Patents

Literature

741results about How to "Diffuse fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Delivery of therapeutic biologicals from implantable tissue matrices

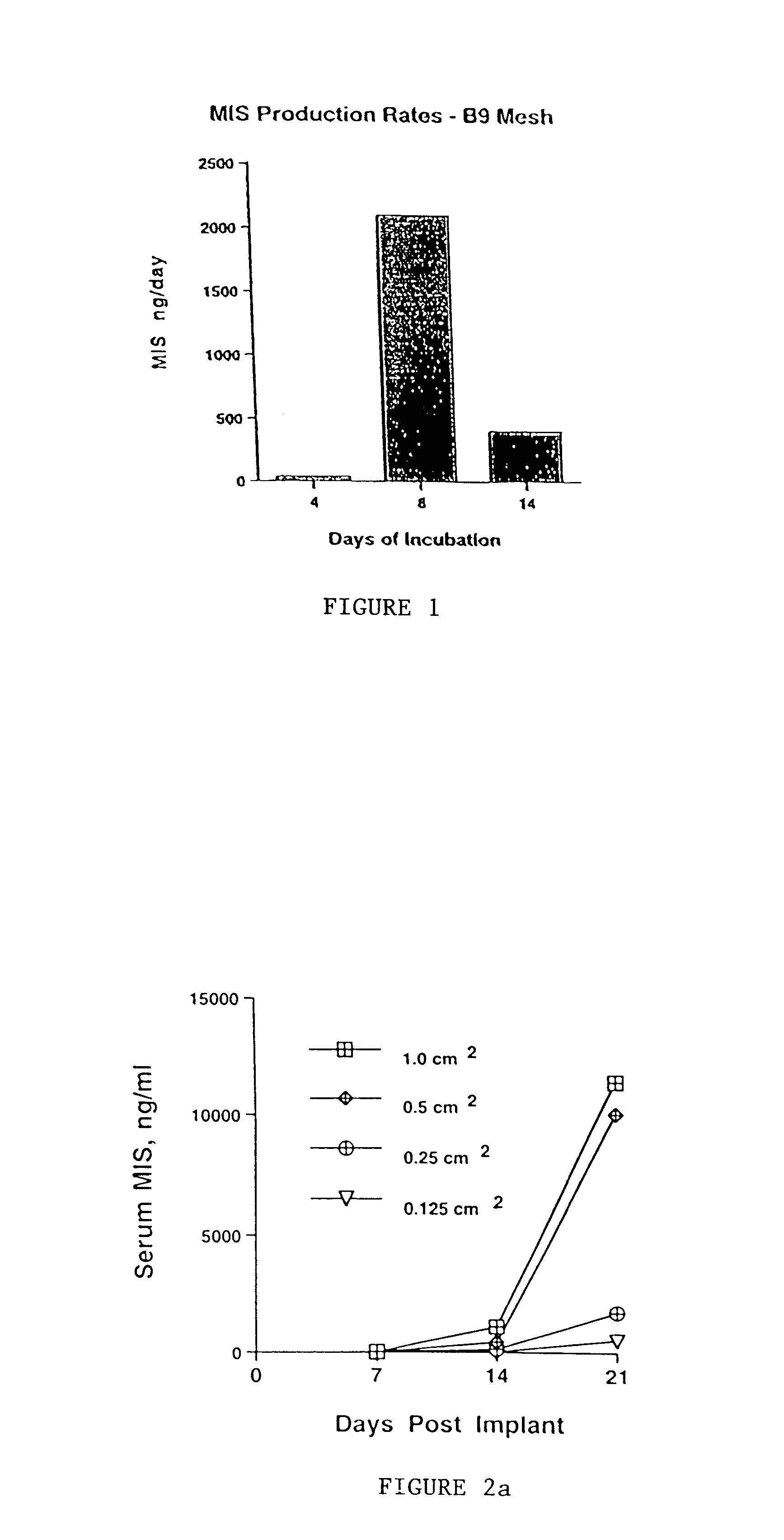

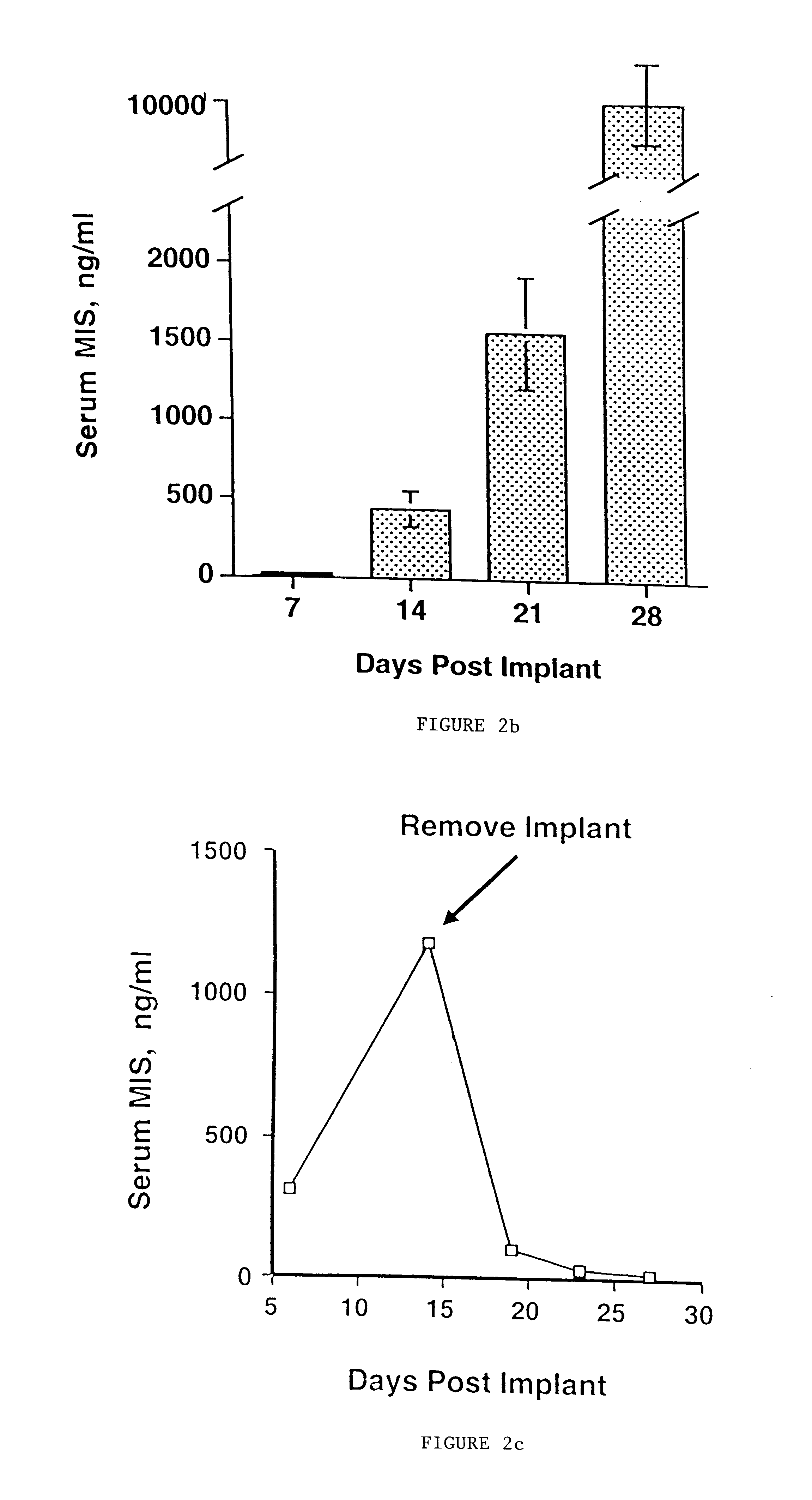

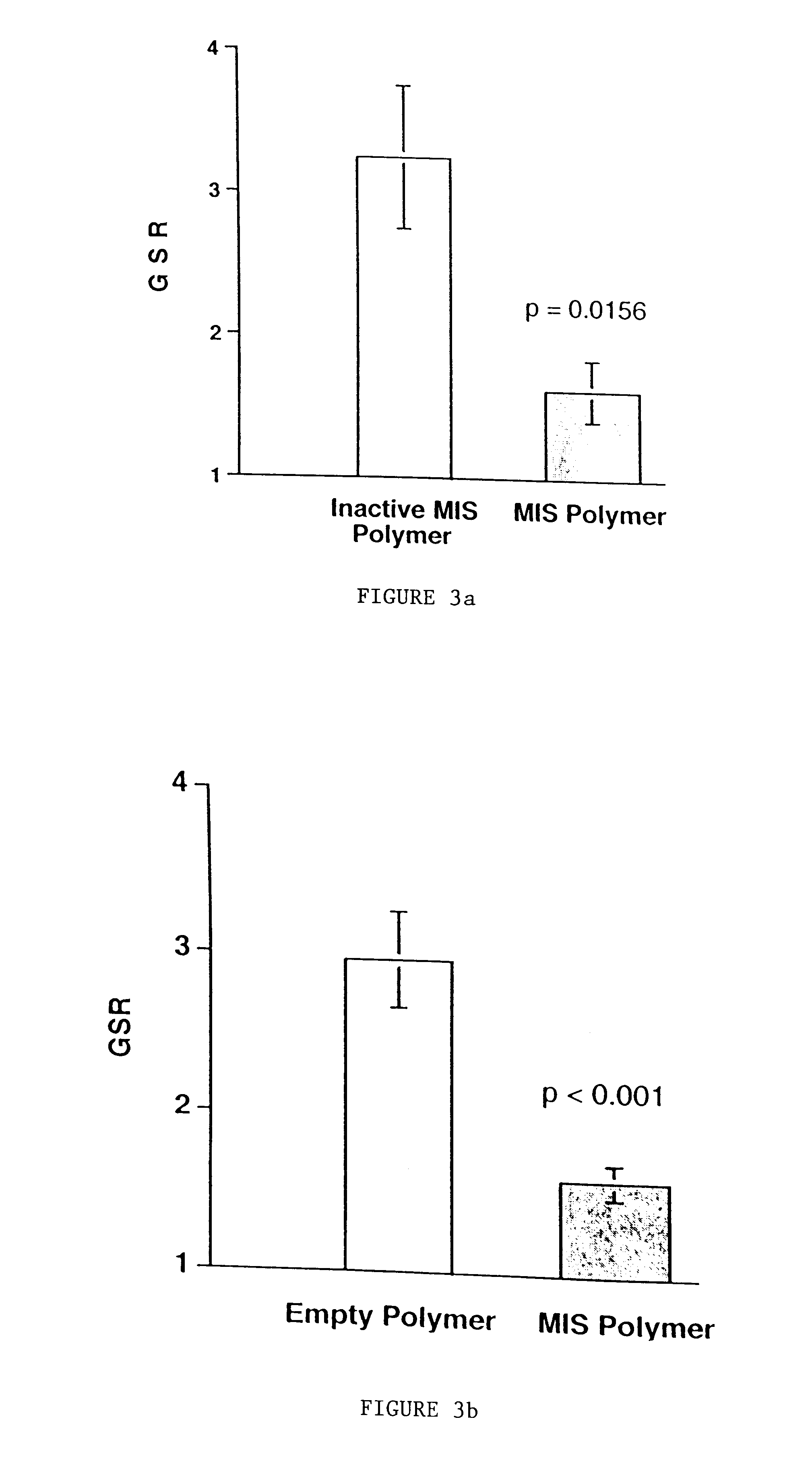

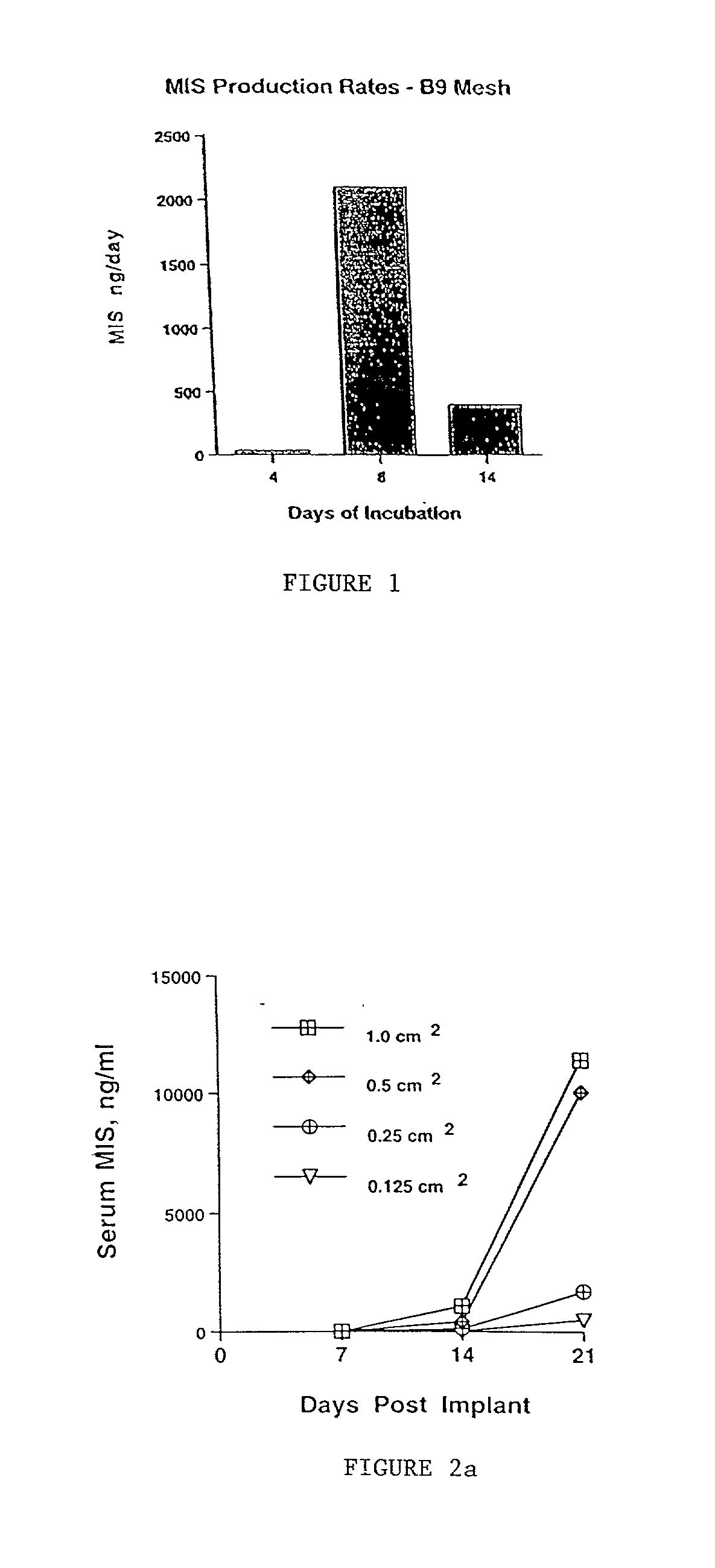

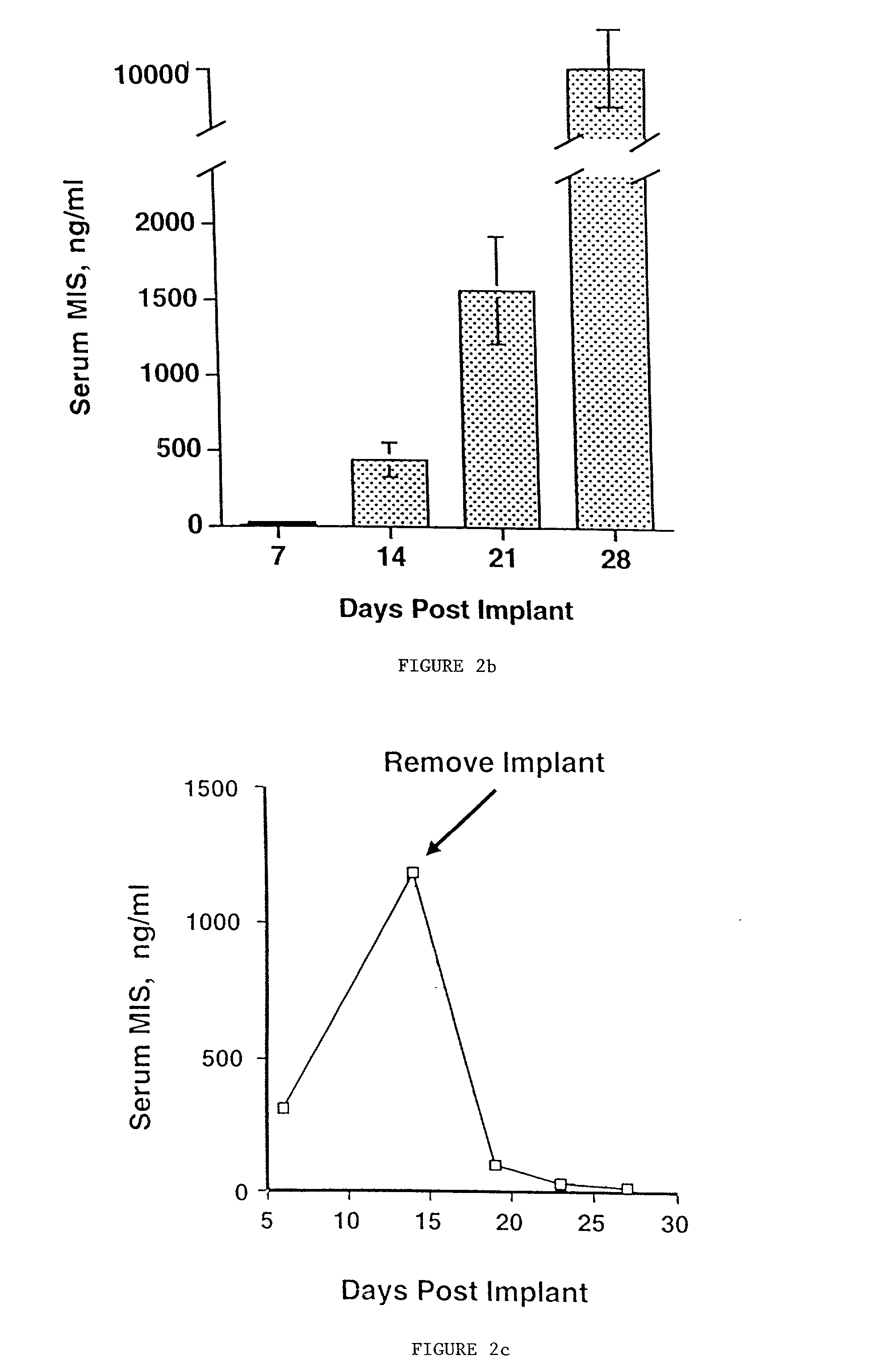

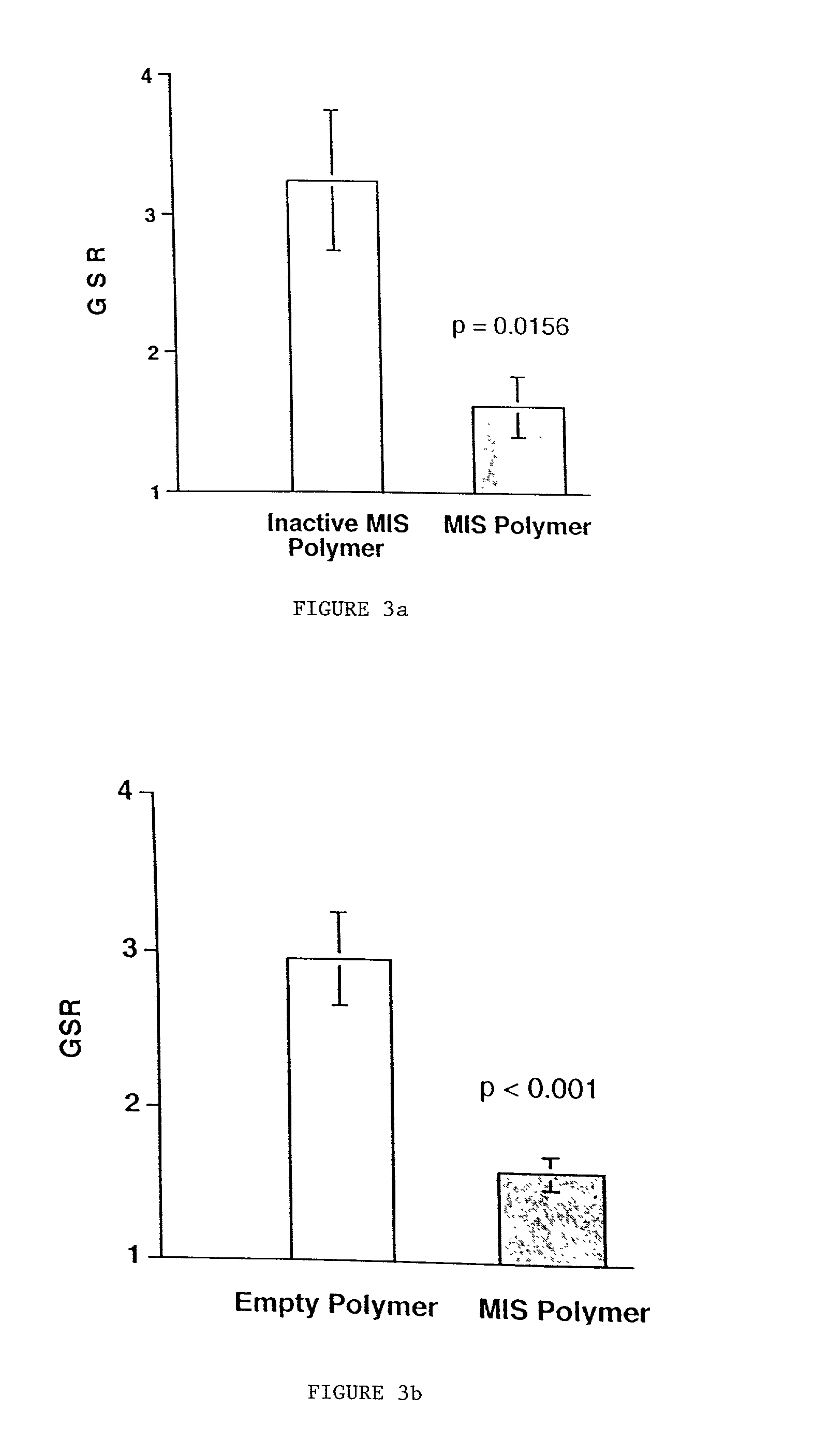

Normal cells, such as fibroblasts or other tissue or organ cell types, are genetically engineered to express biologically active, therapeutic agents, such as proteins that are normally produced in small amounts, for example, MIS, or other members of the TGF-beta family Herceptin(TM), interferons, andanti-angiogenic factors. These cells are seeded into a matrix for implantation into the patient to be treated. Cells may also be engineered to include a lethal gene, so that implanted cells can be destroyed once treatment is completed. Cells can be implanted in a variety of different matrices. In a preferred embodiment, these matrices are implantable and biodegradable over a period of time equal to or less than the expected period of treatment, when cells engraft to form a functional tissue producing the desired biologically active agent. Implantation may be ectopic or in some cases orthotopic. Representative cell types include tissue specific cells, progenitor cells, and stem cells. Matrices can be formed of synthetic or natural materials, by chemical coupling at the time of implantation, using standard techniques for formation of fibrous matrices from polymeric fibers, and using micromachining or microfabrication techniques. These devices and strategies are used as delivery systems via standard or minimally invasive implantation techniques for any number of parenterally deliverable recombinant proteins, particularly those that are difficult to produce in large amounts and / or active forms using conventional methods of purification, for the treatment of a variety of conditions that produce abnormal growth, including treatment of malignant and benign neoplasias, vascular malformations (hemangiomas), inflammatory conditions, keloid formation, abdominal or plural adhesions, endometriosis, congenital or endocrine abnormalities, and other conditions that can produce abnormal growth such as infection. Efficacy of treatment with the therapeutic biologicals is detected by determining specific criteria, for example, cessation of cell proliferation, regression of abnormal tissue, or cell death, or expression of genes or proteins reflecting the above.

Owner:THE GENERAL HOSPITAL CORP

Delivery of therapeutic biologicals from implantable tissue matrices

InactiveUS20020031500A1Many of effectMany of inconveniencePowder deliveryBiocideProgenitorActive agent

Normal cells, such as fibroblasts or other tissue or organ cell types, are genetically engineered to express biologically active, therapeutic agents, such as proteins that are normally produced in small amounts, for example, MIS, or other members of the TGF-beta family Herceptin(TM), interferons, andanti-angiogenic factors. These cells are seeded into a matrix for implantation into the patient to be treated. Cells may also be engineered to include a lethal gene, so that implanted cells can be destroyed once treatment is completed. Cells can be implanted in a variety of different matrices. In a preferred embodiment, these matrices are implantable and biodegradable over a period of time equal to or less than the expected period of treatment, when cells engraft to form a functional tissue producing the desired biologically active agent. Implantation may be ectopic or in some cases orthotopic. Representative cell types include tissue specific cells, progenitor cells, and stem cells. Matrices can be formed of synthetic or natural materials, by chemical coupling at the time of implantation, using standard techniques for formation of fibrous matrices from polymeric fibers, and using micromachining or microfabrication techniques. These devices and strategies are used as delivery systems via standard or minimally invasive implantation techniques for any number of parenterally deliverable recombinant proteins, particularly those that are difficult to produce in large amounts and / or active forms using conventional methods of purification, for the treatment of a variety of conditions that produce abnormal growth, including treatment of malignant and benign neoplasias, vascular malformations (hemangiomas), inflammatory conditions, keloid formation, abdominal or plural adhesions, endometriosis, congenital or endocrine abnormalities, and other conditions that can produce abnormal growth such as infection. Efficacy of treatment with the therapeutic biologicals is detected by determining specific criteria, for example, cessation of cell proliferation, regression of abnormal tissue, or cell death, or expression of genes or proteins reflecting the above.

