Patents

Literature

599 results about "Mineral composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

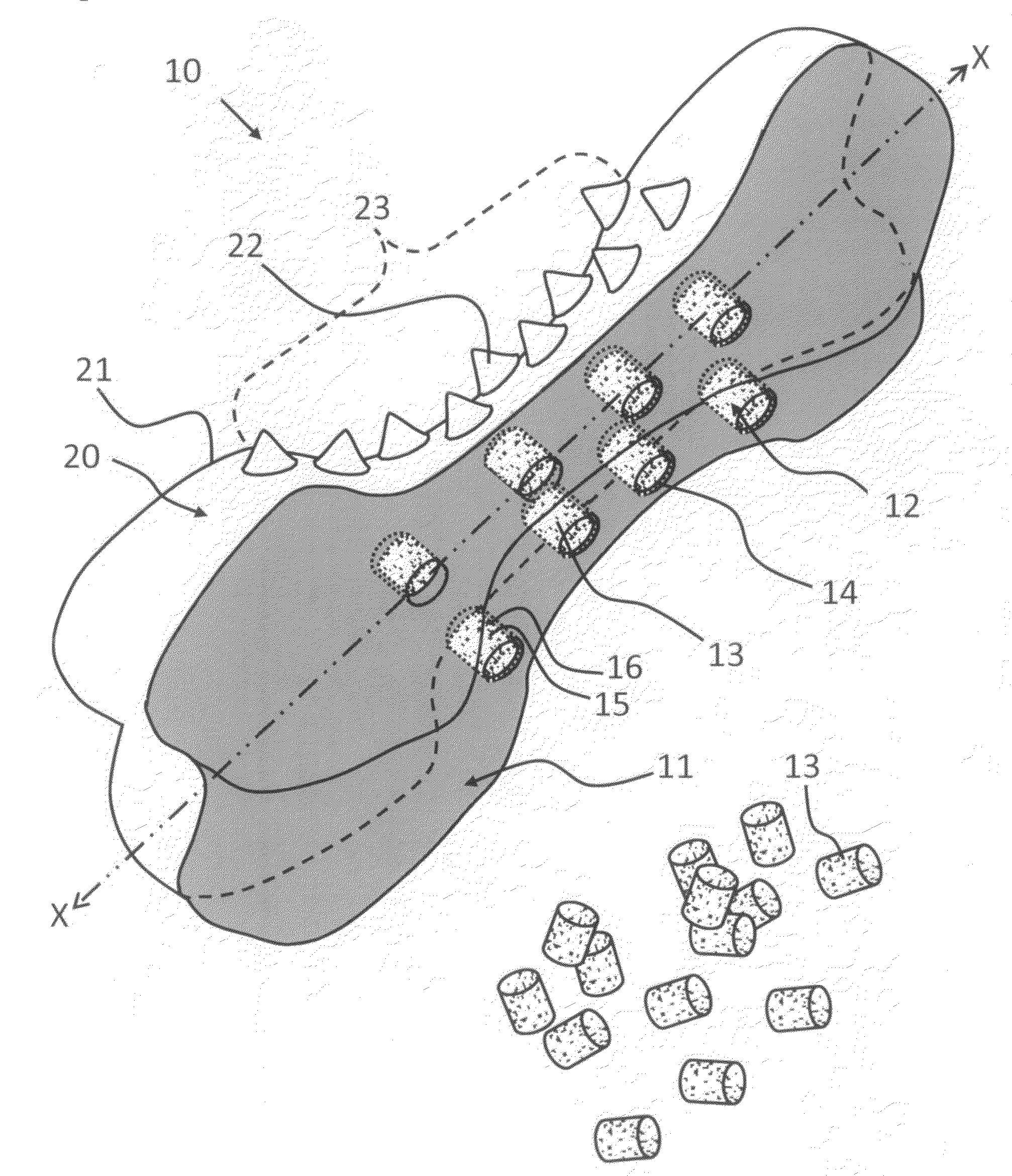

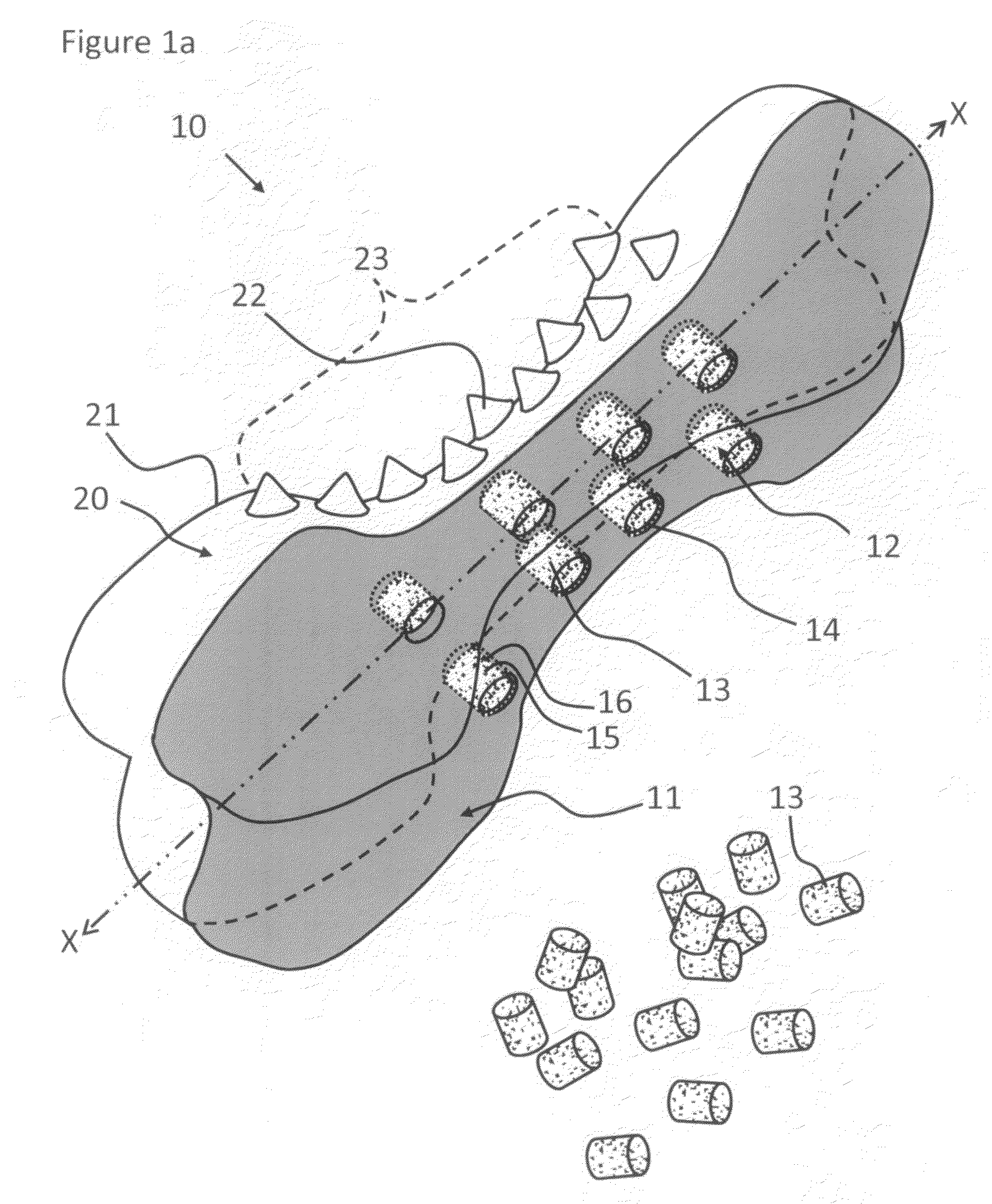

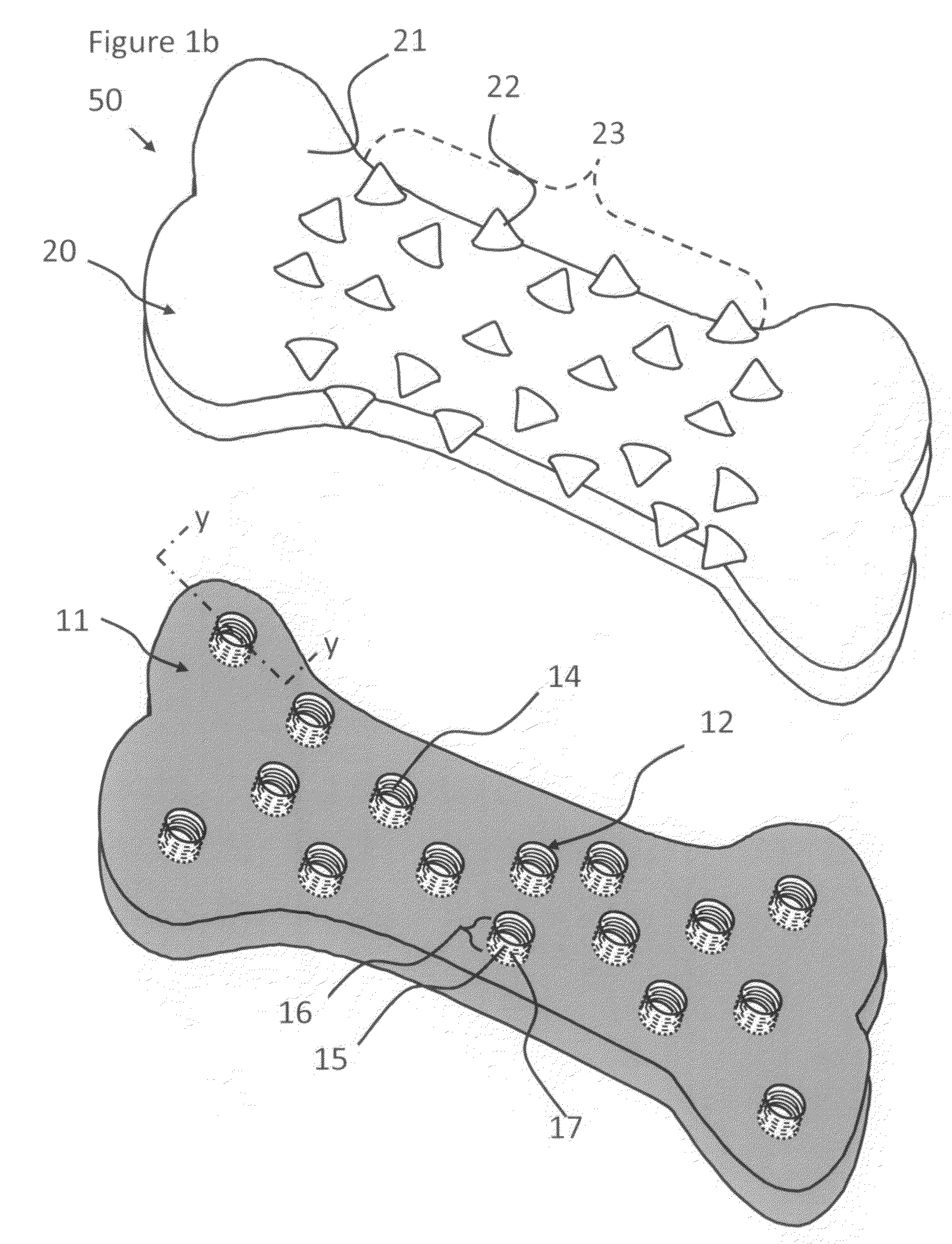

Animal chew toy containing solid food

InactiveUS20080314333A1Easy to processImprove and protect healthPeptide/protein ingredientsBoron compound active ingredientsVitamin CManganese

An animal toy containing food having a first portion with food delivery means integrated therein adapted to securely house solid food treats, including a nutritional pet supplement, to be removed by the animal during play or through chewing action, and a second side with a plurality of gum stimulation teeth integrated within and projecting therefrom that act to massage the gums of the animal. Food delivery means may be provided as a plurality of cavities integrated within the first portion (and optionally, the second portion), preferably having a grooved or threaded interior for securely holding food pieces securely therein. Alternatively, the food delivery means is provided as a food portion composing the first portion. A pet supplement may be utilized, including joint preserving and joint rebuilding compositions comprising chicken collagen type II, glucosamine hydrochloride and chondroitin sulfate, a vitamin composition comprising vitamins C, D and K, a mineral composition comprising calcium, magnesium, zinc, copper, manganese and boron, a herbal anti-oxidant cofactor blend comprising citrus bioflavonoids, red grapes anthocyanins, turmeric rhizome, boswellia resin and fennel seed.

Owner:I DID IT

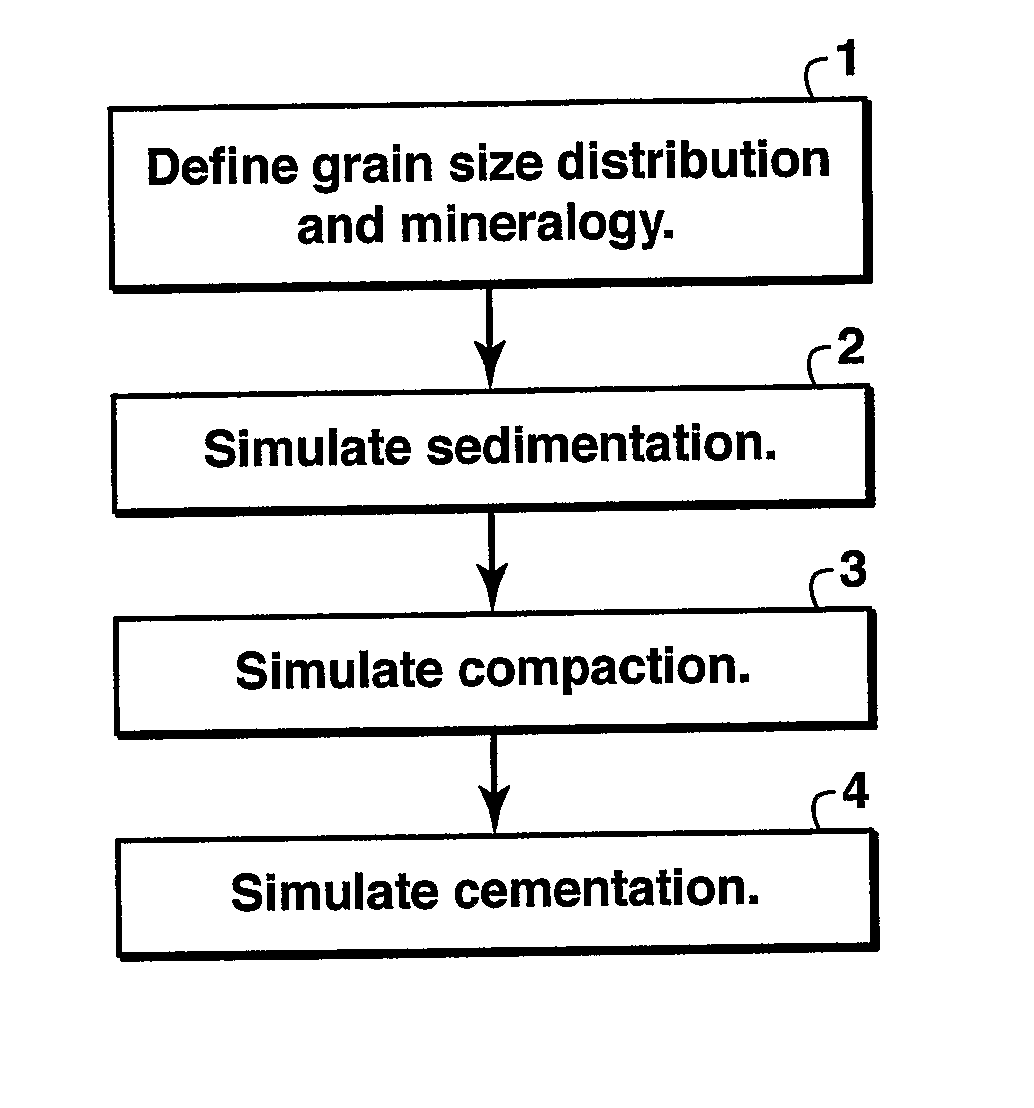

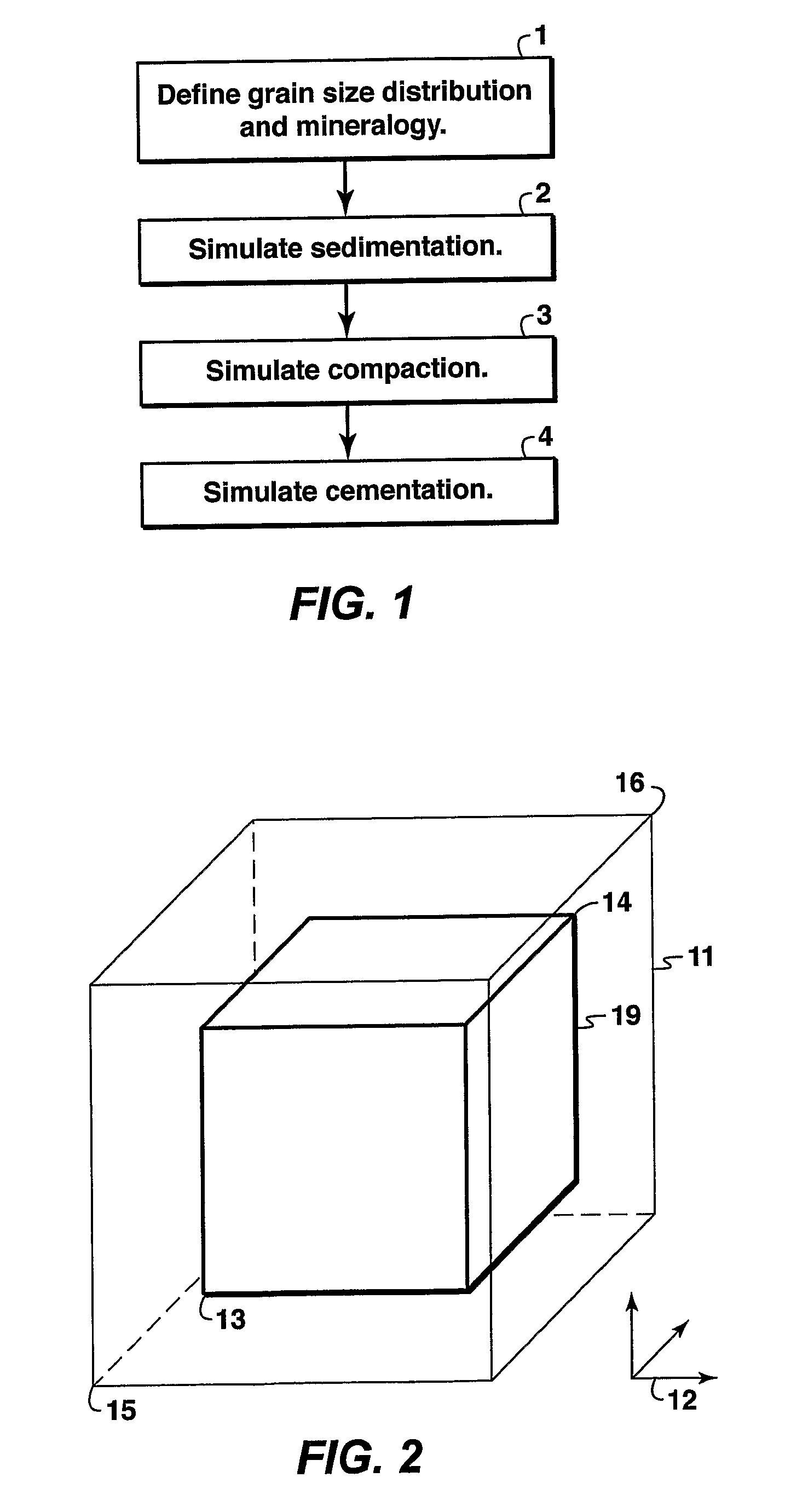

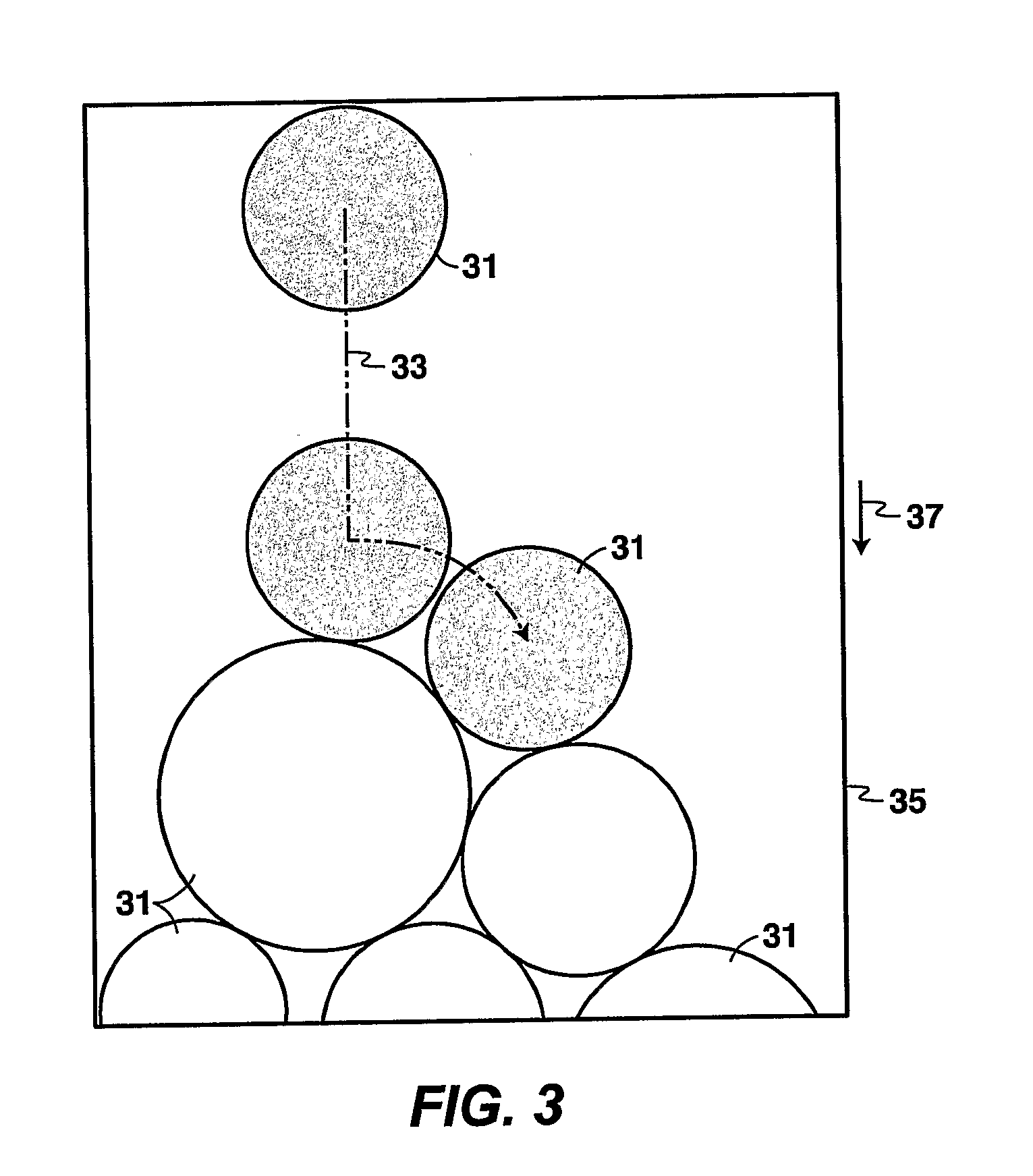

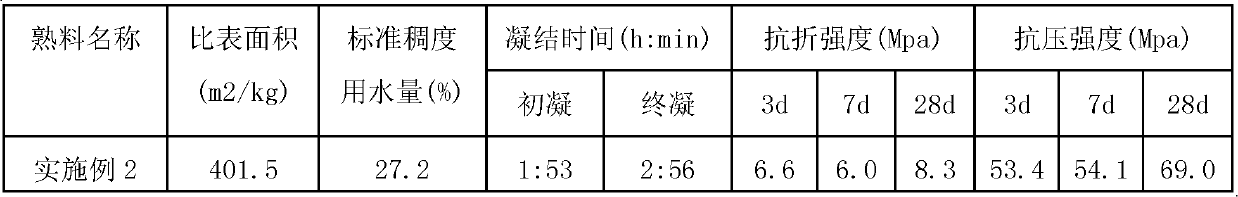

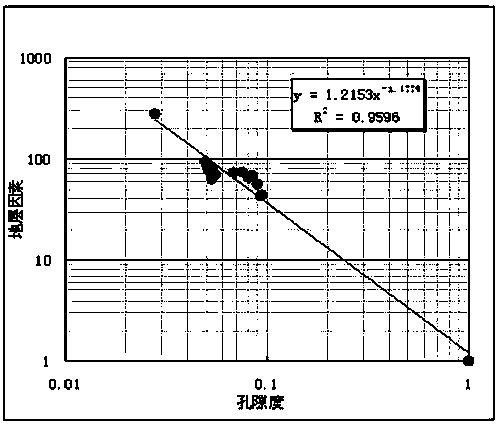

Method For Simulating And Estimating Sandstone Properties

InactiveUS20070203677A1Computation using non-denominational number representationGeological measurementsPorosityMaceral

