Patents

Literature

30results about How to "Precise control of porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

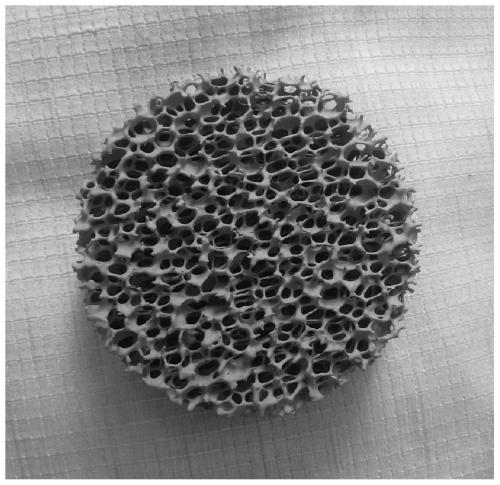

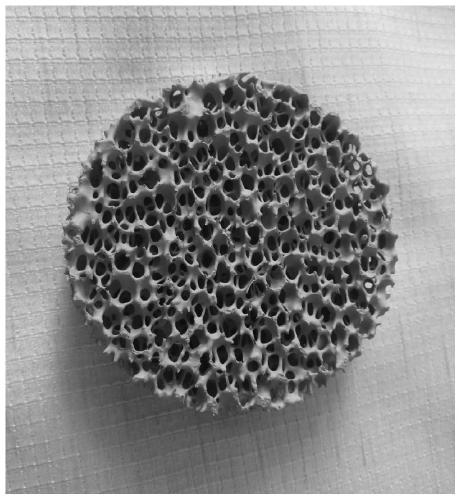

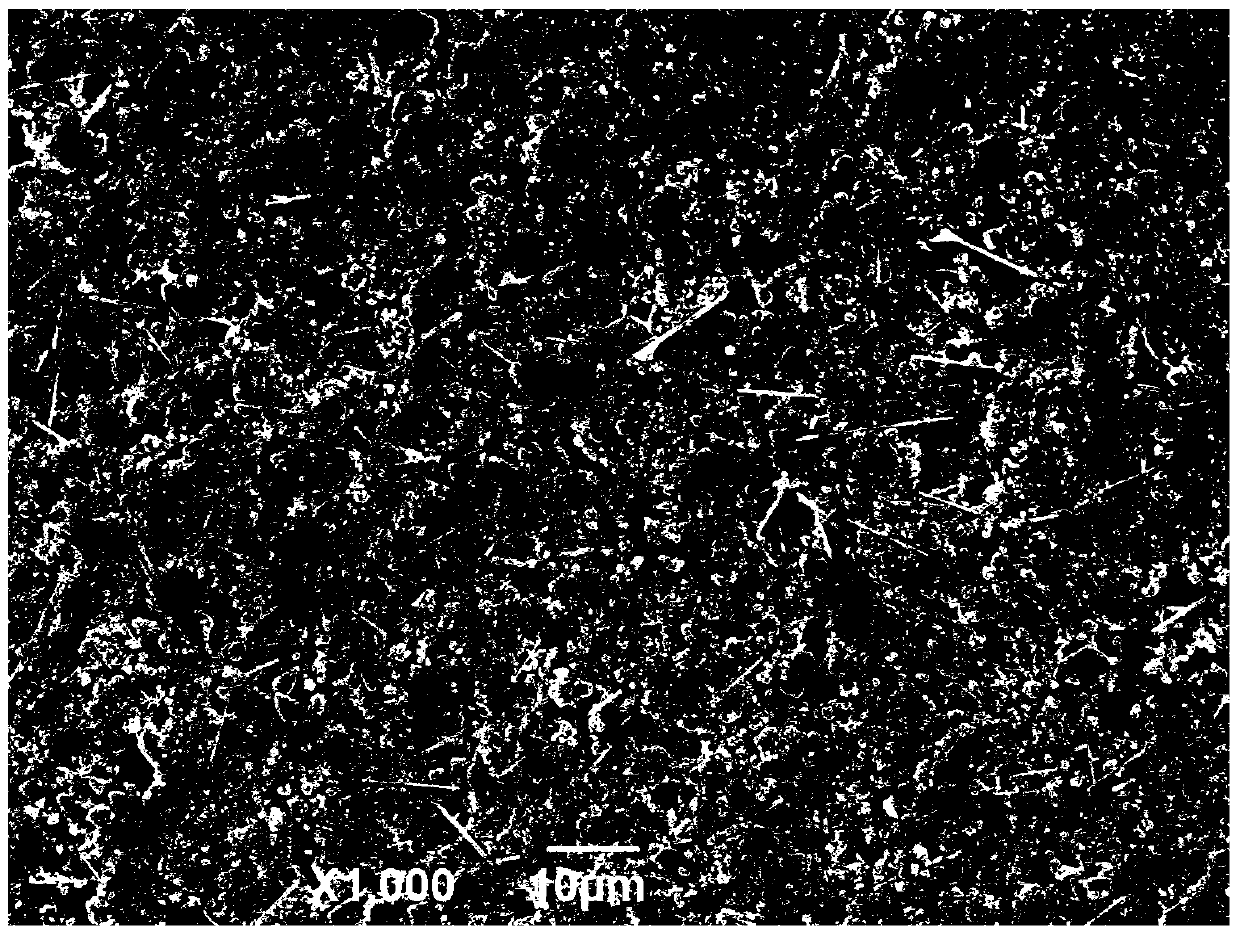

Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure

InactiveCN103462729APrecise control over distributionPrecise Control of ConnectivityBone implantCorrosionAdhesion process

