Patents

Literature

1113results about How to "Lower firing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making thin-film ceramic membrane on non-shrinking continuous or porous substrates by electrophoretic deposition

ActiveUS6887361B1High green densityReduce fire temperature and firing timeElectrolysis componentsFinal product manufactureElectrophoretic depositionSolid-state

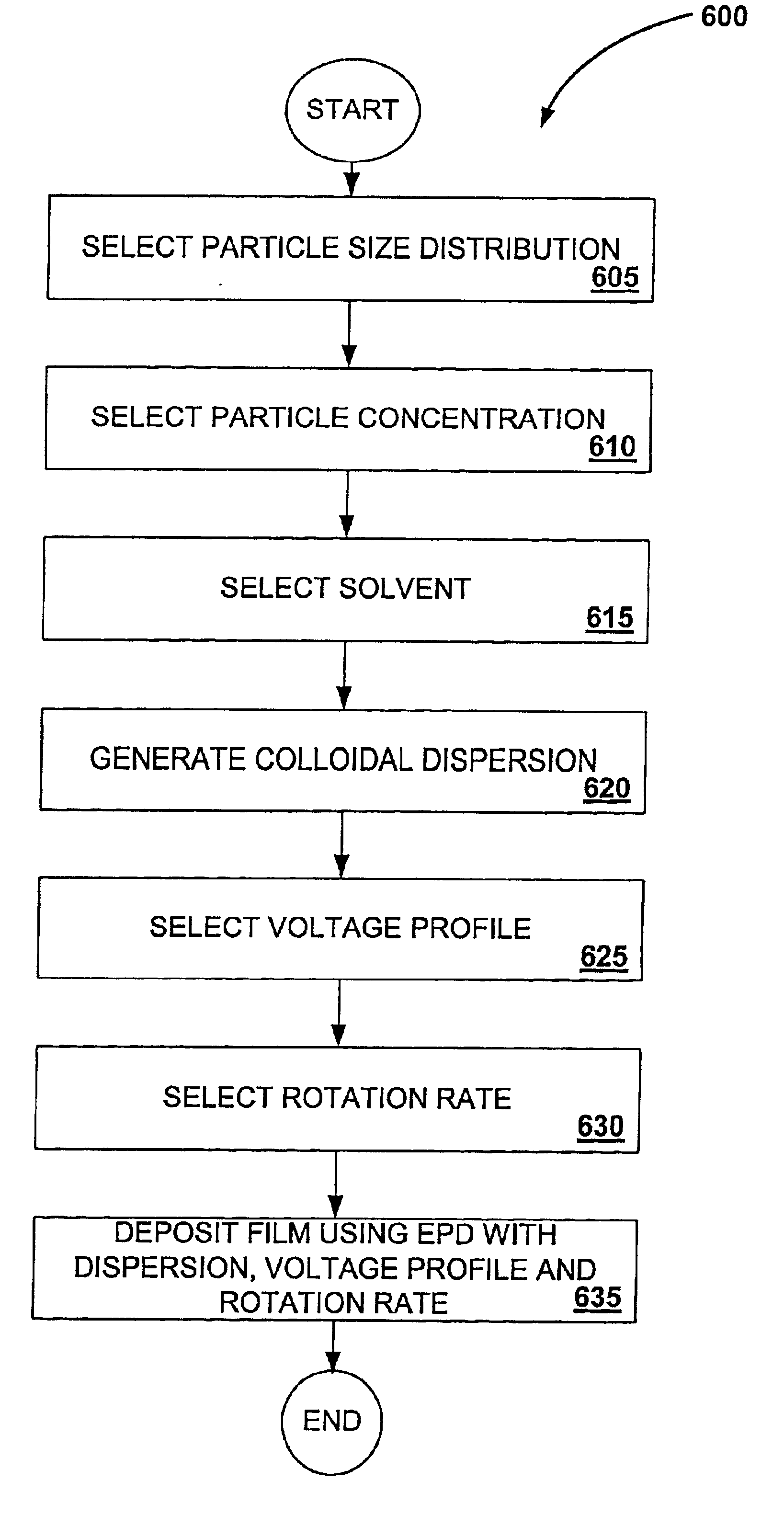

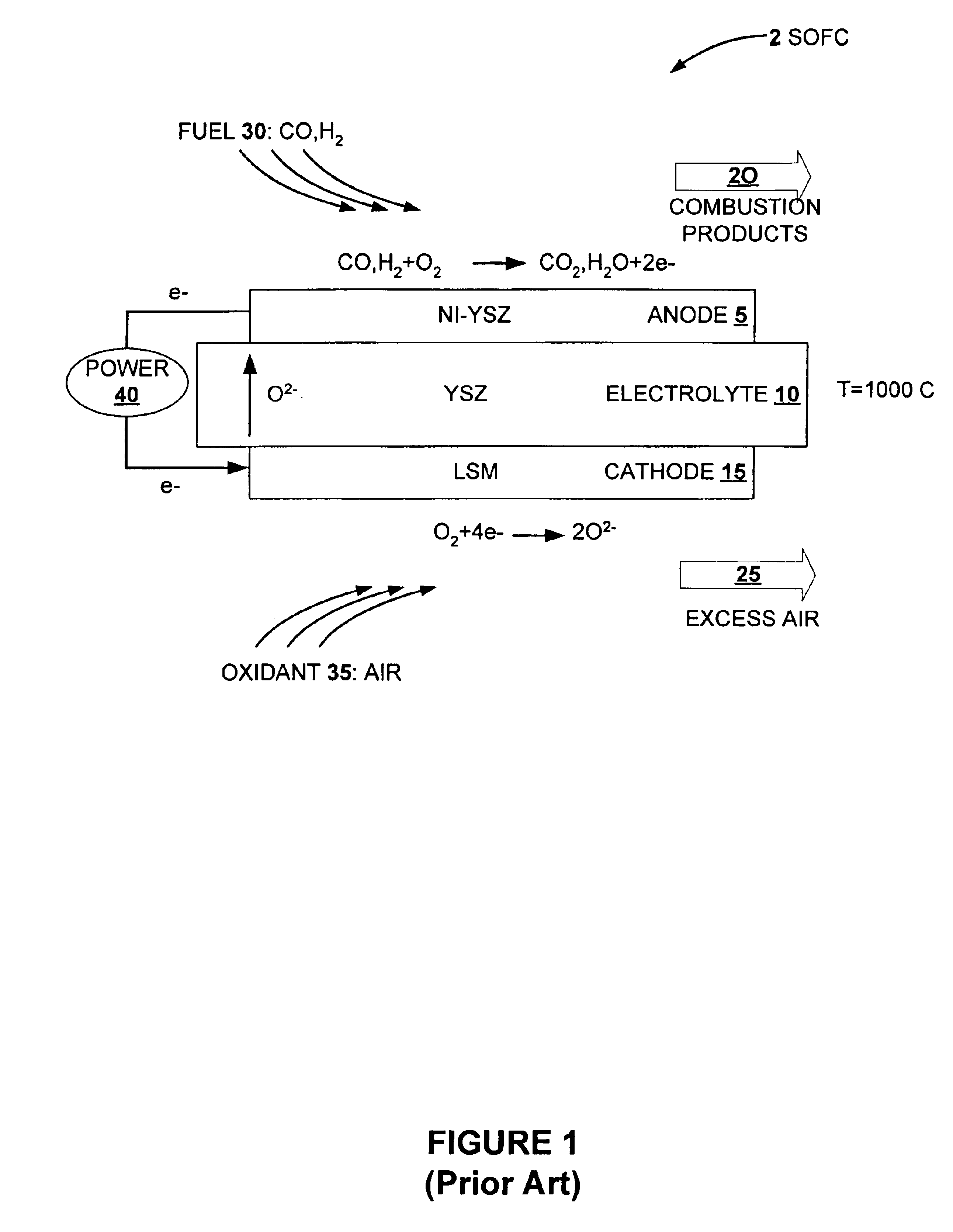

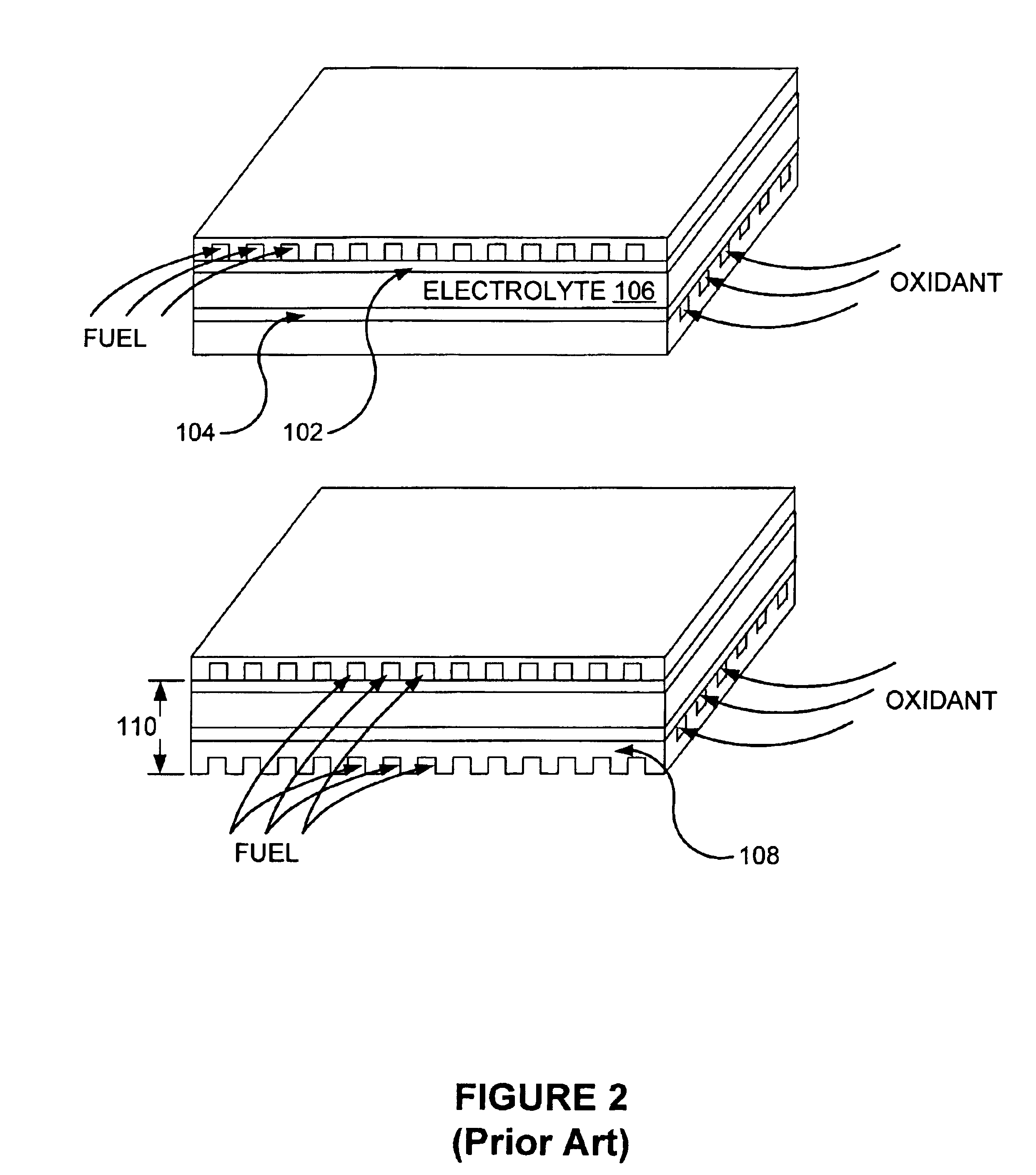

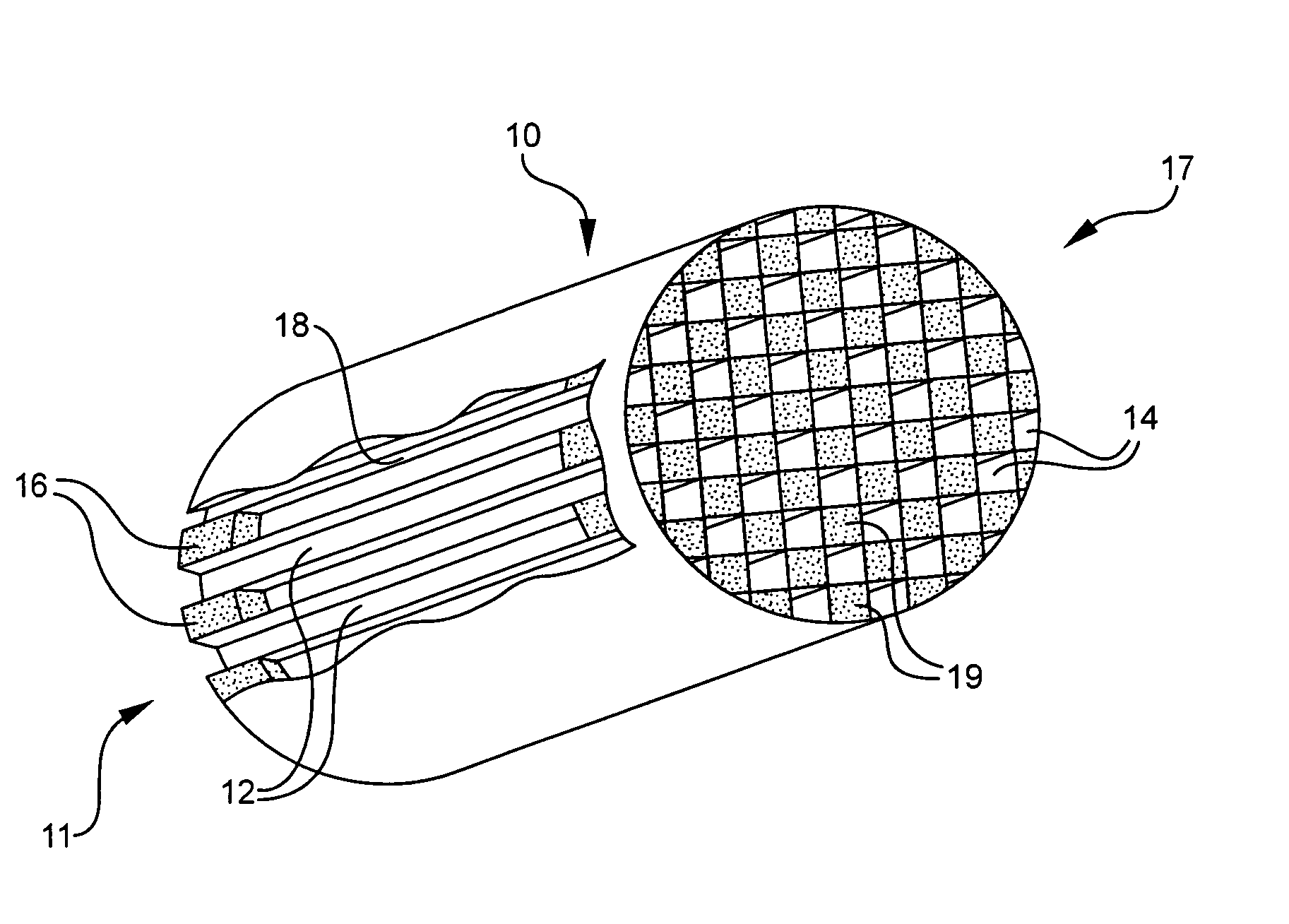

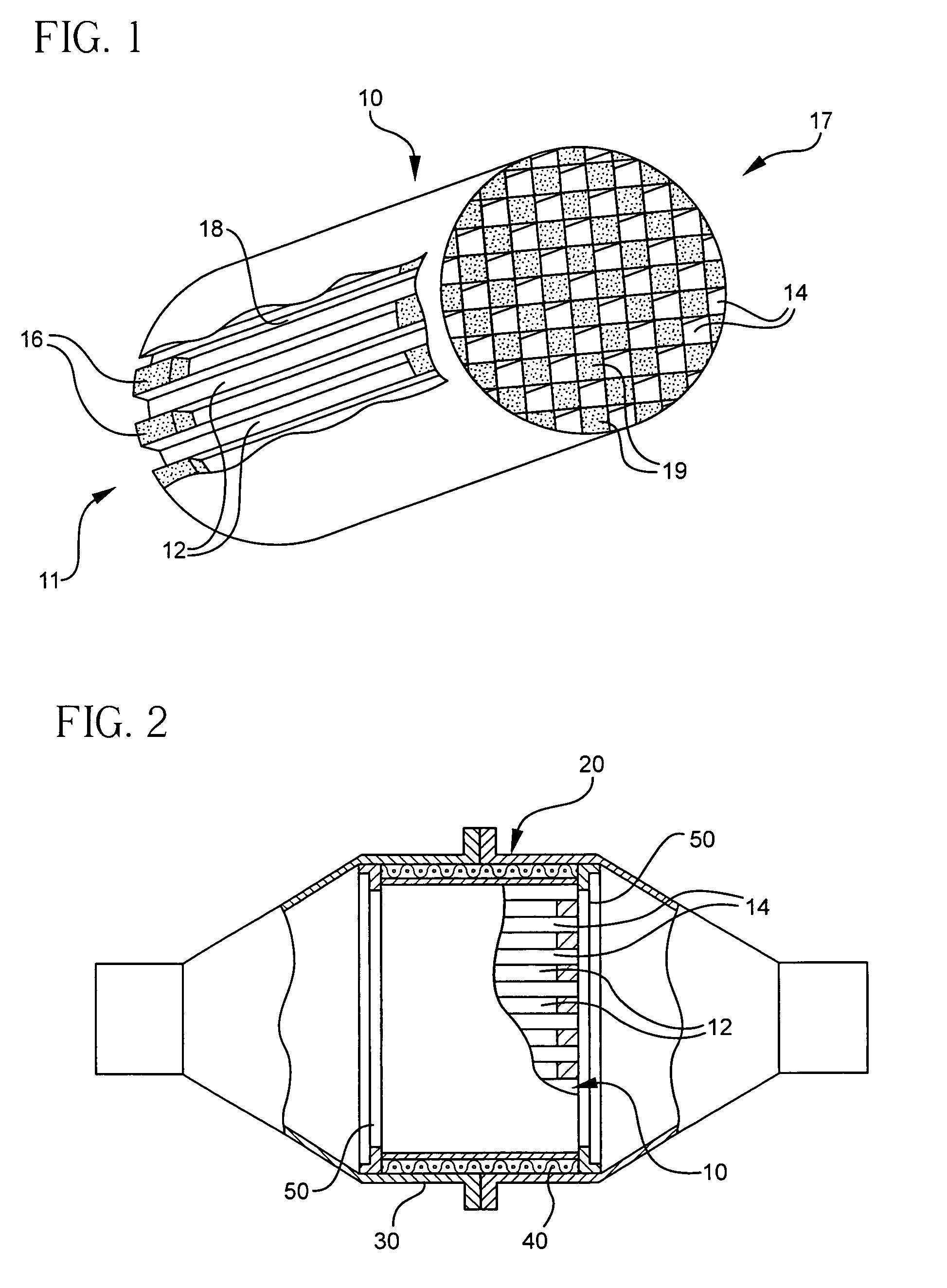

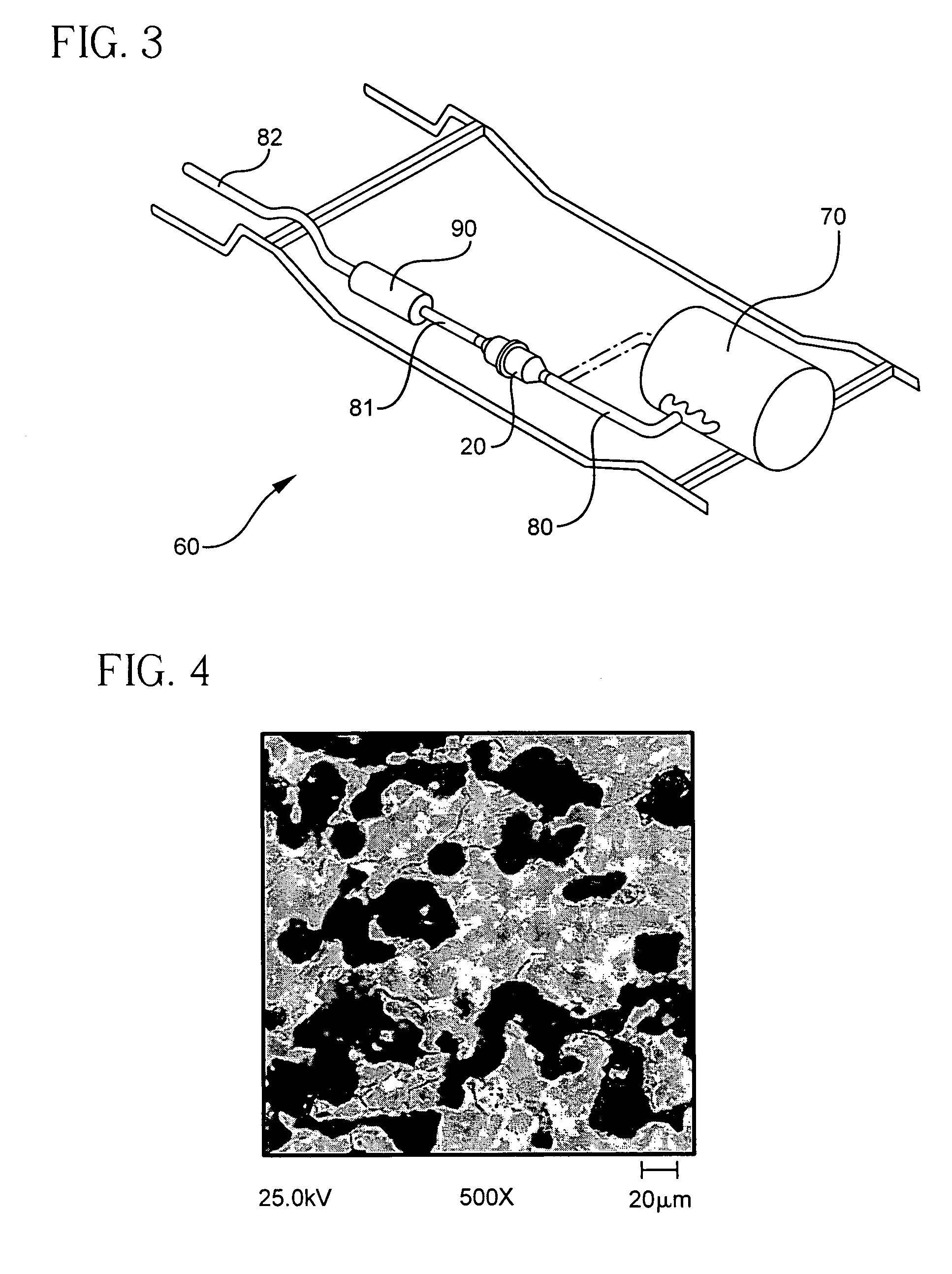

A disclosed method provides techniques for forming low-cost, mechanically strong, highly electronically conductive porous structures for solid-state electrochemical devices. In particular, a method of forming a ceramic film on a substrate using electrophoretic deposition (EPD) is described. The method employs a colloidal dispersion of particles during the EPD process where a distribution of particle sizes is selected to eliminate drying cracks in the ceramic film prior to firing of the ceramic film-coated substrate. The method may be used to provide a high-density green film which can be sintered on to a non-shrinking substrate. For instance, a thin film of YSZ with a high green density may be sintered on to a non-shrinking LSM substrate. In particular embodiments, the distribution of particle sizes used in the EPD process may be selected to reduce a firing temperature and a firing time during sintering of the film coated substrate.

Owner:RGT UNIV OF CALIFORNIA

Aluminum titanate ceramic articles and methods of making same

ActiveUS7259120B2Reduced strengthLower firing temperatureInternal combustion piston enginesSilencing apparatusAlkaline earth metalRare earth

