Patents

Literature

1235 results about "Coal pillar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

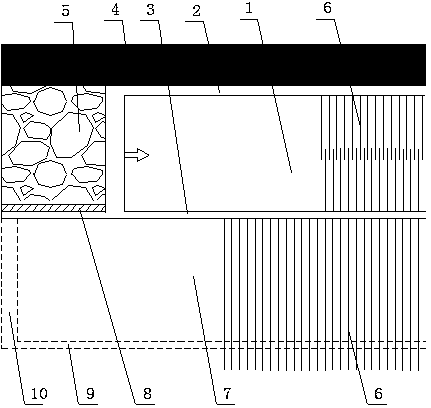

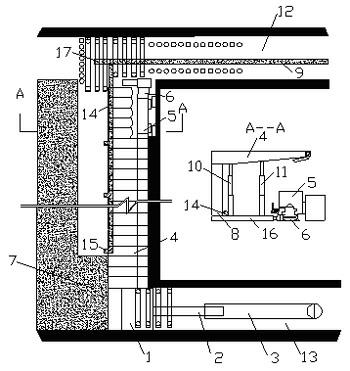

House pillar type cutting and filling method of medium coal seam for controlling movement deformation of overlying rock

InactiveCN102011588AImprove securityIncrease productivityUnderground miningSurface miningEngineeringCoal pillar

