Patents

Literature

1482results about How to "Efficient exclusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

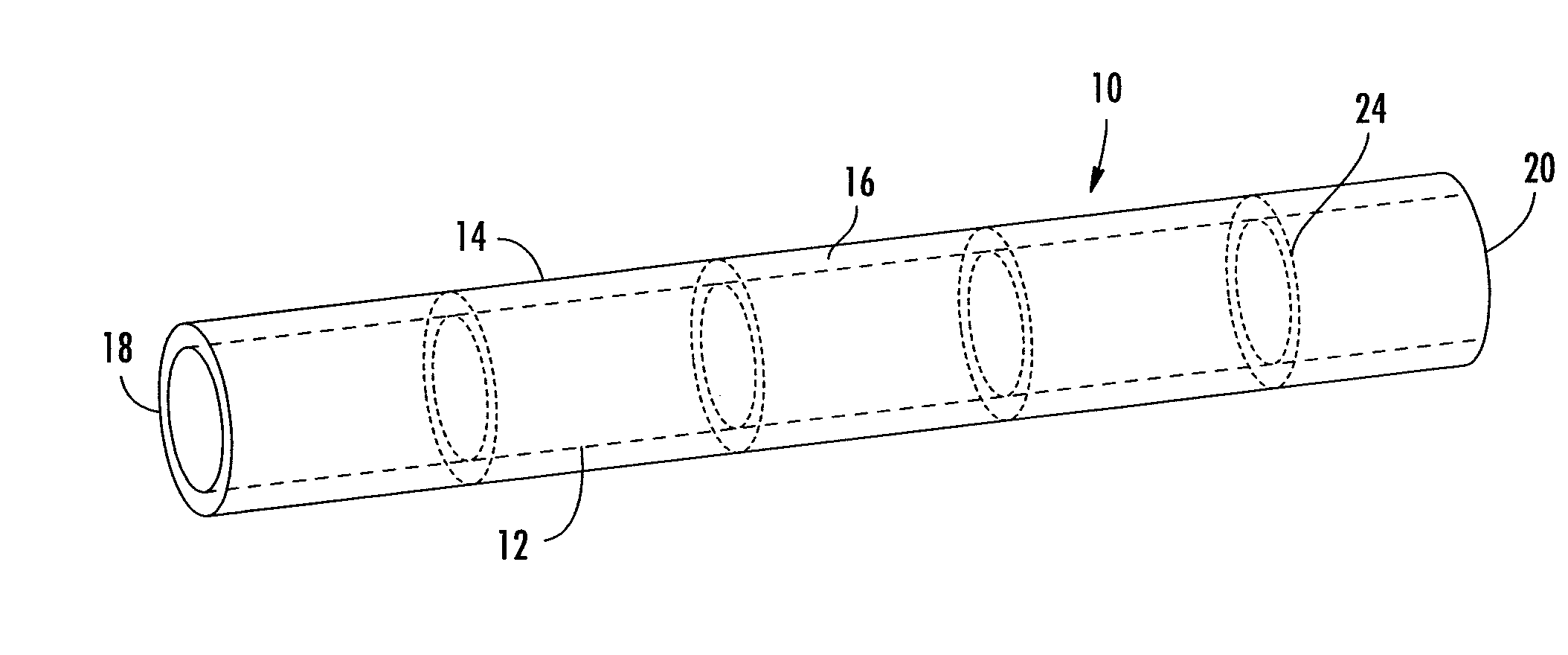

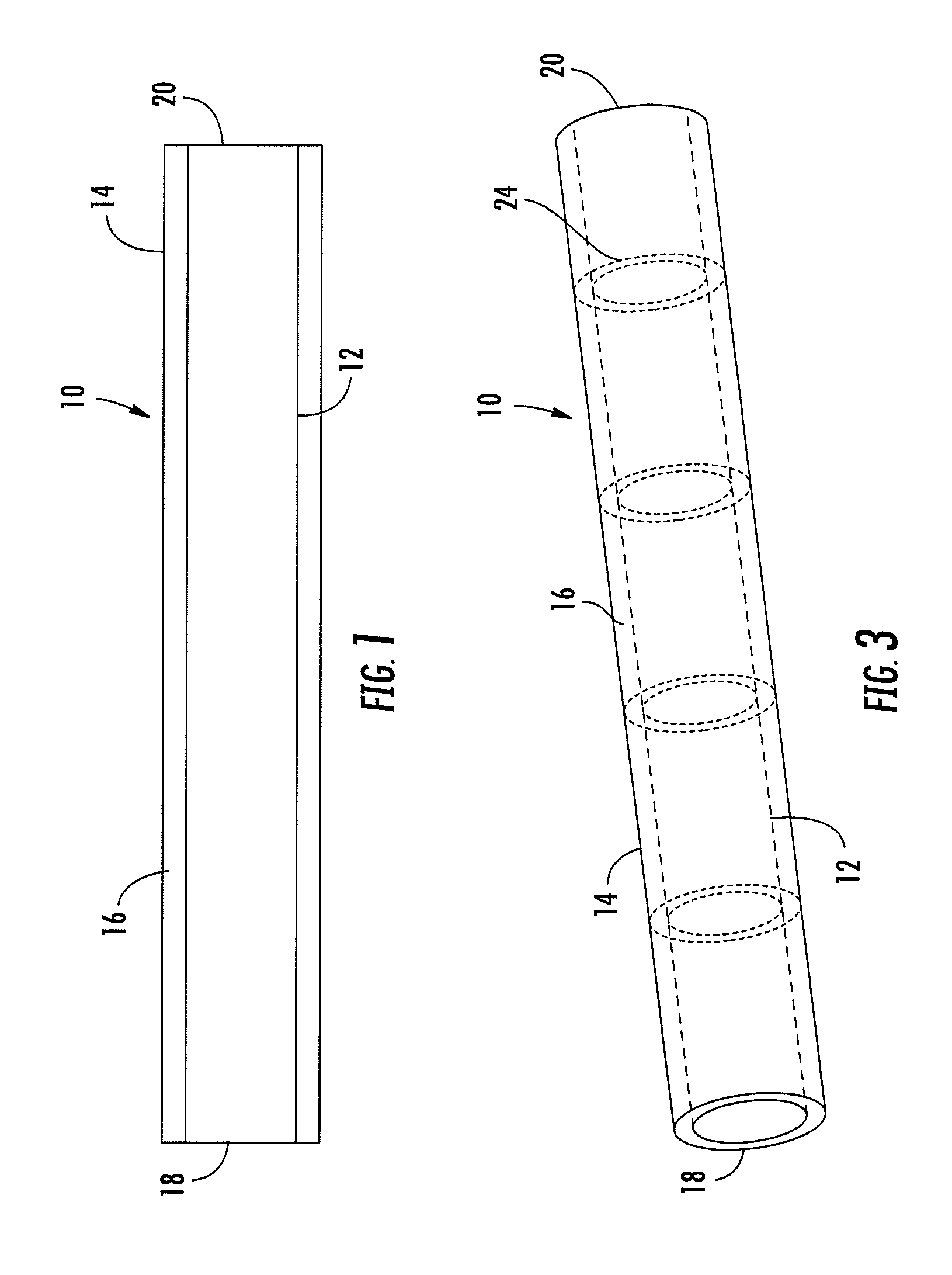

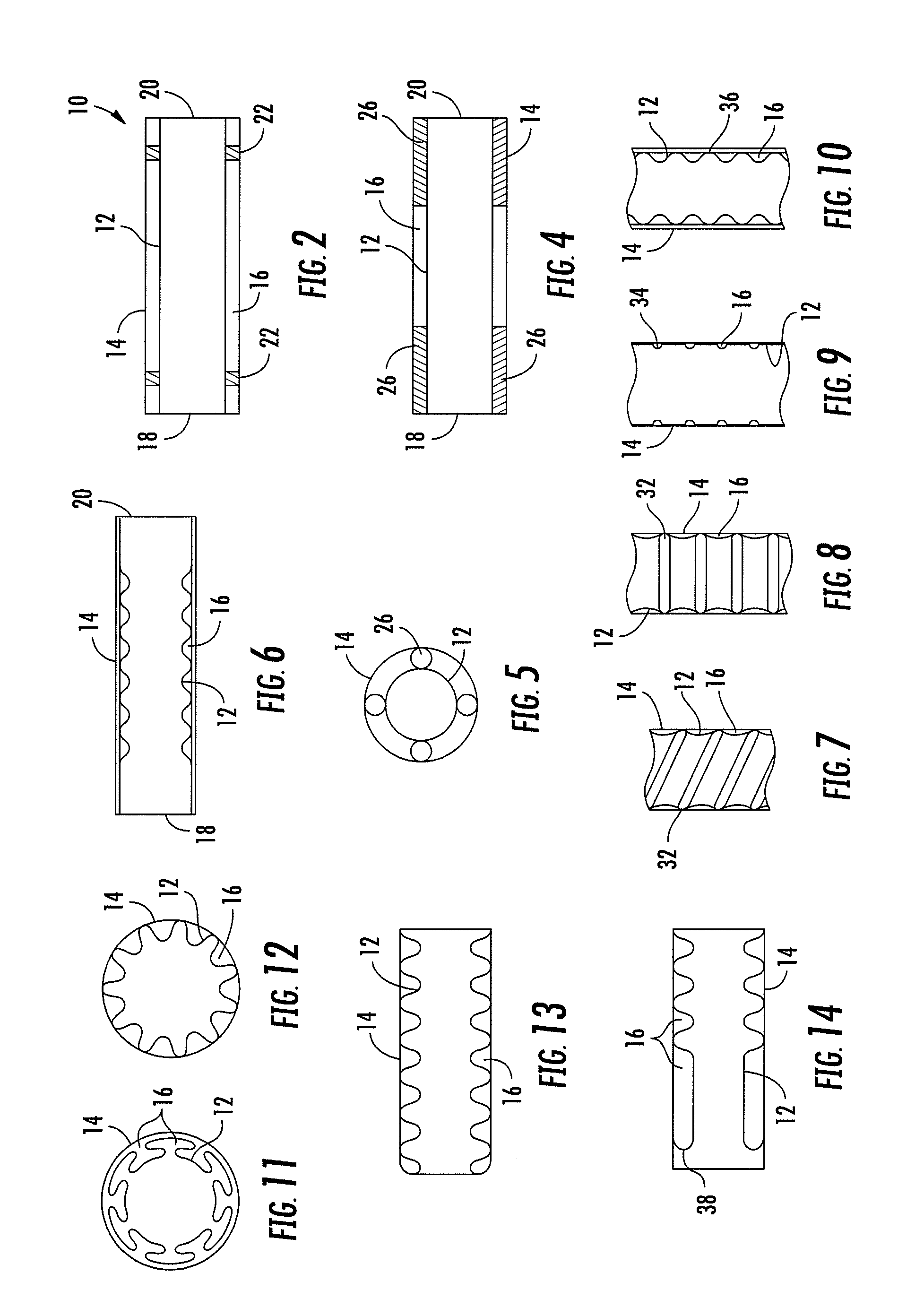

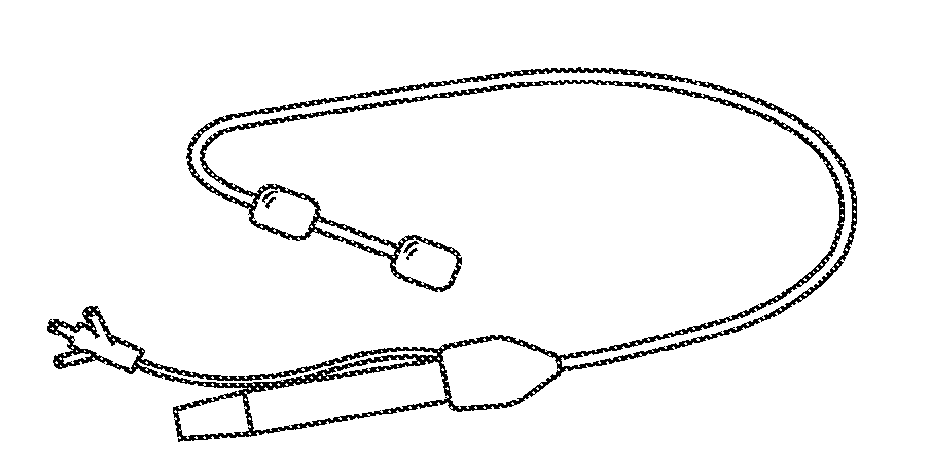

Multi-layer device with gap for treating a target site and associated method

ActiveUS20100106235A1Promote thrombosisEfficient exclusionStentsBlood vesselsLayered structureBiomedical engineering

Embodiments of the present invention provide medical devices and methods for treating a target site within the body. For example, a medical device includes a multi-layered structure comprising an inner layer disposed within an outer layer, wherein each of the inner and outer layers has respective inner and outer surfaces. The multi-layered structure further comprises at least offset located between the inner and outer layers or formed in the inner and / or outer layers to define at least one gap therebetween such that a majority of the outer surface of the inner layer is spaced apart from the inner surface of the outer layer. The multi-layered structure is configured to be deployed within a lumen such that at least a portion of the outer layer is configured to engage the lumen and the at least one gap is configured to promote thrombosis between the inner and outer layers.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

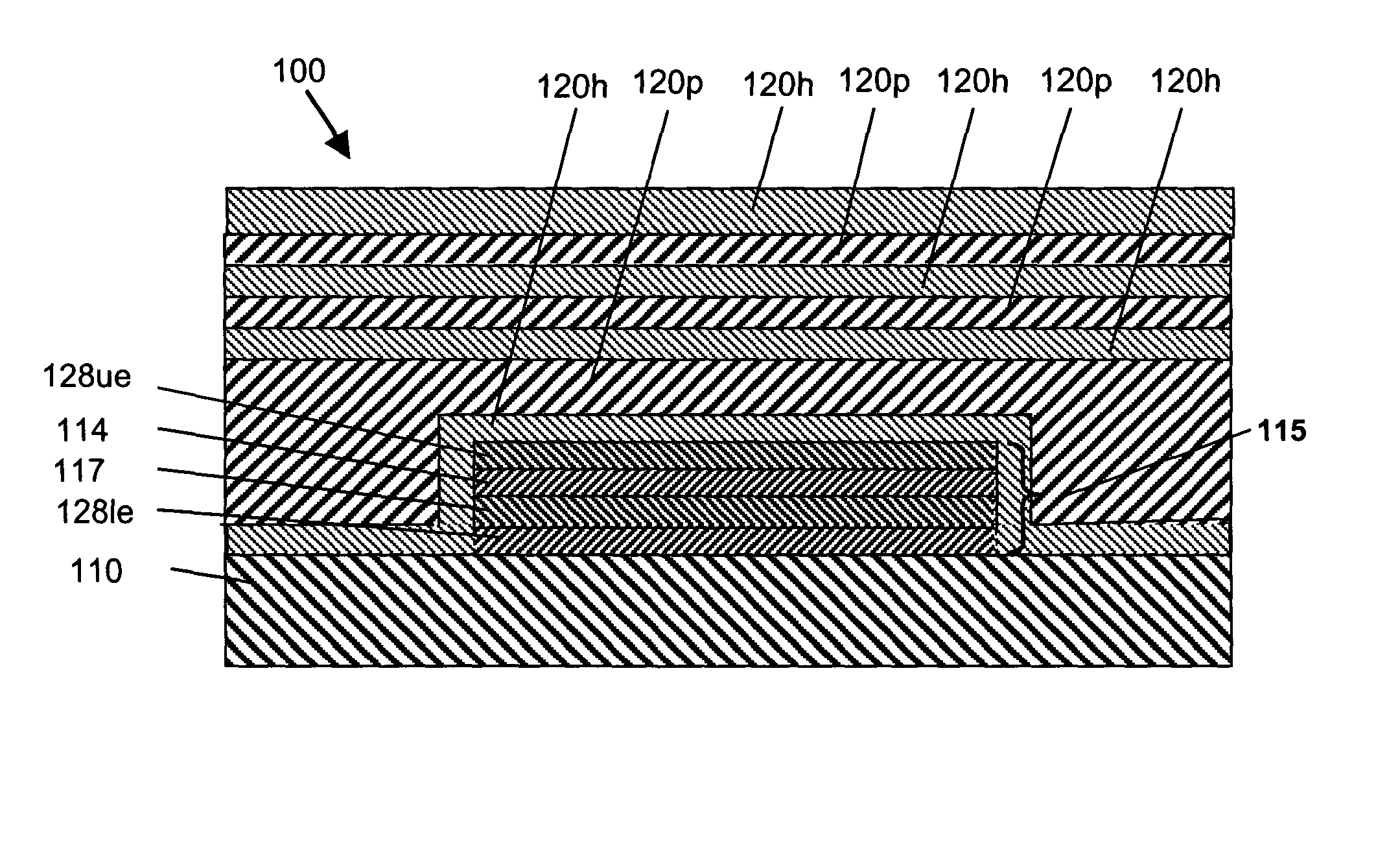

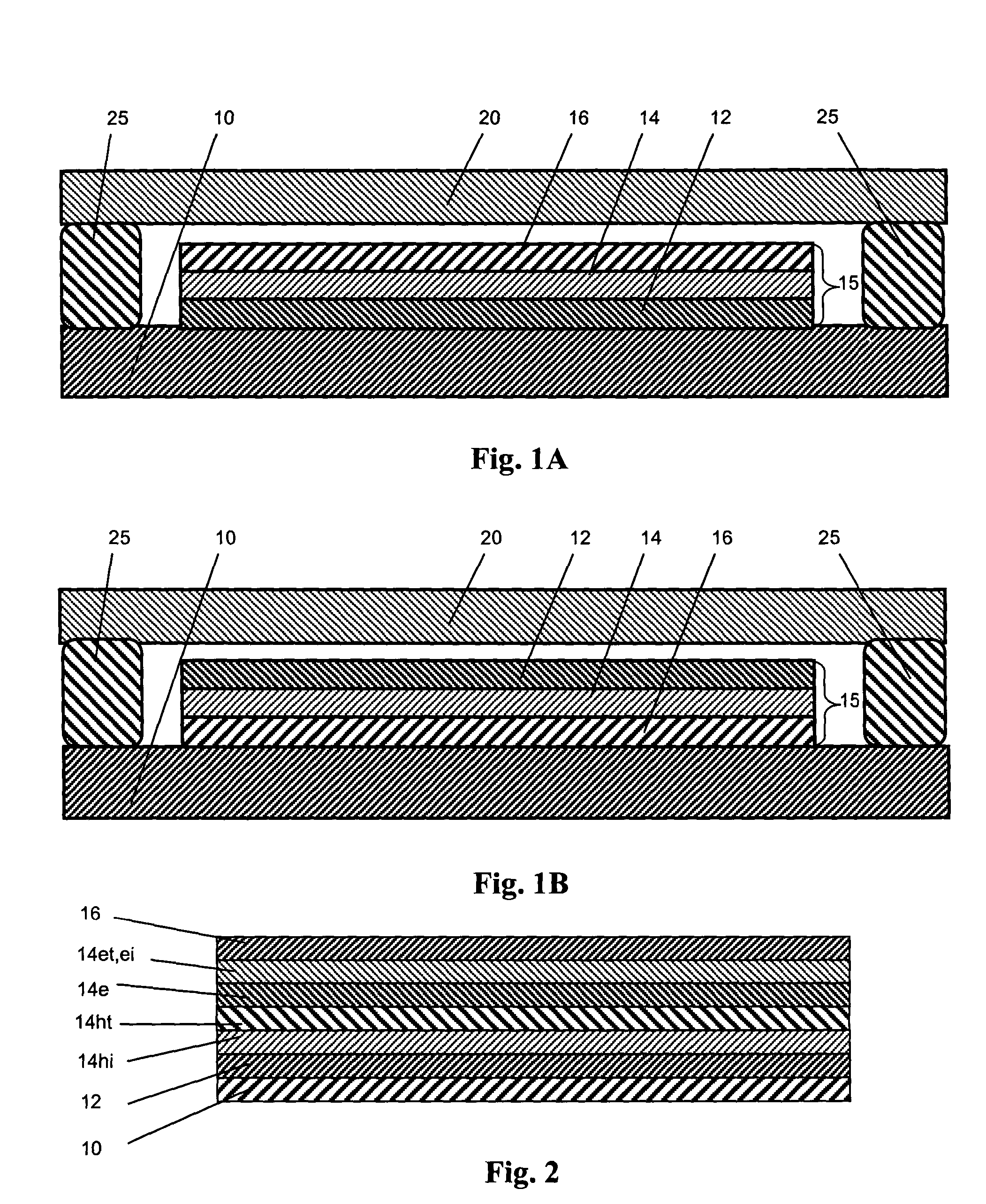

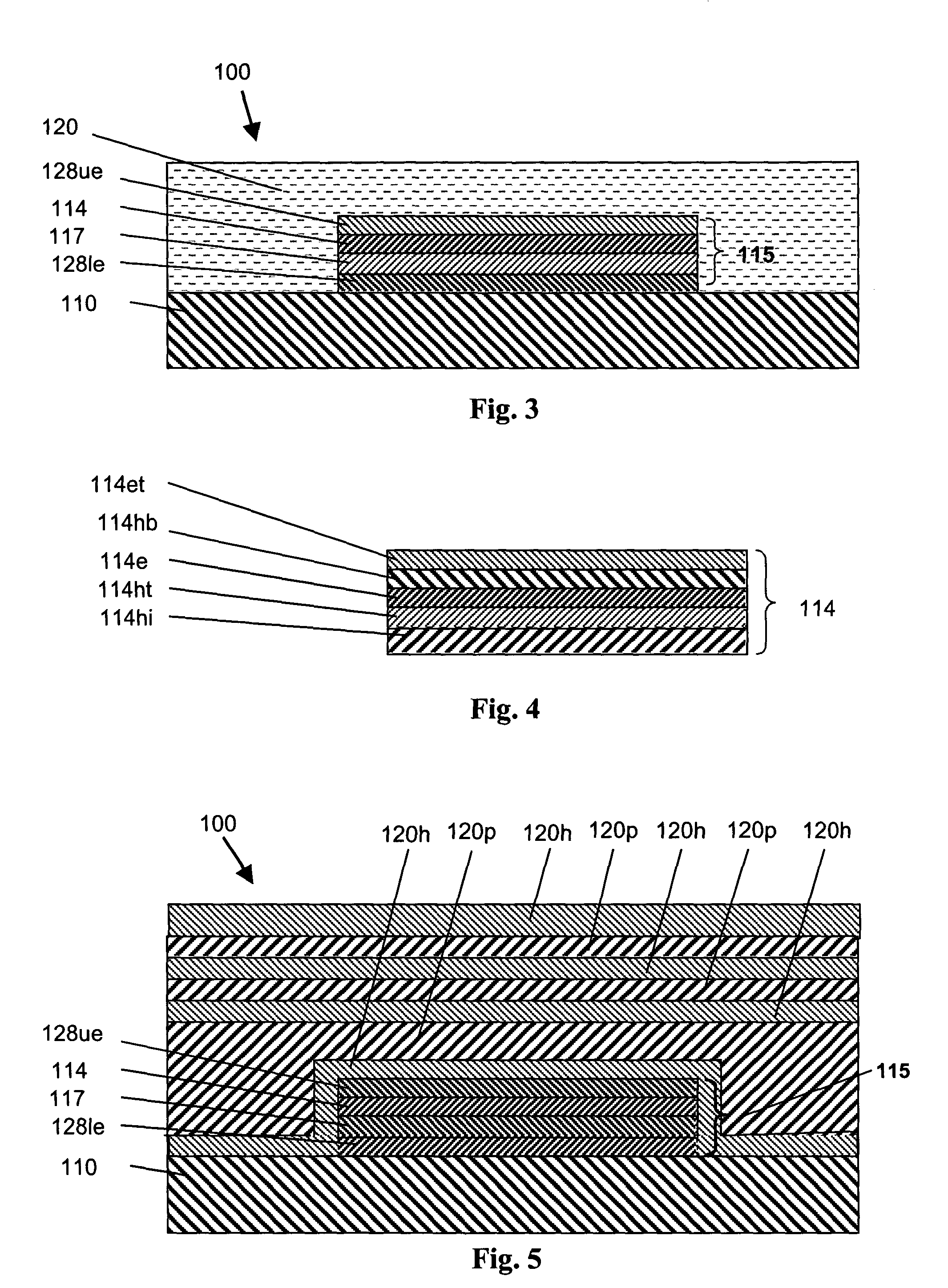

Protected organic electronic devices and methods for making the same

InactiveUS20050023974A1Avoid Display DamageImprove production yieldDischarge tube luminescnet screensLamp detailsHole injection layerConductive polymer

An organic light emitting device structure is provided, which comprises: (a) a substrate; (b) a first electrode disposed over the substrate; (c) a polymeric layer comprising a conductive polymer disposed over the first electrode; (d) an organic layer consisting essentially of small molecule material disposed over and in direct contact with said polymeric layer; (e) a second electrode disposed over the organic layer; and (f) a thin film encapsulation region disposed over the second electrode. An organic light emitting device is also provided, which comprises: (a) a polymer layer comprising a hole injecting conductive polymer and (b) a small molecule layer comprising an emissive small molecule material. In certain embodiments, the small molecule layer further comprises a small molecule hole injection layer.