Owner:THE GENERAL HOSPITAL CORP

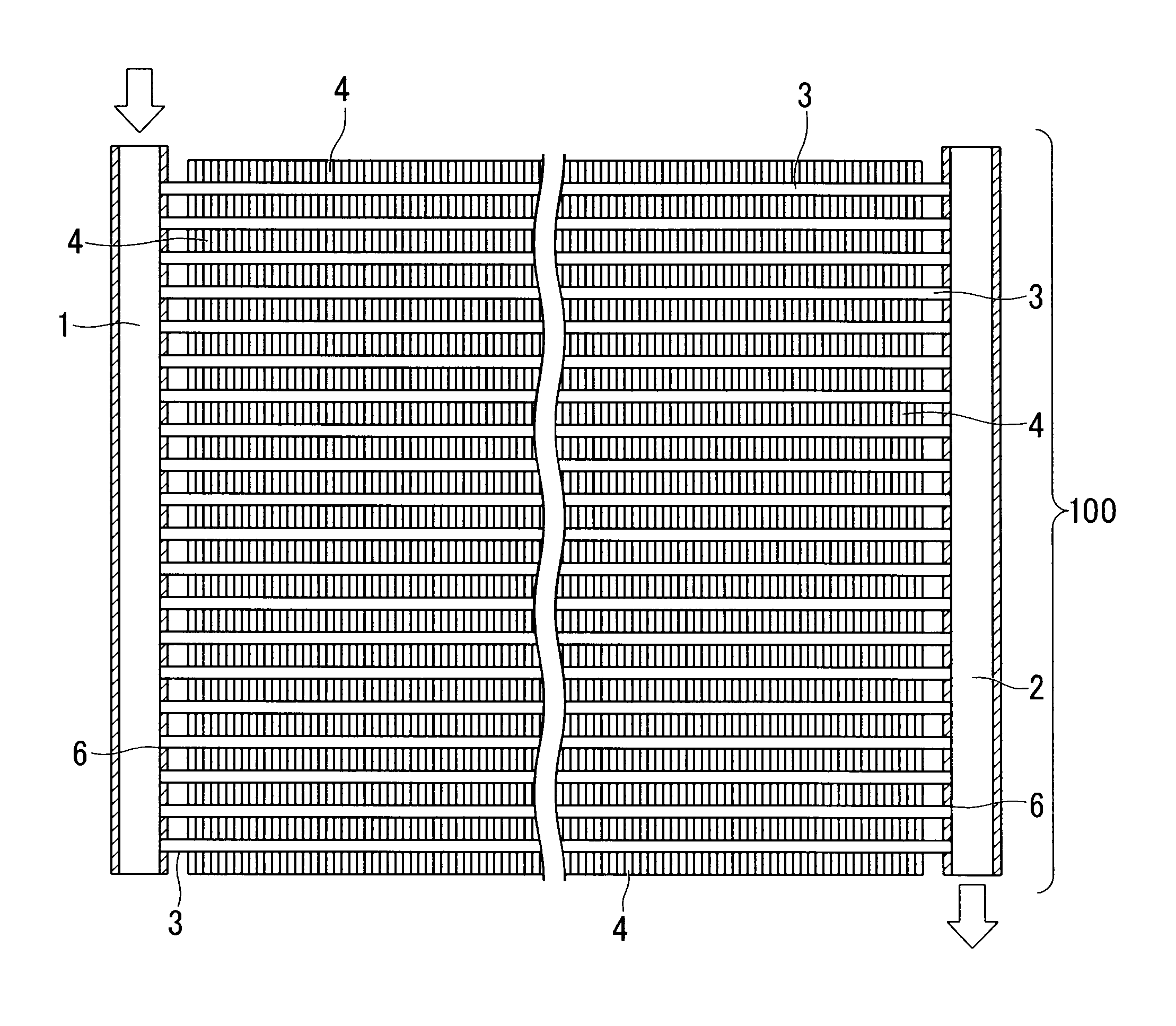

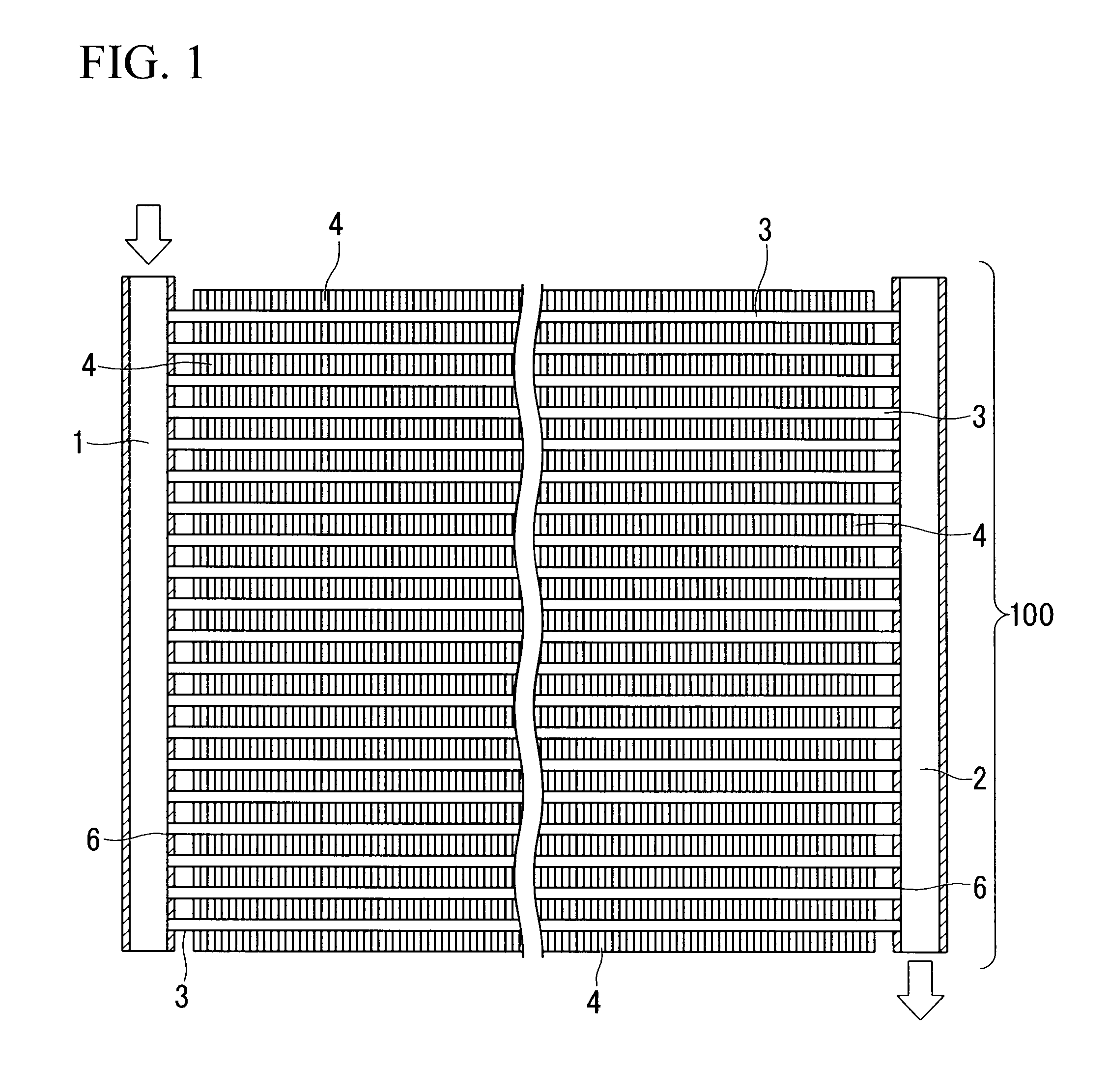

Heat exchanger made of aluminum alloy and method of producing same

InactiveUS20100051247A1Suppression of progressionSuppress separationSoldering apparatusStationary conduit assembliesCorrosionBrazing

A heat exchanger comprising a tube, a fin, and a header pipe, wherein the tube contains, in mass %, 0.15 to 0.45% of Mn, 0.20 to 0.50% of Si, and the balance of Al and unavoidable impurities, and is coated with a coating of brazing composition containing 1.0 to 5.0 g / m2 of Si powder, 4.0 to 10.0 g / m2 of KZnF3, and 0.5 to 3.0 g / m2 of binder; the fin contains, in mass %, 1.20 to 1.80% of Zn, 0.70 to 1.20% of Si, 0.30 to 0.80% of Fe, 0.90 to 1.50% of Mn, one or two or more selected from 0.05 to 0.20% of Zr, 0.01 to 0.10% of V, and 0.01 to 0.10% of Cr, and the balance of Al and unavoidable impurities; and the header pipe comprises a core material, outer sacrificial corrosion protection material, and an inner brazing material.

Owner:CALSONIC KANSEI CORP +1

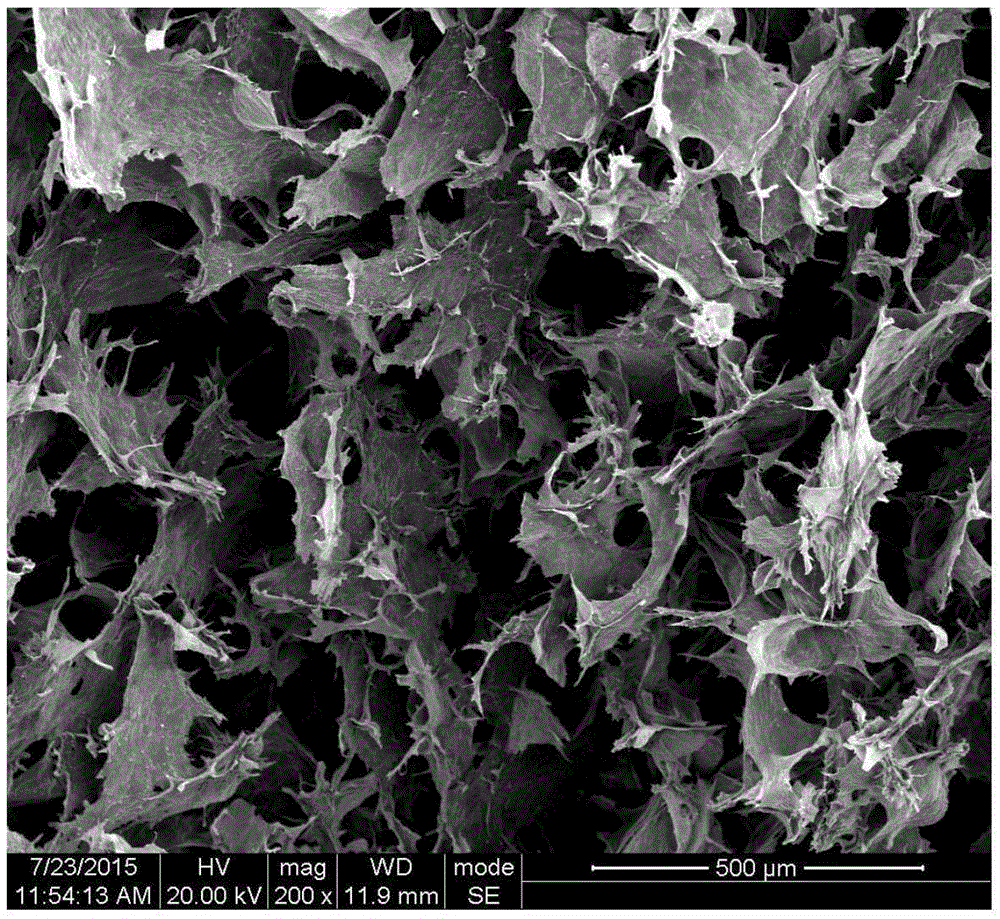

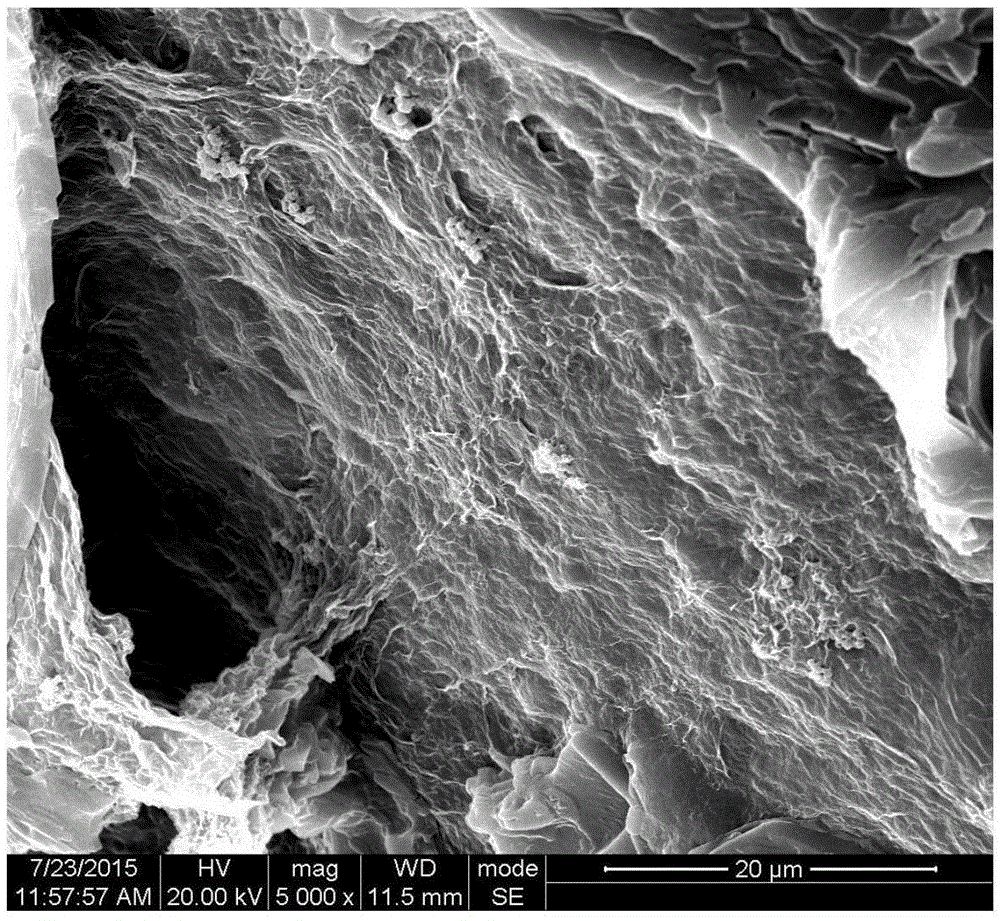

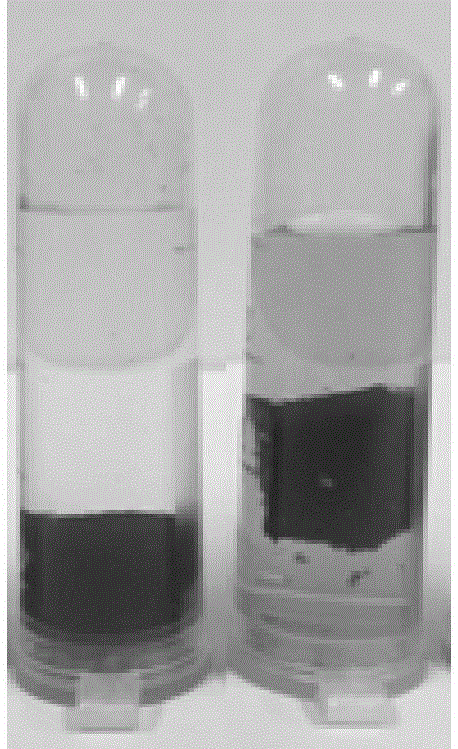

Preparation method for oxidized graphene-poly-dopamine composite aerogel

InactiveCN105254916AIntegrity guaranteedGuaranteed stabilityOther chemical processesAlkali metal oxides/hydroxidesPorosityFreeze-drying

The invention provides a preparation method for oxidized graphene-poly-dopamine composite aerogel. The preparation method comprises the following steps that 1, 0.15-0.7 g of dopamine powder is dissolved in 10-18 ml of distilled water, the dopamine aqueous solutions are mixed with 50-60 ml of oxidized graphene aqueous solutions with the concentration of 5-6 mg / ml, and stirring is performed to obtain oxidized graphene-dopamine mixed solutions; 2, 3-9 ml of tris aminomethane buffer solutions with the concentration of 0.1-0.12 mol / L are dropwise added into the mixed solutions while stirring is performed, stirring is continuously performed for 2-2.5 h, and standing is performed to enable the dopamine to be fully polymerized to obtain oxidized graphene-poly-dopamine composite aquogel; 3, after being placed in an environment with the temperature ranging from minus 20 DEG C to minus 10 DEG C to be frozen for 24-30 h, the composite aquogel is processed through freeze drying, and then the oxidized graphene-poly-dopamine composite aerogel is obtained. The method is simple in technology, and the prepared composite aerogel has the advantages of being high in porosity, excellent in adsorptivity, high in strength and the like.

Owner:SOUTHWEST JIAOTONG UNIV

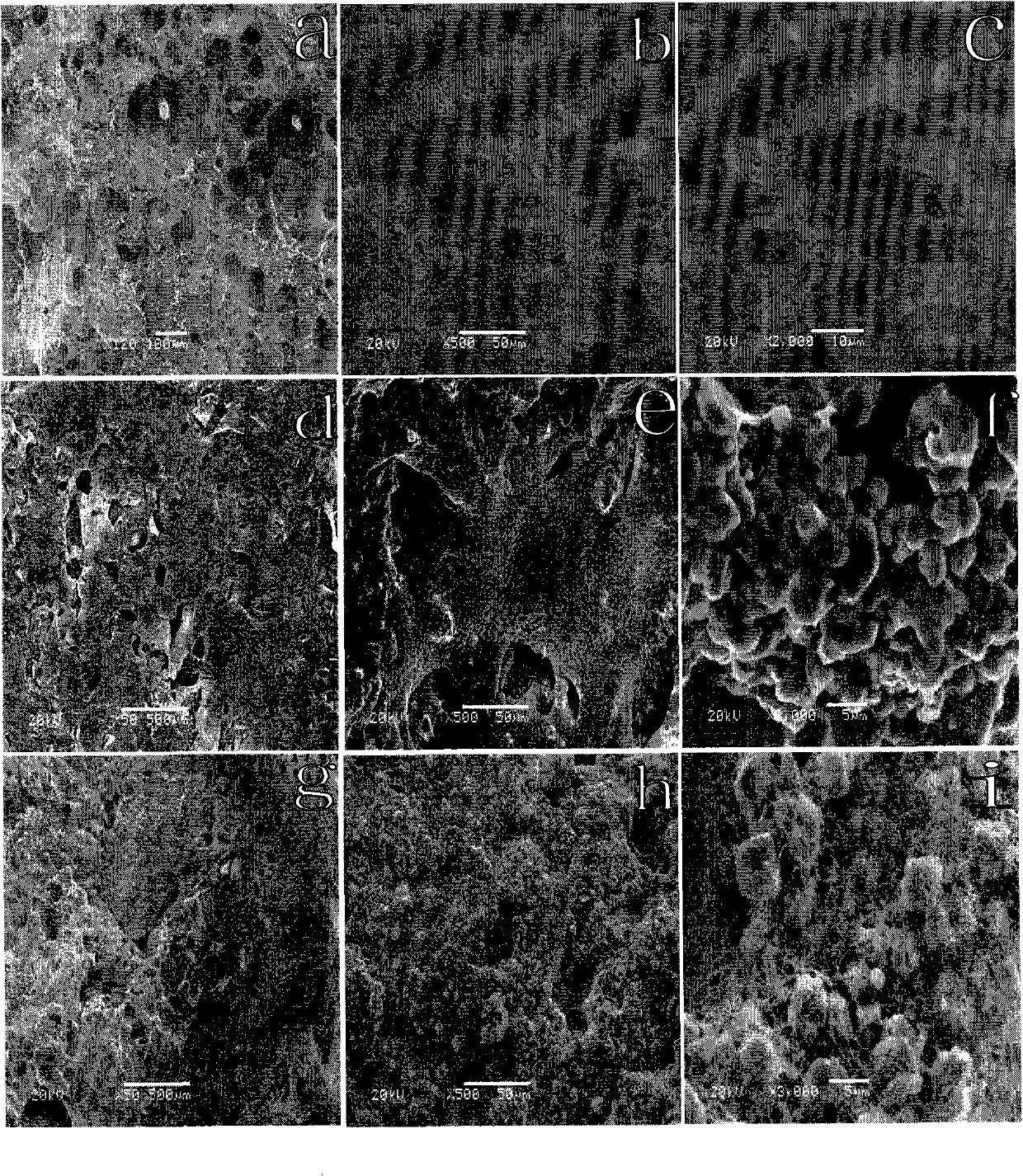

Preparation method of modified biologically-activated filter fillings

InactiveCN101948166APromote growthSpeed up the formation processSustainable biological treatmentBiological water/sewage treatmentNutrientSewage treatment

The invention relates to a preparation method of modified biologically-activated filter fillings, comprising the following steps of: (1) cleaning an inorganic carrier with the grain diameter of 3-8 millimetres, sequentially carrying out acid cleaning, alkaline cleaning and drying to obtain dry fillings; (2) adding the dry fillings to a metal salt solution to carry out soaking and ultraphonic, drying and sintering to obtain sintering charges; (3) naturally cooling and drying the sintering charges to obtain dry sintering charges; (4) adding the dry sintering charges to a polymeric hydrogel solution containing trace elements and nutrient salts, carrying out soaking and ultraphonic and reacting in a saturated boric acid solution or a 3% calcium chloride solution so as to obtain crosslinked fillings; and (5) drying and naturally cooling the crosslinked fillings so as to obtain the modified biologically-activated filter fillings. The invention has the advantages of simple process and easy implementation; and in addition, the obtained modified biologically-activated filter fillings can increase the activity and the number of biomembranes, shorten the membrane-forming periods of biological aerated filter fillings and enhance the sewage treatment efficiency and the stability of a biological aerated filter.

Owner:GANSU GOLDEN BRIDGE GRP CO LTD +1

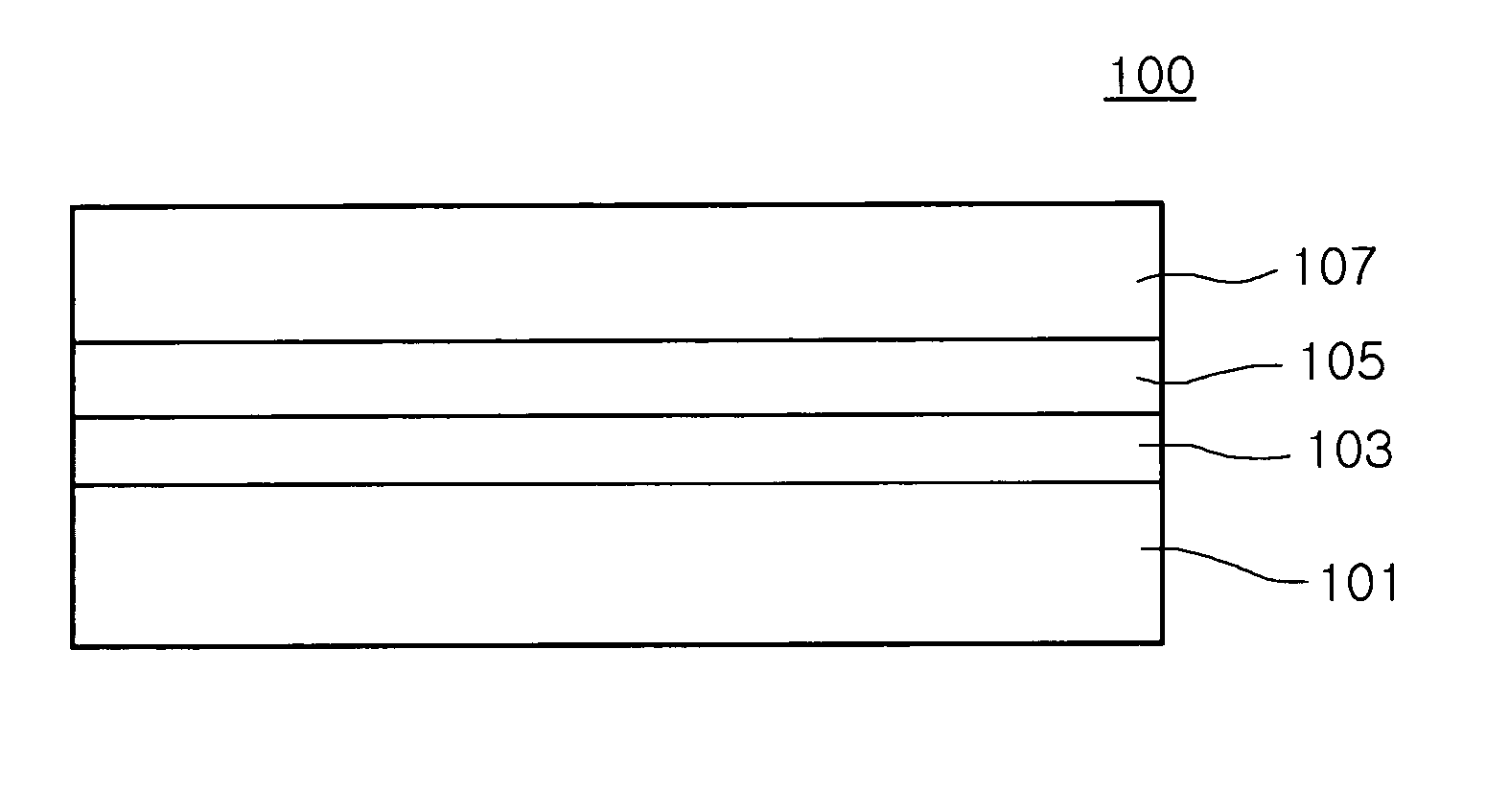

Method for manufacturing nitride-based semiconductor device

InactiveUS20060281205A1Quality improvementPromote growthSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialNucleation

In a method for manufacturing a high-quality GaN-based semiconductor layer on a substrate of different material, an AlN nucleation layer is grown on a substrate, a GaN buffer layer is grown on the AlN nucleation layer, and the substrate annealed. The AlN nucleation layer is formed to have a thickness greater than a critical radius of a nucleus of AlN crystal and less than a critical resilient thickness of AlN, and the GaN buffer layer is formed to have a thickness greater than a critical radius of a nucleus of GaN crystal and less than a critical resilient thickness of GaN. Annealing time is greater than L2 / DGa where L indicates a diffusion distance of Ga, and DGa indicates a diffusion coefficient of Ga in the AlN nucleation layer.

