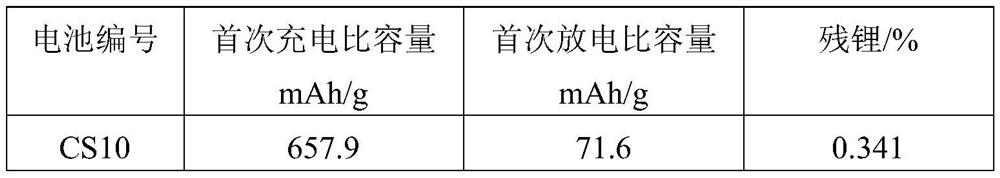

Lithium supplement additive for lithium ion cathode material and preparation method thereof

ActiveCN112490415ATightly boundUniform covering thicknessMaterial nanotechnologyCell electrodesCarbon layerPhysical chemistry

The invention discloses a lithium supplement additive for a lithium ion cathode material. The lithium supplement additive comprises a Li5FeO4 matrix and a coating layer positioned on the surface of the Li5FeO4 matrix, wherein the coating layer comprises a first coating layer carbon layer positioned on the surface of the Li5FeO4 matrix and a second coating layer transition metal oxide layer positioned on the surface of the first coating layer. The invention also discloses a preparation method of the lithium supplement additive, which comprises the following steps: preparing carbon layer coatediron oxide, carrying out wet mixing to prepare surface carbon coated Li5FeO4, mixing with a transition metal ion salt solution and an ammonium hydroxide solution, and carrying out high-temperature sintering to obtain the lithium supplement additive. According to the double-layer coated Li5FeO4 lithium supplementing additive disclosed by the invention, the Li5FeO4 matrix is micron-scale or nano-scale particles, and the particles are uniform and controllable, so that the migration path of electrons and ions is shortened, the lithium supplementing performance of the Li5FeO4 material can be exerted, and the service life of a lithium ion battery is prolonged.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

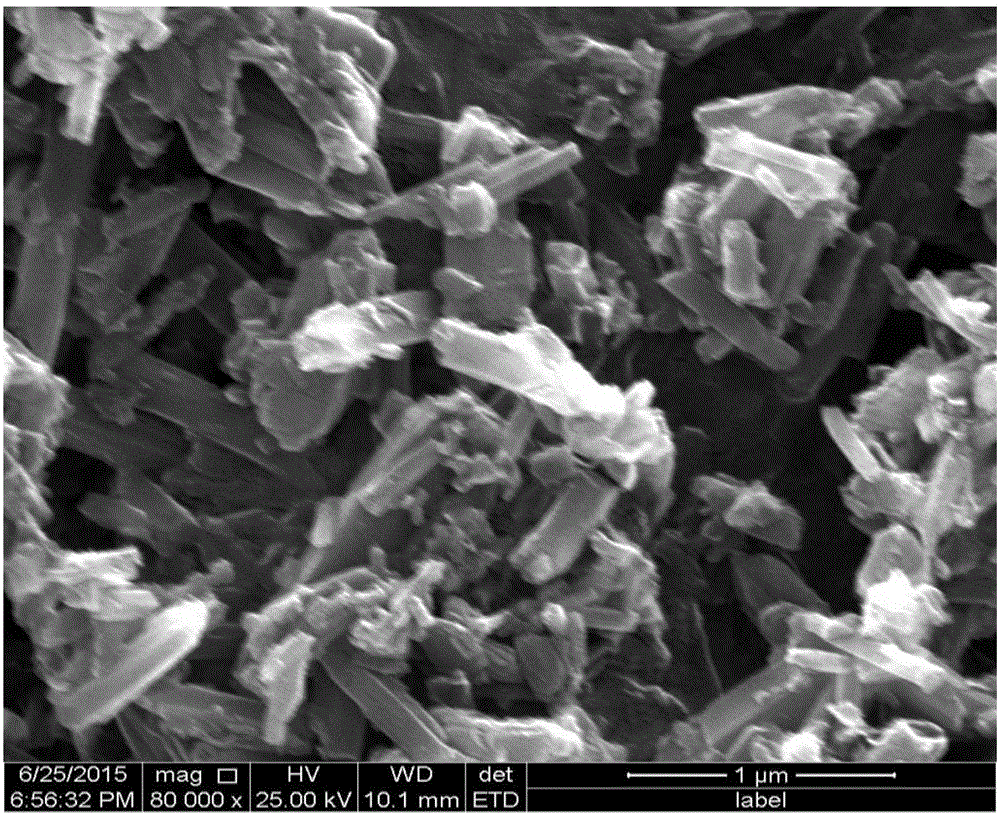

Silicon dioxide carbon composite negative electrode material, modified silicon dioxide carbon composite negative electrode material and preparation methods and application of silicon dioxide carbon composite negative electrode material and modified silicon dioxide carbon composite negative electrode material