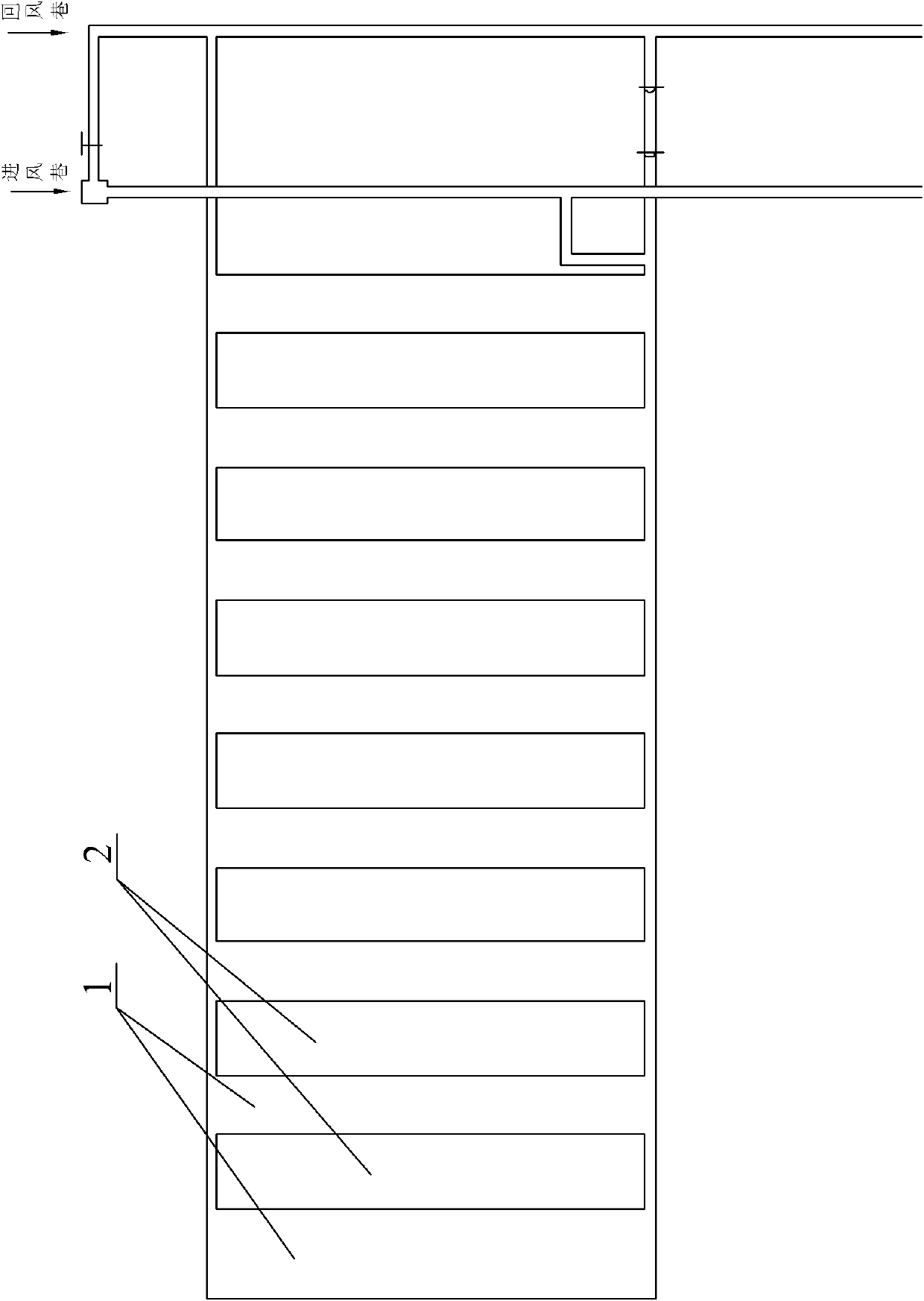

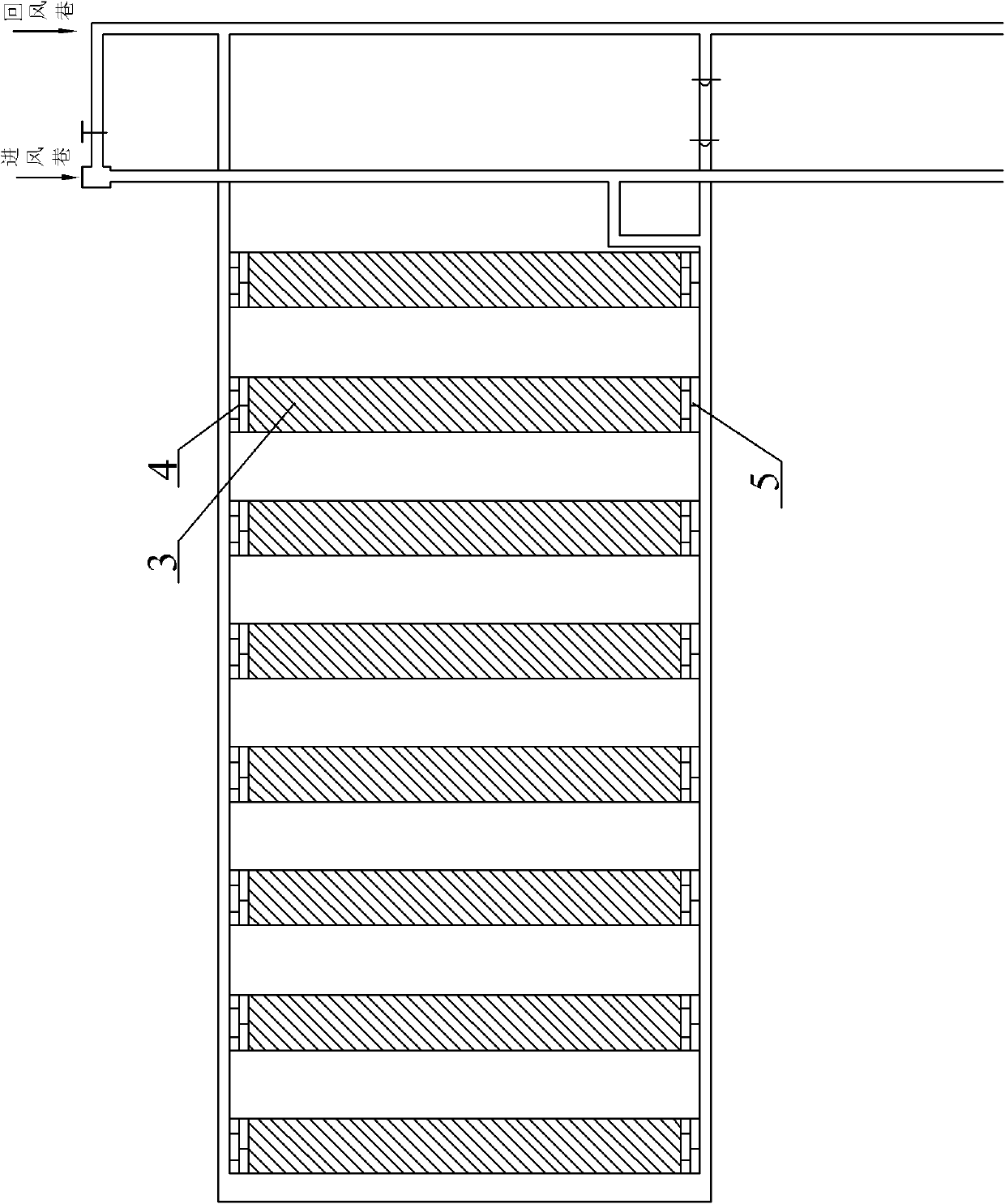

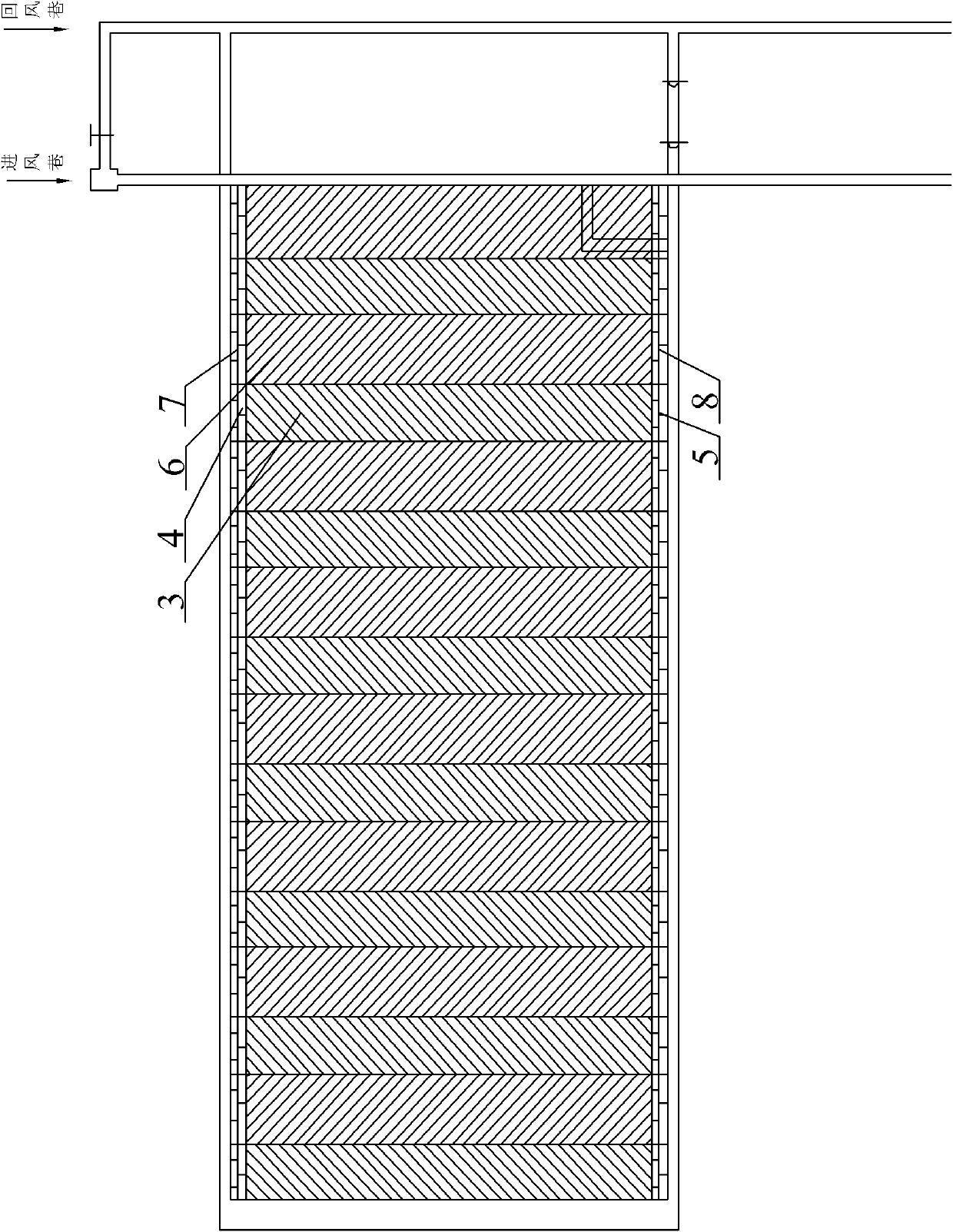

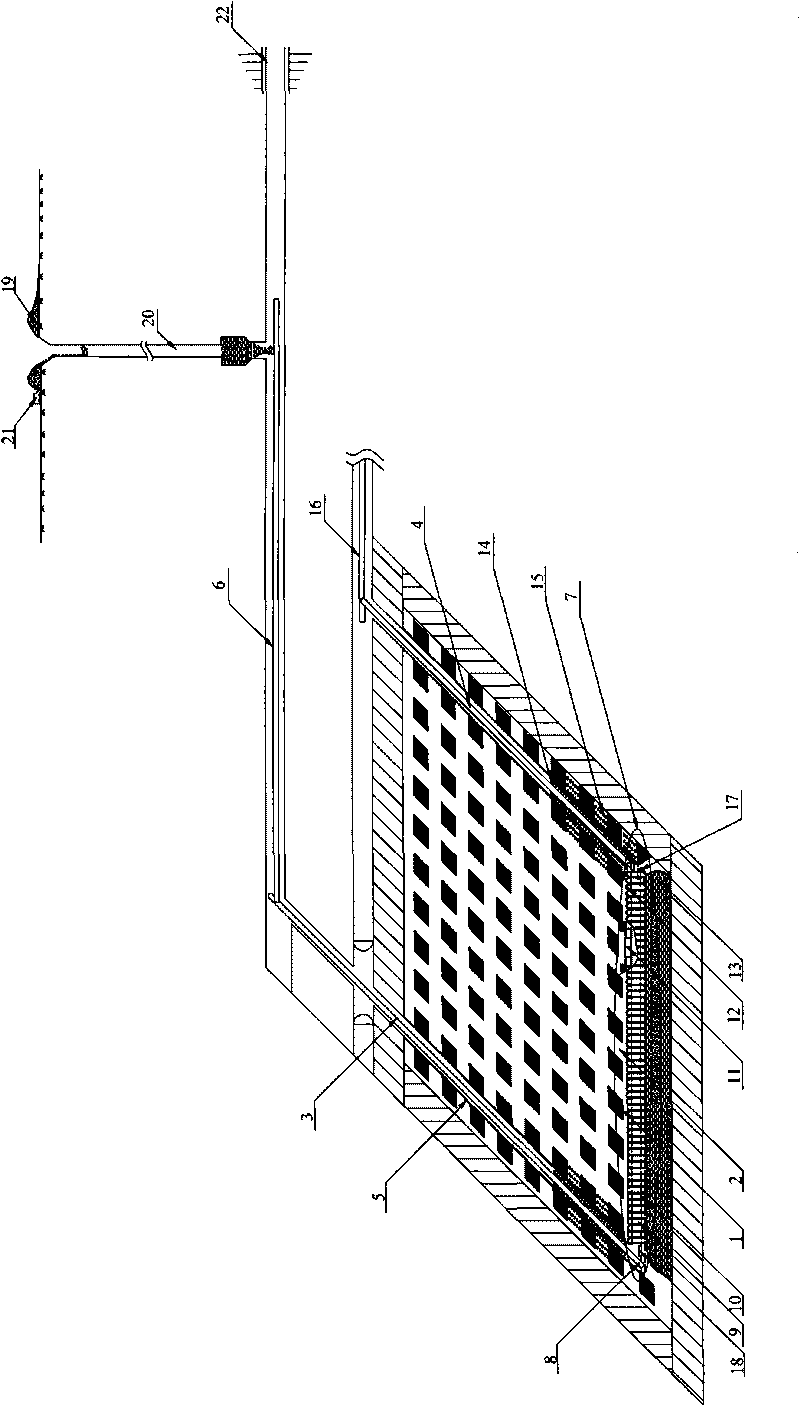

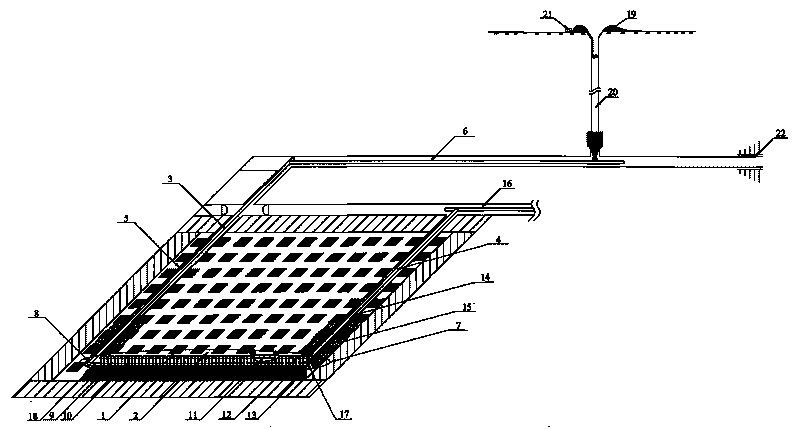

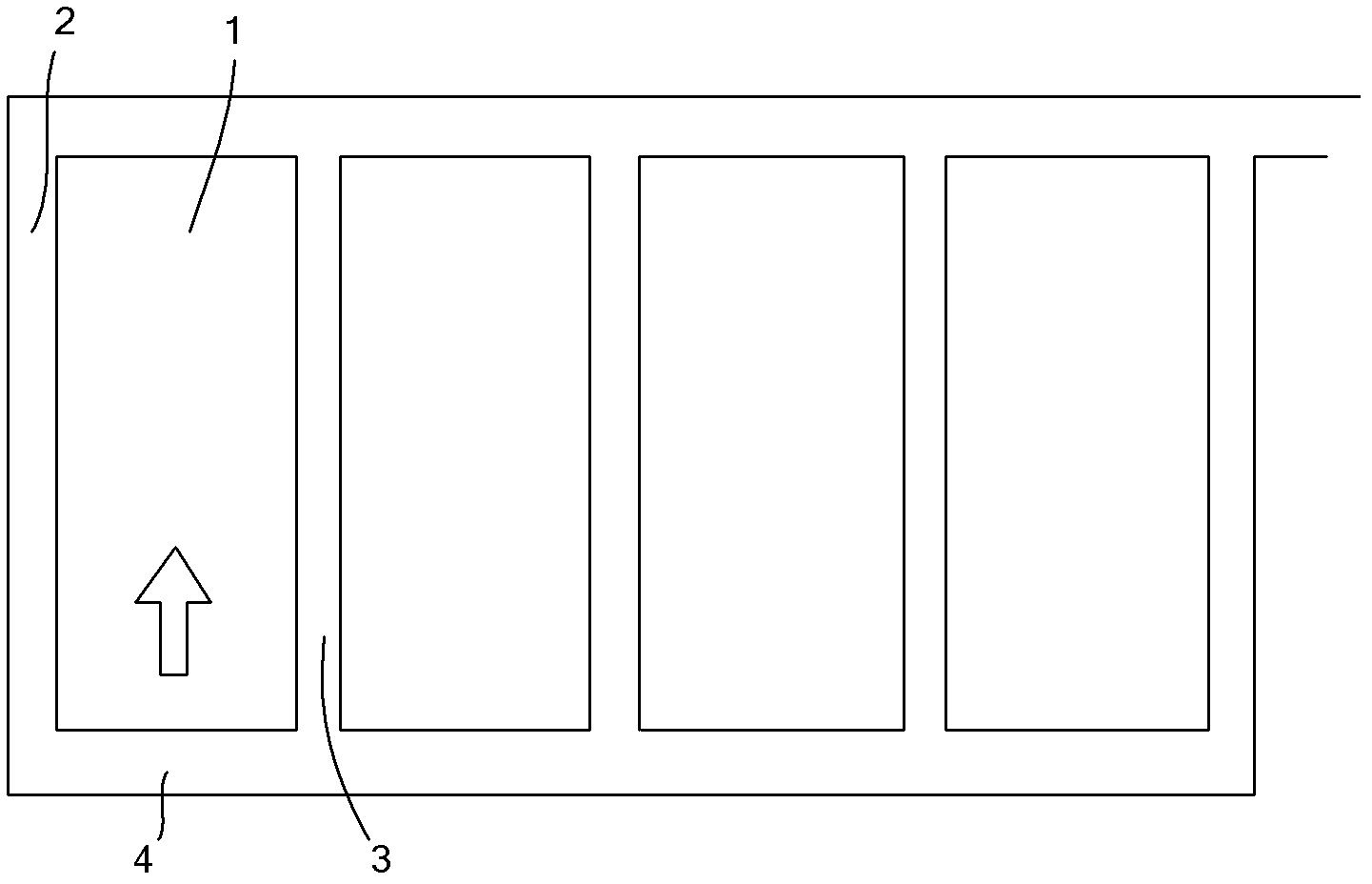

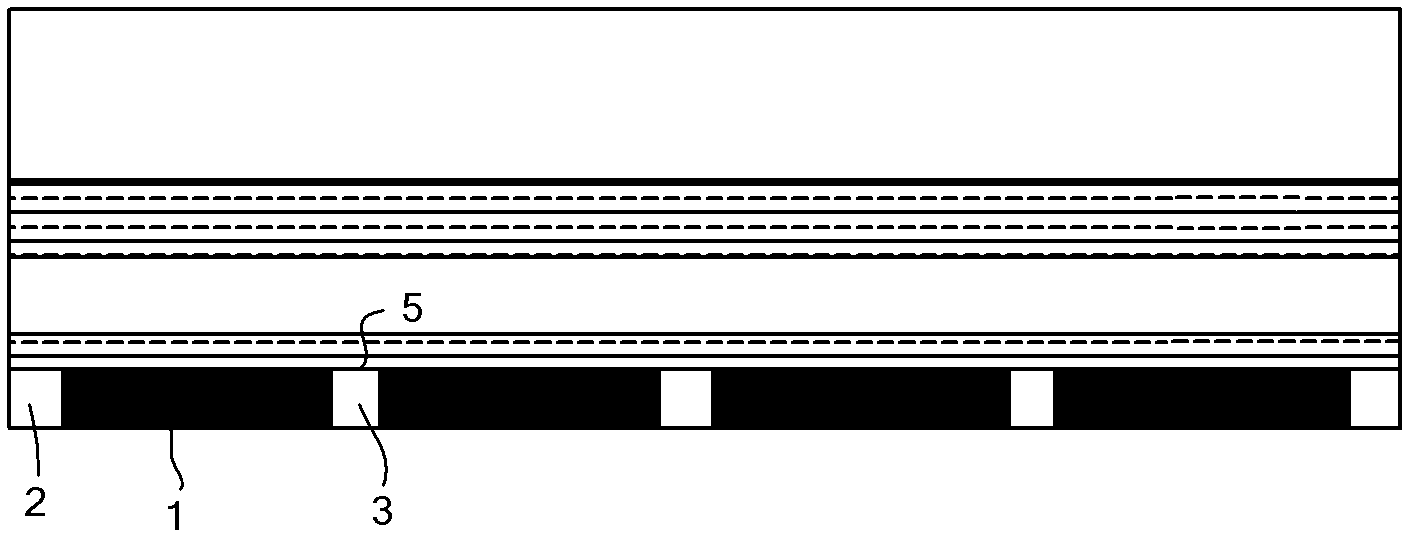

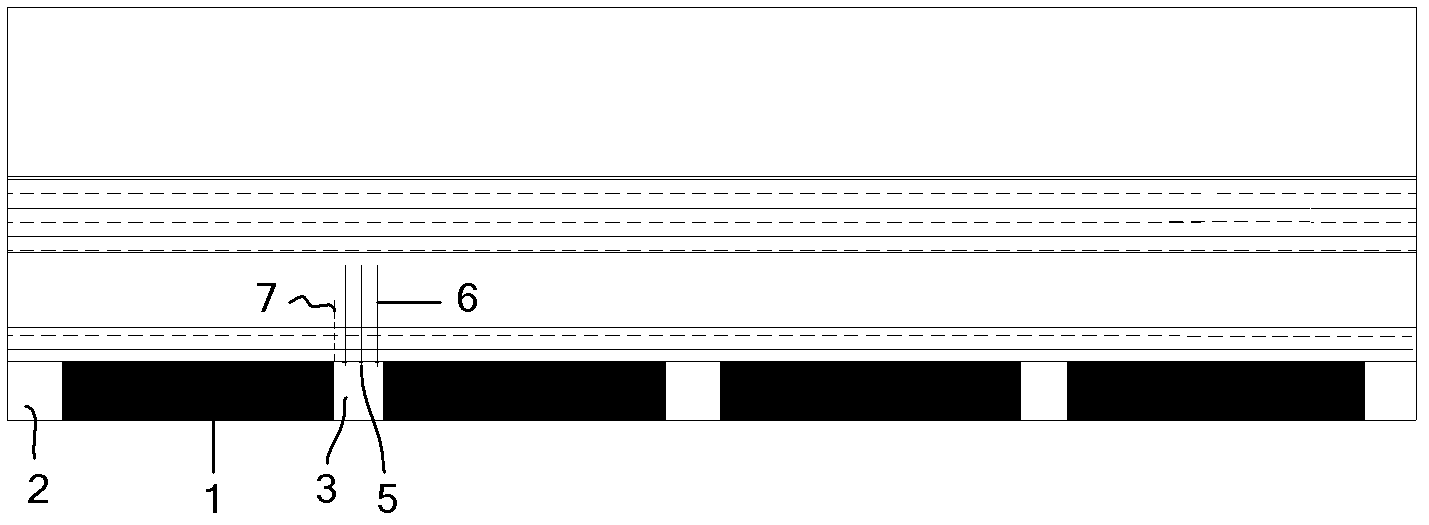

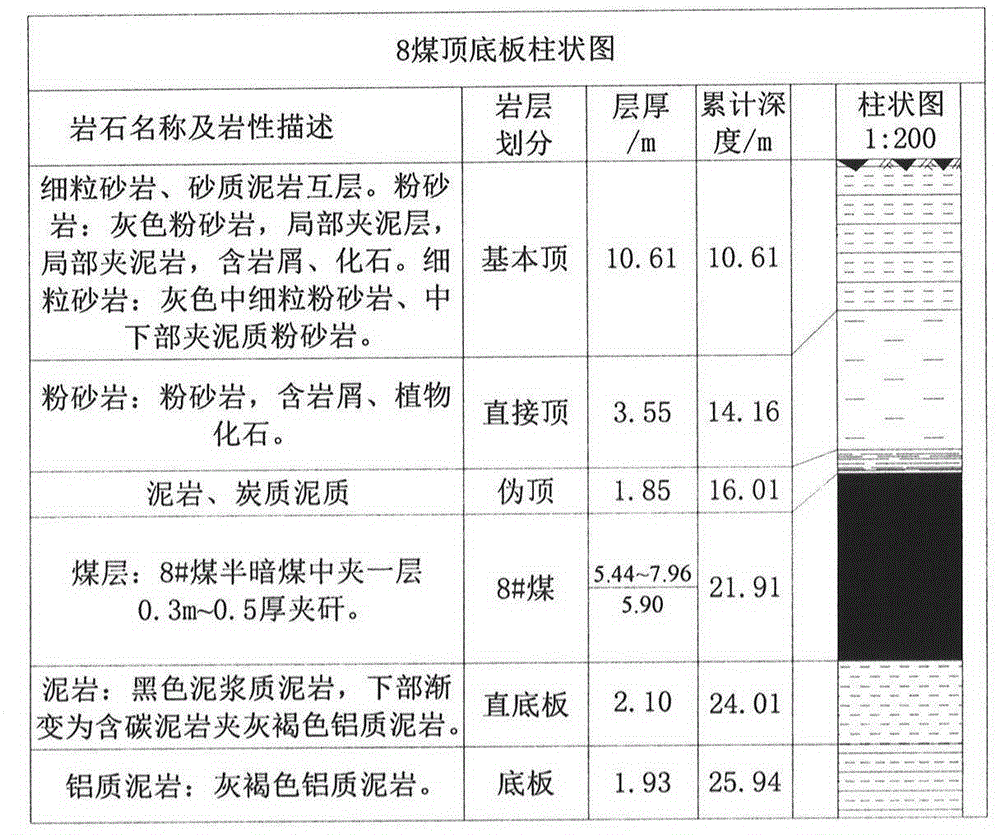

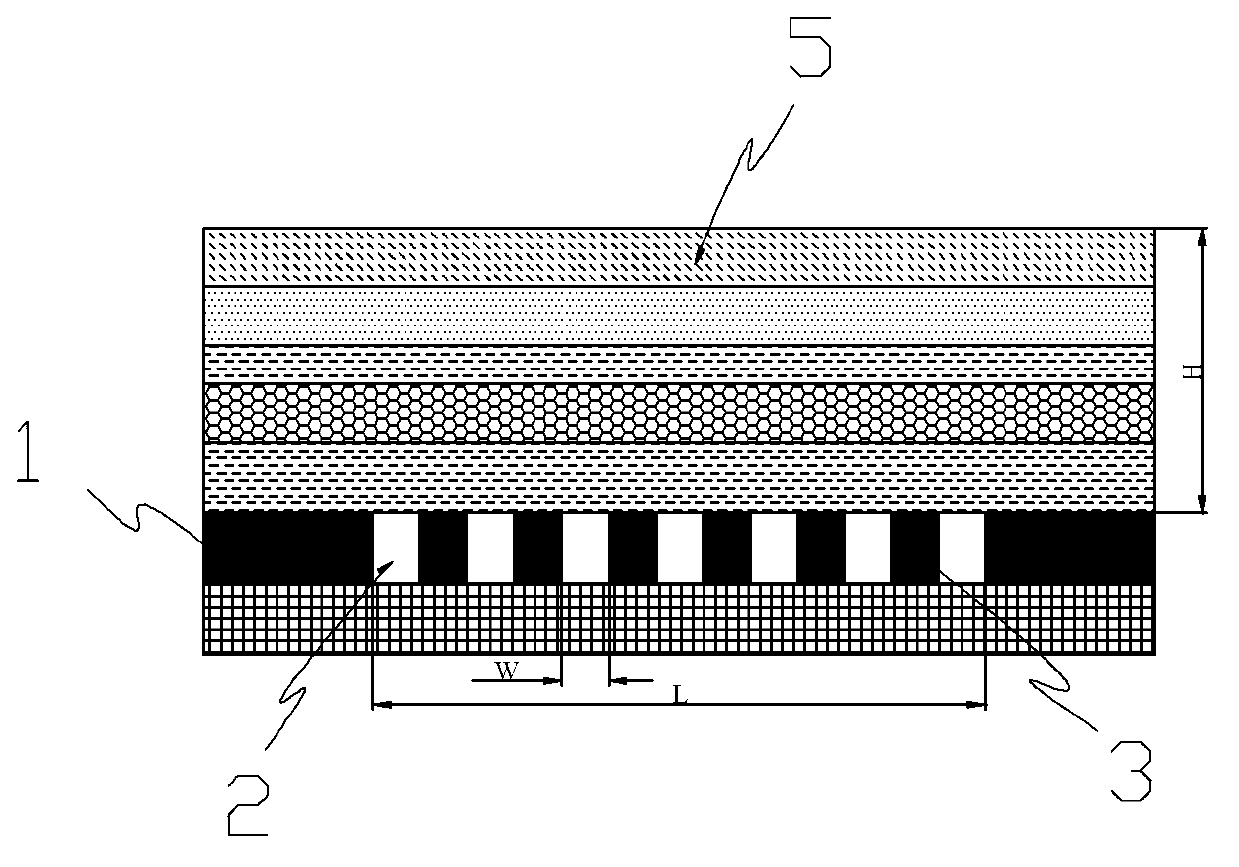

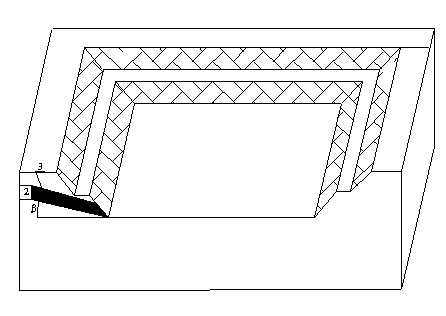

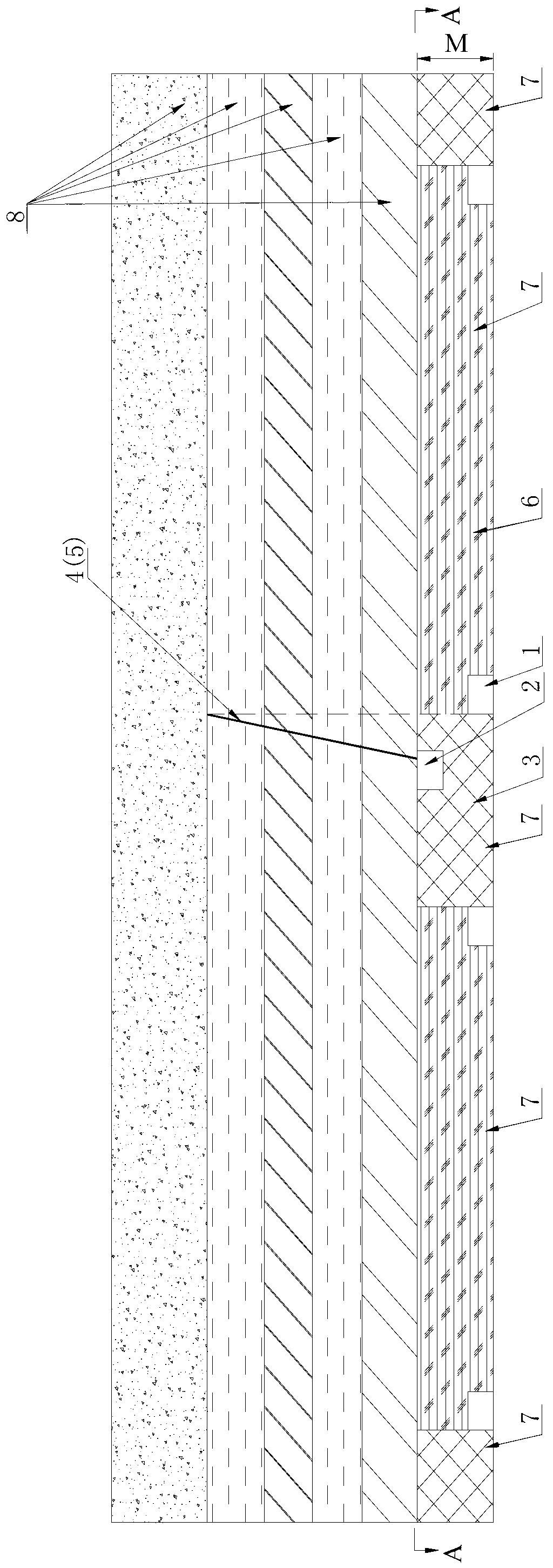

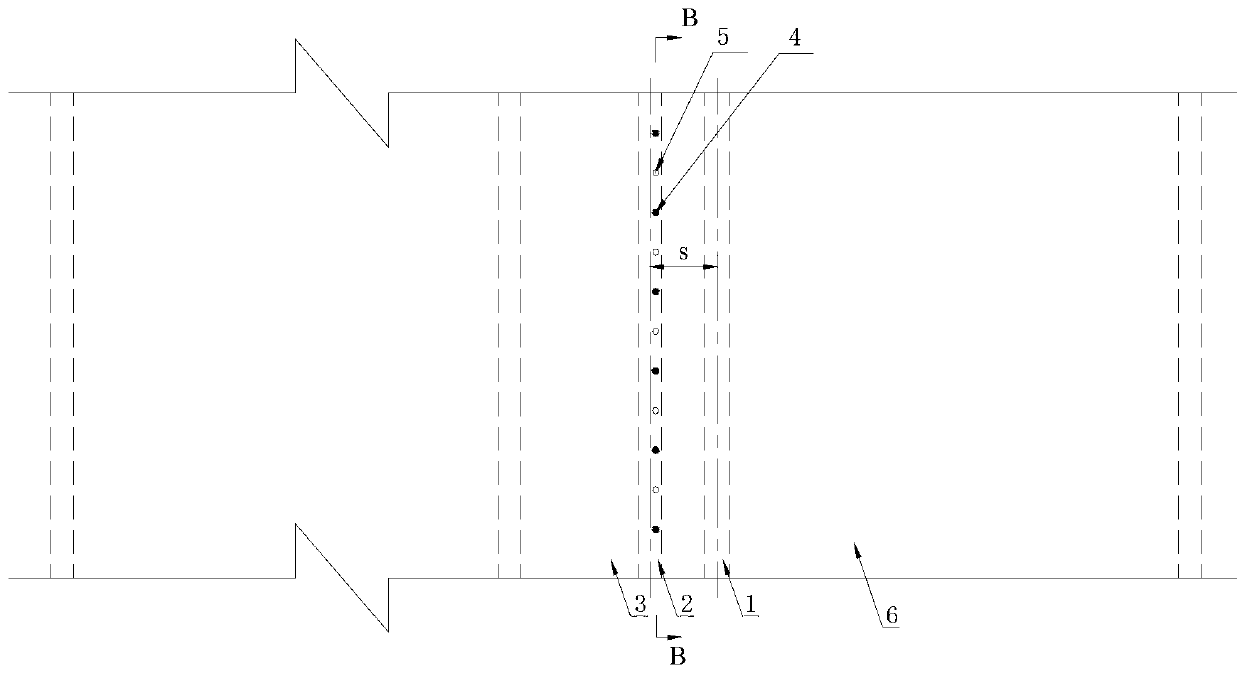

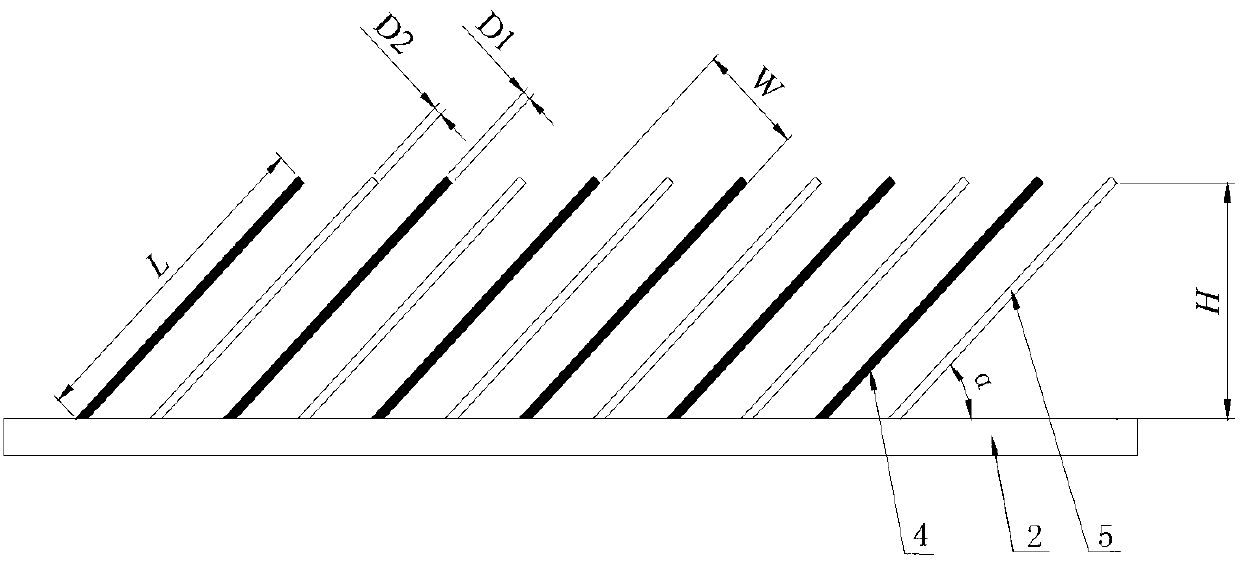

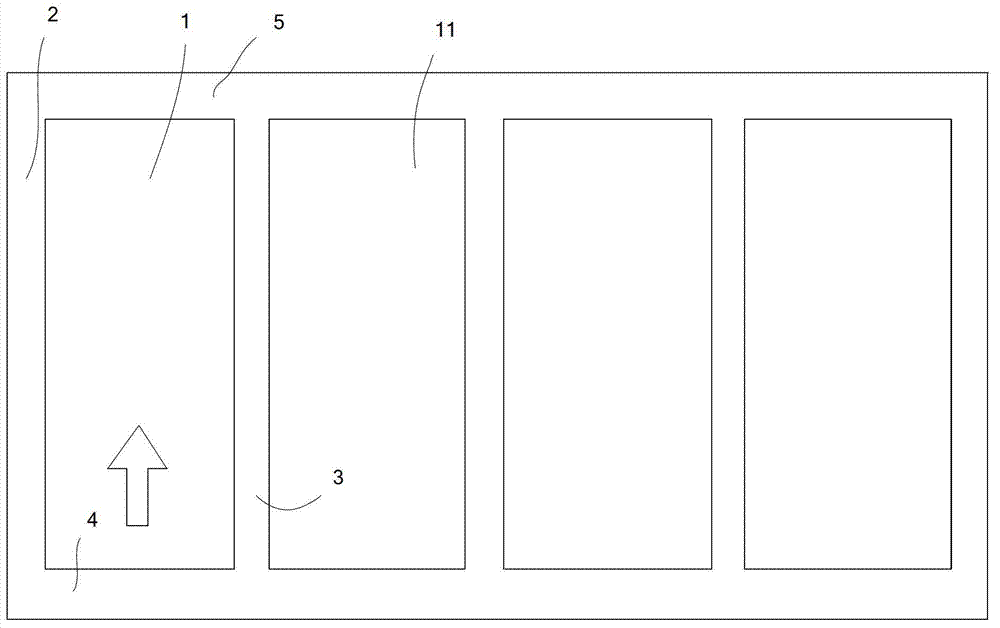

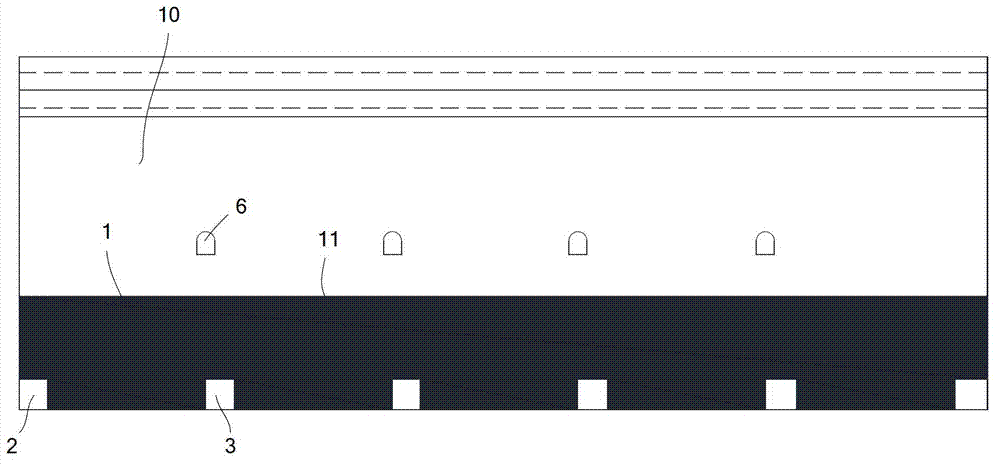

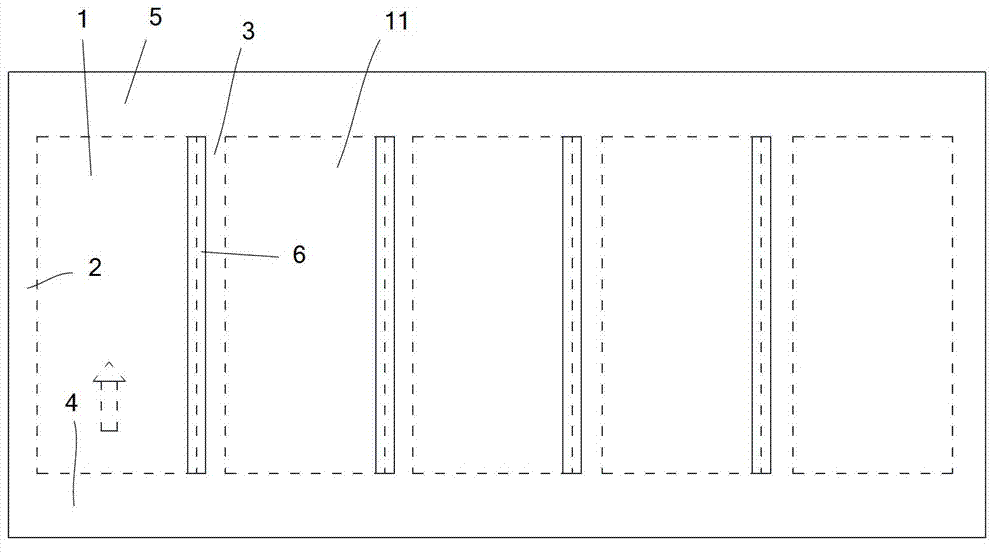

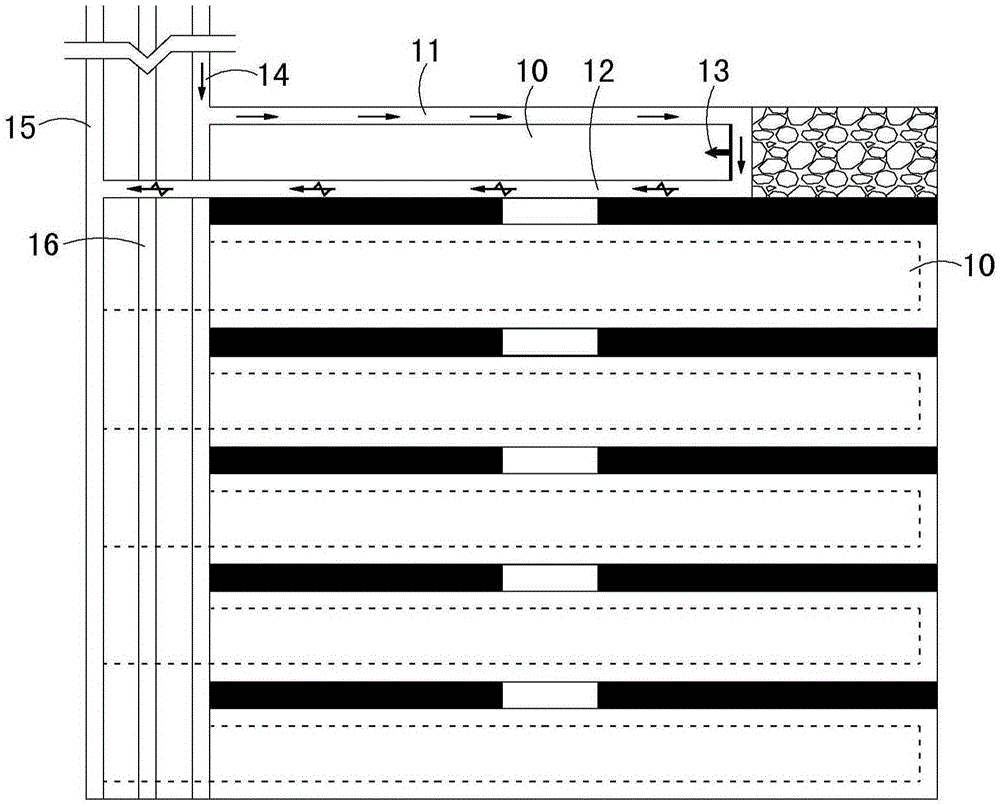

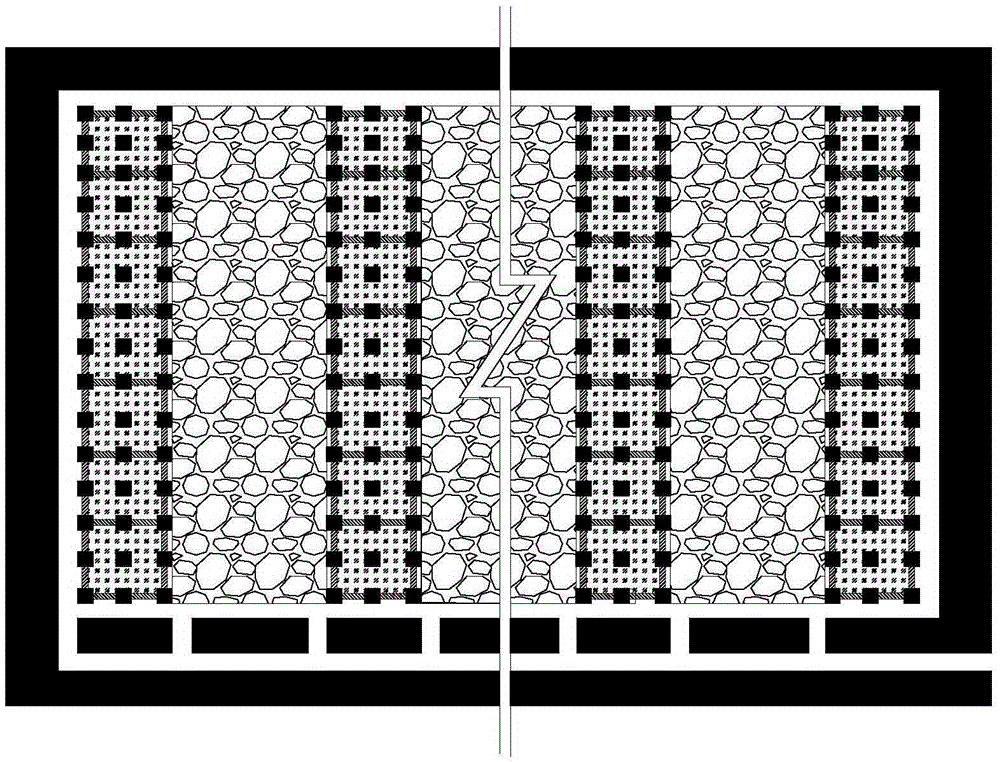

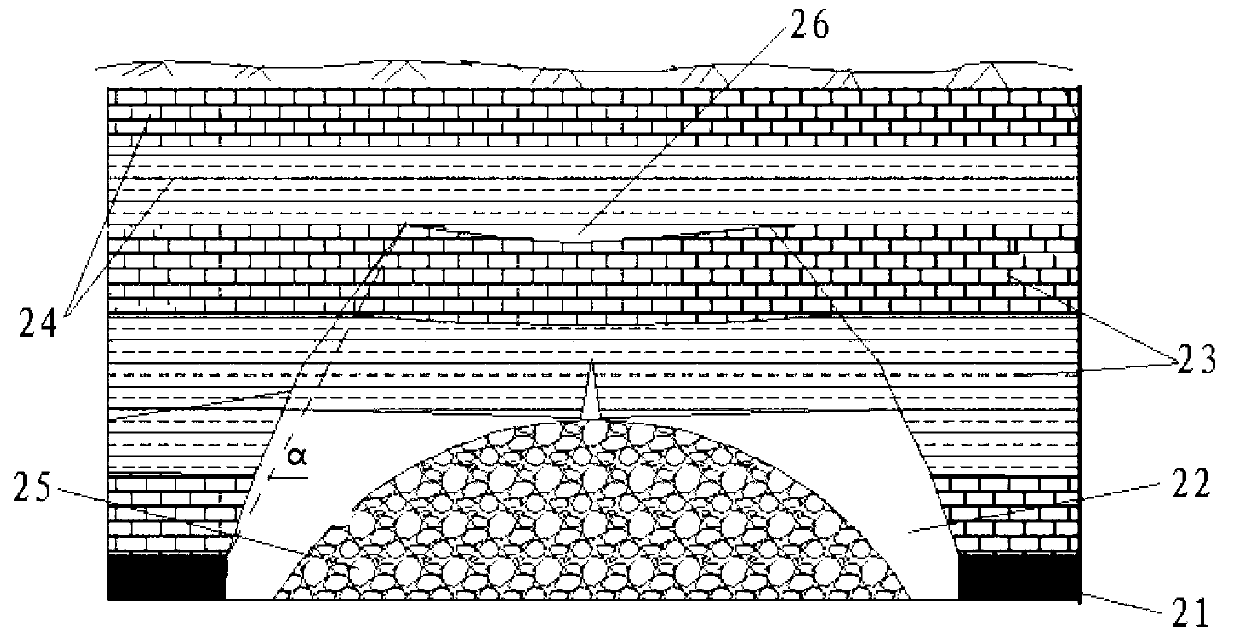

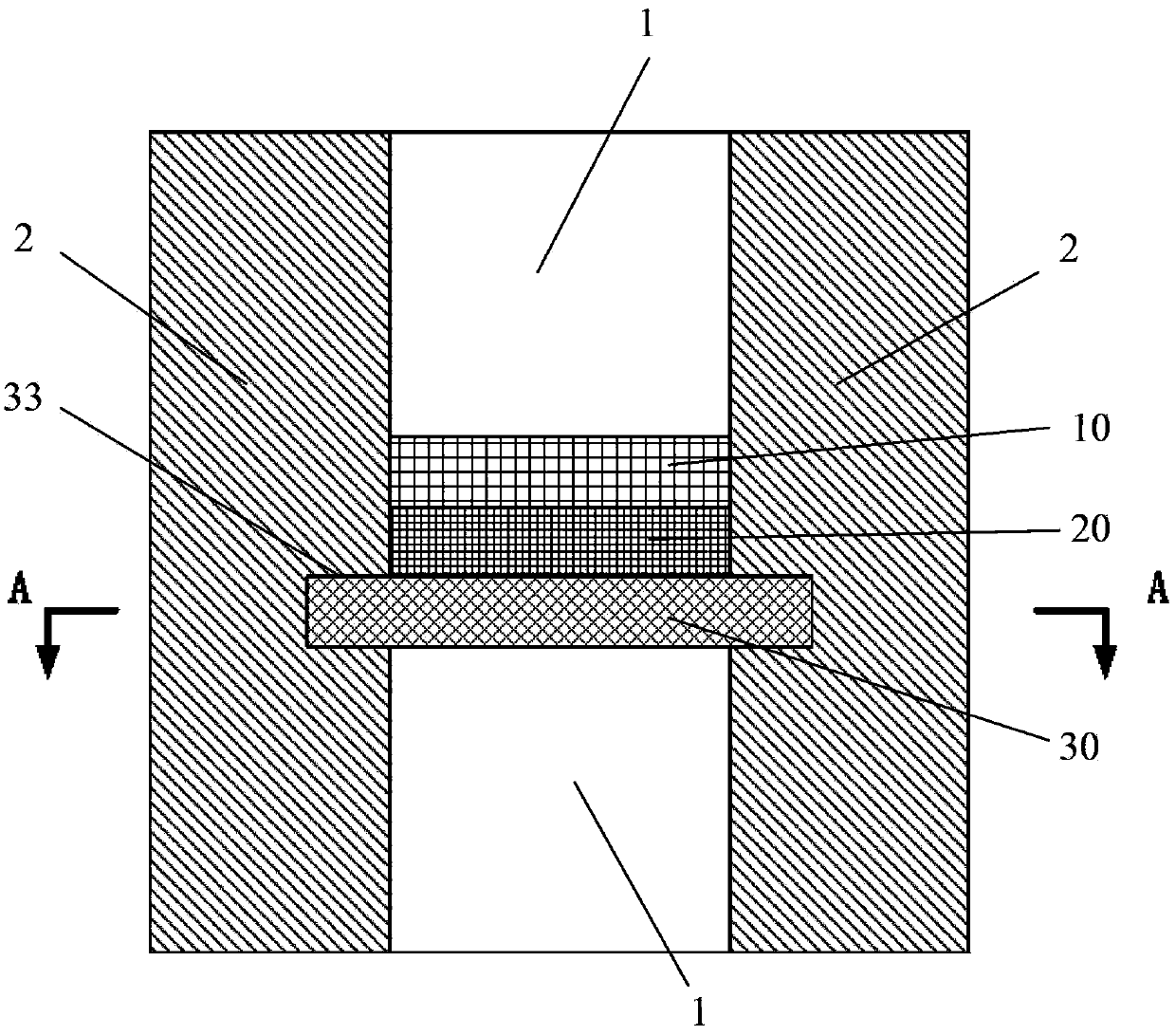

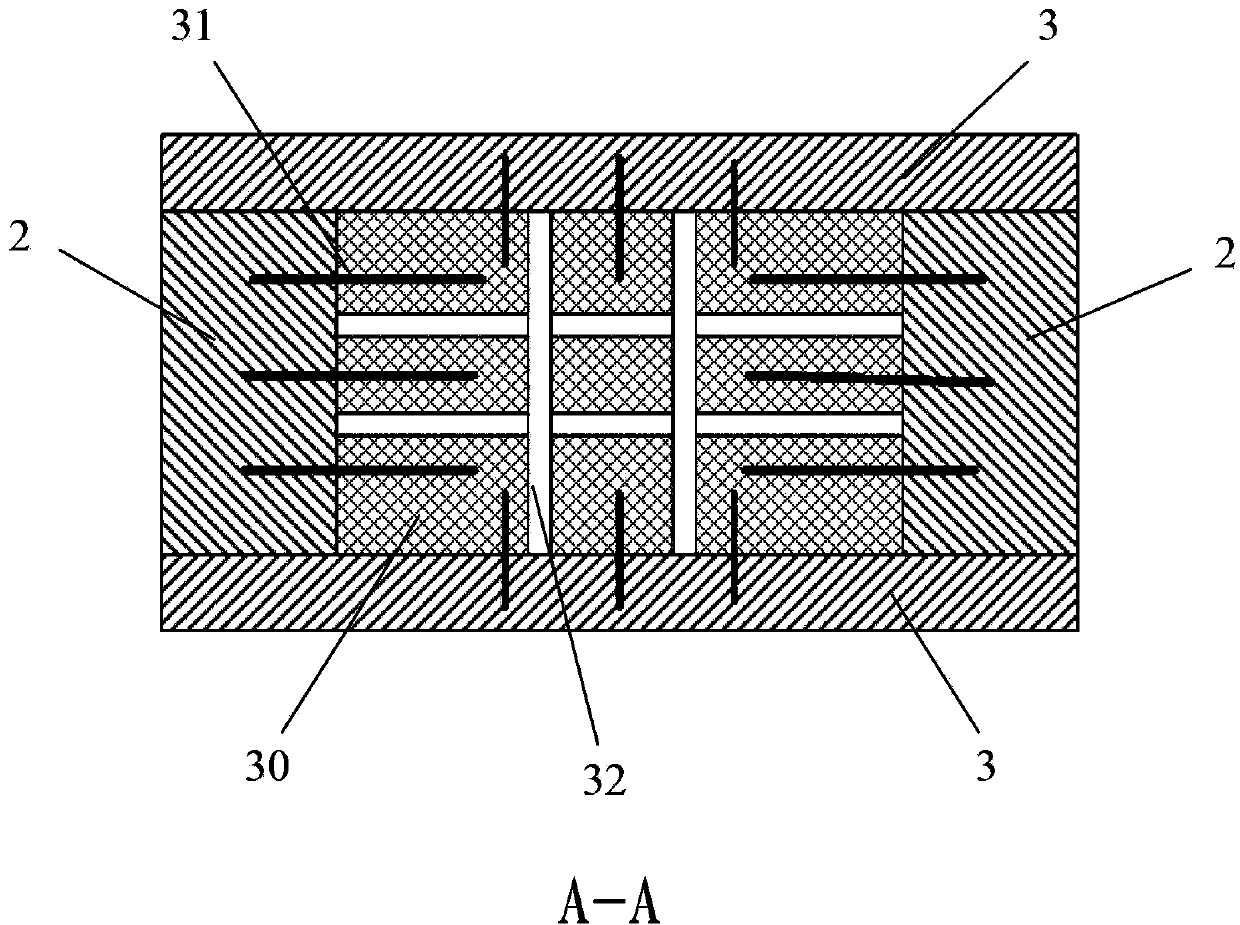

The invention belongs to the field of coal cutting and filling, in particular to a house pillar type cutting and filling method of the medium coal seam for controlling the movement deformation of the overlying rock, which is suitable for the coal face with the coal seam thickness more than 2 meters. The method comprises the following steps: determining the initial weighting interval L and the periodic weighting interval M of the main roof according to the main roof initial weighting interval theory; arranging the rooms and the coal pillars at intervals; and using the material with high expansibility in water during the filling according to the method comprising the following steps of mining the rooms, filling the empty rooms, mining the coal pillars and filling the empty zones of the coal pillars. The method provided by the invention can determine the most economical filling ratio through controlling the key layer to maximize the benefits; the method provided by the invention can control the movement deformation of the overlying rock absolutely within the allowed range when realizing the pulling without pillars, and realize the extremely small gentle uniform sinking of the ground; and the method provided by the invention can realize the mining of the coal resource with high recovery rate under any condition by using the material with high expansibility in water, and greatly enhance the security of coal face. When the rooms are mined, a plurality of coal face of rooms can be arranged at intervals to enhance the working efficiency.

Owner:ZIBO WANGZHUANG COAL MINE

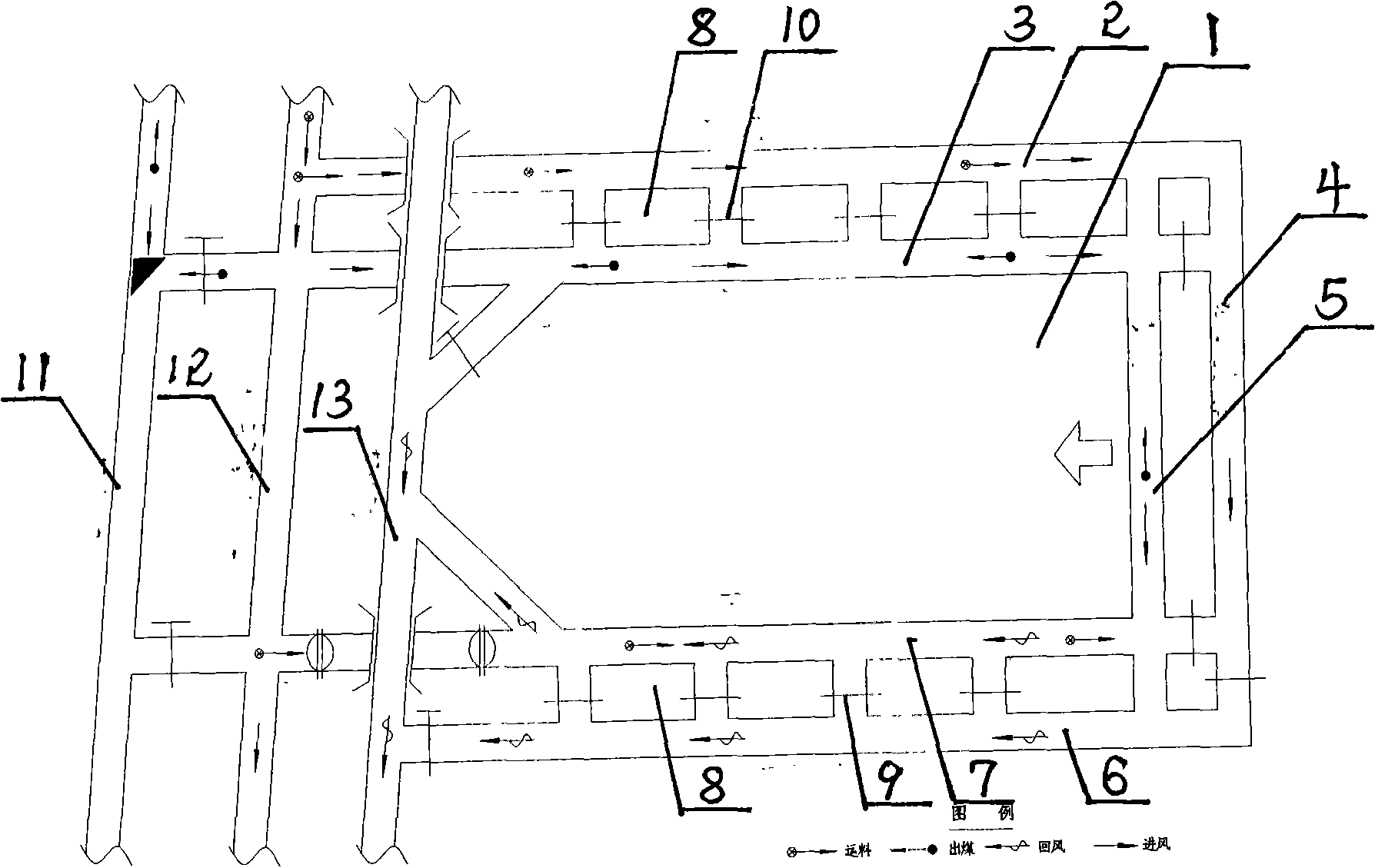

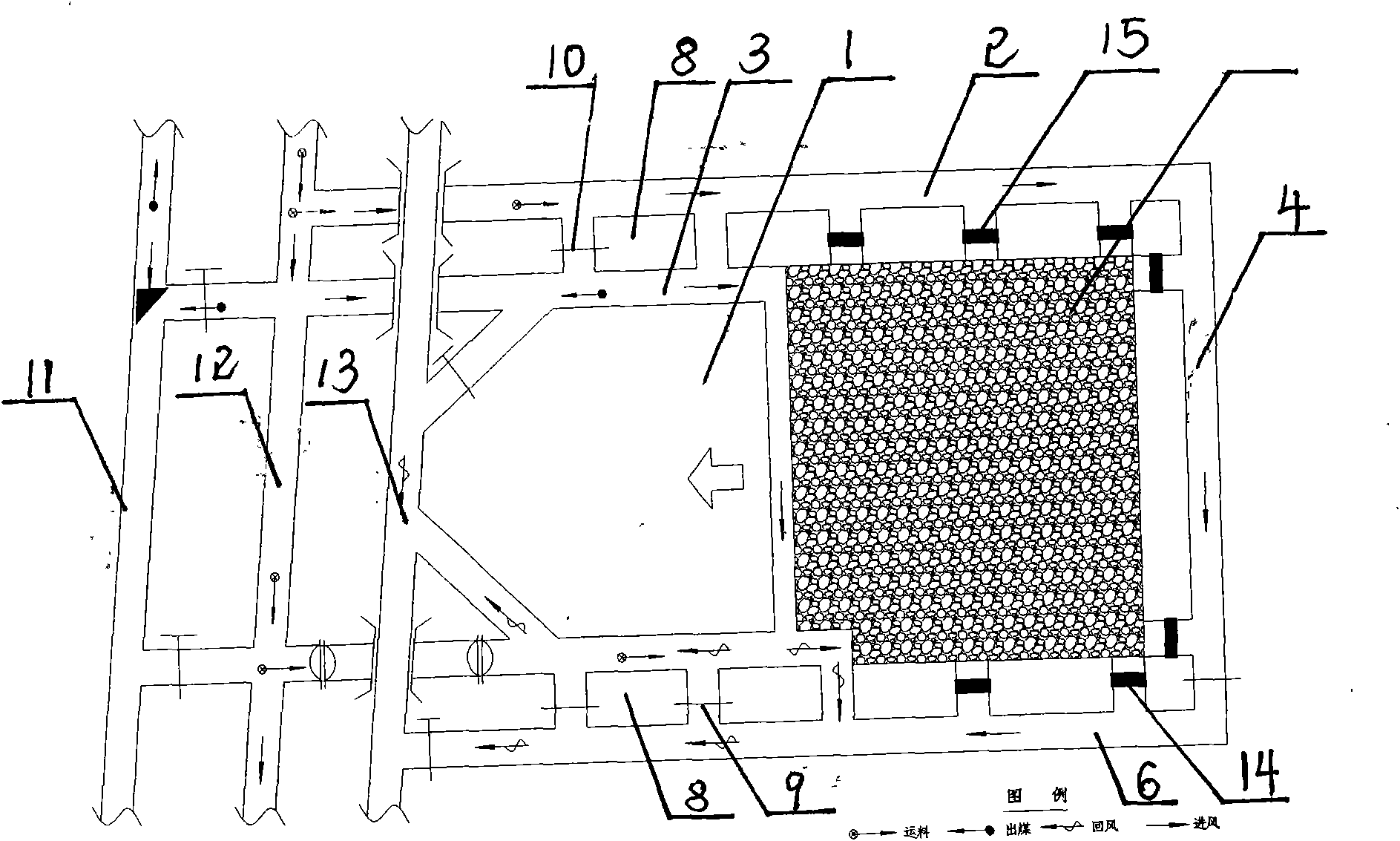

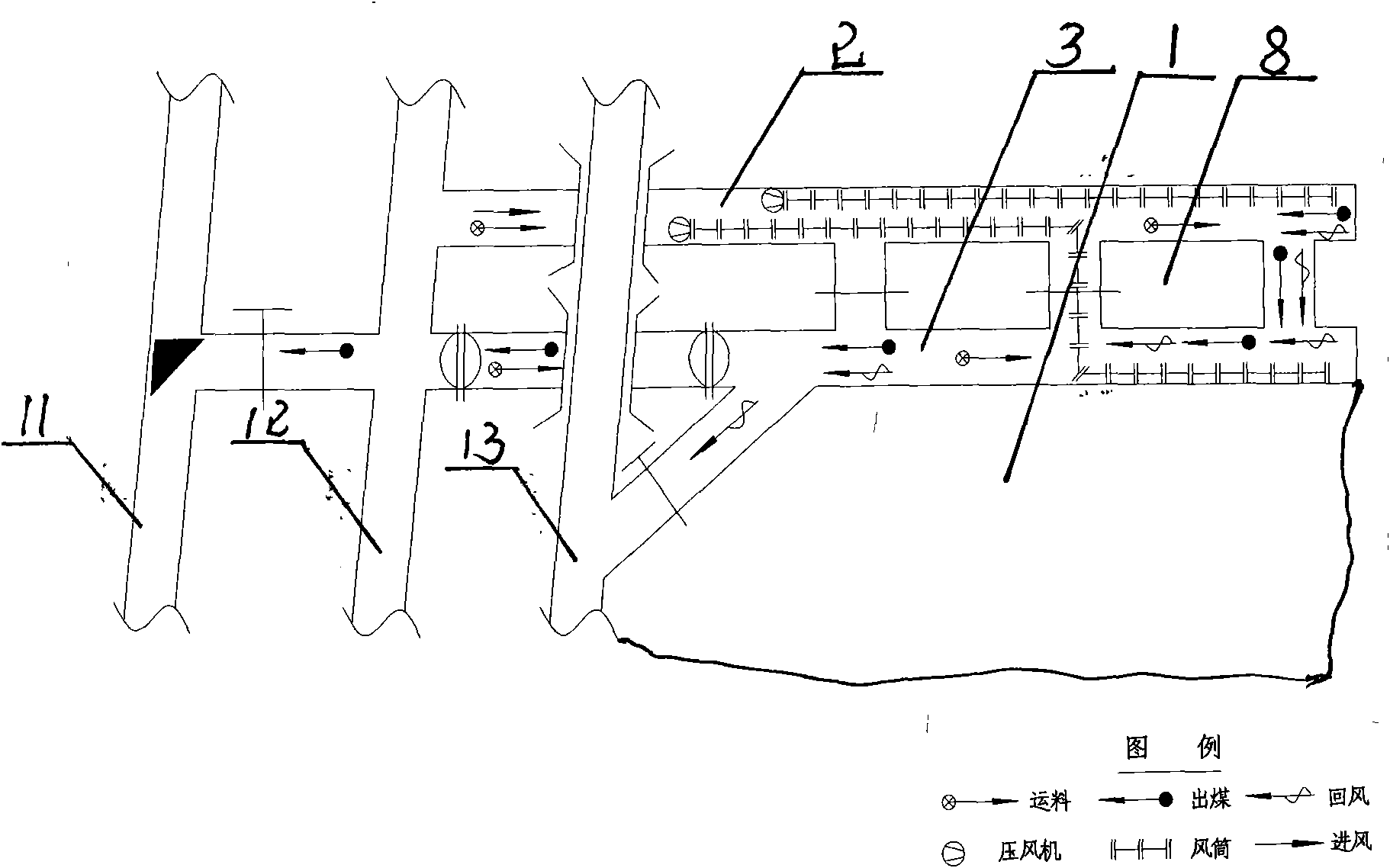

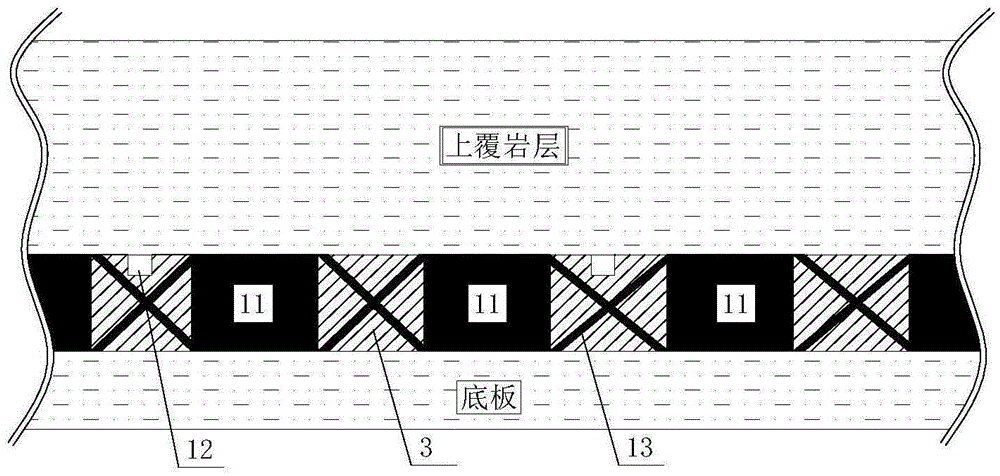

Method for filling solid and fully mechanizing and recovering room type coal pillar

ActiveCN101725352AExtended service lifeHigh recovery rateUnderground miningSurface miningSpontaneous combustionSolid mass

The invention discloses a method for filling solid and recovering and fully mechanizing room type coal pillars, comprising the following steps of: reinforcing and supporting a coal pillar and a coal room top plate in a pre-recovering room type coal pillar area and suspending and hanging a wind curtain to form a solid substance haulage drift and a coal haulage drift which are connected with a large haulage drift; recovering the coal pillars by the conventional method, starting matching equipment after cutting a coal interval and transporting the solid substances to a goaf from the ground for filing and tamping; and cutting coal of next coal interval and filling the goaf, repeating the steps until finishing the recovery of all room type coal