Owner:SAMSUNG ELECTRONICS CO LTD

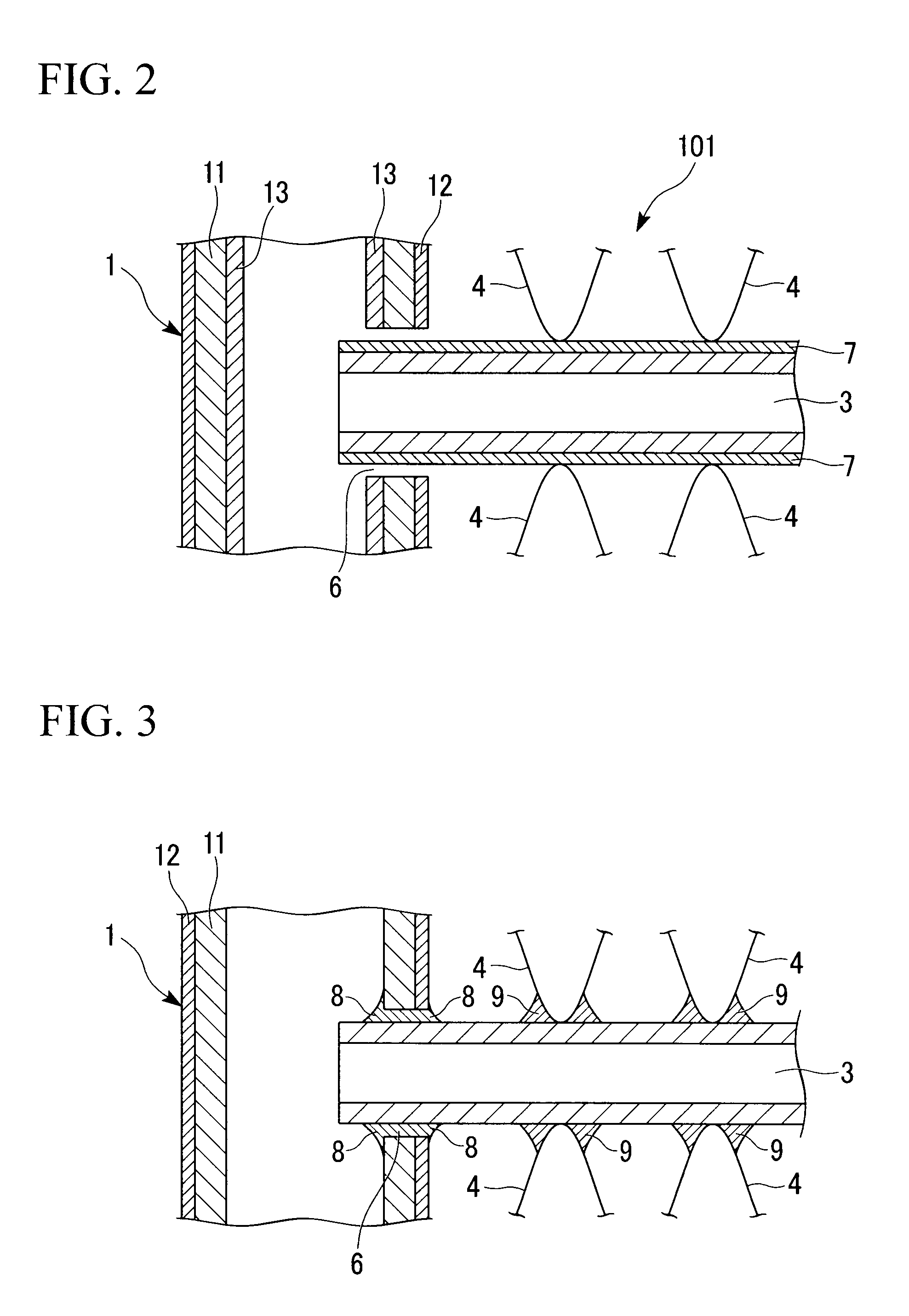

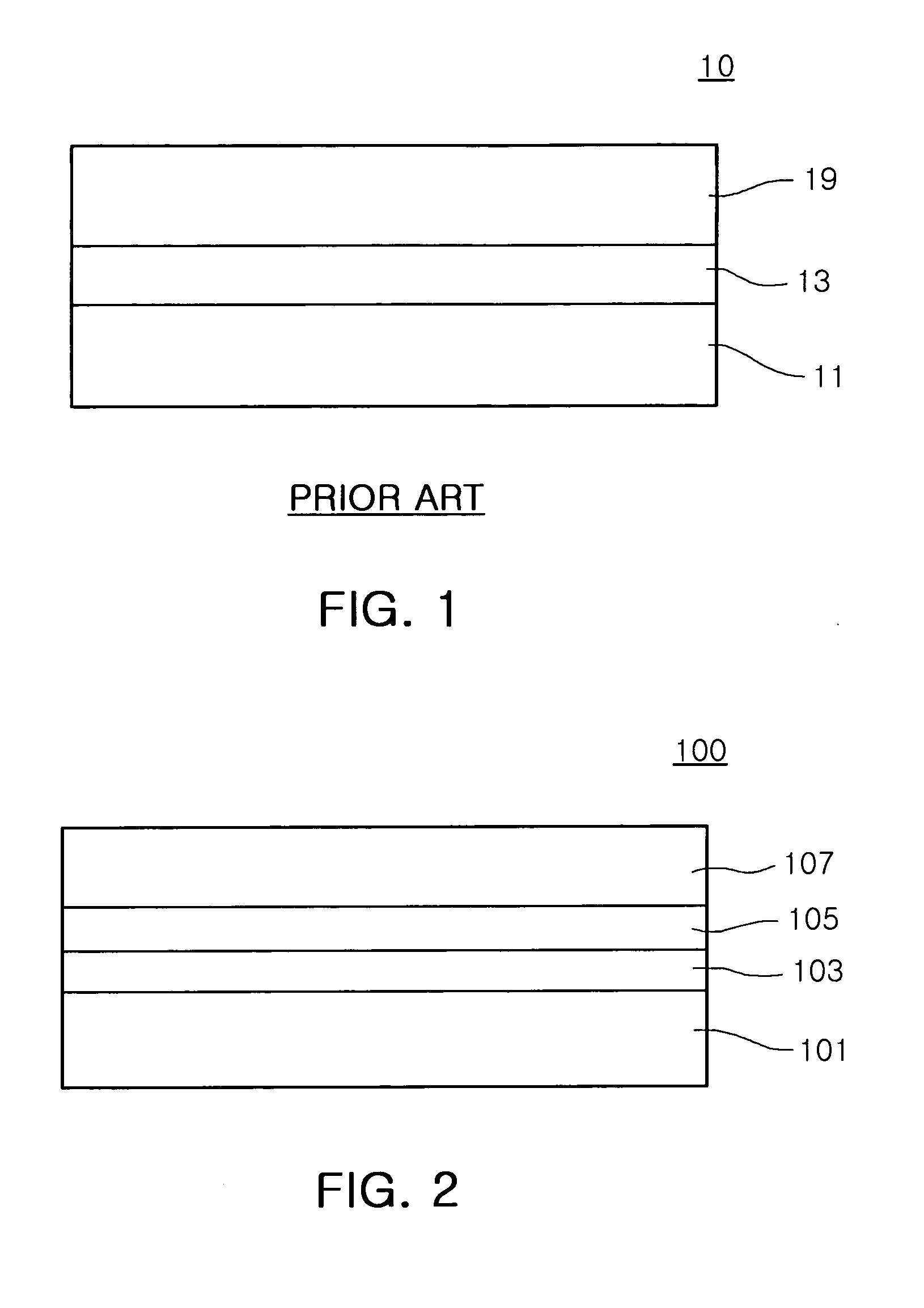

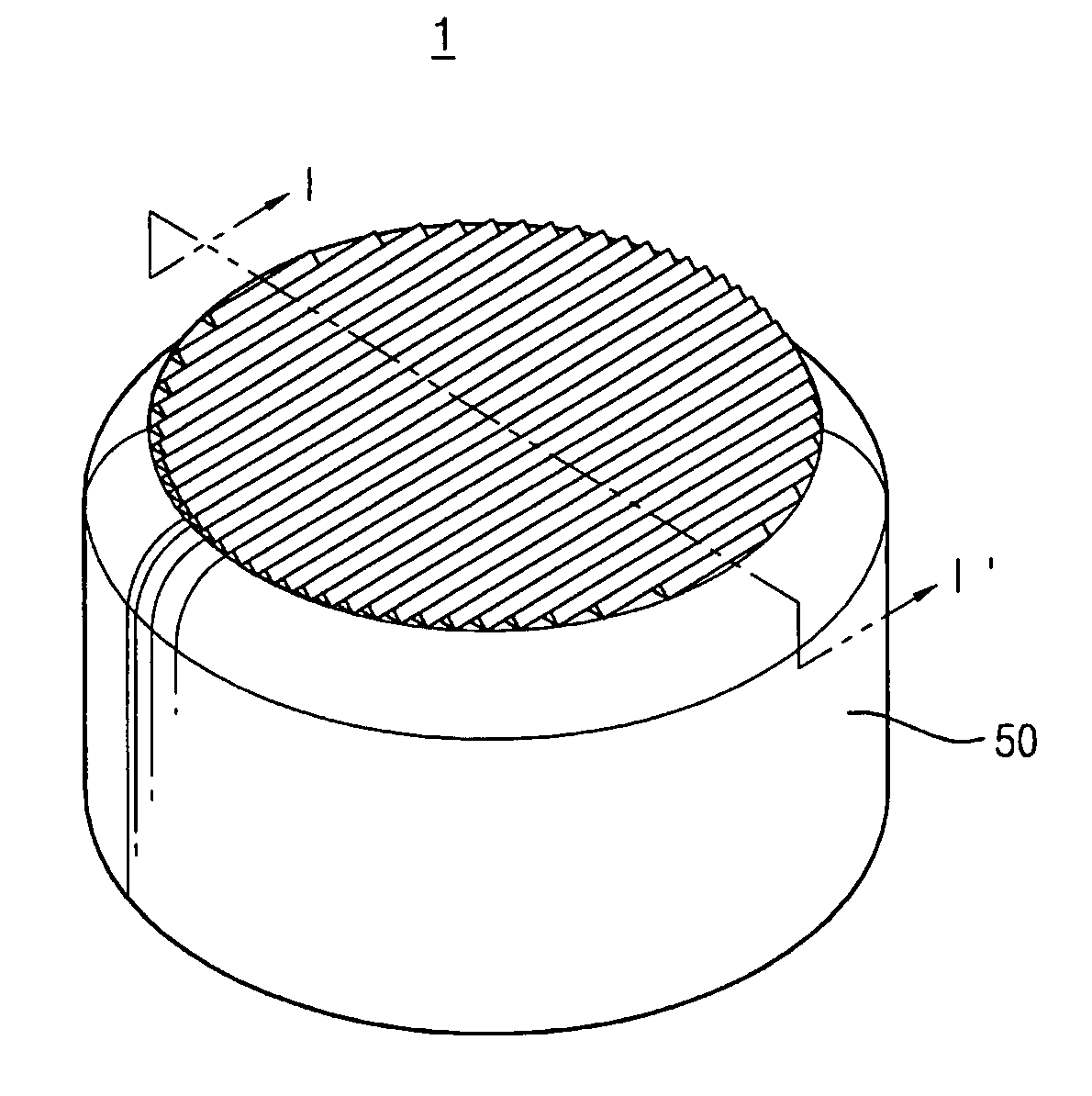

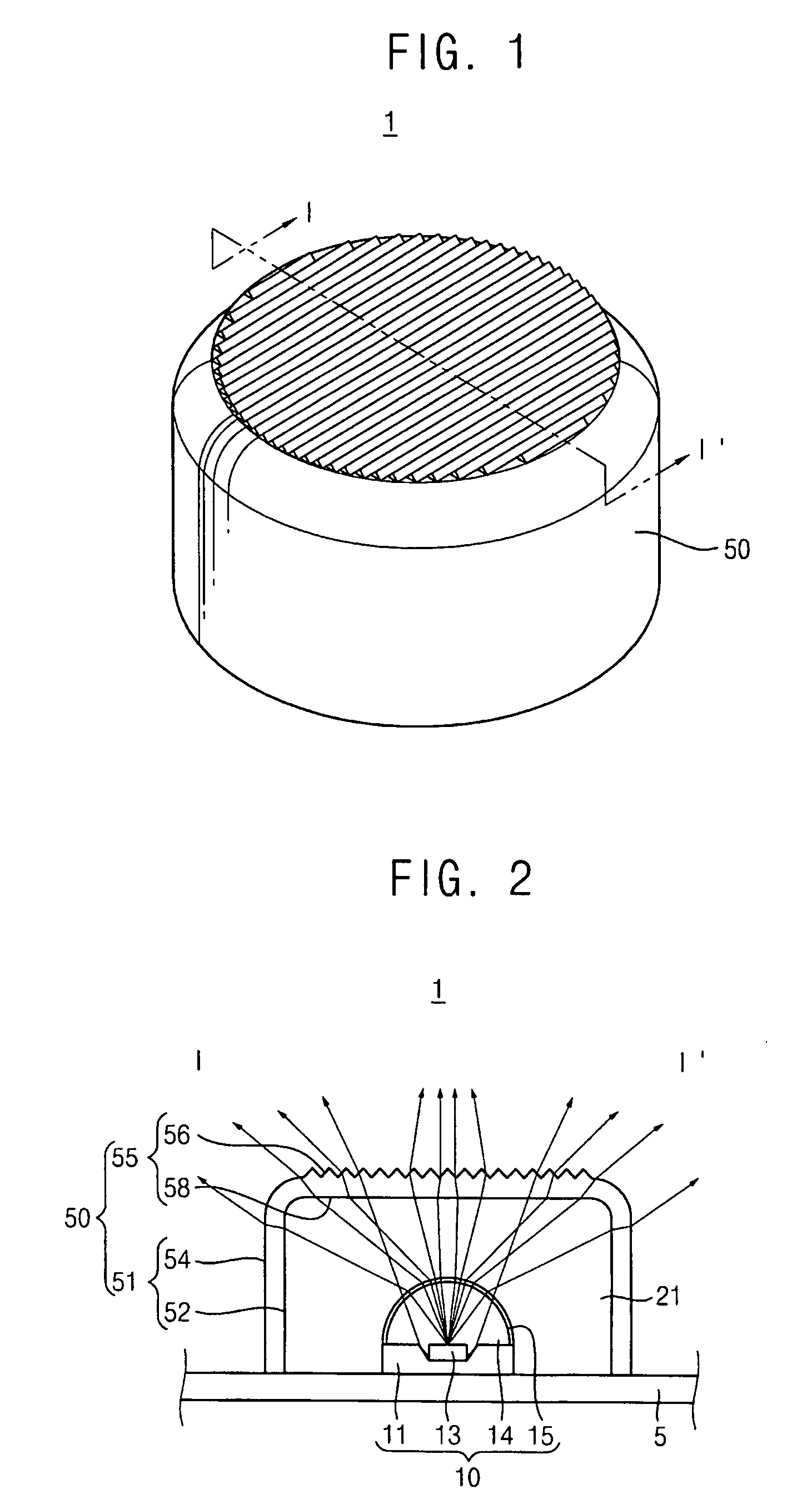

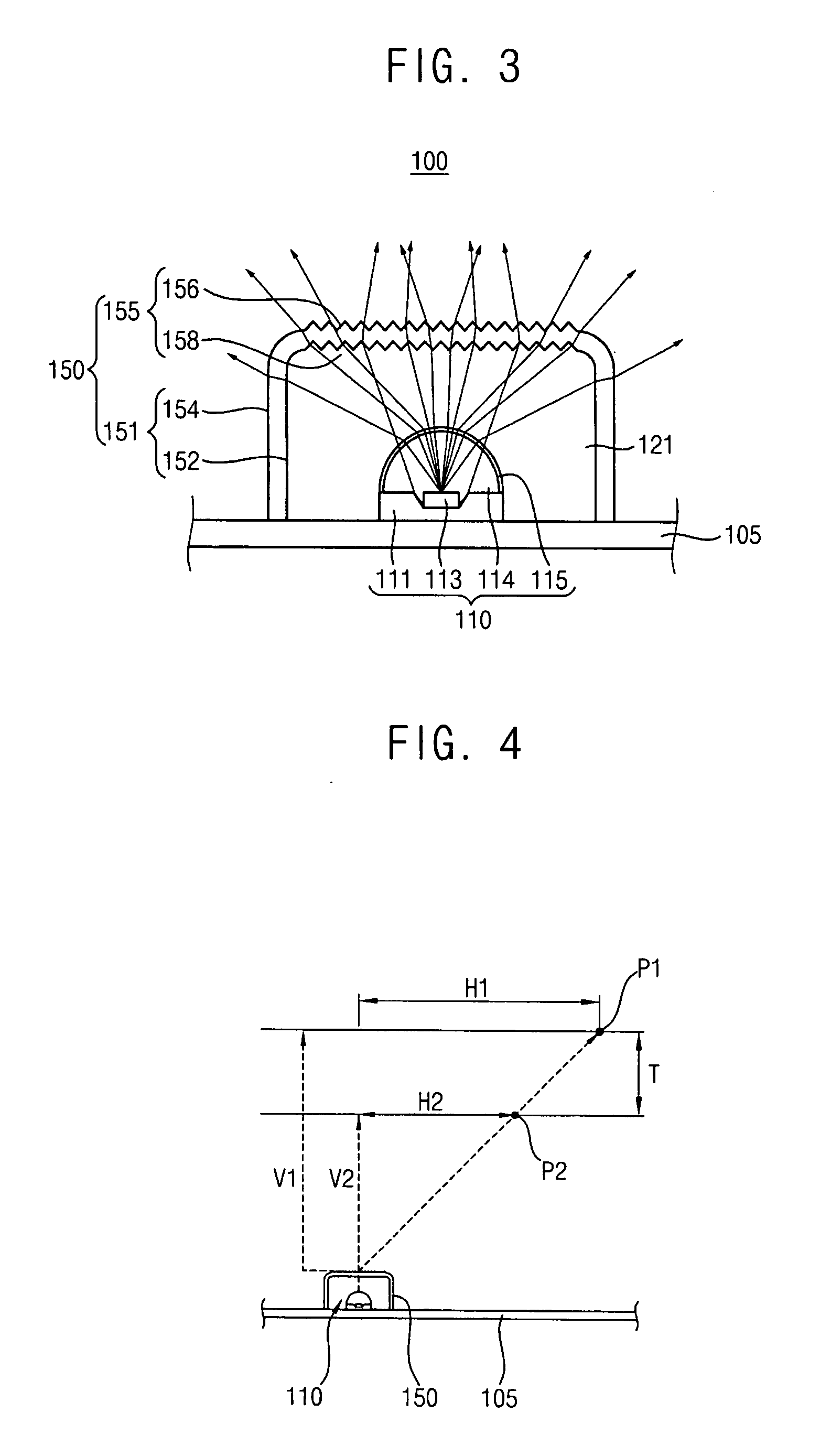

Light-emitting module capable of increasing dispersion diameter

InactiveUS20070258247A1Thin display deviceDiffuse fullyNon-linear opticsRefractorsDisplay deviceEngineering

A light-emitting module that allows a display panel to be made thinner is presented. The light-emitting module includes a point-light source and an optical cap. The point-light source is disposed on a substrate. The optical cap surrounds a side portion and an upper portion of the point-light source and has a first embossing pattern formed thereon. Light is emitted from the point-light source and passes through the optical cap to be diffused, for example by the first embossing pattern. Thus, extra components such as a diffusing plate, a diffusing sheet, etc., may be omitted from the display device, and the display device may be slimmer.

