Patents

Literature

32results about How to "Reduce CTE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

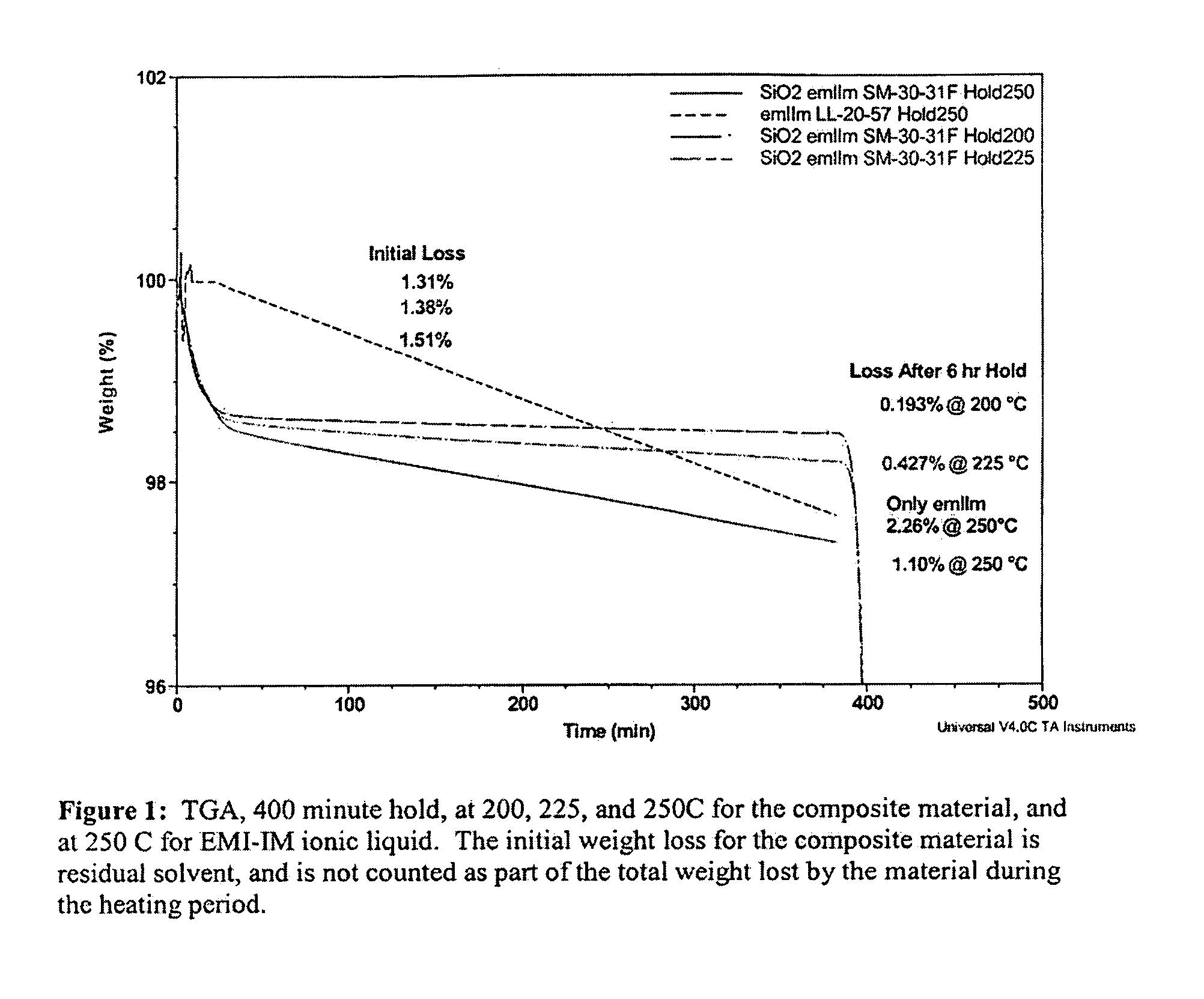

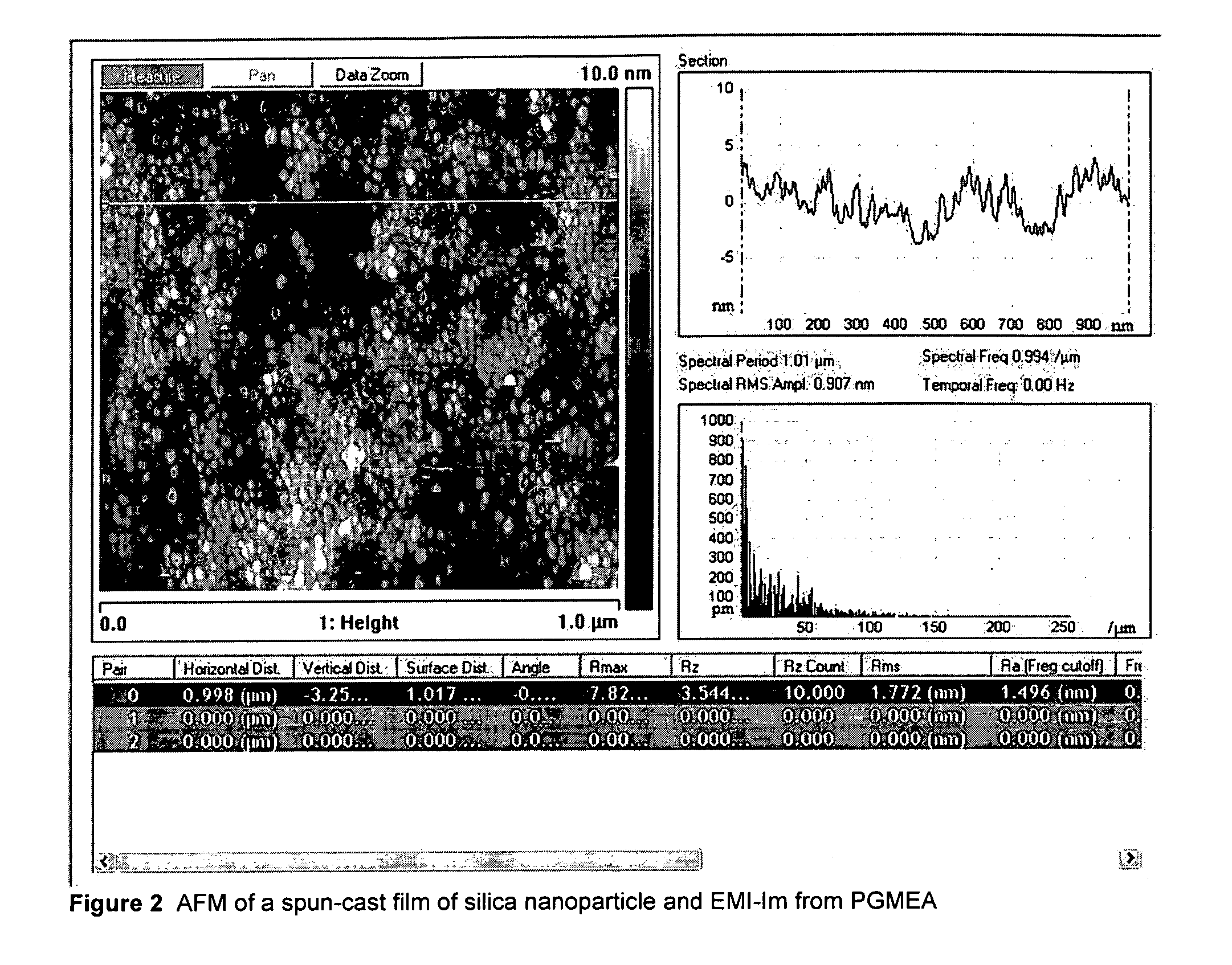

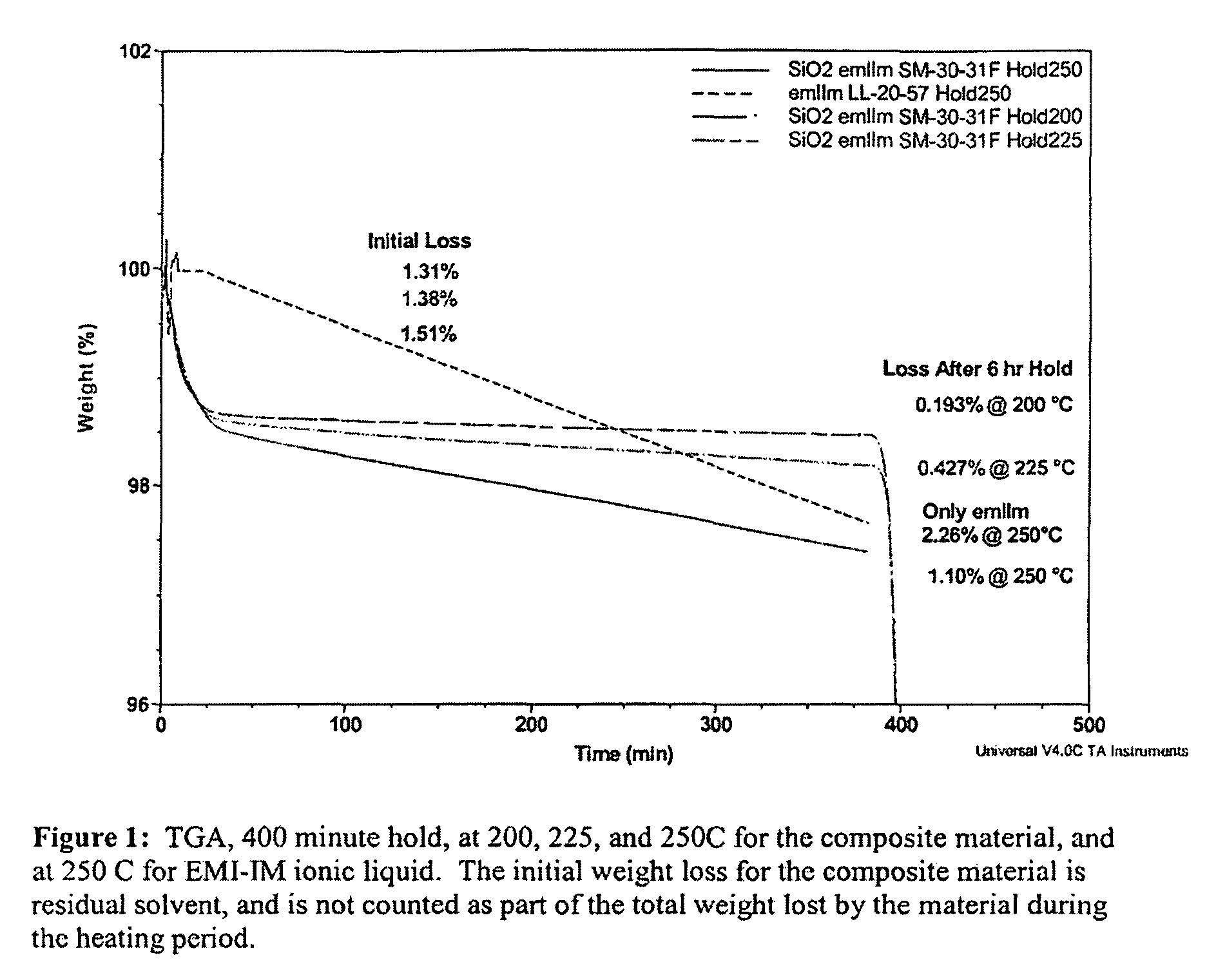

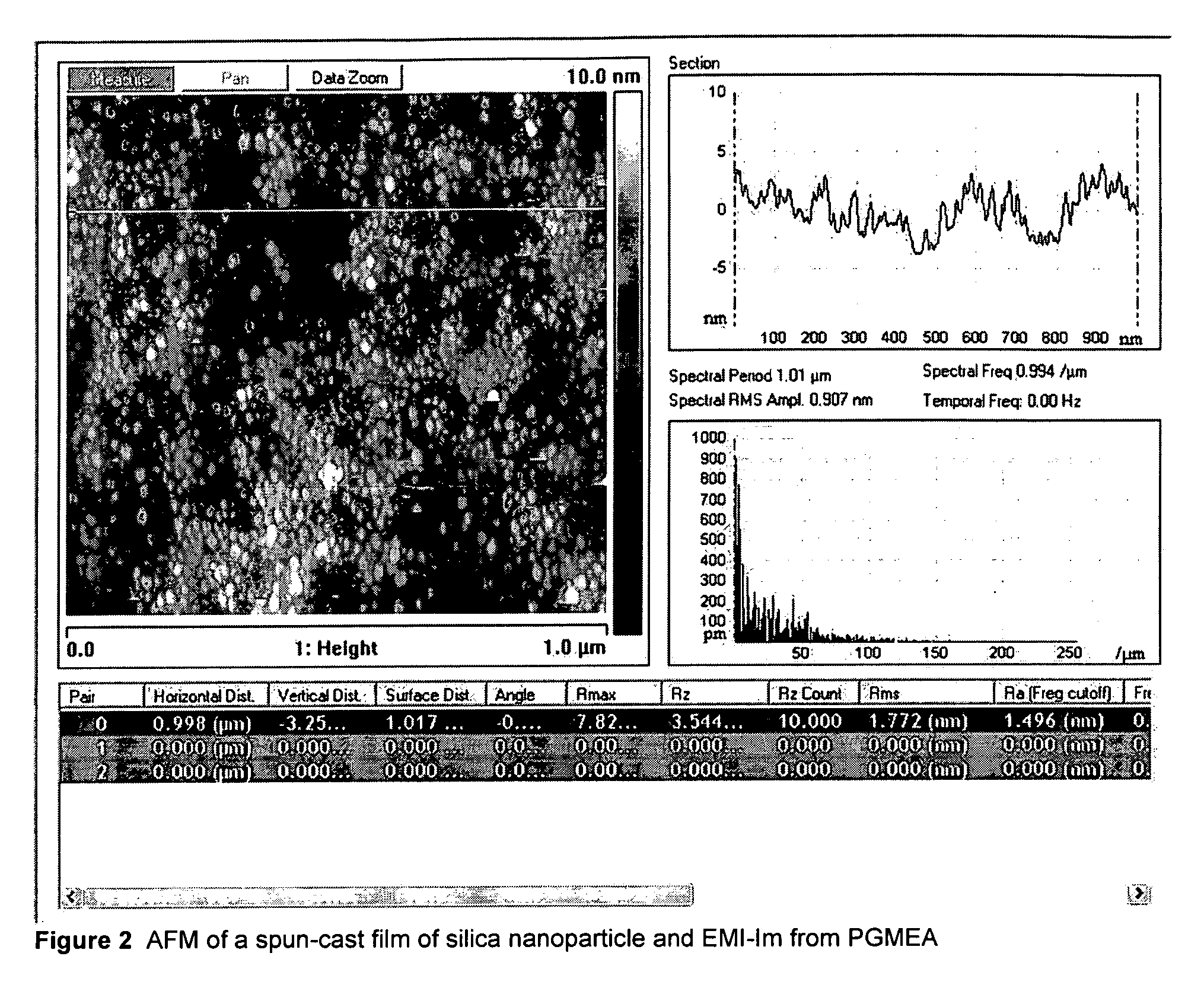

Liquid Composite Compositions Using Non-Volatile Liquids and Nanoparticles and Uses Thereof

InactiveUS20080209876A1Reduce CTEImprove performanceElectrolytic capacitorsCell electrodesOrganic solventNanoparticle

A solvent composition comprising an organic solvent; dispersed nanoparticles; and a non-volatile electrolyte.

Owner:ESIONIC

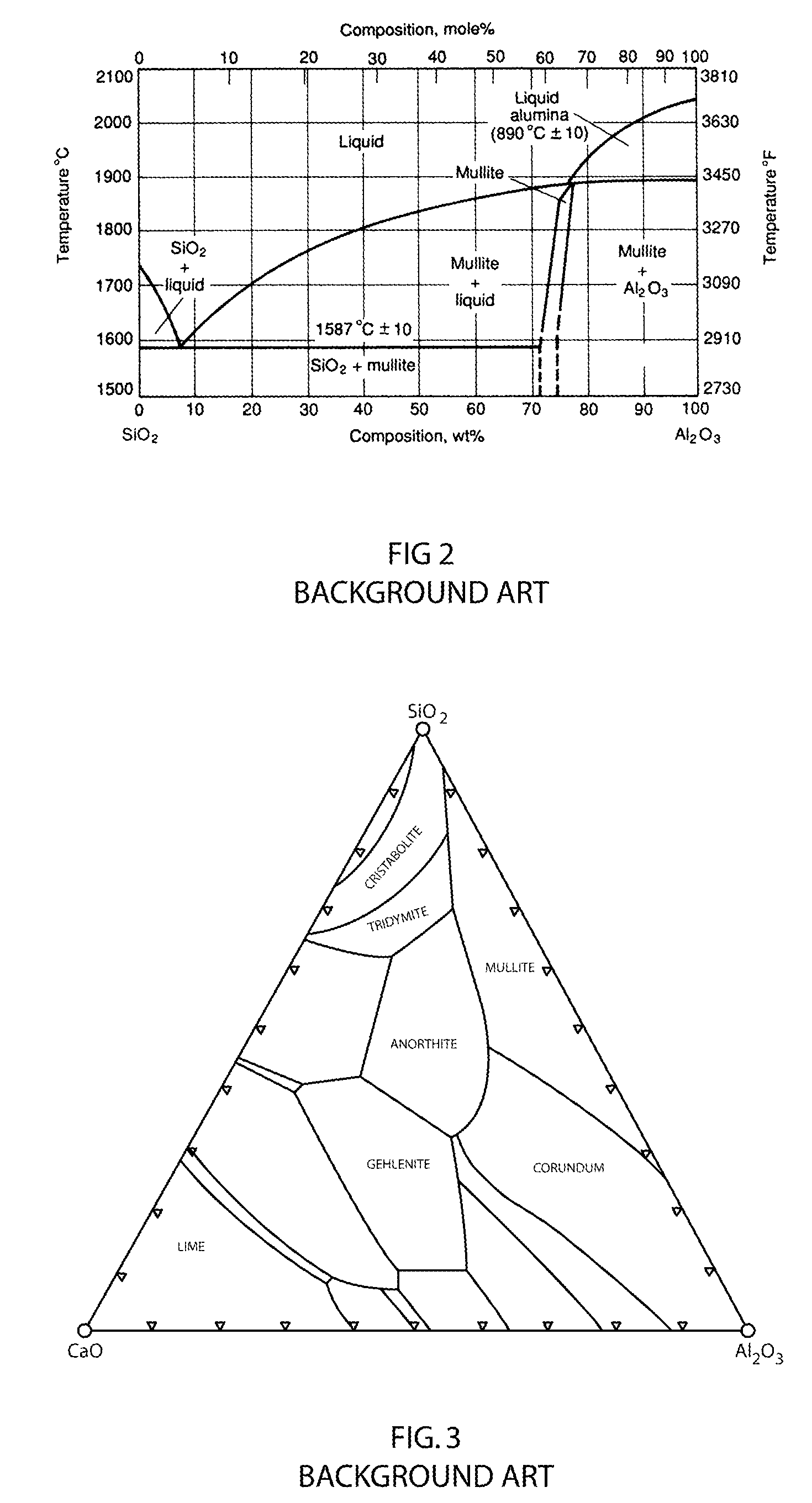

Aluminum titanate ceramic articles and methods of making same

ActiveUS7259120B2Reduced strengthLower firing temperatureInternal combustion piston enginesSilencing apparatusAlkaline earth metalRare earth

An aluminum titanate ceramic article having a predominant crystal phase of aluminum titanate and a material composition including aluminum, titanium, silica, an alkaline earth metal (e.g., at least one selected from the group of strontium, calcium, barium, or combinations), and a rare earth metal (e.g., at least one selected from the group consisting of yttrium, lanthanum, and combinations) and methods of making such aluminum titanate bodies are described. An oxide of yttrium metal or lanthanide metals is preferably used as a sintering aid in combination with the other compositional components to enable firing of the resulting green body at a lower heating temperature of less than 1500° C., and more preferably between 1400°-1450° C., with a preferable hold time of less than 8 hours, more preferably of 6 to 8 hours.

Owner:CORNING INC

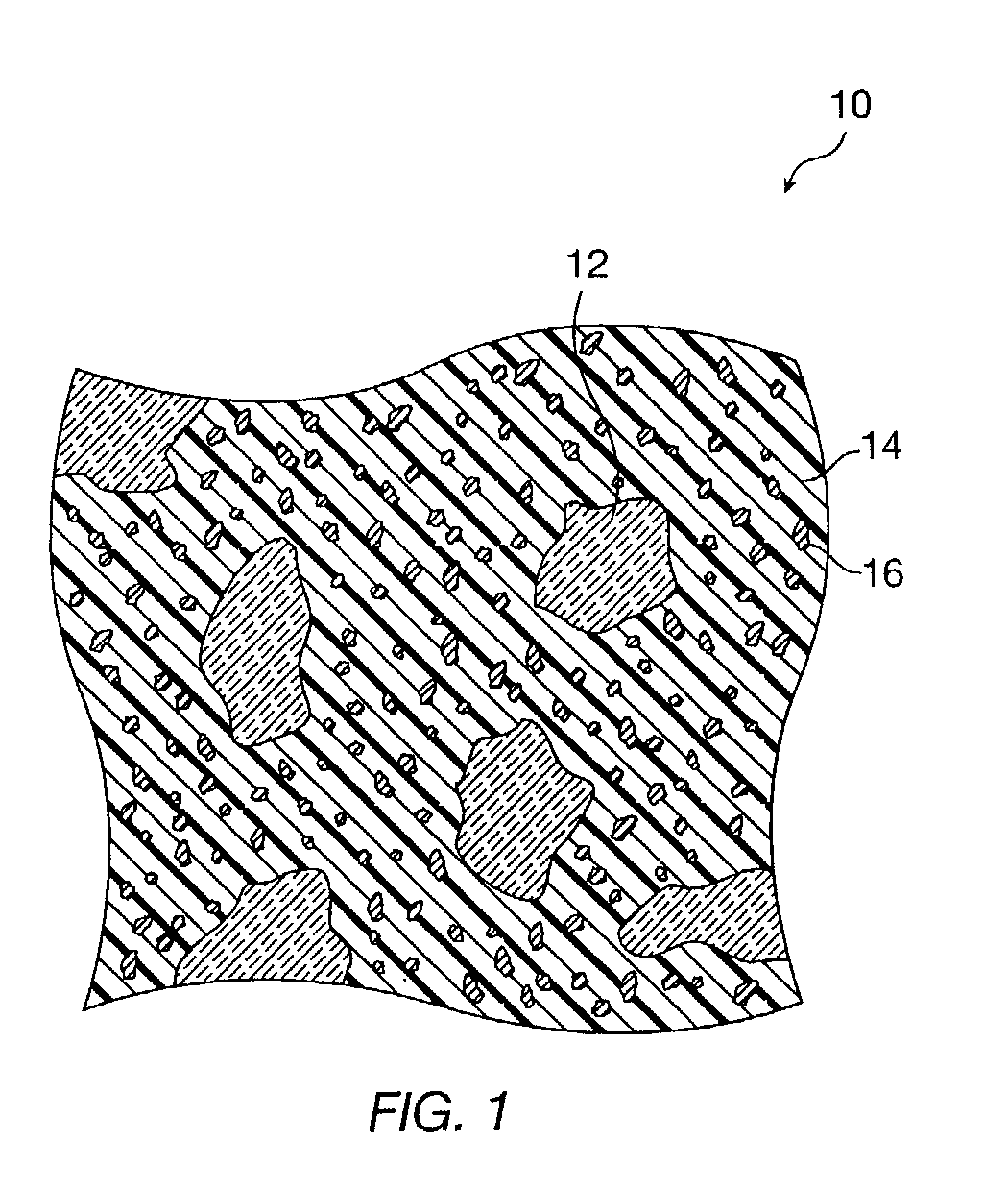

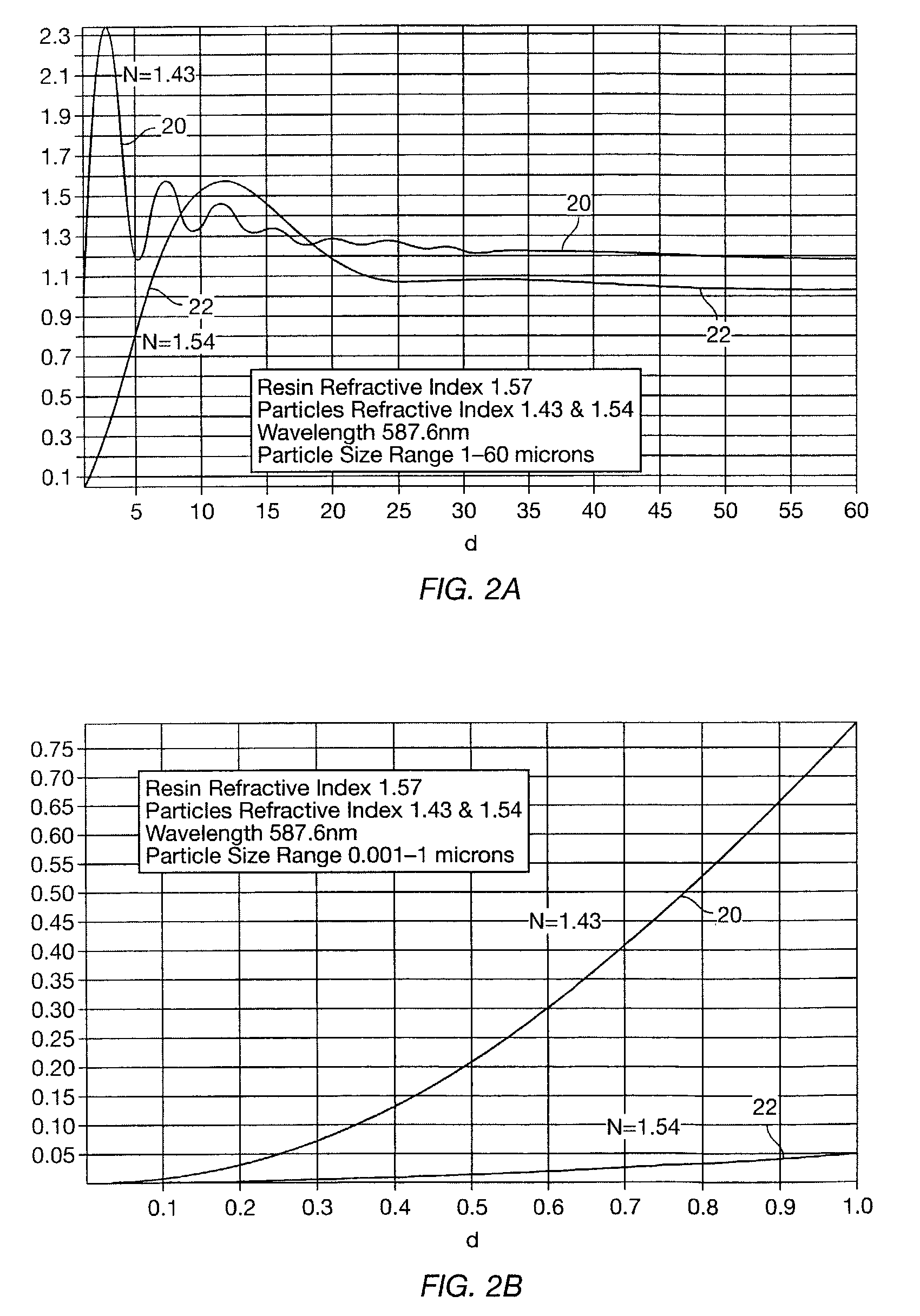

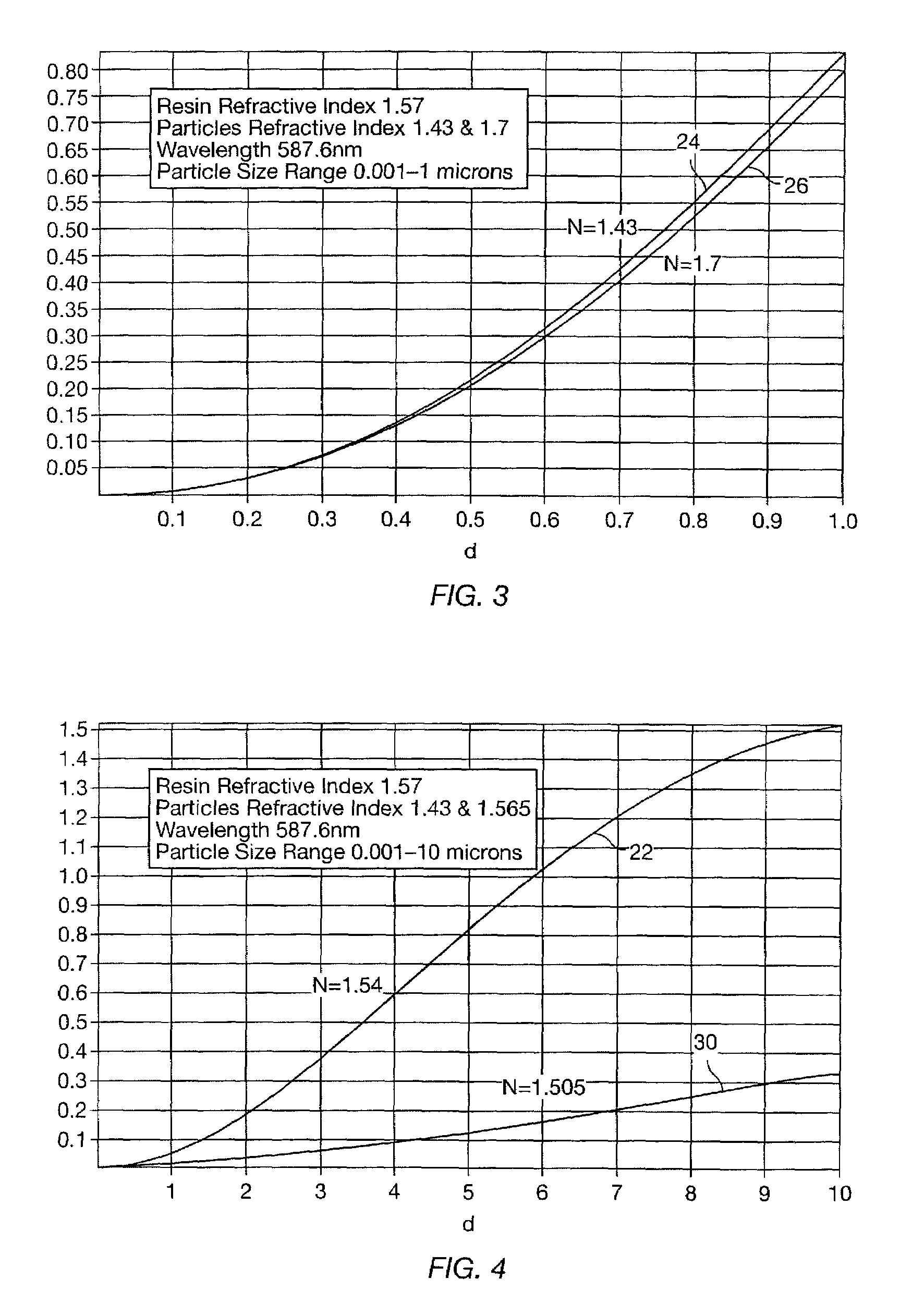

Optical polymer blend with bimodal particle sizes

ActiveUS6979704B1Reduce CTEReduce light scatterMaterial nanotechnologySpecial tyresAdhesiveOptical polymers

An optical polymer blend includes sub-wavelength particles to modify the refractive index of a polymer to match the refractive index of micro-particles added to adjust the bulk coefficient of thermal expansion of the blend. A relatively large amount of material may be added to the resin to adjust the bulk coefficient of thermal expansion without unduly increasing the viscosity of the blend before setting. In some applications blends are used for molded or extruded optical elements, in other applications, blends are used for optical adhesives with low coefficients of thermal expansion.