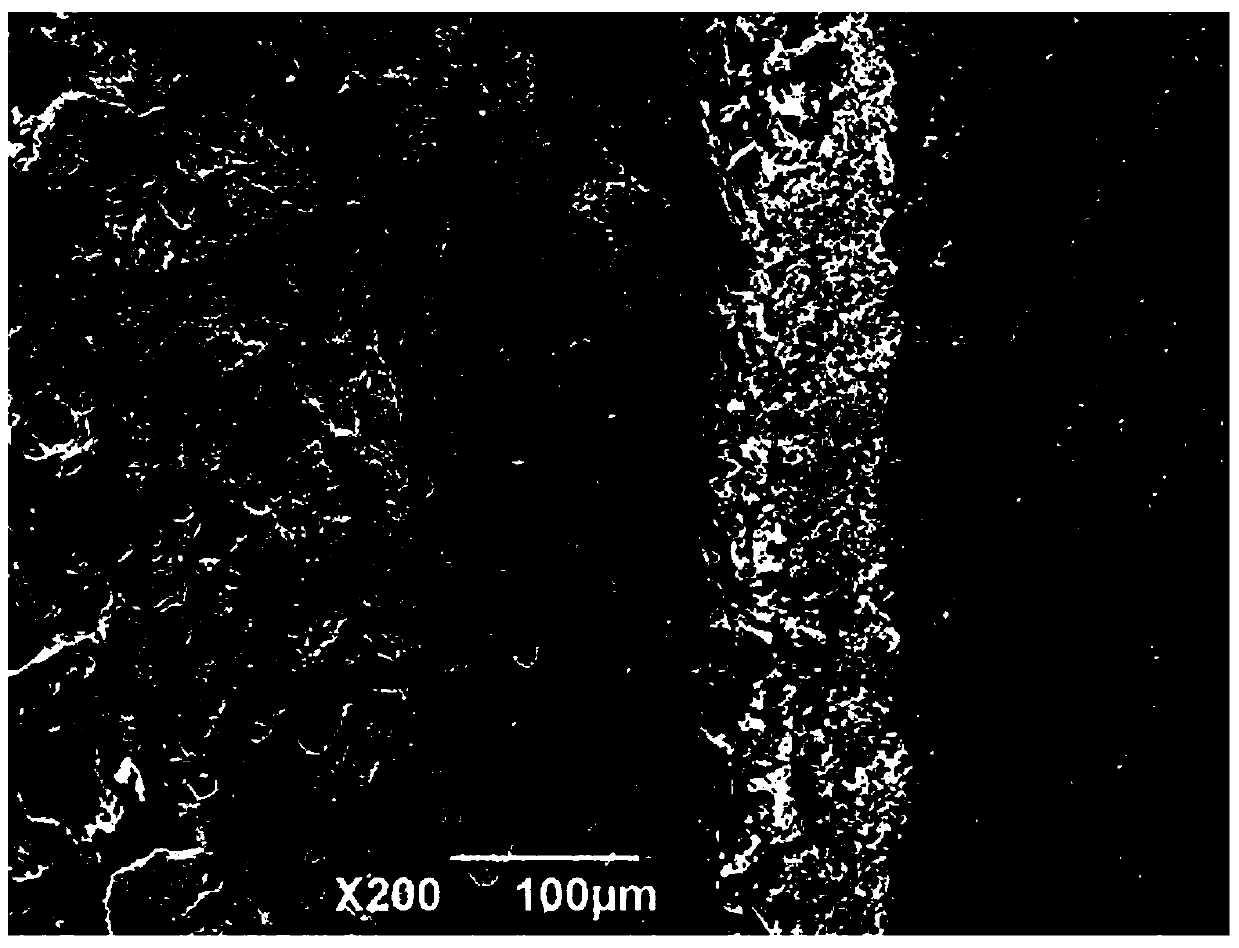

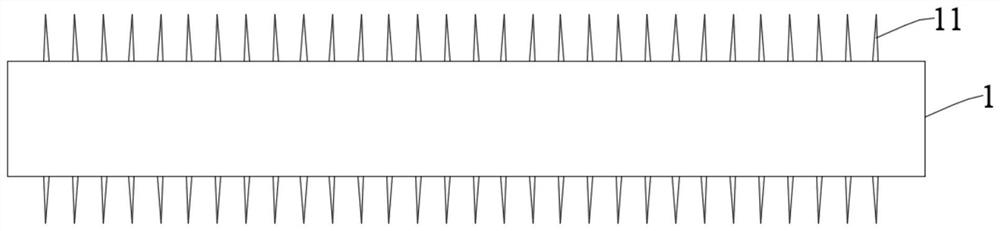

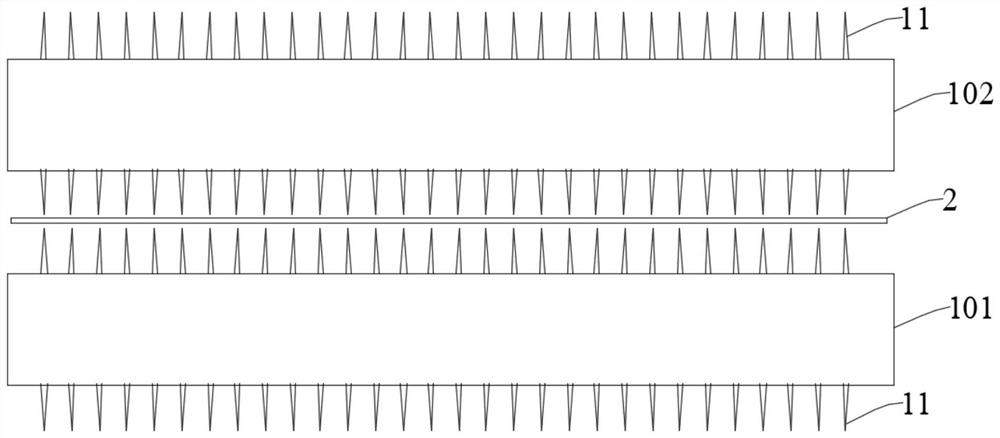

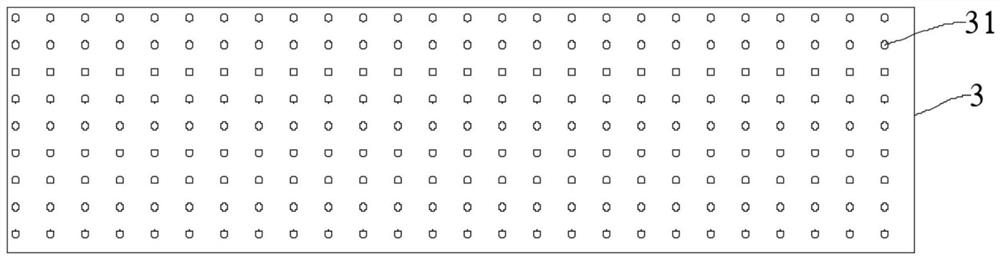

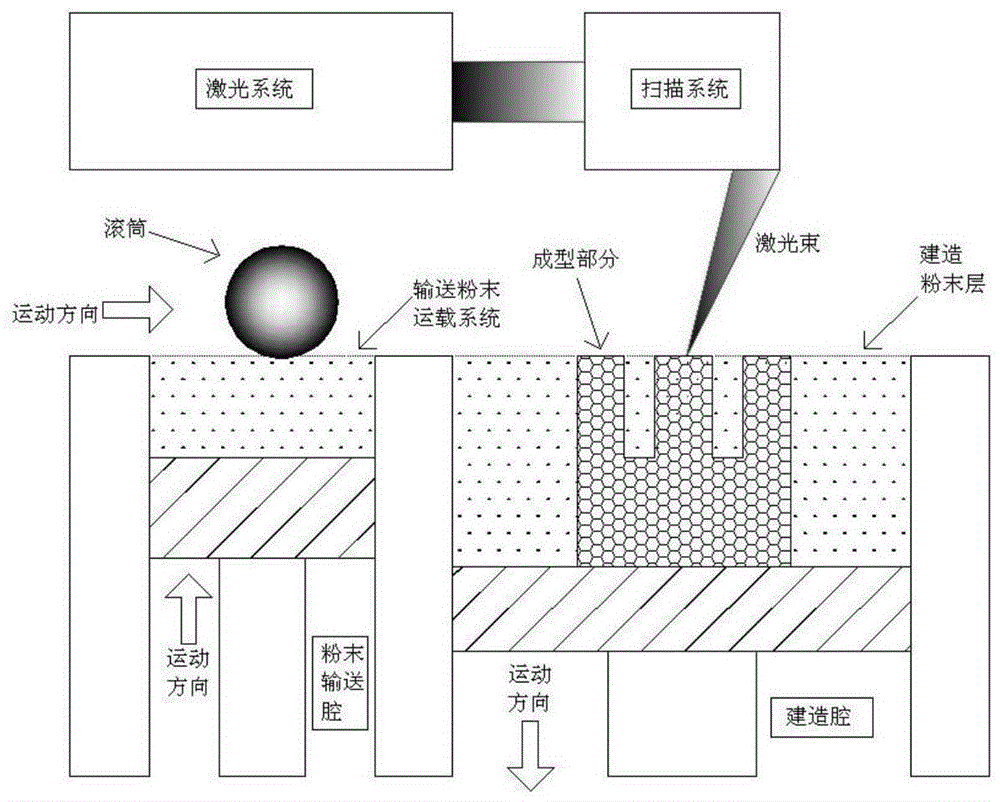

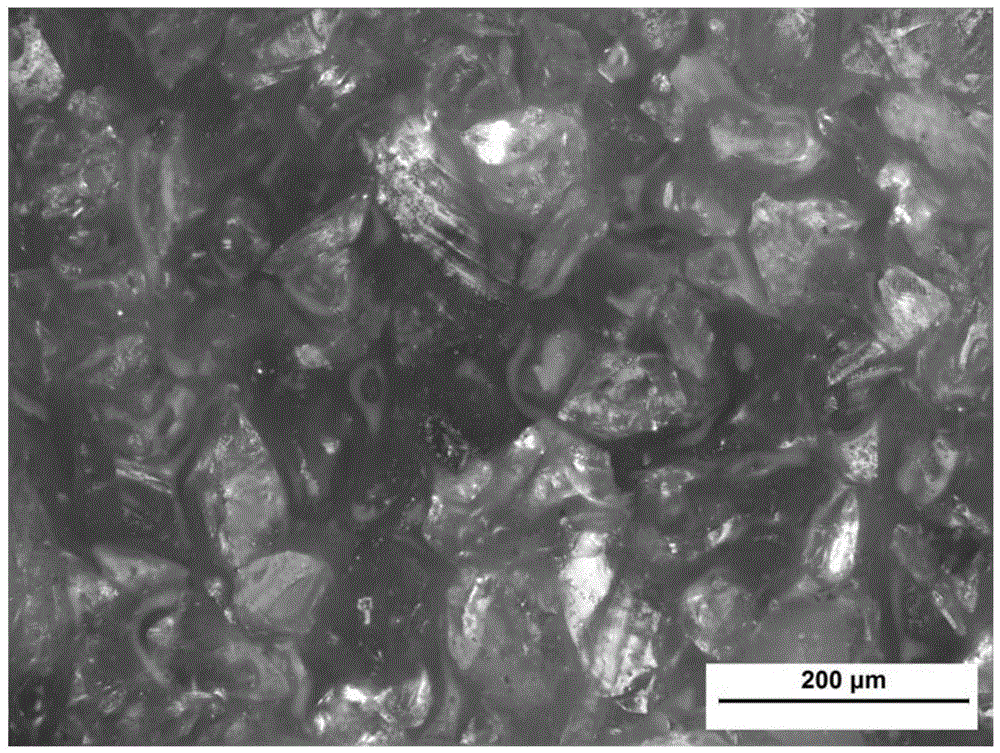

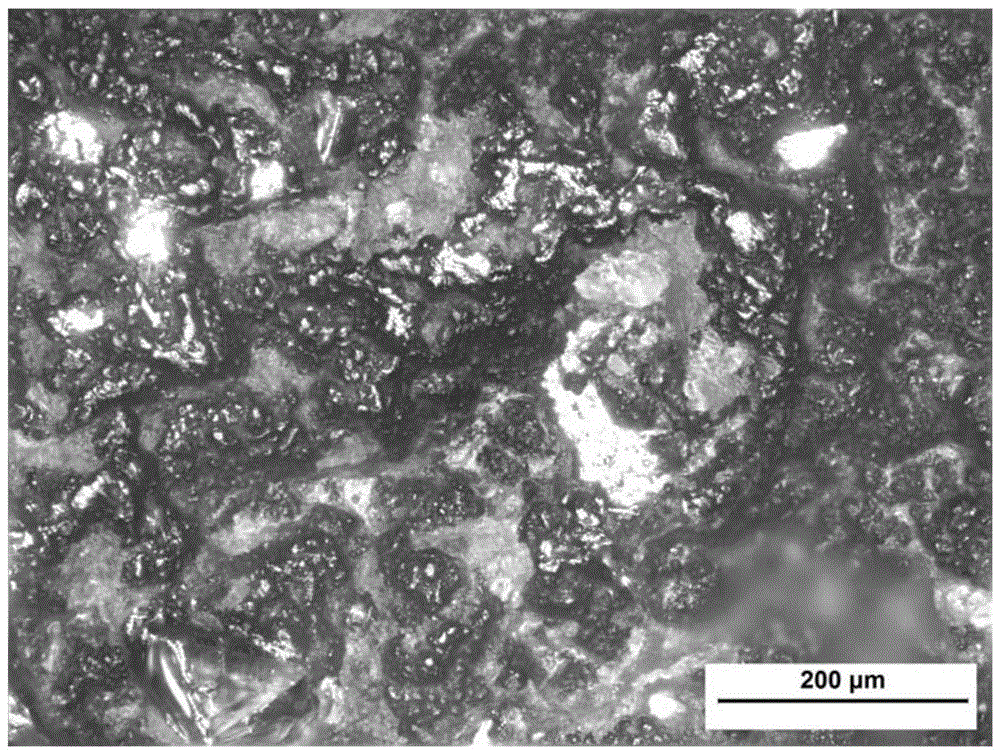

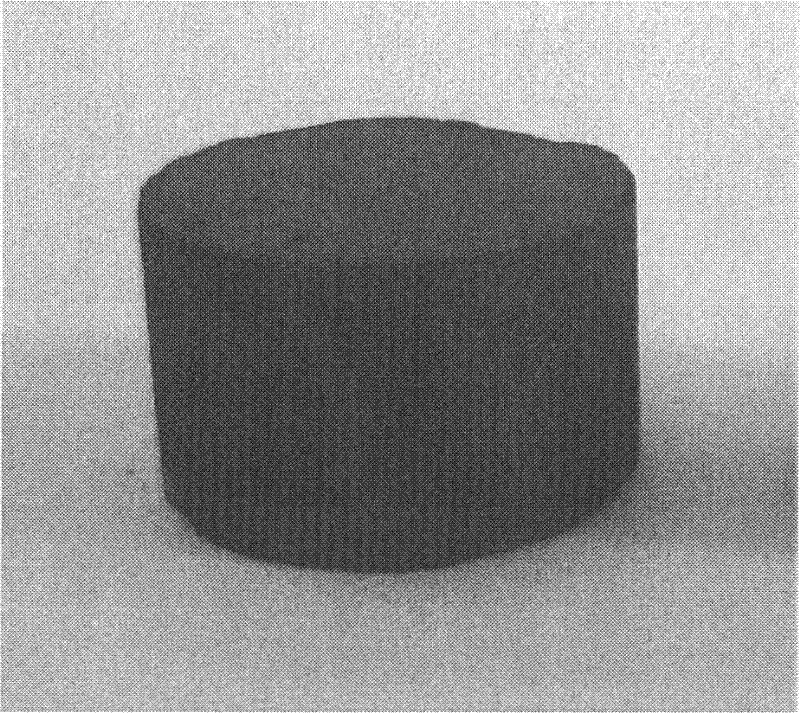

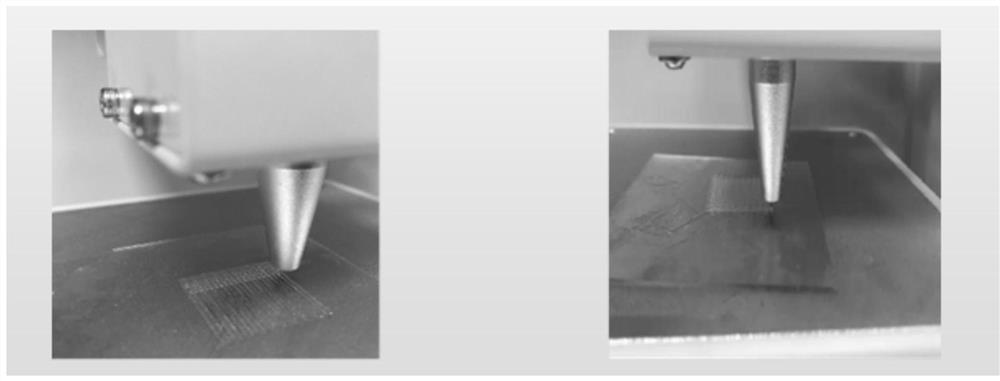

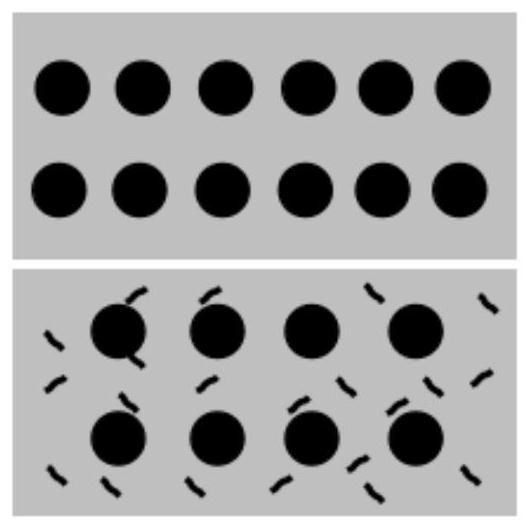

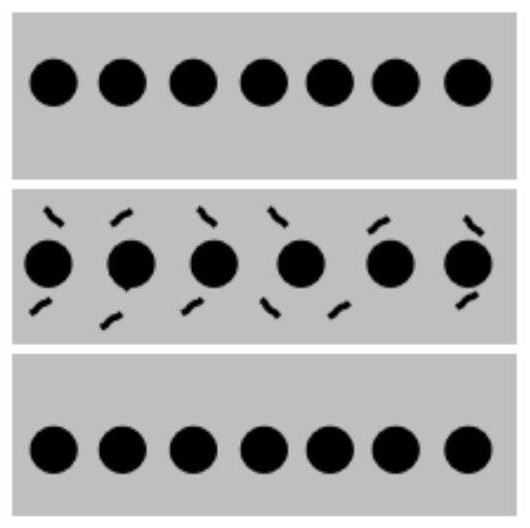

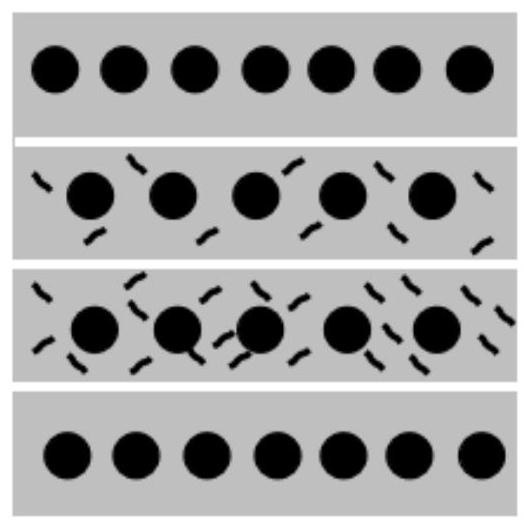

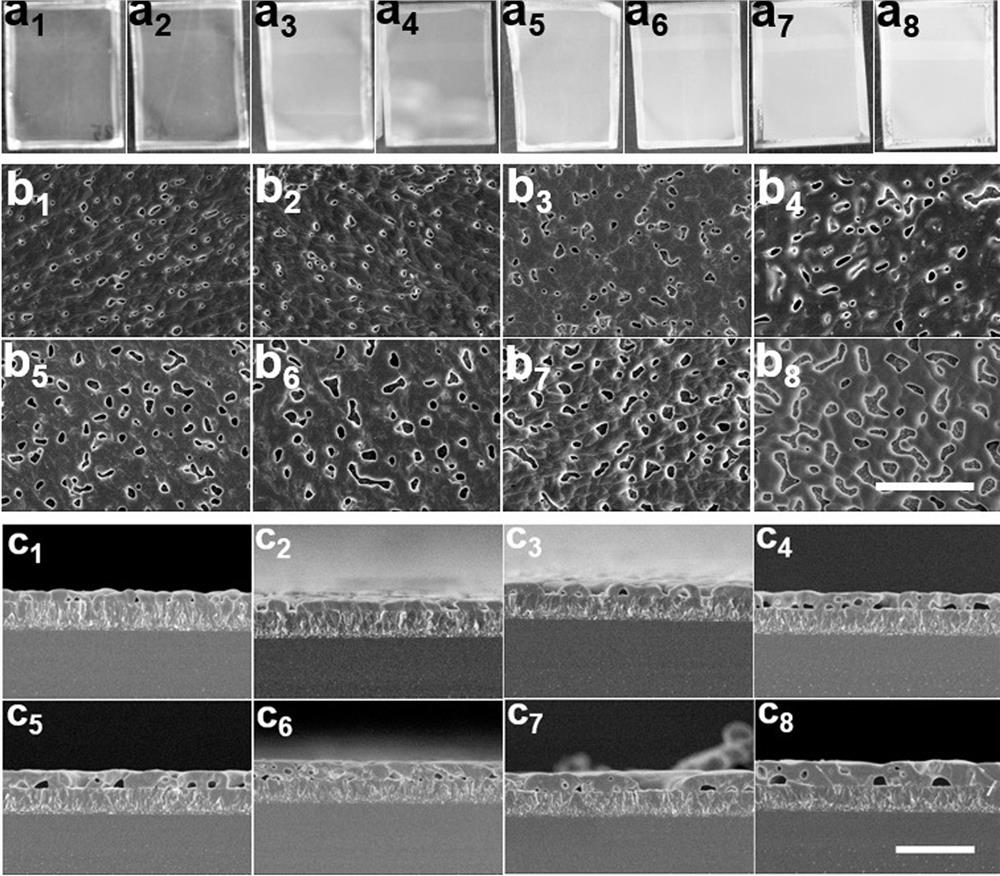

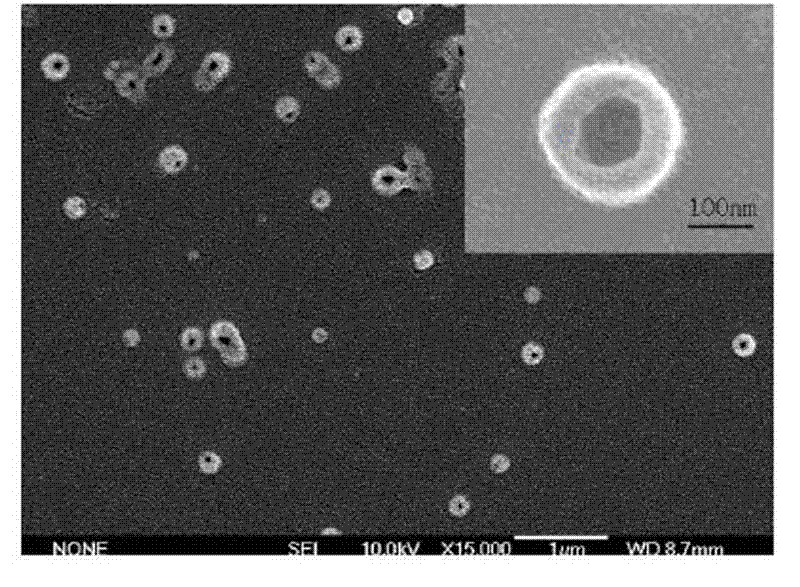

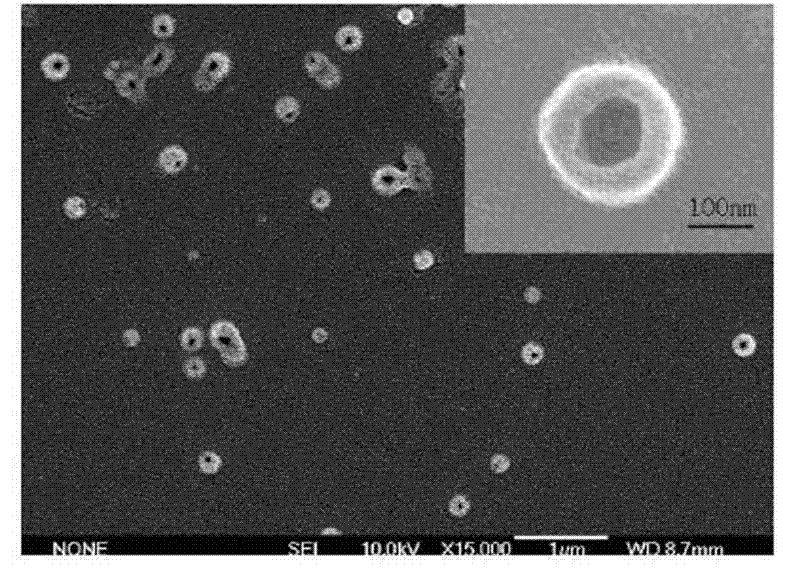

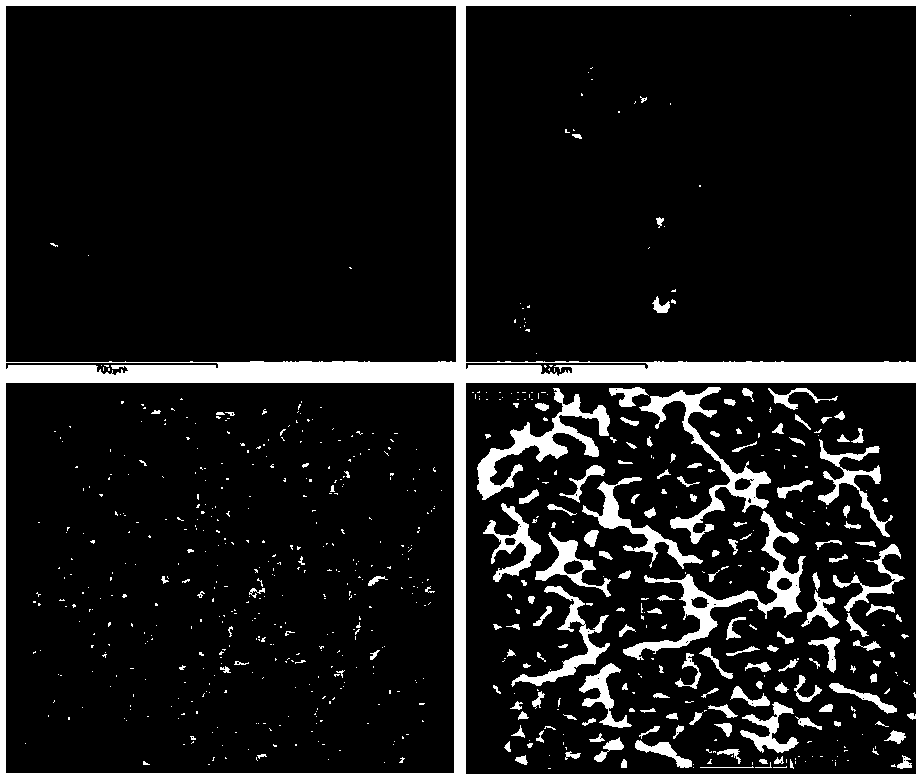

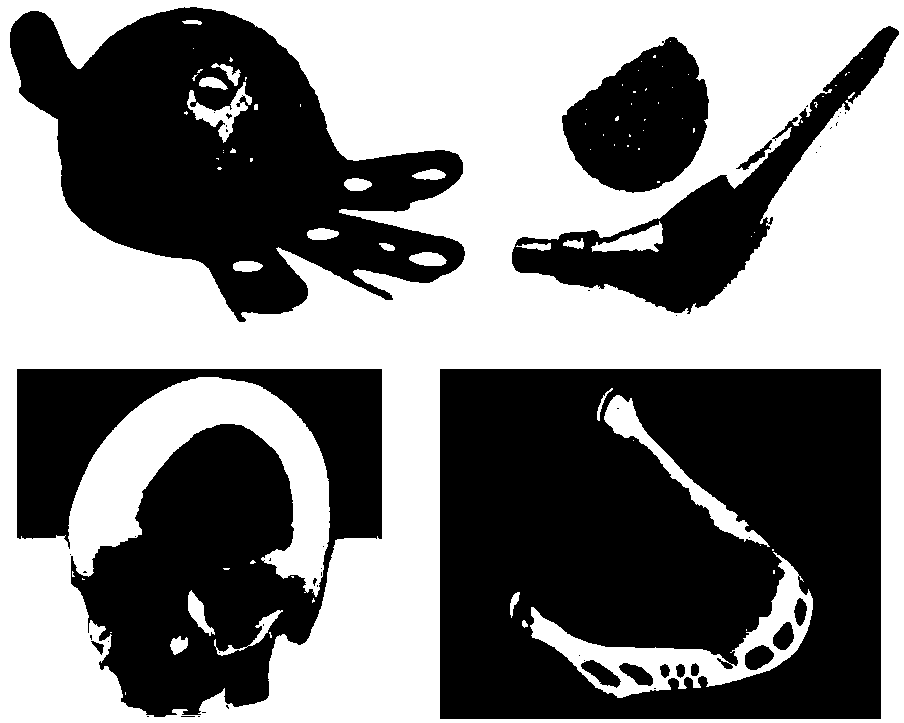

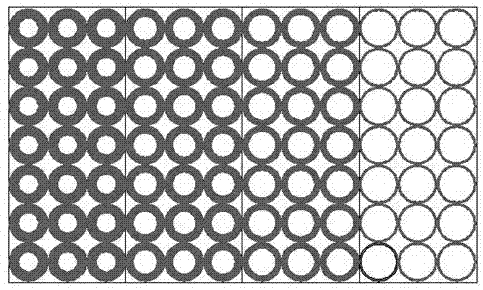

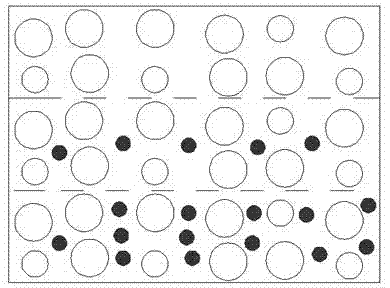

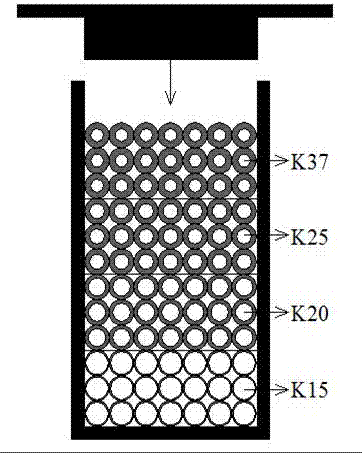

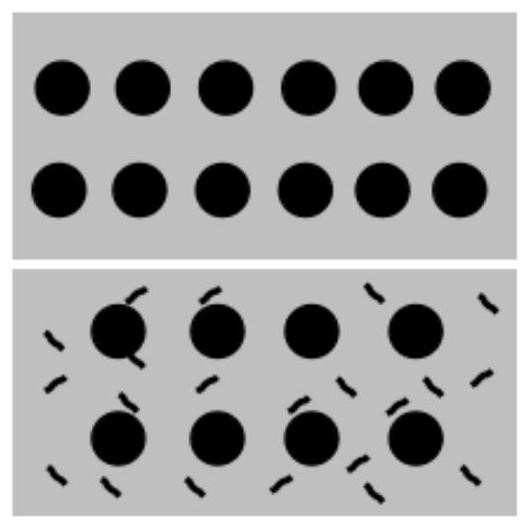

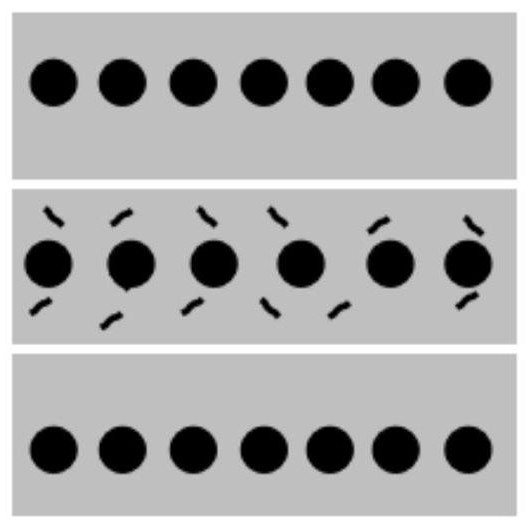

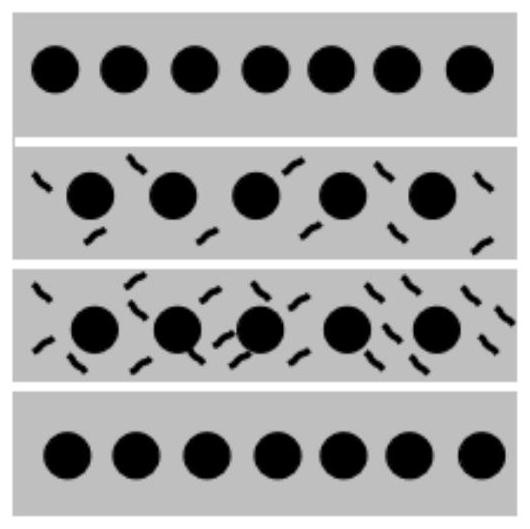

The invention relates to a preparation method of a bionic artificial bone with a multistage [micrometer / nanometer] pore structure. The method is characterized by the following steps of: realizing 150-800 mum gradient through pores by selective laser sintering (the diameter of the light spot is micrometer scale); mixing and performing oxygenolysis on a small amount of high polymer microballoons in the sintering process to form 10-100 mum random spherical pores; finally obtaining the bionic artificial bone which has an three-dimensional hierarchical pore structure similar to that of a natural bone by a method of obtaining irregular pores in tens of nanometer surfaces by a corrosion process. In the invention, according to the requirement of an implanting position, the distribution, connectivity and the like of the gradient through pore can be accurately controlled by adjusting sintering process parameters; the shape, size and the like of the spherical pores can be controlled by precisely controlling the furnace temperature curve and high polymer particle properties; the size, quantity and the like of the nanometer pores can be controlled by controlling the corrosion liquid concentration and corrosion time. The preparation method disclosed by the invention has an important significance in creating a microenvironment beneficial to cell adhesion, proliferation and function exertion, improving forming of new bones, and increasing healing of bones.