Owner:UNIVERSAL DISPLAY

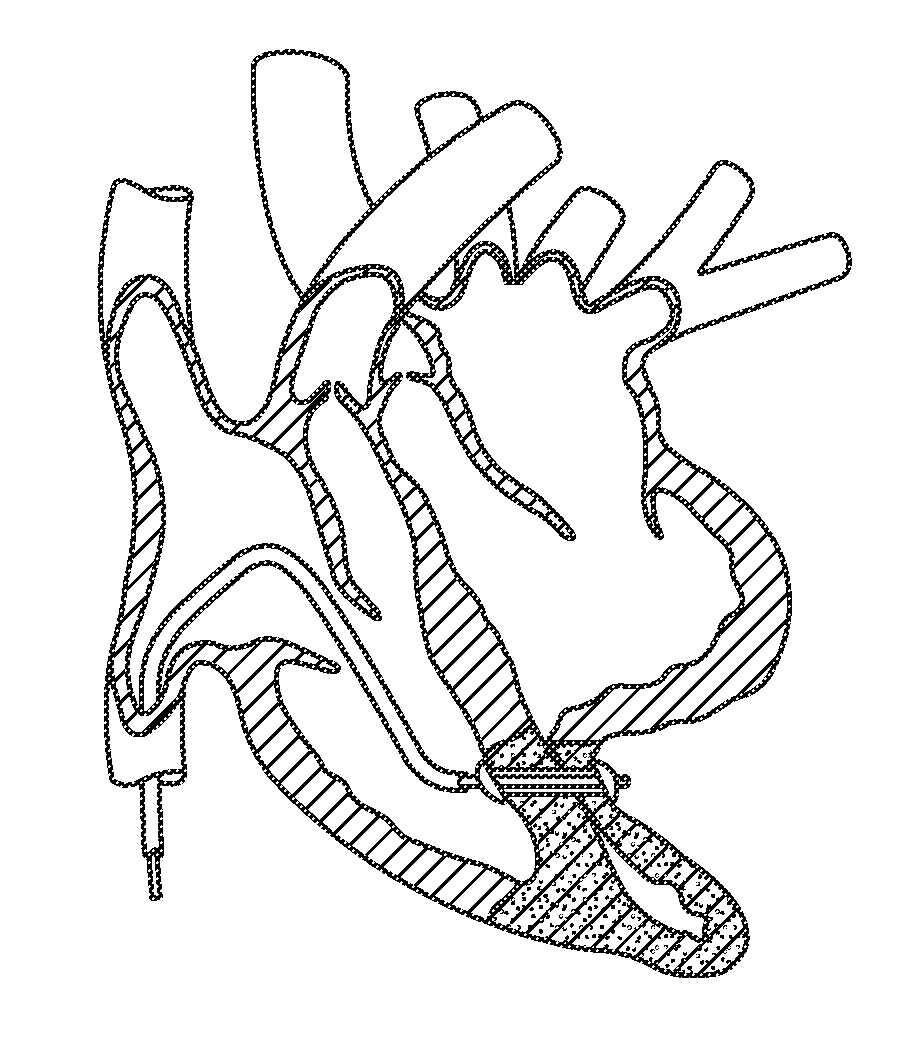

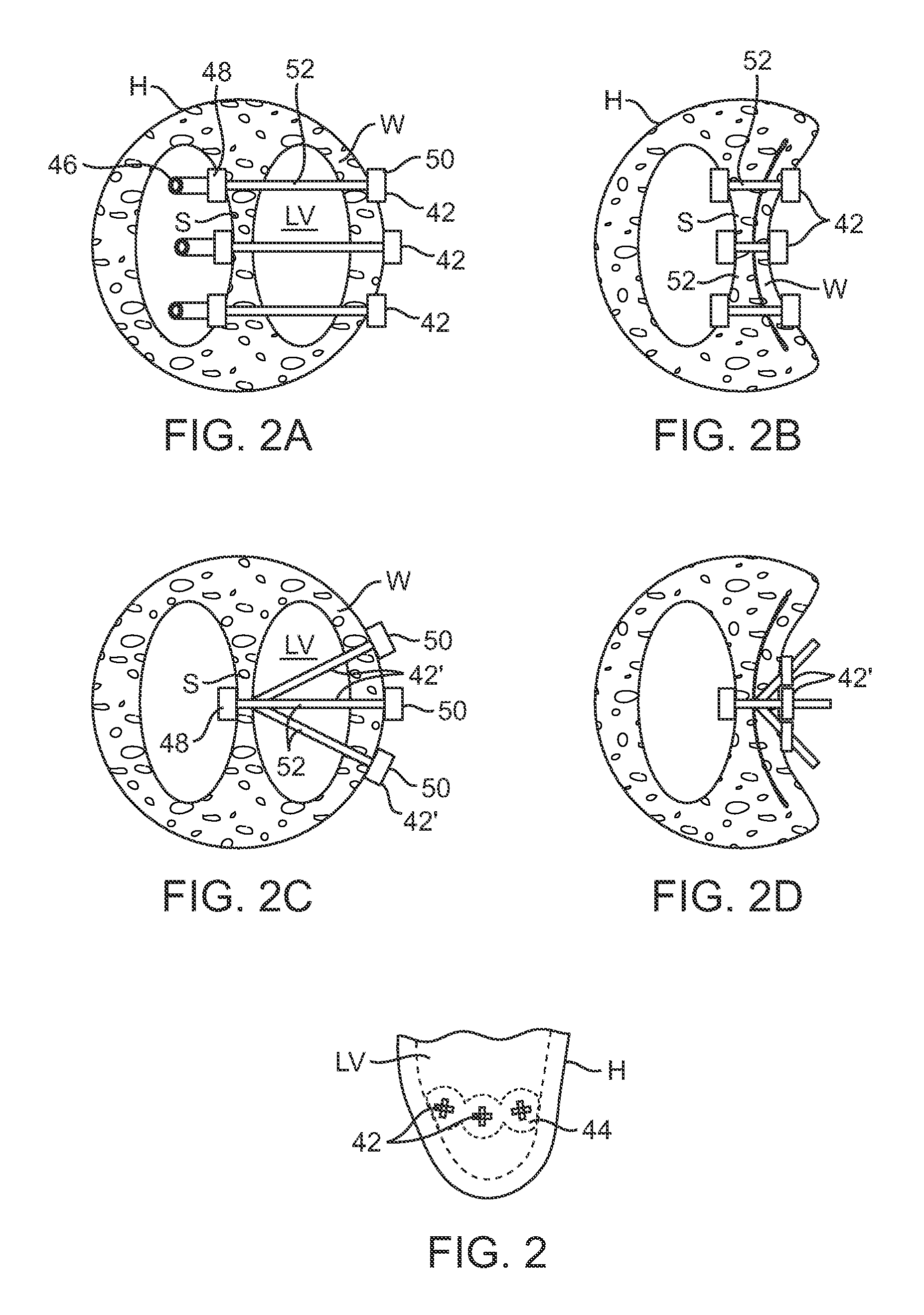

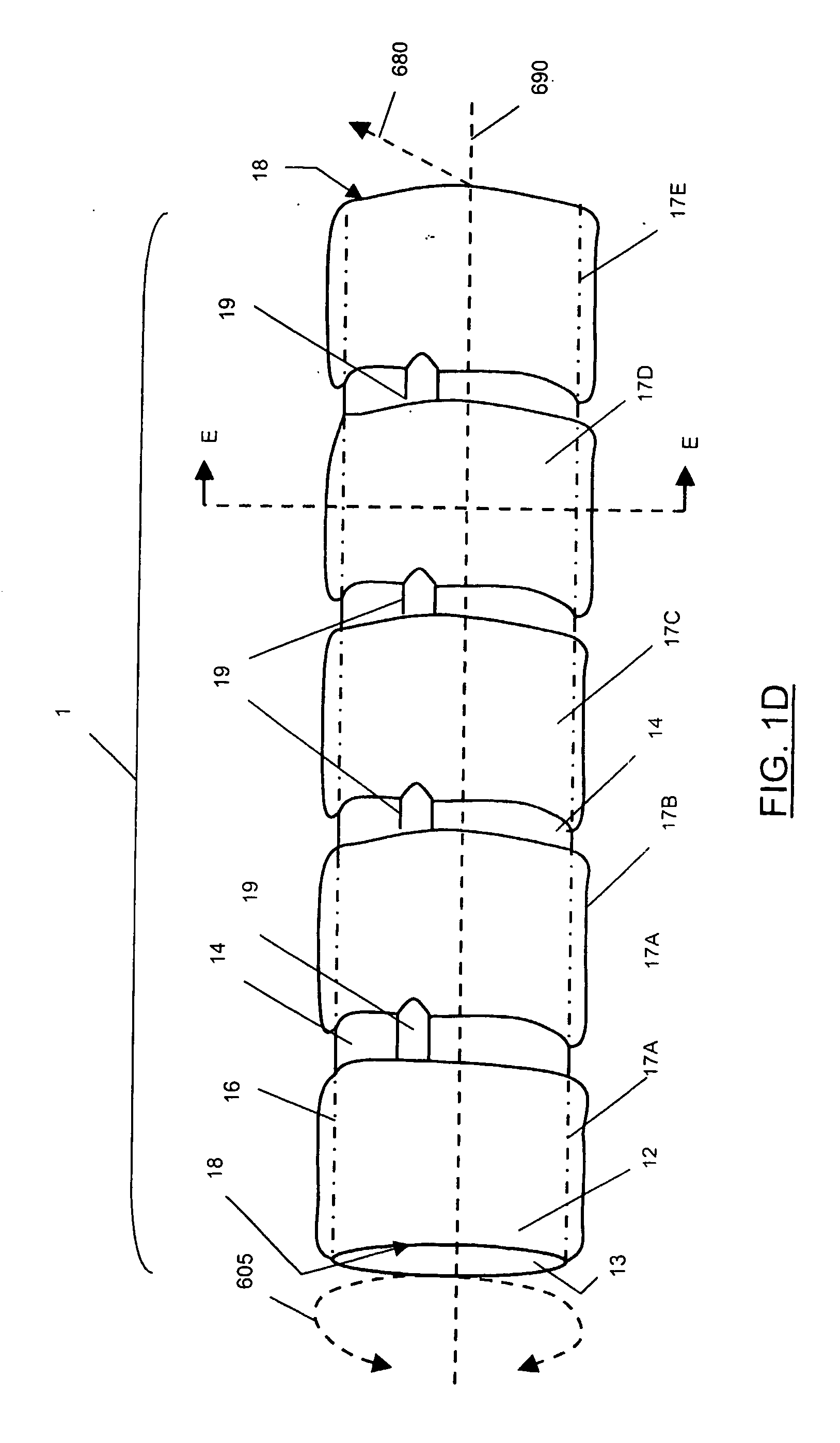

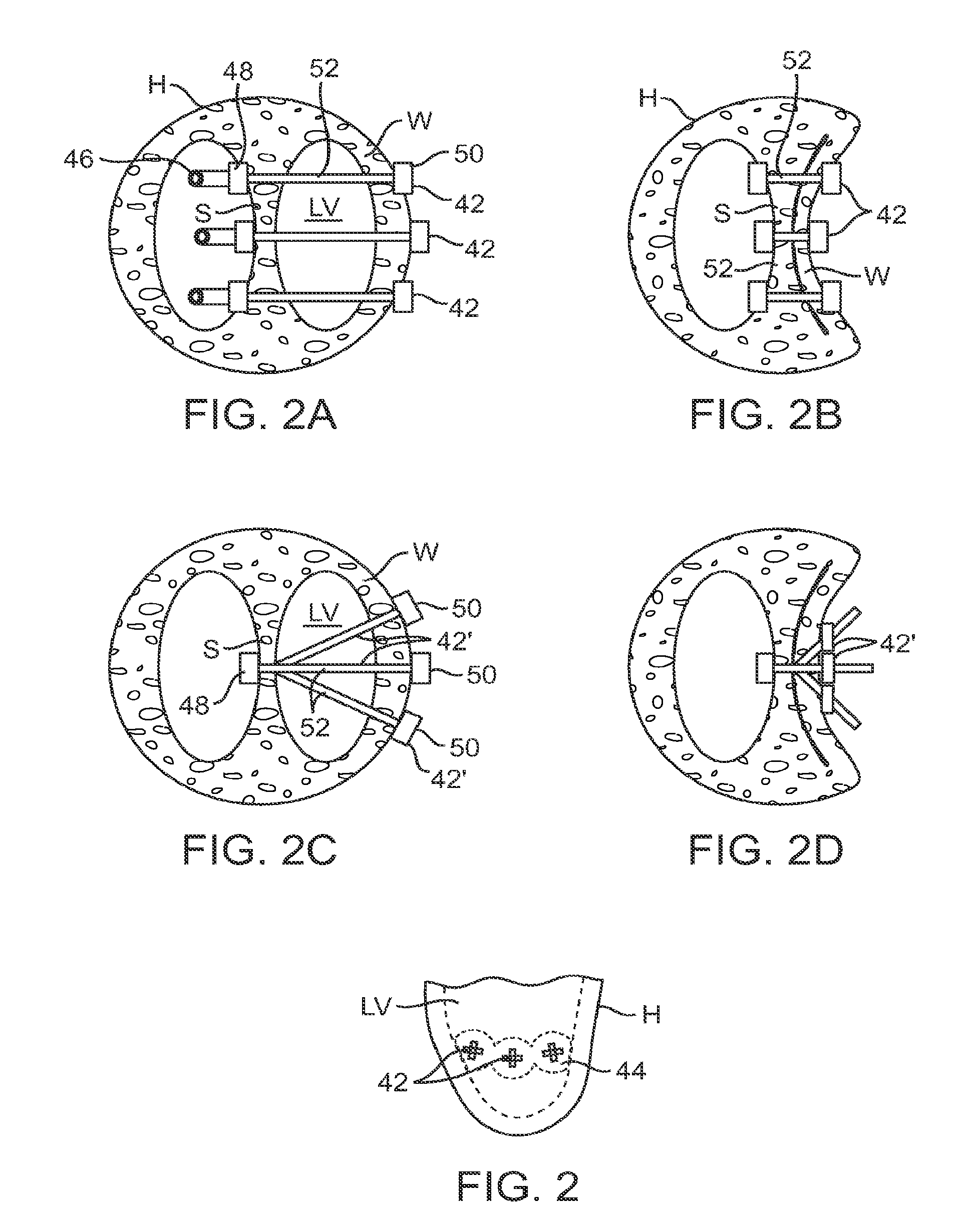

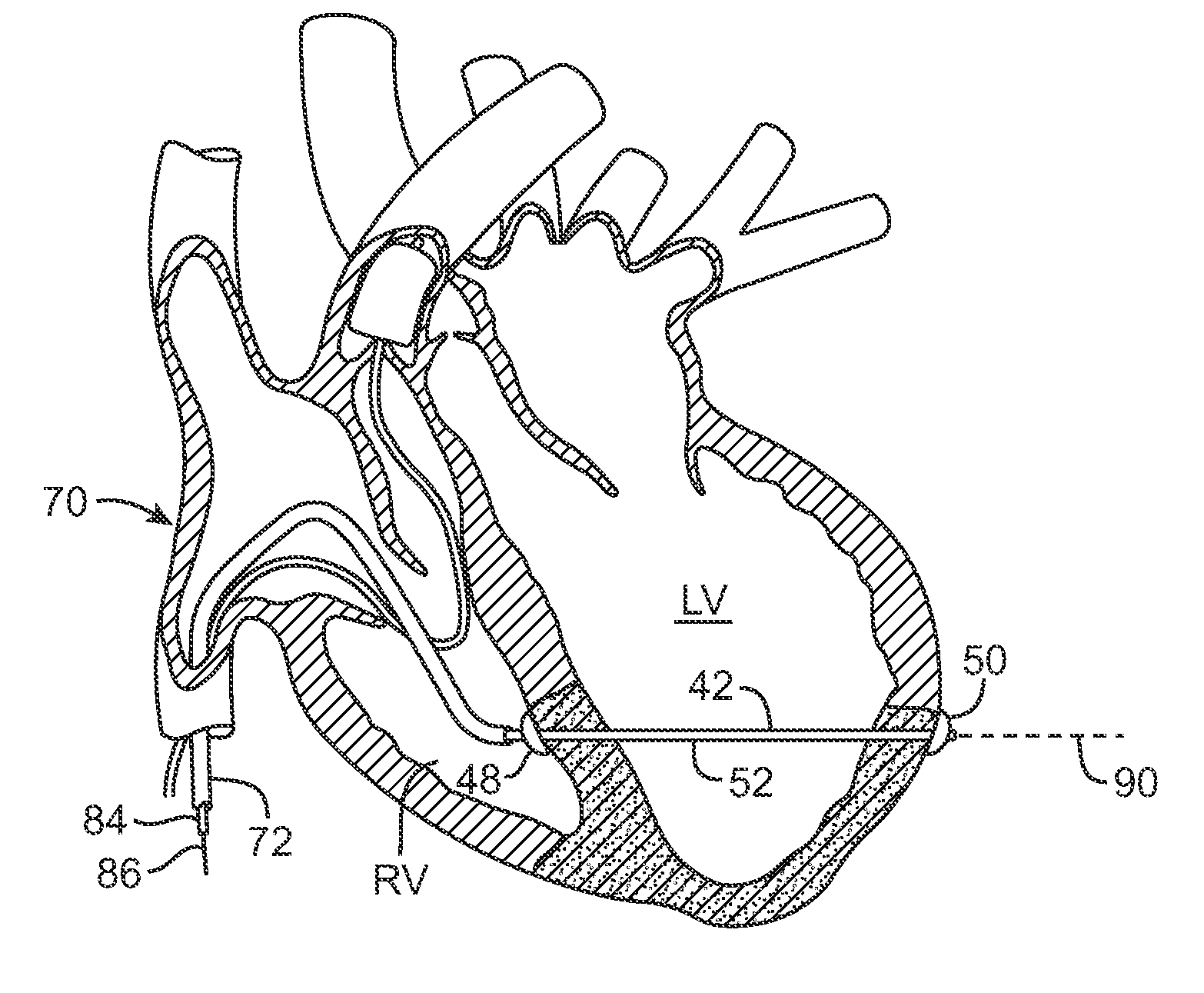

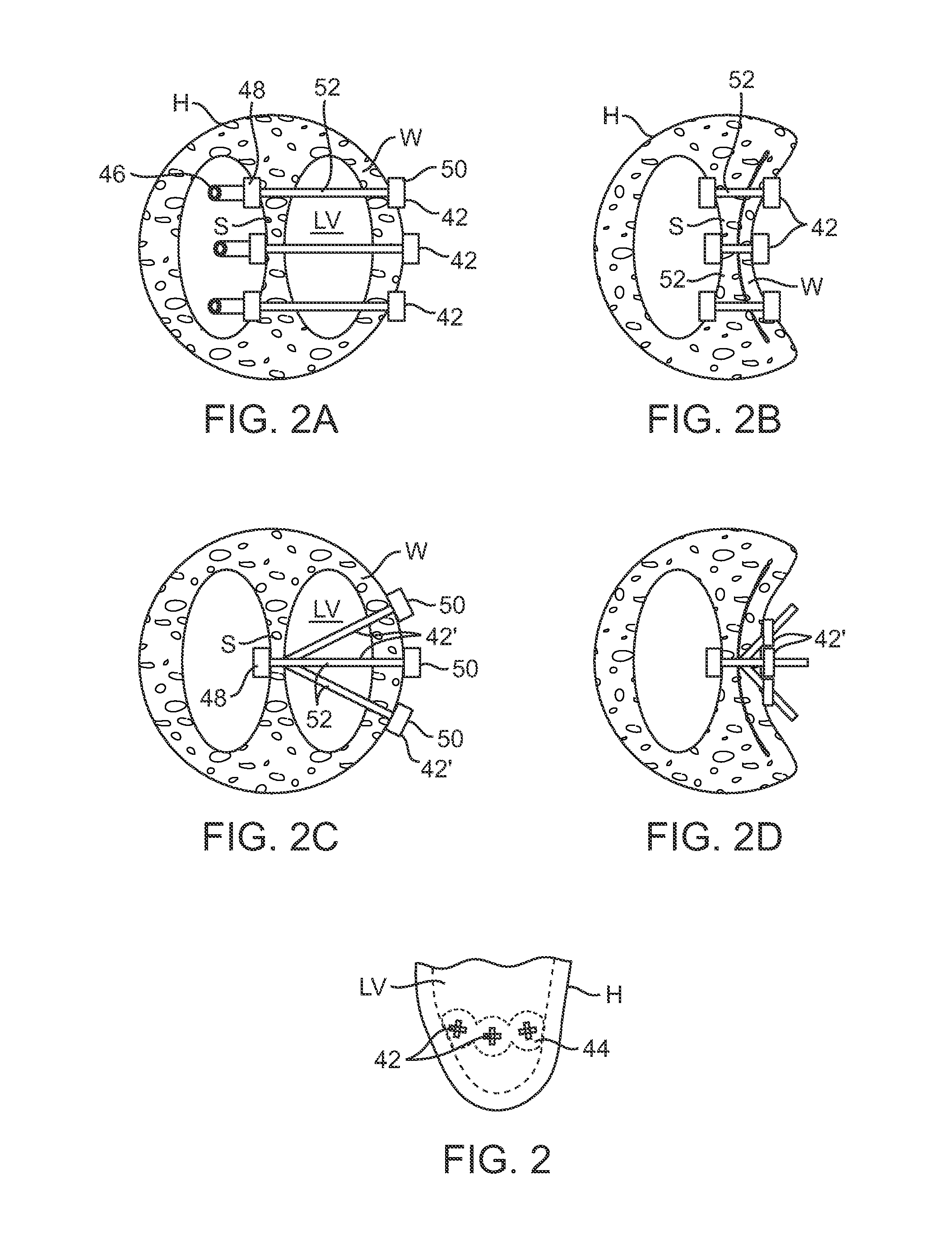

Steerable lesion excluding heart implants for congestive heart failure

ActiveUS7785248B2Improve efficiencyLess traumaticSuture equipmentsElectrocardiographyHeart septumLesion

Devices, systems, and methods for treating a heart of a patient may make use of one or more implant structures which limit a size of a chamber of the heart, such as by deploying a tensile member to bring a wall of the heart toward (optionally into contact with) a septum of the heart.

Owner:BIOVENTRIX A CHF TECH

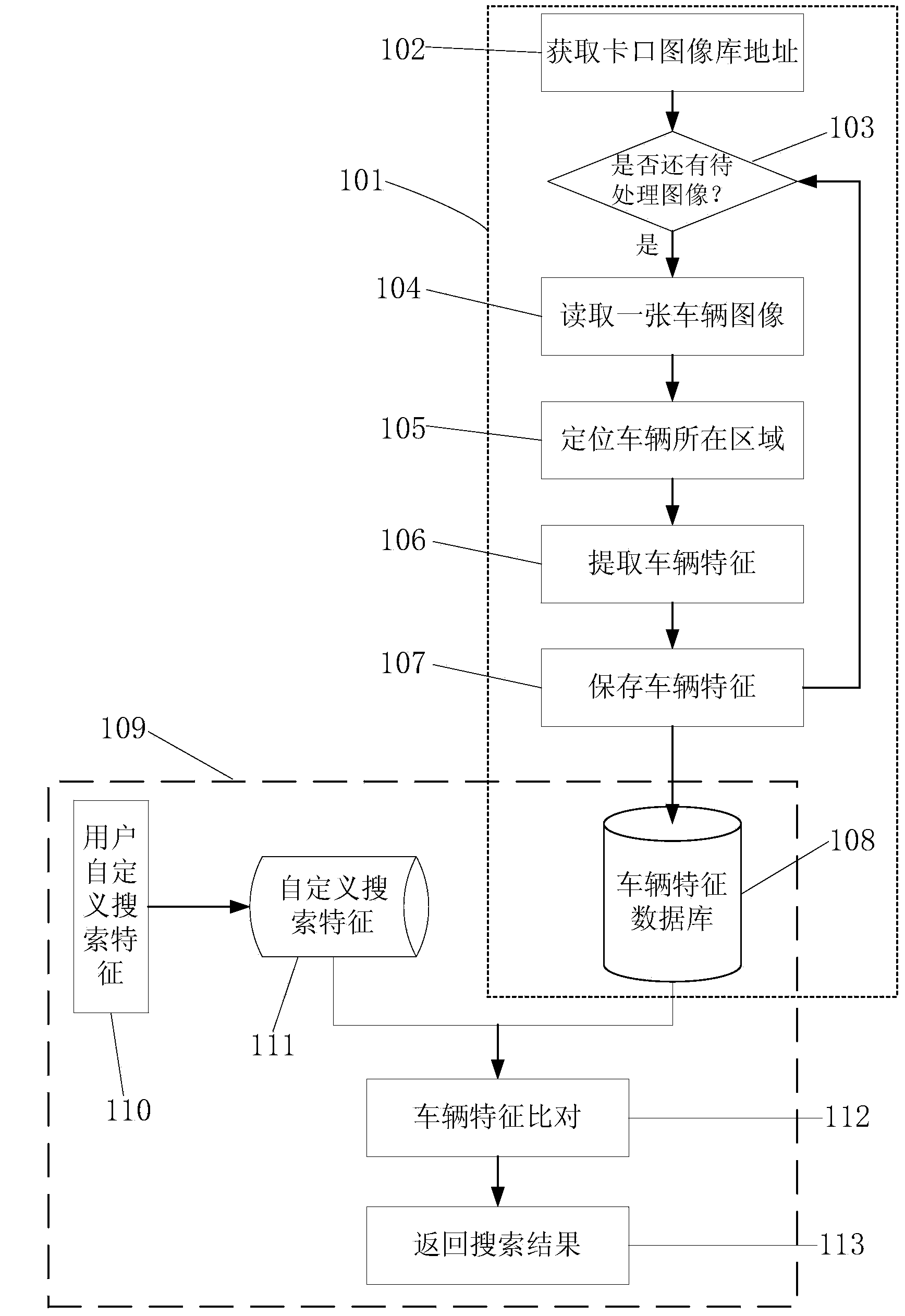

Vehicle searching method and system based on user-defined features

ActiveCN103530366AMeet search needsRich search methodsCharacter and pattern recognitionSpecial data processing applicationsSocial benefitsFeature extraction

The invention relates to a vehicle searching method and system based on user-defined features. The method includes the steps of firstly, extracting features of each vehicle in a vehicle image database shot by a monitoring camera and storing the features; secondly, searching for the vehicle, satisfying the user-defined features, in the vehicle image database shot by the monitoring camera and feeding back the searching result. The system comprises a vehicle image data reading device, a vehicle area positioning device, a vehicle feature extracting device, a vehicle feature storage device, a vehicle searching device and a searching result displaying device. According to the vehicle searching method and system, diversified searching methods can be provided, a user can search for the vehicle according to the user-defined features in the practical situation, the number of images which are manually confirmed by personnel who handling cases is greatly lowered, labor and materials are effectively saved, the case handling efficiency is greatly improved, and very good social benefits and economic benefits can be produced.

