Patents

Literature

107 results about "Optical polymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

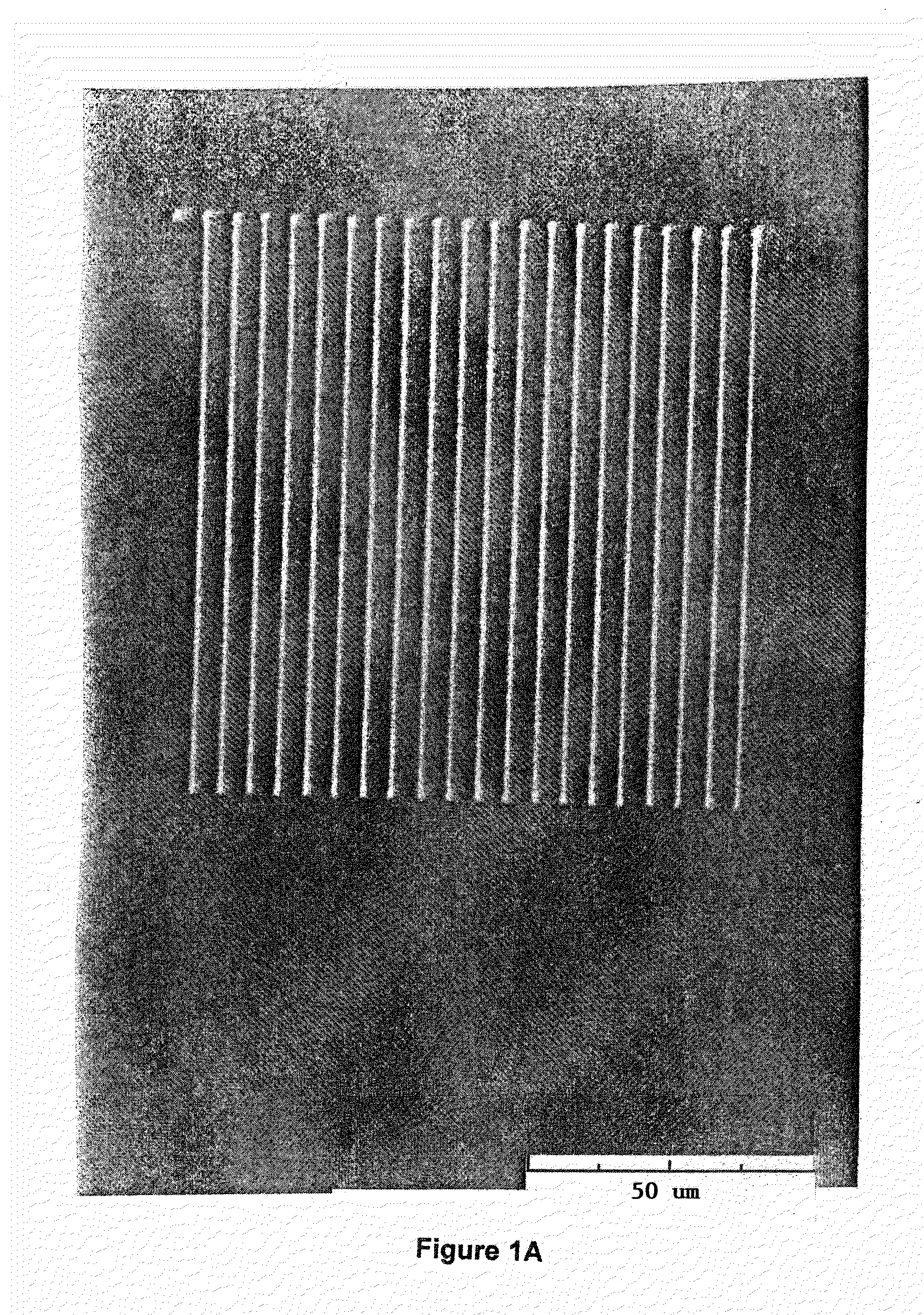

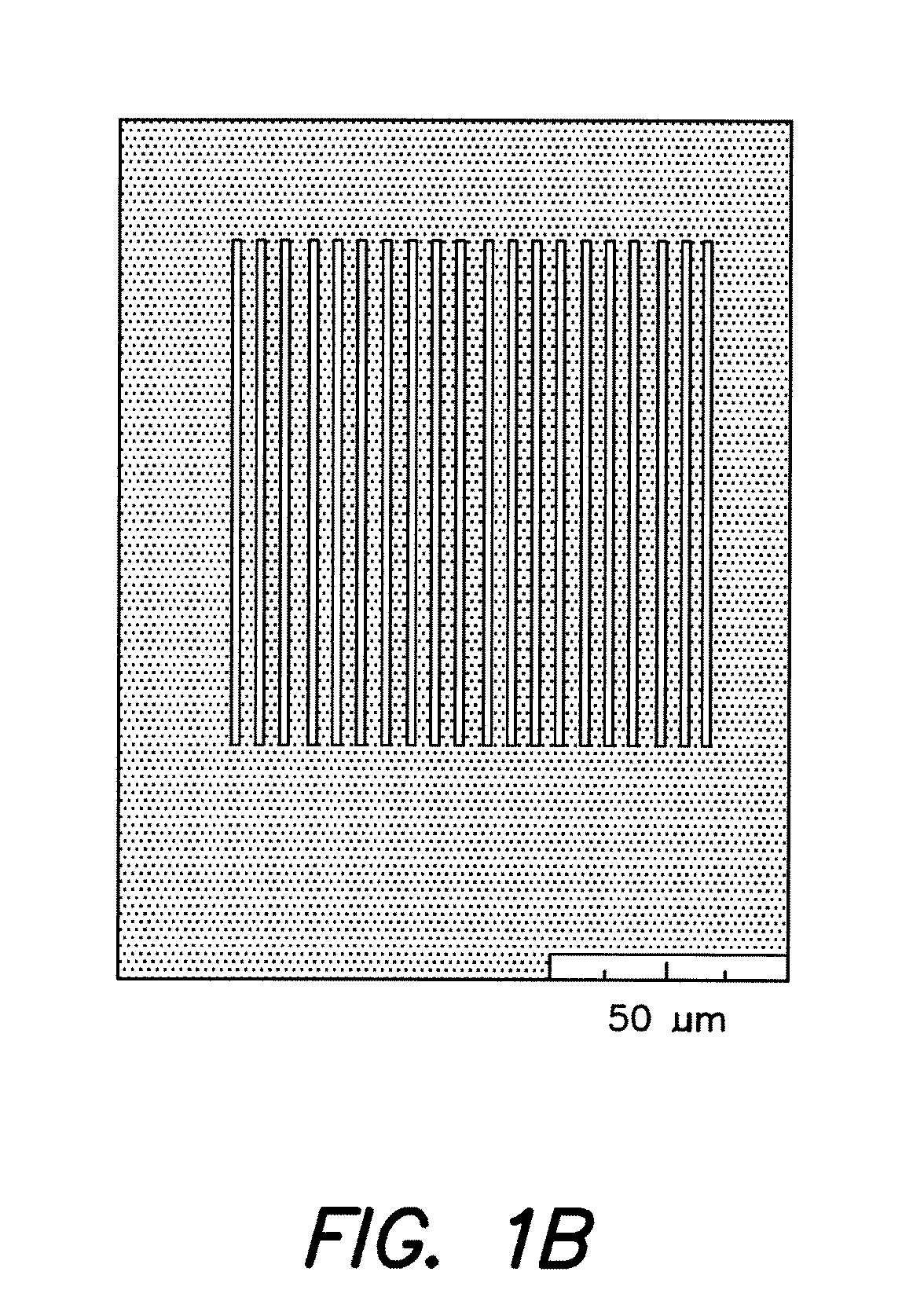

Optical Material and Method for Modifying the Refractive Index

InactiveUS20080001320A1Little and no scattering lossPositive changeSpectales/gogglesLaser surgeryIntraocular lensNear infrared laser