pillars. The method not only solves the problems that unstable coal pillar causes the safety accidents due to the superposition of stress of the front part and two sides of a workface because of the recovery of the traditional coal pillar, but also eliminates the potential safety trouble caused by the hurricane, large-area sinking and the like caused by the spontaneous combustion of the room type coal pillar and the large-area caving of hard top plates in the goaf. The invention has simple method, high production efficiency, low cost and over 85 percent of the recovery rate of the coal pillars.

Owner:CHINA UNIV OF MINING & TECH

Long-wall working face coal pillar-free mining method

ActiveCN102536239AGood conditionIncrease mining rateUnderground miningSurface miningEngineeringCoal pillar

The invention discloses a long-wall working face coal pillar-free mining method which comprises the following steps of: (1) digging an upper gate road tunnel and a lower gate road tunnel; (2) reinforcing a roof plate of the lower gate road tunnel, and drilling an energy collecting hole for presplitting blasting on the roof plate; (3) recovering till that a gob is formed; (4) blasting in response to the energy collecting hole, so that a kerf is formed at the roof plate; (5) breaking and sinking a mining face, so that a new tunnel is formed; (6) taking the original lower gate road tunnel as the upper gate road tunnel of the next mining face, and digging a lower gate road tunnel opposite to the upper gate road tunnel, so that a new mining face is formed; and (7) repeating the steps (2)-(6), and continuously mining coal till that the coal bed is completely mined. Every two mining faces in the method are continuous, and can not be supported by coal pillars, so that the method is high in mining efficiency, free of long-time waiting when the tunnel is formed, and high in working efficiency.

Owner:何满潮

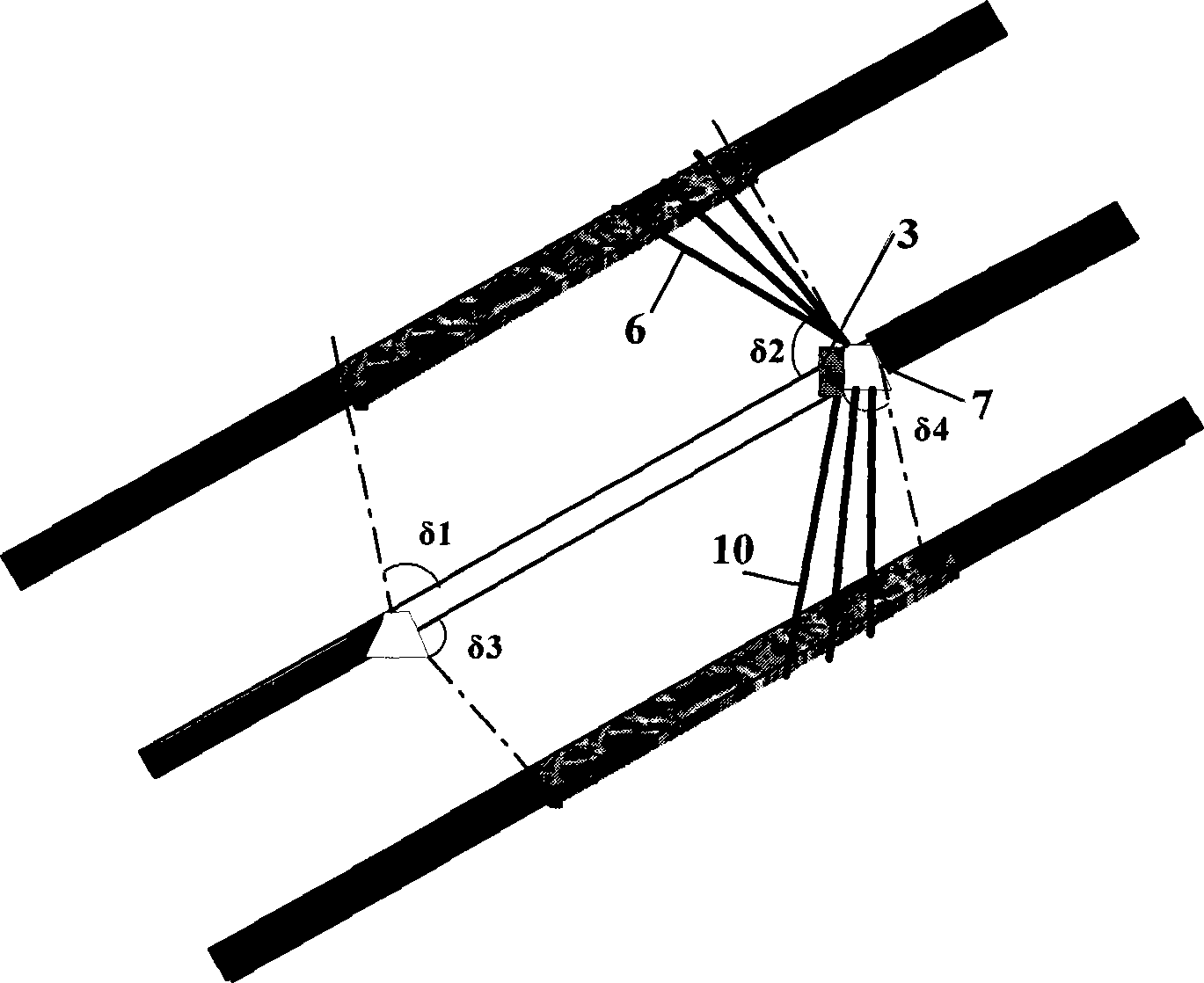

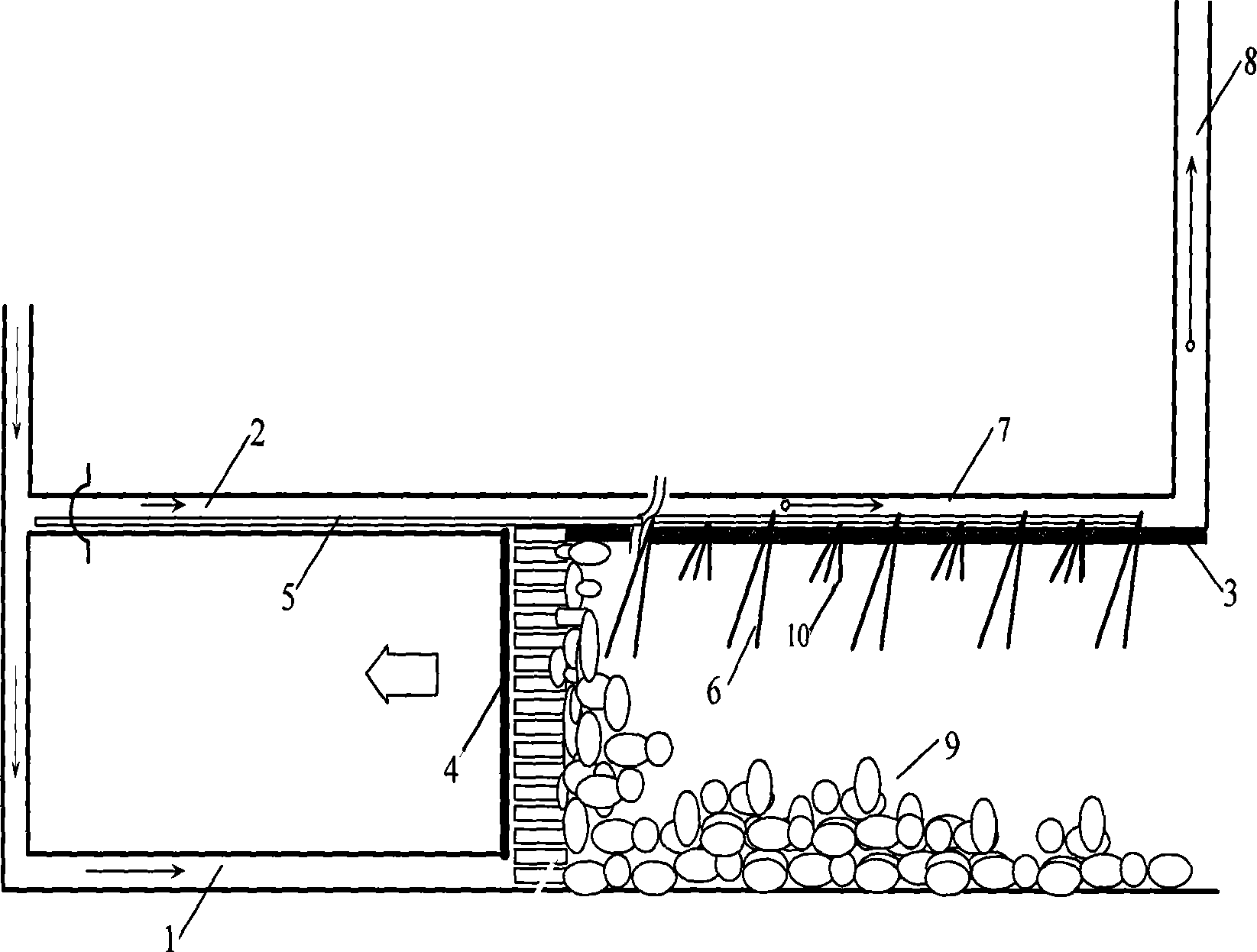

Method for taking out and picking high gassy seam group dislodging gob-side entry retaining Y type ventilated decompression firedamp

The invention relates to a highly gassy coal seam group mining gob-side entry retaining Y-shaped ventilation and decompression gas extraction method. The invention is characterized in that: free desorption gas which comes from an adjacent decompression layer and is gathered into a roof plate decompression crack ring and a bottom plate decompression crack ring through crack channels which are formed by mining affection on roof plate coal seam and strata and bottom plate coal seam and strata is extracted in a gob-side entry through an upward extraction gas drill hole which is arranged inside the roof plate decompression crack ring and a downward extraction gas drill hole which is arranged inside the bottom plate decompression crack ring in a roof plate decompression area and a bottom plate decompression area of a gob-side entry retaining gob of a coal face of a primarily extracted coal seam of a highly gassy coal seam group. The highly gassy coal seam group mining gob-side entry retaining Y-shaped ventilation and decompression gas extraction method solves the problem of low extraction rate of the highly gassy low permeability coal seam group, simultaneously solves the ultralimit problem of airflow gas of spatial angles and return airways on the coal face of the primarily extracted coal seam of the highly gassy coal seam group, and realizes extraction utilization of high concentration gas and highly efficient and safe extraction of the highly gassy coal seam group without coal pillars.