Owner:CENT SOUTH UNIV

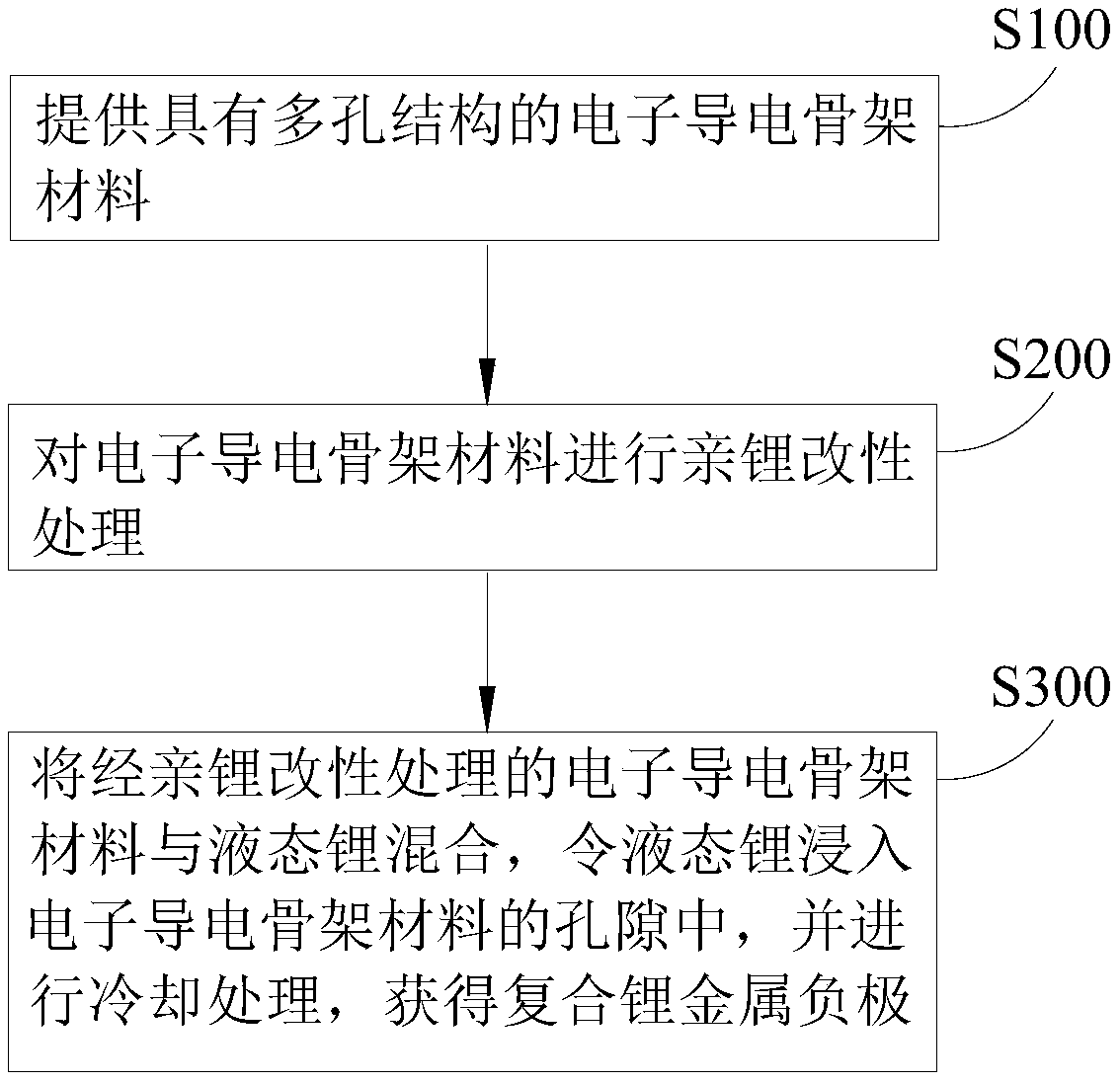

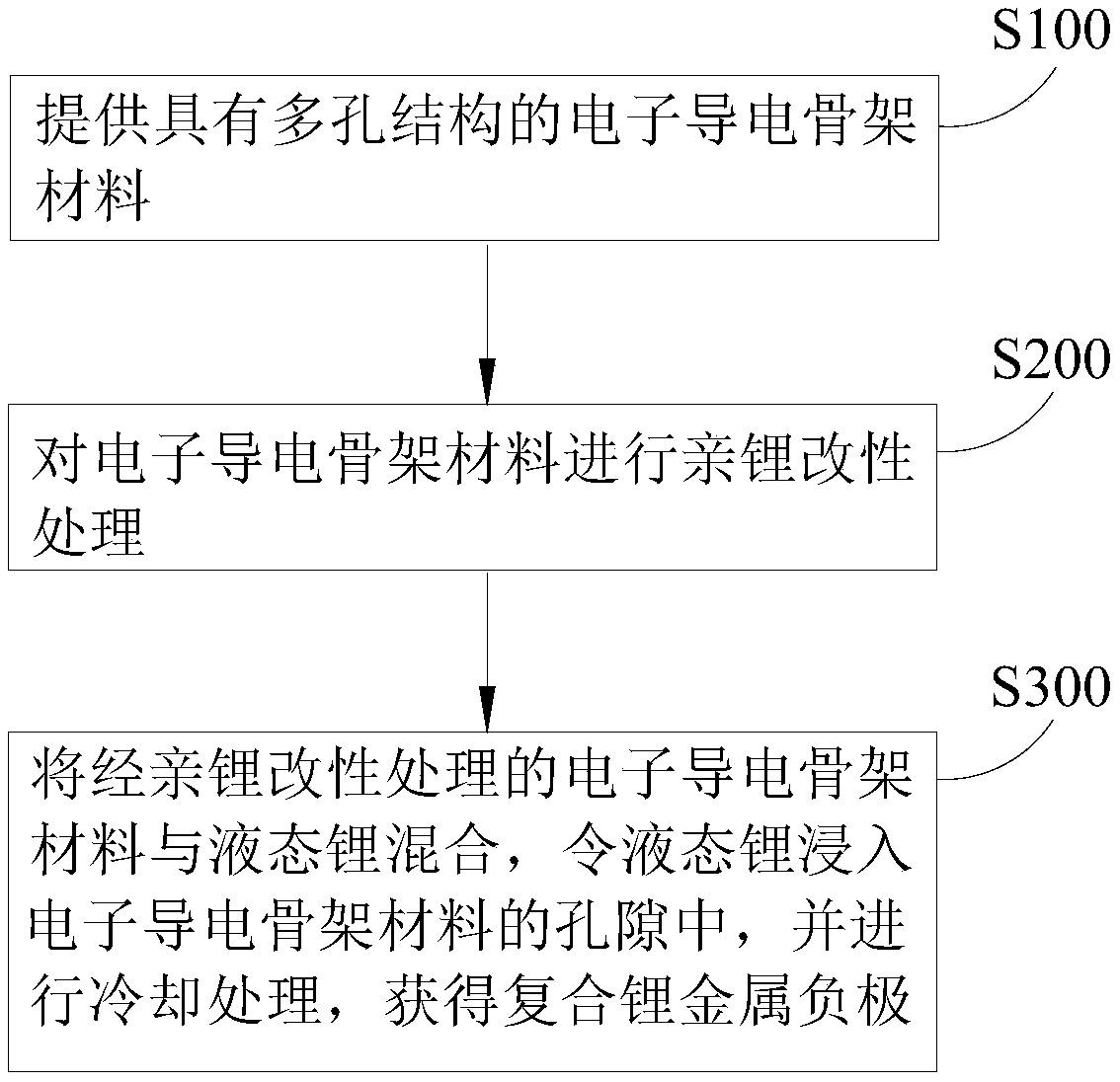

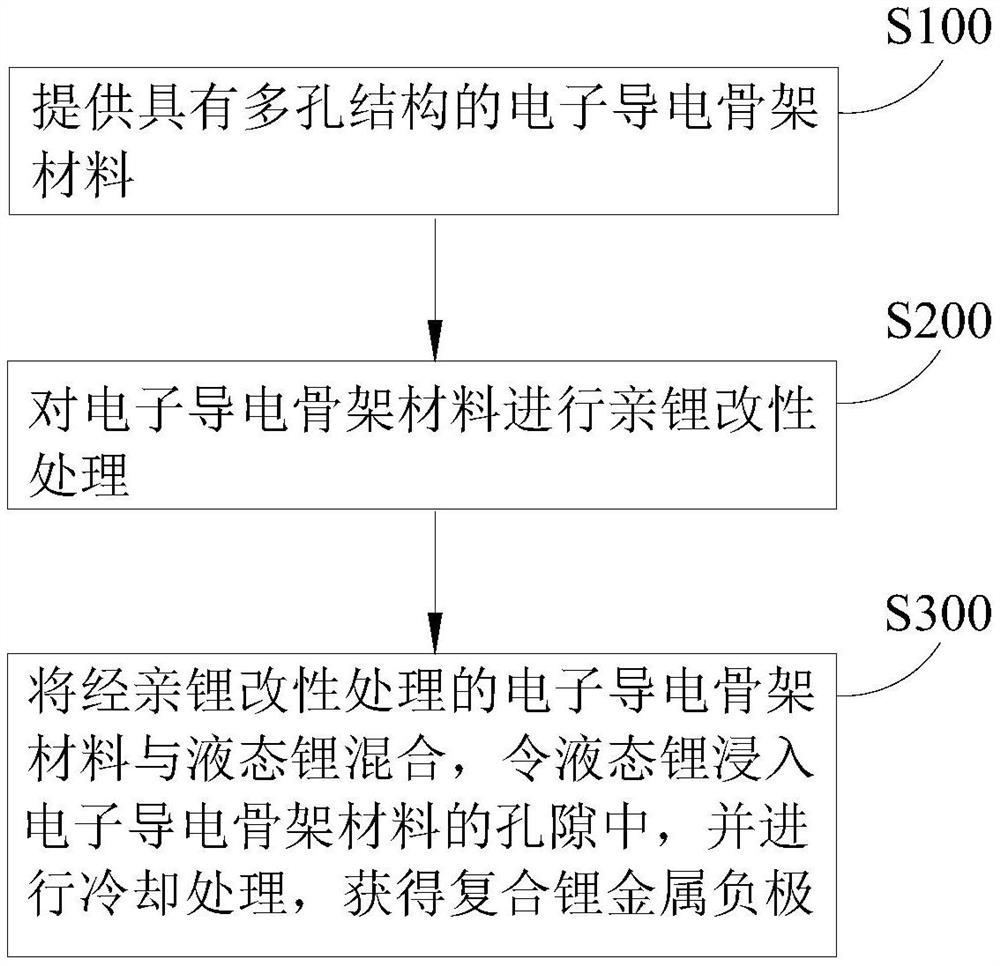

Composite lithium metal negative electrode, preparation method and lithium ion battery

ActiveCN109713224APrecise control of porositySufficient porosityActive material electrodesSecondary cellsPorosityAluminium-ion battery

The invention provides a composite lithium metal negative electrode, a preparation method and a lithium ion battery. The method for preparing the composite lithium metal negative electrode comprises the following steps: providing an electronic conductive framework material with a porous structure; carrying out lithium-philic modification treatment of the electronic conductive framework material; mixing the electronic conductive framework material subjected to the lithium affinity modification treatment with liquid lithium; immersing the liquid lithium into pores of the electronic conductive framework material, and performing cooling to obtain the composite lithium metal negative electrode; controlling the ratio of the volume of the liquid lithium to the total volume of the pores in the electronic conductive framework material to ensure that the porosity of the composite lithium metal negative electrode is 20-98% and lithium content of 0.01-0.01% 10mg / cm2. According to the invention, the porosity and the lithium content of the composite lithium metal negative electrode can be accurately controlled through the method, dendritic crystals are effectively prevented from being formed, and the problems of volume expansion, poor cycle performance, high safety risk and the like of the lithium metal negative electrode are solved, so that a battery applying the composite lithium metal negative electrode has high energy density and long-cycle stability.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Porous conductive MAX phase ceramics and preparation method and use thereof

InactiveCN101747075APrecise control of porosityPorosity adjustablePhysical/chemical process catalystsCeramicwarePorous ceramicsAtmosphere

The invention relates to a porous conductive ceramics, in particular to a porous conductive MAX phase (Ti3SiC2, Ti3AlC2 or Ti2AlC) ceramics with a through hole structure, and a preparation method and a use thereof. The porosity of the porous ceramics is adjustable within the range of 20-65%, the ceramics comprises a through hole structure, and the openporosity is more than 85%. The preparation method comprises the steps of taking MAX phase ceramic powder as a raw material, molding, carrying out pressureless sintering in an atmosphere furnace, keeping the sintering temperature at 1200-1400 DEG C, and leading the sintering time to be 0.5-3 hours. The MAX phase conductive ceramics with the through hole structure prepared by the pressureless sintering method can be used as a catalyst carrier material for automobile exhaust purification. The invention can solve the problems of liquid phase, a large number of closed pores in the generated hole and the like during the sintering process by optimizing the molding pressure, the sintering temperature and the time precise control of the porosity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

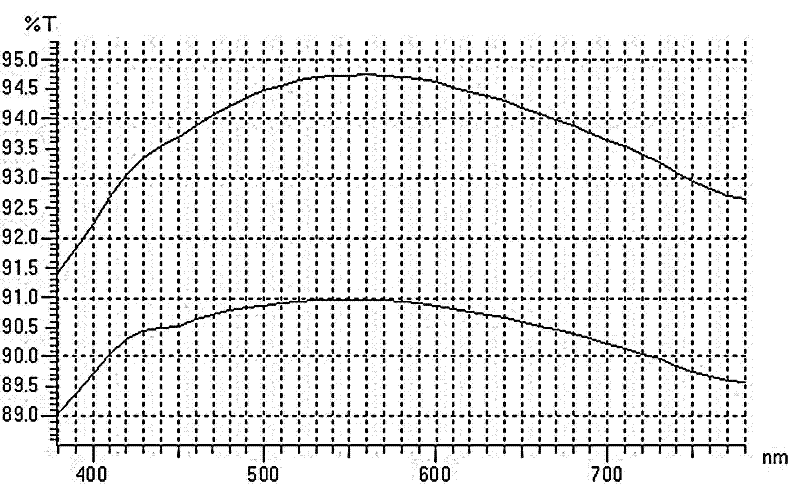

Preparation method of efficient increased-transmission and antireflection glass

The invention discloses a preparation method of efficient increased-transmission and antireflection glass, which comprises the steps as follows: (1) the molar ratio of raw materials comprising silicon sources to deionized water to catalysts to solvents is 1:0.05 to 10:0.01 to 10: 10 to 300, the deionized water, the catalysts and the solvents are firstly mixed, heated and stirred at a uniform speed, when an obtained mixture is heated to 20 to 50 DEG C, the silicon sources are added to the mixture and stirred with the mixture for 2 to 40 hours at a maintained constant temperature and a uniform speed, and then silica nano-particle dispersion liquid is obtained; (2) polystyrene latex spheres are used as templates to be mixed with the silica nano-particle dispersion liquid obtained in the step (1) at a volume ratio of 1:5 to 5:1, and then a blended solution is obtained; (3) the blended solution obtained in the step (2) is coated on the surface of a photovoltaic glass substrate; and (4) the film-coated photovoltaic glass substrate is placed in a temperature condition of 300 to 700 DEG C to be sintered for 5 to 30 minutes, and then the efficient increased-transmission and antireflection glass is obtained. The preparation method has the advantages that the binding force between an antireflection film and the substrate is strengthened, and the durability of the thin film is improved; and besides, through controlling the diameter and the mixing proportion of the polystyrene latex sphere templates, the reflectivity of the thin film is accurately regulated, so that an obvious increased-transmission effect is achieved.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Controlled release coating material containing polymer micro nanoparticles

ActiveCN103435424AUnique Water Solubility PropertiesUniform particle sizeFertilizer mixturesPorosityChemical structure

The invention provides a controlled release coating material containing polymer micro nanoparticles. The controlled release coating material comprises the following components: ethylene-vinyl acetate copolymerization polymer and a blending polymer alloy thereof; polyvinylpyrrolidone and complex microelements and drug thereof; and polymer micro nanoparticles. The controlled release coating material containing the polymer micro nanoparticles is adjustable in chemical structure and has good film-forming property and degradability; by adding the polymer micro nanoparticles with uniform particle size, the porosity and controlled release property of coating can be regulated; besides, by loading specific active substances in a chemical bonding manner, multi-functionalization of controlled-release fertilizer is realized. The controlled release coating material containing the polymer micro nanoparticles can be taken as a coating of an agricultural controlled release fertilizer and can be also taken as a pesticide controlled release coating and coatings of other medical products.