Owner:VIAVI SOLUTIONS INC

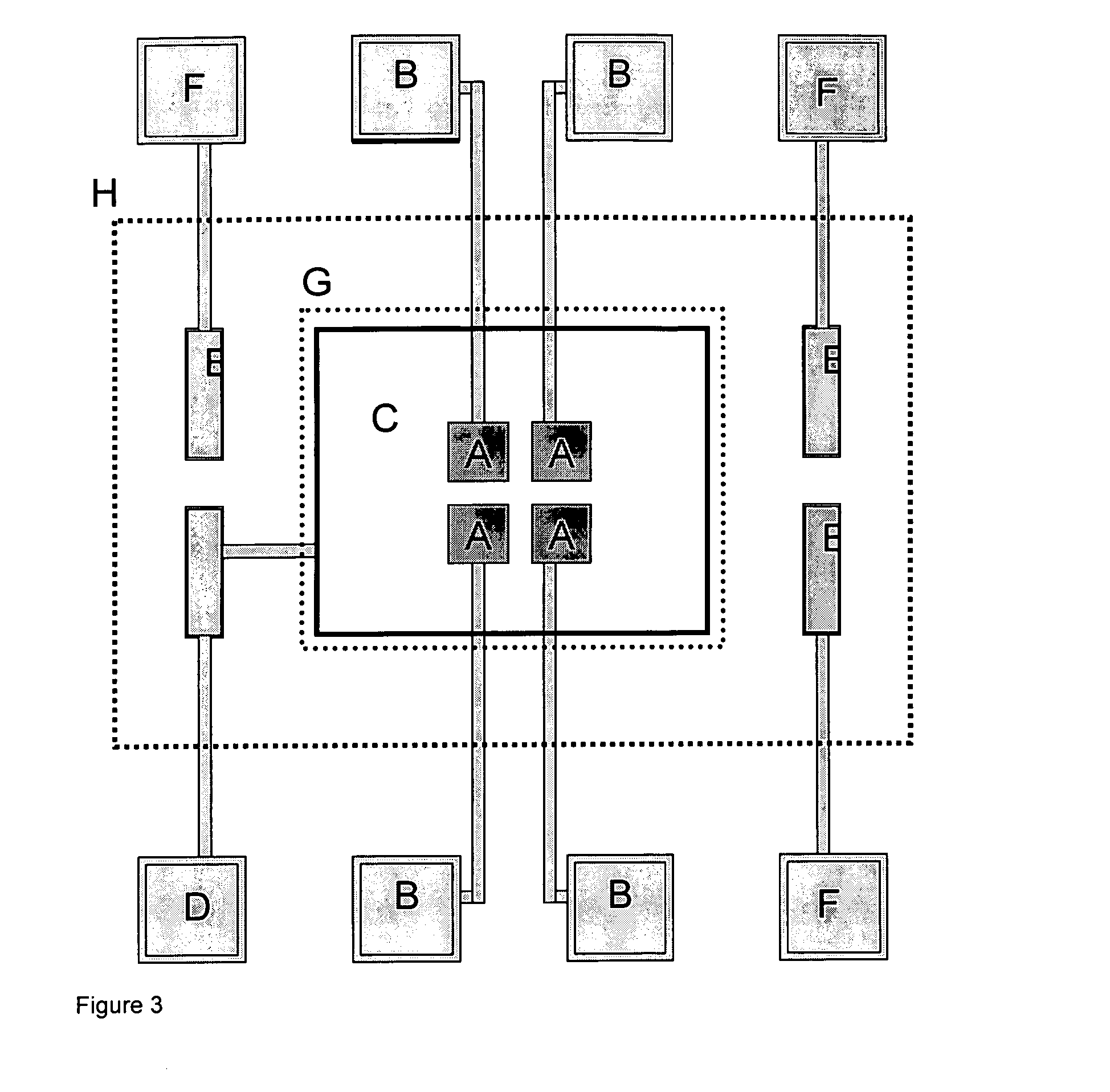

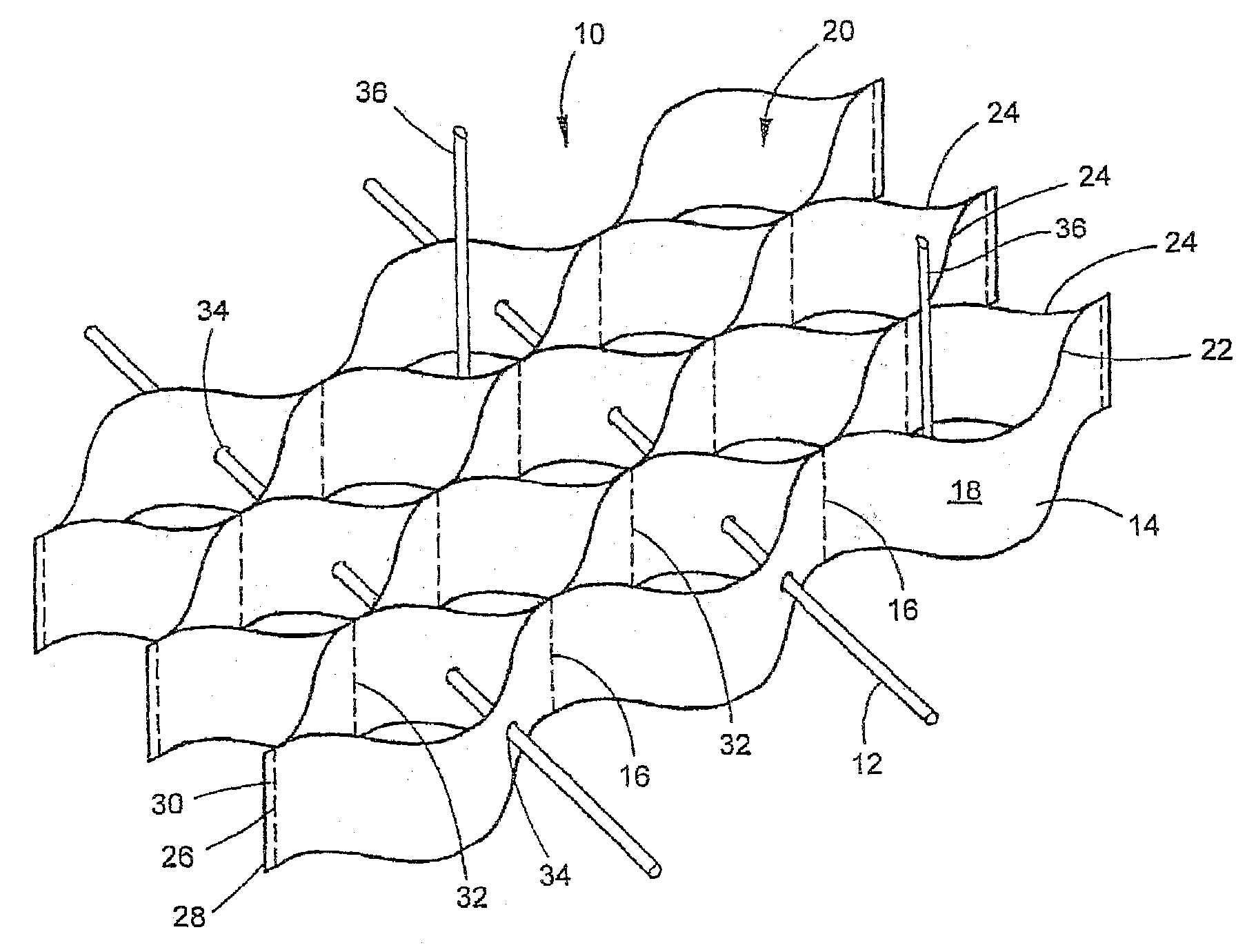

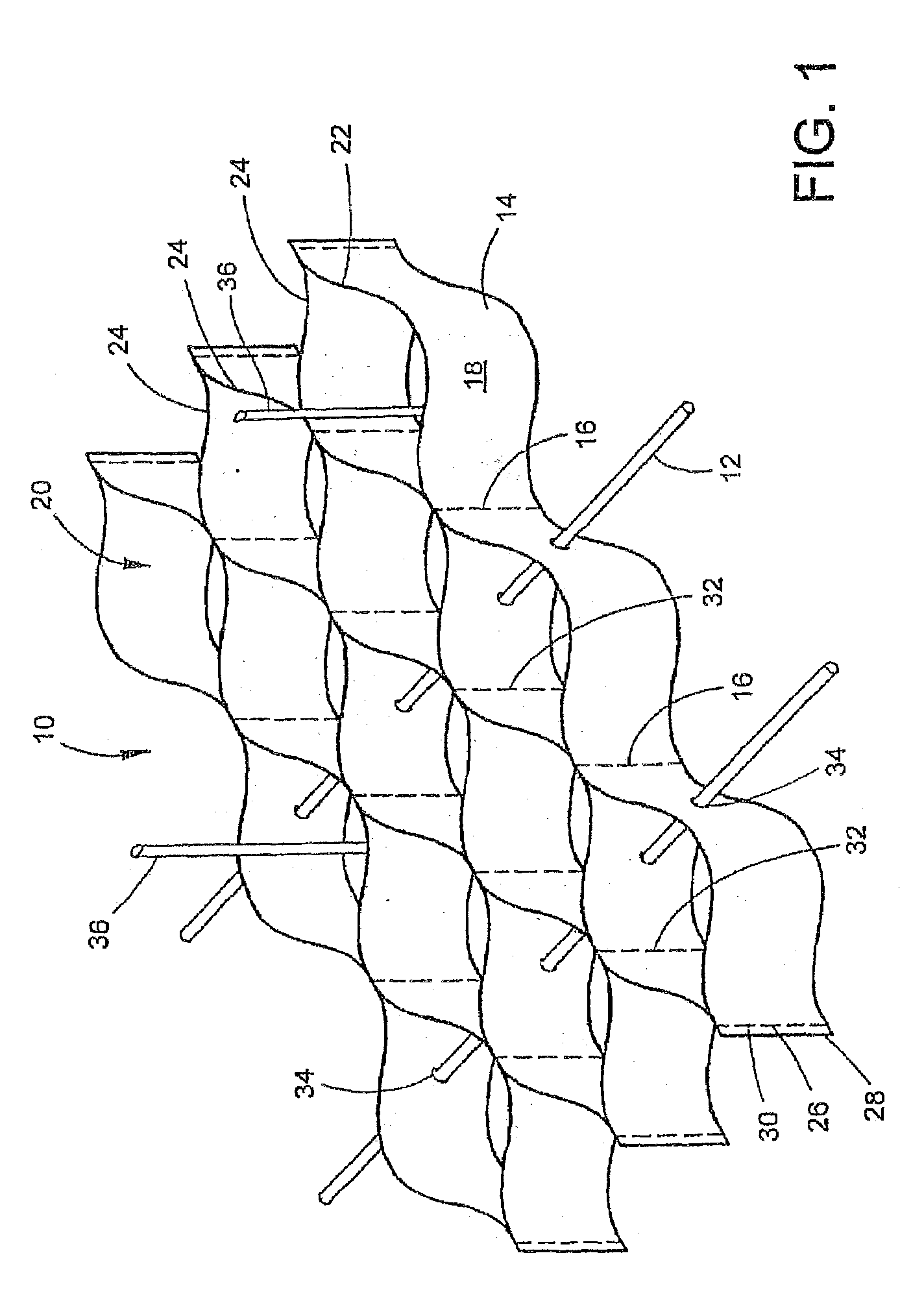

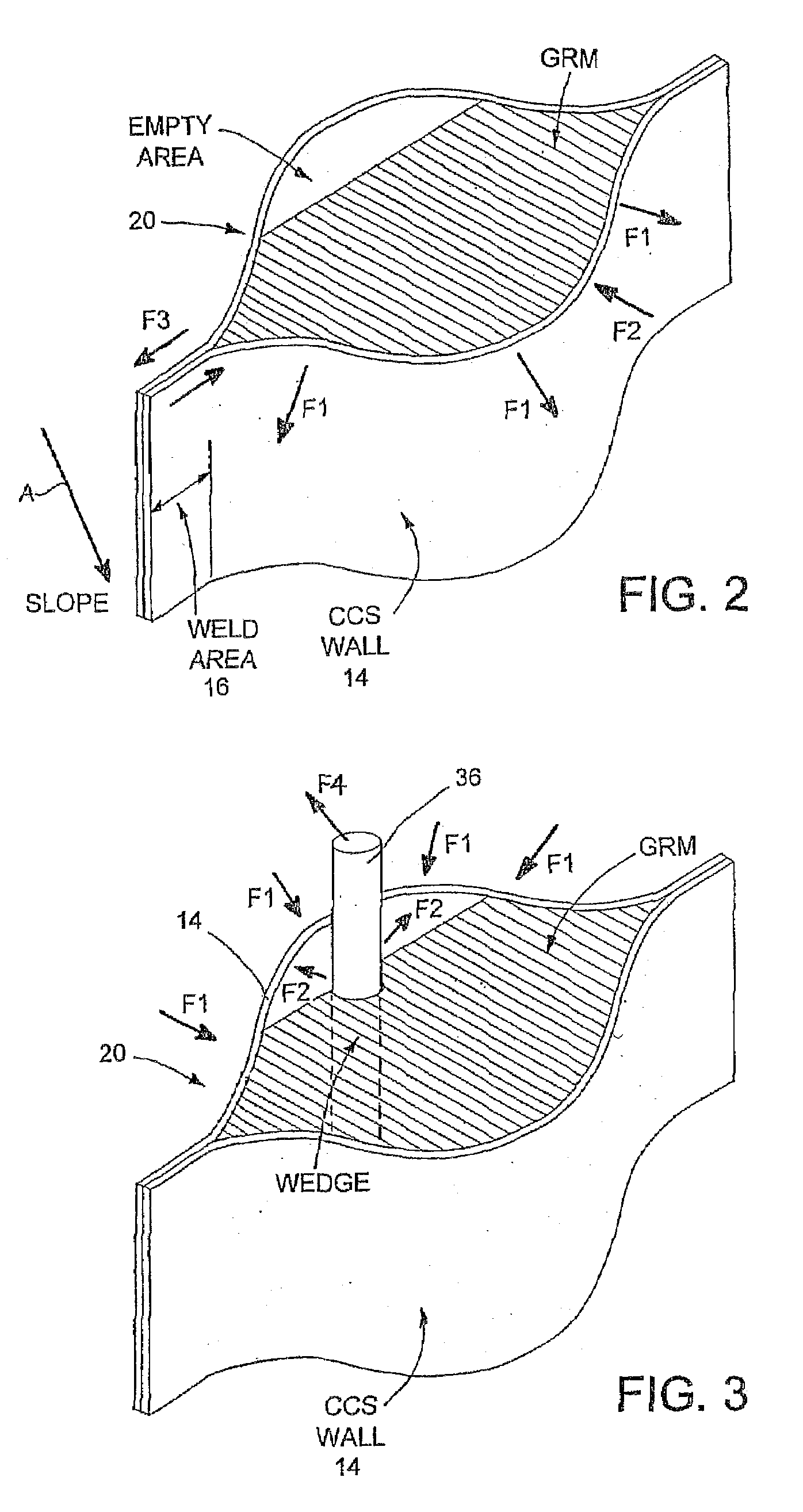

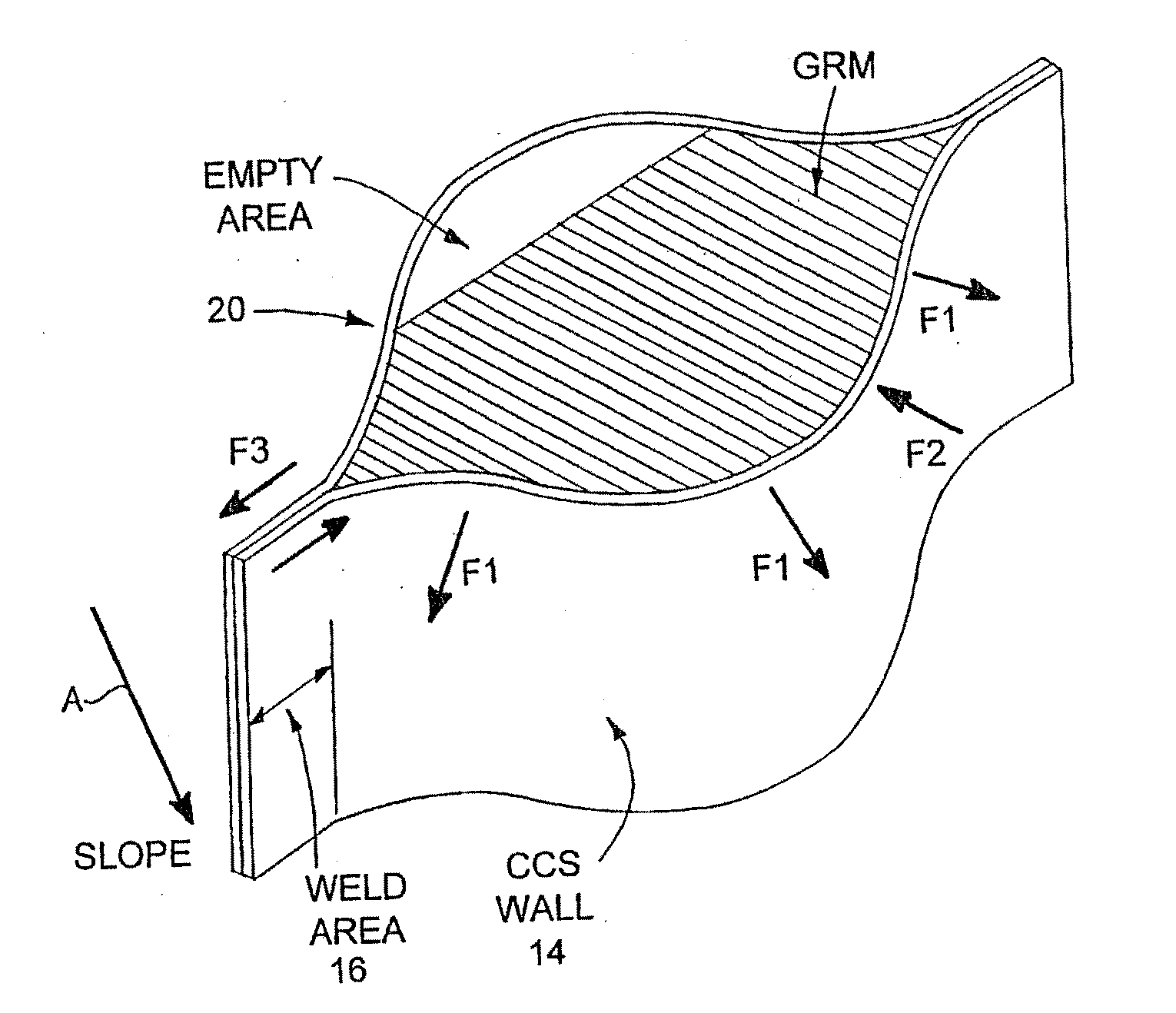

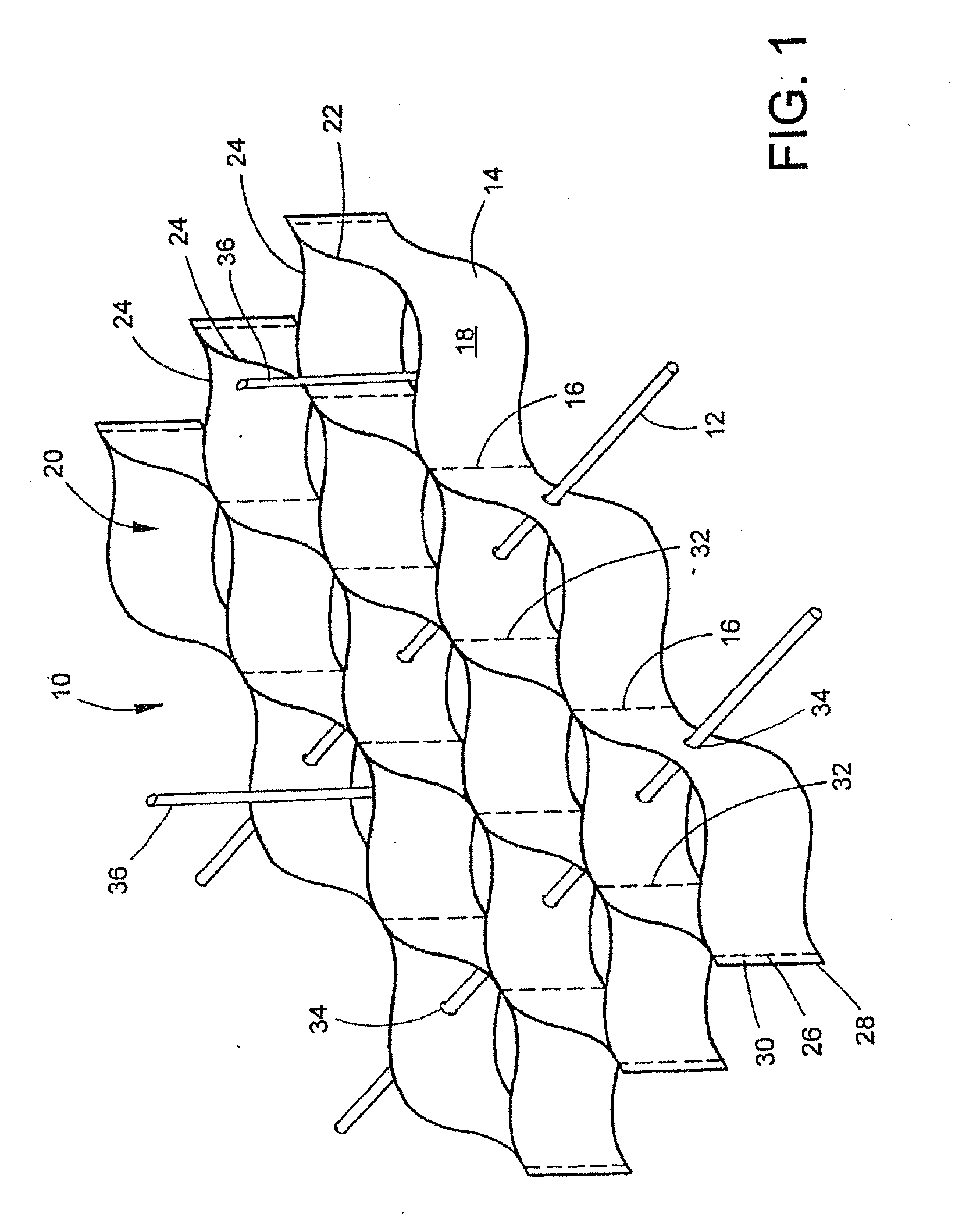

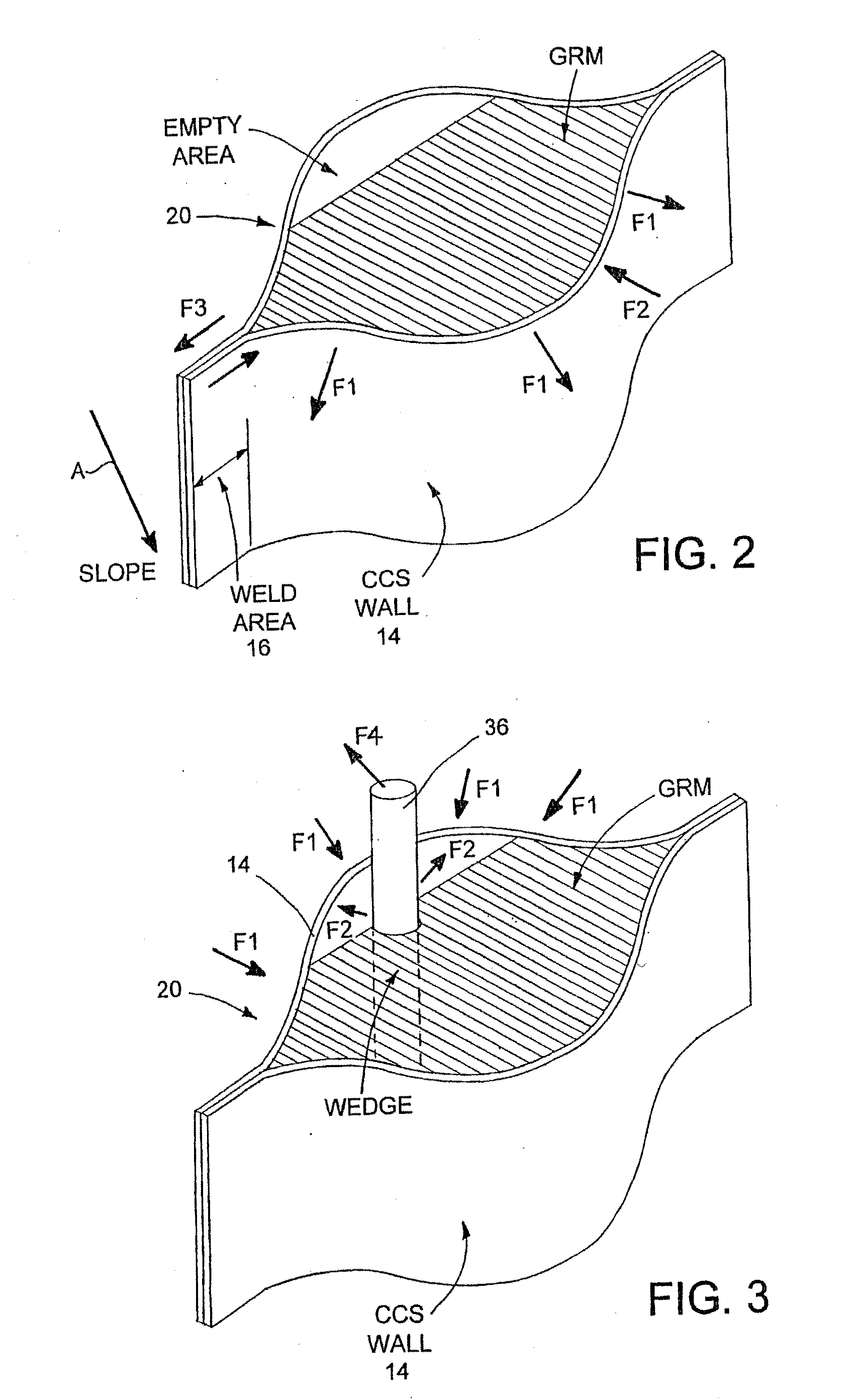

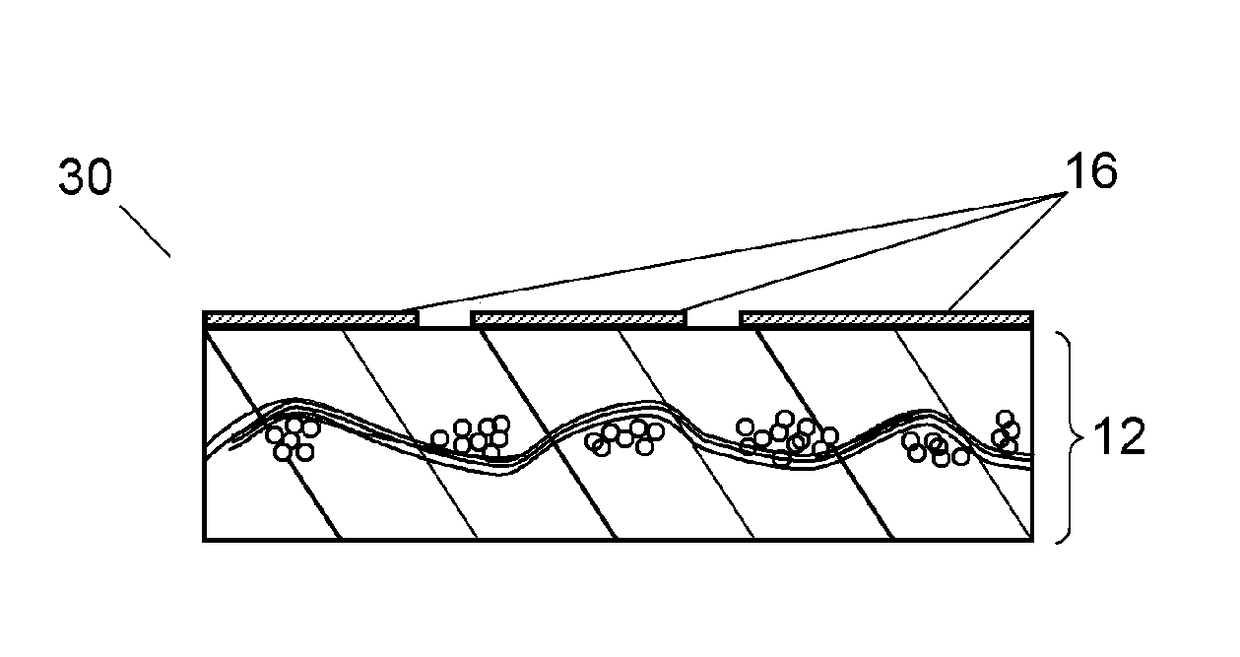

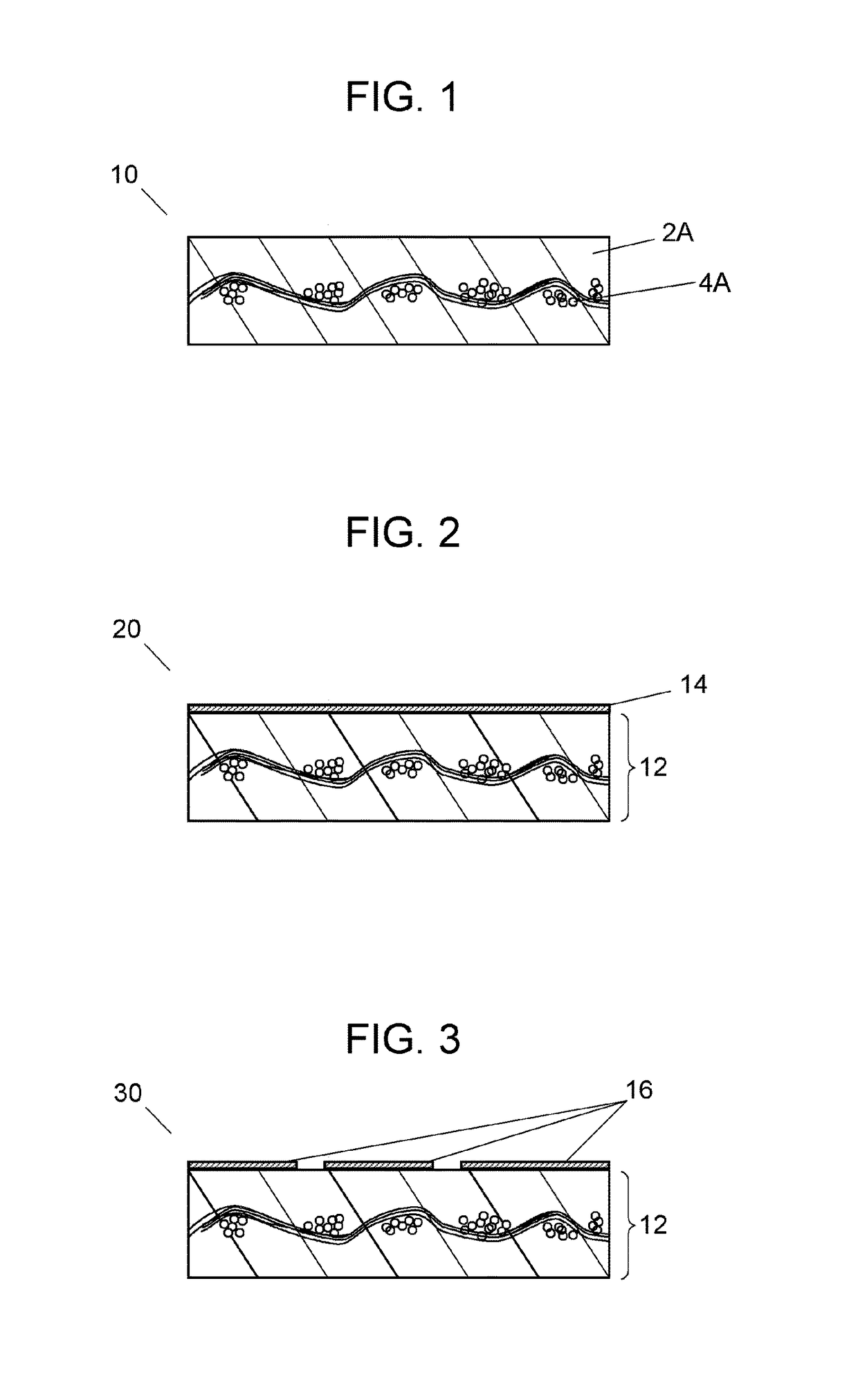

Geotechnical articles

InactiveUS20080213521A1Improve creep resistanceImprove tear resistanceDomestic netsThin material handlingCold areaCellular confinement

A multiphase polymeric material comprises a first rigid continuous phase and a second elastic phase dispersed in the first phase. The multiphase polymeric material may be formed into polymeric strips and used to make a cellular confinement system which is suitable for use in cold areas.