Owner:SAMSUNG ELECTRONICS CO LTD

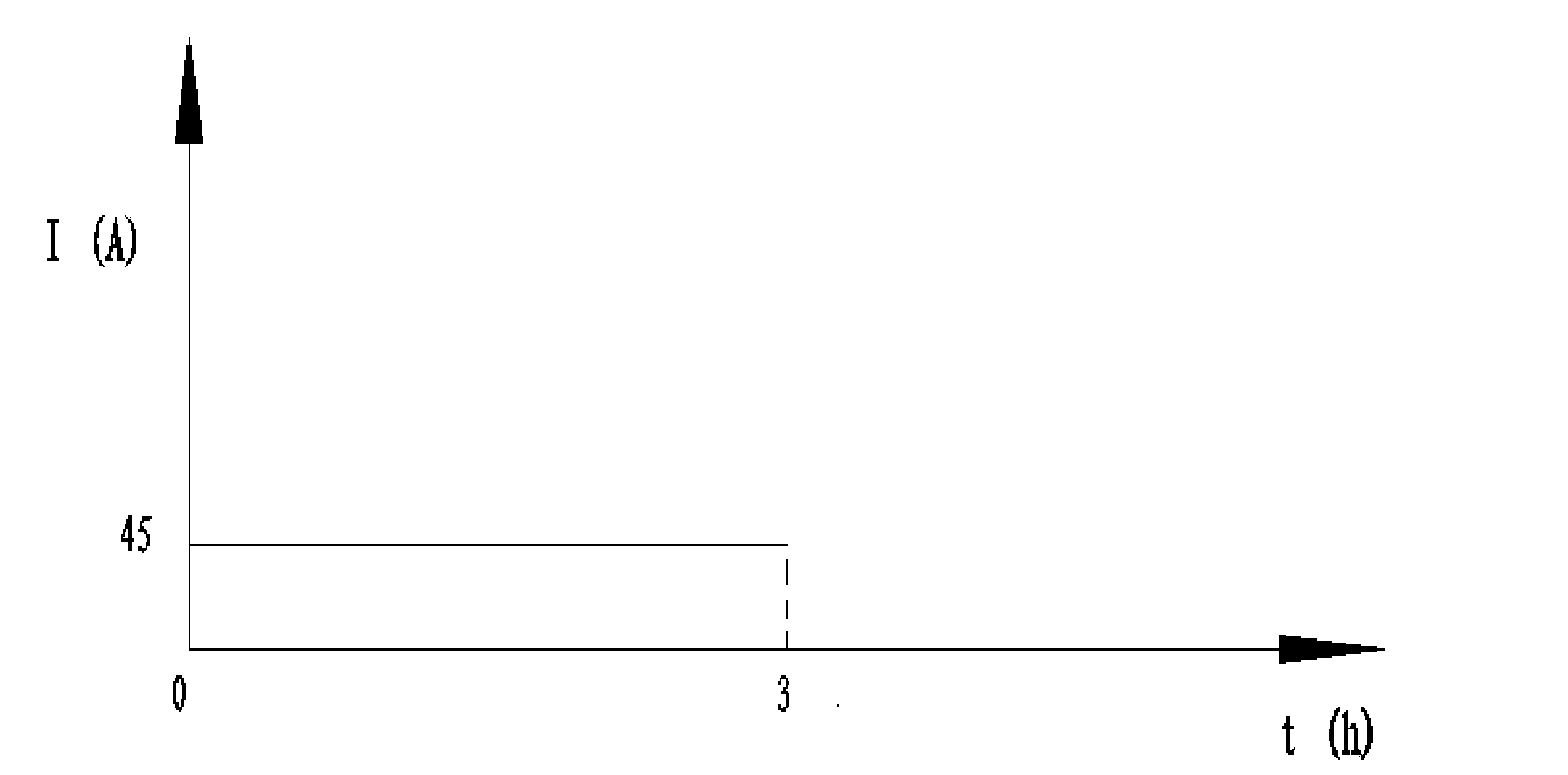

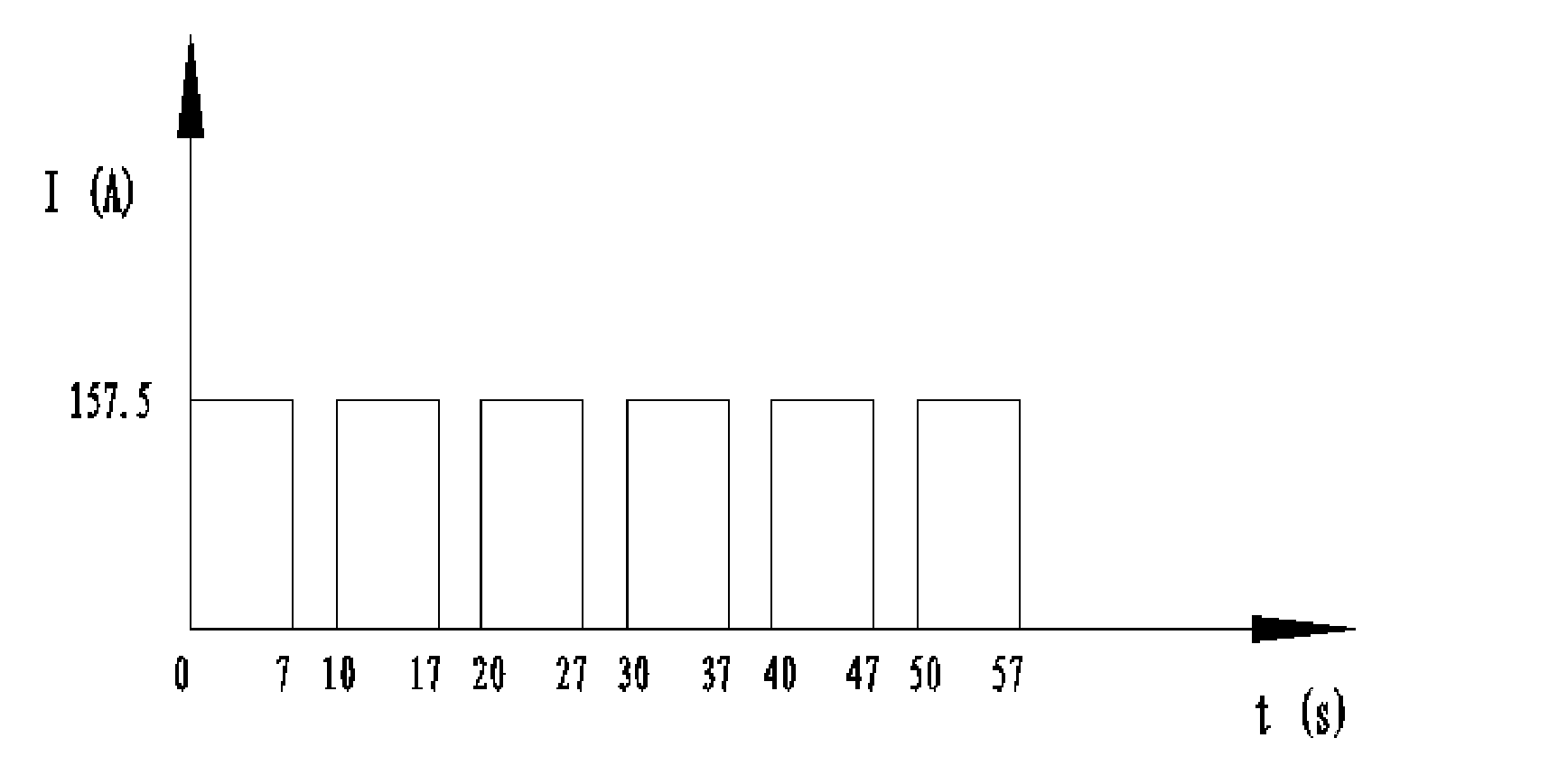

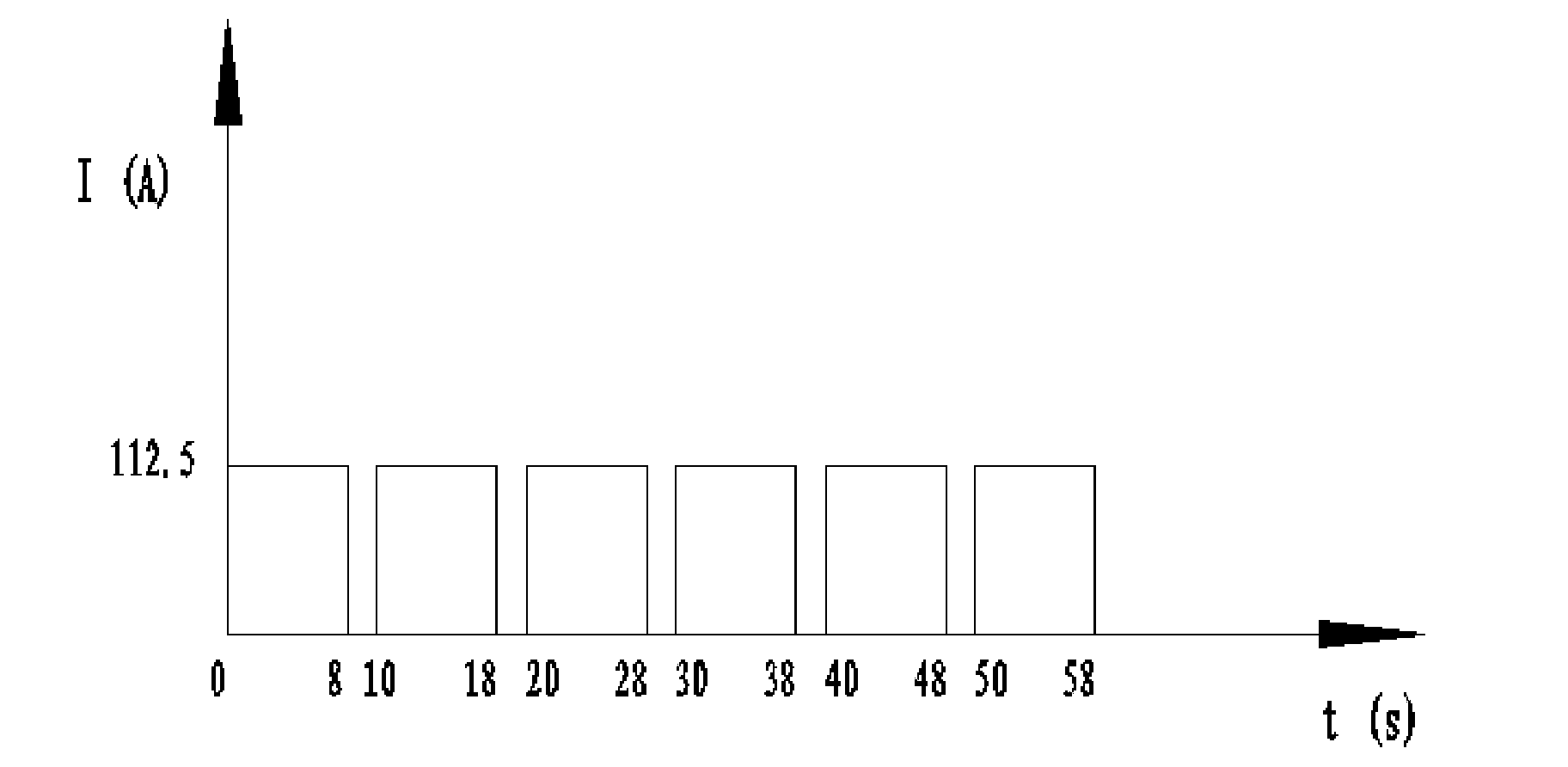

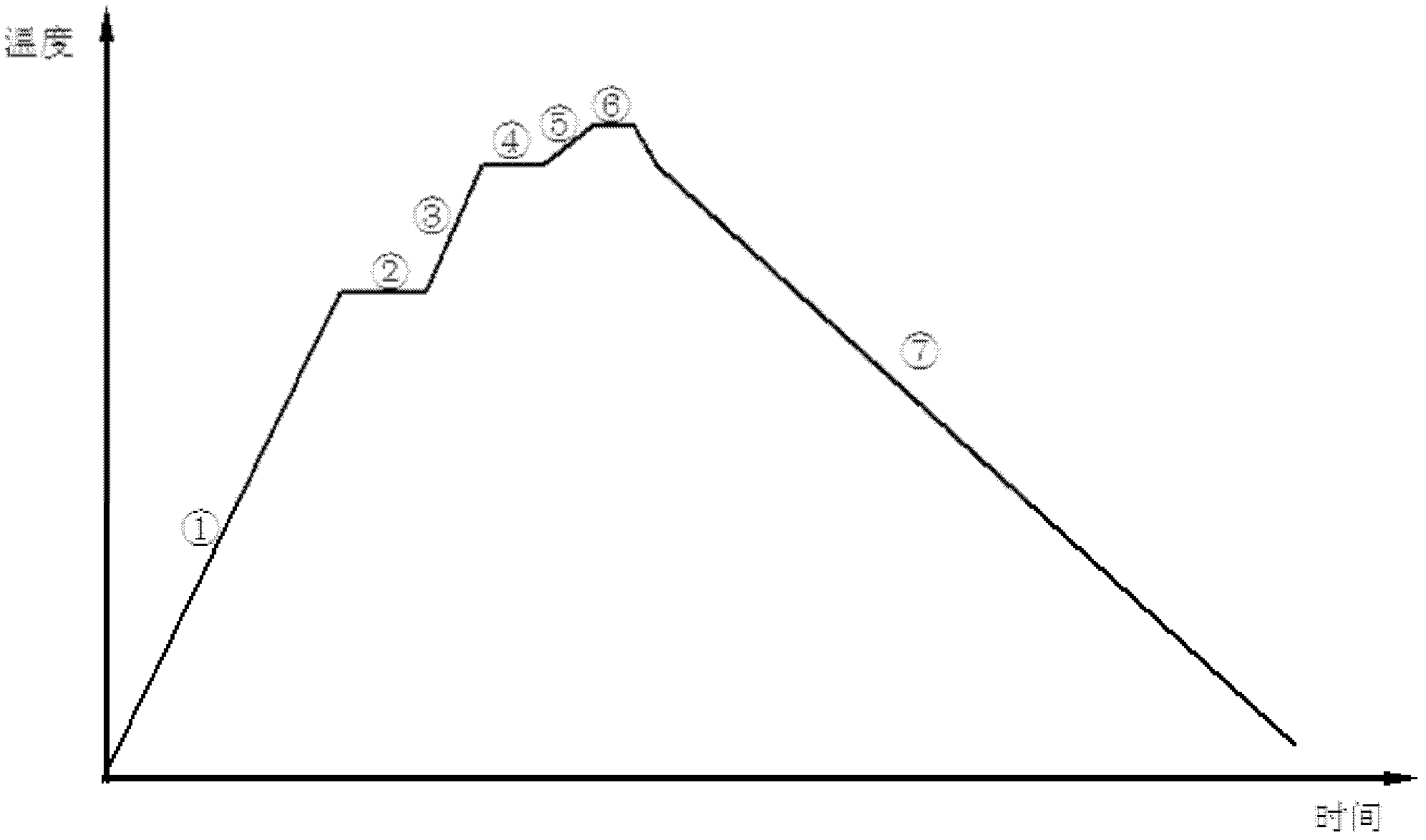

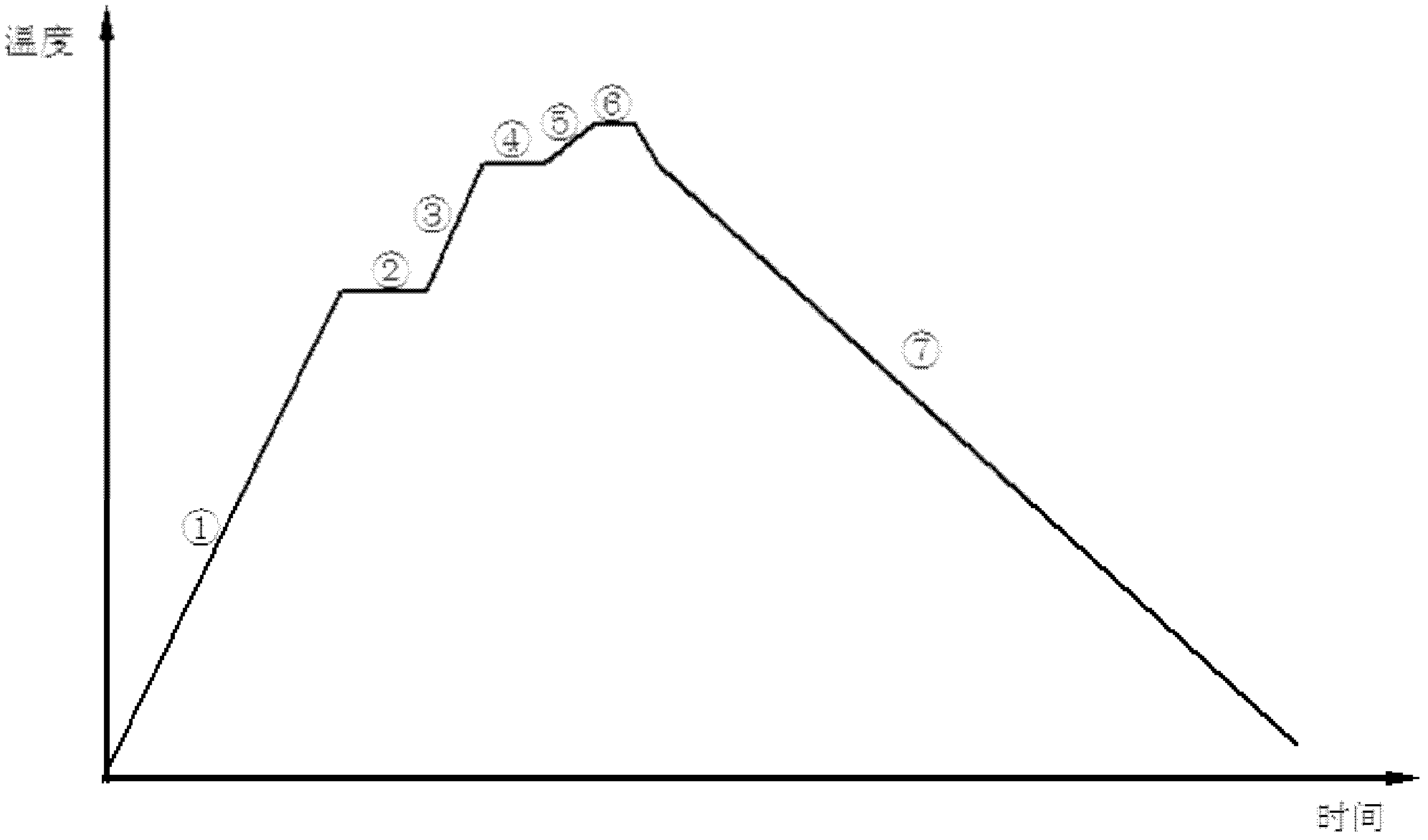

Pulse container formation method for high-capacity lead-acid battery

ActiveCN101877425AReduce shockImprove uniformityFinal product manufactureSecondary cells charging/dischargingEngineeringLow frequency

Owner:HUNAN FENGRI ELECTRIC GROUP

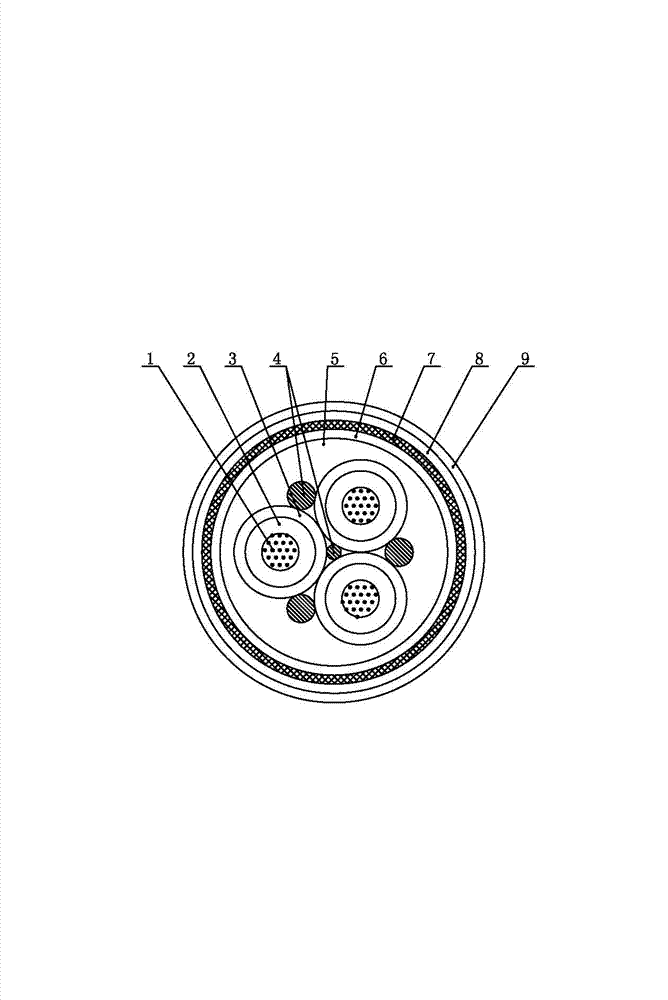

Shielding longitudinal watertight degaussing cable and production method thereof for ships

ActiveCN102855982AEnsure watertight effectImprove sealingInsulated cablesCable/conductor manufactureCopper conductorVulcanization

The invention discloses a shielding longitudinal watertight degaussing cable and a production method thereof for ships. A tinned copper wire is impregnated with a sealant and then twisted into a twisted copper conductor which is impregnated with a conductor sealant layer on the periphery, an electro-insulating rubber layer is extruded on the periphery of the conductor sealant layer to form insulation core wires, chloroprene rubber filling bars are filled into gaps between the insulation core wires, and a plurality of insulation core wires are twisted wholly into a cable core. A cable core inner sealant layer, an inner jacket rubber layer, an armor shielding layer and an outer jacket rubber layer are sequentially arranged on the periphery of the cable core. A single wire of the cable conductor is impregnated with the sealant, the twisted copper conductor is impregnated with the conductor sealant layer on the periphery, the cable core inner sealant layer is extruded on the periphery of the cable core to form multiple sealing, the chloroprene rubber filling bars swell during follow-up vulcanization and can fill in the gaps inside the cable core completely, and tangency between the insulation core wires can be avoided, so that the sealant can permeate to the inside of the cable core to guarantee the watertight effect when the cable core inner sealant layer is extruded.

Owner:嘉兴顾翔制冷设备有限公司

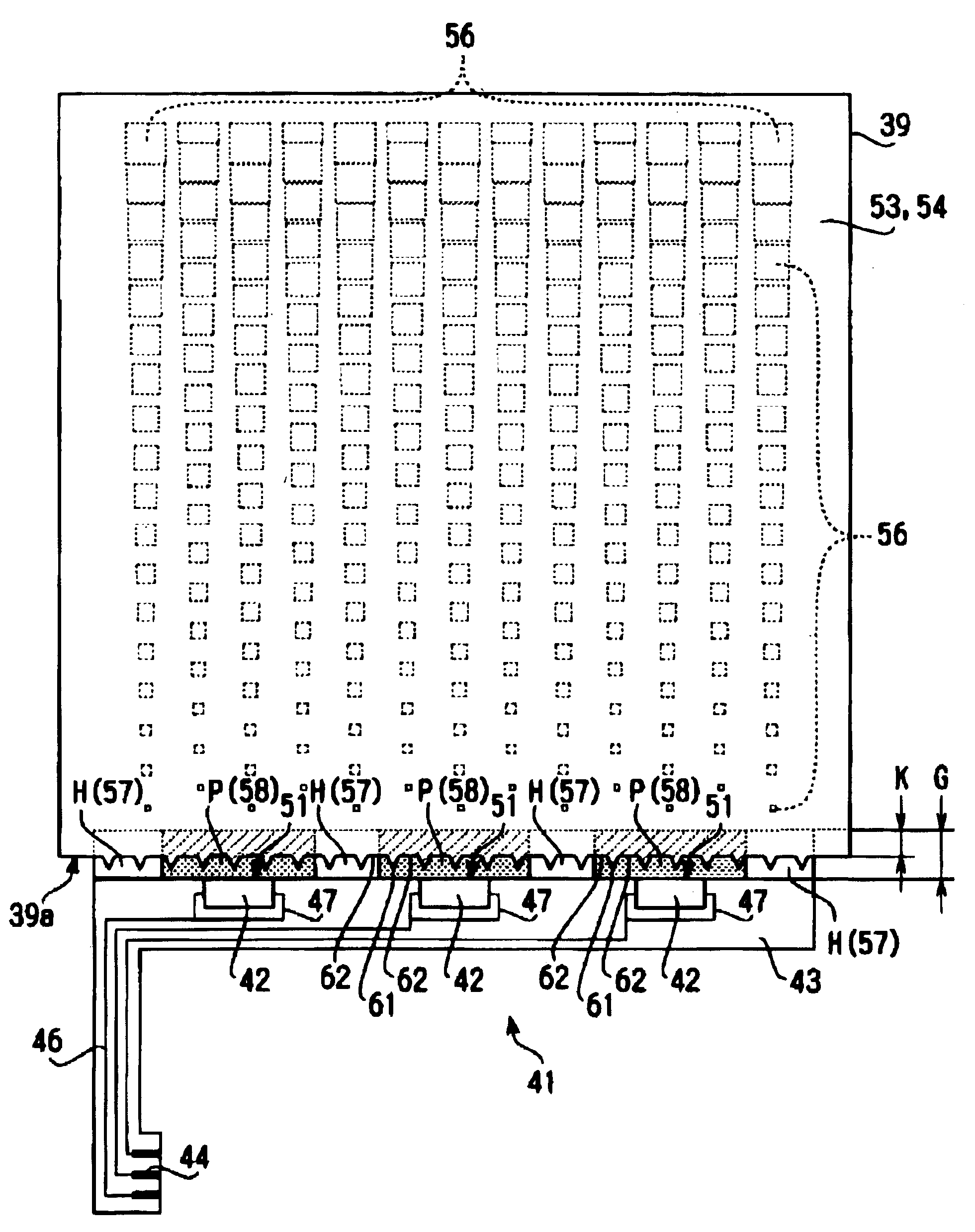

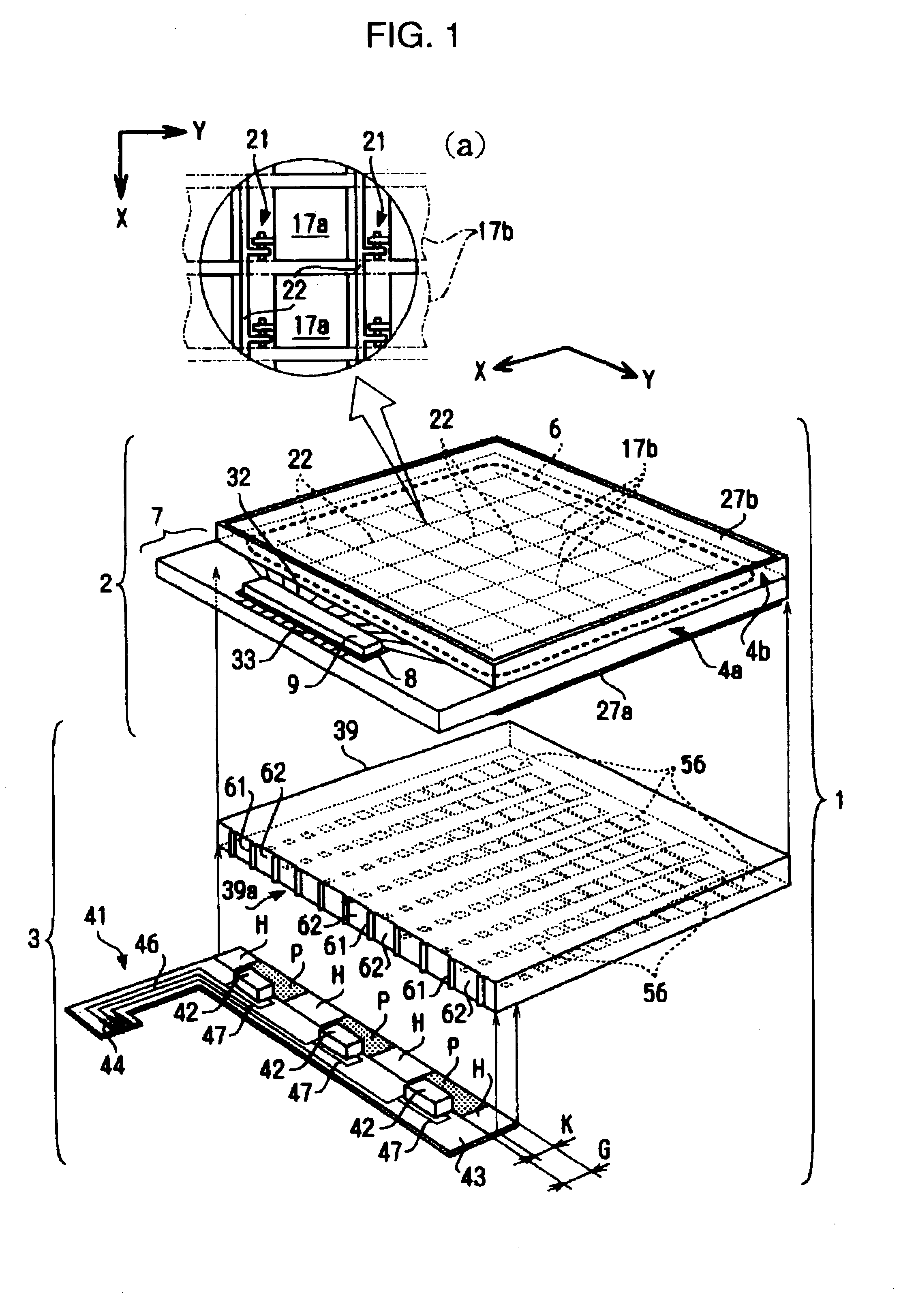

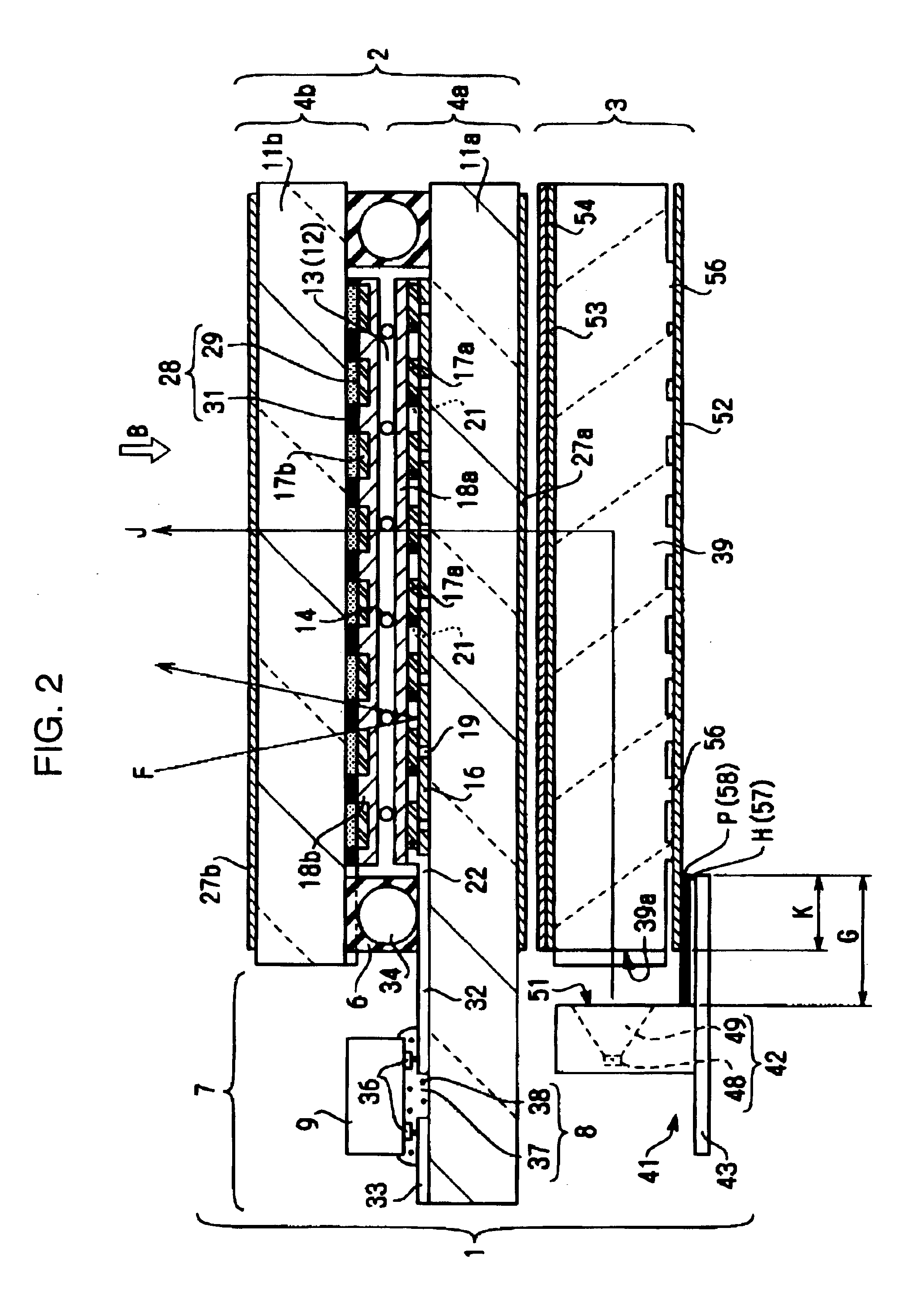

Illumination device, liquid crystal device, and electronic apparatus

InactiveUS7001035B2Avoid areaAvoid it happening againShow cabinetsMechanical apparatusLight guidePrism

An illumination device is provided to solve locally high luminance near point-shaped light sources, while preventing overall decrease in luminance at the light-emitting face of a light guide member. The illumination device includes a light source for generating light, and a light guide member which receives light from the light source at a light input face and emits light from a light emitting face. A continuous optical pattern with prism faces and flat faces is provided on the light input face. Light emitted from the light source is diffused in the plane direction by the optical pattern, so there is no occurrence of locally-high-luminance areas near the LEDs in the light guide member. Moreover, the luminance of the light emitted in a planar manner from the light-emitting face does not decrease.

Owner:BOE TECH GRP CO LTD

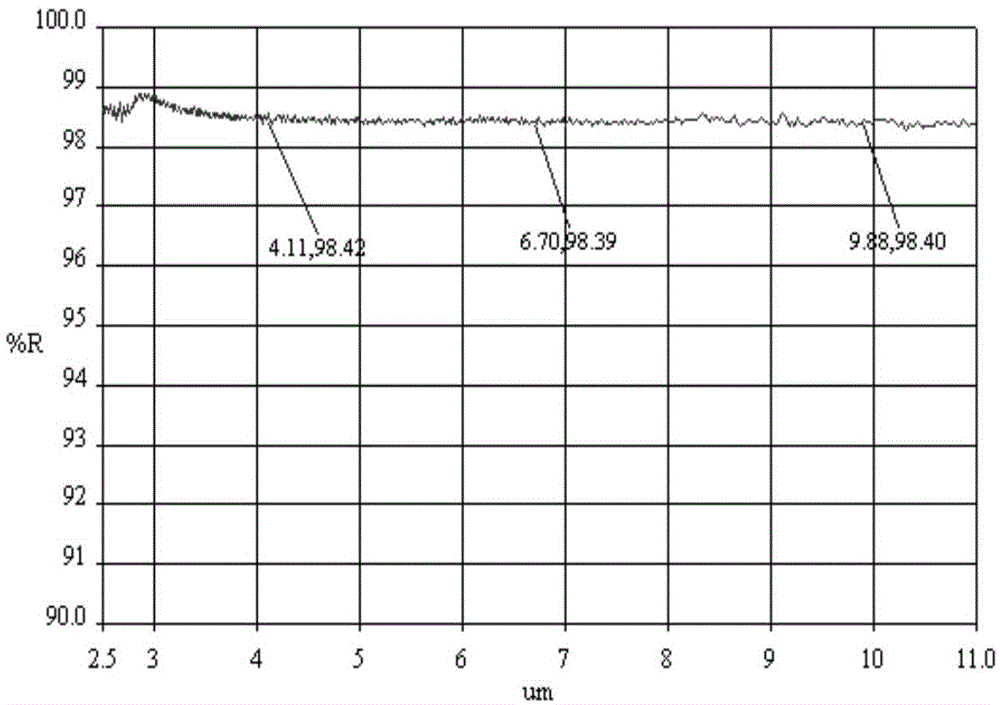

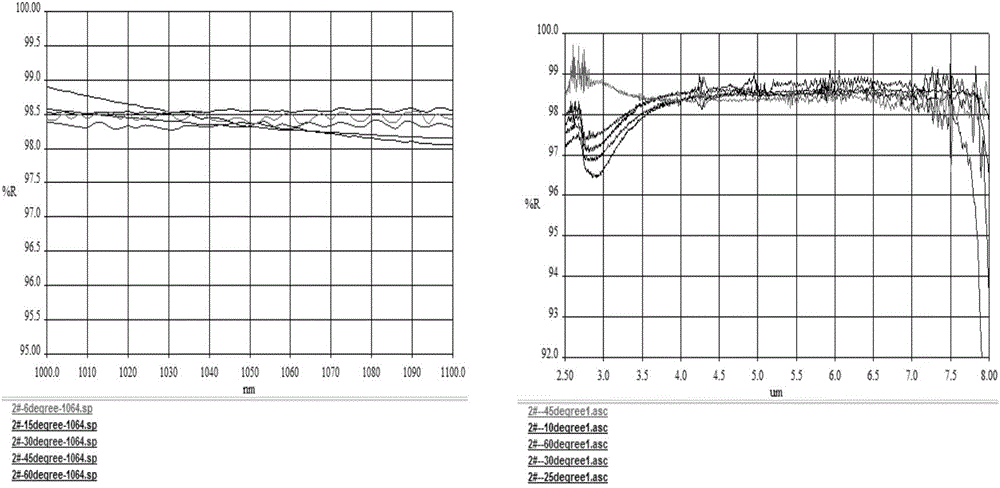

Infrared metal reflecting film with high adhesive force and manufacturing method thereof

ActiveCN104090312AGood physical occlusionImprove adhesionVacuum evaporation coatingSputtering coatingAdhesiveWear resistant

The invention provides an infrared metal reflecting film with high adhesive force and a manufacturing method thereof, wherein the infrared metal reflecting film with high adhesive force is plated on substrates of optical components such as glass, metal and silicon crystals. The infrared metal reflecting film with high adhesive force comprises a substrate, and is characterized in that a first transition layer, a holding-on bonding layer, a metal layer, a stress matching layer, a dielectric enhancement protecting layer and a hard wear-resistant layer are sequentially arranged on the substrate in an evaporation mode. The infrared metal reflecting film has the advantages of being good in film adhesive force, high in reflectivity, resistant to wear and high in environmental suitability, has a high laser damage resistance threshold value level, and can be widely applied to military and civilian photoelectron technical fields such as infrared lasers, refraction-reflection type optical systems and laser / infrared universal photoelectric equipment.