An aluminum titanate ceramic article having a predominant crystal phase of aluminum titanate and a material composition including aluminum, titanium, silica, an alkaline earth metal (e.g., at least one selected from the group of strontium, calcium, barium, or combinations), and a rare earth metal (e.g., at least one selected from the group consisting of yttrium, lanthanum, and combinations) and methods of making such aluminum titanate bodies are described. An oxide of yttrium metal or lanthanide metals is preferably used as a sintering aid in combination with the other compositional components to enable firing of the resulting green body at a lower heating temperature of less than 1500° C., and more preferably between 1400°-1450° C., with a preferable hold time of less than 8 hours, more preferably of 6 to 8 hours.

Owner:CORNING INC

Fuel for firing into rotary kiln cement clinker

A fuel which is used for rotary kiln cement clinker firing is composed of raw materials with the following weight percentage: coal 3-80, straw substances 0-90, forest products wastes 0-95 and food industry by-product residues 0-70. The straw substances refer to rice straws, wheat straws, cotton stalks, sesame stalks, soybean straws, corn stalks, sorghum stalks, rice husks, peanut shells, soybean shells and corn sticks, the forest products wastes refer to defective bamboo, wood, tree branches, leaves, shrubs, faggot straws and sawdust and wood wool corner scrap materials in the bamboo and wood-processing industry, the food industry by-product residues refer to bran, wheat skin, squeezing meal cake, bean dregs and wine lees, and the coal refers to bituminite, anthracite and coke coal powder. The flue raw materials which are used for the rotary kiln cement clinker firing have wide selecting range, simple preparation, convenient use and rapid burning speed and are beneficial for protecting atmosphere circumstances.