Owner:HUAINAN MINING IND GRP +2

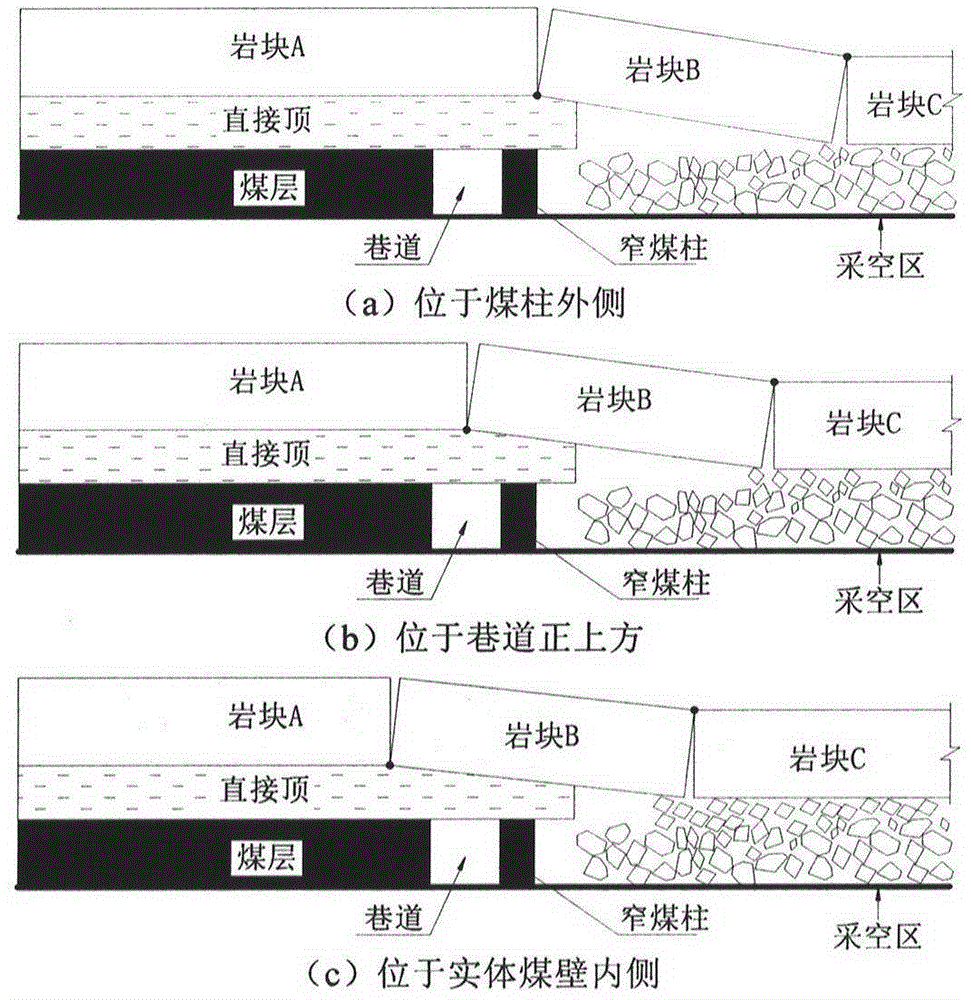

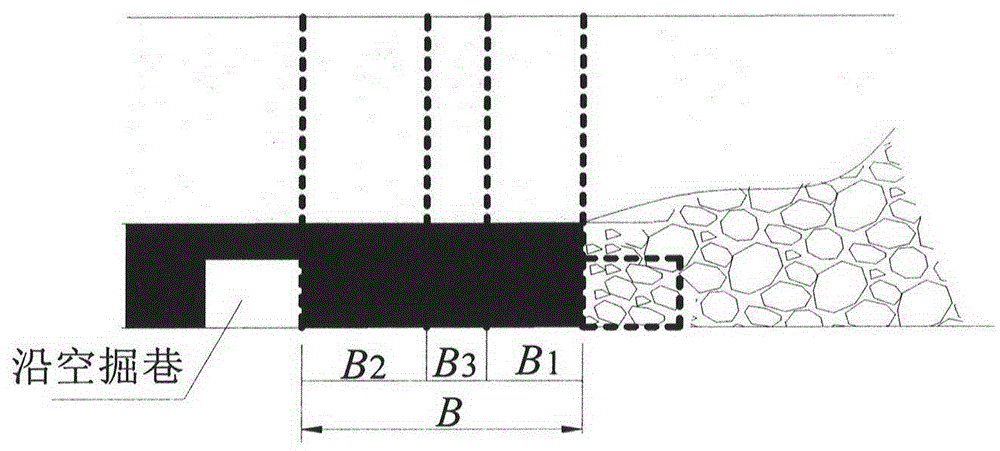

Method for determining reasonable width of gob-side entrydriving narrow coal pillar

InactiveCN104594899AGuaranteed long-term stabilitySafe and efficient miningUnderground miningSurface miningEngineeringFracture line

The invention discloses a method for determining a reasonable width of a gob-side entrydriving narrow coal pillar; theoretical calculation, numerical simulation, field actual measurement and other various means are adopted to determine the reasonable width of the coal pillar, a reasonable gob-side entrydriving position is determined, a fracture line of a main roof is guaranteed to be located at the side, close to a goaf, of the narrow coal pillar, long-term stability of the narrow coal pillar and a roadway is ensured, on one hand, the roadway latter maintenance work amount and maintenance costs are substantially reduced, on the other hand, safe and high-efficiency stoping of a working face is ensured. Therefore, the method for determining the reasonable width of the narrow coal pillar has relatively high theoretical significance and practical value.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

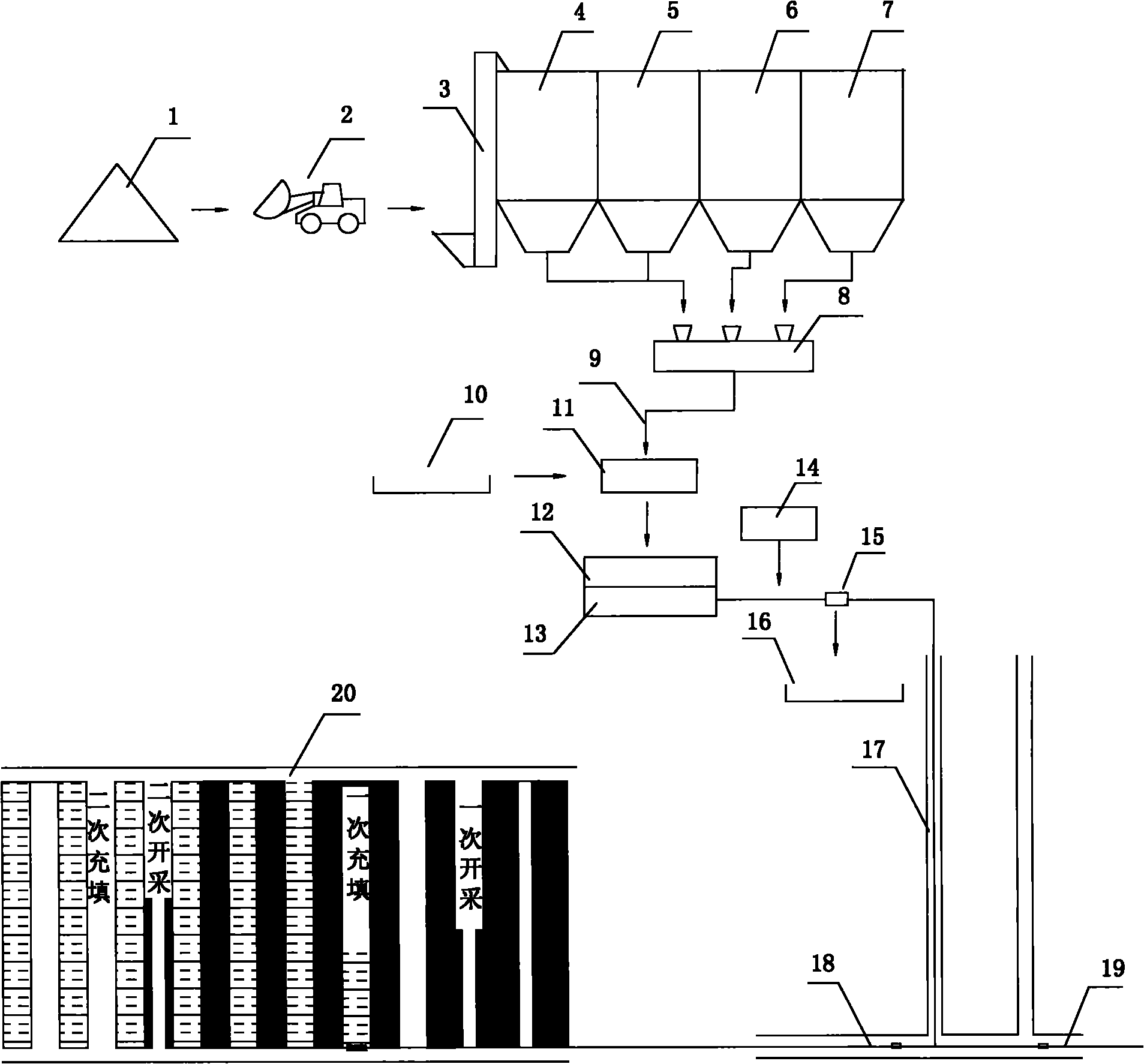

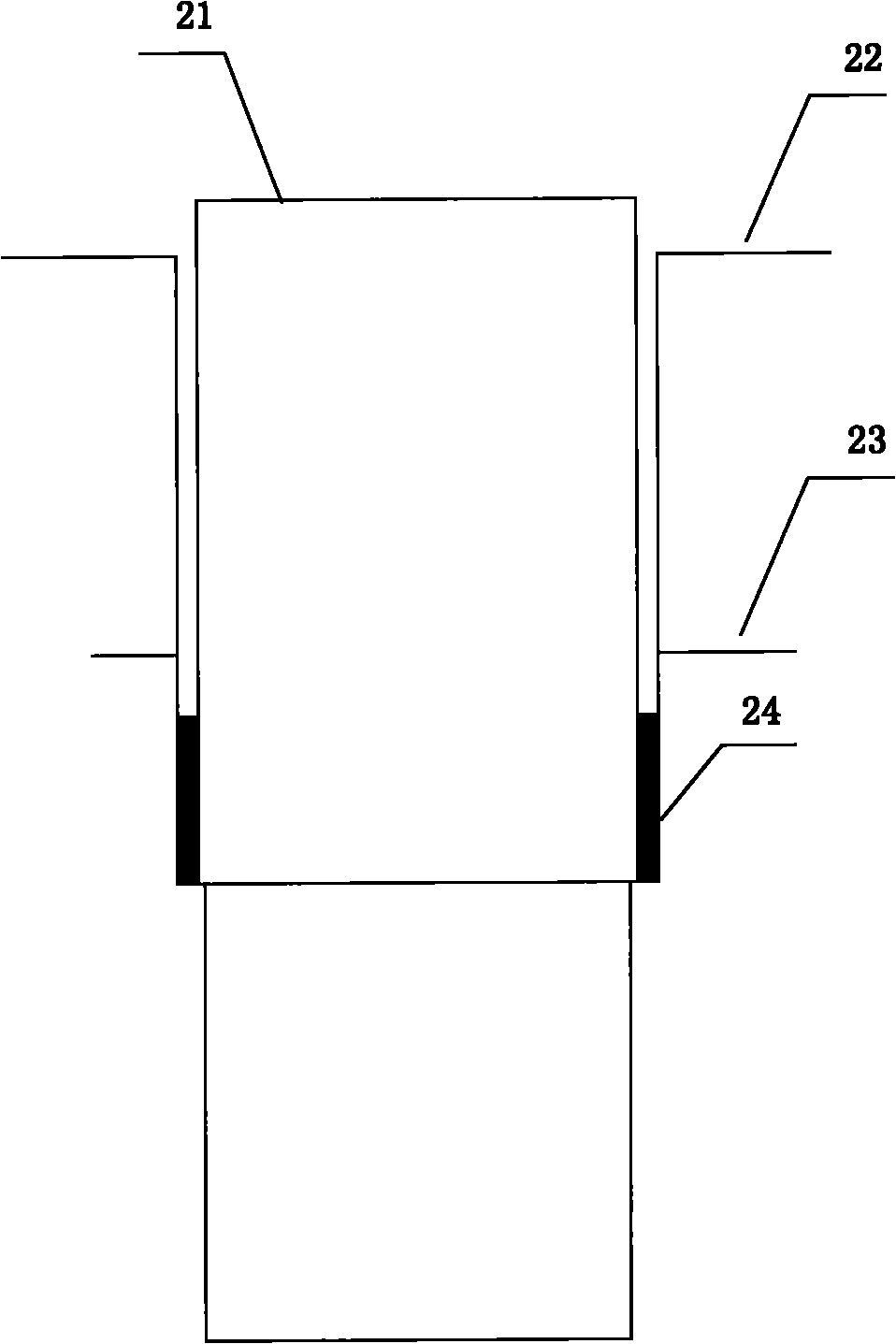

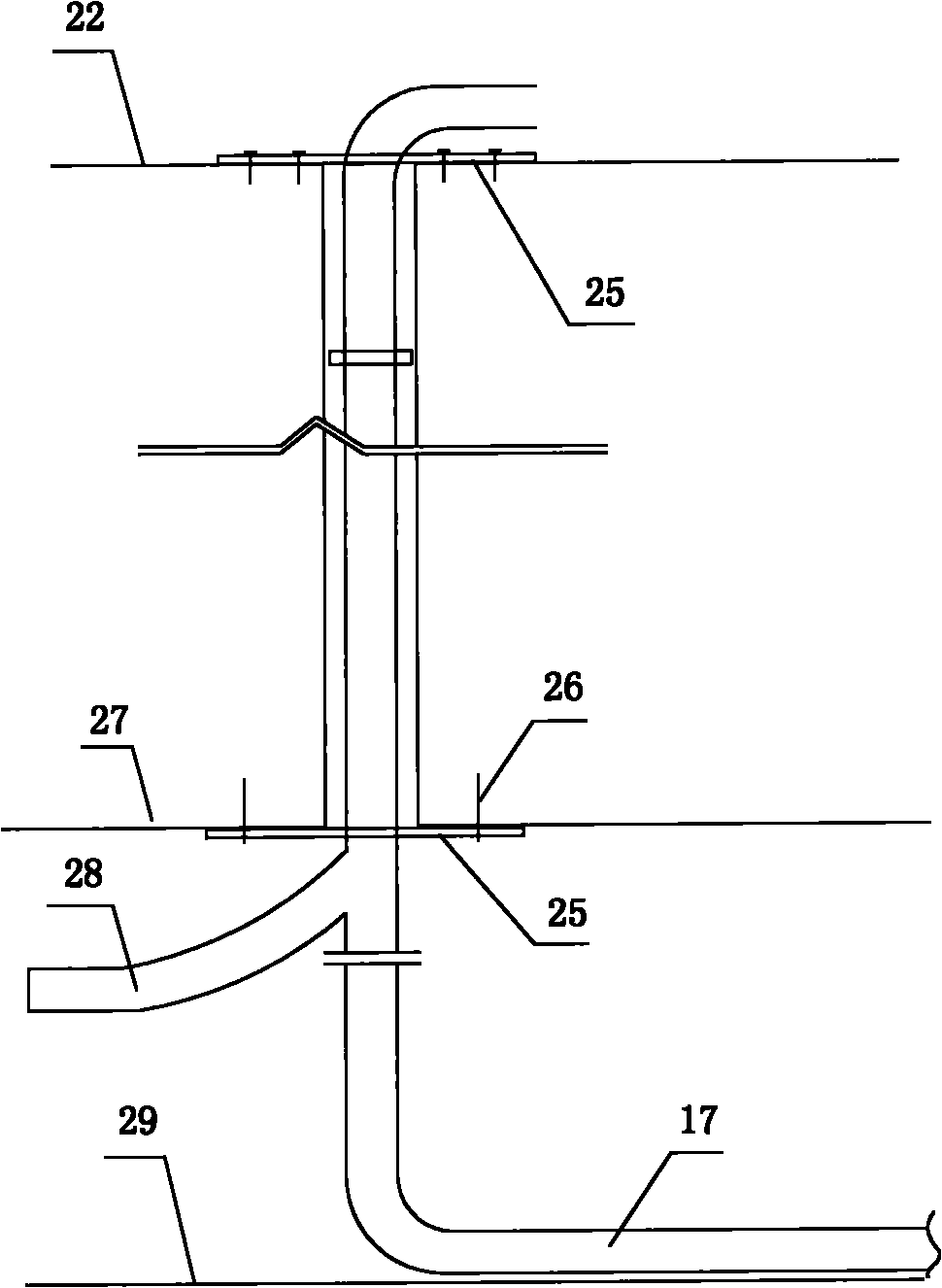

Filling process for recovering coal pillars by filling goaf with paste

The invention provides a filling process for recovering coal pillars by filling a goaf with paste. The filling process comprises three parts: preparing filling paste; conveying the paste via a pipe; and filling the goaf with the paste. The adopted filling paste comprises the following raw materials in percentage by weight: 40%-70% of aeolian sand, 10%-25% of coal ash, 3%-10% of cementing materials, 0.4%-1% of additive and 10%-30% of water. In the filling process, the goaf filling part comprises the procedures of primary filling and secondary filling, wherein, the coal pillars are recovered after primary filling; the whole goaf is fully filled after secondary filling; and roof-contacted supplementary filling is carried out in each filling procedure. The filling process has the advantages that the problems of filling the goaf formed after pillar-support mining and recovering the coal pillars are solved, the mining area environment can be protected more effectively, the increasingly exhausted coal resources are saved, and the filling cost is lowered.

Owner:TIANDI SCI & TECH CO LTD

Method for filling coal-steam-free extraction working surface goaf by coal mine waste rock

InactiveCN1936271ARealize no MasuiImprove the environmentUnderground miningSurface miningMining engineeringCoal pillar

The invention relates to a method to filling non-coal column face workplace by gangue. It includes the following steps: directly transferring the gangue to gangue storehouse, discharging to the slat conveyer through hopper gate, transferring the gangue to face through gangue transferring belt, face slat conveyer, and high speed gangue throwing belt. It needs not to smash the gangue and could realize zero stacking of gangue to improve coal mine environment. The invention supplies a new coal mining method for realizing environment protecting exploitation.

Owner:SHANDONG SHENGQUAN MINING

Stripe gob filling repeated-mining method

InactiveCN103104287AHigh recovery rateEliminate hidden dangers of geological disastersUnderground miningSurface miningFilling materialsInstability

The invention discloses a tripe gob filling repeated-mining method. The method comprises the following steps. A, a fire dam of a main tunnel of the stripe gob is opened to ventilate and discharge possible remained noxious gas. B, the tunnel of the strip gob is cleaned and a cracked roof is fastened and the cracked trail appears in the locality and stagnant is got rid of. C, paste filling materials are adopted to fill a empty stripe of the stripe gob in order to form a filling stripe1. D, after the filling stripe is reinforced, remained striped coal pillar in the stripe gob is stopped. E, a new gangue which is formed by stopping and adopted by the new empty stripe processes with non-cemented filling in order to form a filling stripe2. The strip gob is filled with the filling materials through the adoption of the paste filling method and the remained stripe coal pillar is stopped and the new empty stripe which is formed by stopping is dealt with the non-cemented filling by adopting the gangue. The method has the advantages of not only improving further recovery percent of the coal resources, but also eradicating hidden trouble of geological disaster in mining area caused by the instability of the strip coal pillar.

Owner:SHANDONG UNIV OF SCI & TECH

Top-cutting roadway coal-pillar-free mining method of close-range thin coal seam

ActiveCN103233740AAvoid destructionDoes not cause prominenceUnderground miningSurface miningShotcreteCoal pillar

The invention discloses a top-cutting roadway coal-pillar-free mining method of a close-range thin coal seam. The method comprises the following steps of: (1), excavating an upper crossheading roadway and a lower crossheading roadway; (2), mounting a grouting constant-resistance anchor rope and a grouting constant-resistance anchor rod without grouting at first, and a monomer hydraulic pillar, machining energy-accumulation presplitting top-cutting holes, and blasting to obtain presplitting cutting joints; (3), extracting an upper coal seam till unavailable; (4), allowing a mining field ejection plate to collapse along the shallow energy-accumulation presplitting cutting joints; (5), spraying a concrete spray layer to the rise side wall of the lower crossheading roadway, and grouting the grouting constant-resistance anchor rope and the grouting constant-resistance anchor rod; (6), extracting a lower coal seam till unavailable, and allowing the mining field ejection plate to collapse along the deep energy-accumulation presplitting cutting joints; (7), taking a roadway automatically formed at the original lower crossheading roadway as the upper crossheading roadway of a next mining surface; and (8), repeating steps (2) to (7). According to the method, by using the cutting joints formed by the energy-accumulation presplitting top-cutting holes for blasting the ejection plate, shallow breakage and deep breakage can be performed twice, and twice collapse of the mining field ejection plate is achieved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for arranging roadways on coal-pillar-free stope

InactiveCN102392642ASolve the overrun problemAlleviate mining tensionsUnderground miningSurface miningDual purposeEngineering

The invention discloses a method for arranging roadways on a coal-pillar-free stope. Particularly, the method comprises the following steps: two roadways are arranged on each working face, one is an excavating roadway, and the other is a gob-side retained or excavated roadway on an upper working face; before a present working face is stopped, a roadway and a cut are excavated in advance on a supersedure working face adjacent to the present working face; the cut is connected with the excavating roadway of the present working face; and the excavating roadway and the cut of the supersedure working face serve as the boundary return airway of the present working face during gob-side roadway retaining, and serve as the construction pathway for the gob-side excavated roadway during gob-side entry driving. Therefore, through the adoption of the method, mining without coal pillars is achieved and a two-in and one-out Y+L type ventilation system is formed. In the method, the excavating roadway and the cut of the supersedure working face serve as the return airway of the present working face and one roadway of the supersedure working face, thereby achieving dual purposes and eliminating the excavating of a roadway; and a pressure peak area is avoided, so that more coal pillars can be extracted, the problem of transfinite methane gas is solved, the excavation tight relationship is relieved, and the method can be widely applied to coal mines, metallurgic mines and other industries.

Owner:王晓利

Mining method for replacement of banded coal under building by waste rock

The bone coal displacement strip coal block exploration under an architecture, concentrically sets 3-5 bone coals filling lane at the center of each strip coal block, based on the buried depth, width, laminated rock structure and protective degree required by the architecture build on the surface of each strip coal block, advancing coal mining for the 3-5 bone coals filling lane and then filling bone coals from the interior to the exterior inside the lane that has dug out coals. Ensuring the safety of the architectures, filling the displacement coal with bone coals, it can realize exploration rate no less than 20%, the total recovery rate of the strip mining area no less than 65%; Filling the mine with bone coals dug out can not only eliminates the bone coals on the land, reduces the encroachment of farmland, mitigates air and environmental pollution, gets rid of bone coal landslide or explosion and other hidden accidents that may affects the human life but also using bone coals working as the underground support of the mine and realizing second partial recovery for strip coal blocks under the architectures.

Owner:CHINA UNIV OF MINING & TECH

Steep-coal-seam long wall face non-pillar coal mining method

ActiveCN103195426AAvoid destructionAvoid enteringUnderground miningSurface miningShotcreteEngineering

The invention discloses a steel-coal-seam long wall face non-pillar coal mining method. The method comprises the steps of (1) excavating an upper crossheading roadway and a lower crosshead roadway; (2) mounting a constant-resistance large-deformation anchor rod, processing a row of vertical energy-gathering blasting holes, and implementing blasting and presplitting; (3) erecting a column body for supporting a top plate, and arranging a protective layer on the back of the column body; and (4) carrying out recovery, slipping the top plate of a recovery face along a presplitting kerf; (5) withdrawing the column, hanging a net and spraying concrete to form a support layer; (6) mounting a slip-casting constant-resistance long anchor rod, and grouting; (7) forming a roadway automatically in the original crosshead roadway and taking the roadway as the upper crosshead roadway of the next mining face; and (8) repeating the steps (2)-(7). According to the method, the top plate at a worked out section collapses along the presplitting kerf, and meanwhile, a lower crosshead top plate is prevented from being damaged, and small caving waste rocks are prevented from entering the lower crosshead roadway, so that the roadway is automatically formed in the original crosshead roadway.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Opencast coal mine end slope filling mining method

InactiveCN103758568AReduce wasteSolve the problem of reduced recovery rateMaterial fill-upOpen-pit miningMining engineeringCoal pillar

Provided is an opencast coal mine end slope filling mining method. The opencast coal mine end slope filling mining method includes the steps that a coal pillar reserved at an opencast coal mine end slope is divided into a plurality of stalls which are equal to an end slope coal mining machine roller in width; a stowboard is tunnelled to the position of an earth surface safety boundary line in the coal seam trend direction, and a stowboard is tunnelled in the coal seam inclination direction; an end slope coal mining machine is used for mining the stalls on the side of the stowboard in the coal seam inclination direction at intervals, after mining of the stalls is completed, the end slope coal mining machine is removed, mining openings in the sides of stall side slopes are sealed, and filling is performed on the stalls which are mined at intervals; then, mining is performed on stalls at intervals, the stalls are not mined, filling is performed on the mined stalls, and the steps are repeated until mining of all the stalls which are not mined is completed. According to the opencast coal mine end slope filling mining method, rock and soil discharged by an opencast coal mine can be effectively used, the discharge amount of the rock and soil of the opencast coal mine is reduced, the stripping ratio is lowered, mines end slope coal resources are mined in a maximization mode, meanwhile the side slope safety is guaranteed, and the efficient environment-friendly production process of the opencast coal mine is achieved.

