Patents

Literature

455 results about "Total recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for preparing aromatic hydrocarbon through methanol conversion as well as preparation method and application thereof

InactiveCN102416342AHigh yieldHigh activityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsLiquid productGas phase

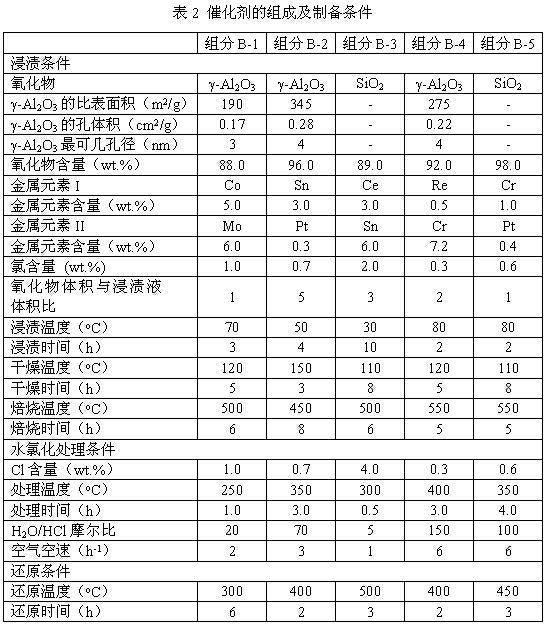

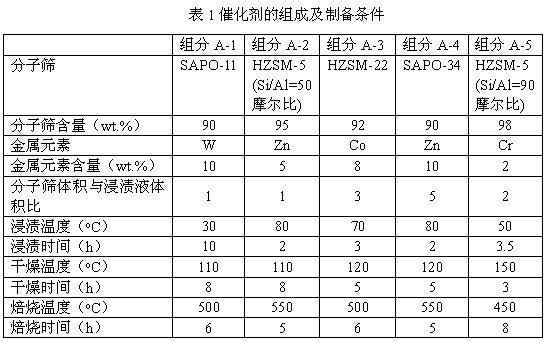

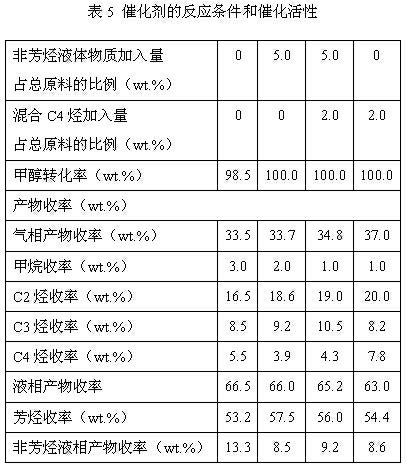

The invention discloses a catalyst for preparing aromatic hydrocarbon through methanol conversion. The catalyst comprises a component A and components B, wherein the mass ratio of component A to components B is 0.25-4; the component A is a modified zeolite molecular sieve and comprises 80-99wt% of molecular sieves and 1-20wt% of molecular sieve modifiers; the components B are oxide loaded metallic elements and halogen and comprise 85-95wt% of oxide, 0.5-10wt% of total metallic elements and 0.1-5wt% of halogen; and the component A and the components B are formed through squashing or extruding after being mixed uniformly. The catalyst has the following characteristics that: (1) the total recovery of benzene, toluene and xylene is higher and selectivity is high; (2) the raw material treatment capacity is large; (3) the non-aromatic hydrocarbon liquid product can serve as the solvent oil or gasoline component; (4) C4 hydrocarbon and non-aromatic hydrocarbon liquid phase products in the gas phase product can circularly enter into the catalyst bed layer, thus not only balancing the reaction heat but also improving the total recovery of the aromatic hydrocarbon; and (5) the catalyst has high activity and long life.

Owner:NORTHWEST UNIV

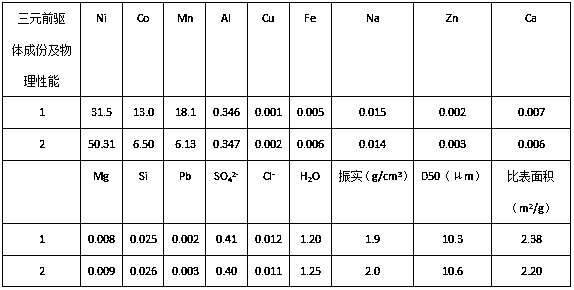

Recycling method for valuable metal from waste nickel-cobalt-manganese lithium ion battery

InactiveCN107653378AReduce lossesLess investmentWaste accumulators reclaimingProcess efficiency improvementSlagManganese

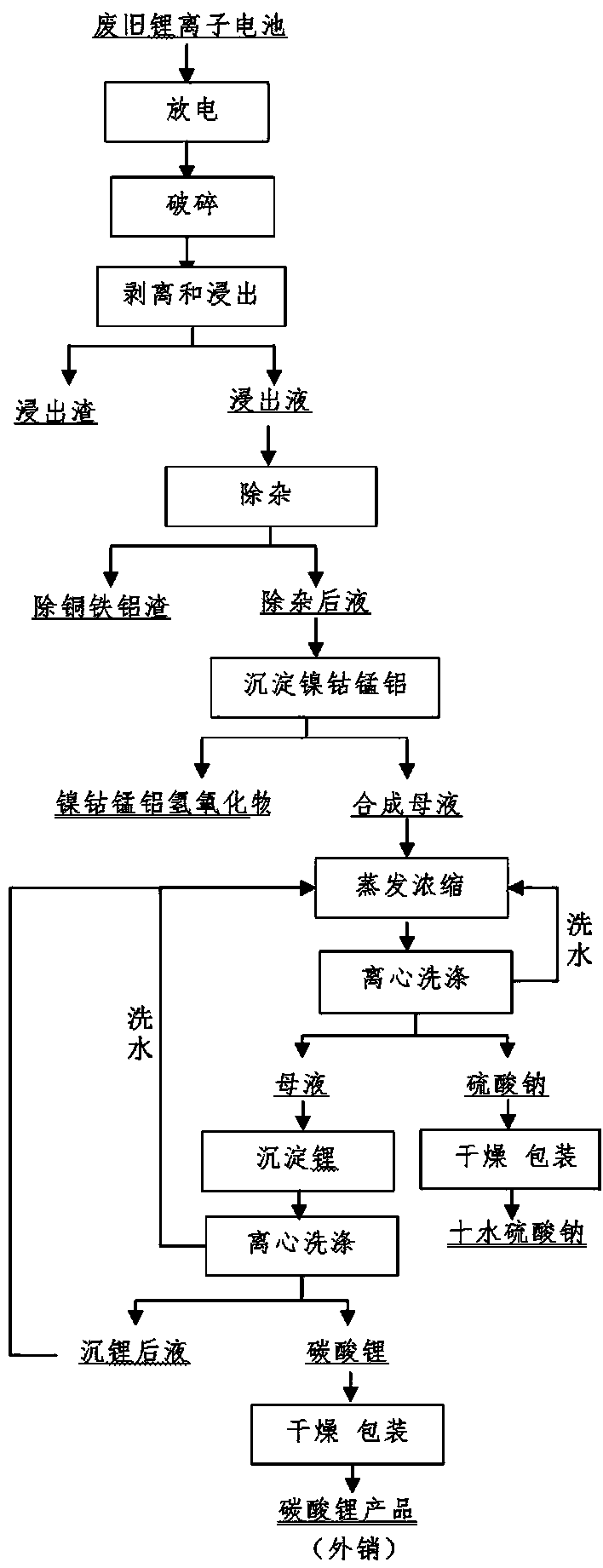

The invention relates to a method for recycling valuable metal from a waste nickel-cobalt-manganese lithium ion battery. The method comprises the following steps of: dismounting, discharging and crushing the battery, soaking crushed waste nickel-cobalt-manganese lithium ions into sulfuric acid with certain concentration, adding a reducing agent to strip positive and negative pole pieces, and leaching valuable metals of nickel, cobalt, manganese and lithium; and replacing leach liquor with iron powder to remove copper, carrying out hydrolyzing to remove iron and aluminum, and dosing an impurity-removed solution to synthesize an aluminum coated nickel, cobalt and manganese ternary positive electrode material precursor, evaporating and concentrating the synthesized solution, adding carbonateor introducing carbon dioxide to recycle lithium. According to the method disclosed by the invention, stripping and leaching are synchronously completed, chemical precipitation is performed to removecopper, iron and aluminum, slag amount is small, slag filter performances are good, and the impurity-removed solution is used for synthesizing the aluminum coated nickel, cobalt and manganese ternaryprecursor, so that the recovery rate of valuable metal is increased; and the recovery rate for nickel, cobalt and manganese is 96% or higher in the whole process, the total recovery rate of lithium is90% or higher, the technological process is short, operation is simple, equipment is less, and the cost is low.

Owner:JINCHUAN GROUP LIMITED +1

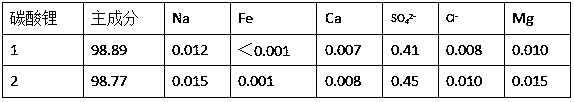

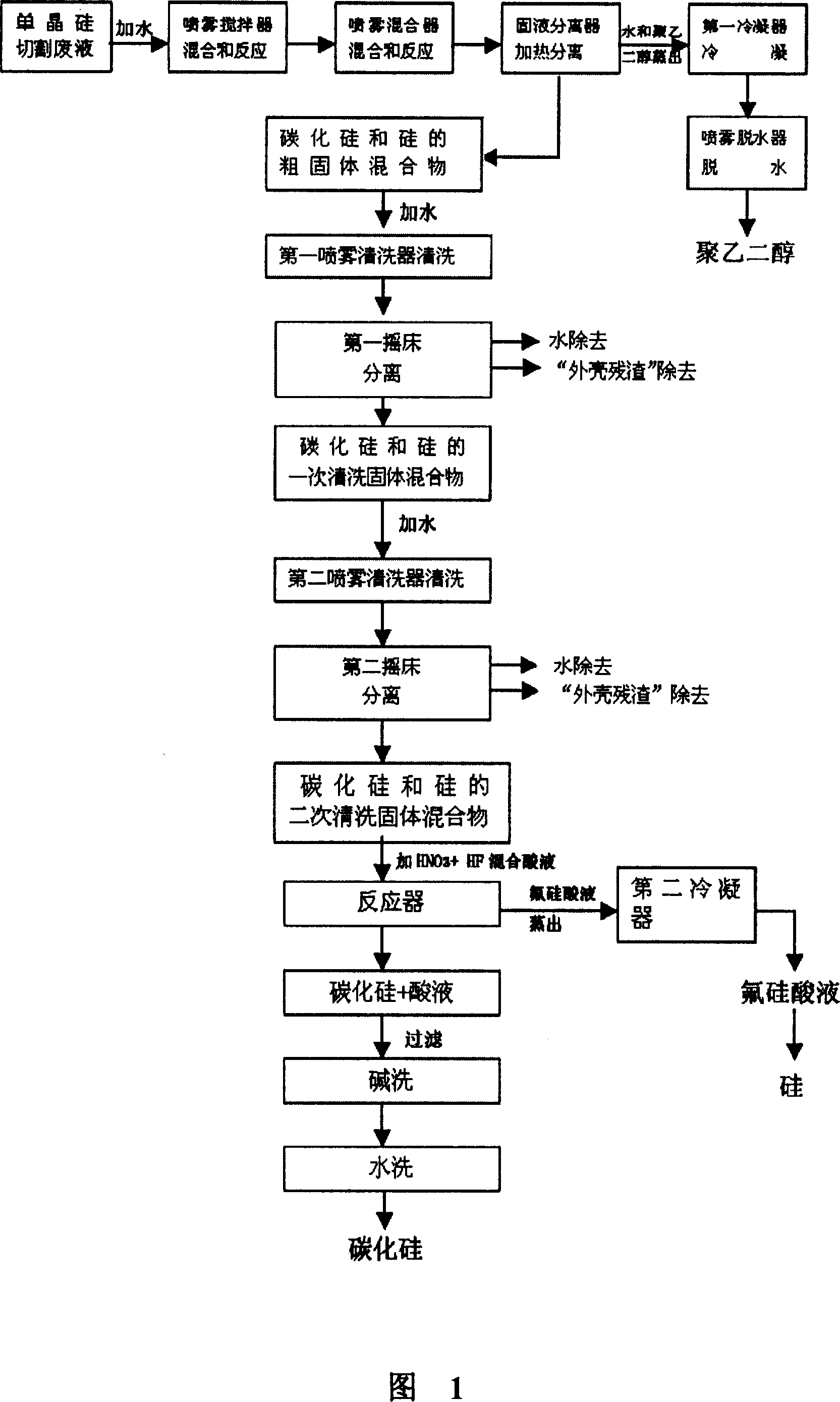

Treatment recovery method for monocrystalline silicon cutting waste liquor

InactiveCN101113029AParticle refinementWell mixedSiliconEnergy based wastewater treatmentRecovery methodLiquid waste

A treatment and reclaim method of single crystal silicon cutting waste liquid comprises the steps: (1). the waste liquid is treated with diluted hydrochloric acid then is stirred and mixed to enable the liquid to become a flowable mixture; (2). the mixed material is heated to separate solid and liquid, by which water and polyethylene glycol are extracted. The polyethylene glycol is obtained by the process of condensation, dehydration and recovery. The solid after being separated is a crude solid mixture of silicon carbide and silicon; (3). the quadratic-cleaning solid mixture of silicon diluted and silicon is obtained after quadratic cleaning to the crude solid mixture obtained in step 2; (4). the mixture is treated by mixed acid liquid comprising HNO3+HF to recover and get silicon diluted and silicon. The method has easy operation, simple equipment, low cost, high efficiency in treatment and recovery. The allover recovery rate calculated based on the weight of waste liquid can reach 26-46 percent and the recovering material can reach or close to the standard index, and can be directly used in solar energy battery production, so the invented method has good economic benefit and also can greatly contribute to environment protective, thereby having large exploration prospect.