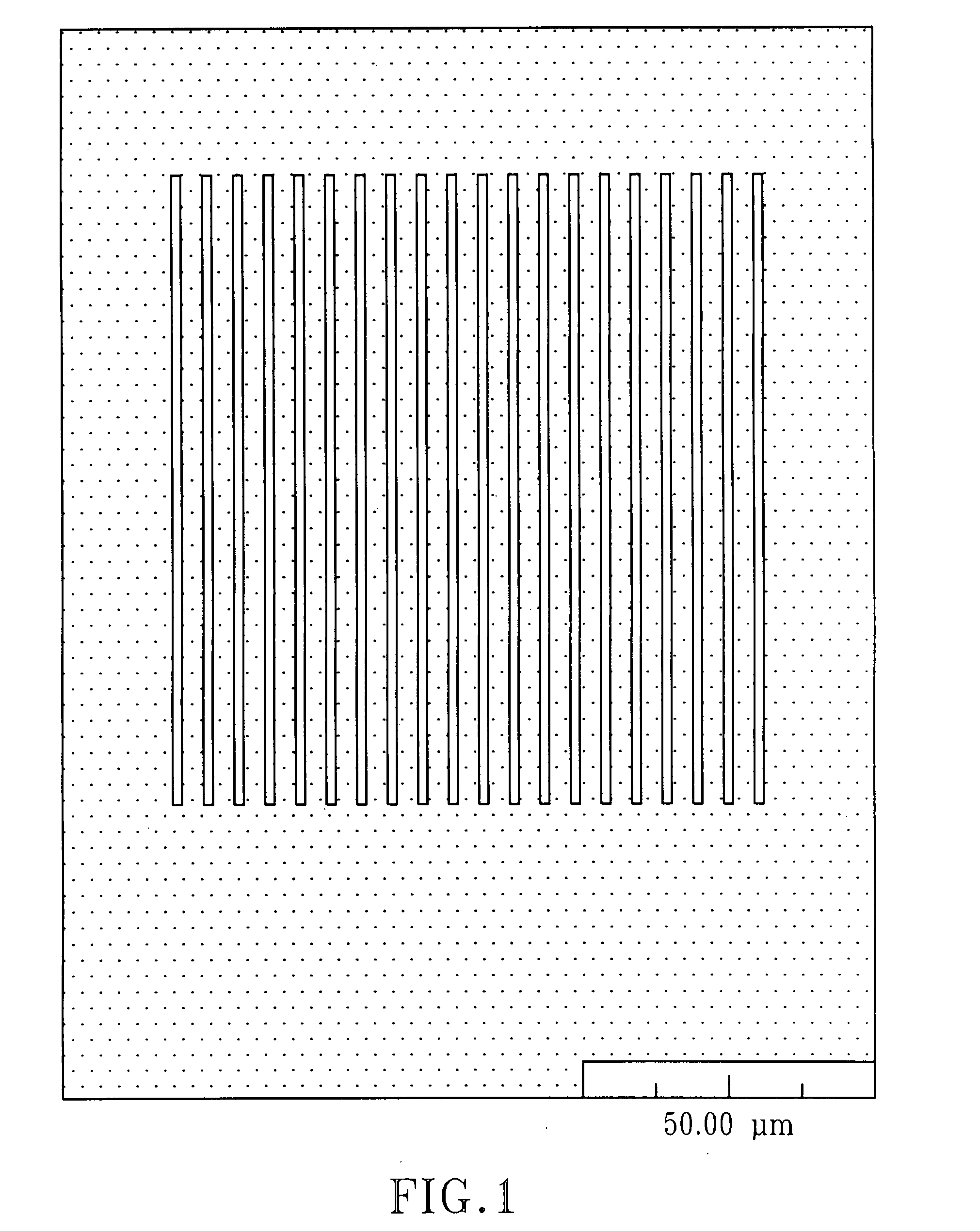

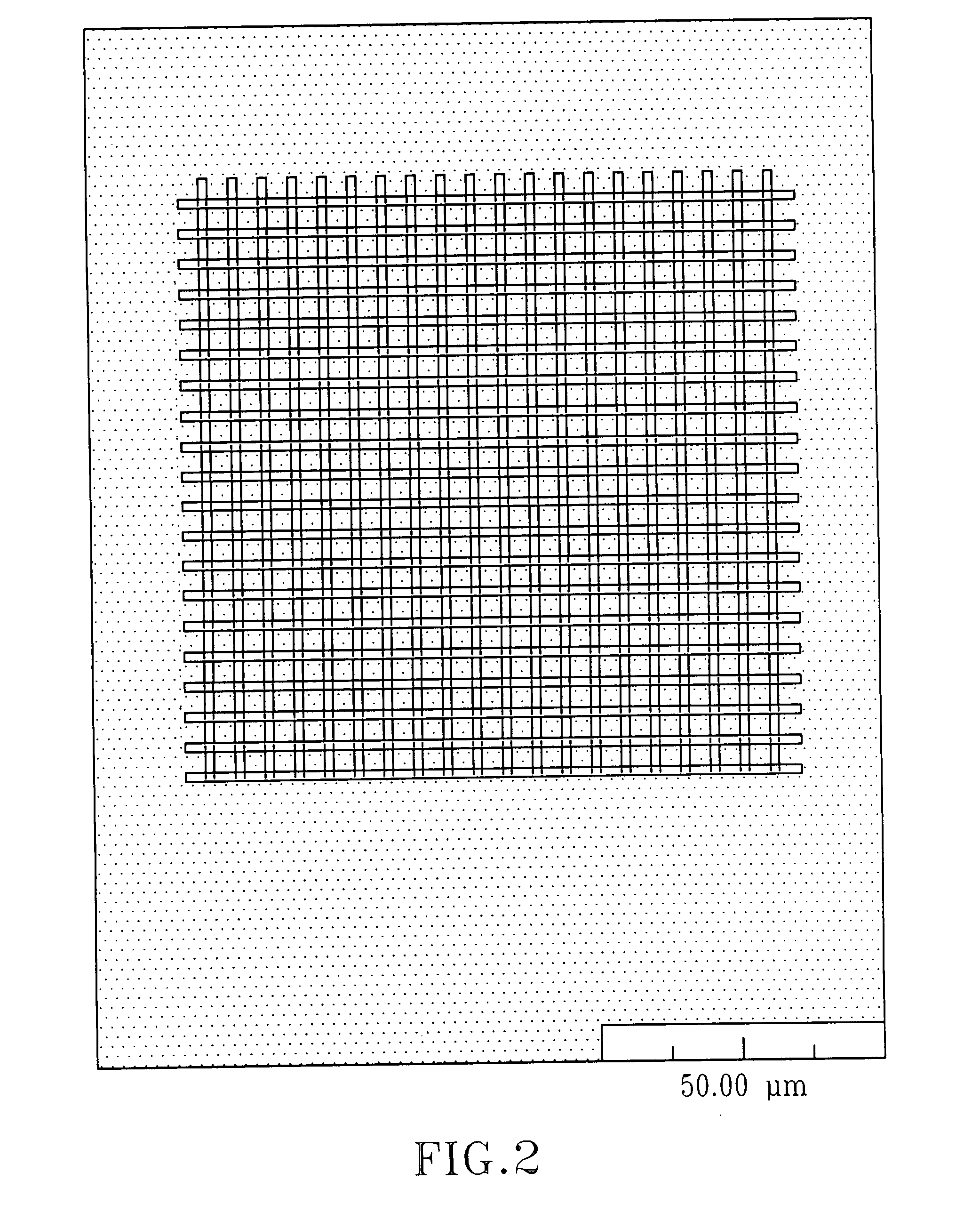

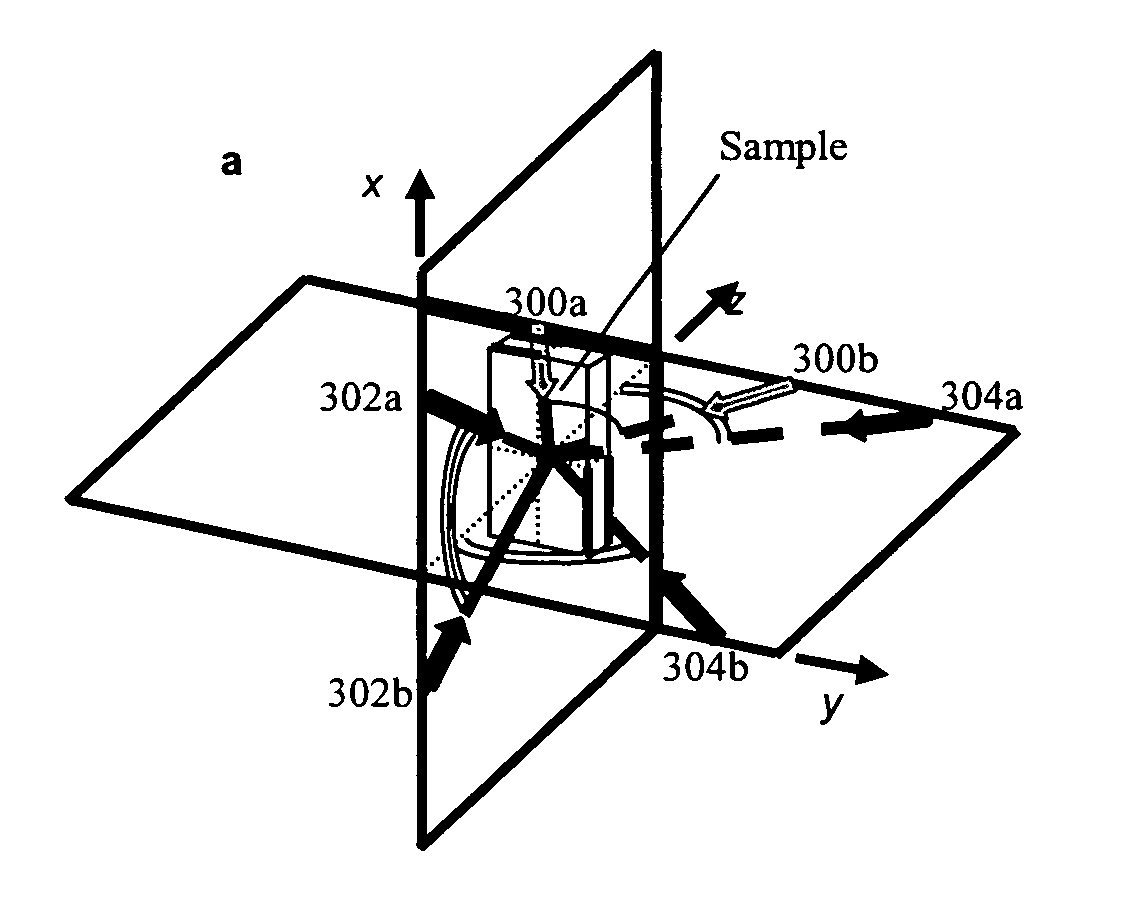

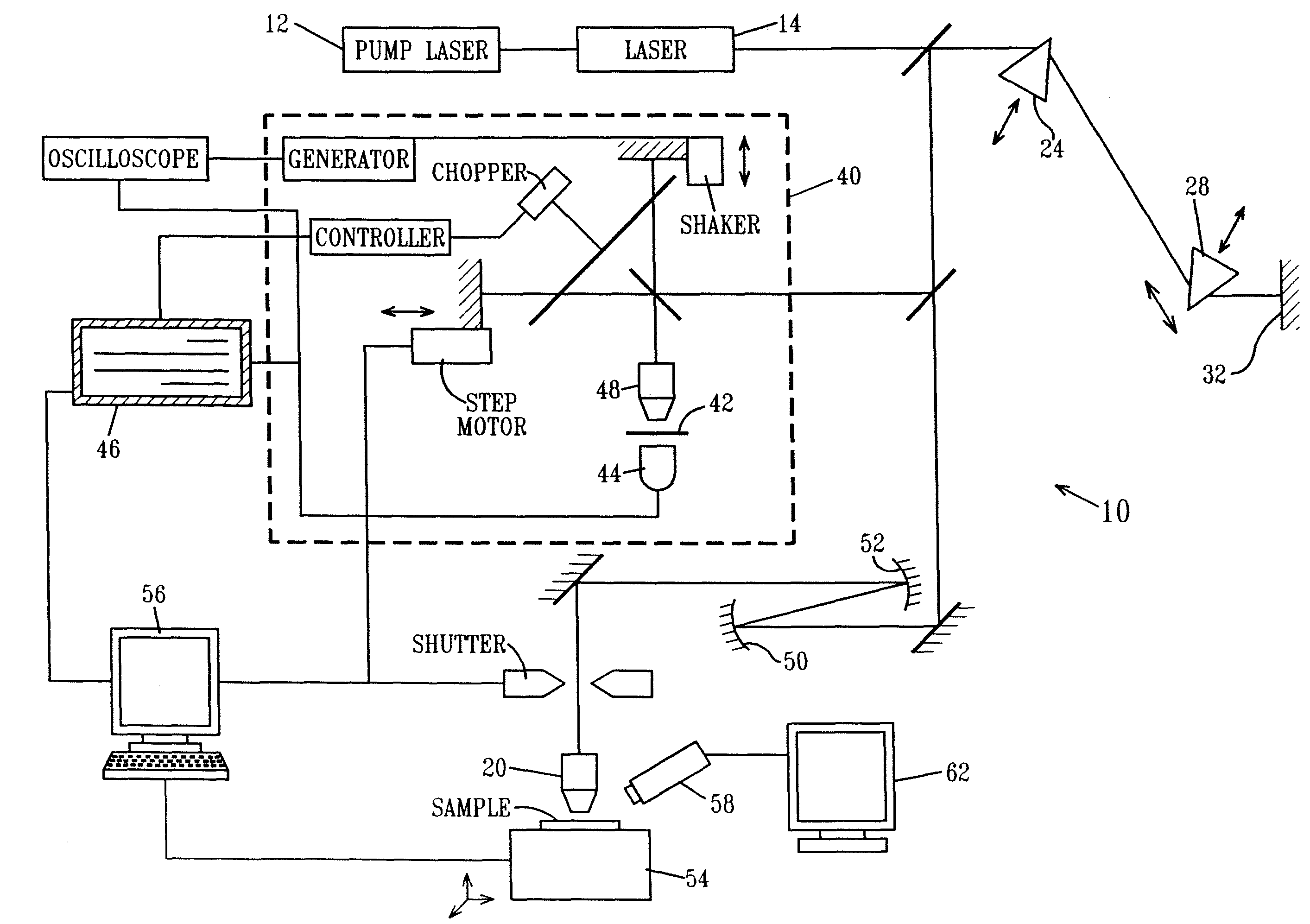

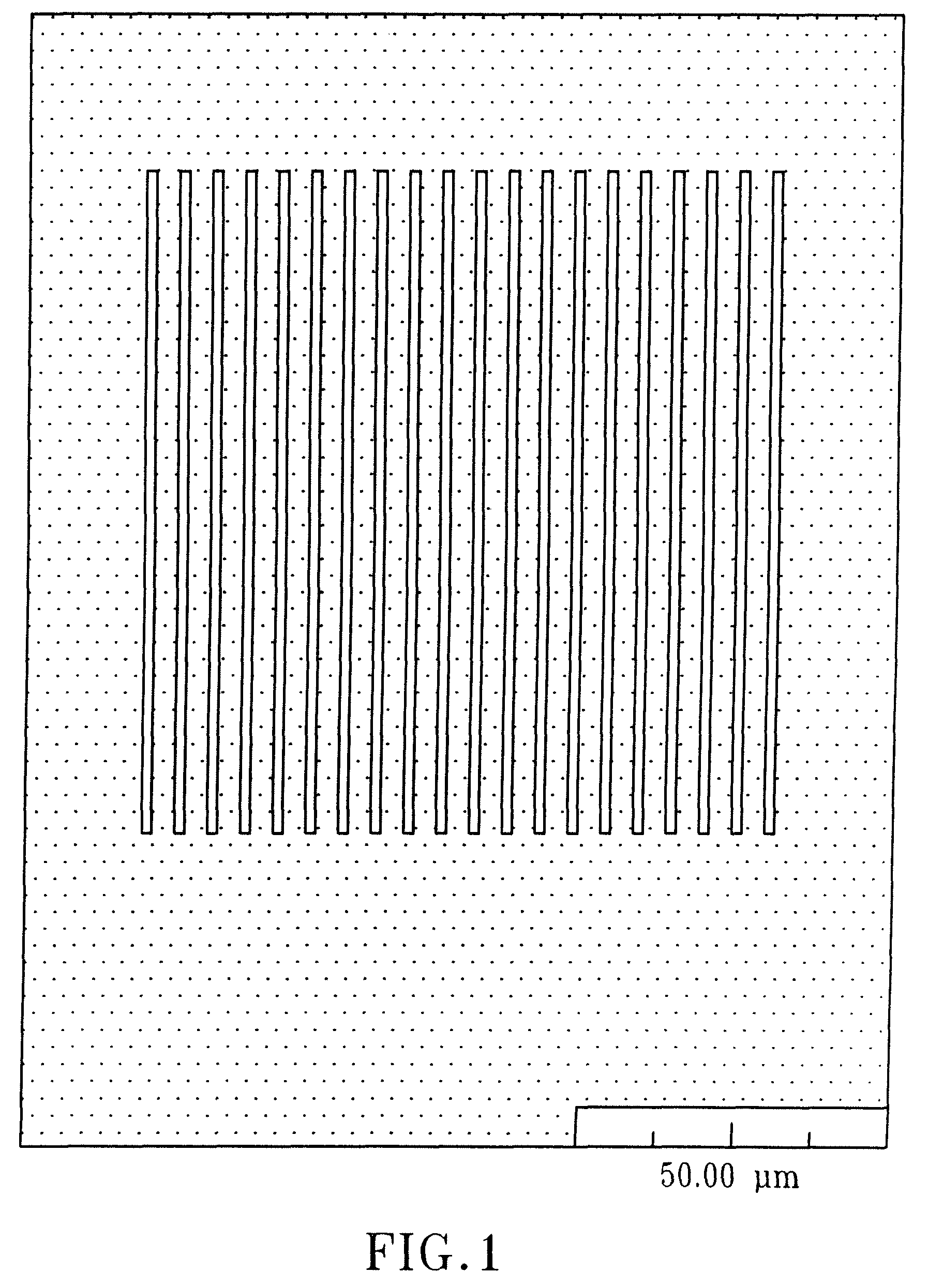

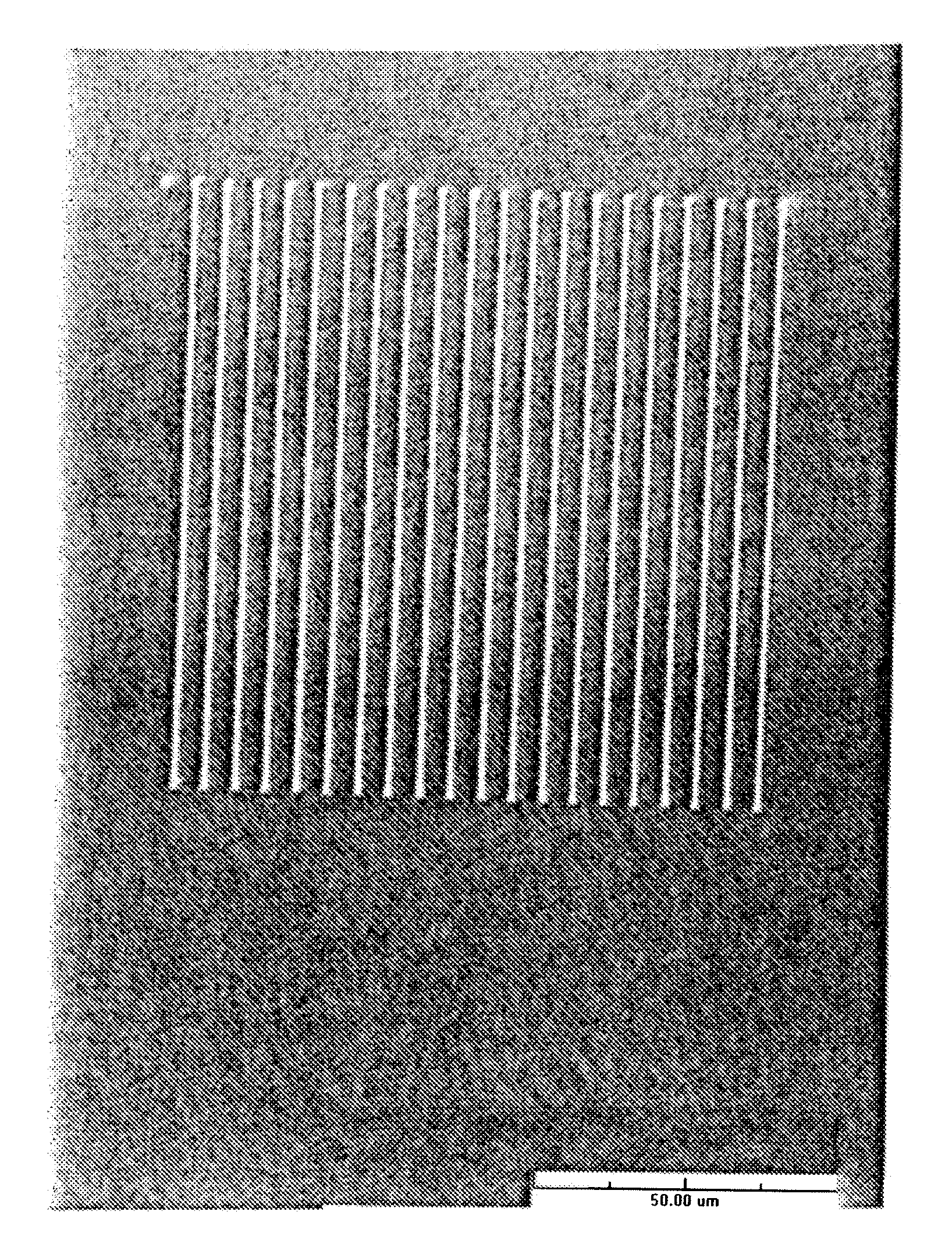

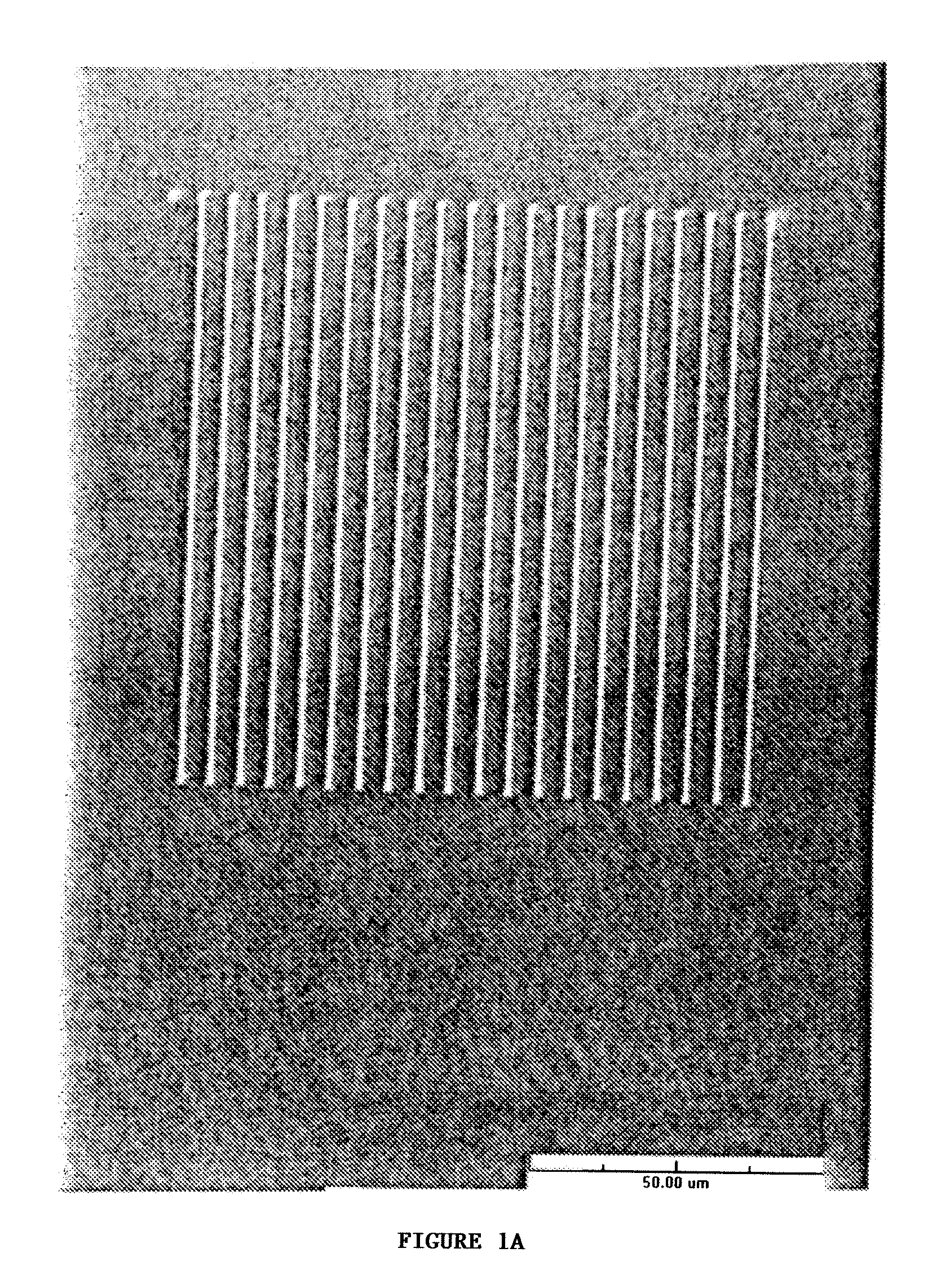

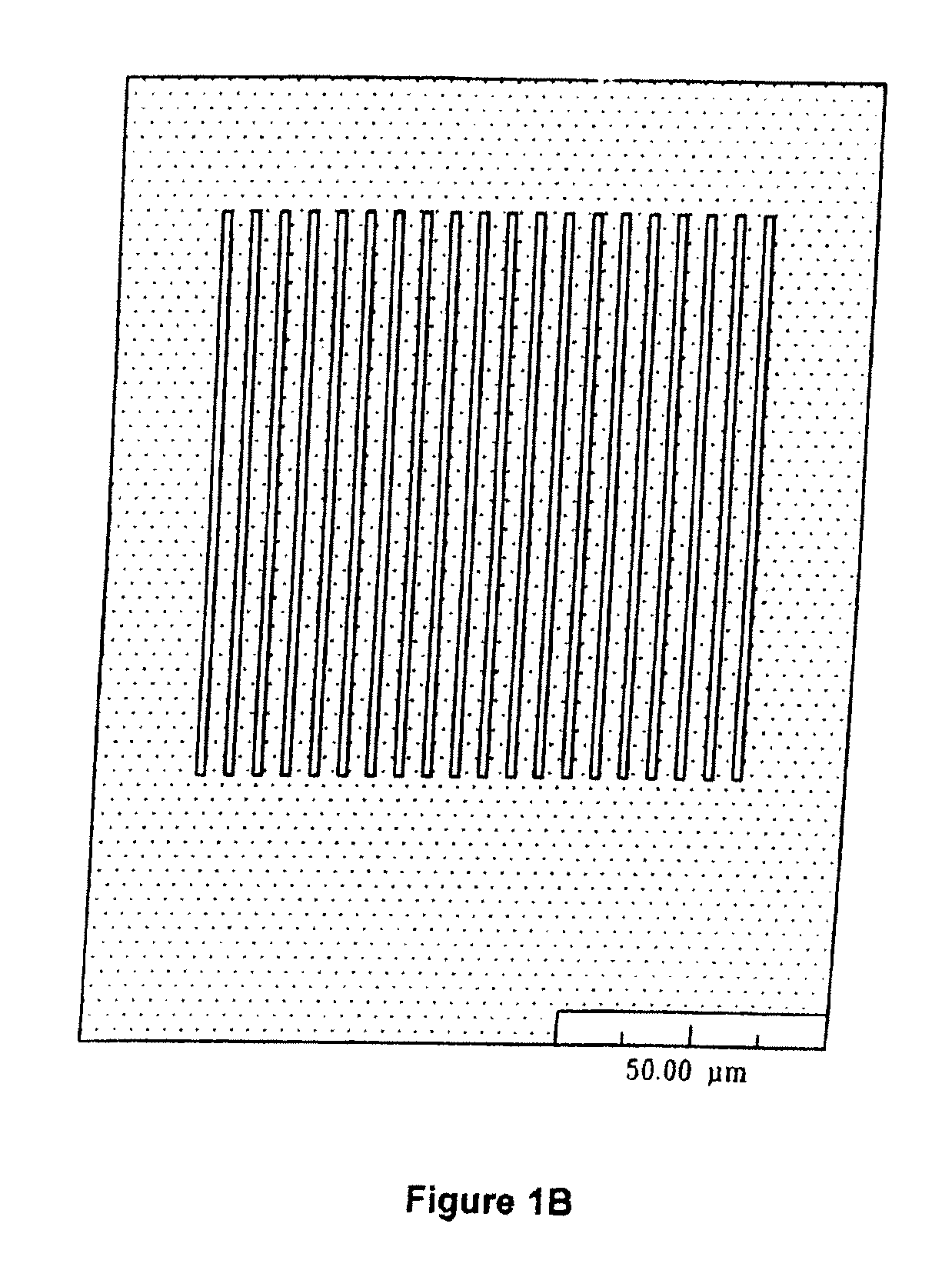

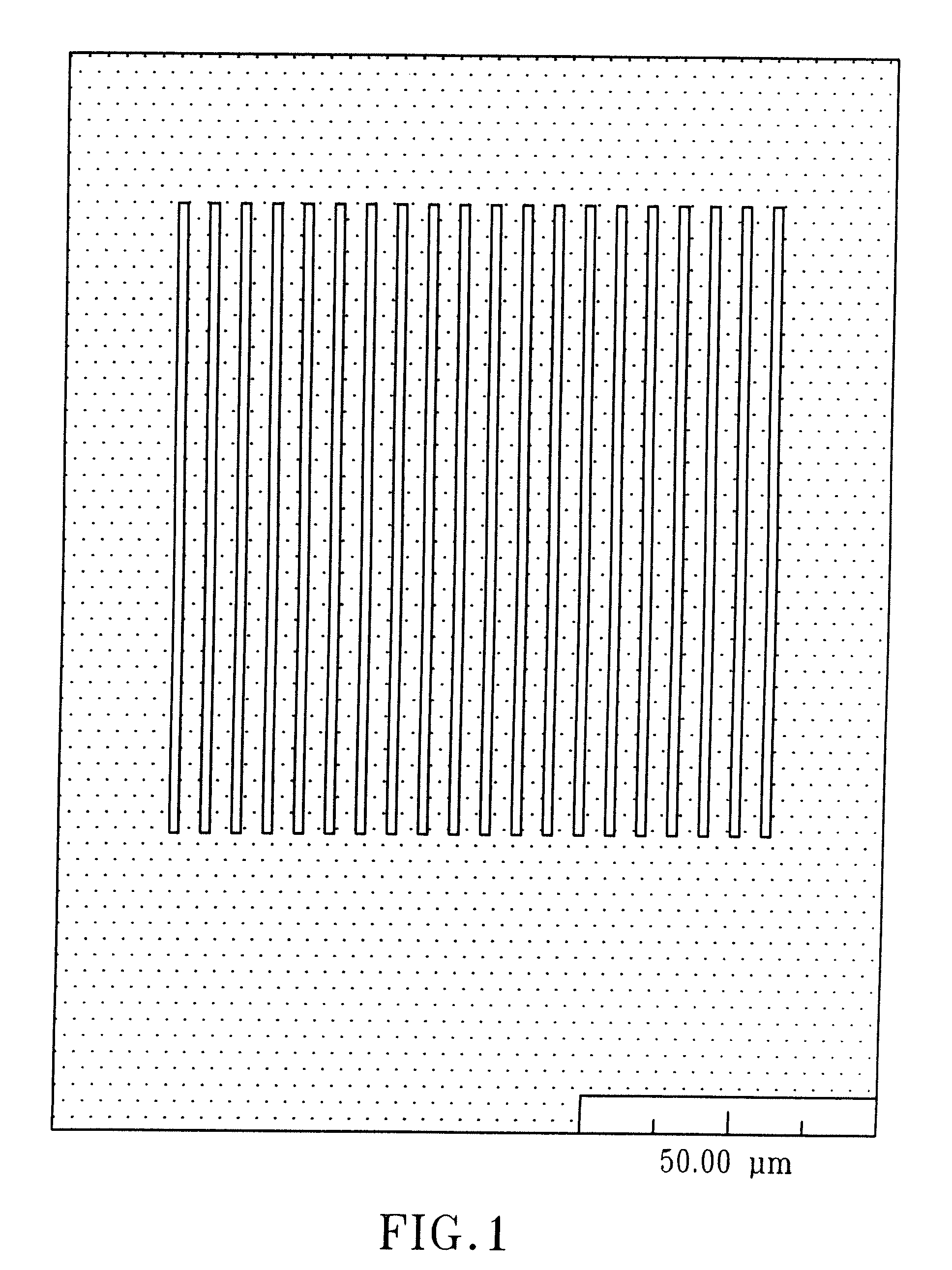

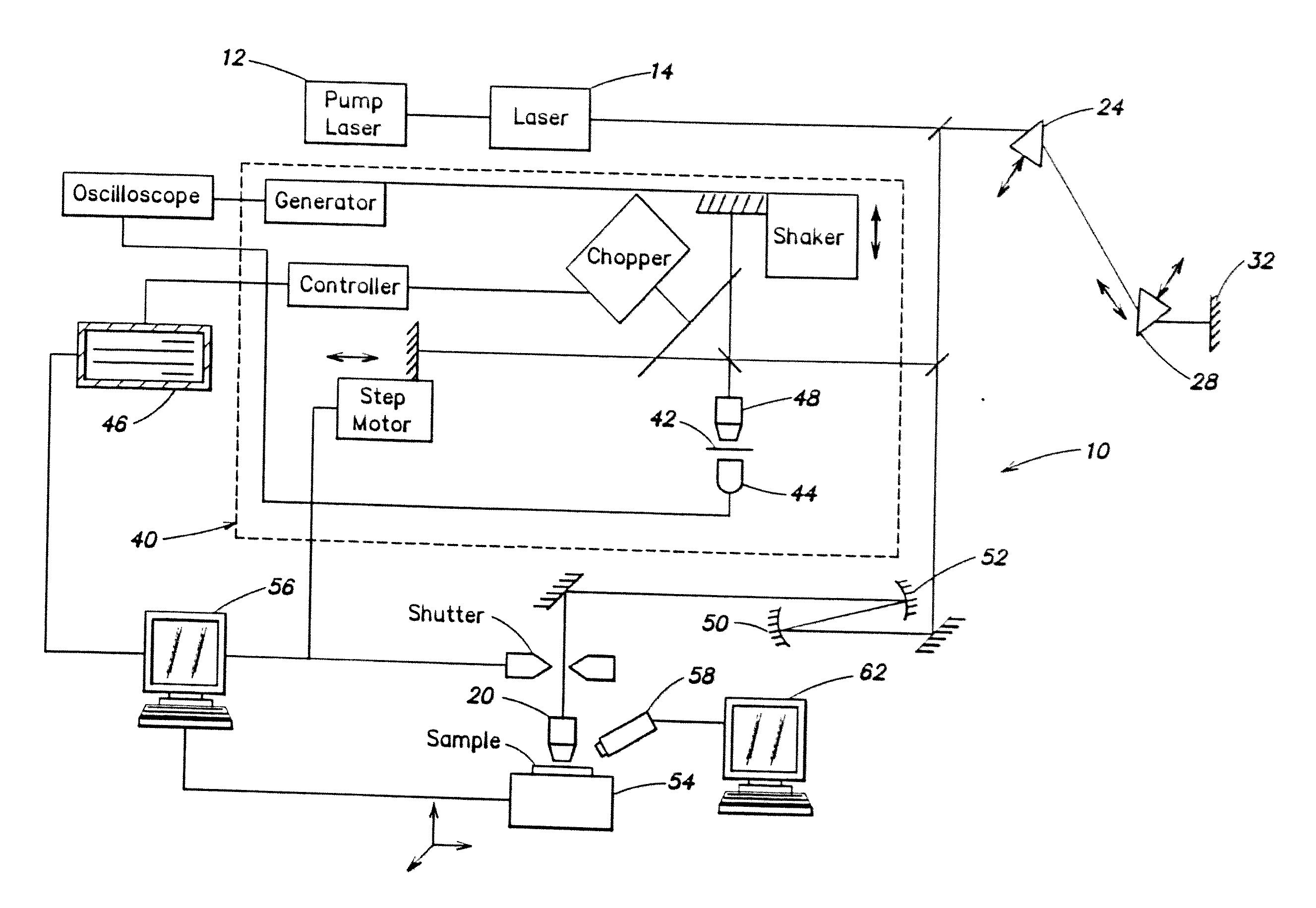

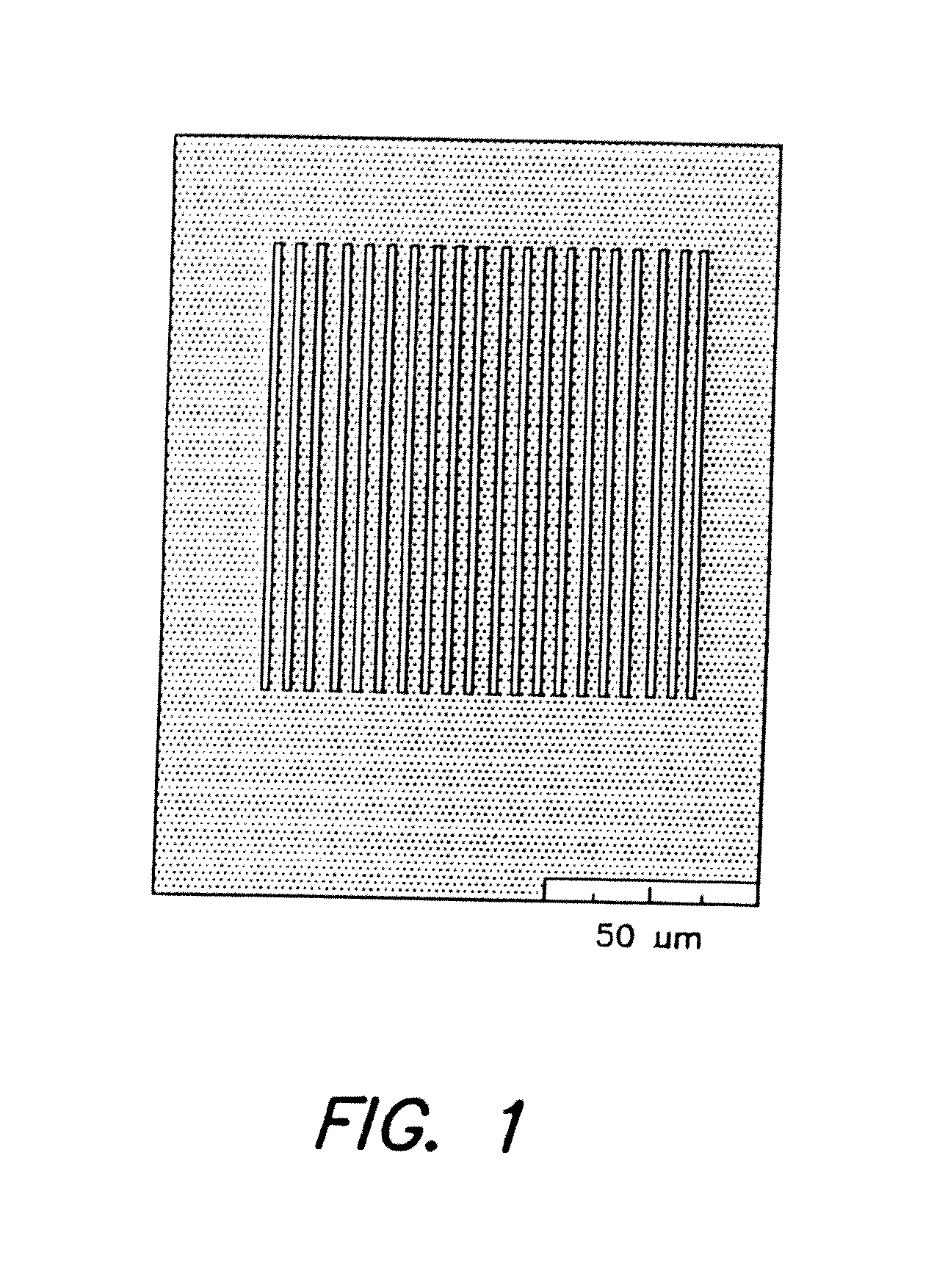

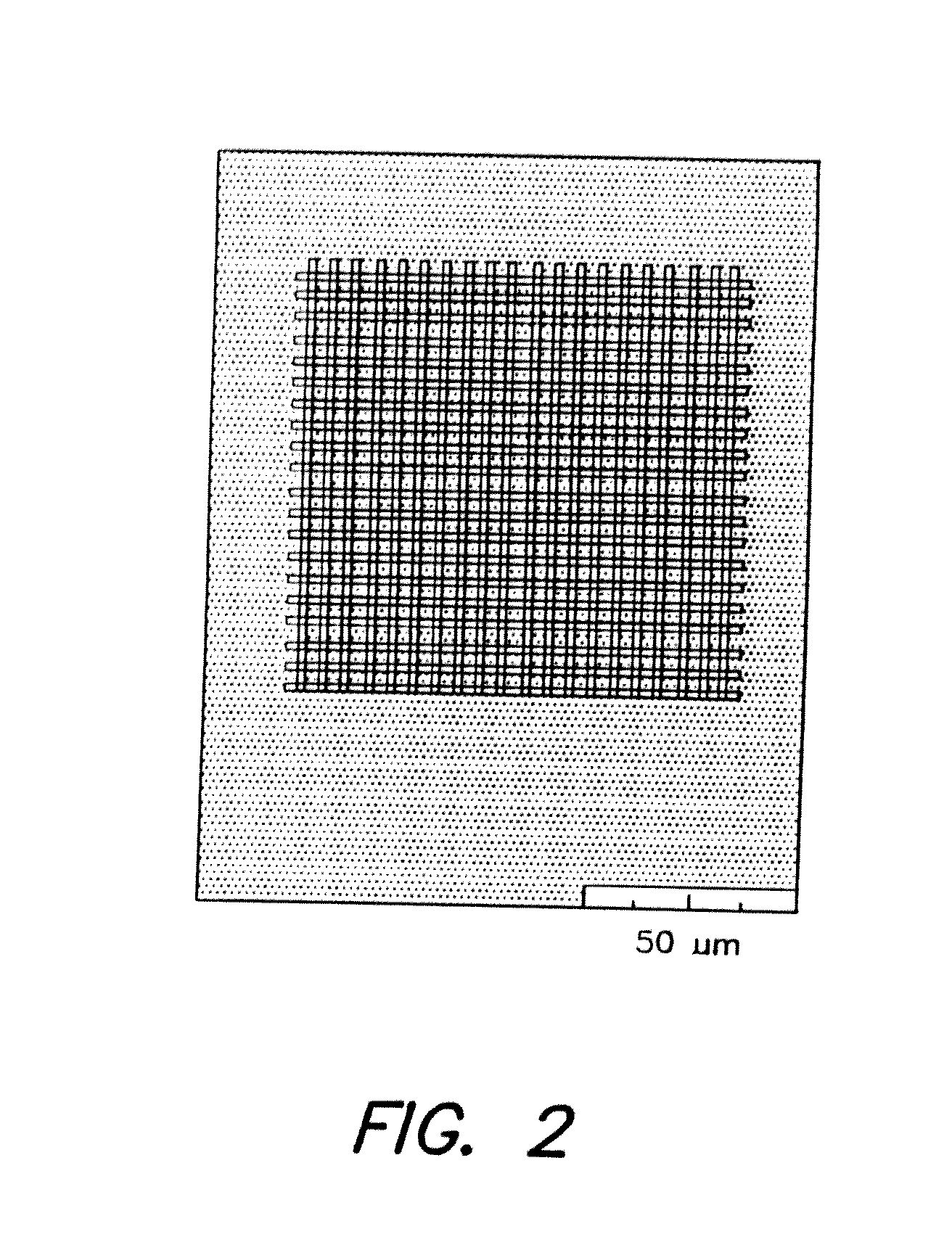

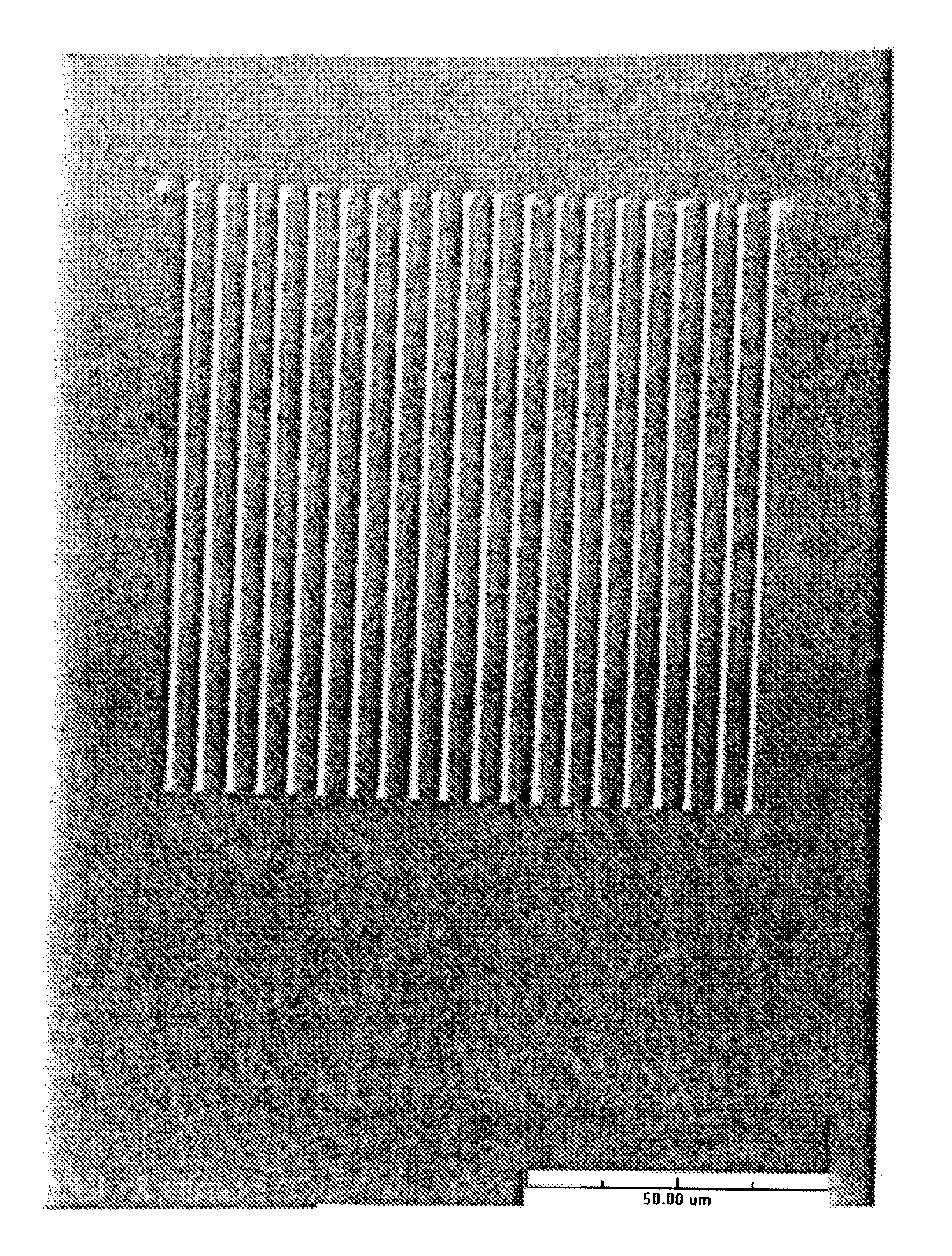

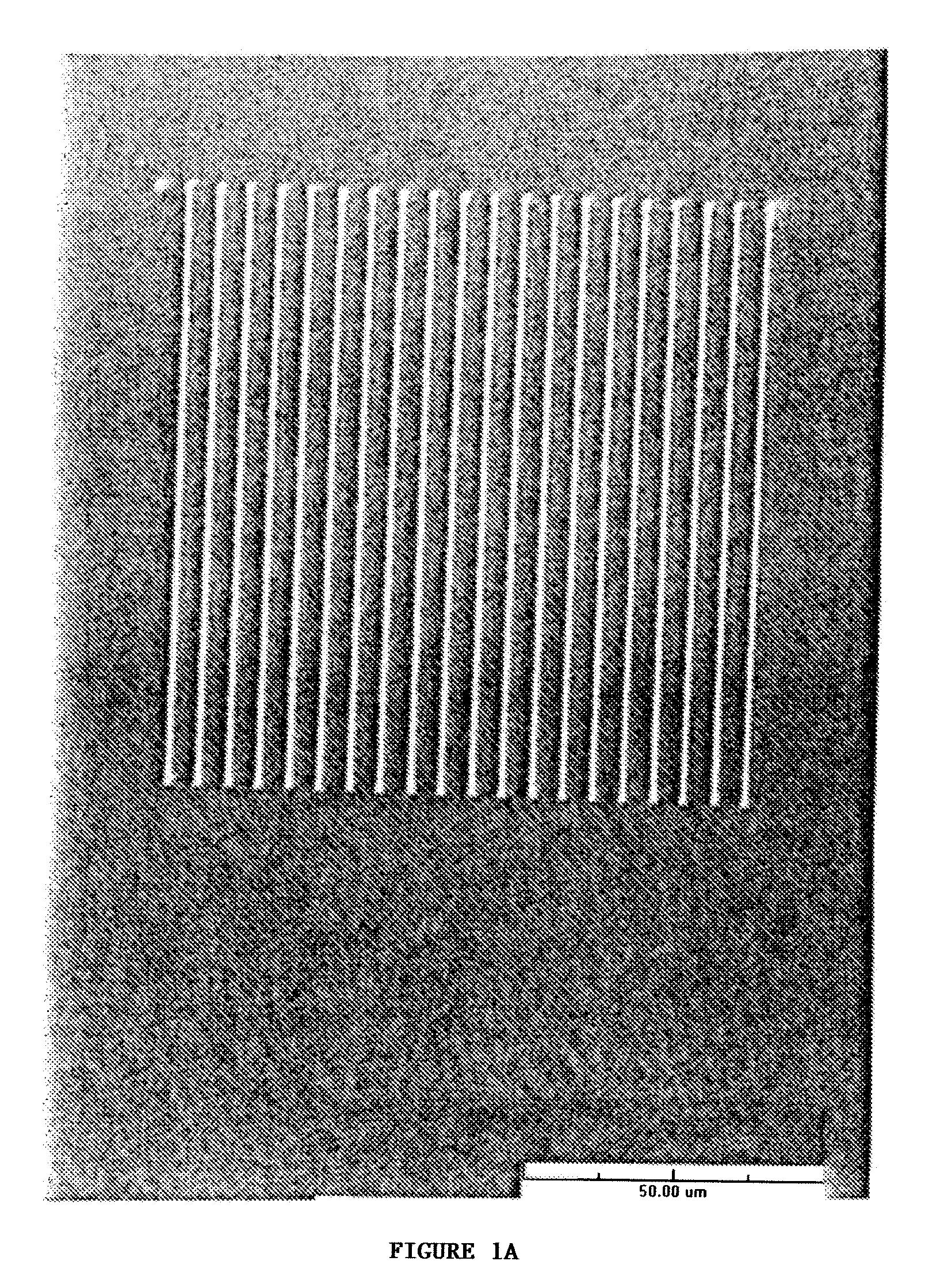

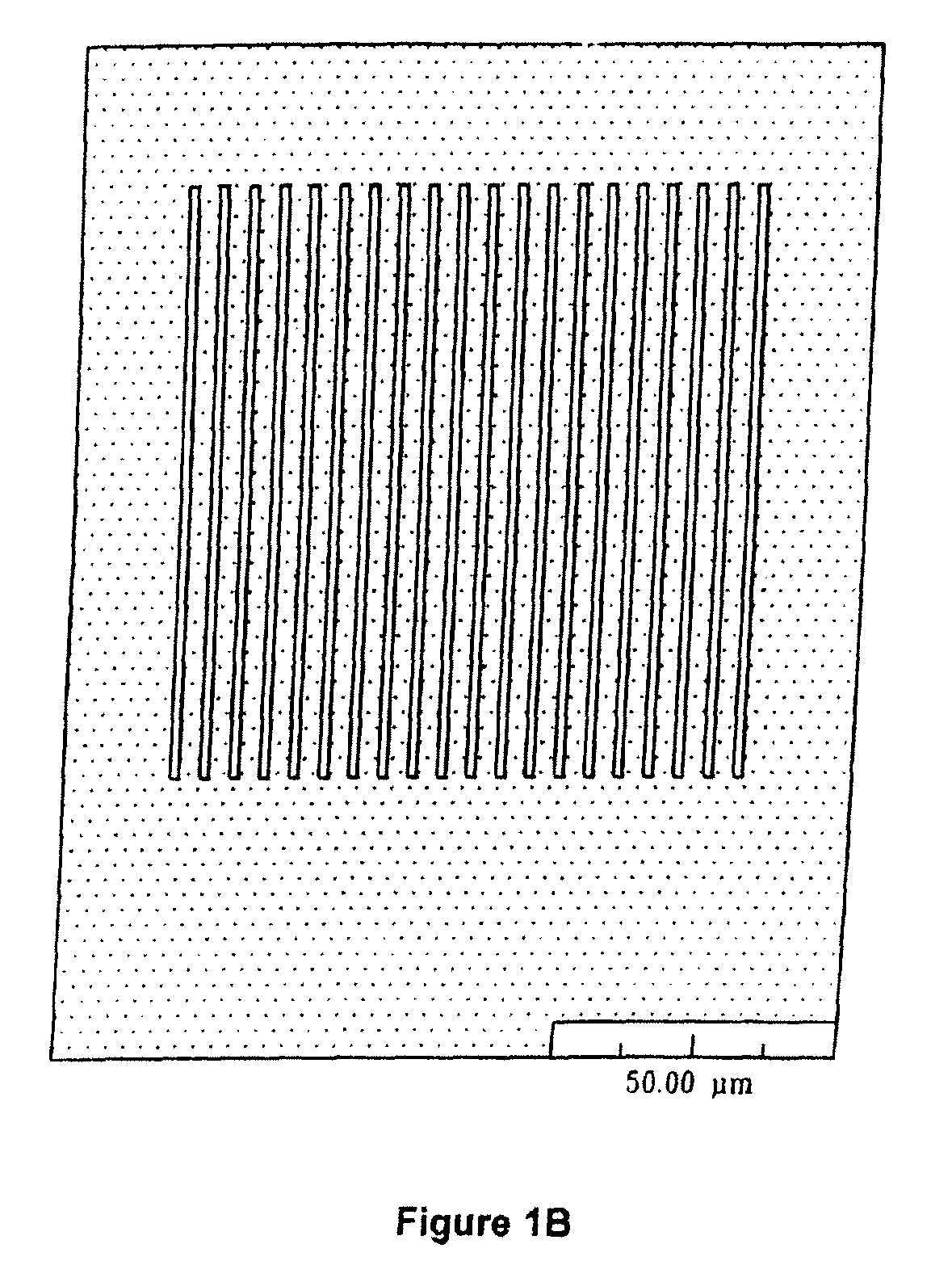

A method for modifying the refractive index of an optical, polymeric material. The method comprises irradiating select regions of the optical, polymeric material with a focused, visible or near-IR laser having a pulse energy from 0.05 nJ to 1000 nJ. The irradiation results in the formation of refractive optical structures, which exhibit little or no scattering loss. The method can be used to modify the refractive index of an intraocular lens following the surgical implantation of the intraocular lens in a human eye. The invention is also directed to an optical device comprising refractive optical structures, which exhibit little or no scattering loss and are characterized by a positive change in refractive index.