Owner:湖北微模式科技发展有限公司

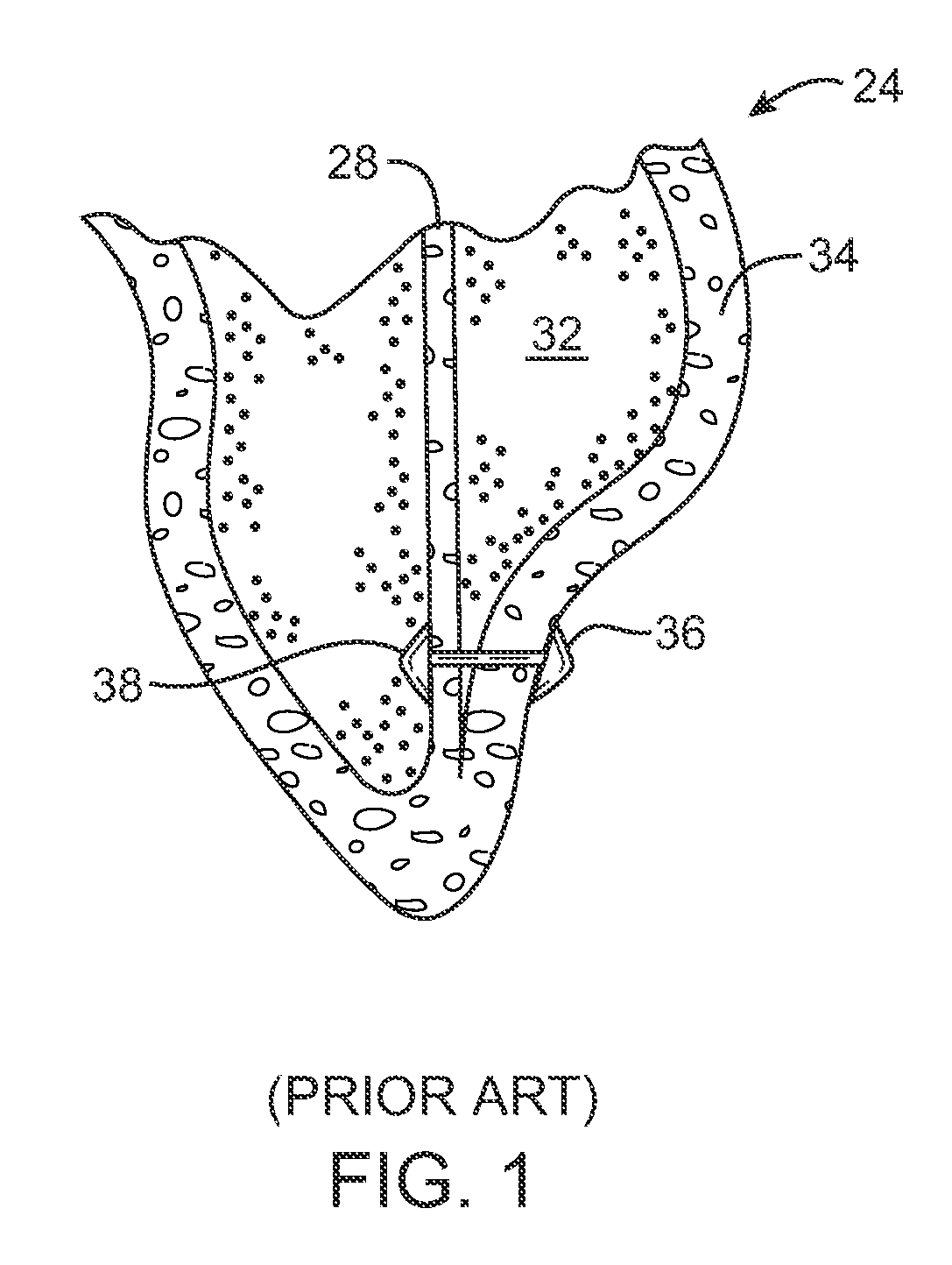

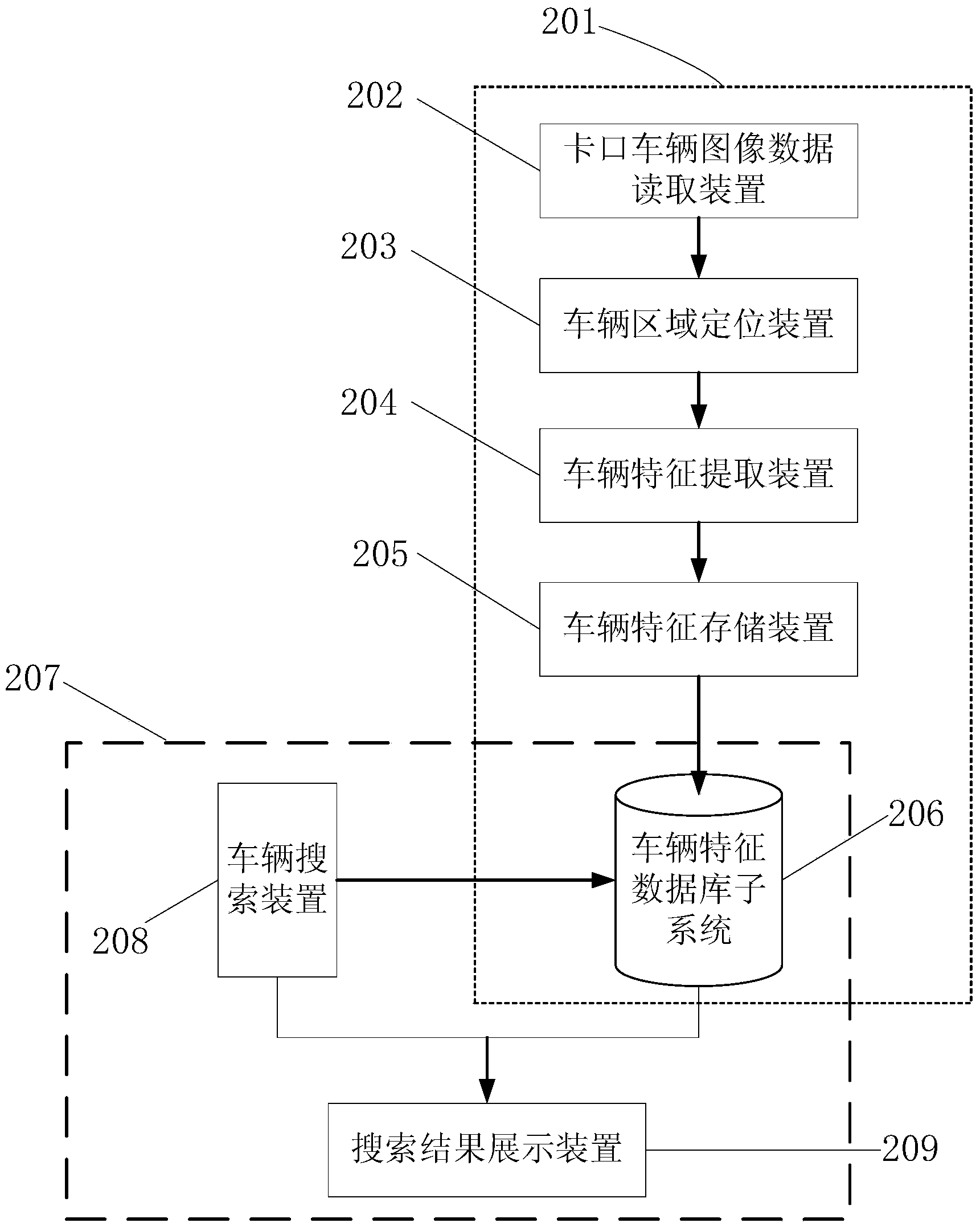

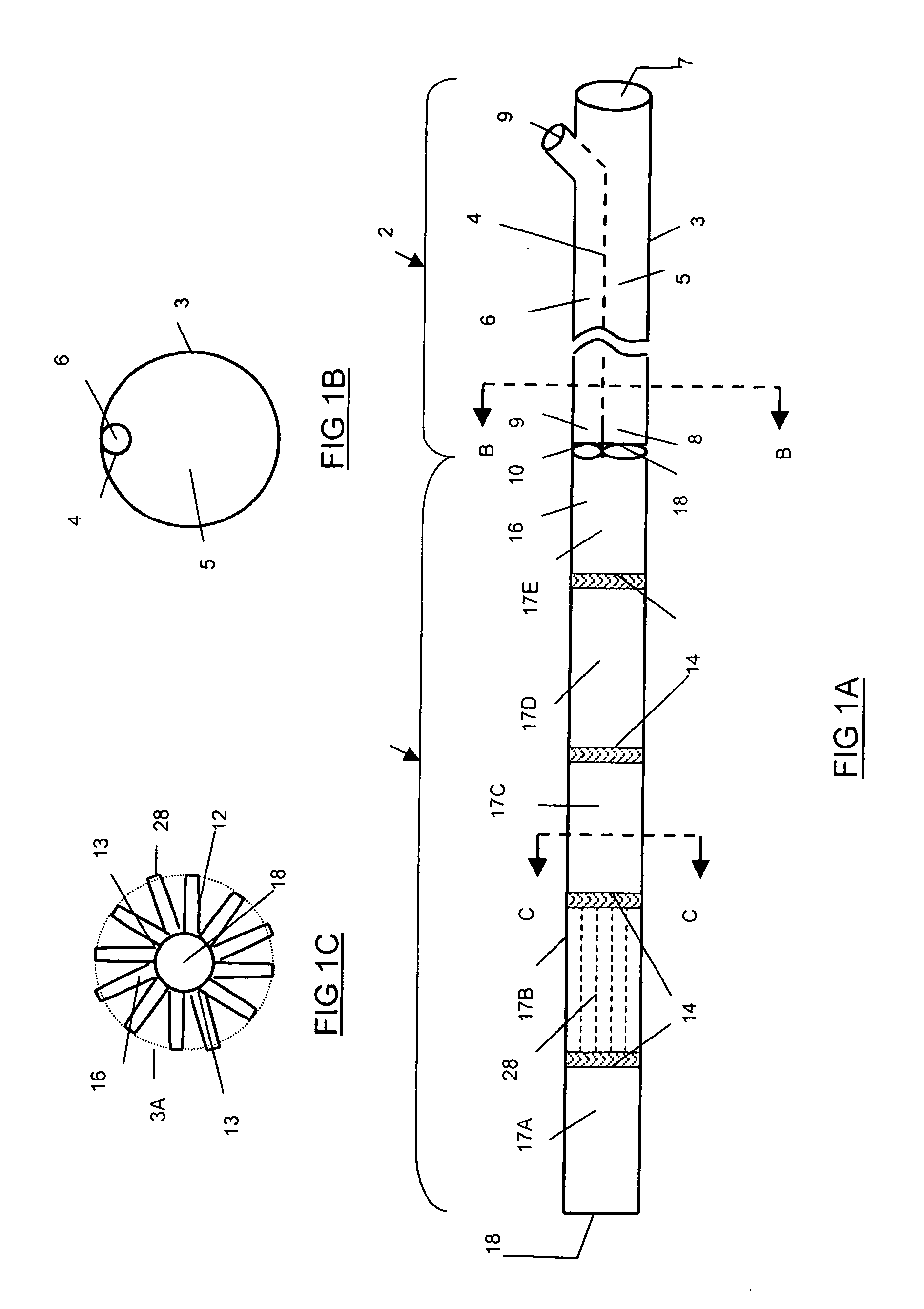

Endovascular balloon graft

InactiveUS20060206197A1Risk of injuryPlace safeStentsBlood vesselsUltimate tensile strengthBlood vessel

A method and apparatus for repair of stenotic and aneurysmic vessels utilizing in situ deployment of an inflatable tubular shaped device (1) having a longitudinally oriented annulus (17). When inflated, the size and rigidity of the device (1) is increased, thereby providing supplemental strength to the vessel wall and a lumen (8) for the passage of fluid.

Owner:MORSI HESHAM

Steerable Lesion Excluding Heart Implants For Congestive Heart Failure

ActiveUS20110160750A1Improve efficiencyLess traumaticSuture equipmentsElectrocardiographyCongestive heart failure chfHeart septum

Owner:BIOVENTRIX INC

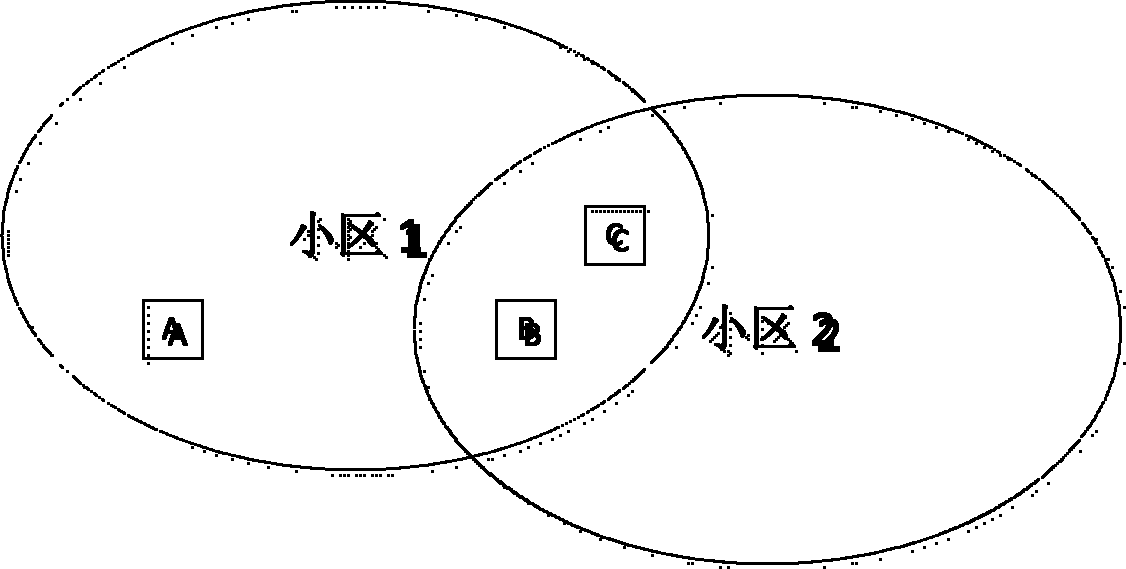

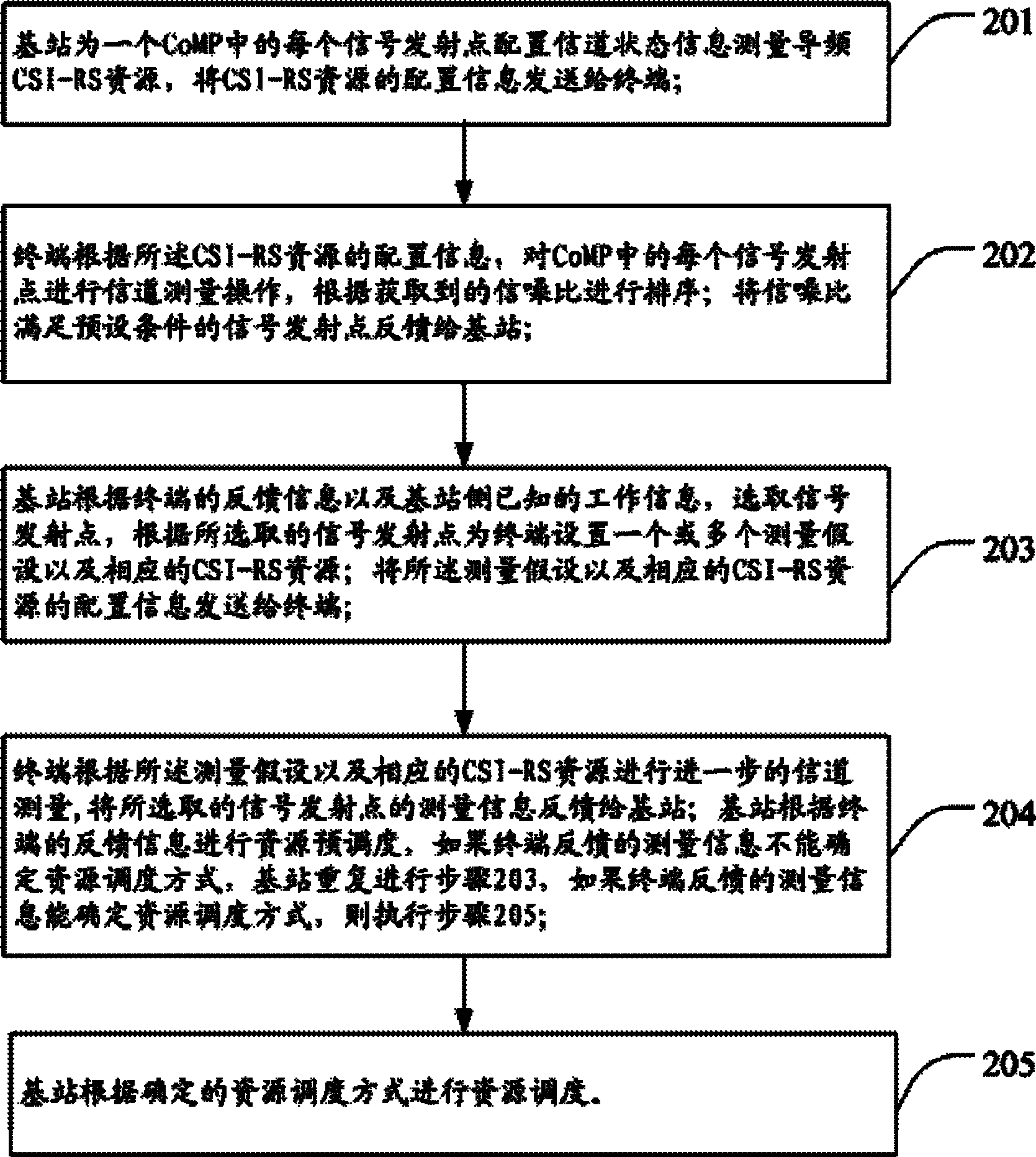

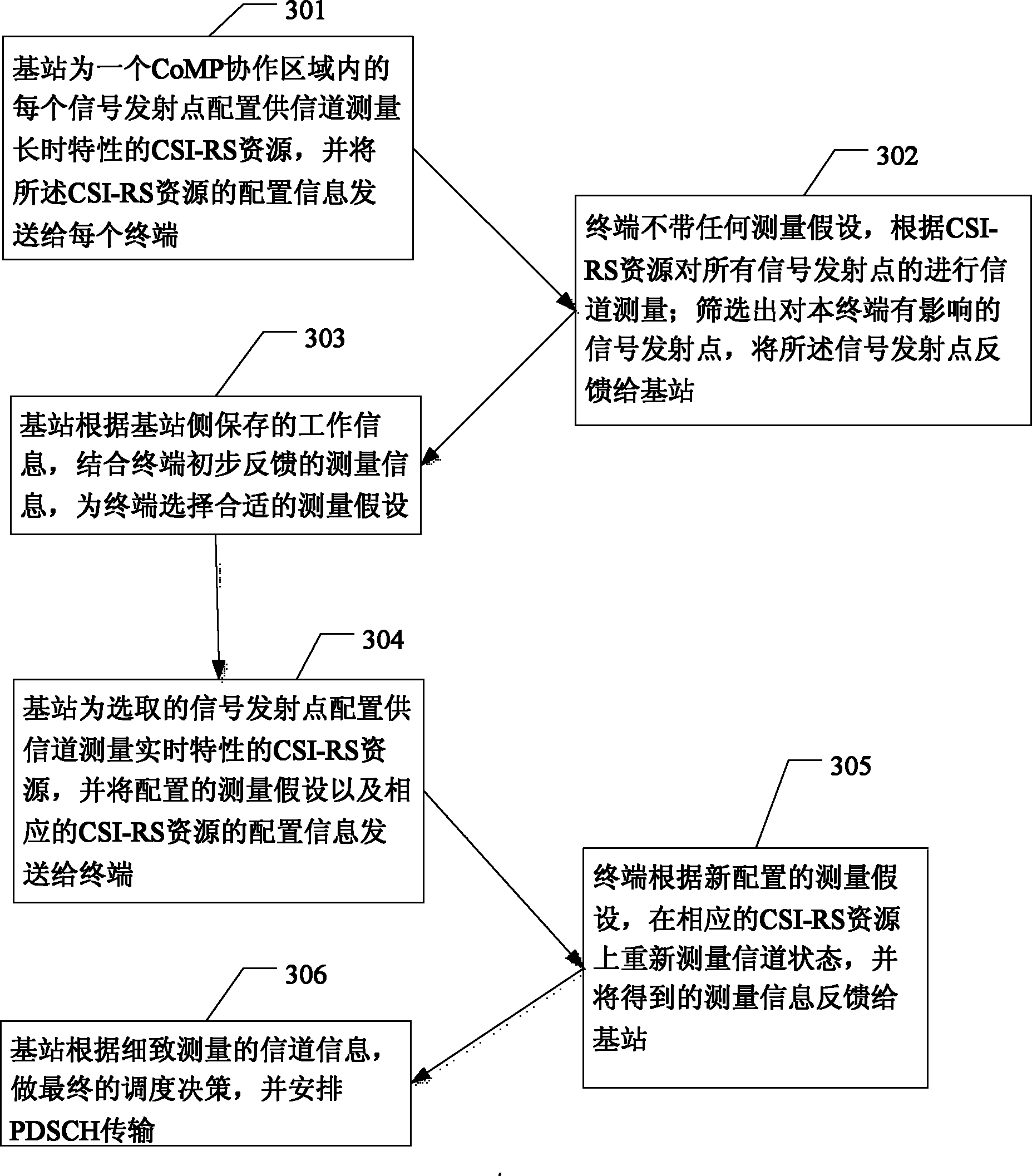

LTE channel measurement and feedback method

InactiveCN102546113ALower requirementReduce computational workloadError preventionTransmission path multiple useSignal-to-noise ratio (imaging)Transmission point

The invention discloses an LTE (Long Term Evolution) channel measurement and feedback method suitable for the CoMP (Coordinated Multi-Point) working mode. A base station configures CSI-RS resources for signal transmission points in the CoMP; a terminal performs channel measurement on the signal transmission points according to the CSI-RS resources, and feed the signal transmission points of which the signal-to-noise ratio satisfies the preset condition back to the base station; the base station selects the signal transmission points according to the feedback information of the terminal and the given working information of the base station side, and sets one or more measurement assumptions and corresponding CSI-RS resources; the terminal performs further channel measurement and feeds back the measurement information according to the measurement assumptions and the corresponding CSI-RS resources; and if the measurement information fed back by the terminal can not determine the resource dispatching mode, the terminal repeatedly performs measurement and feedback till the base station can determine the resource dispatching mode for resource dispatching. The method provided by the invention solves the problem in the prior art that the terminal has large calculated amount due to coexistence of various measurement assumptions.

Owner:沈阳市联盛科技有限公司

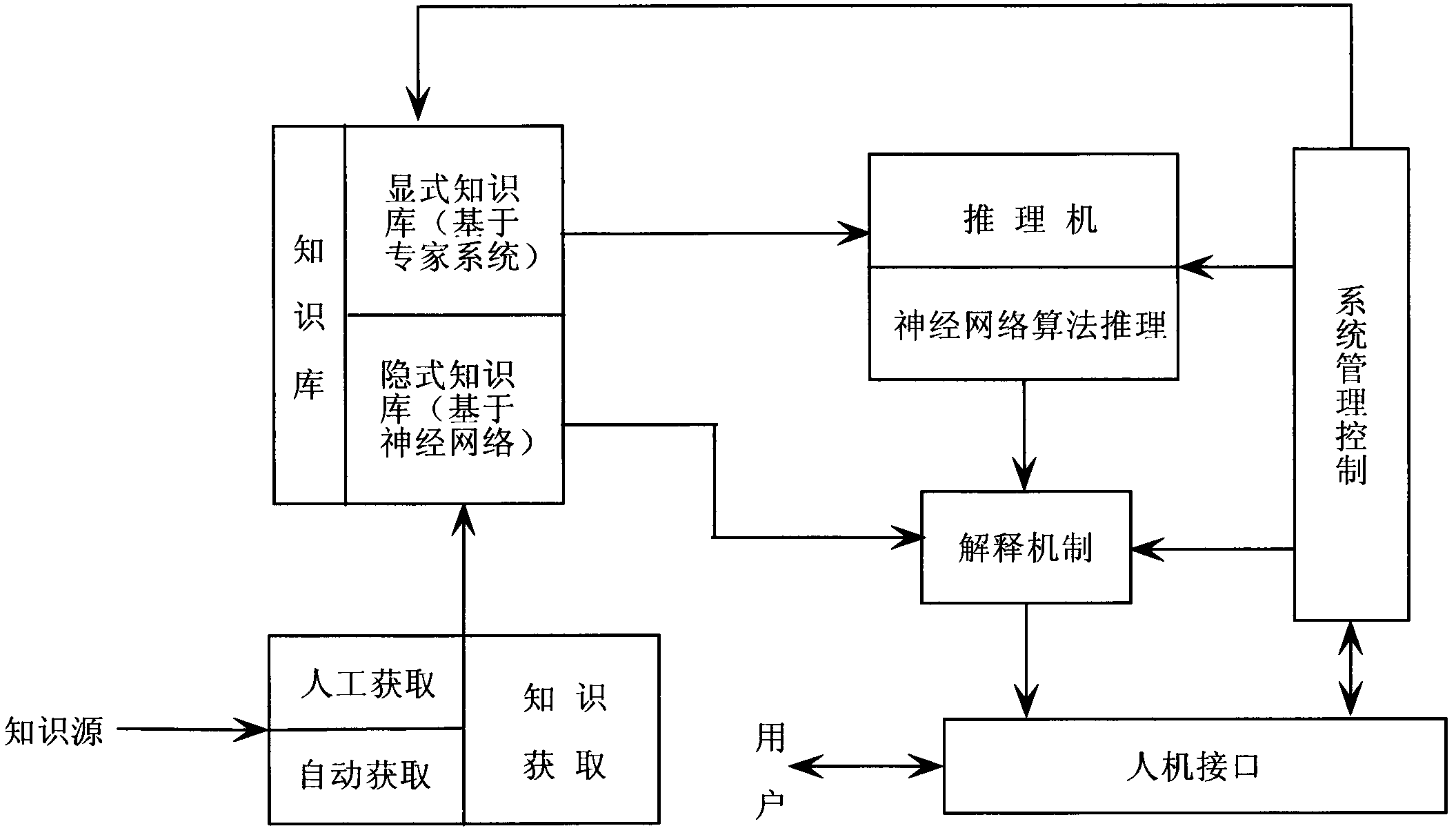

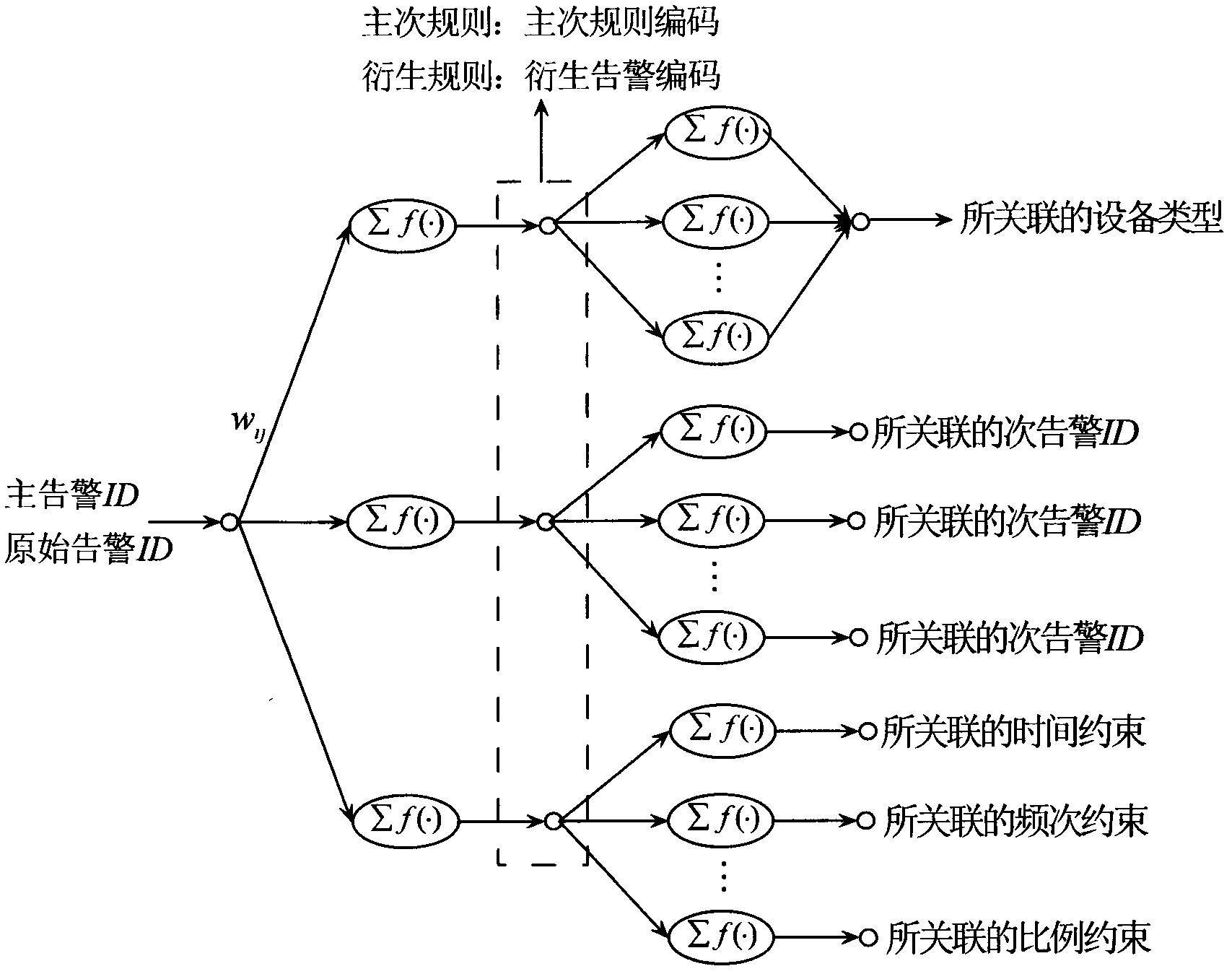

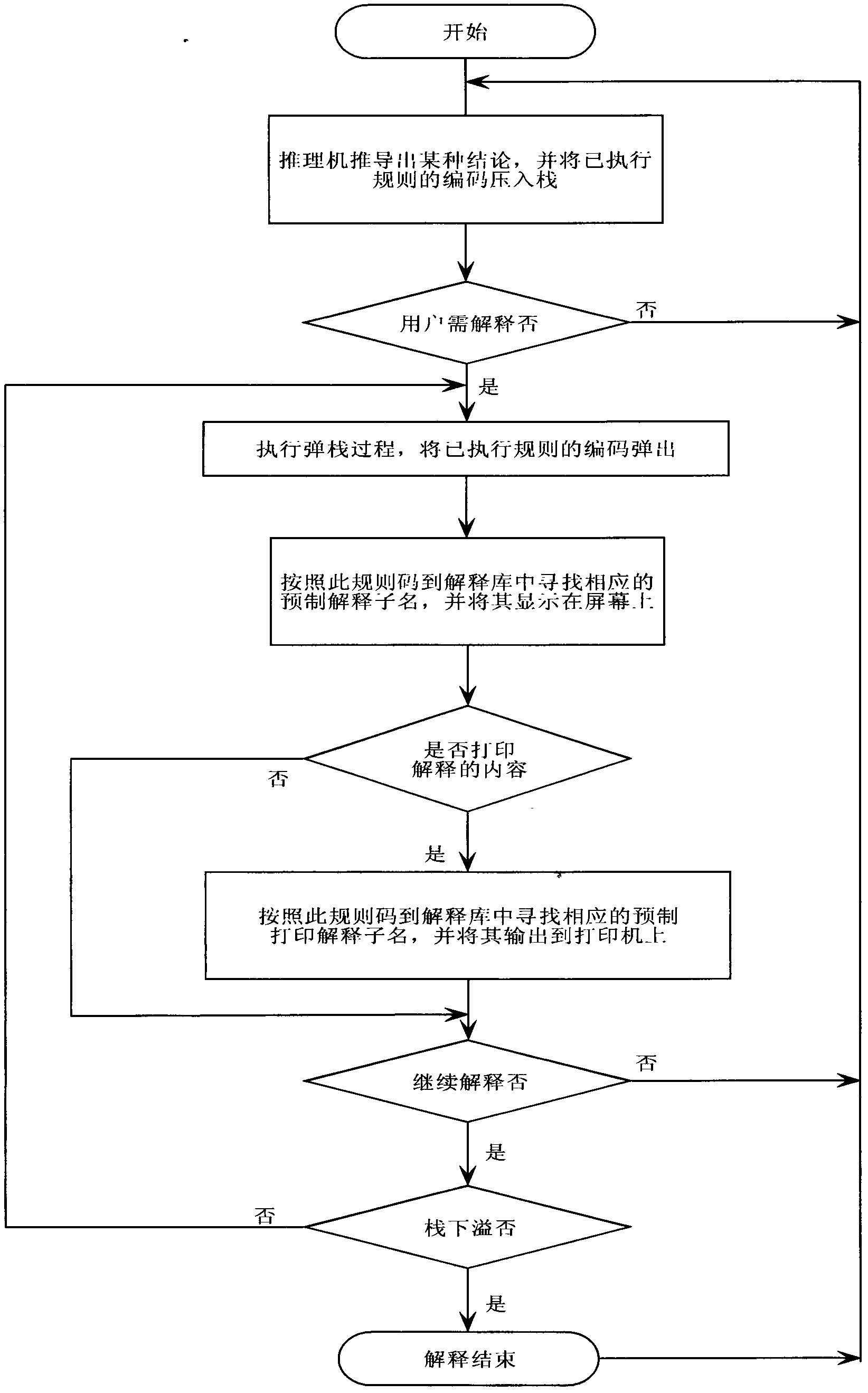

Intelligent alarm monitoring method of neural network

ActiveCN102130783AImplementation of association analysisImprove accuracyData switching networksPositional TechniquePositioning system

The invention provides an intelligent alarm monitoring method of a neural network. A brand-new intelligent communication network comprehensive monitoring analysis and fault locating system is built by adopting an alarm correlation analysis and locating technology based on an expert system of the neural network. The system guarantees effective monitoring of repeated alarming, alarm oscillation, alarm flash and alarm storm by collecting the alarm data of each piece of equipment of each network element system of each major, and filters out a storm alarm, a flash alarm, an invalid alarm and a secondary alarm correctly; and the system can pick out an important alarm event which is really required to be processed from the collected mass alarms based on a deep correlation rule analysis and neural network technology, and can locate and remove a network fault quickly and correctly. The correction rate of network alarm analysis and fault diagnosis can be improved obviously, customer satisfaction is improved, and operating cost and maintenance cost are reduced greatly, so that the aims of reducing the work load of an operator and a maintainer and improving the efficiency of fault management are fulfilled.

