Patents

Literature

313 results about "Rock structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The oolitic structure is characterized by rounded grains or grain aggregates and is typical of carbonate rocks (limestones, dolomites), iron, manganese, and phosphate ores and bauxites. The massive structure is observed in chemogenic rocks with a homogeneous composition (dolomites, limestones, gypsums, anhydrites).

Stability monitoring method for cold high-altitude steep slope

ActiveCN107067333AComprehensive monitoringComprehensive judgmentAnalysing solids using sonic/ultrasonic/infrasonic wavesData processing applicationsSlope stability analysisInstability

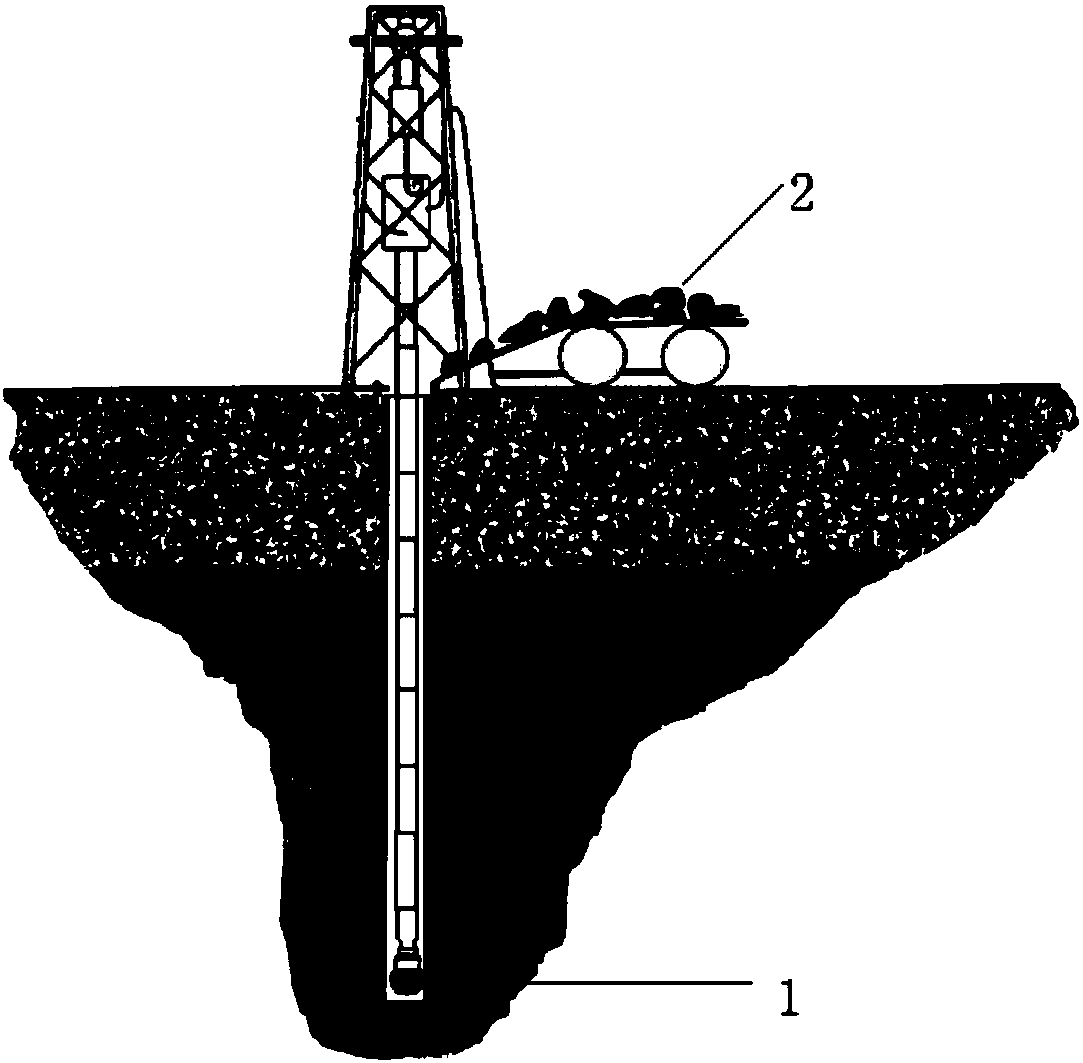

The invention relates to the technical field of mining safe engineering, and particularly to a stability monitoring method for a cold high-altitude steep slope. According to the stability monitoring method, through field engineering geology, hydrogeology survey, engineering geological rock quality evaluation and rock mechanical parameter determining, the lithologic condition, the rock structure, the hydrogeology condition, the slope shape, earthquake parameters, explosion parameters and the like of the slope are determined. Slope stability analysis and a treatment strategy measure are performed. Furthermore a comprehensive monitoring system and a slope instability criterion are established.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

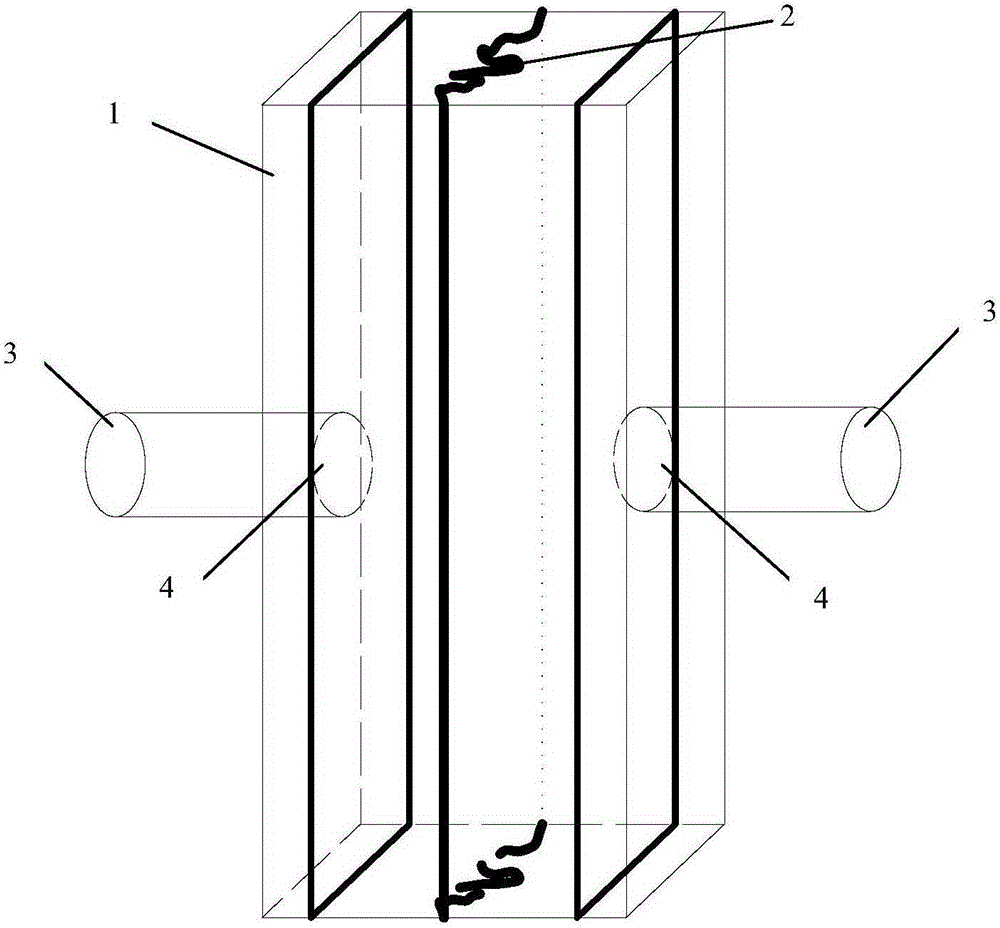

Manufacturing method of simulation fracture for fractured rock mass seepage test

InactiveCN105158039AOvercome limitationsHigh precisionPreparing sample for investigationPermeability/surface area analysisComputer Aided DesignSurface roughness

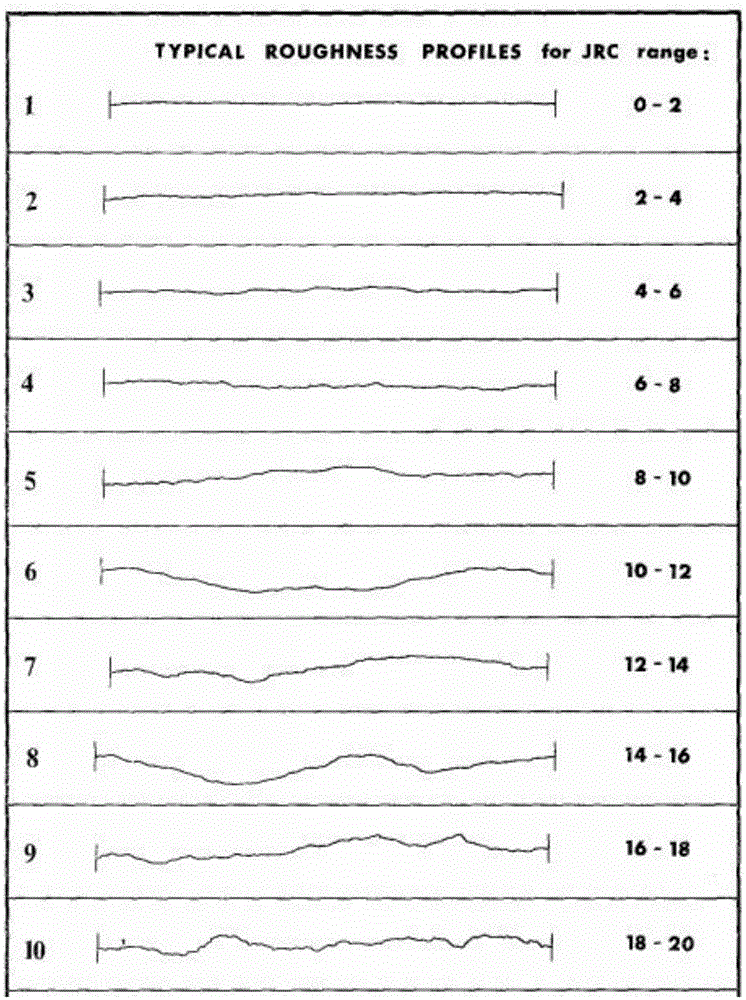

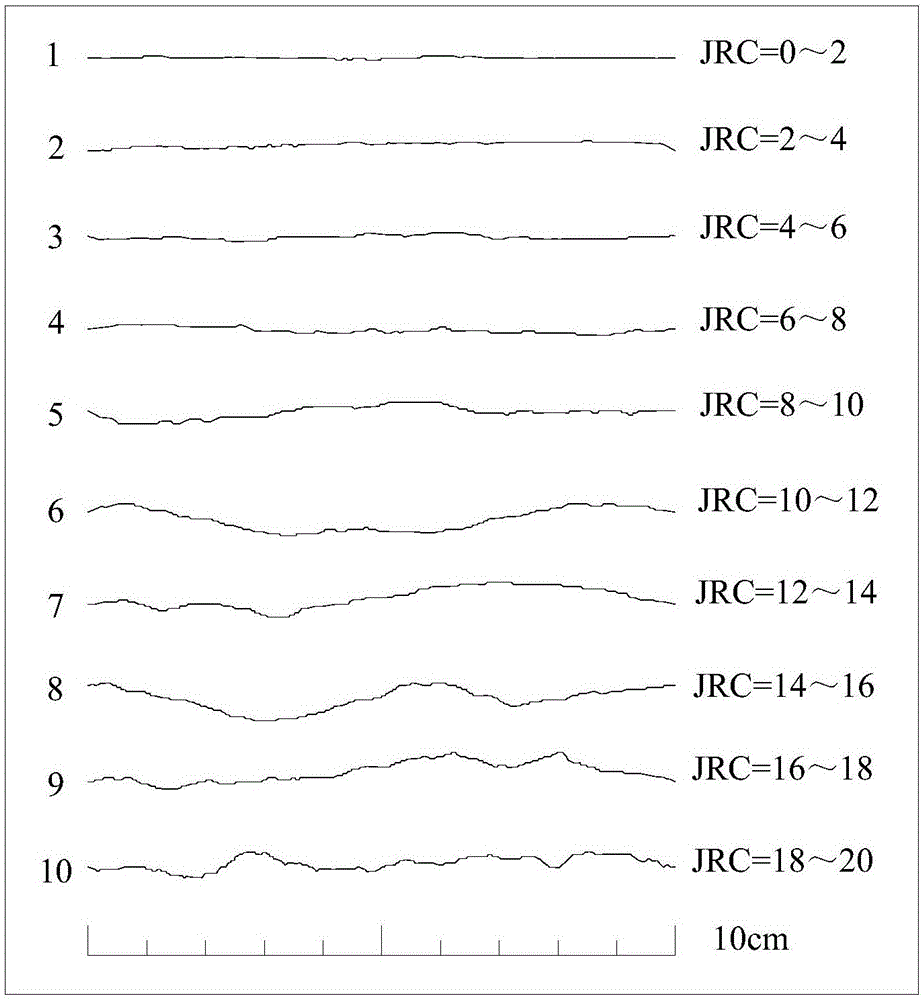

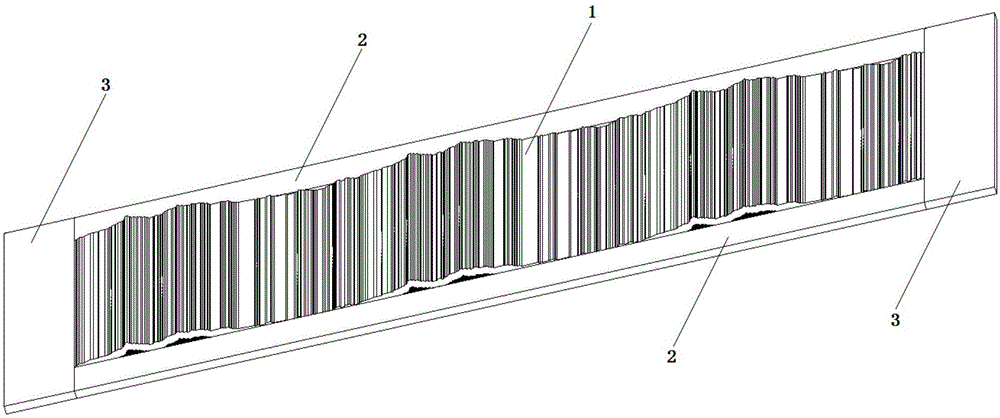

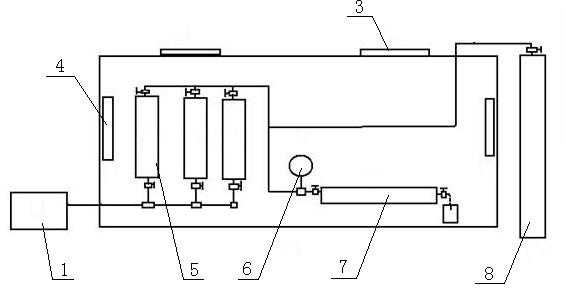

The invention discloses a manufacturing method of a simulation fracture for a fractured rock mass seepage test. The manufacturing method comprises the steps of drawing a fracture digitized profile curve, constructing a fracture three-dimensional model, making a fracture plate through 3D (three-dimensional) printing, making a fracture test piece casting model and performing casting and maintenance of a fracture test piece, specifically, through digitizing a rock structural surface joint roughness profile curve, drawing the fracture three-dimensional model on the basis of CAD (Computer Aided Design) software, making the fracture plate satisfying JRC value fluctuation by adopting a 3D printing technology, making the fracture test piece casting model by combining the fracture test piece, forming by using cement mortar to cast, and making the fracture test piece by performing maintenance in a cement test piece maintenance box for 28 days. The manufacturing method has the beneficial effects: the manufacturing method of rock rough fracture analogue simulation which is easy in observing, simple in manufacturing, convenient in testing, convenient for adjusting fracture opening, and capable of truly and accurately reflect rock mass fracture structural surface roughness is provided, the working procedures are simple and clear, the manufacturing duration is short, economy and efficiency are realized, the accuracy is high, and the adaptability is good.

Owner:HOHAI UNIV

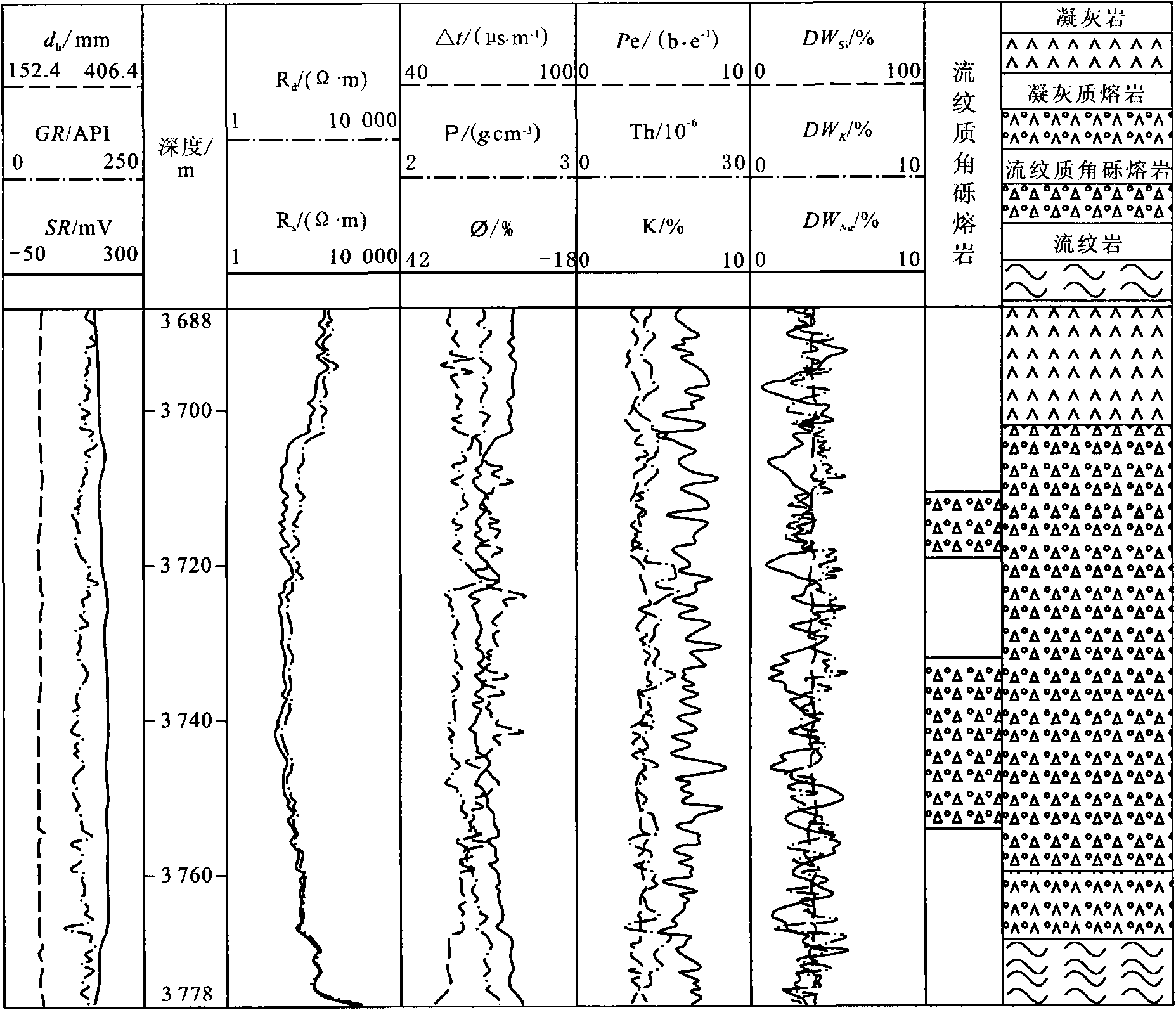

Method for identifying lithology of three-dimensional volcanic rock

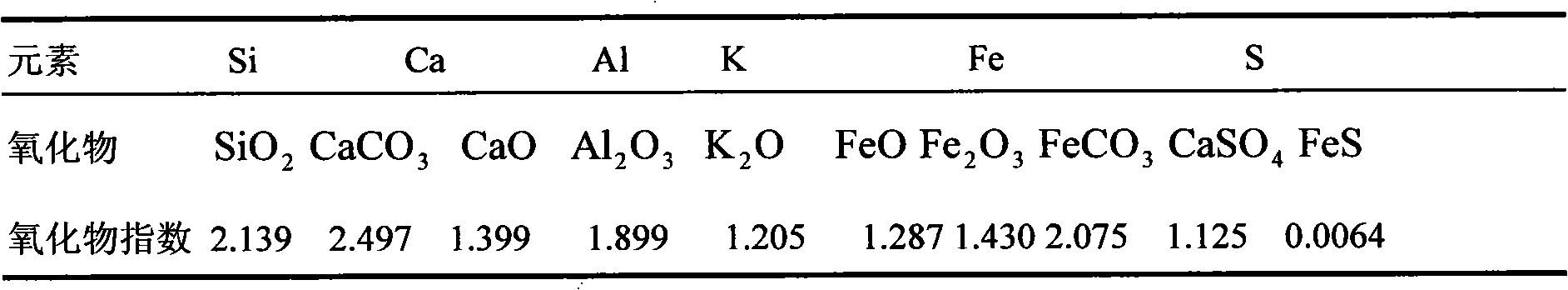

The invention relates to a method for identifying the lithology of volcanic rock. The method comprises the following steps of: determining the types of rock needing lithological identification; calculating the content of each element in stratigraphic rock in percentage by weight by using the theory of oxygen closed mold on the basis of elemental capture spectroscopy logging information; classifying the lithology of volcanic rock by using a silicon-alkali classification method; extracting the rock structure information of different classes of lithology of volcanic rock on the basis of imaging logging information in combination with oilfield on-site coring analysis and geologic description; combining the rock components calculated according to elemental capture spectroscopy logging with therock structure information determined according to the imaging logging information together and converting a TAS two-dimensional plane into a three-dimensional plane by using the rock structure information as a third dimension scale; and realizing three-dimensional volcanic rock lithological identification by using an SVM (Support Vector Machine) method. By adopting the method, the coincidence rate of lithological identification can be improved to reach more than 90%, which is 10 times that of the traditional method.