Owner:CHINA UNIV OF MINING & TECH

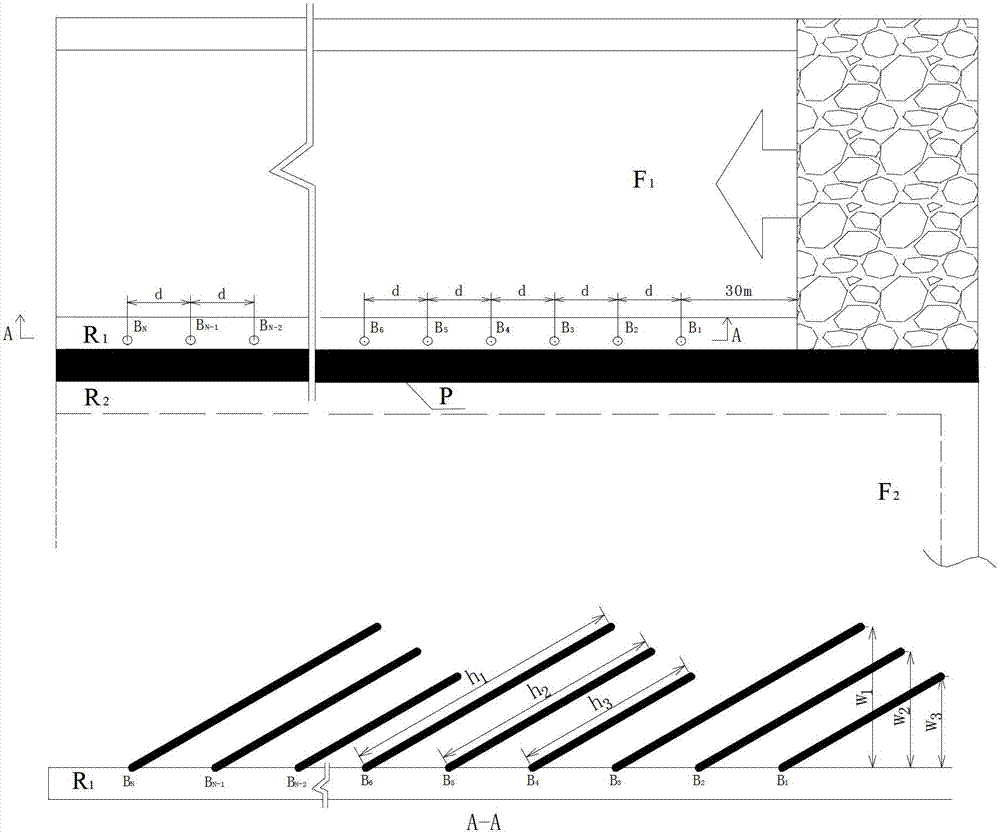

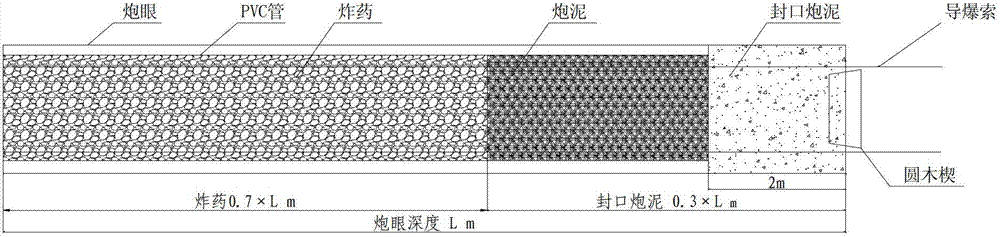

Roof-cutting pressure relief method in hard-roof deep-hole pre-splitting blasting

The invention relates to a roof-cutting pressure relief method in hard-roof deep-hole pre-splitting blasting, belongs to the technical field of blasting pressure relief, relates to a method of controlling coal pillar stress concentration and intense gob-side entry strata behaviors caused by suspension of gob hard roofs in thick seams and super high seams, and solves such problems of coal pillar stress concentration and intense gob-side entry strata behaviors caused by suspension of gob hard roofs in thick seams and super high seams. The method is effective and widely applicable and includes the steps of firstly, reserving a roof-cutting roadway in coal pillars along a seam roof before working face extraction in case of the seam being the super high seam; if the seam is the thick seam, directly using a mining roadway as a roof-cutting roadway; secondly, if the seam is the super high seam, longitudinally reserving blast holes in the roof strata above the roof-cutting roadway; and thirdly, loading explosives, sealing the holes and allowing for roof-cutting blasting.

Owner:LIAONING TECHNICAL UNIVERSITY

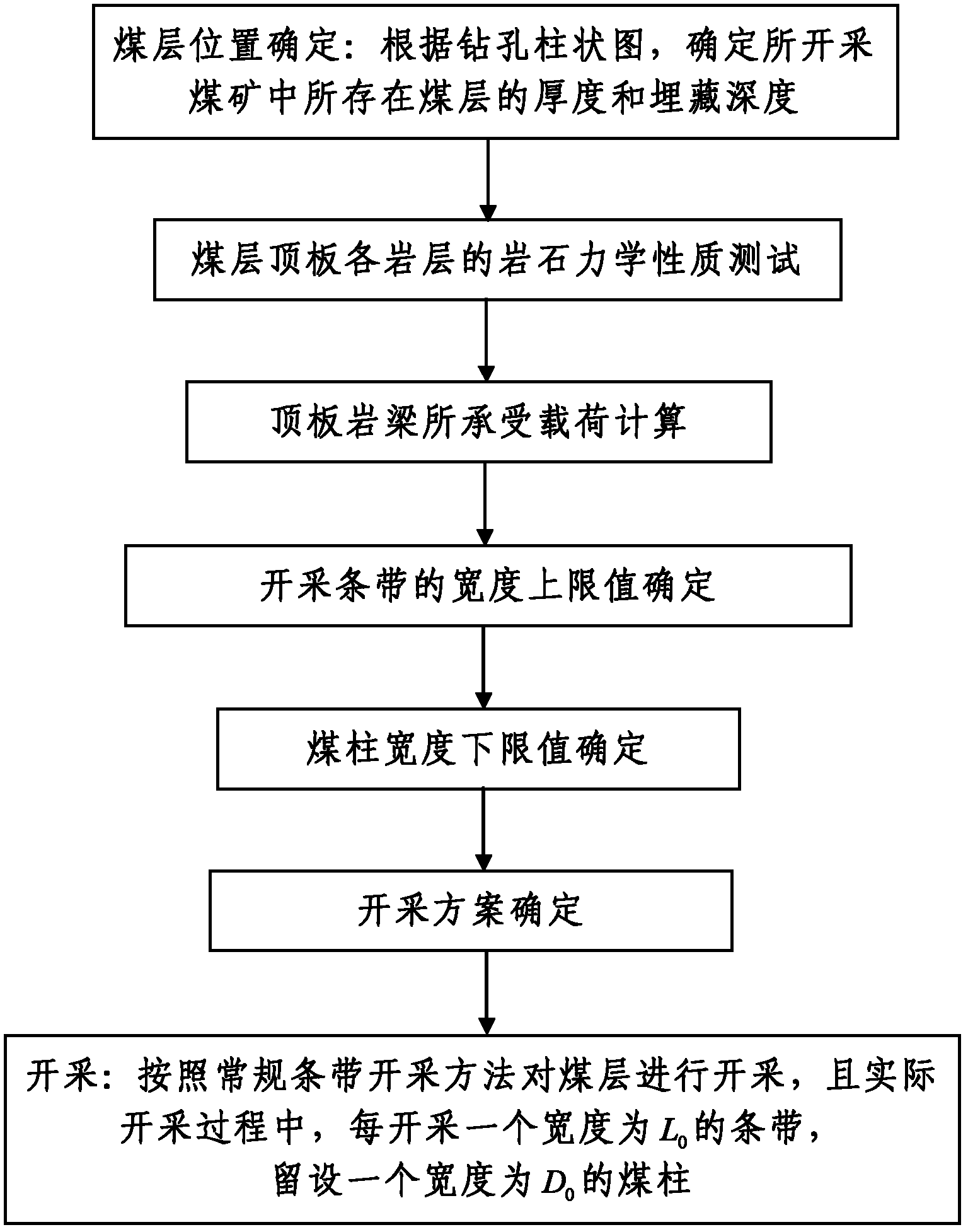

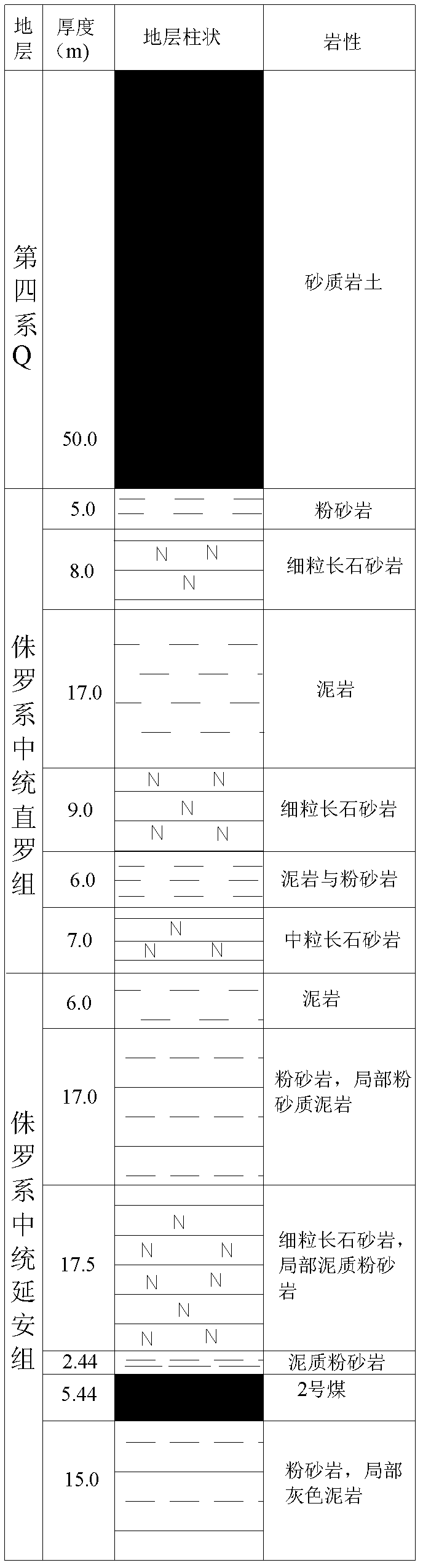

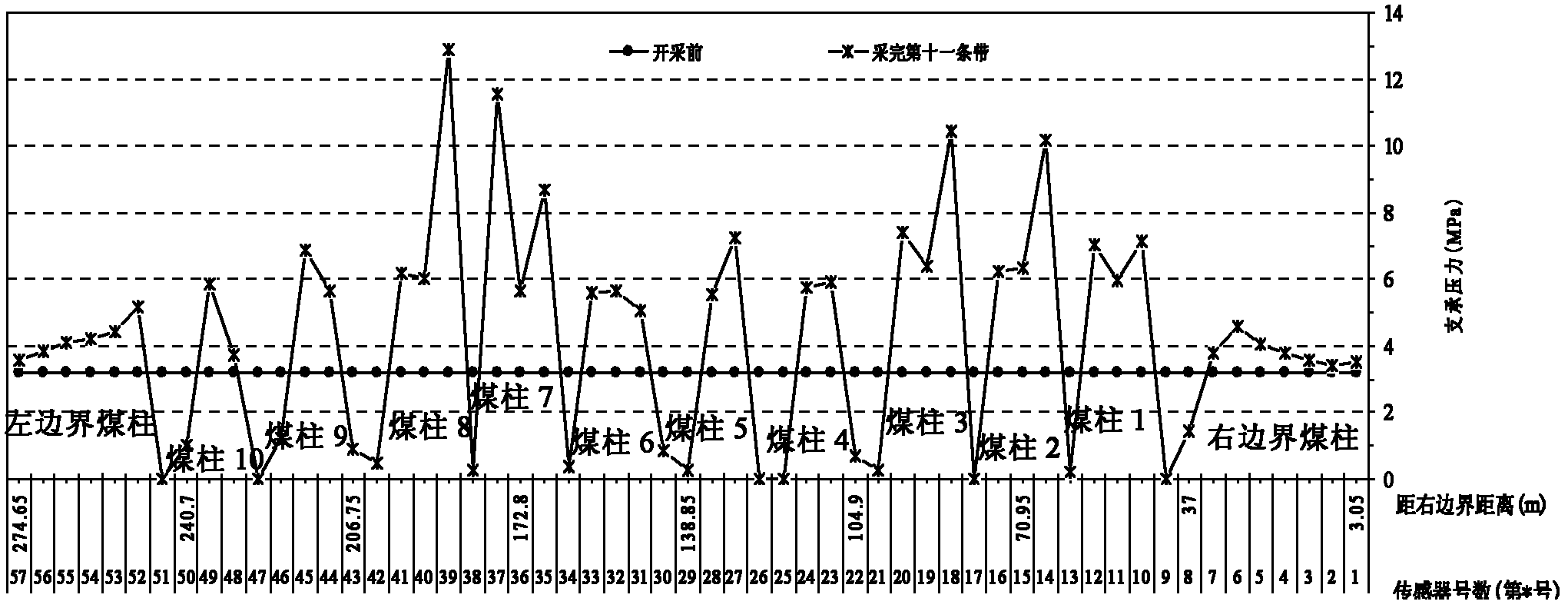

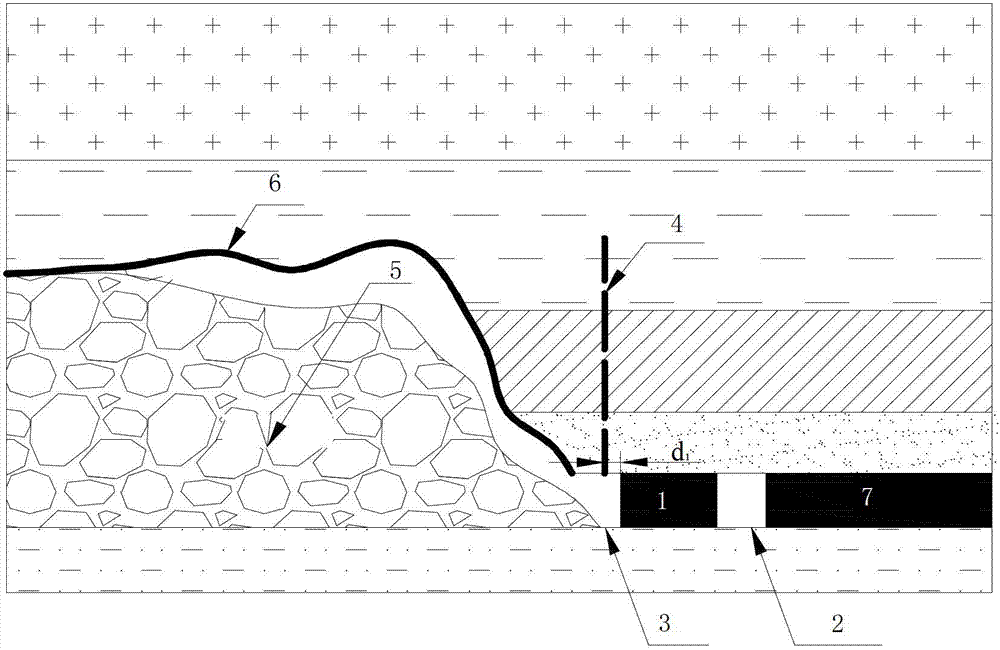

Water conservation coal cutting method for small and medium-sized coal mines in waterhead area

InactiveCN102505943AThe method steps are simpleEasy to implementUnderground miningSurface miningLower limitLimit value

The invention discloses a water conservation coal cutting method for small and medium-sized coal mines in a waterhead area. The method comprises the following steps: 1, defining the position of a coal bed, that is, defining the thickness and the buried depth of the coal bed in an exploited coal mine according to a boring log; 2, defining exploitation parameters, that is, defining a roof rock beambearing load, the higher limit value Lmax of the width of an exploitation strip, and the lower limit value Dmin of the width of a coal pillar; 3, defining an exploitation scheme, that is, defining the mining and the reservation widths during strip exploitation according to the Lmax and the Dmin, wherein the width L0 of a strip exploited during strip exploitation is smaller than or equal to Lmax, and the width D0 of a reserved coal pillar is larger than or equal to Dmin; and 4, exploiting, that is, exploiting the coal bed according to the conventional strip exploitation method, and reserving acoal pillar of which the width is D0 every time when a strip of which the width is L0 is exploited. The water conservation coal cutting method has the advantages that the design is reasonable; the implementation is convenient; the maneuverability is high; the using effect is good; and the problems of easily caused great loss of the phreatic water resource, and poor water conservation coal cuttingeffect during the conventional exploitation of the small and medium-sized coal mines in the waterhead area are solved.