Owner:UNIVERSITY OF ROCHESTER

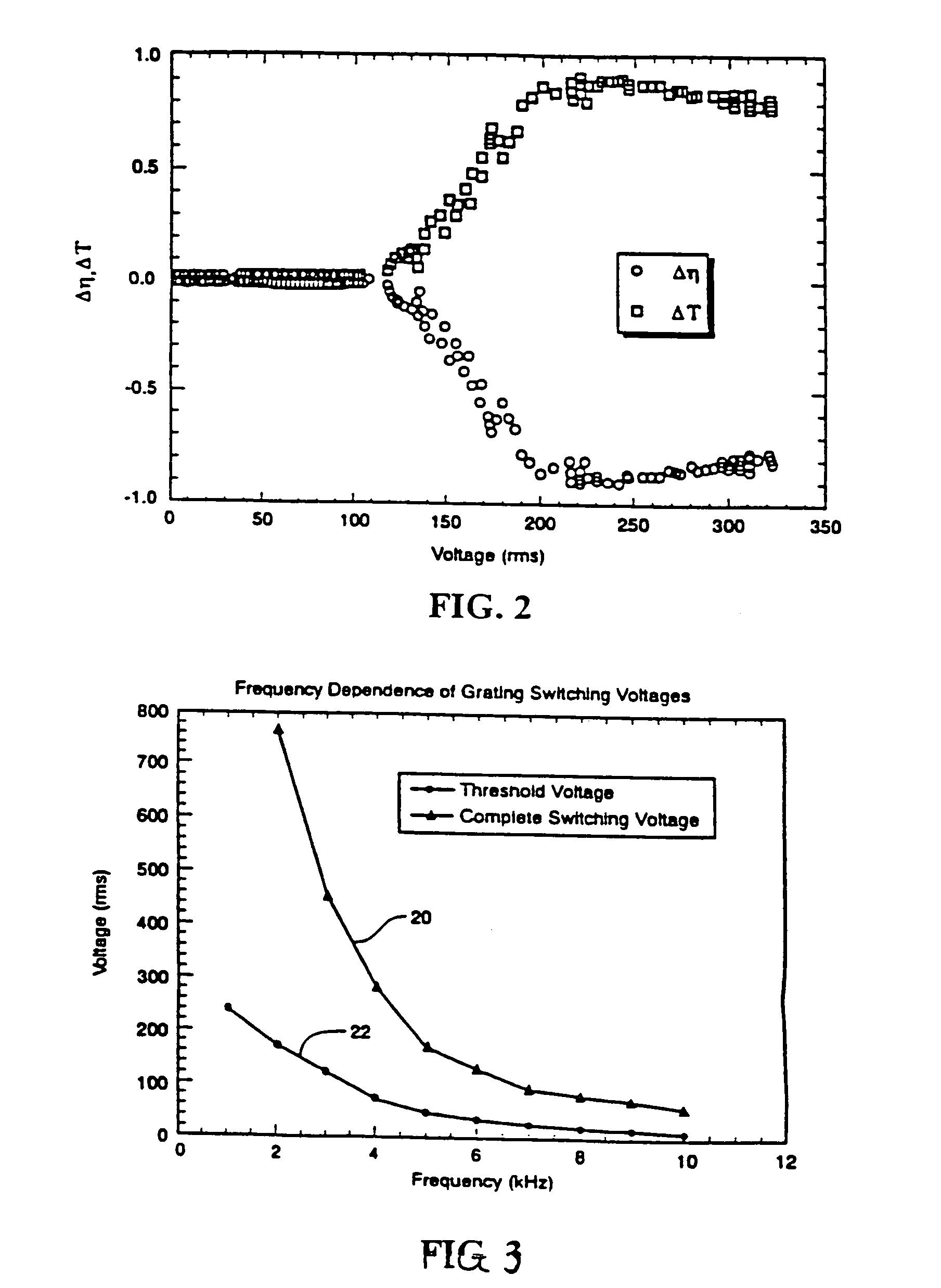

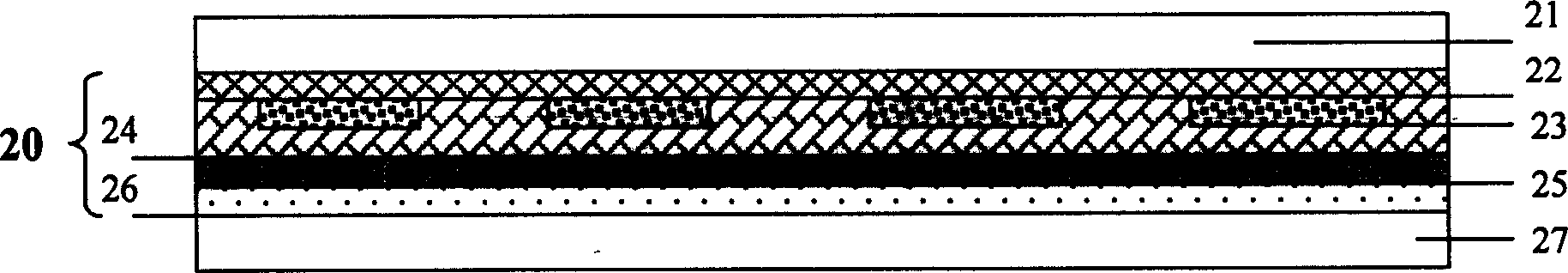

Electrically switchable polymer-dispersed liquid crystal materials

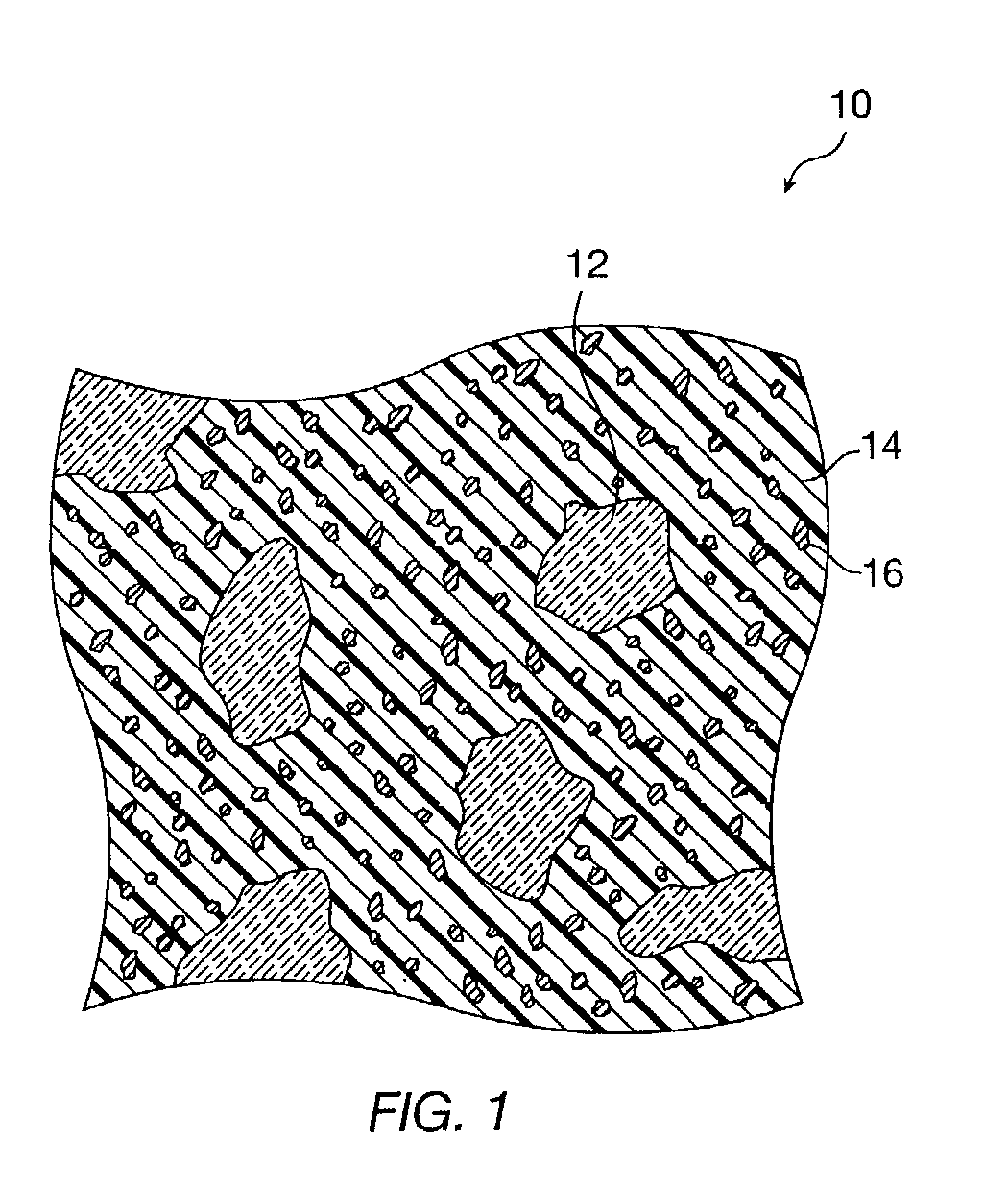

InactiveUS7077984B1Liquid crystal compositionsDiffusing elementsCrystallographyLong chain fatty acid

A method for preparing electro-optical polymer-liquid crystal photonic crystals, comprising: disposing between at least two optically transparent electrode plates, a polymer-dispersed liquid crystal material that comprises, before exposure:(a) a polymerizable monomer comprising at least one acrylate;(b) a liquid crystal;(c) a chain-extending monomer;(d) a coinitiator;(e) a photoinitiator; and(f) a long chain aliphatic acid;and exposing this polymer-dispersed liquid crystal material to light in an interference pattern.

Owner:LEIDOS

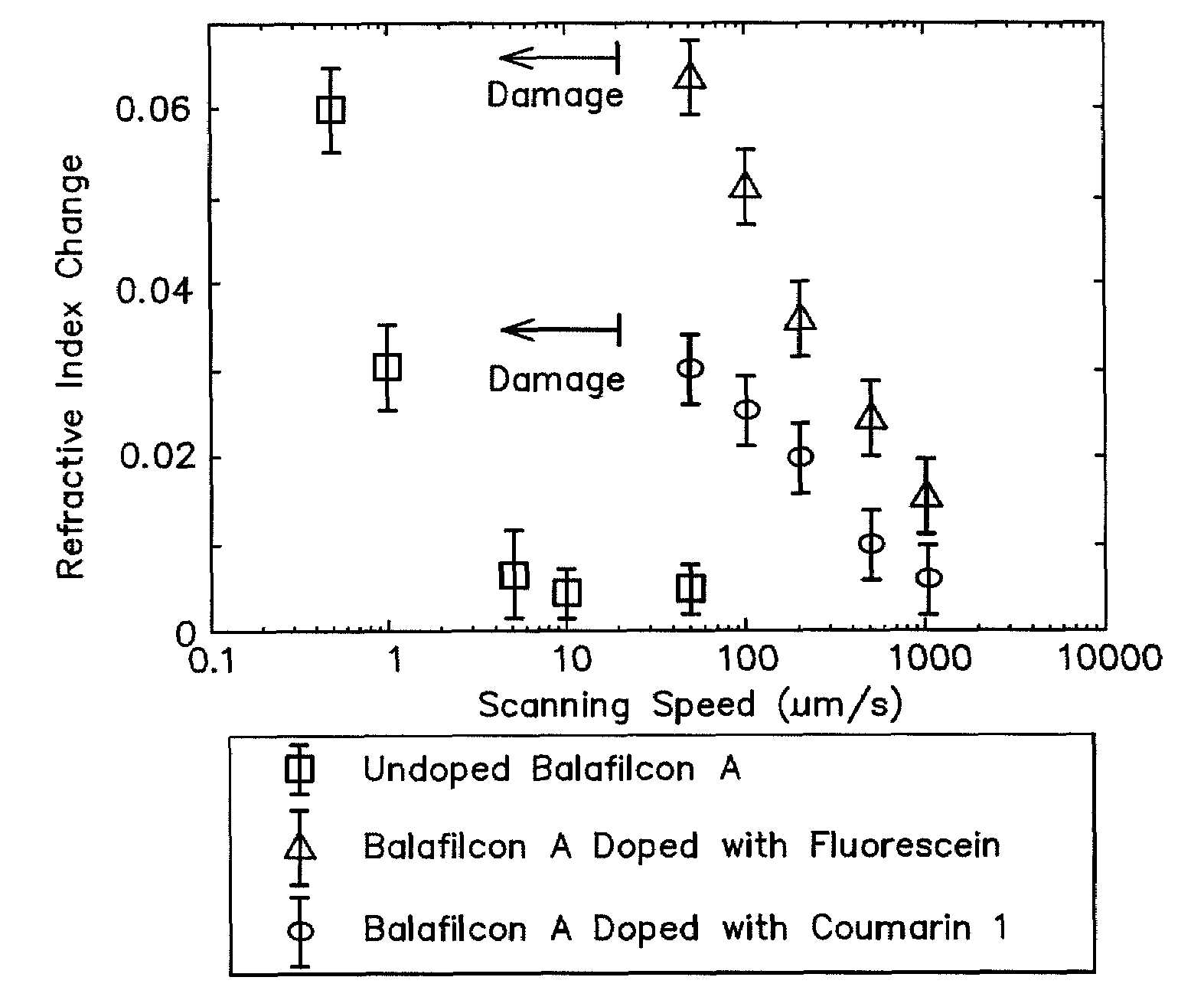

Optical hydrogel material with photosensitizer and method for modifying the refractive index

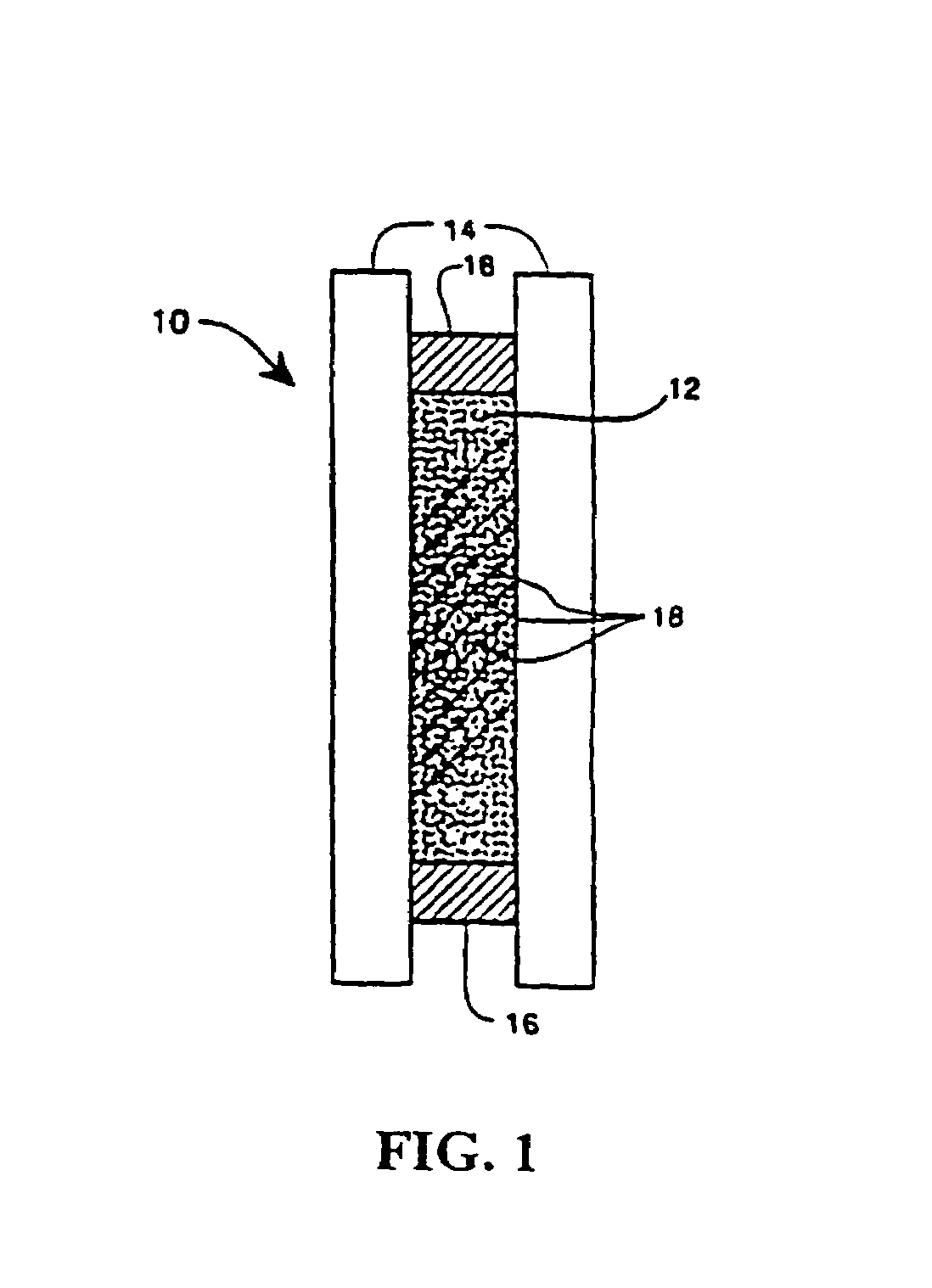

A method for modifying the refractive index of an optical, hydrogel polymeric material. The method comprises irradiating predetermined regions of an optical, polymeric material with a laser to form refractive structures. To facilitate the formation of the refractive structures the optical, hydrogel polymeric material comprises a photosensitizer. The presence of the photosensitizer permits one to set a scan rate to a value that is at least fifty times greater than a scan rate without the photosensitizer in the material, yet provides similar refractive structures in terms of the observed change in refractive index. Alternatively, the photosensitizer in the polymeric material permits one to set an average laser power to a value that is at least two times less than an average laser power without the photosensitizer in the material, yet provide similar refractive structures.

Owner:UNIVERSITY OF ROCHESTER +1

Optical material and method for modifying the refractive index

ActiveUS7789910B2Little and no scattering lossSpectales/gogglesOptical articlesIntraocular lensNear infrared laser

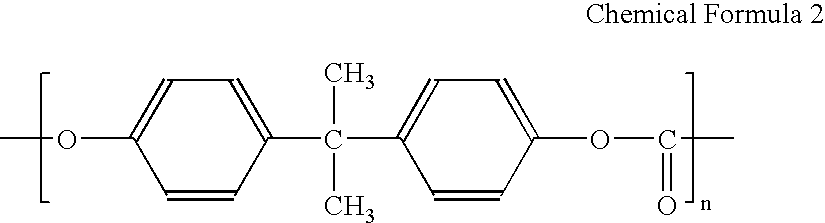

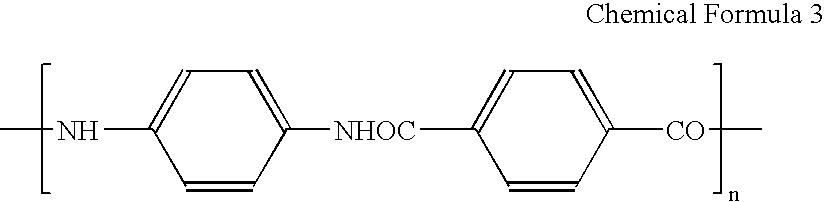

A method for modifying the refractive index of an optical, polymeric material. The method comprises irradiating select regions of the optical, polymeric material with a focused, visible or near-IR laser having a pulse energy from 0.05 nJ to 1000 nJ. The irradiation results in the formation of refractive optical structures, characterized by a change in refractive index, exhibit little or no scattering loss, and exhibit no significant differences in the Raman spectrum with respect to the non-irradiated optical, polymeric material. The method can be used to modify the refractive index of an intraocular lens following the surgical implantation of the intraocular lens in a human eye. The invention is also directed to an optical device comprising refractive optical structures, wherein the refractive structures are characterized by a change in refractive index, exhibit little or no scattering loss, and exhibit no significant differences in the Raman spectrum with respect to the non-irradiated optical, polymeric material.

Owner:UNIVERSITY OF ROCHESTER

Optical polymer blend with bimodal particle sizes

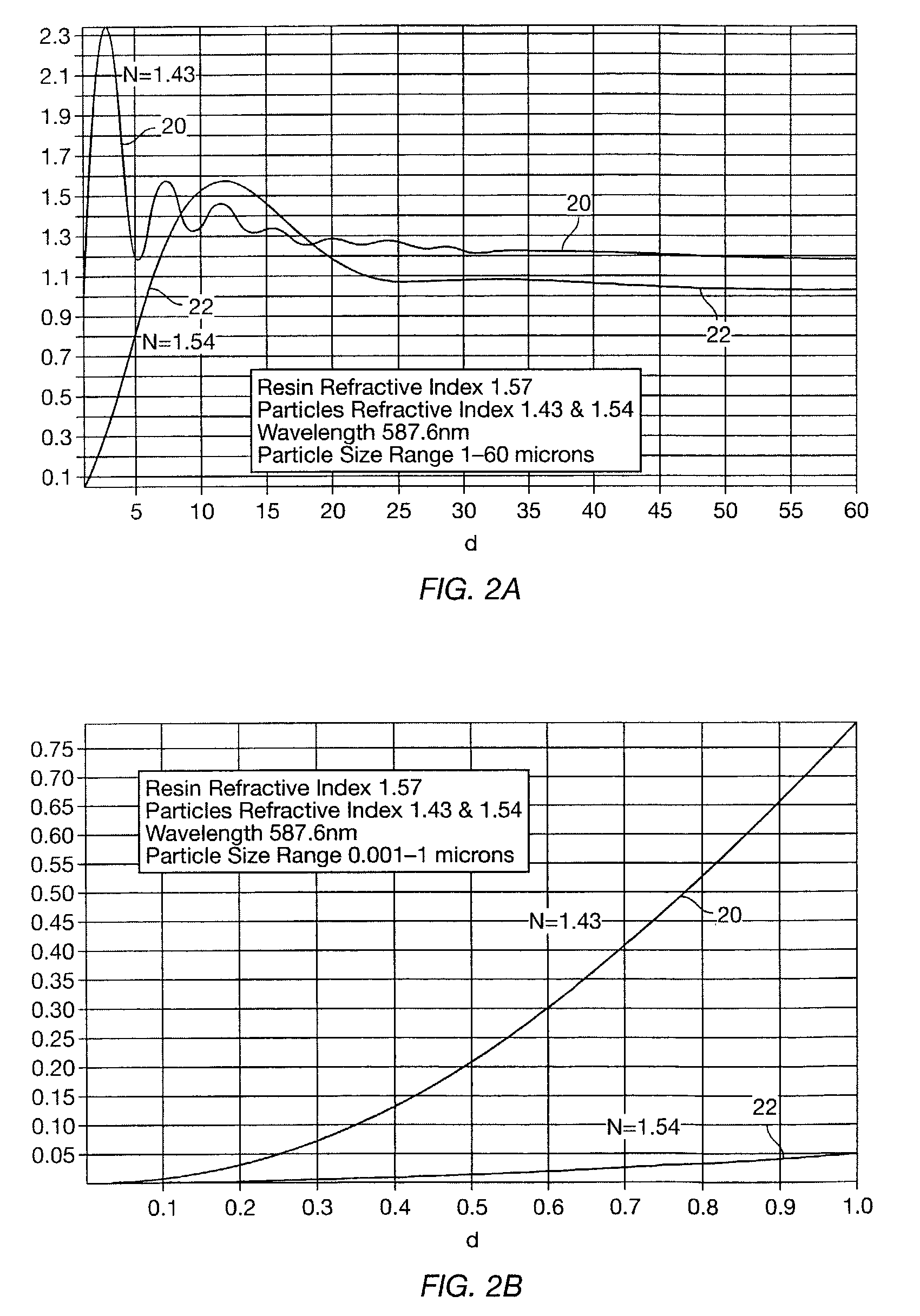

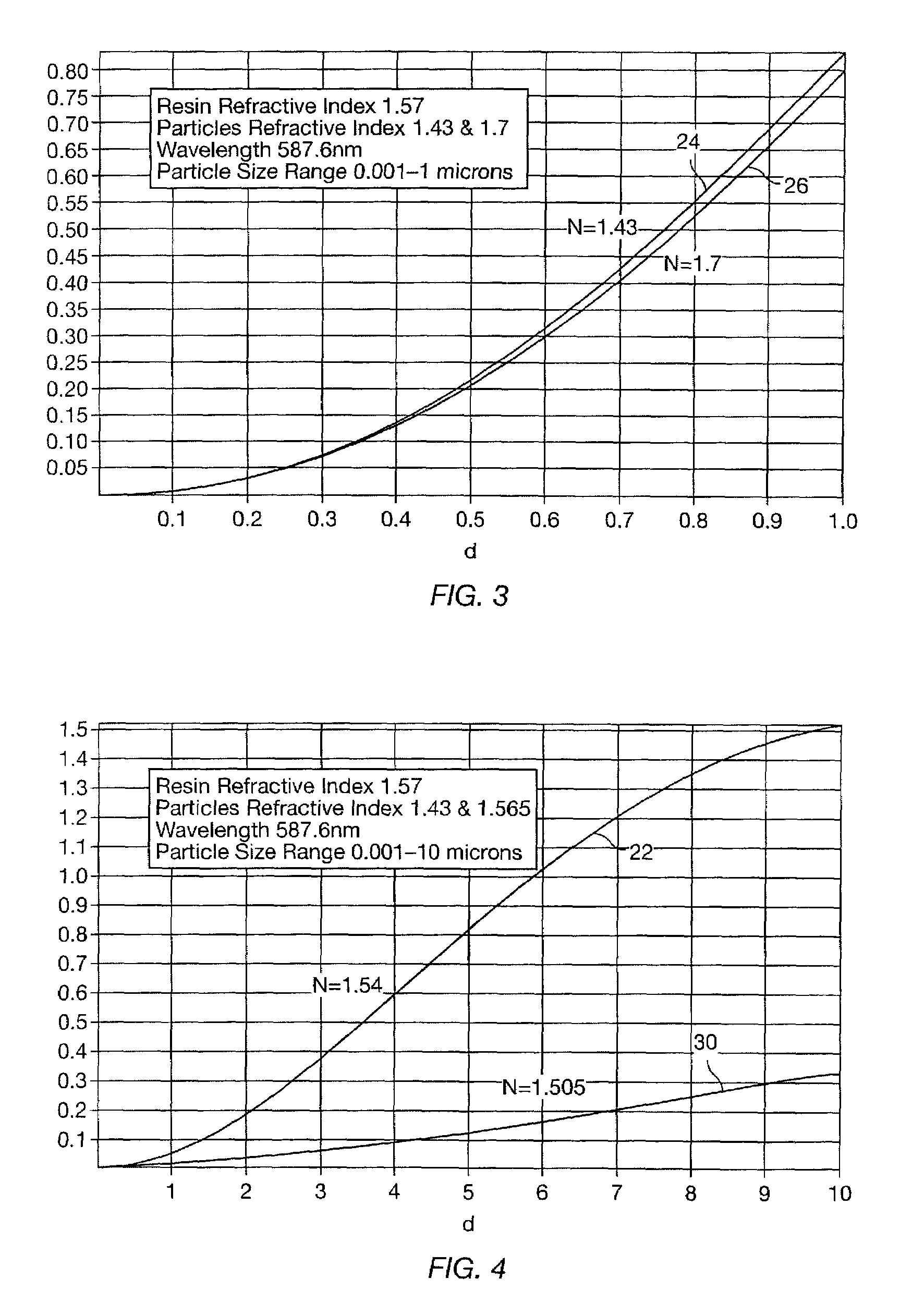

ActiveUS6979704B1Reduce CTEReduce light scatterMaterial nanotechnologySpecial tyresAdhesiveOptical polymers

An optical polymer blend includes sub-wavelength particles to modify the refractive index of a polymer to match the refractive index of micro-particles added to adjust the bulk coefficient of thermal expansion of the blend. A relatively large amount of material may be added to the resin to adjust the bulk coefficient of thermal expansion without unduly increasing the viscosity of the blend before setting. In some applications blends are used for molded or extruded optical elements, in other applications, blends are used for optical adhesives with low coefficients of thermal expansion.