Owner:金柏林

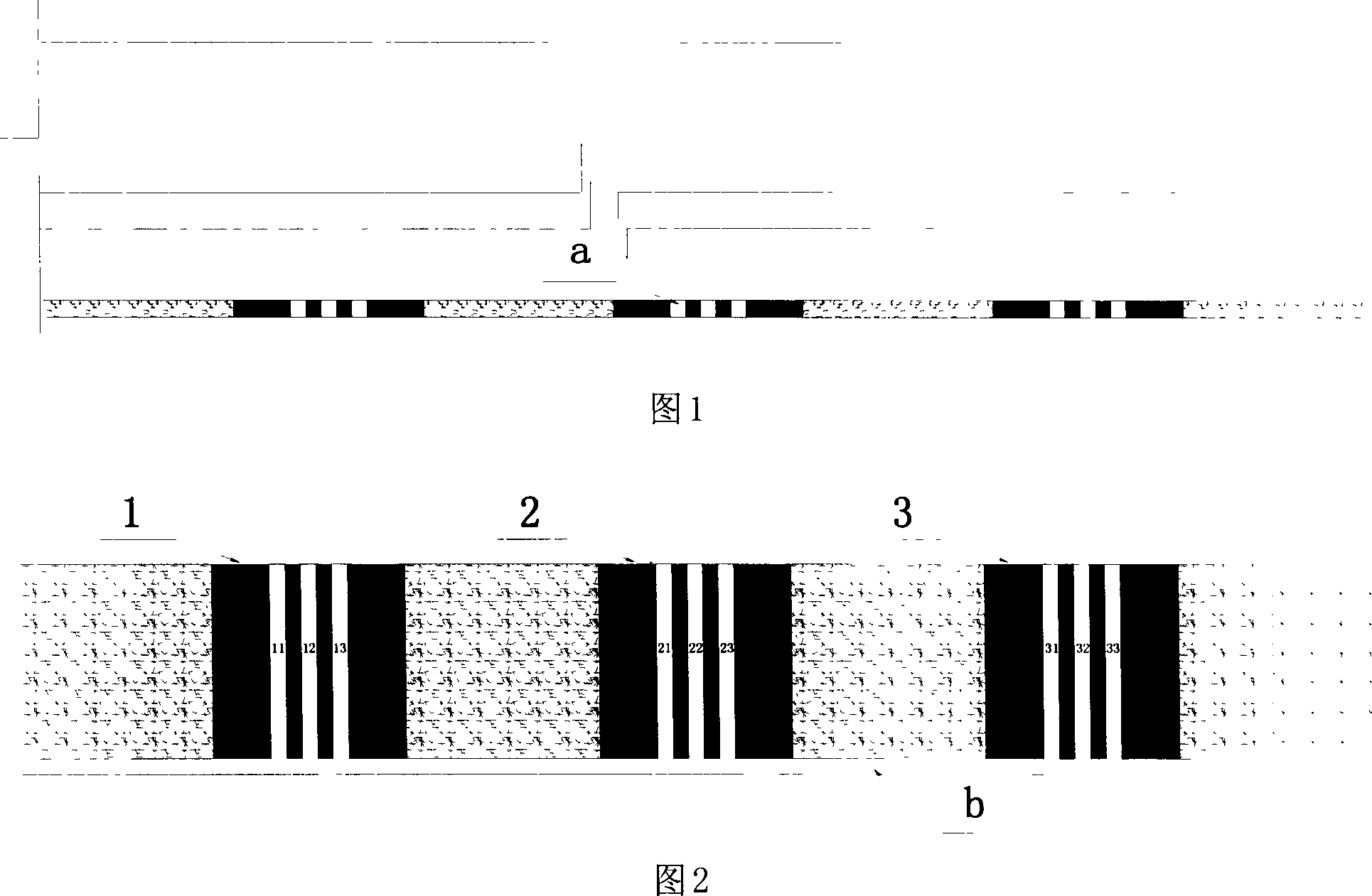

Mining method for replacement of banded coal under building by waste rock

The bone coal displacement strip coal block exploration under an architecture, concentrically sets 3-5 bone coals filling lane at the center of each strip coal block, based on the buried depth, width, laminated rock structure and protective degree required by the architecture build on the surface of each strip coal block, advancing coal mining for the 3-5 bone coals filling lane and then filling bone coals from the interior to the exterior inside the lane that has dug out coals. Ensuring the safety of the architectures, filling the displacement coal with bone coals, it can realize exploration rate no less than 20%, the total recovery rate of the strip mining area no less than 65%; Filling the mine with bone coals dug out can not only eliminates the bone coals on the land, reduces the encroachment of farmland, mitigates air and environmental pollution, gets rid of bone coal landslide or explosion and other hidden accidents that may affects the human life but also using bone coals working as the underground support of the mine and realizing second partial recovery for strip coal blocks under the architectures.

Owner:CHINA UNIV OF MINING & TECH

Olefin catalytic agent prepared by naphtha catalytic cracking and preparation method and application thereof

ActiveCN102861604AModerate acid distributionStable structureMolecular sieve catalystsBulk chemical productionMolecular sieveNaphtha

The invention discloses an olefin catalytic agent prepared by naphtha catalytic cracking, a preparation method of the olefin catalytic agent and application of the olefin catalytic agent. According to the weight content of a final catalytic agent, the olefin catalytic agent comprises 60%-90% of EU-1 / ZSM-5 composite molecular sieve and 0.5%-3% of heteropolyacid. The olefin catalytic agent is prepared by the following methods of: preparing or selecting the EU-1 / ZSM-5 composite molecular sieve, adding a binding agent to mold, and then adopting an impregnation method to load heteropolyacid to prepare the final catalytic cracking catalytic agent. The application of the catalytic agent in preparation of olefin by the naphtha catalytic cracking is that the reaction temperature is 500-700 DEG C, the reaction pressure is 0.01-0.5MPa, the naphtha quality airspeed is 0.3-2h<-1>, the water-oil volume ratio is 0.6-1.2, C5-C10 naphtha serves as a raw material, and total recovery of ethylene and propylene can achieve 67% (of the weight of naphtha). The olefin catalytic agent has the advantages of high olefin yield coefficient, stable catalytic agent, low reaction temperature and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for directly restoring and recovering copper iron from smelting copper slag

ActiveCN102952952AMeet the requirements of energy saving and emission reductionEfficient recyclingProcess efficiency improvementGas emission reductionMolten stateOxygen

The invention belongs to the field of metallurgy, and particularly relates to a method for directly restoring and recovering copper iron from smelting copper slag. The method comprises the following steps of: transferring high-temperature molten state copper slag to a high-temperature reducing furnace by a tundish, jetting oxygen to previously desulfurize, adding slagging constituent to keep temperature, jetting natural gas to carry out smelting reduction, slowly cooling to 1096 DEG C at the speed of 1.5-2 DEG C / min, and keeping the temperature for 1h to obtain 7.3at% Cu-Fe copper alloy melt and gamma pig iron, or slowly cooling to 850 DEG C at the speed of 1.5-2 DEG C / min, and keeping the temperature for 1h to obtain 2.7at% Cu-Fe copper alloy melt and gamma pig iron. According to the method provided by the invention, the total recovery use of valuable components, i.e. copper, iron and the like, can be realized, and the alloy melt obtained by the reduction smelting is slowly cooled and separated to obtain copper-rich alloy and low-sulfur gamma pig iron, so that separation of copper and iron is realized and the additional values of products can be improved.

Owner:NORTHEASTERN UNIV

Coordinate extracting system for extracting lithium from salt lake brine with extraction method

The invention relates to a coordinate extracting system for extracting lithium from salt lake brine with extraction method, which comprises the following steps of (1) acidity of raw material liquid adjustment: adding hydrochloric acid to the salt lake brine to adjust the pH value of the raw material liquid to 1 to 5 so that the raw material liquid is obtained; (2) extracting lithium: carrying out three-stage extraction on the raw material liquid obtained in step (1) by using TBP-BA-FeCl3 solvent naphtha as an extracting agent to obtain an organic phase; (3) organic phase washing: carrying out three-stage washing to the organic phase obtained in the step (2) by using the hydrochloric acid as a washing agent; (4) organic phase reextraction: carrying out three-stage extraction on the organic phase obtained in the step (3) by using hydrochloric acid as a reextraction agent to obtain lithium chloride solution. The invention has the advantages of simple technique, easy control, low reextraction acidity, low requirements on reextraction equipment materials and concentration of lithium in the material brine, and no need of evaporation concentration of thin lithium solution, thereby saving energy, reducing consumption, decreasing the production cost, and simultaneously improving the total recovery rate of the lithium effectively.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

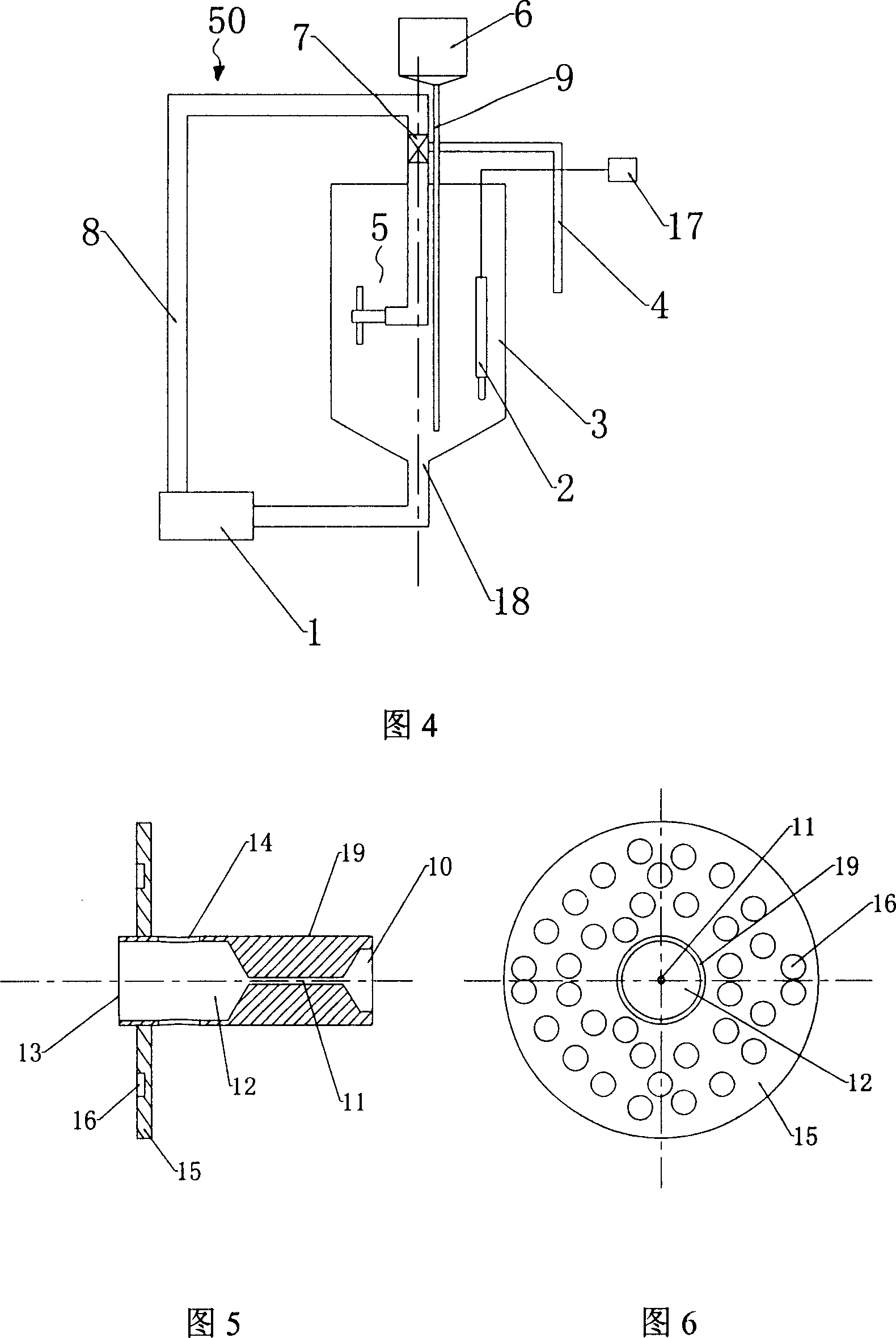

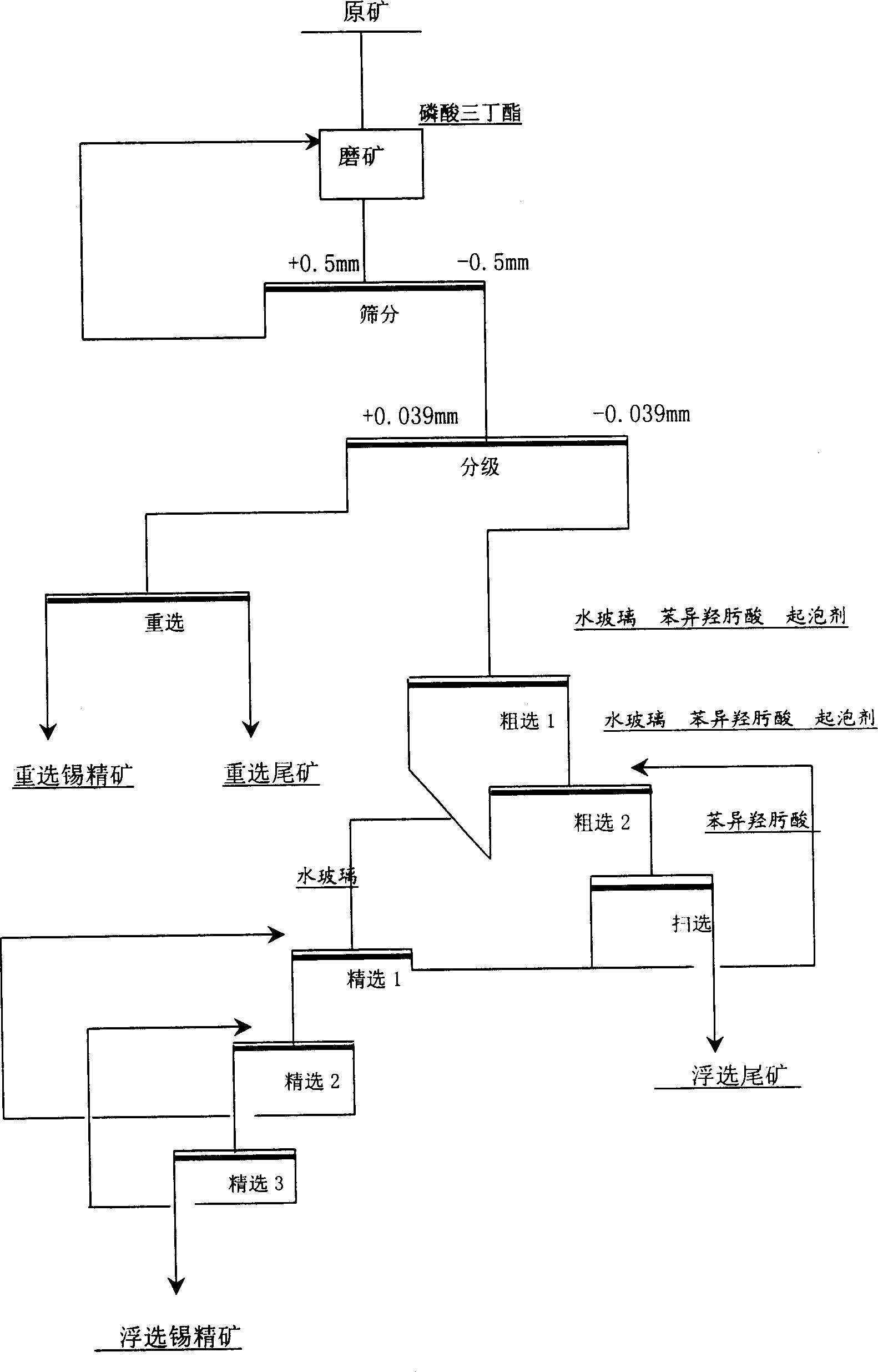

Cassiterite ore separation method

InactiveCN1721080AAvoid over crushingReduce contentFlotationCassiteritePhosphoric acid tributyl ester

Mineral separation for cassiterite ore comprises break, grinding, classification and the floatation for classified fine fraction less than 0.039mm. The floatation takes process of roughing for two times, scavenging for one time and refining for three times. It avoids over breaking, decreases fine ore greatly; as adding TBP, the ore needs not pre-desliming to recovery with floatation for the fine ore of less than 0.039mm. With this invention, for the cassiterite-quartz ore or tin placer with Sn content 0.6~2.0%, the flotation concentrate contains Sn more than 26%, the floatation recovery rate is more than 80%, and compared with traditional technique, the total recovery rate is increased more than 10%.