Owner:PRS MEDITERRANEAN

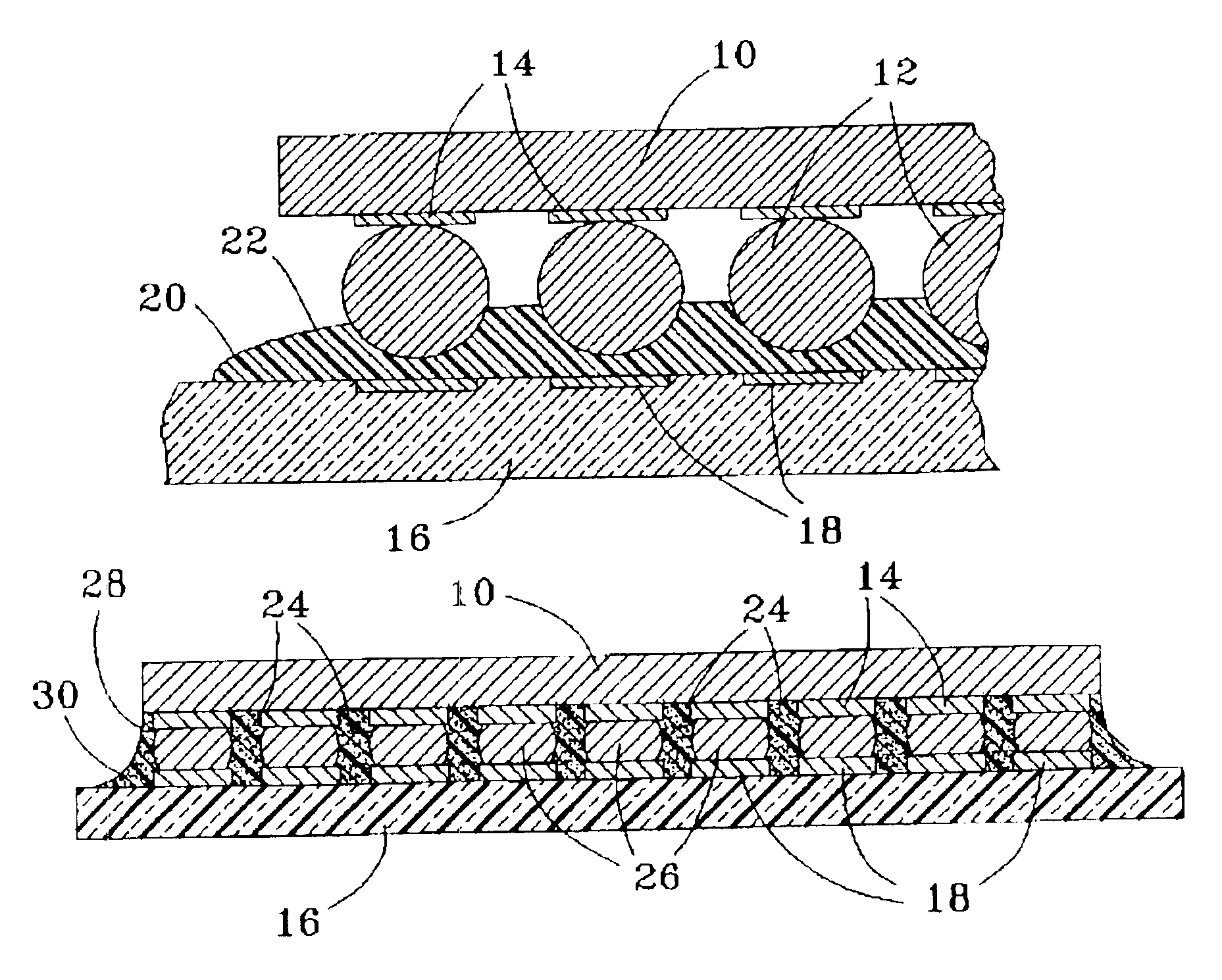

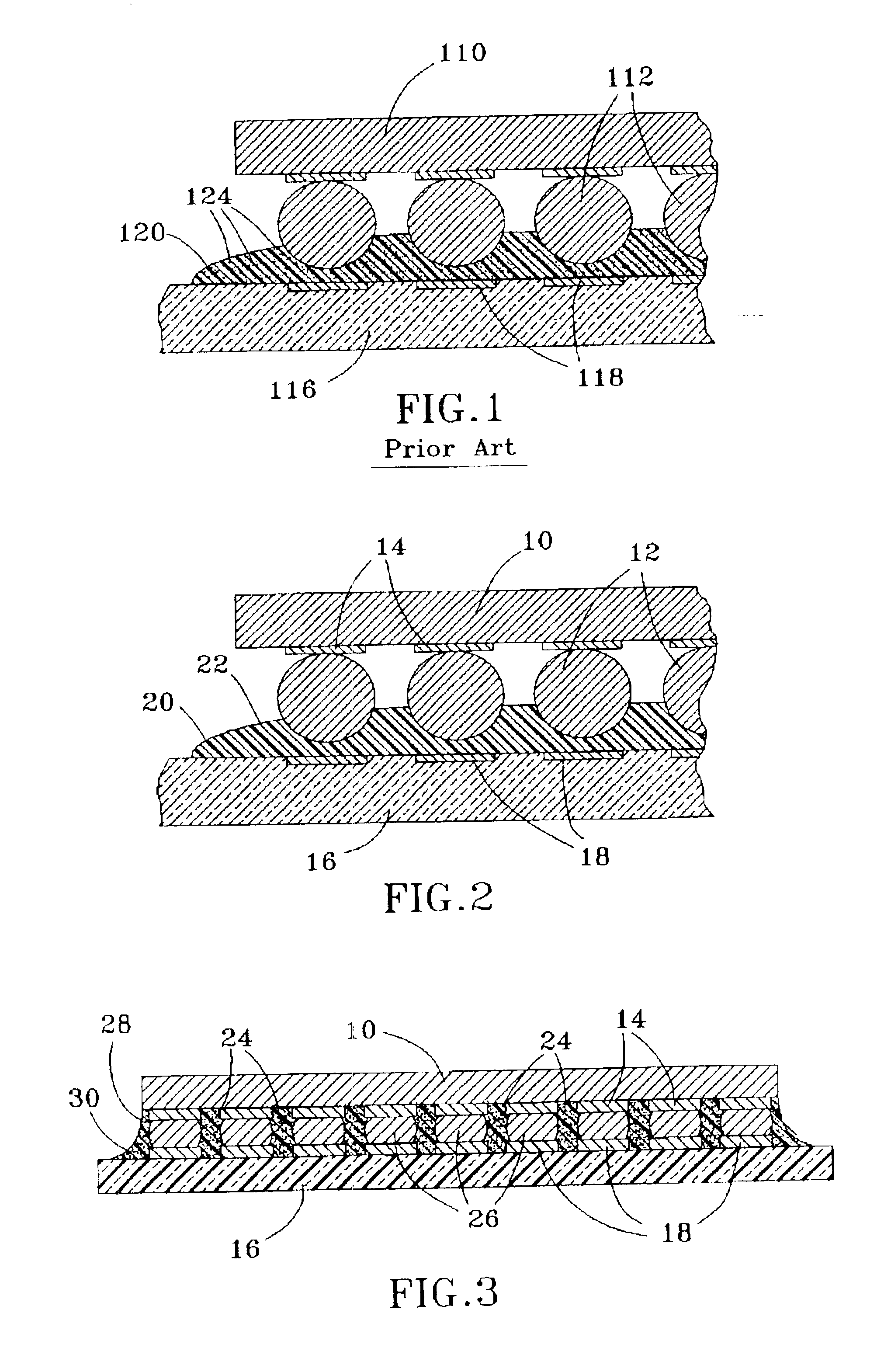

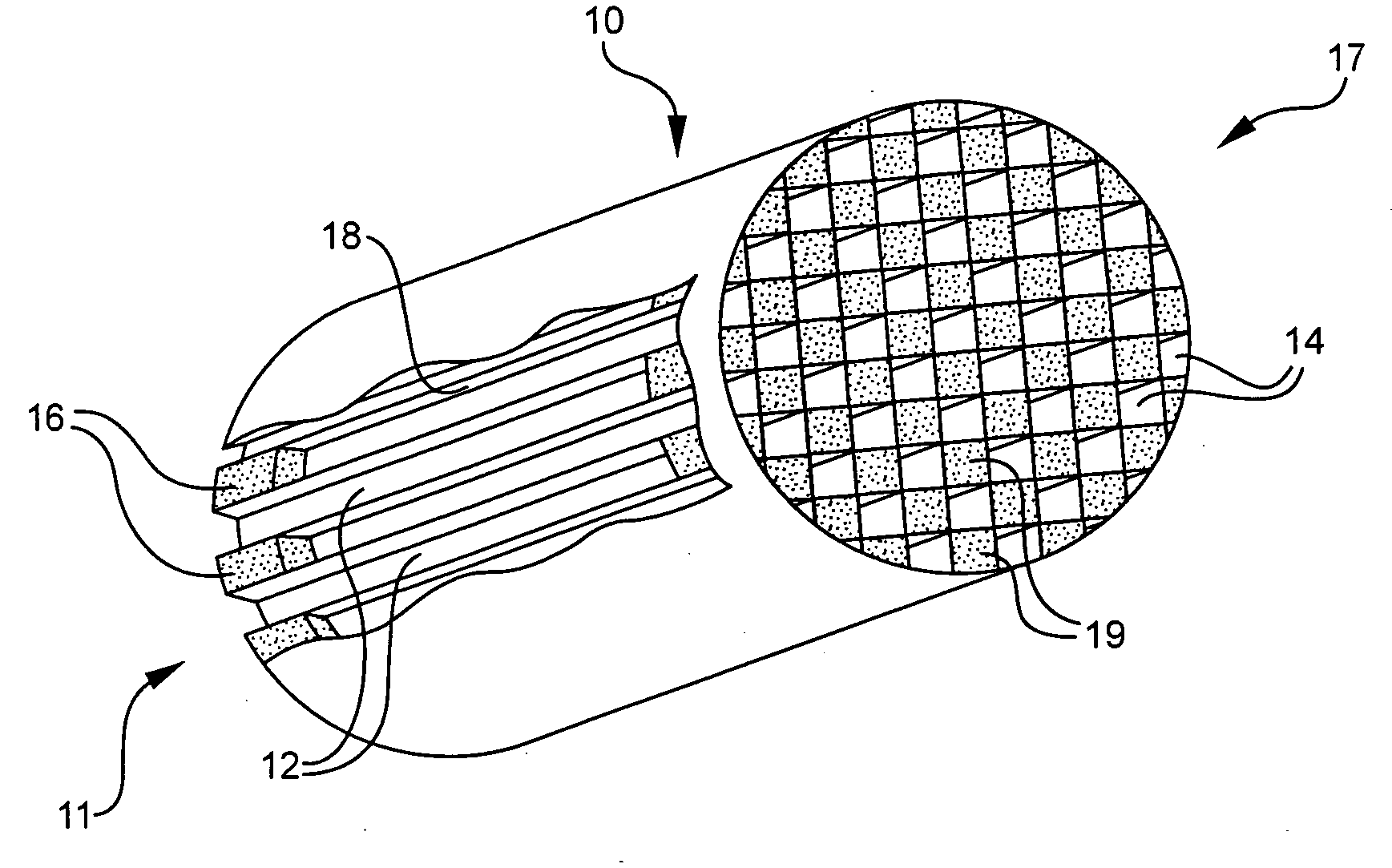

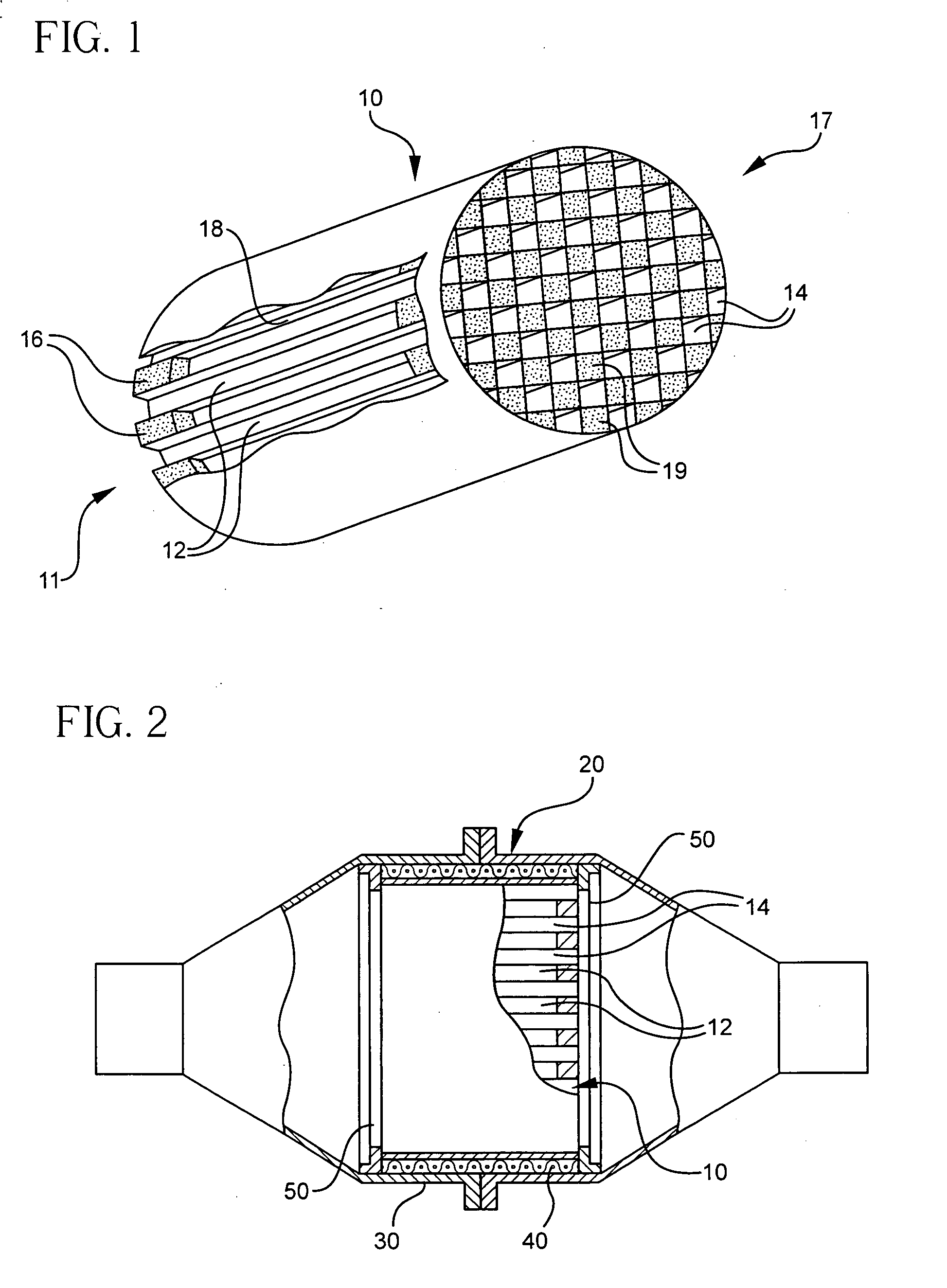

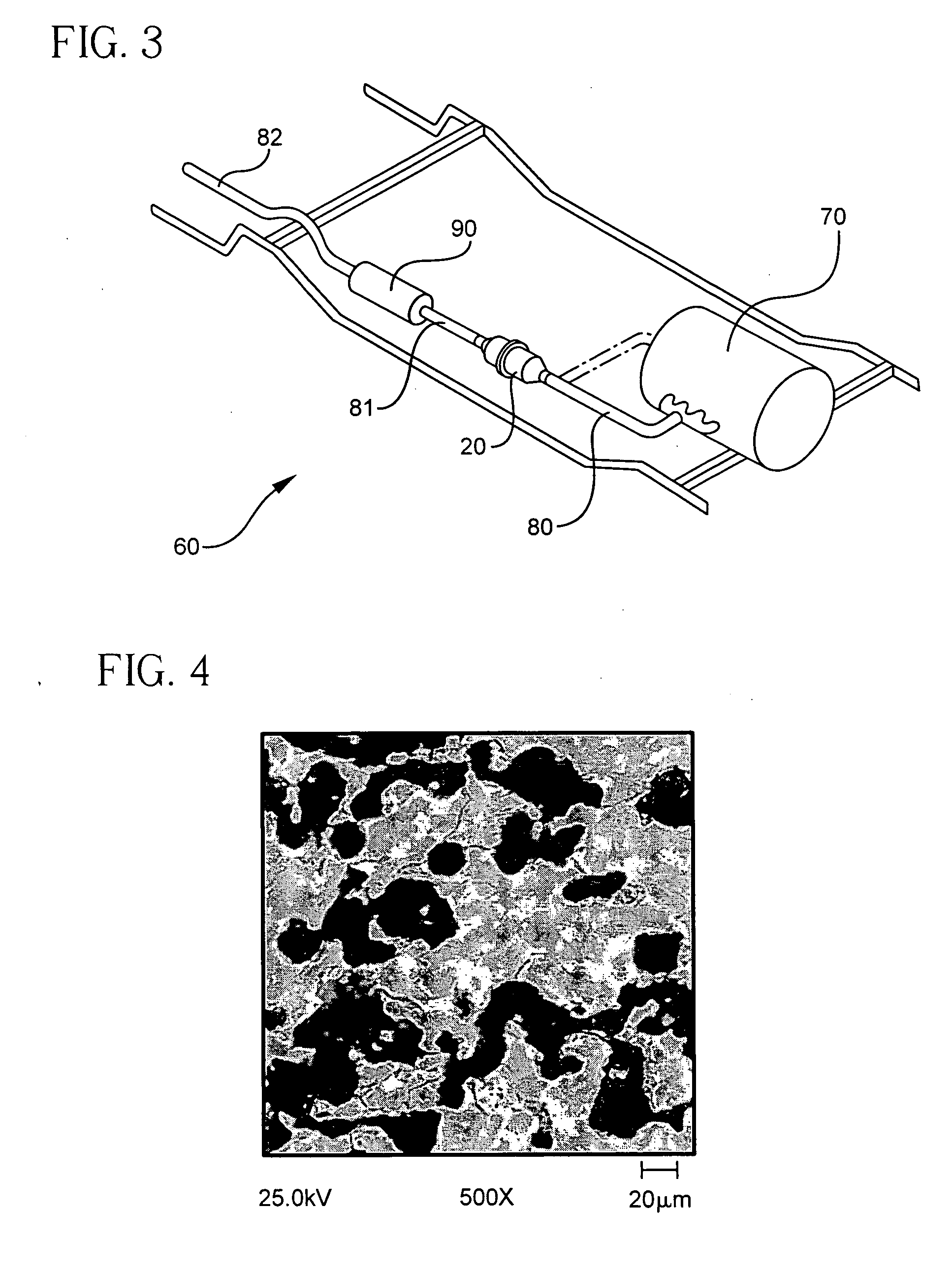

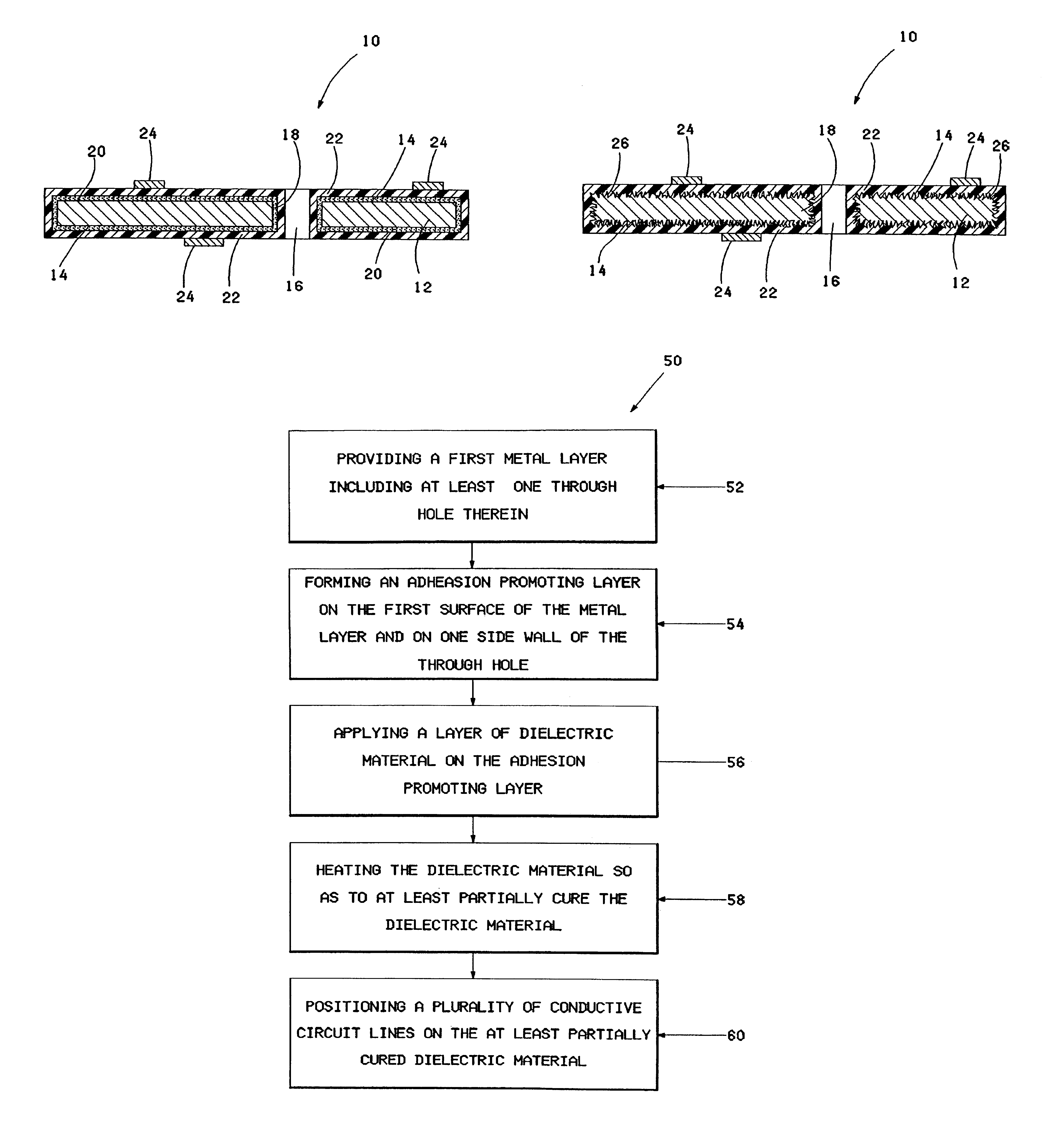

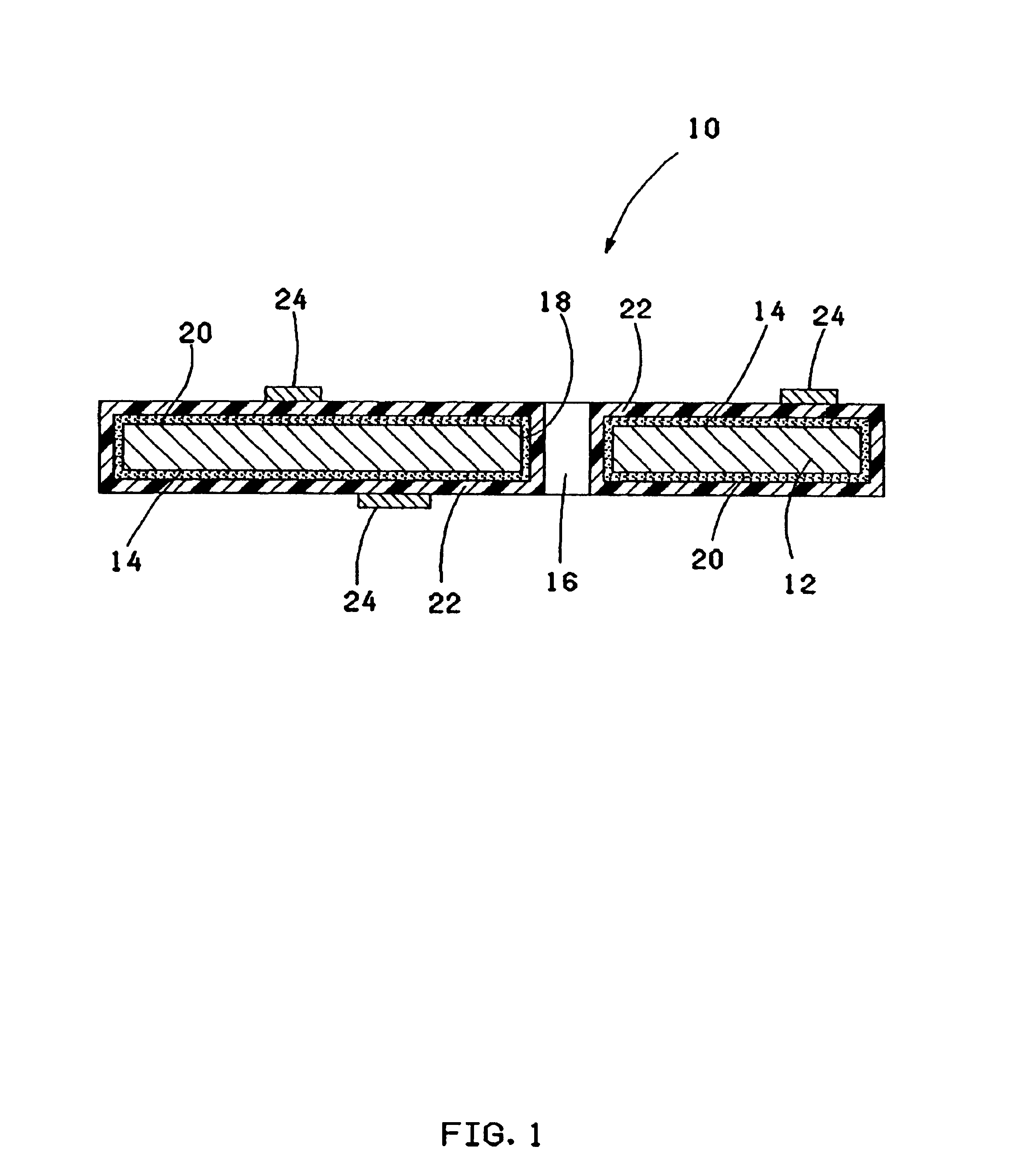

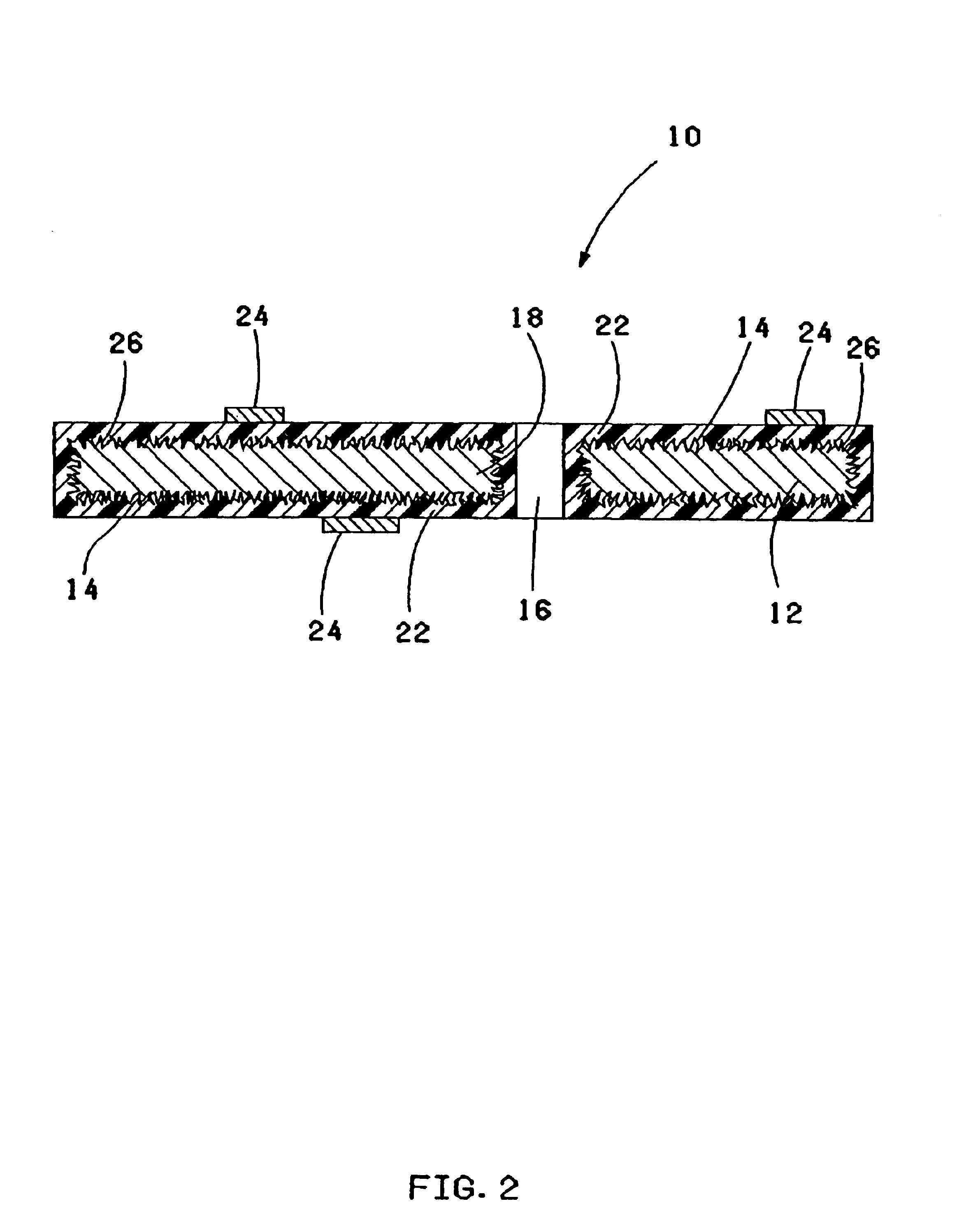

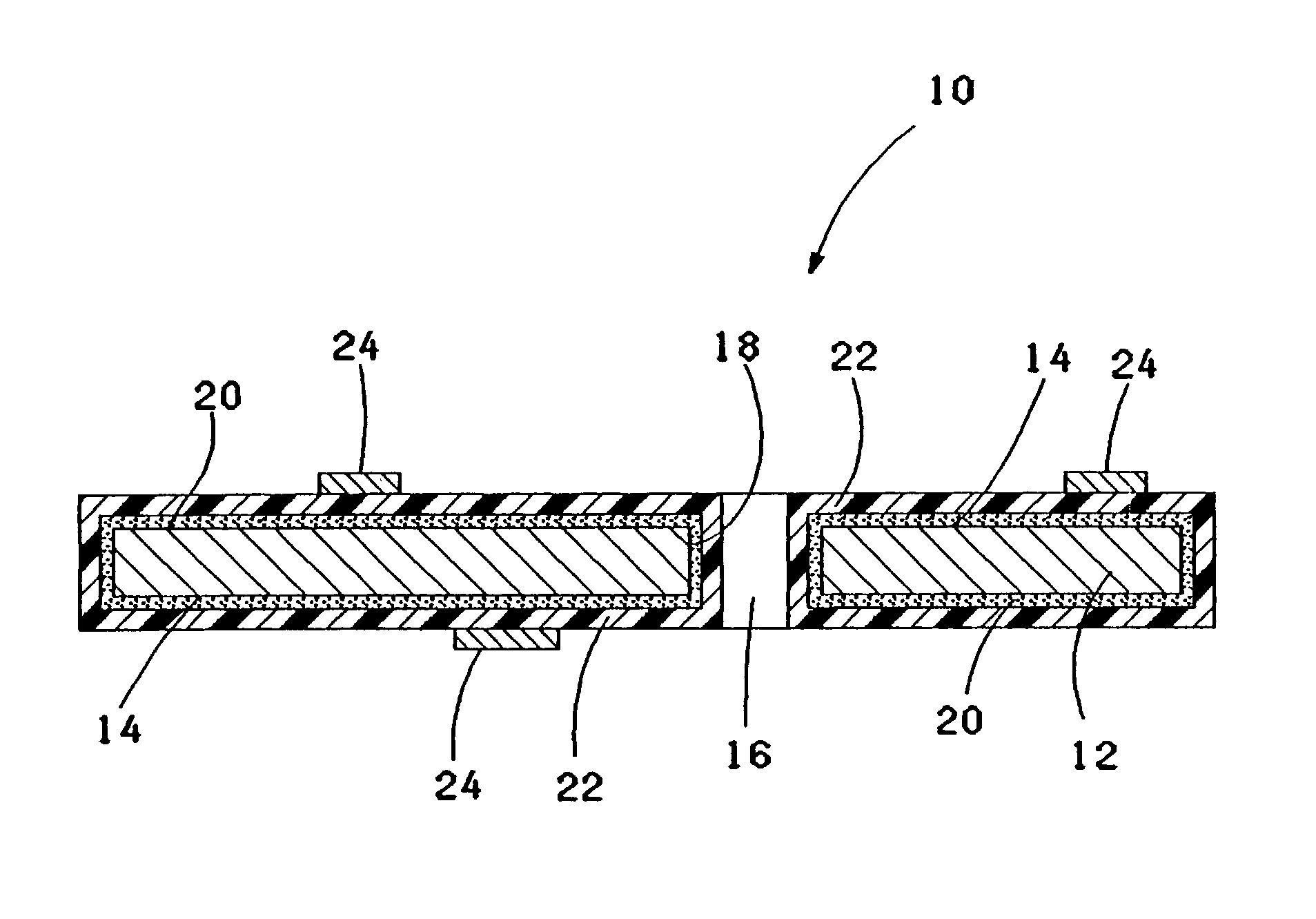

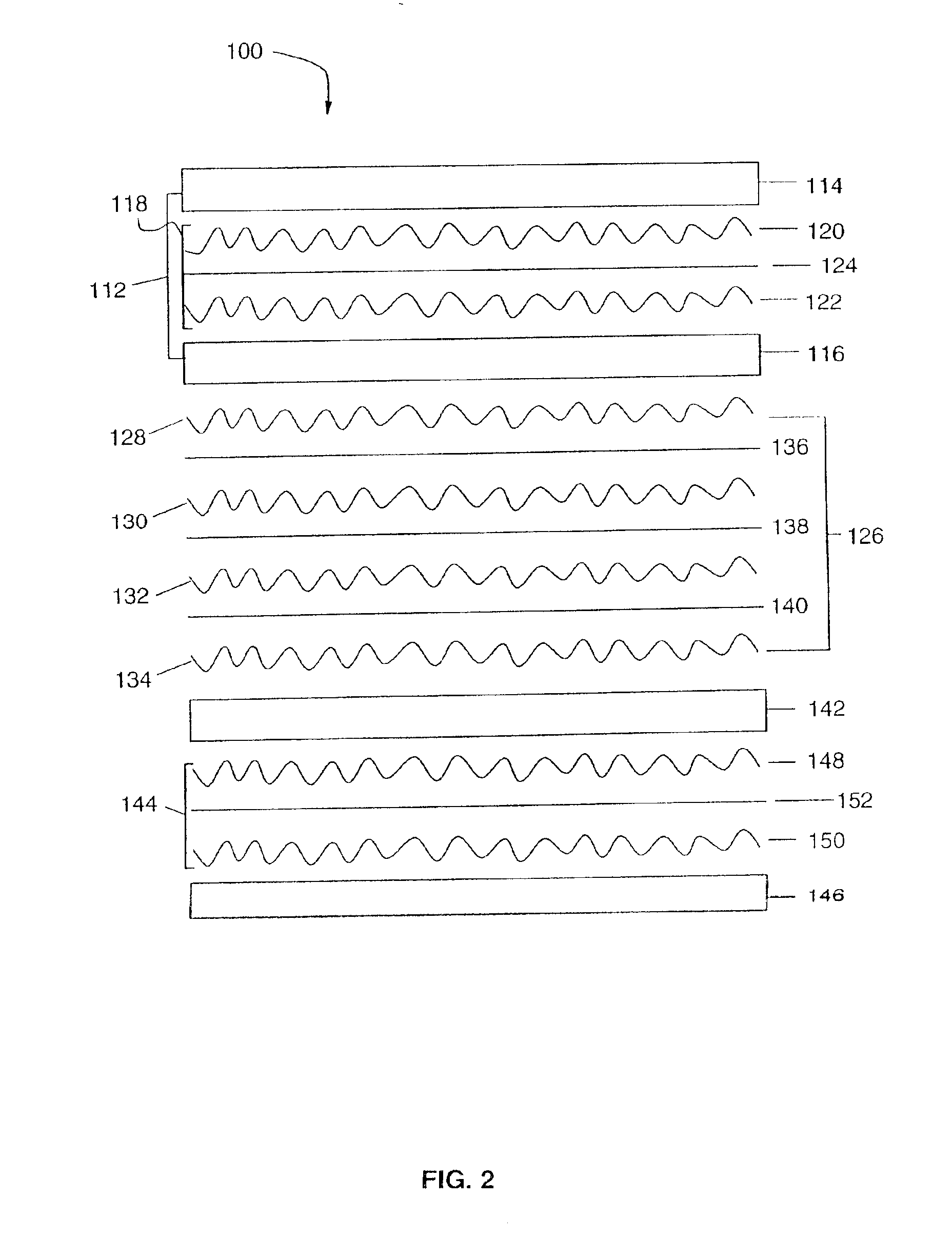

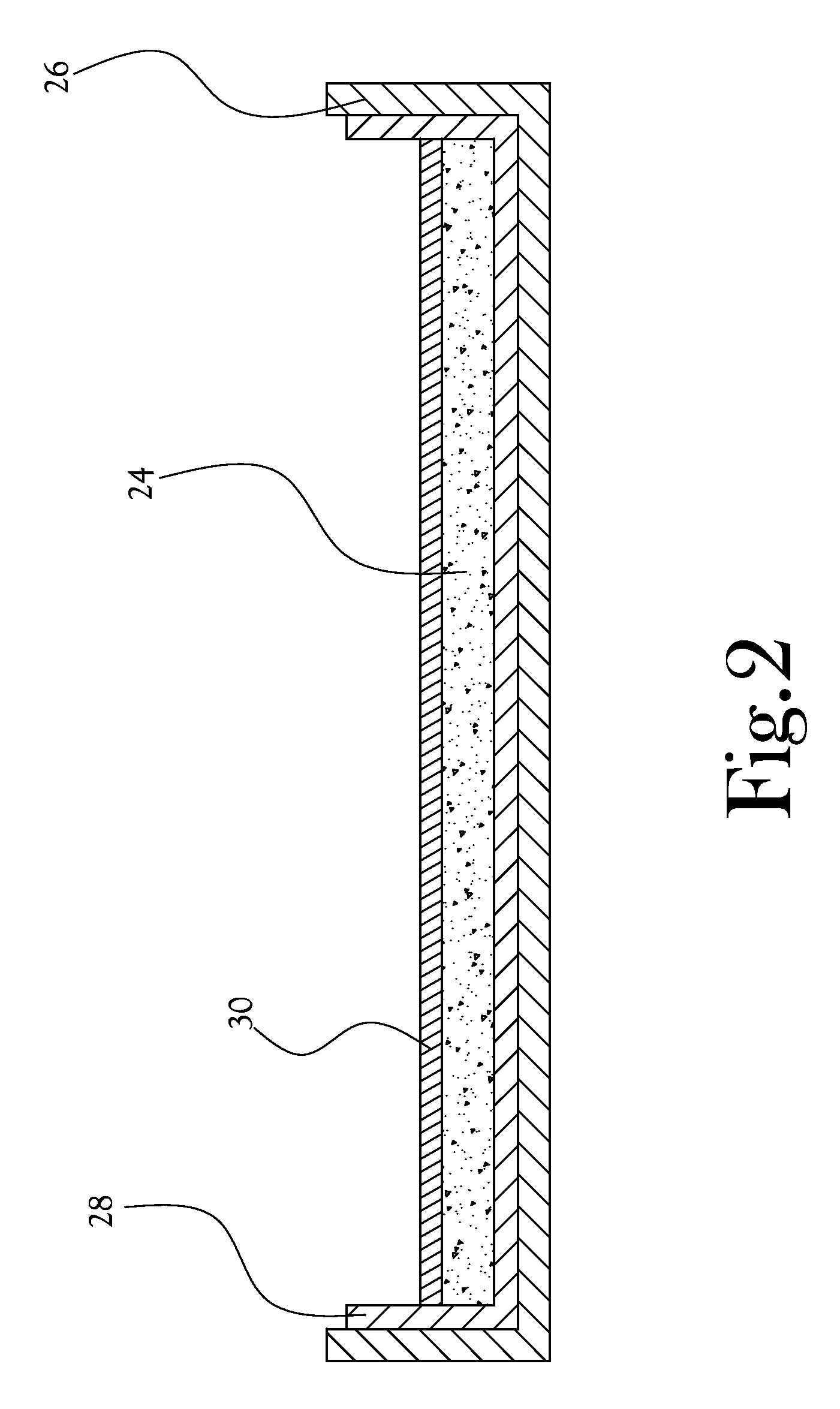

Laminate circuit structure and method of fabricating

InactiveUS6459047B1Low costAvoid the needInsulating substrate metal adhesion improvementPrinted circuit aspectsOptoelectronicsPrinted circuit board

A substrate and a method of making the substrate is provided. The substrate includes a layer of metal with at least one through hole therein, the layer of metal having an adhesion promoting layer thereon. A layer of a partially cured low-loss polymer or polymer precursor is positioned on the adhesion promoting layer and a plurality of conductive circuit lines are positioned on a portion of the partially cured dielectric layer. The substrate can be used as a building block in the fabrication of a multilayered printed circuit board.