ActiveCN105789575AImprove performance and stabilityImprove electrochemical performanceMaterial nanotechnologyCell electrodesCarbon compositesHalloysite

The invention relates to the field of preparation of a lithium ion battery, and particularly discloses a preparation method of a silicon dioxide carbon composite negative electrode material. The method comprises the following steps of (1) mixing halloysite with an organic carbon source in the presence of a solvent, and removing the solvent to acquire a solid product; and (2) roasting the solid product in an inertia atmosphere. The invention also provides a carbon nanotube / nitrogen modification method of the silicon dioxide carbon composite negative electrode material. The silicon dioxide carbon composite negative electrode material and the carbon nanotube / nitrogen modified silicon dioxide carbon composite negative electrode material, obtained according to the preparation methods provided by the invention, have relatively high cycle stability and discharge specific capacity, and are expected to be novel negative electrode materials used at a large scale.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

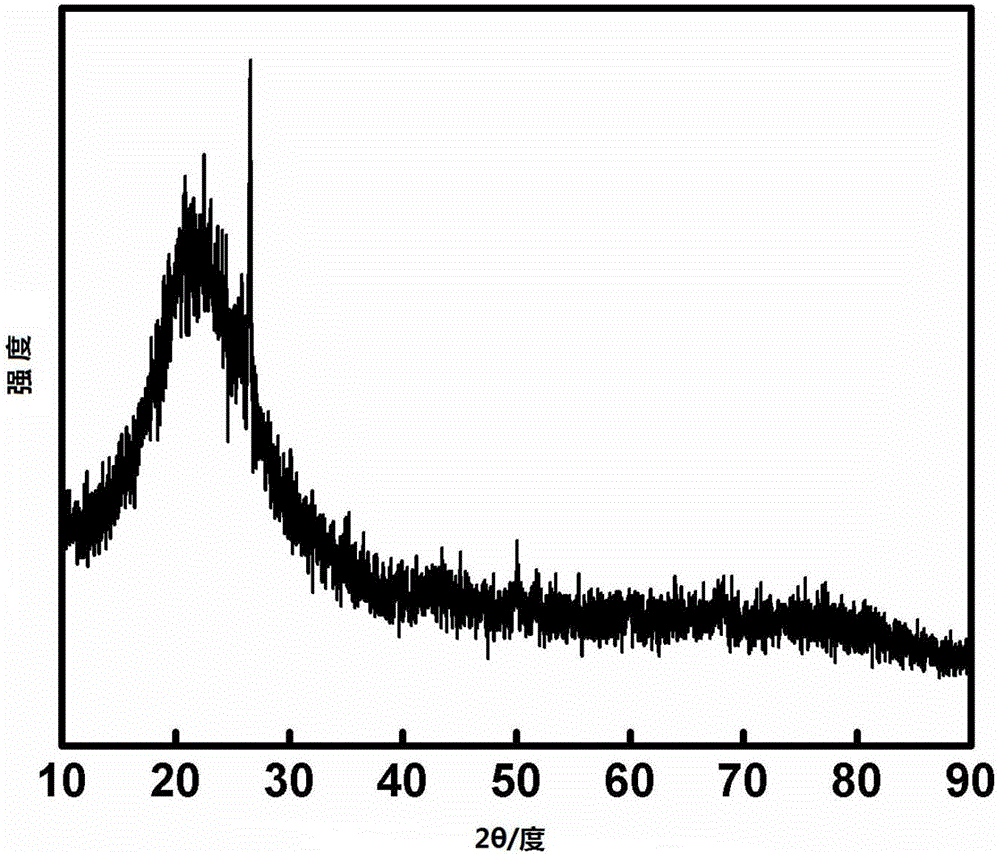

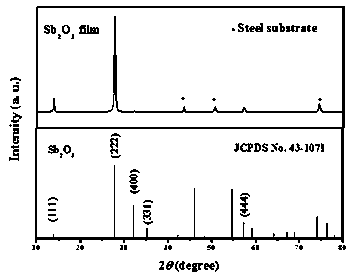

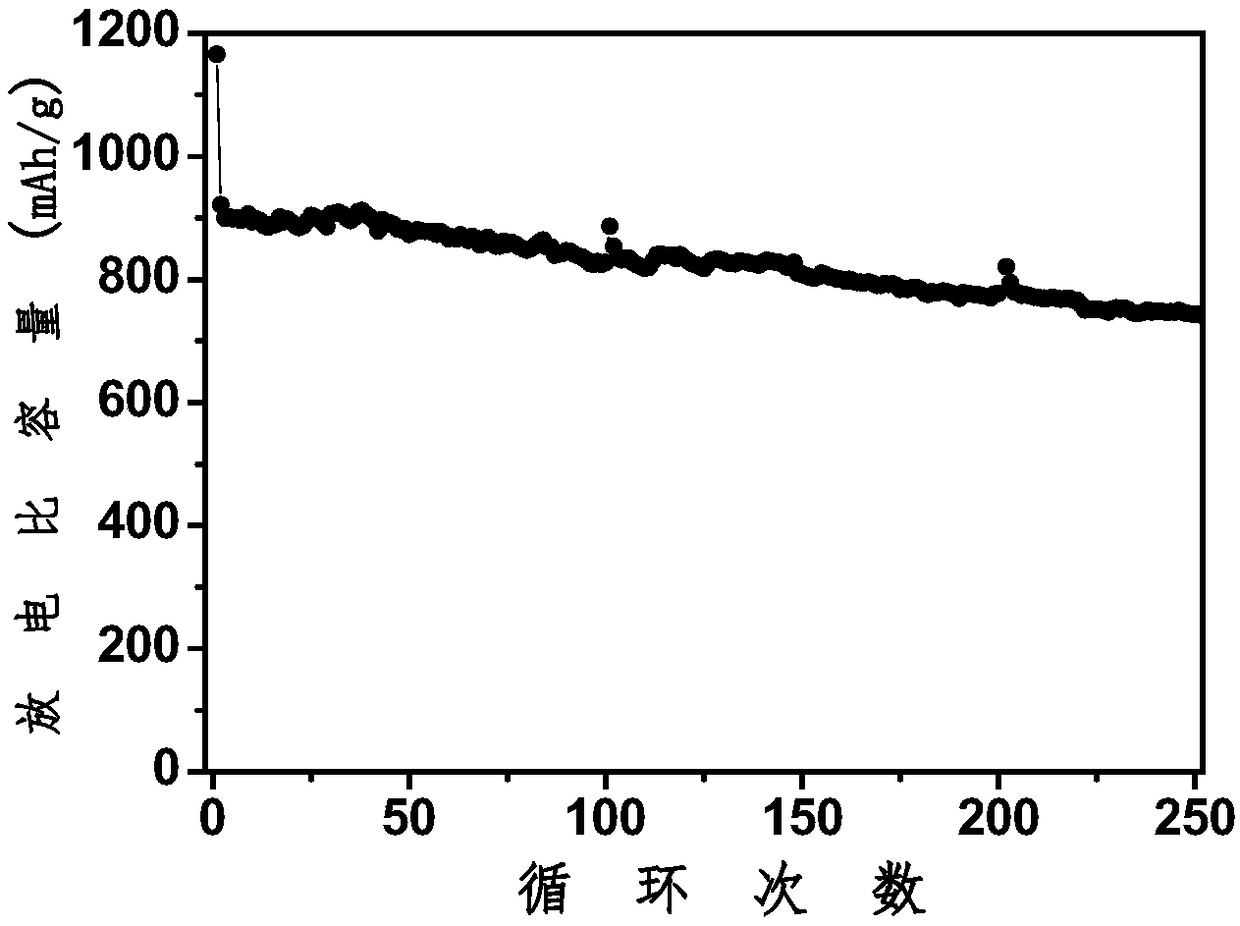

Preparation methods of antimony trioxide and antimony trioxide composite material and applications of antimony trioxide and antimony trioxide composite material in sodium-ion batteries

ActiveCN103943837AHigh specific capacityAlleviate volume expansionNon-aqueous electrolyte accumulatorsCell electrodesElectrical batterySodium-ion battery

The invention discloses preparation methods of antimony trioxide and an antimony trioxide composite material and applications of the antimony trioxide and the antimony trioxide composite material in sodium-ion batteries. The antimony trioxide and the antimony trioxide composite material are used as sodium-ion battery negative electrode materials. The antimony trioxide composite material is prepared from the antimony trioxide, metal or metallic oxides by using a complex method, wherein the metal comprises Ag, Au, Cu, Fe, Sn, Si and Ni, the metallic oxides comprise nickel oxide, copper oxide, tin oxide, cobalt oxide, iron oxide and manganese oxide, and the mass percentage of the antimony trioxide is 50-99%. The antimony trioxide and the antimony trioxide composite material which are prepared by using multiple effective methods are used as the sodium-ion battery negative electrode materials, have the advantages of high specific capacity and good cycling stability, and simultaneously are low in manufacturing cost and suitable for large-scale development and application of the sodium-ion batteries.