Owner:黎东明

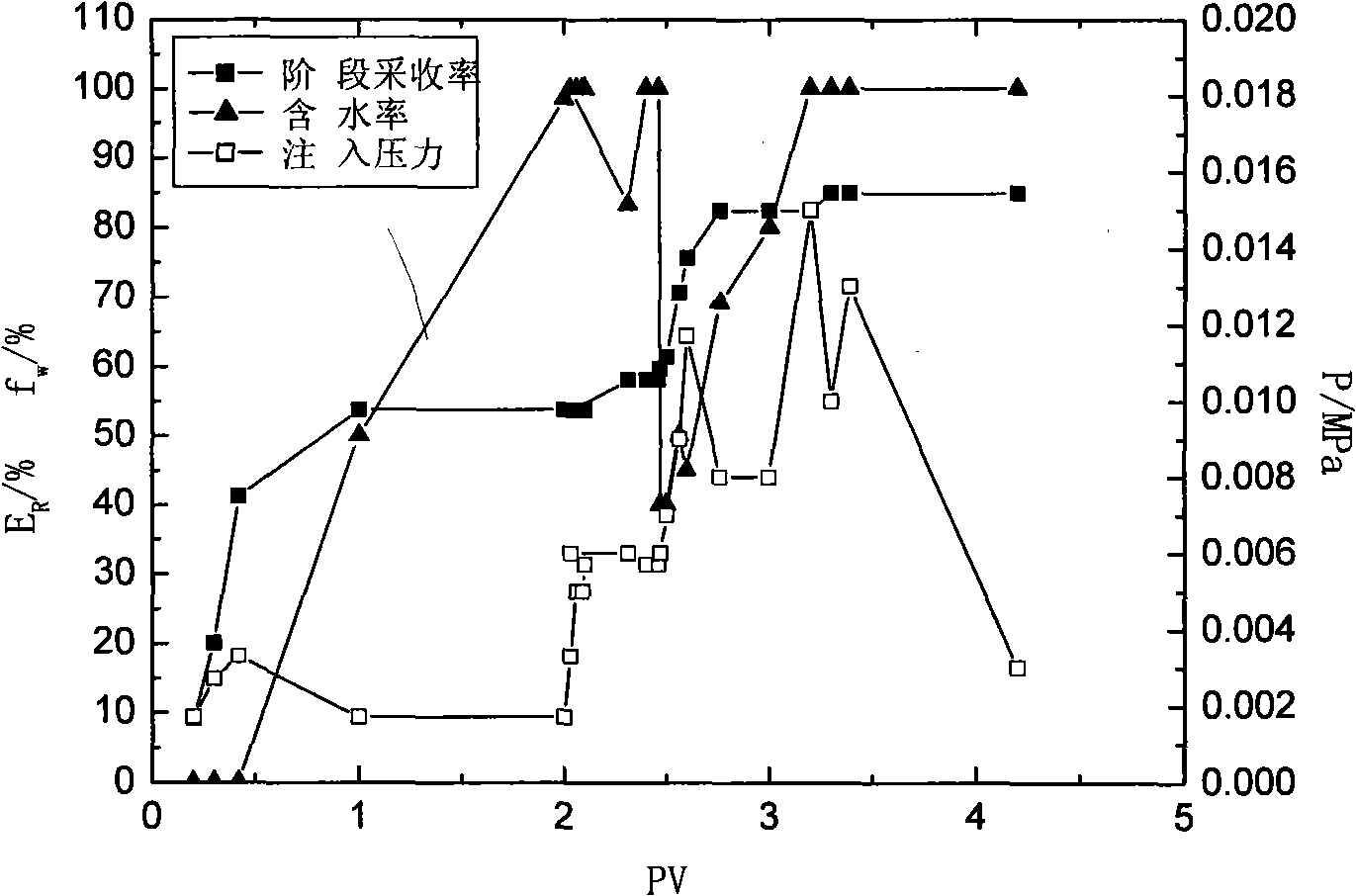

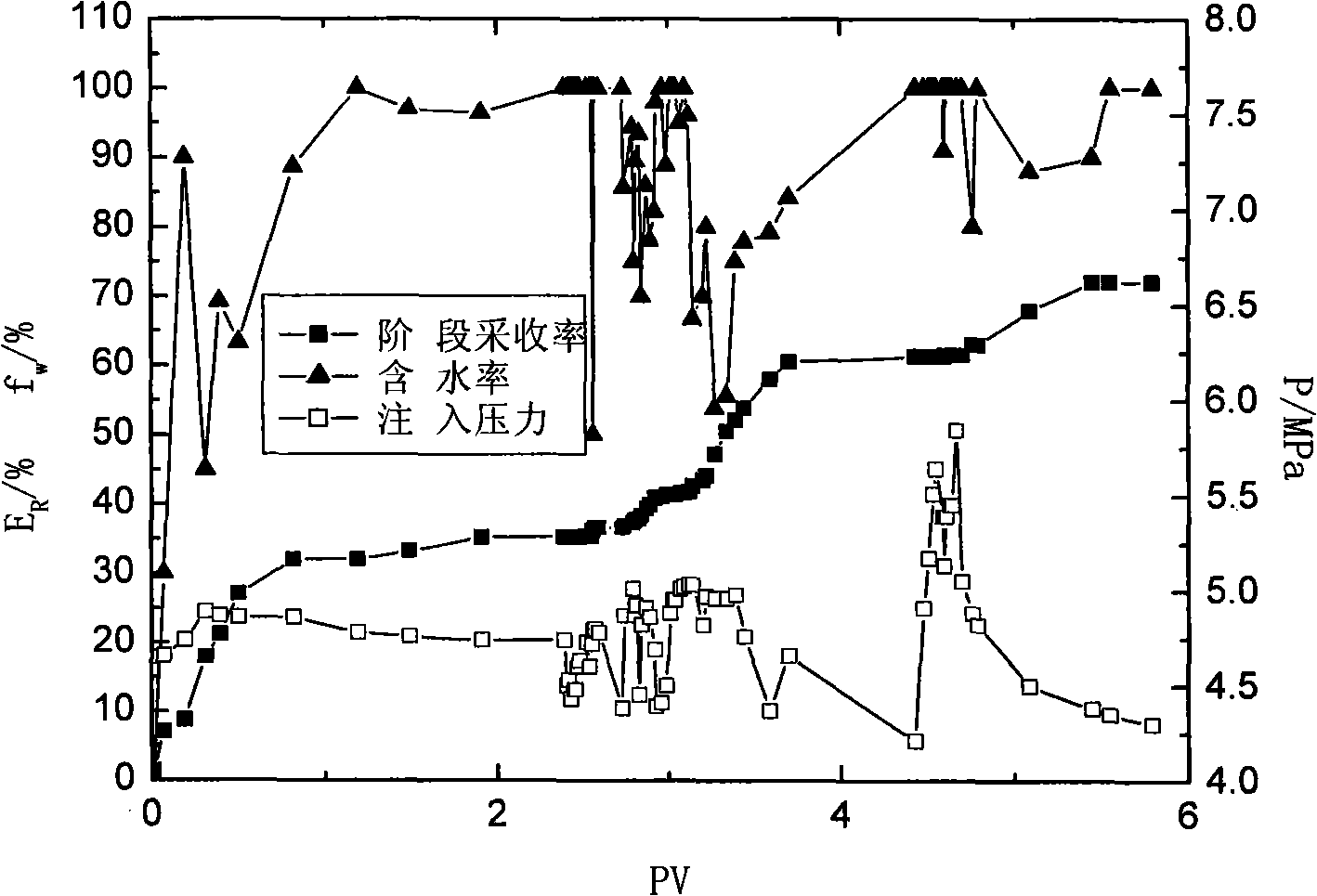

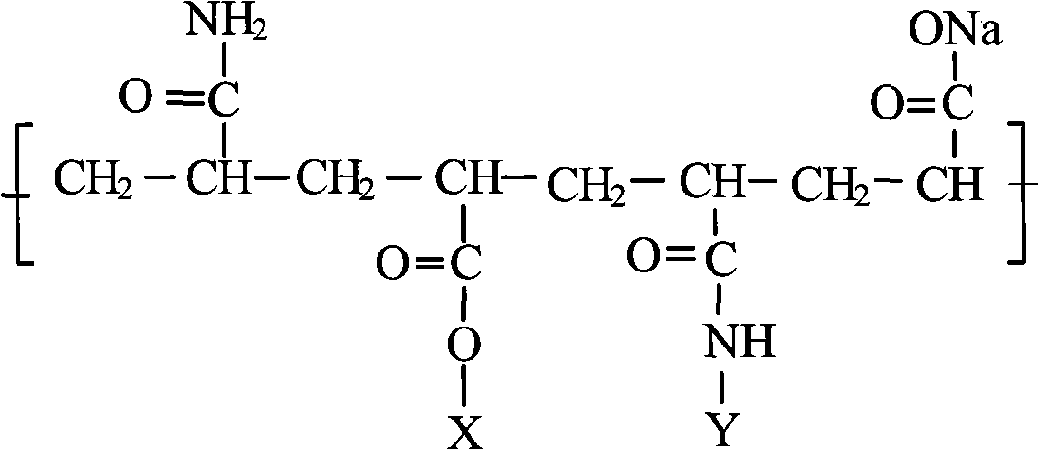

Oil displacement profile control agent, displacement of reservoir oil system and displacement of reservoir oil method

ActiveCN101314710AEnhanced overall recoveryImprove the spread factorFluid removalDrilling compositionFoaming agentEconomic benefits

The invention discloses a foam profile control and displacement agent used for petroleum exploitation. The foam profile control and displacement agent is prepared from functional polymer solution and foaming agent by mixing, wherein the foaming agent has a concentration of 0.05 to 1wt percent. The invention further discloses an oil displacement system formed by using the foam profile control and displacement agent and an oil displacement method. The oil displacement is achieved by using a combined slug consisting of functional polymers from high viscosity to low viscosity and a foam slug consisting of the foam profile control and displacement agent and compressed gas, and is suitable for multiple kinds of anisotropic oil layers to effectively improve oil recovery, reduce ineffective water circulation, and improve economic benefits. Through the effective combination, the system can improve the recovery greatly, improve the total recovery to 71 percent or above and reduce the oil recovery cost greatly, and can be widely used for tertiary oil recovery.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

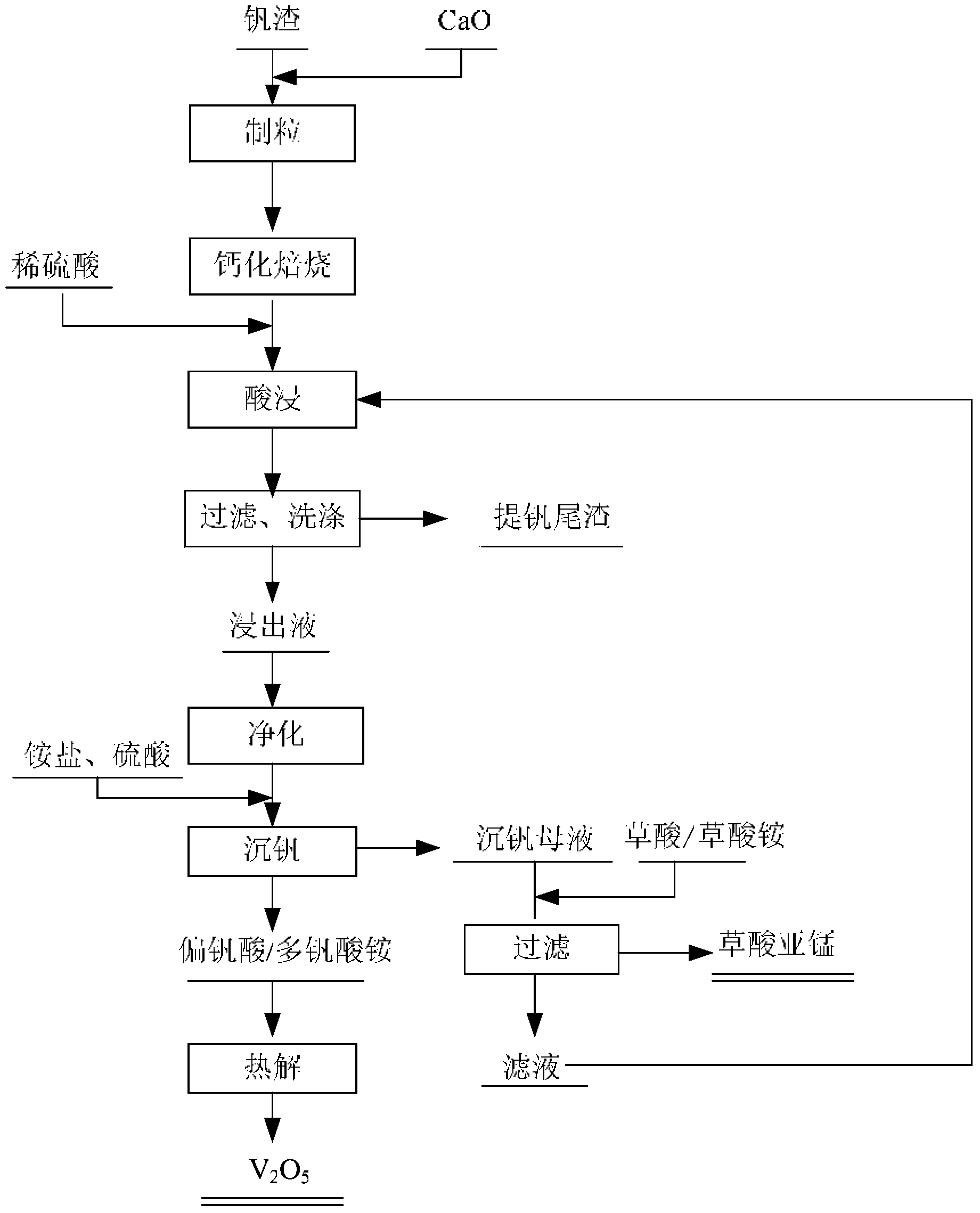

Method for clean production of vanadium pentoxide

ActiveCN104357660AHigh extraction rateNo pollution in the processProcess efficiency improvementTotal recoveryVanadium oxide