Owner:VIAVI SOLUTIONS INC

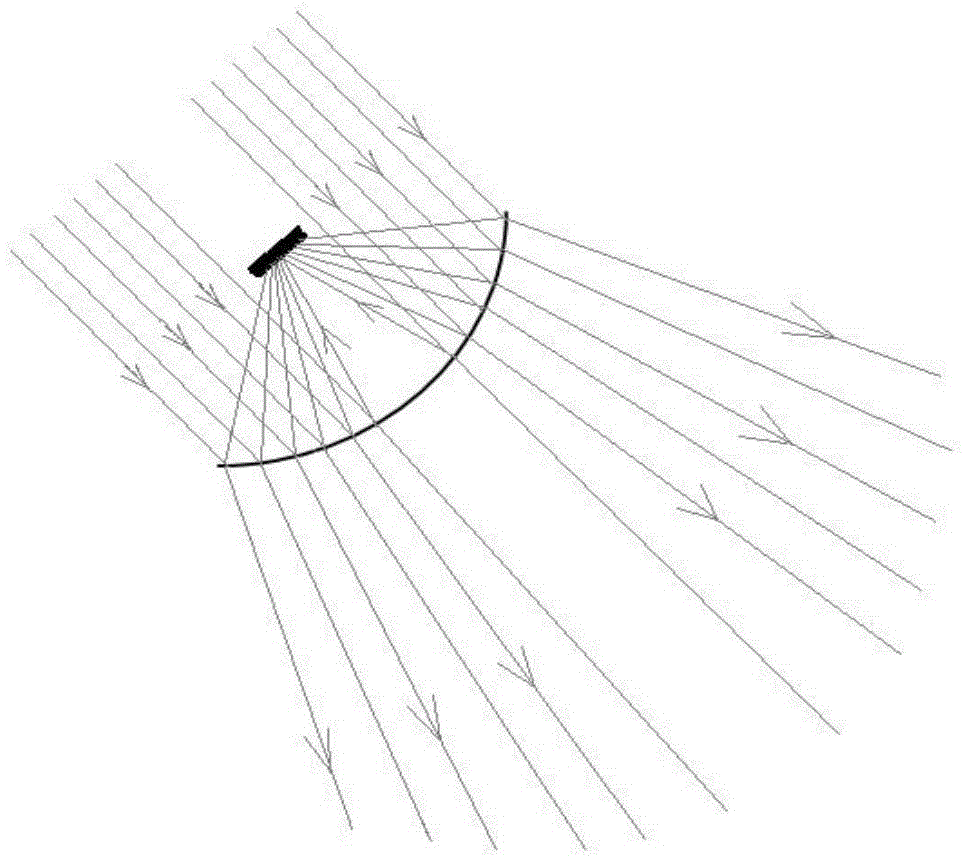

Method for Modifying the Refractive Index of an Optical Material and Resulting Optical Vision Component

ActiveUS20120310340A1Little and no scattering lossSpectales/gogglesLaser surgeryOptical polymersOptical axis

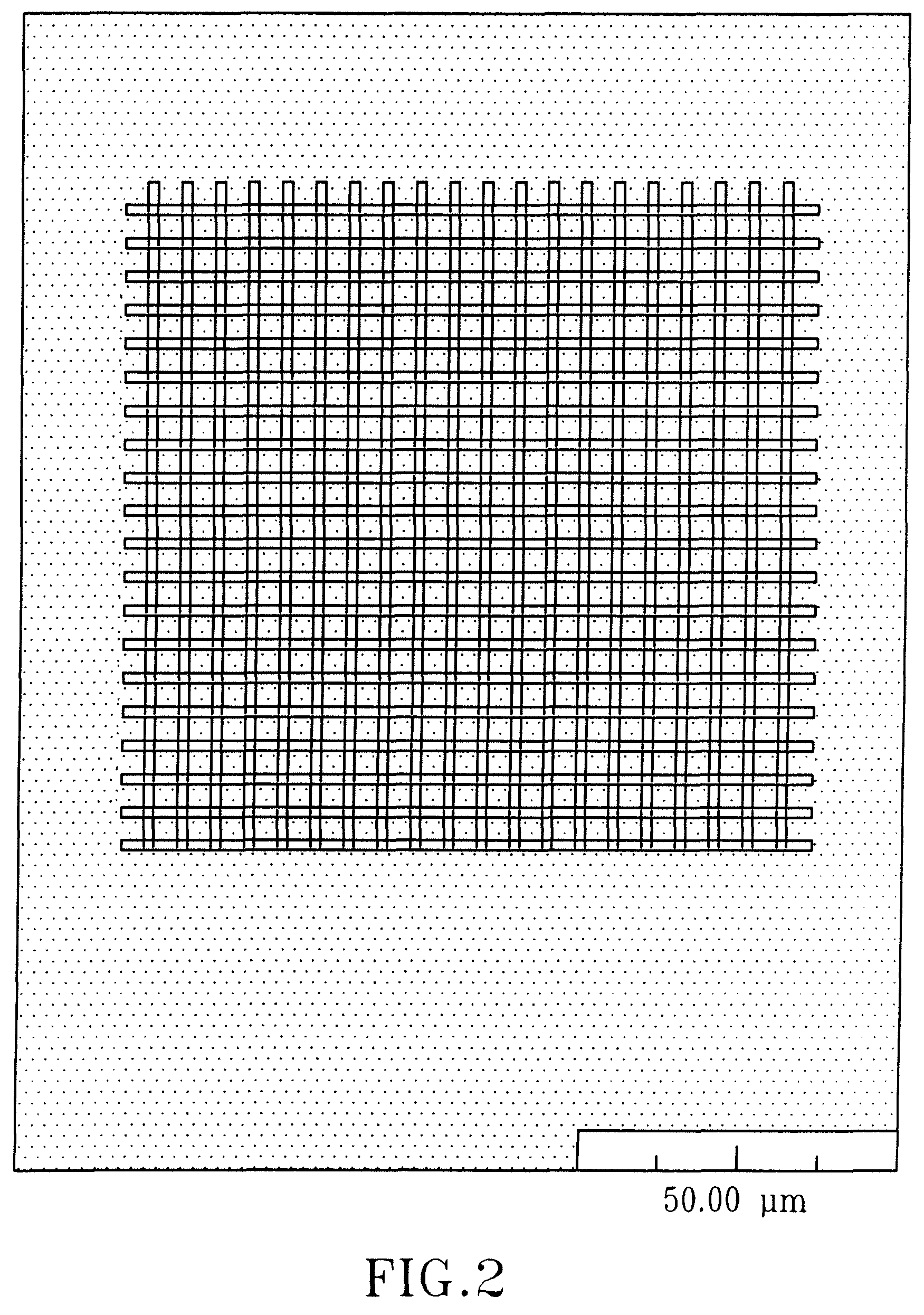

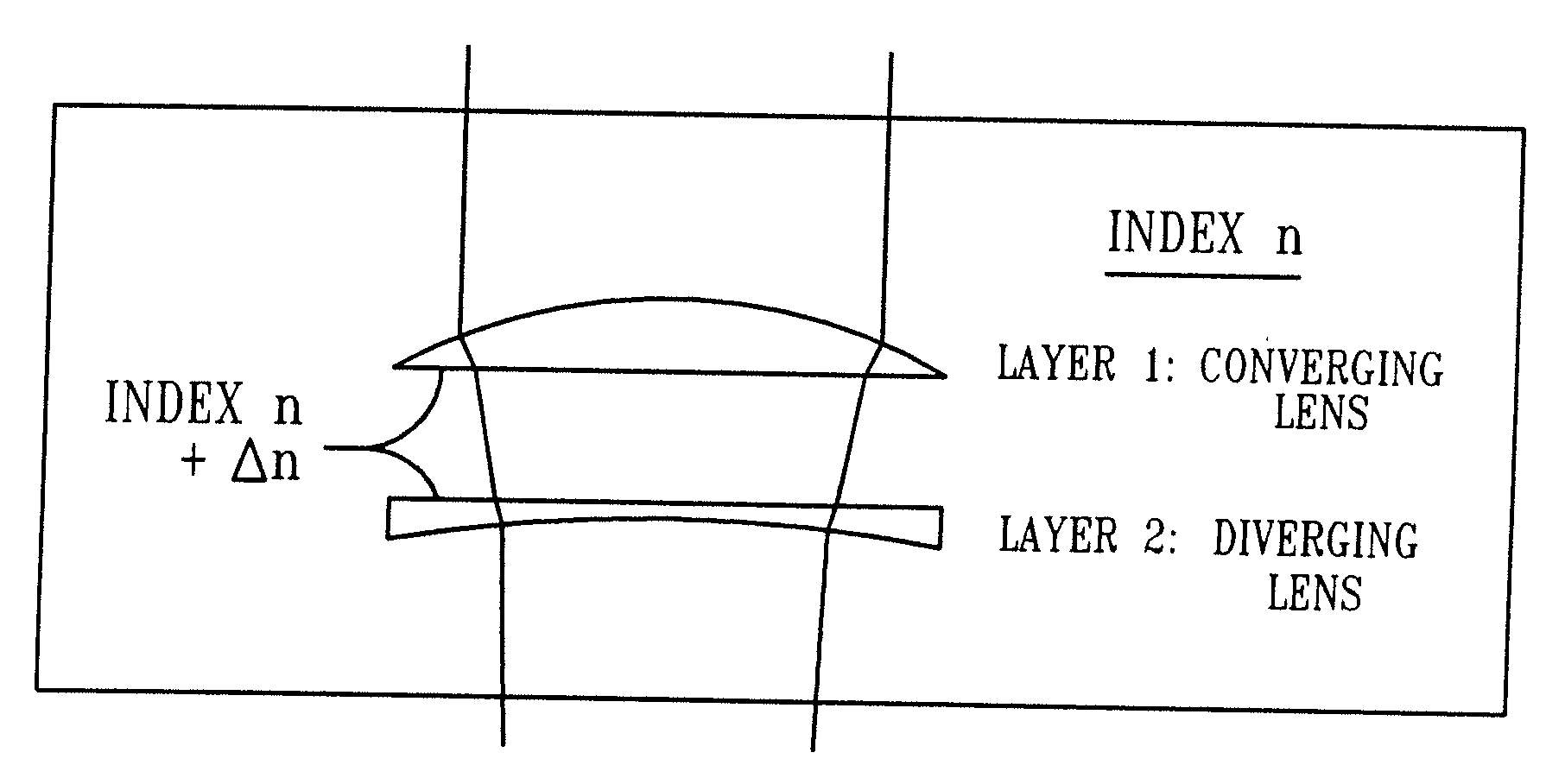

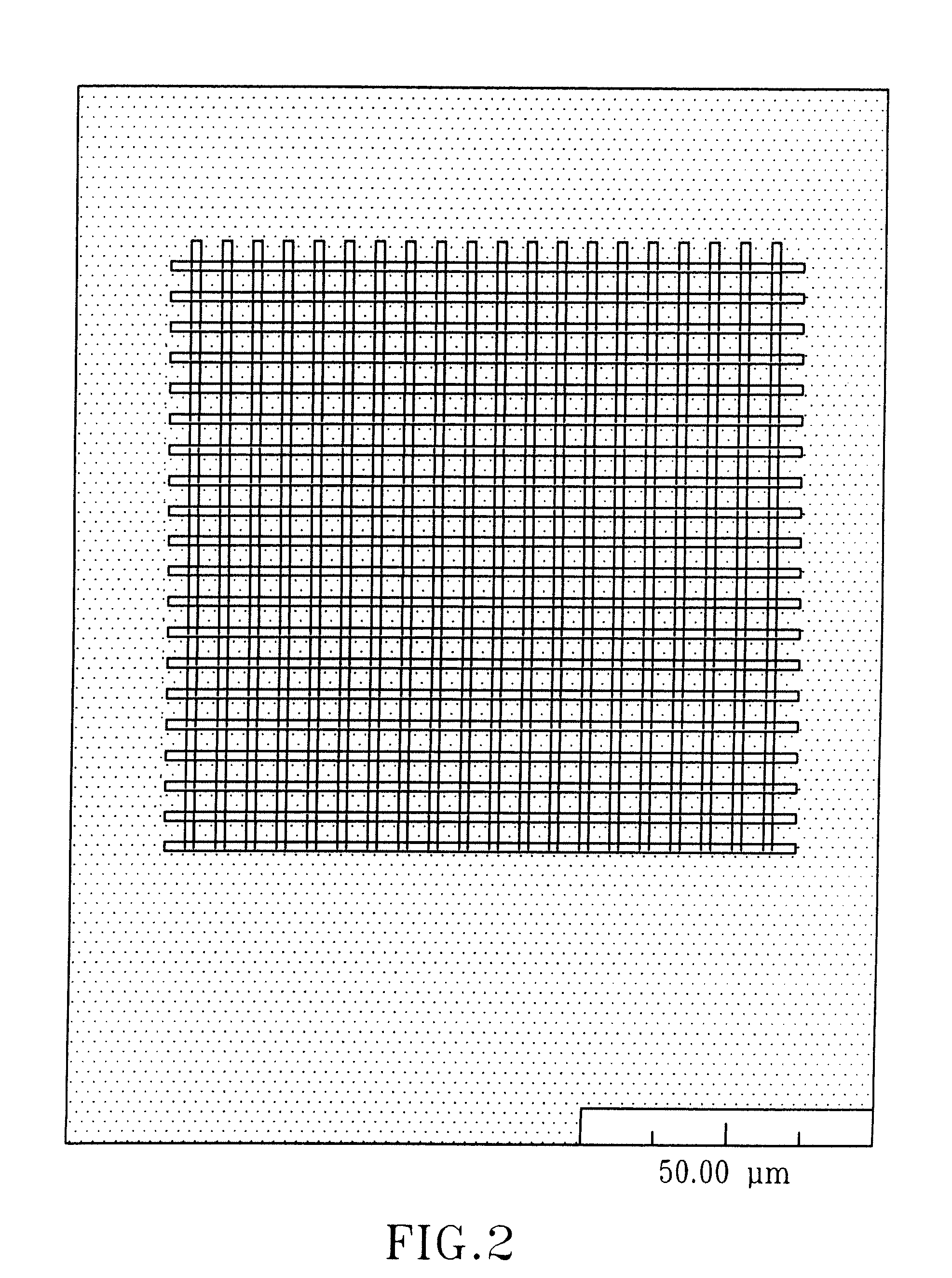

A method for modifying the refractive index of an optical polymeric material. The method comprises continuously irradiating predetermined regions of an optical, polymeric material with femtosecond laser pulses to form a gradient index refractive structure within the material. An optical device includes an optical, polymeric lens material having an anterior surface and posterior surface and an optical axis intersecting the surfaces and at least one laser-modified, GRIN layer disposed between the anterior surface and the posterior surface and arranged along a first axis 45° to 90° to the optical axis, and further characterized by a variation in index of refraction across at least one of at least a portion of the adjacent segments and along each segment.

Owner:UNIVERSITY OF ROCHESTER +1

Optical material and method for modifying the refractive index

ActiveUS20090143858A1Little and no scattering lossSpectales/gogglesOptical articlesIntraocular lensNear infrared laser

A method for modifying the refractive index of an optical, polymeric material. The method comprises irradiating select regions of the optical, polymeric material with a focused, visible or near-IR laser having a pulse energy from 0.05 nJ to 1000 nJ. The irradiation results in the formation of refractive optical structures, characterized by a change in refractive index, exhibit little or no scattering loss, and exhibit no significant differences in the Raman spectrum with respect to the non-irradiated optical, polymeric material. The method can be used to modify the refractive index of an intraocular lens following the surgical implantation of the intraocular lens in a human eye. The invention is also directed to an optical device comprising refractive optical structures, wherein the refractive structures are characterized by a change in refractive index, exhibit little or no scattering loss, and exhibit no significant differences in the Raman spectrum with respect to the non-irradiated optical, polymeric material.

Owner:UNIVERSITY OF ROCHESTER

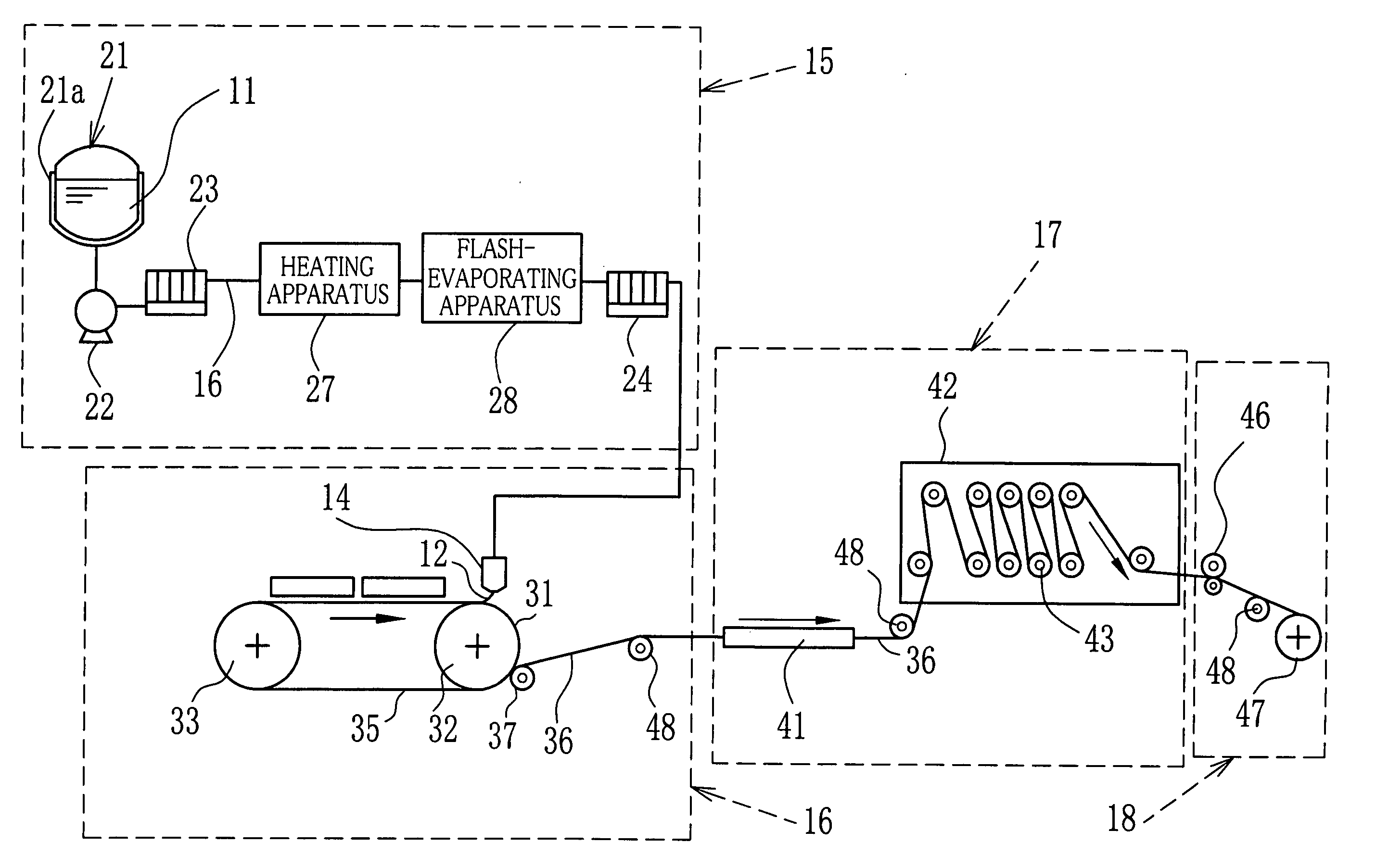

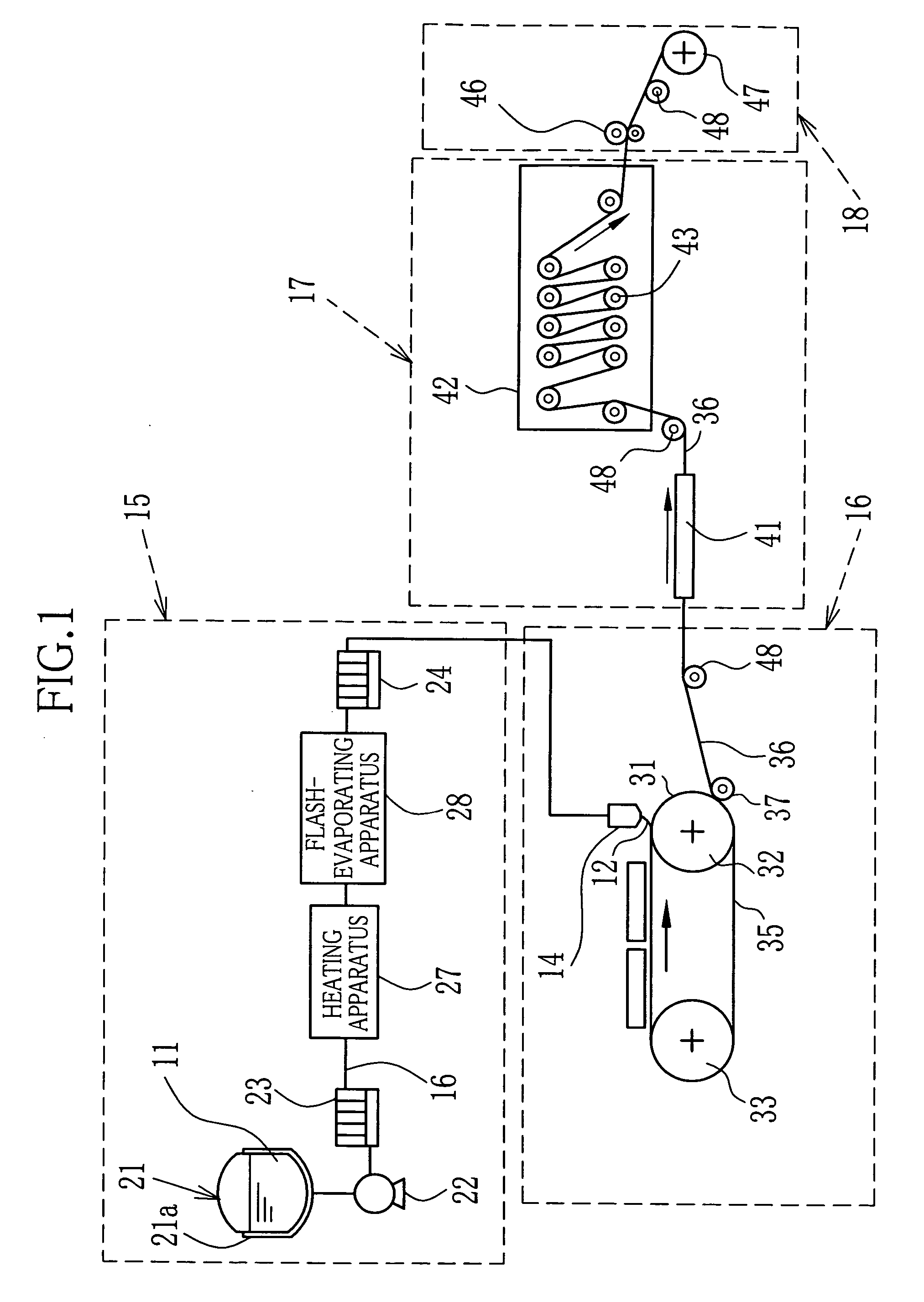

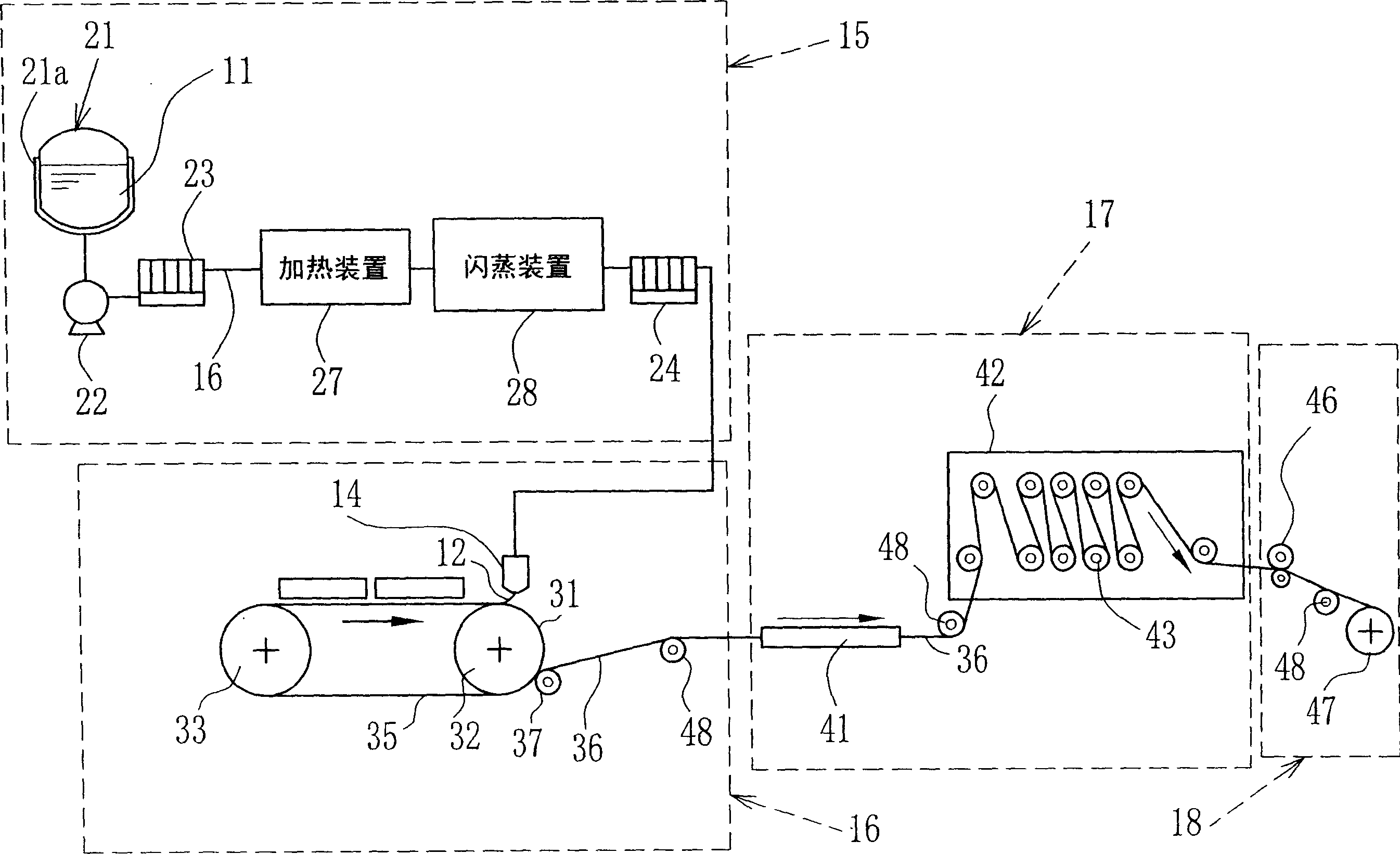

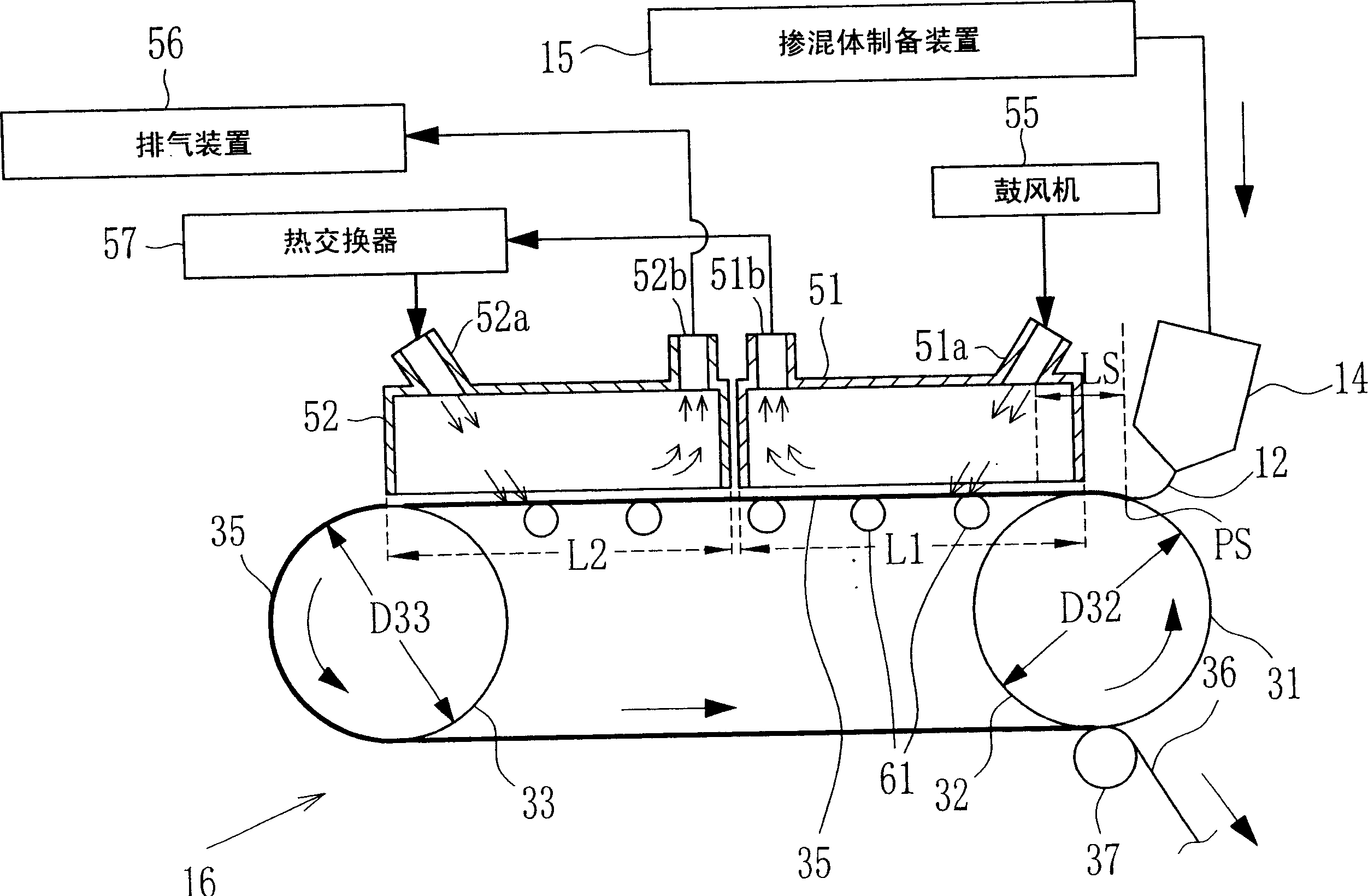

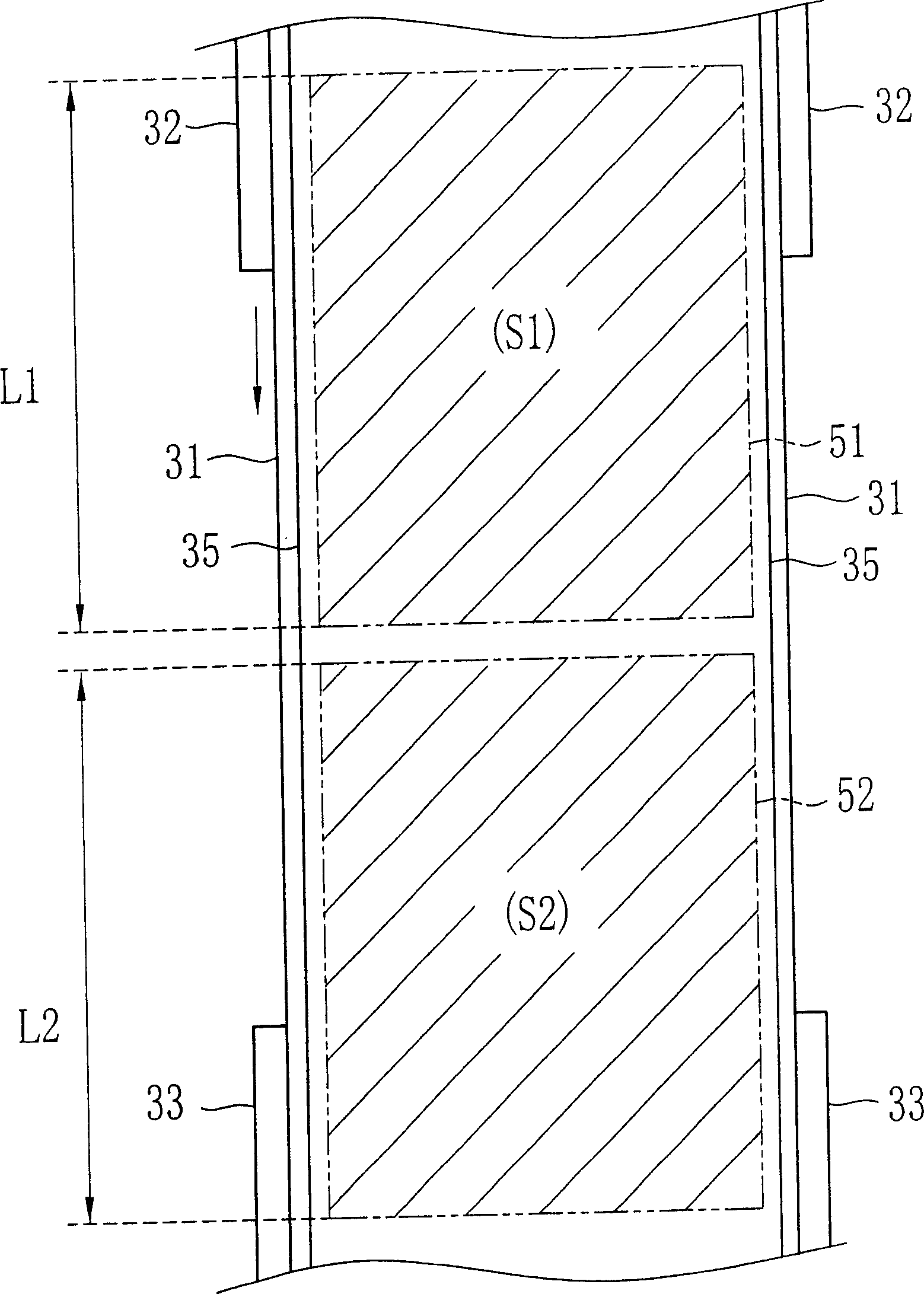

Method of producing film from polymer solution

InactiveUS20040212112A1Good optical performanceEfficient dryingPolarising elementsOptical articlesCelluloseLiquid-crystal display

A dope containing cellulose acylate as a main content of polymer is cast on a moving belt in a method of producing a film. At least first and second drying units are arranged in a moving direction of the belt and disposed near the gel-like film on the belt. A temperature difference between a supplied drying air and an exhausted air in the first drying unit is higher than in the second drying unit. Further, the exhausted air of the first drying unit, in order to use as the drying air of the second drying unit, is heated by a heat exchanger such that the content of solvent is decreased. A produced film is excelling in thickness uniformity, and adequate to used as an optical polymer film. Polarizing filter, protective film, optical functioning film and liquid crystal display in which the film is used are excellent in optical properties.