The invention is a method for simulating sandstone deposition. The sandstone is simulated by estimating the grain size distribution and mineral composition of grains in the sandstone, simulating sedimentation of grains from the grain size distribution and mineral composition of the grains, simulating compaction of the grains, and simulating cementation of the grains. Properties of the sandstone such as porosity and permeability may be estimated from the simulated sandstone. The method permits multiple mineralogies to be simulated during the burial history of sedimentation, compaction and cementation.

Owner:EXXONMOBIL UPSTREAM RES CO

Technique for producing Jinhuaqianliang tea (flower coil tea)

ActiveCN101352191AQuality improvementUniform qualityPre-extraction tea treatmentCooking & bakingThirst

The technology for producing golden flower Qianliang tea (Hua-juan tea) is characterized in that the technology comprises the process steps as follow: plucking criteria-water removing in high temperature-rolling and shaping-pile-fermentation-dry and adding incense-stems picking and sieving-matching and pile-classificaition and weighting-steam softening-moisture detection-adpressing and sizing-premilary test and baking-cultivating golden flower-aerationagitation. The technology is an improved deep processing technology. The processes of the pile-fermentation and the cultivating golden flower ensure that the appearance of the products is ooiu colour, the interior is brown, and even distributed beneficial organism (namely, golden flower)-eurotium cristatum is clearly saw, the shangse is bright red, the taste is pure and aromatic, and the flower is aromatic, and has the health care functions of promoting sleeping, invigorating stomach and promoting digestion, relaxing bowel, slaking thirst and helping produce saliva, antidiabetics, lowering blood pressure, curing bloated, cuing laxness, etc. The technology fully actives microelements such as vitamins contained in tea, mineral composition, 18 amino acid, protein, glucide, folic acid, catchol which are beneficial to human health and easily absorbed, and the cultivation of golden flower has substantial transformation on tea polyphenols, caffeine, and theophylline that are transferred into elements that are beneficial to human health, all ages, expand market, have high cultural value, provide collection opportunity for black tea lovers.

Owner:湖南省安化县晋丰厚茶行有限公司

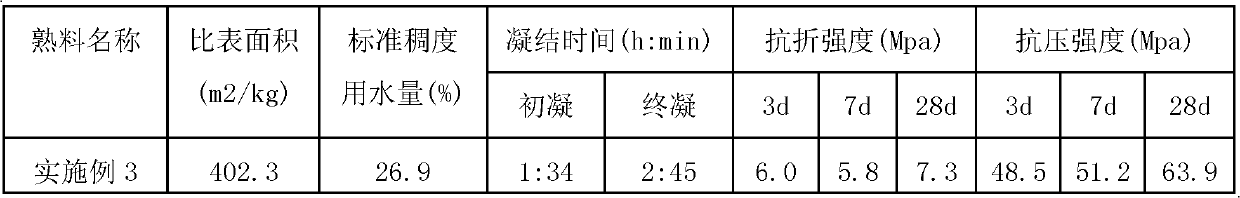

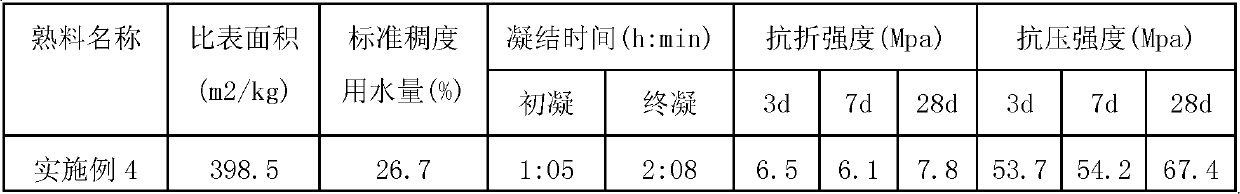

Active belite-sulphate aluminum cement clinker and preparation method for active belite-sulphate aluminum cement clinker

ActiveCN102584045AChange work performanceReduce manufacturing costCement productionAmorphous phaseMaceral

The invention discloses active belite-sulphate aluminum cement clinker, which comprises the following mineral compositions in weight percentage: 25-30 percent of beta-type C2S, 25-30 percent of a-type C2S, 28-40 percent of C4A3S`, 4-12 percent of C4AF and 4-8 percent of amorphous-phase substance. The control of different forms and the change of number of the C2S in the clinker are controlled mainly through special setting on clinker ingredient rate values. The invention also discloses a preparation method for the active belite-sulphate aluminum cement clinker. Compared with traditional common silicate cement clinker, the active belite-sulphate aluminum cement clinker has the advantages that more industrial solid waste residues are used in raw materials by the active belite-sulphate aluminum cement clinker, and thereby, the production cost is reduced, the use proportion of limestone is greatly reduced, and the carbon dioxide emission in clinker production is obviously reduced. Under the condition that the water demand and the setting time of the obtained clinker are basically the same as that of the common silicate cement clinker, the strength of the obtained clinker is superior to that of the common silicate cement clinker.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

Organic and inorganic biological mineral matter mixing fertilizer and method for producing the same

The invention relates to organic-inorganic biological mineral composition composite synusiologic fertilizer and the preparation method thereof. The invention comprises the raw materials as follow in weight proportion: 20 to 30 parts of organic raw material, 30 to 60 parts of inorganic fertilizer, 10 to 20 parts of mineral composition raw material, and 1 to 5 parts of synusiologic mushroom. The invention has the advantages of promoting the absorption of crops, increasing the fertilizer absorption rate from primary 34 percent to more than 60 percent, decreasing the fertilizer residue, promoting the growth of the crops, improving the quality of the crops, ensuring the early development of the crops, the rich branching roots, the rich branches, the rich leaves, and early mature, and increasing the yield by 50 to 80 percent. Besides, the invention also has the advantages of restraining the development of pathogenic bacteria inside the soil, decreasing the disease and the harm to the crops, improving the structure of the soil, activating the nutrient of the soil and achieving the synusiologic planting.

Owner:XICHUAN YUANKE BIOLOGICAL TECH

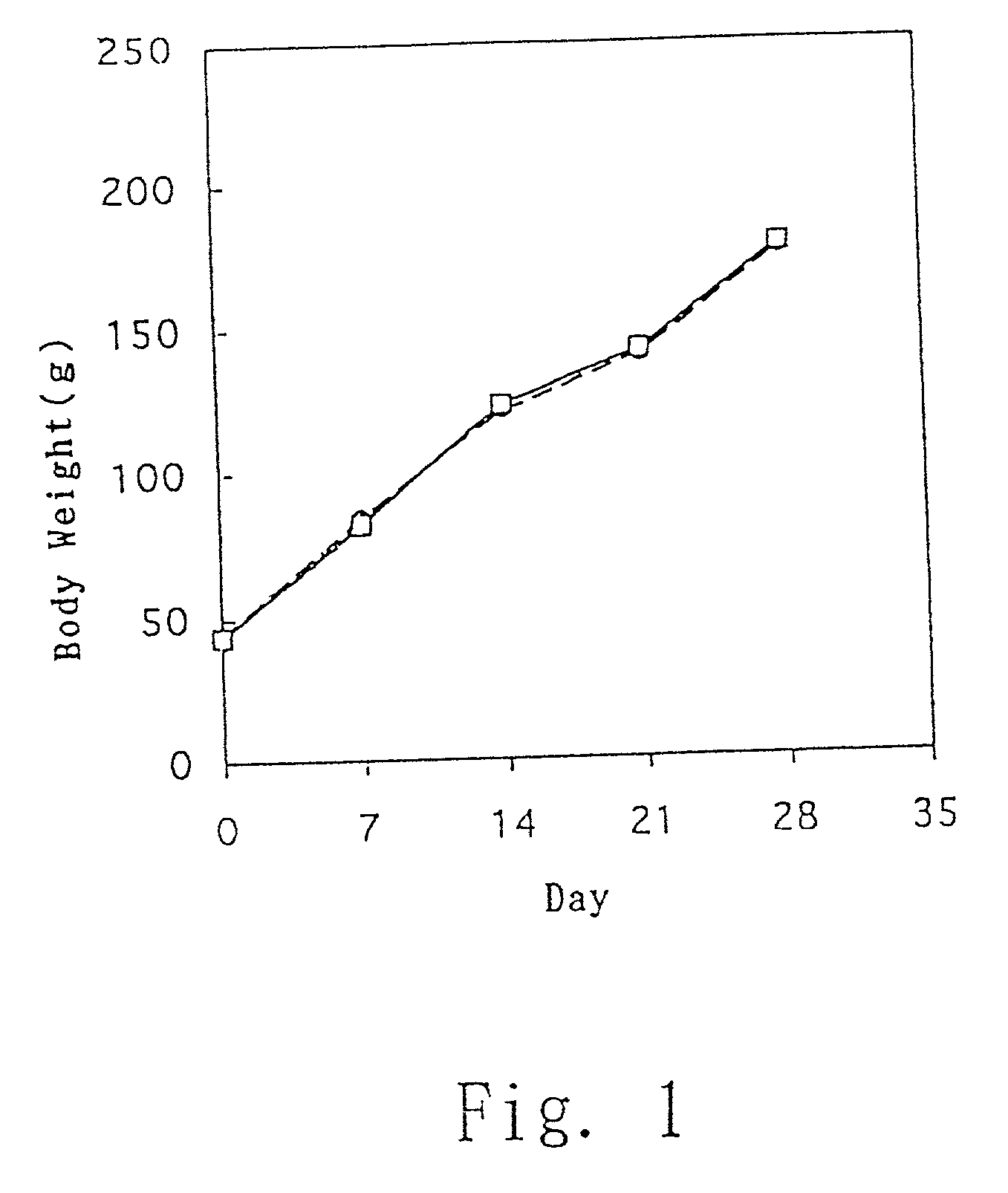

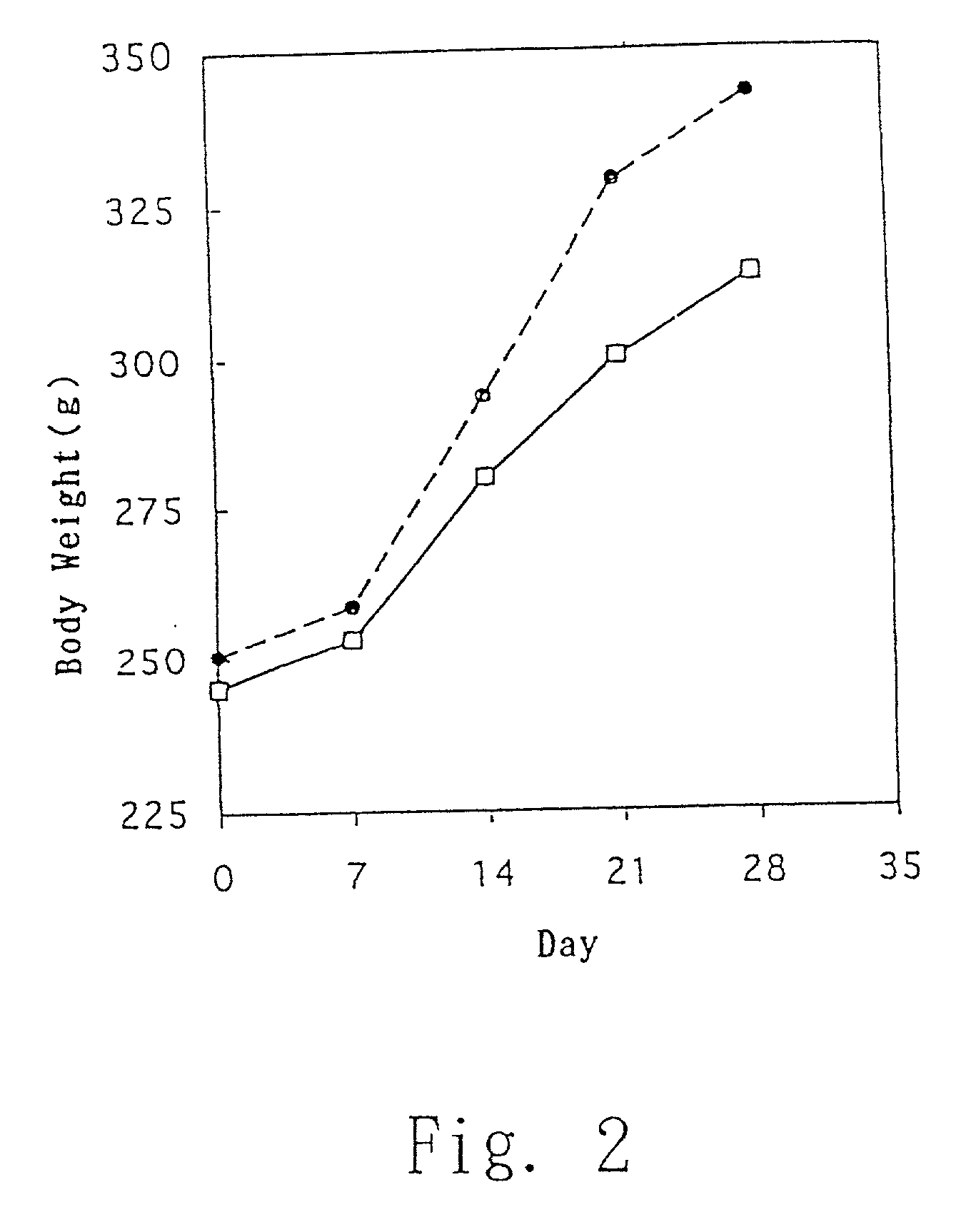

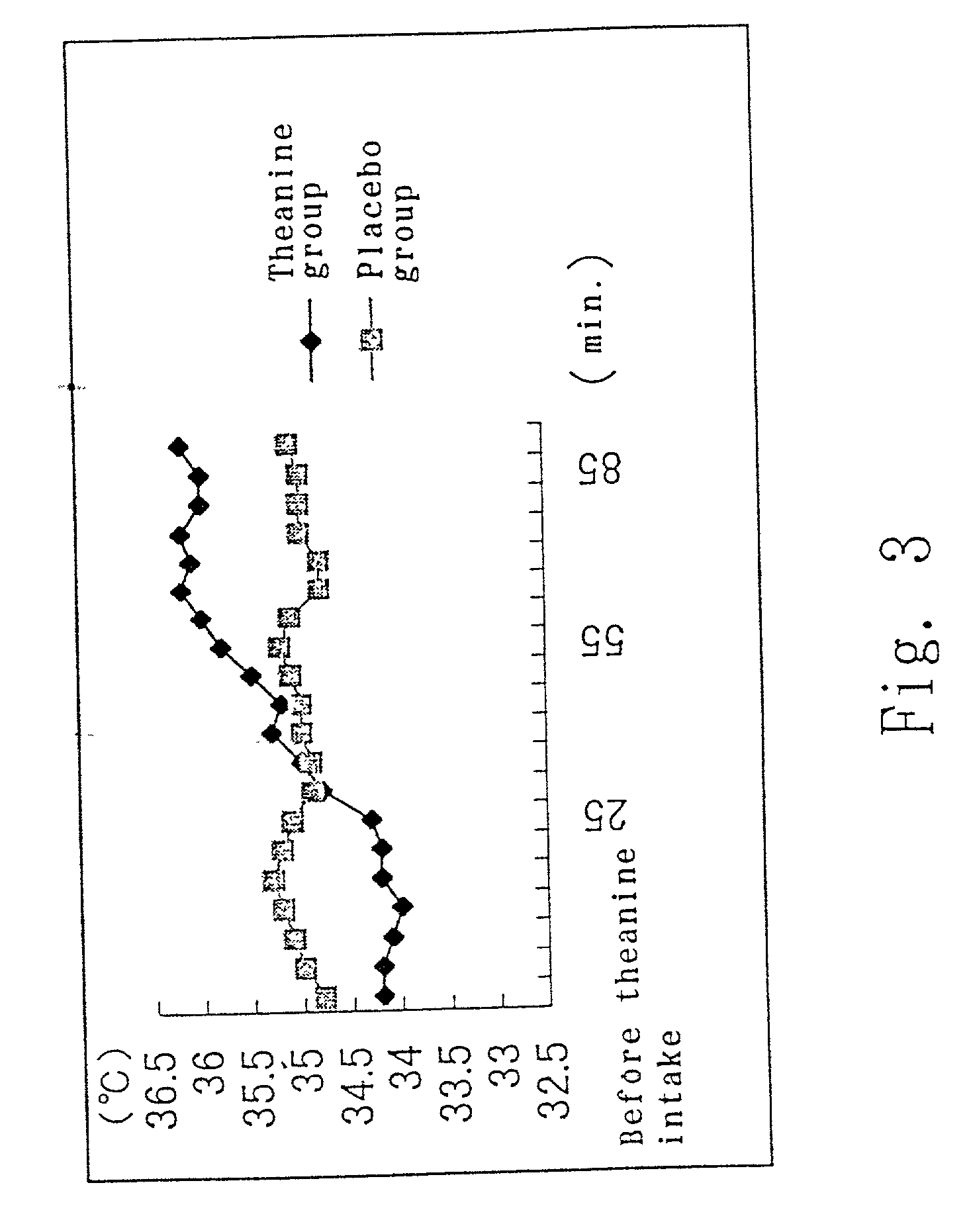

Composition comprising theanine

The present invention relates to a composition for suppressing or ameliorating a symptom accompanying diminished homeostasis, comprising theanine; and a mineral composition comprising theanine and a mineral. According to the present invention, there can be provided a composition for suppressing or ameliorating the above symptoms; and a mineral composition having a reduced peculiar metal taste, of which administration is made easily.