Owner:FUJITSU MICROELECTRONICS LTD +1

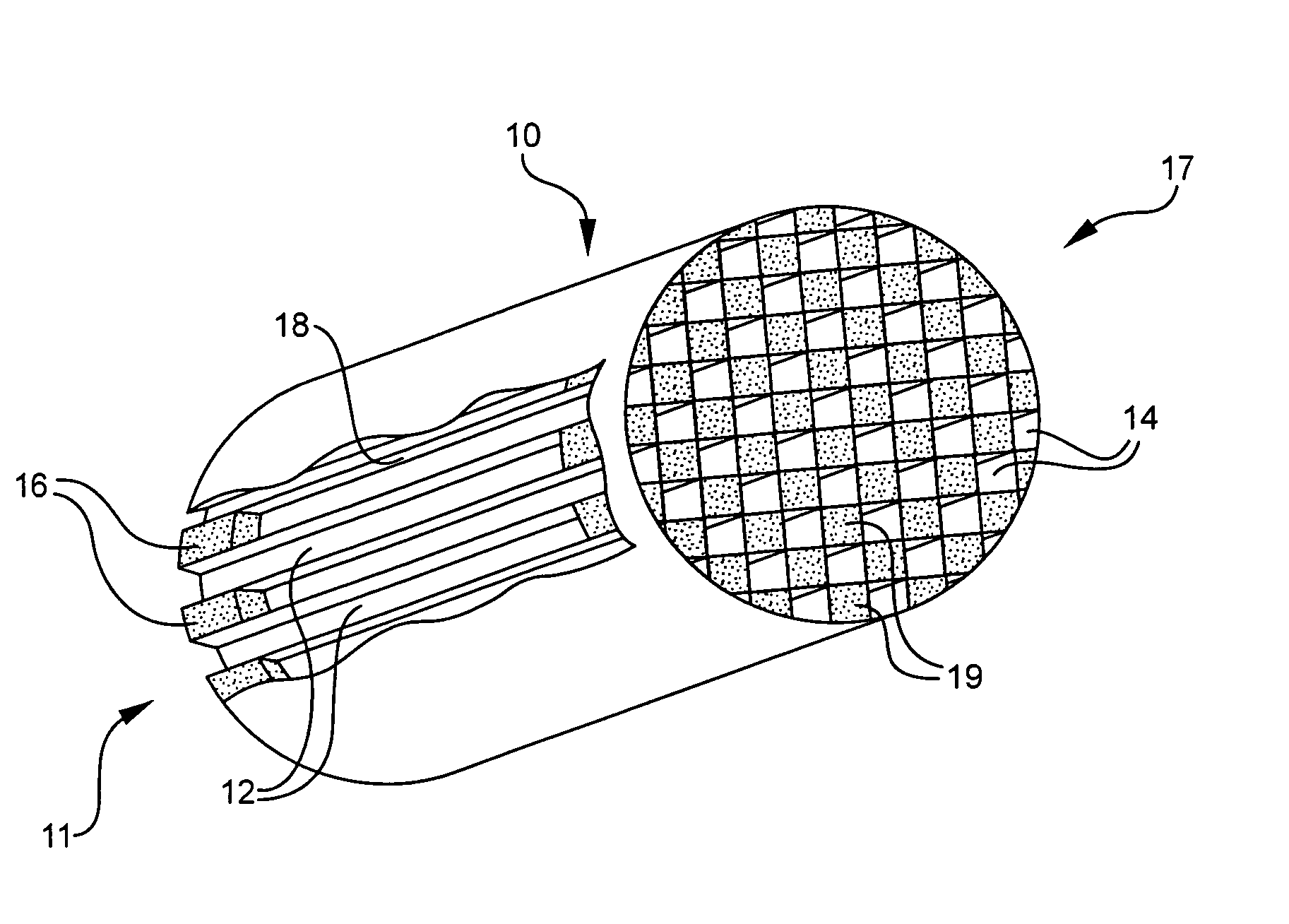

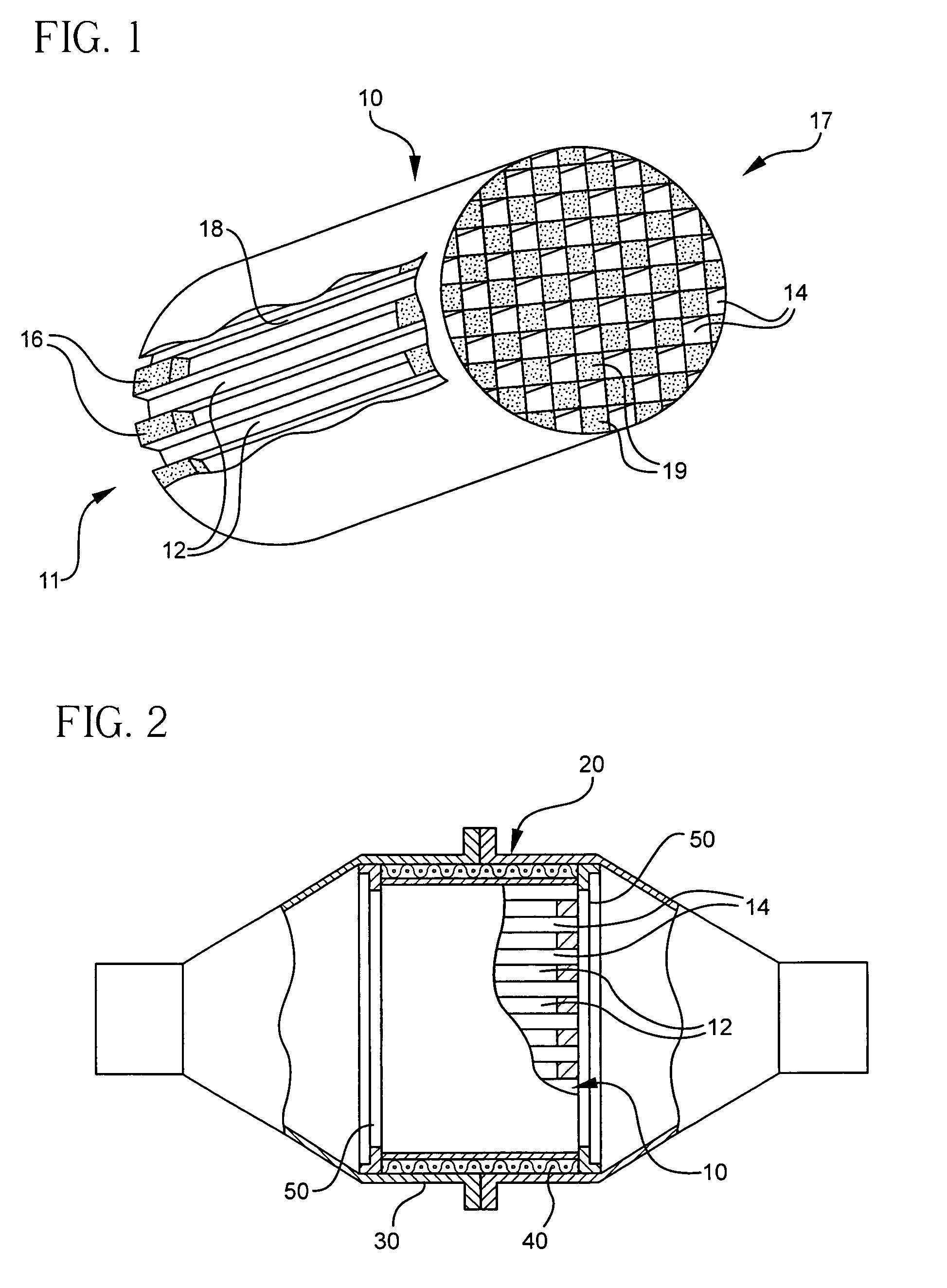

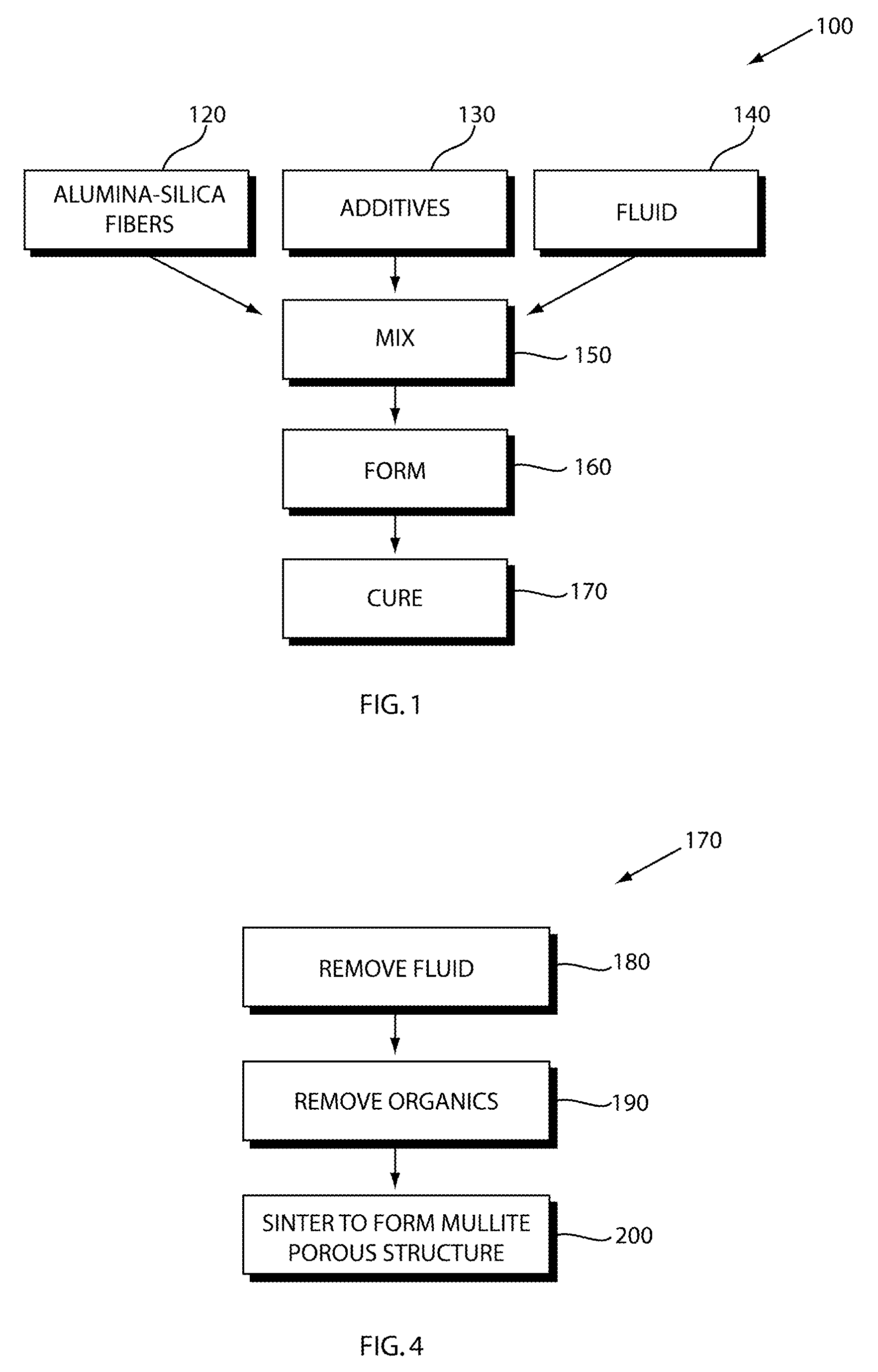

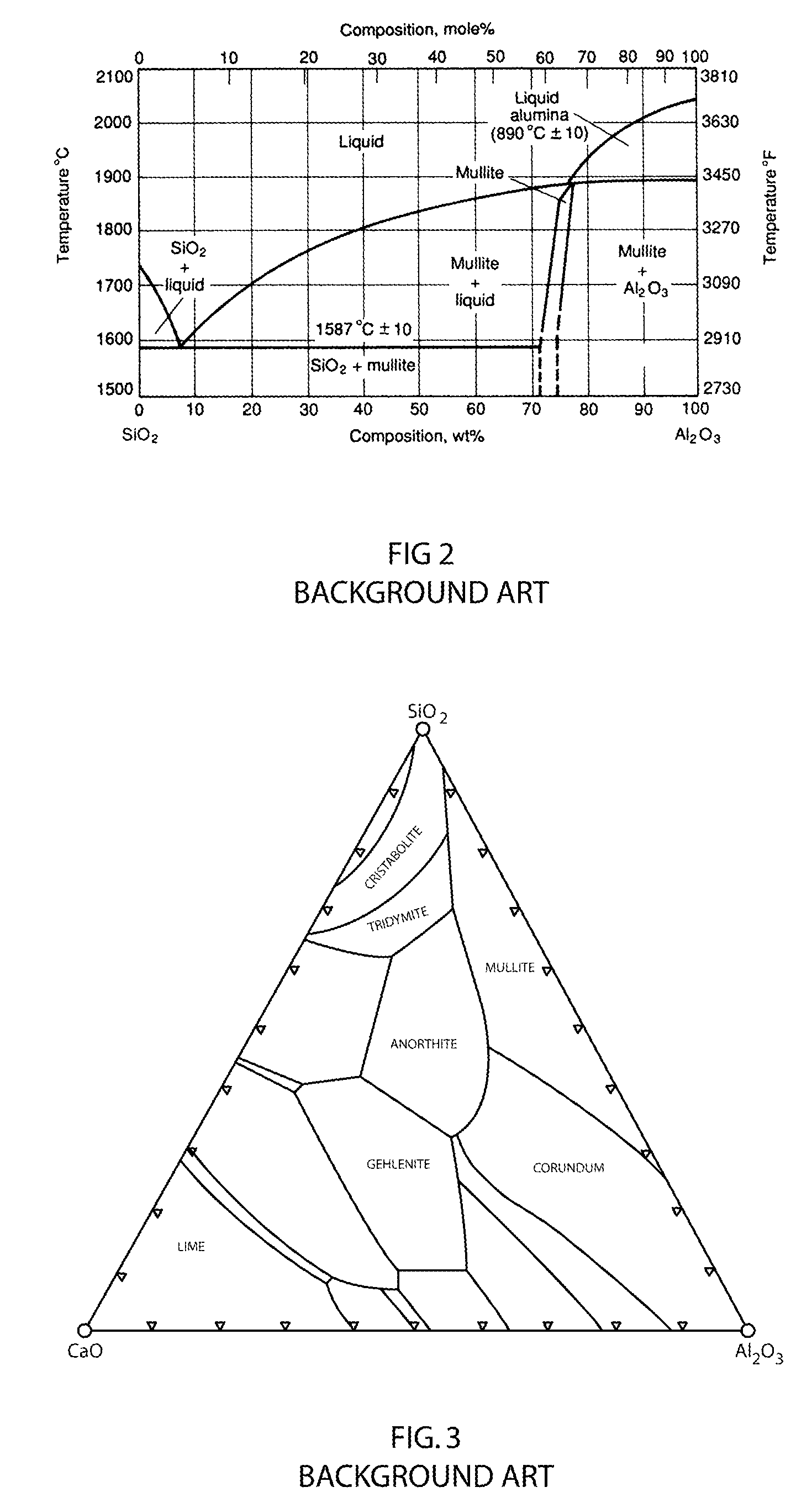

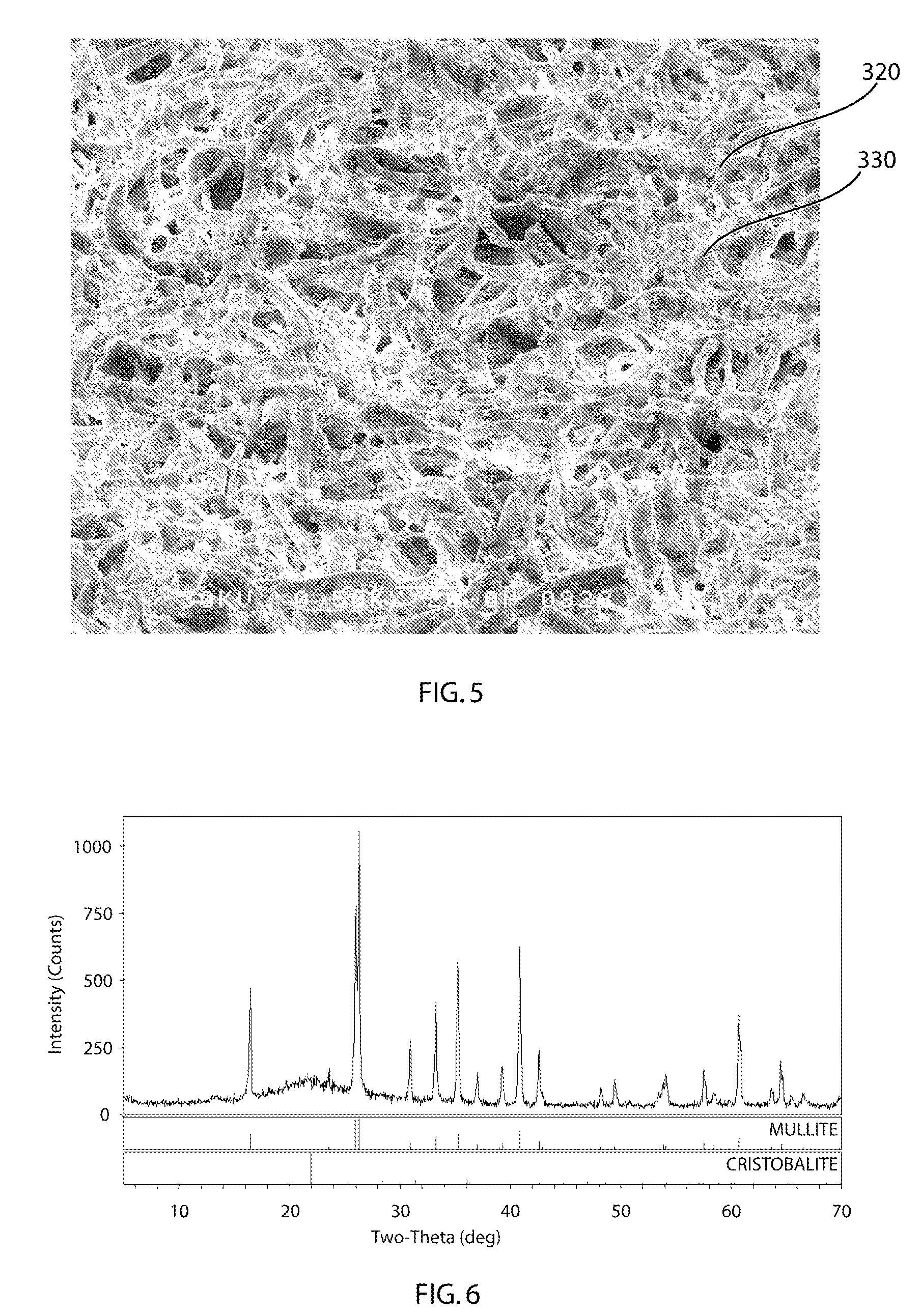

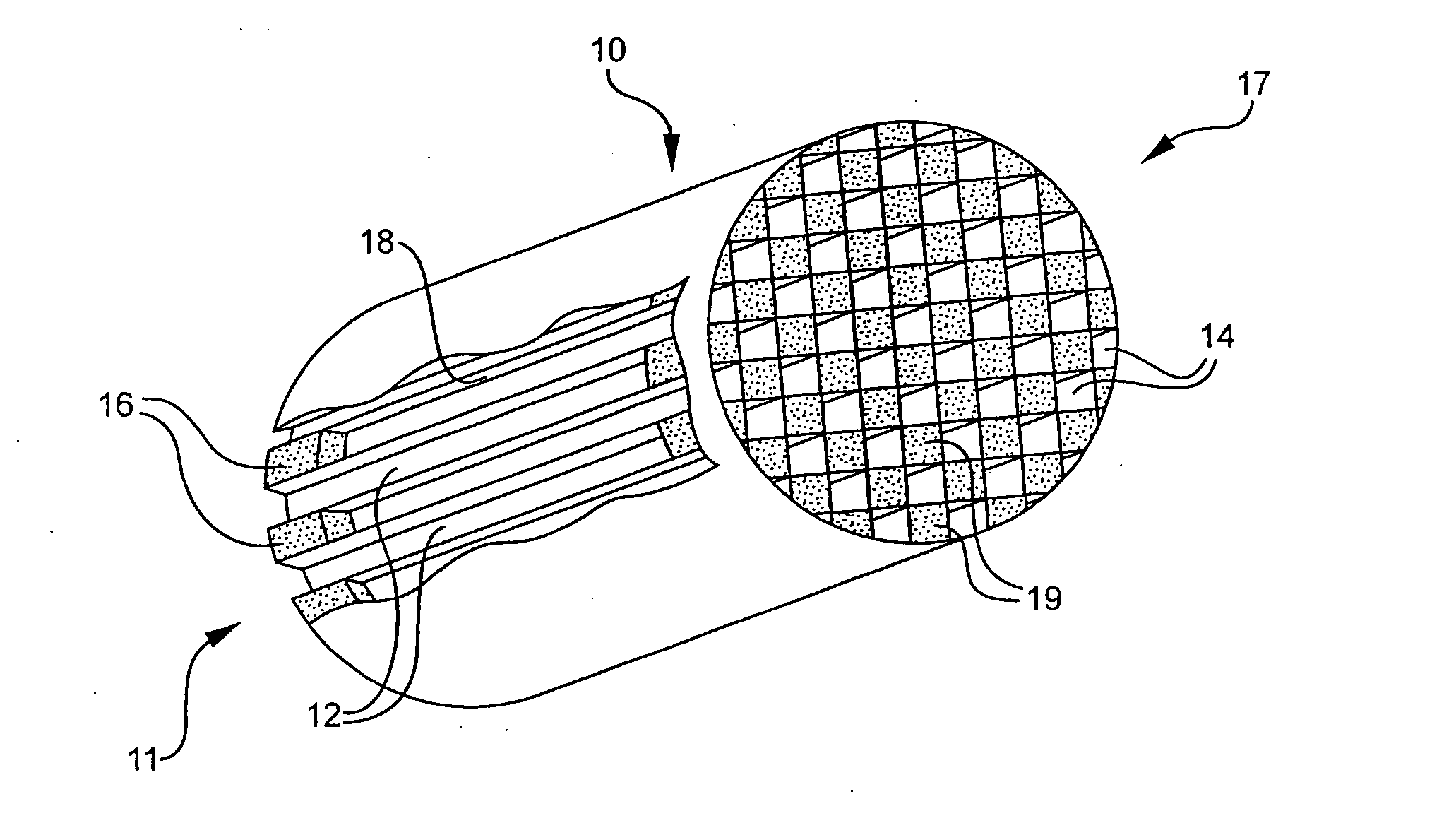

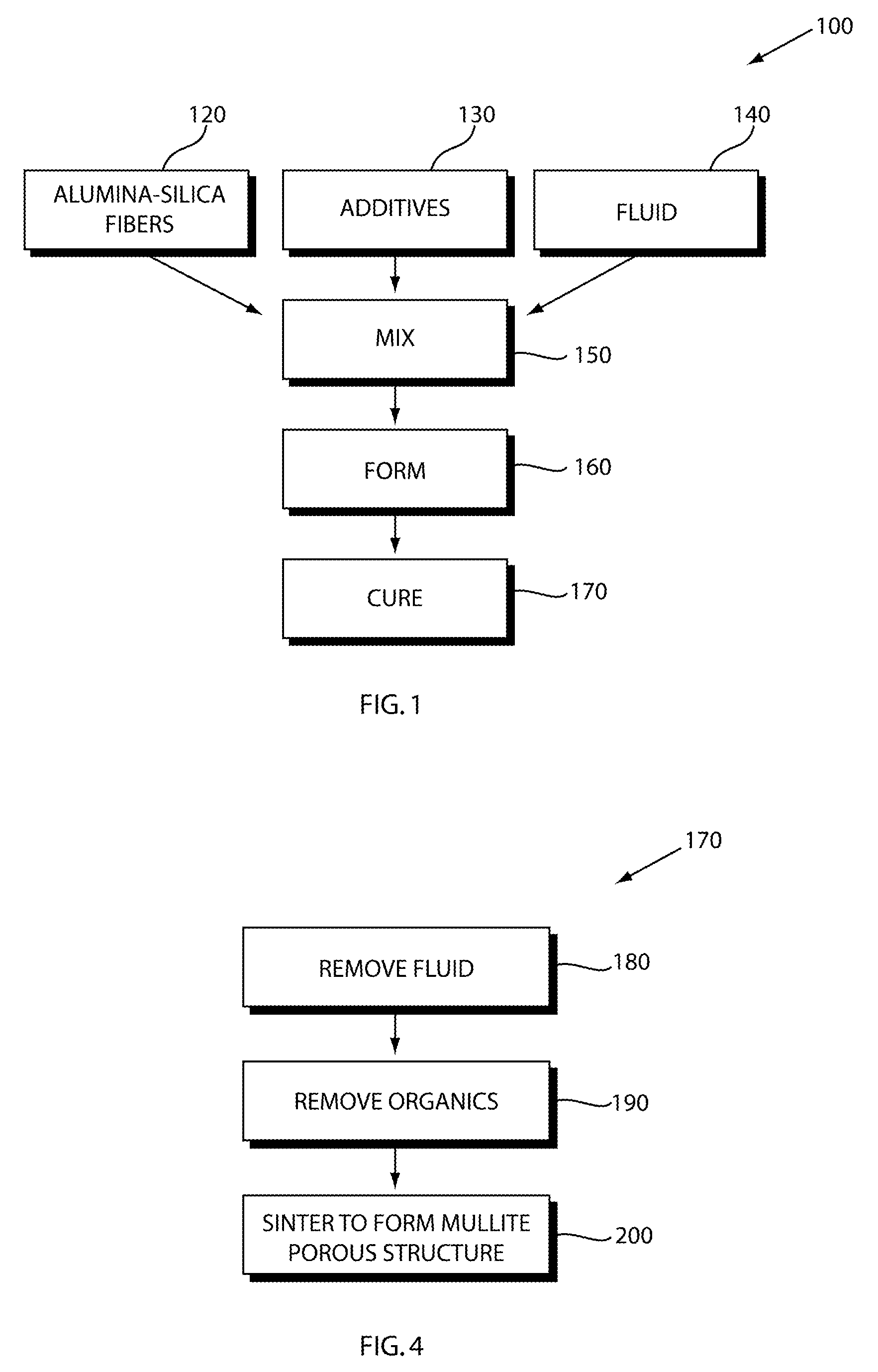

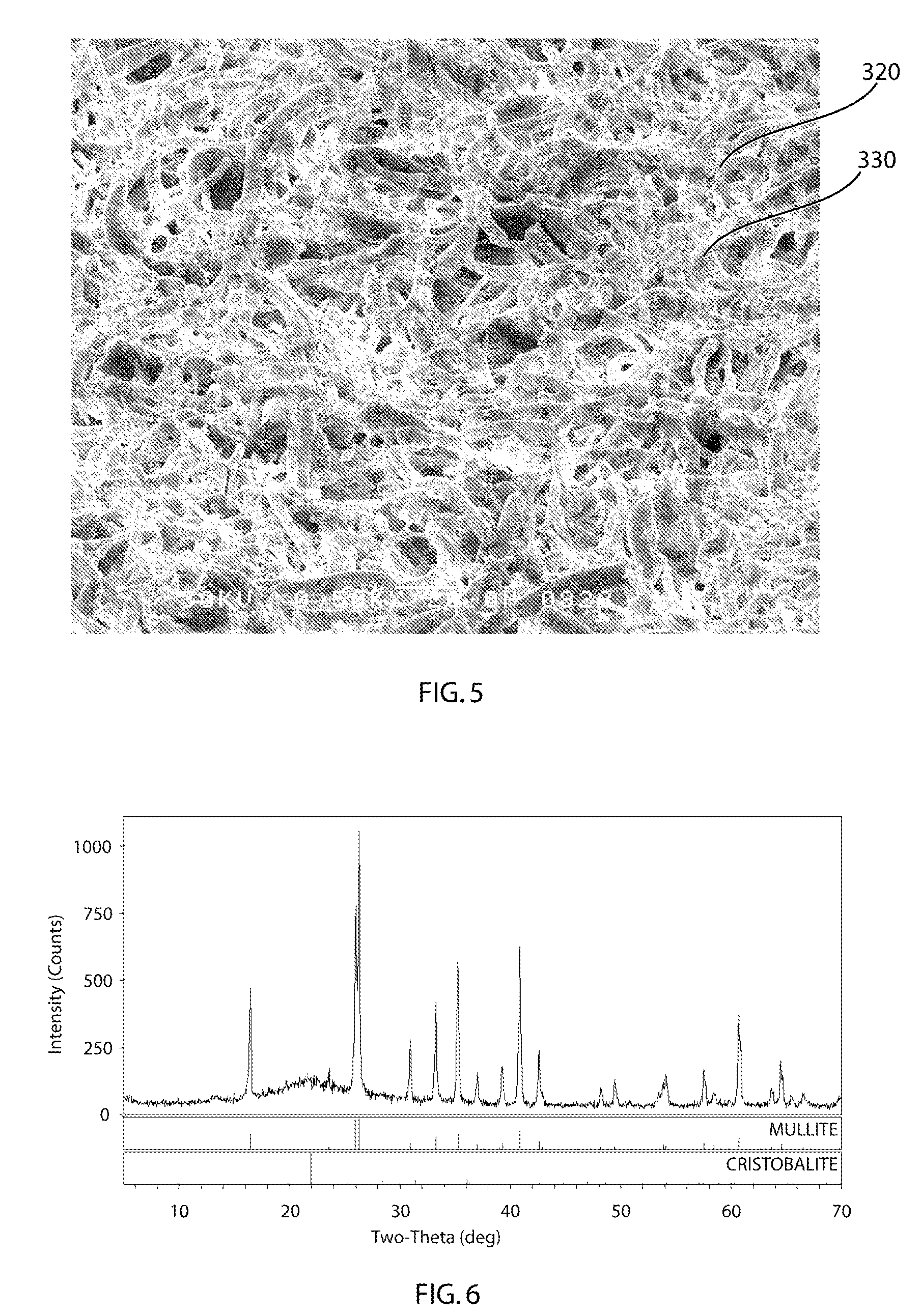

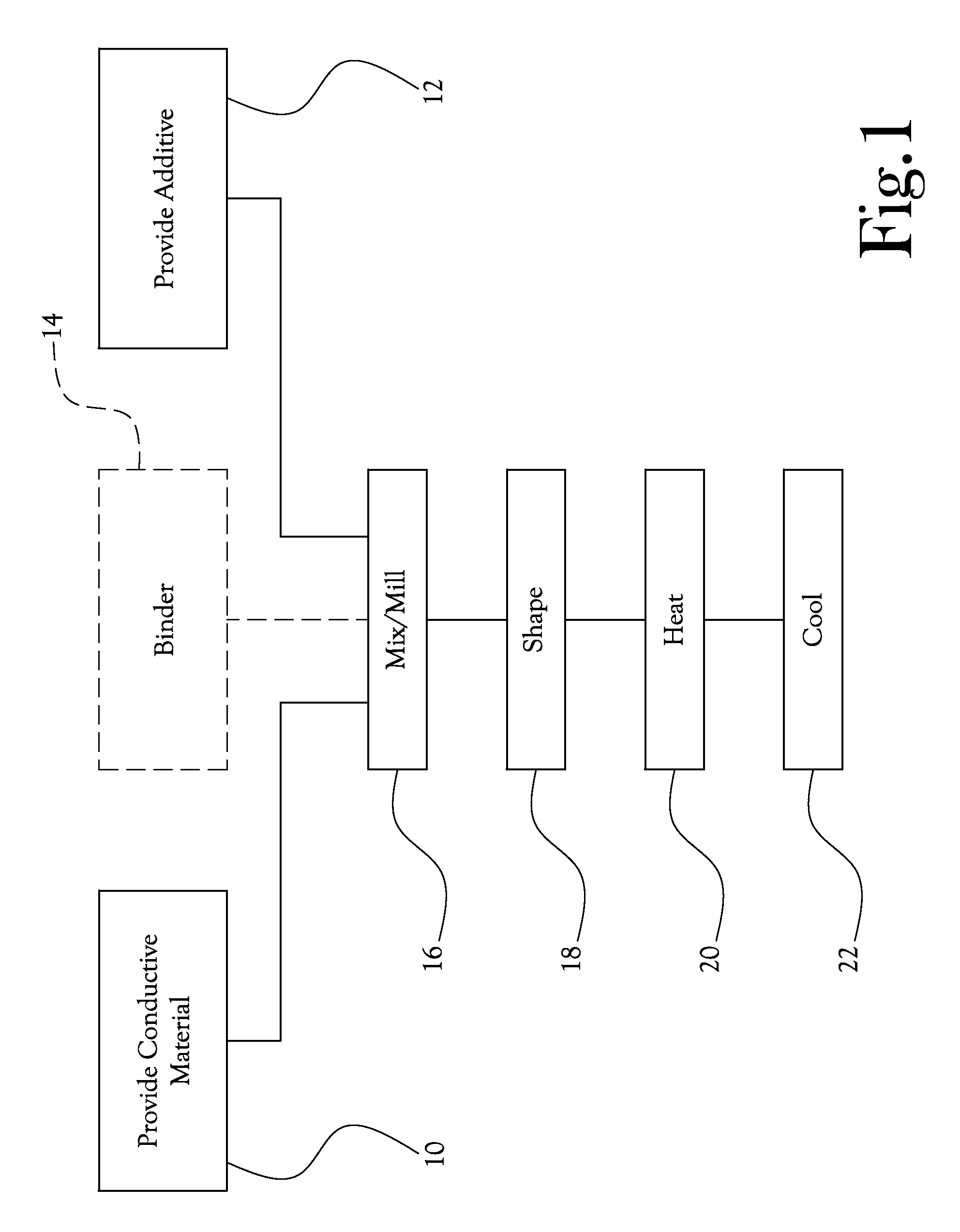

Fiber-Based Ceramic Substrate and Method of Fabricating the Same

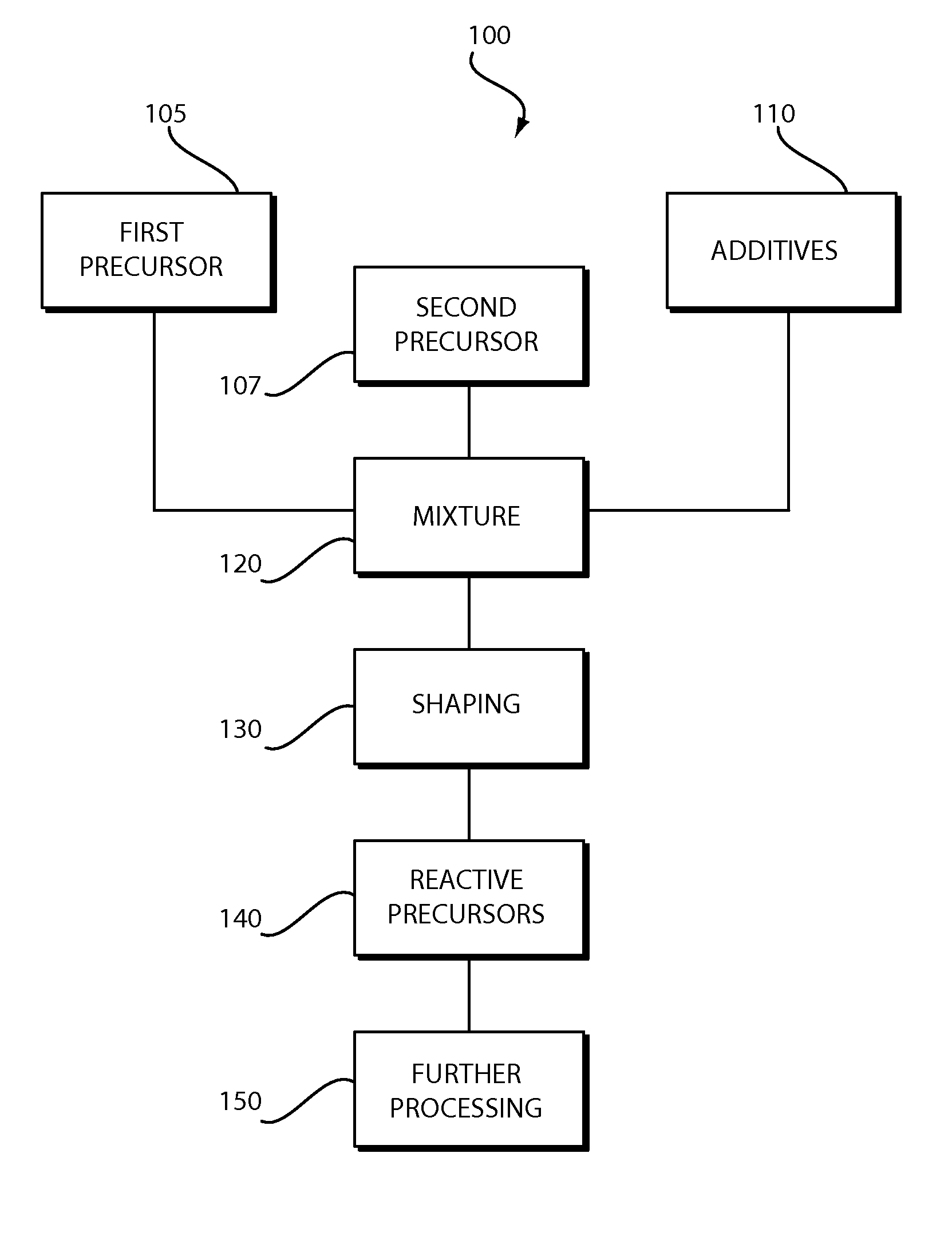

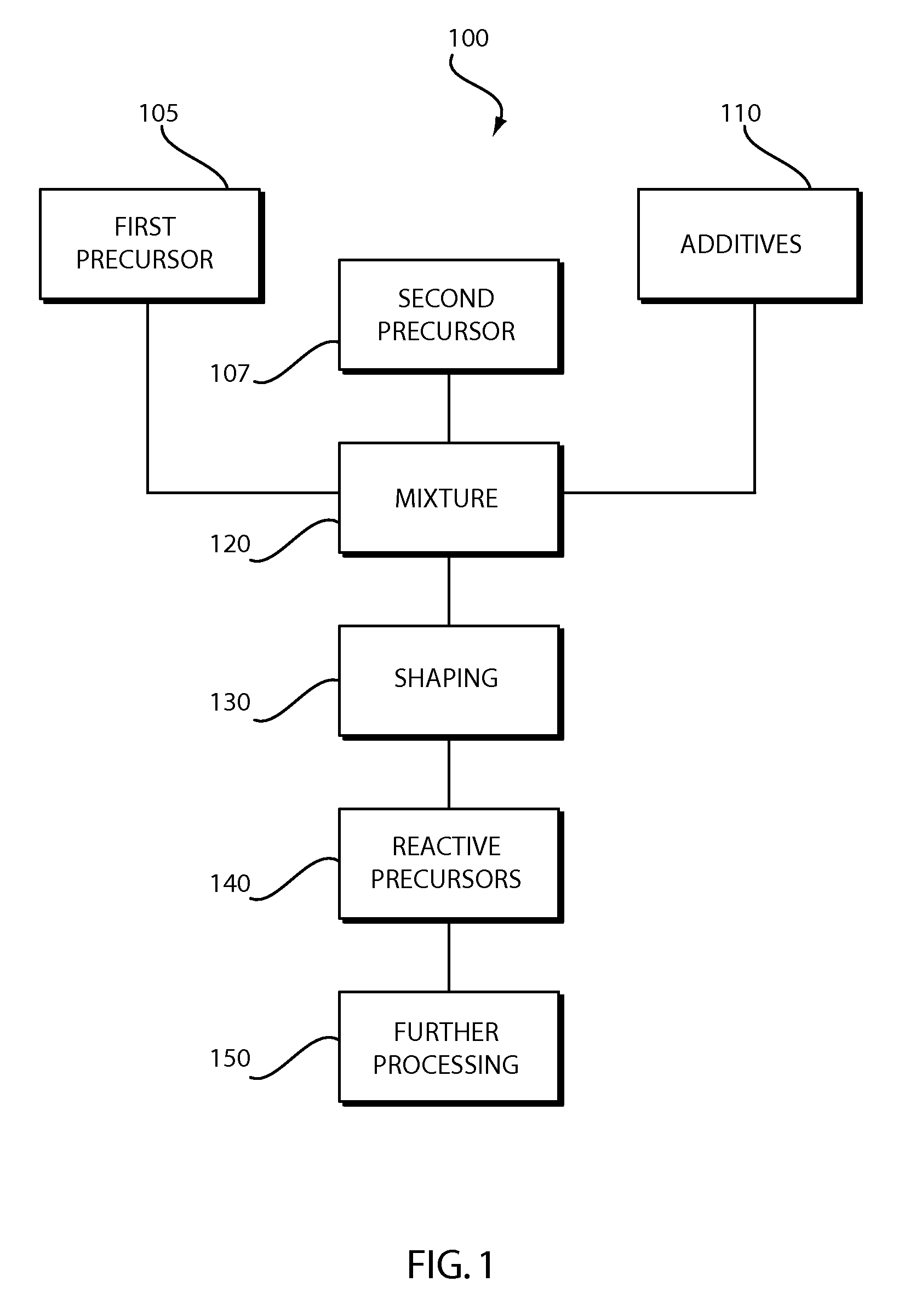

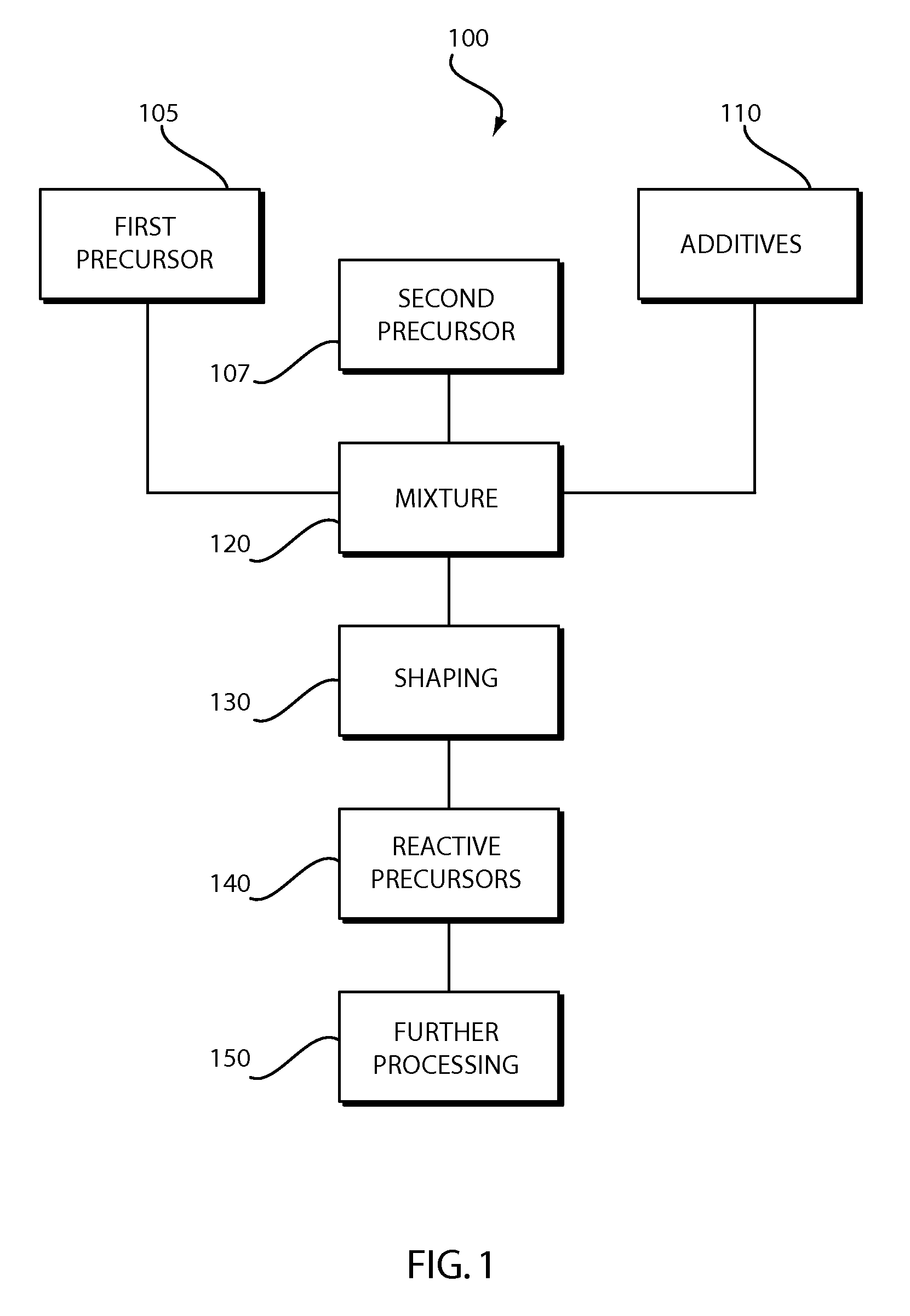

InactiveUS20090035511A1Low costReduce coefficient of thermal expansionLayered productsGlass shaping apparatusFiberChemical reaction

Low cost aluminosilicate fibers are used to form a ceramic substrate material using inorganic binders that promote the formation of stable compounds that inhibit the formation of crystal silica, or cristobalite, when the substrate is used or exposed to high operating temperatures. The aluminosilicate fibers are mixed with additives including organic and inorganic binders and a fluid to form a plastic mixture. The plastic mixture is formed into a green substrate, and subsequently cured into the ceramic substrate. The fiber-based constituents permit the formation of rigid porous structures for filtration, insulation, and high temperature processes and chemical reactions.

Owner:GE02 TECH INC

No-flow underfill process and material therefor

InactiveUS6943058B2Reduce CTESemiconductor/solid-state device detailsSolid-state devicesFilling materialsElectrical interconnect

A no-flow underfill material and process suitable for underfilling a bumped circuit component. The underfill material initially comprises a dielectric polymer material in which is dispersed a precursor capable of reacting to form an inorganic filler. The underfill process generally entails dispensing the underfill material over terminals on a substrate, and then placing the component on the substrate so that the underfill material is penetrated by the bumps on the component and the bumps contact the terminals on the substrate. The bumps are then reflowed to form solid electrical interconnects that are encapsulated by the resulting underfill layer. The precursor may be reacted to form the inorganic filler either during or after reflow.