The invention discloses a method for the clean production of vanadium pentoxide, and belongs to the field of production of vanadium oxide. The method comprises the steps of raw material pretreatment, roasting, diluted acid leaching, vanadium liquid purification, vanadium precipitation, pyrolysis, recovery of Mn in residual vanadium precipitation liquid and the like. According to the method, the discharge of the residual vanadium precipitation liquid is avoided, and vanadium extraction tailings do not contain Na and K, and can be returned to a blast furnace or directly reduced to realize the comprehensive recycling of resources; the total recovery rate of vanadium is higher than that of a conventional sodium salt roasting-water leaching vanadium extraction process in the industry, the V2O5 content of a product is higher than 98 percent, the production cost is lower than that of a process for the sodium treatment vanadium extraction preparation of vanadium pentoxide, and meanwhile, the residual vanadium precipitation liquid can be completely recycled, and the vanadium extraction tailings can be secondarily and comprehensively utilized.

Owner:NORTHEASTERN UNIV

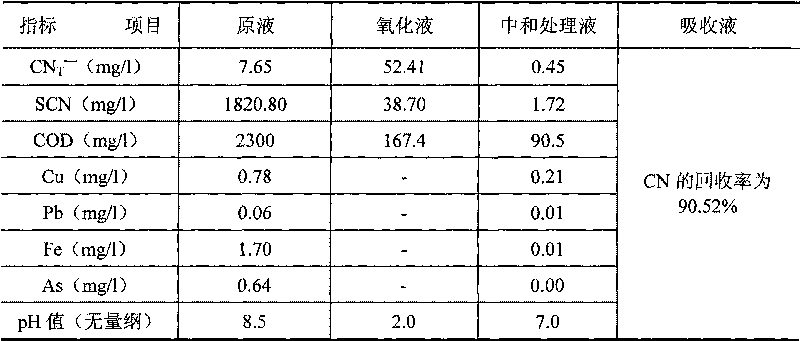

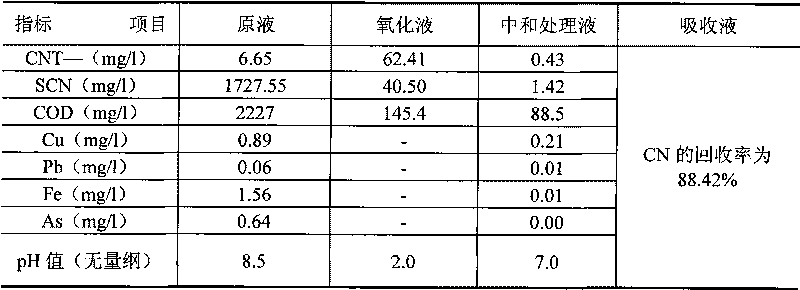

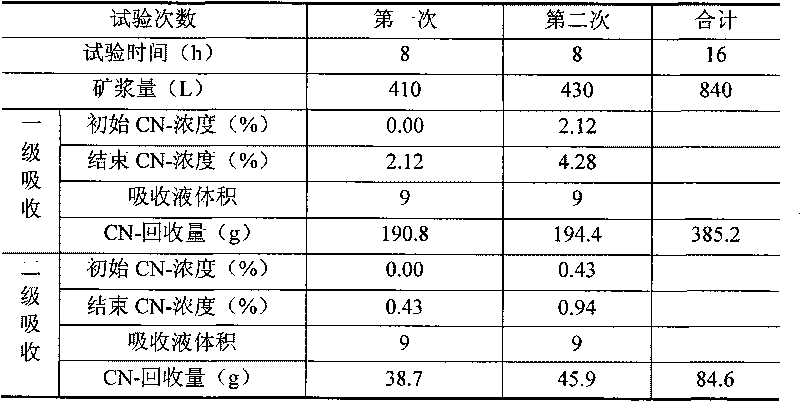

Recycling and harmless treatment method for cyaniding tailing slurry

ActiveCN101759274AIncrease contact areaToxicWaste water treatment from quariesWater contaminantsSlagGas phase

The invention discloses a recycling and harmless treatment method for cyaniding tailing slurry. In the method, the cyaniding tailing slurry containing cyanogen, thiocyanate, heavy metal and arsenic and liquid containing hydrogen peroxide are subjected to direct mixing treatment; the method utilizes high specific surface area of micro-fine granular ore to add the contact opportunity between the thiocyanate and the hydrogen peroxide and the contact area between gas phase and liquid phase through surface adsorption to accelerate a speed of oxidation-reduction reaction and an acidifying and stripping speed, utilizes metallic substances contained in slag to accelerate the reaction rate of the oxidation-reduction reaction without the addition of catalyst, and can reduce cost; meanwhile, in neutralization, Fe3+ in the slag is utilized to meet the requirement of arsenic precipitation without the addition of an arsenic precipitation reagent; when residual cyanides is removed from the hydrogen peroxide liquid, the hydrogen peroxide liquid and cyano complexes which are difficult to remove through the oxidation-reduction reaction form sediment so that the residual thiocyanate is further removed; the method can make the conversion rate of the thiocyanate in the ore slurry more than or equal to 88 percent; and compared with the treatment of filter pressing clear liquid of homogeneous ore slurry, the total reclaiming rate can be increased by over 20 percent.

Owner:CHANGCHUN GOLD RES INST +1

Method for directly producing high-purity electronic level cobaltous sulfate by using cobalt-containing waste

ActiveCN102061390AMeet high purity requirementsImprove overall recoveryProcess efficiency improvementTotal recoveryGoethite

The invention provides a method for directly producing high-purity electronic level cobaltous sulfate by using cobalt-containing waste, in particular a process for producing cobaltous sulfate by using cobalt-containing waste. The method comprises the steps of: checking and classifying raw materials, wet-milling and size-mixing, acid-decomposing, filtering, washing, separating, and extracting copper sponge. The method is characterized by also comprising the steps of: removing iron with a goethite process, extracting P2O4 and removing impurities, separating nickel from cobalt, extracting N235, purifying, concentrating and crystallizing. The high purity electron level cobaltous sulfate is directly regenerated by using various kinds of cobalt wastes, the requirement of the modern high-technology industry on high purity of the cobaltous sulfate is met; the total recovery of the cobalt is higher than or equal to 98 percent; various usable elements can be comprehensively recycled, and coppersponge, tungsten carbide, iron hydroxide and nickel carbonate can be regenerated while the electronic level cobaltous sulfate as a main product is regenerated. The invention has the advantages of comprehensively utilizing waste cobalt resources, recycling the wastes, improving the enterprise benefit, and being beneficial to the development of energy conservation, emission reduction, environment protection and circular economy.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

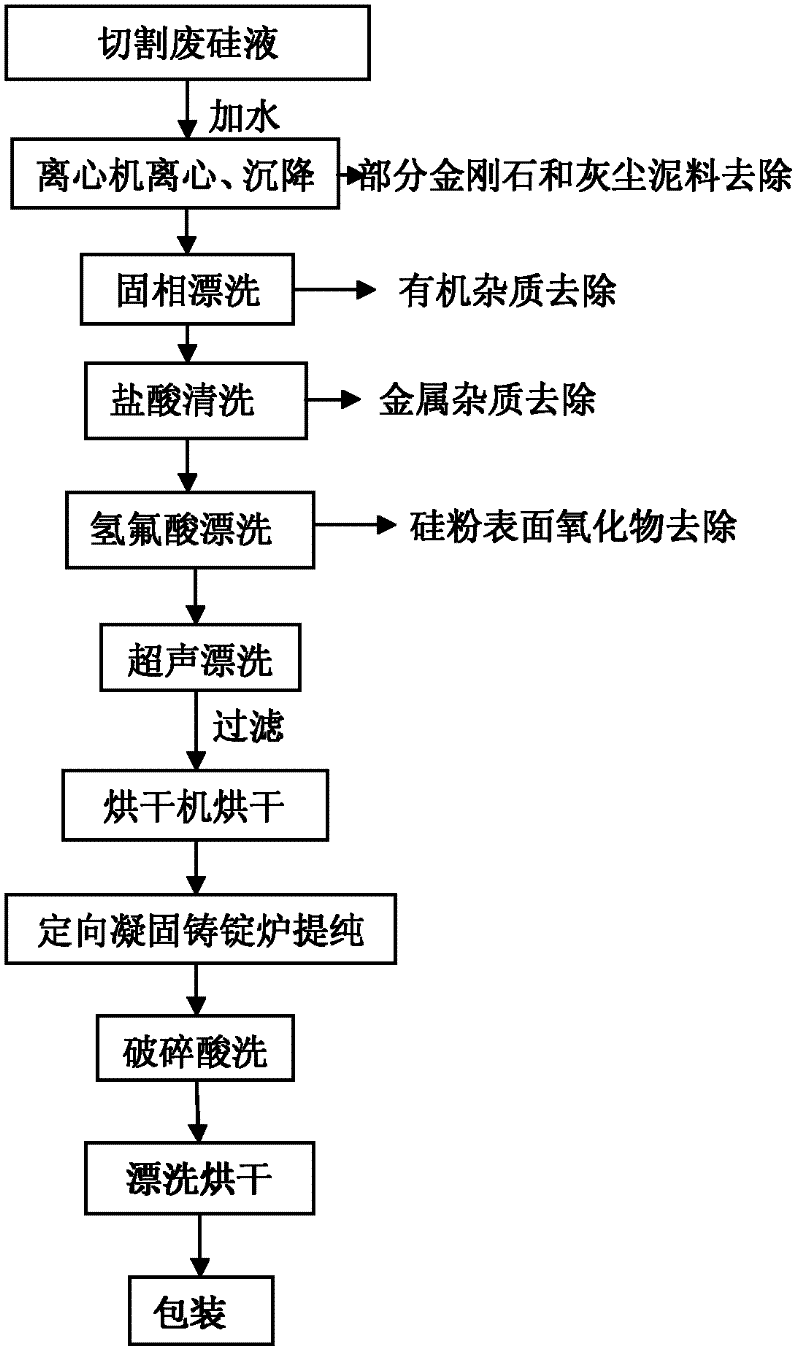

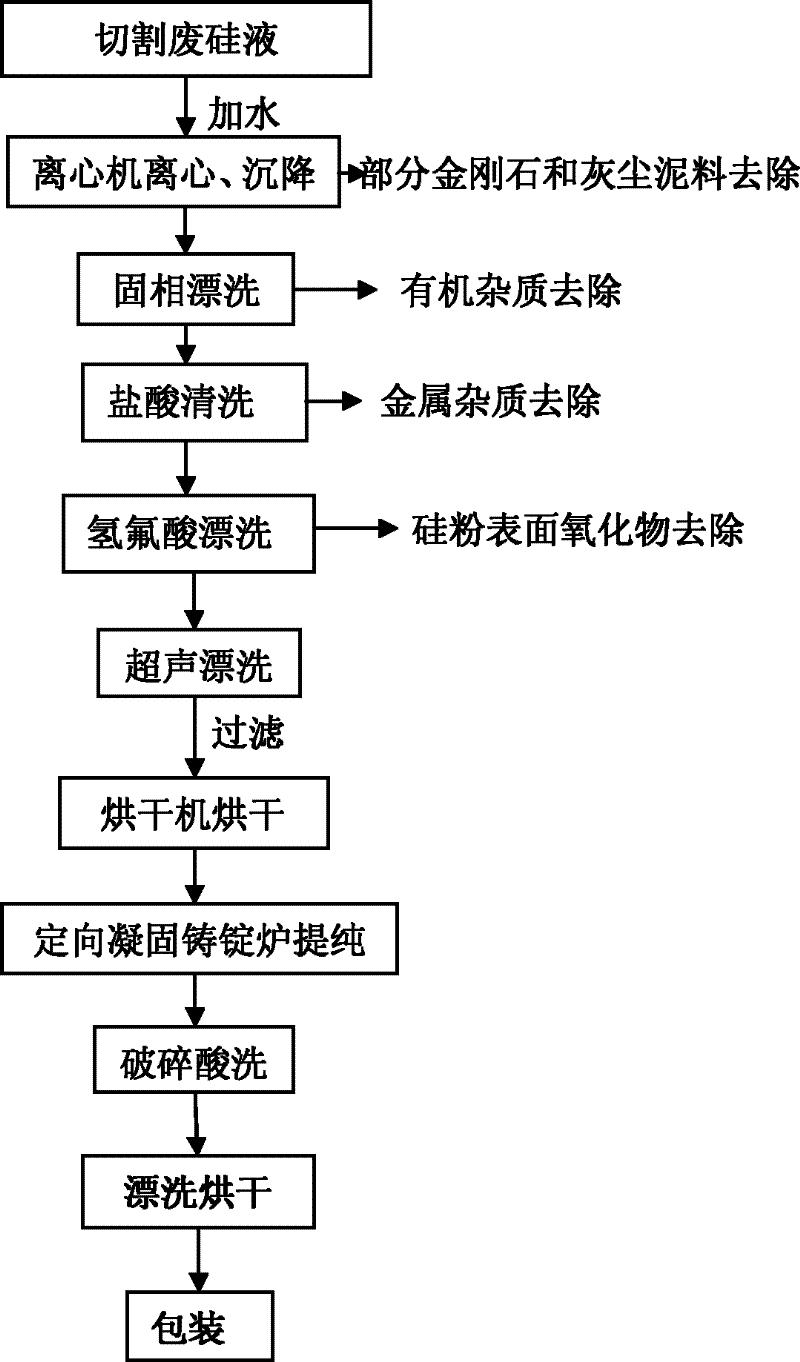

Method for recovering silicon material from waste materials in cutting crystalline silicon by diamond wire

The invention discloses a method for recovering silicon material from waste materials in cutting crystalline silicon by a diamond wire. The method is characterized by comprising the following steps of: feeding the collected waste materials to a centrifugal machine to centrifuge and settle, thus obtaining silicon material sediment; carrying out solid-phase rinsing on the silicon material sediment to remove organic matter type impurities and part of diamond powder from residual liquid in solid, thus obtaining silicon powder with certain purity; pickling the solid-phase silicon powder with hydrochloric acid to remove metal impurities; after rinsing the silicon powder subjected to hydrochloric acid pickling with pure water, rinsing the silicon powder with hydrofluoric acid to remove oxide from the surface of the silicon powder; carrying out ultrasonic rinsing and drying on the silicon material rinsed with hydrofluoric acid; carrying out directional solidification, ingot casting and purification on the dried silicon material, thus obtaining a solar grade silicon material; and at last, carrying out packaging after smashing, pickling, rinsing and drying the silicon material. The method is simple and convenient, the equipment cost is low, the operation is easy to control, the treatment recovery rate is high and the overall recovery rate can achieve over 99.99%.