Owner:吴飞龙

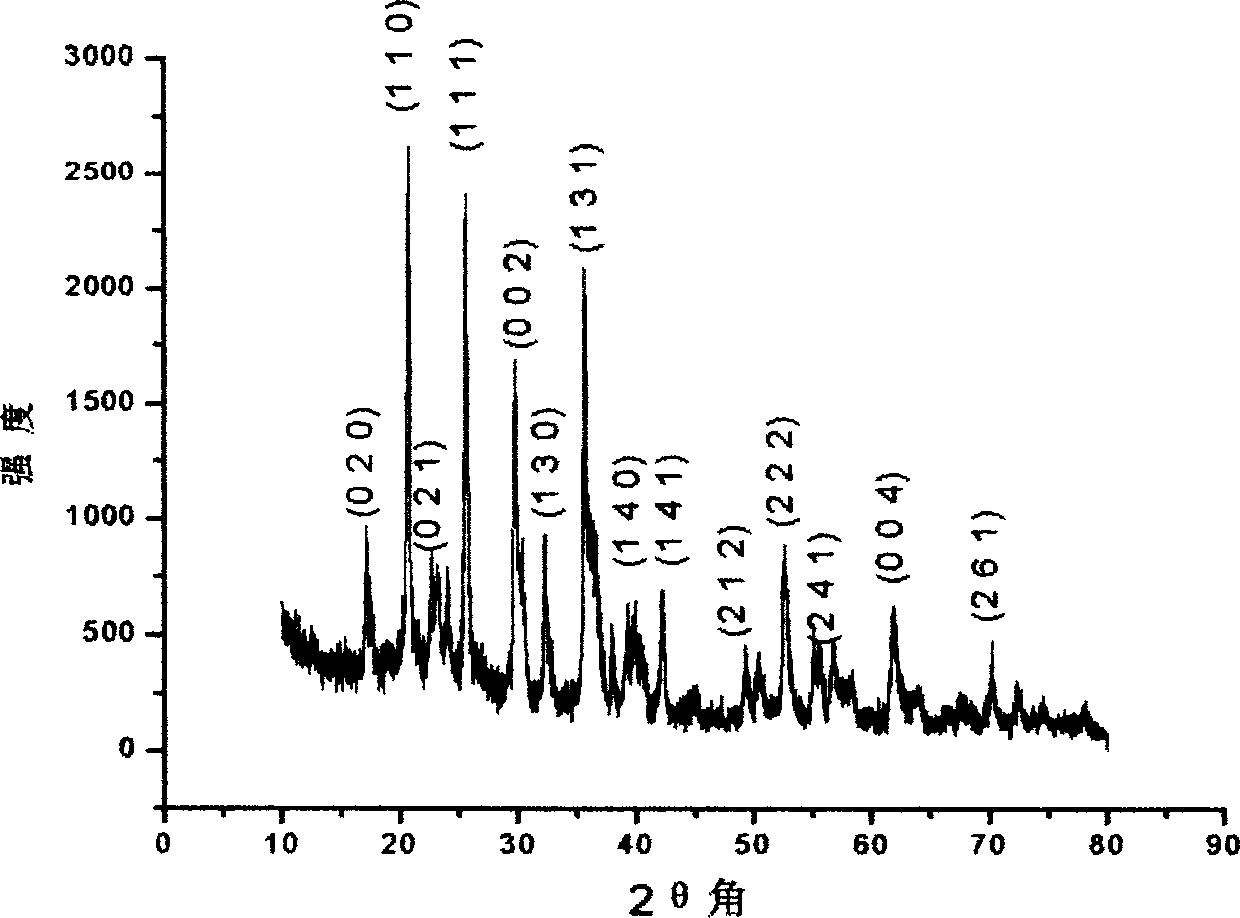

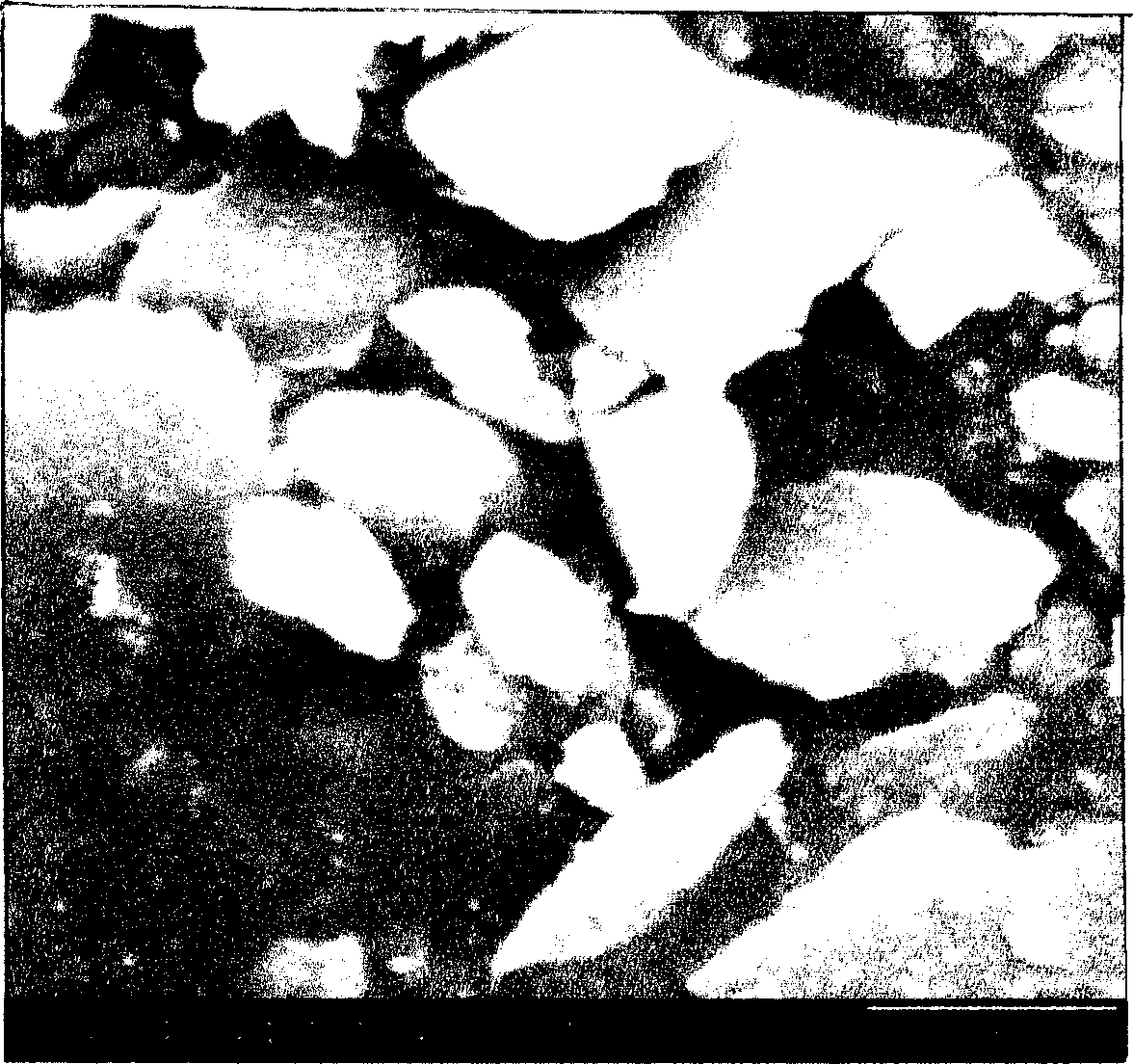

Preparation method of multicrystal LiFePO4 powder having olivine structure

InactiveCN1410349ASolve easy oxidationSolve precipitationCell electrodesRare earth metal compoundsOrganic acidGranularity

A polycrystalline LiFePO4 powder with olivine structure is prepared from Fe(Ac)2, FeSO4.7H2O, Ba(Ac)2 and organic acid by the sol-gel method. Its advantages are short period, low burning temp., low energy consumption, high purity and electric conductivity, and high granularity uniformity. It is suitable for making Li-ion battery.

Owner:TSINGHUA UNIV

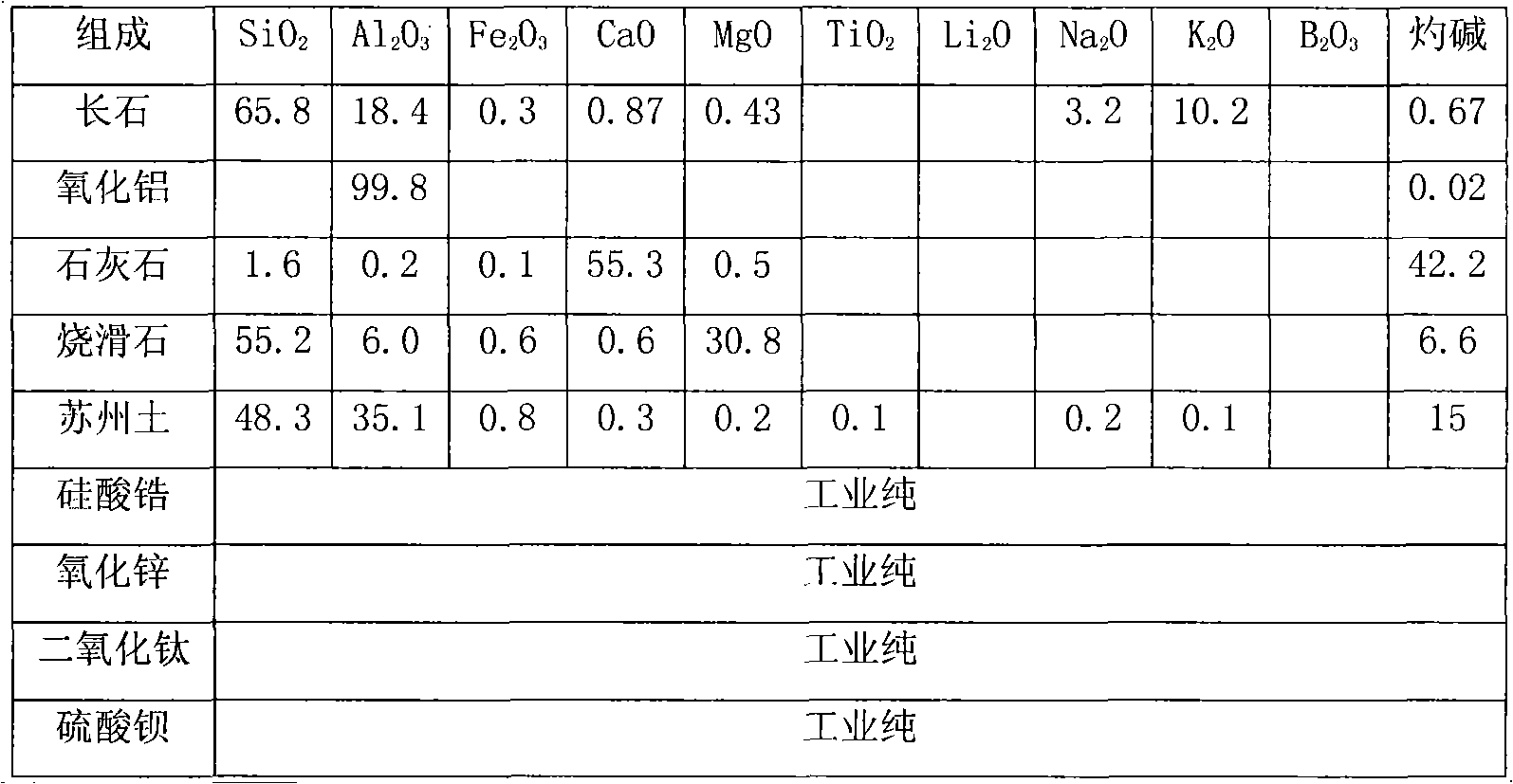

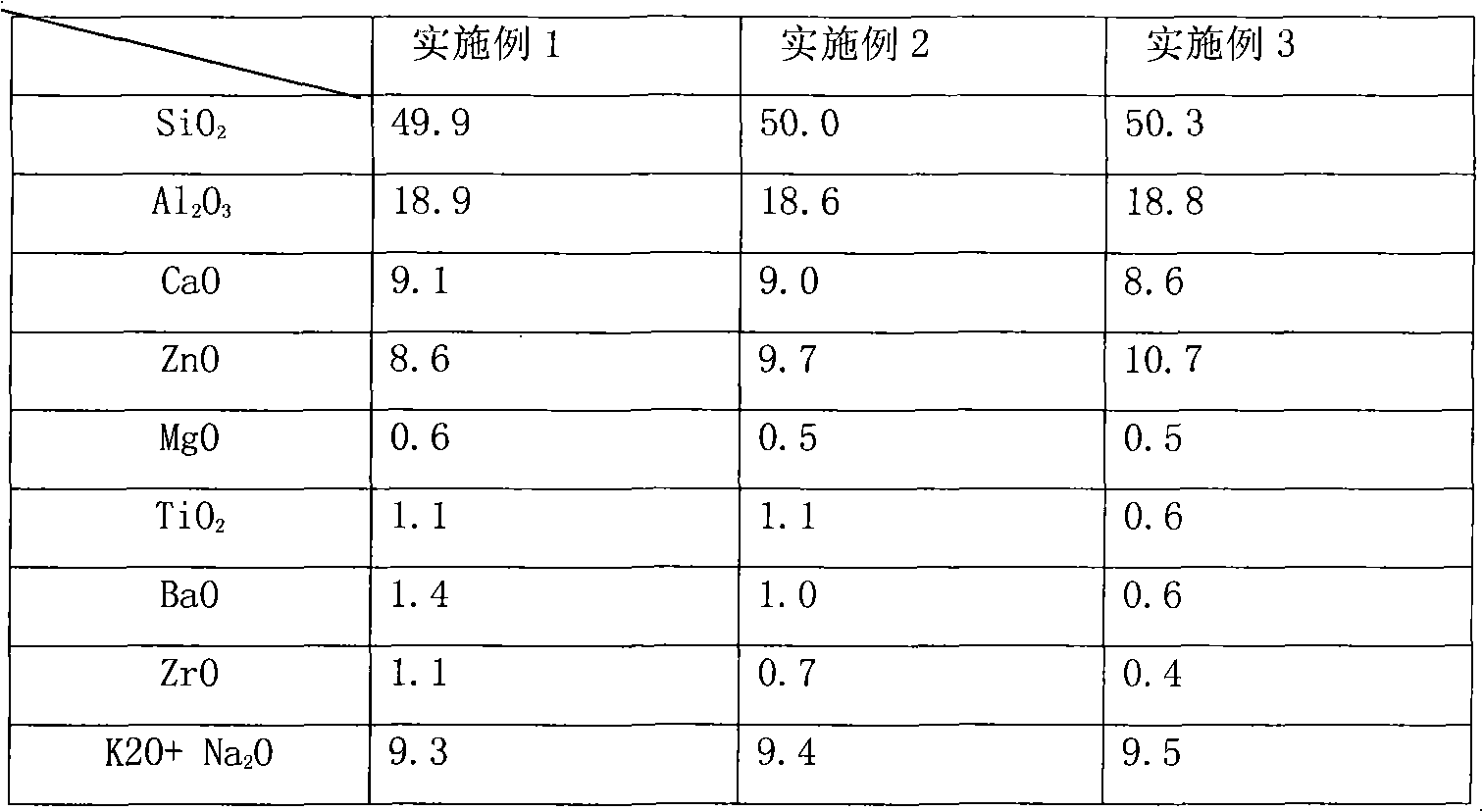

Raw material matting glaze

The invention relates to ceramic glaze, in particular to raw material matting glaze used for producing high-quality matting bone china products. The raw material matting glaze comprises the following chemical components in percent by weight: 48-60 percent of SiO2, 12.0-22.0 percent of Al2O3, 5.0-12.0 percent of ZnO, 5-12 percent of CaO, 0.5-2.0 percent of MgO, 0.0-3 percent of BaO, 0.0-3.0 percent of ZrO2, 0.0-2.0 percent of TiO2 and 5.0-15.0 percent of K2O and Na2O. The feldspar of the mineral raw material is mainly introduced. The invention has simple, scientific and reasonable constituent and is the raw material glaze; and the glaze does not need to be made into frits, therefore, energy sources are largely saved; the blank glaze has good adaptability, low firing temperature and wide firing range; the fired finished-product ceramic glaze surface is fine, moist, smooth and soft and does not have strong reflect light; and the glaze surface has strong corrosion resistance, high mechanical strength and good thermal shock stability and is easy to clean, therefore, the glaze is especially suitable for tableware dish-washing machines. The invention thoroughly solves the problems of the gloss and the texture of high-grade bone china.

Owner:张垠

Aluminum titanate batch compositions and method

ActiveUS8974724B2Reduce amountReduce the amount requiredInternal combustion piston enginesExhaust apparatusTitanateAluminium

Aluminum titanate precursor batch compositions comprising a recycled aluminum titanate component, at least a portion of the recycled aluminum titanate component being comprised of a recycled pre-reacted aluminum titanate composition or alternatively of an un-reacted green aluminum titanate precursor composition, and methods for producing aluminum titanate ceramic articles utilizing the inventive batch compositions.