Owner:邢长民

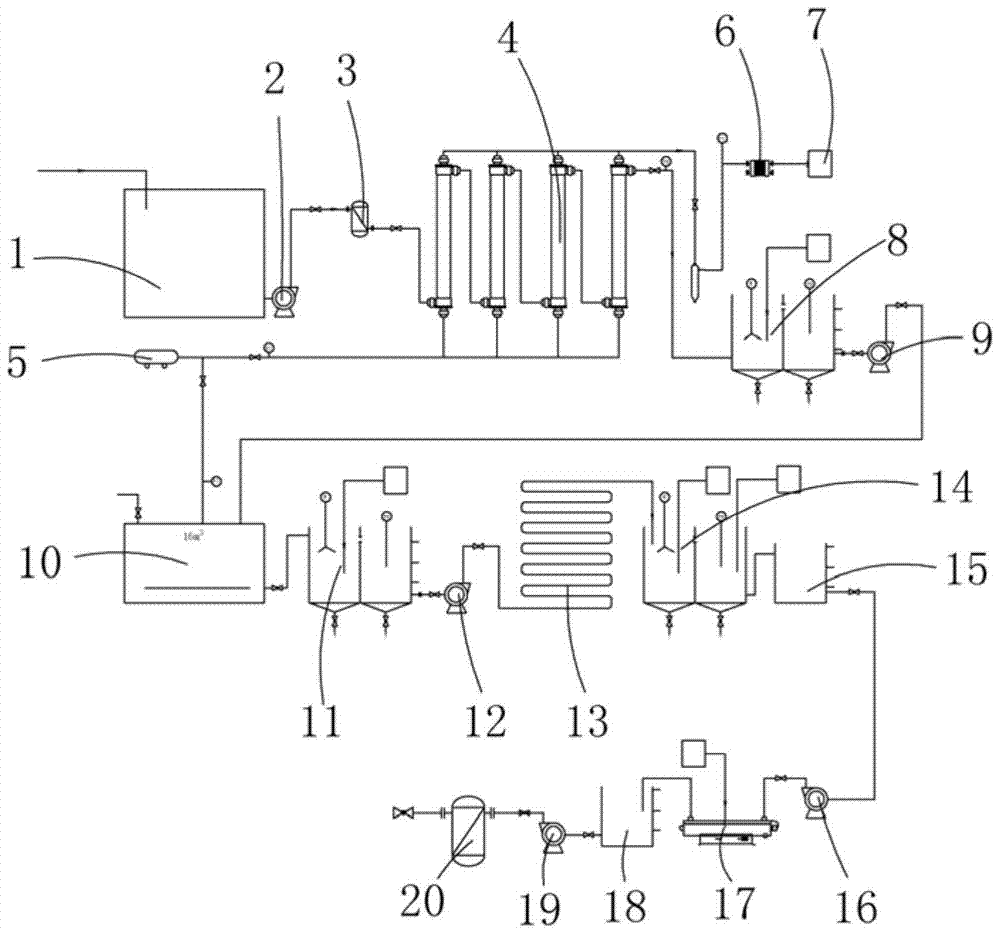

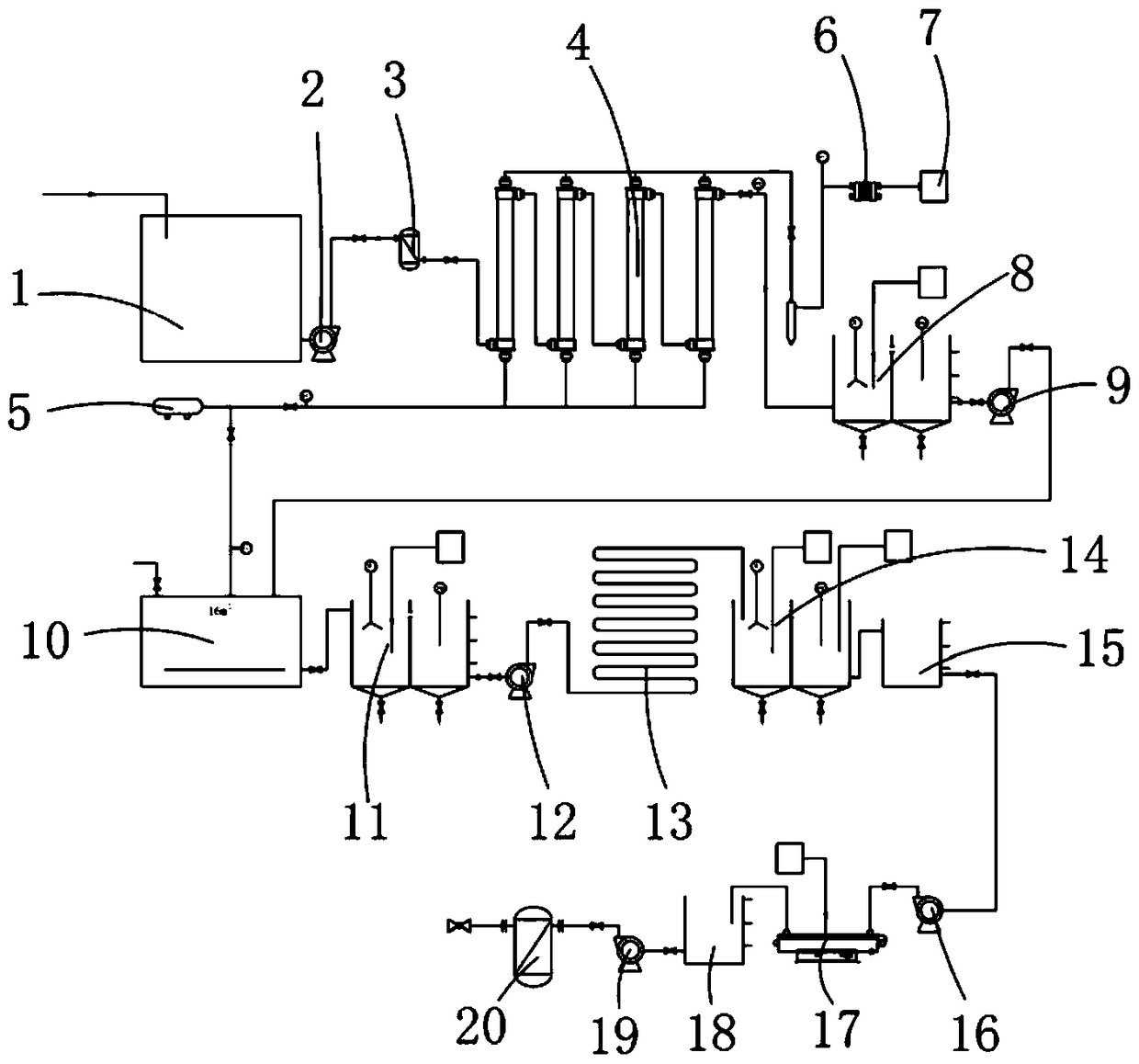

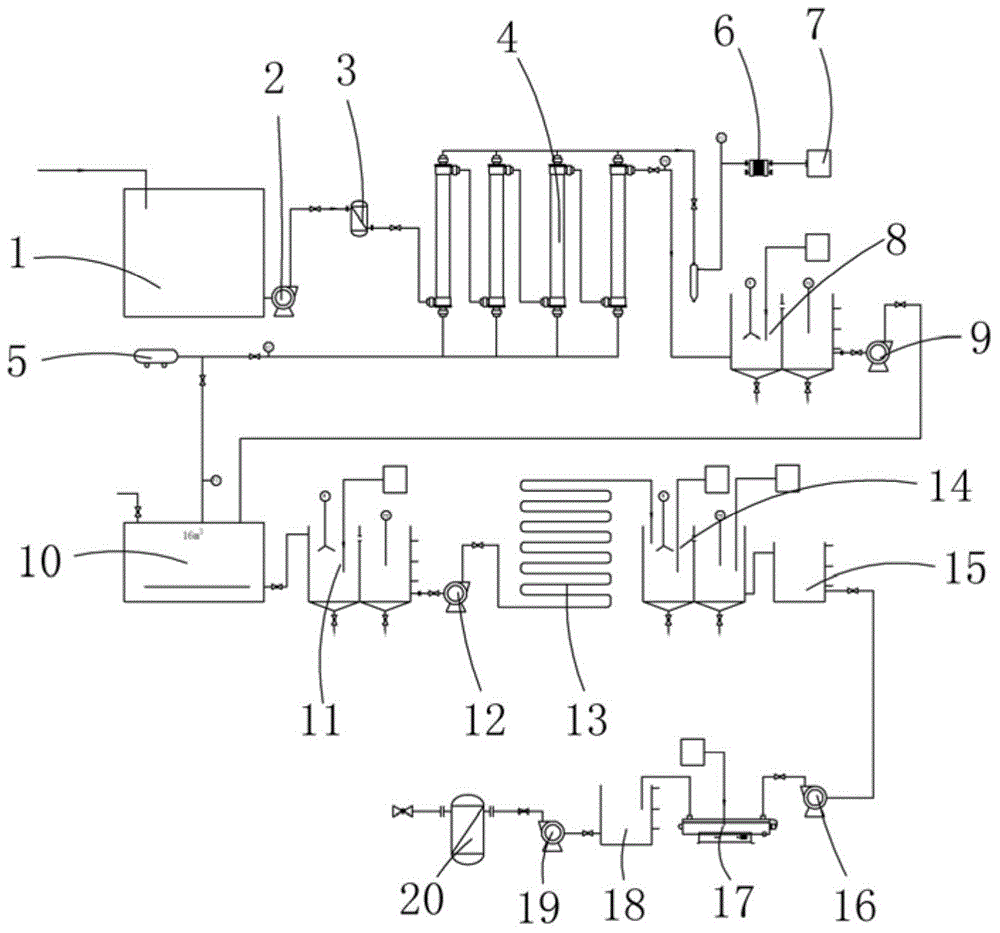

Coating wastewater treatment technology

InactiveCN105060577AReduce COD valueLarge membrane contact areaMultistage water/sewage treatmentHigh concentrationWater discharge

The invention relates to a coating wastewater treatment technology. The technology comprises the following steps: raw water enters an equalizing tank; water in the equalizing tank enters a prepositioned filter through an elevator pump and is filtered, and the filtered raw water enters a degassing and carbonizing linkage system, wherein a carbonization membrane module is arranged in the degassing and carbonizing linkage system; water discharged from the carbonization membrane module goes through a reagent adding pool a and undergoes reagent adding, the reagent added water enters a micro-electrolysis system through a pump in order to realize treatment of high-concentration organic wastewater; water discharged from the micro-electrolysis system goes through a reagent adding pool b and undergoes reagent adding, and obtained water enters a coiled tube through a pump b and undergoes a Fenton reaction, wherein reagent adding of the reagent adding pool b is carried out to adjust the pH value and the content of hydrogen peroxide; water obtained after the Fenton reaction goes through a reagent adding pool c and undergoes reagent adding, and obtained water enters a coagulation and precipitation tank and precipitates; a clear liquid at the upper portion of the coagulation and precipitation tank enters a photocatalysis system through a pump c in order to remove organic matters in the clear liquid; and water obtained after photocatalysis is collected by an intermediate water tank, and enters an enhanced filter through a pump d, and filtered water is discharged. The technology has the advantages of reduction of the COD value of coating wastewater, simple process flow and long service life.

Owner:HUZHOU SENNUO MEMBRANE TECH ENG

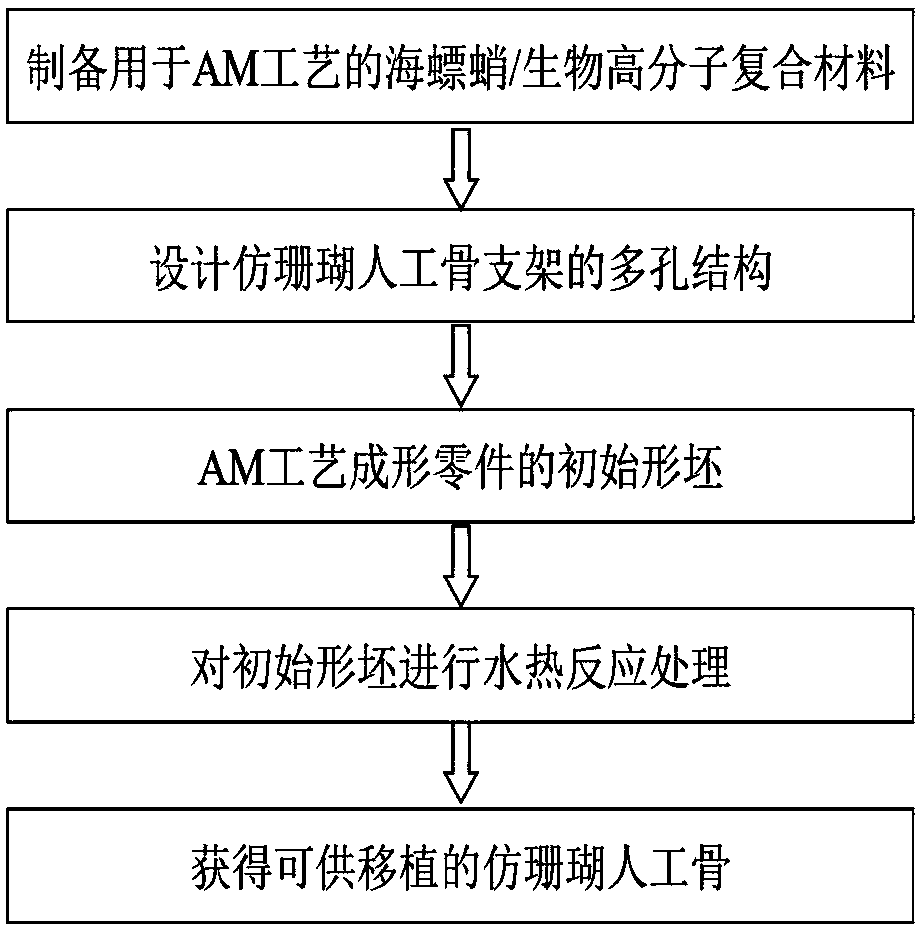

Method used for producing imitated coral artificial bone from cuttlebone, and products of method

InactiveCN107823712AHas a repairing effectRich sourcesAdditive manufacturing apparatusTissue regenerationHydrogen phosphateAdhesive

The invention belongs to the field of additive manufacturing, and discloses a method used for producing imitated coral artificial bone from cuttlebone, and obtained products. The method comprises following steps: a, cuttlebone powder and an adhesive are taken as raw materials, and are mixed so as to obtain a composite material used for additive manufacturing; b, a three dimensional model of the imitated coral artificial bone to be produced is designed, and additive manufacturing is carried out with the composite material obtained in step a based on the three dimensional model so as to obtain aprimary product; c, a diammonium hydrogen phosphate solution is prepared, the primary product is immersed in the diammonium hydrogen phosphate solution for hydrothermal reaction so as to obtain hydroxyapatite and finish production of the imitated coral artificial bone. The imitated coral artificial bone is excellent in artificial bone mechanical properties, and appropriate in degradation rate; the raw materials are widely available, renewable, and low in cost; and the method is of practical value in the medical field of bone repairing.

Owner:HUAZHONG UNIV OF SCI & TECH

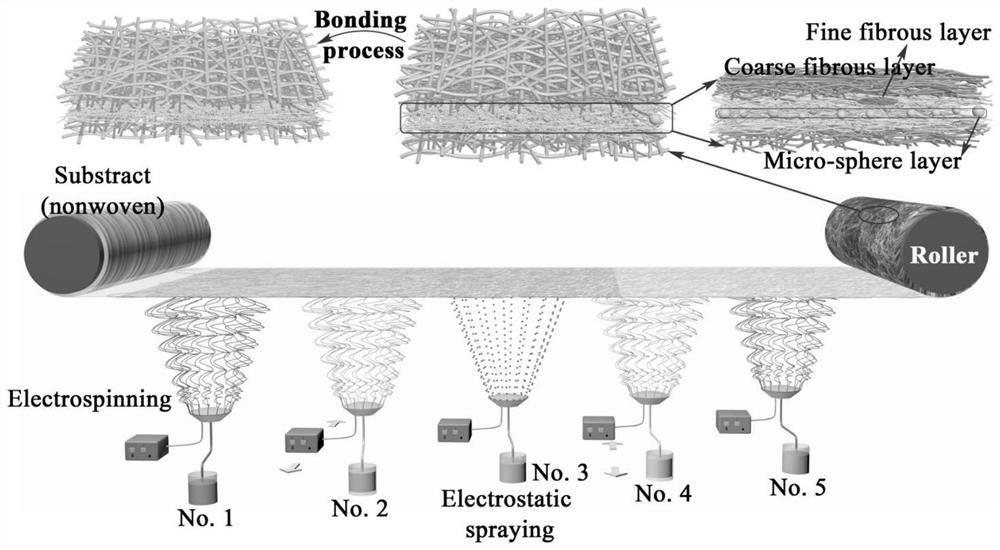

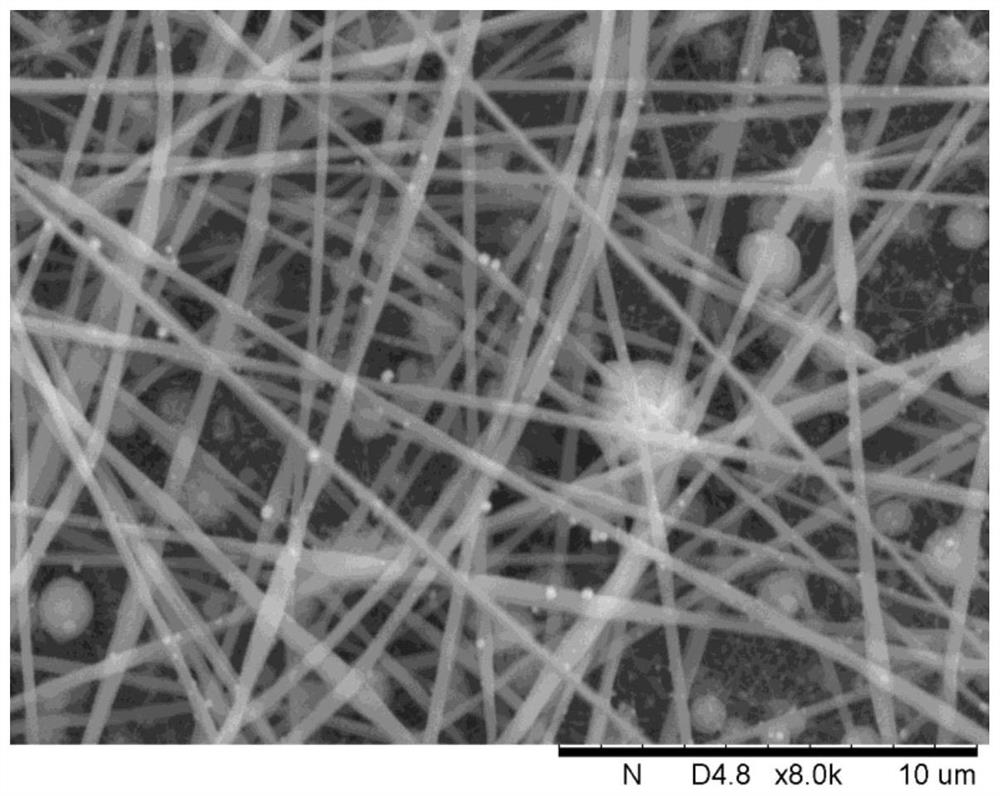

Multi-combination functional electrostatic spinning sub-micron fiber air filtering material and preparation thereof

ActiveCN112755651AImprove uniformitySmall apertureHuman health protectionElectro-spinningFiberPolymer science

The invention relates to a multi-combination functional electrostatic spinning sub-micron fiber air filtering material and preparation thereof. The material is of a sandwich structure formed by sequentially arranging a spun-bonded non-woven fabric, a sub-micron fiber / microsphere composite film and a spun-bonded non-woven fabric. The preparation method comprises the following steps: preparing a low-concentration electrostatic spinning solution with additional functionality, preparing a high-concentration electrostatic spinning solution with additional functionality, preparing an electrostatic spraying polymer solution with additional functionality, preparing a sub-micron fiber composite membrane / non-woven fabric composite material, and preparing the sub-micron fiber air filtering material. The preparation method has simple and controllable process parameters, and the prepared filter material has good structural controllability.