Owner:ZHENJIANG HUANTAI SILICON TECH

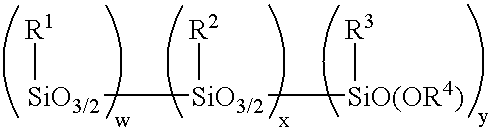

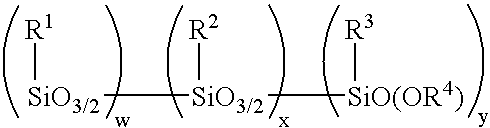

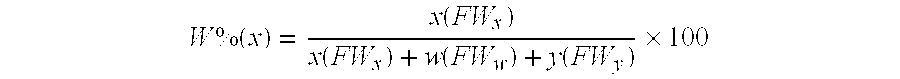

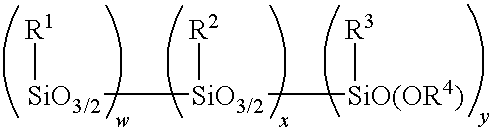

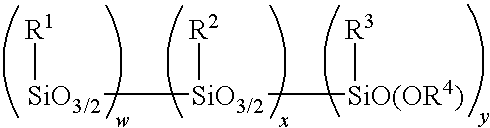

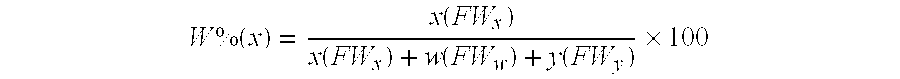

Method for making alkoxy-modified silsesquioxanes

InactiveUS20080293858A1Easy to separateGroup 4/14 element organic compoundsSpecial tyresSolventSilsesquioxane

A method is presented for making alkoxy-modified silsesquioxanes (AMS) or co-alkoxy-modified silsesquioxanes (co-AMS,) comprising the steps of (a) combining as a reaction mixture (i) water, (ii) an acid-stable solvent for the water, (iii) a solid strong cationic hydrolysis and condensation catalyst, and (iv) a trialkoxysilane compound, (b) allowing the reaction mixture to react for about 0.5 hours to about 200 hours to form the alkoxy-modified silsesquioxanes; and (c) recovering the alkoxy-modified silsesquioxanes from the reaction mixture. The use of solid strong cationic catalysts in this reaction system is advantageous because they remain as solids throughout the reaction, allowing simplified separation of the solid catalyst from the soluble AMS or co-AMS products, resulting in total or near total recovery of the AMS or co-AMS products, the products being free of, or substantially free of residual acid catalyst, as well as virtual total recovery of the catalyst for recycling. The improved AMS and co-AMS compounds, vulcanizable rubber compounds containing them, and a pneumatic tire having a component made from the vulcanized rubber compounds are also presented.

Owner:BRIDGESTONE CORP

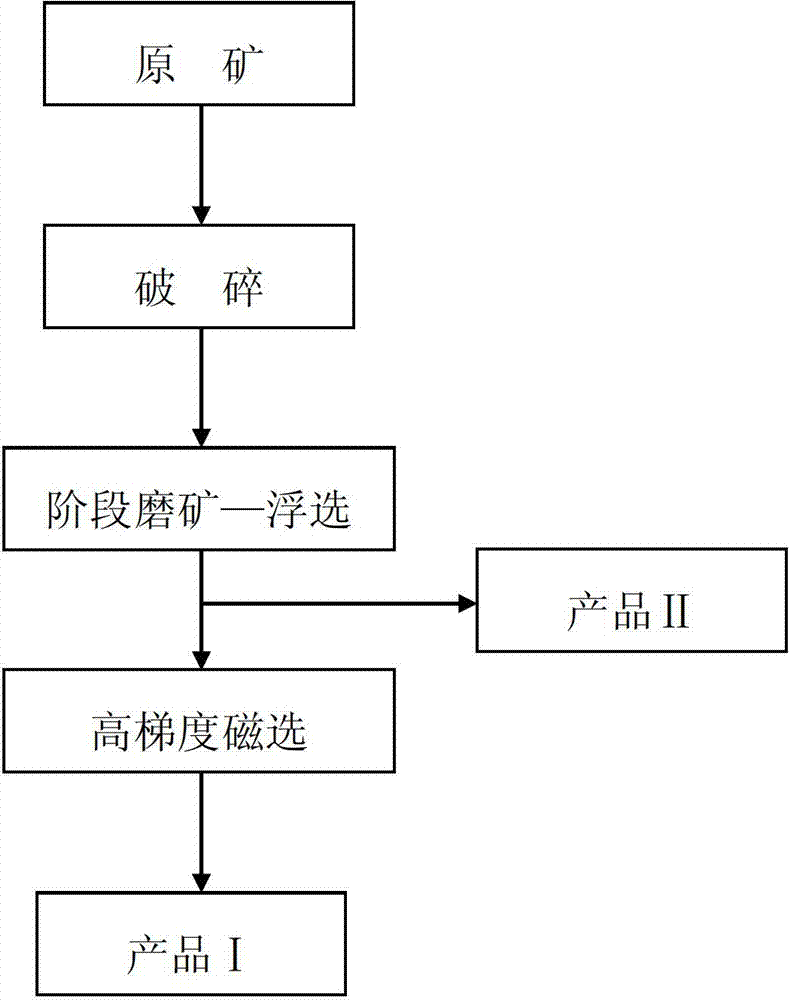

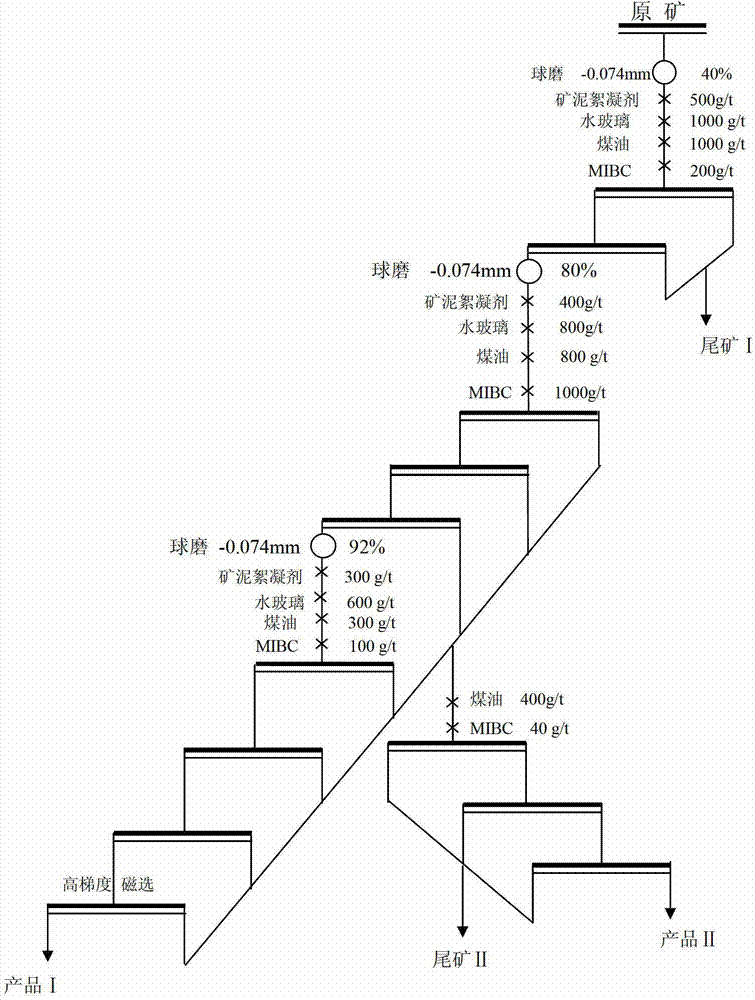

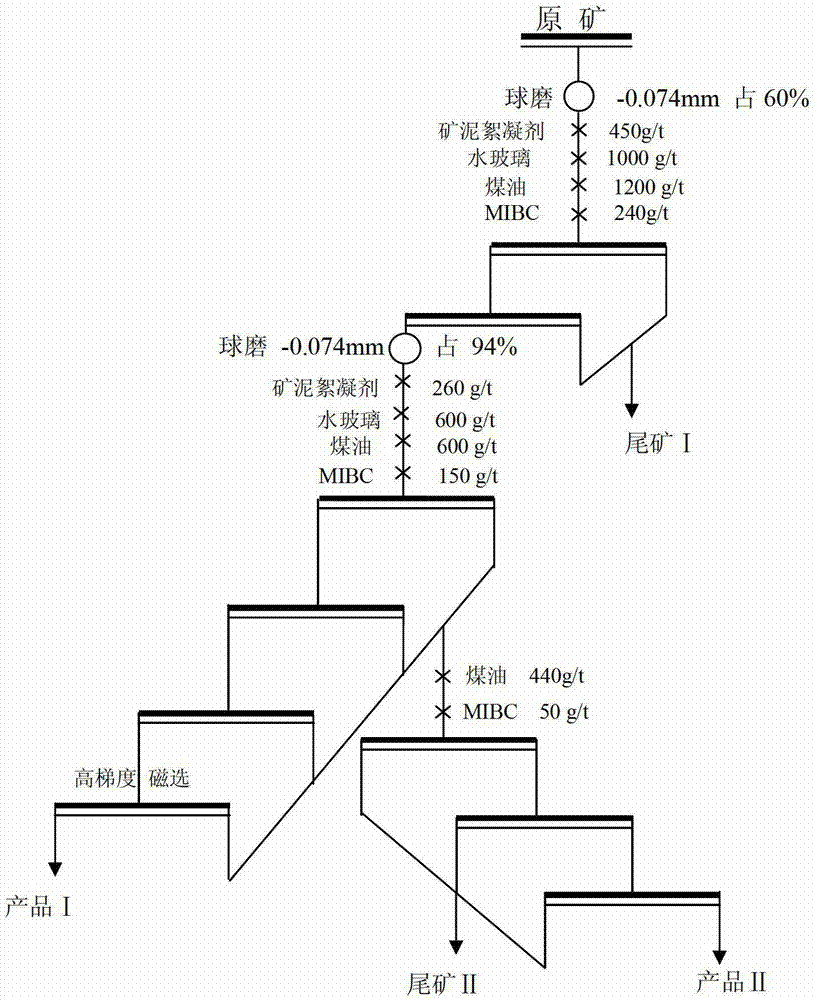

Low-grade aphanitic graphite dressing and purifying method

The invention relates to a low-grade aphanitic graphite dressing and purifying method, belonging to the technical field of graphite purification. The method comprises the following steps: firstly, crushing and grinding aphanitic graphite ores with fixed carbon content of 45-80%; adding a slime flocculant, an inhibitor, a collector and a foamer into the ore pulp, separating by flotation in a mechanical flotation machine, re-grinding and re-separating the flotation concentrate to remove most gangue mineral in the ores, thus obtaining final flotation concentrate; removing iron-contained gangue mineral in the final flotation concentrate by high-gradient magnetic separation, thus being capable of obtaining a product II satisfying the requirements of number WT88 or more. And a product II satisfying the requirements of number W80 can be obtained by re-grinding and re-separating the middling product and concentratedly re-separating the magnetically separated middling product. The total recovery is more than 80%. The low-grade aphanitic graphite dressing and purifying method is low in requirement on fixed carbon content of the ores, capable of effectively reducing iron-contained impurities, large in processing amount, low in production cost and environmental-friendly.