Owner:CORNING INC

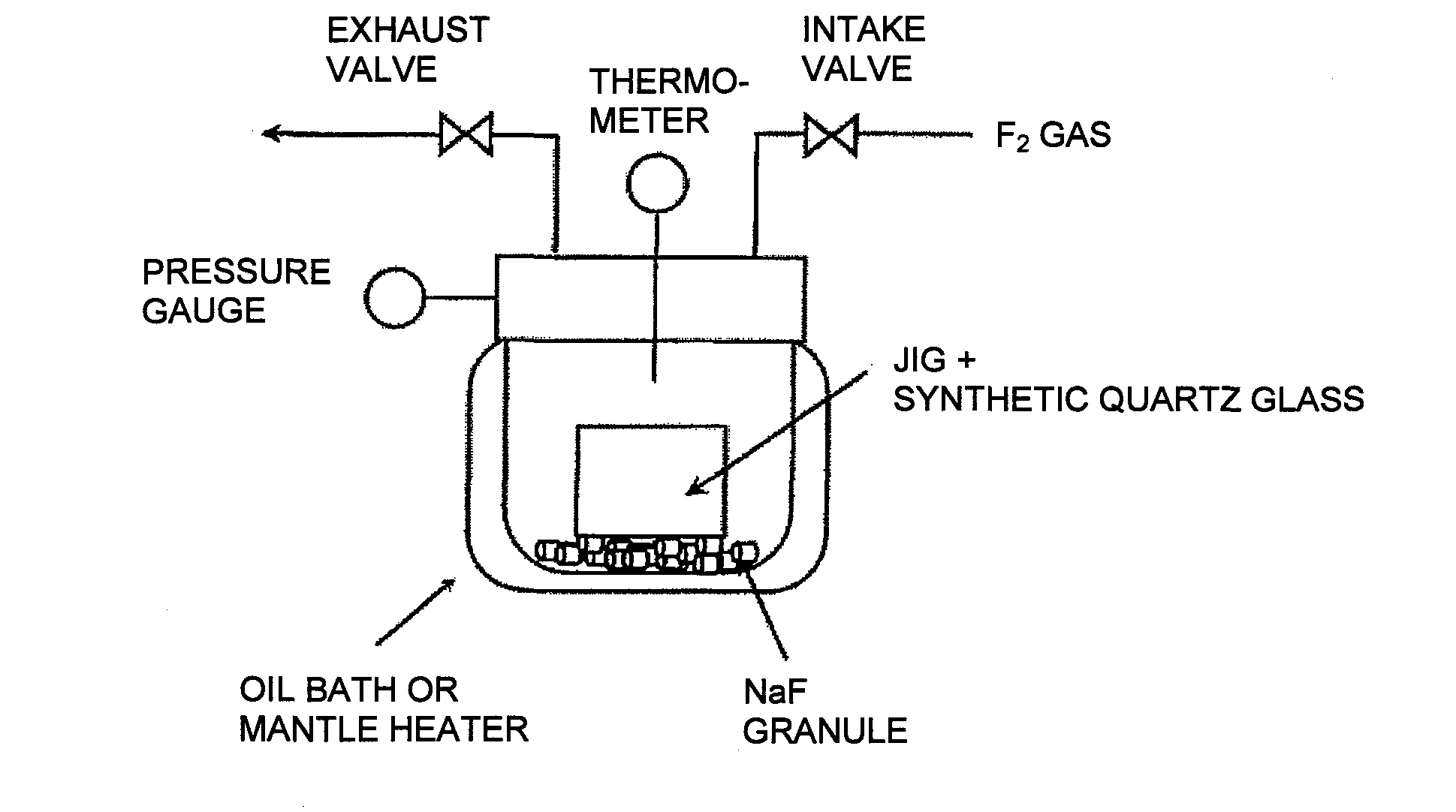

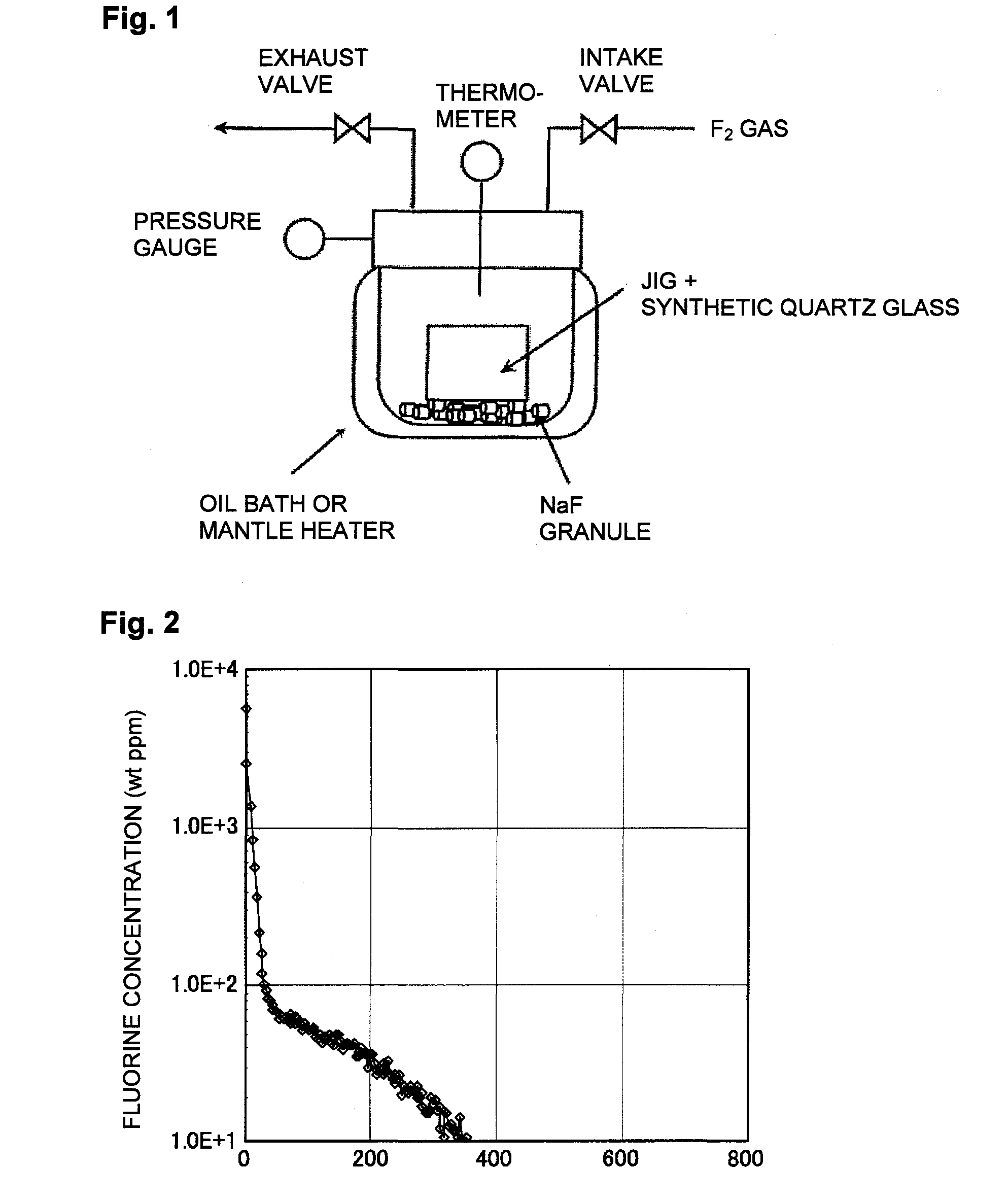

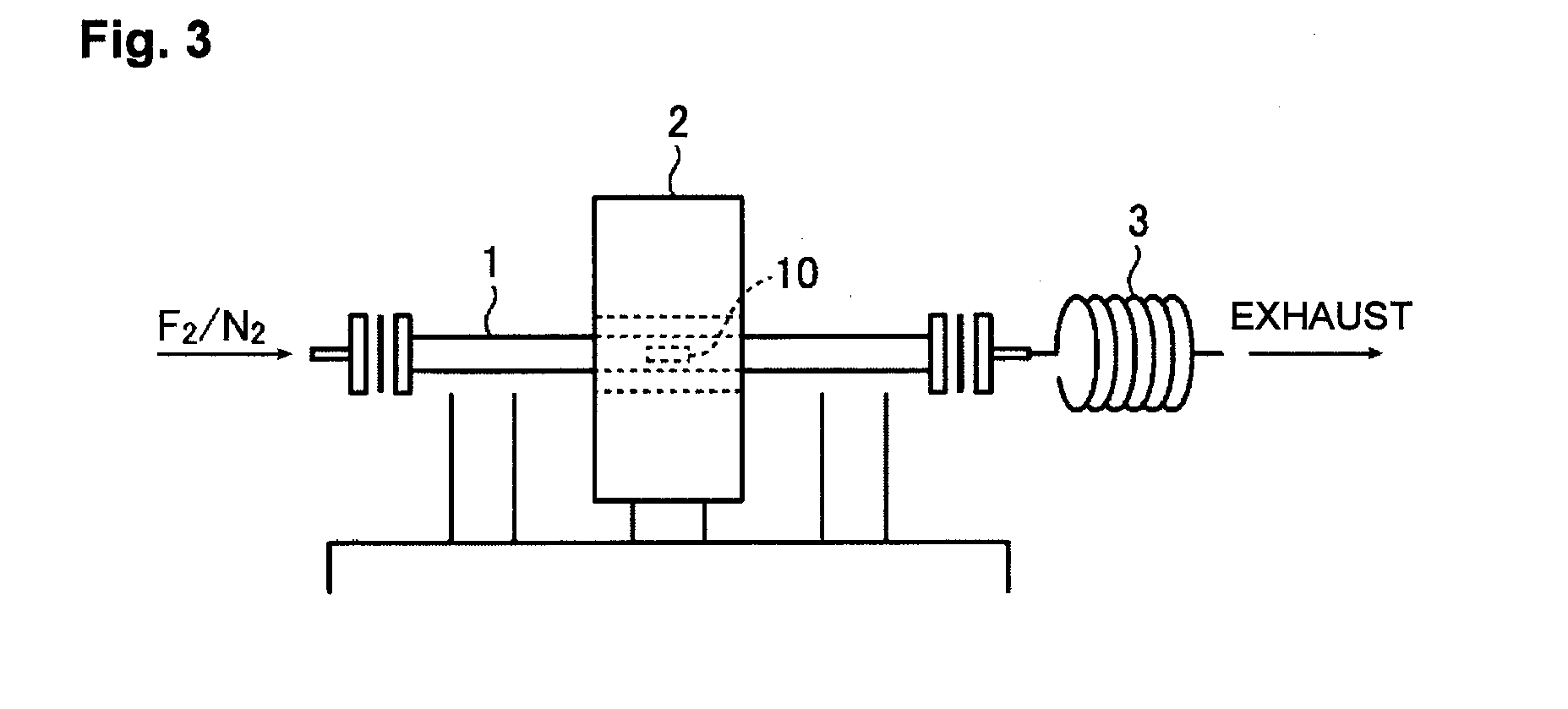

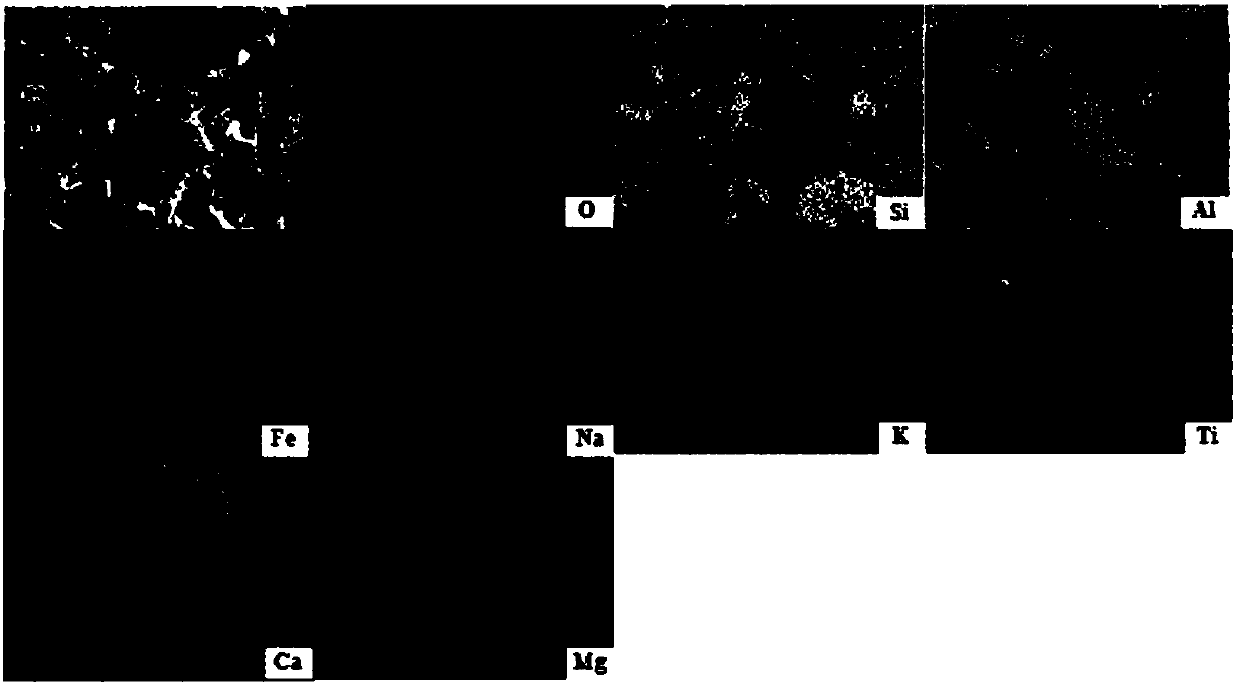

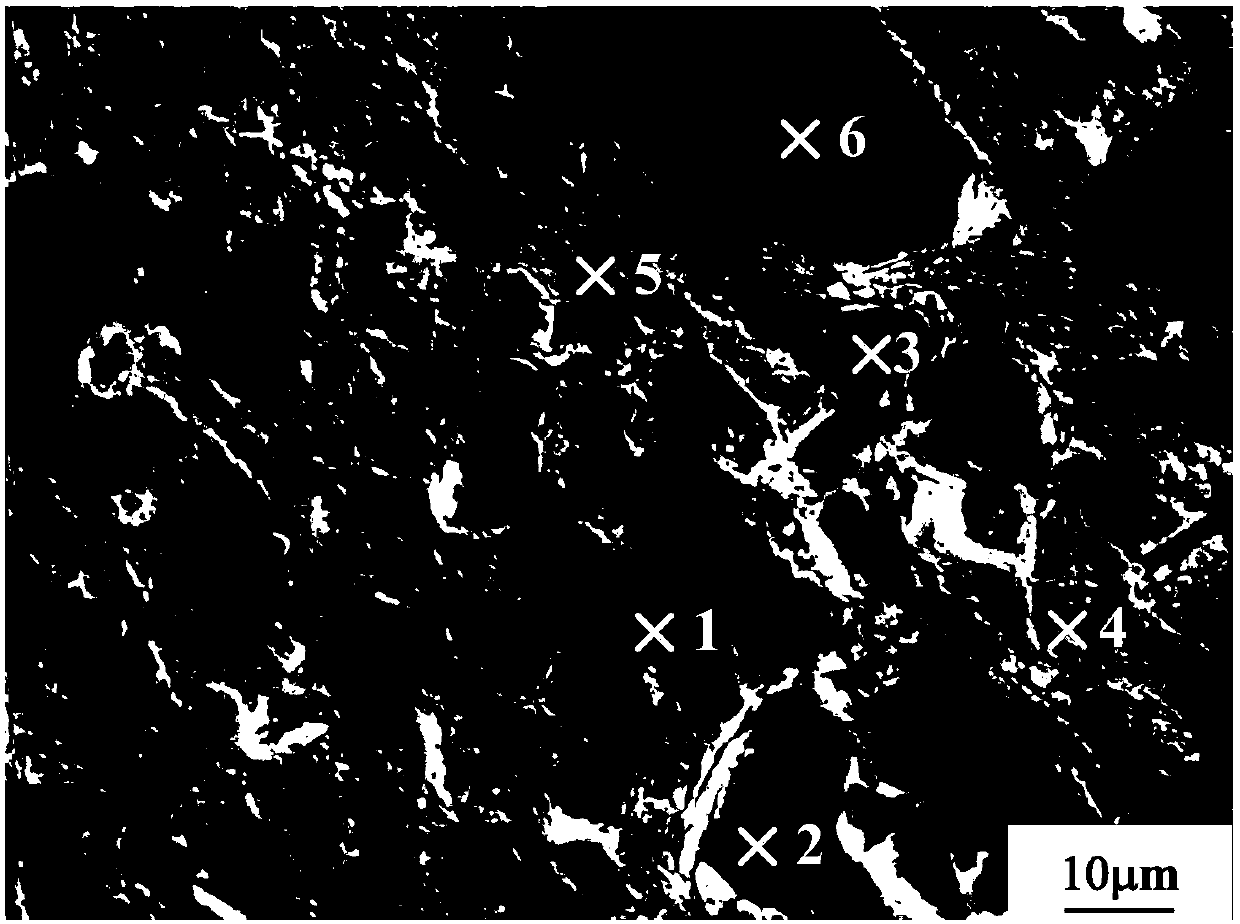

Method for treating surface of oxide glass with fluorinating agent

ActiveUS20100089096A1Low costExcellent adhesiveness without deterioration of the surface propertiesCoatingsOptical partsHydrogen fluorideInert gas dilution

To provide a novel fluorination treatment method whereby the surface of oxide glass can be treated for fluorination at low cost and with excellent adhesiveness.A method for treating the surface of oxide glass, which comprises contacting the surface of oxide glass with a gas of a fluorinating agent or a mixed gas having a fluorinating agent diluted with an inert gas, wherein the fluorinating agent is an elemental fluorine, or a fluorine compound capable of cleaving a bond between an oxygen atom and a metal atom in the framework of the oxide glass and forming a bond between a fluorine atom and the metal atom; and the concentration of hydrogen fluoride at the surface of oxide glass with which the fluorinating agent is in contact, is controlled to be at most 1 mol %.