Owner:TAIYO KAGAKU CO LTD

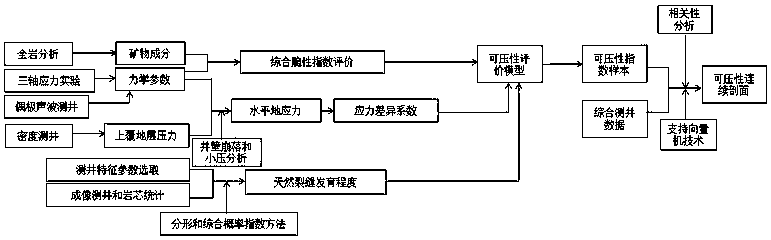

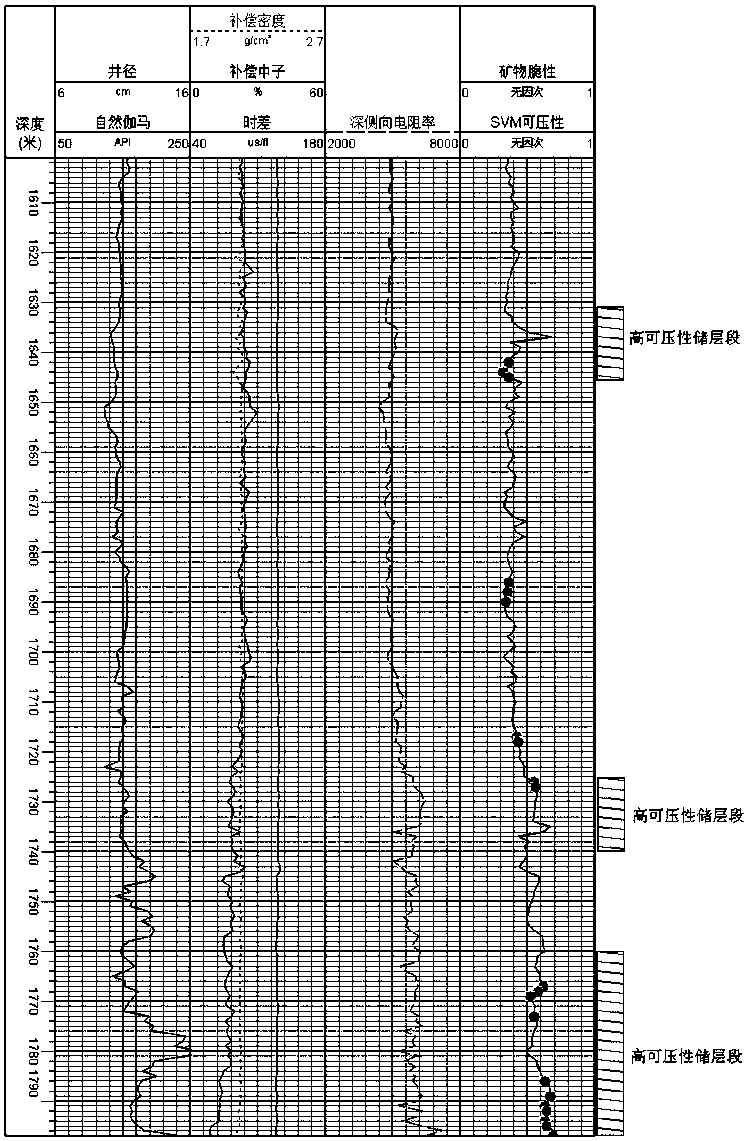

Shale reservoir compressibility evaluation method based on support vector machine technology

ActiveCN108009705AQuickly evaluate qualityDemonstrate comprehensive abilityResourcesSupport vector machinePrincipal stress

The invention relates to a shale reservoir compressibility evaluation method based on a support vector machine technology. The method comprises the following steps: (1) mineral composition quantitative analysis and uniaxial compressive test are firstly carried out; (2) logging characteristic parameters for recognizing a crack are extracted; (3) maximum and minimum horizontal principal stress in different layers is calculated through a combined spring model, and a stress sensitivity degree is then calculated; (4) a compressibility evaluation model is built; and (5) discrete layer stratum compressibility evaluation sample space is then built, and a relationship between a compressibility evaluation result and different response logging curves is subjected to correlation analysis. The shale reservoir compressibility evaluation method based on the support vector machine technology has the beneficial effects that compressibility influencing factors are considered perfectly, the shale gas reservoir compressibility model is built from three aspects of a brittleness index, a natural crack development degree and the stress sensitivity, insufficient consideration on the factors by the existing evaluation method is remedied, and the comprehensive ability of the shale to form a complex crack network during volume cracking can be better reflected.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

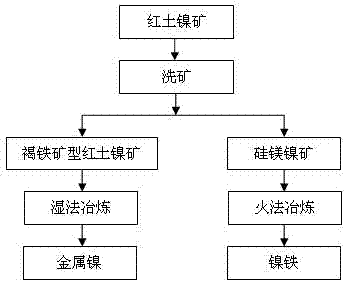

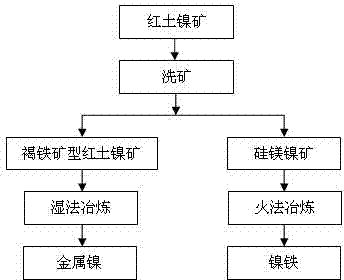

Method for processing laterite-nickel ore

InactiveCN102226232AHigh recovery rateReduce energy consumptionProcess efficiency improvementLateriteMaceral

The invention discloses a method for processing laterite-nickel ore. The method provided by the invention is characterized in that laterite-nickel ore undergoes an ore-washing treatment; noumeite and limonite-type laterite-nickel ore are separated; separated noumeite is melted by the pyrometallurgical process to generate ferronickel; and metallic nickel is extracted from the separated limonite-type laterite-nickel ore by the wet process. According to the method provided by the invention, based on the different mineral compositions of different laterite-nickel ore particle fractions, limonite-type laterite-nickel ore containing high content of iron and low content of magnesium is melted by the wet process to extract metallic nickel, thus leading to low acid consumption; noumeite containing low content of iron and high content of magnesium is melted by the pyrometallurgical process to extract ferronickel, thus leading to high quality of the produced ferronickel, high recovery rate of nickel, low energy consumption and simultaneous recovery of iron.

Owner:广西银亿新材料有限公司

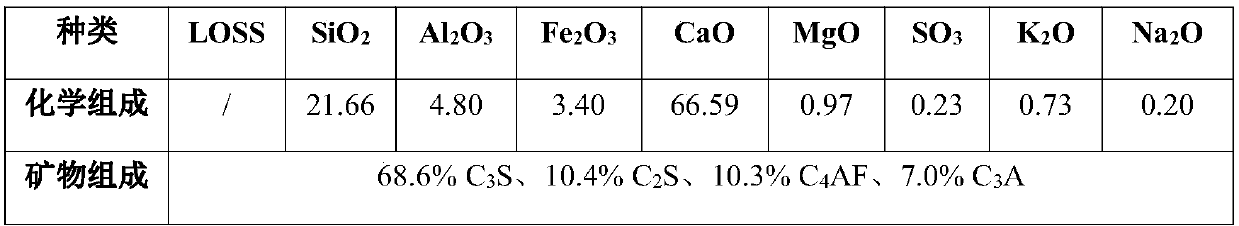

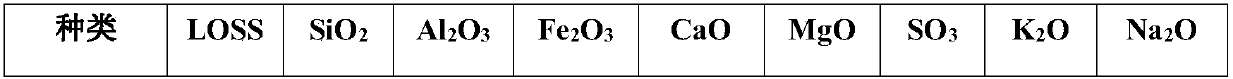

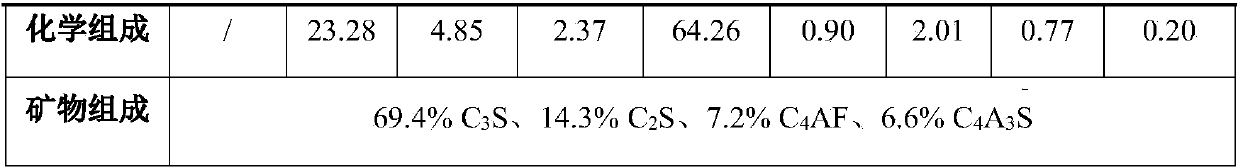

Modified portland cement clinker and preparation method thereof

InactiveCN107601924AImprove early strengthLower firing temperatureCement productionDecompositionMaterials science

Owner:GEZHOUBA SONGZI CEMENT

High-magnesium minimum-inflation low-heat cement and preparation method thereof

ActiveCN102898050AWide variety of sourcesTake advantage ofCement productionHigh magnesiumPortland cement

The invention discloses high-magnesium minimum-inflation low-heat cement and a preparation method thereof. A high-magnesium minimum-inflation low-heat cement clinker comprises the following mineral compositions in percentage by weight: 10-35% of C3S, 40-65% of C2S, 1-5% of C3A, 10-20% of C4AF and 6.0-8.0% of MgO. The concrete prepared by the cement has the characteristics of good liquidity, low water requirement amount, low hydration heat, high long-term strength, good durability and minimum inflation performance, and can be used for compensating the contraction of big-volume concrete and hydraulic concrete and reducing a concrete crack. Compared with the traditional portland cement and the low-heat portland cement, the high-magnesium minimum-inflation low-heat cement is more favorable for realizing the volume stability and the safety of the concrete, and is an ideal cementing material for the major projects, especially the big-volume concrete and hydraulic concrete engineering.

Owner:CHINA BUILDING MATERIALS ACAD

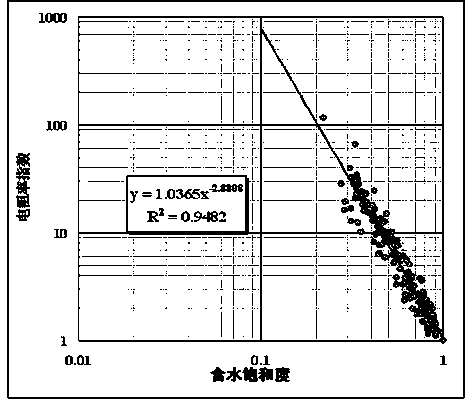

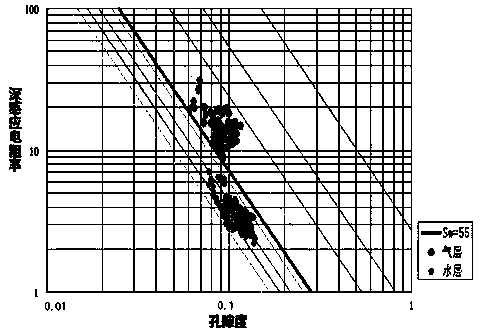

Complex lithology natural gas reservoir interval transit time discriminating method

InactiveCN103867197ASolve the discrimination problemImprove discriminationSurveyLithologyIgneous rock

The invention discloses a complex lithology natural gas reservoir interval transit time discriminating method, and belongs to the technical field of acoustic logging information application. Formation lithology mineral composition, porosity, water saturation and formation water electrical resistivity factors are utilized to calculate an interval transit time theoretical value curve, the interval transit time theoretical value curve obtained through calculation is compared with an interval transit time curve measured actually, and a natural gas reservoir is discriminated according to the different features of the interval transit time theoretical value curve obtained through the calculation and the interval transit time curve measured actually. The complex lithology natural gas reservoir interval transit time discriminating method is especially suitable for being used in discrimination of natural gas reservoirs of clastic rock, carbonate rock, igneous rock and the like, good in application prospect and capable of improving discriminating effect of the natural gas reservoirs.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

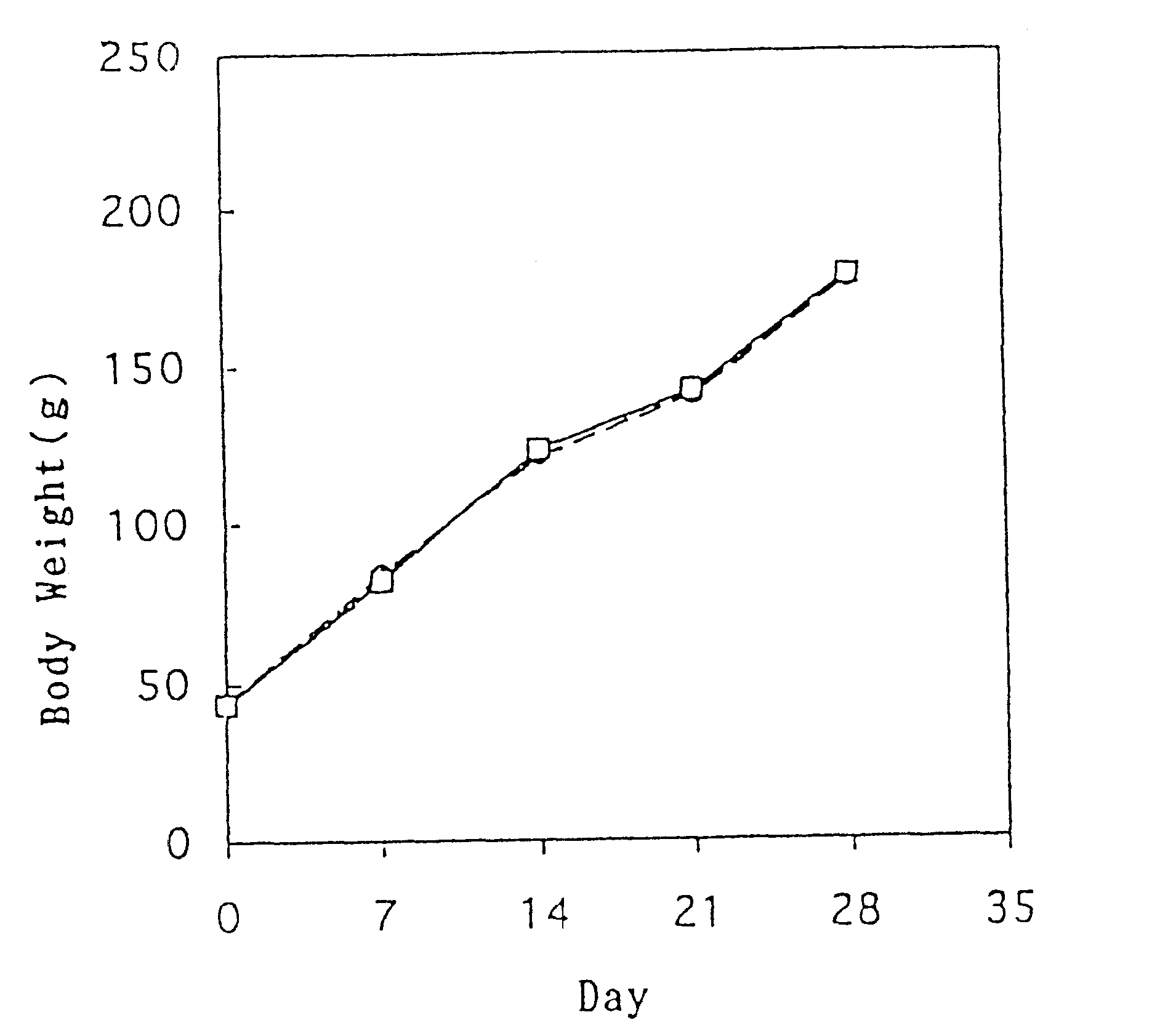

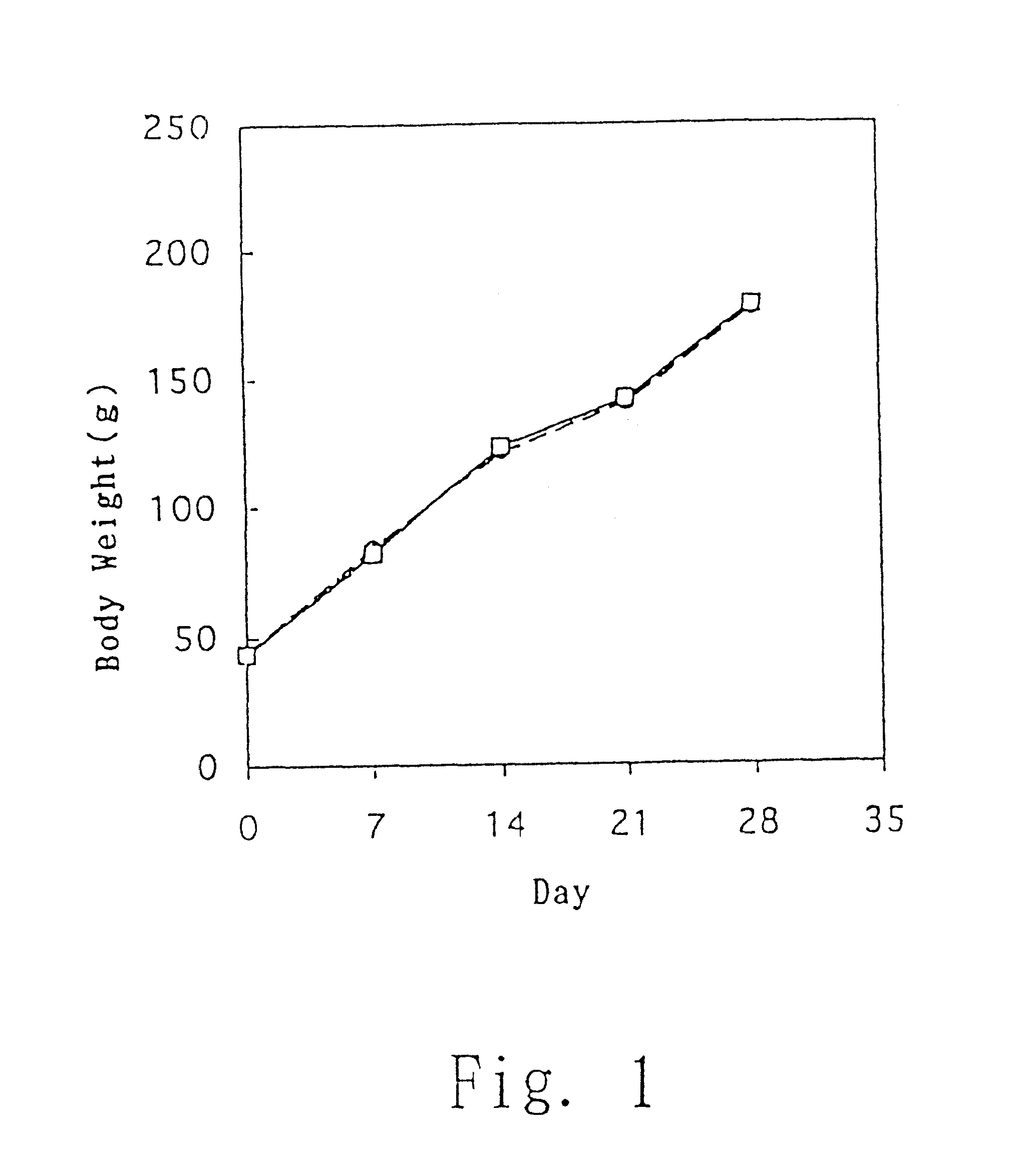

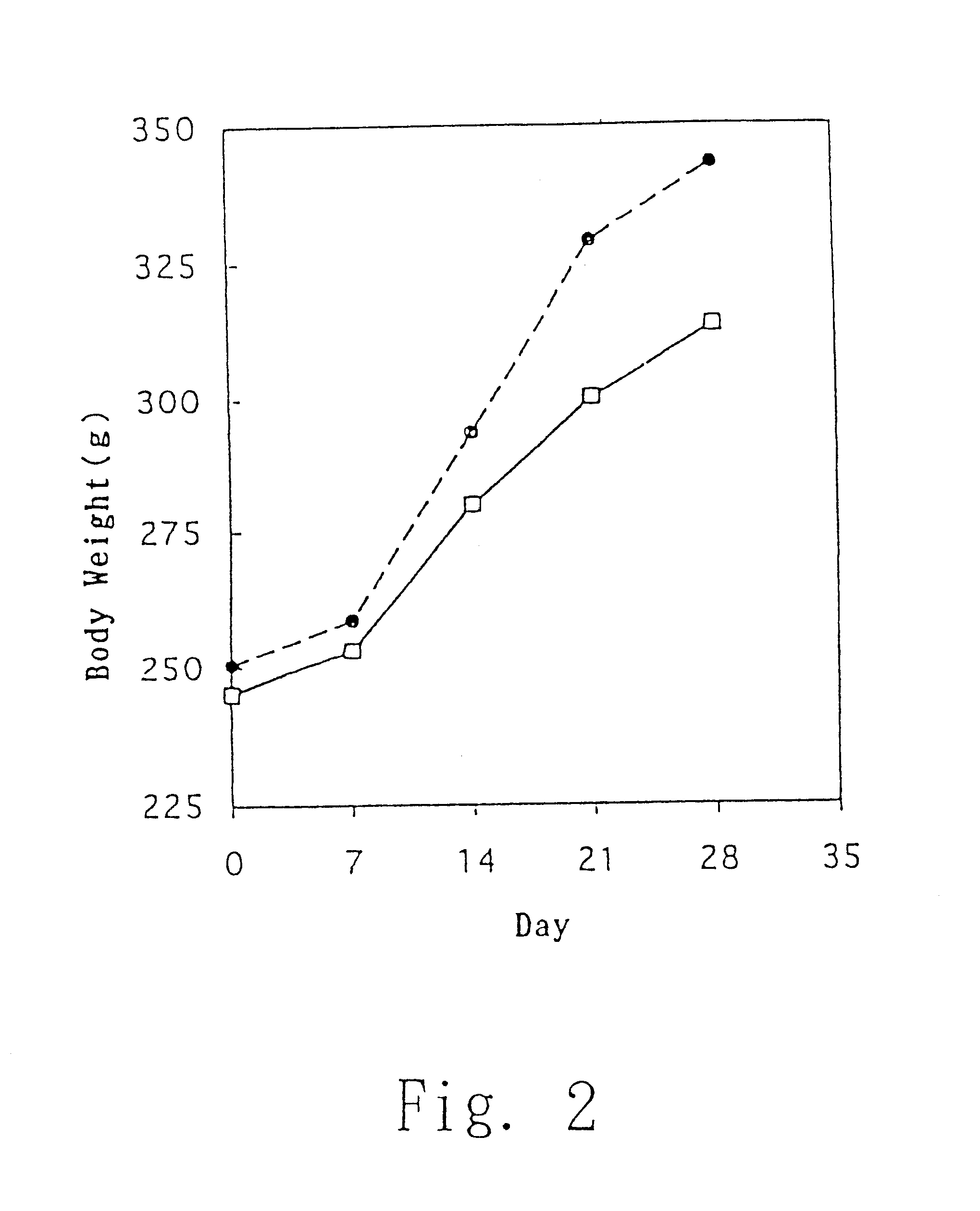

Composition comprising theanine

InactiveUS20010001307A1Low costSuppress symptomsBiocideHeavy metal active ingredientsMedicineTheanine

The present invention relates to a composition for suppressing or ameliorating a symptom accompanying diminished homeostasis, comprising theanine; and a mineral composition comprising theanine and a mineral. According to the present invention, there can be provided a composition for suppressing or ameliorating the above symptoms; and a mineral composition having a reduced peculiar metal taste, of which administration is made easily.