Owner:PETROCHINA CO LTD

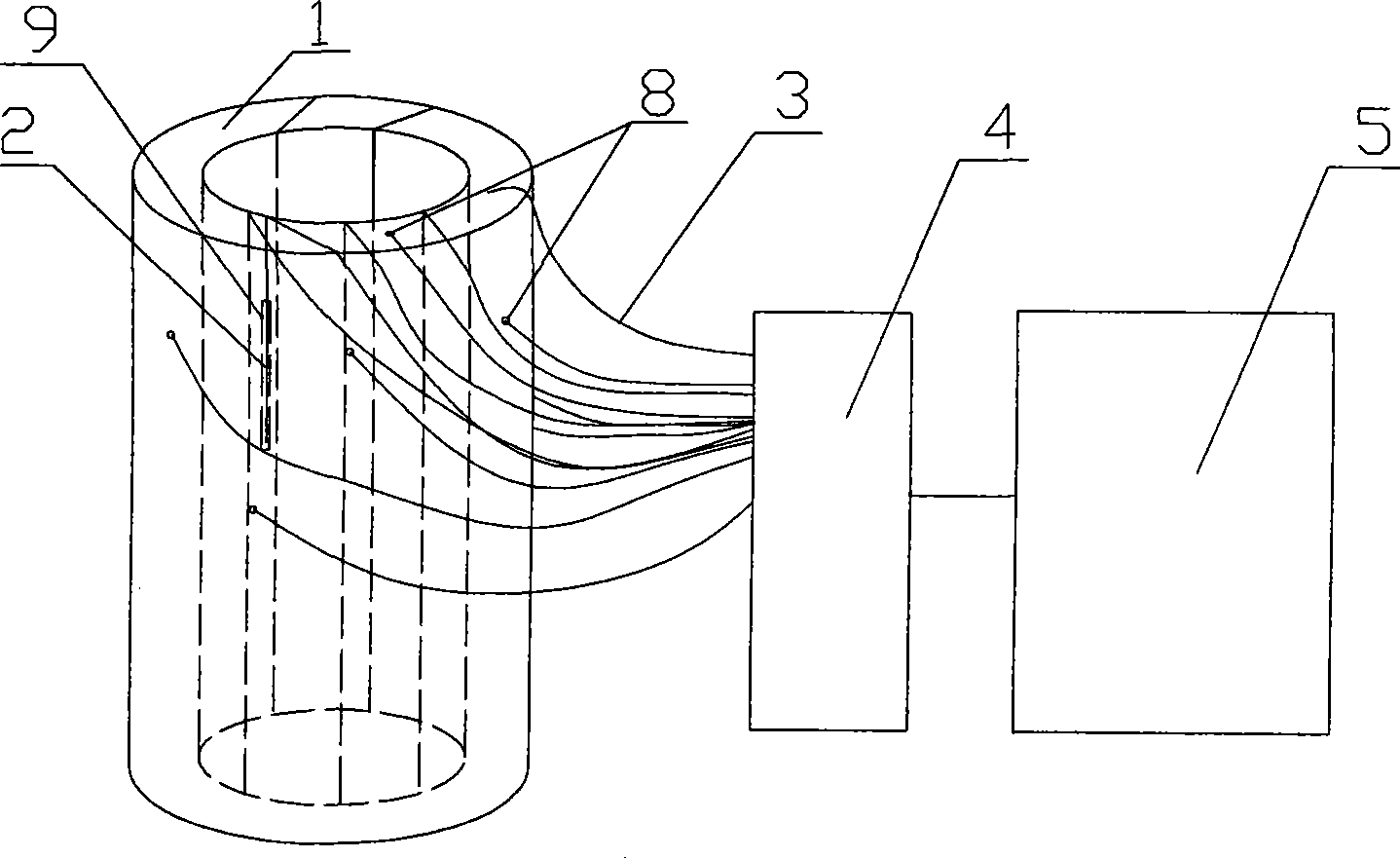

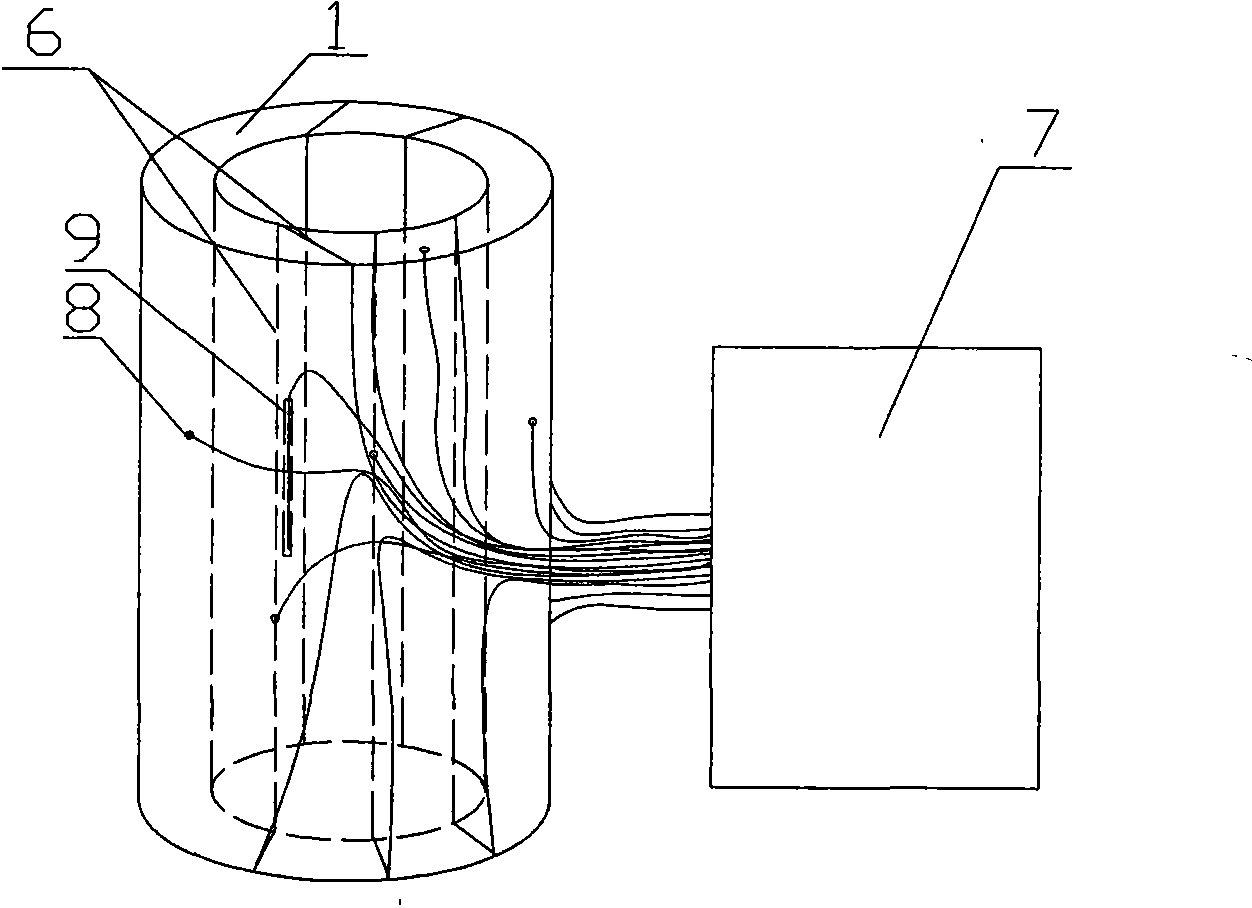

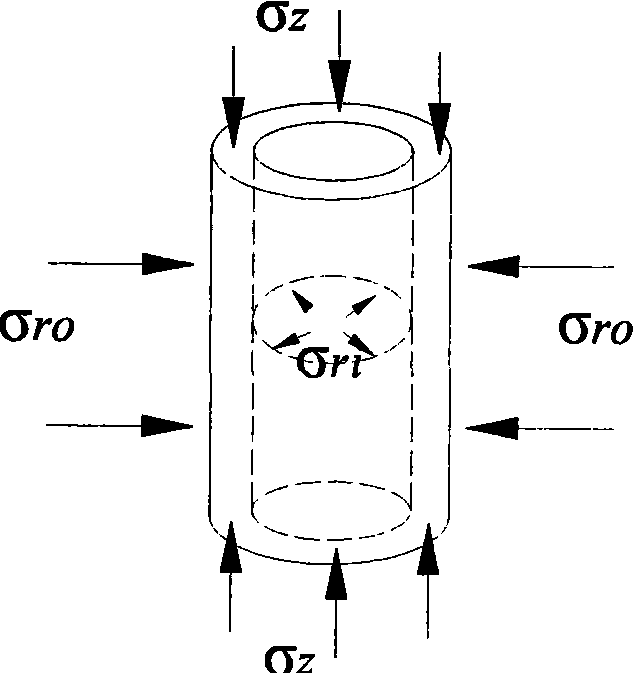

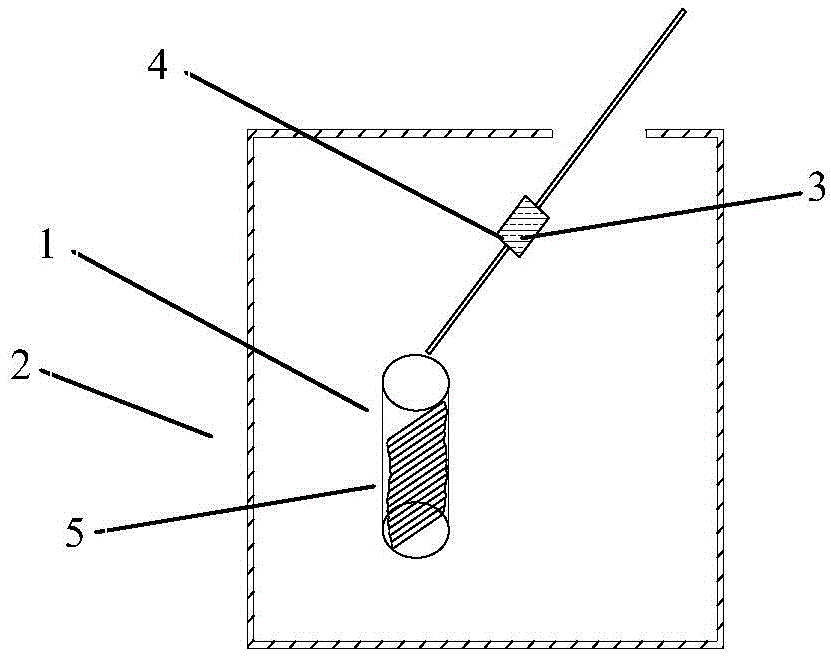

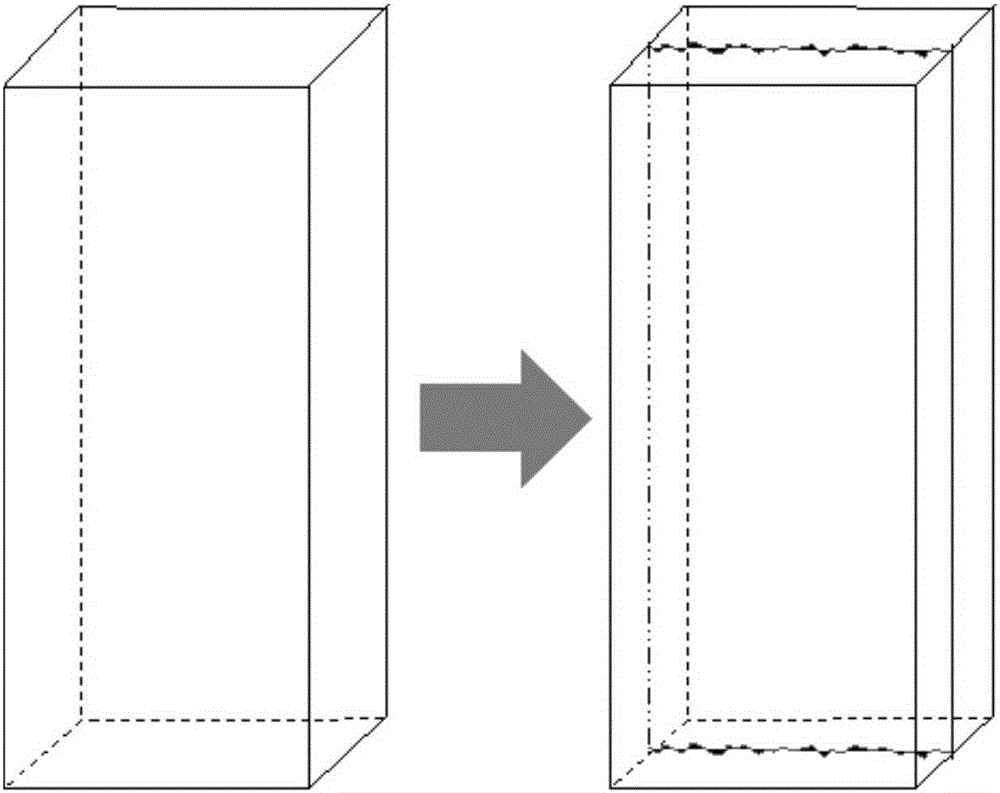

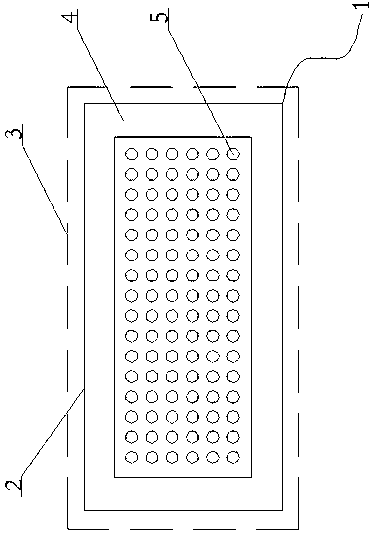

Rock deforming and cracking three-dimensional dynamic testing system based on fiber strain sensing

InactiveCN101520317AIncrease space positionMaterial strength using tensile/compressive forcesUsing optical meansFiber strainInstability

The invention relates to a rock deforming and cracking three-dimensional dynamic testing system based on fiber strain sensing, which comprises a testing piece, wherein the testing piece is laid with a fiber sensor encapsulated with a plurality of testing strains; the fiber sensor is connected with a signal demodulation processing device through a connecting fiber; and demodulated data signals can build three-dimensional testing data of the testing piece and can form a three-dimensional dynamic strain field of the testing piece after interpolation. The system can effectively lay out the fiber sensor inside and on the surface of the real rock testing piece under the pressure of a three-axis presser, enters the rock inside to detect the rock dynamic strain under the premise of not influencing the rock structure and the stress, and can really test the rock dynamic cracking process to obtain the crack initial and expended spatial positions inside the testing piece. The system continuously monitors the generation and expansion of tiny cracks inside brittle materials under the loading action in real time at the same time, and can be widely applied to researching cracking instability mechanisms of materials, such as rocks, concrete and the like.