Owner:ASAHI GLASS CO LTD

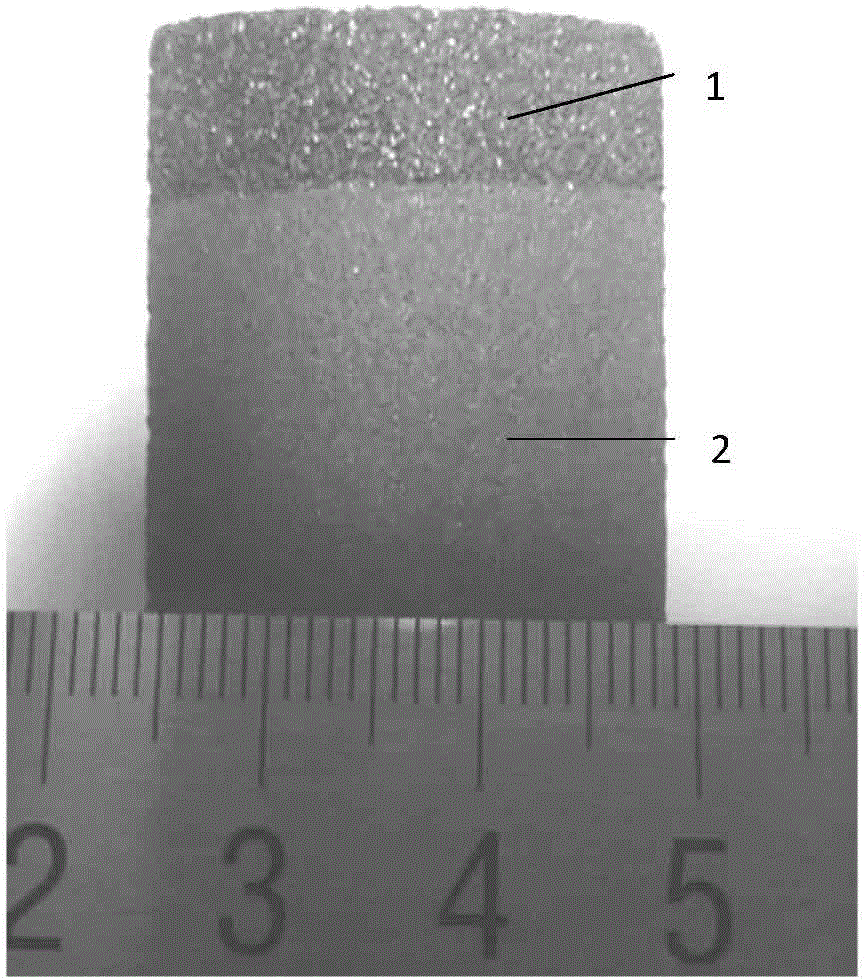

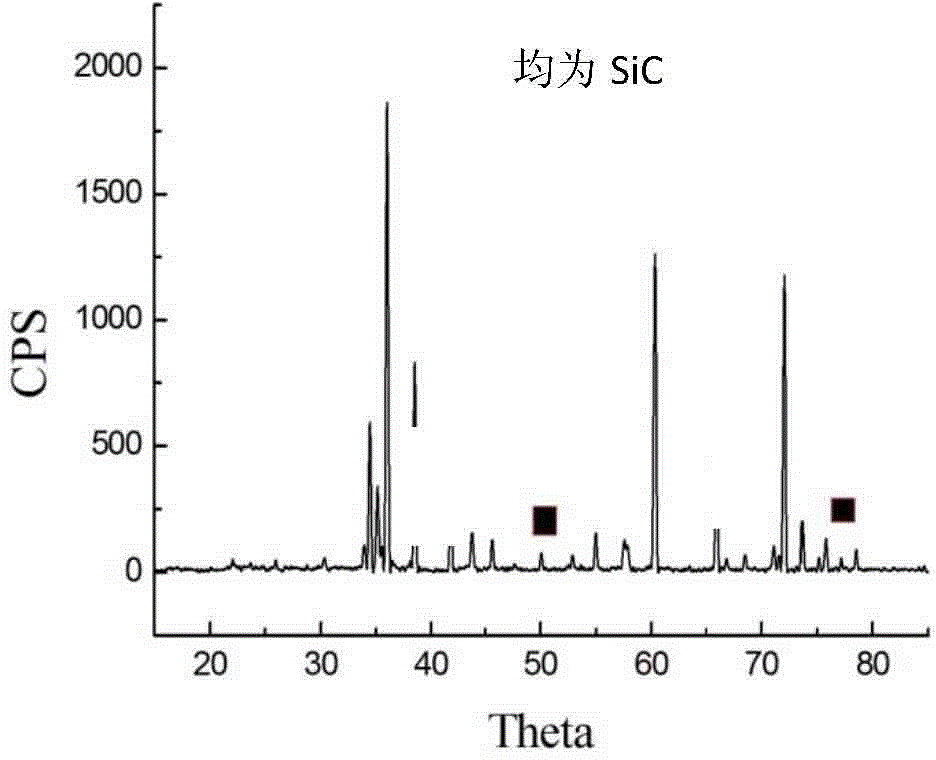

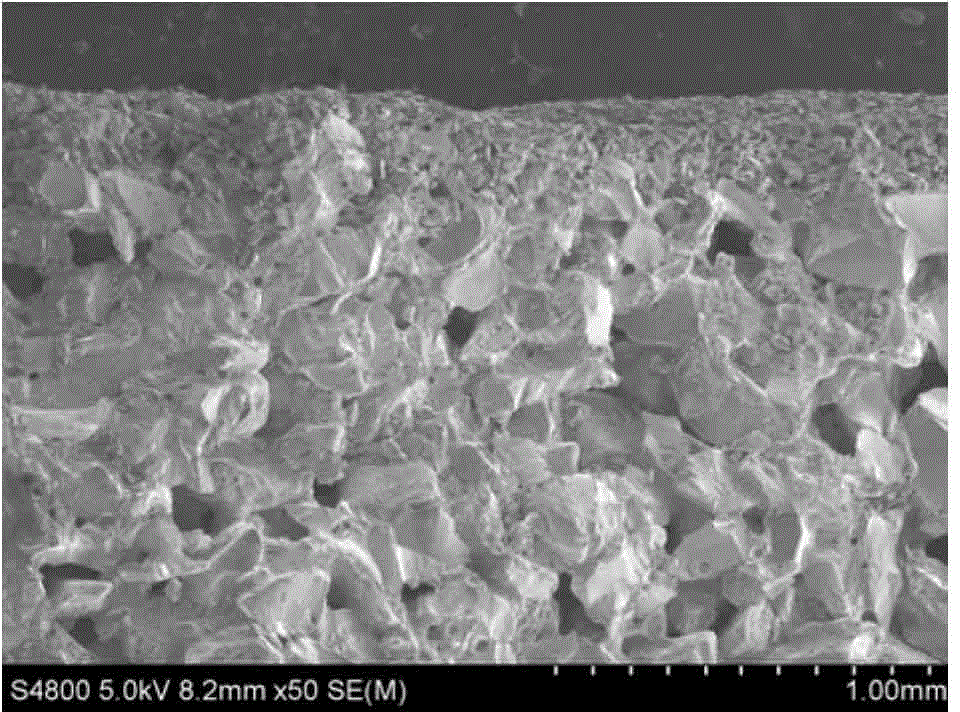

Silicon carbide porous ceramic filter and manufacturing method thereof

The invention relates to a silicon carbide porous ceramic filter and a manufacturing method thereof, in particular to a filter material for high-temperature liquid or gaseous fluid. The ideal silicon carbide porous ceramic filter has the advantages of gradient pore structure, low sintering temperature, high use temperature, high porosity factor, low pressure drop, large geometric surface area, zigzag flow path, high intensity, long service life, low production cost, easy regeneration and repeated use. Moreover, the filter is formed by compounding and sintering a plurality of layers of ceramic materials of different pore structures, and comprises a main body billet layer, a transition compound film layer and a surface compound film layer. Therefore, the filter is suitable for filtration and purification of various high-temperature and low-temperature fluids such as molten metal, high-temperature flue gas, coking gas and automobile exhaust.

Owner:淄博鑫拓耐火材料有限公司

Ceramic material for floor tile and preparation method thereof

InactiveCN102173736AReduce pollutionLower firing temperatureCeramic materials productionClaywaresGypsumPhosphogypsum

The invention relates to a ceramic material for floor tiles and a method for preparing a ceramic material for floor tiles by use of industrial solid wastes such as phosphogypsum and red mud. The major raw materials of the ceramic material for floor tiles are as follows (by weight): 14 to 28 percent of phosphogypsum, 14 to 28 percent of red mud, 9 to 23 percent of feldspar, 20 to 35 percent of kaolin, and 11 to 28 percent of quartz. The preparation method of the ceramic material for floor tiles comprises the following steps of: preparing ceramic slurry, performing spray-drying, preparing blanks and burning final products. The method provided by the invention can effectively utilize the solid wastes to reduce environmental pollution due to industrial solid wastes, and is significant in clayresource conservation and production cost reduction in the conventional wall brick and floor tile industries in China. Besides, the ceramic products made from the ceramic material have the advantagesof high strength and low sintering temperature.

Owner:武汉中理环保科技有限公司

Glaze for fast-fired crystal glaze ceramic tile, and preparation method and applications of ceramic tile

ActiveCN104829268AReduce granularity requirementsSimple manufacturing processManufacturing technologyBrick

The invention provides a glaze for fast-fired crystal glaze ceramic tile and a preparation method and applications of ceramic tile. The glaze comprises basic crystal glaze and a color developing agent, wherein the basic crystal glaze comprises the following raw materials: zinc oxide, titanium dioxide, quartz, cryolite, zinc phosphate, kaolin, and lead frit. A proper amount of zinc phosphate is introduced into the glaze to avoid the raw material frit treatment, which is carried out to ensure the residual amount of nucleating agent, the requirements on the glaze granularity are reduced, the manufacture technologies of crystal glaze and ceramic tiles are simplified, and the technical difficulties that the crystal glaze sintering technology is complicated, the crystal patterns are difficult to control, and the production cost is high are solved. Moreover, the addition amount of quartz and lead frit is precisely controlled to obtain crystal glaze art ceramic tiles which have the advantages of good crystallization effect, strong three-dimensional effect, and good artistic effect. The provided preparation method has the advantages of simpleness, lower sintering temperature, shorter period, and suitability for massive industrial production.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Preparation method of low-cost high-alumina ceramic thin plate

The invention relates to a preparation method of a low-cost high-alumina ceramic thin plate. The preparation method of the low-cost high-alumina ceramic thin plate is characterized by including the steps: 1) raw material treatment; 2) raw material proportioning and mixing: weighing raw materials including, in weight percent, 10%-25% of coal series kaolinite, 10%-25% of calcined bauxite, 20%-30% ofcommon kaolinite, 15%-25% of feldspar, 0-5% of talcum and 18%-25% of quartz to obtain a blank; adding reinforcing agents equivalently accounting for 0.1%-0.25% of the total weight of the blank, performing ball milling for 12-18 hours and uniformly mixing the raw materials to obtain mixed materials; 3) pelleting and aging; 4) semi-dry pressing; 5) drying; 6) glazing; 7) sintering to obtain the low-cost high-alumina ceramic thin plate. The feldspar is formed by mixing potassium feldspar with soda feldspar, and the weight ratio of K2O to Na2O of the mixed feldspar chemical composition is 2:1. The sintering temperature of the high-alumina ceramic thin plate prepared by the method is only 1180 DEG C, so that the ceramic thin plate is low in cost and high in strength.

Owner:WUHAN UNIV OF TECH

Household strengthen porcelain containing bone substances and production technology thereof

The invention relates to ceramics and a production technology thereof, in particular to a household strengthen porcelain containing bone substances and the production technology thereof. The strengthen porcelain body comprises petalite, powdered alumina, bone powder, quartz, Longyan braying, Guizhou soil, Zimo saved soil and humic acid sodium; the glaze comprises spodumene, fritted glaze 317, bone powder, kaolin, zirconia, potassium feldspar and aedelforsite; the production technology of the strengthen porcelain comprises the steps of batching, water adding and ball milling, sifting out, iron removing, filter pressing, primary smelting, ageing, refining, molding, drying, glazing and kiln firing. The product of the invention has the advantages of high mechanical strength, good thermal stability, fine and glossy glaze, high whiteness, good transmittance and the like.

Owner:CHAOZHOU LIANYUAN CERAMICS MFG

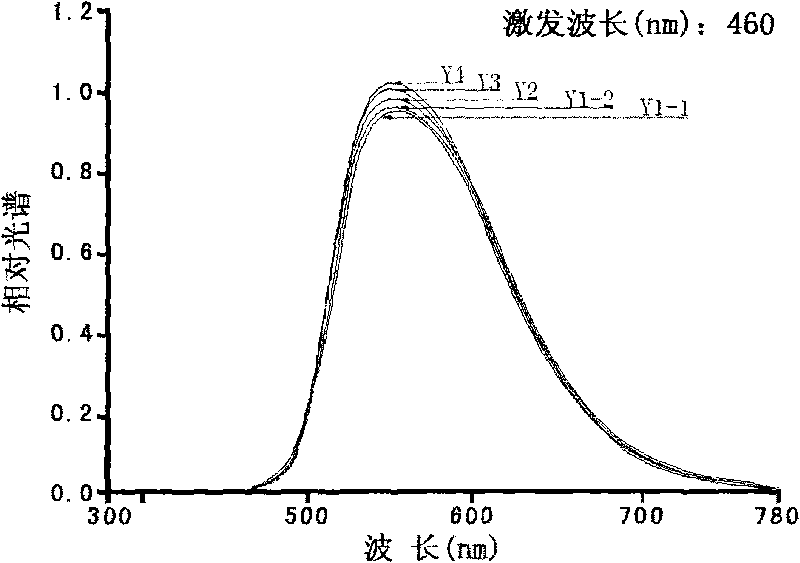

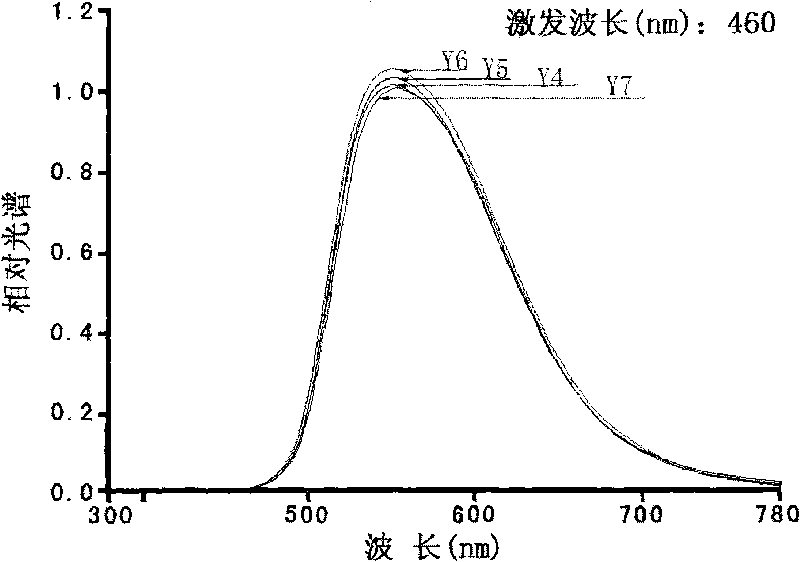

Yellow fluorescent powder used by white light LED and preparation method thereof

ActiveCN101760197ALower firing temperatureIncrease brightnessGas discharge lamp usageLuminescent compositionsCrucibleRadiance

The invention relates to a fluorescent powder used for a white light LED and a preparation method thereof. The chemical formula of the fluorescent powder is (A3-x) (Al5-2mBmCm) FnO12-n: xCe, wherein A is one or more of Y, Gd, La and Tb; B is one or more of Ti, Zr and V; C is one or two of Mn, Zn, Mg and Li; x is more than or equal to 0.03 and less than or equal to 0.1; m is more than or equal to 0.01 and less than or equal to 2; and n is more than or equal to 0 and less than or equal to 3x. The preparation method comprises the steps of coating a layer of high-temperature ceramic glaze material at the joint between a crucible cover and a crucible by using a high-temperature solid phase method and a self-pressurization sealing burning technique, putting the crucible into an atmosphere box type furnace to burn for 2 to 5 hours at 1450 to 1550 DEG C in the nitrogen atmosphere, smashing and screening after cooling so as to acquire the finished product of the fluorescent powder. The fluorescent powder of the invention has high radiance. The method of the invention can efficiently lower the burning temperature of the fluorescent powder and increase the relative brightness.