Owner:FUJIFILM HLDG CORP +1

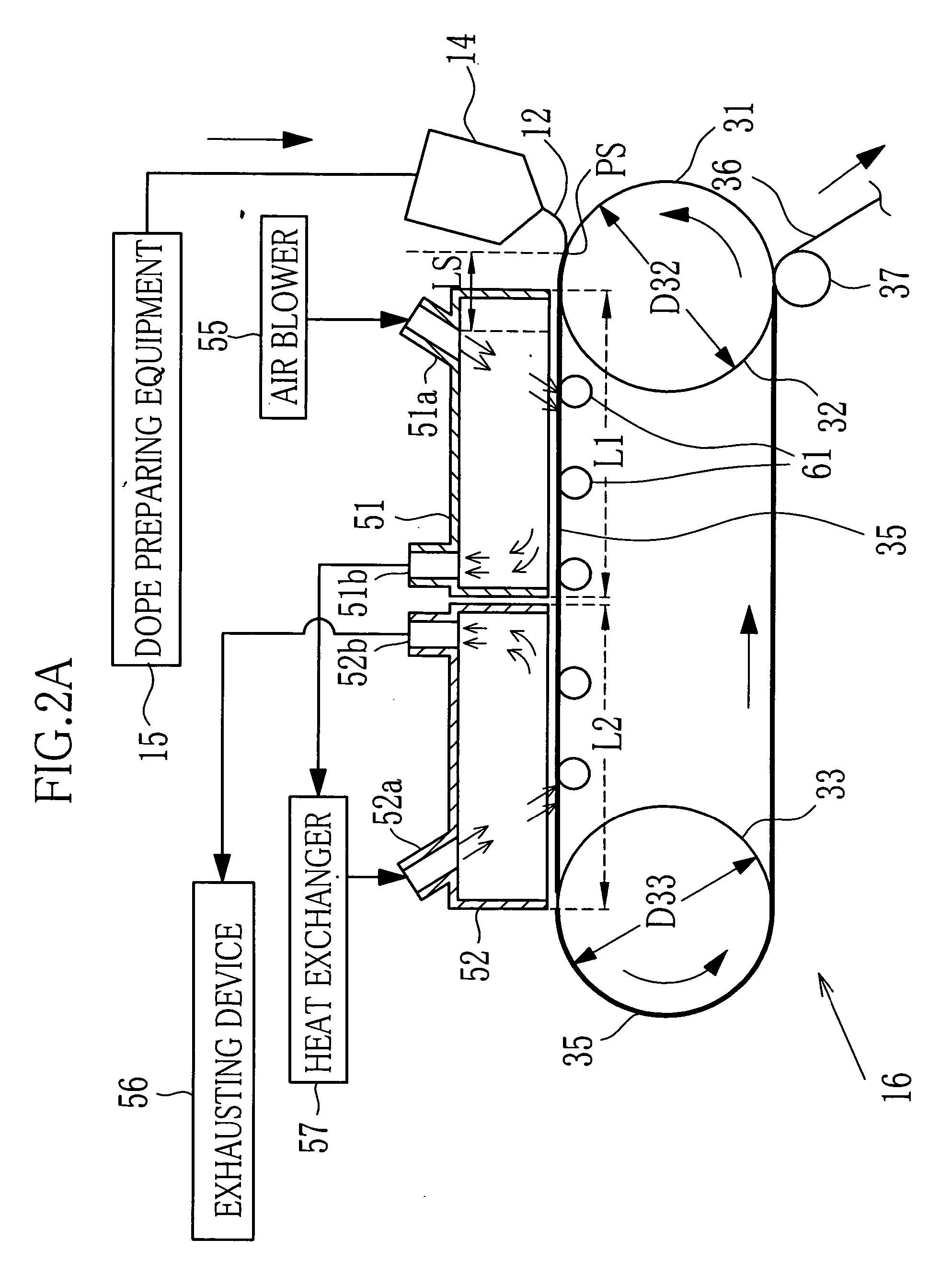

Method and apparatus for producing film from polymer solution, and optical polymer film

A dope containing cellulose acylate as a main content of polymer is cast on a front surface of a moving belt in a method of producing a film from a solution. A drying apparatus is confronted to a back surface of said belt to evaporate a solvent in the gel-like film. Further, a condensers are confronted to a cast surface of said gel-like film to condense a solvent vapor for recovery. A wind speed above and near the gel-like film is from 0.01 m / s to 0.5 m / s, and the belt is transported downwards at the casting position PS. When d (mm) is a distance between the casting surface and each condenser, Tw (° C.) is a temperature of each condenser, and Ts (° C.) is a temperature of the casting dope, conditions are satisfied: Q=(Ts-Tw) / d and 5<Q<100. The obtained film is excellent in thickness uniformity and optical properties, and therefore adequate for the optical film.

Owner:FUJIFILM HLDG CORP +1

Optical Hydrogel Material with Photosensitizer and Method for Modifying the Refractive Index

ActiveUS20130268072A1Promote formationImprove visual effectsSpectales/gogglesLaser surgeryPhotosensitizerOptical polymers

Owner:UNIVERSITY OF ROCHESTER

Method for modifying the refractive index of an optical material

ActiveUS9144491B2Little and no scattering lossSpectales/gogglesLaser surgeryOptical polymersOptical axis

A method for modifying the refractive index of an optical polymeric material. The method comprises continuously irradiating predetermined regions of an optical, polymeric material with femtosecond laser pulses to form a gradient index refractive structure within the material. An optical device includes an optical, polymeric lens material having an anterior surface and posterior surface and an optical axis intersecting the surfaces and at least one laser-modified, GRIN layer disposed between the anterior surface and the posterior surface and arranged along a first axis 45° to 90° to the optical axis, and further characterized by a variation in index of refraction across at least one of at least a portion of the adjacent segments and along each segment.

Owner:UNIVERSITY OF ROCHESTER +1

Vehicle occupant classification system

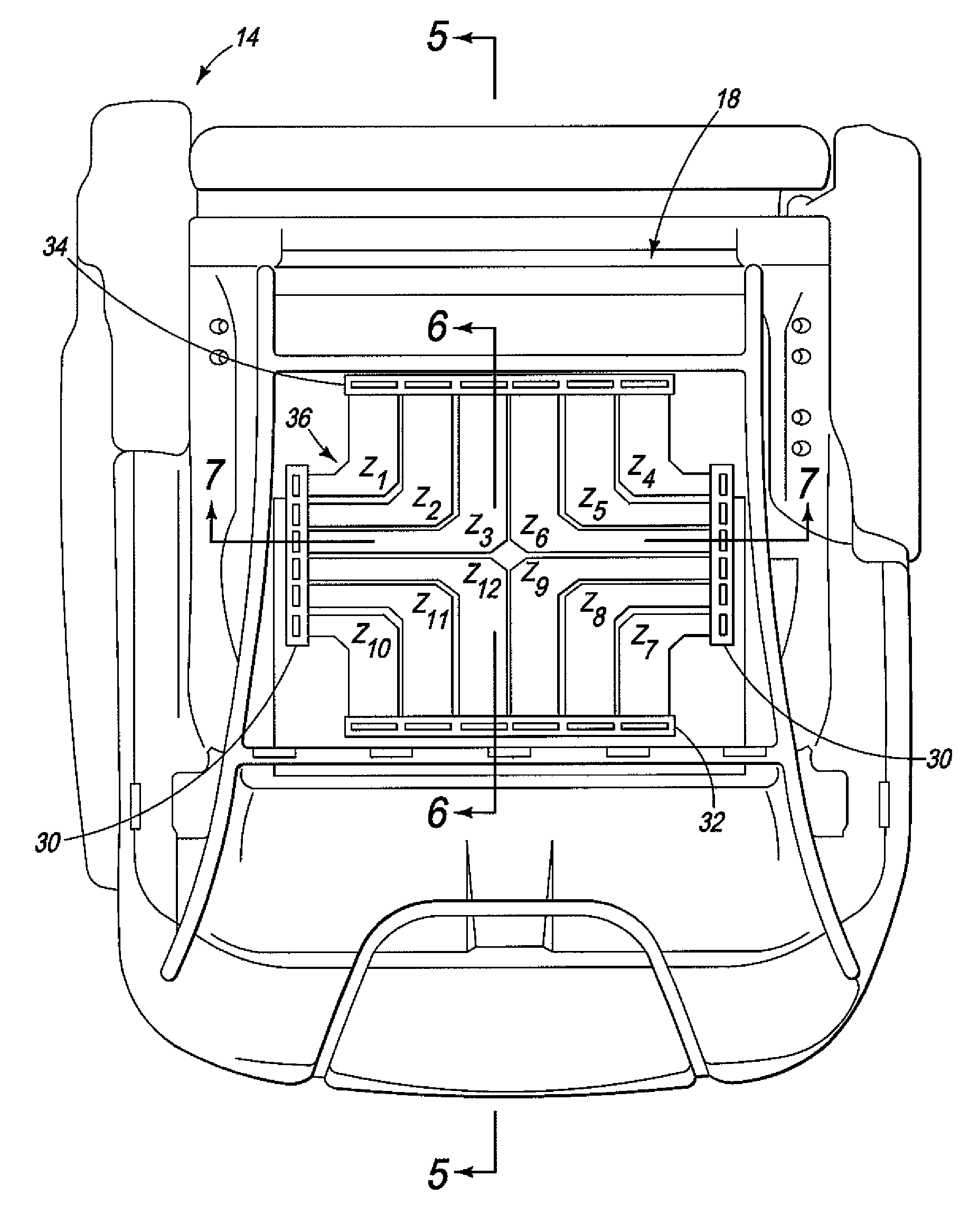

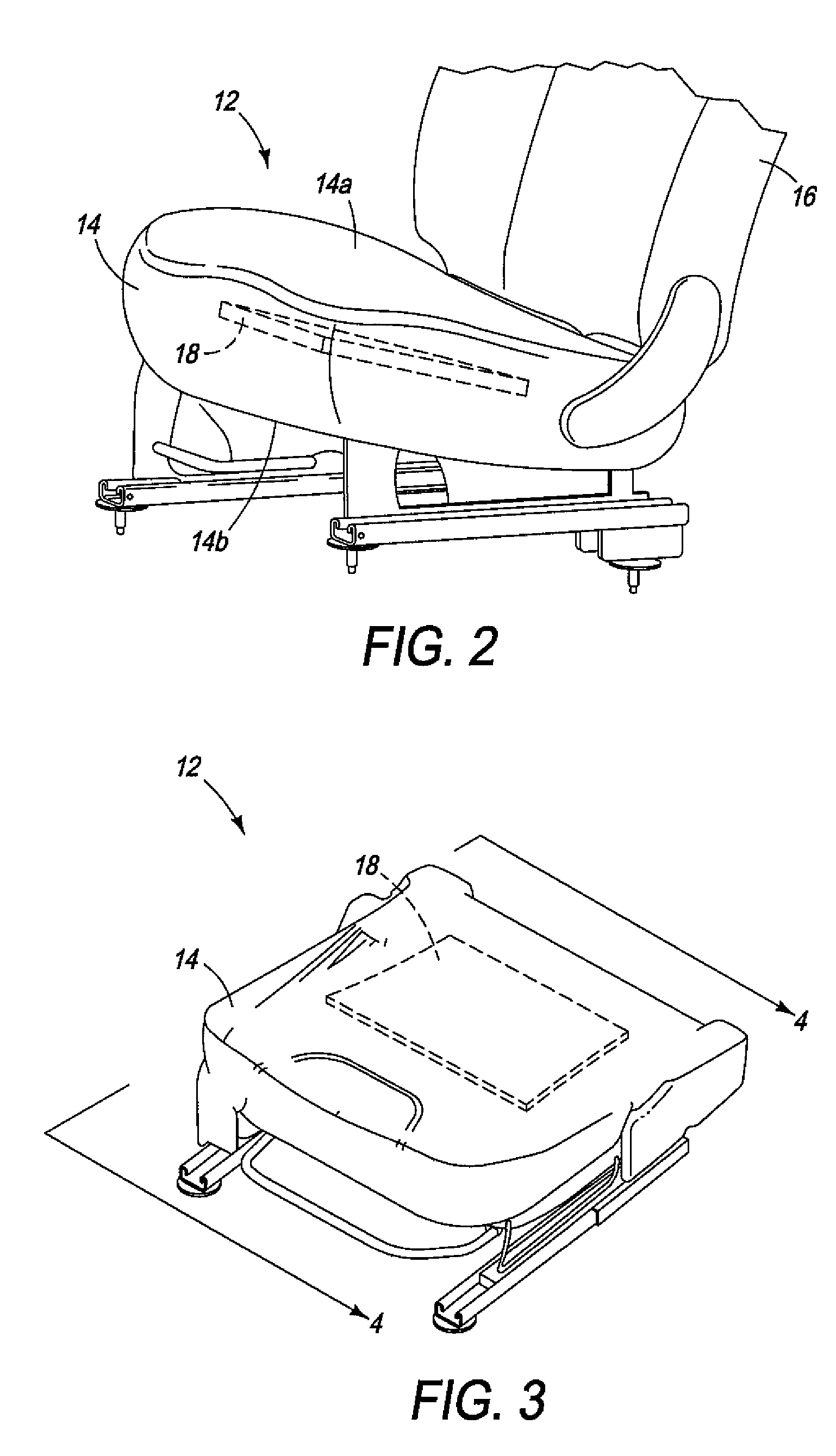

A vehicle seat pressure sensor includes a light source, a non-fiber optical polymer sheet, a boundary layer and a detection unit. The non-fiber optical polymer sheet is composed of non-woven flexible optical polymer material and has a first surface with a peripheral edge surrounding the first surface. The peripheral edge of the optical polymer sheet is aligned with the light source such that light emitted from the light source projects into the optical polymer sheet through the peripheral edge. The boundary layer is disposed along the first surface of the optical polymer sheet. The detection unit is disposed relative to the optical polymer sheet to detect changes in attenuation of light emitted from the peripheral edge of the optical polymer sheet in response to elastic deformation of the boundary layer and the optical polymer sheet.

Owner:NISSAN MOTOR CO LTD

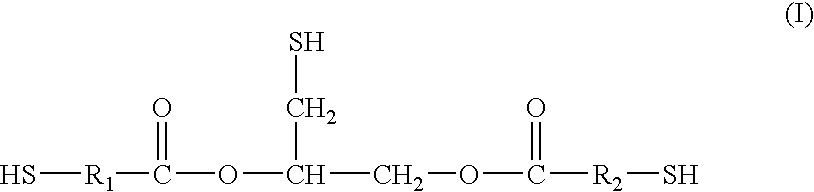

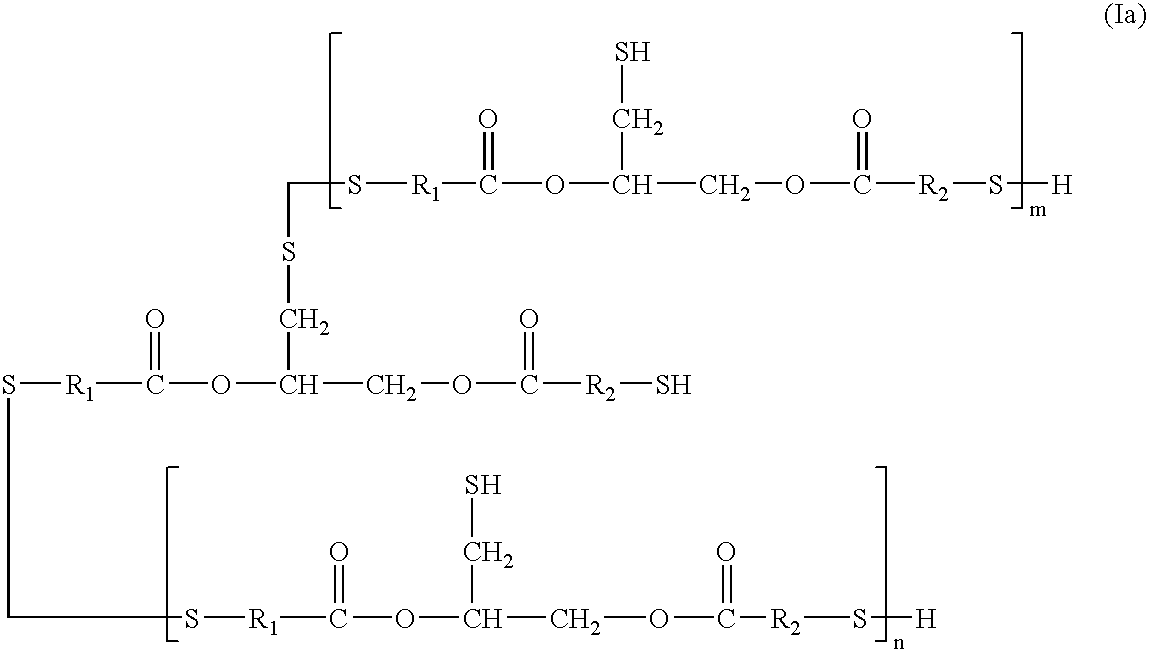

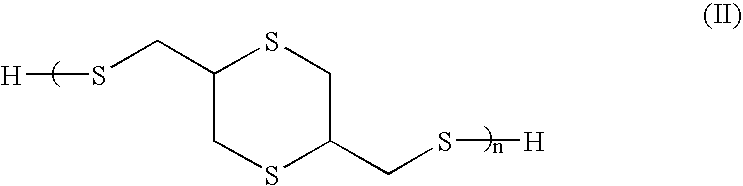

Method of preparing an optical polymerizate

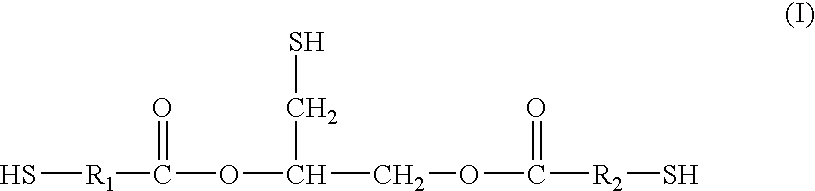

The present invention is directed to a novel method of preparing a polymerizate, which includes the step of polymerizing a two-component composition, which includes: a first component containing at least one polycyanate reactant having at least two functional groups selected from isocyanate, isothiocyanate and combinations thereof, the polycyanate reactant being the reaction product of: a polythiol monomer having at least two thiol groups; and a polycyanate monomer having at least two functional groups selected from isocyanate, isothiocyanate and combinations thereof; and a second component containing at least one polyamine reactant having at least two functional groups selected from primary amine, secondary amine and combinations thereof. The molar equivalent ratio of (NCO+NCS) groups from the first component to (—NH2+—NH—) groups from the second component is from 0.5 to 100. The present invention is also directed to polymerizates prepared according to the method of the present invention. The present invention is further directed to photochromic articles that may be prepared from the polymerizates of the present invention.

Owner:PPG IND OHIO INC

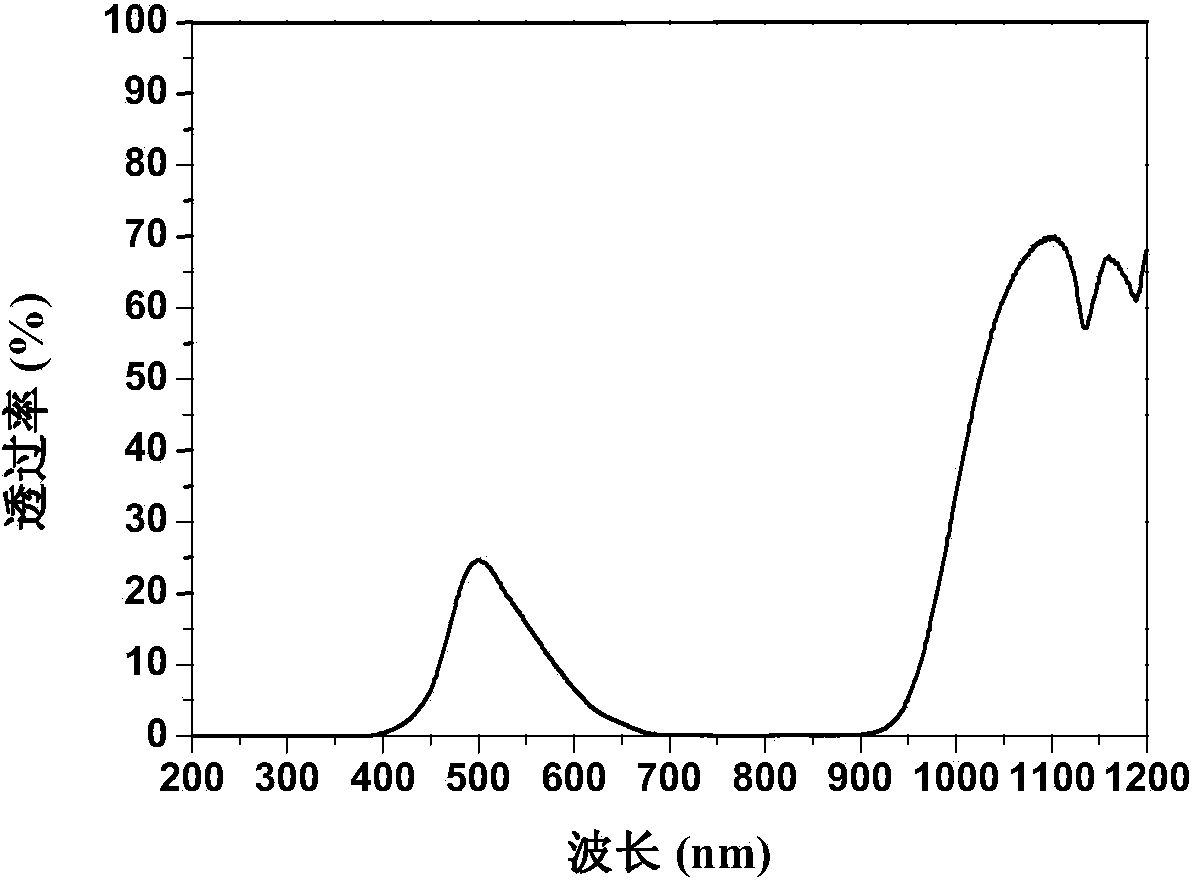

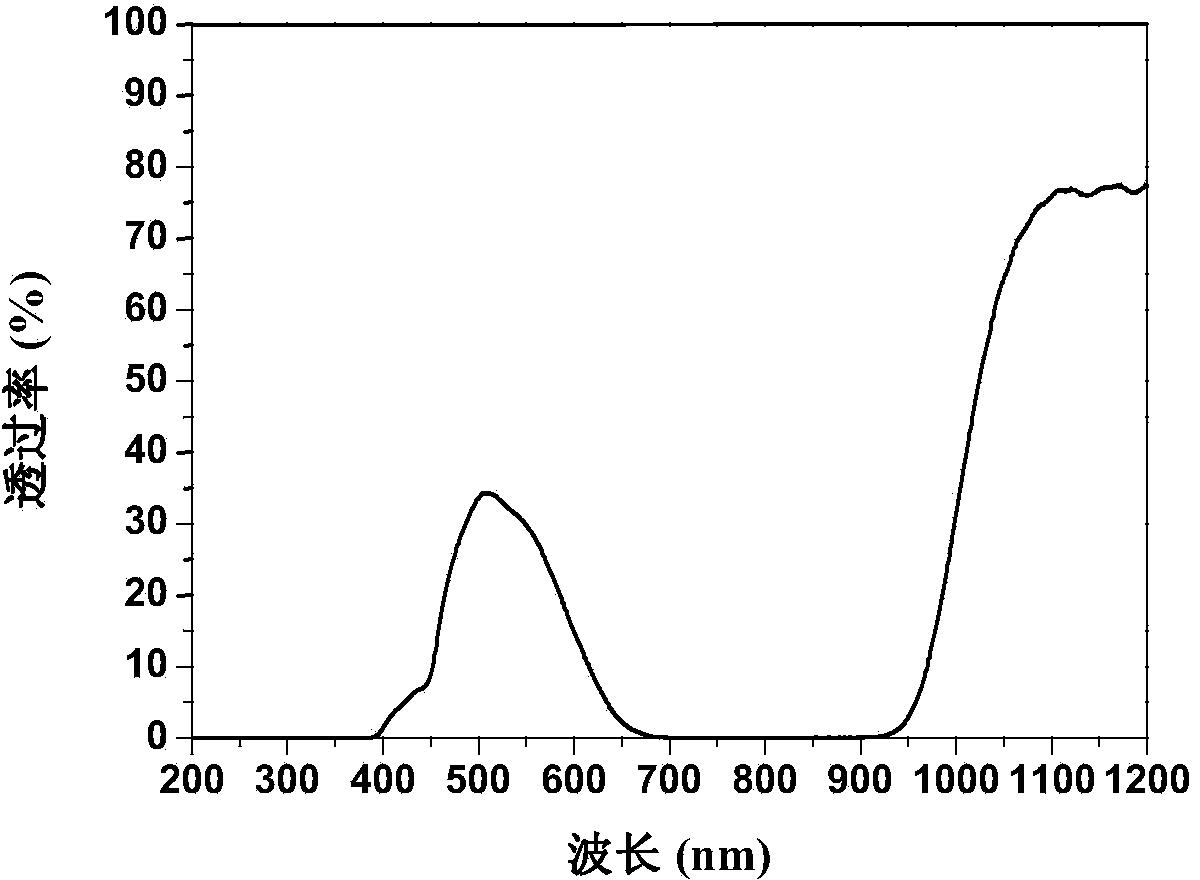

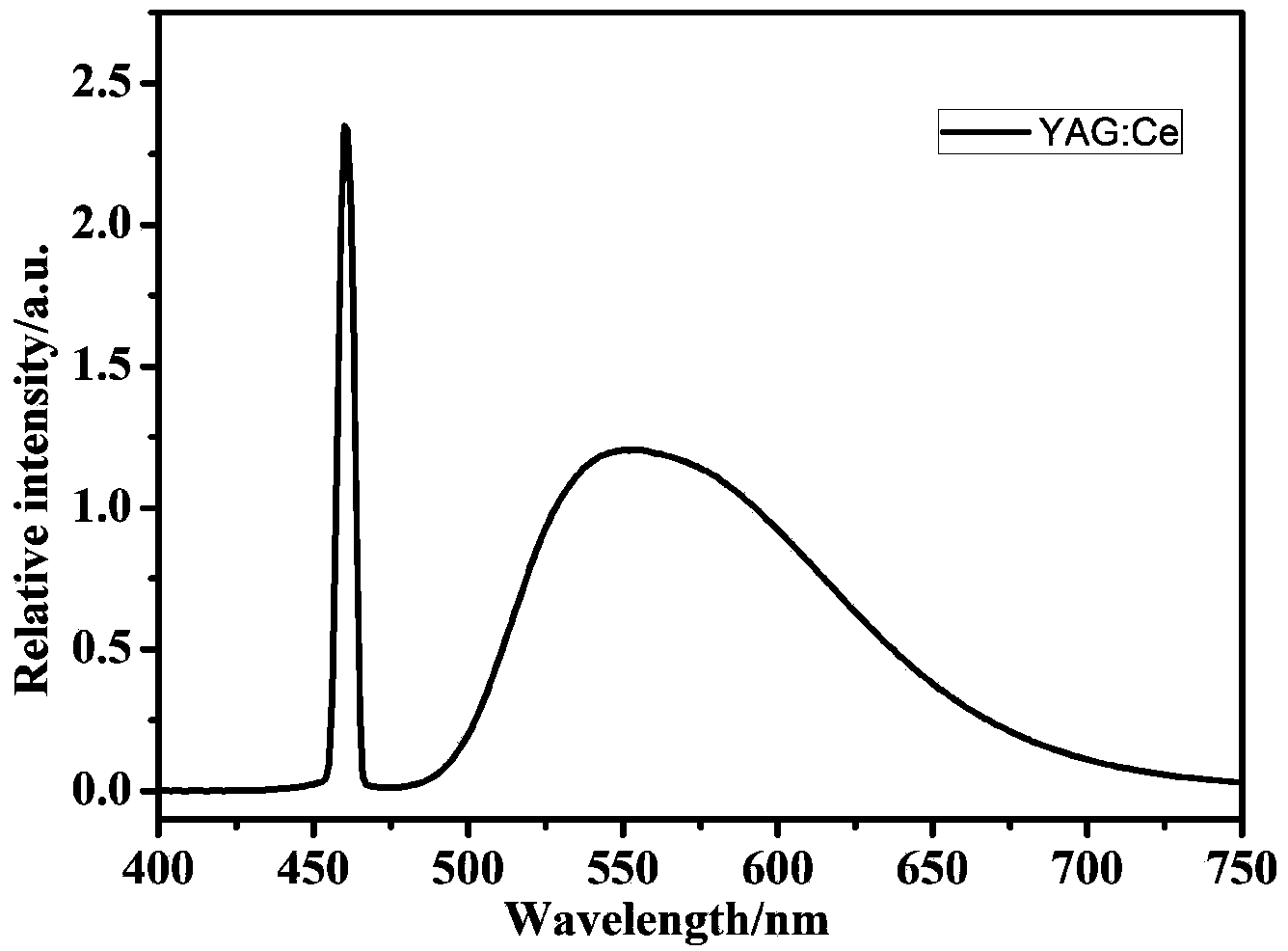

UV (Ultraviolet)-NIR (Near-Infrared) dual band absorbing optical filter and preparation method thereof

ActiveCN103809231AGood optical performanceSimple manufacturing processOptical elementsOptical polymersUltraviolet

The invention relates to a UV (Ultraviolet)-NIR (Near-Infrared) dual band absorbing optical filter and a preparation method thereof. The optical filter comprises the following raw material components in parts by weight: 0.3-0.6 parts of ultraviolet absorbent, 0.02-0.03 parts of low band near-infrared absorbent, 0.03-0.05 parts of high band near-infrared absorbent, 100 parts of optical aggregate granules, and 0.025-0.05 parts of liquid paraffin. The preparation method comprises the steps of selecting an optical polymer with higher visible light transmittance as a base material, and obtaining the optical filter with absorbent molecules uniformly distributed in the optical polymer base material by using a method of injection moulding after optical polymer grains and the absorbent are blended and granulated. The optical filter has a good cut-off property on laser with the wave band ranges of 200-400nm and 700-900nm, and guarantees the certain transmittance of visible light areas simultaneously.

Owner:NANJING UNIV OF TECH

Method of producing film from polymer solution

ActiveCN1569436AGood optical performancePolarising elementsOptical articlesCelluloseLiquid-crystal display

A blend comprising a polymer whose main component is cellulose acylate is cast on a moving belt by a method for producing a film. At least the first and second drying units are arranged along the moving direction of the belt and disposed close to the glue-like film on the belt. A temperature difference between drying air supplied in the first drying unit and exhaust air is higher than a temperature difference between drying air supplied in the second drying unit and exhaust air. In addition, in order to be used as the drying air of the second drying unit, the discharge air of the first drying unit is heated with a heat exchanger to reduce the solvent content. The finished film has excellent thickness uniformity and is suitable for use as an optical polymer film. A polarizing filter, a protective film, an optical functional film, and a liquid crystal display using the film have excellent optical properties.