Owner:INTEL CORP

Aluminum titanate ceramic articles and methods of making same

ActiveUS20060281627A1Low firing temperatureDesirable porosityInternal combustion piston enginesSilencing apparatusAlkaline earth metalRare earth

An aluminum titanate ceramic article having a predominant crystal phase of aluminum titanate and a material composition including aluminum, titanium, silica, an alkaline earth metal (e.g., at least one selected from the group of strontium, calcium, barium, or combinations), and a rare earth metal (e.g., at least one selected from the group consisting of yttrium, lanthanum, and combinations) and methods of making such aluminum titanate bodies are described. An oxide of yttrium metal or lanthanide metals is preferably used as a sintering aid in combination with the other compositional components to enable firing of the resulting green body at a lower heating temperature of less than 1500° C., and more preferably between 1400°-1450° C., with a preferable hold time of less than 8 hours, more preferably of 6 to 8 hours.

Owner:CORNING INC

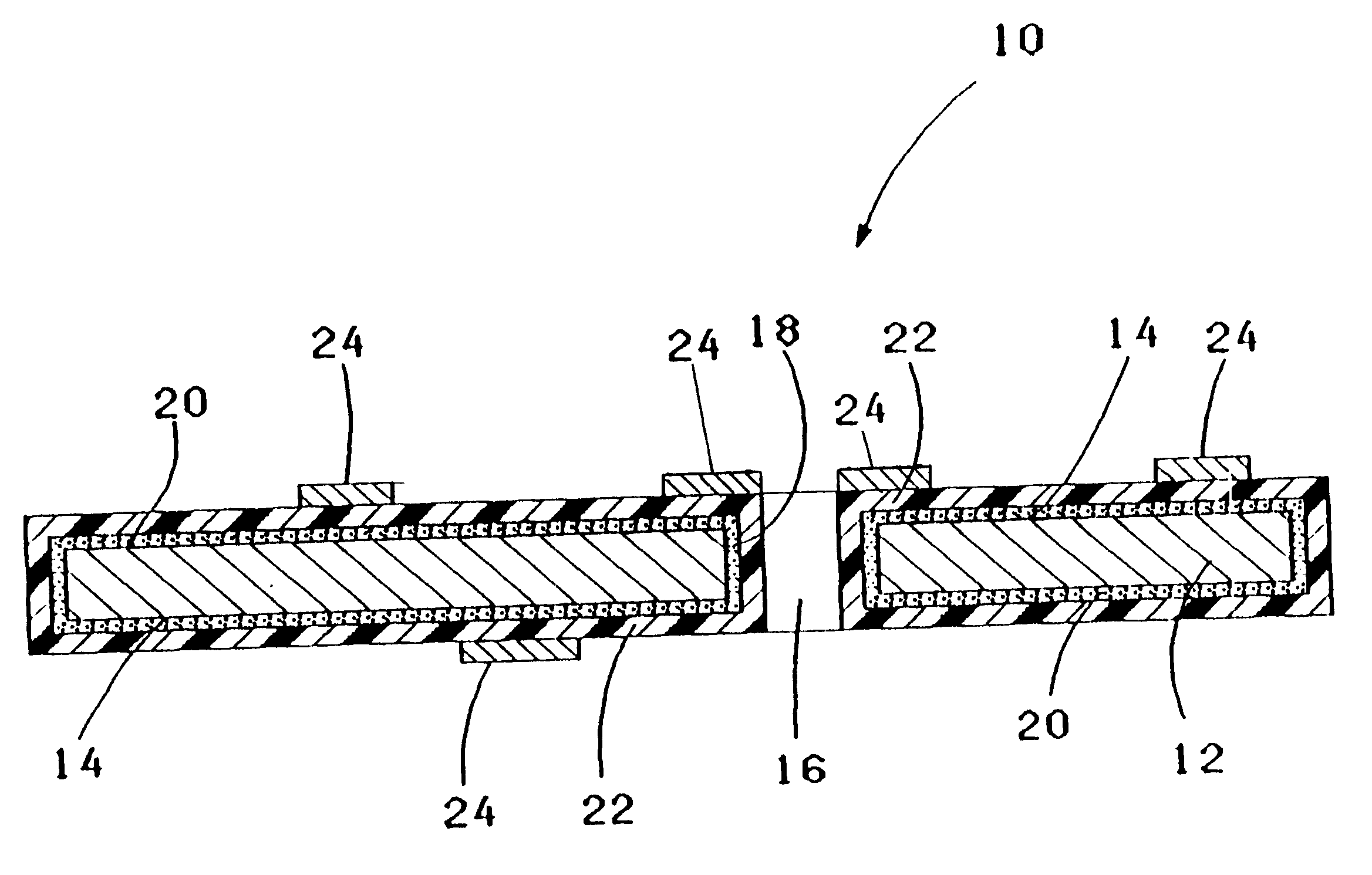

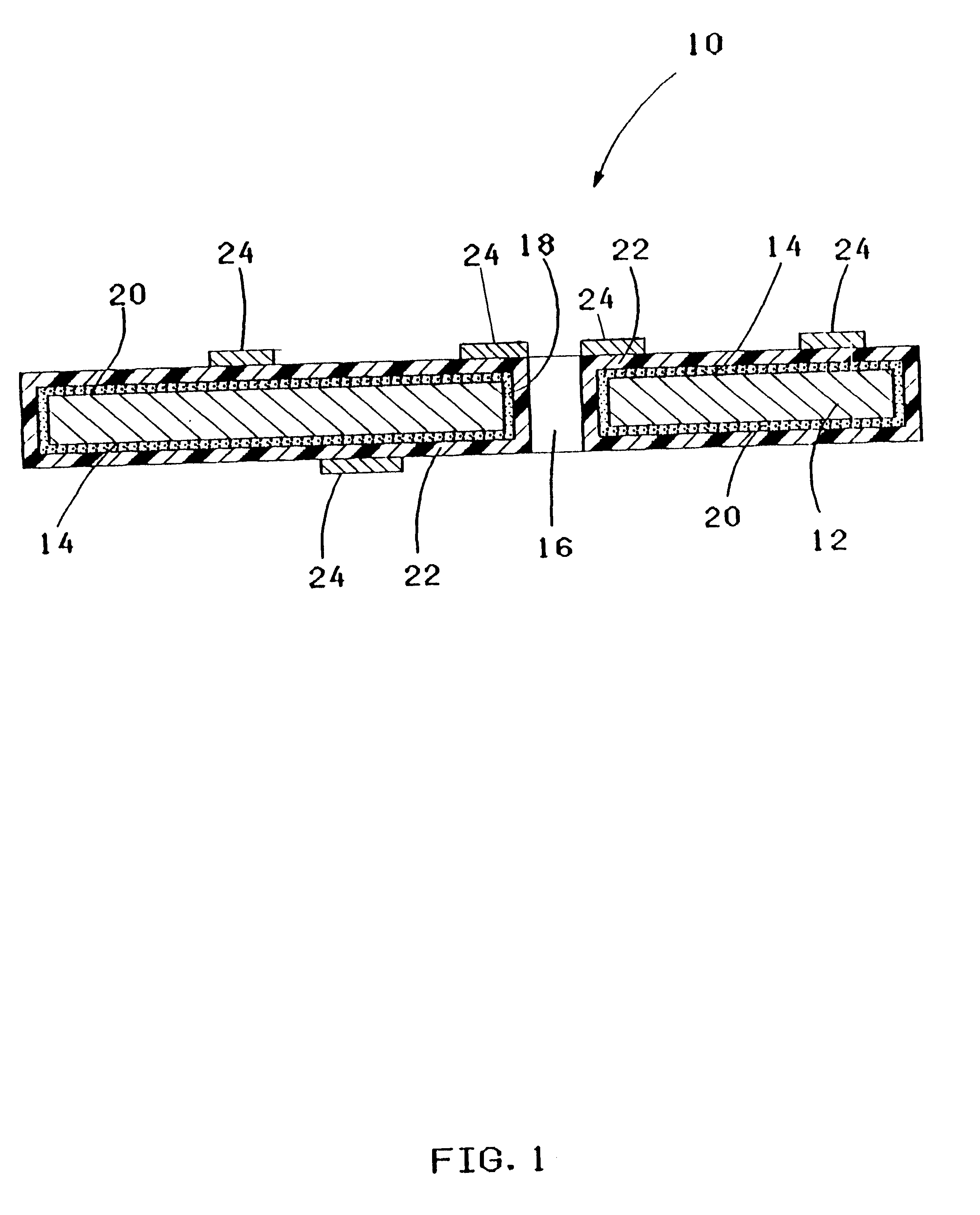

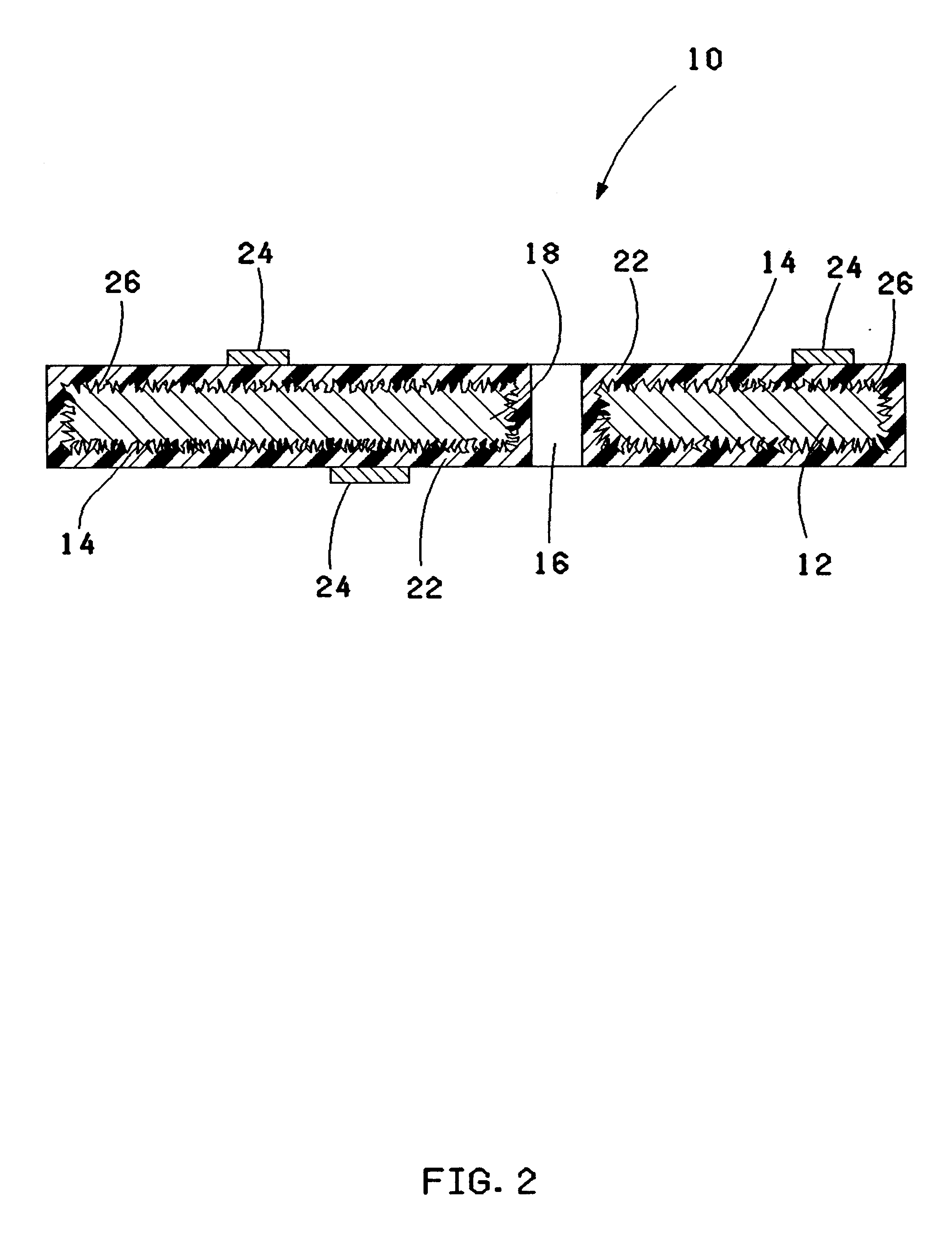

Laminate circuit structure and method of fabricating

InactiveUS6820332B2Low costAvoid the needPrinted circuit assemblingInsulating substrate metal adhesion improvementOptoelectronicsPrinted circuit board

A substrate and a method of making the substrate is provided. The substrate includes a layer of metal with at least one through hole therein, the layer of metal having an adhesion promoting layer thereon. A layer of a partially cured low-loss polymer or polymer precursor is positioned on the adhesion promoting layer and a plurality of conductive circuit lines are positioned on a portion of the partially cured dielectric layer. The substrate can be used as a building block in the fabrication of a multilayered printed circuit board.