Owner:XIANGLING LED

Gelatinization material of phosphoaluminic salt system

InactiveCN1498870AIncreased durabilityIncreased hydration rateCalcium biphosphateChemical composition

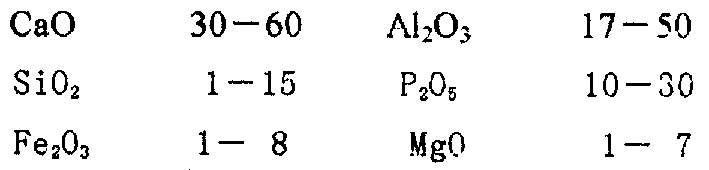

A cementing material is a cement whose main components are calcium phosphoaluminate, calcium aluminate and calcium phosphate. Its clinker contains such chemical components (wt%) as CaO (30-60), Al2O3 (17-50), SiO2 (1-15), P2O5 (10-30), Fe2O3 (1-8) and MgO (1-7). Its advantages are high and early strength, high refractory nature, and high compatibility with existing cement.

Owner:胡佳山

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

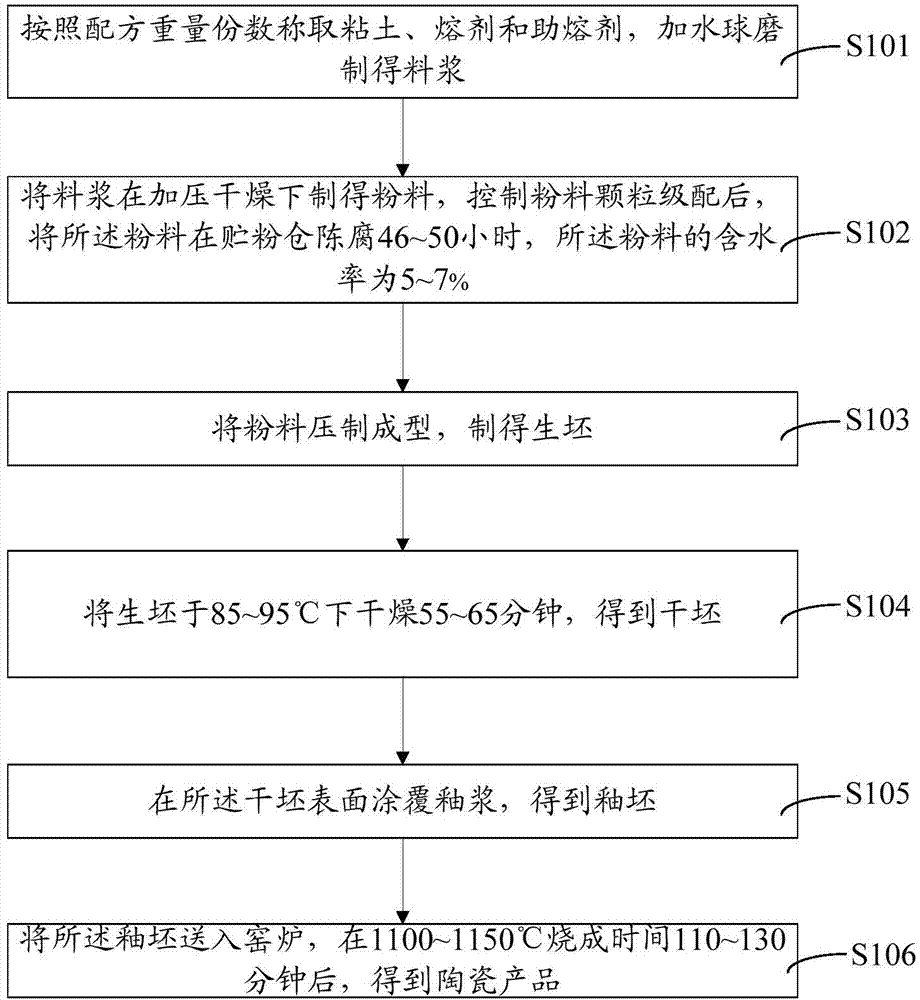

Ceramic formula and preparation method for ceramic product

The invention provides a ceramic formula, comprising, by weight, 55 to 65 parts of clay, 20 to 30 parts of a flux and 15 to 23 parts of a fluxing agent, wherein the clay is a mixture of purple sandshale and china clay mixed according to a weight ratio of 0.67 to 2.0, the flux is shale, and the fluxing agent is one or more selected from the group consisting of limestone, calcite, diopside, wollastonite, dolomite, talcum and industrial waste residue. A preparation method for a ceramic product comprises the following steps: weighing the clay, the flux and the fluxing agent according to the formula, carrying out crushing and screening with a 250-mesh sieve, wherein the weight of screen residue is 1 to 1.5%, adding water, carrying out blending to obtain slurry and then carrying out drying and granulation so as to obtain powder; grading particles and then carrying out molding so as to prepare a green body; carrying out drying so as to prepare a dry body; and carrying out firing so as to prepare a seasonal ceramic body. According to the ceramic formula and the preparation method for the ceramic product in the invention, raw materials are cheap, process is simple, firing temperature is reduced, production cost is decreased, investment for production equipment is lowered down, production efficiency is improved, and energy consumption is reduced.

Owner:怀化市亿智陶瓷有限公司

Energy-saving consumption-reducing technique for preparing haydite by co-disposing polluted soil and desilting sediment

ActiveCN102173850APromote healthy developmentLow running costCeramicwareExpanded clay aggregateWater content

The invention relates to an energy-saving consumption-reducing environment-friendly method for preparing haydite by co-disposing municipal massive solid wastes, which comprises the following steps: directly mixing polluted soil and polluted desilting sediment (without energy-consuming drying), adding a conditioner, granulating, and firing at 900-1200 DEG C for 15-40 minutes. The test indicates that the prepared haydite product has the following properties: the bulk density is 500-900 kg / m<3>, the cylindrical compressive strength is 5.0-10.0 Mpa, and the water absorptivity is 4.8-9.2%; and the leaching toxicities of typical heavy metals are as follows: Cu<0.26 mg / L, As<0.03 mg / L, Cd<0.0002 mg / L, and Hg<0.0001 mg / L. The method provided by the invention fully utilizes the water-content complementarity of the polluted soil and sewage reservoir sediment as well as the characteristic of mutual catalytic degradation of heavy metal pollutants and organic pollutants, implements energy saving and consumption reduction in the technical field of traditional techniques for preparing haydite from solid wastes, lowers the cost and secondary pollution in solid waste disposal industry, enhances the properties of the solid waste haydite, and widens the application field of the solid waste haydite.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Aluminum chrome refractory material

The invention belongs to the technical field of refractory materials, in particular to an aluminum chrome refractory material, which takes white fused corundum as a body and is formed by adding scraps (the scraps are collected and crushed into the synthetic size) generated in the cold processing process of a dense chromic oxide product, Alpha-Al2O3 powder or chrome oxide green or white fused corundum powder and sintering at a high temperature in combination with an inorganic binding agent or an organic binding agent. A product obtained in the invention can be widely applied to a coal water slurry gasification furnace back lining, a hard carbon black reaction furnace inner lining, a residual oil gasification furnace inner lining in the petrochemical industry, a glass wool molten pool inner lining and the like, fully and effectively makes use of the scraps generated in the cold processing process of the dense chromic oxide product and has the characteristics of low impurity content, high refractoriness, excellent physical performance, good thermal shock resistance and strong erosion resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement

ActiveCN105129744AImprove decomposition efficiencyIncrease concentrationSulfur compoundsClinker productionDecompositionPhosphogypsum

The invention relates to the technical field of industrial production of sulfuric acid and cement, the field of industrial solid waste comprehensive utilization, and the field of environment protection and treatment, and particularly relates to a pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement. The method includes the steps of powder grinding of raw materials, multi-stage cyclic pre-heating, high-effective decomposition and kiln gas separation and purification. The method is used for preparing a cement raw material from the phosphogypsum subjected to pre-heating decomposition with clay, sand rock, coke and such auxiliary materials in the process of producing the sulfuric acid from the phosphogypsum with co-production of the cement. The method solves the problems that a pre-heating decomposition technology in the prior art is low in decomposition ratio of phosphogypsum, is low in productivity of sulfuric acid and clinker, is liable to cause crusting and blocking in a kiln and is high in production energy consumption, can reduce the decomposition efficiency of the phosphogypsum and accelerate escape of SO2, and further increase the productivity of the sulfuric acid and cement clinker. The pre-heating decomposition method of producing the sulfuric acid from the phosphogypsum with co-production of the cement can significantly reduce sintering temperature and energy consumption of the clinker, can reduce production cost of sulfuric and cement clinker, and can further increase comprehensive utilization rate of the phosphogypsum.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

Aluminum titanate batch compositions and method

ActiveUS20080125305A1Reduce amountReduce the amount requiredInternal combustion piston enginesExhaust apparatusTitanateAluminium

Aluminum titanate precursor batch compositions comprising a recycled aluminum titanate component, at least a portion of the recycled aluminum titanate component being comprised of a recycled pre-reacted aluminum titanate composition or alternatively of an un-reacted green aluminum titanate precursor composition, and methods for producing aluminum titanate ceramic articles utilizing the inventive batch compositions.

Owner:CORNING INC

Preparation method of ceramsite filter material for water treatment

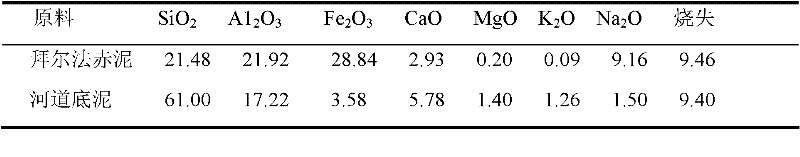

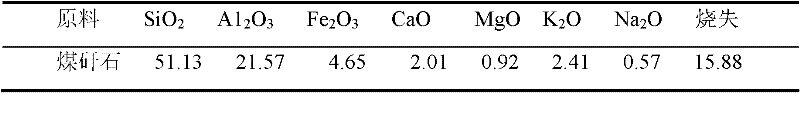

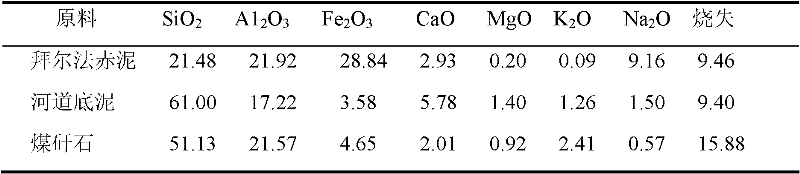

The invention provides a preparation method for a ceramsite filter material for water treatment. The method is characterized by comprising the following steps: (1) mixing Bayer red mud powder in aluminum manufacturers in Shangdong province, river sediment powder in Xiaofu River at the section of Huangtuya in Zibo city of Shangdong province, gangue powder and a pore forming agent according to a mass ratio of 40-50:40-50:0-5:5-10 to obtain a mixture; (2) putting the mixture into a pan granulator and adding water, the mass of which is 20 to 25% of the mixture, for granulation into spherical particles with phi being 3 to 10 mm; (3) sintering and cooling the spherical particles after drying so as to obtain the ceramsite filter material. According to the invention, Bayer red mud powder in aluminum manufacturers in Shangdong province and river sediment powder in Xiaofu River at the section of Huangtuya in Zibo city of Shangdong province are used as the main raw materials and added at an equal or substantially equal amount, and a small amount of the pore forming agent is blended for the preparation of the ceramsite filter material; therefore, low cost is realized, the problem of flood passage capability of rivers is overcome, and environment pollution and land occupation caused by accumulation of Bayer red mud are simultaneously eliminated.

Owner:SHANDONG UNIV OF TECH

Micropore hydrogenated aluminum porcelain tube and preparation thereof

ActiveCN101412619AUniform distribution of microporesLower firing temperatureGas phaseTemperature resistance

The invention relates to the field of an alumina ceramic pipe, in particular to a micropore alumina ceramic pipe and a method for preparing the same, and solves the problems that the prior art can not satisfy four good performances of high temperature resistance, corrosion resistance, high insulativity, and nontoxicity at the same time. The invention provides the micropore alumina ceramic pipe which is prepared from the following raw materials: 88 to 95 percent of alpha aluminum oxide, 2 to 4 percent of suzhou clay, 2 to 4 percent of talcum powder, 0.2 to 2 percent of calcium carbonate, 0.1 to 1.5 percent of strontium carbonate, and 0.2 to 1.5 percent of silicon dioxide. The method uses fluoride containing calcination alpha aluminum oxide powder together with five additives of the suzhou clay, the talcum powder, the calcium carbonate, the strontium carbonate, and the silicon dioxide which are mixed and ground evenly to prepare the micropore alumina ceramic pipe, so that the firing temperature of the ceramic piece is greatly reduced; and through exact formulation design, solid phase, liquid phase and gas phase are collocated reasonably, thus the prepared micropore ceramic piece not only has evenly distributed micropores and good mechanical strength, but also does not change the four good performances of the aluminum oxide.