Owner:DONGHUA UNIV

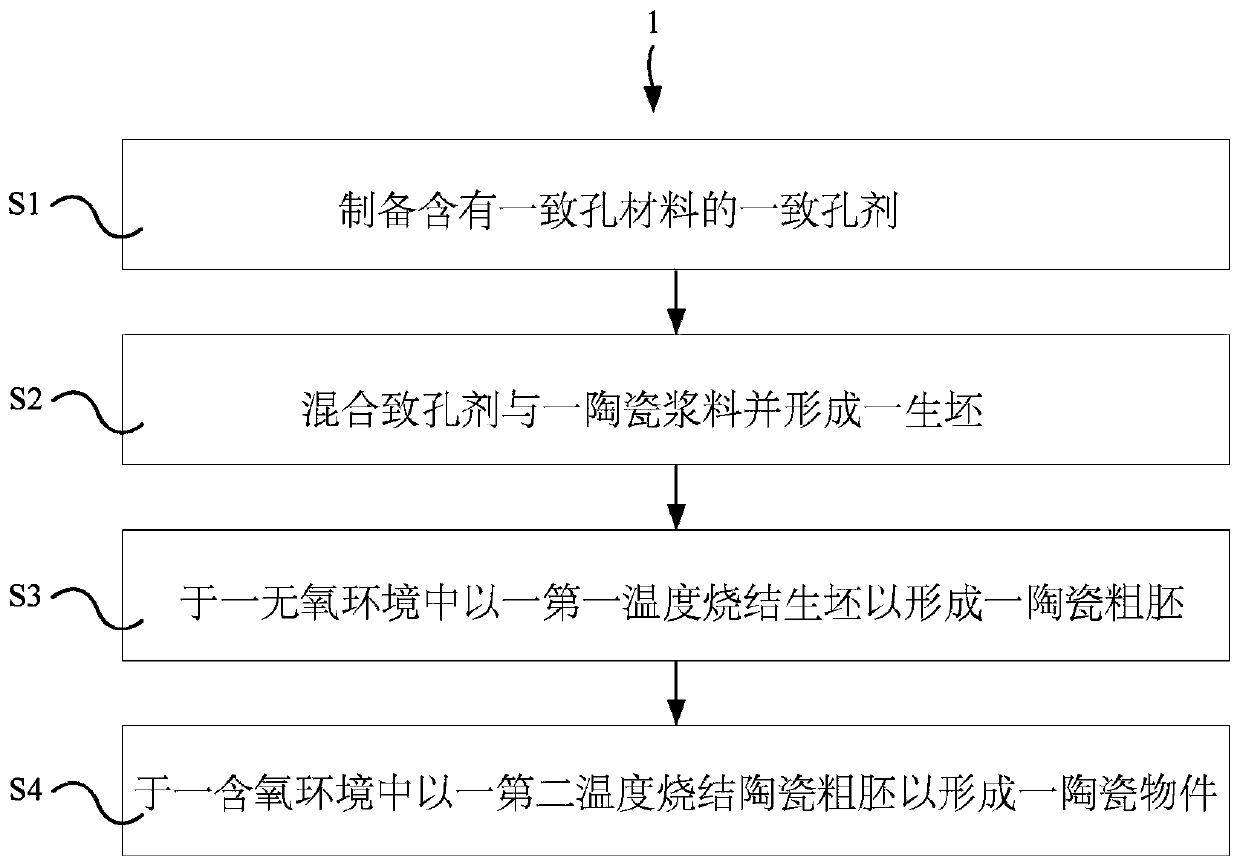

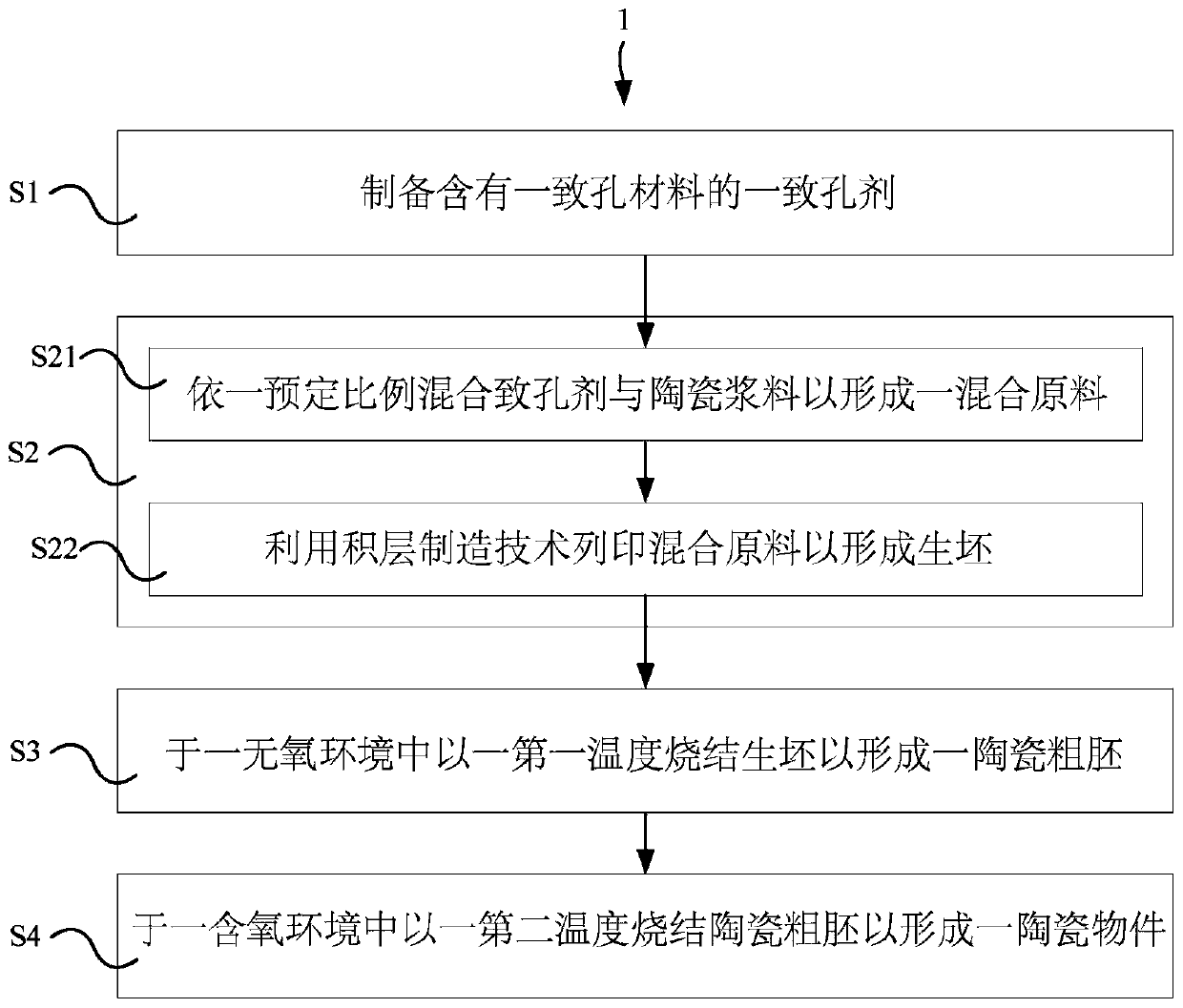

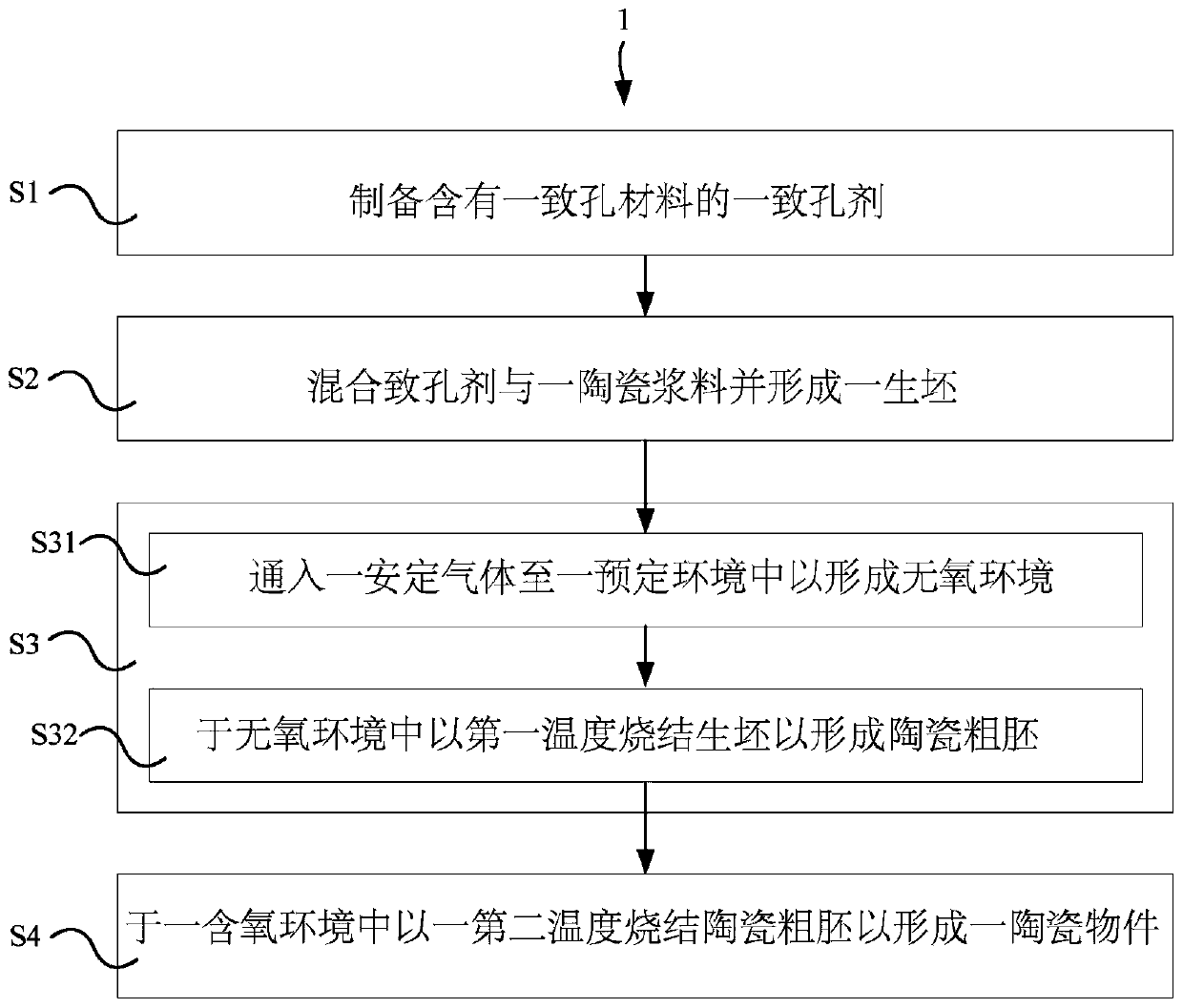

Sintering control method of ceramic manufacturing

InactiveCN110590381AImprove compactnessHigh mechanical strengthAdditive manufacturing apparatusCeramic shaping apparatusPorosityQuality assurance

The present invention provides a sintering control method of ceramic manufacturing. The method includes the following steps: S1: preparing a pore-forming agent containing a porogen; S2: mixing the pore-forming agent with a ceramic slurry and forming a greenpart; S3: sintering the greenpart at a first temperature in an oxygen-free environment to form a semi-finished object; and S4: sintering the semi-finished object at a second temperature in an oxygen-containing environment to form a ceramic article. Wherein, the first temperature is higher than the second temperature. While the porogen is a carbon-based material, the second temperature is from 300 DEG C. to 600 DEG C., and the porosity of the ceramic article may reach 30% to 70%. By this method, the property of the ceramic article (including mechanical strength, porosity, pore shape and size) can be designed according to requirement and controlled for quality assurance.

Owner:REGENBONE BIOMEDICAL INC

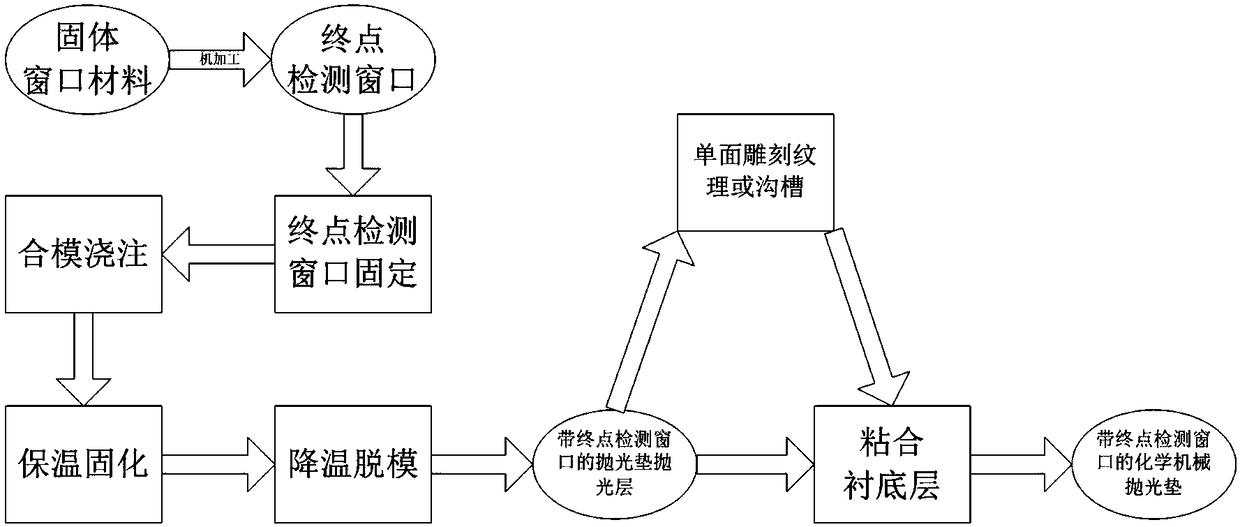

Manufacturing method for chemical mechanical polishing pad as well as product thereof and mould

InactiveCN108453970AWon't hurtSmall size fluctuation rangeGrinding devicesLapping toolsDensity distributionDual effect

The invention provides a manufacturing method for a chemical mechanical polishing pad, the chemical mechanical polishing pad manufactured by the manufacturing method and provided with a final point detecting window, and a matched single-piece or multi-piece combined type casting mould. In the process, the formed solid final point detecting window is embedded and nested into a polishing layer of the chemical and mechanical polishing pad through a once integrated casting and forming process, so that the polishing layer firmly bonded with the window is directly manufactured. The single-piece or multi-piece combined type casting mould is utilized for precisely controlling casting process parameters of the polishing layer with the window, and the obtained product polishing pad body is excellentin density distribution, cavity rate and uniformity of cavity size, so that integral process and quality stability of the polishing pad are obtained. The contact surface between the window of the product and the polishing layer body is bonded under chemical and physical dual effects, so that the bonding effect is extremely good, and therefore, a leakage phenomenon caused by cracks of the contactsurface in a using process is eliminated. Therefore, the manufacturing method has remarkable practical popularization value.

Owner:CHENGDU TIMES LIVE SCI & TECH

Preparation methods for non-macroscopic-interface density gradually-changed type composite foam

The invention belongs to the field of preparation of composite foam and particularly discloses preparation methods for non-macroscopic-interface density gradually-changed type composite foam. Actually, the two preparation methods are provided, specifically, the first method is used for preparing the density gradually-changed type composite foam by changing the wall thicknesses of hollow microspheres, and the other method is used for preparing the density gradually-changed type composite foam by adopting expandable microspheres. The methods are simple and high in designability, the porosity in the composite foam can be accurately controlled, and the density of the composite foam in different parts is controlled according to the design requirements. Due to the fact that all layers of the composite foam are co-cured to be formed by adopting resin matrixes of the same system, the interface of the composite foam of different densities is eliminated, the problems that due to the interface problem, composite foam structures of different densities are poor in adhesion, and sound absorption or sound transmission performance does not meet the requirement are solved, and the foam is mainly used as an energy absorbing material and a sound transmission material.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Functional gradient foamed aluminum and preparation method thereof

The invention relates to the cross technical field of porous metal and metal-based composite materials, in particular to functional gradient foamed aluminum and a preparation method thereof. The gradient foamed aluminum comprises at least one pure foamed aluminum layer and at least one carbon nanotube reinforced foamed aluminum-based composite material layer, wherein the porosity of the adjacent pure foamed aluminum layers is different; and the porosity of the adjacent carbon nanotube reinforced foamed aluminum-based composite material layers is different and / or the content of carbon nanotubes is different. According to the functional gradient foamed aluminum and the preparation method thereof provided by the invention, the density gradient and the component gradient are combined, the functional gradient foamed aluminum with the base material and the density changing at the same time is prepared, the gradient material can be designed in a targeted mode according to the service environment of the material, and the advantages of the gradient foamed material are fully played, so that the good energy absorption effect is achieved; and under the condition that the overall porosity is the same, the gradient foamed aluminum has higher stress level and higher energy absorption capacity compared with uniform foamed aluminum, so that the buffering and energy absorption performance of the gradient foamed aluminum is improved.