Owner:INT BUSINESS MASCH CORP

Liquid composite compositions using non-volatile liquids and nanoparticles and uses thereof

InactiveUS8540899B2Reduce CTEImprove performanceElectrolytic capacitorsCell electrodesOrganic solventNanoparticle

A solvent composition comprising an organic solvent; dispersed nanoparticles; and a non-volatile electrolyte.

Owner:ESIONIC

Aluminum titanate ceramic articles and methods of making same

InactiveUS20070259769A1Low firing temperatureEasy and more cost-effective to manufactureCeramicwareYttriumLanthanum

An aluminum titanate ceramic article having a predominant crystal phase of aluminum titanate and a material composition including aluminum, titanium, silica, an alkaline earth metal (e.g., at least one selected from the group of strontium, calcium, barium, or combinations), and a rare earth metal (e.g., at least one selected from the group consisting of yttrium, lanthanum, and combinations) and methods of making such aluminum titanate bodies are described. An oxide of yttrium metal or lanthanide metals is preferably used as a sintering aid in combination with the other compositional components to enable firing of the resulting green body at a lower heating temperature of less than 1500° C., and more preferably between 1400°-1450° C., with a preferable hold time of less than 8 hours, more preferably of 6 to 8 hours.

Owner:ELLISON ADAM JAMES GILLMAR +2

Fiber-based ceramic substrate and method of fabricating the same

InactiveUS7781372B2Low costReduce coefficient of thermal expansionLayered productsGlass shaping apparatusFiberChemical reaction

Low cost aluminosilicate fibers are used to form a ceramic substrate material using inorganic binders that promote the formation of stable compounds that inhibit the formation of crystal silica, or cristobalite, when the substrate is used or exposed to high operating temperatures. The aluminosilicate fibers are mixed with additives including organic and inorganic binders and a fluid to form a plastic mixture. The plastic mixture is formed into a green substrate, and subsequently cured into the ceramic substrate. The fiber-based constituents permit the formation of rigid porous structures for filtration, insulation, and high temperature processes and chemical reactions.

Owner:GE02 TECH INC

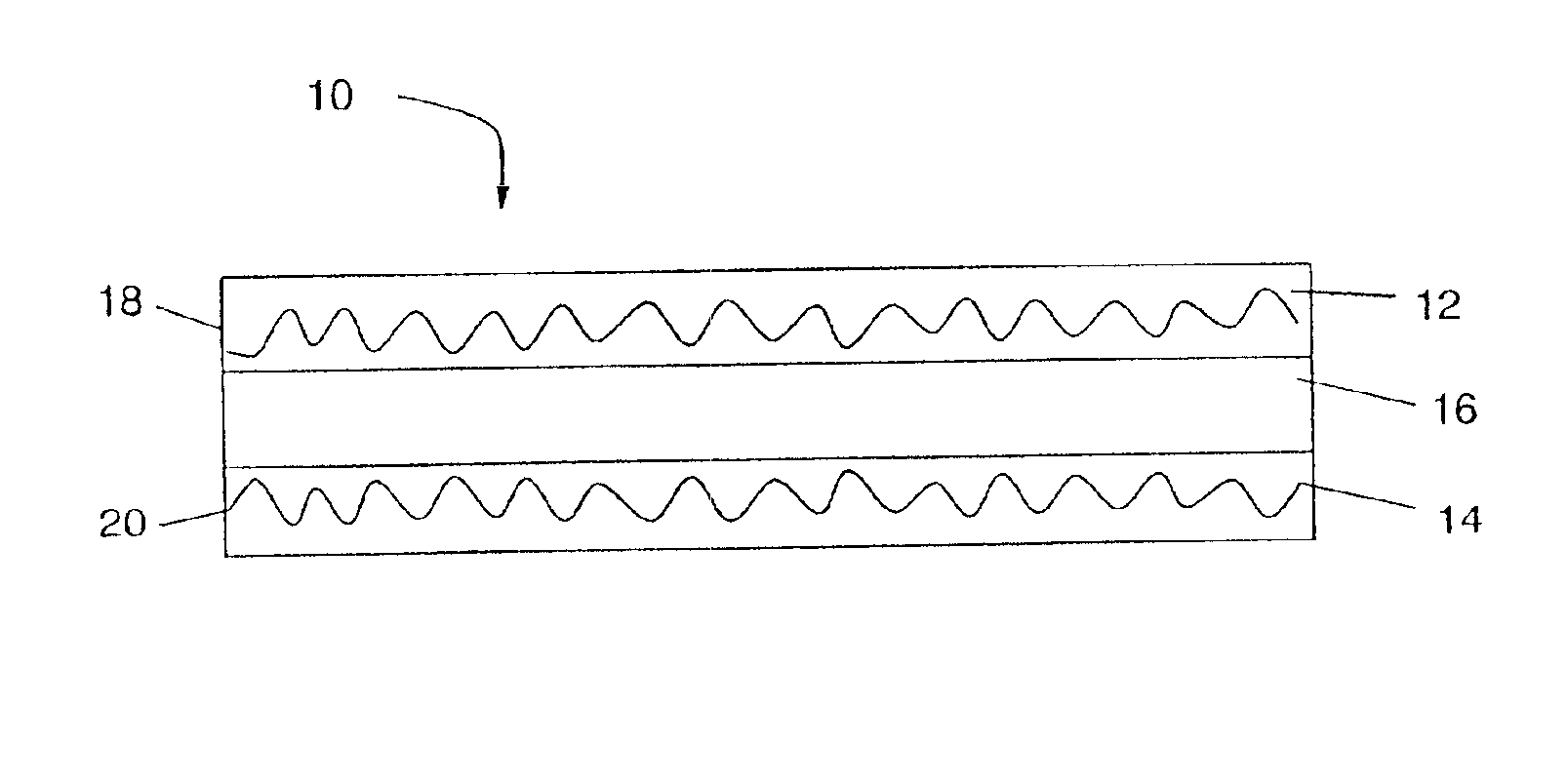

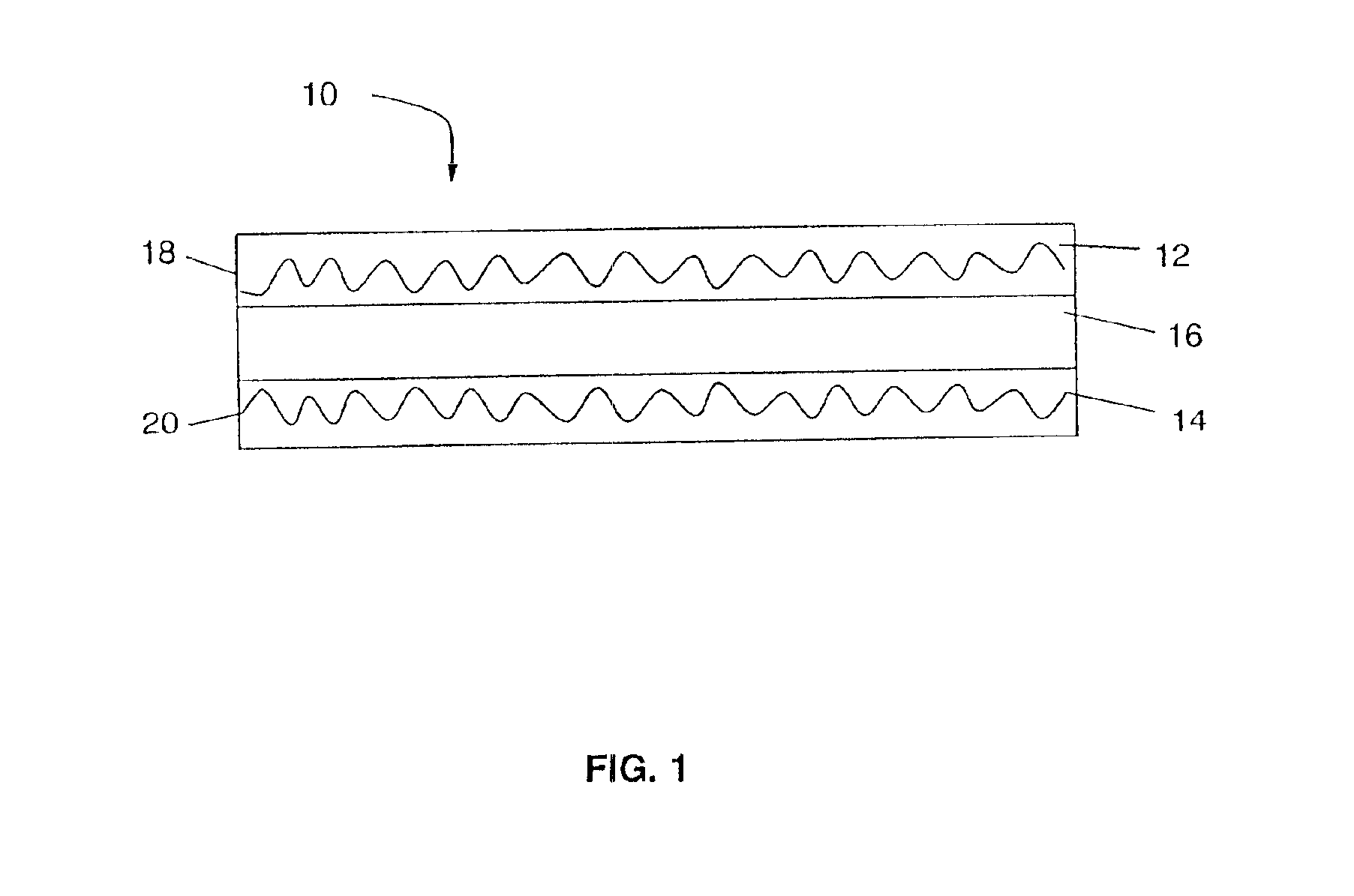

Laminate circuit structure and method of fabricating

InactiveUS20030042046A1Low costAvoid the needPrinted circuit assemblingInsulating substrate metal adhesion improvementOptoelectronicsPrinted circuit board

A substrate and a method of making the substrate is provided. The substrate includes a layer of metal with at least one through hole therein, the layer of metal having an adhesion promoting layer thereon. A layer of a partially cured low-loss polymer or polymer precursor is positioned on the adhesion promoting layer and a plurality of conductive circuit lines are positioned on a portion of the partially cured dielectric layer. The substrate can be used as a building block in the fabrication of a multilayered printed circuit board.