Owner:INSPUR TIANYUAN COMM INFORMATION SYST CO LTD

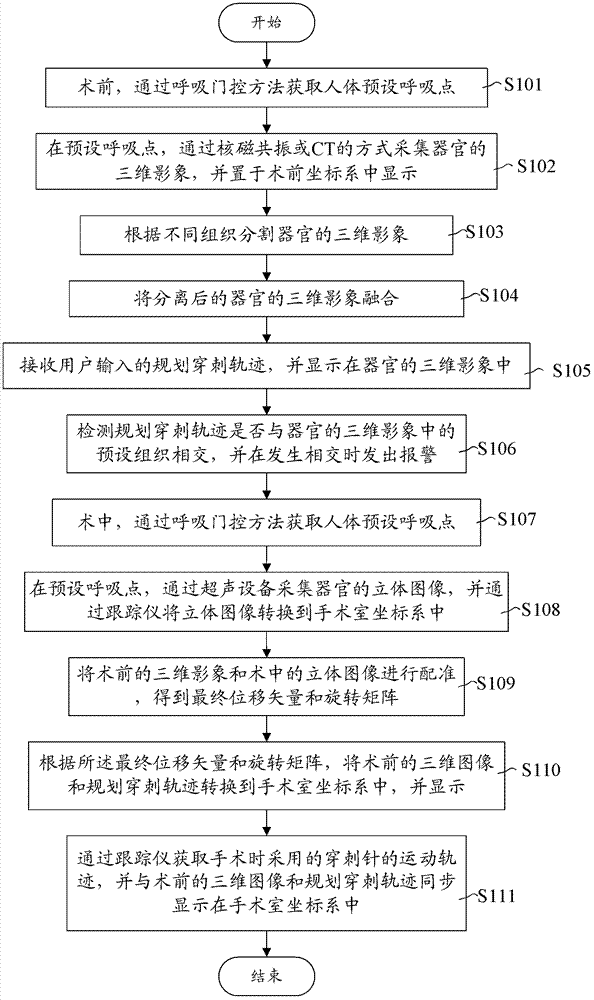

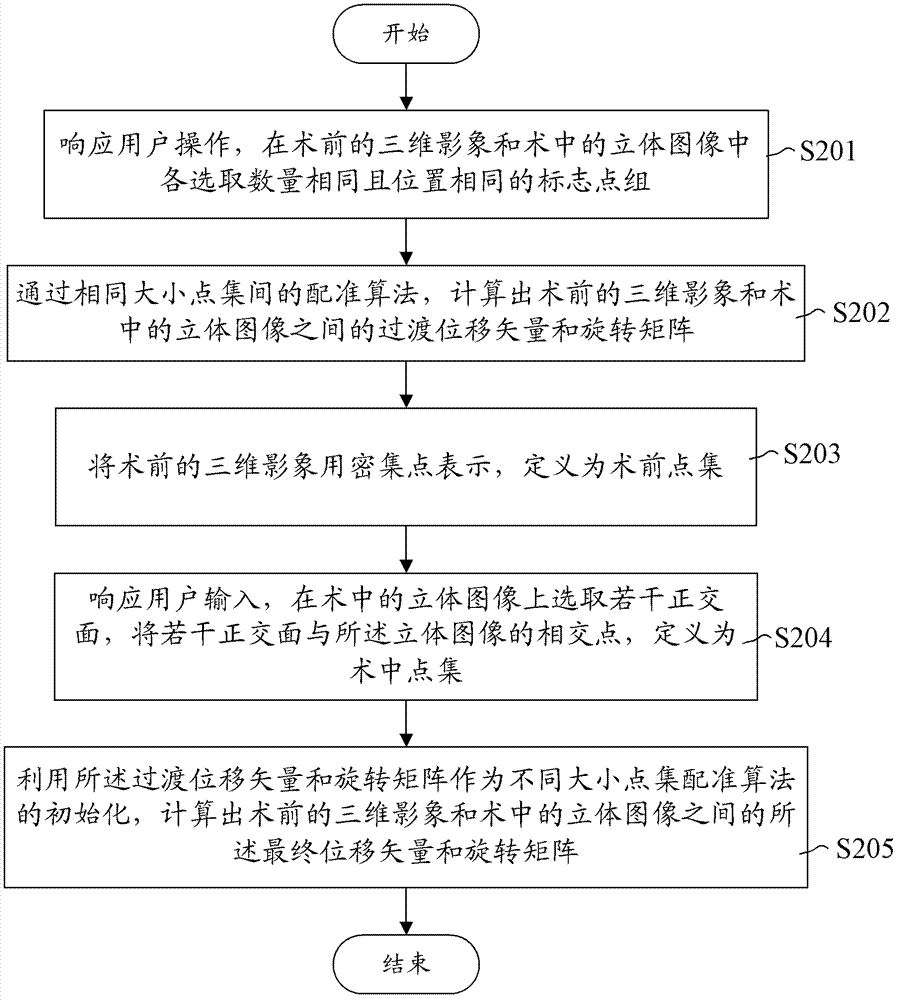

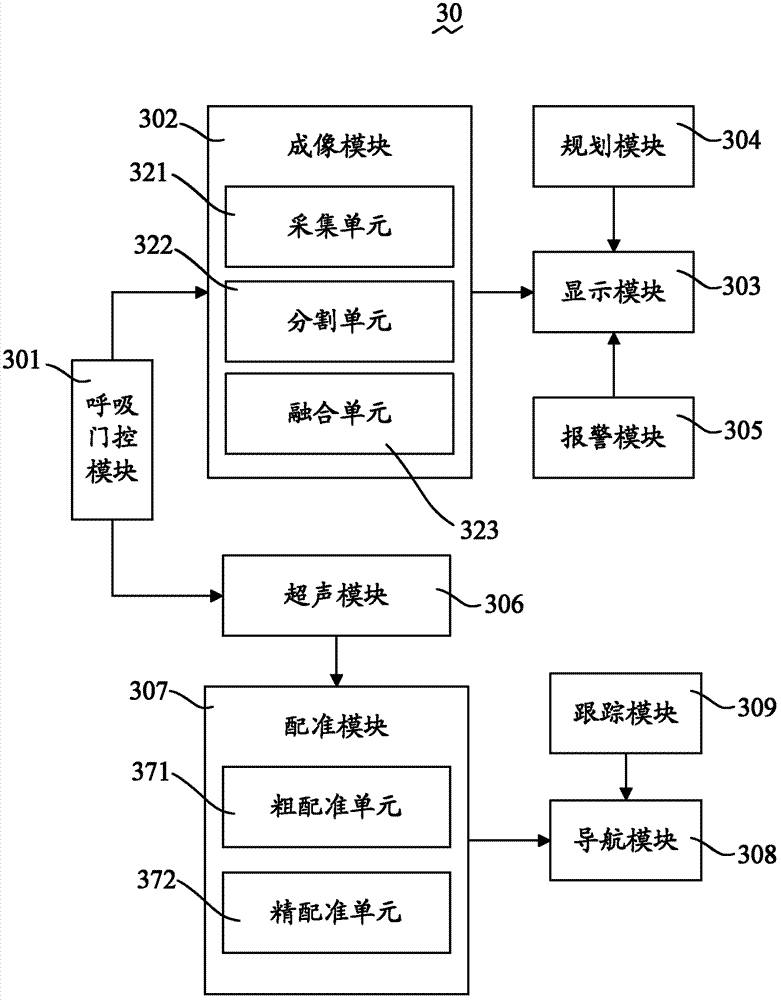

Surgical navigation method and system

ActiveCN103356284ASolve unclear problemsSolve the speed problemDiagnosticsSurgeryNMR - Nuclear magnetic resonanceSonification

A surgical navigation method comprises collecting the three-dimensional images of an organ through nuclear magnetic resonance or CT (computed tomography) before an operation; receiving a planned puncture trace input by a user and displaying the planned puncture trace in the three-dimensional images; collecting the three-dimensional images of the organ through an ultrasonic device during the operation, and converting the three-dimensional images into an operating room coordinate system through a tracer; registering the three-dimensional images before the operation with the three-dimensional images during the operation to obtain final displacement vectors and rotation matrixes; according to the final displacement vectors and the rotation matrixes, converting the three-dimensional images and the planned puncture trace into the operating room coordinate system for displaying; obtaining the motion trace of a puncture needle utilized during the operation through the tracer and displaying the motion trace, the three-dimensional images before the operation and the planned puncture trace in the operating room coordinate system synchronously. The invention also provides a corresponding surgical navigation system. According to the surgical navigation system, blurred images during the operation are replaced by clear images before the operation to provide great help to aspects such as operation, time and image clearness.

Owner:珠海中科先进技术研究院有限公司

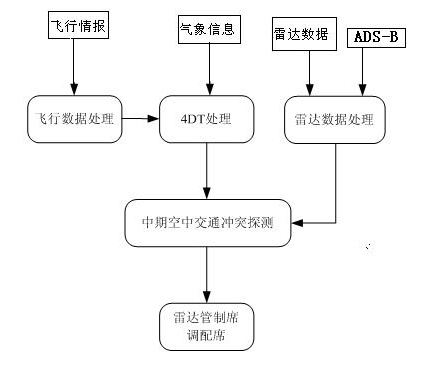

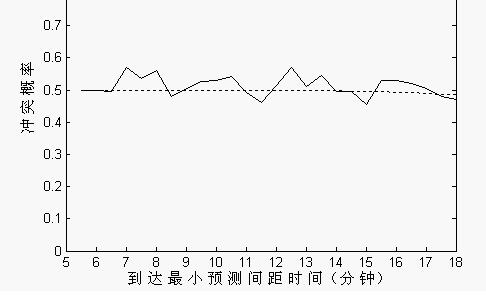

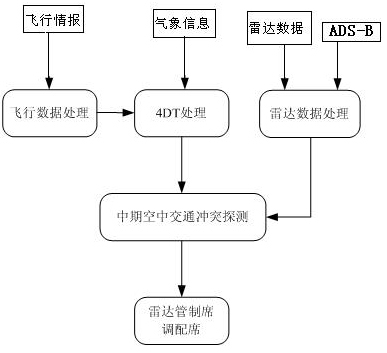

Mid-term air traffic conflict detection method based on 4D flight path and radar data

The invention discloses a mid-term air traffic conflict detection method based on 4D flight path and radar data, which relates to air traffic control automation. In the method, accurate 4D flight path data and real-time radar data are projected onto a display panel of an air traffic control system, each aircraft pair is filtered according to the accurate 4D flight path data and the real-time radar data, and aircrafts which are unlike to come into conflict with other aircrafts in 30 minutes are determined; and the detection is focused on the aircraft pairs which have potential to run into conflicts, the covariance between the relative speed and relative position of the aircraft pairs is calculated by using coordinate transformation according to the vertical interval and time interval of two aircrafts, and then the probability that a predicted position interval is smaller than a safe interval at time t is calculated and a detection report is made. In the invention, the drawbacks of long-term and short-term conflict detection are overcome, and the long-term conflict detection, mid-term conflict detection and short-term conflict detection are combined to ensure flight safety. The average conflict detection time is about 0.028 seconds, and the method has high real-time performance.

Owner:WISESOFT CO LTD

Steerable lesion excluding heart implants for congestive heart failure

ActiveUS20080269551A1Improve efficiencyReducing ventricular volumeSuture equipmentsElectrocardiographyCardiac septumLesion

Devices, systems, and methods for treating a heart of a patient may make use of one or more implant structures which limit a size of a chamber of the heart, such as by deploying a tensile member to bring a wall of the heart toward (optionally into contact with) a septum of the heart.

Owner:BIOVENTRIX A CHF TECH

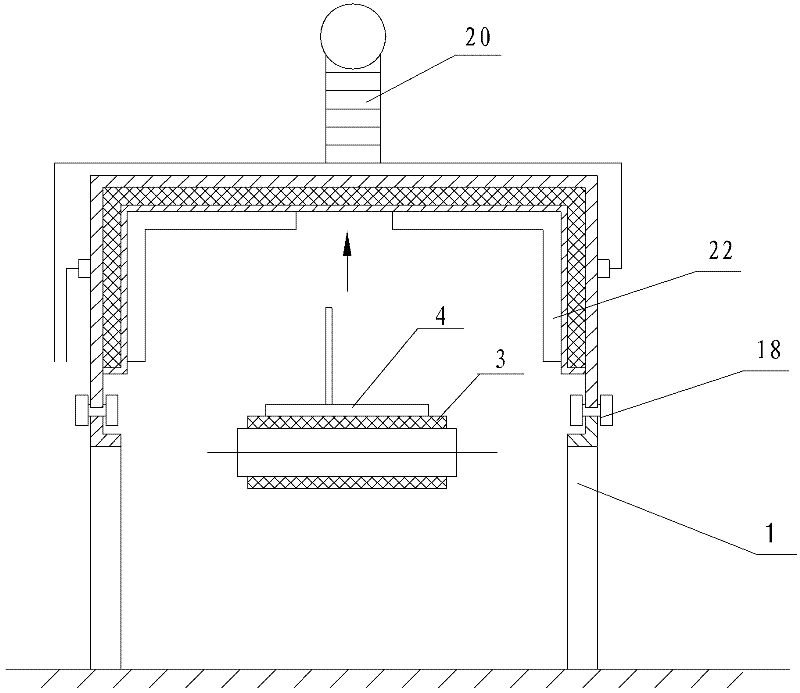

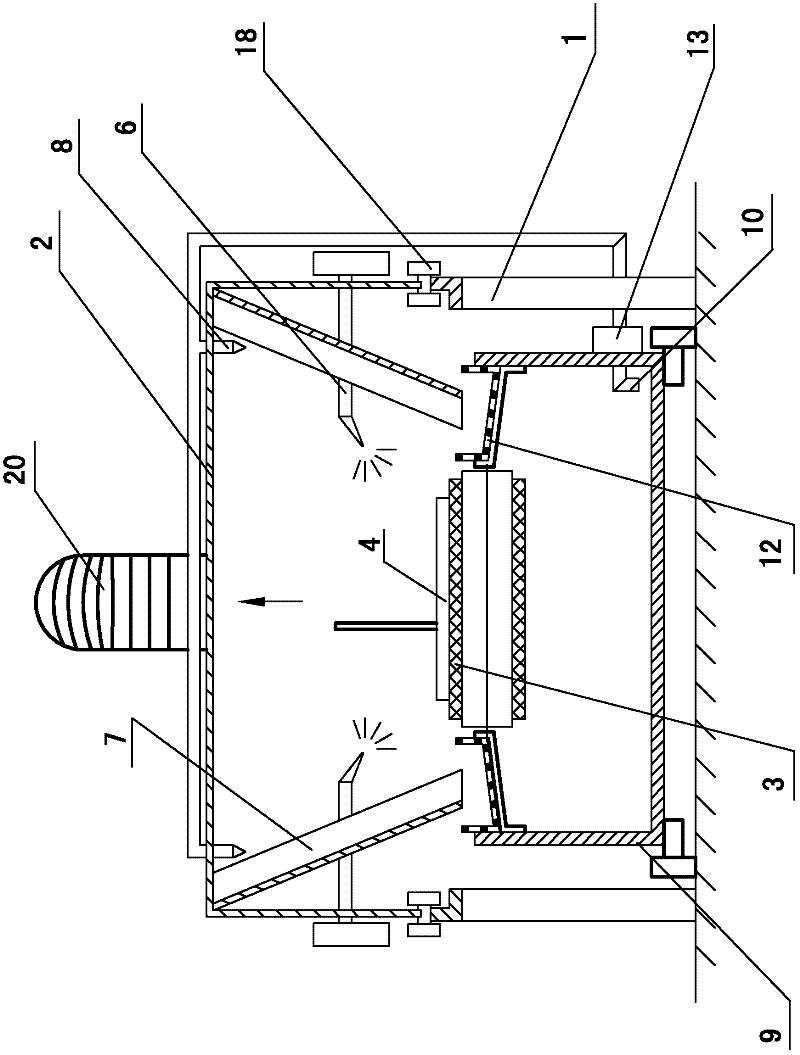

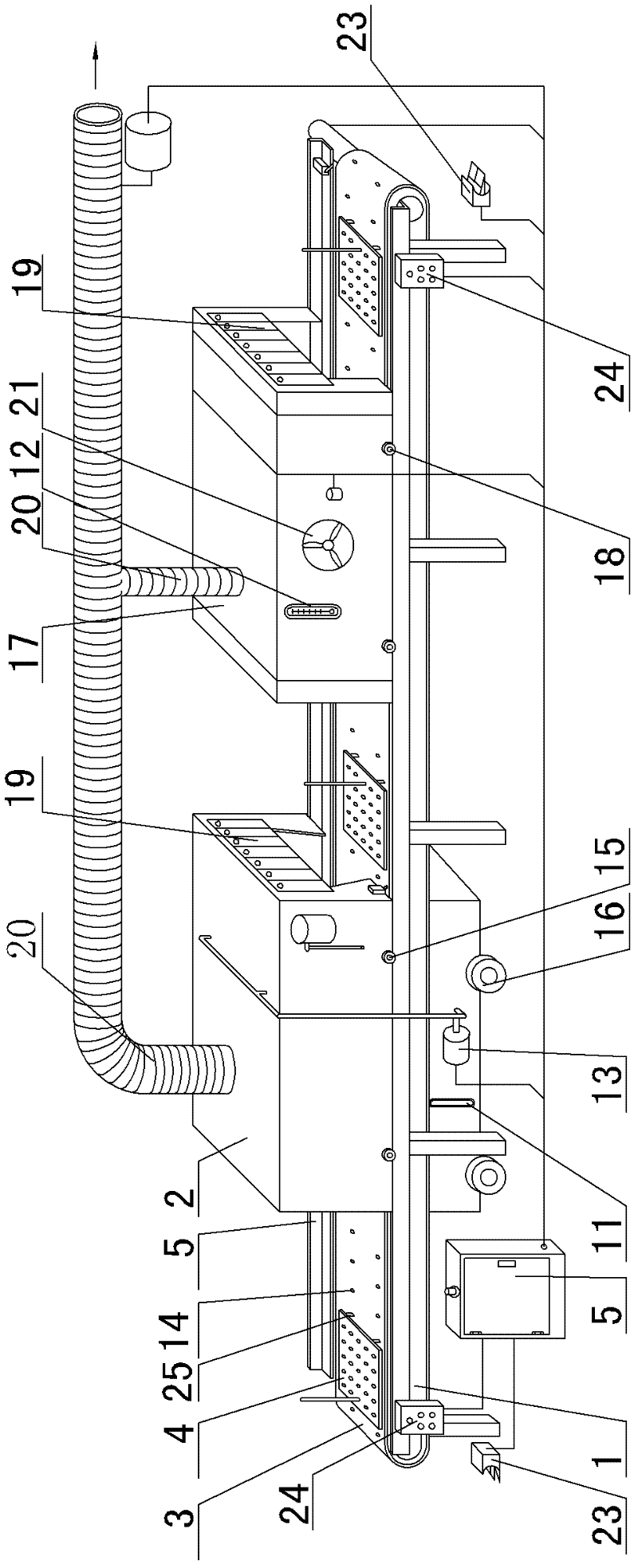

Chopstick spray-paint equipment and chopstick spray-paint method

InactiveCN102335645AHigh degree of automationEasy to operateSpraying apparatusPretreated surfacesProduction rateEngineering

The invention relates to chopstick spray-paint equipment, which comprises a rack, a spray-paint box, a conveyer belt and a chopstick dish, wherein the spray-paint box is arranged on the rack, and the conveyer belt penetrates through the spray-paint box; the chopstick dish is arranged on the conveyer belt; and inserting holes for fixing chopsticks are arranged on the chopstick dish. An electric cabinet for electrically controlling the chopstick spray-paint equipment is also arranged on the spray-paint equipment. The spray-paint box is provided with a front door A and a back door A along the conveying direction of the conveyer belt, and a spray gun for spraying paint is arranged in the spray-paint box. The degree of automation is high, and the chopstick spray-paint equipment replaces manually pulling paint operation and the long-time drying process. The chopstick spray-paint equipment is also provided with a drying box, so that the carrying back and forth among each working procedure and drying and putting area in the paint spraying and drying processes are saved, the labor strength is reduced, the manpower resource is greatly saved, the production rate is increased, the length of a chopstick mold is shortened, and the use ratio of raw materials of chopsticks is increased. Benzene volatile matters and others in the equipment are effectively removed. The spray-paint equipment has simple operation, compact structure and wide practical meaning and marketable value.

Owner:侯唯敏

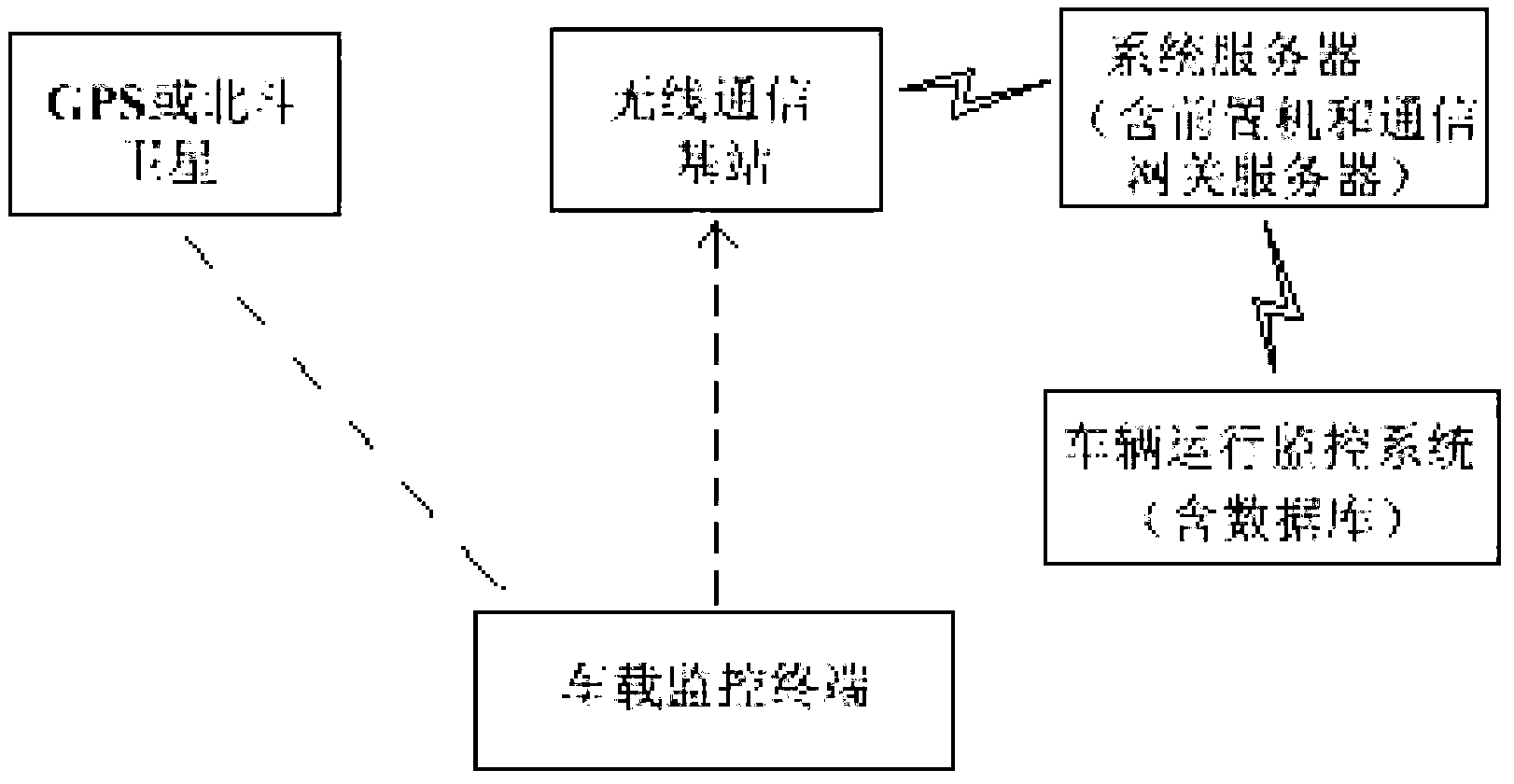

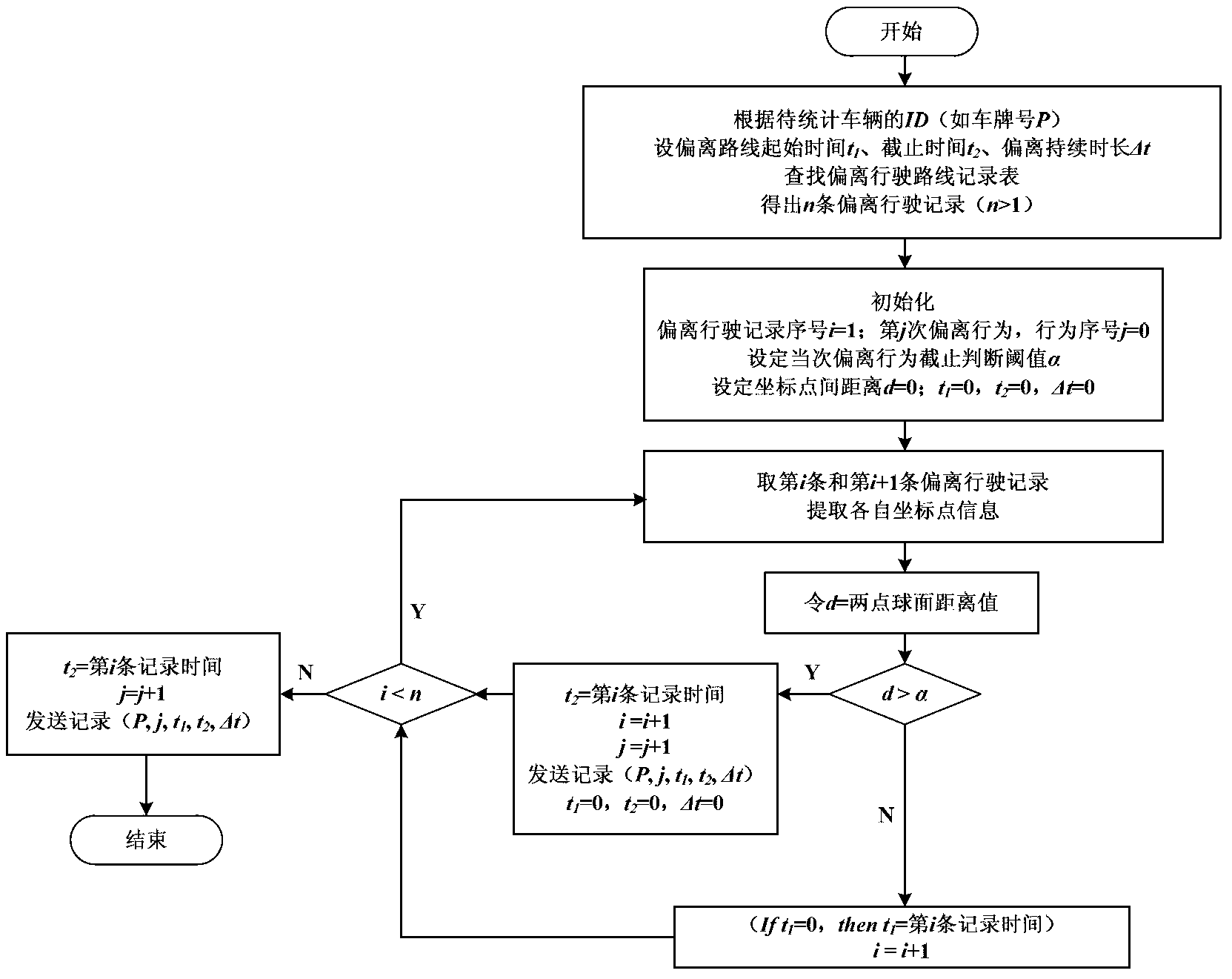

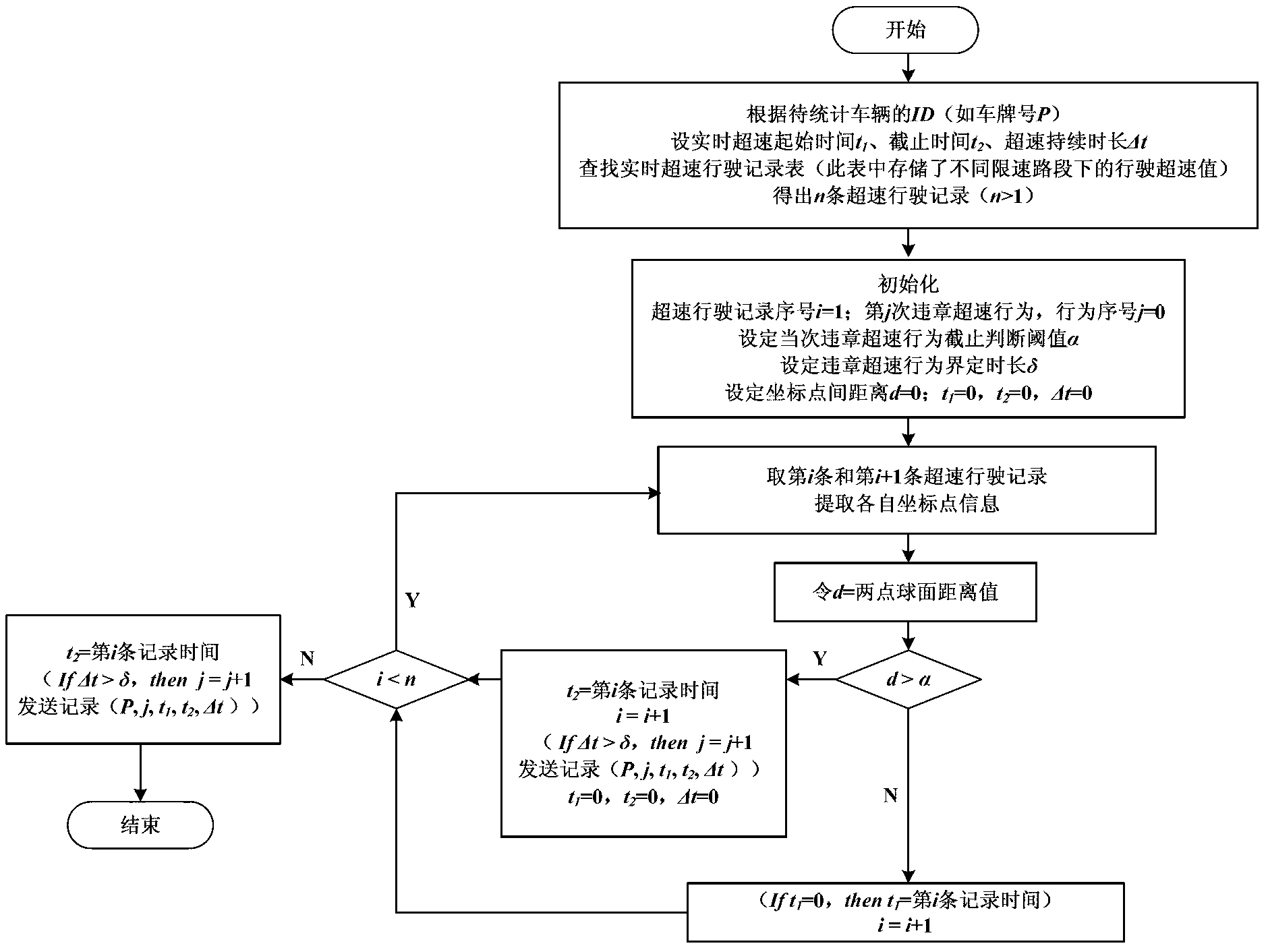

Method for recognizing vehicle violation behaviors with satellite positioning technology