Owner:四川新能源汽车创新中心有限公司

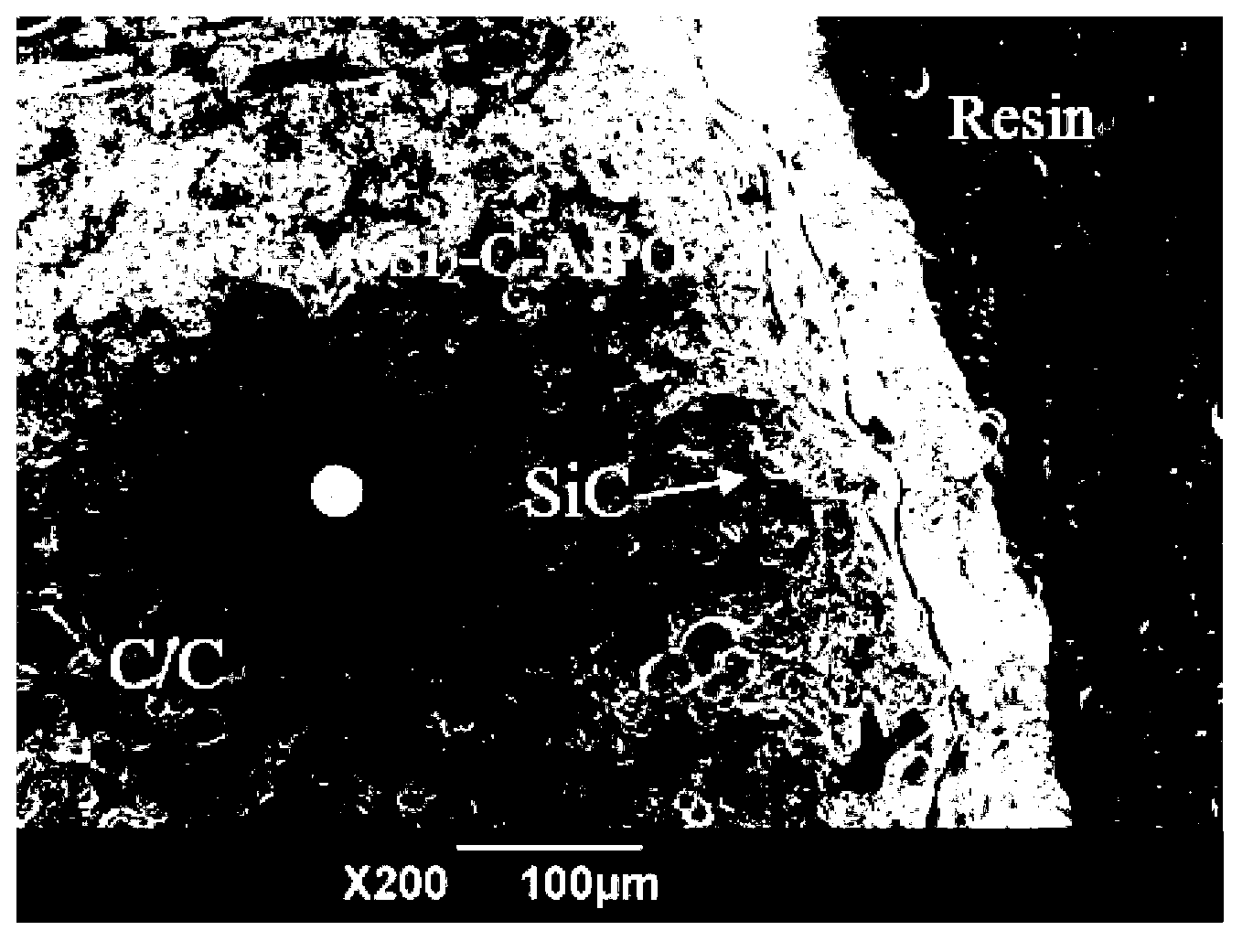

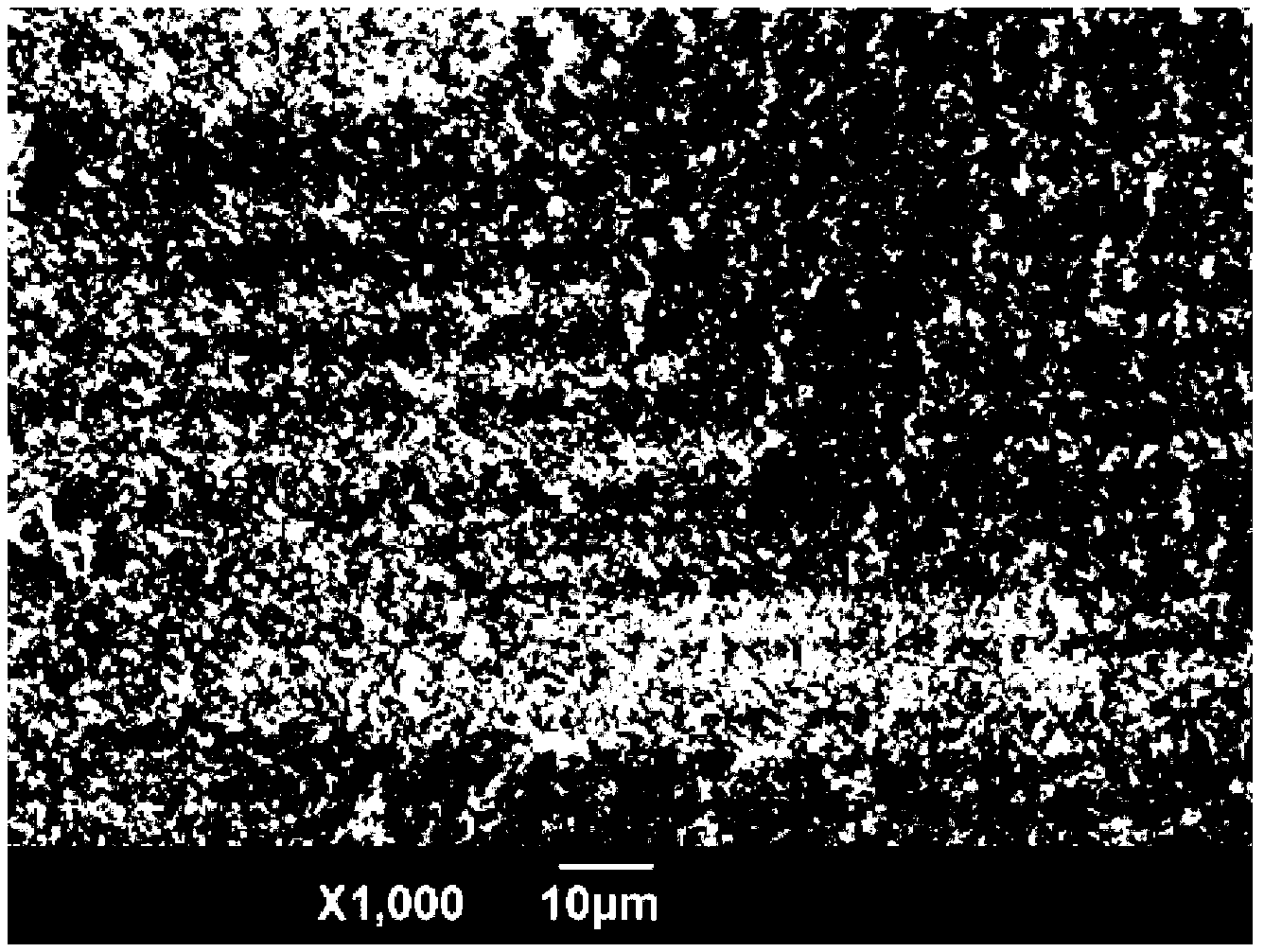

Method for preparing carbon/carbon composite material SiC-MoSi2-C-AlPO4 composite gradient external coating

The invention relates to a method for preparing a carbon / carbon composite material SiC-MoSi2-C-AlPO4 composite gradient external coating, which is completed in a hydrothermal reactor at one time, does not need late heat treatment, maintains uniform thickness and does not generate through holes and cracks. At first, C-AlPO4 powder, silicone carbide nano powder and MoSi2 powder are weighed according to the mass ratio of (1-10):(1-20):(1-10) to be mixed, suspension liquids A, B and C of 20-40 grams / liter are then prepared, are subjected to ultrasonic concussion and magnetic stirring, and are then added with tellurium simple substance to prepare suspension liquids D, E and F with the tellurium simple substance concentrations of 0.5-2.0 grams / liter, an ultrasonic cathode rotary microwave hydrothermal electrophoresis arc discharge sedimentation method is adopted to sequentially deposit the suspension liquids D, E and F on a carbon / carbon composite material sample with a SiC internal coating, and finally, drying is carried out. The method has the advantages of short preparation period, simplicity in technological preparation, convenience in operation, easily-obtained raw materials and low preparation cost.

Owner:XINING GONGJIN NEW MATERIAL TECHNOLOGY CO LTD

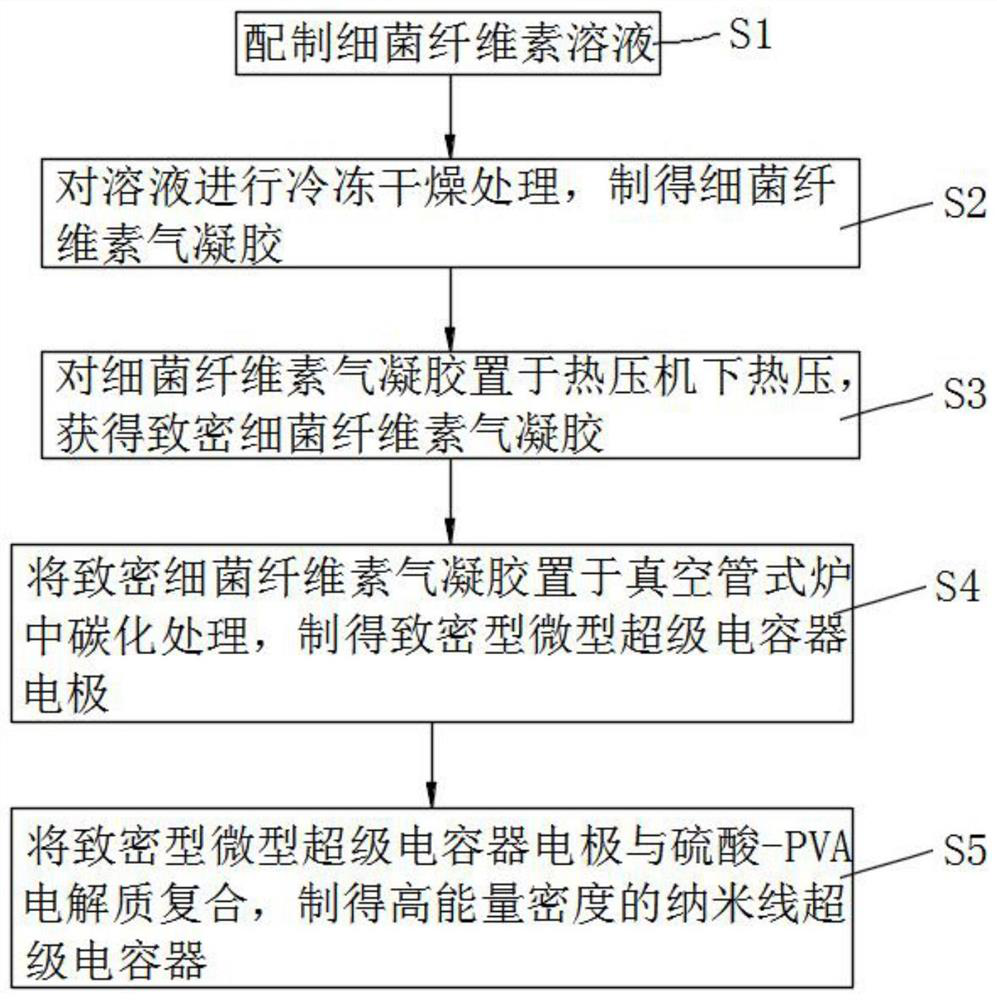

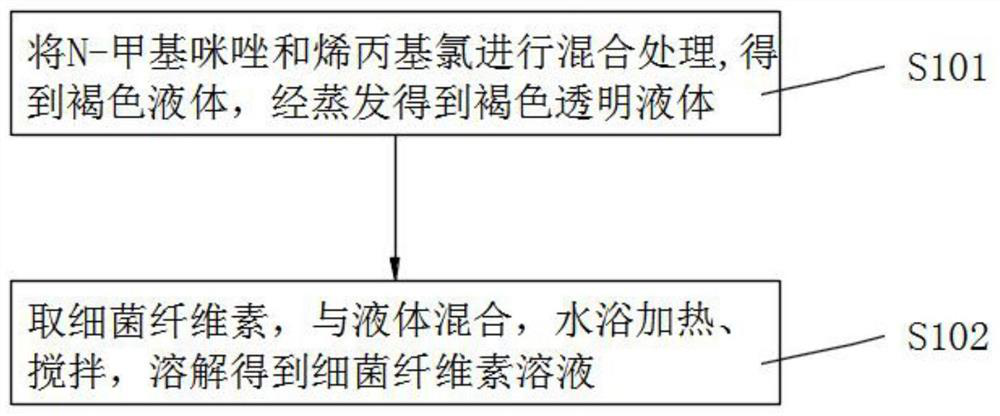

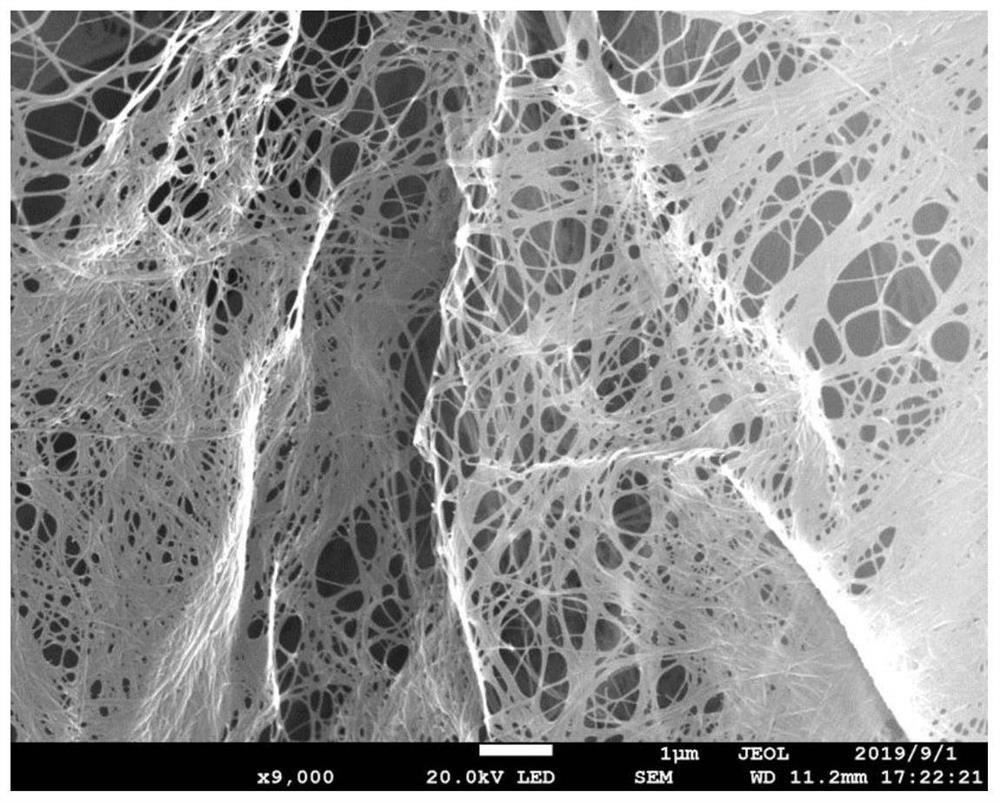

Preparation method of novel staggered communication nanowire supercapacitor electrode

InactiveCN111933457ADensity regulationPrecise load controlMaterial nanotechnologyHybrid capacitor electrodesNanowireFreeze-drying

The invention discloses a preparation method of a novel staggered communication nanowire supercapacitor electrode, and belongs to the technical field of capacitor electrodes. The method comprises thefollowing steps: S1, preparing a bacterial cellulose solution with the concentration of 0.5%; S2, taking the prepared bacterial cellulose solution; freeze drying treatment, preparing the bacterial cellulose aerogel; S3, placing the obtained bacterial cellulose aerogel under a hot press for hot pressing, to prepare the compact bacterial cellulose aerogel; S4, putting the obtained compact bacterialcellulose aerogel into a vacuum tube furnace for carbonization treatment to prepare a compact micro supercapacitor electrode; and S5, compounding the obtained compact micro supercapacitor electrode with the sulfuric acid-PVA electrolyte to prepare the nanowire supercapacitor with high energy density. According to the invention, the density of the nanowire can be regulated and controlled, and the area loading capacity and porosity of the nanowire can be accurately regulated and controlled, so that the supercapacitor with high energy density and high power surface density is obtained.

Owner:WUHAN UNIV OF TECH

Composite lithium metal negative electrode and preparation method, lithium ion battery

ActiveCN109713224BPrecise control of porositySufficient porositySecondary cellsActive material electrodesLithium metalHigh energy

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

A preparation method of bionic artificial bone with multi-level [micro/nano] pore structure

InactiveCN103462729BPrecise control over distributionPrecise Control of ConnectivityBone implantFurnace temperatureSelective laser sintering

The invention relates to a preparation method of a bionic artificial bone with a multistage [micrometer / nanometer] pore structure. The method is characterized by the following steps of: realizing 150-800 mum gradient through pores by selective laser sintering (the diameter of the light spot is micrometer scale); mixing and performing oxygenolysis on a small amount of high polymer microballoons in the sintering process to form 10-100 mum random spherical pores; finally obtaining the bionic artificial bone which has an three-dimensional hierarchical pore structure similar to that of a natural bone by a method of obtaining irregular pores in tens of nanometer surfaces by a corrosion process. In the invention, according to the requirement of an implanting position, the distribution, connectivity and the like of the gradient through pore can be accurately controlled by adjusting sintering process parameters; the shape, size and the like of the spherical pores can be controlled by precisely controlling the furnace temperature curve and high polymer particle properties; the size, quantity and the like of the nanometer pores can be controlled by controlling the corrosion liquid concentration and corrosion time. The preparation method disclosed by the invention has an important significance in creating a microenvironment beneficial to cell adhesion, proliferation and function exertion, improving forming of new bones, and increasing healing of bones.