Owner:NO 717 INST CHINA MARINE HEAVY IND GRP

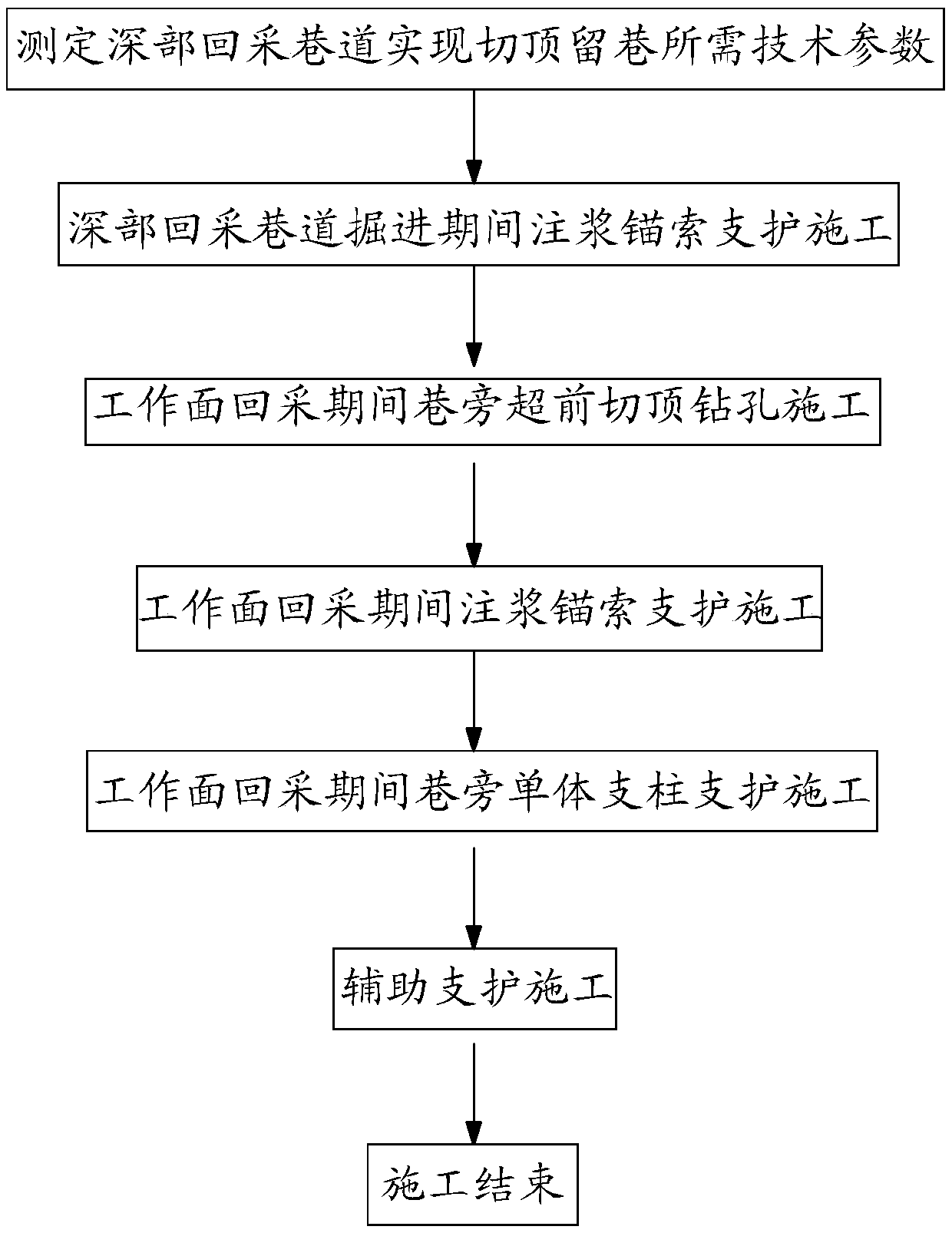

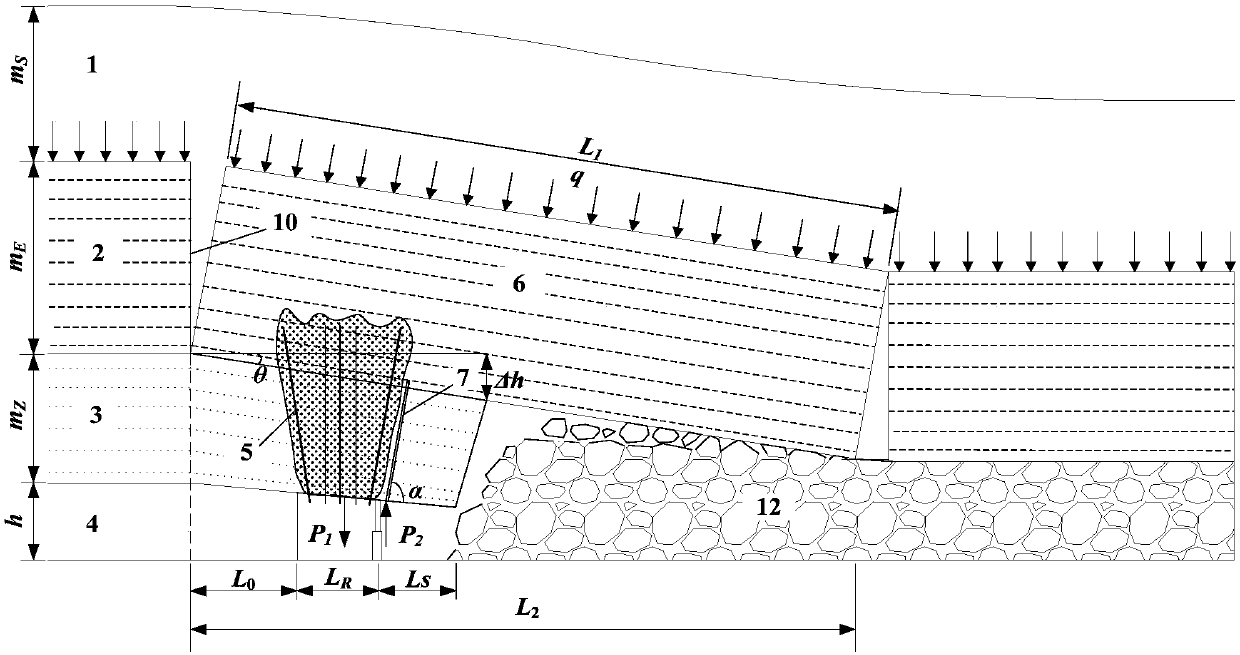

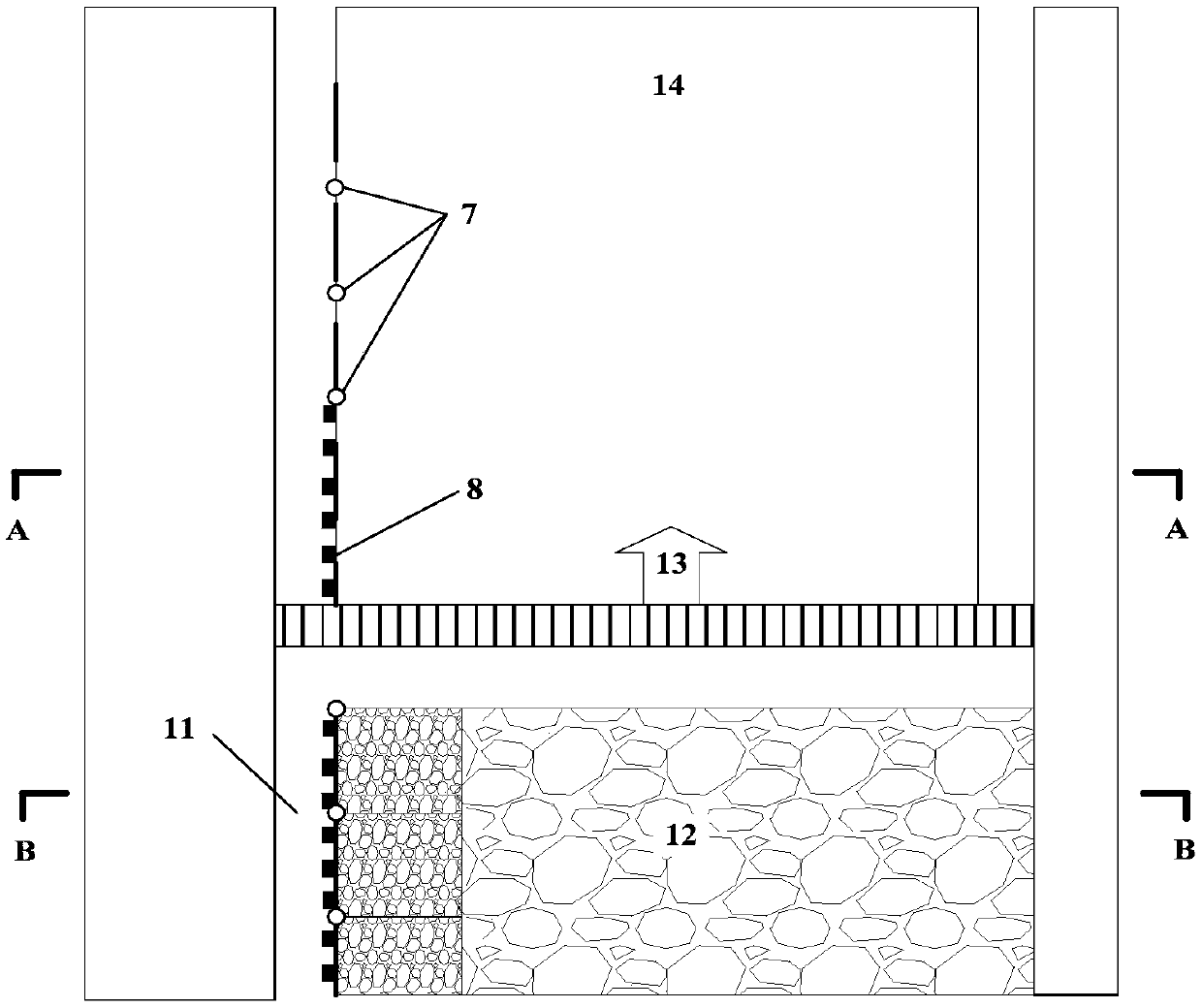

Main control and roadway retaining method for anchor injection and top-cutting in deep mining roadway

ActiveCN108678769AAvoid it happening againReduce stressUnderground chambersTunnel liningDeep miningCoal pillar

The invention provides a main control and roadway retaining method for anchor injection and top-cutting in a deep mining roadway, which comprises the following steps: step 1, determining the technicalparameters required for realizing the top-cut and roadway retaining in the deep mining roadway; step 2, carrying out the grouting anchor cable support construction during the tunnelling period of thedeep mining roadway; step 3, carrying out the advanced overcut and perforating construction at the roadway side during the mining of the working face; step 4, carrying out grouting anchor cable support construction during the mining of the working face; step 5, carrying out monomer strut support construction at the roadway side during the mining of the working surface; step 6, carrying out auxiliary support construction. The method has the advantages that the supporting requirements of the deep gob-side entry can be satisfied when carrying out non-pillar mining construction in the deep mine.

Owner:SHANDONG UNIV OF SCI & TECH

Vacuum brazing solder and process of Mo-Cu alloy and stainless steel

InactiveCN102554509AUniform chemical compositionReduce segregationWelding/cutting media/materialsWelding/soldering/cutting articlesHigh densityElectronic packaging

The invention relates to a vacuum brazing solder and a process of Mo-Cu alloy and stainless steel. The process comprises the steps of placing BNi2 amorphous alloy solder between preprocessed Mo-Cu alloy and surface to be brazed of austenitic stainless steel, controlling the joint gap between 40-80mum, gently placing the assembled Mo-Cu alloy and the stainless steel at a uniform temperature zone in a vacuum brazing furnace, vacuumizing and brazing, wherein the BNi2 amorphous alloy solder comprises the components in percentage by mass: 6.5-7.5% of Cr, 3.0-5.0% of Si, 2.7-3.5% of B, 2.5-3.5% of Fe, less than or equal to 0.02% of C and the balance of Ni. The Mo-Cu alloy and stainless steel joint obtained by the process disclosed by the invention have the advantages of little impurity, high density, strong high temperature resisting ability and the like and can be used for manufacturing instrument and meter elements, electronic packaging and high temperature resisting devices.

Owner:SHANDONG UNIV

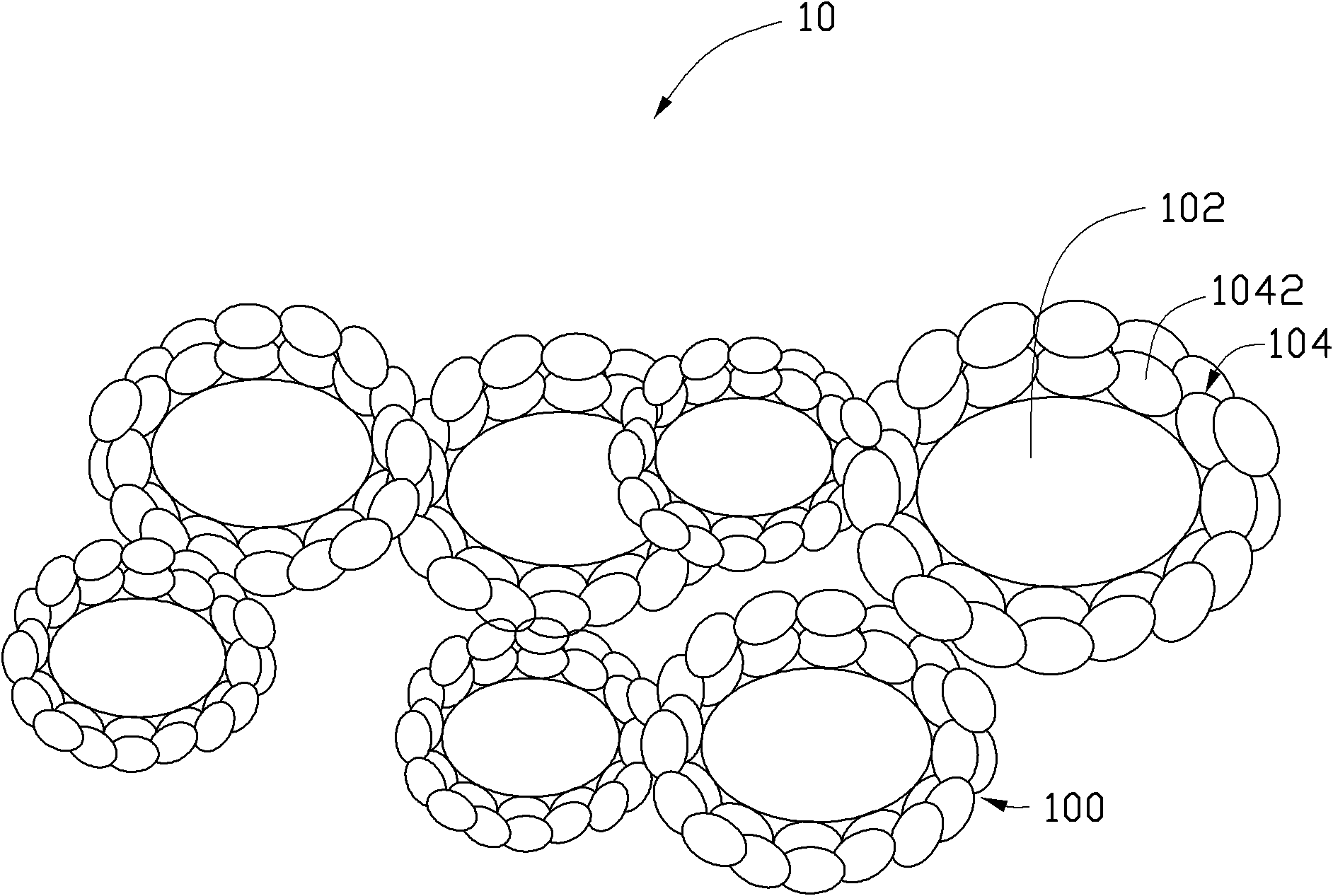

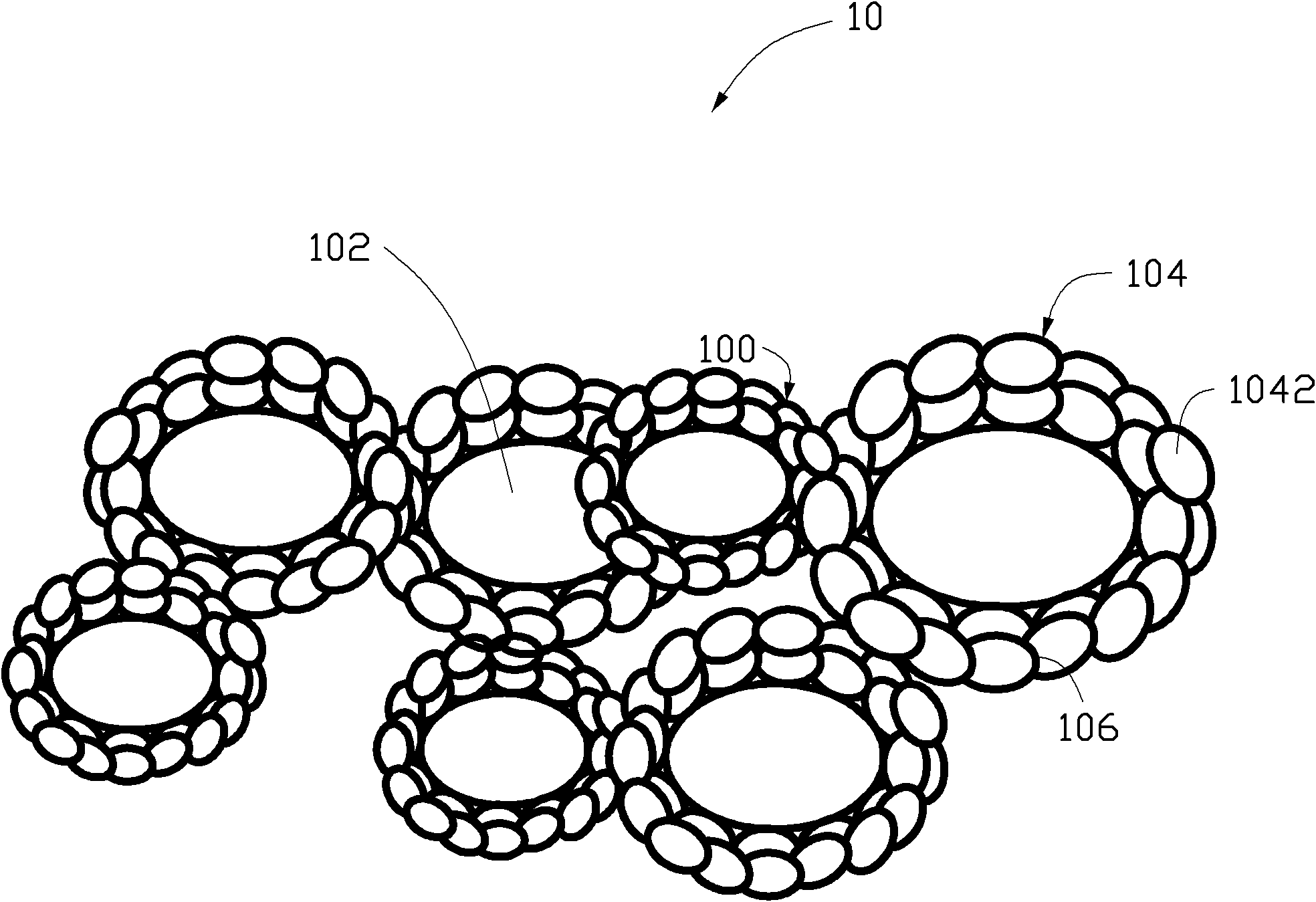

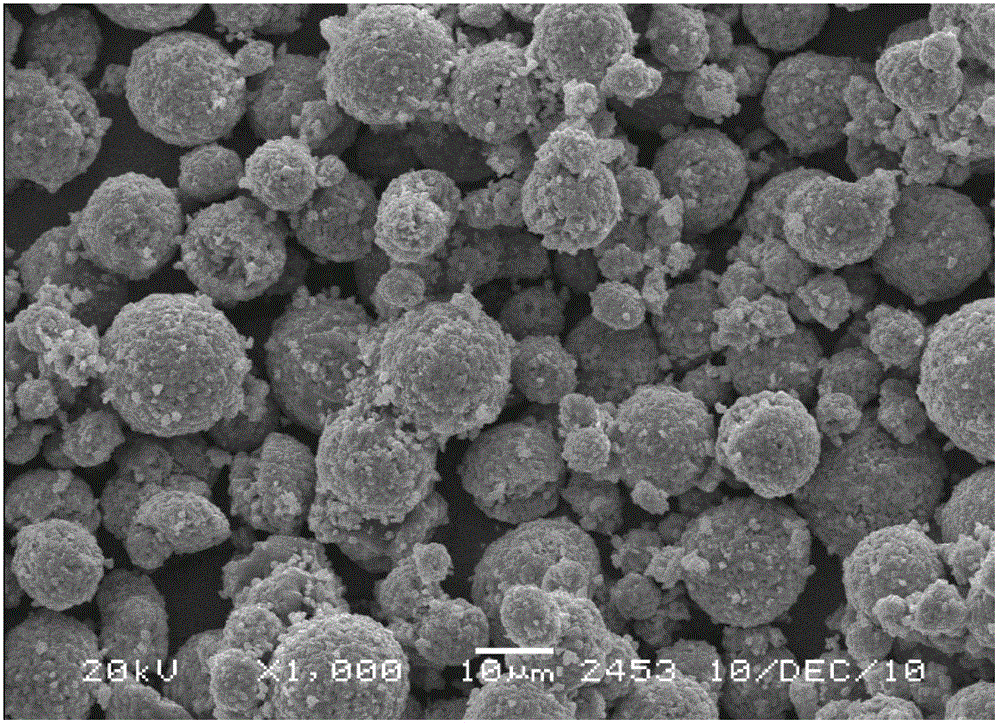

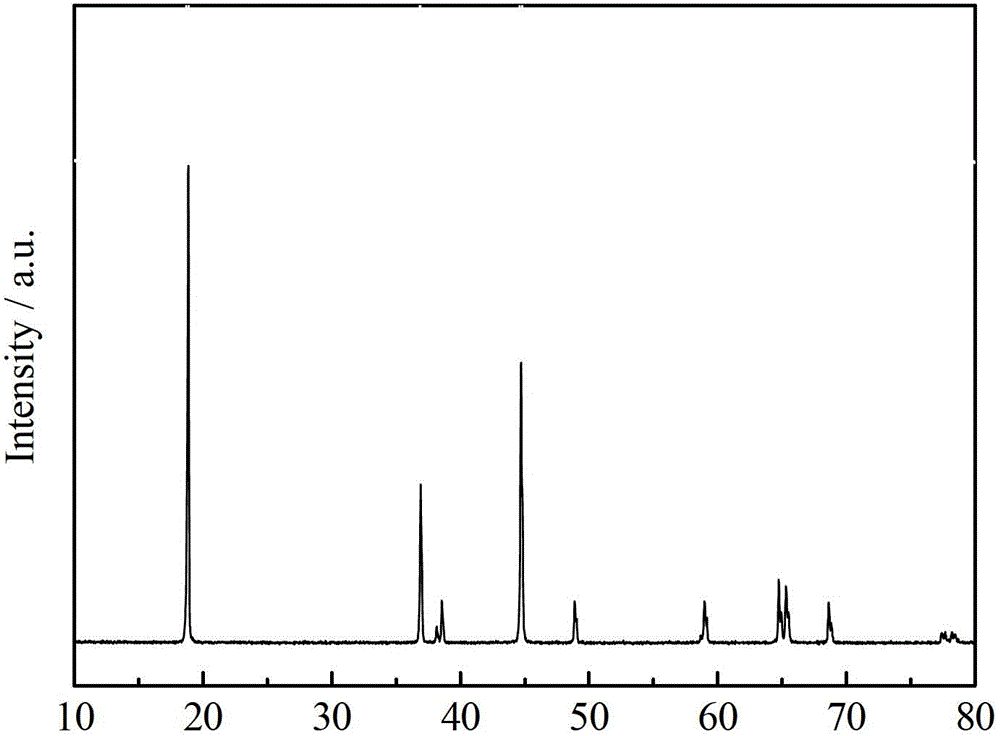

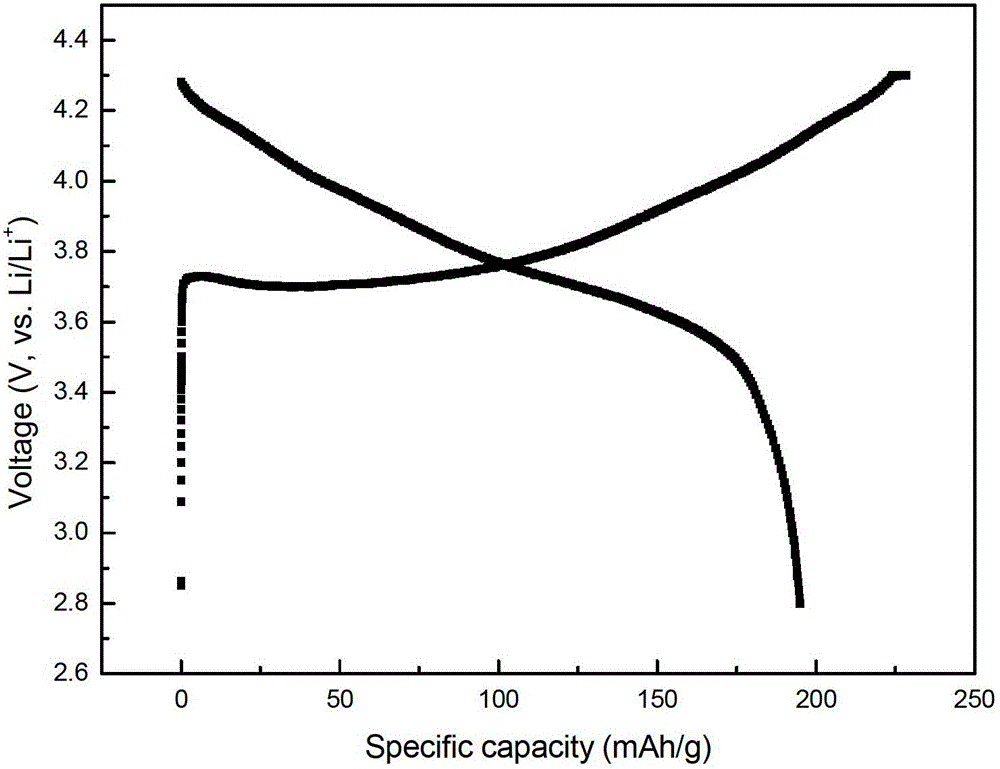

Lithium battery electrode material

ActiveCN101859891AImprove electrochemical performanceDiffuse fullyCell electrodesLithium vanadium phosphate batteryLithium iron phosphate

The invention discloses a lithium battery electrode material, comprising a plurality of uniformly distributed lithium iron phosphate / lithium vanadium phosphate composite particles. The material is characterized in that each lithium iron phosphate / lithium vanadium phosphate composite particle comprises a lithium vanadium phosphate particle and a lithium iron phosphate particle layer uniformly coated on the surface of the lithium vanadium phosphate particle, wherein, the lithium iron phosphate particle layer comprises a plurality of lithium iron phosphate particles.

Owner:TSINGHUA UNIV +1

Preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries

ActiveCN103066257ASolve the problem of complete oxidationPrevent "cation mixing" phenomenonCell electrodesLithium hydroxideOxygen

The invention provides a preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries. The method comprises: step 1, using a nickel-cobalt-aluminum precursor prepared through a coprecipitation method and doped with mixed ions as raw materials, putting the raw materials into a sealed hearth of a pressure furnace, continuously introducing oxygen until a fixed pressure value is formed, then heating to a pre-burning temperature and keeping warm for a period of time, and cooling to obtain an oxidized precursor; and step 2, adding measured lithium salt or lithium hydroxide into the oxidized precursor, ball milling and uniformly mixing; heating the uniformly mixed raw materials to a certain temperature and keeping warm for a period of time, and meanwhile continuously introducing oxygen to complete a sintering process, thereby obtaining the finish product. According to the invention, through a hyperbaric oxygen atmosphere, the oxygen are enabled to fully infiltrate into particles of the raw materials which has a certain accumulation thickness, thereby preventing situations that only surface materials are oxidized under a normal pressure, and ensuring a full conversion of Ni<2+> to Ni<3+> by a full pre-oxidation.