Owner:TAIYO KAGAKU CO LTD

Vitamin/mineral compositions with DHA

InactiveUS7704542B2Lower Level RequirementsReducing potential for clottingBiocideAntinoxious agentsDocosahexaenoic acidDisease

Compositions containing the fatty acid docosahexaenoic acid (DHA) in combination with at least one vitamin and mineral are provided to supplement nutrition in a mammalian diet. DHA is present in the composition in concentrated amounts, advantageously in a carrier such as marinol oil, to allow for quantities of DHA sufficient to supply expectant and new mothers and their children as recommended on a daily basis. This DHA may also be used to treat a variety of disorders in children and adults. The compositions advantageously include vitamins, minerals, and optionally other nutrients to provide a nutritional supplement which may be convenient to swallow and taken once a day.

Owner:SILICON VALLEY BANK

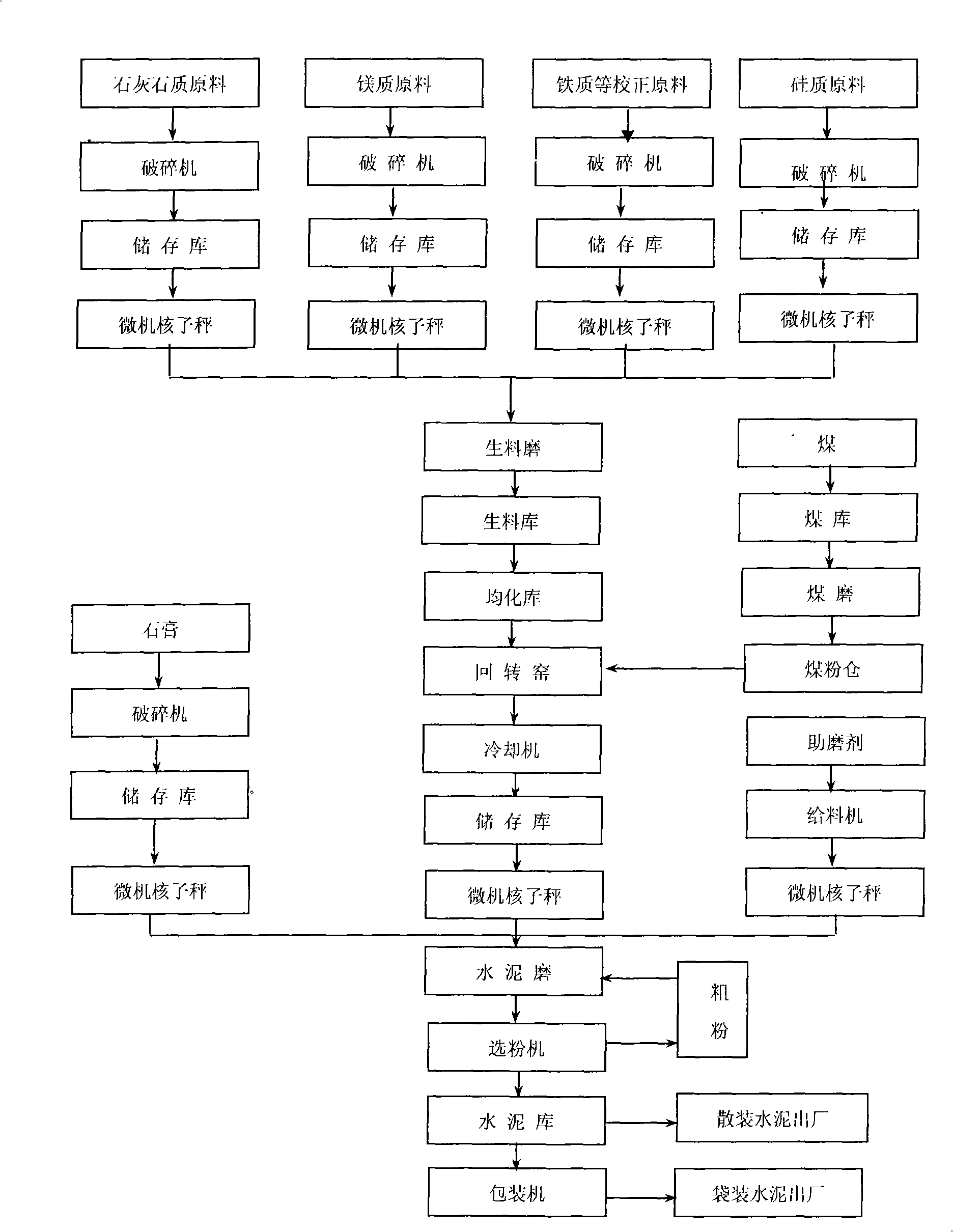

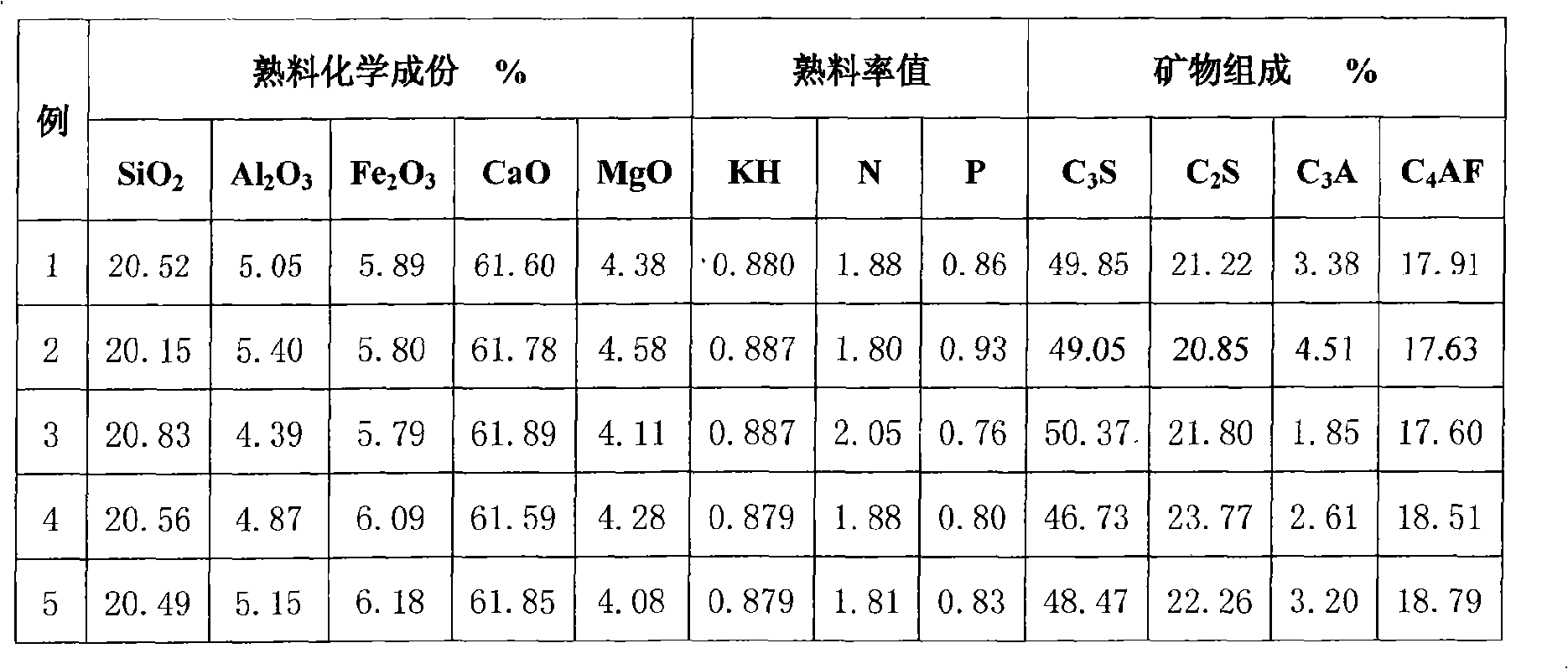

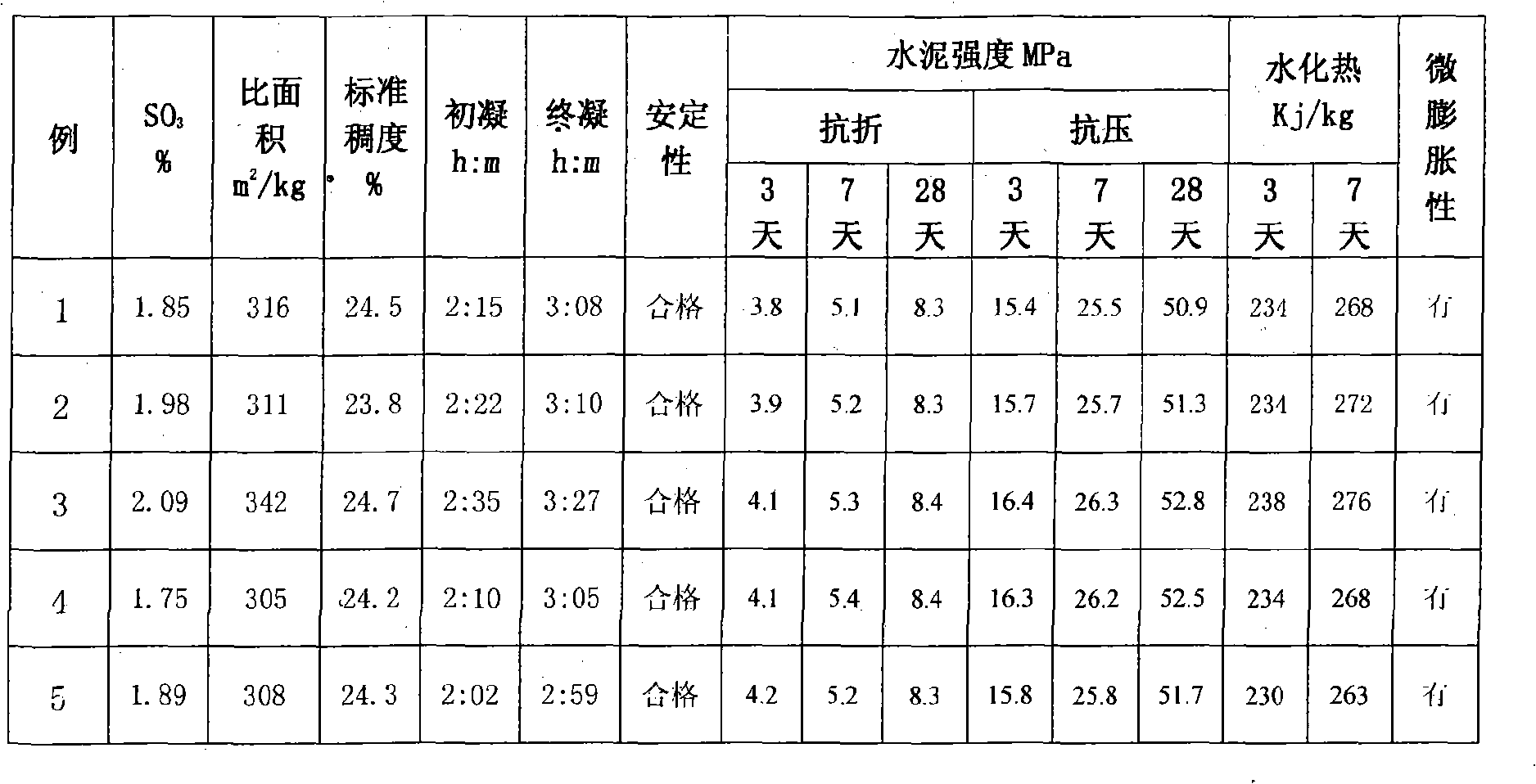

High-magnesium moderate-heat portland cement and production method thereof

InactiveCN101353231AReduce water demandThe micro-expansion property hasClinker productionHigh magnesiumPortland cement

The invention relates to a high-magnesium moderate heat portland cement, which is characterized in that (1) the contents of MgO and SO3 in the cement are 3.0-6.5% and 1.4-2.2% respectively; (2) the weight percentages of the mineral composition for grinding cement clinker are 35-55% of C3S, 15-35% of C2S, 1-6% of C3A and 10-25% of C4AF; and the content of MgO in the cement clinker is 3.0-6.5%; (3) in the raw materials for calcining the clinker, the contents of MgO, CaO and Fe2O3 are respectively controlled at a certain value within the ranges of 2.5-3.8%, 38.0-42.0% and 3.5-4.5%, and the variation ranges thereof are respectively controlled within plus or minus 0.10%, plus or minus 0.20% and plus or minus 0.15%. The production method of the cement mainly comprises three procedures of raw material milling, clinker calcining and cement grinding, namely, 'two grinding and one calcining'. The concrete made from the cement is characterized by good fluidity, low water requirement, moderate cement heat, high later strength, good durability, microdilatancy performance, and the like; compared with the conventional portland cement and moderate heat portland cement, the high-magnesium moderate heat portland cement is more favorable for realizing high performance of the concrete.

Owner:湖南石门特种水泥有限公司

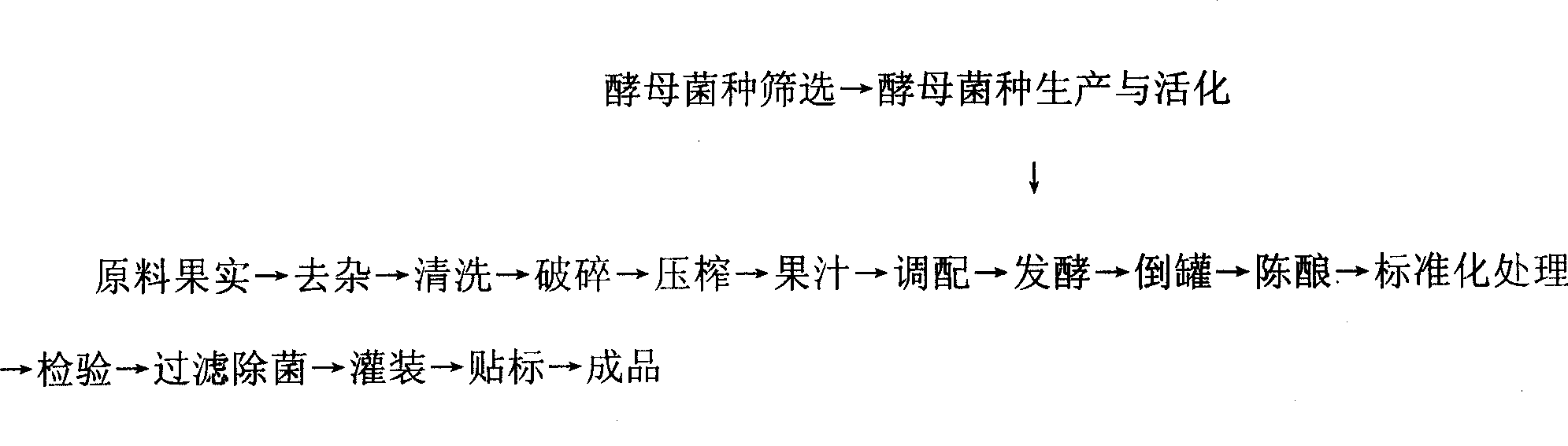

Aroniamelanocarpa fruit wine and brewing method thereof

InactiveCN101481643ARaw materials are uniqueFull of nutritionAlcoholic beverage preparationFruit juiceAntioxidant

The invention relates to an aroniamelanocarpa fruit wine and a brewing method thereof. The fruit of aroniamelanocarpa is taken as raw material and is made into fruit juice, fruit wine microzyme is selected for use and put into the fruit juice according to the proportion being 5-10% of the weight of the fruit juice, and the aroniamelanocarpa fruit wine is brewed with the alcohol content of 5-13% (v / v) and the total sugar content of 4.0-80.0g / L. The brewing technique of the invention comprises preparing the fruit juice, inoculation and fermentation, aging and store maturity, purifying wine body as well as filtration and sterilization, and the most advanced fermenting and purifying technique can be adopted by the production. The product of the invention has unique flavor, slightly acerbic and fresh taste, mellow mouthfeel, pleasing aroma and wide applicable people. The fruit wine contains multiple nutritional functional components such as anthocyanin, flavone, polyphenol active substance, vitamins antioxidant, mineral composition, polyoses, organic acid and the like which are rich in the fruit of aroniamelanocarpa, and has good effects of oxidation resistance, ageing prevention, blood pressure regulation, vessel relaxing, blood-fat reduction, anti-inflammation and detoxification, radiation resistance, etc.

Owner:辽宁省干旱地区造林研究所

Preparation method of cold soluble instant health food of grains, vegetables and fruits

ActiveCN101926463AWide variety of sourcesImprove immunityFood preparationBeta-CaroteneAdditive ingredient

The invention provides to a preparation method of cold soluble instant health food of grains, vegetables and fruits and relates to a novel preparation method of food with complete nutrients and high bioavailability, belonging to the technical field of modern nutritious food preparation. The method comprises the following steps: carrying out nonthermal physical field energy conservation dehydrateddesiccation on fresh plant source food raw materials, namely grains, vegetables and fruits which are unpolluted, green and safe; smashing the raw materials to 80-120 meshes; evenly compounding and mixing micronutrient functional factors with 10%-60% of corn, 10%-50% of vegetables and 10%-40% of fruits in the weight ratio, so as to prepare the all natural nutritious food of grains, vegetables and fruits which can be taken by mixed with cool boiling water. The invention mutually mixes the different grains, vegetables and fruits which are processed, so that the cold soluble instant product contains complete nutrients such as dietary fiber, protein, fat, vitamine, mineral composition, beta-carotene, flavone, natural coloring matter and the like, has high utilization ratio of nutritious components and good taste, and belongs to a novel health food.