Owner:SHANDONG UNIV

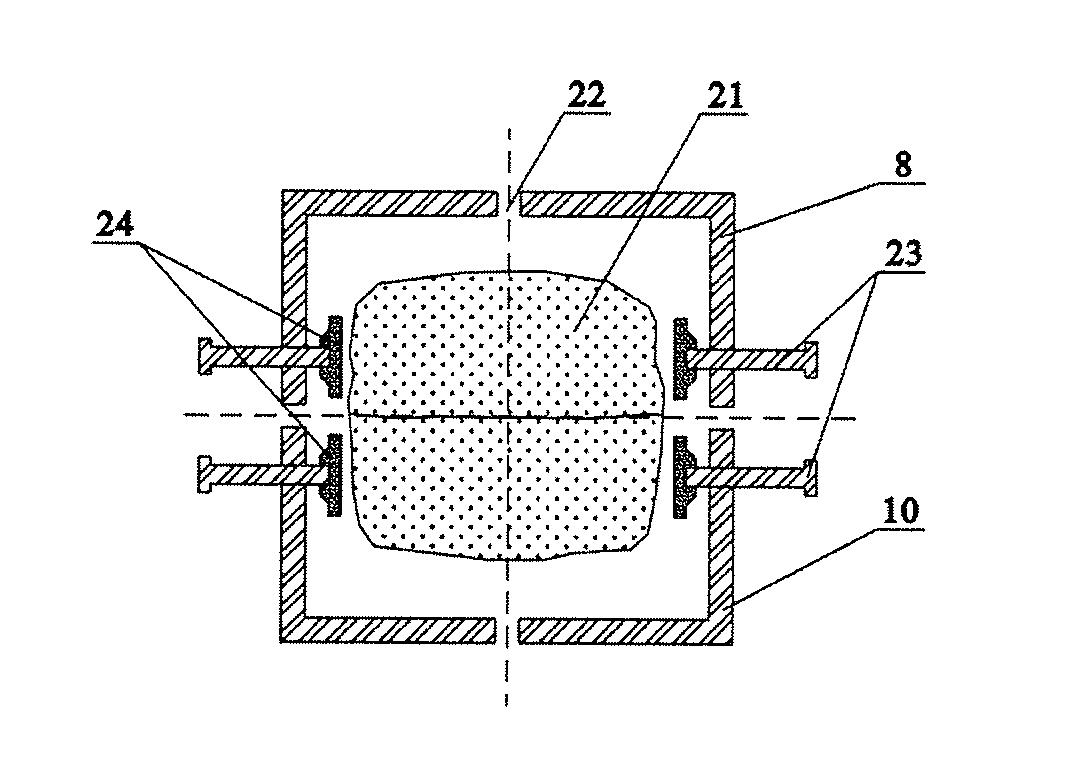

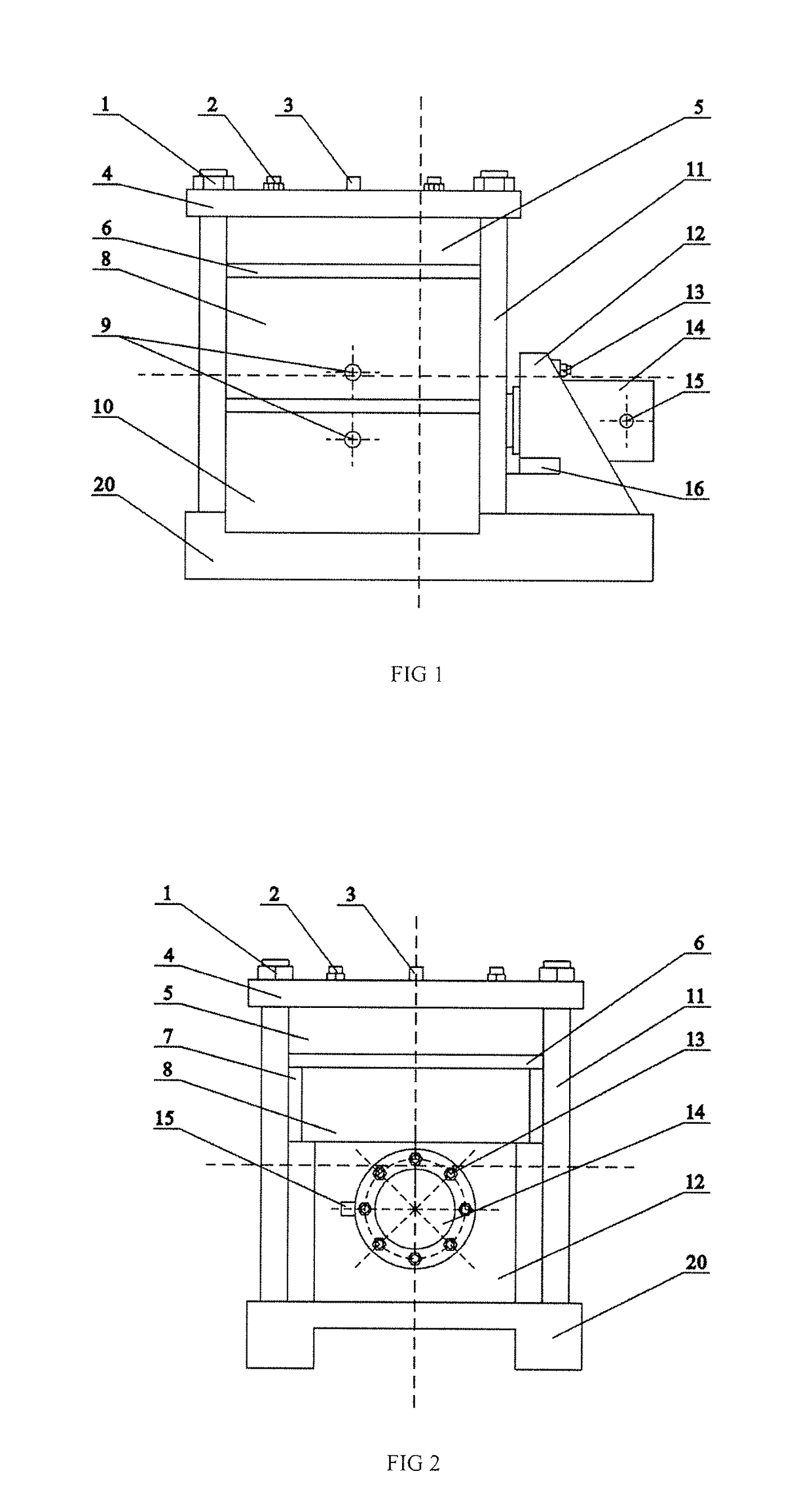

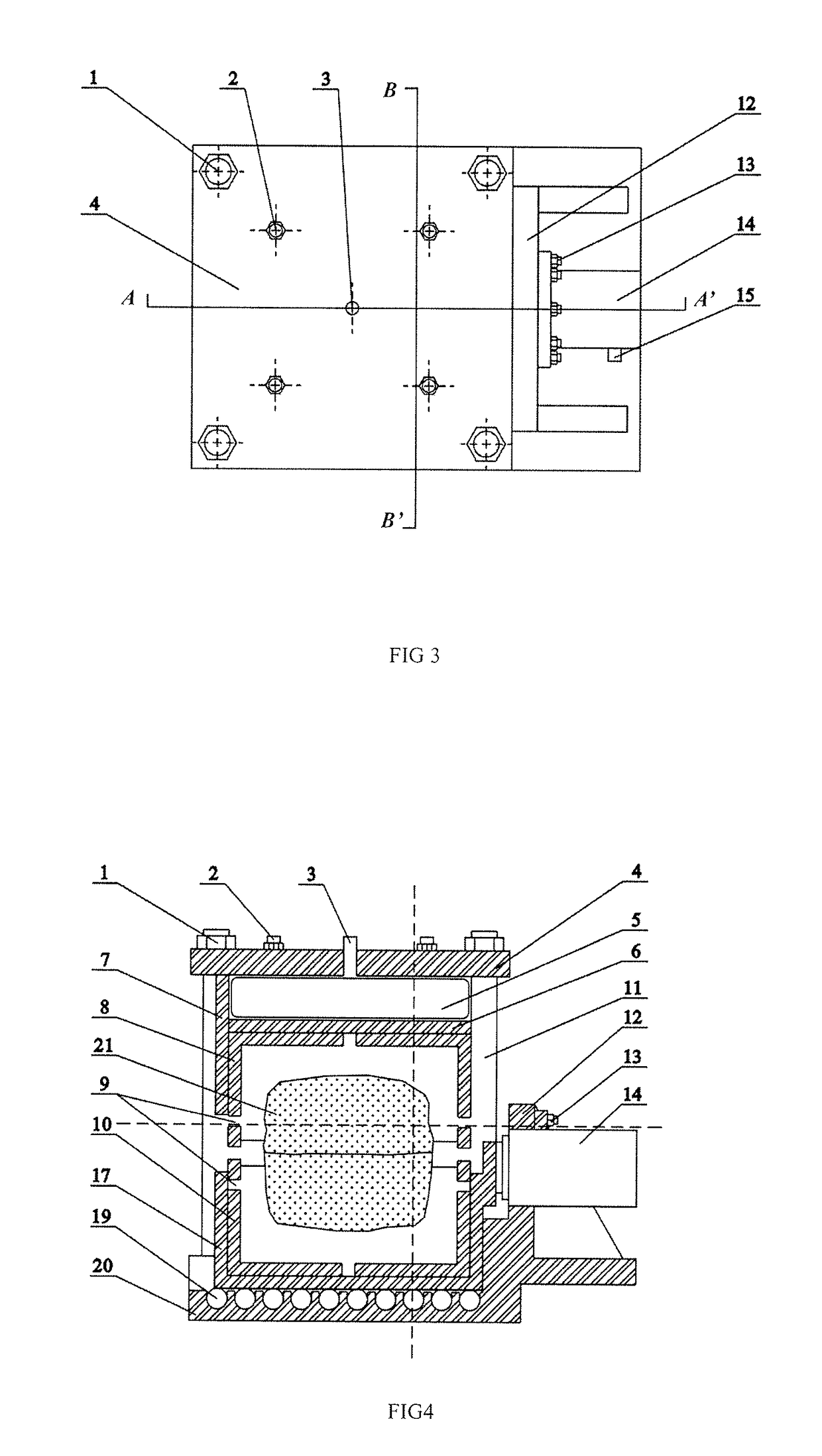

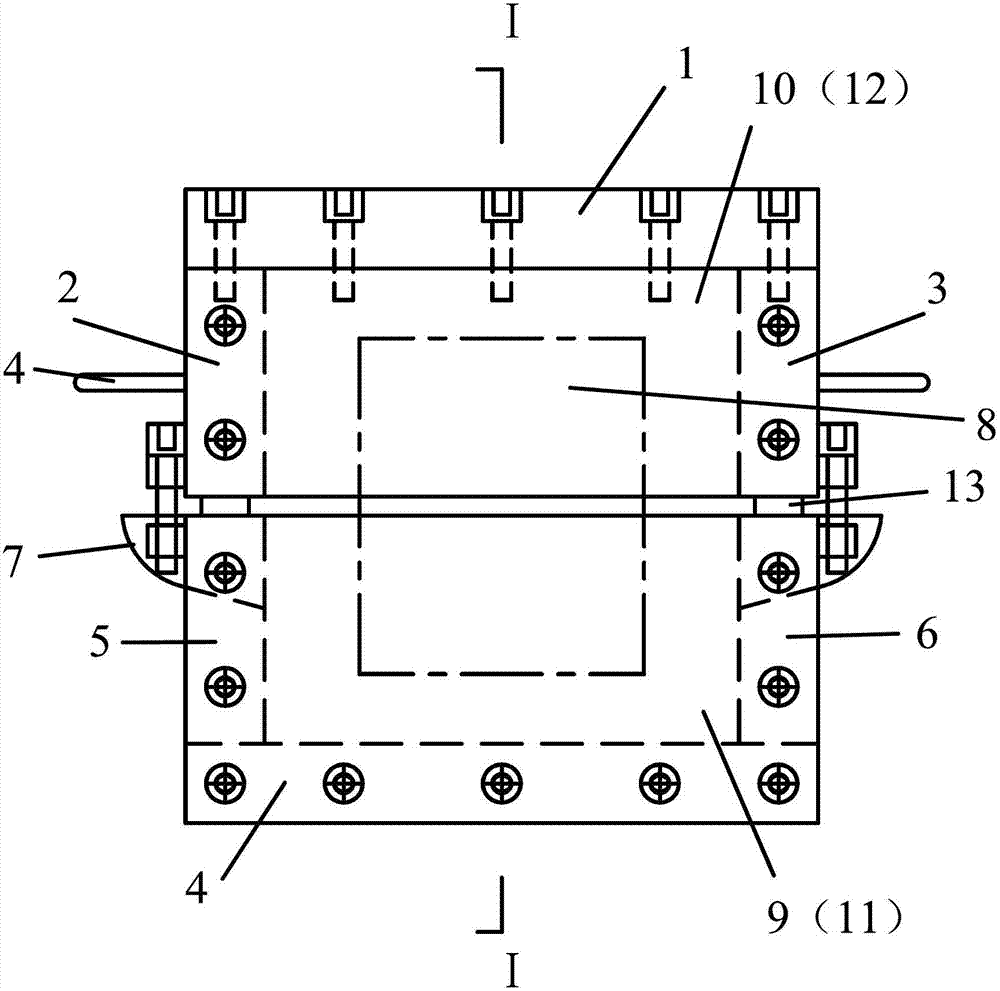

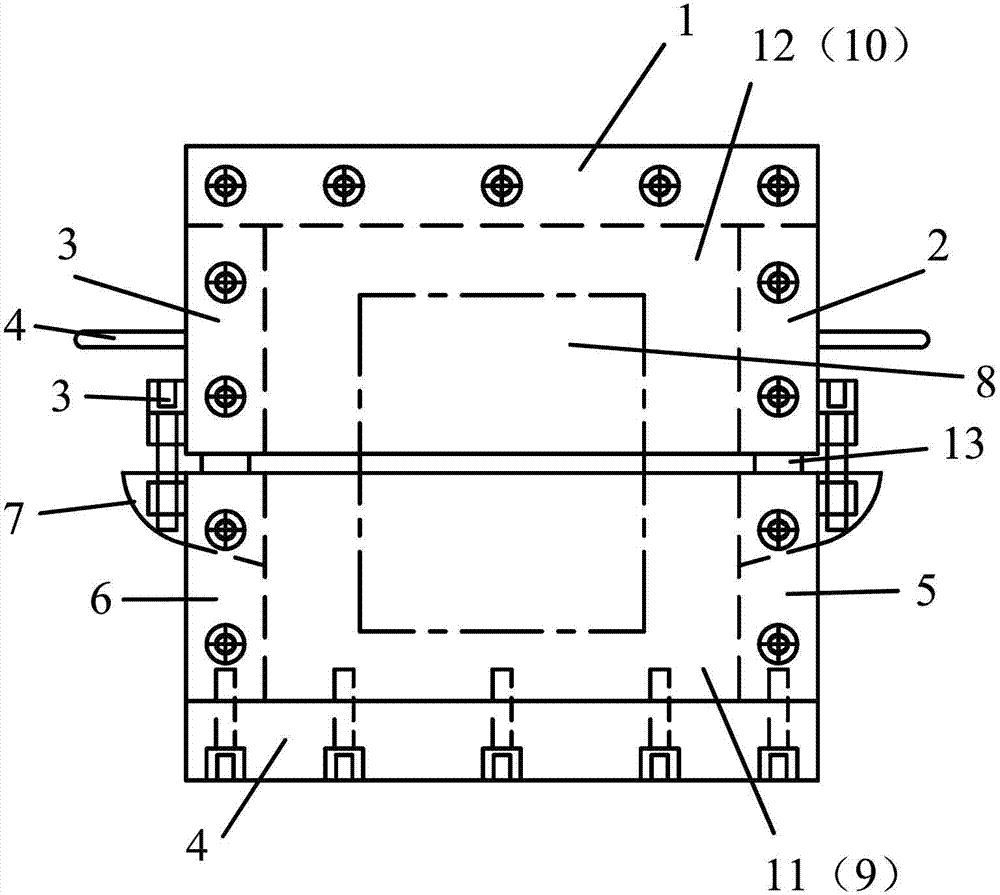

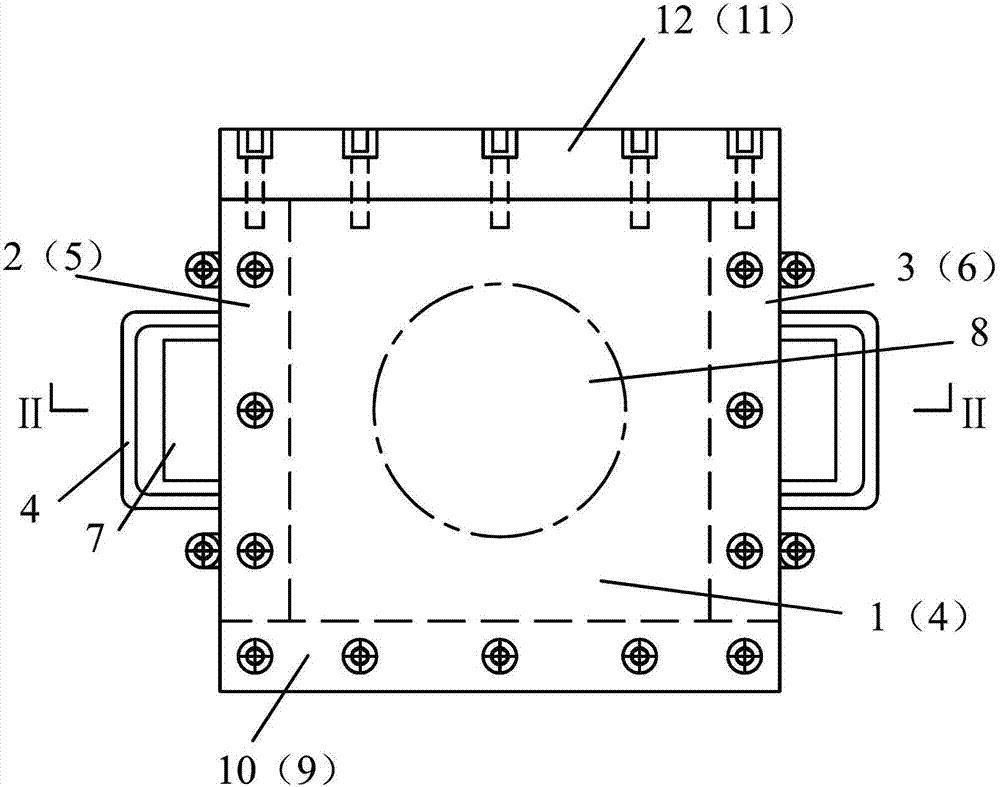

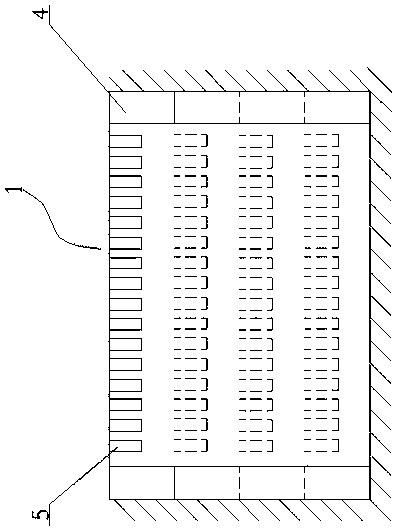

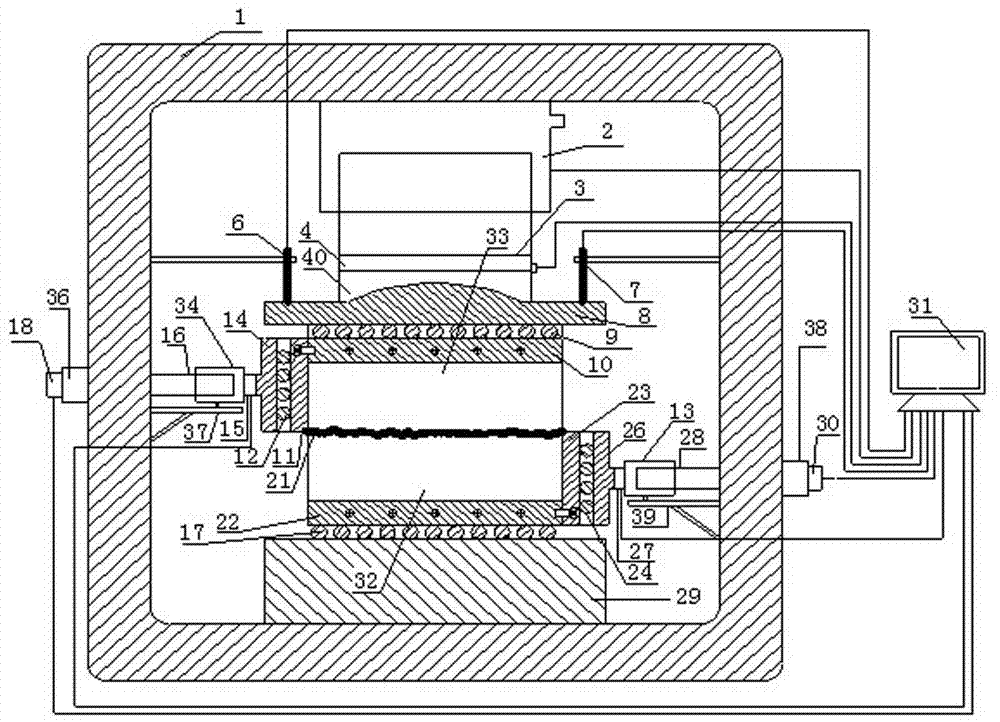

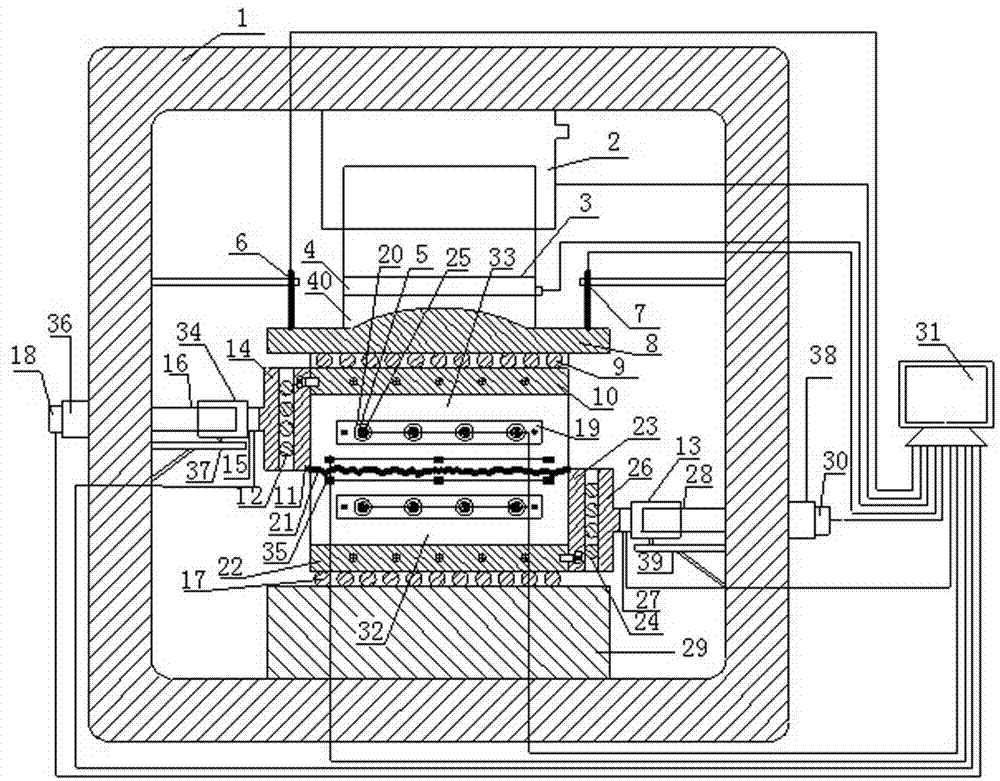

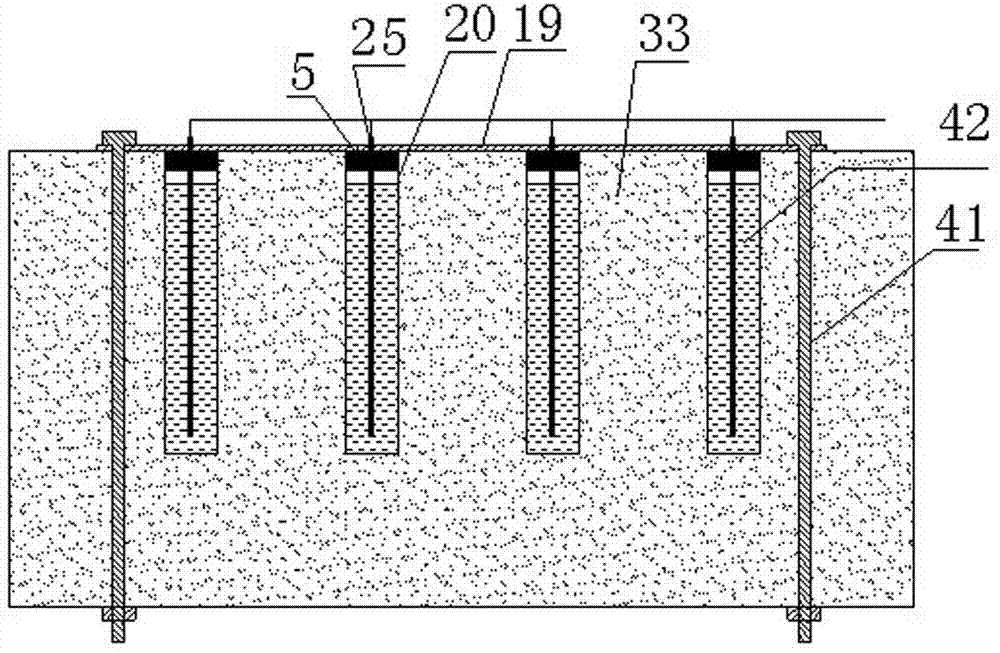

Integrated style shear apparatus for rock structural plane and a shear experimental method for rock structural plane

ActiveUS20170284911A1Reduce distractionsAvoid mistakesMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesHorizontal stressExperimental methods

An integrated style shear apparatus for rock structural plane comprises a frame system, a vertical loading system, a horizontal loading system, and a shearing system. Both the vertical loading system and the horizontal loading system are fixed on, and the shearing system is installed inside the frame system. The shearing system is used to prepare the sample of structural plane and actualize the shear test, the vertical loading system and the horizontal loading system are used to provide normal stress and shear stress for the shearing system respectively. The present invention also provides an experimental method by using the integrated style shear apparatus for rock structural plane, and steps of the method including: sample placement, sample adjustment, sample preparation, sample loading, instrument hookup, exerting normal stress, exerting horizontal stress, measurement and description of shear area, repeating experiment, and normal stress and shear stress calculation. The present invention can effectively reduce sample preparation error and experimental error, and can rapidly and accurately determine shear strength and deformation parameters of rock structural plane.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

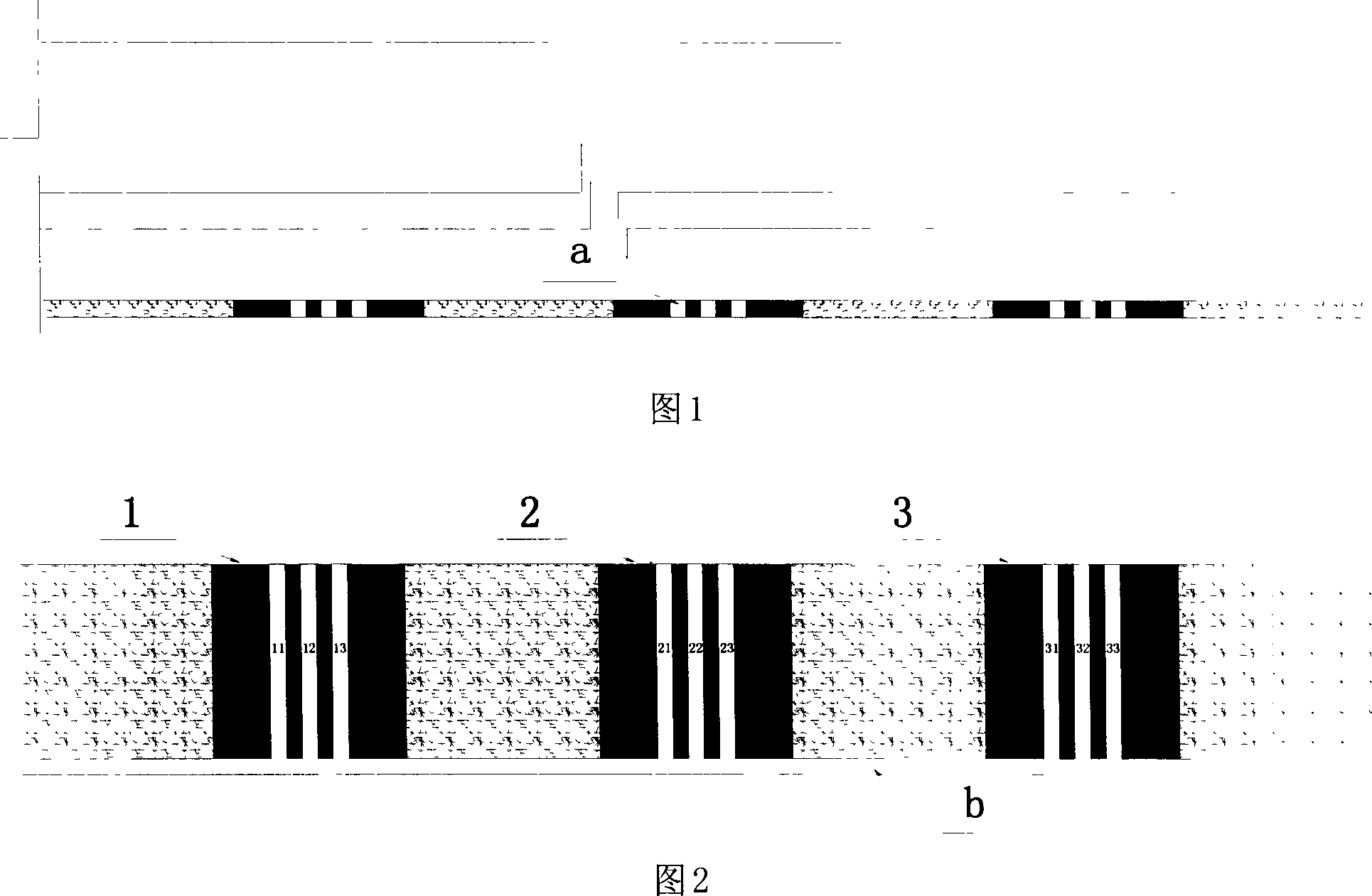

Mining method for replacement of banded coal under building by waste rock

The bone coal displacement strip coal block exploration under an architecture, concentrically sets 3-5 bone coals filling lane at the center of each strip coal block, based on the buried depth, width, laminated rock structure and protective degree required by the architecture build on the surface of each strip coal block, advancing coal mining for the 3-5 bone coals filling lane and then filling bone coals from the interior to the exterior inside the lane that has dug out coals. Ensuring the safety of the architectures, filling the displacement coal with bone coals, it can realize exploration rate no less than 20%, the total recovery rate of the strip mining area no less than 65%; Filling the mine with bone coals dug out can not only eliminates the bone coals on the land, reduces the encroachment of farmland, mitigates air and environmental pollution, gets rid of bone coal landslide or explosion and other hidden accidents that may affects the human life but also using bone coals working as the underground support of the mine and realizing second partial recovery for strip coal blocks under the architectures.