Owner:XIAN UNIV OF SCI & TECH

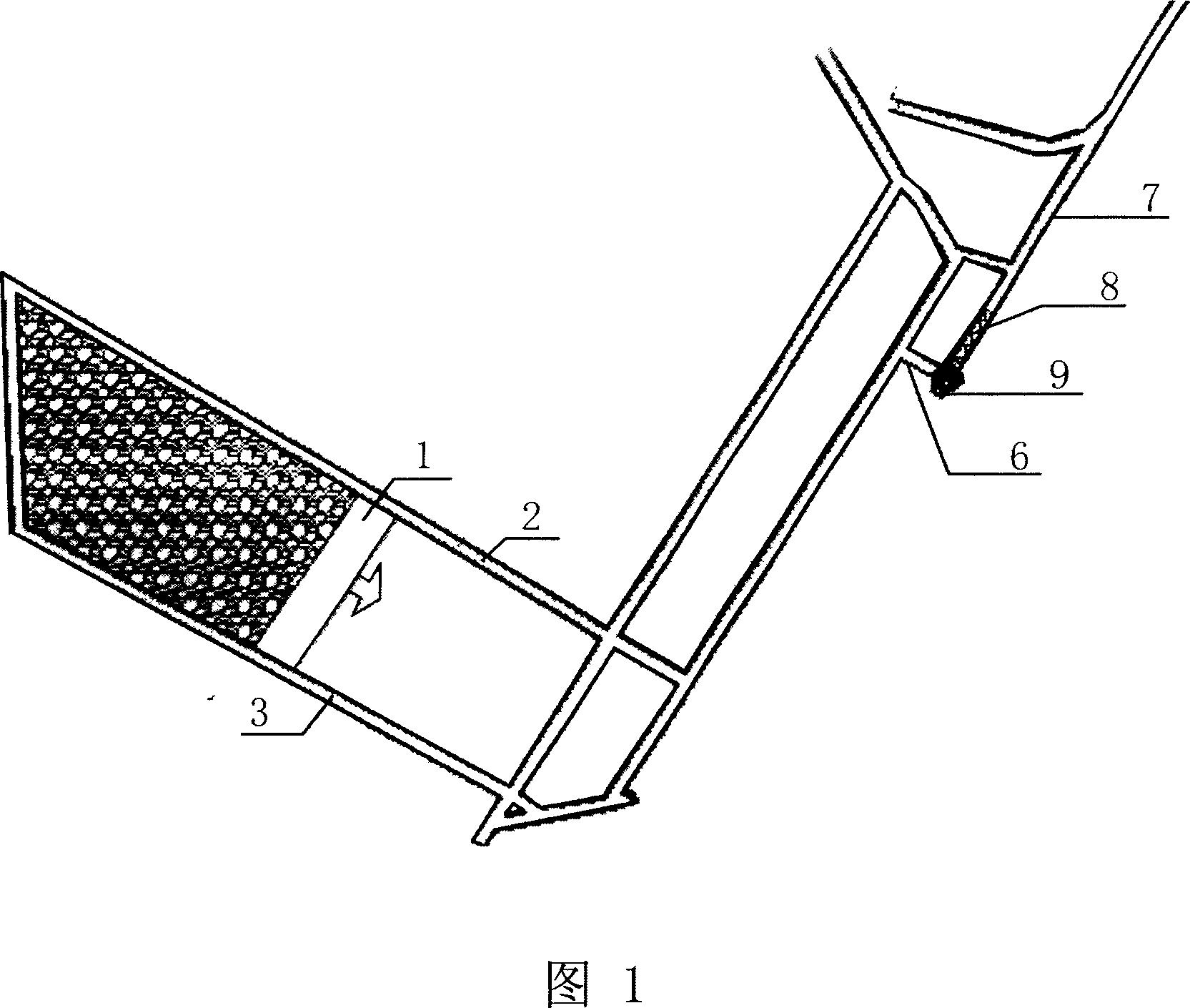

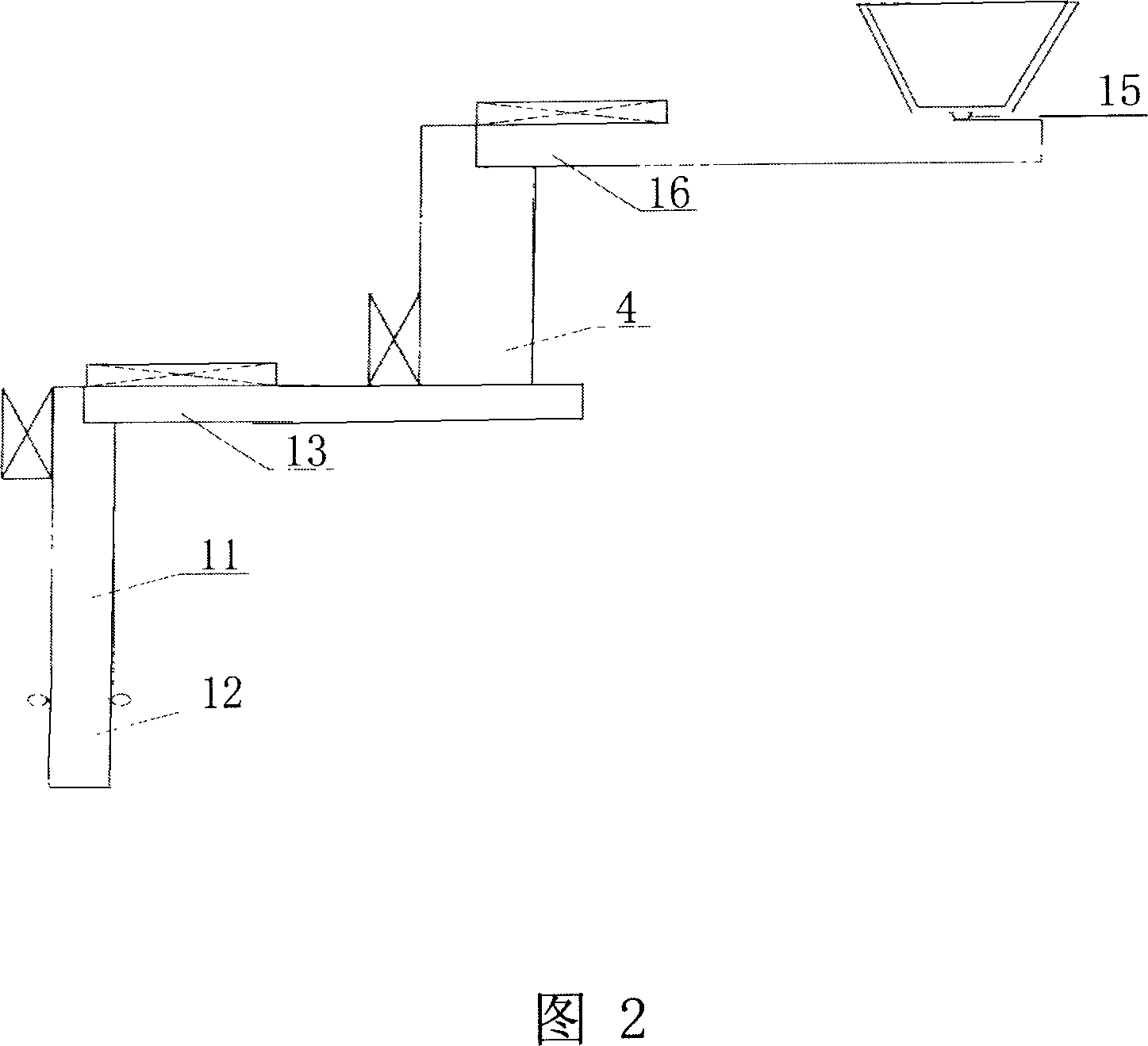

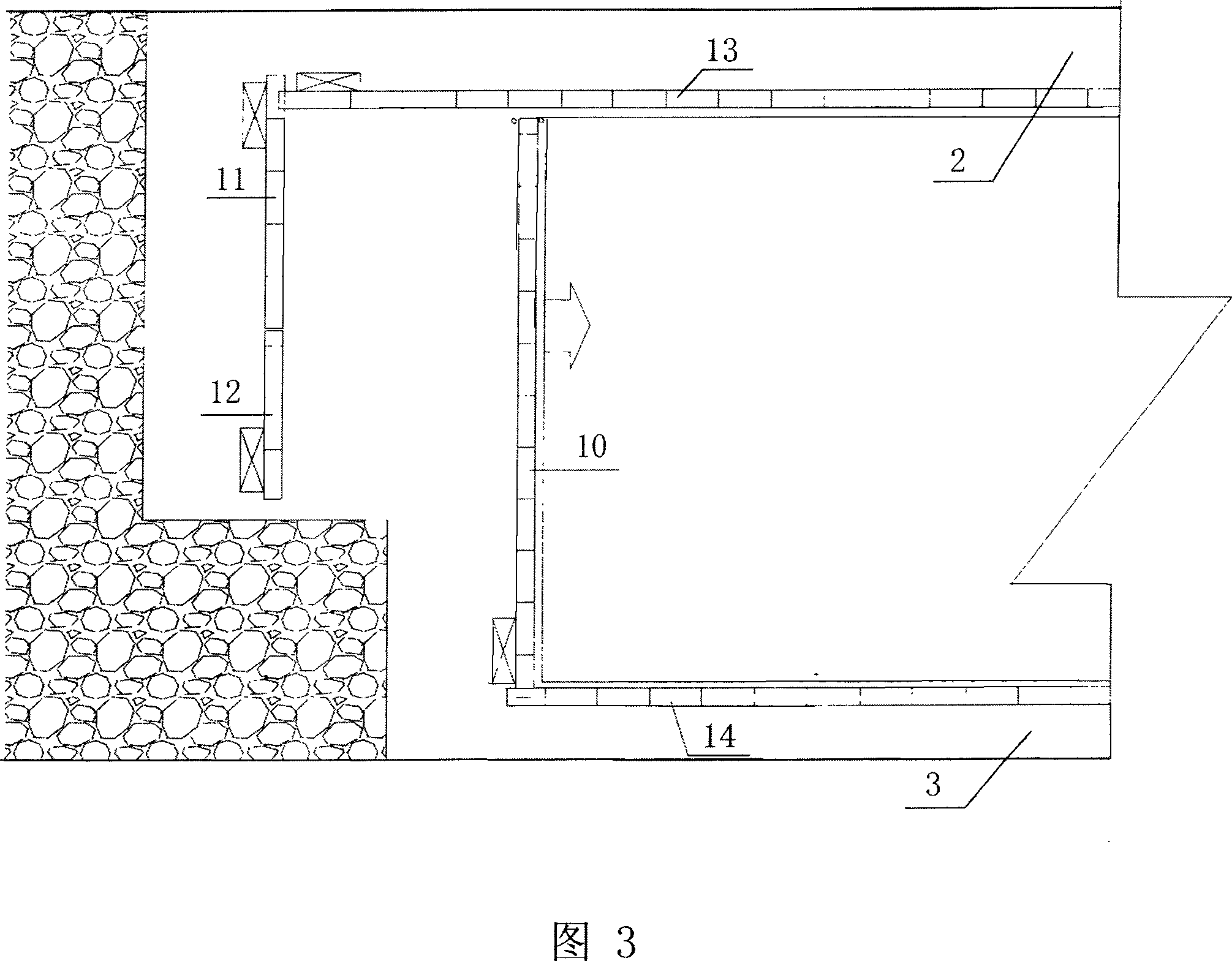

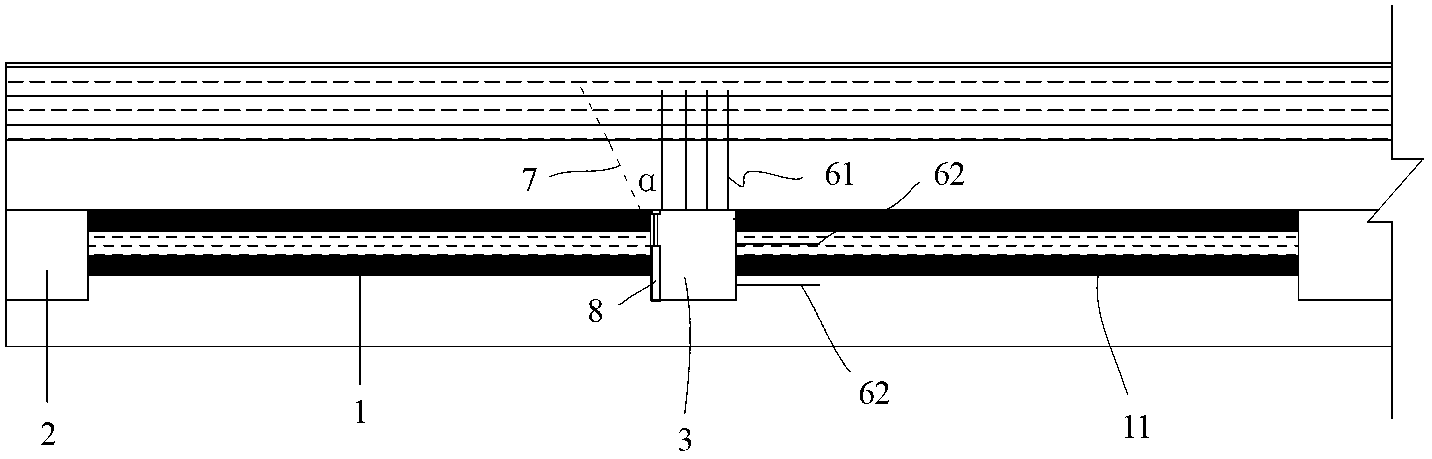

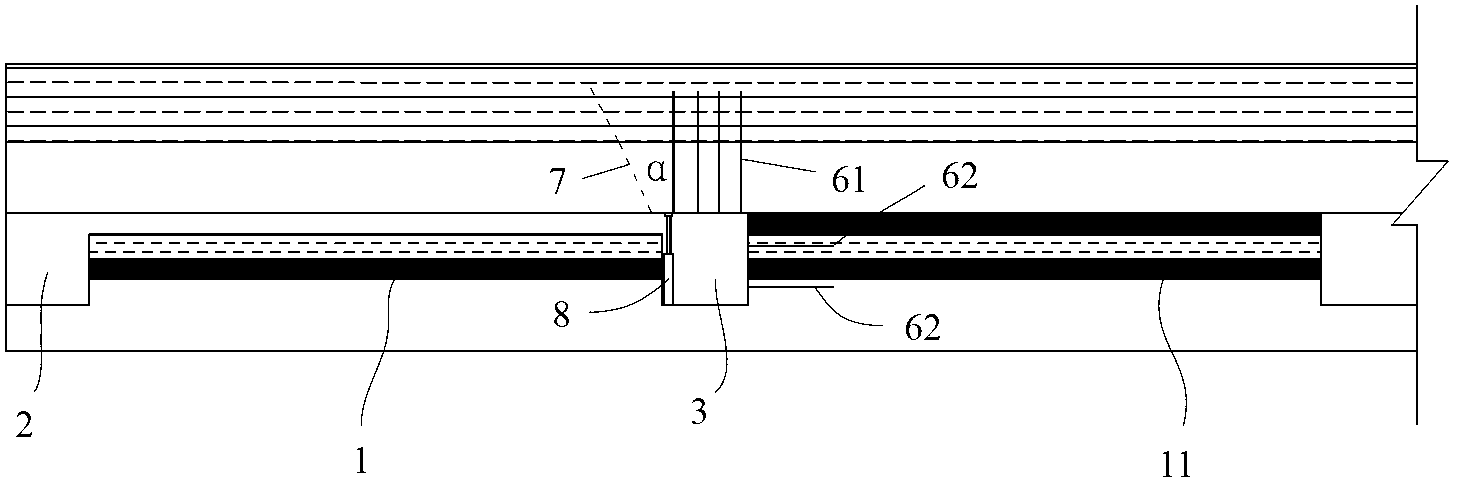

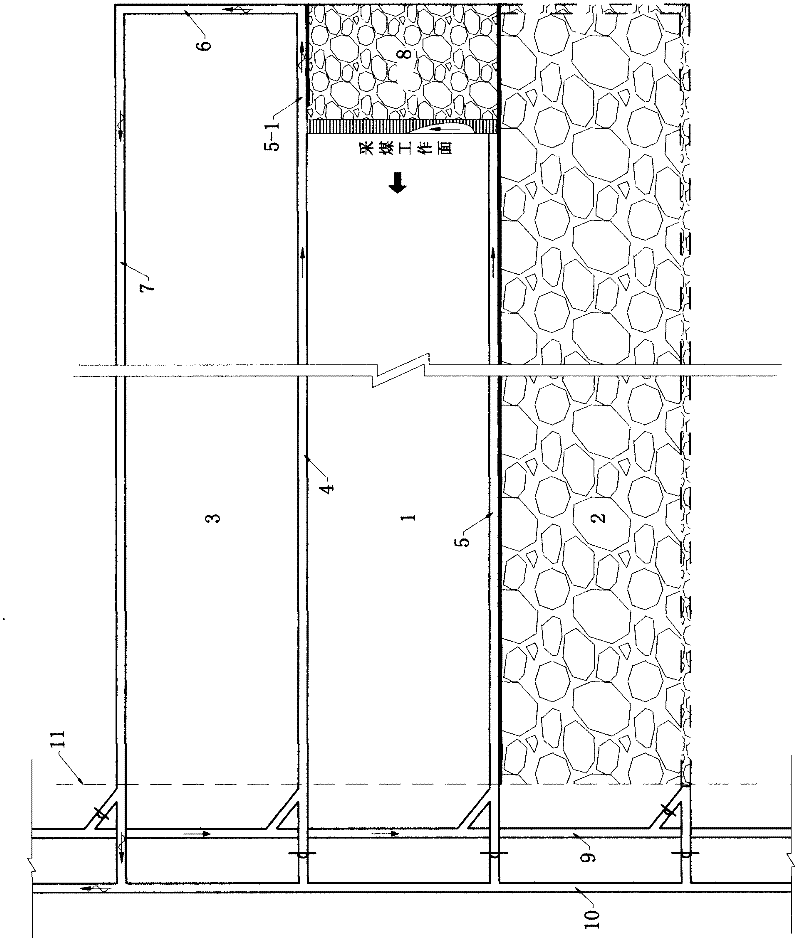

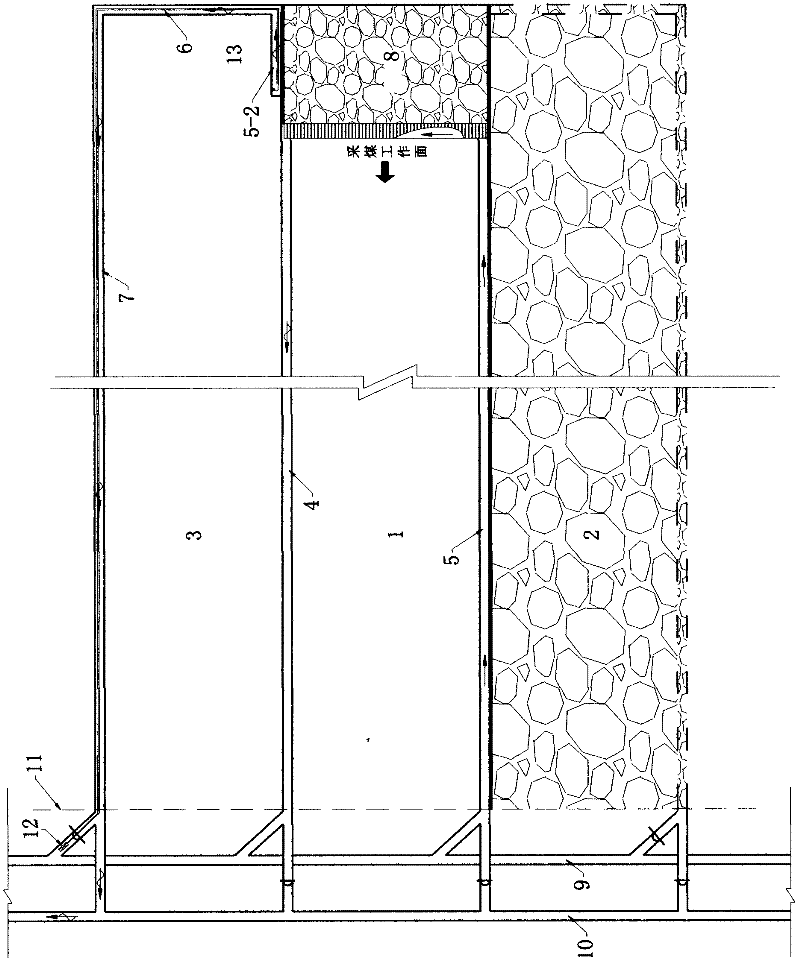

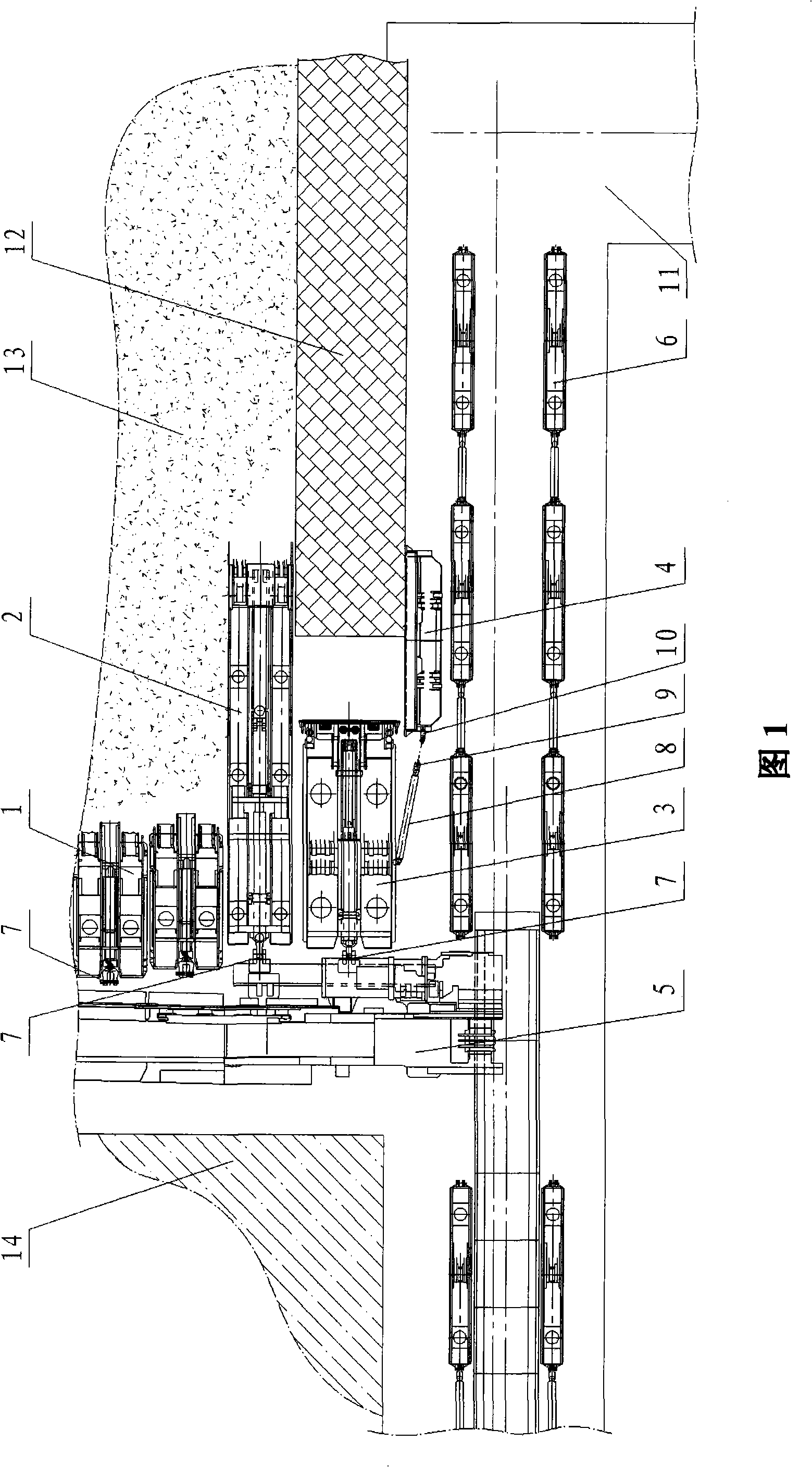

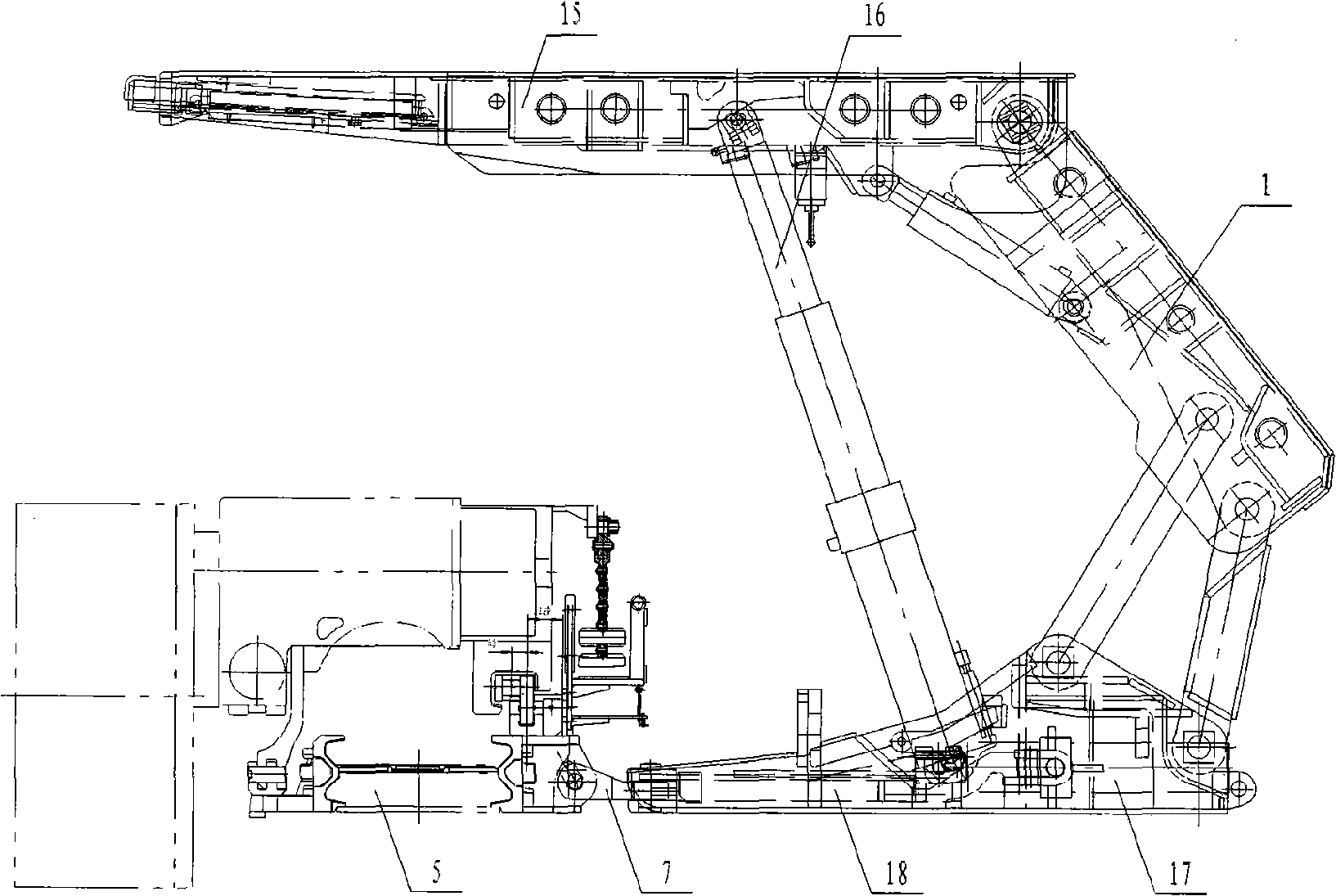

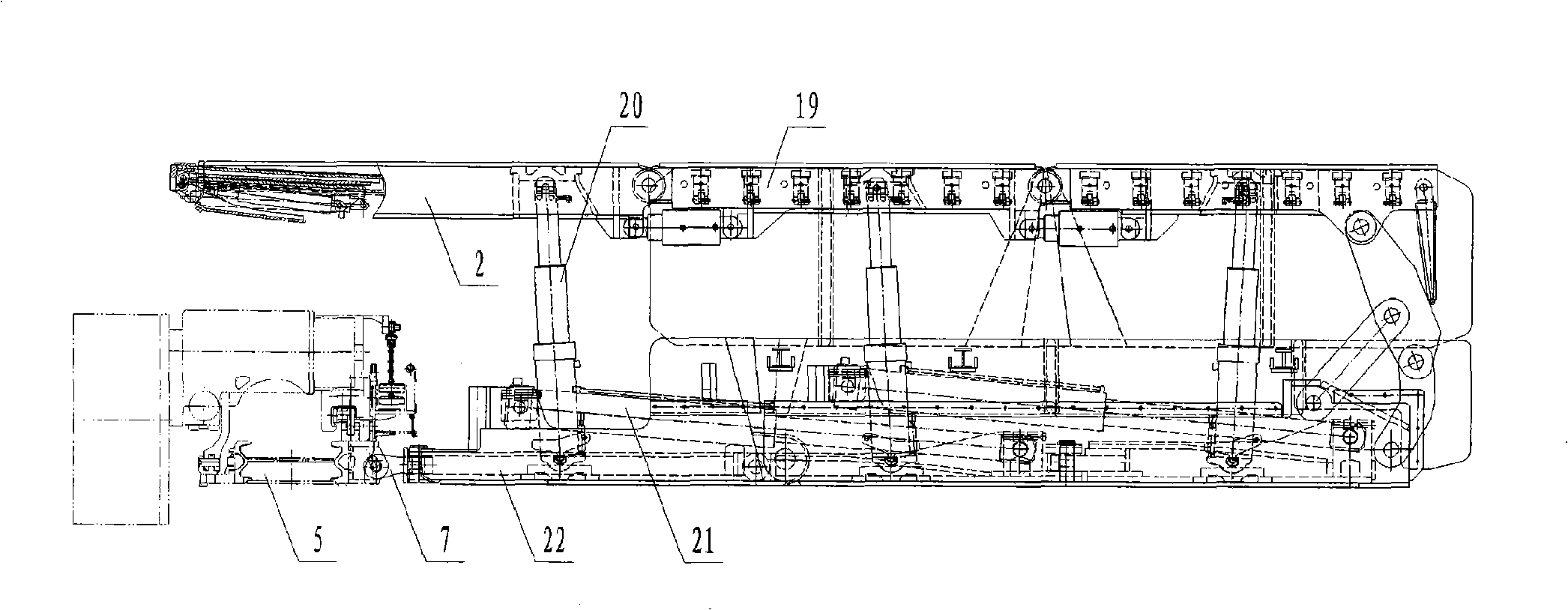

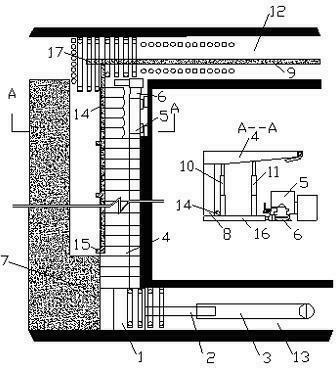

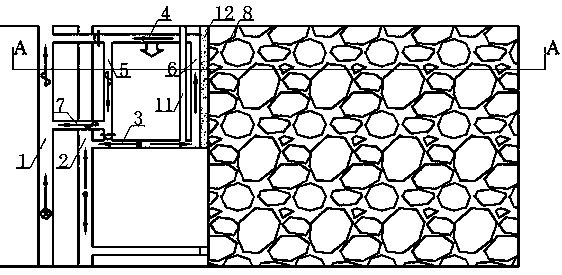

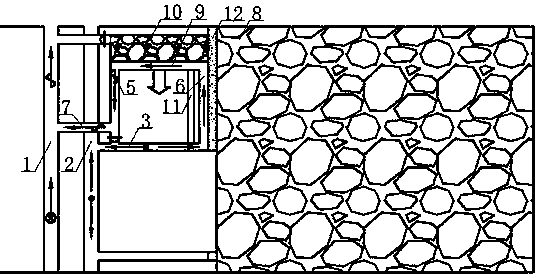

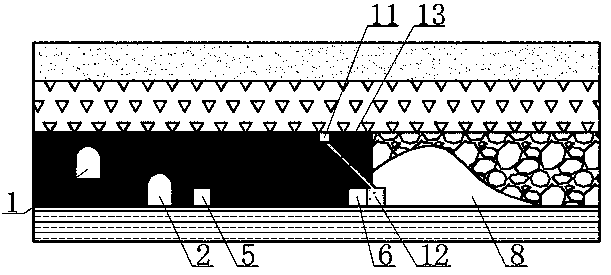

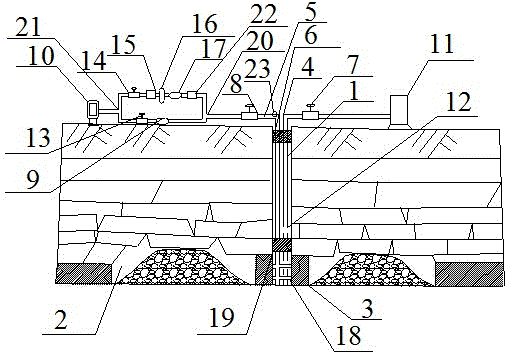

Integrated suspension device for retaining a lane for next sublevel

ActiveCN101289939AMining operation safetyEasy to operateMaterial fill-upMine roof supportsCoal pillarMechanical engineering

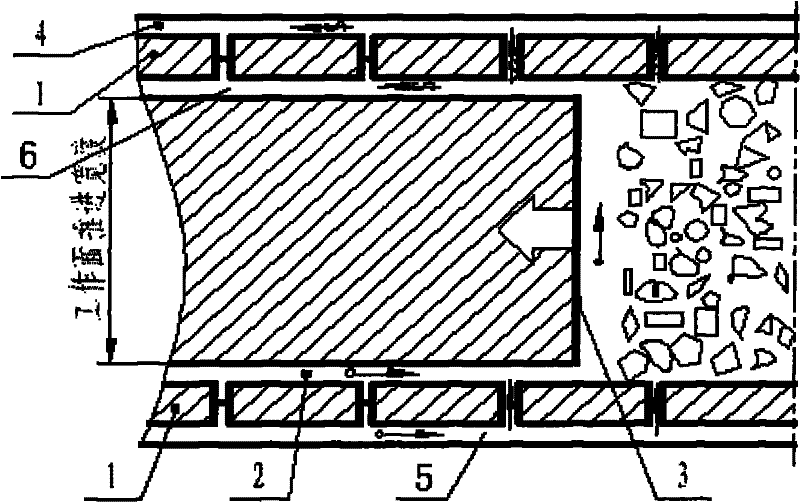

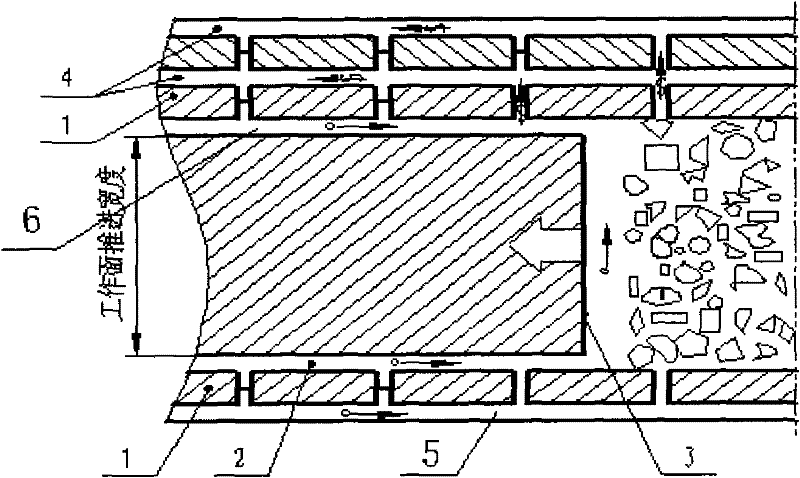

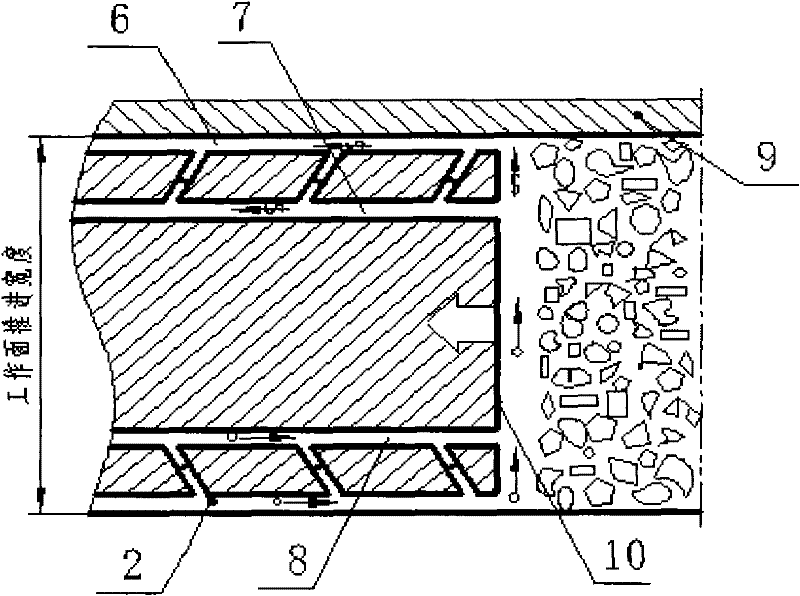

The invention relates to a gob-site entry retaining comprehensive support device, which effectively solves the problems not solved in the prior art that how mechanized formwork erection and whole support are carried out, and realizes difficult problem that filling and coal-mining production are carried out at the same time. The technical key points of the device are as follows: a roadway advancing and retaining support is arranged in a transportation roadway or a return airway; a roadway filling back formwork support, a roadway side filling formwork support and a set of working face hydraulic supports are arranged parallelly in sequence along a roadway; and all supports are vertically connected along the running direction of a transporter; the roadway side filling back formwork support, the roadway side filling formwork support which is arranged on the left of the roadway side filling back formwork support, and an adjustable hydraulic formwork which is arranged on the right of the roadway side filling back formwork support to surround a filling mould cavity which forms a gob-site entry retaining and filling wall. The device has the advantage that the device is favorable for mining a no-coal pillar, is safe and convenient to operate, and is strong in adaptability, can form an insulating gob area in the roadway side and a shield concrete filling wall which is solidified and hardened into a regular wall body, and can shield and match a working face transporter, a coal mining machine and a formwork support to perform normal coal-mining production.