InactiveCN103236166AEfficient exclusionReduce processingDetection of traffic movementSatellite positioningSpeed limit

The invention discloses a method for recognizing vehicle violation behaviors with a satellite positioning technology. The method comprises the following steps that spherical distance values and the like of a satellite positioning coordinate of a vehicle position and the geographical coordinate information of preset routes are compared with satellite positioning data uploaded from a vehicle-mounted terminal and the geographical coordinate information containing the preset routes, sectional speed limit values and other reference determination data which are pre-stored in a system database of a monitoring center so as to judge and calculate the behaviors and the times that a vehicle runs off regulated routes; the violating and over-speed behaviors and times are judged and calculated by comparing the real-time speed of the vehicle, the speed limit information of a current road section, spherical distance values between points, violation thresholds and the like; and whether the vehicle overspeeds or not is judged by comparing the actual arriving and preset arriving time at specific locations. Compared with the prior art, according to the algorithm, a plurality of violating behaviors in an inquiry and statistical process can be separated conveniently and accurately, so that normal over-speed (such as overtaking) and violating over-speed and other behaviors can be distinguished, and the monitoring to the process over-speed is realized.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

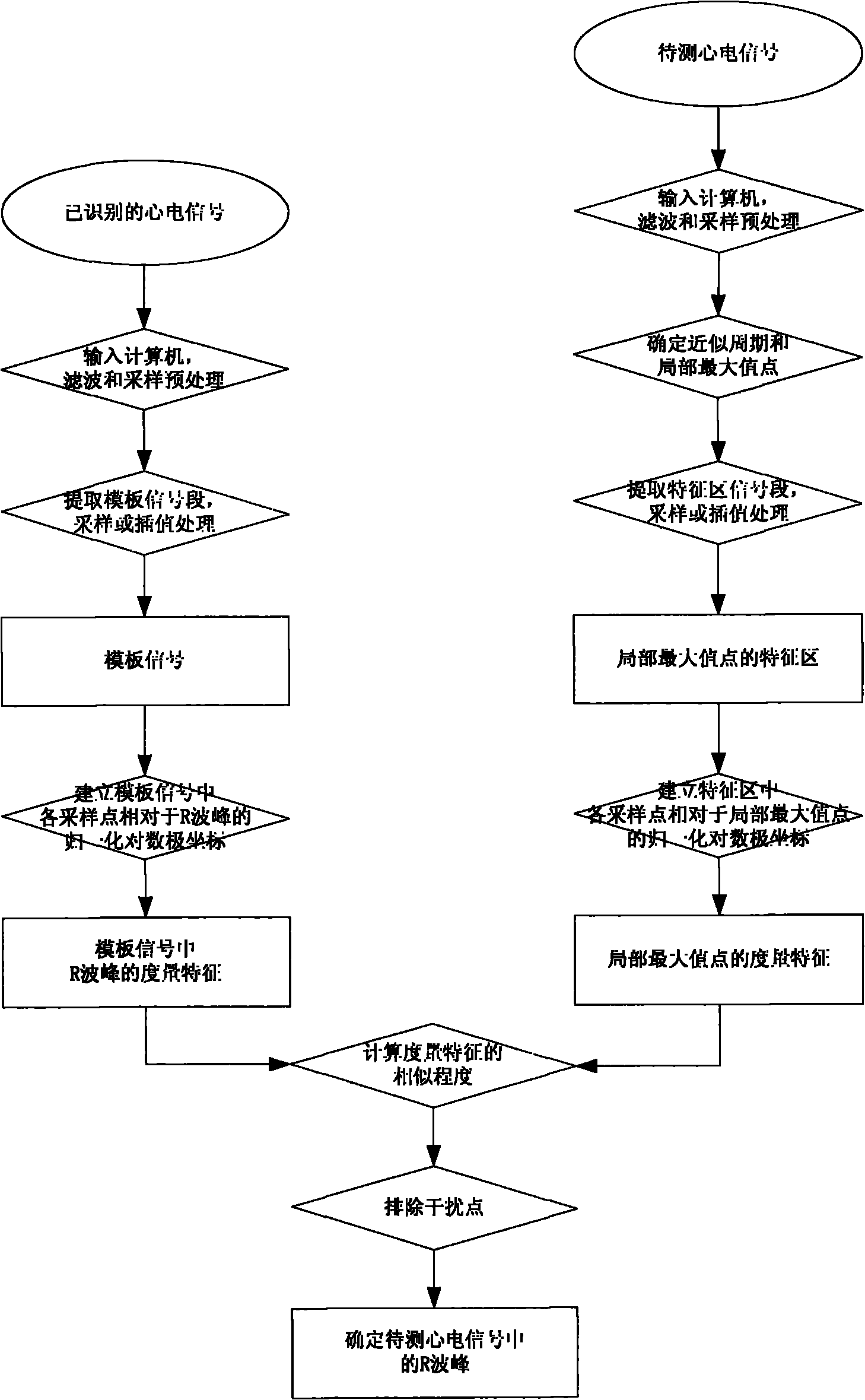

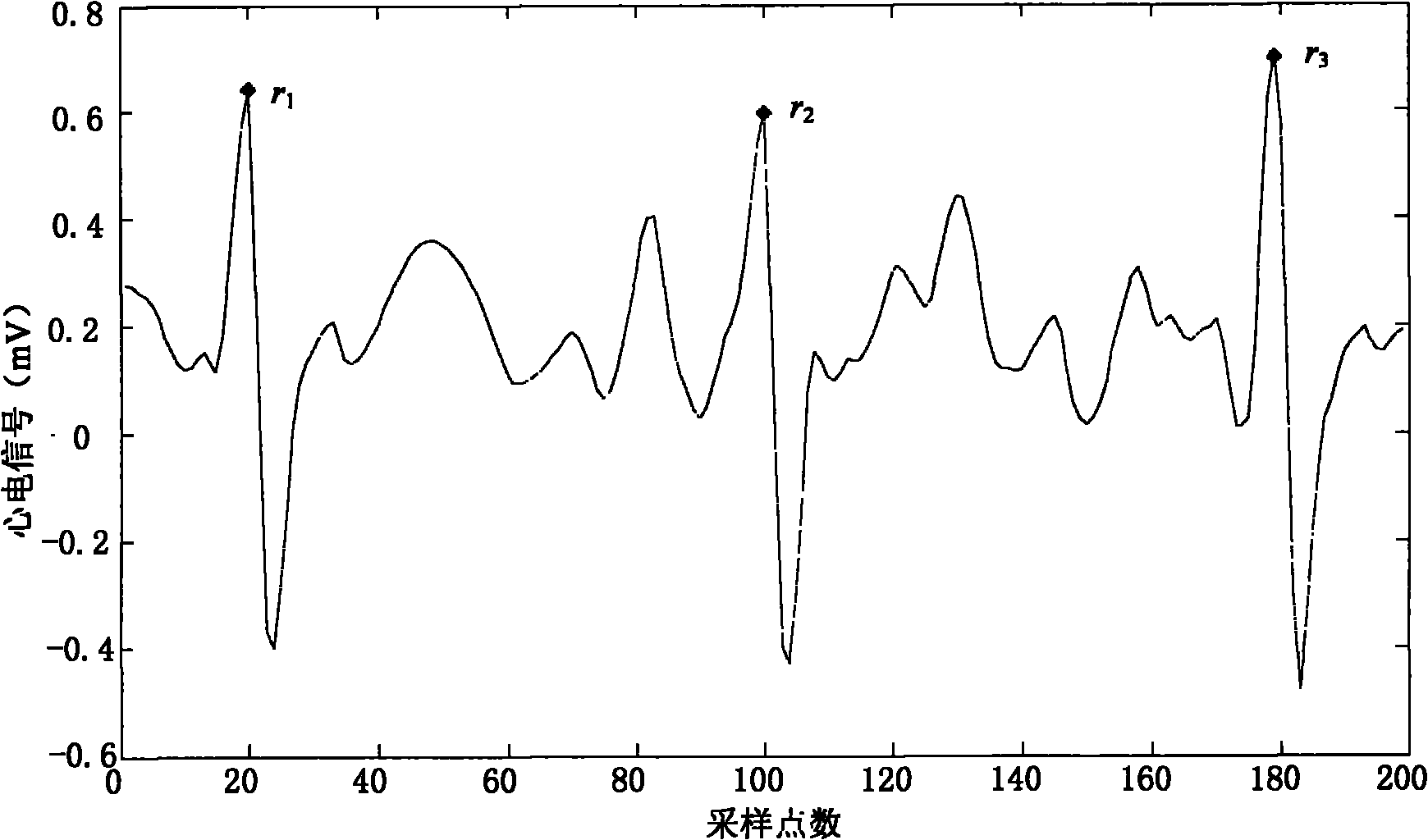

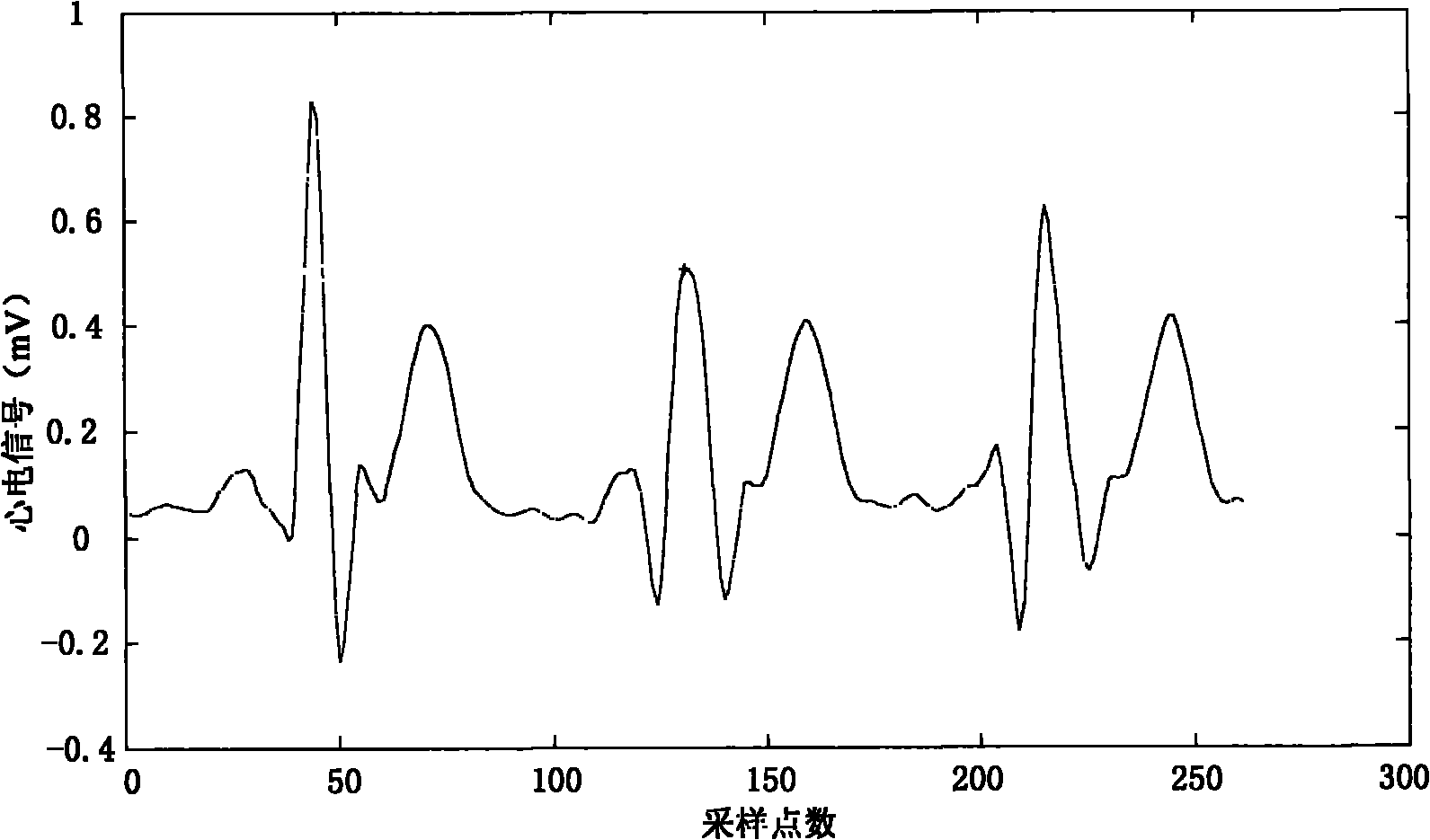

Method for detecting R wave crest of electrocardiosignal

InactiveCN101856225AOvercoming the Effects of DriftRobustDiagnostic recording/measuringSensorsEcg signalComputer science

The invention provides a method for detecting an R wave crest of an electrocardiosignal. The method takes point to point difference vector as a base characteristic. The base characteristic has translational and rotational invariance and can overcome influences of baseline drift of the electrocardiosignal. Meanwhile, logarithm polar coordinate conversion is carried out on the difference vector to measure similarity of waveforms. The measurement is sensitive to morphological characteristics of the adjacent waveforms, can capture the whole contour information of the waveforms at the same time, and has robustness on waveform swing. In addition, the method can effectively eliminate influences of interference signals by setting appropriate thresholds. The method for converting the point to point similarity measurement into measurement of waveforms of the points accurately identifies and detects the R wave crest of the electrocardiosignal. The method is applied to related electrocardiogram analytical instruments, can accurately identify the R wave crest in the electrocardiosignal, and is favorable for improving detection and analysis capabilities of electrocardiogram analytical equipment.

Owner:CHONGQING UNIV

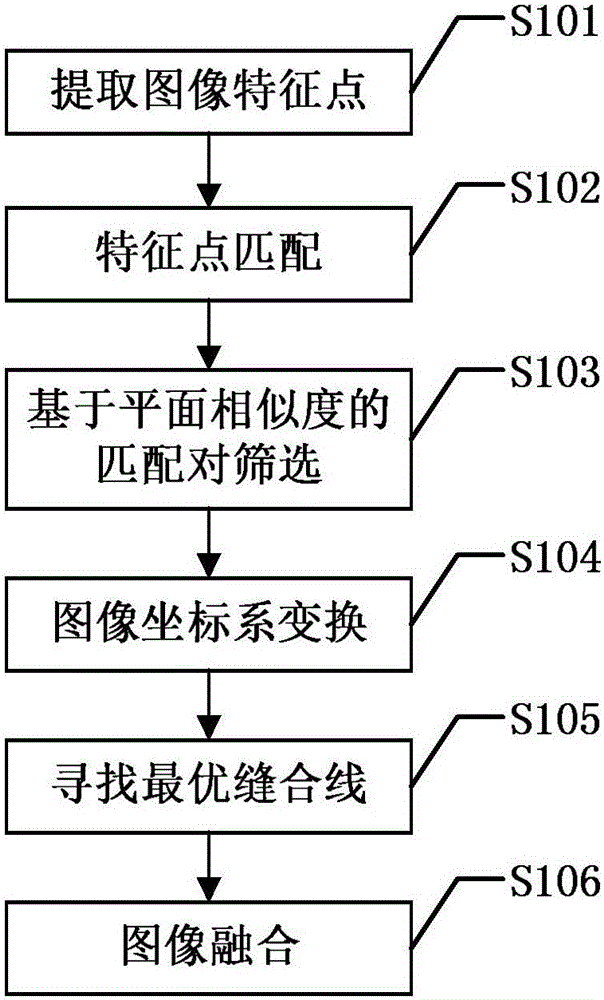

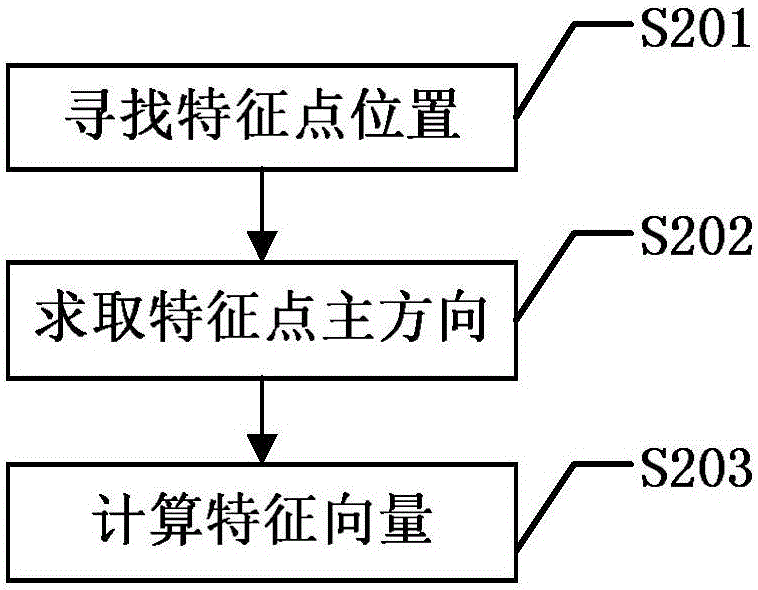

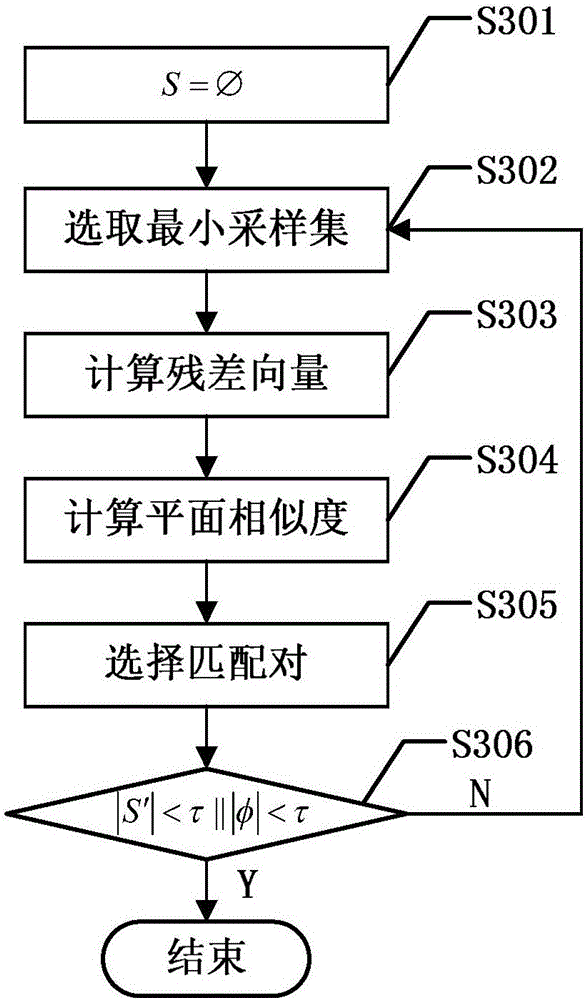

Image stitching method based on characteristic point plane similarity

InactiveCN105957007ATransform accuratelyImprove accuracyGeometric image transformationDetails involving image mosaicingScreening methodEuclidean vector

The invention discloses an image stitching method based on characteristic point plane similarity, comprising first, respectively extracting characteristic points of two images to be stitched; matching the characteristic points to obtain characteristic point matching pairs; screening the characteristic point matching pairs based on plane similarity, the screening method including first randomly selecting a smallest sampling set; calculating the homography matrix of the smallest sampling set; calculating the residual error between each matching pair and a corresponding homography matrix to form a residual vector; and calculating the plane similarity between each two matching pairs according to a residual vector, and furthermore screening the matching pairs; calculating a transformational matrix according to screened matching sets, and transforming two images to be stitched into a same coordinate system; searching for an optimal stitching line; and fusing images according to the optimal stitching line to obtain an image stitching result. The method employs characteristic point matching pairs which are screened based on plane similarity to perform registering and stitching, and can improve image stitching accuracy and robustness.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

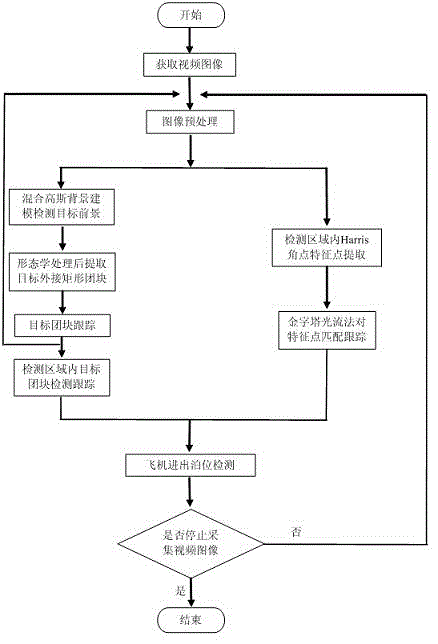

Video-based airplane entry-departure parking lot automatic detection method

ActiveCN104966045AImprove detection efficiencyReduce computational analysis workloadImage analysisCharacter and pattern recognitionJet aeroplaneArrival time

The invention relates to a video-based airplane entry-departure parking lot automatic detection method. A video image of a monitoring area covering an airplane shutdown parking lot area is obtained, a motion object is identified and tracked, characteristic points of an image in a detection area are extracted and tracked in a matching manner, when the number of characteristic points meeting airplane entry or departure direction requirements in a certain number of continuous frames of the video image accords with a required quantity, a judgment about official entry or departure is further made, and when displacement of a characteristic point set is smaller than certain pixels and the motion object does not enter but continuously departs from an airplane shutdown parking lot area, it is determined that an airplane officially parks in place; and when the displacement of the characteristic point set is smaller than or equal to certain pixels and the motion object does not depart from but continuously enters the airplane shutdown parking lot area, it is determined that the airplane officially departs, wherein the detection area is a set are opposite to the airplane shutdown parking lot area on the video image. The method provided by the invention can realize round-the-clock intelligent detection of accurate arrival time of airplane flight and is quite high in detection accuracy.

Owner:北京天睿空间科技股份有限公司

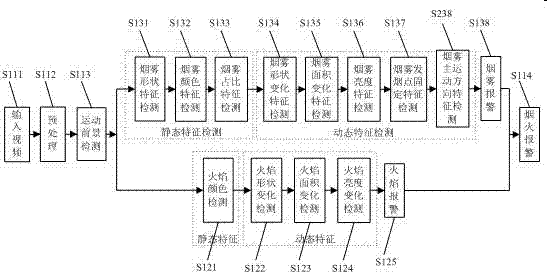

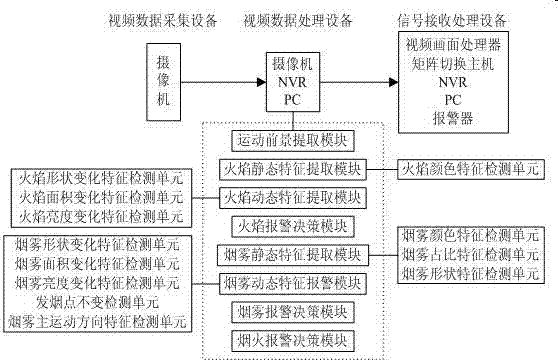

Smog detection method and device based on video analysis

InactiveCN106897720AHigh alarm accuracyReduce false positivesImage enhancementImage analysisData acquisitionVideo image

The invention discloses a smog detection method based on video analysis. The smog detection method based on video analysis comprises steps of video image data acquisition, video image preprocessing, forward target extraction, flame static characteristic detection, flame dynamic characteristic detection, flame alarm decision, smog static characteristic detection, smog dynamic characteristic detection and smog alarm decision. The method is advantaged in that smog and flame are simultaneously detected in a combined static and dynamic characteristic mode, smog detection accuracy and stability are improved, operation complexity is further reduced, hardware realization is convenient, and the method can be applied to relatively complex environments.