Owner:CHINA UNIV OF MINING & TECH

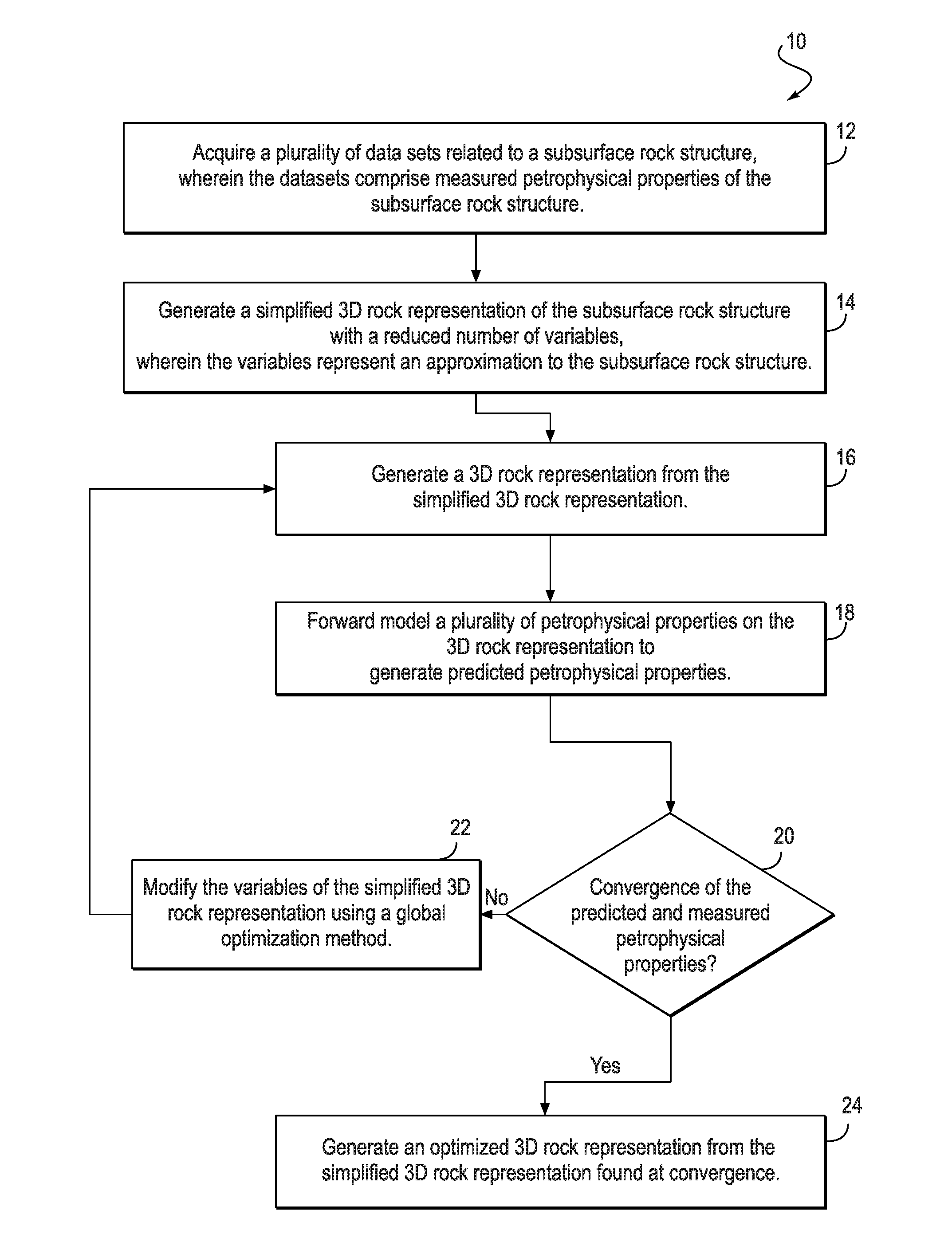

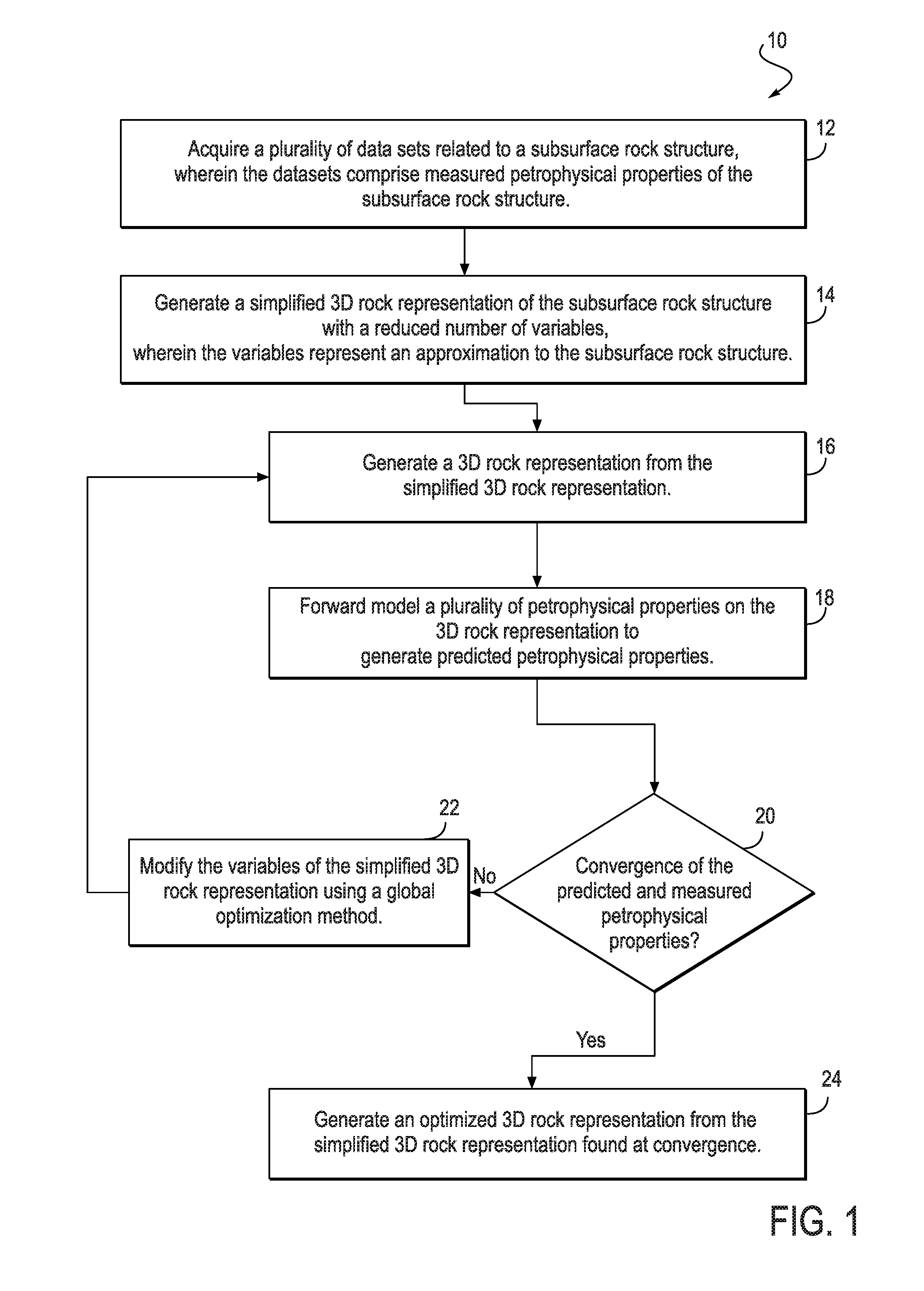

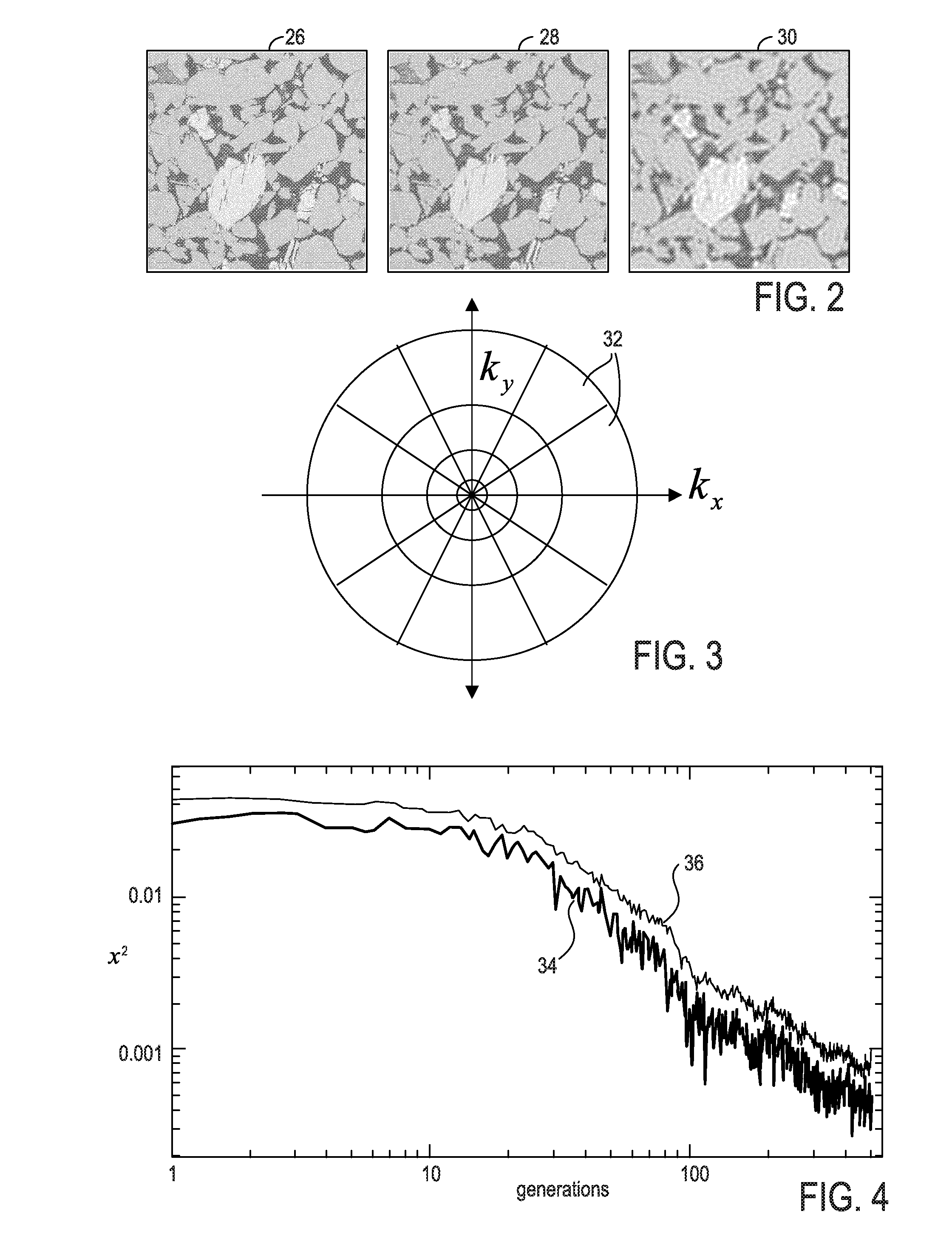

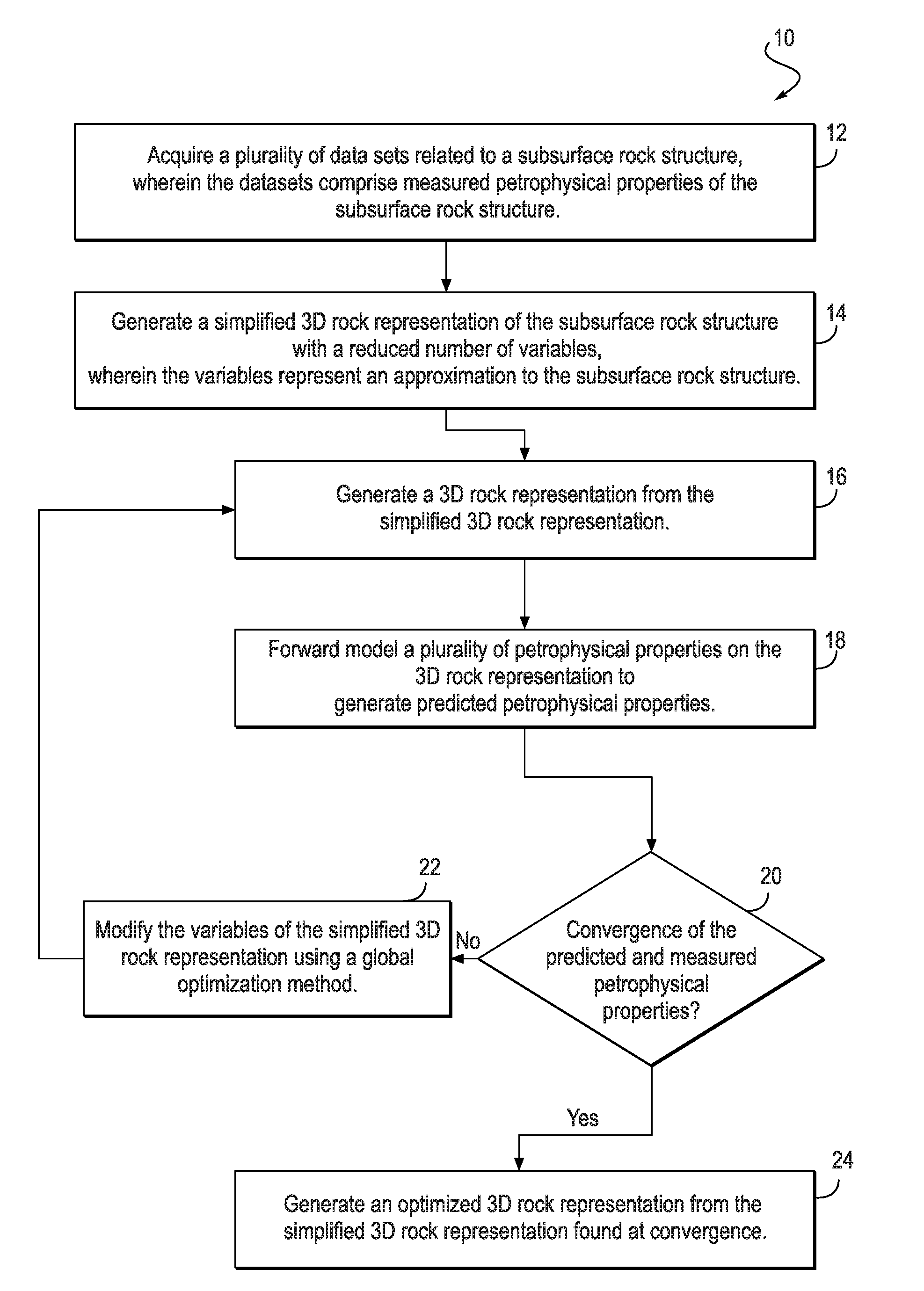

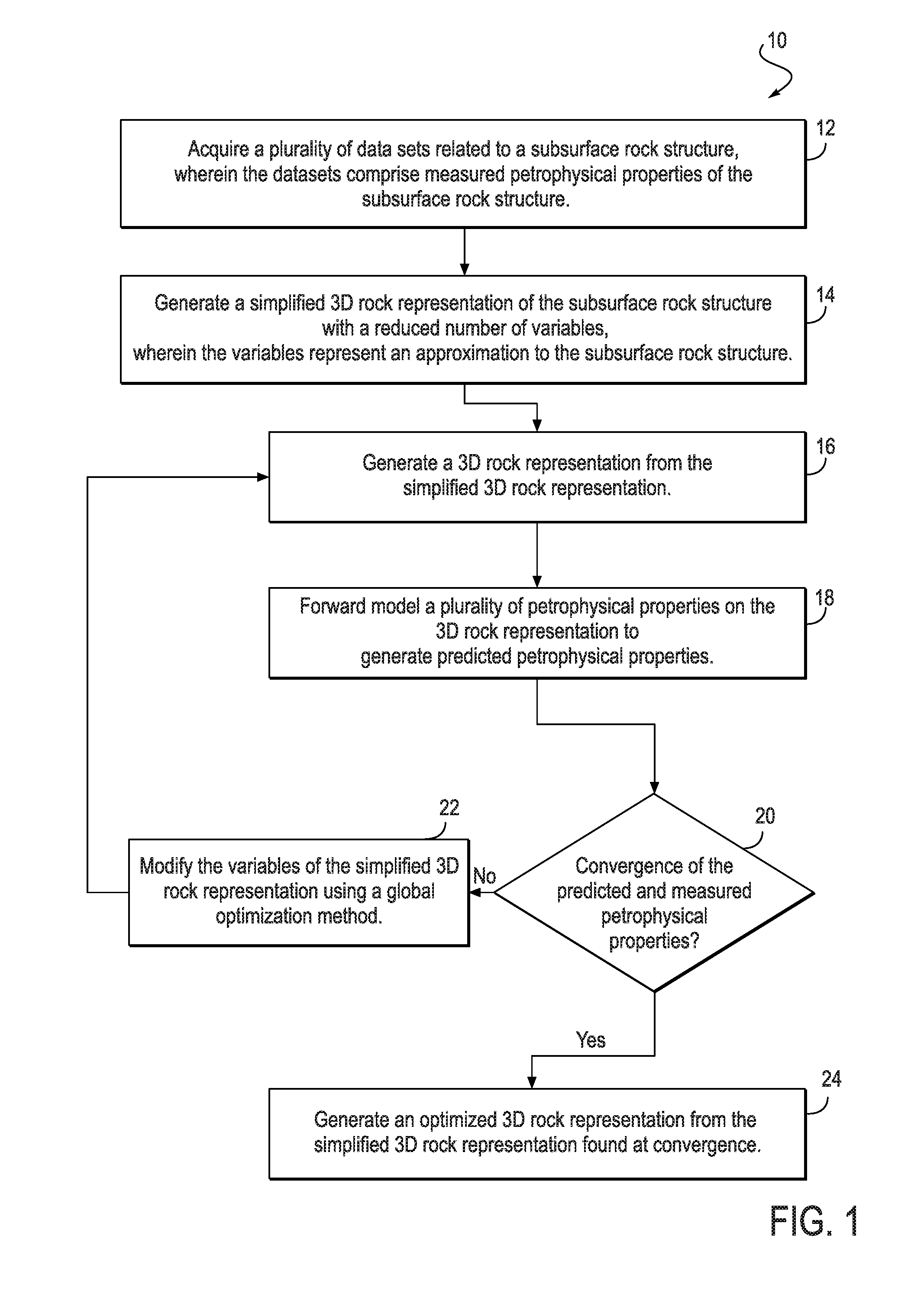

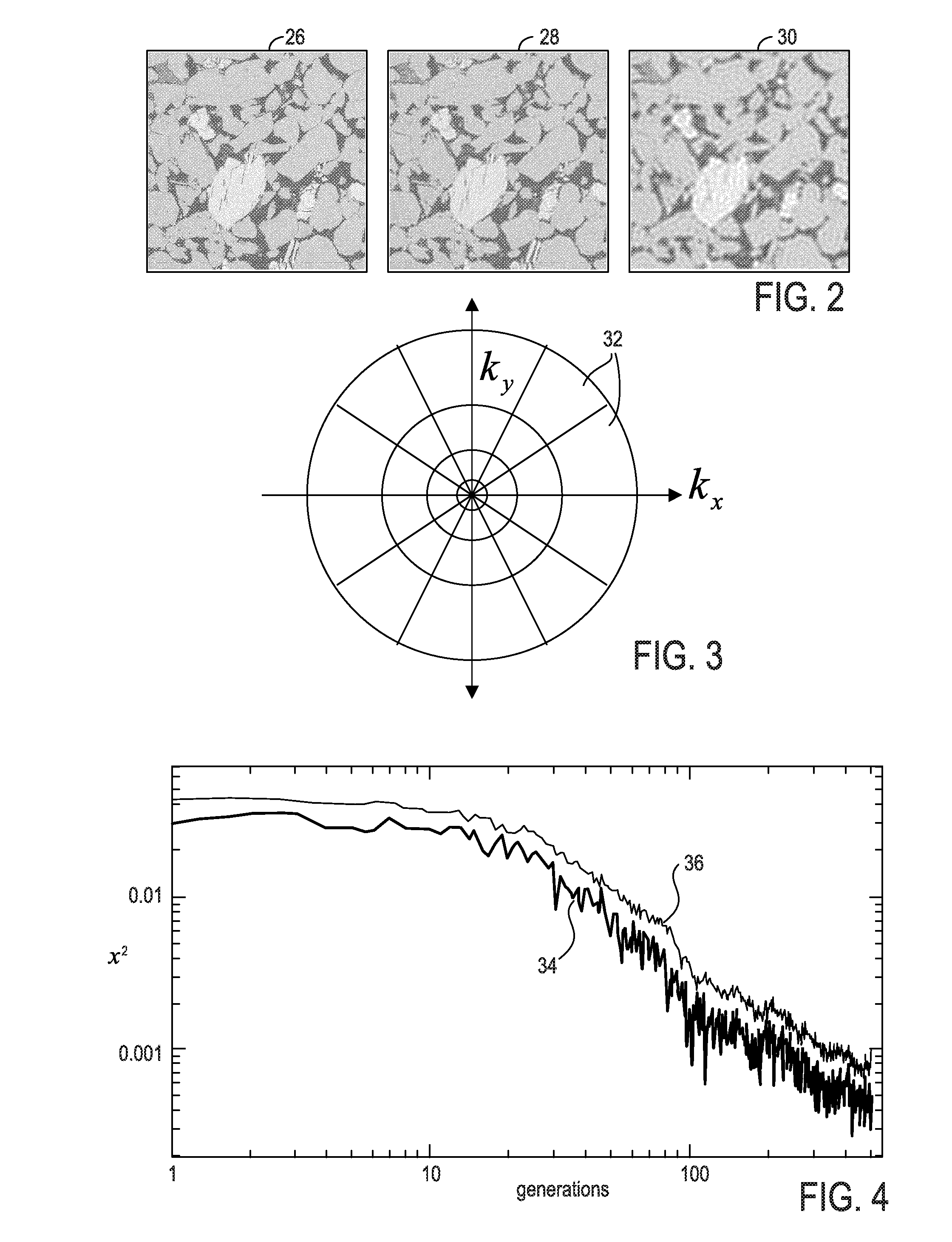

Method for creating a 3D rock representation using petrophysical data

The present invention enables the use of a global optimization method for performing joint-inversion of multiple petrophysical data sets, using forward models based on first principle of physics, to generate a 3D rock representation of a subsurface rock structure. The resulting 3D rock representation captures the internal structure, and honors the measured petrophysical properties, of the subsurface rock structure. The 3D rock representation can then be used to predict additional properties not considered in the inversion, to further characterize the subsurface rock structure.

Owner:CHEVROU USA INC

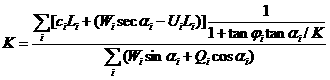

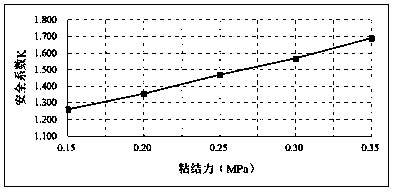

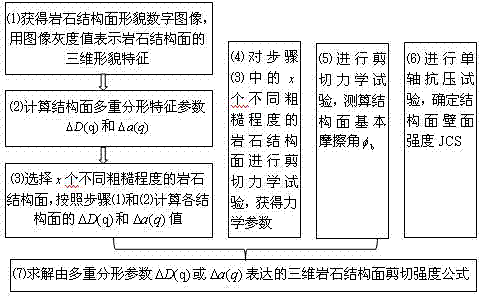

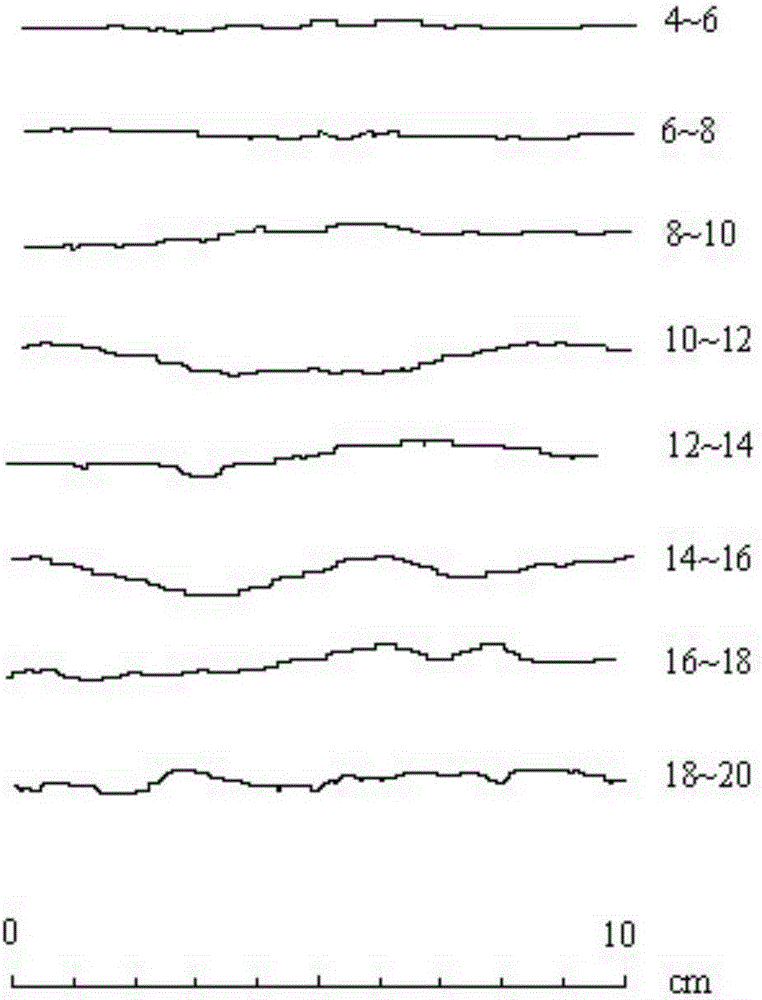

Multi-fractal evaluation method for three-dimensional rock structure surface shear mechanical behavior

InactiveCN103926156ABig subjectivityOvercome the pitfalls of artificial valuationMaterial strength using steady shearing forcesClassical mechanicsStructural engineering

The invention provides a three-dimensional rock structure surface shear strength evaluation method. The method comprises the following steps of (1) acquiring three-dimensional topography data of a rock structure surface; (2) calculating multi-fractal characteristic parameters delta D (q) and delta a (q) of the structure surface according to a multi-fractal calculation formula, and representing the roughness of the three-dimensional rock structure surface by using the delta D (q) and the delta a (q); (3) carrying out a shear mechanics test on the rock structure surfaces with different roughness degrees to obtain shear mechanics parameters, and calculating the values of the delta D (q) and the delta a (q) of all the structure surfaces according to the step (1) and the step (2); and (4) testing a Barton shear formula improved by calculation data fitting by the step (3) to obtain the three-dimensional rock structure surface shear strength formula expressed by the delta D (q) or the delta a (q). Therefore, the rock structure surface shear strength can be evaluated by the three-dimensional rock structure surface shear strength formula in the engineering practice. The formula overcomes the defect that the Barton formula only considers about the two-dimensional characteristic and artificial estimation of joint roughness coefficient (JRC) of the structure surface, so that a method for comprehensively evaluating the shear strength characteristic of the rock structure surface is provided.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

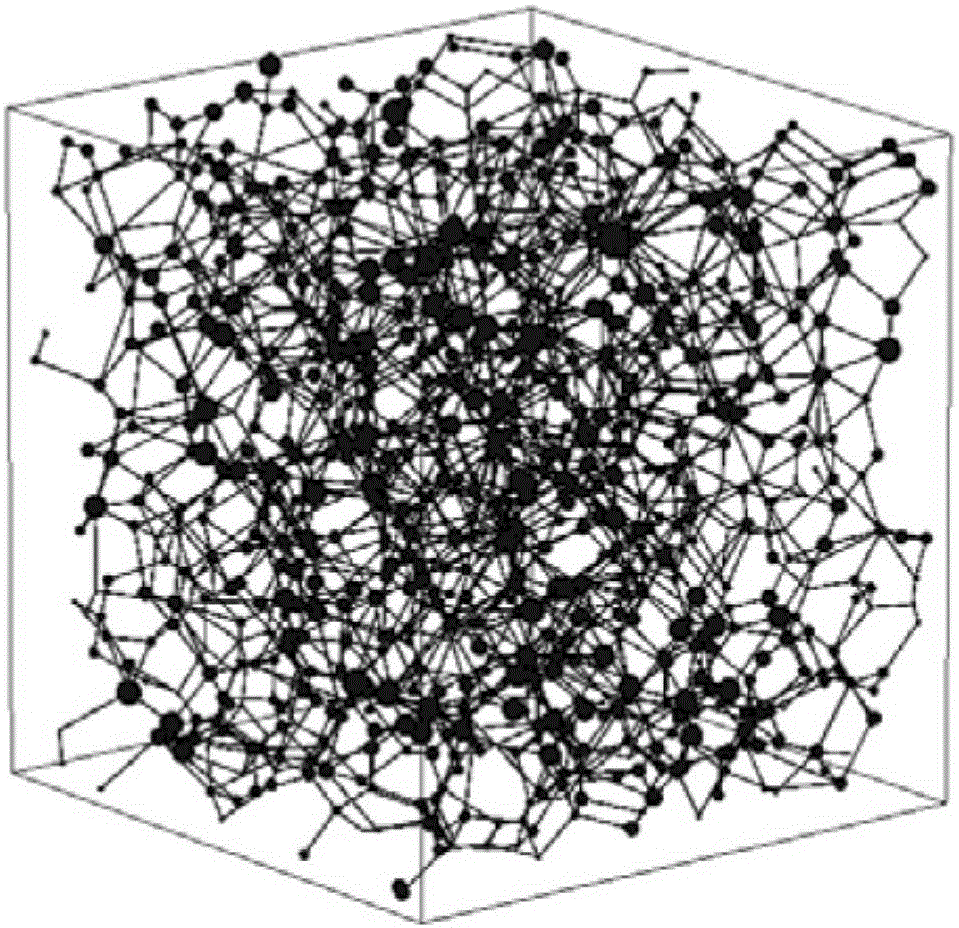

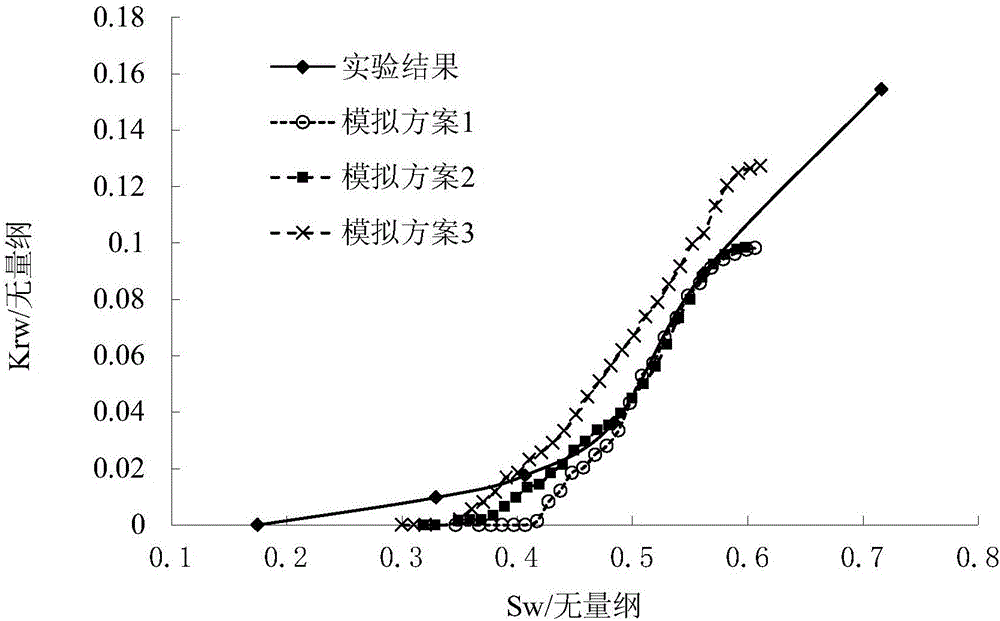

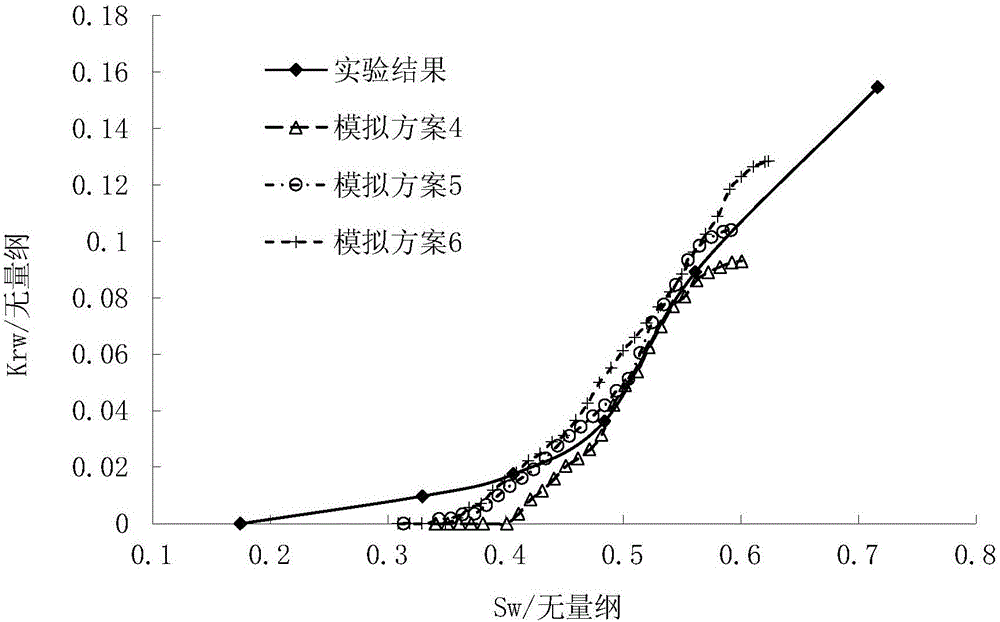

Pore network model-based calculation method of three-phase relative permeability

InactiveCN105021506AReproduce the physical process of flowPermeability/surface area analysisExperimental methodsRock core

The invention relates to a pore network model-based calculation method of three-phase relative permeability. Based on the construction of a pore network model, an underground rock pore structure is reproduced, and under the condition of coexisting of oil-gas-water three phases inside the rock core, flow of fluids is simulated to obtain three-phase relative permeability. By the utilization of an orthogonal design method during the process, design parameters which fit the best with a two-phase relative permeability curve obtained by an experimental method are selected so as to simulate three-phase flowing based on the pore network model. According to the invention, fluid physical properties and rock structure parameters are fully considered, and the physical process of fluids flowing in a porous medium can be well reproduced. Two-phase flow is very easy to realize by a physical experimental method, and the constructed pore network model is greatly screened during the process of matching results of the two-phase flow experiment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

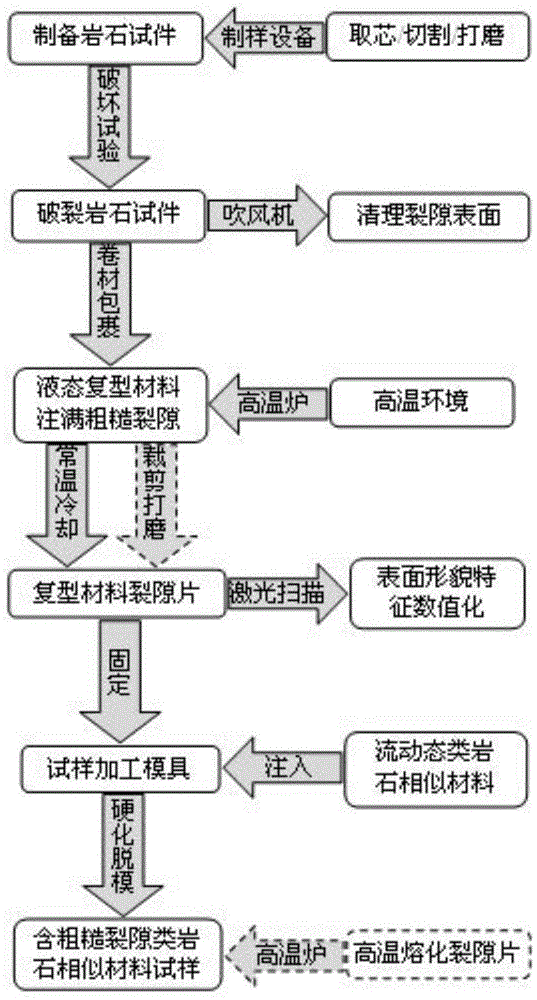

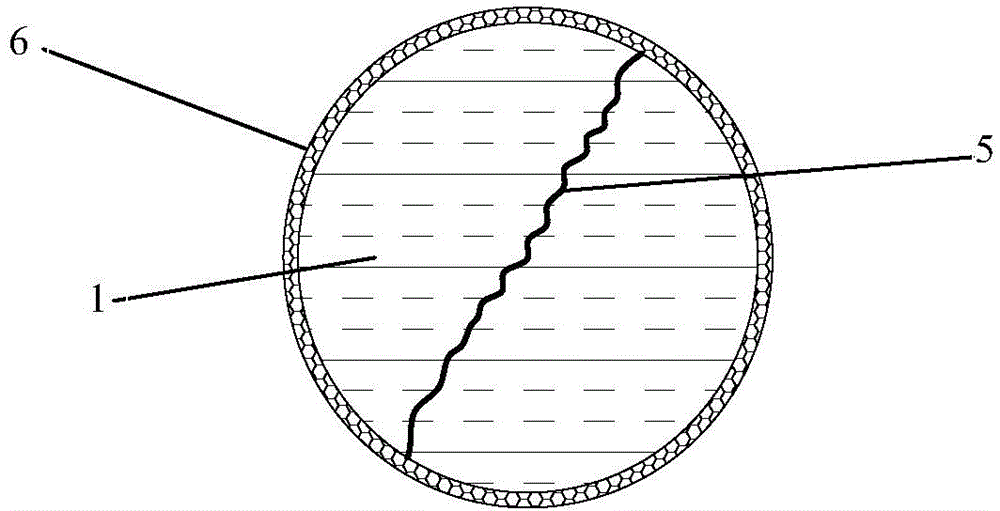

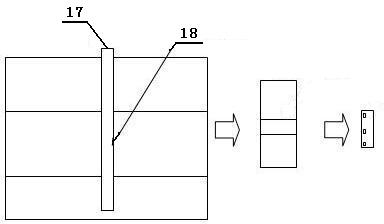

Method for prefabricating rough fractures in rocklike similar material specimen

ActiveCN104865110AAccurately reproduce the stretchAccurate reproduction of propertiesPreparing sample for investigationExperimental methodsStructure of the Earth

The invention relates to a method for prefabricating rough fractures in a rocklike similar material specimen and belongs to experimental methods of rock mechanics. The method comprises the following concrete steps: processing a rock specimen, and carrying out a destruction test with a testing machine, so as to obtain a fractured rock specimen containing a single rough through fracture; then, wrapping the fractured rock specimen with a flexible high-temperature-resistant coil, filling the rough fracture with liquid compound materials at high temperature, and naturally cooling; removing the flexible high-temperature-resisting coil, so as to obtain a compound material fracture piece; digitizing the surface appearance characteristic of the compound material fracture piece with a three-dimensional laser scanner; fixing the compound material fracture piece into a specimen processing mould, and then pouring flowable rocklike similar materials; after a similar material specimen is hardened, demoulding and heating so as to enable the compound material fracture piece to be melted to flow out; cooling, so as to obtain the rocklike material specimen containing rough joints. The method has the characteristics of being simple in process, low in cost, good in repeatability and high in precision and has a wide application prospect in a physical and mechanical property test of rock structure planes.

Owner:CHINA UNIV OF MINING & TECH

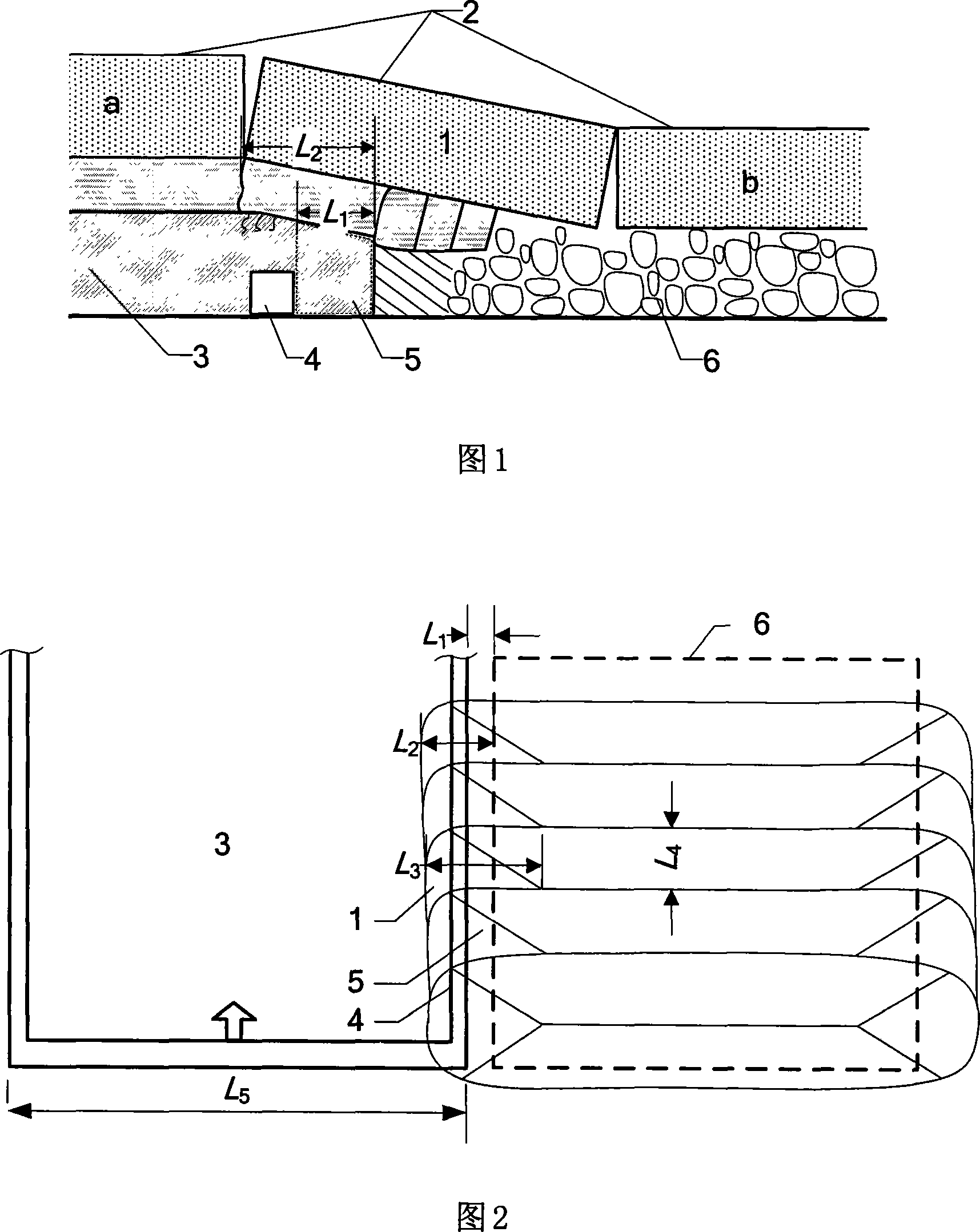

Method for controlling wall rock of fully mechanized coal face goaf side coalbed laneway

A method for controlling the surrounding rock of the side coal seam roadway in the goaf of the fully-mechanized caving face. According to the geology of the fully-mechanized caving face measured on site and the mine pressure data of the adjacent mining face, the stability of the large structure of the overlying rock mass on the roadway is analyzed. Determine the width of the narrow coal pillar reserved on the side of the goaf, so that the roadway is located in the area of relatively low vertical stress in the coal body, and the high-performance bolt support that controls the surrounding rock of the roadway forms a small load-bearing structure in the surrounding rock in the anchorage area . The small structure can make full use of the surrounding rock's own bearing capacity, and has strong adaptability to the deformation of the surrounding rock, ensuring smooth roadway support without repair, low bolt support cost, fast speed, and low labor intensity; it is compatible with large coal pillar roadway protection Compared with the narrow coal pillar protection roadway, the method reduces the loss of coal resources, improves the recovery rate of fully mechanized caving mining, and has good economic and social benefits.