Owner:CENT SOUTH UNIV

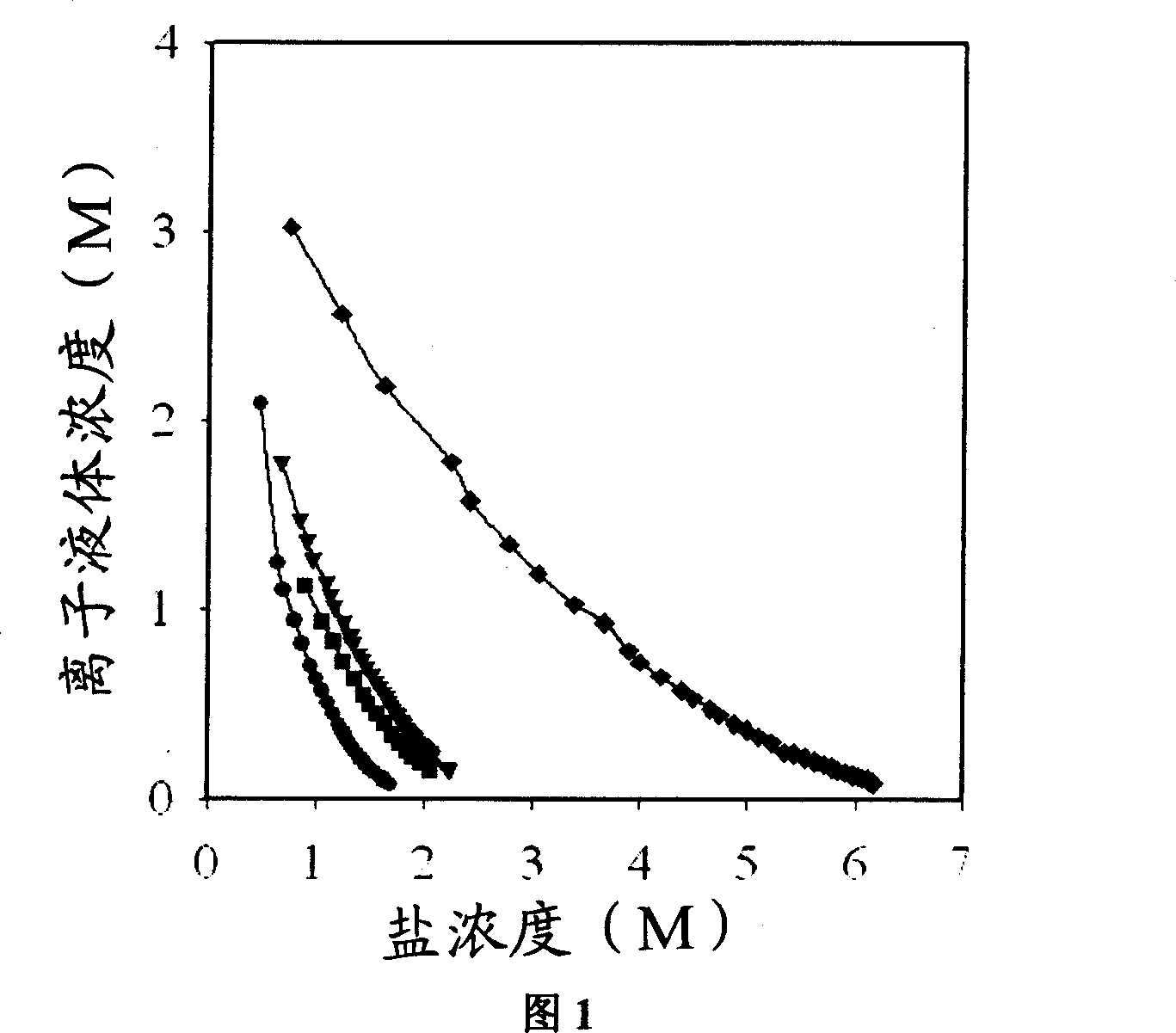

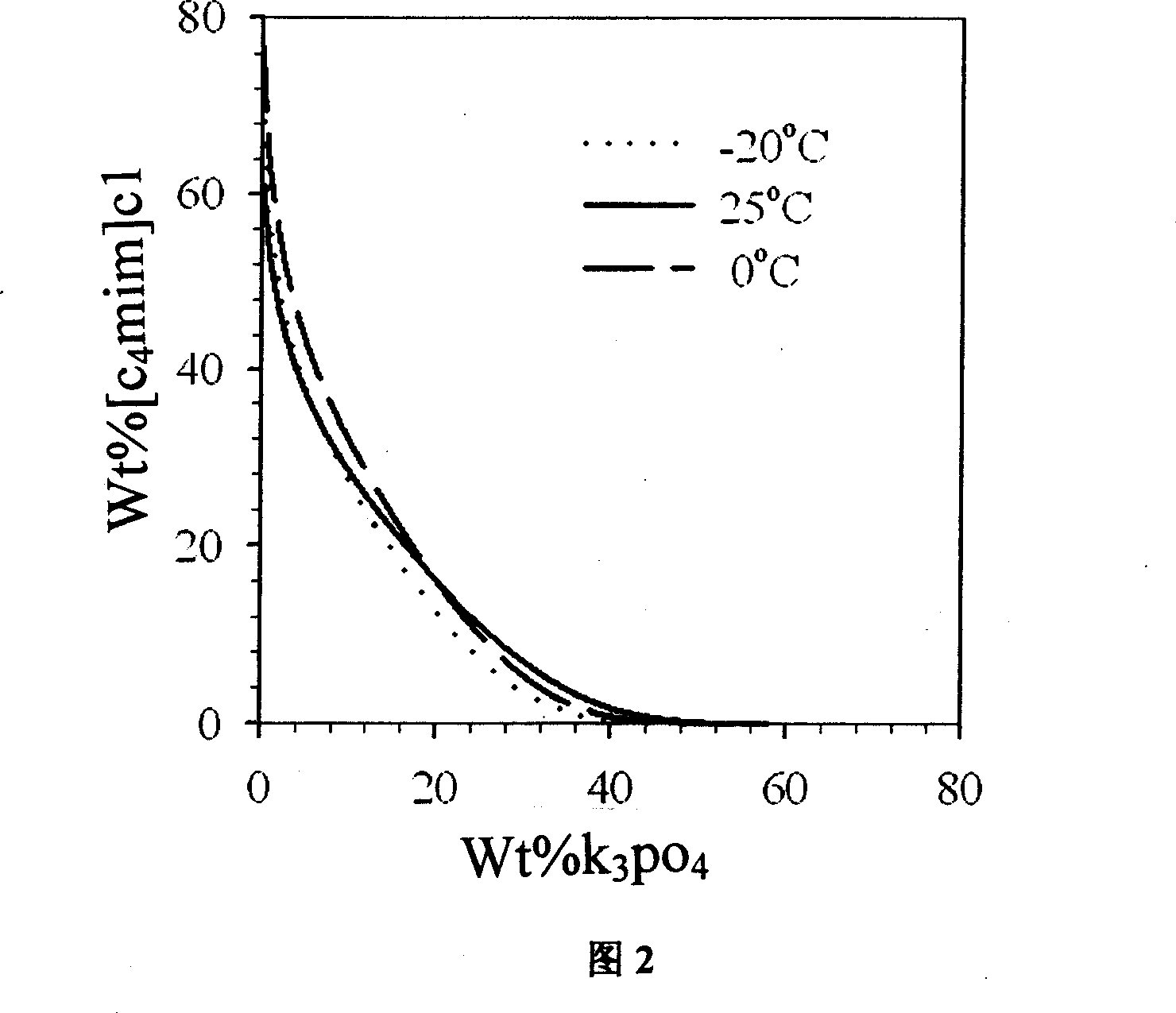

Process of enriching ionic liquid from water solution

InactiveCN1973943AEasy to adjustAchieve multi-level enrichmentLiquid solutions solvent extractionNon-miscible liquid separationEconomic benefitsAqueous solution

The present invention relates to process of enriching ionic liquid from water solution. Ionic liquid and salt in water solution may form a double water phase system, including the upper rich ionic liquid phase capable of enriching ionic liquid in water solution. By means of lowering the temperature of lower rich salt phase to 0 deg.c to -20 deg.c, a new double water phase system may be formed for further enriching ionic liquid. The present invention can reach total ionic liquid recovering rate up to 95-99 % and required water evaporating quantity only about 10 % of conventional process. The present invention can recover and reuse ionic liquid and salt, and has the advantages of great treating amount, simple apparatus, easy operation, low cost, easy combination of several stages, high economic benefit and environment friendship.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

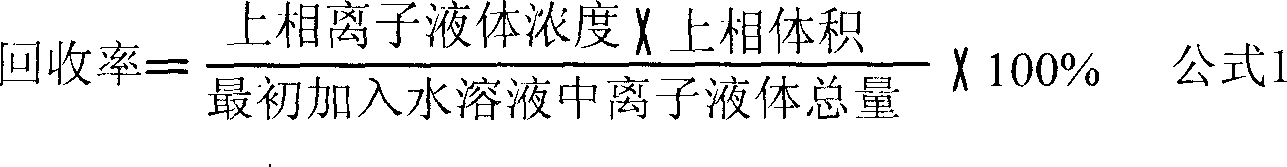

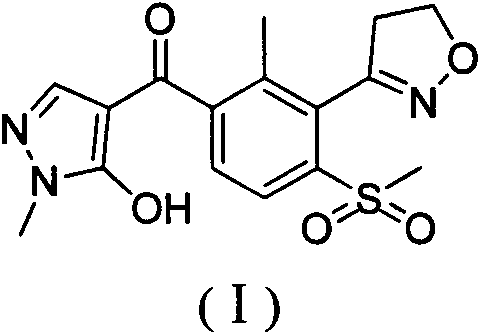

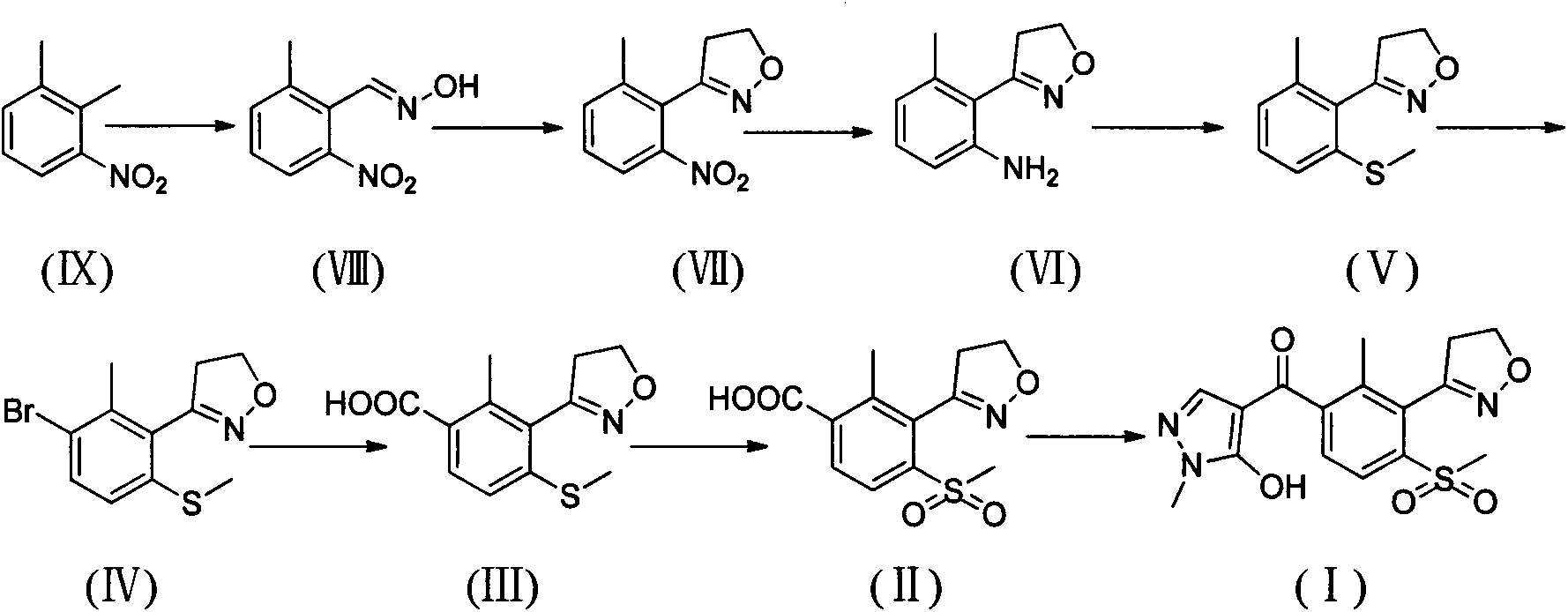

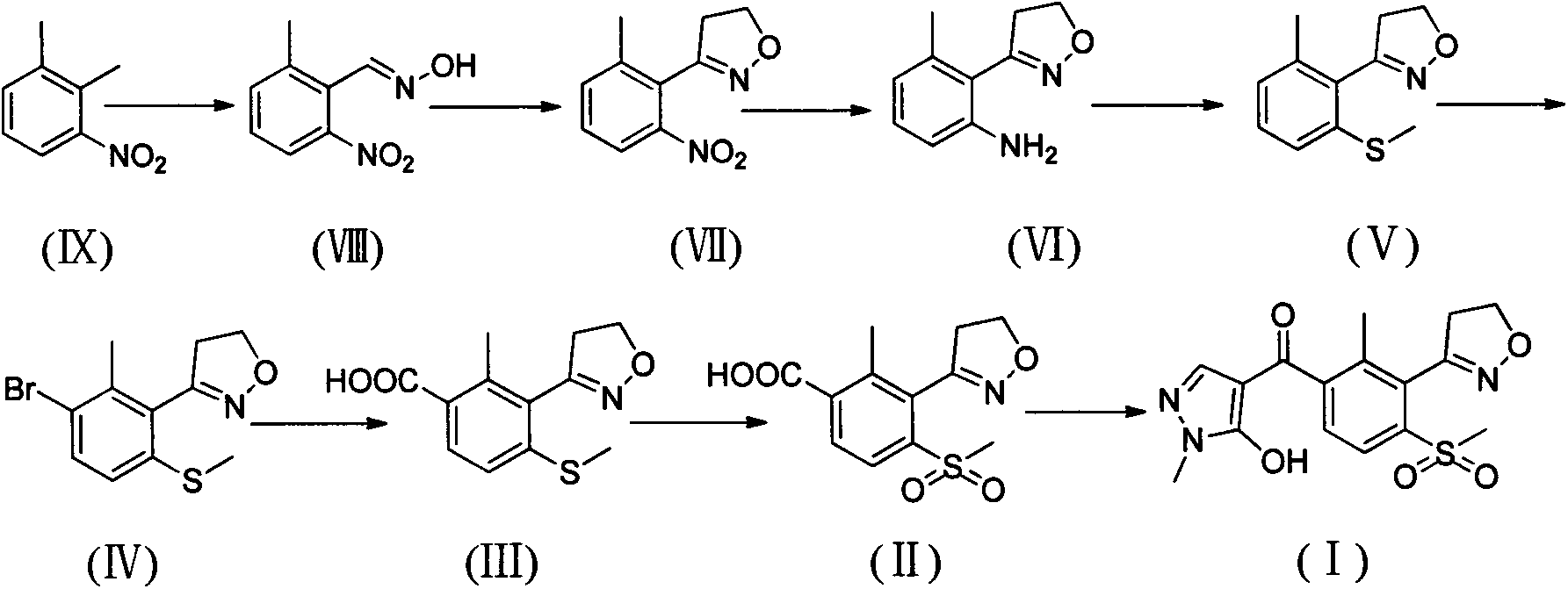

Method for preparing herbicide topramezone

The invention aims to provide a method for synthesis and preparation of [2-methyl-3- (4,5-dihydro-3-isoxazole)-4-(methyl sulfonyl) phenyl]-(5-hydroxy-1-methyl-1H-parazole-4-based) ketone (topramezone). According to the method, raw materials are simple and easy to obtain, post-processing is simple, the total recovery is high, the defects existing in the prior art and the defects concerning cost are overcome, and an important reference can be provided for industrial production.