Owner:JIANGNAN UNIV +1

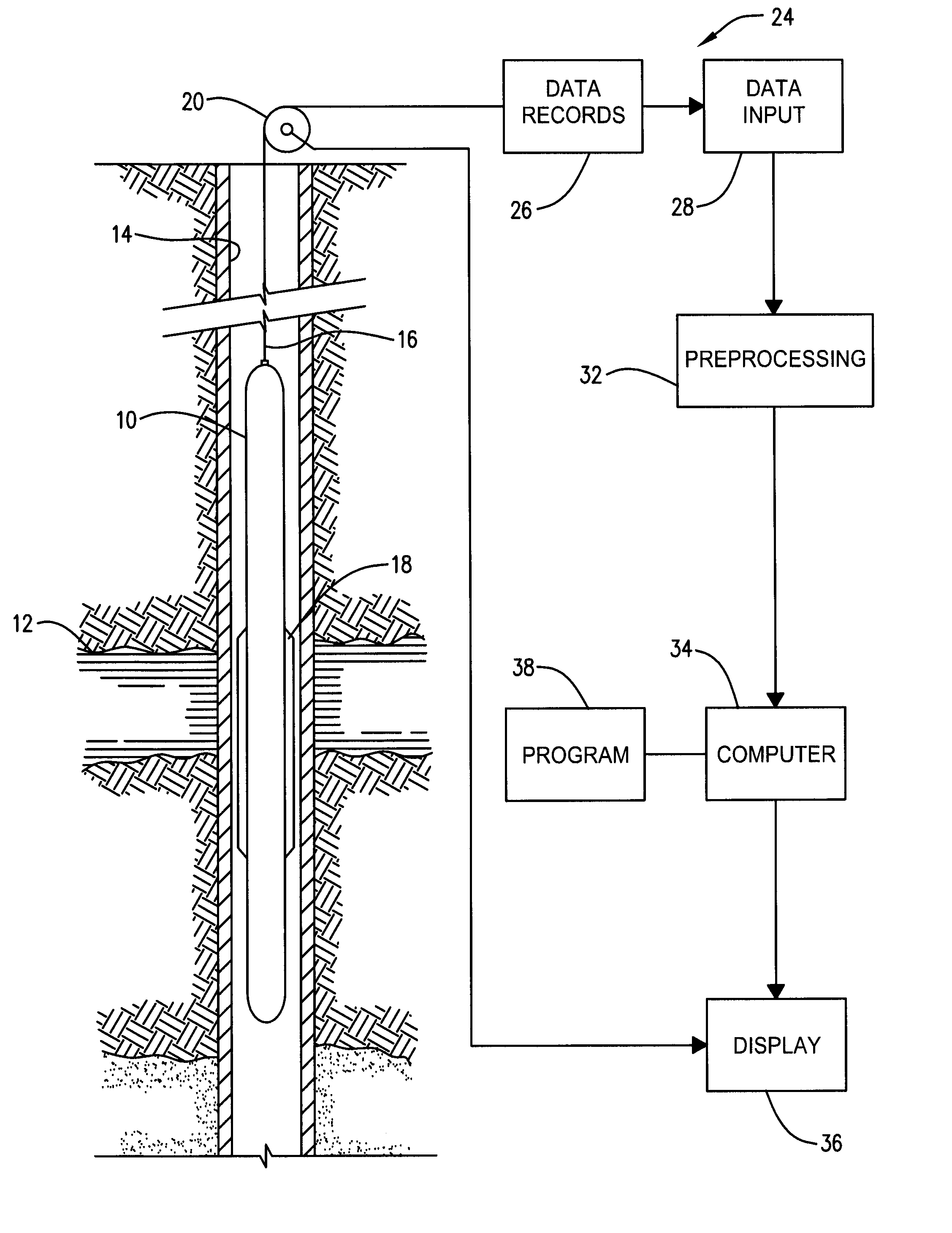

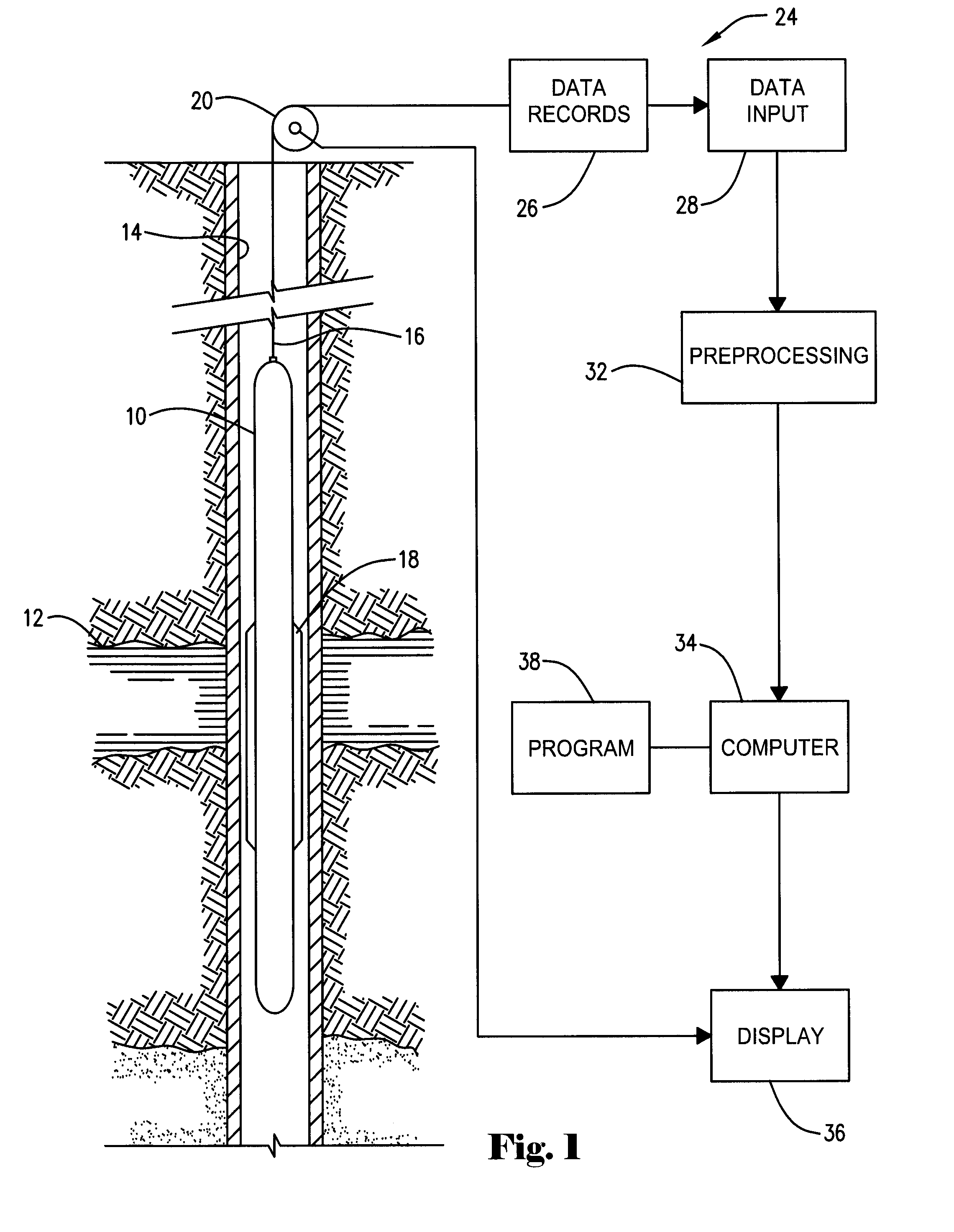

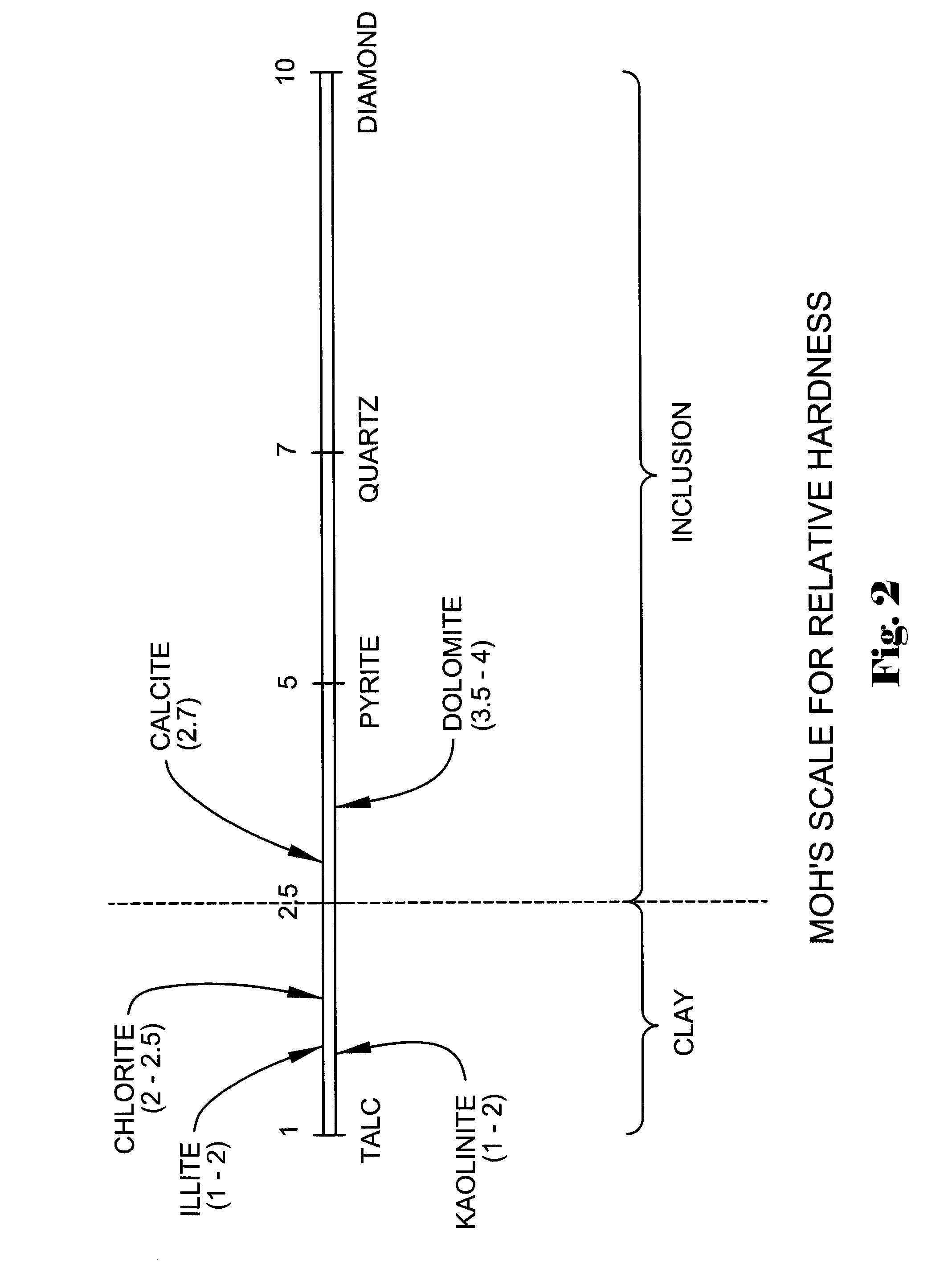

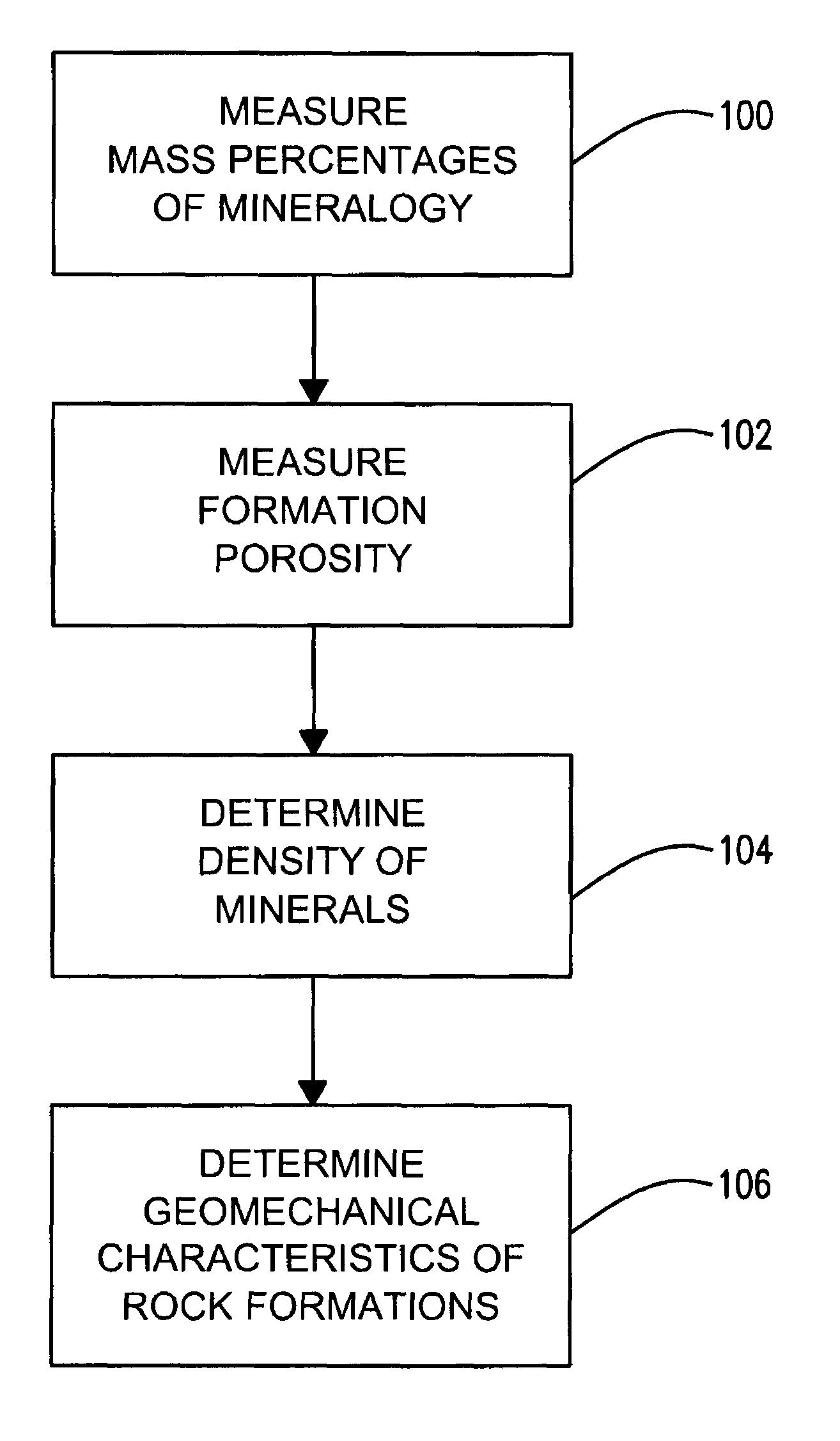

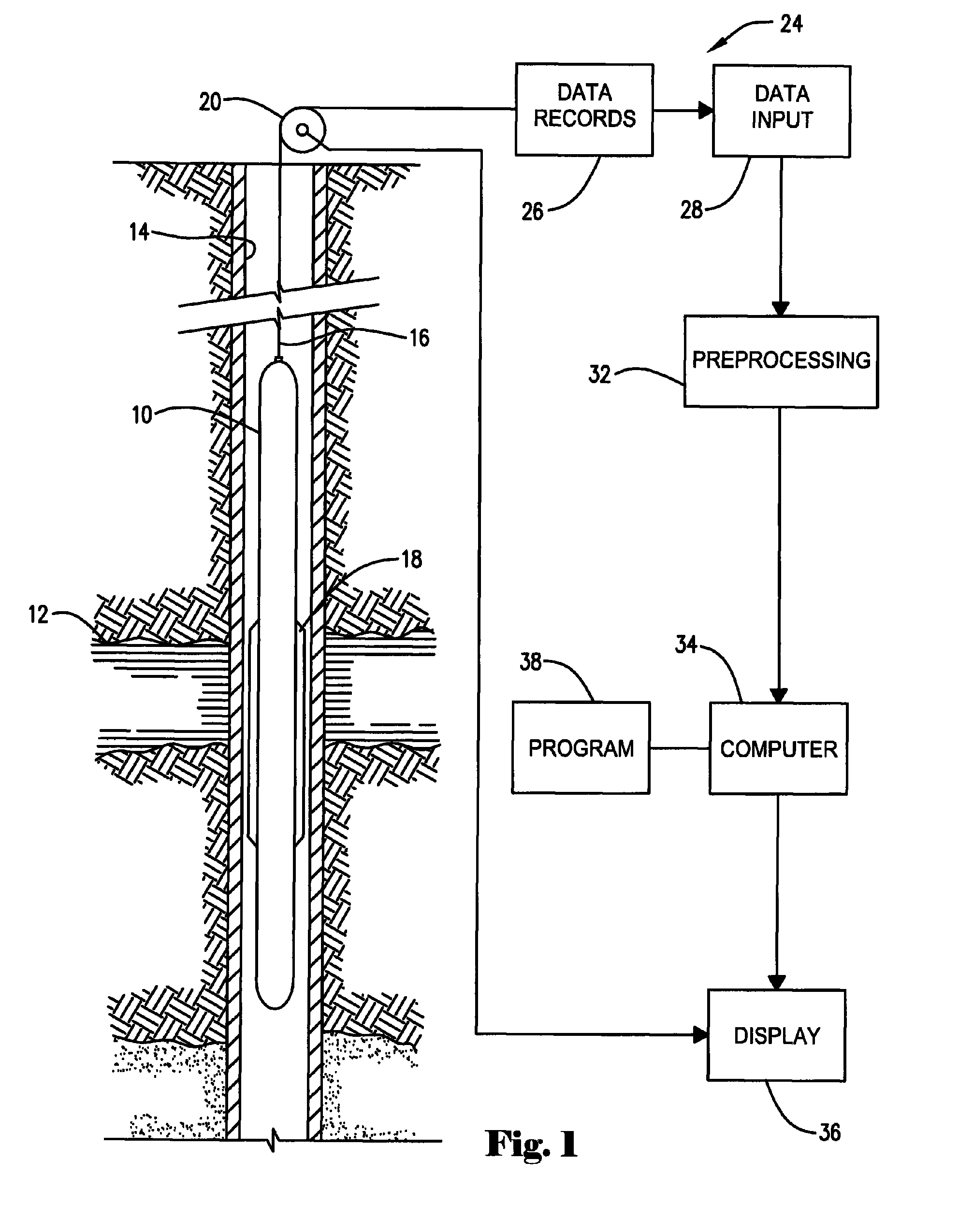

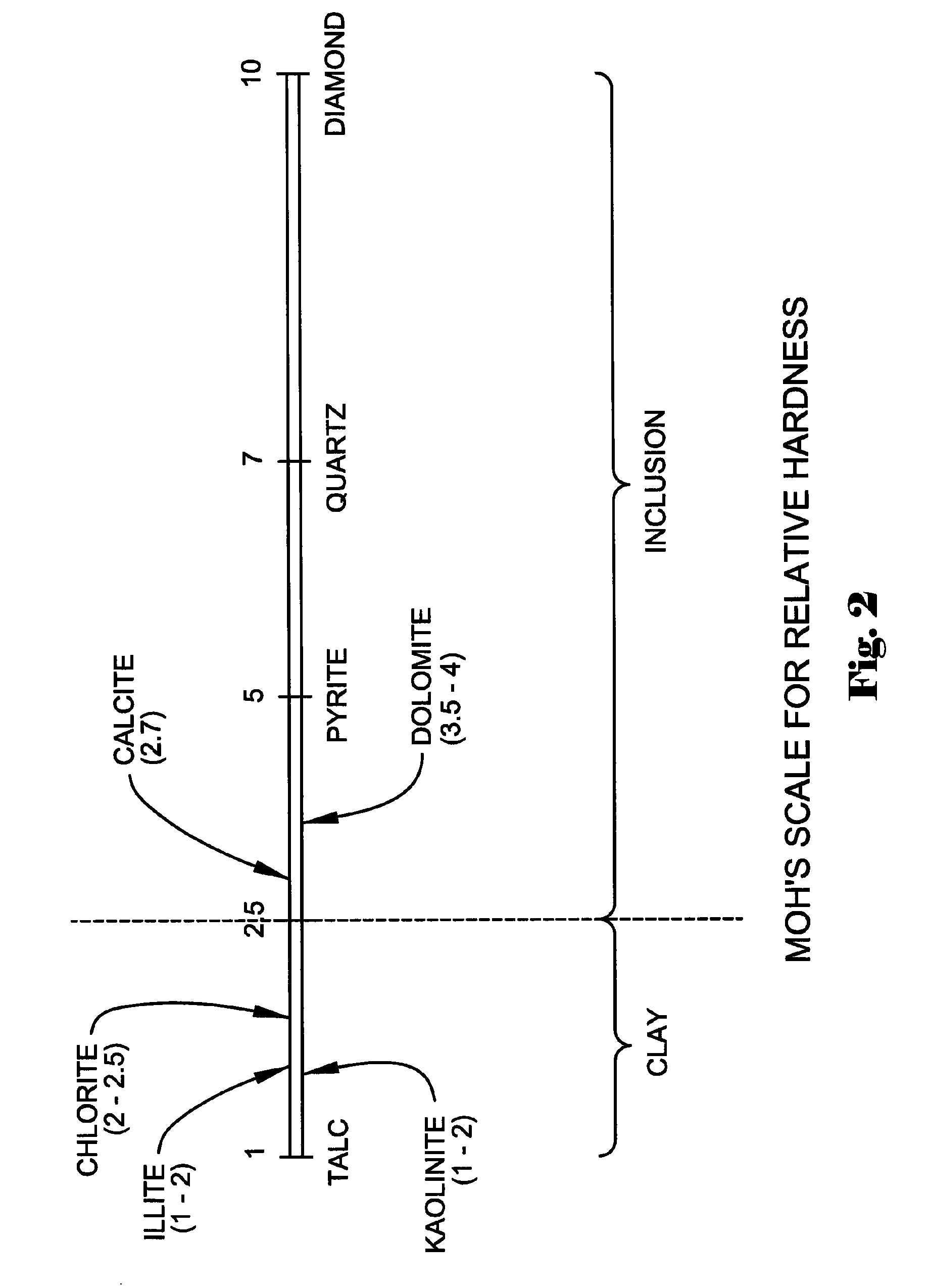

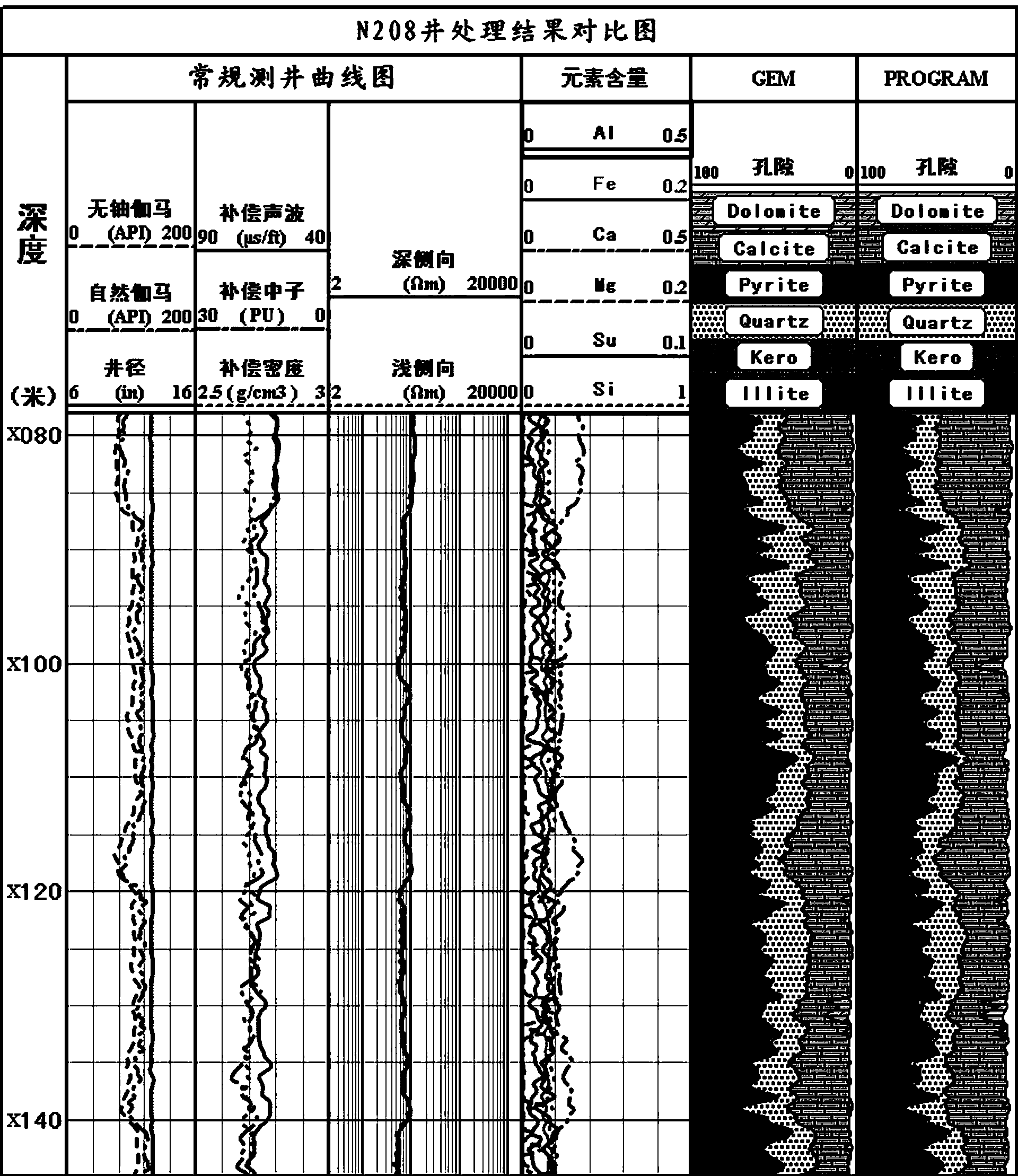

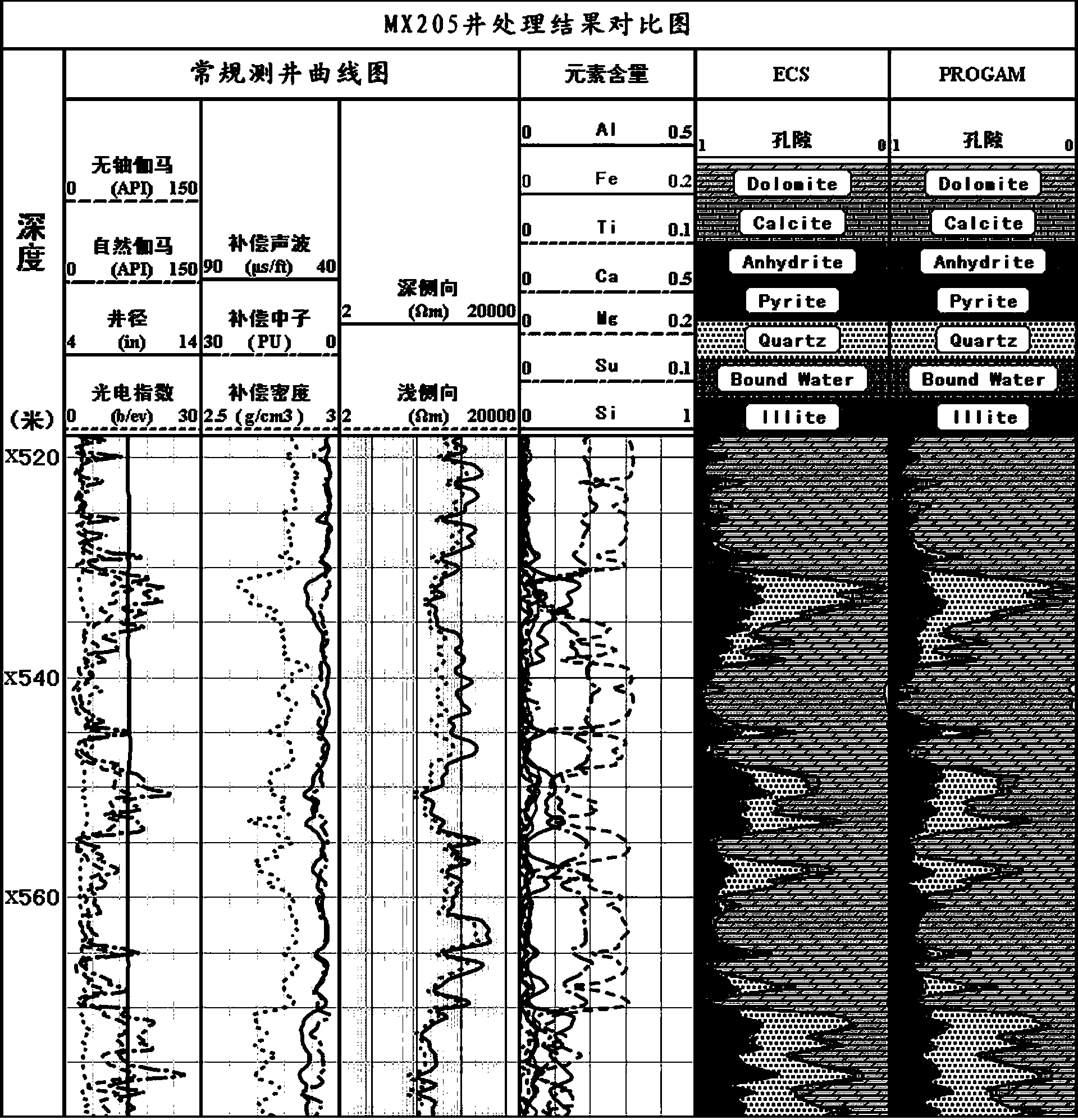

Method of predicting mechanical properties of rocks using mineral compositions provided by in-situ logging tools

ActiveUS20110022320A1Electric/magnetic detection for well-loggingPermeability/surface area analysisPorosityMechanical property

A method for predicting mechanical properties of a transverse isotropic region of a rock formation traversed by a well bore including running a logging tool in the well bore; the mass percentages of minerals present in the rock formation surrounding the well bore are measured with the logging tool. The density of the minerals present in the rock formation surrounding the well bore is determined. The porosity of the rock formation surrounding the well bore is measured. From the porosity and the measured mass percentages and density of the minerals, all the transverse isotropic elastic coefficients of the rock formation are determined in real time.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA +1

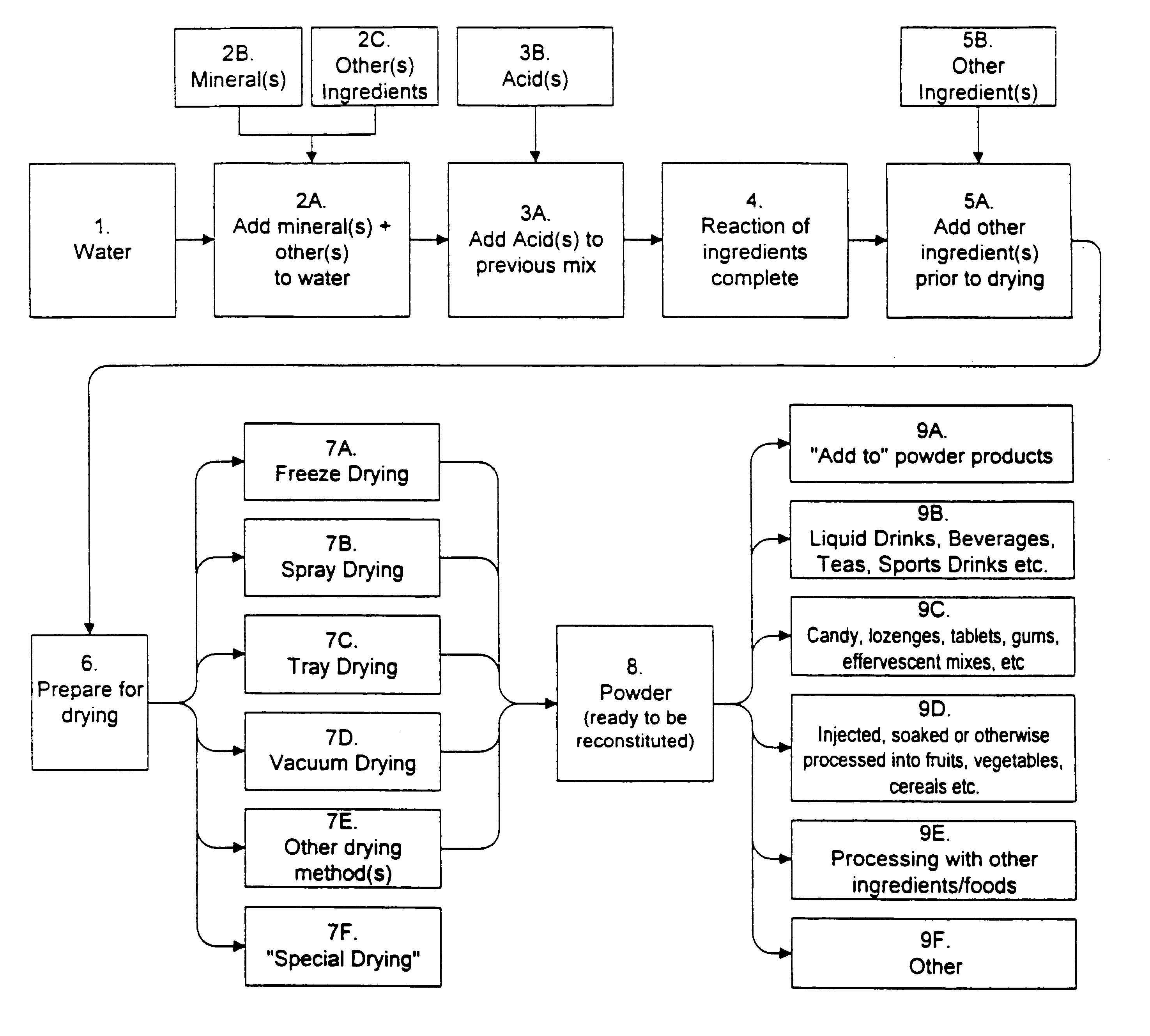

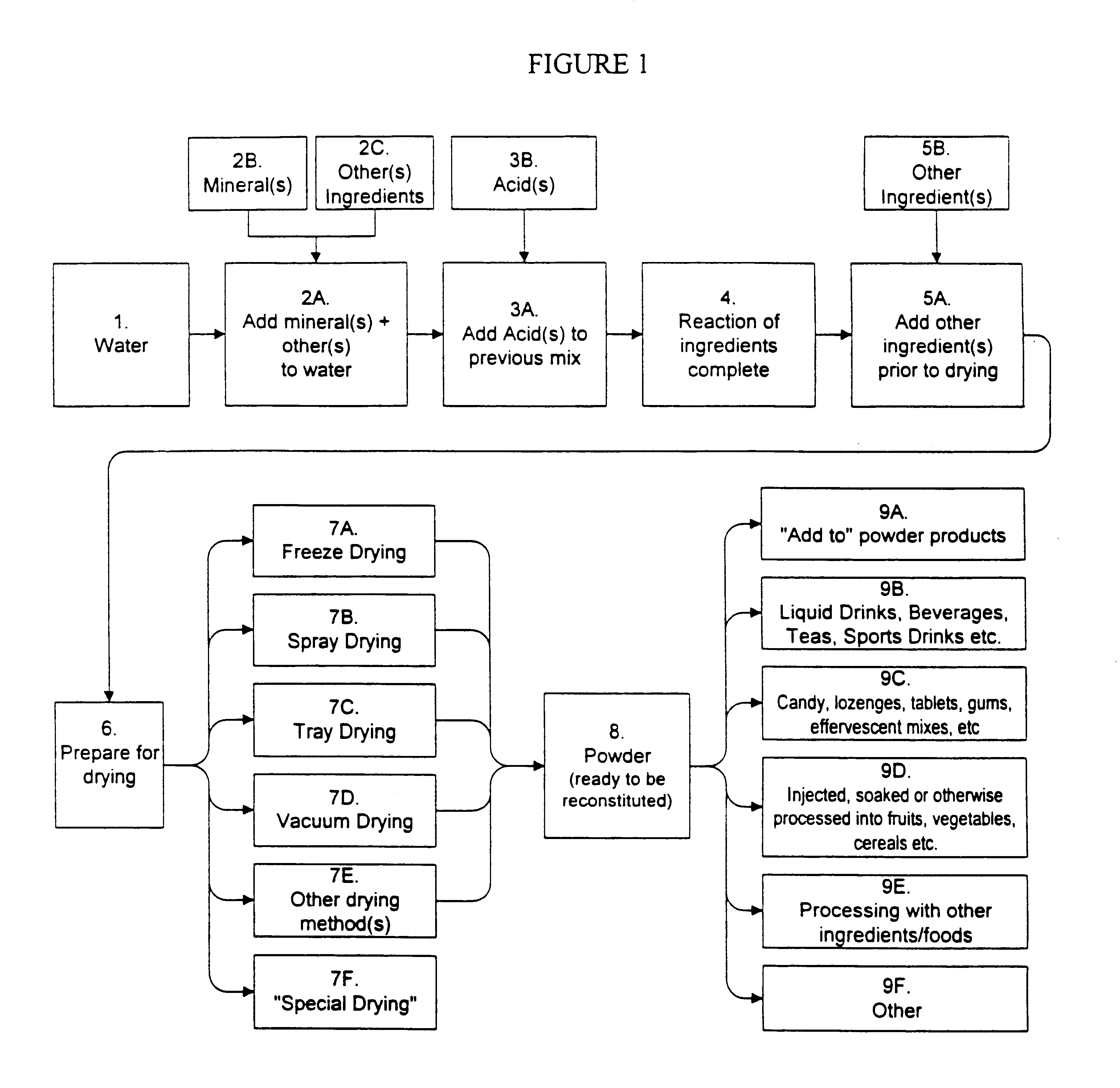

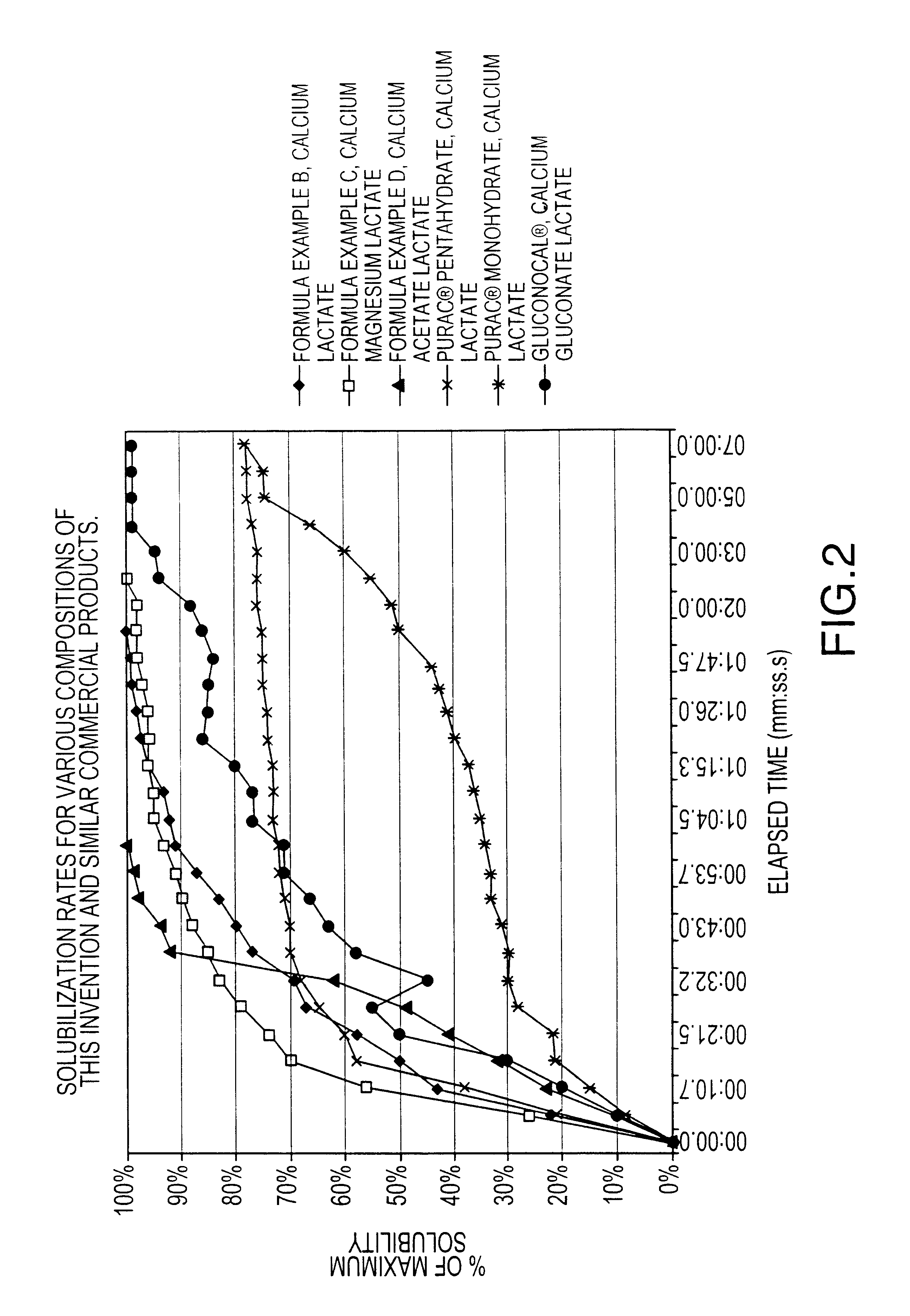

Highly soluble and stable mineral supplements containing calcium and magnesium and methods of making

InactiveUS6569477B2Improve clarityImprove odorConfectioneryAnimal feeding stuffSolubilityHigh concentration

The present invention provides novel compositions containing calcium and / or other minerals (as single mineral compositions or as multiple mineral compositions), methods for making these compositions, and methods for delivering the compositions. The compositions provide soluble bioavailable calcium and / or other minerals at a high concentration due to the high solubility attained through the processing method contained in this patent. Addition by these methods of other mineral(s) to calcium increases the stability and solubility of the calcium. The compositions of the present invention are powders that can be reconstituted in aqueous solutions. The compositions of the present invention also are very stable, allowing for a long shelf life of the compositions and of foods supplemented with the compositions.