Owner:CHINA UNIV OF MINING & TECH

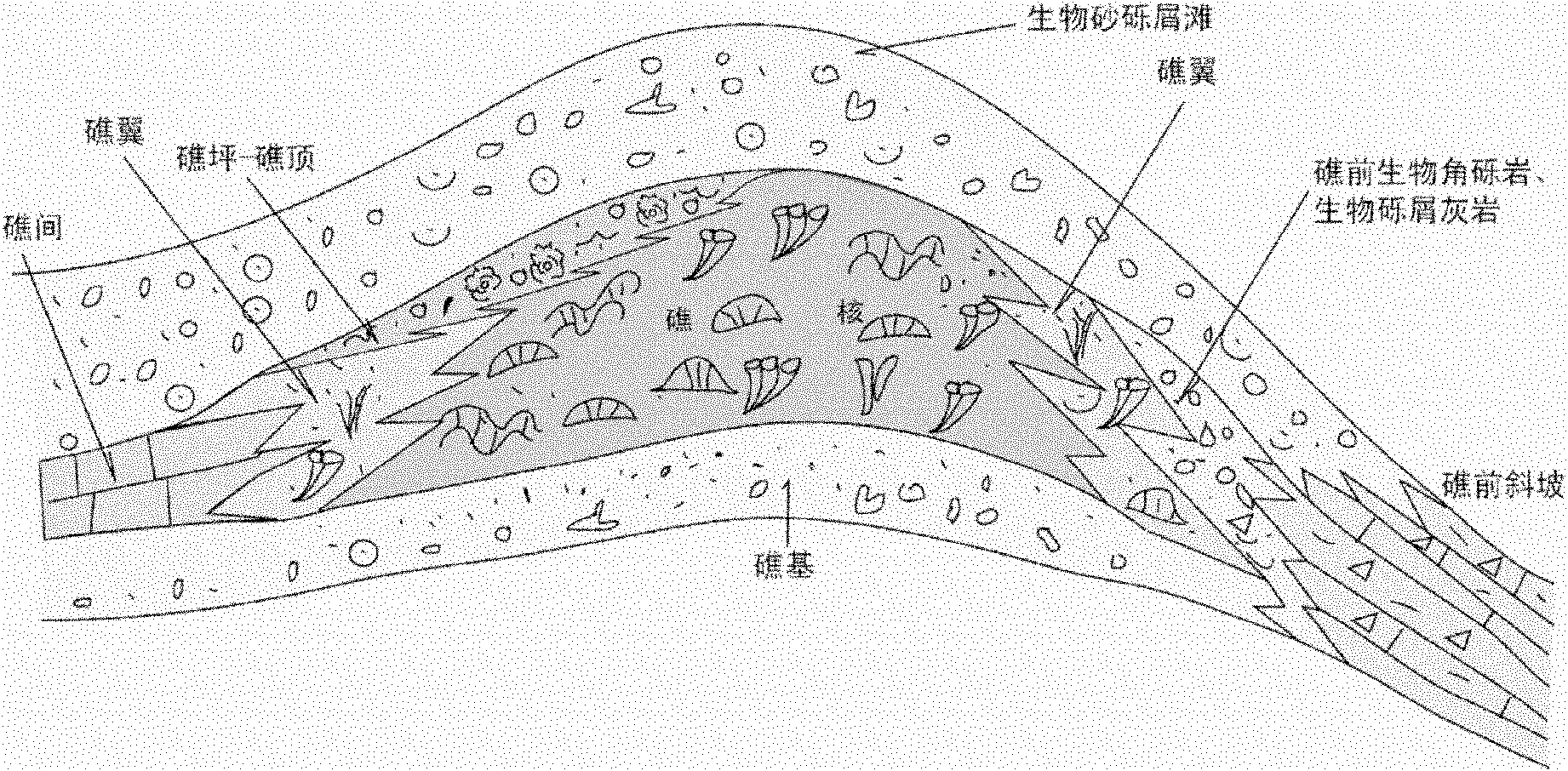

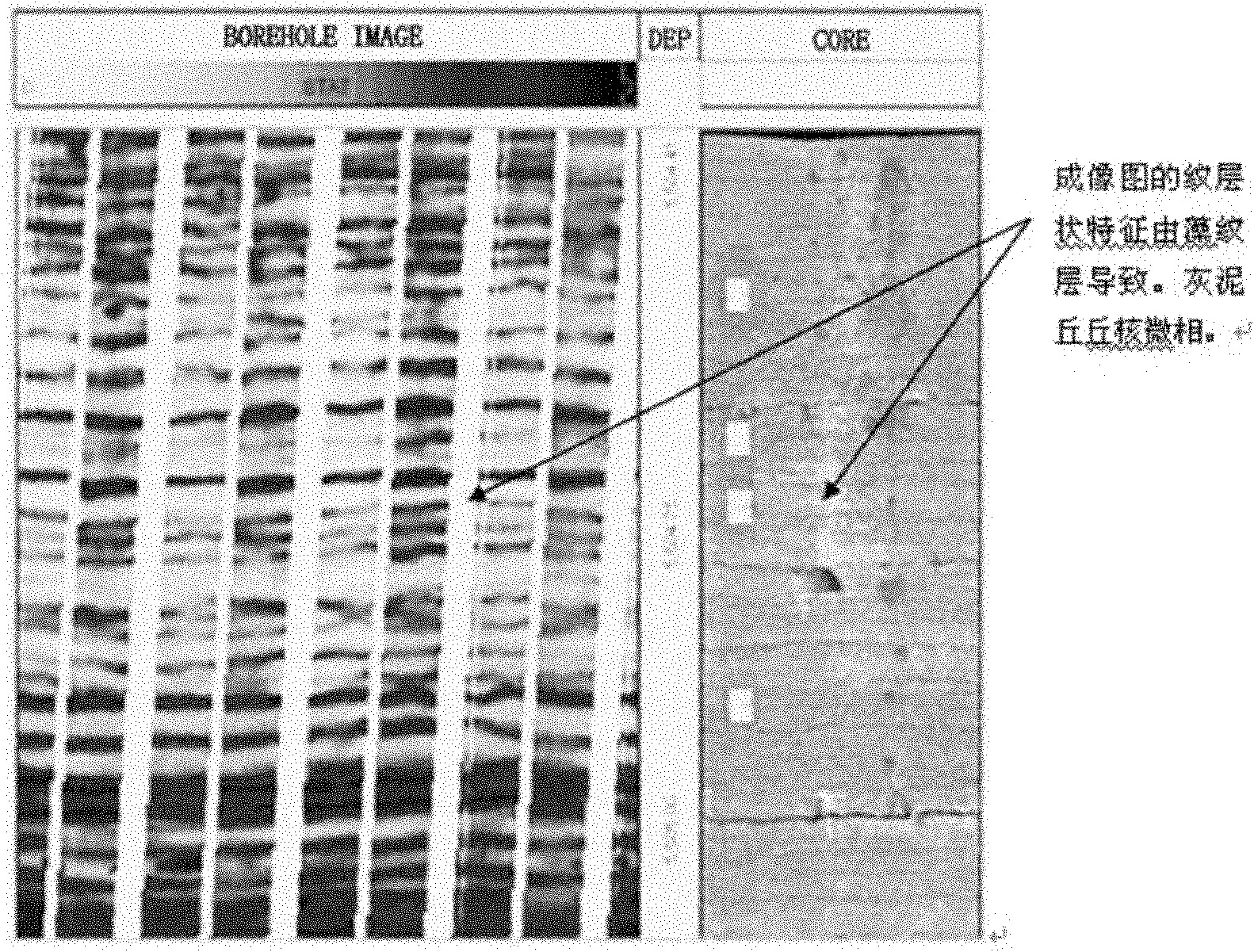

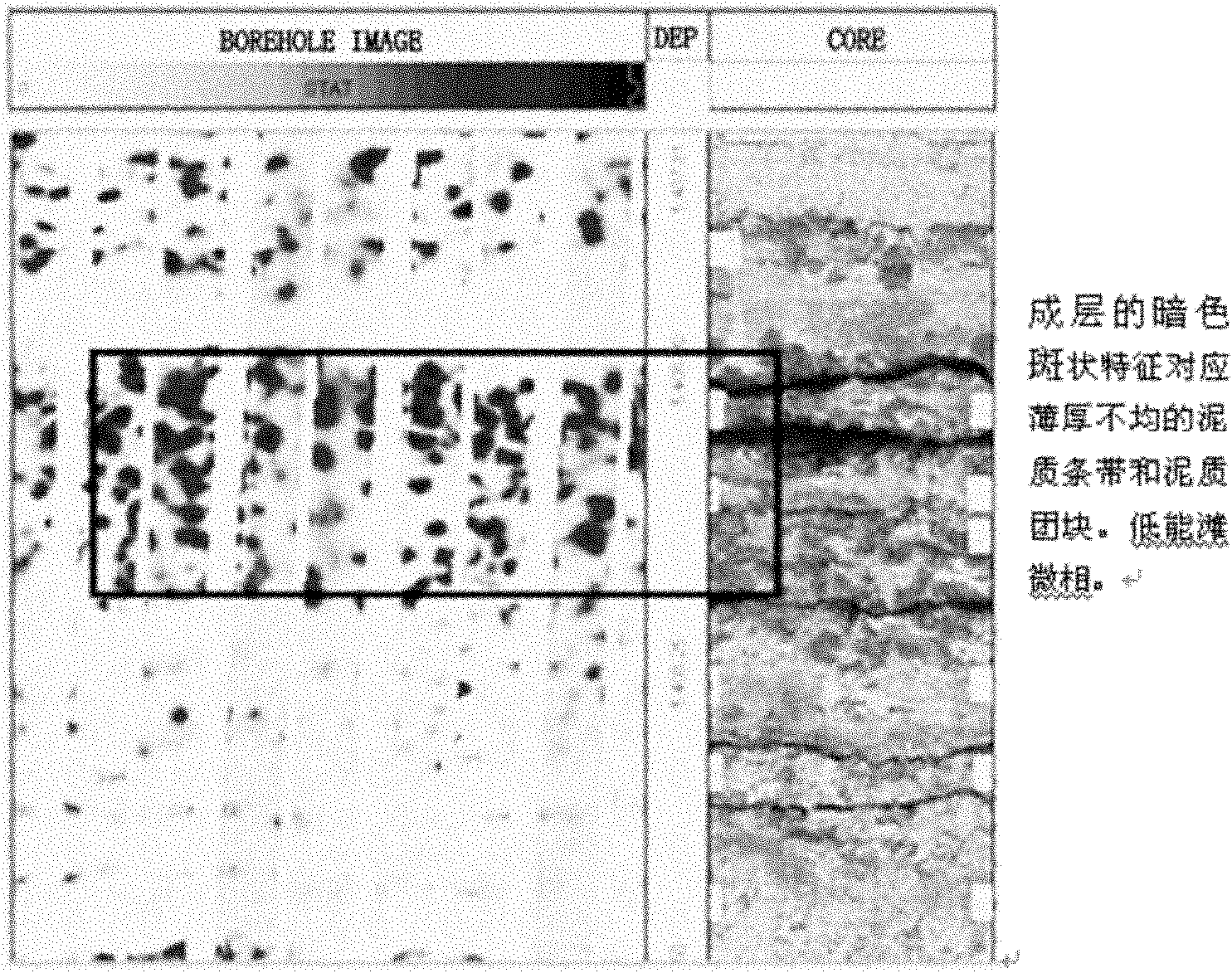

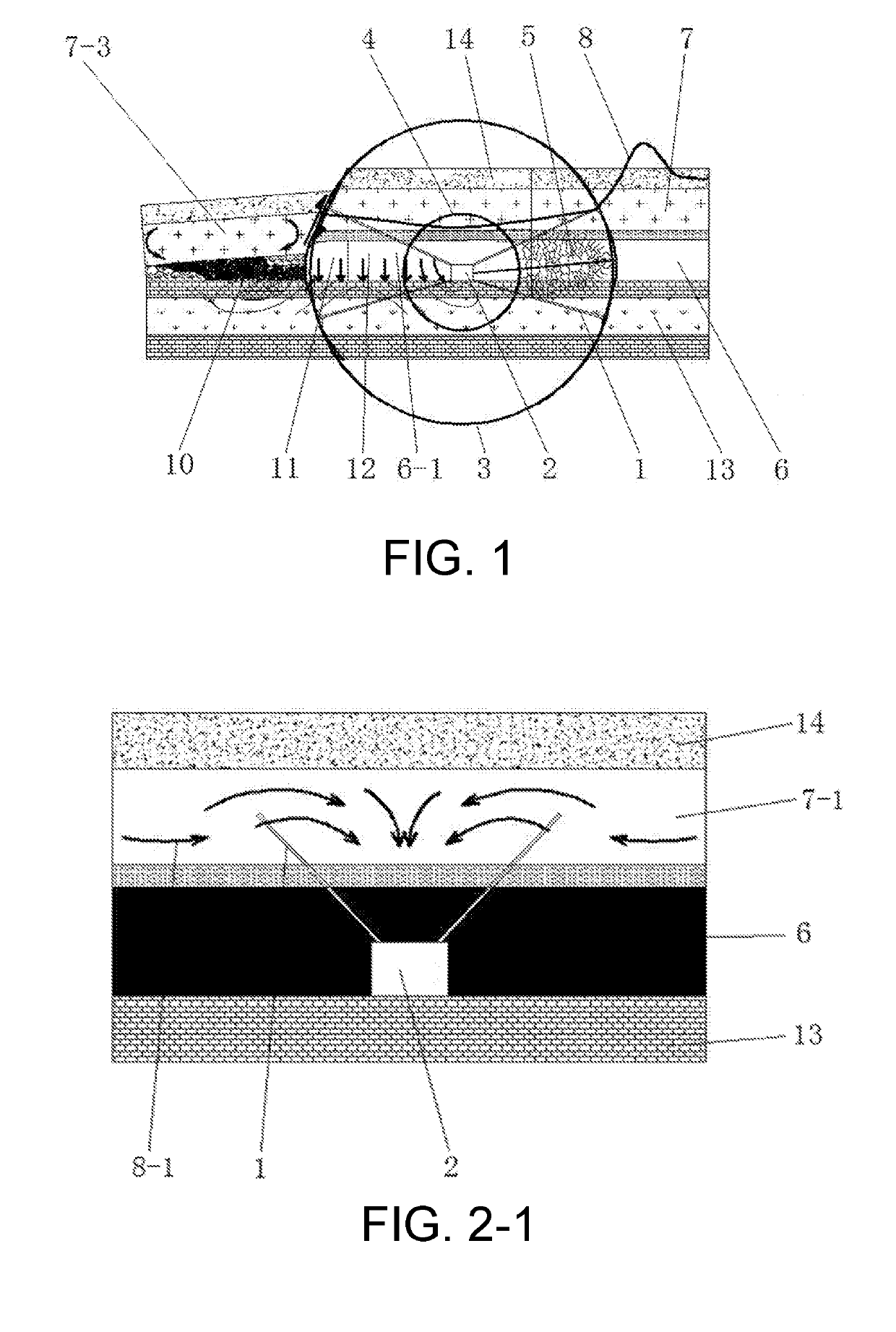

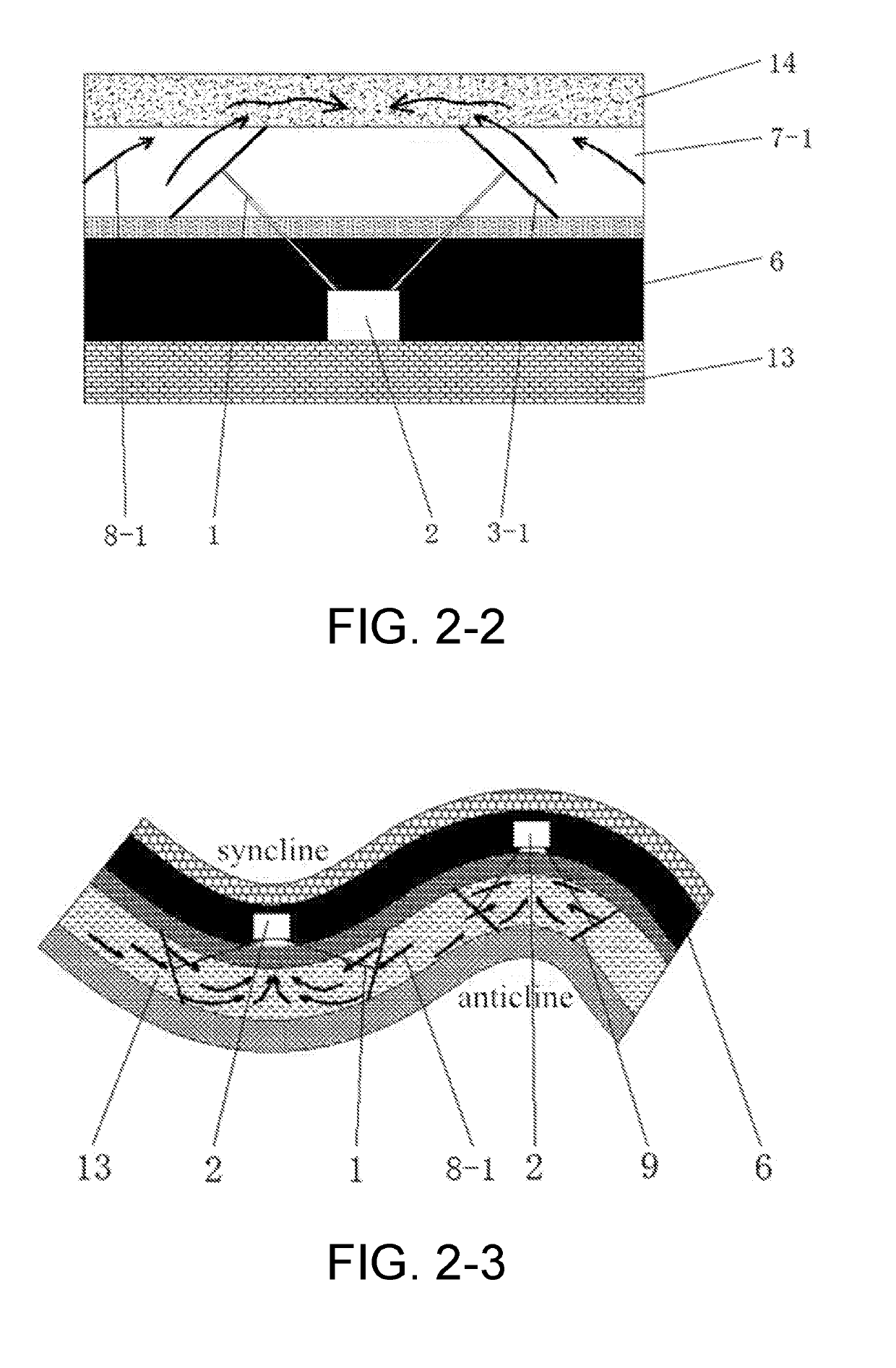

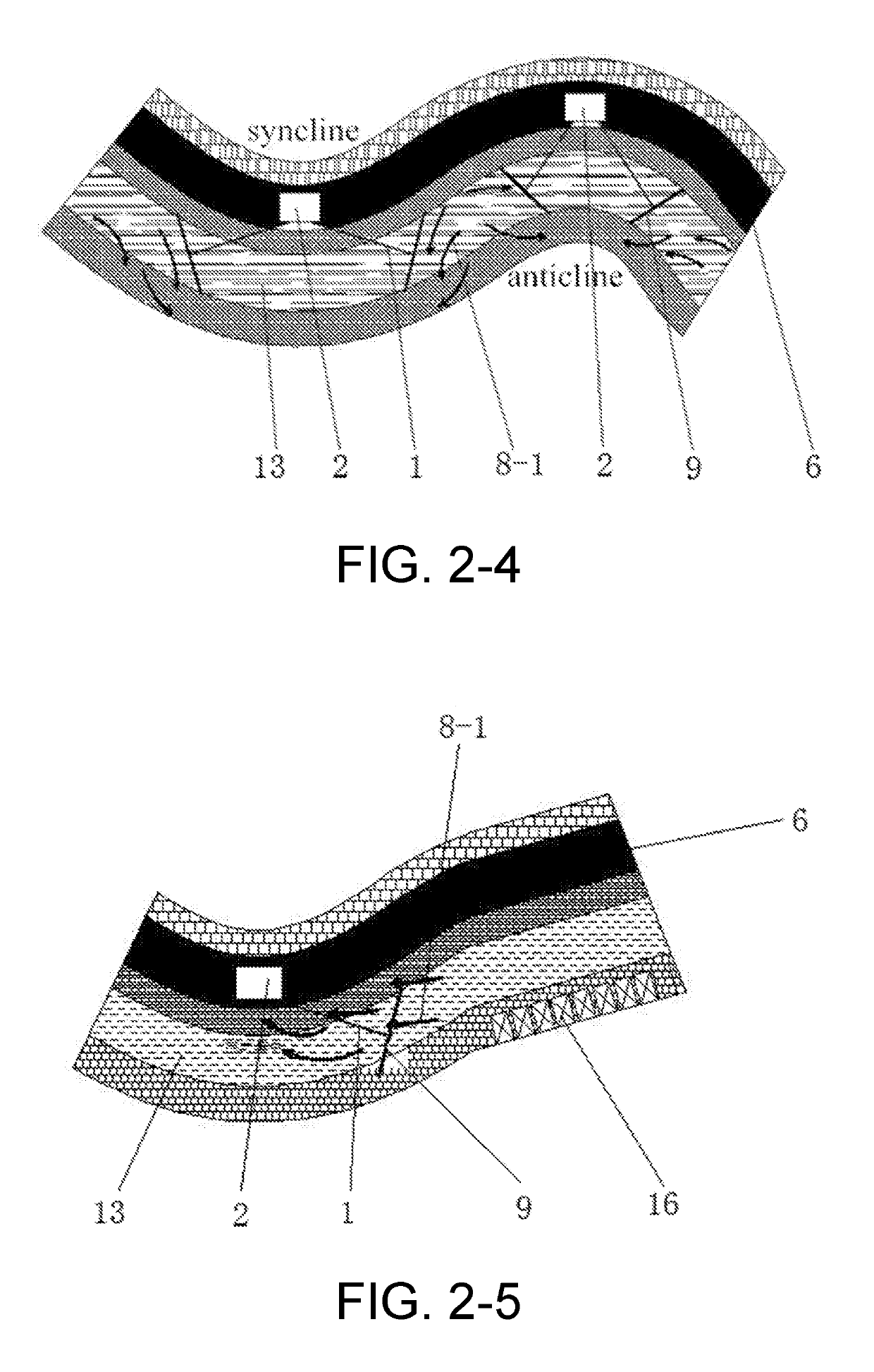

Method for identifying reservoir by combining electrical imaging and reef geologic model

ActiveCN102011583AImprove live interpretationHigh compliance rateCharacter and pattern recognitionBorehole/well accessoriesElectricityWell logging

The invention discloses a method for identifying a reservoir by combining electrical imaging and a reef geologic model, and belongs to the technical field of marine carbonatite well logging interpretation. The method comprises the following steps of: selecting a carbonatite reef reservoir sedimentary facies model according to a reef reservoir sedimentation model; establishing the correspondence between the reef reservoir sedimentation model and an electrical imaging well logging image characteristic based on an electrical imaging well logging image; establishing an electrical imaging image library of a standard reservoir of the carbonatite reef reservoir; performing rock structure characteristic-based image dynamic enhancement contrast according to images in the electrical imaging image library; and determining a part of a reef phase reservoir, through which a well runs, based on a typical image of an electrical imaging reef phase, and comparing with a typical image of a favorable reservoir to determine the quality of the reservoir. The method greatly improves the coincidence rate of well on-site interpretation and test oil, and is fully applied to various related oil fields in China.

Owner:PETROCHINA CO LTD

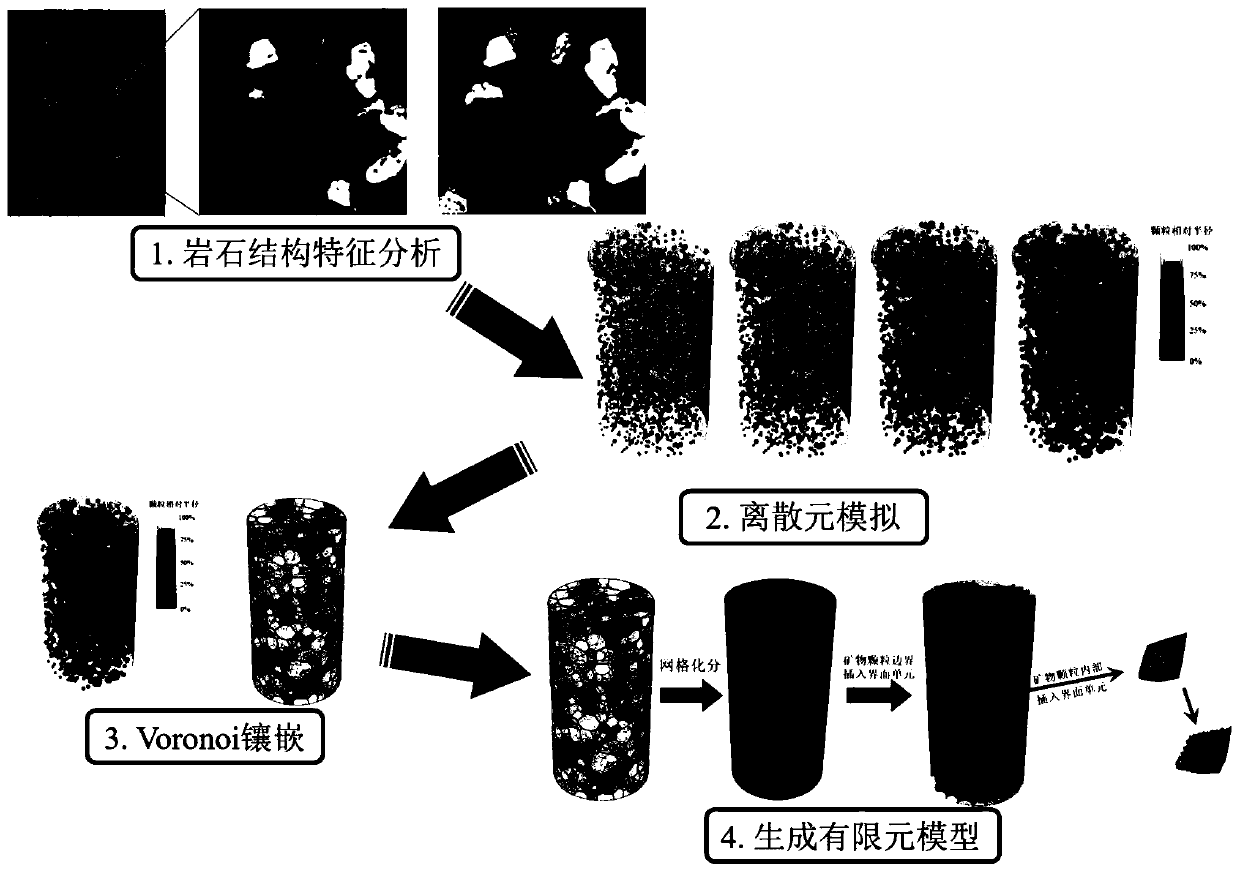

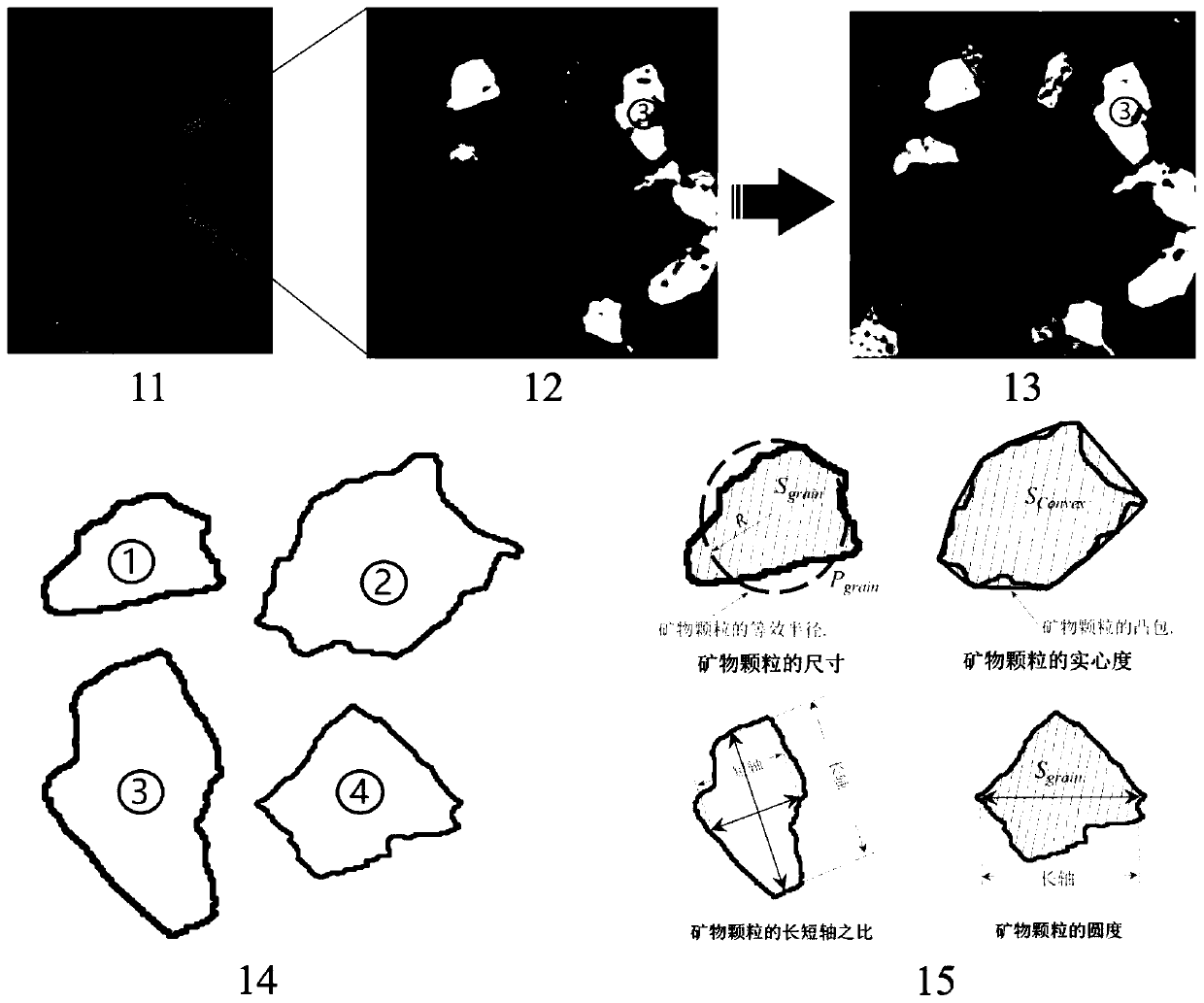

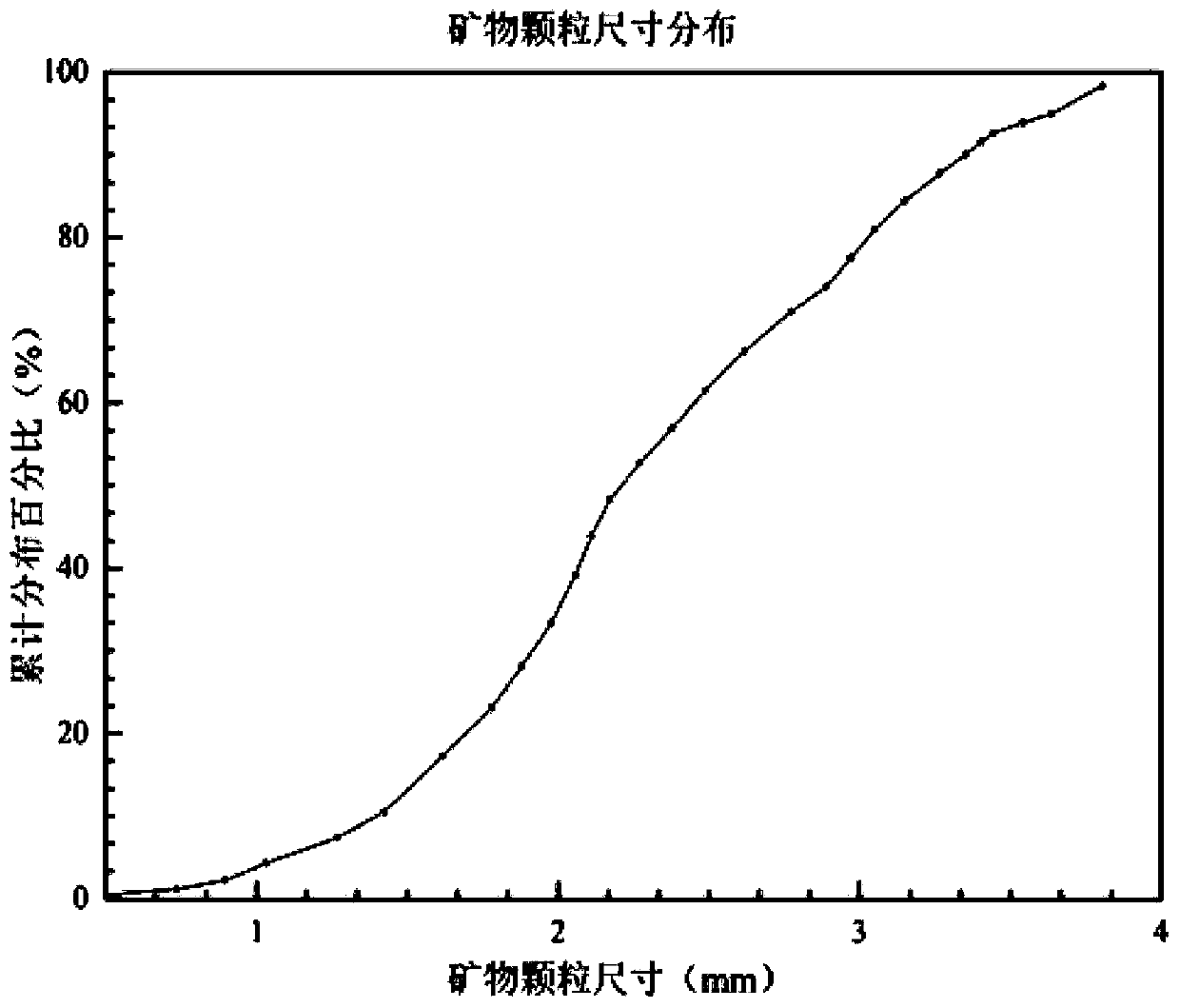

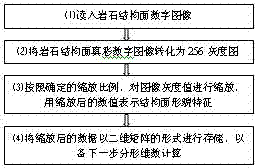

Microscomic numerical model generation method considering rock structure characteristics and mineral composition