Owner:ZHEJIANG UNIV

High-capacity carbon-silicon negative electrode active material and preparation and application methods thereof

ActiveCN109301215AHigh specific capacityImprove cycle lifeCell electrodesSecondary cellsFiberCarbon fibers

The invention discloses a high-capacity carbon-silicon negative electrode active material and preparation and application methods thereof. The high-capacity carbon-silicon negative electrode active material achieves a specific capacity of 800-1500 mAh / g and is formed by mixing carbon-silicon materials and graphite materials, wherein the carbon-silicon materials are microspherical particles prepared by performing ball milling spray-drying and thermal treatment processes on nanosilicon, crystalline flake graphite, carbon nanotubes and a carbon source, the nanosilicon is dispersed on the surfaceof the crystalline flake graphite, the carbon nanotubes are inserted into pores formed between the carbon nanotubes and the crystalline flake graphite, pyrolytic carbon of the carbon source is coatedon the surface of the nanosilicon and the surface and pores of the spherical particles formed by the nanosilicon, the crystalline flake graphite and the carbon nanotubes; the weight of silicon-carbonmaterials is 25%-80% of the total weight of the high-capacity carbon-silicon negative electrode active material. When uniformly mixed with conducting agent and bonding agent, the high-capacity carbon-silicon negative electrode active material can be coated or deposited onto copper foils, foamed nickel, foamed copper or carbon fiber paper as the negative electrode of a lithium ion battery. The preparation method of the high-capacity carbon-silicon negative electrode active material is simple in process, low in cost, applicable to amplified preparation of long-circulation carbon-silicon materials.

Owner:SHAANXI COAL & CHEM TECH INST

Preparation method of nitrogen-doped carbon material

InactiveCN103730638AEasy to synthesizeAlleviate volume expansionCell electrodesCarbon compositesTin dioxide

The invention discloses a preparation method of a nitrogen-doped carbon material. The carbon material has a mesoporous structure and is doped with nitrogen, and the doping content of the nitrogen in the carbon material is controllable; a composite of the carbon material is modified by the carbon material; and the preparation method selects egg white as a raw material to form the nitrogen-doped carbon material through high-temperature calcination and carbonization in the inert atmosphere, and comprises steps as follows: (1), an egg white solution is taken as a solvent for material composition; (2), the egg white is steamed in boiling water and forms tin dioxide jelly similar to yellow cake; and (3), calcination is performed in the inert atmosphere to obtain the nitrogen-doped carbon material. with the adoption of the method, the nitrogen-doped carbon composite material with a carbon coating structure can be prepared, and the content of the nitrogen in the carbon material is controllable; and the prepared nitrogen-doped carbon composite material is suitable for being taken as a Li-ion electrode material, and is simultaneously applicable to the fields of corrosion resistance, gas absorption and the like.