Owner:CHINA PHARM UNIV

Method for making alkoxy-modified silsesquioxanes

InactiveUS7915368B2Easy to separateGroup 4/14 element organic compoundsSpecial tyresSilsesquioxaneSolvent

A method is presented for making alkoxy-modified silsesquioxanes (AMS) or co-alkoxy-modified silsesquioxanes (co-AMS,) comprising the steps of (a) combining as a reaction mixture (i) water, (ii) an acid-stable solvent for the water, (iii) a solid strong cationic hydrolysis and condensation catalyst, and (iv) a trialkoxysilane compound, (b) allowing the reaction mixture to react for about 0.5 hours to about 200 hours to form the alkoxy-modified silsesquioxanes; and (c) recovering the alkoxy-modified silsesquioxanes from the reaction mixture. The use of solid strong cationic catalysts in this reaction system is advantageous because they remain as solids throughout the reaction, allowing simplified separation of the solid catalyst from the soluble AMS or co-AMS products, resulting in total or near total recovery of the AMS or co-AMS products, the products being free of, or substantially free of residual acid catalyst, as well as virtual total recovery of the catalyst for recycling. The improved AMS and co-AMS compounds, vulcanizable rubber compounds containing them, and a pneumatic tire having a component made from the vulcanized rubber compounds are also presented.

Owner:BRIDGESTONE CORP

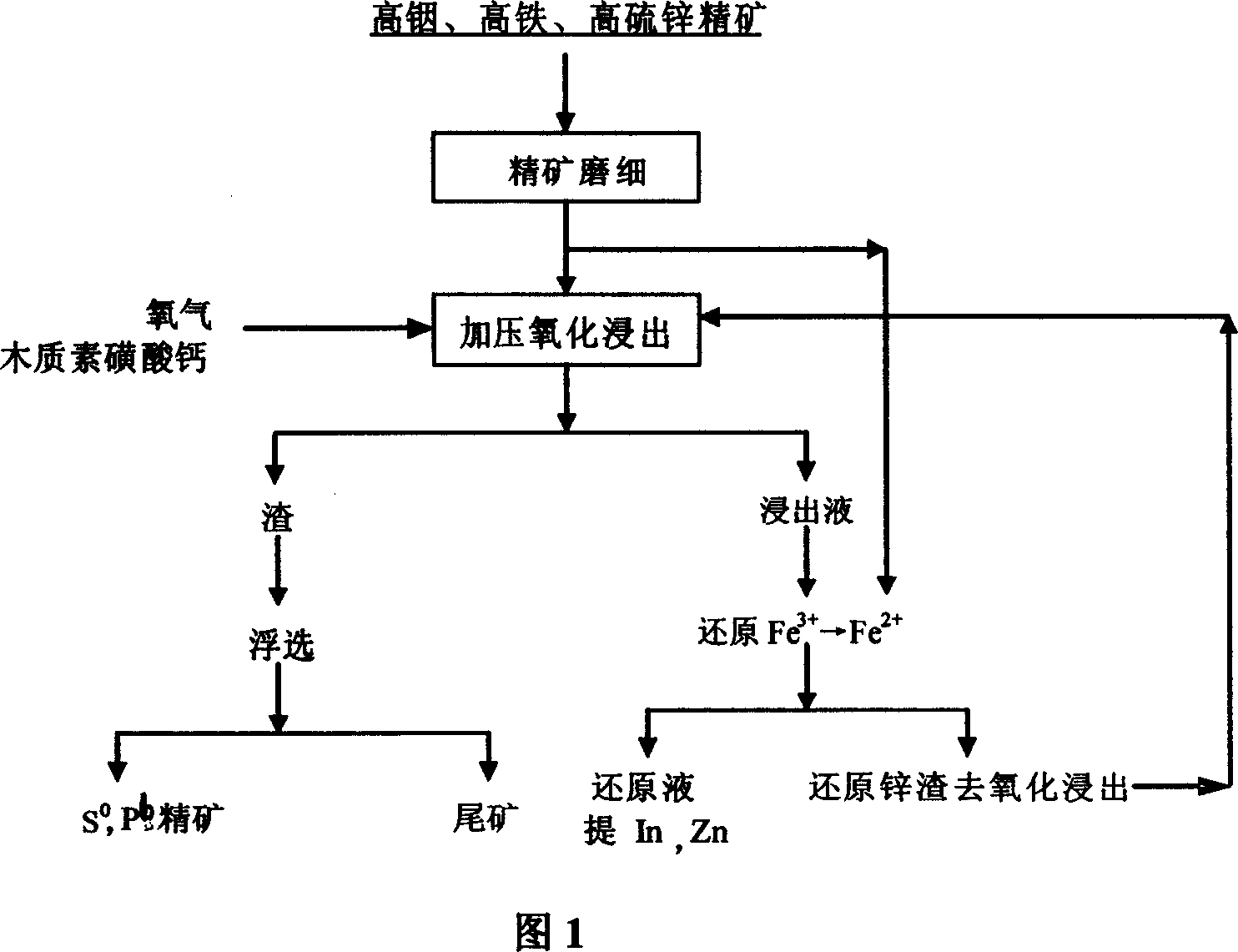

New method for soaking out enriched ores of high indium, high iron, and high sulfur zinc

This invention discloses a wet method for treating high In-Fe-S Zn concentrate by oxidative acid leaching. Compared with traditional high-pressure leaching technique, the method obviously reduces the operation temperature and pressure. Ore slurry composed of Zn concentrate, surfactant and sulfuric acid aqueous solution is operated at 95-105 deg.C under 0.2-0.4 MPa. The surfactant is sodium or calcium lignosulfonate, which can change the hydrophobicity of sulfide and sulfur, raise the leachin speed, and improve the suspension fluidity of the ore slurry. Since the operation temperature is lower than the normal pressure boiling point of the solution system, normal rubber pipe pump can be used to replace oil diaphragm high-pressure slurry pump, and Ti heat exchanger and vacuum flash evaporator are not needed. The leaching rate of Zn and In is up to 95-99%, and the yield of S is higher than 80%. The leaching solution can be treated according to normal method to recover valuable components, with total recovery rate of In up to 90-95%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

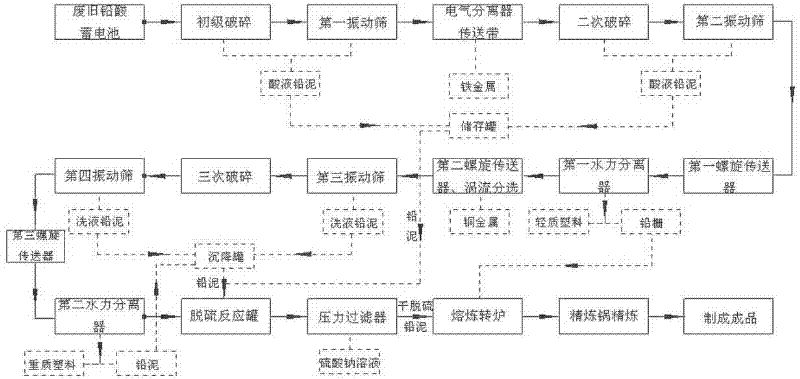

Closed circulating and recycling method of waste lead-acid accumulator

ActiveCN102534220ARealize pollution-free productionMethod environmentally friendlyProcess efficiency improvementFiltrationIngot

The invention relates to a closed circulating and recycling method of a waste lead-acid accumulator, and is used for solving the problem of low recovery efficiency, severe pollution and the like in the existing recycling aspect of the waste lead-acid accumulator due to lagging processing equipment, technical process production scale and the like. The method comprises the steps of: separating materials in the waste accumulator by crushing, oscillating screen sorting, magnetic separation, hydraulic sorting, vortex sorting and other methods, then carrying out desulfurization and pressure filtration treatment on obtained lead mud, then sequentially conveying obtained dried desulfurized lead mud and lead grid to a convertor and a refining kettle for smelting and refining, finally processing the refined molten lead into lead powder, lead grid or lead ingot, and storing for later use or selling as a finished product. The method has the advantages that the mechanical automation degree is high, pollution-free measures are adopted, the materials are thoroughly separated, the recovery rates of the materials are greatly improved, the total recovery rate of lead achieves 98%, the recovery rateof plastic achieves 95%, and the comprehensive utilization rate of resources achieves 98%.

Owner:阳煤集团山西吉天利科技有限公司

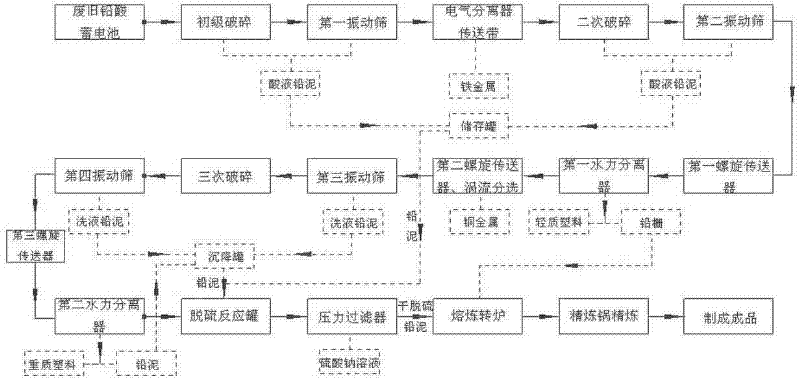

Scheelite beneficiation method

ActiveCN102909130AWith weak magneticEfficient separationFlotationMagnetic separationTotal recoveryMaterials science

The invention discloses a scheelite beneficiation method. The scheelite beneficiation method comprises the steps of: roughly grinding raw mineral with no need of desliming; screening the raw mineral in a sieve with 200-250mu m, roughly grinding the material on the sieve again, carrying out strong magnetic separation and discarding on the mineral under the sieve, wherein mainly magnetic garnets and other magenetic minerals are mainly discarded; carrying out scheelite normal temperature flotation on the nonmagnetic mineral after the nonmagnetic mineral is finely ground; carrying out scheelite warming flotation on concentrate obtained after the rough flotation to obtain scheelite concentrate; and carrying out normal temperature floatation on discarded magnetic concentrate, adding flotation middlings into the nonmagnetic scheelite concentrate to be finely ground. The scheelite beneficiation method aims at the mineral characteristics of the scheelite, the raw mineral contains a large amount of weak magnetism calcium and iron garnet gangue, so the recovery rate can be influenced due to the argillization caused by excessive grinding. The scheelite beneficiation method utilizes a ferromagnetic beneficiation method to effectively separate the magnetic ores, so that the excessive grinding condition is lowered, and the scheelite is preliminarily separated and beneficiated. The scheelite beneficiation method can enhance the mineral grinding efficiency, reduces the mineral grinding energy consumption, enhance the selection grade of the scheelite, reduces the beneficiation amount of the flotation, lowers the dosage of flotation reagents, and enhances the total recovery rate of the scheelite. The scheelite beneficiation method is especially suitable for medium grade and low grade scheelite beneficiation.

Owner:ZHONGXIANG TUNGSTEN IND

Method for extracting tungsten trioxide and molybdenum trioxide by pretreating tungsten-molybdenum concentrates with concentrated acid

InactiveCN101824533AAchieve separationTake advantage ofProcess efficiency improvementSolubilityEconomic benefits

The invention relates to a method for extracting tungsten trioxide and molybdenum trioxide by pretreating tungsten-molybdenum concentrates with a concentrated acid, which comprises eight flows of pretreatment with the concentrated acid, lixiviation, molybdenum precipitation, the preparation of MoO3 by roasting, ammonia leaching, concentration, cooling for crystallization, and the preparation of WO3 by roasting. The flows have the advantages that: 1, the recovery rate is high, the process is simple, the flows are short, the total recovery rate of molybdenum is between 95 and 98.5 percent, and the total recovery rate of the WO3 is between 96 and 97.5 percent; and 2, the separation of tungsten and the molybdenum is realized, in the process flows, the solubility of the molybdenum and the tungsten in the acid is different, and thus, according to the principle, the tungsten content of the molybdenum trioxide is less than or equal to 0.4 percent, the molybdenum content of leaching residues (tungsten concentrates) is less than or equal to 0.3 percent, so that the separation of the tungsten and the molybdenum is realized. Tungsten-molybdenum concentrate resources are utilized fully, so the method has excellent social and economic benefits.

Owner:范颖

Method for synthesizing liraglutide

ActiveCN104004083AReduce carrier usageAvoid couplingPeptide preparation methodsBulk chemical productionAmino acid synthesisCoupling

The invention relates to the field of medicine synthesis, and discloses a method for synthesizing liraglutide. The method includes the steps that three polypeptide fragments of the first to the fourth amino acid, the fifteenth to the sixteenth amino acid and the seventeenth to thirty-first amino acid are synthesized at first according to the amino acid sequence from N end to C end of a main chain of liraglutide, and then the three polypeptide fragments and the other amino acid are connected according to the sequence from the C end to the N end in a coupling mode to synthesize the liraglutide. According to the method, the three fragments can be synthesized simultaneously, coupling and acidolysis with much carrier resin are avoided, the use quantity of resin carriers is greatly reduced, the synthesis cycle is shortened, and the complexity level of synthetic process is simplified on the premise that high total recovery and purity are guaranteed.