Owner:GUANGZHOU LIBODE NEW MATERIAL

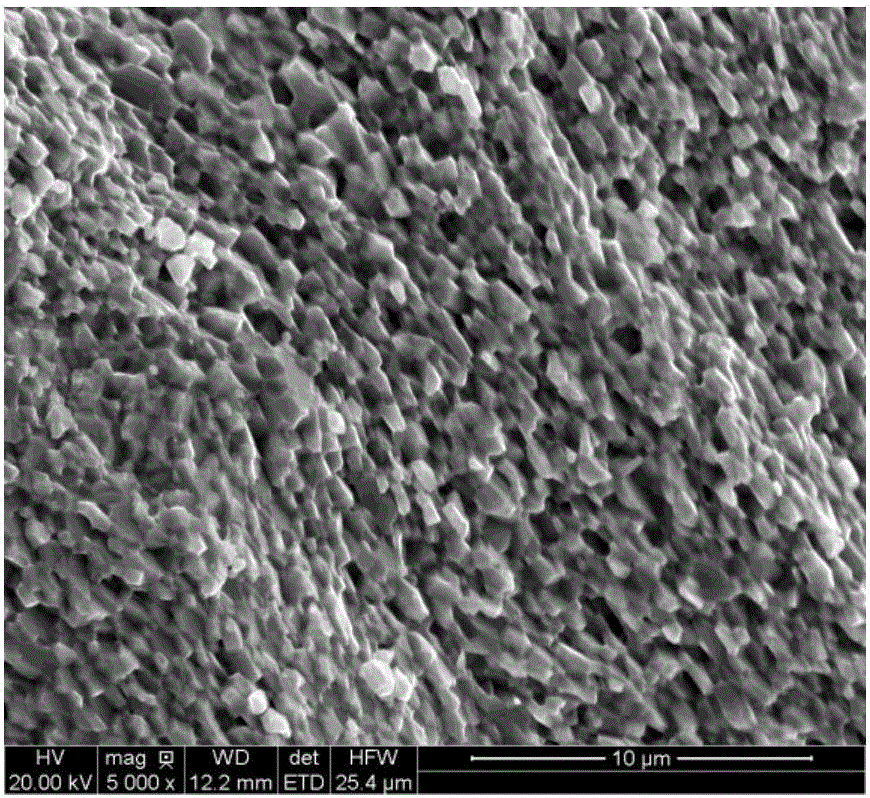

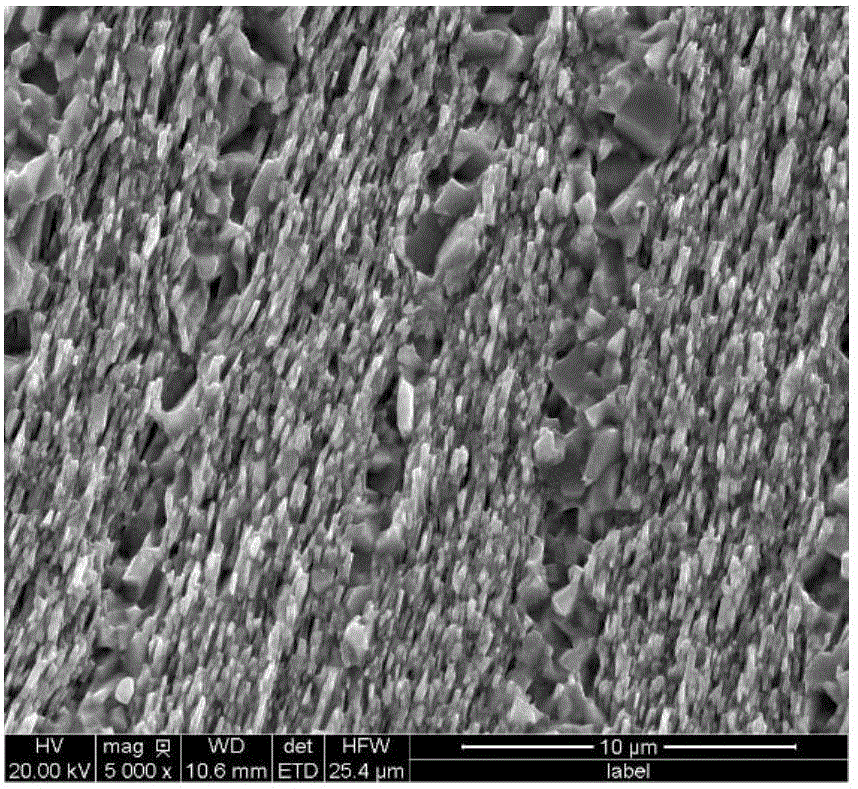

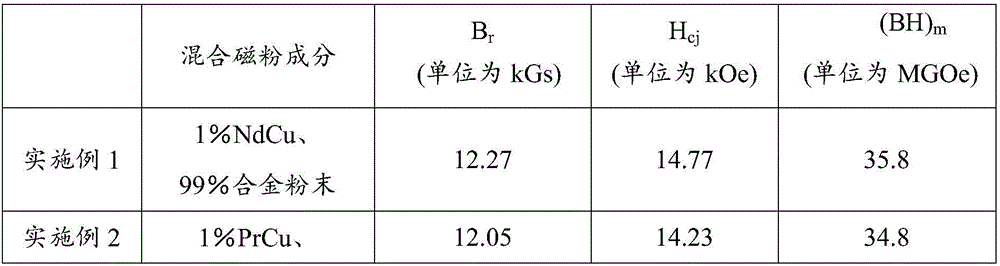

Thermal deformation rare-earth permanent magnet material and preparation method thereof

ActiveCN106548844APromote formationEasy to optimizeInductances/transformers/magnets manufactureMagnetic materialsMass ratioRare earth

The invention relates to a preparation method of a thermal deformation rare-earth permanent magnet material. The method comprises the following steps of (1) providing main magnetic powder and low-melting-point alloy powder separately, wherein a chemical formula of the main magnetic powder is Re<x>Fe<100-x-y-z>M<y>B<z> according to the mass percent, the chemical formula of the low-melting-point alloy powder is ReCu<100-a>, Re is one or more of Nd, Pr, Dy, Tb, La and Ce and a is smaller than or equal to 90 and greater than or equal to 60; (2) mixing the main magnetic powder with the low-melting-point alloy powder evenly to obtain mixed magnetic powder, wherein the mass ratio of the low-melting-point alloy powder in the mixed magnetic powder is greater than 0 and smaller than or equal to 10%; (3) carrying out hydrogenation-disproportionation-dehydrogenation-recombination treatment on the mixed magnetic powder and diffusing a low-melting-point alloy in the treatment process to obtain HDDR magnetic powder; and (4) sequentially carrying out hot-press molding and deformation molding on the HDDR magnetic powder to obtain the thermal deformation rare-earth permanent magnet material. The invention further provides the thermal deformation rare-earth permanent magnet material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

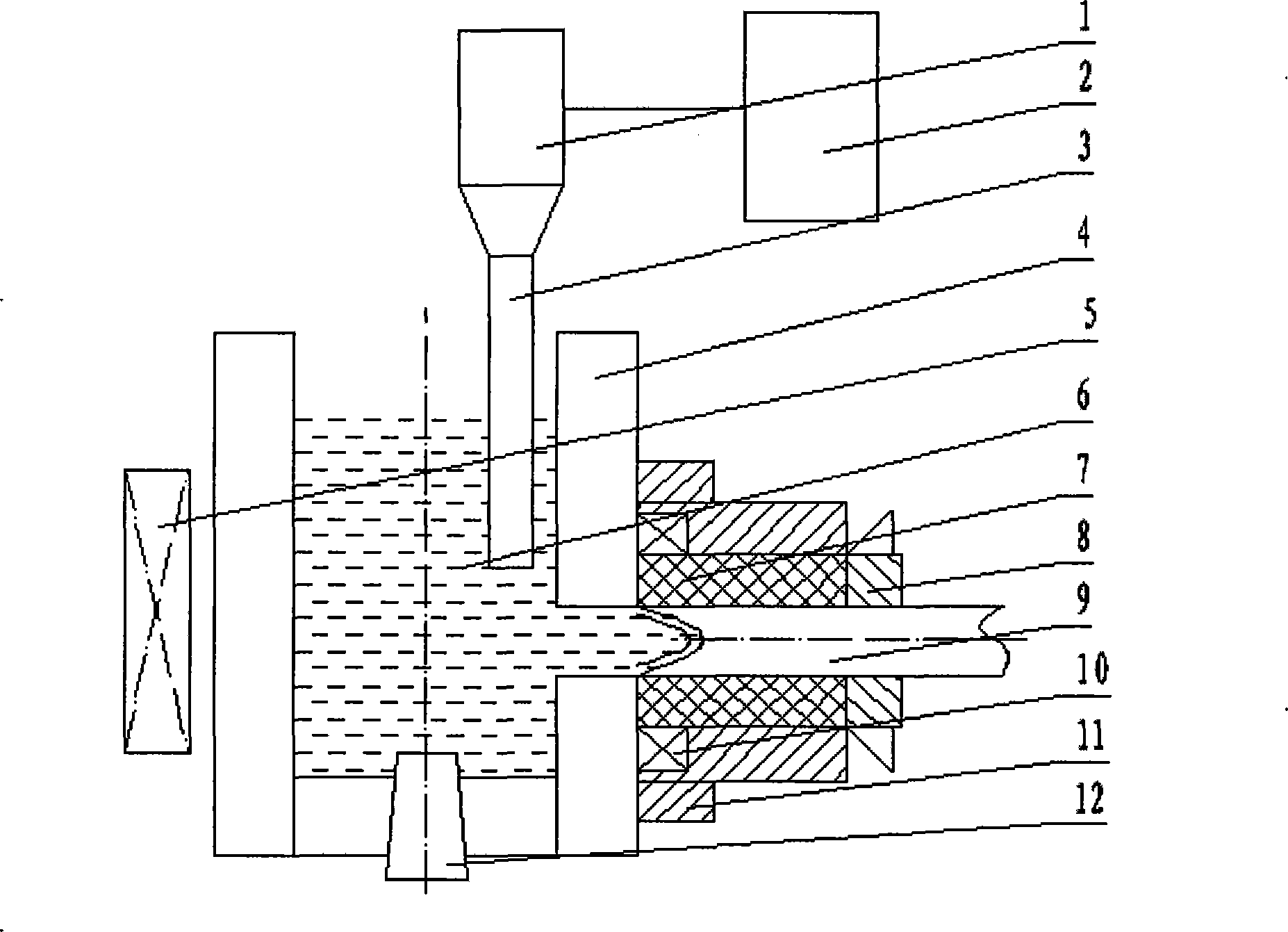

Method and apparatus for improving horizontal continuous casting billet quality by applying composite field

The invention relates to a quality improving method for horizontal continuous casting blanks by applying complex field and the device, belonging to the technical field of preparation of metal material, in particular to the technology of applying complex electromagnetic field and ultrasonic field in the continuous casting process of metal casting blanks. The device is characterized in that a generator of inert gas is arranged at the center of the bottom of a holding furnace; a generator of traveling wave magnetic field is arranged on the side of the holding furnace; a power ultrasonic device is arranged on the holding furnace close to the water port; a restriction electromagnetic coil is arranged on the outer side of a crystallizer. The device has the advantages that: firstly, the production technology is simple, the operation is easy, and the efficiency is high; secondly; the disadvantages of easy broken in rolling and drawing process of casting blank due to more impurity and pores is solved; thirdly, the solidification structure of the casting blanks is uniform, the crystal grain is fine, and the casting blanks can be rolled directly at casting state. The quality improving method and the device are mainly used for the field of metal continuous casting.

Owner:DALIAN UNIV OF TECH

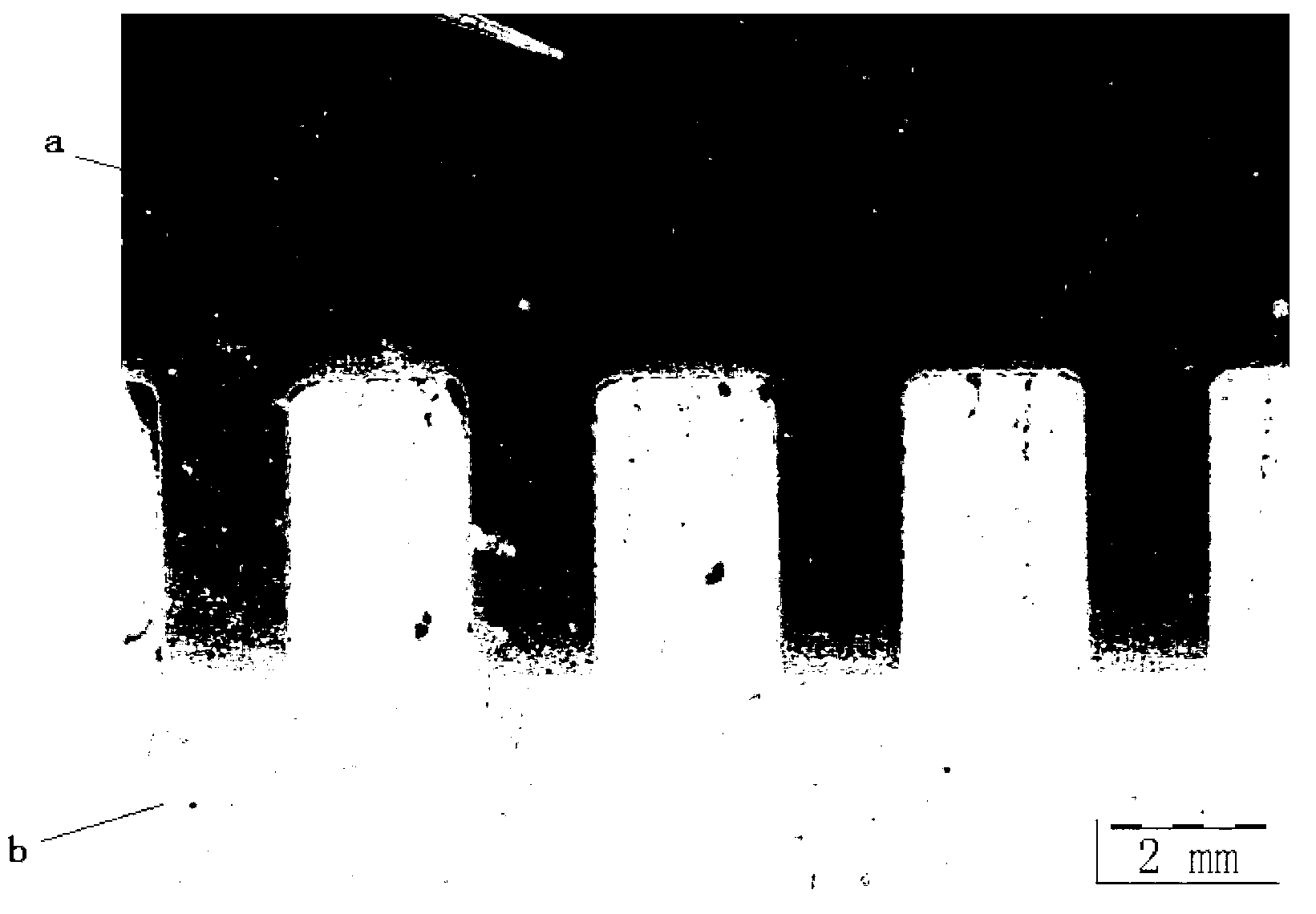

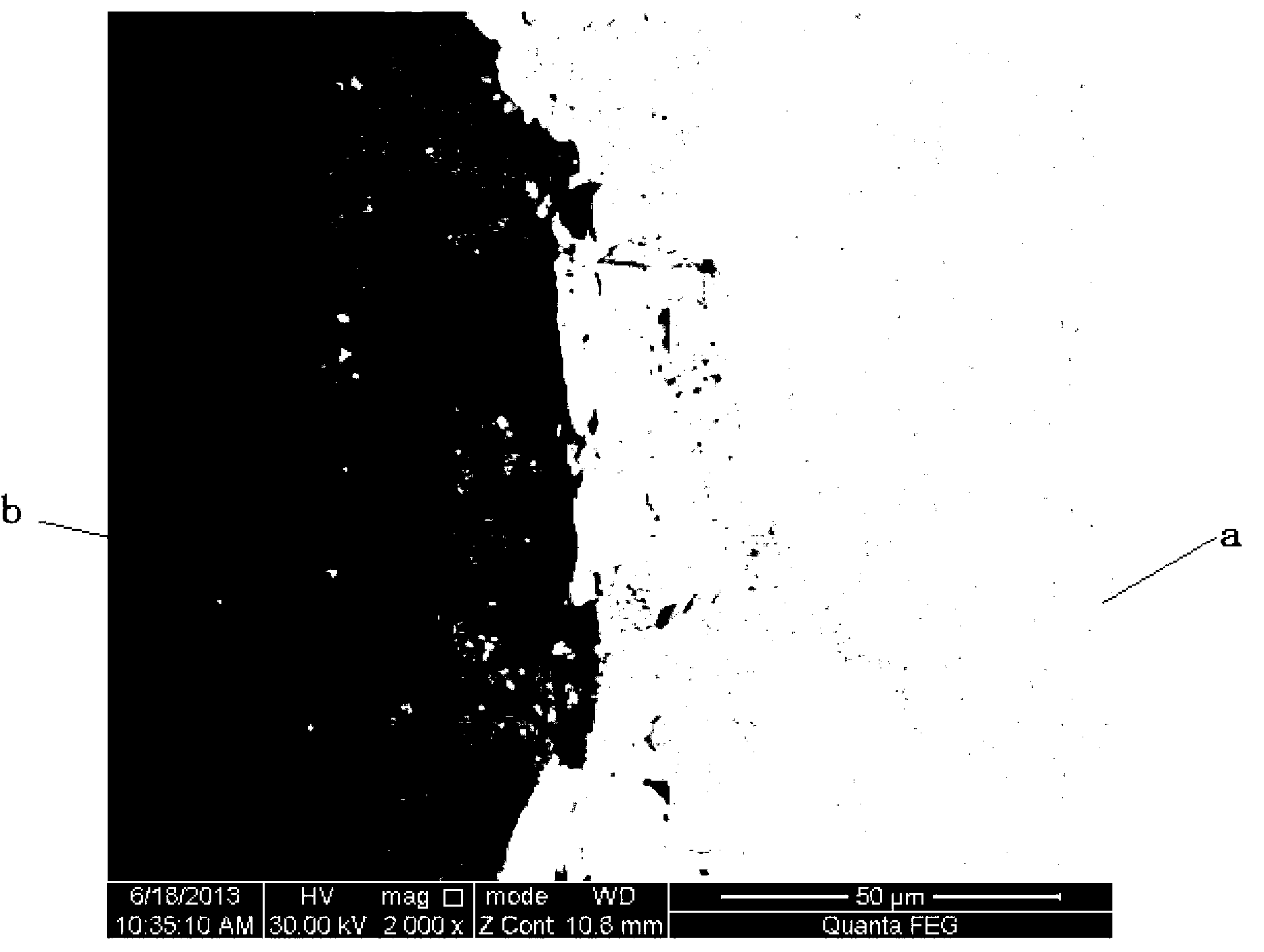

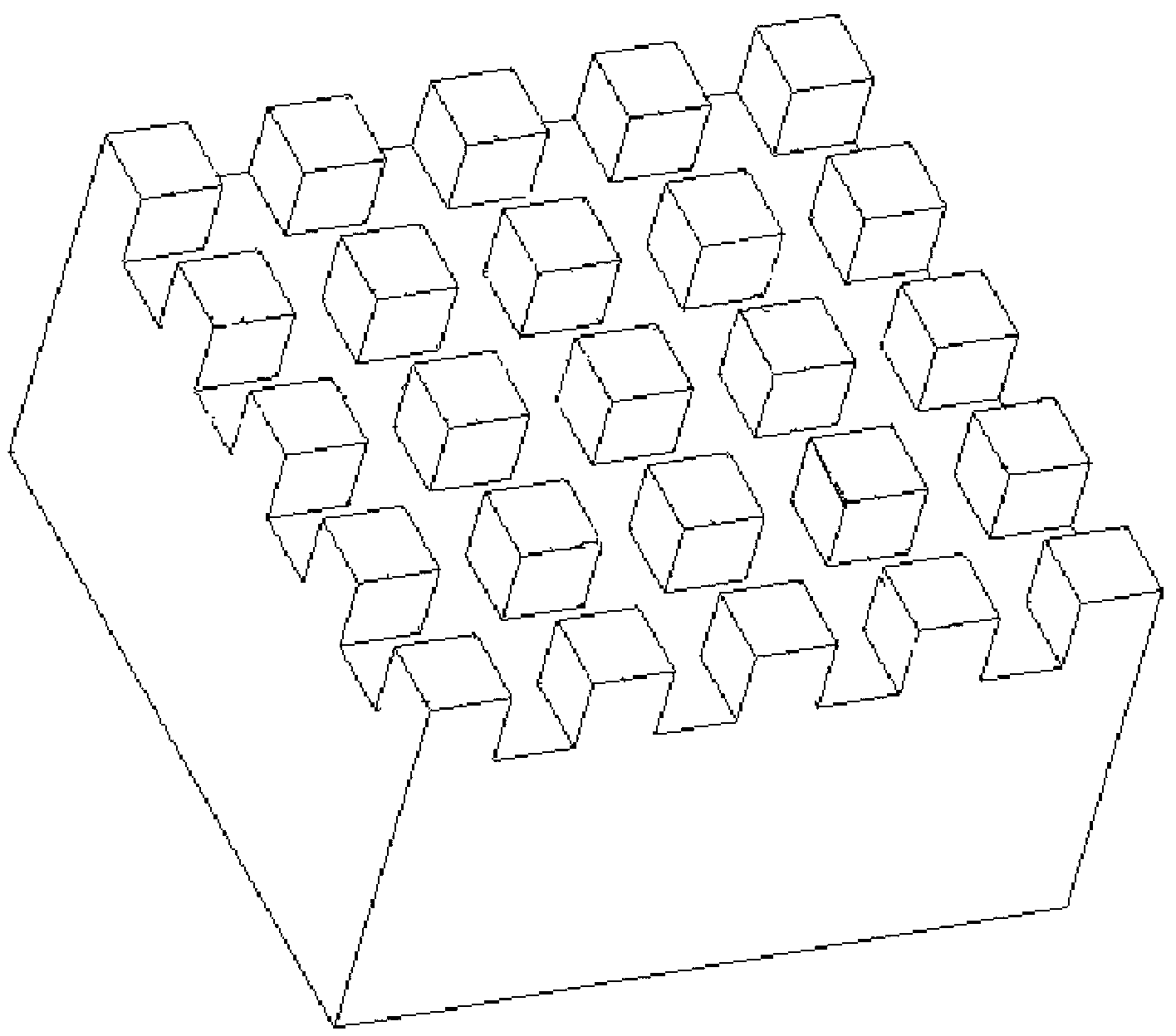

Diffusion bonding method of hard alloy and metal

ActiveCN103302371AIncrease connection areaFacilitates Diffusion and ReactionSoldering apparatusCemented carbideBonding strength

The invention relates to a diffusion bonding method of hard alloy and metal, and aims to solve the problems that the conventional bonding method is complicated in process and low in bonding strength. The diffusion bonding method comprises the following steps: 1, roughening a lug boss; 2, cleaning before welding; 3, performing diffusion bonding: putting the hard alloy and the metal which are cleaned into a diffusion bonding furnace, fixing the hard alloy and the metal with pressing heads, and performing diffusion bonding by the diffusion bonding process to achieve diffusion bonding of the hard alloy and the metal. The diffusion bonding method is simple in process and high in production efficiency; by the diffusion bonding method, metallurgical bonding of the hard alloy and the metal is effectively implemented, the bonding strength is improved, and using requirements of hard alloy / metal structural components can be met; the diffusion bonding method is applicable to the field of brazing.

Owner:哈尔滨瀚霖科技开发有限公司

Biological pesticideíñfoliage fertilizer

A ''biopesticide is multiplied by foliar fertilization'' innovative product is provided, which adopts the Chinese herb simple prescription or the polypharmaceutical with special biotoxin. The invention utilizes the marsh gas fermentation method in the breeding farm radical treatment breeding ''three wastes'' process marsh liquid fully degraded by the anaerobe and the marsh gas flora as the drug preparation mother liquid. The effective toxin in the Chinese herb in the prescription is extracted through natural fermentation of the microorganism and is fully dissolved and uniformly spread in the mother liquid of the drug preparation marsh liquid to acquire the ''biopesticide is multiplied by foliar fertilization'' plant protection novel product which is rich in a plurality of phytotoxin and biotoxin substances, a plurality of B-group vitamins of the animo acid, a plurality of water fresh enzyme and a plurality of plant growth hormones and can be used in developing and producing various green farm produce, various high grade organic agricultural products instead of the traditional chemical pesticide, has disinfecting, killing and inactivating effects on a plurality of plant diseases and insect pests of the crops and provides good nutrient sources for the crops.

Owner:郭以强

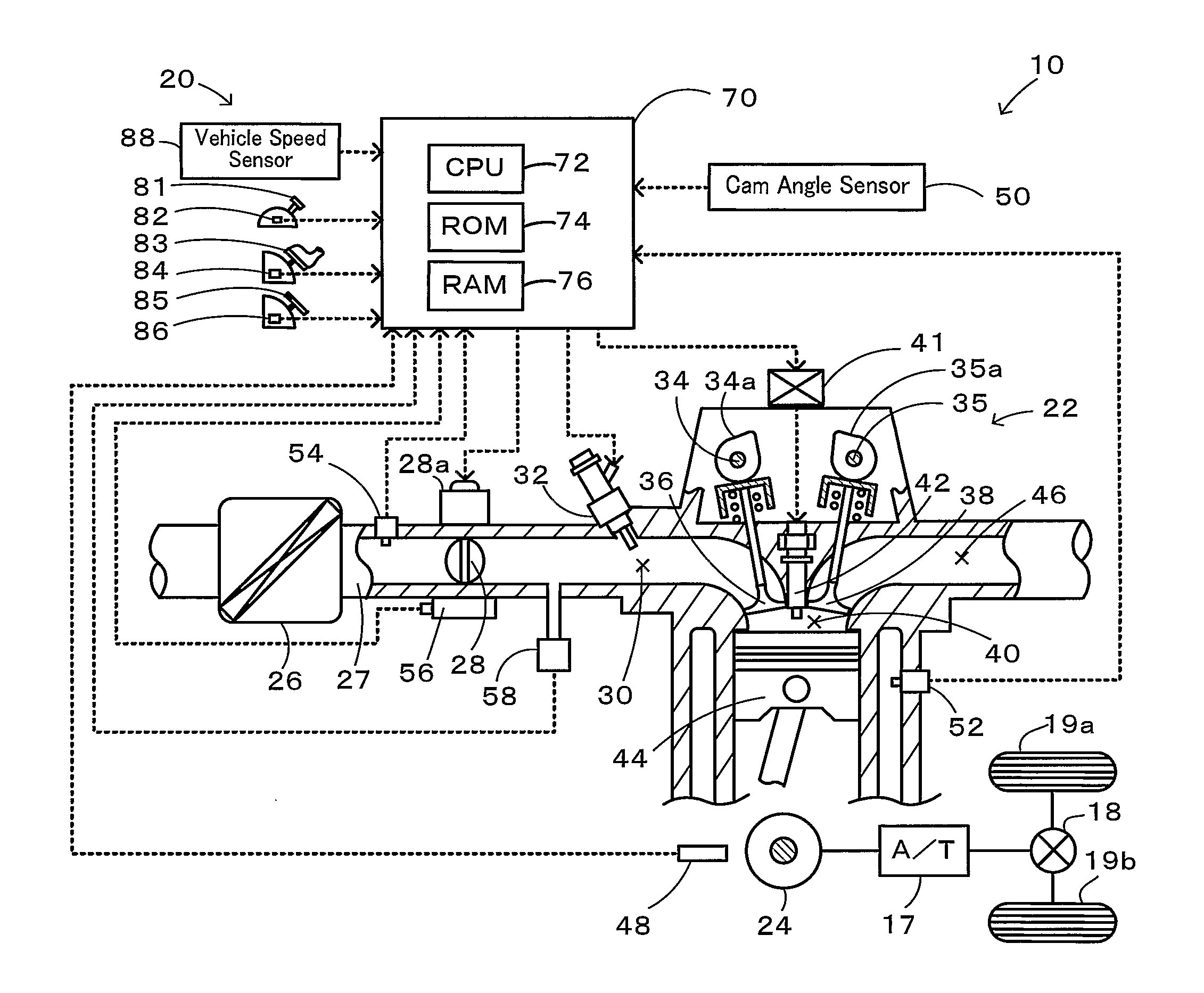

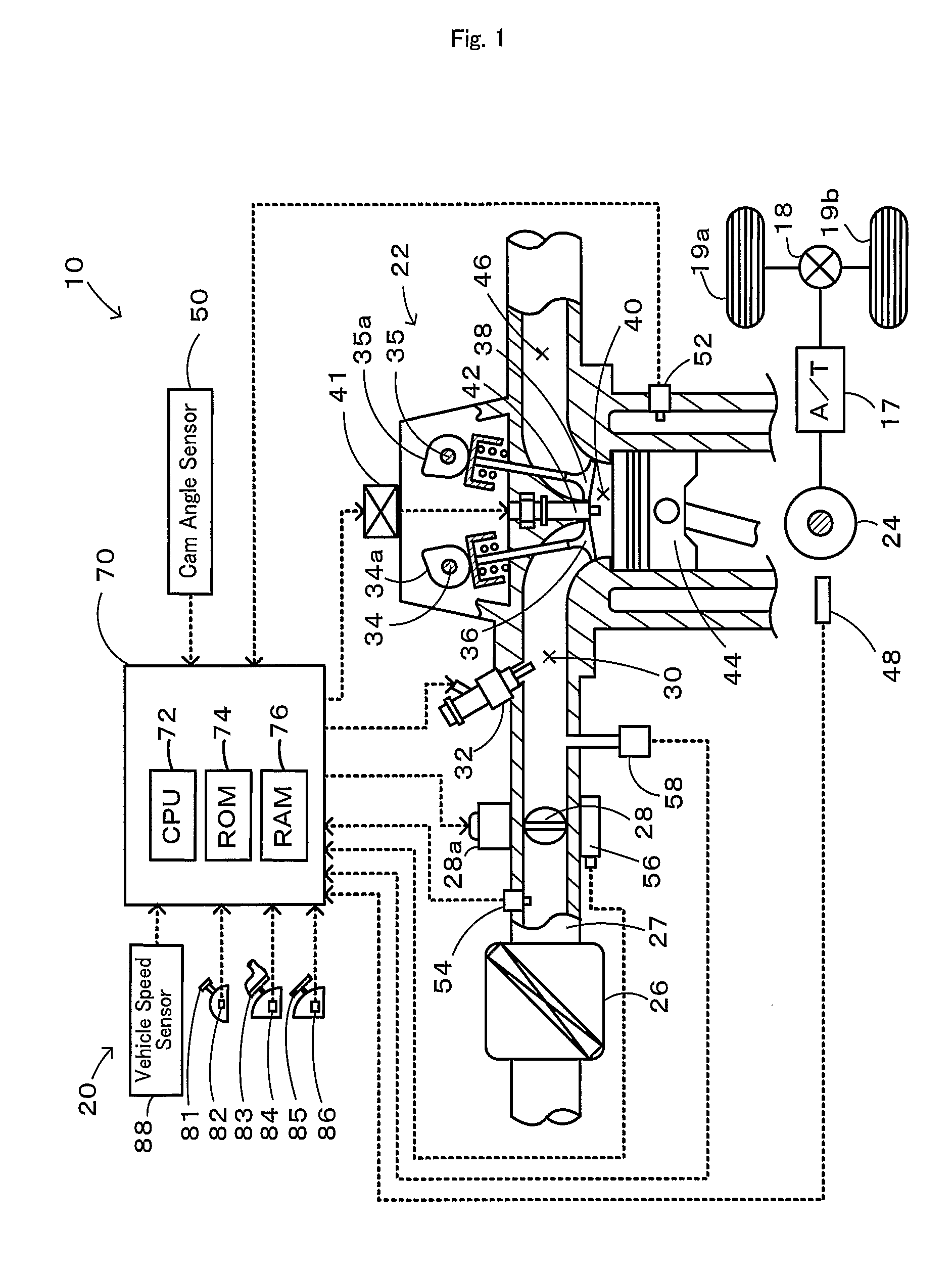

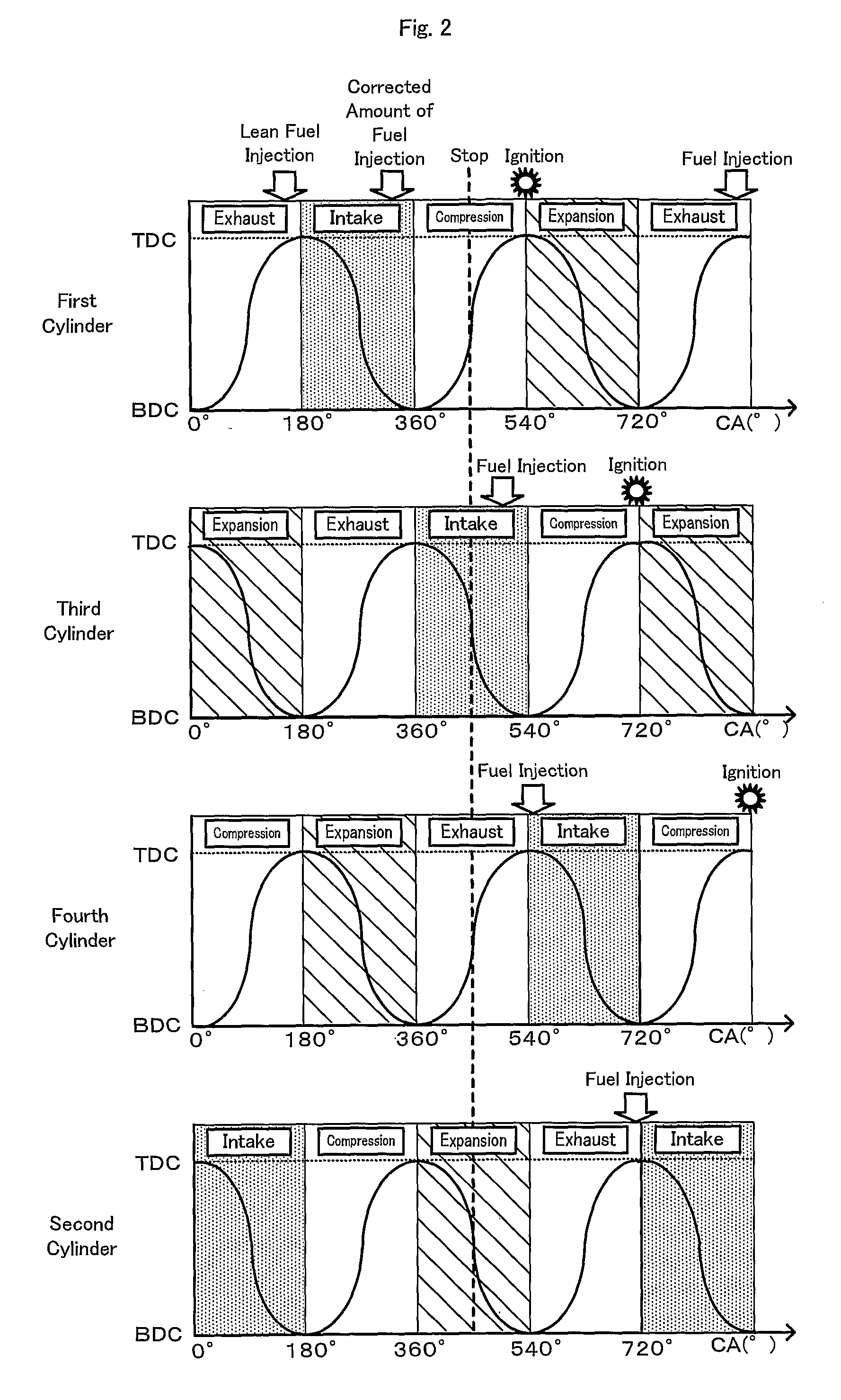

Internal Combustion Engine System and Internal Combustion Engine Control Method

ActiveUS20080091328A1Avoid vibrationStart fastAnalogue computers for vehiclesPower operated startersCombustionTop dead center