Owner:JILIN UNIV

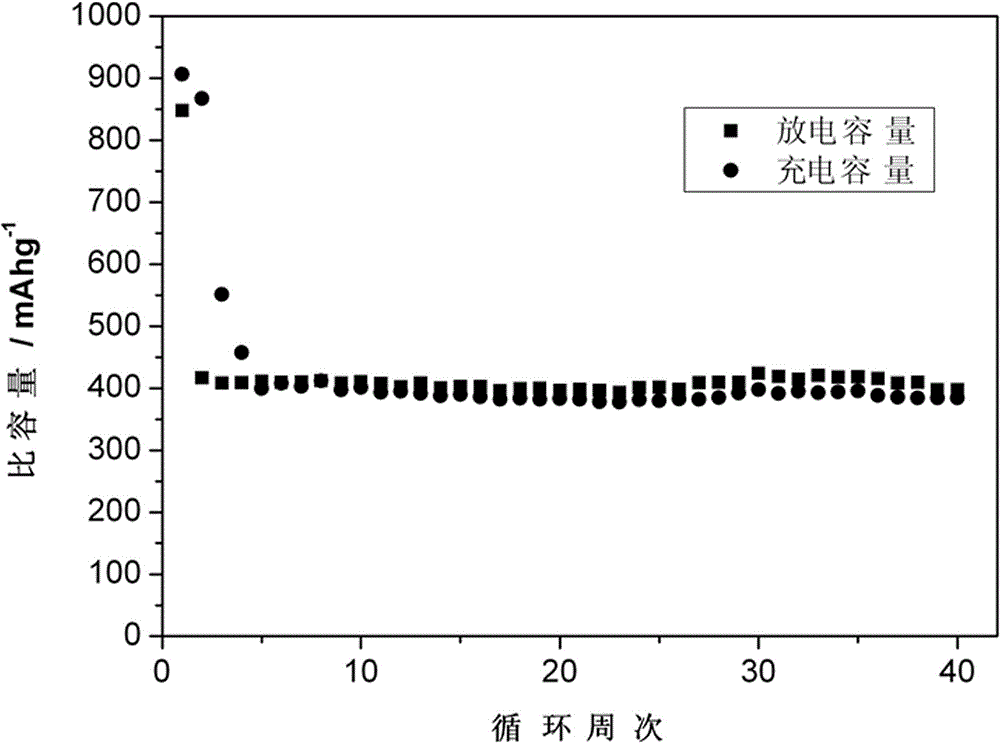

Antimony sulfide negative electrode material with micro-nano structure for sodium-ion battery and preparation method of antimony sulfide negative electrode material

InactiveCN104600293AImprove cycle stabilityHigh specific capacityNon-aqueous electrolyte accumulatorsCell electrodesMicro nanoSodium-ion battery

The invention discloses an antimony sulfide negative electrode material with a micro-nano structure for a sodium-ion battery and a preparation method of the antimony sulfide negative electrode material. Materials with the structure such as a micro-tube, a nano-wire and spherical micro-nano level particles are prepared by a hydrothermal process and a precipitation method; the morphologies of the materials are regular and uniform; the first capacity exceeds 850mAh / g when the current density is 100mA / g; and the capacity is still 90% that of the second week after circulating for 40 weeks. Antimony sulfide powder with the micro-nano structure is synthesized by the hydrothermal process and the precipitation method; and according to the antimony sulfide negative electrode, the preparation method is simple, raw materials are available and the cost is low; the process is easy to control; and the prepared antimony sulfide with the micro-nano structure has excellent electrochemical sodium storage performance, and is a good sodium ion battery negative electrode material.