Owner:FUJIFILM CORP

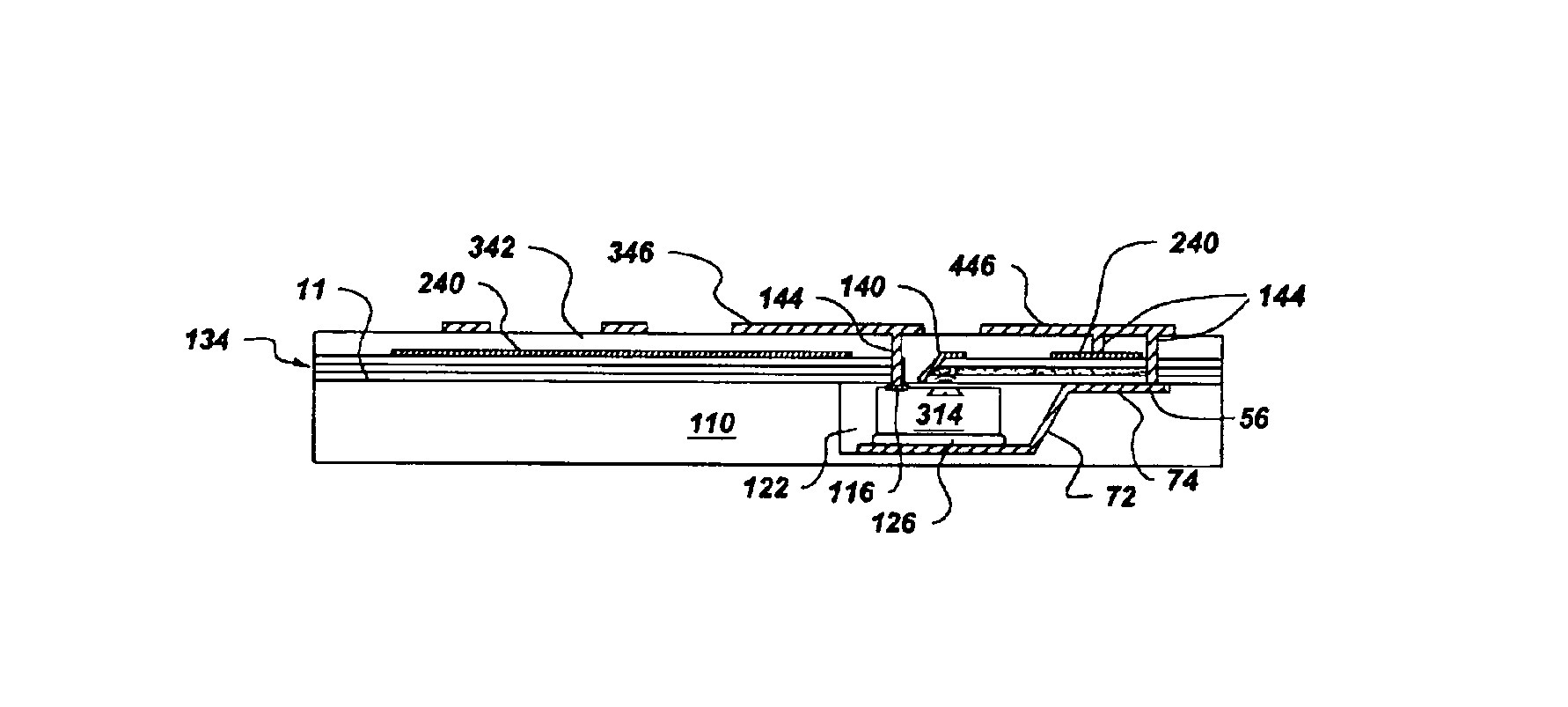

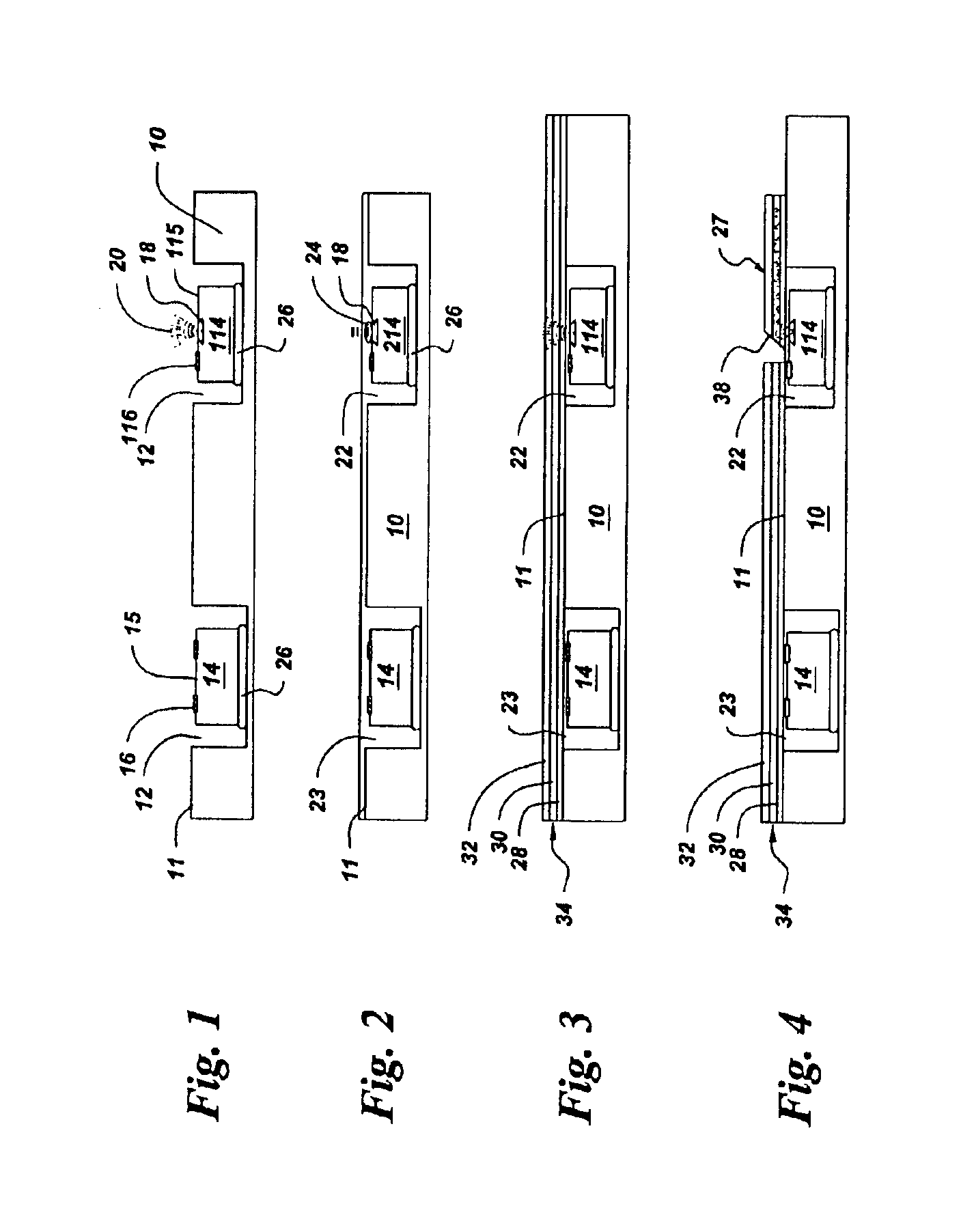

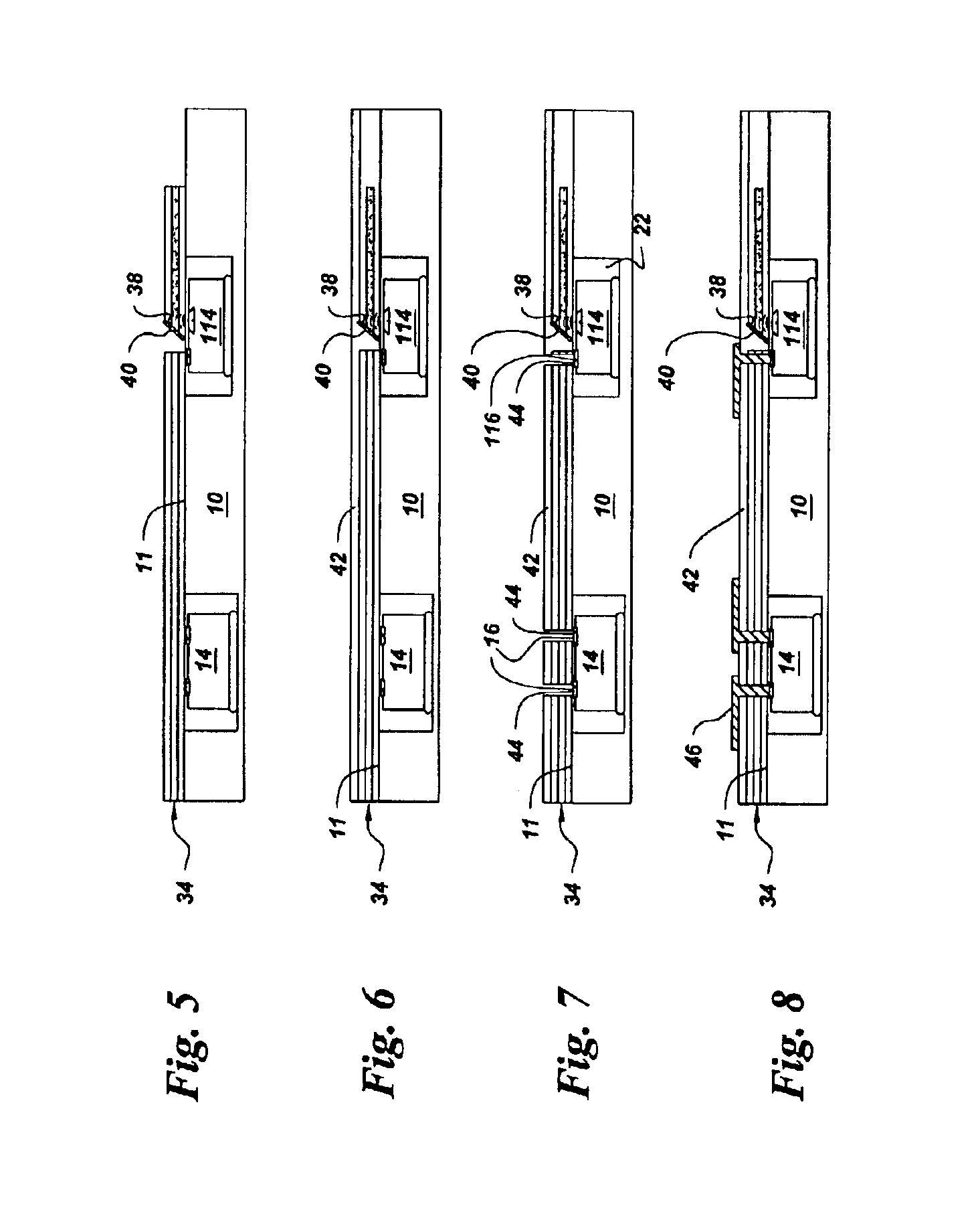

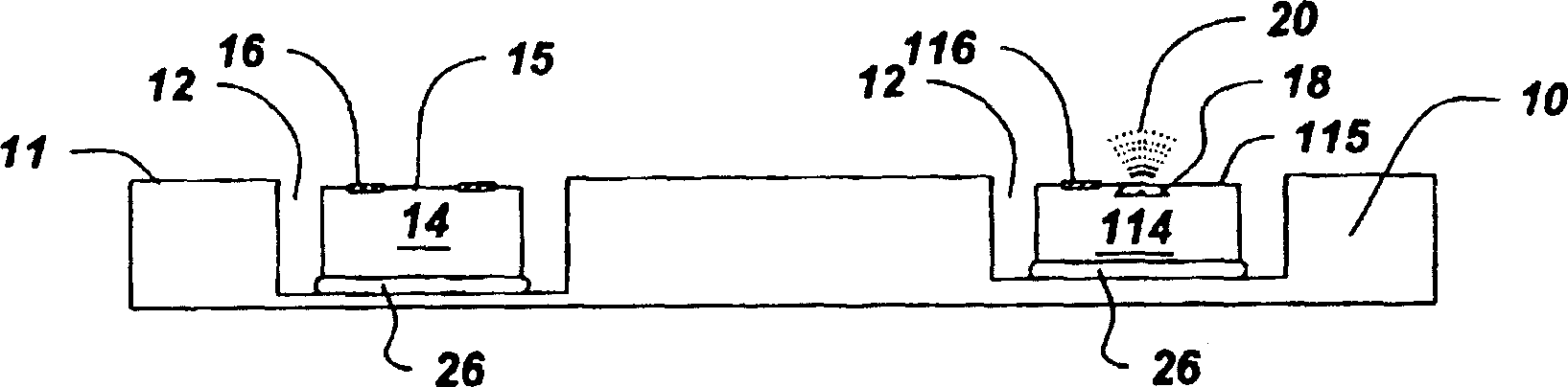

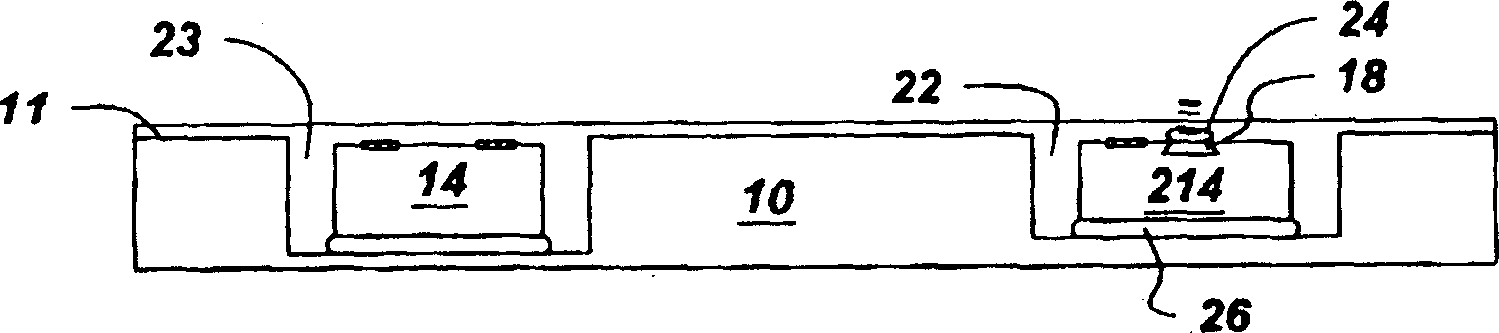

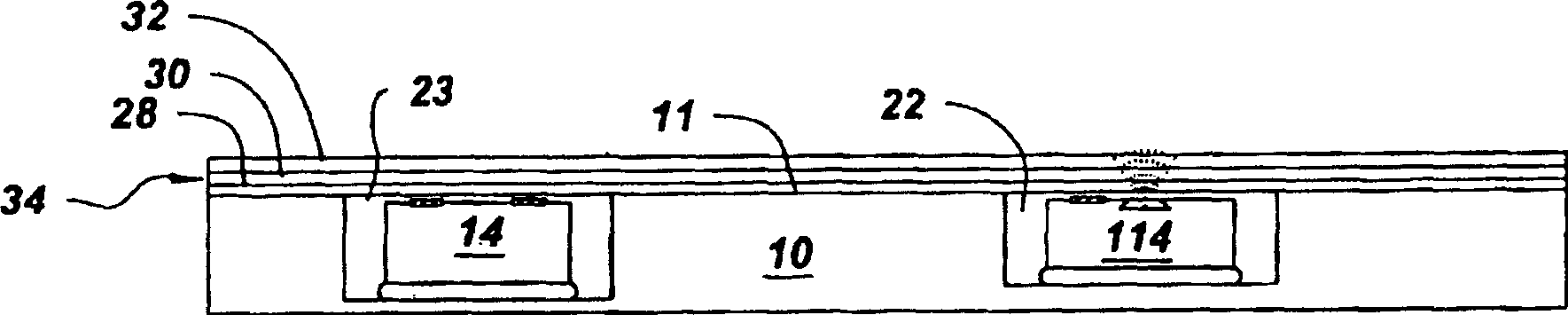

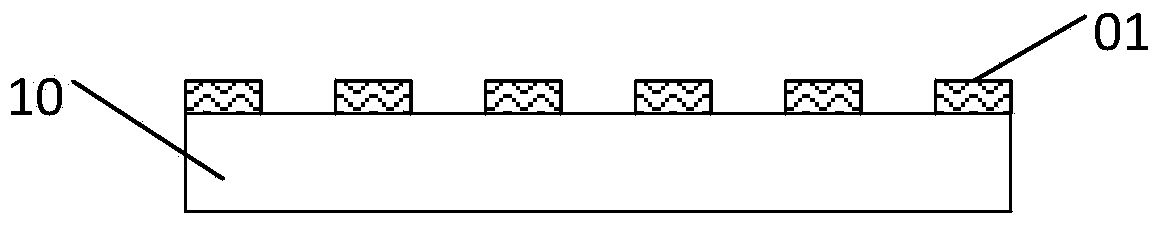

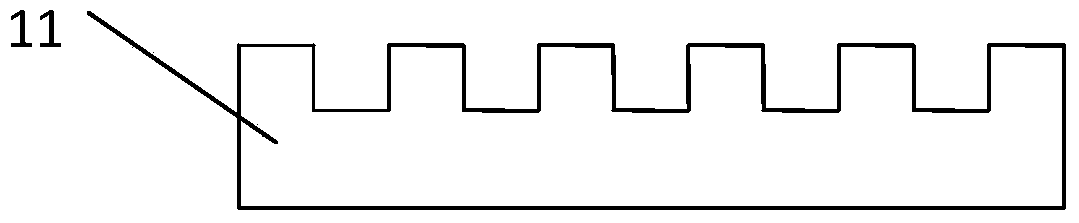

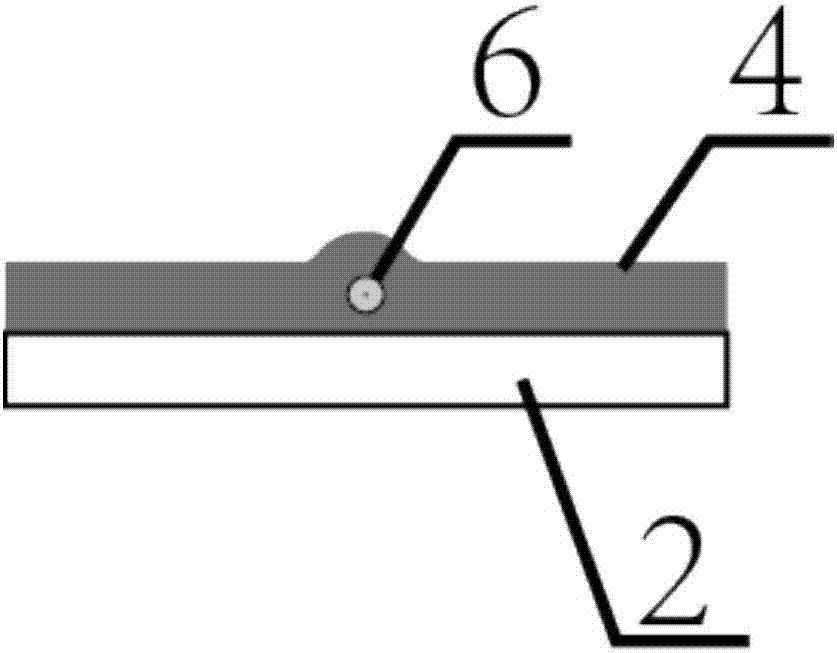

Optoelectronic package and fabrication method

An optoelectronic package is fabricated by a method which includes: positioning an optical device within a window of a substrate active-side up and below a top substrate surface; filling the window with an optical polymer material; planarizing surfaces of the optical polymer material and the substrate; patterning waveguide material over the optical polymer material and the substrate to form an optical interconnection path; and to form a mirror to reflect light from the optical device to the interconnection path; and forming a via to expose a bond pad of the optical device.

Owner:GENERAL ELECTRIC CO

Optoelectronic package and fabrication method

An optoelectronic package is fabricated by a method which includes: positioning an optical device within a window of a substrate active-side up and below a top substrate surface; filling the window with an optical polymer material; planarizing surfaces of the optical polymer material and the substrate; patterning waveguide material over the optical polymer material and the substrate to form an optical interconnection path and to form a mirror to reflect light from the optical device to the interconnection path; and forming a via to expose a bond pad of the optical device.

Owner:GENERAL ELECTRIC CO

Method for manufacturing all-polymer plane optical path

InactiveCN103592721ALow costSimple processOptical waveguide light guideMicro structurePolymer adhesive

The invention discloses a method for manufacturing an all-polymer plane optical path. The method comprises the steps of (1) obtaining an initial master mold by means of ultra-violet lithography and deep-etching technologies, duplicating a metallic nickel mold by means of electrochemical sedimentation, and manufacturing a polymer micro-structure part by means of mini molding; (2) conducting segment treatment on the part by means of the thermal annealing technology to reduce the roughness of the lateral wall and reduce scattering loss during optical wave transmission; (3) applying and filling polymer medium materials and obtaining the core structure of the plane optical path after the polymer medium materials are solidified; (4) combining a bondage layer of an element with an optical polymer substrate to achieve the manufacturing of the buried ridge type polymer plane optical path, wherein a polymer adhesive layer serves as the bondage layer of the element. Compared with a traditional method for manufacturing the polymer plane optical path, the method for manufacturing the all-polymer plane optical path has the advantages that cost is reduced and universality of technologies to materials is high.

Owner:SOUTH CHINA NORMAL UNIVERSITY

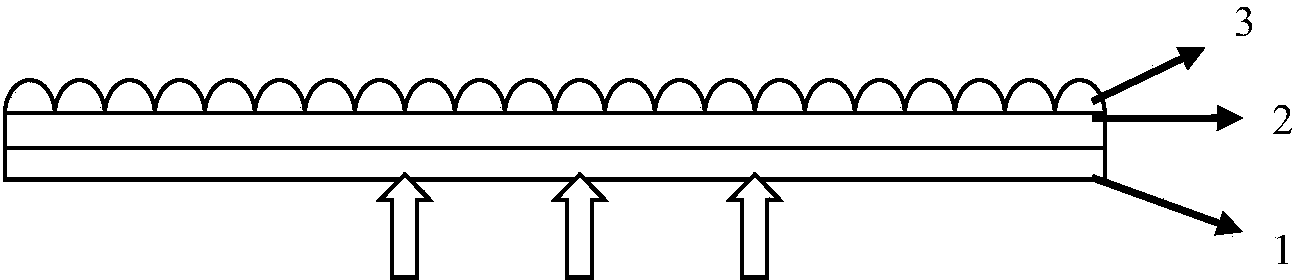

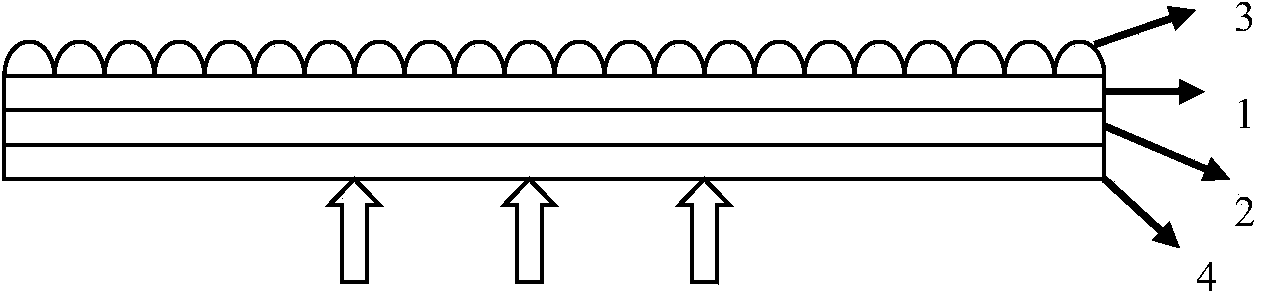

Light-emitting film used for LED lighting and provided with micro-mirror structure and preparing method thereof

ActiveCN103872225ASimple processThickness is easy to controlSemiconductor devicesOptical polymersFluorescence

The invention discloses a light-emitting film used for LED lighting and provided with a micro-mirror structure and a preparing method of the light-emitting film and relates to the technical field of LED lighting and displaying. Binding agents, anti-setting agents, dispersing agents, antifoaming agents and fluorescent powder are processed in a vacuum defoamation mode to prepare fluorescent sizing agents; a screen mesh technology is adopted for printing the fluorescent sizing agents on a substrate, and a fluorescent powder coating is prepared; an impressing technology is adopted for preparing micro-mirror patterns on an optical polymer film material to prepare a micro-mirror structure film; finally, the micro-mirror structure film and the fluorescent powder coating are stuck together to prepare the light-emitting film used for LED lighting and provided with the micro-mirror structure. The prepared fluorescent powder coating is prepared, the technology is simple, and the thickness, the pattern shape and the fluorescent powder content of a film layer are easily controlled. According to the light-emitting film, the service life of a whole LED lamp is effectively prolonged, and the LED lamp has the more stable light-emitting performance.

Owner:YANCHENG INST OF TECH

Method of preparing an optical polymerizate

The present invention is directed to a novel method of preparing a polymerizate, which includes the step of polymerizing a two-component composition, which includes: a first component containing at least one polycyanate reactant having at least two functional groups selected from isocyanate, isothiocyanate and combinations thereof, the polycyanate reactant being the reaction product of: a polythiol monomer having at least two thiol groups; and a polycyanate monomer having at least two functional groups selected from isocyanate, isothiocyanate and combinations thereof; and a second component containing at least one polyamine reactant having at least two functional groups selected from primary amine, secondary amine and combinations thereof. The present invention is also directed to polymerizates prepared according to the method of the present invention. The present invention is further directed to photochromic articles that may be prepared from the polymerizates of the present invention.

Owner:PPG IND OHIO INC

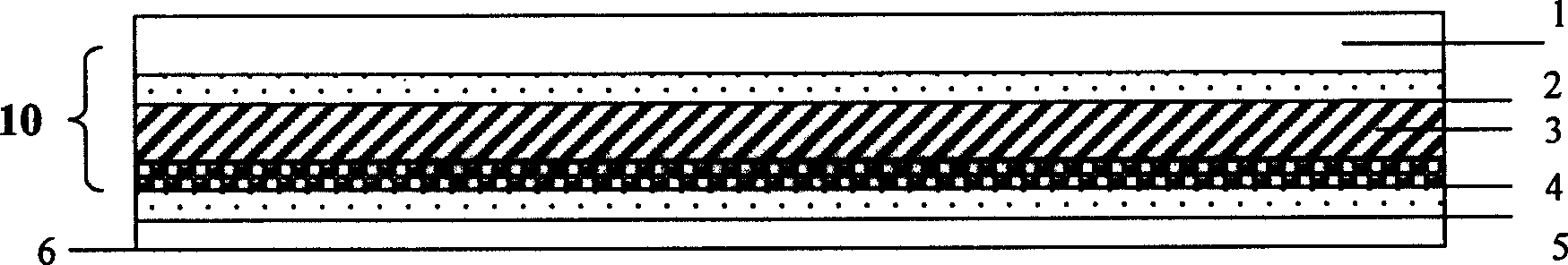

Composite film with reflecting holographic and angular color change information double property

InactiveCN1586917ALight effect designsPhotosensitive composition applicationComposite filmOptical polymers

The composite film with reflecting hologram and angular color changing diagram consists of reflecting holographic layer and angular color changing information diagram layer connected via connecting layer. The reflecting holographic layer consists of surface covering layer, protecting layer, optical polymer information record layer and reinforcing layer compounded successively. The angular color changing information diagram layer consists of isolating layer, light changing function layer of angular color changing material, isolating layer, coloring layer and adhering layer compounded successively. The preparation process of the composite film includes the following steps: preparing reflecting holographic layer and the angular color changing layer separately, laminating or hot compounding the two, and optical copying. The present invention has raised anti-fake effect and may be used in anti-fake widely.

Owner:SHANGHAI TECHSUN ANTI COUNTERFEITING TECH HLDG

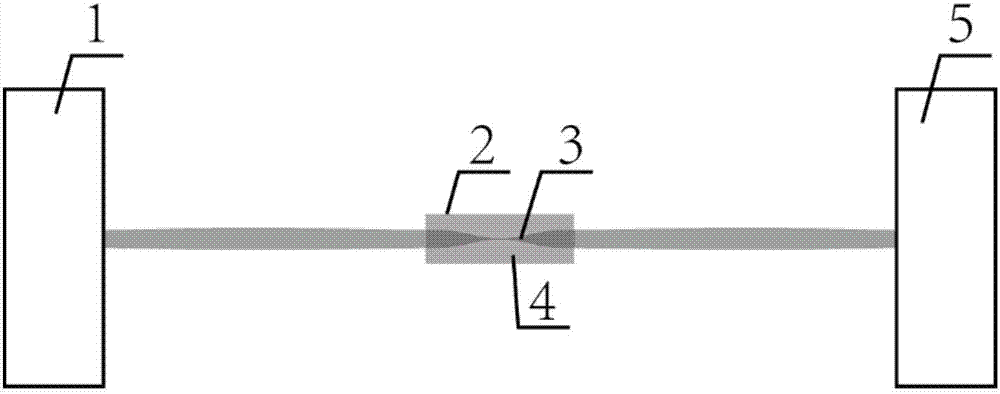

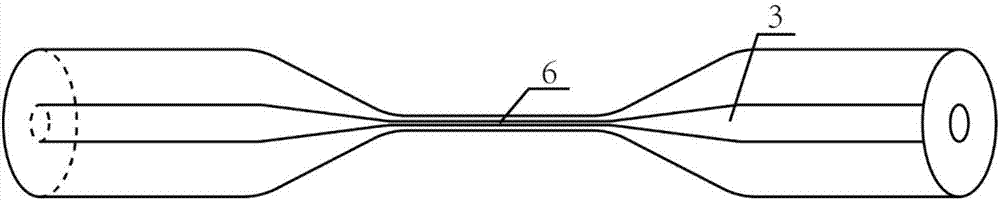

Micro-nanofiber evanescent field and electro-optical polymer-based electric field sensor

ActiveCN106896277AHigh sensitivityHighly integratedElectrostatic field measurementsElectric field sensorOptical polymers

The present invention relates to a micro-nanofiber evanescent field and electro-optical polymer-based electric field sensor, which comprises a laser light source, a single-mode fiber, an electro-optical polymer and a photoelectric detector, wherein the middle section of the single-mode fiber is stretched to be a micro-nanofiber. The laser light source is connected with the micro-nanofiber wrapped in the electro-optical polymer through the single-mode fiber. During the transmission of the light along the micro-nanofiber, a large portion of the energy is transmitted in the form of an evanescent field. The micro-nanofiber enhances the interaction of the light field interaction with external substances. The variation of the external electric field will cause the variation of the refractive index of the electro-optical polymer wrapped with the micro-nanofiber, namely the variation of the refractive index of the surrounding environment of the micro-nanofibe. The variation of the refractive index of the micro-nanofiber and the electro-optical polymer will cause the variation of the energy loss of the evanescent field. Finally, the intensity of the output light is detected by the photoelectric detector. In this way, the information of the external electric field can be obtained.