Owner:IBM CORP

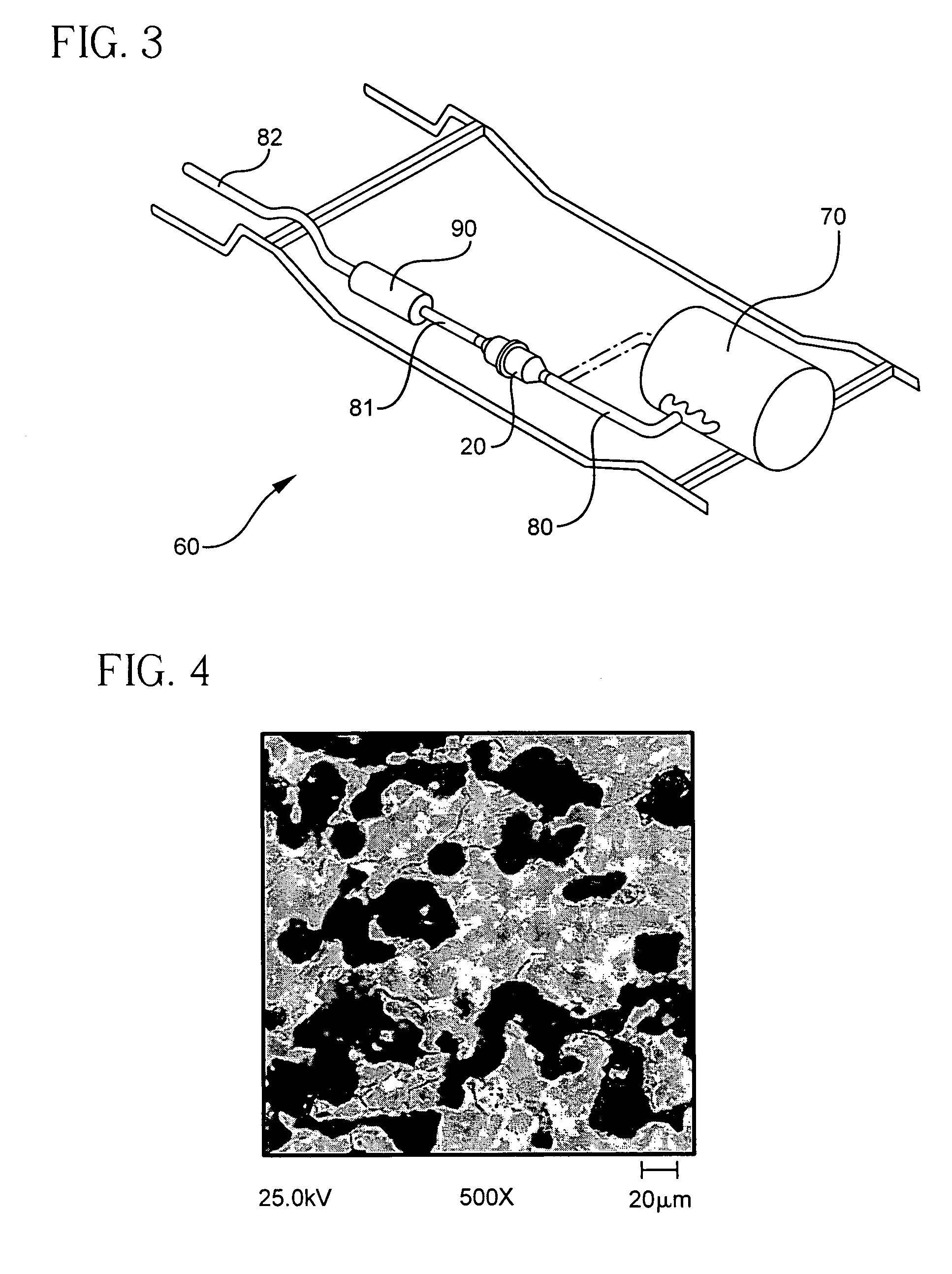

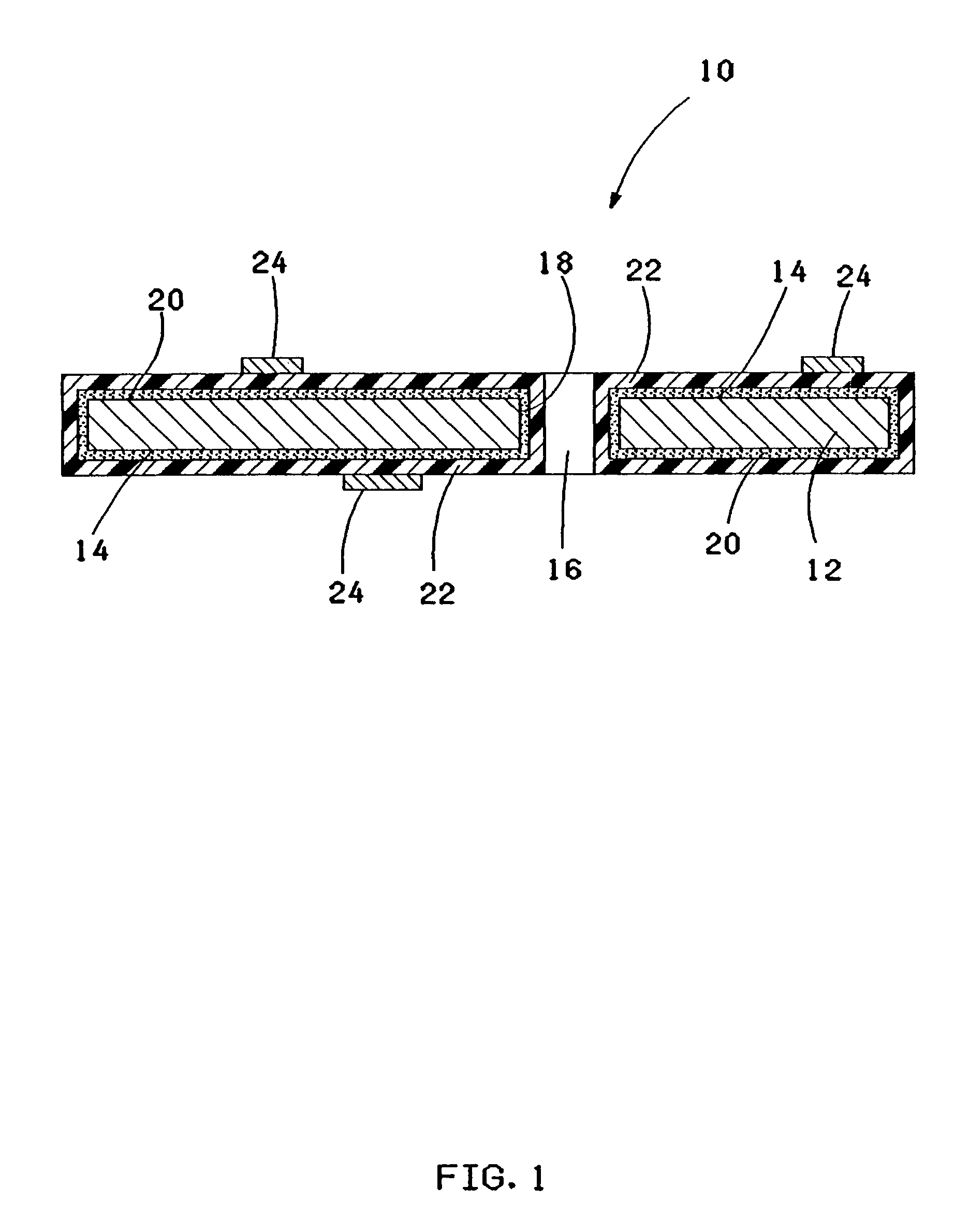

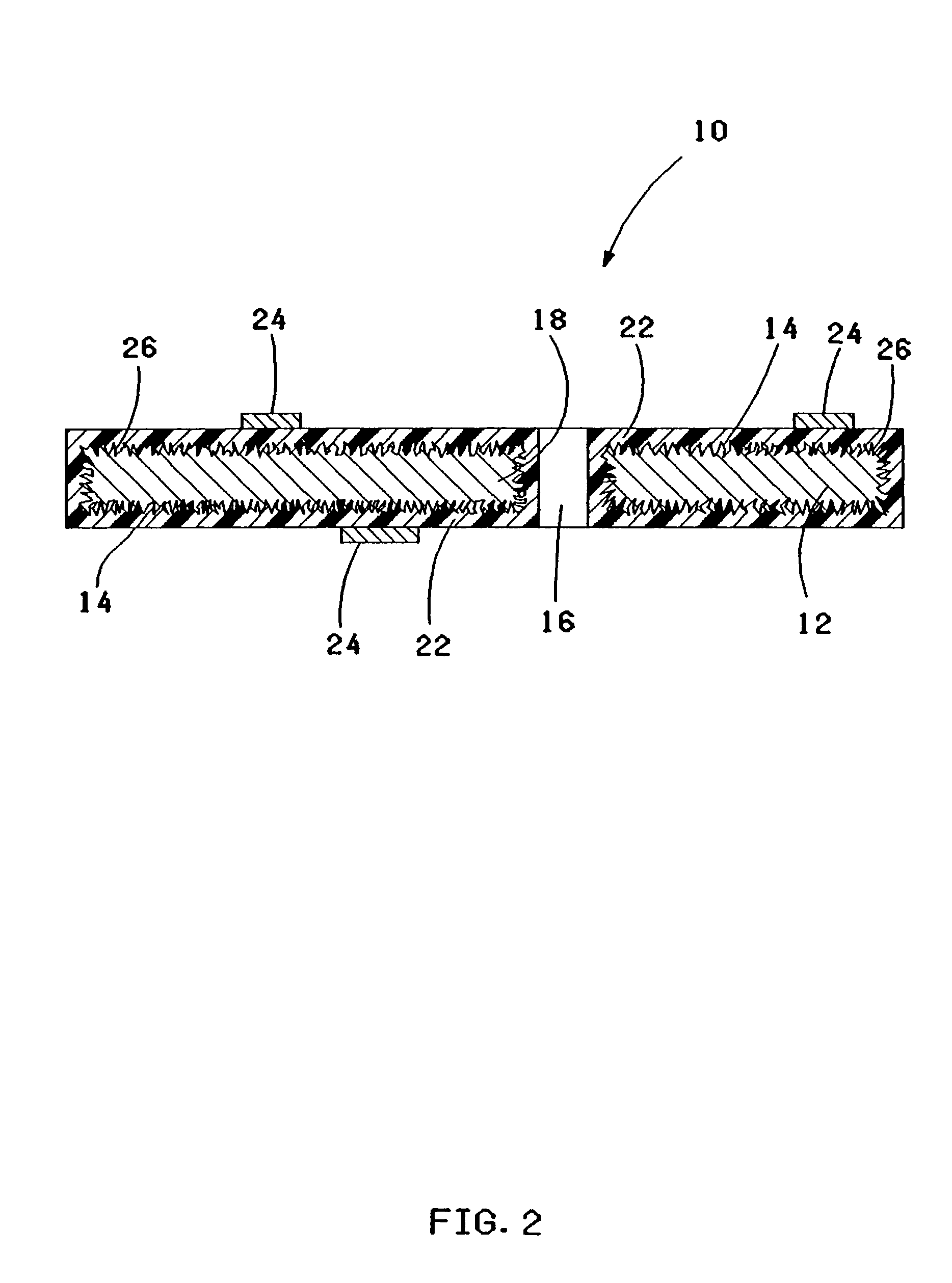

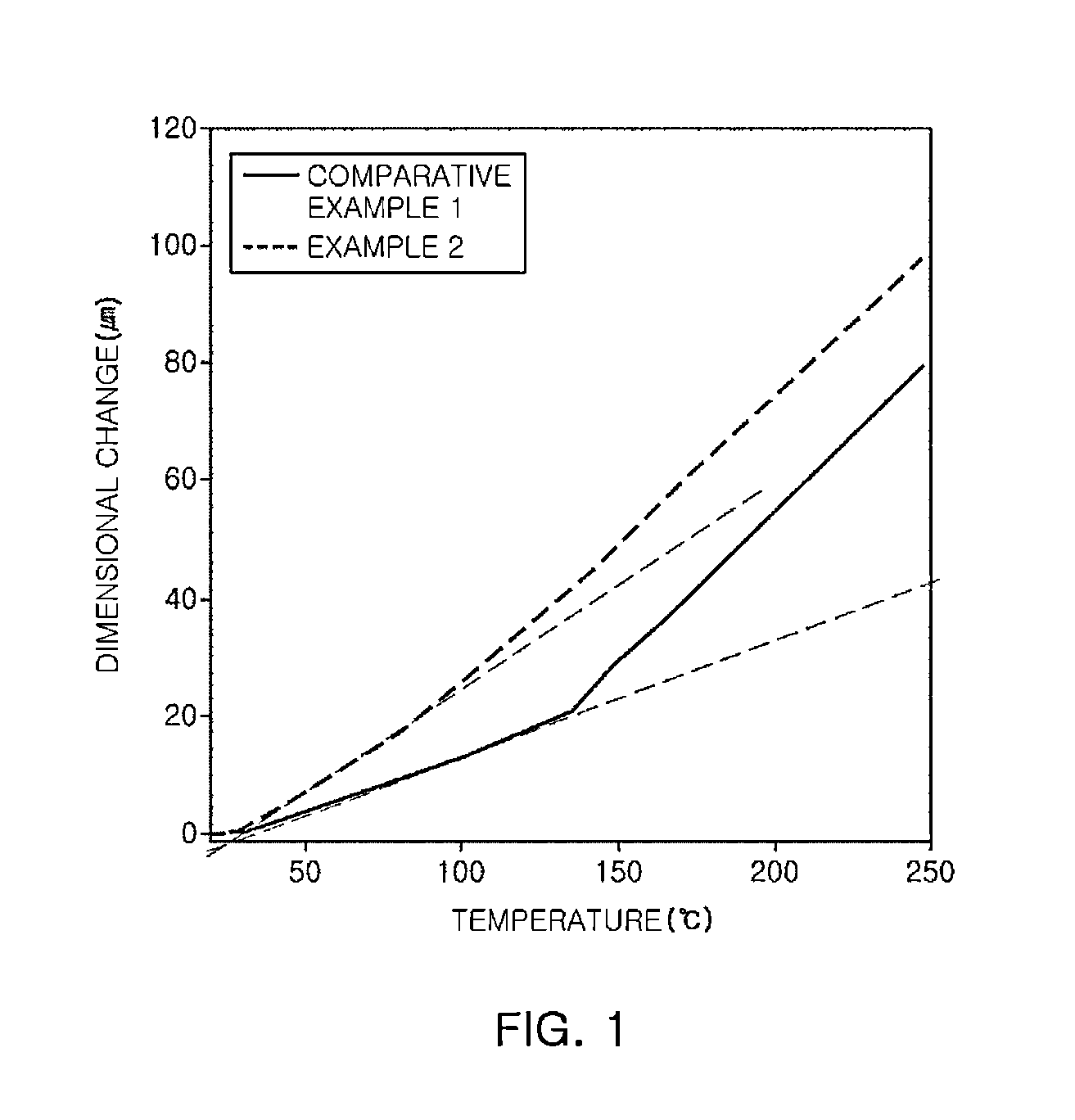

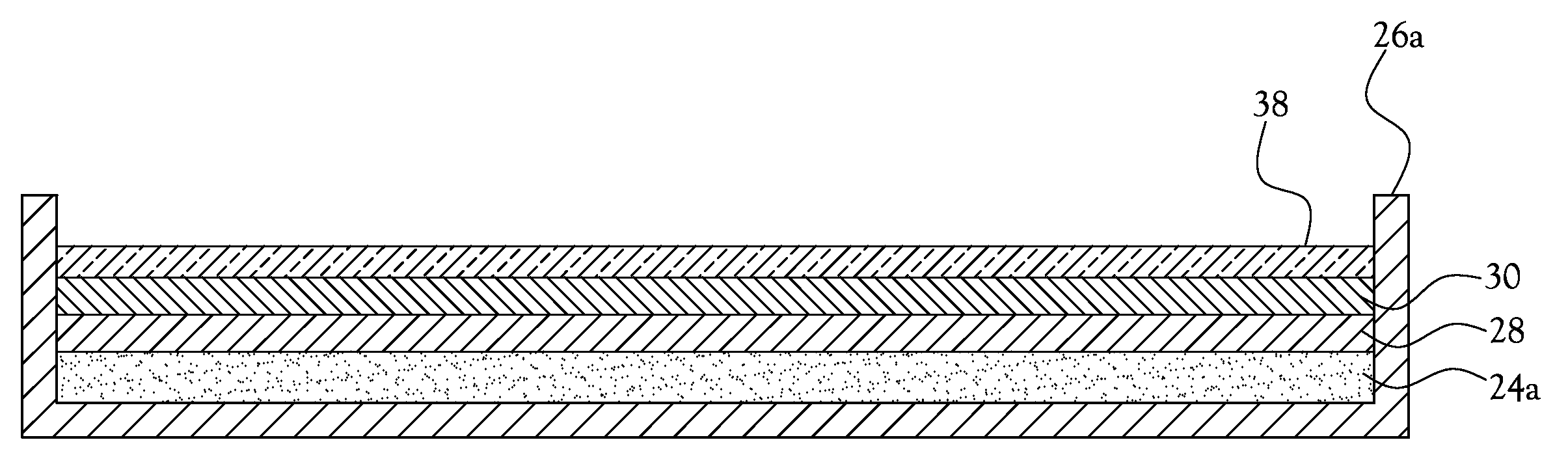

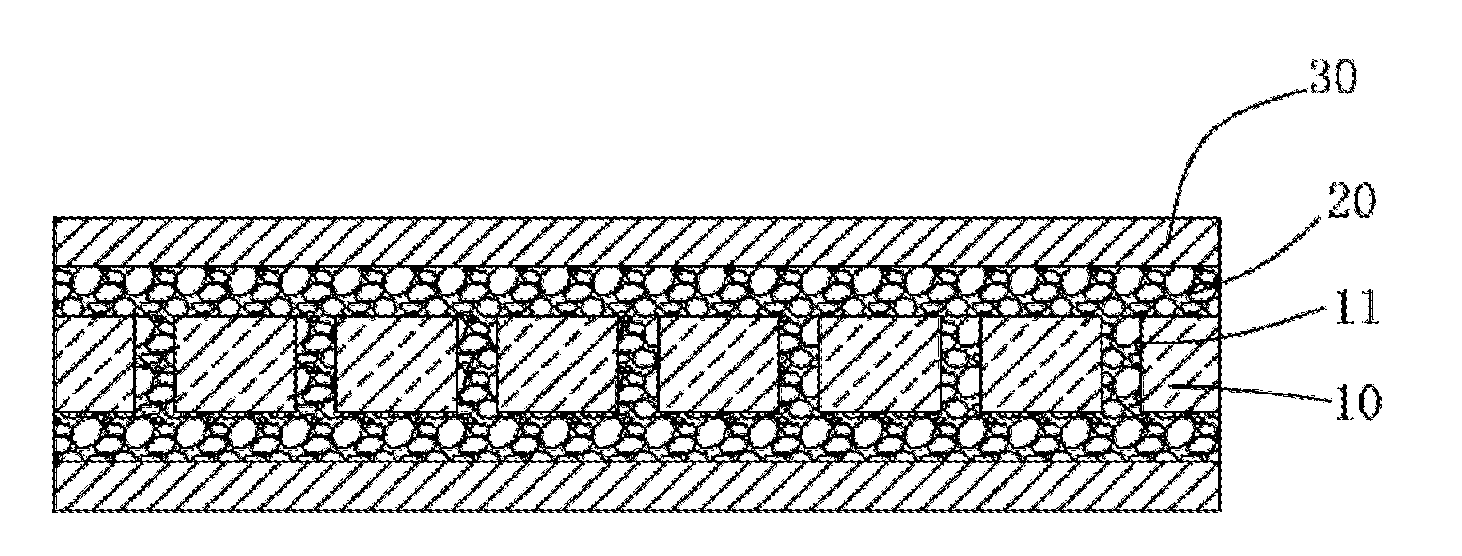

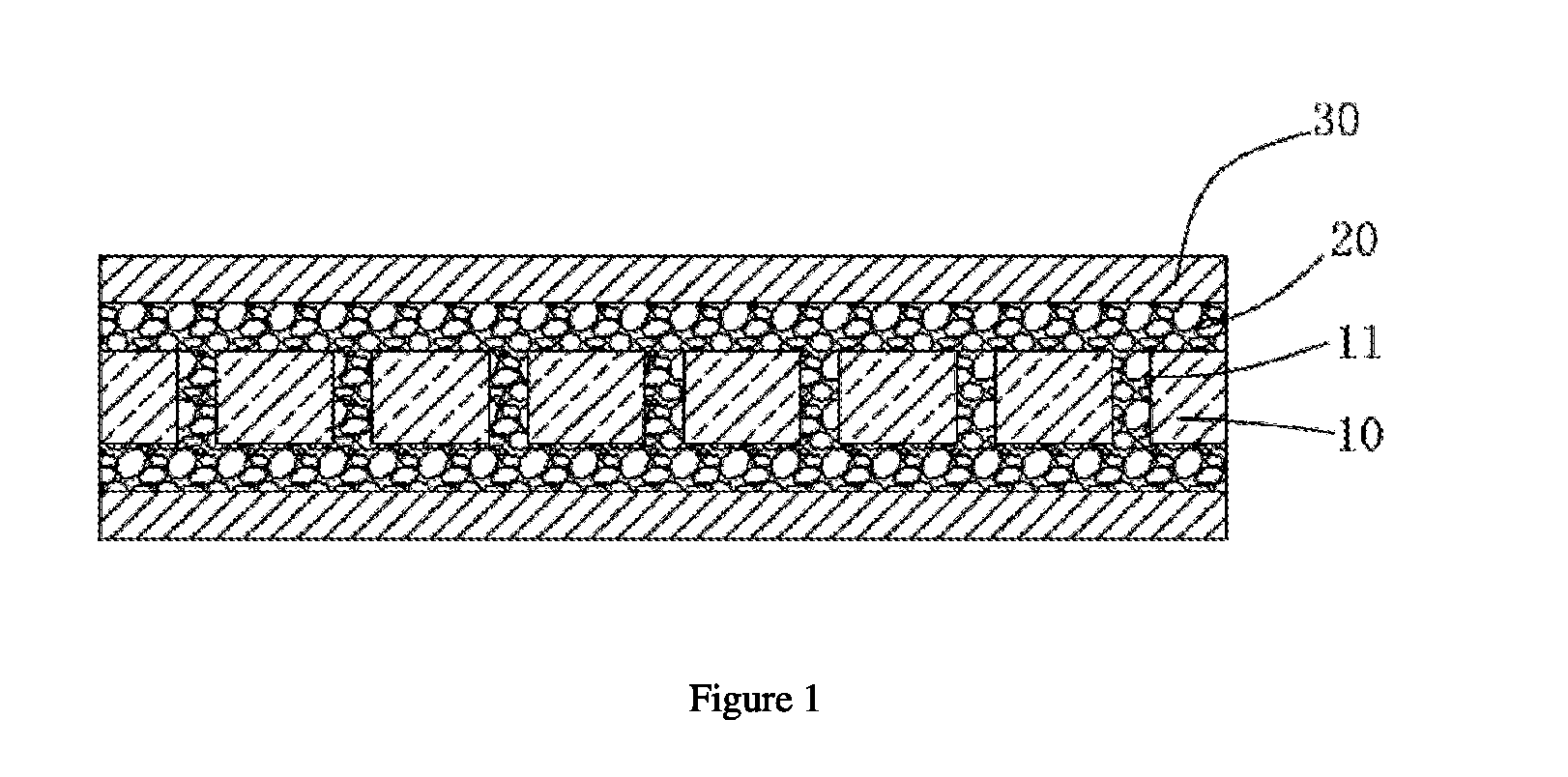

Method for reducing coefficient of thermal expansion in chip attach packages

InactiveUS6841026B2Reduce CTELow CTEPrinted circuit assemblingSynthetic resin layered productsThermal expansionQuartz

A simple, inexpensive, drillable, reduced CTE laminate and circuitized structures comprising the reduced CTE laminate, is provided. One embodiment of the reduced CTE laminate comprises: from about 40% to 75%, preferably from about 55% to 65%, by weight resin; from about 0.05% to 0.3%, preferably from about 0.08% to 0.10%, by weight curing agent; from about 25% to 60%, preferably from about 30% to 40%, by weight, woven cloth; from about 1% to 15%, preferably from about 5% to 10%, by volume, non-woven quartz mat. The method for making reduced CTE laminate and laminate structures comprises the following steps: providing non-woven quartz mat; providing a prepreg, preferably B-stage cured to not more than about 40%, preferably not more than 30% of full cure; sandwiching the non-woven quartz mat between two layers of prepreg, and reflowing the resin of the prepreg into the quartz mat.

Owner:IBM CORP

Epoxy compound having alkoxysilyl group, method of preparing the same, composition and cured product comprising the same, and uses thereof

ActiveUS9150686B2Improve flame retardant performanceImprove bindingGroup 4/14 element organic compoundsSynthetic resin layered productsEpoxyHeat resistance

Owner:KOREA INST OF IND TECH

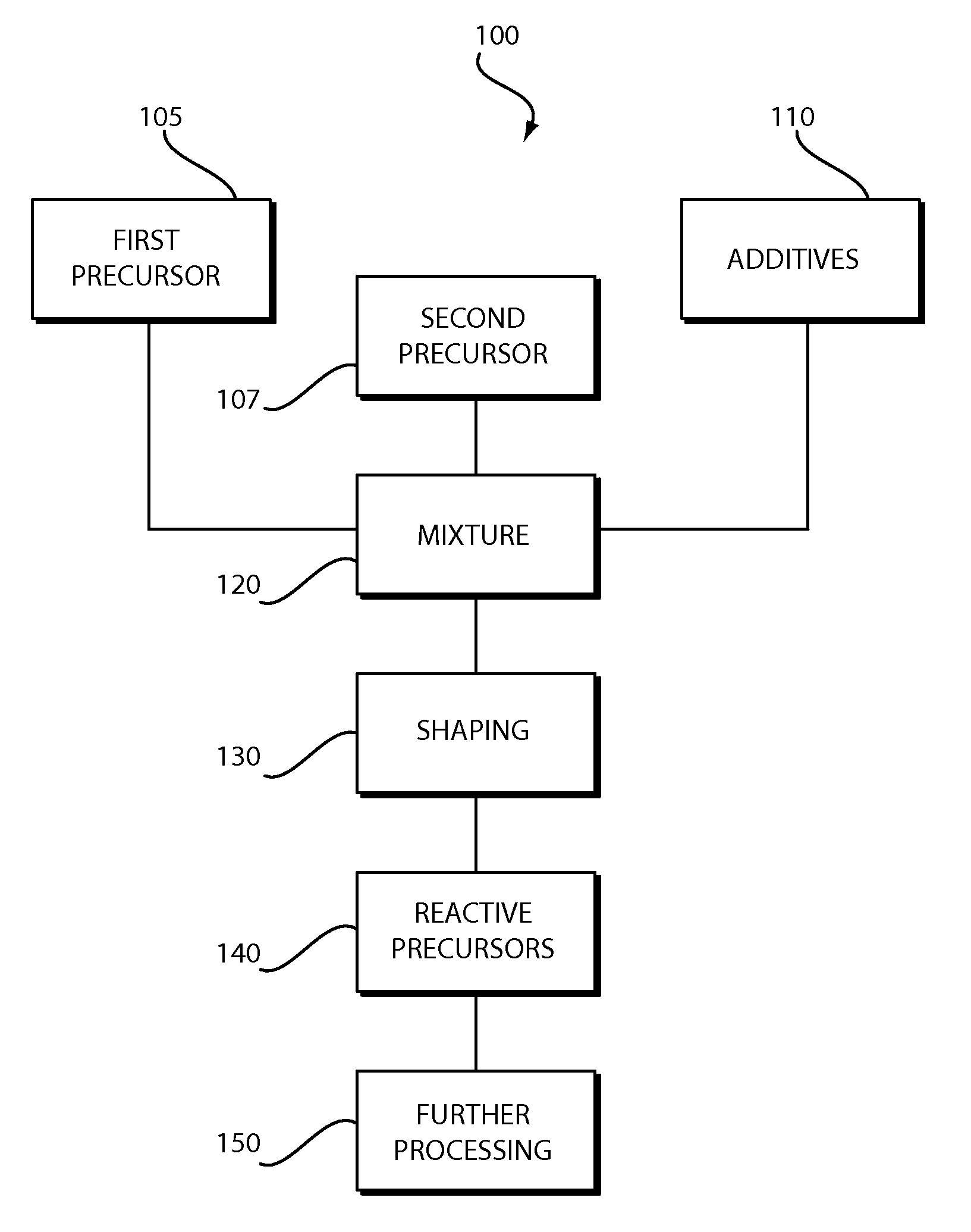

Low coefficient of thermal expansion materials including nonstoichiometric cordierite fibers and methods of manufacture

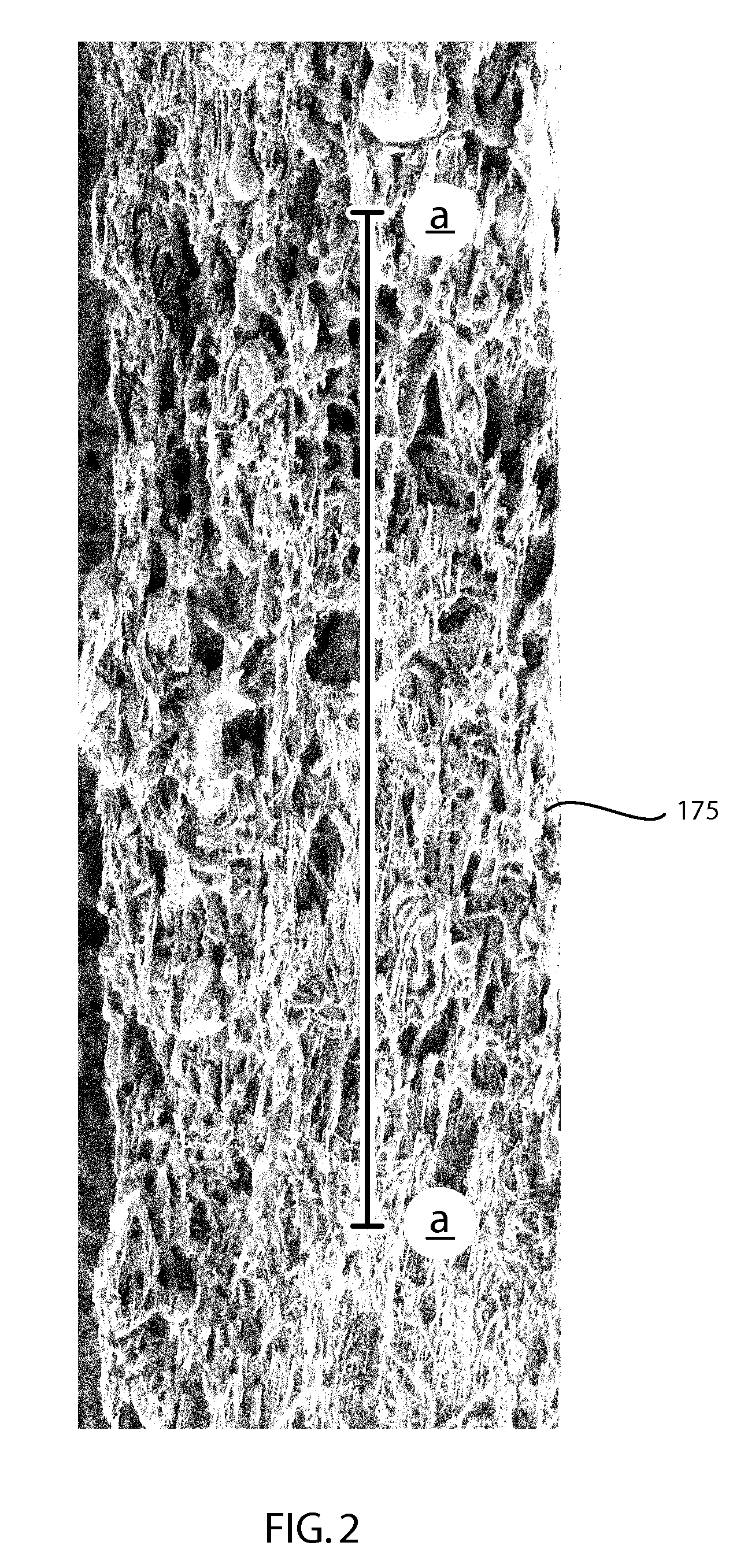

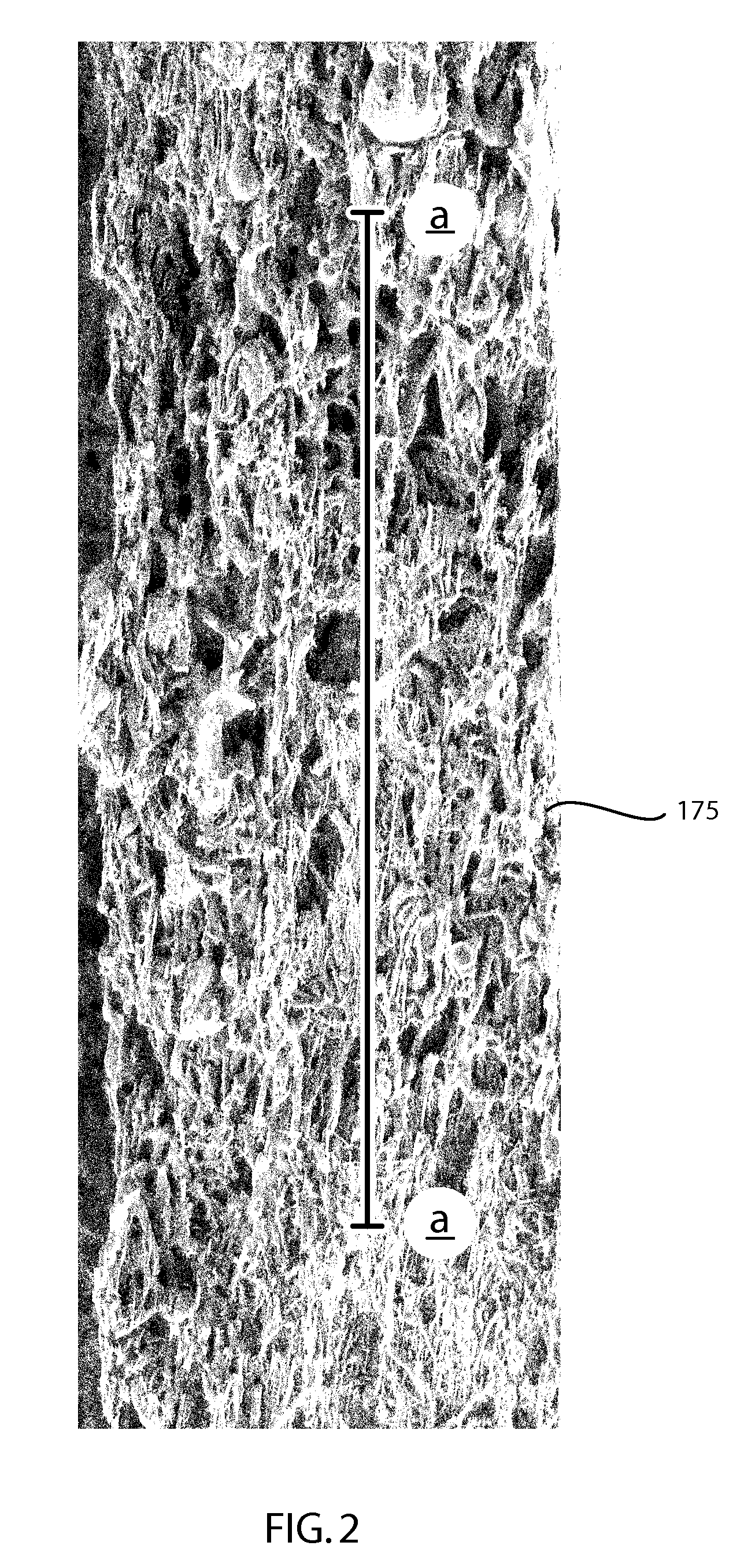

InactiveUS7938876B2Minimal crackingReduce CTECombination devicesAuxillary pretreatmentFiberPolymer science

A fibrous ceramic material comprises a plurality of fibers having a RxMg2Al4+xSi5−xO18 or RxMg2−xAl4Si5O18 compositional structure. The fibrous ceramic material is form by combining two or more RxMg2Al4+xSi5−xO18 or RxMg2−xAl4Si5O18 precursors in which at least one of the two or more RxMg2Al4+xSi5−xO18 or RxMg2−xAl4Si5O18 precursors is in fiber form. The fibrous ceramic material is shaped to form a fibrous body in which at least about 20% of all fibers therein are aligned in a substantially common direction.

Owner:GE02 TECH INC

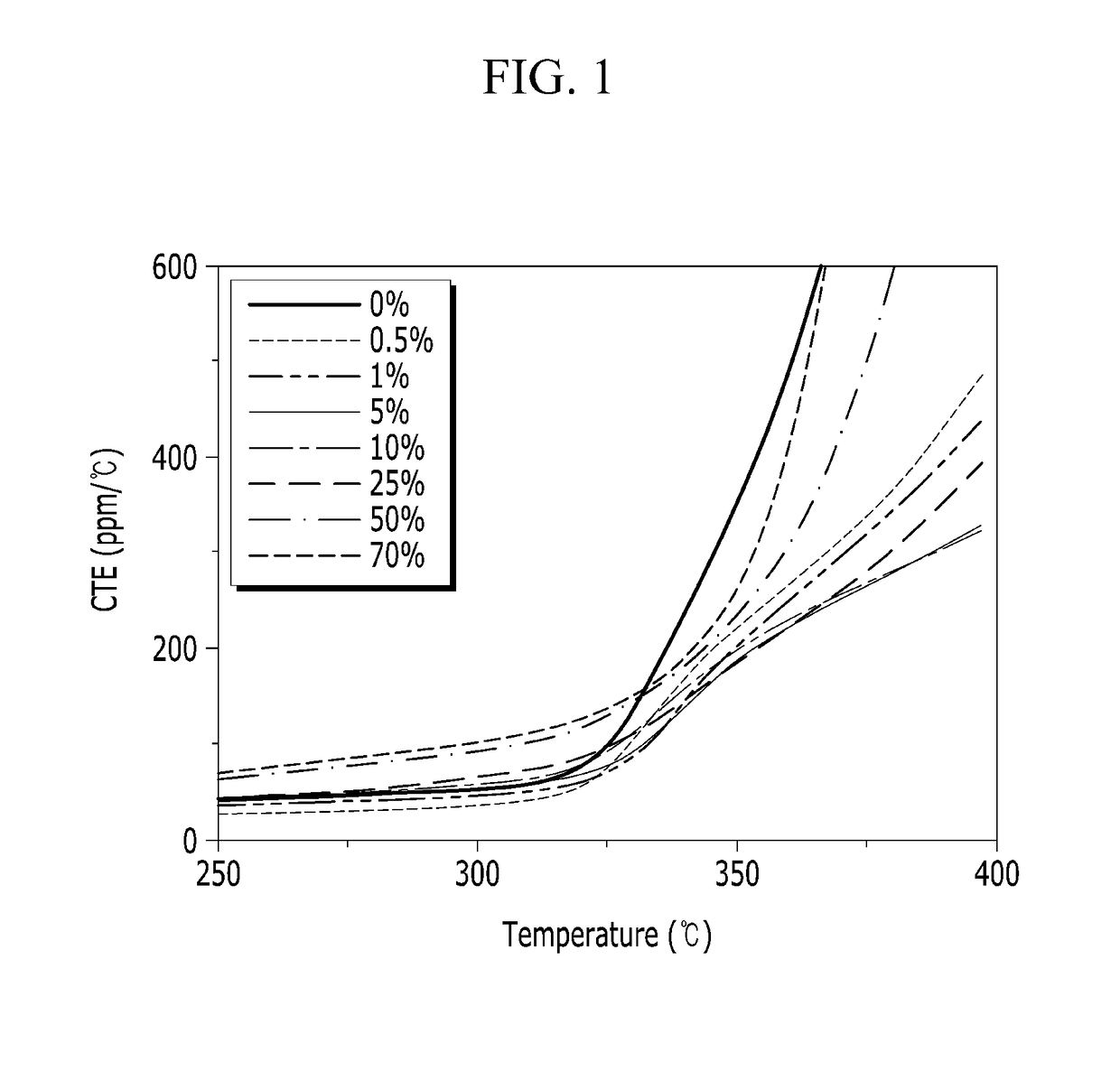

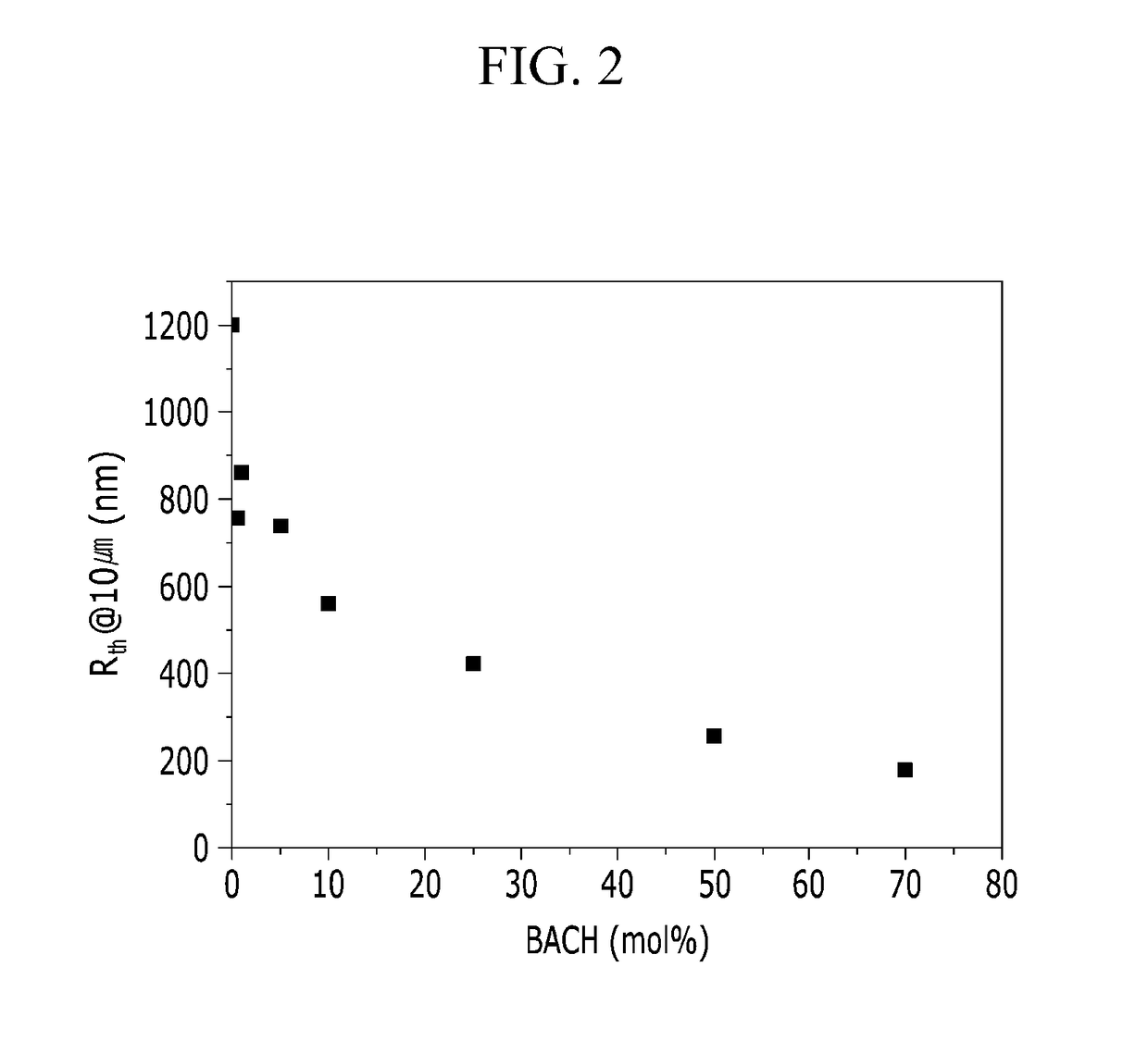

Dielectric Film Forming Composition

ActiveUS20190077913A1Reduce CTEReduce amount of CTESemiconductor/solid-state device detailsSolid-state devicesDielectricMeth-

This disclosure relates to dielectric film forming composition containing at least one fully imidized polyimide polymer; at least one inorganic filler; at least one metal-containing (meth)acrylate compound; and at least one catalyst. The dielectric film formed by such a composition can have a relatively low coefficient of thermal expansion (CTE) and a relatively high optical transparency.

Owner:FUJIFILM ELECTRONICS MATERIALS US

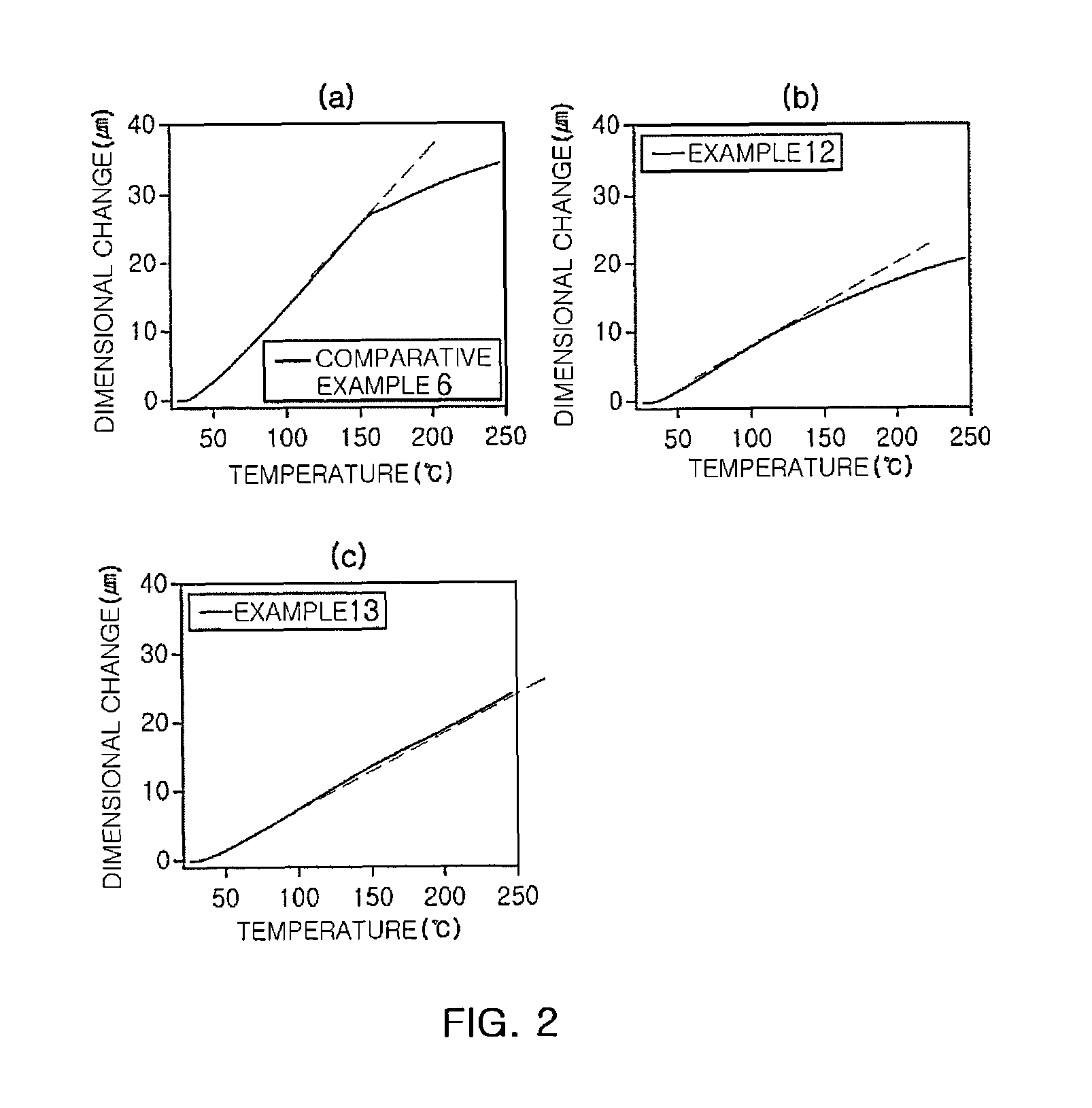

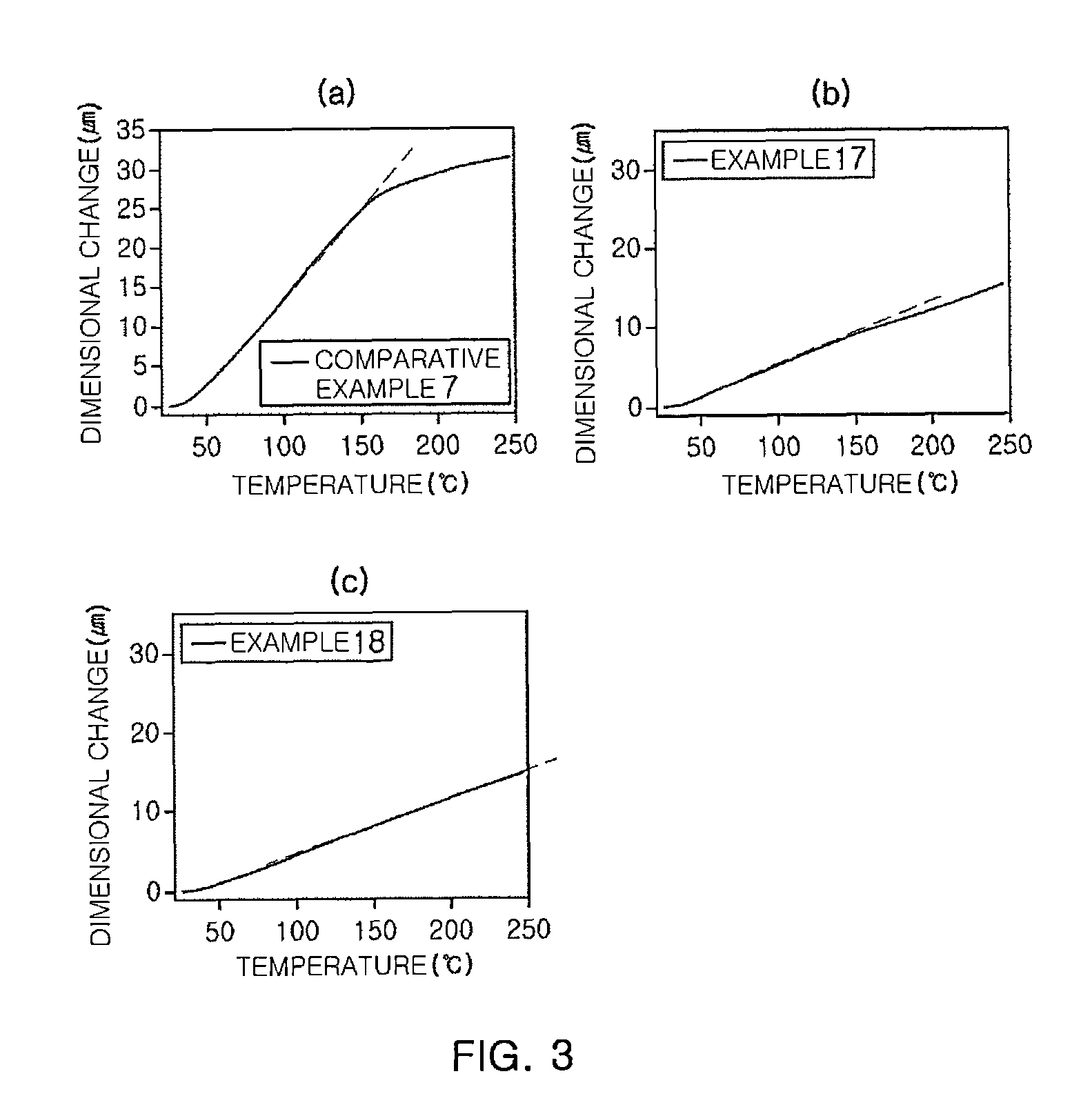

Method for preparing acrylic copolymer resin for optical film and method for fabricating optical film using the same

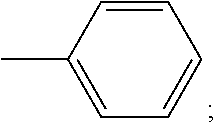

ActiveUS20140015152A1Facilitate controlIncrease in temperatureOptical articlesFlat articlesChemistryGlutaric anhydride

There is provided a method for preparing an acrylic copolymer resin for an optical film includes: suspension-polymerizing an acrylic monomer containing a benzene ring, an alkyl(meth)acrylate monomer, and a (meth)acrylic acid monomer to prepare a copolymer; and thermally treating the copolymer at a temperature ranging from 240° C. to 300° C. As the method for preparing an acrylic copolymer of the present invention, a resin having an effectively lowered CTE can be manufactured by inducing the formation of a glutaric anhydride structure by using suspension polymerization that facilitates adjustment of the molecular weight of a resin.