Owner:CHENGDU SHENGNUO BIOTEC CO LTD

Method for preparing TiCl4 from titanium-containing furnace slag

ActiveCN101418383AChlorination is not easyDoes not destroy the fluidized stateTitanium halidesProcess efficiency improvementSlagReducer

The invention discloses a method for preparing TiCl4 through titanium-contained slag. The TiO2 content in the slag is 30 to 45 percent. The method is characterized in that the titanium-contained slag is directly reduced at a high temperature; and the reduced slag is used to prepare the TiCl4 through low-temperature boiling chlorination. According to the method, the titanium-contained slag, a reducer and a binding agent are mixed evenly and are used to make pellets; the pellets are reduced at the high temperature; the reduced pellets are crushed after being cooled down; and then the TiCl4 is obtained through the low-temperature boiling chlorination. The method has the advantages of low reducing temperature, short technical process, high total titanium recovery rate, and the like.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

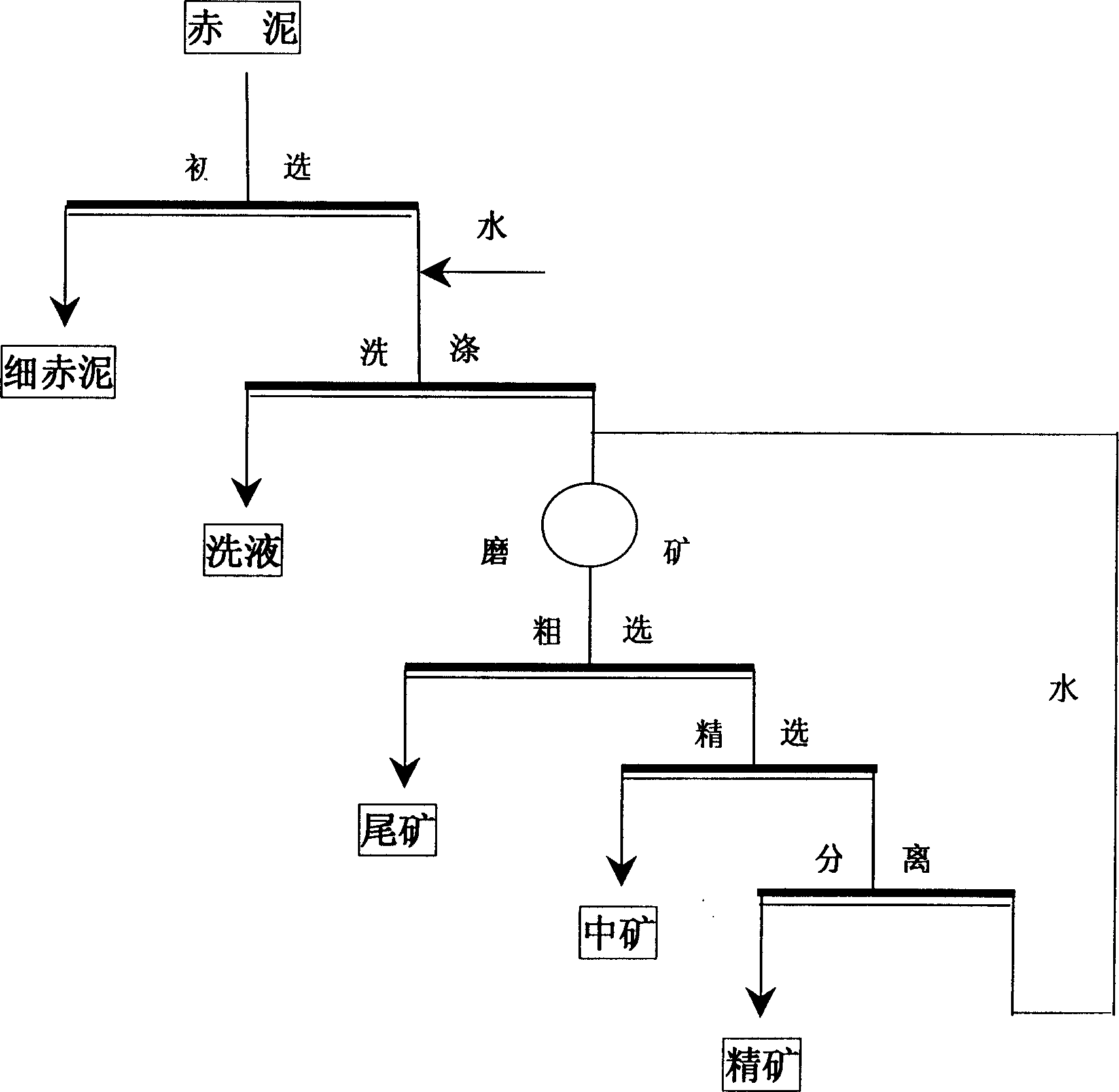

Method for selecting iron ore from red mud

ActiveCN1569341ATo achieve the purpose of comprehensive utilizationHigh yieldMagnetic separationWet separationIronstoneRed mud

The invention is a method for selecting iron ore from red mud. It preprocesses the red mud to eliminate the tiny red mud and acquires the red mud sand, carries on grinding and classification to the red mud sand then eliminates the tail ore through raw selection and acquires the concentrate after choiceness. The picking process uses high background field density and small pulse frequency, the choiceness uses lower background field density and larger pulse frequency. The flow is simple, and the reclaim rate of iron is high, the reclaim rate of iron can reach to 90%. The invention has excellent economical efficiency and social efficiency.

Owner:SHANDONG QIANSHUN MINING & METALLURGY SCI +1

Isolation and purification method of natural salidroside

ActiveCN101392011APromote regenerationSimple separation and purification processSugar derivativesSugar derivatives preparationSalidrosidePurification methods

The invention relates to a separating purification method of a natural rhodioloside, which particularly belongs to the technical field of plant extraction deep-processing and is characterized by comprising the steps that: natural rhodiola sachalinensis is taken as a material which is crashed, subjected to alcoholic solvent extraction, two-step macroporous resin absorption and desorption, absolute ethyl alcohol crystallization, crystal mush centrifugalization and absolute ethyl alcohol washing, and later dried in vacuum so as to obtain high purity natural rhodioloside product. The purity of the rhodioloside extracted by the method can be up to over 99 percent, the total recovery coefficient of the rhodioloside can be up to over 40 percent in the whole process; the method has simple and convenient separating purifying technique and large treatment amount, is applicable to industrializing production, can provide technical support for deep development and utilization of the rhodiola sachalinensis resources, and provide excellent natural materials for medicine and function food industrialization.

Owner:上海国矗生物科技有限公司

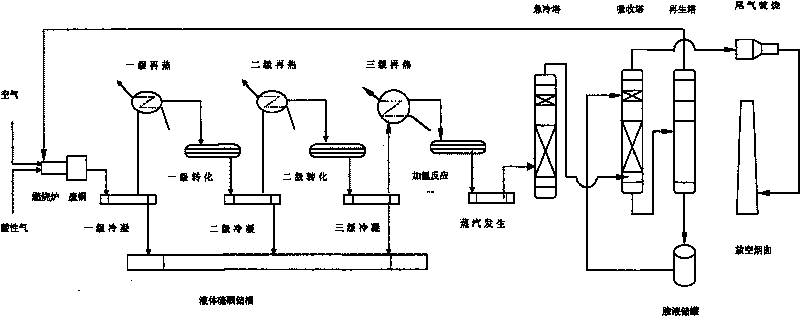

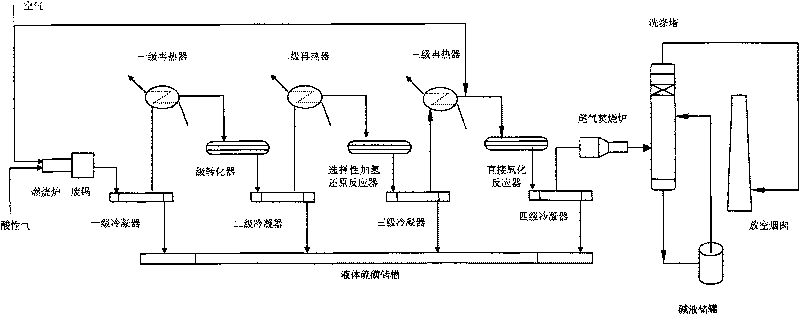

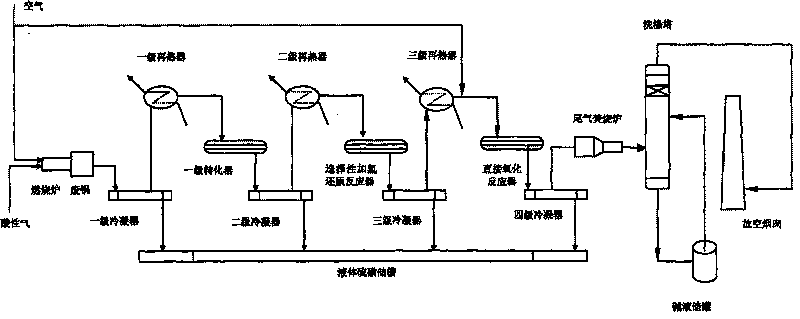

Method for obtaining high-purity sulphur from Claus reactive tail-gases

InactiveCN101693164AReduce design processReduce the amount of additional equipmentChemical industryDispersed particle separationManufacturing cost reductionSingle process

The invention relates to a method for obtaining high-purity sulphur from Claus reactive tail-gases, which belongs to the technical field of environmental protection. The method comprises steps as follows: (1) Claus tail-gas is preheated to reach the temperature between 160 DEG C to 300 DEG C; (2) the preheated gas enters a reduction reaction furnace filled with selective reaction catalysts to perform reduction reaction; (3) liquid sulphur is separated out of the reacted process gas via a condenser; (4) the process gas performs direct oxidization reaction inside a direct oxidizing reactor after being compensated with oxygen and preheated again; (5) liquid sulphur is separated out of gas on an outlet of the reactor via a sulphur condenser and a separator, tail gases after burned are cooled, washed by using an alkaline liquor and then discharged. The method overcomes the shortcoming that sulphur can not be produced by a traditional tail-gas hydrogenation reactor, improves total recovery efficiency of sulphur in a single process, and has the advantages of saving energy, lowering H2 consumption amount, reducing volume of absorption towers, decreasing arranged devices, lowering manufacturing cost and reducing operating load of the overall set of devices.

Owner:邵志辉

Rare earth ore beneficiation method

ActiveCN103962232ACoarse granularityReduce manufacturing costWet separationRare earthSmall footprint

The invention relates to a rare earth ore beneficiation method which is characterized in that grading is carried out after ore grinding is carried out on raw ore; reselection is carried out on coarse fractions to obtain gravity concentrates and tailings; magnetic separation is carried out on fine fractions to obtain strong-magnetic separation concentrates and tailings; reselection is respectively carried out on gravity concentrates and strong-magnetic separation concentrates which are different in fraction through a table to obtain table concentrates, table middlings and table tailings; the table concentrates and the table middlings which are different in fraction are mixed, and wet-type high-gradient magnetic separation is carried out to obtain magnetic separation rare earth ore concentrates and magnetic separation middlings; the magnetic separation middlings and the table tailings are mixed, closed-loop flotation including primary rough concentration, secondary scavenging and secondary fine selection is carried out after ore regrinding is carried out, the middlings are returned in proper sequence, and flotation rare earth ore concentrates and flotation tailings are obtained. The magnetic separation rare earth ore concentrates and the flotation rare earth ore concentrates are total rare earth ore concentrates, the REO grade is higher than 65%, and the total recovery rate ranges from 80% to 87%. The rare earth ore beneficiation method is high in grading efficiency, small in occupied area, continuous in production and low in cost, full-wet dust-free operation is achieved, and industrialization is easy to achieve. The rare earth ore beneficiation method is suitable for beneficiation of light rare earth ore existing in the bastnaesite or parisite mode.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

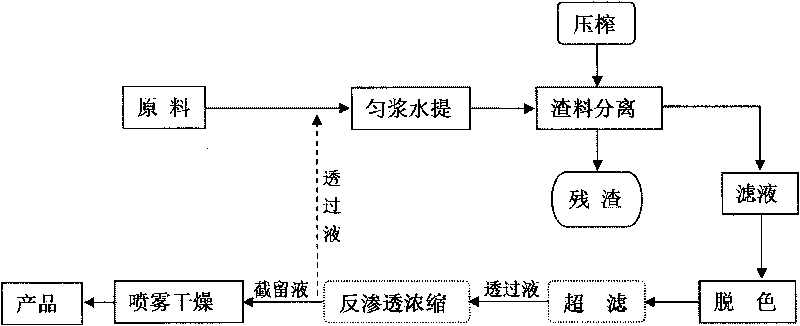

Method for efficiently preparing stachyose from stachys sieboldii

ActiveCN101717415AImprove qualityTake advantage ofSugar derivativesUltrafiltrationUltrafiltrationReverse osmosis

The invention provides a method for efficiently preparing stachyose from stachys sieboldii. The method is characterized by comprising the following steps: taking Chinese traditional vegetable stachys sieboldii as a raw material; extracting the stachyose by adopting a pure water homogenate method; and spraying and drying after the processes of filtering a homogenate by a cloth bag; decolorizing the filtered homogenate with macroporous resin, performing ultrafiltration purification and reverse osmosis concentration, and the like, wherein a reverse osmosis permeate liquid is used as water for the homogenate and the resin decolonization elution in the production and the like, so not only resources can be used fully to meet the requirement on production water supply, but also the influence on the purity of the stachyose in the whole production system, caused by pollutants such as saline matters and the like in a natural water source, can be reduced to further improve the purity and the quality of the stachyose. By using the method of the invention, the extraction rate of the stachyose prepared can reach 75 and 85 percent, the purity of the stachyose in a product reaches over 90 percent, and the total recovery rate of the stachyose in the whole process reaches over 60 percent. The method combines a traditional extraction method and a modern separation method, has a simple process and a large handling capacity, is suitable for industrial production, and simultaneously has high product purity, saves resources and the production cost, and has good economic benefits and ecological benefits.

Owner:上海国矗生物科技有限公司

Method for separating and recycling valuable metal from pressure leached high sulphur slag

InactiveCN101503761ASolve recycling difficultiesAchieve reuseProcess efficiency improvementSlagKerosene

The invention discloses a method for separating and reclaiming valuable metal from high-sulfur slag subjected to pressure leaching. The method comprises: firstly, adding kerosene into the high-sulfur slag subjected to pressure leaching to leach out elemental sulfur, filtering and separating hot kerosene containing the elemental sulfur and desulfurated slag containing antimony and bismuth, and separating out the elemental sulfur after cooling the hot kerosene; secondly, adding the desulfurated slag containing the antimony and the bismuth into a mixed solution of sulfuric acid and sodium chloride, filtering and separating chlorine salt lixivium and copper-containing residue, and returning the copper-containing residue to an arsenic filter cake system for pressure leaching; uniformly adding distilled water into antimony and bismuth lixivium to control the pH value, and obtaining a liquid after antimony precipitation and antimony oxychloride through hydrolysis and precipitation; uniformly adding ammonia water into the liquid after antimony precipitation to control the pH value, and obtaining a liquid after bismuth precipitation and the antimony oxychloride through hydrolysis and precipitation; and returning the liquid after bismuth precipitation to the antimony precipitation process. The total recovery rate of the sulfur reaches 97 to 98 percent, the total recovery rate of the antimony reaches 81 to 82 percent, and the total recovery rate of the bismuth reaches 95 to 96 percent. The invention has the advantages of simple and convenient operation, simple equipment and good application value.

Owner:CENT SOUTH UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com