Owner:温州市润基精密陶瓷件有限公司

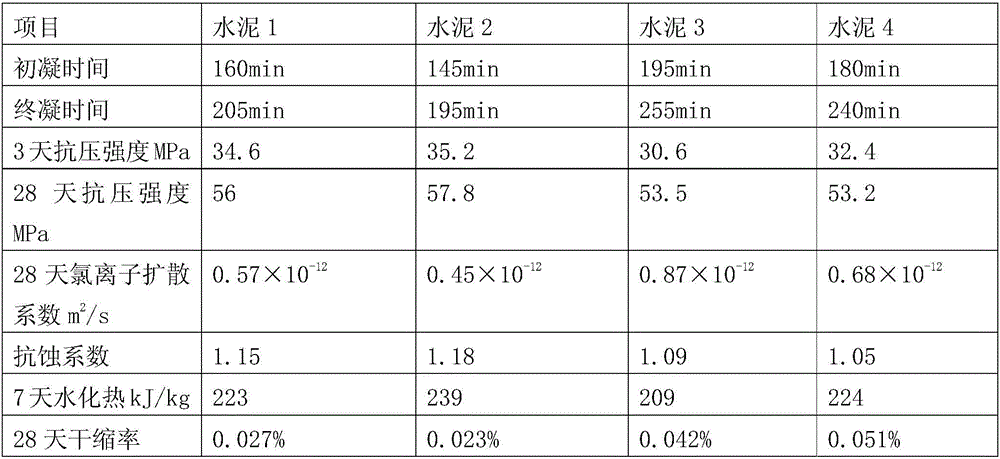

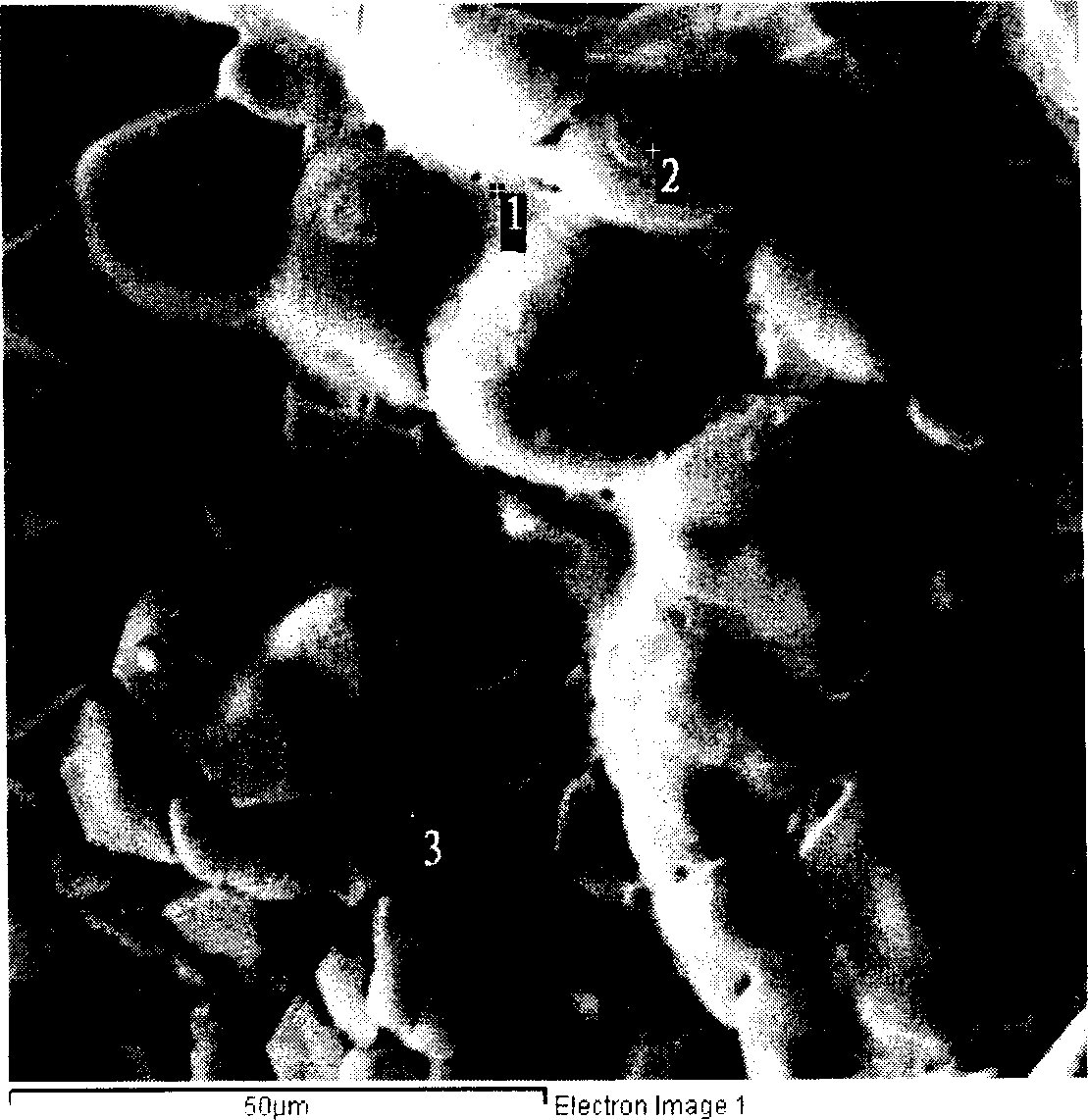

High early strength and high corrosion resistant Portland cement and preparation method thereof

ActiveCN106082724AReduce tricalcium contentExtended service lifeClinker productionMass ratioPortland cement

Belonging to the field of cement production and also relating to the field of building materials, the invention provides a high early strength and high corrosion resistant Portland cement and a preparation method thereof. The high early strength and high corrosion resistant Portland cement is mainly applied to engineering projects in complex marine environments and the west harsh environments. The high early strength and high corrosion resistant Portland cement is characterized by containing, by weight percentage, 60%-90% of a high iron and low calcium cement clinker mineral component, 2%-10% of an auxiliary functional component, 5%-25% of an auxiliary cementitious component, and 3%-7% of industrial gypsum. The high iron and low calcium cement clinker mineral component is mainly prepared from high iron and low calcium Portland cement clinker and high iron and low calcium Q phase cement clinker in a mass ratio of 5-15:1. The cement not only has strong seawater erosion resistance and high early strength, but also has the characteristics of low shrinkage and low hydration heat.

Owner:WUHAN UNIV OF TECH

Method for preparing porous ceramic filter membrane by low-temperature sintering

InactiveCN104587846AImprove stabilityAppropriate viscositySemi-permeable membranesVacuum pressureHigh intensity

The invention discloses a method for preparing a porous ceramic filter membrane by low-temperature sintering. The method comprises the following steps: mixing and stirring ceramic aggregate particles, a sintering aid, deionized water, a dispersant and a defoamer, then carrying out vacuum pressure maintaining to remove a gas in the obtained filter membrane layer slurry; soaking a support body material in the filter membrane layer slurry, then obtaining a membrane layer on the support material by a pulling method, and then sintering at 700-1070 DEG C to obtain the porous ceramic filter membrane. According to the method, the porous ceramic membrane product which is high in strength, resistant to wear and corrosion, long in life and low in cost is obtained by optimally proportioning the sintering aid, the dispersant and the defoamer, preparing the ceramic membrane layer slurry system with high stability and proper viscosity, regulating the pulling method of the ceramic support body with a high porosity and a large hole diameter in the prefabricated membrane layer slurry system, thereby obtaining a uniform and asymmetrical porous ceramic membrane blank on the whole surface of a specified position of the support body material, and finally drying stage by stage and rapidly sintering at a low temperature of 1100 DEG C so as to obtain a porous ceramic filter membrane product with high intensity, abrasion resistance, corrosion resistance, long service life and low cost.

Owner:CHANGAN UNIV

Zirconium oxide plasticizing mullite ceramic material and preparation method thereof

The invention relates a zirconia-toughened mullite ceramic material and manufacturing method thereof, which is manufactured through modern toughening and strengthening technologies with zirconium silicate and Alpha-aluminum oxide as a substrate, yttrium oxide, magnesium oxide, calcium oxide and titanium oxide as a mineralizer, and mullite as a seed crystal. The material is toughened and strengthened through the modifying treatment and the green compact has good uniformity and compactness with the aid of an isostatic pressing. The sintering process is completed within one time in the shuttle kiln under normal pressure and high temperature conditions, having a uniform temperature and low cost. Compared with an aluminum oxide ceramic material, the invention has advantages of high strength, high tenacity, high wear resistance and simple process; the dramatic reduction of sintering temperature can achieve the purpose of energy efficiency.

Owner:湖南泰鑫瓷业有限公司

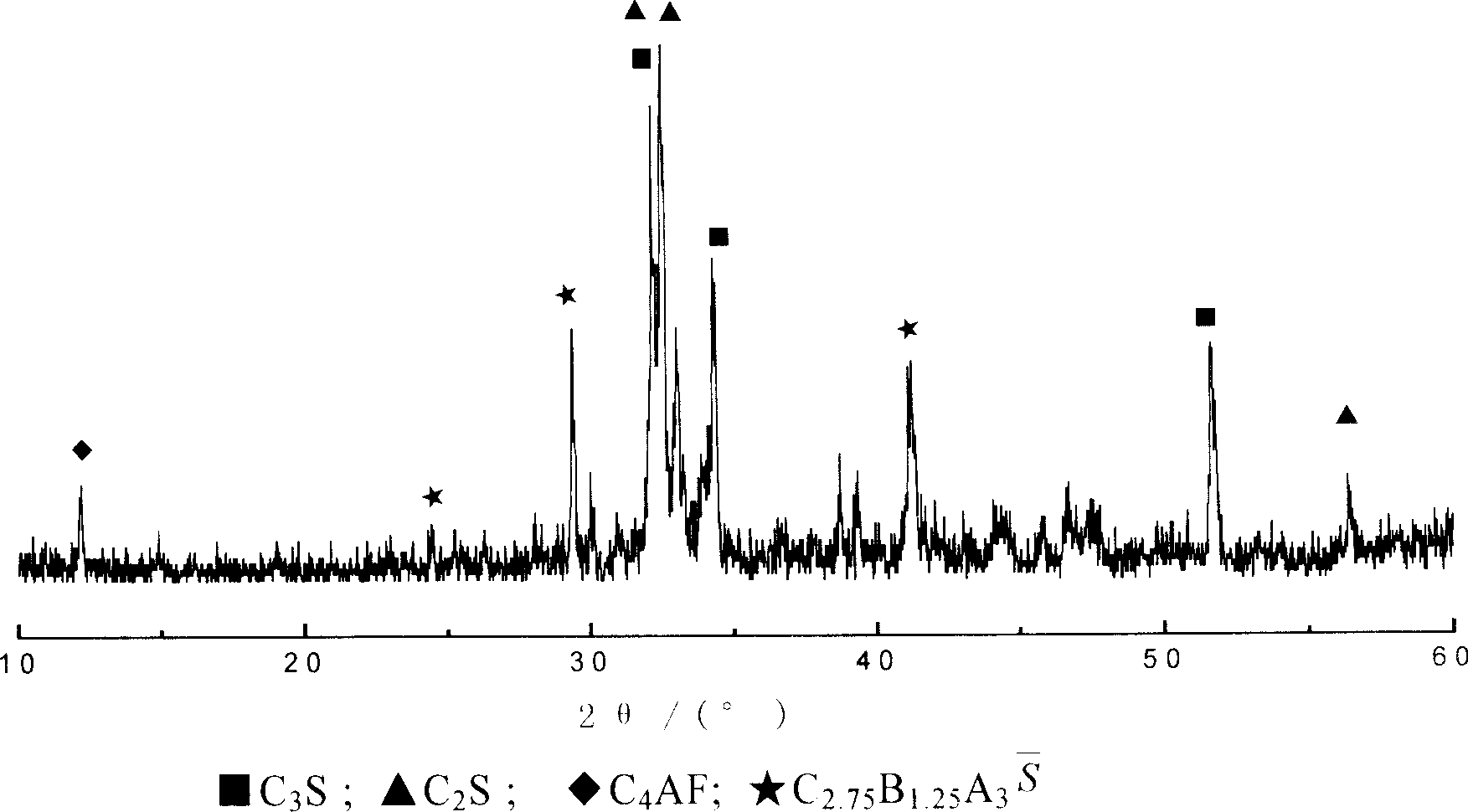

Belite-calcium barium sulphoaluminate cement

InactiveCN1887766ALower firing temperatureReduce dosageCement productionMaceralCalcium aluminoferrite

The present invention belongs to the field of cement material technology, and is especially one kind of Belite-calcium barium sulphoaluminate cement. The cement clinker is mainly one mineral phase system of C2S-CBAS-C3S-C3A-C4AF comprising calcium barium sulphoaluminate 5-45 wt%, dicalcium silicate 30-70 wt%, tricalcium silicate 10-45 wt%, tricalcium aluminate 2-20 wt%, and calcium aluminoferrite 2-20 wt%, where calcium barium sulphoaluminate has the molecular expression of (3-x)CaO .xBaO .3Al2O3 .CaSO4 with x=0.25-3. The present invention has the available of lower firing temperature, utilization of low quality limestone resource, high cement early strength, etc.

Owner:UNIV OF JINAN

Ceramic product prepared from waste ceramic and preparation method thereof

The invention relates to a ceramic product prepared from waste ceramic and a preparation method thereof. The blank formula of the ceramic product comprises the following components in part by weight: 32-36 parts of waste ceramic powder, 25-28 parts of kaolin, 15-22 parts of plastic clay and 17-25 parts of feldspar. The basic glaze formula of the ceramic product comprises the following components in part by weight: 30-35 parts of miniumite, 8-12 parts of limestone, 20-30 parts of feldspar, 8-14 parts of clay and 20-25 parts of quartz. A right amount of coloring metal compounds and / or coloring materials are added into the basic glaze. Compared with the prior art, a large amount of waste ceramic powder is used for replacing the traditional ceramic raw material for the basic glaze formula, and the technological difficulties of waste ceramic powder compounding, grain composition, sintering, decoration and the like are overcome. Not only is the waste changed into the valuable and a large amount of waste ceramic products are fully utilized, but also the sintering temperature of the ceramic product can be lowered, the energy consumption is reduced, the production cost of ceramic manufacturers is lowered, and the market competitiveness of the product is increased.

Owner:FUJIAN DEHUA NINGCHANG CERAMIC

High-density magnesium-stabilized zirconia ceramic

The invention relates to a high-density magnesium-stabilized zirconia ceramic which is prepared from the following raw materials: 80-99 mol% of ZrO2, 0.1-10 mol% of MgO, 0.1-0.5 mol% of Y2O3, 0.1-0.5 mol% of CaO and 0.1-5 wt% of sintering accelerator. The preparation technique comprises the following steps: A. preparing powder; and B. preparing ceramic: a. preparing a mixture, b. granulating, c. making a blank, d. discharging adhesive, and e. sintering at high temperature. According to the invention, the firing temperature of the ceramic material is greatly lowered, and the high-density ceramic material can be obtained only at 1600-1690 DEG C; and the relative density is up to 97% or so. The material has the advantages of high bending strength, favorable thermal shock resistance and high ionic conductivity.