ActiveCN110069844ASimulation is accurateImprove computing efficiencyDesign optimisation/simulationSpecial data processing applicationsFree interfaceMineral particles

The invention discloses a microscomic numerical model generation method considering rock structure characteristics and mineral composition. Microscopic structure characteristics and mineral composition of rock can be considered, a microscopic numerical model reflecting the rock structure characteristics and the mineral composition is established, and rock mechanics numerical simulation can be carried out more truly. The method comprises the following steps: carrying out rock structure characteristic analysis on a rock sample to obtain the size, form, mineral type and other information of mineral particles; simplifying the mineral particles with irregular shapes into balls with reduced sizes, and rearranging the particles by adopting a particle size expansion method, and obtaining a compact structure; secondly, extracting information such as spatial positions and sizes of particles, and performing Voronoi graph-based spatial region division on the particle assembly; and finally, performing finite element mesh division on the obtained Voronoi polycrystal structure, and inserting thickness-free interface units into mineral particle boundaries and the interiors of particles to generate a finite element numerical model capable of reflecting a rock structure and a lithofacies structure.

Owner:WUHAN UNIV

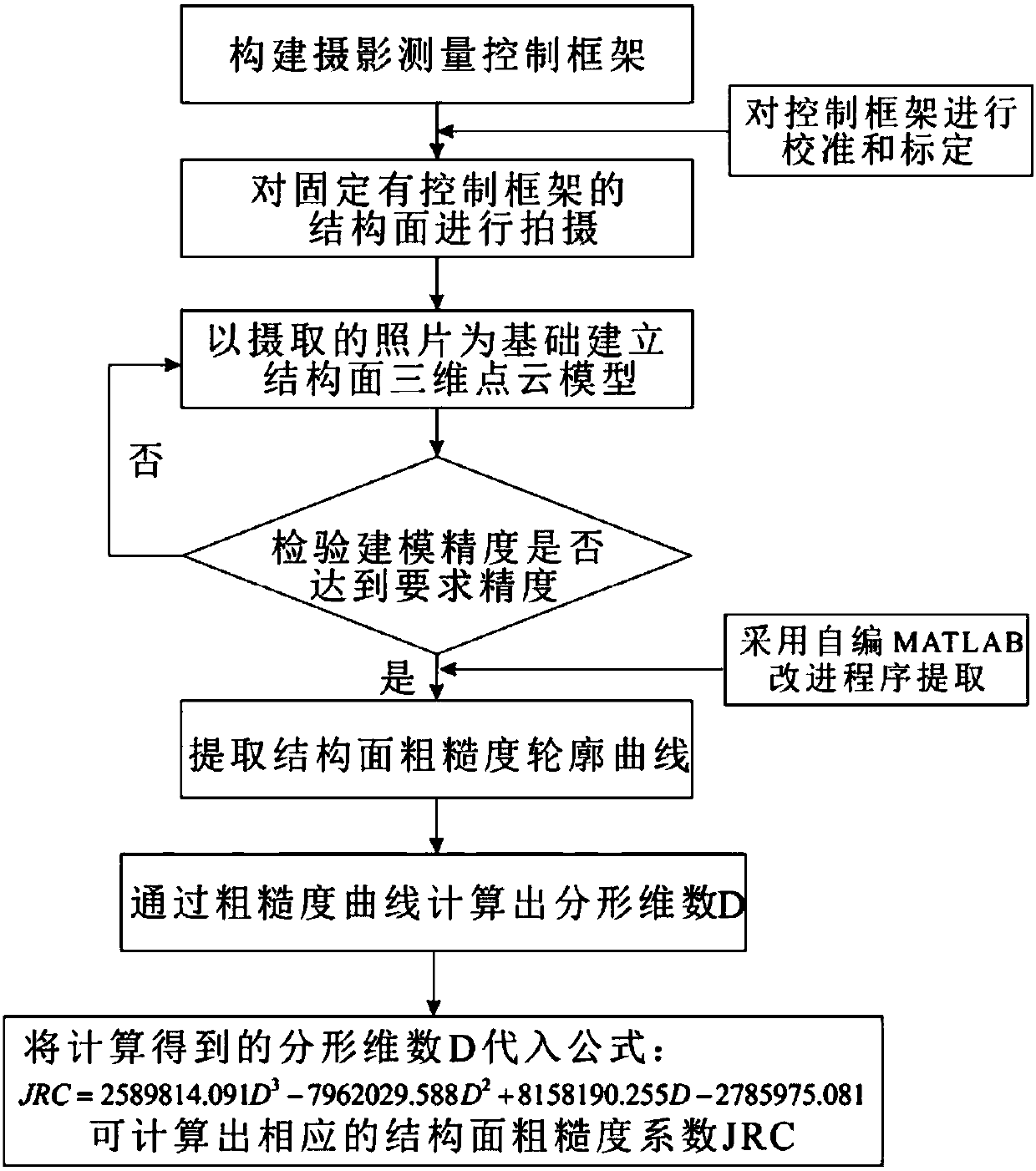

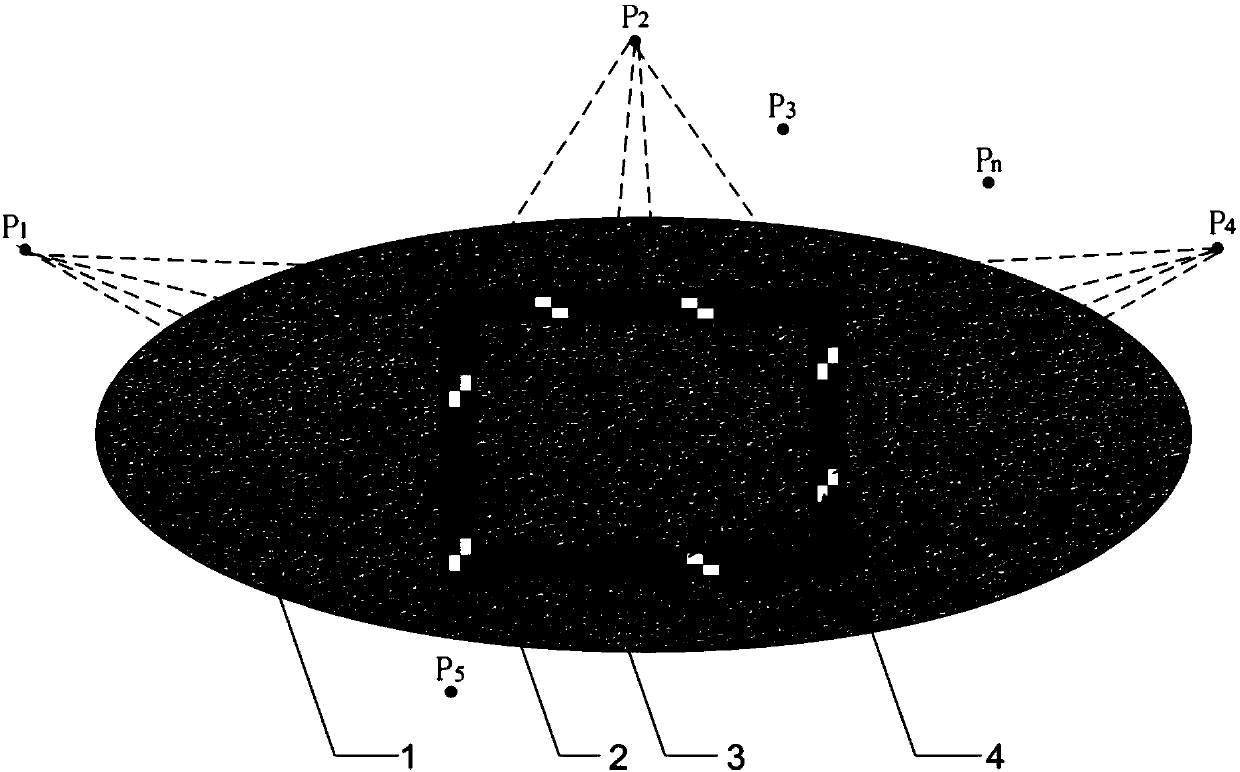

Method for measuring and calculating roughness of field rock structural plane

ActiveCN107655459AReduce biasImprove computing efficiencyPicture interpretationPoint cloudClassical mechanics

The invention discloses a method for measuring and calculating roughness of a field rock structural plane. The method comprises the following steps: constructing a closed control frame by straight battens, and aligning the control frame; fixing the aligned control frame on a to-be-measured structural plane, and photographing different positions of the to-be-measured structural plane, wherein the photographing range comprises the whole frame; establishing a three-dimensional point cloud model of the field rock structural plane by pictures; extracting a roughness profile curve in any direction of the structural plane by the three-dimensional point cloud model; calculating the roughness fractal dimension of the structural plane by the roughness profile curve of the structural plane; and calculating the corresponding roughness coefficient of the rock structural plane by the fractal dimension of the roughness of the rock structural plane. By the method, the calculation precision and efficiency are improved; and meanwhile, the method is suitable for indoor and field environments.

Owner:NANJING UNIV OF SCI & TECH

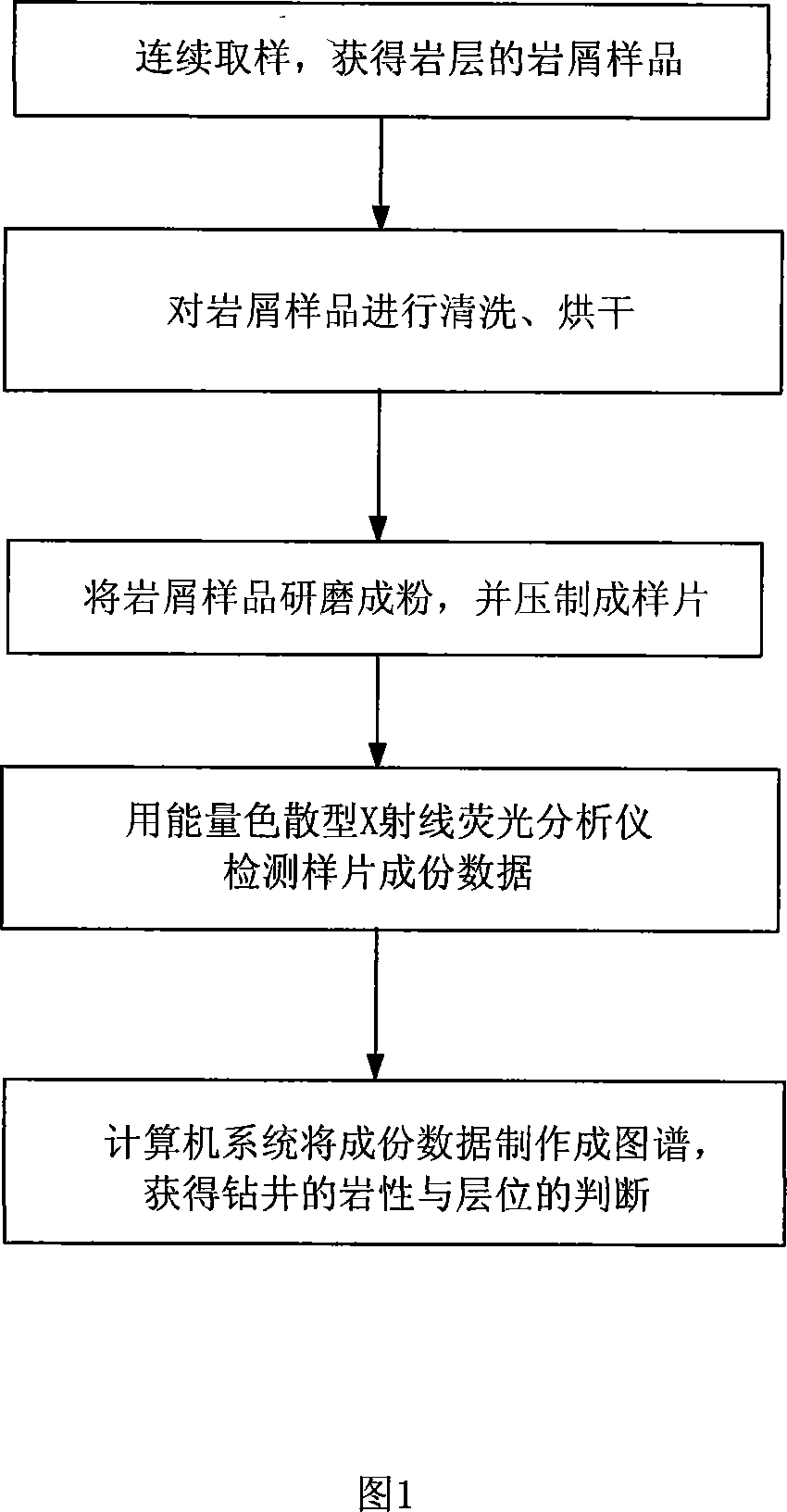

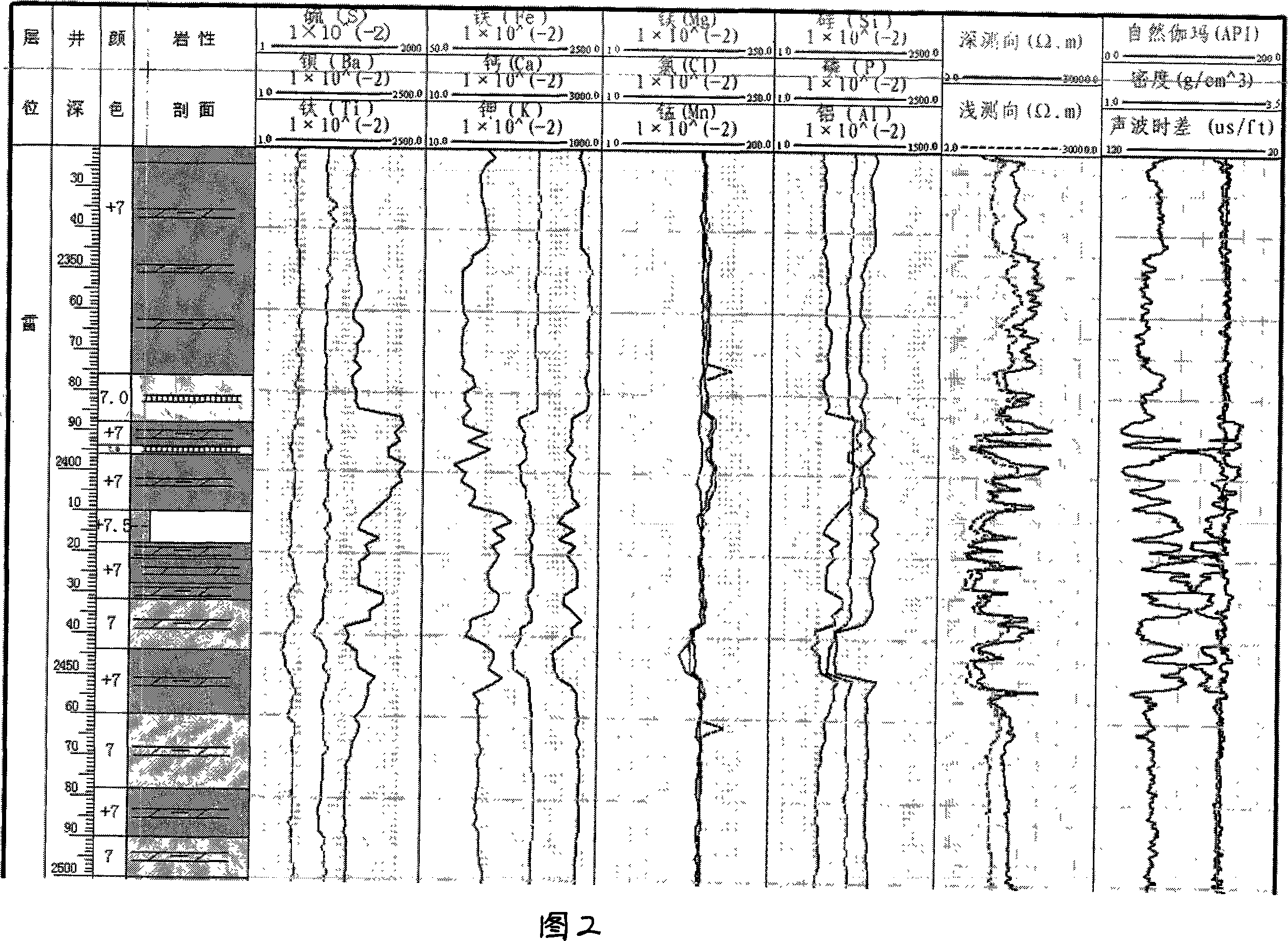

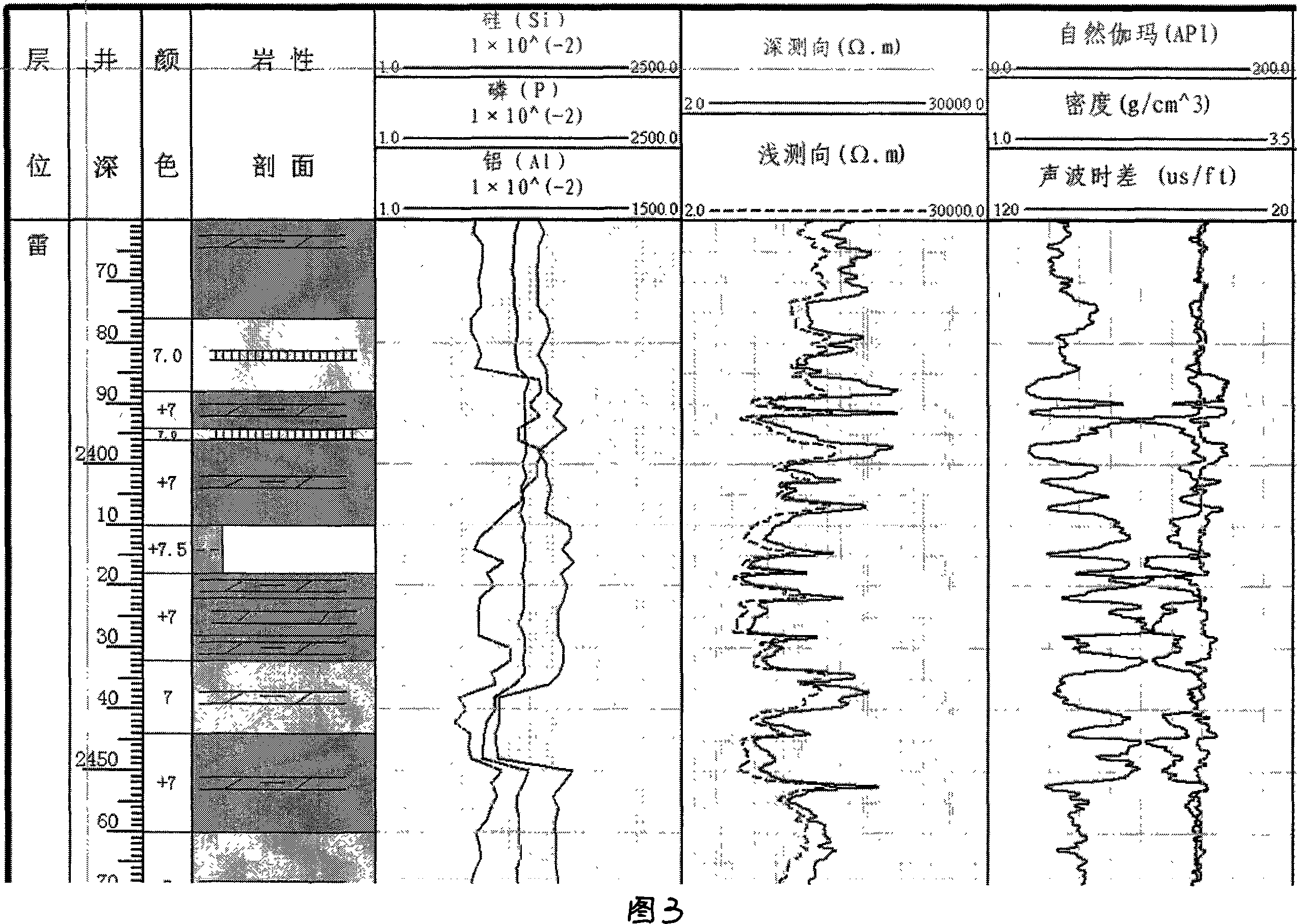

Oil well drilling geological X-ray fluorescent debris logging method

InactiveCN101082277AReduce testing costsGuaranteed accuracyBorehole/well accessoriesLithologyHorizon

An X-ray fluorescence debris recording method of oil drilling geology is characterized in that: it contains the following steps: 1. sample from shallow to deep continuously on the drilling depth to get the debris samples of each drilling depth rock formation. 2. Clear the debris samples of each drilling depth rock formation on the drilling depth and dry these debris samples. 3. Grind the debris samples to powder and put them into the pressing die. Press the powder to print by using the tablemachine under the vacuum. 4. Test the component data of the print sequentially by using the energy dispersing-type X-ray fluorescence analyzer on the drilling depth. 5. The computer system makes the rock component data to the atlas on the drilling depth. Based on the analysis of the data and the atlas, the decision of the drilling lithologic characters and horizon is achieved. The distinct effects of this invention are: the cheap price, the low testing cost, the shorter analysis cyclic, the rock structure can be achieved simultaneously as the drilling speed.

Owner:重庆奥能瑞科石油技术有限责任公司

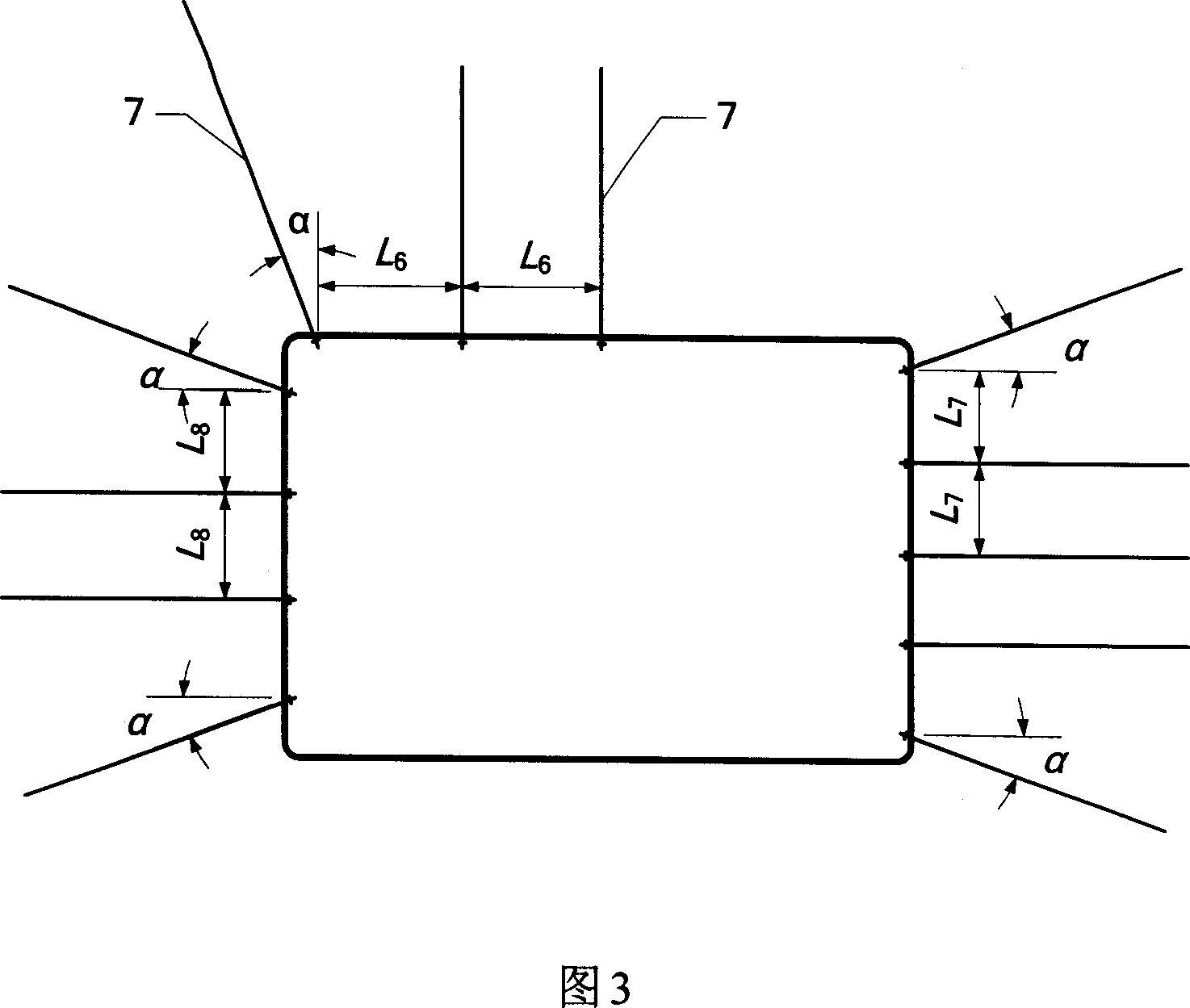

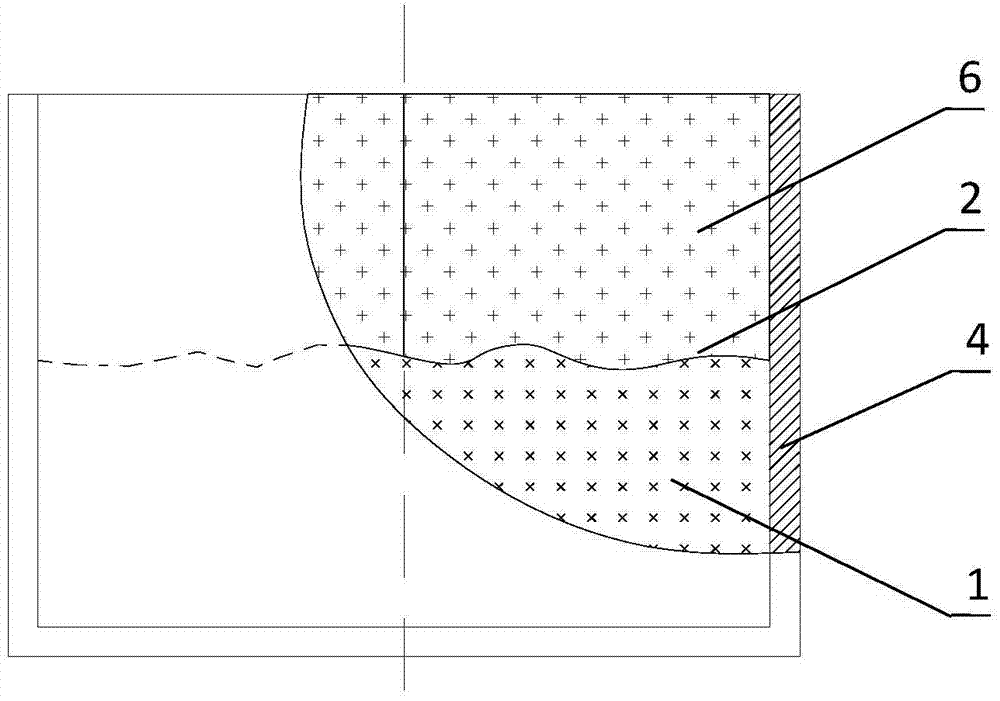

Stress-transfer method in tunnel with high ground pressure based on fracturing ring

ActiveUS20190316454A1Relieve pressureLow rangeMining devicesUnderground miningGeomorphologyStress conditions

A stress-transfer method in tunnel with high ground pressure based on fracturing ring. According to the stress source of the tunnel, fracturing by drilling holes to form artificial weaken zones in surrounding rocks, that's named fracturing ring. The fracturing ring is the weaken zone with some width, whose inner boundary is the protective circle. The fracturing ring with small width is called the cutting and interruption circle and the cutting or interruption arc. The radius of the protective circle is determined by setting a certain width of safety coal pillar barriers at the edge of a support body. The radius of the fracturing ring is determined by the surrounding rock structure and the stress conditions as well as the construction technology. Usually, the higher the stress, the wider the radius of the fracturing ring. The cutting and interruption circle or arc could cut off all of the targeted rock which transmits the stress.