Owner:JINAN JOVISION TECH CO LTD

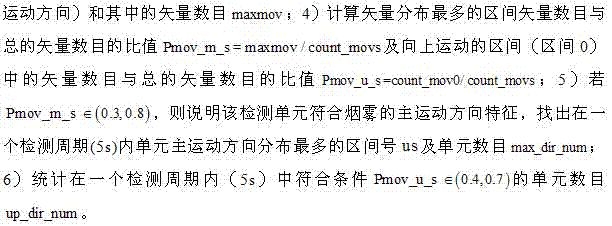

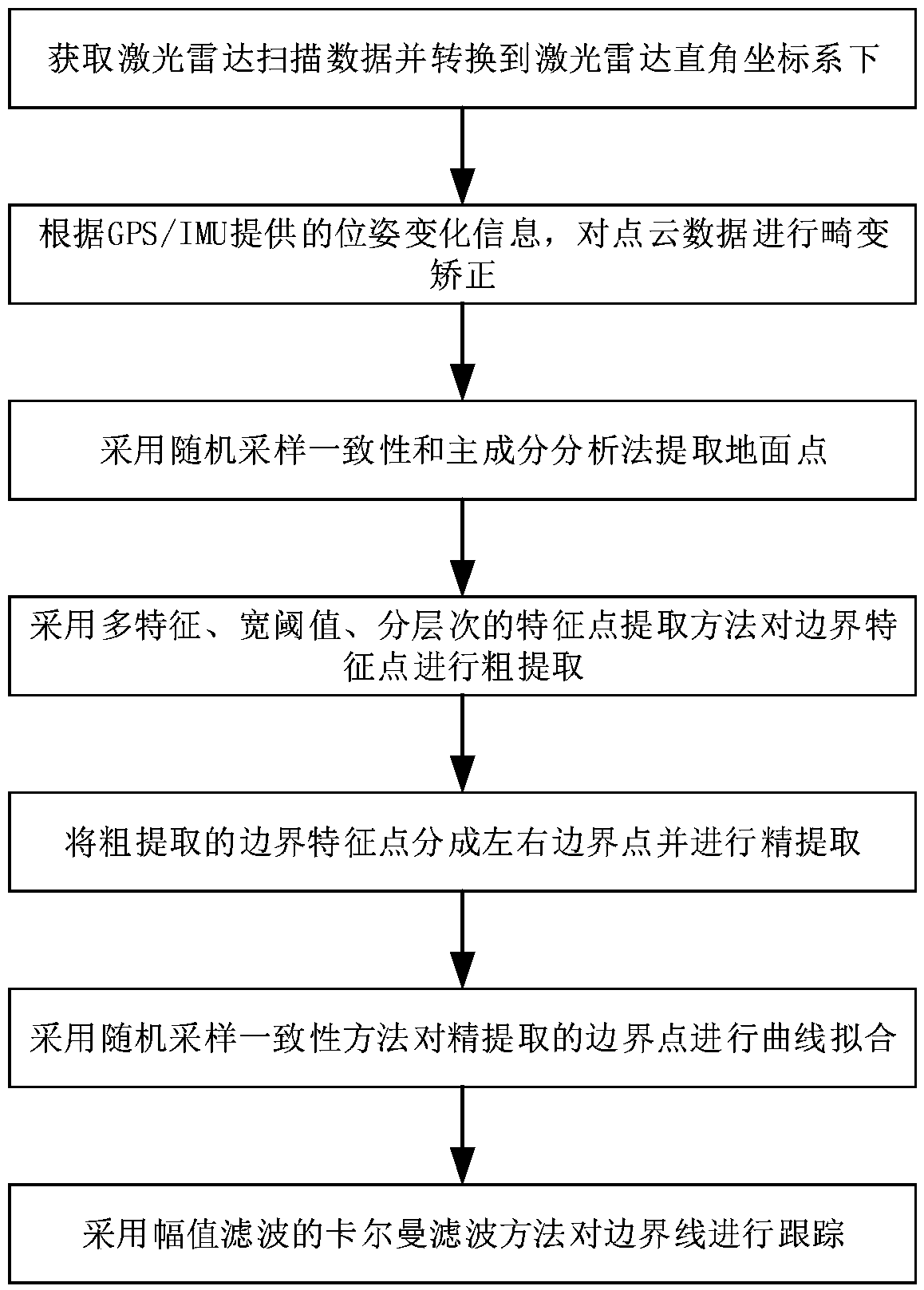

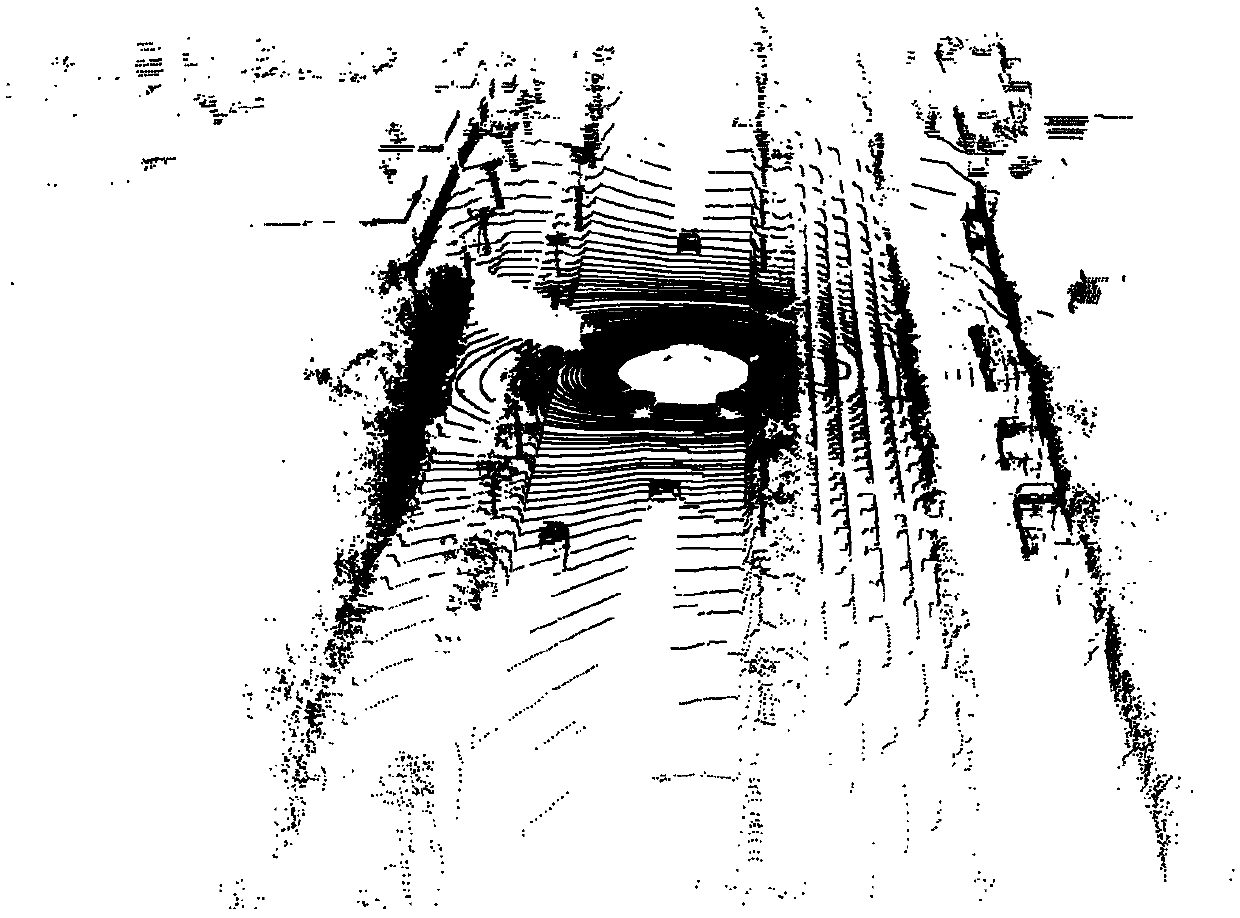

A road boundary detection and tracking method based on a three-dimensional laser radar

ActiveCN109684921AImprove robustnessSolve the above-mentioned deficiencies that existElectromagnetic wave reradiationThree-dimensional object recognitionRectangular coordinatesPrincipal component analysis

The invention relates to a road boundary detection and tracking method based on a three-dimensional laser radar. The method comprises the following steps: converting polar coordinate data of a laser radar scanning point into rectangular coordinate data; Extracting ground points by using a random sampling consistency plane fitting method and a principal component analysis method; Roughly extractingroad boundary feature points by adopting a multi-feature, wide-threshold and hierarchical feature point extraction method; Dividing the roughly extracted road boundary feature points into a left roadboundary feature point and a right road boundary feature point by using a projection-based method by referring to the idea of linear discriminant analysis; Respectively filtering the left road boundary point and the right road boundary point by using a random sampling consistency method to obtain final road boundary points; Fitting the left road boundary line and the right road boundary line by adopting a quadratic polynomial random sampling consistency method; And tracking the road boundary line by adopting a Kalman filtering method based on amplitude filtering. The method can be used for processing various complex scenes and working conditions, and can be widely applied to unmanned driving.

Owner:JILIN UNIV

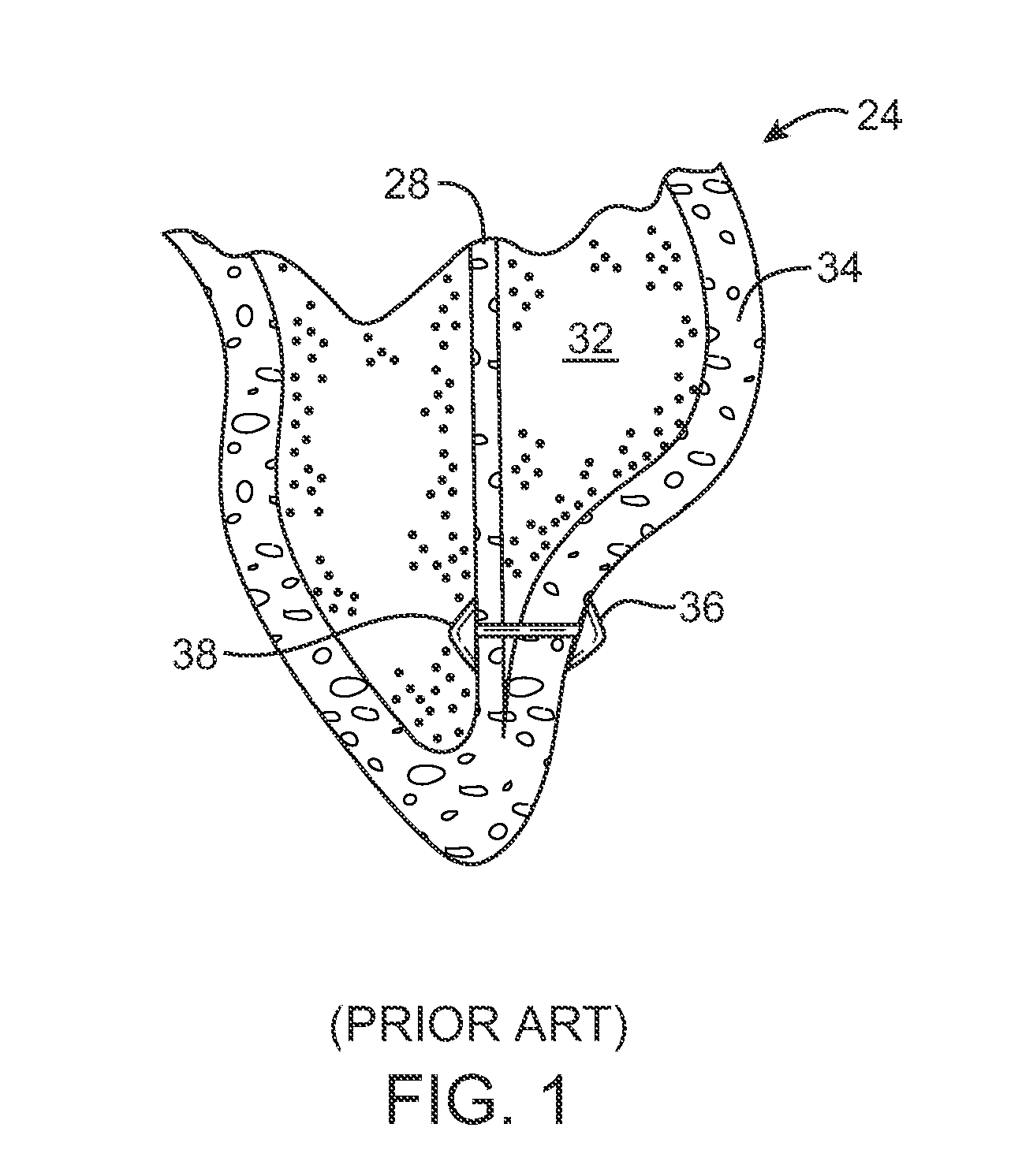

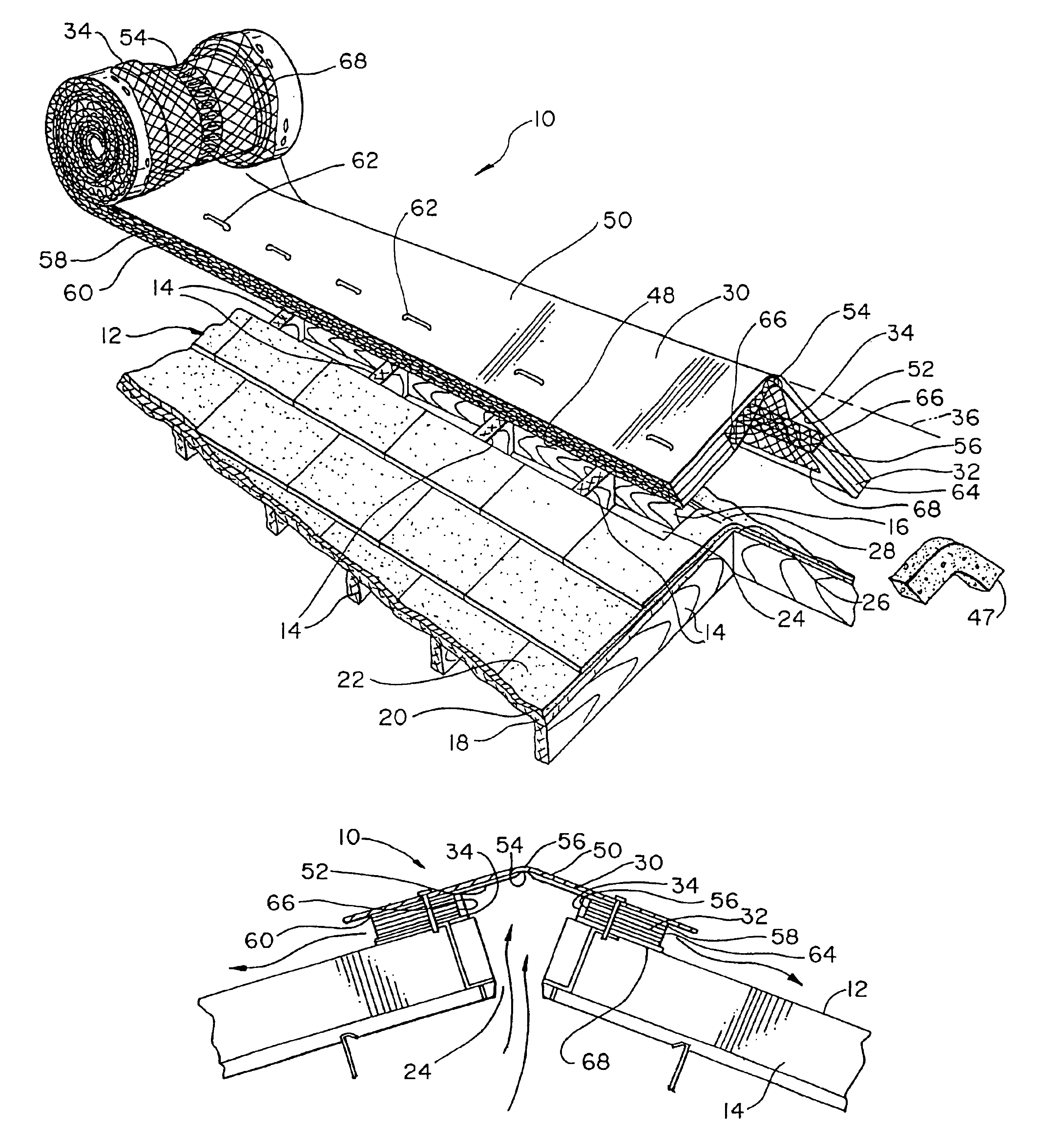

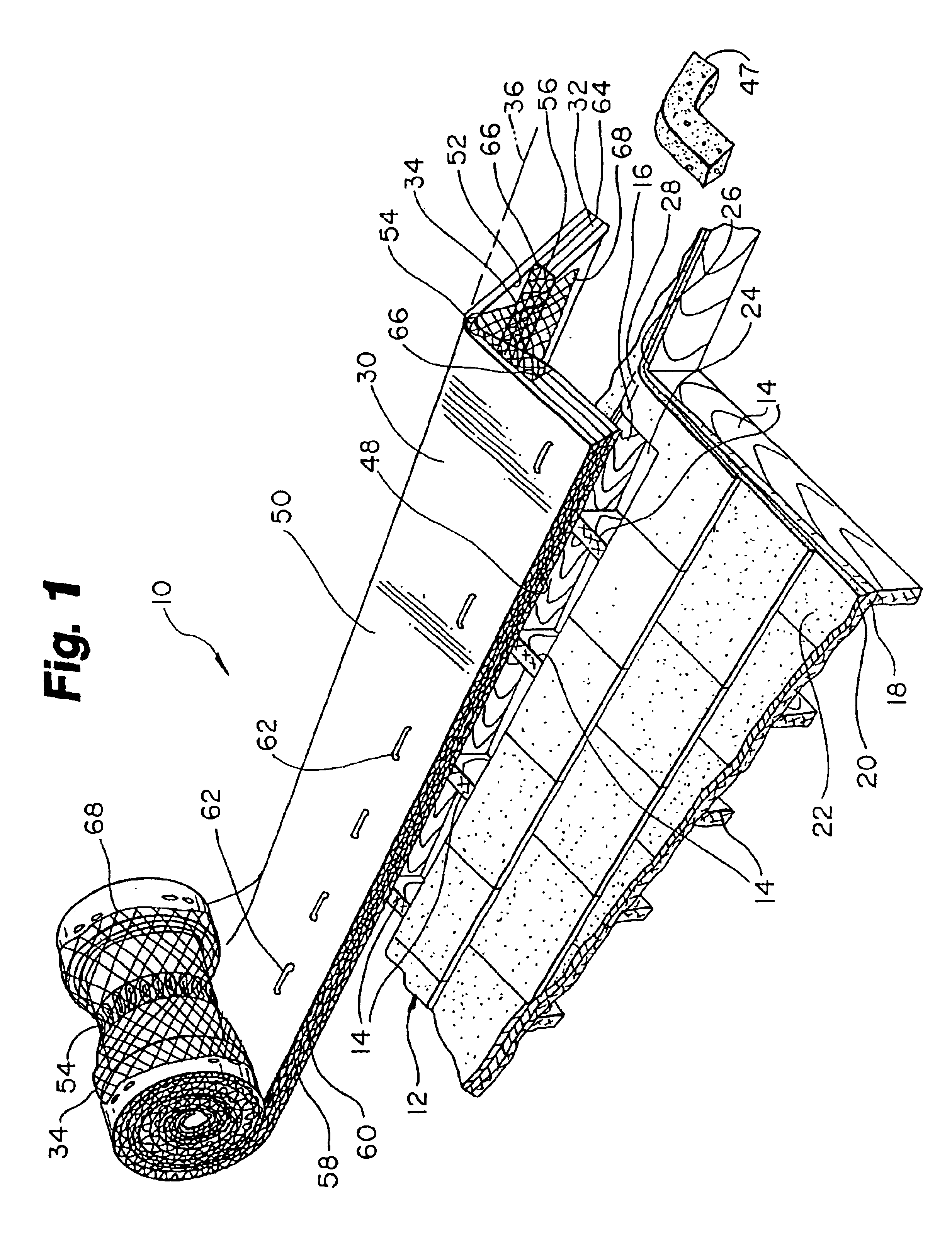

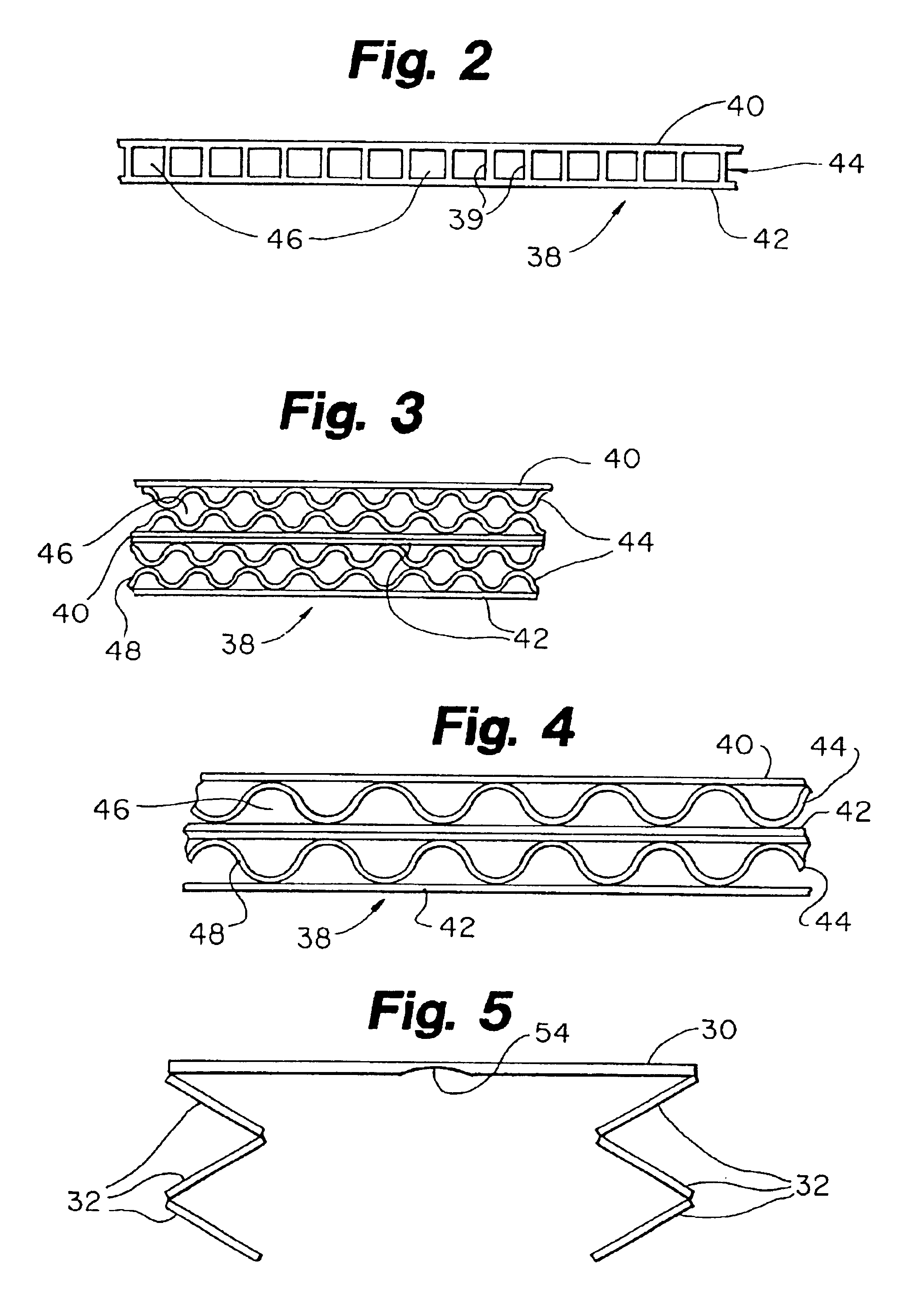

Precipitation resistant ridge vent

InactiveUS6913530B2Efficient exclusionEasy to manufactureBuilding roofsLighting and heating apparatusInterior spaceForeign matter

A precipitation resistant ventilator for a structure enclosing an interior space. The ventilator encloses a space that is in communication with the structure interior space. A thin sheet of air permeable water resistant material is disposed within the ventilator interior. The thin sheet of air permeable water resistant material forms a barrier that excludes the entry of precipitation and other foreign matter into the roof structure while still allowing air exchange.