Owner:MINTECH

Method of predicting mechanical properties of rocks using mineral compositions provided by in-situ logging tools

ActiveUS8380437B2Electric/magnetic detection for well-loggingPermeability/surface area analysisPorosityTransverse isotropy

A method for predicting mechanical properties of a transverse isotropic region of a rock formation traversed by a well bore including running a logging tool in the well bore; the mass percentages of minerals present in the rock formation surrounding the well bore are measured with the logging tool. The density of the minerals present in the rock formation surrounding the well bore is determined. The porosity of the rock formation surrounding the well bore is measured. From the porosity and the measured mass percentages and density of the minerals, all the transverse isotropic elastic coefficients of the rock formation are determined in real time.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA +1

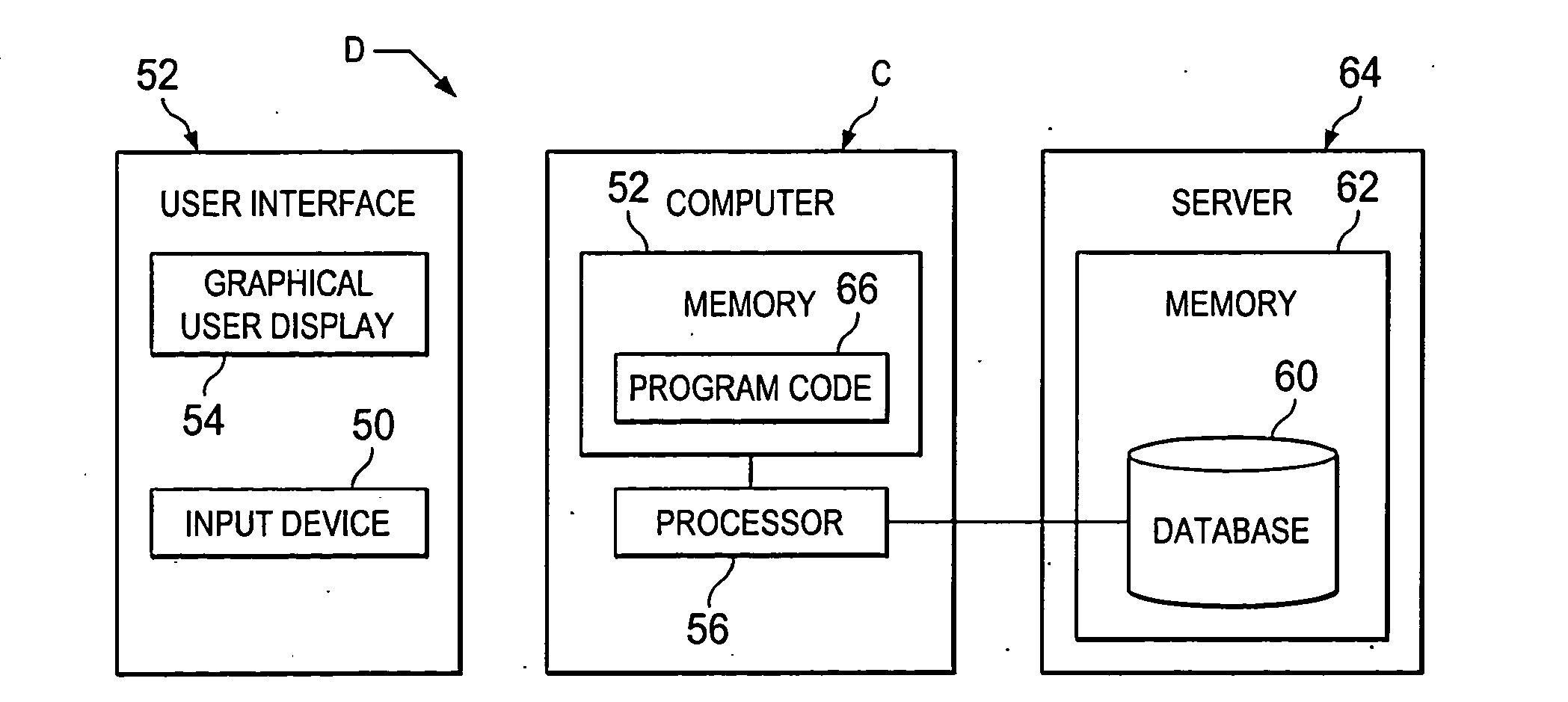

Core-plug to giga-cells lithological modeling

Well core data descriptions are received as input digital data for computer lithofacies modeling. Digital templates are established for carbonate and clastic core description based on reservoir rock formation analysis. Description criteria of the template for carbonate rock can include texture, mineral composition, grain size, and pore type. For clastic rock, the criteria in the template can include grain size, sedimentary structure, lithology, and visual porosity. The data and observations regarding these criteria are entered into a computer 3D geological modeling system directly. Wireline log data are integrated to calibrate with well core description to derive lithofacies. The lithofacies are exported in digital format to be entered into the 3D geological modeling system. A geologically realistic model of the reservoir can be established.