Owner:GUILIN UNIV OF ELECTRONIC TECH

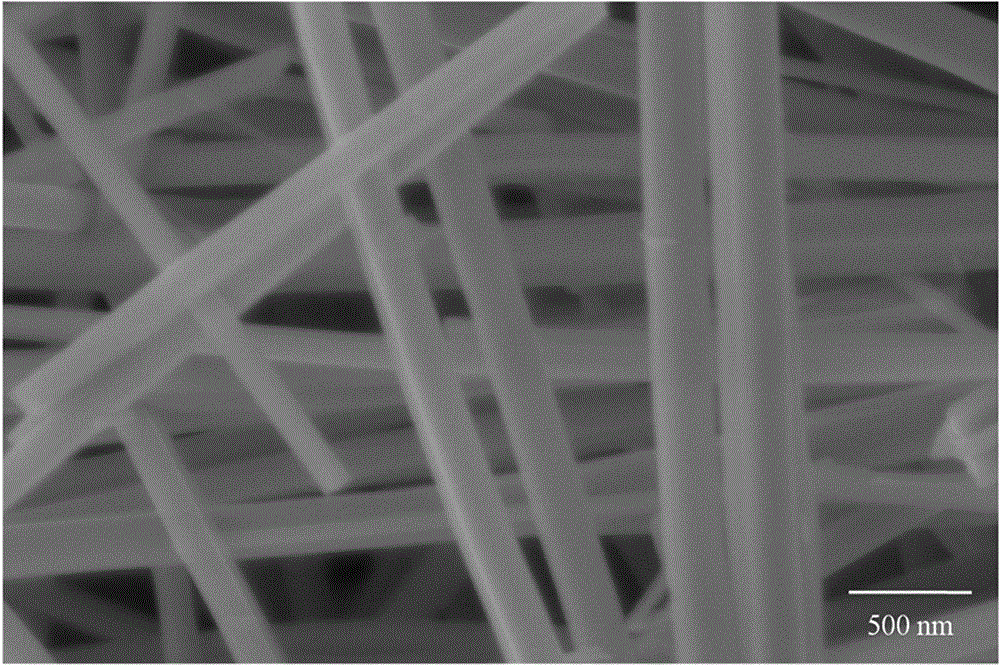

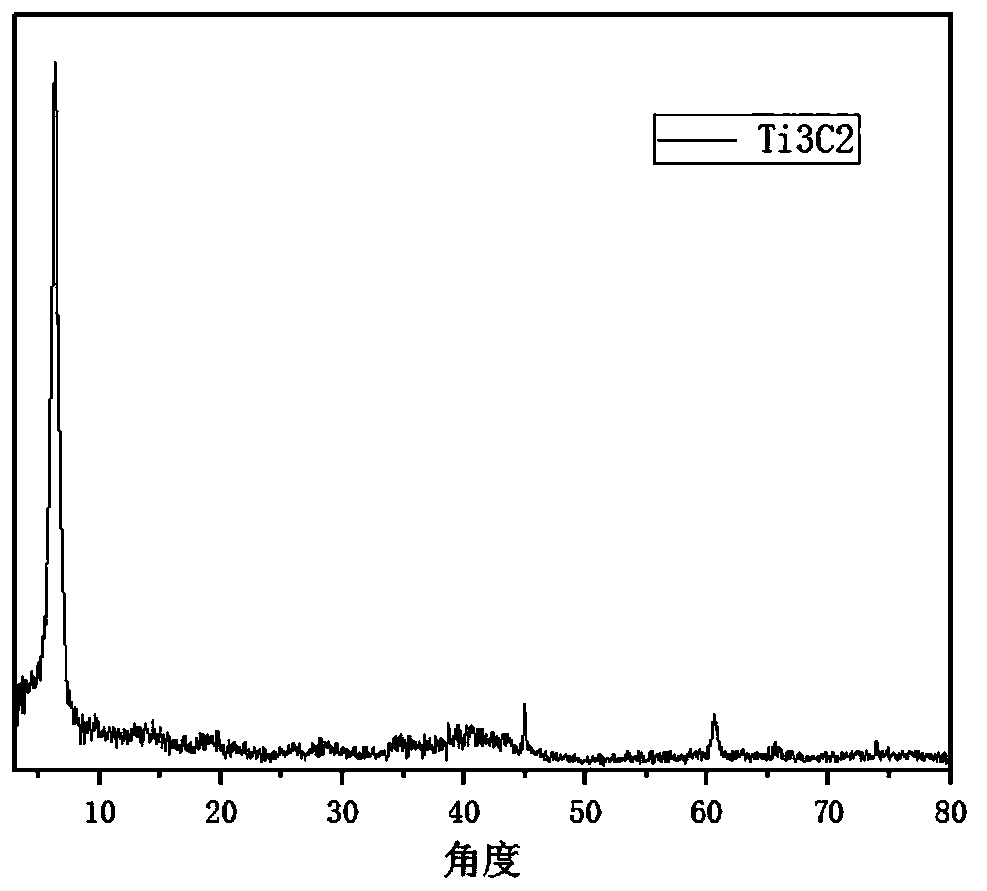

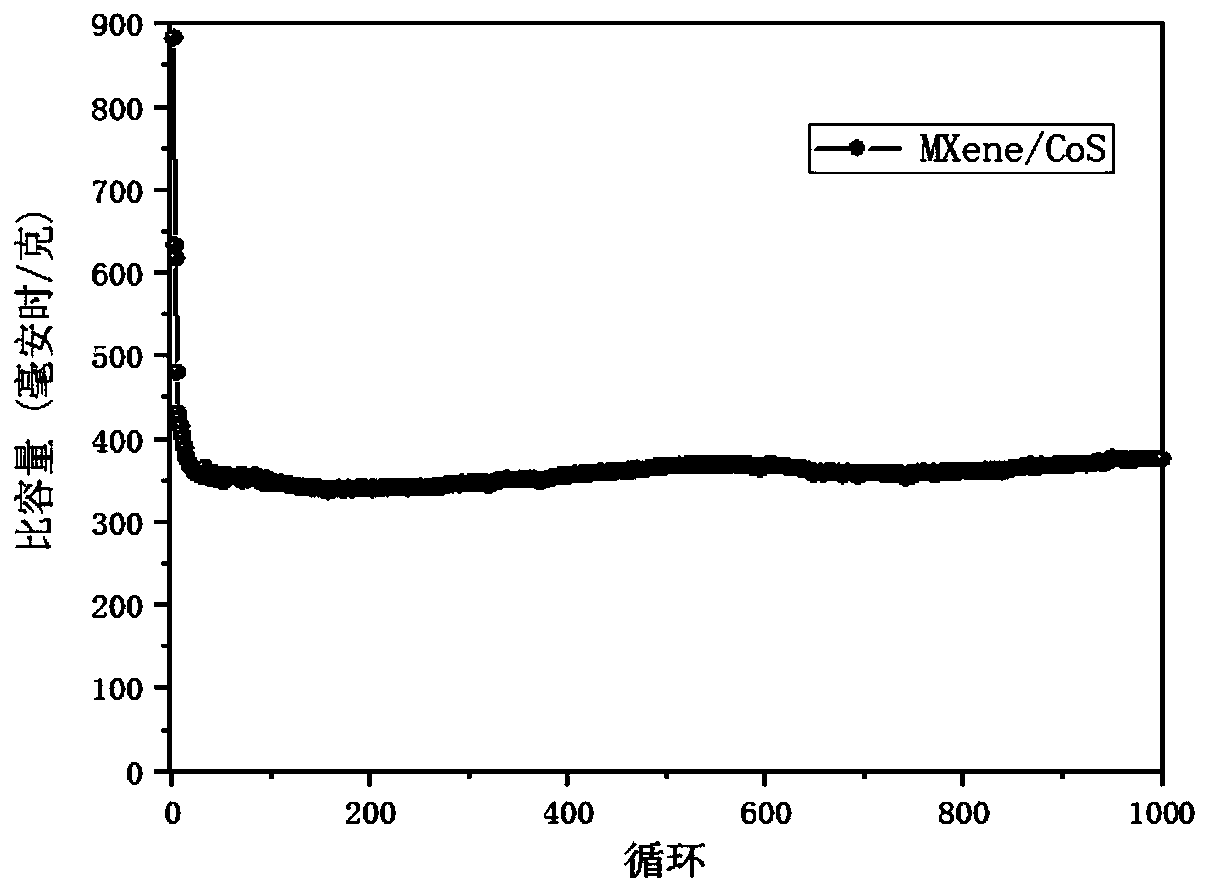