The internal combustion engine control technique of the invention computes a TDC pass rotation speed Ntdc, which represents the rotation speed of an engine when one of multiple cylinders of the engine passes over a top dead center TDC (step S110). The control technique estimates an engine stop crank angle CAs from a map that is experimentally or otherwise obtained to represent a variation in TDC pass rotation speed Ntdc against the stop position of the engine (step S120), and specifies a fuel injection cylinder that stops in a preset cycle range including part of a compression stroke at a stop of the engine (step S130). The specified fuel injection cylinder receives lean fuel injection at a specific fuel injection timing (step S170). When the specified fuel injection cylinder is later presumed not to pass over a top dead center TDC of the compression stroke, a corrected amount of fuel is injected into the specified fuel injection cylinder (step S240). When the specified fuel injection cylinder is later presumed to pass over the top dead center TDC of the compression stroke, on the other hand, the control technique ignites an air-fuel mixture of the intake air and the injected fuel for combustion in the compression stroke, synchronously with fuel injection into a next cylinder that goes into the compression stroke after the specified fuel injection cylinder (step S270).

Owner:TOYOTA JIDOSHA KK

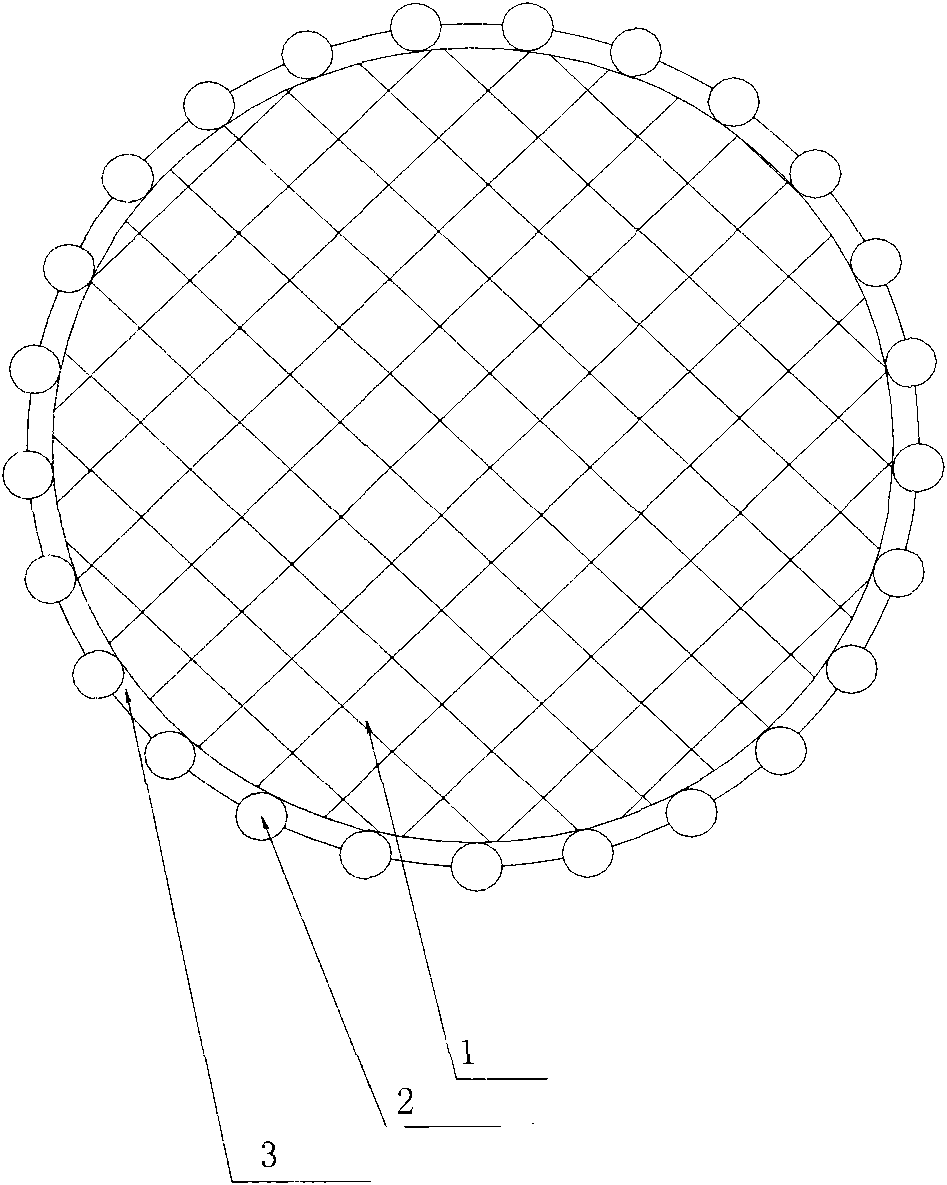

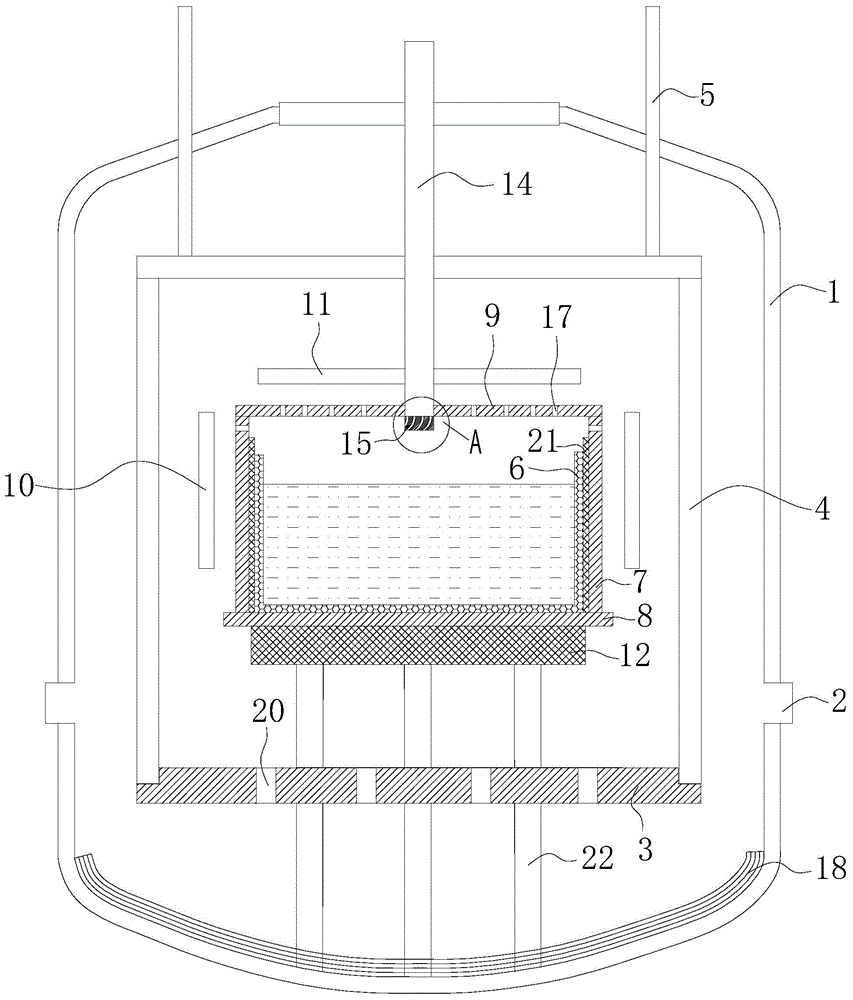

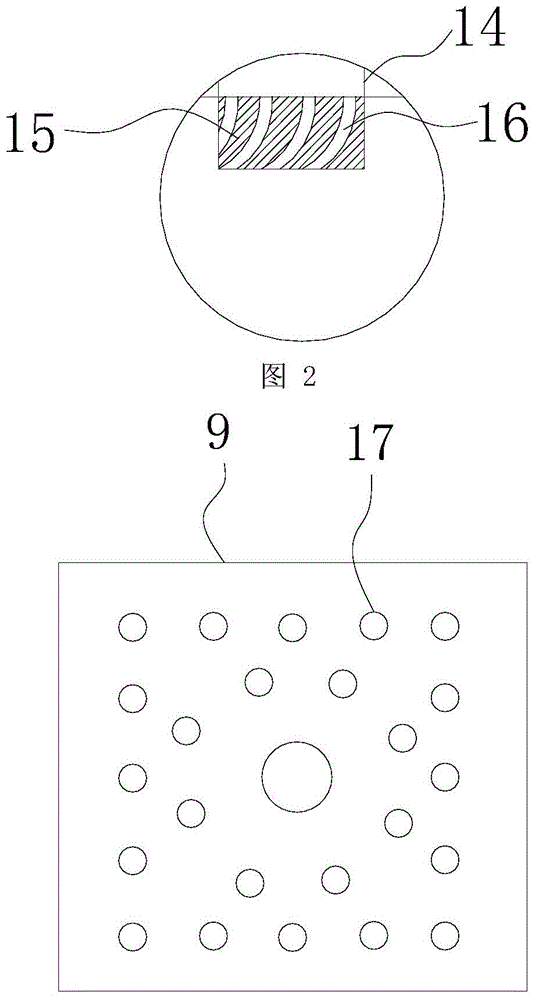

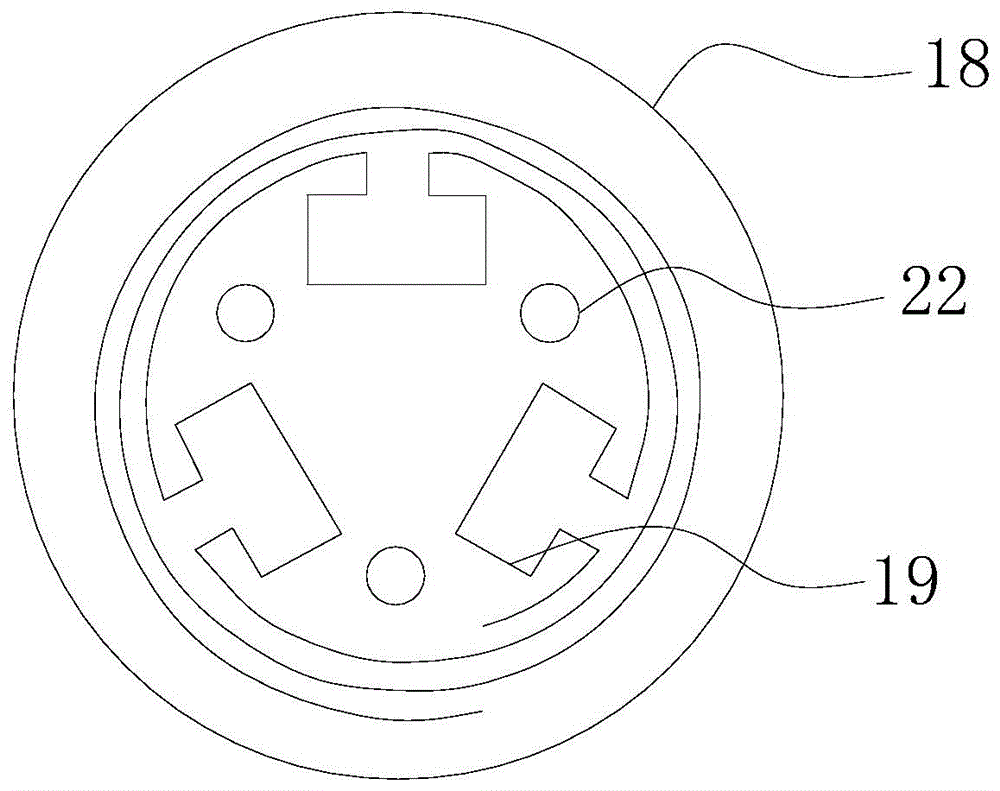

Polycrystalline silicon ingot furnace

ActiveCN103556220ADiffuse fullyAvoid enriched regionsPolycrystalline material growthSingle crystal growth detailsCrucibleIngot

The invention discloses a polycrystalline silicon ingot furnace which can enable the resistivity of a cast ingot to be distributed uniformly. A stop block for sealing a gas outlet is arranged at the gas outlet of a gas inlet pipe of the polycrystalline silicon ingot furnace, a plurality of spiral holes with the same helical direction are formed in the stop block, the plurality of the spiral holes are arranged around the central axis of the gas inlet pipe, inlets of the spiral holes are positioned on the upper surface of the stop block, and outlets of the spiral holes are positioned on the lower surface of the stop block. After argon gas passes through the spiral holes, the gas outlet way of the argon gas is changed from original direct blowing to rotating gas outlet, and the argon gas which is sprayed out of the spiral holes in a rotating manner can drive a silicon solution in a crucible to rotate, so that impurities contained in the silicon solution can be fully diffused in the silicon solution, the distribution of liquid-phase components is uniform, and the uniform distribution of the resistivity of the cast ingot is ensured; furthermore, the stirring of the silicon solution in the crucible can enable the volatile impurities contained in the silicon solution to be volatilized as soon as possible so as to ensure the quality and performance of the cast ingot. The polycrystalline silicon ingot furnace is suitable for popularization and application in the field of polycrystalline silicon production equipment.

Owner:LESHAN TOPRAYCELL

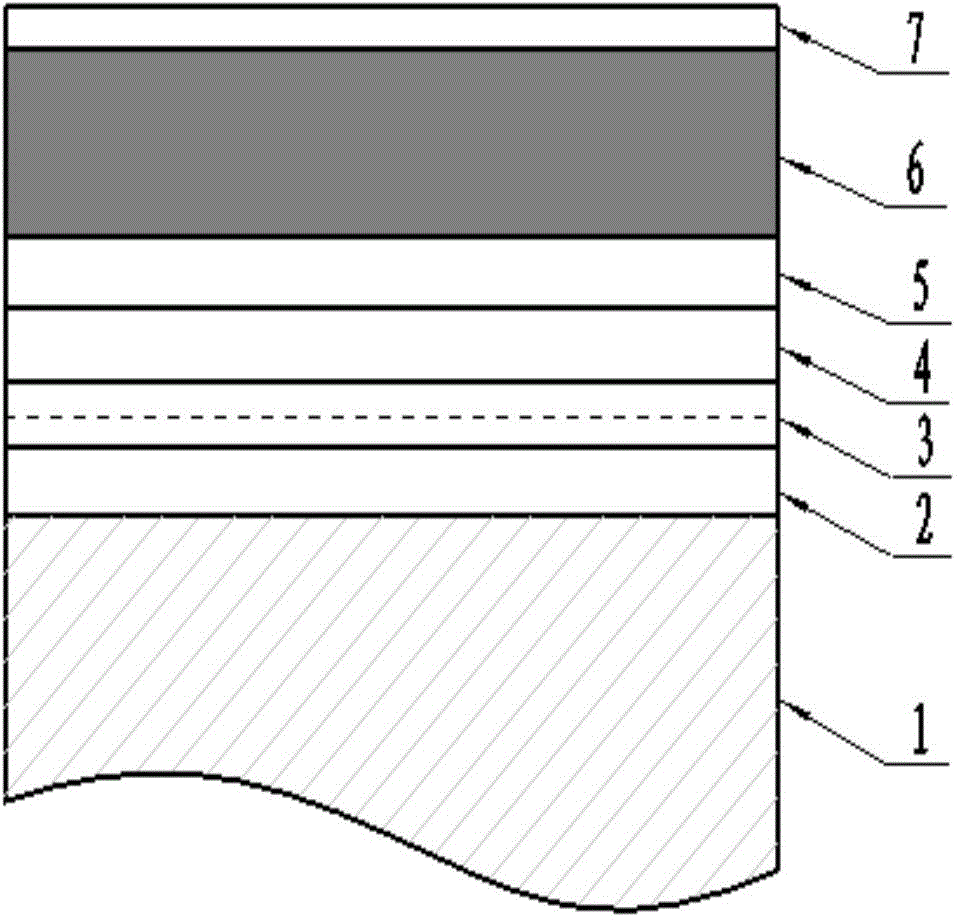

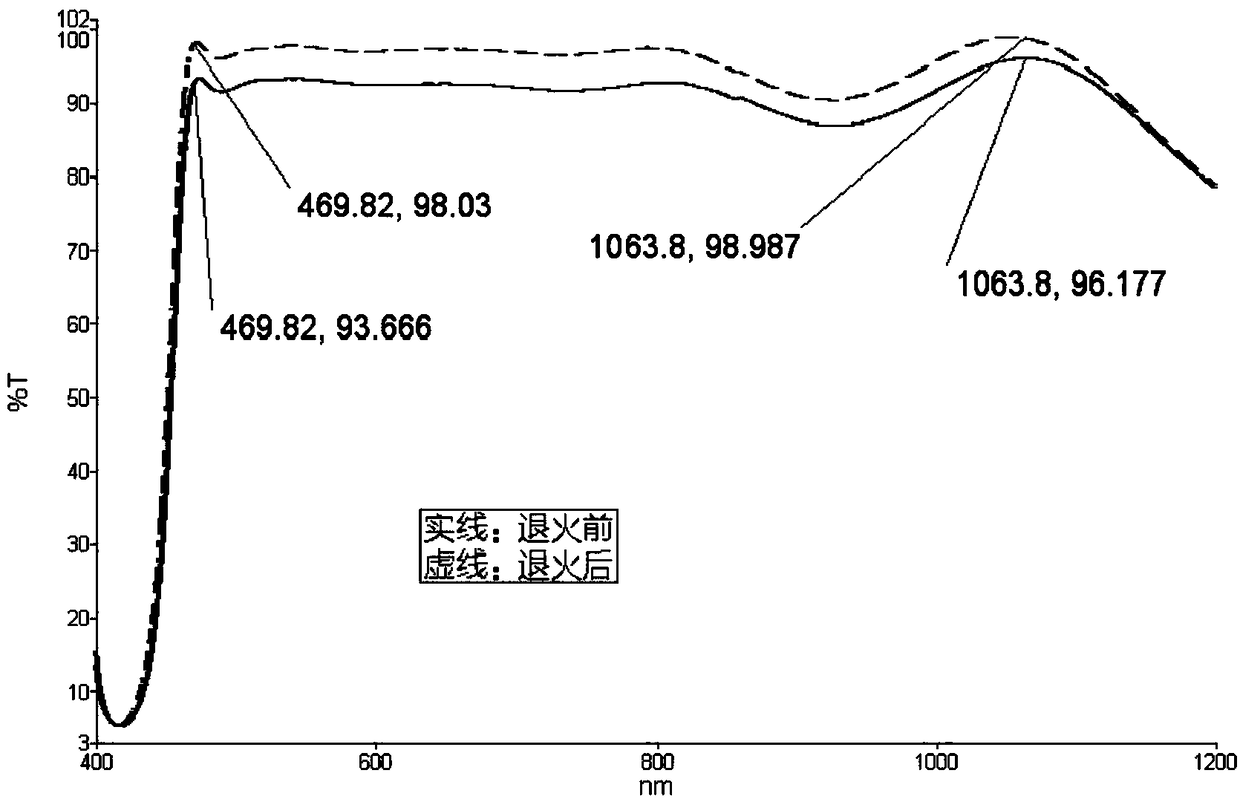

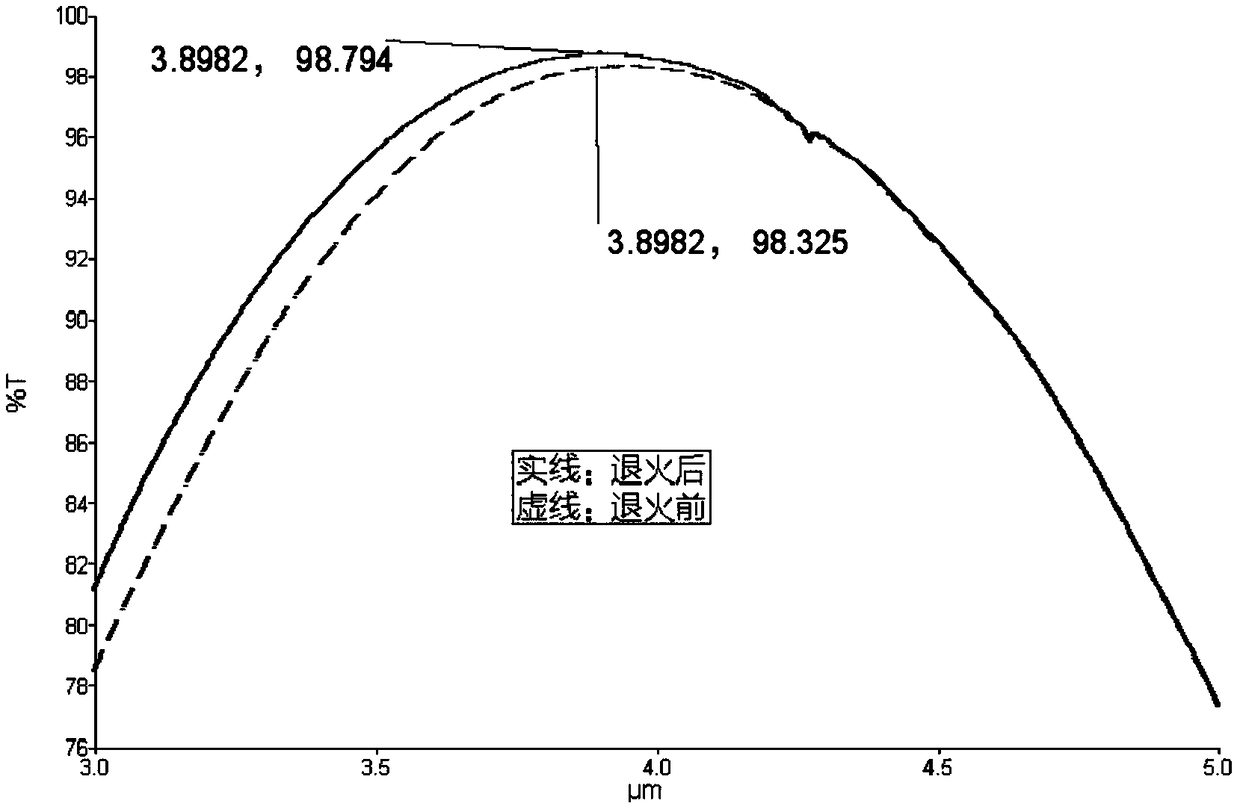

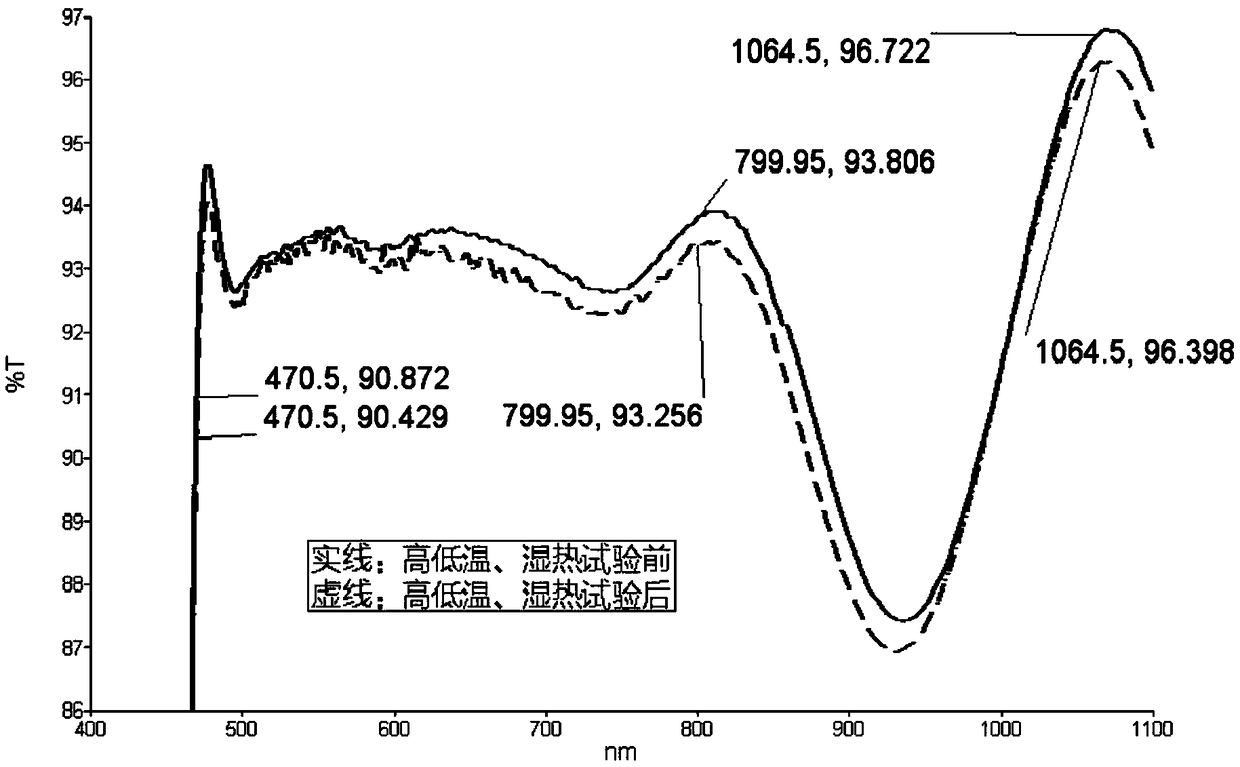

Large-size sapphire substrate multi-spectral hard antireflection film and preparation method thereof

ActiveCN109182972AStress minimizationReduce stress valueVacuum evaporation coatingSputtering coatingRefractive indexIon beam-assisted deposition

The invention discloses a large-size sapphire substrate multi-spectral hard antireflection film and a preparation method thereof. The film comprises a sapphire substrate, a stress matching layer, an oxide material multilayer antireflection film system and a hard wear-resisting protective layer in sequence from bottom to top; the oxide material multilayer antireflection film system is formed by alternated plating of high / low refractive index materials, and ion beam assisted deposition is adopted. Ti3O5 or ZrO2 or Ta2O5 is selected as the high refractive index material, and SiO2 is selected as the low refractive index material. According to the invention, a conventional oxide film material is adopted, and the related technique is easy for transplanting, so that the film coating and film forming quality of the large-size sapphire substrate multi-spectral hard antireflection film does not depend on the hardware state of coating machine strongly, and the optical performance and the mechanical and physical performance of the film are substantially promoted.