Owner:SHENYANG TIAN AN TECH CO LTD +1

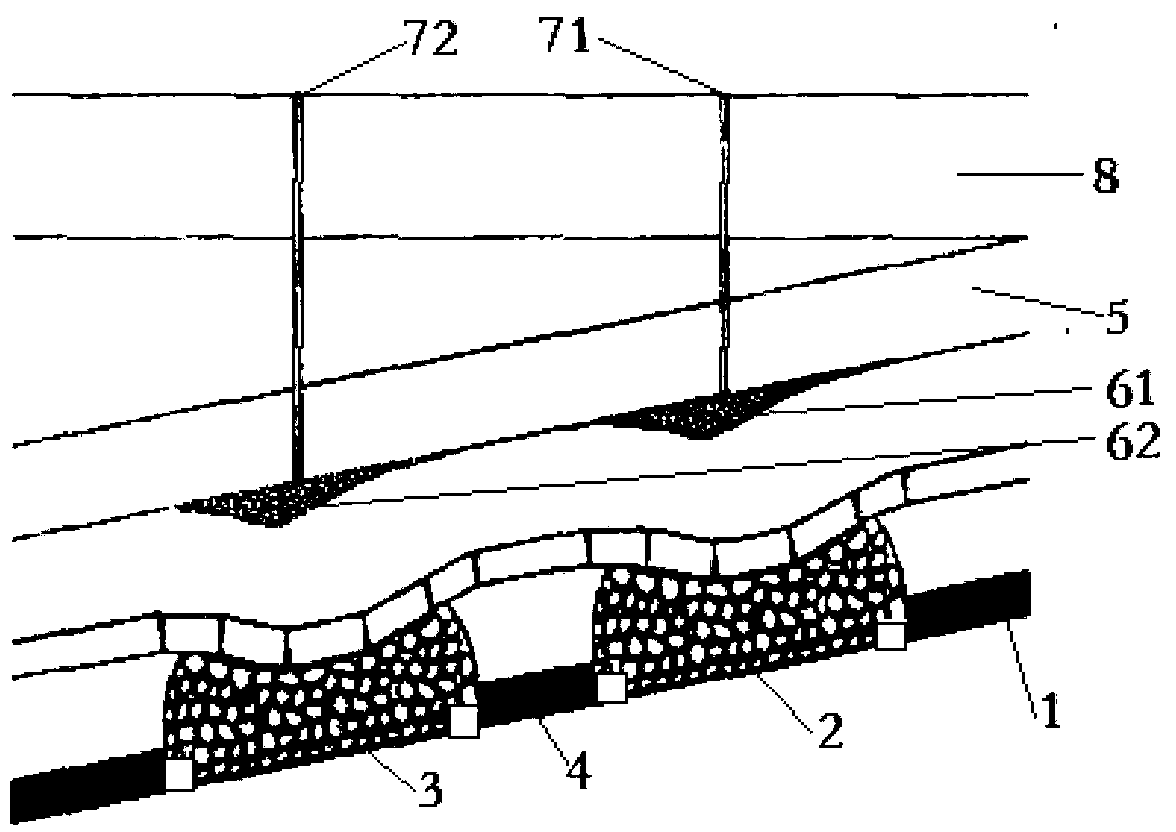

Gob-side entry retaining and sectional coal seam gas pre-extracting method for single low-permeability outburst coal seam

InactiveCN103670496AEmission reductionAchieve miningUnderground miningSurface miningMining engineeringCoal pillar

The invention relates to the field of mine support and gas extraction, in particular to a gob-side entry retaining and sectional coal seam gas pre-extracting method for a single low-permeability outburst coal seam. A plurality of bedding drill holes are drilled in an air inlet crossheading and an air return crossheading of a working surface towards the working surface in the inclined direction of the coal seal in a parallel mode, and a pneumatic gas extraction device is used for carrying out gas extraction; gas of an adjacent working surface is extracted along the inclined bedding drill holes of the coal seam in the downstream direction of a transportation crossheading of the working surface, and an extraction pipeline is communicated for extracting gas of the coal seam of the adjacent working surface; after extraction, robbing is carried out on the coal seal of the working surface; extraction is not stopped until finish, and the steps are repeated until extraction of the coal seam is finished. According to the method, coal mining without pillars is achieved, the recovery rate of coal is improved, the total gas extraction time is saved, the gas extraction effect is improved, and coal mining and gas extracting are achieved at the same time.

Owner:CHINA UNIV OF MINING & TECH

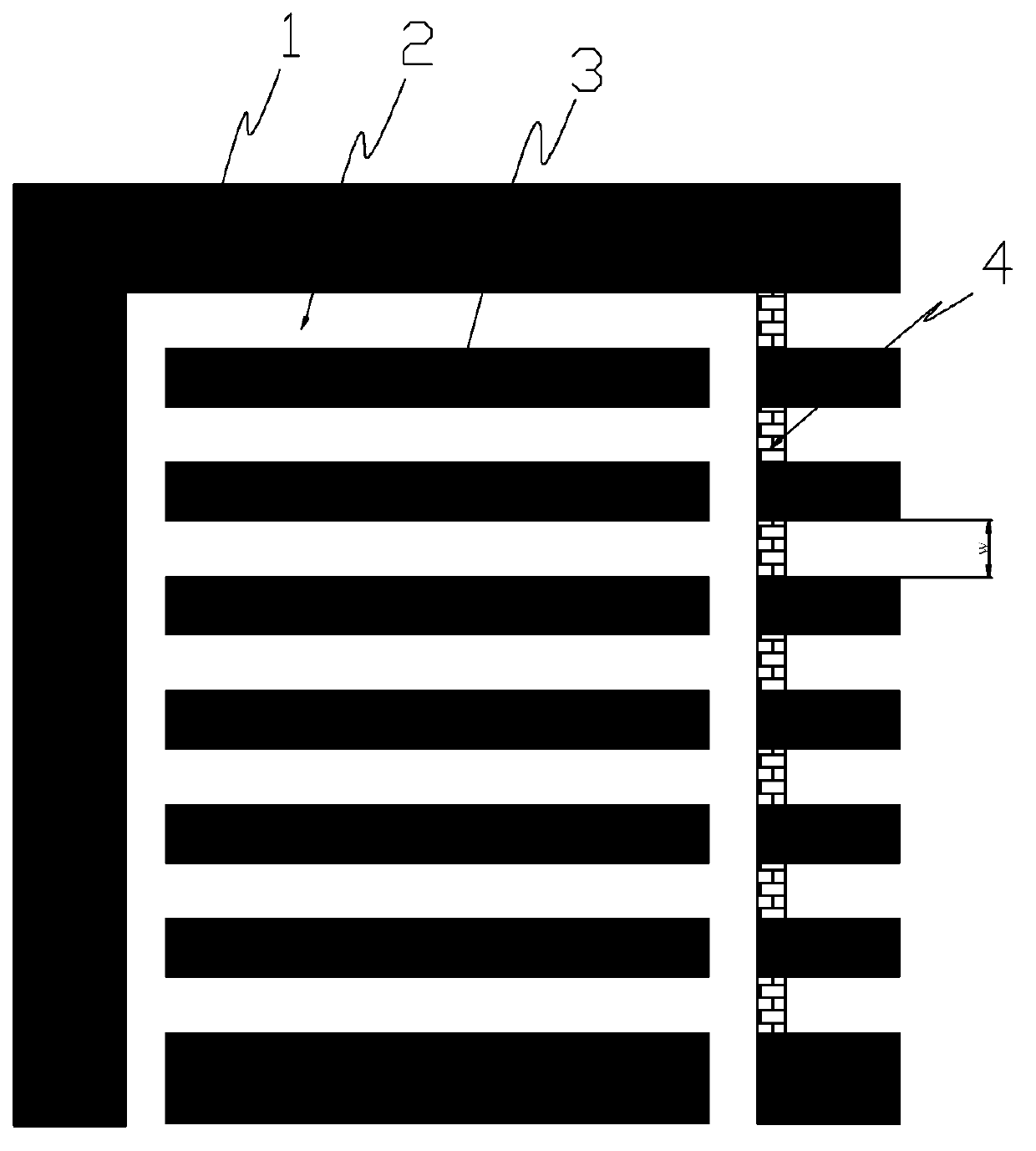

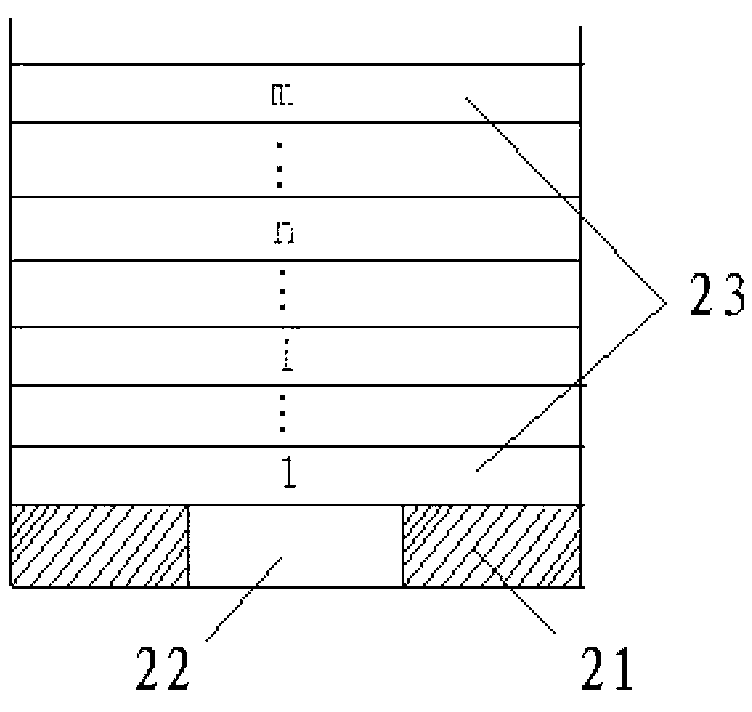

Method for fully mechanized continuously-filling coal mining of steeply pitching coal seam

InactiveCN102493838AIncrease the level of mechanizationReduce labor intensityUnderground miningSurface miningStopped workEngineering

The invention provides a method for fully mechanized continuously-filling coal mining of steeply pitching coal seams, which comprises the following steps: a stoping face is arranged as per the method of long-wall mining along the strike, and fully mechanized mining equipment for the steeply pitching coal seam is adopted; an air cushion and a working face filling pipeline are arranged on a base on the side of a mined out space of rear pillars of a fully mechanized mining support; whenever the working face advances for every 1.4 to 1.8 meters and after the support is moved, the working face filling pipeline is connected with an upper gateway filling main pipeline; the air cushion is filled with air, and auxiliary separation is arranged; paste is conveyed to a filling pipe branch sequentially from low to high so as to ensure filling and compacting, and finally the paste is conveyed to a supplementary filling pipe of the upper gateway; after the paste is coagulated, a portion of air in the air cushion is released, and the working face advances forward continuously; the steps are repeated until the stopping work for the whole working face and the filling work for the mined out space are finished. The method provided by the invention is convenient to operate and simple to carry out, can improve the mechanization level for mining the steeply pitching coal seams under buildings, railways and water bodies, improves the output of the working face, efficiently reduces the roof subsidence and the ground deformation, and realizes coal mining without the pillars and achieves Y type ventilation.

Owner:HUNAN UNIV OF SCI & TECH

Method for second mining mining-stopping line coal column in super thick coal layer

ActiveCN107313778ARecovery is safe and reliableAvoid safety accidentsUnderground miningSurface miningEconomic benefitsEngineering

The invention discloses a method for second mining a mining-stopping line coal column in a super thick coal layer. The method comprises the following steps that (1), positions of a coal column second mining working surface transporting gate trough and a rail gate trough are stimulated; (2) comprehensive probing is conducted on an original working surface goaf area where the super thick coal layer mining-stopping line coal column is located, and potential safety hazard is removed; (3) a roadway in the propelling direction of the coal column second mining working surface is dug at the upper part of the super thick coal layer, and the roadway is filled; (4) a coal column second mining working surface mining returning roadway and a affiliated oblique roadway are dug, so that the coal column second mining working surface mining returning roadway and the affiliated oblique roadway form a completed producing system, and the coal column second mining working surface is arranged; (5) a bottom plate of the roadway is drilled from top to bottom for using as a filled pipeline; (6) filling paste is prepared, the filling paste is evenly injected into one side, close to the original working surface goaf area, of the transporting gate trough along the filled pipeline; and (7) comprehensive mining is conducted on the coal column second mining working surface. According to the method for second mining the mining-stopping line coal column in the super thick coal layer, the compressed coal amount is reduced, waste of coal resources is avoided, the economic benefits of enterprises are improved, and the service life of mines and mining areas is prolonged.

Owner:TAIYUAN UNIV OF TECH

Non-pillar mining method for hard roof coal wall of thick coal seam

ActiveCN102966354AAvoid destructionAvoid enteringUnderground miningSurface miningEngineeringCoal pillar

The invention discloses a non-pillar mining method for a hard roof coal wall of a thick coal seam. The non-pillar mining method comprises the following steps of: (1) excavating an upper crossheading roadway and a lower crossheading roadway; (2) excavating a roof cutting tunnel; (3) arranging a first roof cutting surface and a second roof cutting surface in the roof cutting tunnel; (4) reinforcing the top of the lower crossheading roadway; (5) backstopping a mining surface, and erecting a support protective layer; (6) blasting to cause a hard roof to fracture along the first roof cutting surface and the second roof cutting surface so that the place of the original lower crossheading roadway forms a roadway again; (7) using the roadway automatically formed at the place of the original lower crossheading roadway as an upper crossheading roadway of the next mining surface; and (8) repeating the steps (2)-(7). According to the non-pillar mining method, the roof in a mined-out area fractures along the first roof cutting surface and the second roof cutting surface through the blasting along a first energy gathering blasting roof cutting hole and a second energy gathering blasting roof cutting hole, simultaneously a lower crossheading roof is prevented from being damaged, and small caving gangues are prevented from entering the lower crossheading roadway so that the place of the original lower crossheading roadway automatically forms the tunnel.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

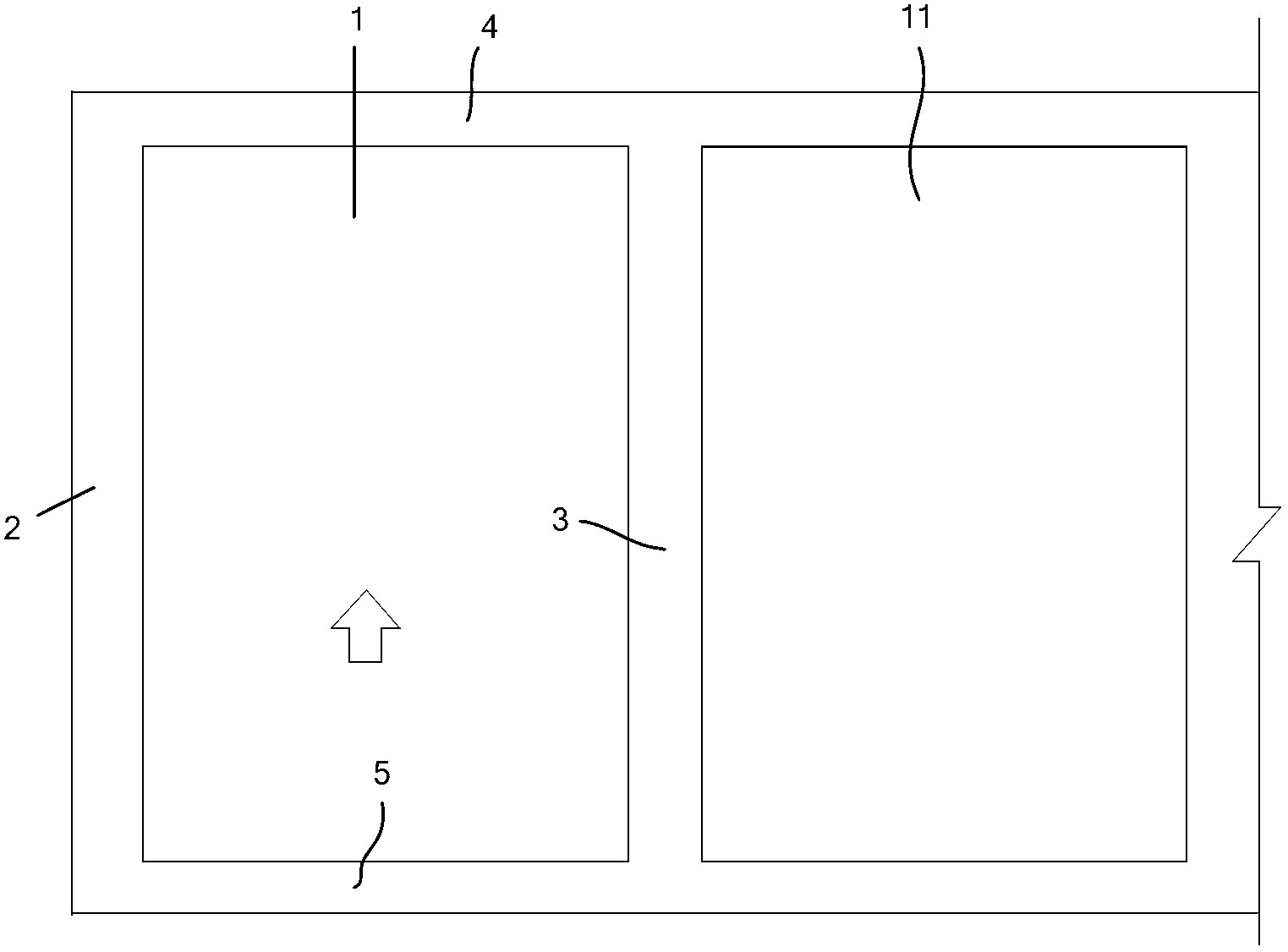

Longwall mining N00 construction method

ActiveCN105240013AGuaranteed ventilation effectSave resourcesUnderground miningTunnel/mines ventillationLongwall miningCoal pillar

The invention discloses a longwall mining N00 construction method, which is characterized in that roadway-free tunneling and coal-pillar-free mining are performed in N working faces of a bran-new panel; the whole panel is provided with an air return downhill passage, a belt downhill passage and a rail downhill passage; the air return downhill passage and the rail downhill passage are positioned at one end of the panel; and the belt downhill passage is communicated with the other end of the panel and is communicated with the air return downhill passage. The longwall mining N00 construction method has the advantages that the ventilation of the whole coal mining region can be ensured; during the mining of each working face in the panel, one part of a goaf is used for implementing roof cutting and pressure relief automatic roadway forming; any crossheading roadway does not need to be tunneled; and coal pillars do not need to be reserved, so that resources are saved, and the efficiency is improved.

Owner:何满潮

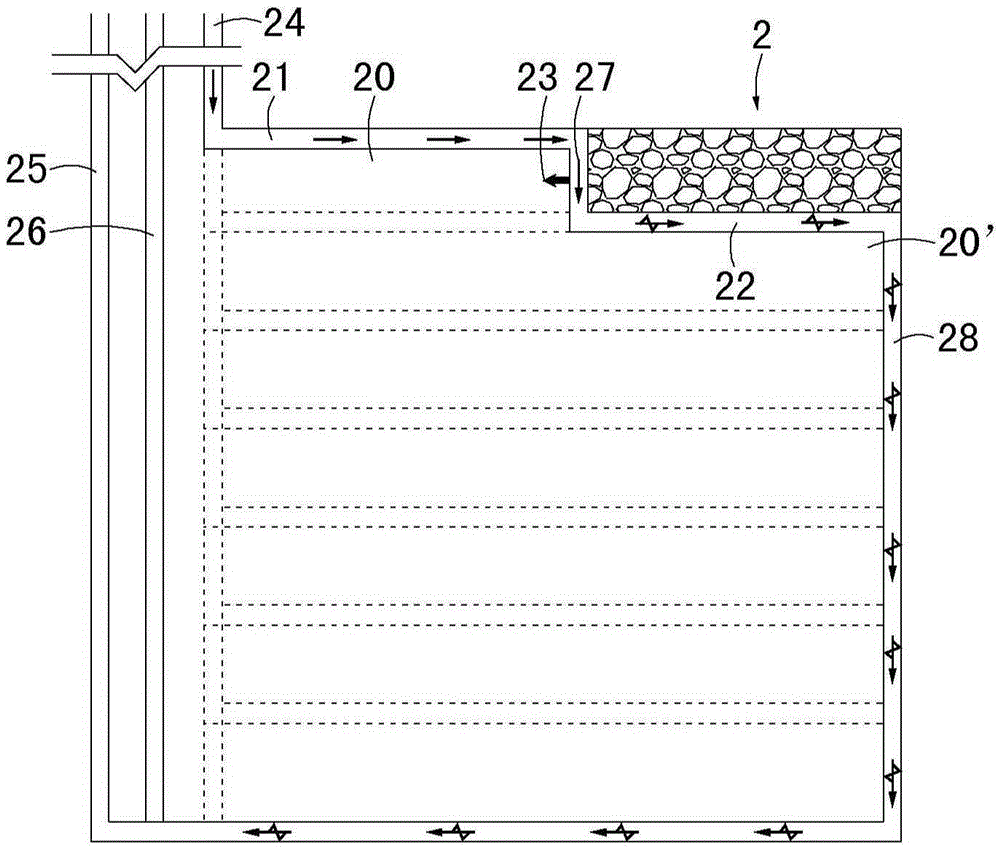

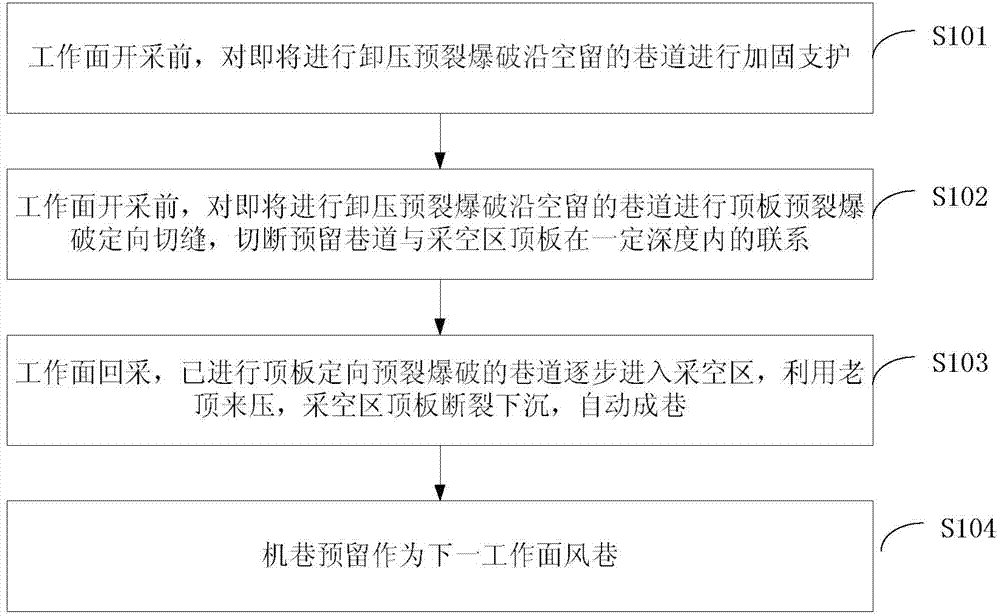

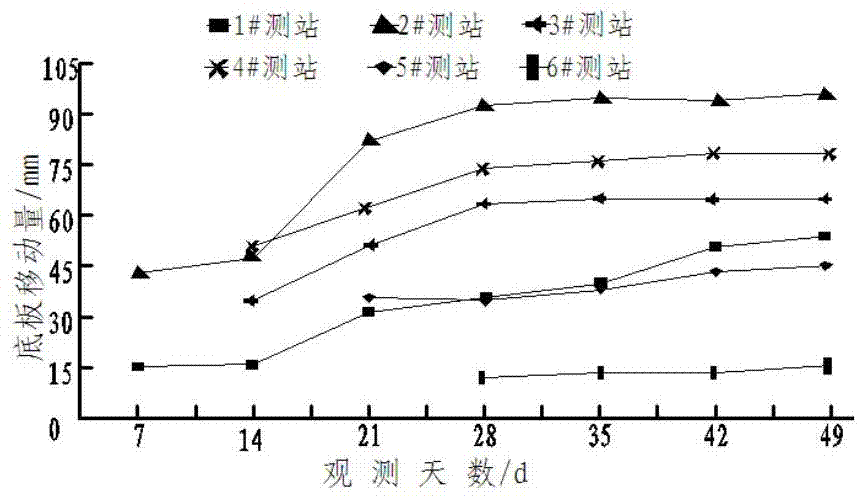

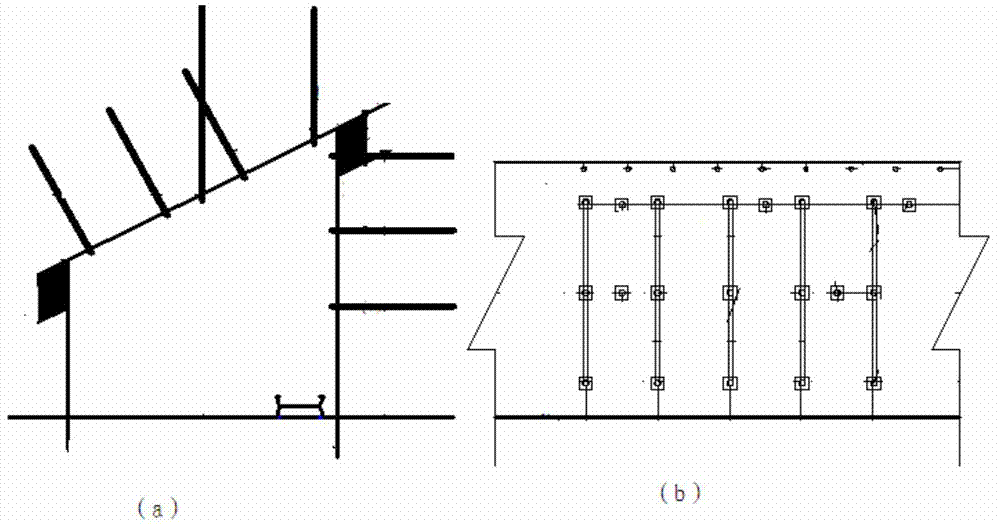

Pressure relief presplitting blasting gob-side entry retaining pillar-free mining method

InactiveCN104763425AEasy maintenanceReduce maintenance costsUnderground miningSurface miningResource recoveryCoal pillar

The invention discloses a pressure relief presplitting blasting gob-side entry retaining pillar-free mining method. The method comprises carrying out reinforced support on a tunnel to be subjected to pressure relief presplitting blasting gob-side entry retaining before working face mining, carrying out roof presplitting blasting oriented joint-cutting before working face mining so that the connection of the reserved tunnel and a goaf roof in a certain depth range, in working face mining, gradually feeding the tunnel subjected to roof oriented presplitting blasting into a goaf, carrying pressing by an upper roof so that the goaf roof is broken and sinks and a tunnel is automatically formed, and utilizing the reserved machined tunnel as an air way of the next working face. The pressure relief presplitting blasting gob-side entry retaining pillar-free mining method is free of slope expansion and dinting of a tunnel, improves a resource recovery rate, relieves excavation replacement, is conducive to tunnel maintenance, reduces a tunnel maintenance cost and reduces worker labor intensity.