Owner:CHINA UNIV OF MINING & TECH +1

Method for fabricating coupling shear specimen containing natural structure surface

InactiveCN104764643APrecise formEnsure full couplingPreparing sample for investigationComputer printingStructural engineering

The invention discloses a method for fabricating a coupling shear specimen containing a natural structure surface, and belongs to the field of rock structure surface test research. The method comprises the following steps of scanning a natural surface of a rock body employing a three-dimensional white-light scanning instrument to obtain point cloud data of the natural structure surface; fabricating a virtual three-dimensional model containing the natural structure surface from the obtained point cloud data employing inverse engineering software; printing an entity die from the generated virtual three-dimensional model through a 3D printer, then putting the printed die into a standard cast iron test die and carrying out shearing specimen fabrication. The method can be used for repeatedly fabricating the coupling shear specimens which are completely consistent in form and contain natural structure surfaces, and is of great significance in research of the shear destruction mechanism of the natural structure surface of the rock body.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

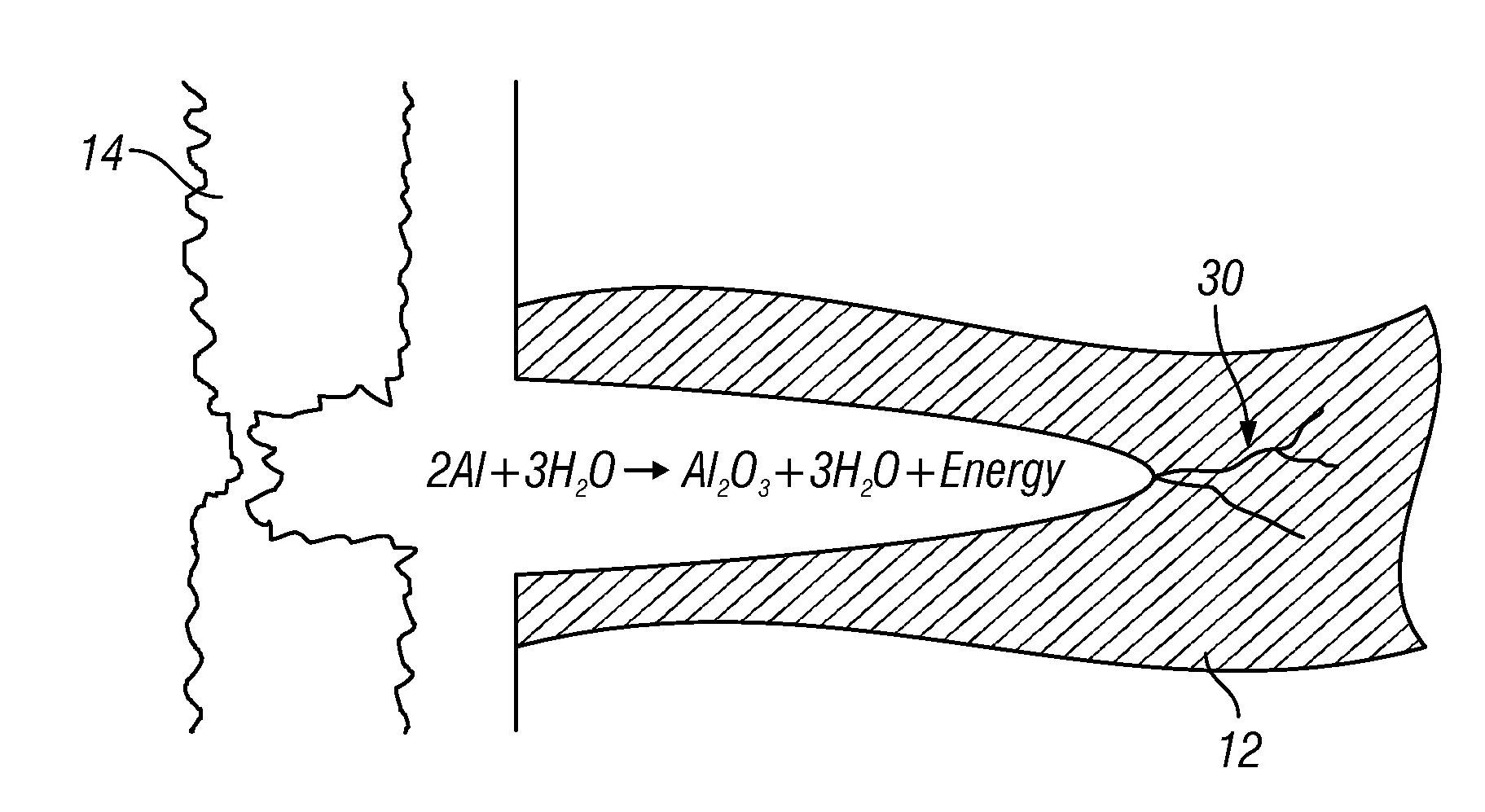

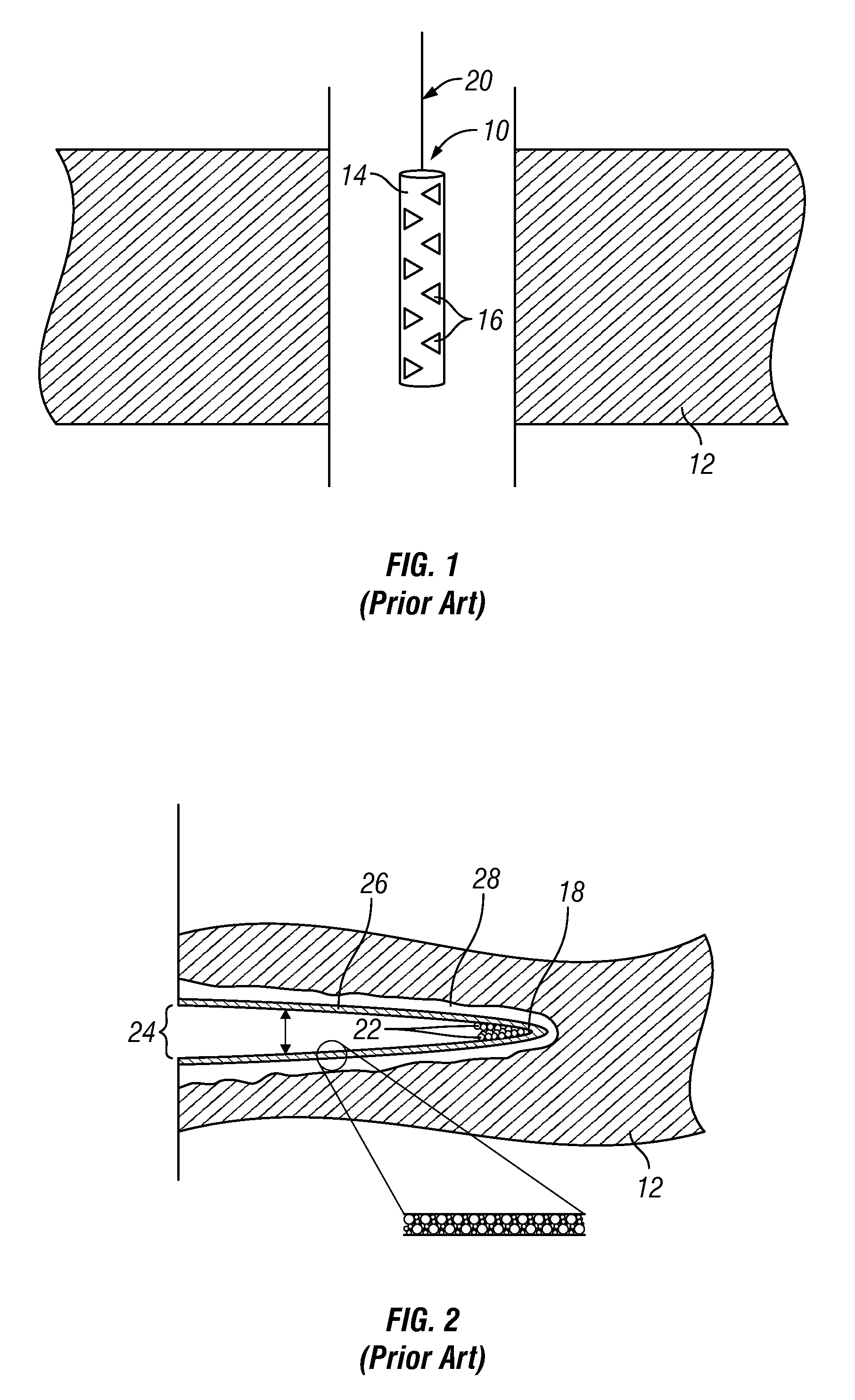

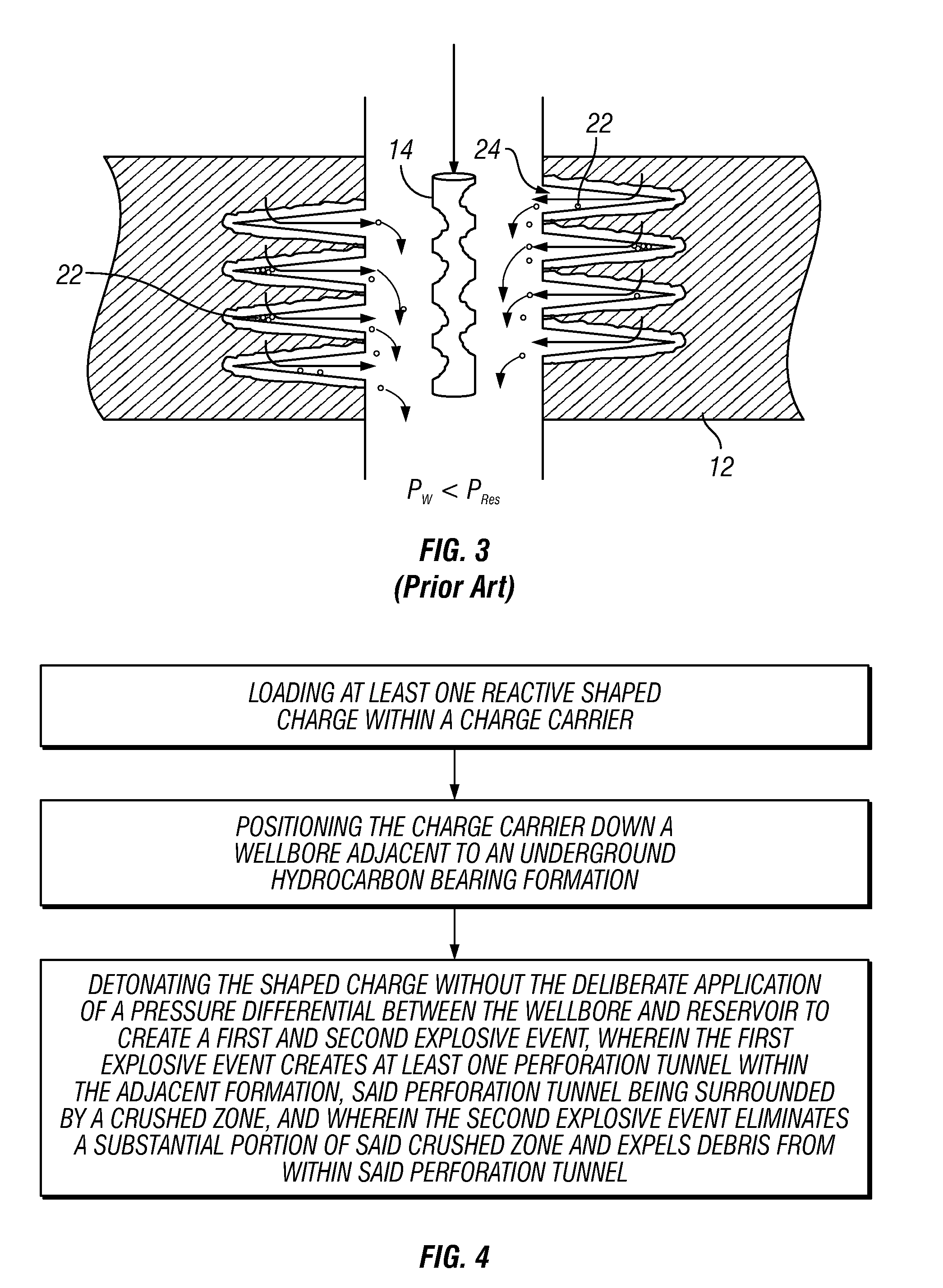

Method for Perforating a Wellbore in Low Underbalance Systems

ActiveUS20100132945A1Improved inflow and/or outflow potentialImprove performanceConstructionsFluid removalShaped chargeBiological activation

By substantially eliminating the crushed zone surrounding a perforation tunnel and expelling debris created upon activation of a shaped charge with first and second successive explosive events, the need for surge flow associated with underbalanced perforating techniques is eliminated. The break down of the rock fabric at the tunnel tip, caused by the near-instantaneous overpressure generated within the tunnel, further creates substantially debris-free tunnels in conditions of limited or no underbalance as well as in conditions of overbalance.

Owner:WELLS FARGO BANK NAT ASSOC +1

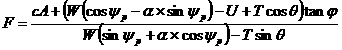

Rock structural surface shear test method and implementation apparatus thereof

ActiveCN102735555ASolve the problem of not being damagedResolve Shear DeformationMaterial strength using steady shearing forcesFilling materialsRock sample

The invention discloses a rock structural surface shear test method and an implementation apparatus thereof. The method mainly comprises the steps that: an upper part and a lower part of a rock sample are respectively fixed in an upper opened shearing box and a lower opened shearing box with opposite opening surfaces through filling, wherein a certain distance is kept between the opening surfaces of the upper and lower shearing boxes, such that the rock sample block shear test structural surface is exposed between the opening surfaces of the upper and lower shearing boxes; a pair of shear loads with opposite directions are implemented on the upper and lower shearing boxes, and the loads act upon the rock sample block through the filling materials in the shearing boxes; the loads further act upon the rock sample block structural surface, such that the shear strength parameter of the rock sample block structural surface is obtained. According to the invention, the rock structural surface is subjected to a shear test, such that structural surface damage of the rock sample block during a moving process is effectively avoided, and test failure caused by damaged structural surface is prevented. The influence of cement upon sample block tests in prior arts is completely eliminated, and the true shear strength parameter of the rock structural surface can be obtained.

Owner:SICHUAN UNIV

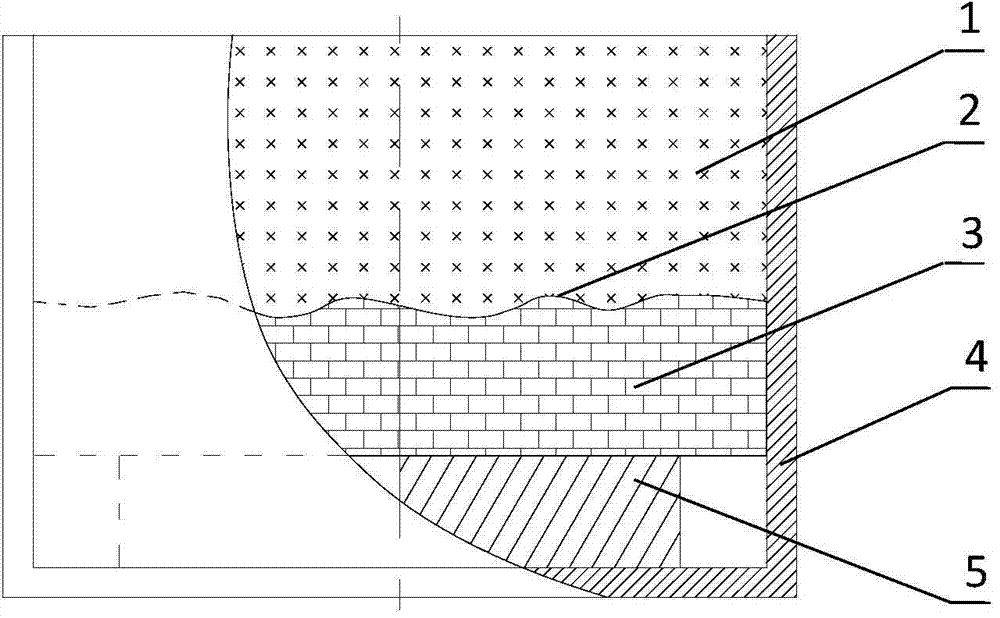

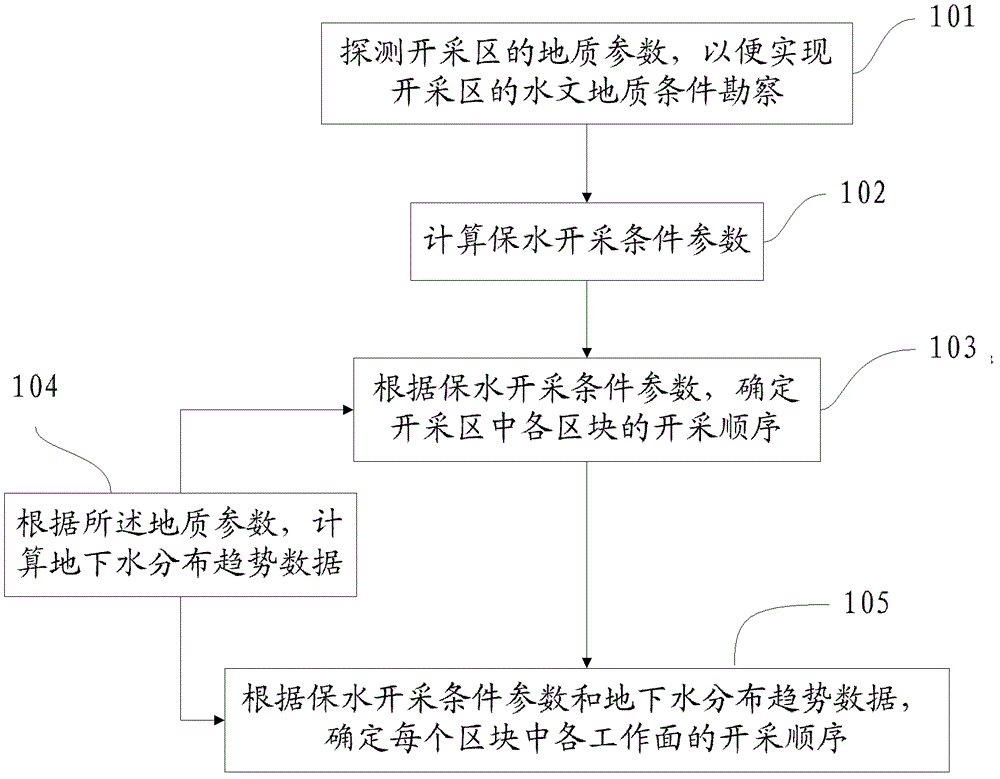

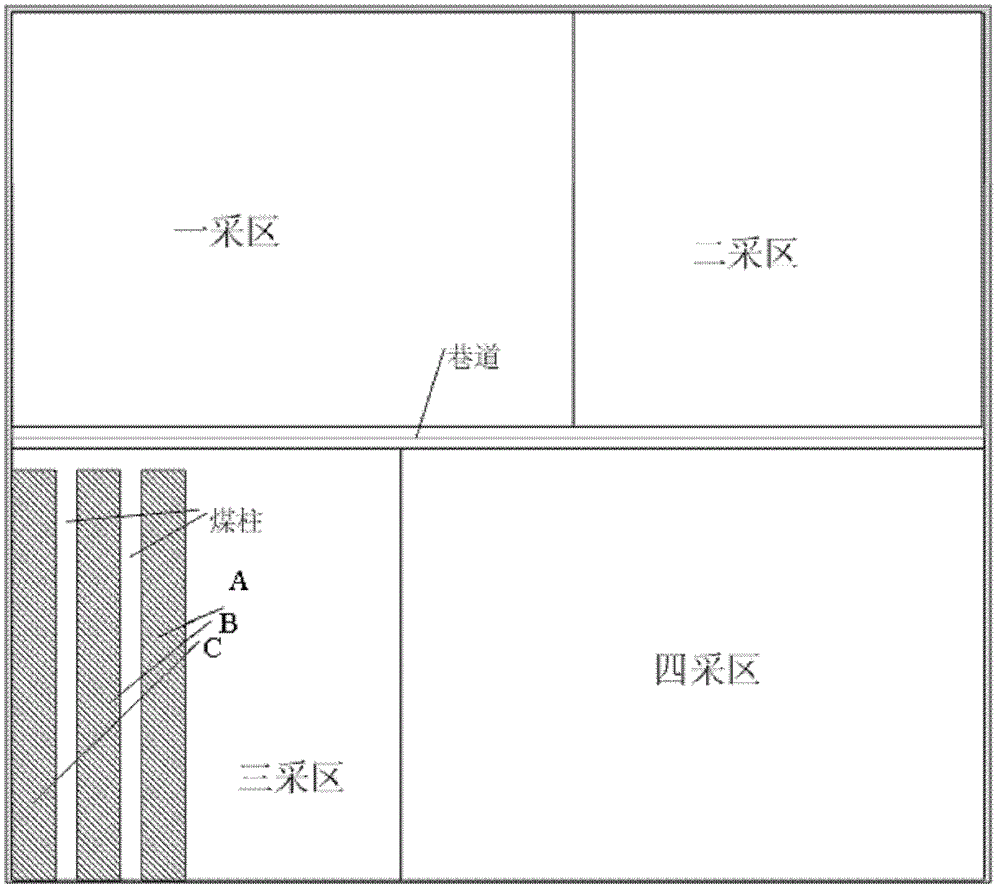

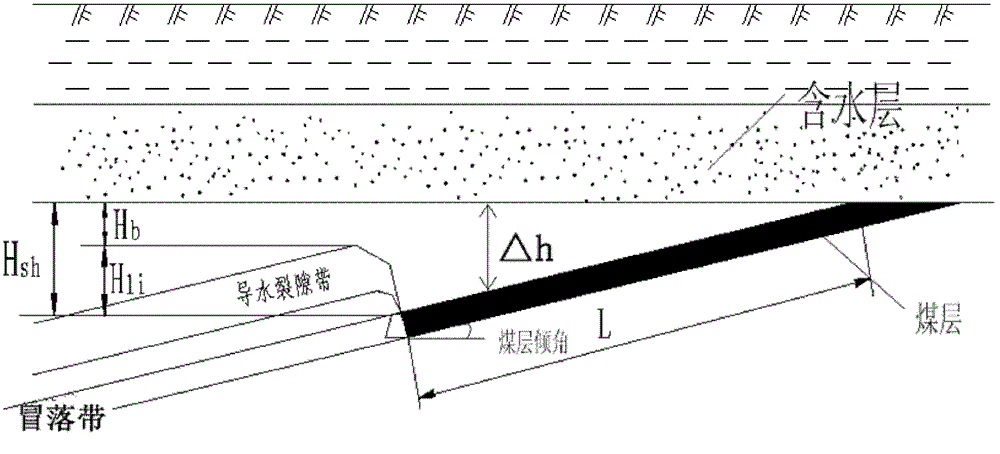

Water-preserved mining method

ActiveCN102865081AAccurate detectionUnderground miningSurface miningEcological environmentWater resources

The invention discloses a water-preserved mining method, which comprises the following steps of: performing geological survey in a mining region to obtain geological parameters; calculating water-preserved mining condition parameters according to the geological parameters; calculating underground water distribution trend data according to the geological parameters; determining the mining sequence of each block in the mining region according to the water-preserved mining condition parameters and the underground water distribution trend data; and determining the mining sequence of each working surface in each block according to the water-preserved mining condition parameters and the underground water distribution trend data. Due to the adoption of the water-preserved mining method disclosed by the invention, the geological and hydrogeological conditions of the mining region can be accurately explored, and the situations of coal thickness variation, an overlying rock structure and the like are comprehended; and different mining ways and mining parameters are adopted specific to different geological conditions, so that the influences of coal mining on underground water resources and the ecological environment are reduced.

Owner:CHINA SHENHUA ENERGY CO LTD +1

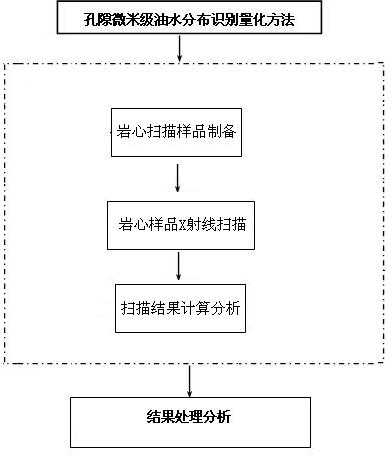

Pore micron-sized oil water distribution recognition and quantification method

InactiveCN102628354AEffective response distributionThe preparation process is simple and reliableSurveyFluid removalX-rayQuantification methods

The invention relates to a pore micron-sized oil water distribution recognition and quantification method. A flooding experiment scheme is firstly designed according to the research purpose, in different chemical flooding phases, iodide ions serving as a scanning standardizing reagent are added to a displacement chemical reagent, after each chemical flooding phase is over, a test sample is prepared, then an X ray scanning test is carried out, a scanning result is calculated and analyzed and automatically recorded by a computer, an X ray gray level distribution data graph obtained by scanning is transmitted to a data processing workstation unit of a microcosmic scanning system to be subjected to two-dimensional image reconstruction, gray level recognition and pore interior oil water distribution computing, so that core pore parameters and core pore interior oil water actual distribution image and quantification proportion are obtained. According to the invention, the sample preparation is simple and reliable, no damage is caused to the rock structure, the oil water distribution states in pores of a natural core and an artificial core in different chemical flooding phases are effectively reflected, the quantitative description is also provided, and the applicability of test results is good.