Owner:CENT SOUTH UNIV

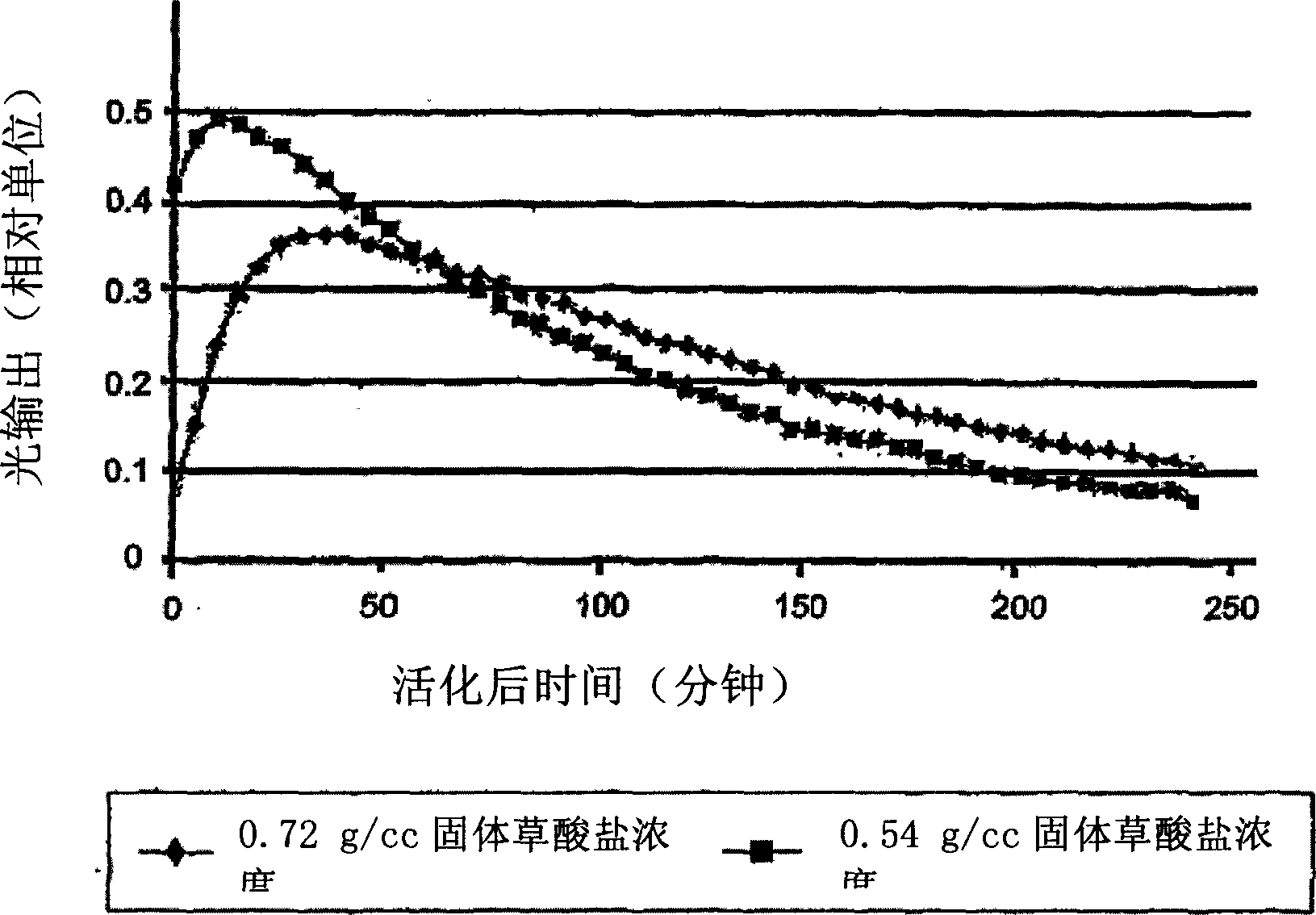

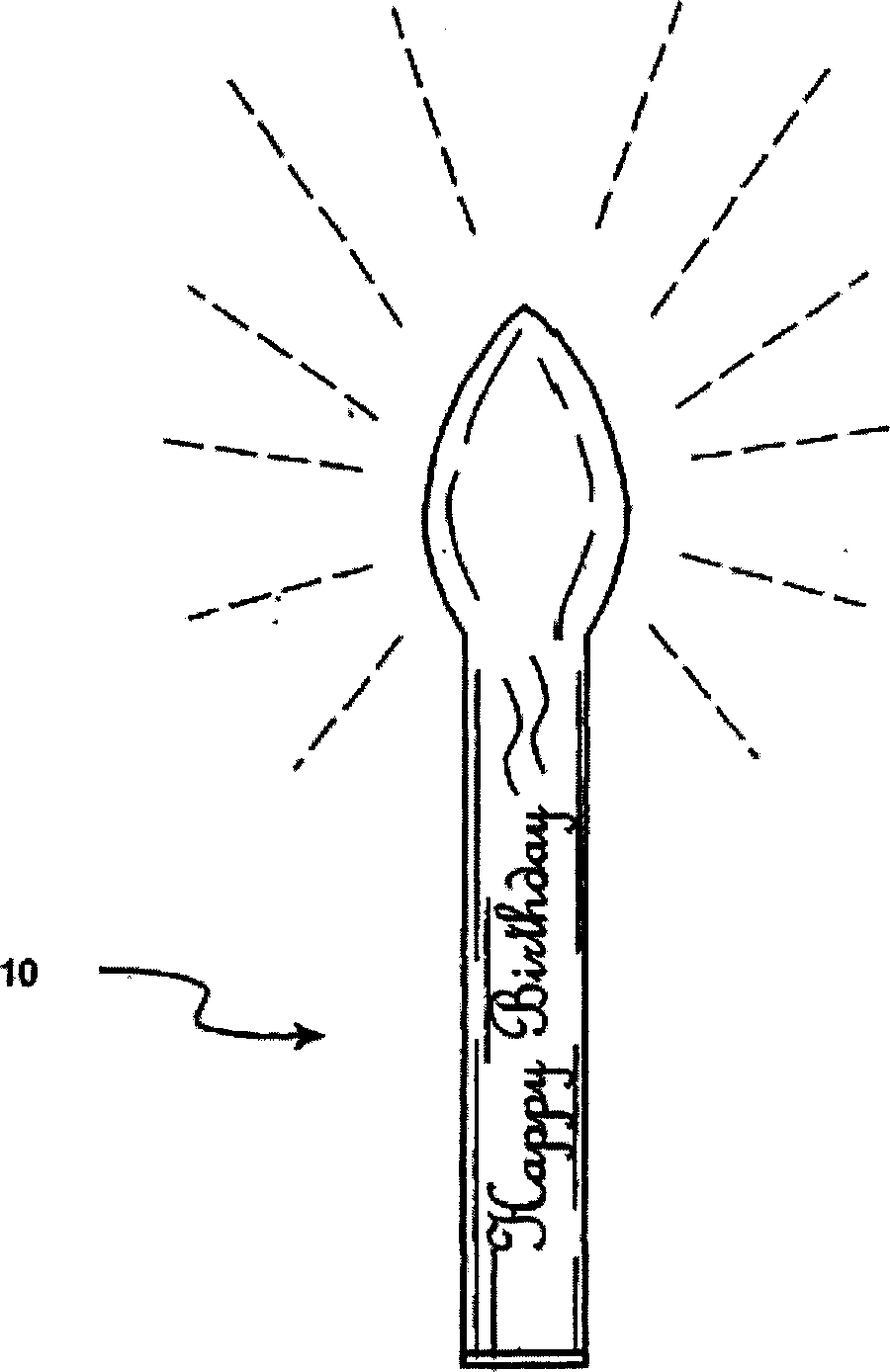

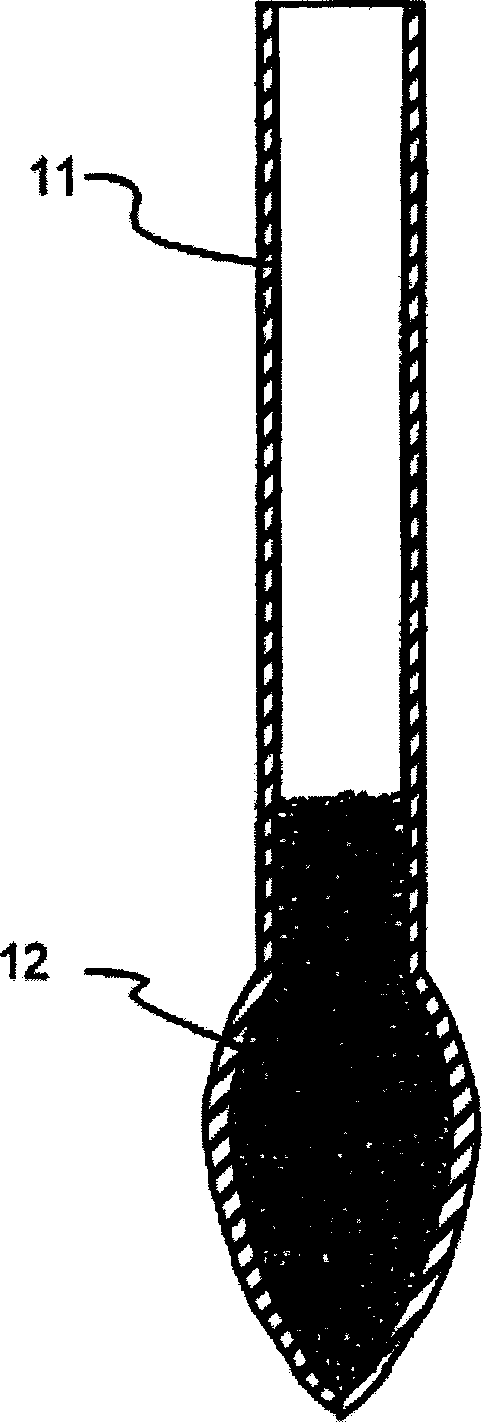

Formable, porous, chemiluminescent reactant compositions and device therefor

InactiveCN1643103APrecise control of porosityLittle or no dark areasOther chemical processesLuminescent compositionsReagentChemiluminescence response

A formable, porous chemiluminescent reactant composition, device (11) therefore, and a process for production thereof is disclosed. The fluidizable solid admixture (12) of the instant invention may be cured to a more or less rigid form with or without the use of a mold. The cured solid is useful as a chemiluminescent reactant component and is useful in a variety of environments.

Owner:奥美尼发光产品公司

Preparation method of zno linear resistor with adjustable porosity

ActiveCN109020534BAdjust porosityEfficient exclusionResistor manufactureElectrical resistance and conductancePhysical chemistry

The invention discloses a method for preparing ZnO linear resistance with adjustable porosity. No additional process is added in the process of preparing ZnO linear resistance, the method is simple and easy to operate, and graphite powder introduced in the process of preparing ZnO linear resistance can effectively exclude. The graphite powder used is non-toxic, low in price, easy to obtain, and the volatilization of organic matter and carbon gasification products in the sintering process are easy to collect and process, without environmental pollution, and without residue after sintering. Without changing the composition of the ZnO linear resistance element and without affecting the performance of the ZnO linear resistance element, the precise control of the porosity of the ZnO linear resistance element can be realized, so as to meet the various needs of heat dissipation, strength and light weight. The prepared ZnO linear resistance element can meet the application requirements of more occasions.

Owner:SHANGHAI UNIV

Method for preparing ZnO linear resistor with adjustable porosity

The invention discloses a method for preparing a ZnO linear resistor with adjustable porosity. No additional process is added in the process of preparing the ZnO linear resistor, the method is simpleand easy to operate, and graphite powder introduced in the process of preparing of the ZnO linear resistor can be effectively excluded. The graphite powder used is non-toxic, inexpensive, and easy toobtain. Organic matter volatilization and carbonization gasification products in the sintering process are easy to collect and treat, and have no environmental pollution and no residue after sintering. The precise control of the porosity of the ZnO linear resistive element can be achieved without changing the composition of the ZnO linear resistive element and without affecting the performance ofthe ZnO linear resistive element, various needs of heat dissipation, strength and weight reduction can be met, and the prepared ZnO linear resistive element can meet the application requirements of more occasions.

Owner:SHANGHAI UNIV

A coating wastewater treatment device

ActiveCN105060586BReduce COD valueLarge membrane contact areaMultistage water/sewage treatmentActivated carbonFenton reaction

Owner:湖州京兰环保科技有限公司

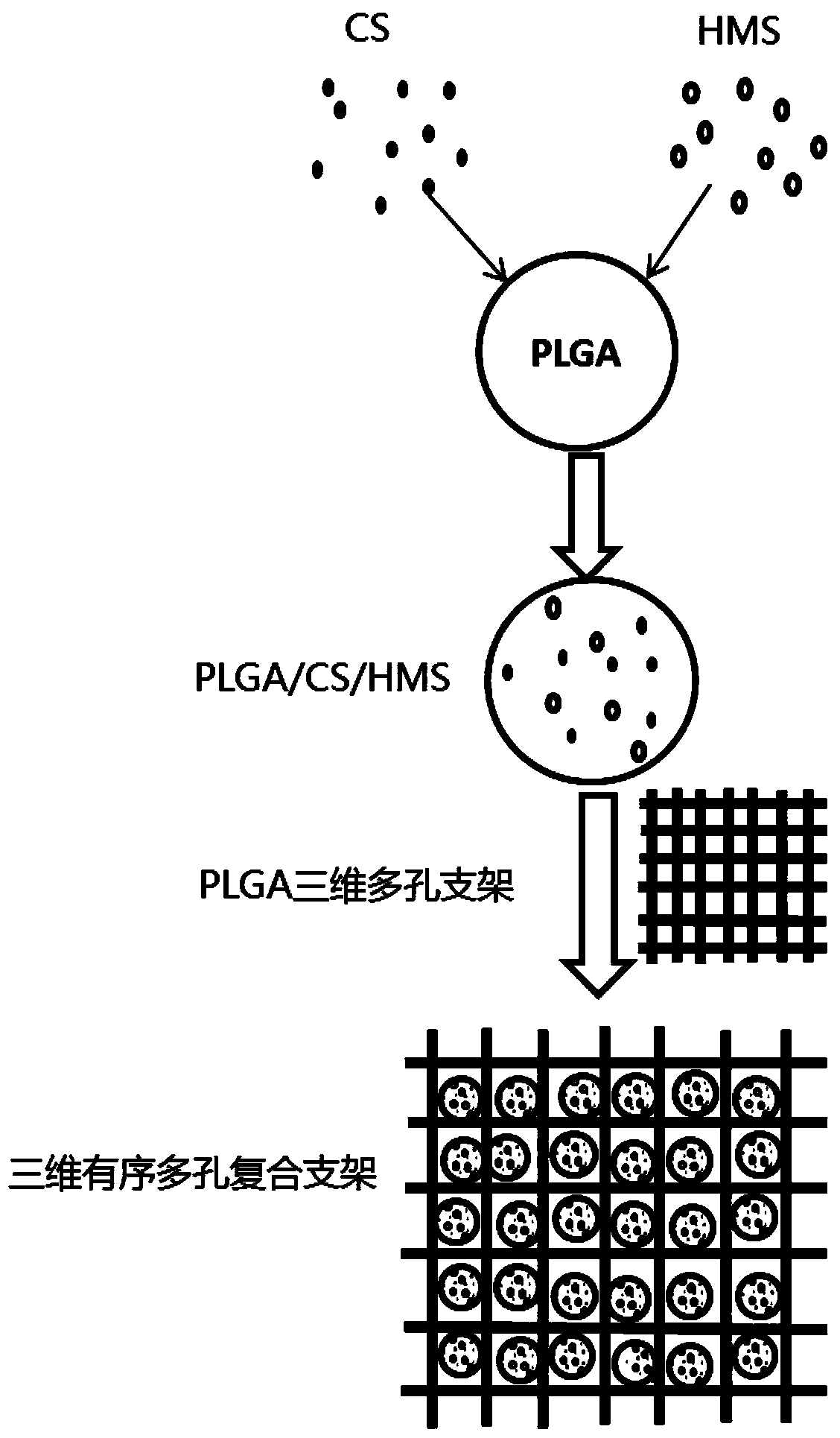

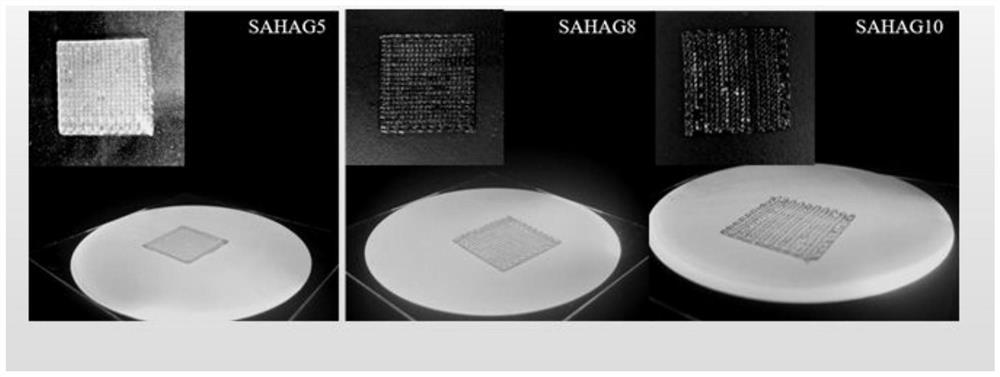

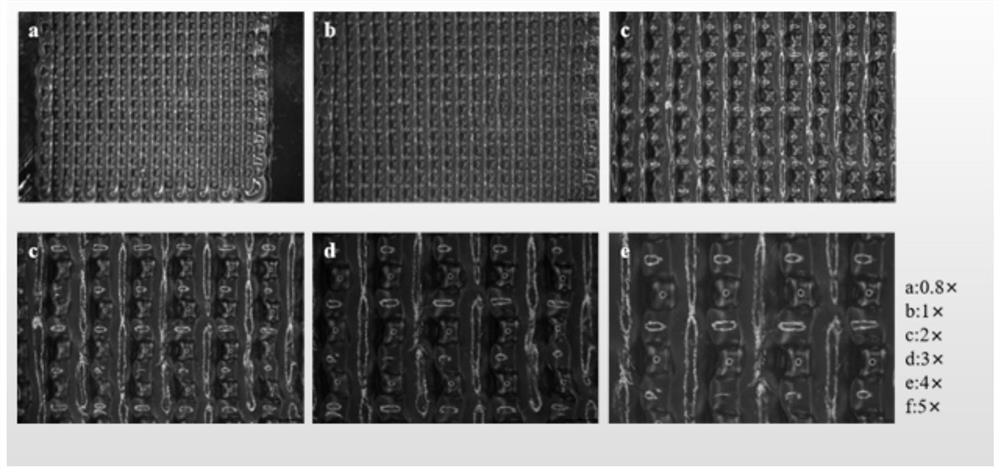

Porous composite scaffold for bone repair based on 3d-bioplotter printing technology and its preparation method

ActiveCN105031718BPrecise Control of GeometryPrecise control of apertureProsthesisCalcium silicateMicrosphere

A bone repair porous compound stent based on 3D-Bioplotter printing technology and a preparation method therefor. The stent is formed by compounding a matrix provided with a 3D macroporous structure and a drug carrying microsphere. The preparation method comprises the following steps: printing a stent matrix having a regular 3D macroporous structure by means of 3D-Bioplotter; preparing a drug carrying microsphere compounding hexagonal mesoporous silica (HMS), calcium silicate (CS) powder and PLGA by means of an emulsion solvent volatilization method; finally, fixing the compound microsphere into the matrix by means of low-temperature sintering, so as to obtain the bone repair porous compound stent based on 3D-Bioplotter printing technology.