Owner:HUAZHONG PHOTOELECTRIC TECH INST (CHINA SHIPBUILDING IND CORP THE NO 717 INST)

Sustained release microparticles and sustained release microparticle-containing preparations

[Problem]Provision of sustained release microparticles having excellent characteristics, in which the microparticles for supporting a substance or substances can fully control the release of the supported substances, can sufficiently diffuse the supported substances in a medium such as water, and can effect sustained release of more than one kind of the supported substances differing in water solubility, each at the respectively desired rate; and also to provide preparations which contain said sustained release microparticles.[Means of Solution]Sustained release microparticles comprising a supported substance, microgranular form and coating agent, said microgranular form having an average particle size within a range of from 20 to 300 μm; and preparations which contain the sustained release microparticles.

Owner:KYOYU AGRI

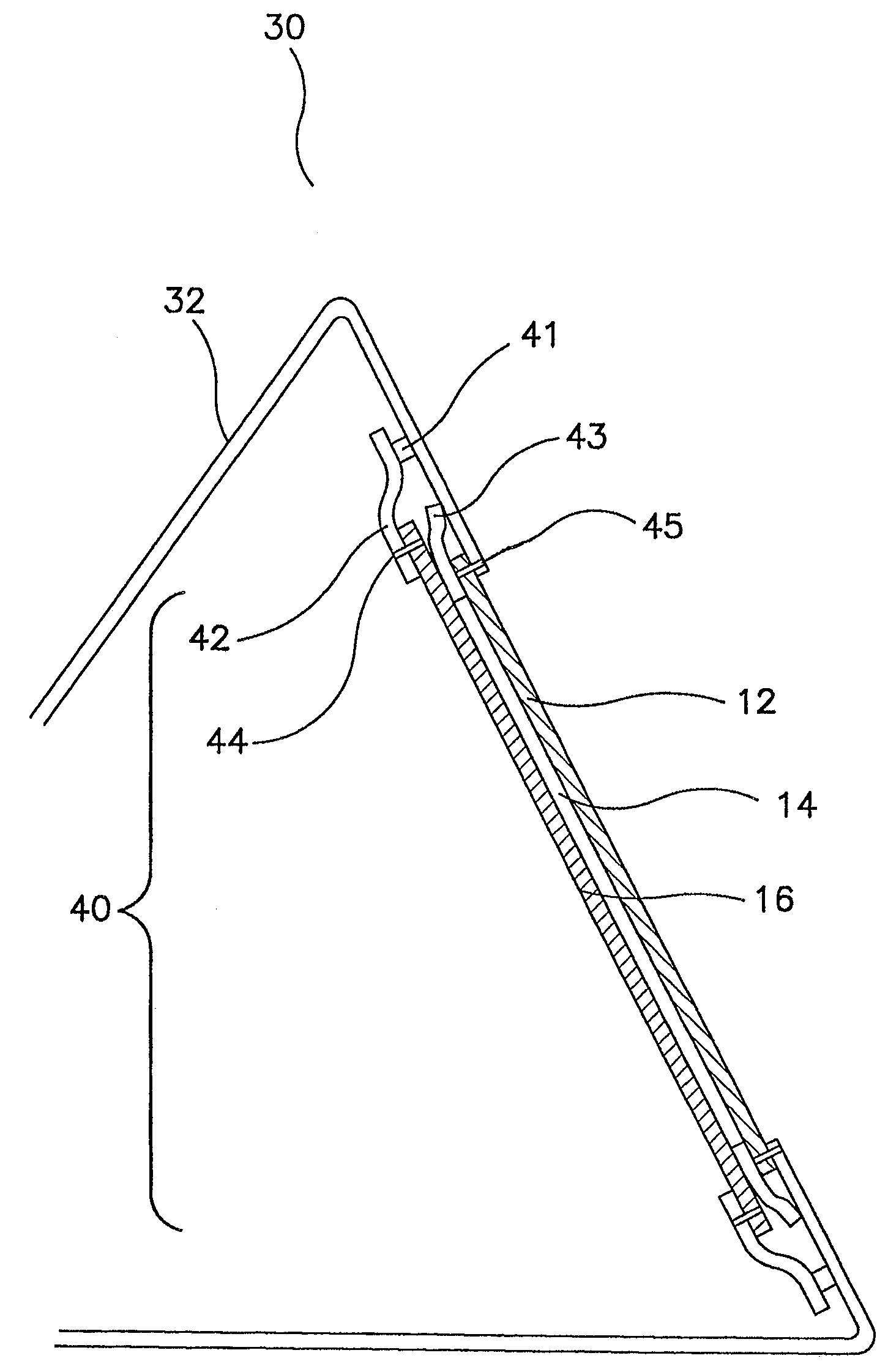

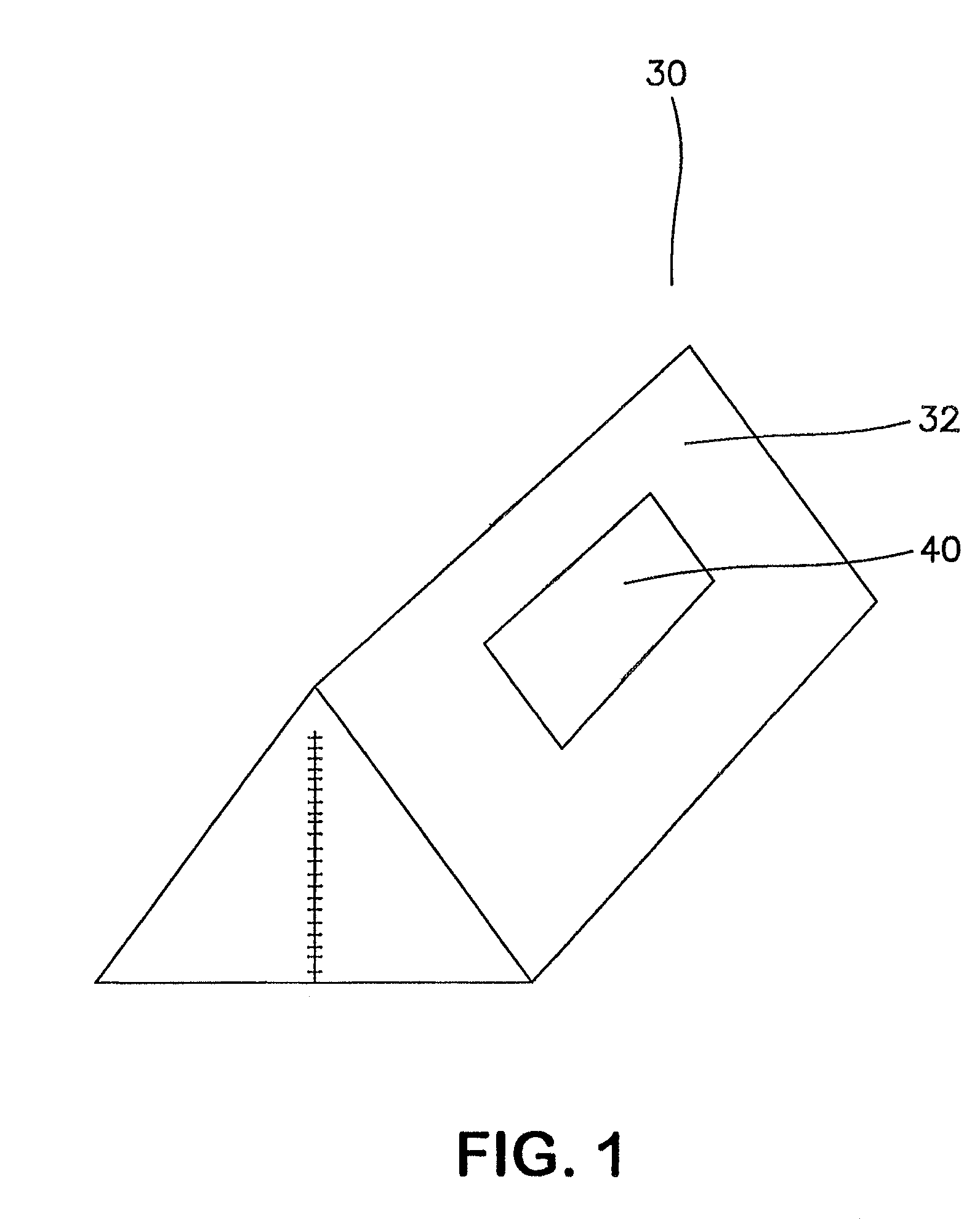

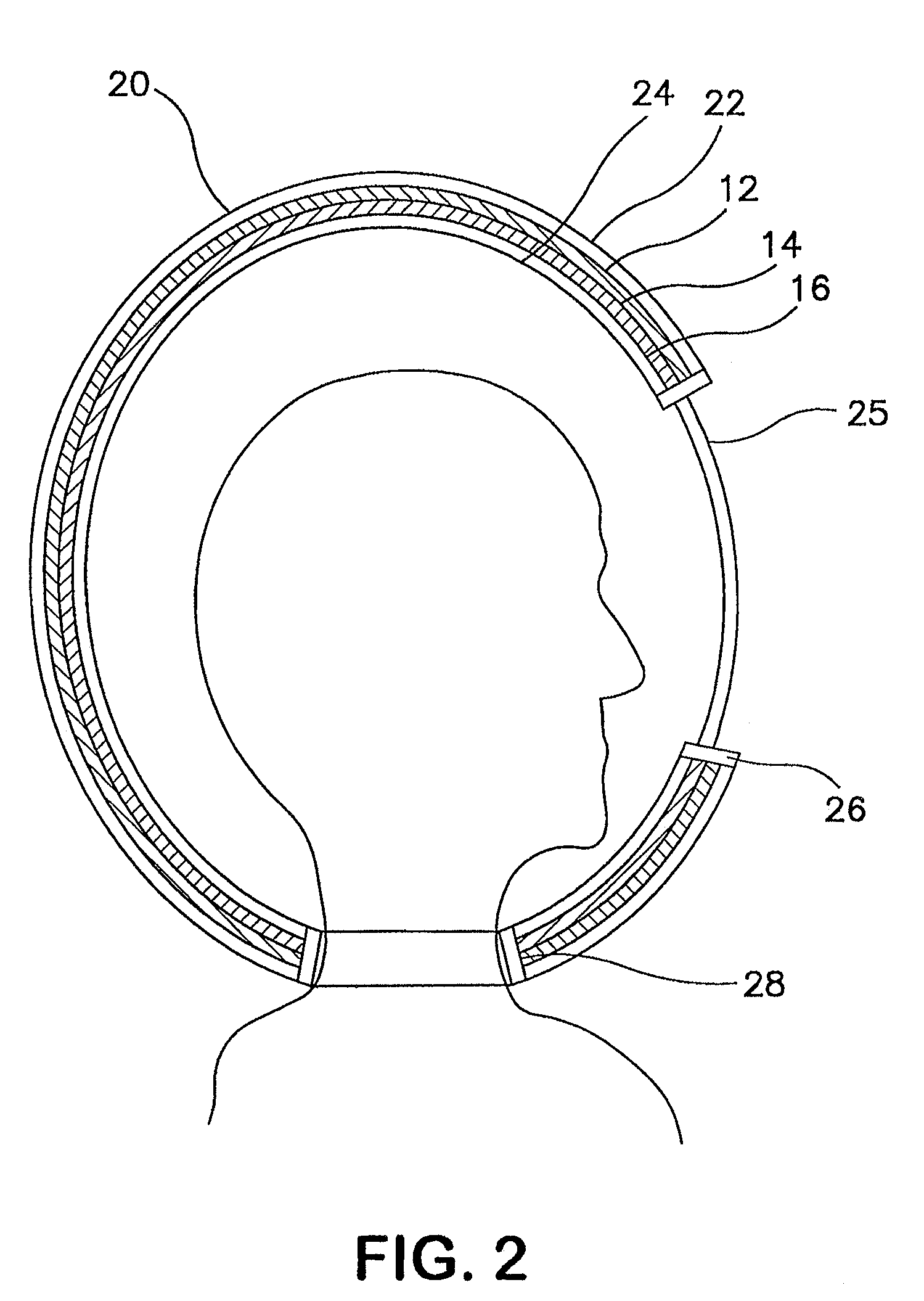

Protective enclosure

InactiveUS7549431B1High protection levelSustain lifeChemical protectionHeat protectionDiffusionEngineering

Owner:WL GORE & ASSOC INC

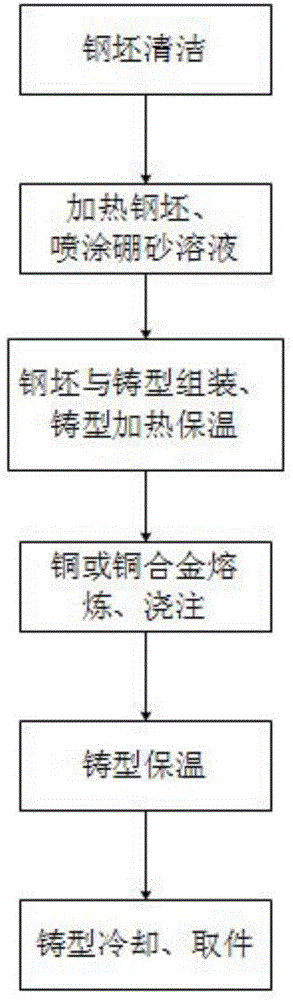

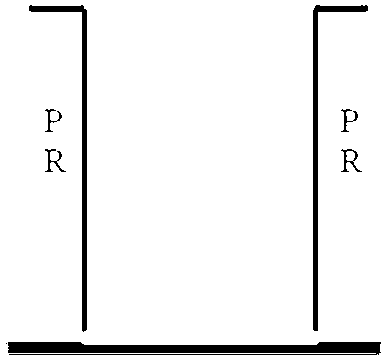

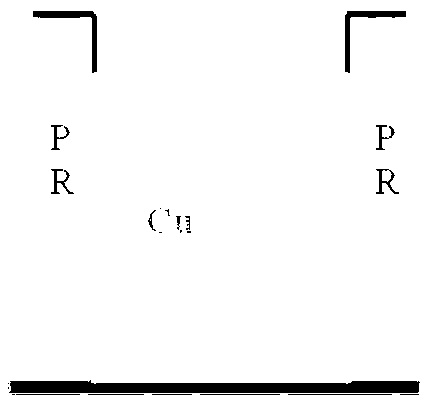

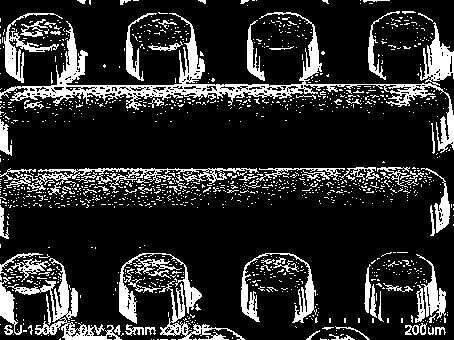

Copper and steel bimetallic casting application technology

The invention provides a copper and steel bimetallic casting application technology. Copper or copper alloy with certain thickness is directly cast on a steel base body by a static casting mold casting method. The technology mainly comprises the following steps of cleaning a steel billet, heating the steel billet, spraying a borax solution, combining a casting mold, heating and insulating heat, melting and casting the copper or the copper alloy, and insulating the heat of the casting mold at high temperature. The copper and steel bimetallic casting application technology has the advantages that a copper or copper alloy layer with certain thickness and without segregation can be cast on various shapes and various sizes of steel billets, and the good metallurgical combination between the copper or copper alloy layer of a casting and the steel billets is realized.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

High-speed embossment electroplating method applied to copper interconnection

ActiveCN103103585AFast depositionCrystal fineCellsSemiconductor devicesPolyethylene glycolFatty alcohol

The invention discloses a high-speed embossment electroplating method applied to copper interconnection. A sulfonic acid copper system electroplating liquid is adopted to carry out copper column embossment electroplating; the electroplating conditions are as follows: the current density is 1-25A / dm<2>, and the temperature is 15-35 DEG C; the electroplating liquid comprises 160-350g / L high-purity methanesulfonic acid copper salt, 30-180g / L high-purity methanesulfonic acid and 10-80mg / L chloride ions; the electroplating liquid further comprises 1-10ml / L of an accelerator and 1-10ml / L of a leveling agent; the accelerator is UPB3221A and comprises one or a mixture of several of polydithio dipropane sodium sulfonate, alcohlpropane sulfonate, phenyl dithio propane sodium sulfonate, 3-sulfenyl-1-propanesulfonic acid sodium salt and dimethyl-dithio formamide sulfonic acid; and the leveling agent is UPB3221L and comprises one or a mixture of several of polyethylene glycol, a fatty alcohol alkoxy compound, an ethylene oxide-propylene oxide block copolymer of which the molecular weights are respectively 400, 1,000, 6,000 and 20,000. The high-speed embossment electroplating method applied to copper interconnection, disclosed by the invention, ensures that a copper column has good reliability and uniformity, and at the same time has a relatively high electroplating speed.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Pressure container steel plate resistant to hydrogen induced cracking and manufacturing method thereof

ActiveCN105886909AHigh strengthImprove low temperature impact toughnessFurnace typesHeat treatment furnacesNon-metallic inclusionsHardness

The invention relates to a pressure container steel plate resistant to hydrogen induced cracking. The steel plate comprises, by weight, 0.16%-0.20% of C, 0.15%-0.40% of Si, 1.05%-1.20% of Mn, less than or equal to 0.008% of P, less than or equal to 0.002% of S, less than or equal to 0.01% of Nb, less than or equal to 0.01% of V, less than or equal to 0.01% of Ti, less than or equal to 0.0005% of B, and the balance Fe and inevitable impurity elements. The carbon equivalent Ceq is less than or equal to 0.42%, and a calculation formula for the carbon equivalent Ceq is Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The steel plate is high in strength and low-temperature impact toughness, low in hardness and good in HIC resistance. The steel plate has fine grains and low nonmetal inclusion content, and obvious banded structures do not exist. After long-time simulation of postweld heat treatment at a high temperature, the strength and the low-temperature impact toughness of the steel plate are not obviously weakened.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Method for manufacturing nitride-based semiconductor device

InactiveUS7691651B2Quality improvementPromote growthSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialNucleation

In a method for manufacturing a high-quality GaN-based semiconductor layer on a substrate of different material, an AlN nucleation layer is grown on a substrate, a GaN buffer layer is grown on the AlN nucleation layer, and the substrate annealed. The AlN nucleation layer is formed to have a thickness greater than a critical radius of a nucleus of AlN crystal and less than a critical resilient thickness of AlN, and the GaN buffer layer is formed to have a thickness greater than a critical radius of a nucleus of GaN crystal and less than a critical resilient thickness of GaN. Annealing time is greater than L2 / DGa where L indicates a diffusion distance of Ga, and DGa indicates a diffusion coefficient of Ga in the AlN nucleation layer.

Owner:SAMSUNG ELECTRONICS CO LTD

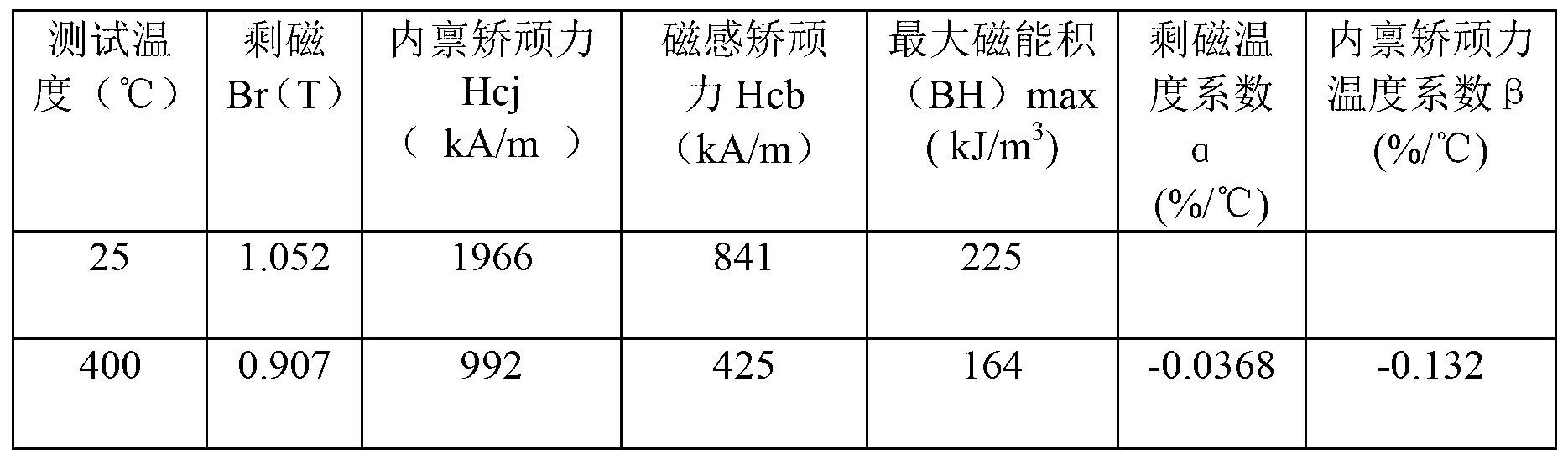

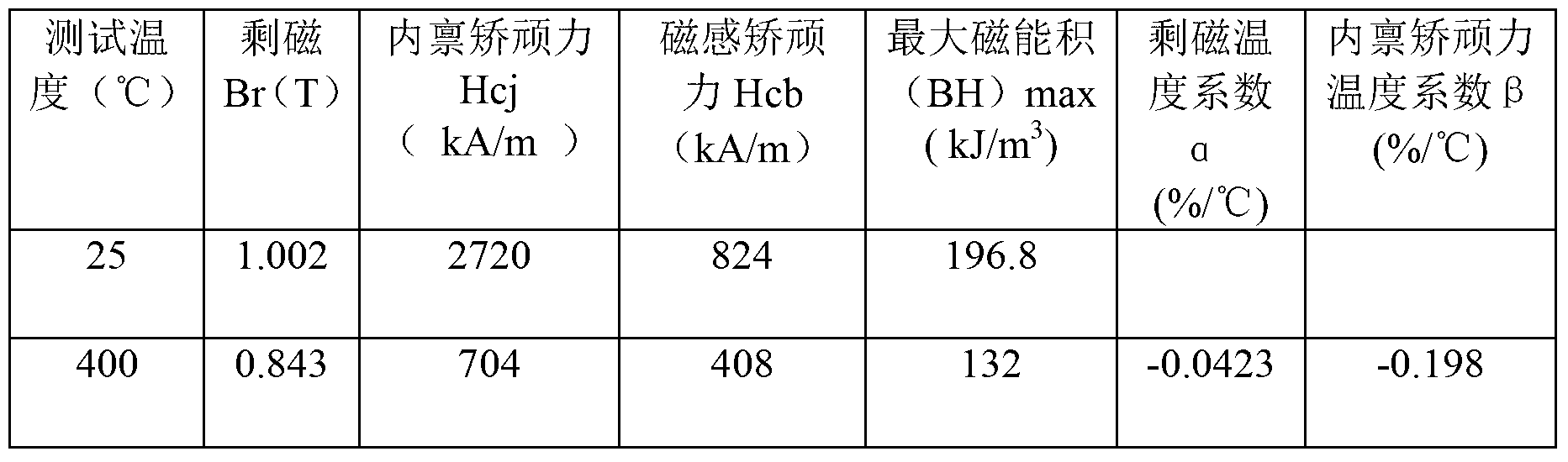

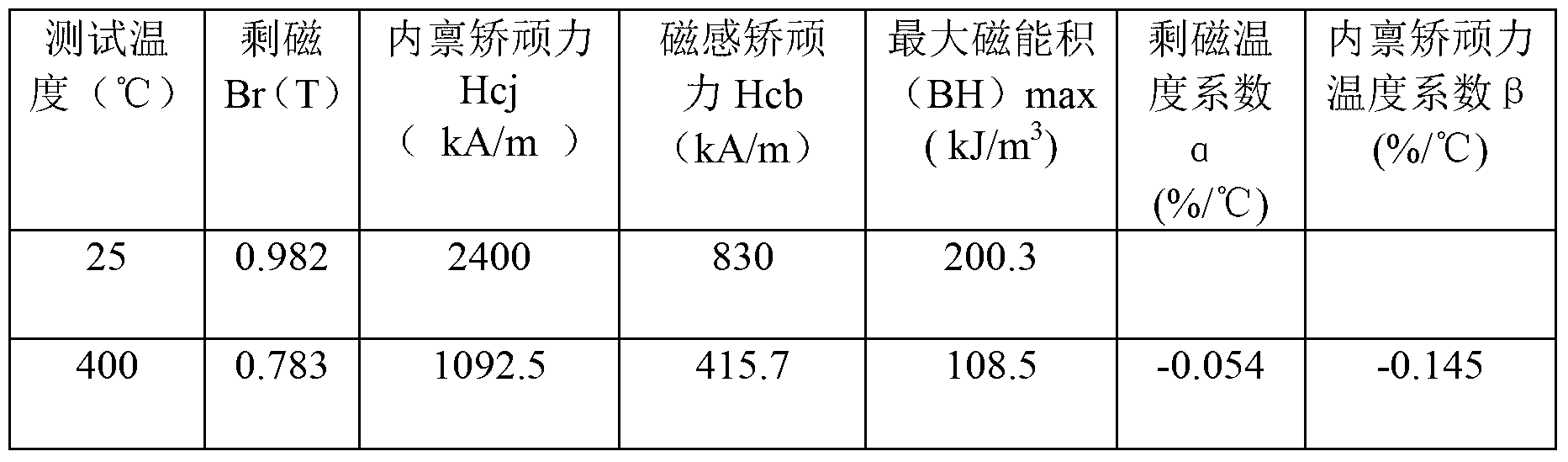

Samarium cobalt permanent magnetic material and preparation method thereof

InactiveCN103325513AHigh cost of preparationReduce raw material costsMagnetic materialsTemperature coefficientChemical Ingredients

The invention discloses a samarium cobalt permanent magnetic material and a preparation method thereof. The samarium cobalt permanent magnetic material is prepared from the following chemical ingredients by mass percent: 24.5-26% of samarium, 52-56% of cobalt, 7.5-12% of iron, 6.5-8% of copper, and 2-4% of zirconium. The samarium cobalt permanent magnet disclosed by the invention has high coercivity and low temperature coefficient; the magnetic performance at the temperature of 400-450 DEG C is that the residual magnetism Br is 0.783-0.907 T; the intrinsic coercivity Hcj is 704-1092.5 kA / m; the maximal magnetic level (BH)max is 108.5-164 kJ / m<3>; the temperature coefficient alpha of the residual magnetism is -0.0368% / DEG C to -0.054% / DEG C; and the temperature coefficient beta of the intrinsic coercivity is -0.132% / DEG C to -0.198% / DEG C. Thus, the samarium cobalt permanent magnetic material is simple in process and low in manufacturing cost.

Owner:湖南航天有限责任公司

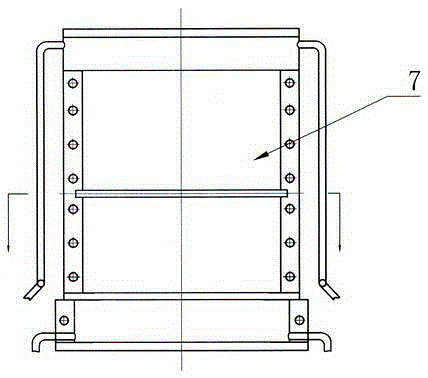

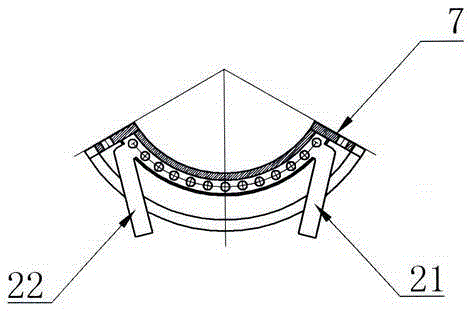

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com