Owner:杨洪兴

Laneway disposed by using large U to sleeve small u

InactiveCN101649741ARealize continuous excavationImprove governance effectUnderground miningTunnel/mines ventillationEngineeringCoal pillar

The invention relates to a laneway disposing shape of a coal mine, in particular to a laneway disposed by using large U to sleeve small u, which solves the problems of driving along a groove and gas control of a stope in the prior laneway disposing mode. The laneway comprises a stope, a small u-shaped laneway is arranged at the periphery of the stope, the small u-shaped laneway comprises a belt laneway and a return airway which are arranged on both sides of the stope, the front side of the stope is provided with a cutting hole, a large U-shaped laneway is arranged outside the small u-shaped laneway and comprises a head-to-tail connection device, a ventilation laneway, a ventilation connection laneway and a gas tail laneway, wherein the head-to-tail connection device and the ventilation laneway are positioned outside the belt laneway, the ventilation connection laneway is arranged outside the cutting hole, the gas tail laneway is positioned outside the return airway, and a plurality ofentity supporting coal pillars are arranged between the large U-shaped laneway and the small u-shaped laneway. The laneway disposing shape solves the problem of gas control of the stope and increaseswork efficiency.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

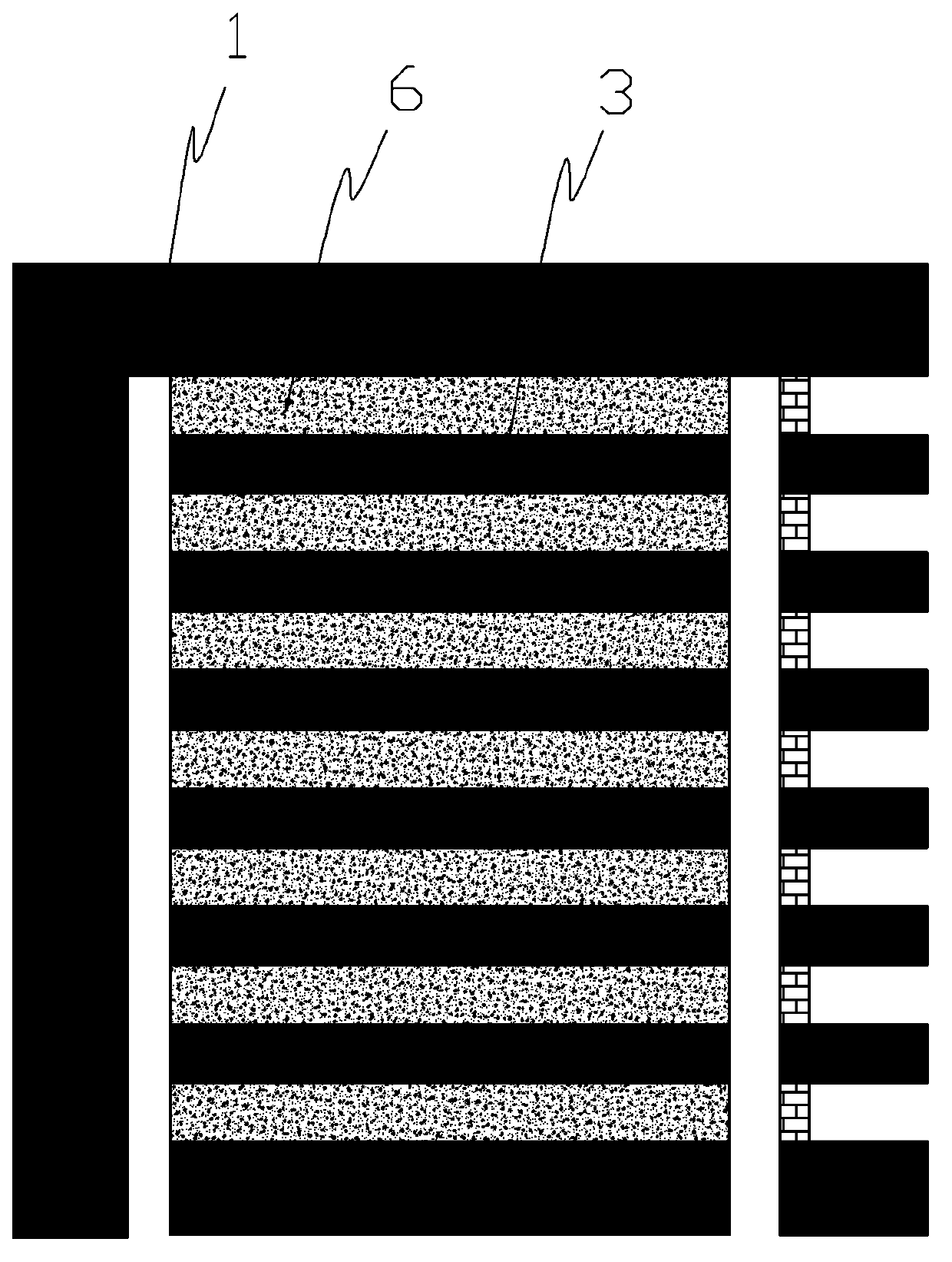

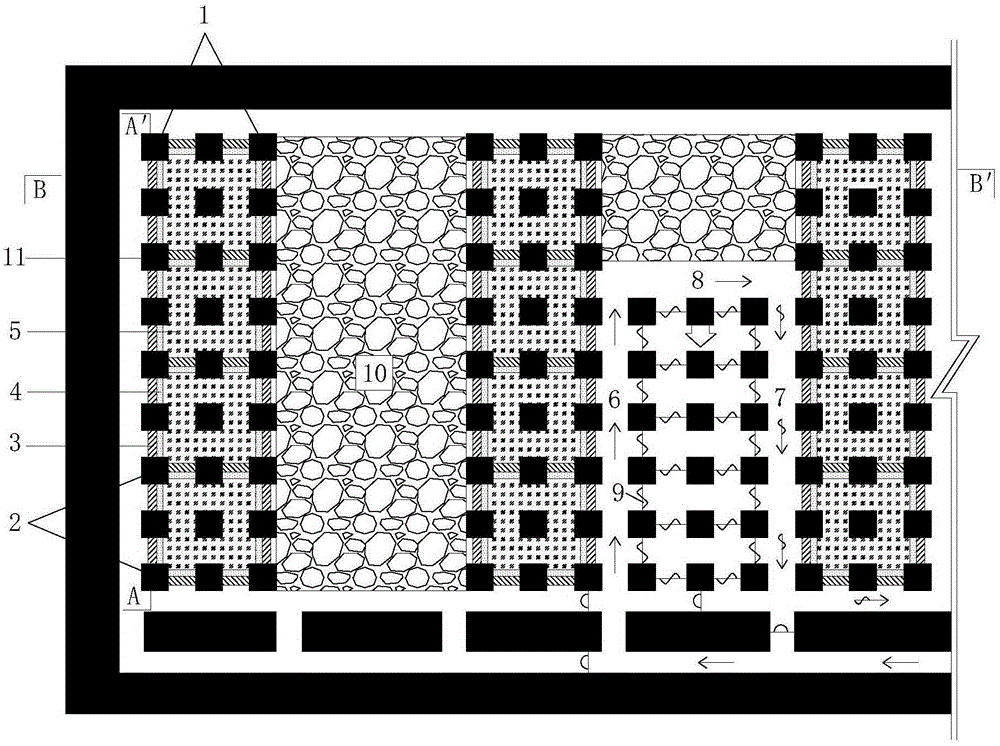

Method for reclaiming house type remaining coal pillars based on filling and rebuilding of entry protection coal-pillar band

ActiveCN105240014AThe method of filling and remanufacturing is simpleImprove recycling efficiencySolid waste managementUnderground miningRecovery methodResource utilization

The invention discloses a method for reclaiming house type remaining coal pillars based on filling and rebuilding of entry protection coal-pillar band, and belongs to reclaiming methods of house type remaining coal pillars in coal goafs. The reclaiming method of remaining coal pillars comprises the following steps: estimating and grading the stability of house type remaining coal pillars in a coal goaf; determining the width of entry protection coal pillars to be filled and rebuilt and the length of a band working face; performing an entry protection coal pillar filling and rebuilding technology; and performing a coal pillar reclaiming method and technology. According to the method, the minimum width of the entry protection coal pillars to be rebuilt, and the largest length of the band working face are determined according to the grades of the stability of the remaining coal pillars in the coal goaf; through the adoption of method for filling and rebuilding entry protection coal pillars, the stability of original coal pillars is greatly improved, so that the surface subsidence is controlled, and remaining coal pillar resources are reclaimed to the greatest extent; the purposes that the surface subsidence is reduced, the life and property safety of people in mining districts are protected, and the utilization ratio of resources is increased are realized. The method disclosed by the invention has the advantages of being simple, easy to operate, high in efficiency for filling and rebuilding entry protection coal pillars, and low in cost; the targets that the waste of resources is reduced, and the surface subsidence is controlled are realized, and the method can be widely applied.

Owner:CHINA UNIV OF MINING & TECH

Beside-roadway escribing pressure relief method of roadway driving along gob of small coal pillar influenced by dynamic pressure

InactiveCN102778182AShorten exercise timeEliminate mining dynamic pressureBlastingEngineeringCoal pillar

The invention discloses a beside-roadway escribing pressure relief method of roadway driving along a gob of a small coal pillar influenced by dynamic pressure. The method includes the following steps: adopting roadway roof deep hole blasting as the escribing method, arranging escribing shot holes within the overall length range of an adjacent working surface crossheading of the roadway driving along the gob, and implementing stage blasting operation during back production of the working surface, wherein the escribing shot holes need to be close to the small coal pillar as far as possible, the depth of the escribing shot holes is determined according to the mining height of the back production working surface and the free caving height of the roof of the working surface, the shot holes need to be arranged with a distance away from the working surface, and the distance among the shot holes need to be determined reasonably; then performing explosive filling and hole blocking; performing ahead blasting operation in front of the working surface or lag blasting operation after the shot holes enter a gob area; and instantly performing roadway driving along the gob when the bad influence on the essence of the roadway driving along the gob of the small coal pillar caused by dynamic pressure of the working surface can be basically eliminated when back production of the adjacent working surface is finished. By means of the beside-roadway escribing pressure relief method, normal production of a back production working surface is ensured, and the cost and difficulty in roadway support along the gob are greatly reduced.

Owner:SHANDONG UNIV OF SCI & TECH

System and method for increasing drainage quantity of coal bed gas of ground well drainage goaf

ActiveCN105114038AExtend the effective service periodLow extractionFluid removalMining engineeringCoal pillar

The invention discloses a system and a method for increasing drainage quantity of coal bed gas of a ground well drainage goaf and belongs to the technical field of coal bed gas drainage. The method includes: constructing a drainage well between adjacent goaf holes, sequentially sending a drainage pipe and a flow injection pipe in, and arranging sealing sections I and II; opening a valve I and a valve III, injecting 30-60 MPa of supercritical CO2 into the flow injection pipe until pressure indicating number declines suddenly; opening a valve II to enable a ground drainage station to drain the coal bed gas, recording initial gas flow, repeating replacement of coal bed gas with CO2 when coal bed gas flow declines 30% of the initial gas flow again, and stopping coal bed gas drainage until the coal bed gas flow declines to 16% of the initial gas flow finally. By the system and the method, concentration of drained coal bed gas is increased effectively, and cost for separation and purification is lowered; supercritical CO2 jet flow is adopted to break coal columns, so that threshold pressure is low, breaking speed is high, no pollution is caused to a coal bed gas reservoir, and rock breaking efficiency can be improved substantially.

Owner:TAIYUAN UNIV OF TECH

Method for reducing subsidence of stope overburden bed separation by grouting

InactiveCN103216236AImproving the effect of grouting filling to reduce settlementSave equipmentUnderground miningSurface miningEngineeringCoal pillar

The invention relates to a method for reducing subsidence of stope overburden bed separation by grouting, which comprises the following steps: determining all key layer positions over the stope; injecting grouting into the bed separation below a object key layer; along with the exploitation of the working face and the bed separation extending above a new goaf, continuously injecting grouting into the bed separation from an injection grouting aperture. Coal pillars are not kept between working faces, thereby improving the recovery rate of the mining area and forming continuous bed separations; the grouting injecting work is carried out after a fully mining degree of a rock stratum below the bed separation, thereby improving the effect for reducing subsidence by injecting and filling grouting. Further, there is no need to arrange a set of grouting injecting system along the tendency of the bed separation over every working face, thereby saving equipment and engineering investment.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Coal mining method with direct coal pillar recovery

The invention relates to a coal mining method, in particular to a coal mining method with direct coal pillar recovery, full-width heading of the coal pillar in a stope and arrangement of a single coal curtain between adjacent working surfaces, which solves the problem of low resource recovery rate in the prior coal mining technology. The coal mining method comprises the following steps: firstly, arranging a gate roadway respectively on the two sides of the large-width coal mining working surface; secondly, arranging the rest ventilation connections and service roadways between the gate roadways on the two sides of the working surface according to the need; thirdly, arranging coal mining equipment along the large-width working surface between the two gate roadways; fourthly, operating a coal cutter to cut coal from one side of the large-width working surface to the to the other side thereof. The involved coal curtains can be all mined once. Accordingly, the coal in the entire large-width working surface can be all cut out; the essence of the coal mining method is to move the coal pillars into the heading range of the working surface and changing non-mineability into direct mining.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

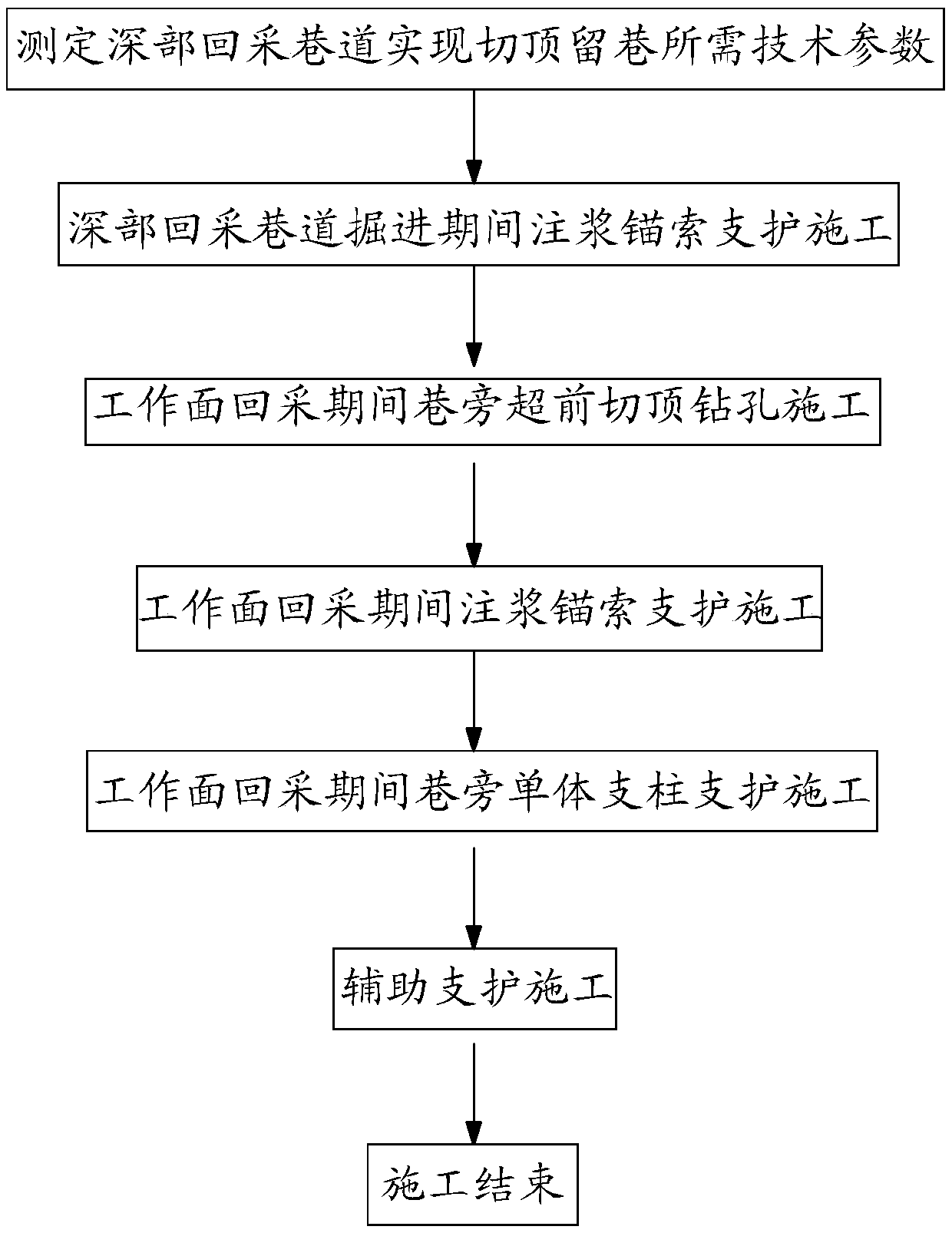

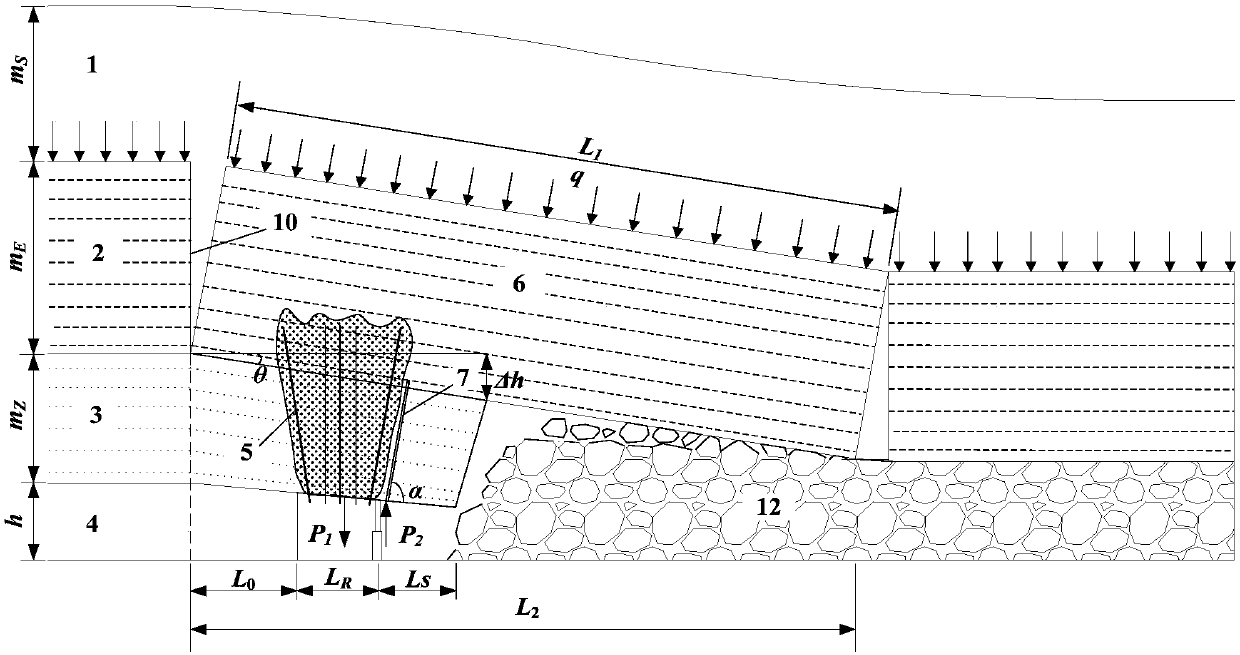

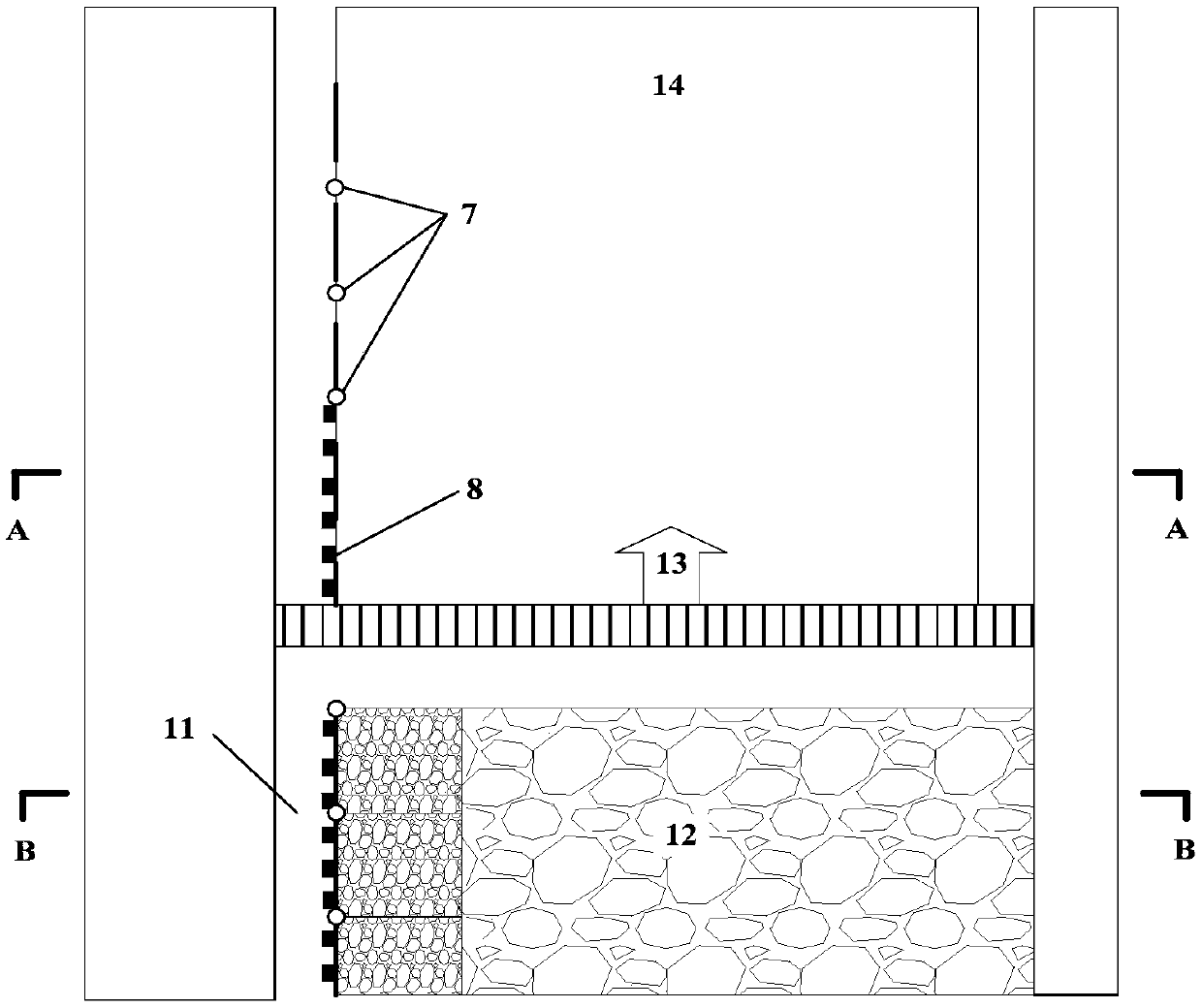

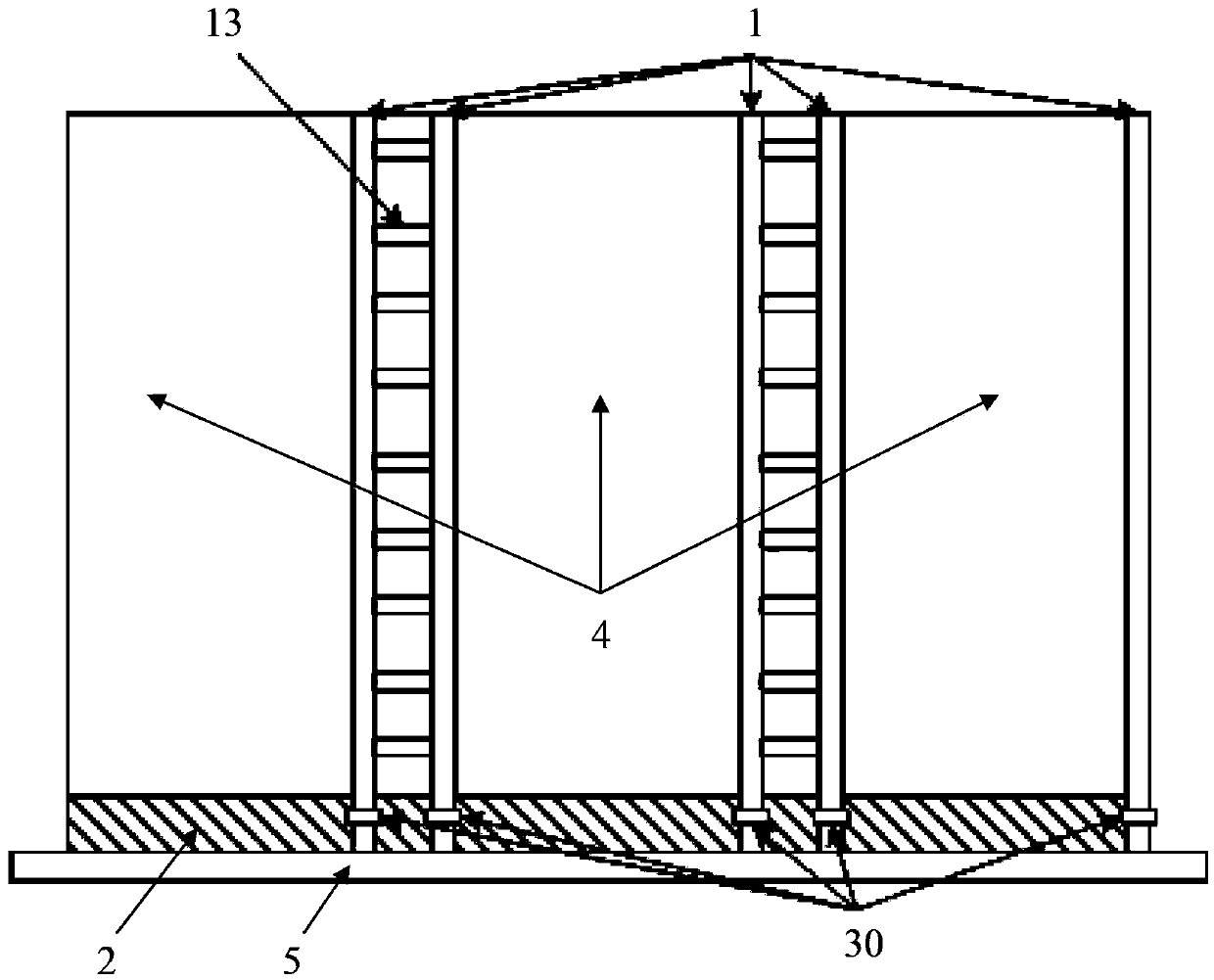

Main control and roadway retaining method for anchor injection and top-cutting in deep mining roadway

ActiveCN108678769AAvoid it happening againReduce stressUnderground chambersTunnel liningDeep miningCoal pillar

The invention provides a main control and roadway retaining method for anchor injection and top-cutting in a deep mining roadway, which comprises the following steps: step 1, determining the technicalparameters required for realizing the top-cut and roadway retaining in the deep mining roadway; step 2, carrying out the grouting anchor cable support construction during the tunnelling period of thedeep mining roadway; step 3, carrying out the advanced overcut and perforating construction at the roadway side during the mining of the working face; step 4, carrying out grouting anchor cable support construction during the mining of the working face; step 5, carrying out monomer strut support construction at the roadway side during the mining of the working surface; step 6, carrying out auxiliary support construction. The method has the advantages that the supporting requirements of the deep gob-side entry can be satisfied when carrying out non-pillar mining construction in the deep mine.

Owner:SHANDONG UNIV OF SCI & TECH

Artificial retaining dam for coal mine distributed underground reservoir and damming method thereof

The invention discloses an artificial retaining dam for a coal mine distributed underground reservoir. The artificial retaining dam comprises a supporting layer, an impermeable layer and a concrete structural layer which are sequentially formed in an auxiliary roadway from inside to outside; the concrete structural layer is embedded into security coal pillars and / or surrounding rocks around the auxiliary roadway. The invention also discloses a damming method of the artificial retaining dam for the coal mine distributed underground reservoir. The concrete structural layer is embedded into the security coal pillars and / or the surrounding rocks around the auxiliary roadway, so that the artificial retaining dam is combined with the security coal pillars to form a retaining dam for the underground reservoir together. Moreover, due to the multilayer design, impermeability and structural intensity of the artificial retaining dam can meet the requirement of the underground reservoir on water storage.

Owner:CHINA SHENHUA ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com