Owner:LIBERTY DIVERSIFIED INDS

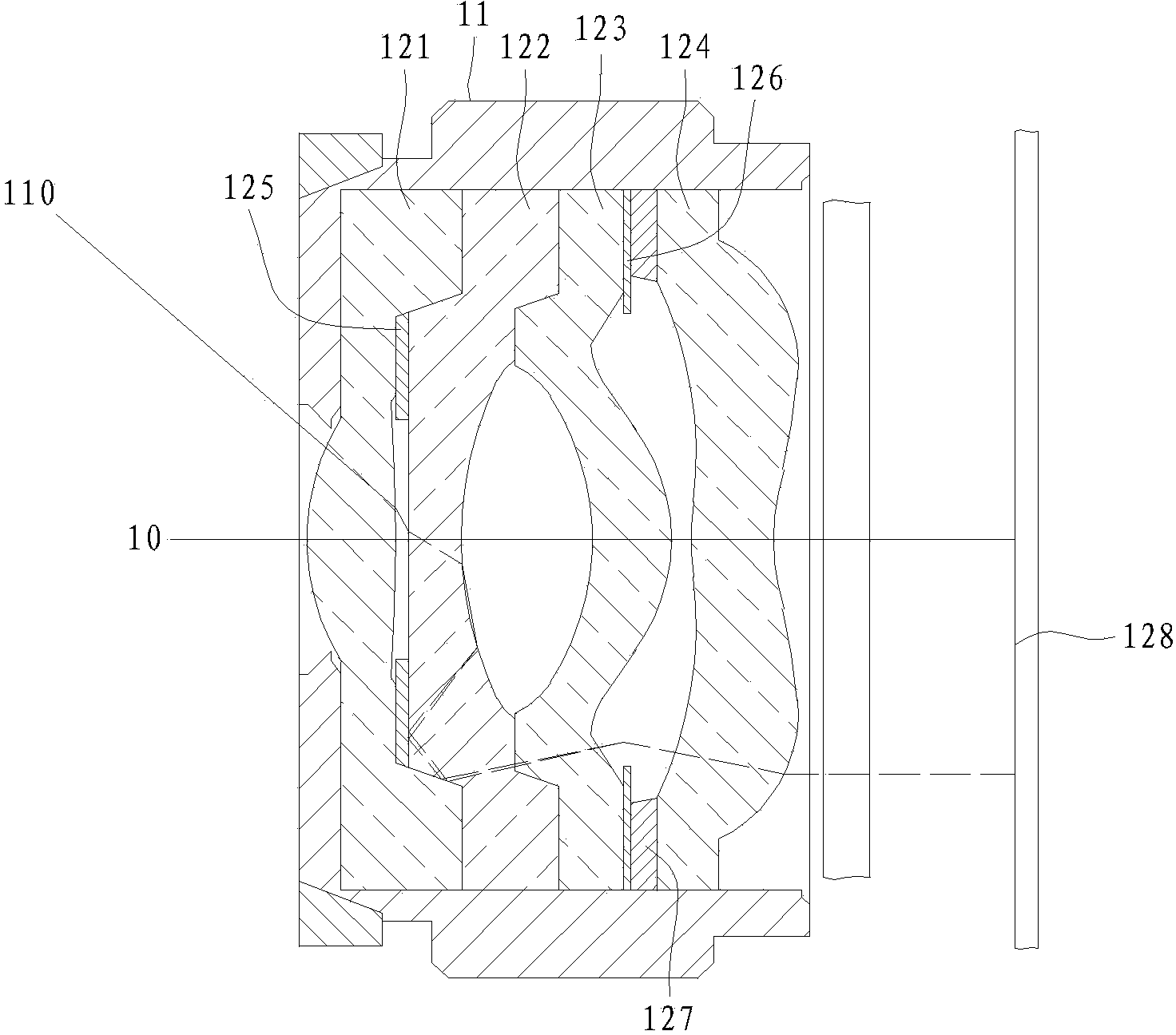

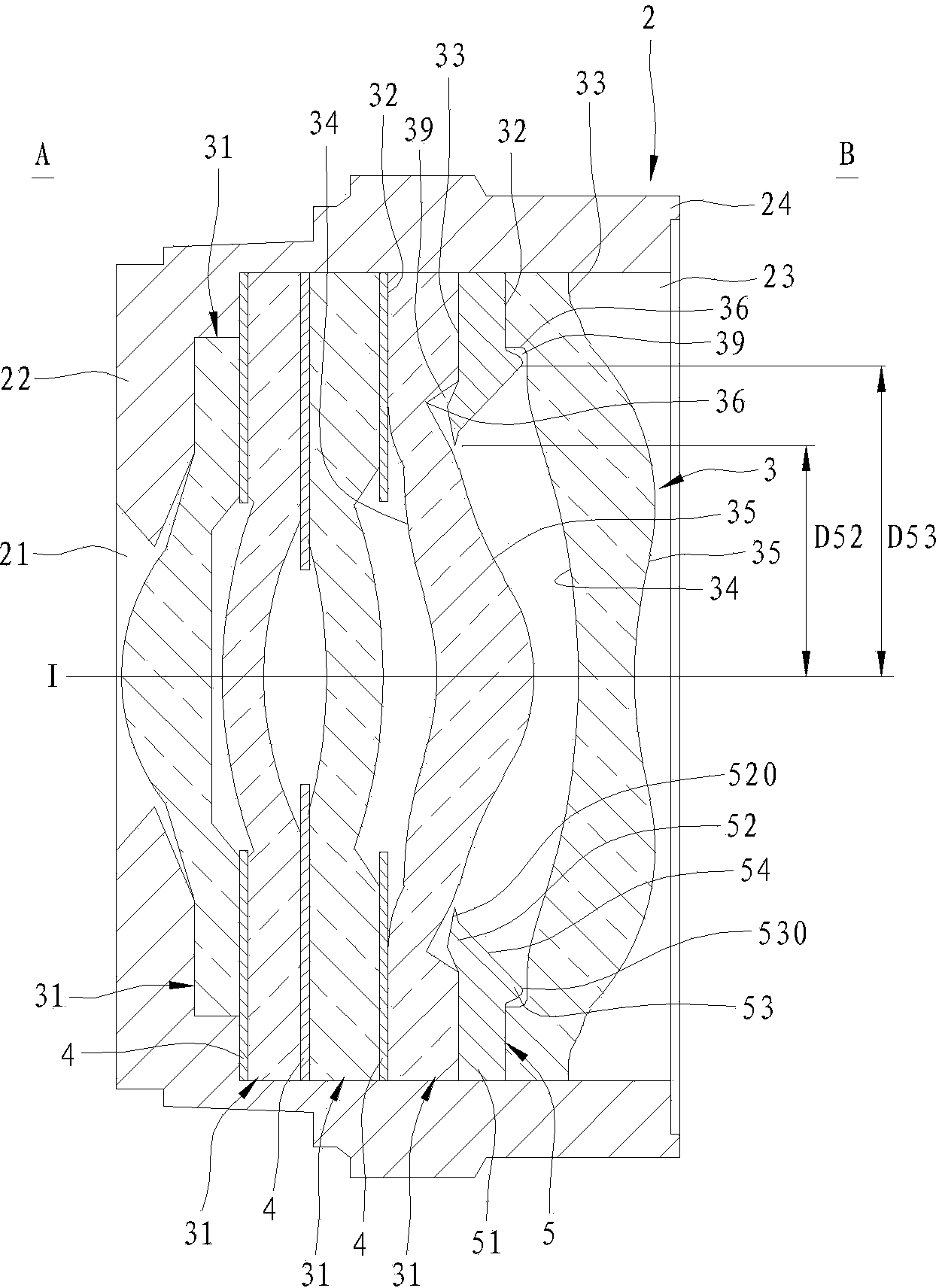

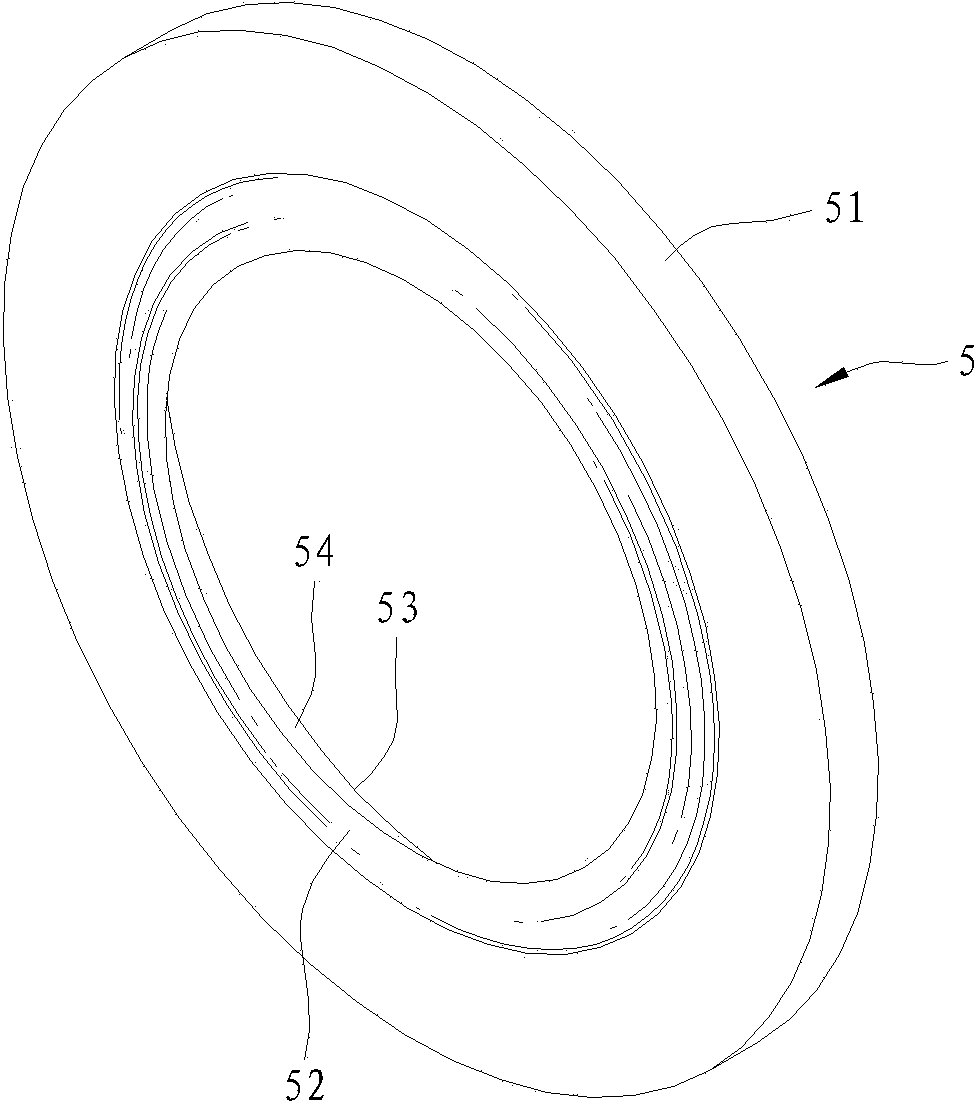

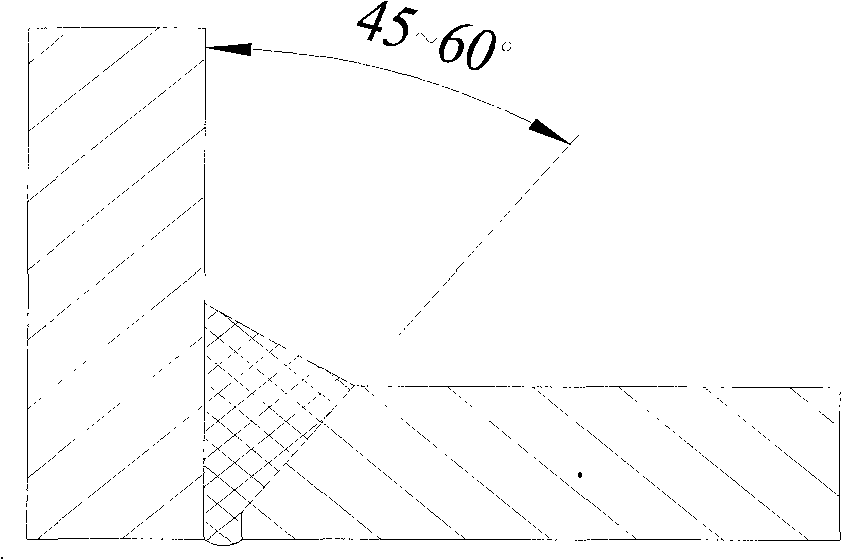

Imaging lens capable of eliminating stray light

The invention relates to an optical imaging lens capable of being applied to a lens module for image shooting and picture recording. The imaging lens capable of eliminating stray light comprises a lens cone, an imaging unit arranged in the lens cone and a shading assembly arranged in the imaging unit. The shading assembly comprises a fixing portion arranged on the imaging unit in a clamping mode, an object side protruding portion and an image side protruding portion, the object side protruding portion protrudes from the inner periphery, close to an object side, of the fixing portion, extends inwards in a tilted mode and ends at a tail end edge, and the image side protruding portion protrudes from the inner periphery, close to an image side, of the fixing portion, extends inwards in a tilted mode and ends at a tail end edge. The fixing portion of the shading assembly enables the shading assembly to be located and assembled easily, so that good assembly accuracy can be maintained; the object side protruding portion and the image side protruding portion can effectively eliminate the stray light so as to reduce unnecessary influences of the stray light during imaging. The imaging lens has higher imaging quality.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

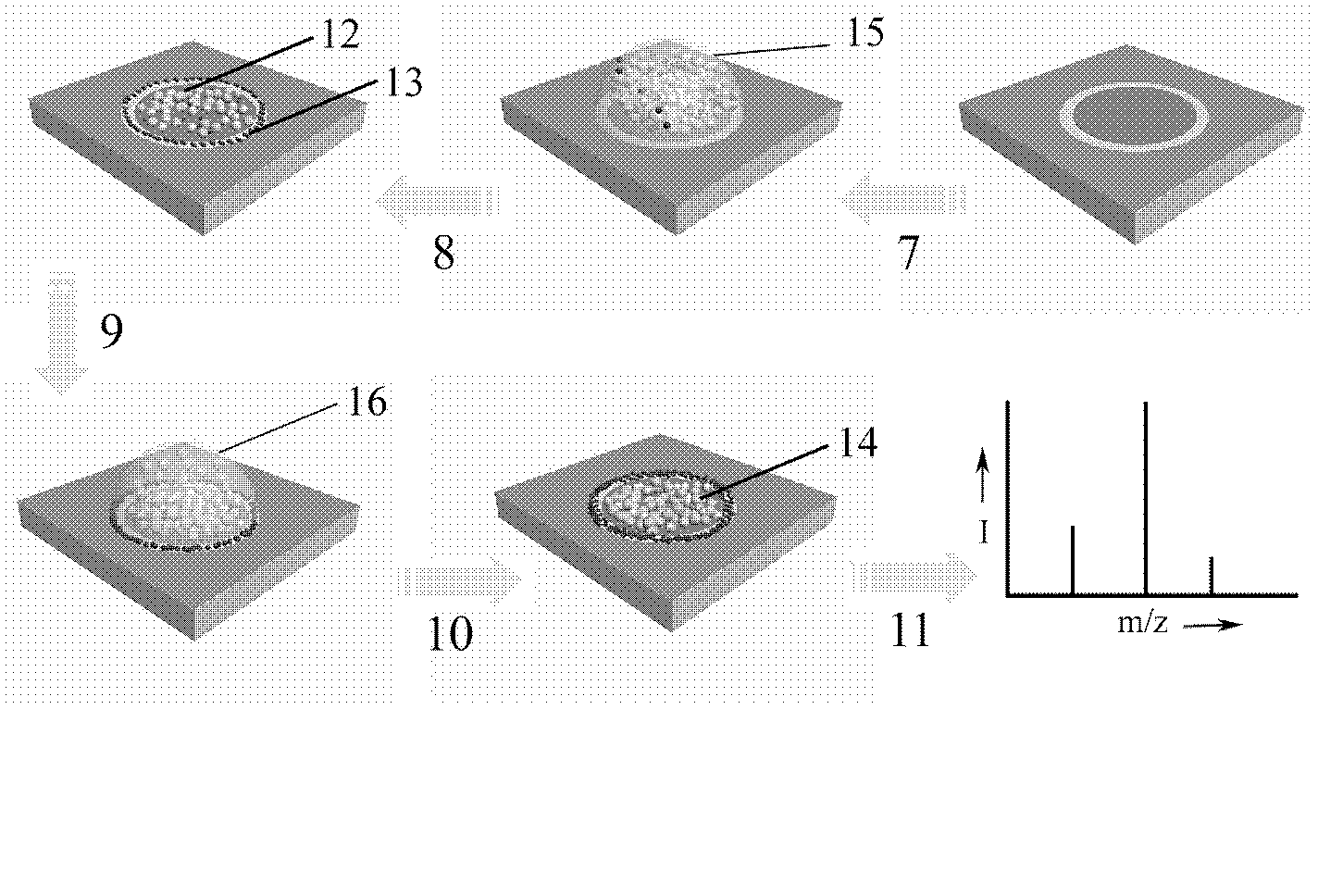

Concentration and demineralization purification treatment method of biological samples

InactiveCN102519779AAchieve desalinationTo achieve the effect of enrichmentPreparing sample for investigationHydrophilic hydrophobicPre treatment

The invention belongs to the field of biochemistry analysis technology, and specifically relates to a one-step concentration and demineralization purification treatment method of biological samples by the use of patterning surface. The patterning surface can be widely applied in pretreatment and detection of biological samples. The method comprises the following steps of: constructing sealing patterning surface of hydrophobic-hydrophilic-hydrophobic region on substrate; dropping a polypeptide or protein solution onto the patterning surface prepared by the above step, naturally drying at room temperature to obtain dried sample points; dropping a substrate solution onto the above dried sample points, and naturally drying at room temperature and forming uniform cocrystallization of the sample and substrates on the patterning surface, so as to realize the concentration and demineralization purification treatment of biological samples. By the use of the patterning surface constructed in the invention, in MALDI-TOF MS detection, signal noise ratio, sensitivity and salt tolerance are significantly improved. The method has a great practical application value.

Owner:JILIN UNIV

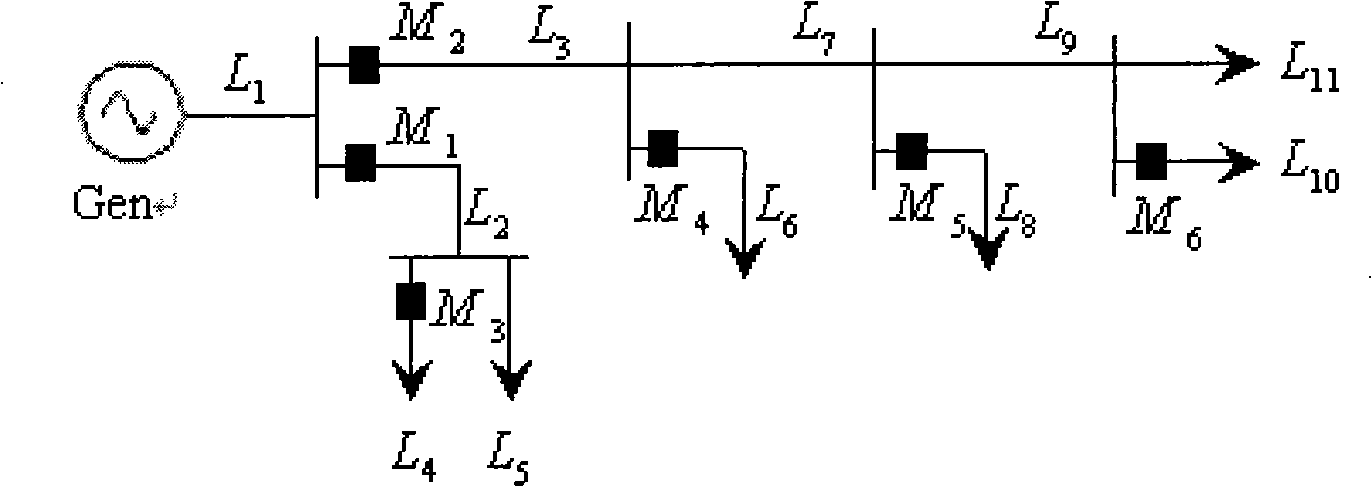

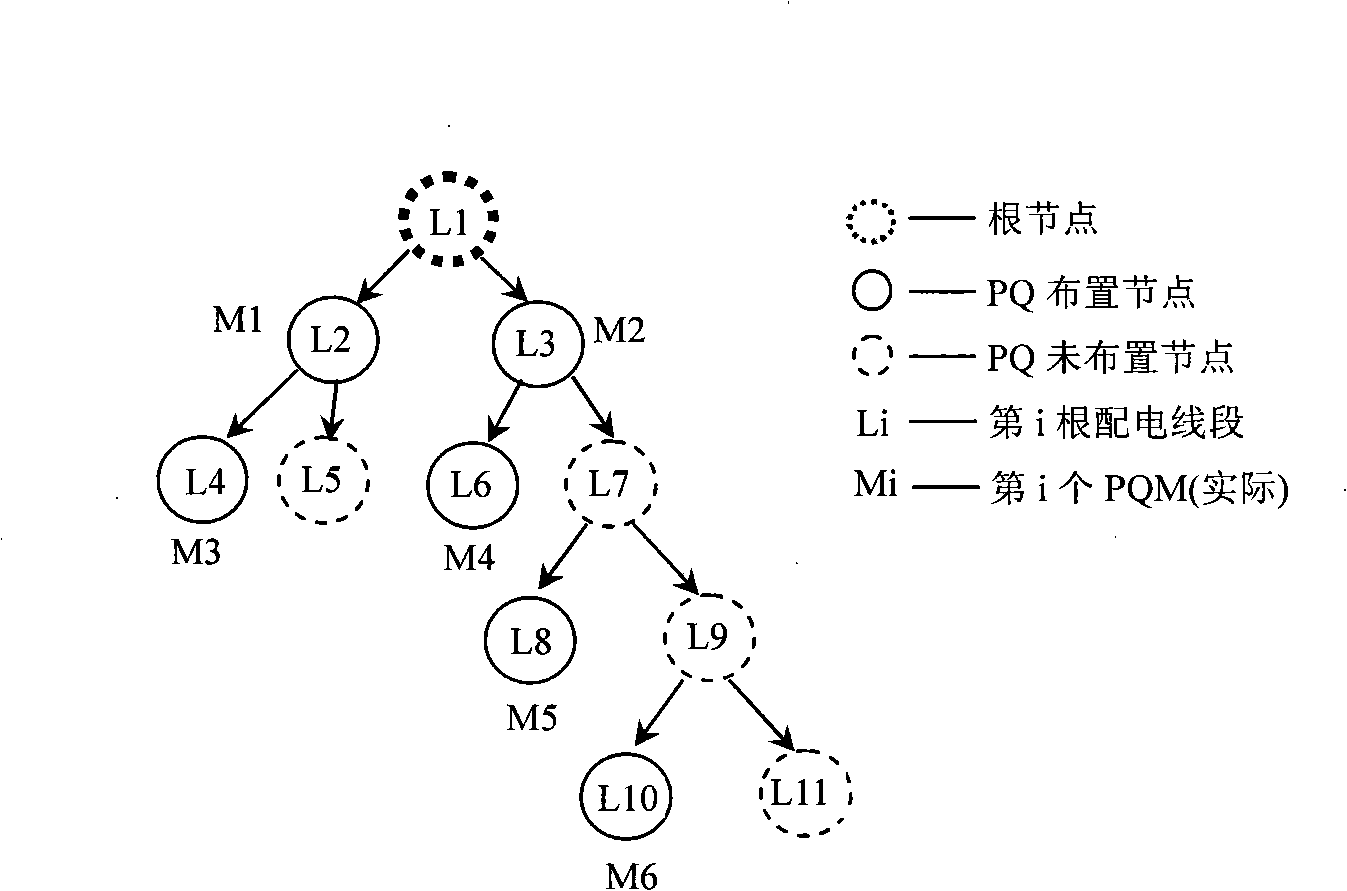

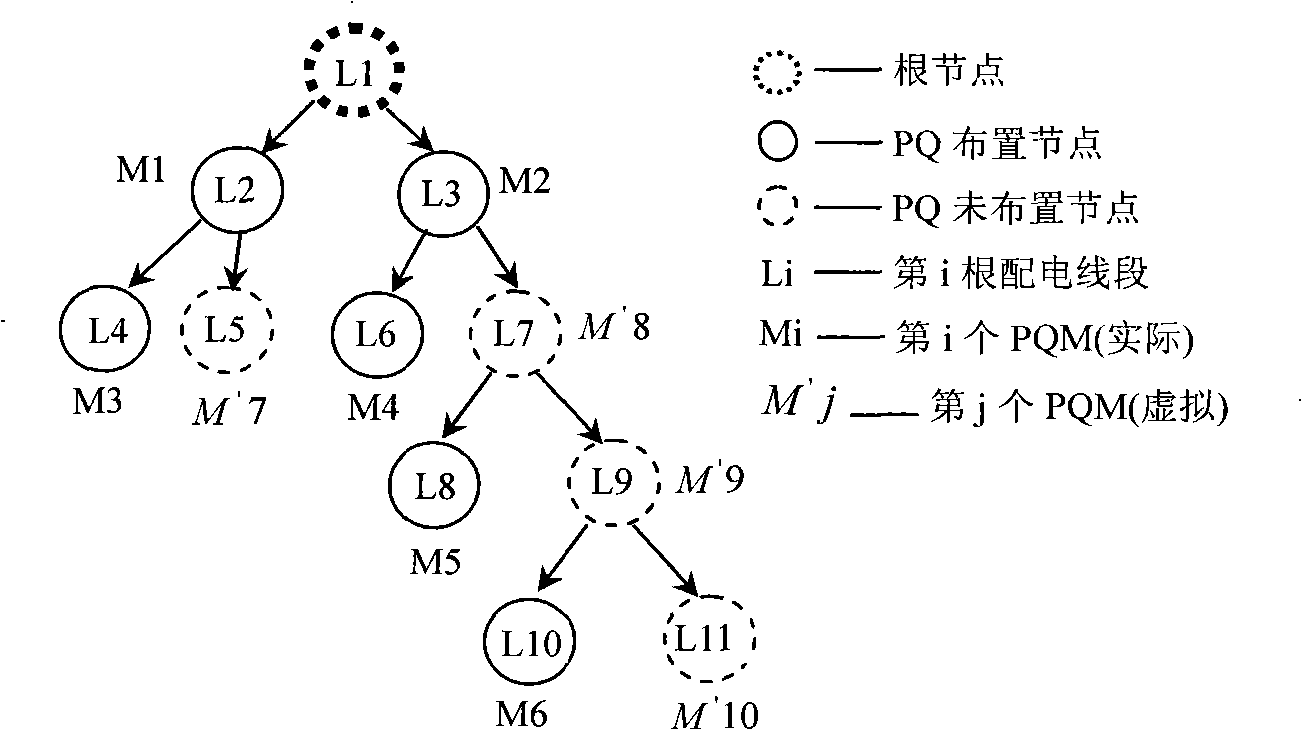

An automatic method for power quality interference source of distribution grid

InactiveCN101267116AEasy programmingPrecise positioningElectrical testingAc network circuit arrangementsPower qualityElectric power distribution

The present invention provides an automatic location method of distribution network power quality disturbance source, including: (A) constructing a network power quality monitor system in the distribution network; (B) constructing a rooted tree of the distribution system according to the topology of the distribution network; (C) establishing a system covering matrix according to the position relation between each node of the rooted tree and the each power quality monitor device; (D) establishing a system direction matrix according to the judging result of disturbance direction of each PQM when the disturbance is happened; (E) processing primary disturbance source location operation according to the system cover matrix and the system direction matrix. The invention provides a disturbance source location by itself, a disturbance source location method of the distribution network power quality having high efficiency.

Owner:ZHEJIANG UNIV OF TECH

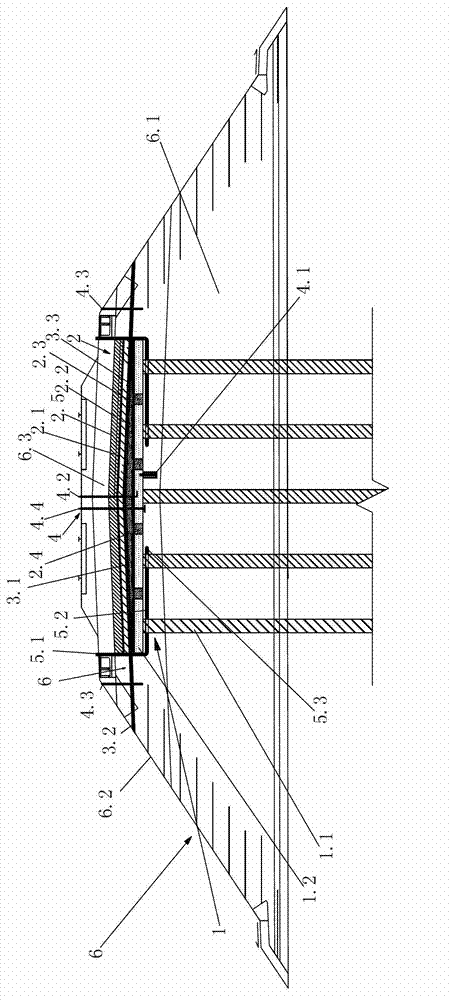

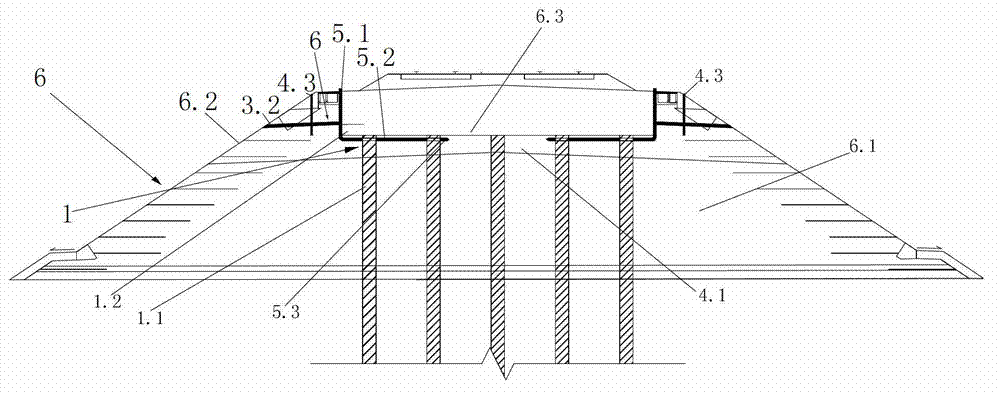

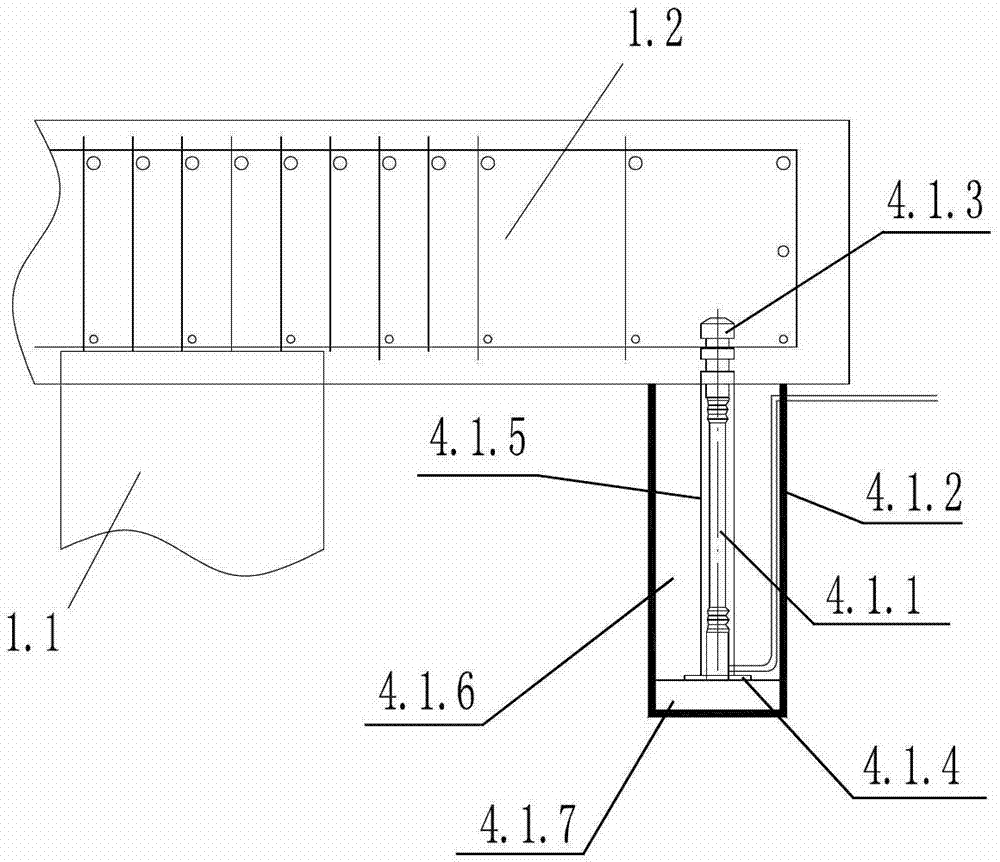

Reinforcement method and reinforcement structure for treating railway soft soil roadbed settlement overweight before operation

ActiveCN102926304AReduce damageThe construction period of the main structure is shortRoadwaysFoundation testingOverweightObservation system

The invention discloses a reinforcement method and a reinforcement structure for treating railway soft soil roadbed settlement overweight before operation. The reinforcement structure mainly consists of five parts, namely a main bearing structure system, a reinforced cushion layer structure system, a foundation bed drainage system, a settlement observation system and a reserved grouting system. The technical problems that the existing roadbed is greatly damaged, the construction period is long, the construction property is low, the quality is difficult to control and the problem that the soft soil roadbed settlement overweight is caused in the conventional technical scheme are effectively solved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Process for smelting and lower-pressure casting of aluminum alloy wheel hub

The invention discloses a process for the smelting and low-pressure casting of an aluminum alloy wheel hub, which comprises: 1, putting an aluminum alloy smelting material into a smelting furnace for smelting, and when the temperature in the smelting furnace reaches 740 to 760 DEG C, introducing nitrogen into the smelting furnace to blow a refining agent into the body of the furnace for refining;2, transferring the molten aluminum alloy to a tundish from the liquid outlet of the smelting furnace, adding an Al-Sr intermediate alloy, mischmetal (Re) and an Al-Zr intermediate alloy into the tundish to perform modification and refinement treatment under a condition of a temperature of 710 to 730 DEG C, and blowing nitrogen to the tundish to perform secondary degassing of the molten aluminum alloy; 3, transferring the molten aluminum alloy in the tundish to a casting holding furnace, adding a slag decomposing agent into the holding furnace to remove slag and blowing nitrogen into the holding furnace to perform tertiary degassing; and 4, pressing the molten aluminum alloy into a mold by a method of prepressing, pressure stabilizing, pressurizing and pressure keeping to perform casting.The process can effectively discharge slag and degas, has excellent modification and refinement effects and contributes to improvement in product quality.