Owner:BEIHANG UNIV

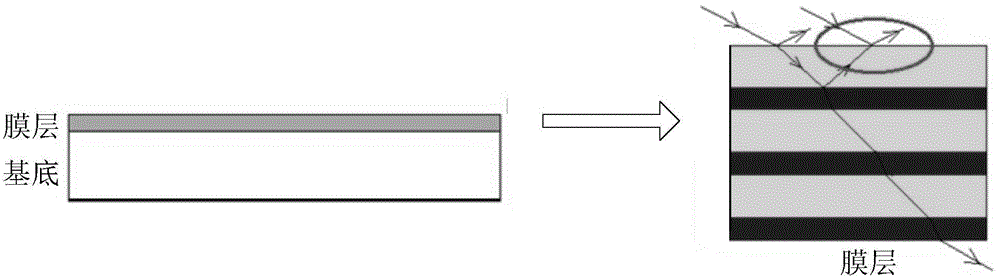

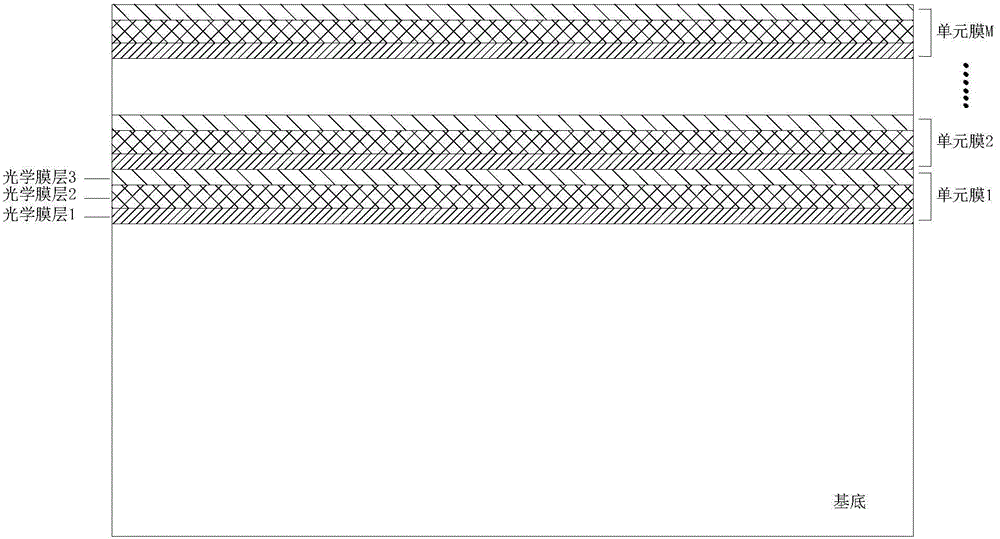

Novel optical polymer composite film and manufacturing method and application thereof

InactiveCN104459833AMeet the requirements of different optical propertiesOptical properties are adjustableOptical elementsBlow moldingOptical property

The invention discloses a novel optical polymer composite film and a manufacturing method and an application of the novel optical polymer composite film. An optical film covers the surface of a substrate, the substrate is made of polymer materials, and the optical film is formed by overlapping M unit films. Each unit film is formed by overlapping N optical film layers made of polymer materials, wherein N=2 or 3, each optical film layer has preset thickness, and every two adjacent optical film layers have different refraction indexes; the multiple optical film layers are overlapped on the surface of the substrate through pressing to form the novel optical polymer composite film, or a multi-layer optical film is manufactured in a multi-layer co-extrusion blow molding mode and pasted to the surface of the substrate in a covering mode to form the novel optical polymer composite film. According to actual application needs, through designing the number of the unit films in the optical film and the thicknesses, the refraction indexes and the distribution of all the optical film layers in each unit film, different optical characteristics of the optical film can be achieved. The novel optical polymer composite film is simple in technology, low in cost and capable of being widely applied to the field of agricultural planting.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

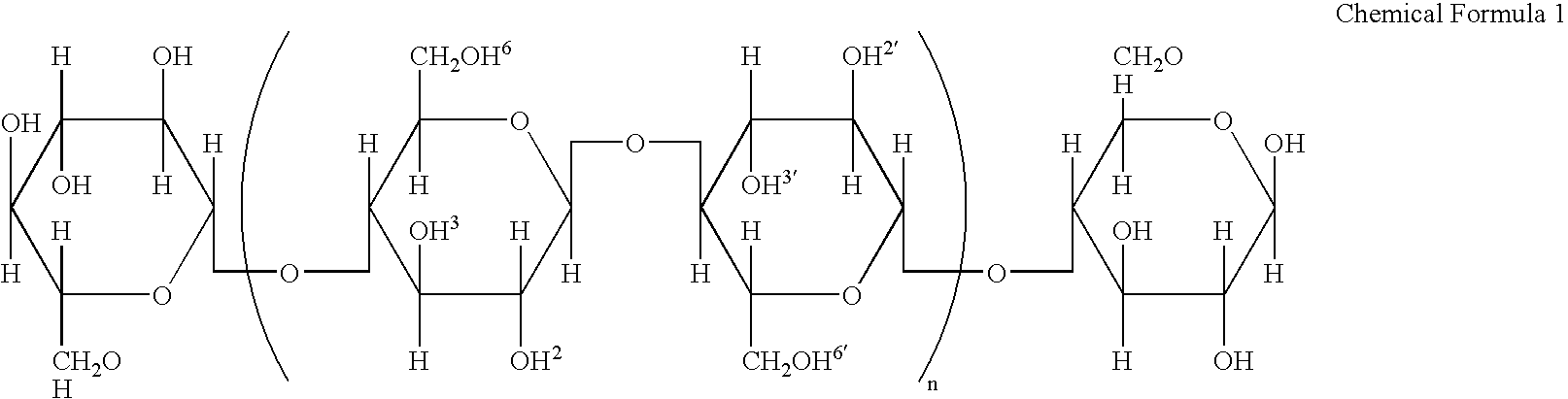

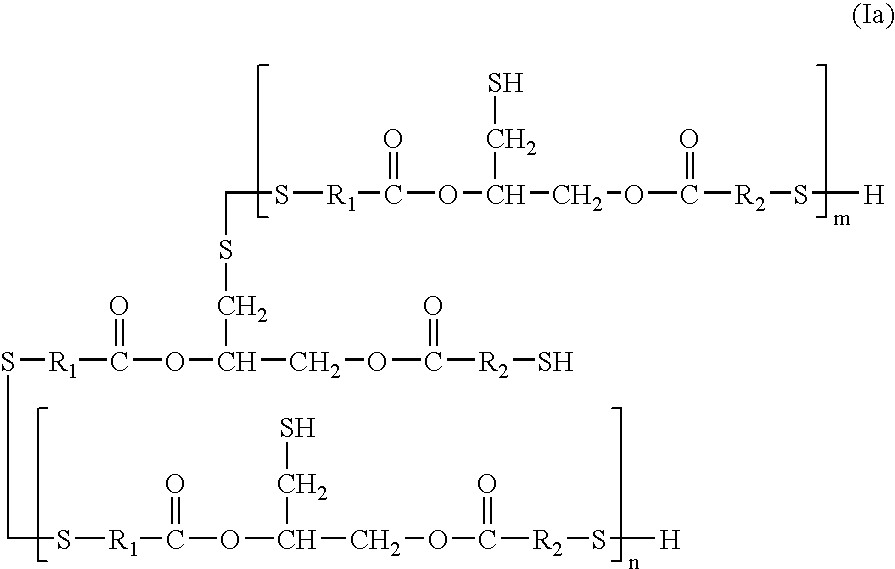

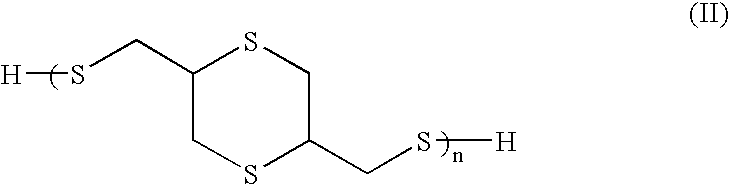

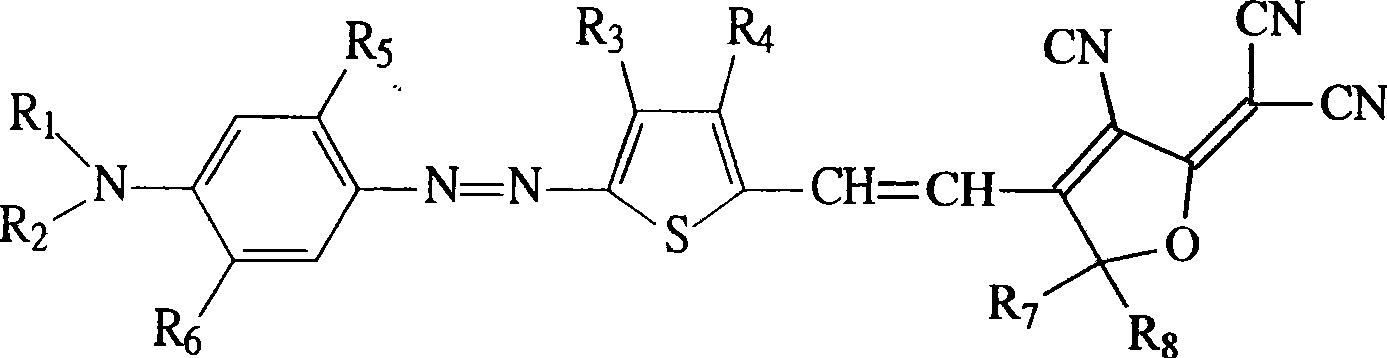

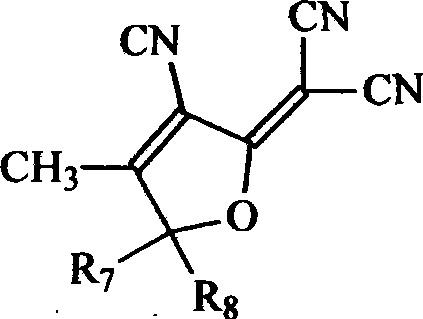

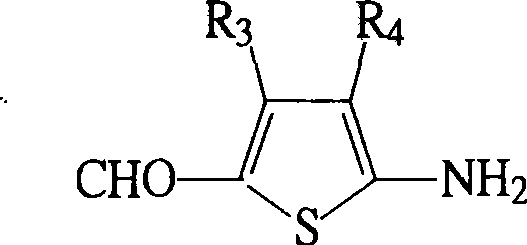

Second-order non-linear optical polymer containing azo and thiophene ring, and its synthesizing method and use

The invention relates to the field of nonlinear optical materials, in particular to a class of second-order nonlinear optical polymers containing azo and thiophene rings with the Optical polymers prepare cross-linked polyurethane-based polymers or polarized polymer films. The novel high-performance second-order nonlinear optical polymer containing azo and thiophene rings of the invention greatly improves photochemical stability because N=N bonds are used to replace C=C bonds. This type of material contains two or more -OH, which can be further reacted to prepare crosslinked polymer films or polarized polymer films, which have higher thermal stability and light stability than non-crosslinked polymers. Sexuality and orientation stability. Furthermore, since such azo compounds or their azo intermediates are blue to red compounds, they are also useful as pigments, dyes, paints, and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

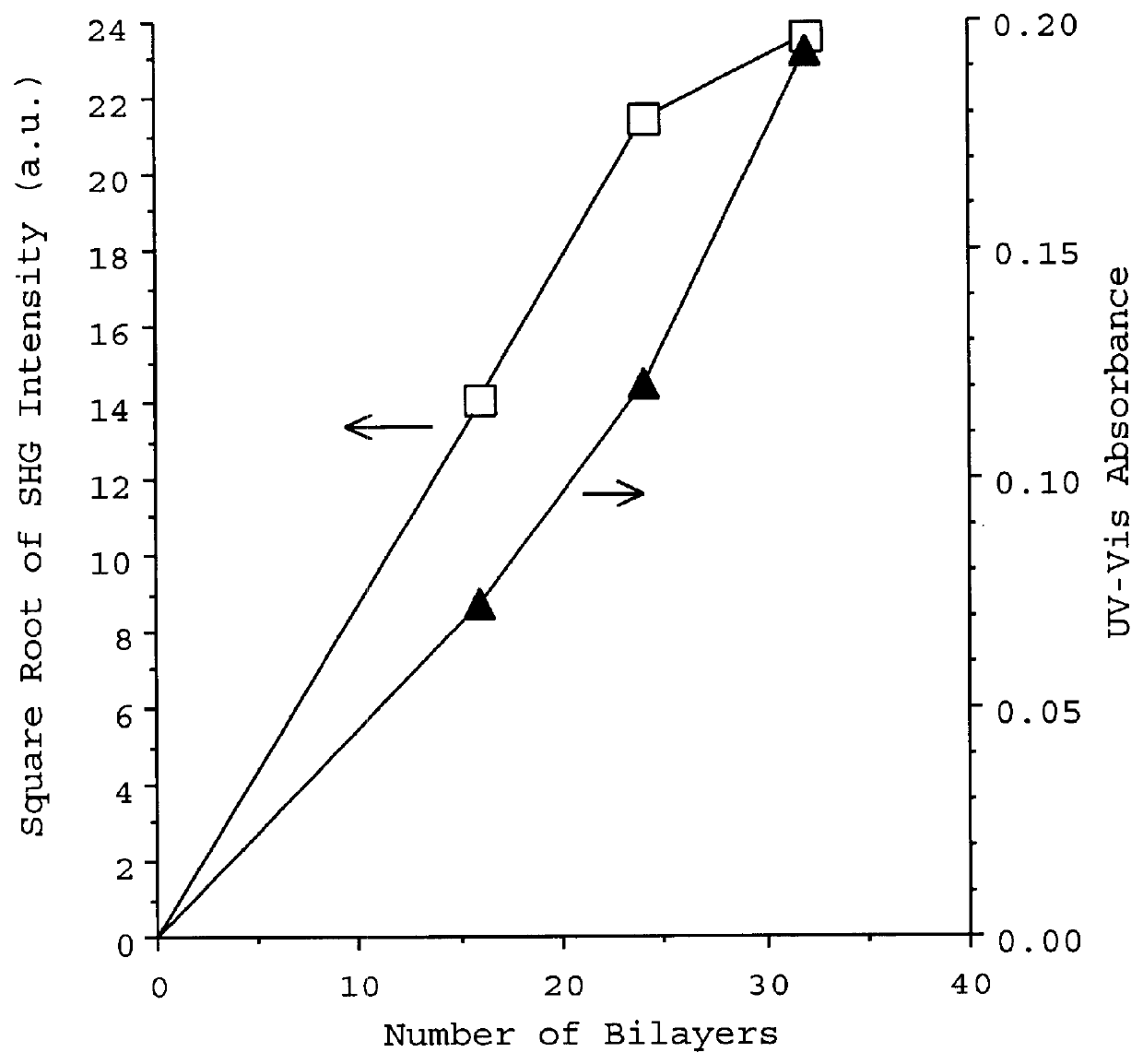

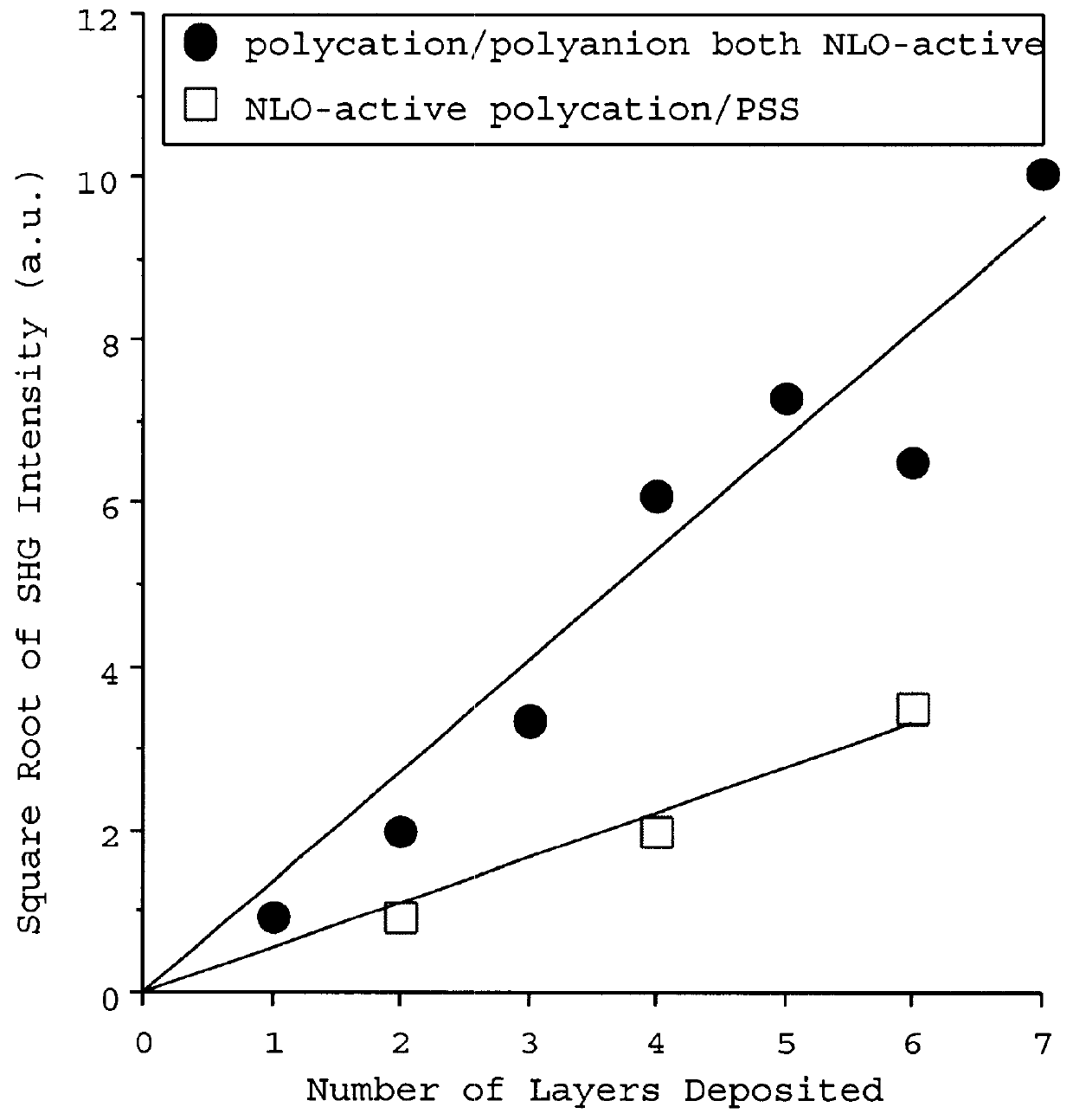

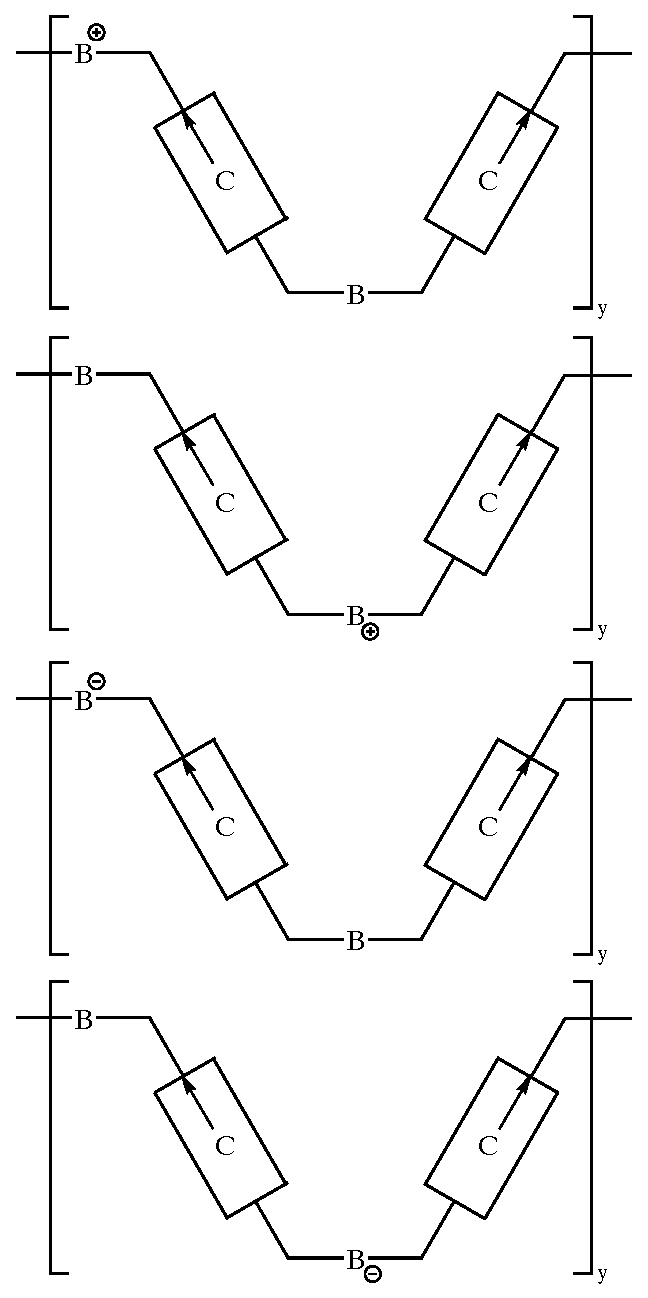

Process for mass producing uniform multi-layer non-linear optical polymer thin polar films

A process that lends itself to automation for producing multi-layer second-order nonlinear optical polymer (NLOP) thin films by the forming of a polycation layer containing an NLO-active cationic polymer, having non-centrosymmetric chromophores, on a substrate followed by the forming of a polyanion layer, also having non-centrosymmetric chromophores, on the polycation layer. A predetermind number of the polycation and the polyanion layers may be alternated upon the surface as well as one or more buffer layers. An added benefit is the formation of an ultra-smooth surface of the same order of roughness as the substrate upon which the layers are formed.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

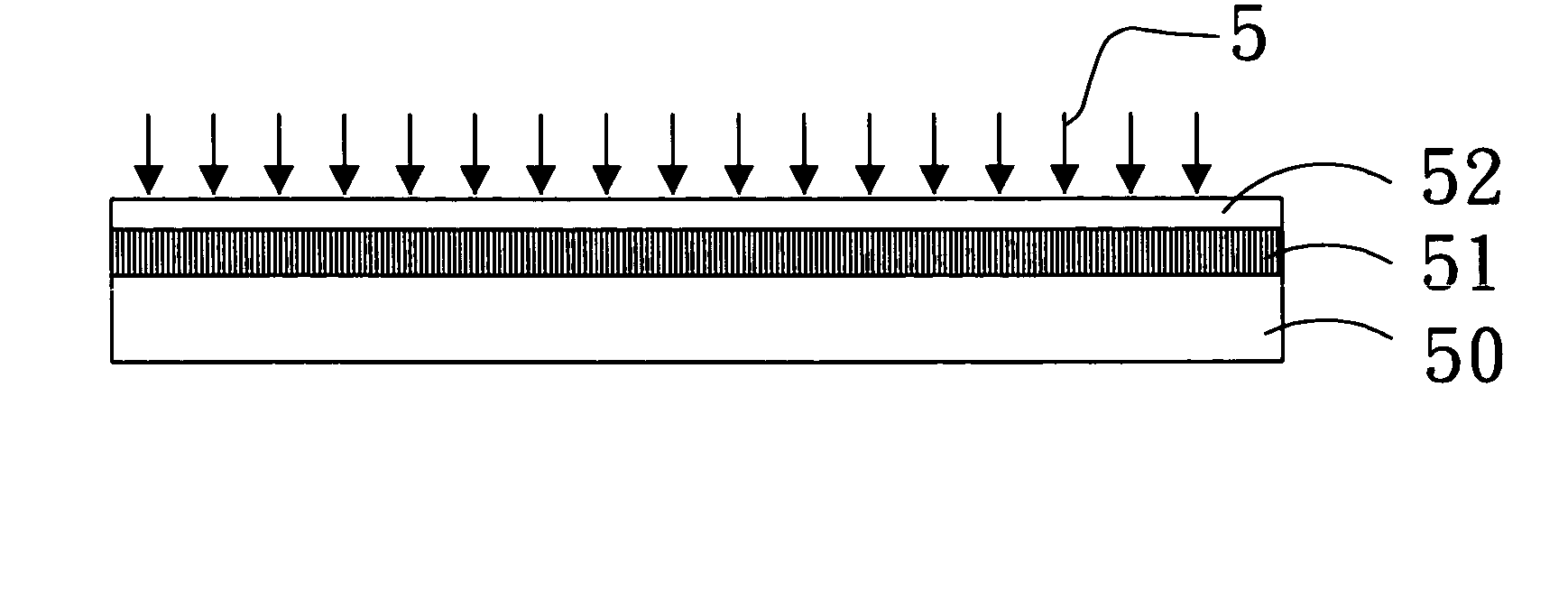

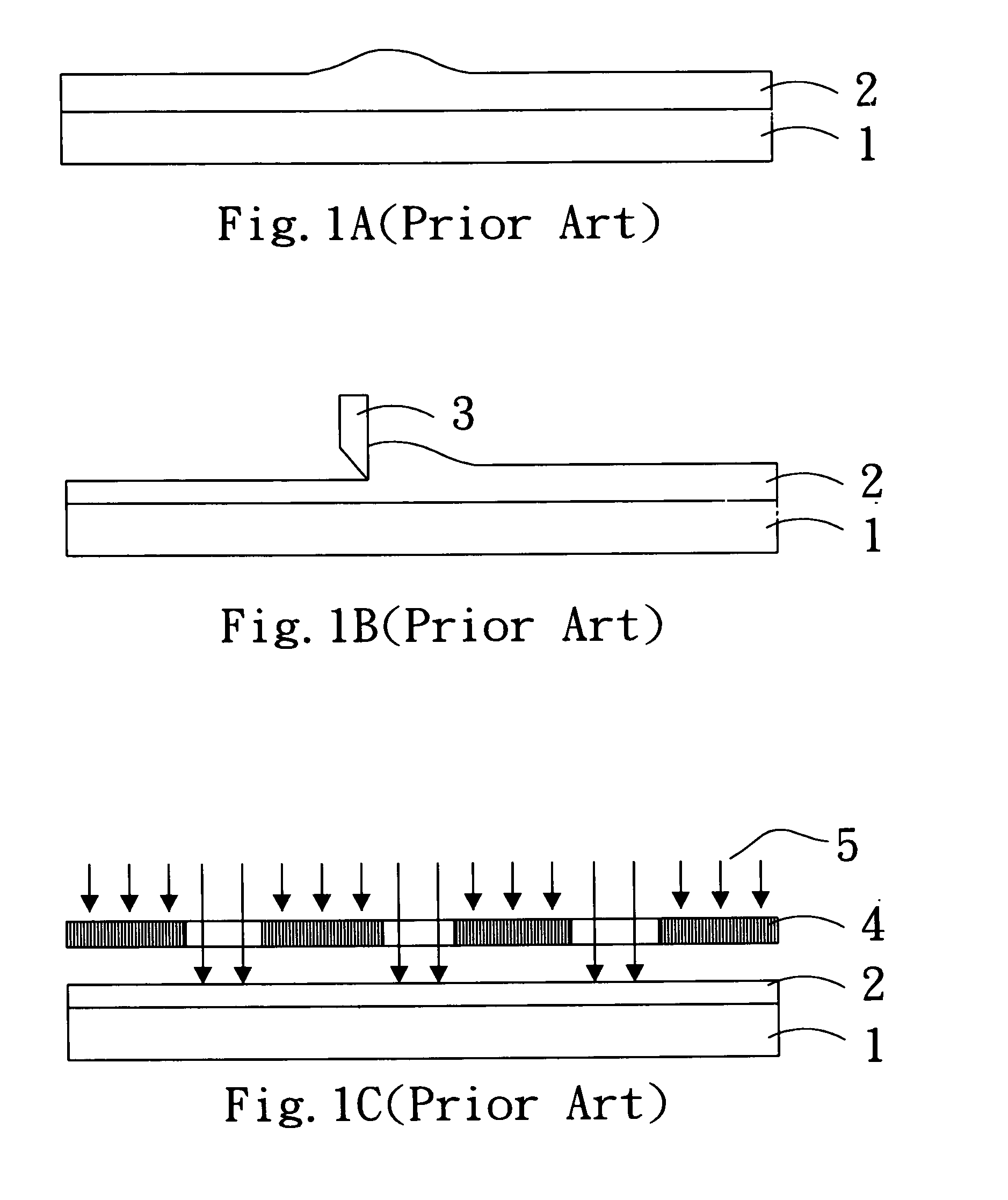

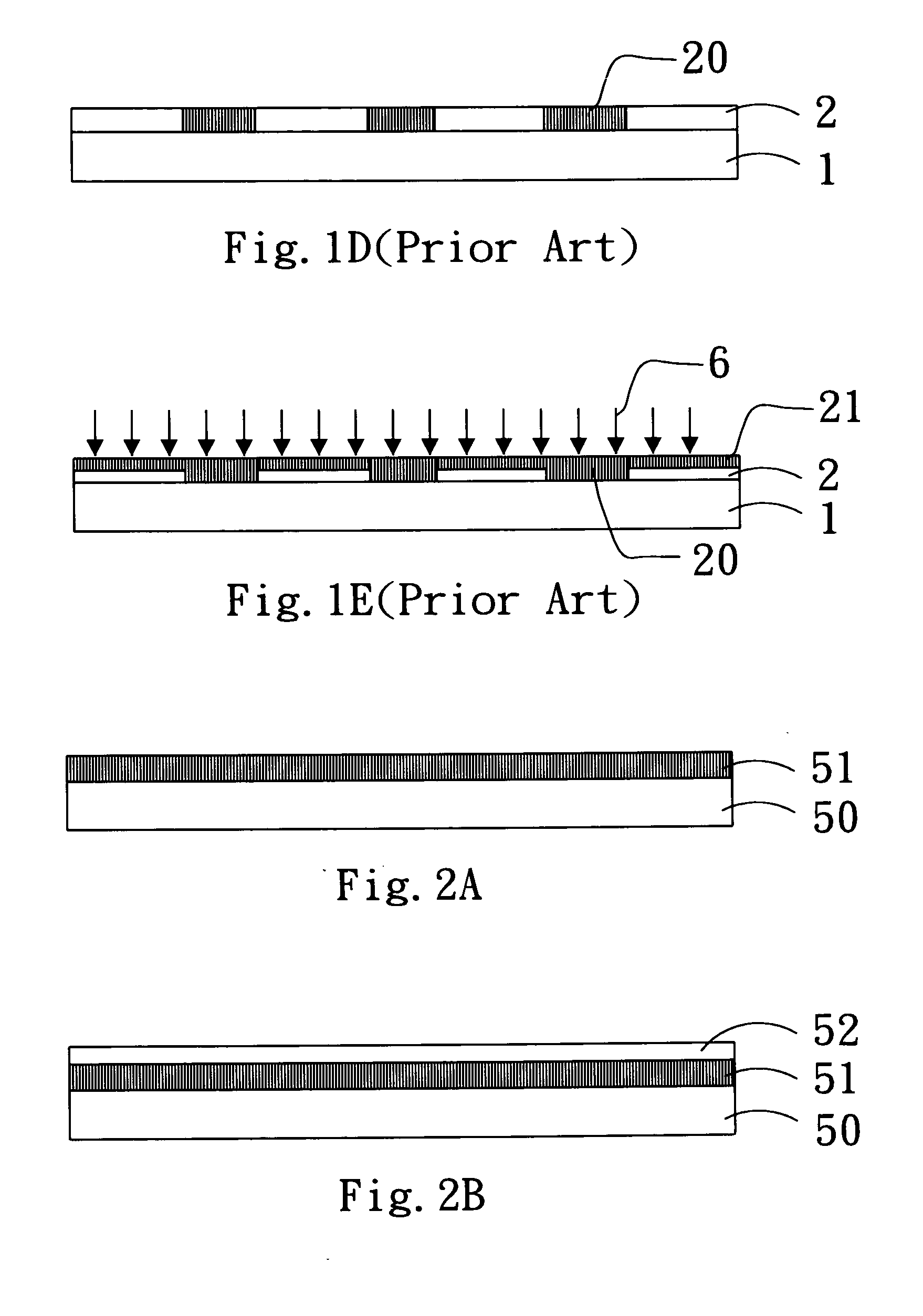

Manufacturing method for an electrophoretic display

InactiveUS20050045478A1Electrolysis componentsVolume/mass flow measurementPolymer scienceOptical polymers

a manufacturing method for an electrophoretic display applying optical polymer material is provided. The main characteristic is that the charged pigment particles are confined with optical polymer material so as to achieve electrophoretic display. In the manufacturing process, a first layer of optical polymer material is coated on an auxiliary substrate having a buffer layer for performing an optical polymerization manufacturing process. After the polymerization, on the first layer of the optical polymer material layer, the manufacturing process required by the electrophoretic display is further performed. After a second layer of optical polymer material is coated on a substrate required by the electrophoretic display having a plurality of electrode patterns, by using a mask exposure, the optical polymer material is solidified to form a polymer wall, or a molding method is applied with ultraviolet irradiation for solidifying the optical polymer material so as to form the polymer wall. Next, in a hole formed by the polymer wall, the mixture formed by the charged pigment particles and a few amount of optical polymer material is filled, and the auxiliary substrate is aligned with the substrate so as to perform the mask exposure polymerization manufacturing process. Therefore, the auxiliary substrate is combined with the substrate. Finally, the auxiliary substrate is stripped out so as to finish the manufacturing of a single substrate electrophoretic display.