Owner:SAUDI ARABIAN OIL CO

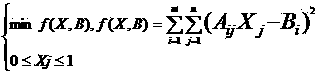

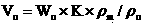

Method of calculating mineral components of rock in formations through element contents

InactiveCN103617345AEasy to implementImprove calculation accuracySpecial data processing applicationsBorehole/well accessoriesPorosityLithology

The invention discloses a method of calculating mineral components of rock in formations through element contents. According to the method, formation element content curves obtained by element logging and conventional logging curves are used as input information; the volume contents of rock mineral contents in complex lithological formations are calculated according to the input information and areal geological parameter. The method is applicable to the determination on rock mineral components in various complex lithological formations, and rock mineral components and porosity thereof can be calculated more accurately.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

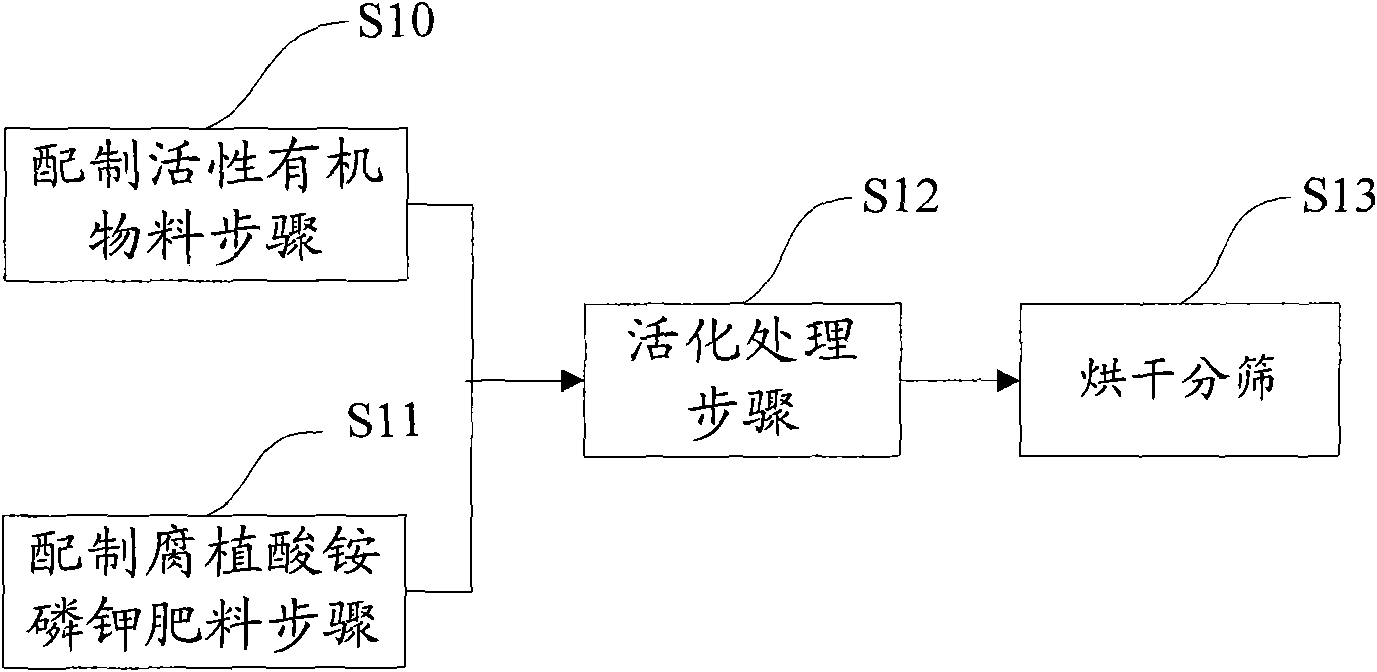

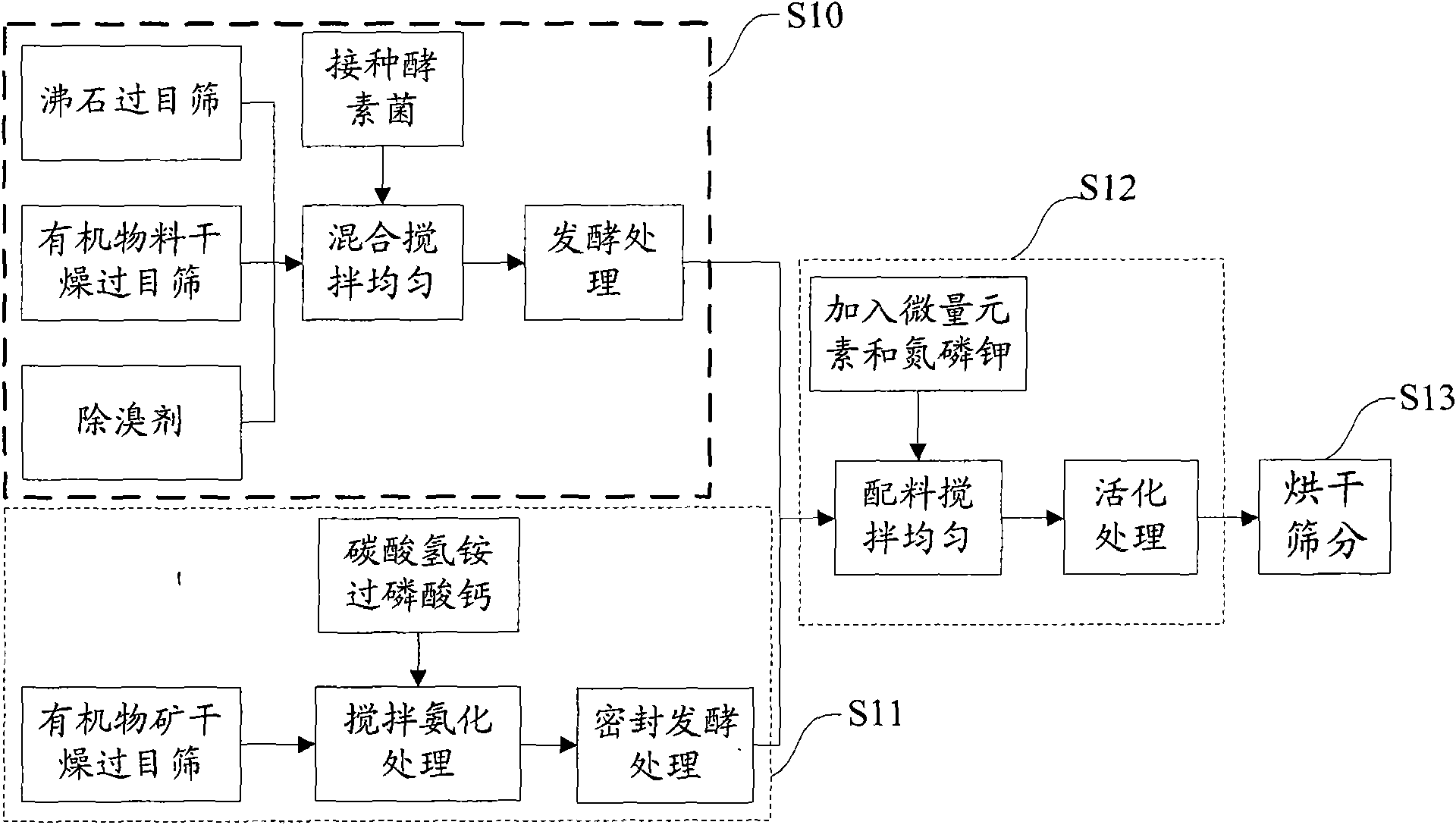

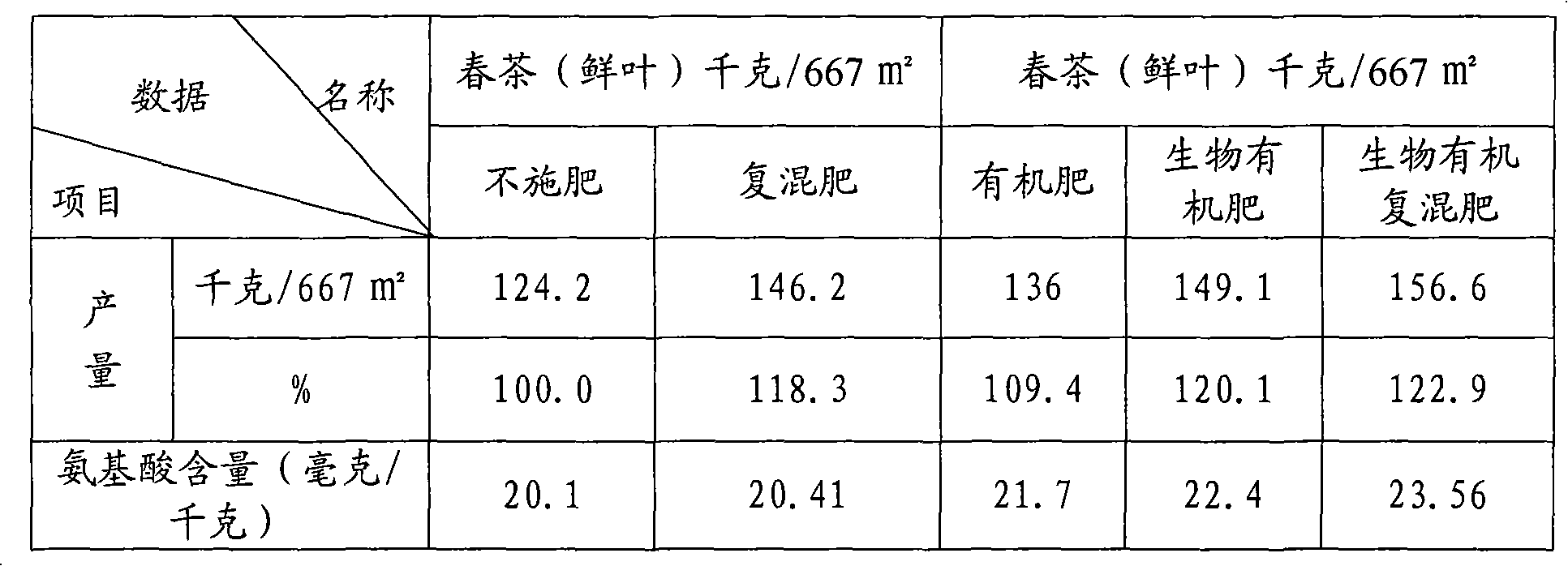

Organic compound fertilizer special for tea and preparation method thereof

InactiveCN101575252AGrow fastImprove qualityBio-organic fraction processingClimate change adaptationPotassiumOrganic compound

The invention discloses an organic compound fertilizer special for tea, comprising: 19-24 percent of humic acidic ammonium phosphorus kalium fertilizer, 5-6 percent of phosphate fertilizer, 5-6 percent of potassium fertilizer, 20-22 percent of nitrogenous fertilizer, 1-4 percent of microelement and 45-50 percent of active organic materials. As the organic compound fertilizer special for the tea provides more nutrition, tea can grow fast, and the yield of tea can be improved. Moreover, the tea with the organic compound fertilizer special for the tea contains more mineral composition and microelement which are essential to the health of human beings so as to improve the quality of the tea. The invention also provides a preparation method of the organic compound fertilizer special for the tea.

Owner:GUIZHOU HUANONG BIO FERTILIZER

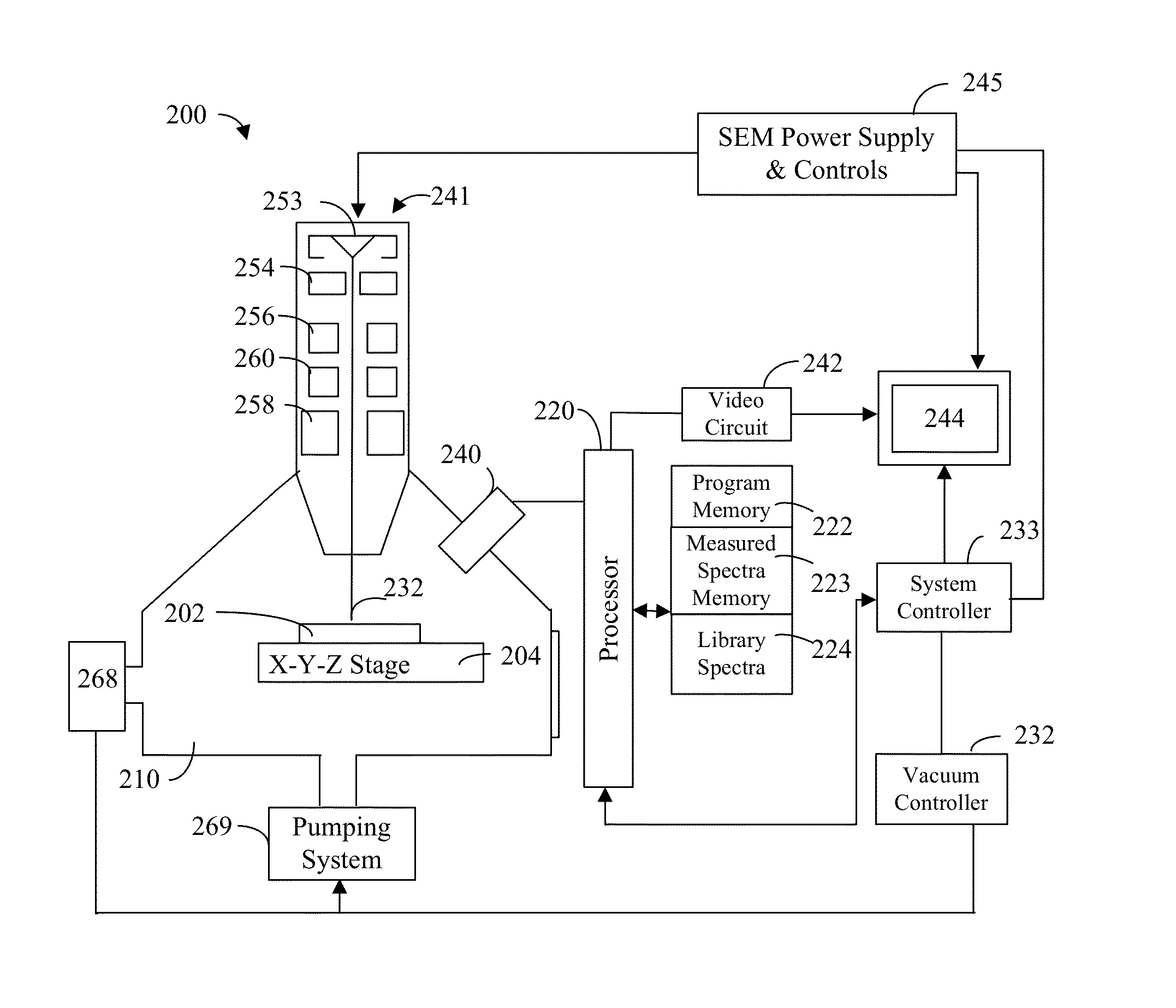

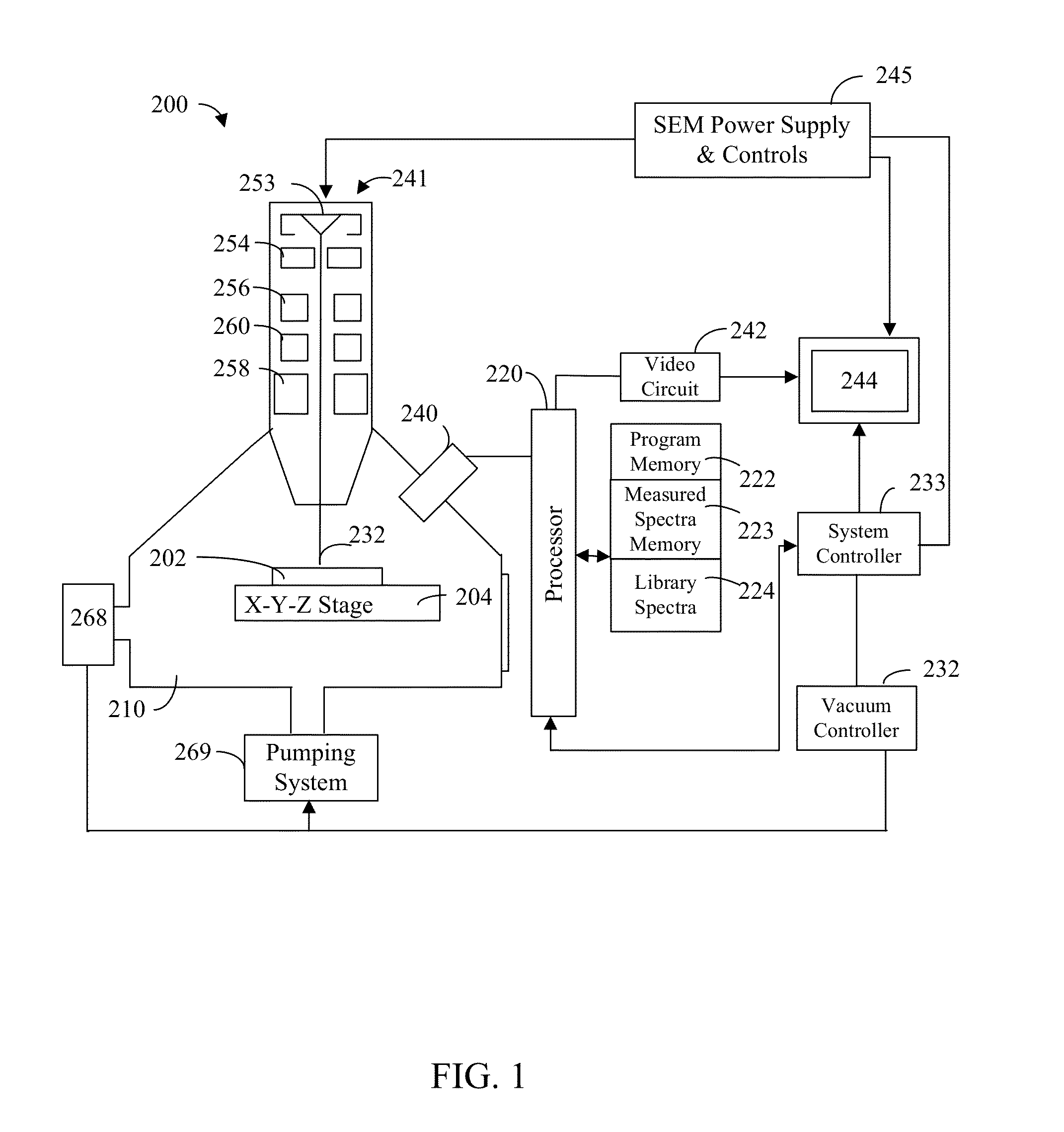

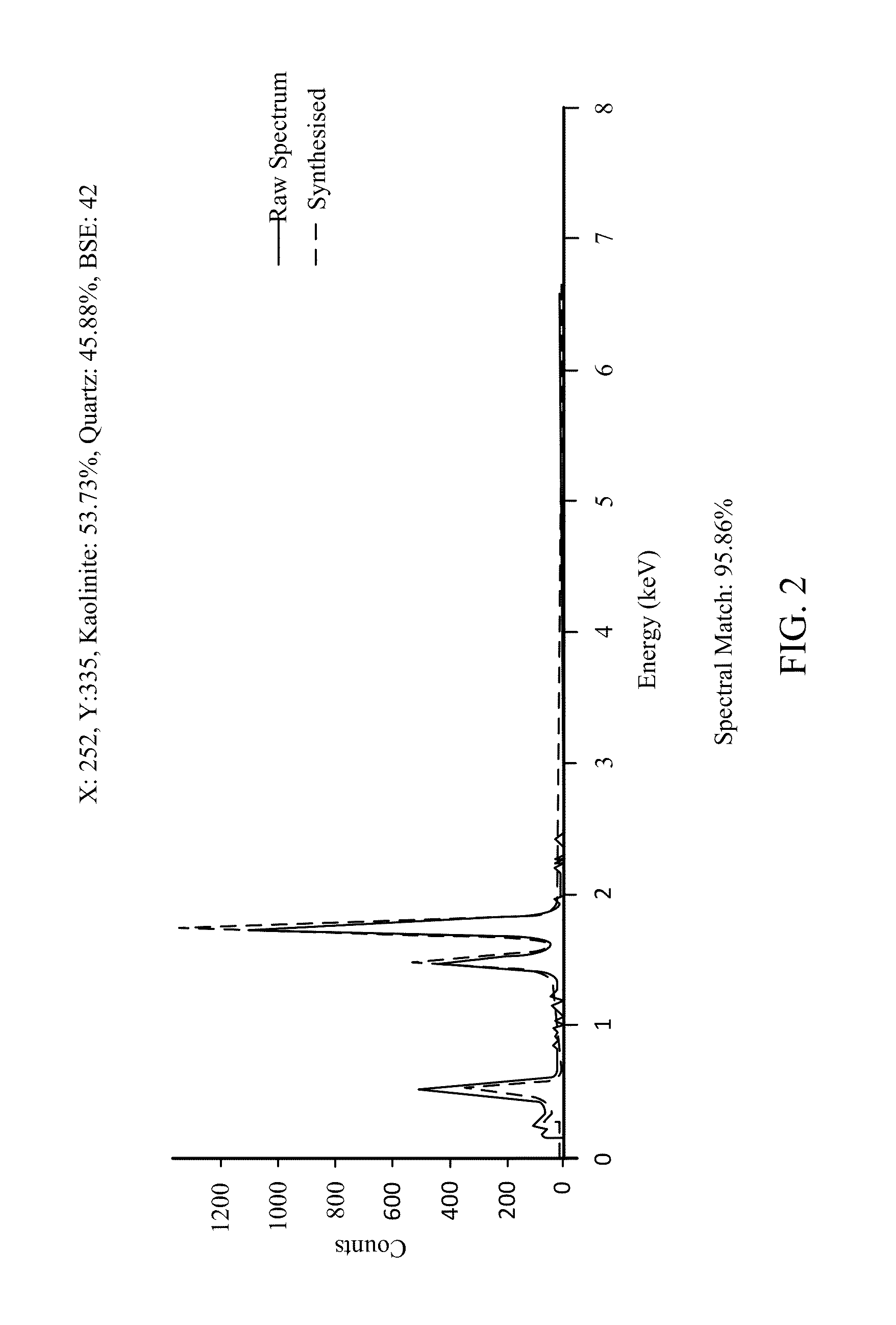

Sub-pixel Analysis and Display of Fine Grained Mineral Samples

ActiveUS20150122992A1Material analysis using wave/particle radiationElectric discharge tubesMaceralCharged particle beam

Method and apparatus for analysis and display of fine grained mineral samples. A portion of the sample is illuminated with a charged particle beam. Emitted radiation is detected, and a sample emission spectrum is generated and fit with a plurality of standard emission spectra of minerals in a candidate mineral composition. A mineral composition whose emission spectrum best fits the sample emission spectrum is selected from a plurality of candidate mineral compositions. An assigned color is received for each mineral in the selected mineral composition, and the assigned colors are blended according to the proportion of each mineral in the selected mineral composition. An image pixel corresponding to the portion of the sample is rendered for display.