Owner:ZHEJIANG ZENT AUTO WHEEL

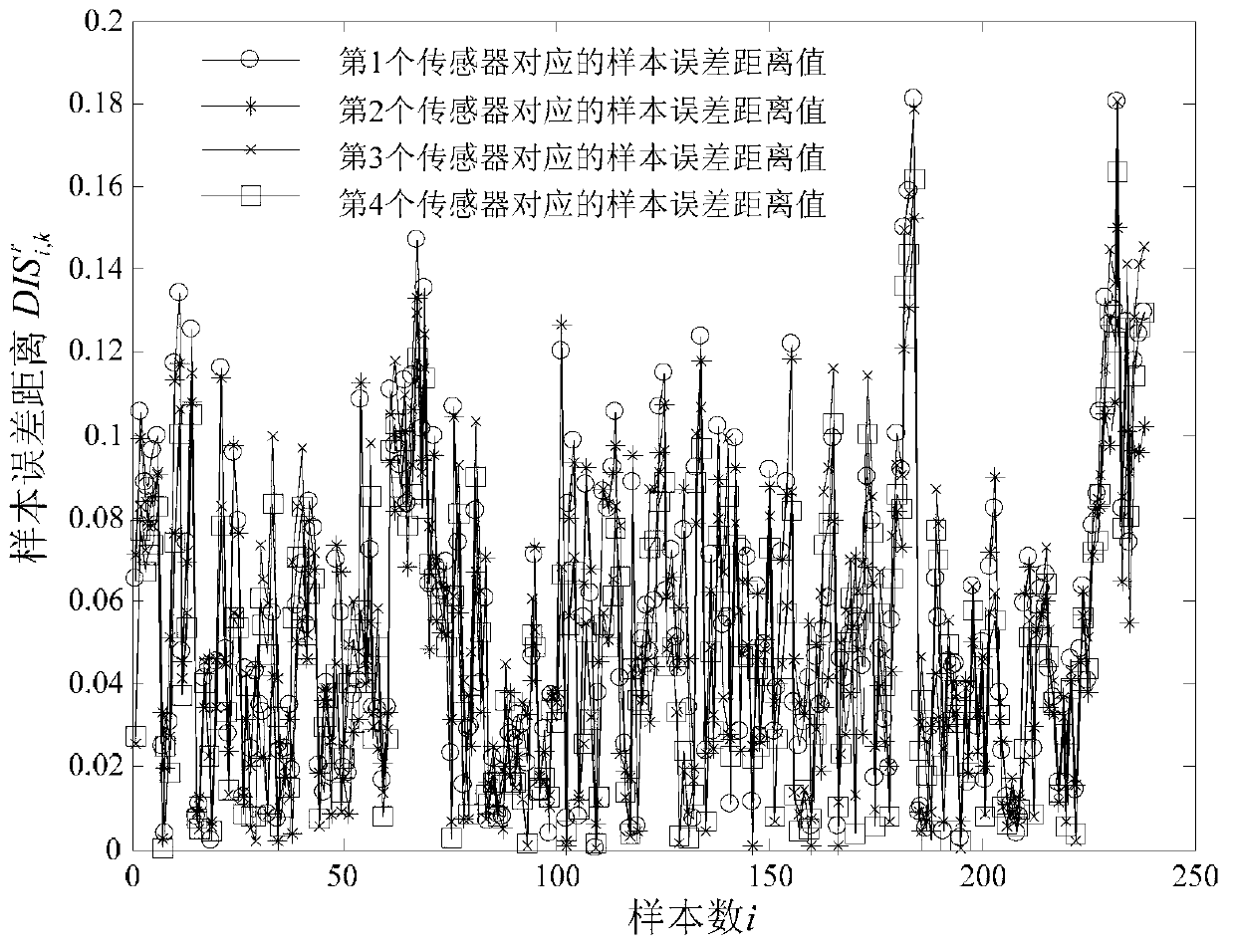

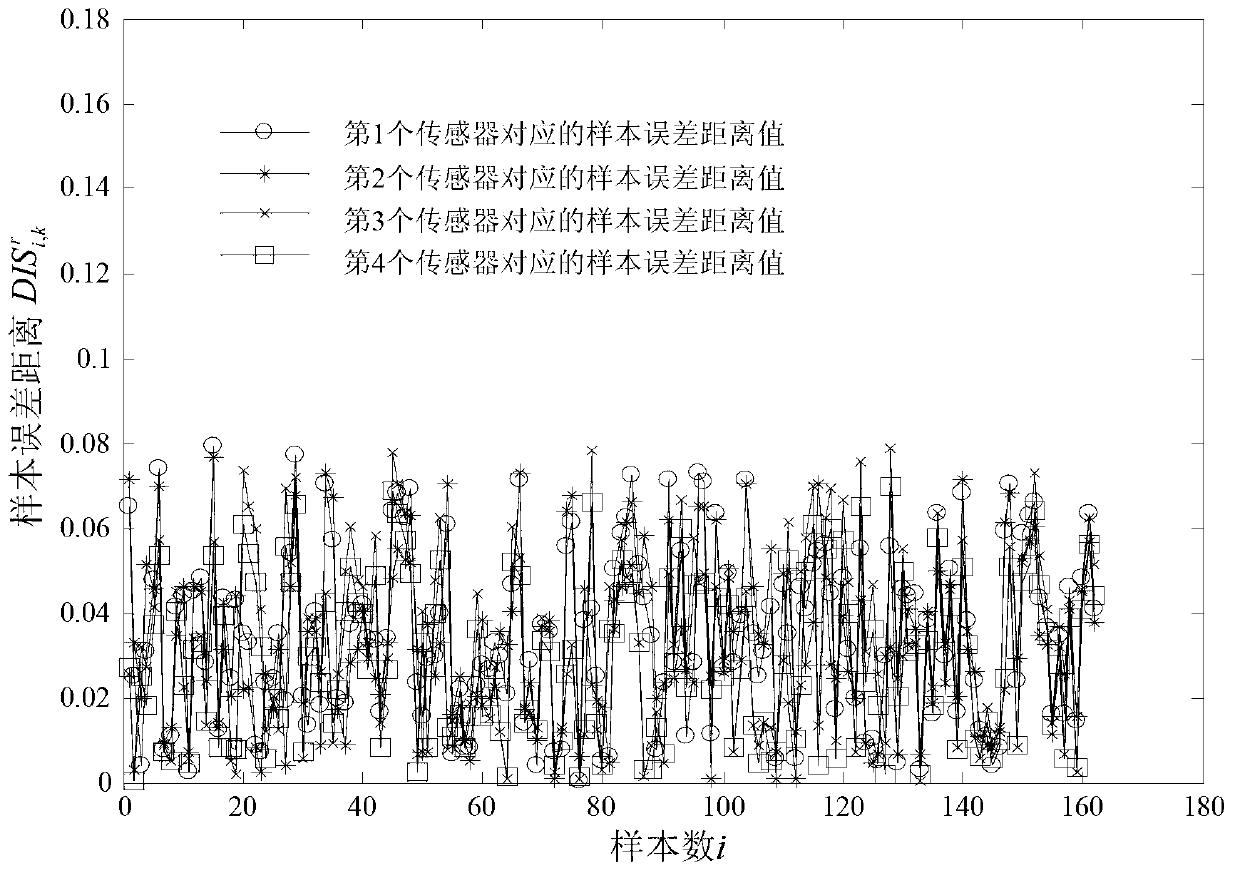

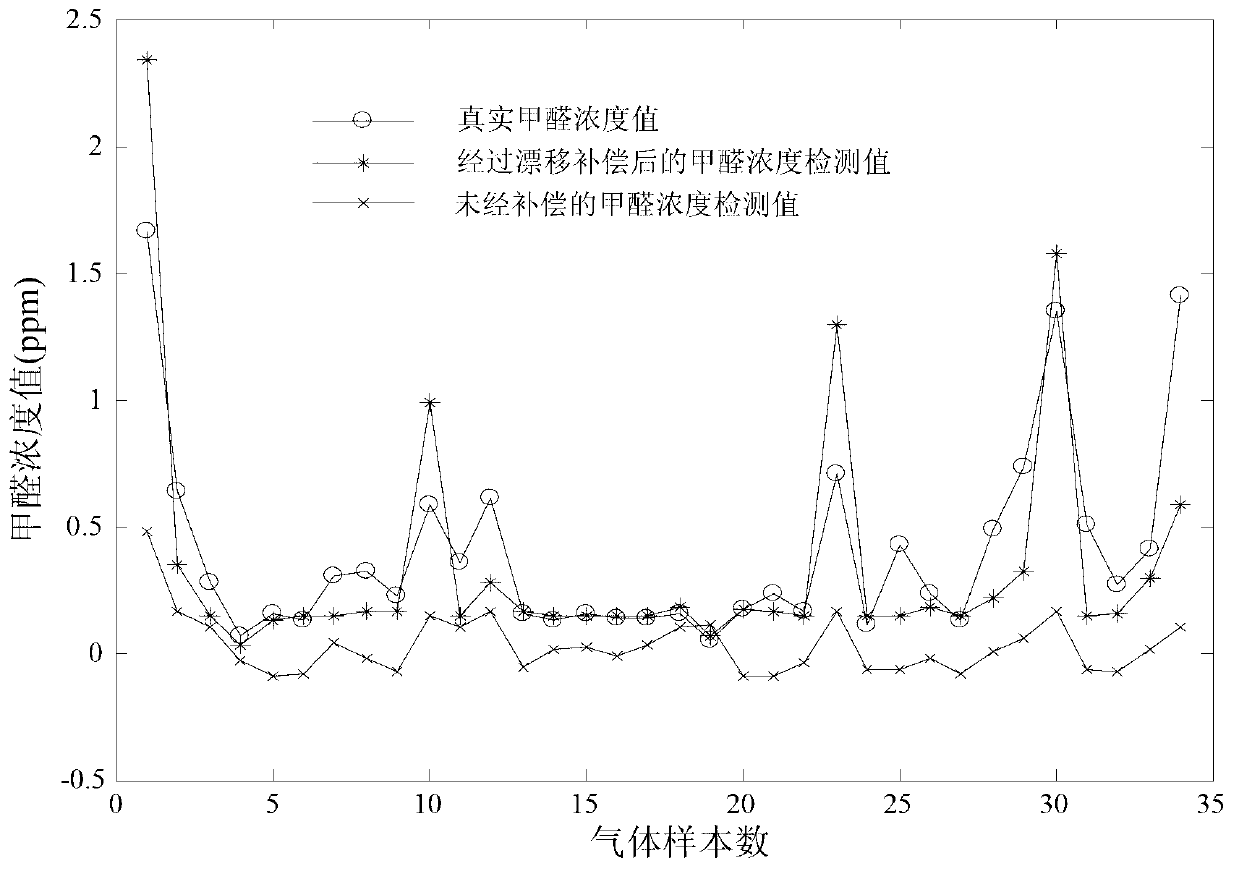

Metal-oxide gas sensor array concentration detecting method based on drift compensation

ActiveCN102944583AGuaranteed accuracyImprove estimation accuracyMaterial resistanceSensor arrayIndependent component analysis

The invention provides a metal-oxide gas sensor array concentration detecting method based on drift compensation. According to the method, the independent component analysis is utilized, the influence of abnormal values caused by the environment temperature, the environment humidity and environment factors to the drifting regulation and the drifting quantity estimation is shielded, the law that a independent concentration component changes along with the time drifting under the condition of base line responses is found out, subsequently, and when the concentration detection treatment on a gas sample is subjected to the concentration detection treatment by a metal-oxide gas sensor array, the drifting quantity of the concentration independent component is estimated by using the law that the independent concentration component changes along with the time drifting under the condition of the base line responses, so as to carry out drifting compensation on the independent concentration component in concentration detection response data; and the prediction calculation is carried out through using a concentration prediction function by virtue of the independent concentration component subjected to the drifting compensation in the concentration detection response data, so as to obtain a sensitive gas concentration detection result. The precision in estimating the drifting law and the drifting amount can be effectively improved, and the accuracy of concentration detection of the metal-oxide gas sensor array is ensured.

Owner:CHONGQING UNIV

Battery classifying method of retired electric cars

The invention provides a battery classifying method of retired electric cars. The method comprises the steps that power batteries are subject to self-discharging detection, voltage drop-out value of the power batteries is obtained, and materials of the power batteries are combined for judging whether the power batteries meet the first echelon utilization requirement or not; the power batteries are subject to performance detection, the capacity retention ratio of the power batteries is obtained, and according to the capacity retention ratio, whether the power batteries meet the second echelon utilization requirement or not is judged; the power batteries are subject to temperature rise effect detection, the temperature rise amplitude of the power batteries is obtained, and according to the temperature rise amplitude, whether the power batteries meet the third echelon utilization requirement or not is judged; and according to the battery parameter threshold value range of the application condition of the power batteries, the application method of the power batteries is determined. According to the method, the batteries with the high potential safety hazard can be rapidly and effectively removed, the threshold value range of parameters of the retired power batteries applied under different conditions is determined, and the safety of the batteries in the application process is improved.

Owner:STATE GRID CORP OF CHINA +3

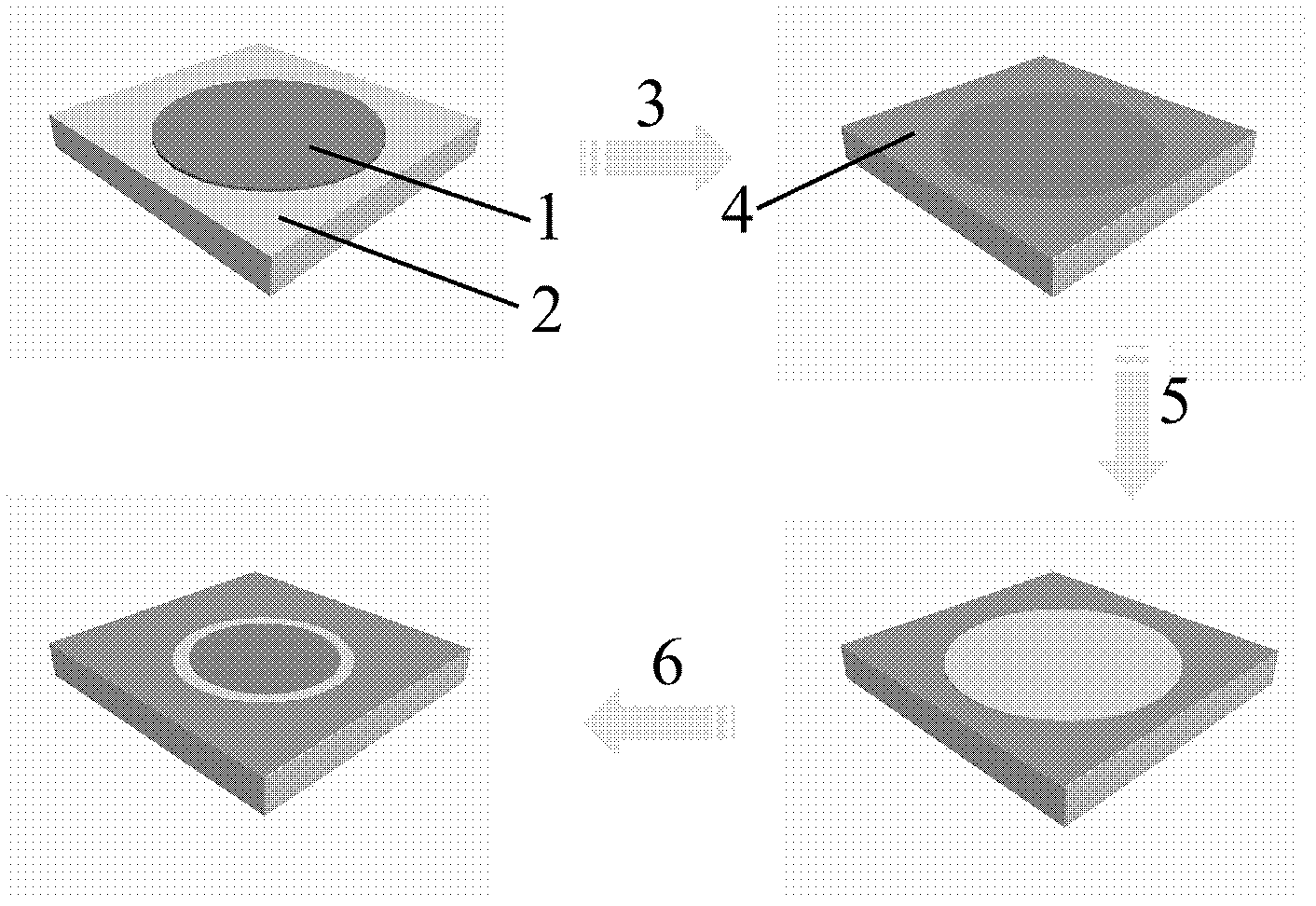

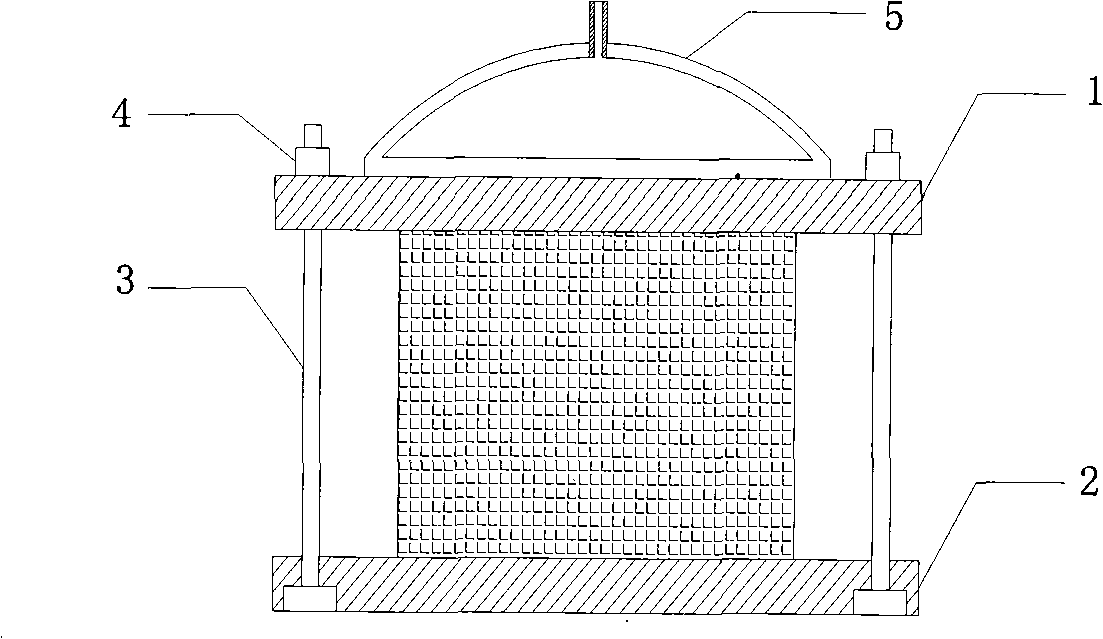

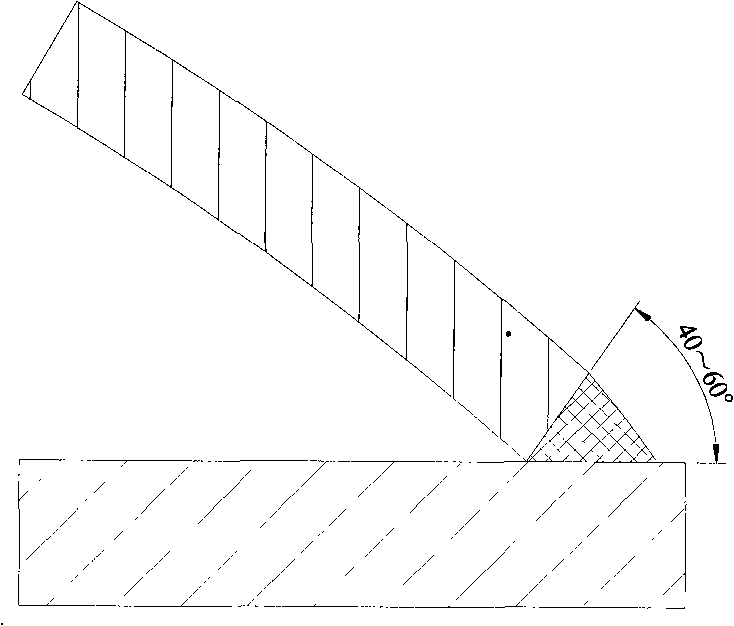

Stainless steel plate fin type heat exchanger core body high-temperature brazing jig and manufacturing process thereof

InactiveCN101301714ADiffuse fullyFit closelyWelding/cutting auxillary devicesArc welding apparatusPlate fin heat exchangerMaterials science

The invention relates to a clamp used for high-temperature brazing of a stainless steel plate fin-typed heat exchanger core, which is characterized in that the clamp consists of an upper clamping plate (1), a lower clamping plate (2), a bolt (3), a nut (4) and a pressure vessel (5), wherein, the bolt (3) and the nut (4) are used for clamping the upper clamping plate (1) and the lower clamping plate (2); the core of the stainless steel plate fin-typed heat exchanger is placed between the upper clamping plate (1) and the lower clamping plate (2); the pressure vessel (5) is directly and flatly placed on the upper clamping plate (1); the vessel is internally filled with argon which expands under the high temperature and generates uniform pressure so as to lead the equipment elements of the core to be closely contacted with each other and ensure the welding quality of the core of the fin-typed heat exchanger. The clamp of the invention can meet the manufacture requirement of the core of the stainless steel plate tin-typed heat exchanger, generates uniform pressure under high temperature and greatly improves the qualified rate of the products.

Owner:NANJING UNIV OF TECH

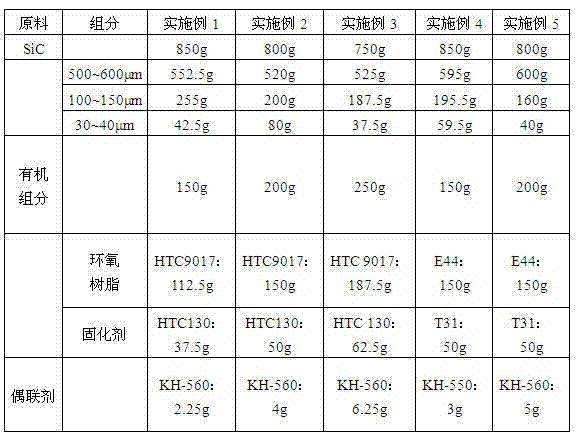

SiC/epoxy resin composite material and method for manufacturing pump components with it

ActiveCN102408677AImproved erosion and wear resistanceClosely arrangedPump componentsPumpsEpoxyEpoxy resin composite

The invention discloses a SiC / epoxy epoxy resin composite material, wherein raw material components based on weight percentages are as follows: 75-85 wt% of SiC particles, 15-25 wt% of organic component and coupling agent with a mass of 1.5-2.5% of the organic component; the particle size distributions of the SiC particles are as follows: 500-600 microns taking up 65-75 wt%, 100-150 microns taking up 2-30 wt% and 30-40 microns taking up 5-10wt%; the organic component is composed of epoxy resin and curing agent; the mass ratio of the epoxy resin to the curing agent is 3: 1. A preparation method for pump component with SiC / epoxy epoxy resin composite material, comprising the following steps: (1), heating and stirring in vacuum way; (2), pressure pouring; (3), vacuum vibrating and forming; (4), heating and curing. The invention is characterized by simple technology and low production cost. The prepared SiC / epoxy epoxy resin composite material pump component can resist abrasion and corrosion.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

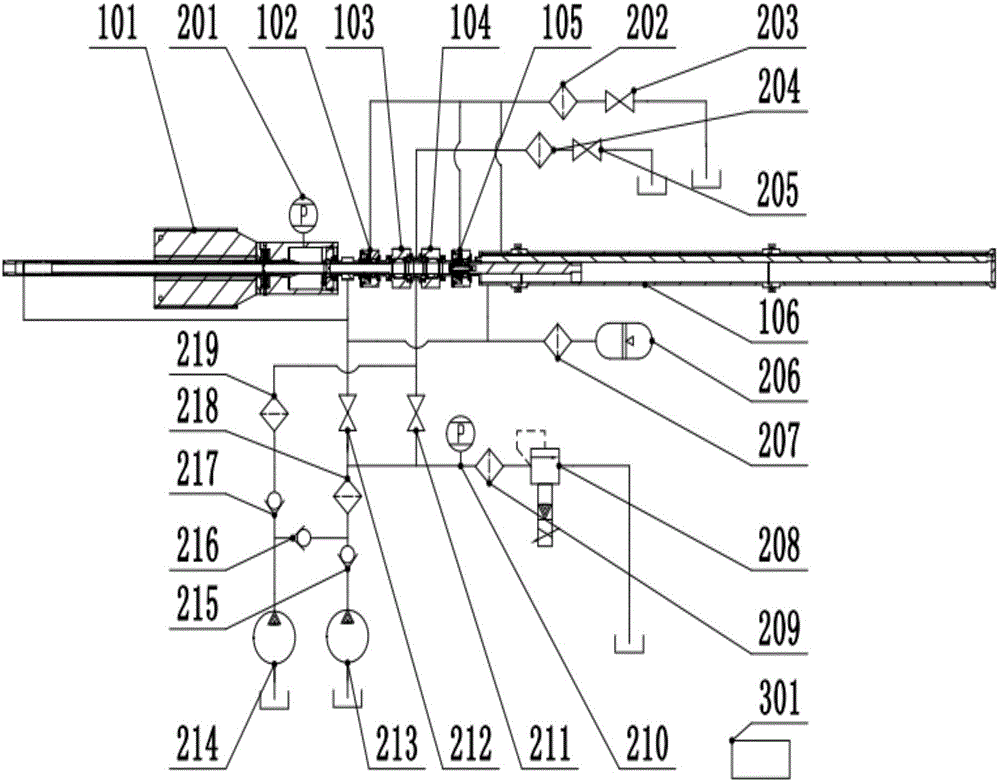

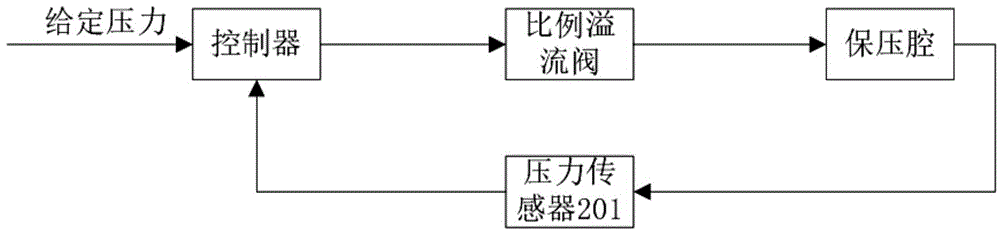

Pressure-regulating and pressure-retaining system for pressure-retained transferring of deep-sea sediments and control method of pressure-regulating and pressure-retaining system

ActiveCN104535395AAutomatic adjustment of overflow pressureTo achieve the purpose of maintaining pressurePreparing sample for investigationInternal pressureCommunicating vessels

The invention relates to the technical field of hydraulic transmission and aims to provide a pressure-regulating and pressure-retaining system for pressure-retained transferring of deep-sea sediments and a control method of the pressure-regulating and pressure-retaining system. The pressure-regulating and pressure-retaining system for pressure-retained transferring of the deep-sea sediments comprises a low-pressure pump, a high-pressure pump, check valves, filters, pressure sensors, stop valves, an energy accumulator and a proportional overflow valve. The control method is used for realizing a pressure-retained transferring process of a pressure-retained transferring device and comprises the processes of a pressurizing and pressure-retaining process of the pressure-retained transferring device, a pressurizing and pressure-retaining process of a subsample transferring cylinder, and a process of mounting a communicating vessel between ball valves I and II and pressurizing. According to the pressure-regulating and pressure-retaining system, a deep-sea environment at any depth can be simulated within a specialized range, the pressure in a deep-sea sediment sampler can be measured through the pressure sensor I and the overflow pressure of the pressure-retained transferring device can be automatically adjusted, so that the pressure in the pressure-retained transferring device and the pressure in the sampler are consistent and the purpose of pressure retaining is achieved.

Owner:ZHEJIANG UNIV

Water-base metal antirusting agent and preparation method thereof

InactiveCN101660148AThe mechanism of action is simple and scientificImprove rust resistanceMetallic material coating processesTriethanolamineBenzotriazole

The invention relates to a water-base metal antirusting agent and a preparation method thereof. The antirusting agent comprises the components by weight percentage of 1-3% of dicarboxylic acid, 3-4% of triethanolamine, 0.5-1% of monoethanolamine, 5-10% of synthesized borate, 3-10% of polyethylene glycol, 1-3% of antiseptic, 0.1-1% of benzotriazole and the balance of water. The preparation method mainly comprises the following steps of: firstly preparing an antirusting agent body and subsequently adding and mixing the antiseptic, the polyethylene glycol, benzotriazole and the like, thus preparing the antirusting agent. In the invention, the action mechanism is simple and scientific, the cleaning and antirusting effect achieves the best by the cooperative function of all components; the antirusting agent contains the antiseptic that can effectively prevent the antirusting agent from cankering during the memory and working process, the polyethylene glycol can help forming film so that theantirusting agent has good water-repellent function and the antirusting capability can be effectively improved.

Owner:华阳新兴科技(天津)集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com