Owner:ZHONGXIANG ZHONGYUAN ELECTRONICS

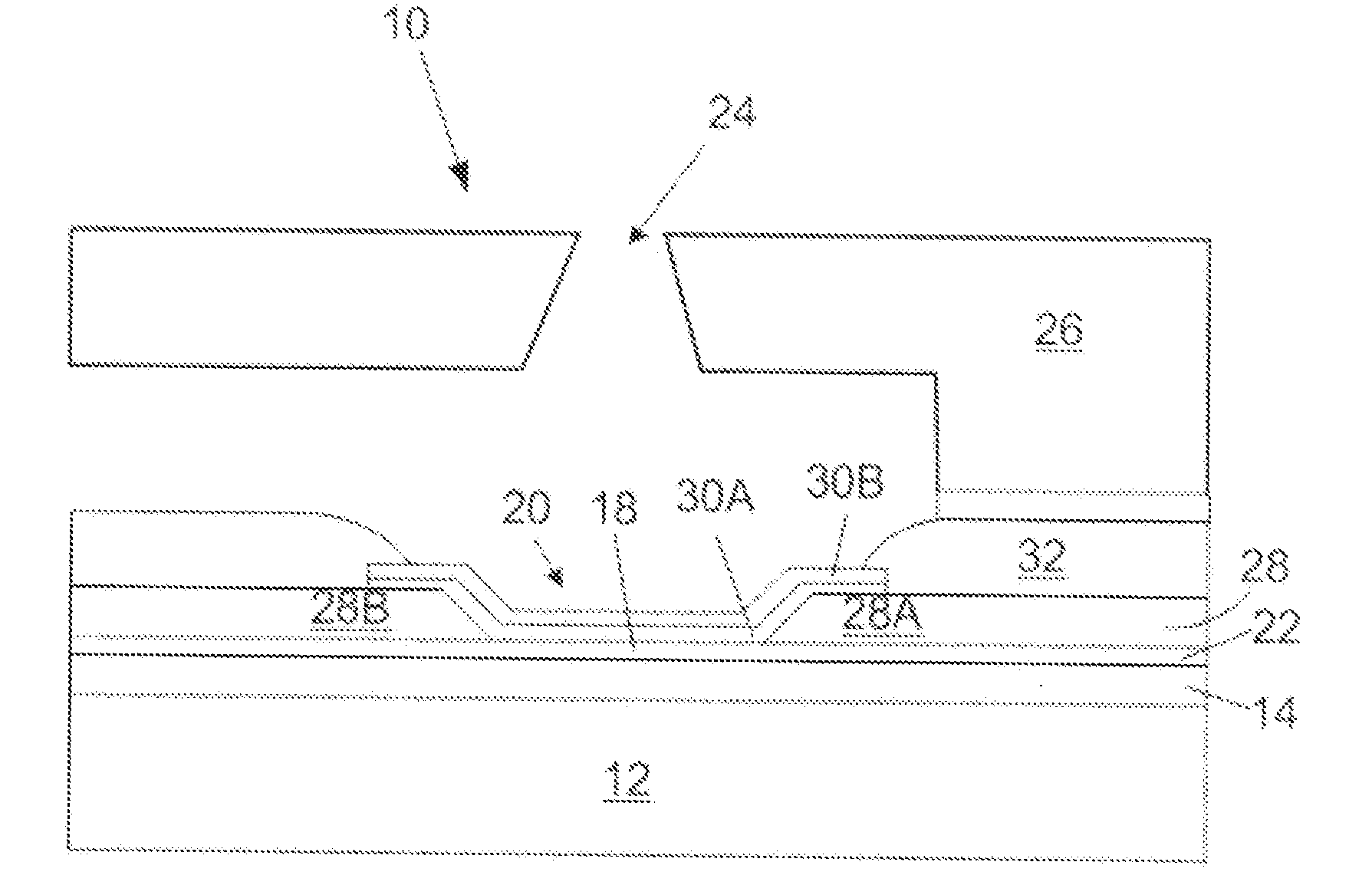

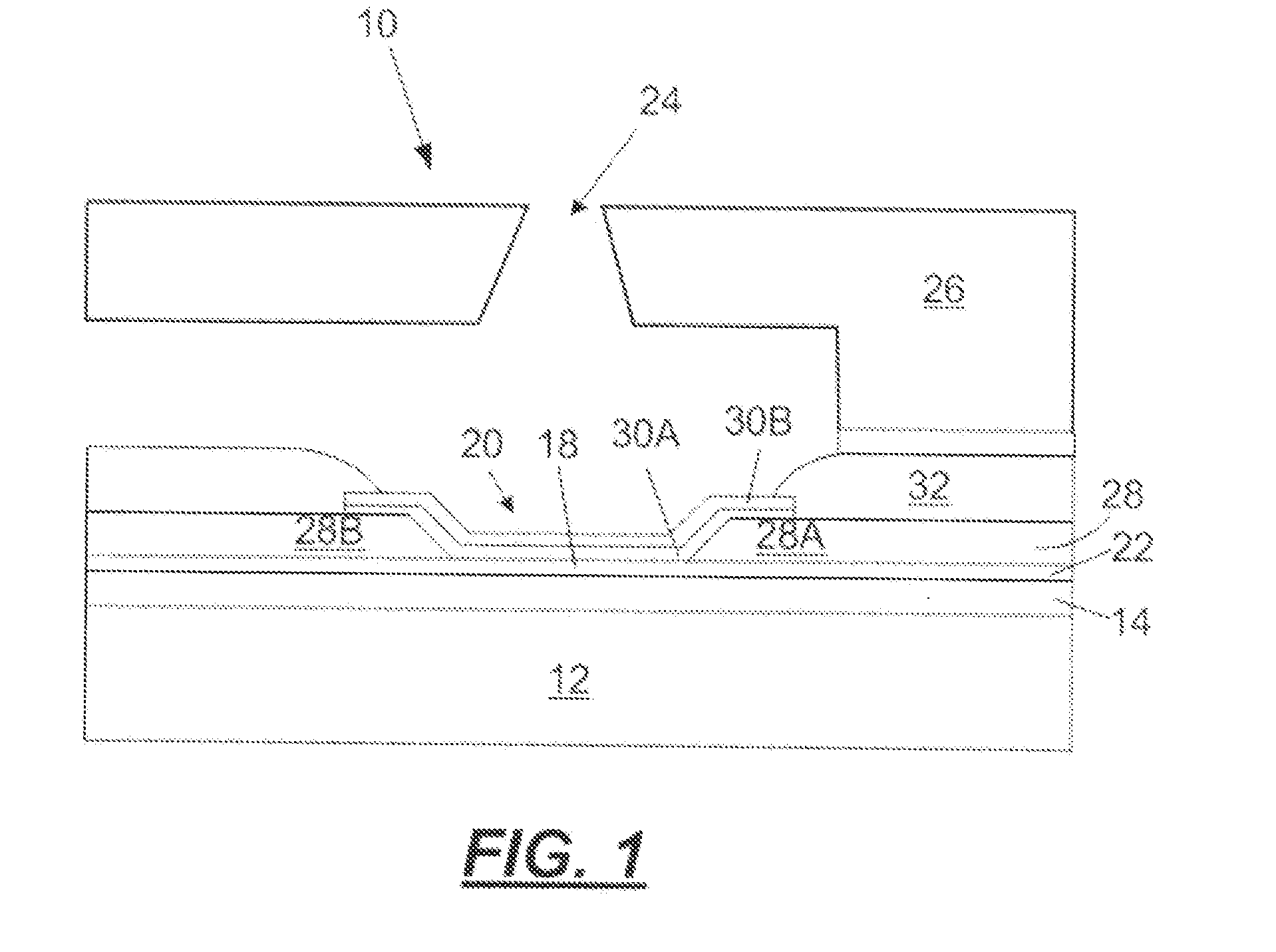

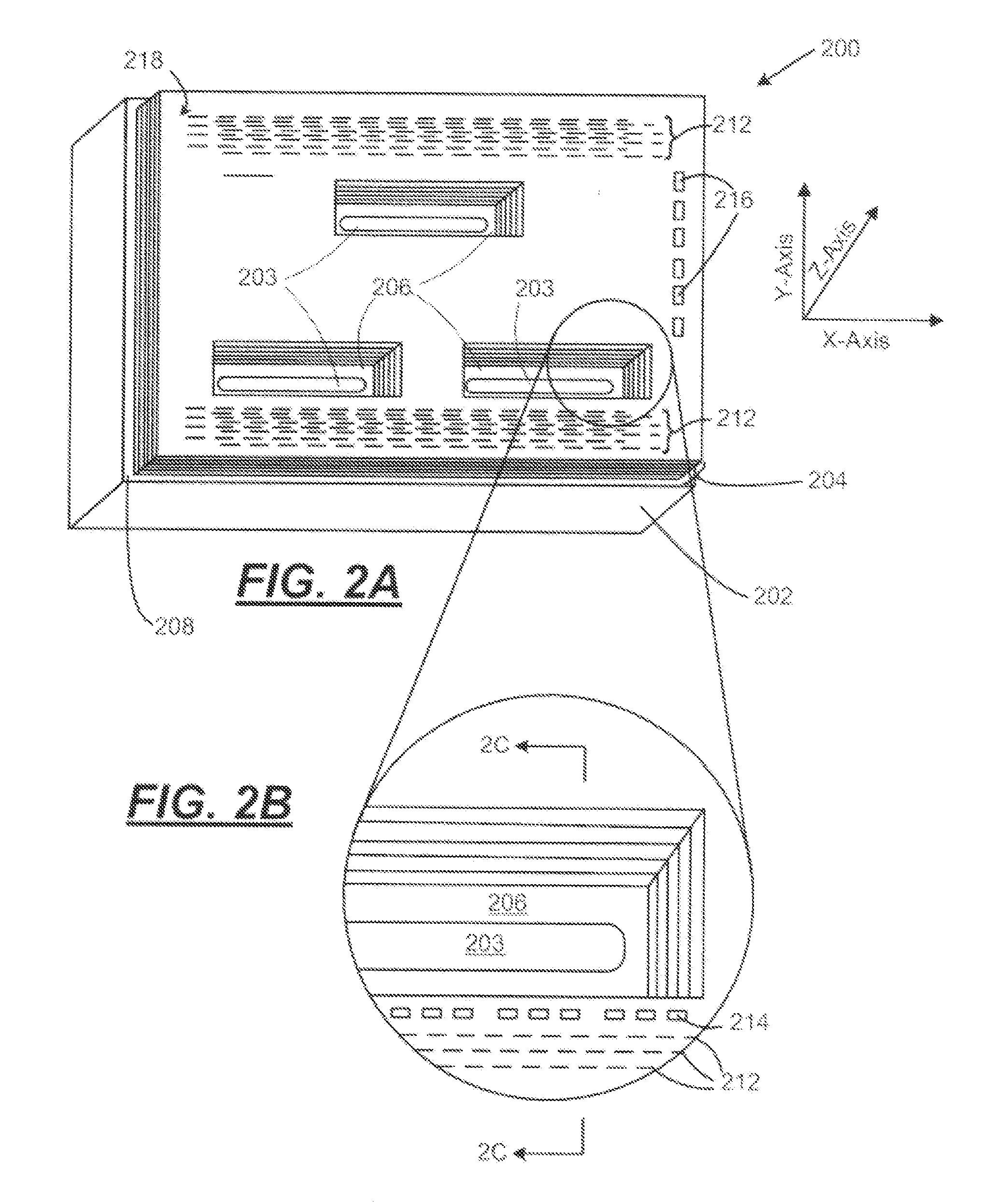

Composite Ceramic Substrate For Micro-Fluid Ejection Head

InactiveUS20080299361A1Improve flatnessEasy to packInking apparatusCeramic layered productsElectrical conductorComposite ceramic

A composite ceramic substrate for receiving an ejection head chip for a micro-fluid ejection head and a method for making the composite ceramic substrate. The substrate includes a high temperature previously fired ceramic base having a substantially planarized first surface and at least one fluid supply slot therethrough. A low temperature co-fired ceramic (LTCC) tape layer bundle having at least two LTCC tape layers is attached to the ceramic base at an interface between the LTCC tape layer bundle and the first surface of the ceramic base. The LTTC tape layer bundle has at least one chip pocket therein and at least one of the LTCC tape layers includes a plurality of conductors.

Owner:FUNAI ELECTRIC CO LTD

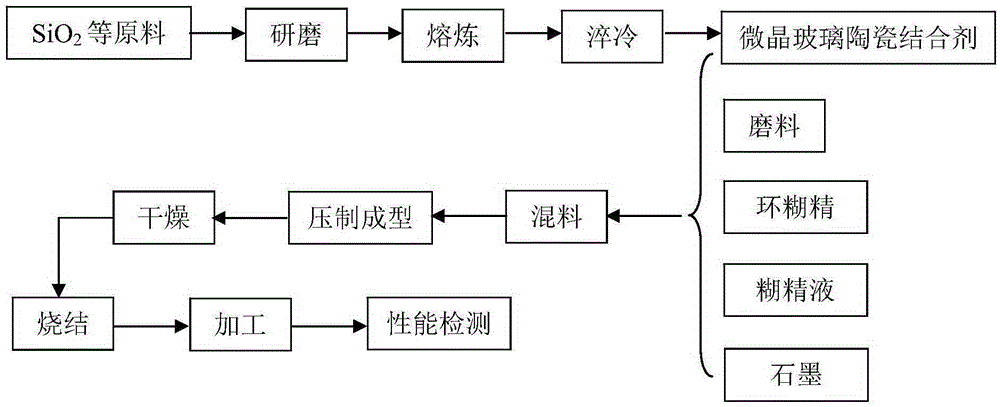

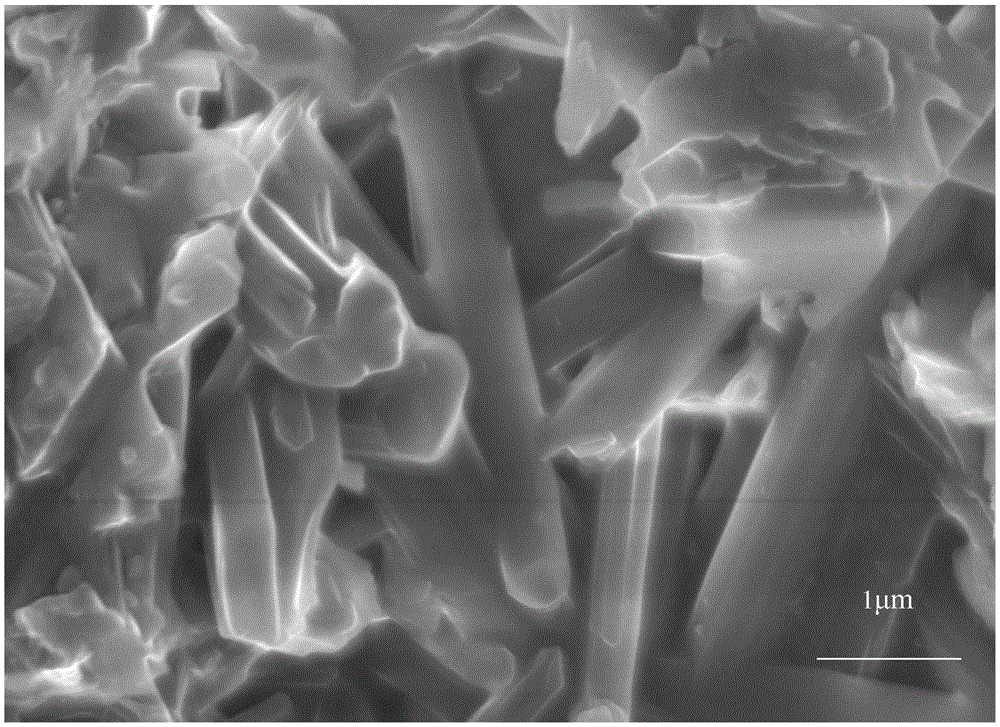

Microcrystalline glass ceramic binding agent, preparing method thereof, SG grinding wheel and preparing method thereof

ActiveCN105252435ASmall coefficient of thermal expansionLow crystallization temperatureAbrasion apparatusGrinding devicesTO-18Materials science

The invention discloses a microcrystalline glass ceramic binding agent, a preparing method thereof, an SG grinding wheel and a preparing method thereof. The binding agent is prepared from, by weight percentage, 40% to 65% of SiO2, 6% to 20% of Al2O3, 5% to 18% of Na2O, 0.5% to 5% of CaO, 3% to 10% of K2O, 8% to 35% of B2O3, 0.5% to 2% of MgO and 2% to 6% of TiO2. The microcrystalline glass ceramic binding agent is formed by reasonably selecting the raw materials, the scientific ratio is adopted, the binding agent has the beneficial effects of being low in thermal expansion coefficient and crystallization temperature and high in strength accordingly, the microcrystalline glass ceramic binding agent is suitable for being used as a binding agent of the SG grinding wheel, the firing temperature of the SG grinding wheel is greatly reduced, and the firing time of the SG grinding wheel is greatly shortened; and meanwhile the work efficiency and the machining accuracy of the SG grinding wheel are improved, grinding heat is reduced, and the service life of the grinding wheel is prolonged.

Owner:白鸽磨料磨具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com