Owner:FEI CO

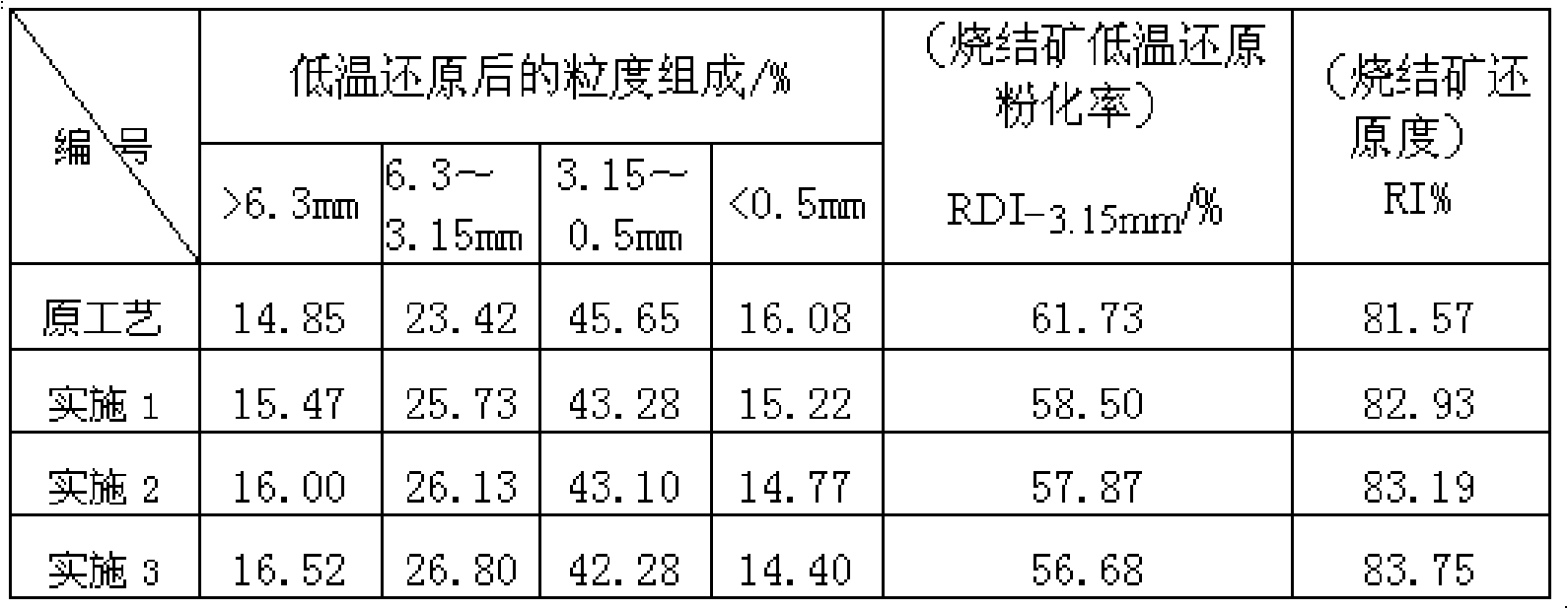

Pelletisation process for iron ore concentrate sintered mix

The invention relates to a granulating method of iron ore concentrate sintering mixture, and belongs to the metallurgical field. The method solves the technical problem that the granulating method of the iron ore concentrate sintering mixture is provided, wherein, the granulating method can increase the quality of sintering minerals. The granulating method of the iron ore concentrate sintering mixture adopts a secondary granulating method for granulating. The granulating method of the iron ore concentrate sintering mixture improves the grain-size composition and the granulation property of the sintering mixture, and increases the ventilation property and the sintering speed of a sinter bed, thereby increasing the sinter output; the granulation of the iron ore concentrate is strengthened, the intensity of the granulating pellets is increased, and the increase of the sinter strength is facilitated; partial high basicity of the iron ore concentrate is formed during the pre-granulating produces, the generation of partial calcium ferrite is promoted, the total content of the calcium ferrite and silicate, the mineral compositions and structure of sintering ore is facilitated to be improved, and the intensity and the finished product rate of the sintering ore are increased; the metallurgical property of the sintering ore is improved, the technical and economic index of blast furnace smelting is increased, and the wide application prospect is realized.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

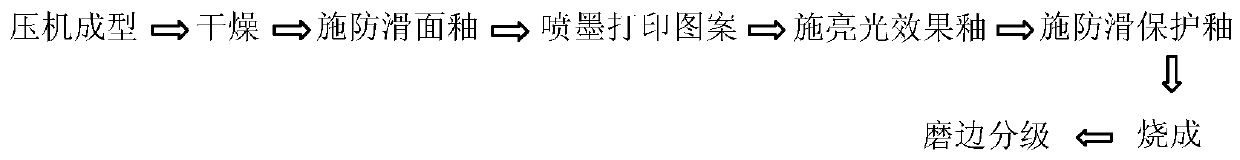

Wet water high anti-skid ink-jet ceramic tile with sunken glaze effect and preparation method of tile

The invention provides a wet water high anti-skid ink-jet ceramic tile with a sunken glaze effect and a preparation method of the tile. The preparation method includes sequentially applying anti-skidsurface glaze, decorative patterns, bright effect glaze and anti-skid protective glaze on a blank body, and then firing, wherein the mineral composition of the composition of the anti-skid surface glaze comprises 40-50% of potassium feldspar, 0-10% of albite, 7-10% of kaolin, 8-12% of quartz, 8-11% of calcined alumina, 0-5% of nepheline, 2-4% of zinc oxide, 7-10% of zirconium silicate and 6-10% ofbarium carbonate; and the mineral composition of the composition of the anti-skid protective glaze comprises 48-58% of potassium feldspar, 0-10% of albite, 10-20% of kaolin, 0-5% of quartz, 0-4% of nepheline, 2-5% of calcined alumina, 10-15% of barium carbonate and 5-8% of zinc oxide. The anti-skid ceramic tile can be used as a decorative material with a good decorative effect, excellent pollution resistance and anti-skid performance, and can be applied to the field of home decoration.

Owner:MONALISA GRP CO LTD

Method for producing feed silage

The invention relates to a preparation method of an ensilage. When the ensilage which contains the mineral composition of mulberry leaves is prepared, the grinded mulberry leaves with the weight portions of 5-50 are mixed with one or a plurality of cut roughages with the weight portions of 95-50, the water is adjusted so as to achieve the fermentation, and the ensilage is then prepared. The cut maize plant or cut maize plant and corn ears are preferably adopted by the roughages. The invention provides the ensilage preparation method which can uniformly prepare the ensilage by uniformly dispersing the mineral composition of the mulberry leaves.

Owner:韩一桥 +1

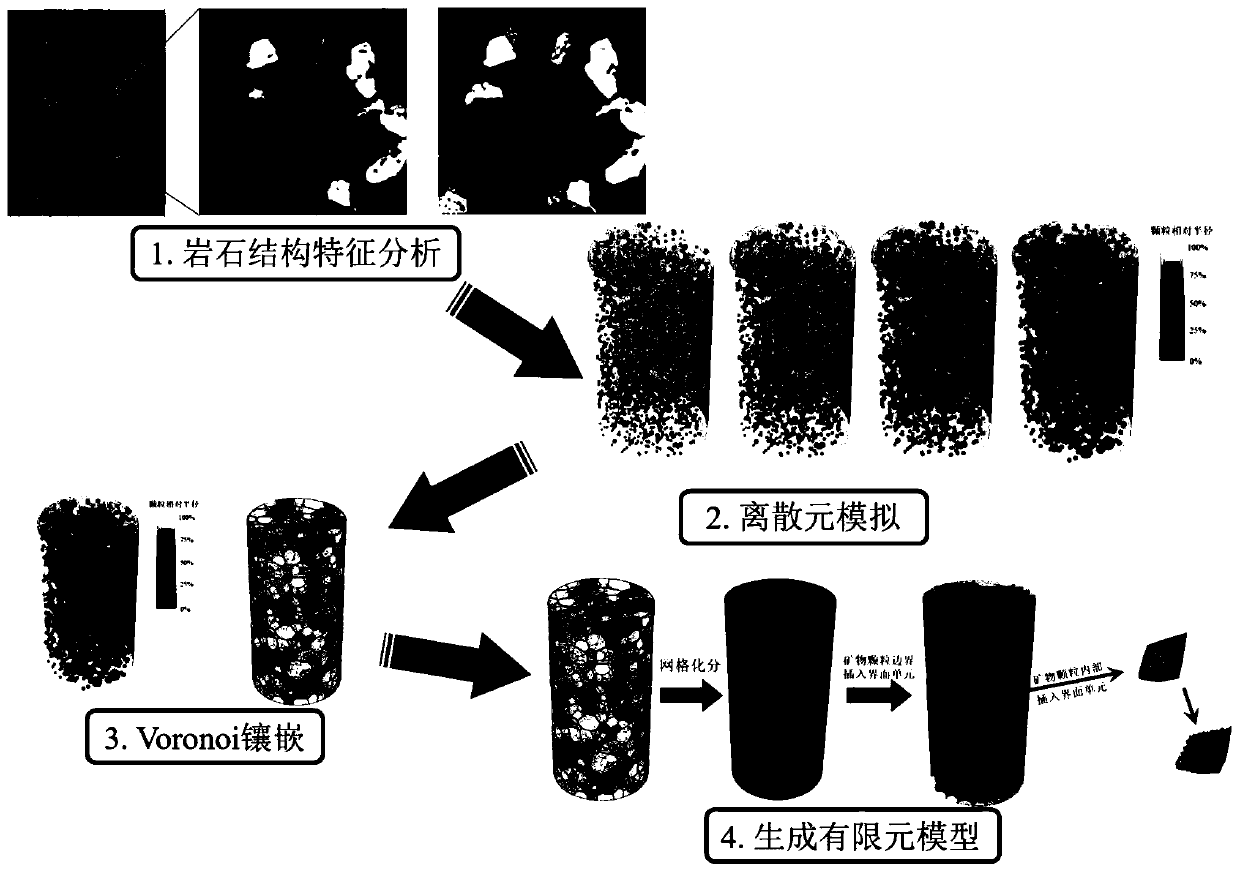

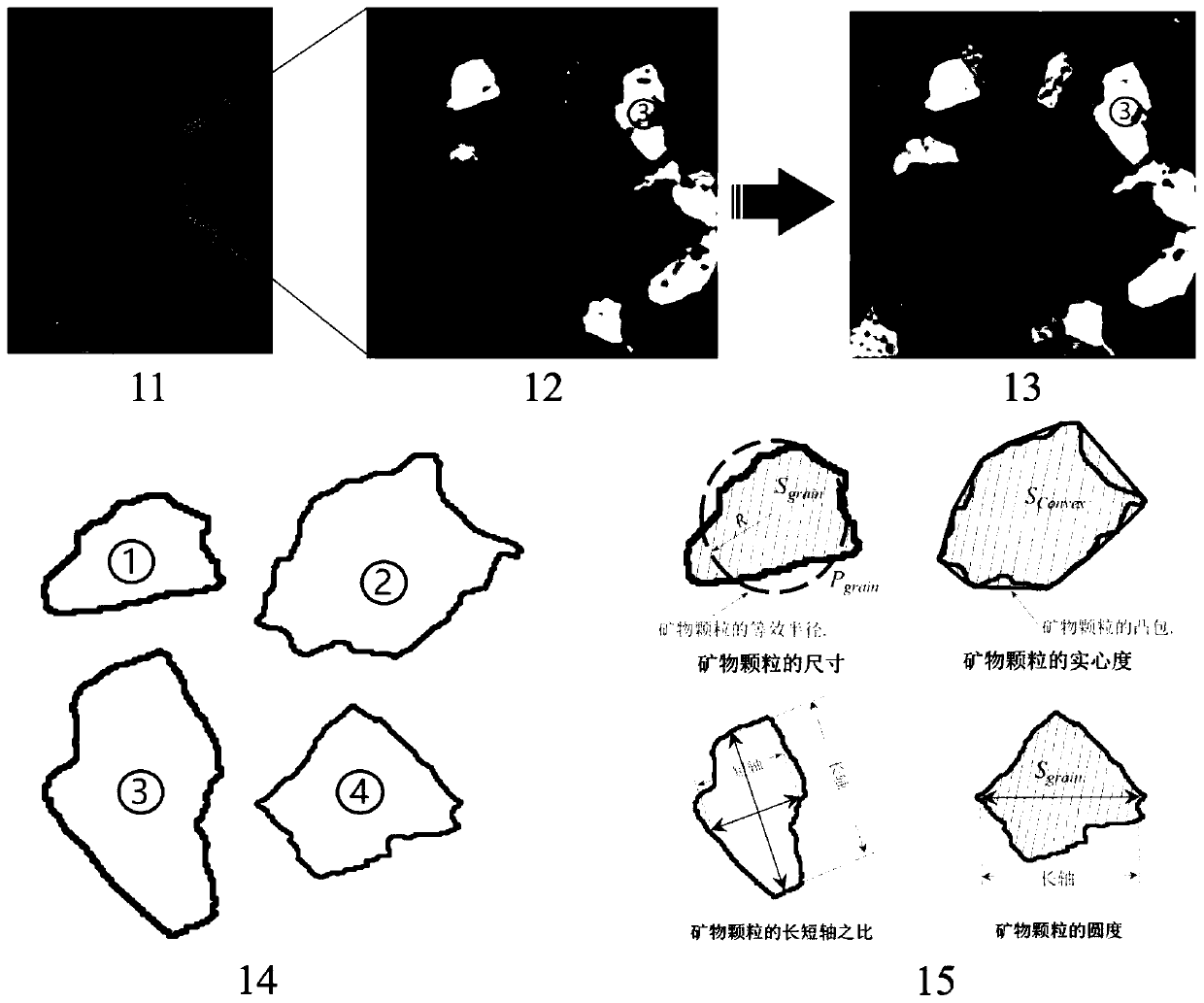

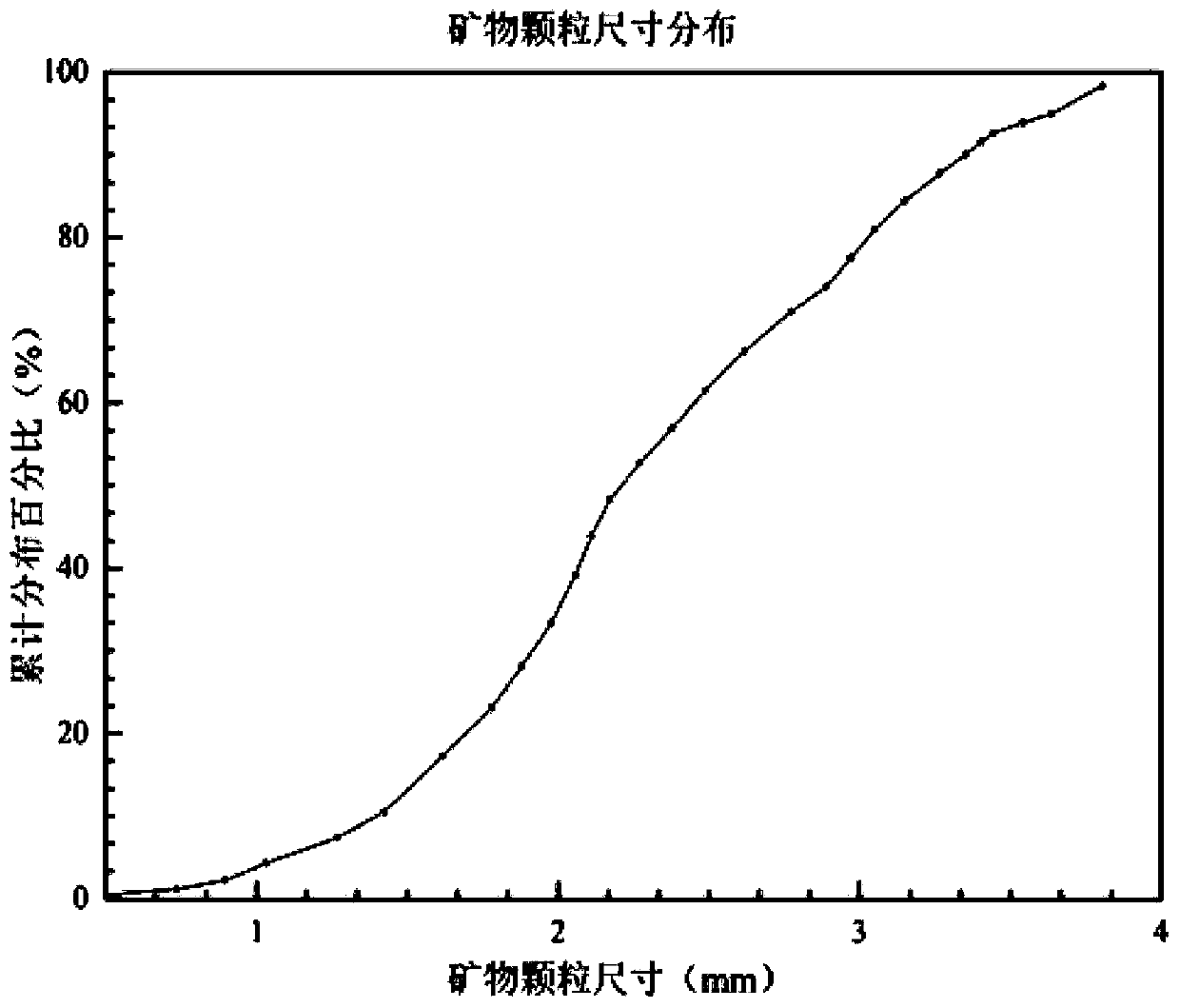

Microscomic numerical model generation method considering rock structure characteristics and mineral composition

ActiveCN110069844ASimulation is accurateImprove computing efficiencyDesign optimisation/simulationSpecial data processing applicationsFree interfaceMineral particles

The invention discloses a microscomic numerical model generation method considering rock structure characteristics and mineral composition. Microscopic structure characteristics and mineral composition of rock can be considered, a microscopic numerical model reflecting the rock structure characteristics and the mineral composition is established, and rock mechanics numerical simulation can be carried out more truly. The method comprises the following steps: carrying out rock structure characteristic analysis on a rock sample to obtain the size, form, mineral type and other information of mineral particles; simplifying the mineral particles with irregular shapes into balls with reduced sizes, and rearranging the particles by adopting a particle size expansion method, and obtaining a compact structure; secondly, extracting information such as spatial positions and sizes of particles, and performing Voronoi graph-based spatial region division on the particle assembly; and finally, performing finite element mesh division on the obtained Voronoi polycrystal structure, and inserting thickness-free interface units into mineral particle boundaries and the interiors of particles to generate a finite element numerical model capable of reflecting a rock structure and a lithofacies structure.

Owner:WUHAN UNIV

Organic and inorganic biological mineral matter mixing ecological fertilizer and method for producing the same

InactiveCN101172910APromote germinationEarly germinationSuperphosphatesMagnesium fertilisersDiseasePlant disease

The invention relates to organic-inorganic biological mineral composition composite synusiologic fertilizer and the preparation method thereof. The invention comprises the raw materials as follow in weight proportion: 20 to 30 parts of organic raw material, 30 to 60 parts of inorganic fertilizer, 10 to 20 parts of mineral composition raw material, and 1 to 5 parts of synusiologic mushroom. The invention has the advantages of promoting the absorption of crops, increasing the fertilizer absorption rate to more than 60 percent, decreasing the fertilizer residue, promoting the growth of the crops, improving the quality of the crops, ensuring the early development of the crops, the rich branching roots, the rich branches, the rich leaves, and early mature, and increasing the yield by 50 to 80 percent. Besides, the invention also has the advantages of restraining the development of pathogenic bacteria inside the soil, decreasing the disease and the harm to crops, improving the structure of the soil, activating the nutrient of the soil and achieving the synusiologic planting.

Owner:闫虎成

Method for producing aluminum oxide from fly ash

ActiveCN102351226AIncrease productivityReduce trafficSolid waste disposalAluminium oxides/hydroxidesSlagAluminium hydroxide

The invention relates to a method for producing aluminum oxide from fly ash, particularly a technique for producing metallurgical-grade aluminum oxide or non-metallurgical-grade aluminum oxide by comprehensively utilizing fly ash resources. The method is characterized by comprising the following steps: (1) adding fly ash and limestone powder or lime powder into an alkaline solution to obtain a raw slurry; (2) firing the raw slurry into clinker; (3) carrying out alkaline leaching on the clinker; (4) after carrying out desiliconizing treatment on the leach solution, carrying out liquid solid separation; (5) carrying out carbonating decomposition on the desiliconized solution subjected to liquid solid separation, thereby obtaining aluminum hydroxide; and (6) roasting the aluminum hydroxide to obtain the aluminum oxide product. The method provided by the invention can be used for treating the fly ash raw materials, which have different sources, different chemical compositions and different mineral compositions, to produce the aluminum oxide; the technology is mature and reliable; compared with the existing acid-process production technique, the invention does not need expensive corrosion-resistant equipment; and compared with the existing alkali-process production technique, the invention has the advantages of low material flow rate and low solid-phase slag amount, and is beneficial to environmental protection.

Owner:河南华慧有色工程设计有限公司 +1

Shale classification method

The invention discloses a shale classification method. The method includes the first step of determining the types of macroscopic structures of shales by observing shale cores, the second step of determining organic matter types and total content of organic carbon through kerogen and organic carbon analysis and obtaining the volume fraction of organic matter components through the total content of organic carbon, a conversion coefficient, the organic matter density and the rock density, the third step of determining mineral composition of the shales and obtaining the volume fraction of calcareous mineral components, the volume fraction of felsic mineral components and the volume fraction of clay mineral components through thin section authentication and total rock mineral analysis, the fourth step of classifying the shales according to the four-component three-end-member principle, and the last step of classifying the shales and conducting reasonable simplification through a core macroscopic structure and rock type combined method. The shale classification method is applicable to laboratory studies and outside work, is a method with reasonable logic and high operability for classification of the shales, solves the problems that the shale classification methods are varied and the organic matter components are ignored, and can be used for studying formation causes of the shales conveniently and guiding field logging and fracturing transformation.

Owner:董春梅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com