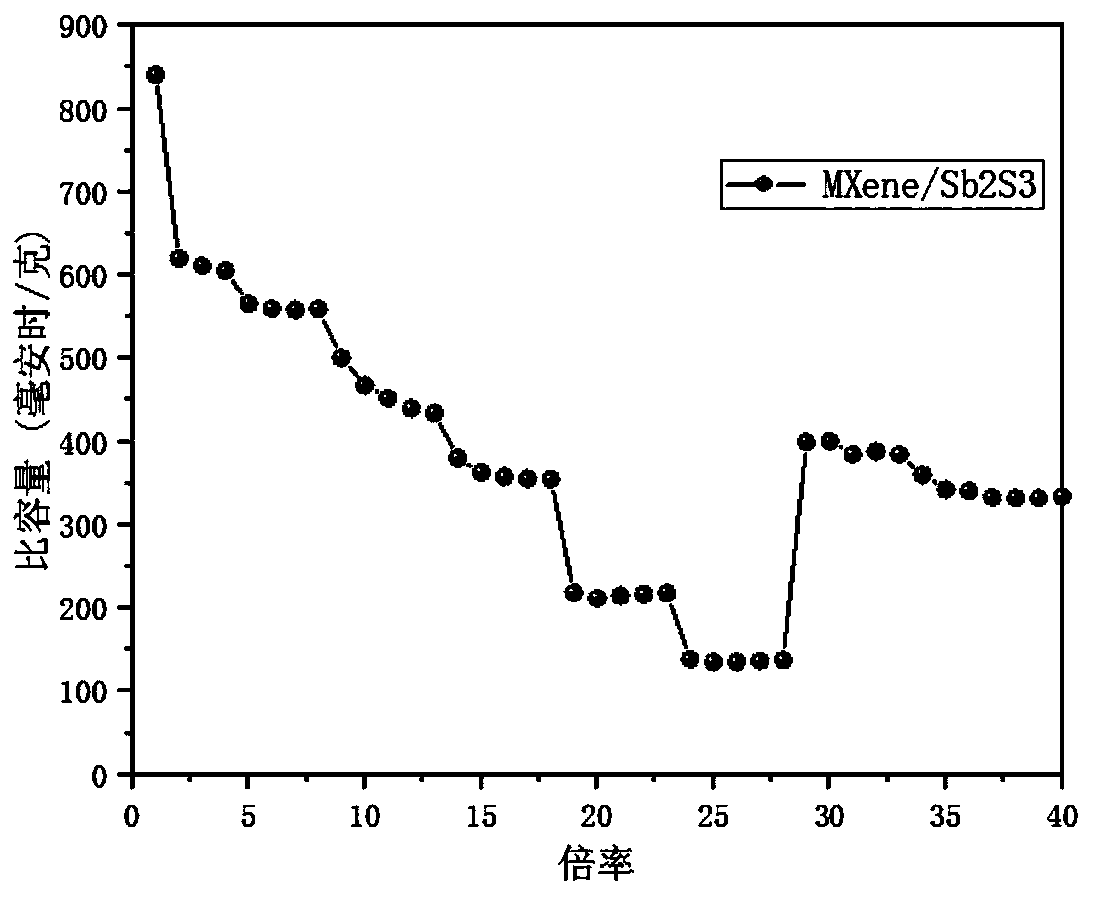

MXene/metal sulfide composite material, anode material and preparation and application