Owner:LG CHEM LTD

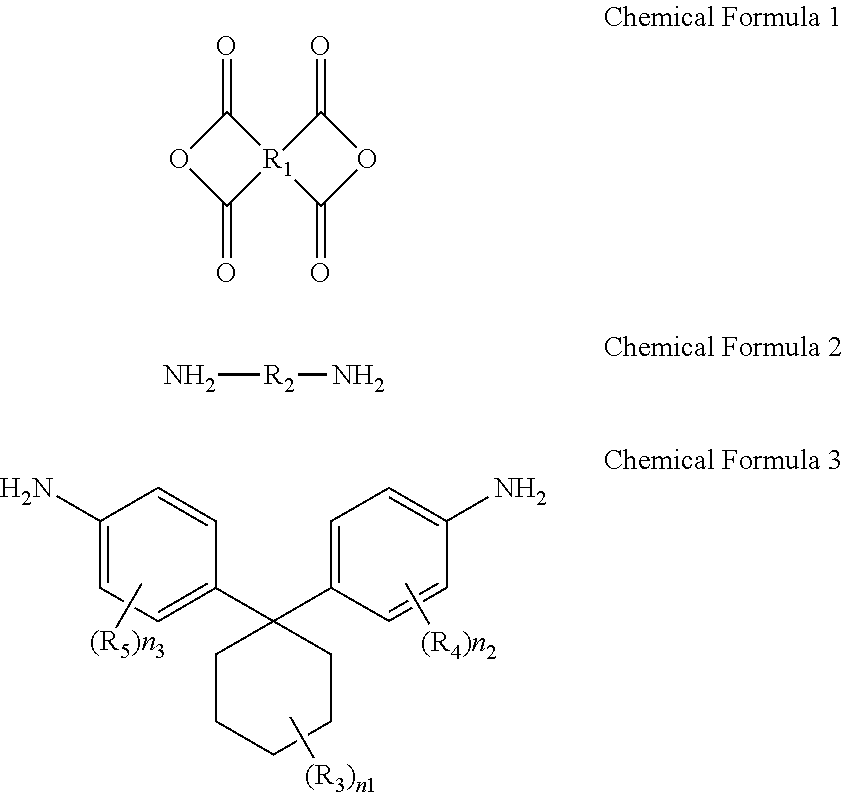

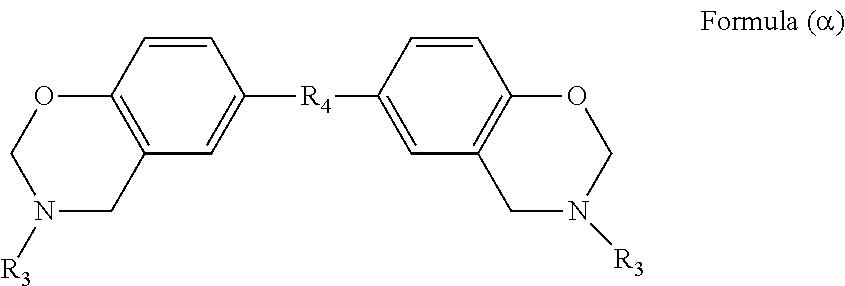

Polymer for optical film, and optical film including the same

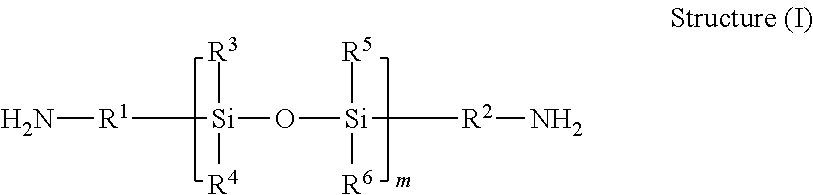

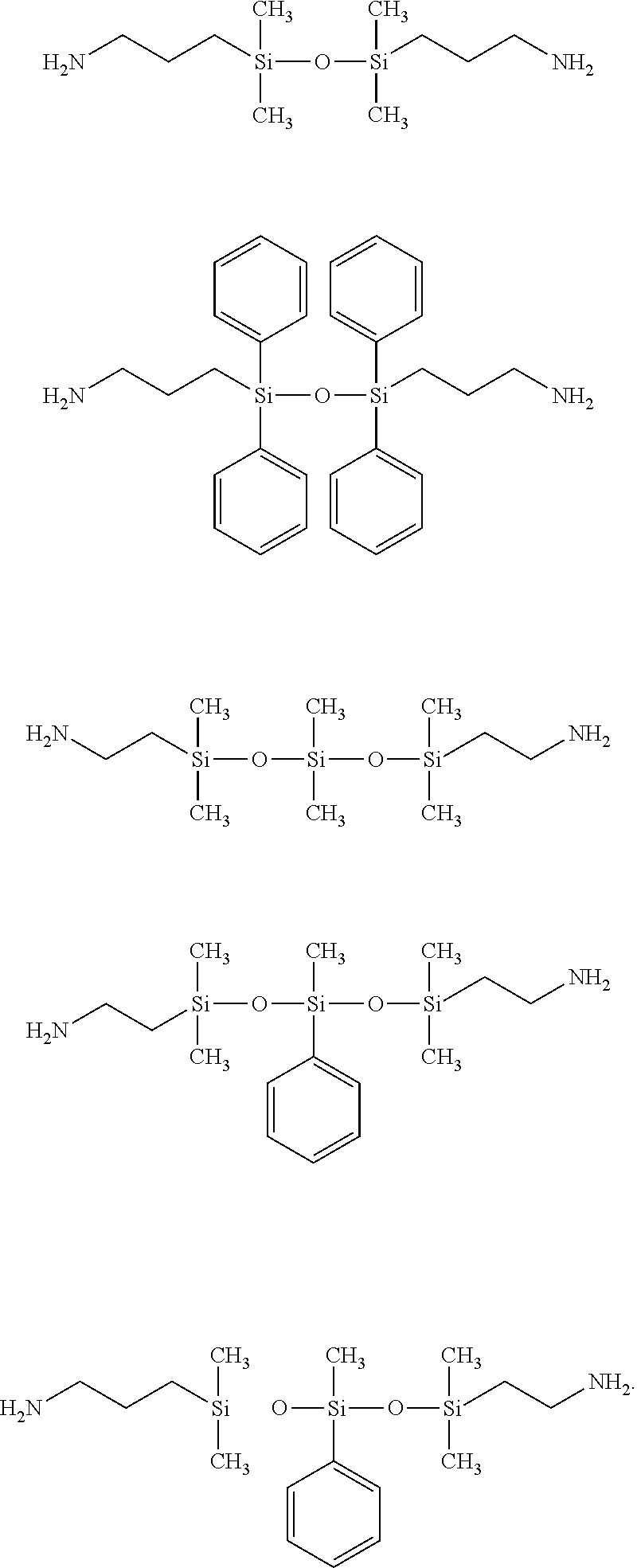

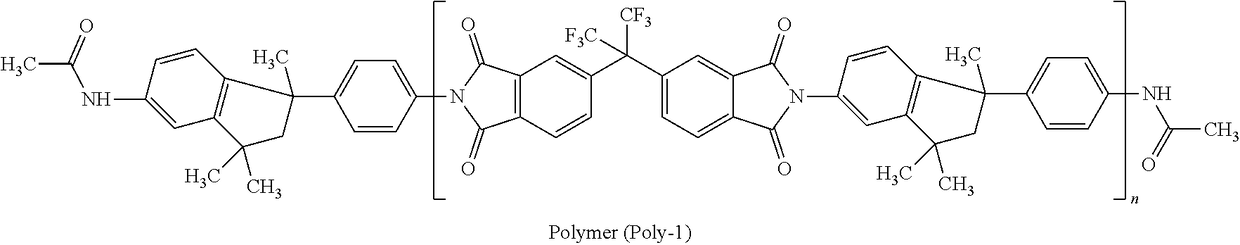

ActiveUS20170081478A1Maintain good propertiesReduce CTECoatingsNon-linear opticsOptical thin filmDiamine

A composition for preparing an optical film, comprising a tetracarboxylic acid dianhydride represented by Chemical Formula 1, a first diamine represented by Chemical Formula 2, and a second diamine represented by Chemical Formula 3, wherein an amount of the second diamine represented by Chemical Formula 3 is equal to or less than 30 mol % based on the total amount of the first and second diamines:wherein, R1 to R5, n1 to n3 are defined in the specification.

Owner:SAMSUNG ELECTRONICS CO LTD

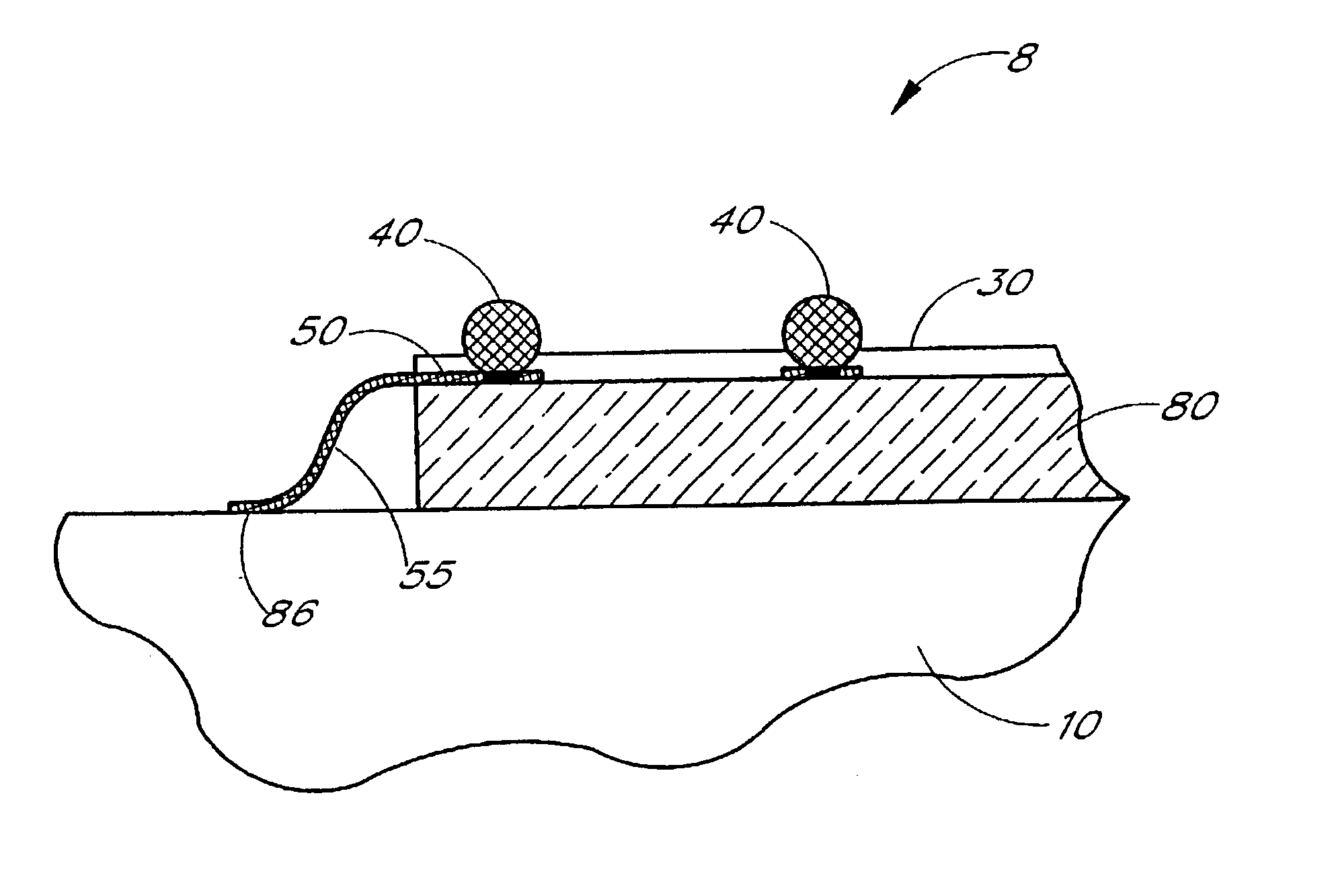

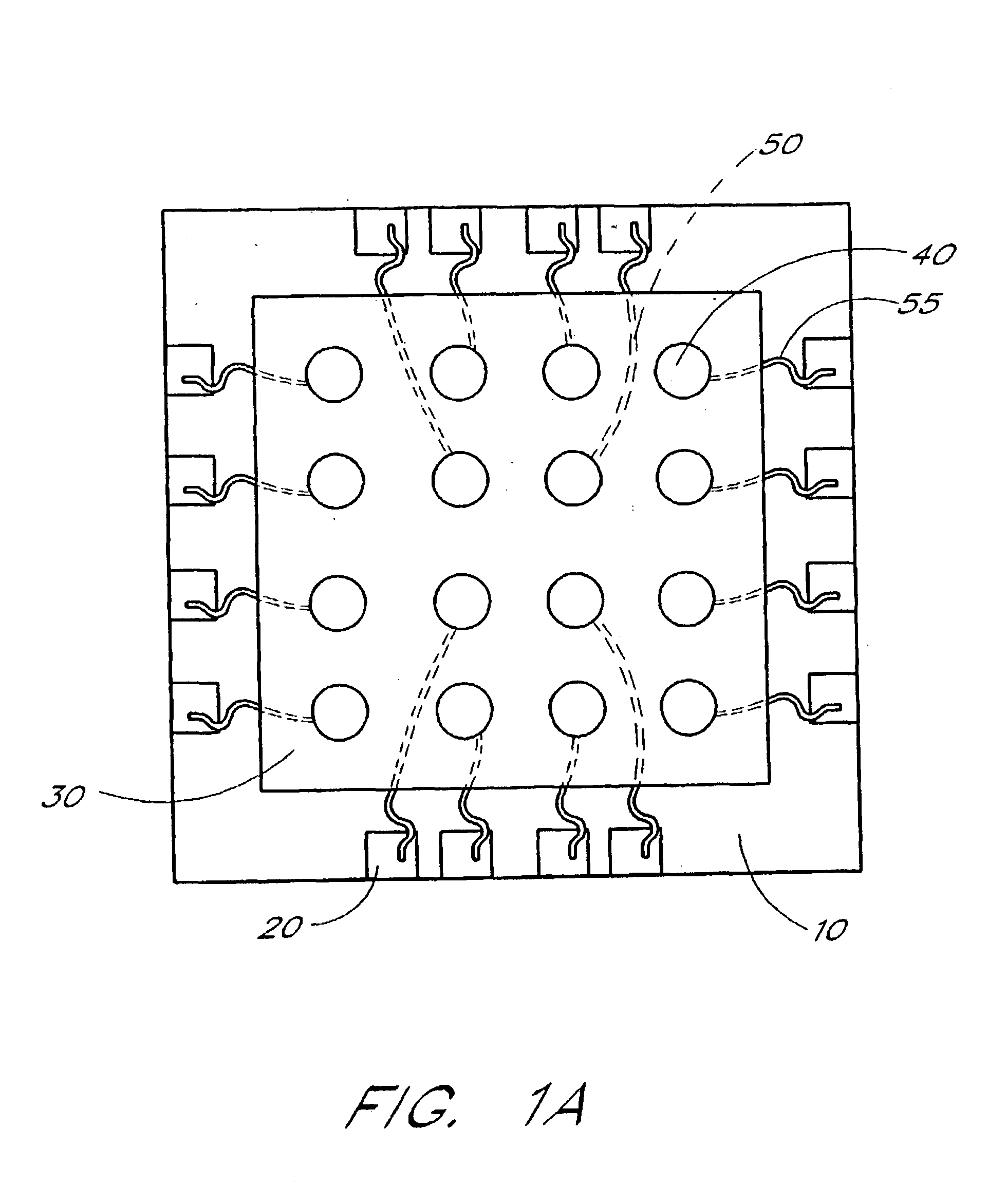

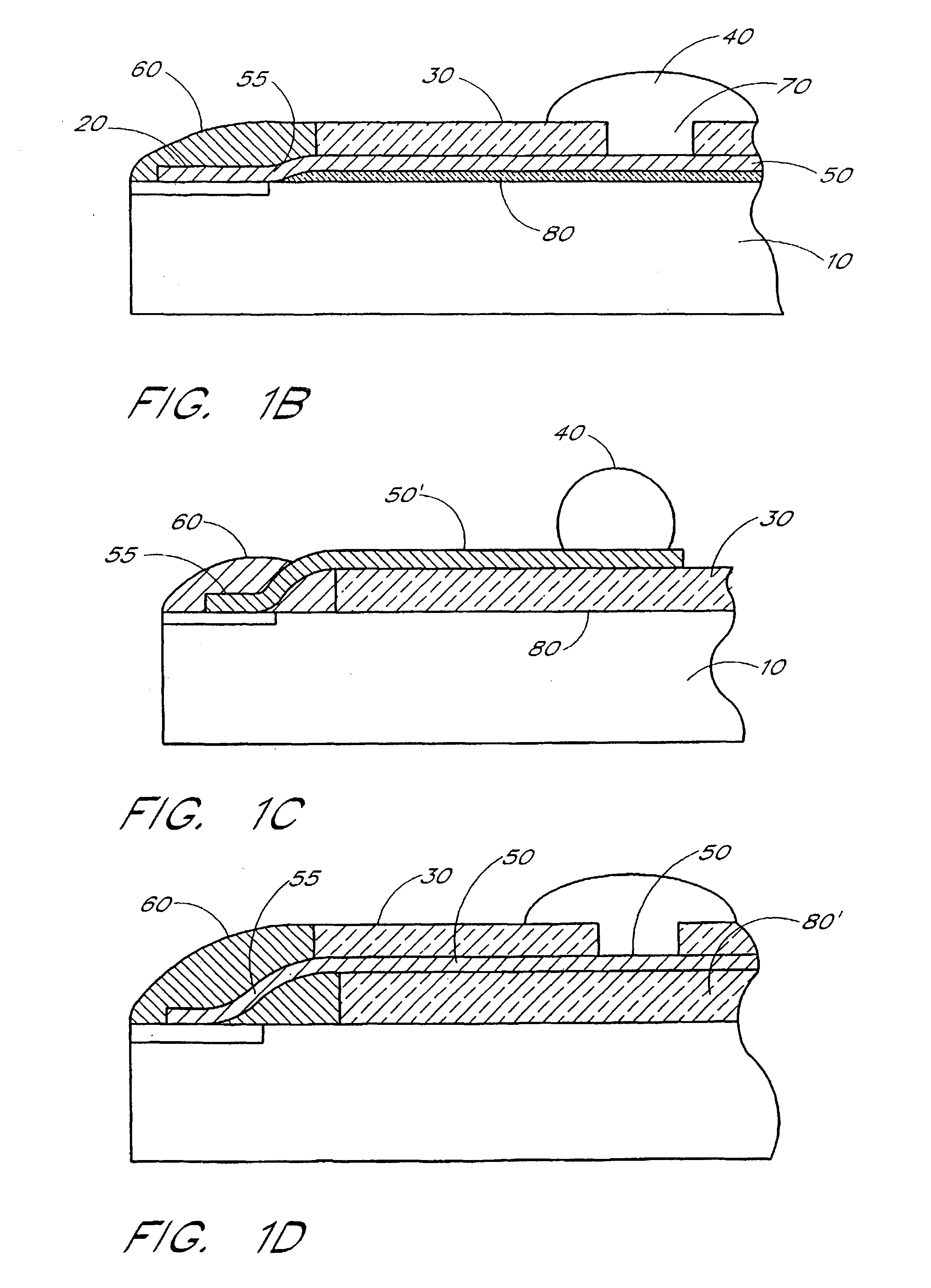

Method of making a flexible substrate with a filler material

InactiveUS7071030B2Improve thermal conductivityImprove rigiditySemiconductor/solid-state device detailsPrinted circuit aspectsFilling materialsInterposer

A method of adding a thermally conductive, electrically nonconductive filler to a flexible substrate such as a polyimide core. The substrate may be used, for example, as a part of a polyimide core for a tape or an interposer in a BGA or similar integrated circuit package. The resulting substrate has a higher thermal conductivity as compared to conventional substrates without fillers, thereby increasing the thermal dissipation through the substrate and enabling the device to cool more efficiently. The filler also reduces the coefficient of thermal expansion of the substrate to more closely match the die and reduce stresses. Furthermore, the filler increases the rigidity of the substrate, thereby enabling the device to be handled and carried more easily, for example, without a metal frame carrier.

Owner:ROUND ROCK RES LLC

Substrate for use in preparing solar cells

InactiveUS8828791B2Improve conductivityReduce CTEAluminium silicatesFinal product manufactureParticulatesConductive materials

Conductive material is combined with other substances to form a composite material for use as a conductive back face substrate for a thin silicon wafer solar cell. In at least one embodiment, a conductive composite substrate material is fabricated by filling granular conductive material with a mineral or ceramic or other small particulate with a low CTE; the composite is cast and fired so that it has an electrically conductive continuous phase and a discontinuous phase that will control and match the CTE of the substrate to be equal to or close to that of silicon, thereby diminishing the effects of bowing from CTE-mismatch.

Owner:MOSSEY CREEK TECH

Low coefficient of thermal expansion materials including nonstoichiometric cordierite fibers and methods of manufacture

InactiveUS20080242530A1Minimal crackingReduce CTECombination devicesAuxillary pretreatmentFiberPolymer science

A fibrous ceramic material comprises a plurality of fibers having a RxMg2Al4+xSi5−xO18 or RxMg2−xAl4Si5O18 compositional structure. The fibrous ceramic material is form by combining two or more RxMg2Al4+xSi5−xO18 or RxMg2−xAl4Si5O18 precursors in which at least one of the two or more RxMg2Al4+xSi5−xO18 or RxMg2−xAl4Si5O18 precursors is in fiber form. The fibrous ceramic material is shaped to form a fibrous body in which at least about 20% of all fibers therein are aligned in a substantially common direction.

Owner:GE02 TECH INC

Circuit substrate and manufacturing method thereof

InactiveUS20140377534A1Improve bindingCircuit substrate reducedDecorative surface effectsAdhesive processes involving weldingMetal foilBinding force

A circuit substrate, including a porous glass film with the volume percentage ratio of the glass being above 45%, a resin adhesion layer located on either side of the glass film respectively, and a metal foil located in the outside of resin adhesion layer. The glass film, the resin adhesion layer and the metal foil join together through suppressing, and the resin of the resin adhesion layer is filled in the gaps of the glass film. The circuit substrate employs a porous glass film as a carrier material, so that the resin adhesion layer and the surface of the glass film surface have a good binding force, and the CTE of the circuit substrate in the direction of X and Y is reduced compared to instances before, and has good formability, which is simple and convenient in process operation. In addition, also provided is a manufacturing method for a circuit substrate.

Owner:GUANGDONG SHENGYI SCI TECH

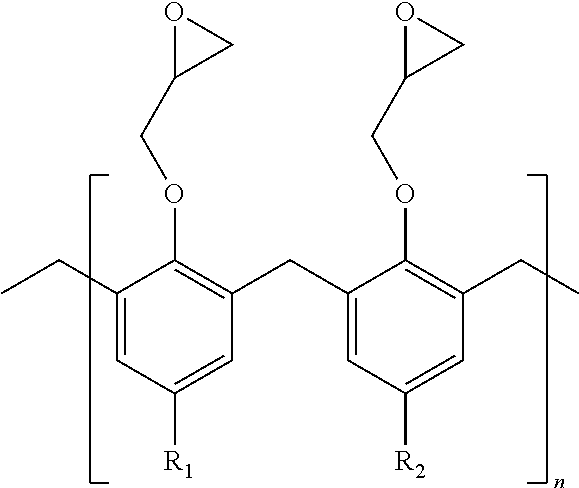

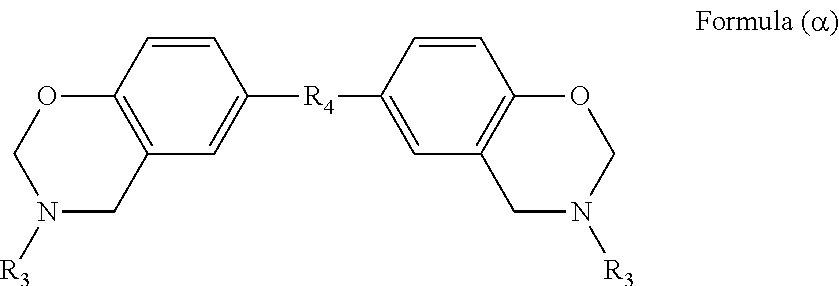

Halogen-free Flame Retardant Resin Composition, Prepreg and Copper Clad Laminate Prepared Therefrom

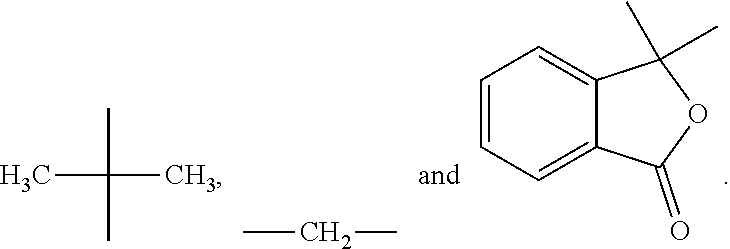

InactiveUS20180371232A1Promote aggregationExcellent dielectric propertiesSynthetic resin layered productsPrinted circuit aspectsSolid componentEpoxy

The present invention relates to a halogen-free flame retardant resin composition, a prepreg and a copper clad laminate prepared therefrom. The composition of the present invention comprises, based on the weight parts of solid components, (A) from 5 to 80 parts by weight of alkylphenol epoxy resin, (B) from 10 to 80 parts by weight of benzoxazine resin, (C) from 2 to 30 parts by weight of styrene maleic anhydride resin, (D) from 1 to 30 parts by weight of a flame retardant, and (E) from 0.5 to 100 parts by weight of an acidic filler having a pH of 2-6. The present invention further provides a prepreg and a copper clad laminate prepared from the halogen-free flame retardant resin composition. While ensuring a higher glass transition temperature and excellent moisture heat resistance, the halogen-free flame retardant resin composition of the present invention effectively improves the dielectric properties and the peel strength stability of the resin composition, and provides the prepregs and copper clad laminates with excellent comprehensive performances.

Owner:GUANGDONG SHENGYI SCI TECH

Epoxy compound, mixture, composition, and cured product comprising same, method for preparing same, and use thereof

ActiveUS10597412B2Improve heat resistanceImprove flame retardant performanceGroup 4/14 element organic compoundsEpoxyThermal dilatation

The present invention relates to a novel epoxy compound, a method for preparing same, a composition and cured product comprising same, and use thereof, wherein the compound shows excellent heat-resistant properties—specifically, a low thermal expansion property and a high glass transition temperature (including Tg-less which does not show a glass transition temperature), a flame retardant property and processability—specifically, a viscosity-control property, does not require a separate silane coupling agent, and has improved brittleness in a composite. According to one aspect of the present invention, provided are: an epoxy compound having at least one non-reactive silyl group, alkenyl group or combination thereof together with at least two epoxy groups and at least one alkoxysilyl group; a method for preparing the epoxy compound through alkoxysilylation and alkylsilylation; an epoxy composition comprising same; and a cured product.

Owner:KOREA INST OF IND TECH

Geotechnical articles

InactiveUS20080319112A1Reduce CTEImproved resistance against UV lightPigmenting treatmentLayered productsMaterials sciencePolymer

A multiphase polymeric material comprises a first rigid continuous phase and a second elastic phase dispersed in the first phase. The multiphase polymeric material may be formed into polymeric strips and used to make a cellular confinement system which is suitable for use in cold areas.

Owner:PRS MEDITERRANEAN

Method for preparing acrylic copolymer resin for optical film and method for fabricating optical film using the same

ActiveUS9429682B2Weight optimizationReduce CTEPolarising elementsFlat articlesGlutaric anhydrideMeth-

There is provided a method for preparing an acrylic copolymer resin for an optical film includes: suspension-polymerizing an acrylic monomer containing a benzene ring, an alkyl(meth)acrylate monomer, and a (meth)acrylic acid monomer to prepare a copolymer; and thermally treating the copolymer at a temperature ranging from 240° C. to 300° C. As the method for preparing an acrylic copolymer of the present invention, a resin having an effectively lowered CTE can be manufactured by inducing the formation of a glutaric anhydride structure by using suspension polymerization that facilitates adjustment of the molecular weight of a resin.

Owner:LG CHEM LTD

Prepreg, metal-clad laminated board, and printed wiring board

ActiveUS9944766B2Reduce inhibitionGood molding effectSynthetic resin layered productsElectrical equipmentPolymer chemistryMetal

A prepreg includes a fiber base material and a thermosetting resin composition impregnated into the fiber base material. The thermosetting resin composition contains a thermosetting resin including an epoxy resin; a curing agent; an inorganic filler; and an acrylic acid ester copolymer having a weight average molecular weight of 10×104 or more and less than 45×104. A content of the inorganic filler is 150 parts by mass or more relative to a total of 100 parts by mass of the thermosetting resin and the curing agent. A content of the acrylic acid ester copolymer is more than 30 parts by mass and 90 parts by mass or less relative to the total of 100 parts by mass of the thermosetting resin and the curing agent.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Process for preparing resin composition comprising benzoxazine, prepreg and laminate prepared therefrom

ActiveUS20180362762A1Promote polymerizationDecrease curing temperaturePrinted circuit aspectsSynthetic resin layered productsChemistryFlexural strength

The present invention relates to a process for preparing a resin composition comprising benzoxazine, a prepreg and a laminate prepared therefrom. Said resin composition comprising benzoxazine is prepared by adding an acidic filler into the resin composition comprising benzoxazine, wherein said resin composition comprising benzoxazine comprises a benzoxazine resin, an epoxy resin A1 having an epoxy equivalent of 150-450, and an epoxy resin A2 having an epoxy equivalent of 451-1000. By adding an acidic filler into the resin composition, the present invention greatly promotes the polymerization of benzoxazine and epoxy resins, and decreases the curing temperature needed for the polymerization of benzoxazine and epoxy resins. The laminates prepared from the resin composition added with an acidic filler have a high anti-stripping stability, a high glass transition temperature, a low water absorption, a high heat resistance, a high bending strength and a better processability, and can achieve a low coefficient of thermal expansion.

Owner:GUANGDONG SHENGYI SCI TECH

Method of producing needle coke for low CTE graphite electrodes

ActiveUS9777221B2Reduction factorWithout excessive expenditureSolid fuelsTar working-up by distillationCoal tar distillateGraphite electrode

A method of producing low CTE graphite electrodes from needle coke formed from a coal tar distillate material having a relatively high initial boiling point.

Owner:GRAFTECH INT HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com