Owner:IND TECH RES INST

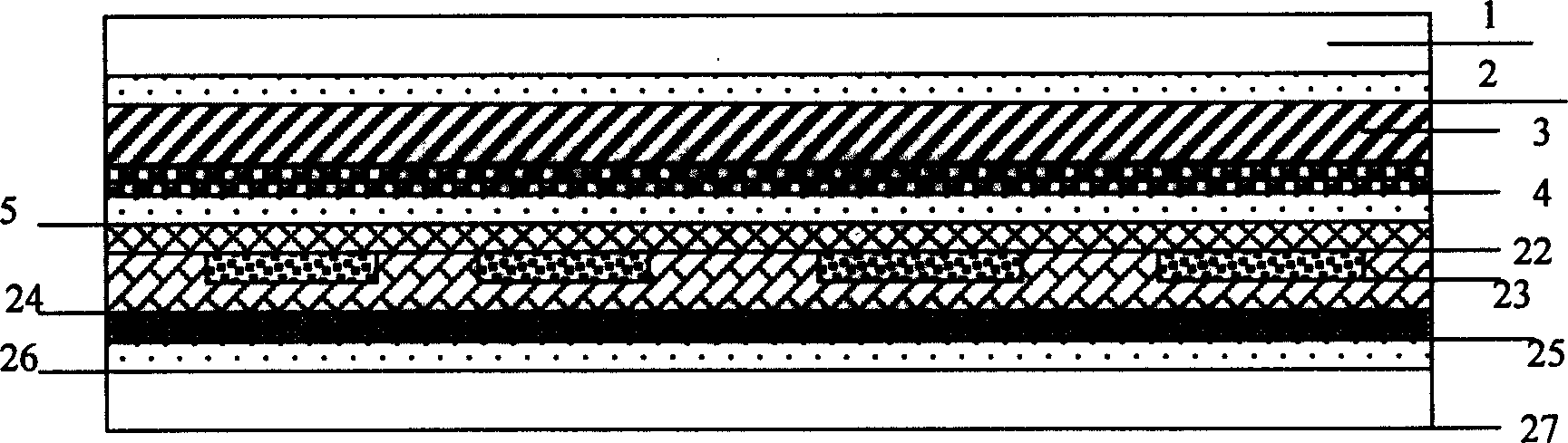

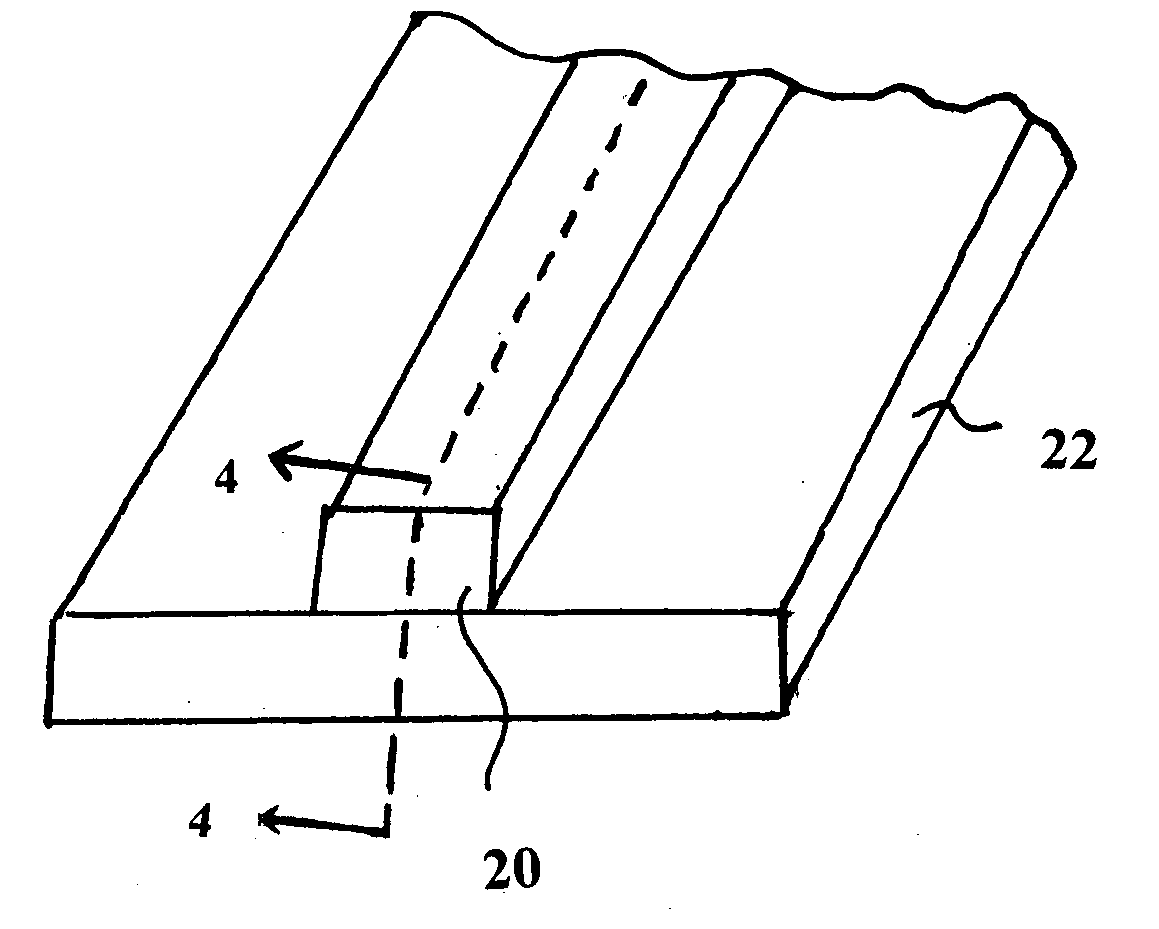

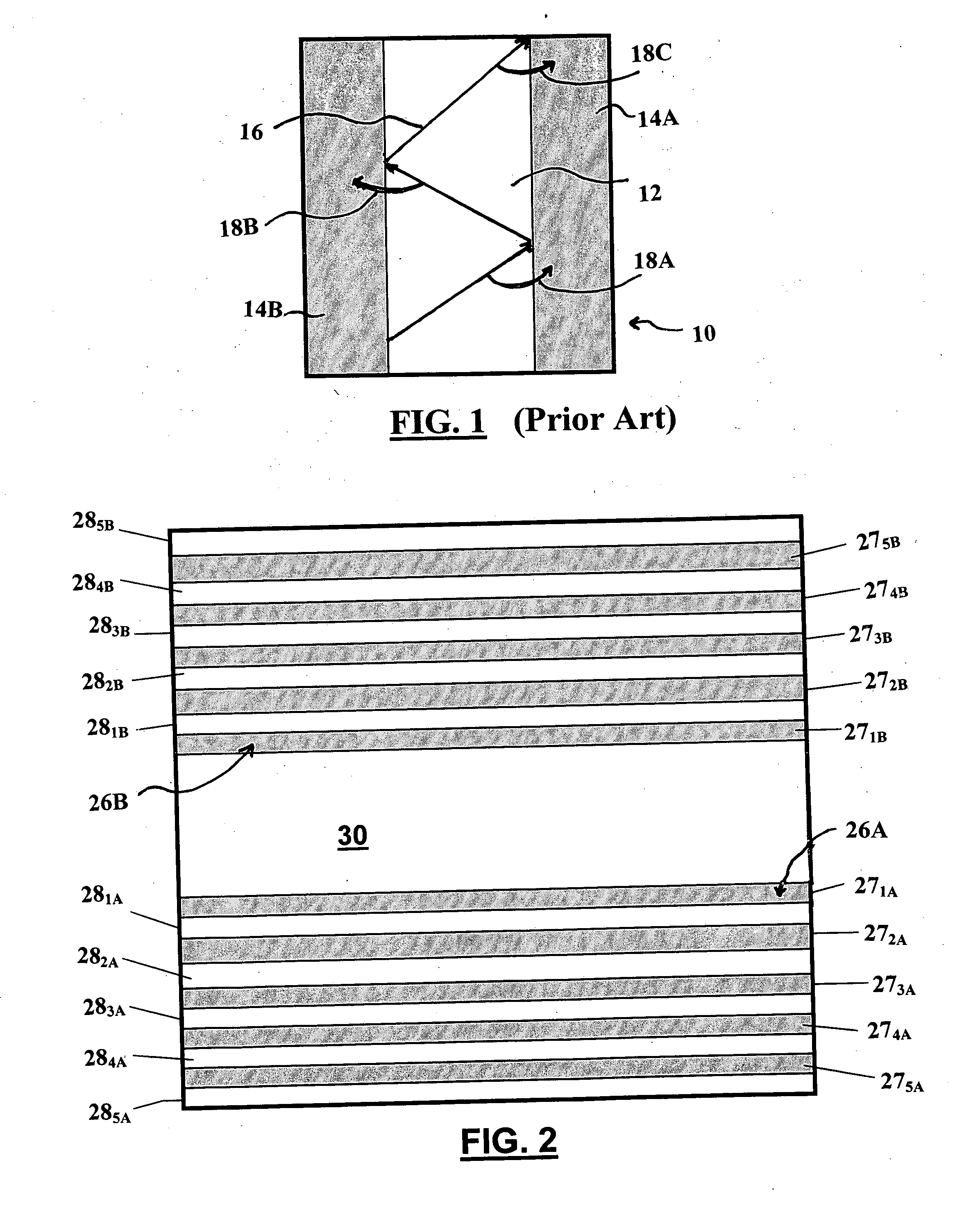

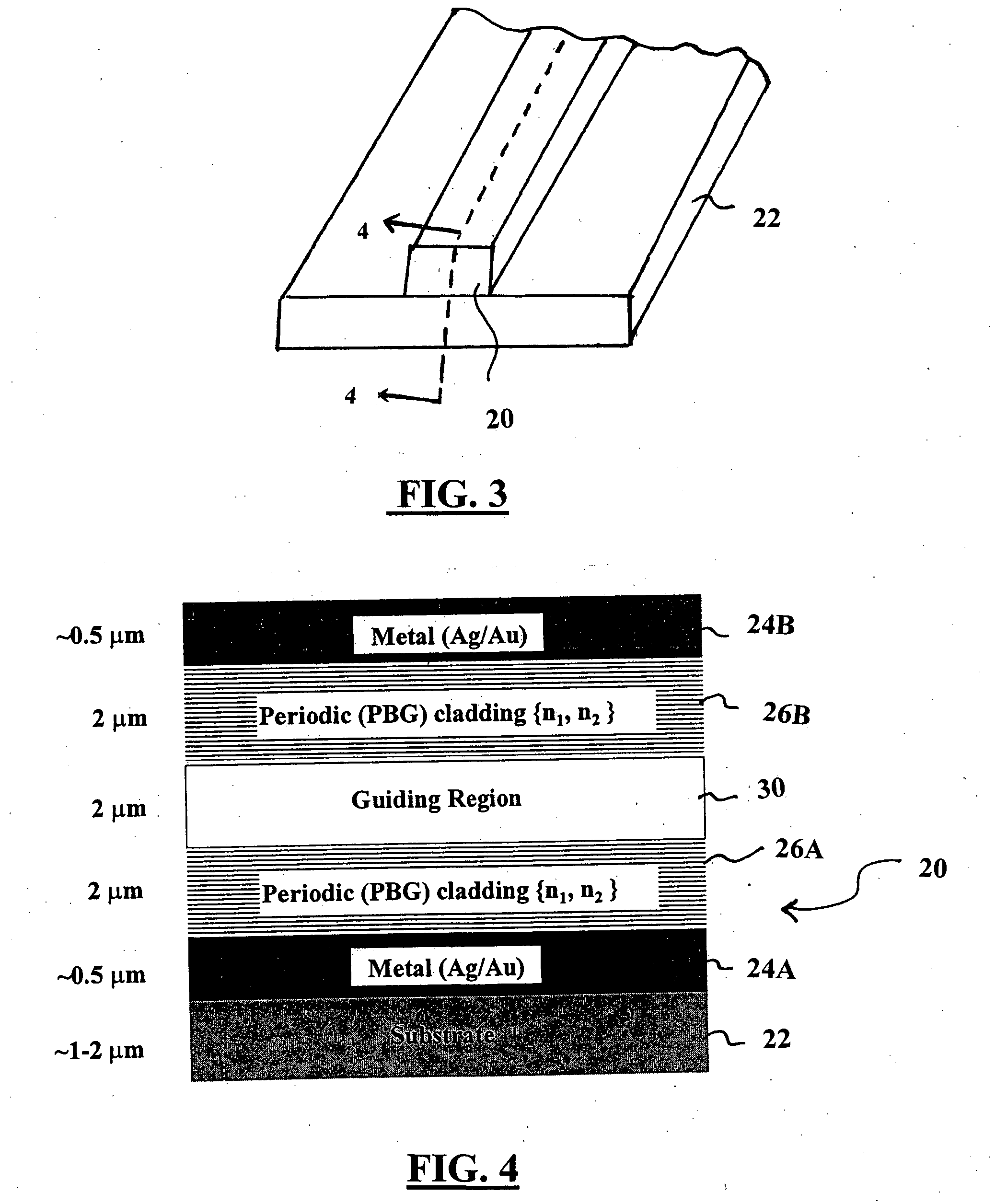

Photonic crystal-based optical waveguide modulator

InactiveUS20070019919A1Coupling lossImproves spatial economyNanoopticsOptical waveguide light guideOptical polymersPhotonic bandgap

A waveguide has upper and lower cladding regions. A core of the waveguide made of a non-linear optical polymer is positioned between the upper and lower cladding regions. A first electrode is connected to the upper cladding region and a second electrode is connected to the lower cladding region. The upper cladding region and the lower cladding region are made of photonic band gap materials and have multiple periods of cladding layers with each period having a first layer having a linear refractive index of n1 and each period having a second layer having a linear refractive index of n2. The waveguide allows for minimal distances to exist between the electrodes while allowing for virtual lossless cm-long transmission of propagating light. By applying a voltage to the electrodes, the propagated light can be modulated.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BYTHE SEC OF THE ARMY

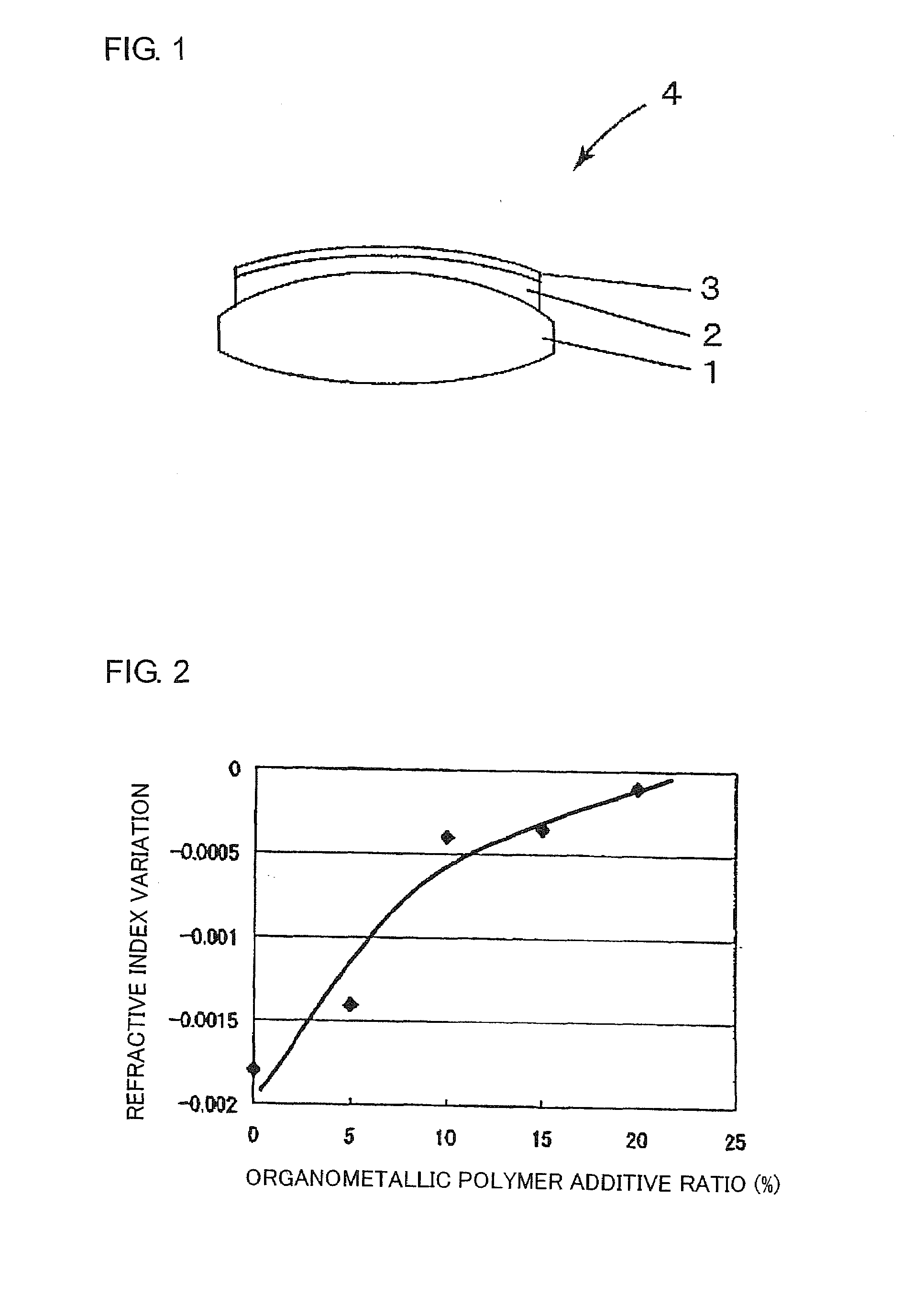

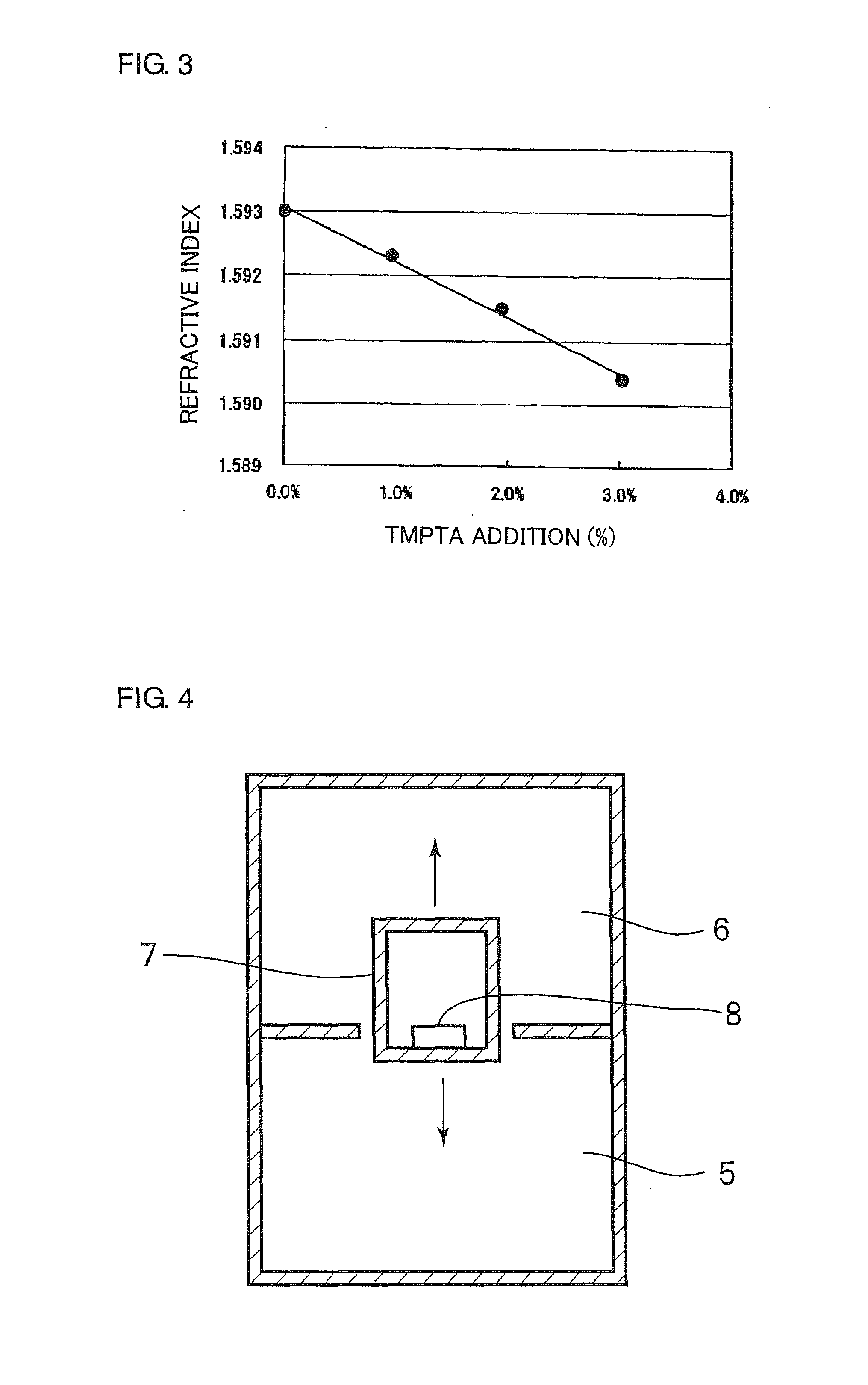

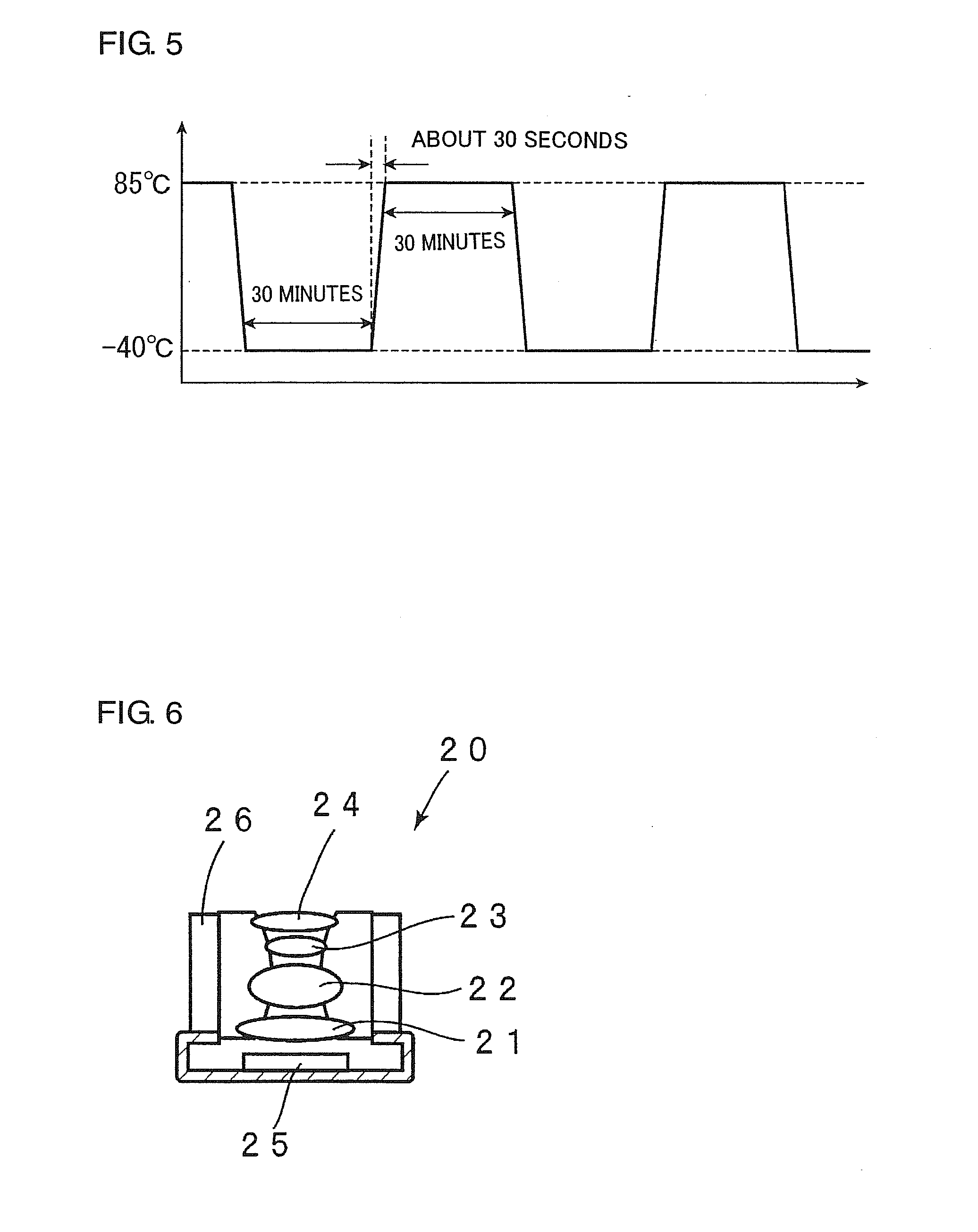

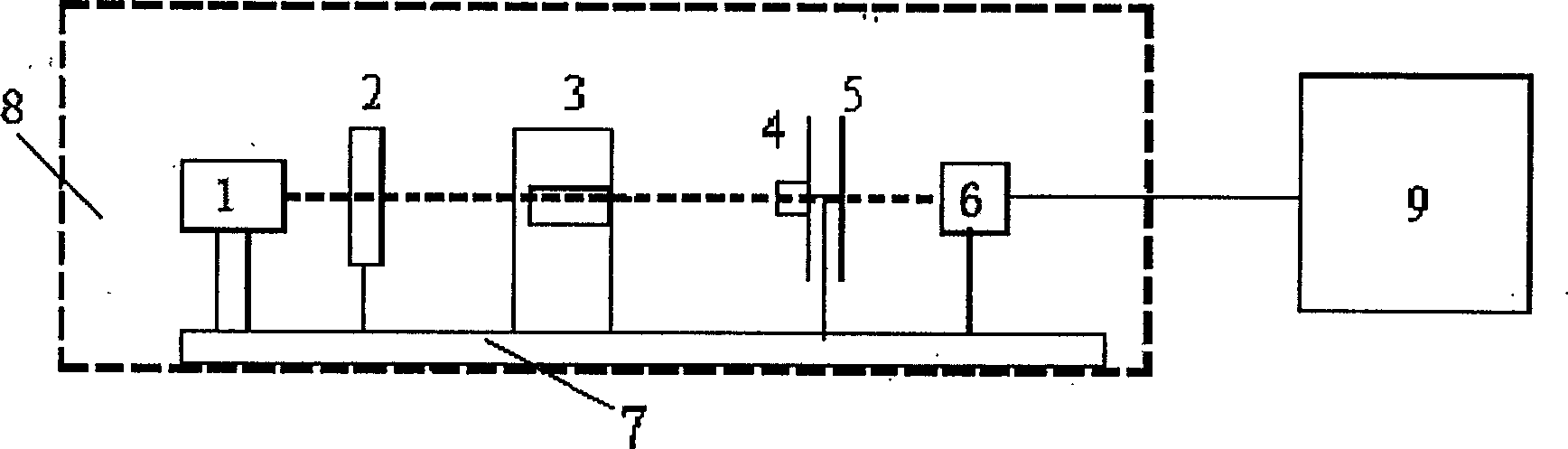

Optical polymer material and optical component

InactiveUS20080233417A1Low viscosityHigh refractive indexSynthetic resin layered productsThin material handlingArylMeth-

The invention provides an optical polymer material having a low viscosity before curing, a high refractive index of a cured product, little alteration of refractive index under high temperature and high humidity, and an excellent heat resistant shock property and an optical component using the optical polymer material.The optical polymer material is characterized in that the material contains a fluorene compound having four (meth) acryloyl groups and a (meth) acrylate having an aryl group and may further contain -M-O-M- bond (M is a metal atom), an organometallic polymer having an aryl group, a monofunctional (meth)acrylate and / or a polyfunctional (meth)acrylate.

Owner:SANYO ELECTRIC CO LTD

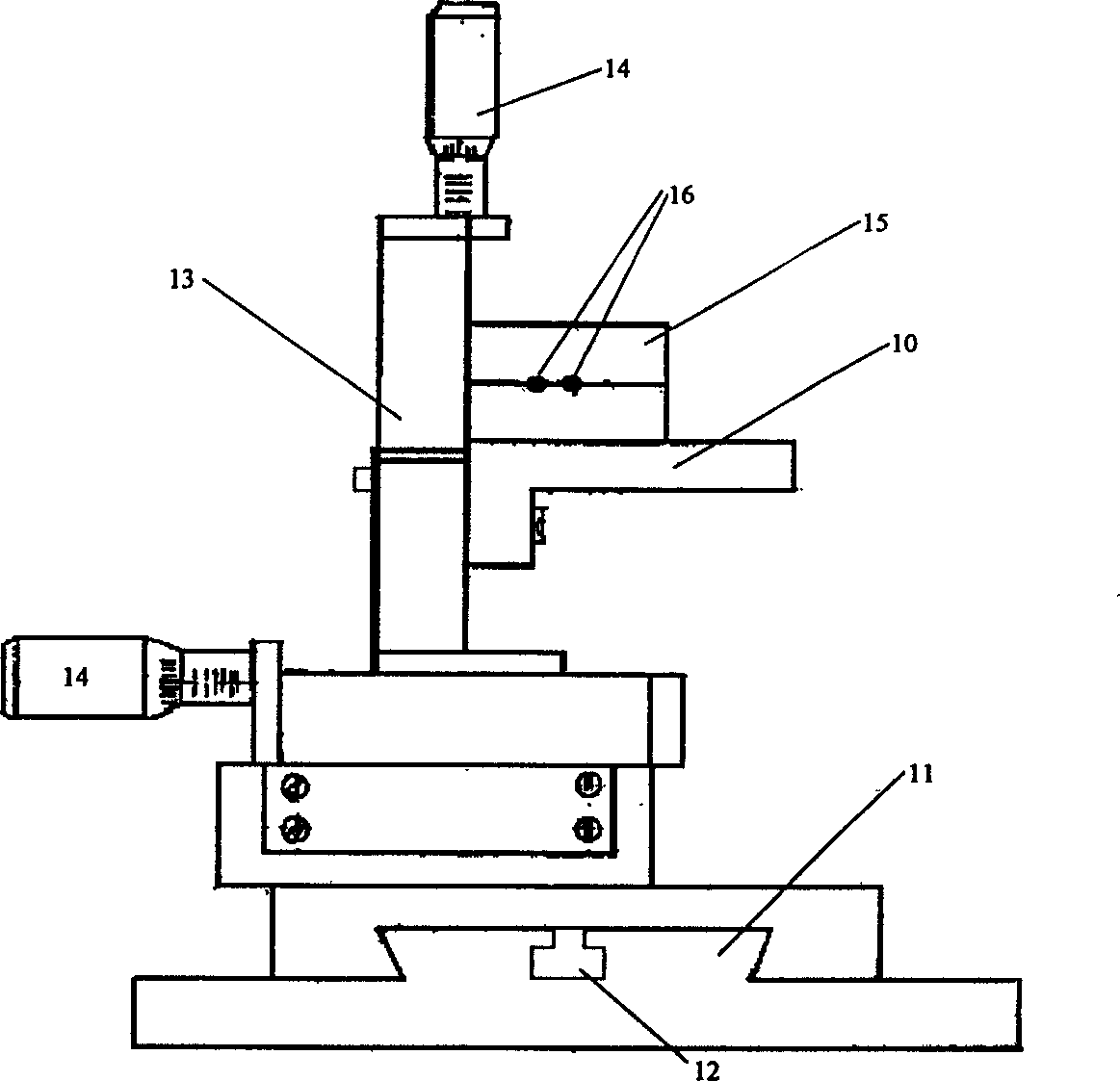

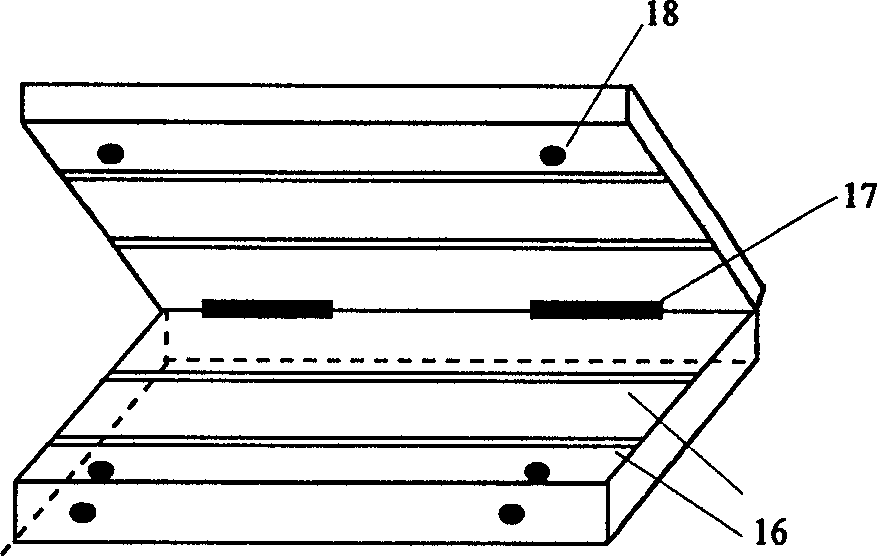

Polymer optical fiber characteristic parameter testing apparatus and its testing method

InactiveCN1493846AHigh measurement accuracyHigh degree of automationMeasurement devicesMeasuring instrumentOptical polymers

A tester for testing the geometric and optical parameters of an optical polymer fibre is composed of an imaging system and an image processing system. Said imaging system consists of light source, attenuator, object carrier with transparent clamper of optical fibre, microscope, optical diaphragm and CCD camera. Its advantages are high accuracy and automation level, and casy regulation. Its test method is also disclosed.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com