ActiveCN111180694AHigh theoretical capacityLow costNegative electrodesSecondary cellsHigh energyMetallic sulfide

The invention belongs to the technical field of high-performance / high-energy-density lithium ion battery negative electrodes, and particularly relates to an MXene / metal sulfide composite material, ananode material and preparation and application. The preparation method comprises the following steps: mixing and stirring a metal salt of a transition metal element and an MXene material, and carryingout solid-liquid separation and drying to obtain an MXene / metal salt mixture; and under a protective atmosphere, mixing the MXene / metal salt mixture with a sulfur source, and carrying out heat treatment to obtain the MXene / metal sulfide composite material. The invention also provides a sulfur-doped MXene / metal sulfide-based composite battery anode material. The anode material comprises the MXene / metal sulfide composite material. The anode material provided by the invention has good long-cycle stability, high energy density and excellent rate capability, and can be applied to various fields.

Owner:GUANGDONG UNIV OF TECH +1

Silicon carbon anode material for lithium ion battery and preparation method thereof

InactiveCN110311125AAlleviate volume expansionIncrease transfer rateSecondary cellsNegative electrodesPorosityCarbon layer

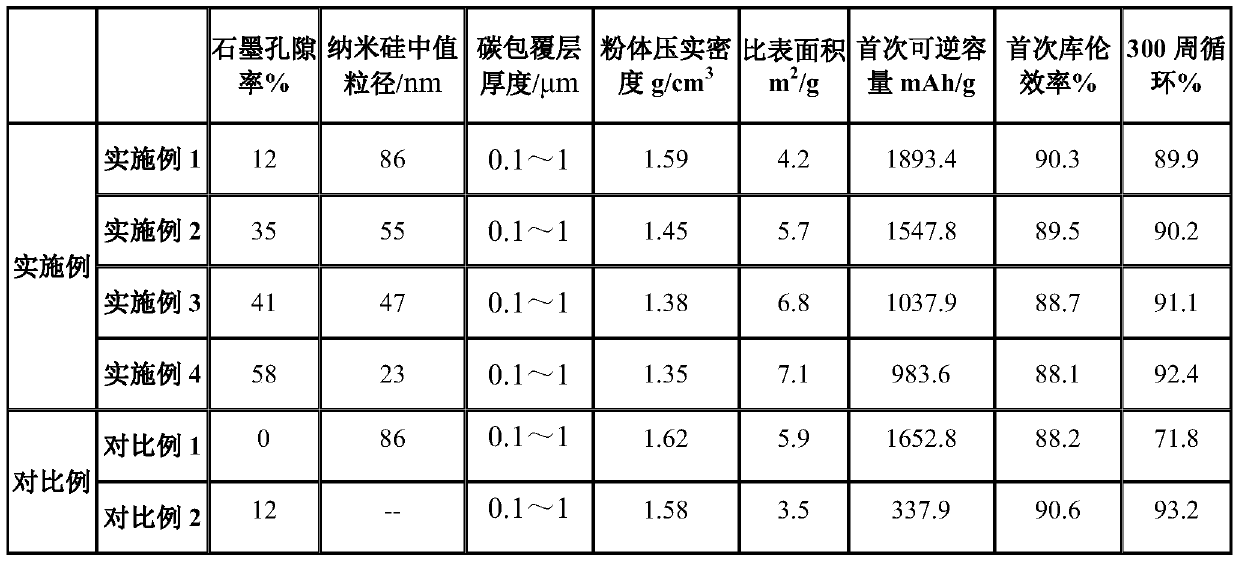

The invention belongs to the technical field of lithium ion batteries and particularly relates to a silicon carbon anode material for a lithium ion battery and a preparation method thereof. The anodematerial is a core-shell structure, wherein the core comprises porous graphite and nano-silicon; the pores of the graphite are formed through strong base erosion; the nano-silicon is deposited in thepores of the graphite by CVD deposition; the shell is an organic cracked carbon layer; the porosity of the porous graphite is 10 to 60%; the median diameter of the nano-silicon is 20-100 nm; and a carbon coating layer has a thickness of 0.1 to 1[mu]m. Compared with the prior art, the silicon carbon anode material for the lithium ion battery prepared by the method uses the porous graphite to reserve a space for the volume expansion of the nano-silicon so as to greatly alleviate the volume expansion of the nano-silicon and increase ion and electron transport rates. The silicon carbon anode material for the lithium ion battery has excellent electrochemical performance and stable structure. The preparation method is simple in process, low in cost, and suitable for industrial production.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com