Owner:SOUTH CHINA UNIV OF TECH

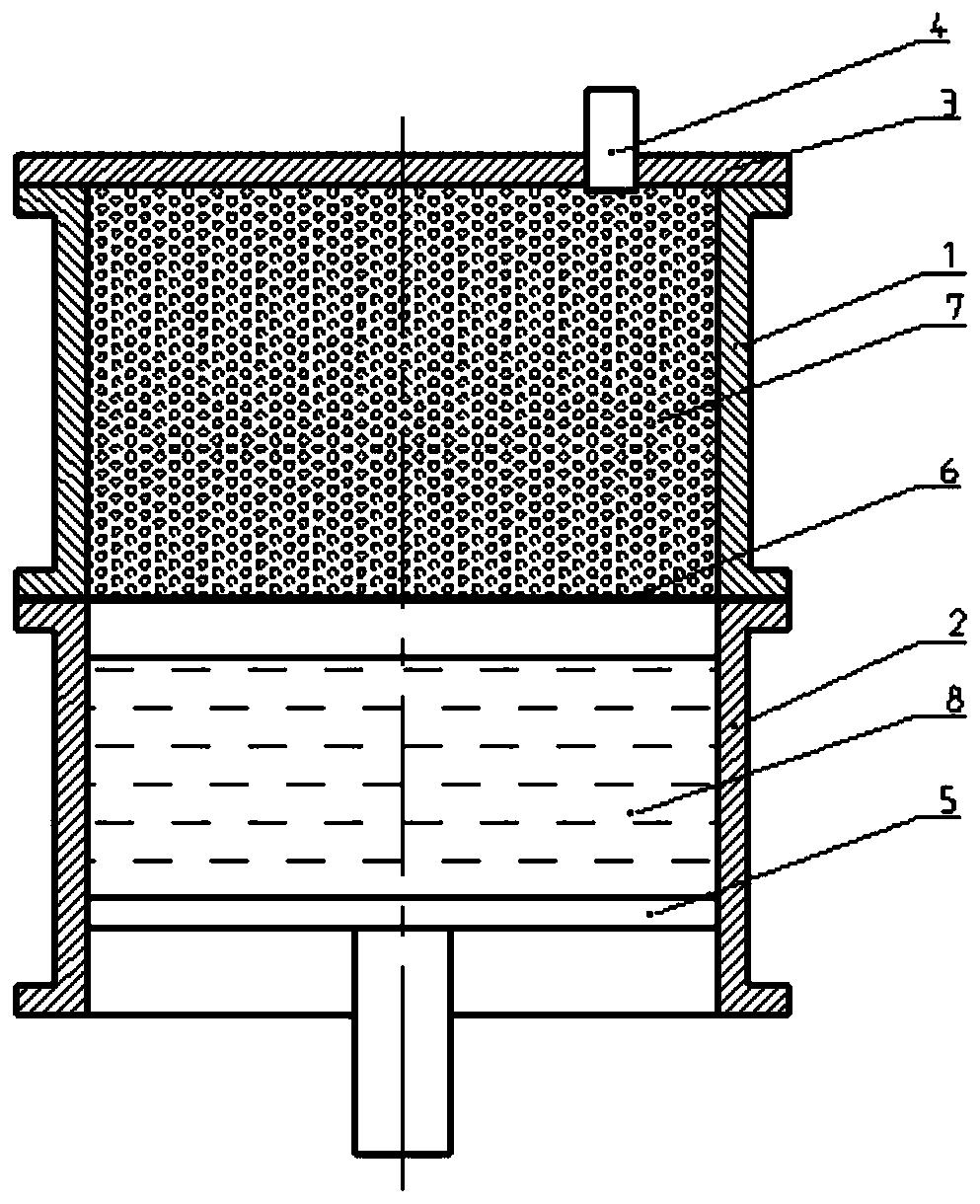

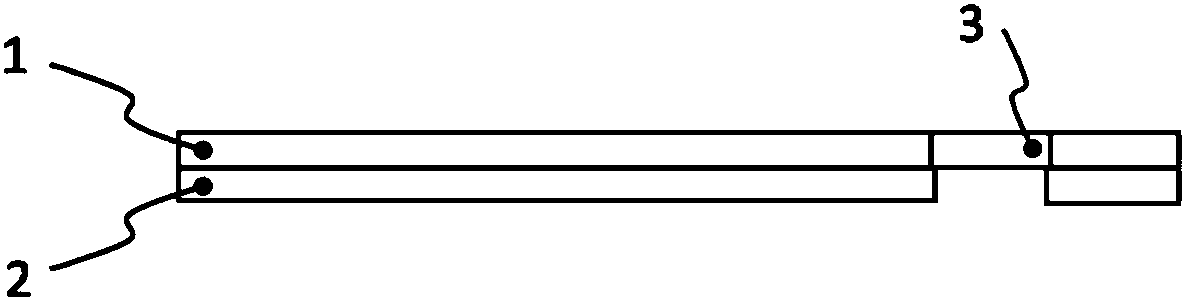

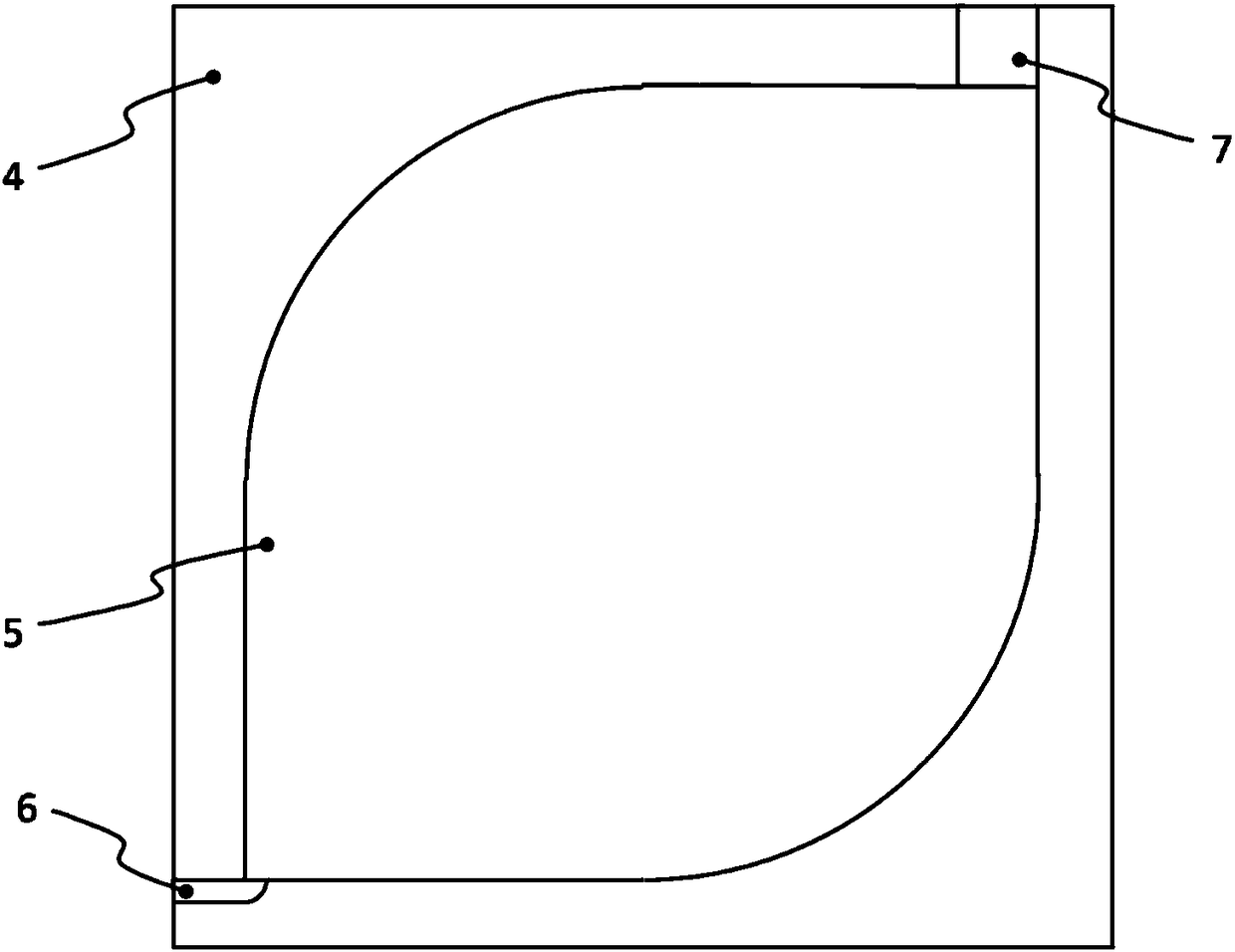

Device for preparing porous ceramic and method for preparing porous ceramic by using polystyrene foam particles

InactiveCN111391065AReduce manufacturing costPrecise control of porosityCeramic shaping apparatusCeramicwarePolystyreneSlurry

The invention provides a device for preparing porous ceramic and a method for preparing porous ceramic by using polystyrene foam particles, and belongs to the technical field of porous ceramic. The device comprises a foaming cylinder body 1 with a lower opening and a ceramic slurry cylinder body 2 communicating with the foaming cylinder body 1 through a metal net 6, wherein the metal net 6 is arranged at the joint of the foaming cylinder body 1 and the ceramic slurry cylinder body 2, the foaming cylinder body 1 is provided with an upper cover 3, the upper cover 3 is provided with a gas inlet 4, and a pressurizing piston 5 is arranged at a lower opening of the ceramic slurry cylinder body 2. The device is simple in structure, the porous ceramic is prepared by using the polystyrene foam particles as a pore forming agent by using the structure, the cost is low, and the market competitiveness is high; the specific volume of the polystyrene foaming particles is low, and smoke pollution generated in the roasting process is small; and the porosity of the porous ceramic can be accurately controlled by adjusting the compactness of the polystyrene foamed particles and the introduction time of the foaming gas.

Owner:SHANDONG UNIV OF TECH

A paint wastewater treatment process

InactiveCN105060577BReduce COD valueLarge membrane contact areaMultistage water/sewage treatmentHigh concentrationElectrolysis

The invention relates to a paint wastewater treatment process, which includes the following process: the raw water enters the adjustment pool; the water in the adjustment pool enters the pre-filter through the lifting pump and is filtered, and then enters the degassing and carbonization linkage system. The degassing and carbonization linkage system is equipped with Carbonized membrane module; the effluent of the carbonized membrane module passes through the dosing tank a and enters the micro-electrolysis system through pump a to treat high-concentration organic wastewater; The Fenton reaction is carried out in the shaped tube, and the medicine tank b is added to adjust the pH value and hydrogen peroxide content; after the Fenton reaction, the effluent enters the coagulation sedimentation tank for precipitation after the dosing tank c is added; the clear liquid in the upper part of the coagulation sedimentation tank Enter the photocatalytic system through pump c to remove organic matter in the clear liquid; the photocatalytic effluent is collected in an intermediate water tank, and then enters the enhanced filter through pump d to be discharged. The invention reduces the COD value of paint wastewater, has simple technological process and long service life.

Owner:HUZHOU SENNUO MEMBRANE TECH ENG

Carbon/carbon compositesyb 2 the si 2 o 7 Whisker toughened yb 2 sio 5 Preparation method of composite coating

The invention discloses a preparation method for a carbon / carbon composite Yb2Si2O7 whisker toughened Yb2SiO5 composite coating.The preparation method comprises the following steps that 1, Yb2SiO5 powder and Yb2Si2O7 whiskers are dispersed in isopropanol to prepare a Yb3+ mixture A with the concentration of 30-45 g / L; 2, the mixture A is subjected to ultrasonic concussion and then stirred to prepare suspension liquid A; 3, elementary substance iodine is added into the suspension liquid A to obtain a mixture B, and the mixture B is subjected to ultrasonic concussion for 30-60 min and then stirred while being heated to prepare suspension liquid B; the suspension liquid B is added into a hydrothermal kettle, a graphite electrode serves as an anode, a conductive substrate serves as a cathode, a carbon / carbon composite sample with an SiC inner coating is clamped to the cathode in the hydrothermal kettle, and the hydrothermal kettle is put into an electromagnetic induction heater for a reaction; 5, after the reaction is over, the carbon / carbon composite sample with the SiC inner coating is taken out and dried, and then the carbon / carbon composite Yb2Si2O7 whisker toughened Yb2SiO5 composite coating is prepared.According to the method, the process equipment is simple, the reaction period is short, cost is low, and the method has broad development prospects.

Owner:SHAANXI UNIV OF SCI & TECH

Porous current collector and preparation method thereof

PendingCN114843525AHigh precisionPrecise control of porosityElectrode thermal treatmentElectrode carriers/collectorsMetallic substrateMetal substrate

The invention discloses a porous current collector and a preparation method thereof. The preparation method comprises the following steps: providing a metal substrate; the metal base material is conveyed to an extrusion roller to be extruded, and pricking needles are arranged on the surface of the extrusion roller and used for pricking the metal base material; cleaning the extruded metal base material so as to form a through hole in the metal base material; and carrying out drying treatment on the etched metal base material. The preparation method is simple to operate, the size of the through hole is adjustable, the precision is high, the porosity is adjustable, the cost is low, and the yield is high.

Owner:佛山市中技烯米新材料有限公司

A kind of preparation method of metal matrix composite electronic package containing high volume fraction sic

ActiveCN104658917BPrecise control of volume fractionPrecise control of porosityAdditive manufacturing apparatusSemiconductor/solid-state device manufacturingPorosityMulti segment

The invention relates to a preparation method of an electronic packaging device, in particular to a preparation method of a metal matrix composite electronic packaging device containing high-volume-fraction SiC. The preparation method comprises the following steps: taking an adhesive and SiC particles according to the mass ratio of 1: (3-5) and uniformly mixing; after a SiC preform standby material is obtained, obtaining an SiC green body with the set size and shape through a 3D printing technology; successively obtaining an SiC porous preform by adopting a low-temperature multi-segment sintering mode; then performing molten metal impregnation treatment to obtain a finished product. According to the preparation method, the electronic packaging device with any complicated shape can be prepared, the forming process can be controlled with high precision, and the volume fraction SiC, porosity, preform aperture and hole length can be accurately controlled, so that the mechanical property and the thermo-physical property of materials are accurately controlled.

Owner:CENT SOUTH UNIV

Porous conductive MAX phase ceramics and preparation method and use thereof

InactiveCN101747075BPrecise control of porosityPorosity adjustablePhysical/chemical process catalystsCeramicwarePorous ceramicsCatalyst support

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

3D bioprinted active biofilm for improved amic technology cartilage repair and its preparation method

ActiveCN111588908BLow immunogenicityGood biocompatibilityAdditive manufacturing apparatusTissue regenerationCartilage repairCytokine

A modified AMIC bio-3D printed active biofilm for cartilage repair, characterized in that: the biofilm uses sodium alginate / gelatin / hyaluronic acid as raw materials to prepare a mixed hydrogel, and the hydrogel is mixed with pre-cartilage Somatic cells and fibronectin, using depositional bio-3D printing technology to construct a porous hydrogel biofilm, and chemically cross-linked to enhance mechanical properties by soaking in calcium chloride. The materials used in the invention are all natural materials, have low immunogenicity, good biocompatibility, wide sources, and have certain mechanical properties to provide good support for cartilage regeneration. As far as the preparation method is concerned, the gaps of 300-500 microns can promote cartilage regeneration, and the excellent porosity structure can also promote the exchange and communication of substances between cells, which is conducive to the adhesion of cytokines or cells, and is beneficial to cells in its environment. Internal growth and proliferation.

Owner:NANJING FIRST HOSPITAL

A kind of functional gradient aluminum foam and preparation method thereof

ActiveCN113667855BIncreased stress levelsHigh energy absorptionTransportation and packagingMetal-working apparatusPolymer scienceEnergy absorption

The invention relates to the cross-technical field of porous metal and metal-matrix composite materials, in particular to a functional gradient aluminum foam and a preparation method thereof. The gradient aluminum foam of the present invention comprises at least one layer of pure foamed aluminum layer and at least one layer of carbon nanotube reinforced foamed aluminum matrix composite material layer; the porosity of adjacent pure foamed aluminum layers is different; adjacent carbon nanotubes reinforced foamed aluminum matrix composite The material layers differ in porosity and / or in carbon nanotube content. The present invention combines the density gradient with the composition gradient to prepare functionally gradient aluminum foams with simultaneous changes in matrix material and density. The gradient material can be designed according to the service environment of the material, and the advantages of the gradient foam material can be fully utilized, with good absorption. Energy effect; in the case of the same overall porosity, the gradient aluminum foam of the present invention has a higher stress level and higher energy absorption than uniform aluminum foam, thereby increasing its cushioning energy absorption performance.

Owner:四川新能源汽车创新中心有限公司

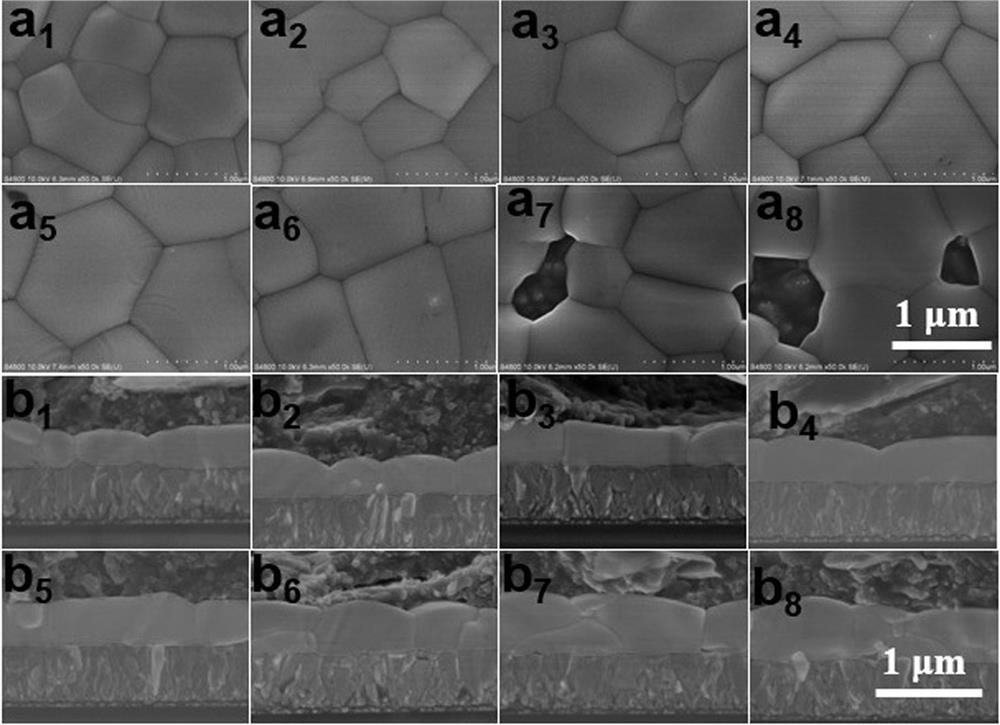

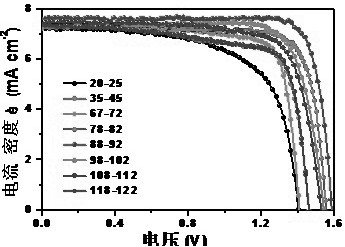

Based on pbbr 2 Micropore-regulated all-inorganic cspbbr 3 Perovskite solar cell and its preparation method and application

ActiveCN110289327BPrecise control of porosityFast penetrationFinal product manufactureSemiconductor devicesPerovskite (structure)Solar battery

The present invention provides based on PbBr 2 Micropore-regulated all-inorganic CsPbBr 3 Perovskite solar cells and their preparation methods and applications, specifically spin-coating quantum dot solutions on conductive film substrates to prepare electron transport layers, and then spin-coating PbBr after heating 2 solution, annealed to form PbBr 2 Porous film, followed by multiple spin-coating of CsBr solution to prepare CsPbBr 3 perovskite thin film. By changing PbBr 2 Crystallization temperature regulation of PbBr 2 Porosity in the film to allow rapid diffusion of CsBr to PbBr 2 Preparation of Large Grain CsPbBr in Thin Films 3 film. PbBr 2 The microporous structure of the film is large grain CsPbBr 3 The growth provides space and reduces the residual compressive stress of the perovskite grains. The all-inorganic CsPbBr provided by the present invention 3 The largest crystal grain of the film can reach 1.62 microns, and the solar cells assembled from it have good stability and high photoelectric conversion rate, which has important practical and economic value for promoting the industrialization process of perovskite solar cells.

Owner:青岛亿恩方能源环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure](https://images-eureka.patsnap.com/patent_img/031953b7-3dc4-47ad-a8f2-372d94761e6e/HSA00000729923200011.PNG)

![Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure](https://images-eureka.patsnap.com/patent_img/031953b7-3dc4-47ad-a8f2-372d94761e6e/HSA00000729923200012.PNG)

![Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure](https://images-eureka.patsnap.com/patent_img/031953b7-3dc4-47ad-a8f2-372d94761e6e/HSA00000729923200013.PNG)

![A preparation method of bionic artificial bone with multi-level [micro/nano] pore structure A preparation method of bionic artificial bone with multi-level [micro/nano] pore structure](https://images-eureka.patsnap.com/patent_img/194cd7b7-3665-4efa-9657-c4f1755af14b/HSA00000729923200011.PNG)

![A preparation method of bionic artificial bone with multi-level [micro/nano] pore structure A preparation method of bionic artificial bone with multi-level [micro/nano] pore structure](https://images-eureka.patsnap.com/patent_img/194cd7b7-3665-4efa-9657-c4f1755af14b/HSA00000729923200012.PNG)

![A preparation method of bionic artificial bone with multi-level [micro/nano] pore structure A preparation method of bionic artificial bone with multi-level [micro/nano] pore structure](https://images-eureka.patsnap.com/patent_img/194cd7b7-3665-4efa-9657-c4f1755af14b/HSA00000729923200013.PNG)