Owner:NORTHEAST GASOLINEEUM UNIV

Prefabrication method of standard roughness joint surface of rock-like test piece

ActiveCN105203359AEasy to processLow costPreparing sample for investigationNumerical controlLiquid state

The invention provides a prefabrication method of a standard roughness joint surface of a rock-like test piece, and belongs to rock mechanics test methods. The method comprises the steps that a roughness curve is input in a numerical controlled flame cutting machine to cut stainless steel plates, and standard joint surface mold plates with different roughness are obtained; a mold for making the rough joint surface is obtained through assembling, a joint surface mold plate with the corresponding roughness is selected, and spaces between standard joint mold plates are adjusted according to opening of the prefabricated joint surface; a machining groove is filled with liquid replication materials, and after cooling forming is conducted, replication material joint pieces are obtained through demolding and cutting; the joint pieces are fixed on preset positions of a test piece machining mold, and liquid rock-like materials are injected into the mold; demolding is conducted after forming, the rock-like test piece is subjected to high temperature, the joint pieces are melt and flow out, and the rock-like test piece with the joint surface with specific roughness is obtained. The method has the advantages of being easy and convenient to operate, easy to repeat, low in cost, high in accuracy and the like, and the method has a wide application prospect in test research of physical and mechanical property of rock structure surfaces.

Owner:CHINA UNIV OF MINING & TECH

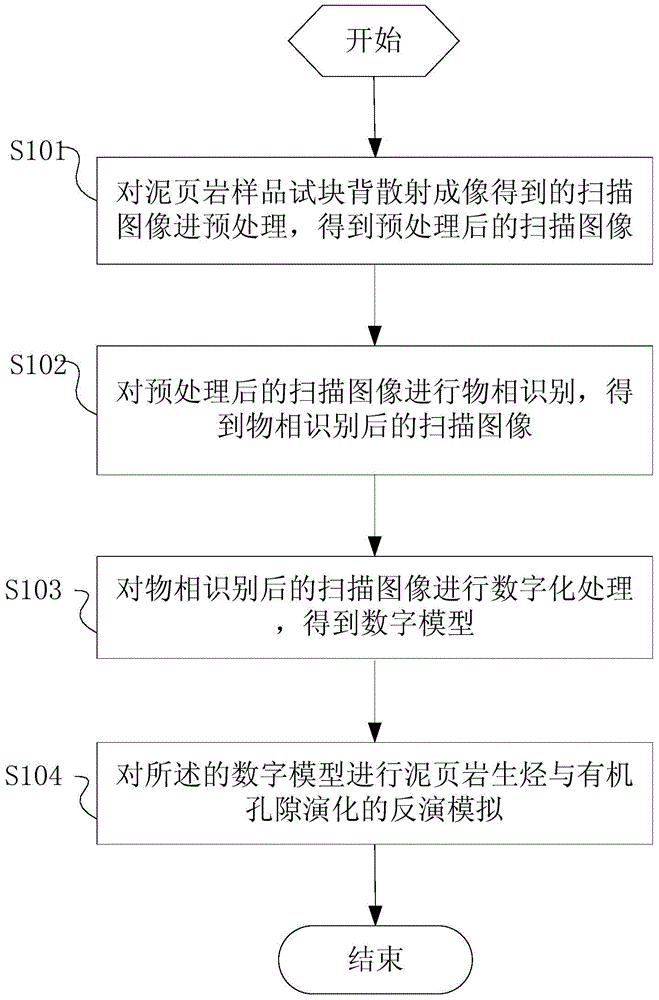

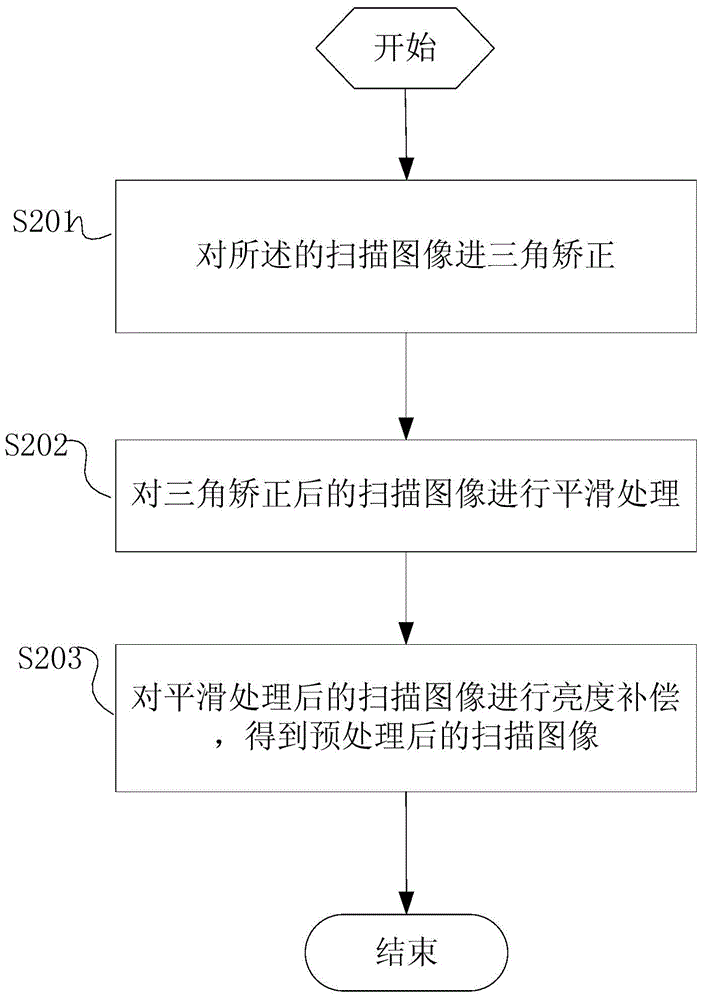

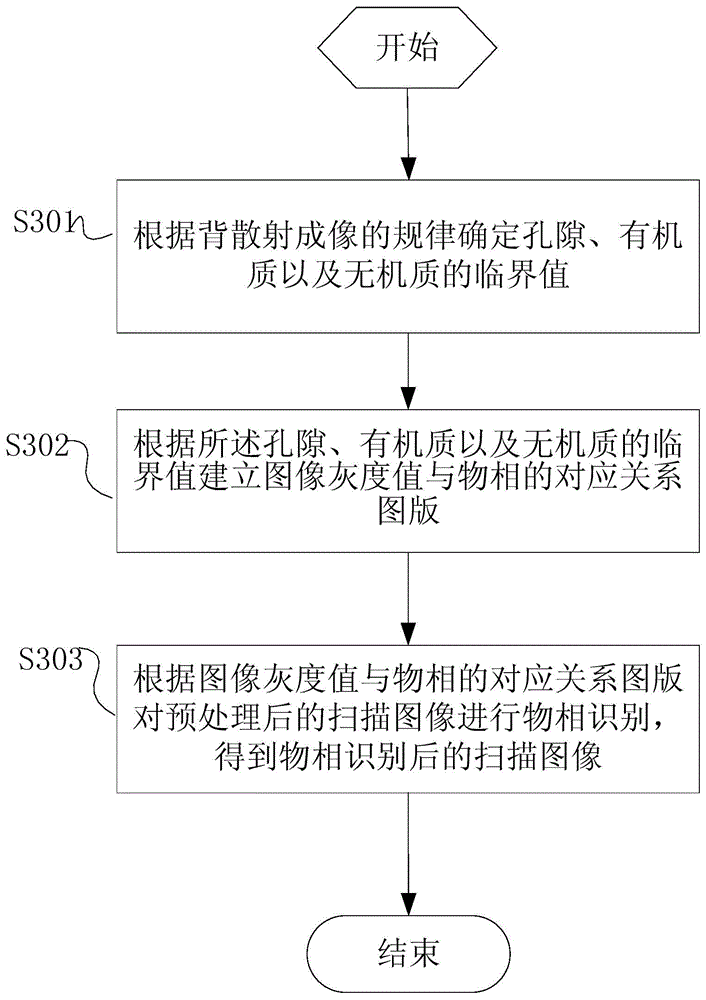

Simulation method and system of hydrocarbon generation of shale and organic pore evolution

The invention provides a simulation method and system of hydrocarbon generation of shale and organic pore evolution. The method includes the steps that a scanned image obtained by conducting back scattering imaging on a shale sample block is preprocessed to obtain a preprocessed scanned image; phase identification is conducted on the preprocessed scanned image to obtain a scanned image obtained after phase identification is conducted; digital processing is conducted on the scanned image obtained after phase identification is conducted so as to obtain a digital model; inverse simulation of hydrocarbon generation of the shale and organic pore evolution is conducted on the digital model. The microscopic rock structure characterization technology is used for establishing a model for shale thermal evolution simulation, then the hydrocarbon source rock thermal evolution process is simulated, the thermal evolution process can be represented quantitatively and visually, and powerful technical support can be provided for unconventional oil and gas resource research, especially shale oil research.

Owner:PETROCHINA CO LTD

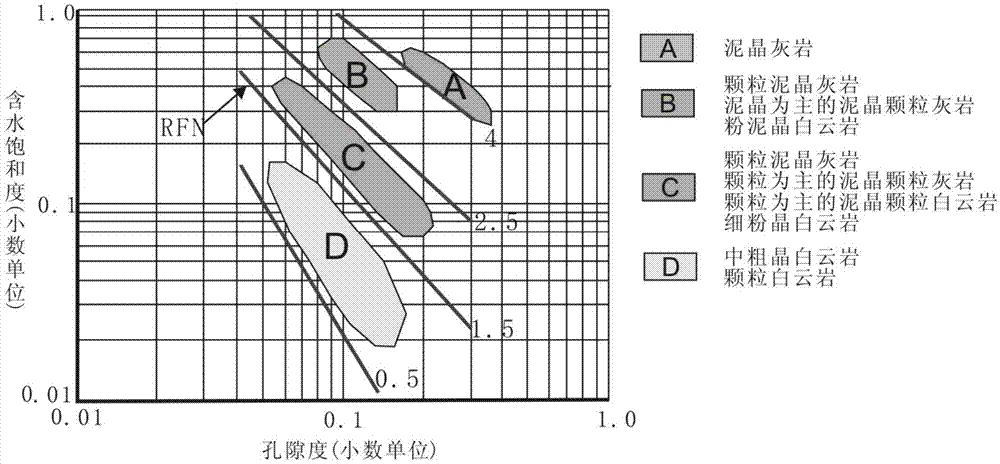

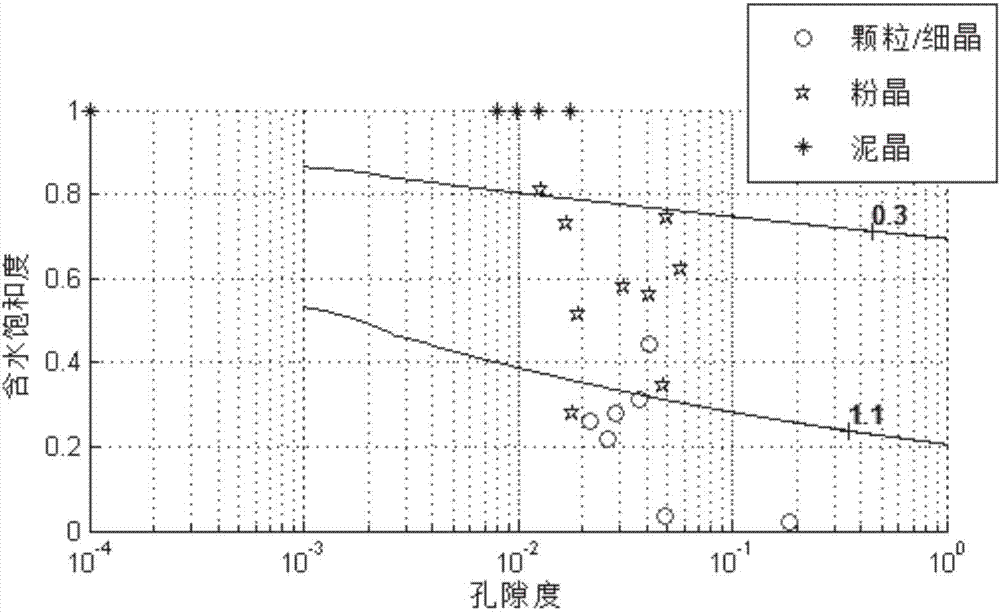

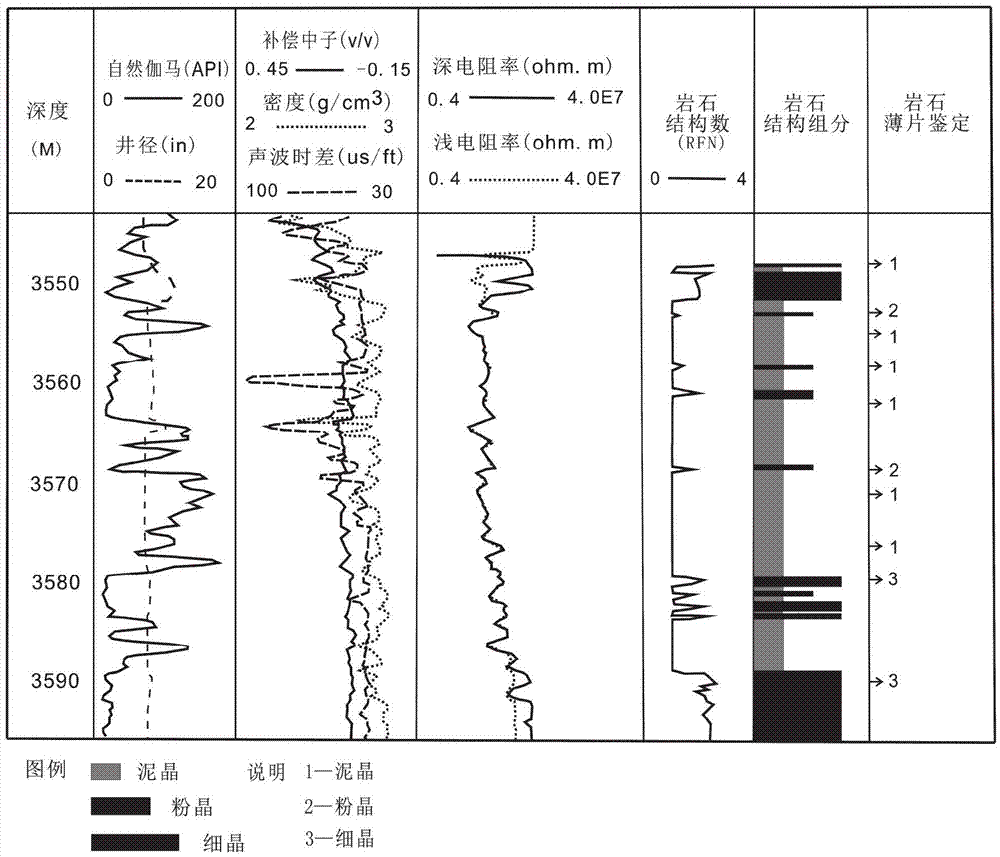

Carbonate rock structure ingredient well logging quantitative recognition method and purpose thereof

ActiveCN103698811ARealize identificationSeismic signal processingSeismology for water-loggingAdditive ingredientCrystal structure

The invention discloses a carbonate rock structure ingredient well logging quantitative recognition method and a purpose thereof. The method mainly comprises three parts including porosity and water saturation well logging calculation, rock structure number parameter calculation and rock structure ingredient identification. When RFN obtained through calculation is smaller than 0.3, the structure is a micrite structure; when the RFN is between 0.3 and 1.1, the structure is a powder crystal structure; when the RFN is greater than 1.1, the structure is a fine crystal or particle structure. The sound wave time difference logging curve is adopted for calculating the porosity, the deep lateral resistivity well logging curve and the porosity are utilized for calculating the stratum water content saturability, a rock structure number formula is utilized for calculating the rock structure number parameter, and different rock structure ingredients are identified through cutoff values. The method provided by the invention is practically applied to the stratum of Majiagou formation of Ordovician system in Wuqinan region of Ordos Basin, and a better effect is obtained.

Owner:PETROCHINA CO LTD

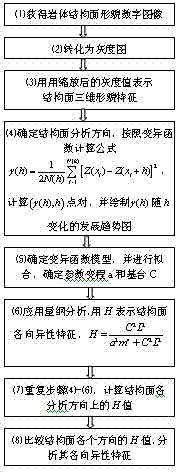

Rock structure surface shape anisotropism evaluation method

The invention provides a rock structure surface shape anisotropism evaluation method which comprises the steps that (1) rock structure surface three-dimensional shape data are obtained; (2) according to an experiment variation function formula, a point pair in the structure surface analyzing direction is computed, and a development tendency chart following changing is drawn; (3) a variation function model is determined, function model fitting is carried out, and then a model parameter range a and a base table C are determined; (4) a dimensional method is used, and H (represented by a and C) is used for representing structure surface anisotropism features; and (5) values in all directions of structure surfaces are computed according to the steps (2), (3) and (4), and accordingly the anisotropism features of the rock structure surfaces are analyzed. According to the method, the rock structure surface shape anisotropism can be effectively represented in a quantification mode, convenience and accuracy are achieved, and a basis is provided for further and comprehensive evaluation of rock structure surface shearing strength.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Controlled blasting construction method for rock foundation pit

The invention relates to a controlled blasting construction method for a rock foundation pit. The method comprises the following steps: detecting a cutting line; with the cutting line as a reference line, locating the periphery of a foundation pit to excavate a damping groove; vertically excavating a damping groove in the cutting line, wherein the interior of the damping groove is a blasting area and the exterior of the damping groove is a protective area; blasting and excavating the foundation pit: crushing rocks after blasting and removing slag; and cutting and blasting the foundation pit in a layered way: repeating excavation of the damping groove and blasting of the blasting area, excavating the damping groove in a layered way, blasting and excavating the foundation pit until the foundation pit is completely excavated. The damping groove is excavated in the excavating area of the rock foundation pit so as to stop blasting vibration propagation in the excavating area and reduce vibration influences on the rock wall and the surrounding structure of the foundation pit; a cutting reference is randomly corrected by using an outwardly moving rechecking line of the foundation pit cutting line so as to satisfy requirements on foundation pit excavating accuracy; the controlled blasting construction method for the rock foundation pit, provided by the invention, has the advantages of simple process and no damage to a foundation pit surrounding rock structure and is suitable for excavating various earth-rock foundation pits; both excavating efficiency and safety can be taken into account; and the foundation pit blasting safety and the foundation pit excavating accuracy are enhanced.

Owner:TAIXING FIRST CONSTR INSTALLATION

Rock structure surface shearing device and method

ActiveCN103884608AGet the shear strengthGet propertiesMaterial strength using steady shearing forcesHeater RodData acquisition

The invention relates to a rock structure surface shearing device and method. The rock structure surface shearing device comprises a test piece system, a pressure plate system, a loading system and a data acquisition system, wherein the test piece system comprises an upper rock and a lower rock with heating holes on a rock structure surface, the loading system can be used for performing normal pressure loading, left shearing force loading and right shearing force loading, and the pressure plate system comprises two 7-shaped loading plates; the rock structure surface shearing device also comprises a roll set system which includes four groups of press rolls for connecting the loading system and the pressure plate system to reduce friction of a test piece and the loading system; the rock structure surface shearing device further can comprise a heating system which adopts heating rods to control the temperature of high-quality heat-resisting silicone oil in the heating holes to heat the upper rock and the lower rock on the rock structure surface; the data acquisition system can be used for acquiring data of pressure, displacement and temperature. The rock structure surface shearing device can bidirectionally shear the test piece of the rock structure surface and realize research to the shearing characteristic of the rock structure surface at different temperatures.

Owner:HUNAN UNIV OF SCI & TECH

Method for creating a 3D rock representation using petrophysical data

The present invention enables the use of a global optimization method for performing joint-inversion of multiple petrophysical data sets, using forward models based on first principle of physics, to generate a 3D rock representation of a subsurface rock structure. The resulting 3D rock representation captures the internal structure, and honors the measured petrophysical properties, of the subsurface rock structure. The 3D rock representation can then be used to predict additional properties not considered in the inversion, to further characterize the subsurface rock structure.

Owner:CHEVROU USA INC

Oil-gas field on-site while-drilling cuttings scanning system and method

InactiveCN107620593AAvoid the process of samplingReduce research costsDirectional drillingFlushingLithologyPetroleum

The invention mainly belongs to the field of oil and gas exploration and development, and particularly relates to an oil-gas field on-site while-drilling cuttings scanning system and method. The oil-gas field on-site while-drilling cuttings scanning system comprises a sample preparation mould and a table-type mineral analysis scanning electron microscope; oil-gas field on-site while-drilling cuttings are prepared to a scanning sample through the sample preparation mould; the table-type mineral analysis scanning electron microscope comprises a secondary electronic probe, a backscattered electron probe, an energy spectrum probe and an electron microscope operation module; and the table-type mineral analysis scanning electron microscope is small in weight, small in land occupation, easy to carry and is suitable for the severe environment in a well field. According to an oil-gas field on-site while-drilling cuttings scanning method, the on-site while-drilling cuttings are fully utilized, mineral elements, mineral types and rock structures are rapidly analyzed, and lithology classification is quickly conducted; and the oil-gas field on-site while-drilling cuttings scanning method has the advantage of on-site real-time guidance drilling and oil-gas field exploration and development, limitation that a laboratory traditional mineral analysis electron microscope scanning system cannot be carried to the site for application is overcome, and the oil-gas field exploration precision and speed are improved.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

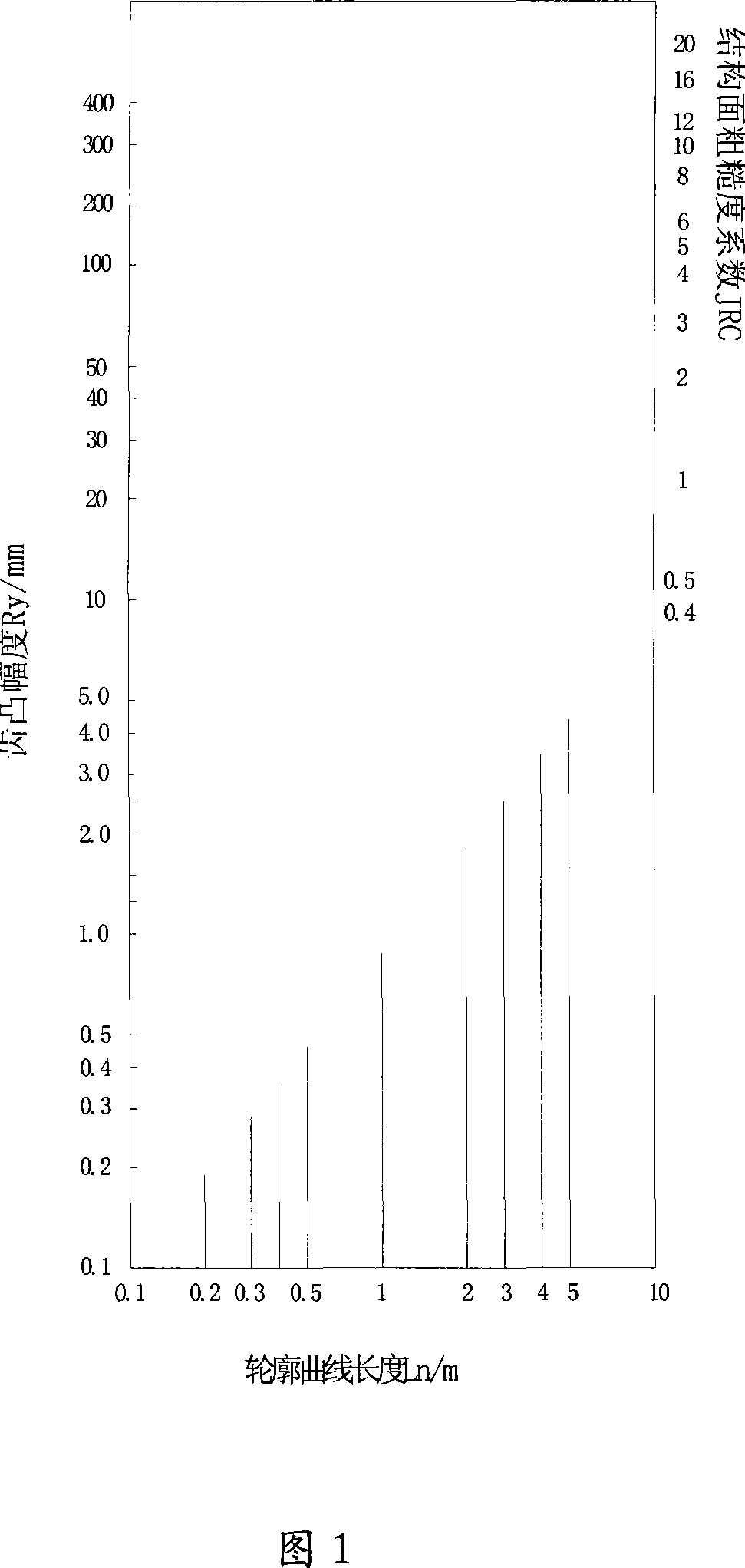

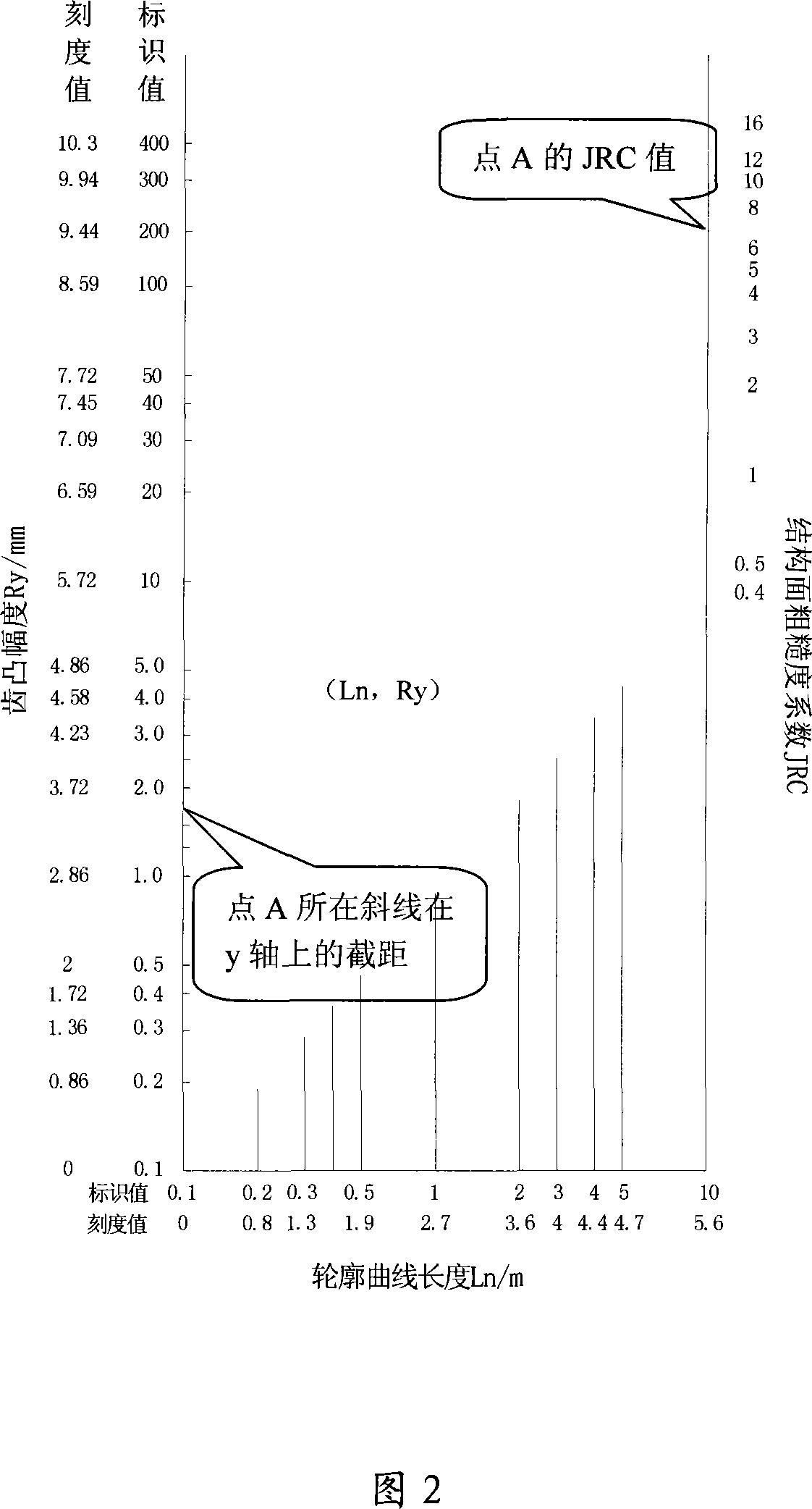

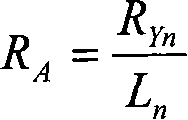

Simple measurement method for rock structural plane roughness coefficient

The invention relates to a simple method for measuring roughness coefficient of rock structure surface, including the following steps of: measuring convex tooth amplitude Ryn of rock structure surface; calculating the relative convex tooth amplitude value RA of rock structure surface profile curve with sampling length Ln using the formula RA=RYn / Ln; obtaining the roughness coefficient of rock structure surface profile curve with sampling length Ln by substituting the RA into the formula JRCn=400RA. The method which is simple and convenient for operation and calculation quickly can be performed without the influence of human factor and have great value and social economical benefit with satisfied precision.

Owner:ZHEJIANG COLLEGE OF CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com